Patents

Literature

4789results about "Vessels or leading-in conductors manufacture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

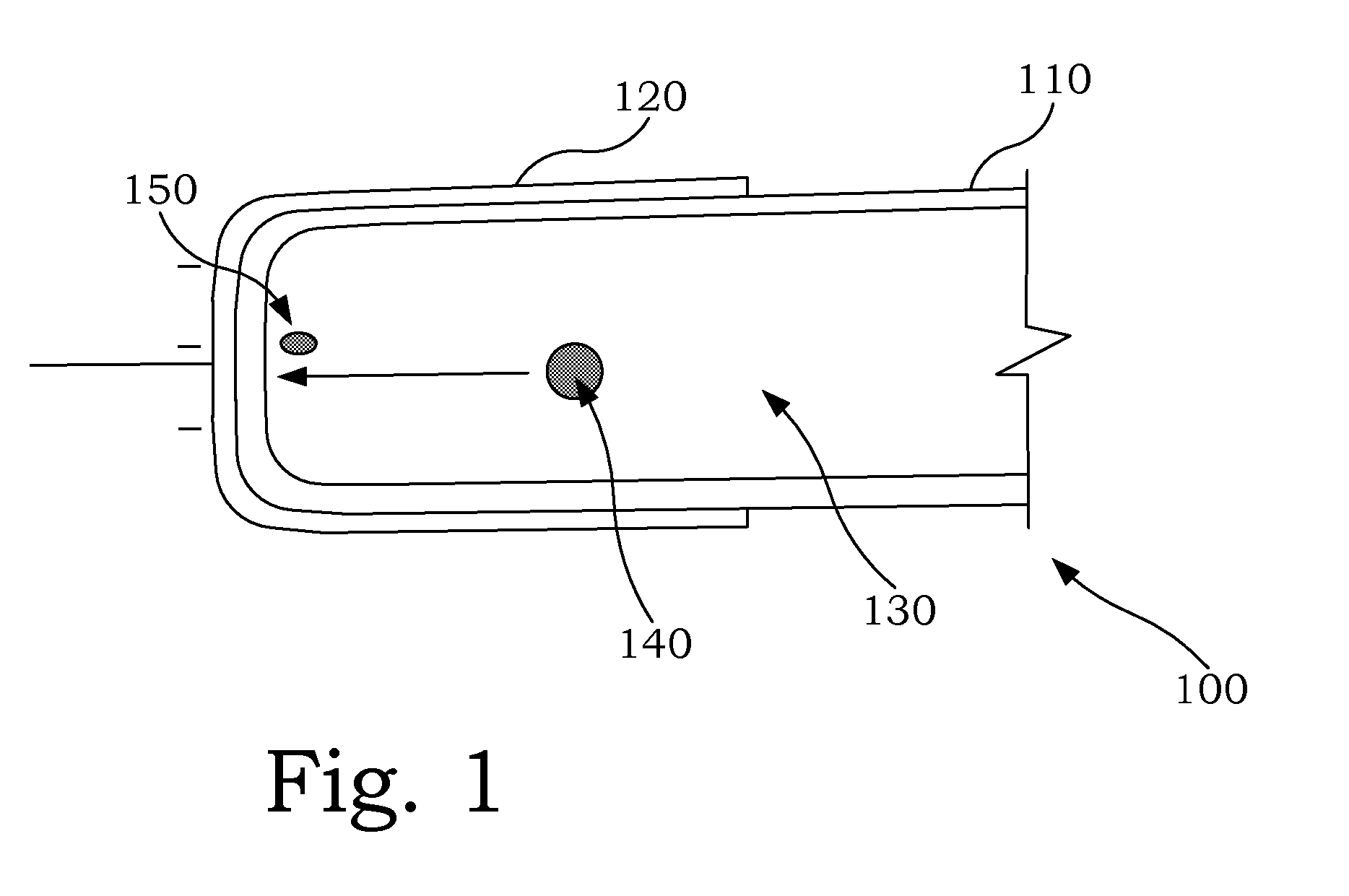

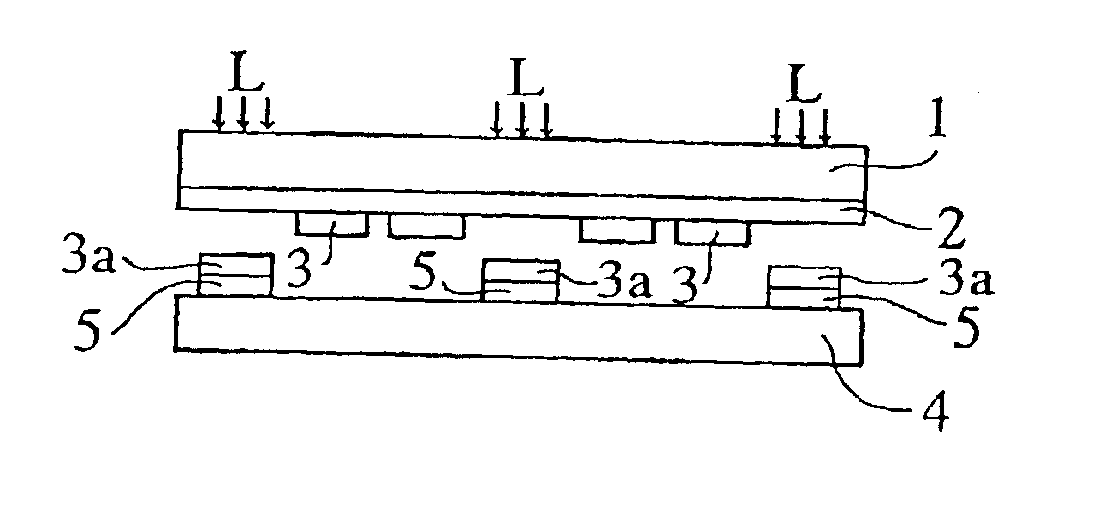

Method and apparatus for filling liquid crystal display (LCD) panels

InactiveUS6055035AElectroluminescent light sourcesVessels or leading-in conductors manufactureLiquid-crystal displayEngineering

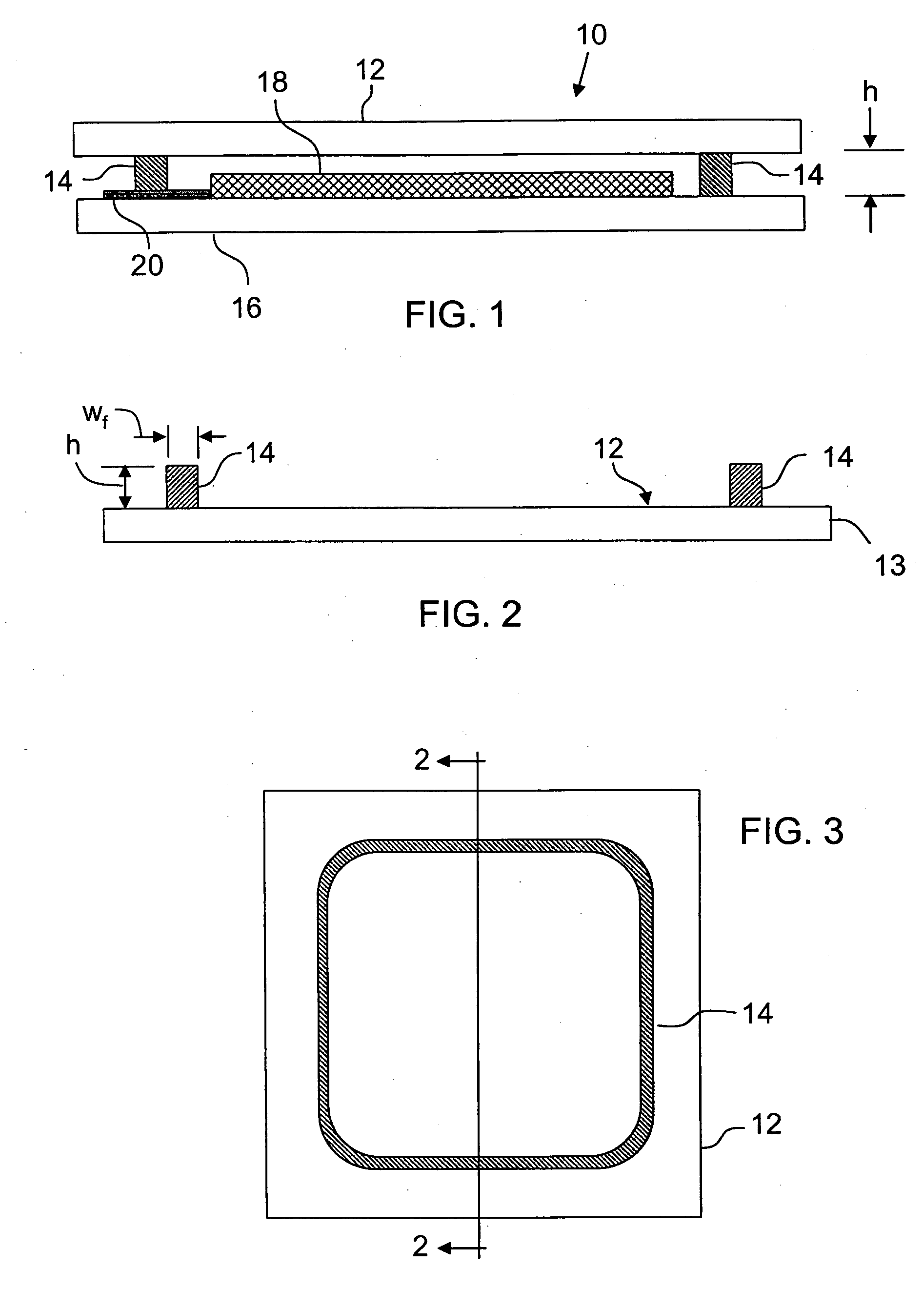

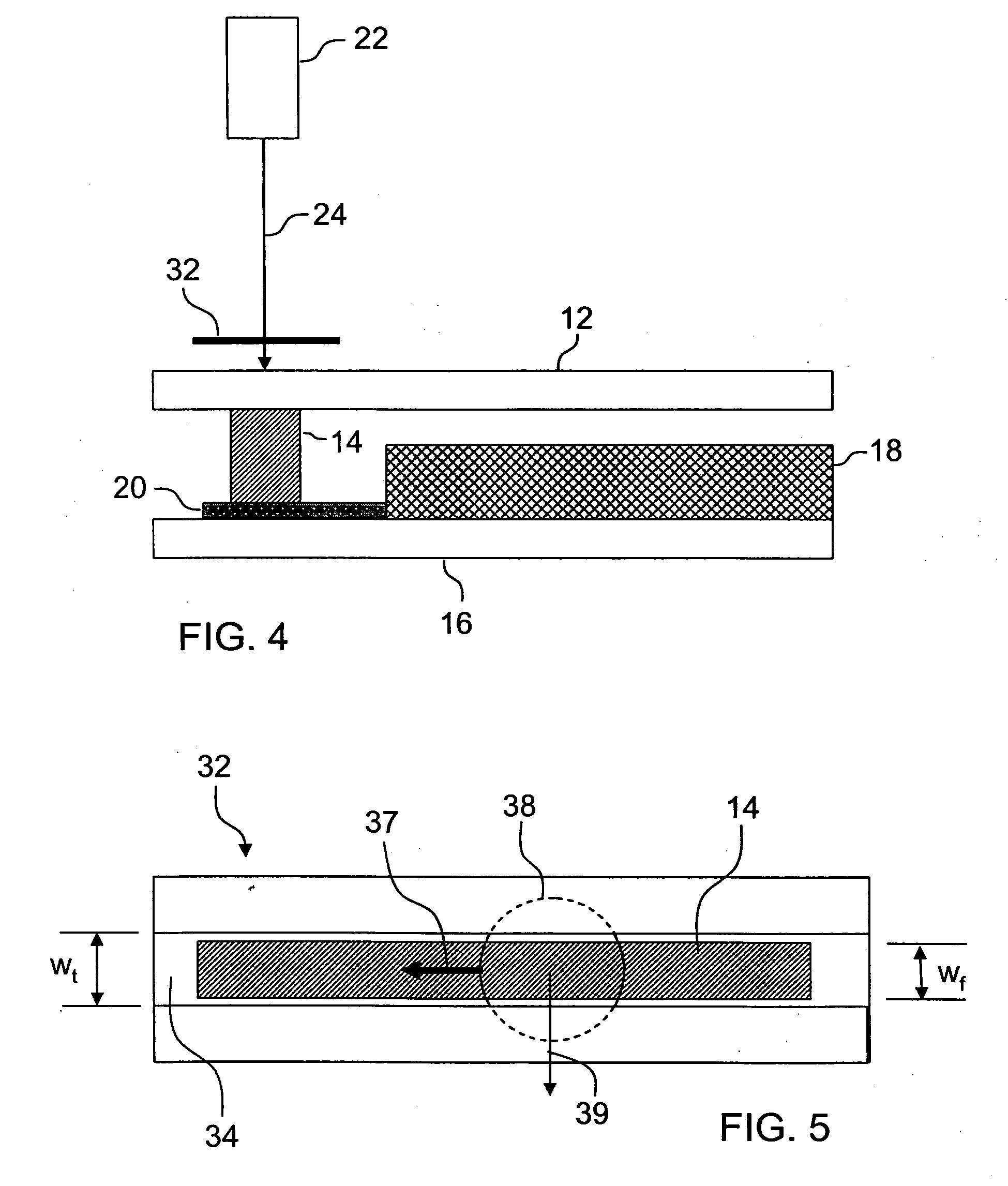

A system, apparatus, and method for filling a display panel having first and second plates, with liquid crystal material, includes a nozzle for depositing a layer of liquid crystal material over a surface of a first plate of the panel, a scanning arm, coupled to the nozzle, for uniformly forming the layer of liquid crystal material over the surface of the first plate of the panel, and an attachment mechanism for placing the second plate over the first plate having the liquid crystal material thereover, thereby to form the display panel.

Owner:AU OPTRONICS CORP

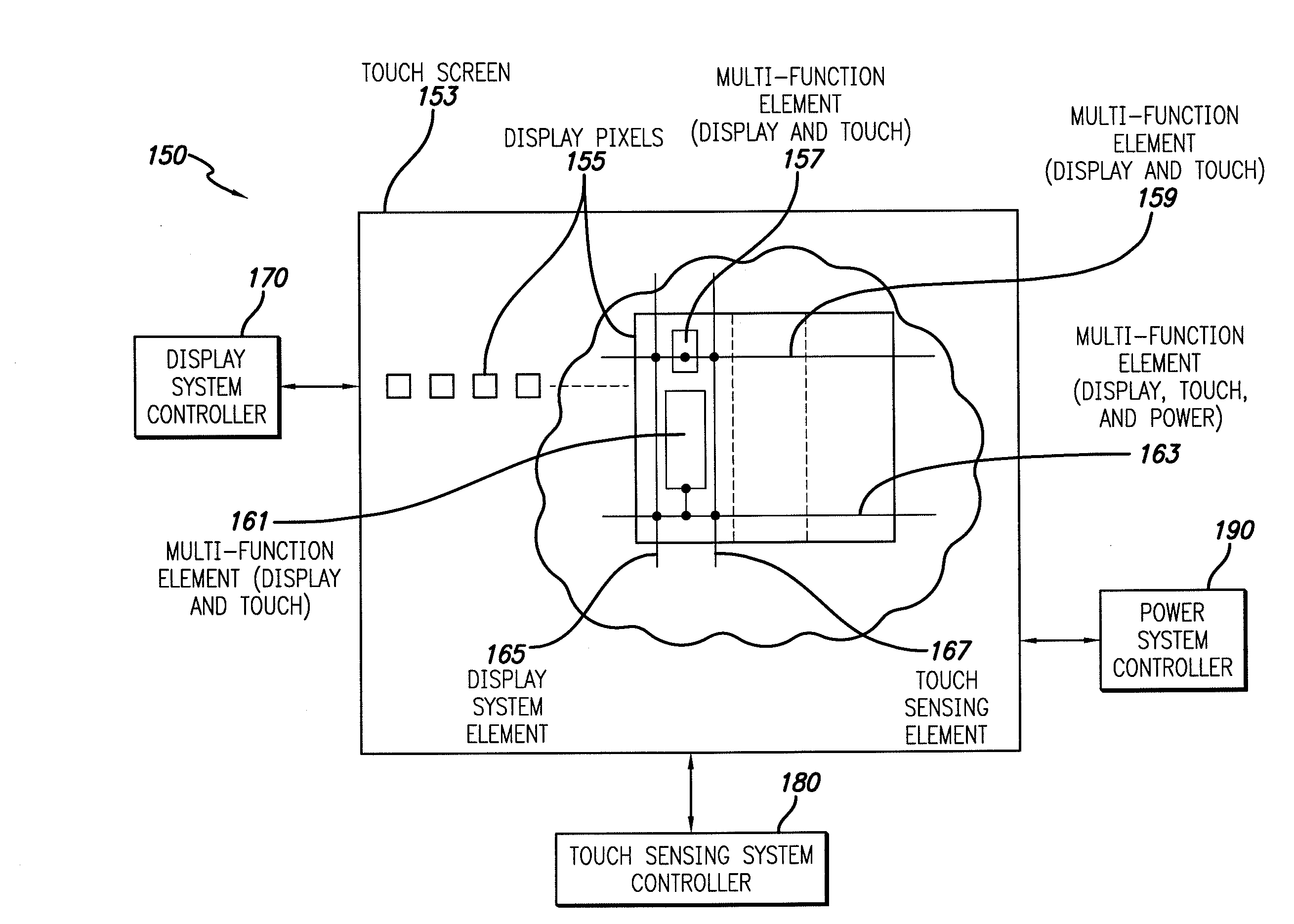

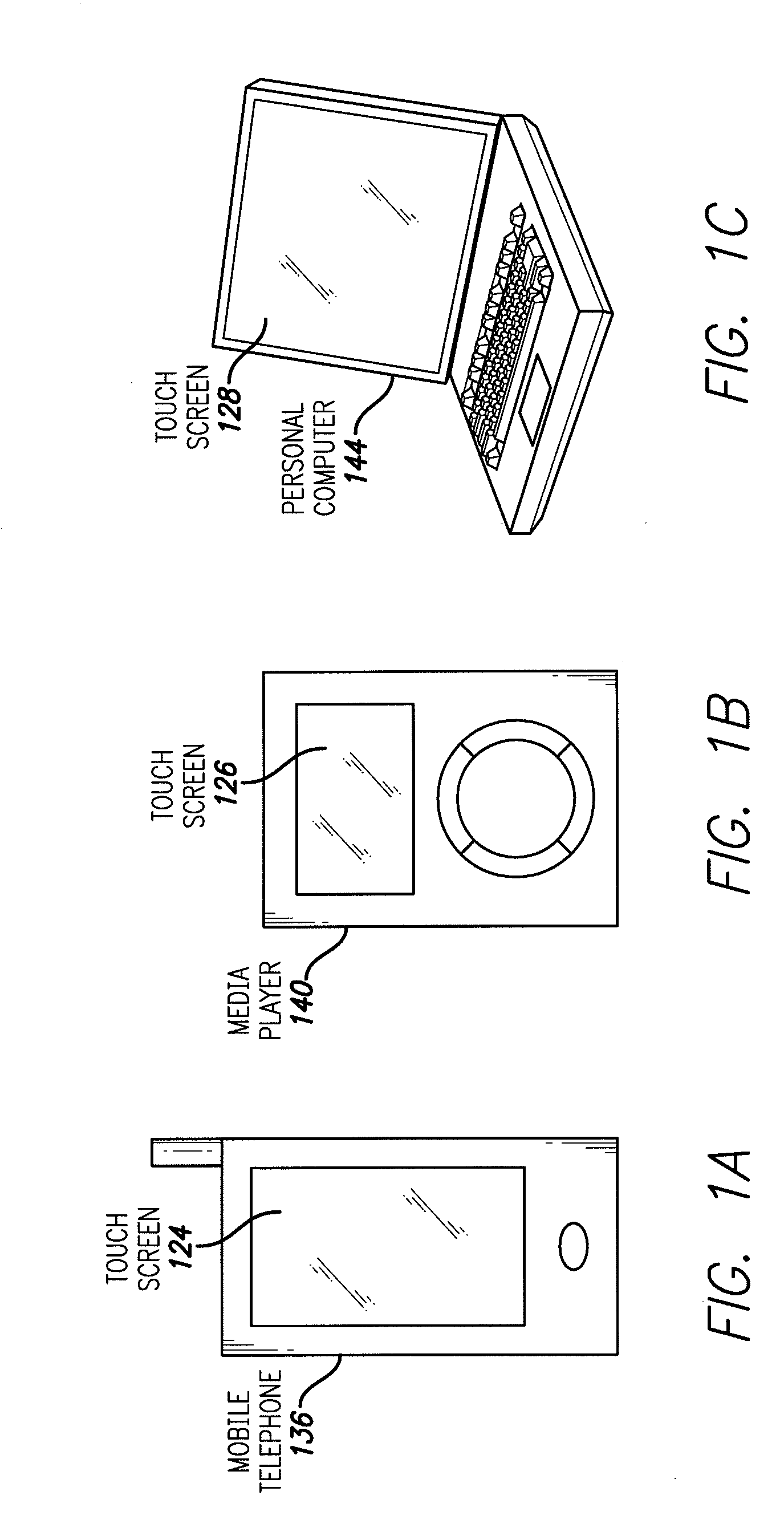

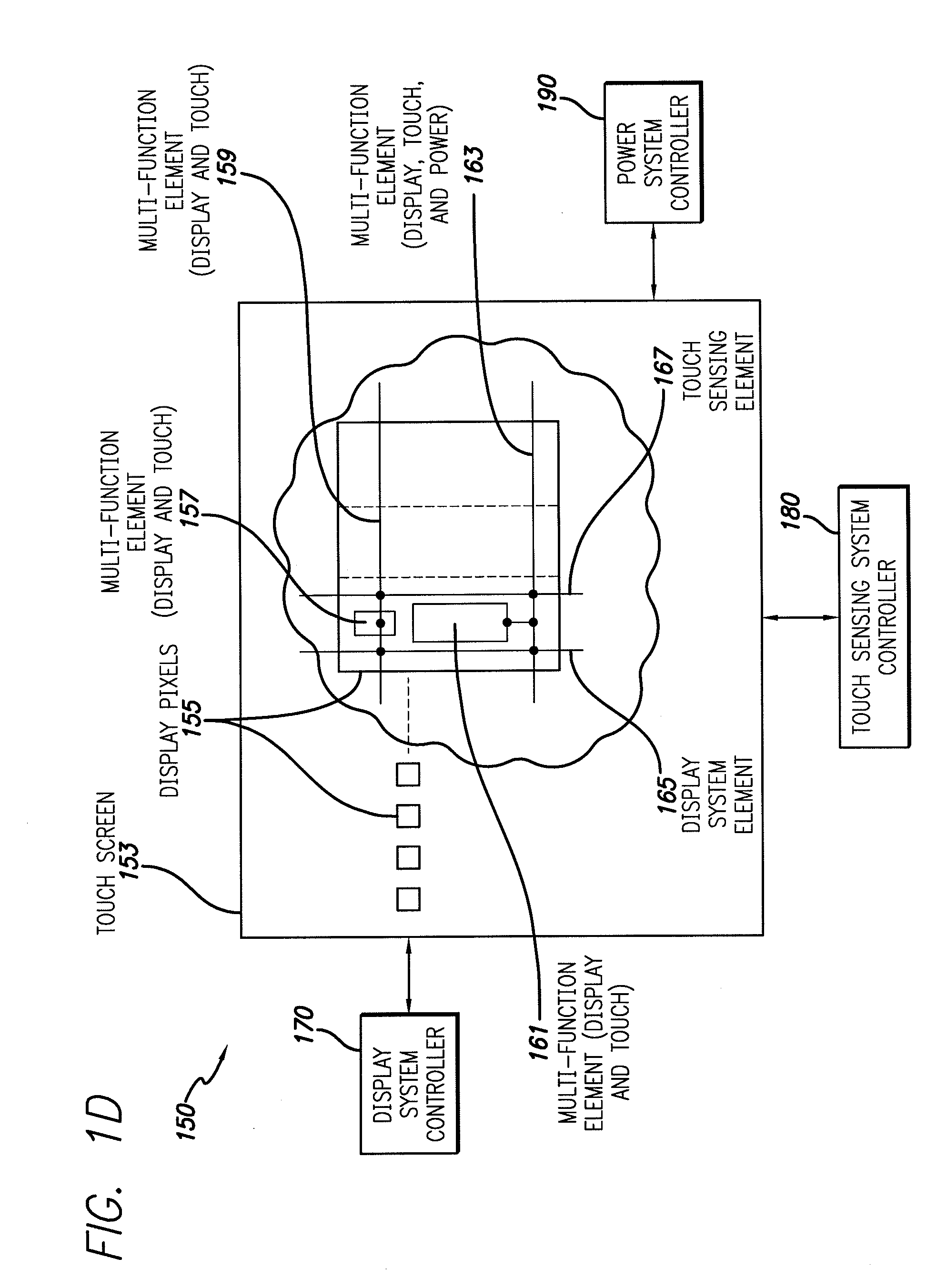

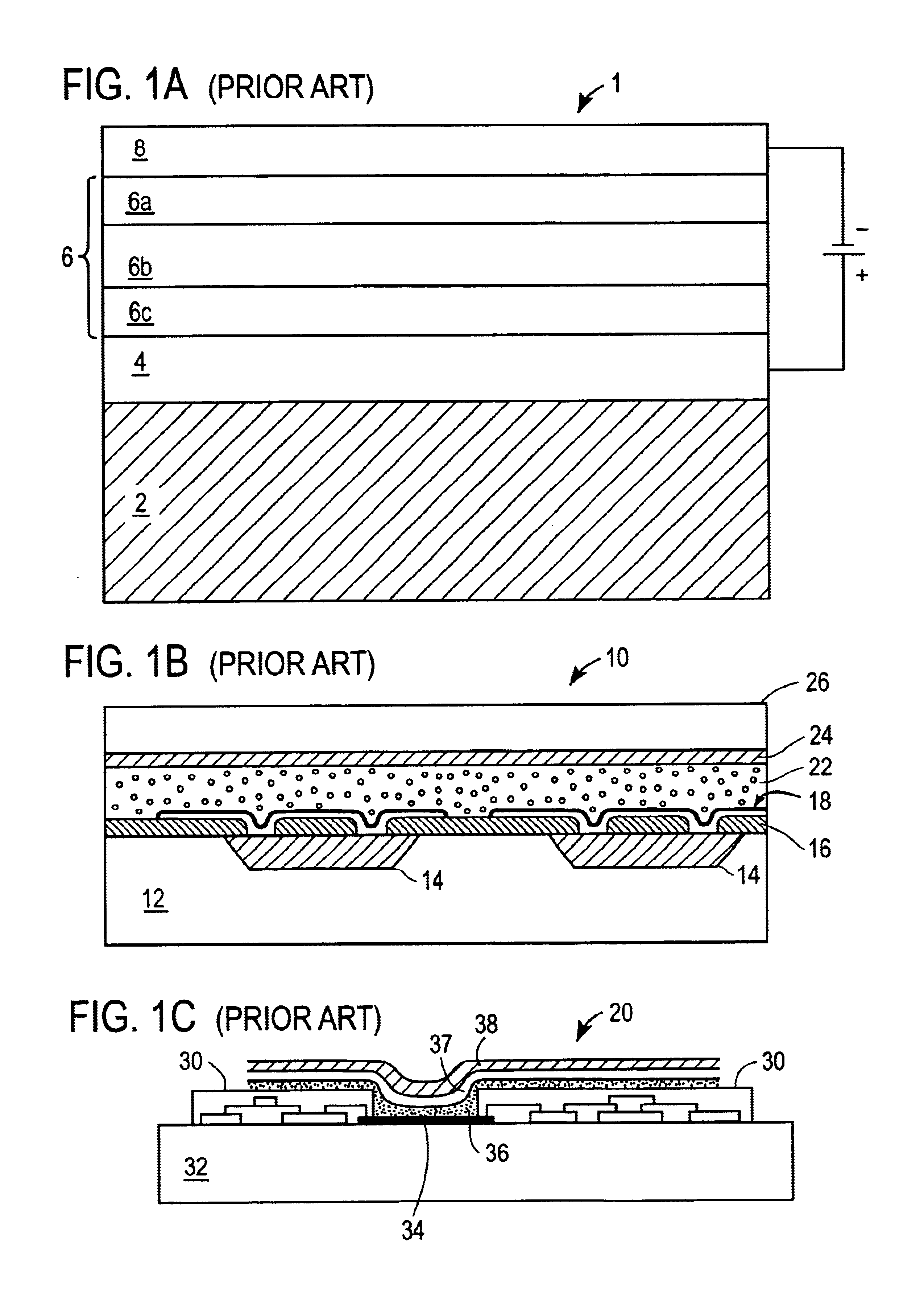

Integrated Touch Screen

ActiveUS20100194697A1Less powerFew partsStatic indicating devicesVessels or leading-in conductors manufactureTouch SensesDisplay device

Displays with touch sensing circuitry integrated into the display pixel stackup are provided. Circuit elements, such as touch signal lines, such as drive lines and sense lines, grounding regions, in the display pixel stackups can be grouped together to form touch sensing circuitry that senses a touch on or near the display. An integrated touch screen can include multi-function circuit elements that can operate as circuitry of the display system to generate an image on the display, and can also form part of a touch sensing system that senses one or more touches on or near the display. The multi-function circuit elements can be, for example, capacitors in display pixels that can be configured to operate as storage capacitors / electrodes, common electrodes, conductive wires / pathways, etc., of the display circuitry in the display system, and that may also be configured to operate as circuit elements of the touch sensing circuitry.

Owner:APPLE INC

External electrode fluorescent lamp with optimized operating efficiency

InactiveUS20080036354A1Improve electron emission rateReduce functionGas-filled discharge tubesVessels or leading-in conductors manufactureDisplay deviceEngineering

An EEFL-type fluorescent lamp for backlighting of displays or screens, whereby the encapsulating glass and / or a (partial) coating of the interior surface of the encapsulating glass are provided which possess a low work function Wa for the electrons of <6 eV, preferably <5 eV, more preferably 0 eV<Wa<5 eV, especially preferably 0 eV<Wa<4 eV, more especially preferably 0 eV<Wa<3 eV. This allows for the operating efficiency to be optimized and the firing voltage to be lowered.

