Patents

Literature

193results about How to "Good moisture wicking effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polyester flax-like type different shrinkage composite yarn and preparation method thereof

ActiveCN108130624ASimple preparation processImprove fluffinessMelt spinning methodsConjugated synthetic polymer artificial filamentsYarnPolyester

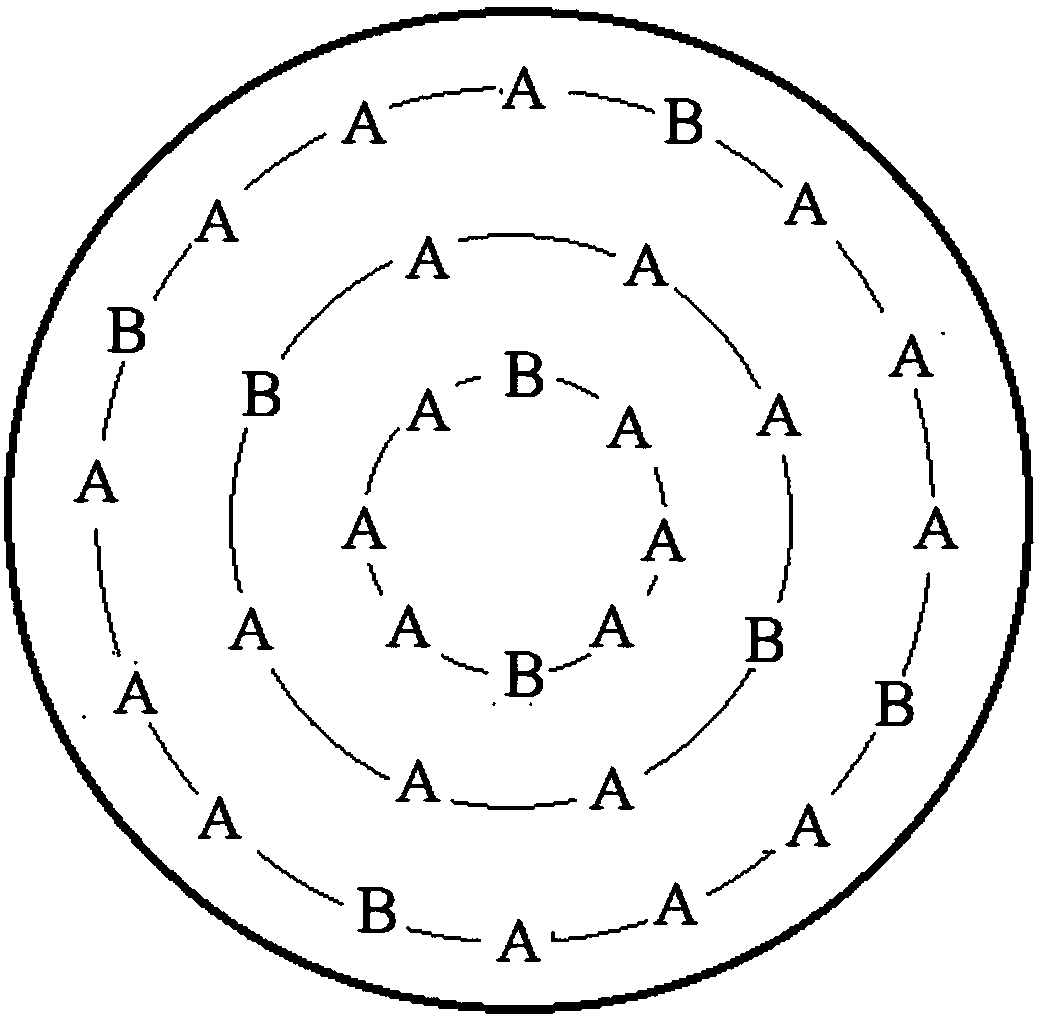

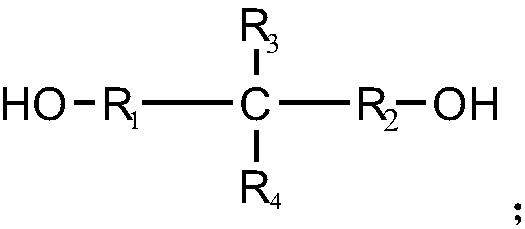

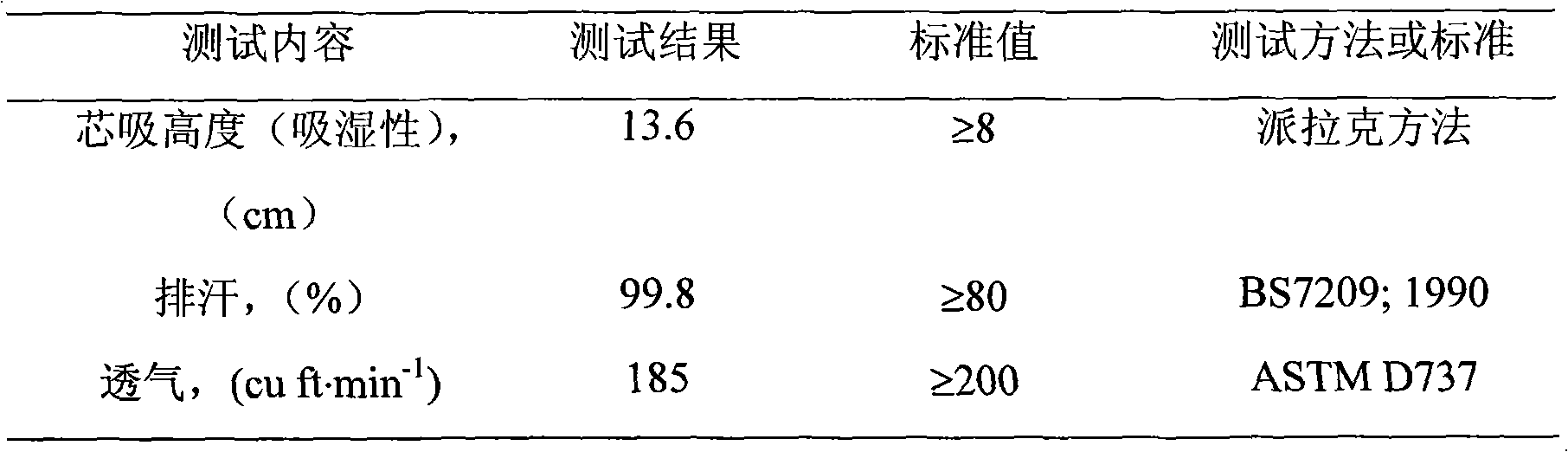

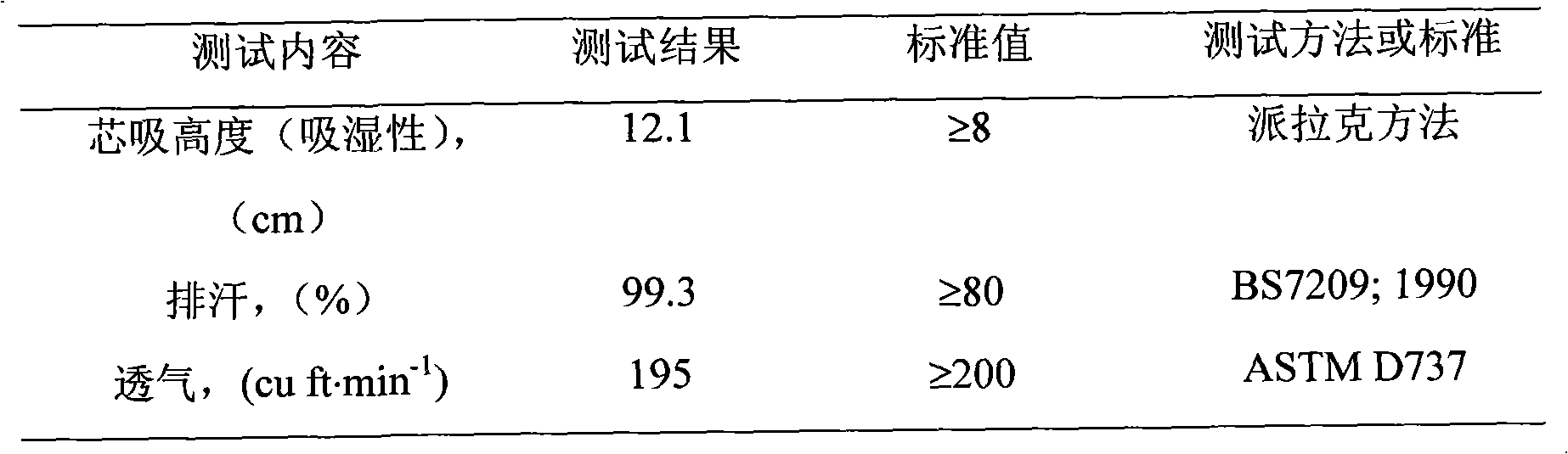

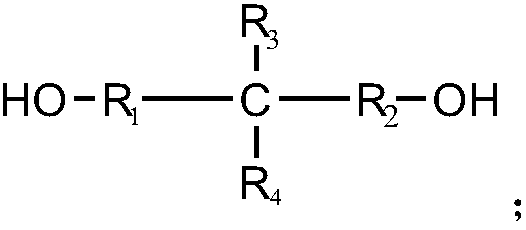

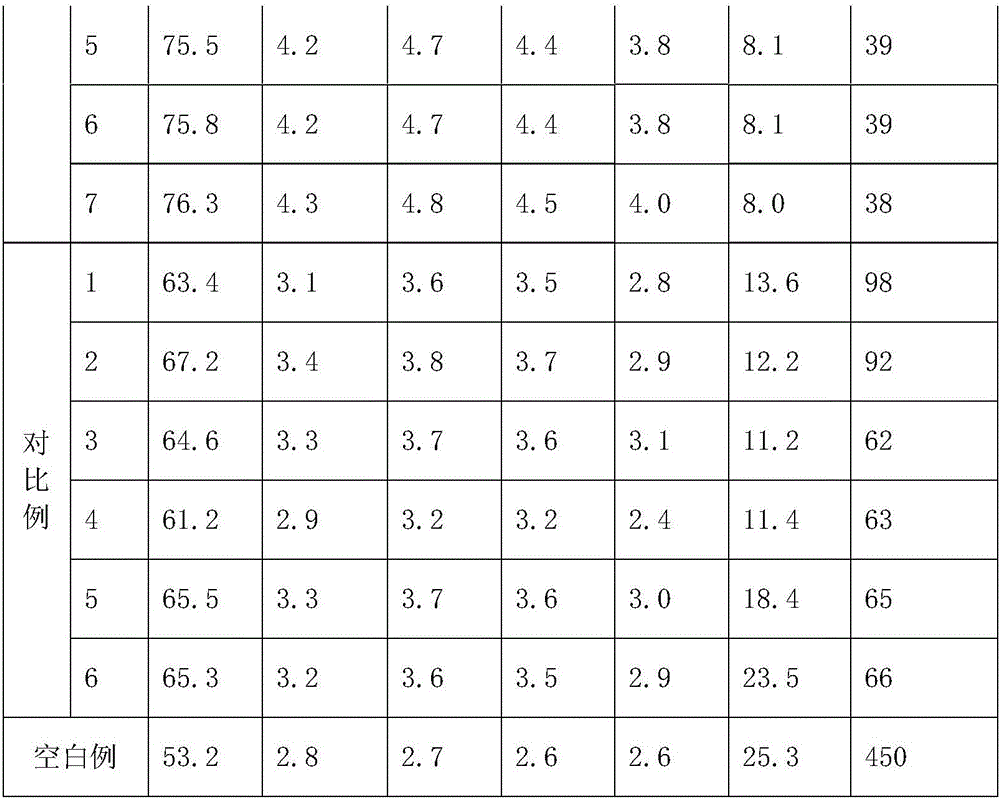

The invention relates to a polyester flax-like type different shrinkage composite yarn and a preparation method thereof. Firstly, a modified polyester yarn POY and a modified polyester yarn FDY are prepared respectively, then the modified polyester yarn POY and the modified polyester yarn FDY are compounded to prepare the polyester flax-like type different shrinkage composite yarn; the chromatic aberration [delta]E of the prepared polyester flax-like type different shrinkage composite yarn is less than 0.200; a bundle of the yarn POY or FDY extruded by a same spinneret plate contains a singleyarn shaped in a Chinese character 'wang' manner and a five-leaf single yarn; a molecular chain of modified polyester consists of a diol chain segment with a branched chain, and diol with the branchedchain has the structural formula defined in the specification, wherein R1 and R2 are straight-chain alkylene with the carbon atom number of 1-3 , R3 is alkyl with the carbon atom number of 1-5, and R4 is alkyl with the carbon atom number of 2-5. The method is simple and reasonable, and the prepared composite yarn has good fluffy property and moisture absorption and perspiration elimination properties.

Owner:JIANGSU HENGLI CHEM FIBER

Rachael blanket made from Modal cotton

A raschel blanket of modyhr-cotton is prepared form 35-50 wt.% of modyhr, 30-40 wt.% of cotton and 15-30 wt.% of polyester. Its manufacturing process includes warping polyester filament, warping wool yarn blended by modyhr and cotton, weaving for fabric, splitting and opening fine hair, inspecting and sending inspected material to warehouse of semi-finished product.

Owner:上海海欣大津毛织有限公司

Method for dyeing and finishing pure-cotton high-count high-density fabric

ActiveCN101532230AReduce trafficEmission reductionTextile storage in superimposed formSingeingHigh densityMoisture absorption

The invention discloses a method for dyeing and finishing pure-cotton high-count high-density fabric, which includes steps of singeing, cold dome, desizing and boiling-off, bleaching, mercerization, dyeing, moisture absorption and breath, no-iron sorting, tentering, pre-shrinking and packaging. The fabric dyed and finished by the present invention has advantages of high rebound, moisture absorption and breath, crease-resistance and soft feel.

