Patents

Literature

290results about How to "Evenly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rachael blanket made from Modal cotton

A raschel blanket of modyhr-cotton is prepared form 35-50 wt.% of modyhr, 30-40 wt.% of cotton and 15-30 wt.% of polyester. Its manufacturing process includes warping polyester filament, warping wool yarn blended by modyhr and cotton, weaving for fabric, splitting and opening fine hair, inspecting and sending inspected material to warehouse of semi-finished product.

Owner:上海海欣大津毛织有限公司

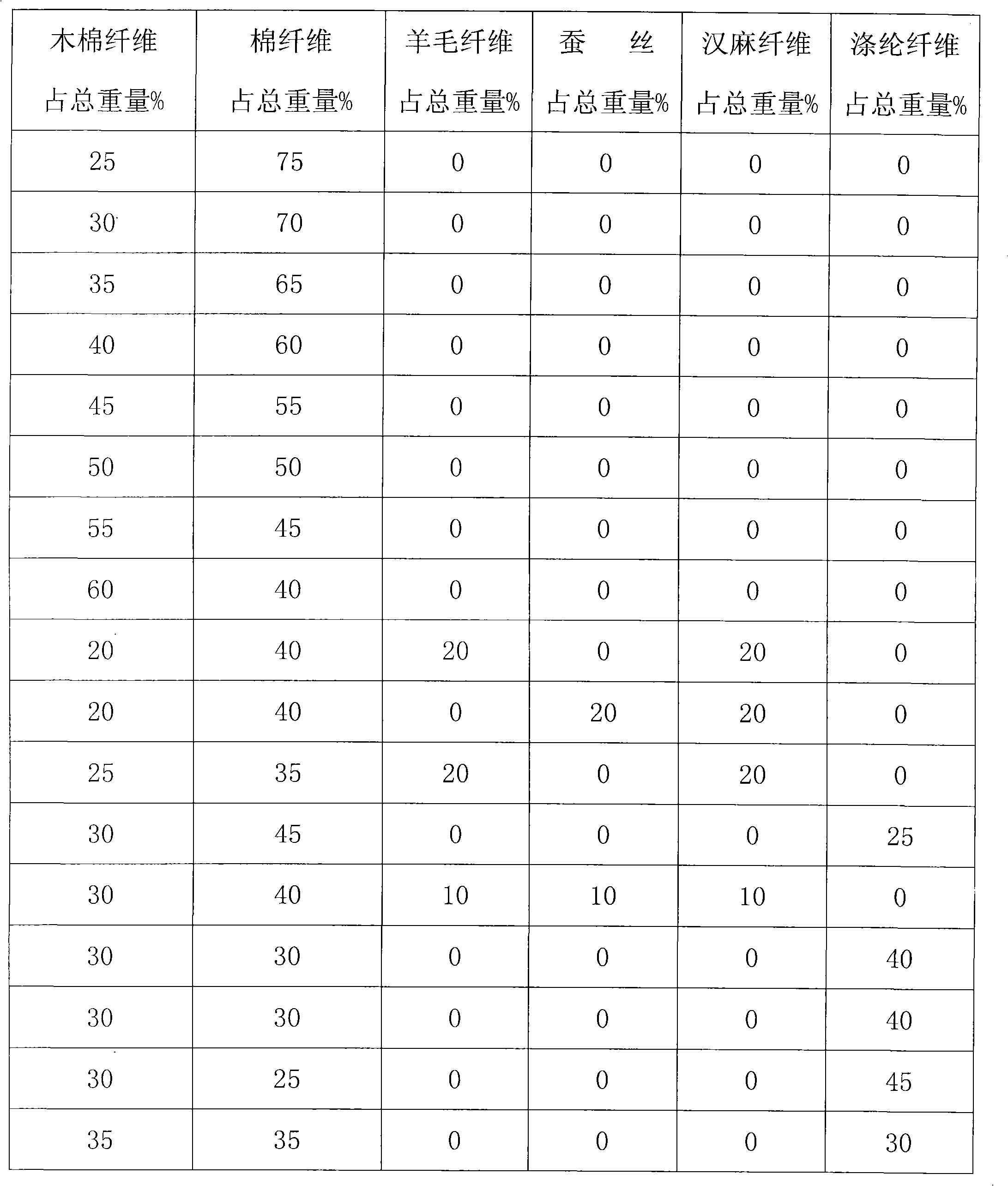

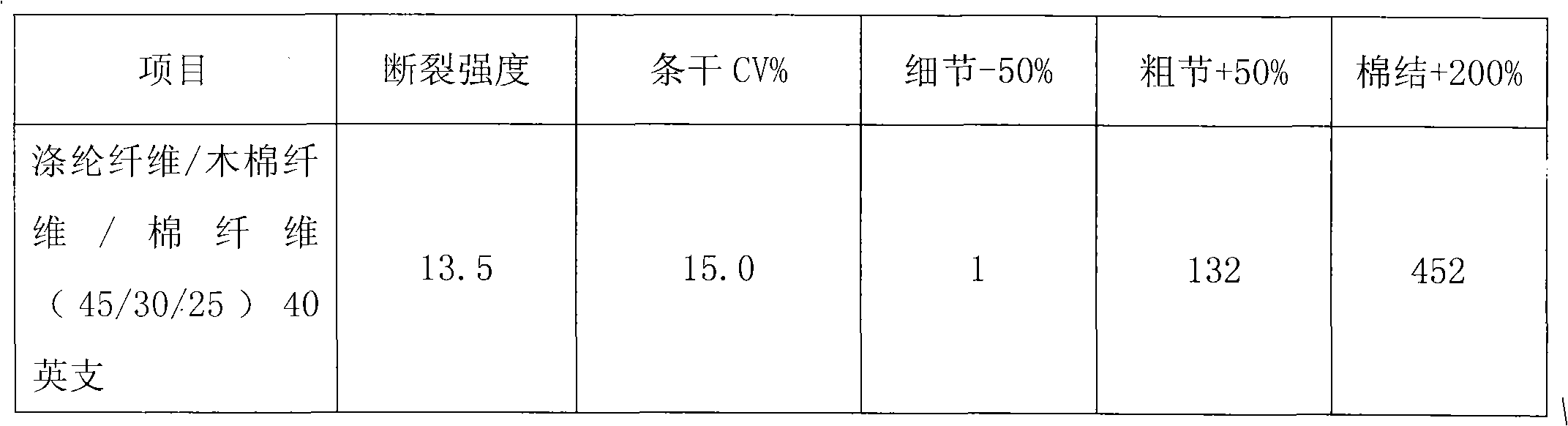

Process for manufacturing kapok fiber blended yarns

The invention discloses a process for manufacturing kapok fiber blended yarns, comprising the steps of selecting a plurality of kapok fibers, cotton fibers, wools, silks, hemp fibers and terylene fibers, wherein the content of the kapok fibers is 25-60% of the total blended yarns; the content of the cotton fibers, wools, silks, hemp fibers and terylene fibers is 40-75% of the total blended yarns; weighing the kapok fibers and other spinning fibers, dividing the fibers into small stacks, and obtaining multi-component blended yarns by mixing, blowing, cotton carding, drawing, roving and spinning, wherein the relative humidity of the production environment of each process is 60-65%; the products produced by the invention can be manufactured to be kinds of blended fabric materials; a fabric product which is pure natural, green, environment-friendly, soft and warming is increased in the spinning field.

Owner:JIHUA 3542 TEXTILE CO LTD

Terylene fine-denier triangle super bright FDY filament and preparation method thereof

InactiveCN101139741AGood flexibilityFeel goodFilament/thread formingMonocomponent polyesters artificial filamentMaterials scienceFilament yarn

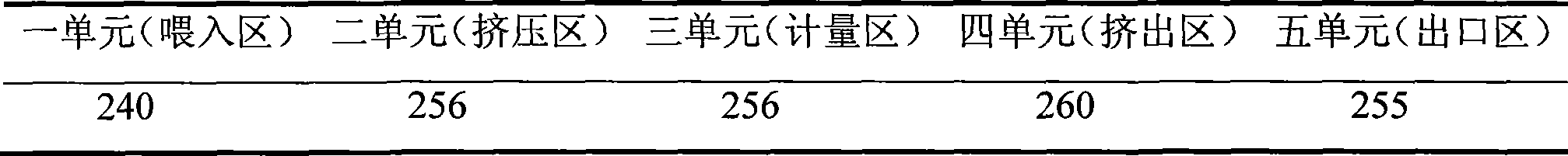

The invention discloses a terylene fine denier triangular super-glossy FDY filament and relevant preparation method, and belongs to the technical field of terylene fibers. During the course of filature preparation, the invented fine denier triangular super-glossy terylene filament can lower filature speed, shorten calm zone distance and milden air blow cooling conditions; meanwhile, the fiber adopts nozzle oiling mode to improve oiling position, in order to successfully prepare fine denier triangular super-glossy FDY terylene filament with denier no more than 0.7dtex, fiber corss section similar to regular triangle and super-bright glossy. The terylene filament has advantages of extremely perfect flexibleness, excellent hand feeling, and moreover, the product is characterized by fewer broken filament, fewer short ends, more uniform yarn more stable quality.

Owner:JIANGSU HENGLI CHEM FIBER

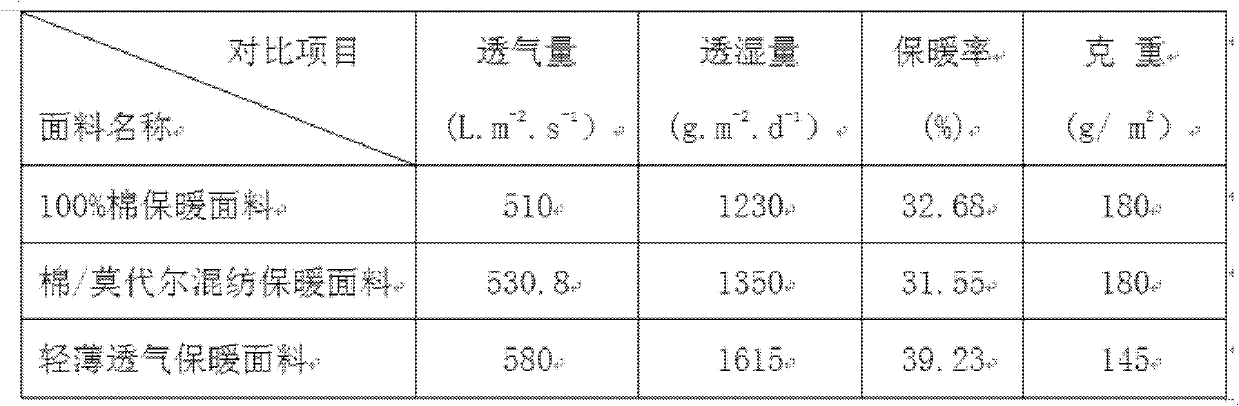

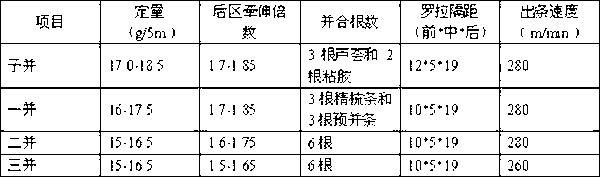

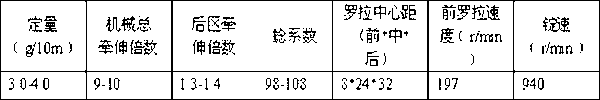

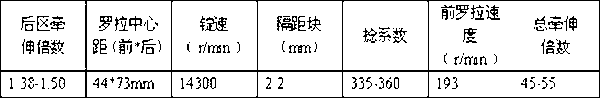

Thin breathable warm fabric and manufacture method thereof

InactiveCN102605523AHigh standardFullnessWeft knittingLiquid/gas/vapor treatment of propelled fabricsYarnMoisture absorption

The invention relates to a thin breathable warm fabric, comprising a surface fabric and an inner layer fabric, wherein the inner layer fabric is a moisture absorption and heating layer; the surface fabric is a warm breathable and moisture-leading layer; the moisture absorption and heating layer is formed by blending 30-60% of moisture absorption and heating EKS fibers and 40-70% of ordinary acrylic fibers; the warm breathable and moisture-leading layer is formed by blending 15-40% of bulk acrylic fibers, 20-60% of superfine acrylic fibers and 0-65% of modal fibers. The invention further relates to a manufacture method of thin breathable warm fabrics, comprising the steps of preparing yarns, weaving, sanding, dyeing, finishing softly and shaping; and the thin breathable warm fabric provided by the invention has the advantages of high wearing comfort, good thin and breathable performance as well as good anti-dropping, anti-static and warmth retention performances.

Owner:SHENZHEN HUIJIE GROUP

Cotton fiber, aloe fiber and viscose fiber blended yarn and yarn spinning process thereof

The invention discloses cotton fiber, aloe fiber and viscose fiber blended yarn and a yarn spinning process thereof. The blended yarn comprises the components by fiber-content blended ratio: 50 percent of cotton fiber, 30 percent of aloe fiber and 20 percent of viscose fiber, and the fibers are spun into the yarn through a blending process. The aloe fiber and the viscose fiber are subjected to coating mixing, and card slivers formed through working procedures such as blowing and cotton carding and cotton-fiber fine combing slivers are subjected to sliver mixing to form the yarn. A compact Siro spinning technique and the reasonable raw material collocation are adopted, so that the problems that the fiber of the aloe fiber is short, the viscose fiber is easy to deform, the elastic recovery properties are poor, the abrasive resistance is poorer, the fiber is not resistant to acid and the like are solved, and the advantages of the aloe fiber, the viscose fiber and the cotton fiber are exerted. A mixing mode of one pre-drawing and three mixing-drawing is adopted, the accurate blending ratio is favored, and the components are uniform. The produced single yarn evenness is uniform, the single yarn strength is high, the neps are less, and the yarn defects are less.

Owner:山东超越纺织有限公司

Bamboo carbon fiber underwear fabric and manufacture method thereof

InactiveCN101532204AFully reflect the decomposition of odorFully reflect the functionWeft knittingYarnFiberTextile technology

The invention relates to a bamboo carbon fiber underwear fabric and a manufacture method thereof, belonging to the technical field of textiles. The bamboo carbon fiber underwear fabric consists of a lining layer and an external layer, and is characterized in that the lining layer consists of bamboo carbon fibers and cotton fibers according to the weight ratio of 15-30:70-85; the external layer consists of cotton fibers, Newdal fibers and polyurethane elastic fibers according to the weight ratio of 43-54:40-54:3-6. The manufacture method comprises that: the bamboo carbon fibers and the cotton fibers, the cotton fibers and the Newdal fibers are respectively spun into Sirospun blended yarns; the Sirospun blended yarns are interwoven with polyurethane elastic fibers to form a knitted underwear fabric; and the knitted underwear fabric forms a final finished product, namely the bamboo carbon fiber underwear fabric through dyeing, drying, sanding and shaping treatment. The fabric and the manufacture method have the advantages that the bamboo carbon fiber underwear fabric not only has good skin-friendly property, low pilling tendency and comfortable elasticity, and has functions of good odor decomposition, smell elimination and the like.

