Patents

Literature

521results about How to "Uniform light output" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

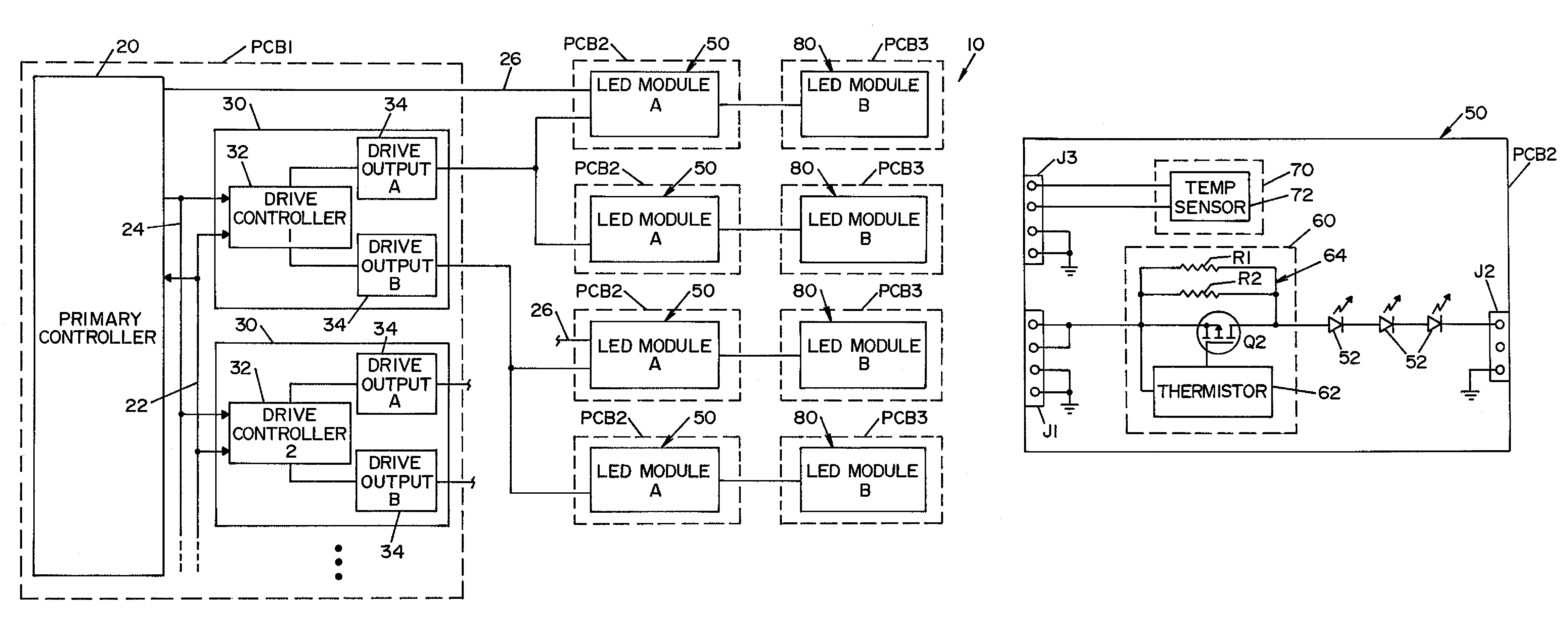

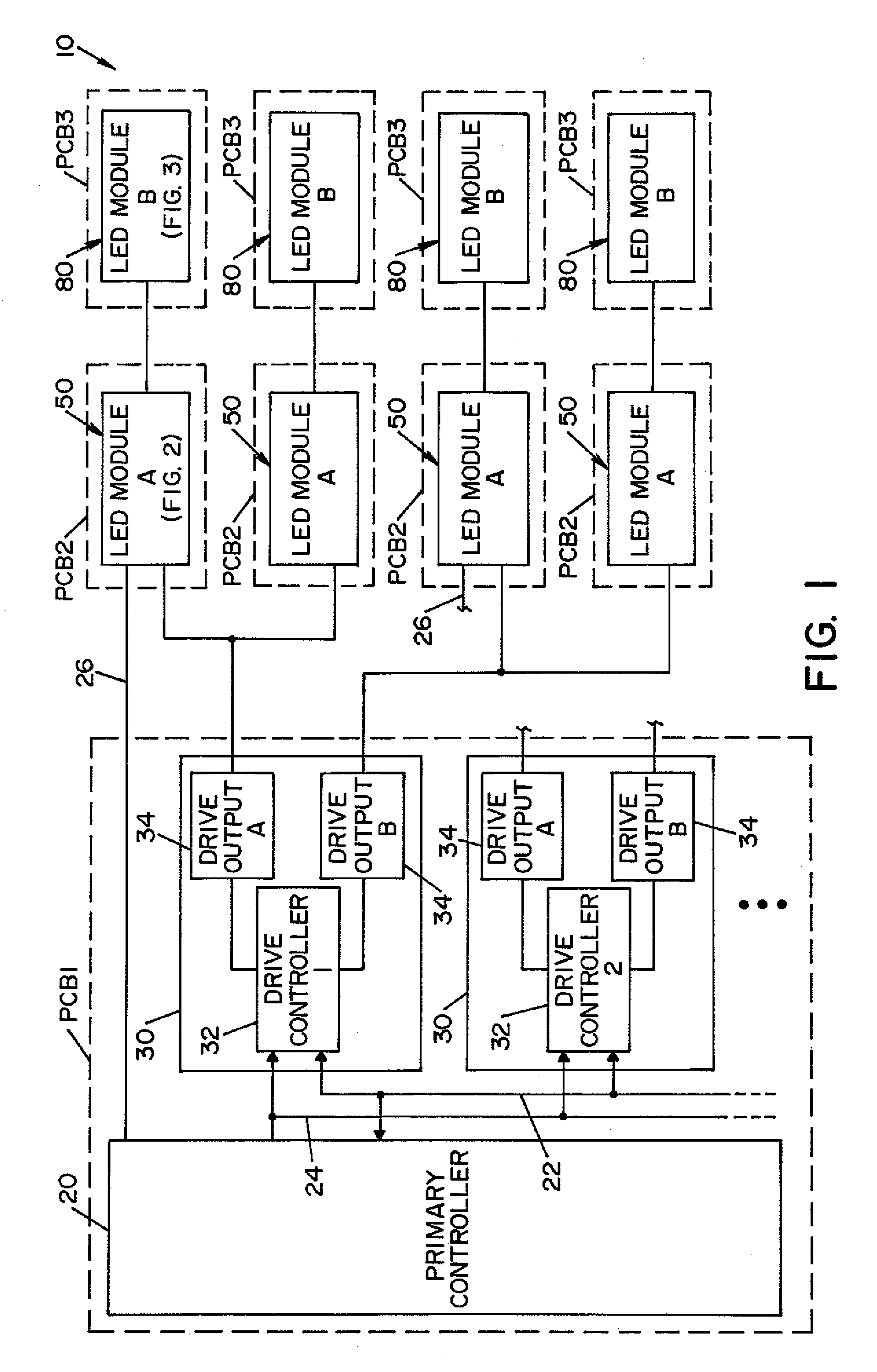

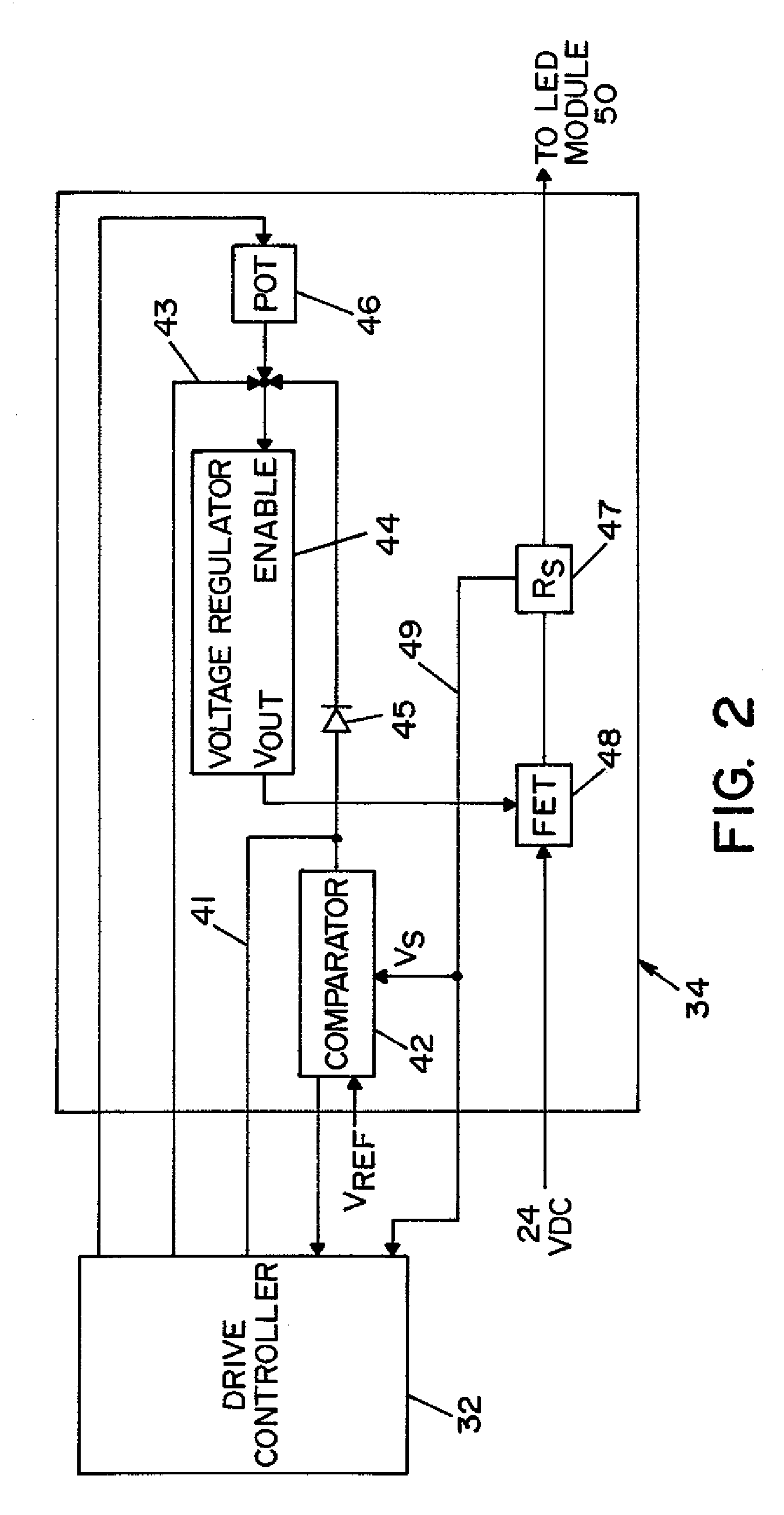

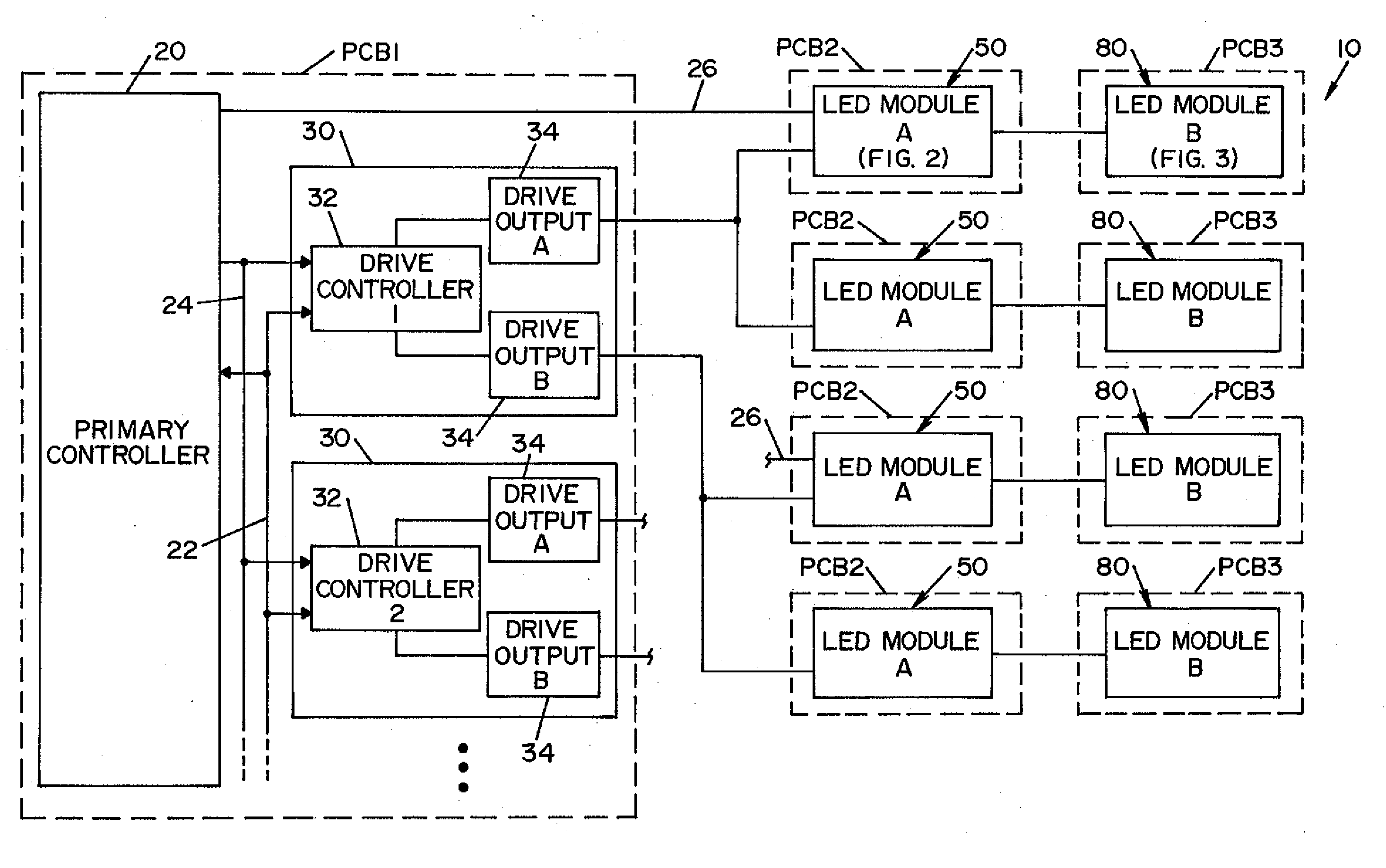

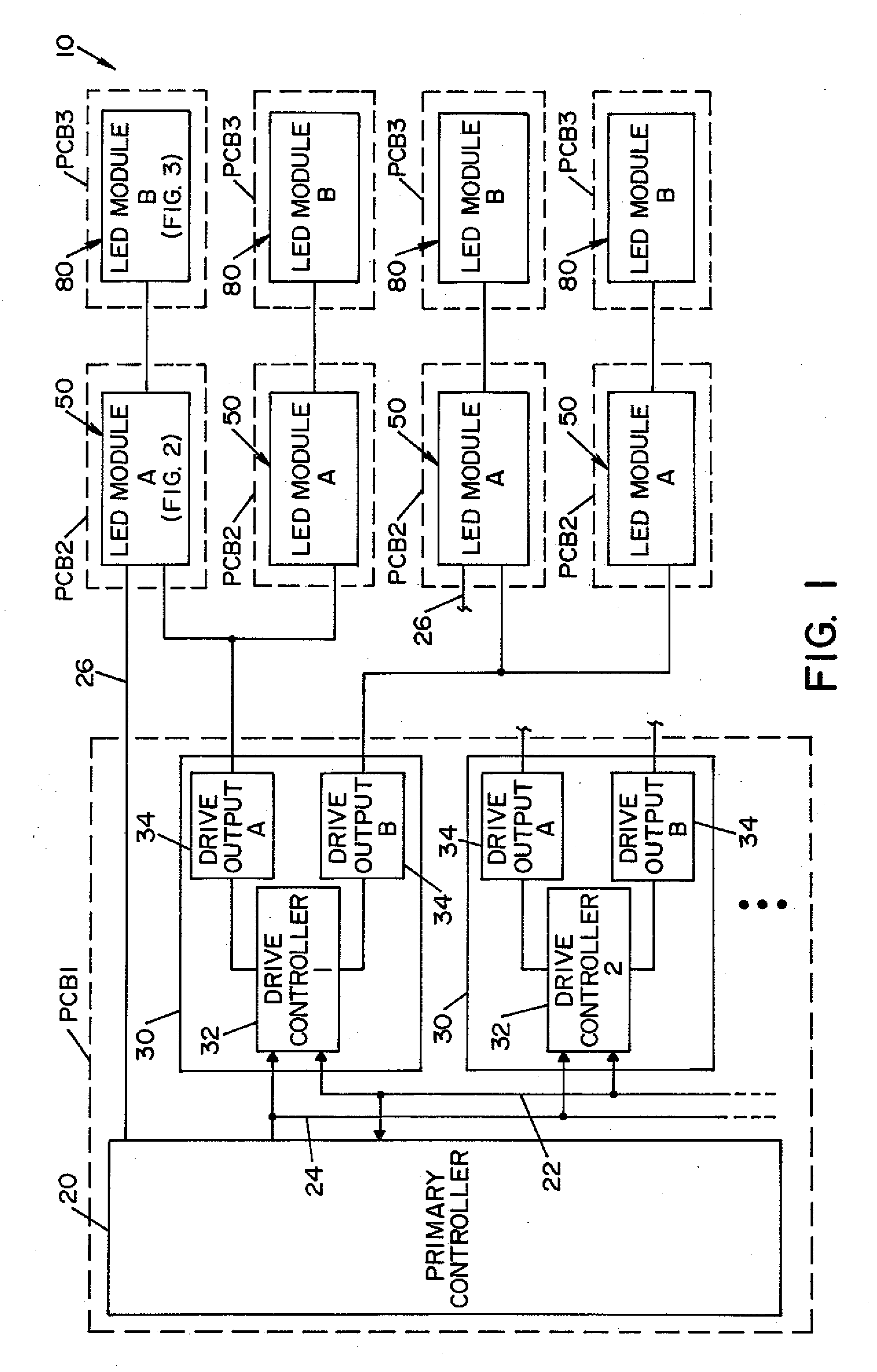

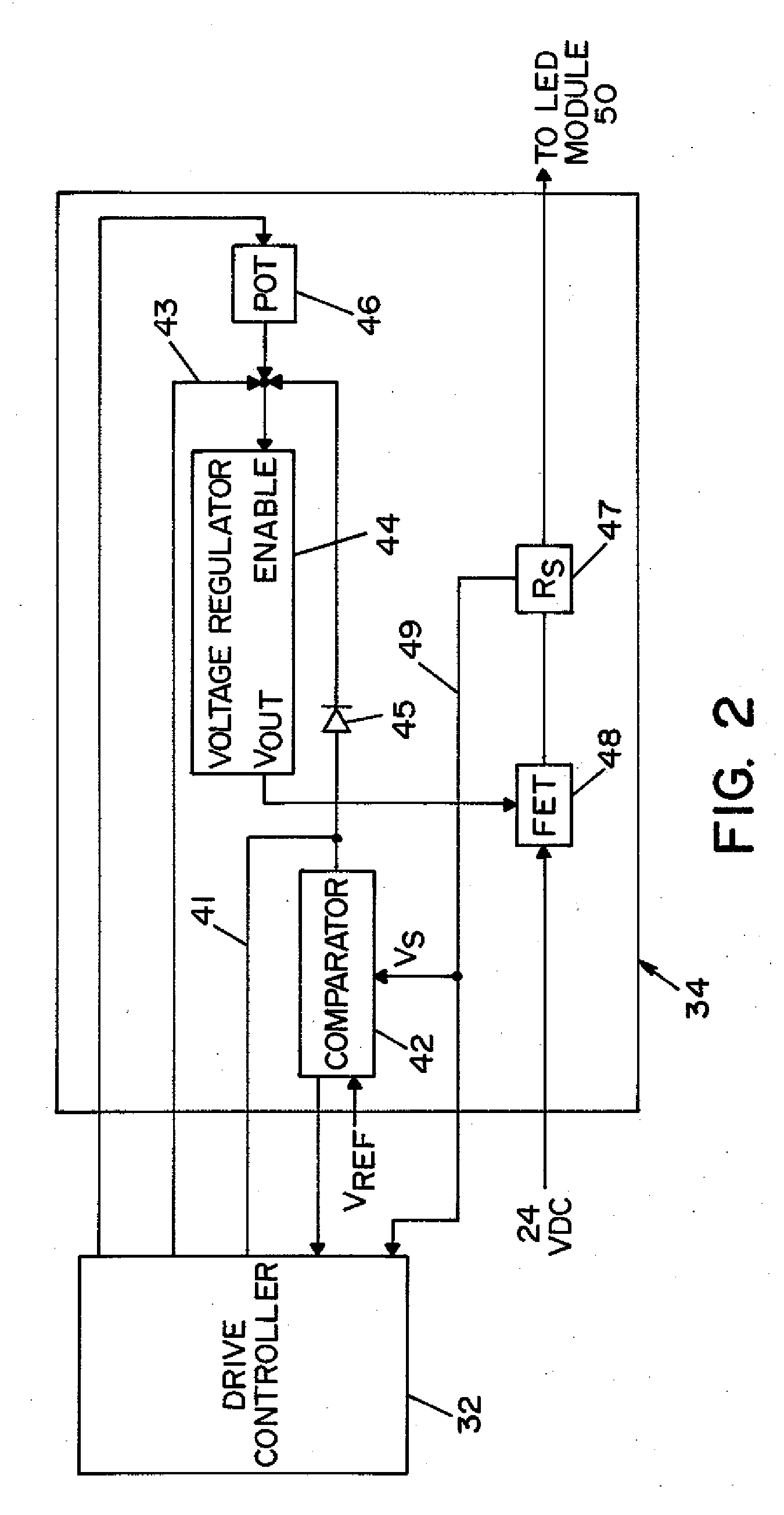

Lighting control system having temperature compensation and trim circuits

ActiveUS7701151B2Compensation effectUniform light outputElectrical apparatusElectroluminescent light sourcesEffect lightForward voltage

A lighting control system suitable for a surgical lighting device. The lighting control system includes circuitry that compensates for the effects of temperature changes in a lighting device, and that compensates for forward voltage variations among LED lighting modules to provide substantially uniform light output.

Owner:AMERICAN STERILIZER CO

Lighting control system for a lighting device

ActiveUS20090102396A1Compensation effectUniform light outputElectrical apparatusElectroluminescent light sourcesLight equipmentEffect light

A lighting control system suitable for a surgical lighting device. The lighting control system includes circuitry that compensates for the effects of temperature changes in a lighting device, and that compensates for forward voltage variations among LED lighting modules to provide substantially uniform light output.

