Patents

Literature

2515 results about "Led packaging" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

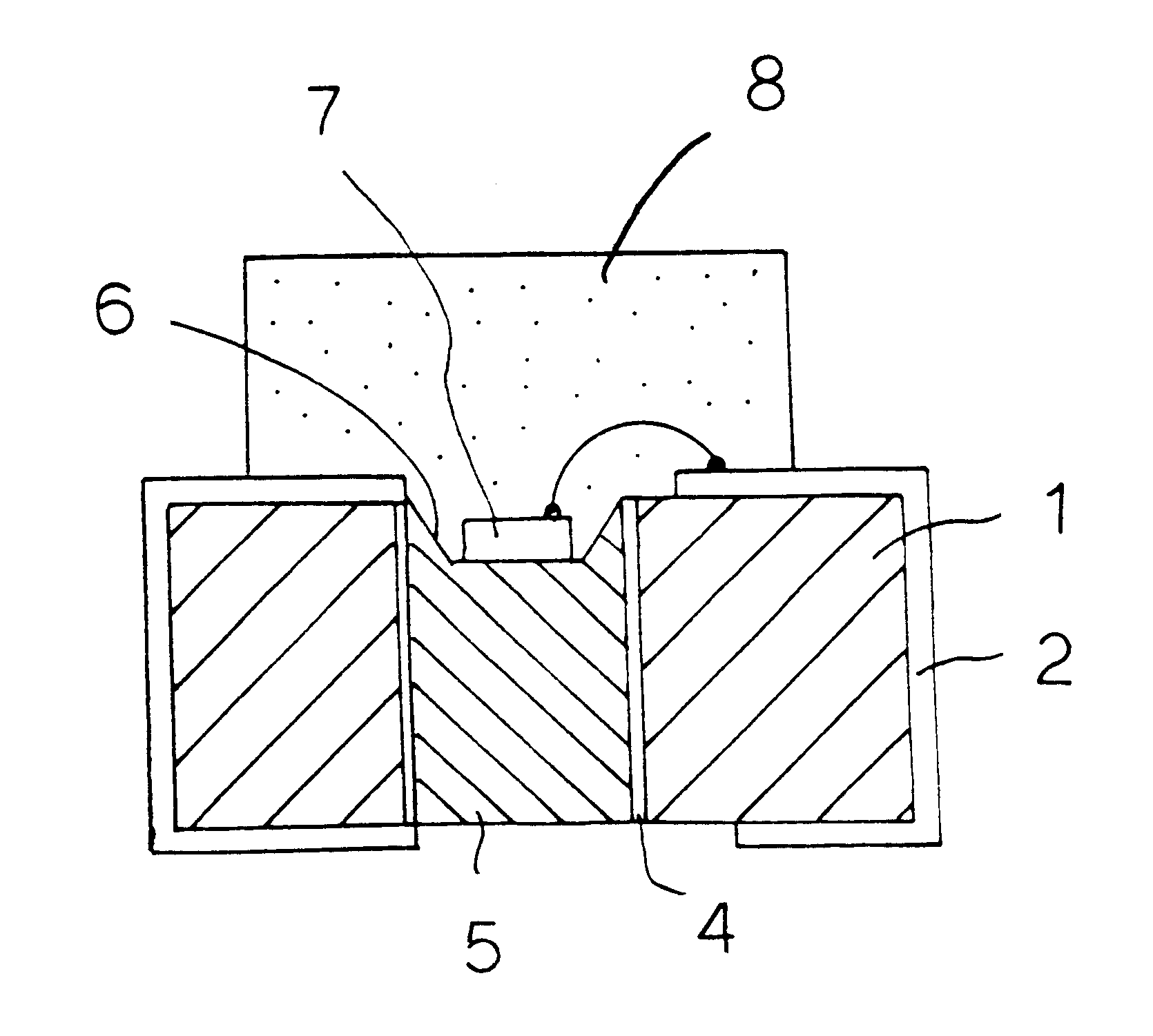

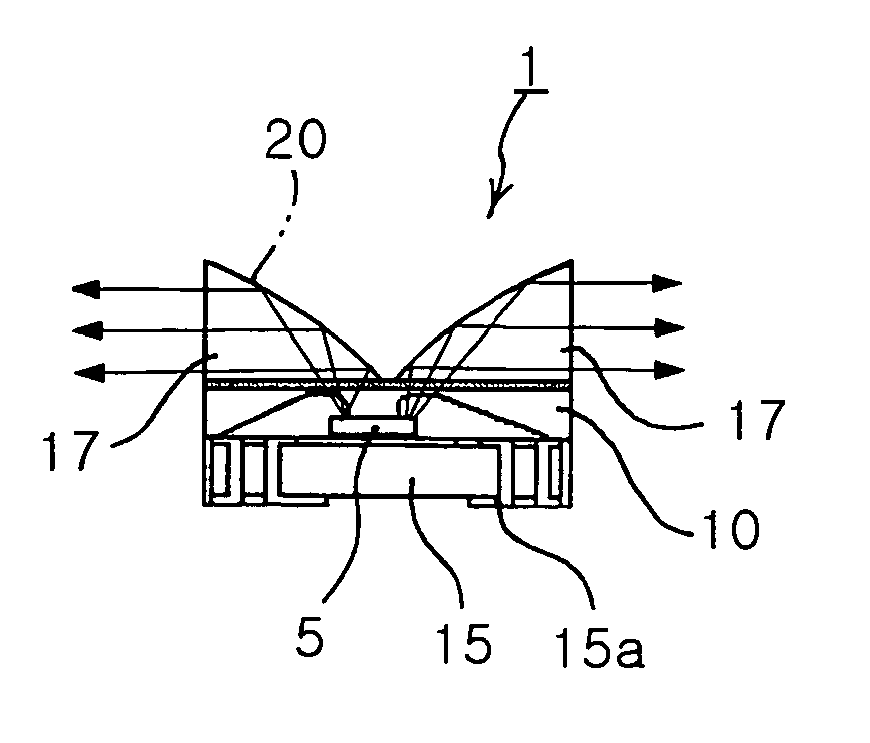

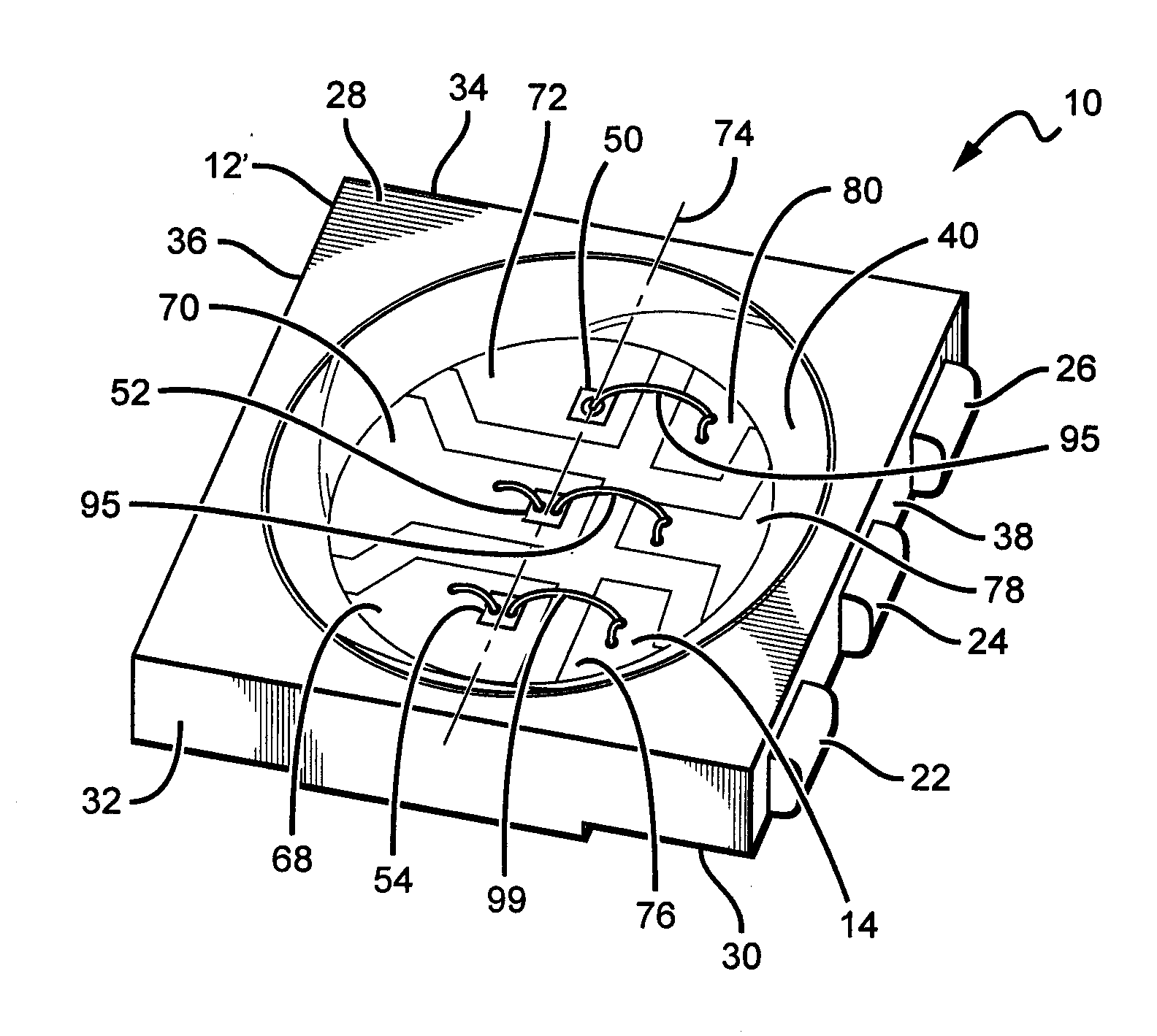

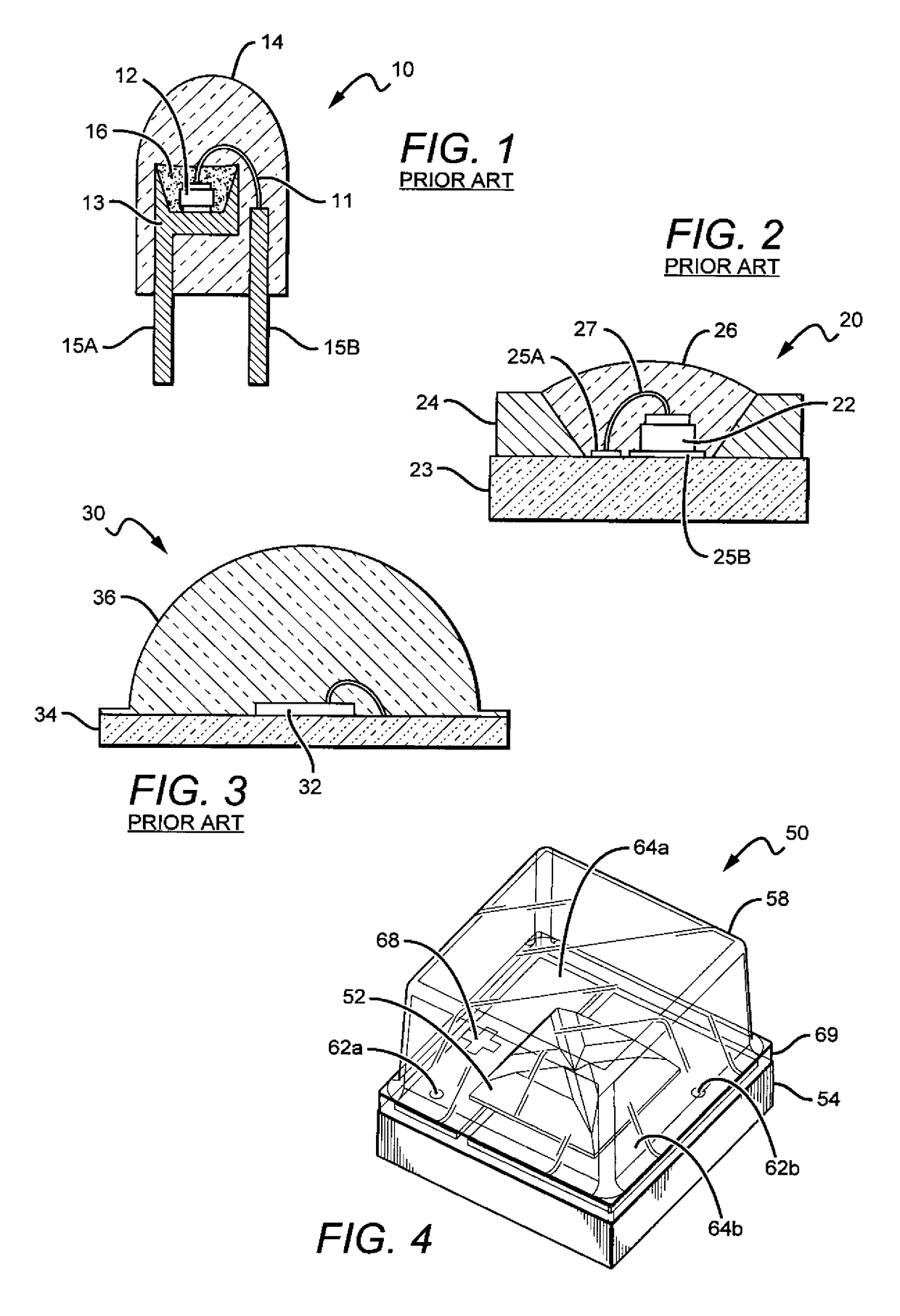

Method and apparatus for using light emitting diodes

InactiveUS20050231983A1Milk preservationLighting heating/cooling arrangementsThermal energyEngineering