Owner:SHANGHAI PLANDOO TEXTILE TECH DEV

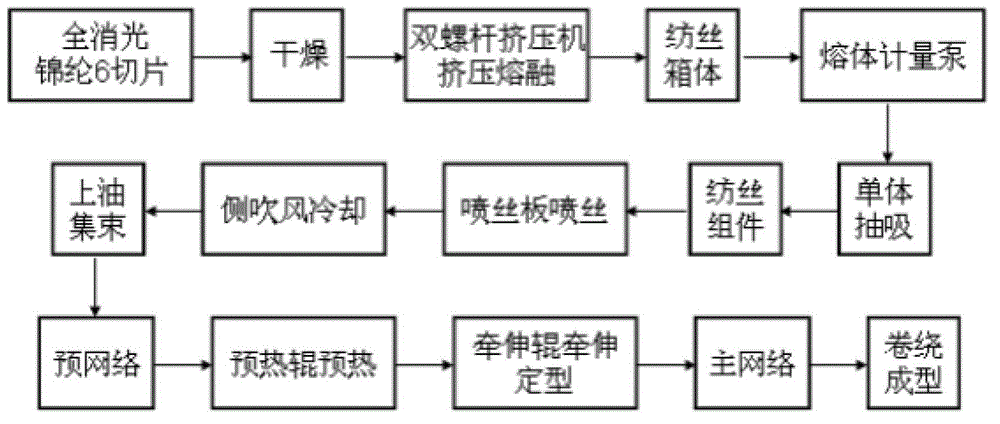

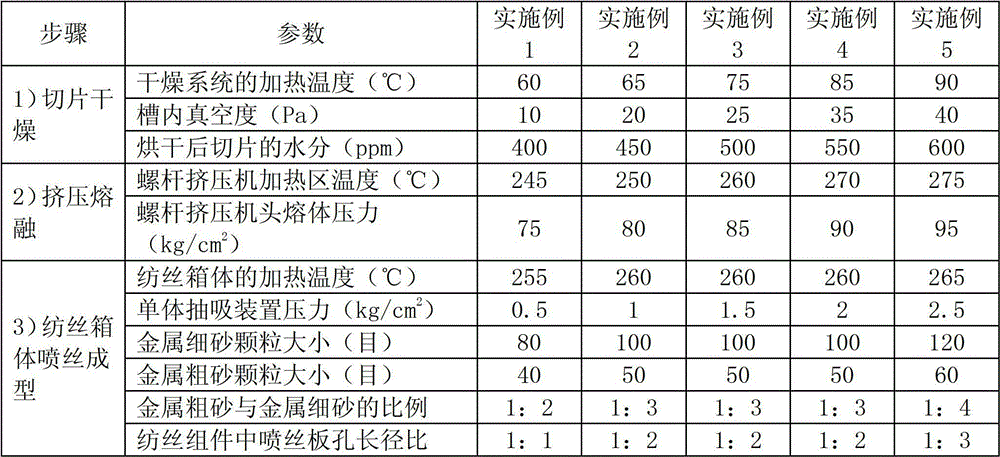

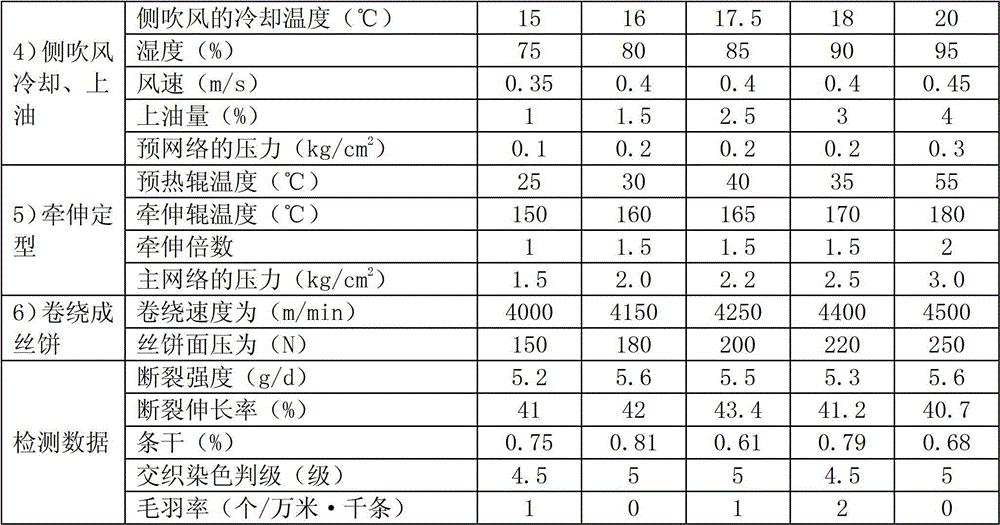

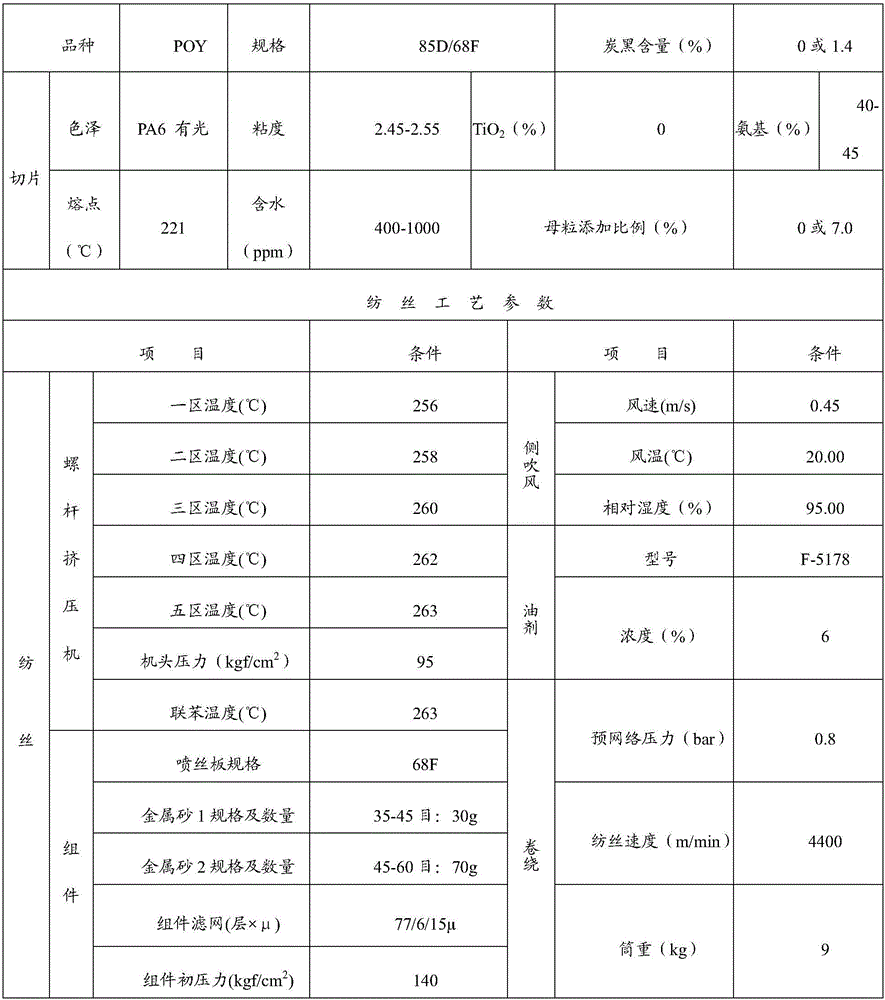

Production method for 20D/24F complete-extinction nylon 6 fully-drawn yarn

ActiveCN102747438ASimple processReduce processing costsFilament forming substance formingMelt spinning methodsYarnExtinction

The invention belongs to the field of synthetic fiber processing, relates to a preparation method for a nylon 6 fiber and discloses a production method for a 20D / 24F complete-extinction nylon 6 fully-drawn yarn. The production method comprises the following steps of: (1) slicing and drying until the water content is 400-600ppm; (2) extruding and melting by a twin-screw extruder; (3) extracting excessive monomer impurities by a single sucking device and performing spinneret and forming by a spinning manifold; (4) laterally blowing, cooling and oiling at constant temperature and humidity; (5) drafting and setting; and (6) winding to form a silk cake. The production method disclosed by the invention has the advantages of simple and feasible process and low processing cost as well as stable product quality, uniform evenness, low hairness ratio, favorable dyeing effect and excellent mechanical property by optimizing parameters.

Owner:浙江嘉华特种尼龙有限公司 +1

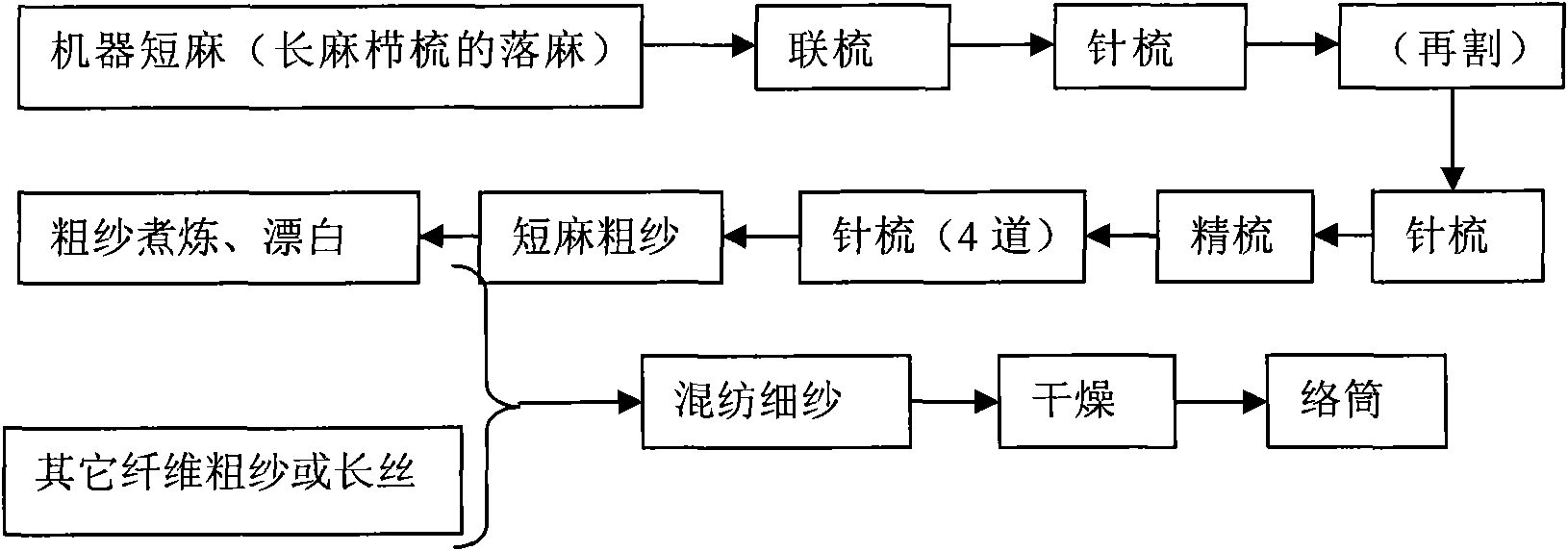

Blending method using hemp fiber as main material

InactiveCN101871147AIncrease the degree of splittingImprove impurity removalHackling machinesBleaching apparatusImpurityMaterials science

The invention relates to a blending method using a hemp fiber as a main material. The method comprises the following steps of: firstly, processing the hemp fiber into rovings; secondly, mixing the roving yarns of the hemp fiber with the rovings or filaments of other fibers in proportion to form bunch yarns; and finally, spinning the mixed bunch yarns in the second step into spun yarns. The blending method has the advantages of improving the disintegration degree of the hemp fiber and removing impurity without damaging the performance of the blended fibers, ensuring a high spinning yam count and quality of the blended yarns and greatly improving the quality of the blended yarns of the hemp fiber along with simple process.