Owner:AMERICAN STERILIZER CO

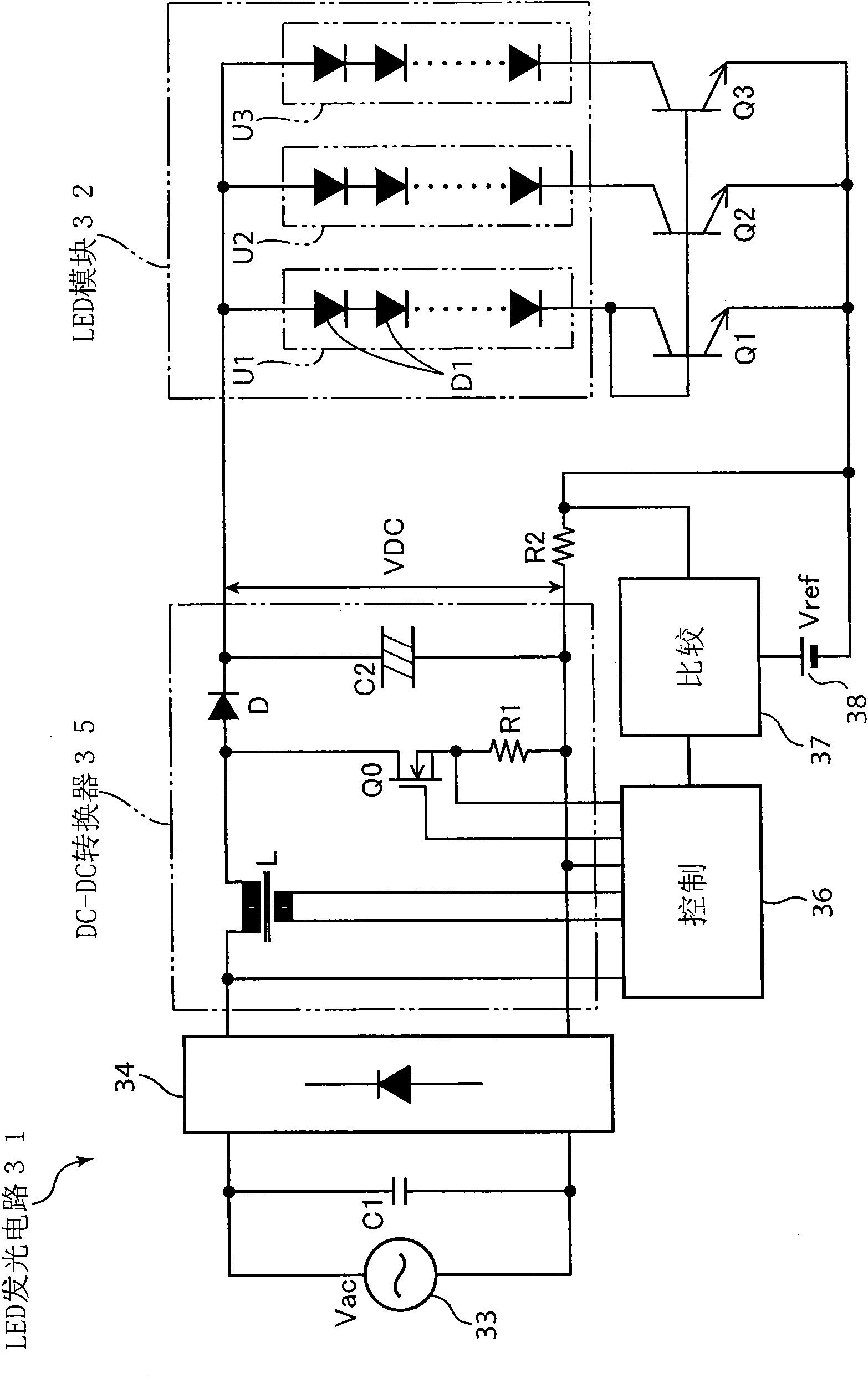

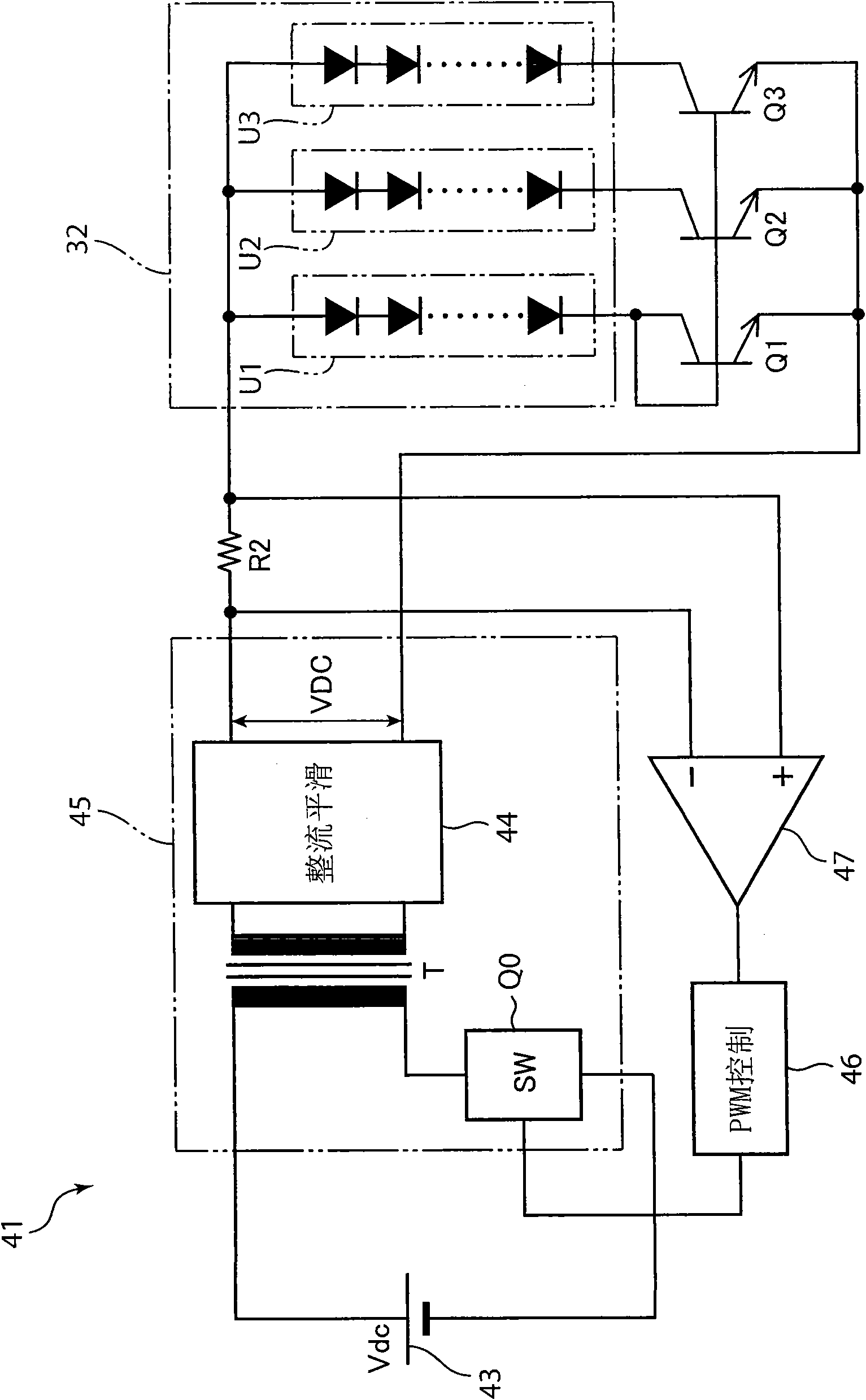

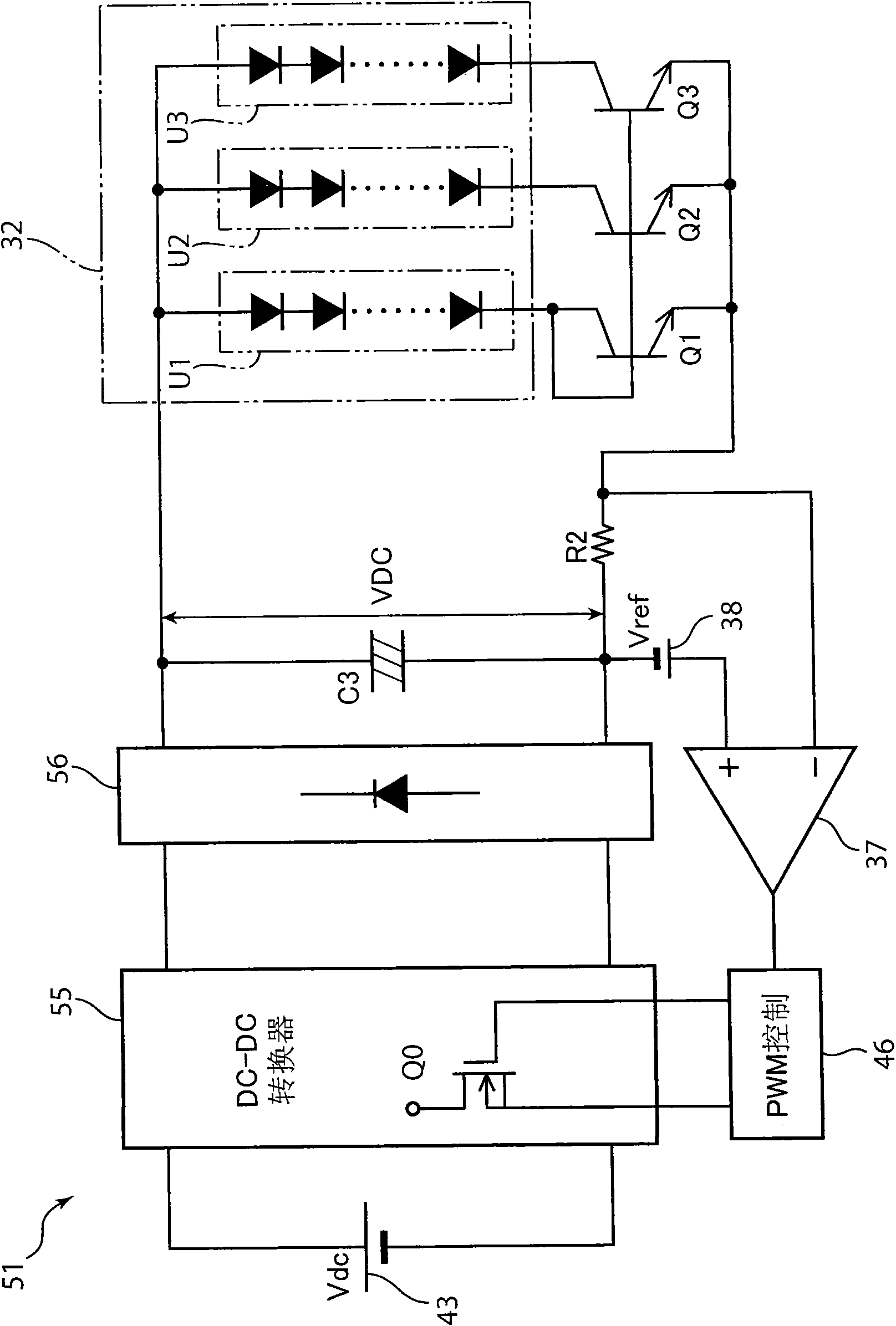

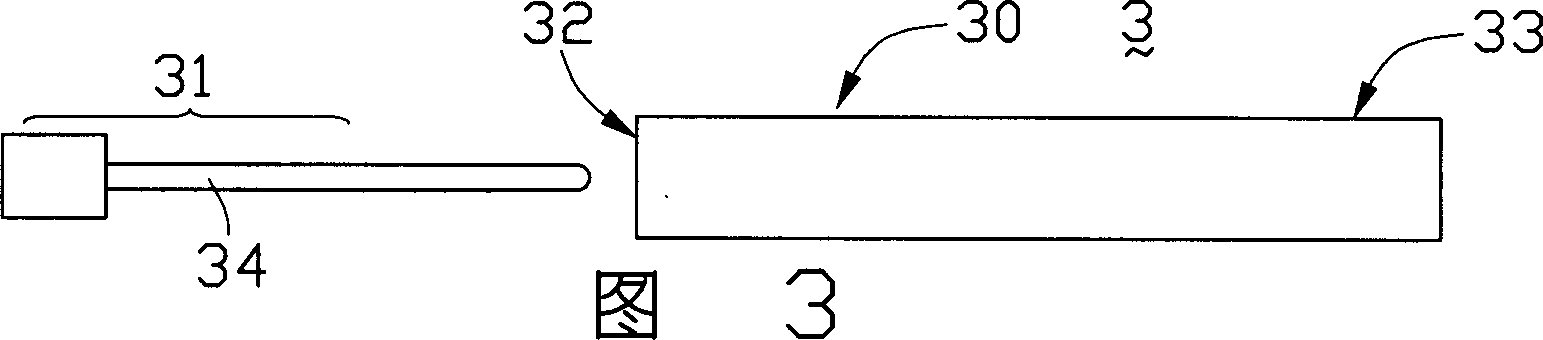

Led lighting circuit and illuminating apparatus using the same

InactiveCN101529983AHomogenization of light outputAvoid circuit lossElectric light circuit arrangementSemiconductor devicesLoad circuitCurrent mirror

The invention provides a LED lighting circuit and illuminating apparatus using the same. Light outputs from many LEDs are uniformized and power consumption required for such uniformizing is suppressed, in an LED lighting circuit to be used for illuminating apparatus and the like. Currents flowing from a DD converter (35) to an LED module (32) are detected by a current detection resistor (R2) and compared with a reference voltage (Vref) from a reference voltage source (38) by a comparison circuit (37). Corresponding to the comparison results, a control circuit (36) controls the DD converter (35), and the currents flowing to the LED module (32) are controlled to be constant currents at the same time. Furthermore, in LED load circuits (U1-U3) configuring the LED module (32), control elements (Q1-Q3) configuring a current mirror circuit are arranged in series, a corresponding control element (Q1) is permitted to have a diode structure by having a circuit (U1) with the highest sum of the LED ON voltages as a reference, the flowing current values of the control elements (Q2, Q3) of the remaining circuits (U2, U3) are interlocked, and the LED load circuits (U1-U3) are balanced.

Owner:PANASONIC CORP

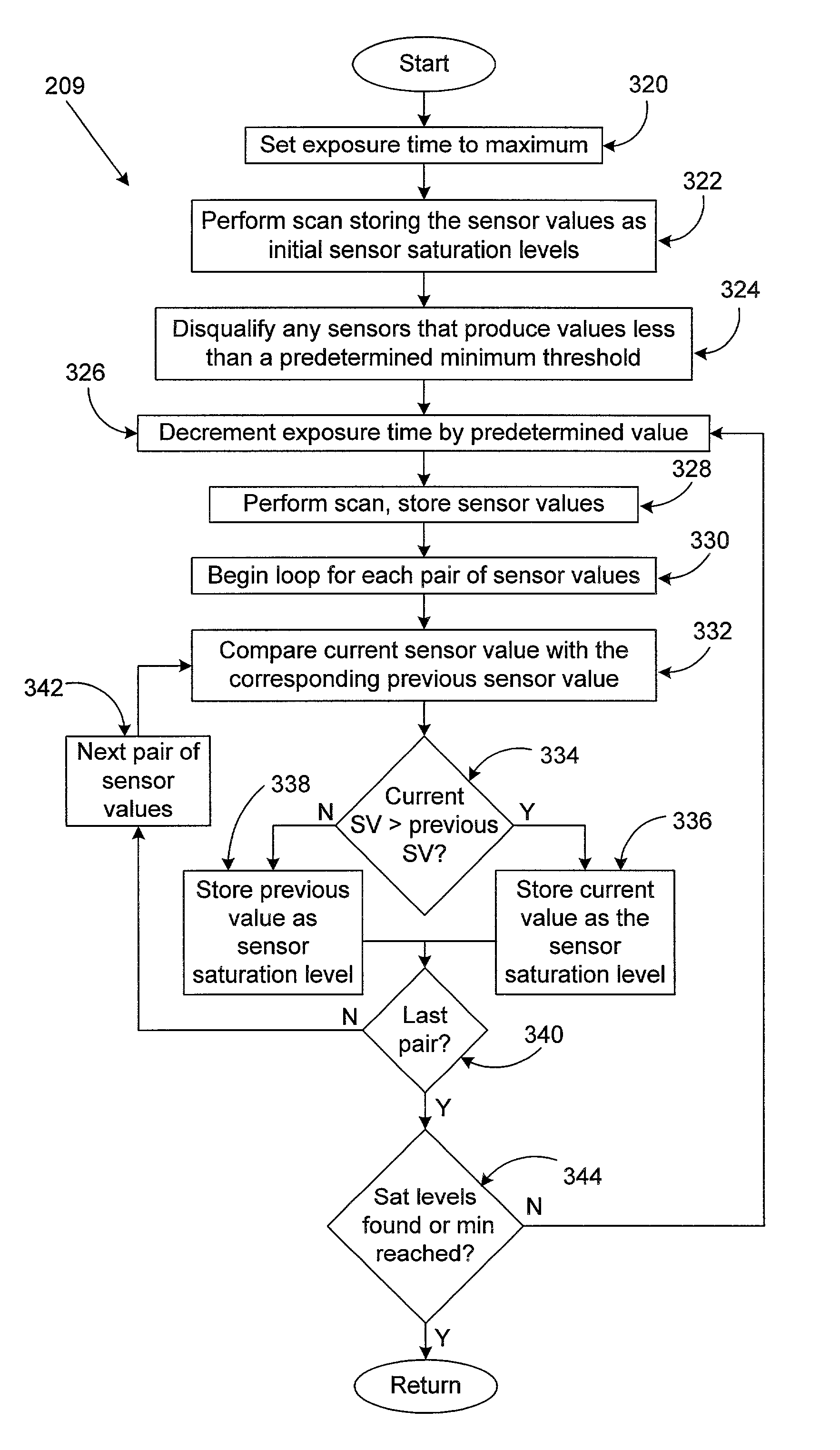

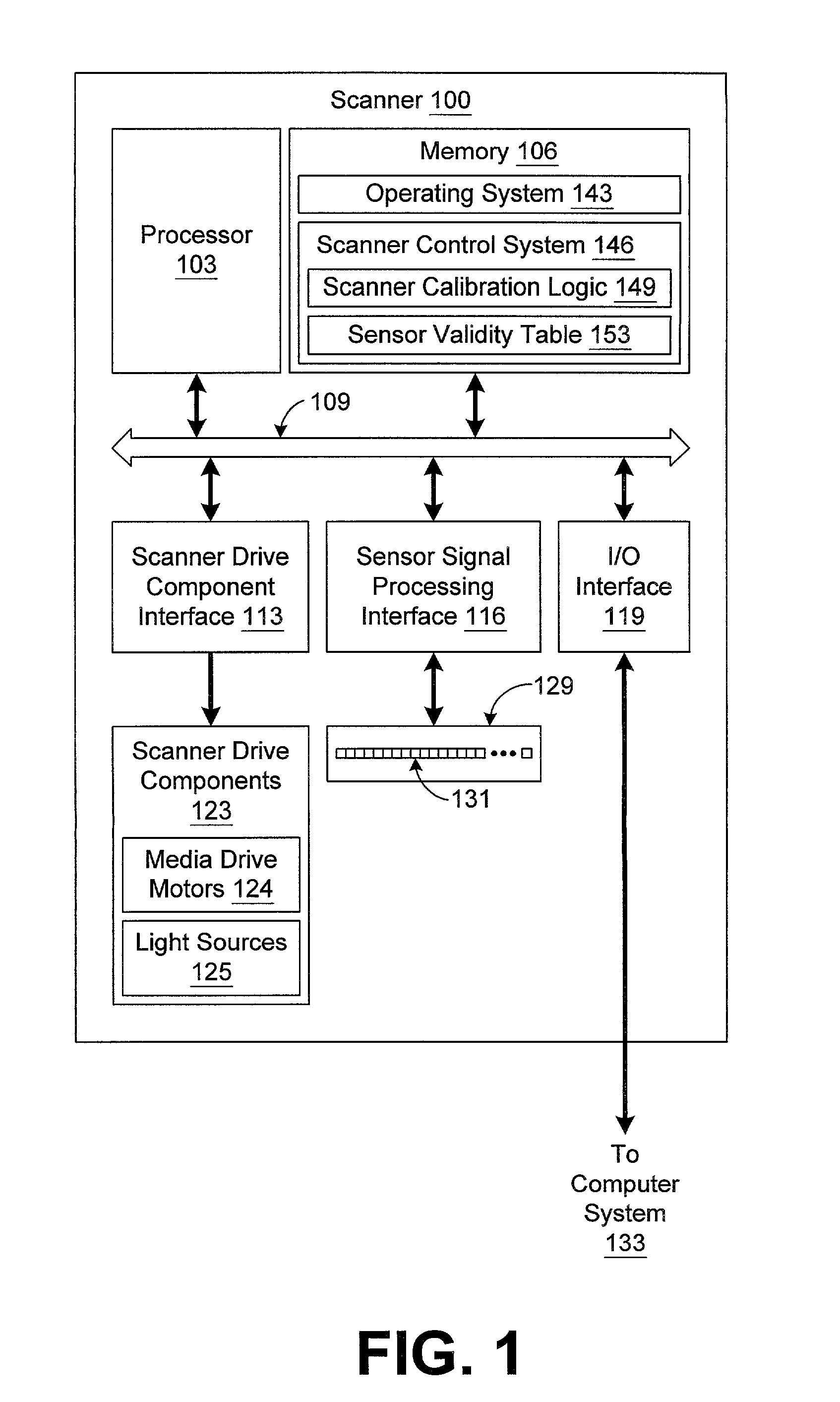

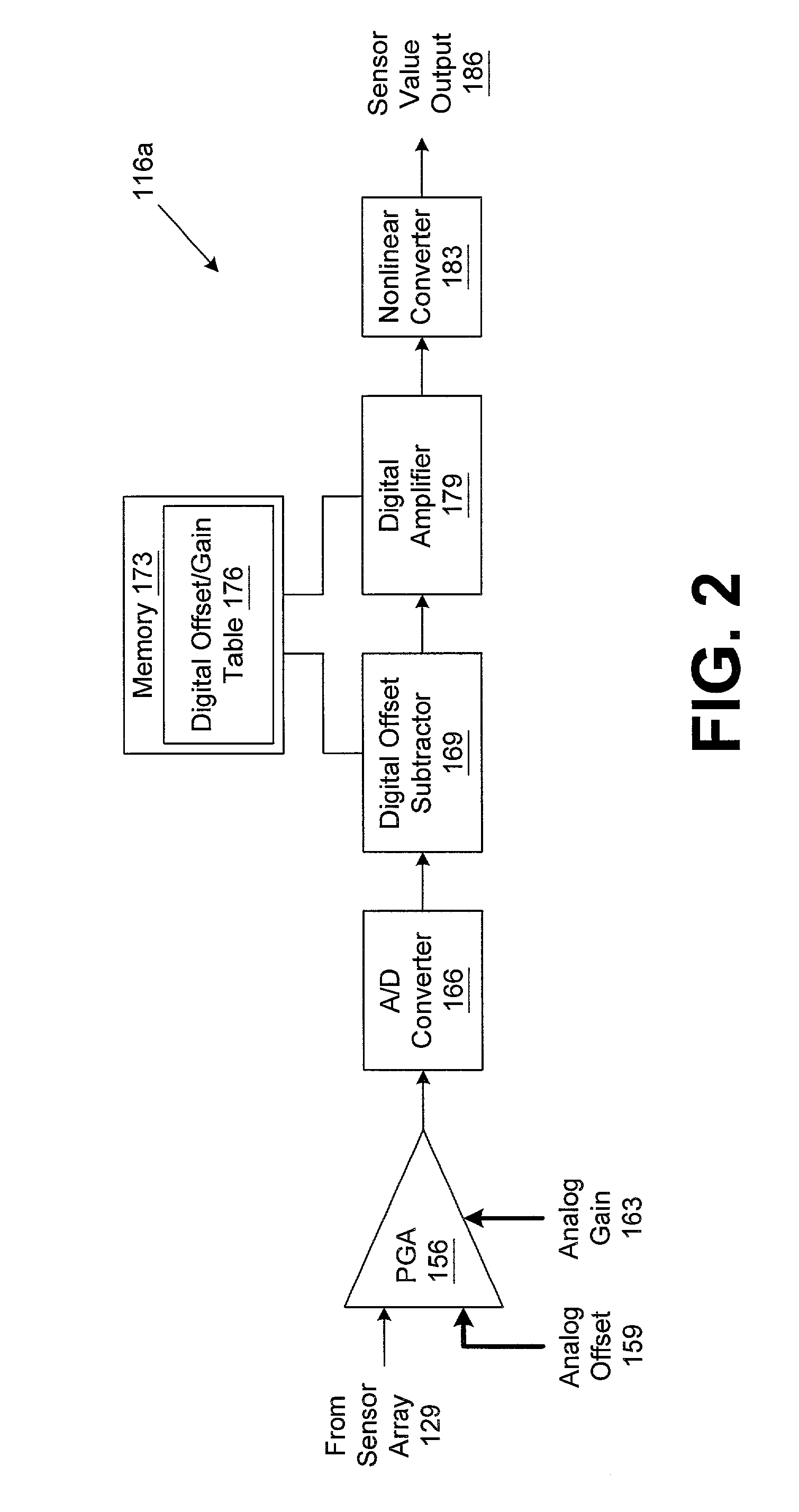

System and method for determining light source current

ActiveUS7308375B2Uniform light outputResistance/reactance/impedencePhotometryLight-emitting diodeControl logic

A system and method are provided for determining a light output of a light emitting diode (LED) in a scanner. The system includes a processor circuit to execute current control logic to obtain an optimum light output from the LED. The current control logic repeatedly applies increasing or decreasing currents to the LED until a saturation point is identified. This may be accomplished, for example, by comparing two measures of the light output of the LED for two different currents applied to the LED. When a difference equaling a predetermined threshold between the two measures is detected, then the saturation point is identified.