Owner:SUNTEX

Moisture absorption and perspiration fiber with hydrophilic function

InactiveCN101982572APracticalImprove moisture wicking efficiencyFibre typesMelt spinning methodsFiberPolyester

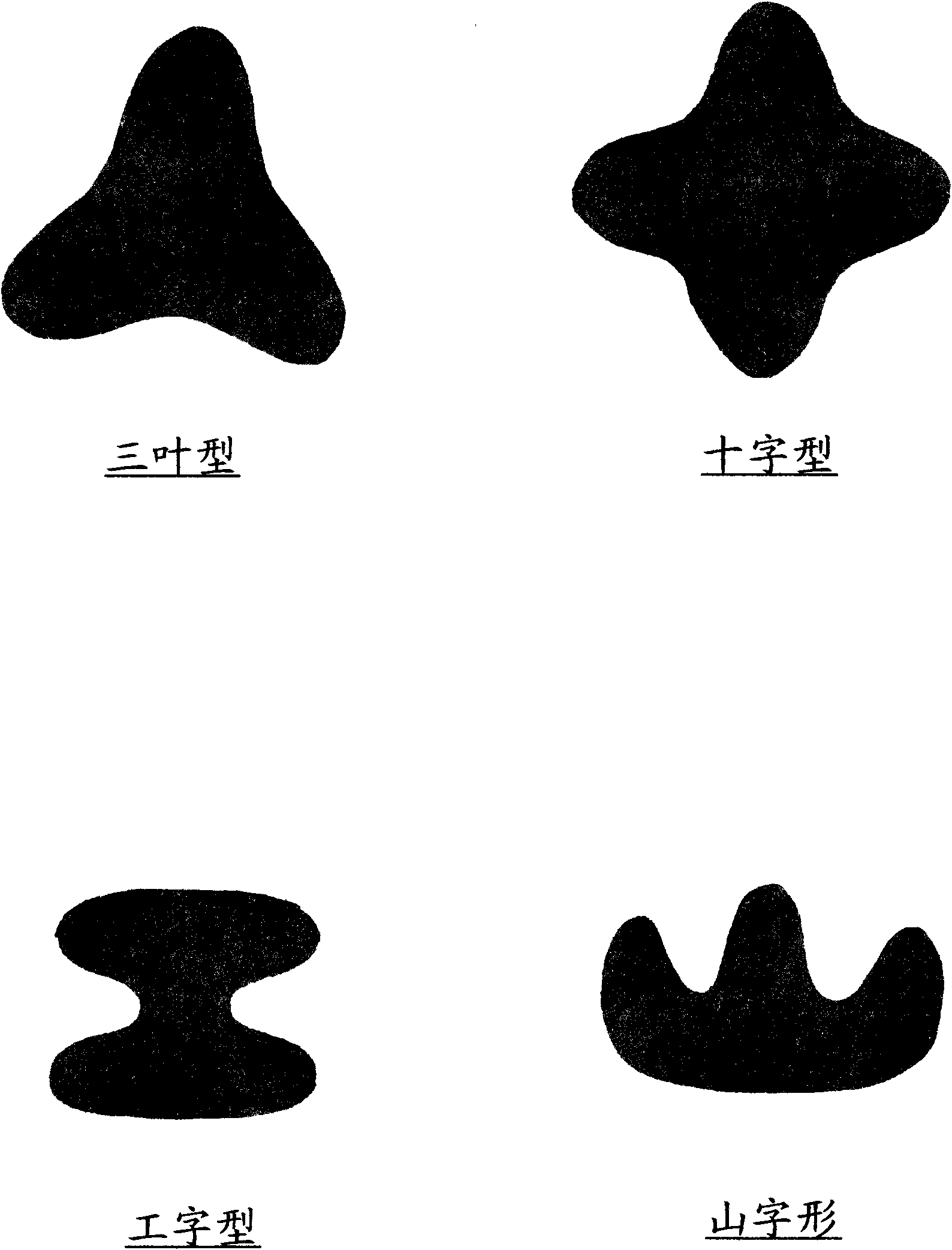

The invention relates to a moisture absorption and perspiration fiber with a hydrophilic function, comprising filaments and chopped fibers. The preparation process comprises the following steps: modifying conventional polyester to obtain hydrophilic modified polyester; mixing the conventional polyester, the hydrophilic modified polyester and water soluble polyester according to a certain proportion for carrying out composite spinning; extruding the mixture by a profile spinneret and carrying out postprocessing process for spinning to obtain the hydrophilic moisture absorption and perspiration polyester filaments or chopped fibers. Alkaline solution treatment is carried out on fabrics made from the fiber provided by the invention to form multiple micropores and trenches in the surfaces of the fabrics, so that the fabrics are dry and comfortable with water absorption and perspiration and ventilation properties, thus the fabrics can be manufactured into sportswear and underwear. In the invention, structural design and chemical modification of the fiber are combined, so that the moisture absorption and perspiration property is greatly enhanced; and in addition, as the fiber is free from influence of blend fiber or the manufacturing process, the applicability is wide.

Owner:SHANGHAI VITA SCI & TECH

Processing technique of profile fiber having functions of moisture absorption and bacteria resistance and products thereof

InactiveCN101555633AGood moisture wicking effectImprove antibacterial propertiesFilament/thread formingArtifical filament manufactureFiberPolymer science

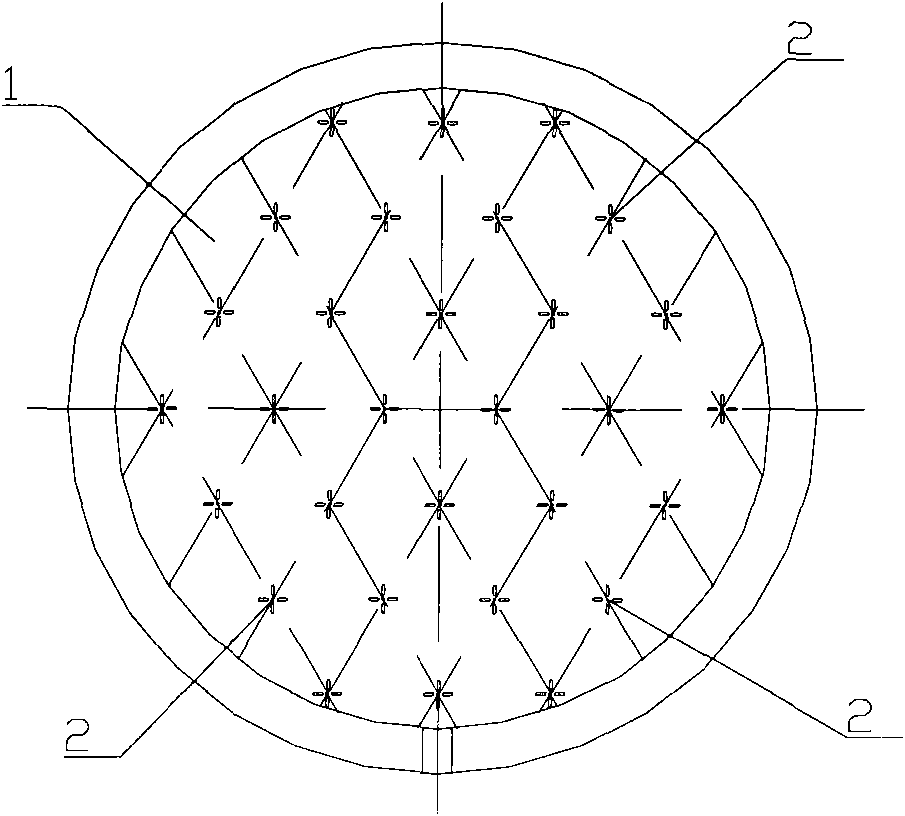

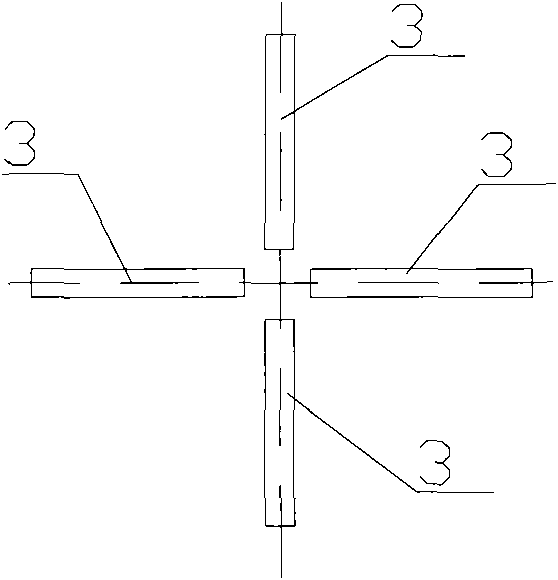

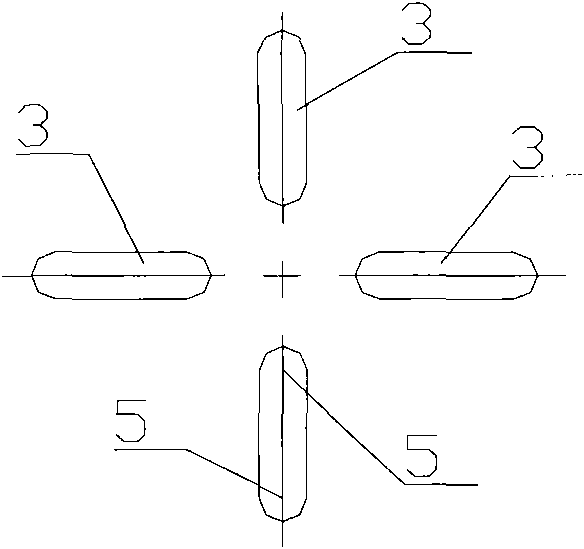

The invention discloses a processing technique of profile fiber having functions of moisture absorption and bacteria resistance and a product thereof. The processing technique at least comprises the following steps: matrix polymer is mixed with bacteria resisting additive or bacteria resisting additive master batch; the mixture is heated and pressurized to form high polymer fusant and the high polymer fusant is jetted out through the jetting slit of each spinneret orifice, or a modified polymer mixed with bacteria resisting additive is directly heated and pressurized to form high polymer fusant and the high polymer fusant is jetted out through the jetting slit of each spinneret orifice; and the high polymer fusants jetted out through the spinneret orifices swell owing to Barus effect, and are mutually adhered to form the profile fiber; wherein, the bacteria resisting additive is inorganic additive, organic additive or polymeric additive. The profile fiber processed by adopting the technique of the invention has high degree of profile, good effect of moisture absorption and sweat volatility and excellent bacteria resistance.

Owner:GUANGDONG XINHUI MEIDA NYLON

Hydrophilic hygroscopic and sweat-releasing polyester fiber and preparation method thereof

ActiveCN103320889ALarge specific surface areaHigh hollownessFibre typesMonocomponent polyesters artificial filamentChemistryWoven fabric

The invention discloses a hydrophilic hygroscopic and sweat-releasing polyester fiber and a preparation method of the hydrophilic hygroscopic and sweat-releasing polyester fiber. The method comprises the following steps of: slicing and respectively drying hydrophilic modification polyester, water-soluble polyester, and calcium carbonate powder-containing hydrophilic polyester master batch, mixing and melting according to certain mass percentage, extruding for spinning by a profile spinneret, and carrying out post-treatment to obtain polyester filament yarn or short fiber. Regardless of acid or alkali dyeing or processing environment, a great amount of micropores or grooves can be formed on the surface, better hydrophilic hygroscopic and sweat-releasing effects can be achieved, and the flexible and simple and convenient technique requirements can be reached; and the fiber can also obtain ultrahigh hygroscopic and sweat-releasing effects through superposition of dyeing or processing procedures. The profile hygroscopic and sweat-releasing fiber obtained by adopting the method is flexible in production technique no matter in pure or blended Dacron yarn weaved fabric, and achieves the changeability adjustability of the hygroscopic and sweat-releasing effects.

Owner:SHANGHAI VITA SCI & TECH

Method for producing fine-denier cross special-shaped polyester filament yarn and product thereof

InactiveCN101139740AIncrease shear rateGuaranteed spinnabilityFilament/thread formingMonocomponent polyesters artificial filamentFiltrationSlow cooling

The invention discloses a production method and relevant products for fine denier cross-type deformed terylene filament, and belongs to the technical field of terylene fibers. During production of the fine denier cross-type deformed terylene filament, the invention adopts metal sand with features of high stability, high filature pressure and high deformed extent to perform melt body filtration; meanwhile, a cooling process is utilized on a cross air flow device integrated with a calm zone and a slow cooler, and combined with slow cooling and intensive cooling; moreover, suitable improvement is done to an oiling position, so as to successfully spin fine denier cross-type deformed terylene POY and DTY filament. Monofilament size of the POY filament is 0.78 to 1.19 d.p.f; monofilament size of the DTY filament is 0.5 to 0.7 d.p.f; corss sections of the fibers are similar to a regular cross shape. The invented fine denier cross-type deformed fiber has advantages of high speed of water absorption, water delivery, diffusion and volatilization, and maintaining users' skin dry and cool. Meanwhile, small monofilament size of the fiber can greatly increase flexibleness and perfect hand feeling of the fabric.

Owner:JIANGSU HENGLI CHEM FIBER

Finishing method of dry-touch and cool knitted underwear or fabric

InactiveCN101353864AFast water absorptionFast water deliveryNatural fibresBiomedical engineeringTemperature sensitive

The invention relates to a method for sorting dry and cool knitted underwear or shell fabrics, comprising the steps of: (1) preliminary treatment according to a conventional method of the enterprise; (2) washing with water; (3) the sorting of a temperature-sensitive type micro-capsule with hydrophobic core material; and (4) post-processing by using a hydrophilic agent. The underwear produced by using the method of the invention has good wet permeability and drying functions, can not only absorb the sudor perspired from the skin of a human body, but also drain the water in the clothes, thus causing the human body to be dry, cool and comfortable.

Owner:DONGHUA UNIV +1

Polyester wool-like different-shrinkage composite wire and preparing method thereof

ActiveCN108130605AConsistent extrusion speedGood moisture wickingArtificial filament heat treatmentMelt spinning methodsPolyesterAlcohol

The invention relates to a polyester wool-like different-shrinkage composite wire and a preparing method thereof. The method comprises the steps of firstly, modified polyester POY and FDY wires are produced separately; then, the POY and FDY wires are compounded to produce the polyester wool-like different-shrinkage composite wire, wherein the chromatic aberration delta E of the produced compositewire is smaller than 0.200. A bunchof POY or FDY wires extruded through the same spinneret plate contain double-cross single wires and trilobal single wires simultaneously, a modified polyestermolecular chain contains a dihydric alcohol chain section with a branch chain, and the structural formula of the dihydric alcohol chain section with the branch chain is shown in the description, wherein R1 and R2 are straight chain alkylidenes of which the number of carbon atoms is 1-3, R3 is an alkyl of which the number of carbon atoms is 1-5, R4 is an alkyl of which the number of carbon atoms is 2-5, and a matt agent in modified polyester is a mixture of amorphous titanium dioxide and amorphous silicon dioxide or calcium carbonate and amorphous silicon dioxide. The preparing method is simple and reasonable, and the prepared composite wire has good fluffy and hygroscopic and sweat releasingperformance.