Owner:肇融亚麻纺织有限公司

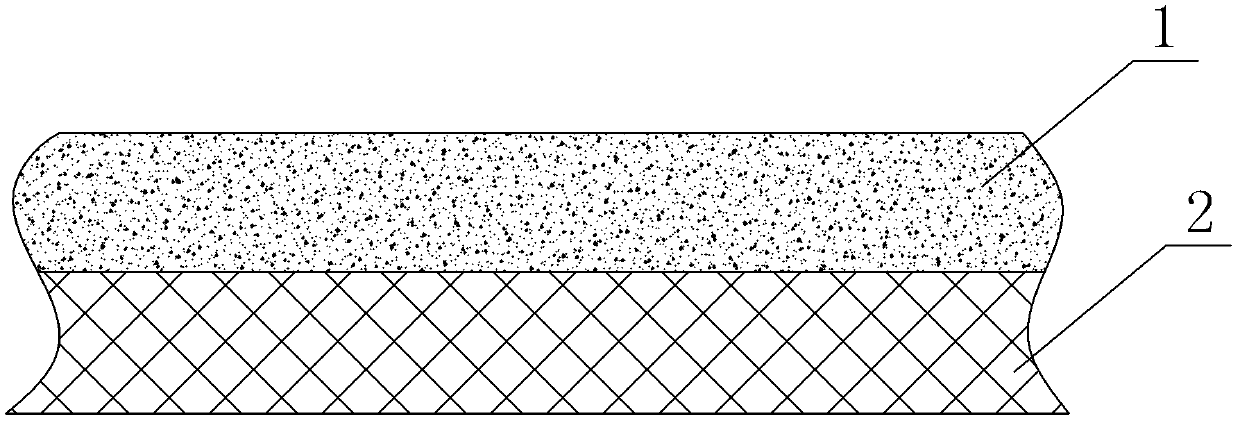

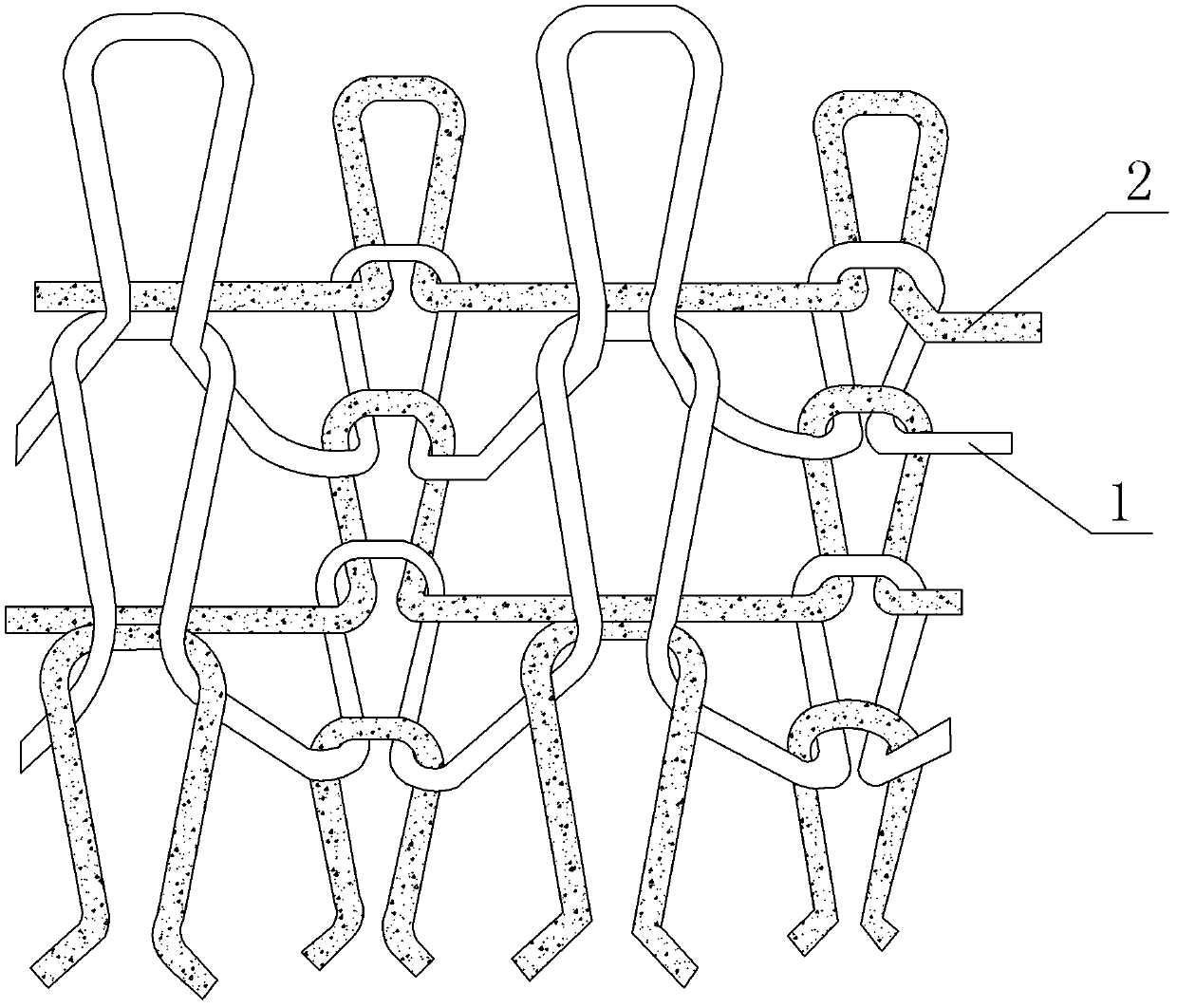

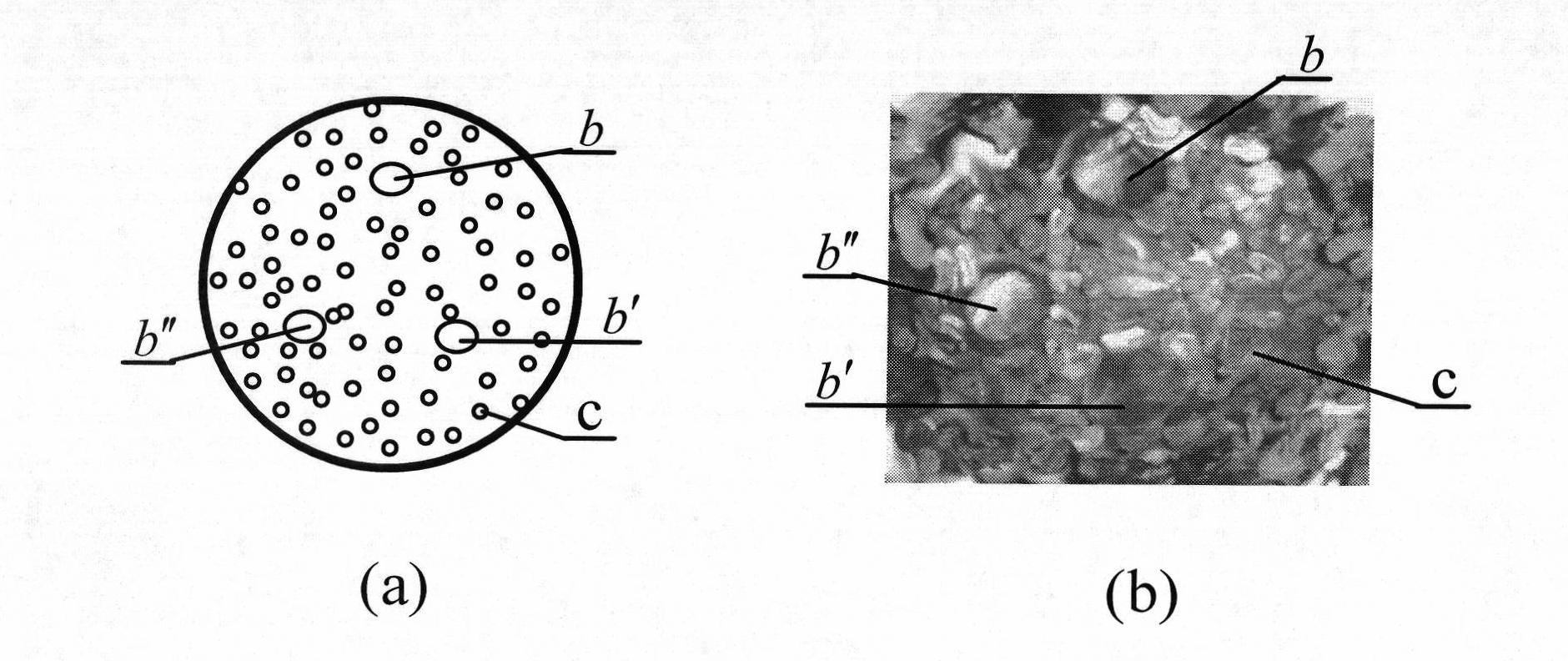

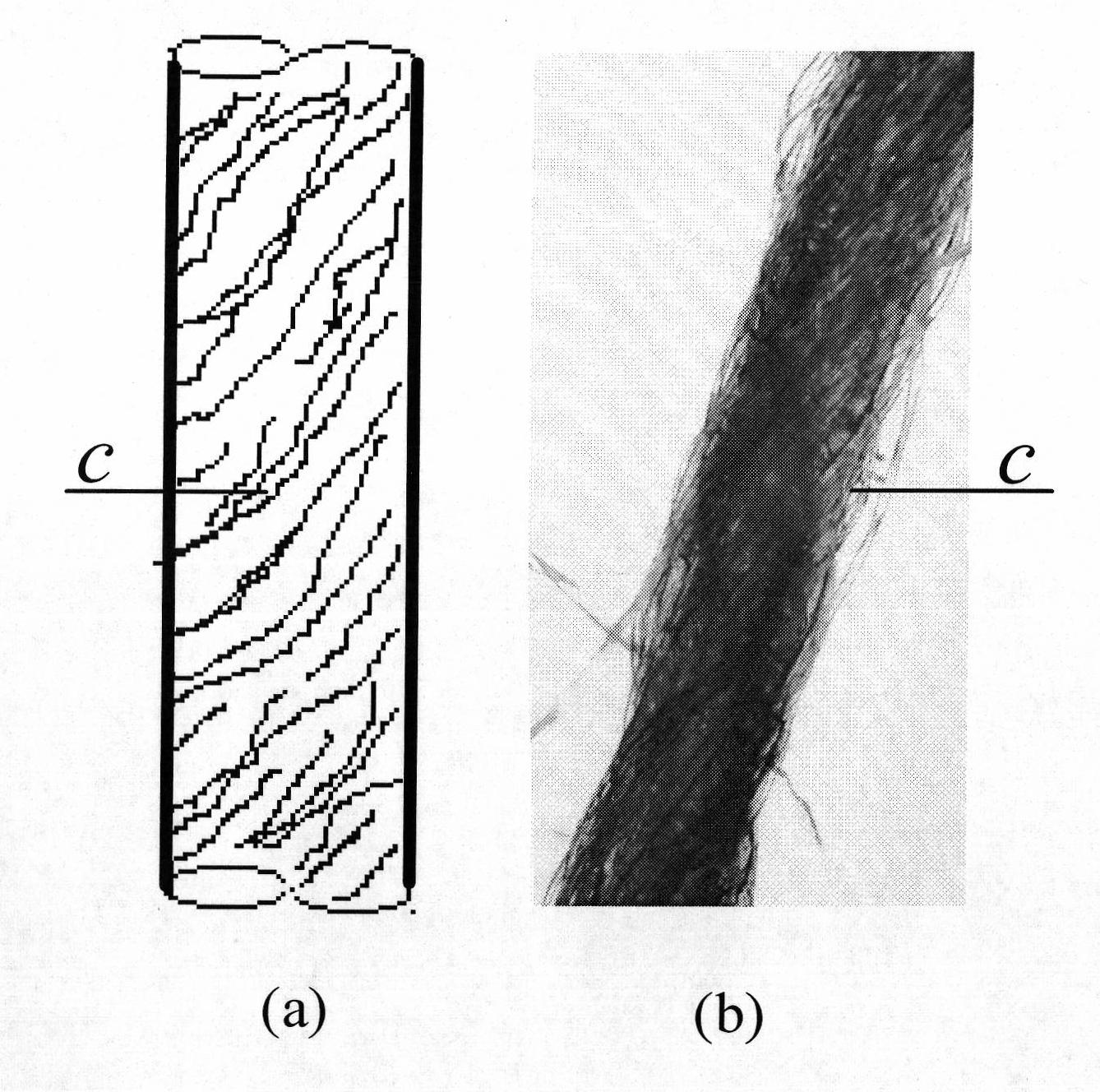

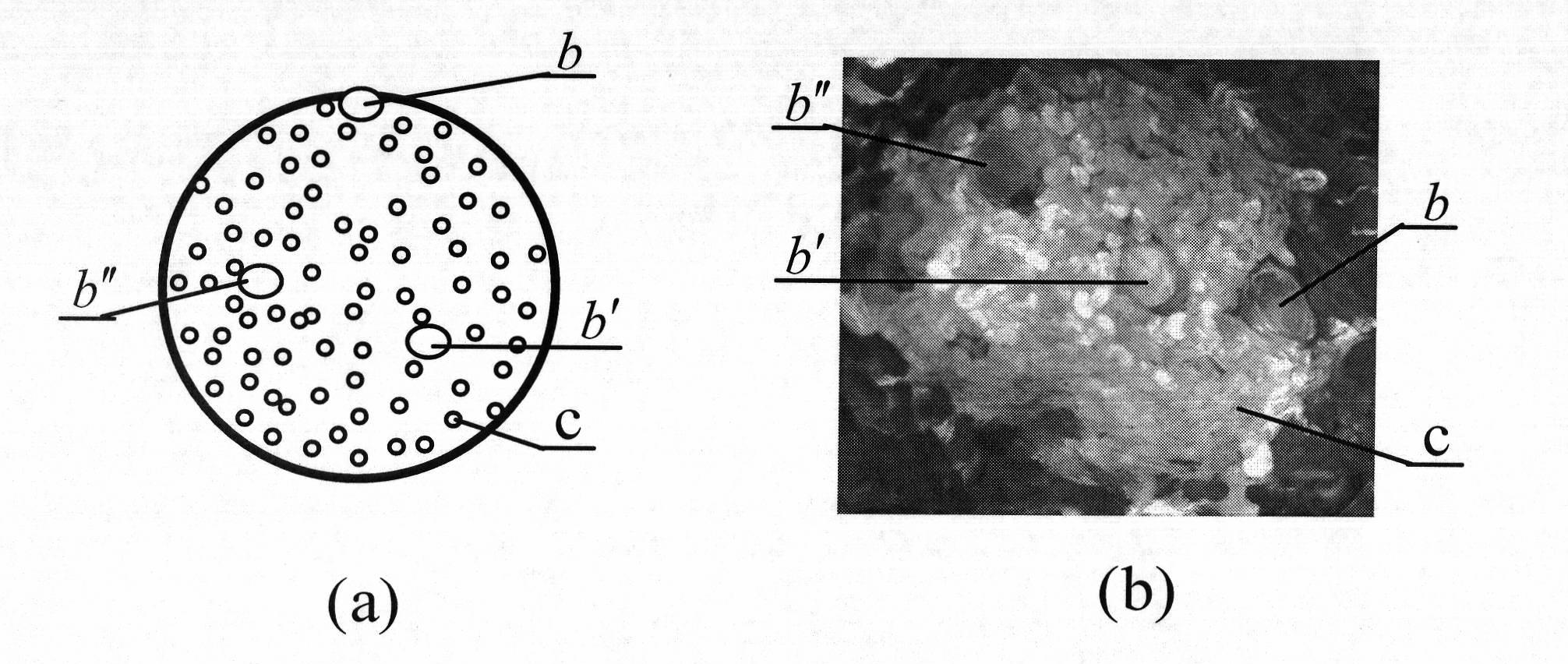

Filament short-fiber composite yarn

The invention relates to filament short-fiber composite yarn with a novel structure, which is formed by compositely twisting filament and short fiber. The yarn is characterized in that the filament in the yarn is generally three or more than three monofilaments or multifilaments which are respectively and dispersedly distributed and form organic combination with short fiber. According to the distribution position of the filament and short fiber in the cross section of the yarn, the composite yarn can be of a structure that the filament is coated by the short fiber or of a structure that the filament is distributed both inside and outside and short fiber is coated by the filament and short fiber on external faces. The filament can be silk, chemical fiber filament or metal wire, and the short fiber can be natural fiber or chemical short fiber. The invention has the advantage of increasing the strength, wear resistance, flexural rigidity and the like of the yarn. The composite structure yarn can be used for dress and clothes and special type yarns, and has the advantages of convenient and fast processing and both the properties of the filament and the short fiber.

Owner:重庆三峡技术纺织有限公司 +1

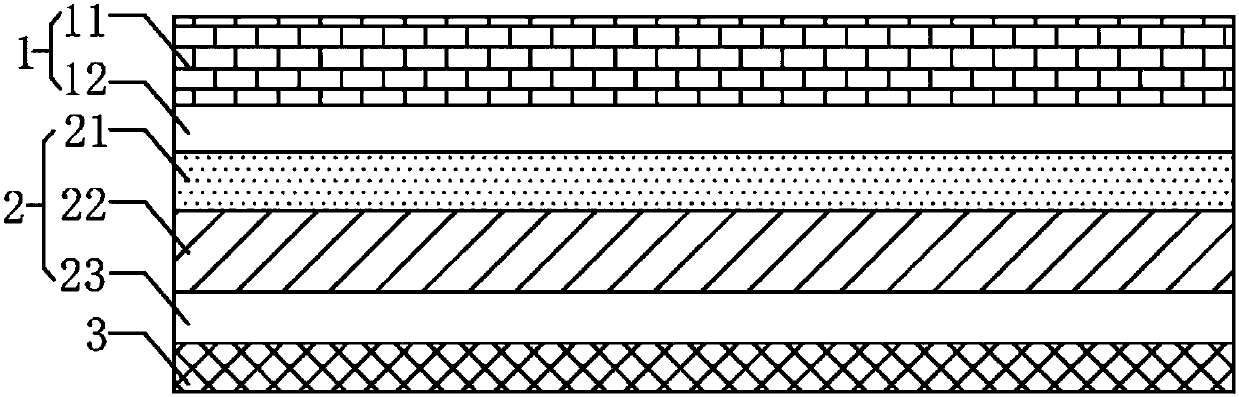

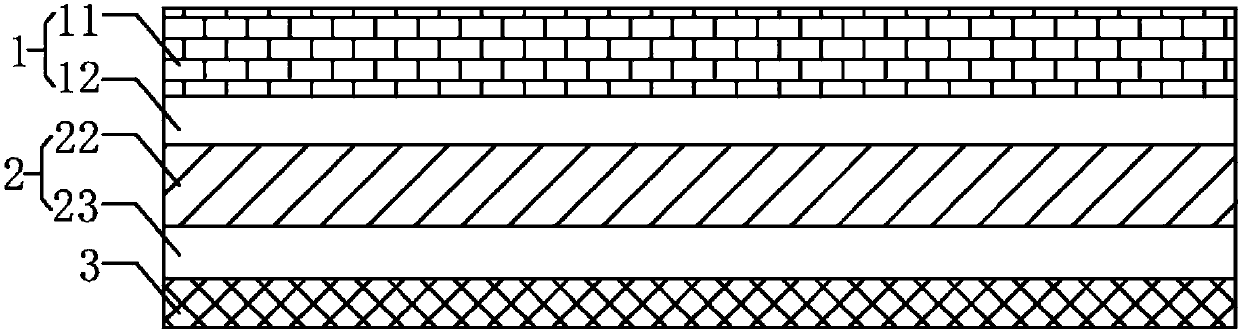

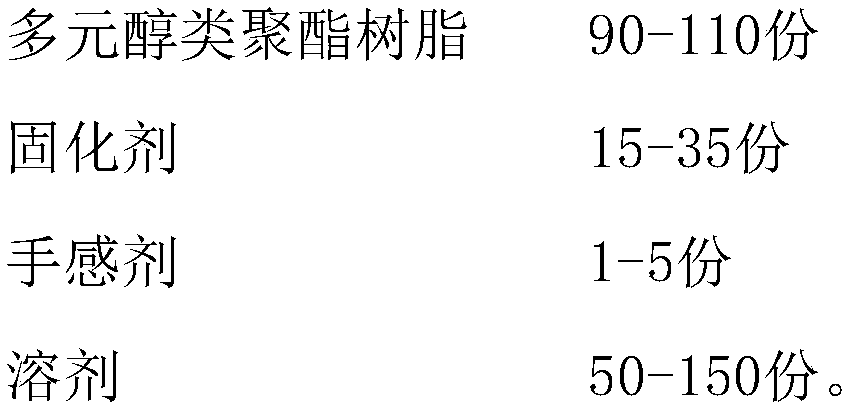

Flexible all-coating soft film and preparation method thereof

ActiveCN107936860AEvenlyGood flexibilityPolyureas/polyurethane adhesivesPressure sensitive film/foil adhesivesTectorial membraneEngineering

The invention relates to the technical field of protective films, and particularly relates to a flexible all-coating soft film and a preparation method thereof. The flexible all-coating soft film comprises a film protecting layer, a using layer and a stripping layer which are sequentially adhered from top to bottom; the protecting film layer comprises a base material layer and a film protecting glue layer which are sequentially adhered from top to bottom; the using layer comprises a self-repairing layer, a flexible soft film layer and a using glue layer which are sequentially adhered from topto bottom; the lower surface of the film protecting glue layer is adhered to the upper surface of the self-repairing layer; and the lower surface of the using layer is adhered to the upper surface ofthe stripping layer. The flexible all-coating soft film provided by the invention has smooth hand feeling and large stripping force, a curved screen can be all coated, relatively good resilience and self-repairing effect can be achieved, scratch marks can be repaired automatically, and the service life of the flexible all-coating soft film is prolonged. The preparation method provided by the invention is simple, the operation control is convenient, conventional production processes are simplified, the production efficiency is high, the production cost is low, the prepared product is high in yield and stable in quality, and the preparation method is suitable for large-scale industrial production.

