White LED light source package

A technology of LED light source and LED chip, which is applied in the direction of electrical components, electric solid-state devices, circuits, etc., can solve the problems of uniform coating of phosphor layers and uneven output light, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

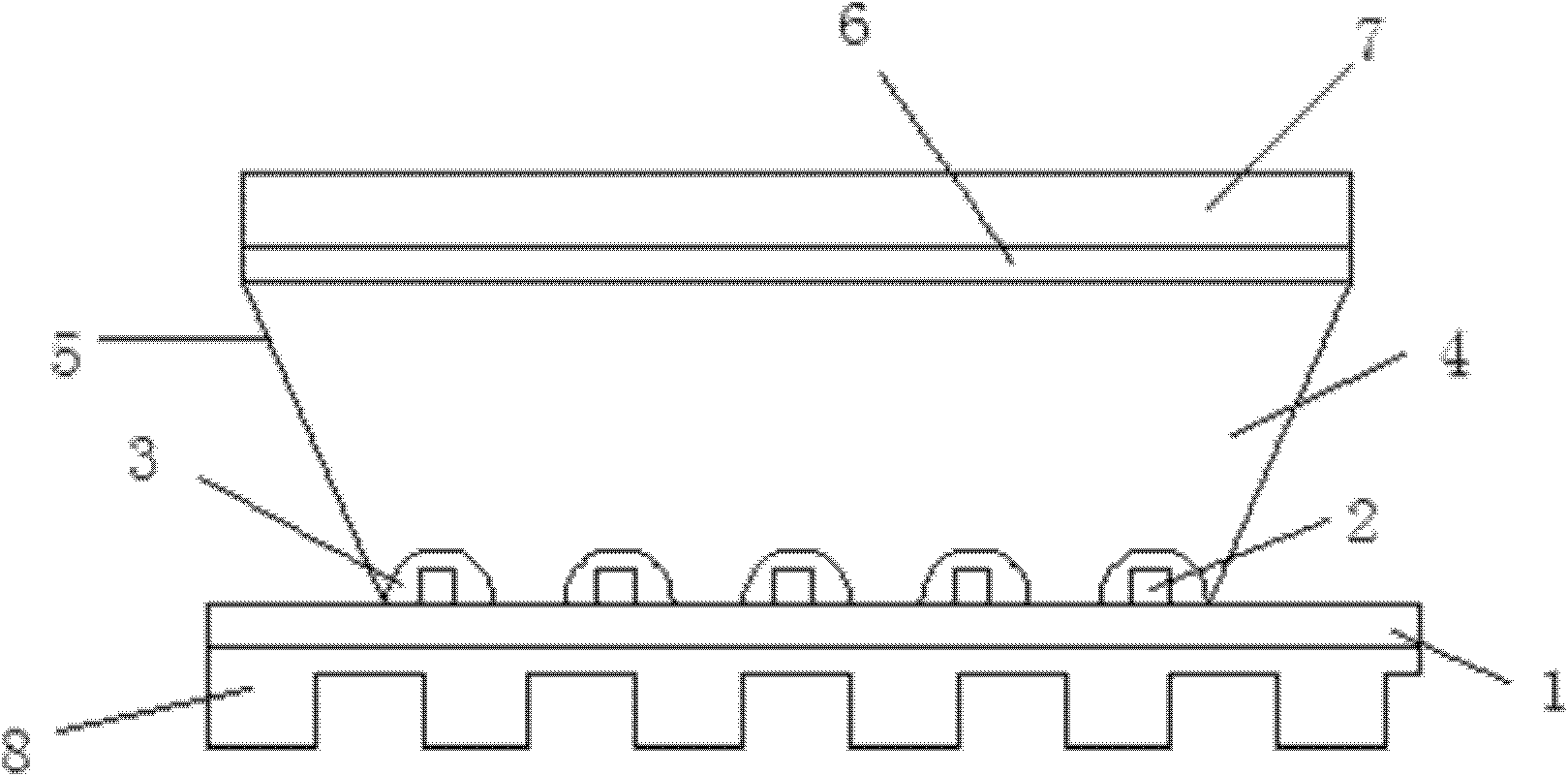

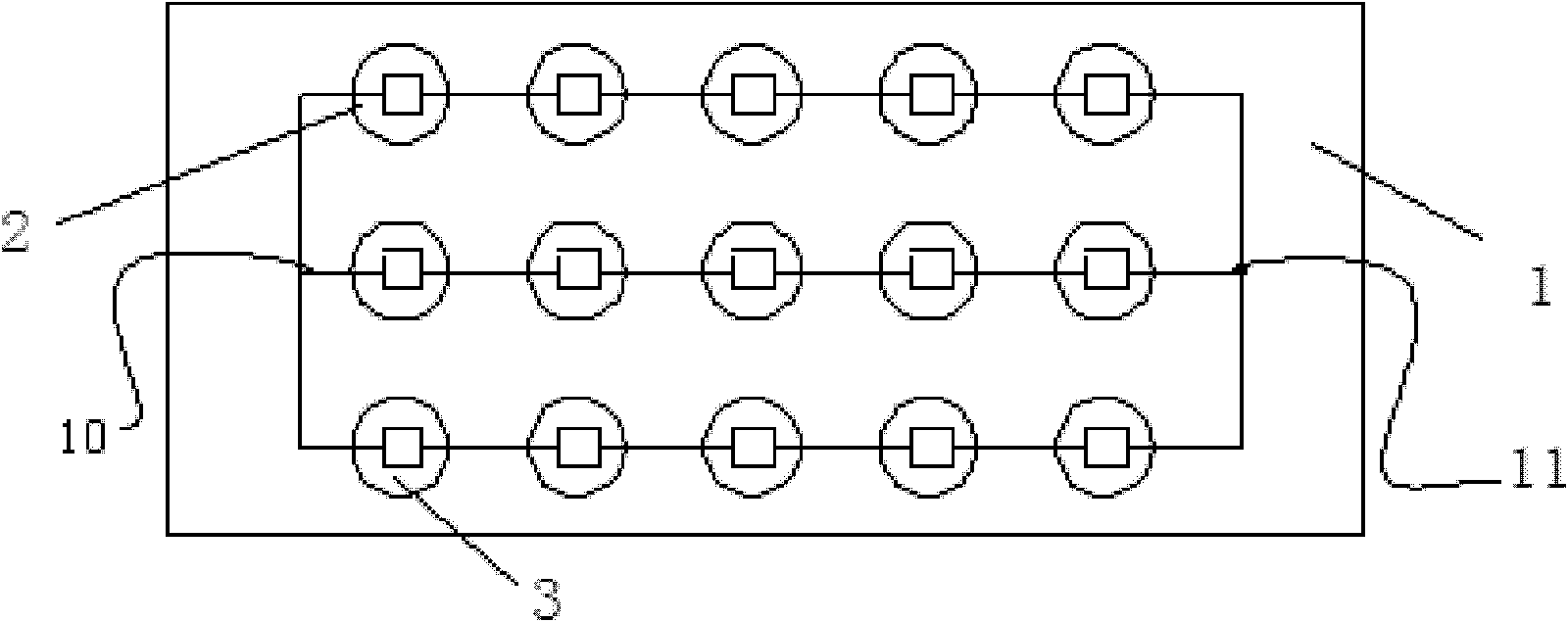

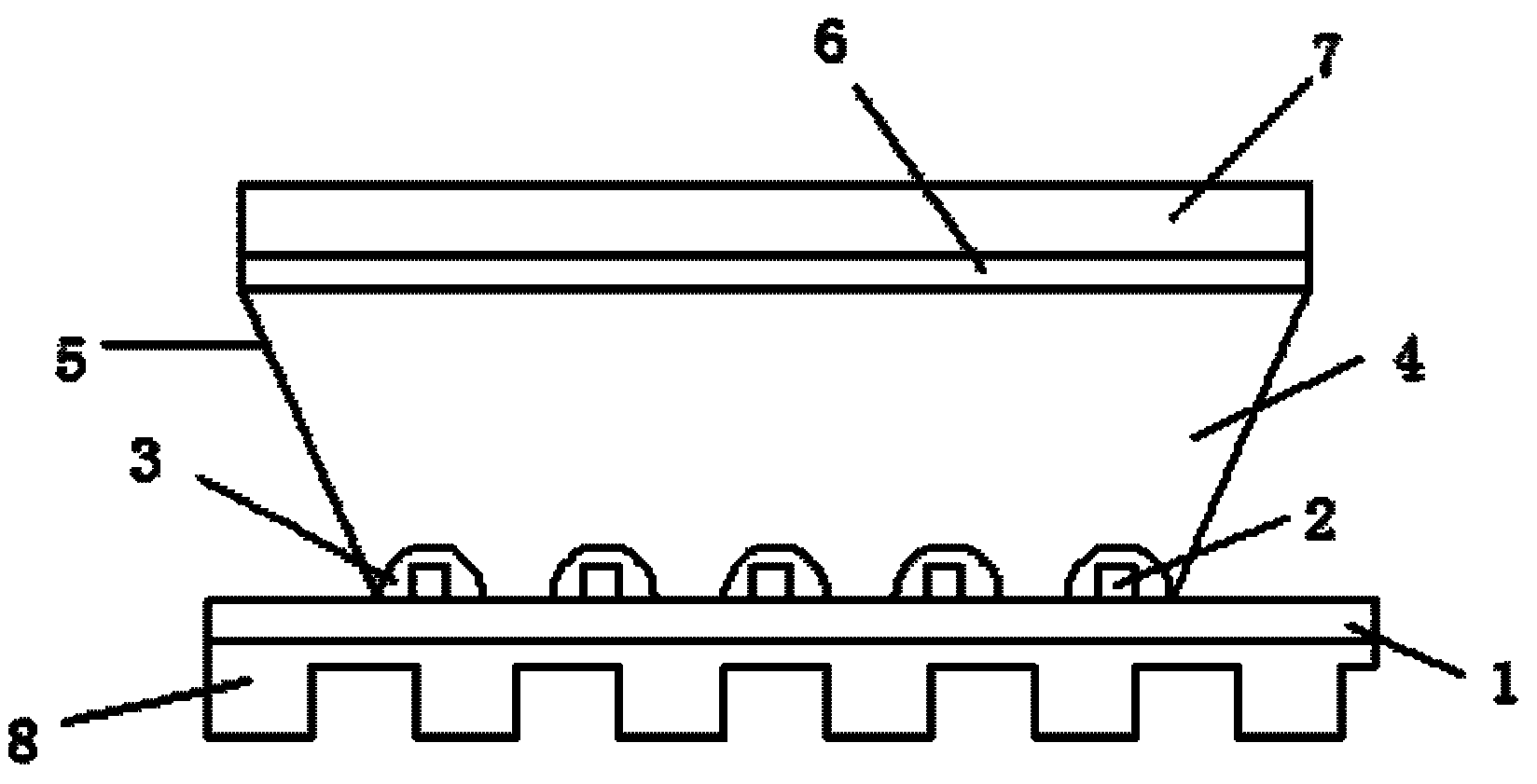

[0012] The white LED light source package of the present invention is described in detail below in conjunction with the accompanying drawings: please refer to figure 1 As shown, the white LED light source package of the present invention includes a heat sink 8, an insulating substrate 1 bonded to the upper surface of the heat sink 8, a plurality of LED chips 2 bonded to the upper surface of the insulating substrate 1 and arranged in an array, and bonded to the insulating substrate 1. A number of reflective focusing cups 3 on the substrate 1 and surrounding each LED chip 2, an epoxy resin film 4 coated on the upper surface of the insulating substrate 1, and reflective cups coated on both sides of the epoxy resin film 4 The cup 5 , the phosphor layer 6 coated on the upper surface of the epoxy resin film 4 , and the glass 7 coated on the upper surface of the phosphor layer 6 , and the power supply are respectively connected to the electrodes at both ends of the LED chip 2 .

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com