Patents

Literature

389results about How to "Avoid chromatic aberration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

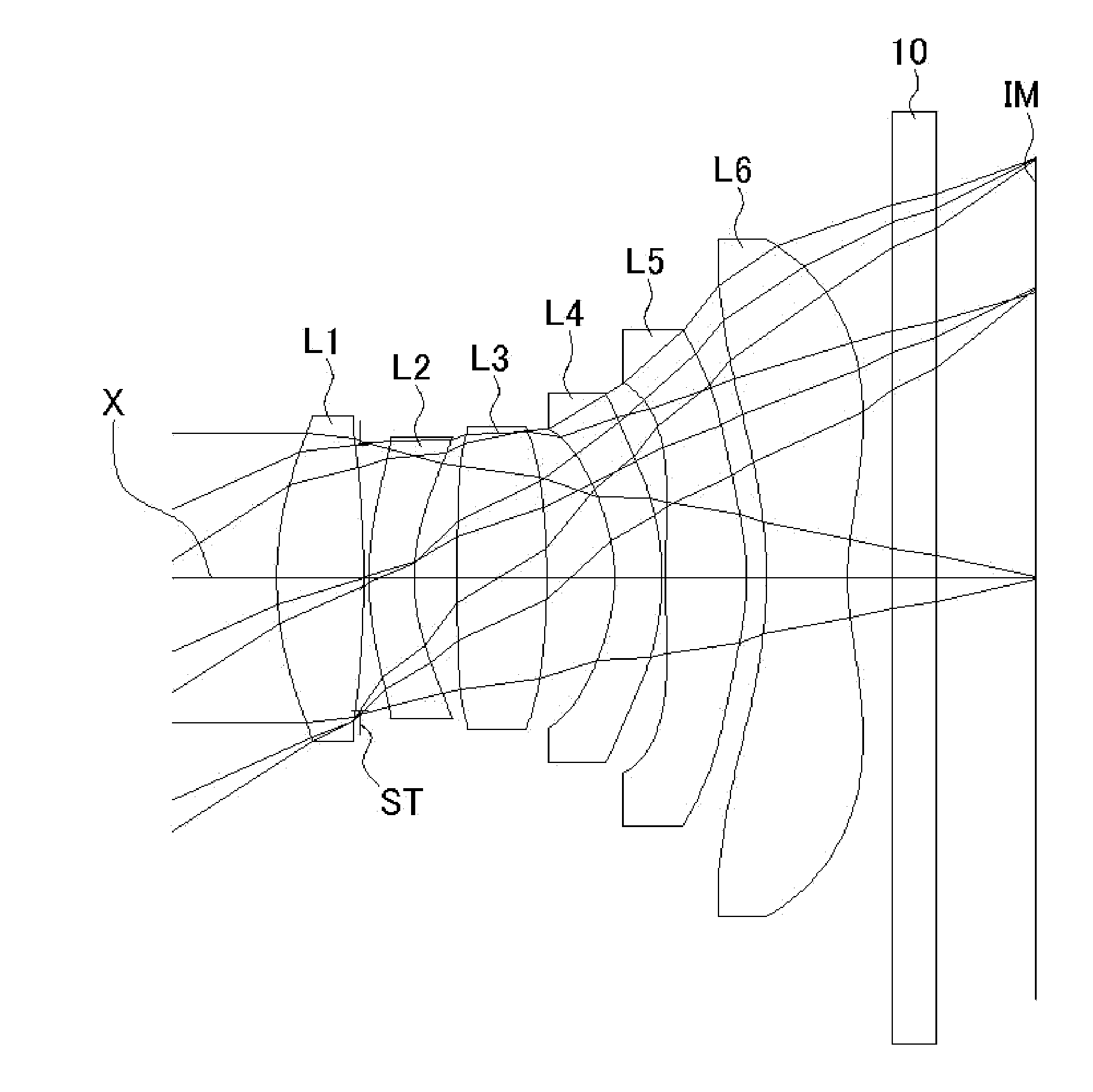

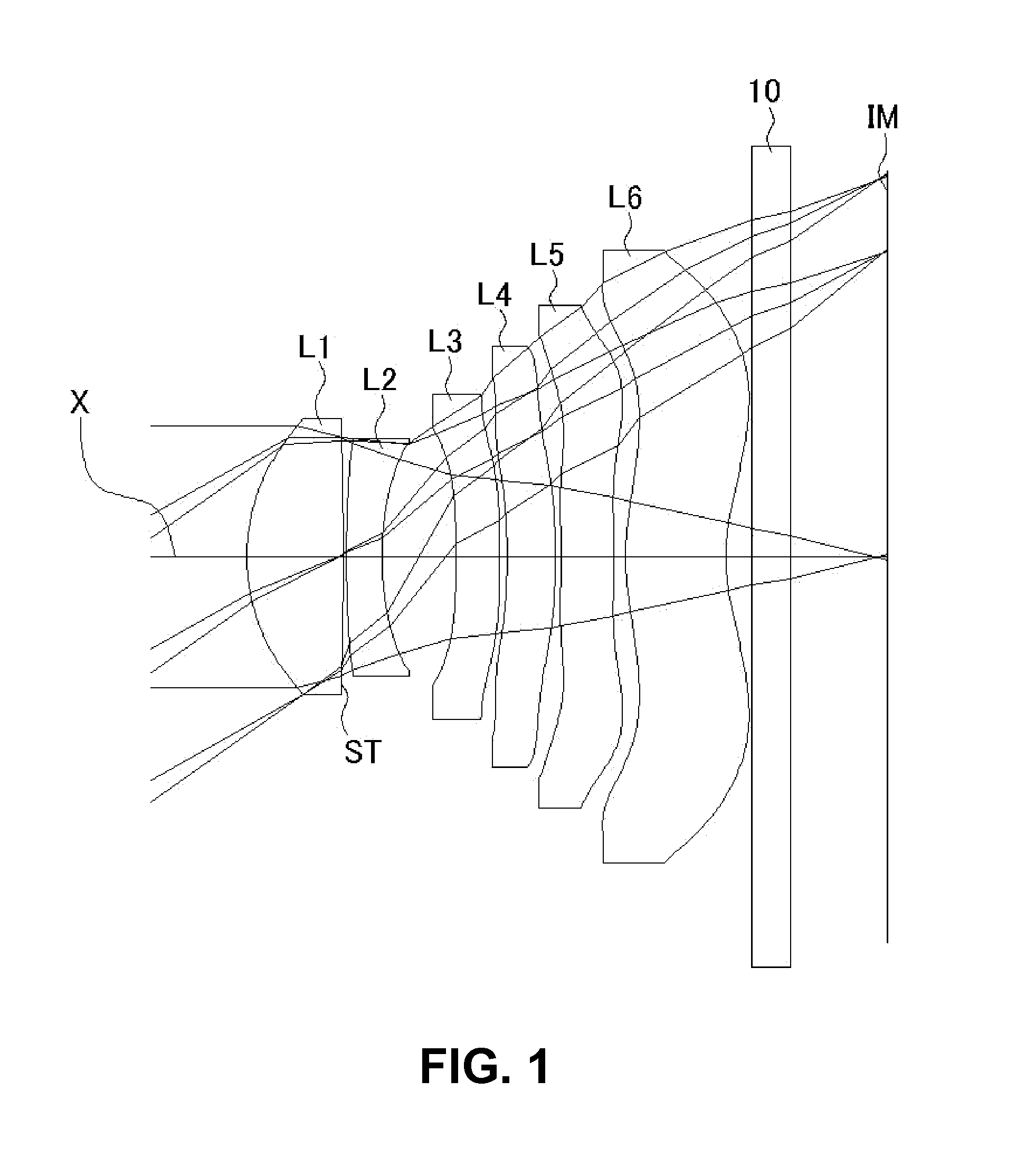

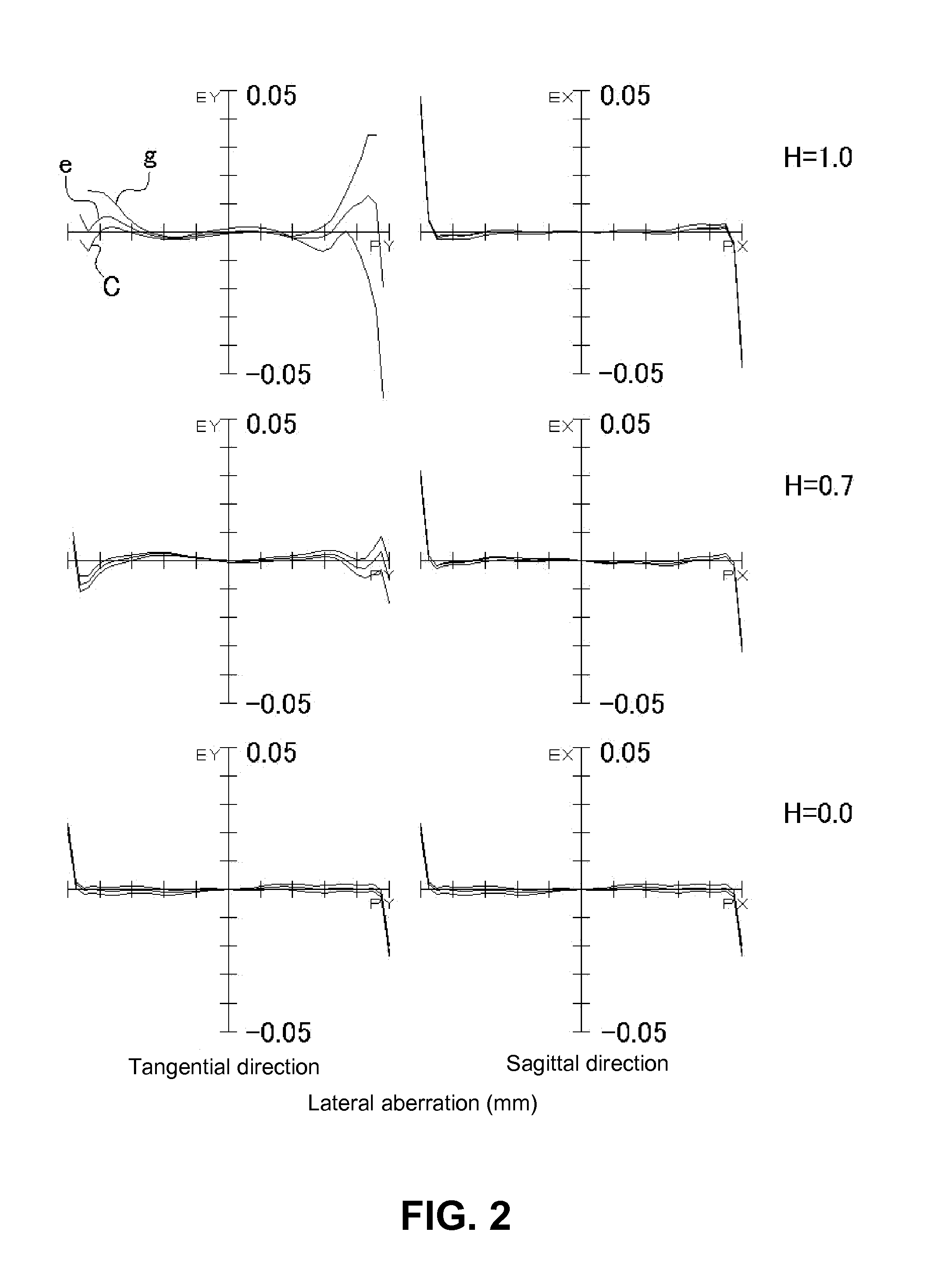

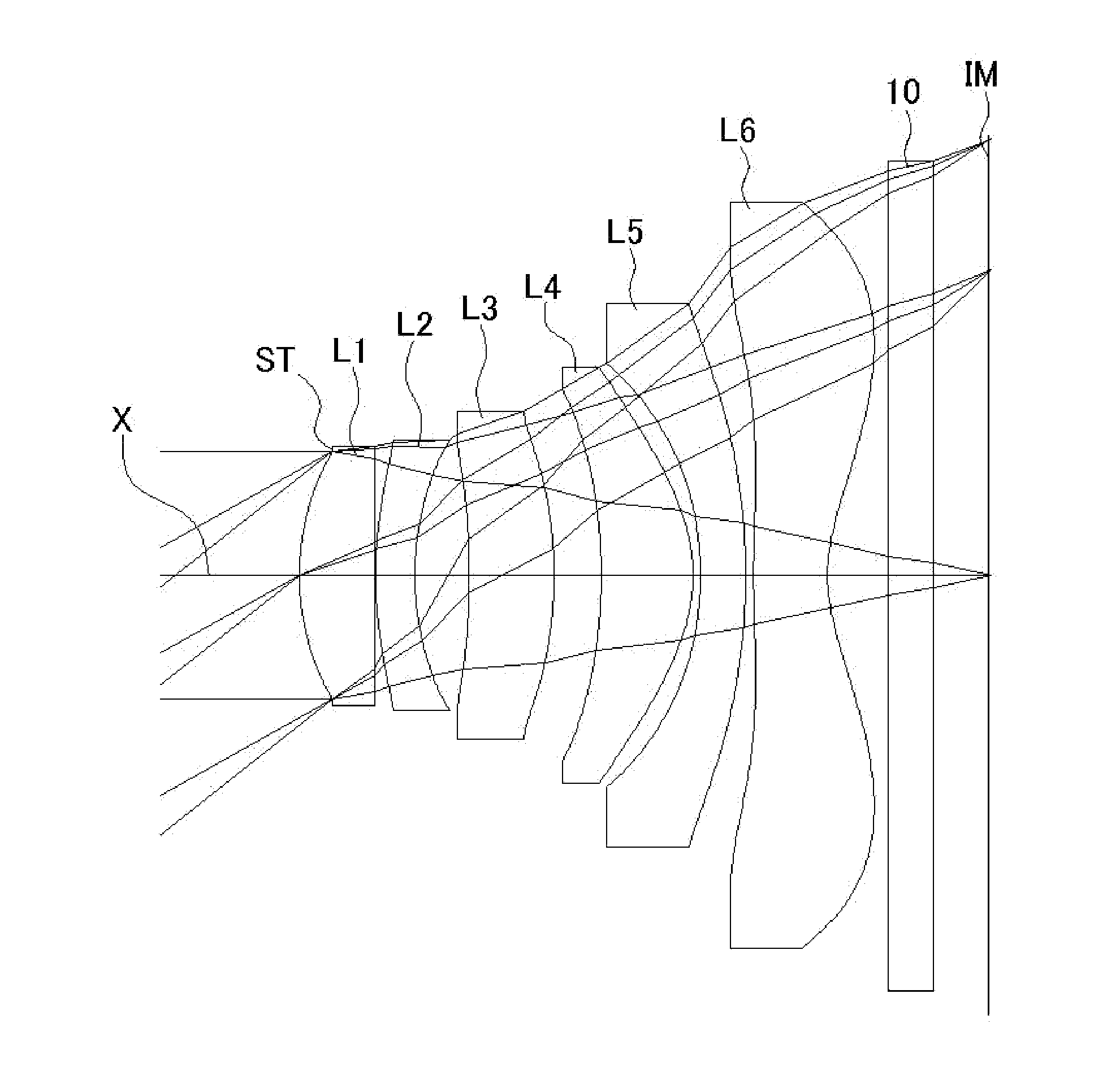

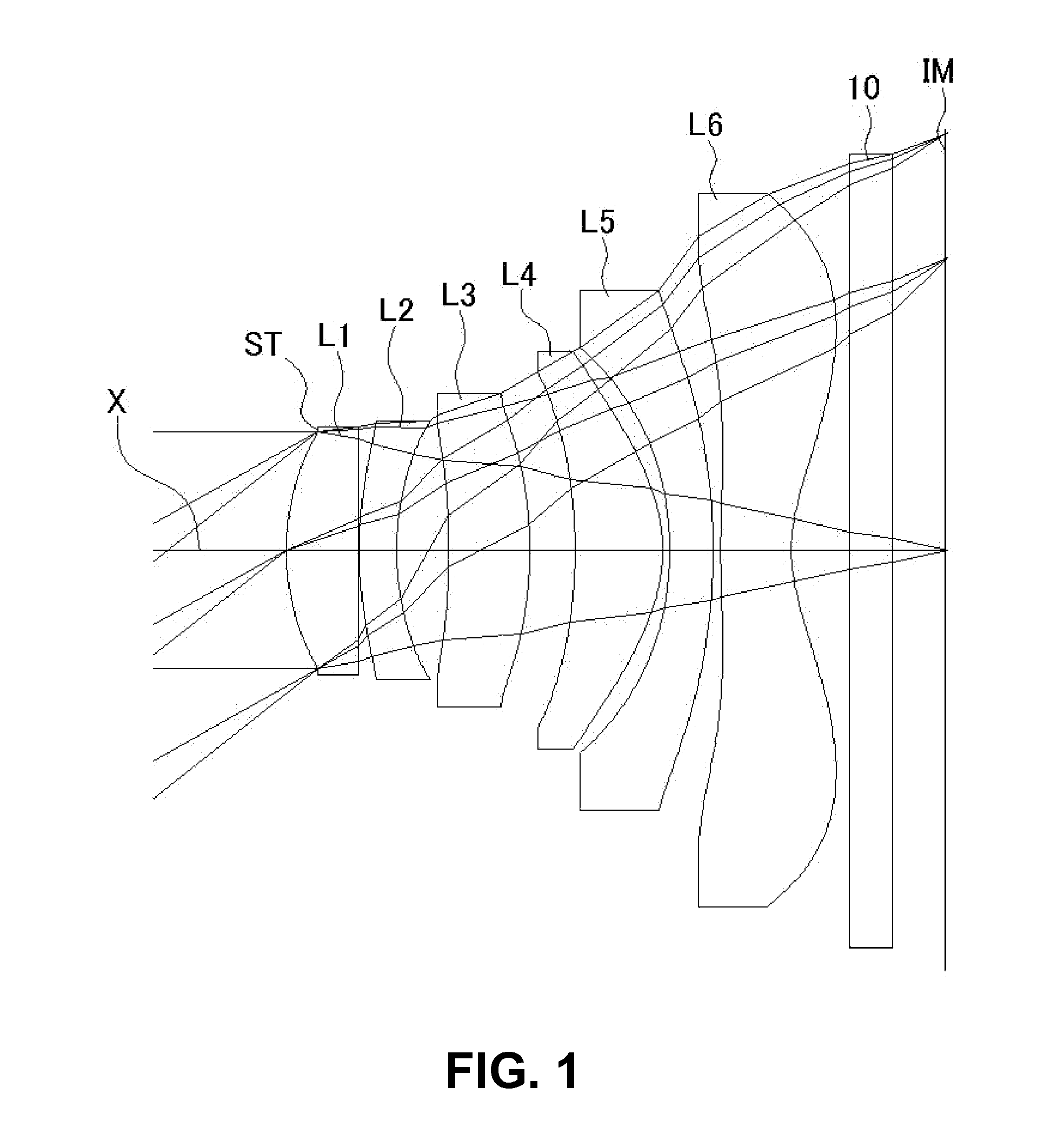

Imaging lens

An imaging lens includes a first lens; a second lens; a third lens; a fourth lens; a fifth lens; and a sixth lens, arranged in this order from an object side to an image plane side. The first lens has a surface thereof on the object side having a positive curvature radius. The second lens has surfaces on the object side and the image plane side having positive curvature radii. The third lens has a surface on the object side having a positive curvature radius and a surface on the image plane side having a negative curvature radius. The fifth lens is formed has an aspheric shape surface on the object side. The sixth lens has an aspheric shape surface on the image plane side. The first to fourth lenses have refractive power weaker than that of the fifth and sixth lenses.

Owner:TOKYO VISIONARY OPTICS CO LTD

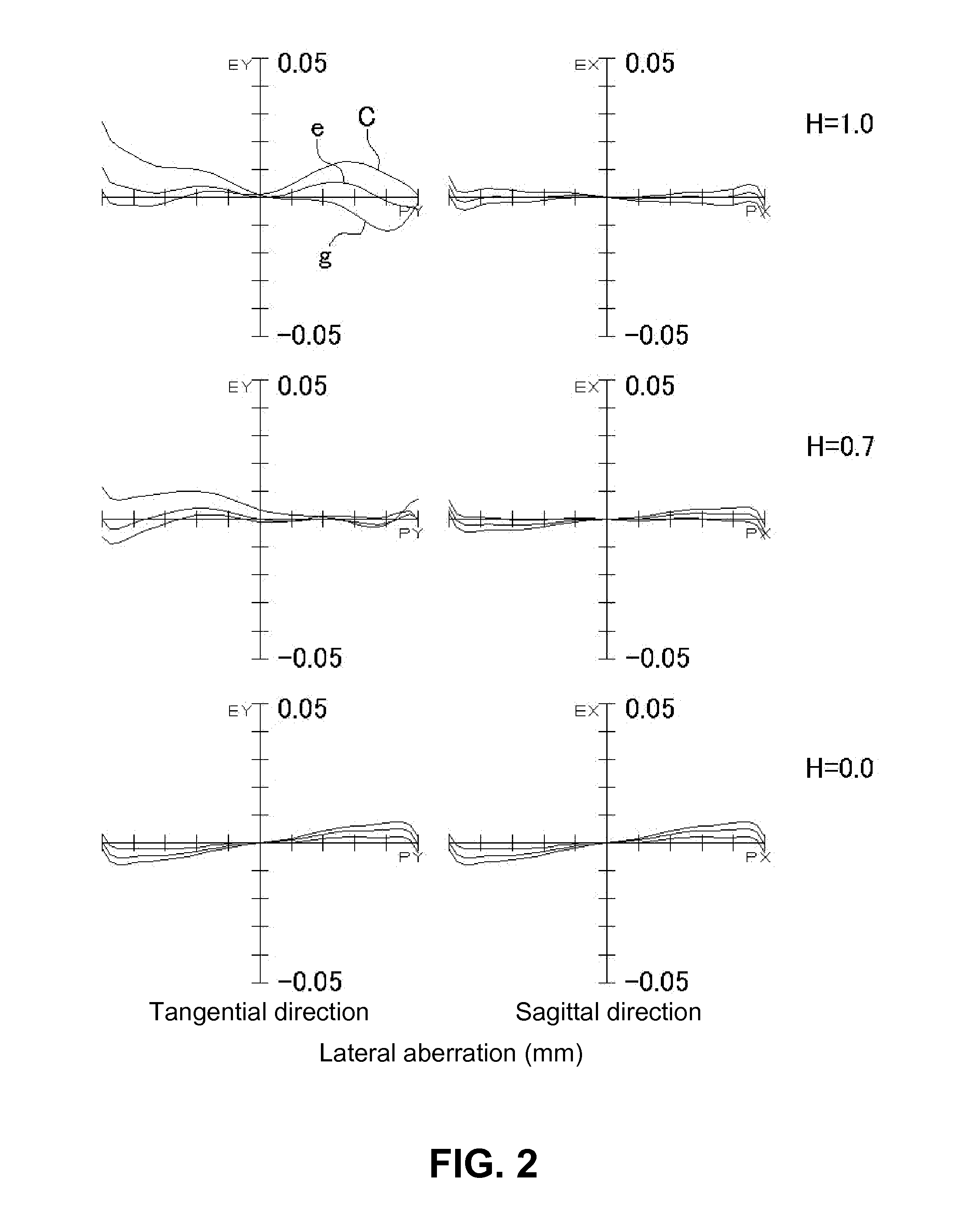

Imaging lens

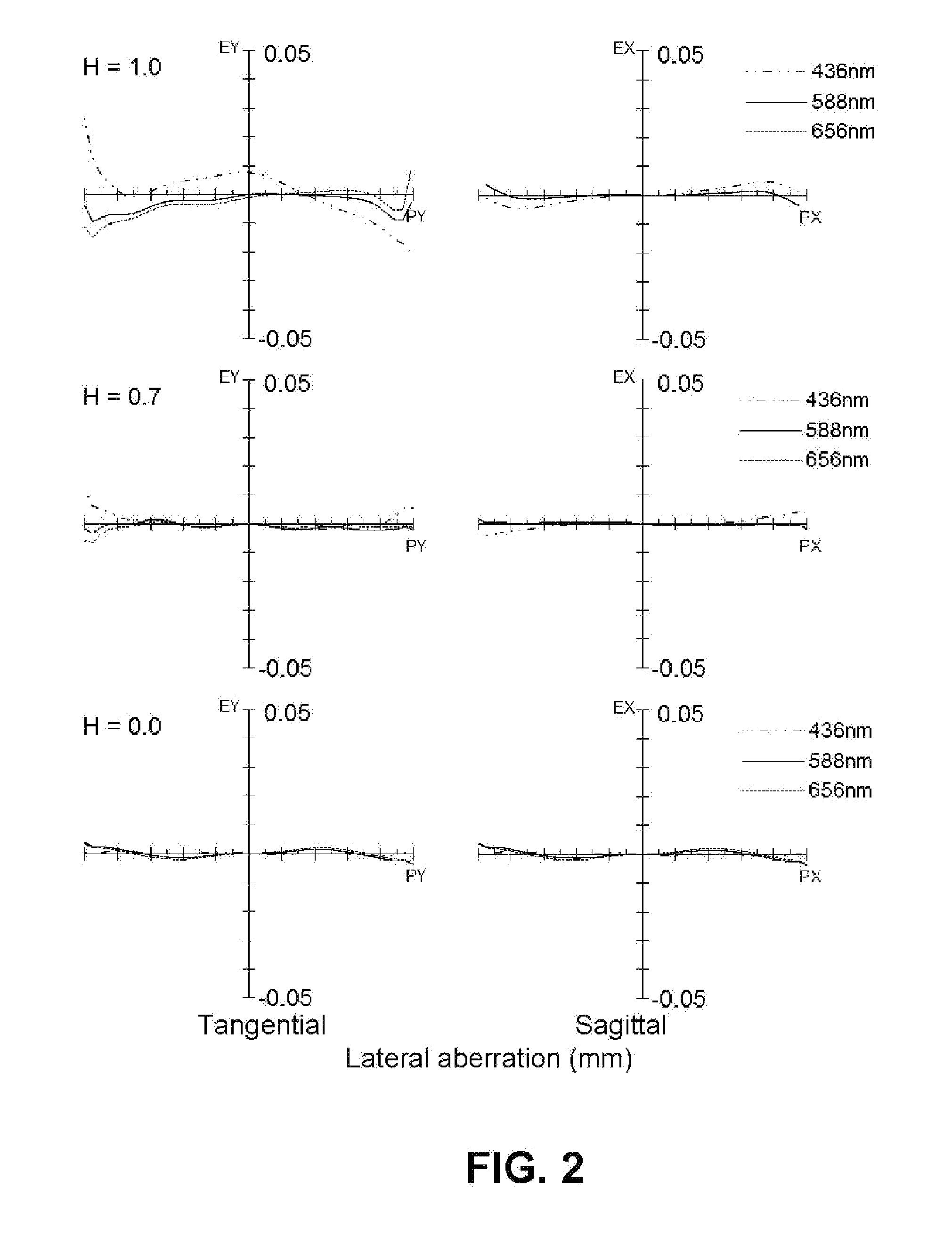

ActiveUS20130314804A1Refractive power of becomes strongCorrected satisfactorilyOptical elementsImaging lensImage plane

An imaging lens includes a first lens having positive refractive power; a second lens having negative refractive power; a third lens; a fourth lens having negative refractive power; a fifth lens having positive refractive power; and a sixth lens, arranged in this order from an object side to an image plane side. The first lens is formed so that a surface thereof on the object side has a positive curvature radius. The second lens is formed so that a surface thereof on the image plane side has a positive curvature radius. The fifth lens is formed so that a surface thereof on the object side and a surface thereof on the image plane side have negative curvature radii. Each of the third lens, the fourth lens, the fifth lens, and the sixth lens has refractive power weaker than that of each of the first lens and the second lens.