Owner:HEWLETT PACKARD DEV CO LP

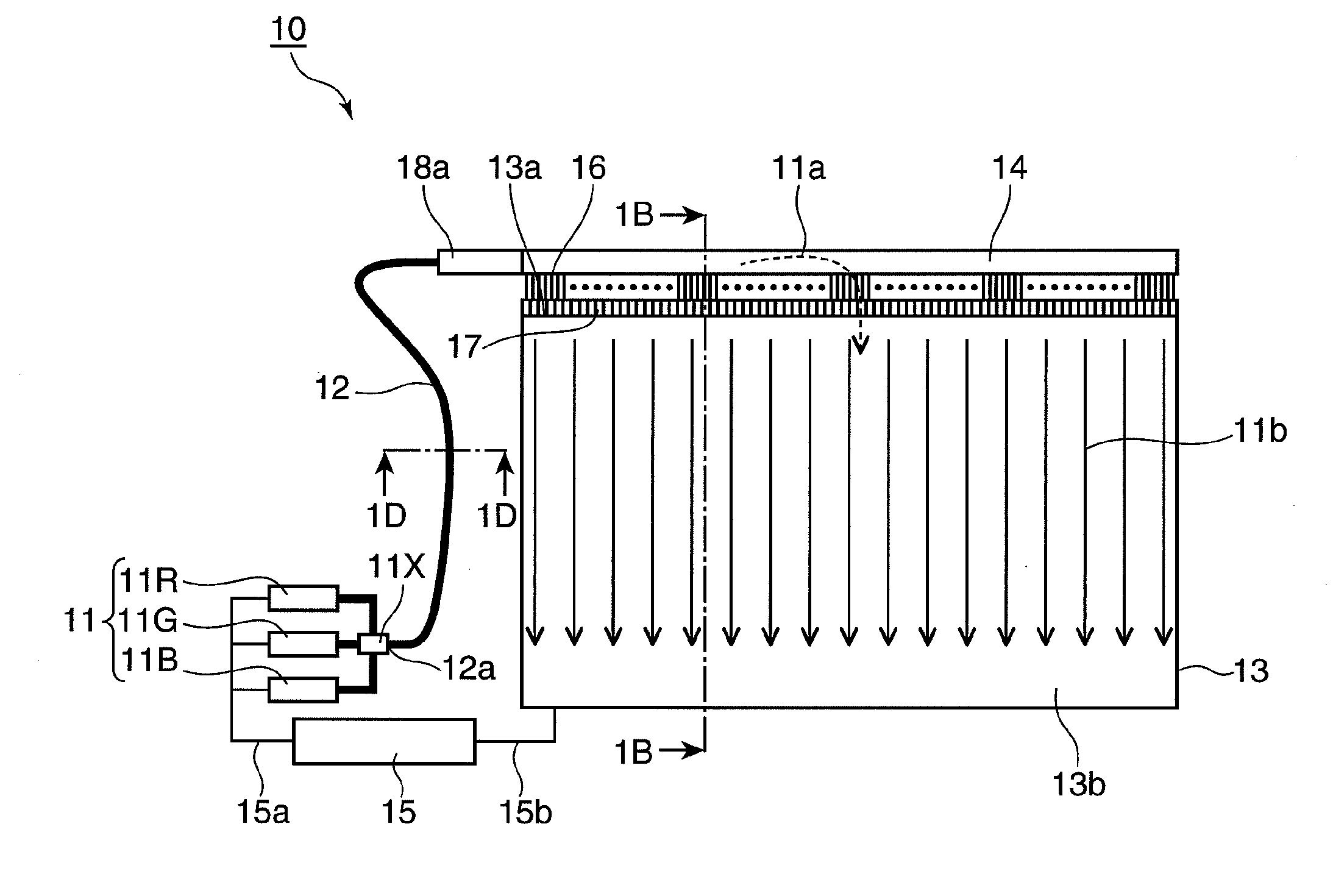

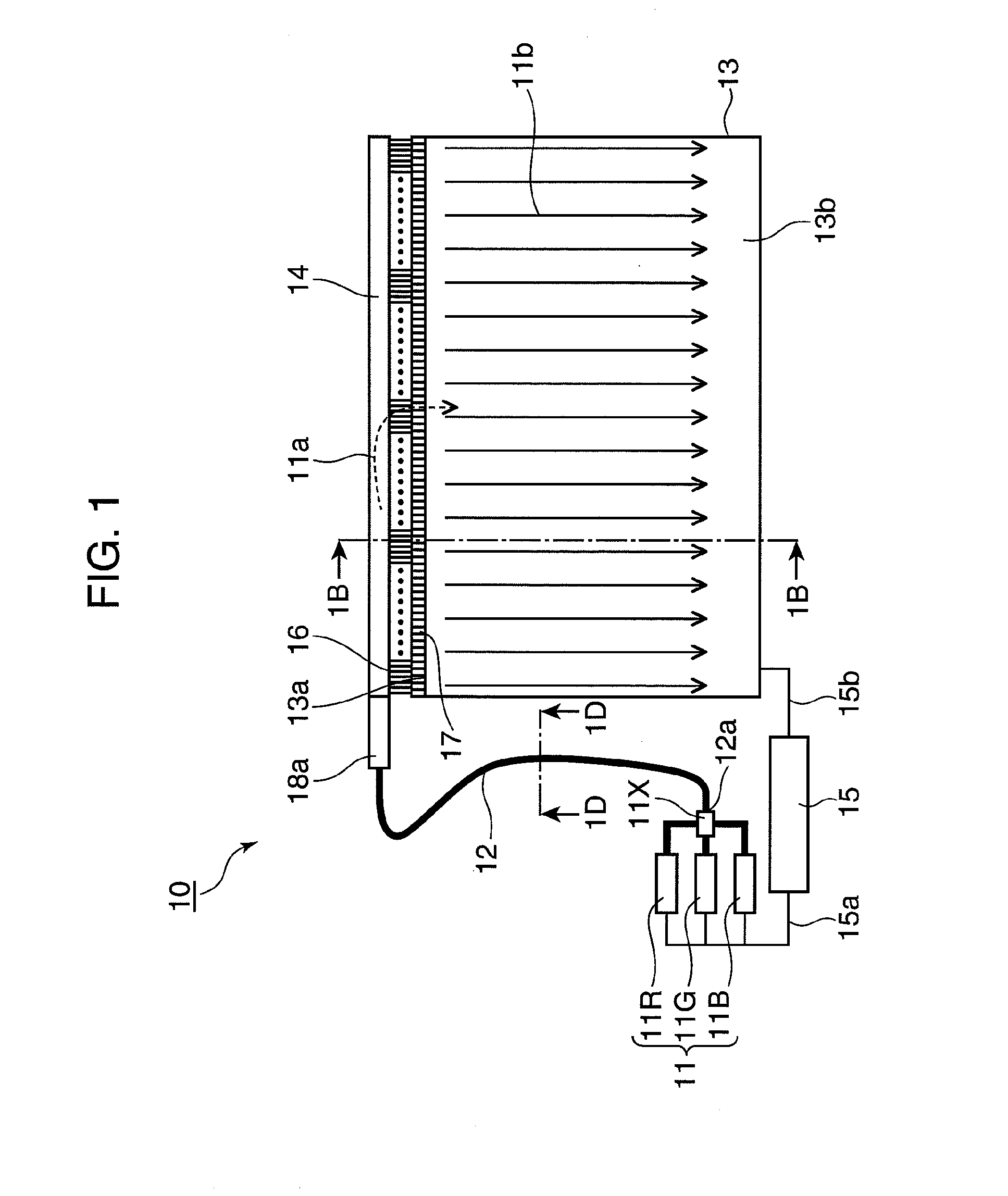

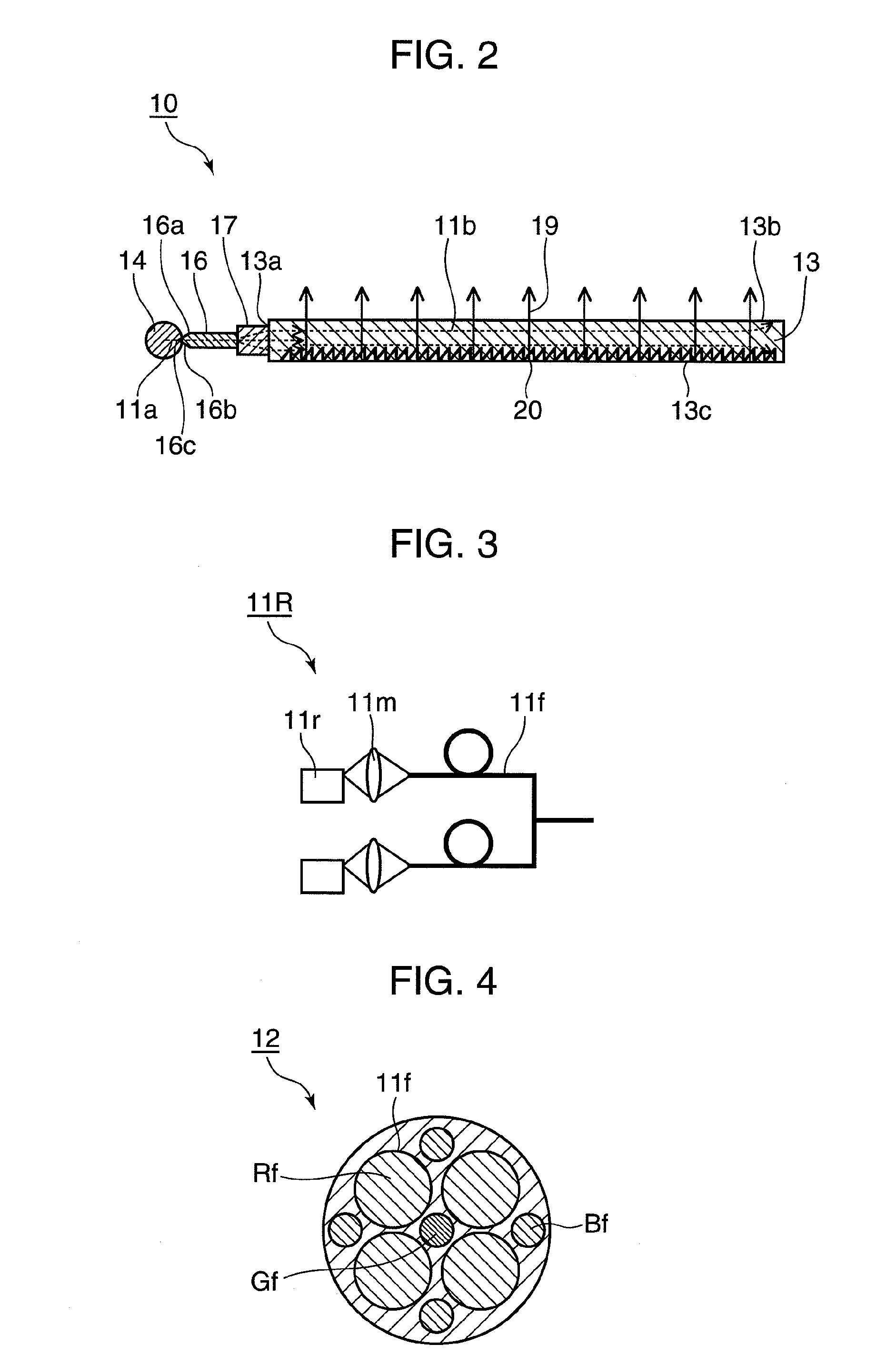

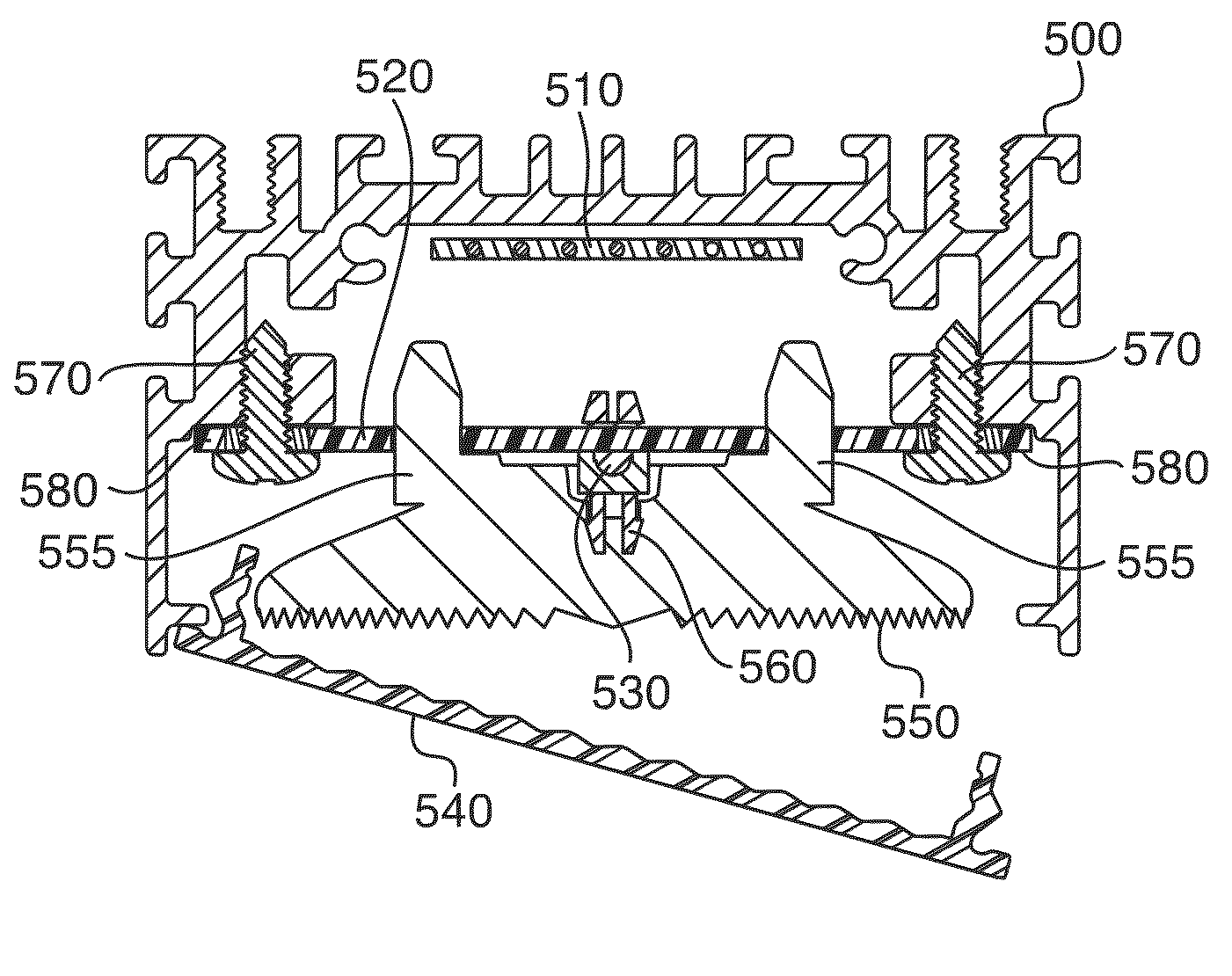

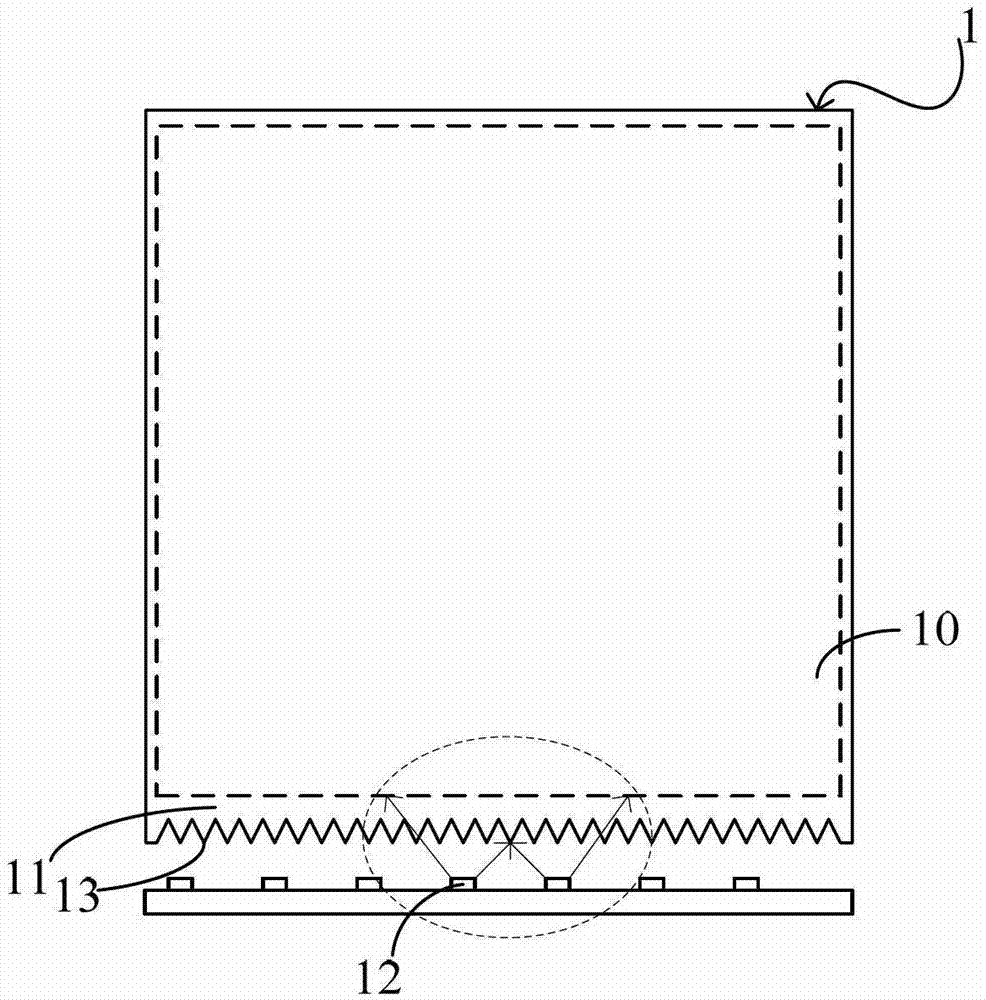

Planar illumination device and liquid crystal display device using the same

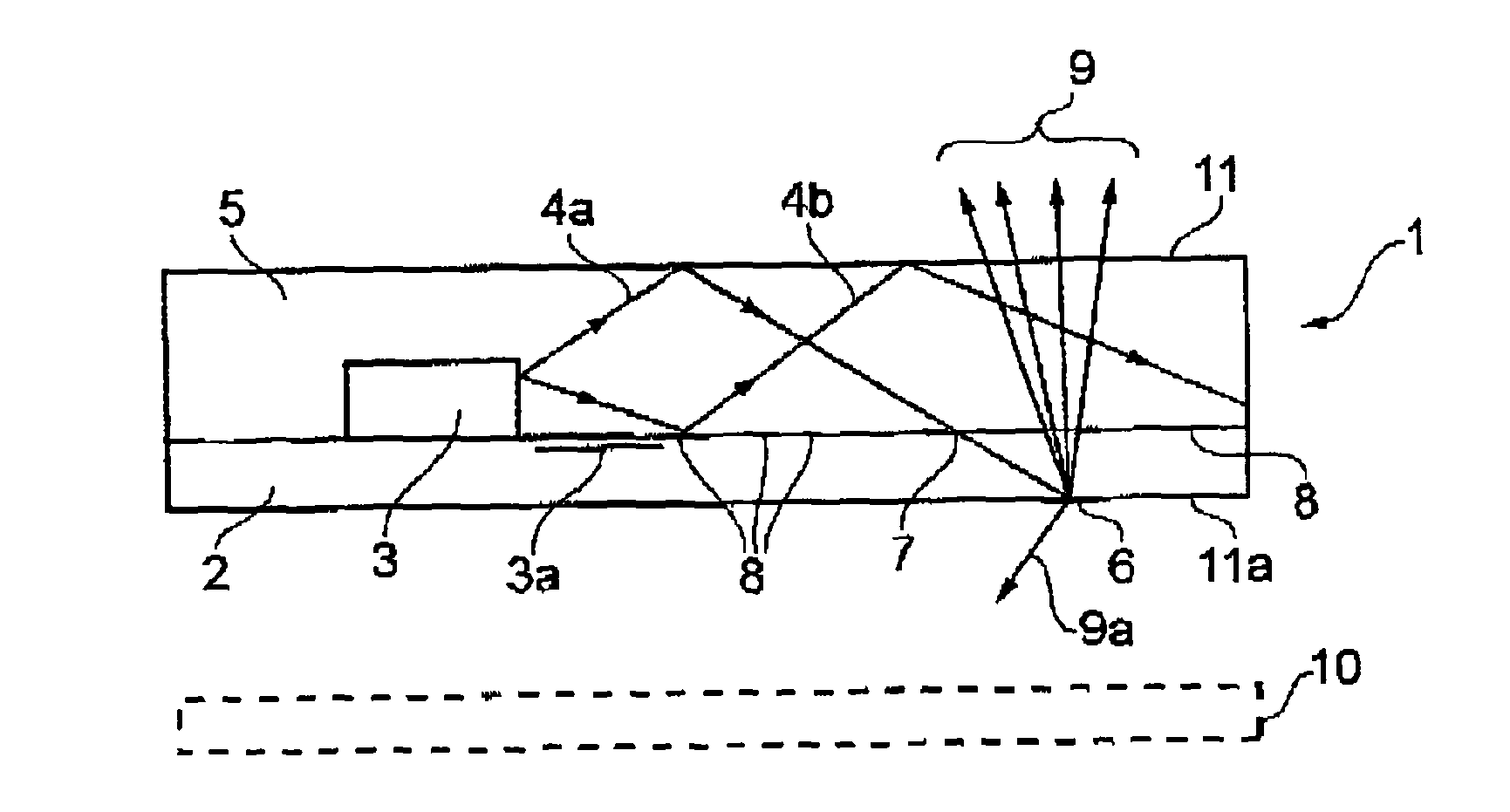

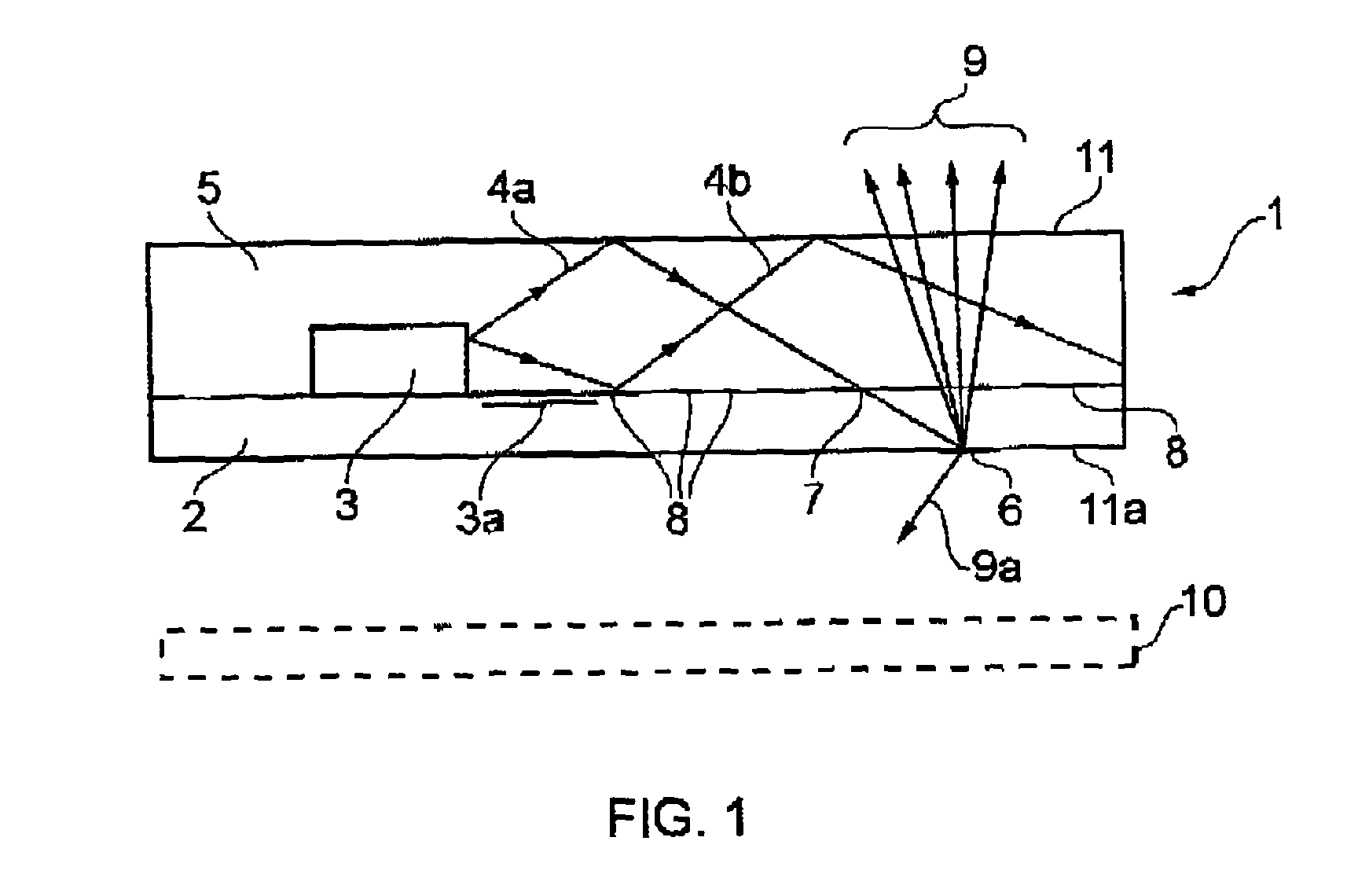

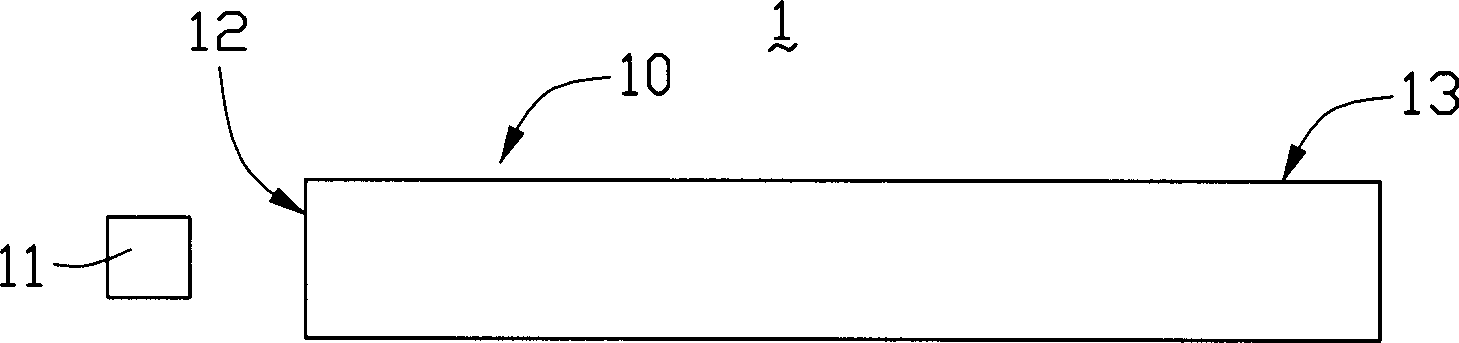

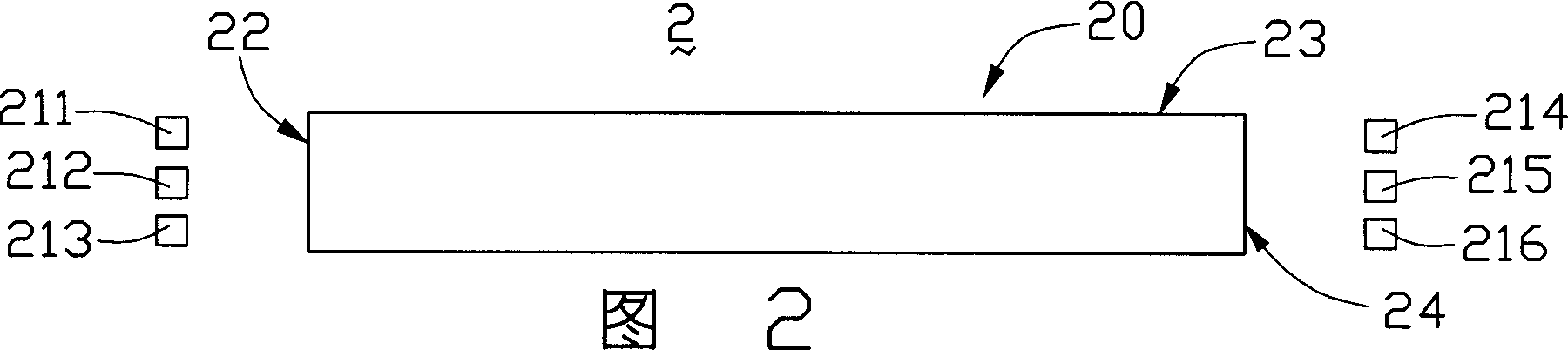

InactiveUS20100073600A1Reduce power consumptionAccurate UniformityMechanical apparatusBundled fibre light guideFiberLiquid-crystal display

A planar illumination device 10 is provided with a laser light source 11 for emitting laser light, a light source side bundle fiber 12 having one end surface thereof optically connected with the laser light source 11, a flat light guide plate 13, a plurality of connection side fibers 16 planarly arranged in parallel with each other at a side surface of the light guide plate 13, and a light guiding fiber 14 for guiding the laser light from the light source side bundle fiber 12 to the plurality of connection side fibers 16. The laser light is incident on the side surface of the light guide plate 13 from the plurality of connection side fibers 16 via a plurality of fiber collimators 17 and output light is uniformly emitted from one principal surface of the light guide plate 13.

Owner:PANASONIC CORP

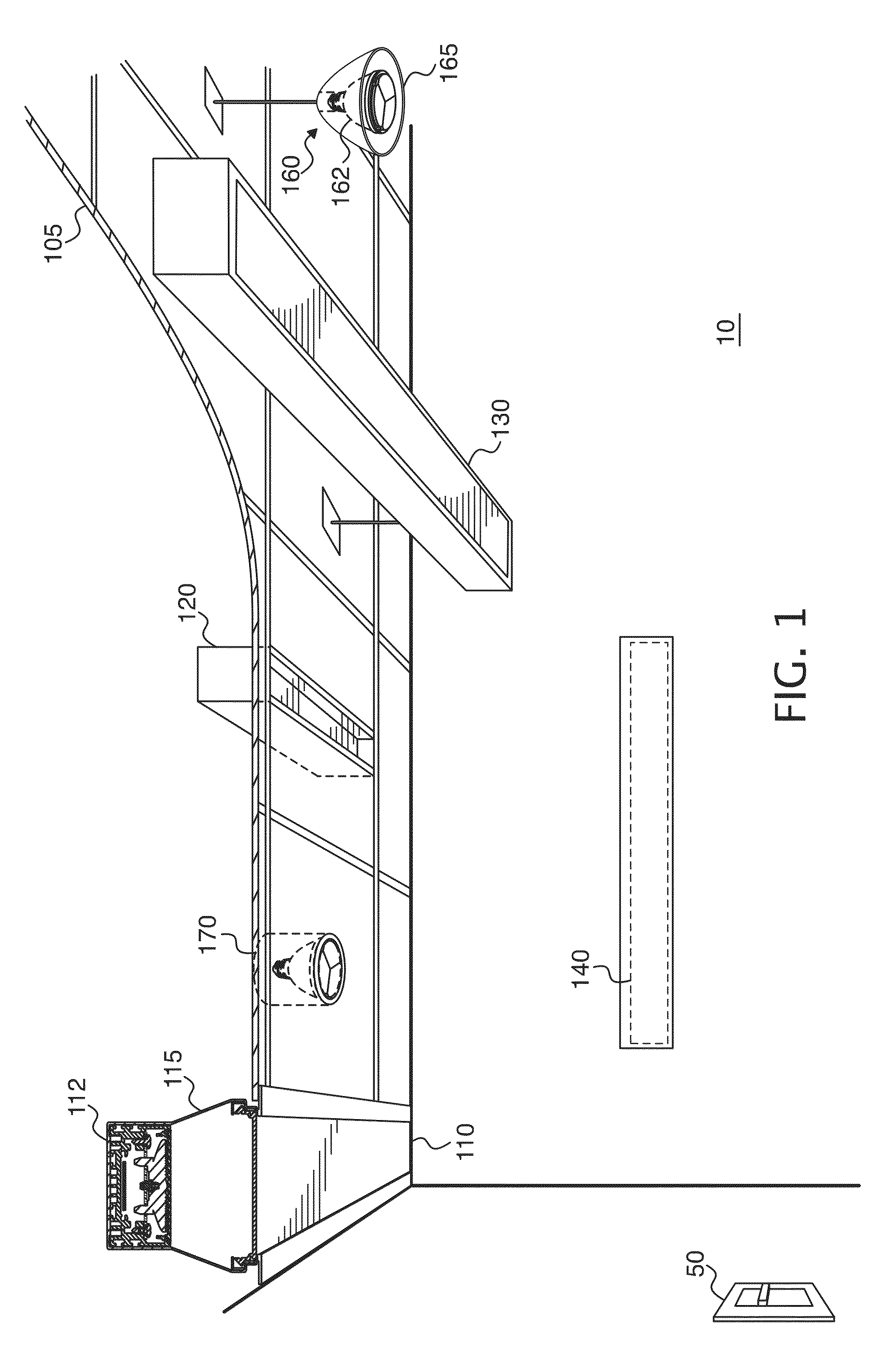

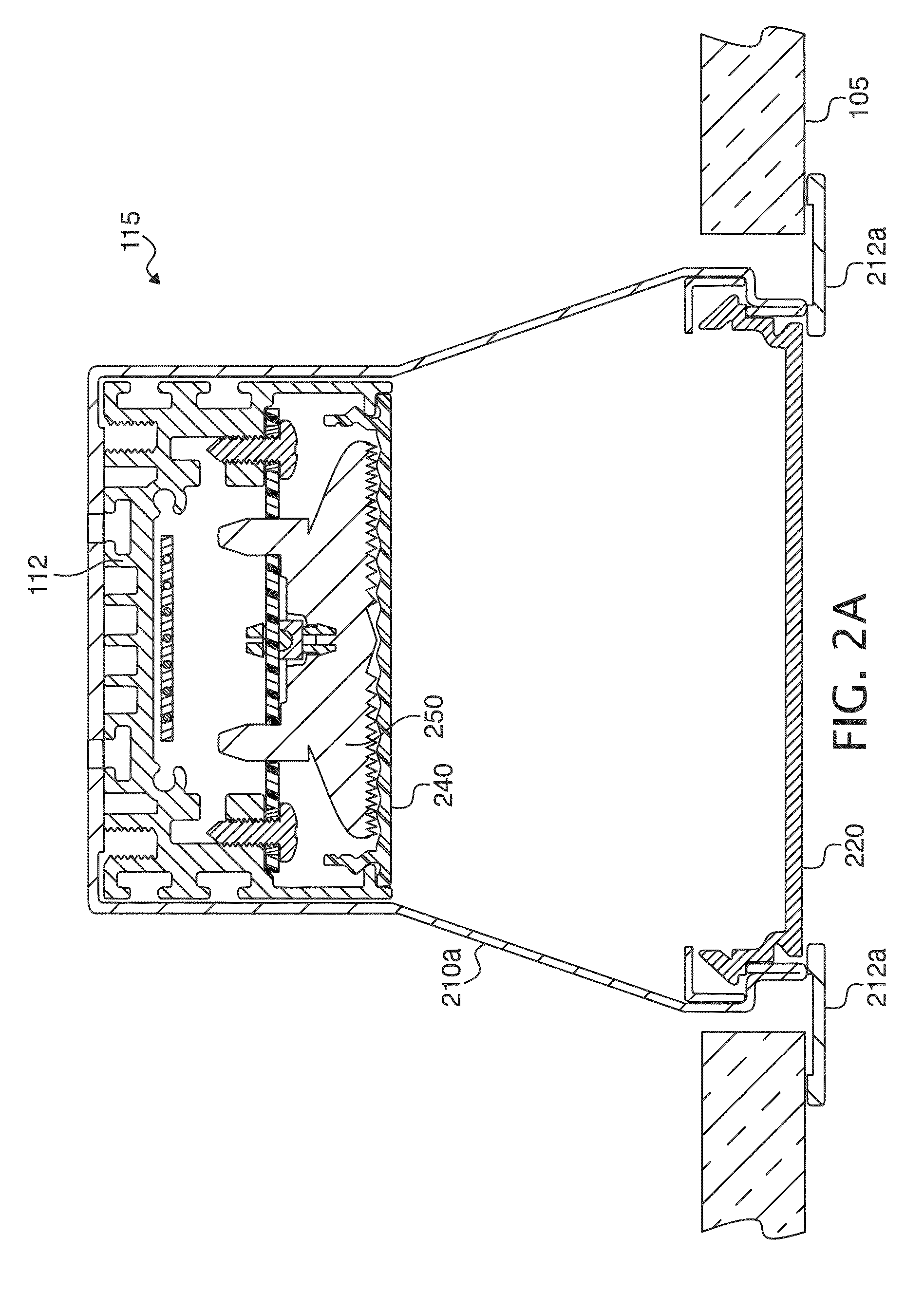

Dimmable, high-efficiency LED linear lighting system with interchangeable features

InactiveUS20160076743A1Thin profileUniform light outputPoint-like light sourceElectrical apparatusLighting systemLight-emitting diode

A light emitting diode (LED) light fixture may include a heat sink, at least one LED for outputting light in a Lambertian optical pattern, and a first optical structure configured to internally reflect light received from the at least one LED. The first optical structure may disperse the received light through the first optical structure to give the appearance that the first optical structure is uniformly outputting light and output the received light in a non-Lambertian optical pattern.

Owner:LINEAR LIGHTING

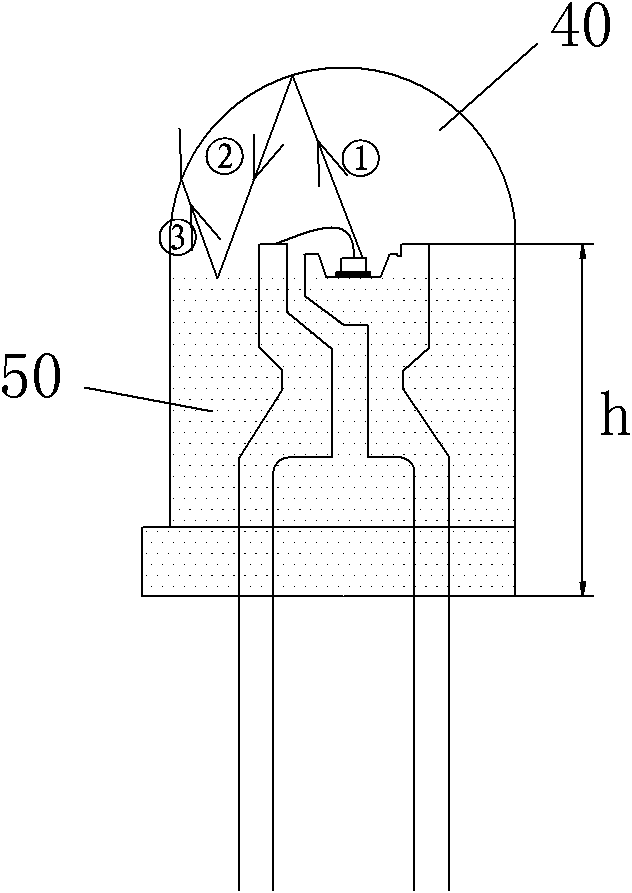

White-light LED light source with sterilization effect and manufacturing method thereof

InactiveCN105304801ASufficient heat dissipationImproves UV resistanceSemiconductor devicesEffect lightEngineering

The invention discloses a white-light LED light source with a sterilization effect, which comprises a PCT bracket with heat sink, a UV wafer, a blue-light wafer, a gold wire and fluorescent glue, wherein the UV wafer and the blue-light wafer are fixed in the PCT bracket, the UV wafer is connected with the blue-light wafer in a welded mode through the gold wire, and the fluorescent glue is coated inside the PCT bracket and covers the UV wafer and the blue-light wafer. The invention further discloses a manufacturing method of the white-light LED light source with the sterilization effect. The PCT bracket with the heat sink is adopted, the heat sink ensures that a device has sufficient heat dissipation performance, a PCT material is better in UV resistant performance compared with common PPA materials, and the UV resistant performance of the device is improved; and UV resistant wafer fixing glue and UV resistant potting silica gel are adopted, so that the UV resistant performance of the device is improved. According to the invention, UV light is contained in white light in the device, and light emission is uniform. Meanwhile, the white-light LED light source has functions of sterilization and lighting, does not need to carry out light source matching, is convenient to use and has reliable and stable performance at the same time.