Owner:JIANGSU HENGLI CHEM FIBER

Process for preparing polyester fabrics

ActiveCN101974857AReduced shear stiffnessEliminate auroraFibre typesDyeing processDisperse dyeFire retardant

The invention relates to a process for preparing polyester fabrics, which comprises the steps of gray polyester fabric selection, alkali deweighting finishing, dyeing and antiflaming processing, drying, baking, washing and drying, wherein the dyeing and the antiflaming processing are in same bath fluid, and the bath ratio of the two is 1: (18 to 22); a way of soaking gray polyester fabrics for two times and rolling the gray polyester fabrics for two times is adopted, and the liquid retention is 50 to 70 percent; the pH value of the bath fluid for dyeing and antiflaming processing is 3 to 6.5, and the bath fluid comprises the following compositions: disperse dyes X, 10 to 20 percent of flame retardant (weight content), 1.7 to 2.5 g / l of dispersing agent, and 1.7 to 2.5 g / l of penetrating agent, wherein the flame retardant is phosphorus flame retardant. The polyester fabrics prepared by using the process of the invention have the advantages of good flame-retardant performance and low temperature resistance (- 43 DEG C), and meet the requirements for clothing performance in the military field and the entertainment items such as climbing and skiing and the like. In addition, the process of the invention is simple, and easy to operate.

Owner:WUJIANG FUHUA WEAVING

Modified PET polyester as well as preparation method and application thereof

ActiveCN107312166AFree from destructionShorten the replacement periodFlame-proof filament manufactureSilicon compoundsPolyethylene terephthalateSlurry

The invention relates to modified PET (Polyethylene terephthalate) polyester as well as a preparation method and application thereof, and belongs to the field of modified polyester. The modified PET polyester comprises aerogel particles and polyethylene terephthalate; the aerogel particles are dispersed between the molecular chains of the polyethylene terephthalate uniformly; the particle size of the aerogel particles is 2 to 3 microns; the content of the aerogel particles in the modified PET polyester is 1 to 10 percent by weight. Modified PET is prepared by the steps of adding the aerogel powder into glycol, putting into a grinding machine, grinding to prepare mixed slurry, mixing the mixed slurry and terephthalic acid, and performing esterification reaction and polymerization reaction. Modified PET fiber is prepared by slicing the modified PET, metering, spinning, cooling, applying oil, stretching, performing heat setting and performing winding formation. The aerogel particles are introduced before polymerization of the PET polyester, so the prepared PET has high spinnability, can produce modified PET fibers with various thickness, has wide application range and can meet the production requirement of various fabrics.