Owner:TOKYO VISIONARY OPTICS CO LTD

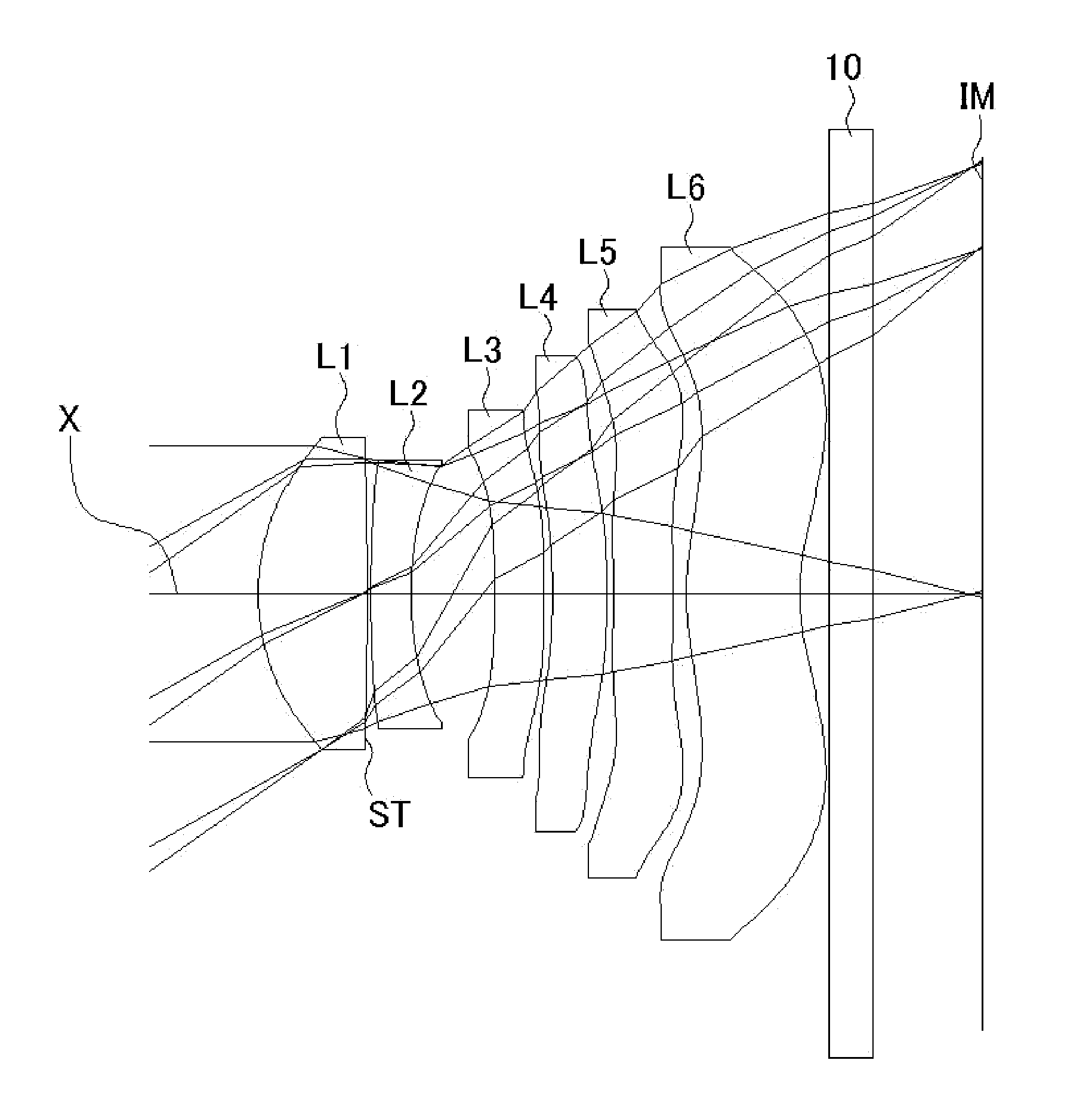

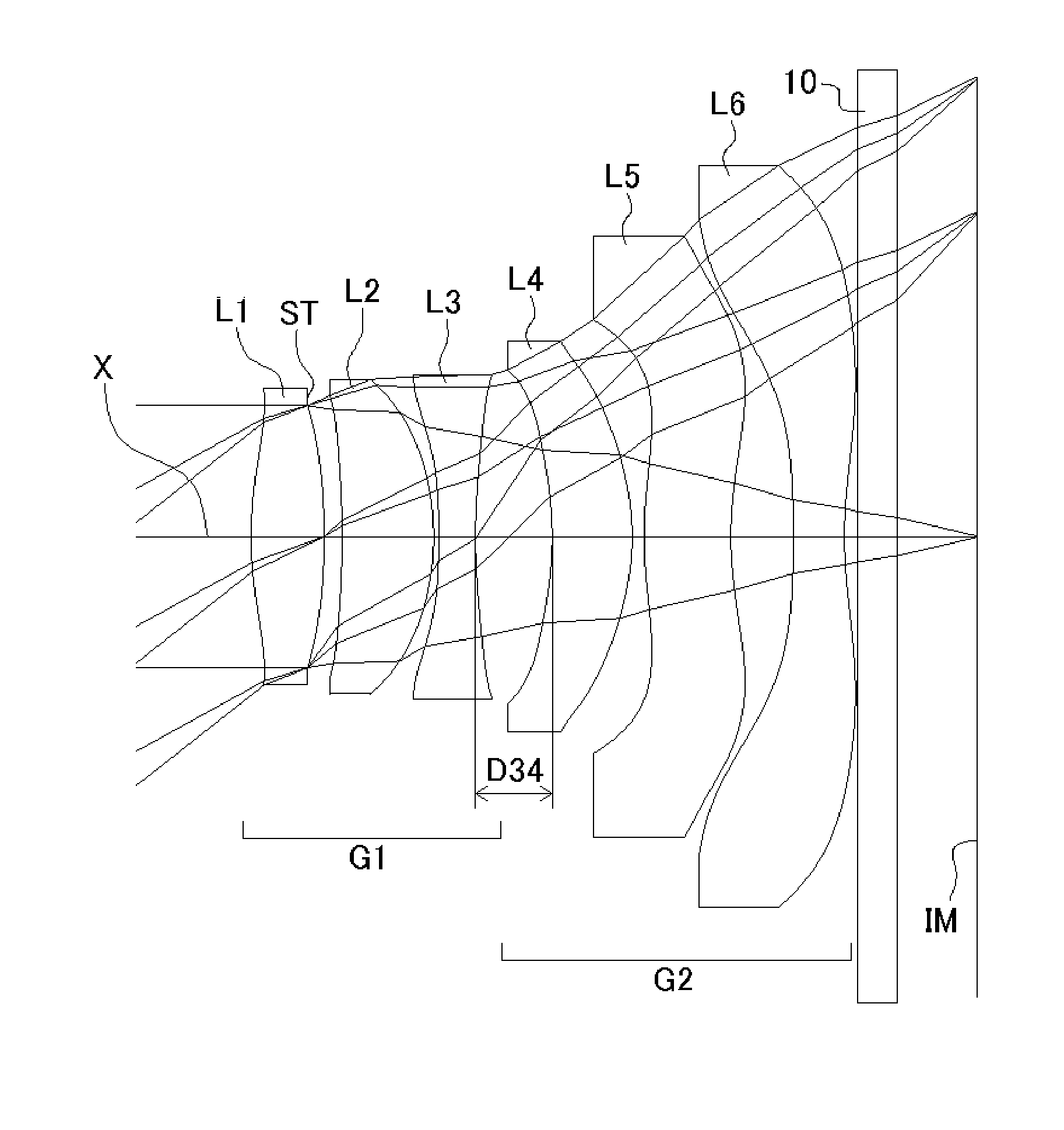

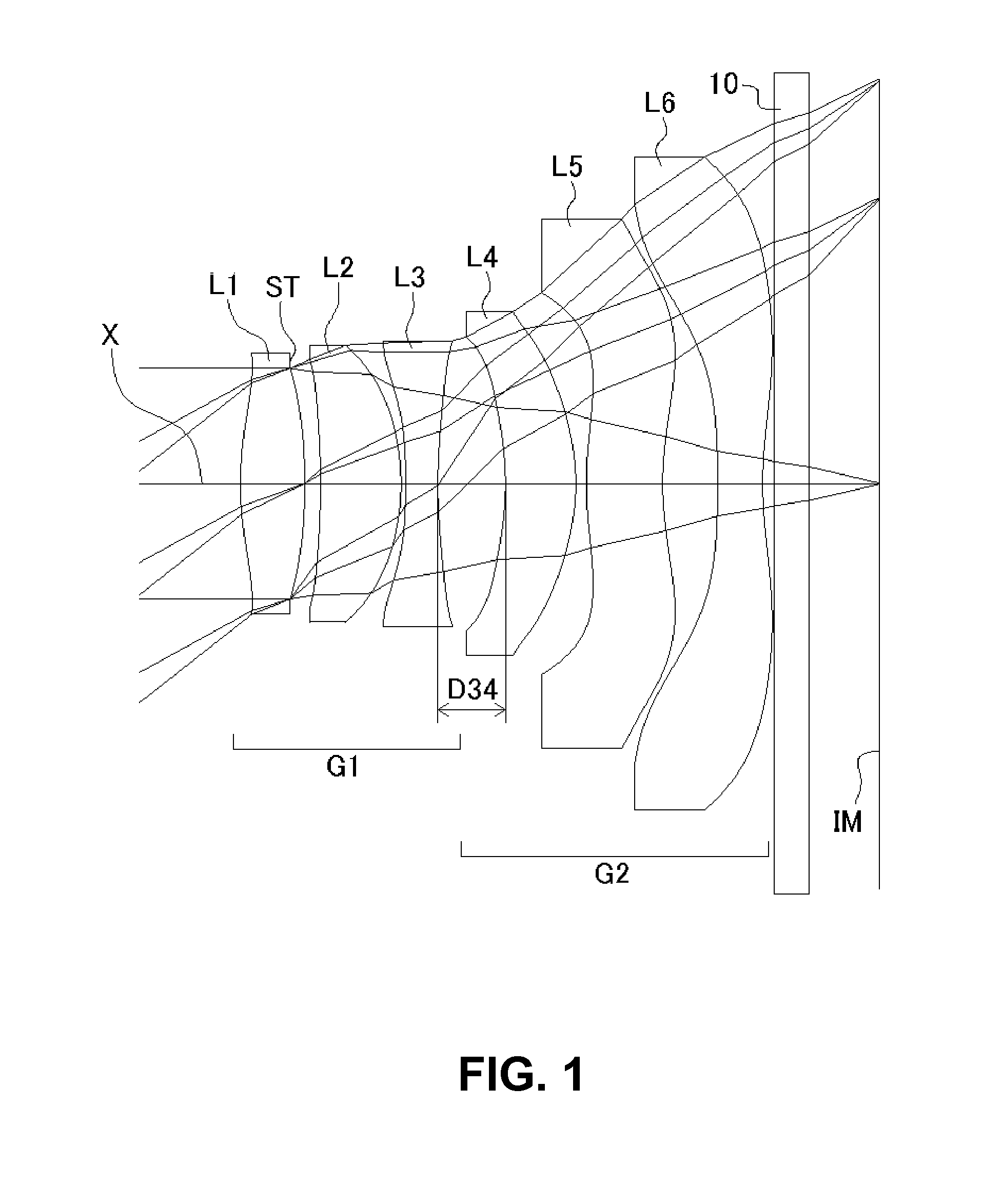

Imaging lens

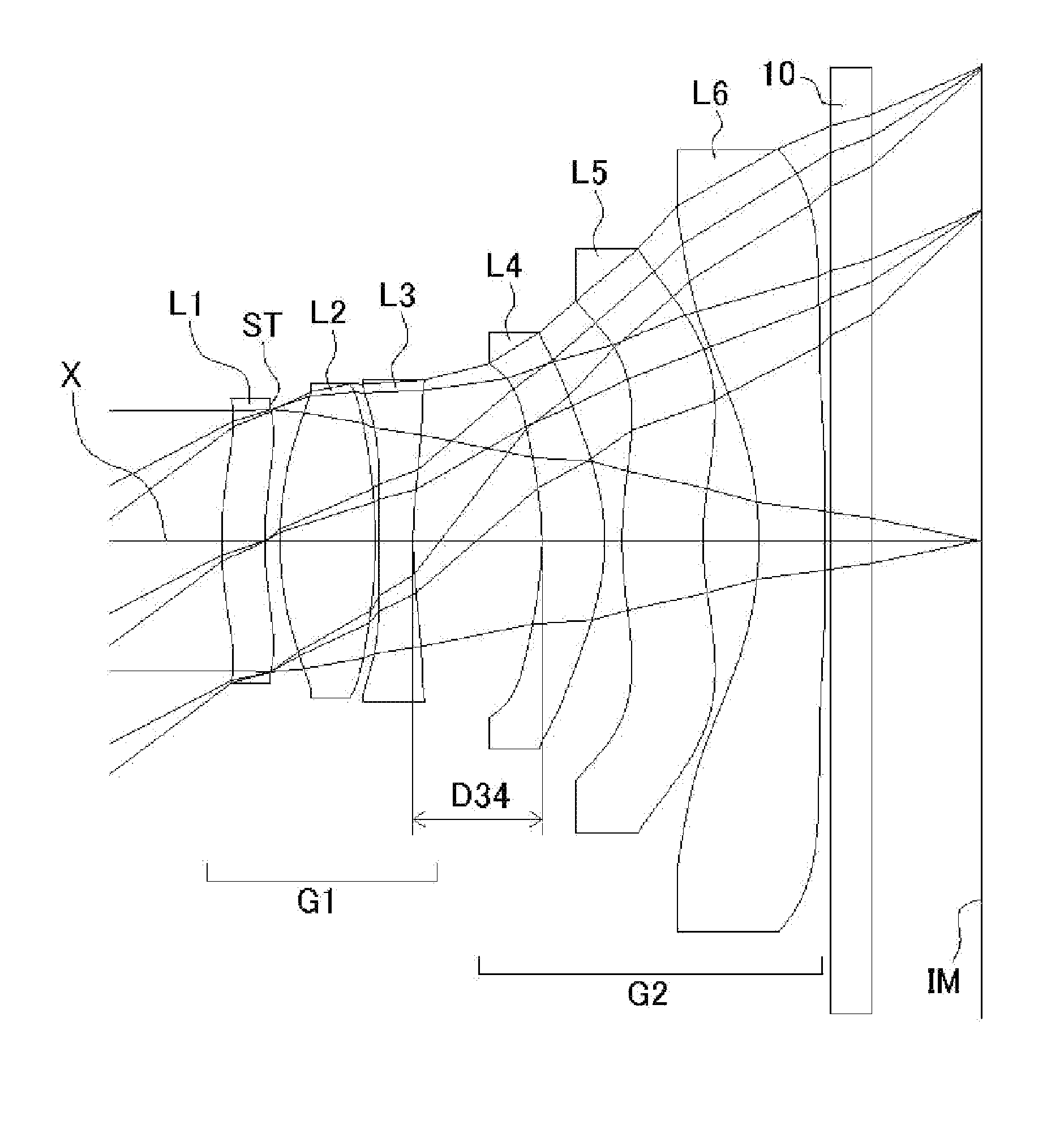

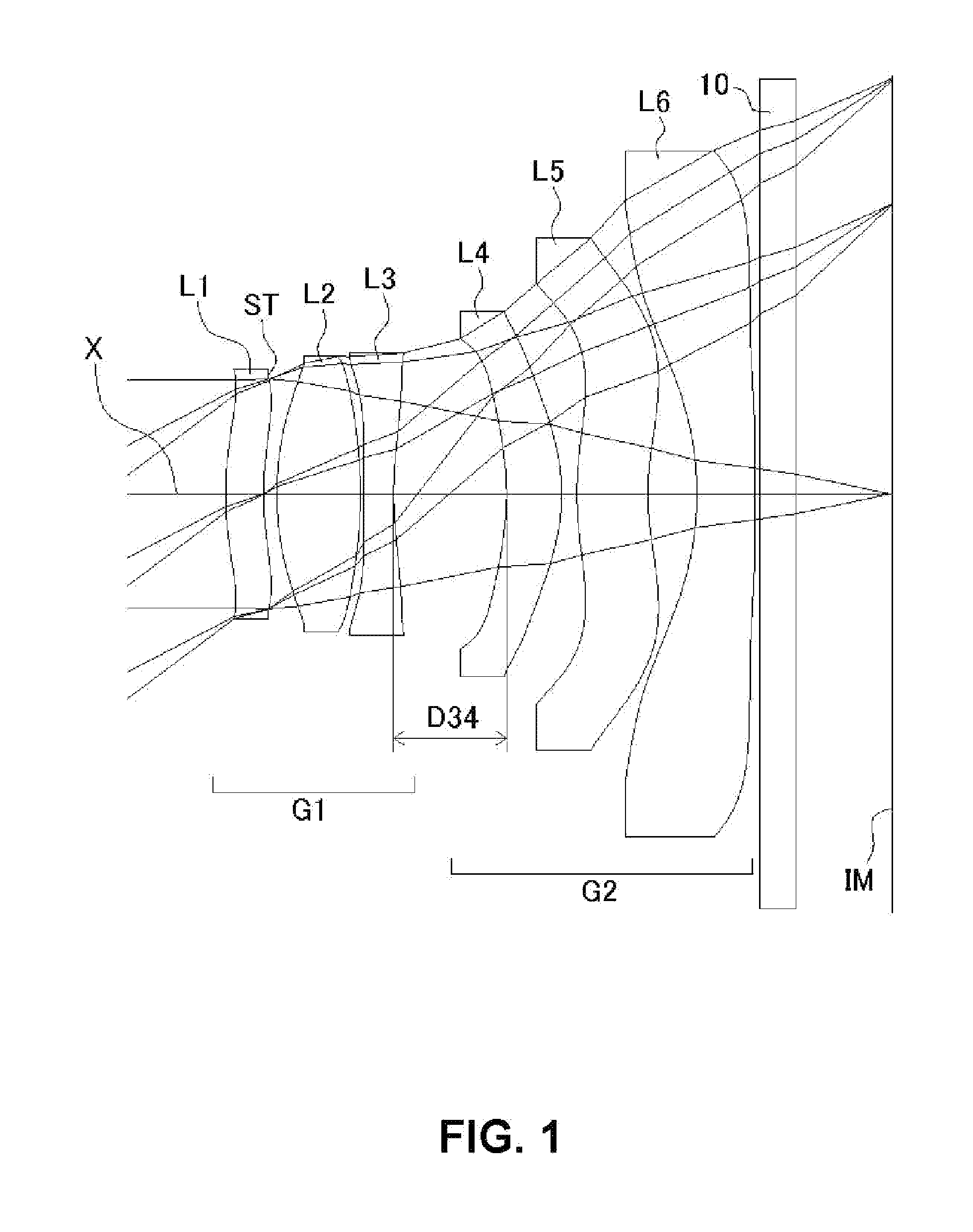

An imaging lens includes a first lens group having positive refractive power and a second lens group having negative refractive power, arranged in this order from an object side to an image plane side. The first lens group includes a first lens having positive refractive power, a second lens having positive refractive power, and a third lens having negative refractive power. The second lens group includes a fourth lens having positive refractive power, a fifth lens, and a sixth lens having negative refractive power. The first lens has a specific focal length. The first to third lenses have specific Abbe's numbers.

Owner:TOKYO VISIONARY OPTICS CO LTD

Exterior wall color surface decoration mortar and preparation method thereof

The invention relates to a building material, and in particular relates to an exterior wall color surface decoration mortar and a preparation method thereof. The exterior wall color surface decoration mortar comprises the following raw materials by weight: 20%-30% of white cement, 50%-60% of quartz sand, 0.1%-0.5% of chopped fiber, 10%-20% of heavy calcium carbonate, 0.2%-1% of latex powder, 0.3%-0.5% of cellulose ether, 1%-5% of an inorganic pigment, 0.2%-0.4% of a water repellent, 5%-10% of coal powder ash, 0.1%-0.15% of a defoaming agent, 1%-3% of metakaolin, 0.2%-0.5% of a thixotropic lubricant and 1%-2% of a water reducing agent. The exterior wall color surface decoration mortar has the advantages of crack resistance, weather resistance, good ultraviolet resistance, permanent and uniform color, good whiskering resistance, and the like, can be well combined with various inorganic base layer materials, is good in coating density, and can be widely used in the building fields such as exterior wall decoration and the like.