Owner:SCHOTT AG

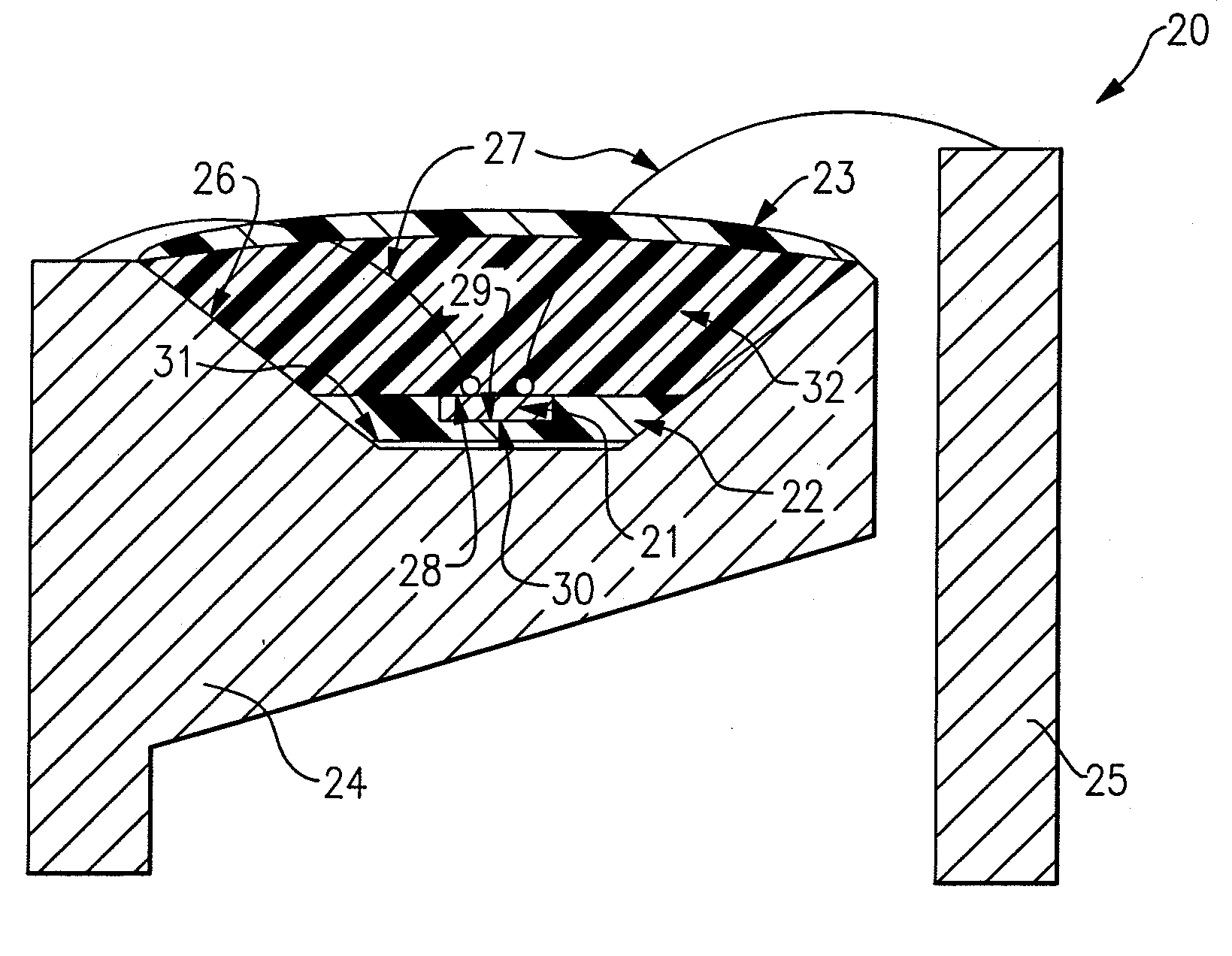

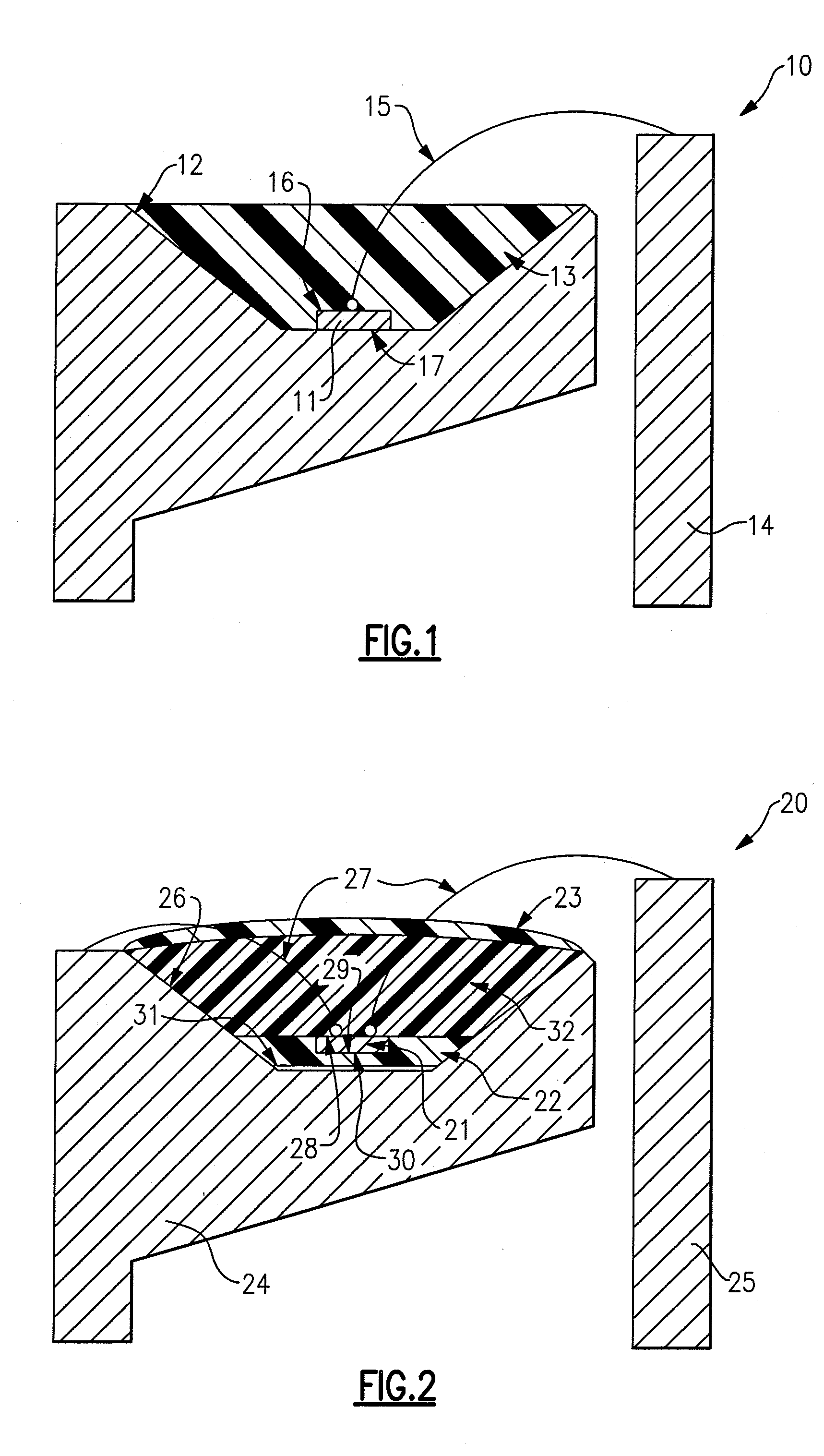

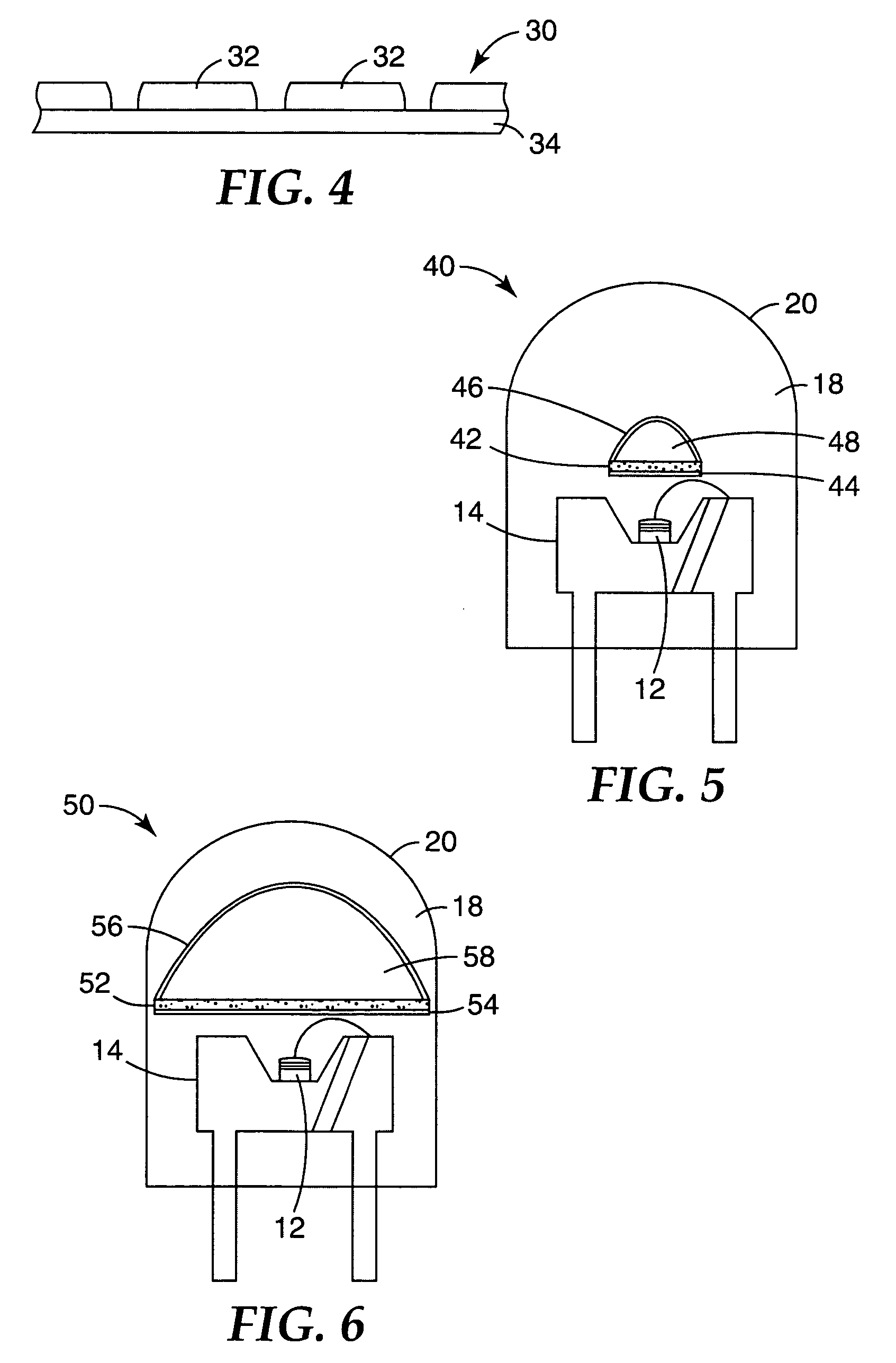

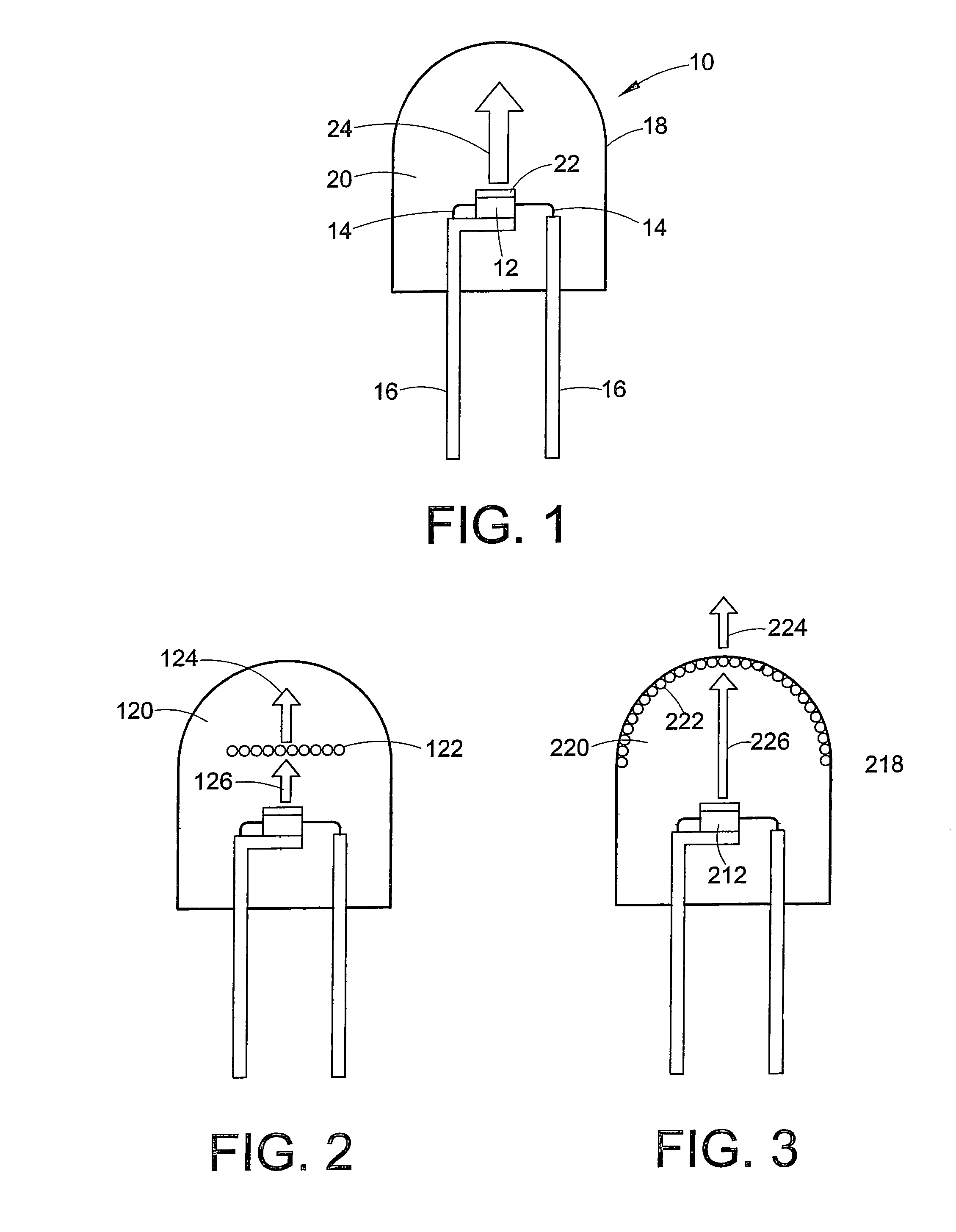

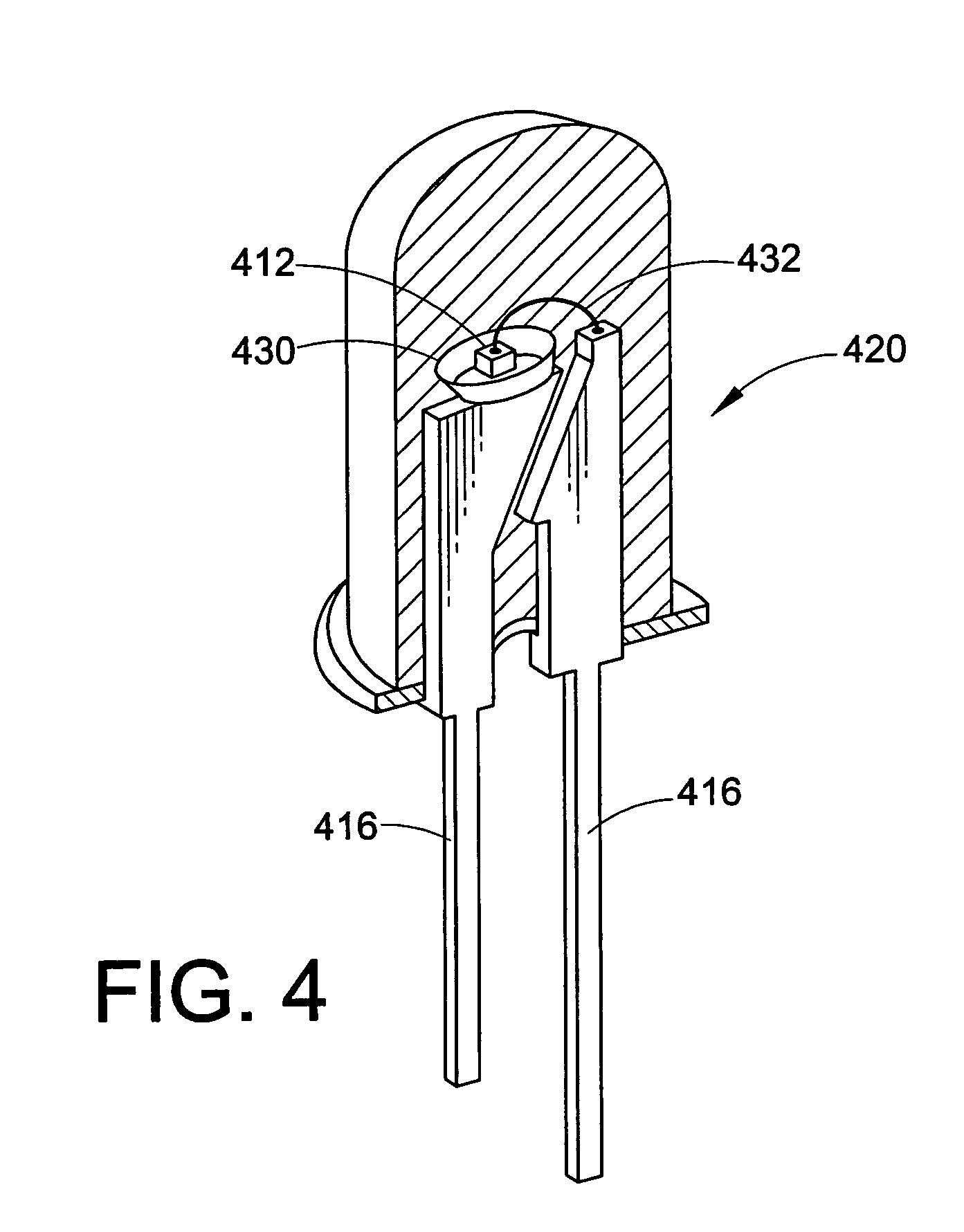

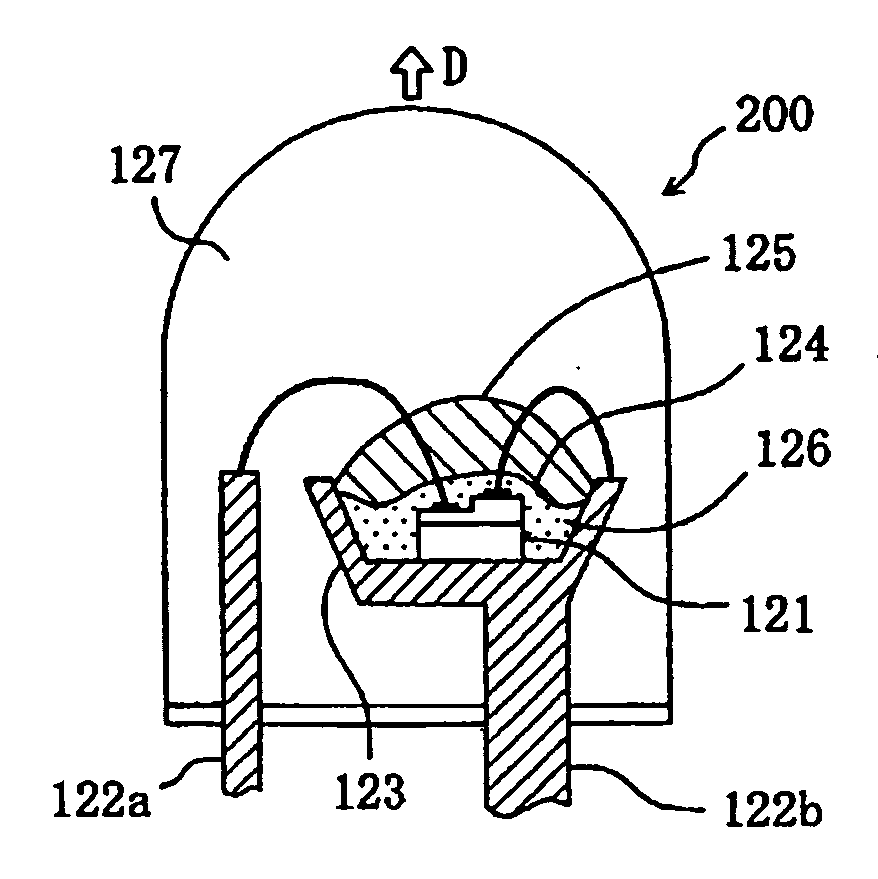

Lighting device and method of making same

ActiveUS20080089053A1Simple materialReducing performance (intensity)Solid-state devicesVessels or leading-in conductors manufactureEffect lightEngineering

A lighting device comprising a light emitter chip, a reflective cup and a lumiphor positioned between the chip and the cup. Also, a lighting device comprising a light emitter chip, a wire bonded to a first surface of the chip and a lumiphor which faces a second surface of the chip. Also, a lighting device comprising a light emitter chip, and a lumiphor, a first surface of the chip facing a first region of the lumiphor, a second surface of the chip facing a second region of the lumiphor. Also, a lighting device comprising a light emitter chip and first and second lumiphors, a first surface of the chip facing the second lumiphor, a second surface of the chip facing the first lumiphor. Also, methods of making lighting devices.