Owner:天津朗华科技发展有限公司

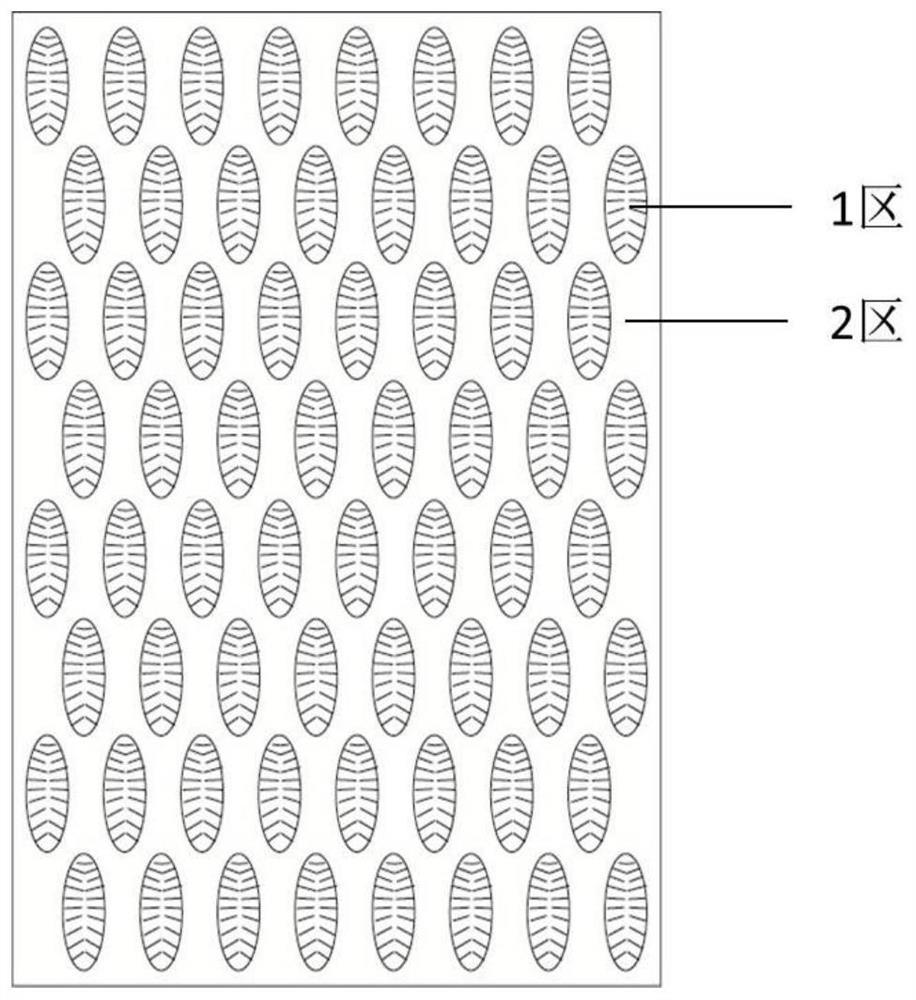

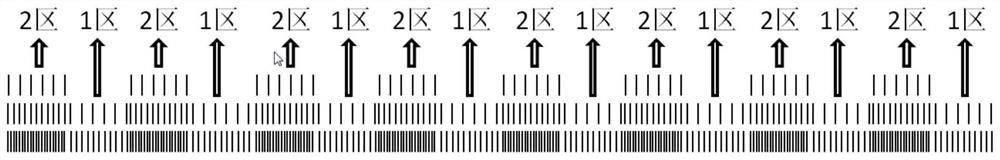

Fabric incorporating polymer filaments having profiled cross-section

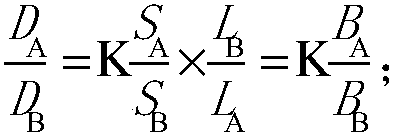

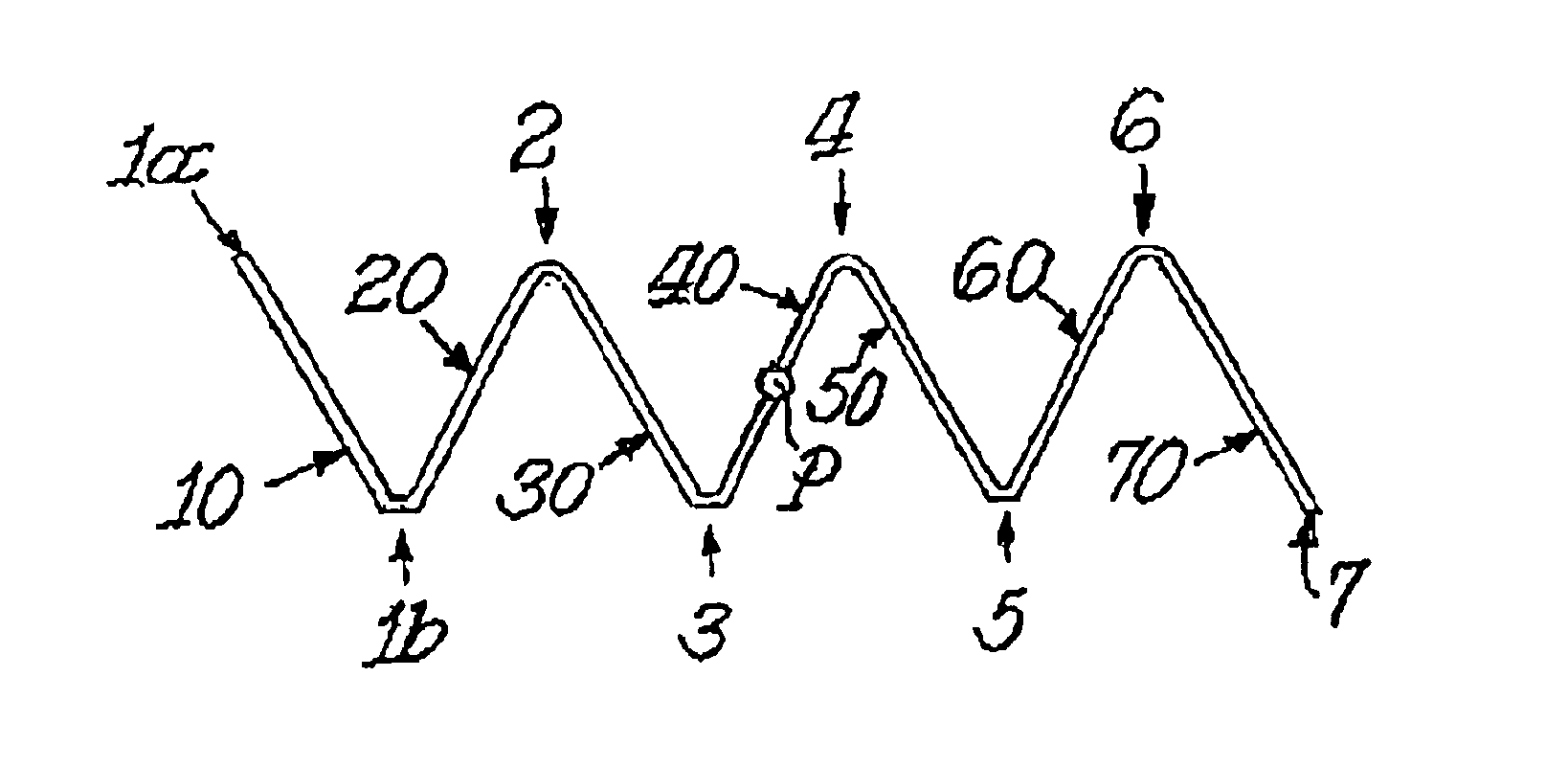

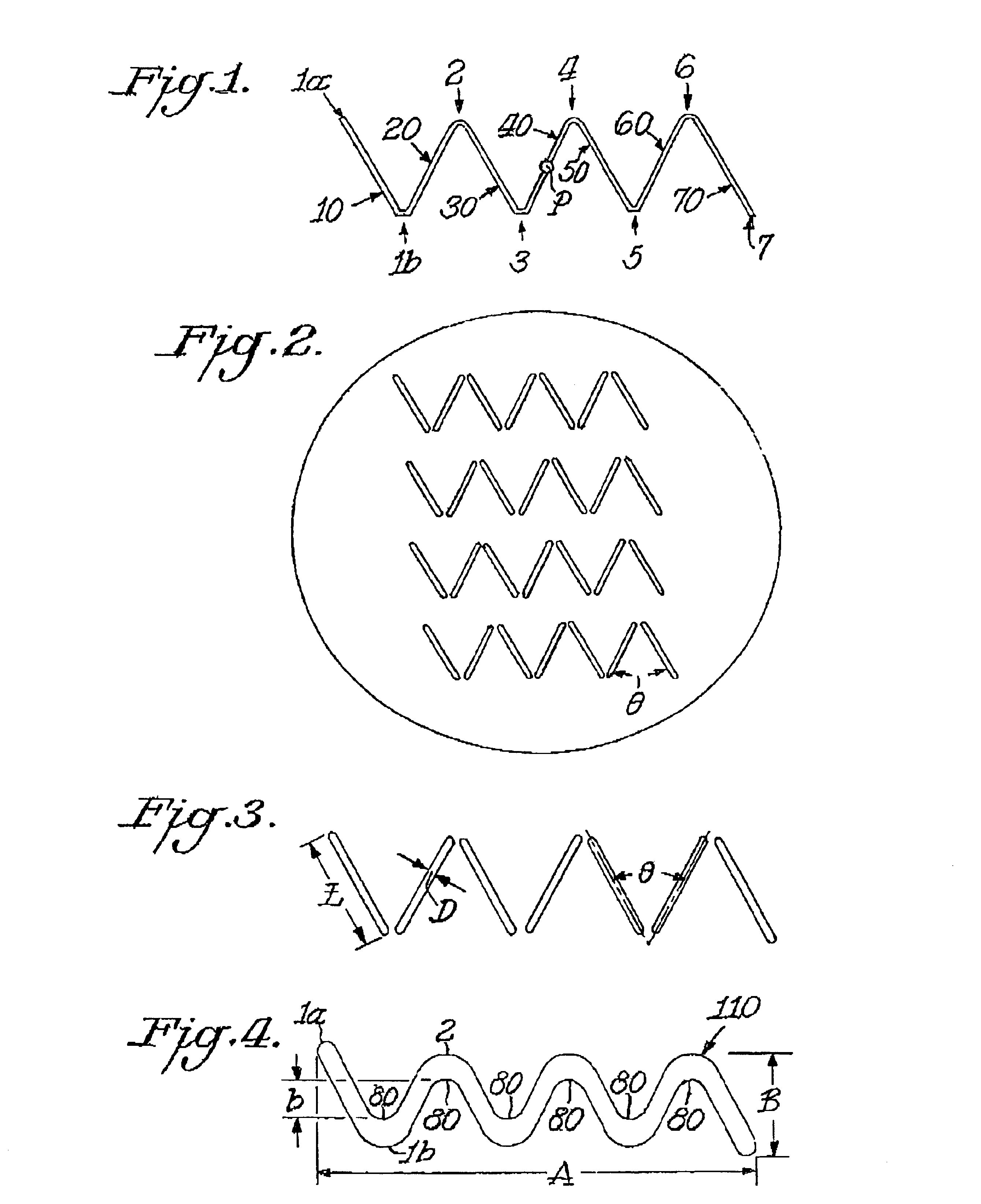

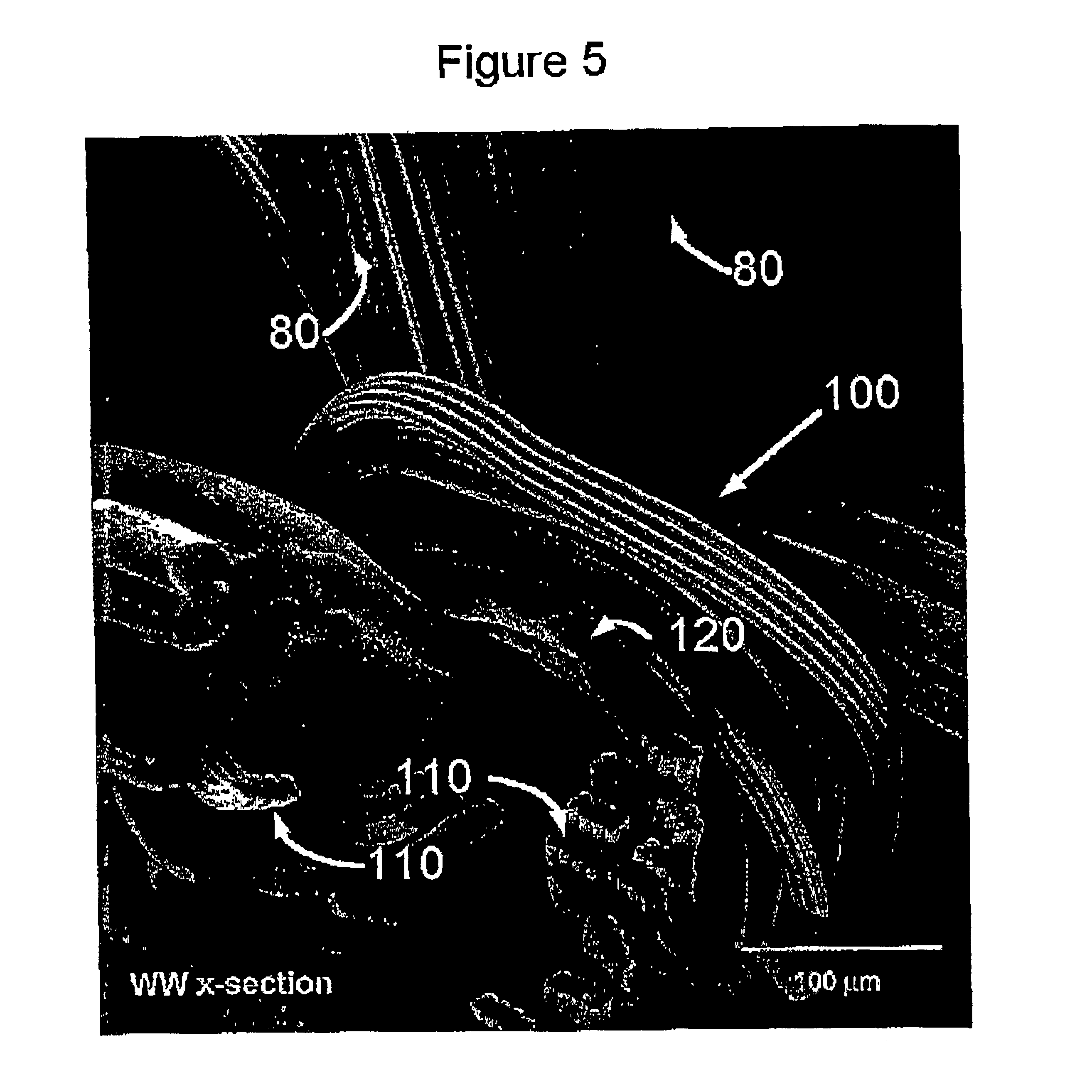

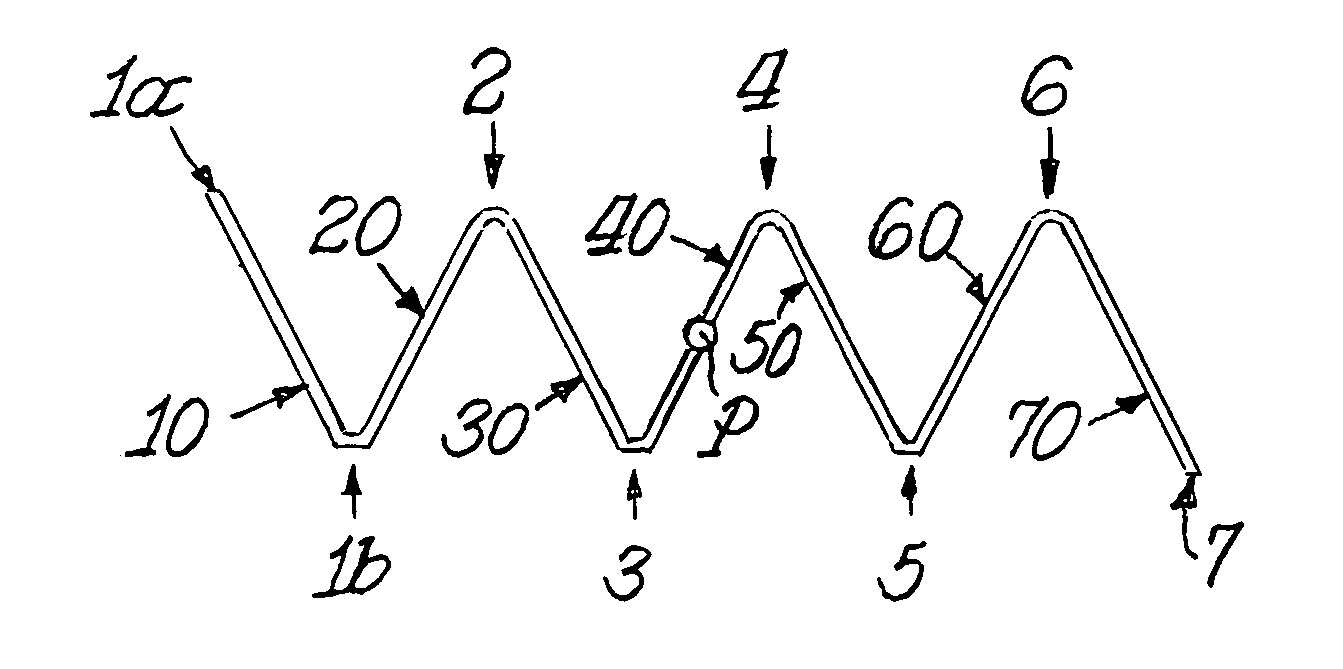

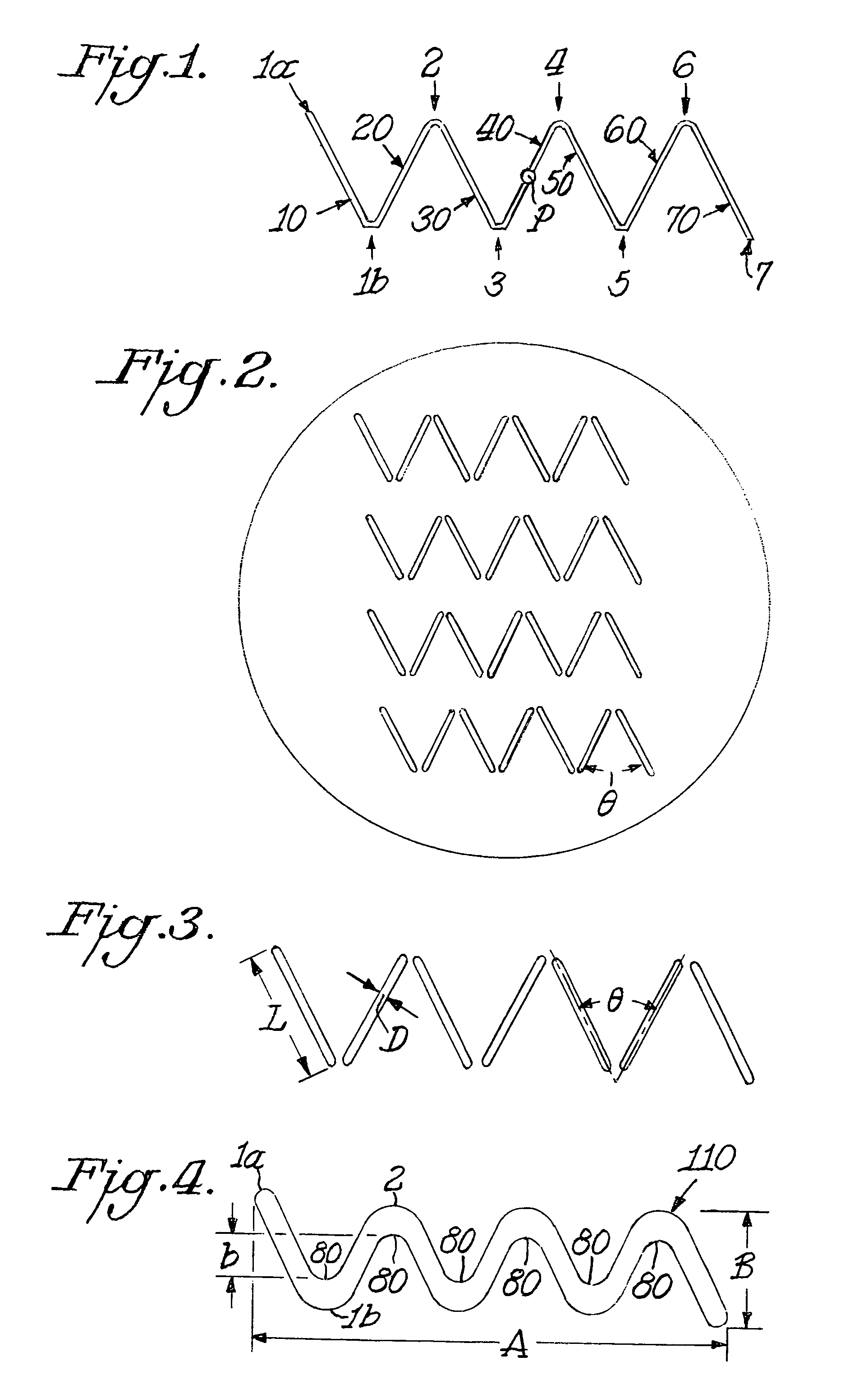

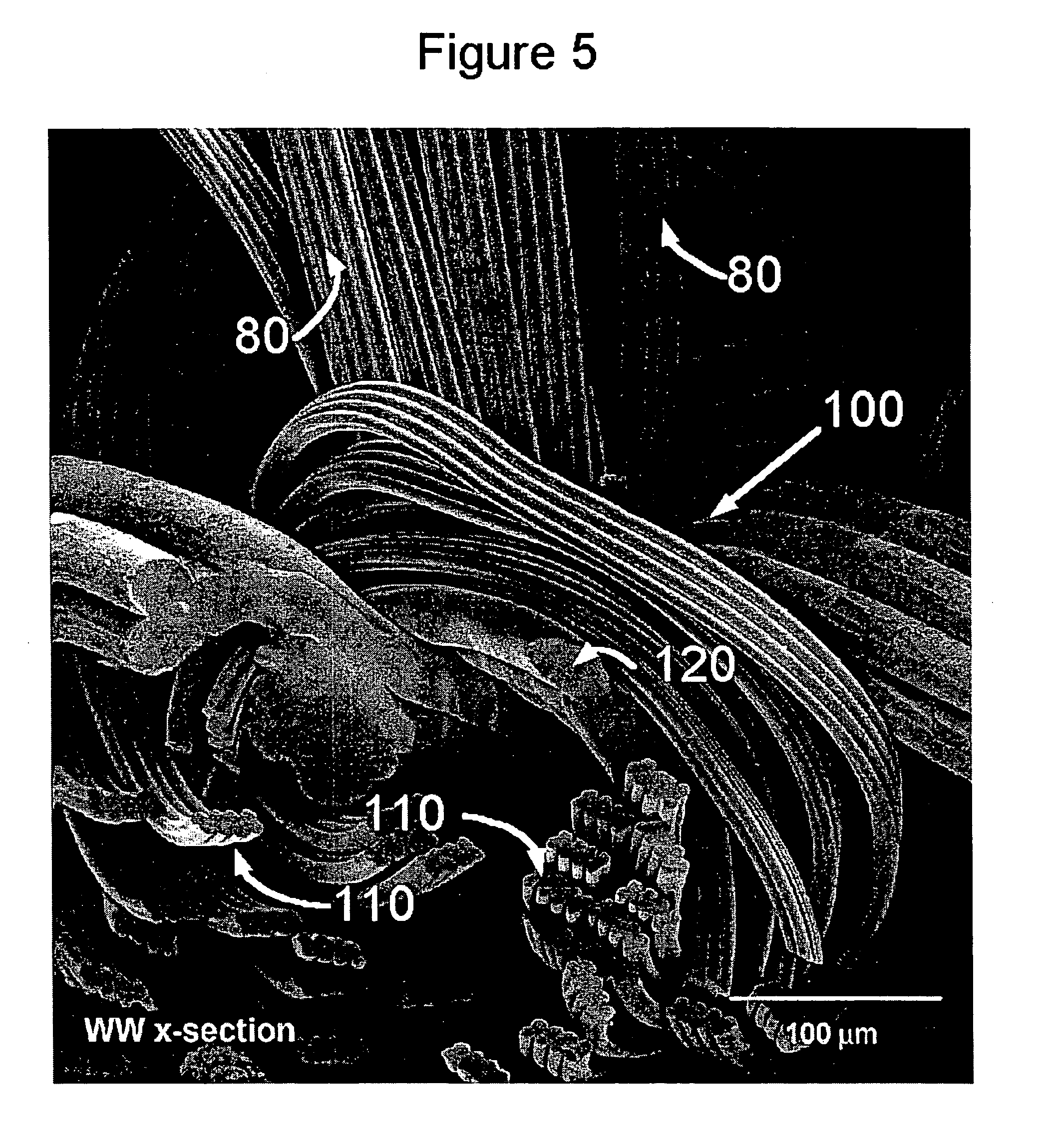

InactiveUS6884505B2Good moisture wicking effectSoft handFilament/thread formingYarnEngineeringMoisture

The present invention is directed to a multi-filament yarn formed at least in part from filaments having cross-sectional zig-zag or double “W” shape with a 180 degree axis of symmetry. The filaments have a denier per filament generally in the range of about 0.1 to about 4.0. Fabrics made from yarns formed with the filaments have high moisture wicking, soft hand, and a silk-like lustrous appearance.

Owner:THE LYCRA CO LLC

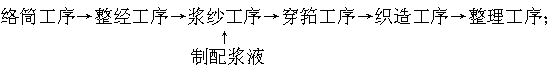

Shirt fabric weaving process

The invention discloses a technical scheme of a shirt fabric. The process steps are as follows: spooling process, warping process, size preparation, slashing process, denting process, weaving process and finishing process. A triple cloth of warp single weft triple is woven on a conventional jet loom, JC / T (75 / 25) 40S yarns are distributed at the outer layer of the fabric, and 75D polyester DTYs (drawn textured yarns) are distributed in the middle layer of the fabric, so that the fabric has shaping and enhancing functions; yarns JC / H (70 / 30) 40S are distributed at the inner layer of the fabric and are in contact with the skin, so that sweat is timely absorbed and released by utilizing the excellent moisture absorption and sweat releasing properties of China-hemp to keep the body feel refreshed. A T75D18D static wire is arranged at the intermediate layer every 1.8cm, so that the fabric has an excellent antistatic effect.

