Patents

Literature

188results about "Liquid/gas/vapor open-width material treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for preparing coated fabric with glaring and charming visual effect

InactiveCN101608404AVisual Effects SavingsSave raw materialsLiquid/gas/vapor open-width material treatmentSynthetic resin layered productsEngineeringPre treatment

The invention provides a process for preparing a coated fabric with a glaring and charming visual effect, belonging to the technical field of coated fabric preparation process. The process is characterized by comprising the following steps: a, coating the fabric which is subjected to pre-treatment, dyeing or dyed printing and presetting, wherein, the coating process is divided into two parts: (1) first coat: the first coat adopts PA transparent adhesive tape for dry coating; (2) top coat: the top coat adopts PA adhesive mixed with fantasy pearlescent powder or colorful pearlescent powder for dry coating; and b, after finishing: the after finishing comprises the following steps: preparing a stiff and water resistance finishing solution for the fabric, and padding the coated fabric on a setting machine with a groove. The fabric prepared by the process not only can emit pearly luster, and has glaring and charming visual effect, but also has the functions of stiffness and water resistance, is particularly suitable for manufacturing umbrella fabrics, curtains, bath curtains and other products, and has wide application range. Furthermore, the preparation process saves raw materials and energy consumption.

Owner:RIXIN TEXTILE

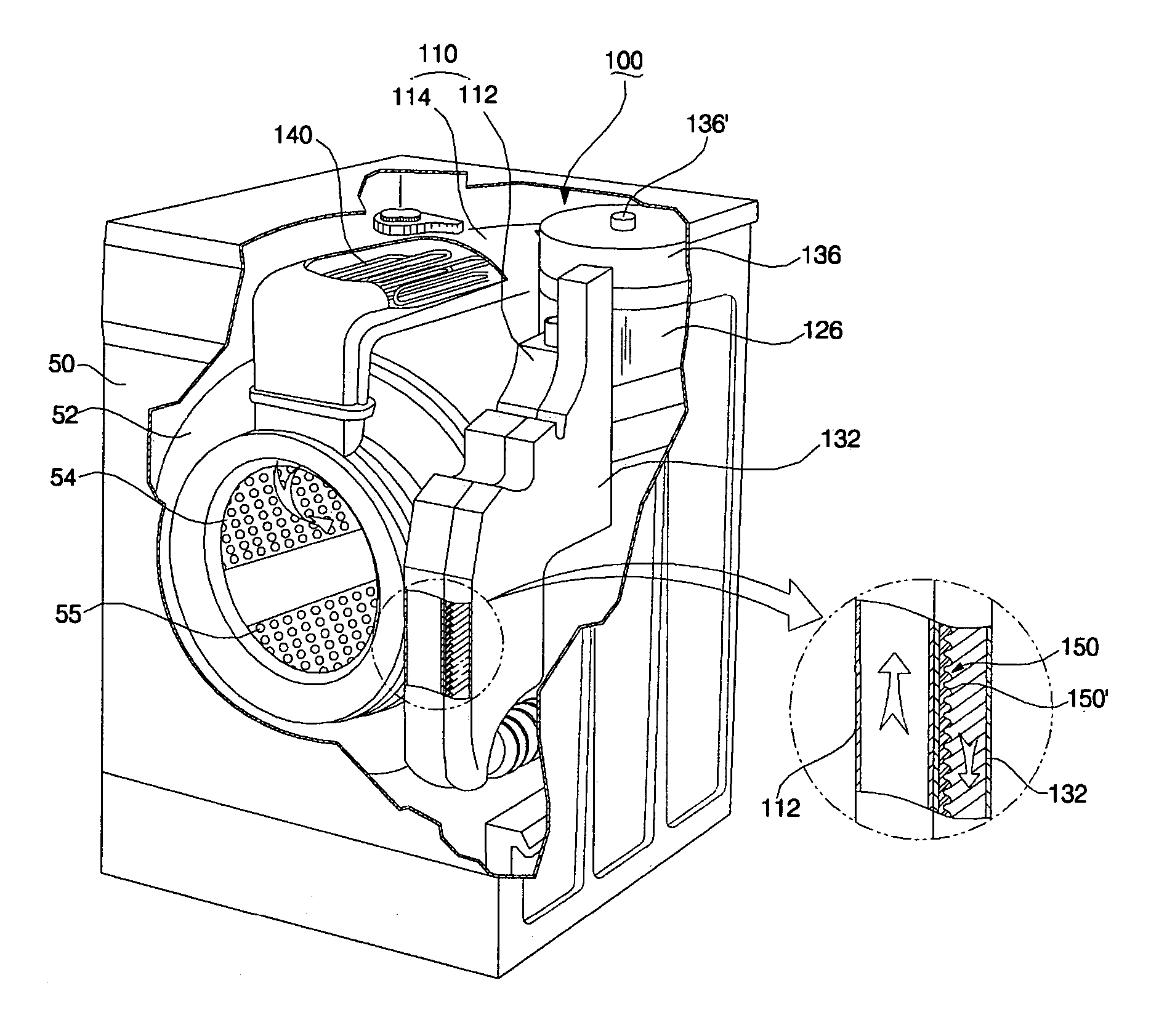

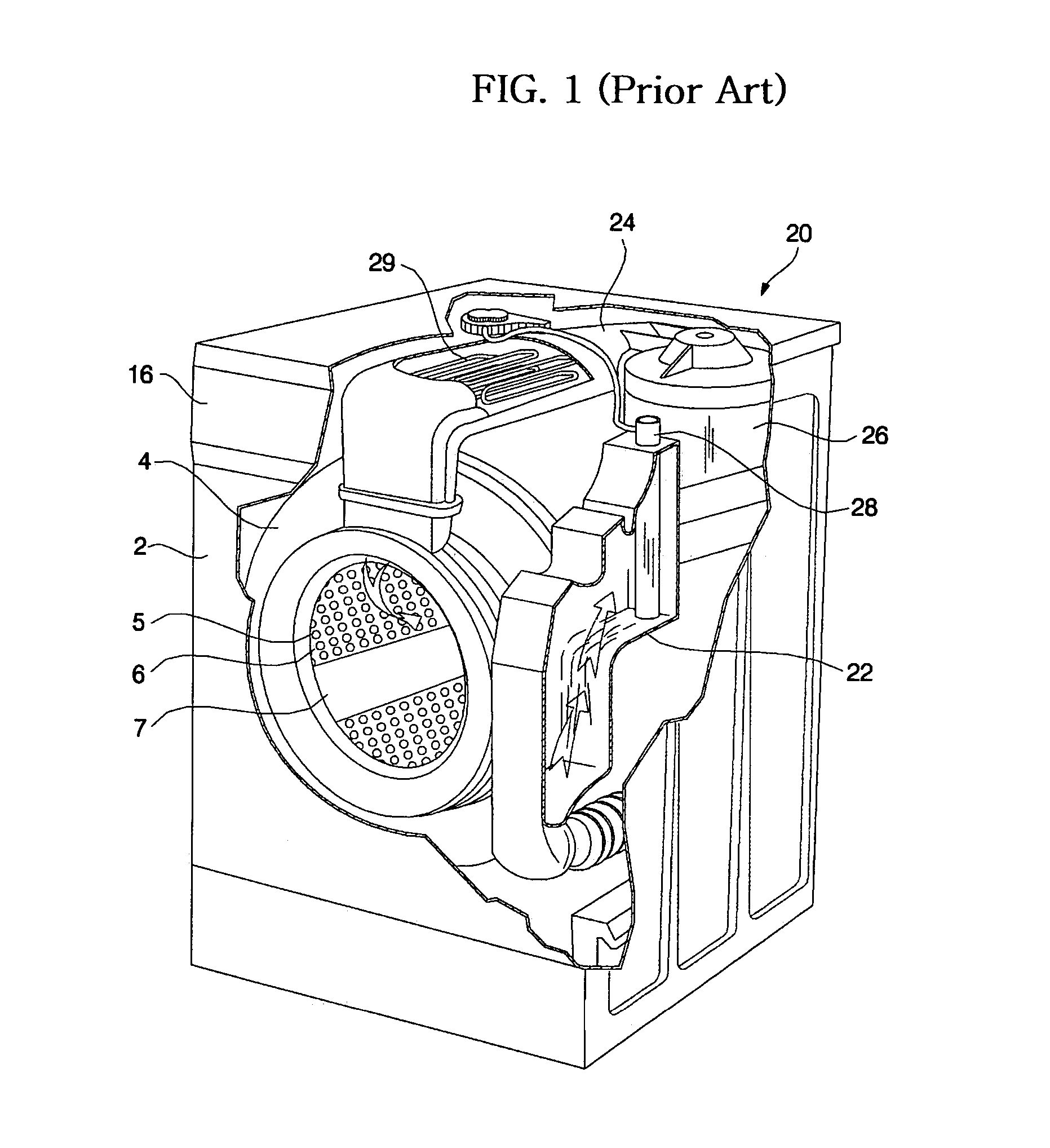

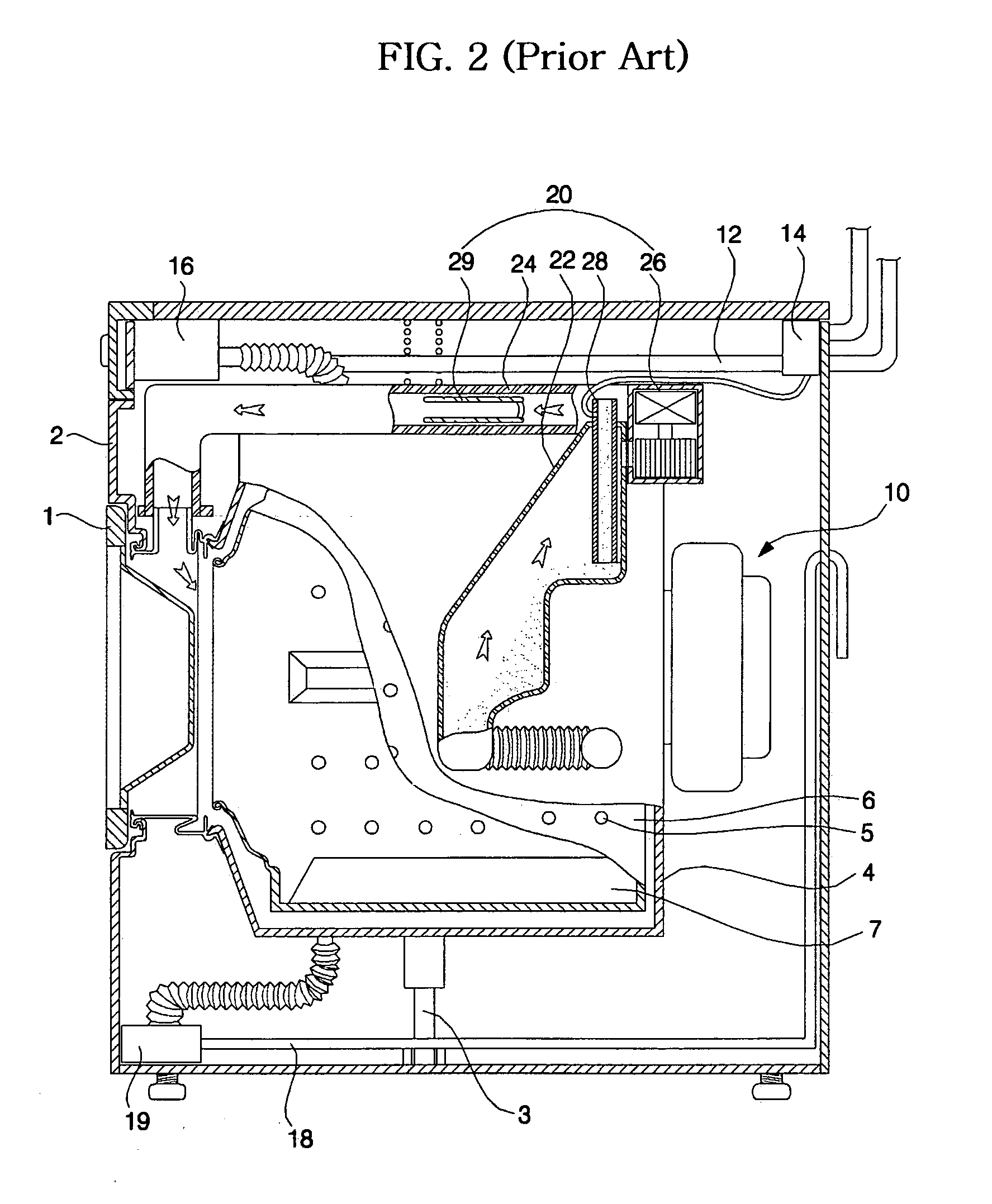

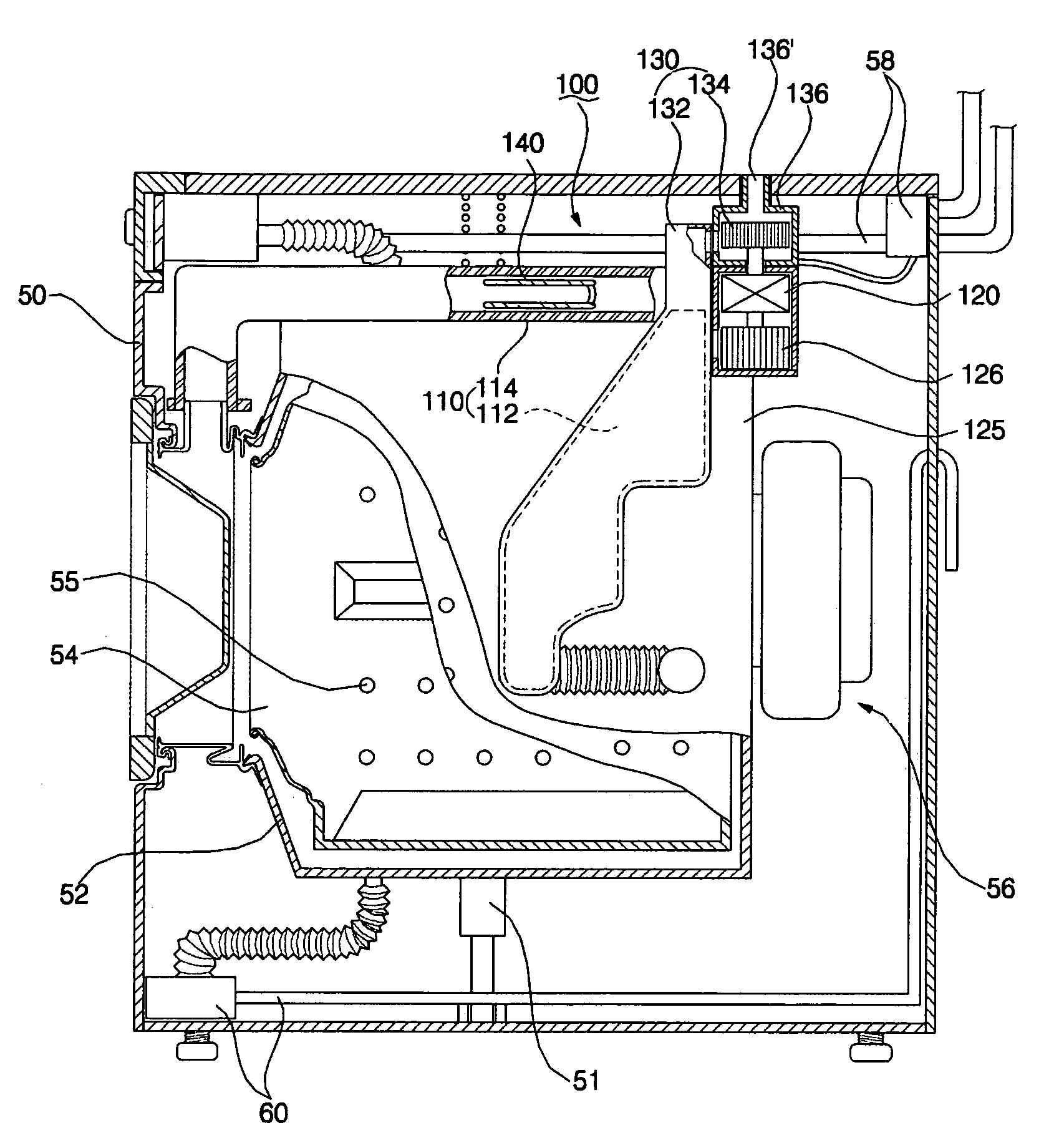

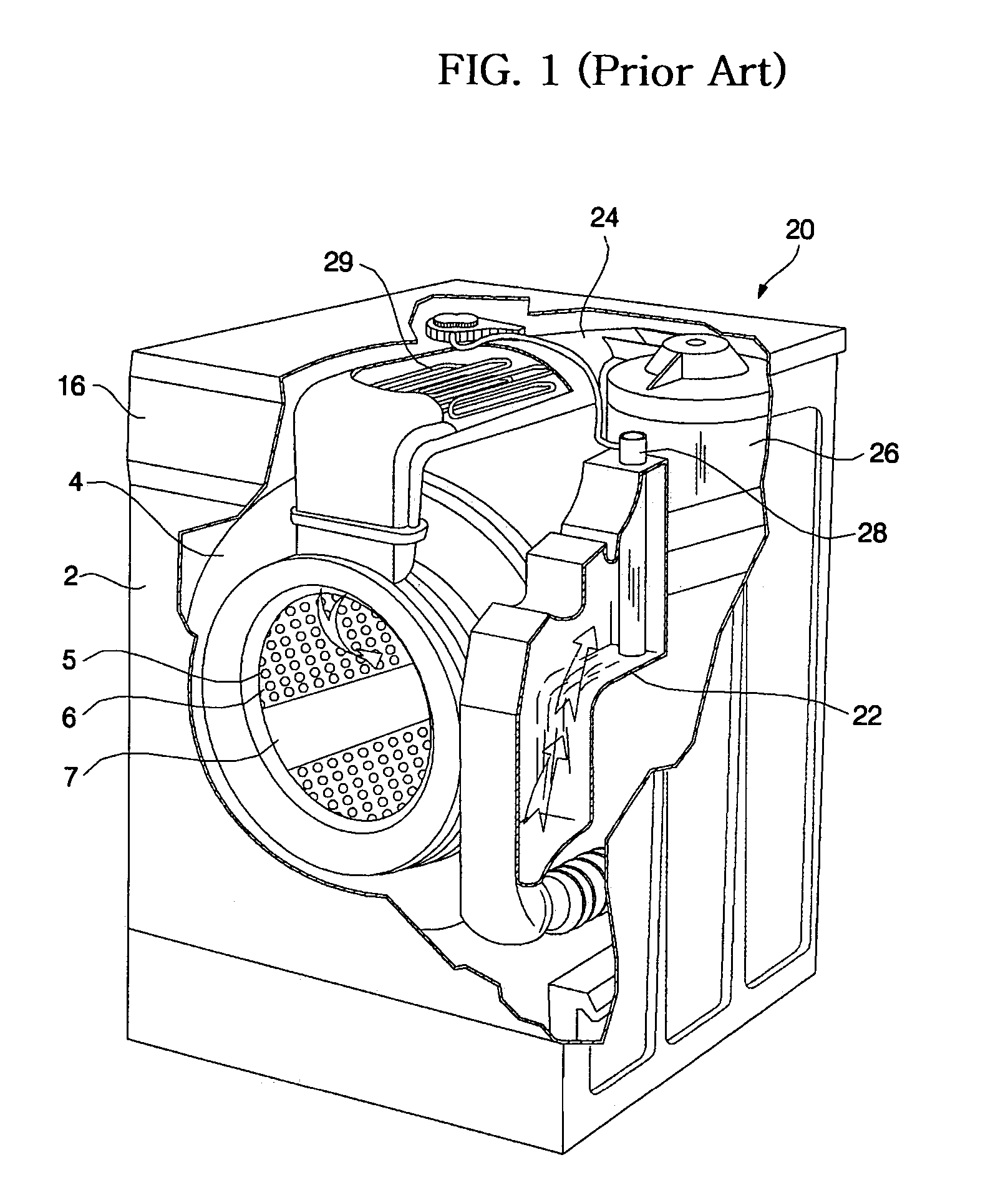

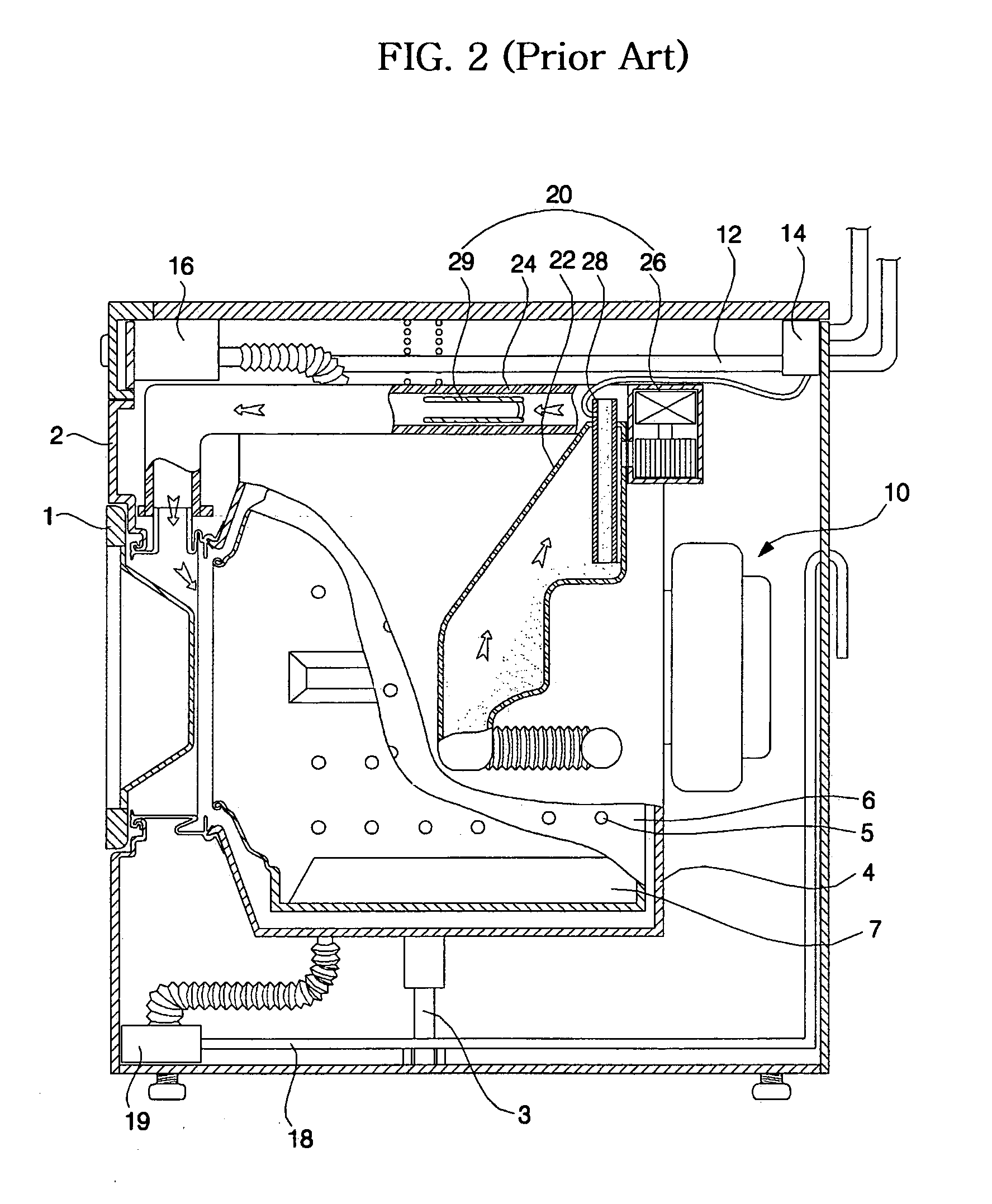

Drying unit for washing machines

InactiveUS20050223583A1Reduce consumptionLiquid/gas/vapor open-width material treatmentDrying gas arrangementsCold airPulp and paper industry

Disclosed herein is a drying unit for washing machines that is capable of fully drying the wet laundry using hot wind. A condensing duct and a drying duct are connected to a tub to circulate air in the tub. Between the drying duct and the condensing duct is disposed a drying fan. To the condensing duct is attached air cooling device for condensing air in the condensing duct by means of cool air. In the drying duct is mounted a drying heater for heating air in the drying duct to change the air into hot wind. During the drying operation of the washing machine, the air passing through the condensing duct is condensed by air, which is an unlimited resource. Consequently, consumption of energy and resources is minimized during the drying operation of the washing machine.