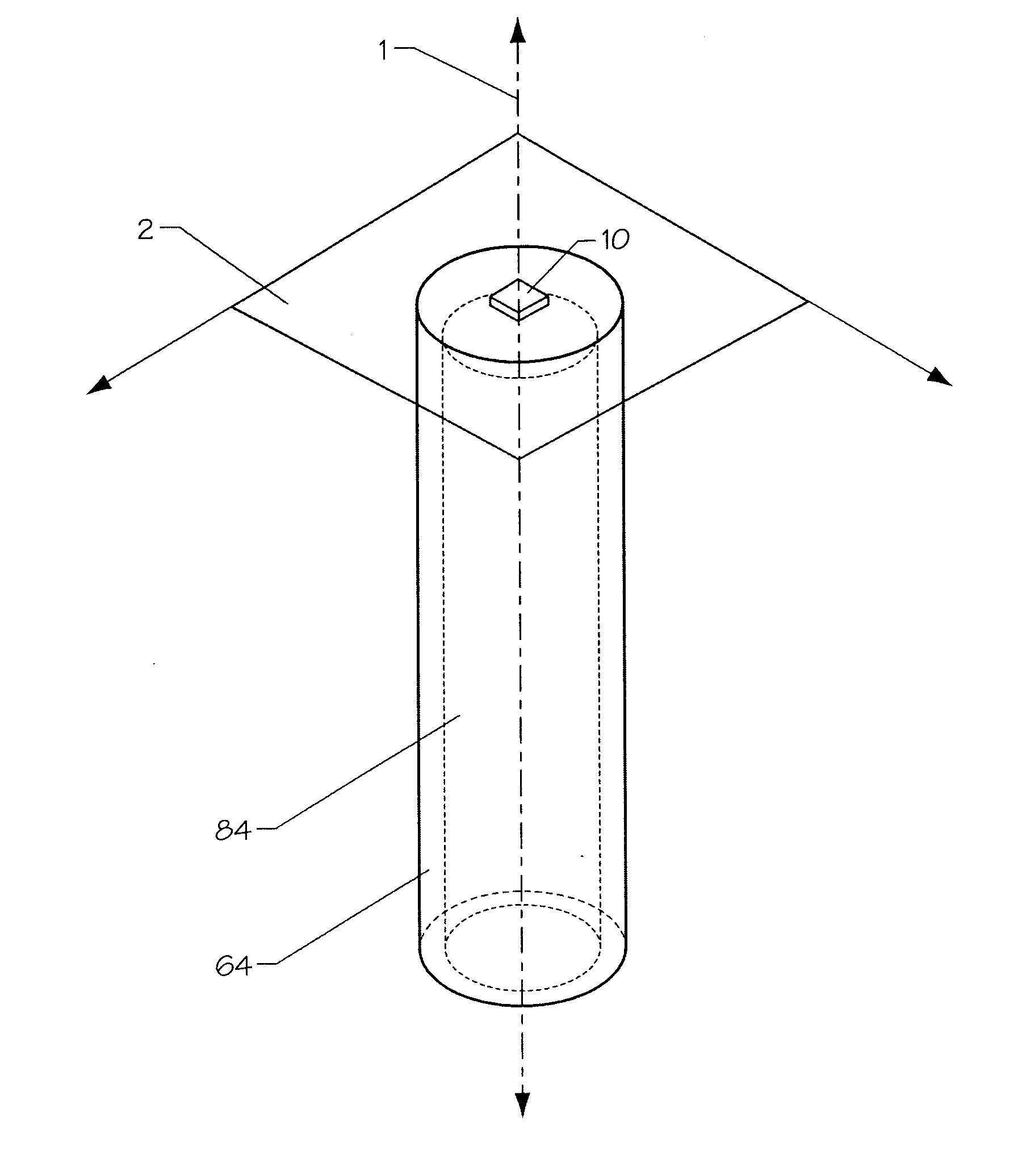

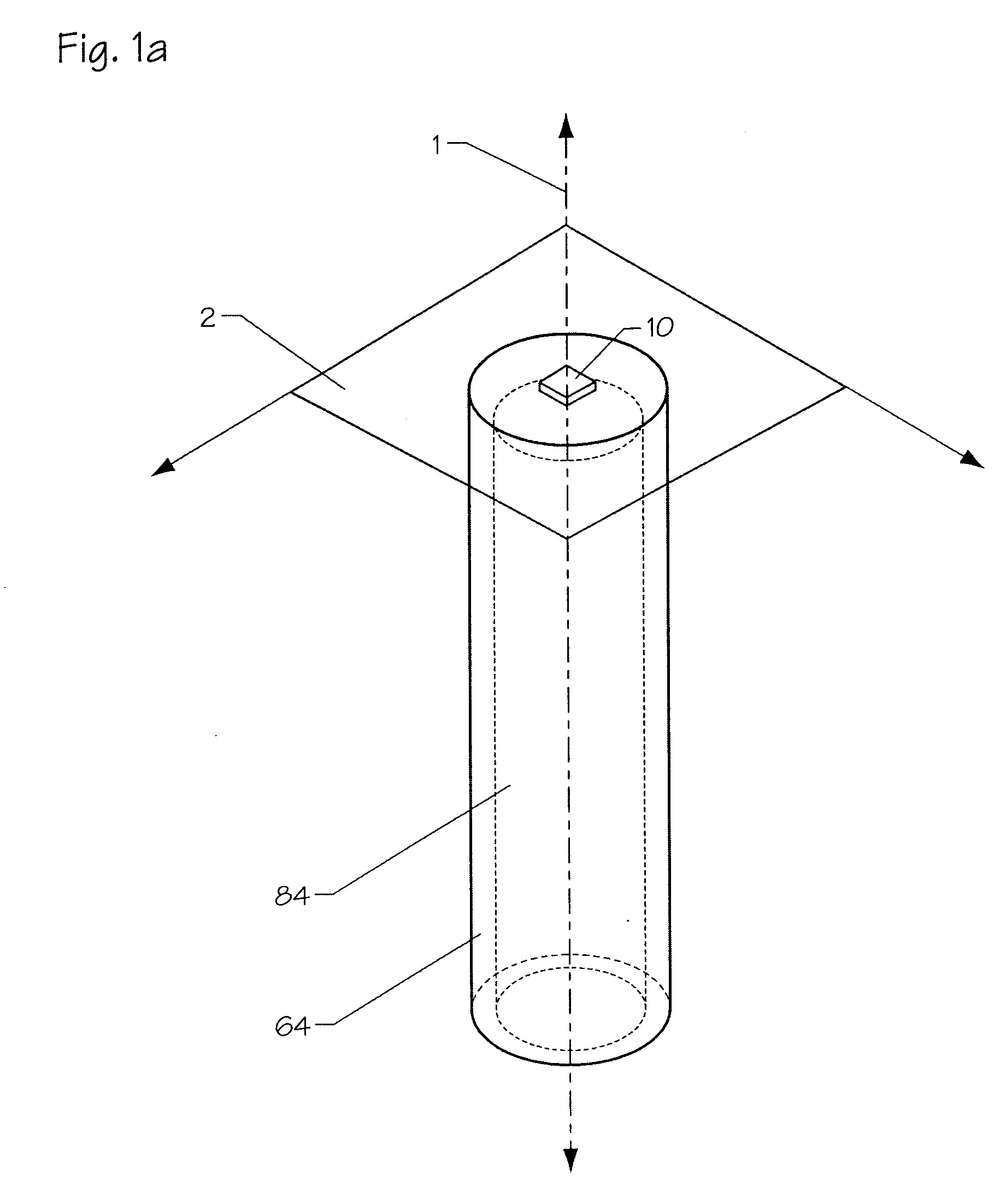

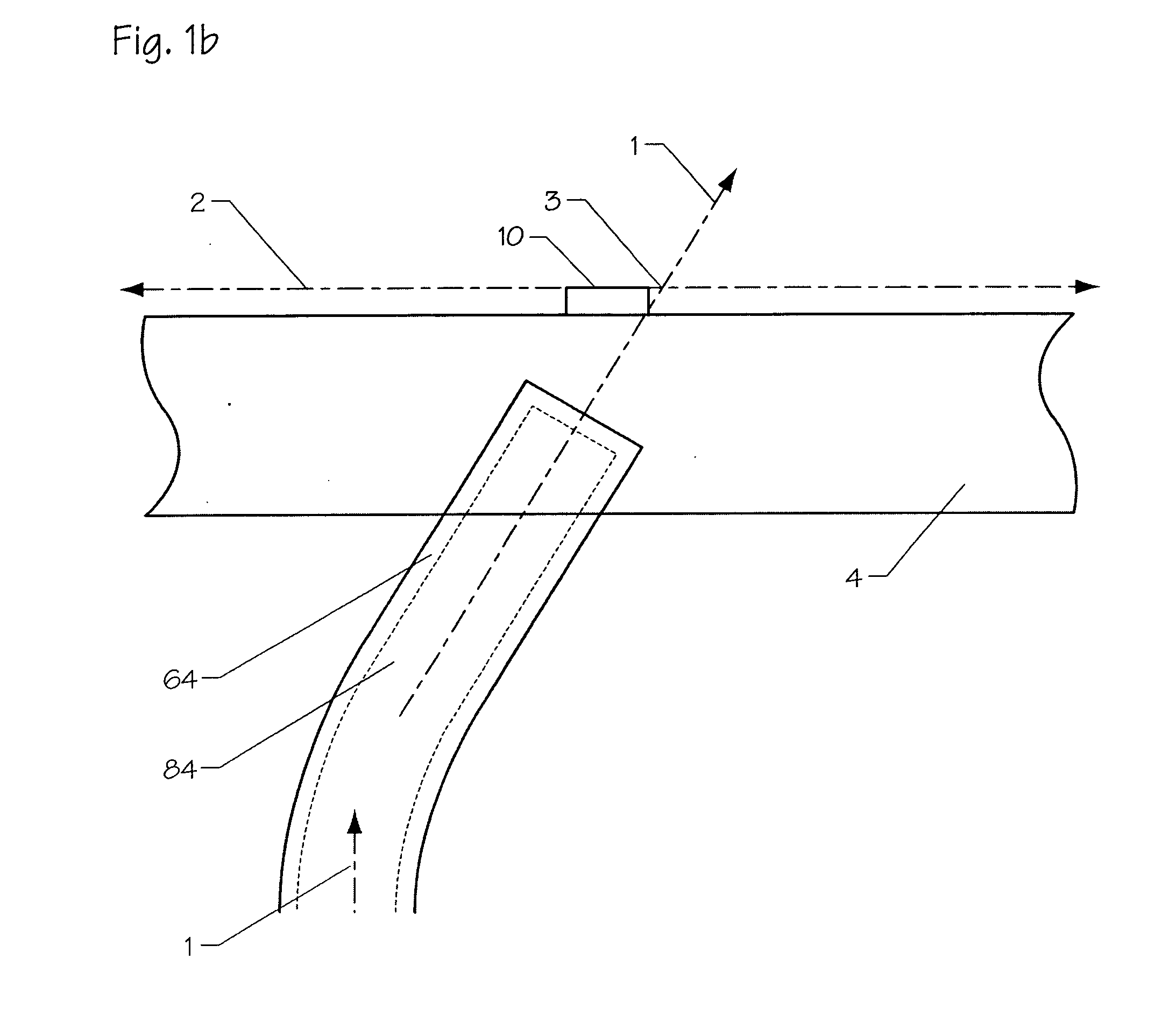

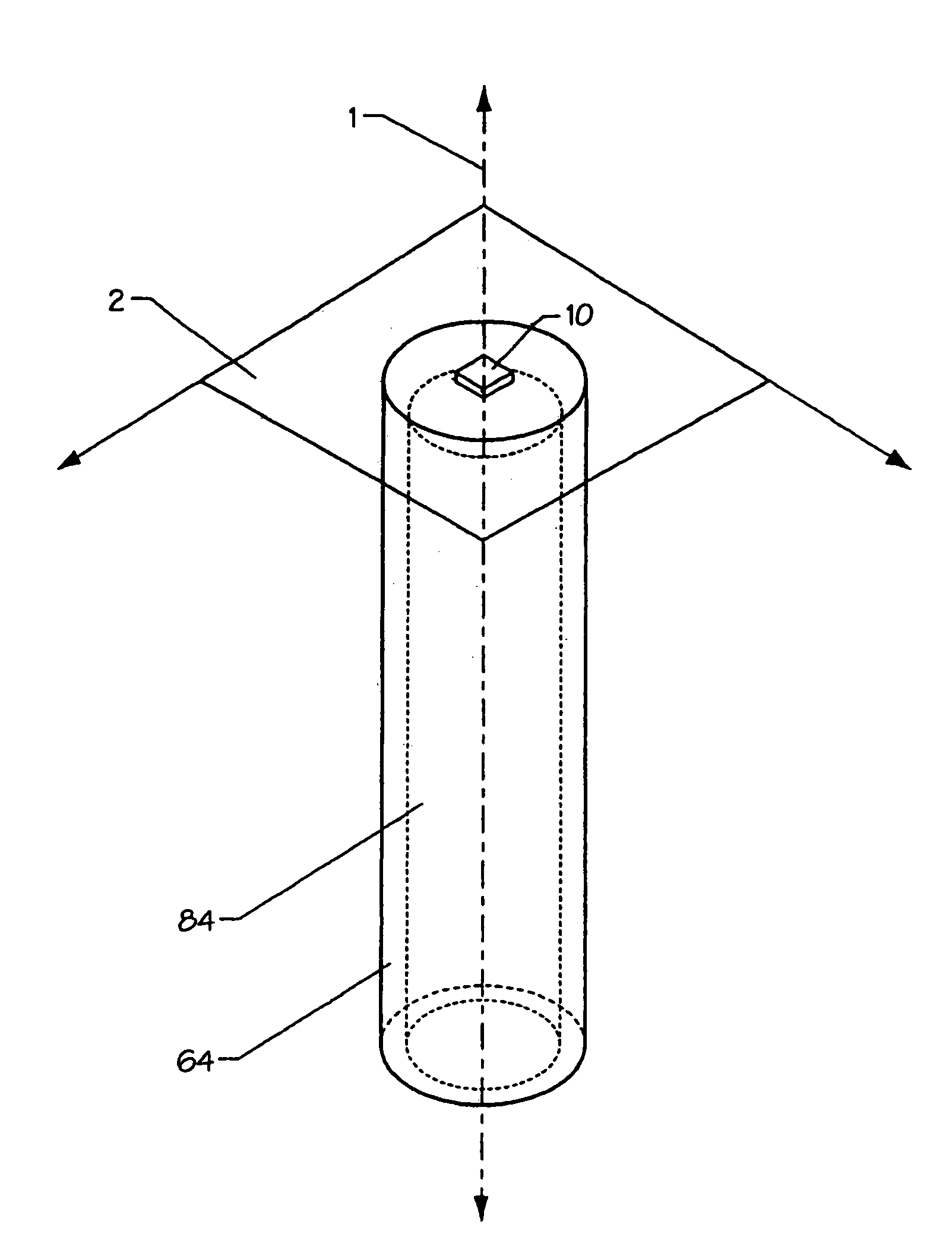

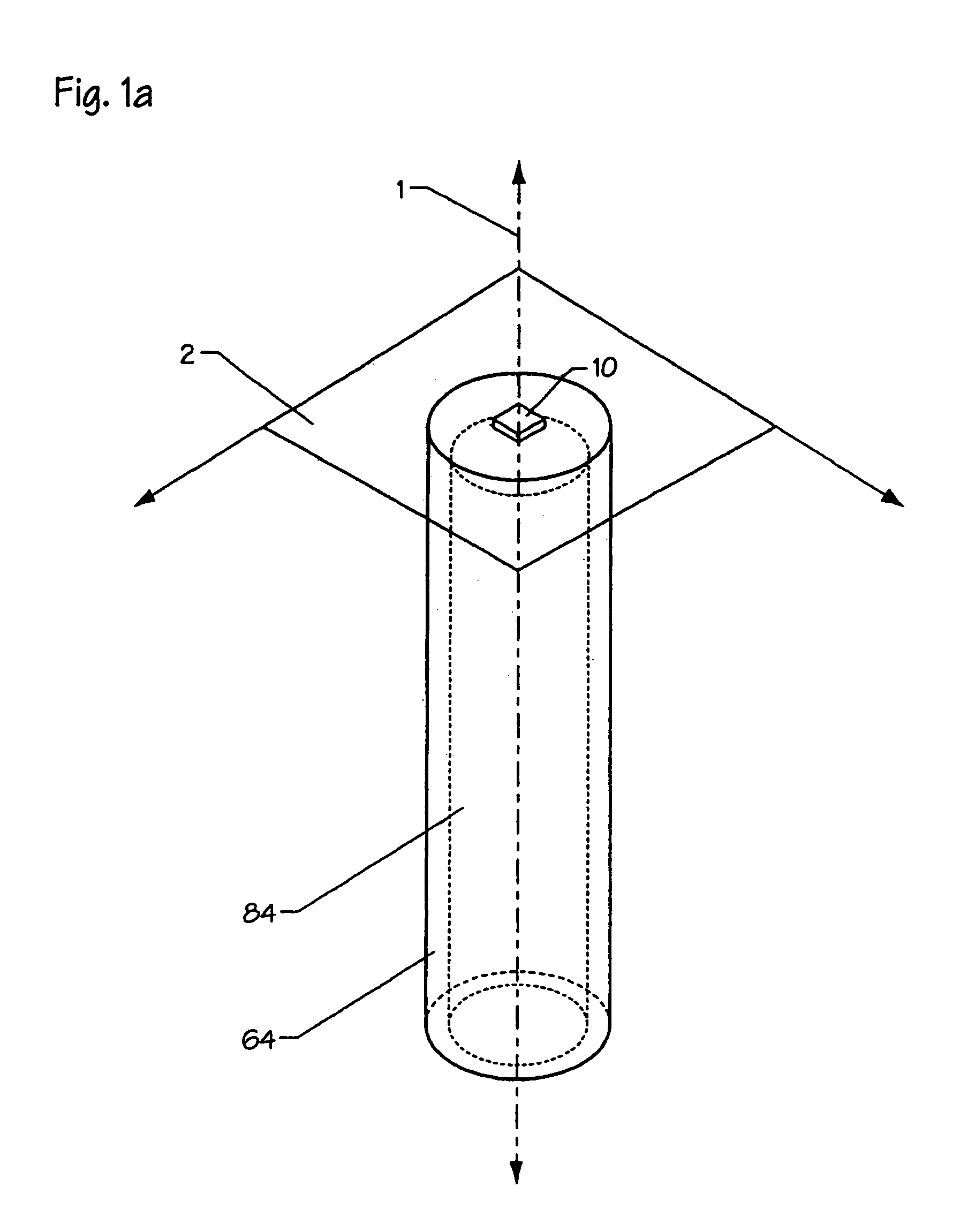

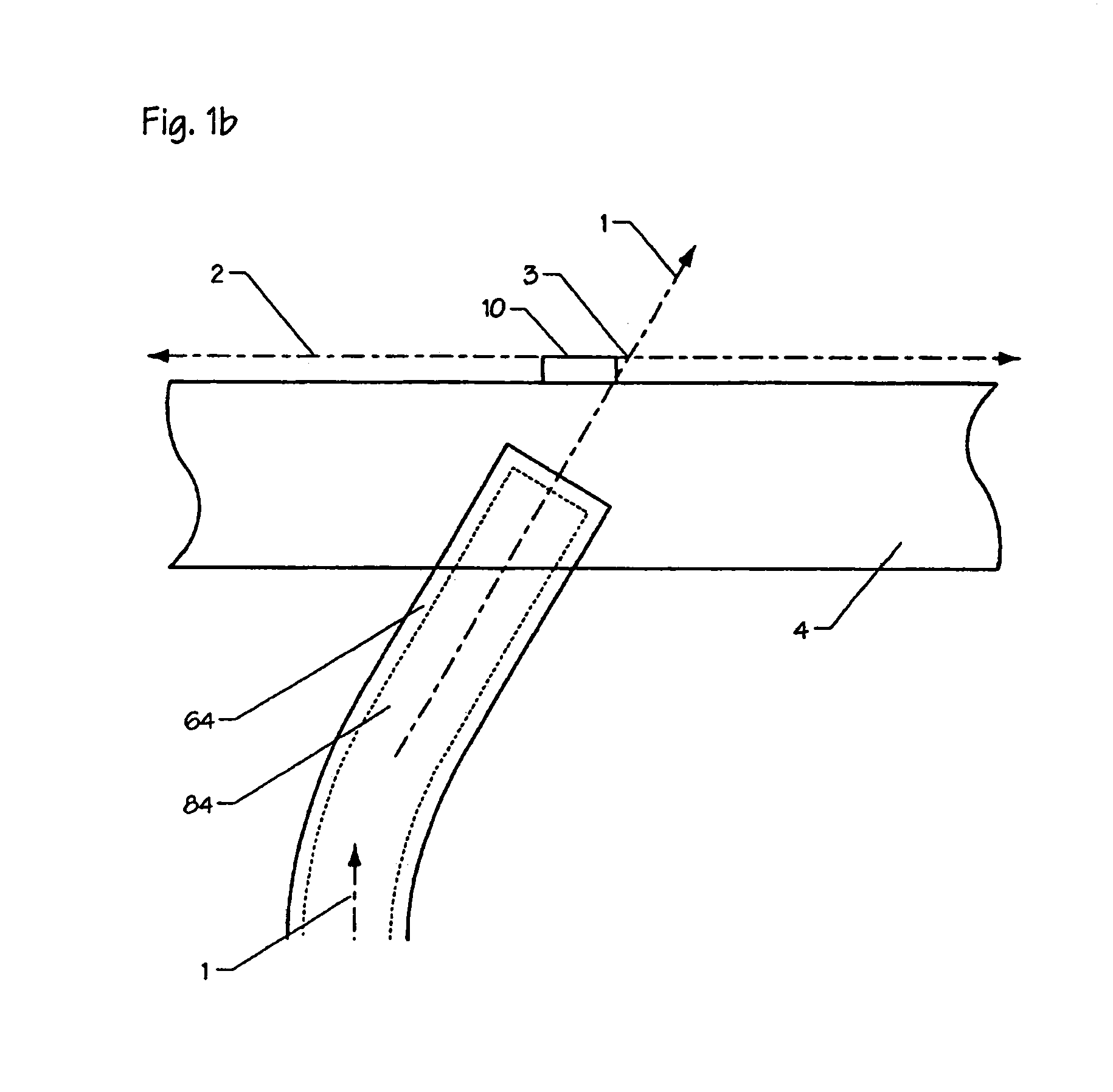

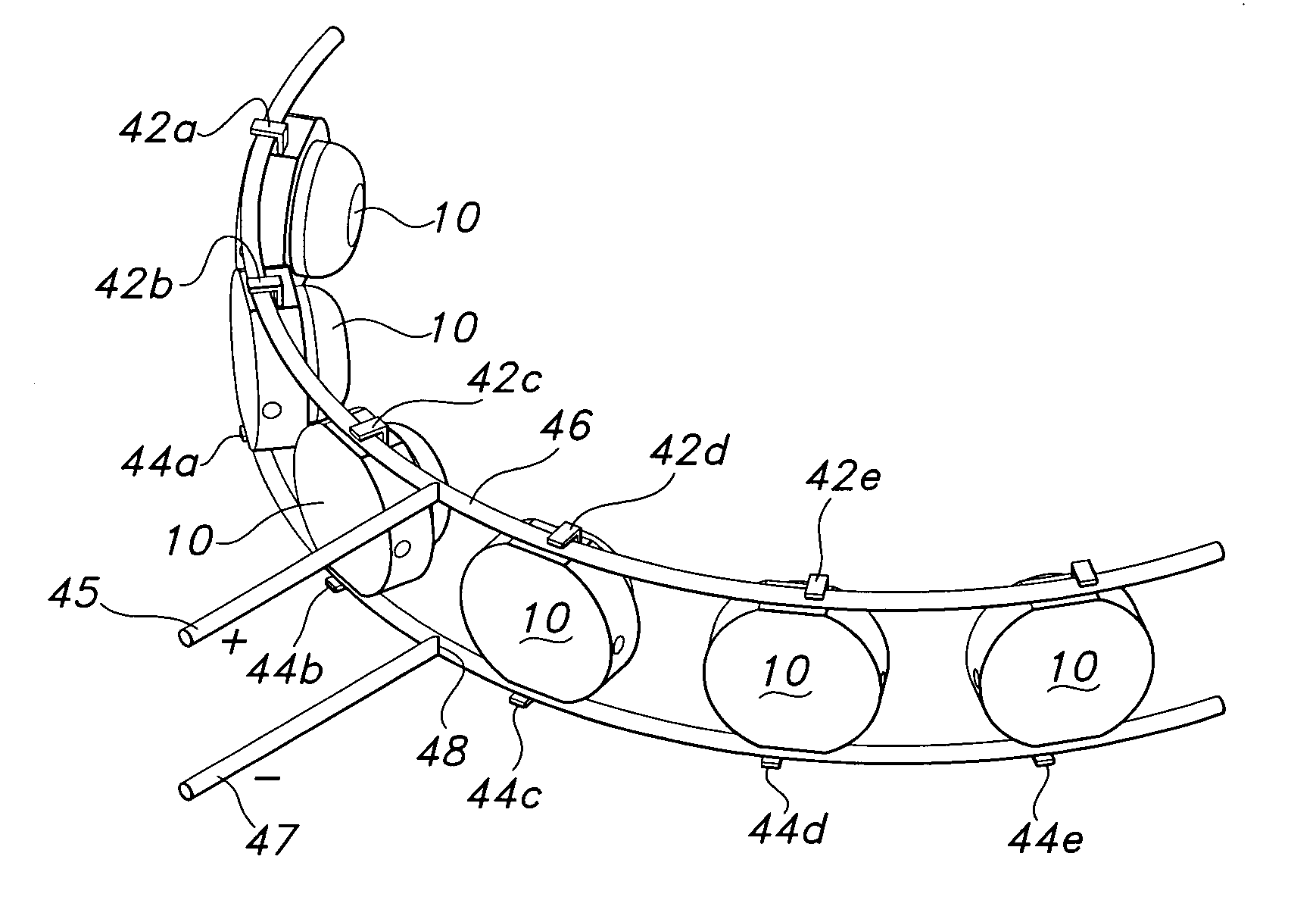

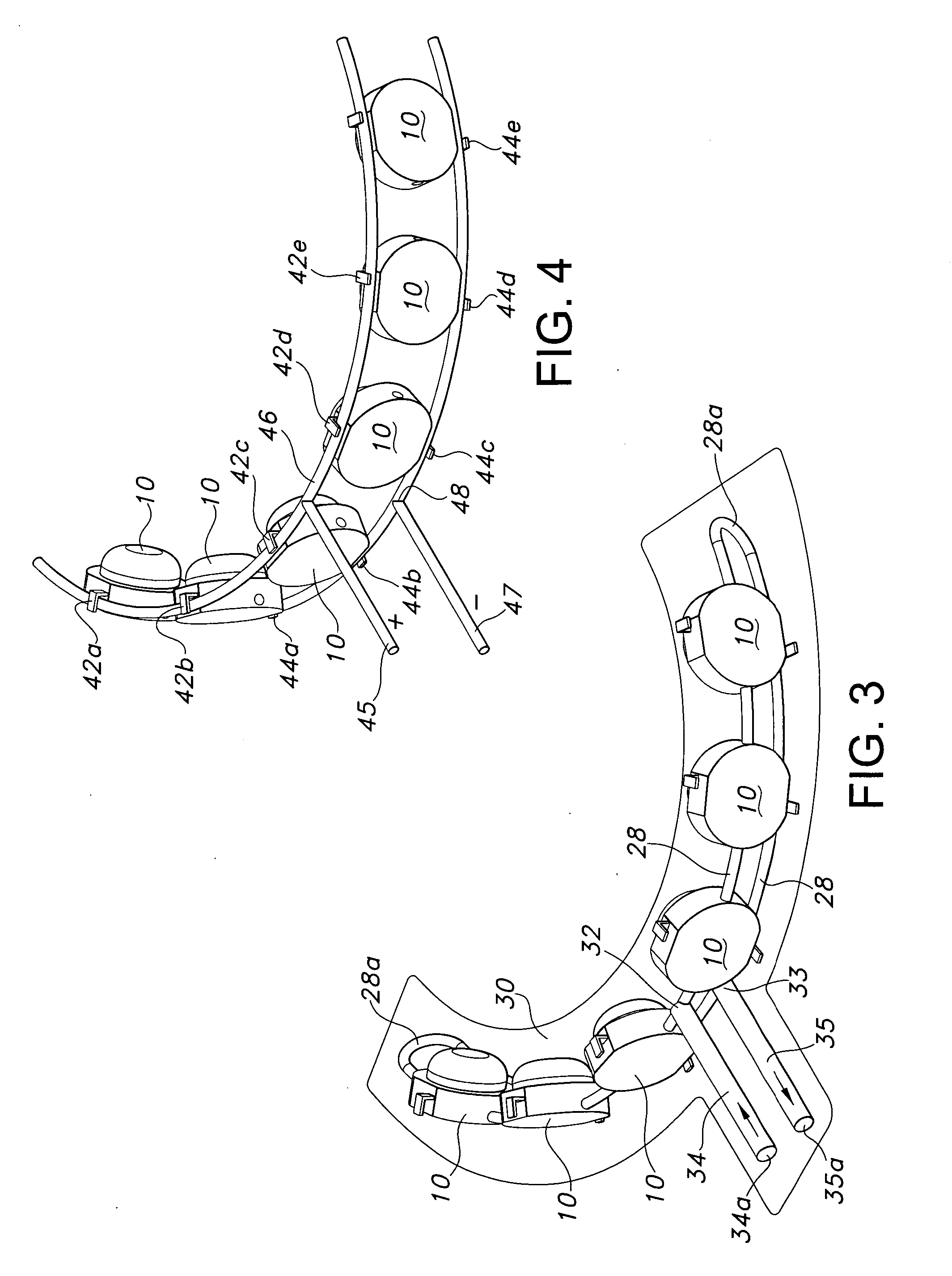

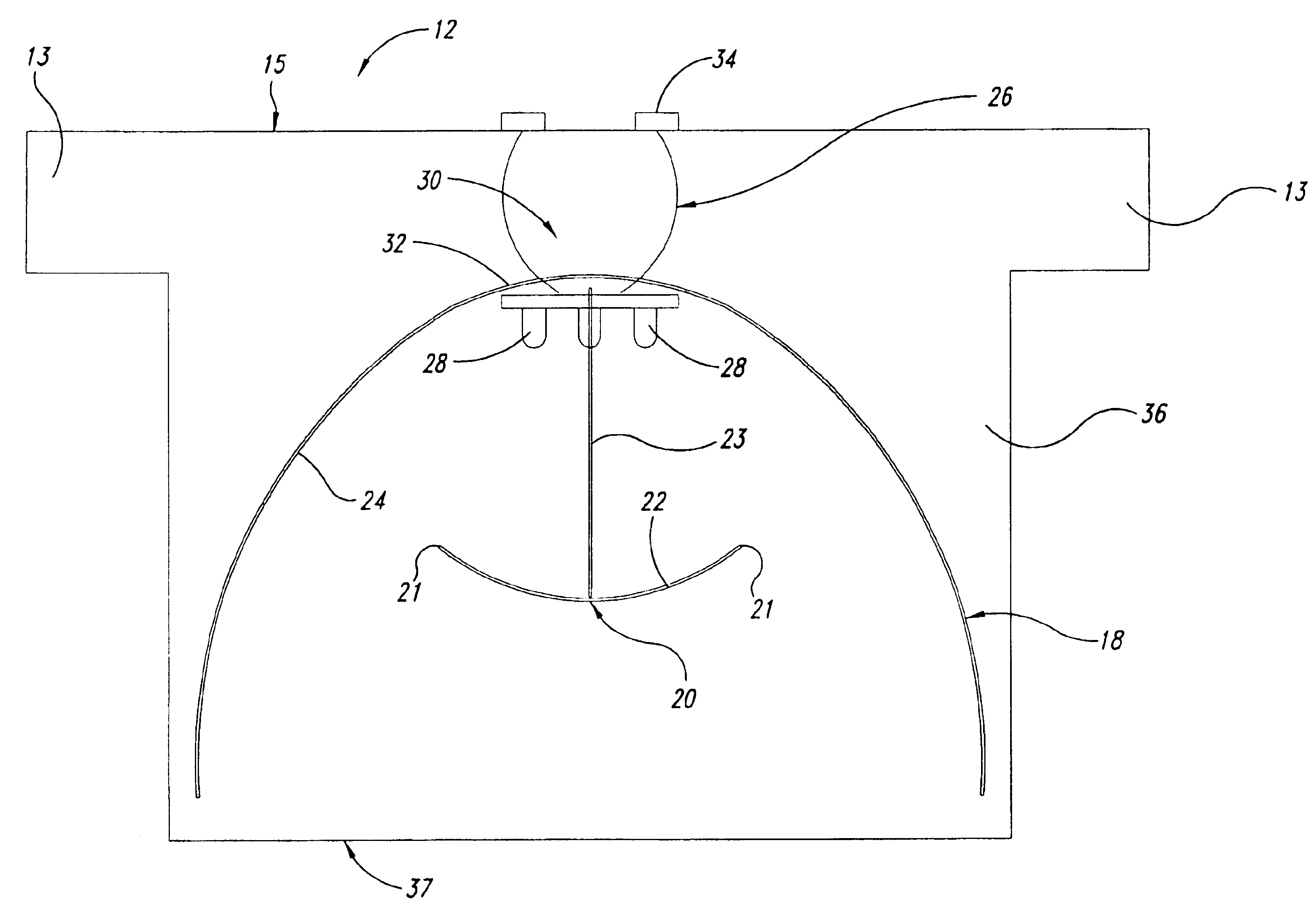

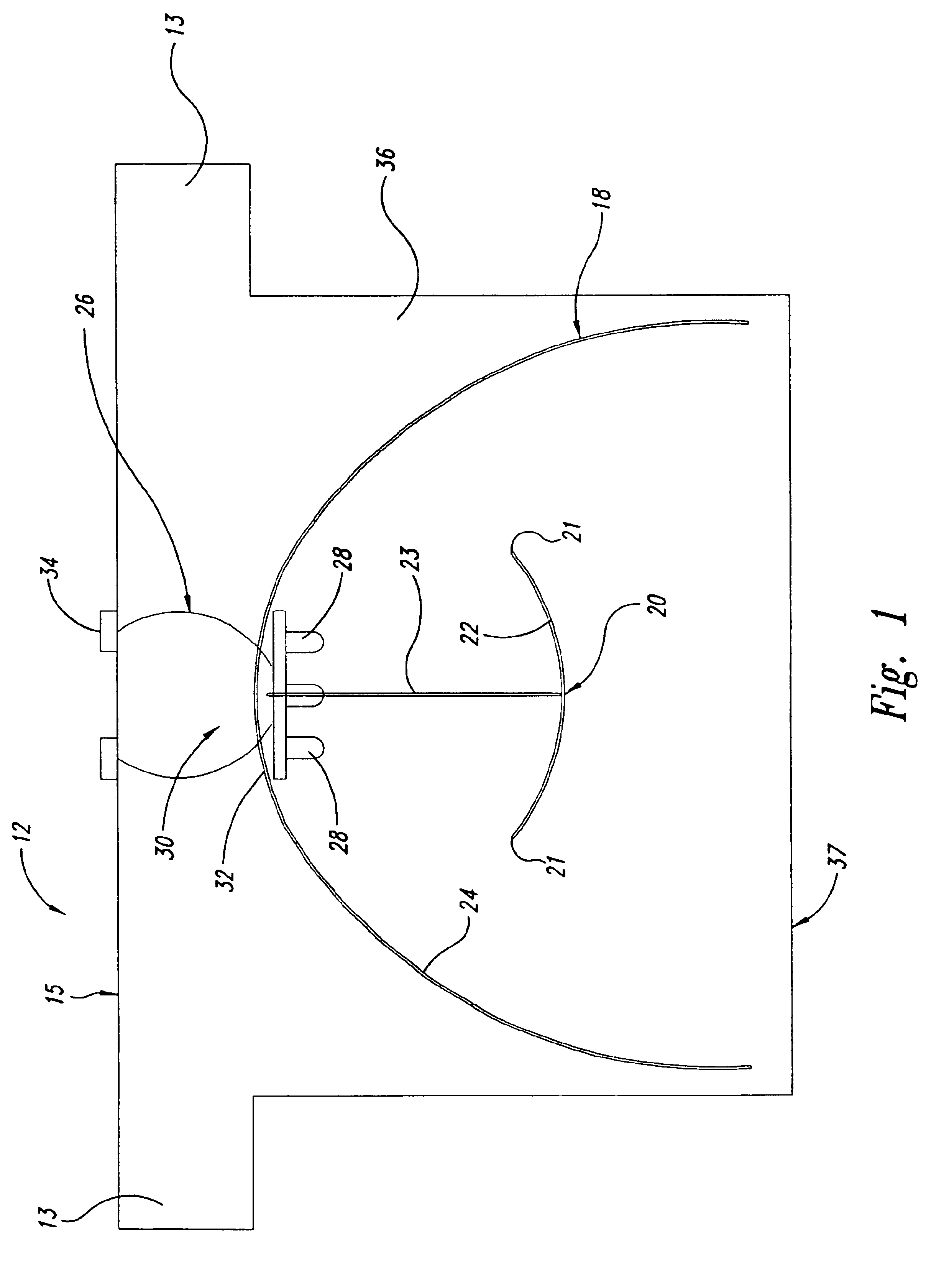

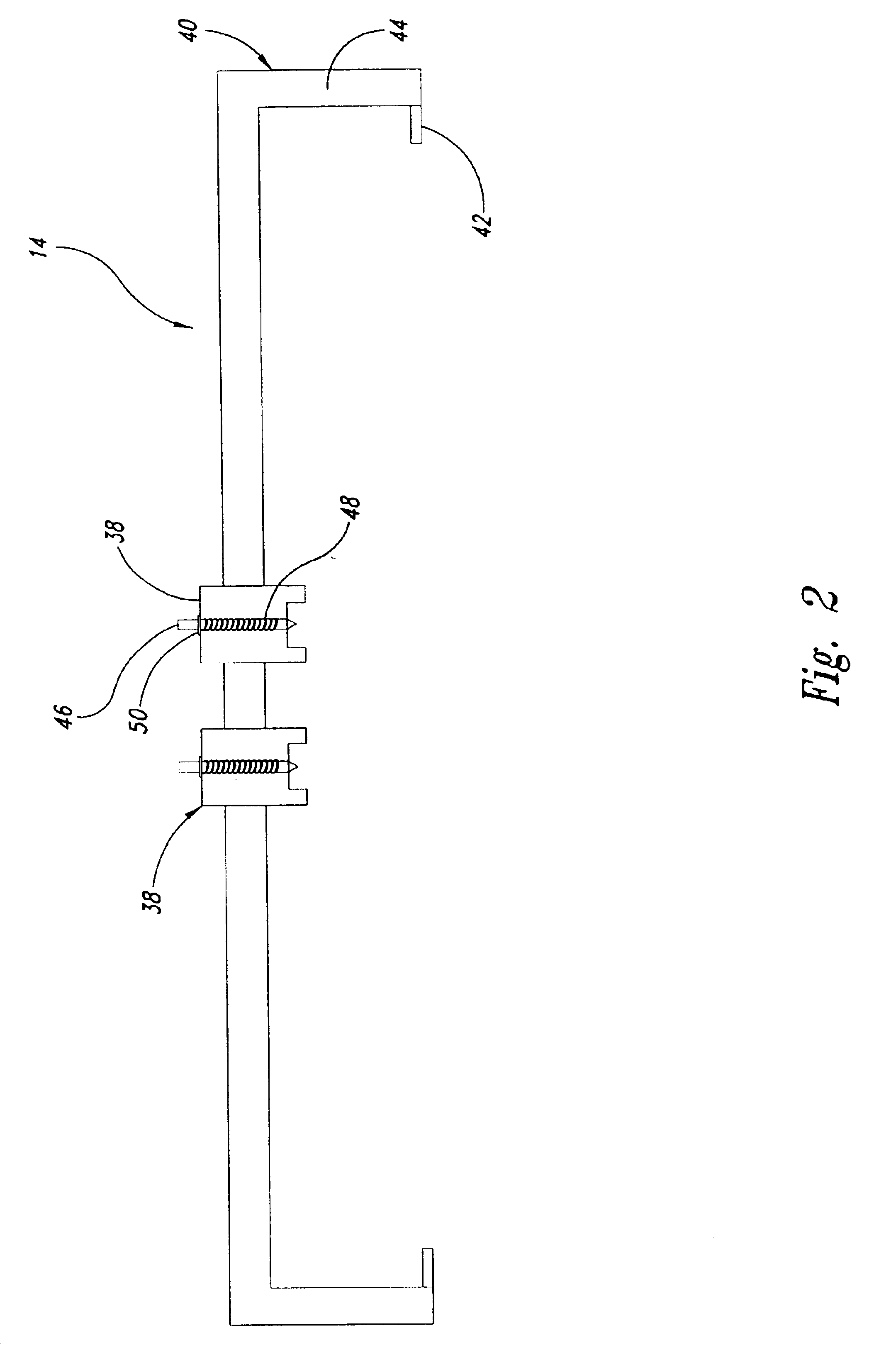

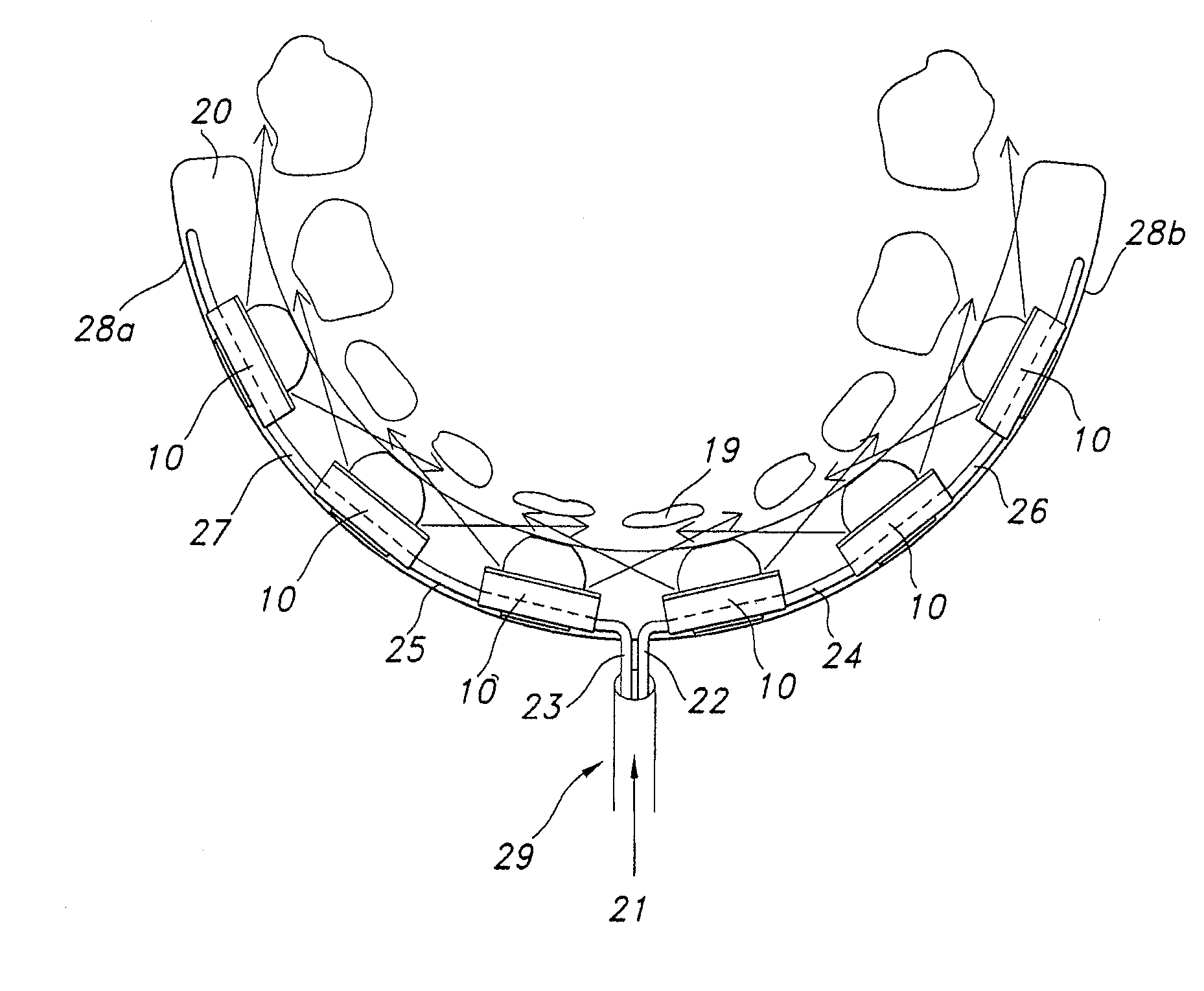

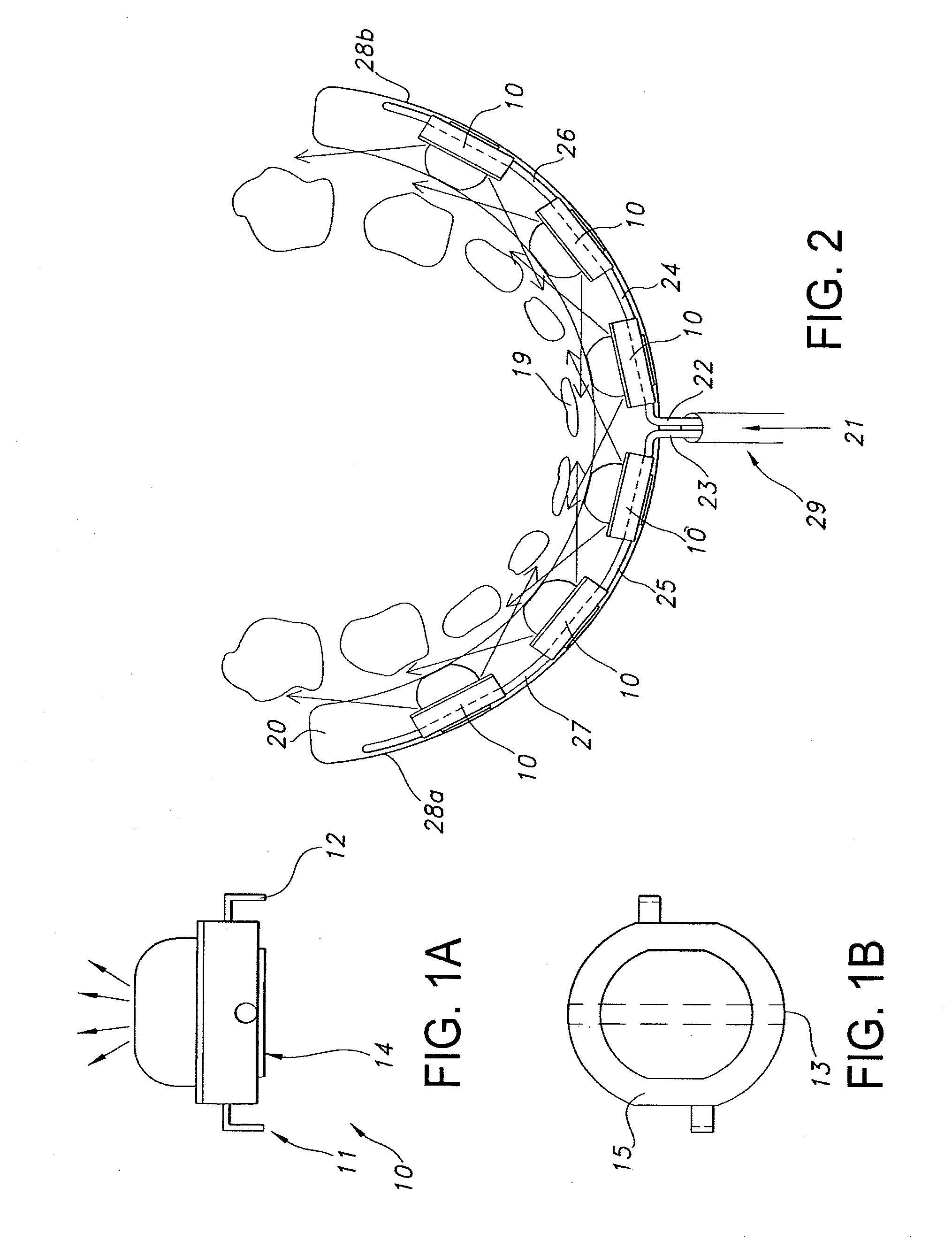

The present invention provides a method and apparatus for using light emitting diodes for curing and various solid state lighting applications. The method includes a novel method for cooling the light emitting diodes and mounting the same on heat pipe in a manner which delivers ultra high power in UV, visible and IR regions. Furthermore, the unique LED packaging technology of the present invention utilizes heat pipes that perform very efficiently in very compact space. Much more closely spaced LEDs operating at higher power levels and brightness are possible because the thermal energy is transported in an axial direction down the heat pipe and away from the light-emitting direction rather than a radial direction in nearly the same plane as the “p-n” junction.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

Light emitting apparatus

The present invention provides a method and apparatus for using light emitting diodes for curing and various solid state lighting applications. The method includes a novel method for cooling the light emitting diodes and mounting the same on heat pipe in a manner which delivers ultra high power in UV, visible and IR regions. Furthermore, the unique LED packaging technology of the present invention utilizes heat pipes that perform very efficiently in very compact space. Much more closely spaced LEDs operating at higher power levels and brightness are possible because the thermal energy is transported in an axial direction down the heat pipe and away from the light-emitting direction rather than a radial direction in nearly the same plane as the “p-n” junction.

Owner:KONINK PHILIPS ELECTRONICS NV

Method and apparatus for using light emitting diodes for curing

The present invention provides a method and apparatus for using light emitting diodes for curing in various applications. The method includes a novel method for cooling the light emitting diodes and mounting the same on heat pipe in a manner which delivers ultra high power in UV, visible and IR regions. Furthermore, the unique LED packaging technology of the present invention that utilizes heat pipes performs far more efficiently in much more compact space. This allows much more closely spaced LEDs operating at higher power and brightness.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

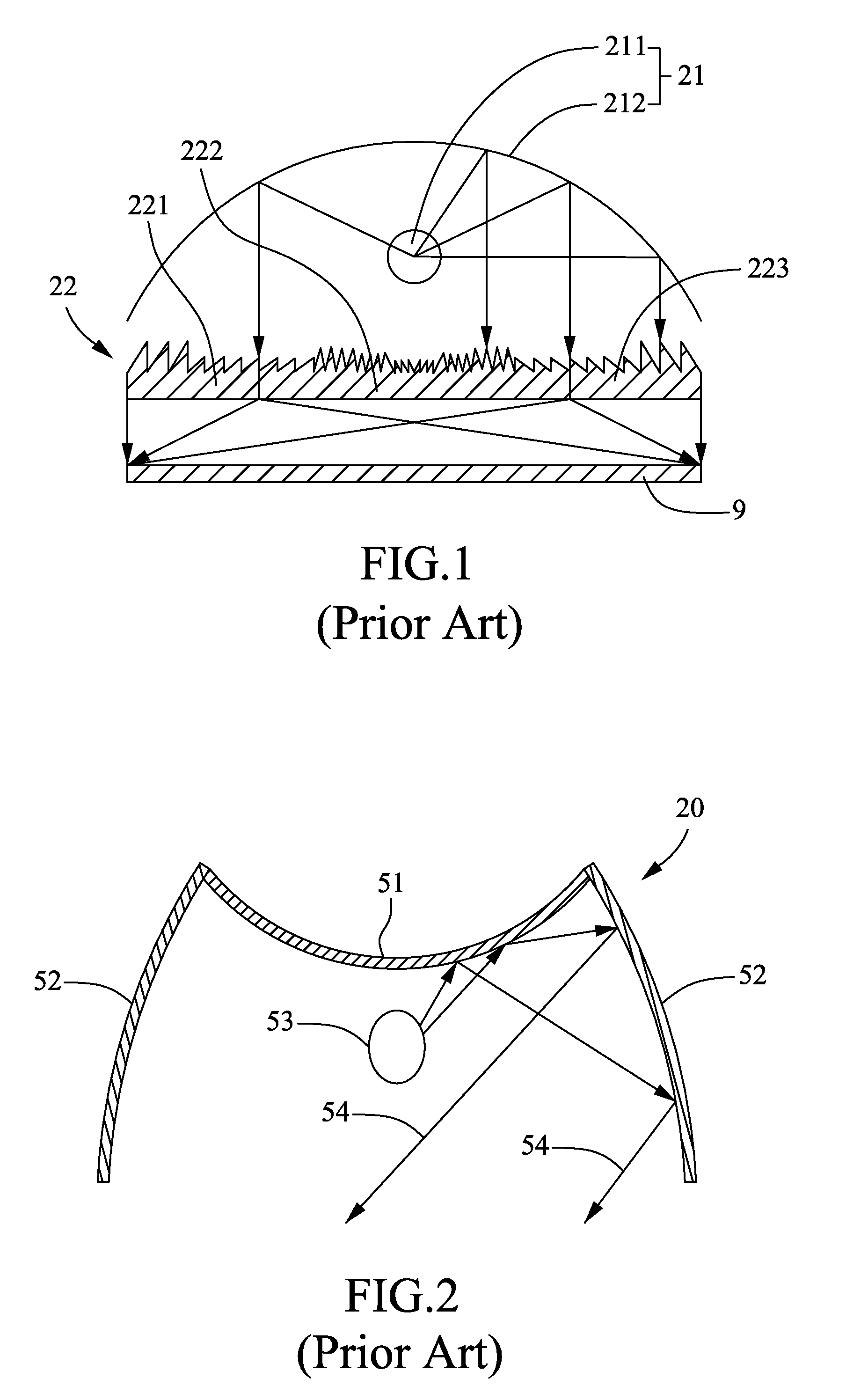

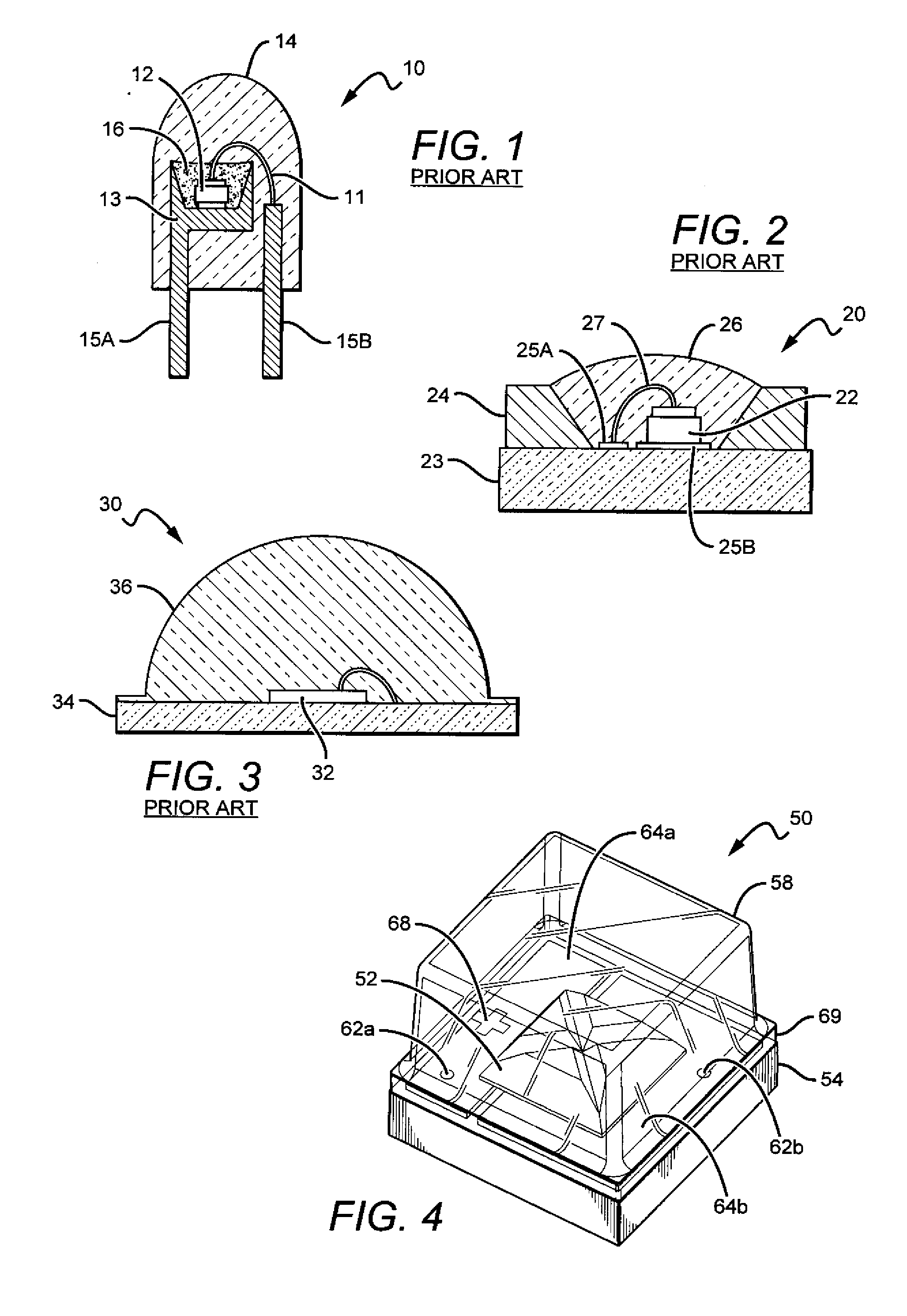

Light emitting diode lamp having parabolic reflector and diffuser

A light fixture consists of one or more light emitting diode (LED) packaging systems within a housing. Each LED packaging system includes one or more LED light sources that simultaneously shines onto opposing reflecting surfaces, then shines forward through encapsulation material. The housing consists of a cluster of prewired sockets with an outer reflective surface. Electrical wiring runs from the rear of the first socket and then to an adjacent socket in a daisy chain fashion. Each socket includes connectors configured to provide each LED packaging system with a source of electricity. The housing has diffusers that adjust the light to an evenly distributed appearance.