Owner:CREELED INC

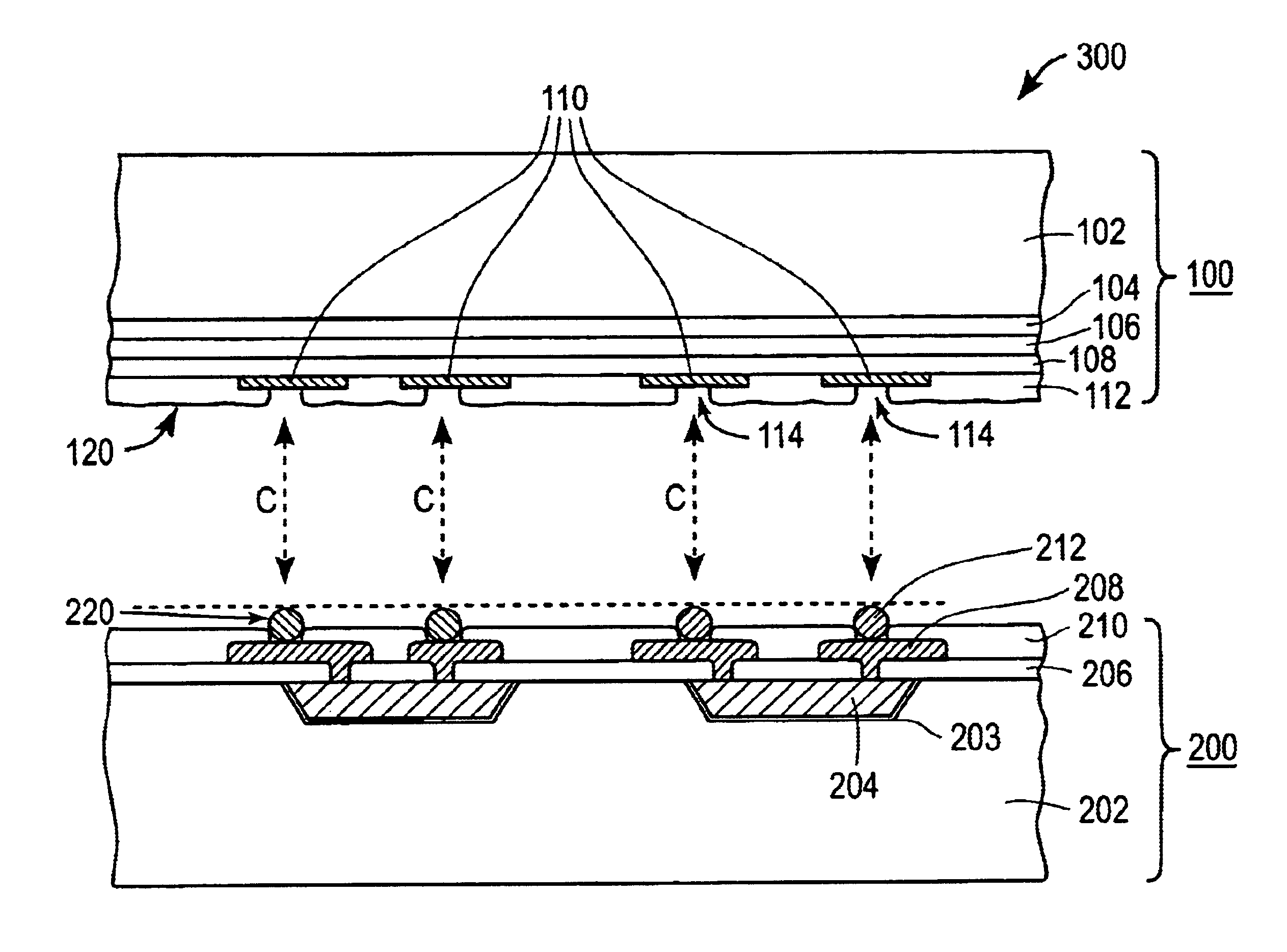

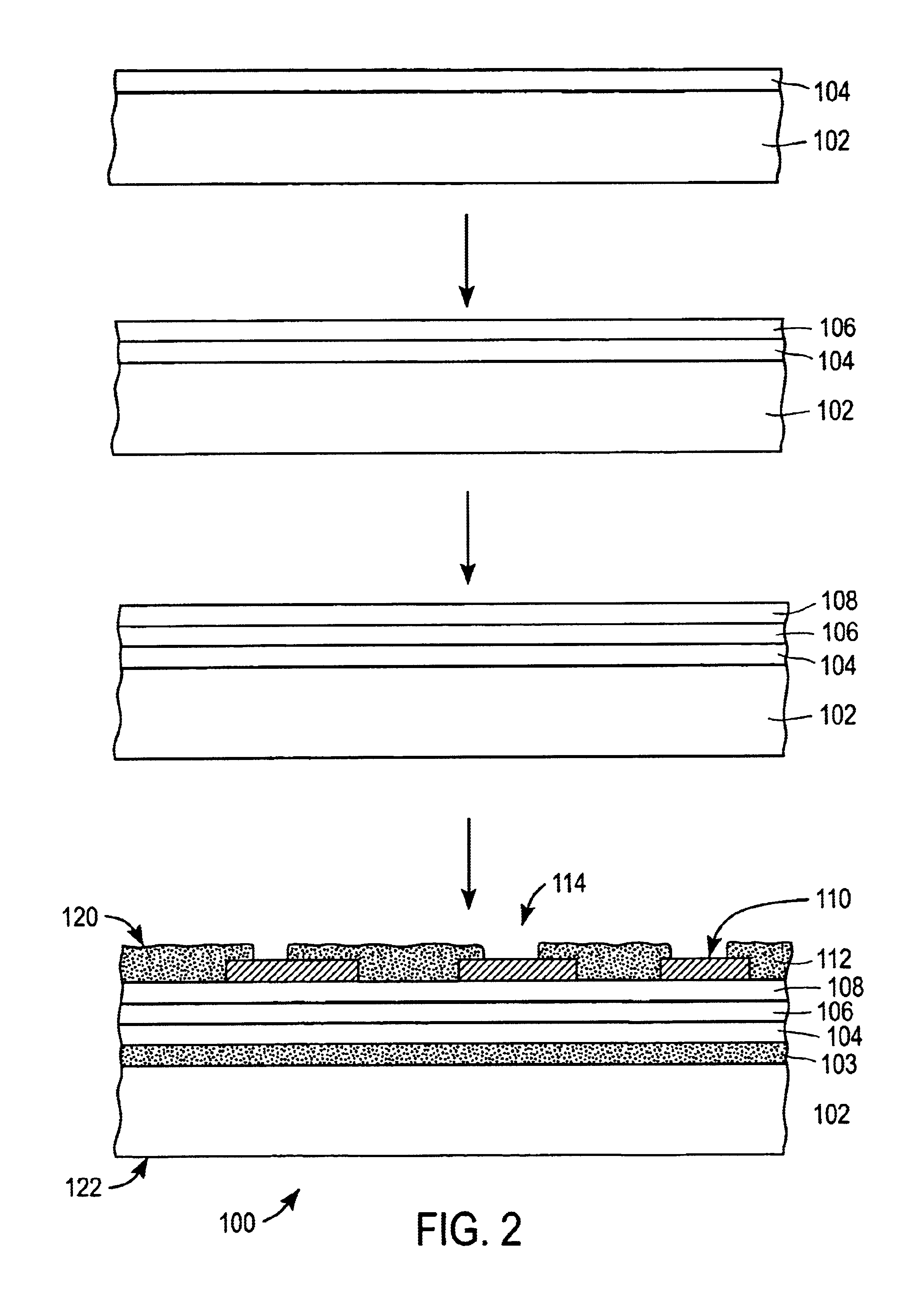

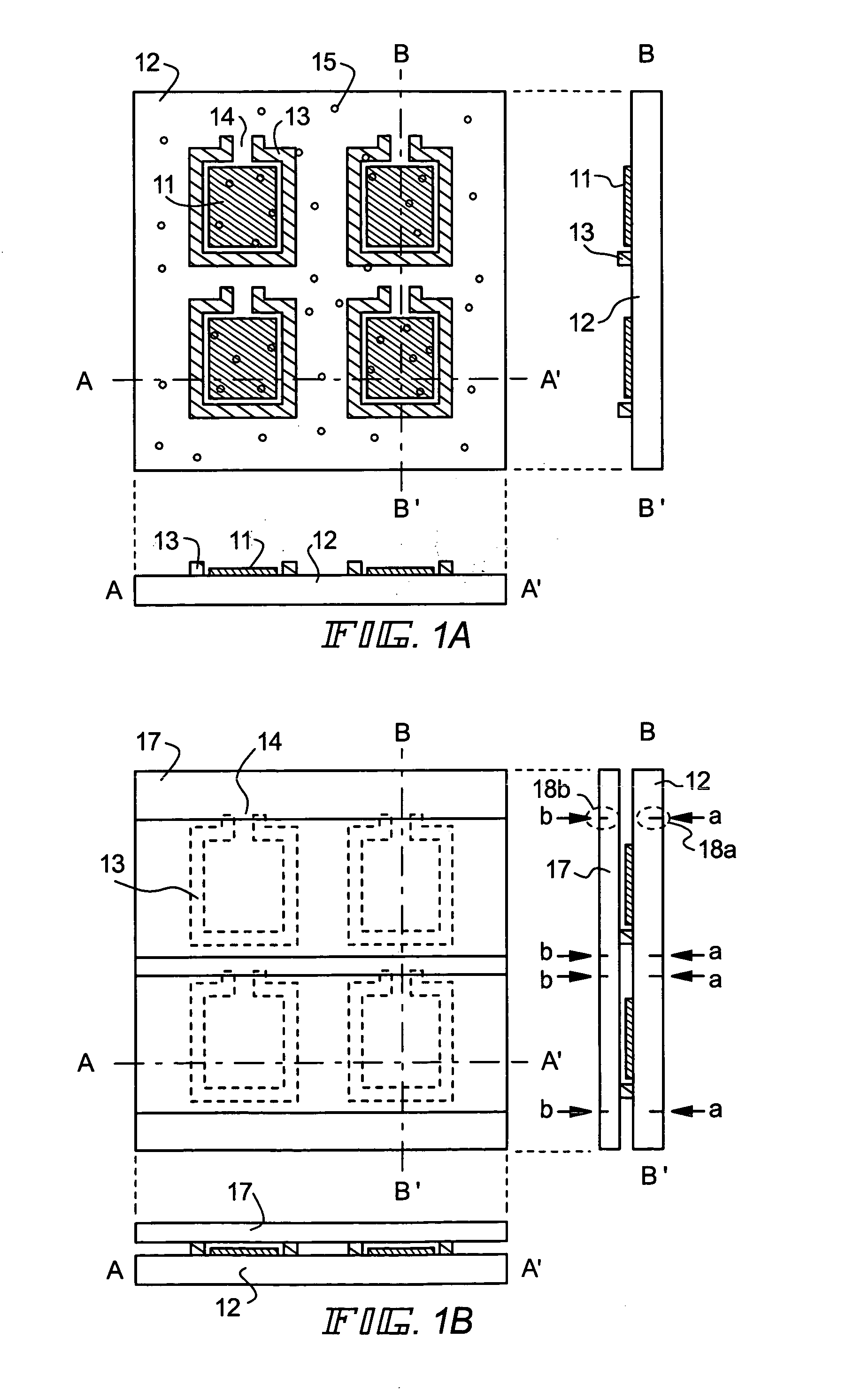

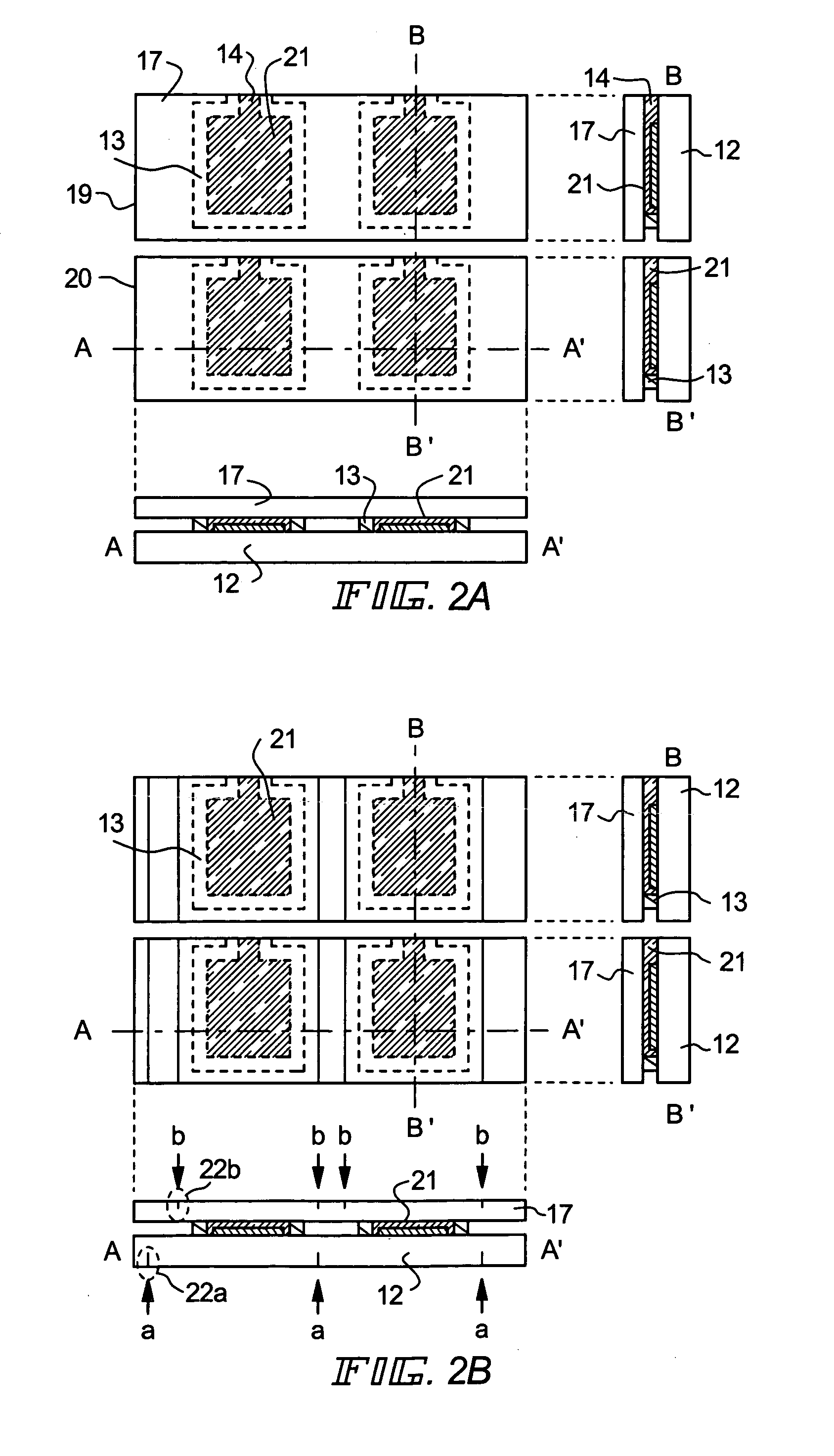

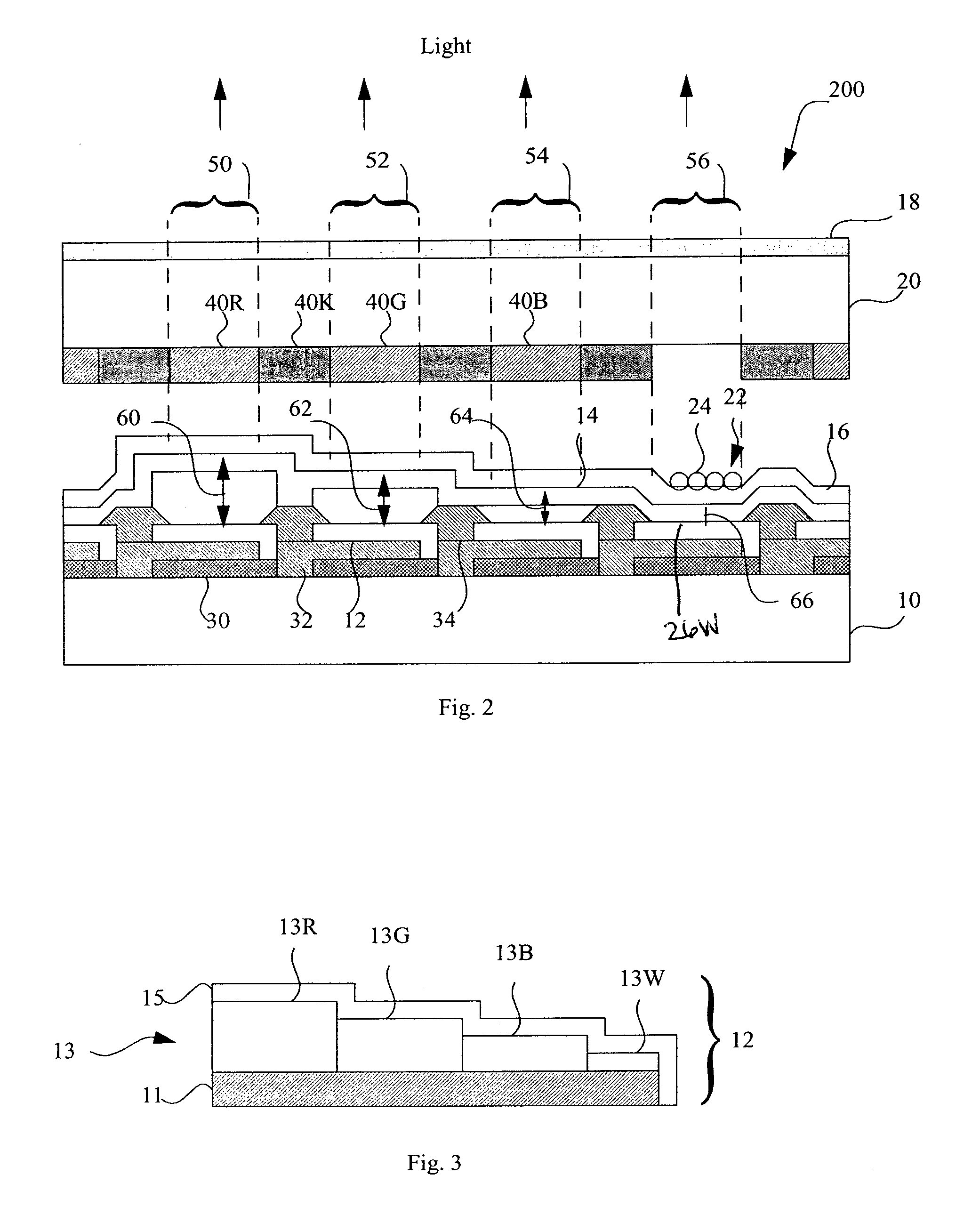

Split-fabrication for light emitting display structures

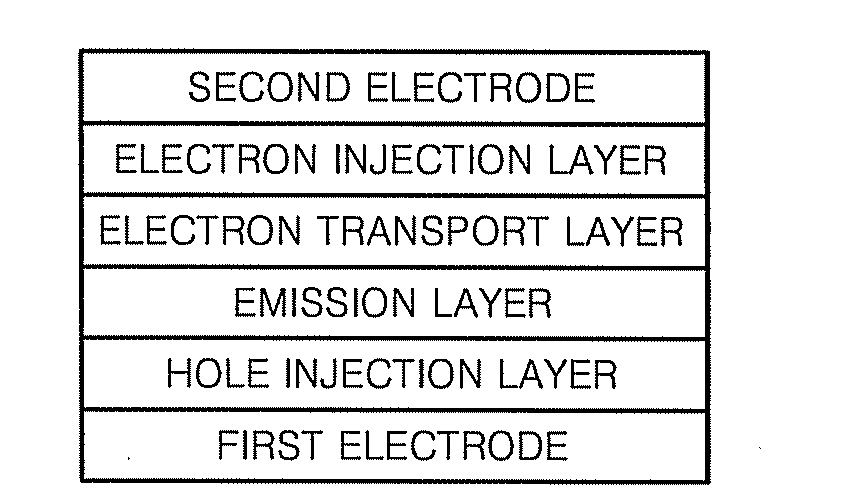

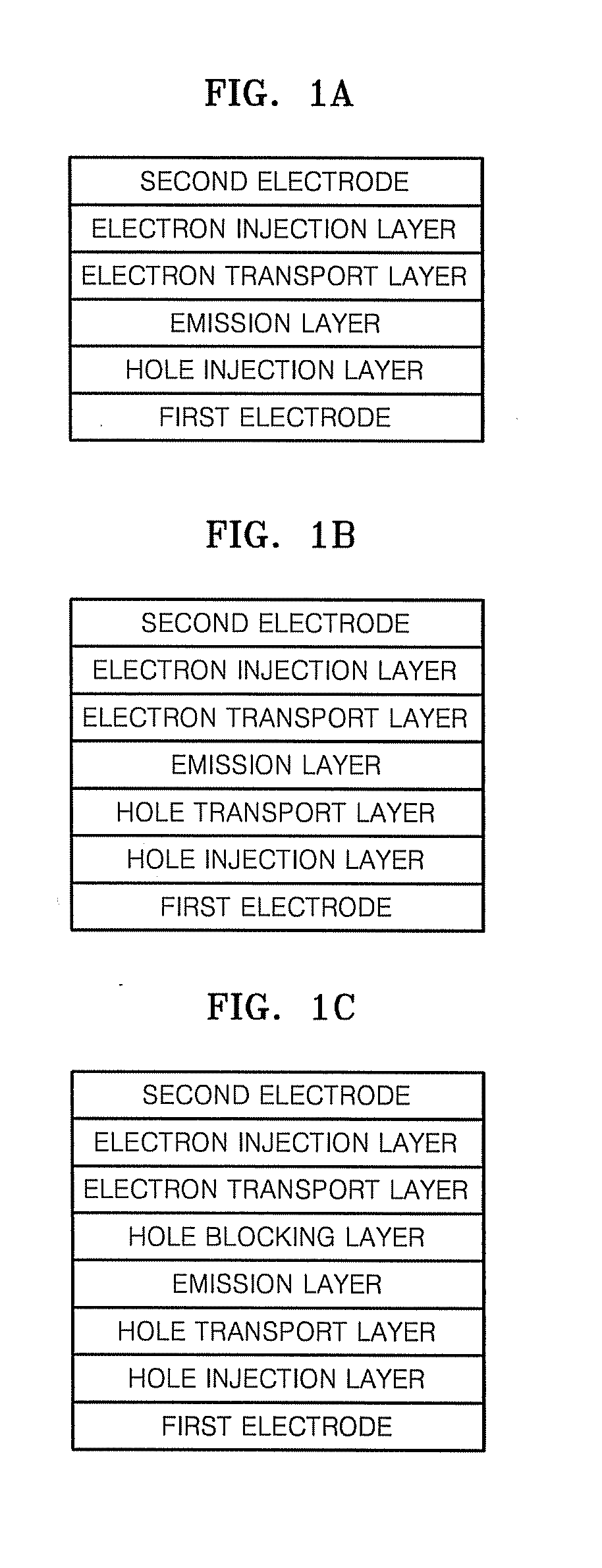

Methods and apparatuses for fabricating an electroluminescent display structure. A method including coupling a frontplane to a backplane wherein a frontplane top surface laminates to a backplane top surface. The frontplane and the backplane are fabricated separately. A first electrode layer which is transparent is disposed over the frontplane. A display medium which produces electro-optical effects upon a voltage application is disposed over the first electrode. A second electrode layer which is pattered is disposed over the display medium. The second electrode layer includes a plurality of connecting regions. The backplane is electrically active to provide driving signals for the display medium wherein the backplane includes a plurality of output pads to match the plurality of connecting regions.

Owner:RUIZHANG TECH LTD CO

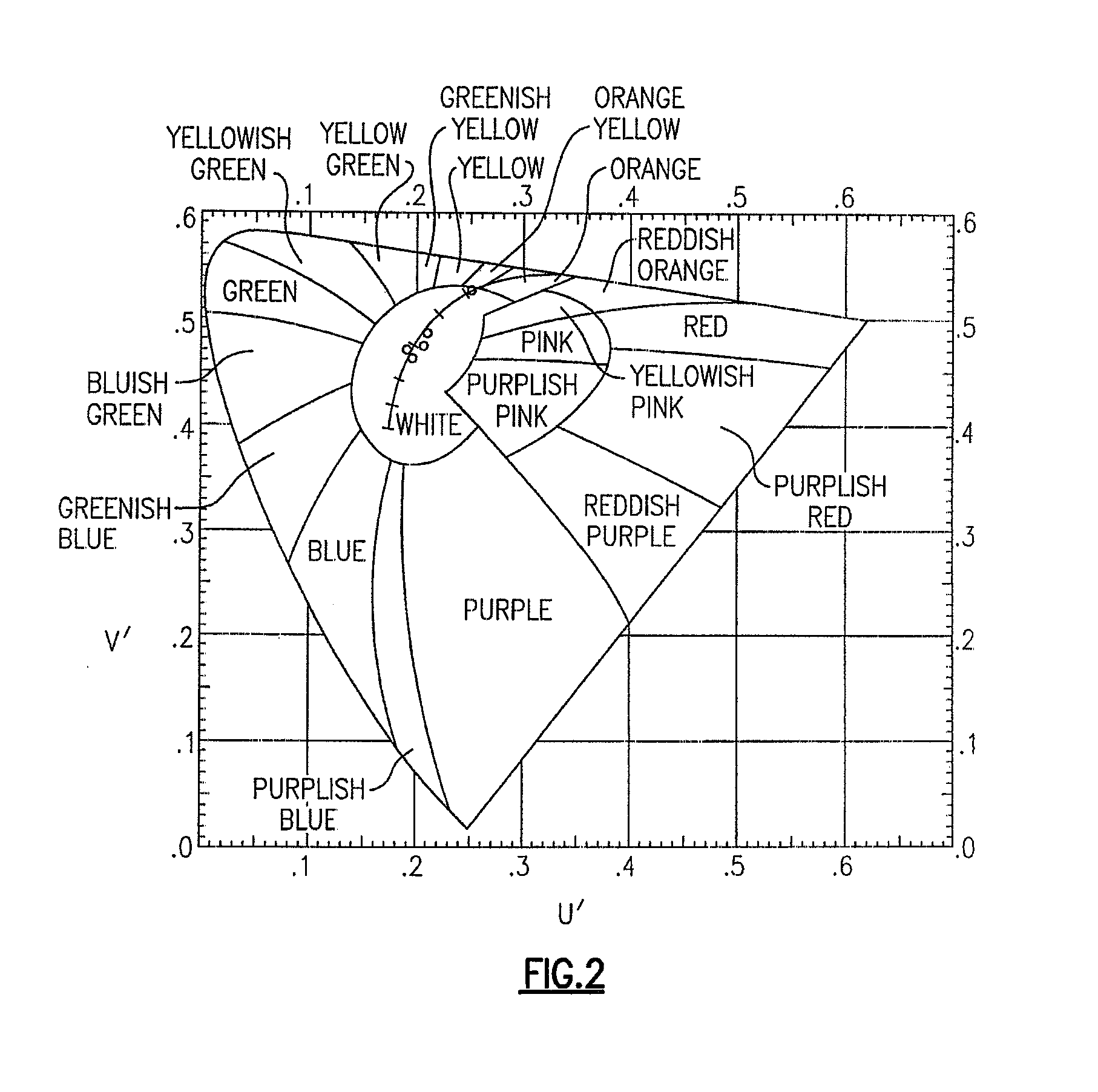

Lighting device and lighting method

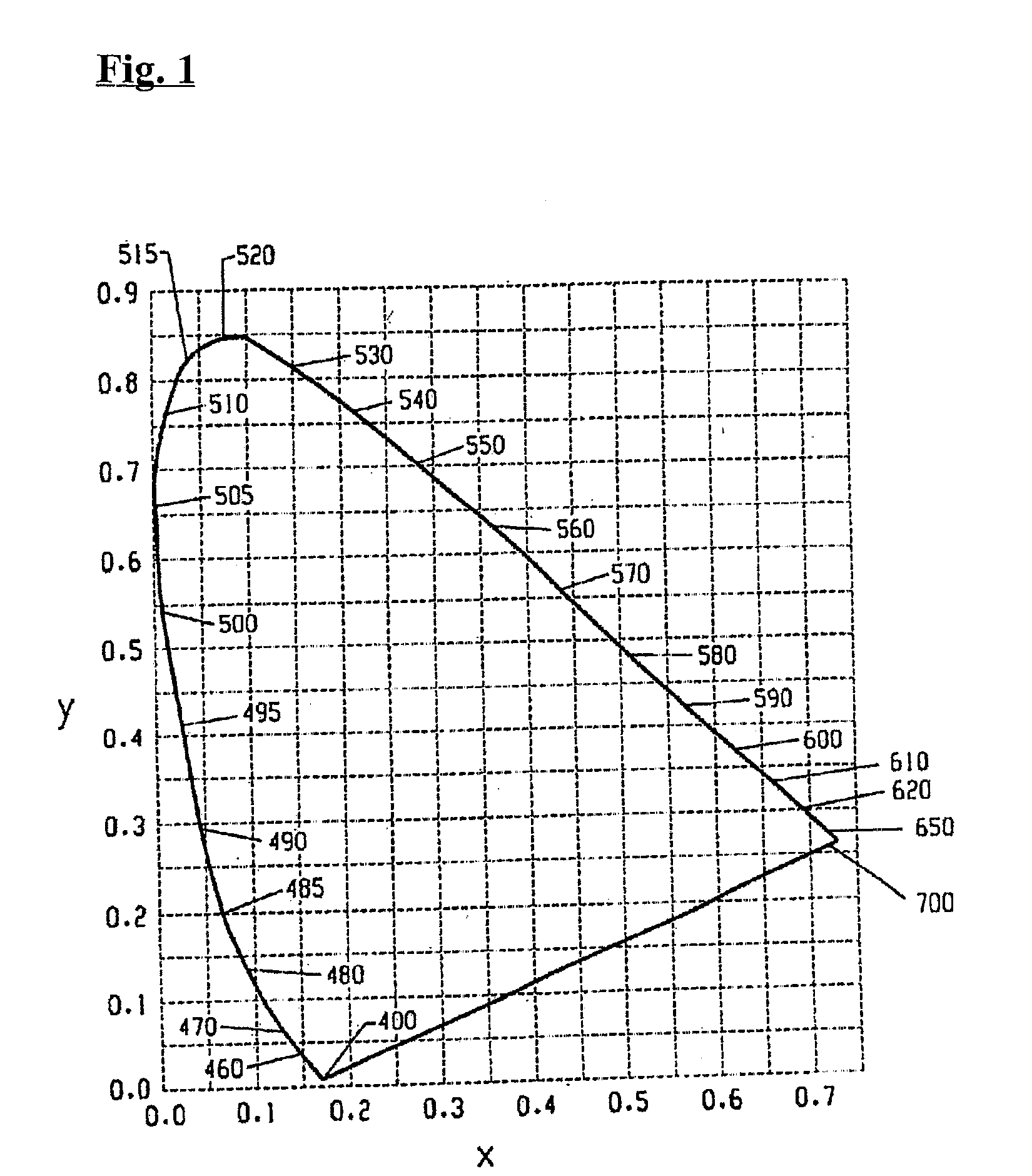

ActiveUS20080136313A1Low efficiencyIncreased complexityDischarge tube luminescnet screensPoint-like light sourceEffect lightLight emitter

A lighting device comprising first, second and third groups of solid state light emitters, and first and second groups of lumiphors. A mixture of light emitted from the first group of emitters and the first group of lumiphors has x,y color coordinates within an area defined by coordinates (0.36,0.48), (0.43,0.45), (0.5125,0.4866), and (0.4087,0.5896) (or (0.41,0.455), (0.36,0.48), (0.4087,0.5896), and (0.4788,0.5202)). A mixture of light emitted from the second group of emitters and the second group of lumiphors is within an area defined by (0.32,0.40), (0.36,0.38), (0.30,0.26), and (0.25,0.29). A mixture of light from the first and second groups of emitters and the first and second groups of lumiphors is within an area defined by (0.32,0.40), (0.36,0.48), (0.43,0.45), (0.42,0.42), and (0.36,0.38) (or (0.32,0.40), (0.36,0.38), (0.41,0.455), and (0.36,0.48)). A mixture of light from all of these emitters and lumiphors is within ten MacAdam ellipses of the blackbody locus. Also, methods of lighting.

Owner:IDEAL IND LIGHTING LLC

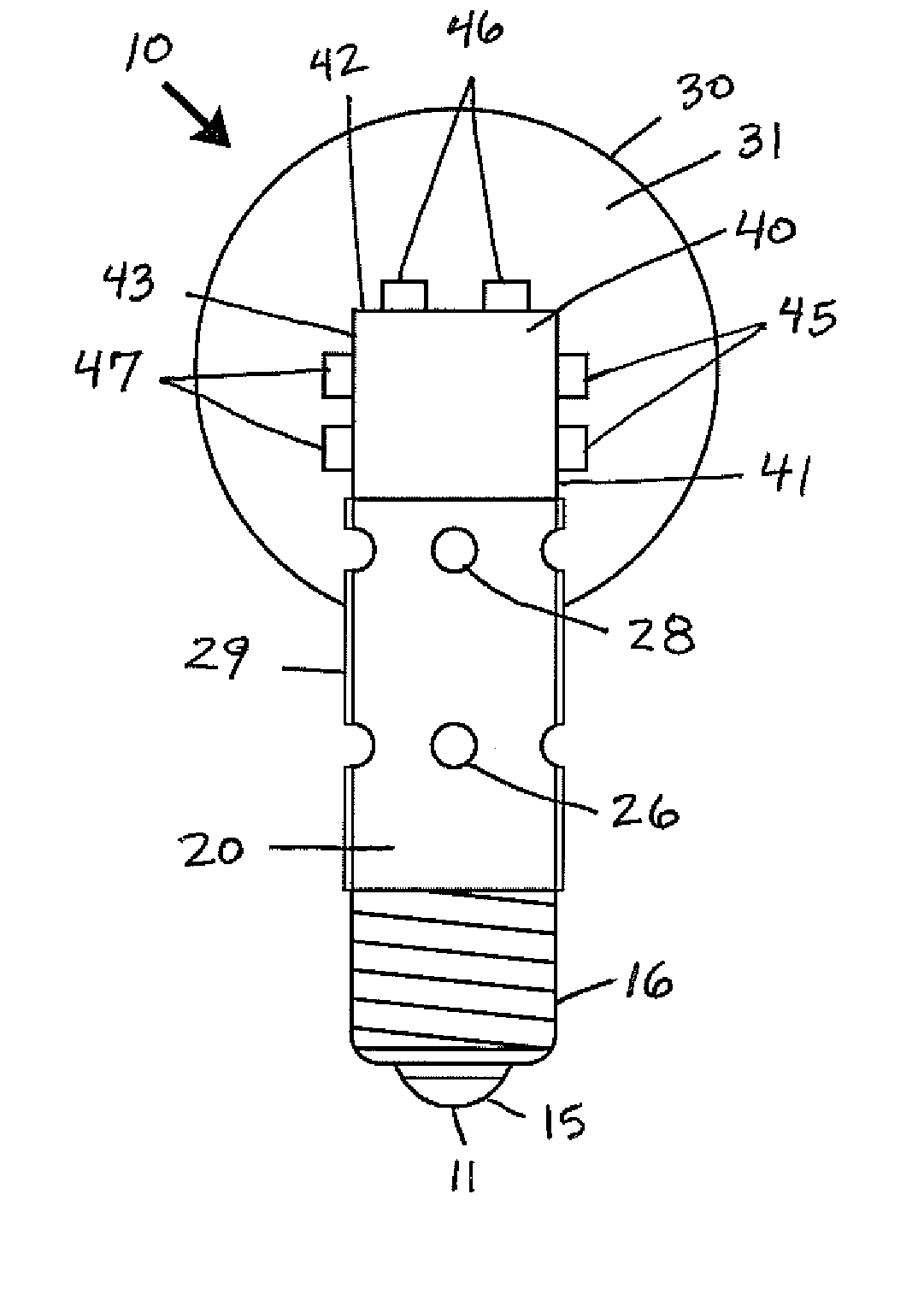

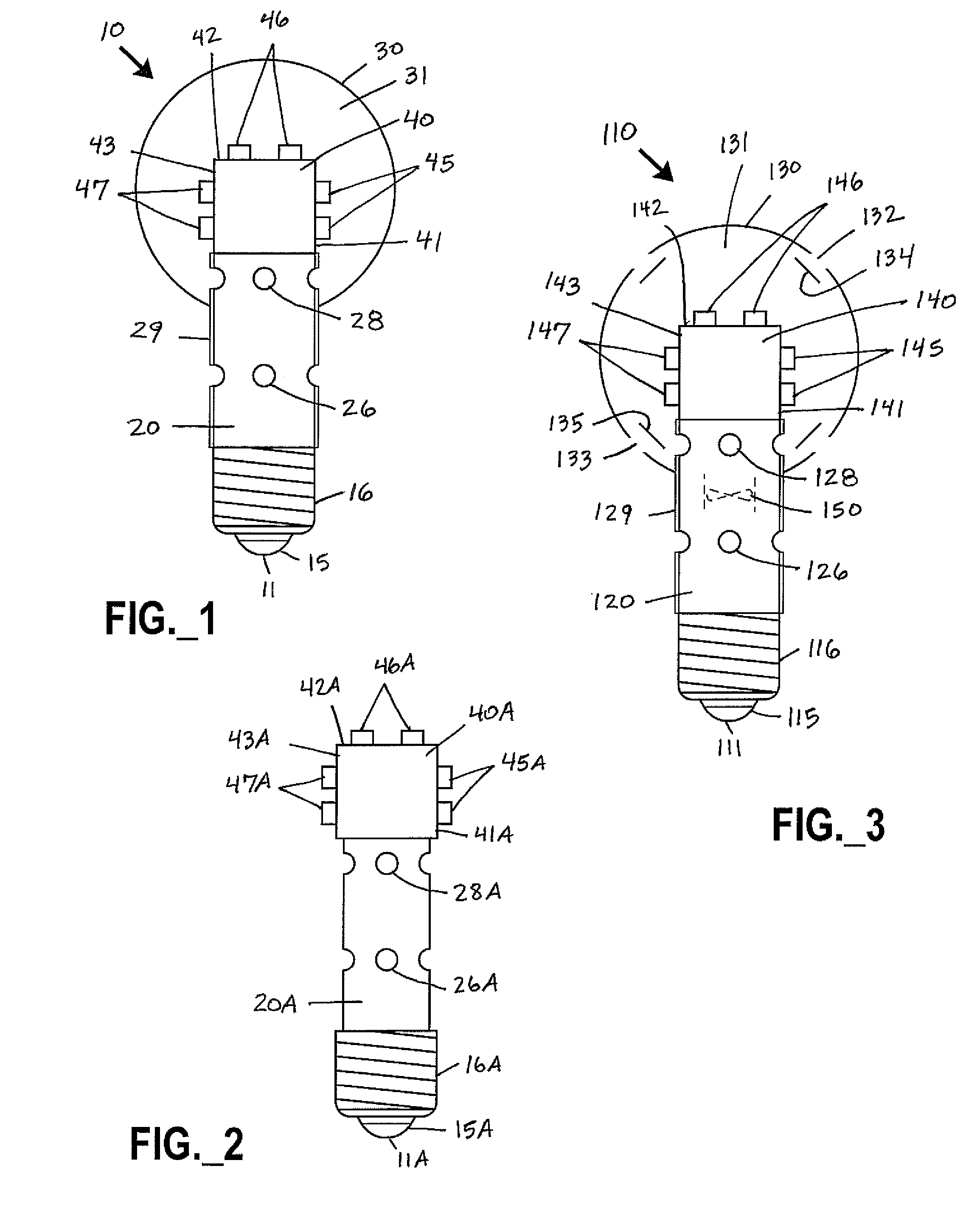

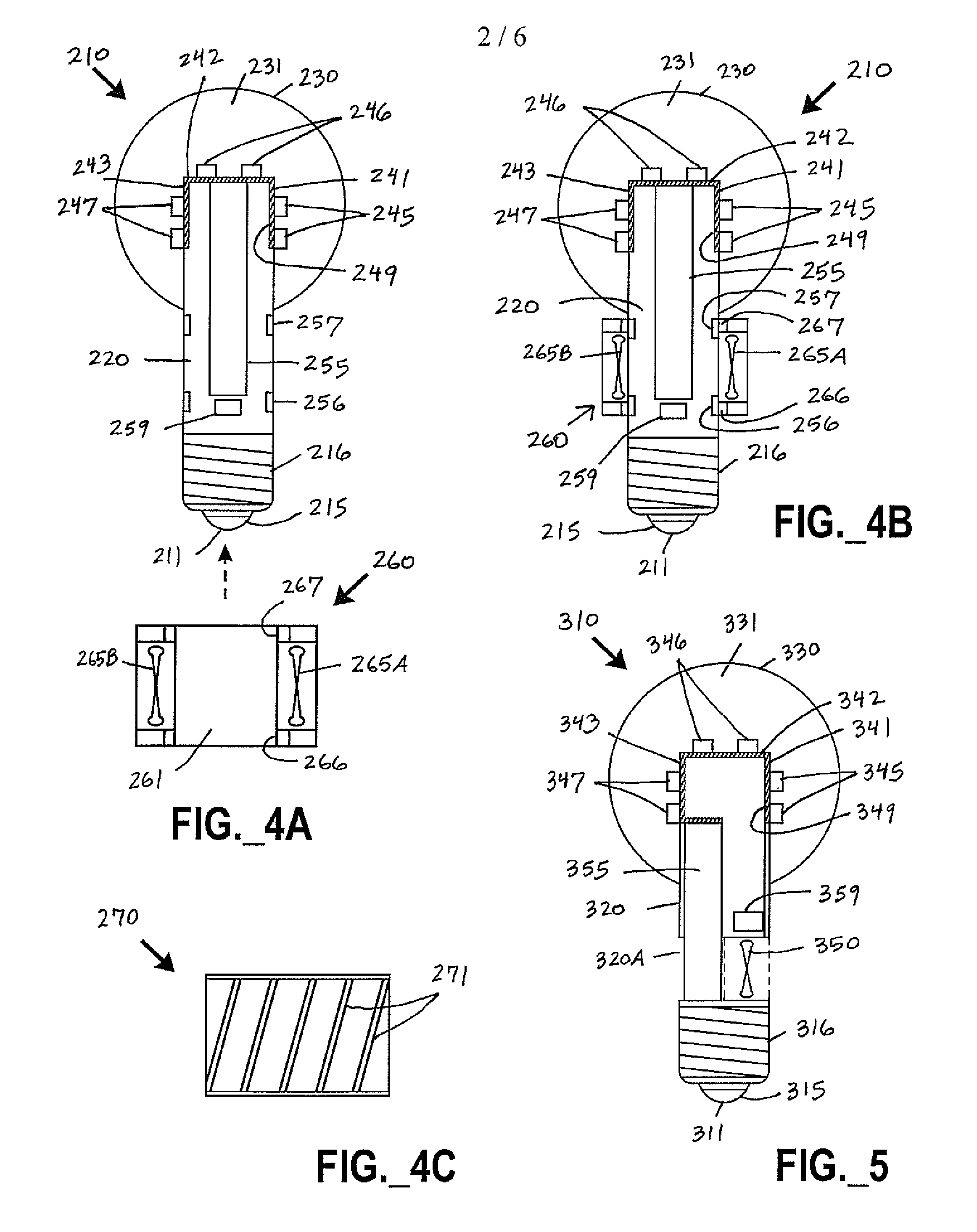

LED light bulbs

ActiveUS20110298371A1Address limitationsPlanar light sourcesPoint-like light sourceEngineeringLED lamp

LED light bulbs include openings in base or cover portions, and optional forced flow elements, for convective cooling. Thermally conductive optically transmissive material may be used for cooling, optionally including fins. A LED light engine may be fabricated from a substrate via planar fabrication techiques and shaped to form a substantially rigid upright support structure. Mechanical, electrical, and thermal connections may be made between a LED light engine and a LED light bulb.

Owner:IDEAL IND LIGHTING LLC

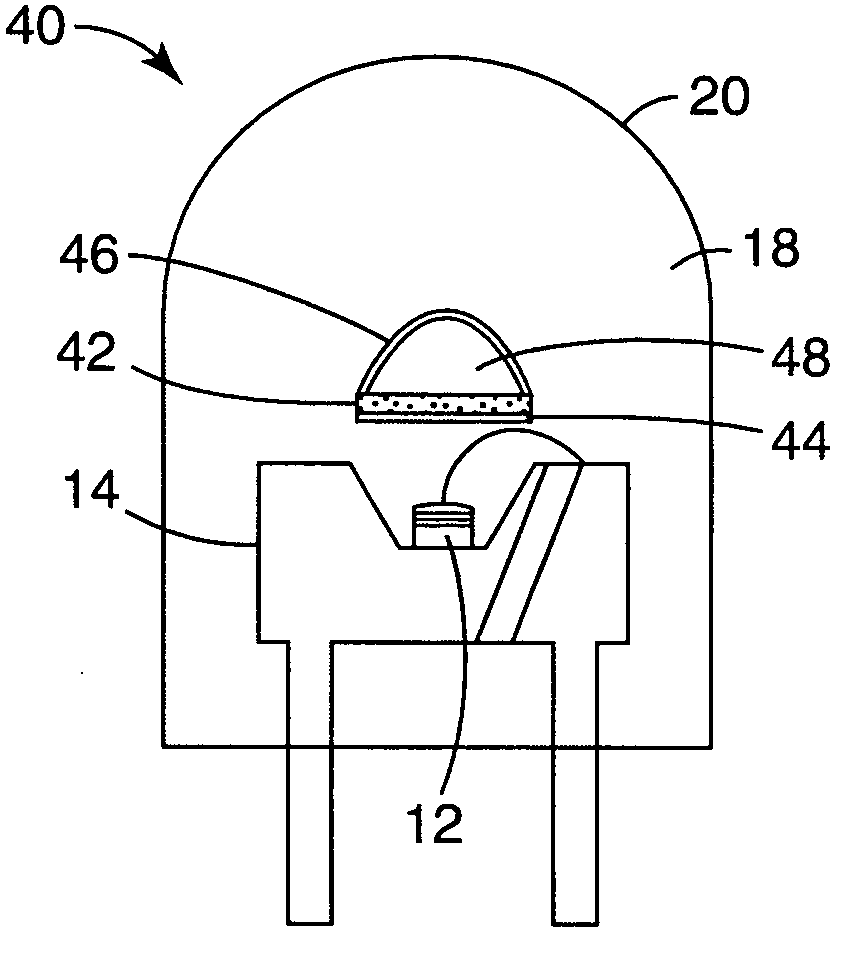

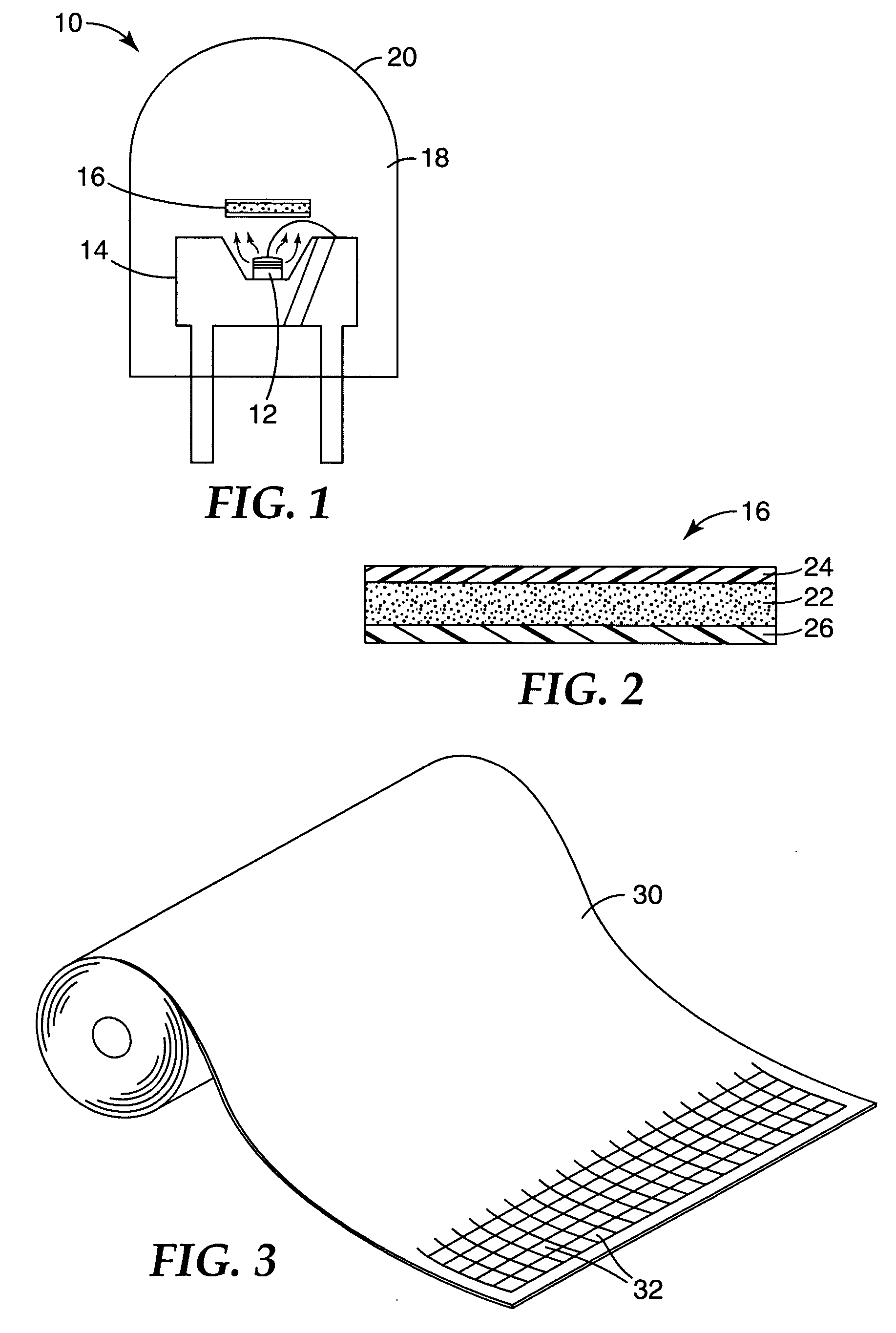

Methods of making phosphor based light sources having an interference reflector

ActiveUS20040116033A1Maintain reflectivityPrevent leakageLayered productsSolid-state devicesPhosphorLight source

A method of manufacturing a light source includes the steps of providing a first flexible sheet comprising a first multilayer interference reflector, providing a carrier film to carry the reflector, dividing the reflector into individual pieces carried by the carrier film, and positioning at least one of the individual pieces proximate an LED capable of emitting light that excites a phosphor material.