Owner:LG ELECTRONICS INC

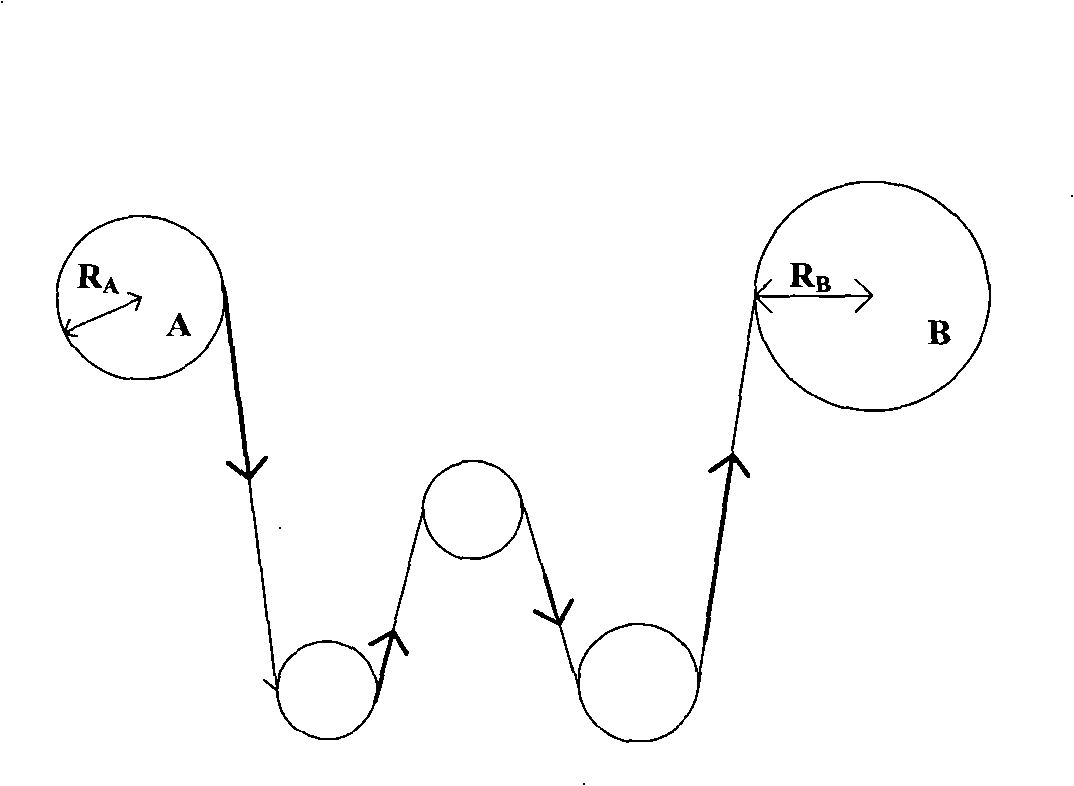

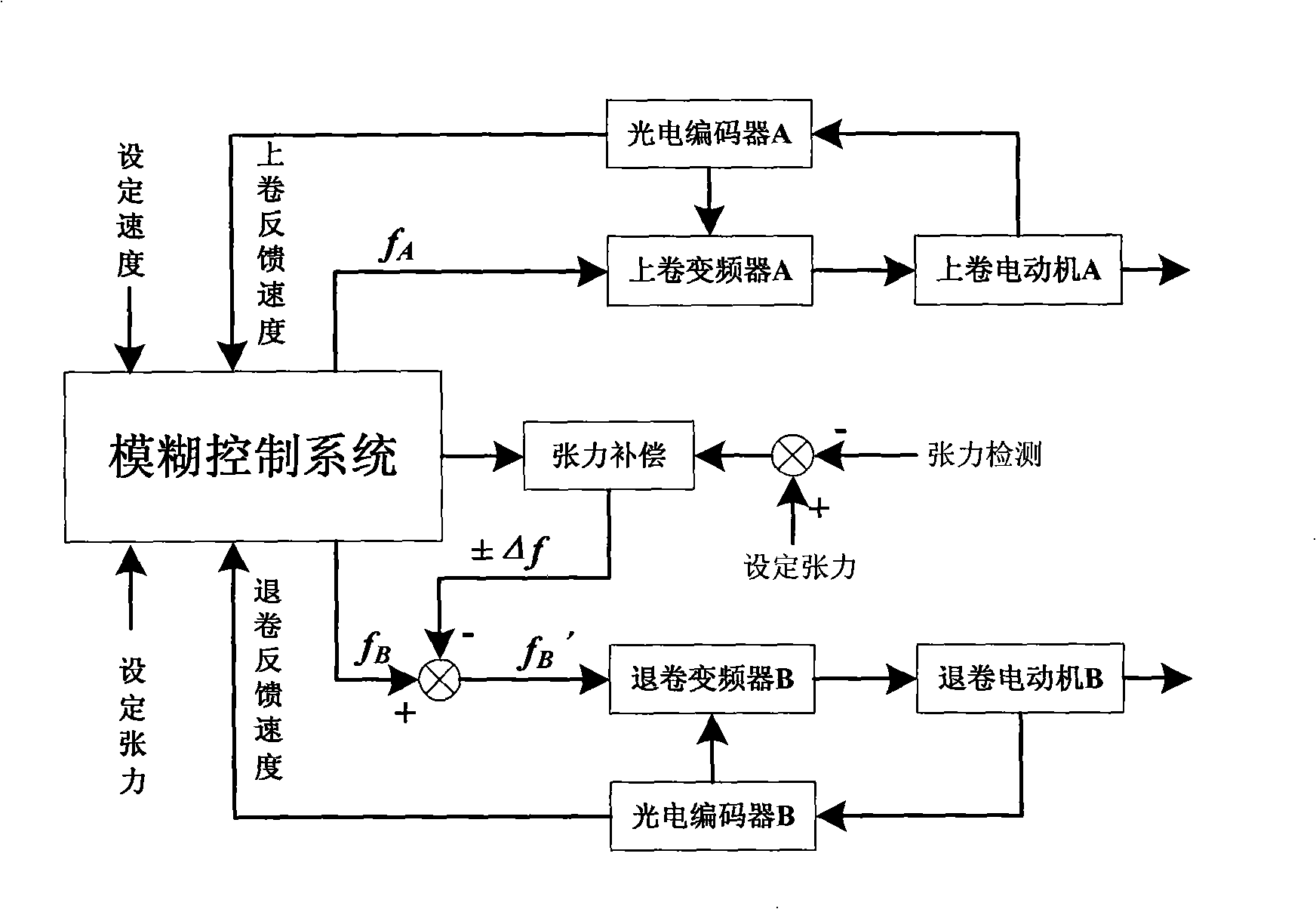

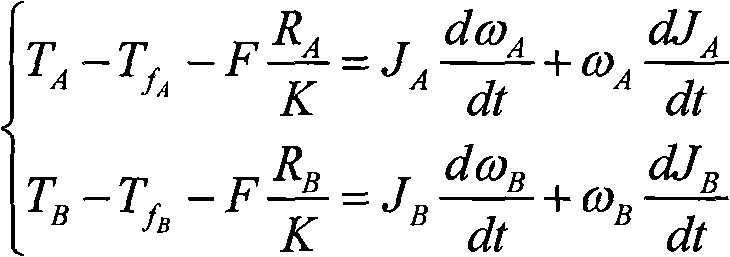

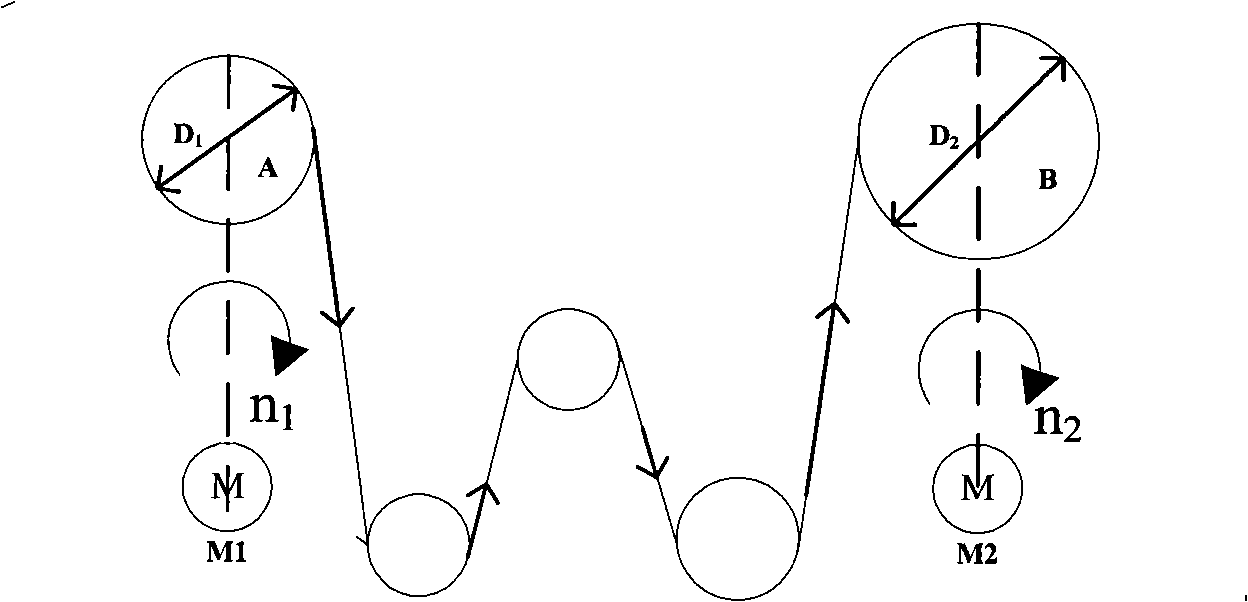

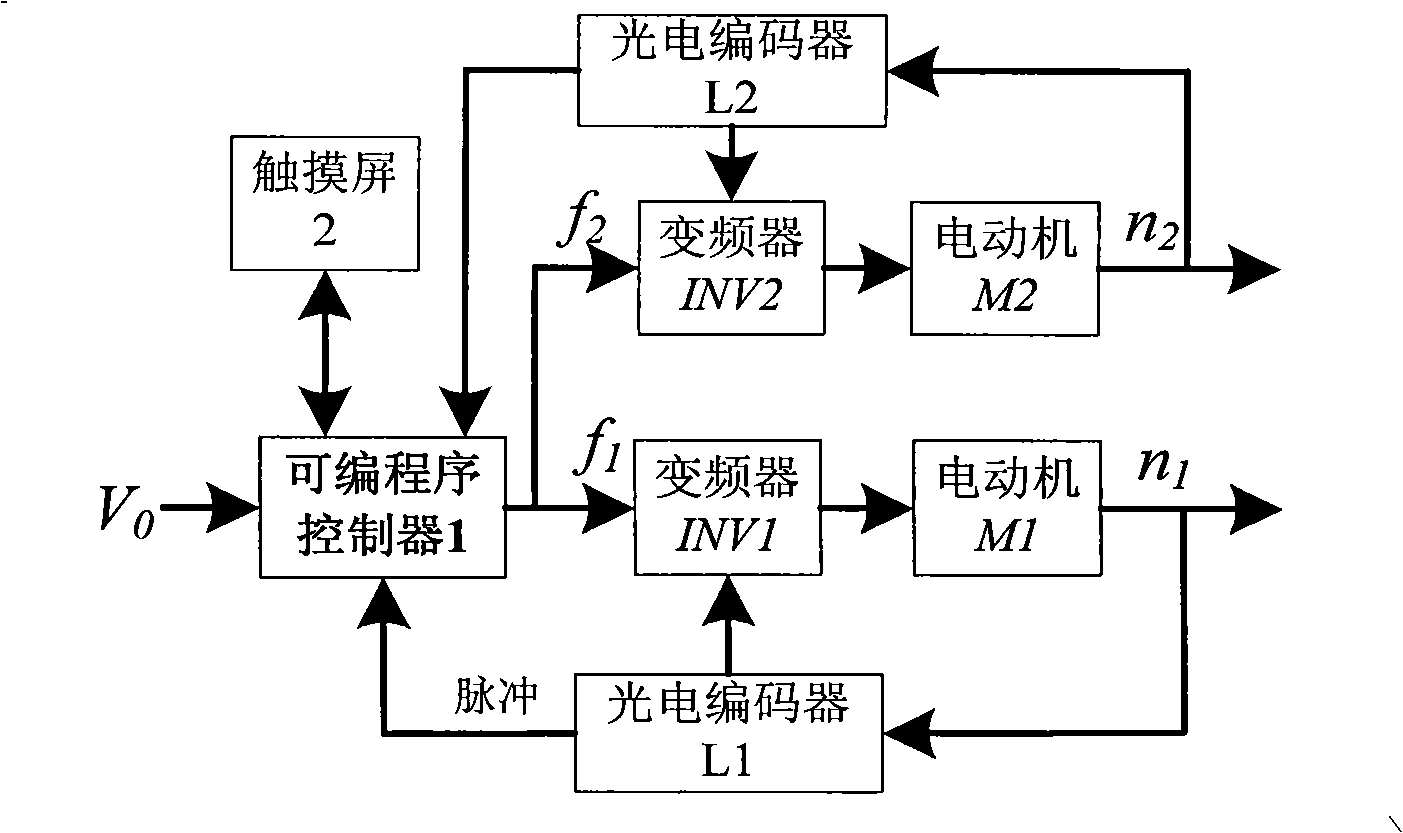

Beam dyeing machine cloth velocity-tension coordinating control method

InactiveCN101308363AImprove dyeing qualitySolve the coupling problemLiquid/gas/vapor open-width material treatmentTextile treatment machine arrangementsWire speedVelocity constant

The invention discloses a speed-tension coordination control method for jigger fabrics; the method mainly uses a fuzzy control system to compare the sampling speed of a photoelectric coder with the set speed, and compare the tension-detection value of a tension detection device with the set tension, so as to timely adjust the control rules according to the dynamic changes of the errors to subsectionally and alternately control the speed and the tension to respectively obtain a coiling frequency fA and an unwinding frequency fB needed in maintaining the equal linear velocity constant tension of dyeing fabrics; a coiling electromotor and an unwinding electromotor are respectively controlled by a coiling transducer working in speed mode and an unwinding transducer working in torque conversion mode. The method solves the coupling problem between the speed and the tension of the jigger fabrics and makes more accurate speed-tension coordination control of the double-input / double-output, coupled and time-varying non-linear system of jiggers, so as to reduce dyeing color difference caused by instable speed and tension and improve the dyeing quality of fabrics.

Owner:ZHEJIANG UNIV

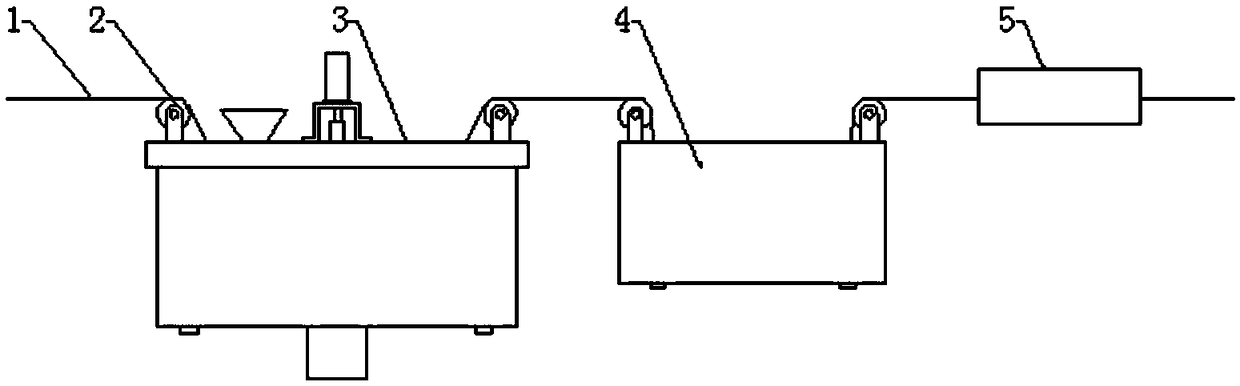

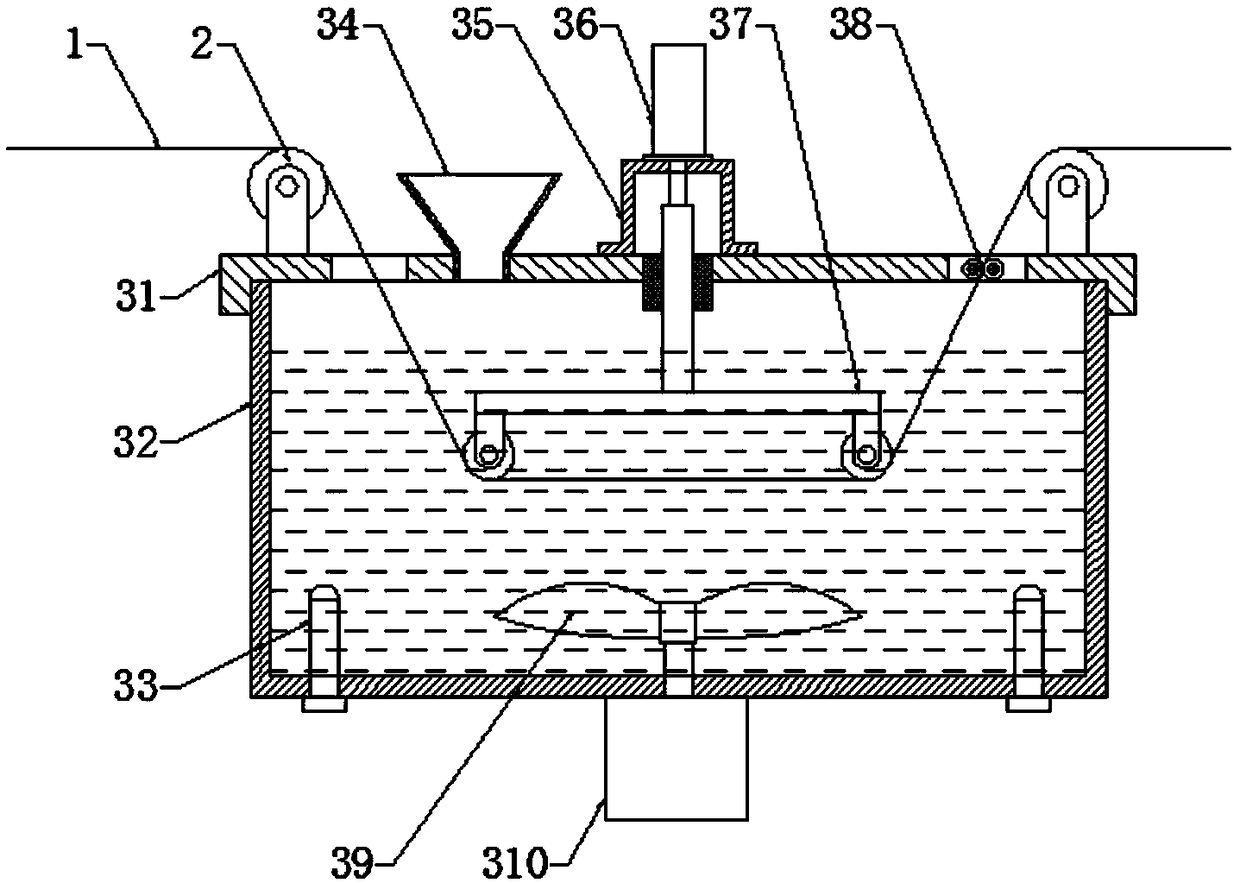

Polyester yarn dyeing device and method

InactiveCN109281097ARealize flow dyeingRealize streamlined dyeing processLiquid/gas/vapor open-width material treatmentSucessive textile treatmentsPolyesterYarn

The invention discloses a polyester yarn dyeing device and method. The polyester yarn dyeing device comprises polyester yarn, a dyeing mechanism, a washing mechanism and a drying mechanism; the washing mechanism and the drying mechanism are arranged on one side of the dyeing mechanism in sequence, the polyester yarn penetrates through the dyeing mechanism, the washing mechanism and the drying mechanism in sequence, and yarn guide wheels are arranged at the left and right ends of the upper surface of the dyeing mechanism and the left and right ends of the upper surface of the washing mechanismrespectively. According to the polyester yarn dyeing device and method, the polyester yarn is subjected to flow dyeing through the yarn guide wheels and dyeing guide wheels of the dyeing mechanism, surface dye of the polyester yarn is washed through the washing mechanism, finally, the polyester yarn is dried through the drying mechanism, and thus flow dyeing processing of the polyester yarn is achieved; no repeated dyeing operation is needed, and time and labor are saved; meanwhile, extruding rollers extrude out redundant dye carried by the polyester yarn, redundant dye is prevented from beingcarried out, and thus resource waste is greatly reduced.