Owner:KUNSHAN JIANGUO CONCRETE PROD CO LTD

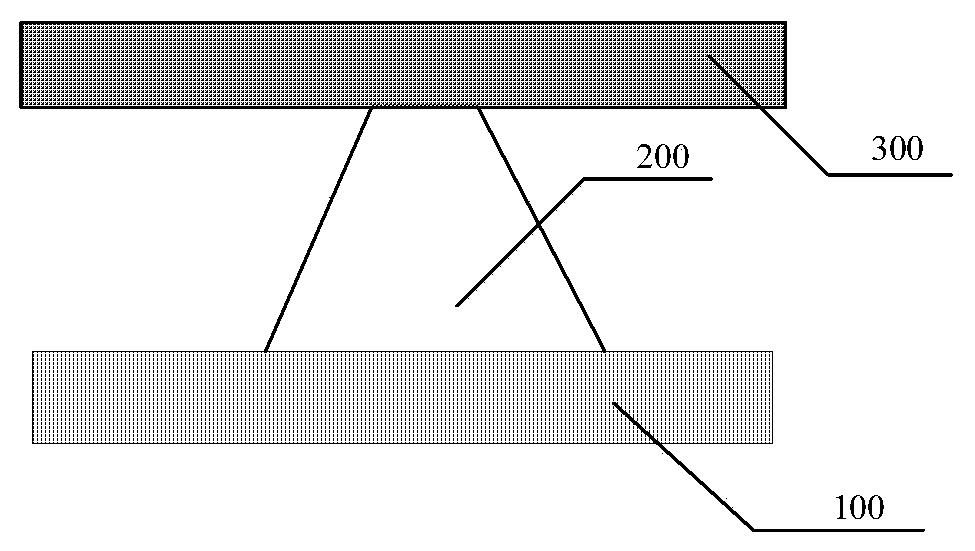

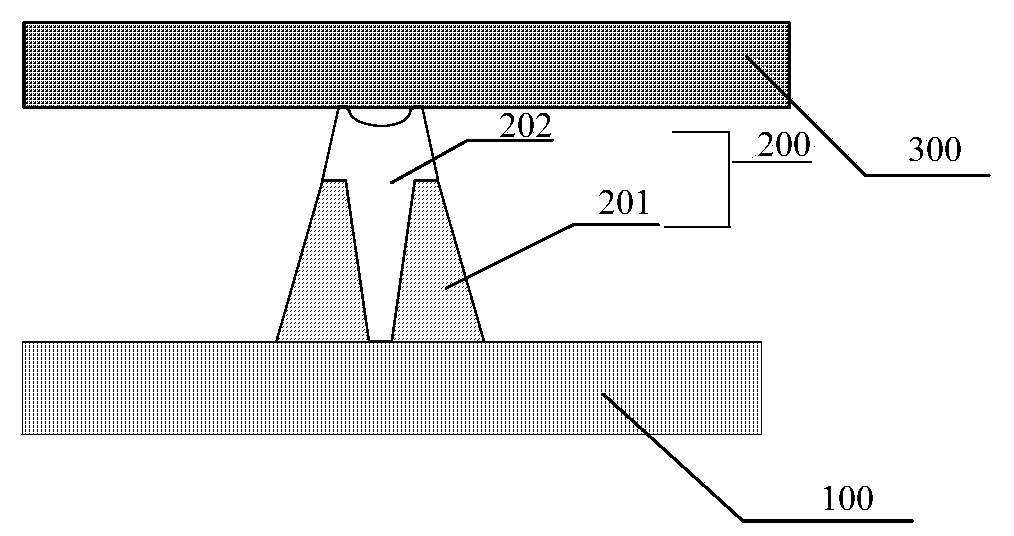

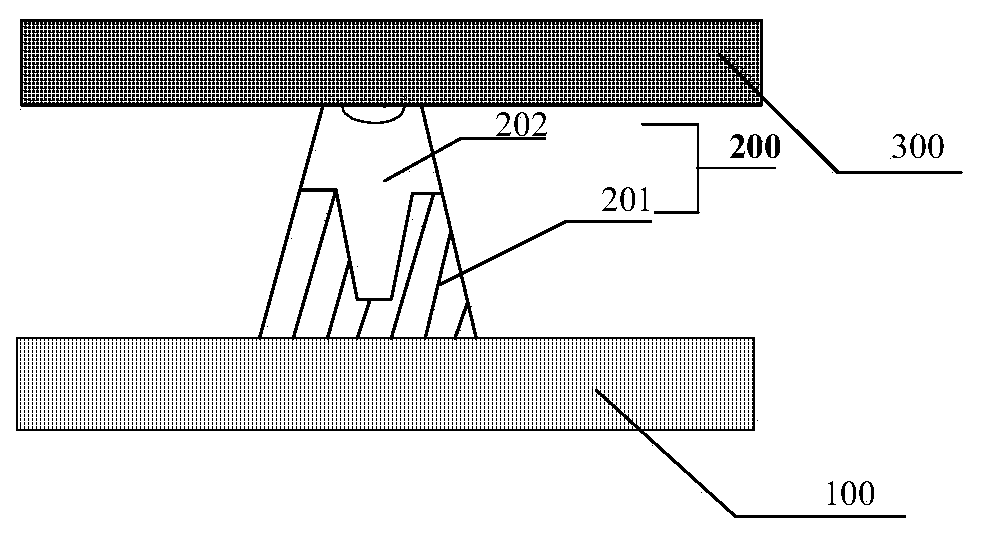

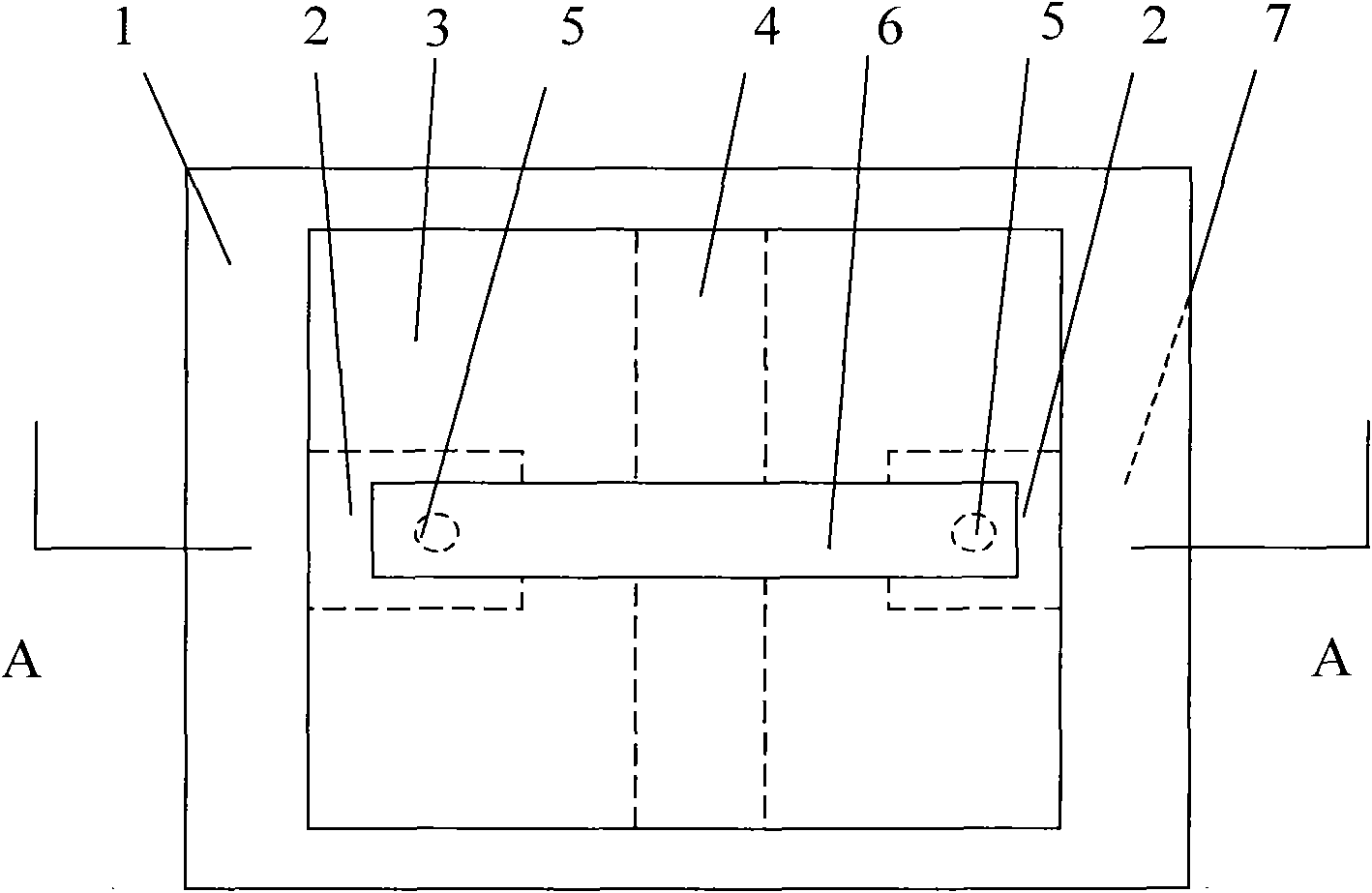

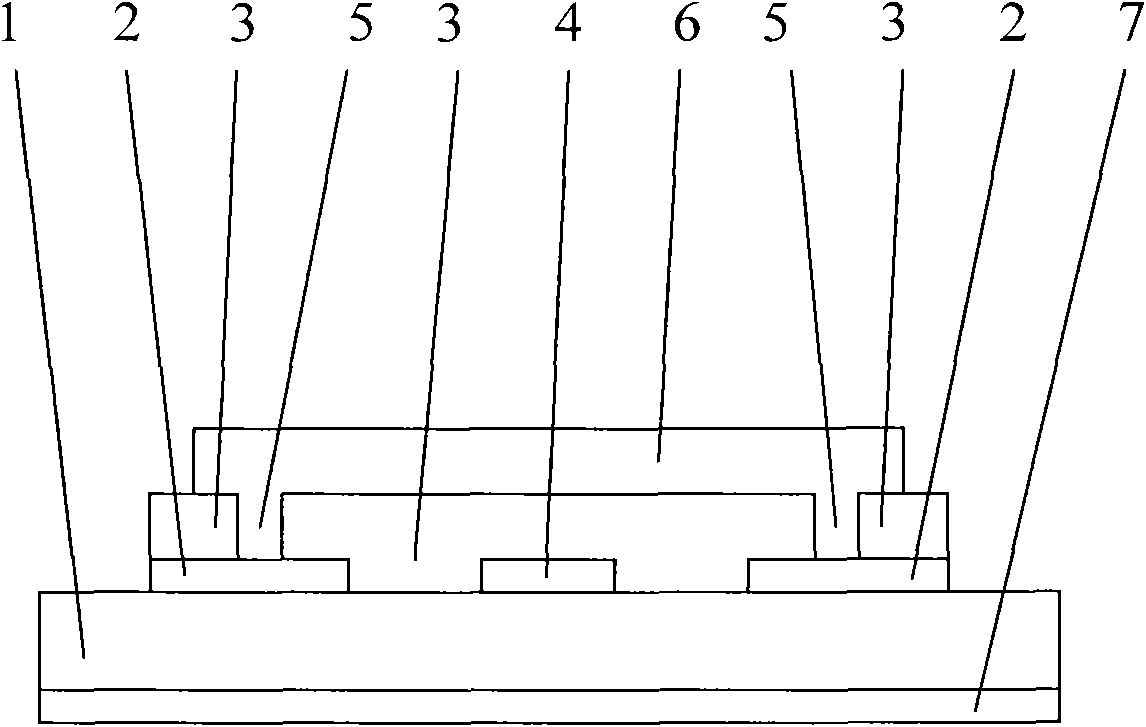

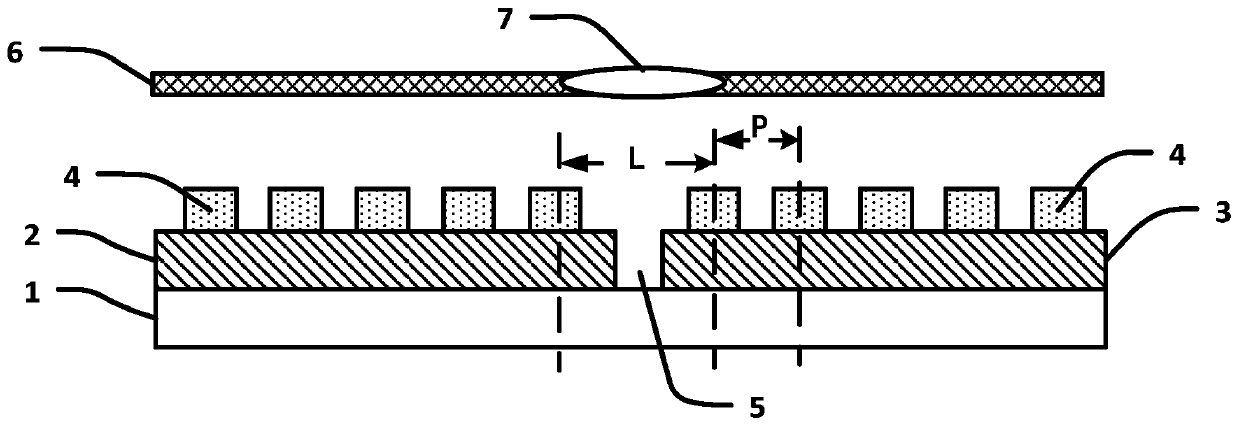

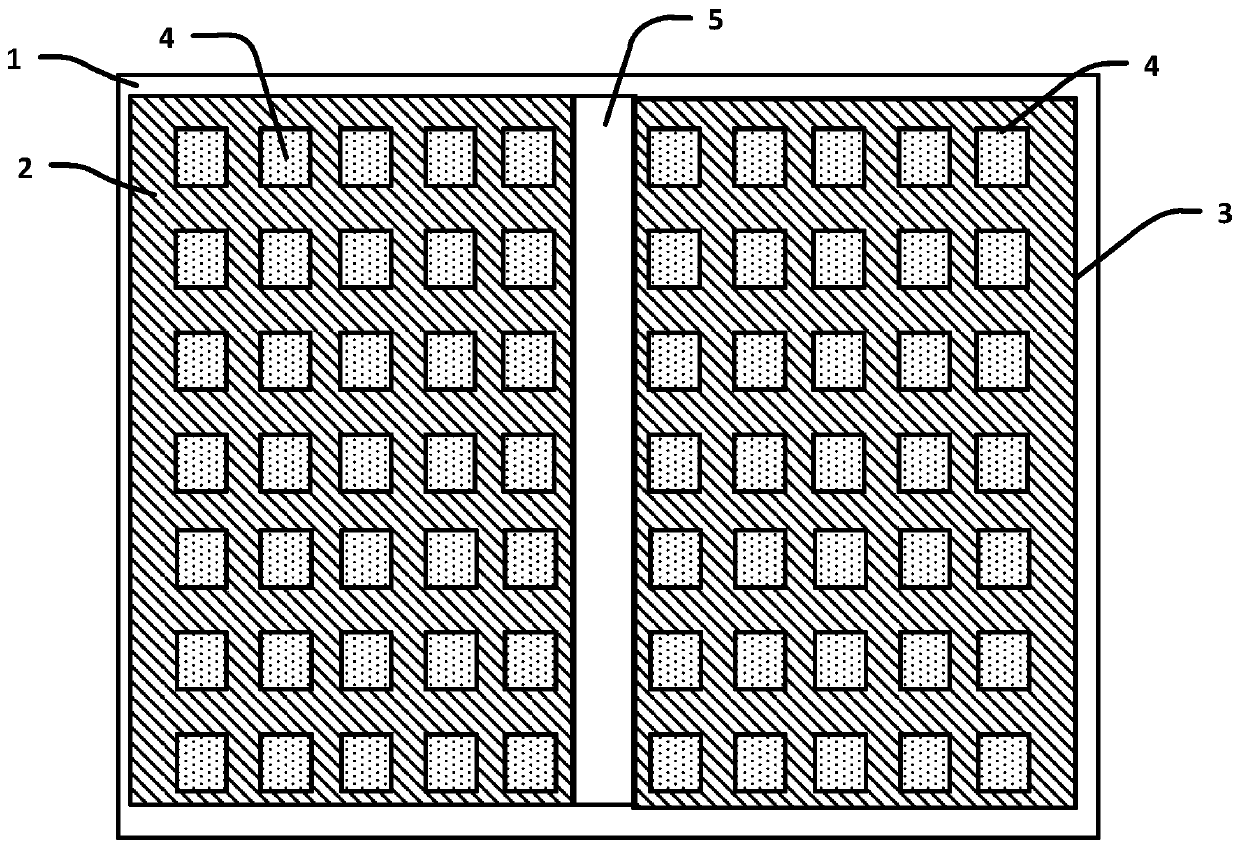

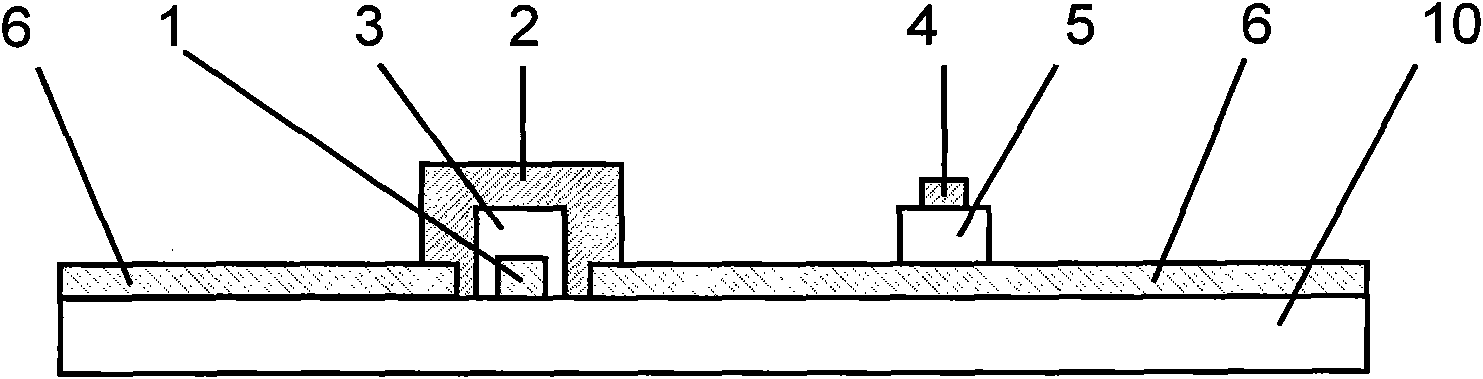

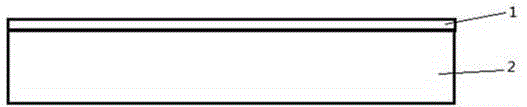

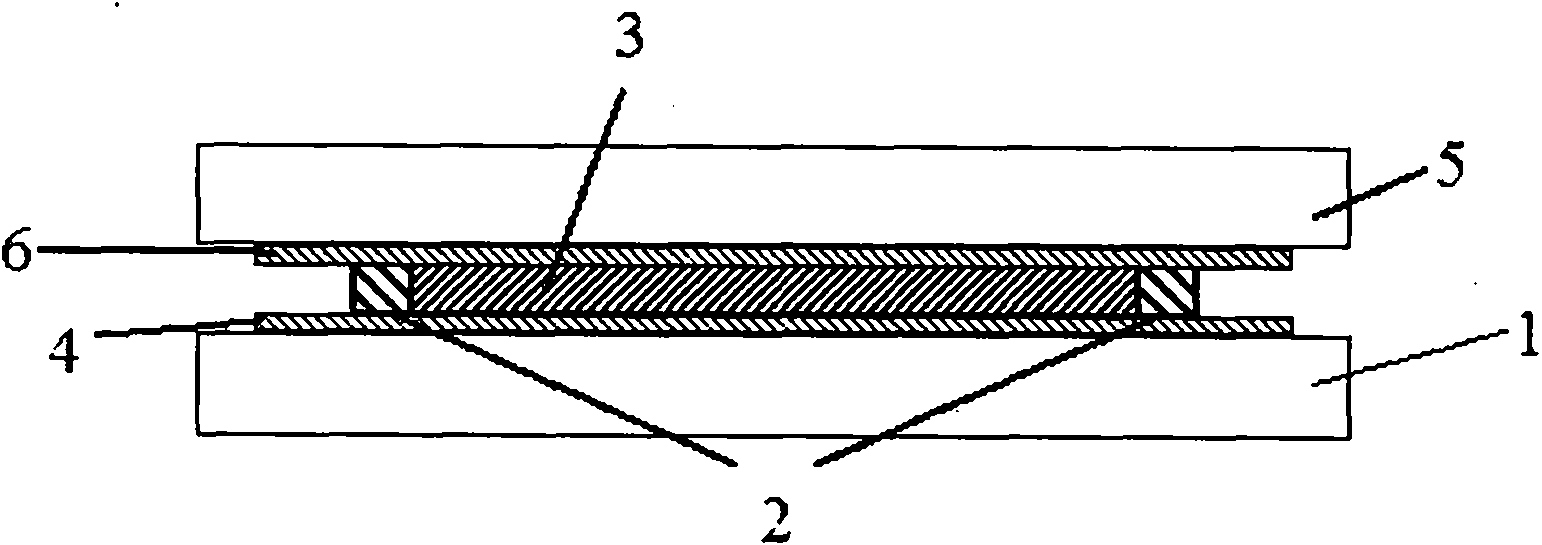

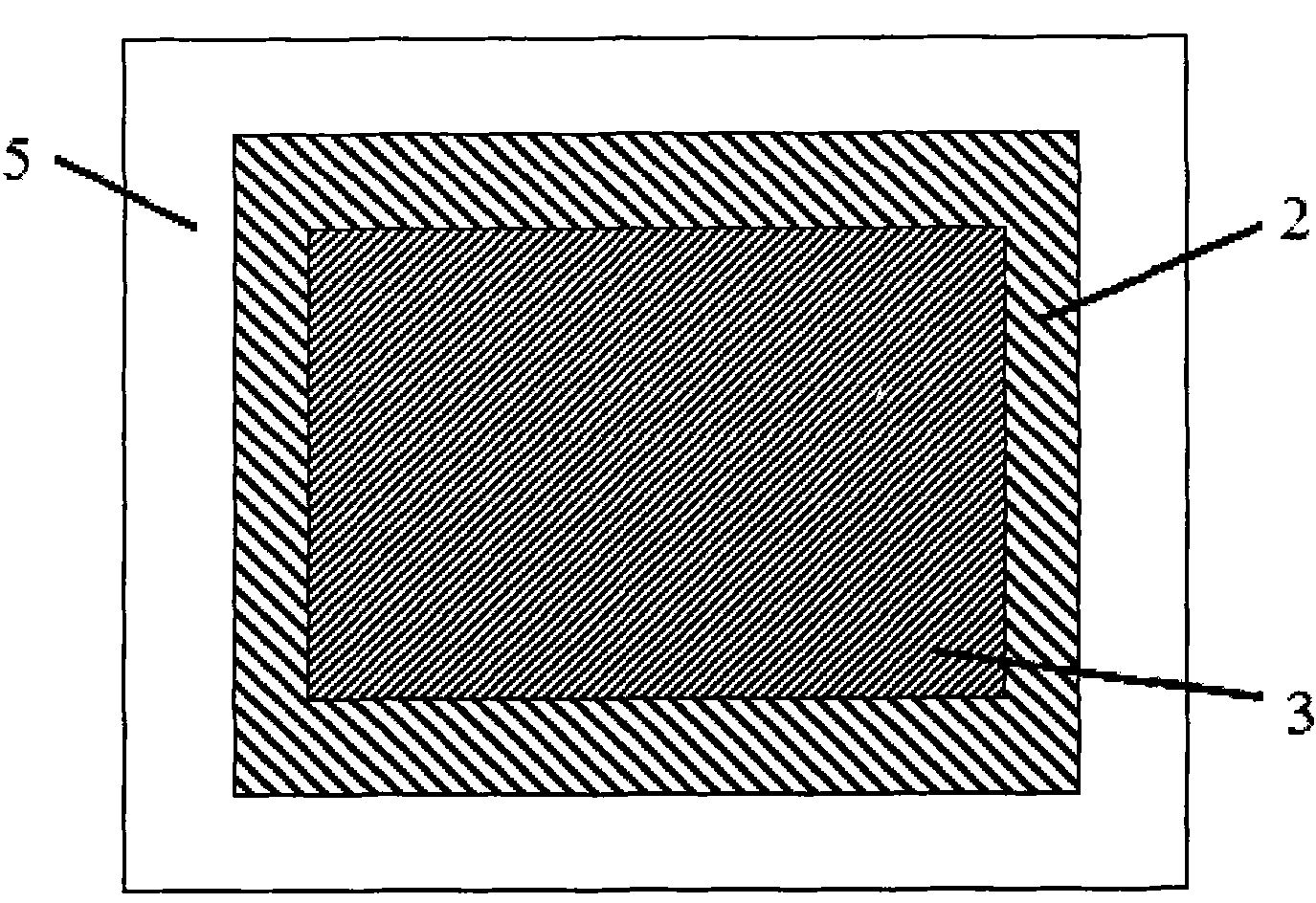

Shock insulator, preparation method of shock insulator and liquid crystal panel

ActiveCN103439836AEasy to prepareEasy to implementNon-linear opticsLiquid-crystal displayLiquid crystal

The invention provides a shock insulator, a preparation method of the shock insulator and a liquid crystal panel, belongs to the technical field of crystal liquid display, and solves the problems that when being subjected to external force action, the shock insulator made of a harder material can scratch a base plate contacted with the shock insulator, and the aberration can be generated during the displaying of the liquid crystal panel as the shock insulator made of a material with better elasticity can be deformed. The shock insulator is arranged between a color membrane substrate and an array substrate of the liquid crystal panel; the shock insulator comprises a first part and second part; the first part is arranged on the array substrate or the color membrane substrate; the height of the first part along the vertical central axis direction is smaller than the height of the shock insulator; the second part is arranged on the first part; the first and second parts are of a convex-and-concave matched structure; the first part is larger than the second part in hardness while the second part is larger than the first part in elasticity.

Owner:HEFEI BOE OPTOELECTRONICS TECH +1

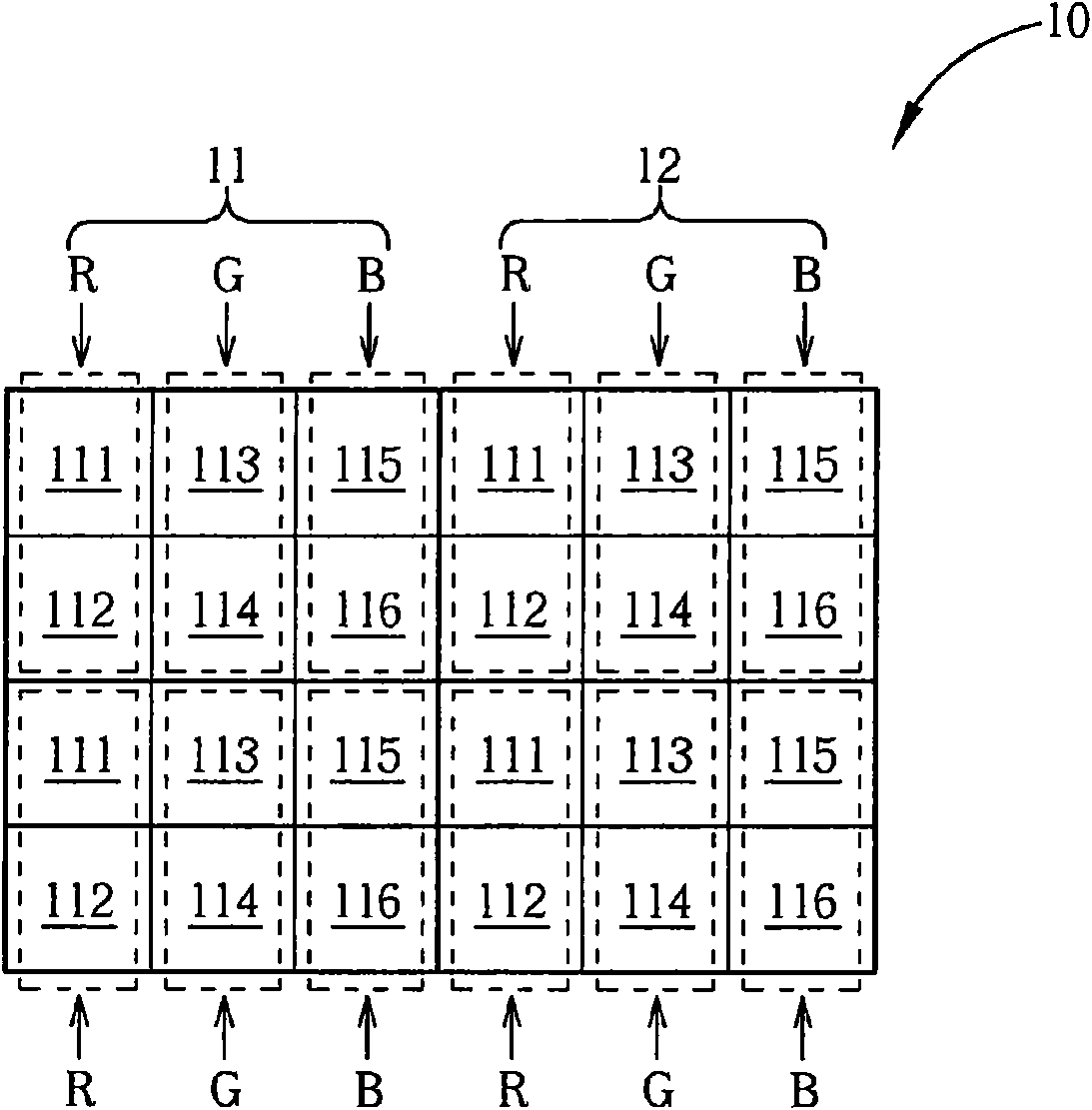

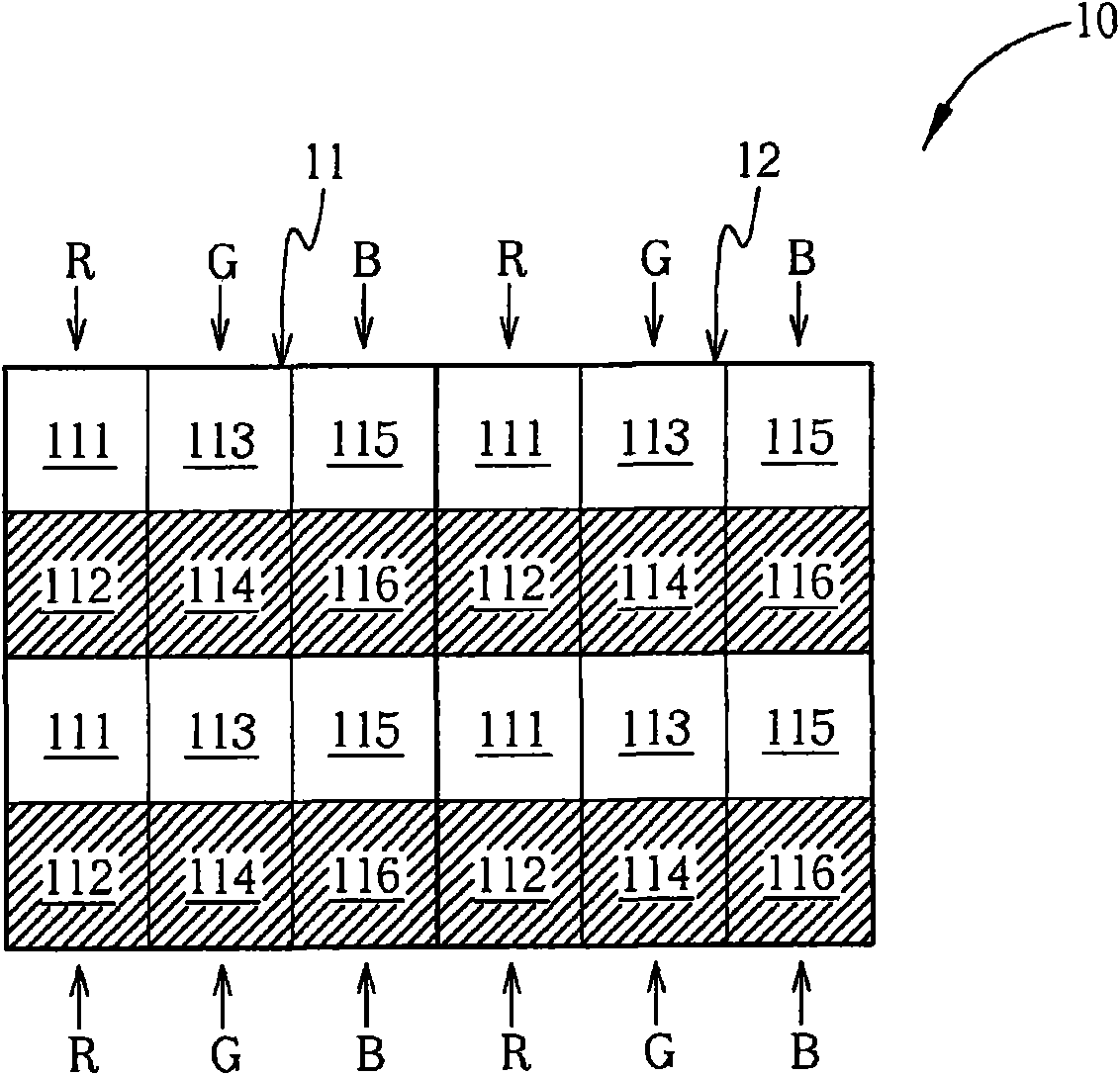

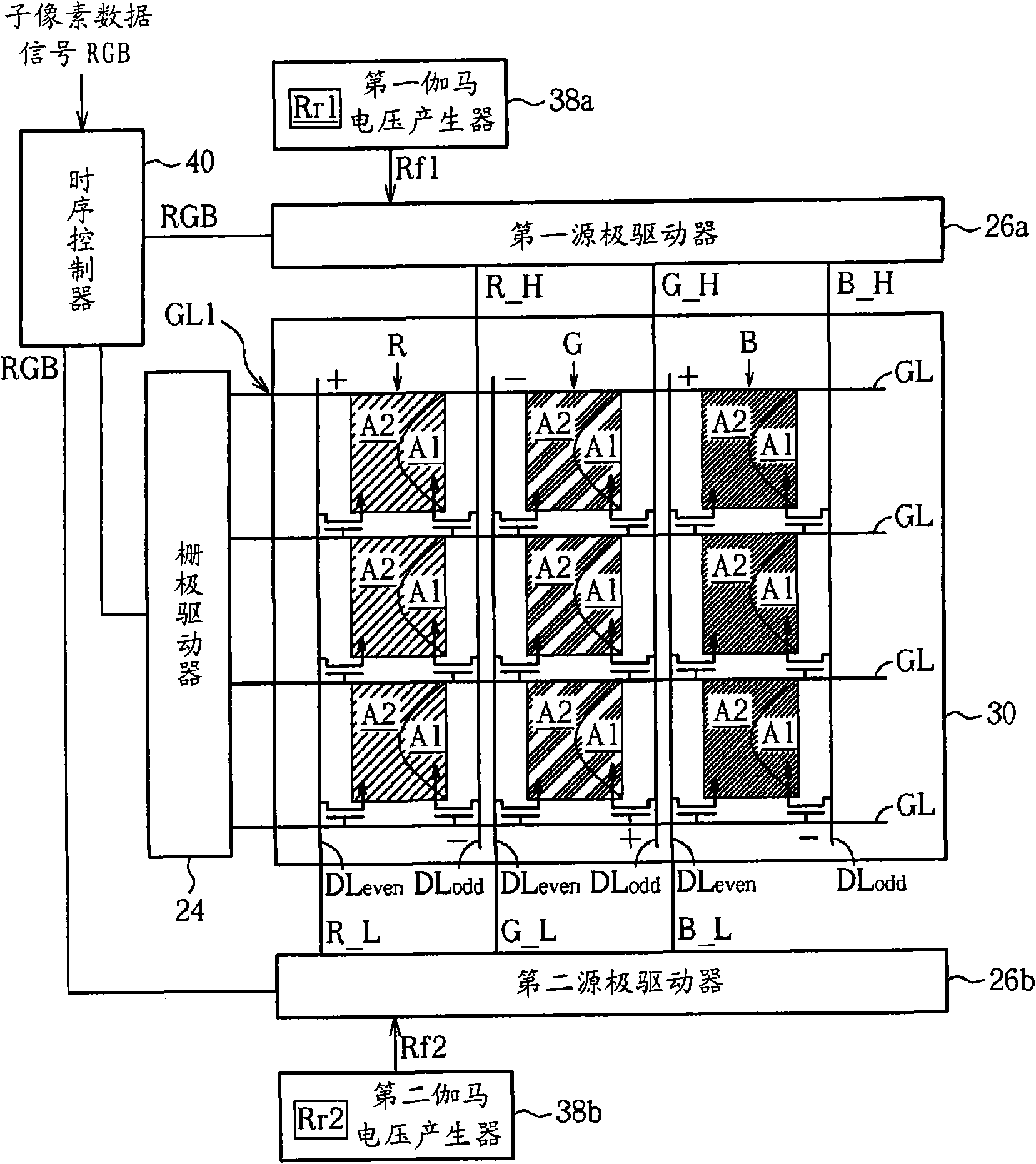

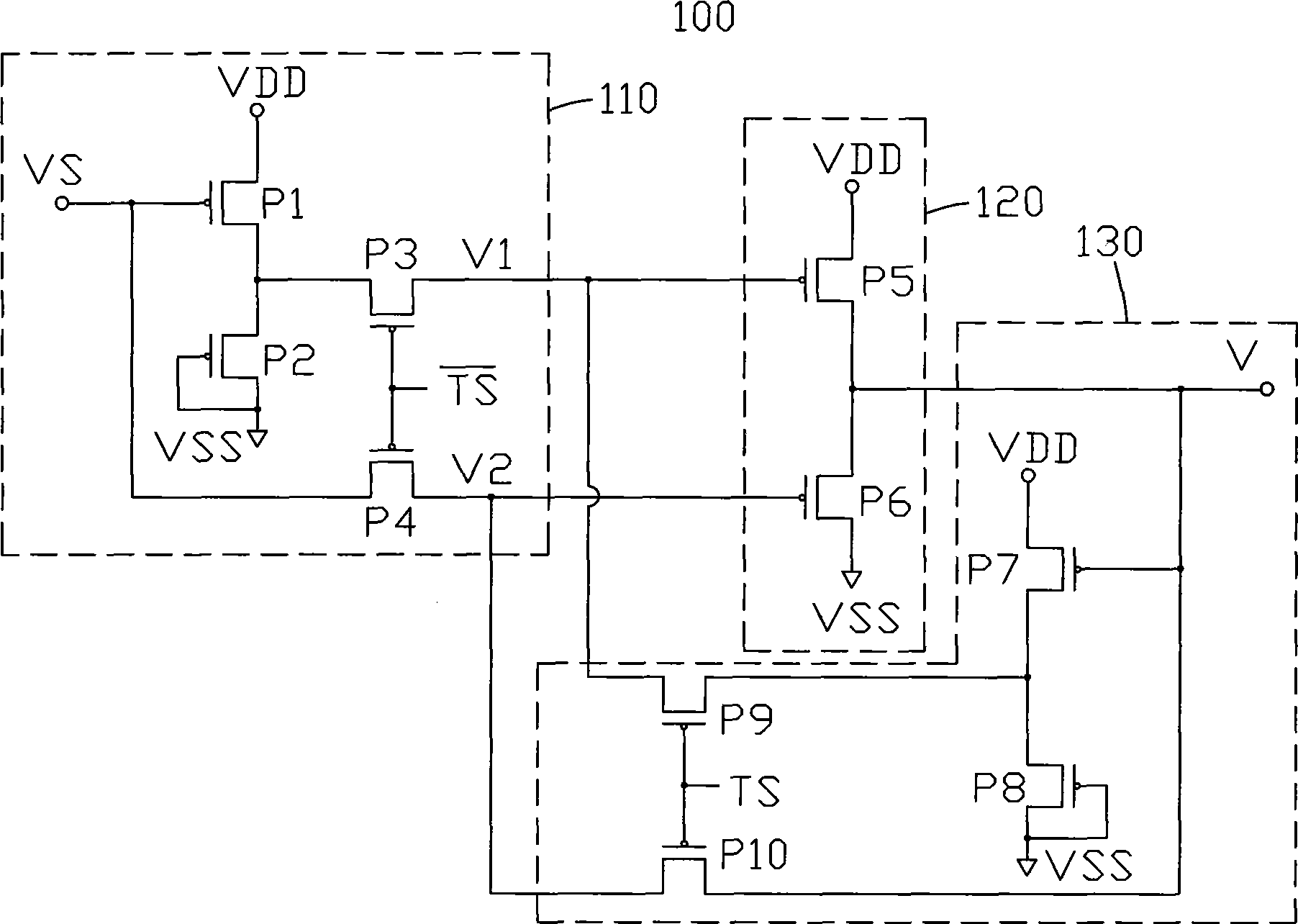

Liquid crystal display device and driving method thereof

InactiveCN101800035AAvoid chromatic aberrationCathode-ray tube indicatorsVoltage generatorLiquid-crystal display

The invention relates to a liquid crystal display device, which comprises a first gamma voltage generator and a second gamma voltage generator, wherein the first gamma voltage generator and the second gamma voltage generator are connected to a first source electrode driver and a second source electrode driver respectively and generate first grayscale gamma reference voltage and second grayscale gamma reference voltage according to a first gamma curve and a second gamma curve respectively; the first source electrode driver and the second source electrode driver are respectively to an odd data wire and an even data wire, and the odd data wire and the even data wire control a first grayscale area and a second grayscale area of each sub-pixel respectively; and the first source electrode driver and the second source electrode driver convert data signals inputted from the external into a first grayscale data signal and a second grayscale data signal according to the first grayscale gamma reference voltage and the second grayscale gamma reference voltage respectively, and respectively provide the first grayscale data signal and the second grayscale data signal to the odd data wire and the even data wire respectively.

Owner:HANNSTAR DISPLAY CORPORATION

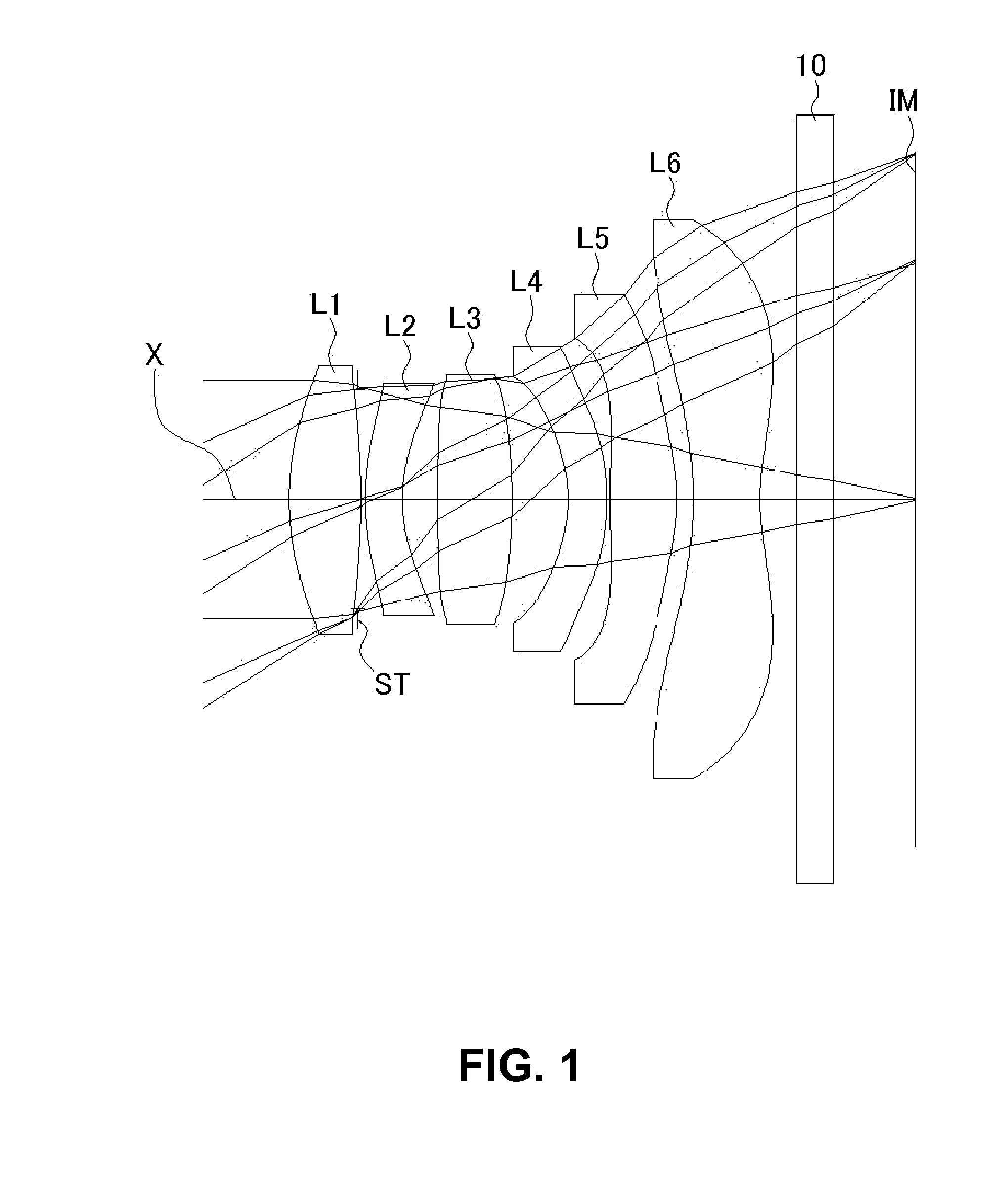

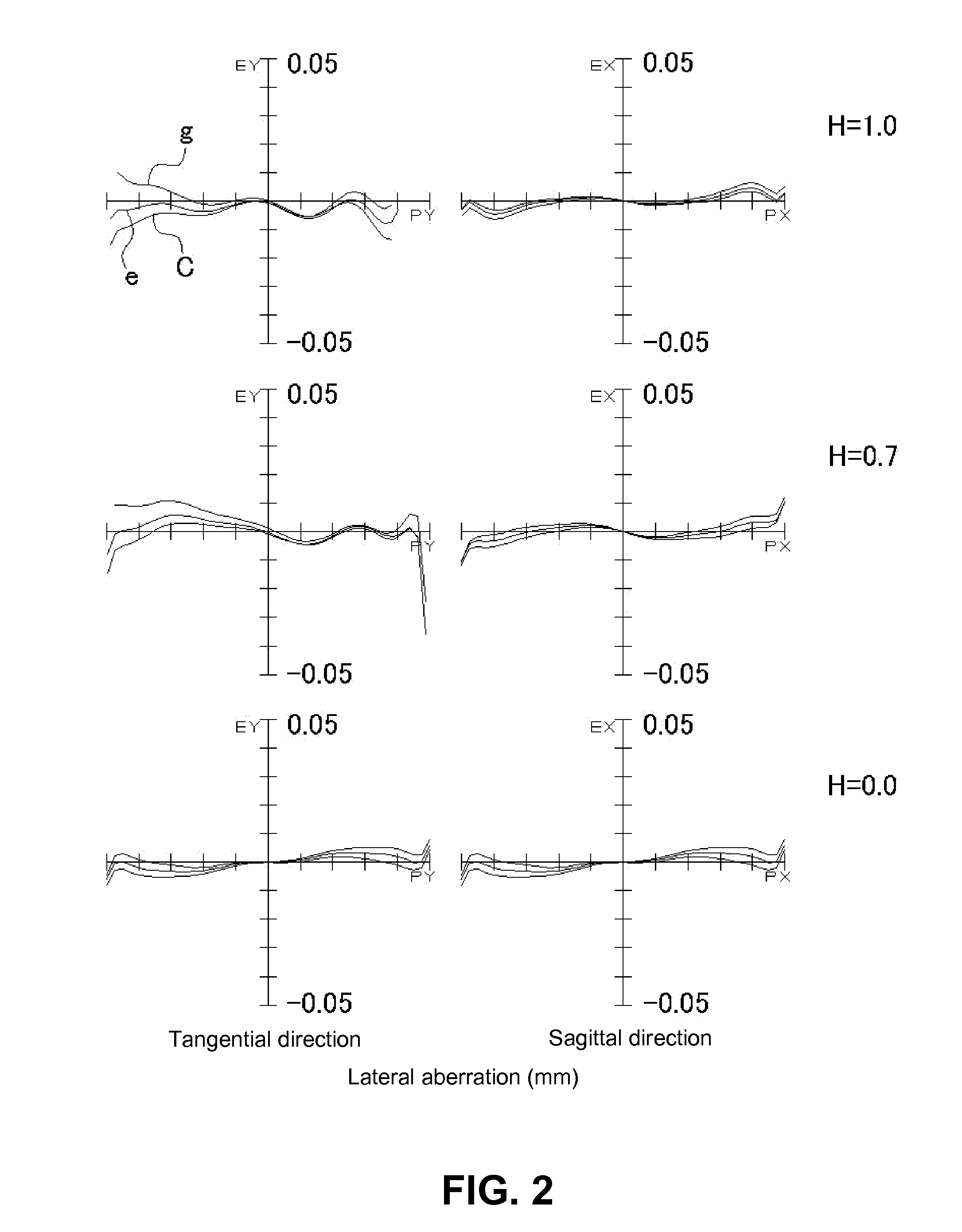

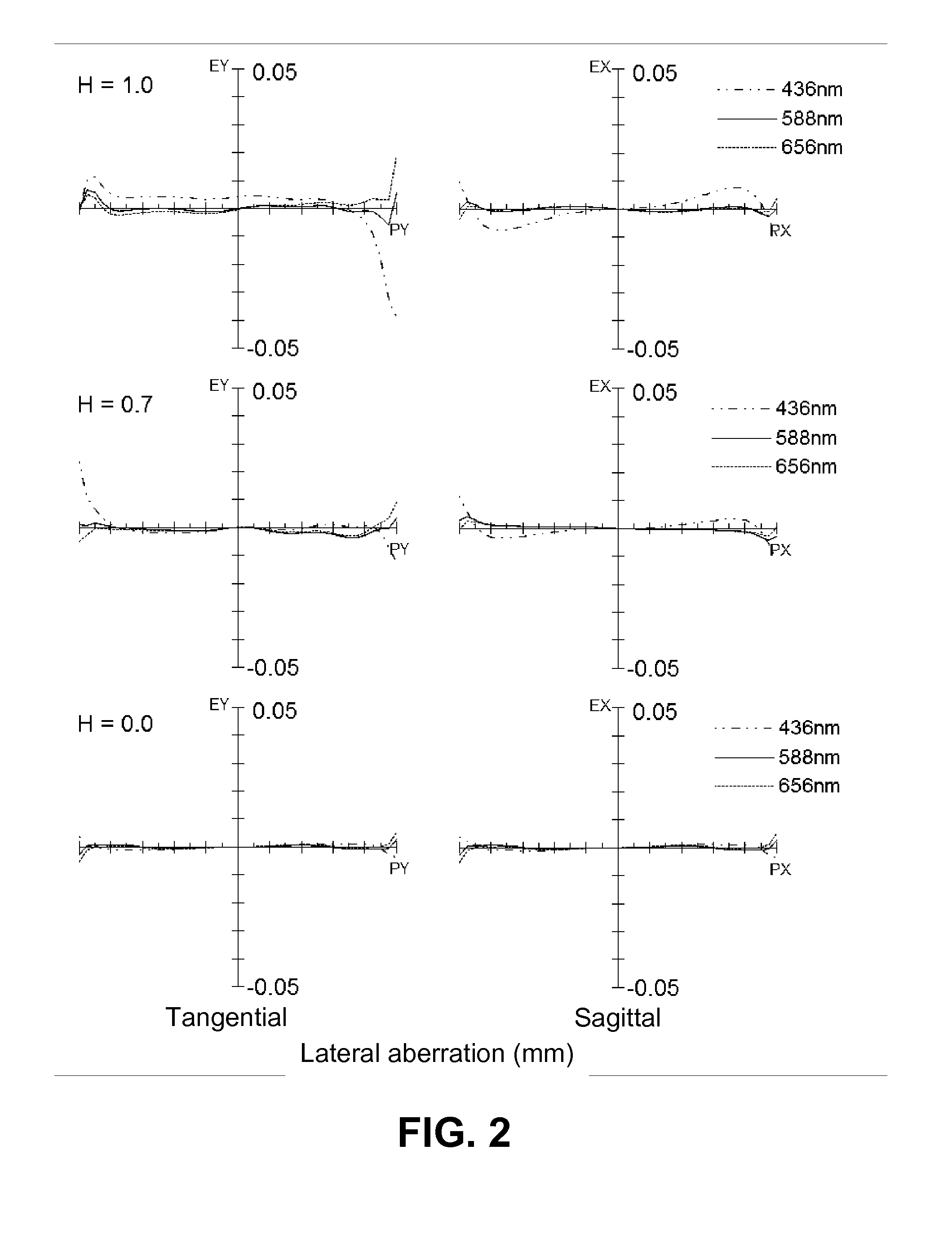

Imaging lens

ActiveUS20140049843A1Satisfactorily corrected aberrationSuitable for installationLensCamera lensImaging lens

