Preparation method and application of ceiba fiber in spinning and weave field

A kapok fiber and processing method technology, applied in textiles and papermaking, textile material processing, fiber processing and other directions, can solve the problems of uneven evenness, difficulty in forming large-scale products or commodities, and inability to realize kapok fibers, and achieve yarn quality. Even branches dry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 7

[0048] The kapok fiber obtained by embodiment 2-6 is spun under the same conditions, tested, and calculates the average value, and the results are as follows:

[0049] 1. Strong test comparison:

[0050] Cotton yarn strength is >8.8CN / tex

[0051] Kapok yarn strength is > 8.2CN / tex

[0052] 2. Test and comparison of coefficient of variation of evenness of yarn count:

[0053] Coefficient of variation (CV%) of evenness of cotton evenness 11.0

[0054] Kapok evenness coefficient of variation (CV%) 11.24

[0055] 3. Diameter comparison between kapok yarn and cotton yarn:

[0056] Cotton 0.357mm

[0057] Kapok 0.371mm

Embodiment 9

[0069] In short, the fabrics and four-season clothing made of kapok fiber are characterized by light, soft, comfortable, smooth, bright, antistatic, not easy to tangle, moisture absorption and moisture conduction, no mildew and moth, and acid and alkali resistance at room temperature. Green natural environmental protection product.