Owner:福建省天和纺织实业有限公司

Method of staining copper ammonia fiber and tencel interwoven cloth

ActiveCN101016683AFeel goodIncrease elasticityLiquid/gas/vapor open-width material treatmentDyeing processCuprammonium rayonCellulose

The invention relates to a dying method of copper ammonia fiber and silk interwoven cloth, comprising that (1) washing with water, (2) refining, (3) washing with cellulose, (4) dying. And the fur burning process is purpose to remove silk fiber exposed outside the interwoven cloth and the short flannel, eyebrow and foreign material adhered on the face of cloth. The water washing process is purposed to clean the dirt on the face of interwoven cloth. The refining process is purposed to remove the slurry, grease of wrap and the dirt on the face of cloth. The cellulose washing process is purposed to remove the hair generated by fibrosis, to avoid balling. The inventive product has the appearance of silk brocade cloth and improves bacteria resistance function.

Owner:WUJIANG DEYI FASHIONS CLOTHS

Dye process of mixed fabric of cuprammonium fiber and rayon

InactiveCN101046068AAnti-crack performanceFeel goodLiquid/gas/vapor open-width material treatmentDyeing processCuprammonium rayonEngineering

The dyeing process of cuprammonium rayon includes the following steps: water washing, refining and dyeing. In the water washing step, stains on the cuprammonium rayon is eliminated initially; the refining step eliminates sizing material, grease and stains, improves the hand feeling, and raises the dyeing permeability and homogeneity. The dyed cuprammonium rayon fabric is hygroscopic, air permeable and comfortable.

Owner:WUJIANG DEYI FASHIONS CLOTHS

Dyeing method for copper ammonia fiber and cotton, cotton brocade core-spun yarn interwoven cloth

ActiveCN101082183AIncrease elasticityFeel goodLiquid/gas/vapor open-width material treatmentBiochemical fibre treatmentYarnCuprammonium rayon

The present invention relates to the process of dyeing interwoven fabric of cuperammonium fiber and cotton / cotton-Jinlun covering yarn. The dyeing process includes the following steps: water washing, refining, leaching, cellulose water washing, and dyeing. Thus dyed interwoven fabric has the style similar to silk fabric, good hydroscopic and permeating performance, high elasticity, and other advantages, and is fashionable.

Owner:WUJIANG DEYI FASHIONS CLOTHS

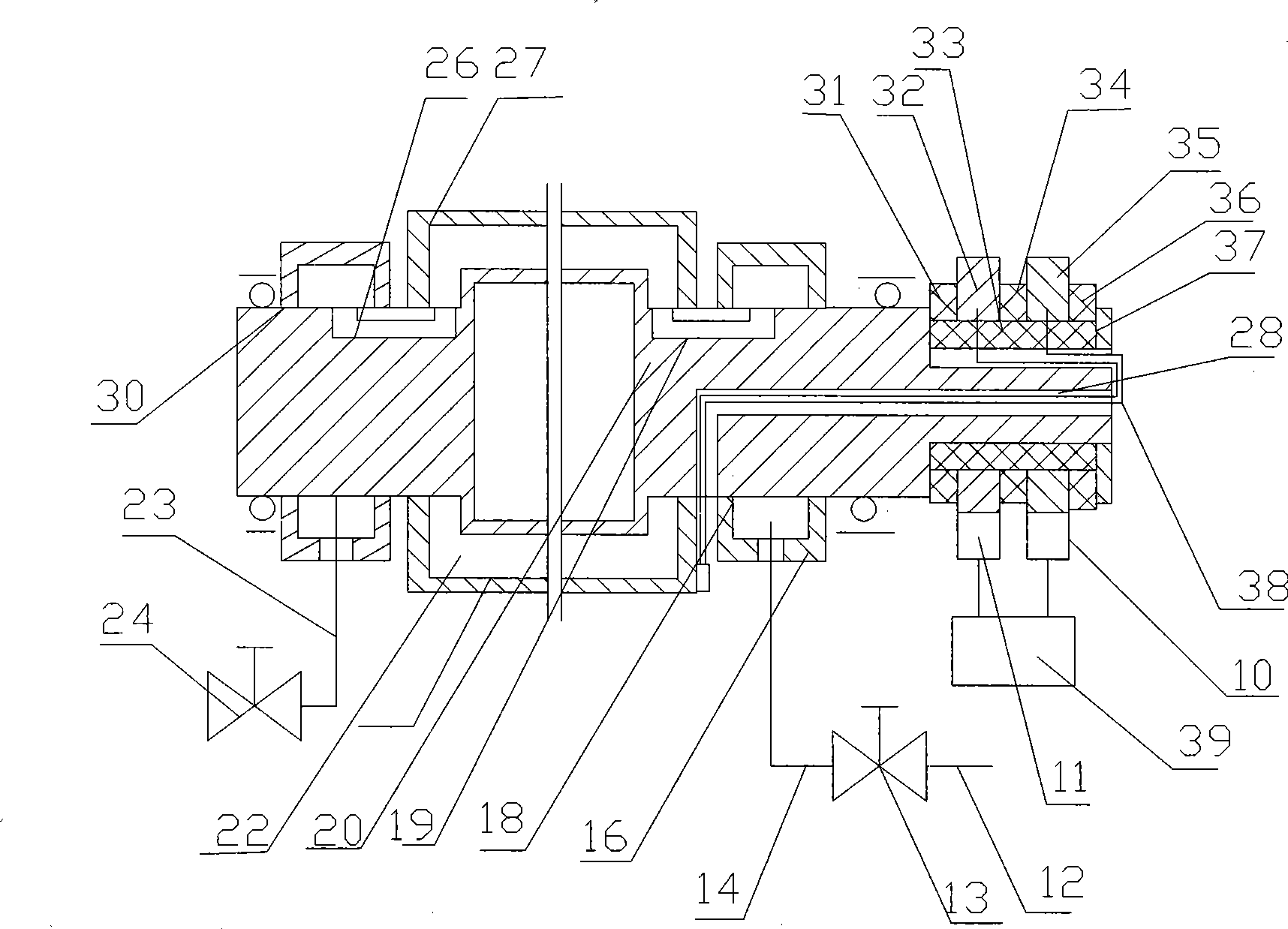

Steam heating device for cloth roller of beam dyeing machine

InactiveCN101463539AConsistent temperatureSolve the problem of temperature differenceLiquid/gas/vapor open-width material treatmentTextile treatment machine arrangementsControl systemTemperature difference

The invention discloses a steam heating device for a cloth roller of a jig dyeing machine. The invention is characterized in that the device comprises a cloth roller ring-shaped heating cavity arranged inside a cloth roller crust, a steam inlet revolving joint and a steam outlet revolving joint are respectively arranged at the two sides of the cloth roller crust, a steam inlet hole which can be connected with the cloth roller ring-shaped heating cavity and the steam inlet revolving joint is arranged on a cloth roller inner core, a steam inlet tube is connected with the steam inlet revolving joint, a control system which is used to measure the temperature of the cloth roller crust and control the quantity of steam entering the cloth roller ring-shaped heating cavity according to the measured temperature. The steam heating device in the invention solves the problem that temperature difference exists between the cloth roller and the dyeing solution, thus eliminating the color deviation between initial dyeing of the cloth and the final dyeing of the cloth.

Owner:靖江市华信科技创业园有限公司

Drying unit for washing machines

InactiveUS7188437B2Reduce consumptionLiquid/gas/vapor open-width material treatmentDrying gas arrangementsCold airProcess engineering

Disclosed herein is a drying unit for washing machines that is capable of fully drying the wet laundry using hot wind. A condensing duct and a drying duct are connected to a tub to circulate air in the tub. Between the drying duct and the condensing duct is disposed a drying fan. To the condensing duct is attached air cooling device for condensing air in the condensing duct by means of cool air. In the drying duct is mounted a drying heater for heating air in the drying duct to change the air into hot wind. During the drying operation of the washing machine, the air passing through the condensing duct is condensed by air, which is an unlimited resource. Consequently, consumption of energy and resources is minimized during the drying operation of the washing machine.

Owner:LG ELECTRONICS INC

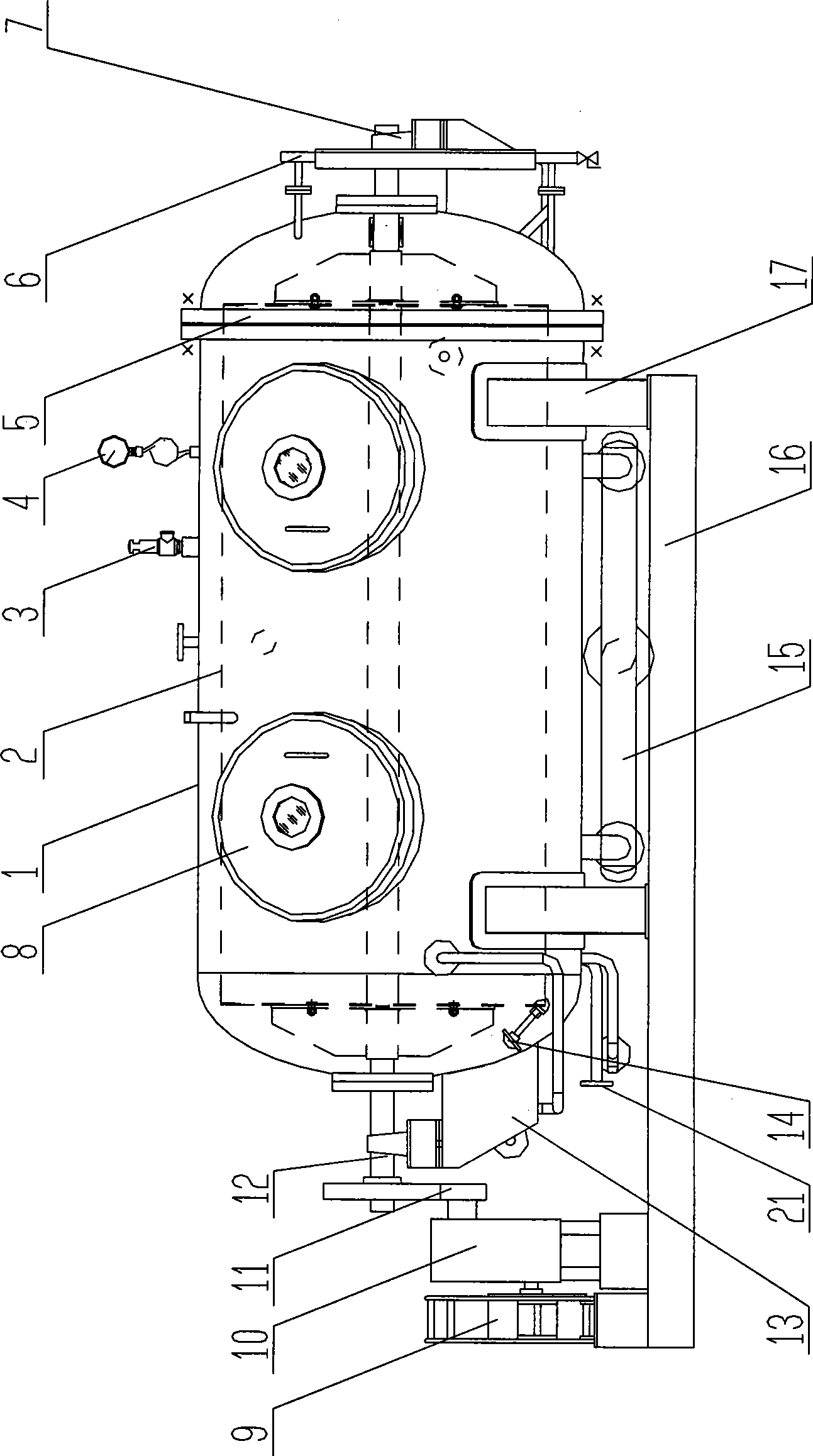

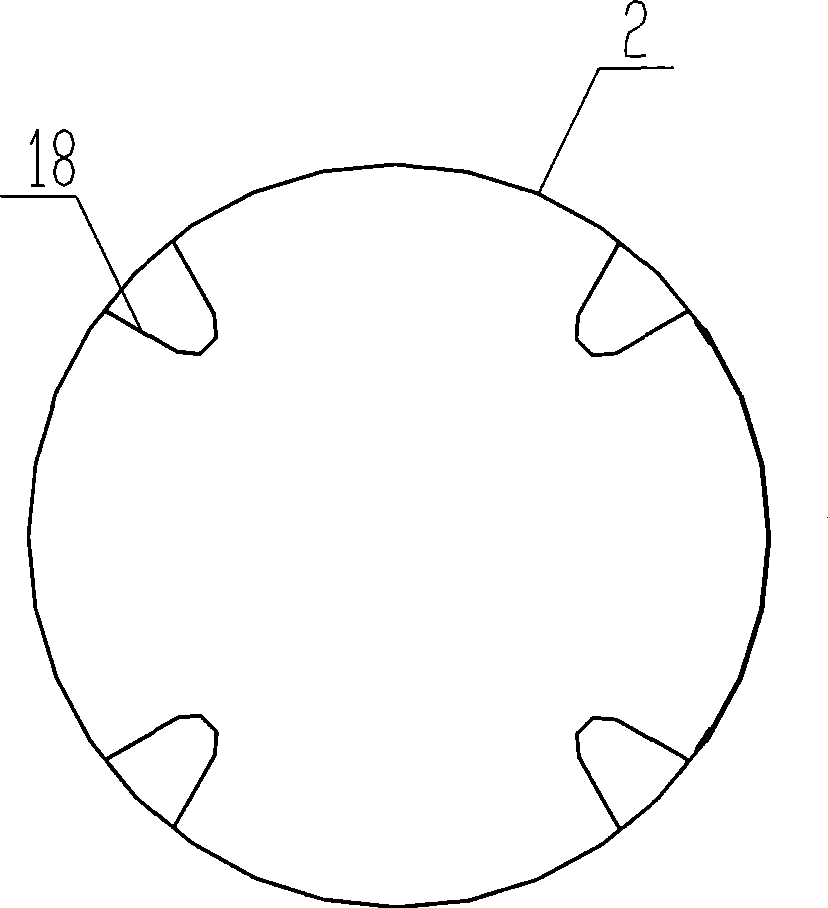

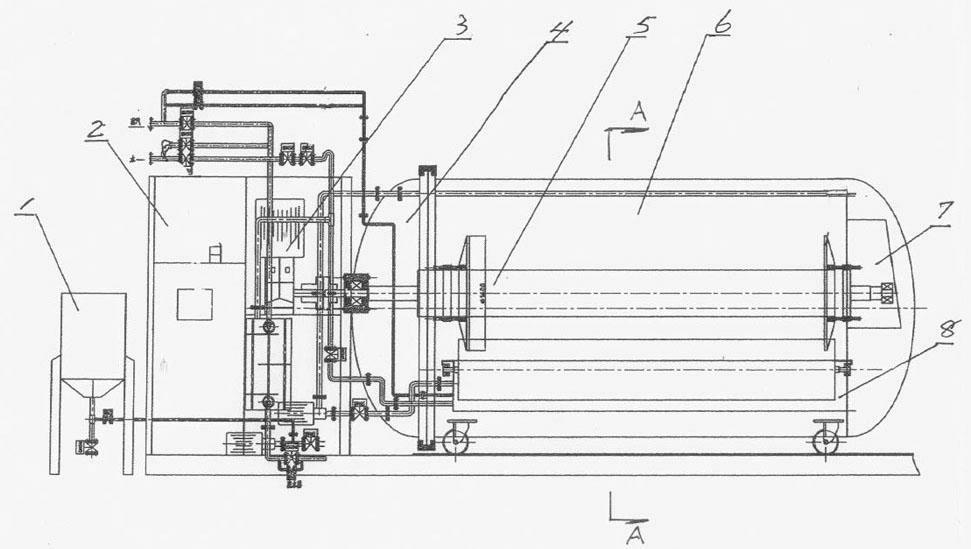

Rotary drum type dyeing machine

InactiveCN101476220AReduce laborReduce processing timeLiquid/gas/vapor open-width material treatmentTextile treatment rollersDrive shaftEngineering

A drum type dyeing machine comprises a pressure-bearing drum body, a safe accessory, a stirring transmission device, a heating device, a controlling means and a base. The stirring transmission device comprises an inner drum, a power reduction box, a transmission shaft and a braking device; both ends of the inner drum are fixed with the transmission shaft; the transmission shaft is installed on the bearing seat outside of the pressure-bearing drum body through mechanical seal, while connected with the power reduction box and the braking device in series. Under a certain pressure and temperature condition, the fabric is dyed while rotating in the drum, consequently, the labor amount in the dyeing process is reduced, the processing time is shortened greatly and the dyeing energy consumption is reduced; the whole dyeing process is performed under high temperature and high pressure, consequently, the mixing operation is performed fully, and better dyed color and dye fixation effect are achieved; all the equipments are mounted on the same base, consequently, the volume is more compact and the mounting is more convenient.

Owner:石建明

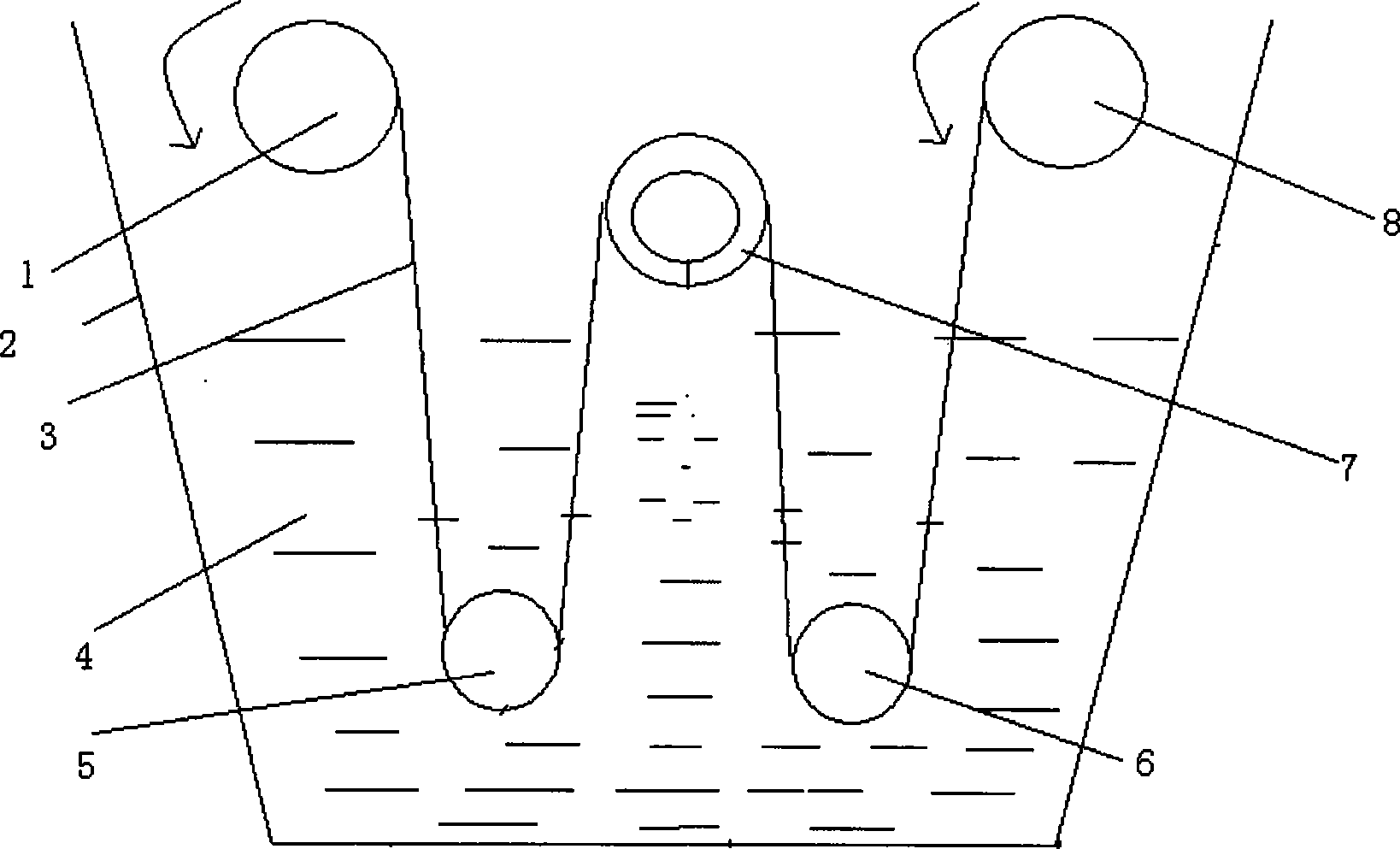

Dyeing device for processing soft cotton knitted fabric and fabric processing method

ActiveCN108625068AReduce tensionIncrease contact areaLiquid/gas/vapor open-width material treatmentHeating/cooling textile fabricsElectric machineryPulp and paper industry

The invention discloses a dyeing device for processing a soft cotton knitted fabric and a fabric processing method. The dyeing device comprises a box body, and a dyeing cavity and a heating cavity areformed in the box body; a first roller and a second roller are arranged in the dyeing cavity, and motors are connected to the first roller and the second roller; a bottom plate and a liquid outlet pipe are arranged at the bottom of the dyeing cavity, and supporting rollers are uniformly arranged on the top face of the bottom plate; a dyeing roller is arranged between the first roller and the second roller, the dyeing roller is fixedly connected to a lifting mechanism through a supporting rod, and the lifting mechanism is connected to the top of the box body through a clamping and positioningmechanism. The processing method comprises the steps of weaving, boiling and bleaching, biological enzyme washing, dyeing, softening, dewatering, scutching, drying, padding, finishing liquid treatment, calendering, shaping and pre-shrinking. The fabric has the advantages that the processing steps are simple, the practicability is high, and the size stability and resilience of the fabric are greatly improved, so that the cotton knitted fabric is smooth, soft, small in shrinkage, flat, washable, durable and free of deformation.

Owner:SHENGZHOU SHENGTAI KNITTING

Dyeing method for cuprammonium fabric

ActiveCN1888184AGood hygroscopicityImprove breathabilityLiquid/gas/vapor open-width material treatmentDyeing processCuprammonium rayonFiber

The present invention relates to a dyeing method of cuprammonium rayon fabric. Said method successively includes the water washing process, scouring process and dyeing process. The water washing process is used for debatching and primarily cleaning the grease and blob on the fabric surface, and the scouring process is used for removing size mixture and grease contained in the cuprammonium rayon fabric and blob on the fabric surface and can be used for raising permeability of coloring agent and uniformity of color absorption.