Owner:JIHUA 3542 TEXTILE CO LTD

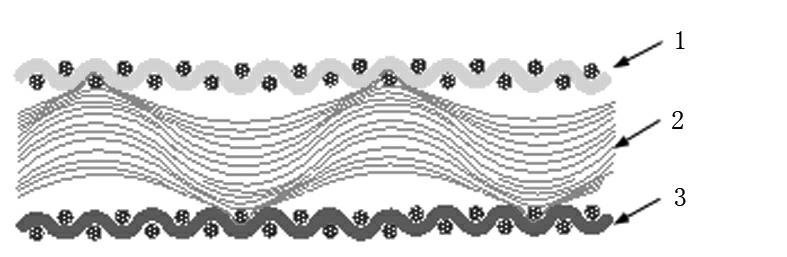

Novel moisture absorption temperature regulation antibacterial summer quilt and production technology thereof

InactiveCN102488426ASoft touchStrong hygroscopicityMulti-ply fabricsVegetal fibresPolyesterAcrylic fibre

The invention belongs to the textile field, and particularly relates to a novel moisture absorption temperature regulation antibacterial summer quilt and production technology thereof. The fabric structure of the summer quilt is formed by three layers, an upper surface layer adopts Outlast acrylic fibers, a lower surface layer adopts bamboo pulp fibers, and a middle layer adopts moisture absorption perspiration discharging polyester filament. The health care summer quilt has hot wet comfort of moisture absorption and temperature regulation, has an antibacterial function simultaneously, has good hygiene, unique and elegance appearance and strong washability, is formed in one-step in the production process, saves cost and energy, and has high additional value.

Owner:HENAN INST OF ENG

Nightclothes capable of removing sweat, drying quickly and preventing colds and making process thereof

ActiveCN107280099AFast perspirationNot easy to catch a coldLiquid repellent fibresGrip property fibresFiberEngineering

The invention discloses nightclothes capable of removing sweat, drying quickly and preventing colds and a making process thereof. The making process includes the steps that S1, hydrophilic finishing liquor is prepared; S2, fabric is dipped in the hydrophilic finishing liquor, the dipped fabric is dried after being dehydrated, and fabric capable of removing sweat, drying quickly and preventing colds is obtained; S3, the fabric capable of removing sweat, drying quickly and preventing colds is processed into the nightclothes after being tailored according to the conventional nightclothes making process and requirements. According to the nightclothes capable of removing sweat, functional fiber with a groove structure is adopted, so that sweat is quickly removed, and a wearer is not likely to catch a cold; a lot of research work is done for improving the hydrophilicity of the fabric, the hydrophilic finishing liquor is prepared for finishing the fabric, the purpose of improving the surface hydrophilicity of the fabric is achieved, the problem that existing fabric can not remove sweat easily and brings the discomfort of stuffiness to the wearer is solved, and the nightclothes have an excellent moisture absorbing and sweat removing effect and will not adhere to the skin to bring a cold and wet feeling when the wearer sweats, thereby protecting the wearer from a cold; the nightclothes especially have the effects of removing sweat, drying quickly and preventing colds.

Owner:上海小蓝象服装有限公司

Preparation method of hollow polyester fiber with controllable hollowness

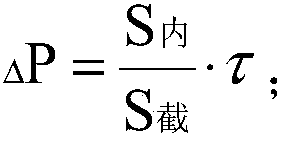

InactiveCN102453967AGood moisture wicking effectImprove hydrolysis efficiencyHollow filament manufactureMelt spinning methodsAbnormal shapedChemistry

The invention relates to a preparation method of hollow polyester fiber with controllable hollowness. In the method, two screw extruders are used for respectively feeding materials for a cover / core spinneret plate assembly, a cover layer which is made of polyester and water-solubility polyester and a core layer which is water-solubility polyester are melted in a certain proportion for composite spinning, and then postprocessing processes are carried out to prepare polyester staple fiber; and fabric made of the obtained fiber is treated with an alkaline solution to remove the water-solubility polyester from the core layer and the cover layer, and thus the fiber is of a hollow structure, and lots of micropores, trenches and through holes are formed on inner and outer surfaces of the fiber at the same time. Since hollow holes are formed after the core layer is removed through melting, deformation of hollow holes, caused by extrusion in a stretching process in the preparation of hollow fiber spun with a profile hole spinneret plate spinning method, can be avoided, and hollowness is reduced; and moreover, through the change of the proportion of raw materials for spinning, the polyester fiber with controllable hollowness being 5-75% is prepared.

Owner:SHANGHAI VITA SCI & TECH

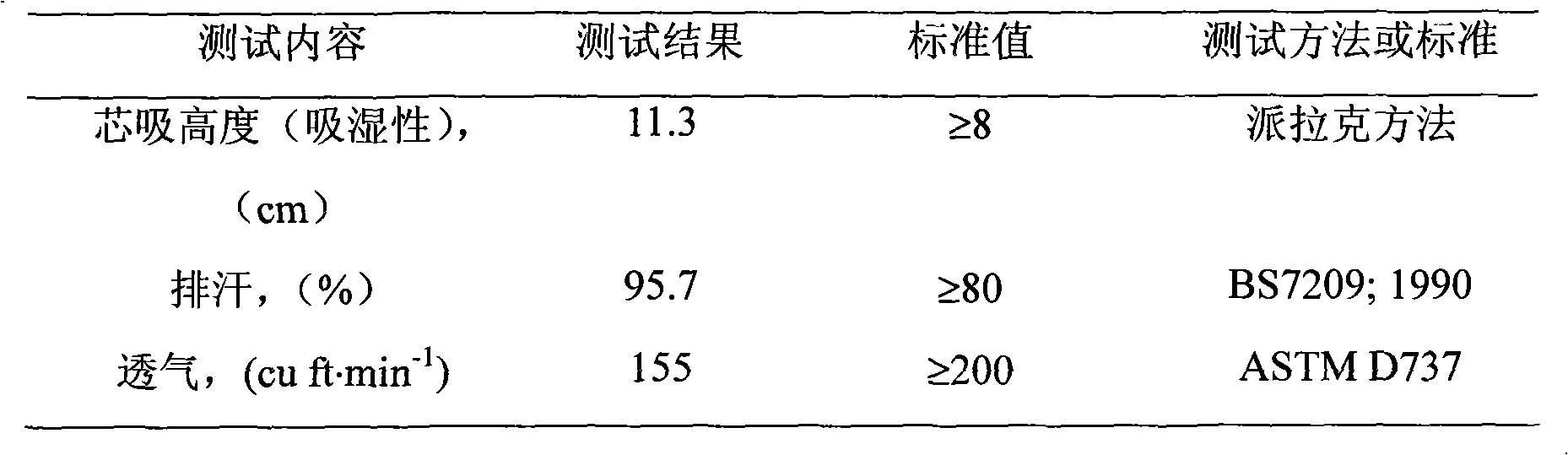

Cotton COOLPLUS covering hygroscopic and sweat-releasing functional fabric as well as processing technique thereof

InactiveCN102080291AGood moisture absorption and perspirationComfortable to wearDyeing processWoven fabricsDyeingYarn

The invention relates to a cotton COOLPLUS covering hygroscopic and sweat-releasing functional fabric as well as a processing method thereof. The fabric warp adopts 70 / 30coolplus / JC 16.1tex*2, the fabric weft adopts 70 / 30coolplus / JC 21.4tex*2, and the fabric has the warp density of 368 / 10cm, the weft density of 208 / 10cm, the fabric width of 151cm and the texture of 3 / 2 twill.. The processing technique adopts a special processing method on spinning, weaving and dyeing processes. The invention has the advantages that covering yarn is formed by COOLPLUS fiber and cotton, and the fabric thereof has excellent hygroscopic and sweat-releasing effects and is comfortable to wear. The processing technique thereof has a special processing method and remarkably improves the quality and the grade of the product. The research and the development of the product and the breakthrough of the process thereof provide lessons for developing high-grade and individualized textile fabric, provide guidance for marketing and create favorable economic benefits for enterprises.

Owner:TIANJIN TIANFANG INVESTMENT HLDG

China hemp cotton air vortex spinning product and preparing method thereof

InactiveCN103132208AGood moisture wicking effectMoisture absorption and quick dryingWoven fabricsYarnYarnCarding

The invention provides a China-hemp cotton vortex spun yarn product which has few feathers, is anti-pilling, has a soft and smooth yarn body and is good in hydroscopic and fast dry performance. Warps and wefts of the China-hemp cotton air vortex spinning product are China hemp fiber / cotton fiber vortex spun yarns, wherein the content of China hemp fibers occupies 60%, and the content of cotton fibers occupies 40%. The preparing method of the China-hemp cotton vortex spun yarn product comprises the following steps of a, preprocessing: the China hemp fibers are softened through emulgator before processing, the weight ratio of the emulgator, antistatic oiling agent and water satisfies the equation that ZY-06A:ZY-06B:water=1:0.5:5, and solution is prepared according to the ratio; the solution is evenly sprayed on the China hemp fibers according to 7% of the weight of the China hemp fibers; and the China hemp fibers are stored for 96 hours in the environment at the temperature of about 25 DEG C, and the China hemp fibers are turned over for a couple of times during storage; b, blending of the China hemp fibers and the cotton fibers: the China hemp fibers and the cotton fibers are mixed according to a portion inside a cotton box, and then blowing, carding, sliver lapping, combing and two combination processes are conducted; c, preceding spinning which comprises opening picking, cotton carding, combing and drawing; and d, vortex spinning: the temperature of a working workshop is 30 DEG C, and relative humidity is 65%.

Owner:JIANGSU YDTEX GRP LTD

Clothing softener and preparation method thereof

InactiveCN106758249AImprove breathabilityGood moisture wicking effectGrip property fibresPolyesterSurface-active agents

The invention provides a clothing softener and a preparation method thereof, and relates to the technical field of fabric after finishing. The clothing softener is prepared from the following ingredients in parts by mass: 2 to 8 parts of hydrophilic silicon oil softening agents, 1 to 5 parts of hydrophilic polyester-polyether block copolymerization softening agents, 5 to 15 parts of cationic surface active agents, 70 to 85 parts of softening water and 10 to 15 parts of accessory ingredients. The clothing softener solves the technical problems that the hydrophilic permeability of synthetic fiber clothing is still poor, so that people cannot smoothly perspire after wearing the synthetic fiber clothing and people feel uncomfortable. The clothing softener achieves the technical effects that the treated natural fiber and synthetic fiber clothing is smooth, soft, fluffy and antistatic; the synthesized fiber clothing has good moisture absorbing and sweat releasing properties; the wearing comfort of the synthetic fiber clothing can be obviously enhanced.