Owner:3M INNOVATIVE PROPERTIES CO

Optical-interference type display panel and method for making the same

InactiveUS20040147198A1Semiconductor/solid-state device manufacturingVessels or leading-in conductors manufactureIndium tin oxideTransparent conducting film

An optical-interference type display panel and a method for making the same are disclosed, wherein the display panel has a substrate on which multiple first conductive optical film stacks, supporting layers and multiple second conductive optical film stacks are formed. The substrate further has a plurality of connecting pads consisting of a transparent conductive film of the first conductive optical film stacks. Since the transparent conductive film is made of indium tin oxide, these connecting pads have the excellent anti-oxidation ability at their surface.

Owner:SNAPTRACK

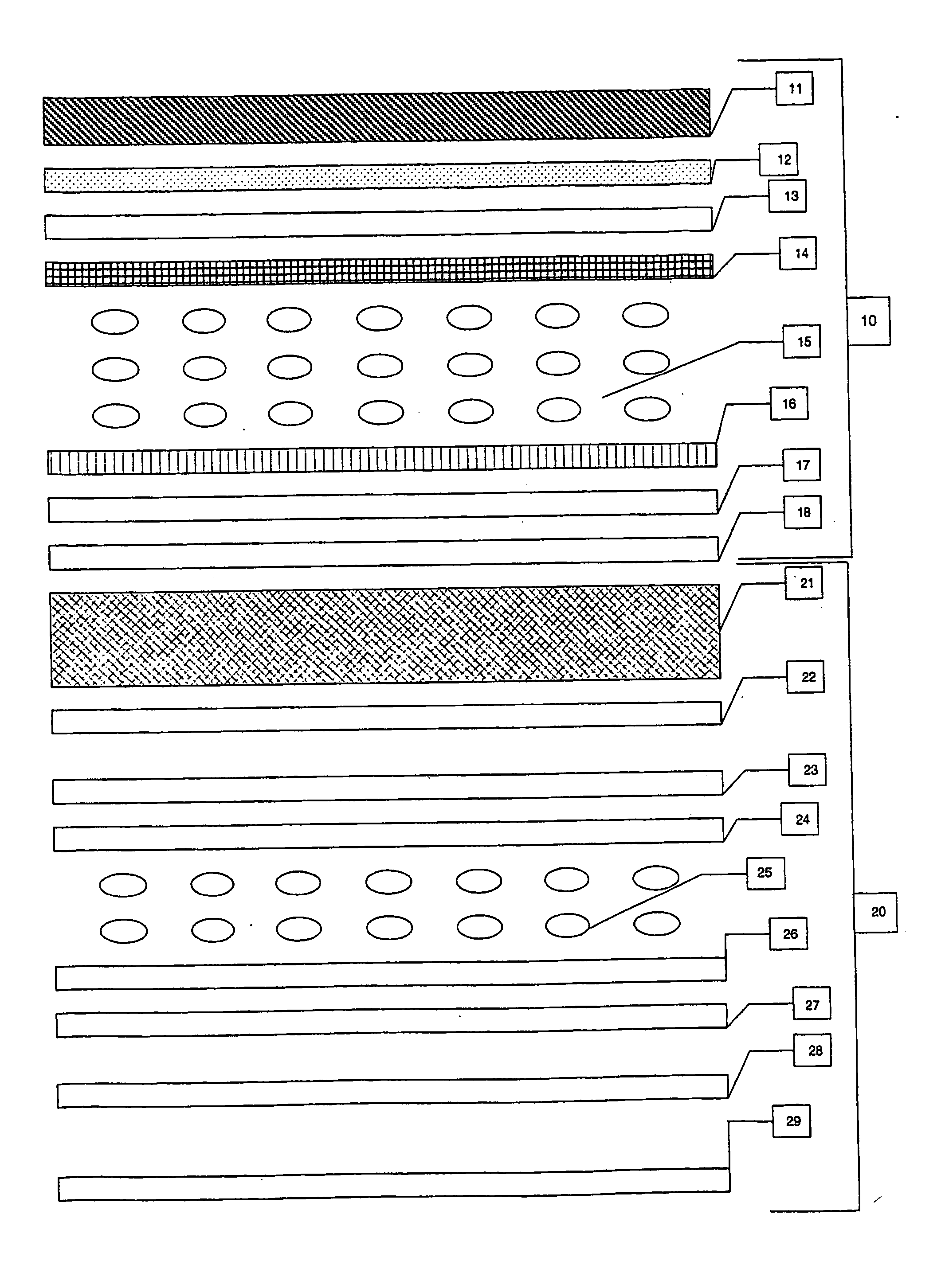

System and process for fabricating an organic electroluminescent display device

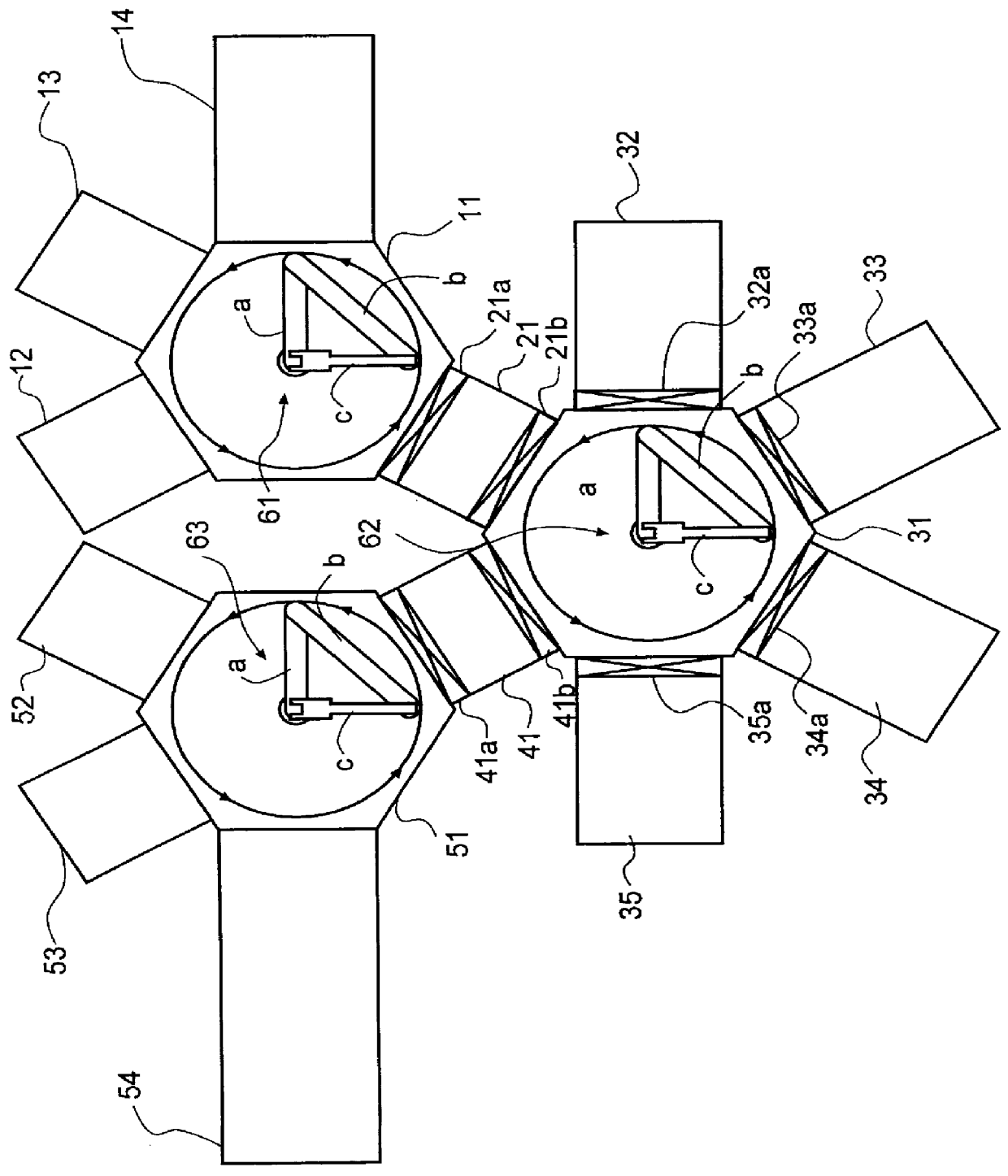

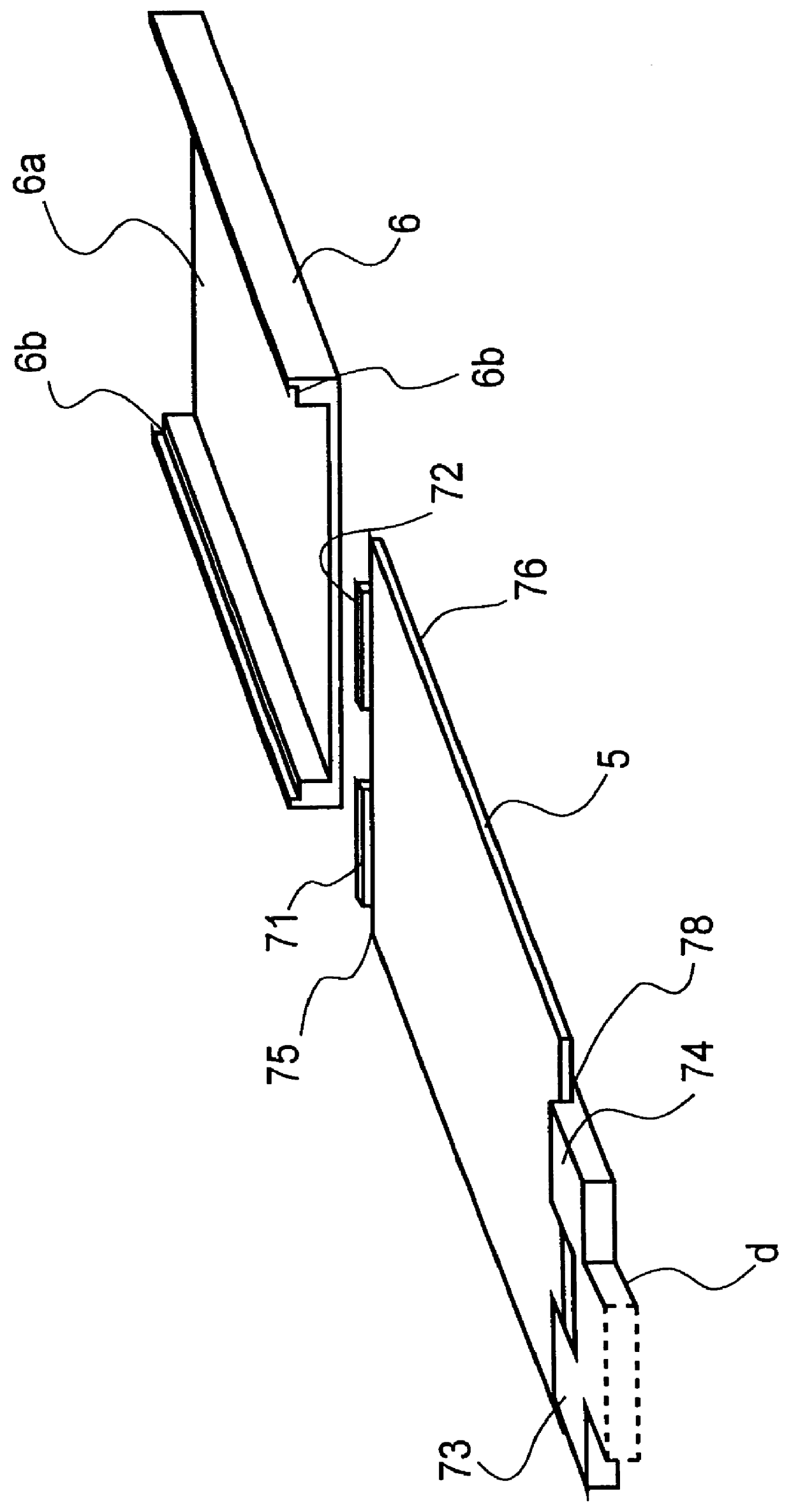

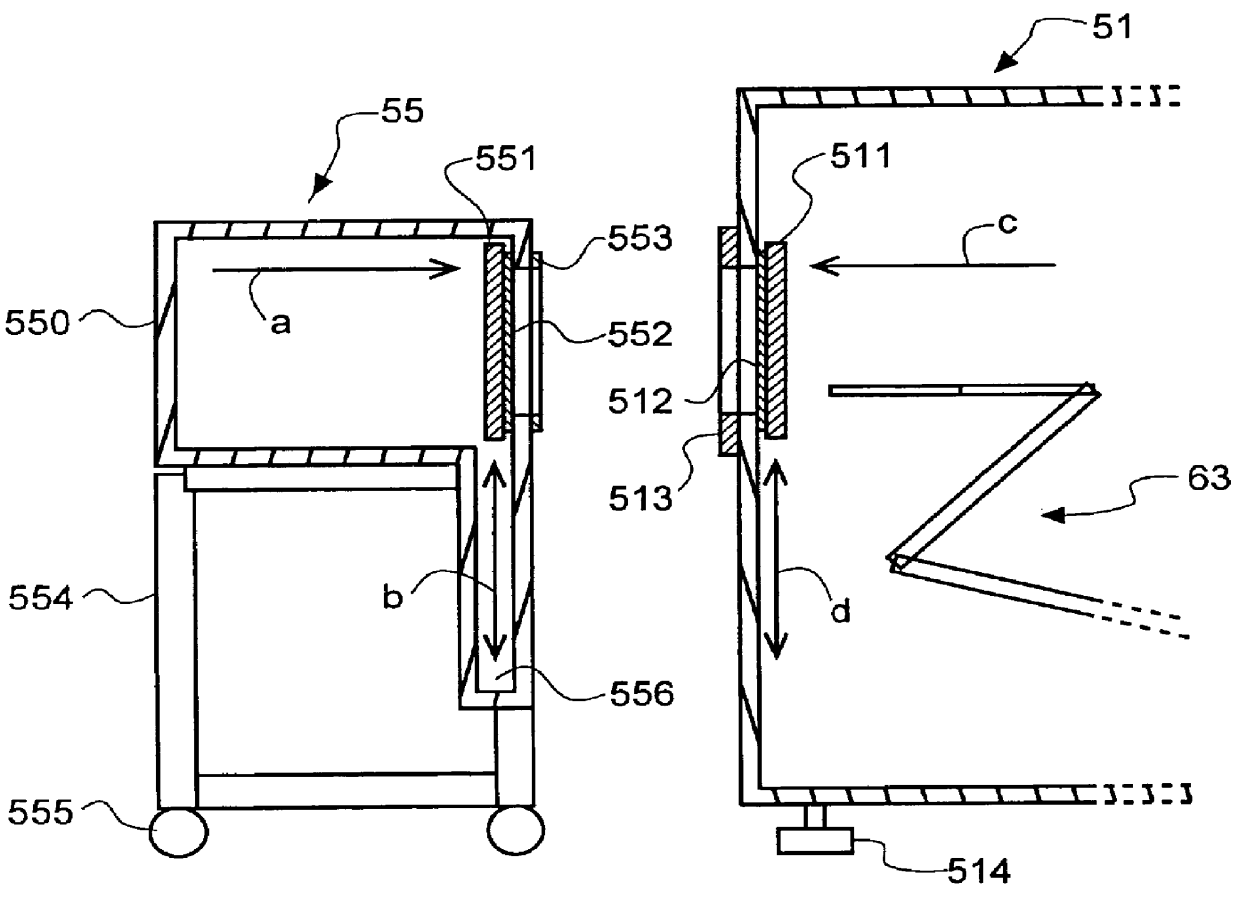

InactiveUS6132280ALow costHigh yet stabilized qualityElectroluminescent light sourcesSolid-state devicesEngineeringVacuum delivery

The invention provides an organic EL display device fabrication system comprising a loading side normal-pressure delivery chamber 11 including a first substrate delivery means 61 for delivering a substrate with no film formed thereon, and a loading chamber 21 connected thereto for introducing the substrate from loading side normal-pressure delivery chamber 11 at normal pressure into a vacuum delivery chamber 31 at a vacuum. The vacuum delivery chamber 31 is connected to loading chamber 21 and includes a second substrate delivery means 62 for delivering the substrate in a vacuum, and has one or two or more film formation chambers 32 to 35 connected thereto. The system further comprises an unloading chamber 41 connected thereto for delivering the substrate out of vacuum delivery chamber 31 at a vacuum into an unloading side normal-pressure delivery chamber 51 at normal pressure. The unloading side normal-pressure delivery chamber 51 is connected to unloading chamber 41 and includes a third substrate delivery means 63 for delivering a substrate with films formed thereon. An inert gas atmosphere having a moisture content of up to 100 ppm is maintained in both unloading chamber 41 and unloading side normal-pressure delivery chamber 51 at normal pressure. The invention also provides an organic EL display device fabrication process using this fabrication system.

Owner:FUTABA CORPORATION

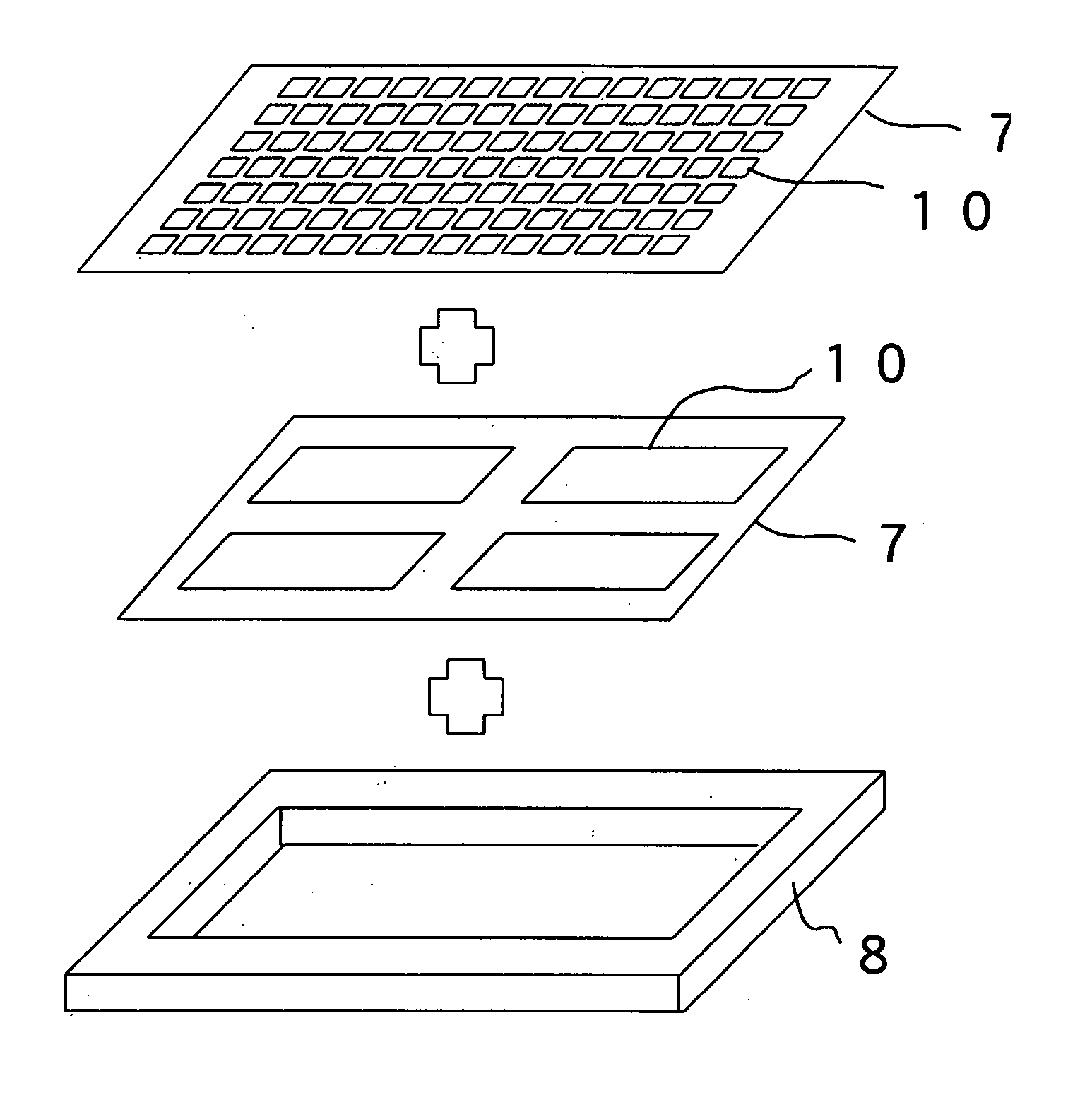

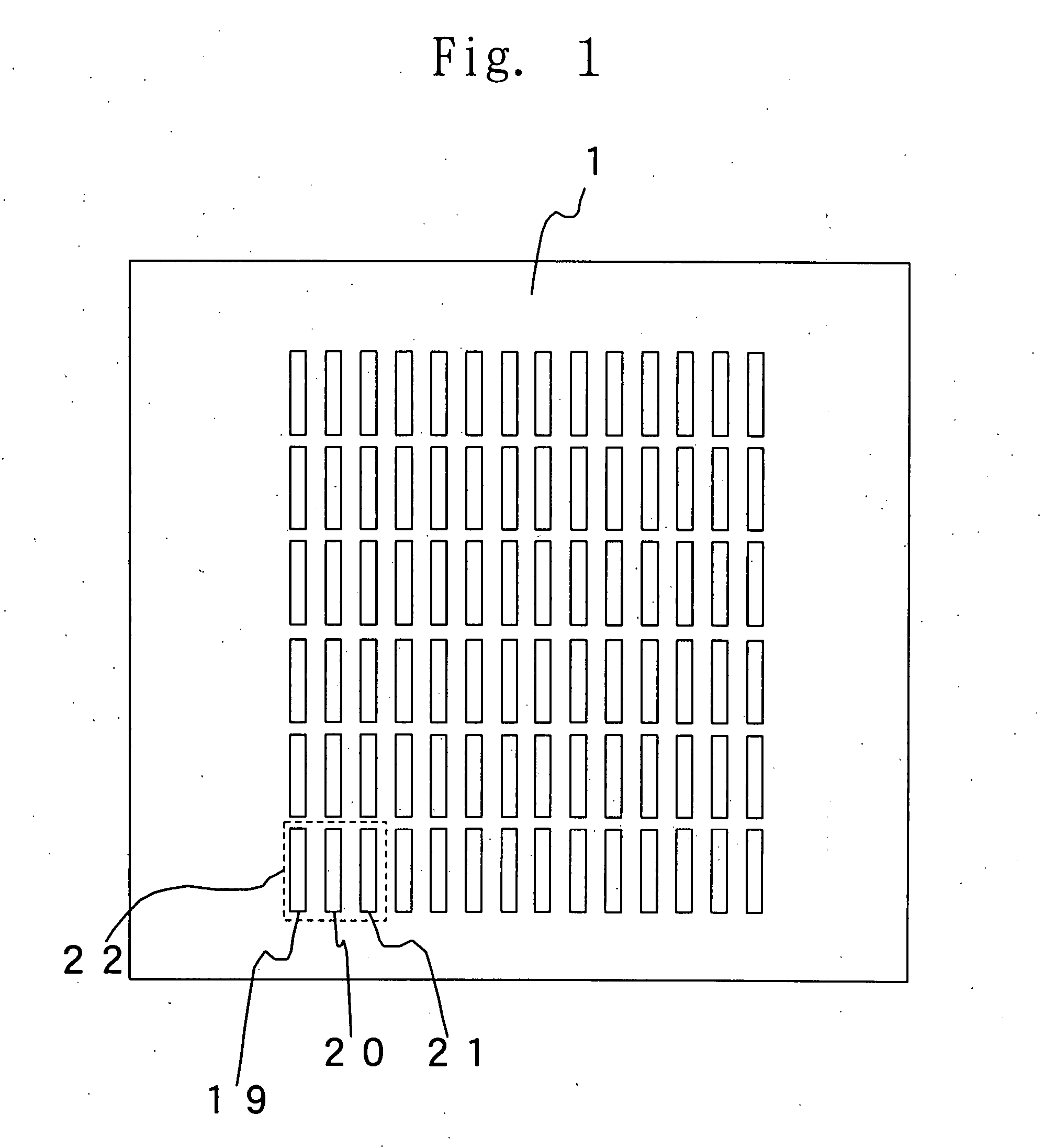

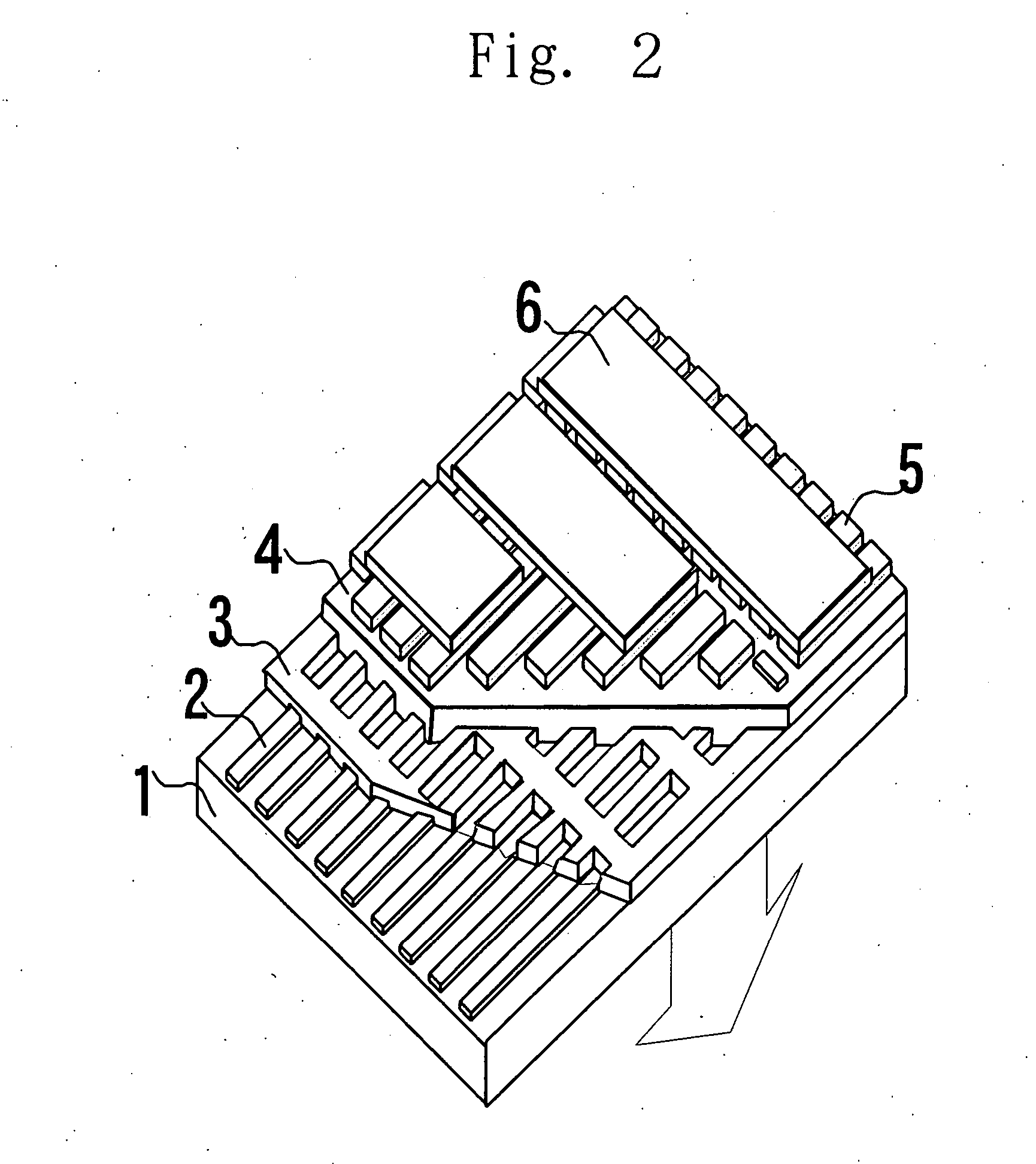

Light emitting device and method of manufacturing the same

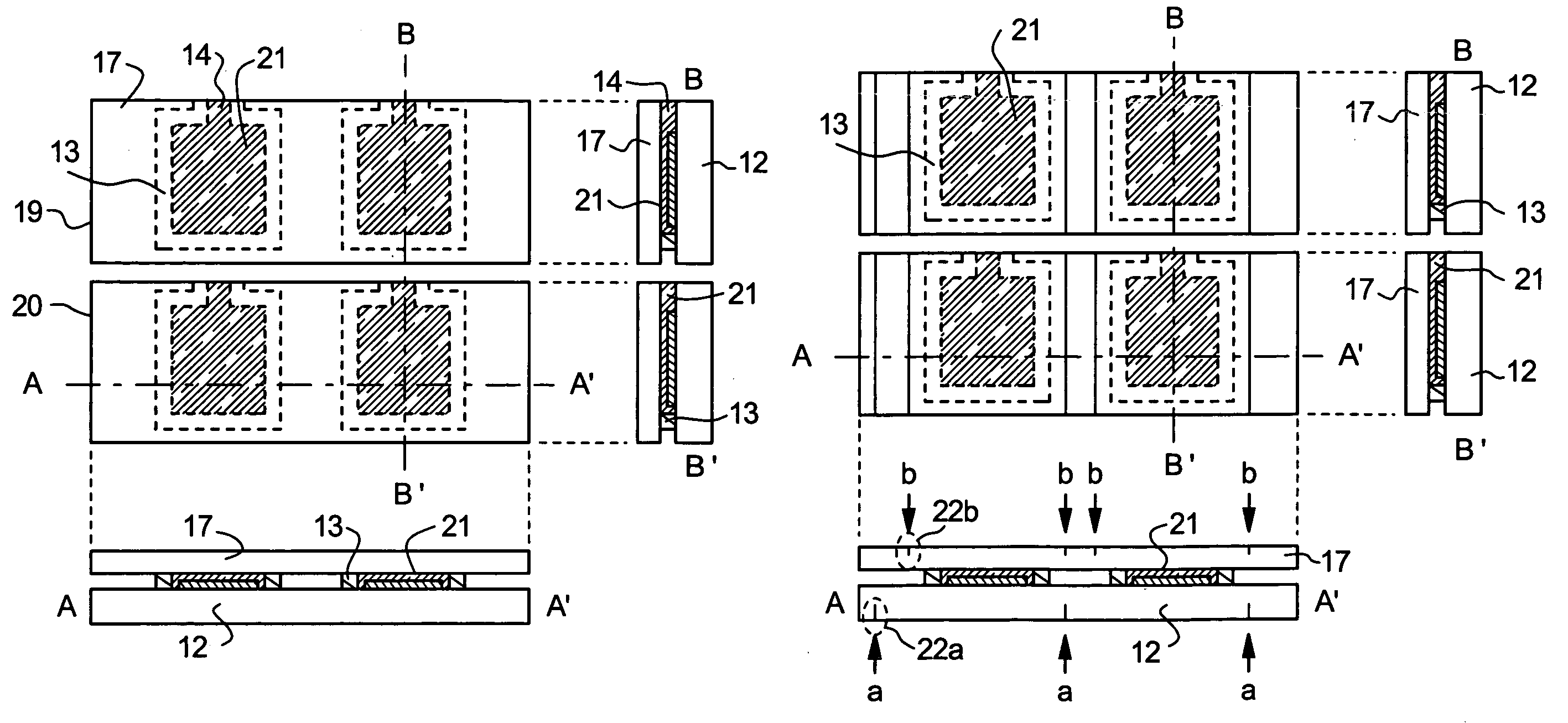

ActiveUS7112115B1Improve throughputHigh yieldDischarge tube luminescnet screensElectroluminescent light sourcesManufacturing cost reductionEngineering

Technology to reduce the manufacturing cost of a manufacturing process of a light emitting device is provided. The manufacturing cost of a device using a light emitting element can be reduced by using a multilayout process for forming a plurality of light emitting devices from a large-sized substrate. In particular, an existing line for manufacturing liquid crystal cells can be diverted to a process of encapsulating light emitting elements, which can greatly reduce the manufacturing cost including the investment in plant and equipment.