Owner:WUJIANG DEYI FASHIONS CLOTHS

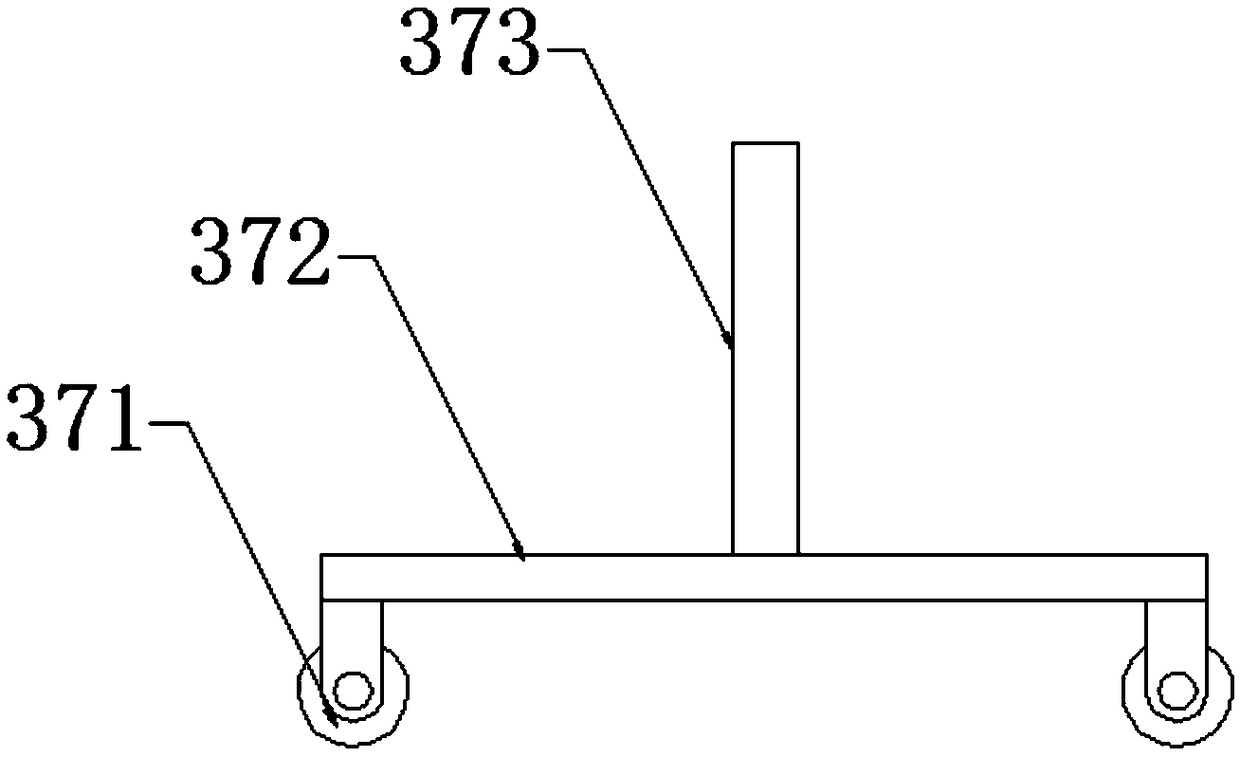

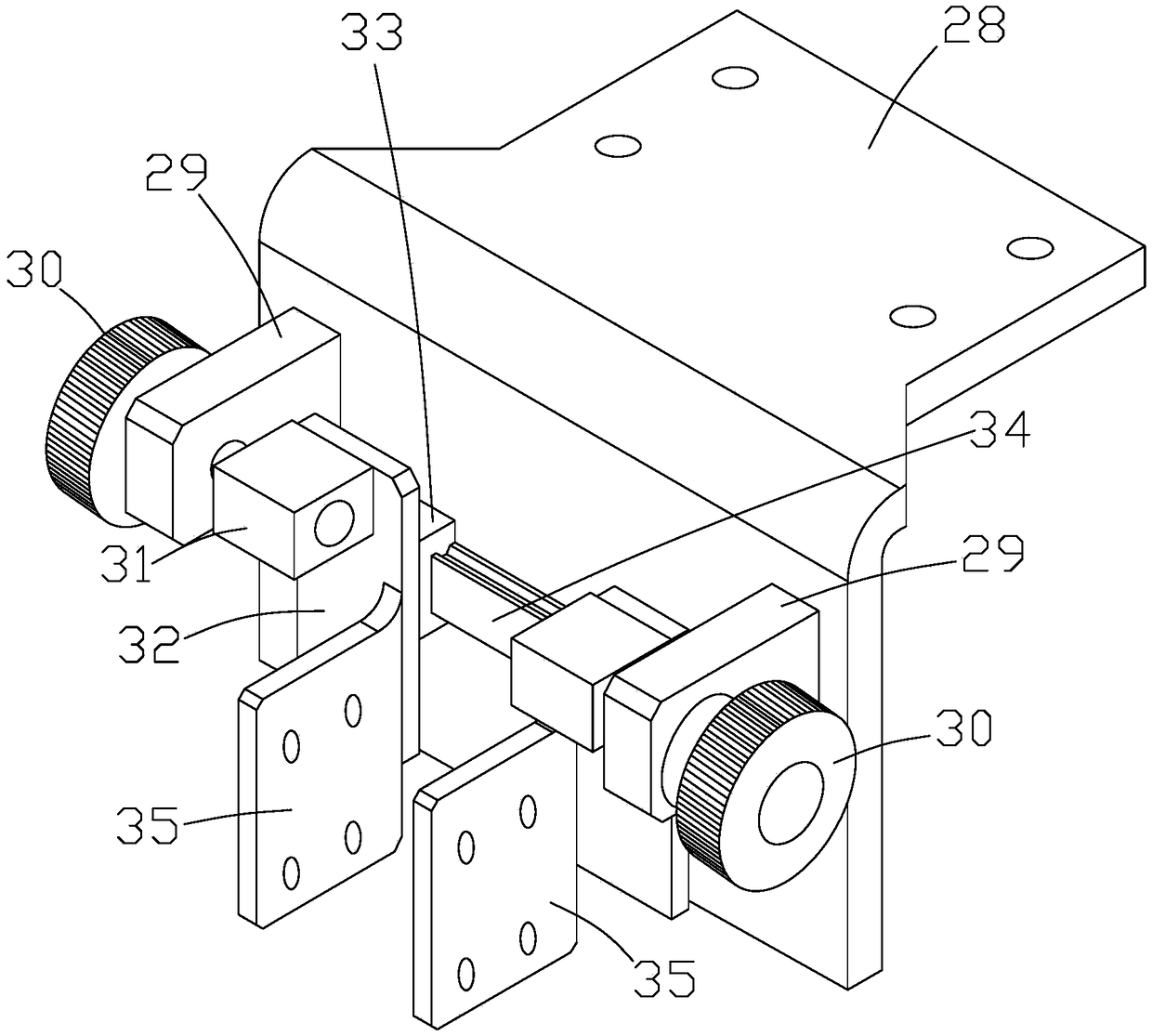

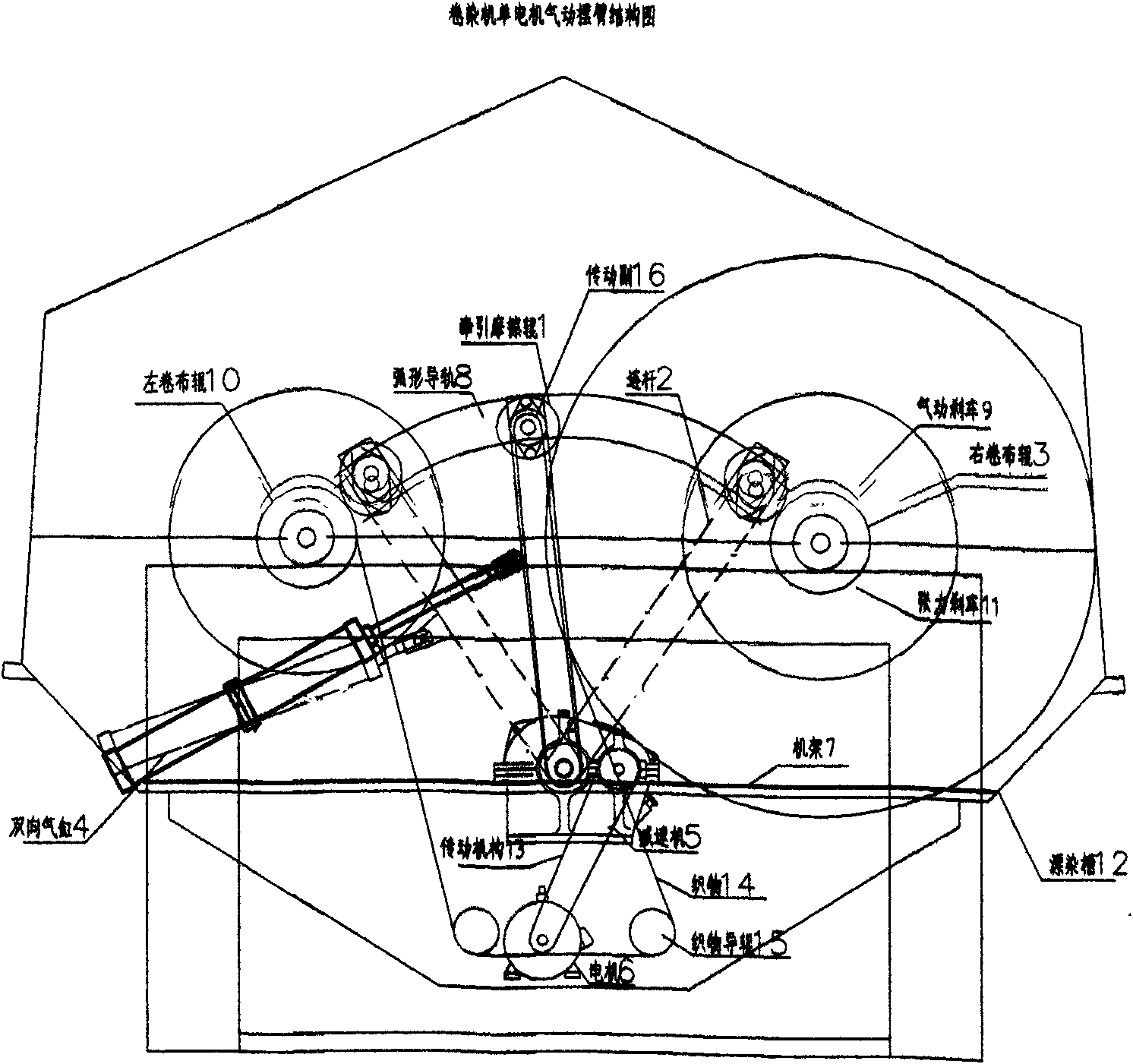

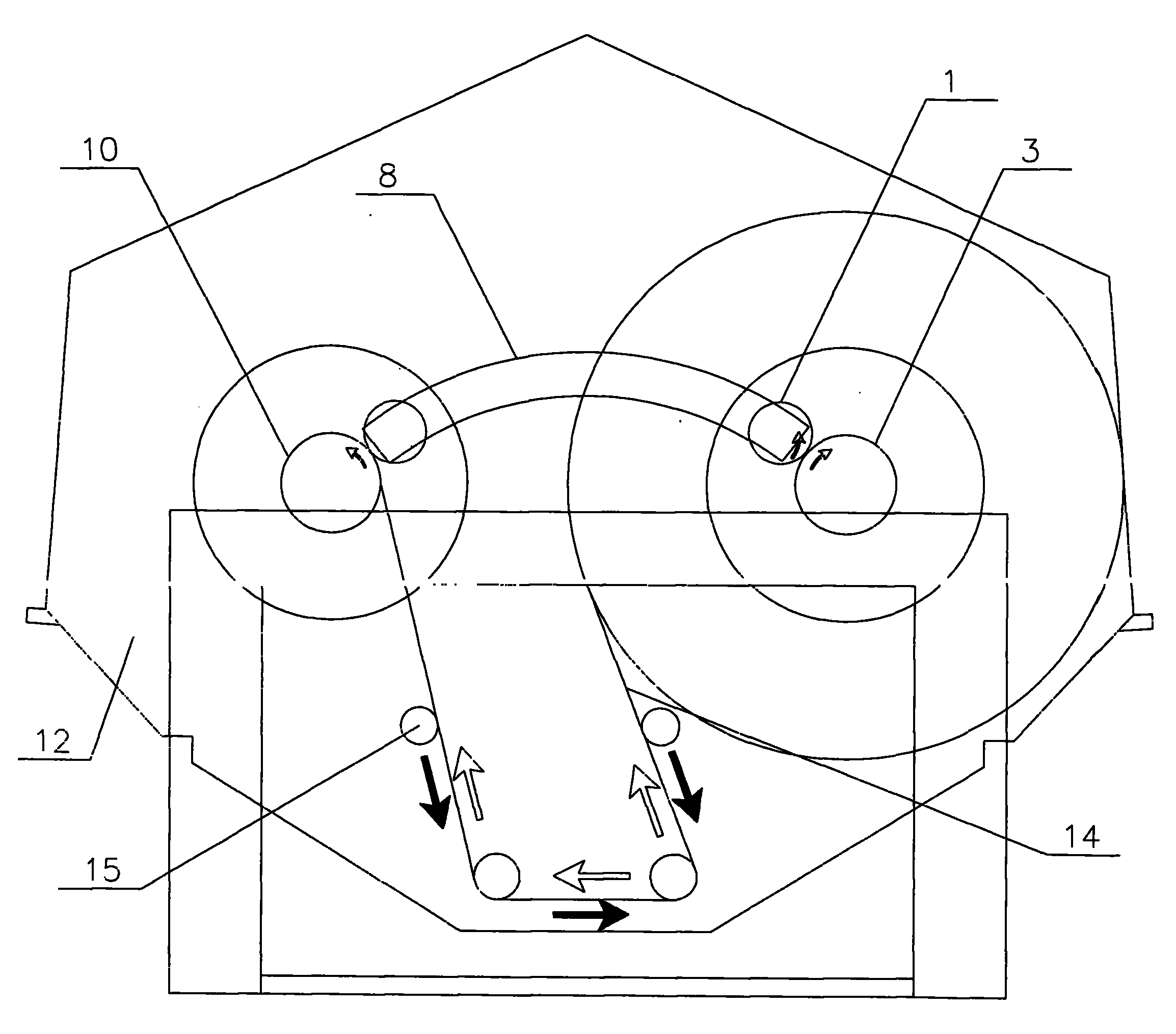

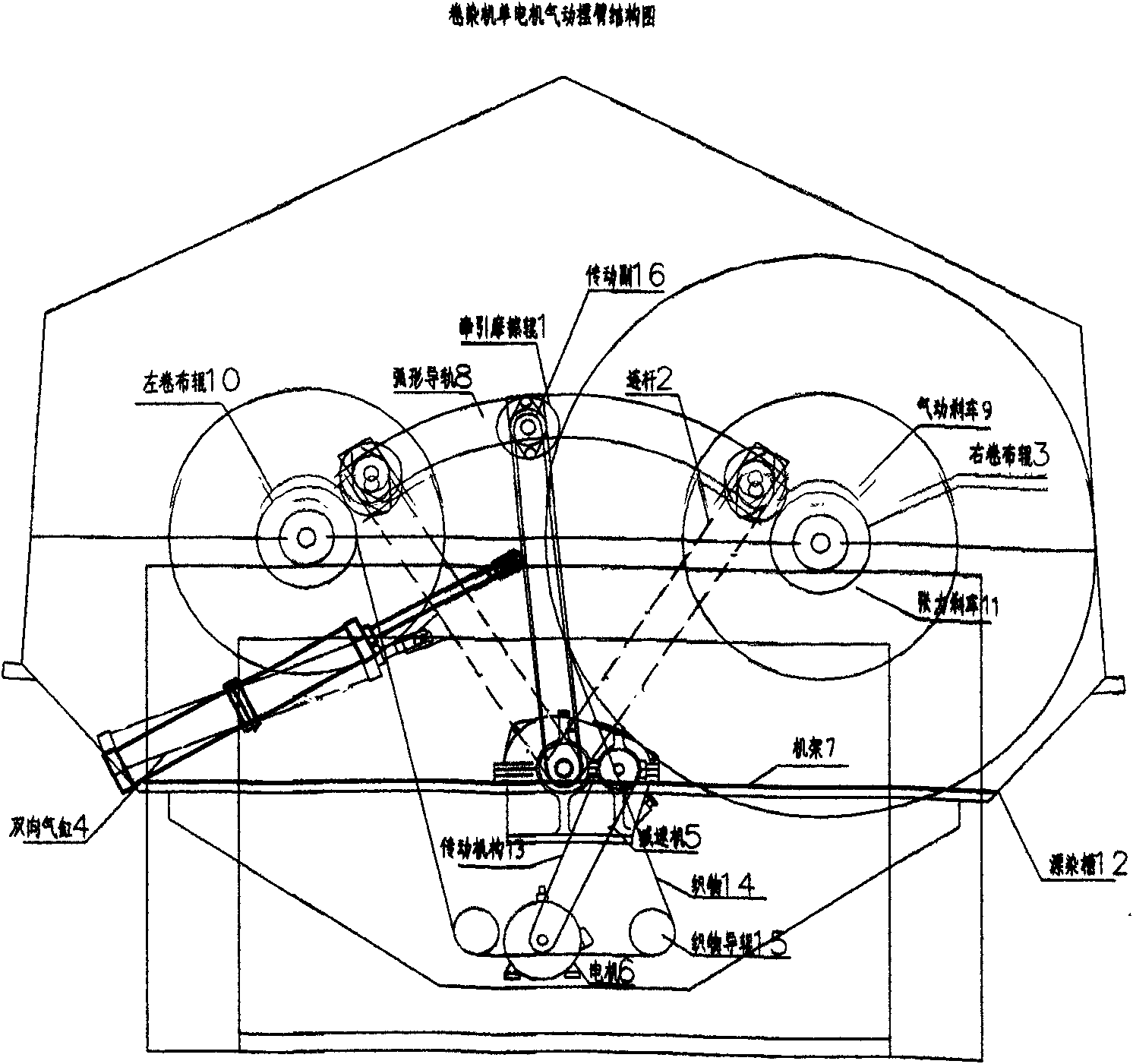

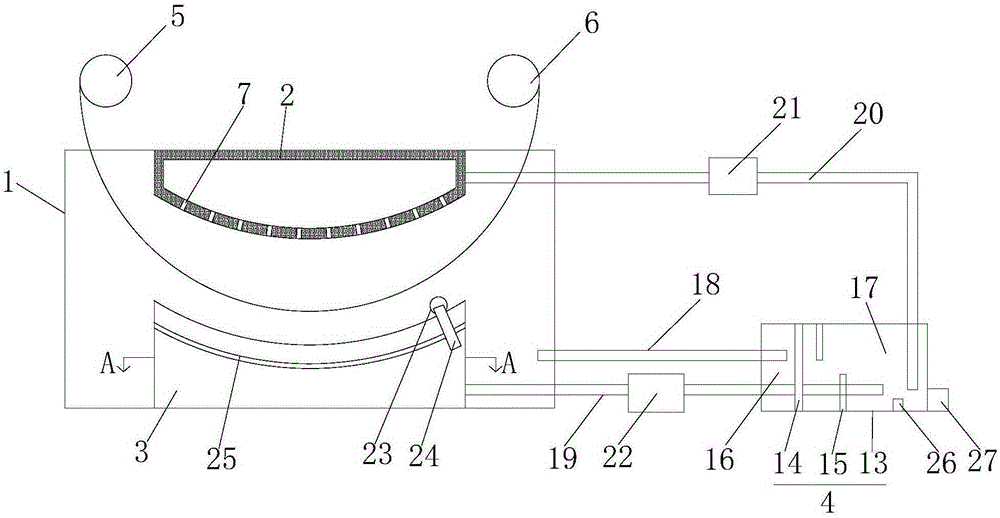

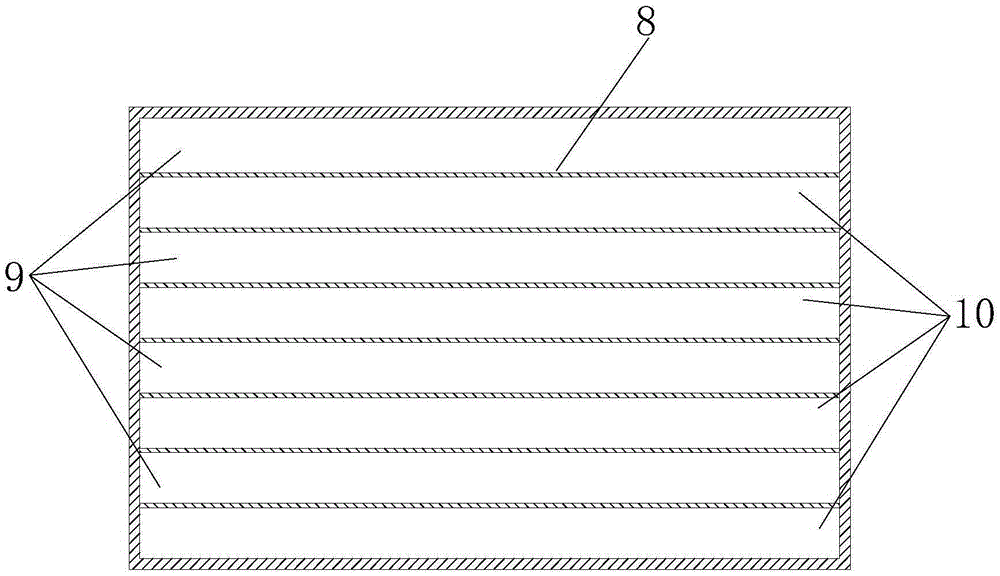

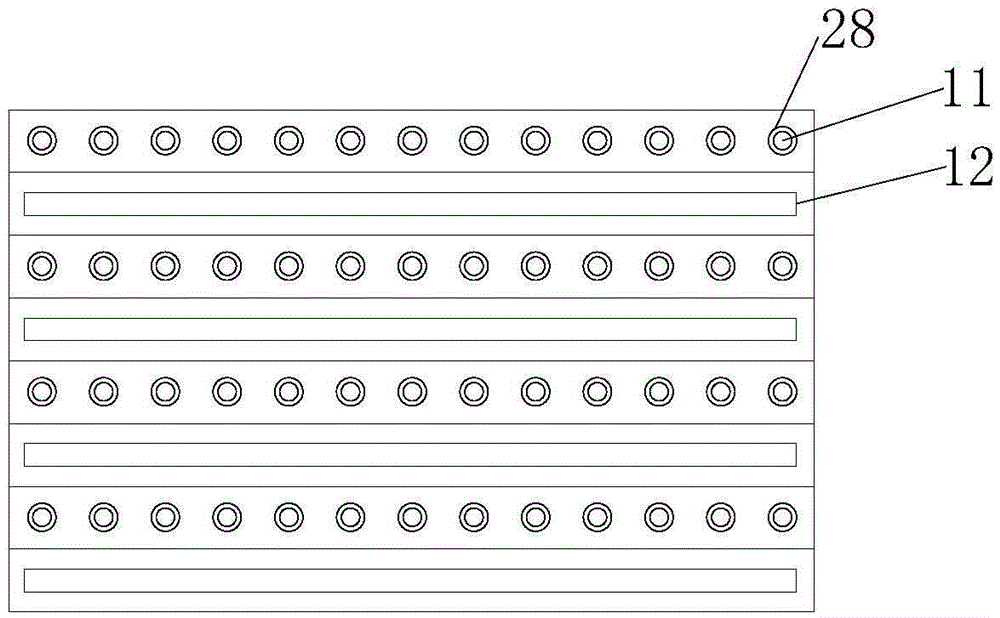

Single-motor pneumatic oscillating arm of jig dyeing machine

InactiveCN101988239AConstant speedImprove dyeing effectLiquid/gas/vapor open-width material treatmentLiquid/gas/vapor removal by squeezing rollersReducerPulp and paper industry

The invention discloses a single-motor pneumatic oscillating arm of a jig dyeing machine. The invention relates to the jig dyeing machine in the technical field of printing and dyeing machines. The existing jig dyeing machine uses double motors for reversing fabric, and the running speed of the fabric is non-constant. The single-motor pneumatic oscillating arm adopts the single motor for dragging, and the reversing function of the fabric 14 in a bleaching and dyeing pond 12 is completed by a transmission mechanism consisting of an arc-shaped guide rail 8, a connecting rod 2, a two-way cylinder 4 and a friction roller 1. Assembly holes are arranged at two ends of the connecting rod 2, a guide rod mounting hole for the cylinder 4 is arranged between the two assembly holes for connecting the cylinder 4, and the fulcrum of the cylinder 4 is fixed on a frame 7. The two ends of the connecting rod 2 are assembled at the shaft end of the friction roller 1 and an output shaft of a speed reducer 5. The arc-shaped guide rail 8 is mounted on the side wall, the connecting rod 2 can oscillate through expansion and contraction of the cylinder 4, and the friction roller 1 can slide along the arc-shaped guide rail 8 and be in close contact with cloth rollers 3 and 10 for compressing the fabric 14. A tension brake 11 can prevent relaxation of the fabric 14. The running speed of the fabric 14 can realize constant speed by linear speed of the friction roller 1, and the press dehydration role can reduce the number of times of bleaching and dyeing, thereby saving steam, water, electrical energy and auxiliaries.