Owner:苏州市拧盟新材料科技有限公司

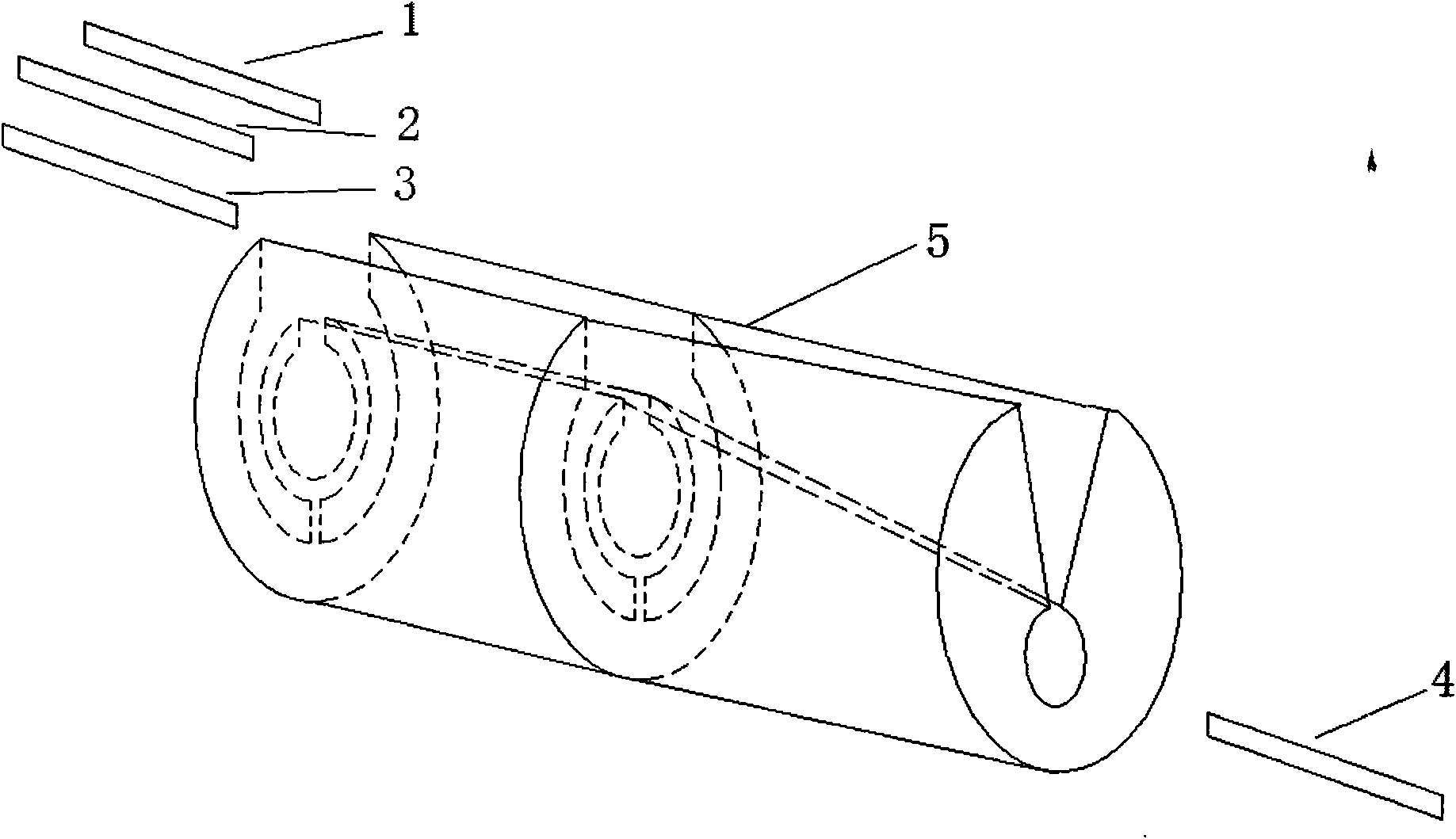

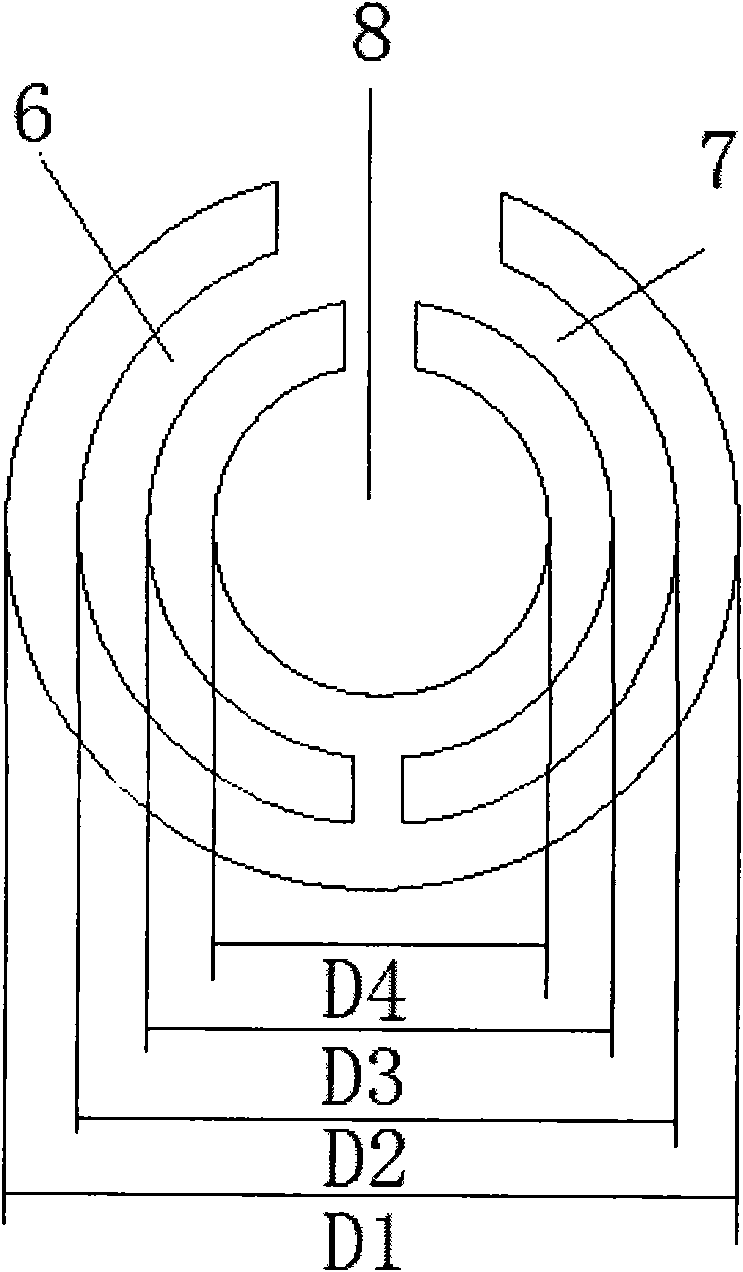

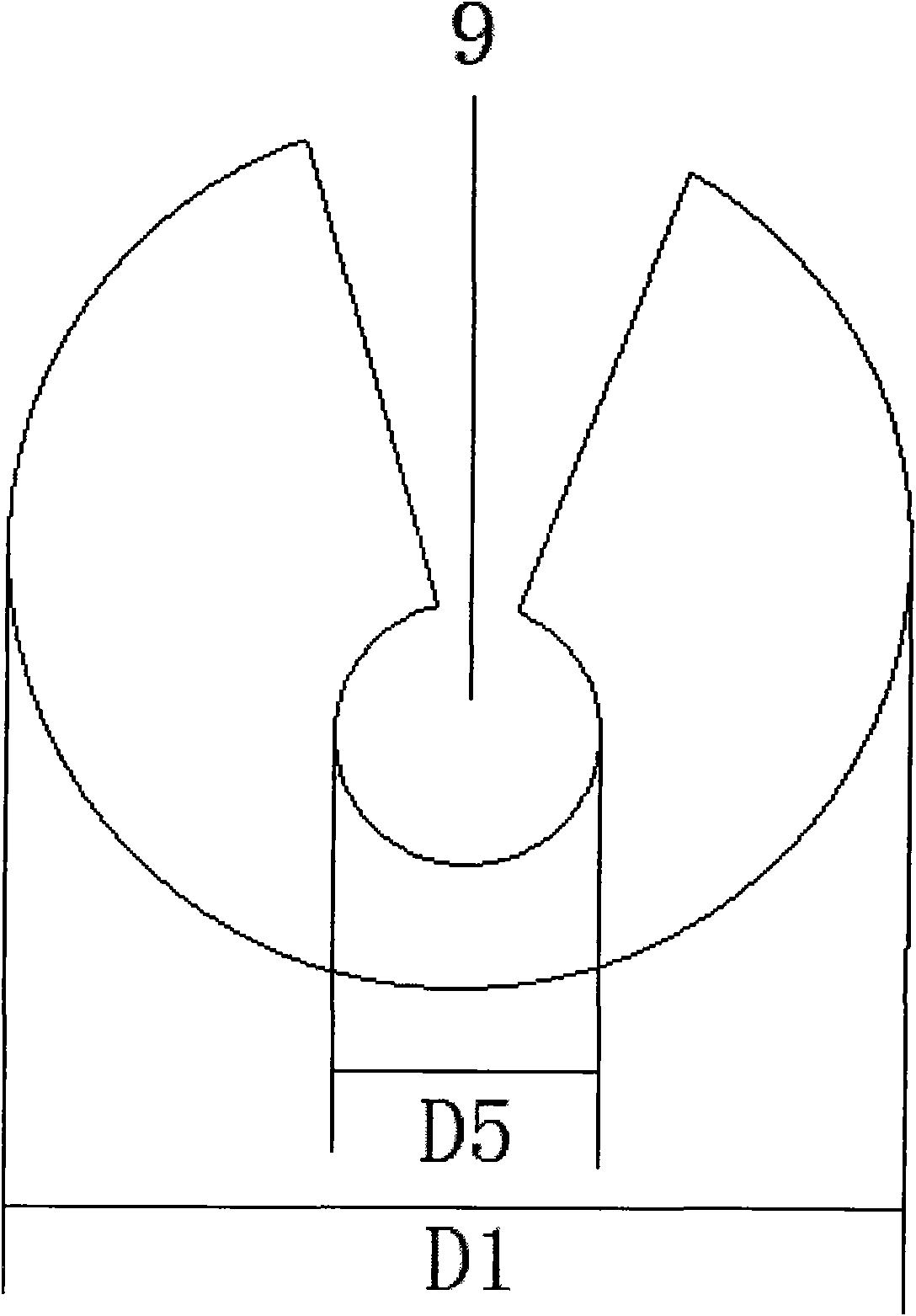

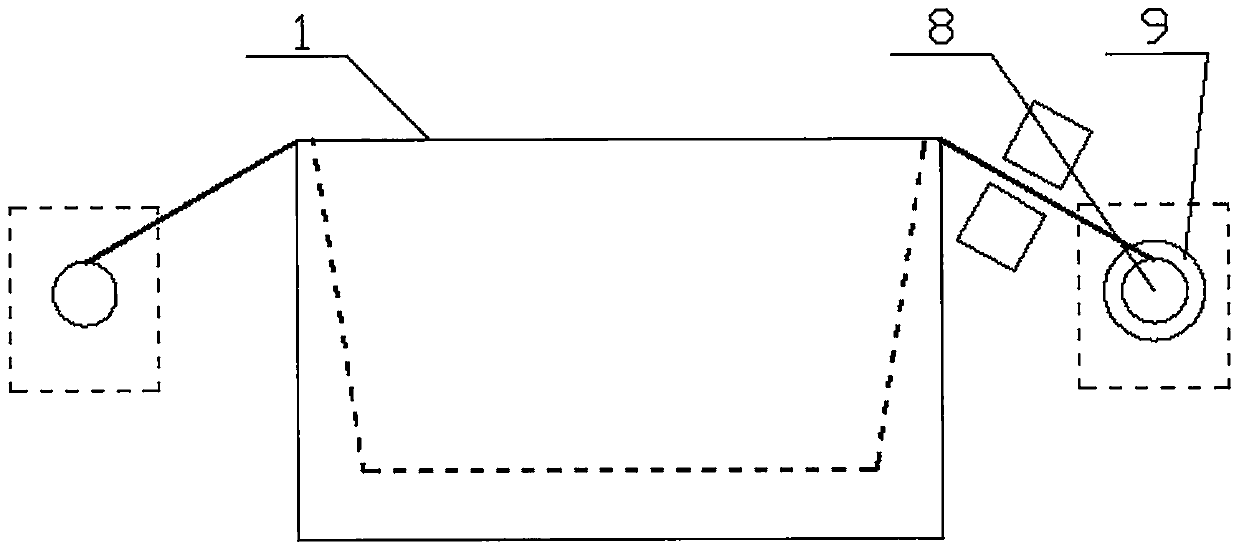

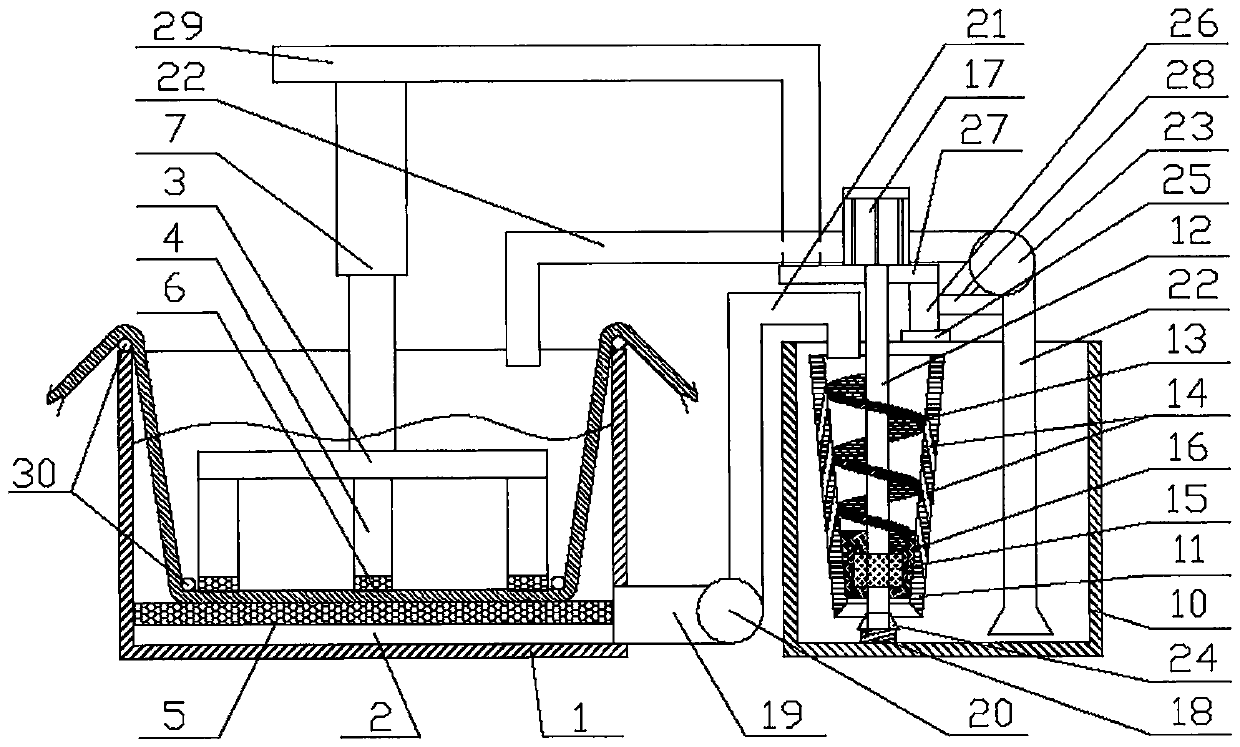

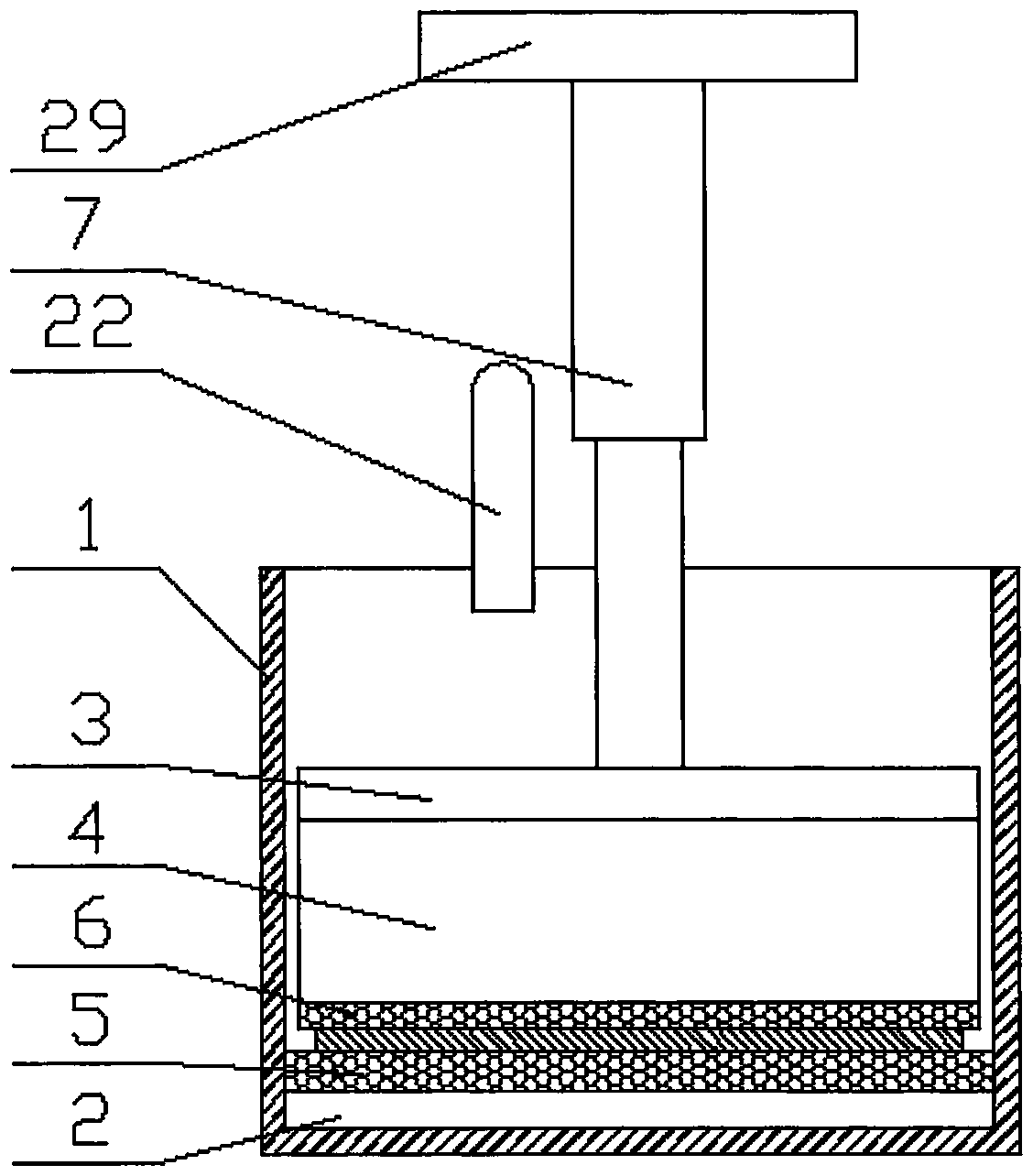

Processing device of polyester and viscose blended yarn in binary structure and method thereof

The invention relates to a processing device of polyester and viscose blended yarn in binary structure and a method thereof. A three-port collector (5) is fixed at the front part of a rear roller (11), a V-shaped opening collector (10) is fixed in a position close to the rear roller (11) between the rear roller (11) and a middle roller (12), openings in the same structure are respectively arranged at the front part, the middle part and the rear part of the three-port collector (5), a middle inlet (8) is arranged in the middle, inlets (6 and 7) at both sides are arranged on the periphery, openings are respectively arranged above the three inlets (6, 7 and 8), the rear opening is in a V-shaped structure, a round hole outlet (9) is arranged below, and the V-shaped opening collector (10) is rectangular and provided with a V-shaped groove in the middle. The invention can solve the problem of uncontrollable fiber mixing in the prior art.