An imaging lens includes a first lens having positive refractive power; a second lens having negative refractive power; a third lens having positive refractive power; a fourth lens having positive refractive power; a fifth lens having negative refractive power; and a sixth lens having negative refractive power. The first lens has an object-side with a positive curvature radius. The second lens has object-side and image plane-side surfaces with positive curvature radii. The third lens has an image plane-side surface with a negative curvature radius. The fourth lens has object-side and image plane-side surfaces with negative curvature radii. The fifth lens has object-side and image plane-side surfaces with negative curvature radii. The sixth lens has strong positive refractive power close to a periphery, and an aspheric image plane-side surface having an inflexion point. The first to sixth lenses have specific Abbe's numbers to satisfy specific conditions.

Owner:TOKYO VISIONARY OPTICS CO LTD

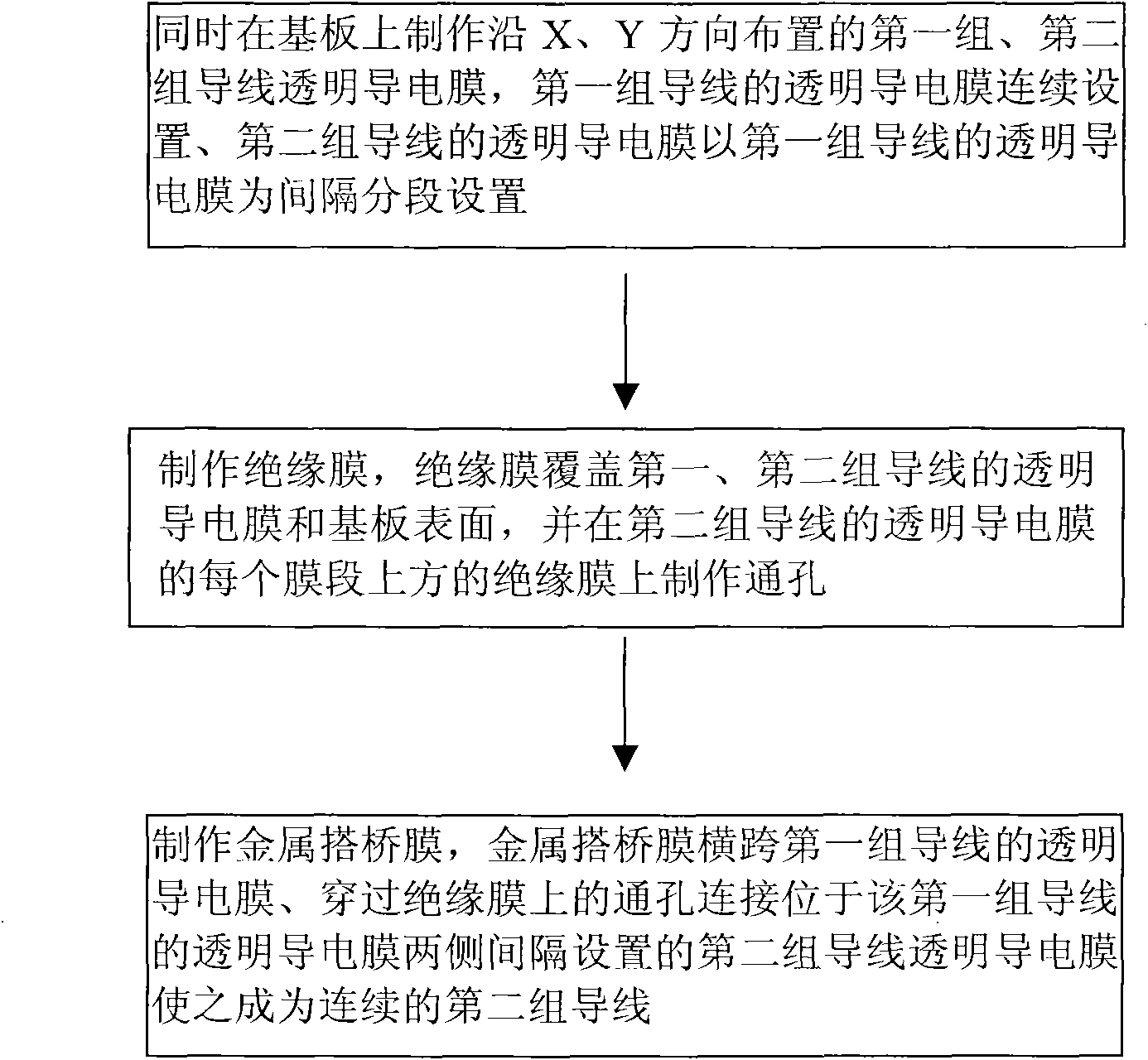

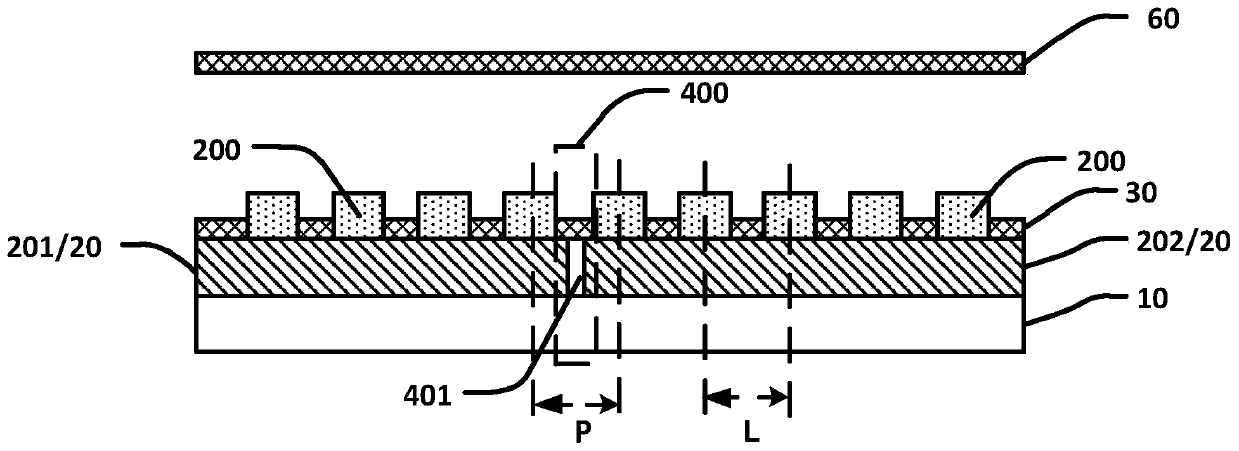

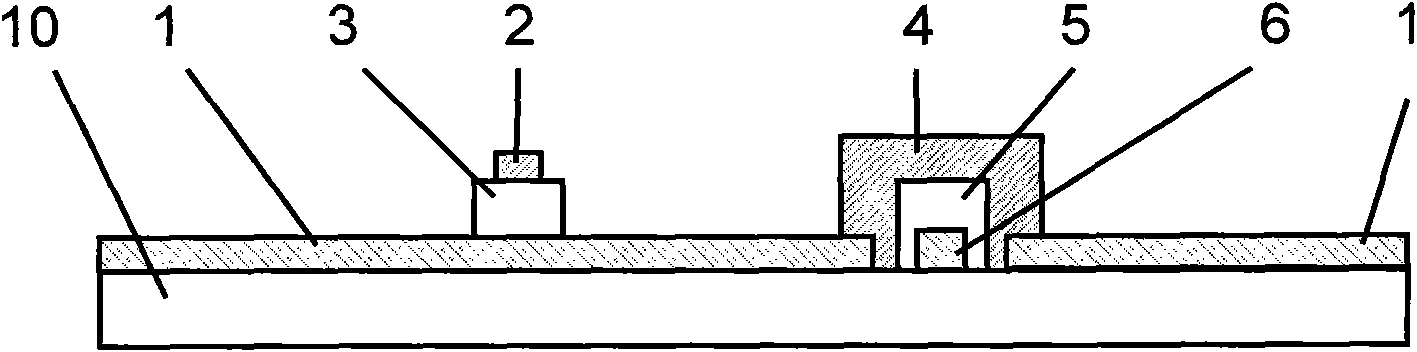

Capacitance type touch screen and manufacturing method thereof

InactiveCN101630215AImprove continuityLess prone to disconnectionInput/output processes for data processingElectrical resistance and conductanceCapacitance

The invention relates to a capacitance type touch screen and a manufacturing method thereof. The capacitance type touch screen comprises a substrate, two sets of transparent conducting films of conducting wires, an insulating film and a metal bridging beam film. In the two sets of conducting wires, the first set of transparent conducting films are continuously arranged, and the second set of transparent conducting films are piecewise arranged by using the transparent conducting films of the first set as intervals. The insulating film covers the surfaces of the two sets of transparent conducting films, and the insulating film above each film section of the second set of transparent conducting films comprises a through hole. The metal bridging film is attached on the insulating film, crosses the first set of transparent conducting films and is connected with the second set of transparent conducting films which are arranged at intervals on both sides of the first set of transparent conducting films by passing through the through hole on the insulating film so as to form the continuous second conducting wires. The method comprises the following steps: manufacturing the first set of transparent conducting films, the second set of transparent conducting films, the insulating film and the metal bridging film to achieve the structure of the touch screen. The invention adopts the metal bridging film, thereby improving the continuity of the second set of conducting wires, reducing the resistance of the second set of conducting wires and the color difference of the touch screen and improving the performance of the touch screen and the product quality.

Owner:SHENZHEN LAIBAO HI TECH

Imaging lens

An imaging lens includes a first lens group having positive refractive power and a second lens group having negative refractive power, arranged in this order from an object side to an image plane side. The first lens group includes a first lens having positive refractive power, a second lens having positive refractive power, and a third lens having negative refractive power. The second lens group includes a fourth lens having positive refractive power, a fifth lens, and a sixth lens having negative refractive power. The first lens and second lens have specific focal lengths. The first to third lenses have specific Abbe's numbers.

Owner:TOKYO VISIONARY OPTICS CO LTD

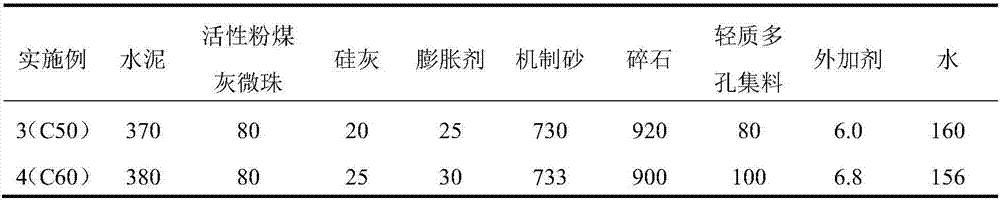

Backlight module and display panel

The invention provides a backlight module and a display panel. The backlight module comprises a back plate, lamp panels and a reflecting layer, wherein a plurality of lamp panels are arranged on an upper surface of the back plate in an array splicing manner, splicing areas are arranged between every two adjacent lamp panels, each splicing area is provided with a splicing seam, light supplementingmaterials are arranged in the splicing seams, and the reflecting layer is arranged on upper surfaces of the lamp panels and the splicing areas. The backlight module is advantaged in that the splicingseam is filled with the light supplementing materials and an emission sheet is arranged between a Mini-LED of a first column / row and a Mini-LED of a second column / row, the Mini-LED of the first column / row is closest to the Mini-LED of the second column / row, the Mini-LED is arranged in the splicing area so that light emitted by the Mini-LED is reflected to a reflector plate, the reflector plate reflects the light to the position of the splicing areas, the light-emitting hue of the splicing position is consistent with that of a normal area, brightness of the splicing areas is improved, chromaticaberration of the splicing areas is avoided, and the quality of light emitted by a backlight module is improved.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