Owner:ZAOZHUANG FUYUAN ENVIRONMENTAL PROTECTION & ENERGY SAVING MACHINERY MFG CO LTD

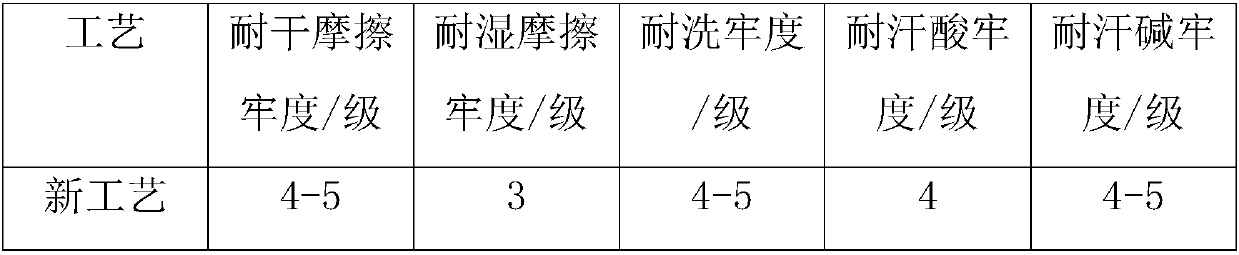

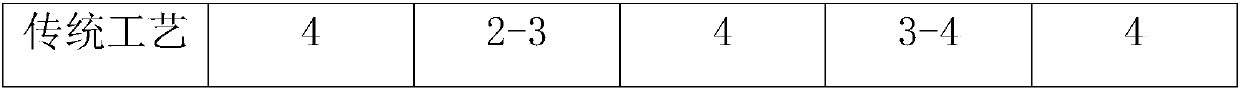

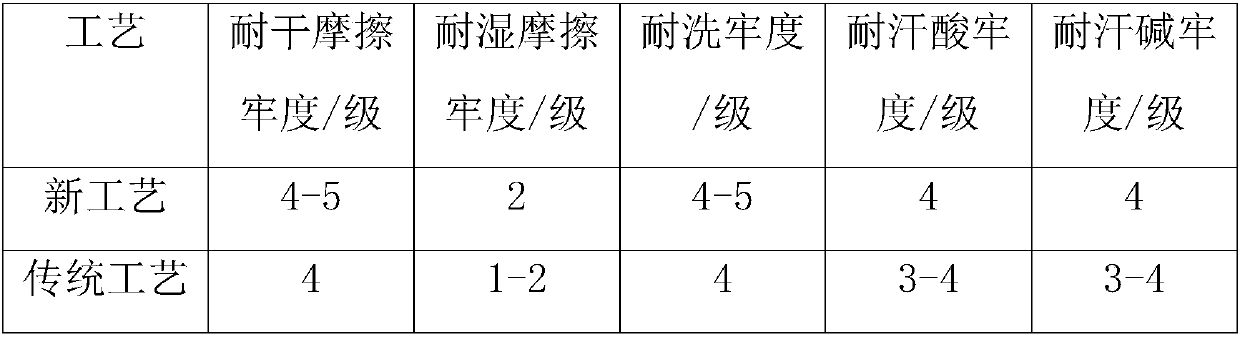

Process method for improving woven dark cloth wet rubbing fastness

ActiveCN107916518AImprove wet rubbing fastnessTightly bondedTextile storage in superimposed formLiquid/gas/vapor open-width material treatmentSurface finishProduct inspection

The invention discloses a process method, and particularly relates to a process method for improving woven dark cloth wet rubbing fastness. The process method includes the steps: (1) cloth distribution; singeing, cooling reaction and desizing; scouring and bleaching; mercerizing; pad dyeing or jig dyeing; wet rubbing fastness improver and auxiliary selection and preparation; wet rubbing fastness improver finishing; over-soft sizing; pre-shrinking; finished product inspection. According to the process method for improving the woven dark cloth wet rubbing fastness, production processes of all procedures are controlled, the capillary effect of a fabric is effectively improved, the surface finish degree of the fabric is improved, friction resistance is reduced, surface dyeing is decreased by strengthening soaping and washing after dyeing, wet rubbing fastness improvers of waterborne polyurethane complexes (Jiangxi Luxi County Xianghua Fine Chemical Co., Ltd., similarly hereinafter) are added after dyeing, under the assistant effects of assistant stabilizers 203 and cracking agents 109, the process method effectively solves the problem that oil floating points are generated in continuous production for 2000 meters or more when single wet rubbing fastness improvers are added in the past, the wet rubbing fastness of dark dyed cloth is improved by one level or more, corresponding washing fastness is improved, pH (potential of hydrogen) values meet requirements, continuous production and product quality are ensured, and a cloth surface has a certain color-deepening effect and softening effect, so that customer satisfaction is achieved.

Owner:佛山市顺德金纺集团有限公司

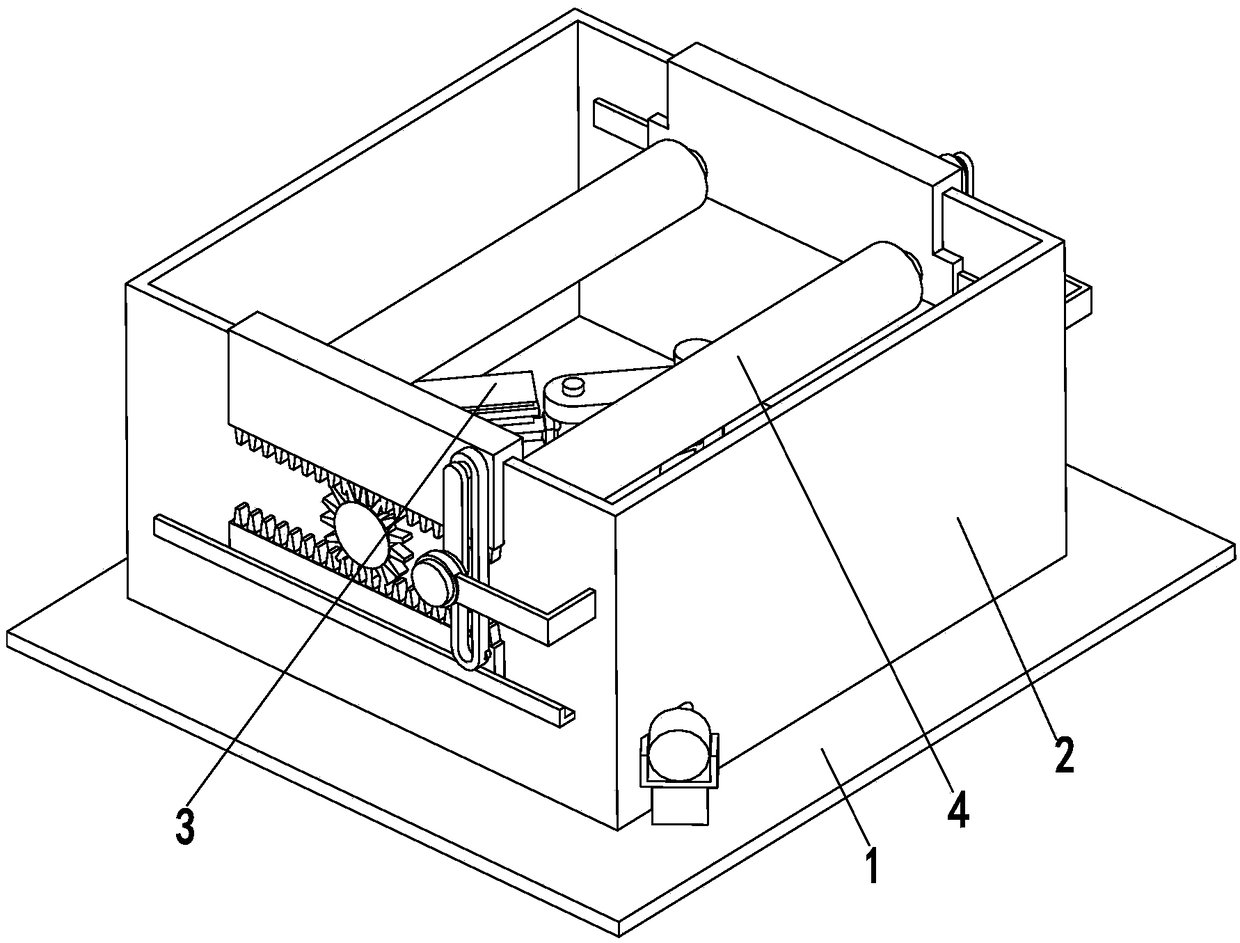

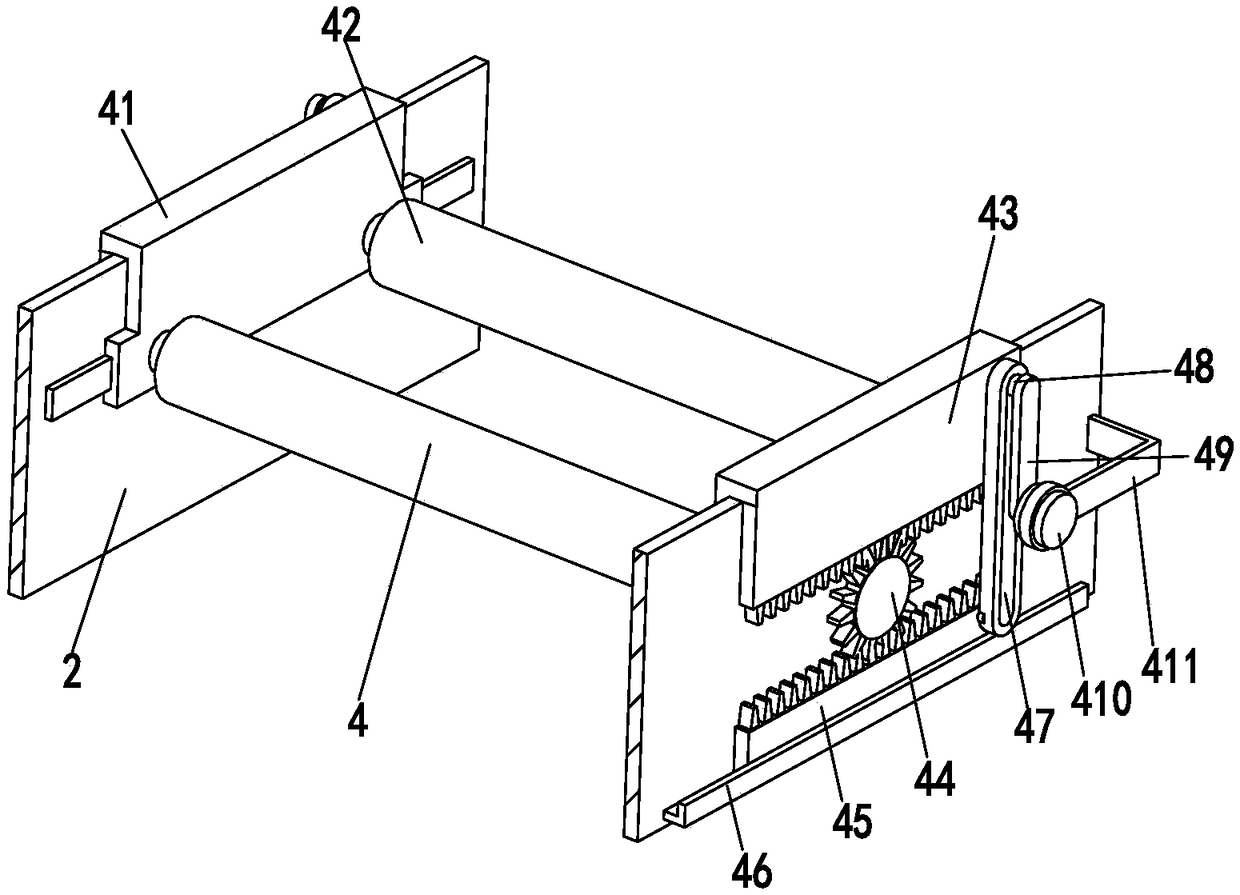

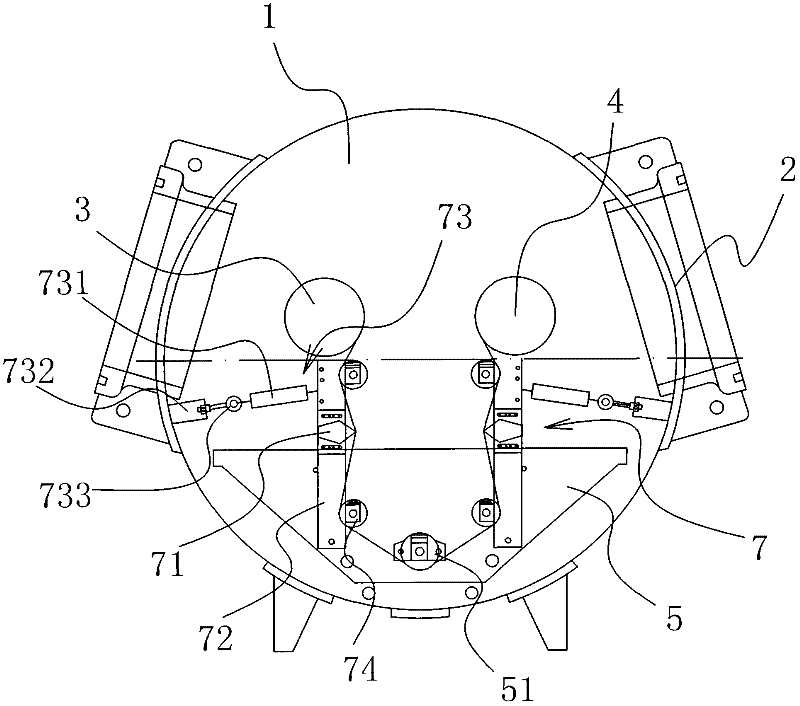

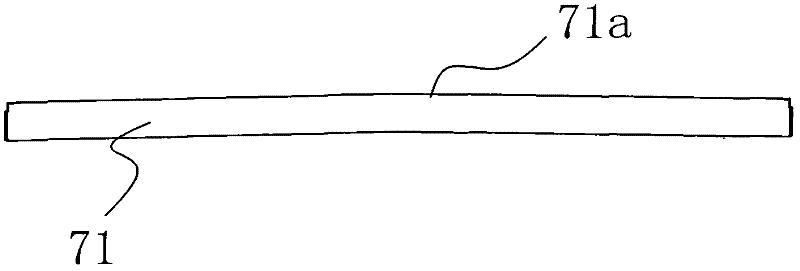

Dye vat for jig dyeing of textiles and automatic dye stirring technology

ActiveCN108754949AGuaranteed to proceed normallyExpand the scope of workLiquid/gas/vapor open-width material treatmentTextile treatment machine arrangementsEngineeringFixed Slide

The invention relates to a dye vat for jig dyeing of textiles and an automatic dye stirring technology. The dye vat comprises a bottom plate, a tank, a stirring mechanism and an oscillating mechanism,the tank is mounted on the bottom plate, the stirring mechanism is mounted at the bottom of the tank, and the oscillating mechanism is mounted on sidewalls of the tank. The stirring mechanism comprises a fixed column, a sliding rack, connection columns, stirring racks, first connection plates, rotating shafts, second connection plates, a stirring motor and a fixed support. The oscillating mechanism comprises oscillating racks, auxiliary rollers, oscillating racks, gears, auxiliary racks, fixed slide grooves, working racks, protruding columns, rotating racks, rotating motors and mounting racks. The dye vat solves the problems of uneven dye distribution, uneven dyeing and the like of an existing jig dyeing process, can automatically stir dye in the dye vat and has the advantages of even dyedistribution, dyeing evenness and the like.

Owner:浙江旺盛控股集团股份有限公司

Weaving process of home textile product containing phase-change material

InactiveCN101831750AEasy to takeTurn down the pressureLiquid/gas/vapor open-width material treatmentWoven fabricsYarnCotton fibre

The invention discloses a weaving process of home textile product containing a phase-change material, comprising steps of winding, warping, weaving and post-processing grey cloth. The yarns applied in the weaving process are at least two of a phase-change material yarn made from the phase-change material viscose, cotton yarn made from cotton fibres, and a blended yarn made from the phase-change material viscose and the cotton fibres; and the content of the phase-change material viscose in the home textile product is not less than 30 wt%. The invention is woven by the phase-change material viscose or the blended yarn of the phase-change material viscose and the cotton, and the content of the phase-change material viscose in the home textile product is not less than 30wt%. The home textile product not only has good service performance, but also ensures that the phase-change material in the home textile product can function well, and the purpose of adjusting the temperature is achieved.