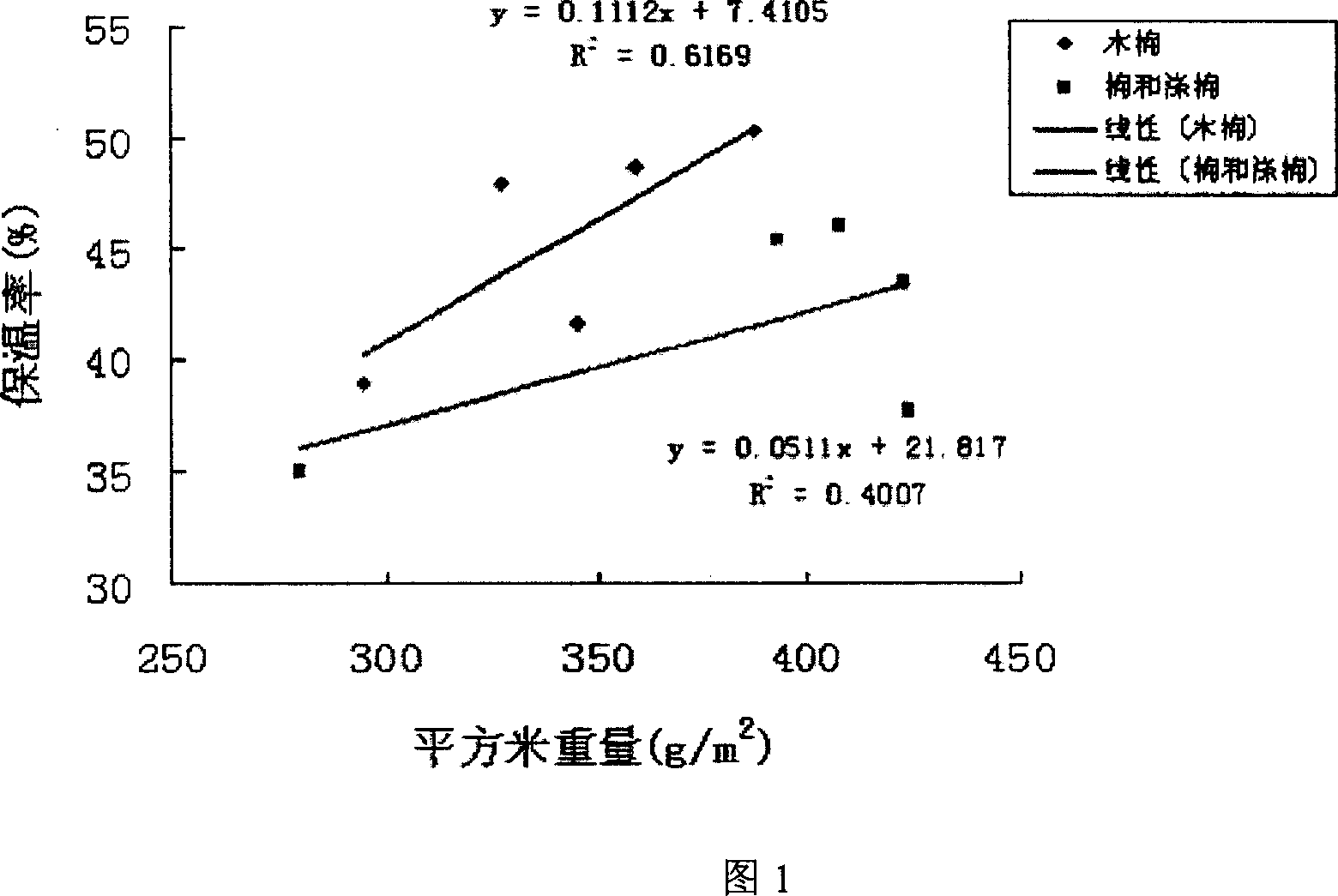

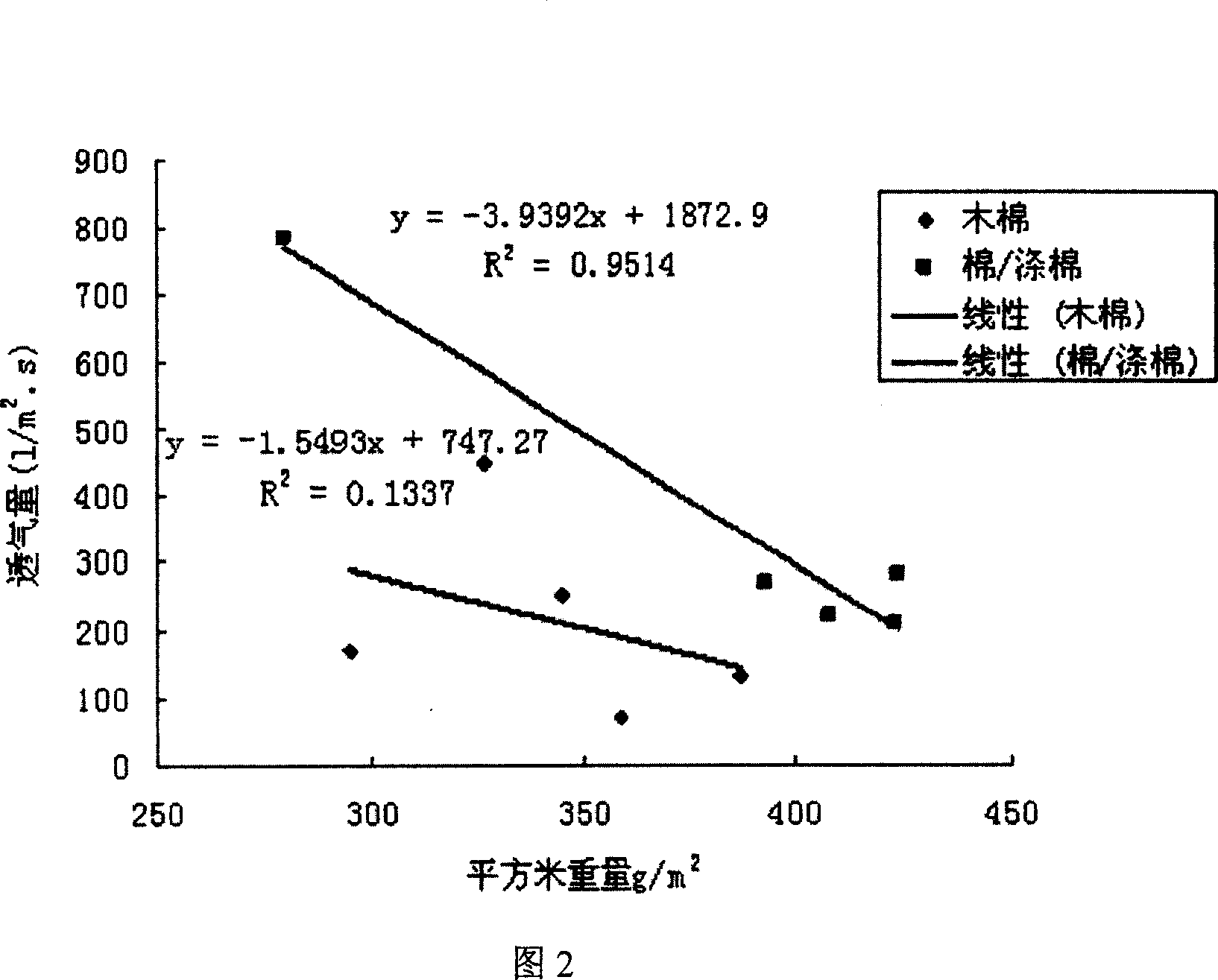

[0070] The following is the test data of kapok fiber, cotton and other fibers in the manufacture of various thermal underwear for reference:

[0071] my country's industry standards stipulate that the warmth retention rate of thermal clothing should not be less than 30%. The series of kapok high-efficiency thermal insulation underwear developed by our company has good thermal insulation effect, and the average thermal retention rate is about 50%, which is better than cashmere and down. The conduction thermal resistance is more than 20% higher than that of cotton products, the convective thermal resistance is 2-3 times that of cotton products, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com