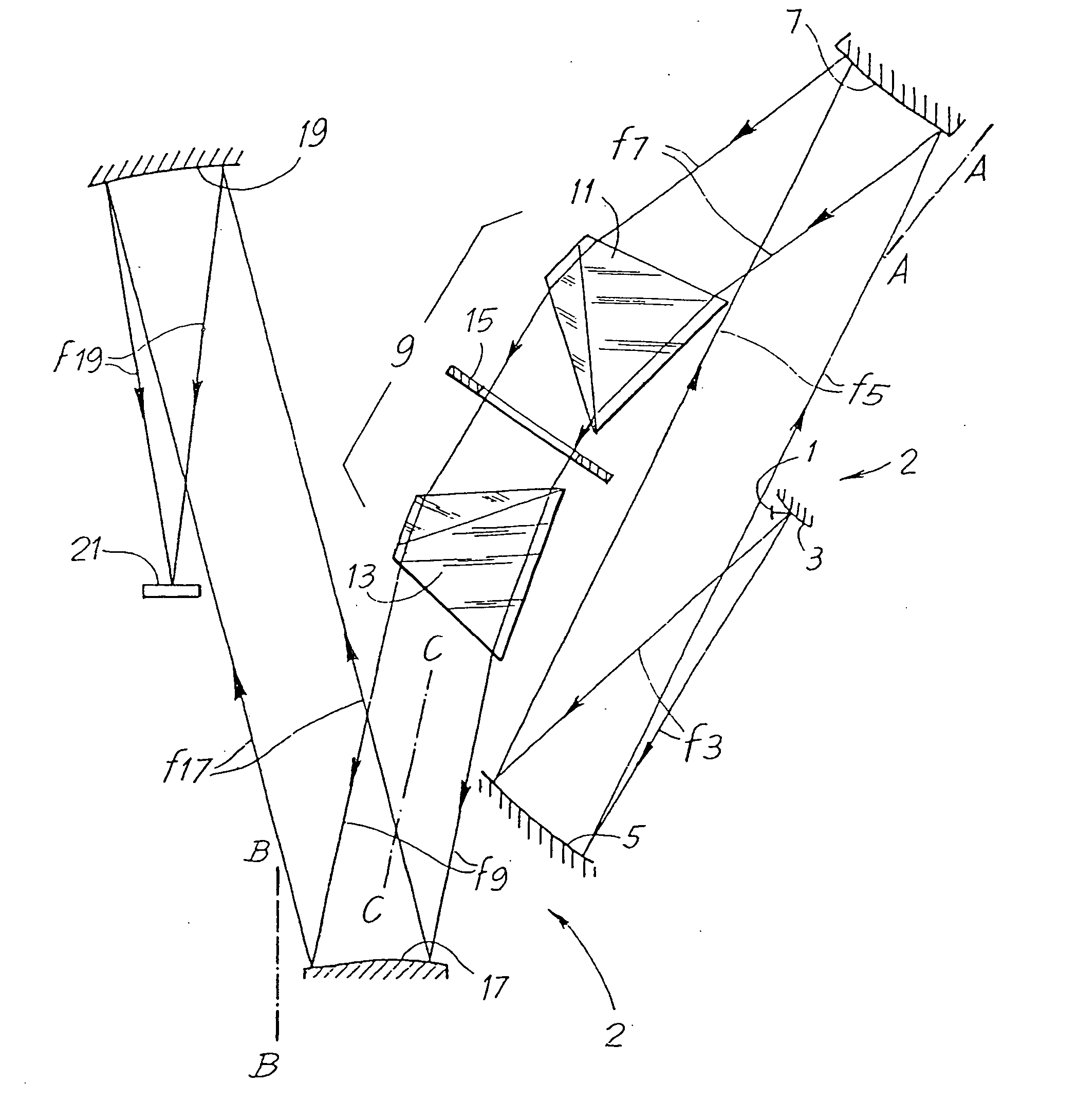

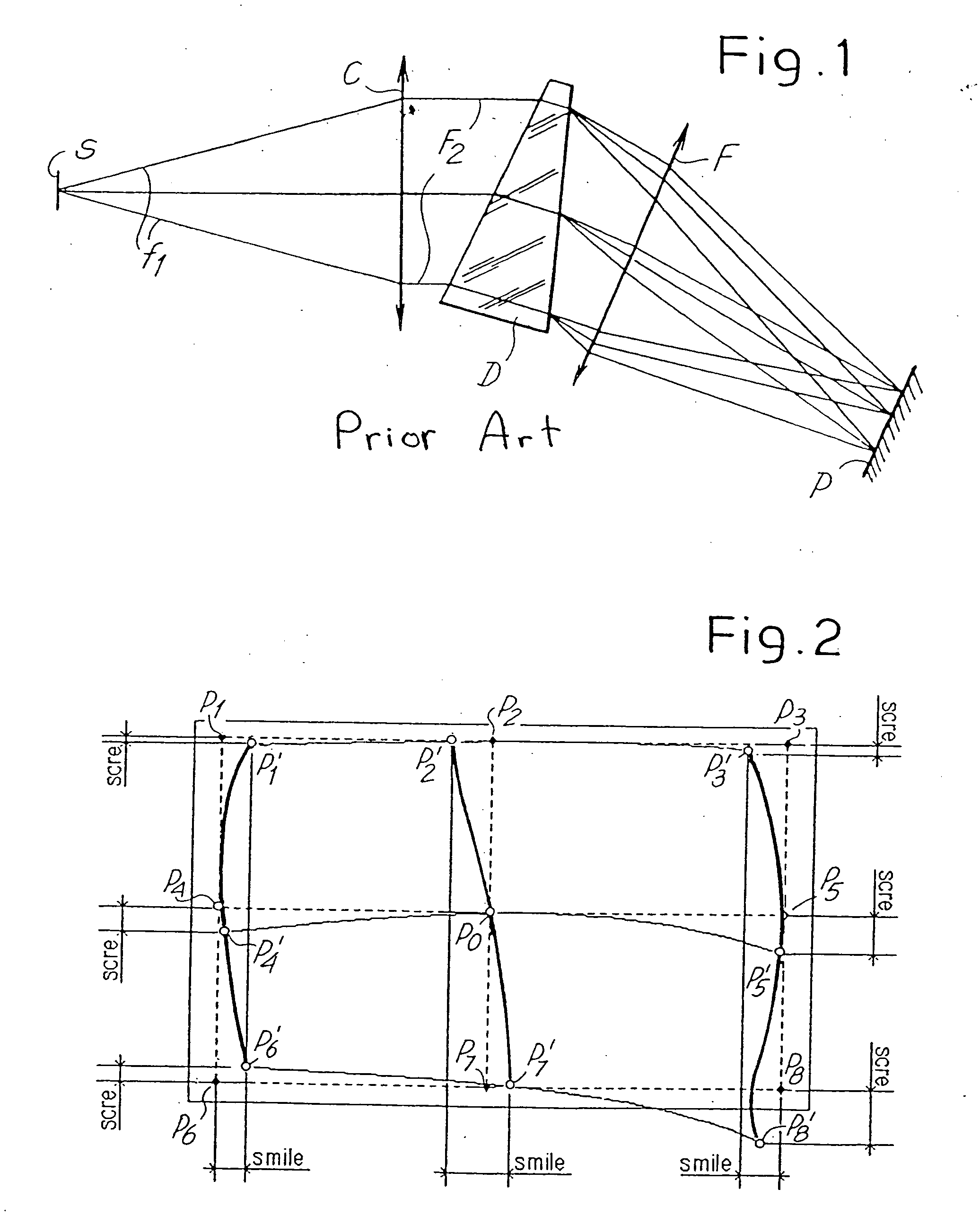

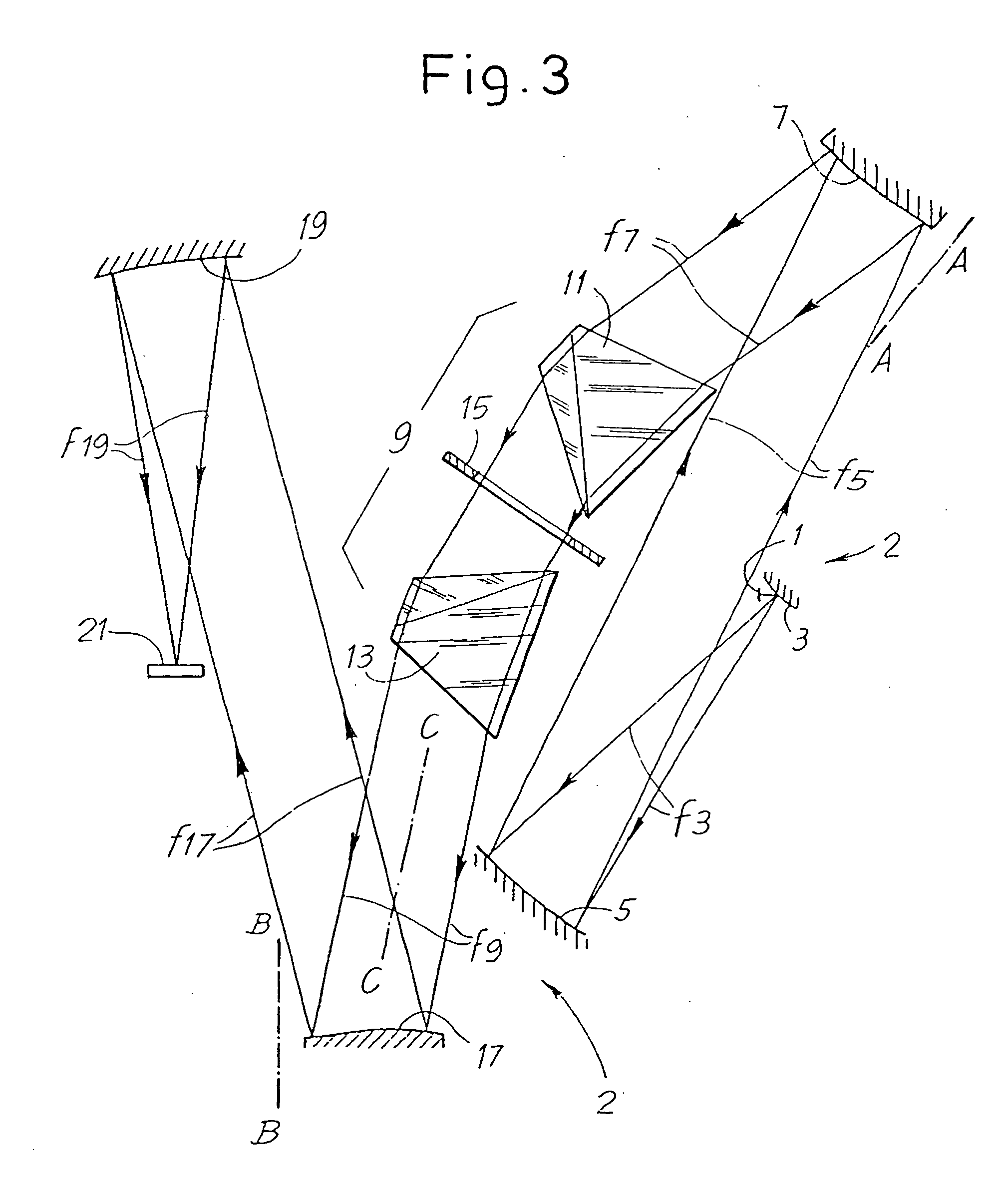

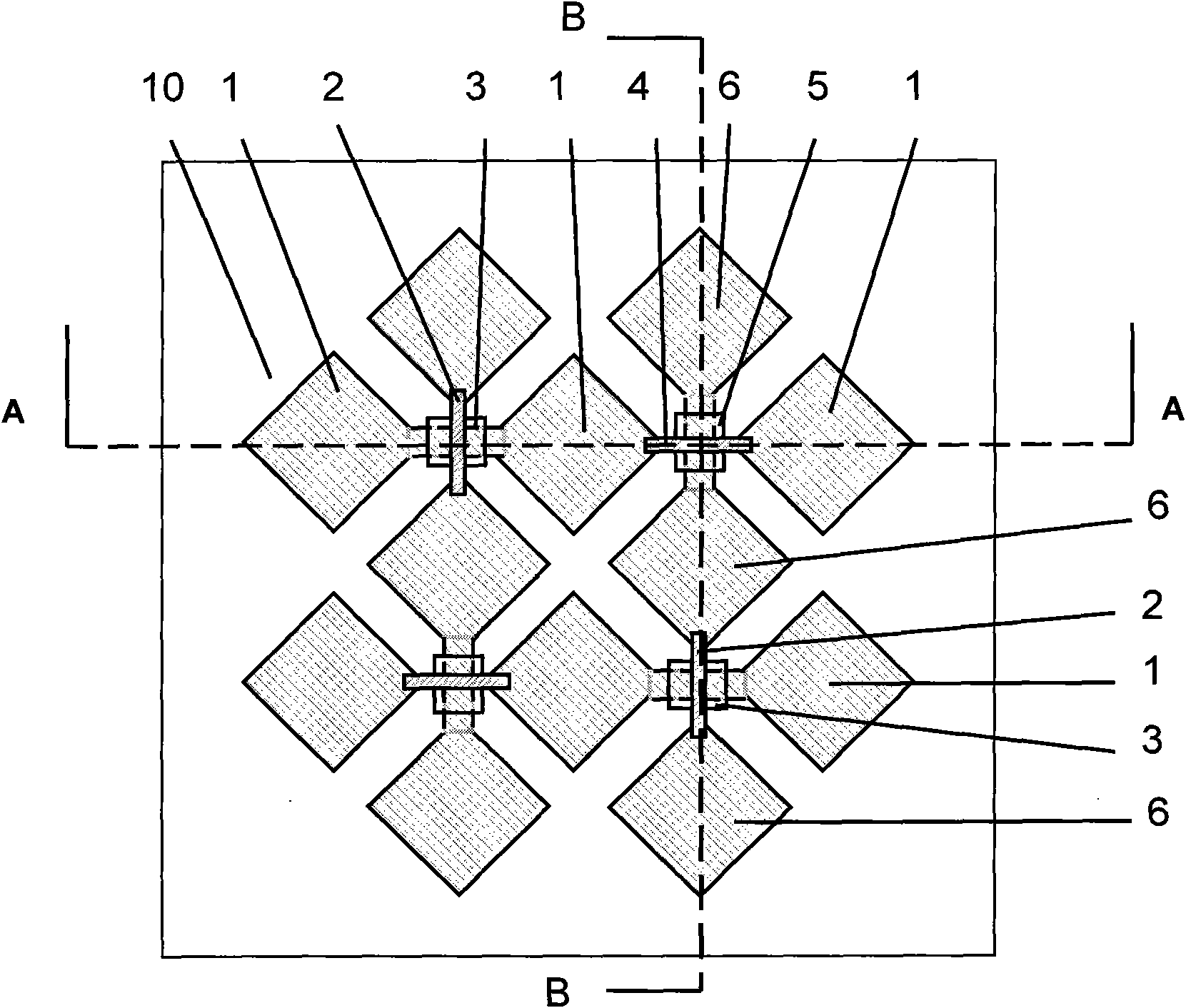

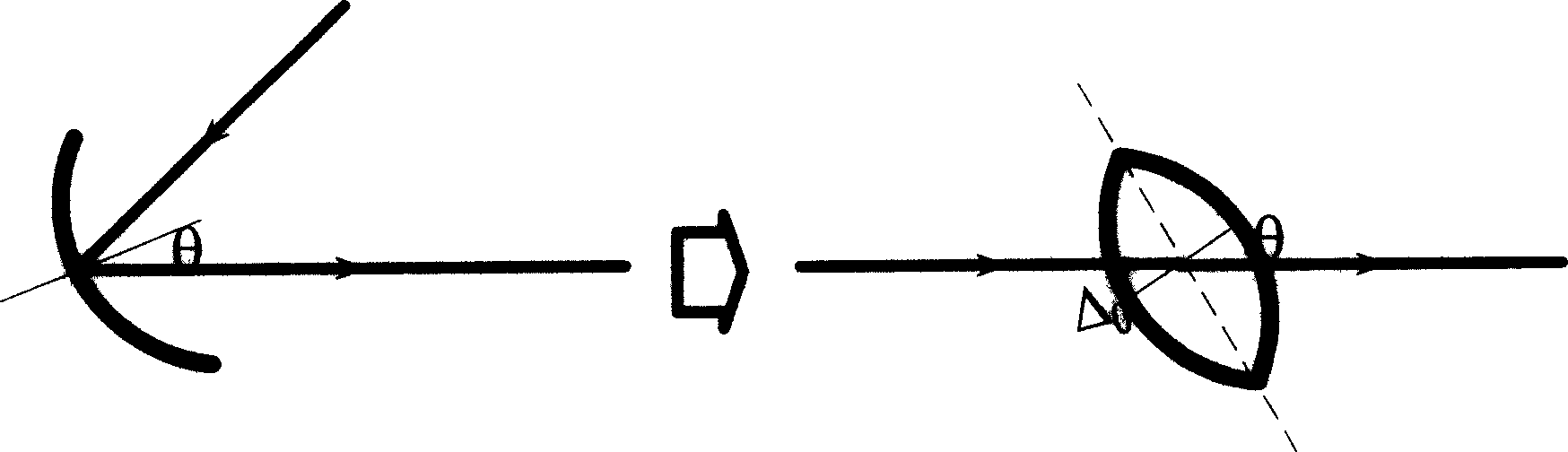

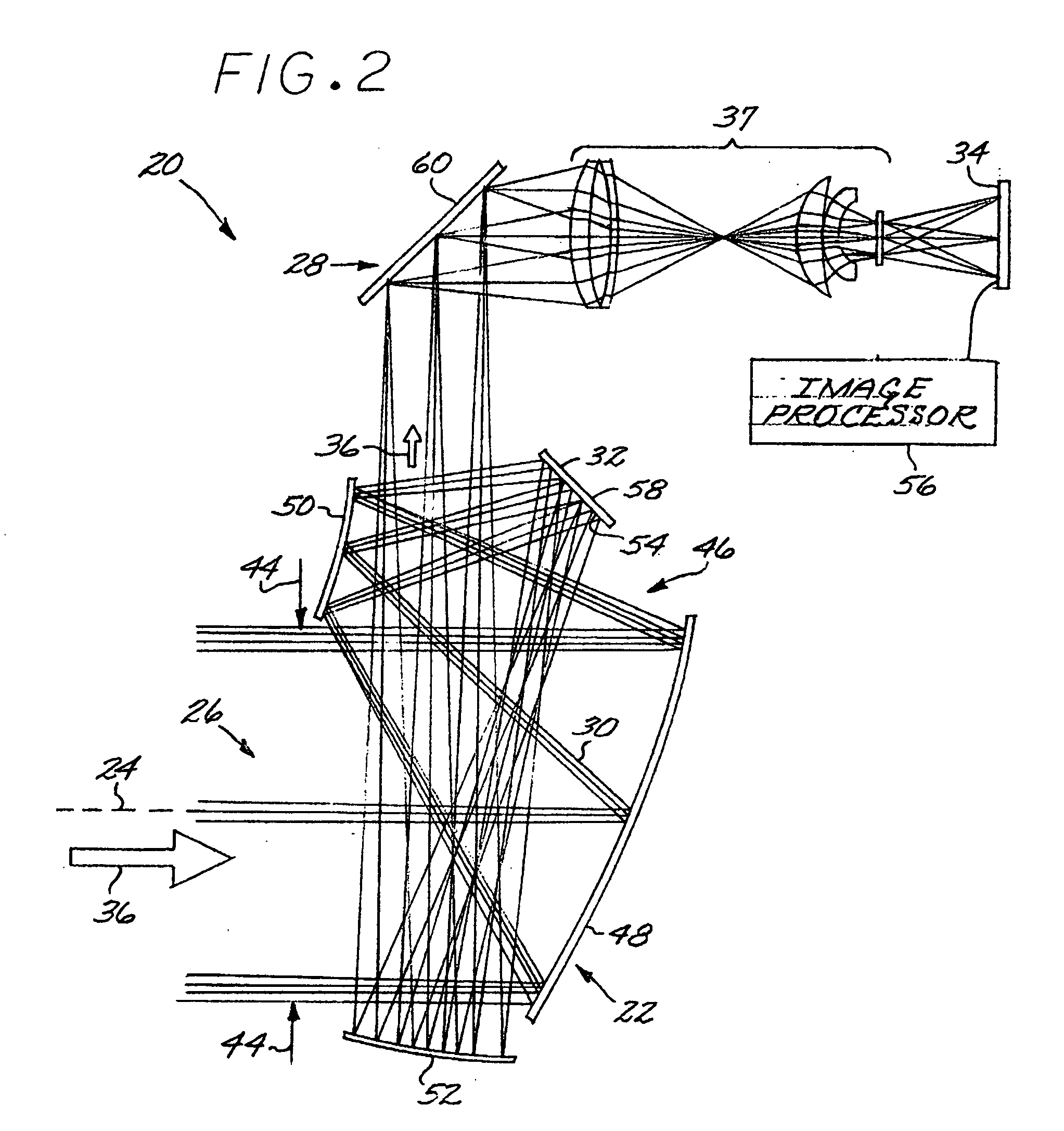

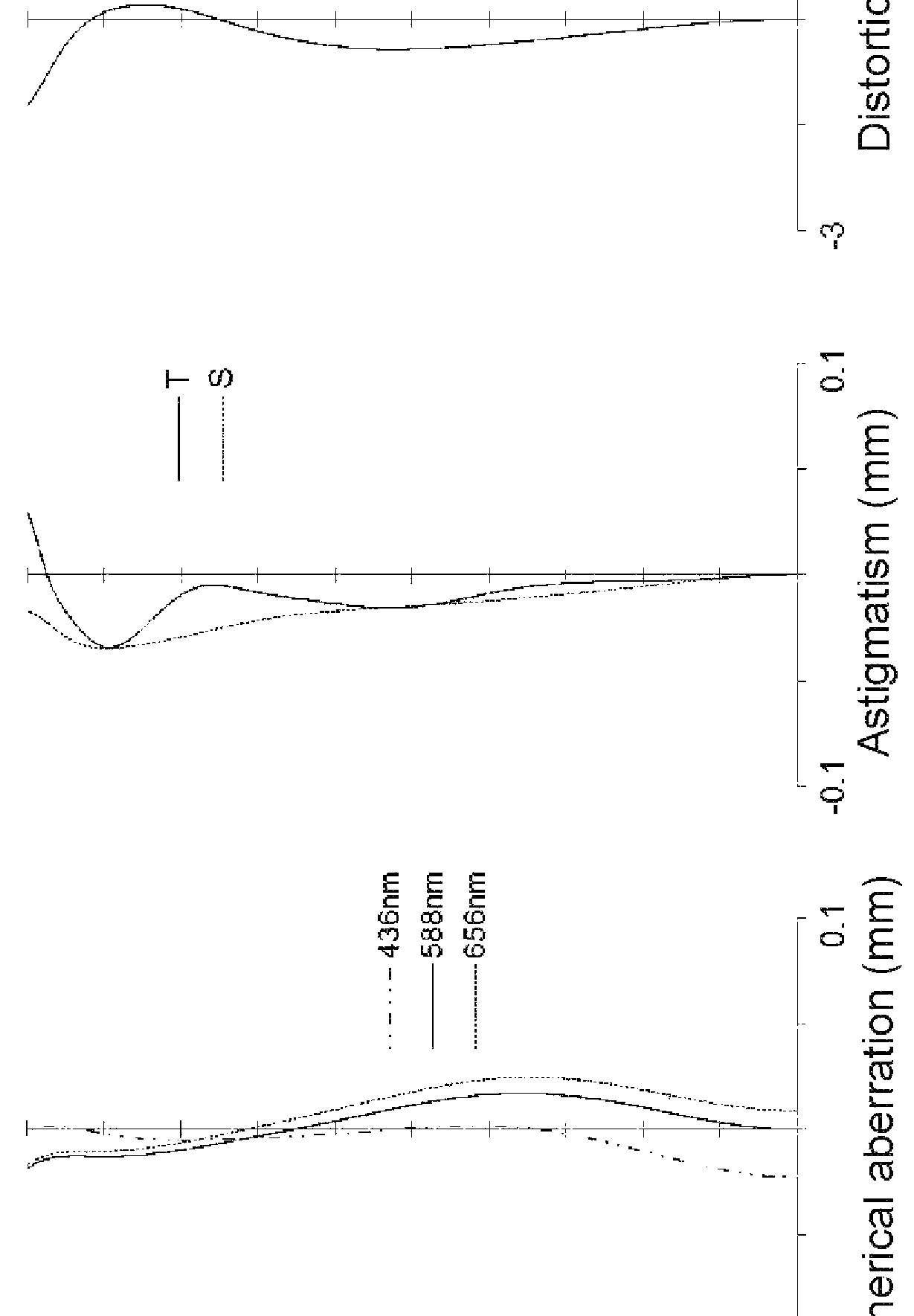

Wide-band spectrometer with objective comprising an aspherical corrector mirror

InactiveUS20050128477A1Reduce errorsReduce eliminateRadiation pyrometrySpectrum investigationLight beamElectromagnetic radiation

The spectrometer comprises at least a first optical path for a beam of electromagnetic radiation, along which the following are set: a beam-entry slit (1) for an incoming beam; a collimator (5) comprising a convergent spherical mirror for collimation of the incoming beam; a first dispersor (9) for dispersion of the beam into its chromatic components; a first focusing system (19); and a first detector (21) which receives the beam dispersed and focused by said first focusing system. Set along the first optical path there is set at least one first aspherical corrector element (7; 17) comprising an aspherical mirror for correction of spherical aberration.

Owner:GALILEO AVIONICA

Wiring method and manufacturing method of capacitive touch screen

ActiveCN101634922AImprove product qualityAvoid chromatic aberrationInput/output processes for data processingElectrical resistance and conductanceEngineering

The invention relates to a wiring method and a manufacturing method of a capacitive touch screen, wherein the wiring method comprises the step of arranging two groups of wire transparent conducting films in X and Y directions, an insulating film and a bridging film on a basal plate, wherein the surface resistance of the bridging film is lower than the surface resistance of the transparent conducting films, an intersection structure of the transparent conducting films in the two directions comprises continuous connection and bridging connection, wherein the continuous connection structure is a continuation of transparent conducting film material at two sides of the intersection point, and the bridging connection structure has the structures that the transparent conducting film in X or Y direction is continuously connected and positioned on the basal plate at the intersection point, the transparent conducting film in the other direction is disconnected at the intersection point, the insulating film is covered on the transparent conducting films that are continuously connected at the intersection part, and the bridging film stretches over the transparent conducting films that are continuously connected at the intersection point and is covered on the insulating film and connected with the transparent conducting film disconnected at the intersection point; and the method comprises the step of manufacturing two groups of wire conducing film, the insulating film and the bridging film. The invention can avoid color difference and improve the sensitivity, the standard ratio and the quality of the touch screen.

Owner:SHENZHEN LAIBAO HI TECH

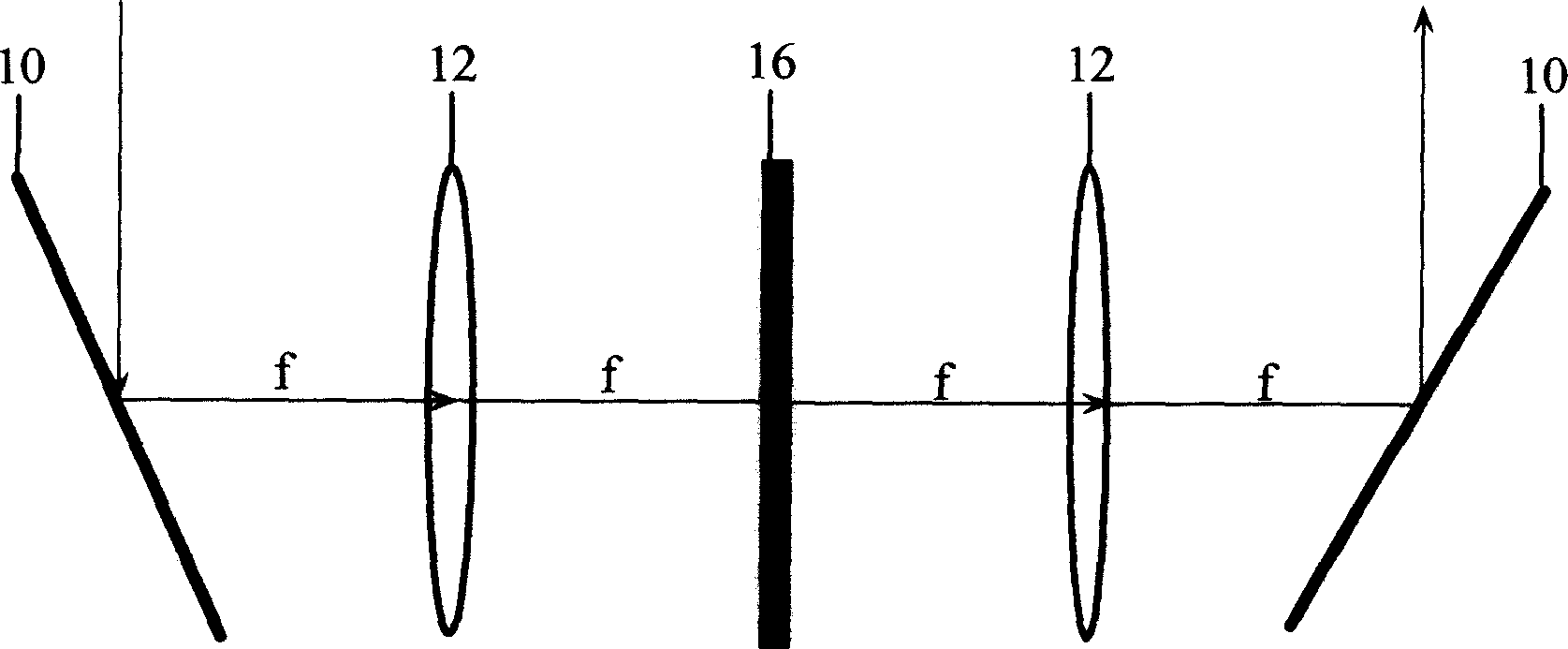

Pulse shaping unit

The present invention provides a pulse shaping device. It includes two grating, which can be used for separating lasers with different frequencies at an angle or combining them; two concave mirrors, which can be used for making conversion of time domain and frequency domain of laser pulse; and a light modulator, which is positioned in central position of first concave mirror and second concave mirror, and can be used for modulating amplitude or phase of laser pulse; and the distance between every two optical devices is identical fixed value so as to can obtain accurate Fourier transform of reflected light passed through said concave mirrors. Said light modulator is a liquid crystal space light modulator, it can utilize the change of voltage applied to liquid crystal to control arrangement of liquid crystal molecules to change refractivity of medium so as to regulate amplitude and phase of laser pulse.

Owner:EAST CHINA NORMAL UNIVERSITY

Method for direct preparation of coloured polylactic acid fiber by polylactic acid polymer melt

InactiveCN101597814AEnsure color consistencyAvoid chromatic aberrationNon-woven fabricsPigment addition to spinning solutionFiberPolymer science

The invention relates to a method for direct preparation of coloured polylactic acid fiber by polylactic acid polymer melt, belonging to the technical field of high polymer material application. The method comprises the following steps: conveying raw white polylactic acid polymer melt obtained from polymerization reaction in a polylactic acid polymerization reaction device to a melt mixing device through a termination device of the polylactic acid polymerization reaction device; mixing the raw white and colored polylactic acid melt in the melt mixing device to obtain colored polylactic acid mixed melt; leading the colored polylactic acid mixed melt into a spinning tank to be spun to obtain colored polylactic acid fiber. The method of the invention has the following advantages: avoiding causing chromatic aberration in the process of dying fiber or fabrics; saving energy, and preventing waste water generated by printing from polluting the environment; saving resources, and avoiding causing damage to the soil and water source after abandonment of the coloured polylactic acid fiber; providing technical guarantees for promotion and application of the polylactic acid fiber and products produced therewith.

Owner:恒天长江生物材料有限公司

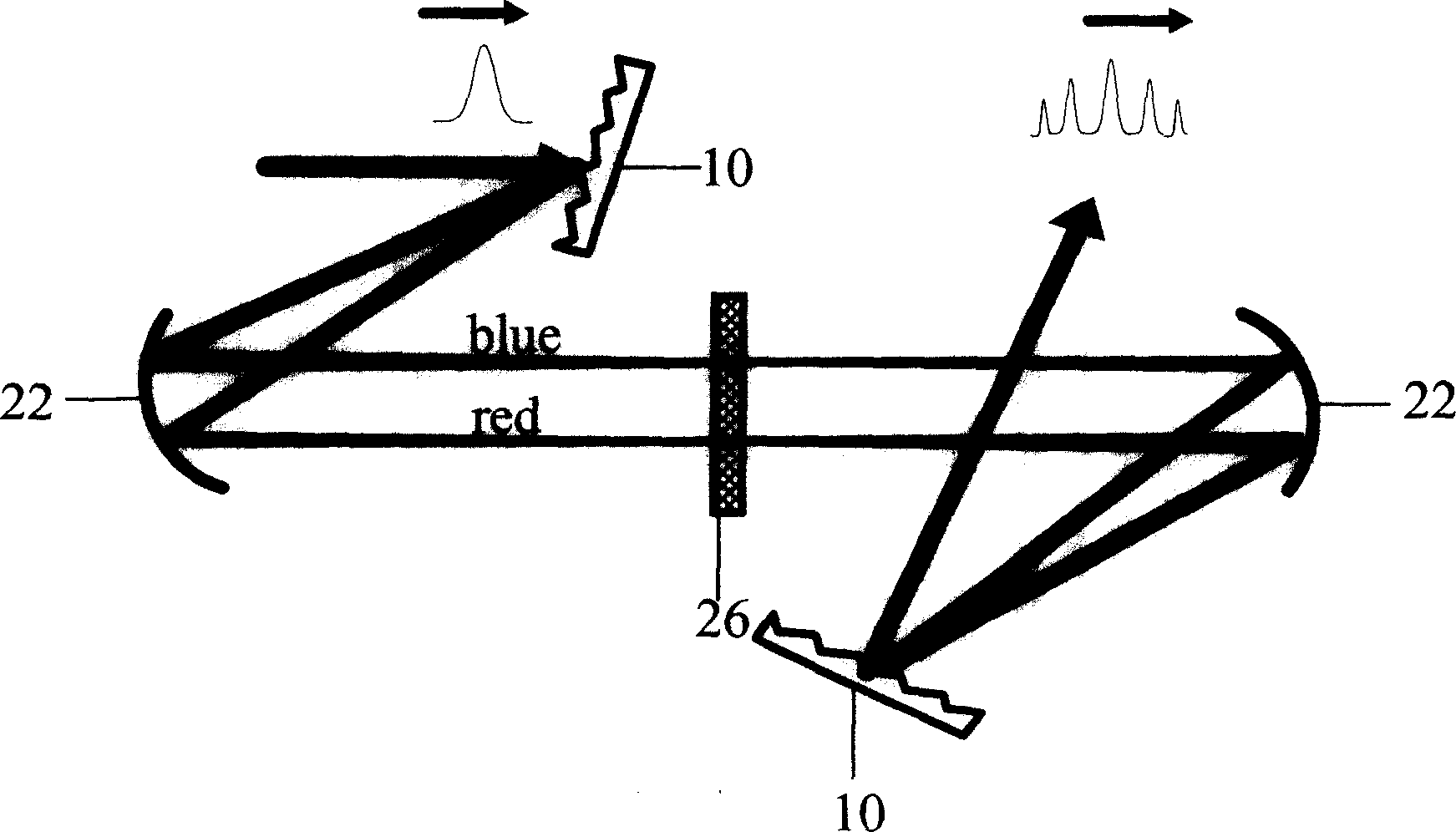

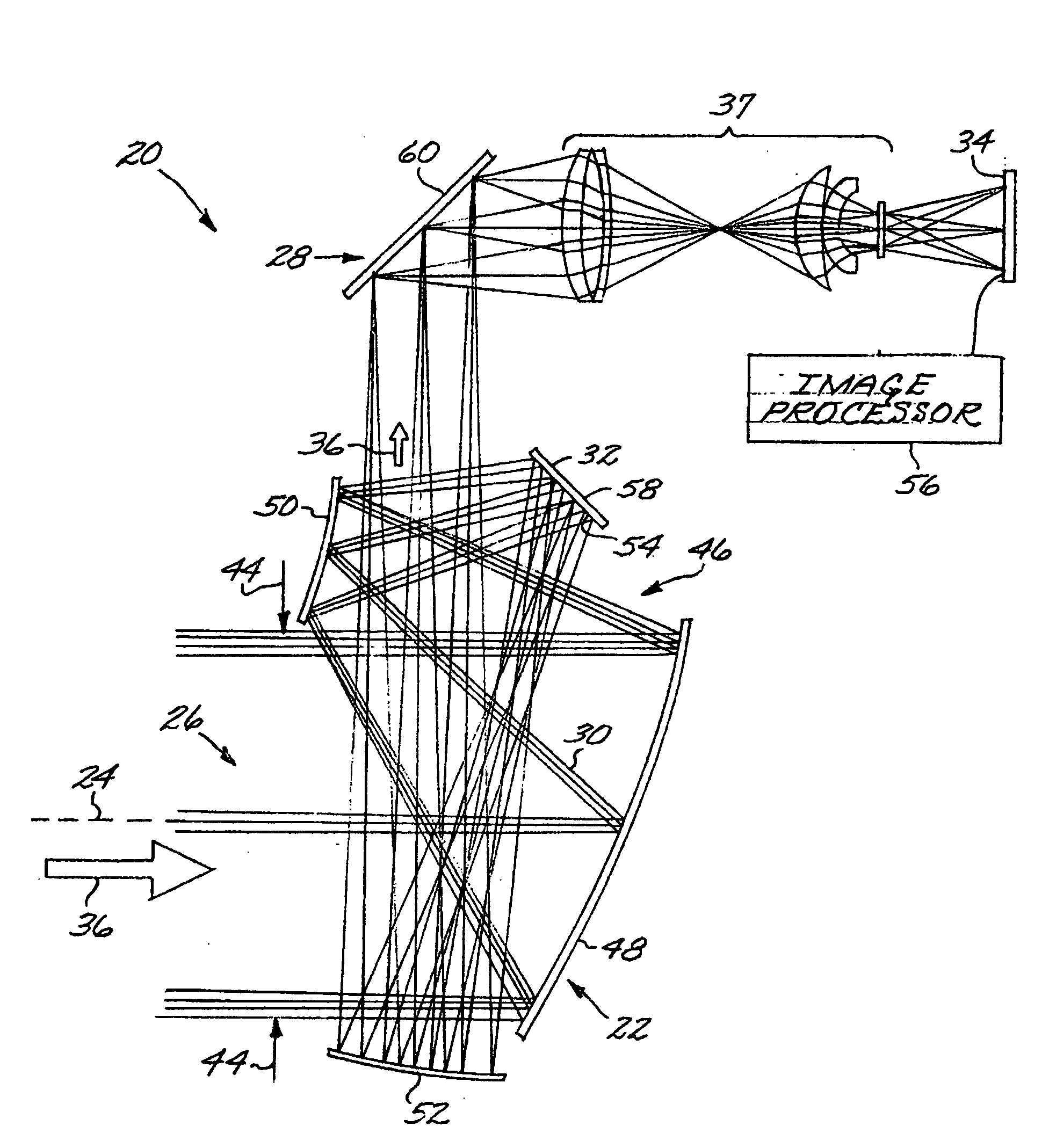

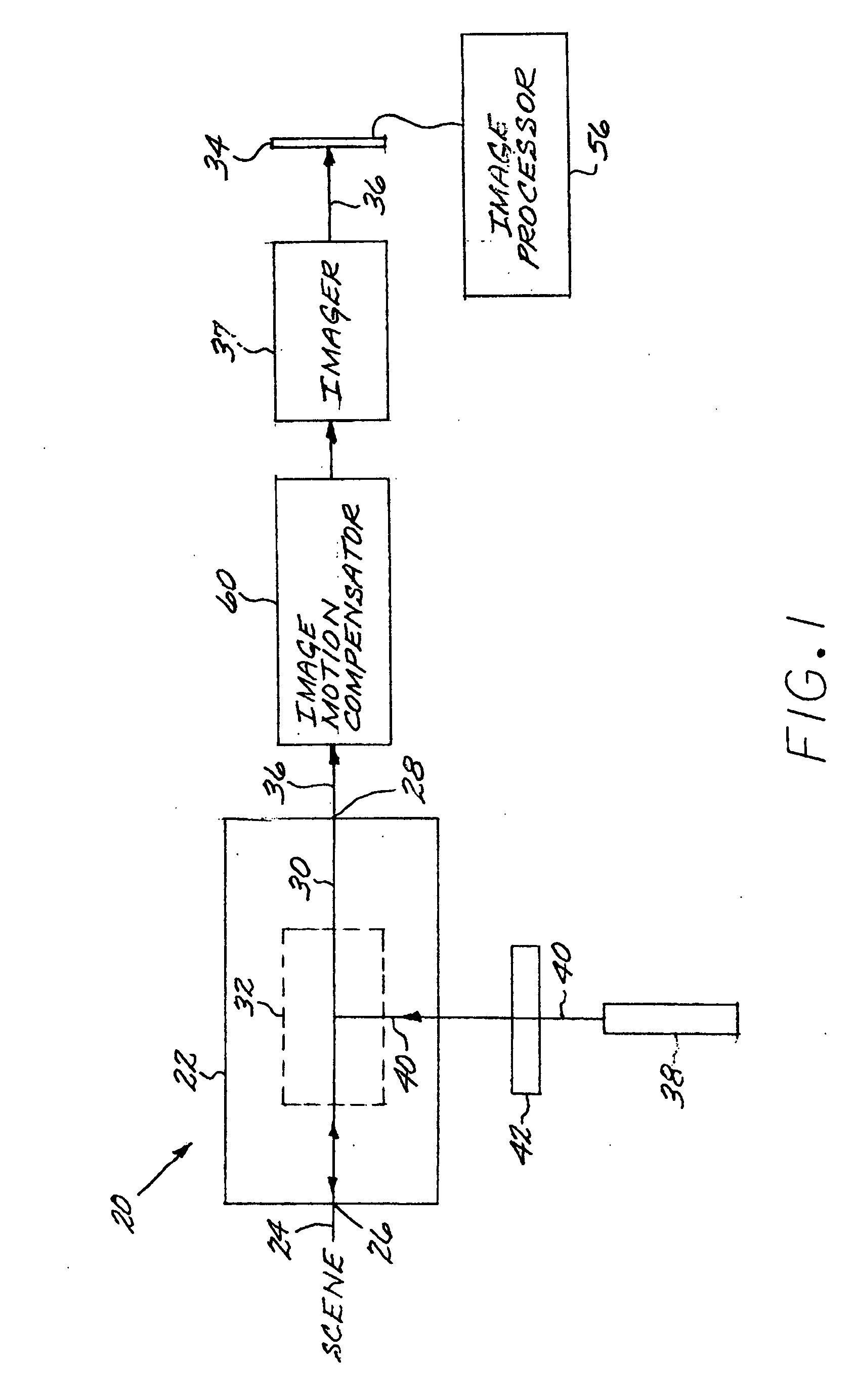

Common-aperture optical system incorporating a light sensor and a light source

ActiveUS20080186568A1Avoid misalignmentLight weightWave based measurement systemsSighting devicesReflecting telescopeBeam splitter

A common-aperture optical system includes a reflective telescope having a common boresight, an entrance pupil, an exit pupil, and a beam path extending from the entrance pupil to and beyond the exit pupil. A beam splitter intersects the beam path so that the beam path is incident upon the beam splitter. A light sensor is positioned to receive an input light beam traveling along the beam path after the beam path intersects the beam splitter and passes the exit pupil of the reflective telescope. A light source produces an output light beam incident upon the beam splitter and positioned to inject the output light beam into an inverse of the beam path and toward the entrance pupil of the reflective telescope. A diverger corrects at least one of the input light beam and the output light beam.

Owner:RAYTHEON CO

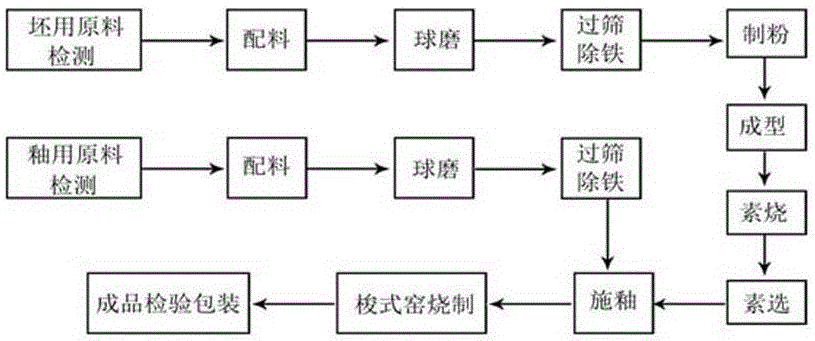

Single-layer glazed transmutation brick and preparation method thereof

The invention discloses a single-layer glazed transmutation brick and a preparation method thereof and relates to production of architectural ceramic glazed bricks. The method comprises the following steps: (1) preparation of green body slurry; (2) preparation of a glazing material; (3) forming and biscuit firing of a green body; (4) glazing of the green body; (5) firing of the transmutation brick. The glazed green body is fired in a kiln after drying and is subjected to a transmutation reaction through two times of temperature increasing and decreasing, and the single-layer glazed transmutation brick is obtained. The method has the advantages as follows: firstly, the problem about combination of the green body and glaze is solved, the product qualification rate is increased, and the method is suitable for large-scale production; secondly, a ground coat and cover glaze are combined into single glaze layer, a glazing process is simplified, color difference caused by different thickness of the ground coat and the cover glaze is avoided, and the brick can adapt to large-area paving for architectural decoration; thirdly, the firing temperature and firing time for the transmutation glaze are reduced, energy is saved, and consumption is reduced; fourthly, through optimization of a green body formula and a firing process, the brick is magnetized while is not hardened too much, and construction cutting is facilitated.

Owner:JIANGXI GANXIN CRAFT CERAMICS CO LTD

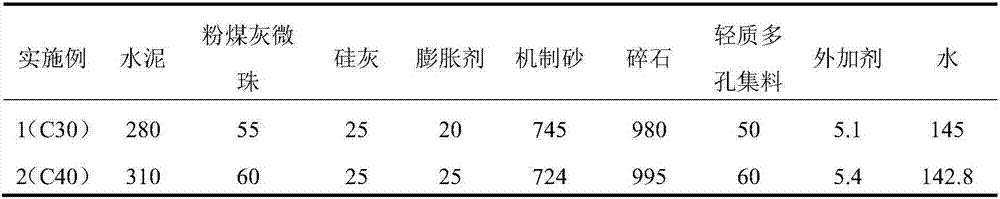

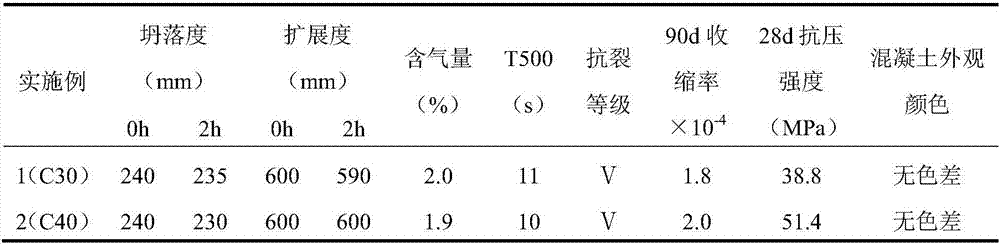

Bridge self-compaction anti-crack bare concrete prepared by utilizing high fine powder content machine-made sand

The invention discloses a bridge self-compaction anti-crack bare concrete prepared by utilizing high fine powder content machine-made sand. The bridge self-compaction anti-crack bare concrete is prepared from cement, activated fly ash microbeads, silica fume, an expanding agent, machine-made sand, gravel, a light-weight porous aggregate, a high-performance additive and water. The bridge self-compaction anti-crack bare concrete provided by the invention adopts the high fine powder content machine-made sand to replace common natural river sand, utilizes the activated fly ash microbeads and the silica fume for adjusting the viscosity and the fluidity of the concrete so as to improve the homogeneity of a concrete slurry, and further additive is used for reducing the gas content of the concrete, so that a working performance and a fluidity keeping performance of the concrete are improved; meanwhile, the expanding agent and the light-weight porous aggregate are combined, so that the volume stability and an anti-early-age cracking behavior of the bare concrete can be effectively improved. The self-compaction anti-crack bare concrete obtained through the invention has wide adaptability on different fine powder content machine-made sand, excellent working performance, mechanical property, volume stability performance and anti-cracking ability, uniform appearance and color, and better mirror surface effect.