Owner:JIANGSU WENRUN OPTOELECTRONICS

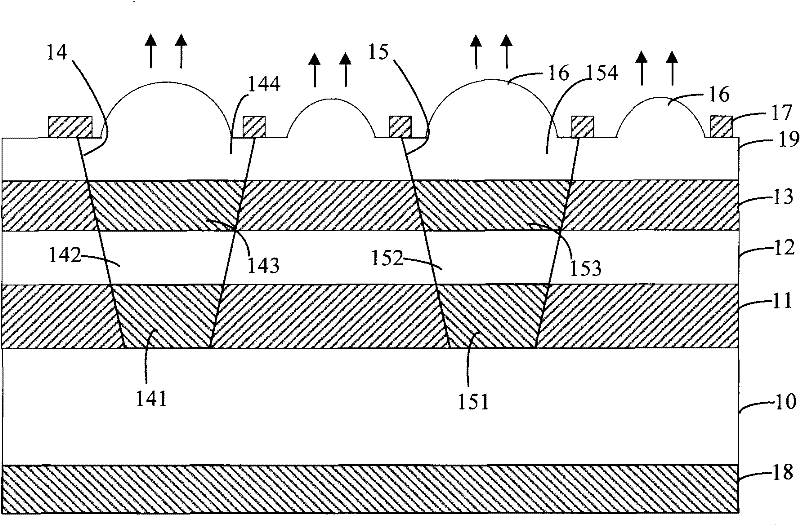

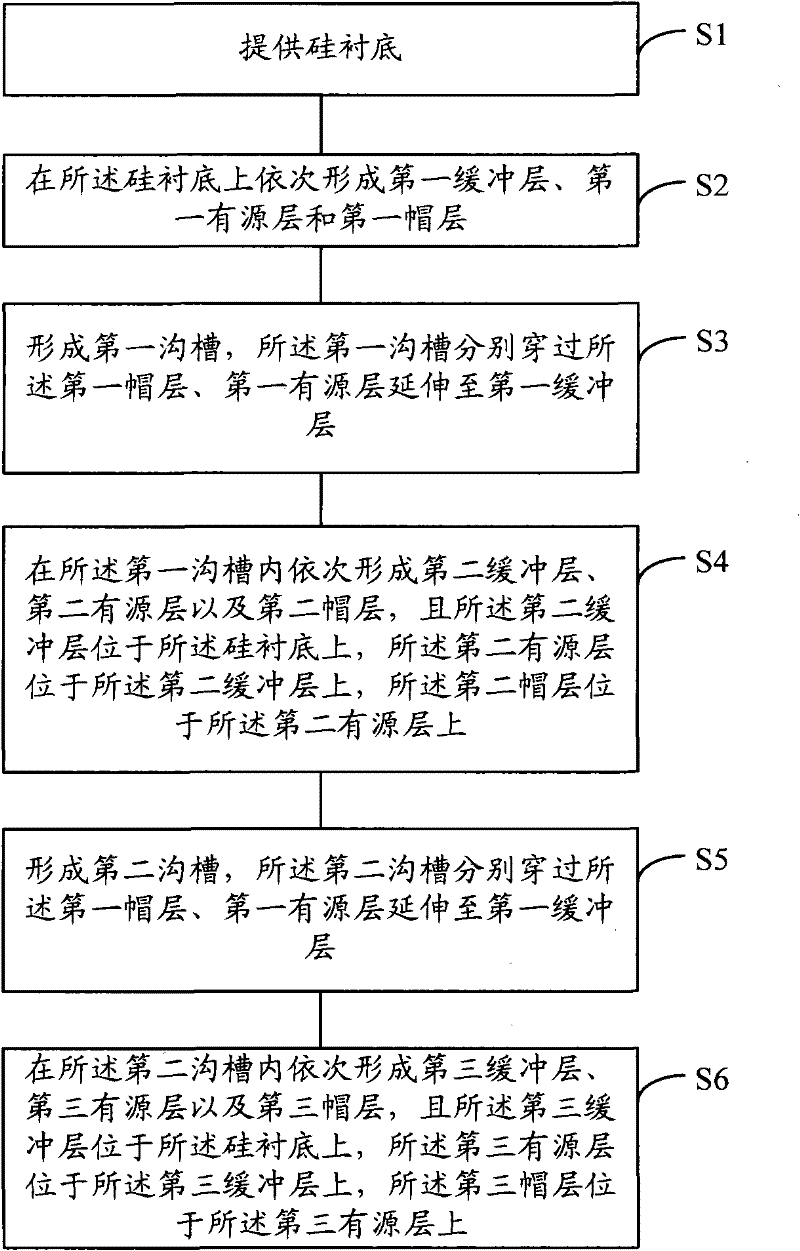

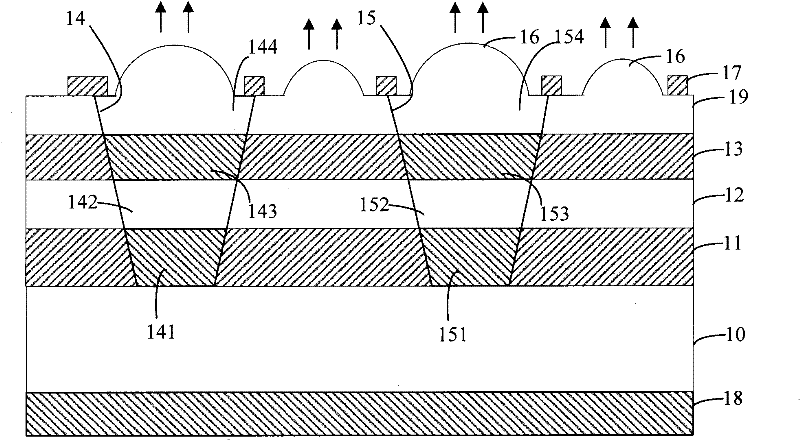

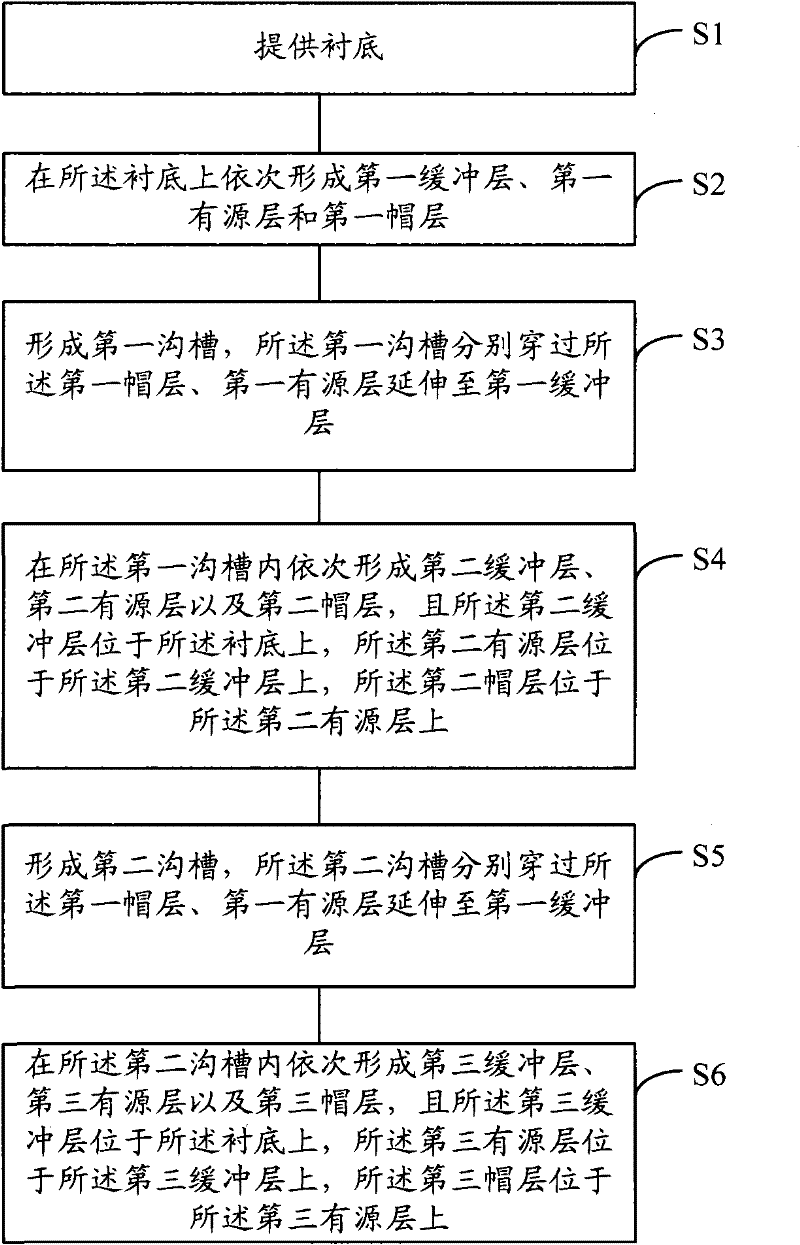

White LED chip and forming method thereof

InactiveCN102130144AEasy to controlReduce dislocationSolid-state devicesSemiconductor devicesCrystal orientationCrystal plane

The invention relates to a white light-emitting diode (LED) chip and a forming method thereof. The white LED chip comprises a silicon substrate, a first buffer layer, a first active layer, a first cap layer, a first groove and a second groove, wherein the first buffer layer, the first active layer and the first cap layer are positioned on the silicon substrate sequentially; the first groove passes through the first buffer layer and the first active layer respectively to extend to the first cap layer, and a second buffer layer, a second active layer and a second cap layer are arranged in the first groove; the second groove passes through the first buffer layer and the first active layer respectively to extend to the first cap layer, and a third buffer layer, a third active layer and a third cap layer are arranged in the second groove; and the first active layer, the second active layer and the third active layer are selected from one of a blue light active layer, a green light active layer and a red light active layer respectively and are the active layers with different colors. When used, the white LED chip can emit red light, green light and blue light simultaneously, and can emit white light after the light with three colors is mixed; and due to the adoption of the silicon substrate which deviates 1 to 9 degrees from a crystal plane (111) in the crystal orientation, dislocation between the buffer layers and the silicon substrate can be reduced.

Owner:ENRAYTEK OPTOELECTRONICS

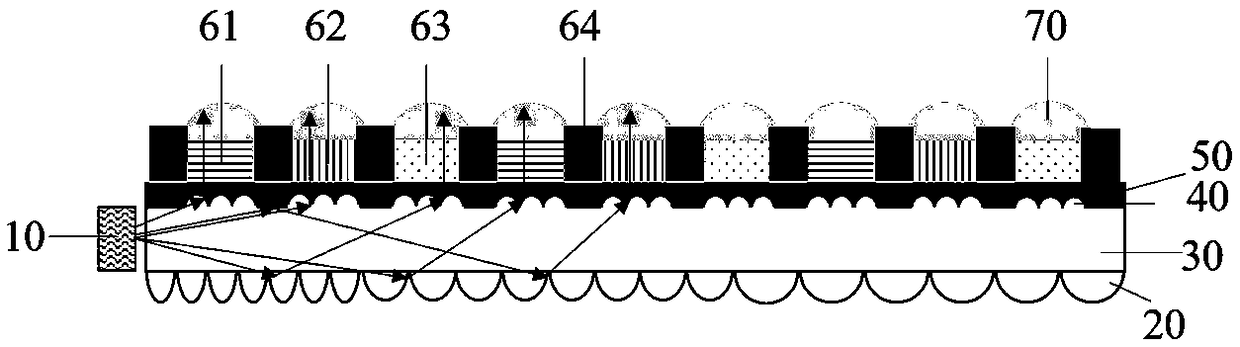

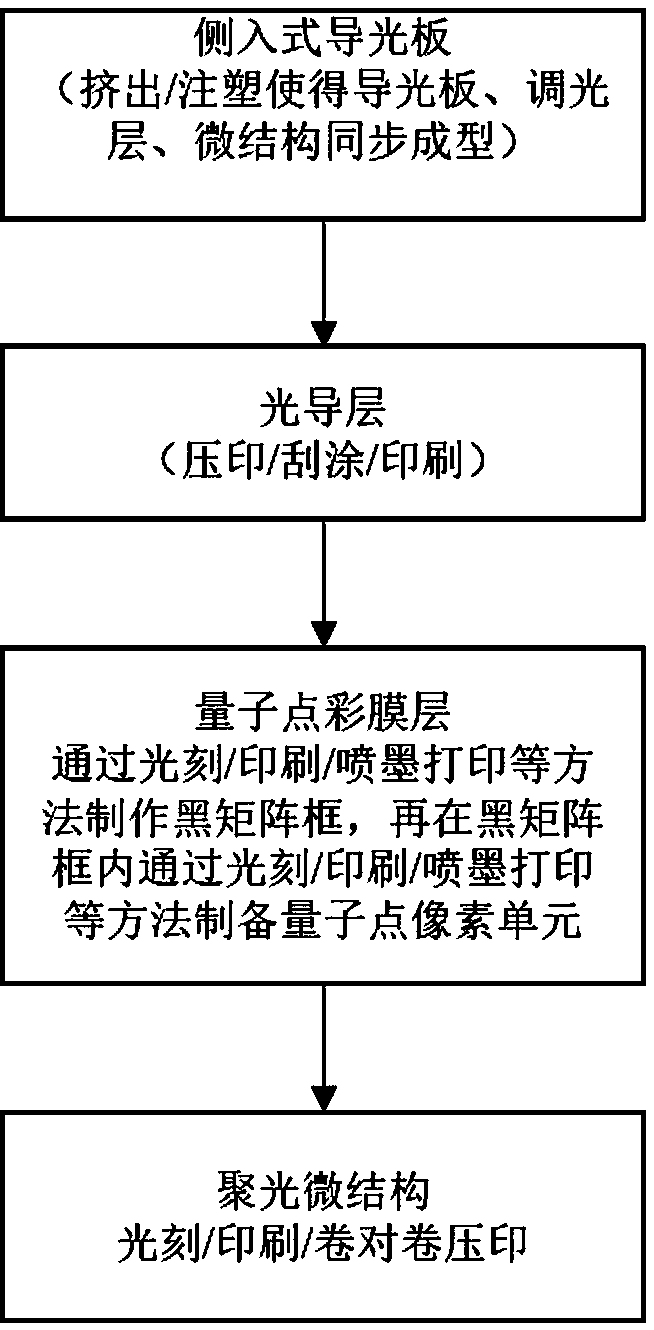

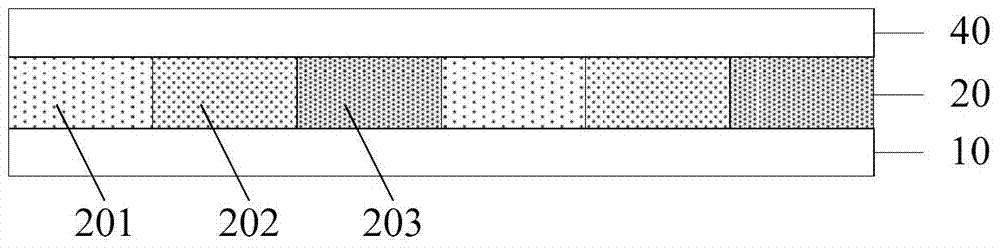

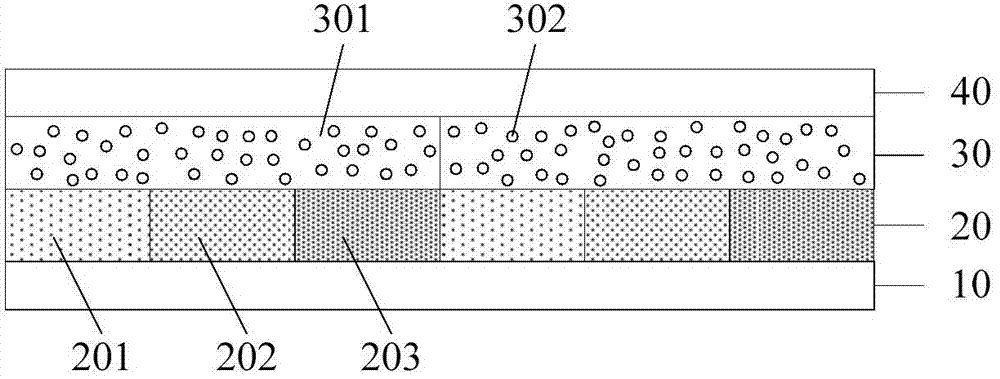

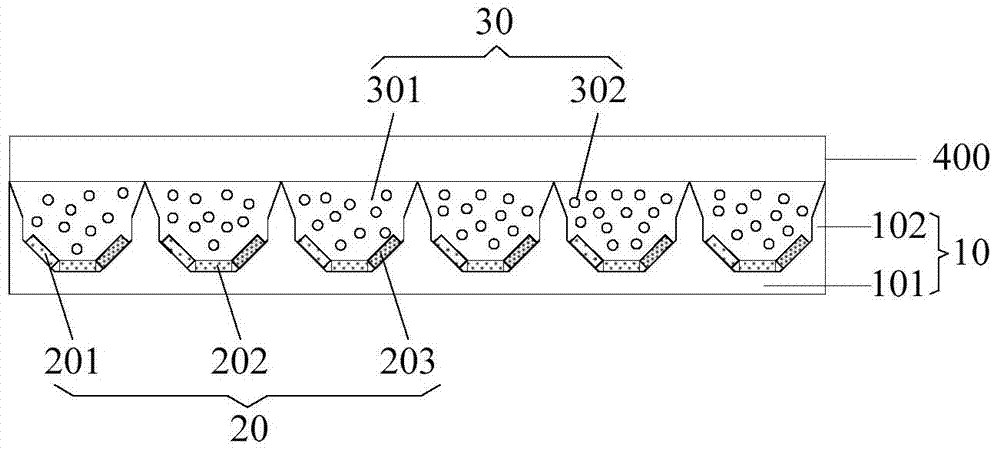

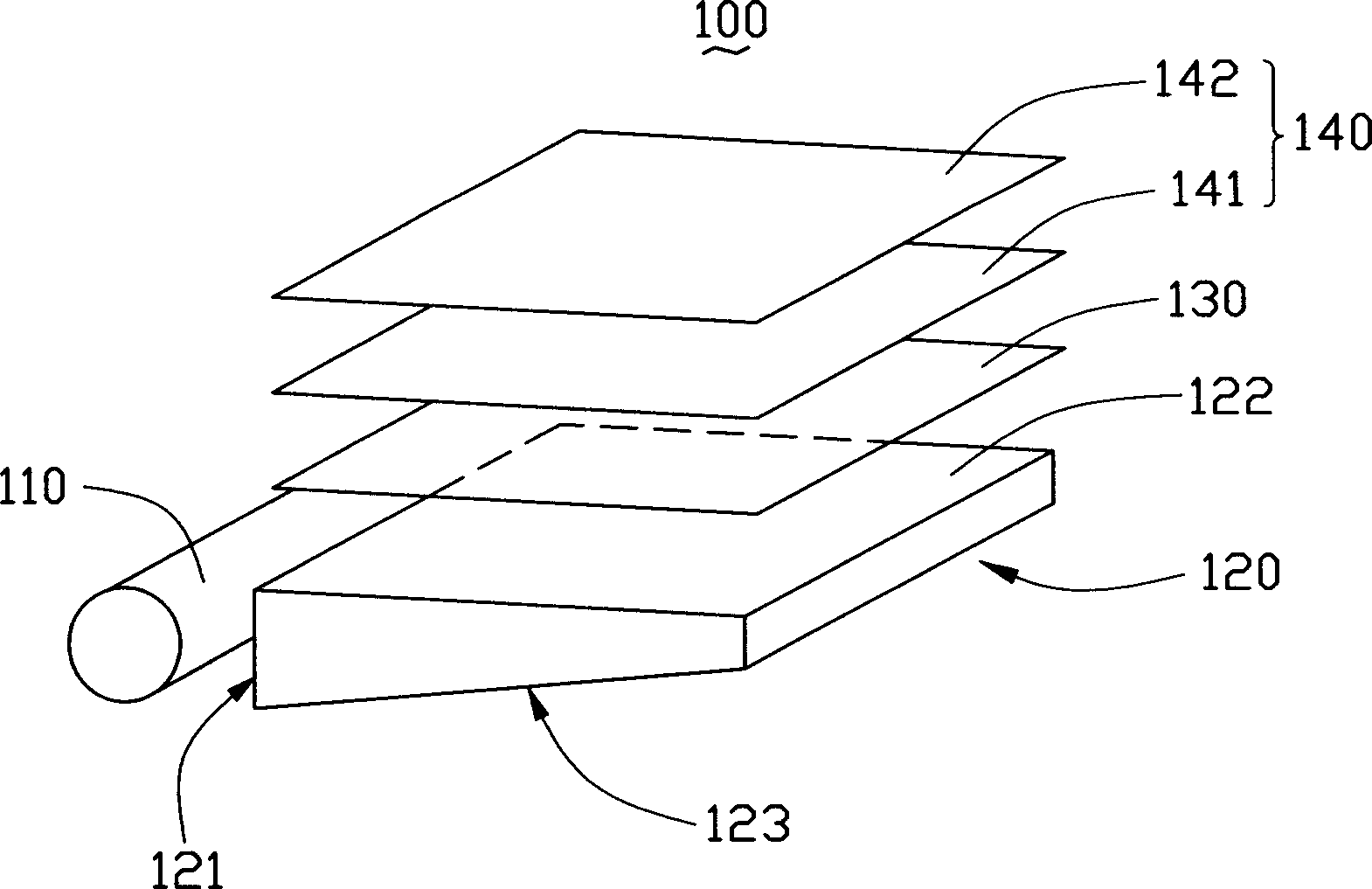

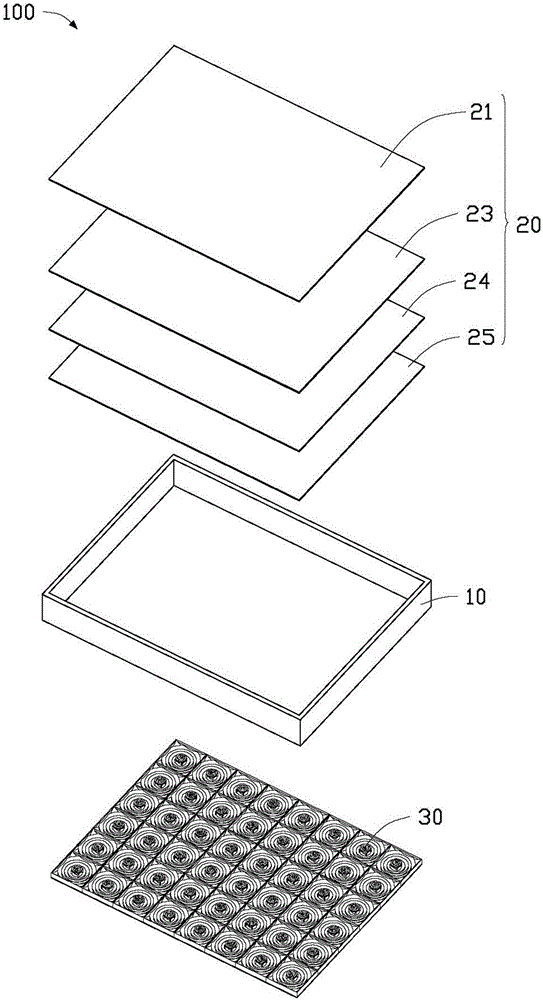

Backlight illumination structure based on double-sided light-dimming light guide plate and manufacturing method of backlight illumination structure

ActiveCN108845454ASimple device structureReduce thickness and volumePlanar/plate-like light guidesNon-linear opticsColor gelQuantum dot

The invention relates to a backlight illumination structure based on a double-sided light-dimming light guide plate and a manufacturing method of backlight illumination structure. The illumination structure comprises a side-entry type light source, a light guide plate, a base plate light-guiding layer, a quantum dot colored film layer and a spot light micro-structure, wherein the side-entry type light source, the light guide plate, the base plate light-guiding layer, the quantum dot colored film layer and the spot light micro-structure are sequentially arranged; a colored light filter in a liquid crystal panel is moved into backlight through the backlight structure, and is combined with a light-dimming scattering micro-structure of a scattering layer so as to perform light dimming; due tolight extraction of the light-guiding layer and light modulation of the micro-structure, the phenomenon that the structure has uniform light output is ensured simultaneously, optical film plates are integrated, so that the size and the thickness of the device are reduced, the device structure is simplified, and light energy can be fully and effectively utilized; by utilizing the design including the size, the position and the like of the micro-structure in the backlight, color adjustment is directly carried out, light dimming of a pixel array micro-structure is realized on the backlight, and the backlight illumination structure has the characteristics of simplicity, integration and the like; moreover, the luminous efficacy can be greatly enhanced, the purity of the color and the color domain are promoted, and the market competitiveness of liquid crystal display is greatly improved.

Owner:FUZHOU UNIVERSITY

Light-emitting device

InactiveCN103928594AImprove brightness unevennessAchieve mutual mixingLight source combinationsPoint-like light sourceDisplay deviceEngineering

The embodiment of the invention provides a light-emitting device, and relates to the technical field of display and illumination. The light-emitting device can increase the light-emitting area and achieve uniform and mixed light emergence. The light-emitting device comprises a back plate, a packaging structure, a light-emitting structure and a scattering layer, wherein the light-emitting structure and the scattering layer are arranged between the back plate and the packaging structure, the scattering layer is located at a light emergence side of the light-emitting structure, the light-emitting structure is separated into a plurality of light-emitting units, the scattering layer is separated into a plurality of scattering units, and the multiple light-emitting units correspond to the multiple scattering units one to one. Each light-emitting unit comprises a first light-emitting sub-unit, a second light-emitting sub-unit and a third light-emitting sub-unit and is applied to manufacturing of a display device and an illumination lamp.

Owner:BOE TECH GRP CO LTD

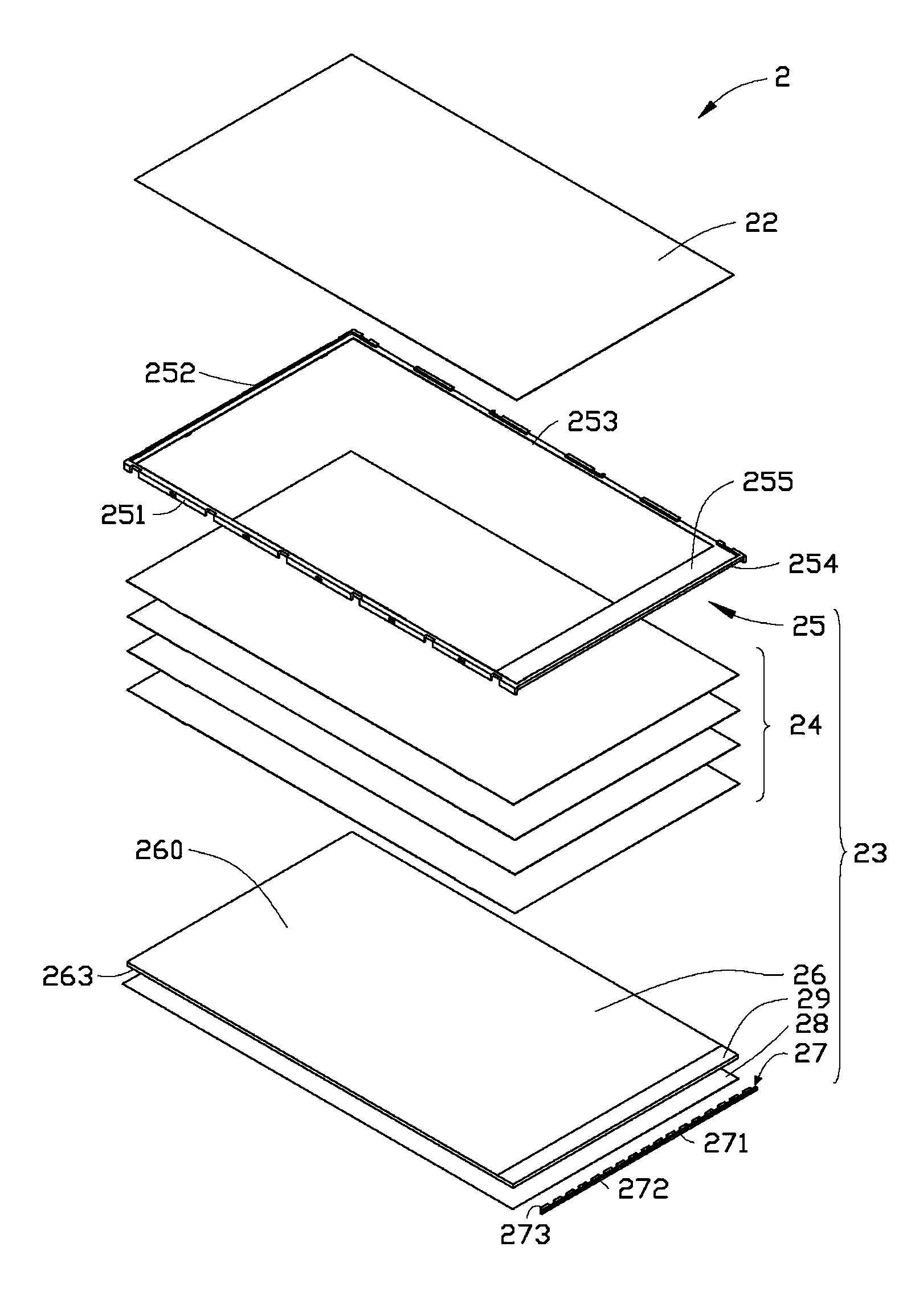

Backlight module, liquid crystal display device and light source module

InactiveCN103511913AUniform light outputNarrow borderDiffusing elementsPlanar/plate-like light guidesPoint lightLiquid-crystal display

The invention relates to a backlight module, a liquid crystal display device and a light source module. The backlight module comprises at least two point light sources and a light guiding element which receives light emitted by the at least two point light sources. The backlight module further comprises a light diffusing component which comprises a first light transmittance layer and a second light transmittance layer. The refractive index of the first light transmittance layer is larger than that of the second light transmittance layer. The refractive index of the second light transmittance layer is larger than the refractive index of the light guiding element. Light rays generated by the at least two point light sources enter the light diffusing component through the first light transmittance layer, then the light rays are refracted through the interface of the first light transmittance layer and the second light transmittance layer and then enter the second light transmittance layer, the second light transmittance layer emits the light rays out of the light diffusing component, and the light rays enter the light guiding element. A frame of the backlight module is narrow.