Owner:NALI OPTICAL MATERIAL DONGGUAN

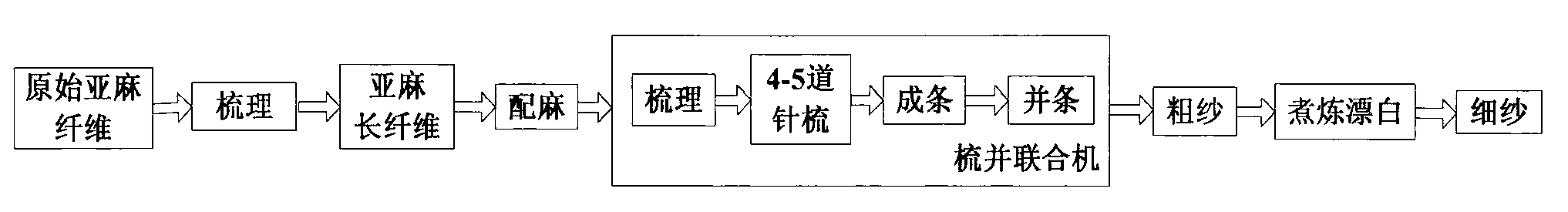

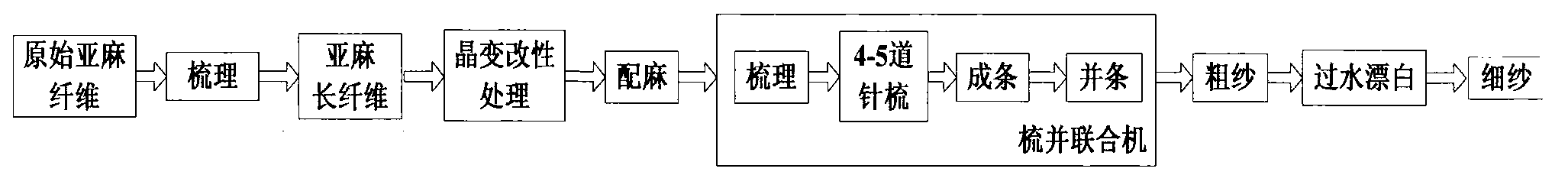

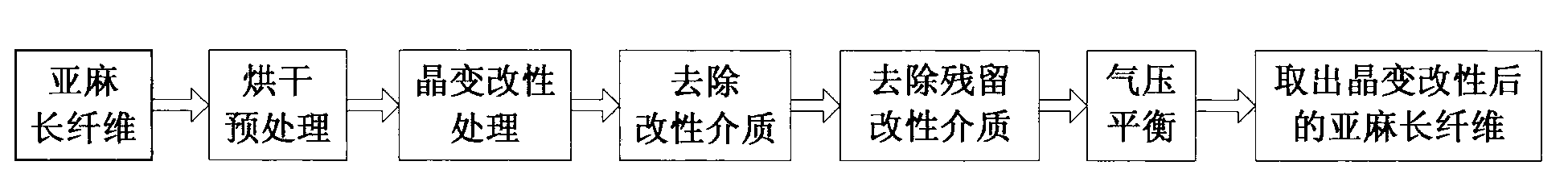

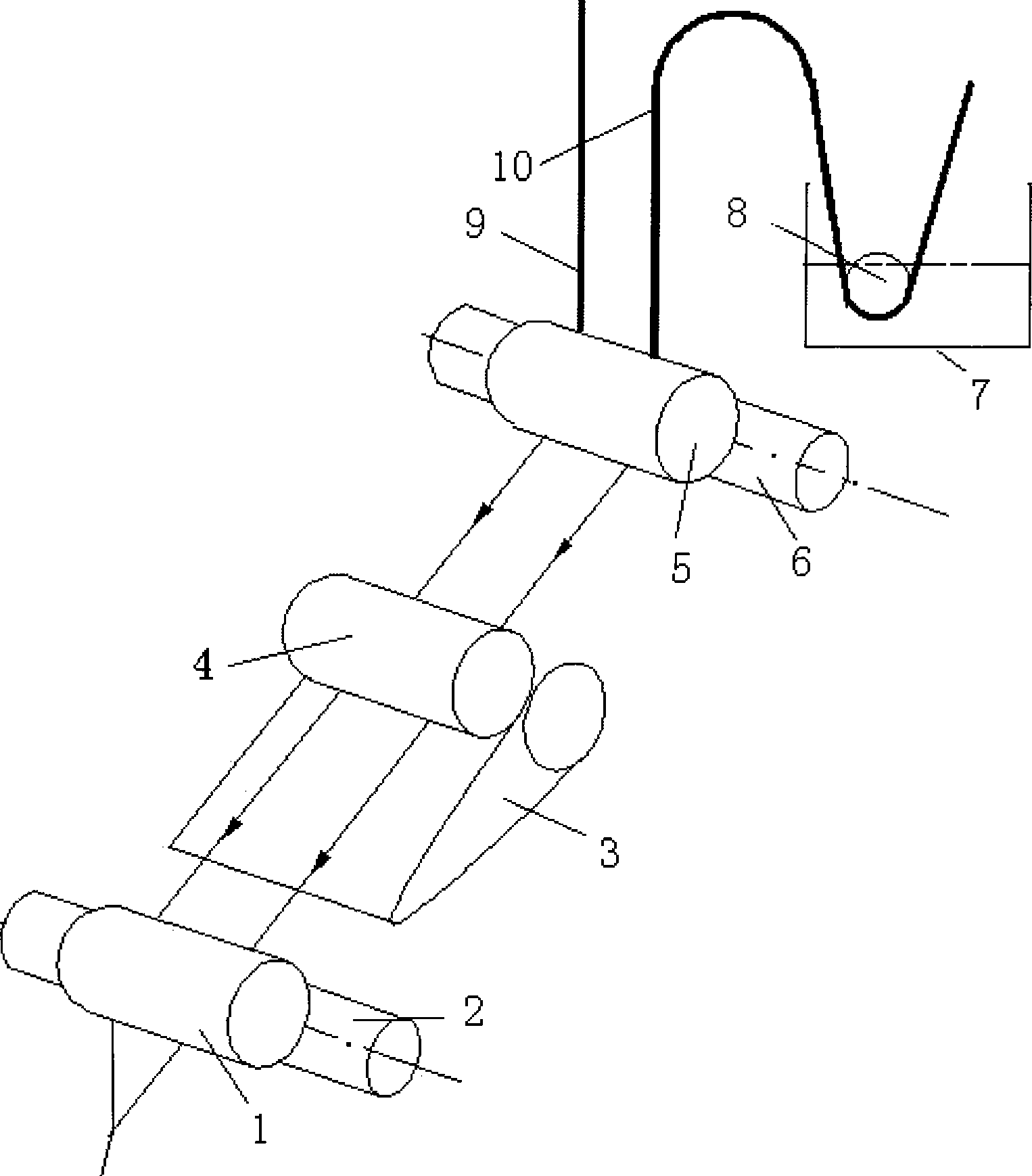

Wet spinning method of low-proportion high-spun flax macrofiber

The invention provides a wet spinning method of low-proportion high-spun flax macrofiber, which comprises the steps of: a first step, combing original flax fiber to obtain flax macrofiber; a third step, carrying out hemp proportioning on the flax macrofiber obtained after crystal transition modification in a former step, gilling, paralleling and spinning by a roving process to obtain flax roving; and a fifth step, carrying out wet spinning on the flax roving obtained after water blanching in a former step by a wet spinning frame to obtain the flax yarn. The wet spinning method is characterized in that a second step of carrying out crystal transition modification treatment on the flax macrofiber is performed between the first step and the third step, and a fourth step of carrying out water blanching on the flax roving is performed between the third step and the fifth step. The method has the advantages that the utilization ratio of the flax macrofiber is greatly improved and reaches more than 70%, and the material resources are saved; high-count linen yarn can be spun according to the fiber proportion of the traditional wet spinning method; and the water blanching replaces the scouring blanching in the traditional wet spinning method, so that the process is simplified, the energy sources are saved and the cost is lowered.

Owner:DONGHUA UNIV +1

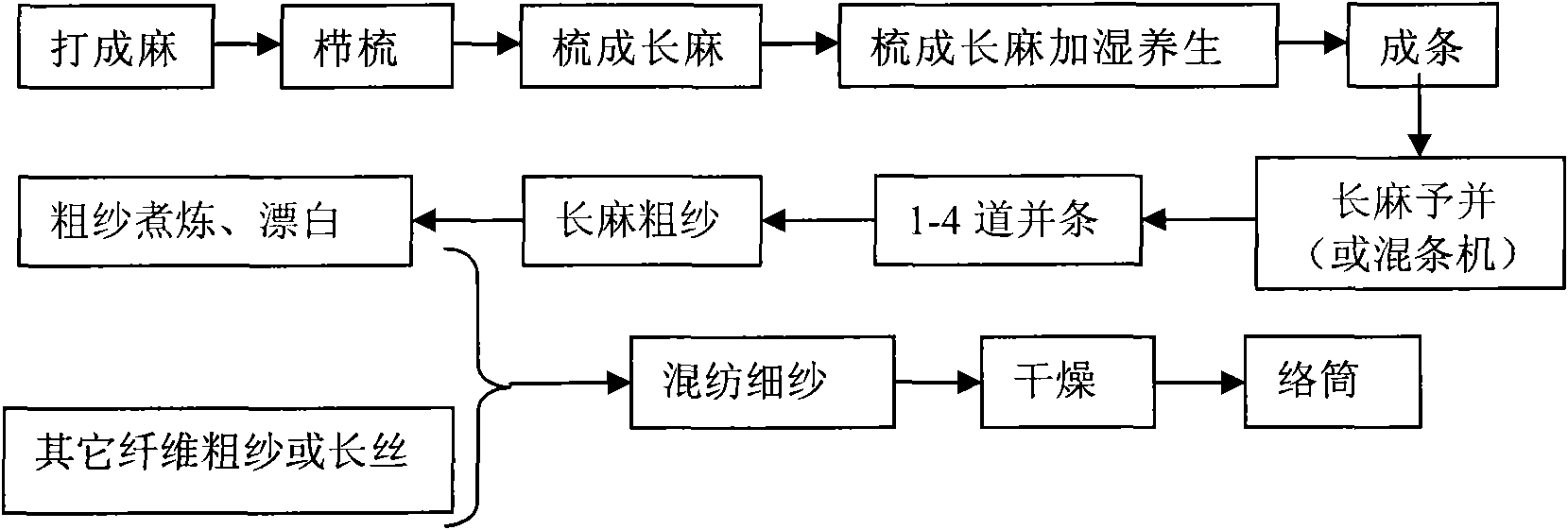

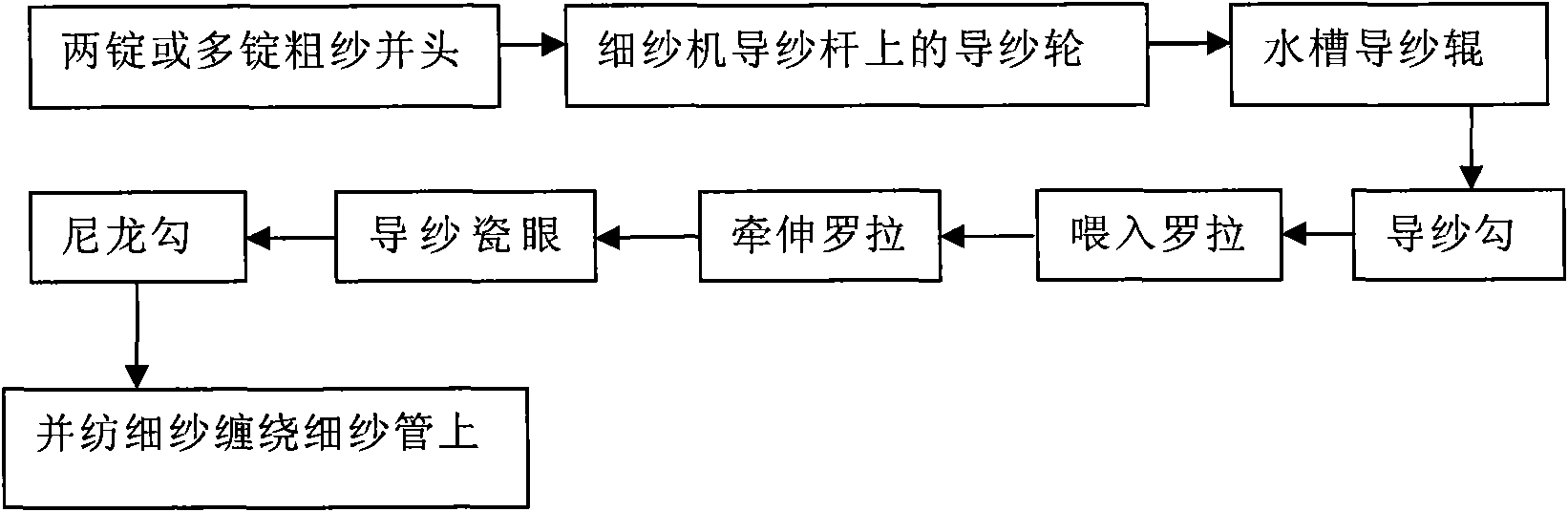

Blended spinning method of long spinning and damp spinning for bast fibers

The invention provides a method integrated with long spinning, wet spinning and blended spinning for bast fibers. The method comprises the following steps: the bast fibers are scotched into flax; the flax is humidified and soaked for a period of time; the flax is carded into long flax; and the long flax is subjected to matching, silvering, drawing, roving, scouring, bleaching, spinning, drying and winding. The method is characterized in that after the bast fibers are bleached, the obtained rove of the bast fibers and rove or filaments of other fibers are blended on a spinning machine. With the method, blended fibers are not bleached and scoured together with the bast fibers, so the defect that the performance of blended yarn is affected due to the damage of bleaching and scouring agents to the blended fibers in the prior wet spinning and blended spinning is overcome, and the obtained blended yarn has the characteristics of bright and clean yarn body, less hairness, evenness and good wear resistance. In addition, the method can fully play a role in respective advantages of the bast fibers and the blended fibers, complement respective disadvantages of the bast fibers and the blended fibers, has simple process, is favorable for improving the quality of blended yarn of the bast fibers, and realizes the high count, high grade and diversification of varieties of the bast fibers.

Owner:DONGHUA UNIV

Cotton fiber and jutecell fiber blended yarn and spinning process thereof

The invention discloses a cotton fiber and jutecell fiber blended yarn and a spinning process thereof. The blended yarn comprises jutecell fiber with fiber content blending ratio as 70% and 30% fine staple cotton. The fibers are spun into yarns through the blended spinning process. Raw materials of the yarns are composed of the jutecell fiber and the fine staple cotton. Compared with the prior art where long staple cotton and jutecell fiber are used for blended spinning, the process is low in cost and high in cost performance. The blending mode of one pre-blending and three mixed-blending is adopted, so that the blending spinning ratio is accurate, and components are even. The blended yarns produced in the production process are high in single yarn strength, even in yarn levelness and few in nep and yarn fault. The yarn structure can further improve textile comfortableness, improve textile hand feel and improve lining grade.

Owner:山东超越纺织有限公司

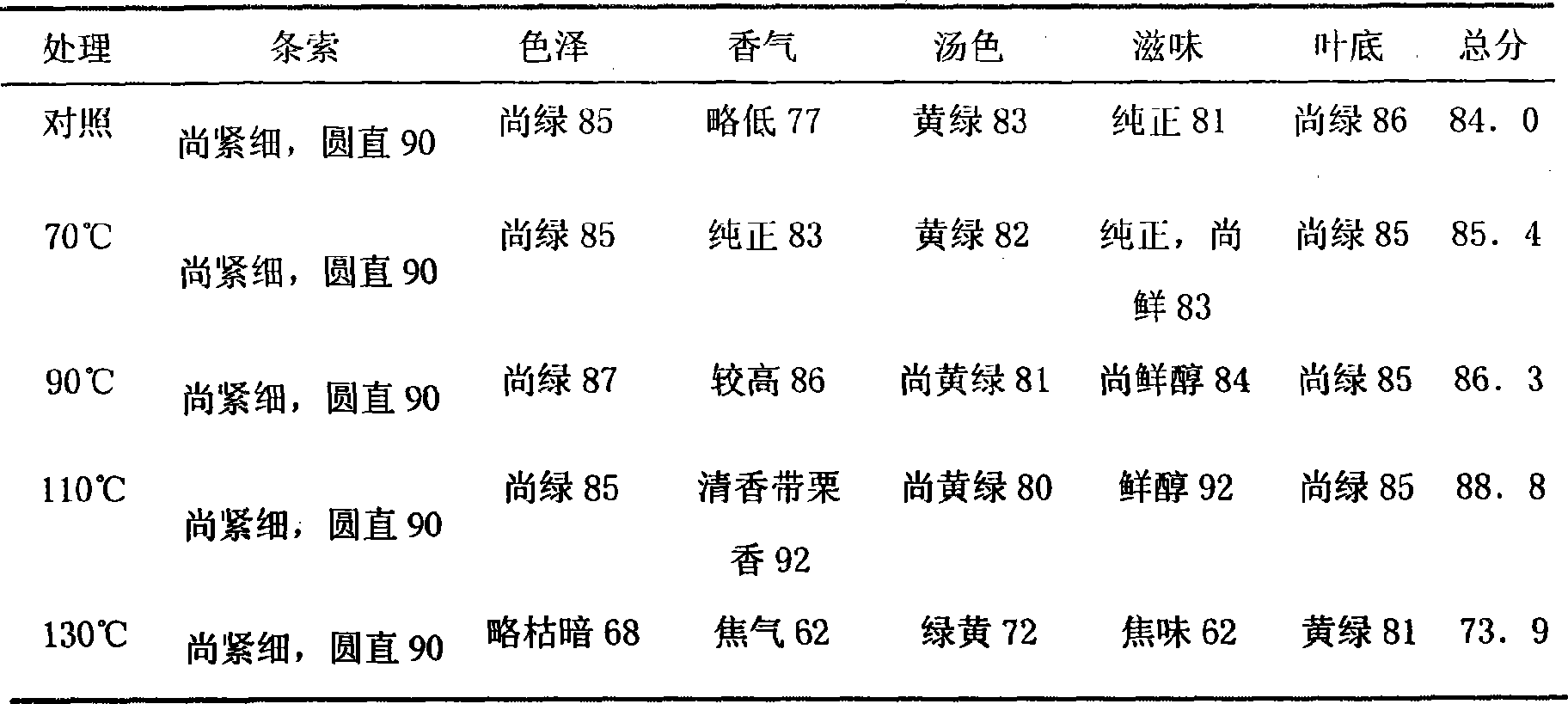

Mechanized method for processing styliform green tea

InactiveCN101366419AThe shape is tight, thin, round and straightBright green colorPre-extraction tea treatmentGreen teaEnzyme

The invention belongs to the technical field of tea manufacture, in particular to a method for mechanically processing acicular green tea. The method is characterized in that fresh green tea leaves are prepared into tea with acicular shape through spreading, enzyme deactivating, tightening, sorting, solidifying, drying, flavoring and other steps. The acicular well-known tea has the characteristics of tight, thin, round and straight strips, shape similar to pine straw, bright and green color and luster, silver tip exposedness, pure fragrance, fresh and rich taste, tender green and bright liquor color, tender and uniform leaves and the like. The tea quality can completely reach the level of manually processing, and the method is applicable to mechanical processing production.