Owner:WUHAN UNIV OF TECH +2

Method for producing organic solderability preservative on surface of circuit board

InactiveCN104918417AModerate roughnessUniform colorNon-metallic protective coating applicationOrganic filmEtching

The invention belongs to the circuit board production technical field and relates to a method for producing an organic solderability preservative on the surface of a circuit board. According to the method of the invention, sand blasting and board grinding procedures are omitted in a pretreatment process, and technological parameters of pickling and micro-etching are adjusted, and therefore, the problem of the smash of fine sands onto a board surface and the problem of high roughness and unevenness of a copper surface when a grinding brush is adopted to perform board grinding can be solved, and the roughness of the copper surface of the circuit board can be moderate and uniform, and the thickness of a formed organic film can be basically consistent with the thickness of etched copper; the circuit board is arranged in an antioxidant cylinder before the production of the organic film, a cylinder dragging plate is adopted to perform cylinder dragging processing at first, so that impurities in an antioxidant solution can be removed, and production parameters can be stabilized, and the concentration of Cu<2+> in the solution is controlled below 15ppm, and therefore, the organic film can be effectively prevented from blackening or color difference of the organic film can be effectively prevented, and yield can be improved; technological methods and parameters in various links are modified, and optimal parameter combinations can be explored, and therefore, the color of the organic film formed on the copper surface can be uniform.

Owner:JIANGMEN SUNTAK CIRCUIT TECH

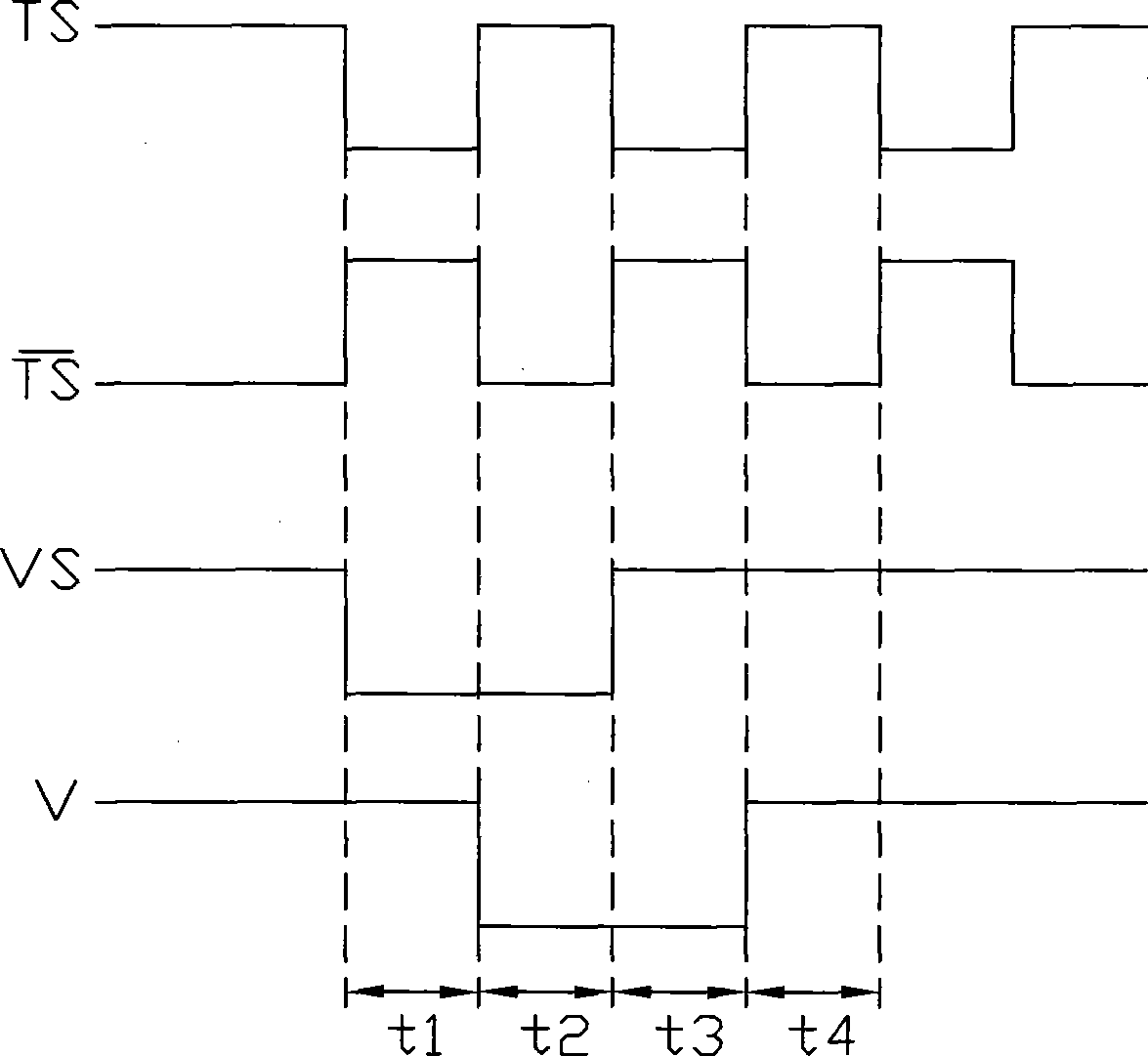

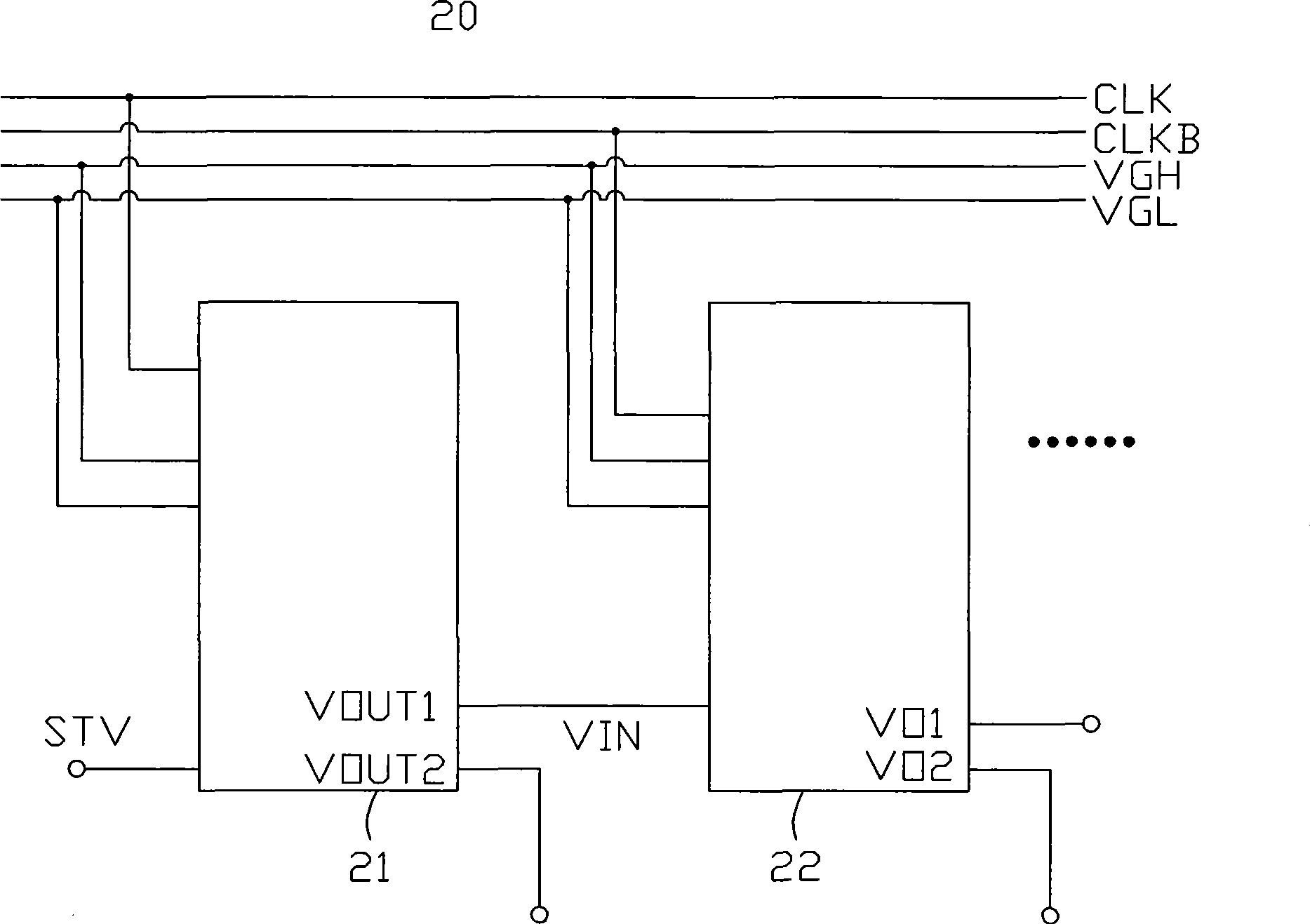

Shifting register and LCD

ActiveCN101388253ANo overlapping of signalsAvoid chromatic aberrationStatic indicating devicesDigital storageShift registerLiquid-crystal display

The invention relates to a shift register and a liquid crystal display using the shift register. The liquid crystal display comprises a liquid crystal panel, a data driving circuit and a scan driving circuit, wherein the data driving circuit and the scan driving circuit comprise the shift register, each shift register comprises a plurality of shift register units, clock signals which are received by two adjacent shift registers are reverse, output signal of a front shift register unit is an input signal of a next shift register unit, and each shift register unit comprises a signal output circuit, a signal input circuit and a logic circuit. The shift register and the liquid crystal display and a driving method of the shift register have no interference to output signals.

Owner:INNOCOM TECH (SHENZHEN) CO LTD +1

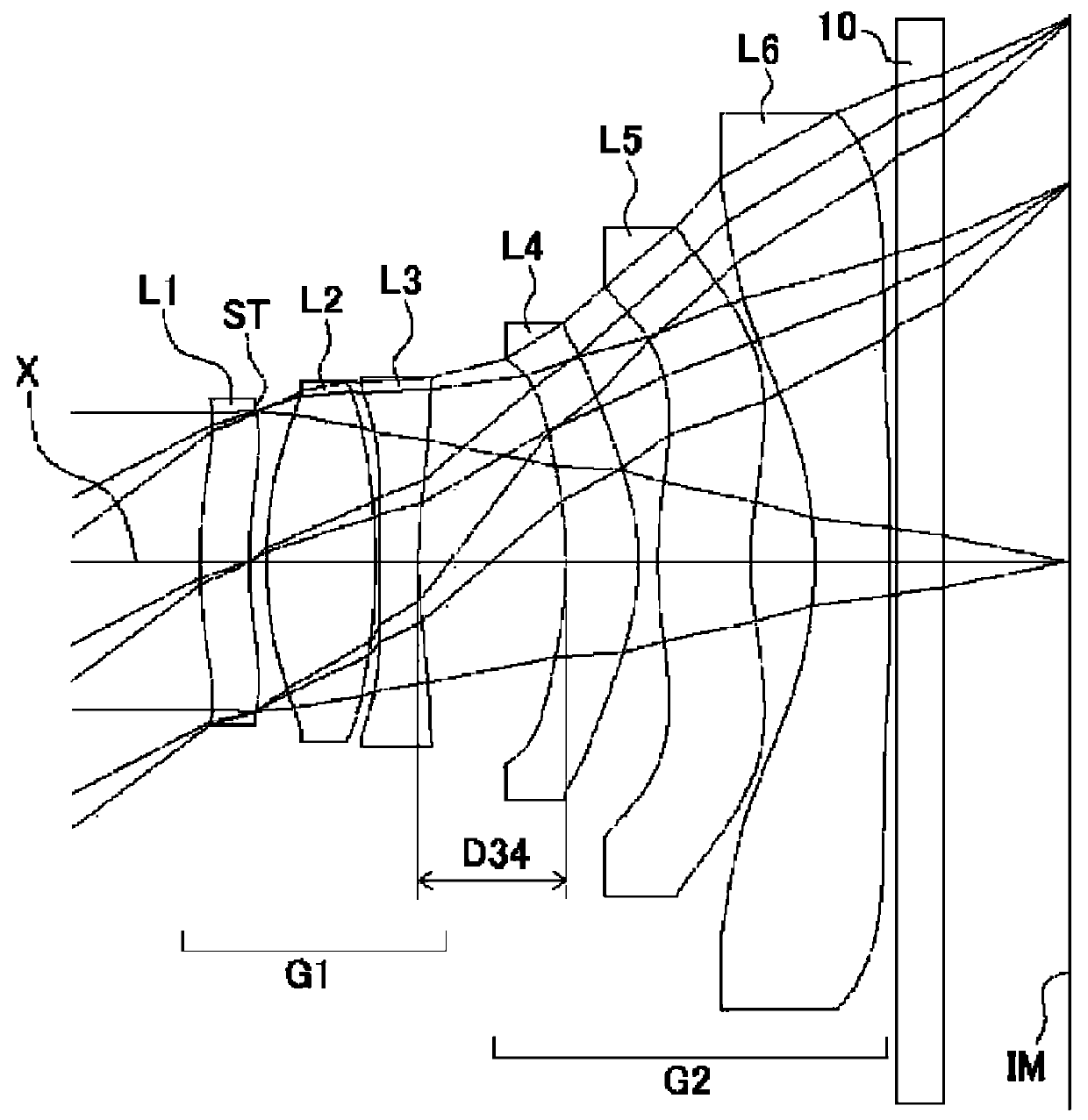

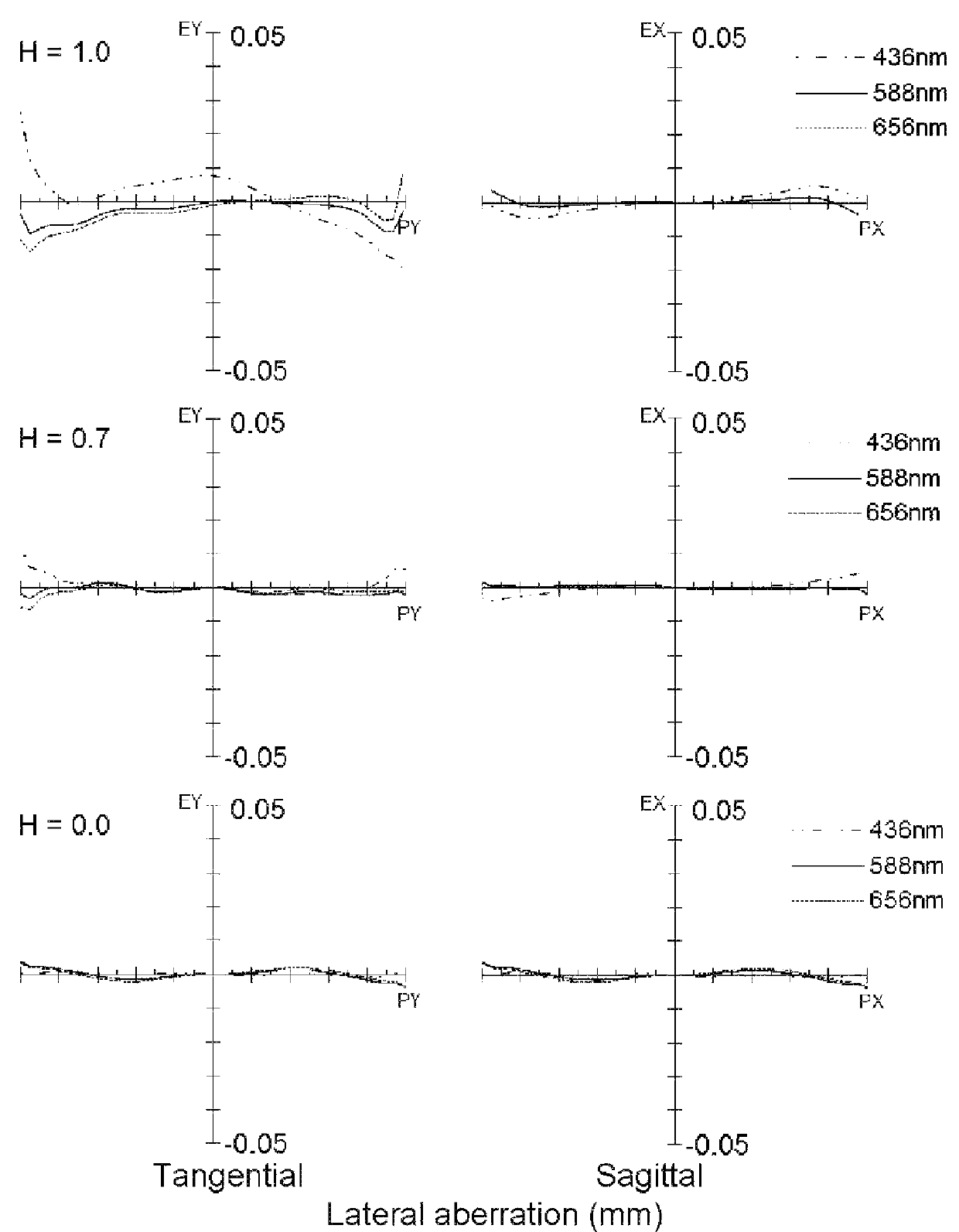

Imaging lens

ActiveUS9341822B2Avoid it happening againCorrected satisfactorilyOptical elementsImaging lensImage plane

An imaging lens includes a first lens group having positive refractive power and a second lens group having negative refractive power, arranged in this order from an object side to an image plane side. The first lens group includes a first lens having positive refractive power, a second lens having positive refractive power, and a third lens having negative refractive power. The second lens group includes a fourth lens having positive refractive power, a fifth lens, and a sixth lens having negative refractive power. The first lens has a specific focal length. The first to third lenses have specific Abbe's numbers.

Owner:TOKYO VISIONARY OPTICS CO LTD

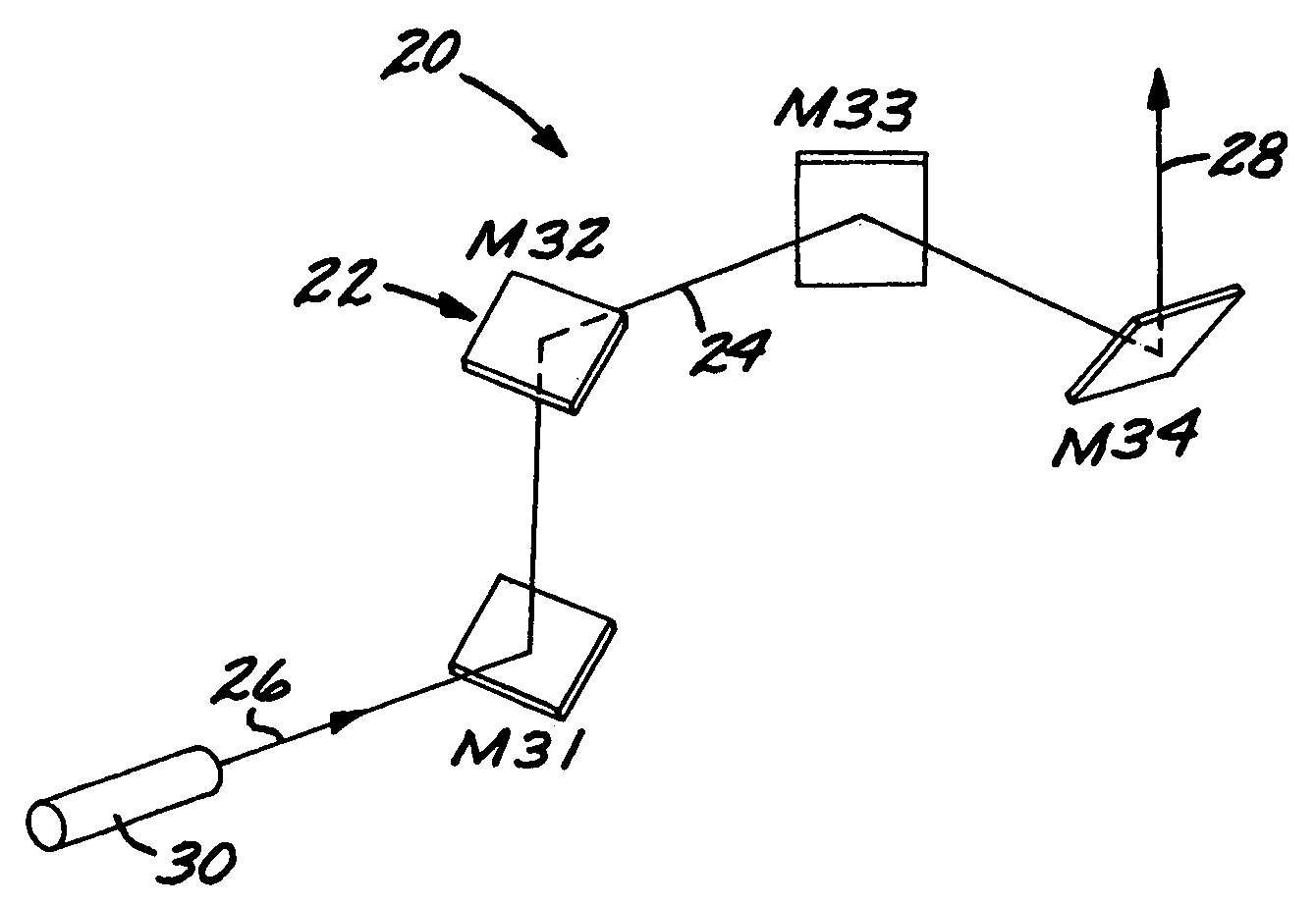

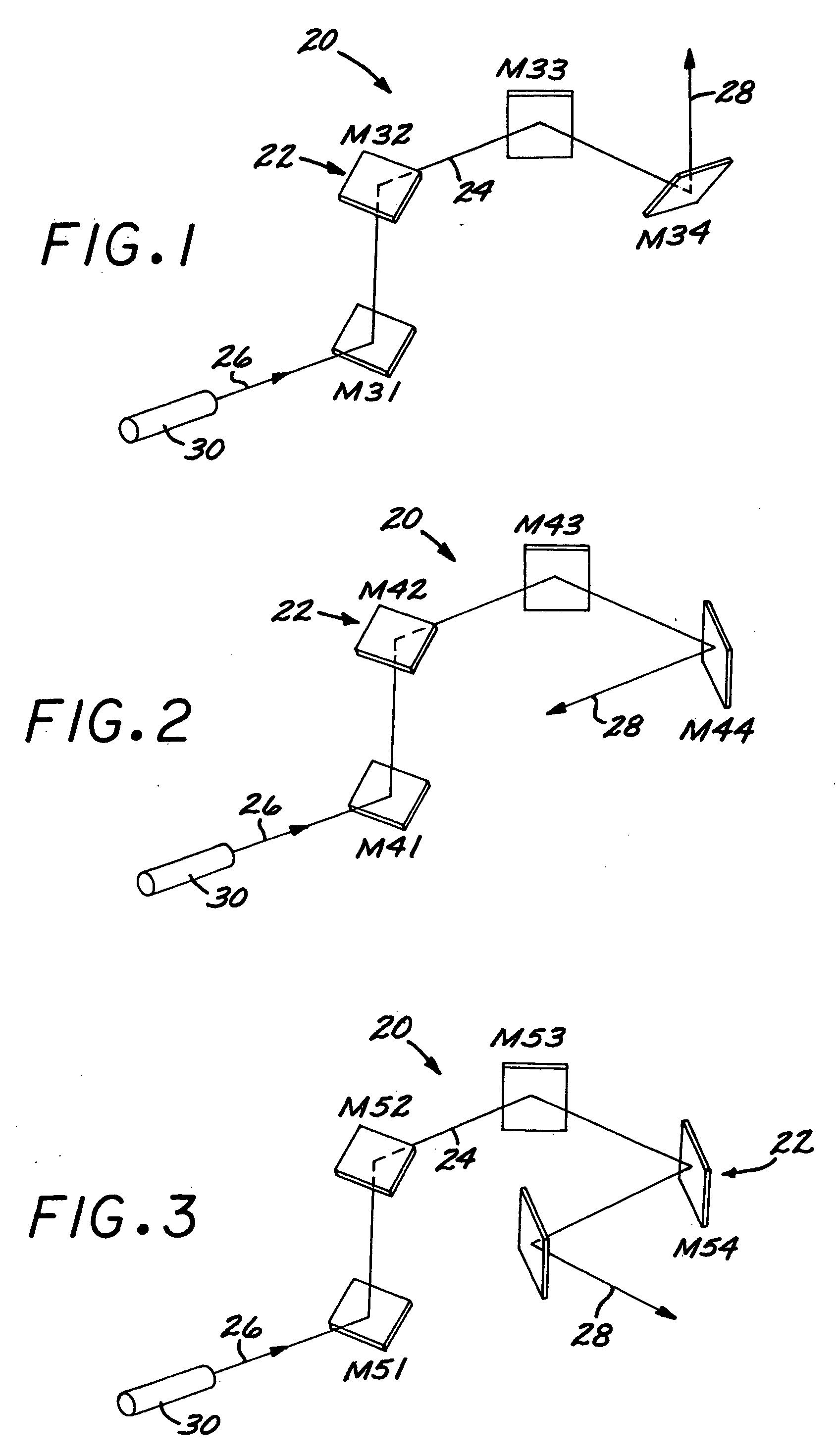

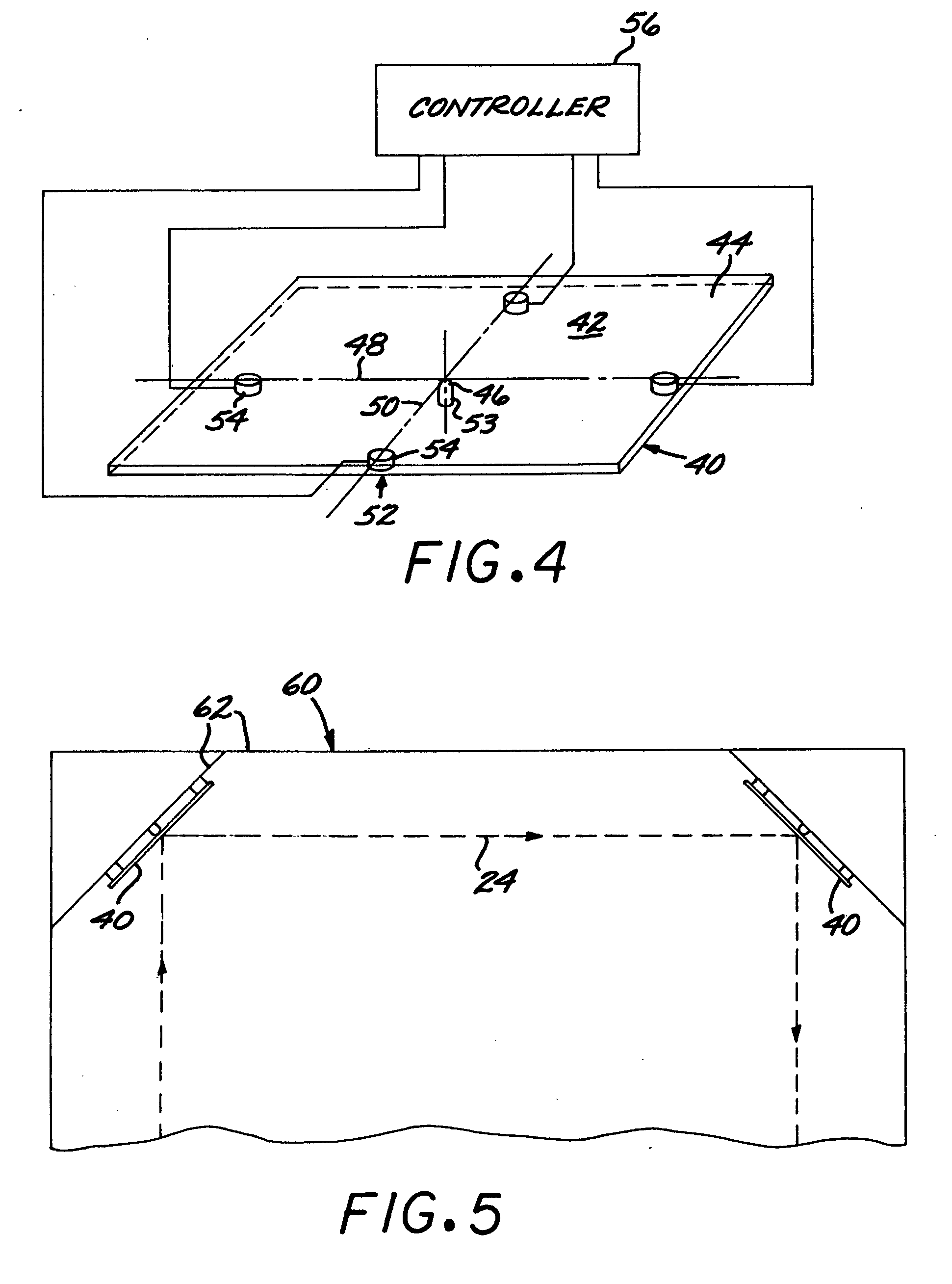

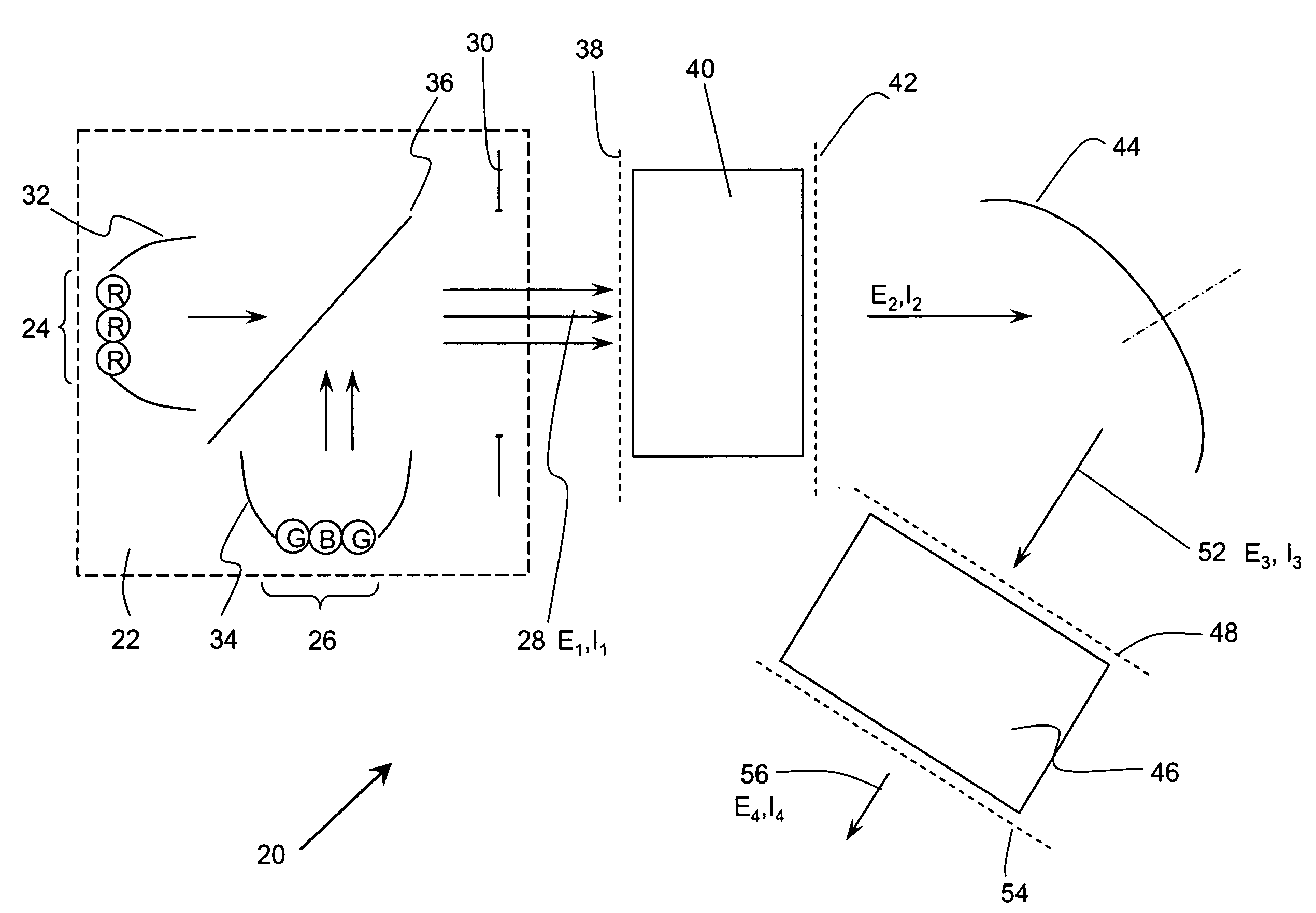

Beam-steering apparatus having five degrees of freedom of line-of-sight steering

A beam-steering apparatus comprises a set of planar tiltable mirrors positioned to define a light beam path therebetween. The set of planar tiltable mirrors comprises from three to five planar tiltable mirrors. Each of the planar tiltable mirrors has a center of rotation lying in a plane of the mirror and each of the planar tiltable mirrors is tiltable about one axis of rotation or two orthogonal axes of rotation that lie in the plane of the mirror. The total number of axes of rotation about which the planar tiltable mirrors of the set of planar tiltable mirrors can tilt is at least five. A mirror drive system tilts each respective planar mirror about its respective axis of rotation or axes of rotation. With this apparatus, an input or output light beam path is steerable over two angular, one rotational, and two lateral-position degrees of freedom.