Owner:XINCHENG TECH CHENGDU +1

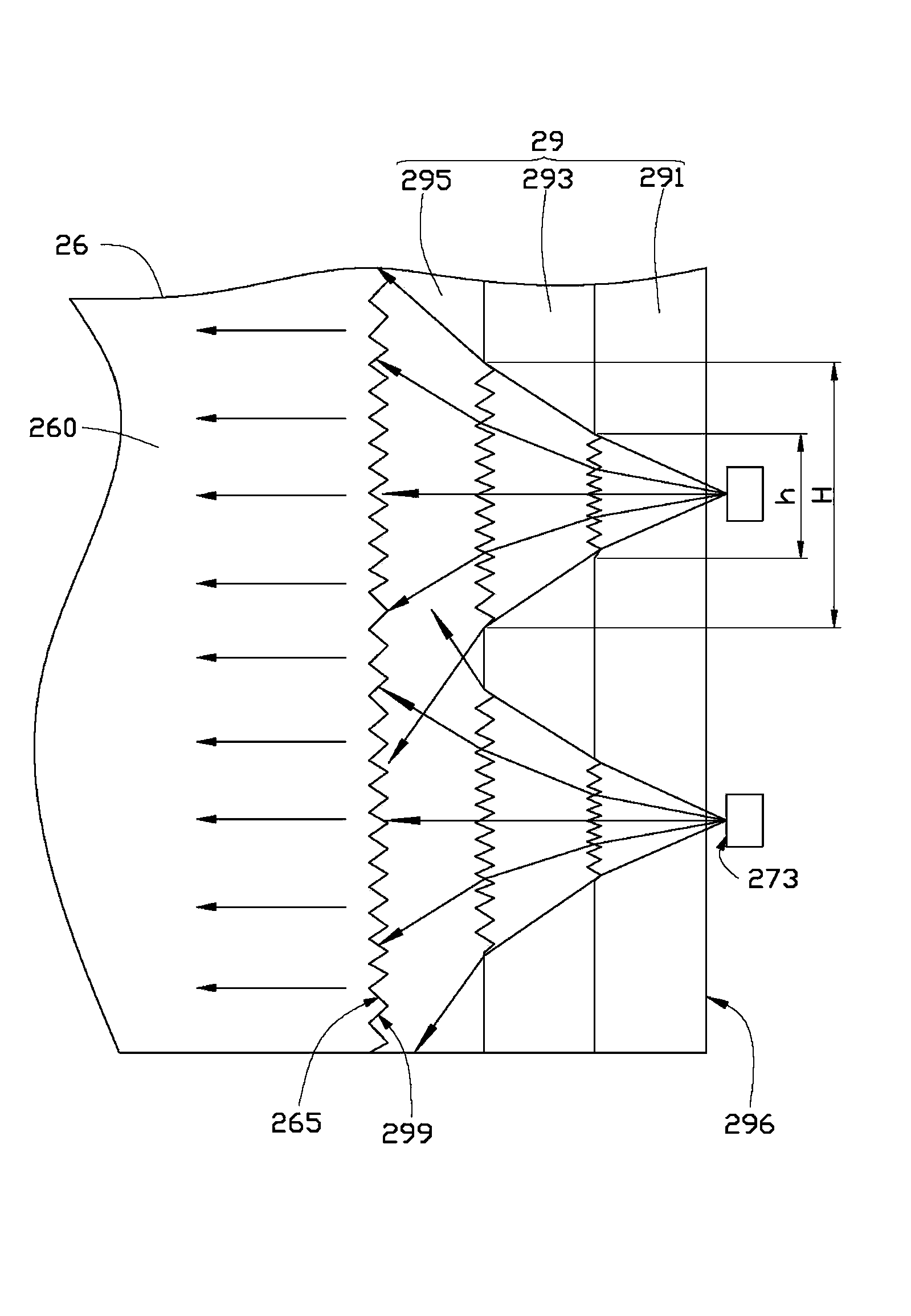

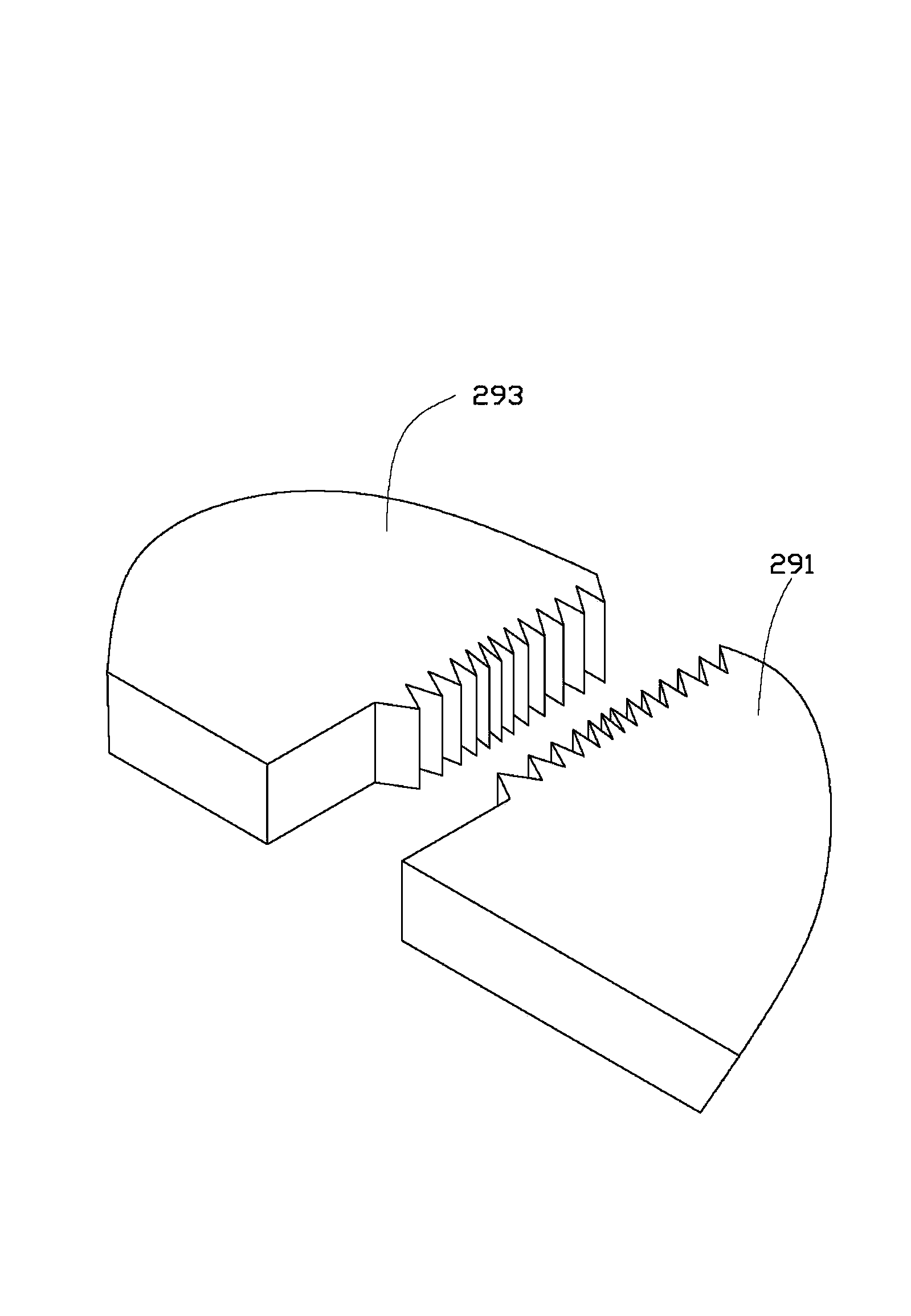

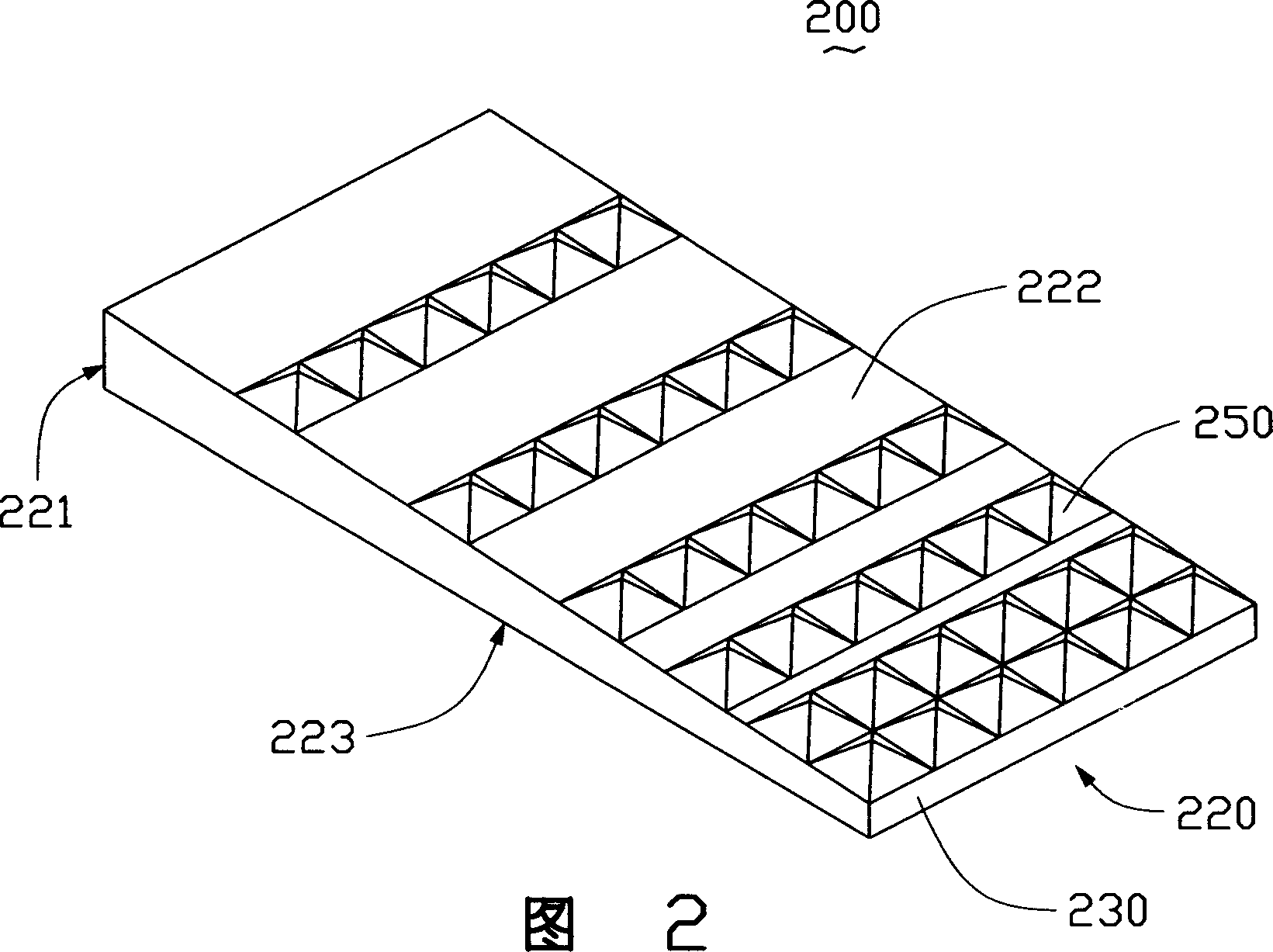

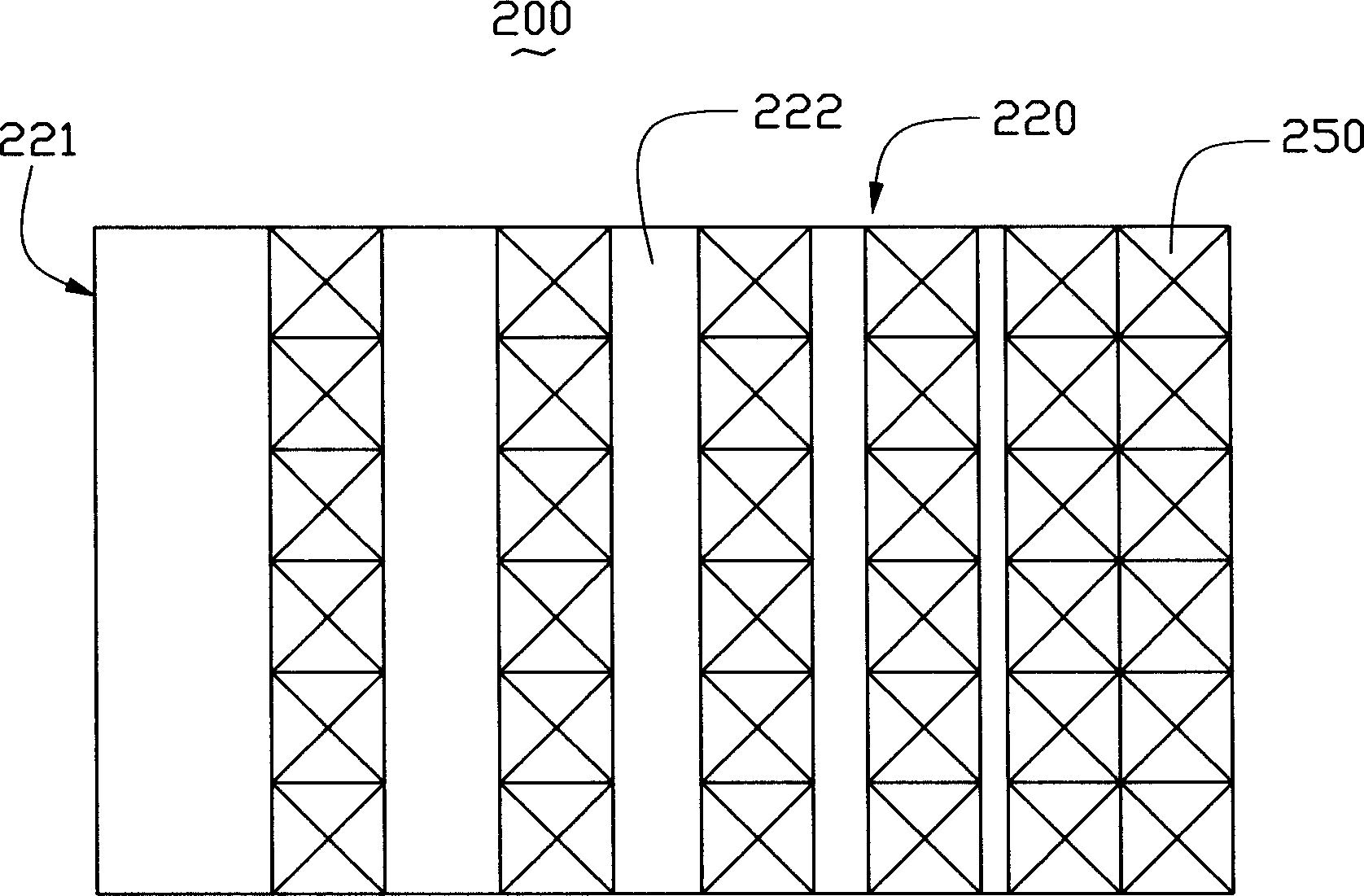

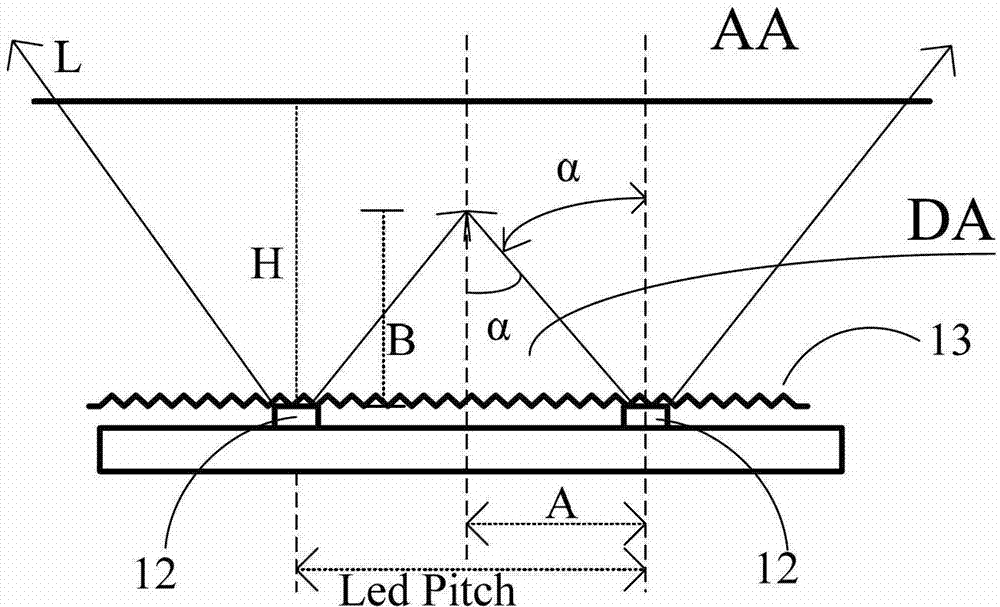

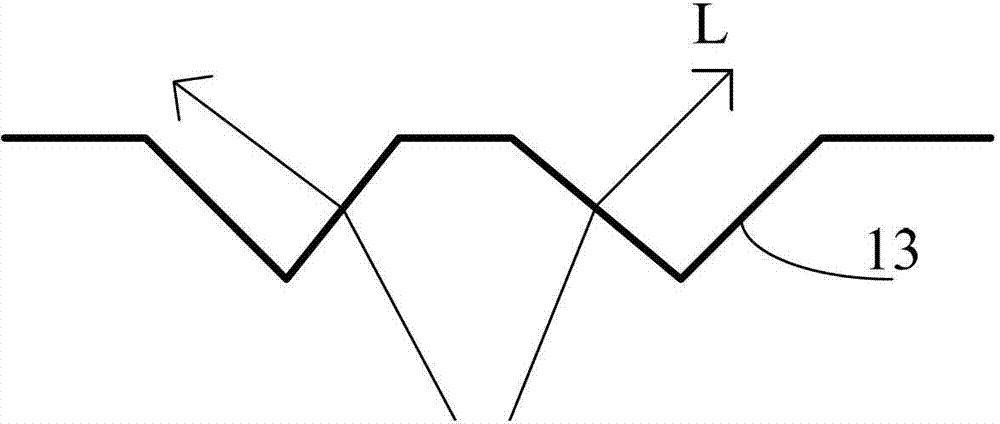

Back light system

InactiveCN1508601AUniform light distributionUniform light outputDiffusing elementsNon-linear opticsPhysicsExit surface

The invention is a kind of light-back system, which includes a light board and a source, the light board contains an entrance face, a back surface and a exit face, the entrance face is used to receive the beam, the back surface connects with the entrance face, the exit face opposites to the back surface, which is used to guide the beam out of the light board, the source is set at one side of the entrance face. There sets many mesh spots and V type slots on the back surface, the exit surface has many even ladder type prisms structure. The prisms gather the exit lights in order to enhance the density of the exit beam of light board.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Light guides

InactiveUS20120268963A1Uniform light outputImprove optical efficiencySemiconductor/solid-state device manufacturingPlanar/plate-like light guidesLiquid-crystal displayLight guide

This invention relates to light guide devices and methods of manufacture. The light guide device is suitable for use in a range of applications, particularly in connection with the backlighting of displays, for example, liquid crystal displays.

Owner:ITI SCOTLAND

White LED chip and forming method thereof

InactiveCN102130143AEasy to controlUniform light outputSolid-state devicesSemiconductor devicesActive layerWhite light

The invention discloses a white LED and a forming method thereof. The white LED chip comprises a substrate, a first groove and a second groove, wherein the substrate is provided with a first buffer layer positioned on the substrate, a first active layer positioned on the first buffer layer and a first cap layer positioned on the first active layer; the first groove respectively penetrates through the first buffer layer and the first active layer and extends to the first cap layer; a second buffer layer, a second active layer and a second cap layer are arranged in the first groove; the second buffer layer is positioned on the substrate; the second active layer is positioned on the second buffer layer; the second cap layer is positioned on the second active layer; the second groove respectively penetrates through the first buffer layer and the first active layer and extends to the first cap layer; a third buffer layer, a third active layer and a third cap layer are arranged in the second groove; the third buffer layer is positioned on the substrate; the third active layer is positioned on the third buffer layer; and the third cap layer is positioned on the third active layer. By using the white LED, one LED chip can simultaneously emit red, green and blue light which are mixed to emit white light.

Owner:ENRAYTEK OPTOELECTRONICS

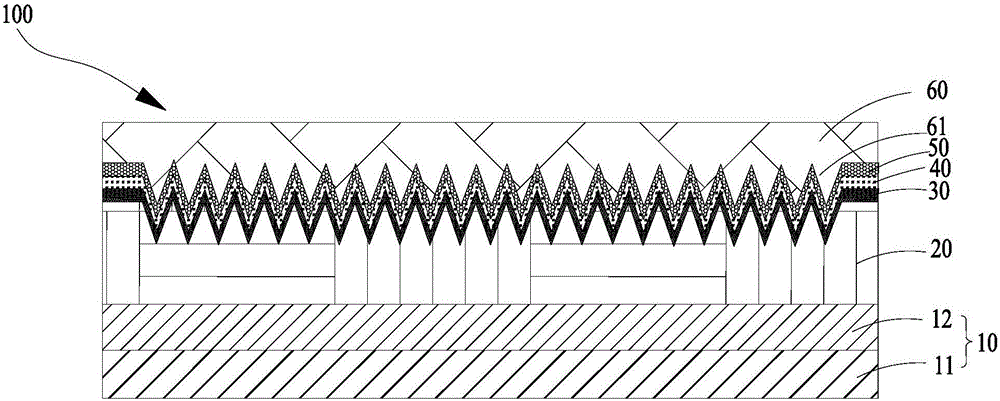

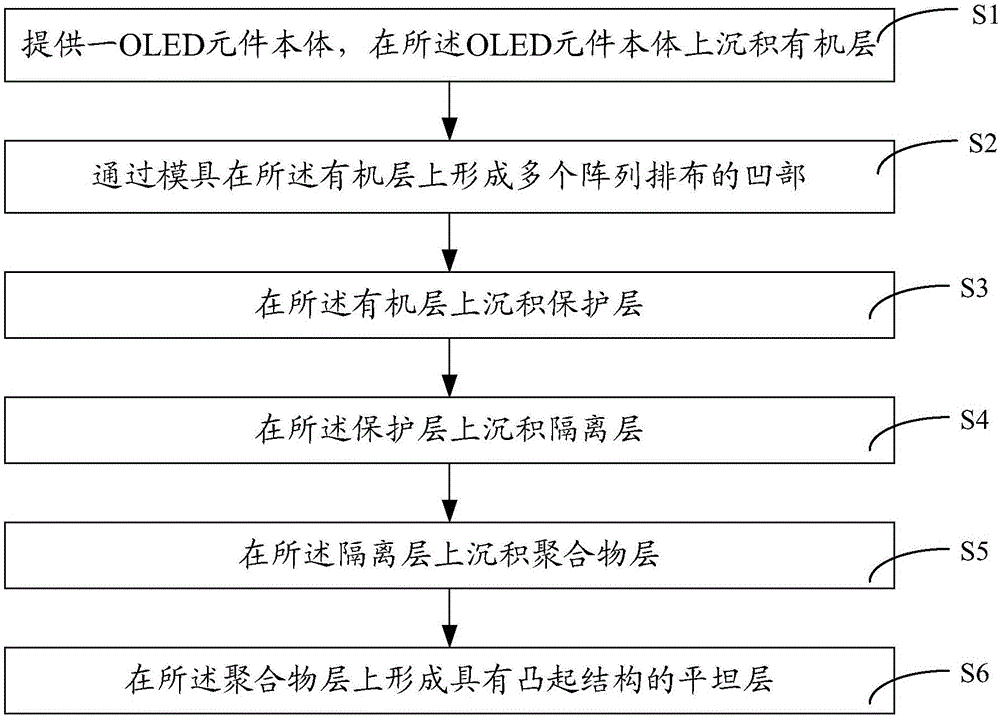

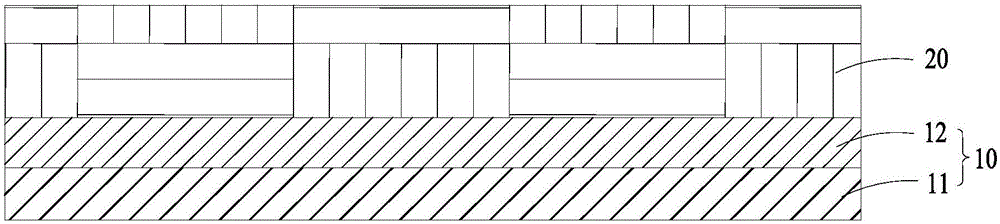

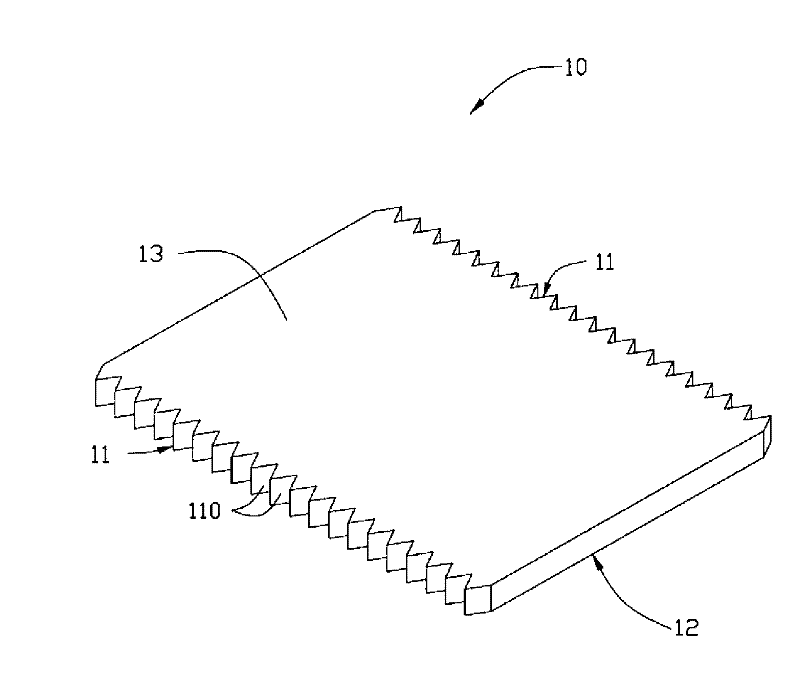

OLED (organic light emitting diode) device package structure, OLED device and display screen

ActiveCN106450036AReduce reflectionImprove light outputSolid-state devicesSemiconductor/solid-state device manufacturingFlexible organic light-emitting diodeCavity resonance

The invention provides an OLED (organic light emitting diode) device package structure and a method for manufacturing the same. The method includes forming an organic layer with regular array structures on an OLED component by the aid of mold plates with array protrusions; sequentially forming a protective layer, a barrier layer, a stress layer and a flat layer by the aid of further deposition processes; forming protrusions with regular array structures on the flat layer. The OLED device package structure and the method have the advantages that internal total reflection effects and micro-cavity resonance effects of an OLED device can be reduced by the aid of refraction effects of the protrusions and various film layers, and accordingly the light emergent efficiency of the OLED device can be improved; the protective layer can protect the array structures of the organic layer against being damaged; the barrier layer can prevent the OLED device from being eroded by water and oxygen, and accordingly the quality of the OLED device can be further improved; the OLED device can be normally used even in certain curled and bent states owing to the stress layer.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

Light guide plate

InactiveCN102128417AImprove uneven brightness and darknessUniform light outputMechanical apparatusLight guides for lighting systemsMesh pointEngineering

The invention relates to a light guide plate, comprising two opposite light-incident surfaces, a bottom surface and a light-emergent surface, wherein the bottom surface is connected with the two light-incident surfaces; the light-emergent surface is connected with the two light-incident surfaces and is opposite to the bottom surface; the bottom surface comprises a plurality of mesh points. From the two sides where the light-incident surfaces are arranged to the central position, the density of the mesh points positioned at the main part of the bottom surface is reduced gradually while the diameter is increased gradually. The light guide plate has good light-emergent uniformity.