Owner:SEMICON ENERGY LAB CO LTD

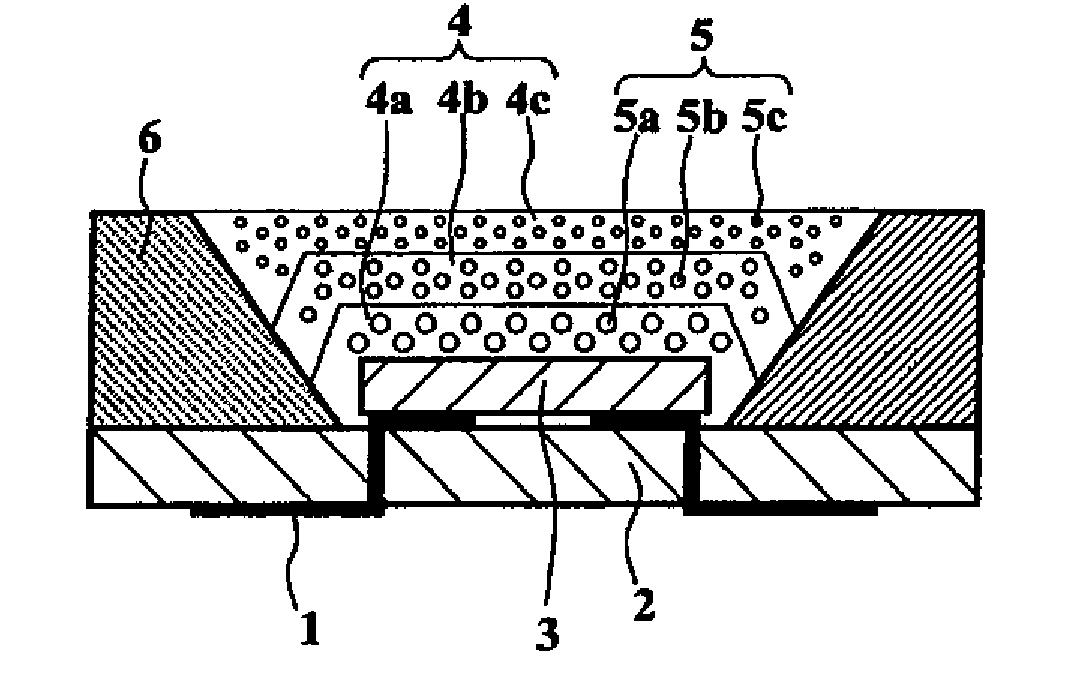

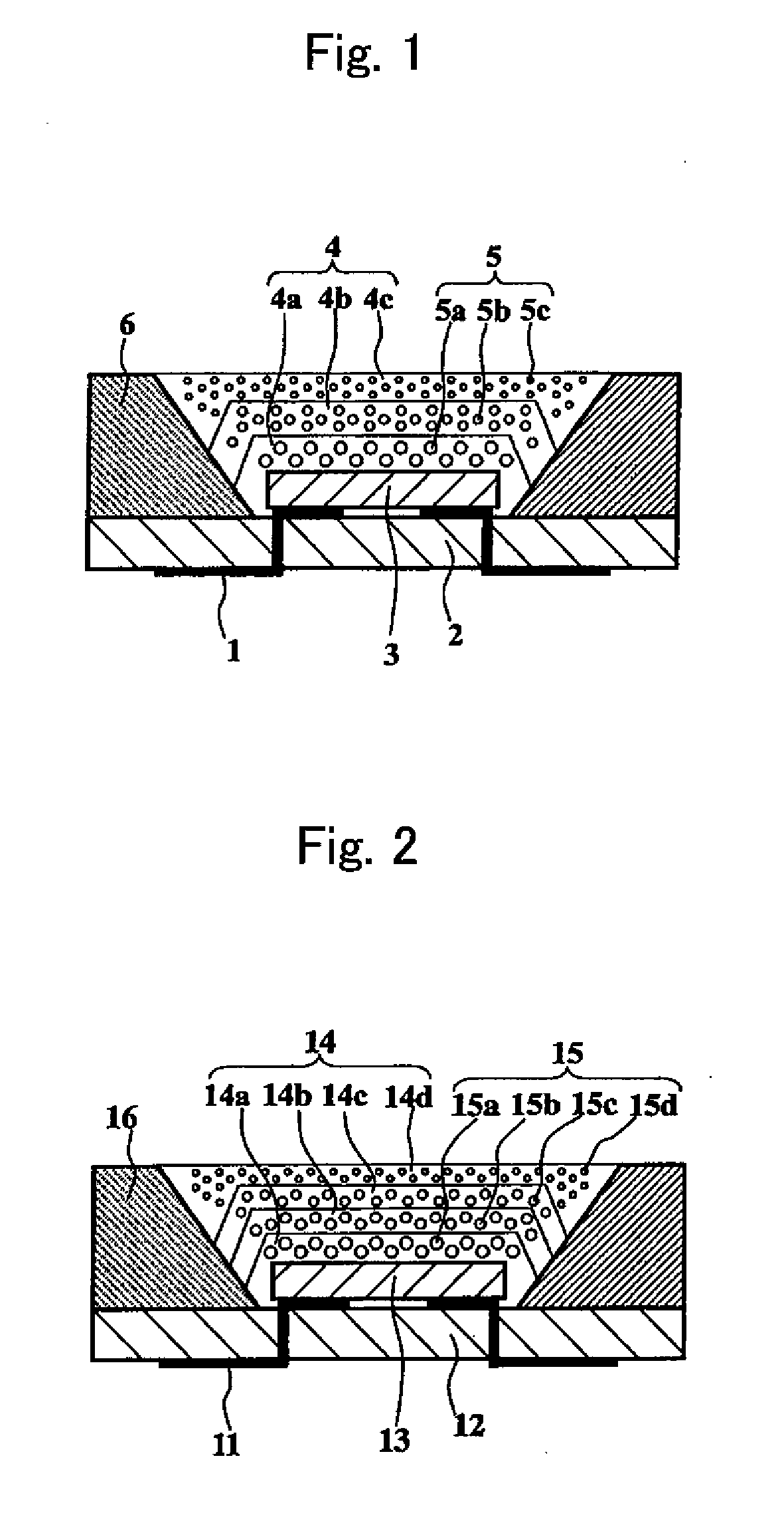

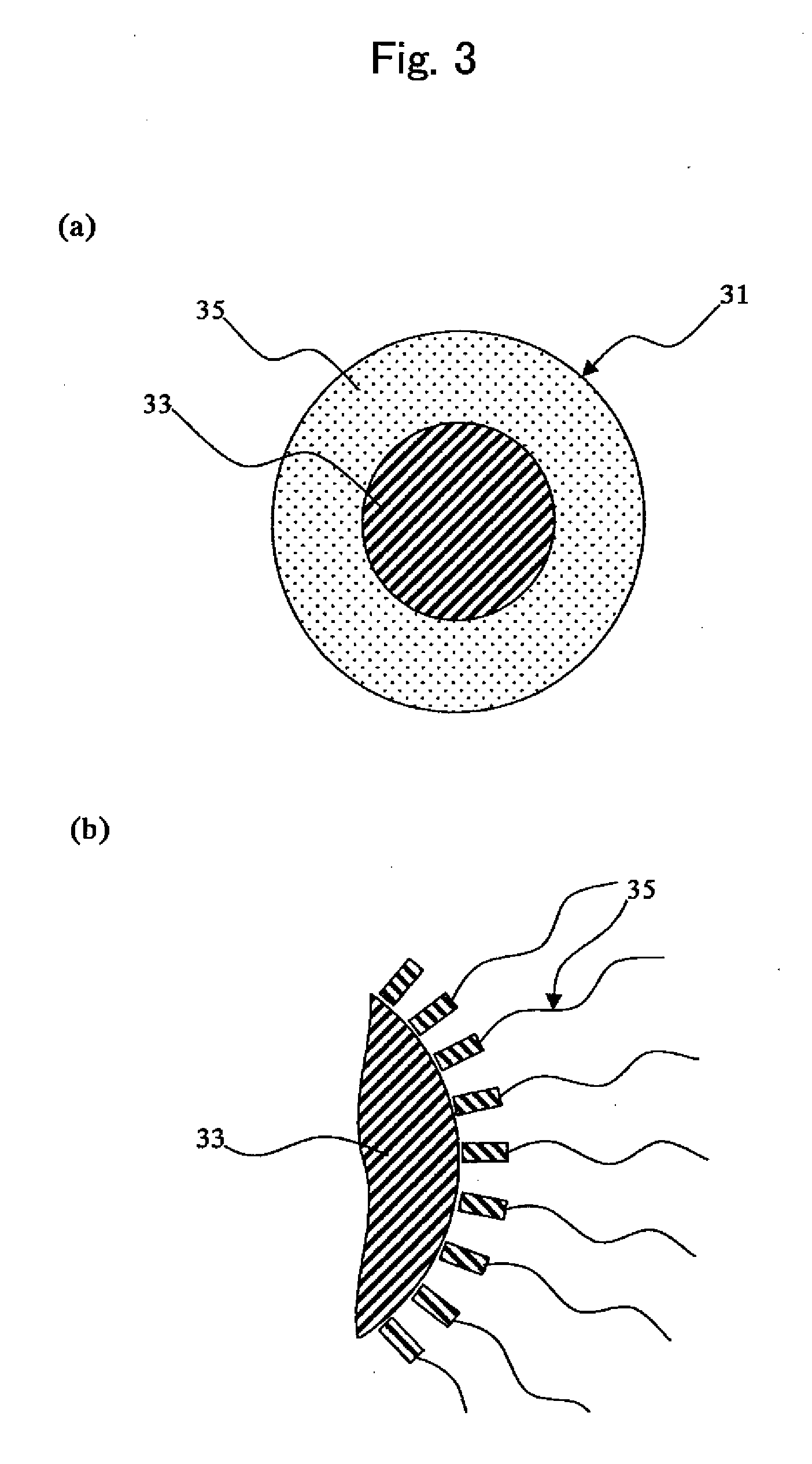

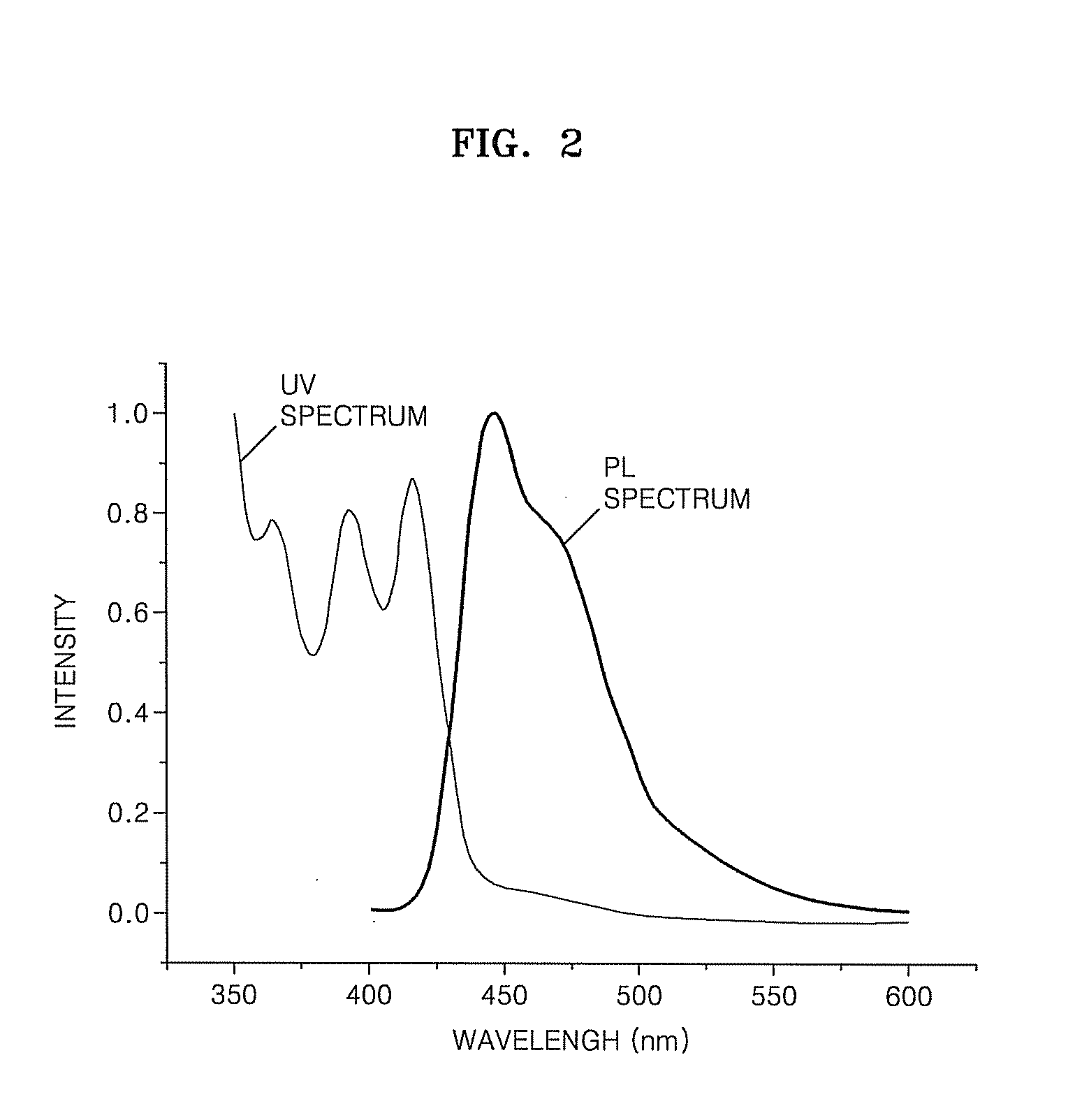

Wavelength Converter, Light-Emitting Device, Method of Producing Wavelength Converter and Method of Producing Light-Emitting Device

InactiveUS20080231170A1Reduce self-quenchingSolve low luminous efficiencyDischarge tube luminescnet screensLamp detailsPhosphorFluorescence

A light-emitting device comprises a light-emitting element 3 that is provided on a substrate 2 and emits excitation light, and a wavelength converter 4 that converts the excitation light into visible light. The visible light is output light. The wavelength converter 4 comprises a plurality of wavelength conversion layers 4a, 4b and 4c which respectively contain, as phosphors, at least one type of semiconductor ultrafine particles having a mean particle size of not more than 20 nm and at least one type of fluorescent substance having a mean particle size of not less than 0.1 μm in a resin matrix. Thereby, self-quenching of phosphors is reduced and high luminous efficiency is attained.

Owner:KYOCERA CORP

Organic Electroluminescent Device and Manufacturing Method Thereof

InactiveUS20080018236A1Improve display qualityHigh-precision patternLiquid surface applicatorsDischarge tube luminescnet screensOrganic electroluminescenceLight-emitting diode

A highly fine organic electroluminescent device is provided. A method for manufacturing the organic electroluminescent device is provided for patterning a very fine light emitting layer, and a deposition mask is provided to be used in the patterning. For deposition of the light emitting layer, a mask member is provided with apertures (effective apertures) for forming the light emitting layer to be used for light emitting pixel and apertures (dummy apertures) not to be used for forming the light emitting pixel around an area (effective aperture area) separated by the outer edge of a group of the apertures. The light emitting layer is deposited by using the deposition mask.

Owner:TORAY IND INC

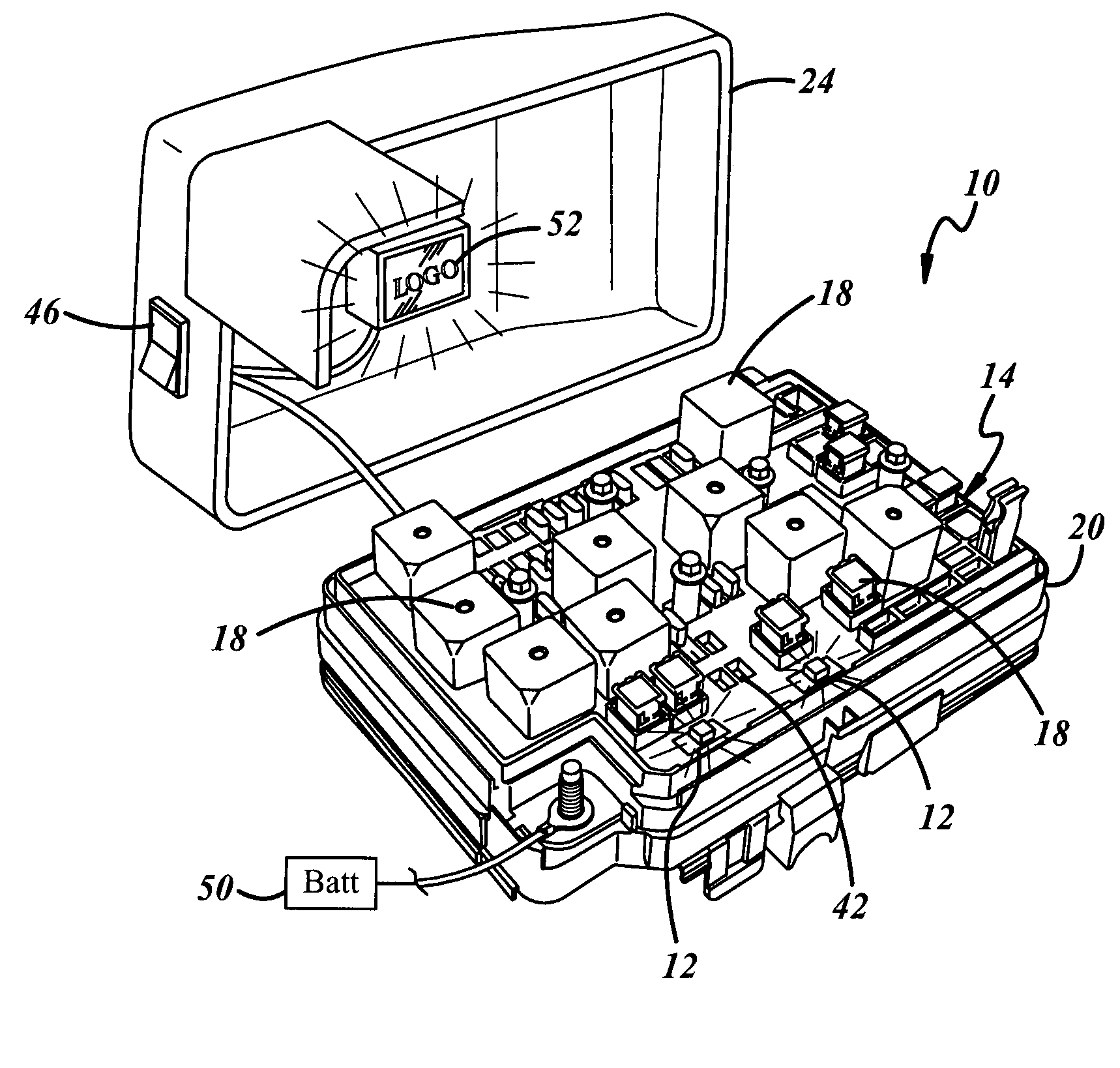

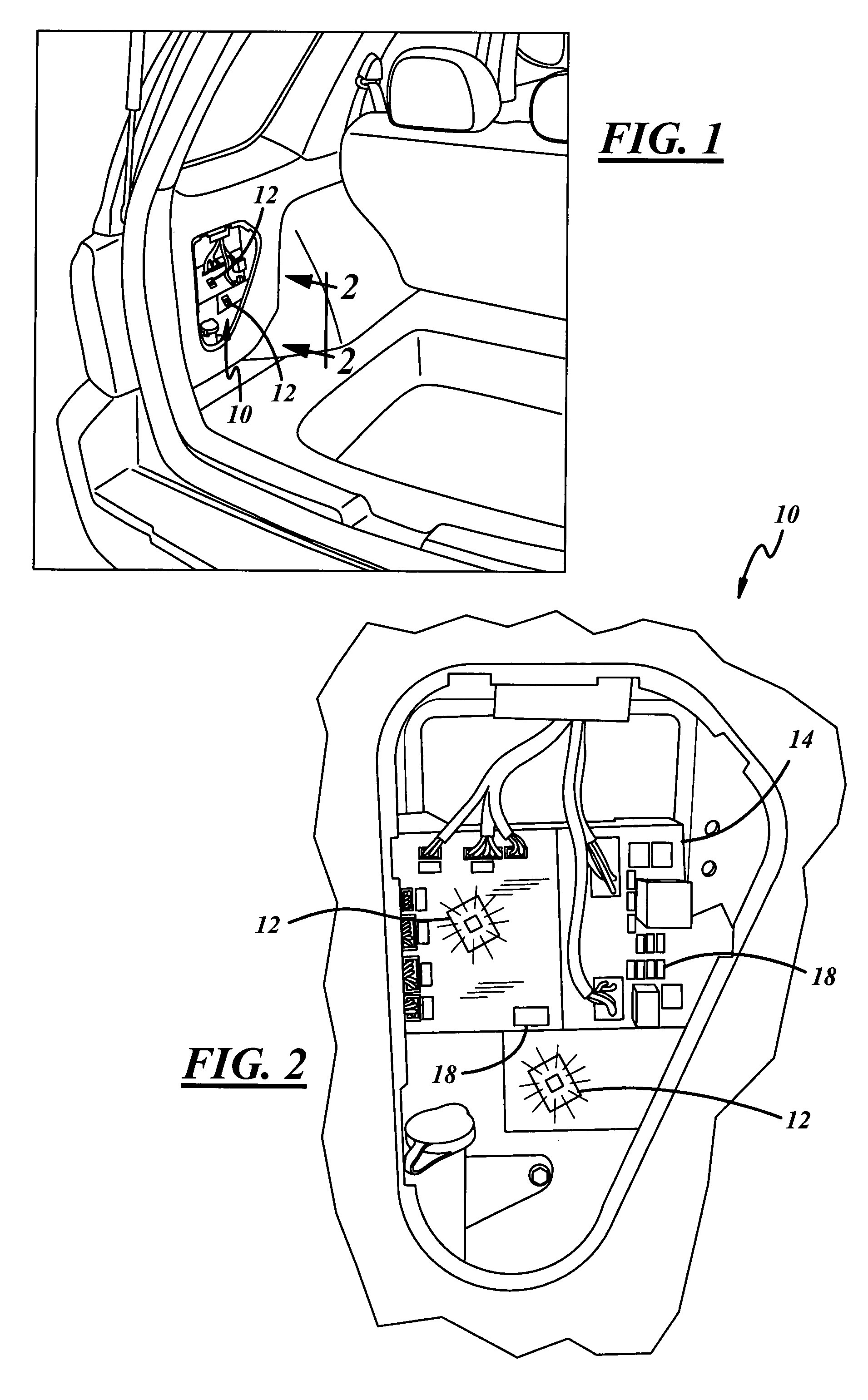

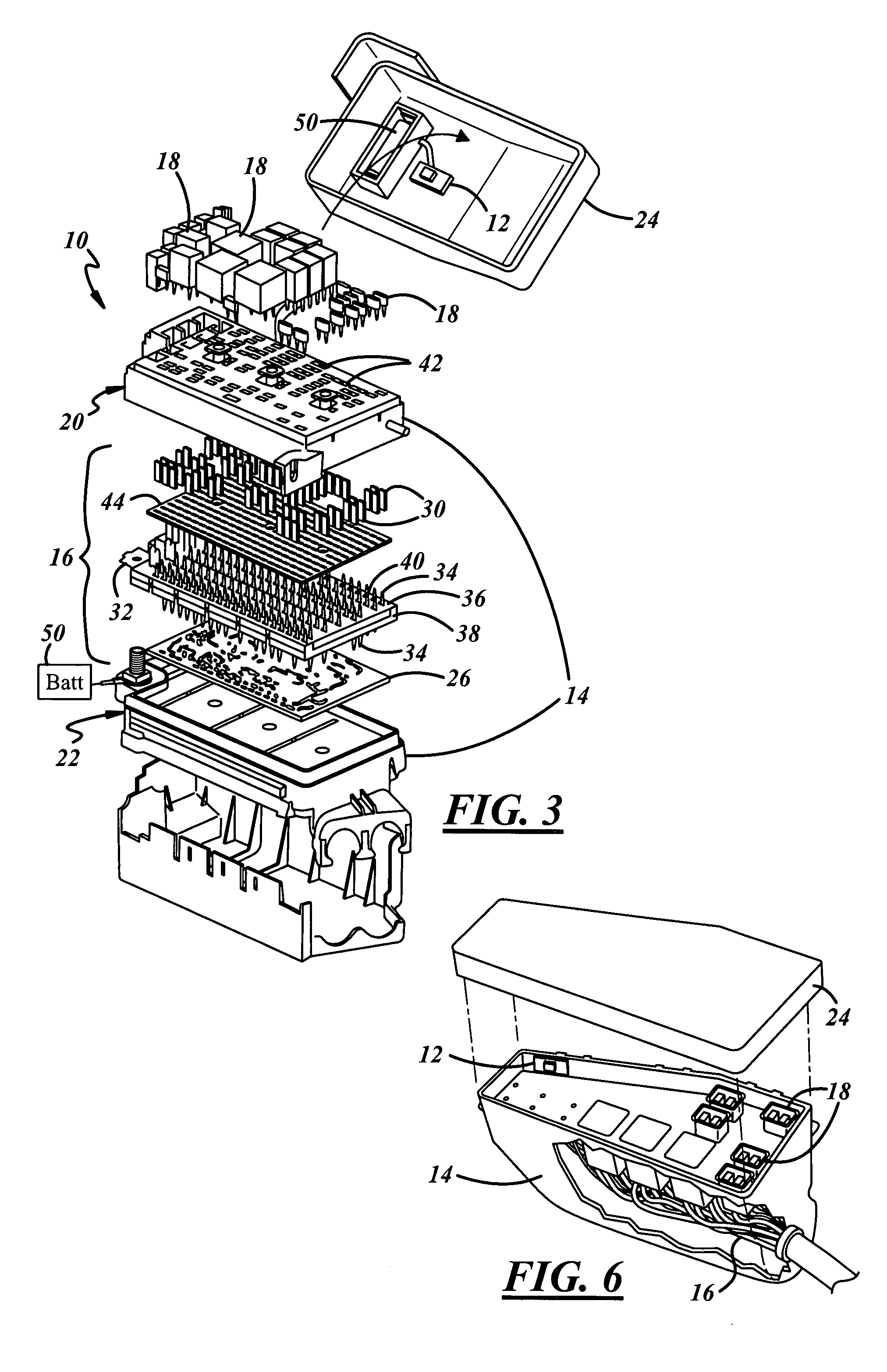

Illuminated electrical center

InactiveUS7635212B2Easy to useElectrically conductive connectionsLighting support devicesEngineeringLight-emitting diode

Owner:APTIV TECH LTD

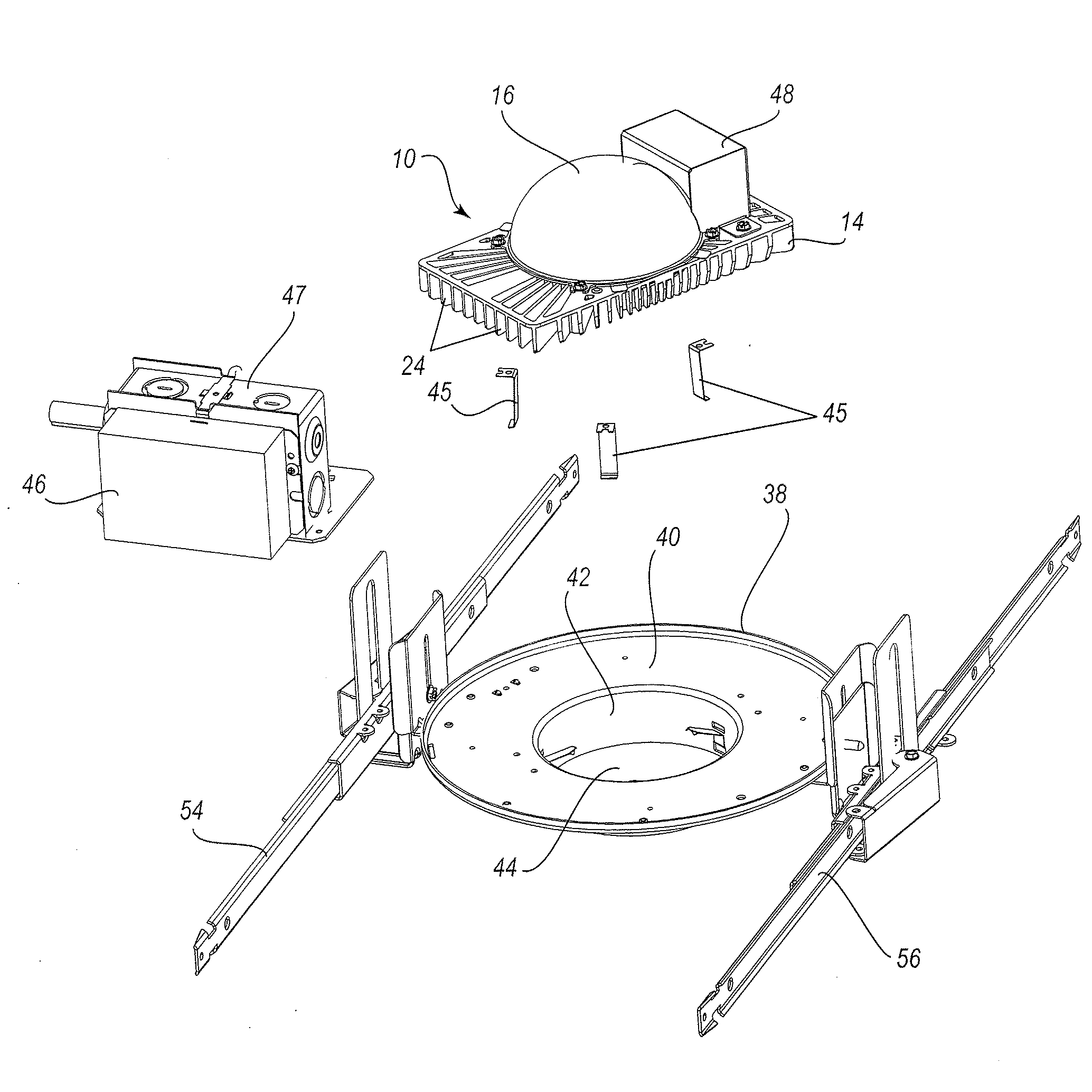

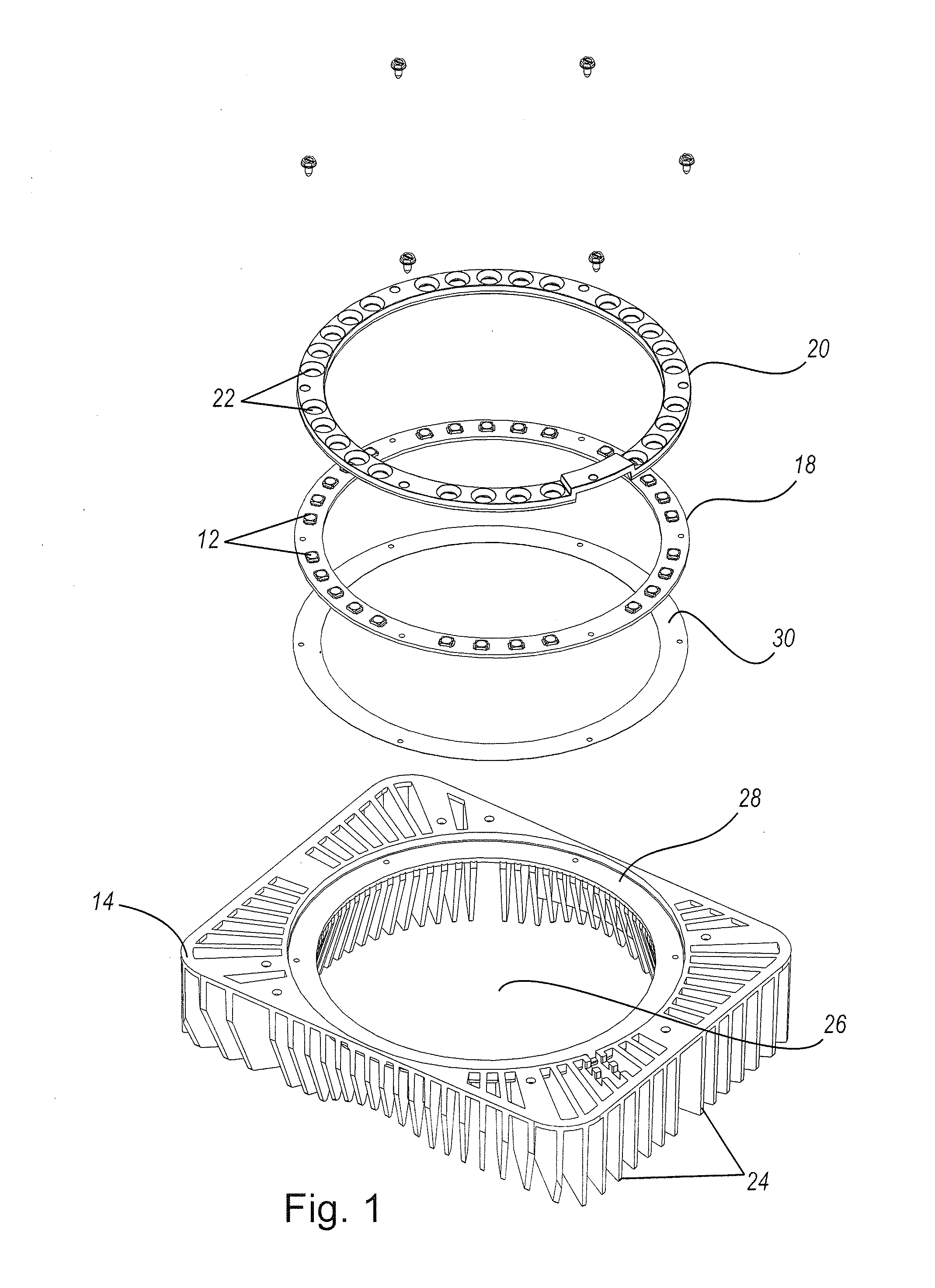

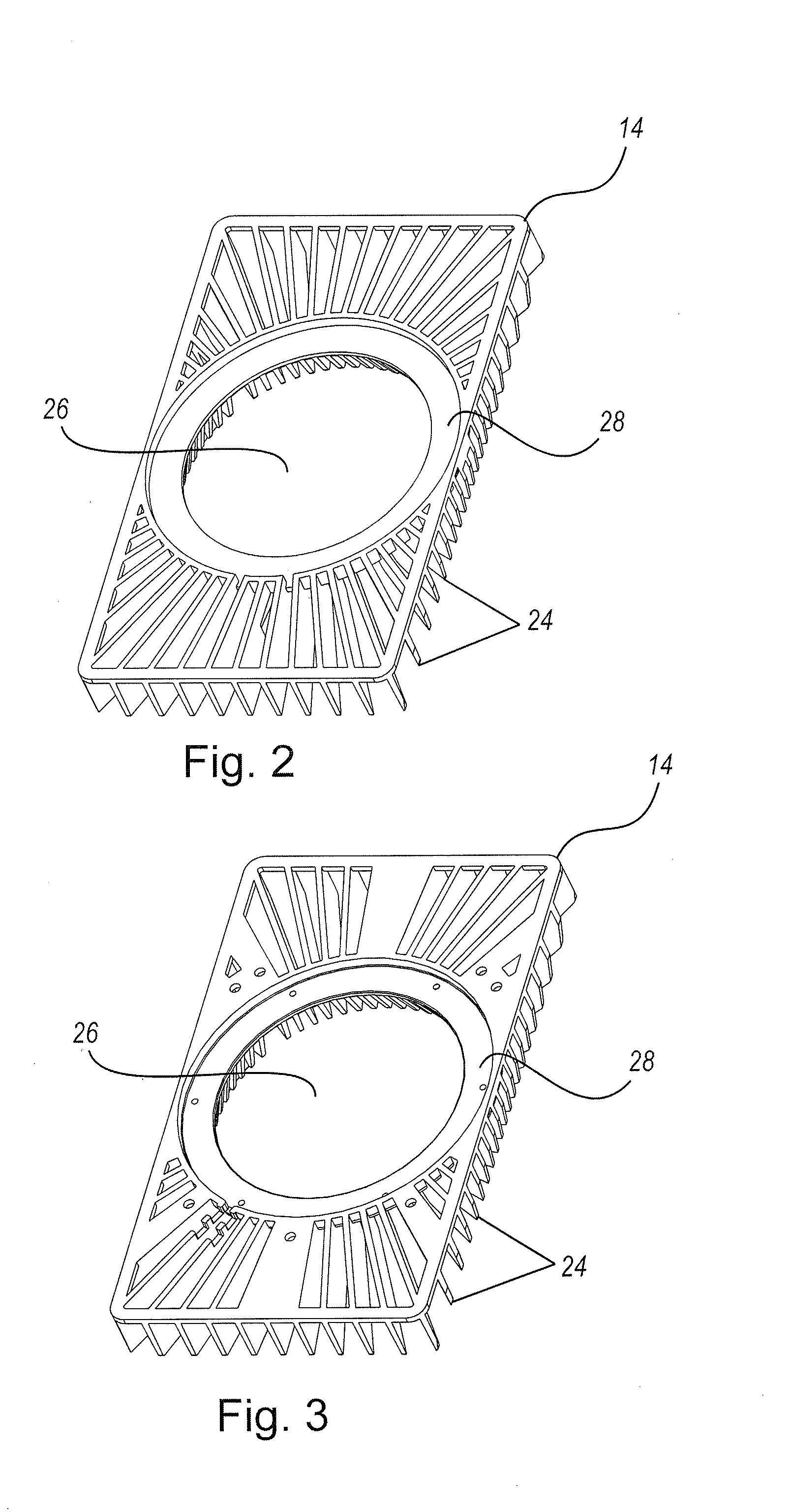

Lighting fixture

InactiveUS20090290343A1Easy to upgradeImprove surface reflectivityNon-electric lightingPoint-like light sourceModularityEffect light

Embodiments of the invention provide lighting assemblies for installation in lighting fixtures. Lighting assemblies include at least one light source, at least one heat sink, and at least one reflector. Other embodiments of the lighting assembly may also include an outer surface of the reflector comprising a heat sink. In some embodiments, it may be desirable to direct light toward a wall. In those situations, a wall wash trim may be included. The lighting assemblies disclosed herein may be modular and thus replaced without having to uninstall the entire fixture. In some embodiments, a circuit board containing at least one light emitting diode in an existing lighting assembly may be replaced with another circuit board containing light emitting diodes of a different color temperature or a different color.