Owner:SUNVIM GROUP

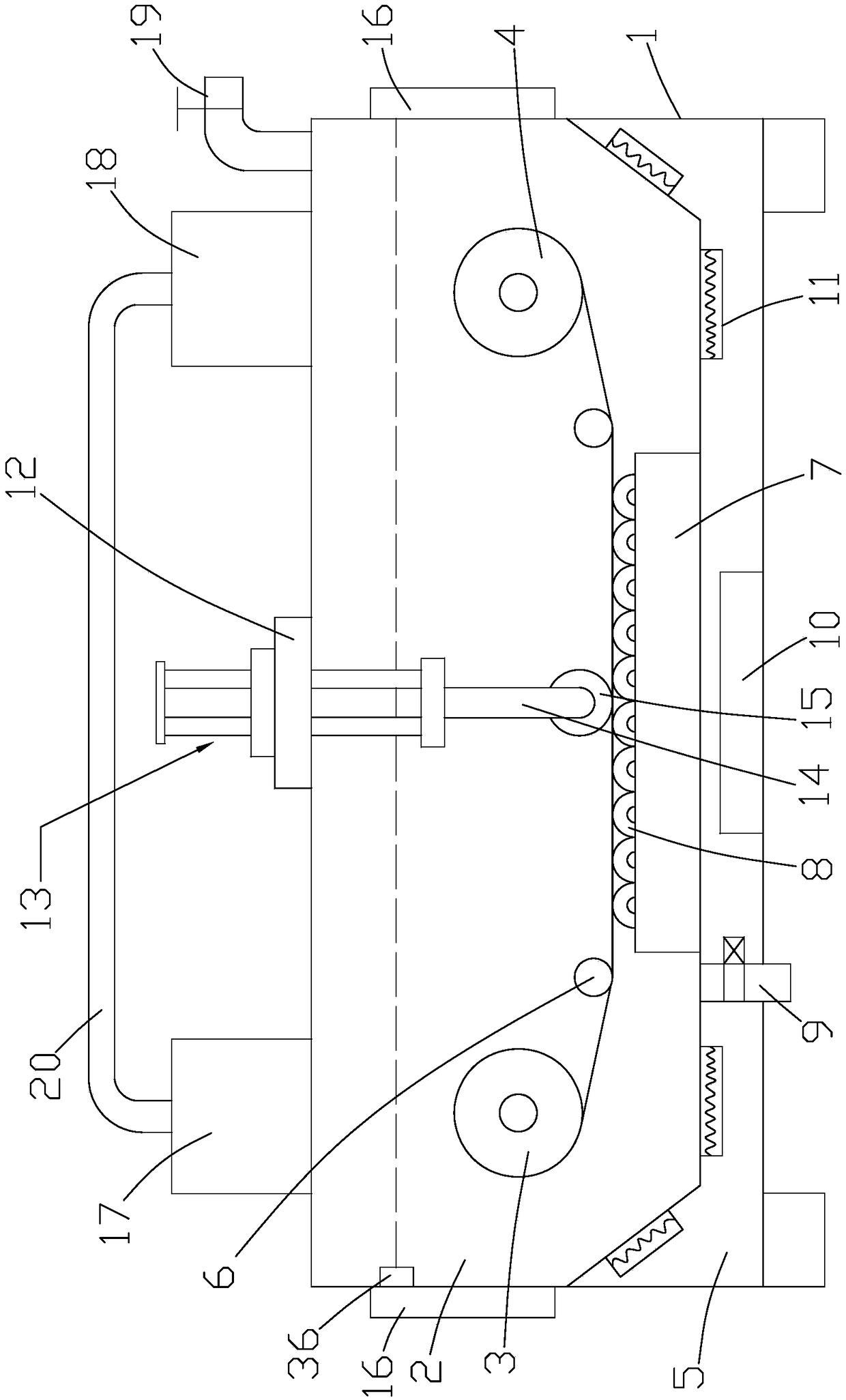

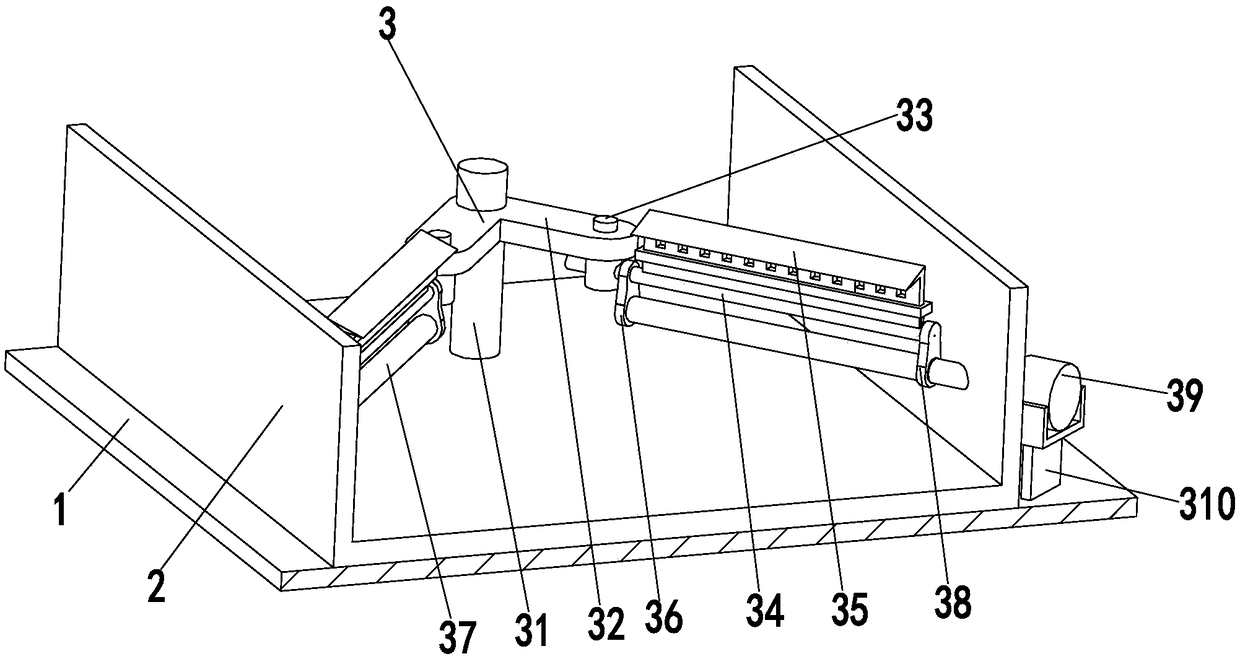

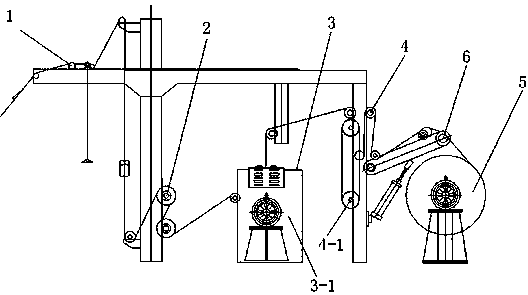

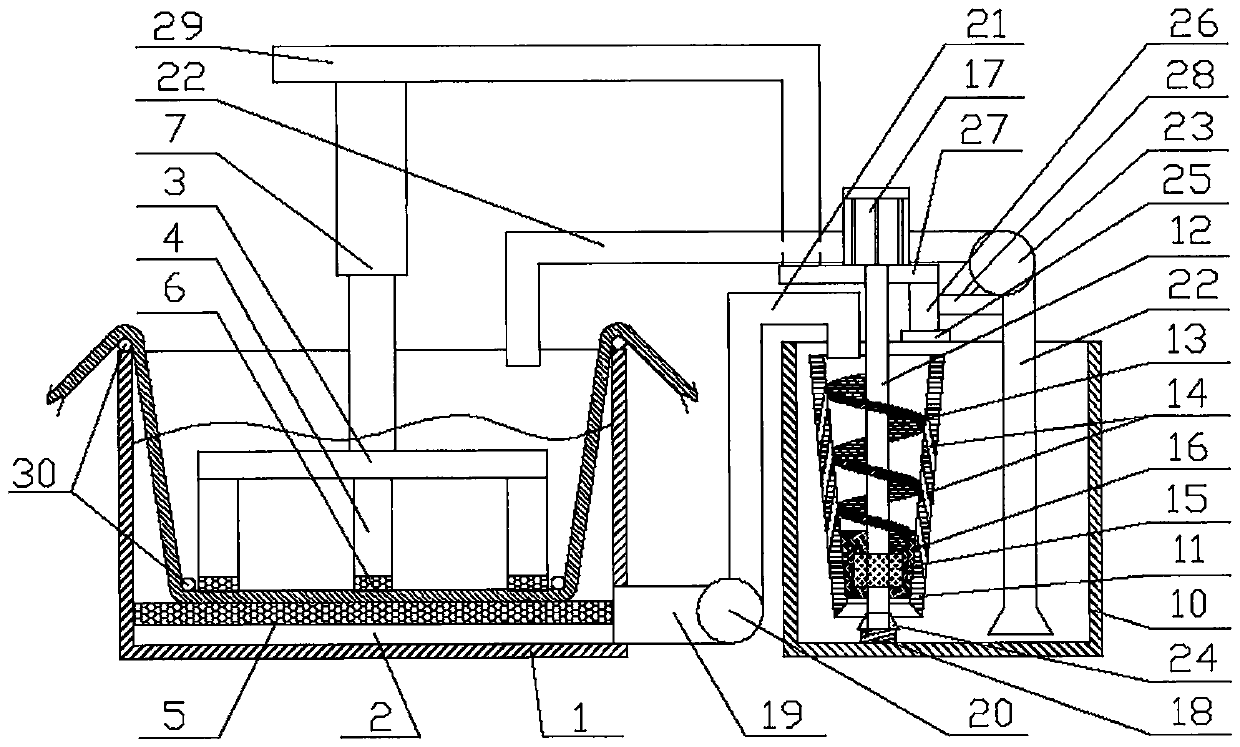

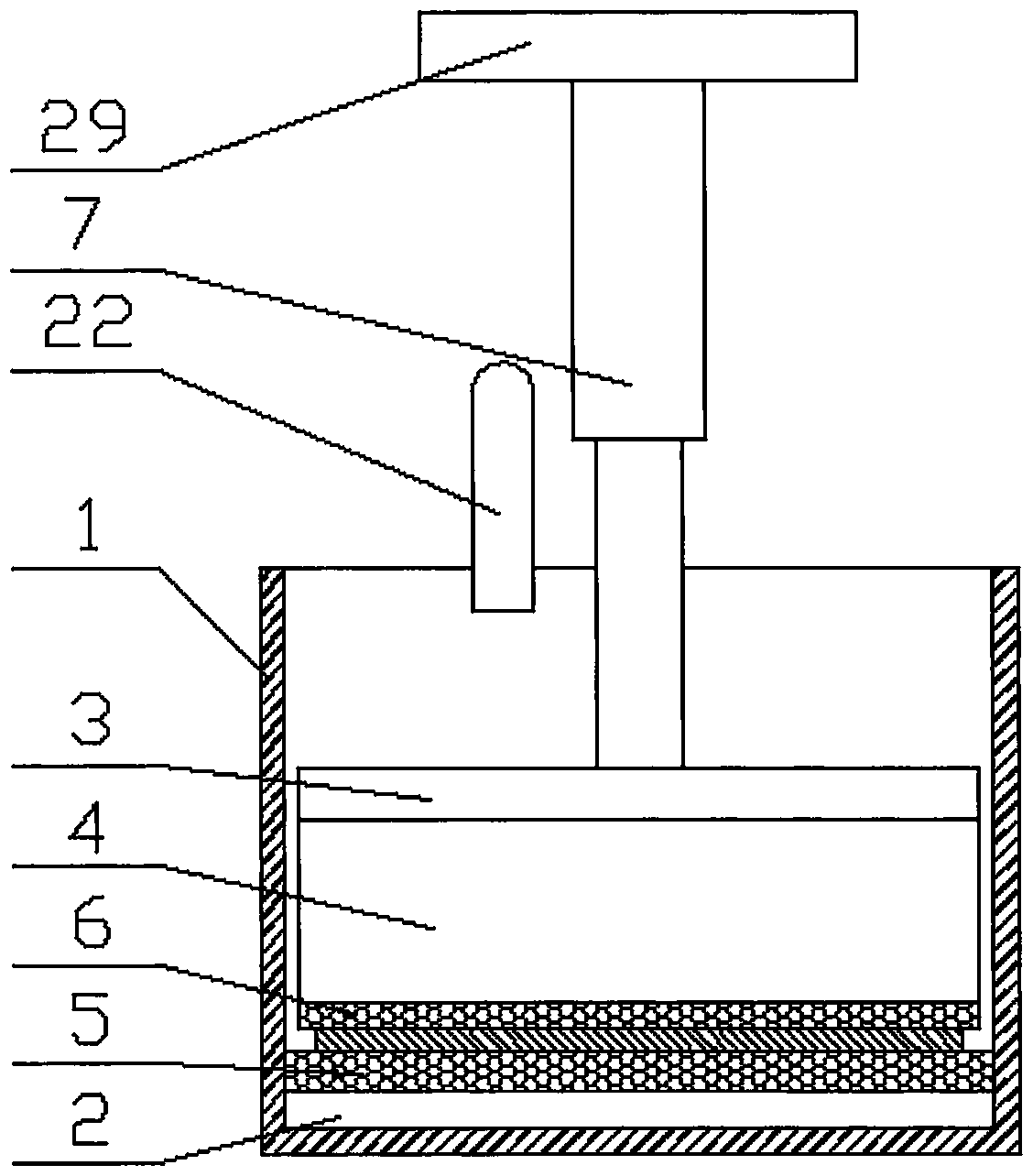

Ultrasonic-assisted cold pad-batch dyeing machine

InactiveCN103938389AReduce consumptionReduce water consumptionLiquid/gas/vapor open-width material treatmentTextile treatment machine arrangementsUltrasonic assistedEngineering

The invention relates to an ultrasonic-assisted cold pad-batch dyeing machine which comprises a machine frame. The machine frame is provided with a cloth feeding device, a cooling device, a tension control device and an active winding device. An evenness padder is arranged between the cooling device and the tension control device, the tension control device is connected with the active winding device through a bearing arm, a roller is arranged between the evenness padder and the tension control device, the evenness padder comprises an ultrasonic penetration groove, and the active winding device is a constant low tension active winding system. Compared with an existing dyeing process, dyeing is achieved through ultrasonic waves, far infrared drying is not needed, steam does not need to be consumed, water consumption is small, pollution is little, consumption of dye and auxiliaries is little, the process is simple and reliable, preparation cycles are short, labor cost is reduced, equipment investment is little, the occupied area is small, and maintenance cost is low.

Owner:扬州市江都区东盛印染机械厂

Special process for dyeing and finishing multi-F viscose rayon

InactiveCN101880975AImprove verticalityImprove breathabilityLiquid/gas/vapor open-width material treatmentDyeing processAcetic acidCuprammonium rayon

The invention relates to a special process for dyeing and finishing multi-F viscose rayon, comprising the following steps of desizing by using sodium carbonate, neutralizing by using glacial acetic acid, rinsing by using tap water and the like. After the multi-F viscose rayon is specially dyed and finished, fabrics woven by the multi-F viscose rayon has a silk-imitating effect superior to that of fabrics woven by cuprammonium rayon raw materials produced in Japan, and the fabrics woven by the fibers have the advantages of favorable smoothness, air permeability and moisture absorption and bright luster after dyed.

Owner:王水泉

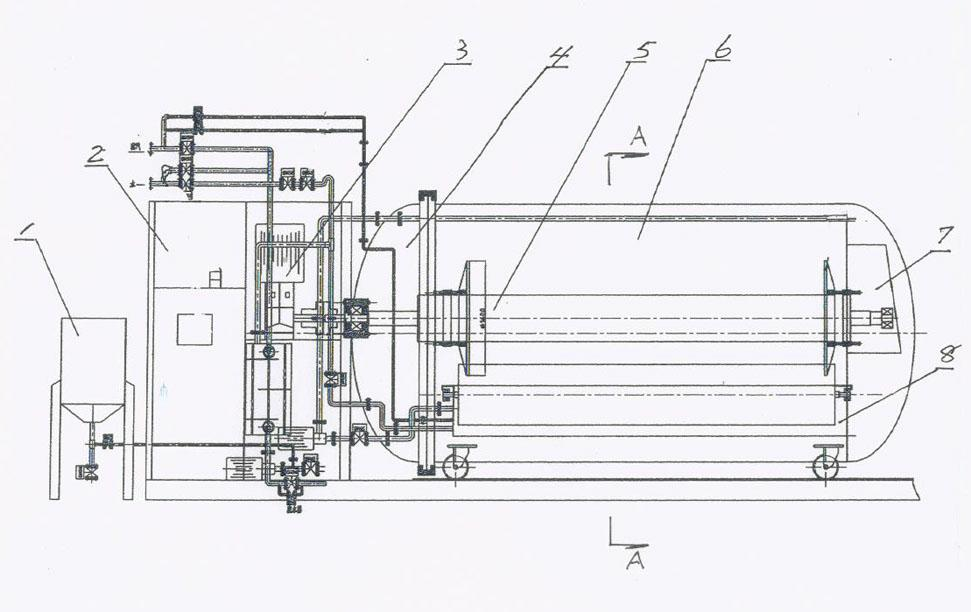

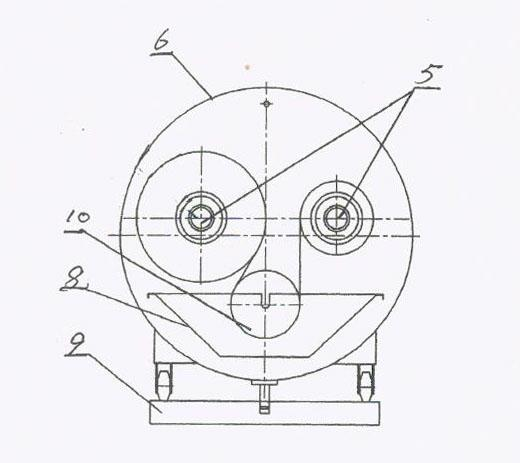

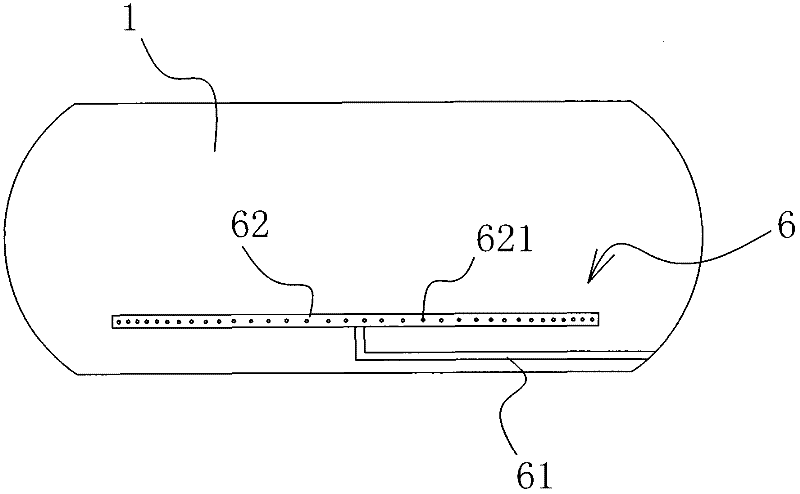

Reciprocating type yarn jig dyeing machine

InactiveCN102330302AQuality improvementLabor savingLiquid/gas/vapor open-width material treatmentLiquid/gas/vapor yarns/filaments treatmentYarnPulp and paper industry

The invention relates to a reciprocating type yarn jig dyeing machine which comprises a cylinder body and is characterized in that the cylinder body is arranged horizontally, and one end of the cylinder body is provided with a cylinder cover capable of being opened and closed. A dye vat is arranged in the cylinder body, two winding shafts are arranged above the dye vat, the dye vat and the winding shafts are parallel, the middles of the cylinder body at two ends of the dye vat are provided with brackets, and two ends of the winding shafts are respectively rotatably arranged on the two brackets. The same ends of the two winding shafts penetrate through the cylinder body and extend outside as well as respectively connected with an output shaft of a power mechanism. A transition roller is arranged on the mouth part of the dye vat, and two ends of a roller shaft of the transition roller can be rotatably arranged on upper edges of two ends of the dye vat. During working, yarns on one winding shaft are wound from the lower side of the transition roller, and then wound on the other winding shaft. By adopting the reciprocating type yarn jig dyeing machine, the labor intensity and the production cost of operators can be reduced, and the quality of dyed yarns can be improved. The reciprocating type yarn jig dyeing machine is suitable for yarn dyeing of yarn dye industries.

Owner:郑国洪

Production method of modal fibre and polyester filament interwoven broad-width jacquard double-color woven fabric

ActiveCN107142758ASimple production processEasy to operateLiquid/gas/vapor open-width material treatmentDry-cleaning apparatus for textilesDisperse dyeBreaking strength

The invention discloses a production method of a modal fibre and polyester filament interwoven broad-width jacquard double-color woven fabric. The production method mainly comprises the following production process flow: sewing, slight singeing, amylase desizing with a cold pad-batch process, pretreatment with a dyejigger, dyeing with the dyejigger, formaldehyde-free shrink-proof finishing, anti-pilling finishing, mechanical pre-shrinking, inspection and packaging. As for a product, the warp and weft washing size change rate is -3.0 percent to +1.0 percent, the anti-pilling level is larger than or equal to 4 level, the light fastness is 4 level, the breaking strength is larger than or equal to 260N, and the product completely reaches quality indexes of a superior product. According to the production method, polyester filaments are dyed by a low temperature disperse dye on a normal-pressure dyejigger, the production process is simple, and the operation is convenient.

Owner:NANTONG JINSHAIDA SPECIAL FAB CO LTD

Pure-white modal wide pile fabric and production method thereof

ActiveCN105780256ASoft and plumpSimple processLiquid/gas/vapor open-width material treatmentSolvent-treatmentBreaking strengthEngineering

The invention discloses a pure-white modal wide pile fabric and a production method thereof.The technical process includes: slight singeing, enzyme desizing by a dye jigger, Bu-gong tea saponin scouring and bleaching by the dye jigger, drying, napping, anti-shrinking finishing, tentering, mechanical pre-shrinking, and inspecting and packaging.The front of this fabric is provided with a layer of loose piles, and after weft-wise washing, the fabric is -3% to +1.0% in size variation rate, > / =82% in reflectivity and > / =260 N in breaking strength.The process is simple, operating is convenient, and the product has excellent properties.

Owner:NANTONG JINSHAIDA SPECIAL FAB CO LTD

Antibacterial thermal fabric and preparation method thereof

ActiveCN111098564AGood hygroscopicityGood moisture wicking effectLiquid/gas/vapor open-width material treatmentSynthetic resin layered productsYarnPolymer science

The invention discloses an antibacterial thermal fabric and a preparation method thereof, and belongs to the technical field of textile silk yarns. The fabric comprises the following components (by weight): 30 to 45 parts of bamboo fiber, 10 to 20 parts of Coppron copper ion fibers, 30 to 45 parts of cotton fibers, 20 to 30 parts of kapok fibers, 10 to 15 parts of filament goose down, and 10 to 15parts of thermal fibers. The preparation method comprises the following steps: firstly, blending the cotton fibers and the filament goose down fibers into silk yarns A; blending kapok fibers and partof bamboo fibers into silk yarns B; twisting the two kinds of silk yarn together to be woven into a first fabric, then blending the Coppron copper ion fibers and the remaining bamboo fibers into silkyarns C, weaving the silk yarns C and the thermal fibers into a second fabric, then bonding the two kinds of fabric together to obtain a gray fabric, and then dyeing the gray fabric and shaping. Theantibacterial thermal fabric prepared according to the preparation method provided by the invention has efficient antibacterial thermal performance, and is relatively good in air permeability and comfort.