Owner:LEYSATH JOSEPH A

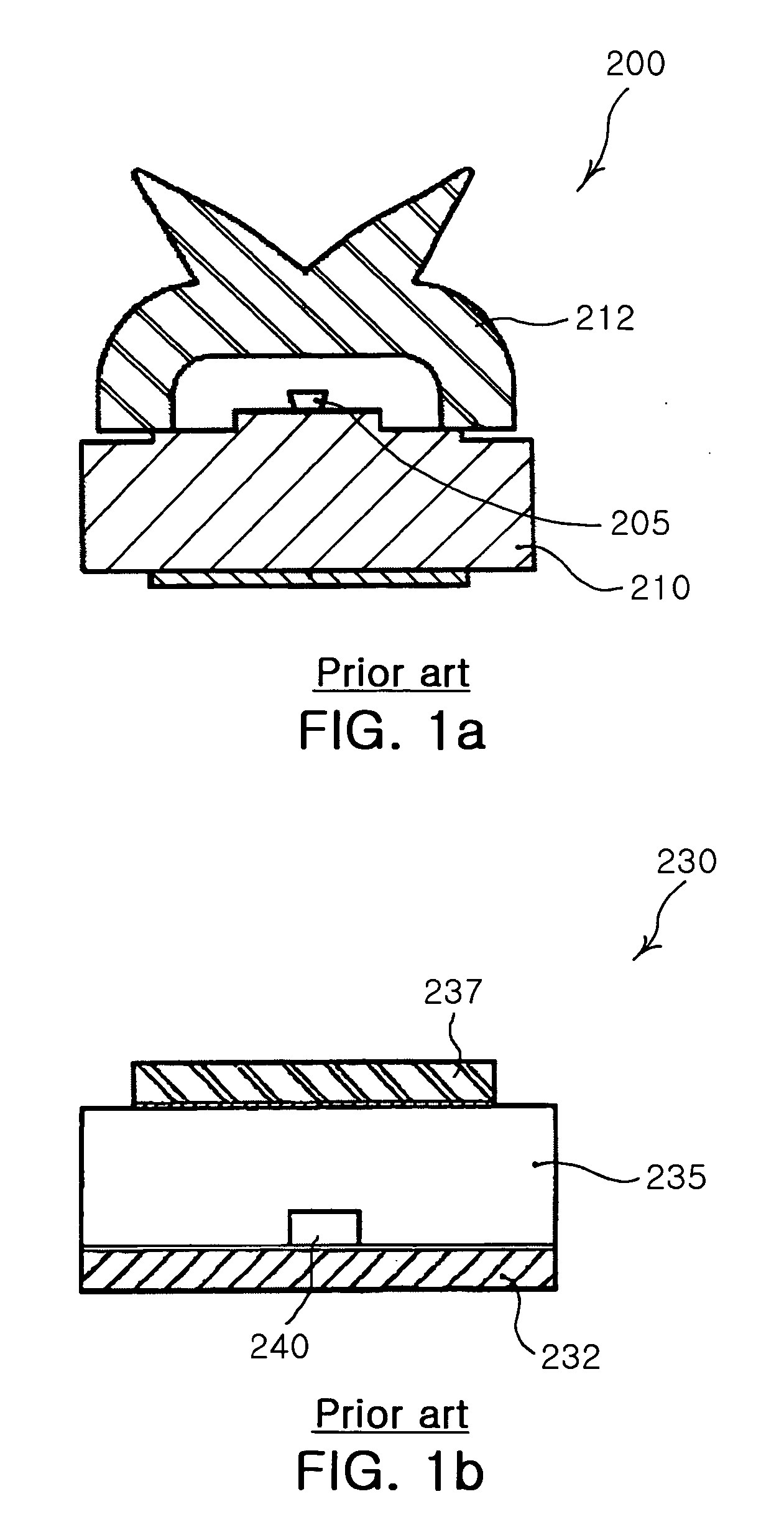

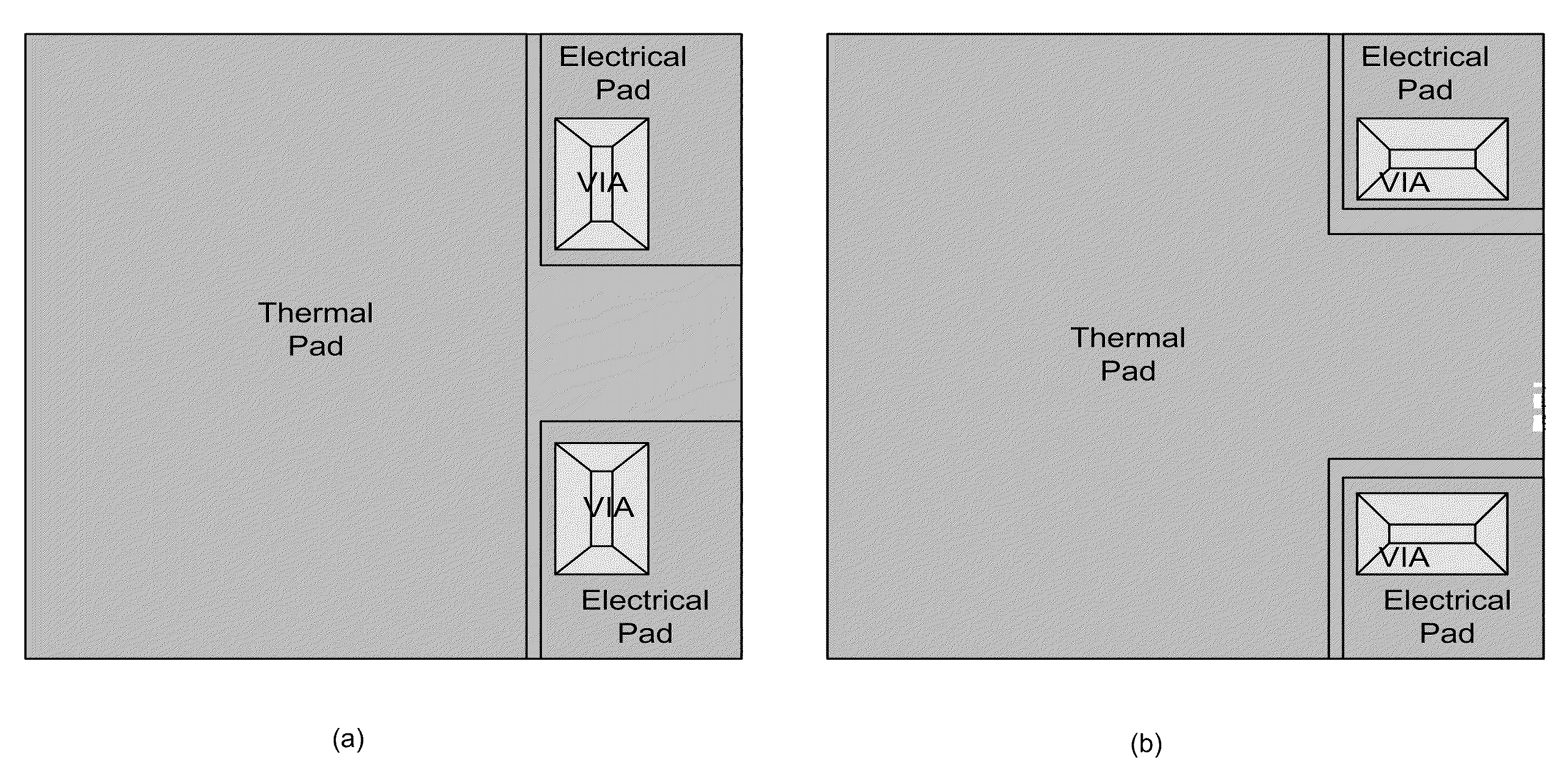

Wafer level package for very small footprint and low profile white LED devices

ActiveUS20070202623A1Low costEmission of light is minimalSolid-state devicesSemiconductor/solid-state device manufacturingSurface mountingPhosphor

A surface mount LED package having a tight footprint and small vertical image size is fabricated by a method comprising: forming light emitting diode chips each having a substrate and a plurality of layers configured to emit electroluminescence responsive to electrical energizing; forming electrical vias in a sub mount, the electrical vias passing from a front side of the sub-mount to a back-side of the sub-mount; flip chip bonding the light emitting diode chips on the front-side of the sub mount such that each light emitting diode chip electrically contacts selected electrical vias; thinning or removing the substrates of the flip-chip bonded light emitting diode chips; and after the thinning, disposing a phosphor over the flip chip bonded light emitting diode chips.

Owner:GE LIGHTING SOLUTIONS LLC

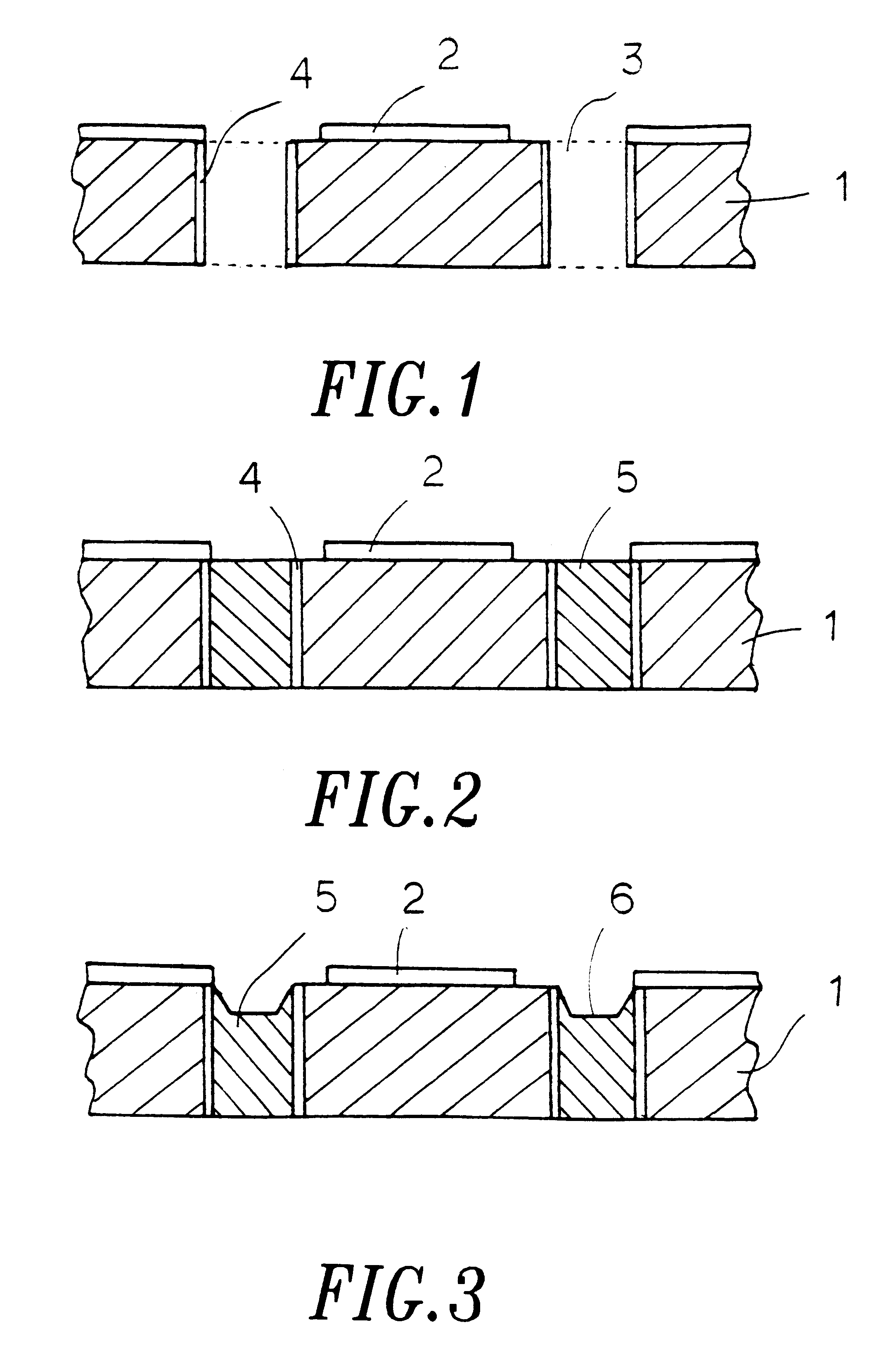

Packaging types of light-emitting diode

InactiveUS6562643B2Affect performanceIncrease temperaturePrinted electric component incorporationSolid-state devicesElectrical conductorEngineering

A LED packaging process is to place LED chips at predetermined positions on the printed circuit board substrate, followed by drilling holes to penetrate the substrate, followed by passing the printed circuit board through the solder furnace to completely fill the through-hole position with solder points, followed by using molds to make the soldering points into a groove reflector, followed by placing LED chips in the groove reflector, followed by wire bonding and using encapsulation resin for packaging to form SMD LED with reflectors. In the present invention, the filling with metal conductor in electrode through holes on the printed circuit board to form the groove reflector can enhance the heat dissipation of LED and the brightness of LED, which has the advantageous effects that traditional SMD LED can not have.

Owner:SOLIDLITE CORP

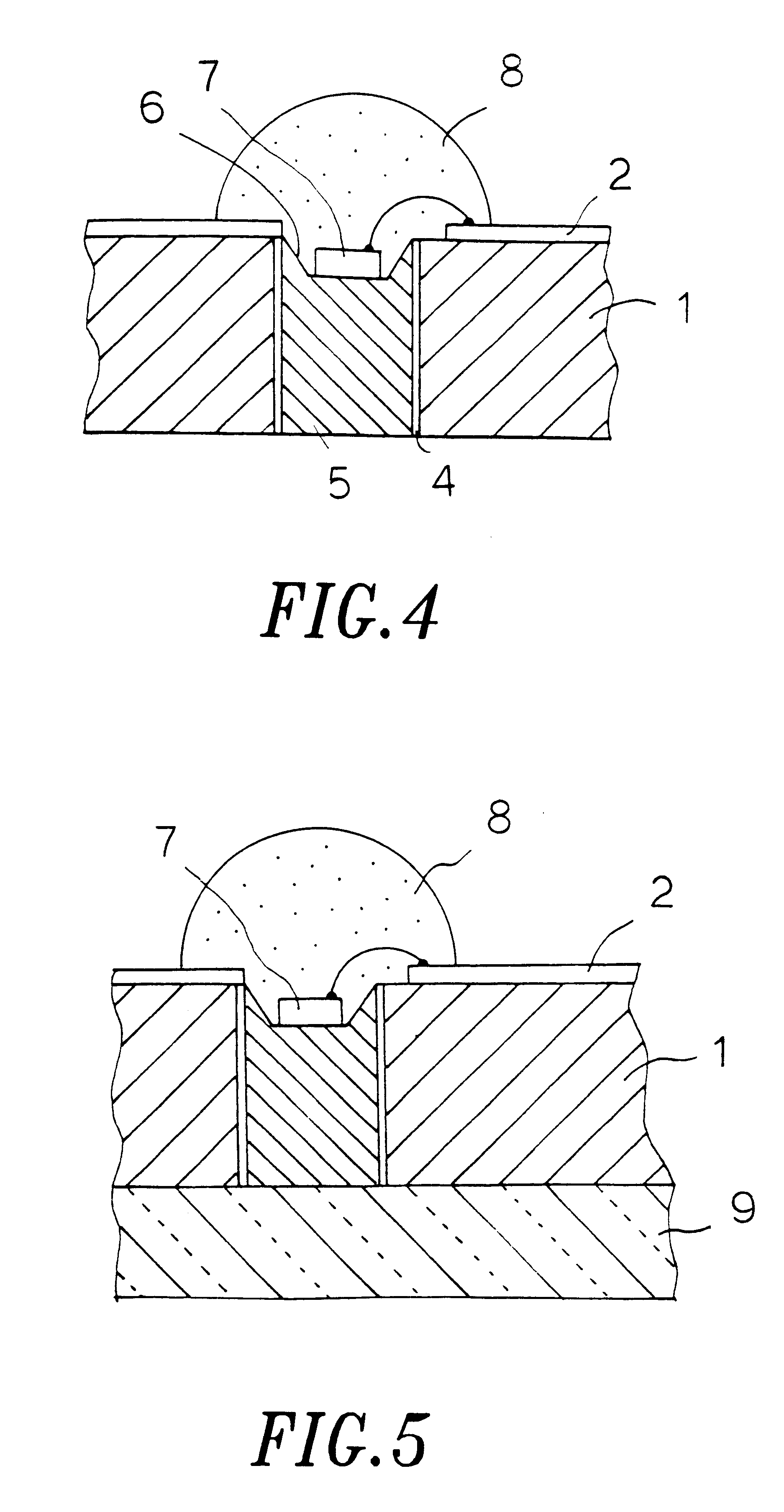

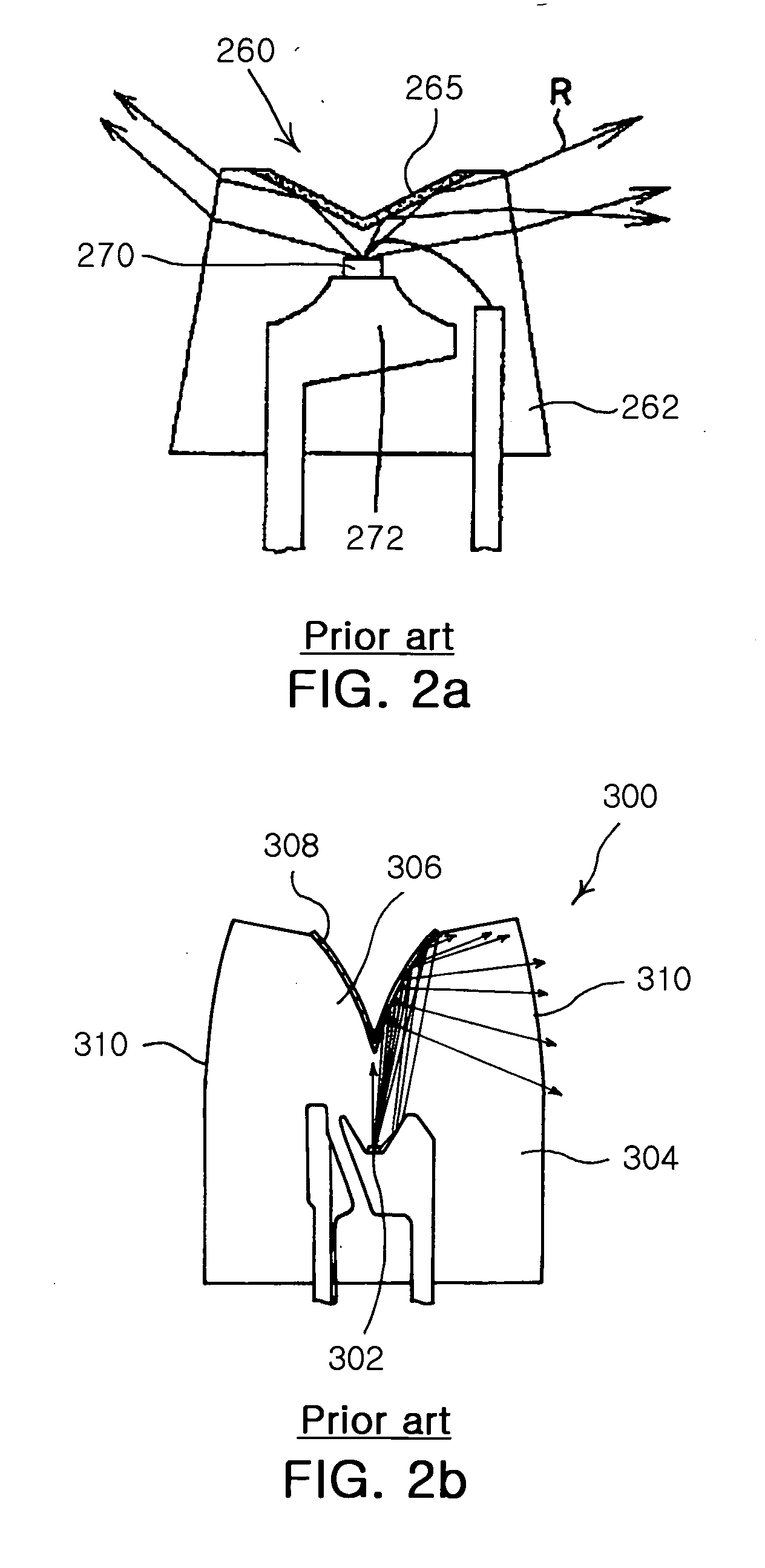

Side-emitting LED package and method of manufacturing the same

InactiveUS20060273337A1Effective reflectionEasy to manufactureSolid-state devicesSemiconductor devicesChip sizeEngineering

The invention relates to a side-emitting LED package and a manufacturing method thereof. The side-emitting LED package includes a substrate with an electrode formed thereon, and a light source disposed on the substrate and electrically connected to the electrode. The side-emitting LED package also includes a molded part having an upper surface with a center thereof depressed concavely, covering and protecting the substrate and the light source, and a reflection layer covering an entire upper surface of the molded part to reflect light sideward from the molded part which forms a light transmitting surface. The package is not restricted in the shape of the molded part and is not affected by the LED chip size, enabling a compact structure. The invention can also process a substrate by a PCB process, enabling mass-production.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

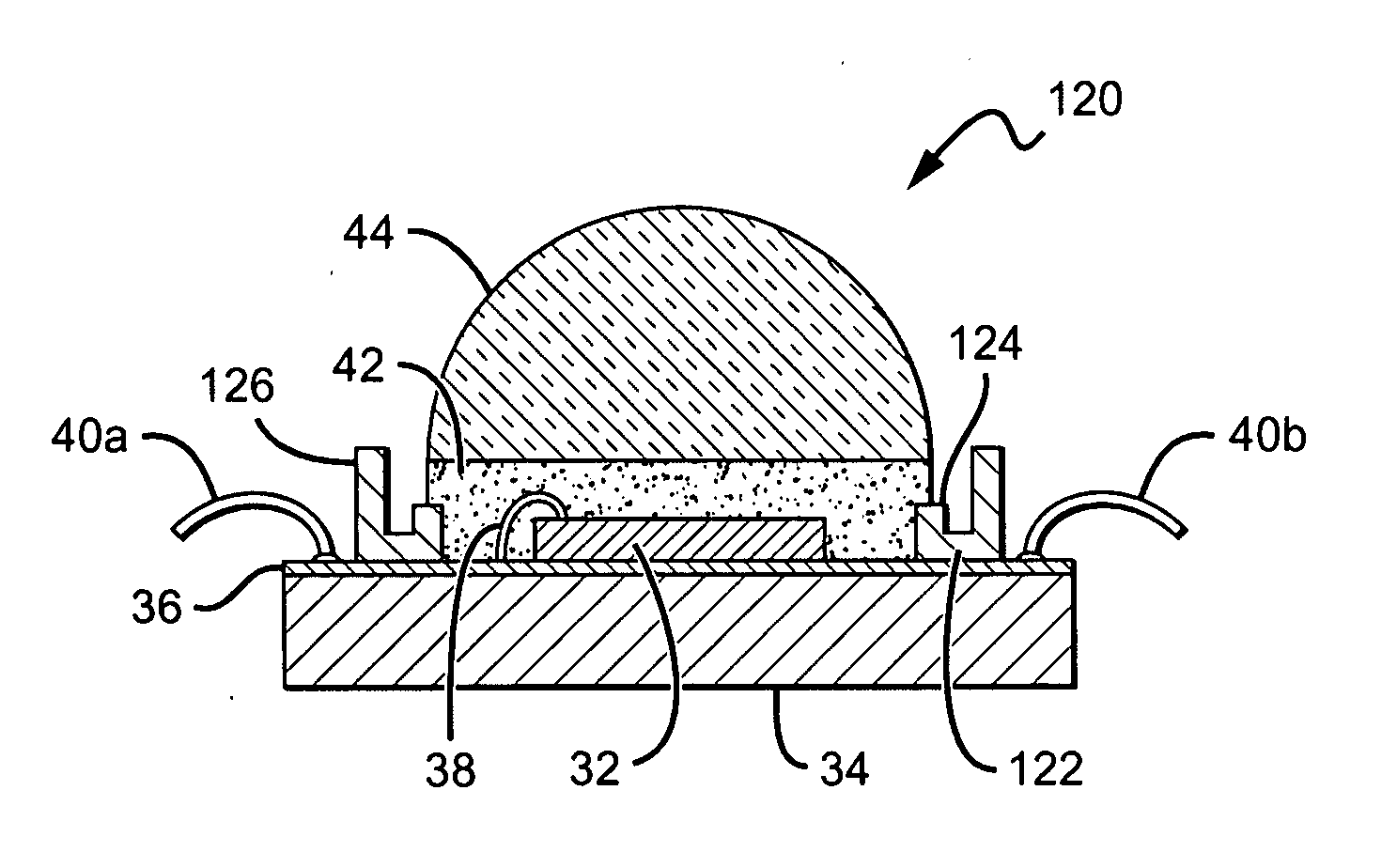

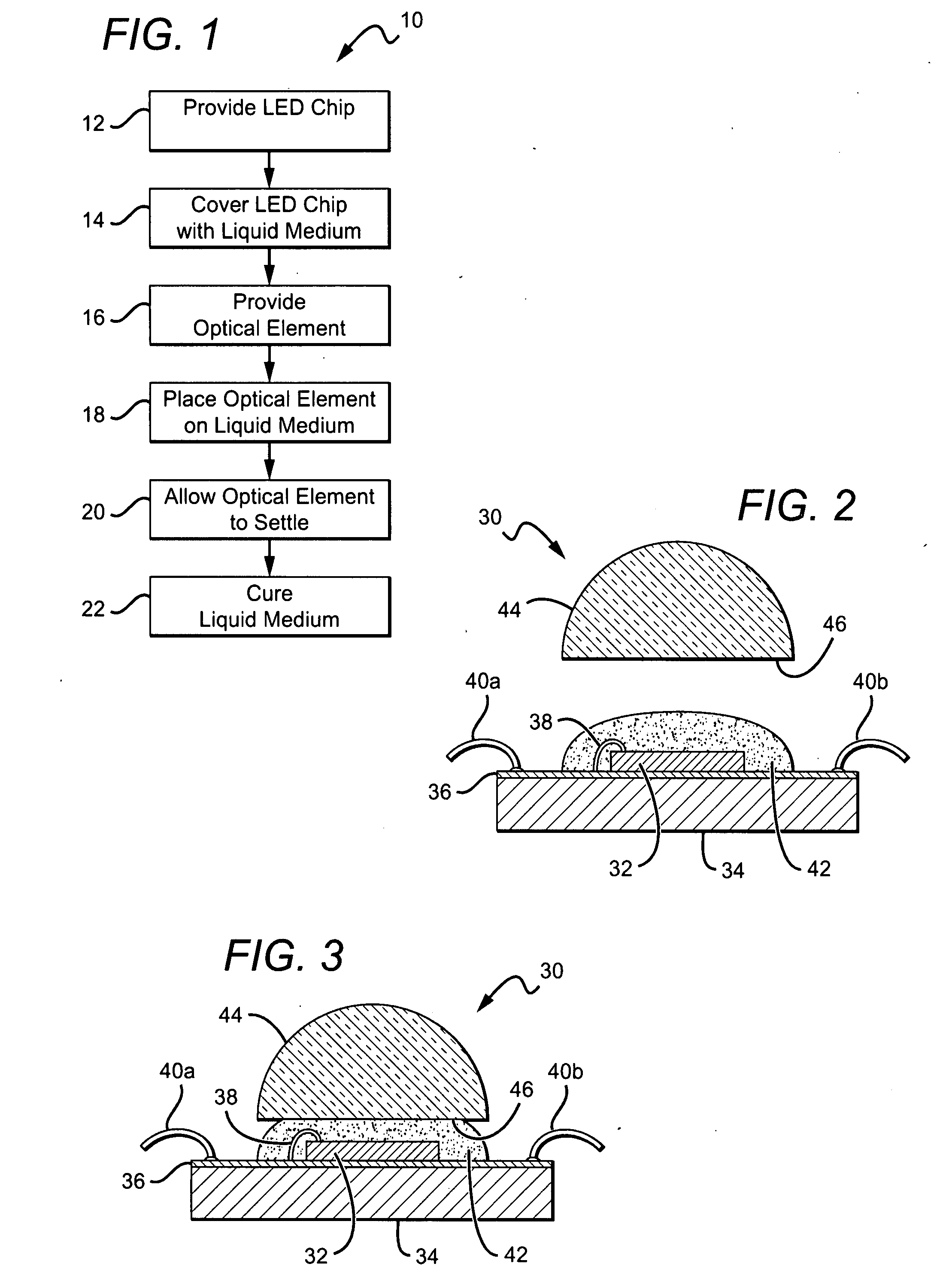

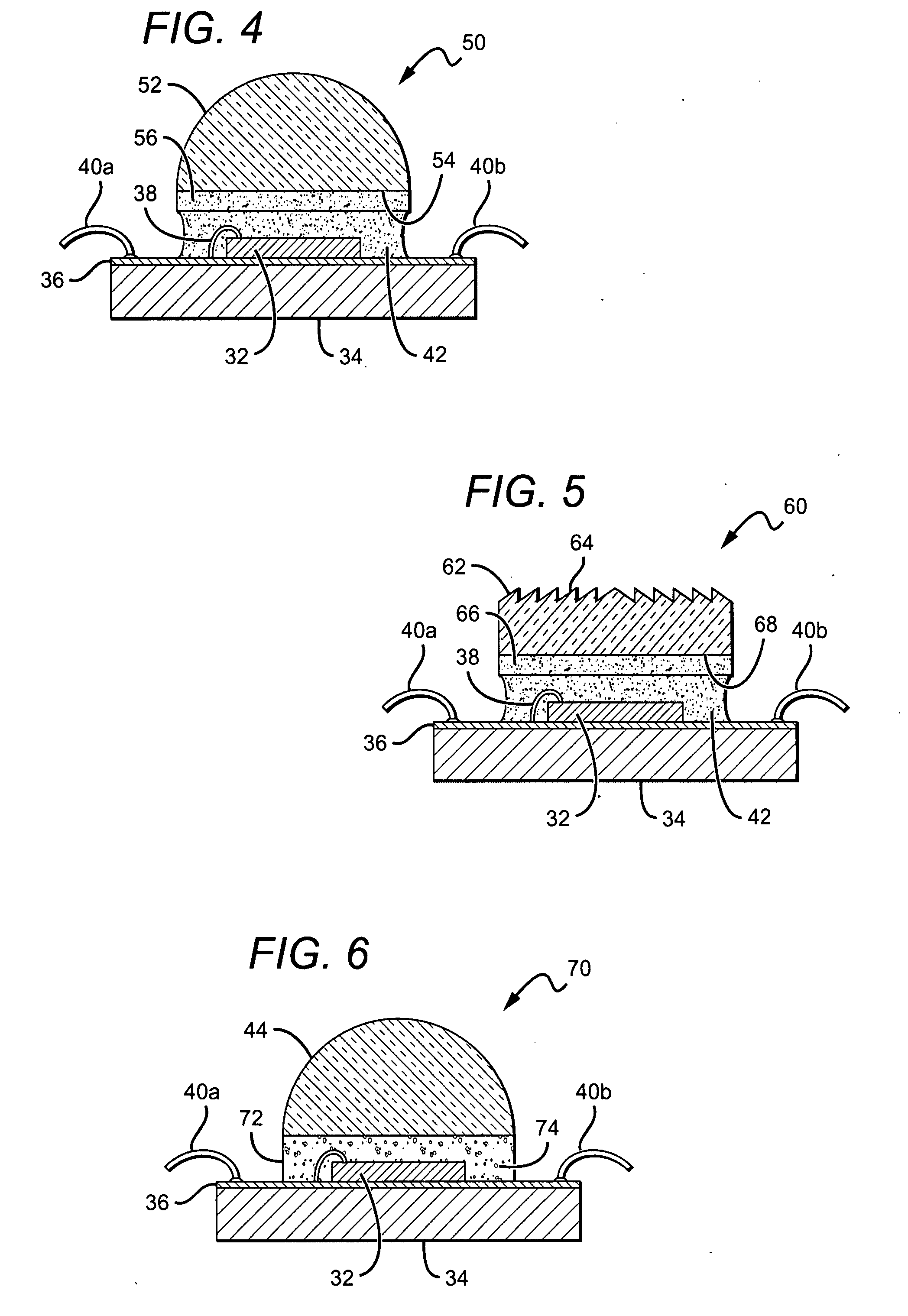

Method of uniform phosphor chip coating and led package fabricated using method

ActiveUS20080079017A1Solid-state devicesSemiconductor/solid-state device manufacturingLiquid mediumPhosphor

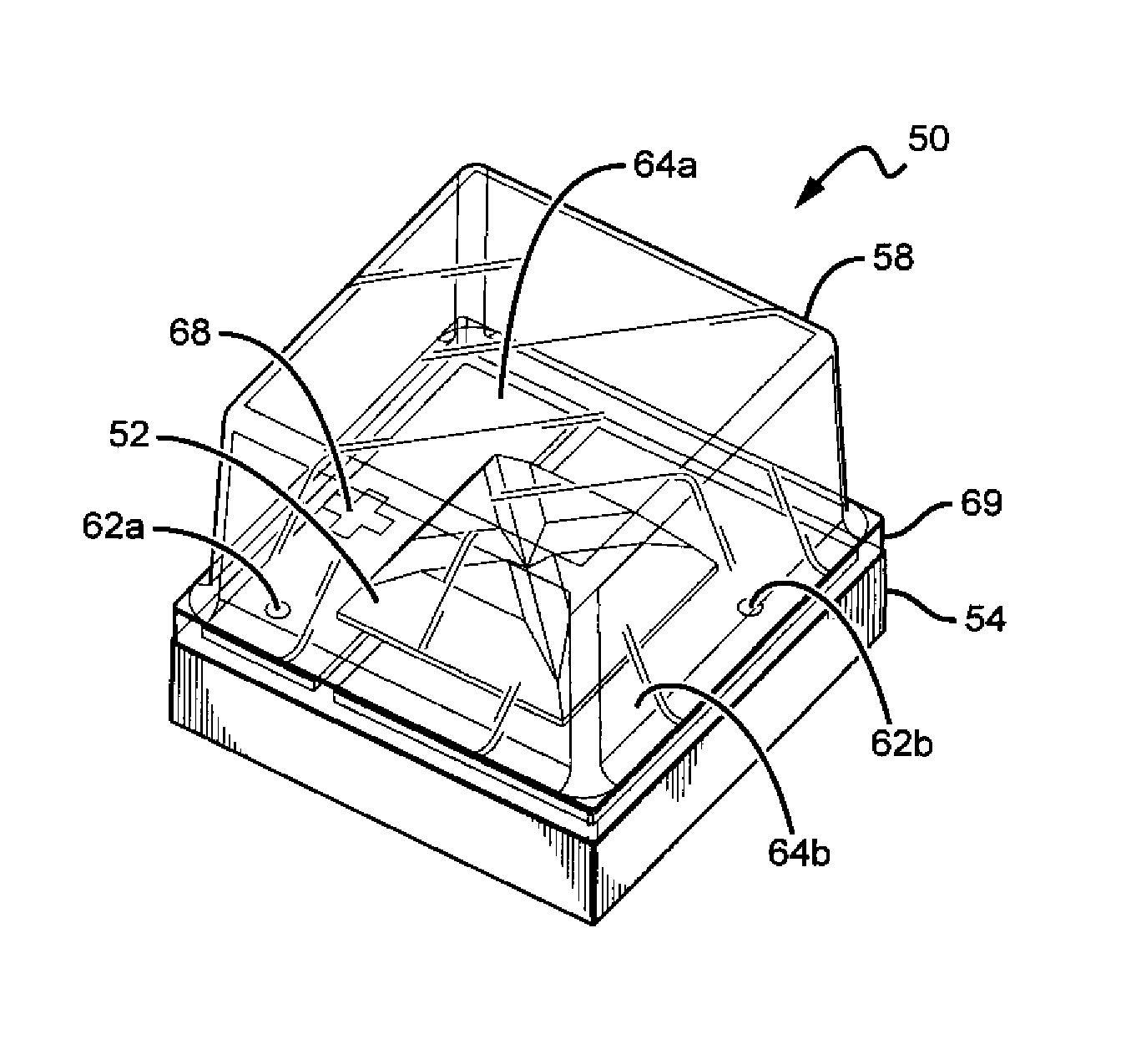

Methods for fabricating LED packages comprising providing an LED chip and covering at least part of it with a liquid medium. An optical element is provided and placed on the liquid medium. The optical element is allowed to settle to a desired level and the liquid medium is cured. LED packages are also disclosed that are fabricated using the disclosed methods.

Owner:CREELED INC

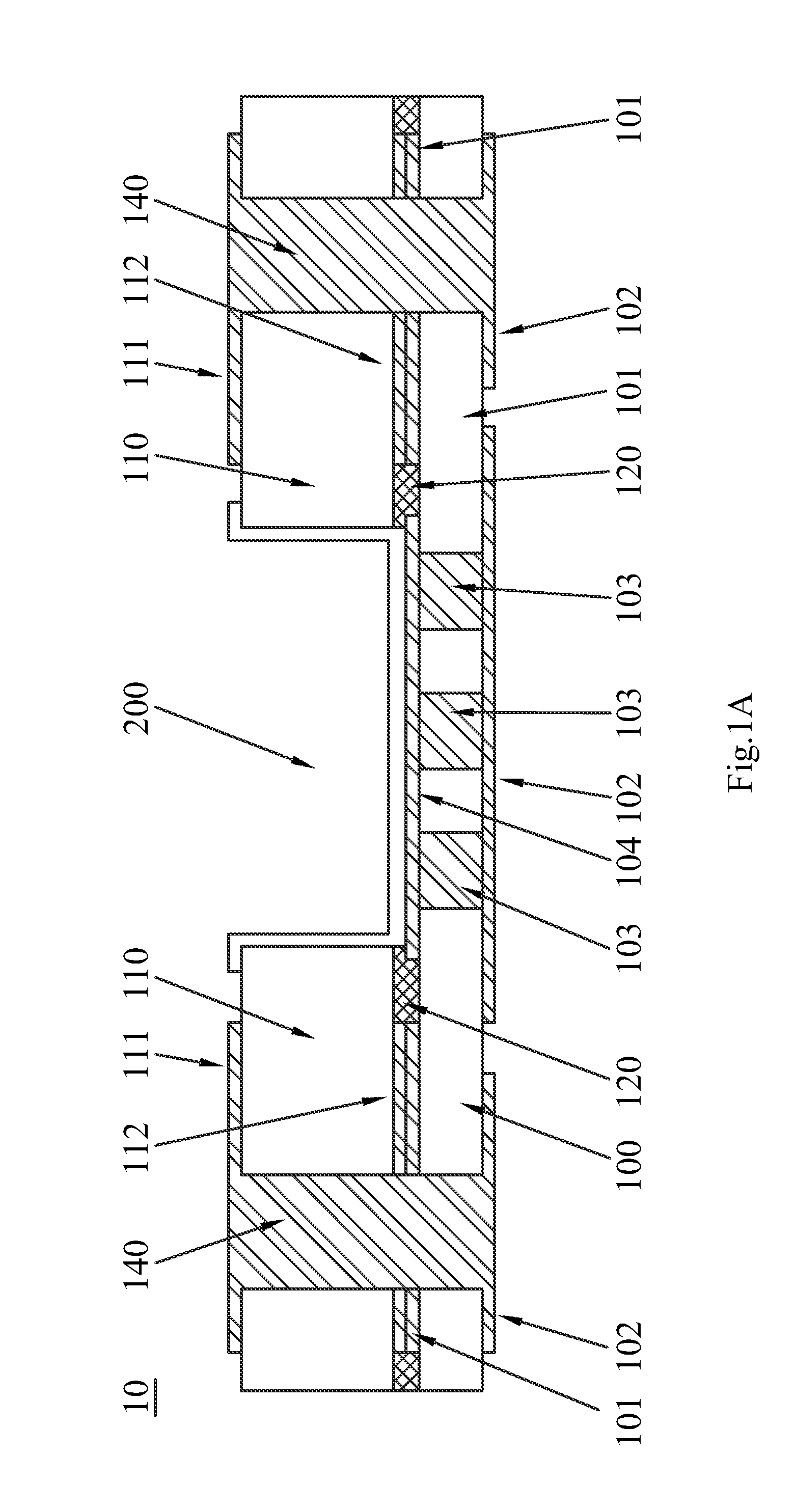

Substrate Structure of LED (light emitting diode) Packaging and Method of the same

InactiveUS20120037935A1Improve luminous efficiencyConduct heat moreSolid-state devicesSemiconductor/solid-state device manufacturingThermal conductivityLed packaging

The present invention provides a substrate for LED packaging and a fabrication method thereof. The substrate can dissipate heat quickly and enhance light emitting efficiency. For this purpose, several via holes are formed in the substrate and metal layers are coated to act as light reflector. In the substrate, the via holes are filled with the material with high thermal conductivity, such as Copper, to conduct the heat efficiently; and the reflector are coated the metal with high reflection factor to visible light, such as Ag, Au, Al, to enhance the light emitting efficiency.