Owner:ABL IP HLDG

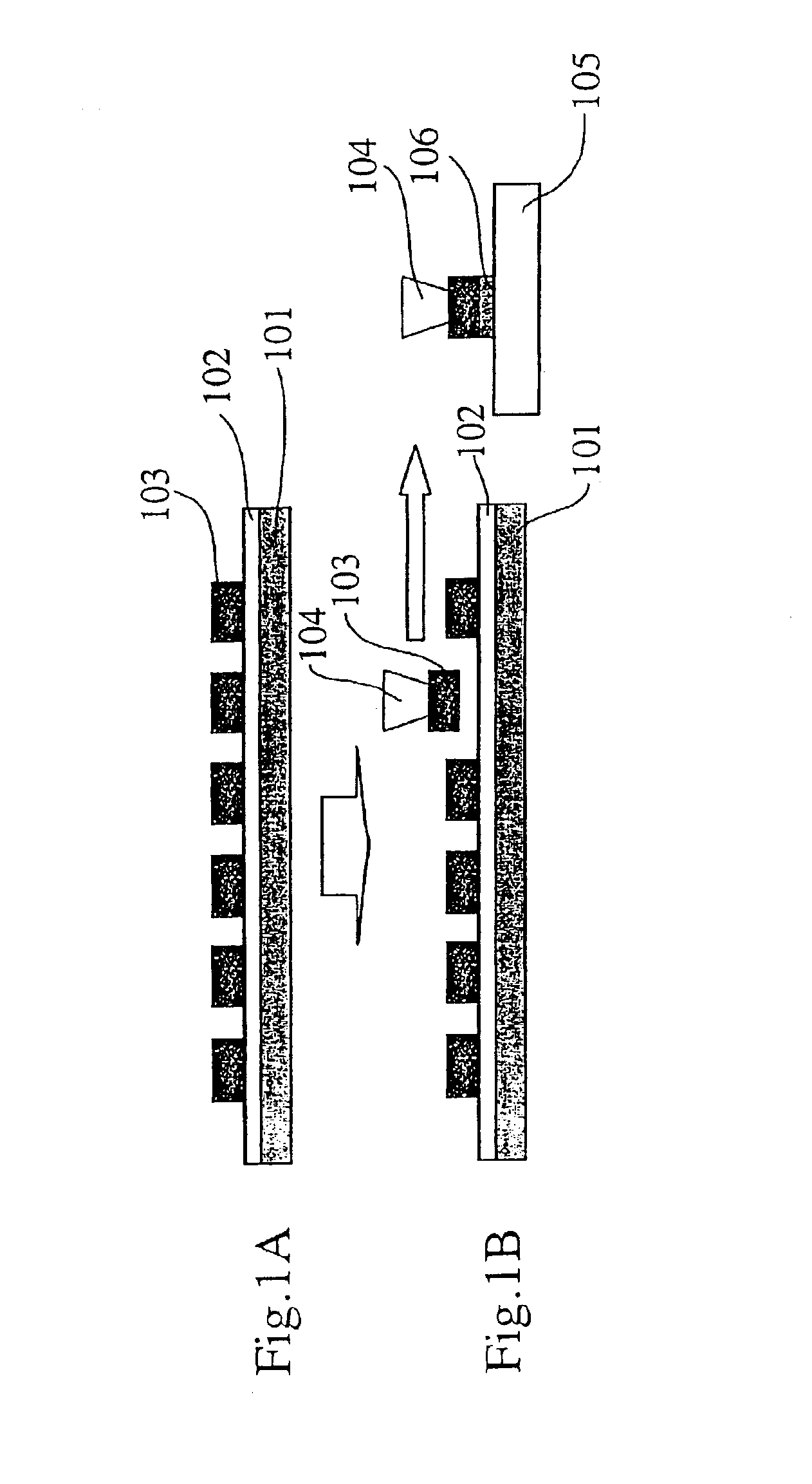

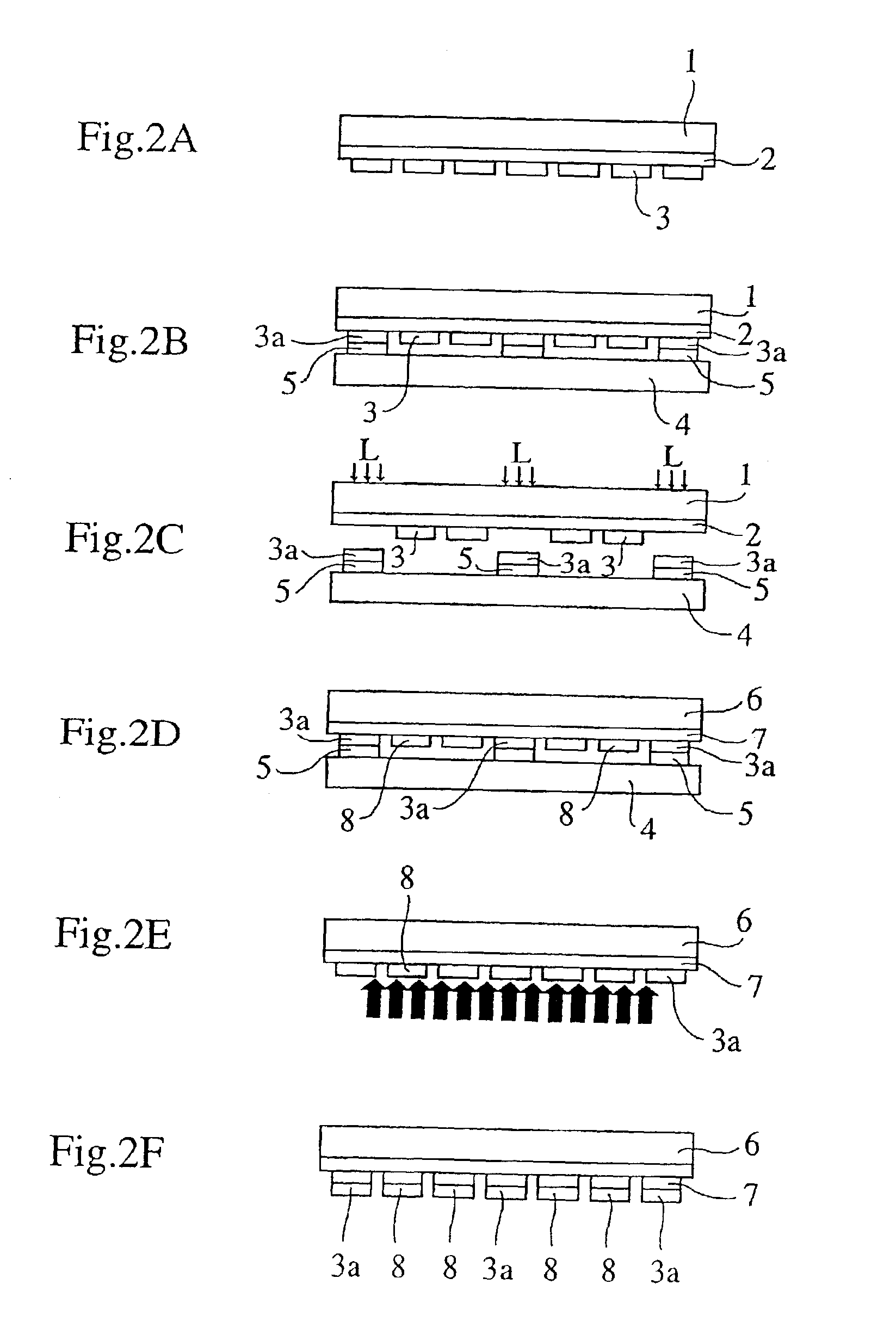

Device transferring method, and device arraying method and image display unit fabricating method using the same

InactiveUS6872635B2Efficiently and accurately transferringEfficiently re-arrayDecorative surface effectsSolid-state devicesIrradiationMaterials science

Owner:XIAMEN SANAN OPTOELECTRONICS CO LTD

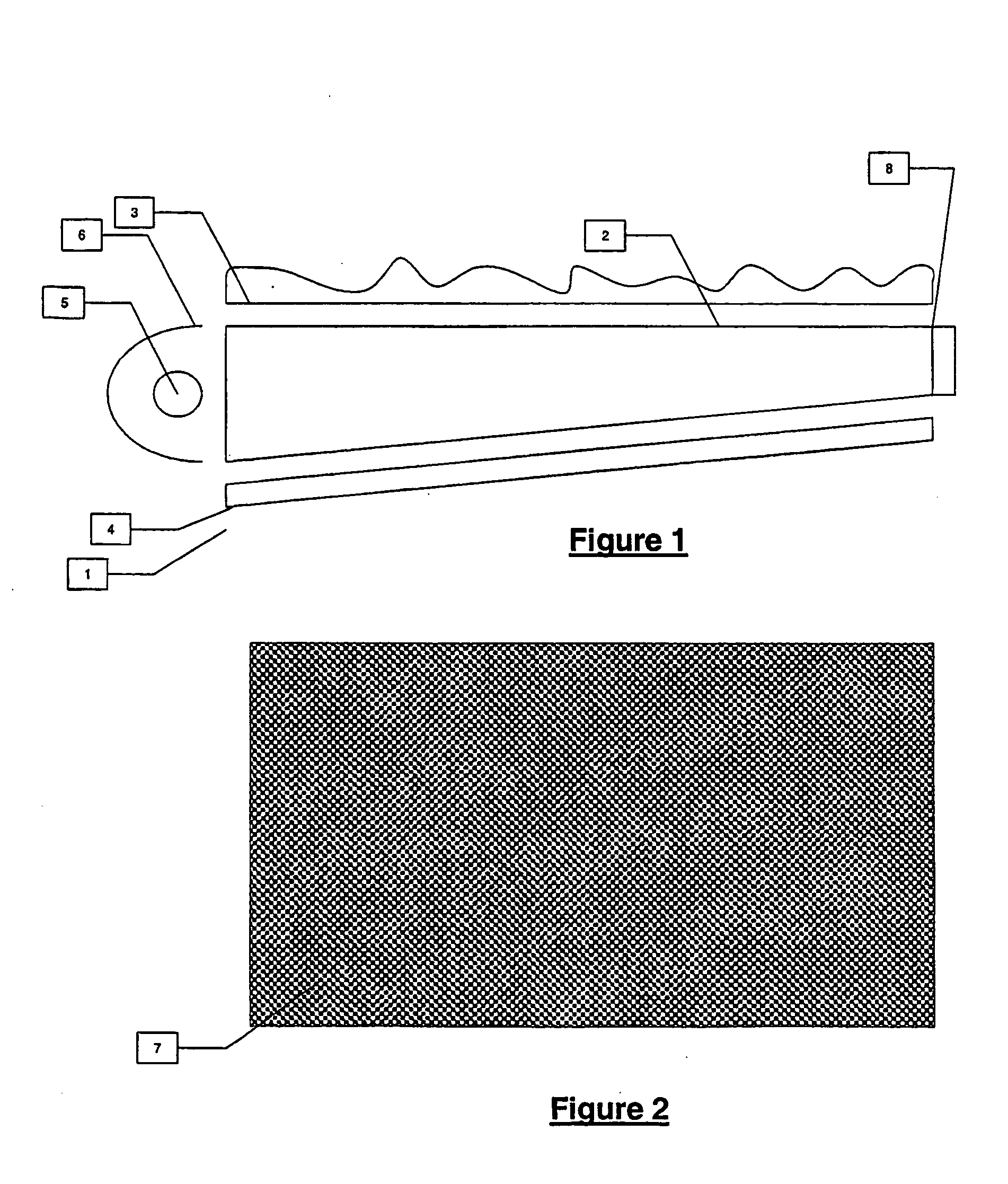

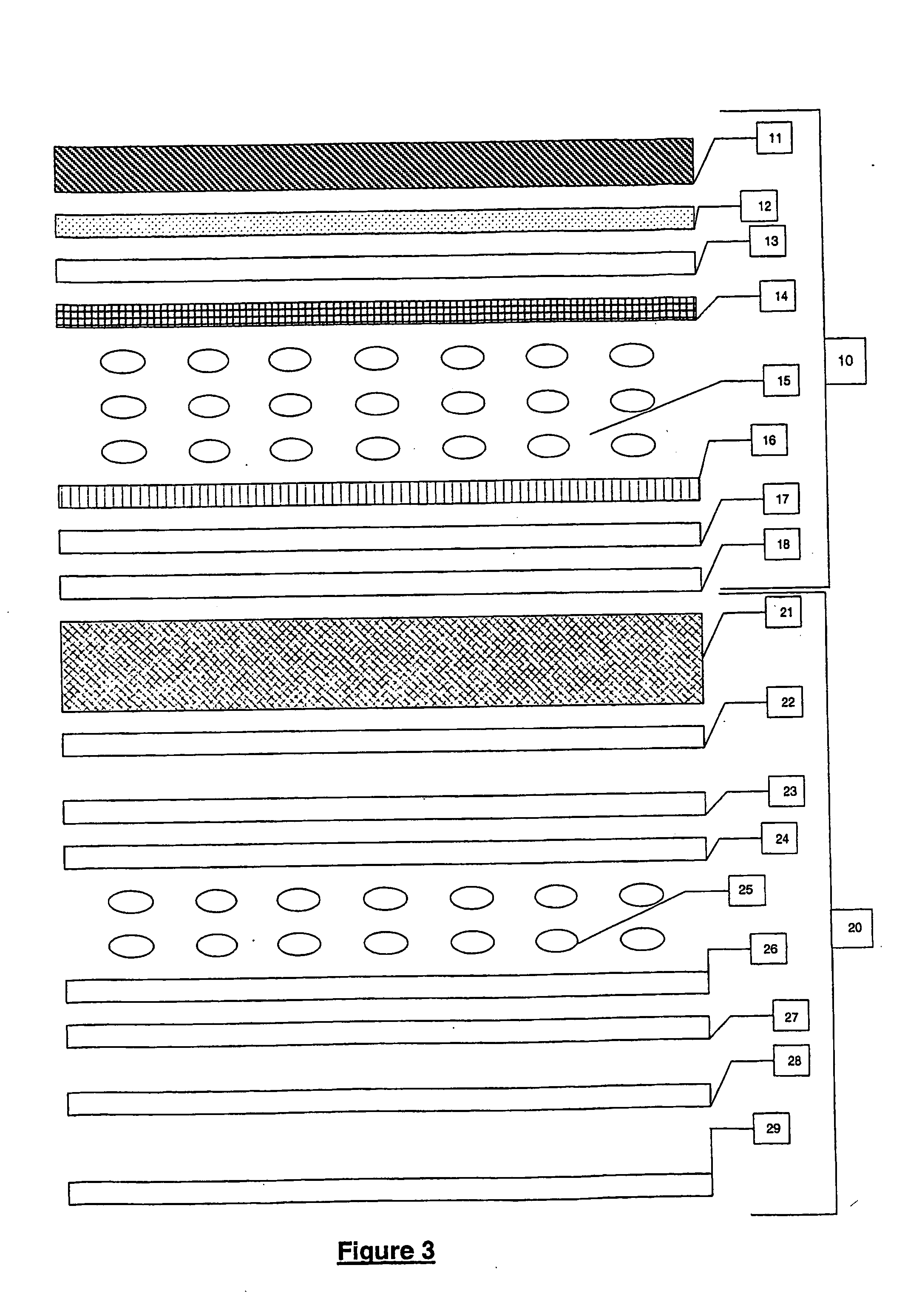

Visual display unit illumination

ActiveUS20050062410A1Increased intensityUniform light intensityDischarge tube luminescnet screensElectroluminescent light sourcesPhysicsTransparent display

A method of adapting a visual unit having a first screen (10) in a first focal plant by the addition of one or more at least partially transparent display screens (20) at least partially overlapping said first screen (10) and located in focal planes distinct from said first focal plane, characterised in that an at least partially transparent emissive layer (21) is provided between said first screen (10) and at least one said additional display screen (20).

Owner:APTIV TECH LTD

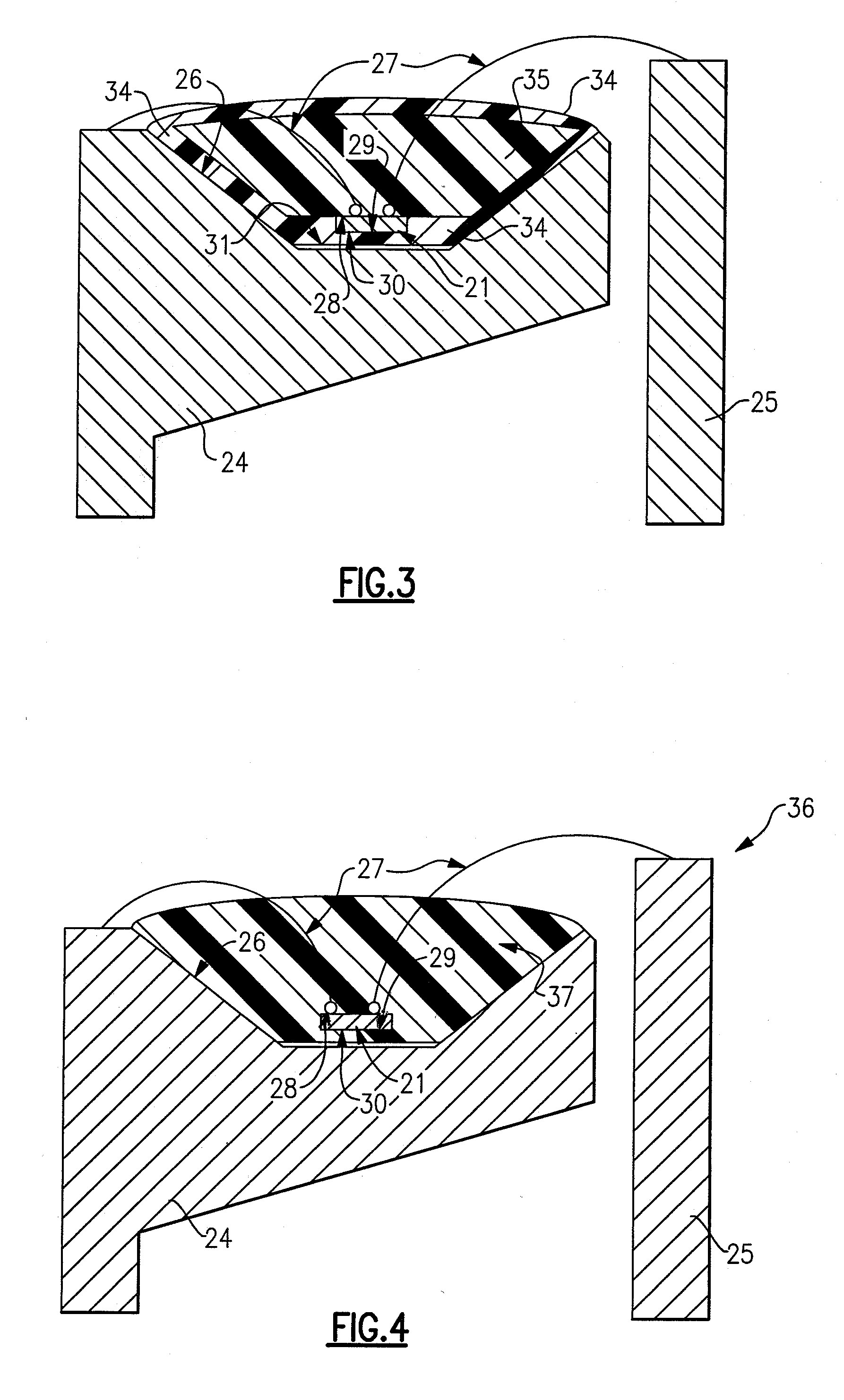

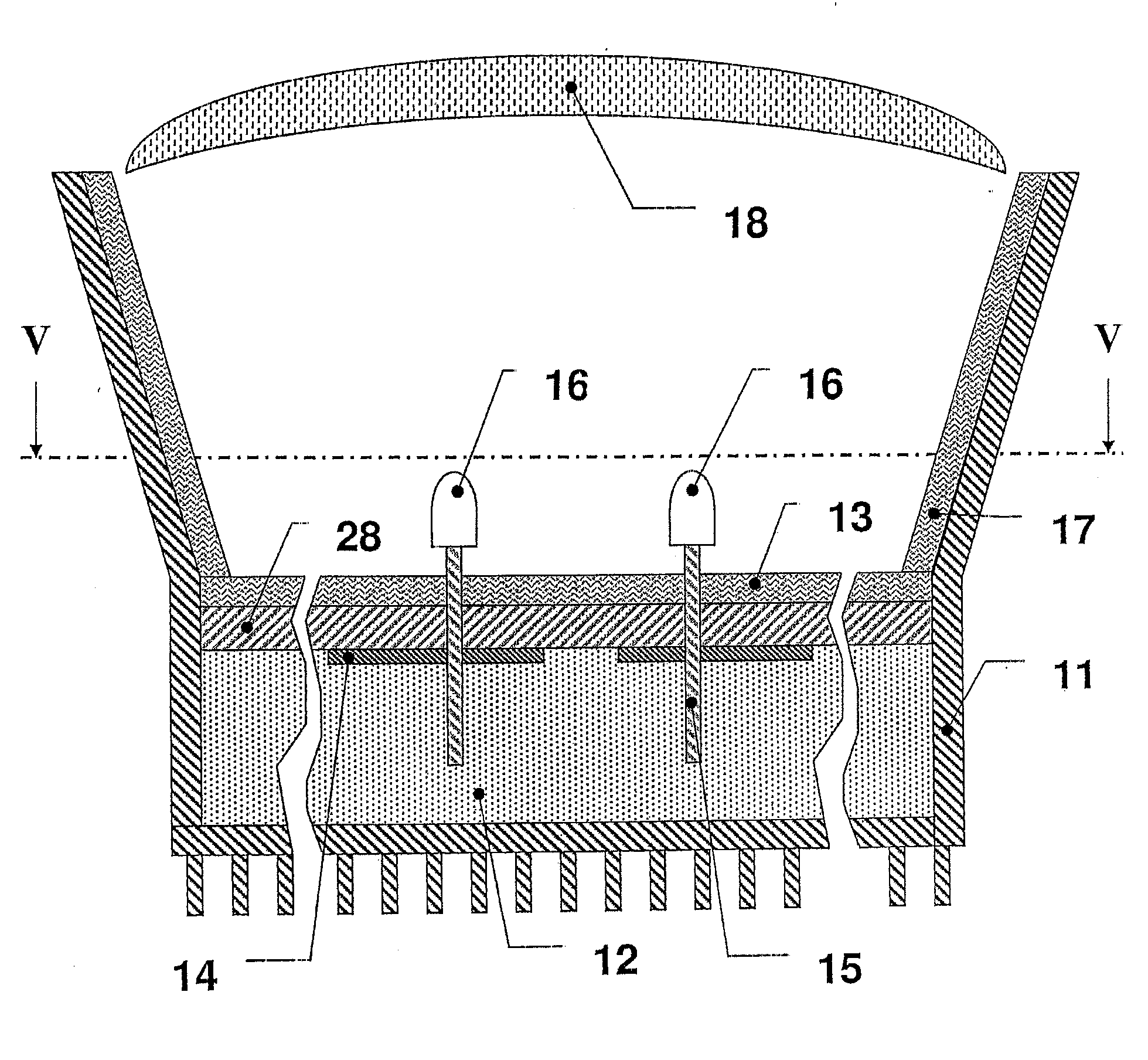

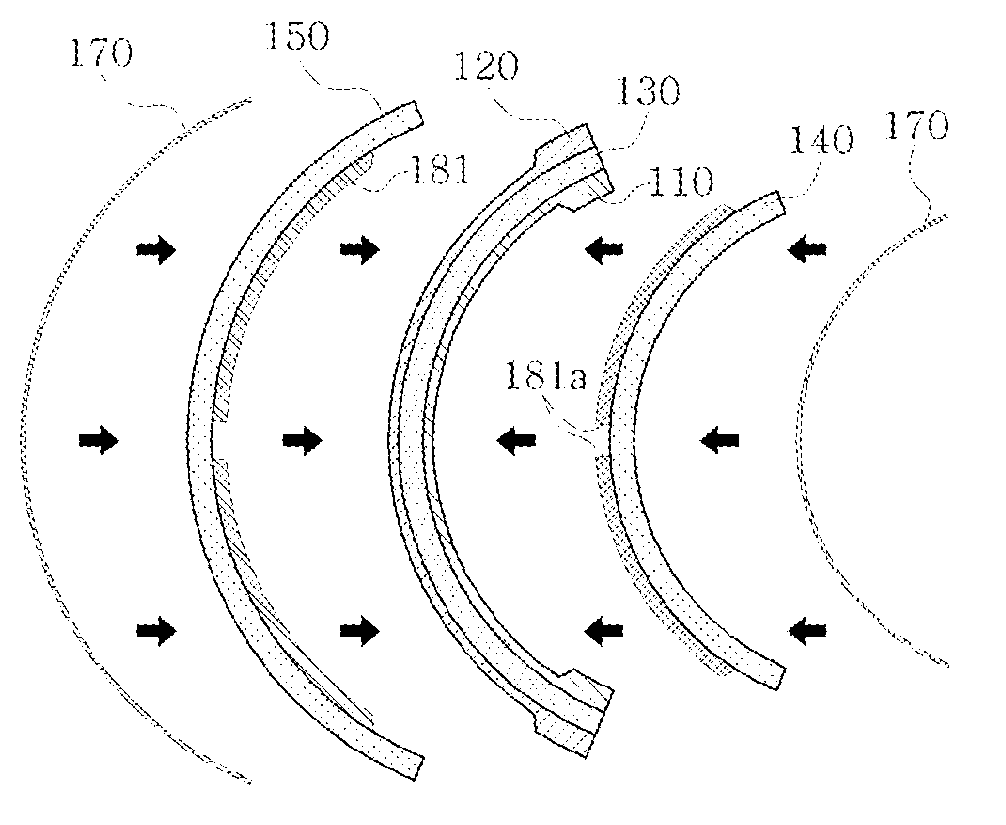

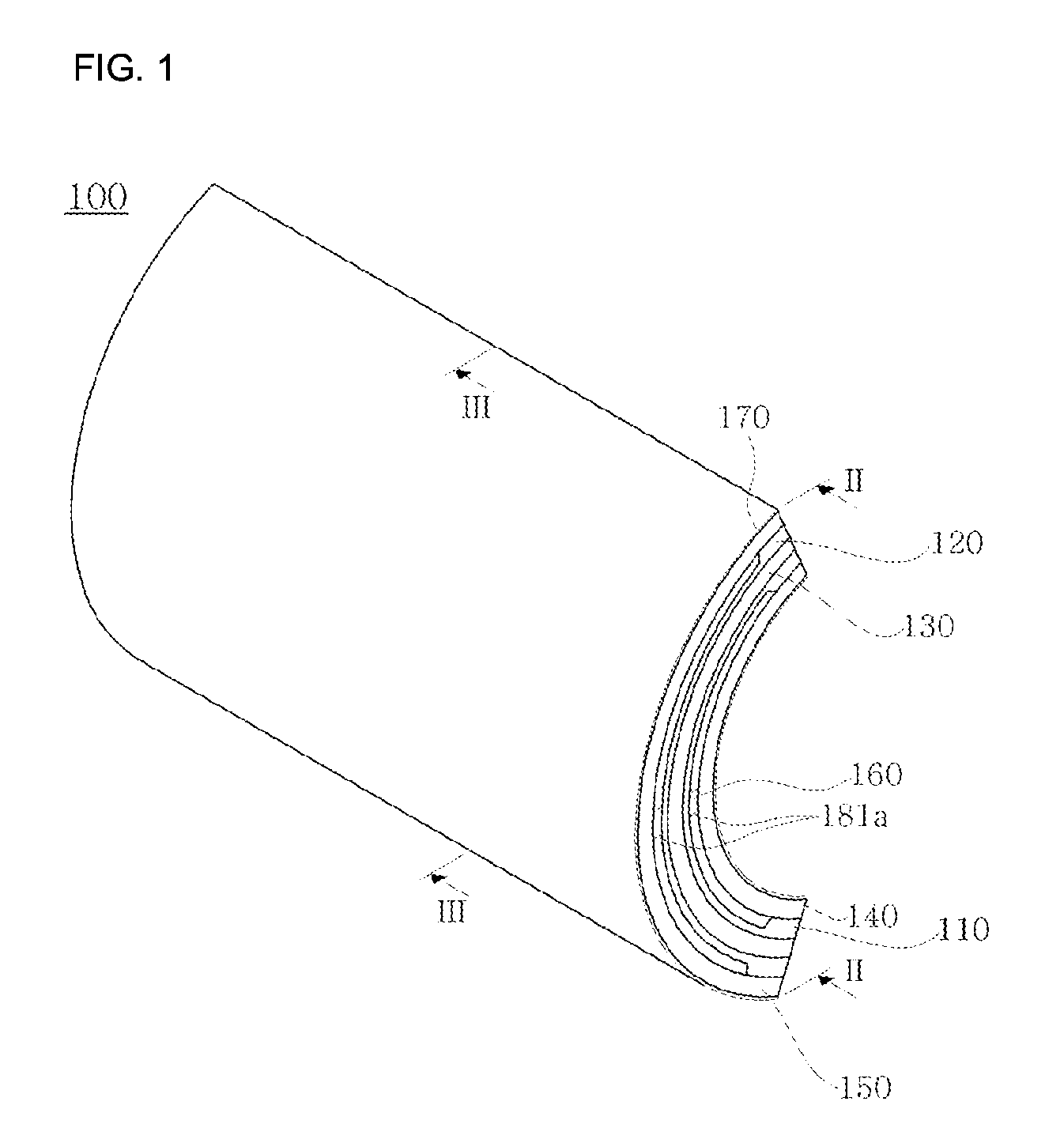

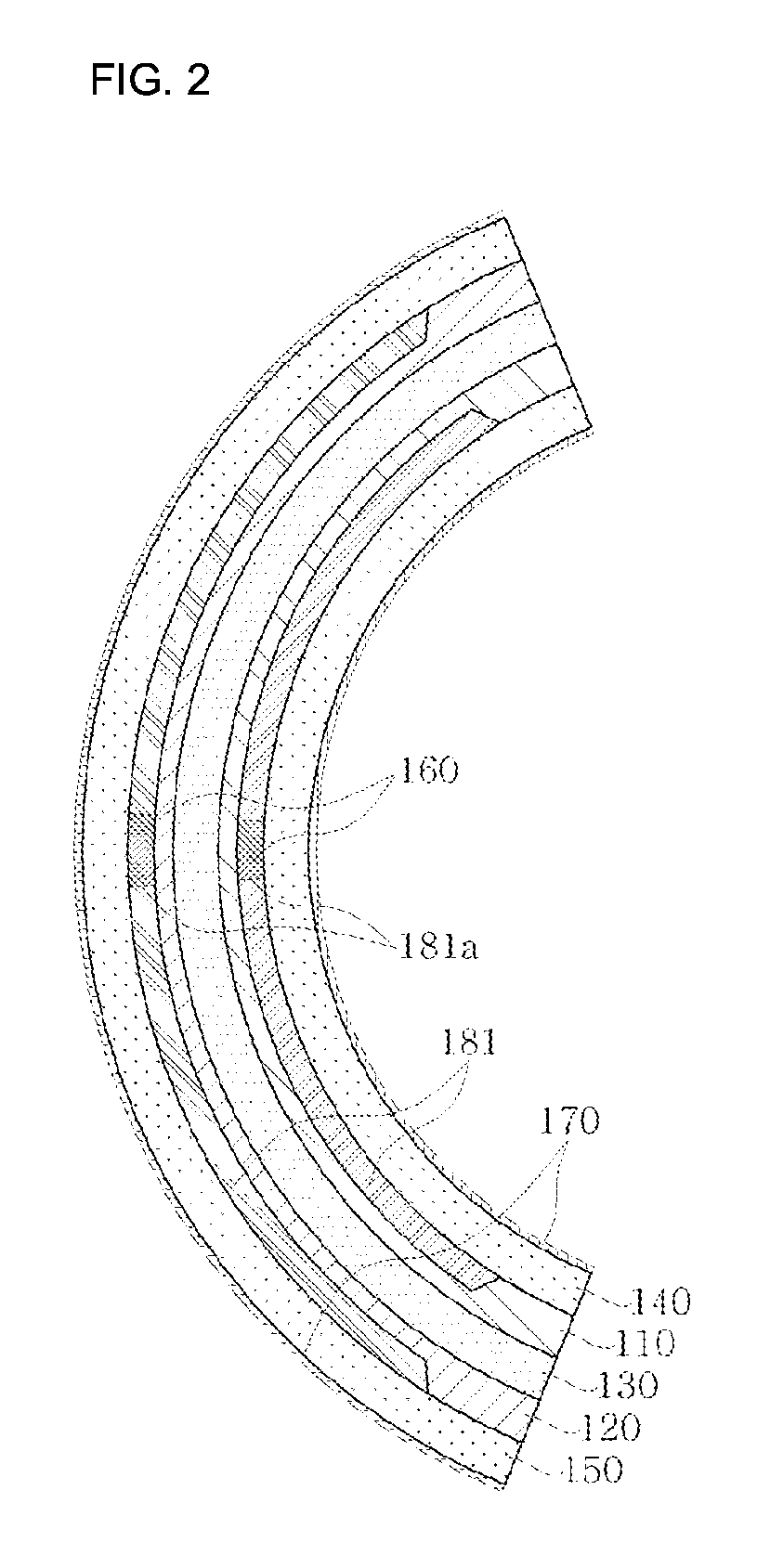

Curved-surface display panel fabrication method, curved-surface display panel using same, and multi-image display device using same

ActiveUS8982545B2Reduce thicknessSimple processDigital data processing detailsVessels or leading-in conductors manufactureSurface displayMulti-image

A curved-surface display panel fabrication method for fabricating a curved-surface display panel using a flat display panel having a first substrate and a second substrate includes: paring partially outer surfaces of the first substrate and the second substrate so as to reduce thicknesses thereof to a predetermined thickness; bending the pared flat display panel to a desired curved shape; attaching a first guide member which has a shape corresponding to the desired curved shape to the first substrate with a predetermined gap from the pared outer surface thereof and attaching a second guide member with has a shape corresponding to the desired curved shape to the second substrate with a predetermined gap from the pared outer surface thereof; and forming light transmitting reinforcing layers respectively in a space between the first guide member and the first substrate and a space between the second guide member and the second substrate.