Owner:INNOCOM TECH SHENZHEN +1

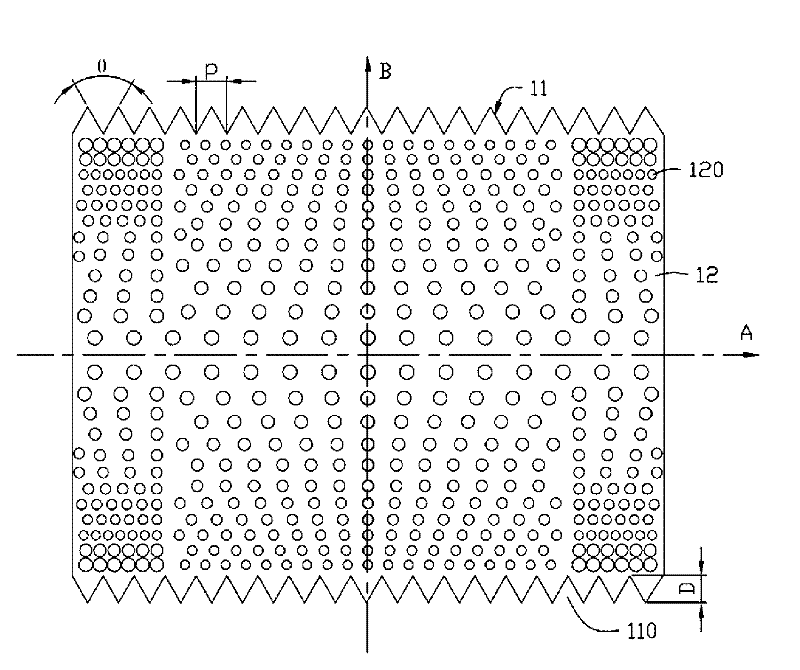

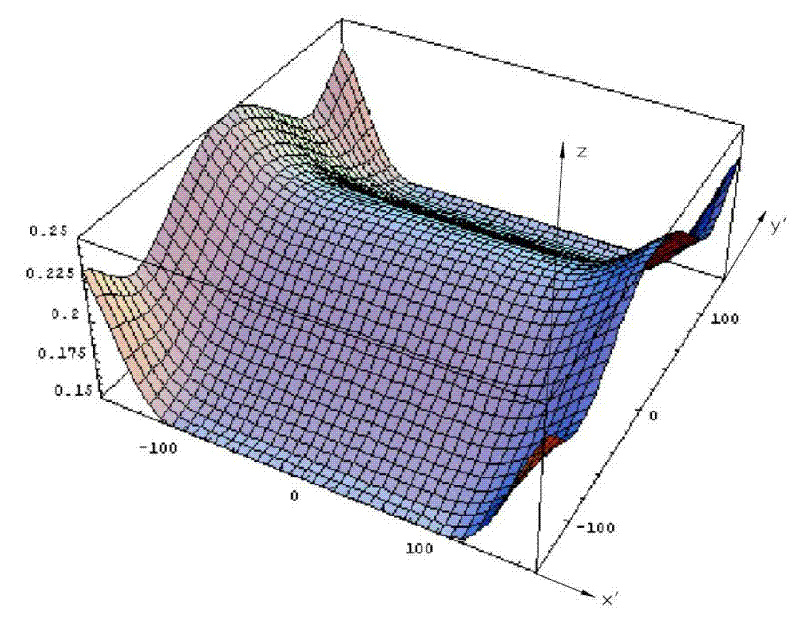

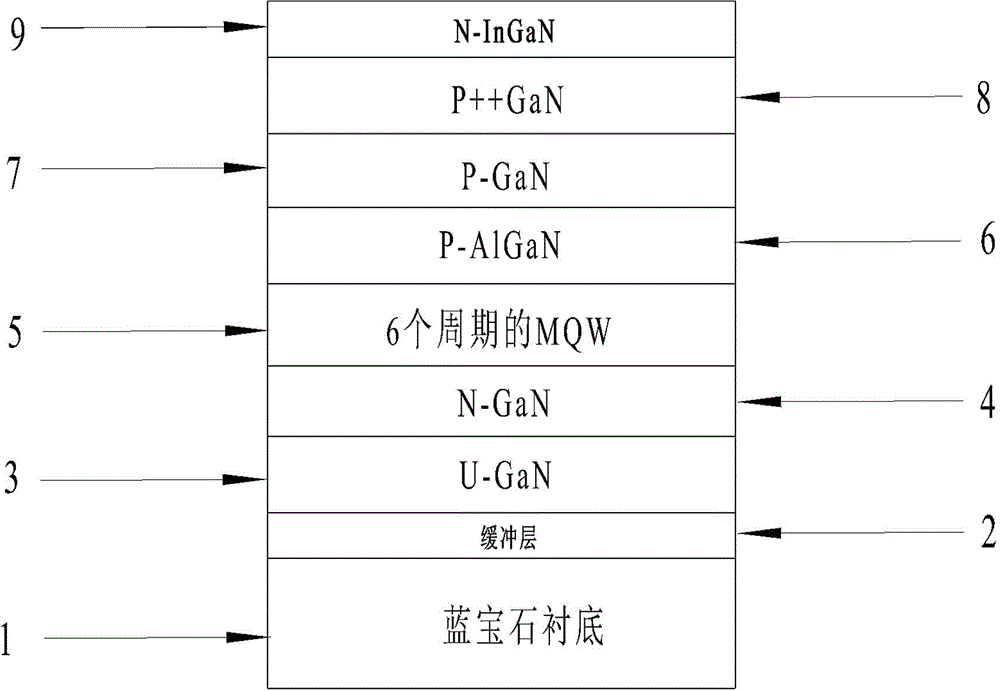

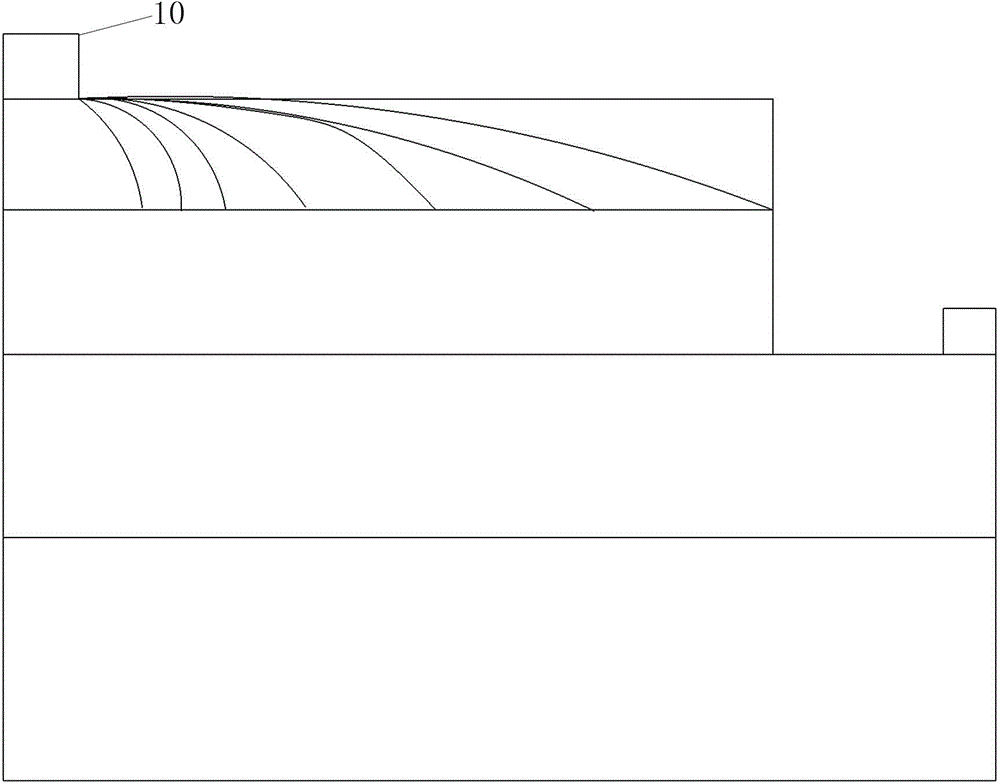

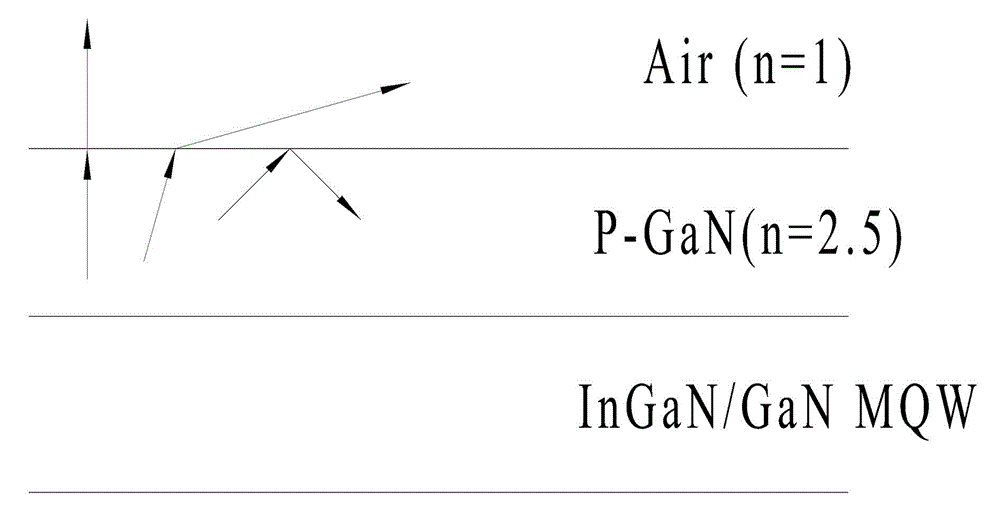

GaN-based light-emitting diode structure improving light extraction rate and preparation method

ActiveCN104157761AIncrease the carrier concentrationImprove acceleration performanceSemiconductor devicesNon dopedLead structure

The invention belongs to the field of photoelectric devices, and particularly relates to a GaN-based light-emitting diode structure improving the light extraction rate and a preparation method. The GaN-based light-emitting diode structure improving the light extraction rate and the preparation method solve the technical problems that the carrier concentration of a P-type area of an existing LED structure is not high, currents are distributed unevenly, and the light emitting efficiency is low. The GaN-based light-emitting diode structure improving the light extraction rate comprises a substrate, a GaN buffer layer growing on the substrate, a non-doped GaN layer growing on the GaN buffer layer, a Si-doped GaN layer growing on the non-doped GaN layer, multiple-quantum well structures, growing on the Si-doped GaN layer, of six periods, a p-AlGaN electronic blocking layer growing on the multiple-quantum well structures, a Mg-doped p-type GaN layer growing on the p-AlGaN electronic blocking layer, a heavily-doped p-type GaN layer growing on the Mg-doped p-type GaN layer, and an n-type InGaN layer growing on the heavily-doped p-type GaN layer. According to the GaN-based light-emitting diode structure improving the light extraction rate and the preparation method, the currents are distributed evenly, the light emitting efficiency is high, and the preparation process is simple.

Owner:太原理工大学建筑设计研究院有限公司

Automobile lamp and automobile provided with same

ActiveCN103994387AReduce distanceReduce the anglePoint-like light sourceOptical signallingEngineeringLight source

The invention discloses an automobile lamp and an automobile provided with the automobile lamp. The automobile lamp comprises a substrate, light source parts, a lens, diffusion pieces, a total reflection mirror and a half reflection cover. The light source parts are installed on the substrate. The lens is installed on the substrate, located in the light emergence direction of the light source parts and provided with a light emergence surface. The diffusion pieces are arranged in the light emergence direction of the light source parts and located between the light source parts and the lens. The total reflection mirror is installed on the lens and provided with a total reflection face. The half reflection cover is arranged on the substrate in a covering mode. The light source parts, the diffusion pieces, the lens and the total reflection mirror are located in the half reflection cover, and the light emergence surface and the total reflection surface face toward the half reflection cover. According to the embodiment of the automobile lamp, the automobile lamp has the advantages of being even in light emergence, good in visual effect, convenient to assemble and the like.

Owner:MIND ELECTRONICS APPLIANCE CO LTD

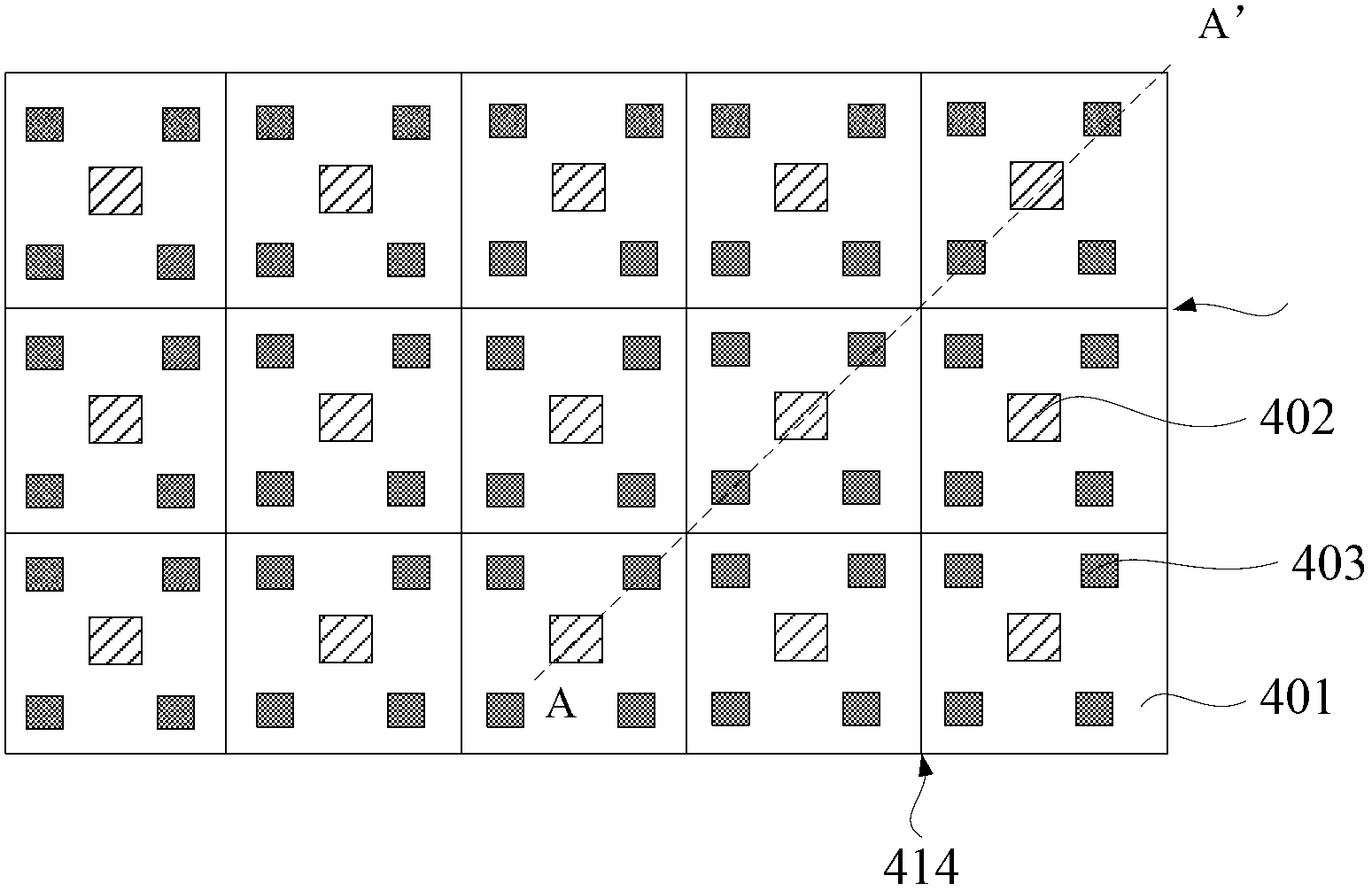

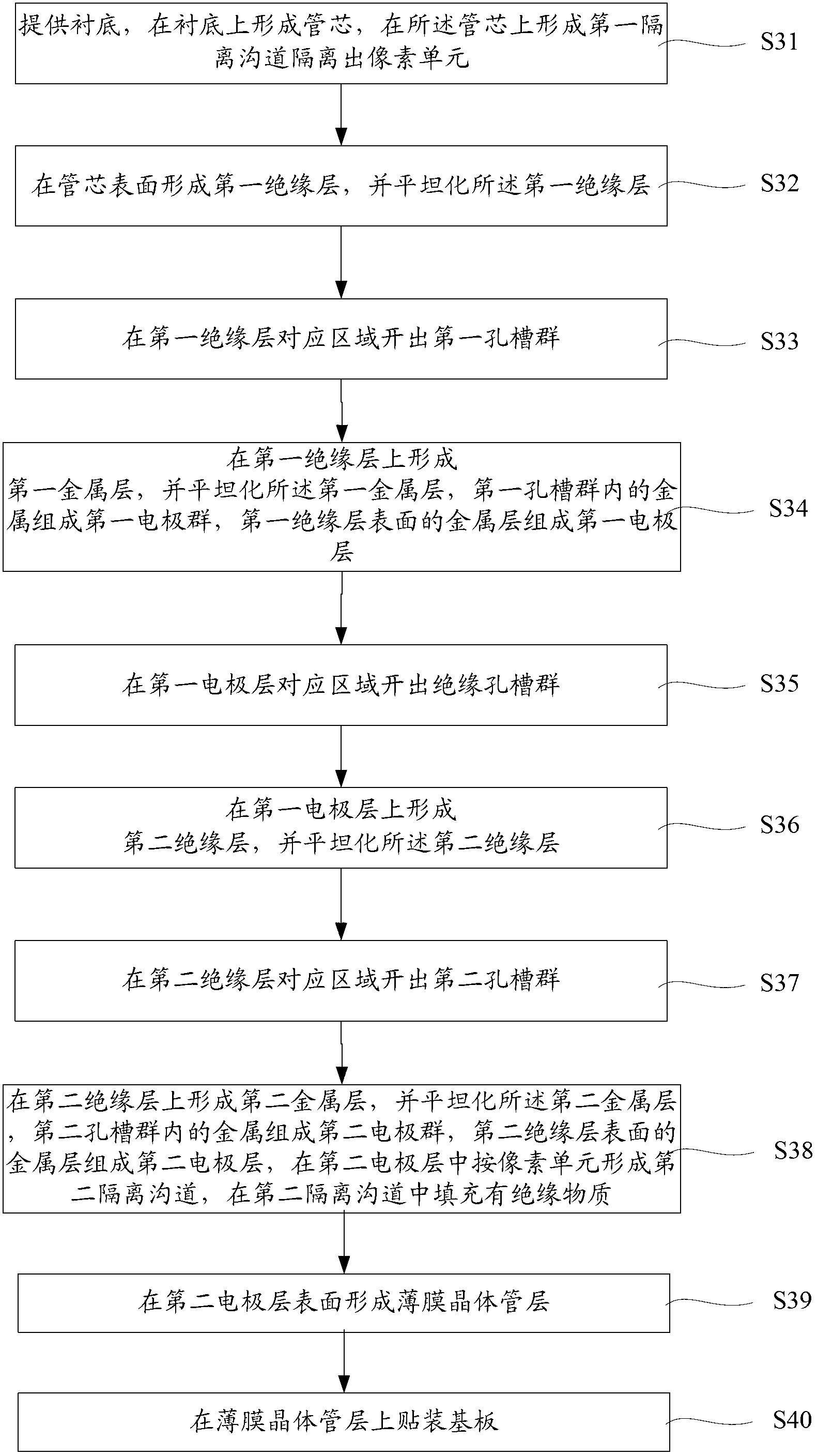

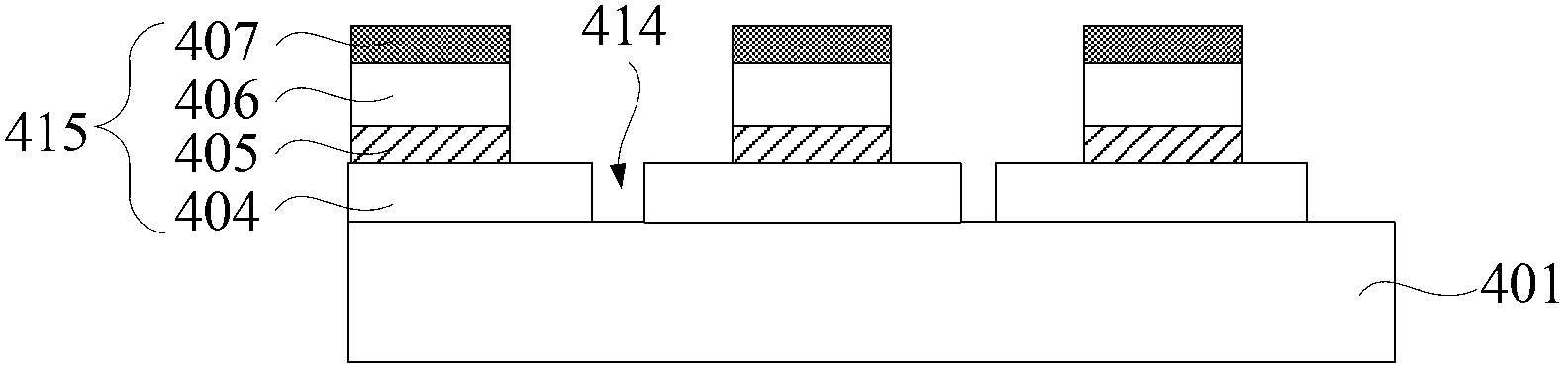

LED (light emitting diode) display screen and manufacture method thereof

InactiveCN103219286AImprove clarityControl thicknessSemiconductor/solid-state device manufacturingSemiconductor devicesPower flowInsulation layer

The invention discloses an LED (light emitting diode) display screen and a manufacture method thereof. A pixel module of the LED display screen is a single LED chip, and a gap between every two pixels can be effectively controlled, thus the definition of the LED display screen is improved. Meanwhile, the traditional upside-down mounting chip process is optimized to the process that after an electrode group is generated, structures of an electrode layer, an insulation layer and the like are generated, so that the thickness of a chip is effectively controlled, the traditional arrangement of a pair of electrodes is divided into a first electrode group and a second electrode group which are distributed in the corresponding area of a tube core, by adopting the structure, sufficient current expansion can be obtained, current is enabled to be uniformly distributed, a device is enabled to obtain excellent luminescent efficiency and uniform glaring rate, and the requirement that a chip size is further increased can be met.

Owner:ENRAYTEK OPTOELECTRONICS

Light guiding plate, backlight module and display device

ActiveCN103926645AUniform light outputIncrease brightnessMechanical apparatusPoint-like light sourceLight guideDisplay device

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD +1

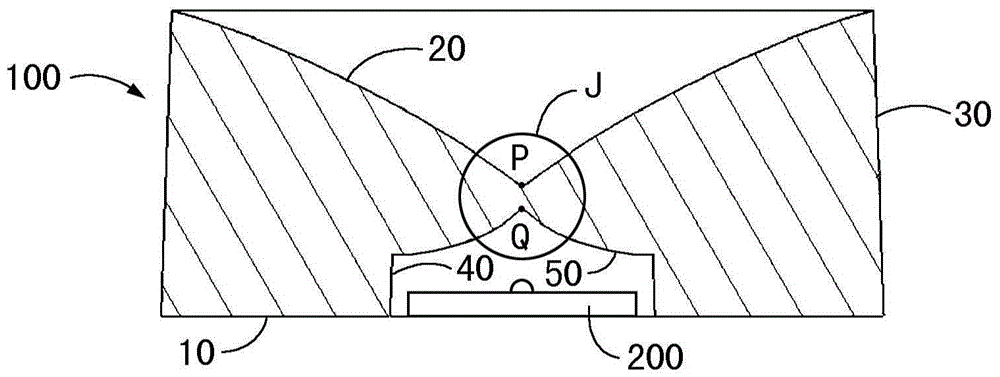

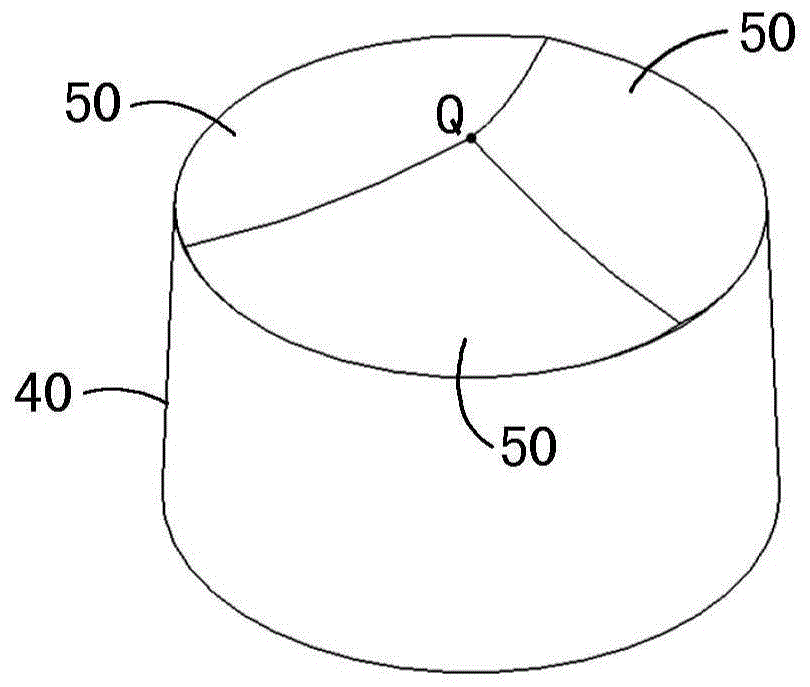

Lens and light-emitting device

ActiveCN104565885AEvenly distributedAvoid chromatic aberrationElectric lightingSemiconductor devices for light sourcesLight emitting device

The invention provides a lens and a light-emitting device. The lens comprises a column-shaped lens main body, wherein the column-shaped lens main body is provided with a bottom surface, a top surface and a circumference surface; the middle of the bottom surface concaves inwards to form a light incoming surface; the top surface is a total reflection surface in the shape of a smooth transitional curved surface and is provided with a center vertex; the circumference surface is a light extracting surface; the light incoming surface comprises a first cylindrical light incoming surface connected with the bottom surface and a second pyramid light incoming surface connected with the first light incoming surface; the second pyramid light incoming surface is provided with a pyramid vertex and pyramid surfaces in the shapes of smooth transitional curved surfaces; the center vertex of the total reflection surface and the pyramid vertex of the second light incoming surface are both on the axis of the lens main body; incident ray getting into the lens main body from the first light incoming surface is directly emitted out by the light extracting surface to form a plurality of first emergent rays upwardly inclined by 0-40 degrees relative to the bottom surface; incident ray getting into the lens main body from the second light incoming surface is reflected by the total reflection surface and then emitted out by the light extracting surface to form a plurality of top emergent rays which are upwardly or downwardly inclined. According to the invention, light leaking is effectively reduced.

Owner:THE HONG KONG POLYTECHNIC UNIV

Laser physical evidence exploration instrument

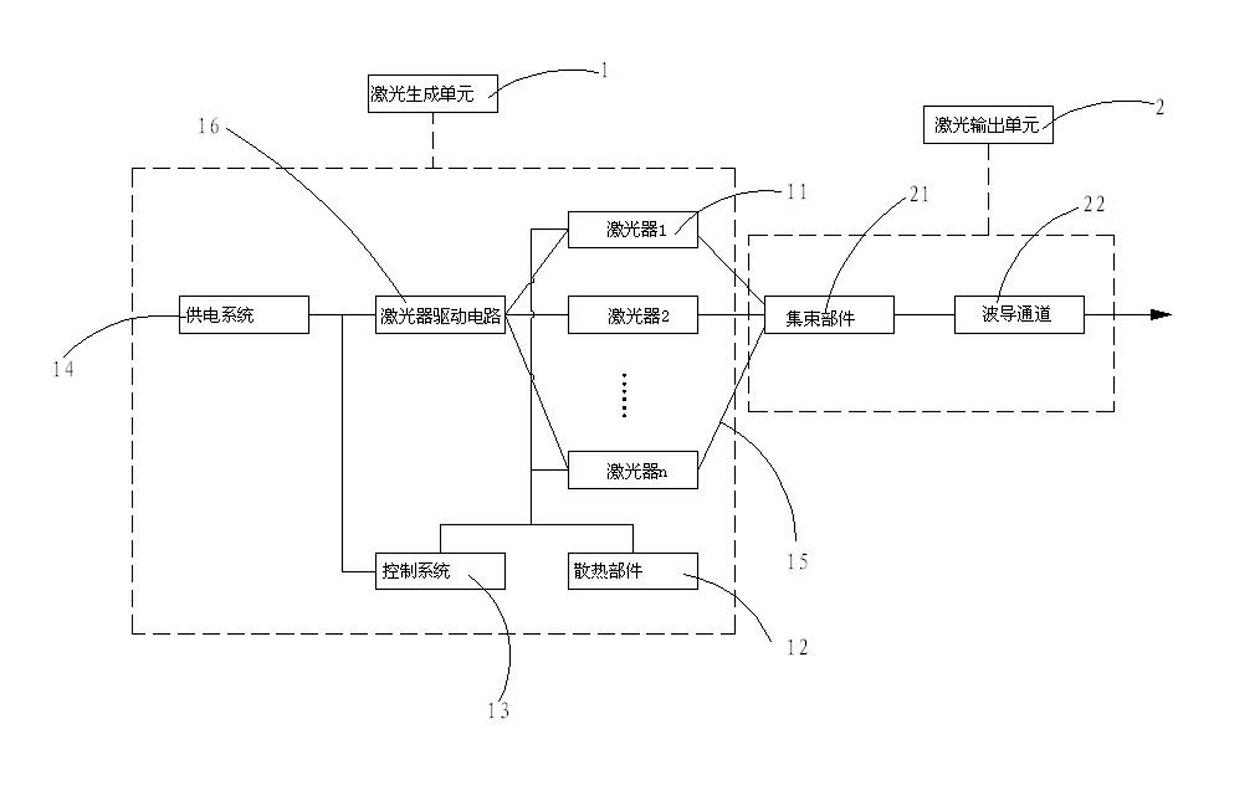

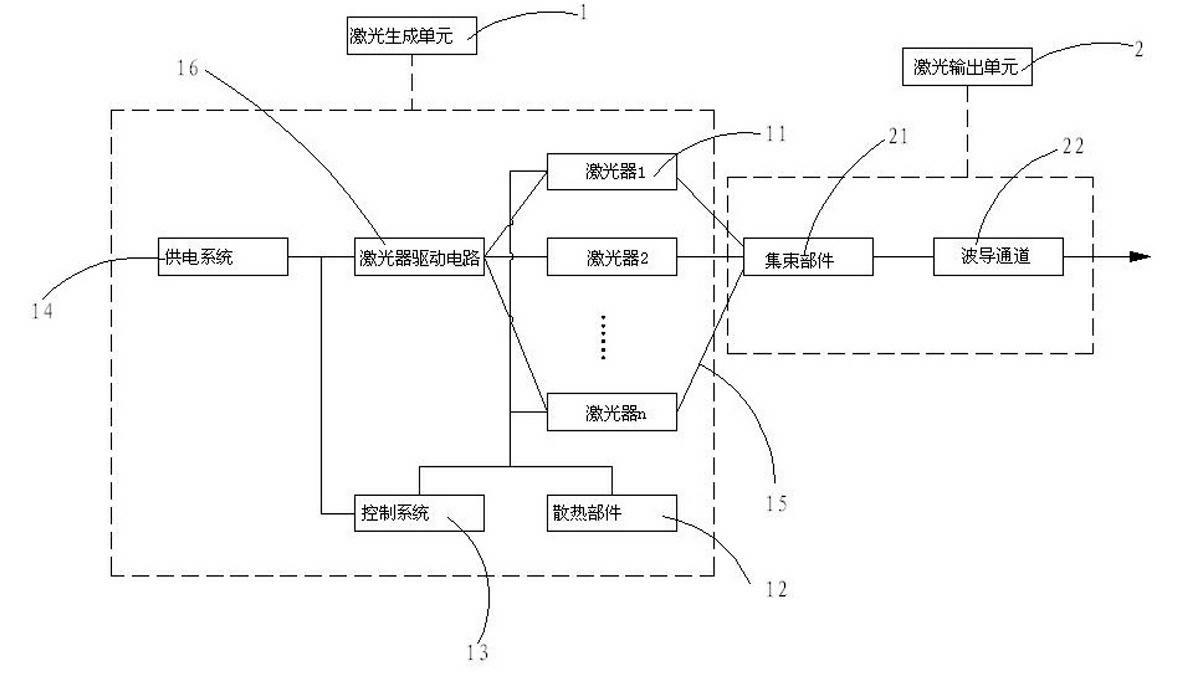

ActiveCN102175643APowerfulUniform light outputColor/spectral properties measurementsControl systemRed laser

The invention relates to a laser physical evidence exploration instrument comprising a laser generation unit and an laser output unit, wherein the laser generation unit comprises a plurality of lasers and a control system, wherein the plurality of lasers are selected from at least two of a blue laser, a green laser, an orange laser and a red laser and respectively connected with the control system; the lasers are independently started to work, and the lasers started to work are the lasers with same colors at a same time point, wherein the lasers with the same colors indicate lasers of the plurality of lasers, which generate lasers with same colors; the laser output unit comprises a clustering part which can collect the lasers; the laser output end of each laser is respectively connected with the inlet end of the clustering part through one optical fiber; and the lasers generated by a laser module can be clustered and collected after penetrating through the clustering part. The laser physical evidence exploration instrument outputs the multispectral lasers together through a single light path, has uniform outgoing light and is especially suitable for the field of criminal exploration.