Owner:DONGHUA UNIV +1

Denim fabric with bamboo-joint effect

The invention discloses a denim fabric with bamboo-joint effect. The denim fabric which is interwoven by a warp and a weft is characterized in that warp is cotton, polyester fiber and hemp blended yarn comprising, by mass, 35-40% of cotton, 30-40% of polyester fibers and 25-35% of hemp; the weft is made of composite fibers which are formed by coating polyester fibers and spandex with polyester PBT / PET composite fibers and modal fibers and particularly comprises, by mass, 10-45% of cotton, 50-86% of polyester PBT / PET composite fibers, 2-4% of polyester fibers and 2-3% of spandex. The denim fabric has clear and fine grains and has crisscross bamboo-joint effect, and is high in stereoscopic impression, good in elasticity, soft, stiff and smooth in touch, less prone to crinkling and good in elastic recovery.

Owner:NANTONG FANGKE TEXTILE TECH

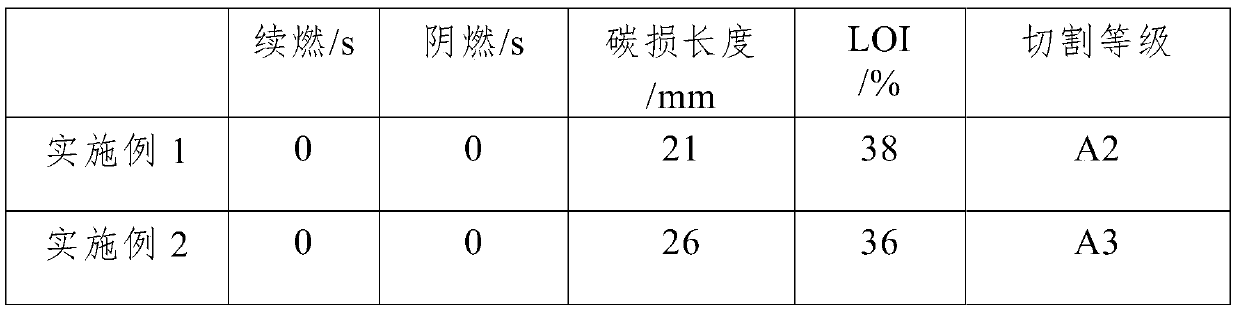

Modified polyphenylene sulfide based flame-retardant anti-cutting yarn, preparation method and gloves

The present invention relates to a modified polyphenylene sulfide based flame-retardant anti-cutting yarn. The yarn comprises the following components in percentage by mass: 20-80% of modified polyphenylene sulfide fibers, 5-40% of flame-retardant fibers and 5-40% of cutting reinforced filaments; and the modified polyphenylene sulfide fibers are polyphenylene sulfide fibers subjected to oxidationmodification, part or all of sulfur atoms in a polyphenylene sulfide structure are oxidized into sulfonyls or sulfoxide groups by oxidation modification, and the modified polyphenylene sulfide fibershave the characteristics of no melting under the high temperature, no melting shrinkage, instant quenching away from fire and the like. Protective gloves prepared from the yarn have ideal cut resistance and flame-retardant protection performance, the wearing comfort of the flame-retardant anti-cutting gloves is improved, and the cost is lower. In the field of labor protection gloves, compared witharamid fibers, the flame-retardant anti-cutting yarn has a certain advantage of substitutability.

Owner:SHANDONG XINGYU GLOVES

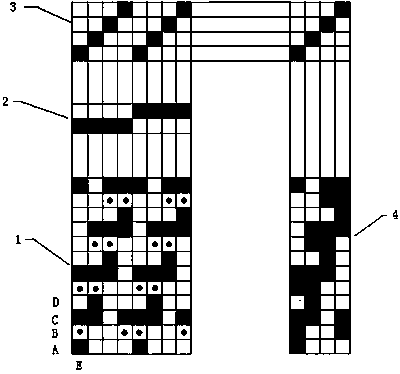

Embedded fabric and weaving process thereof

InactiveCN104514063AReduce consumptionSolve the problem of being unable to produce embeddedMulti-ply fabricsLiquid/gas/vapor yarns/filaments treatmentFiberMoisture absorption

The invention provides an embedded fabric and a weaving process thereof. The embedded fabric comprises a 3 / 1 surface fabric, a 2 / 2 medium fabric and a 1 / 3 inner fabric. The process comprises the steps of spooling; beaming; slashing; denting; weaving; finishing. According to the embedded fabric and the weaving process, the inner fabric is woven according to the process requirement; twill strips are formed on the fabric surface and are connected to form the embedded fabric; the types of embedded yarns can be adjusted; low-elastic yarns can be embedded to improve the comfort, conductive yarns can be embedded to prevent static, and breathable fiber yarns can be embedded to improve the capacity of moisture absorption and sweat releasing; therefore, the corresponding functions can be achieved, and the problem that the embedded weaving cannot be performed in the traditional weaving process can be solved; embedded fabric has the characteristics of being simple in process, small in difficult at weaving and little in consumption of special weaving devices; an embedded fabric type textile product is added for the textile field.

Owner:JIHUA 3542 TEXTILE CO LTD

Fabric including polymer filaments having profiled cross-section

InactiveUS7018946B2Good moisture wicking effectSoft handEngine sealsSynthetic resin layered productsAbnormal shapedEngineering

The present invention is directed to a multi-filament yarn formed at least in part from filaments having cross-sectional zig-zag or double “W” shape with a 180 degree axis of symmetry. The filaments have a denier per filament generally in the range of about 0.1 to about 4.0. Fabrics made from yarns formed with the filaments have high moisture wicking, soft hand, and a silk-like lustrous appearance.

Owner:THE LYCRA CO LLC

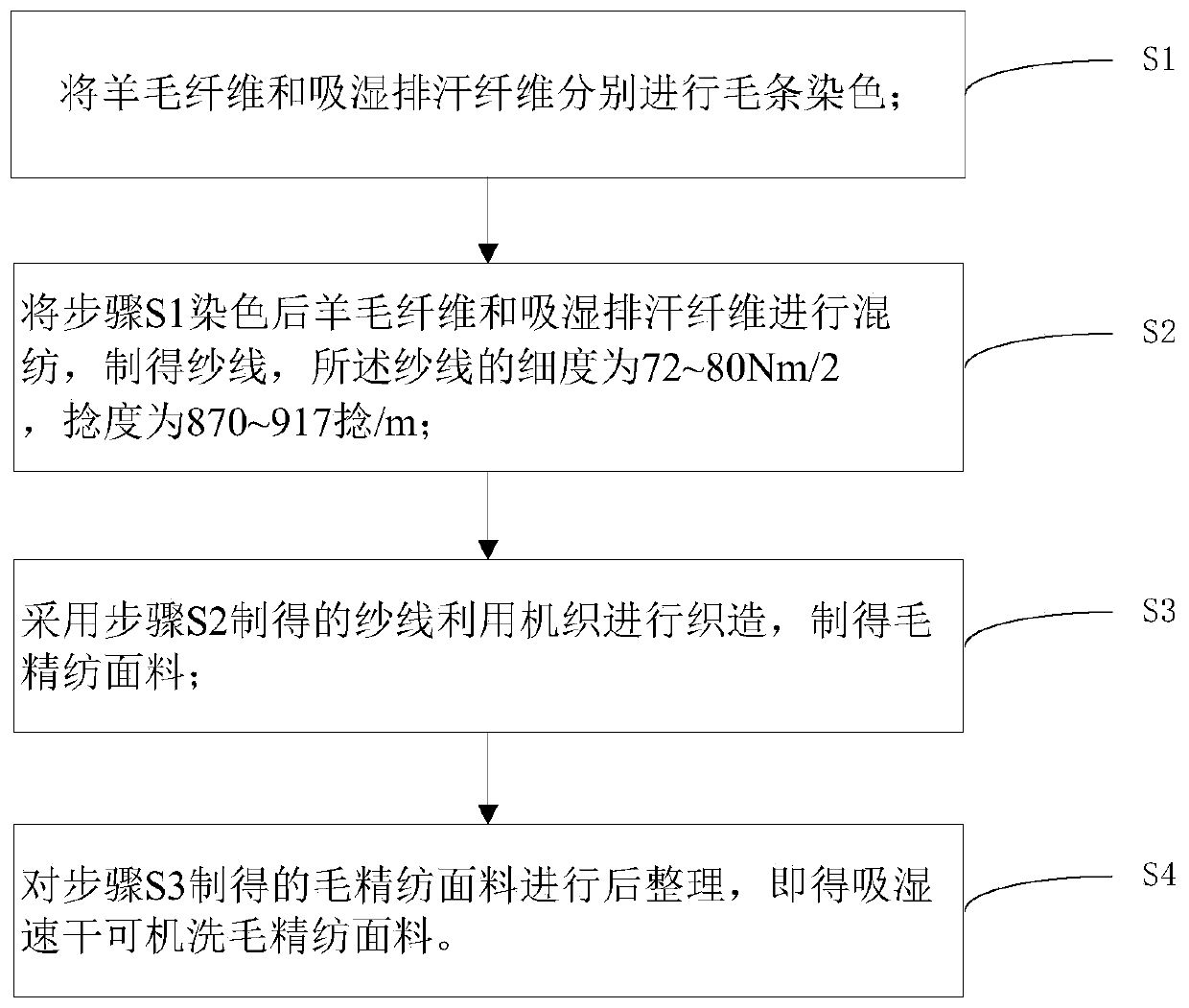

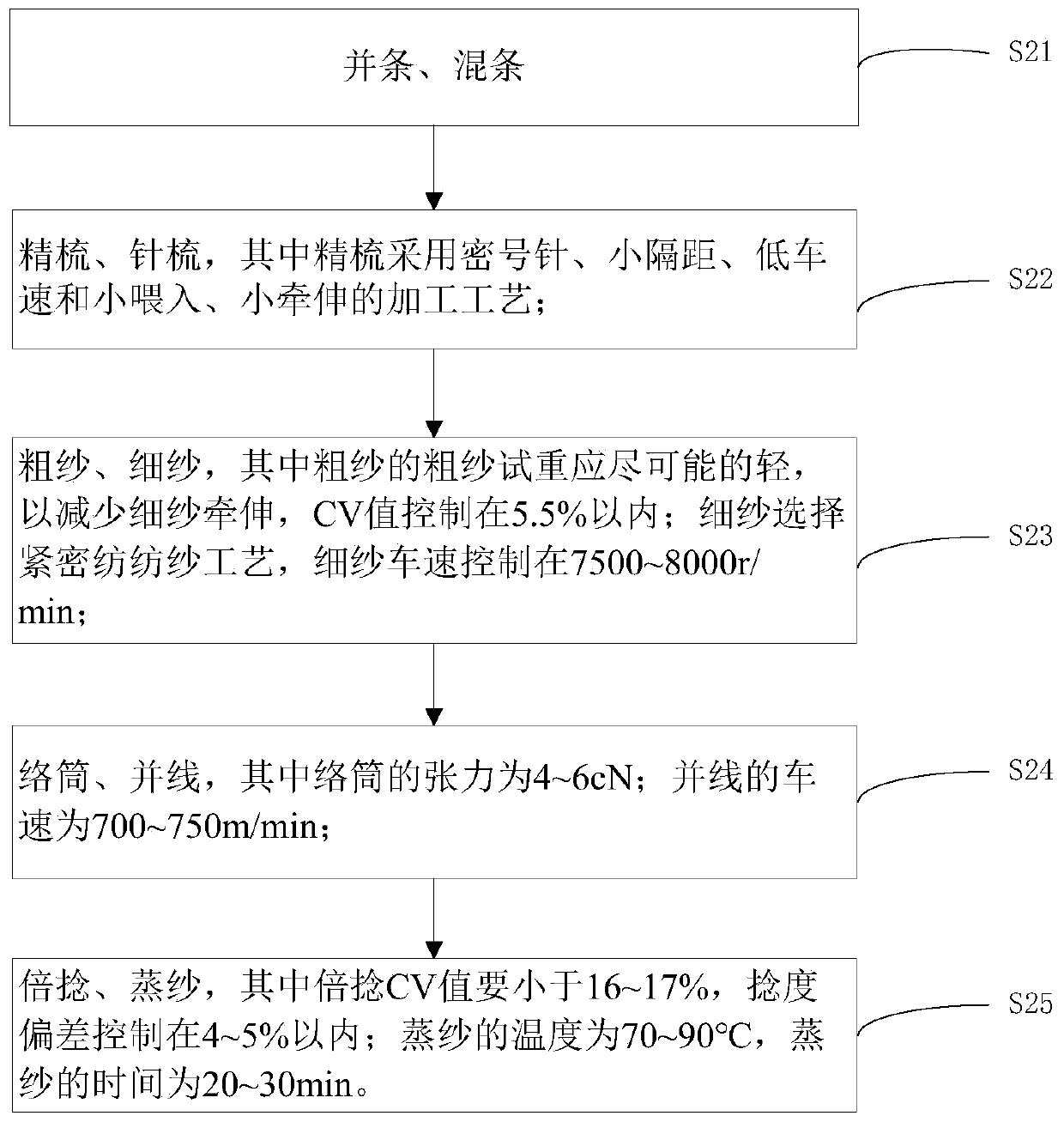

Moisture absorbing and quick-dry machine washable wool worsted fabric and production method thereof

ActiveCN109825925ASolve stuffySolve the shortcomings of poor moisture absorption and perspirationFilament/thread formingDyeing processYarnAfter treatment

The invention relates to a moisture absorbing and quick-dry machine washable wool worsted fabric and a production method thereof. The fabric is formed by blending wool fiber and moisture absorbing andperspiring fiber through wool top dyeing, spinning, weaving and after-treatment; the production method comprises the steps that wool fiber and the moisture absorbing and perspiring fiber are dyed separately, then, the dyed wool fiber and the moisture absorbing and perspiring fiber are blended to obtain blended yarn with the fineness being 72-80 Nm / 2 and the twist degree being 870-917 twist / m, theblended yarn is woven by means of a weaving machine to obtain the wool worsted fabric, and finally after-treatment is performed to obtain the moisture absorbing and quick-dry machine washable wool worsted fabric. The problems that in the prior art, a pure wool fabric is stuffy in summer and poor in moisture absorbing and perspiring performance are solved, and the wool worsted fabric is thin in texture, good in touch, good in breathability, good in moisture absorbing and quick-dry performance, stable and lasting in function and environmentally friendly and saves energy, and has the machine washable function; the application limit of wool fiber as the summer fabric is broken through, the various requirement for modern society is met, and the good application and popularization value is achieved.