Owner:HUAZHONG AGRI UNIV

Preparation method of tin oxide fiber precursor and tin oxide crystal fibers

ActiveCN103556303AUniform diameterGood whitenessInorganic material artificial filamentsTin oxidesElectrospinningPhotocatalysis

The invention relates to a preparation method of a tin oxide fiber precursor and tin oxide crystal fibers. The preparation method comprises the following steps: carrying out a replacement reaction on halides of tin and potassium (sodium) acetate to synthesize the tin oxide fiber precursor which takes acetic acid as a ligand; concentrating a precursor solution to obtain a spinning solution and carrying out centrifugal silk spinning to obtain tin oxide precursor fibers; and carrying out procedures of special atmosphere pre-treatment, high-temperature heat treatment and the like on the precursor fibers to obtain the tin oxide crystal fibers. According to the preparation method, the long-diameter ratio of the tin oxide crystal fibers is greater than 1000, the tensile strength of the fibers is 0.8GPa-1.1GPa, the whiteness of the fibers is good and the color and luster of the fibers are soft. The preparation method is simple in preparation process, moderate in condition and stable in quality of fibers in batches; spinning sol does not go bad after being placed for a long time. The tin oxide crystal fibers can be applied to the fields of photocatalysis, air sensitivity, humidity sensitivity and the like. The tin oxide fiber precursor can also be used for preparing oxide thin films, nano powder and nano wires or preparing tin-containing functional materials including nano tin oxide fibers and the like by an electrostatic spinning method.

Owner:SHANDONG UNIV

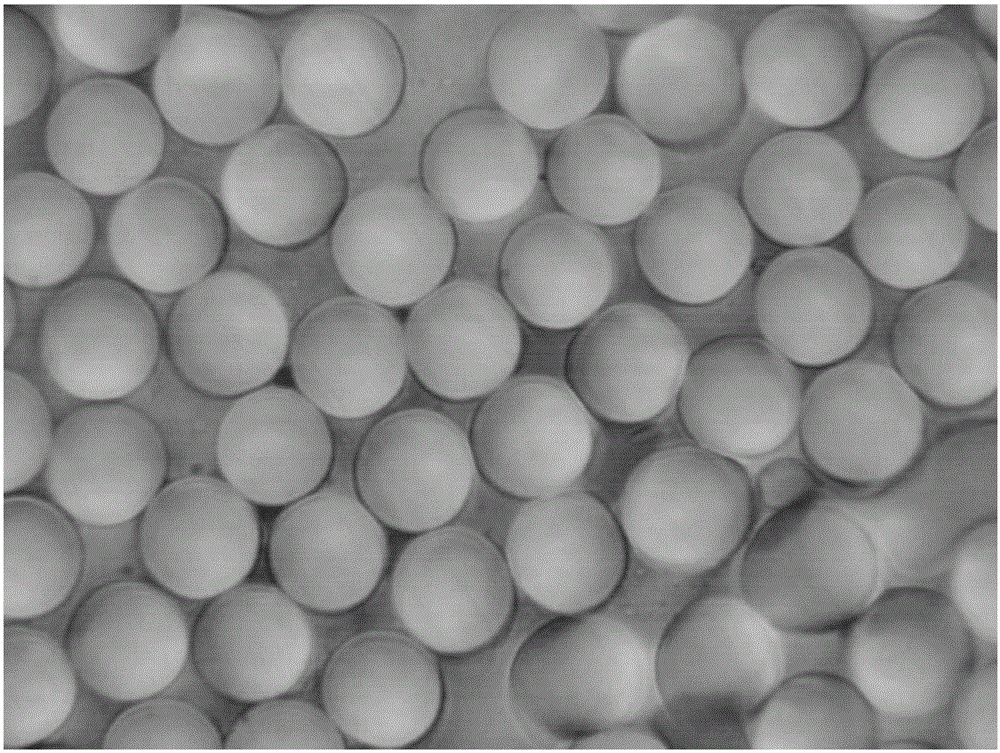

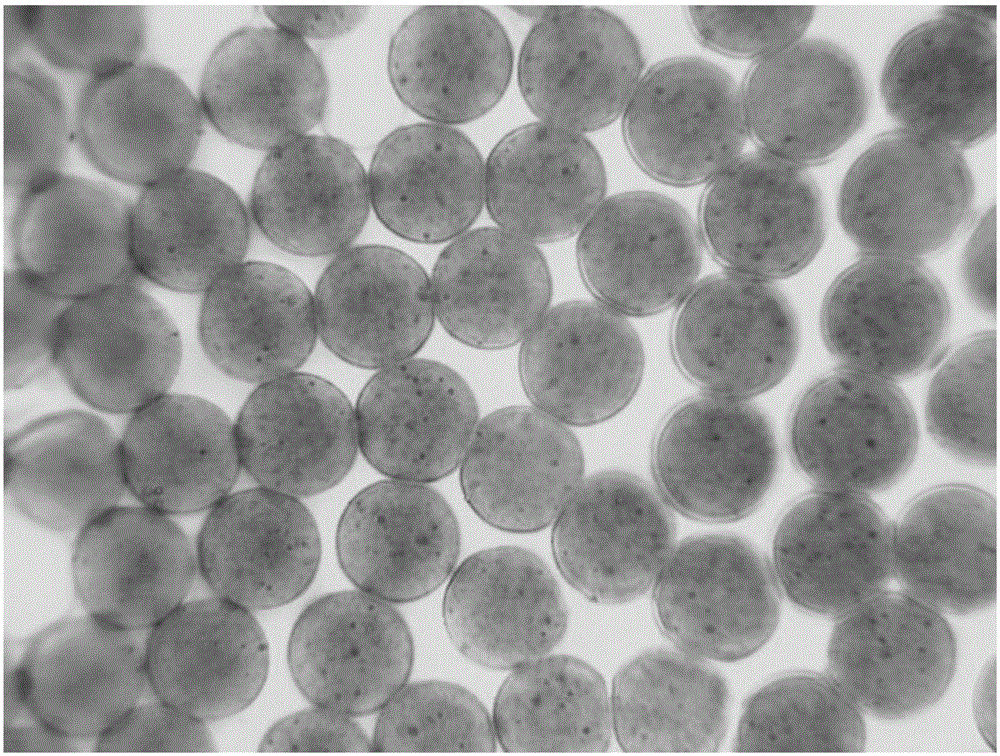

Method for preparing nano-pearl colored polyester fiber

InactiveCN101519808ASmall fluctuationInhibit unstable factorsHollow filament manufactureFilament/thread formingPolyesterFiber

The invention relates to a method for preparing nano-pearl colored polyester fiber, which comprises the following steps that: (1) pearls are sheared and ground to obtain crude pearl powder, then the crude pearl powder is mixed with water, a water dispersion of the pearl powder with a grain diameter of between 50 and 100 nm is obtained through high-pressure crushing, a thermal stabilizer, an antioxidant and an emulsifying agent are added into the water dispersion of the pearl powder, and the drying treatment is performed; (2) the obtained product is mixed evenly with a compatilizer at normal temperature, then the mixture is added into polyester chips, and granulation is performed on the mixture by a double screw extruder; and (3) nano-pearl polyester chips, the polyester chips and color master batch are blended for spinning. The method can be finished on the prior spinning equipment, tows are even and have evenly distributed color and luster; fabric is smooth, and has the characteristic of soft luster; the method is widely applied in the fields of apparel, decoration and industry; and at the same time, the blended color master batch can be used for preparing fibers with various lusters, and the prepared fibers have good nutrition and health care effects on human bodies.

Owner:ZHEJIANG JINXIA NEW MATERIAL TECH CO LTD

Novel polyester cotton blended yarn and production process thereof

The invention relates to novel polyester cotton blended yarn and a production process thereof. The novel polyester cotton blended yarn comprises positive ion upgraded modified polyester fibers and combed cotton, and the novel polyester cotton blended yarn is fixed by evenly mixing 65% of the polyester fibers and 35% of the combed cotton. The polyester cotton blended yarn adopts the positive ion upgraded modified polyester fibers and the combed cotton for blending. The production process comprises the steps of processing of the polyester fibers, processing of the combed cotton and blending of the polyester fibers and the combed cotton. The novel polyester cotton blended yarn has the advantages of being high in yarn levelness, little in yarn hairiness, soft in hand feeling and the like. Fabrics made of the novel polyester cotton blended yarn can be dyed through a normal pressure boiling dyeing process, production costs are greatly saved, the degree of dyeing is high and can reach 97%, and the novel polyester cotton blended yarn is bright in color, can be dyed in dark colors easily, is high in wash fastness and rubbing fastness and is much better than ordinary homogeneous yarn on the aspect of resistance to pilling.

Owner:NANTONG HUAQIANG CLOTH IND

Production method of plush compound woolen fabric

The invention discloses a production method of a plush compound woolen fabric, which comprises the following steps of (1) cashmere silvering; (2) broken filament semi-fine spinning; (3) fine spinning; and (4) special trimming to obtain a finished product of the plush compound woolen fabric. By using the production method, the mixing spinning of plush long staple fibers is realized, the process is reasonable and compact, the yarn evenness is good, less neps and plume are generated; the obtained matte product has good surface luster through the special trimming, the fabric texture is light and thin and has good warmth retention property, so that the fabric is not only suitable for a suit fabric, but also is suitable for top-quality down coat fabric and casual fabric.

Owner:JIANGSU REGAL LEYE TECHNOLOGY CO.,LTD.

Method for preparing nano silicon dioxide modified polyester fibers

InactiveCN102330188AInhibit unstable factorsEvenlyFilament/thread formingMonocomponent polyesters artificial filamentPolyesterFiber

The invention relates to a method for preparing nano silicon dioxide modified polyester fibers, which comprises the steps of preparing a nano silicon dioxide modified polyester slices and spinning by a blending FDY (Fully Drawn Yarn) technology. The method disclosed by the invention can be completed on conventional spinning equipment. Tows have good evenness. Glossy distribution is uniform. A textile fabric is smooth and flat. The nano silicon dioxide modified polyester fibers have the characteristic of soft gloss, can be widely applied to the clothing field, the decoration field and the industry field.

Owner:JIANGSU YINGXIANG FIBER

Preparation method of nano zinc oxide modified polyester fiber

InactiveCN102345179AInhibit unstable factorsEvenlyFilament/thread formingMonocomponent polyesters artificial filamentNano zinc oxidePolyester

The invention relates to a preparation method of a nano zinc oxide modified polyester fiber, and the method comprises the following steps: preparing the slices of the nano zinc oxide modified polyester fiber; and spinning by virtue of a blended FDY (Fully Drawn Yarn) technology. The preparation method disclosed by the invention can be finished on the common spinning equipment, silk flock strips are dry and even, colors are evenly distributed, the fabric is flat, and the polyester fiber has soft gloss. The preparation method can be widely applied to the fields of clothes, decoration and industry.

Owner:JIANGSU YINGXIANG FIBER

Spinning method of terylene-viscose blended yarn

The invention provides a spinning method of terylene-viscose blended yarn, which comprises the following steps: opening and cleaning cotton, combing the cotton, making ribbons, spinning coarse yarn and spinning fine yarn; while spinning the coarse yarn, feeding two pieces of coarse yarn in parallel into the same drawing mechanism of a spinning machine at 9-13 mm intervals so as to simultaneously draw the two pieces of coarse yarn in parallel. The method applies a Sirospun technology to the spinning of the terylene-viscose blended yarn. The two pieces of coarse yarn are simultaneously fed intothe spinning machine, the single yarn twist area is shorter, and the applied degree of twist is low, so that the included angle of the fiber spiral yarn and the yarn shaft in the single yarn is relatively small, and the single fiber in the single yarn can not transversely protrude out of the outer surface of the yarn due to the strong effect of the twisting force. Thus, the terylene-viscose blended yarn has the advantages of little filoplume, smooth surface, even yarn, high strength and few defects. The method enhances the quality grade of the terylene-viscose blended yarn.