Owner:KING DRAGON INT

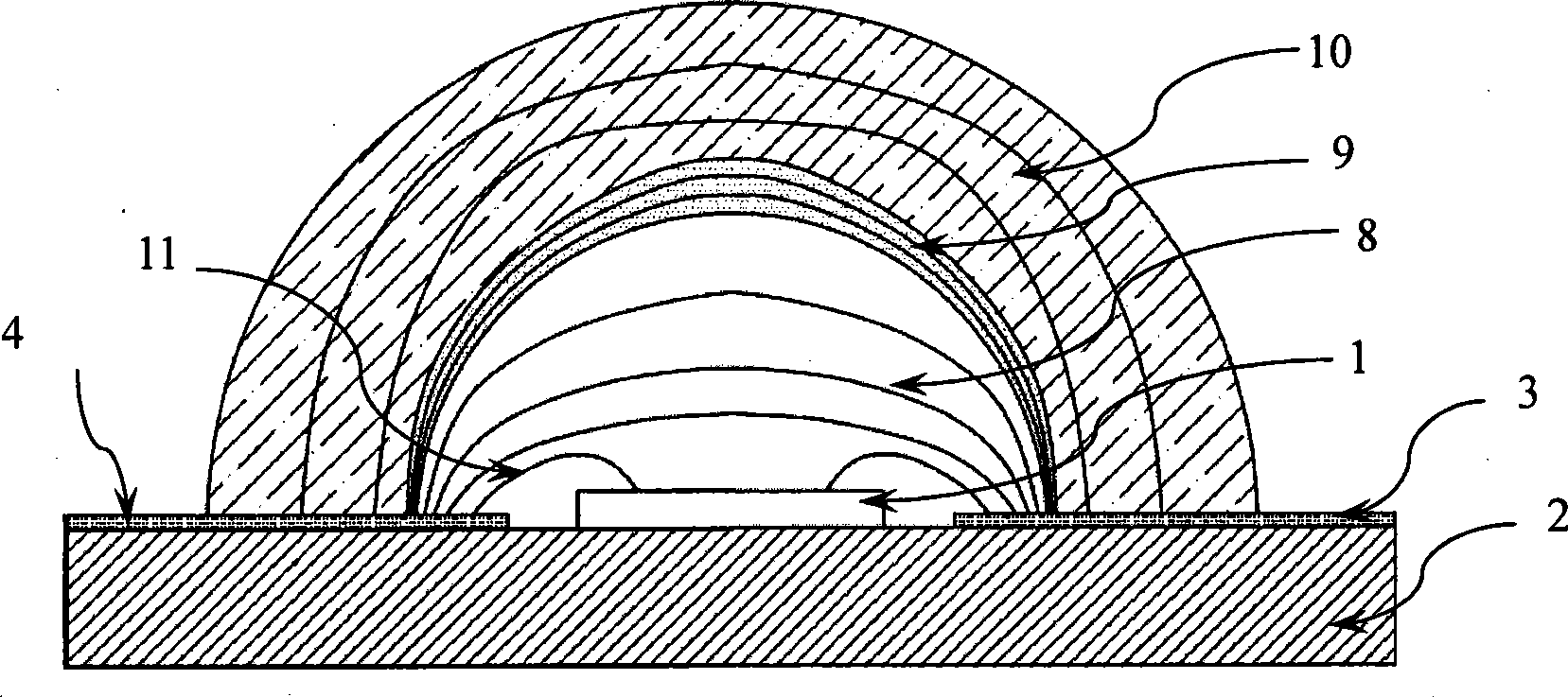

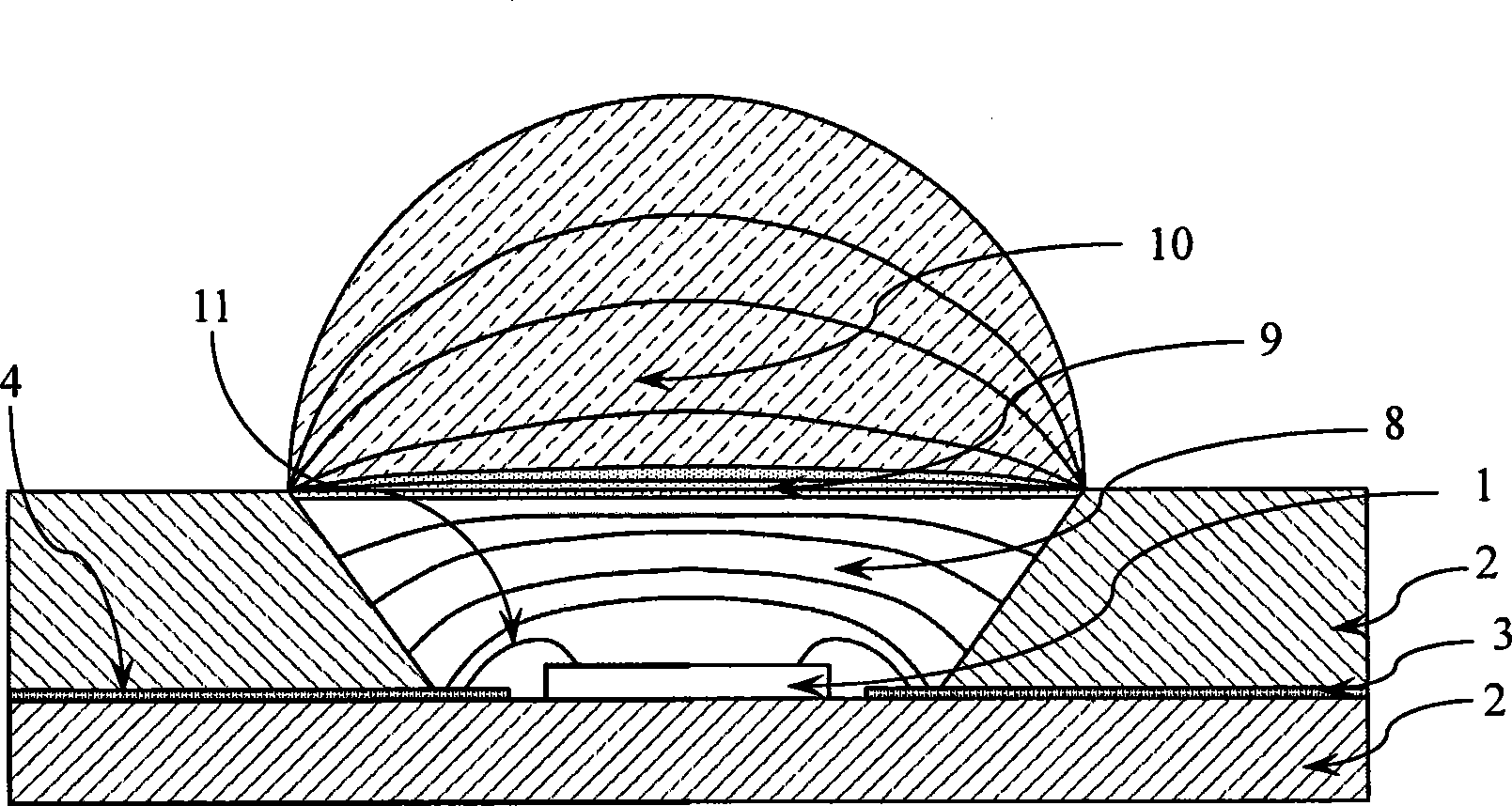

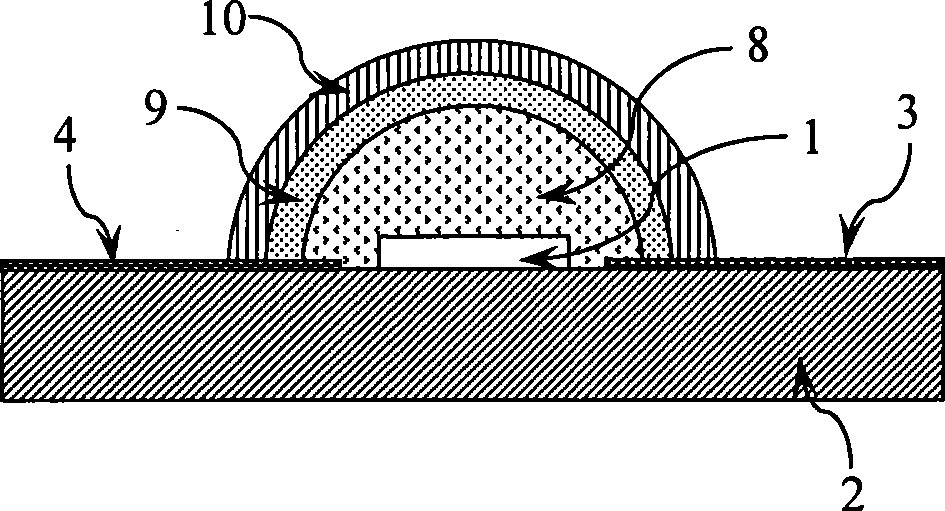

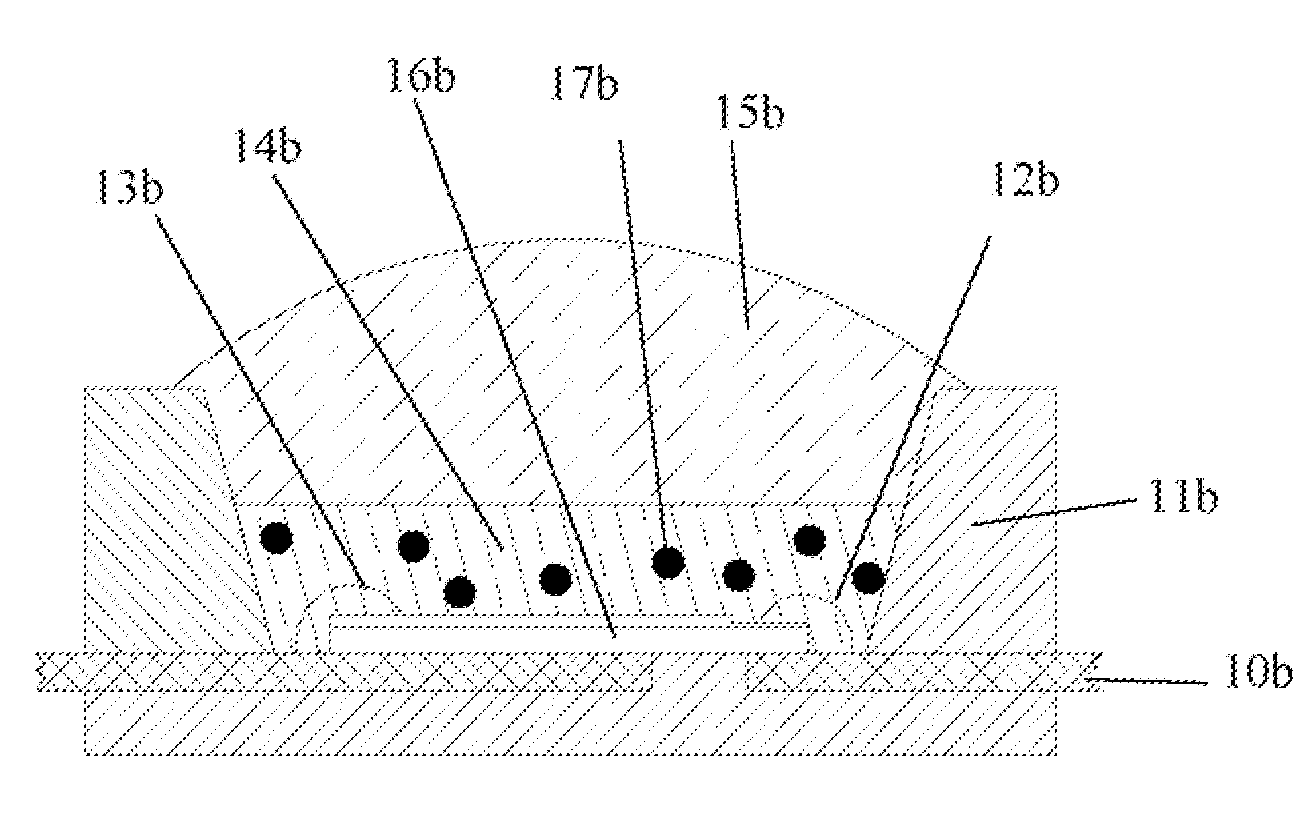

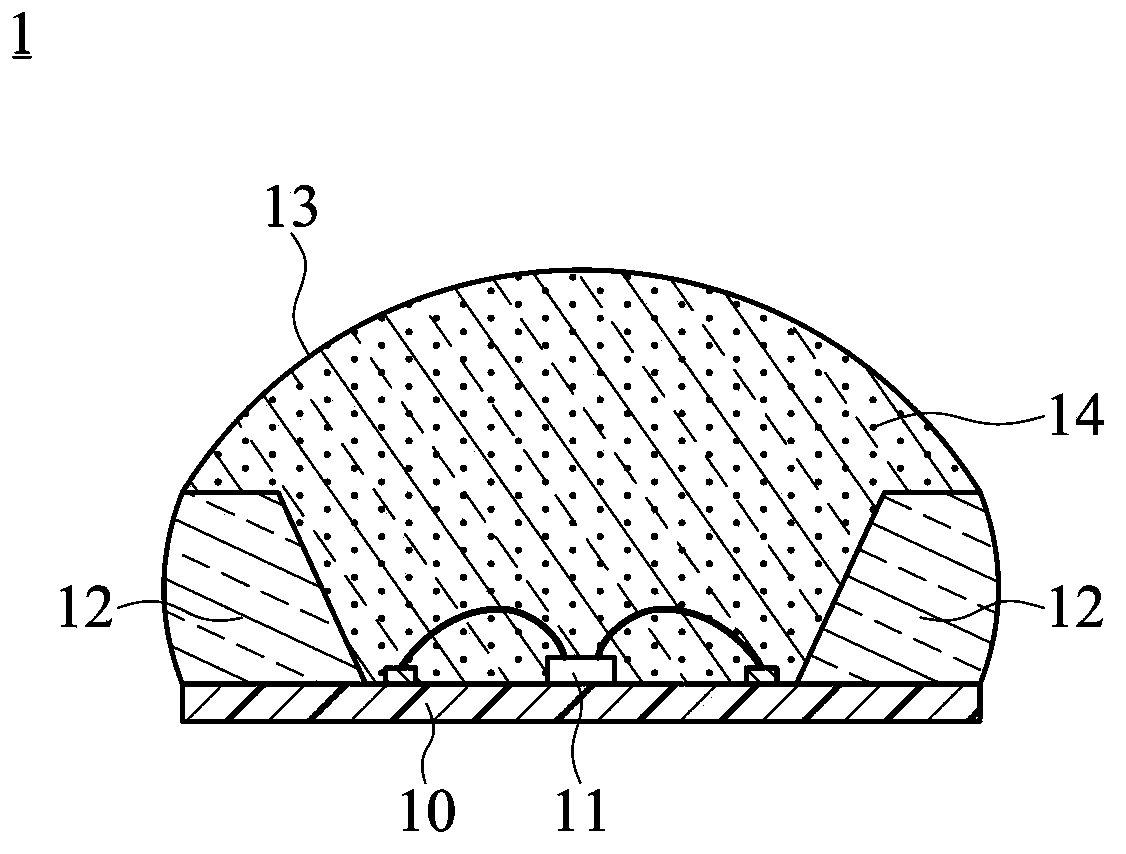

Packaging structure and method for high power white light LED

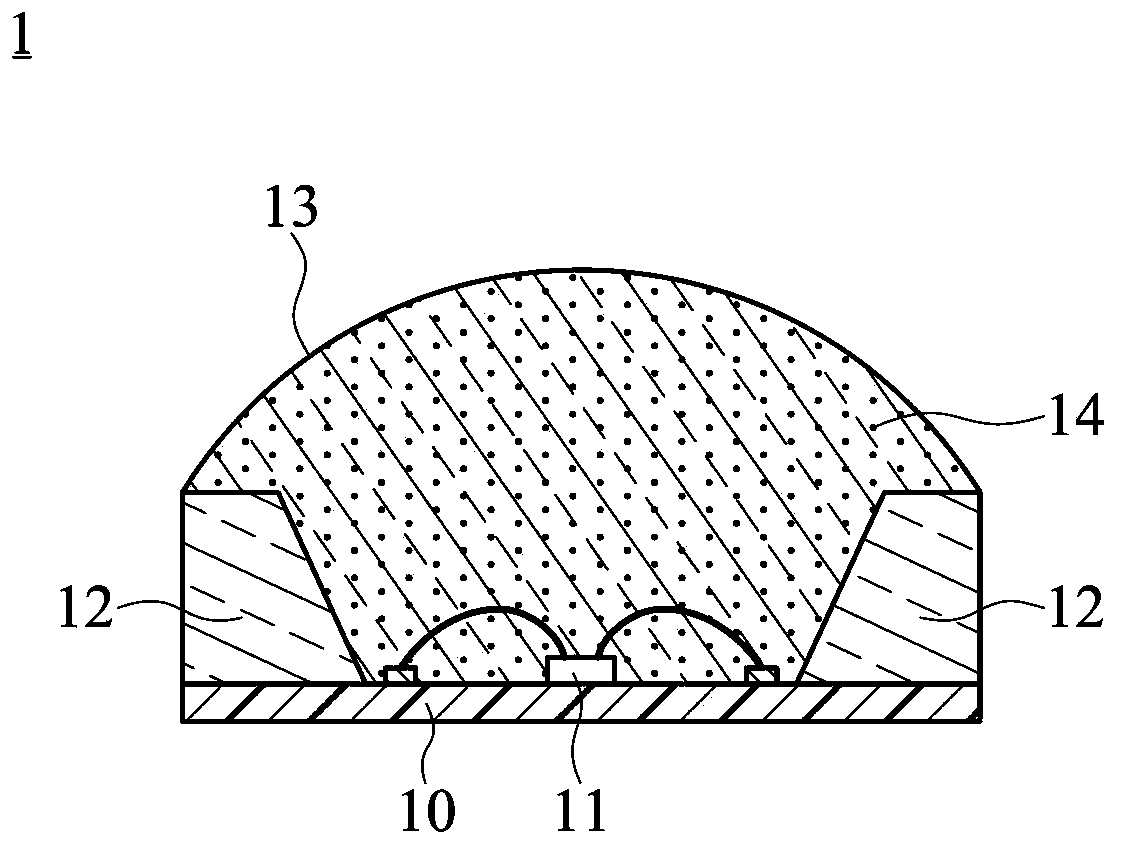

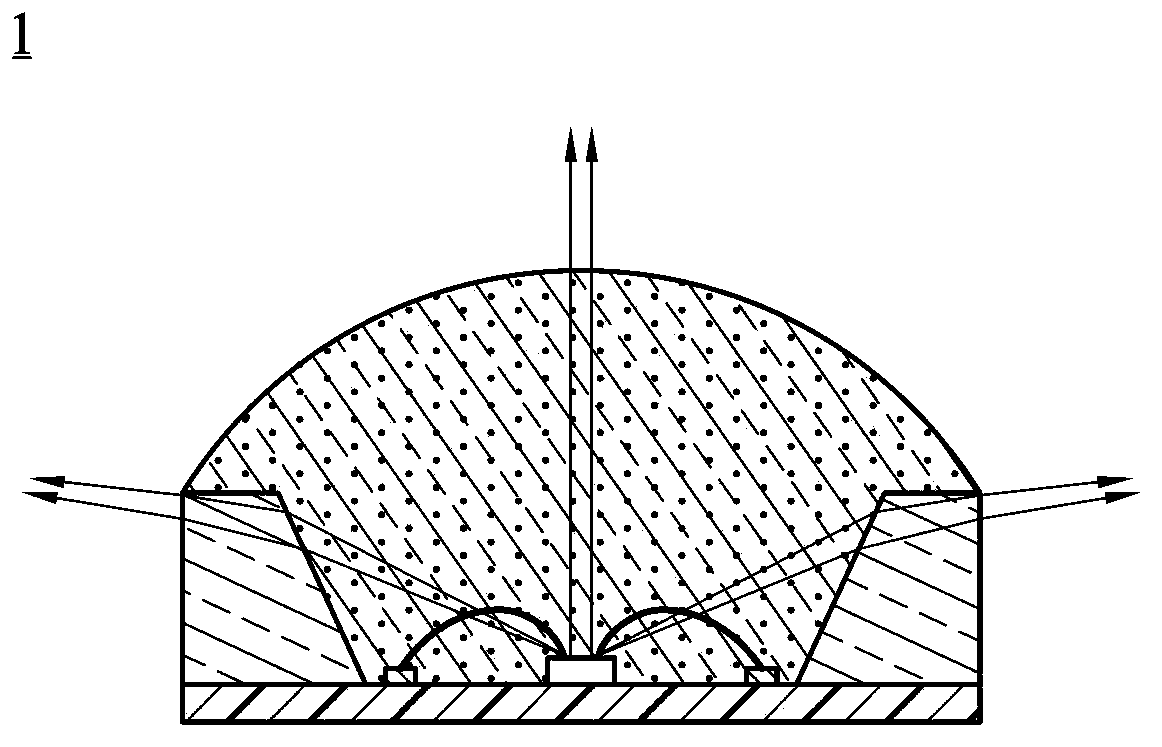

InactiveCN101369614AReduce the chance of total reflectionAchieve independent diffusionSolid-state devicesSemiconductor devicesFluorescenceColloid

The invention discloses a high power white light emitting diode (LED) packaging structure and a packaging method. The high power white LED packaging structure mainly comprises an LED chip, a substrate, an internally sealed colloid, a fluorescent powder layer or a fluorescent powder adhesive layer and an externally sealed lens. The invention is characterized in that the LED chip is stuck on the substrate, a chip electrode is connected with a circuit layer on the substrate, the LED chip is covered by the internally sealed colloid, the outer surface of the internally sealed colloid is wrapped by the fluorescent powder layer or the fluorescent powder adhesive layer, and the outer surface of the fluorescent powder layer or the fluorescent powder adhesive layer is wrapped by the externally sealed lens. The invention has the advantages of promoting the light emitting effect of each layer through optically designing and packaging each layer of enveloped colloid of the LED chip, realizing mutually separate heat diffusion through a suitable process flow manufacture to isolate the fluorescent powder and the chip, having high light emitting efficiency and good light emitting stability, and being applied to packaging high power and high brightness LED.

Owner:刘胜

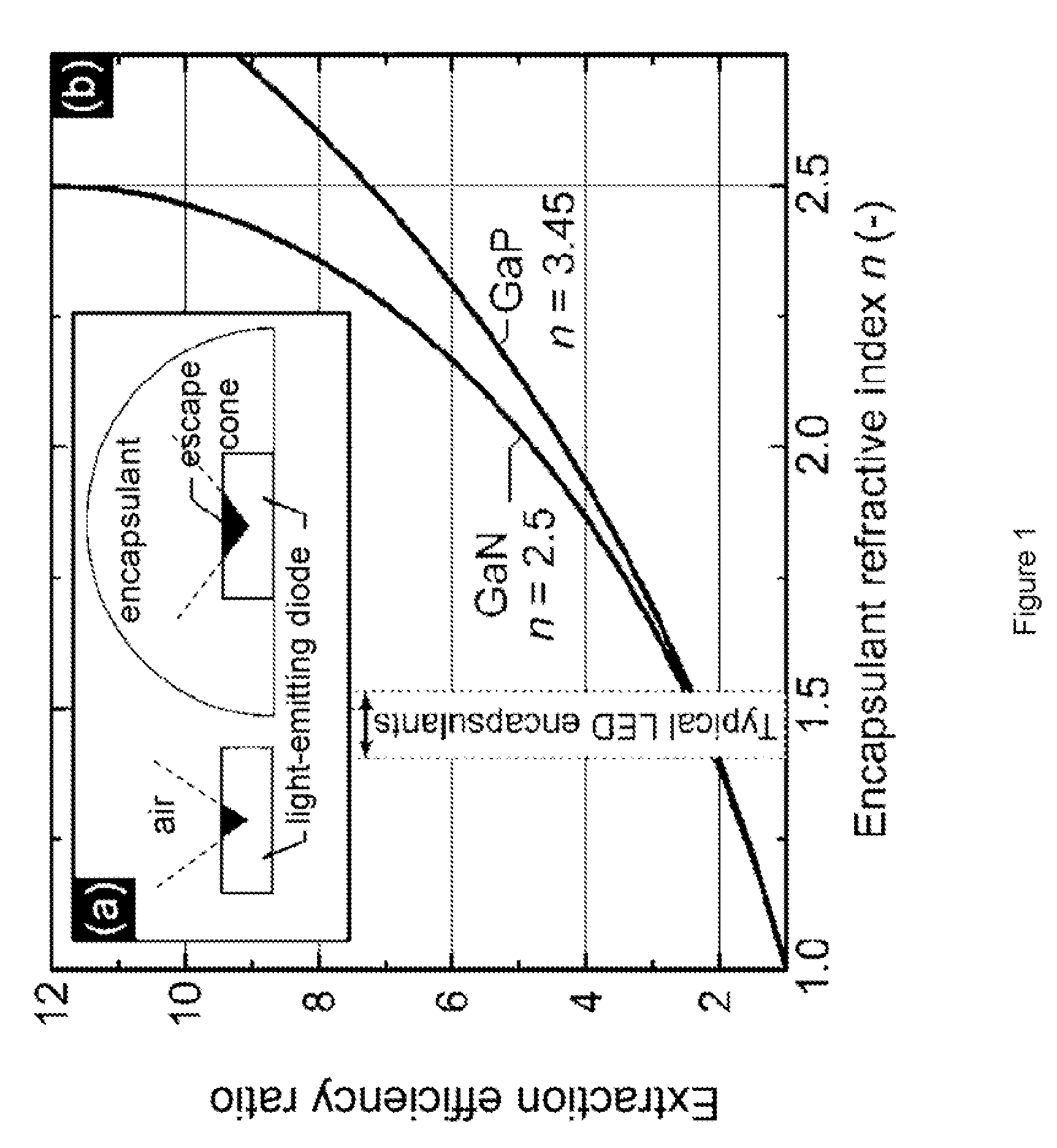

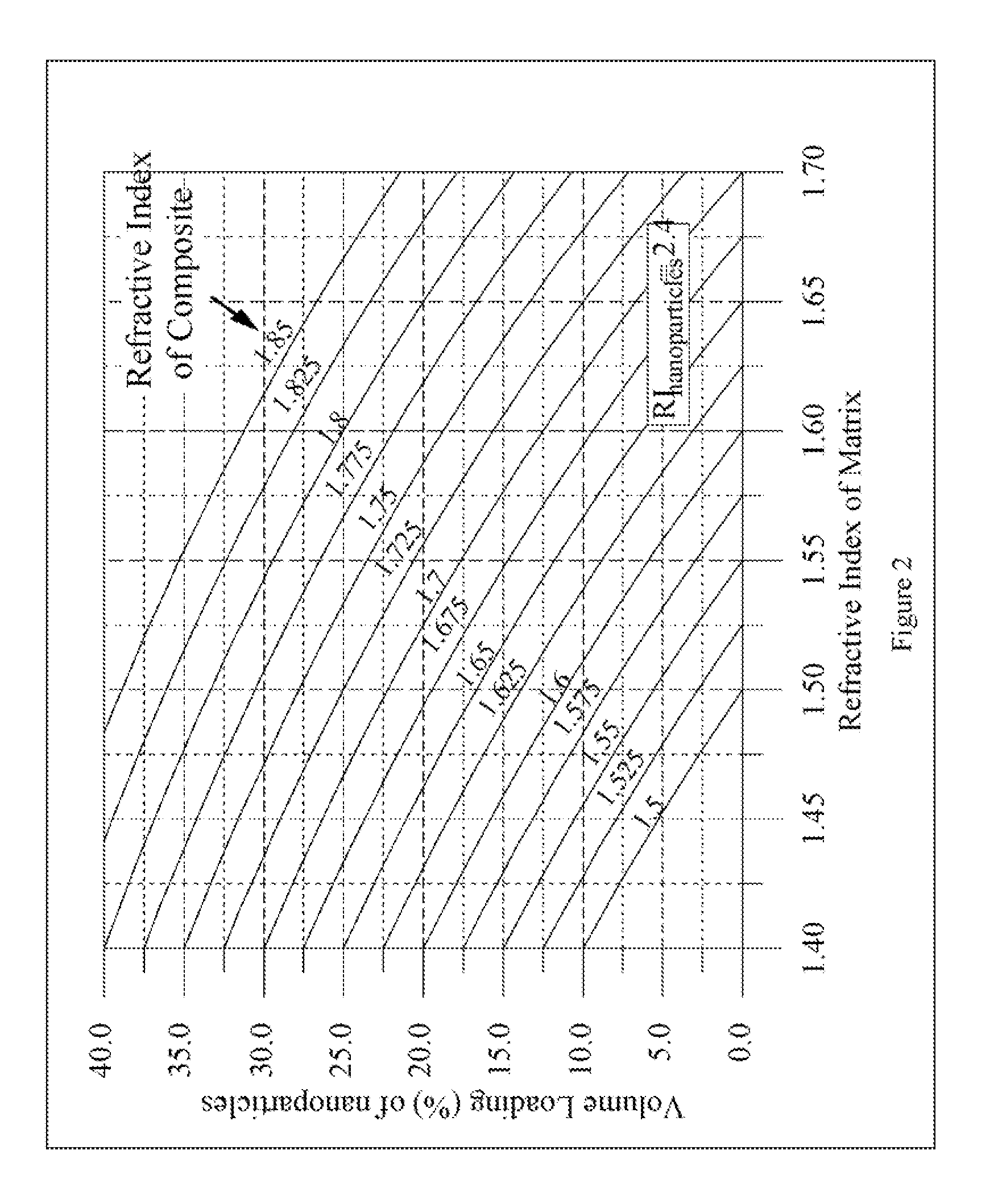

Composites Comprising Nanoparticles

This invention discloses composite materials utilizing high refractive index materials, their manufacturing methods and their use. Some of the preferred applications are in LED packaging and as deformable fillers in polymers.

