Semiconductor device

a semiconductor device and semiconductor technology, applied in the direction of fluid pressure measurement, fluid pressure measurement by electric/magnetic elements, instruments, etc., can solve the problems of unstable installation of semiconductor devices mounted on printed circuit boards, difficulty in accurately detecting pressure variations due to vibration, and trouble for human operators (or workers) in precisely arranging the cover member in connection with the printed board

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

1. First Embodiment

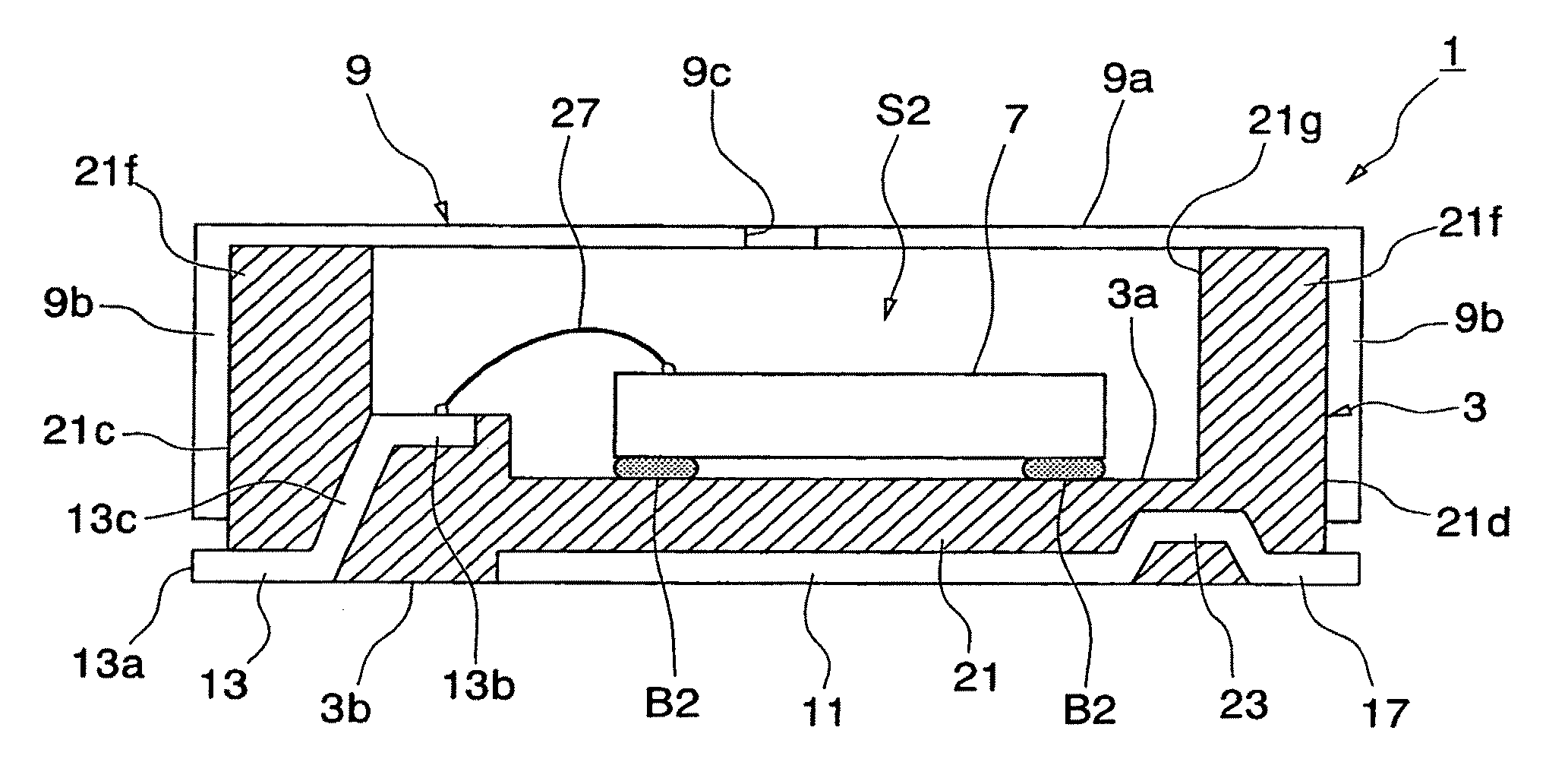

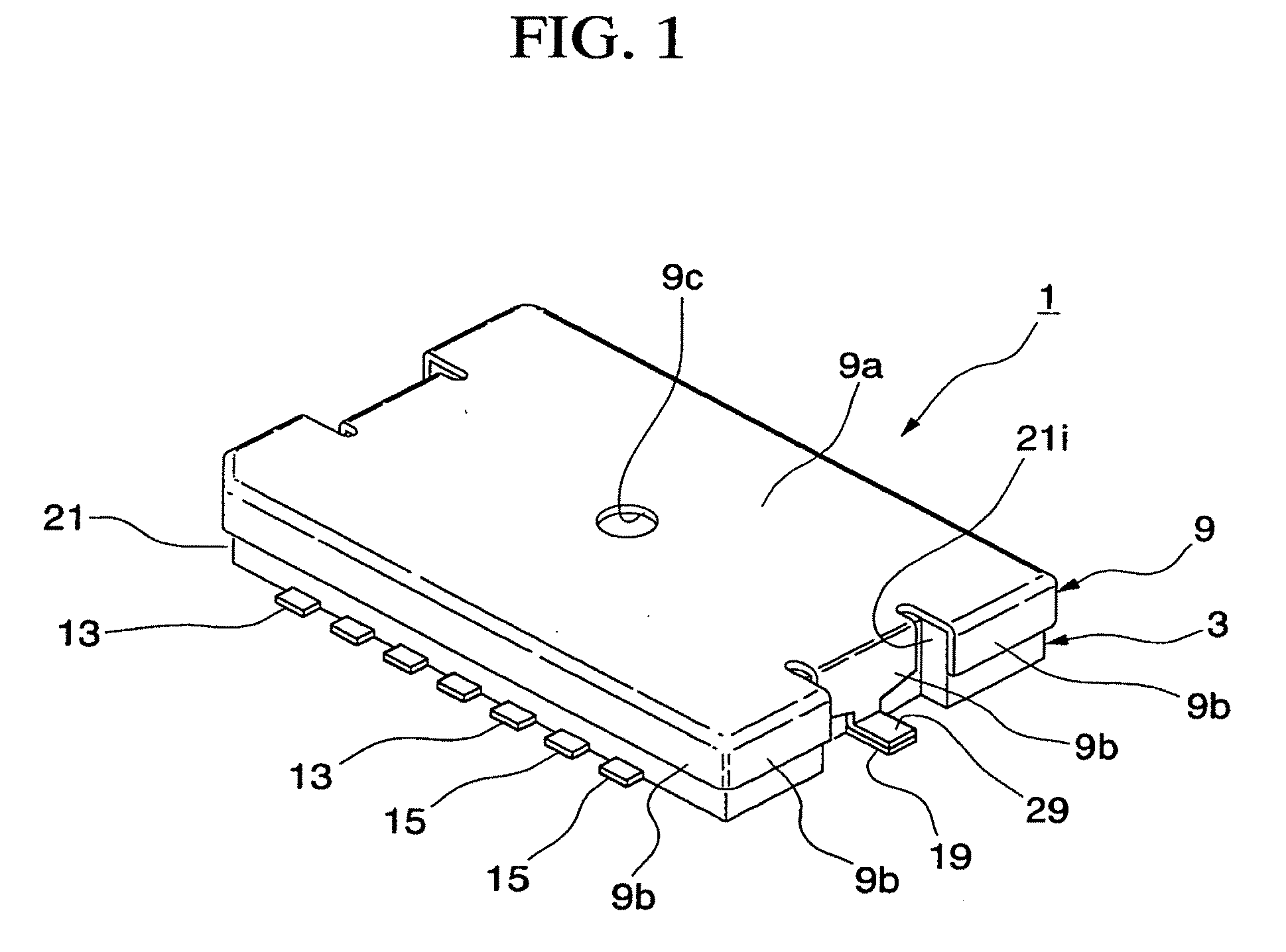

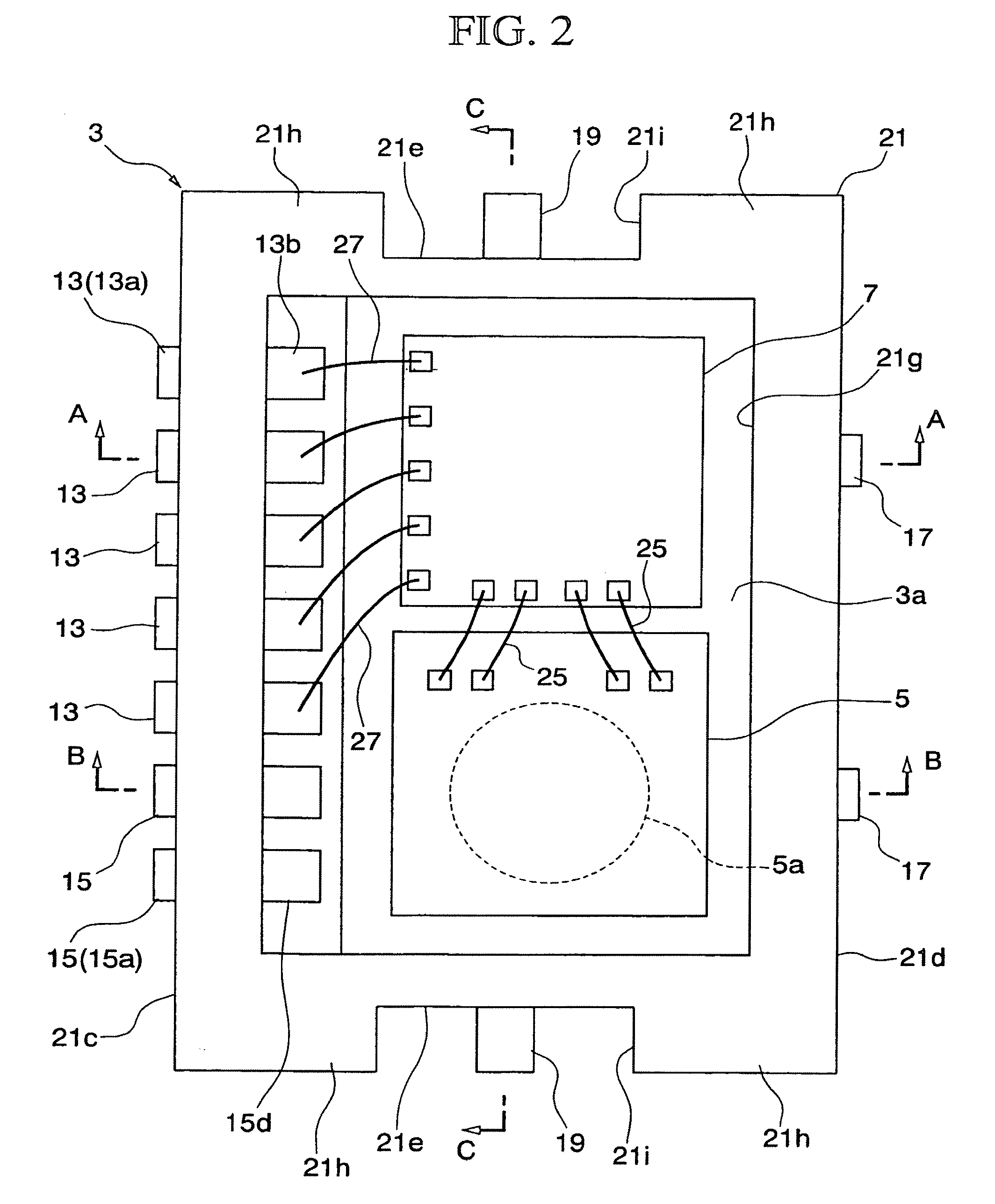

[0131]With reference to FIGS. 1 to 7, a semiconductor device 1 will be described in detail in accordance with a first embodiment of the present invention. The semiconductor device 1 of the first embodiment is designed to detect sound pressure such as sound pressure generated externally thereof and in particular directed to a surface-mount-type semiconductor device, which is manufactured using a lead frame. Specifically, the semiconductor device 1 is of the SON (i.e., Small Outline Non-leaded package) type corresponding to the surface mount type.

