Lens and light-emitting device

A lens and cylindrical lens technology, applied in the field of lenses and light-emitting devices, can solve the problems of the market expansion of direct-lit backlight modules, the high cost of backlight modules, and the incompatibility of LEDs with different structures, so as to eliminate hot spots. , Improve the uniformity of light and the effect of uniform light

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

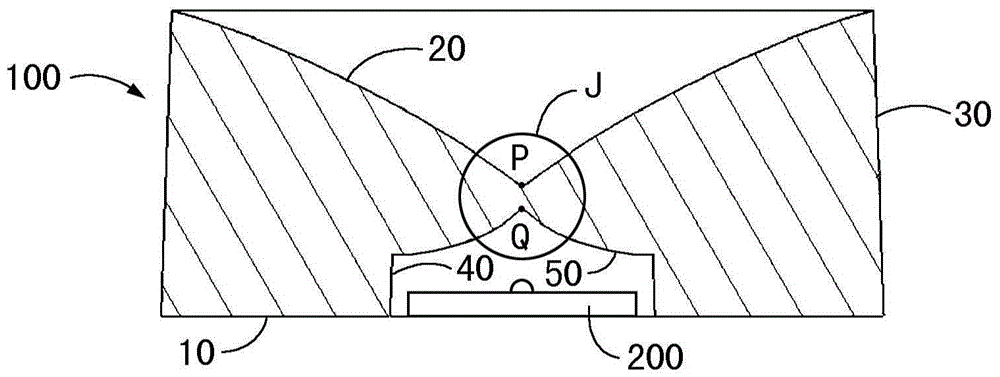

[0049] see figure 1 . The first embodiment of the lens of the present invention includes a lens body 100, and the lens body 100 has a bottom surface 10, a top surface and a peripheral surface. The middle part of the bottom surface 10 of the lens body 1 is concave inward to form a light incident surface, the top surface of the lens body 100 is a total reflection surface 20 , and the peripheral surface of the lens body 100 is a light output surface 30 .

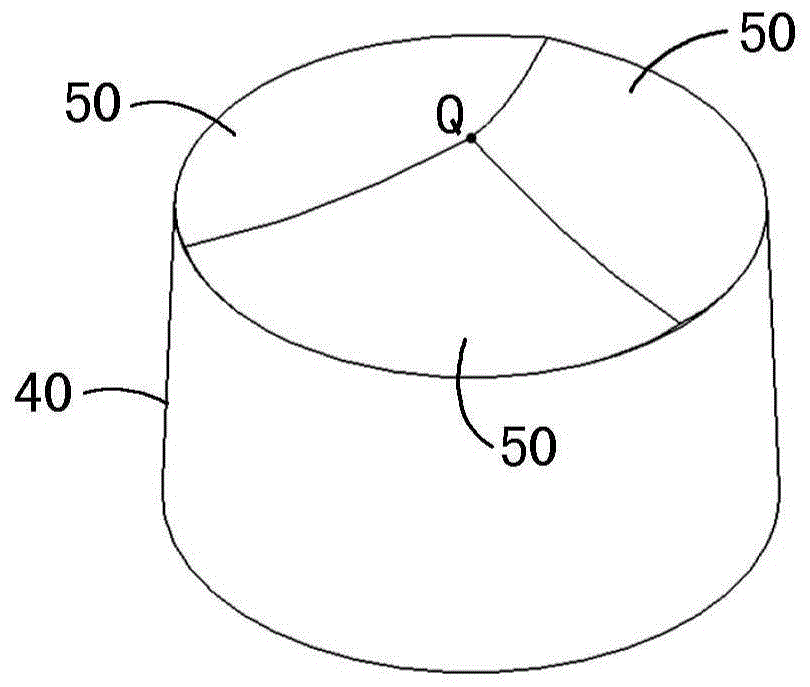

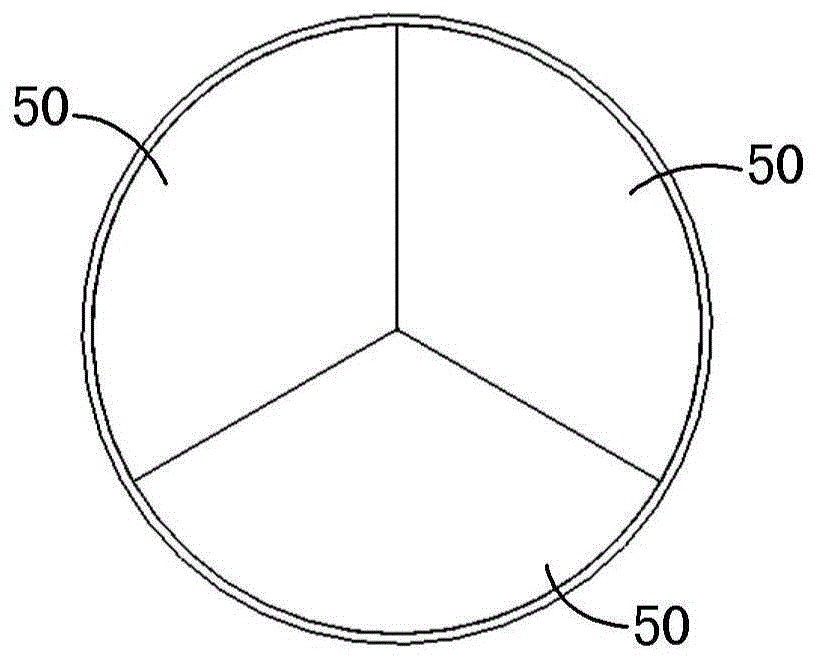

[0050] see figure 1 , Figure 2A to Figure 2D . The light incident surface includes a first light incident surface 40 and a second light incident surface 50 , wherein the first light incident surface 40 is cylindrical and its bottom end is connected to the bottom surface 10 of the lens 100 . The second light incident surface 50 is in the shape of a pyramid, and has a pyramid surface in the shape of a smooth transition surface and a pyramid apex Q. The bottom end of the second light incident surface 50 is connected to the t...

Embodiment approach 2

[0063] see Figure 6 and Figure 7 . The second embodiment of the lens of the present invention differs from the first embodiment only in that:

[0064] The second light incident surface 50 includes a second lower light incident surface 51 and a second upper light incident surface 52, and several upper outgoing light rays include several second outgoing light rays corresponding to the second lower light incident surface 51 and corresponding to the second light incident surface 52. Several third outgoing rays, several second outgoing rays and several third outgoing rays of the upper light incident surface 52 are arranged continuously. The height H3 of the second lower light incident surface 51 is 0.3 times of the height H4 of the second upper light incident surface 52, but not limited thereto, the height H3 of the second lower light incident surface 51 is the second upper light incident surface 52 The range of 0.2 to 0.5 times of the height H4 is feasible; the width W3 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com