Owner:JIANGYIN CITY HUAXIAO TEXTILE

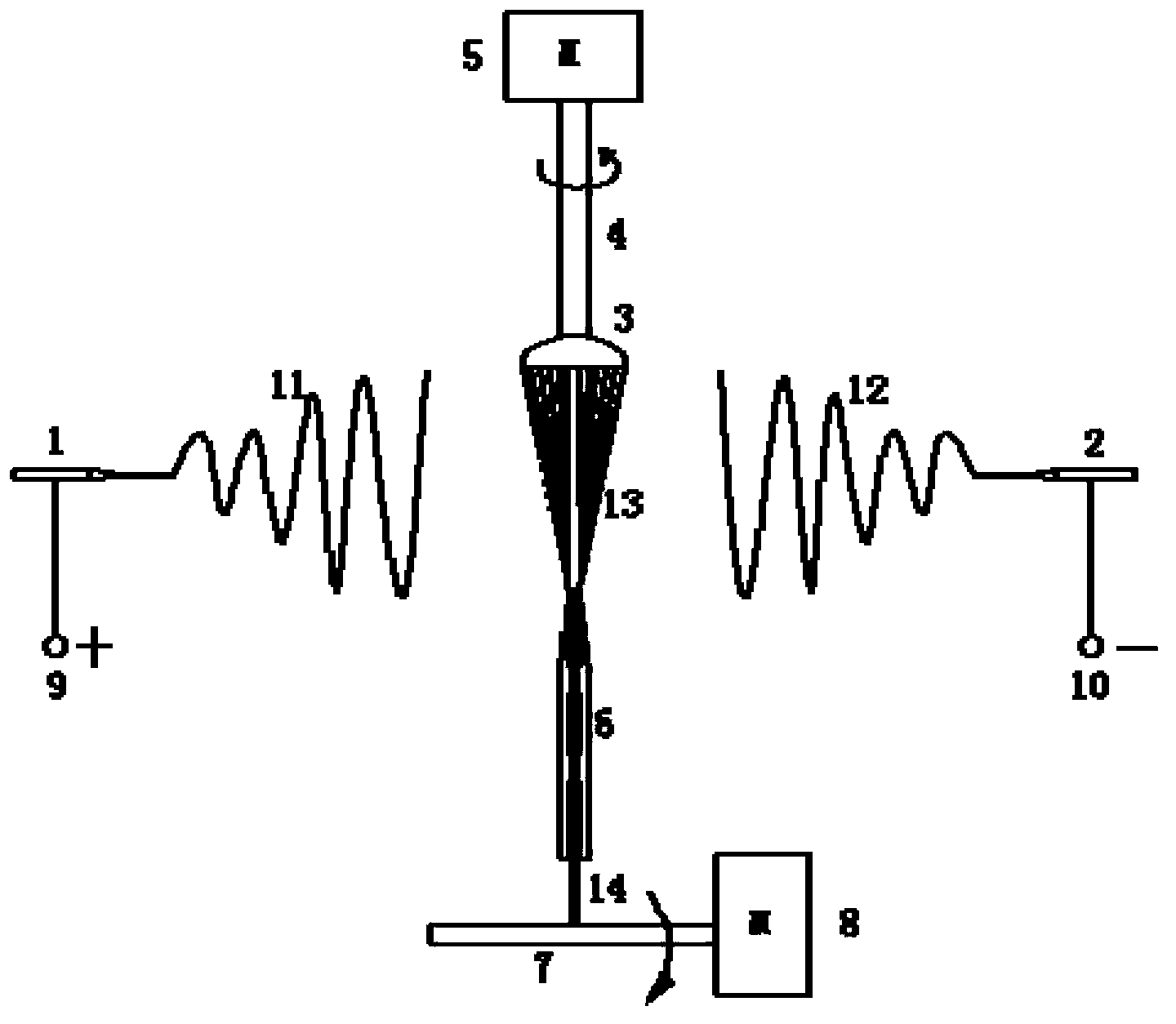

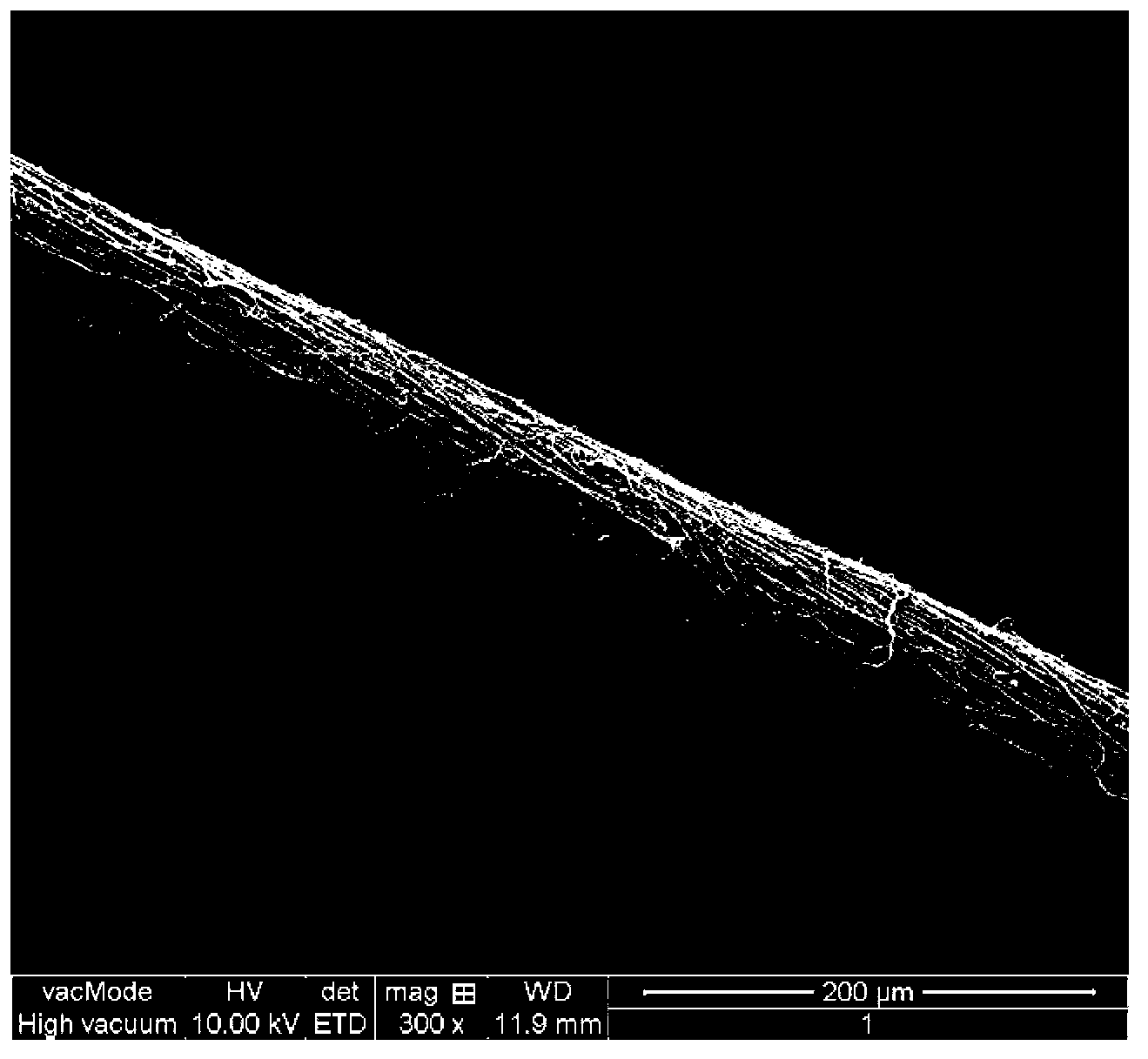

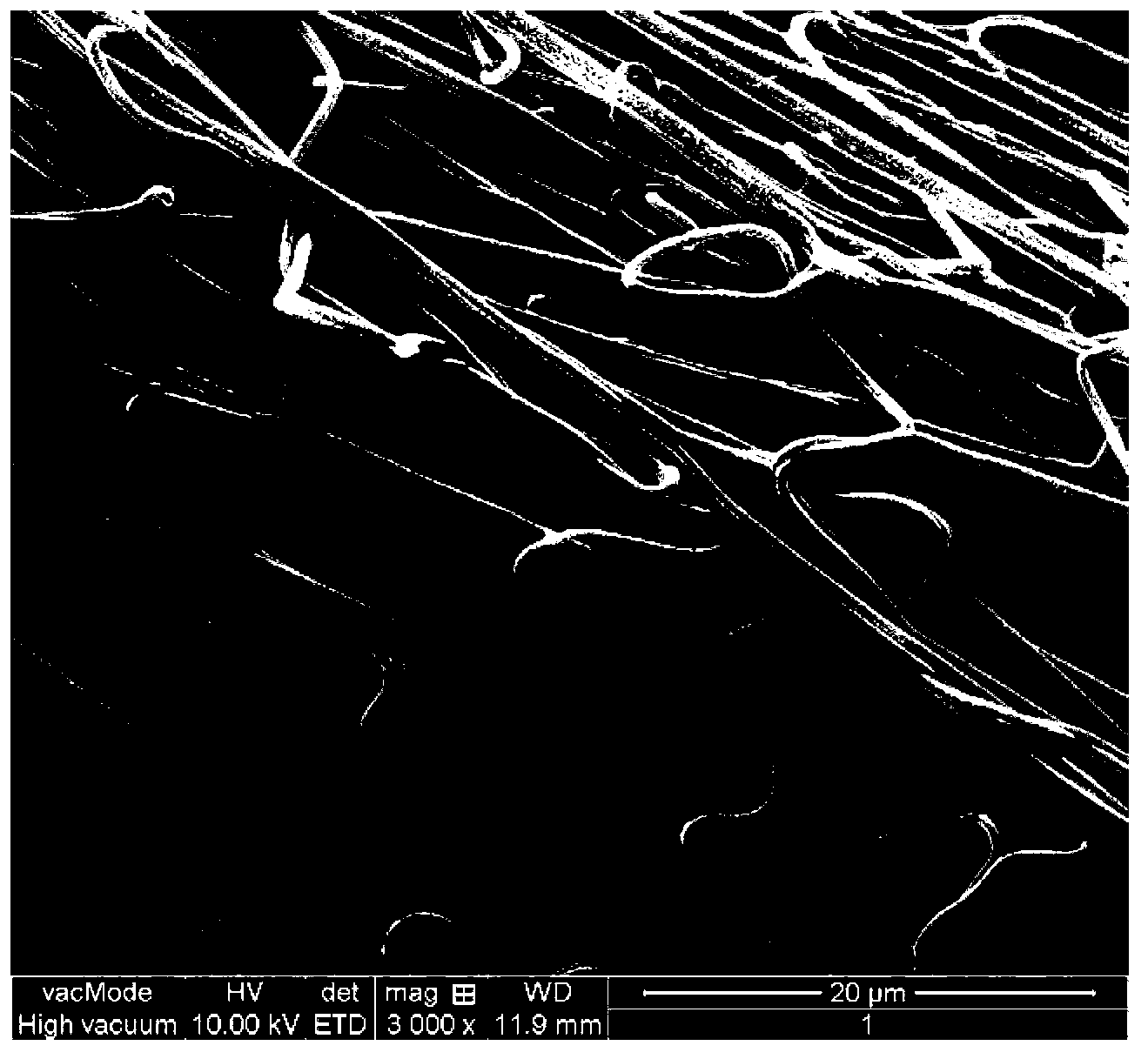

Method and device for preparing polyacrylonitrile pre-oxidation nanofiber yarns through electrostatic spinning

InactiveCN103305931AEasy to prepareEasy to operateFilament manufactureFilament/thread formingYarnCarbon fibers

The invention relates to a method and a device for preparing polyacrylonitrile pre-oxidation nanofiber yarns through electrostatic spinning. Two spinning jets of the device are respectively connected with a positive electrode and a negative electrode of a high-voltage electrostatic generator; a metal round target is connected with an insulation rod of which one end is connected with a motor; a hollow metal rod is fixed and is provided with a tip; and except for the tip, the rest part of the hollow metal rod is sprayed with insulation paint. The method comprises the following steps: (1) preparing polyacrylonitrile spinning solution; (2) performing electrostatic spinning by adopting an electrostatic spinning device, forming oriented nanofiber bundles by jet flow sprayed from the two spinning jets, and molding through twisting and winding to obtain polyacrylonitrile nanofiber yarns; and (3) carrying out pre-oxidation heat setting on the polyacrylonitrile nanofiber yarns to obtain the polyacrylonitrile pre-oxidation nanofiber yarns. The method is simple to operate. The polyacrylonitrile nanofiber yarns obtained by adopting the device to carry out eletrostatic spinning have the advantage of evenness, and the device is expected to be widely applied in the carbon fiber manufacturing field.

Owner:DONGHUA UNIV

Standardized planting technology for liquorice

The invention discloses a standardized planting technology for liquorice. The technology comprises the following steps of: a, seed selection and treatment; b, soil treatment; c, soil sealed weeding; d, precise seeding and water-saving irrigation; e, water dripping seedling growth; f, seedling period irrigation; g, soil measuring fertilization; h, seedling period pest and disease prevention and treatment; and i, harvesting. The standardized planting technology for liquorice provided by the invention has the advantages that the liquorice yield and the glycyrrhizic acid and liquiritin content can be improved, and in addition, the cost can be saved.