Owner:山东如意毛纺服装集团股份有限公司 +1

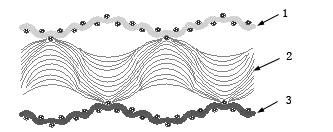

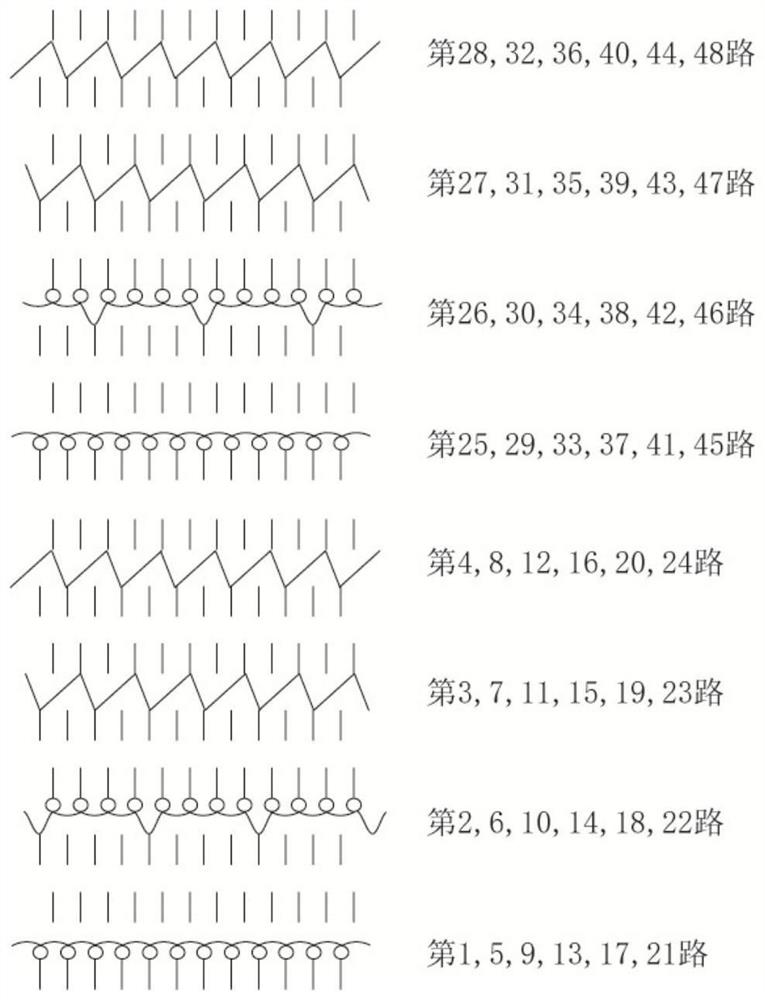

Three-dimensional one-way moisture-conducting elastic fabric based on knitted structure and preparation method thereof

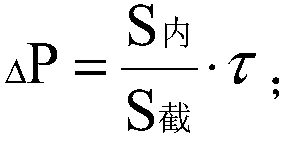

InactiveCN112226888AImprove one-way moisture transfer performanceAvoid damageWeft knittingHollow filament manufacturePolymer scienceElastic fiber

The invention relates to a three-dimensional one-way moisture-conducting elastic fabric based on a knitted structure and a preparation method thereof. The three-dimensional one-way moisture-conductingelastic fabric is of a three-layer weft knitting structure; a surface layer is of a double-sided weft knitting structure with tucks; an inner layer is of a single-sided weft knitting plain stitch structure; a middle layer is of a double-sided tucking structure; the surface layer is composed of hydrophilic fiber yarns and elastic fiber yarns; the middle layer is composed of moisture-conducting fiber yarns; the inner layer consists of hydrophobic fiber yarns and the elastic fiber yarns; the monofilament number of hydrophobic fibers, moisture-conducting fibers and hydrophilic fibers is sequentially decreased progressively; the F numbers of the hydrophobic fiber yarns, the moisture-conducting fiber yarns and the hydrophilic fiber yarns are gradually increased in sequence; and the preparationmethod includes the steps of selecting a double-faced circular knitting machine; knitting the fabric; and carrying out stentering on the fabric. According to the three-dimensional one-way moisture-conducting elastic fabric based on the knitted structure and the preparation method thereof, the weft-knitted spacer fabric with excellent elasticity and a one-way moisture-conducting function is prepared, and can be used for sports fabric of racing competitive clothing, so that the problem that a large amount of water vapor generated by a human body cannot be quickly discharged out of the body underthe condition of high-speed sports is solved.

Owner:DONGHUA UNIV

Antibacterial thermal fabric and preparation method thereof

ActiveCN111098564AGood hygroscopicityGood moisture wicking effectLiquid/gas/vapor open-width material treatmentSynthetic resin layered productsYarnPolymer science

The invention discloses an antibacterial thermal fabric and a preparation method thereof, and belongs to the technical field of textile silk yarns. The fabric comprises the following components (by weight): 30 to 45 parts of bamboo fiber, 10 to 20 parts of Coppron copper ion fibers, 30 to 45 parts of cotton fibers, 20 to 30 parts of kapok fibers, 10 to 15 parts of filament goose down, and 10 to 15parts of thermal fibers. The preparation method comprises the following steps: firstly, blending the cotton fibers and the filament goose down fibers into silk yarns A; blending kapok fibers and partof bamboo fibers into silk yarns B; twisting the two kinds of silk yarn together to be woven into a first fabric, then blending the Coppron copper ion fibers and the remaining bamboo fibers into silkyarns C, weaving the silk yarns C and the thermal fibers into a second fabric, then bonding the two kinds of fabric together to obtain a gray fabric, and then dyeing the gray fabric and shaping. Theantibacterial thermal fabric prepared according to the preparation method provided by the invention has efficient antibacterial thermal performance, and is relatively good in air permeability and comfort.

Owner:YANCHENG SILIDE COCOON SILK

Sweat discharge naked feeling triple antibacterial underpants and manufacturing method thereof

ActiveCN109938419AAchieve leapfrog upgradesExquisite technologyWeft knittingVegetal fibresFiberMoisture absorption

The invention discloses sweat discharge naked feeling triple antibacterial underpants and a manufacturing method thereof. The manufacturing method of the sweat discharge naked feeling triple antibacterial underpants comprises the following steps: (1) preparing an antibacterial finishing liquid; (2) carrying out lining antibacterial finishing; and (3) cutting and sewing a large body fabric, a rubber rib and an antibacterial lining into underpants by using a common method, thereby obtaining the sweat discharge naked feeling triple antibacterial underpants. By adopting the sweat discharge naked feeling triple antibacterial underpants and the manufacturing method thereof, the lining is made of an X-STATIC and bamdal fiber and is further subjected to antibacterial finishing, a naked feeling fabric is adopted as the large body fabric, the obtained sweat discharge naked feeling triple antibacterial underpants are good in moisture absorption and sweat discharge, soft and breathable, high in yellowing resistance, high in washing resistance, remarkable in antibacterial property after multiple times of washing and comfortable to wear, and the remarkable and long-lasting antibacterial propertyis beneficial to human body health.

Owner:上海小蓝象服装有限公司

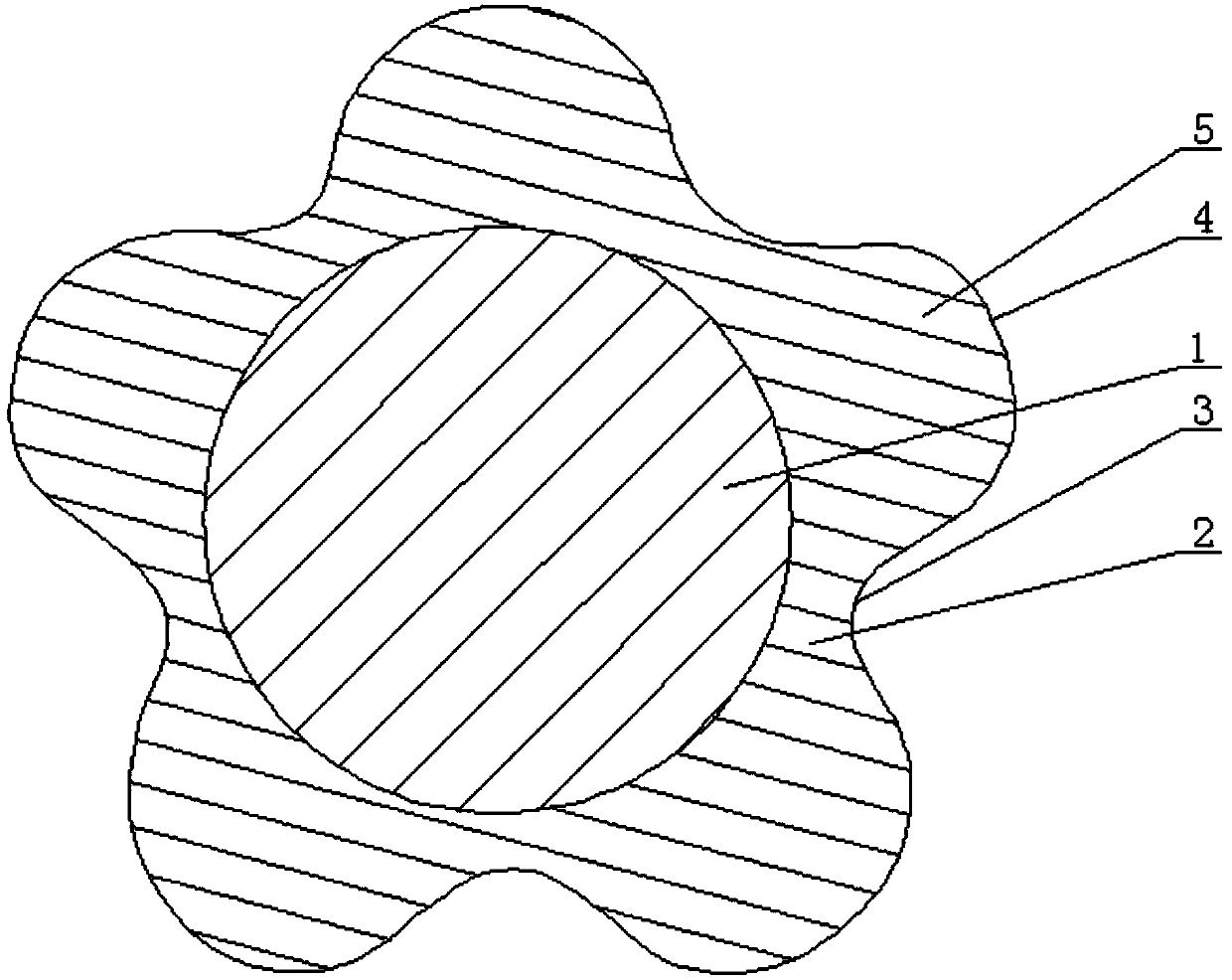

Efficient moisture-absorbing and sweat-releasing composite fiber with antistatic property

InactiveCN109898167AImprove hydrophilicityImprove antistatic performanceElectroconductive/antistatic filament manufactureFilament/thread formingFiberPolyester

The invention discloses an efficient moisture-absorbing and sweat-releasing composite fiber with an antistatic property. The efficient moisture-absorbing and sweat-releasing composite fiber comprisesa core layer with a circular cross section, and a sheath layer covering the periphery of the core layer. The cross section of the sheath layer is in the shape of five leaves. Five leaf margins are evenly distributed on the sheath layer in the circumferential direction, and diverge around the center point of the core layer. Transition of the outer ends of the leaf margins is realized through curvedsurfaces, and an arc-shaped groove is formed between every two adjacent curved surfaces. The core layer is made from polyesters, and the sheath layer is made from blends of co-polyether esters and polyesters. The efficient moisture-absorbing and sweat-releasing composite fiber with the antistatic property has a low cost, good moisture absorbing and sweat releasing effects and the antistatic property.

Owner:SHAOXING JINCHEN BIOLOGICAL TECH CO LTD

Preparation method of polylactic acid fiber/polyester fiber blended fabric with moisture absorbing and perspiration functions

The invention discloses a preparation method of polylactic acid fiber / polyester fiber blended fabric with moisture absorbing and perspiration functions. The method comprises the steps that acrylic acid monomers are taken as modified monomers, and modified acrylic acid fiber is obtained by adopting an in-situ aggregation method; a layer of nano silica is condensed on the surface of the modified acrylic acid fiber; finally the fabric is obtained by covering the modified polylactic acid fiber with the polyester fiber and blended. The fabric prepared by means of the method has good moisture absorbing and permeability and is soft, comfortable, simple to prepare and low in cost.

Owner:DONGGUAN LIANZHOU INTPROP OPERATION MANAGEMENT CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com