Owner:RAYTHEON CO

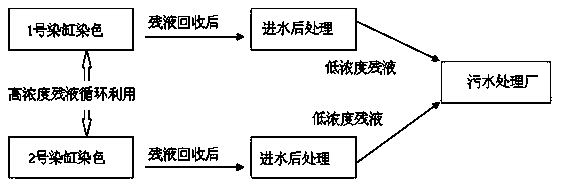

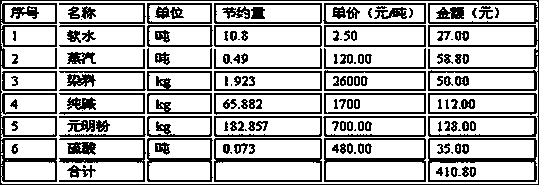

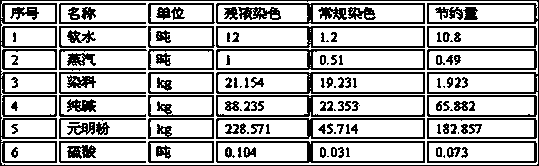

Residual liquid dyeing process of cheese

ActiveCN103741526AReduce consumptionEmission reductionTextile treatment machine arrangementsDyeing processYarnPulp and paper industry

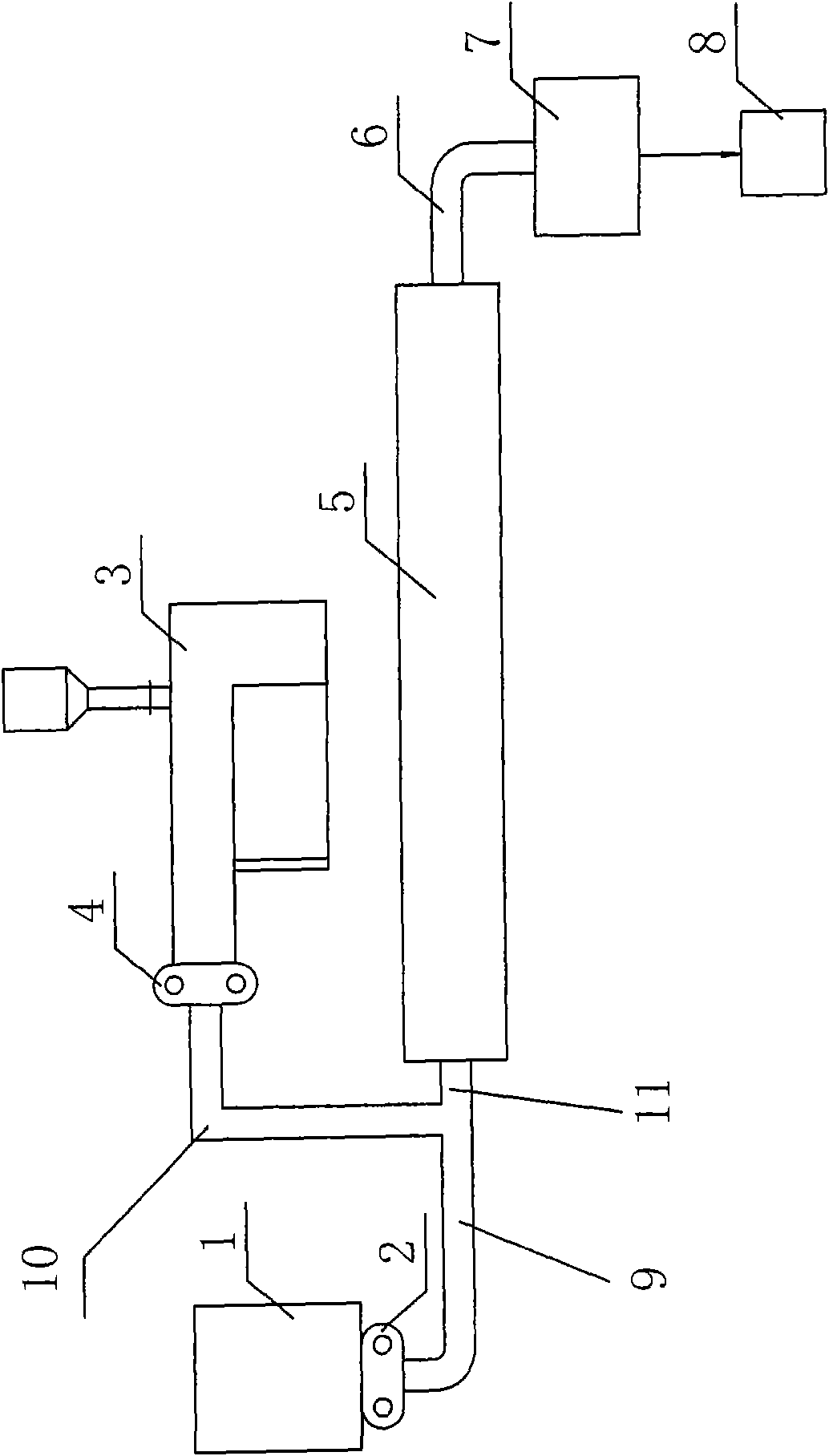

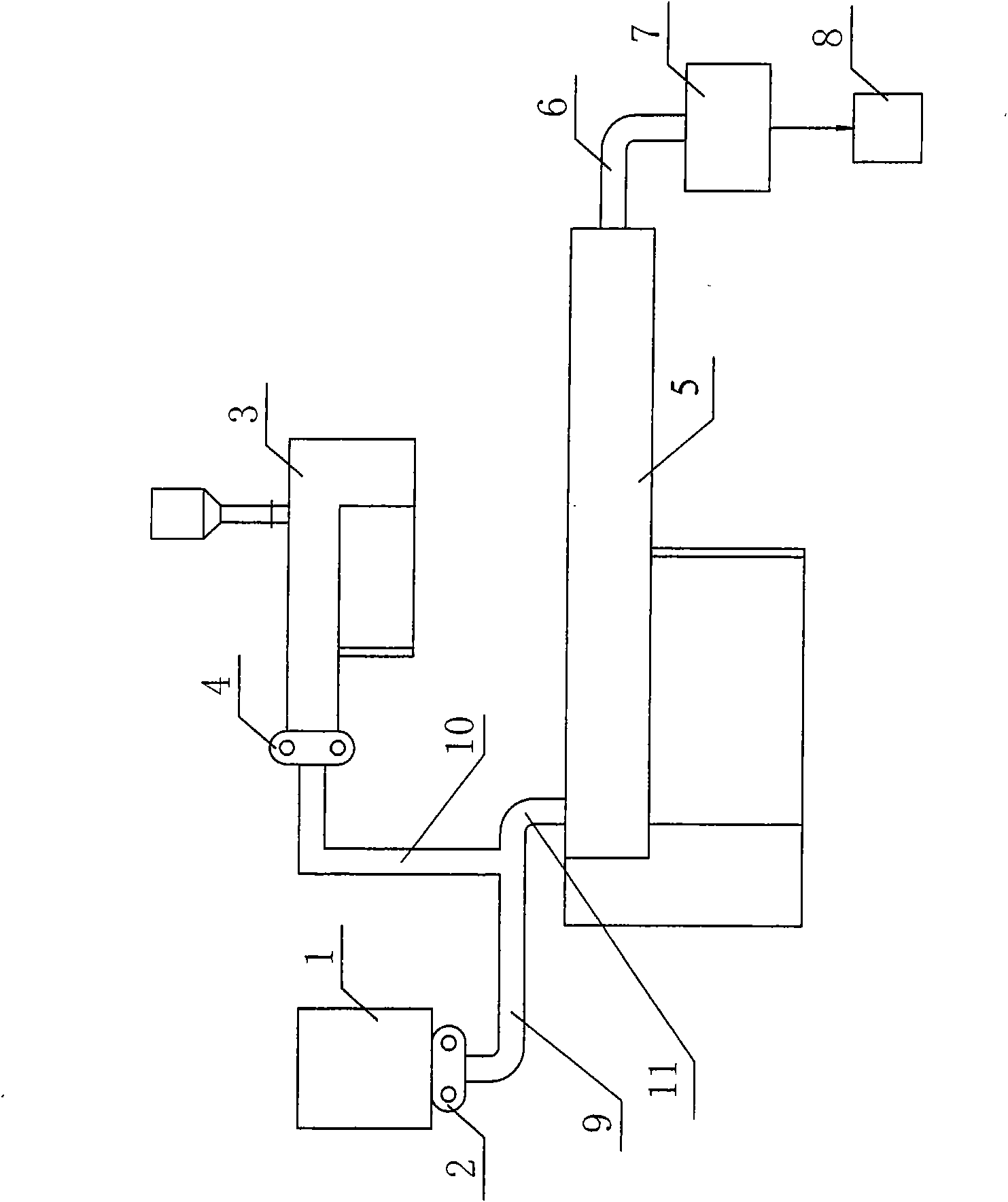

The invention provides a residual liquid dyeing process of cheese in order to reduce the dye consumption for cheese dyeing. The residual liquid dyeing process is characterized in that a dye vat No.1 and a dye vat No.2 are connected through a pump, after yarns in the dye vat No.1 are dyed for the first time, a dyeing solution is pumped into the dye vat No.2, and after the yarns in the dye vat No.2 are dyed, the dyeing solution is returned to the dye vat No.1 to dye undyed yarns; the dyeing solution is recycled for dyeing between the dye vat No.1 and the dye vat No.2 according to the method; and after the dyeing solution is exhausted each time, a post-processing stage is entered, the dyed yarns are taken out after the post-processing is completed, and the undyed yarns are hung to wait for the import of the dyeing solution. According to the residual liquid dyeing process disclosed by the invention, the water consumption and sewage discharge are reduced from the source, resource consumption and environment pollution are reduced, and the cyclic utilization of resources and clean production are realized.

Owner:HMEI THREAD CO LTD OF YINBIN SICHUAN +1

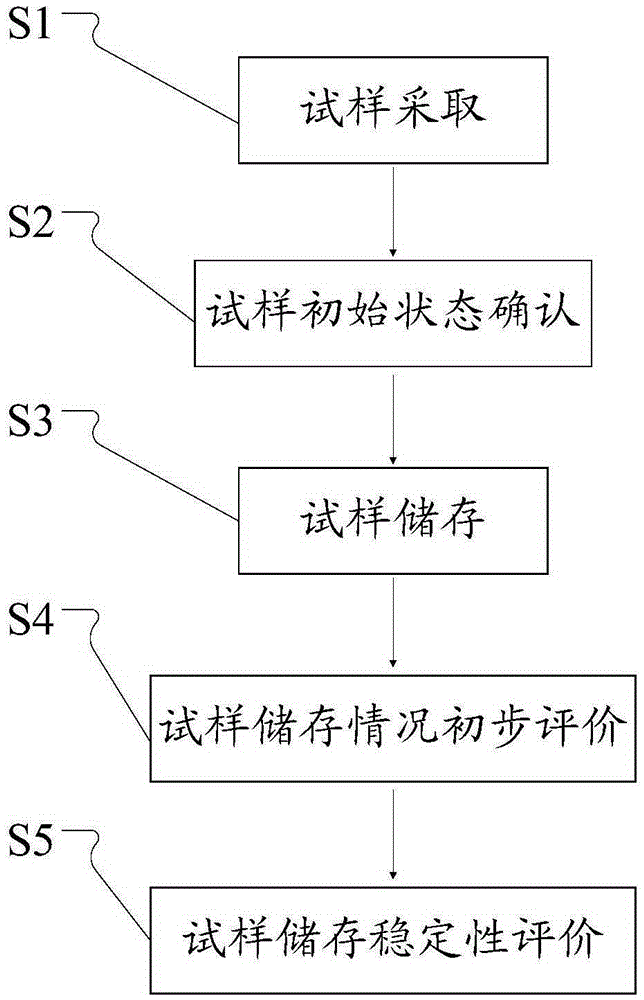

Method for testing and evaluating storage stability of water paint

InactiveCN105259075APrevent discolorationAvoid chromatic aberrationFlow propertiesMaterial testing goodsHydrogenLacquer

The invention relates to the technical field of paint detection and discloses a method for testing and evaluating storage stability of water paint. According to the method, a storage environment condition of a sample of the water paint in the storage stability testing process is determined on the basis of a traditional solvent-type paint storage stability detection method GB 6753.3-86: the sample is stored for 30 days at the temperature of 20 DEG C or stored for 10 days at the temperature of 30 DEG C or stored for 6 months in natural environment; evaluation conditions of checking of skinning, corrosion and a stale flavor, checking of the sedimentation degree, checking of paint film particles, glue blocks and brush marks, checking of a PH (potential of hydrogen) value, checking of a viscosity value and a paint film hue value and the like are determined. According to the method for testing and evaluating the storage stability of the water paint, whether the storage stability of different kinds of water paint or the water paint provided by different suppliers is good can be judged conveniently, and a basis is provided for determination of the storage cycle of the water paint.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

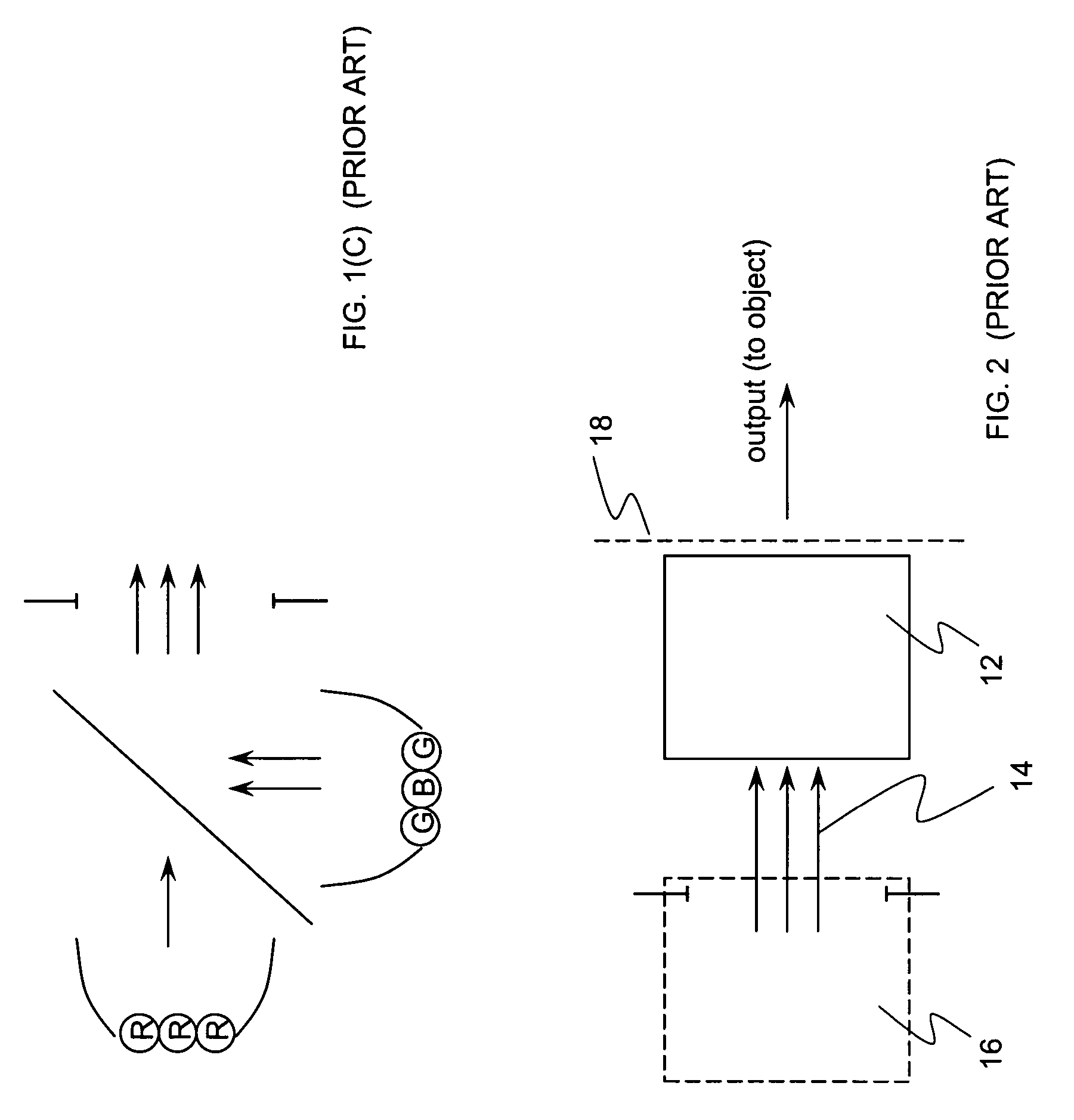

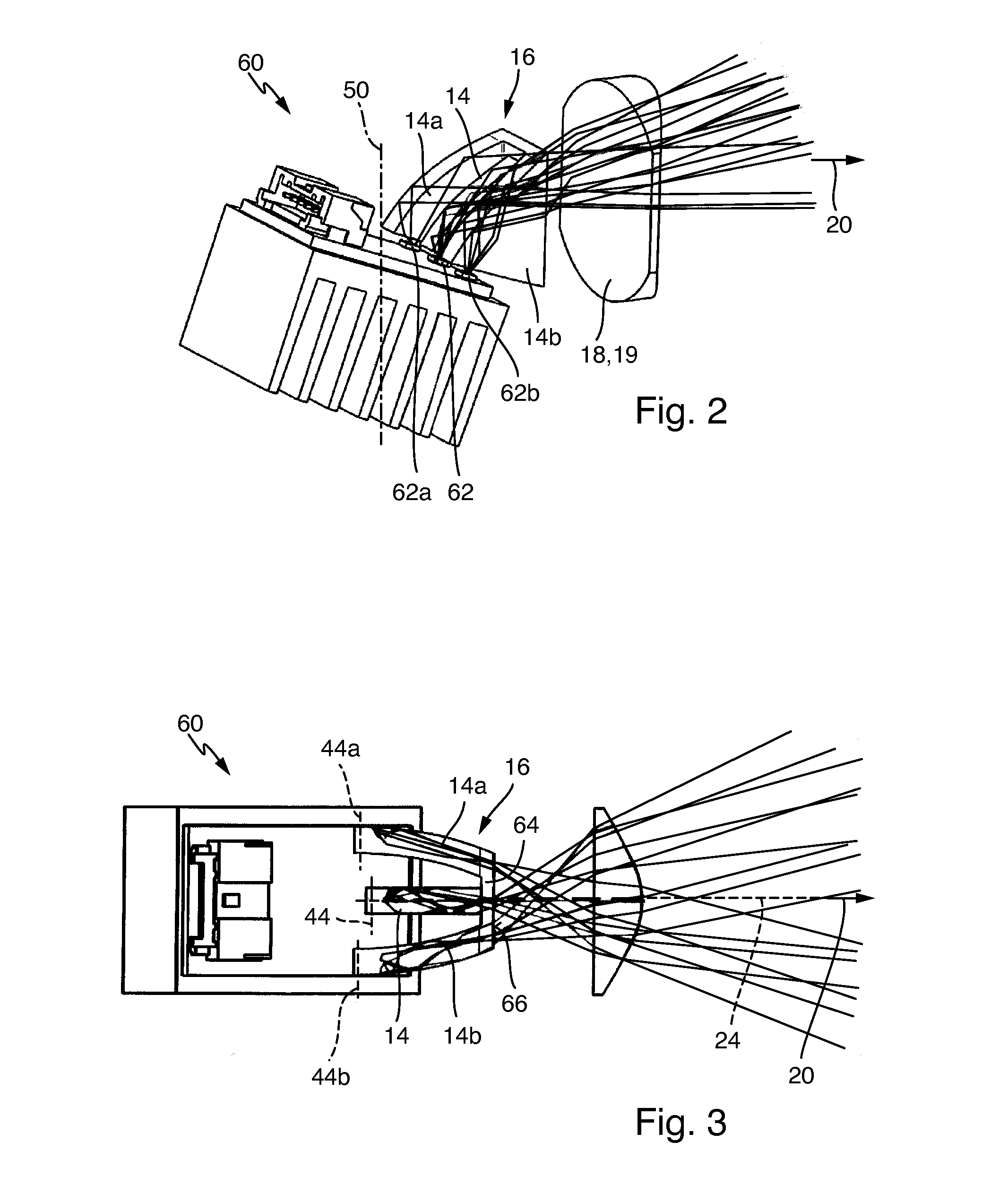

Light-pipe integrator for uniform irradiance and intensity

InactiveUS7352510B2Avoid chromatic aberrationImprove fill factorMountingsLight controlIntegratorLight pipe

Two integrating light pipes are optically coupled to a focusing element to produce light with uniform irradiance and intensity profiles. The first ILP stage is used to receive spatially non-uniform light from a single or multi-color source and produce a uniform irradiance distribution while leaving the intensity distribution substantially unaltered. The focusing optical element swaps the irradiance and intensity distributions received from the output of the first ILP and feeds it to a second ILP stage which, in turn, completes the spatial homogenization of the light by transforming the non-uniform irradiance received from the focusing element into an output of uniform irradiance. As a result of this sequence of transformations, a homogeneous multi-color light output, both in intensity and irradiance, is produced.

Owner:EDMUND OPTICS

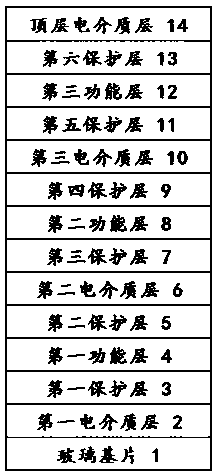

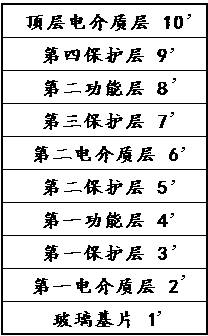

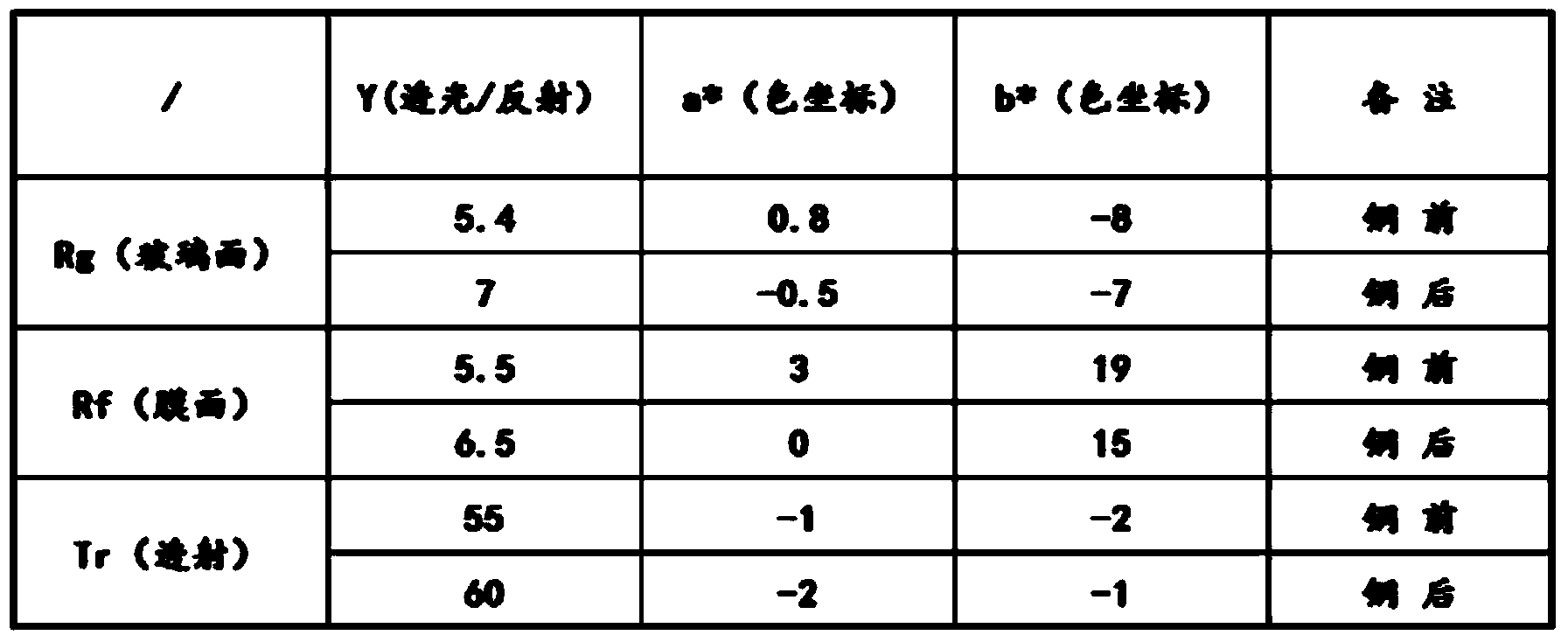

Tempering low-emissivity coated glass containing silver alloy

ActiveCN103802379AGrain refinementHigh hardnessGlass/slag layered productsMetal layered productsLow emissivityHardness

The invention provides tempering low-emissivity coated glass containing silver alloy. The glass comprises a glass substrate and a coating layer deposited on the glass substrate, and is characterized in that the coating layer comprises two or more functional layers, at least one of the functional layers is a silver alloy layer, and the silver alloy layer is made from one of Ag-Cu-Ni or Ag-Cu-Al or Ag-Cu-Pt. According to the tempering low-emissivity coated glass containing the silver alloy provided by the invention, a traditional Ag layer is substituted by the silver alloy layer, a small quantity of alloy metal elements are doped in the Ag layer, Ag crystal particles are refined, the hardness, the abrasive resistance and the burning loss resistance of silver are improved, the optical performance of Ag is changed, the overall glass is perspective and grey, the outdoor color is neutral and is close to natural color which is real and beautiful, and thus the demand of people on the color is satisfied; meanwhile, the processability of the glass is improved, and the oxidation resistance of the glass is enhanced.

Owner:CHANGJIANG GLASS TAIBO

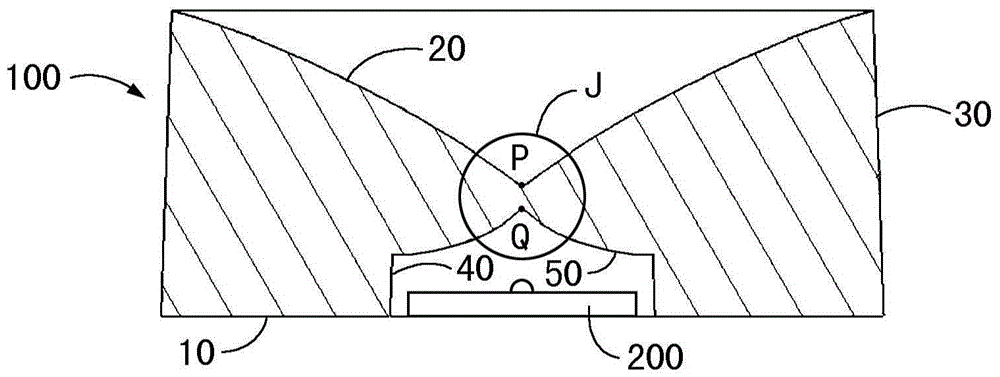

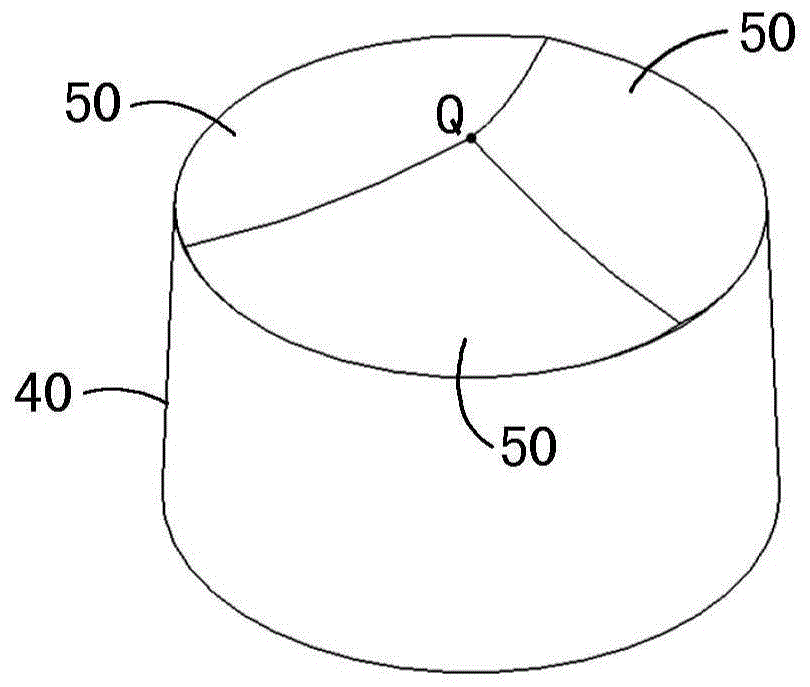

Lens and light-emitting device

ActiveCN104565885AEvenly distributedAvoid chromatic aberrationElectric lightingSemiconductor devices for light sourcesLight emitting device

The invention provides a lens and a light-emitting device. The lens comprises a column-shaped lens main body, wherein the column-shaped lens main body is provided with a bottom surface, a top surface and a circumference surface; the middle of the bottom surface concaves inwards to form a light incoming surface; the top surface is a total reflection surface in the shape of a smooth transitional curved surface and is provided with a center vertex; the circumference surface is a light extracting surface; the light incoming surface comprises a first cylindrical light incoming surface connected with the bottom surface and a second pyramid light incoming surface connected with the first light incoming surface; the second pyramid light incoming surface is provided with a pyramid vertex and pyramid surfaces in the shapes of smooth transitional curved surfaces; the center vertex of the total reflection surface and the pyramid vertex of the second light incoming surface are both on the axis of the lens main body; incident ray getting into the lens main body from the first light incoming surface is directly emitted out by the light extracting surface to form a plurality of first emergent rays upwardly inclined by 0-40 degrees relative to the bottom surface; incident ray getting into the lens main body from the second light incoming surface is reflected by the total reflection surface and then emitted out by the light extracting surface to form a plurality of top emergent rays which are upwardly or downwardly inclined. According to the invention, light leaking is effectively reduced.