Owner:TOVIS

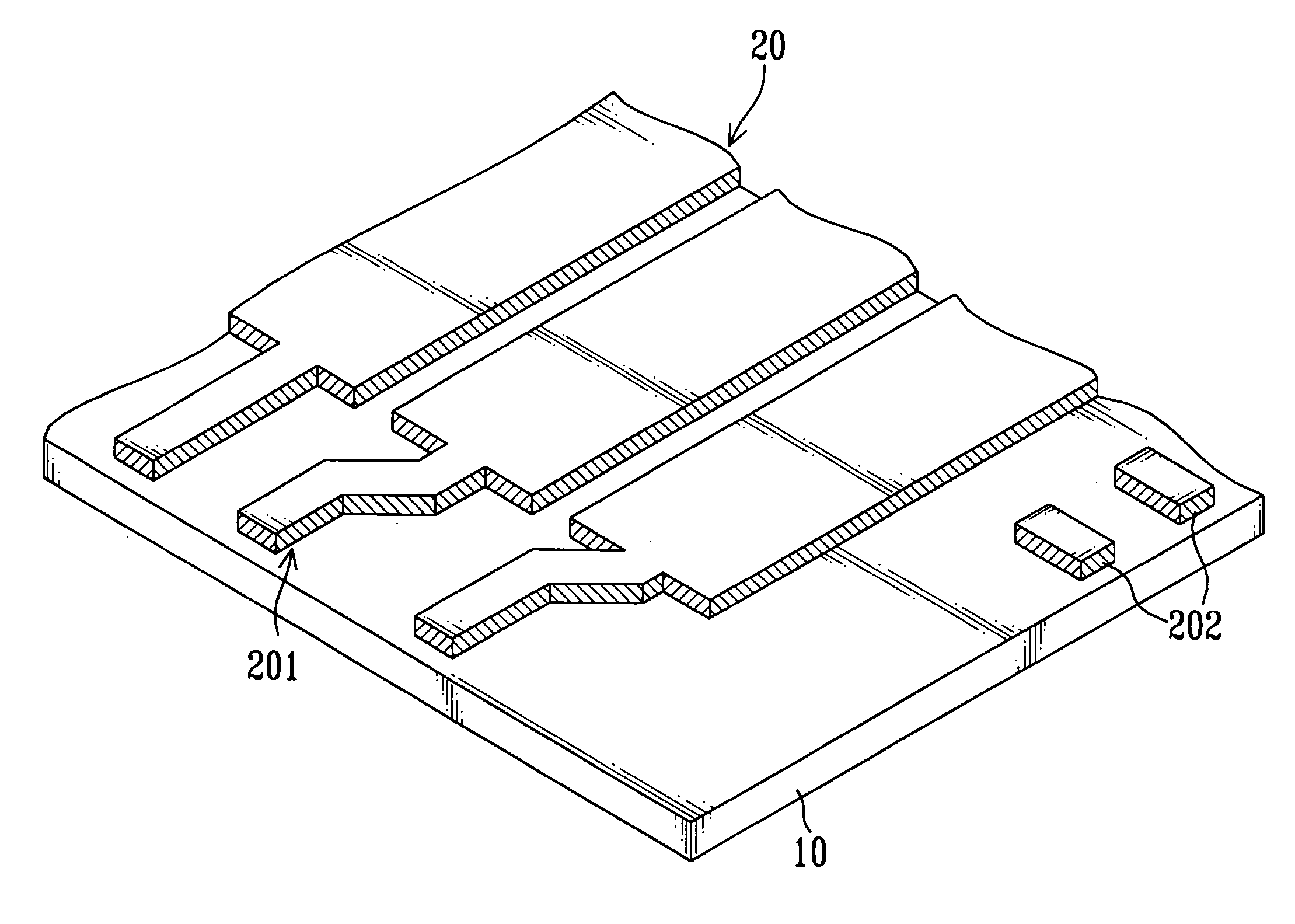

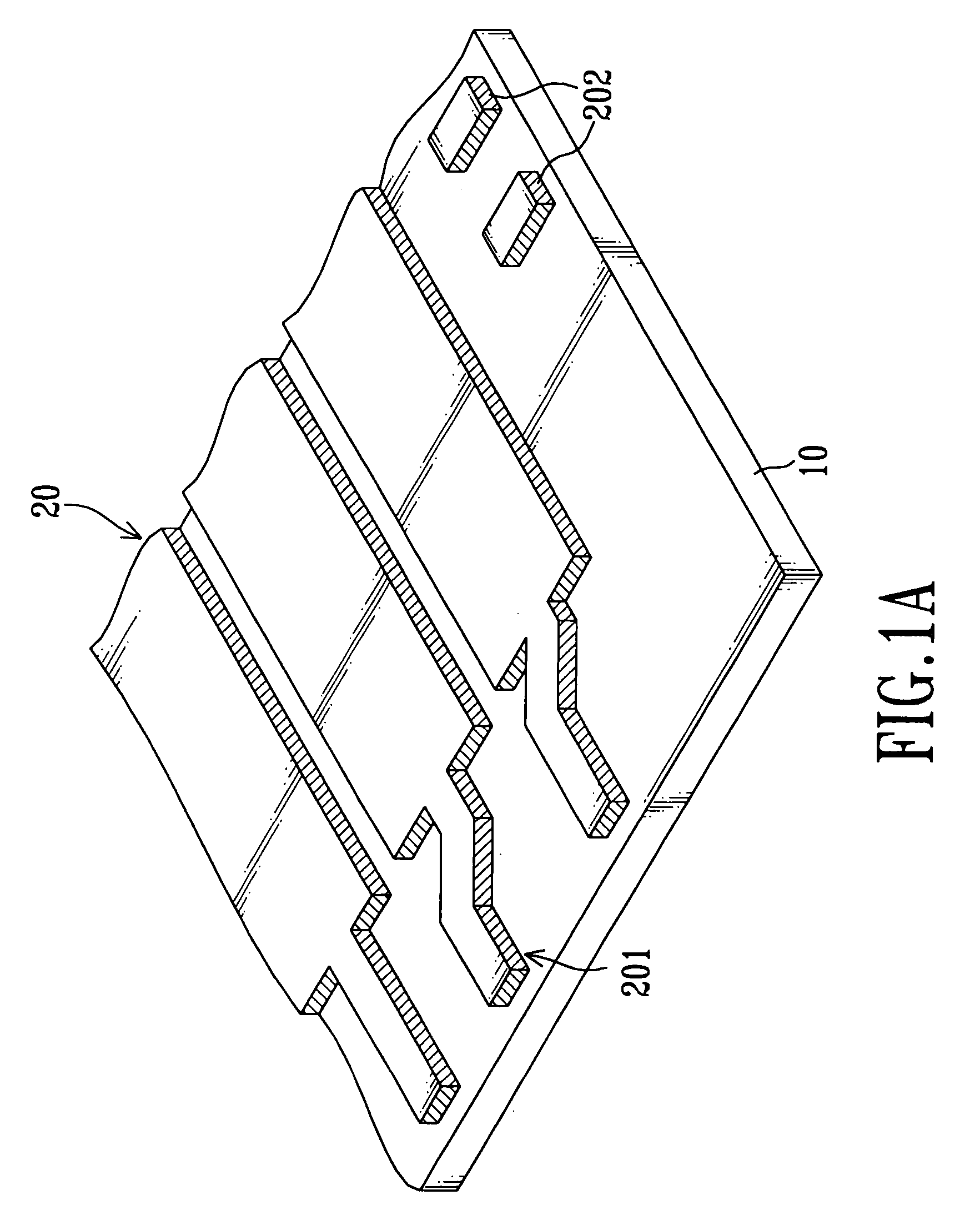

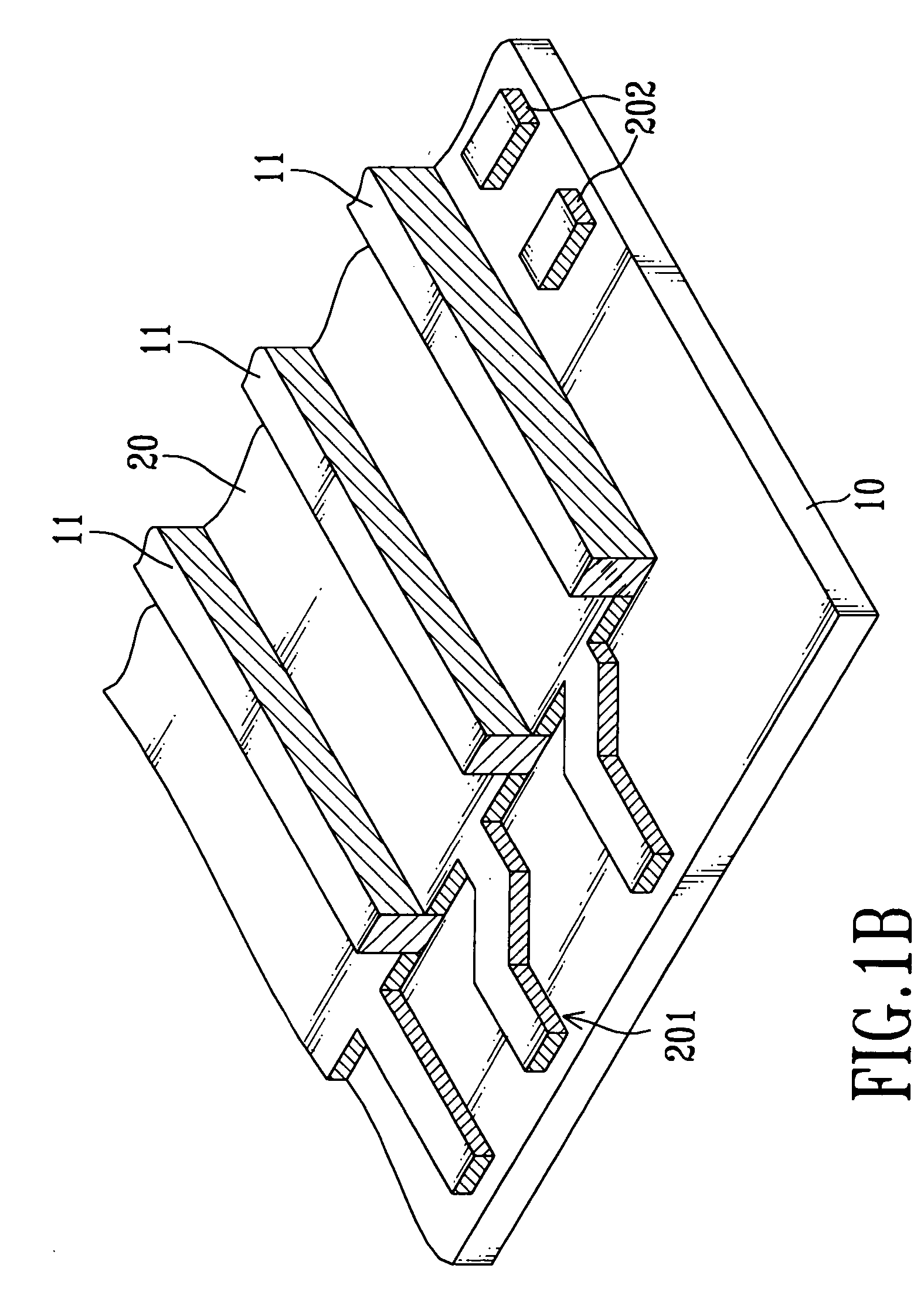

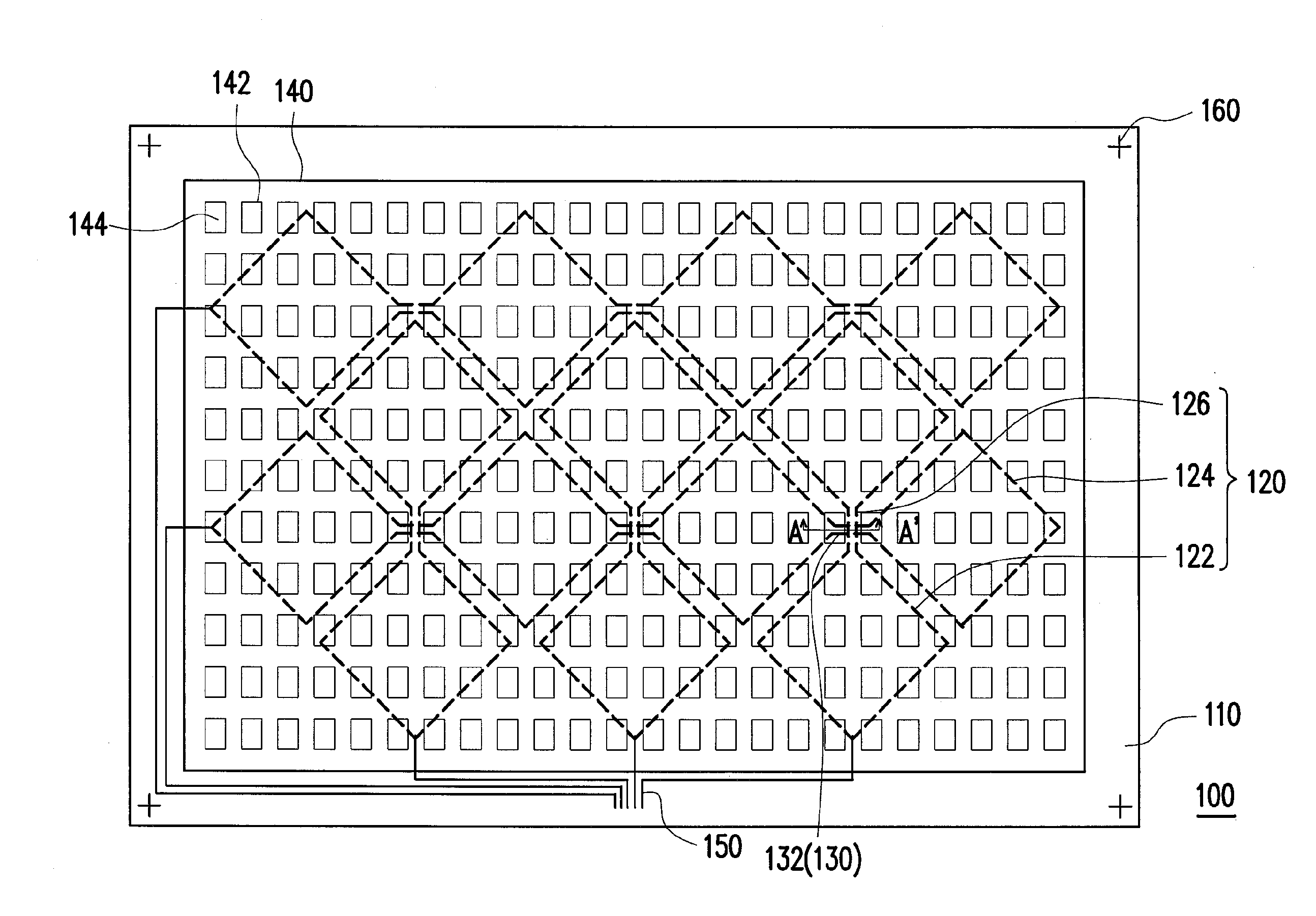

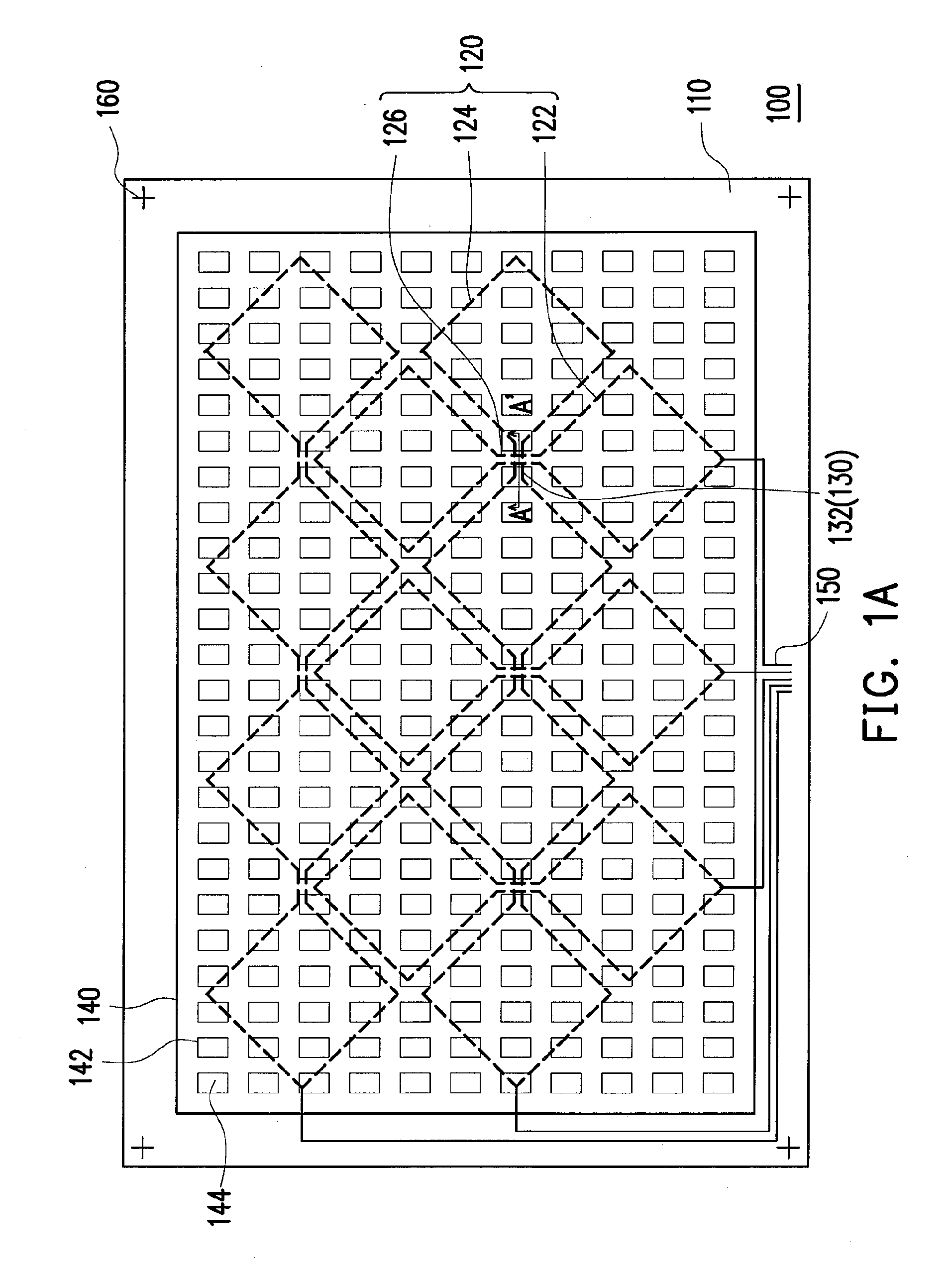

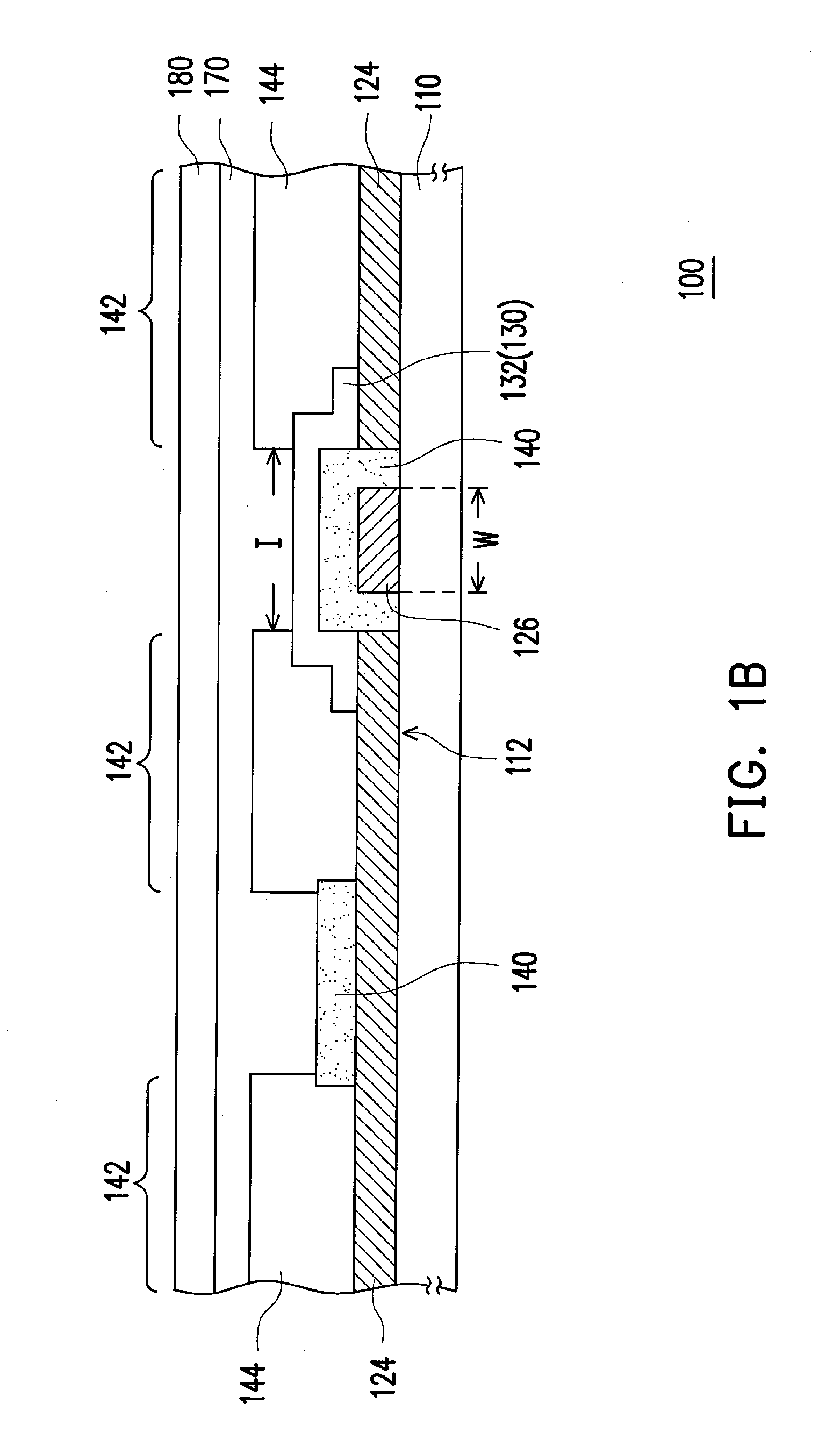

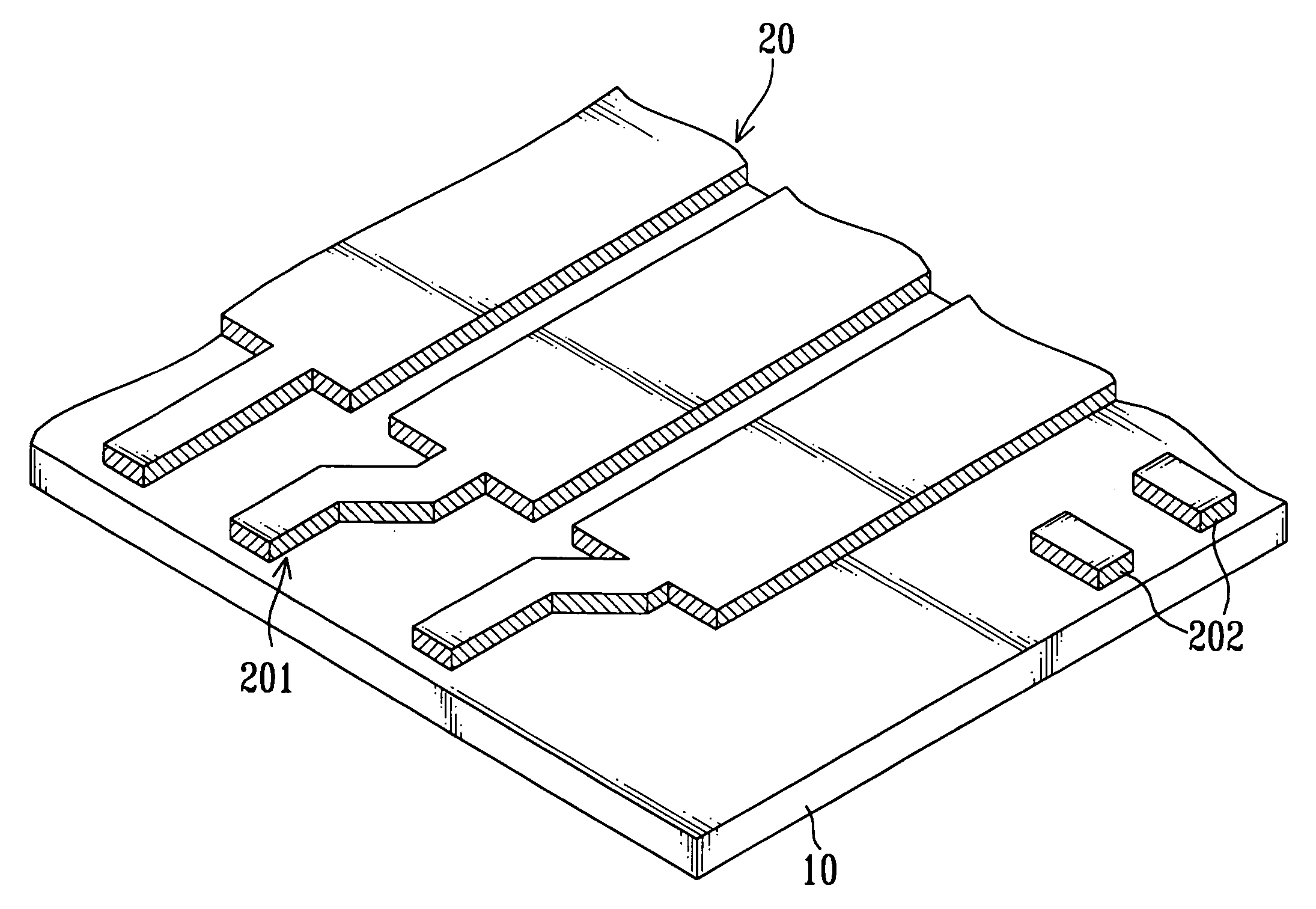

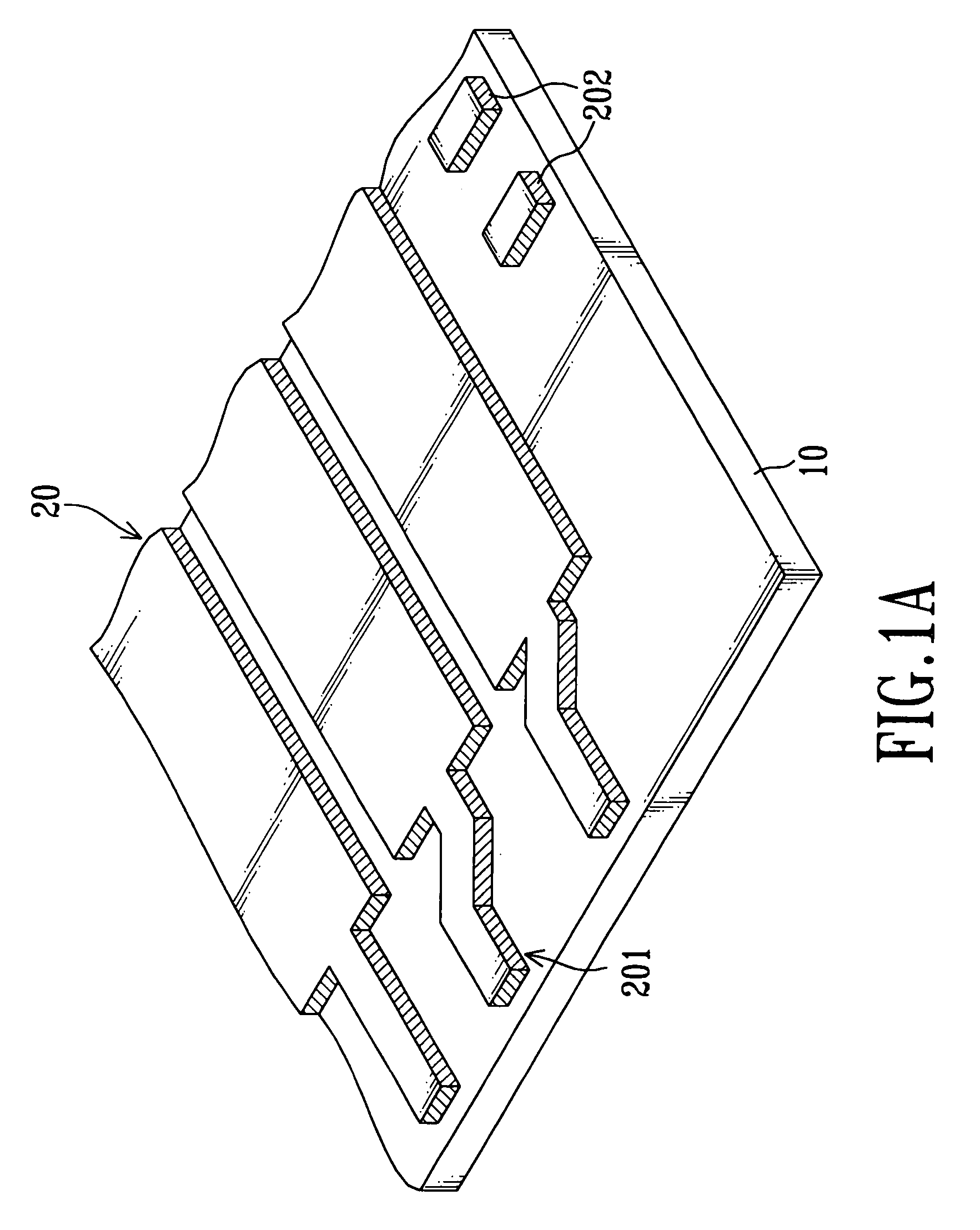

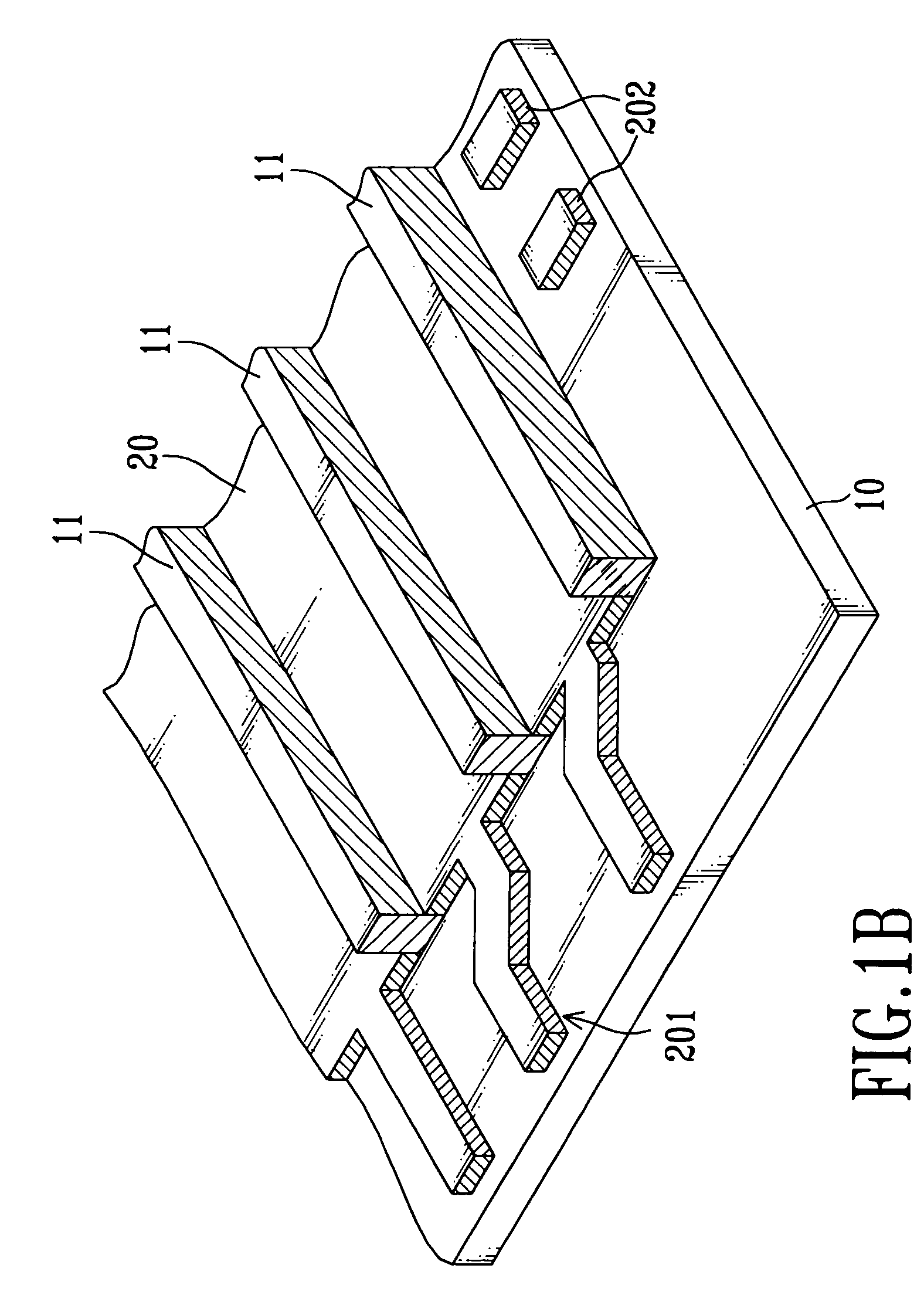

Color filter touch sensing substrate and display panel and manufacturing methods of the same

ActiveUS20100149117A1Small touch sensing areaReduce decreaseVessels or leading-in conductors manufactureNon-linear opticsTouch SensesEngineering

A manufacturing method of a color filter touch sensing substrate is provided. Firstly, a first film is formed on a substrate. The first film includes a plurality of first and second touch sensors and a plurality of first bridge lines for electrically connecting the first touch sensors in the same column. Then, a second film is formed on the substrate. The second film includes a plurality of second bridge lines for electrically connecting the second touch sensors in the same row. Next, a light shielding pattern layer is formed between the first and the second films. The light shielding pattern layer is used to define a plurality of sub-pixel regions on the substrate. Afterward, a plurality of color filter pattern layers is formed in the sub-pixel regions. Furthermore, a color filter touch sensing substrate, a display panel and manufacturing methods thereof are also provided.