Owner:XINJIANG KANGLONG TECH CO LTD

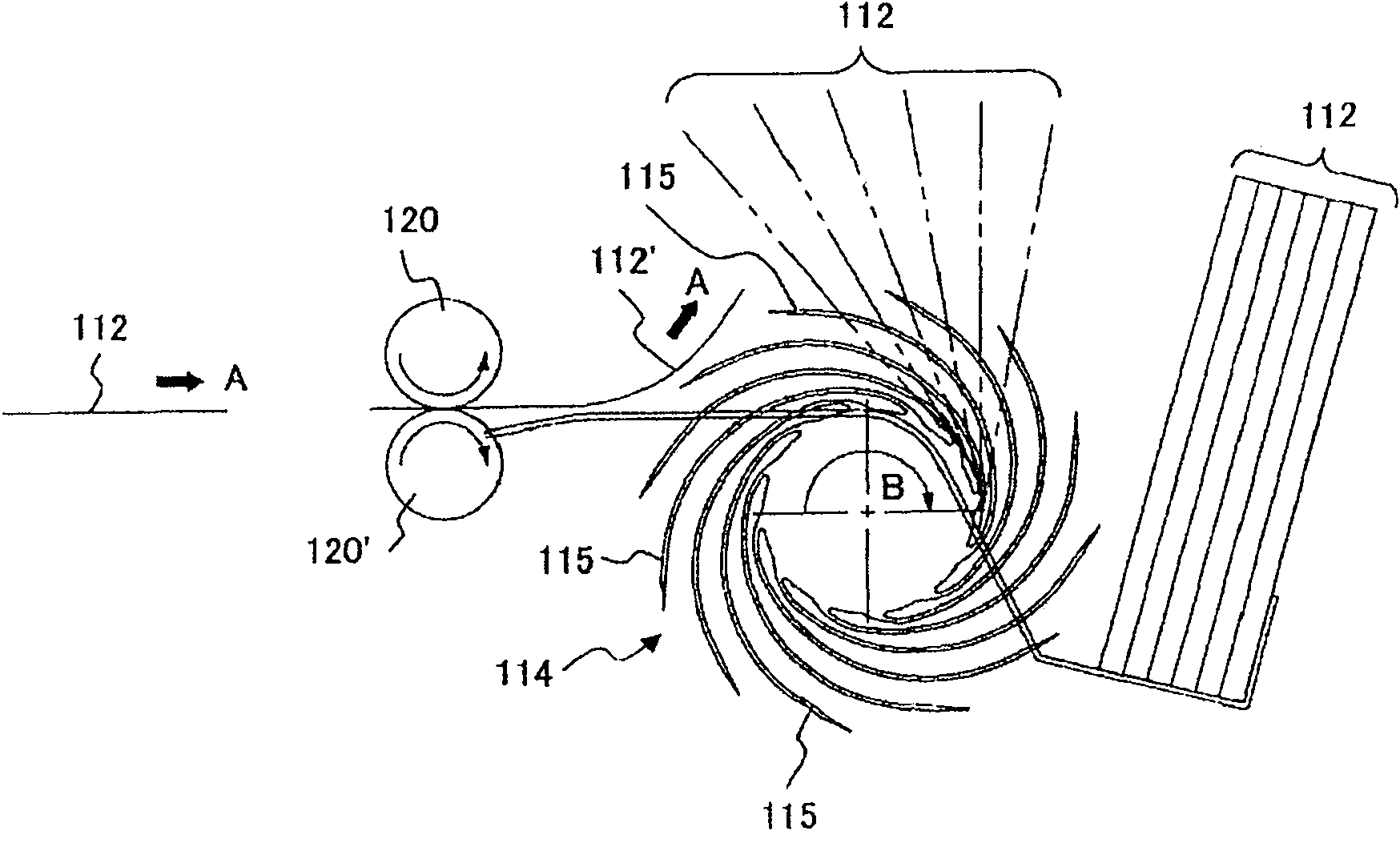

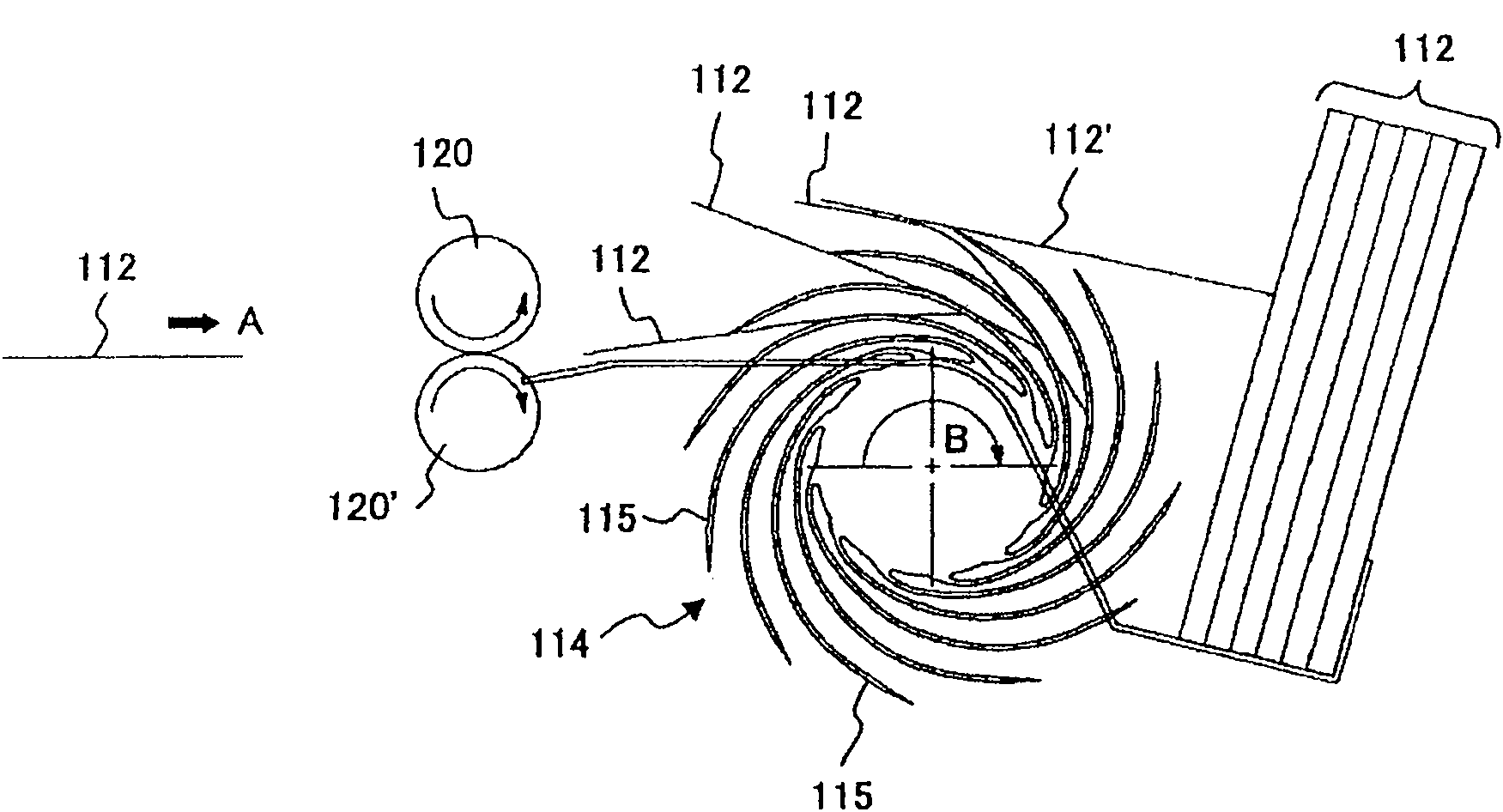

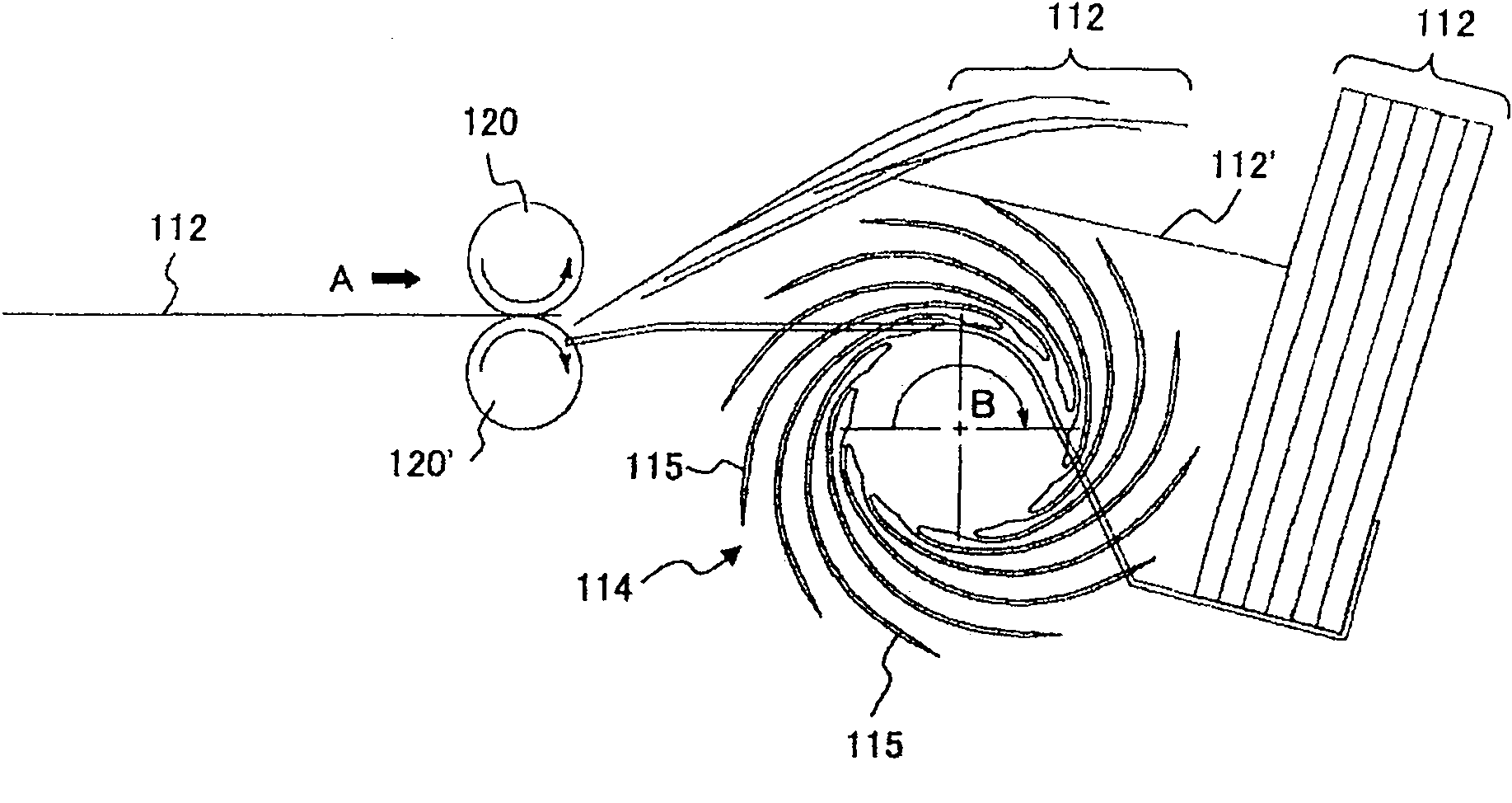

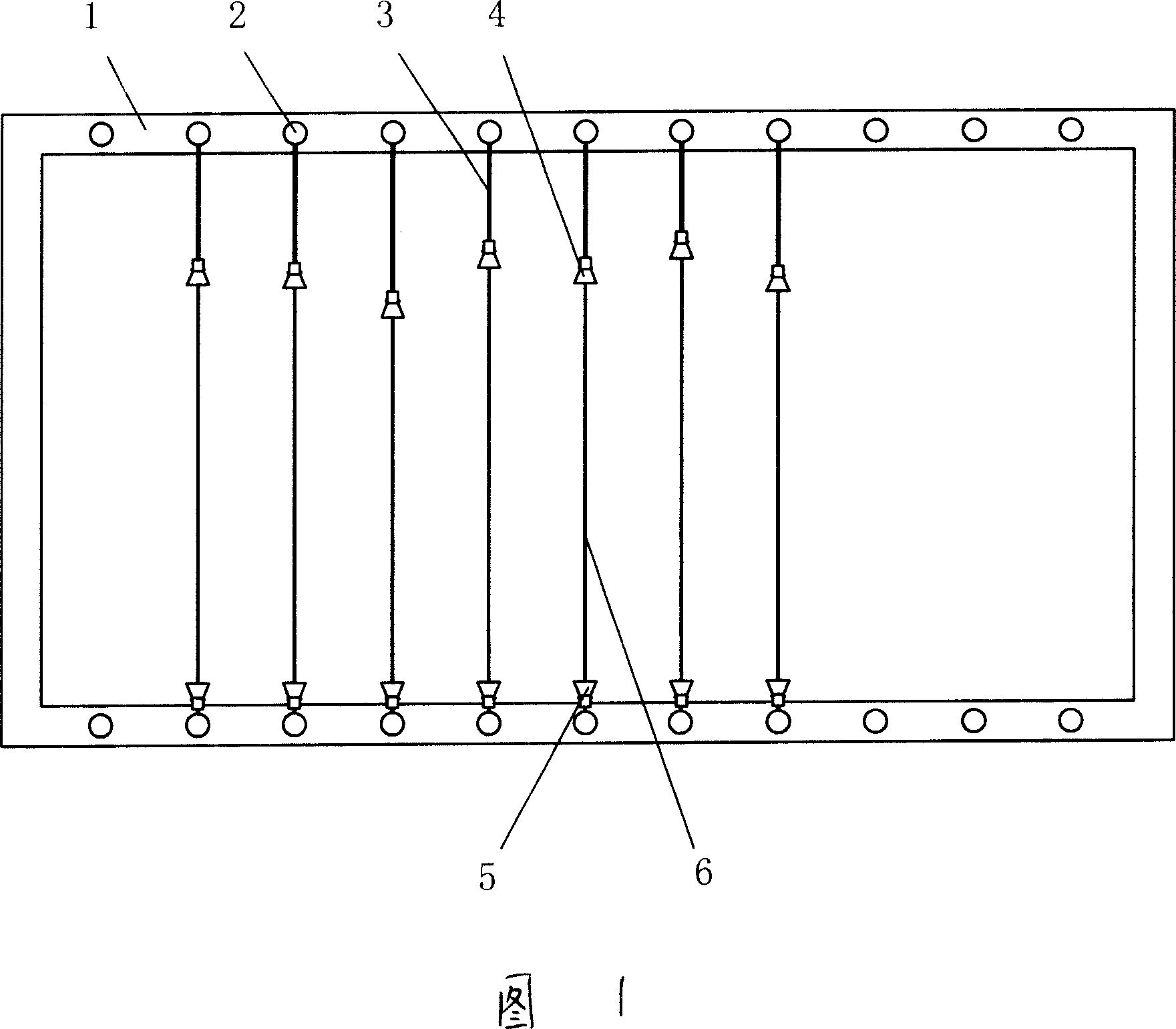

Paper type collecting device

The invention provides a paper type collecting device, which can reliably receive bank notes between adjacent blades, prevent bank notes collected between adjacent blades from scattering and can evenly laminate bank notes in order in a collecting part. A paper type collecting device (10) comprises an impeller (14) which is provided with a plurality of blades (15) at peripheral surfaces and receive bank notes (12) between adjacent blades and conveys bank notes by rotation, a collecting part (16) which collects bank notes conveyed by the impeller, and a guiding component (18) which abuts against the conveying top end of the bank notes to guide the bank notes to the collecting part. The impeller comprises a first impeller (14A) and a second impeller (14A') in symmetry which are fixed to a driving shaft (22) with a interval narrower than the width of the bank note, and a third impeller (14B). The third impeller is in the shape as the first and the second impeller, and is fixed to the driving shaft between the first and the second impellers. The third impeller is disposed in a manner that the rotation phase of the third impeller staggers with that of the first and the second impellers.

Owner:FUJITSU FRONTECH LTD

Production method of flax blended knitting yarns

The invention discloses a production method of flax blended knitting yarns. In the method, flax and modal fibers are blended according to a ratio of 15:85 to 85:15. The method comprises a spinning process and a rotor spinning process. The modal fibers selected in the invention are the most ideal material for light and thin knitted fabrics for their sweat-absorbing, thermal-insulation and cooling properties and integration of the comfortableness of cotton, the drapability of adhesive, the strength of terylene and the handfeel of real silk. The flax-modal blended knitting yarns exploit development space for high-quality flax light and thin knitted fabrics. Although the flax and modal fibers are susceptible to generating hairiness, the rotor spinning used in the invention is one-step bobbin forming and therefore reduces the hairiness of finished fibers and ensures the knitted fabrics are clear and full in appearance. The rotor spun yarns also have the advantages of few yarn faults, high elasticity, pilling resistance, wear resistance and the like. The method has the advantages that: the process flow is short; the cost is low; high grade flax knitting yarns with high balance of various performance indexes such as high fineness, little hairiness, yarn levelness and soft handfeel; and the application value in textile processing field is high.

Owner:QIQIHAR UNIVERSITY

Black masterbatch, nylon 6 fiber and preparation method of black masterbatch and nylon 6 fiber

InactiveCN106633834AEvenly dispersedStable color intensityPigment addition to spinning solutionMonocomponent polyamides artificial filamentMasterbatchBreaking strength

The invention relates to a porous fine-denier dope dyeing nylon 6 fiber. The nylon 6 fiber is prepared from the following raw materials in parts by weight: 7-10 parts of black masterbatch and 90-93 parts of polyamide 6 slices, wherein the black masterbatch is prepared from the following raw materials in parts by weight: 20-30 parts of carbon black, 5-15 parts of a dispersant, 0.05-0.15 parts of an antioxidant and 54-75 parts of polyamide 6 slices. The invention further provides a preparation method of the black masterbatch and the porous fine-denier dope dyeing nylon 6 fiber. The porous fine-denier dope dyeing nylon 6 fiber has the characteristics of fewer broken filaments, good evenness, higher breaking strength, uniform color, high color fastness and the like and meets the post-processing use requirement, and the prepared porous fine-denier dope dyeing nylon 6 fiber has fewer ossified and broken filaments, higher breaking strength, uniform color and high color fastness and meets requirements of customers.

Owner:FUJIAN JINJIANG TECH

Method for producing nutria tendon tissue medical suture and straining device for the same

InactiveCN101085373AEasy to useSmooth suture surfaceSuture equipmentsSuturing needleUltimate tensile strength

The invention discloses a production method of suture prepared from nutria tendon tissue and its tensioner. The method comprises extracting tendon tissue from nutria, dewatering, degreasing, sterilizing, air-drying under tensile force, screening to obtain qualified tissue, separating out suture of different specification, and matching with non damage perforate pin or notch pin according to specification, and preparing into sutural line with pin. The inventive suture needle has smooth surface, uniform strip, accurate linear diameter, and good tensile force.