Owner:THE HONG KONG POLYTECHNIC UNIV

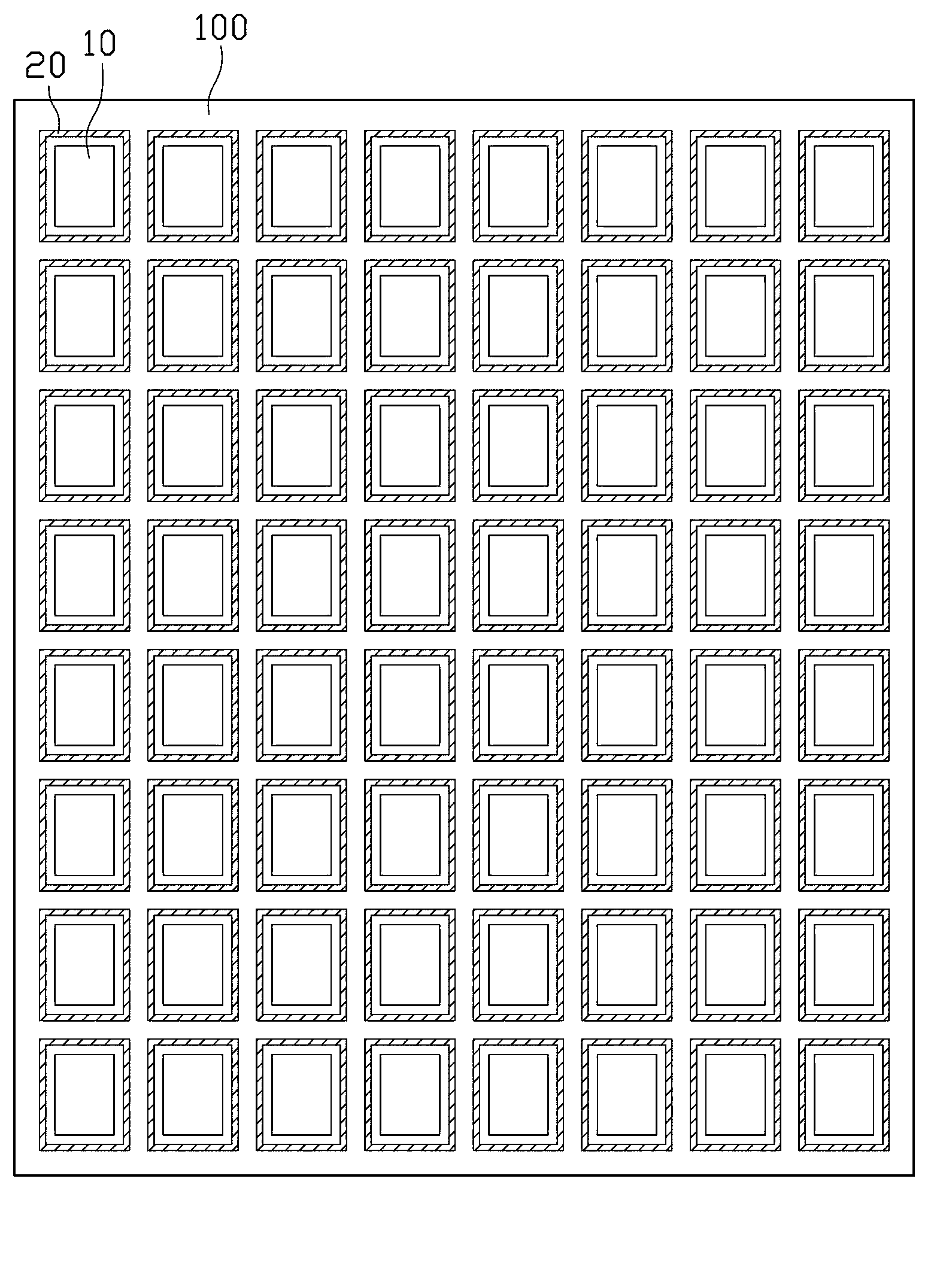

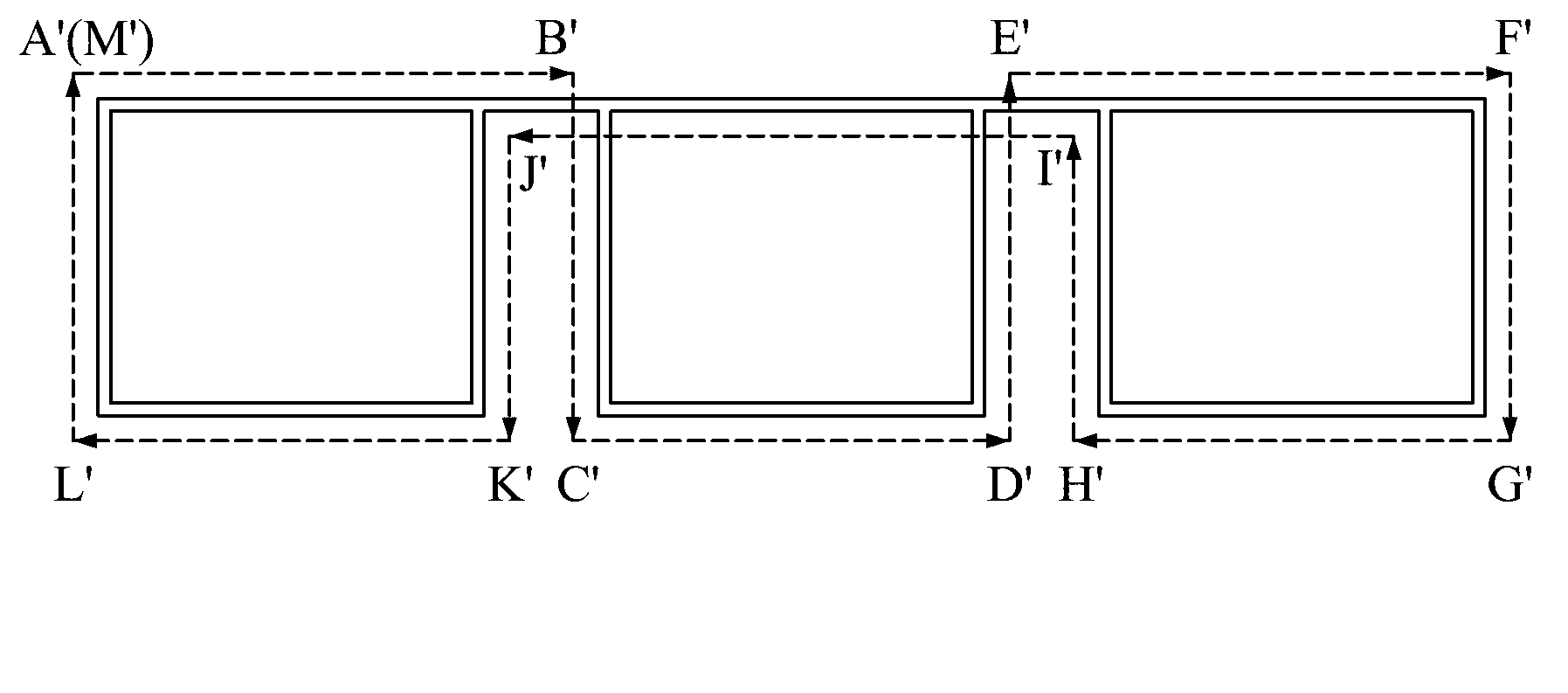

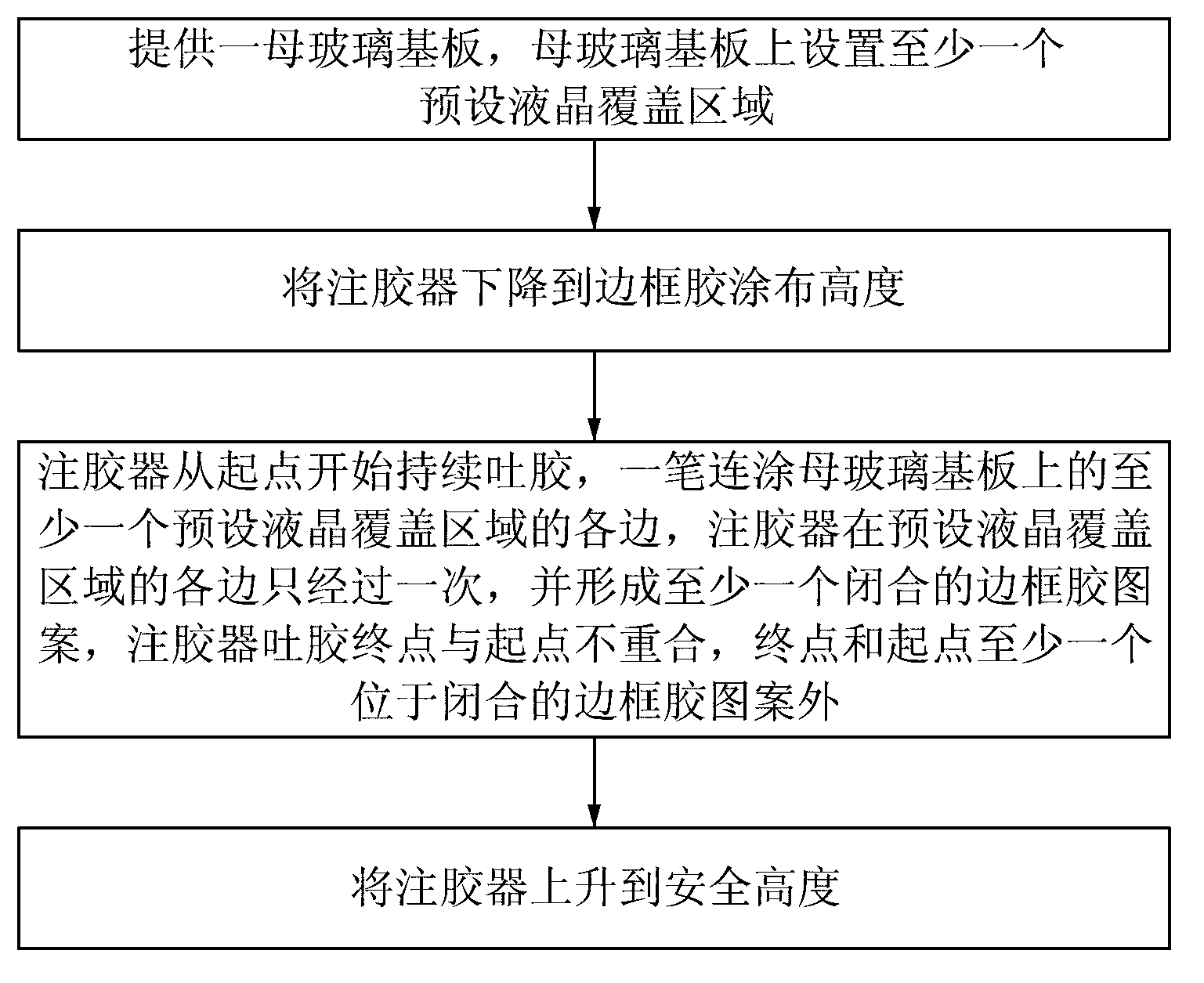

Method for applying liquid crystal display panel border adhesive

InactiveCN103018971APrevent leakageAvoid chromatic aberrationLiquid surface applicatorsCoatingsLiquid-crystal displayAdhesive

The invention provides a method for applying a liquid crystal display panel border adhesive, which comprises the following steps that a female glass substrate is provided, and at least one preset liquid crystal covering area is formed on the female glass substrate at intervals; an adhesive injector is dropped down to the border adhesive applying height; the adhesive injector continuously injects the adhesive from the starting point, and each side of the at least one preset liquid crystal covering area is continuously applied once, so as to form at least one closed border adhesive pattern; the end point of the adhesive injector for injecting the adhesive does not coincide with the starting point, and at least one of the end point and the starting point is positioned outside the closed border adhesive pattern; and the adhesive injector is lifted to the safety height.

Owner:KUSN INFOVISION OPTOELECTRONICS

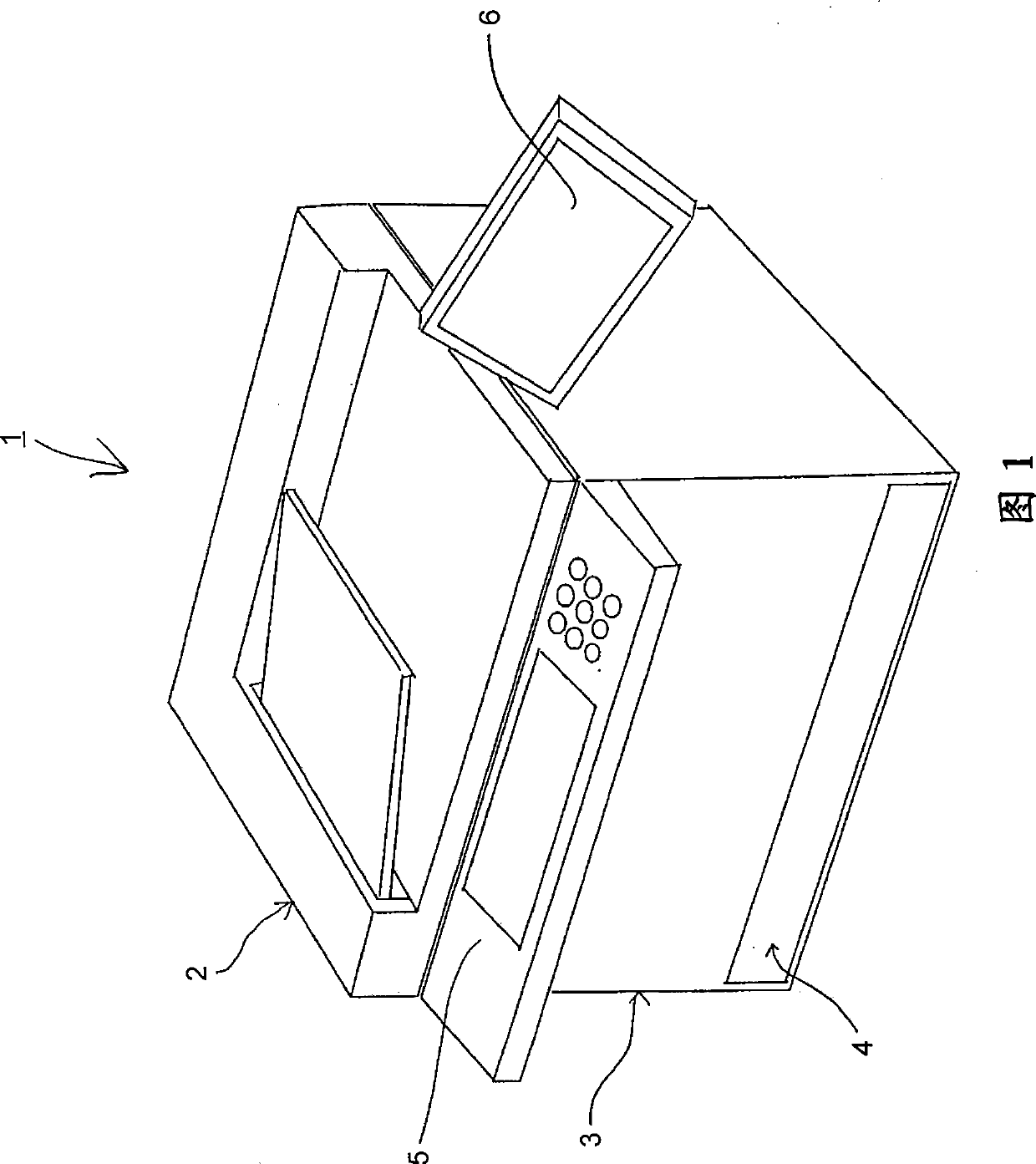

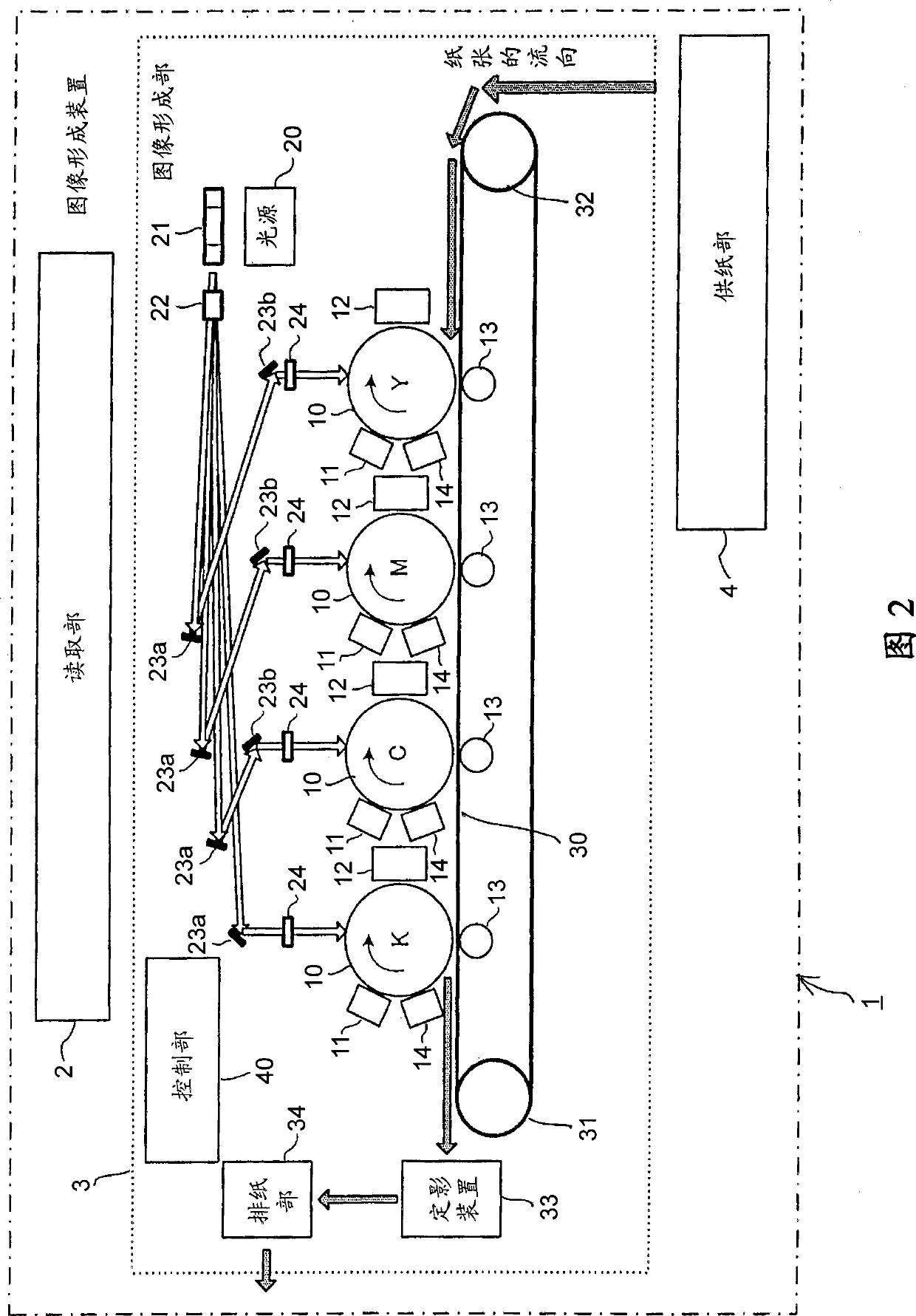

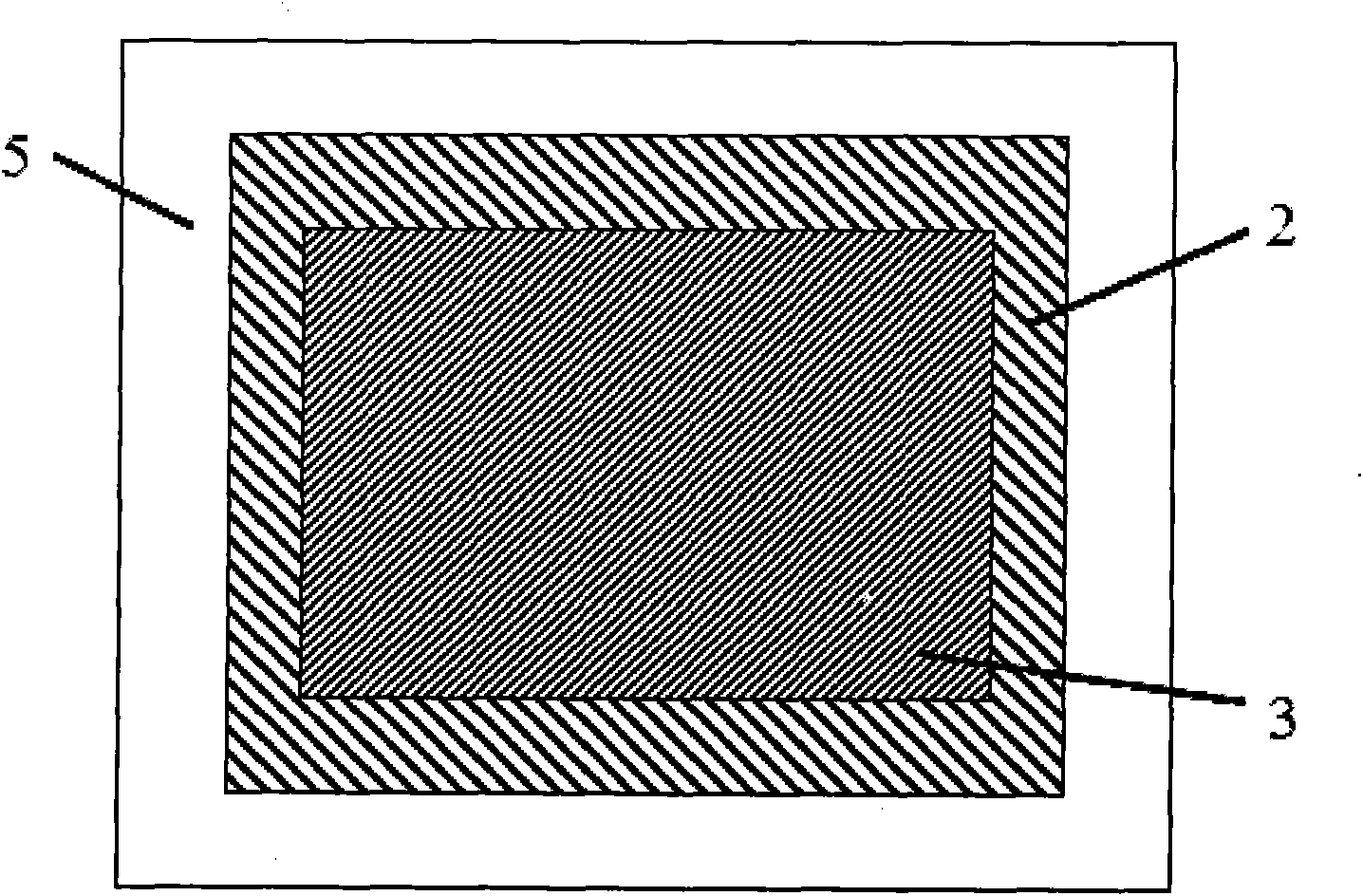

Image forming apparatus and control method thereof

InactiveCN101373355AGood reproducibilityReduce biasElectrographic process apparatusData controlImaging quality

An image forming apparatus of the invention includes: a laser beam source; a laser beam source control unit configured to control the laser beam source based on image data; a plurality of photoconductive members respectively corresponding to a plurality of colors; a single piece of polygon mirror whose reflection surfaces are disposed in a rotation direction thereof with a plurality of different inclination angles respectively corresponding to the plurality of colors, scans the photoconductive members sequentially for each of the colors in a main scanning direction; a beam detector that is disposed adjacent to the photoconductive member on an upstream side of the photoconductive member in the main scanning direction; and an adjustment data control unit configured to change, in synchronization with a detection signal coming from the beam detector, color-based adjustment data for adjusting variations of an image quality parameter resulted from the optical paths and the photoconductive members varying with the colors.

Owner:KK TOSHIBA +1

Prepreg mould-pressing composite material moulding process

The invention belongs to the technical field of material preparation and relates to a prepreg mould-pressing composite material moulding process. The prepreg mould-pressing composite material moulding process aims to solve the problems that pinholes and aberration are generated on the surface of the composition material prepared by the conventional moulding process easily and the like. The invention provides a composite material moulding process. The composite material moulding process at least increases a step of adding a protective film on the surface of the composite material so as to solve the problems at the very least.

Owner:上海晋飞碳纤科技股份有限公司 +1

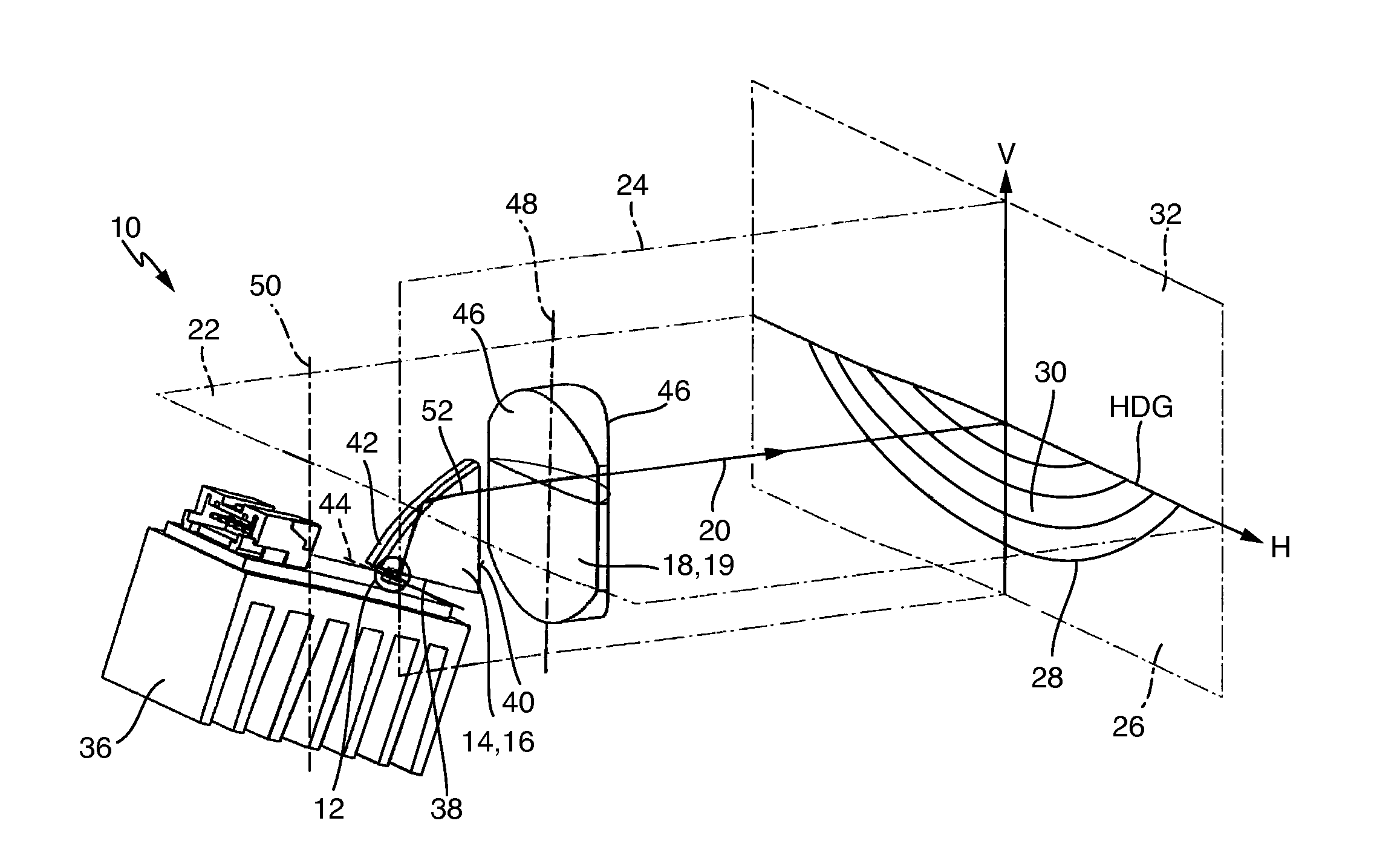

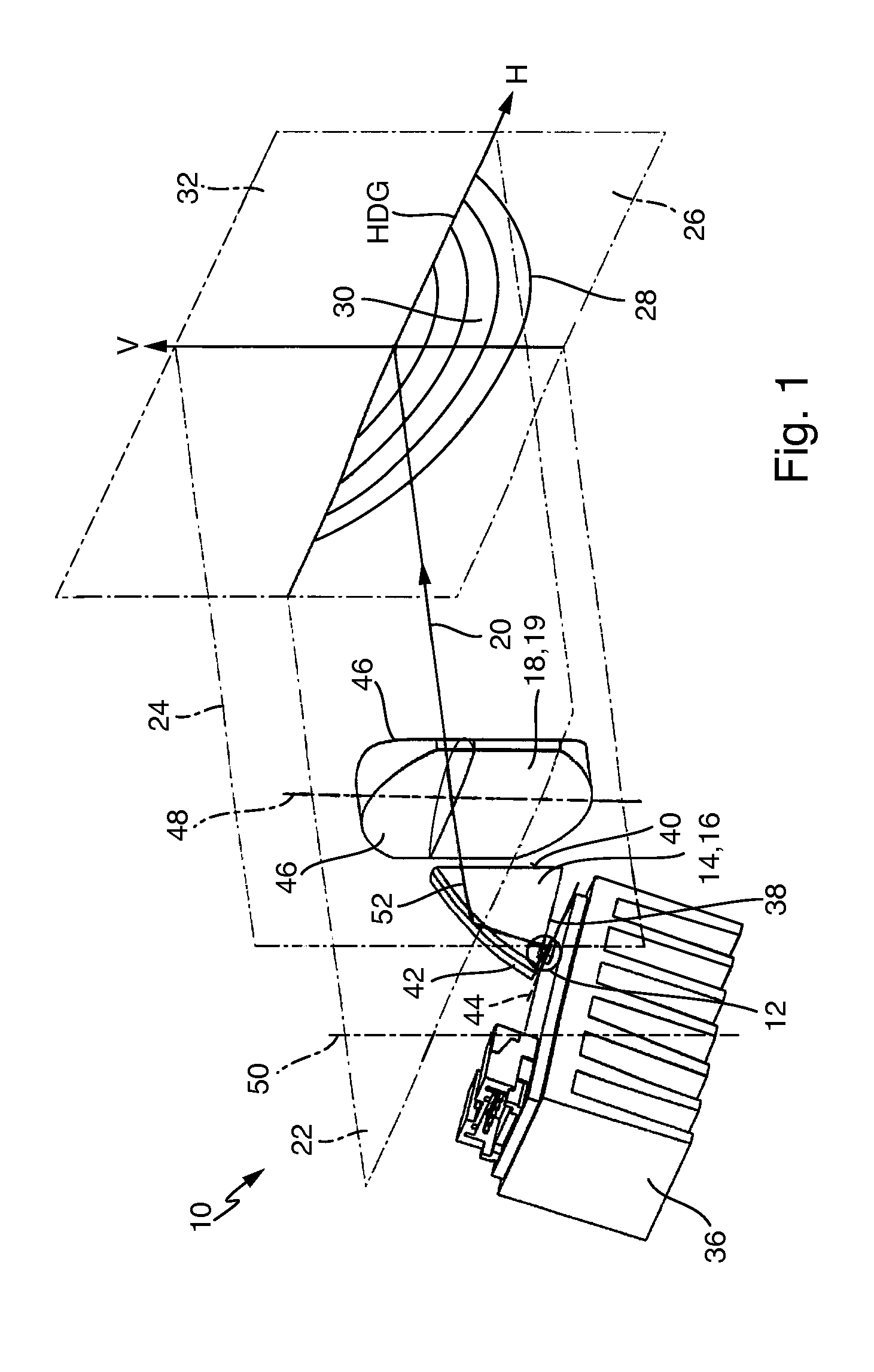

Light module

ActiveUS20140104864A1Avoid chromatic aberrationImprove optical efficiencyVehicle headlampsVehicle lighting systemsSagittal planeCoupling

A light module, comprising numerous semiconductor light sources for emitting light, a primary lens element for concentrating the light emitted from the semiconductor light sources in section perpendicular to a sagittal plane of the light module, wherein the primary lens element exhibits numerous disk-like light conducting sections, extending in a plane perpendicular to the sagittal plane, wherein each light conducting section exhibits a light coupling surface and a light decoupling surface, and is designed for conducting light, subjected to a total reflection, from the light coupling surface to the light decoupling surface, wherein a semiconductor light source is allocated to each light conducting section such that light form the semiconductor light source can be coupled with the respective light coupling surface in the light conducting section.

Owner:AUTOMOTIVE LIGHTING REUTLINGEN GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com