Owner:YANCHENG SILIDE COCOON SILK

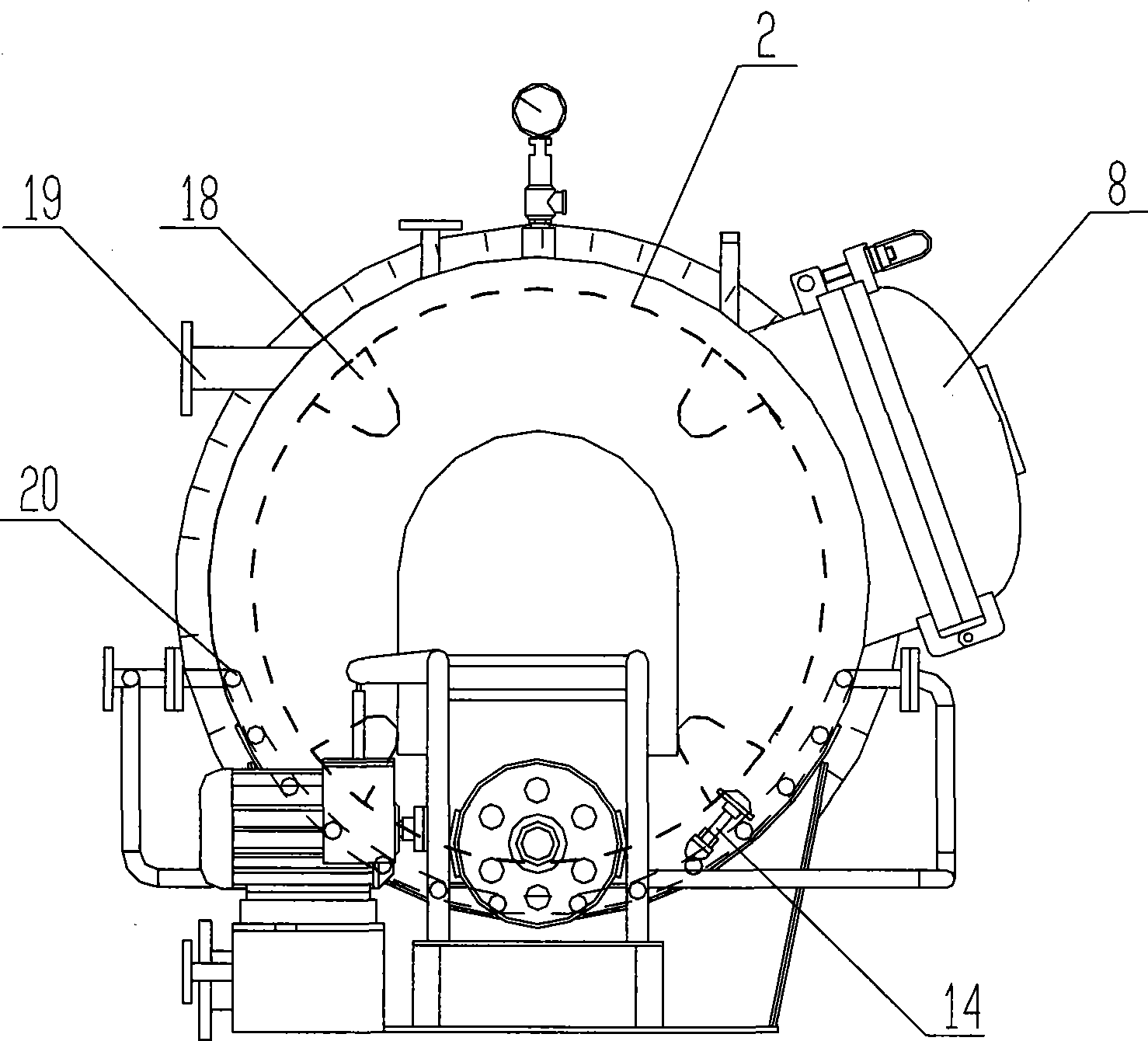

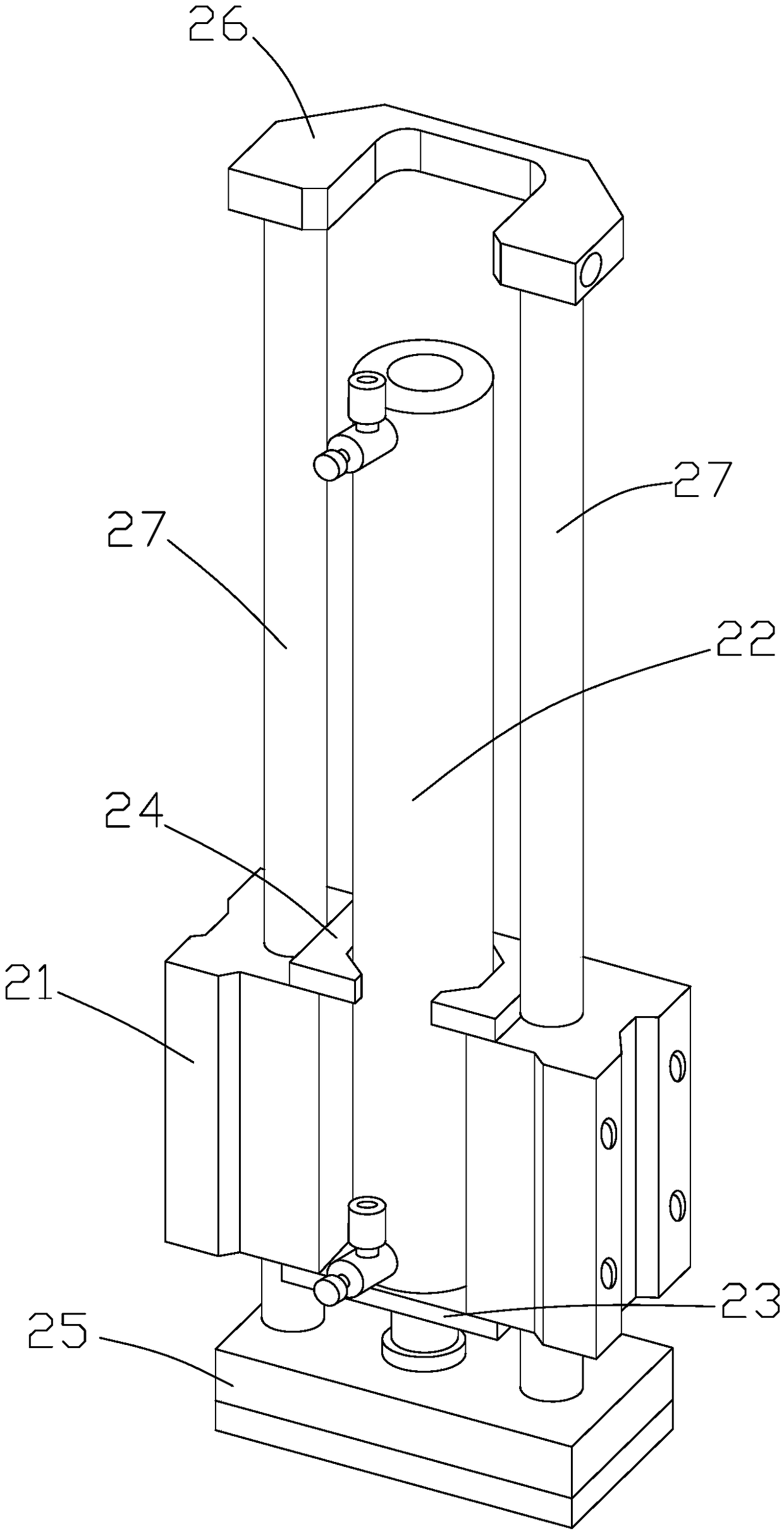

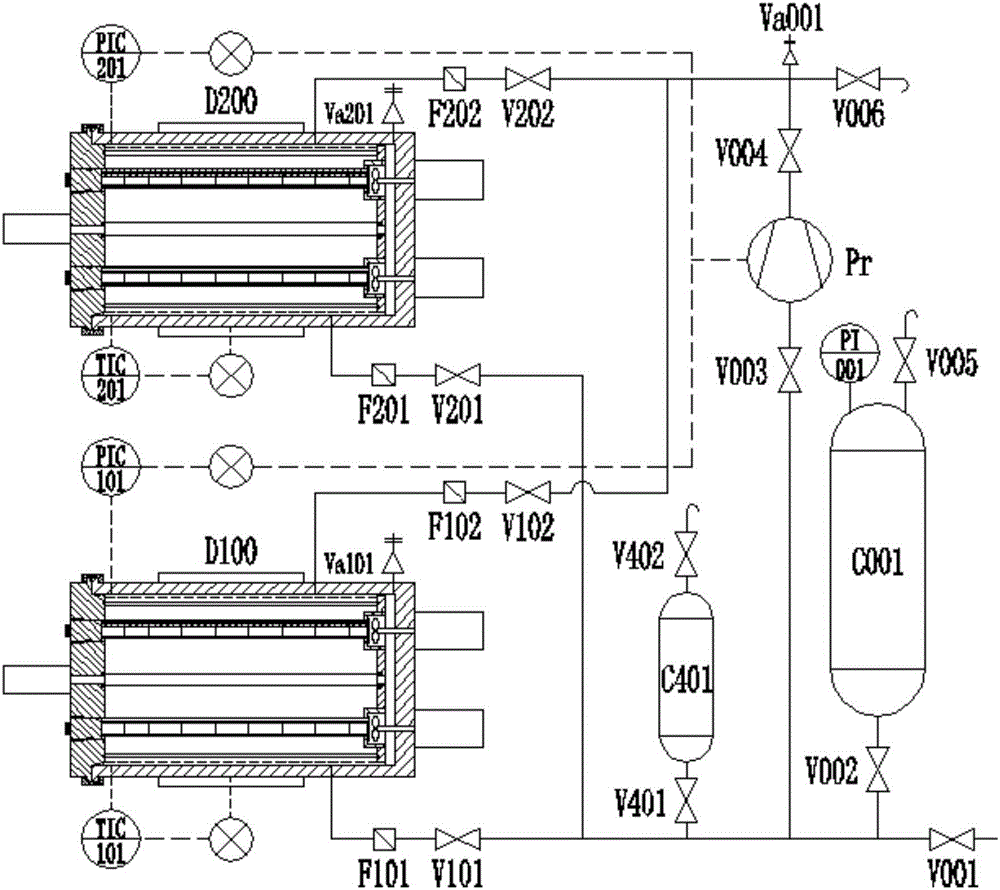

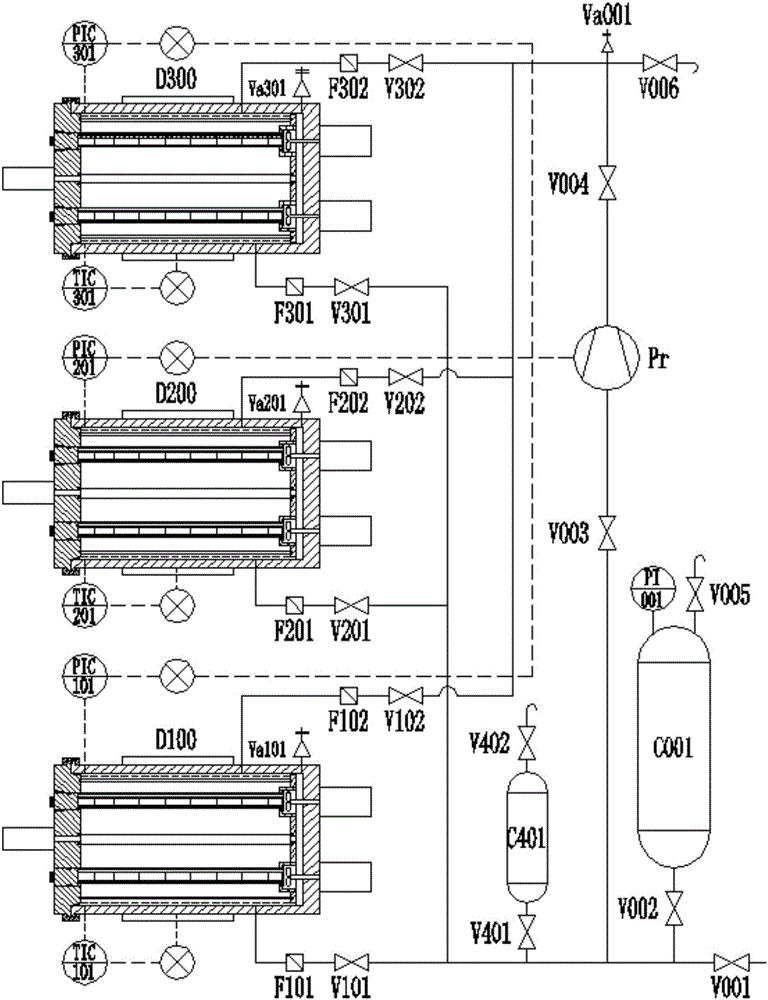

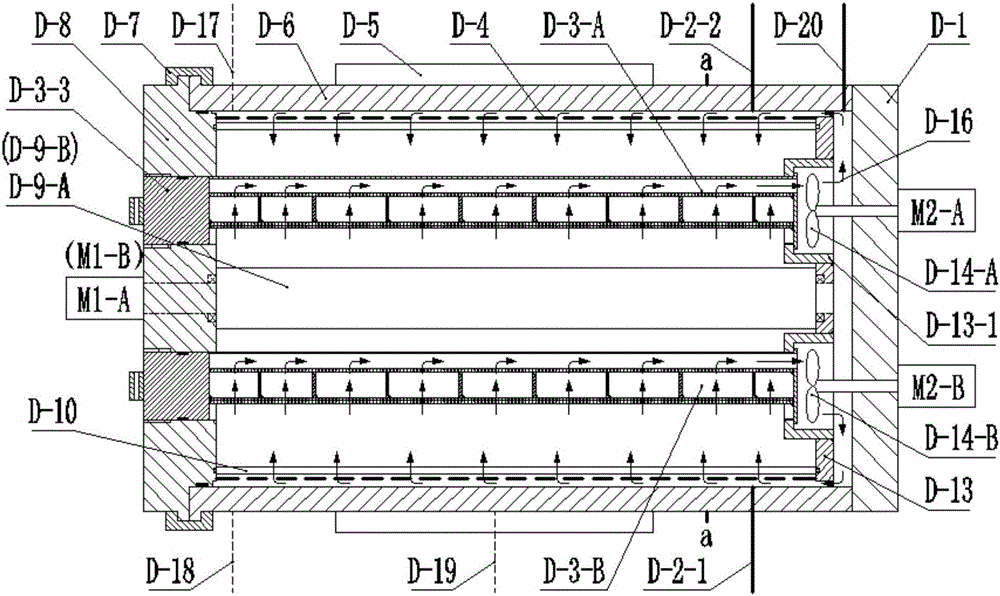

Continuous jig dyeing device for supercritical fluid and dyeing technology

ActiveCN106835556AMinimize the numberQuantity reductionLiquid/gas/vapor open-width material treatmentTextile treatment machine arrangementsTemperature controlPipe fitting

The invention relates to the field of textile dyeing, in particular to a continuous jig dyeing device for supercritical fluid and a dyeing technology. The double-integrated jig dyeing device or three-integrated jig dyeing device continuous jig dyeing device for supercritical fluid is composed of two or three integrated jig dyeing devices, filters, a booster, a supply tank, a buffering tank, switching valves, a supply valve, blow-off valves, an emptying valve, safety valves, a pressure display gauge, pressure control gauges, temperature control gauges, pipes and pipe fittings. The technology includes the steps that 1, system is initialized; the integrated jig dyeing devices are initialized; 3, feeding of supercritical fluid media, supercriticality and jig dyeing are carried out on the integrated jig dyeing devices; 4, feeding of supercritical fluid media, supercriticality and rinsing are carried out on the integrated jig dyeing devices again; 5, pollutants are discharged from the integrated jig dyeing devices. According to the device and the dyeing technology thereof, the process is simple and convenient to implement, preparation time before dyeing is short, equipment investment is small, production efficiency is high, operation cost is low, and emissions of the supercritical fluid media are low.

Owner:QINGDAO GUOBANG IND TECH DEV CO LTD +1

Spraying type jig dyeing machine

ActiveCN105350201AAvoid damageSpray evenlyLiquid/gas/vapor open-width material treatmentTextile treatment machine arrangementsEngineeringMechanical engineering

The invention discloses a spraying type jig dyeing machine which comprises a printing and dyeing box, an upper spraying box, a lower spraying and recycling box and a heating filtering box. The bottom wall of the upper spraying box is in a downward protruding arc shape. The top wall of the lower spraying and recycling box is in a downward concave arc shape. An arc-shaped distribution channel is formed between the bottom wall of the upper spraying box and the top wall of the lower spraying and recycling box. The bottom wall of the upper spraying box is provided with multiple upper spraying holes. The section of the top wall of the lower spraying and recycling box in the normal plane is in sine or cosine shape. Partition boards divide the inner cavity of the lower spraying and recycling box into spraying cavities and recycling cavities. The spraying cavities are opposite to the peak position. The peak position is provided with multiple lower spraying holes. The recycling cavities are opposite to the trough position provided with a recycling groove. The spraying cavities are sequentially communicated, and the recycling cavities are communicated with the printing and dyeing box. The heating filtering box comprises a heat-preserving box body, a filtering screen and a heating bar. The heating bar is arranged in a second cavity and close to the filtering screen. A first cavity is communicated with the printing and dyeing box through a first pipe. The printing and dyeing effect is good, printing and dyeing are uniform, and dye is saved.

Owner:ANHUI YAYUAN PRINTING & DYEING CO LTD

Cotton bamboo fiber blending broad width woven fabric and production method thereof

ActiveCN106939464AHigh surface glossRetain AntibacterialLiquid/gas/vapor open-width material treatmentTextile storage in superimposed formFiberTechnical specifications

The invention discloses a cotton bamboo fiber blending broad width woven fabric and a production method thereof. The production technical flow process sequentially comprises the steps of blank cloth turning and stitching, singeing, amylase desizing, boiling-off, oxygen bleaching, pre-tentering, half mercerizing, dyeing, tentering, formaldehyde-free anti-shrinkage sorting, pre-shrinking, calendering and the like. The cotton bamboo fiber blending broad width woven fabric has the advantages that the surface glossiness is high; the warp and weft water washing dimension change rate is -3.0 percent to +1.0 percent; the fastness to soaping is greater than or equal to 4 stage; the fracture strength is greater than or equal to 280 N. The production method of a product has the advantages that the operation is easy; the environment-friendly effect is achieved; the product safety can reach requirements of GB18401 National Textile Product Basic Safety Technical Specification class A: baby and infant products.

Owner:NANTONG JINSHAIDA SPECIAL FAB CO LTD

High-temperature high-pressure dyejigger

InactiveCN102493139AReasonable designSimple structureLiquid/gas/vapor open-width material treatmentTextile treatment machine arrangementsFrequency conversionEngineering

The invention belongs to the technical field of printing and dyeing equipment, in particular to a high-temperature high-pressure dyejigger which solves the technical problems that the prior art is not reasonable enough in design, and the like. The high-temperature and high-pressure dyejigger comprises a pressure container, wherein the side part of the pressure container is provided with a window, and a side cover is arranged at the window; a first roller and a second roller are arranged in the pressure container, wherein a dye vat is arranged below the first roller and the second roller; a steam input mechanism is connected to the pressure container; the first roller and the second roller are respectively connected with a first frequency-conversion drive device and a second frequency-conversion drive device; a vertical tensioning mechanism is arranged between the first roller and the dye vat; and another vertical tensioning mechanism is arranged between the second roller and the dye vat. The high-temperature high-pressure dyejigger disclosed by the invention has the advantages of reasonable design, simple structure, difficulty in generating chromatic aberration, easiness in operation and use, time and labor saving, high working efficiency and capability of effectively ensuring the evenness of fabrics. According to the high-temperature high-pressure dyejigger, pressure balance and temperature evenness in the pressure container can be realized, the dyeing quality is effectively ensured, and the product quality is good.