Owner:湖南然元医用高科技蛋白线有限公司

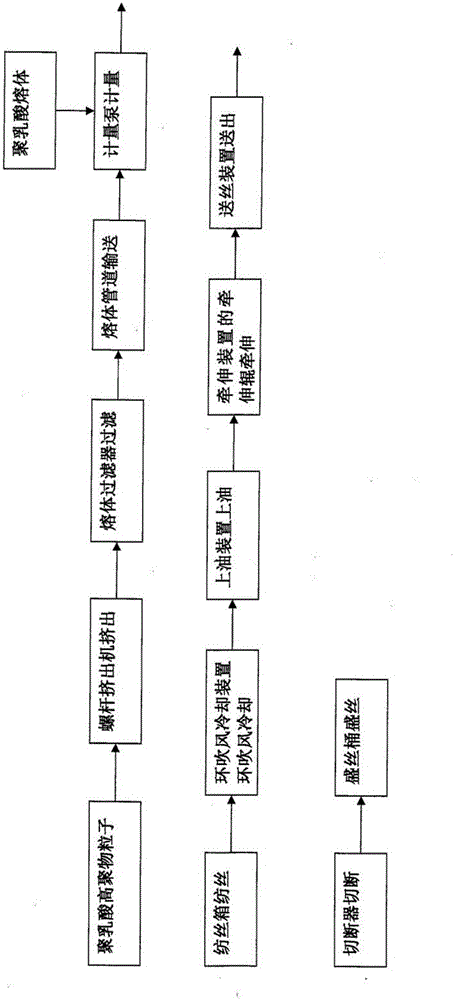

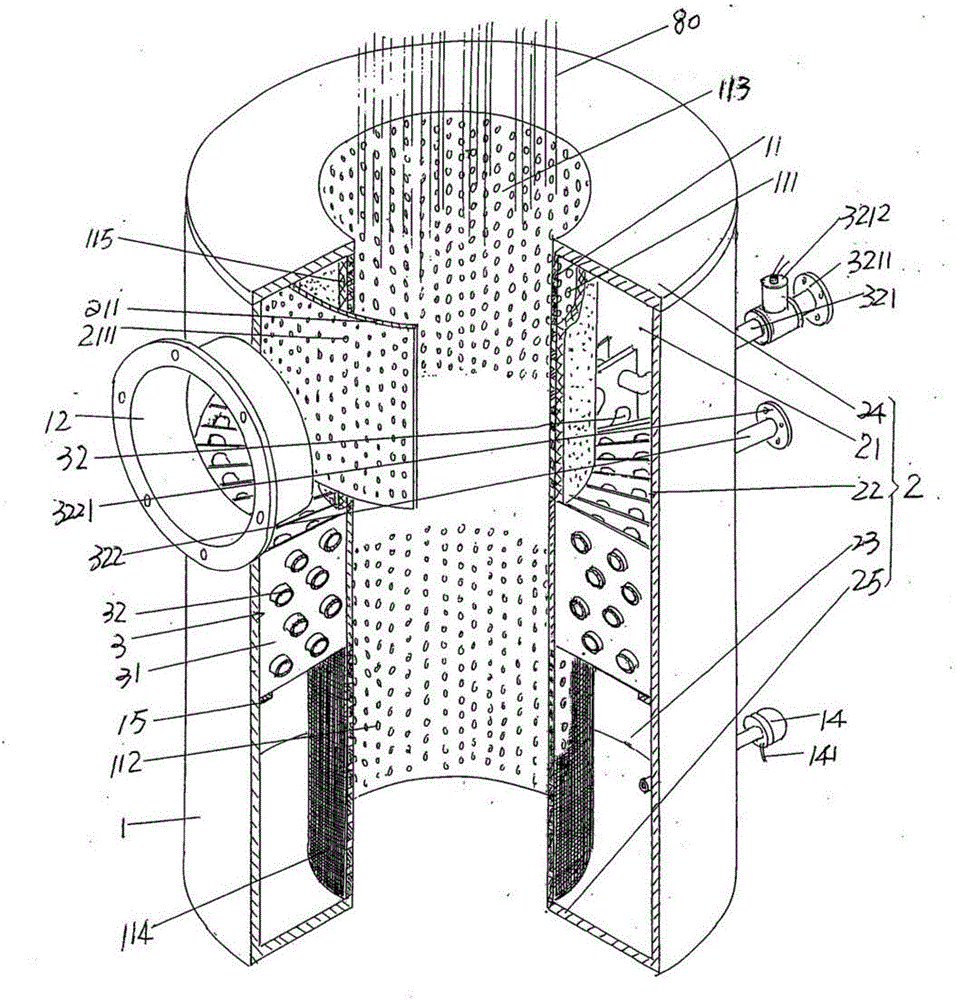

High-speed spinning method of polylactic acid fiber

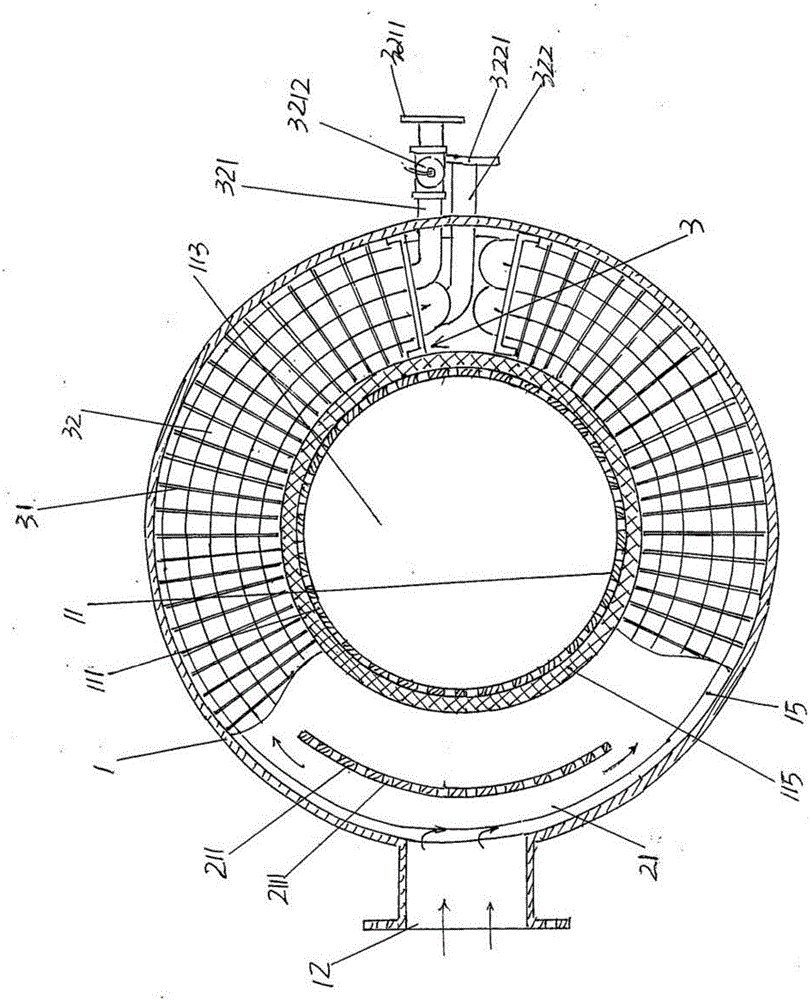

ActiveCN106480523AMeet rapid cooling requirementsAvoid influenceArtificial thread manufacturing machinesMelt spinning methodsFiberMetering pump

Disclosed is a high-speed spinning method of polylactic acid fiber. The method includes steps of introducing polylactic acid high polymer particle in a screw extruder to melt and extrude; after being filtered, introducing a metering pump; after metering, introducing to a spinning box to spin; stretching strands through an annular blowing air-cooling device and an oiling device orderly; introducing to a silk holding barrel after being delivered and cut off by a feeding device, and obtaining the polylactic acid fiber. The high-speed spinning method of the polylactic acid fiber is characterized in that the annular blowing air-cooling device includes a cooling cylinder in which an inner guide flow sleeve is provided; a surface cooler, which is arranged between the cooling cylinder and the inner guide flow sleeve; the oil feeding device includes an oil disk on which an upper oil wheel is provided; an oil disk supply pipe of which oil outlet is stretched to an oil disk cavity; a self-circulation adjusting mechanism of the oil disk agent is connected with the oil disk bottom plate; the feeding device comprises a column body, and the middle thereof is provided with a strand absorbing hole, a strand transition cavity and a strand center guide hole; one side of the column body is provided with a lifting groove; a gas cavity sealing ring, which is fixed with the column body; a lifting groove opening and closing cover, which is arranged on the column body. The high-speed spinning method can meet the rapid cooling of melt strands and oil application of high-speed spinning, and ensure the spinning quality.

Owner:CHANGSHU GOLD SPRING CHEM FIBERS & KNITTINGS

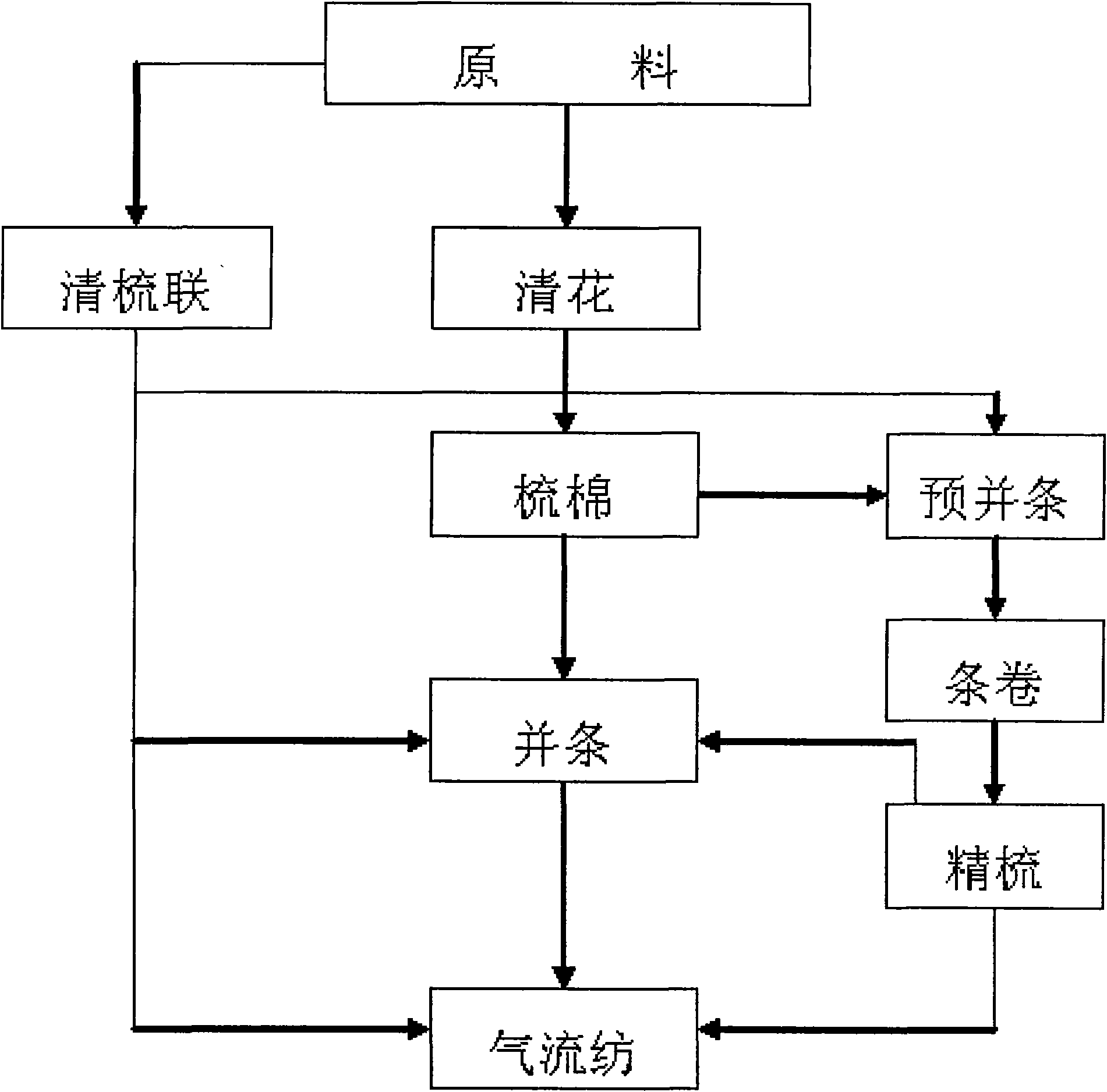

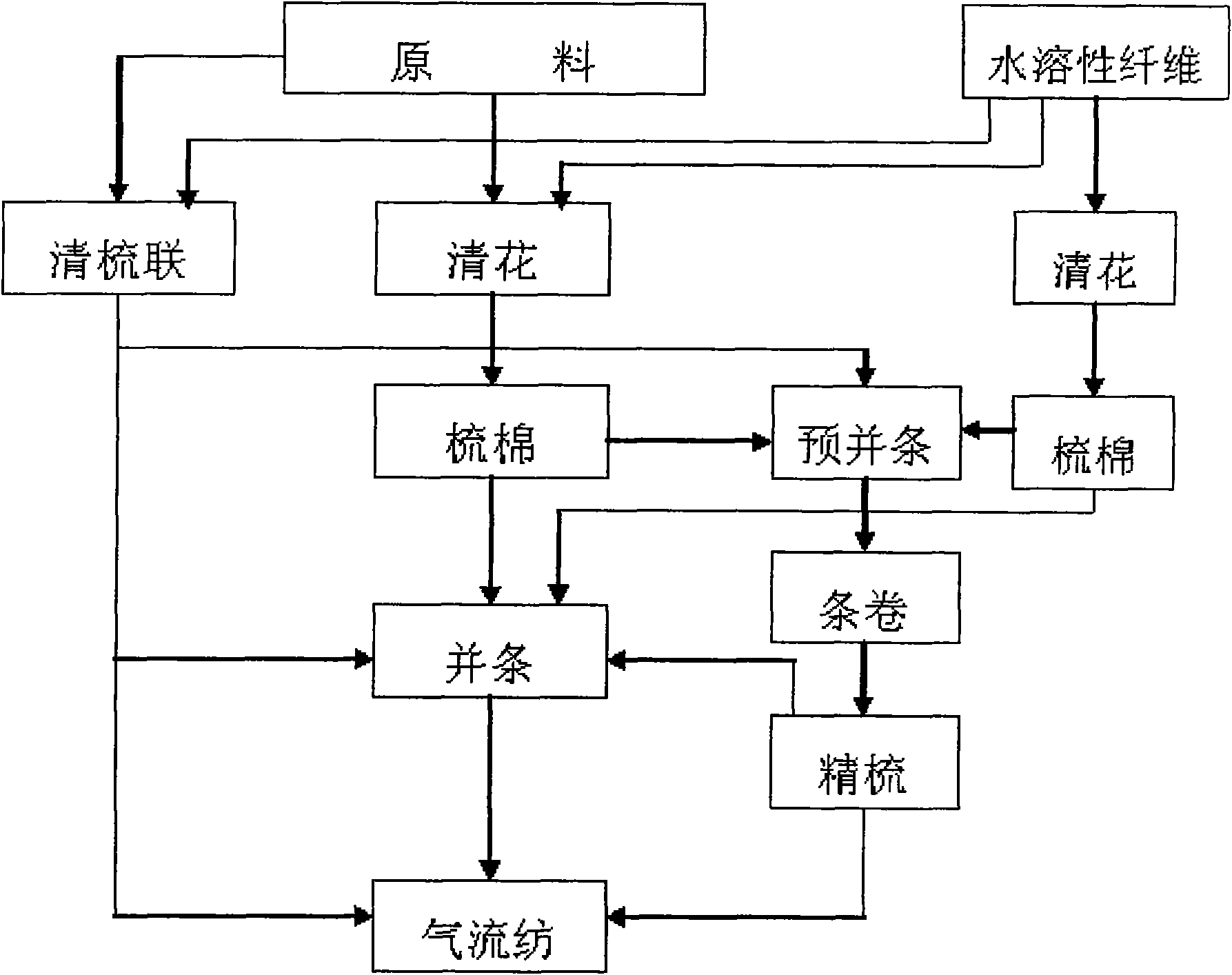

Production process for airflow-spinning stocking yarns

The invention discloses a production process for airflow-spinning stocking yarns, which comprises the following steps: performing airflow-spinning on a main fiber raw material after the step of blowing-carding, or the blowing-carding and drawing, or blowing, cotton carding and the drawing, or the blowing, the cotton carding, pre-drawing, sliver lap and the drawing, or a cross step of the four modes so as to form airflow spinning; before performing the step of the airflow spinning, adding water-soluble fibers into the main fibers; and after performing the step of the airflow spinning, performing knitting processing to form knitted fabrics, and using hot water to dissolve the water-soluble fibers in the knitted fabrics to obtain airflow-spinning knitted fabrics. The airflow-spinning stocking yarns produced by the process not only has even yarn levelness, smooth appearance and fewer hair feathers, but also soft knitted fabric hand feeling after the water-soluble fibers are dissolved, thereby sufficiently satisfying the processing requirements of knitting apparel textiles, improving the processing performance of the airflow spinning, and expanding the application range of the airflow spinning.

Owner:JIANGSU WEIFANG TEXTILE GARMENT

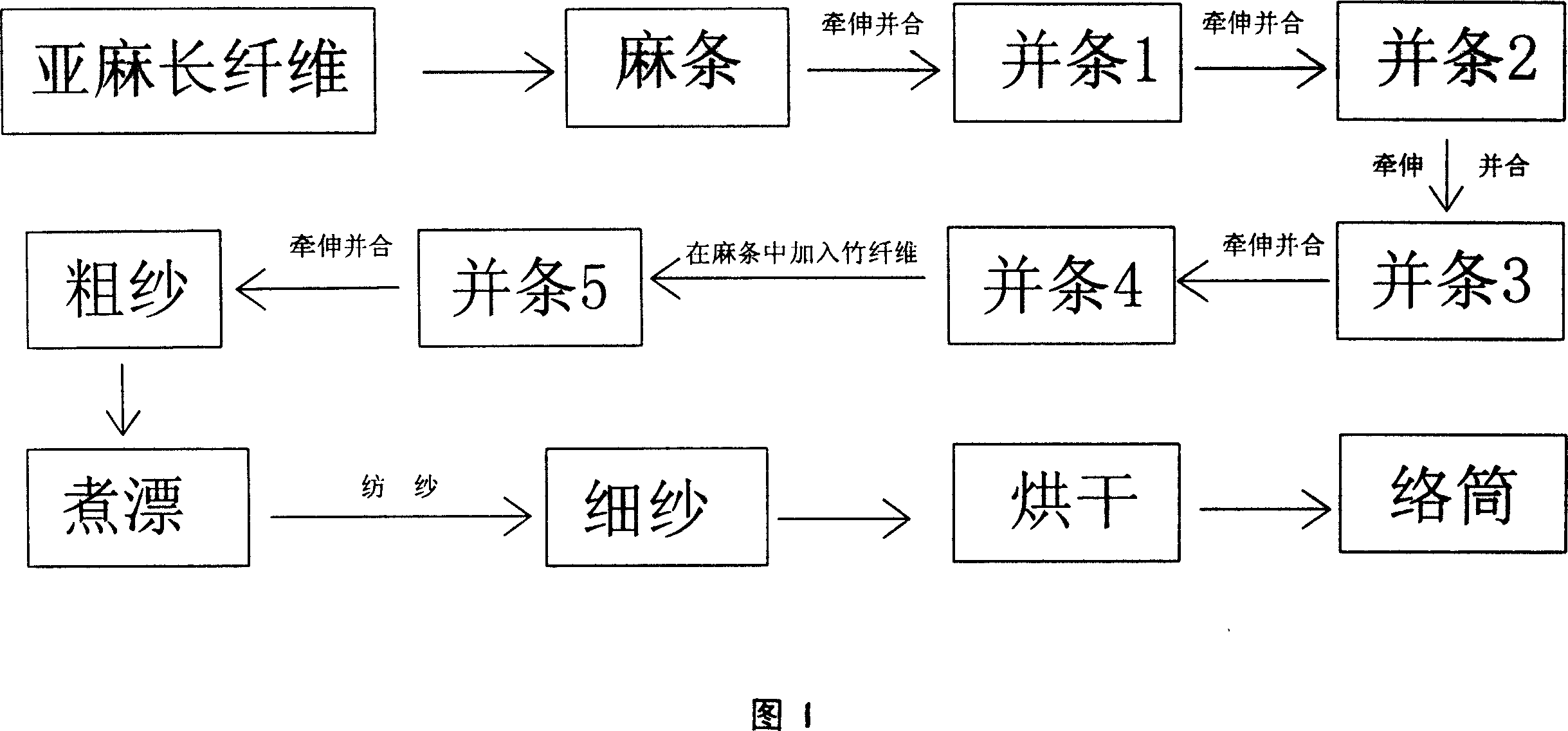

Flax blended spinning preparation process

The invention discloses a method for producing flax blended yarn used in clothes and face fabric, comprising that: preparing flax long fiber into flax bars; combing bars via at least five processes; adding bamboo fibers into combining process, while the bamboo fibers are 8-75mass% of total blended yarn mass; combing them and drawing to prepare rove; boiling and bleaching the rove; spinning into spun yarn; drying, coiling and shaping. The invention has simple process, while the product has uniform bars, beautiful appearance and smooth surface.

Owner:ZHEJIANG JINYUAN FLAX

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com