[0132]As shown in FIGS. 1, 2, and 6, the semiconductor device 1 includes a substrate 3 having a rectangular shape in plan view, and a semiconductor sensor chip 5 and an amplifier 7, both of which are arranged on an upper surface 3a of the substrate 3, and a cover member 9, which covers the semiconductor sensor chip 3 and the amplifier 7 on the substrate 3.

[0133]As shown in FIGS. 2 to 6, the substrate 3 has a stage 11 having...

second embodiment

2. Second Embodiment

[0205]A semiconductor device 100A of a second embodiment will be described in detail with reference to FIGS. 12 to 17, FIGS. 18A and 18B, and FIG. 19. The semiconductor device 100A is of a QFN (Quad Flat Non-leaded package) type and is designed to detect sound pressure.

[0206]As shown in FIGS. 12 to 16, the semiconductor device 100A includes a stage 101 having a rectangular shape; a plurality of external terminals 102 whose first ends 102a are connected to the stage 101 and whose second ends 102b extend externally of the semiconductor device 100A; a plurality of leads 103 which extend from the prescribed sides of the semiconductor device 100A toward the stage 101 so that first ends 103a thereof are positioned in proximity to the stage 101; a resin layer 104 which seals the stage 101, the external terminals 102, and the leads 103 therein and which has an opening hole 104c running through from an upper surface 104a (substantially matching the upper surface of a subs...

third embodiment

3. Third Embodiment

[0274]Next, a third embodiment of the present invention will be described in detail with reference to FIGS. 28 to 30. The third embodiment is directed to a semiconductor device of an SOP (Small Outline Package) type, which is a surface mount type package manufactured using a lead frame.

[0275]As shown in FIGS. 28 to 30, a semiconductor device 201 includes a substrate 203 having a rectangular shape; a semiconductor sensor chip 205 and an amplifier 207, which are attached onto an upper surface 203a of the substrate 203; a cover member 209 for covering the upper portion of the substrate 203 including the semiconductor sensor chip 205 and the amplifier 207; and a stage 211 having a flat-plate-like shape, which is positioned below the semiconductor sensor chip 205 and the amplifier 207 and which forms the upper surface 203a of the substrate 203.

[0276]A plurality of leads 213 are formed on both sides of the stage 211, and a lead 215 is formed on the prescribed side of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com