Owner:AJJER

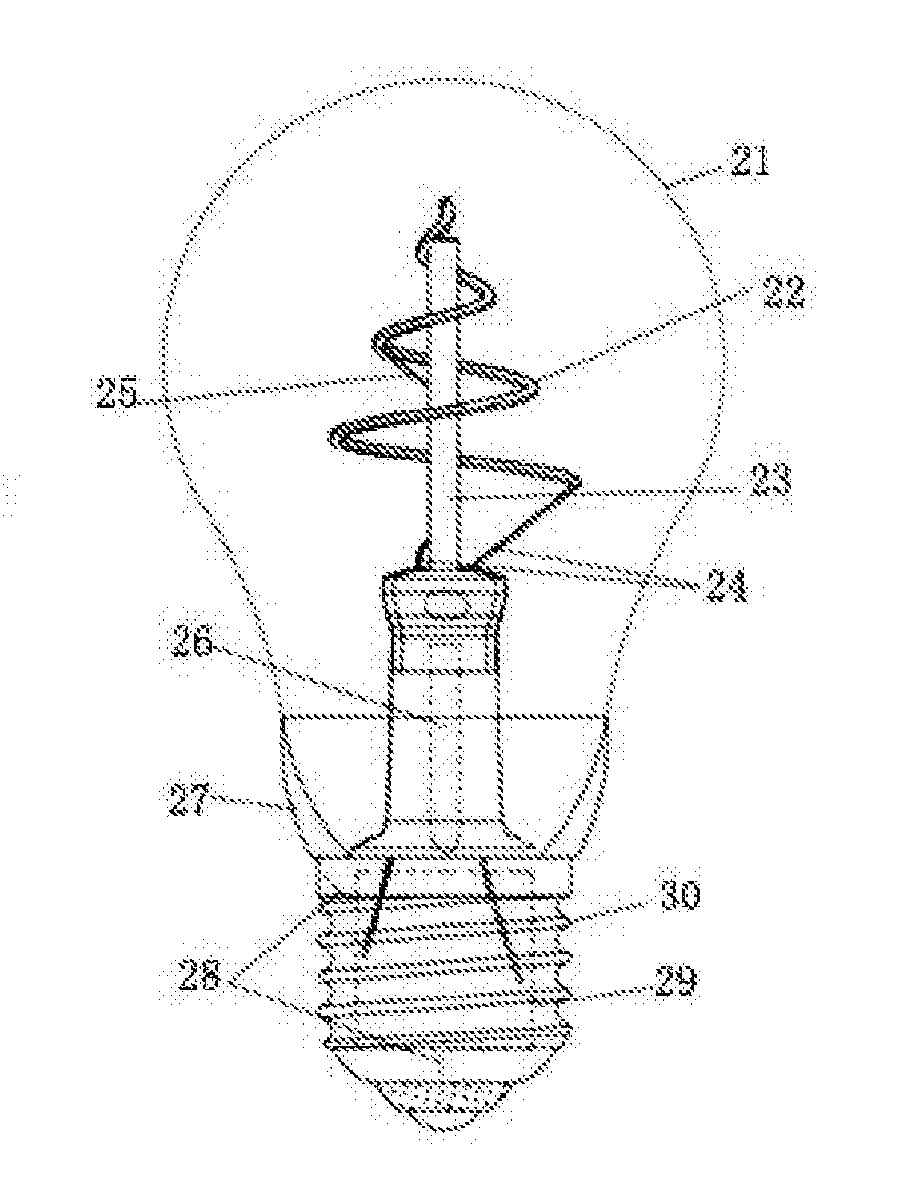

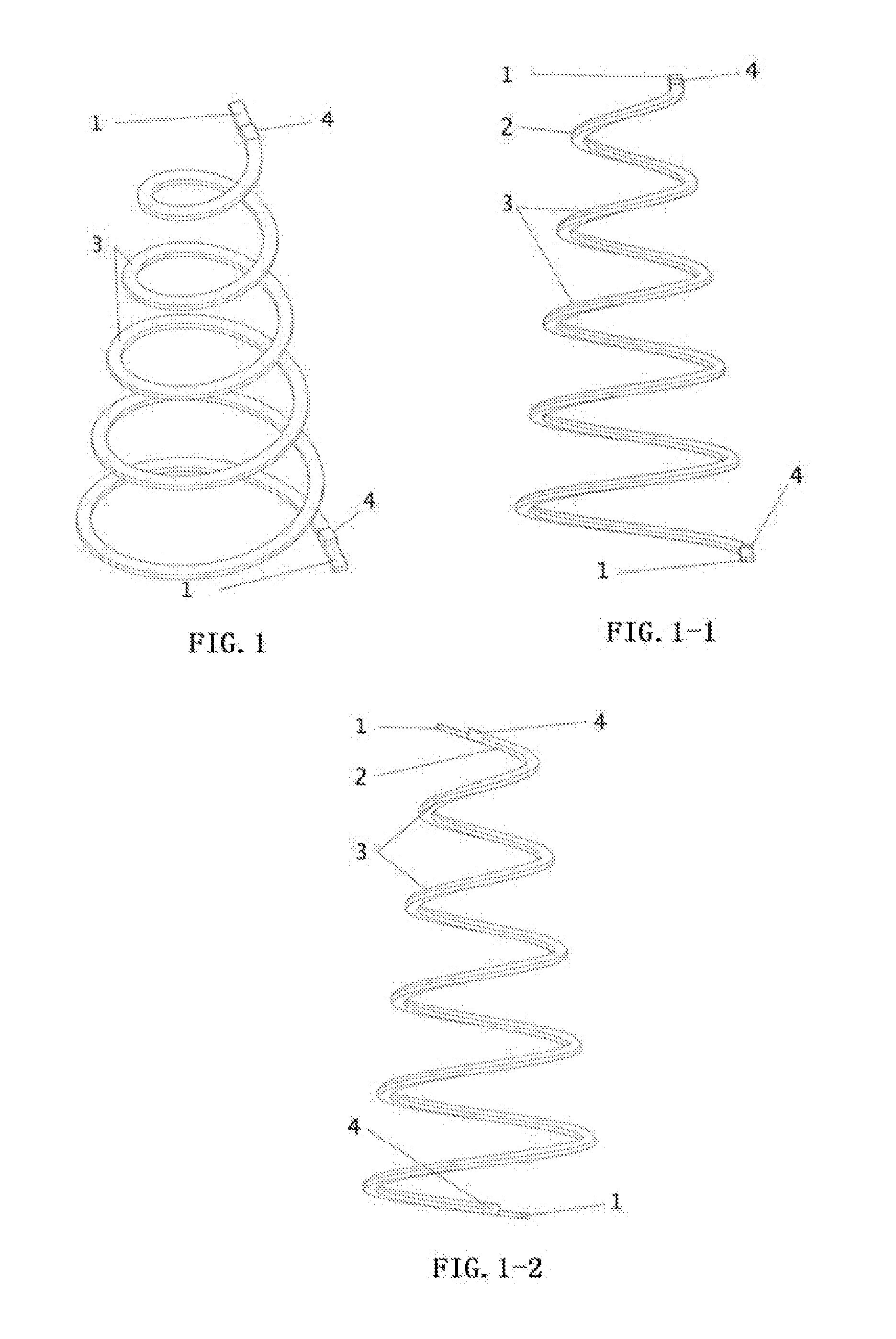

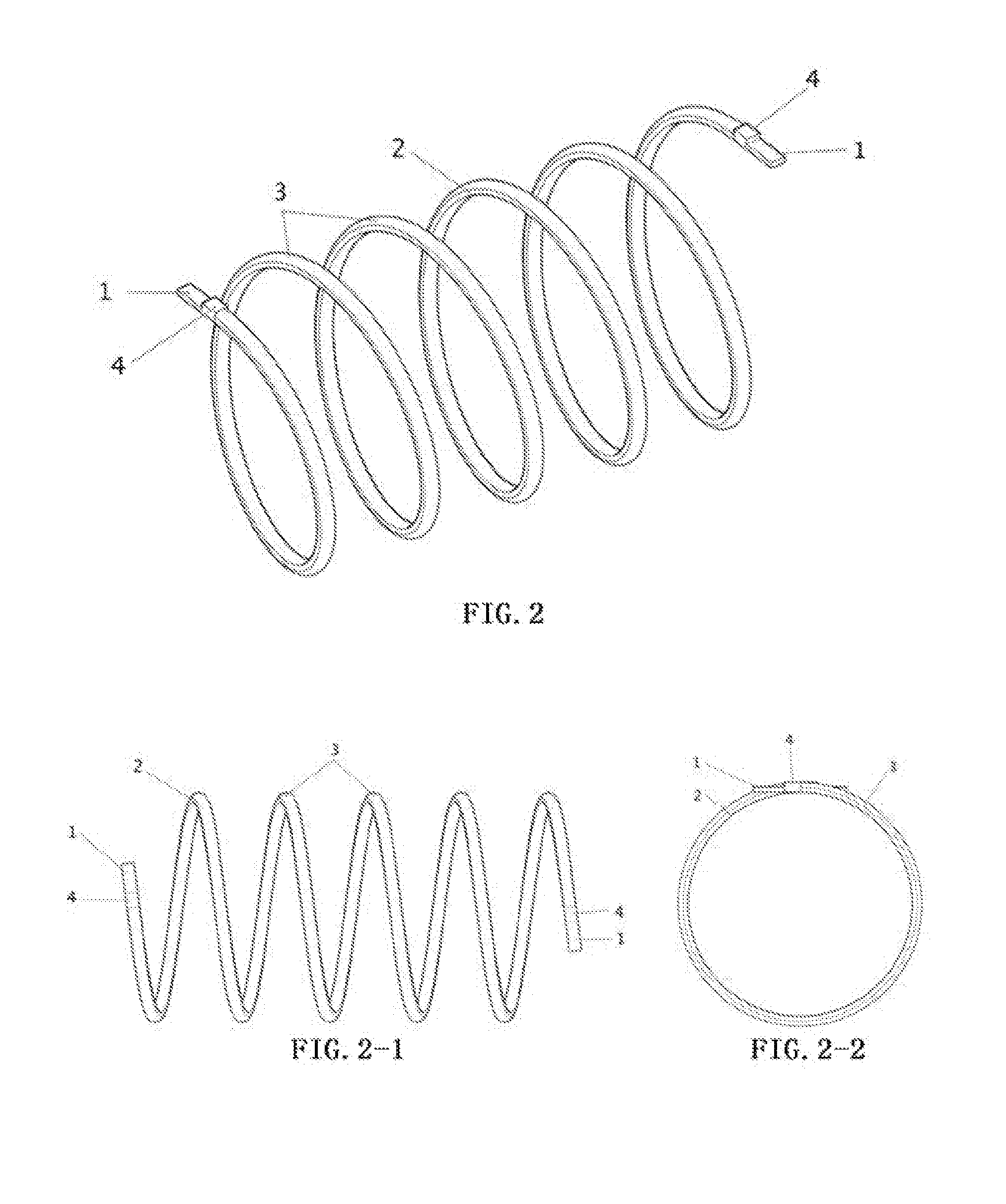

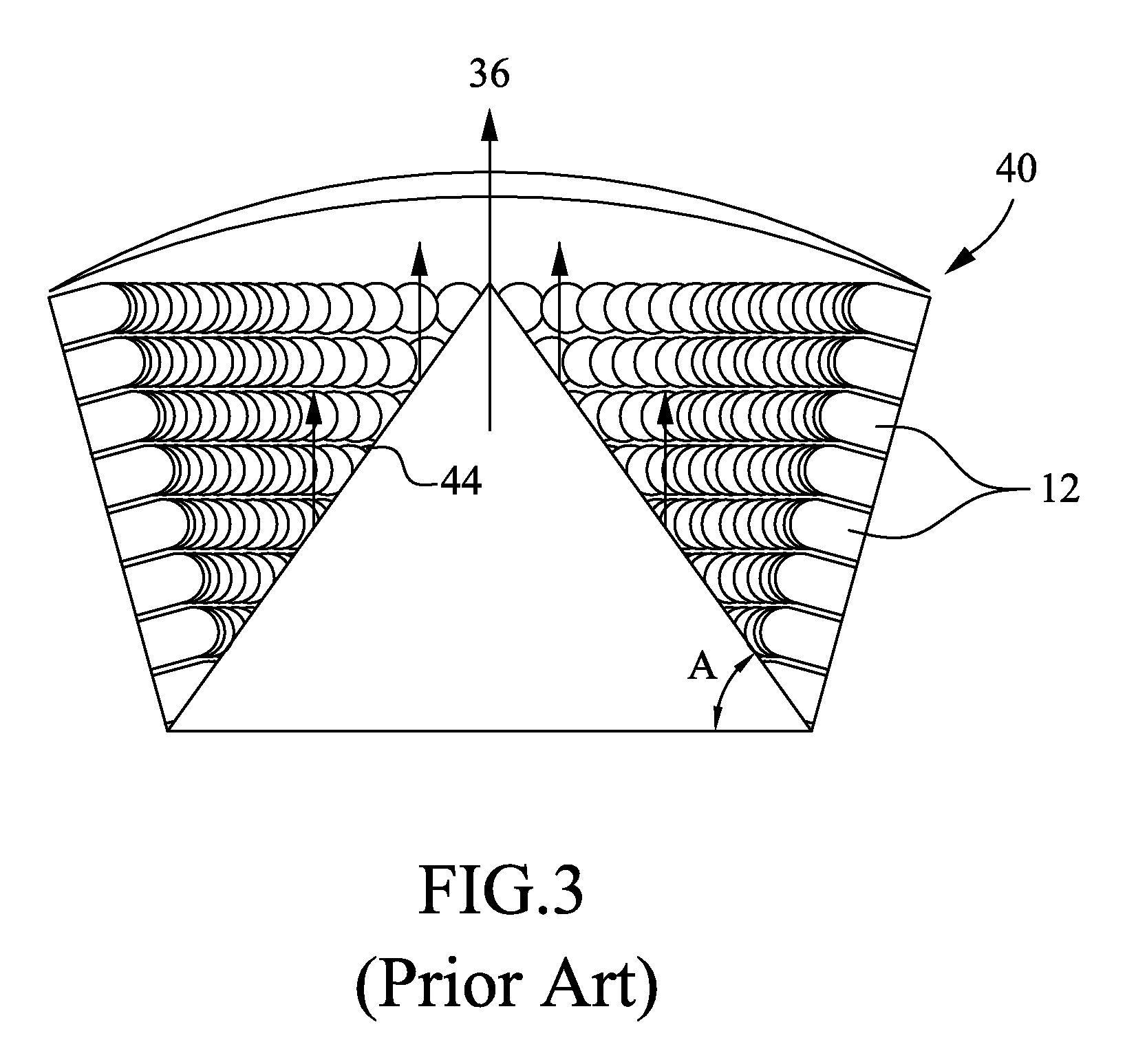

Spiral LED filament and light bulb using spiral LED filament

ActiveUS20160377237A1Simple manufacturing processImprove light distribution designElectric circuit arrangementsSolid-state devicesEngineeringElectrical connector

A spiral LED packaging filament comprises a substrate, a plurality of LED chips disposed on the top surface of the substrate, a medium layer sealing the plurality of LED chips and the top surfaces of the substrate into a sealed LED package; two electrode wires being electric connected to the plurality of LED chips, wherein the sealed LED package has a spiral shape. A light bulb with the spiral LED packaging filament comprises a bulb shell; a stem having a supporting pole, an electrical wire and a stem exhaust pipe, at least one spiral LED packaging filament is fixed on the stem; the electrode wire is connected to the electrical connector via the drive; and the bulb shell and the stem are respectively sealed.

Owner:GENERAL ELECTRIC SA

Light module

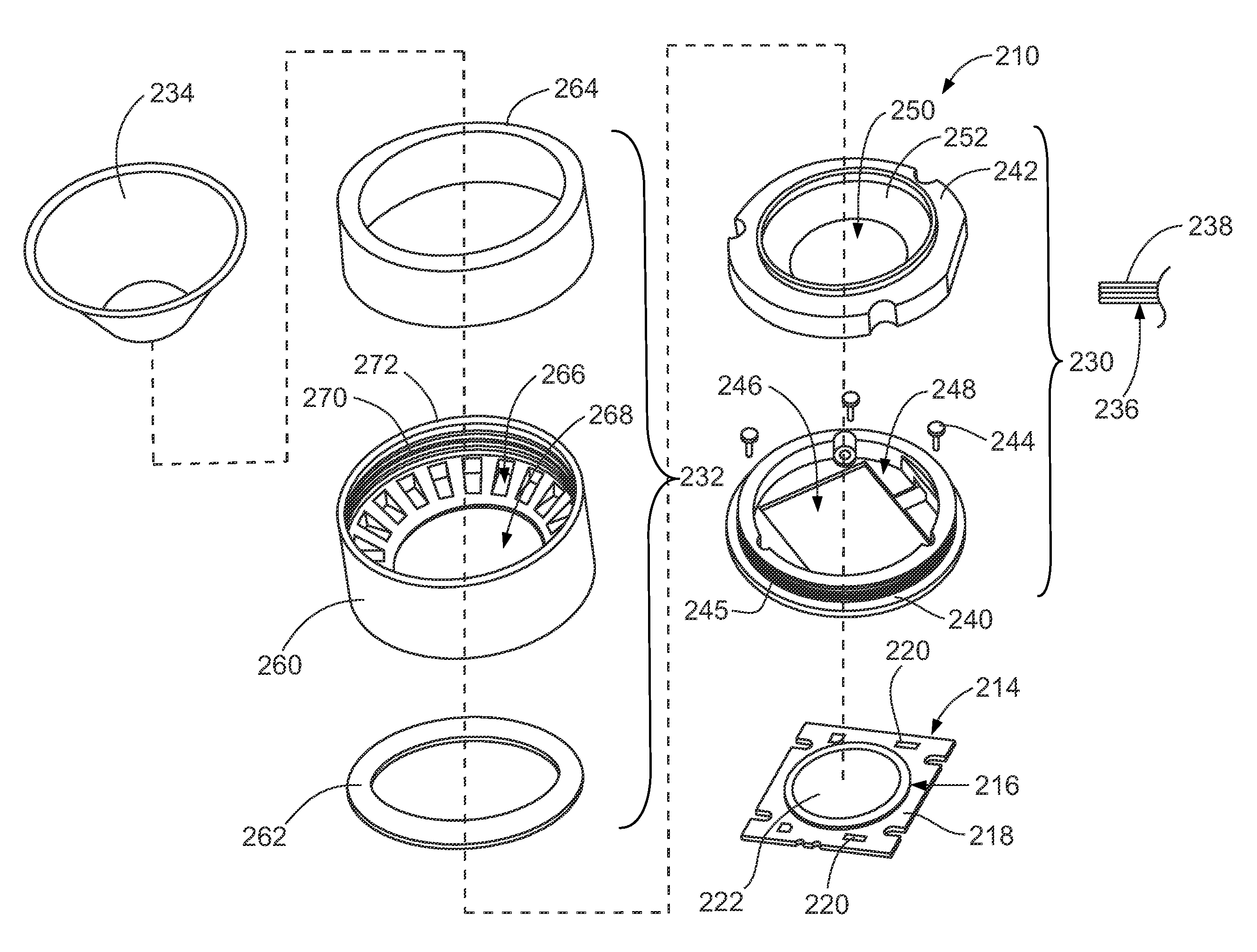

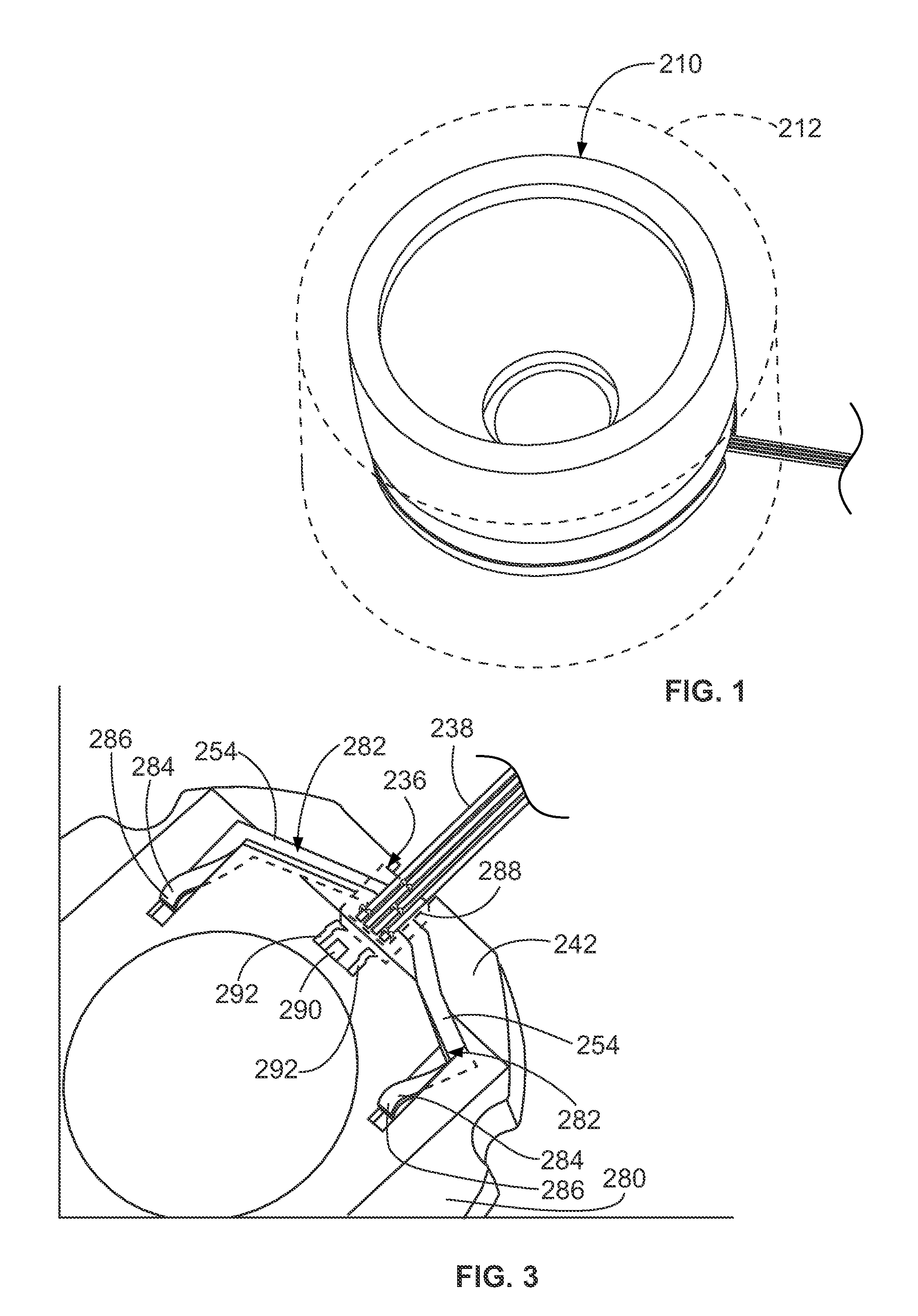

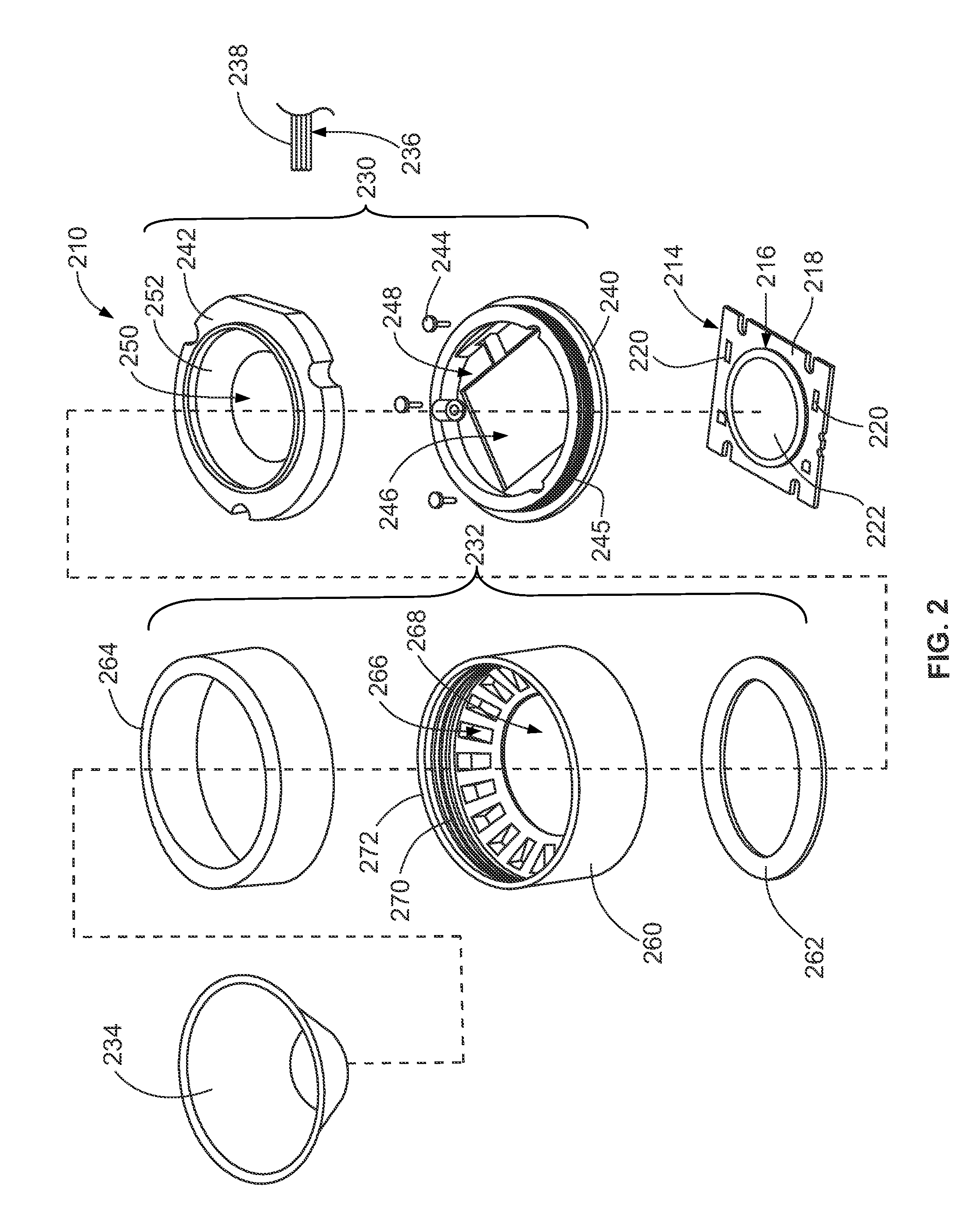

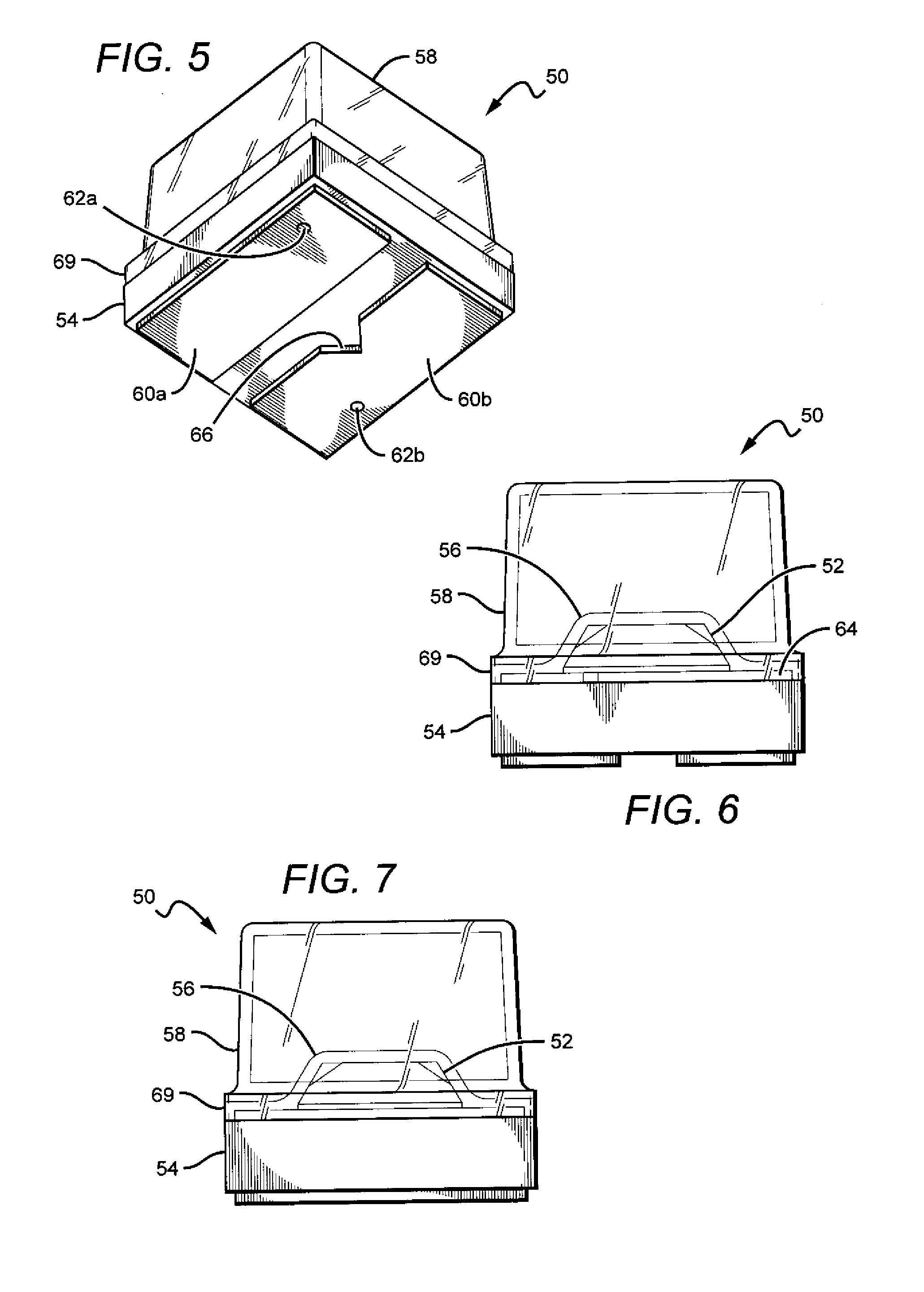

A light module includes a light engine that has an LED package having power terminals. A base ring assembly holds the light engine. The base ring assembly has a base ring configured to be mounted to a supporting structure. The base ring has a securing feature. The base ring assembly has a contact holder that holds power contacts. The power contacts are spring biased against the power terminals to create a separable power connection with the power terminals. A top cover assembly is coupled to the base ring. The top cover assembly has a collar surrounding the base ring. The top cover assembly has a securing feature that engages the securing feature of the base ring to couple the collar to the base ring. The collar has a cavity and the optical component is received in the cavity. The optical component is positioned to receive light from the LED package and the optical component is configured to emit the light generated by the LED package.

Owner:TYCO ELECTRONICS NETHERLAND BV +1

LED module and packaging method thereof

ActiveUS20100157595A1Semiconductor/solid-state device testing/measurementLighting support devicesOn boardEffect light

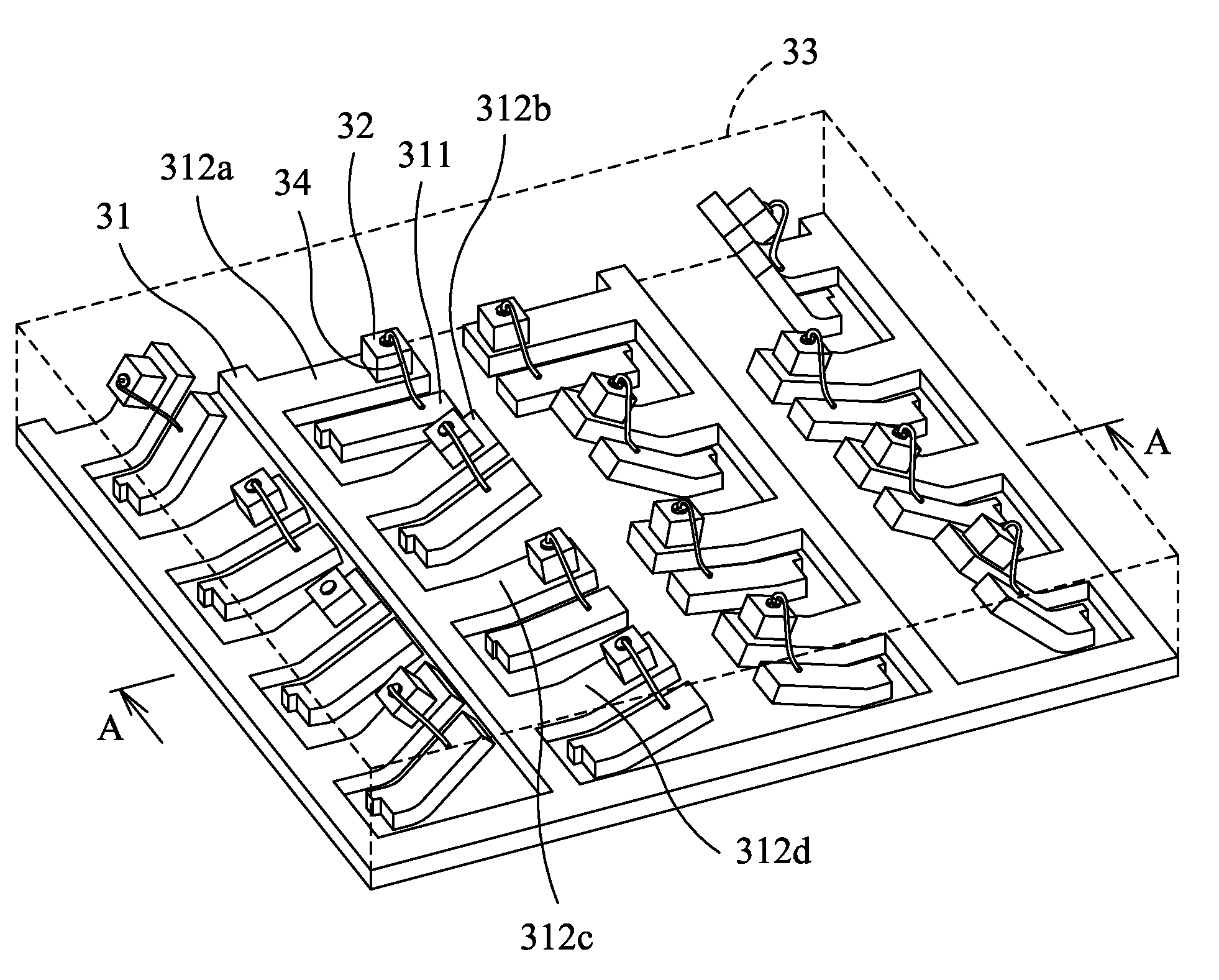

A light-emitting diode (LED) module and an LED packaging method. As the LED module is packaged under the consideration of candela distribution, each of the lead frames of the LED chips packaged in the LED module is bended for tilting the LED chips by different angles to exhibit various lighting effects. Meanwhile, in the LED packaging method, a plurality of LED chips can be loaded on board rapidly and aligned by one operation to result in less deviation in the candela distribution curve.

