Reciprocating type yarn jig dyeing machine

A technology of a reciprocating, jigger, used in yarn dyeing in the yarn-dyed industry. , In the field of reciprocating yarn jiggers, it can solve the problems of high production cost, laborious addition of dyeing liquid and yarn, and more dyeing liquid, etc., and achieve the effect of low production cost, low labor intensity and improved quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

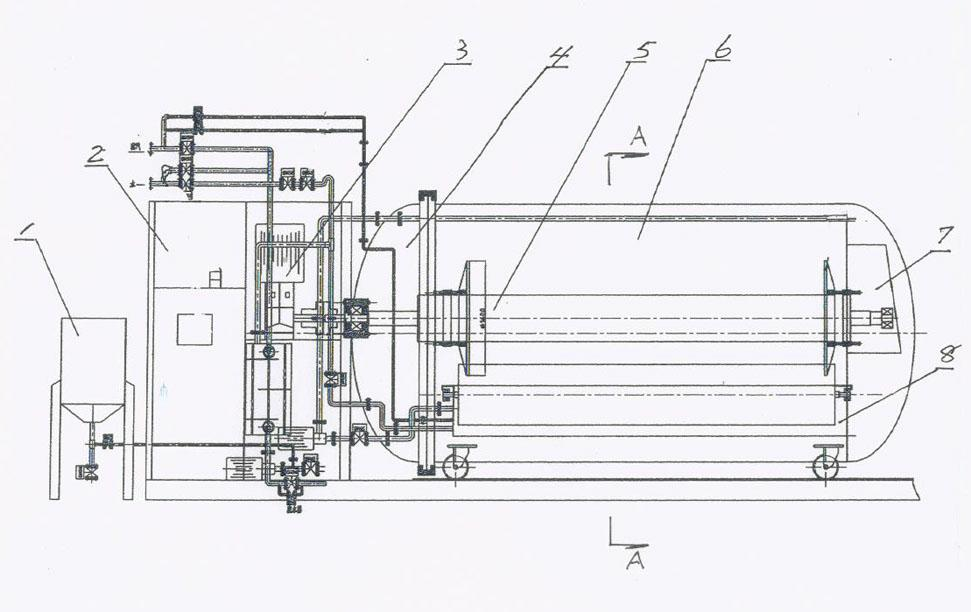

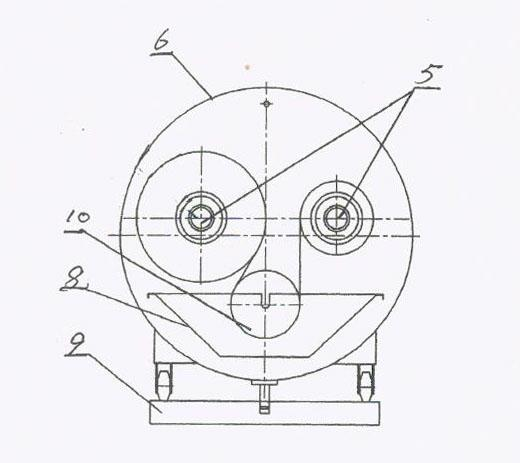

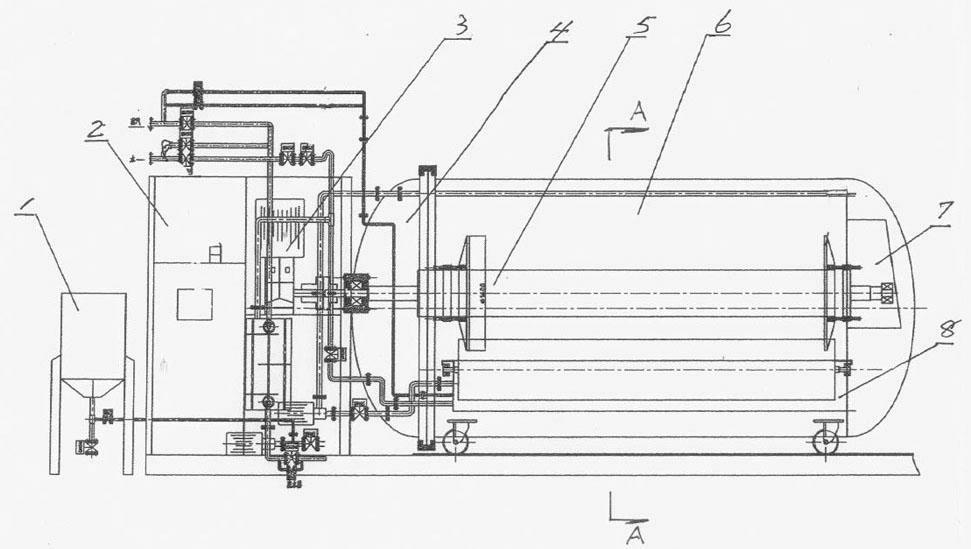

[0014] Such as figure 1 and figure 2 As shown, the reciprocating yarn jigger of the present invention includes a cylinder 6 arranged horizontally, one end of the cylinder 6 is closed, and the other end is equipped with a cylinder cover 4 that can be opened and closed. The cylinder body 6 is provided with a dye solution tank 8, which is a long tank, which is placed at the bottom of the cylinder body 6 inner cavity through a base 9, and two winding shafts 5 are arranged above it. The dye solution tank 8 and the two winding shafts 5 are parallel to each other, and brackets 7 are arranged in the cylinder body 6 at both ends of the dye solution tank 8. on bracket 7. The cylinder cover 4 is processed with a through hole, and the same end of the winding shaft 5 protrudes out after passing through the cylinder cover 4 of the cylinder body 6 and is connected with the output shaft of a power mechanism (motor and reducer) 3 respectively. The mouth of the dye liquor tank 8 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com