Owner:SUZHOU XIAOSONG TECH DEV

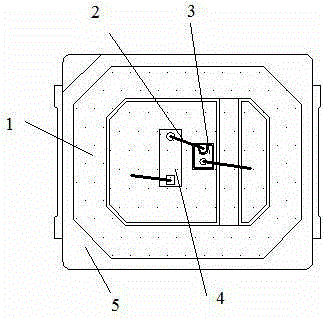

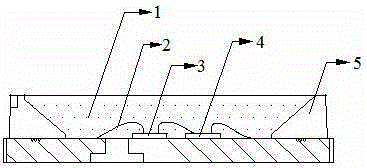

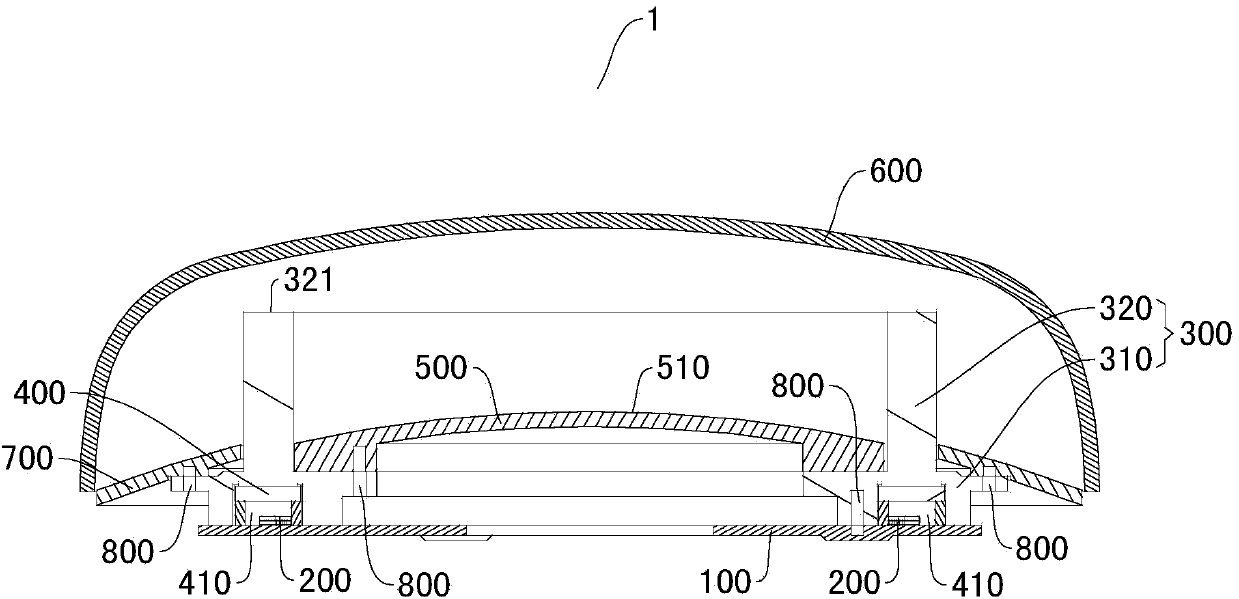

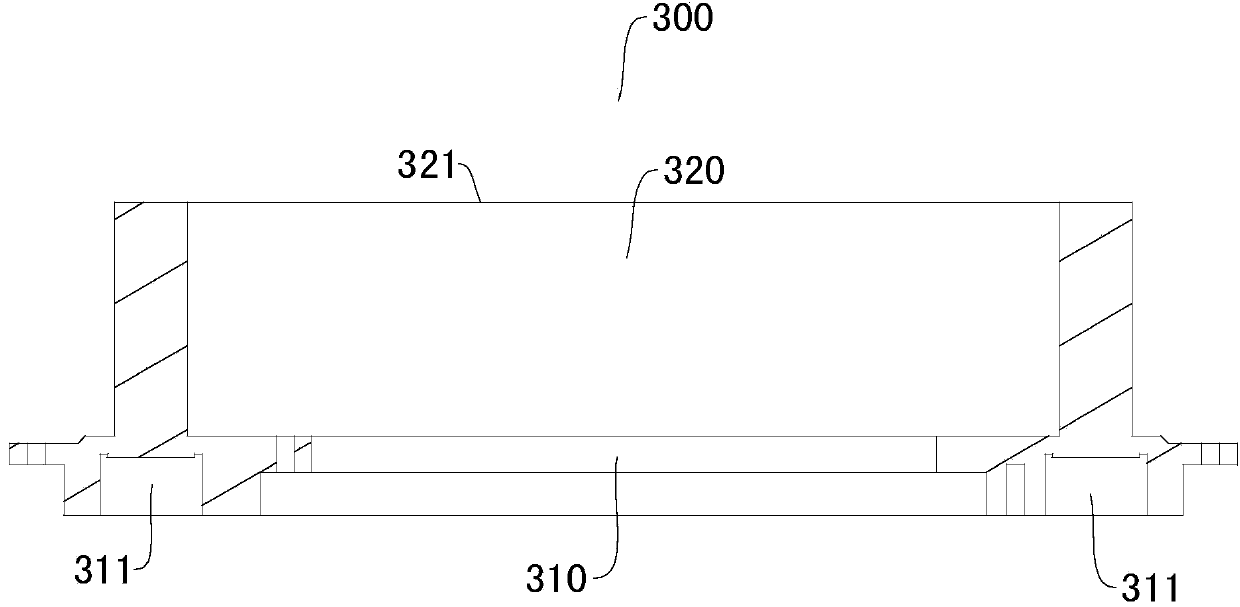

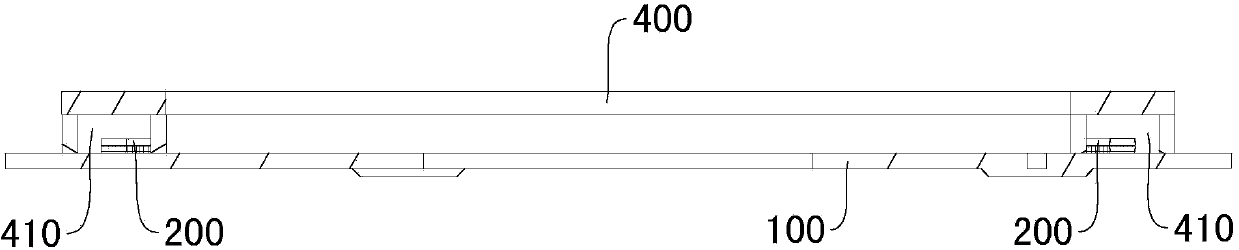

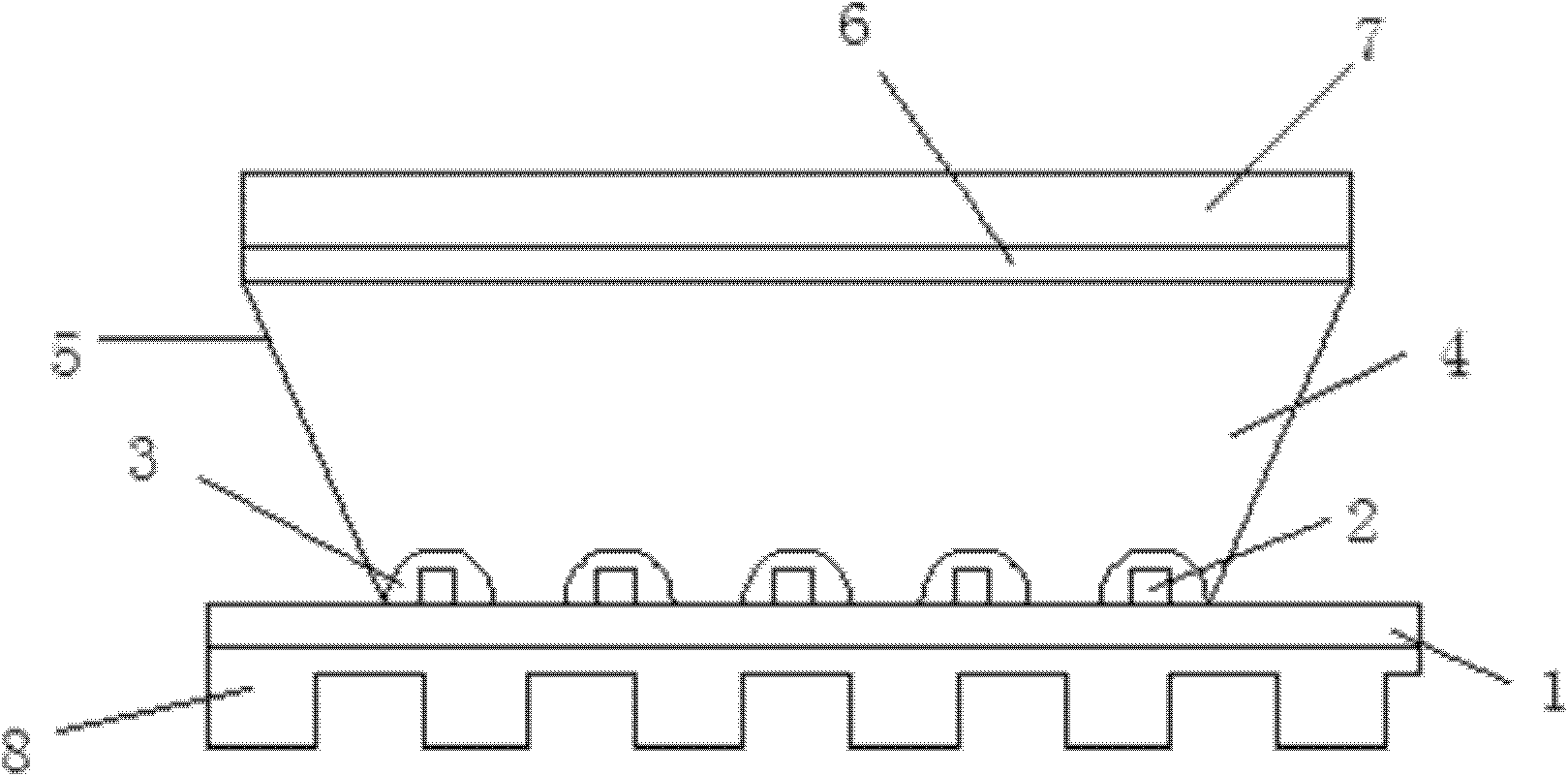

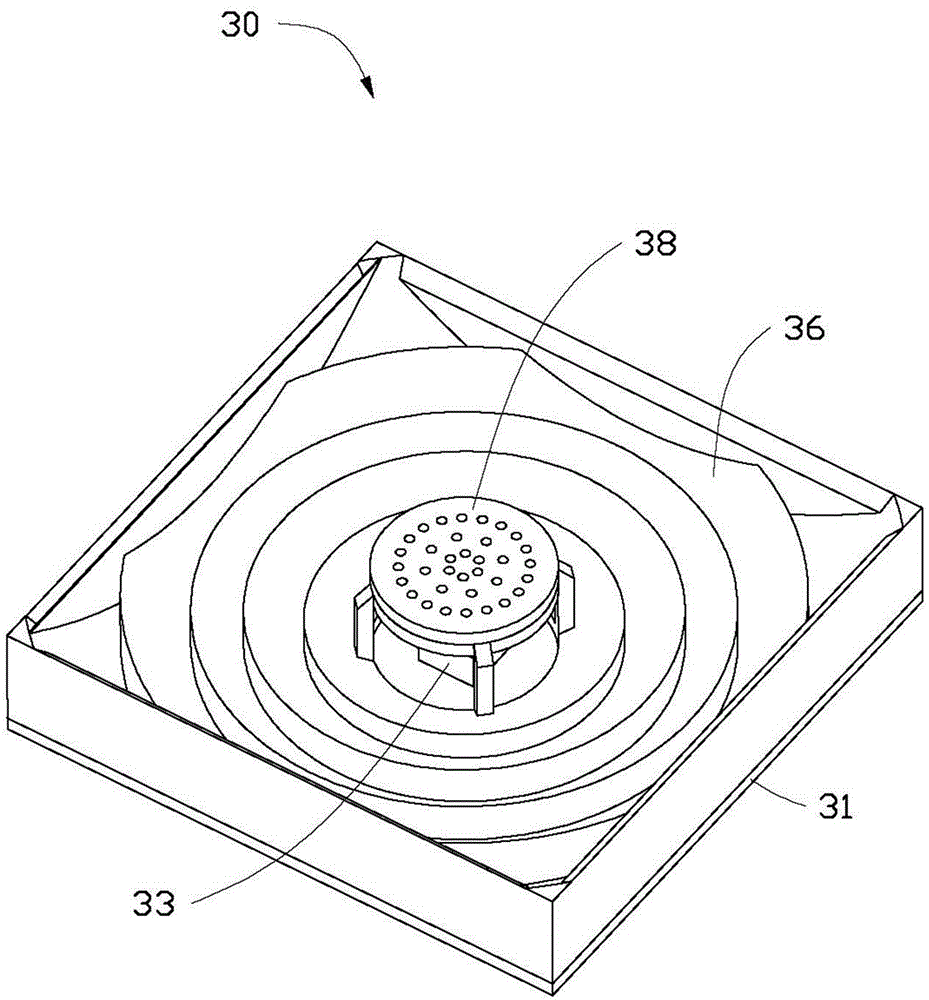

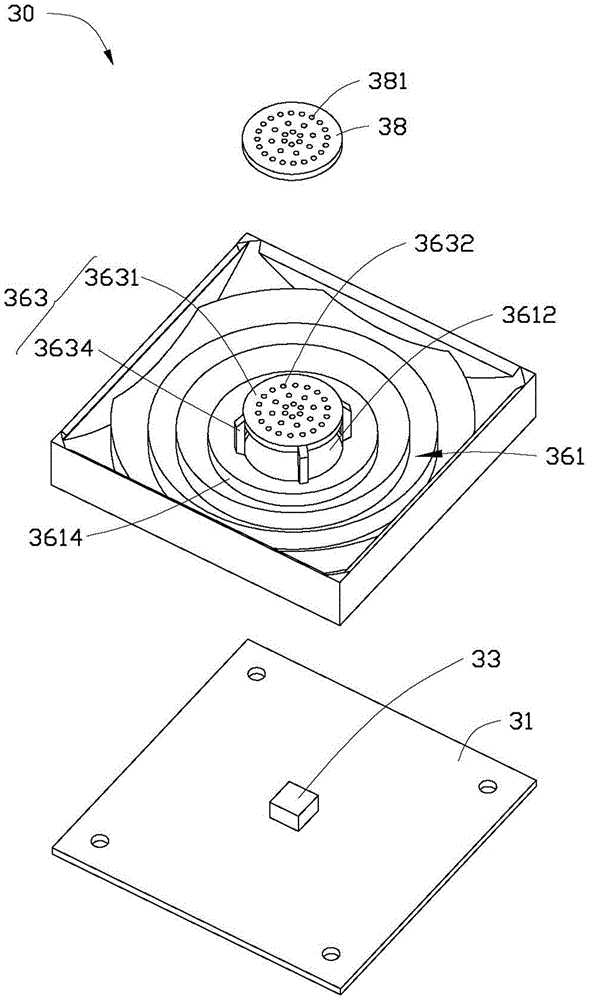

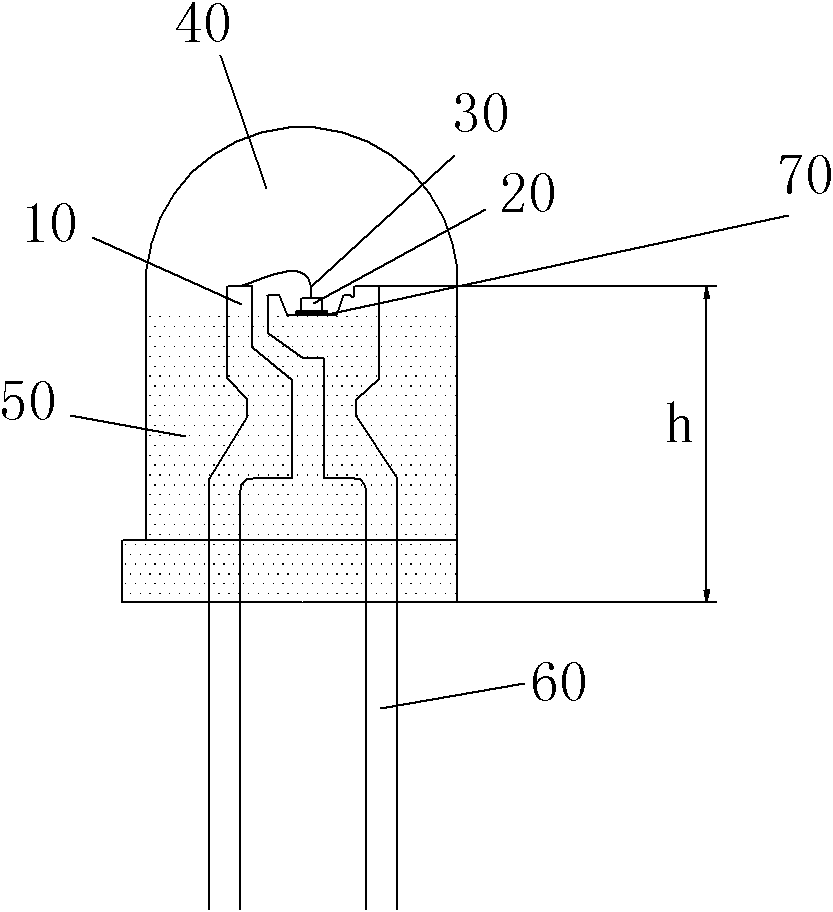

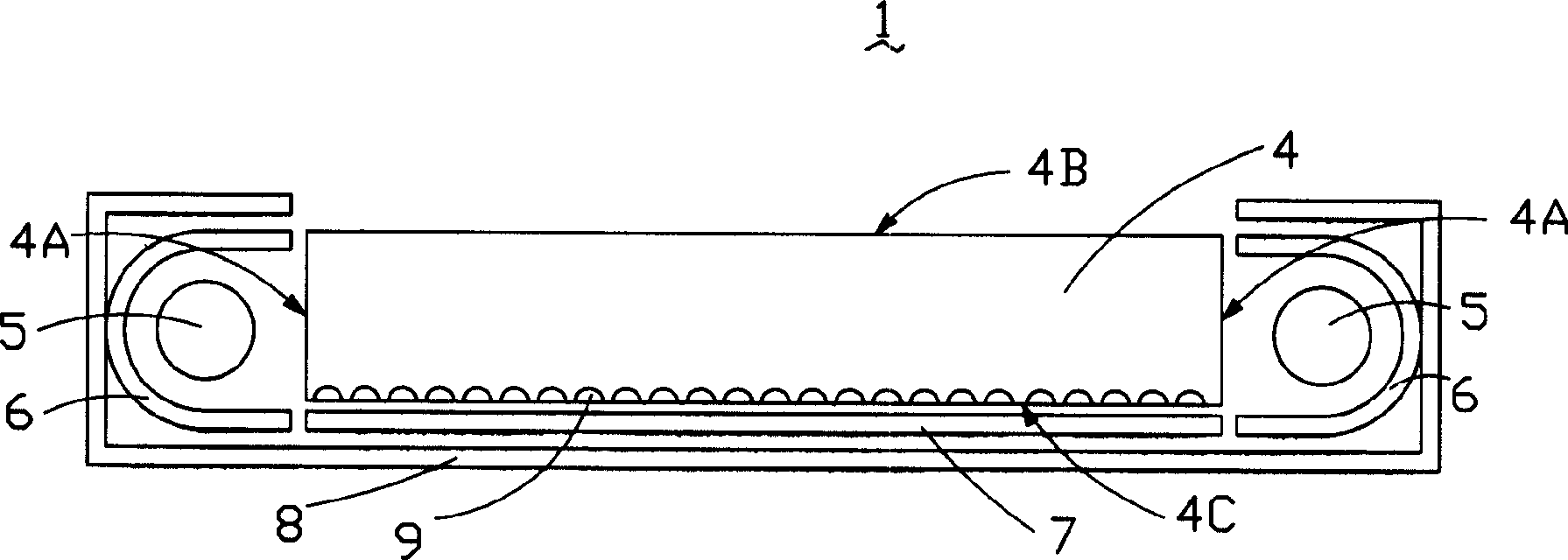

White LED light source package

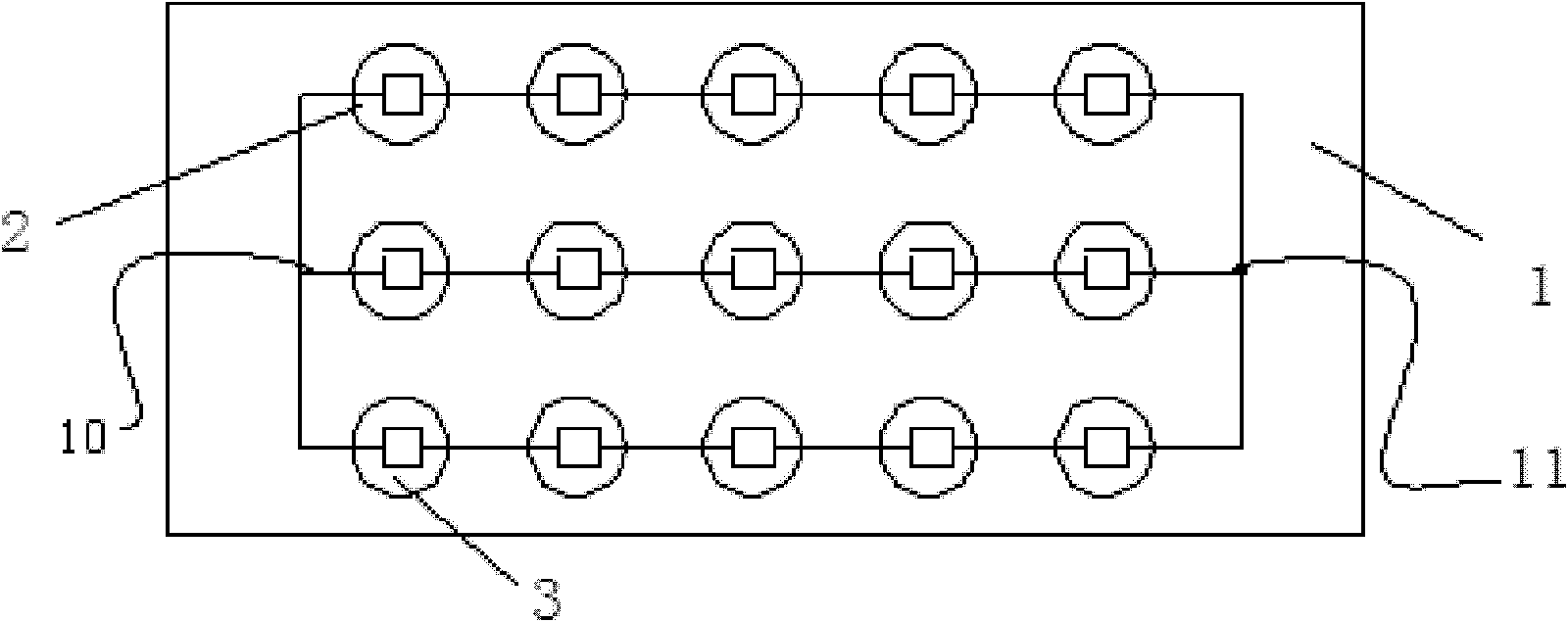

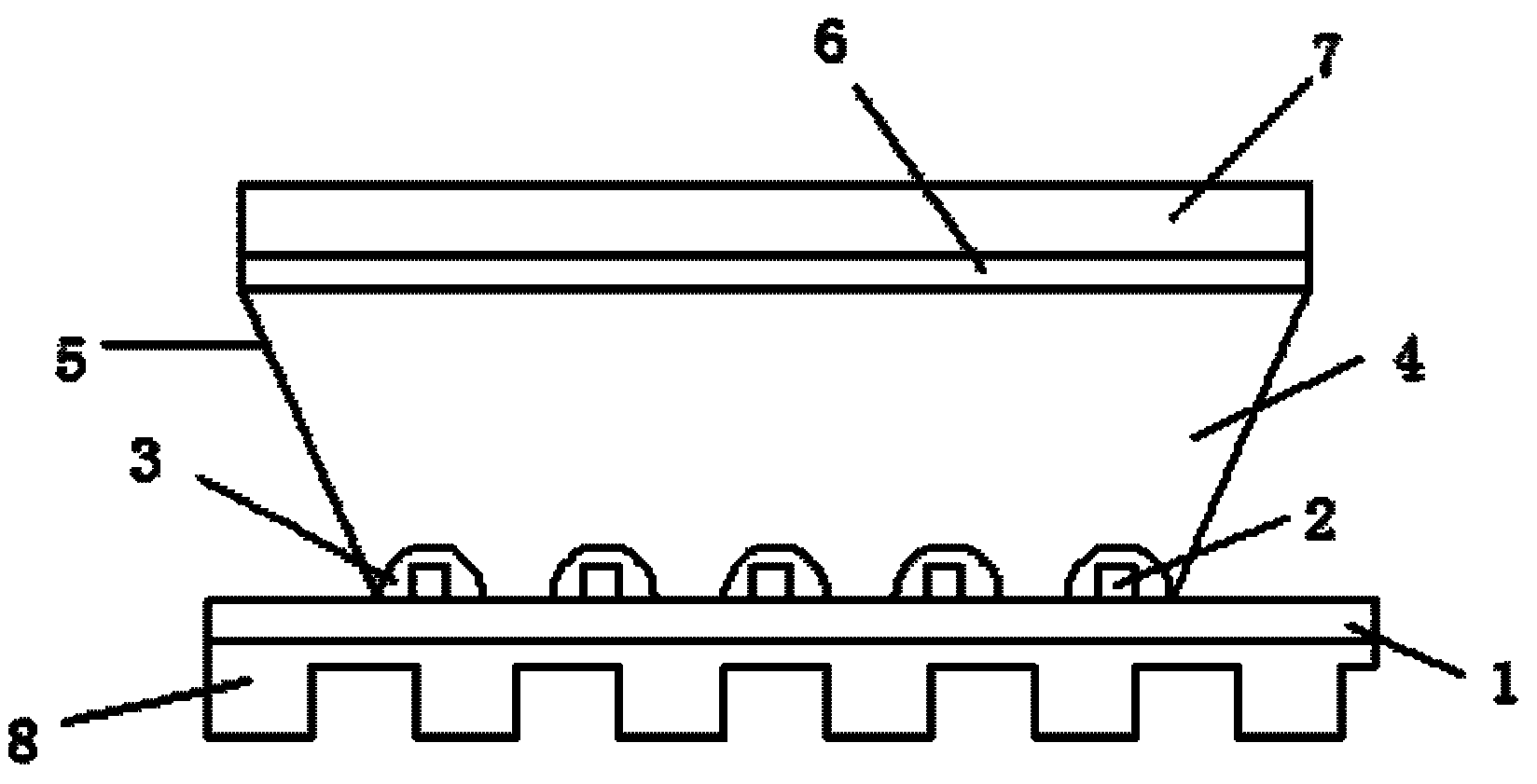

InactiveCN101859759AUniform light outputImprove uniformitySolid-state devicesSemiconductor devicesFluorescenceHeat sink

The invention provides a white LED light source package, which comprises a heat sink (8), an insulating substrate (1) bonded on the upper surface of the heat sink (8), an LED chip (2) bonded on the upper surface of the insulating substrate (1), a reflection spotlight cup (3) arranged around the LED chip, an epoxy resin layer (4) fixed on the upper surface of the insulating substrate (1), reflection cups (5) coated at both side surfaces of the epoxy resin layer (4), a fluorescent powder layer (6) coated on the upper surface of the epoxy resin layer (4), and glass (7) covering the upper surface of the fluorescent powder layer (6), wherein a power source is connected on an electrode of the LED chip (2), and the LED chip (2) array is arranged on the upper surface of the insulating substrate, so the emergent light of the white LED light source package is more uniform.