Owner:IND TECH RES INST

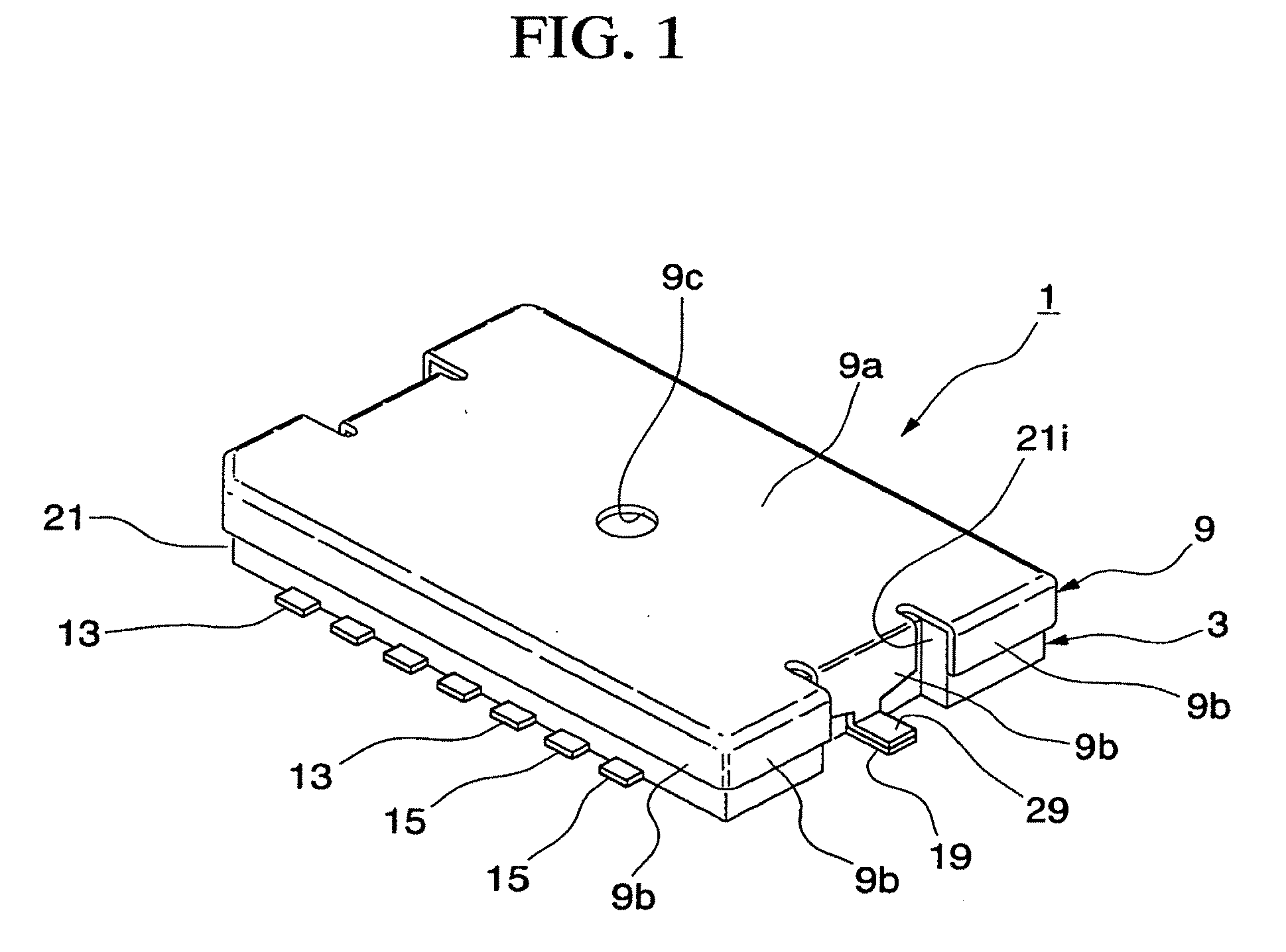

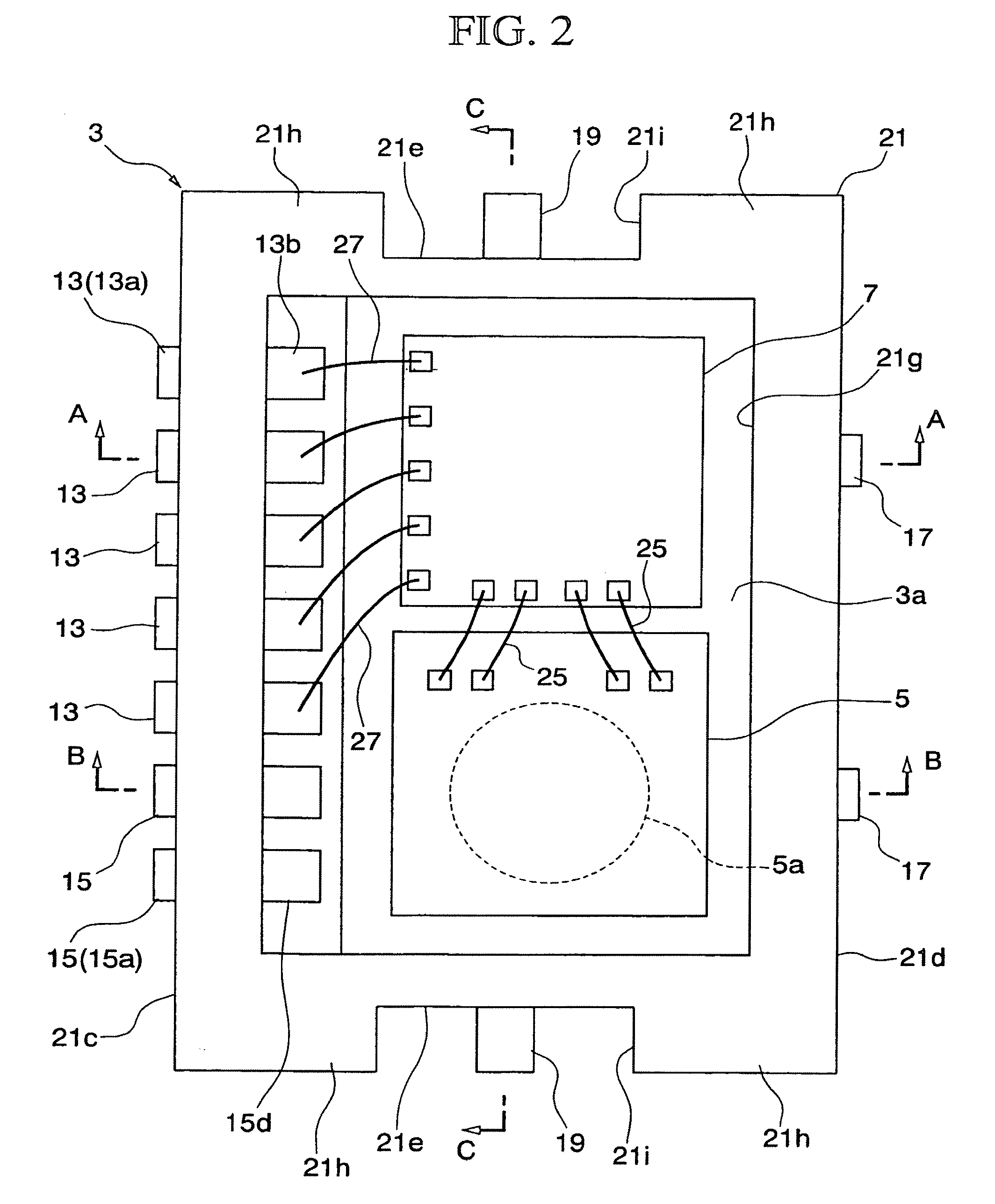

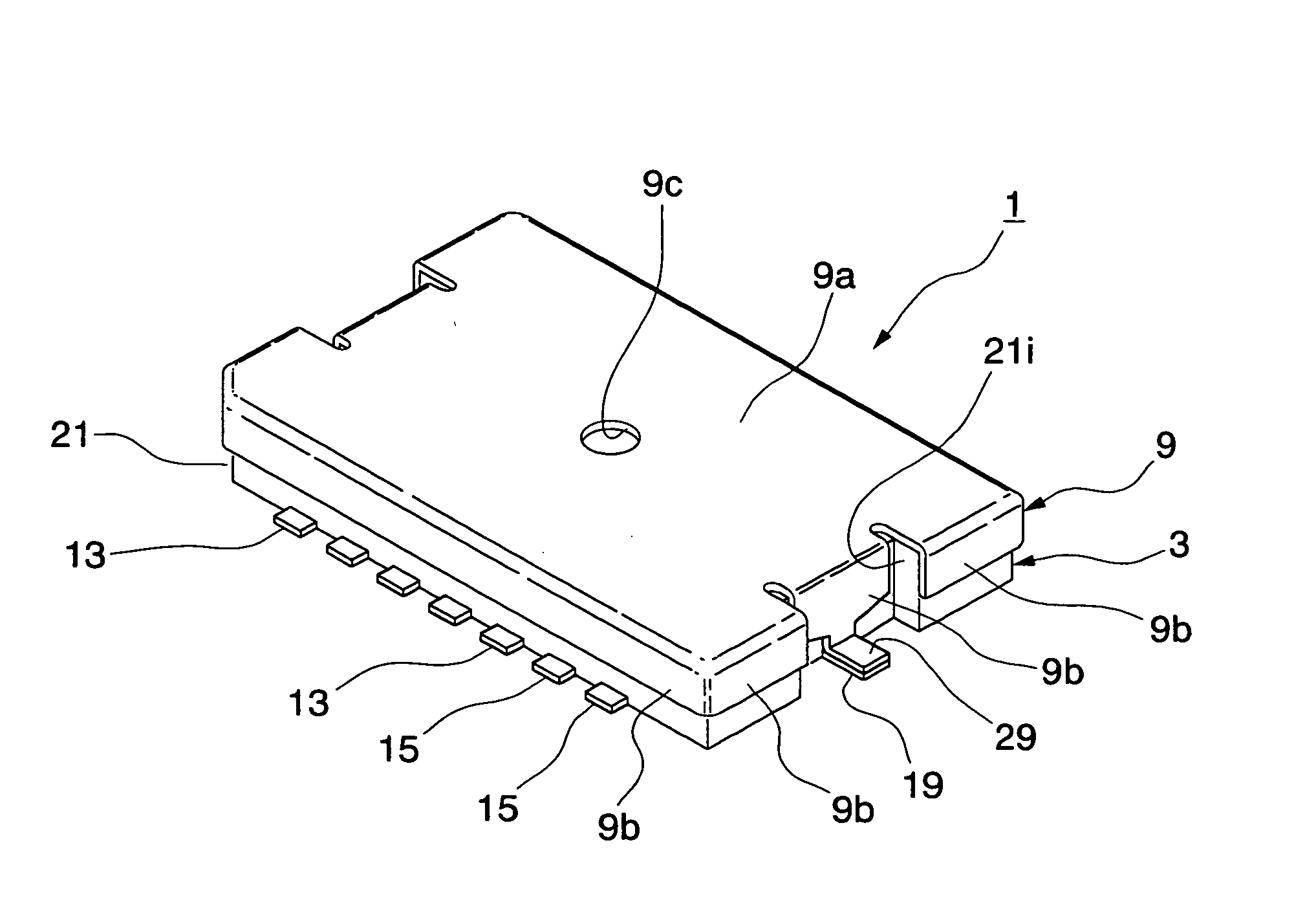

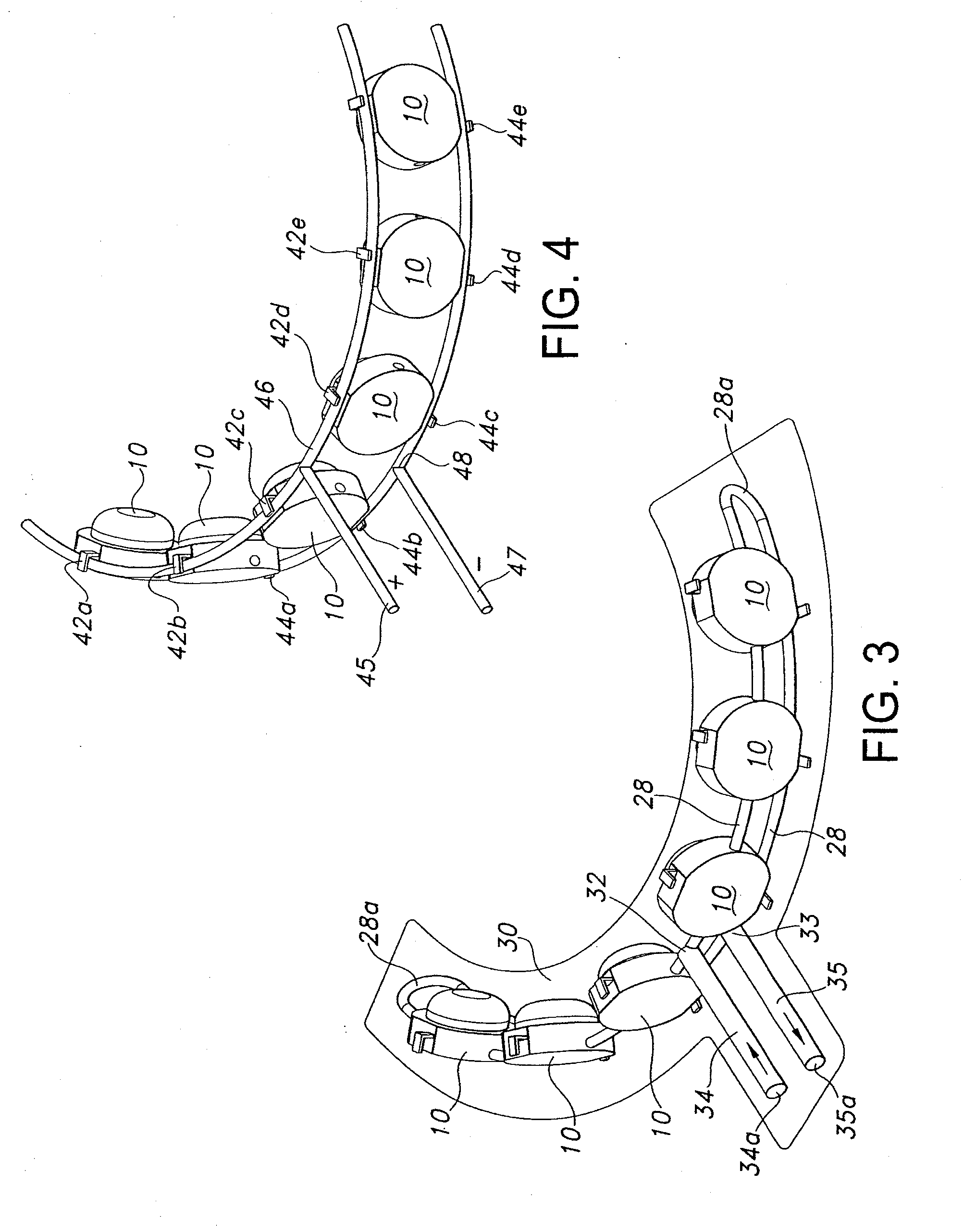

Semiconductor device

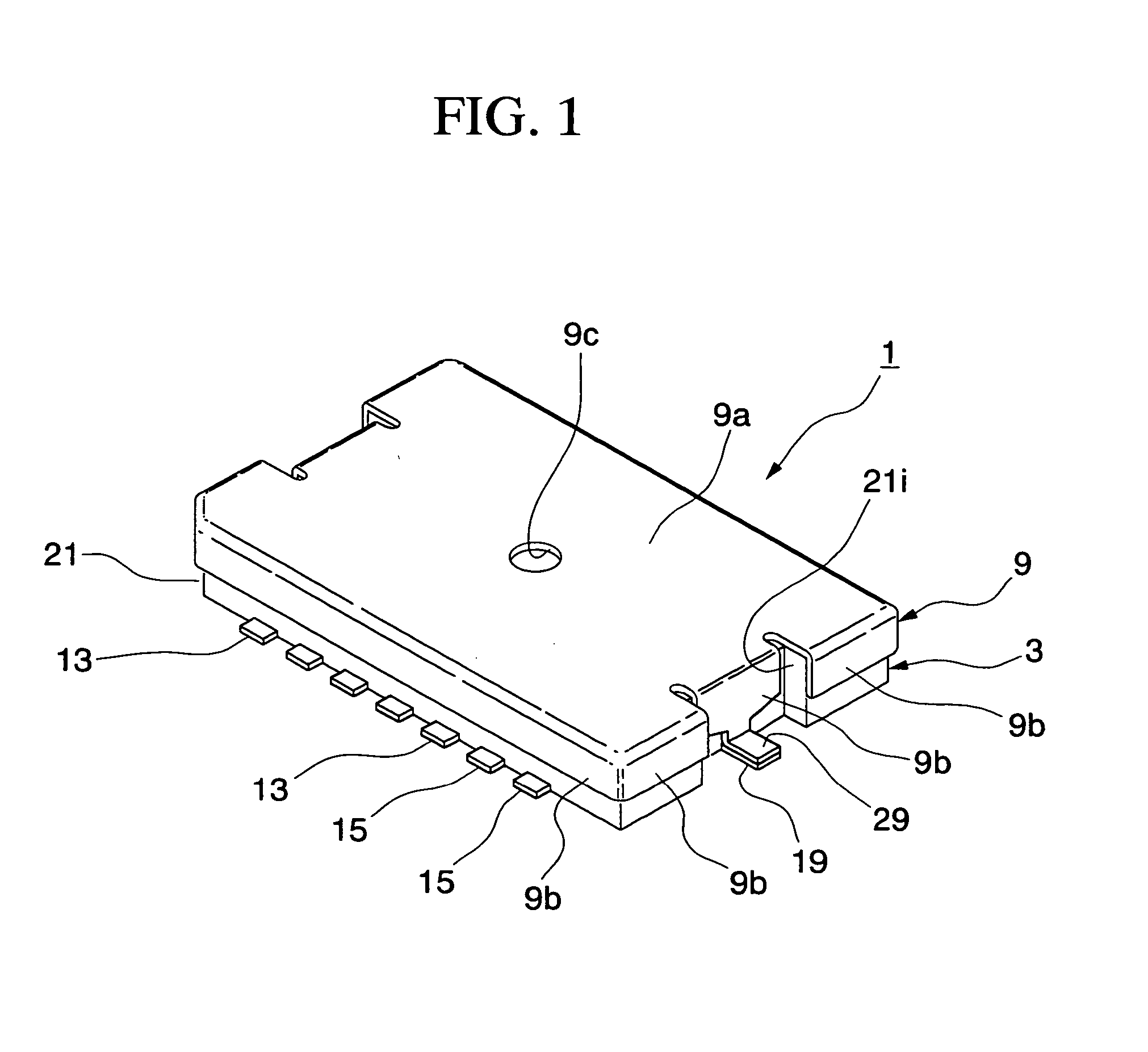

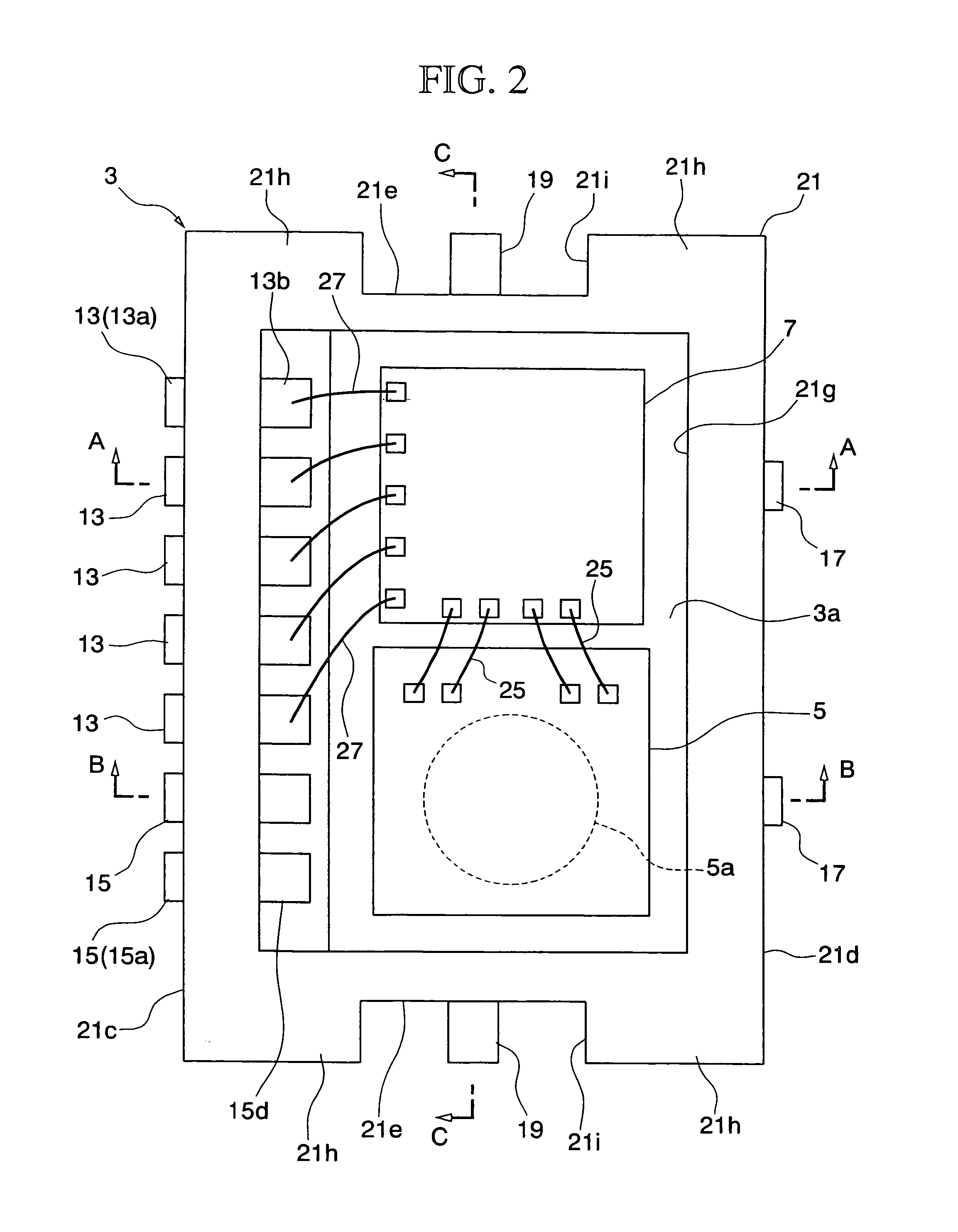

InactiveUS20090096041A1Formed with easeSemiconductor/solid-state device detailsFluid pressure measurement by electric/magnetic elementsSemiconductor chipSemiconductor sensor

A semiconductor device is designed such that a semiconductor sensor chip having a diaphragm for detecting pressure variations based on the displacement thereof is fixed onto the upper surface of a substrate having a rectangular shape, which is covered with a cover member so as to form a hollow space embracing the semiconductor sensor chip between the substrate and the cover member. Herein, the substrate is sealed with a molded resin such that chip connection leads packaging leads are partially exposed externally of the molded resin; the chip connection leads are electrically connected to the semiconductor sensor chip and are disposed in line along one side of the semiconductor sensor chip; and the packaging leads are positioned opposite the chip connection leads by way of the semiconductor sensor chip. Thus, it is possible to downsize the semiconductor device without substantially changing the size of the semiconductor sensor chip.

Owner:YAMAHA CORP

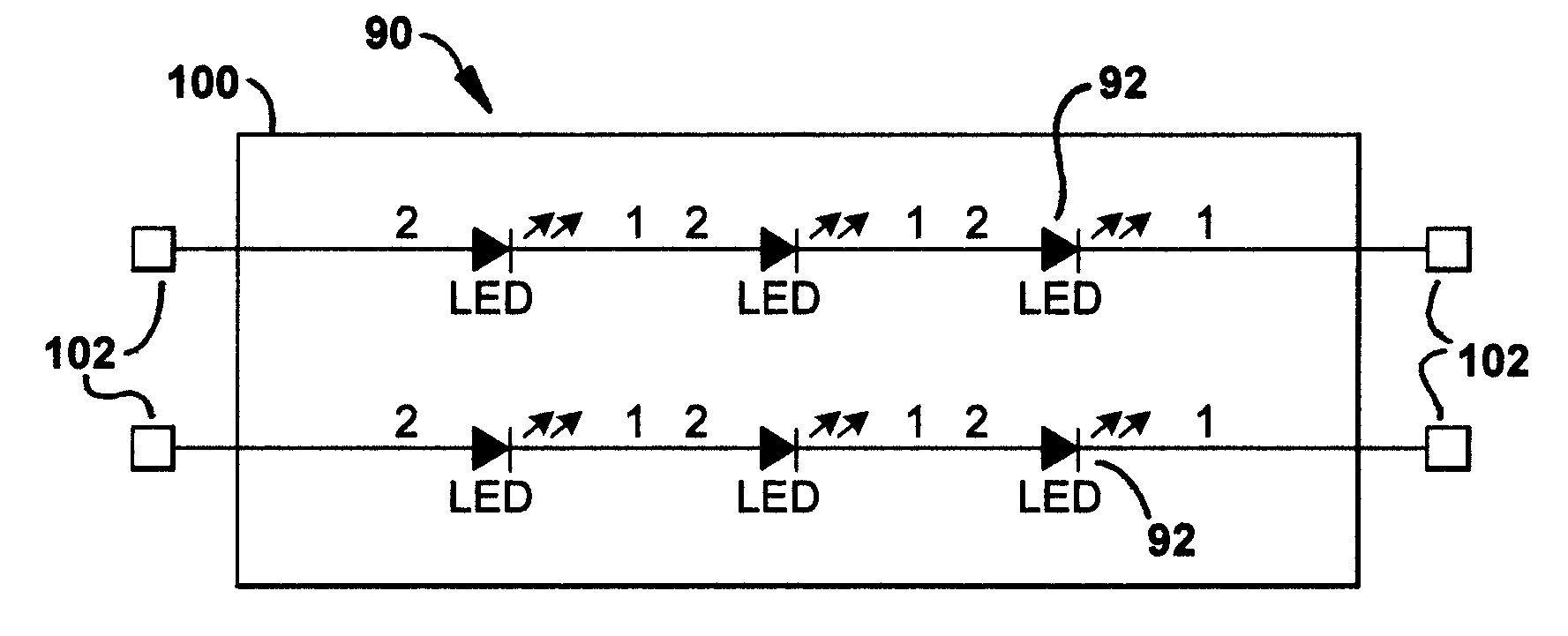

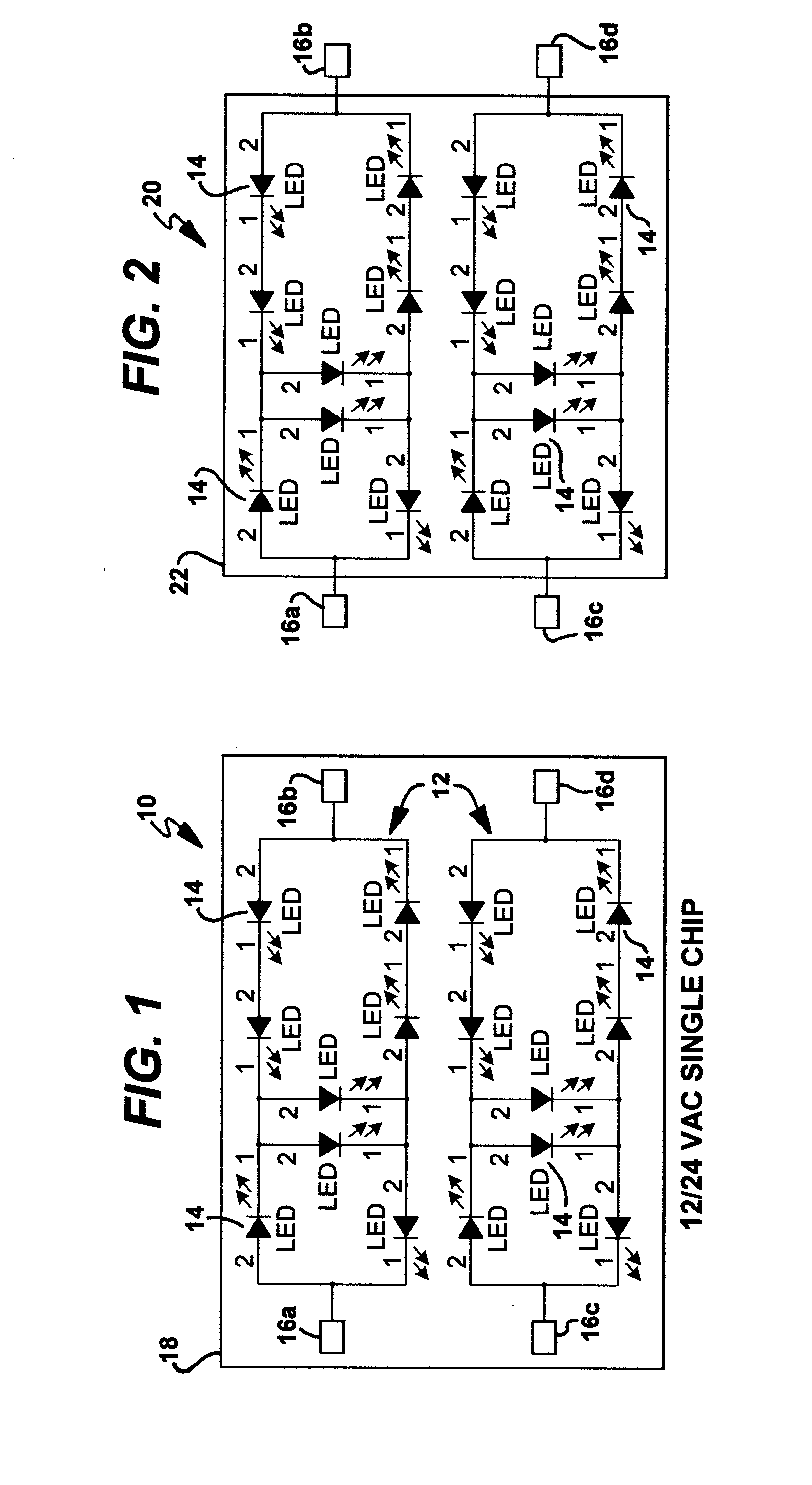

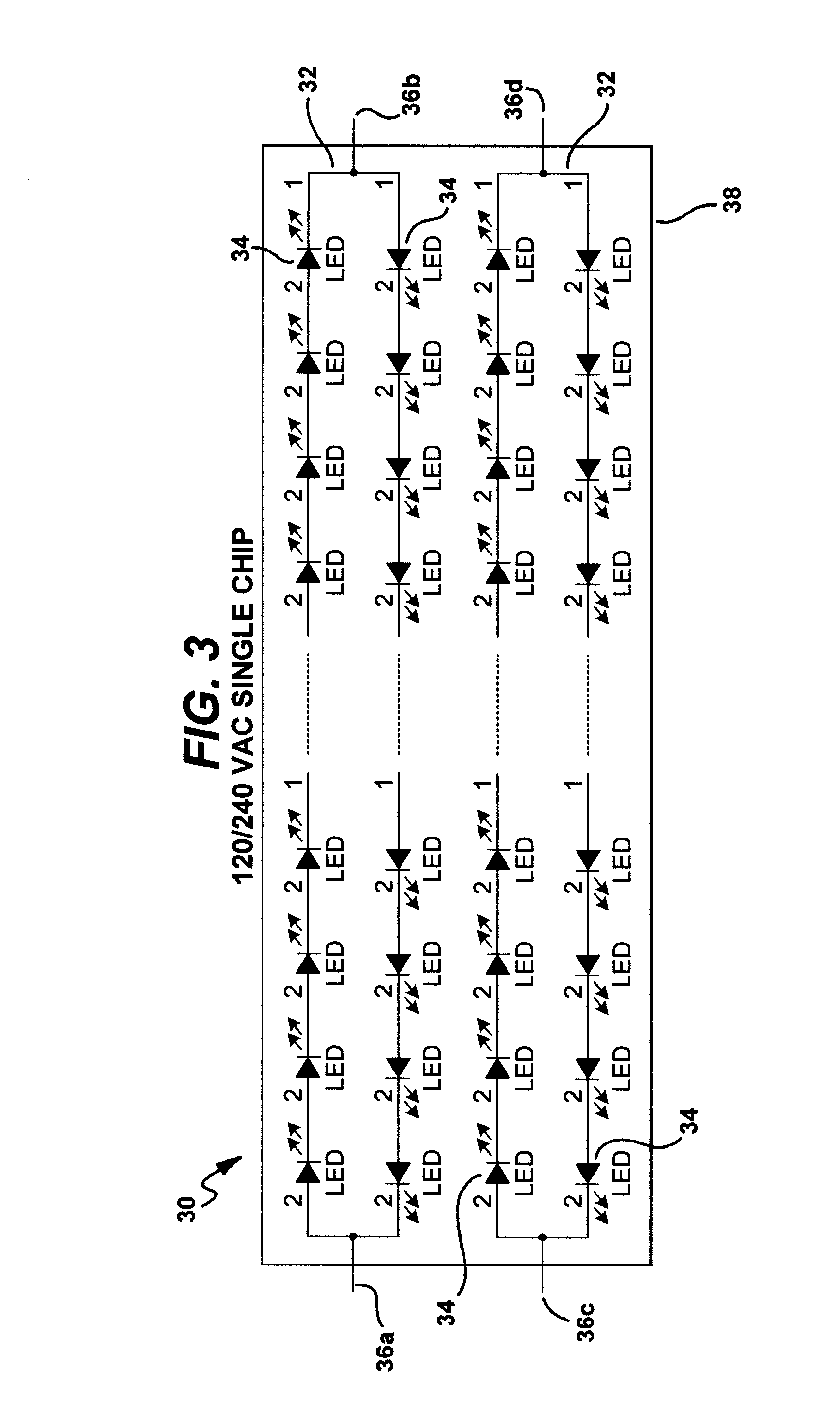

Multi-voltage and multi-brightness LED lighting devices and methods of using same

ActiveUS20120069560A1Increase brightnessWave amplification devicesElectroluminescent light sourcesElectricityElectrical connection

A single chip multi-voltage or multi-brightness LED lighting device having at least two LED circuits having at least two LEDs connected seπes, and electrically unconnected in a parallel relationship, a forward operating dπve voltage of at least six volts and are monolithically integrated on a single substrate, configurable by means of connecting the circuits so as to provide optional operating voltage level and / or desired brightness level wherein the electrical connection at the LED packaging level when the single chips are integrated into the LED package Alternatively, the LED package may have external electrical contacts that match the integrated chips within Optionally allowable, the drive voltage level and / or the brightness level select-ability may be passed on through to the exterior of the LED package and may be selected by the LED package user, the PCB assembly facility, or the end product manufacturer.

Owner:LYNK LABS INC

Low-stress epoxy/organic silicon/POSS nano hybrid material, and preparation method and application thereof

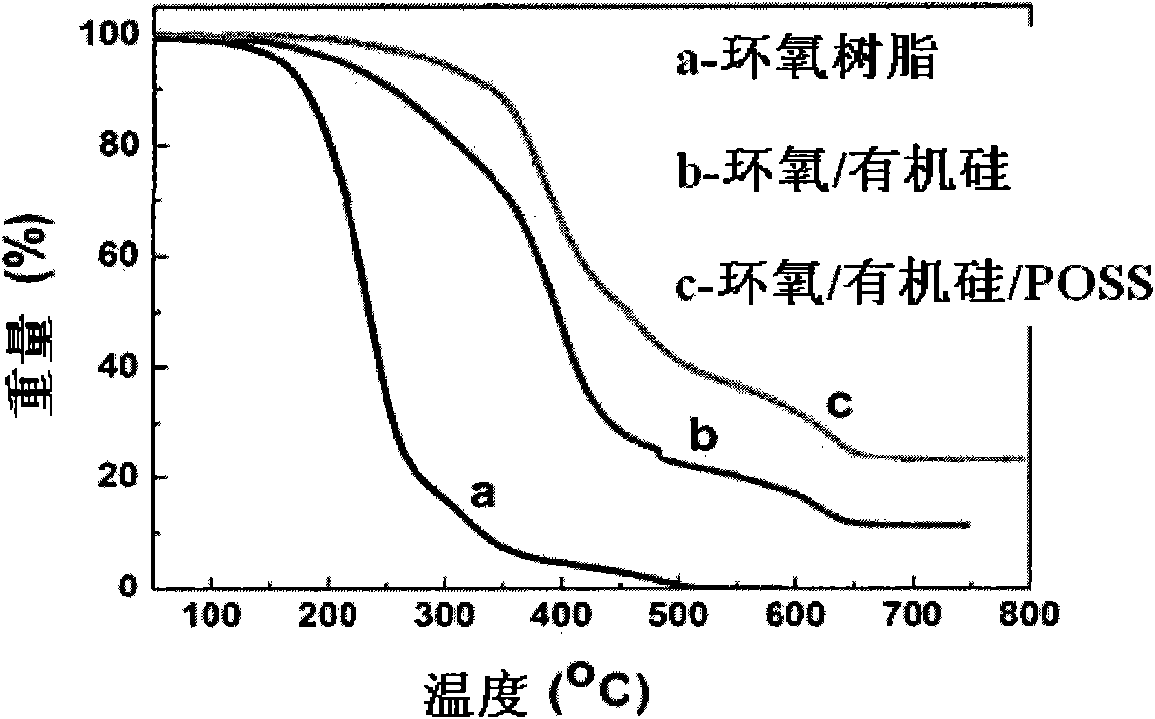

InactiveCN101974227AImprove thermal stabilityHigh light transmittanceEpoxy resin adhesivesEpoxy resin coatingsChemical industryEpoxy

The invention relates to the technical fields of photoelectricity and chemical industry, in particular to a low-stress epoxy / organic silicon / POSS nano hybrid material, and a preparation method and application thereof. The epoxy / organic silicon / POSS nano hybrid material comprises (a) an epoxy resin, (b) a polyorganosiloxane, (c) a cage-type polysilsesquioxane (POSS), (d) an epoxy hardener, (e) non-essential silane oxycompound and (f) non-essential assistants, wherein the polyorganosiloxane contains epoxy groups and silane oxygen groups. The cured nano hybrid system has excellent reticular cross-linked structure and does not have microphase separation. The epoxy / organic silicon / POSS nano hybrid material has the advantages of high mechanical strength, favorable heat resistance, favorable cohesive property, high chemical stability, favorable ultraviolet aging resistance, favorable optical transparency and other excellent properties, has the functions of low internal stress and pressure buffer, and can be used as an LED packaging material, optical protection material, circuit protection coating material, adhesive paint and the like.

Owner:FUDAN UNIV +1

Semiconductor device

ActiveUS20070210392A1Formed with easeSemiconductor/solid-state device detailsSolid-state devicesDevice materialSemiconductor sensor

A semiconductor device is designed such that a semiconductor sensor chip having a diaphragm for detecting pressure variations based on the displacement thereof is fixed onto the upper surface of a substrate having a rectangular shape, which is covered with a cover member so as to form a hollow space embracing the semiconductor sensor chip between the substrate and the cover member. Herein, the substrate is sealed with a molded resin such that chip connection leads packaging leads are partially exposed externally of the molded resin; the chip connection leads are electrically connected to the semiconductor sensor chip and are disposed in line along one side of the semiconductor sensor chip; and the packaging leads are positioned opposite the chip connection leads by way of the semiconductor sensor chip. Thus, it is possible to downsize the semiconductor device without substantially changing the size of the semiconductor sensor chip.

Owner:INFINEON TECH AG

Small-size led packaging structure for enhancing light emitting angle

InactiveCN103489986AImprove applicabilityImprove coloring performanceSolid-state devicesSemiconductor devicesGamutFluorescence

A small-size LED packaging structure for enhancing a Sight emitting angle includes an opaque base and at least one light emitting chip. The light emitting chip is installed on the opaque base, and the opaque base includes a transparent sidewall disposed around the base and a concave-cup space, and the transparent sidewall is formed by a molding method, and the concave-cup space is filled with a packaging gel by a dispensing method, and the packaging gel is doped with at least one phosphor powder. Therefore, the transparent sidewall can increase the light emitting angle to 140°~180° and reduce the amount of internal reflected light significantly to avoid the occurrence of a yellow ring phenomenon, and the phosphor powder can enhance the color manifestation and the color gamut.

Owner:UNITY OPTO TECH CO LTD

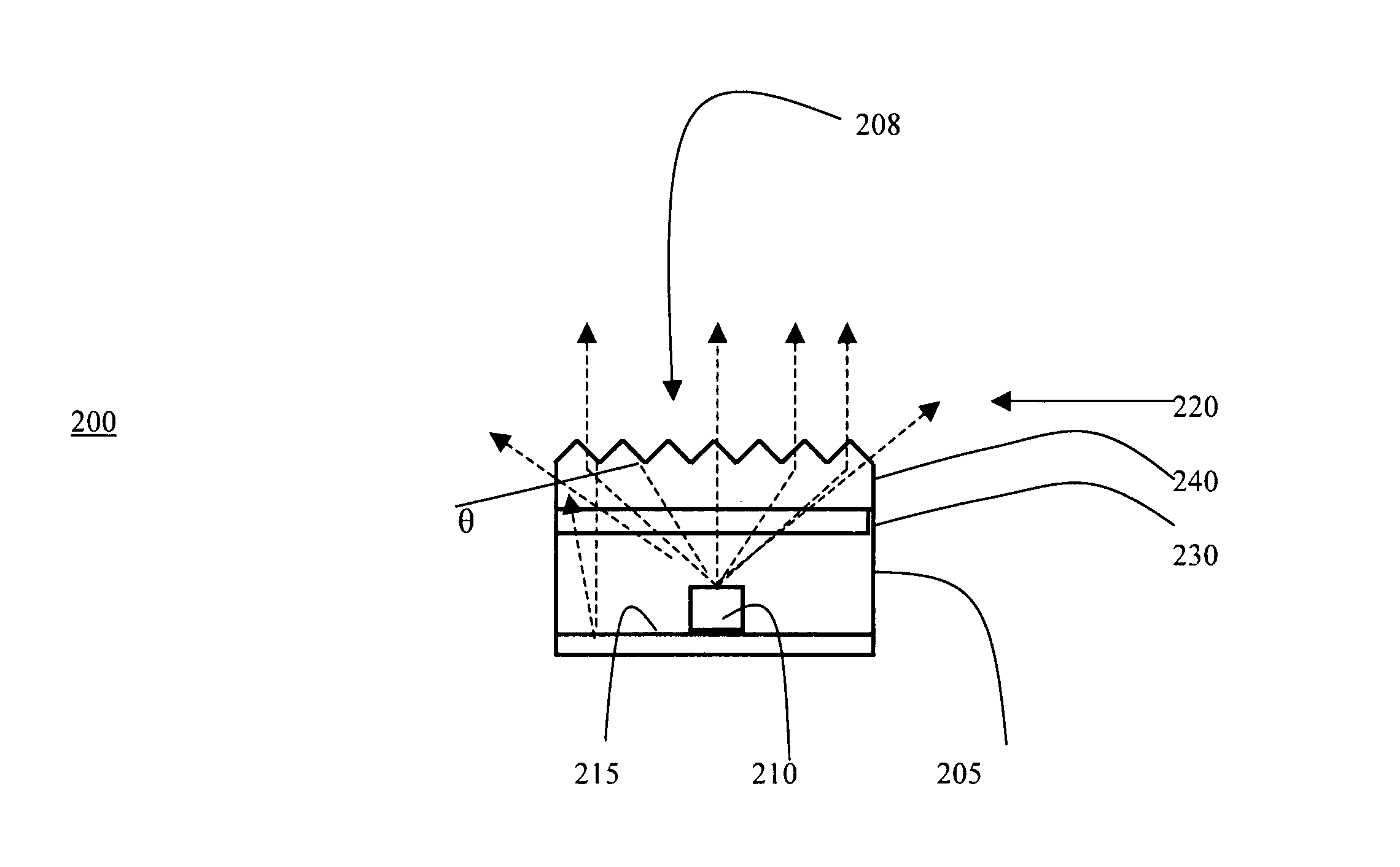

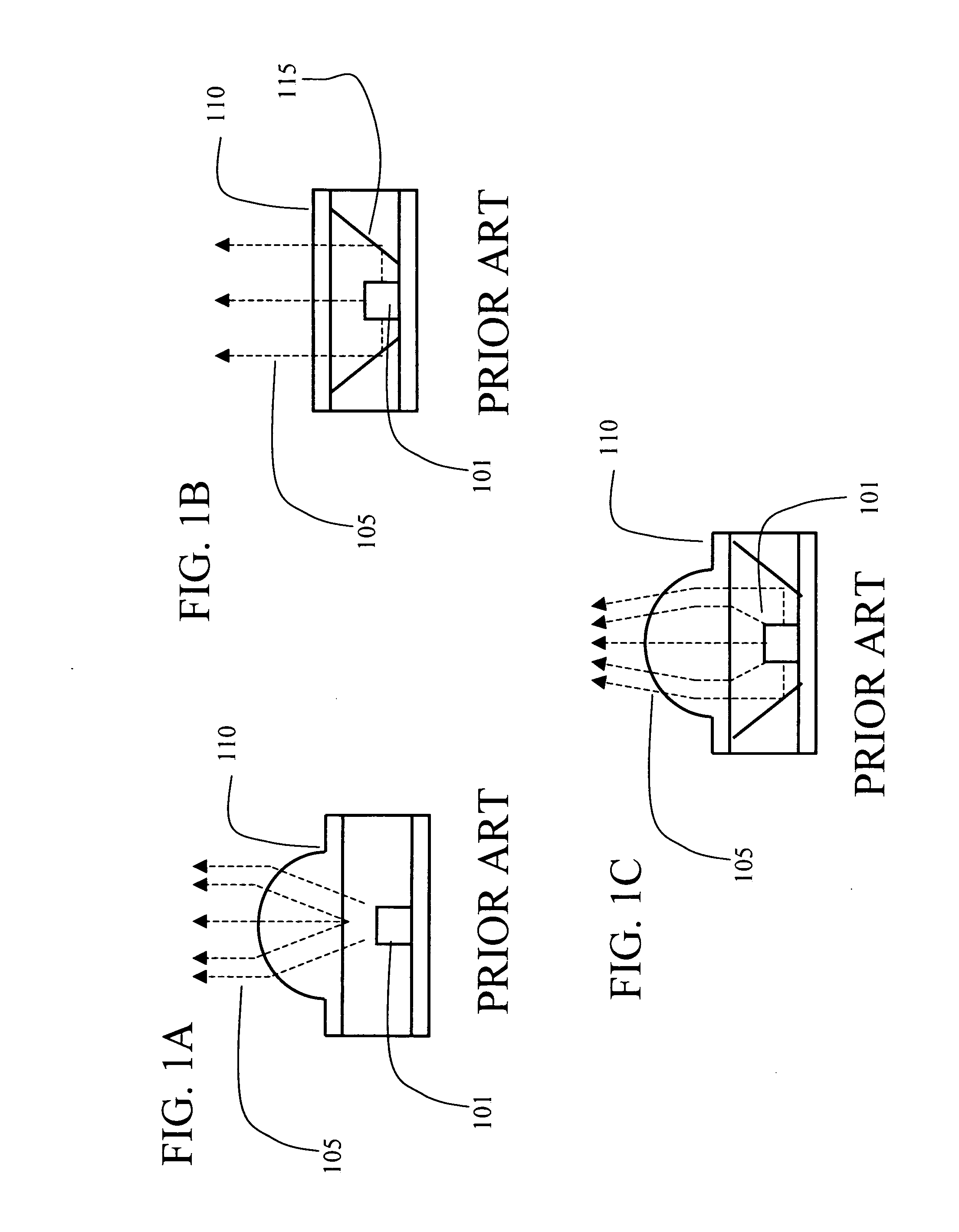

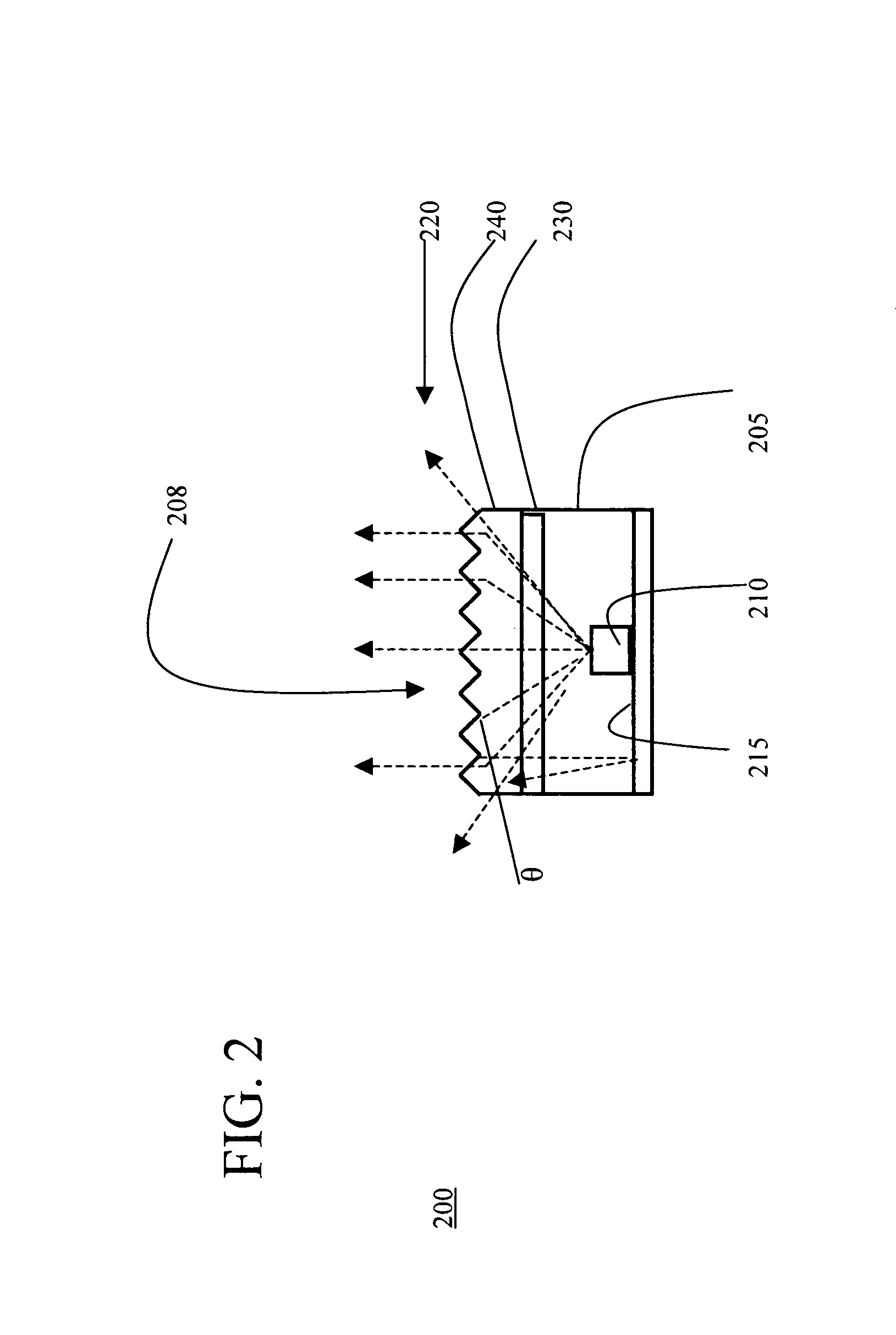

Compact LED package with reduced field angle

A light emitting diode system includes a housing including a light emission opening and a light emitting diode disposed within the housing. A first film layer covers the light emission opening and includes a uniaxial collimating film configured to direct light from the light emitting diode along a first axis.