Owner:骆玛丽

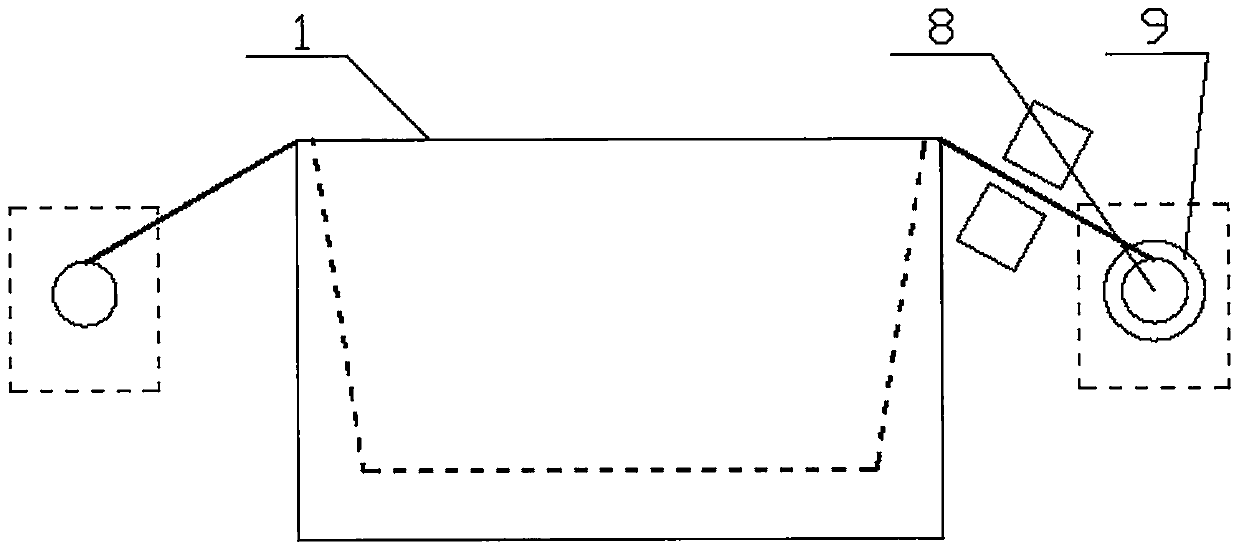

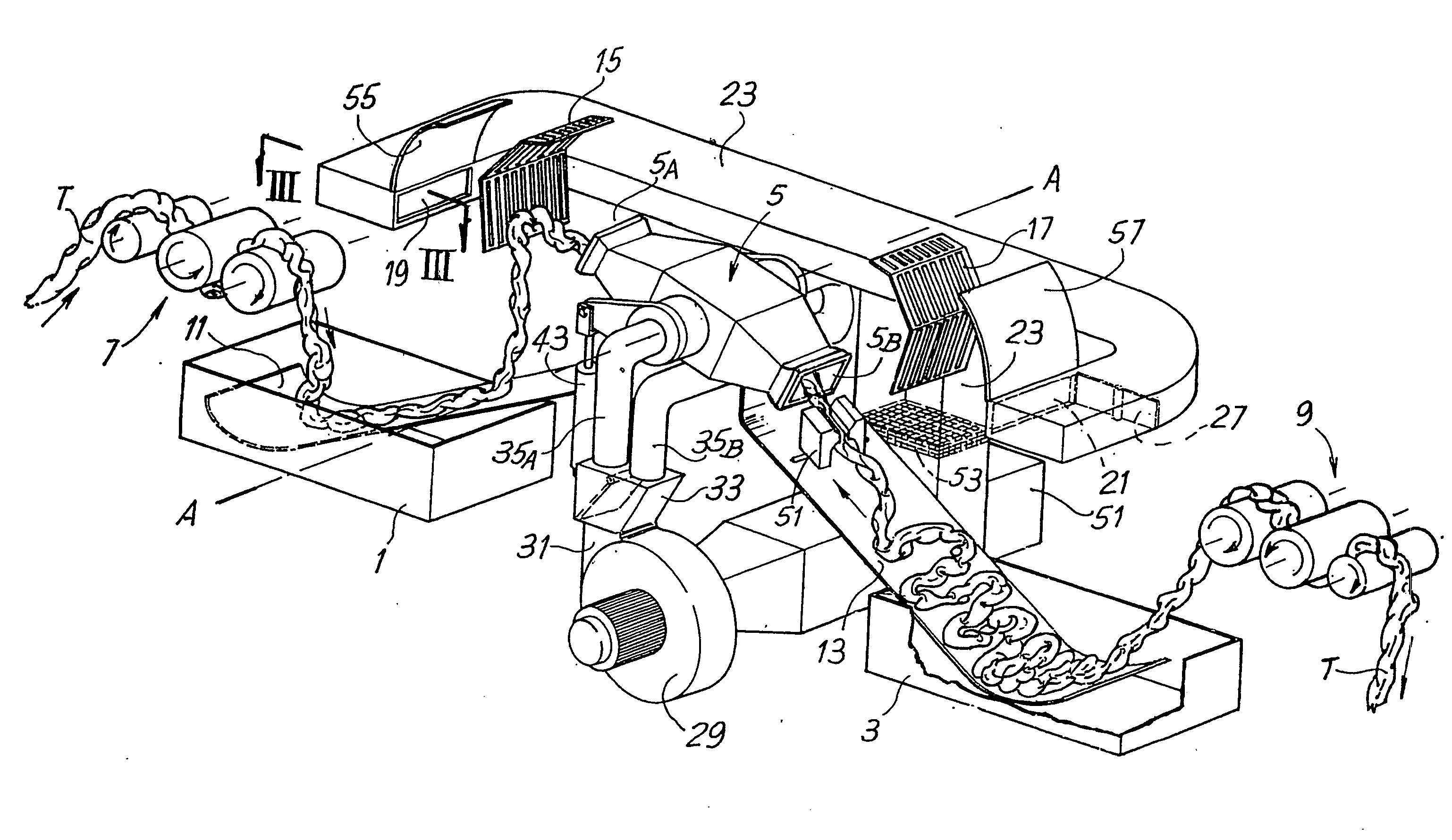

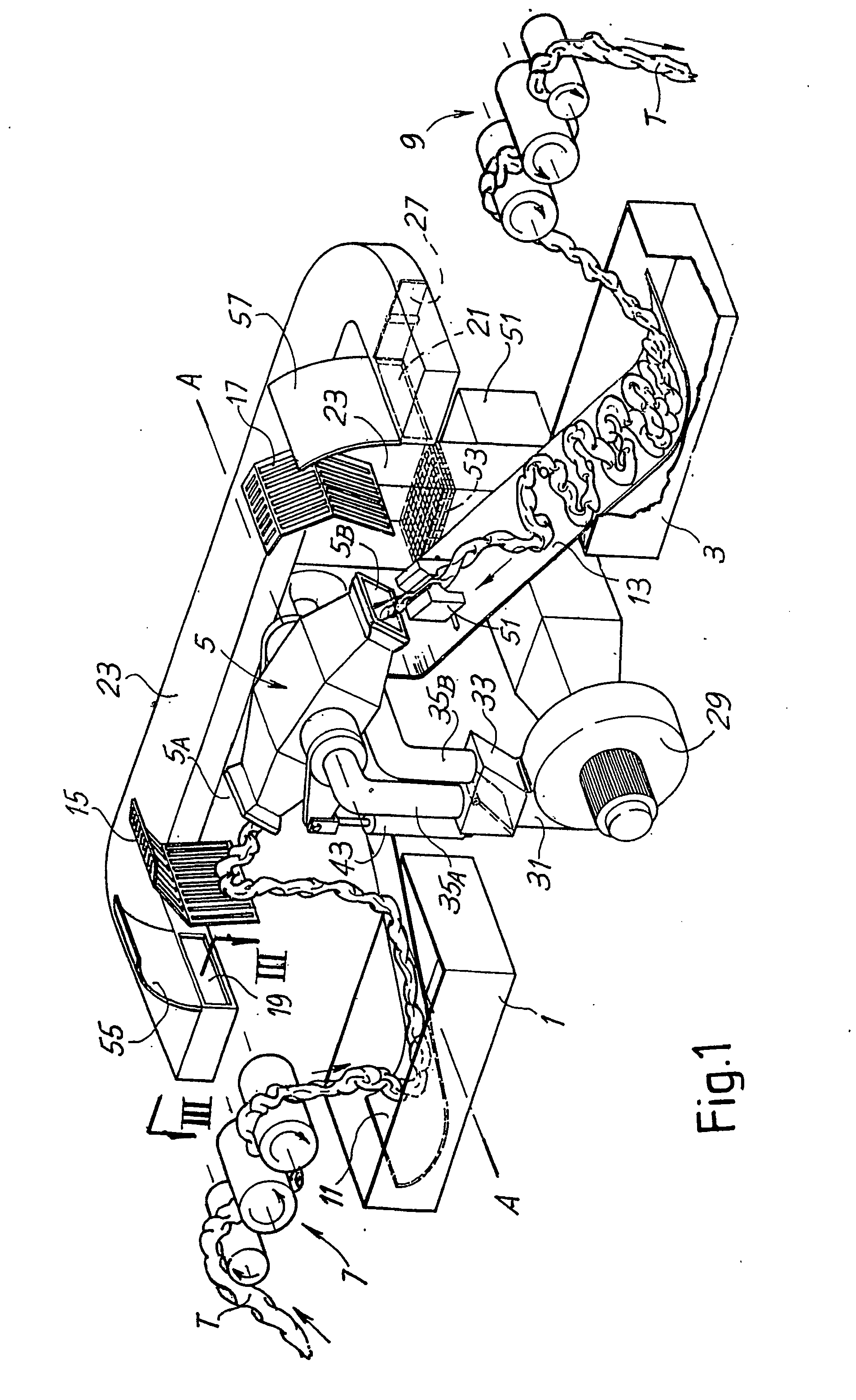

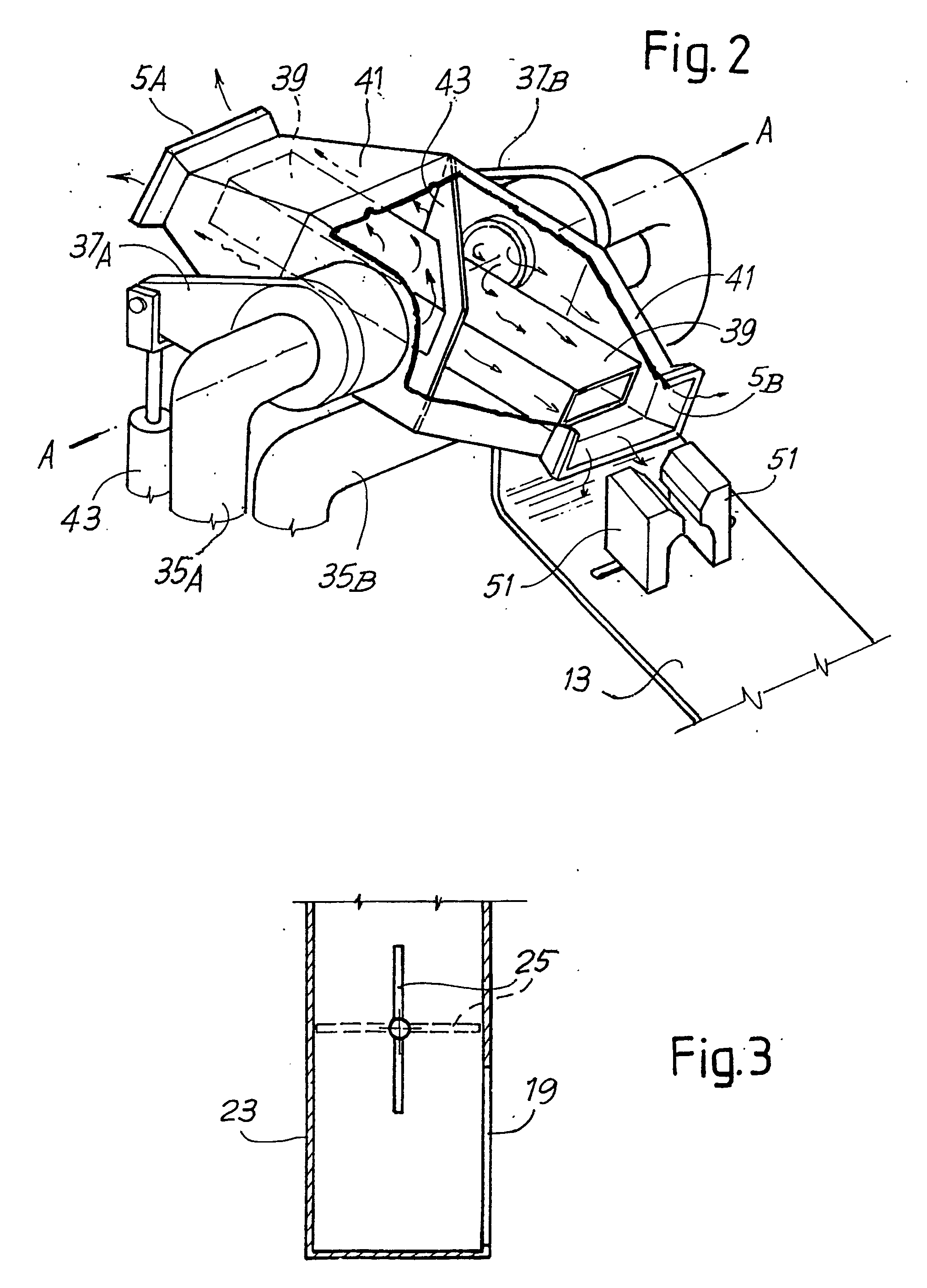

Machine and method for the continuous treatment of a fabric

InactiveUS20050066694A1Efficient methodEasy extractionLiquid/gas/vapor open-width material treatmentFabric breaking/softeningEngineeringMechanical engineering

The machine comprises in combination: means (7) for supplying the fabric (T); means (9) for extracting the fabric; at least one first tank (1) and one second tank (3) which are positioned in series and between which a pneumatic transfer member (5) for transferring the fabric alternately from the first tank to the second tank and vice versa is arranged. The pneumatic transfer member is pivotable so as to assume at least two positions depending on the direction of feeding of the fabric through said pivoting transfer member.

Owner:CORAMTEX

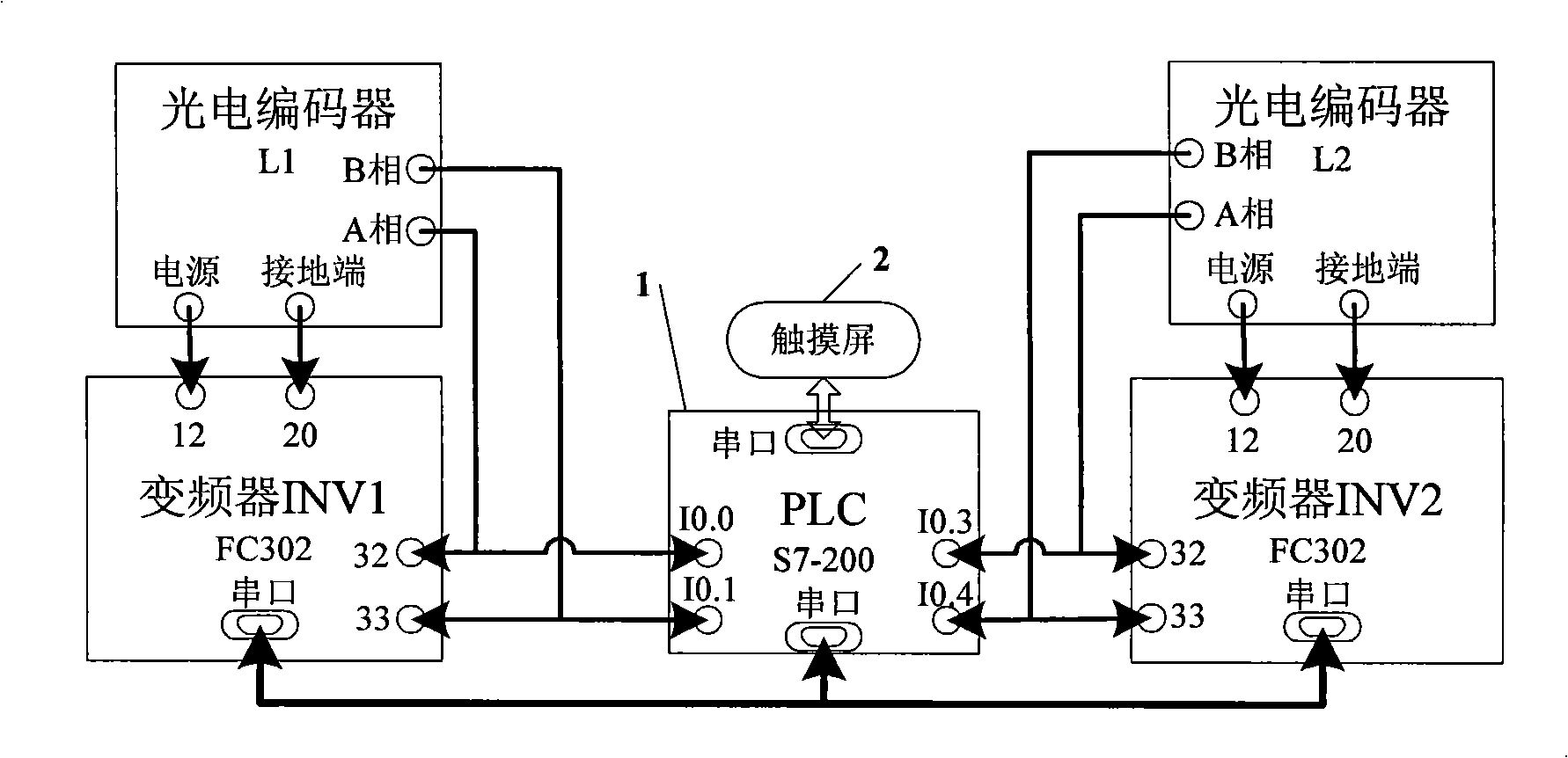

Jig dyeing cloth linear velocity detection device

InactiveCN101302691AImprove dyeing qualityHigh precisionLiquid/gas/vapor open-width material treatmentTextile treatment machine arrangementsFrequency changerEngineering

The invention discloses a linear speed detecting device of fabric of a jig dyeing machine, and comprises a programmable controller, a touch screen that is used for setting and displaying speed, and two control units that are used for coil loading and coil unloading. Each control unit comprises a photoelectric encoder and a servo system which consists of a frequency converter and an electric motor driving a roller, the photoelectric encoder of each control unit is arranged on a rear shaft of the electric motor, a signal output end of the photoelectric encoder is respectively connected with an input end of the programmable controller and an input end of the frequency converter of the control unit, an output end of the programmable controller is connected with the other input end of the frequency converter, and an output end of the frequency converter is connected with the electric motor; the touch screen is connected with the programmable controller through a serial port. The linear speed detecting device of fabric of the jig dyeing machine can implement real-time linear speed detection of the fabric in a jig dyeing production process with high precision and stable working, ensure precise linear speed control of the fabric in the jig dyeing production process, and improve the dyeing quality of the fabrics.

Owner:ZHEJIANG UNIV

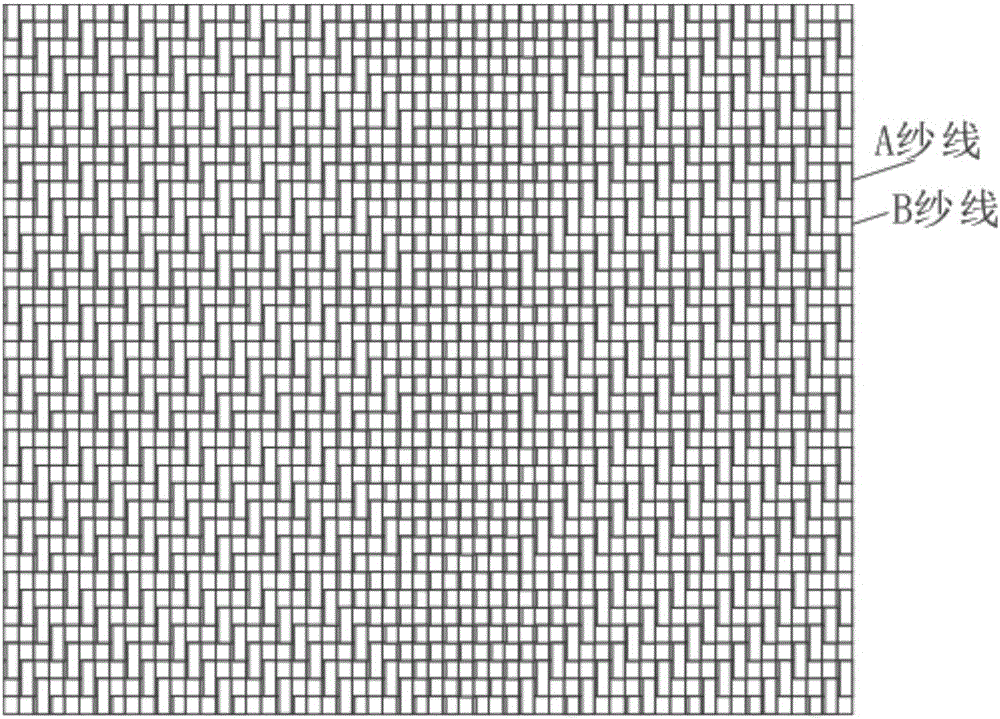

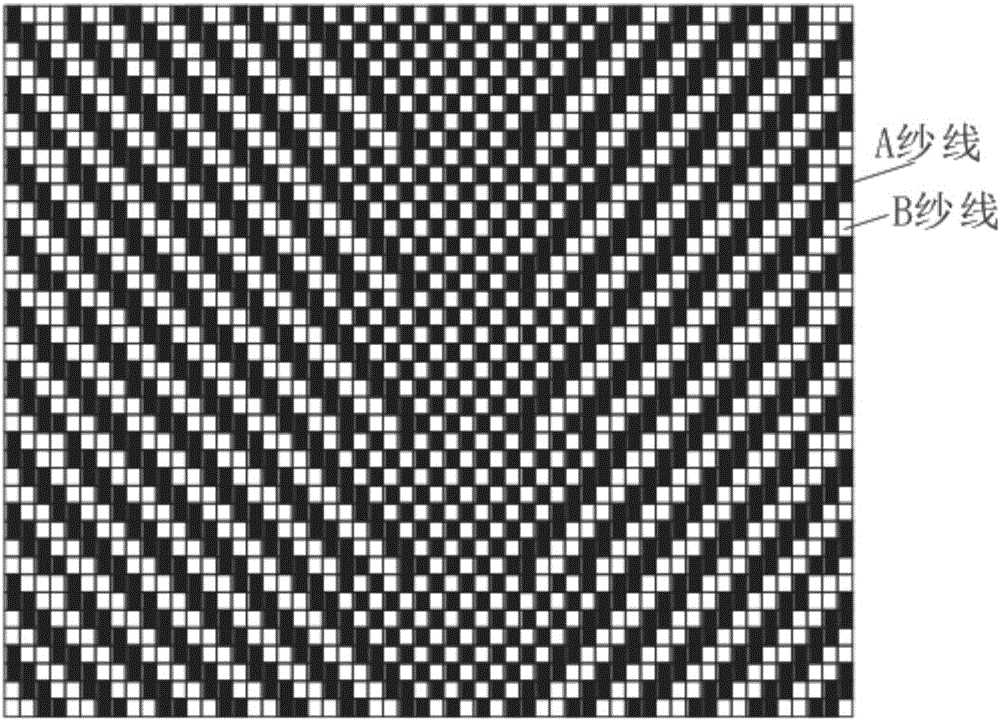

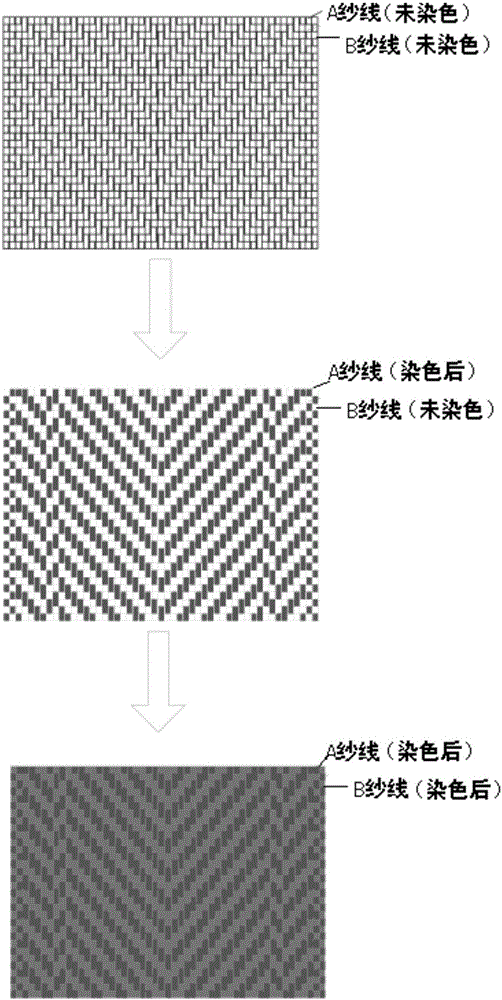

Processing method of zipper cloth strap

InactiveCN105862223APure colorHigh color fastnessLiquid/gas/vapor open-width material treatmentTextile treatment machine arrangementsYarnAfter treatment

The invention discloses a processing method of a zipper cloth strap. The method comprises steps as follows: 1) a to-be-dyed zipper cloth strap is provided, is formed by tatting yarn A and yarn B and adopts a herringbone structure, a plain structure or a twill structure, wherein the yarn A and the yarn B are different in material and adopt the specification of 300D; 2) a dye for dyeing the yarn A is used for dyeing the to-be-dyed zipper cloth strap, and a semi-finished dyed zipper cloth strap product is obtained; 3) a dye for dyeing the yarn B is used for dyeing the semi-finished dyed zipper cloth strap product, after-treatment is performed, and a finished zipper cloth strap product is obtained, wherein the dye for dyeing the yarn A and the dye for dyeing the yarn B are different in color; or the semi-finished dyed zipper cloth strap product is subjected to after-treatment, and the finished zipper cloth strap product is obtained. The cloth strap obtained through dyeing processing is pure in color and good in color fastness; besides, with the adoption of the method, the weaving time is shortened, and the zipper cloth strap production efficiency is improved.

Owner:ZHEJIANG WEIXING IND DEV

Exhaust dyeing and cold batching process in low liquor ratio

InactiveCN101798734AEvenly distributedLow costLiquid/gas/vapor open-width material treatmentDyeing processFiberHydrolysis

The invention discloses an exhaust dyeing and cold batching process in a low liquor ratio, which achieves an effect of dyeing uniformly by adopting the low liquor ratio, repeated dipping and feeding in batches, makes up inadequate machine color fixation by a mode of relaxing at the low temperature, fixing the color by adding alkaline and performing cold batching, makes reactive dye and fibers bond sufficiently, and greatly reduces the hydrolysis reaction of a dye. The exhaust dyeing and cold batching process in the low liquor ratio has the characteristics of reducing pollution, saving energy source and improving benefit.

Owner:江苏AB集团股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com