Owner:SHAANXI UNIV OF SCI & TECH

Light source device and backlight module thereof

InactiveCN1629690AReduce usageUniform light outputCoupling light guidesNon-linear opticsMultiple pointOptoelectronics

A light source device includes multiple point light sources with at least two luminous colors and a fiber-coupling device constituting multiple input ends and output ends, said input ends are set corresponding to said multiple point light sources. Said device can emit uniform color variable lights.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

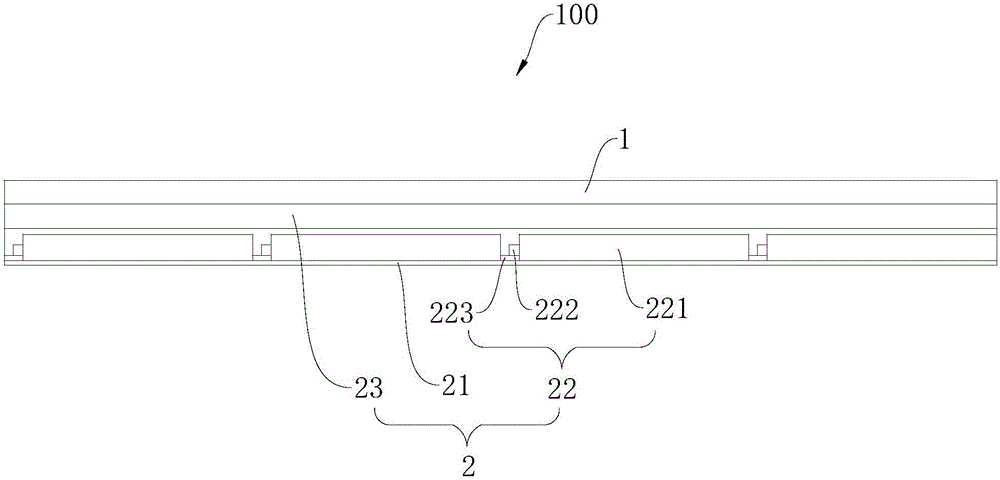

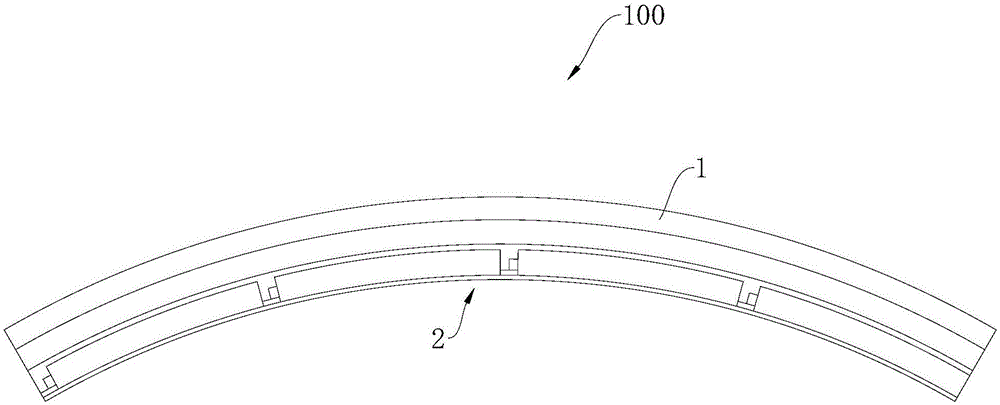

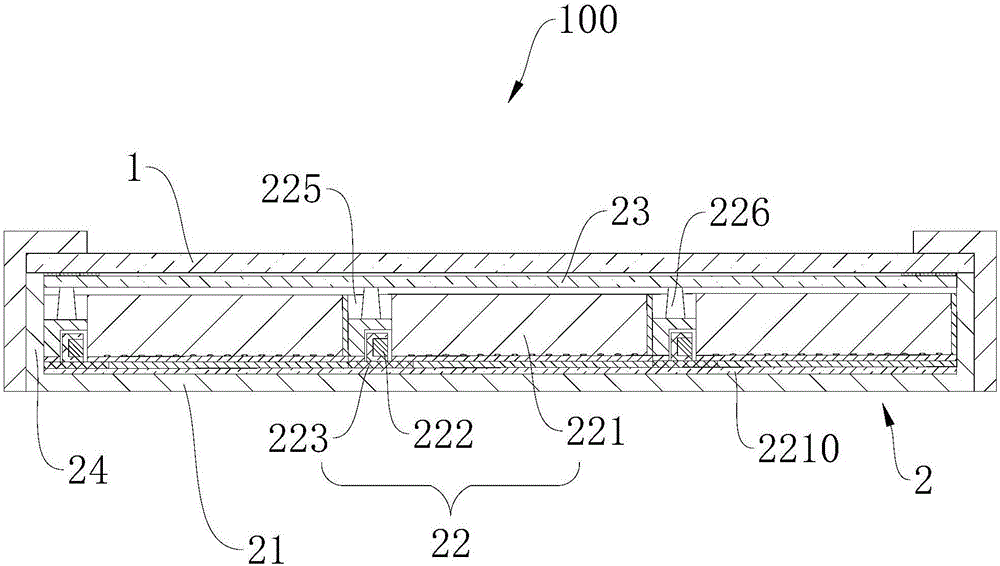

Backlight module and display device

InactiveCN106773297AImprove display qualityUniform light outputOptical light guidesNon-linear opticsBackplanePrinted circuit board

The invention discloses a backlight module. The backlight module comprises a backplane and a plurality of out-light units spliced in sequence and fixedly mounted on the backplane, the out-light unit comprises a light guide plate, a plurality of light sources and a flexible printed circuit board for loading the plurality of light sources, the light guide plate comprises an out-light surface and a mounting surface which are arranged relatively, and an in-light surface connected between the out-light surface and the mounting surface, a flexible printed circuit board is arranged adjacent to the in-light surface and used for making the light emitted from the plurality of light sources get into the light guide plate, the mounting surface is fixedly connected with the backplane, the backplane and the light guide plate are all flexible materials, the plurality of out-light units are used for lightening a display panel collectively to make the display panel emit light evenly. The backlight module emits light evenly. The invention further discloses a display device.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

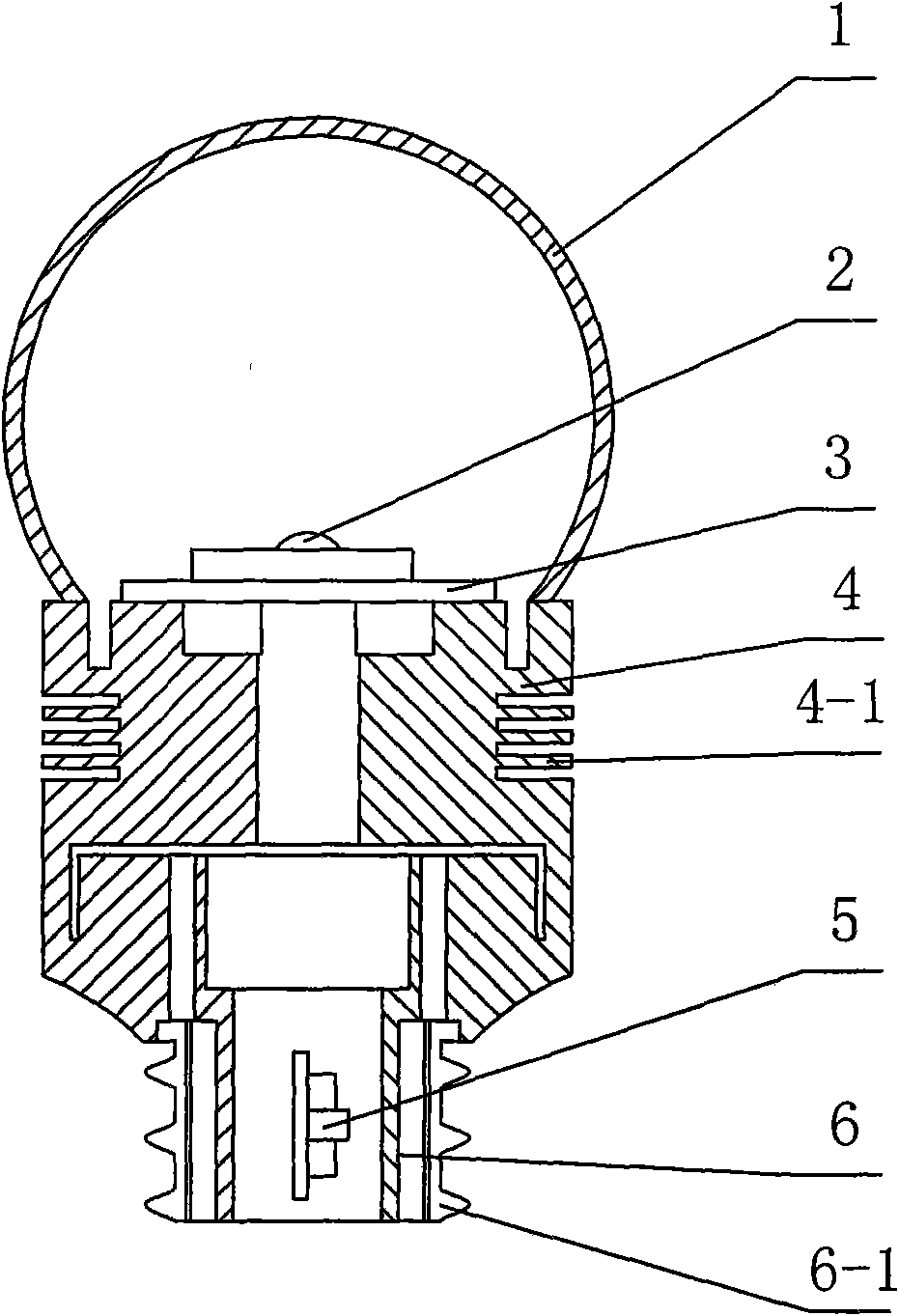

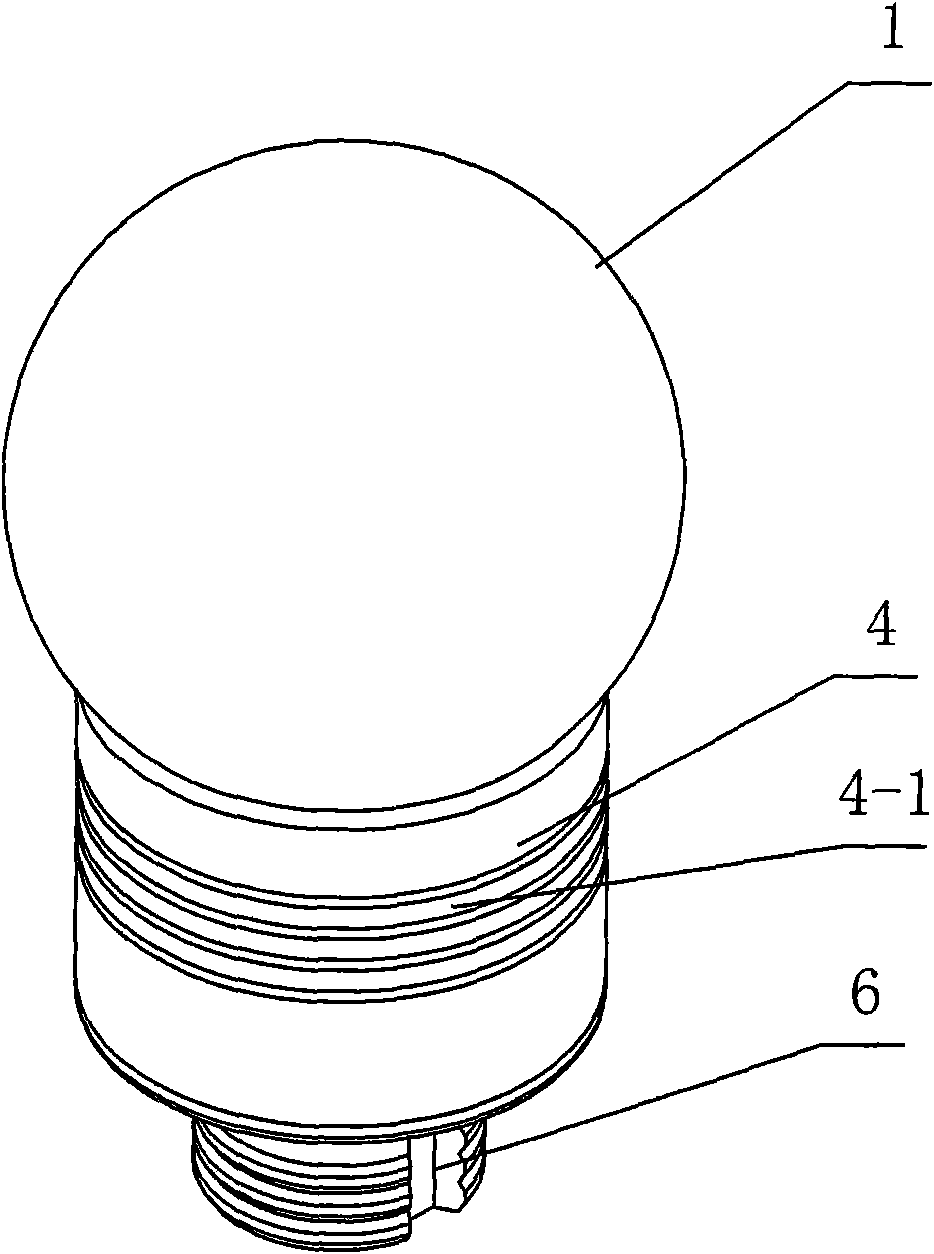

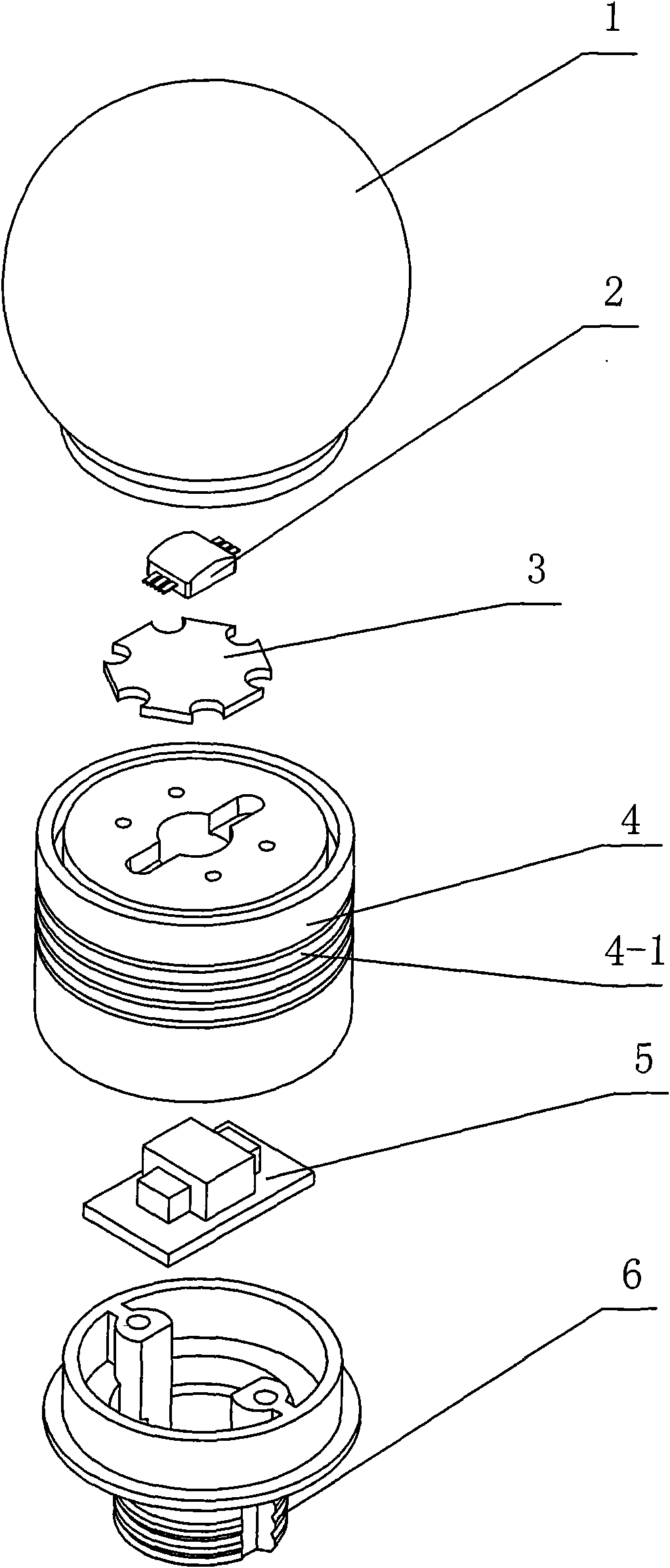

High power LED bulb

InactiveCN101614344AIncrease brightnessImprove performancePoint-like light sourceElectric circuit arrangementsEngineeringConstant current

The invention relates to a high power LED bulb, which comprises a connector for being connected with an illuminating lamp interface, an LED constant-current driving device, a radiator, an LED light source, a bulb cover and a circuit board, wherein the connector is provided with a cavity, and the LED constant-current driving device is fixed in the cavity; the radiator is a ceramic radiator with an annular radiating fin, and the upper part of the connector is fixedly connected with the lower part of the radiator; the circuit board is an aluminum-based circuit board, and the LED light source is fixed on the circuit board; and the circuit board is fixed at the top end of the radiator, the bulb cover is arranged above the radiator, and the lower part of the bulb cover is fixedly connected with the radiator. The high power LED bulb has the advantages of high luminescent efficiency, good heat dissipation effect, low cost, simple production and reliable performance.

Owner:JIANGSU GUOXING ELECTRIC EQUIP

Backlight module and light source assembly thereof

ActiveCN104696780AUniform light outputAvoid problemsPoint-like light sourceDiffusing elementsLight guideEngineering

A light source assembly includes a base plate, a light source secured on the base plate, a first reflection member, a second reflection member, and a diffusion plate. The first reflection member includes a base portion secured on the base plate and a plurality of protrusions with reflection surfaces inclined to the base plate. A through hole is defined on the base portion to receive the light source. Each protrusion protrudes from a side of the base portion away from the base plate and extends around the through hole. The second reflection member includes a reflection portion defining a plurality of light holes. The diffusion plate covers the second reflection member. Light emitting from the light source transmits to the light guide assembly via the reflection portion and the reflection surfaces.

Owner:FUTAIHUA PRECISION ELECTRONICS ZHENGZHOU

LED encapsulating structure and method thereof

InactiveCN101887940AUniform light outputImprove uniformitySolid-state devicesSemiconductor devicesEngineeringLight-emitting diode

The invention discloses an LED encapsulating structure and a method thereof. The encapsulating structure comprises a bracket, an LED wafer, a wire, transparent external encapsulating glue and external encapsulating glue in which a dispersant is added, wherein the transparent external encapsulating glue is in up-and-down hierarchical connection with the external encapsulating glue in which the dispersant is added; the bracket comprises two parallel electrodes; the end surface of one end of the electrodes is provided with a groove supporting seat; the LED wafer is fixed on the bottom of the groove supporting seat by primer; the wire is connected with the LED wafer and the electrodes; the transparent external encapsulating glue is used for coating the LED wafer, the wire and the part of the bracket where the groove supporting seat is located; the transparent external encapsulating glue is higher than the groove supporting seat and is used for coating the LED wafer; the external encapsulating glue in which the dispersant is added is lower than the groove supporting seat, wherein the dispersant is distributed on the external encapsulating glue in which the dispersant is added; and no dispersant is distributed on the transparent external encapsulating glue. By adopting the encapsulating structure, good spot and uniform illumination of the light emitted by an LED are realized without reducing the brightness.

Owner:LEDMAN OPTOELECTRONICS

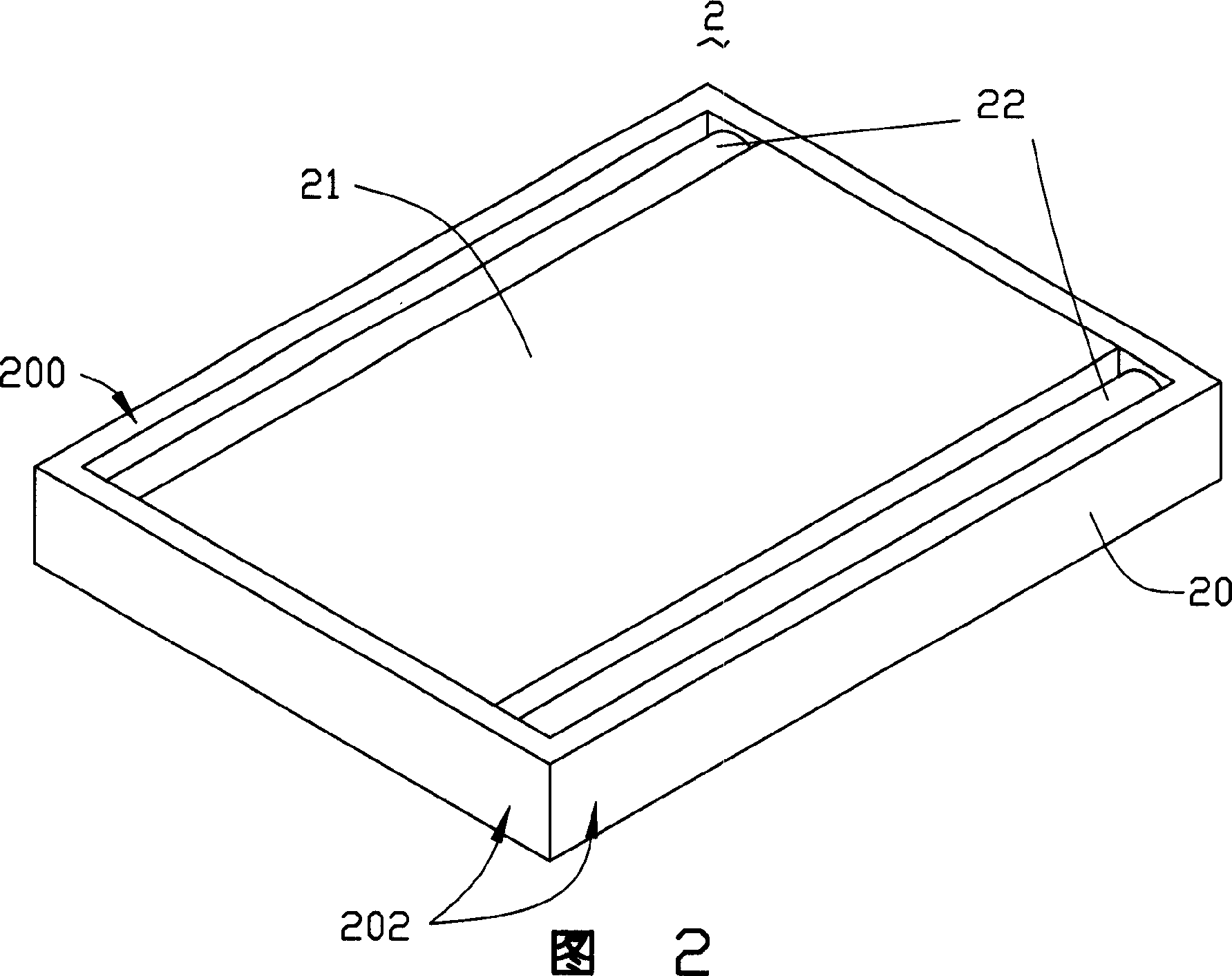

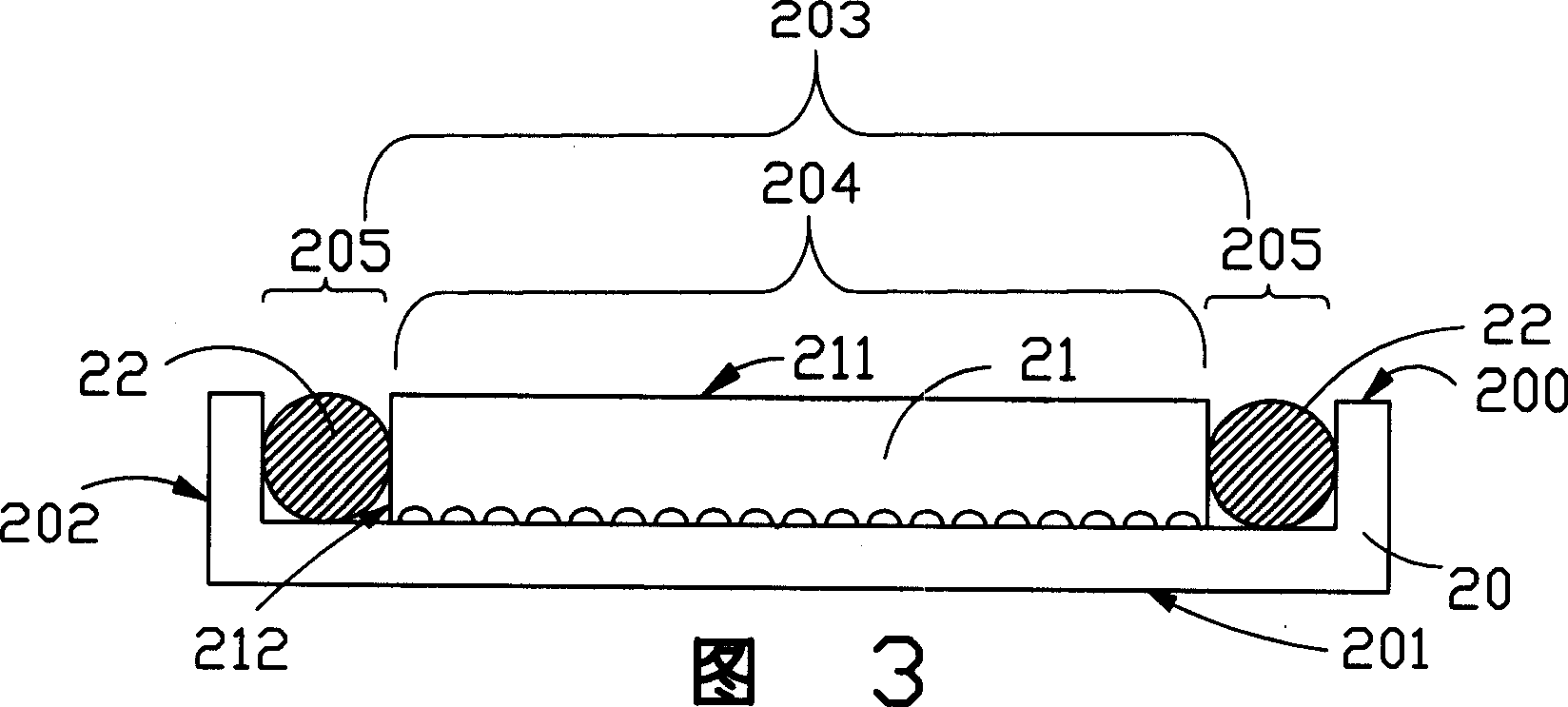

Back-to-light system

InactiveCN1591123AUniform light outputLow costDiffusing elementsNon-linear opticsLight guideEngineering

The present invention relates to a backlight system, it includes a frame body, a light-conducting plate and at least one light source. Said frame body has a recessed region whose opening is upward, said recessed region has a first space and at least a second space, said second space in arranged close to said first space. Said light-conducting plate is placed in said first space of said recessed region, in which said light-conducting plate and said frame body are made into integrally-formed structure.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Improved LED packaging method and packaging structure

ActiveCN105304772ALow costImprove luminous brightness and thermal performanceSemiconductor devicesLed packagingChemistry

The invention discloses an improved LED packaging method and packaging structure. The packaging method comprises the following steps: 1, coating the surface of an LED chip with phosphor and a liquid-state organic silica gel composition after the phosphor and the liquid-state organic silica gel composition are well mixed; 2, placing the LED chip processed in step one under the condition of a first temperature for heating so as to realize deposition of the phosphor, wherein the firs temperature is greater than a room temperature and smaller than a crosslinking temperature of the organic silica gel composition; and 3, placing the LED chip processed in step two under a heating and / or illumination condition to enable the organic silica gel composition to be solidified. According to the invention, LED packaging can be rapidly and simply realized at a low cost, conformal deposition of the phosphor on the surface of the LED chip can be realized in a packaging process under the condition that less phosphor is consumed, the light emitting quality of an LED device is substantially improved (for instance, light is emitted more uniformly, light spots are basically free from blue-circle and yellow-circle phenomena, and the like), and the luminescence brightness and the heat dissipation performance of the LED device can also be effectively improved. Therefore, the application prospect is wide.

Owner:FLORY OPTOELECTRONICS MATERIALS SUZHOU CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com