Owner:AVAGO TECH ECBU IP (SINGAPORE) PTE LTD

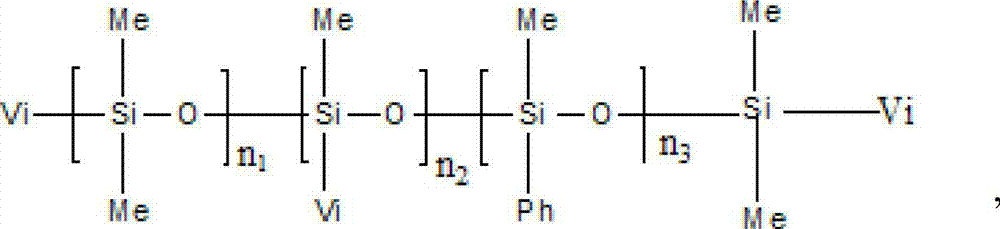

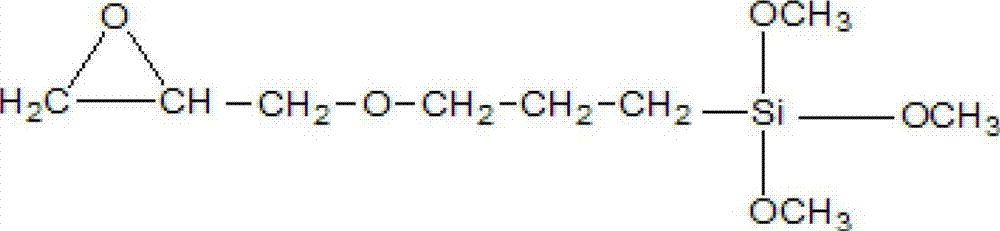

Vulcanization-proof LED (light-emitting diode) packaging silica gel

InactiveCN102965069AStrong adhesionIncrease dosageNon-macromolecular adhesive additivesMacromolecular adhesive additivesVulcanizationAdhesive

The invention relates to an LED (light-emitting diode) packaging silica gel, and in particular relates to a vulcanization-proof LED packaging silica gel, belonging to the technical field of adhesives. The vulcanization-proof LED packaging silica gel comprises a component A and a component B, wherein the weight ratio of the component A to the component B is 1: 1; the component A comprises raw materials based on parts by weight: 50-60 parts of methyl phenyl vinyl silicone oil, 30-60 parts of methyl vinyl MQ resin, 0.1-0.3 part of platinum catalyst and 3-5 parts of bonding agent; and the component B comprises raw materials based on parts by weight: 40-50 parts of methyl phenyl vinyl silicone oil, 30-50 parts of methyl vinyl MQ resin, 5-15 parts of cross-linking agent and 0.1-0.3 part of inhibitor. The vulcanization-proof LED packaging silica gel has excellent adhesive force for silver, phenyl-propanolamine (PPA), glass and the like, and has the light transmittance of more than 98%; and phenyl-containing functional groups and branched chain type vinyl are introduced into the LED packaging silica gel, and the dosage of the vinyl MQ resin is increased, so that the crosslinking density and the curing handness are improved, and therefore, the vulcanization resistance of a packaging adhesive layer can be improved.

Owner:YANTAI DEBANG ADVANCED SILICON MATERIALS

Waterproof surface mount device package and method

ActiveUS20120132937A1Improves Structural IntegrityImprove reliabilitySolid-state devicesSemiconductor/solid-state device manufacturingSurface mountingLead bonding

The present invention is directed to LED packages and methods utilizing waterproof and UV resistant packages with improved structural integrity. In some embodiments, the improved structural integrity is provided by various features in the lead frame that the casing material encompasses to improve the adhesion between the lead frame and the casing for a stronger, waterproof package. Moreover, in some embodiments the improved structural integrity and waterproofing is further provided by improved adhesion between the encapsulant and the casing. Some embodiments also provide for improved wire bonds, with the length, thickness, and loop height of the wire bonds controlled and optimized for improved adhesion between the wire bonds and the encapsulant as well as improved reliability.

Owner:CREE HUIZHOU SOLID STATE LIGHTING

LED package with encapsulant having curved and planar surfaces

ActiveUS20140027795A1Effective lightingBroad emission profileSolid-state devicesSemiconductor devicesEngineeringWavelength

LED packages are disclosed that are compact and efficiently emit light, and can comprise encapsulants with curved and planar surfaces. The packages can comprise a submount with a one or a plurality of LEDs, and in those with a plurality of LEDs each of the LEDs can emit the same or different wavelengths of light than the others. A blanket conversion material layer can be included on at least some of the LEDs and the submount. The encapsulant can be on the submount, over at least some of the LEDs, with each of the planar surfaces being vertical and aligned with one of the edges of the submount. The encapsulant can also have a upper curved surface with a relatively large radius of curvature, with the combination of curved and planar surfaces resulting in efficient emission of light with a relatively narrow emission profile.

Owner:CREELED INC

Method and apparatus for using light emitting diodes

The present invention provides a method and apparatus for using light emitting diodes for curing in various applications. The method includes a novel method for cooling the light emitting diodes and mounting the same on heat pipe in a manner which delivers ultra high power in UV, visible and IR regions. Furthermore, the unique LED packaging technology of the present invention that utilizes heat pipes performs far more efficiently in much more compact space. This allows much more closely spaced LEDs operating at higher power and brightness.

Owner:DAHM JONATHAN S

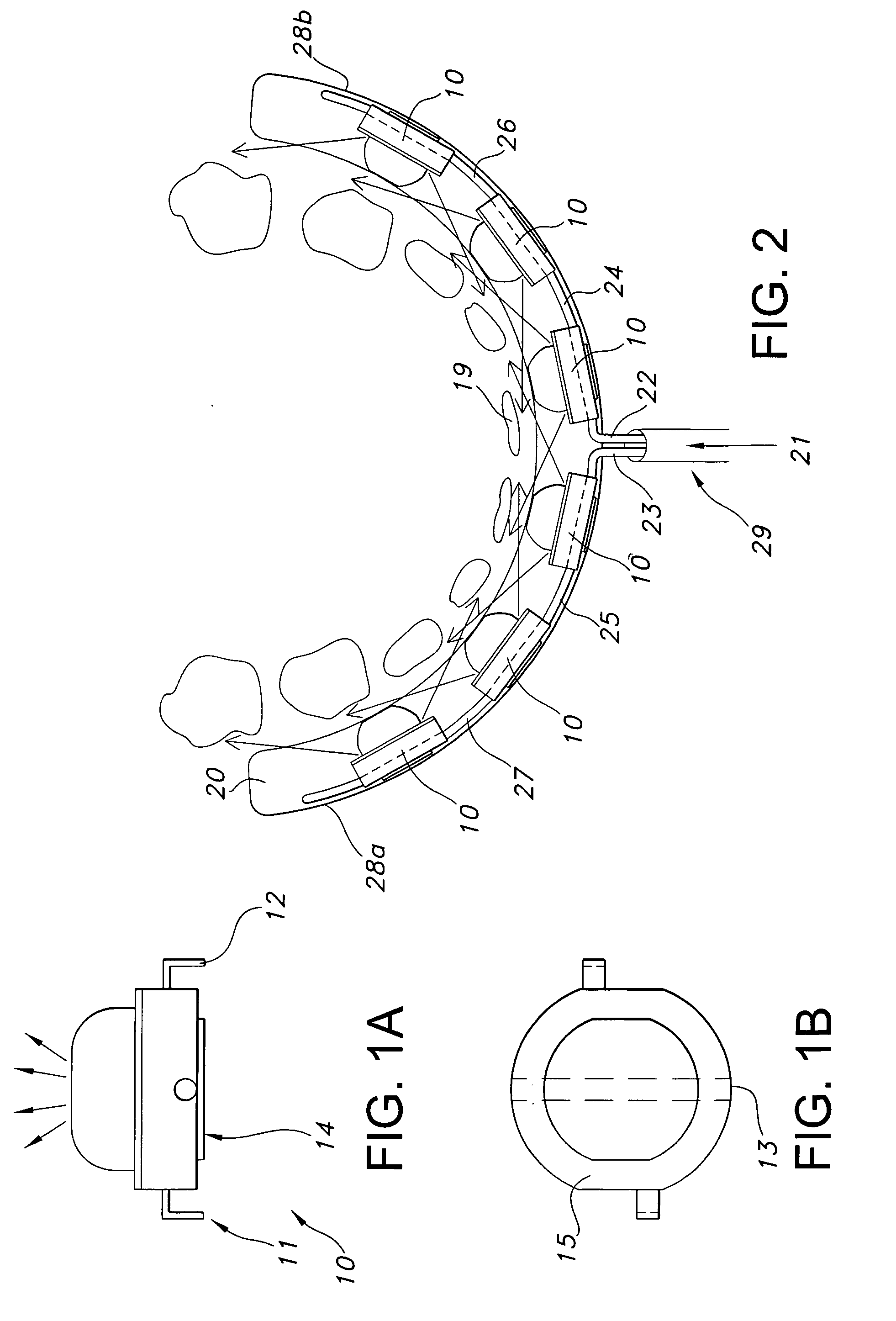

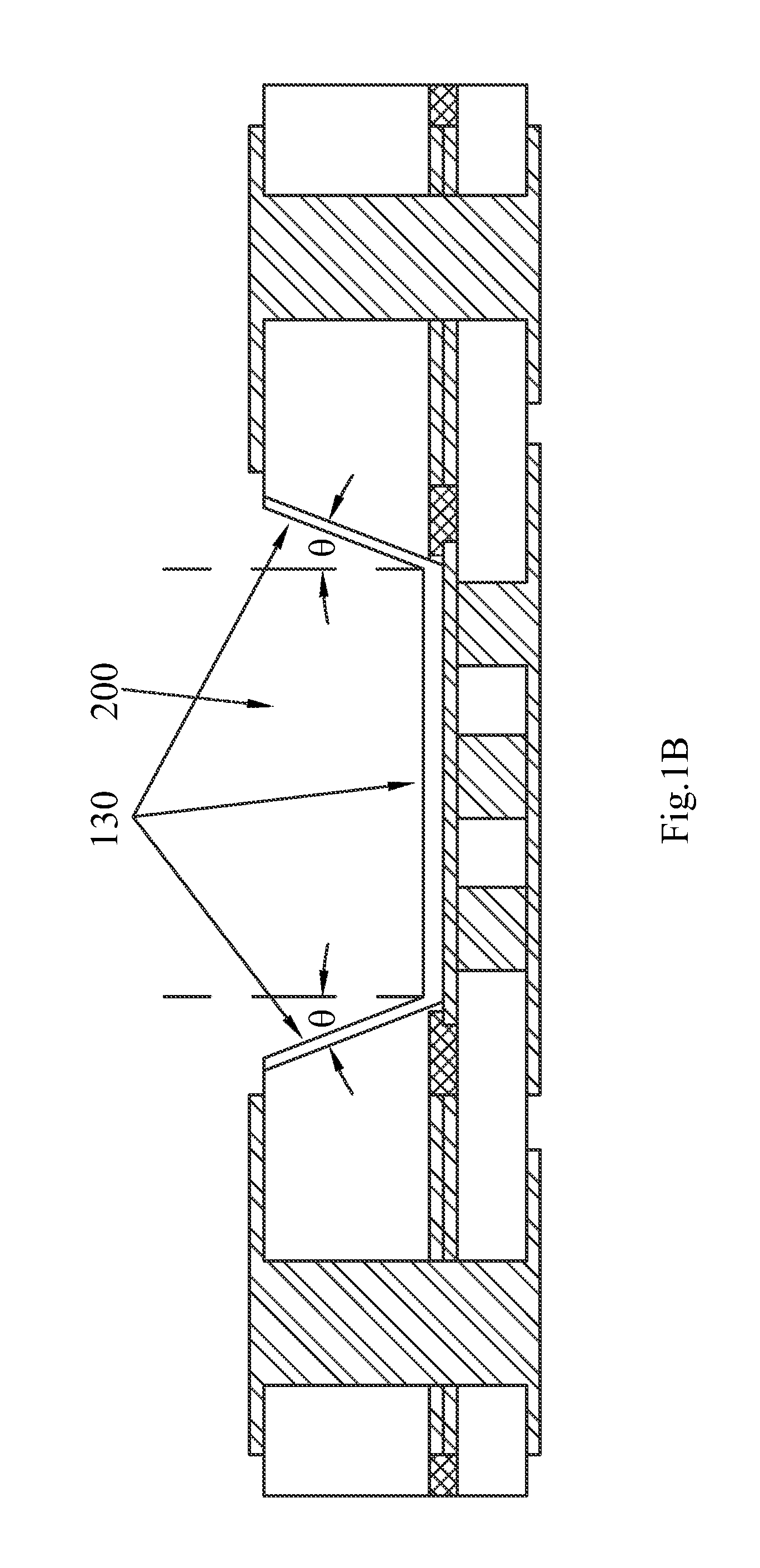

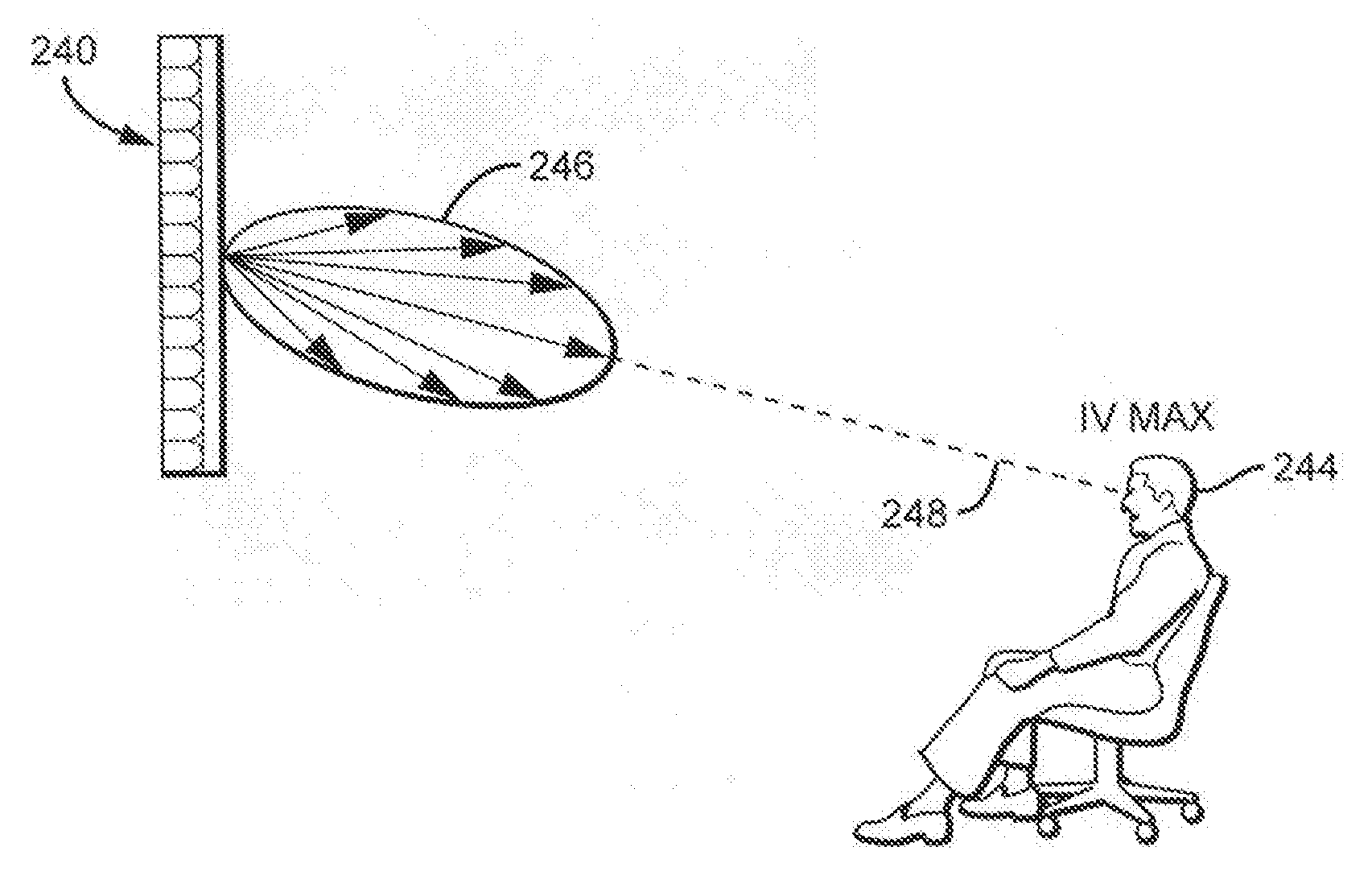

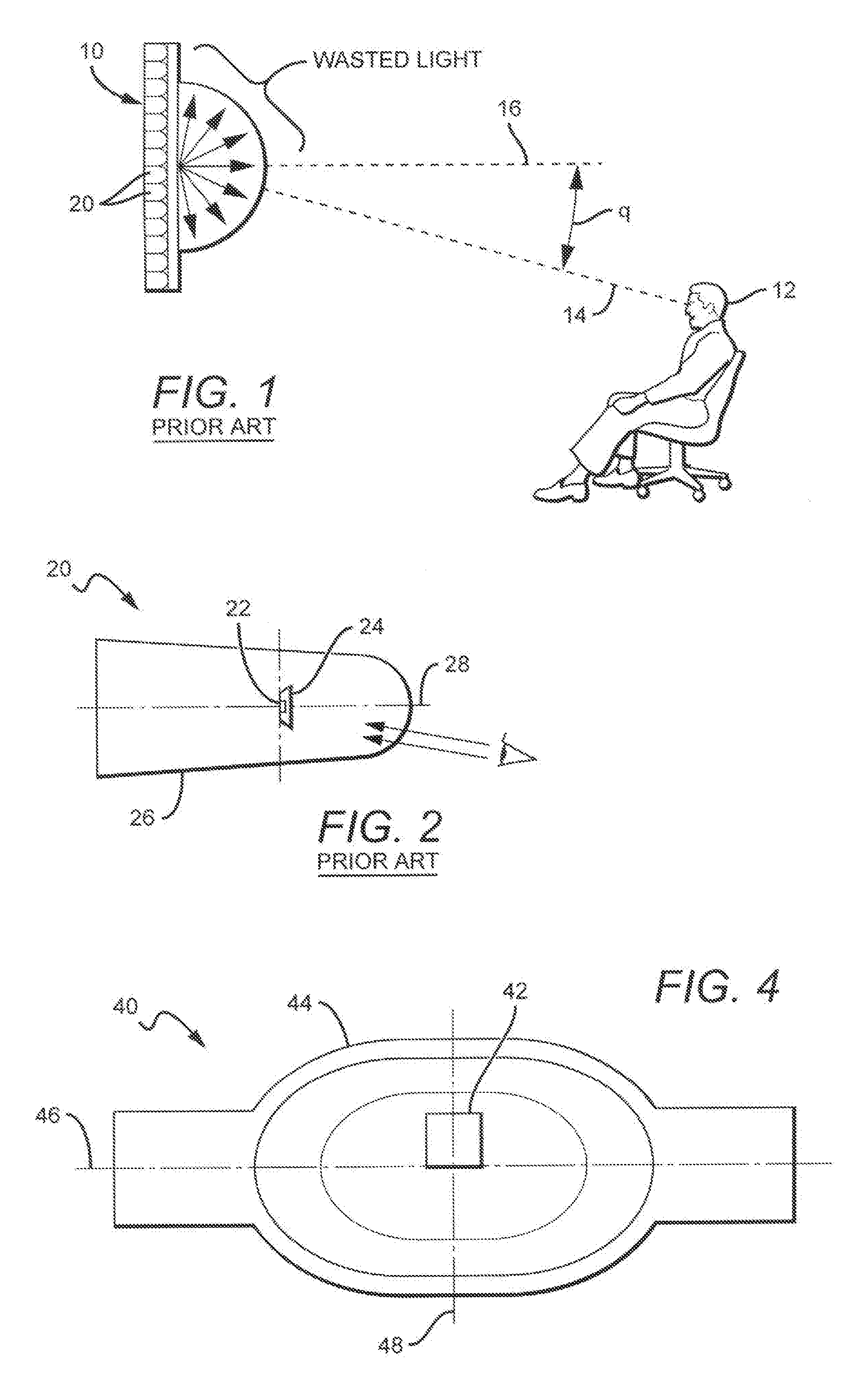

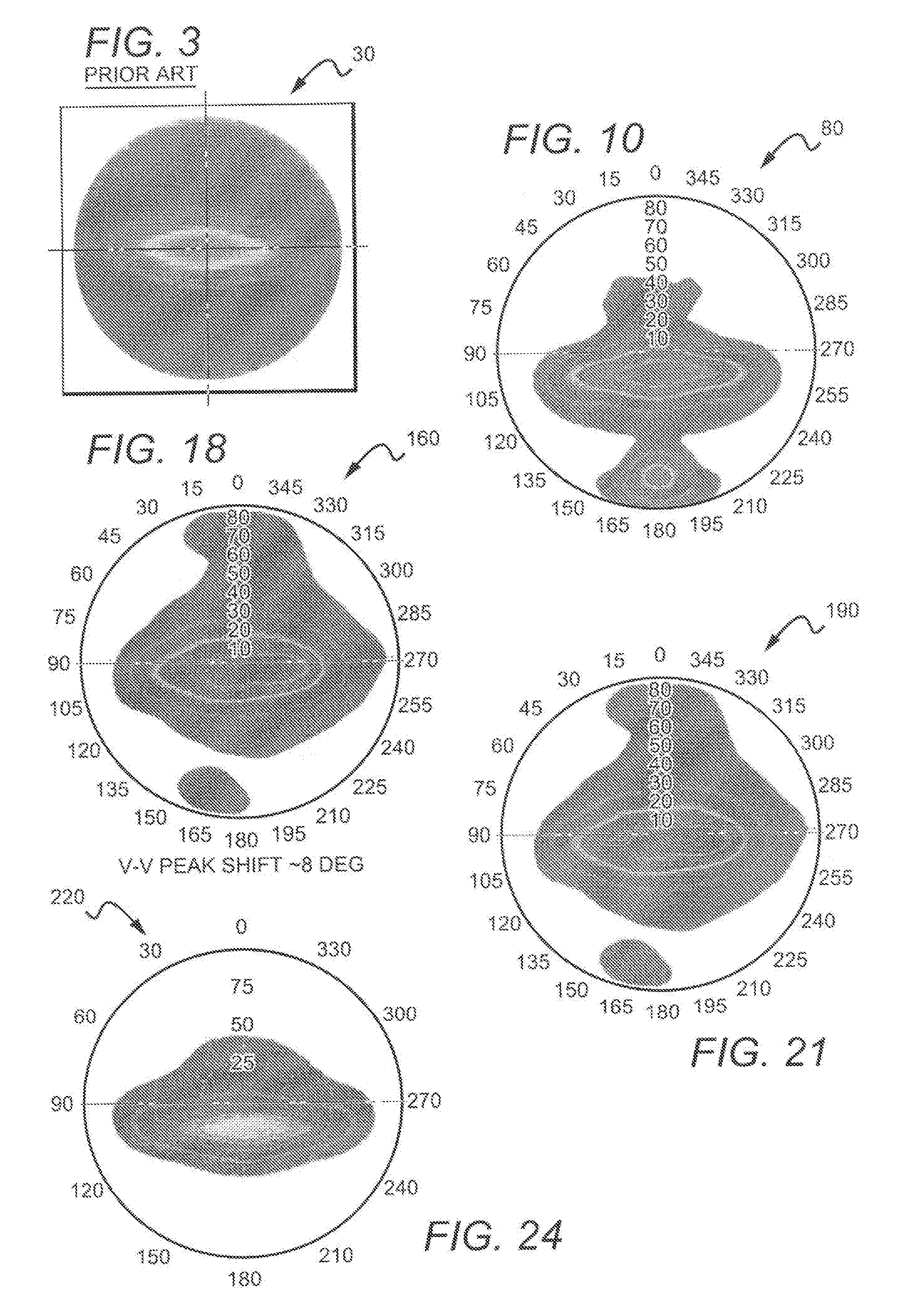

Light emitting diode display with tilted peak emission pattern

LED packages and LED displays utilizing the LED packages are disclosed where the peak emission of the LED display can be tilted or shifted to customize its peak emission to the mounting height or location of the LED display. One embodiment of an LED display comprises a plurality of LED package where the peak emission from at least some of the LED packages is tilted off the package centerline. The LED packages are mounted within the display in such a way as to generate an image having a peak emission that is tilted off the perpendicular emission direction of the display.

Owner:CREE HUIZHOU SOLID STATE LIGHTING

LED package with encapsulant having curved and planar surfaces

ActiveUS9887327B2Broad emission profileNarrow profileSolid-state devicesSemiconductor devicesEngineeringWavelength

Owner:CREELED INC

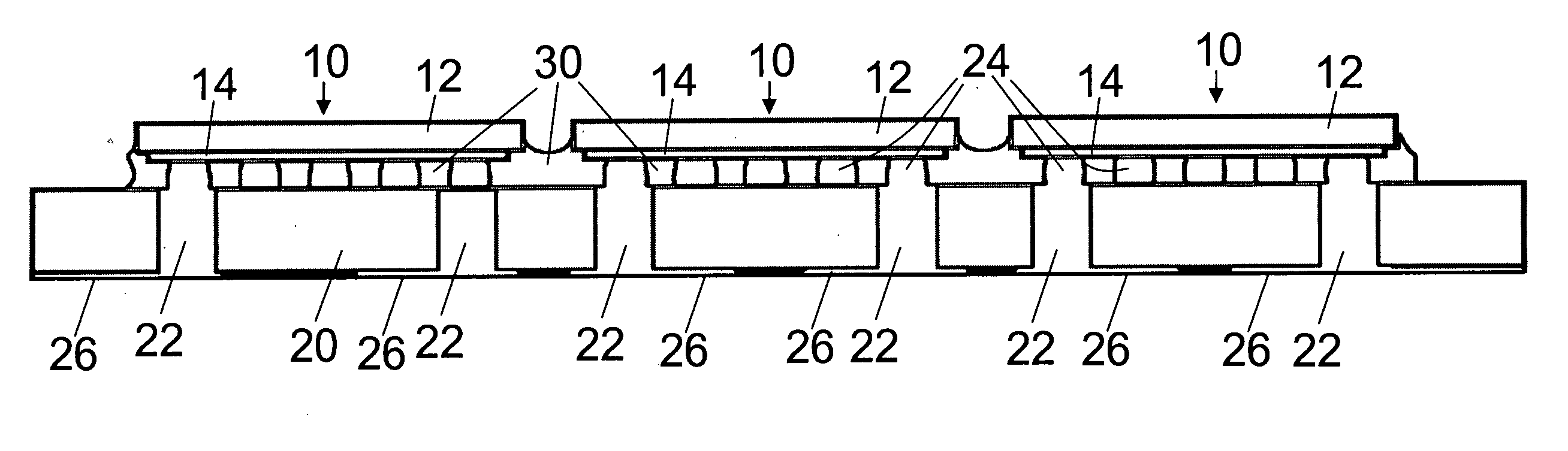

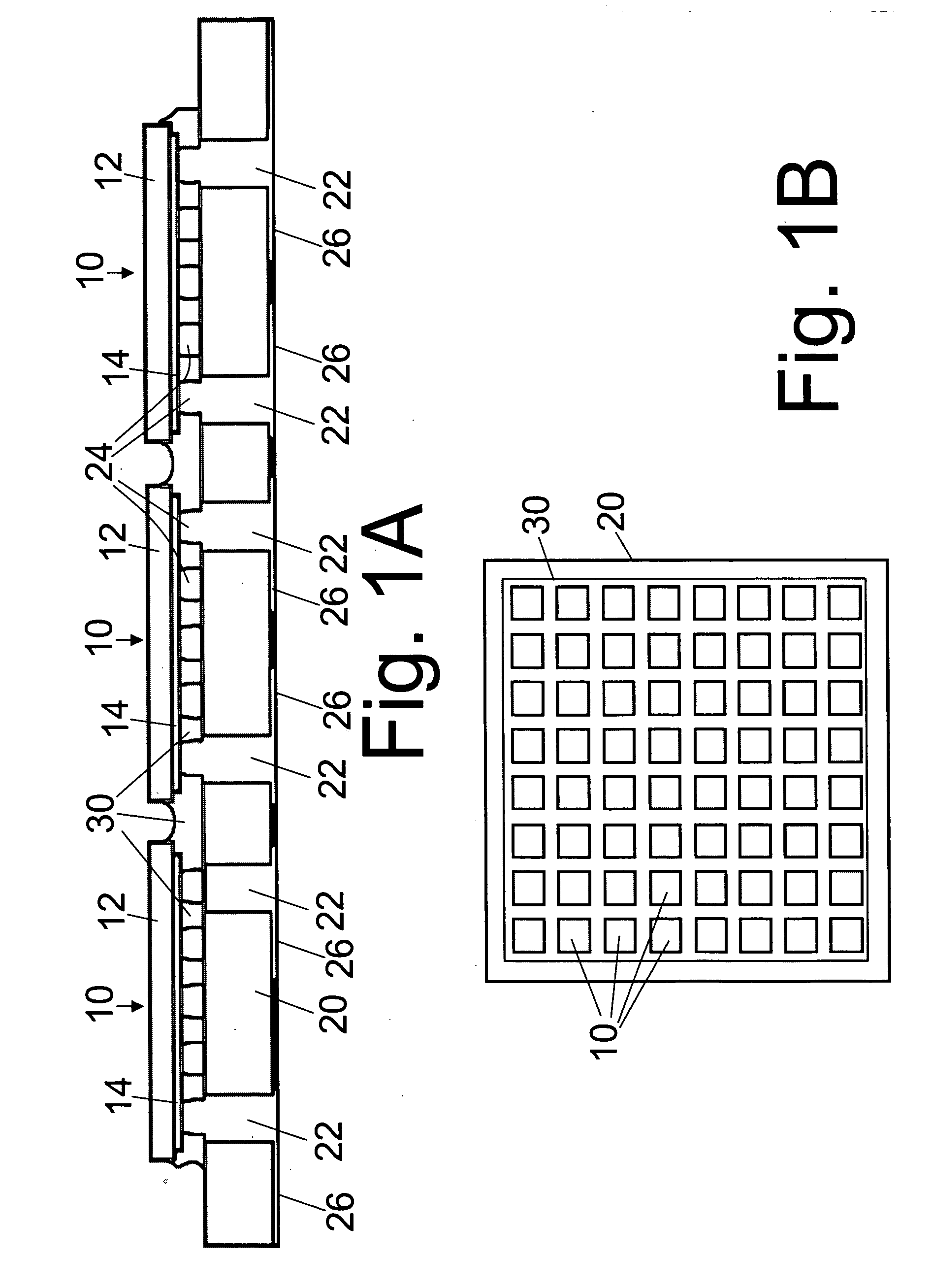

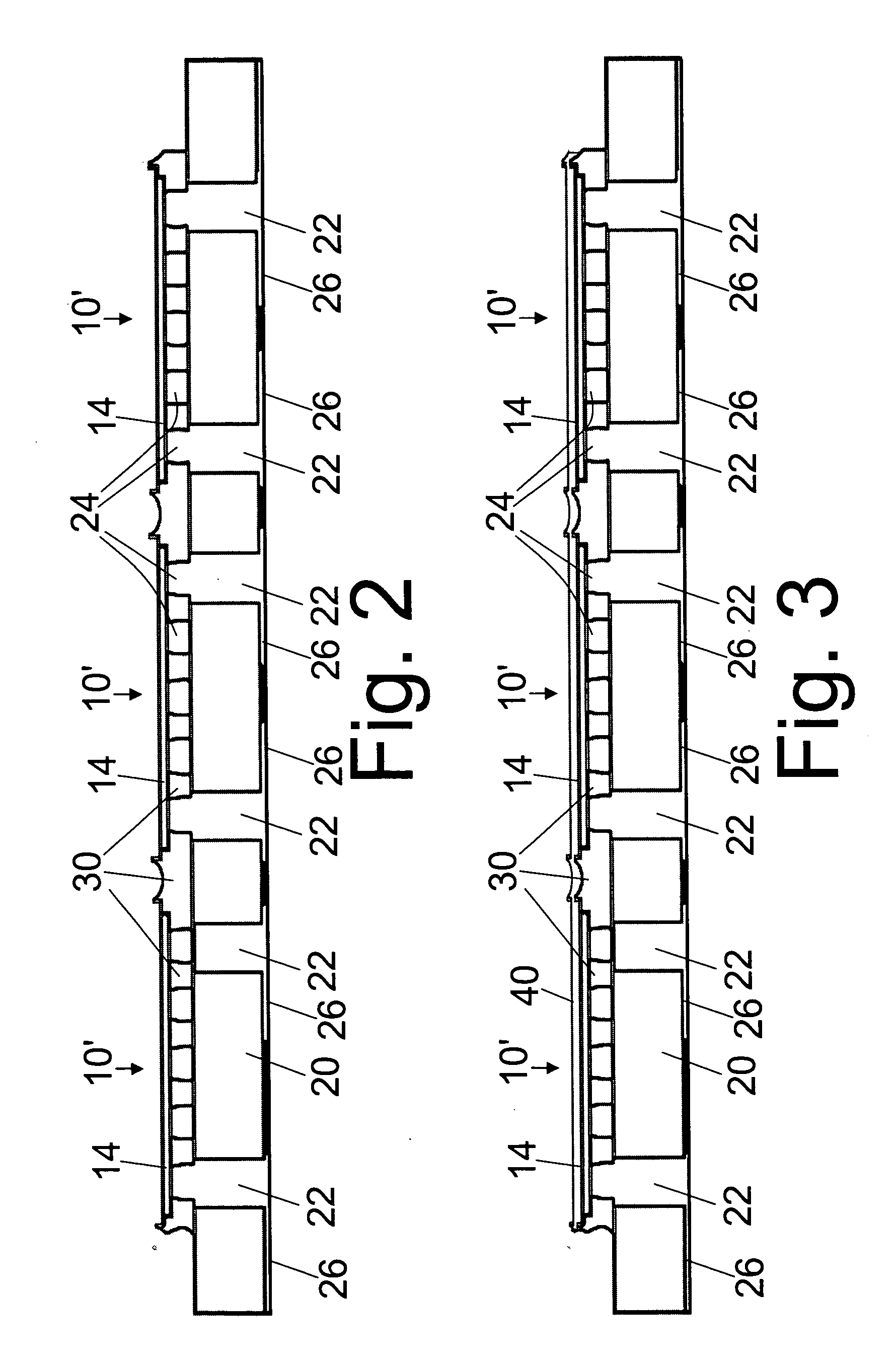

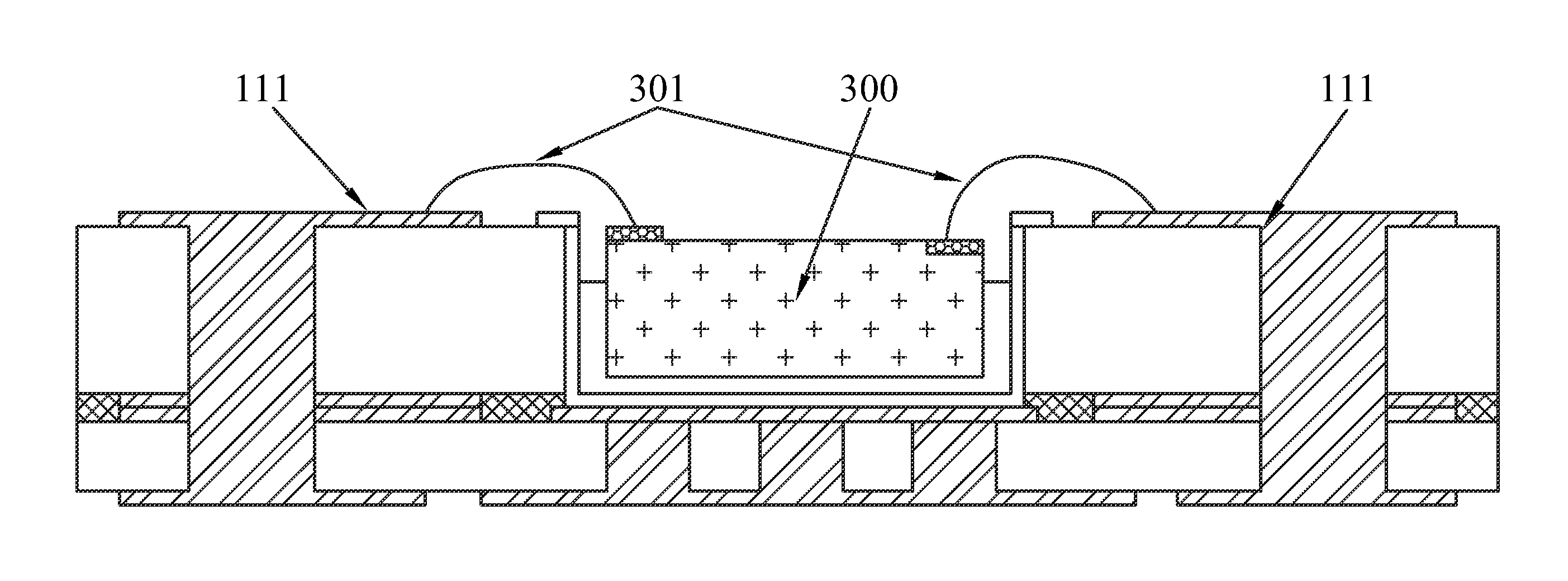

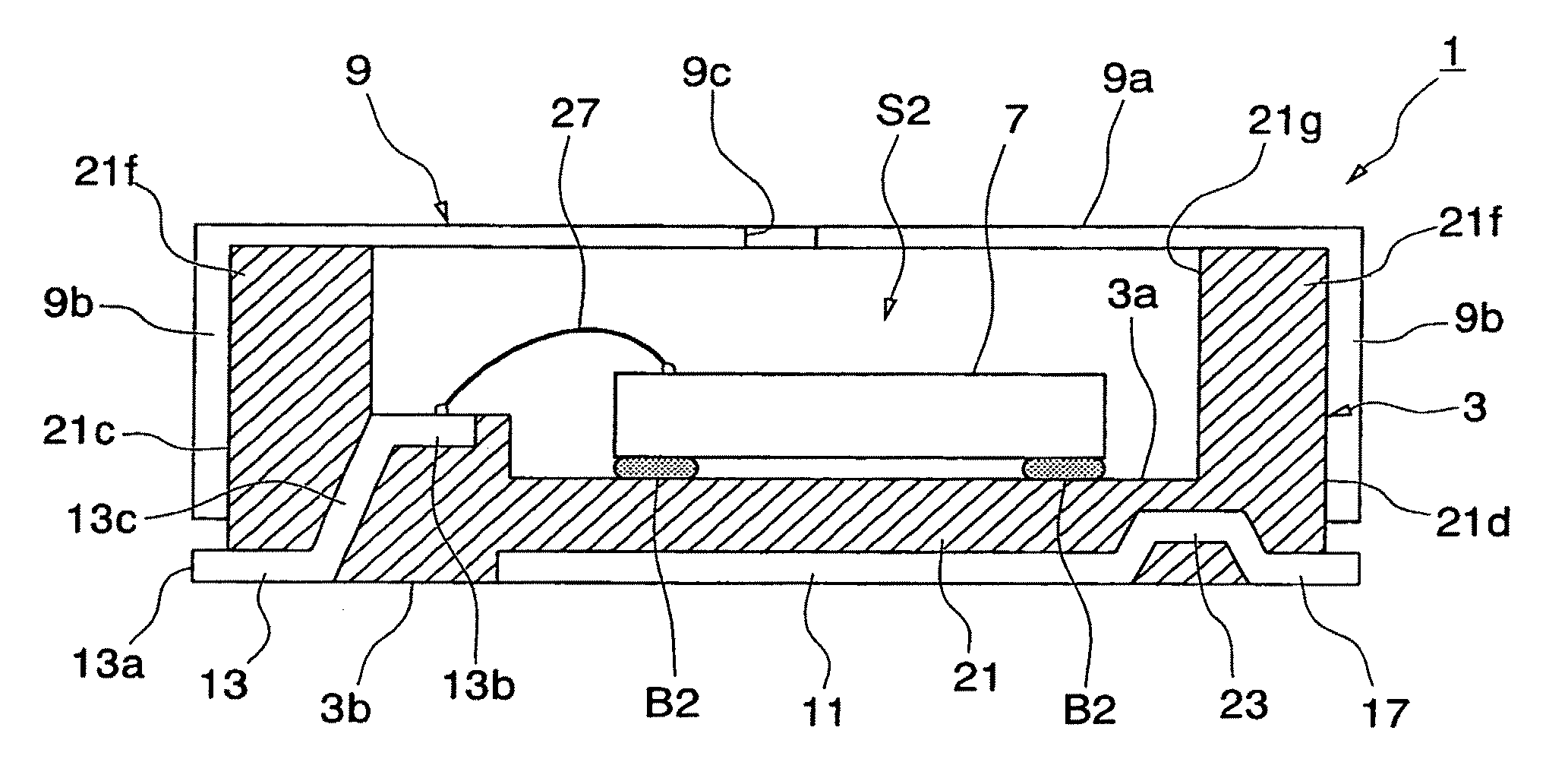

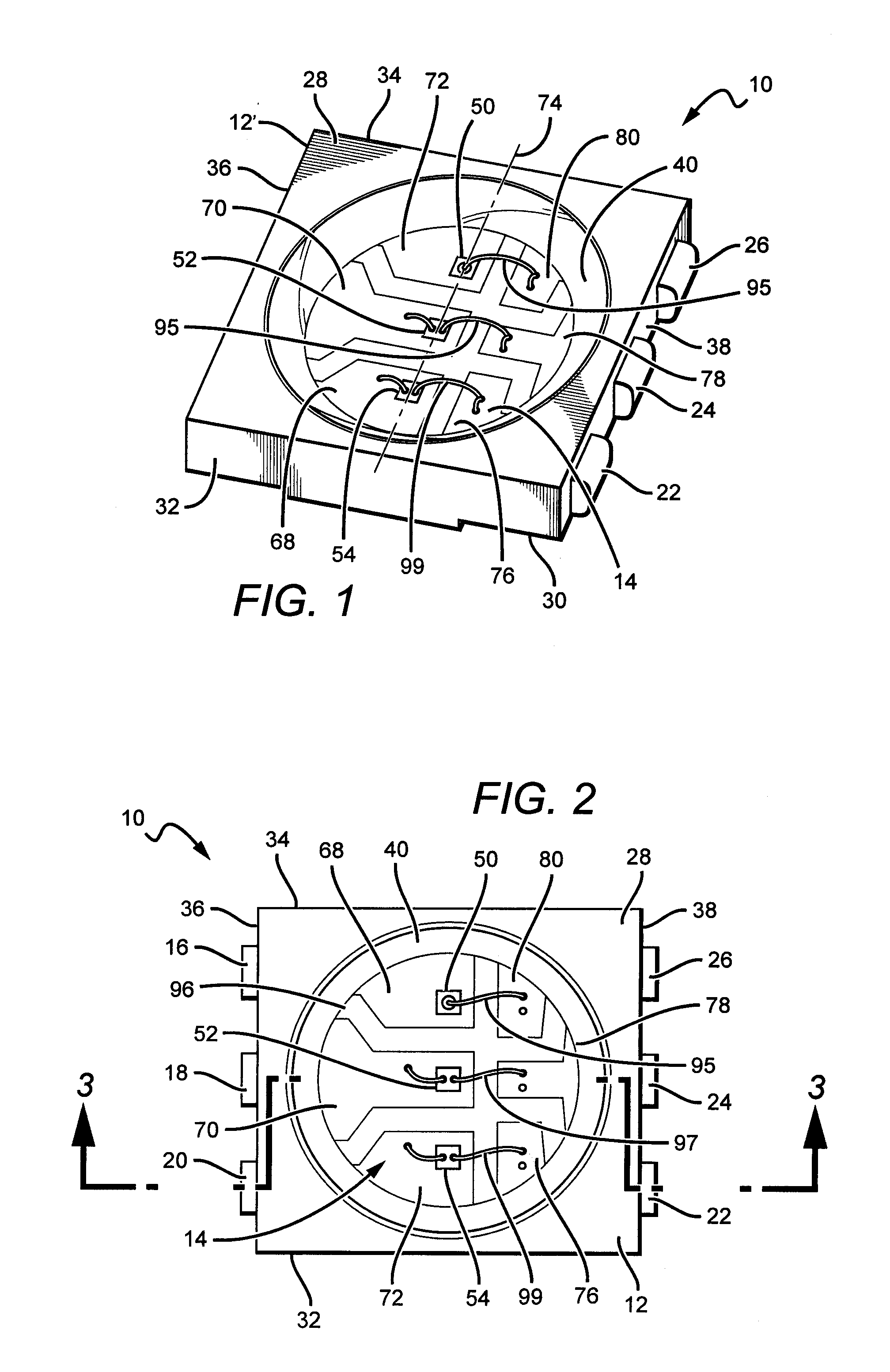

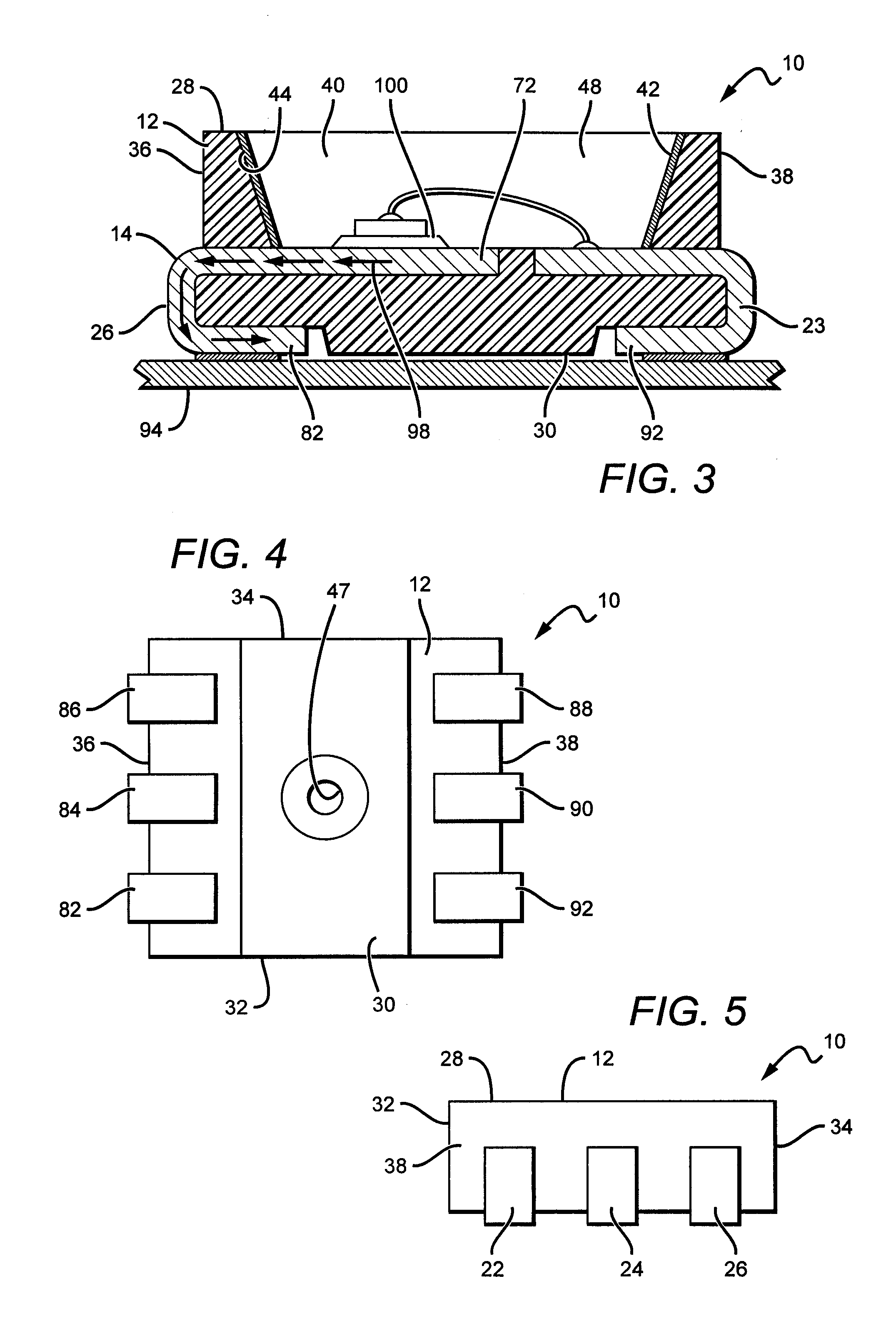

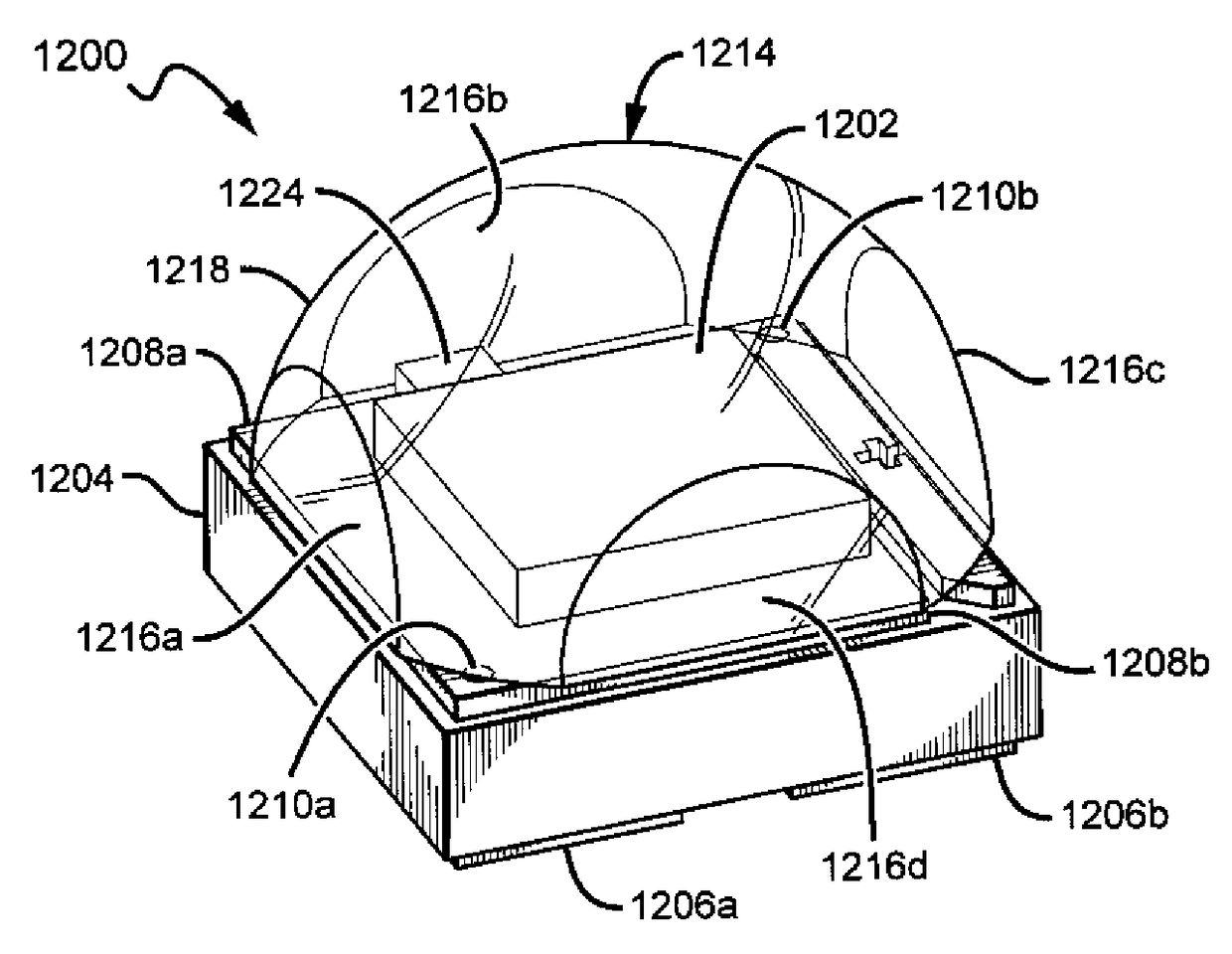

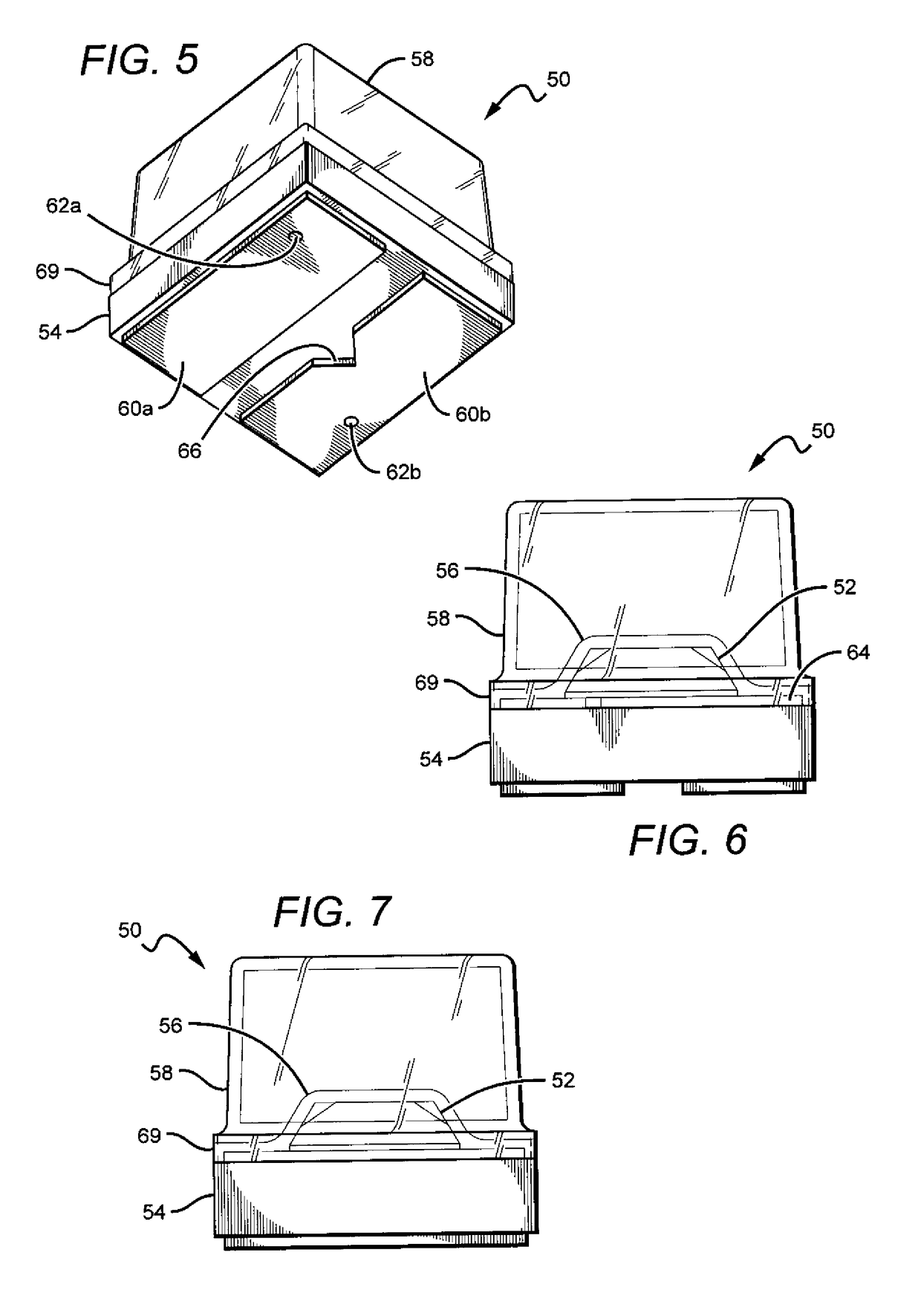

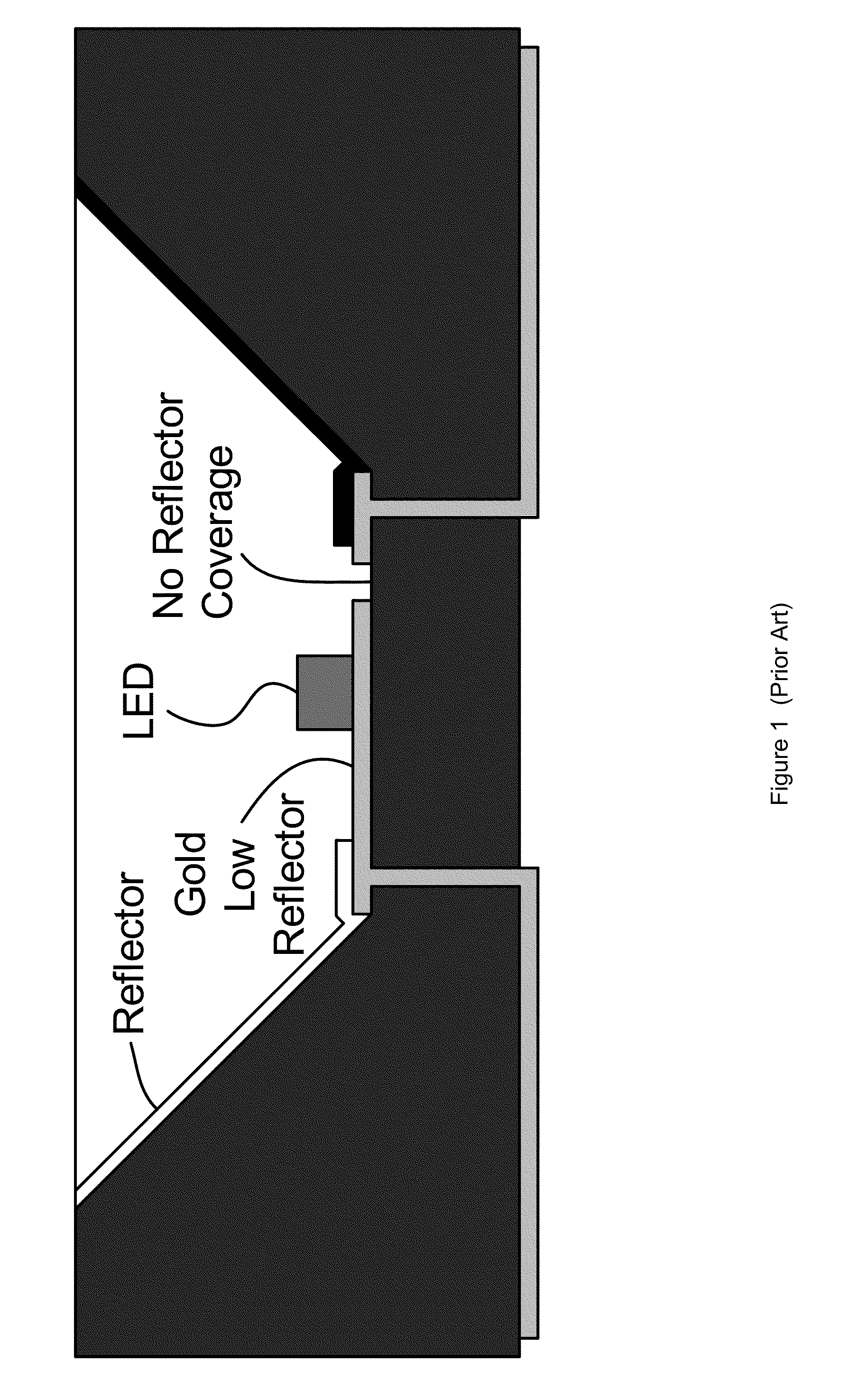

System and method for LED packaging

ActiveUS8207554B2Improve thermal conductivityIncreasing the thicknessSemiconductor/solid-state device detailsSolid-state devicesEngineeringConductive materials

System and method for LED packaging. The present invention is directed to optical devices. More specifically, embodiments of the presentation provide LED packaging having one or more reflector surfaces. In certain embodiments, the present invention provides LED packages that include thermal pad structures for dissipating heat generated by LED devices. In particular, thermal pad structures with large surface areas are used to allow heat to transfer. In certain embodiments, thick thermally conductive material is used to improve overall thermal conductivity of an LED package, thereby allowing heat generated by LED devices to dissipate quickly. Depending on the application, thermal pad structure, thick thermal conductive layer, and reflective surface may be individually adapted in LED packages or used in combinations. There are other embodiments as well.

Owner:KORRUS INC

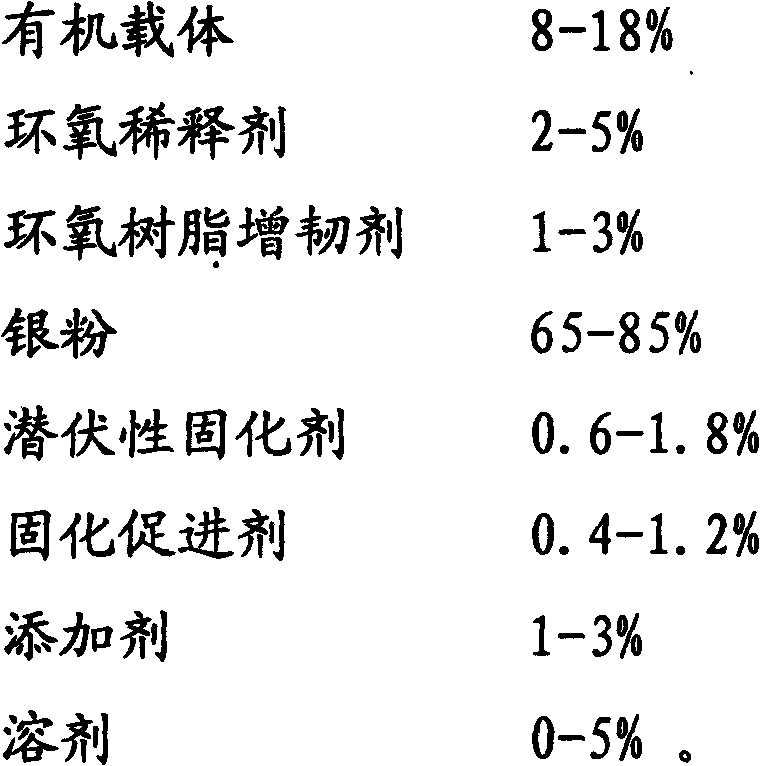

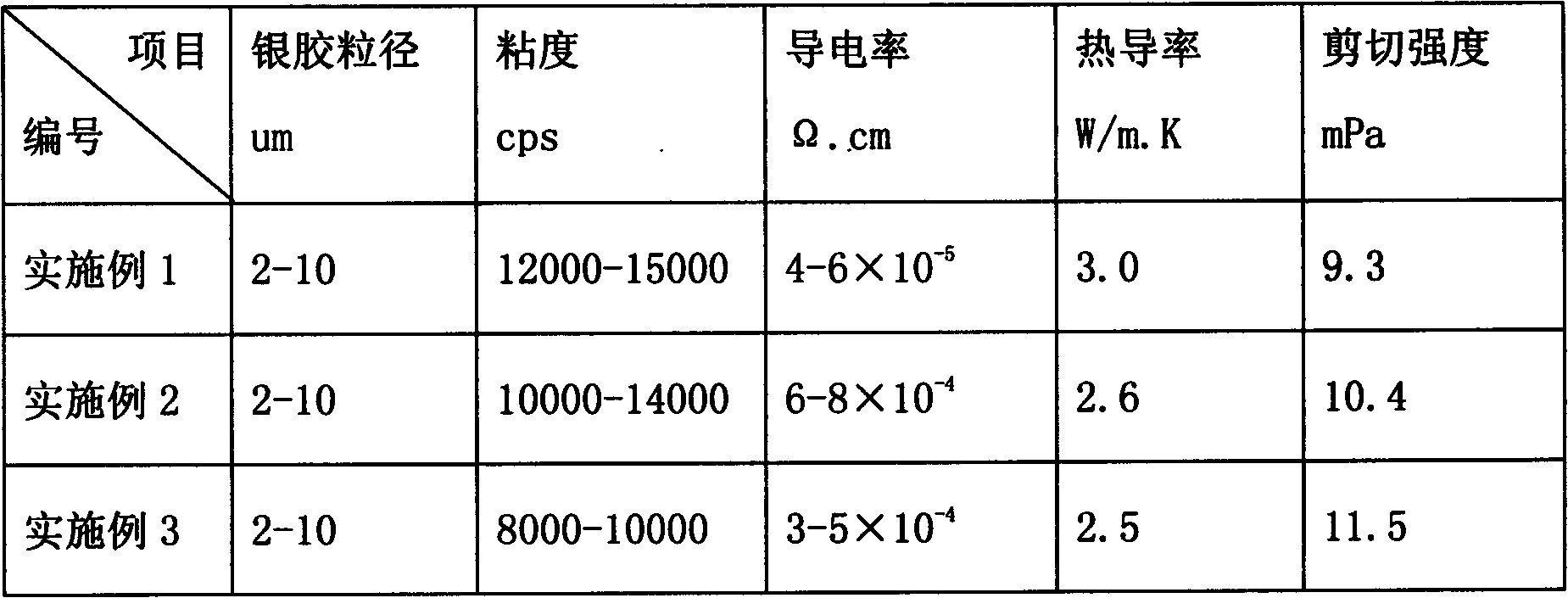

Epoxy conductive resin applicable to binding of LED (light-emitting diode) chips, and preparation method thereof

ActiveCN102634313ALow resistivityStrong impact resistanceEpoxy resin adhesivesElectrically-conducting adhesivesEpoxyUltimate tensile strength

The invention discloses epoxy conductive resin applicable to binding of LED (light-emitting diode) chips. A preparation method comprises the steps of: adding 8-18% of an organic carrier and 2-5% of epoxy diluent, evenly stirring, conducting vacuum defoamation for 15-20 minutes, adding and evenly mixing 0.6%-1.8% of a latent curing agent, 0.4-1.2% of a curing accelerator, 1-3% of epoxy resin flexibilizer, and 1-3% of an additive into a reaction kettle, conducting vacuumizing for 30-60 minutes with the vacuum degree of minus 0.1MPa; and finally adding 65-85% of silver powder into a three-dimensional stirred tank, and fully stirring evenly and grinding in a three-roll machine for one to three times, thus obtaining the epoxy conductive resin. The epoxy conductive resin has low resistivity, strong impact resistance, high heat conducting coefficient, strong mechanical strength, and good heat-resistant and aging-resistant performances, and can meet the active technology demand of LED packaging industry.

Owner:GUANGZHOU BAIYUN CHEM IND

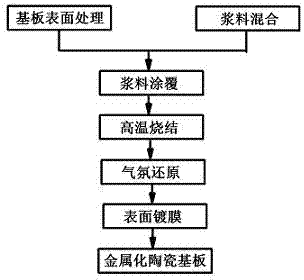

Preparation method of ceramic substrate for high-power LED packaging

The invention provides a preparation method of a ceramic substrate for high-power LED packaging, comprising the following steps of: preparing for the surface-processed ceramic substrate, covering the ceramic substrate with prepared cuprous oxide slurry, forming a circuit diagram, drying, sintering, reducing and plating a film to prepare ceramic substrate with a smooth and compact metal surface. With the combination of a thick film technology and a bonded copper principle on the surface of the ceramic substrate, metallization is realized without coating equipment and a complex technology required by a thin preparation technology and a special technology for direct bonded copper. In addition, with the combination of a direct bonded copper principle, the bonding strength of the metal layer and ceramic is raised and the spalling problem caused by thermal shock is minimized. According to the invention, the technology is simple; large-scale equipment is not required; raw materials are low-priced; the yield is high; metal patterning is convenient; surface fineness is high; and the copper layer thickness on the surface of the substrate is especially controllable so as to make the operation of a power electronic device more stable.

Owner:江苏景邦照明科技有限公司

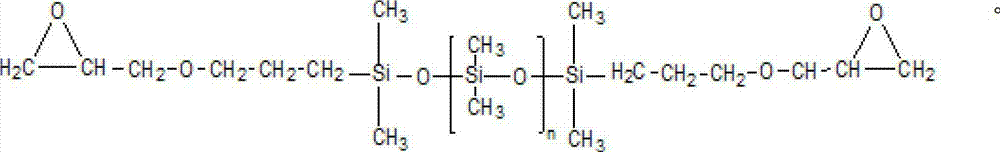

High refraction and high adhesion large power LED packaging organosilicon material and preparation method thereof

ActiveCN102936414ASolve the problem of incomplete hydrolysis and condensationReduce air permeabilitySemiconductor devicesChemical synthesisPtru catalyst

The present invention relates to a high refraction and high adhesion large power LED packaging organosilicon material and a chemical synthesis method thereof. The organosilicon packaging material is prepared by carrying out mixing matching on a component A and a component B according to a mass ratio of 1:1, wherein the component A comprises vinyl phenyl polysiloxane, vinyl phenyl silicone oil, a platinum-containing polysiloxane catalyst and a tackifier, the component B comprises hydrogen-containing phenyl polysiloxane, dihydrideterminated phenyl polysiloxane, vinyl phenyl polysiloxane and an inhibitor, the tackifier is prepared by carrying out addition on isocyanate, methoxy silane and epoxy silane, and provides strong adhesion for PPA and a silver surface, the curing agent is prepared by compounding hydrogen-containing phenyl polysiloxane and dihydrideterminated phenyl polysiloxane, and a compounding mass ratio is preferably 4:1-2, such that the packaging material has moderate hardness and flexibility after curing so as to effectively solve contradiction of strength and cracking of the cured adhesive. With the present invention, the organosilicon packaging material with characteristics of refraction of 1.54, suitability for industrialization and fully meeting of large power LED packaging requirements can be obtained.

Owner:湖北环宇化工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com