Owner:AU OPTRONICS CORP

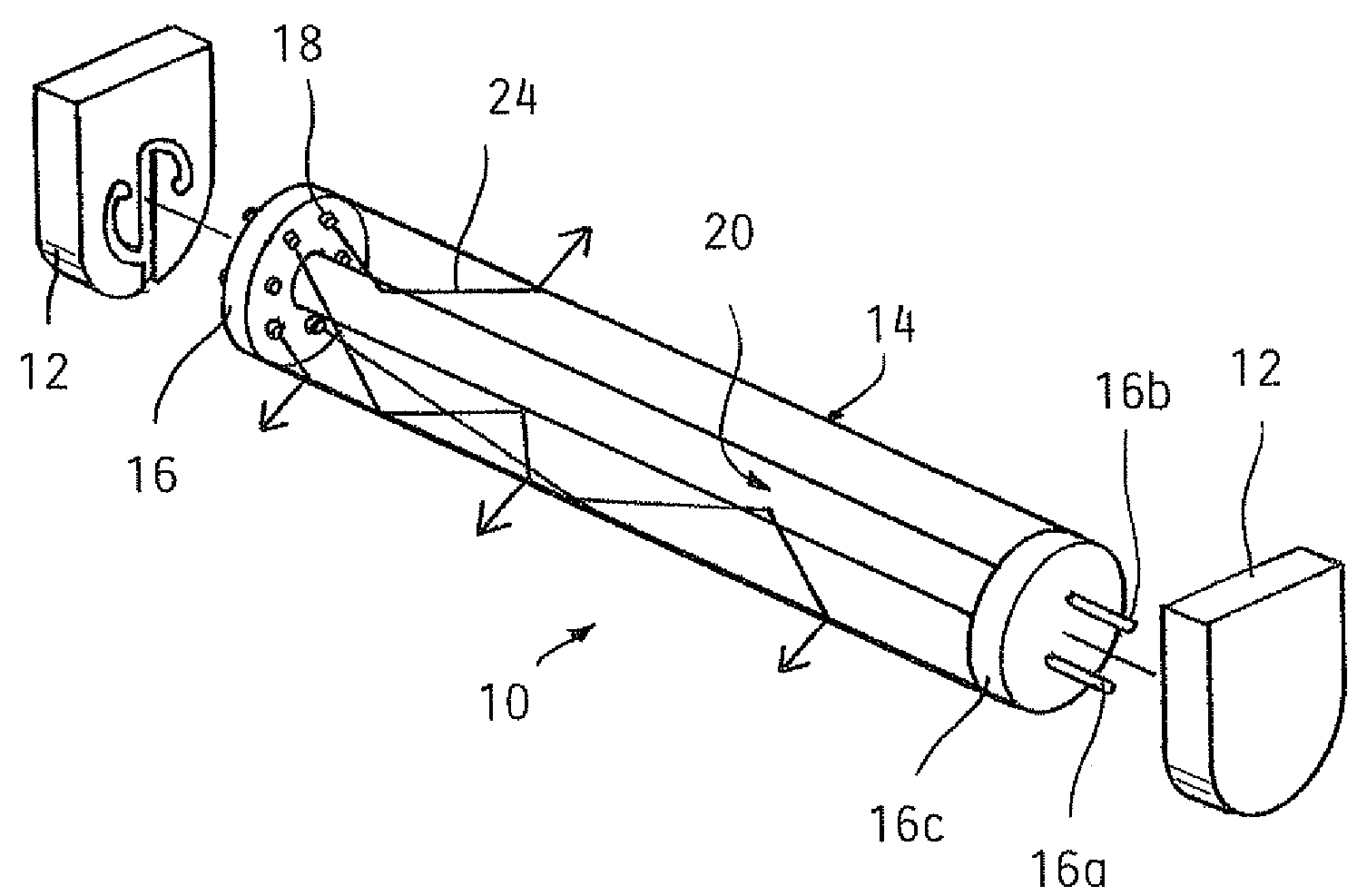

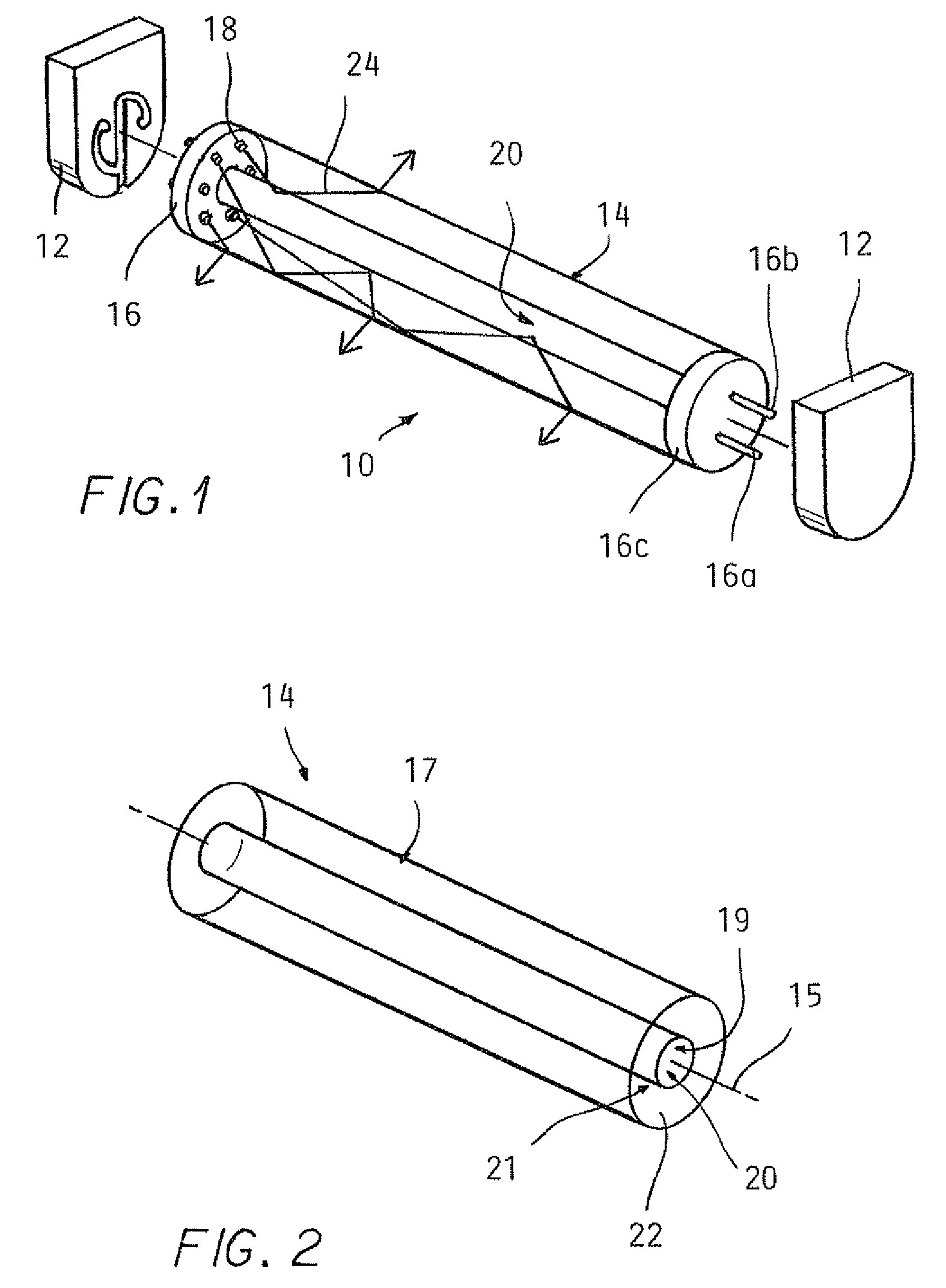

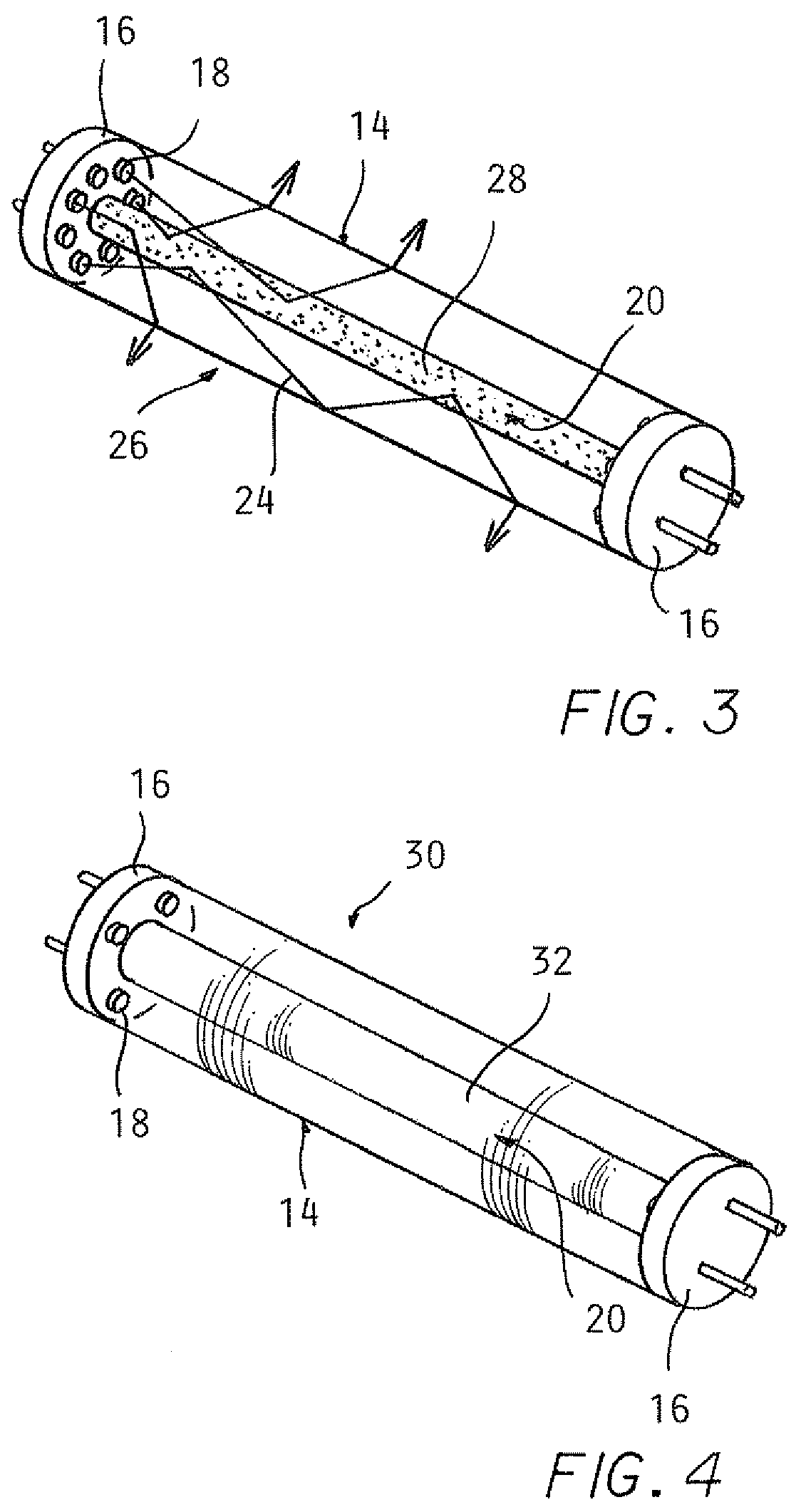

Fluorescent tube replacement having longitudinally oriented LEDs

An LED-based light for replacing a conventional fluorescent tube in a fixture is provided. The LED-based light includes an elongate light transmitting rod defining a bore and at least one LED positioned at one or both ends of the rod and oriented to produce light longitudinally into a portion of the rod radially outward of the bore. At least one connector is physically coupled to an end of the rod and electrically coupled to the at least one LED. The at least one connector is adapted for physical and electrical connection to the fixture. In operation, the directional light produced by the at least one LED is dispersed by way of reflection, refraction, and / or diffusion while traveling longitudinally through the rod to reduce the appearance of bright spots.

Owner:ILUMISYS

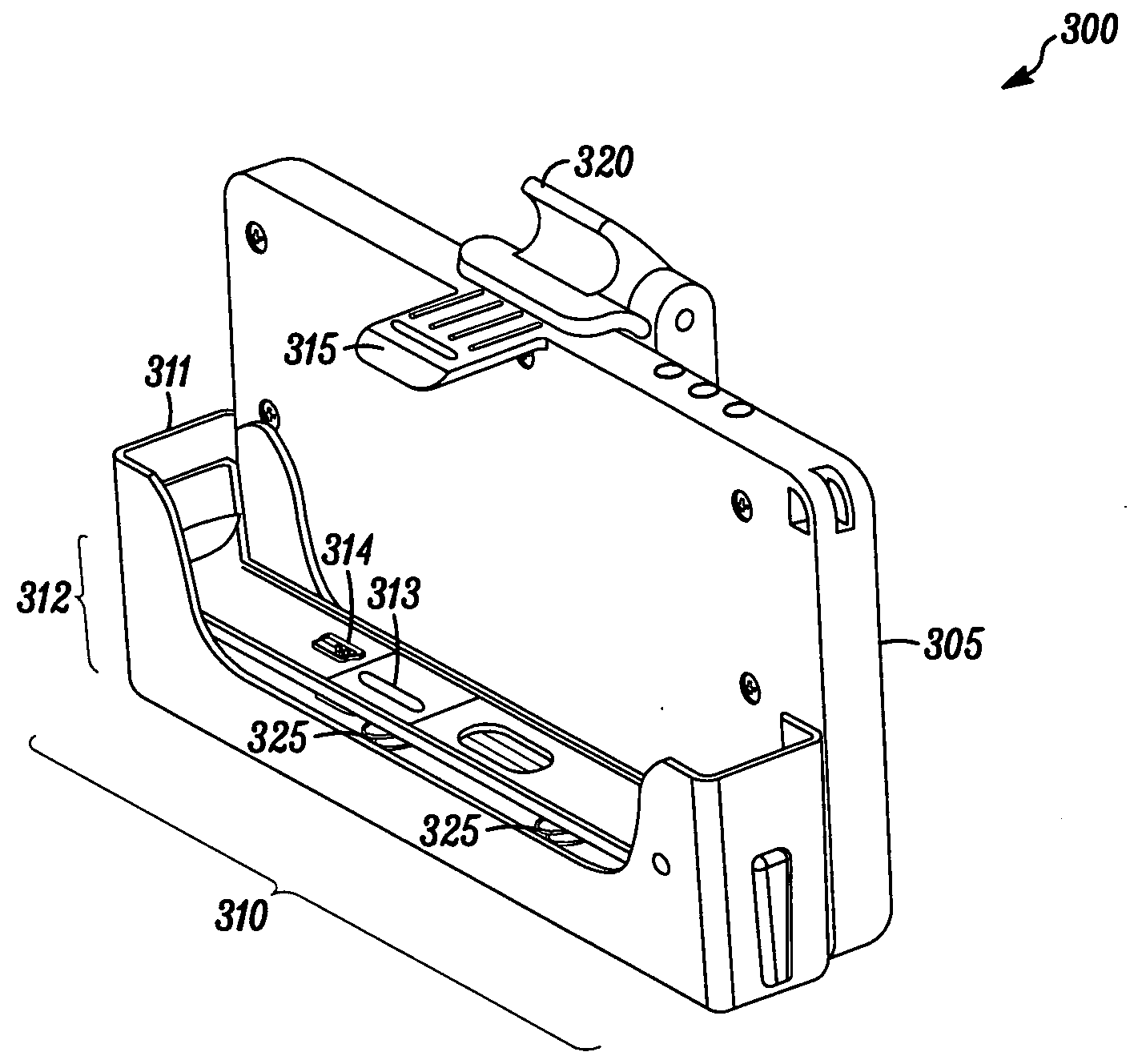

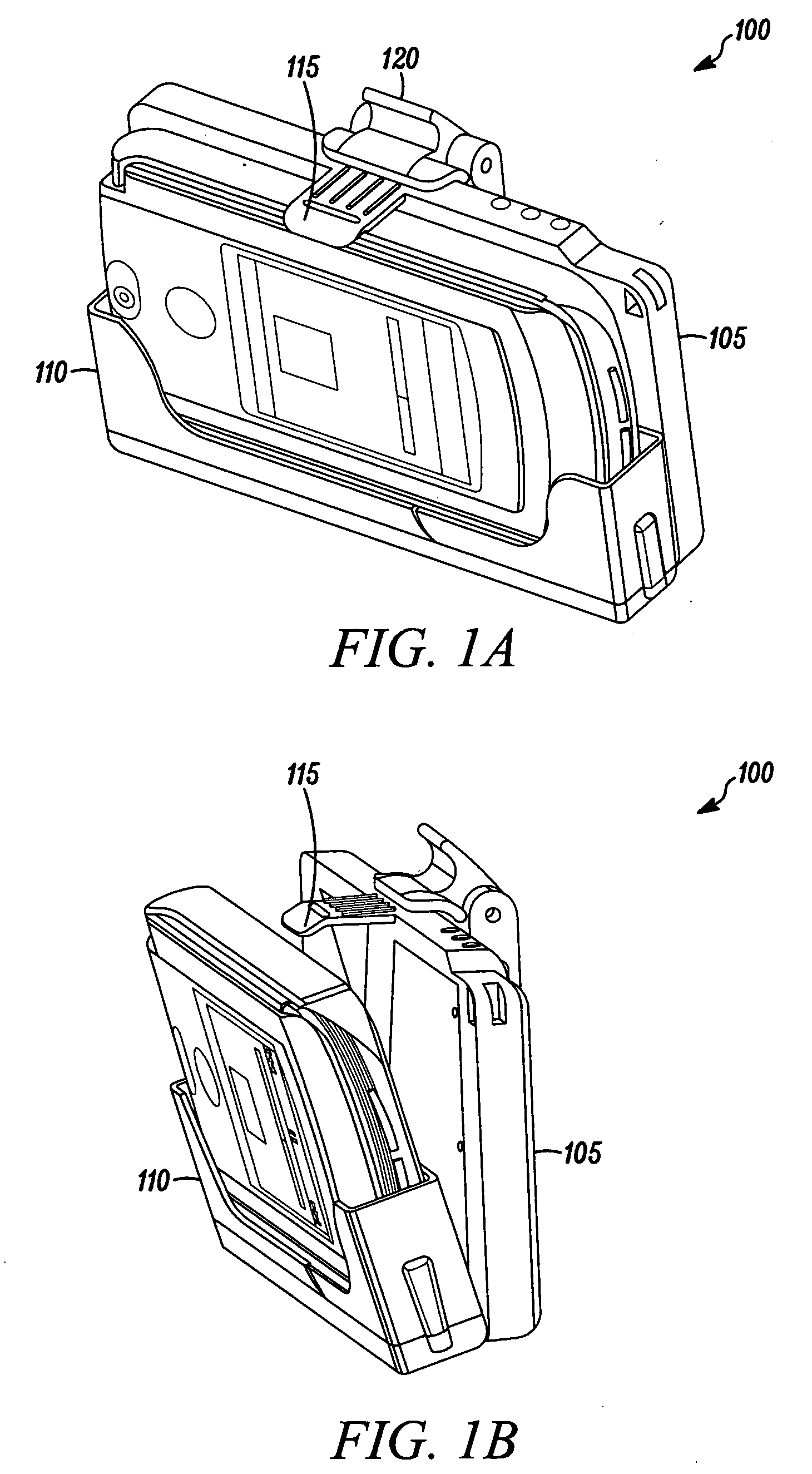

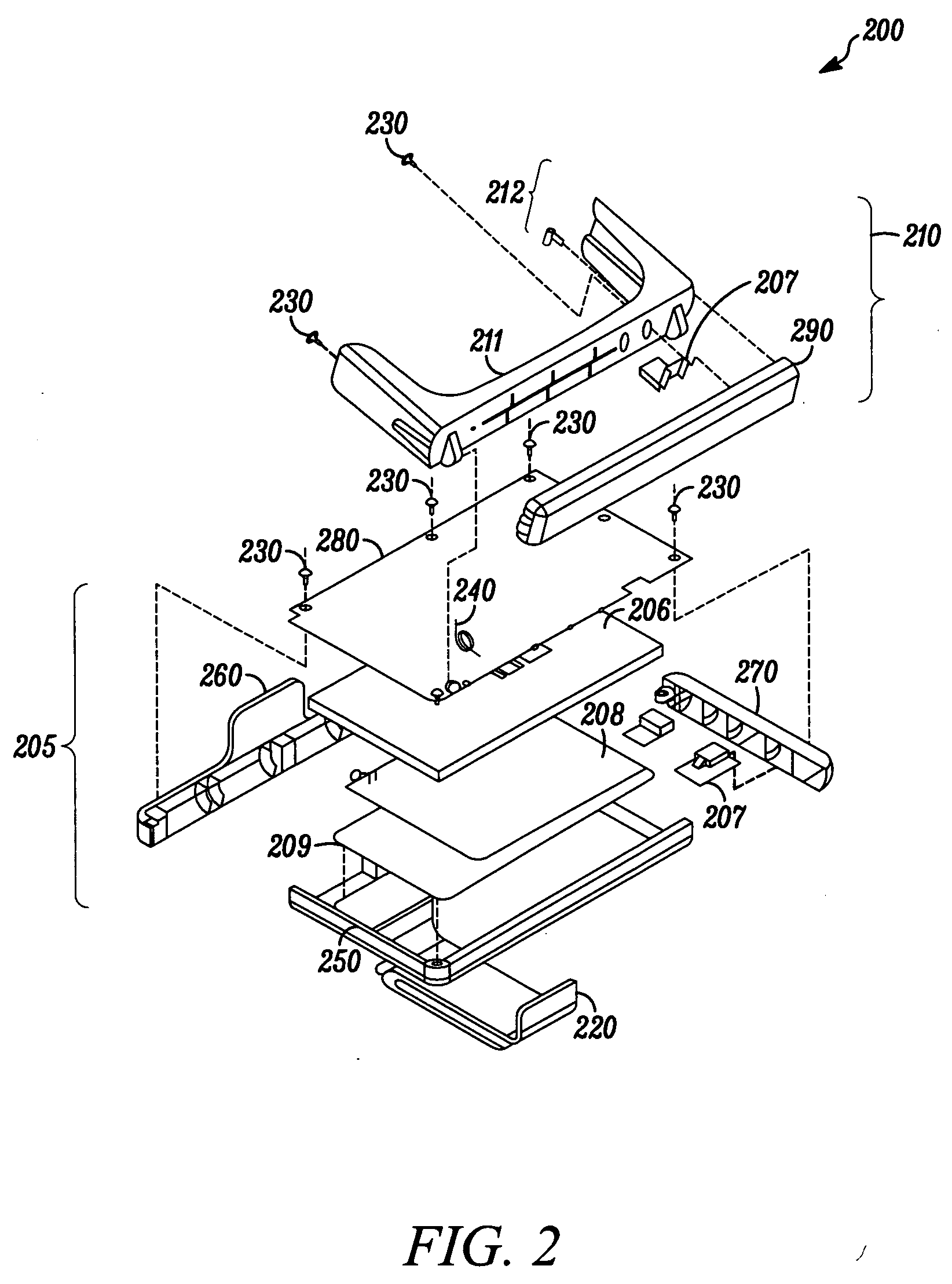

Portable and universal hybrid-charging apparatus for portable electronic devices

InactiveUS20090284216A1Great efficiency in transfer of chargeDifferent batteries chargingVessels or leading-in conductors manufactureEmbedded systemBattery charger

The teachings relate to a power supply that can be used to carry, charge, and power a portable electronic device, as well as be operable by a user while mobile, between or during uses of the portable electronic device. The power supply comprises a modular hybrid-charger assembly operably connected to a device holder. The modular hybrid-charger assembly comprises a rechargeable internal battery connected to a port operable to function as a tetherless connection to a portable electronic device, a power management engine embodied in a computer readable medium, and an untethered solar energy source. The device holder comprises a framework operable to receive, hold, and release the portable electronic device; and an alignment mechanism that facilitates a mating of the portable electronic device with the hybrid-charger assembly. The modular hybrid-charger assembly can comprise a form factor that is interchangeable and operable with each of several different device holder form factors.

Owner:IPOWERUP

Optical-interference type display panel and method for making the same

InactiveUS7172915B2Improve antioxidant capacityConnecting qualitySemiconductor/solid-state device manufacturingVessels or leading-in conductors manufactureIndium tin oxideTransparent conducting film

Owner:SNAPTRACK

Deep red phosphor for general illumination applications

A light emitting device including a UV semiconductor light source and a phosphor blend including a blue emitting phosphor, a green emitting phosphor and a deep red emitting phosphor comprising (Ba,Sr,Ca)3MgxSi2O8:Eu2+, Mn2+, wherein 1≦x≦2. Also disclosed is a phosphor blend comprising a blue emitting phosphor, a phosphor, a green emitting phosphor and a red emitting phosphor comprising (Ba,Sr,Ca)3MgxSi2O8:Eu2, Mn2+.

Owner:GENERAL ELECTRIC CO

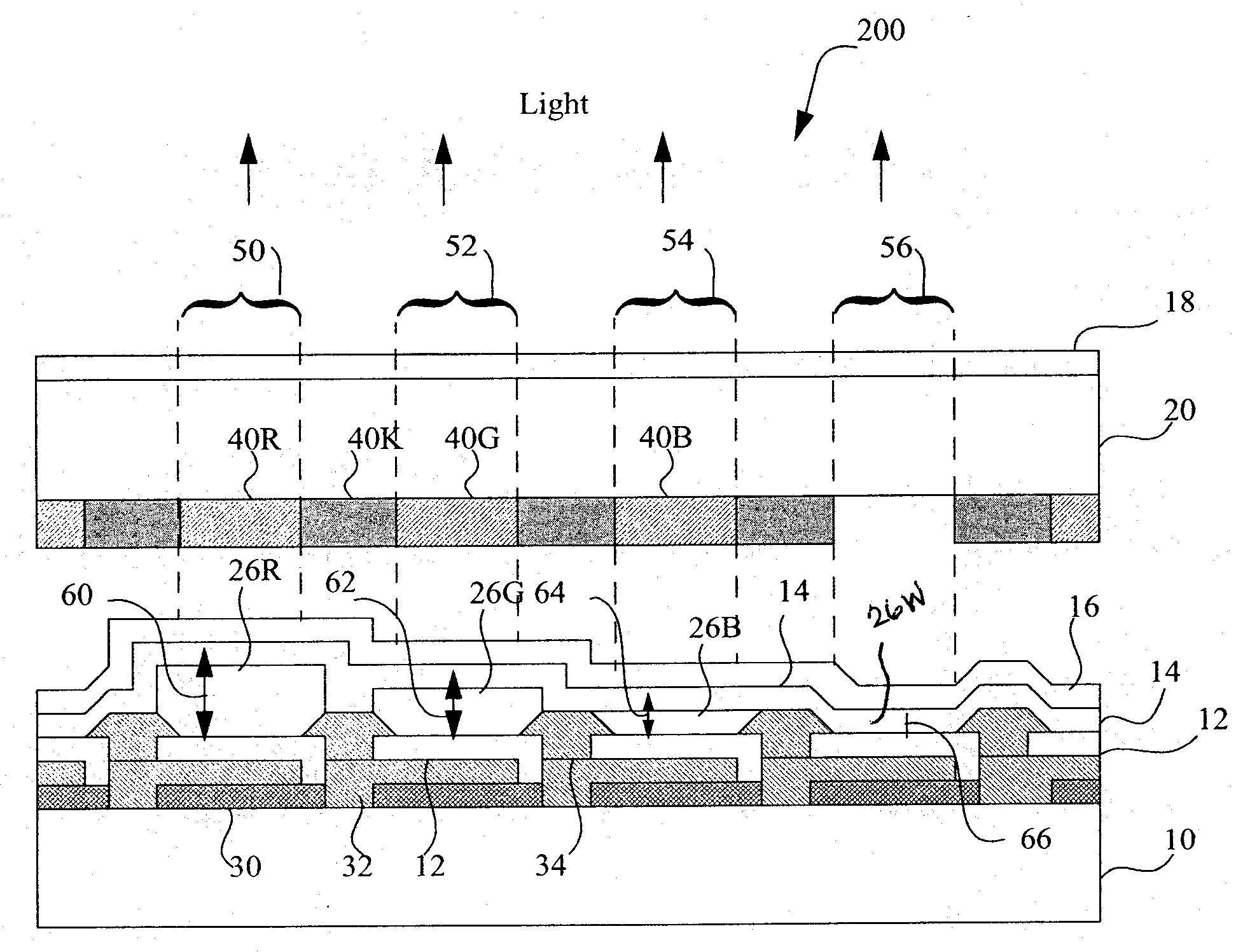

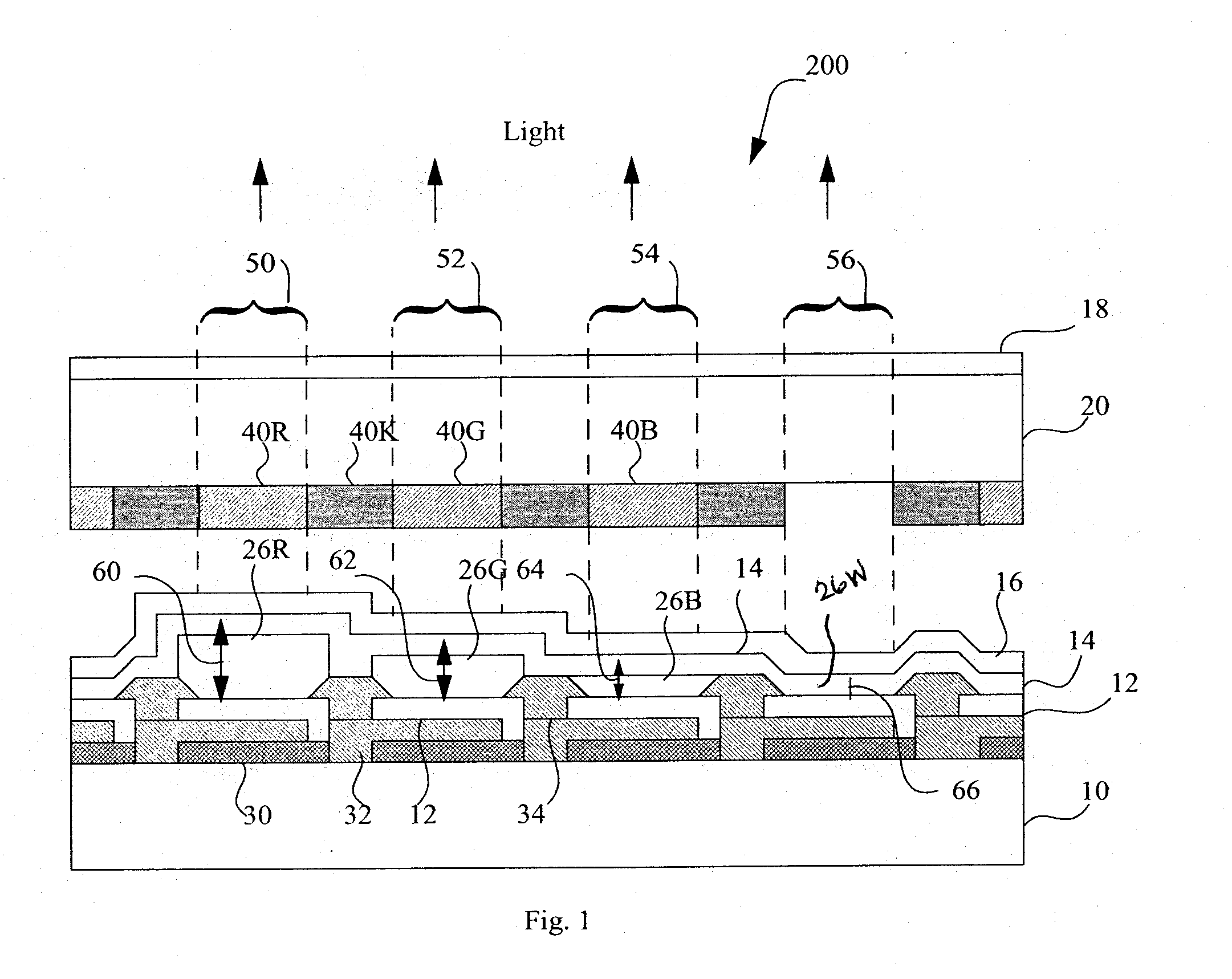

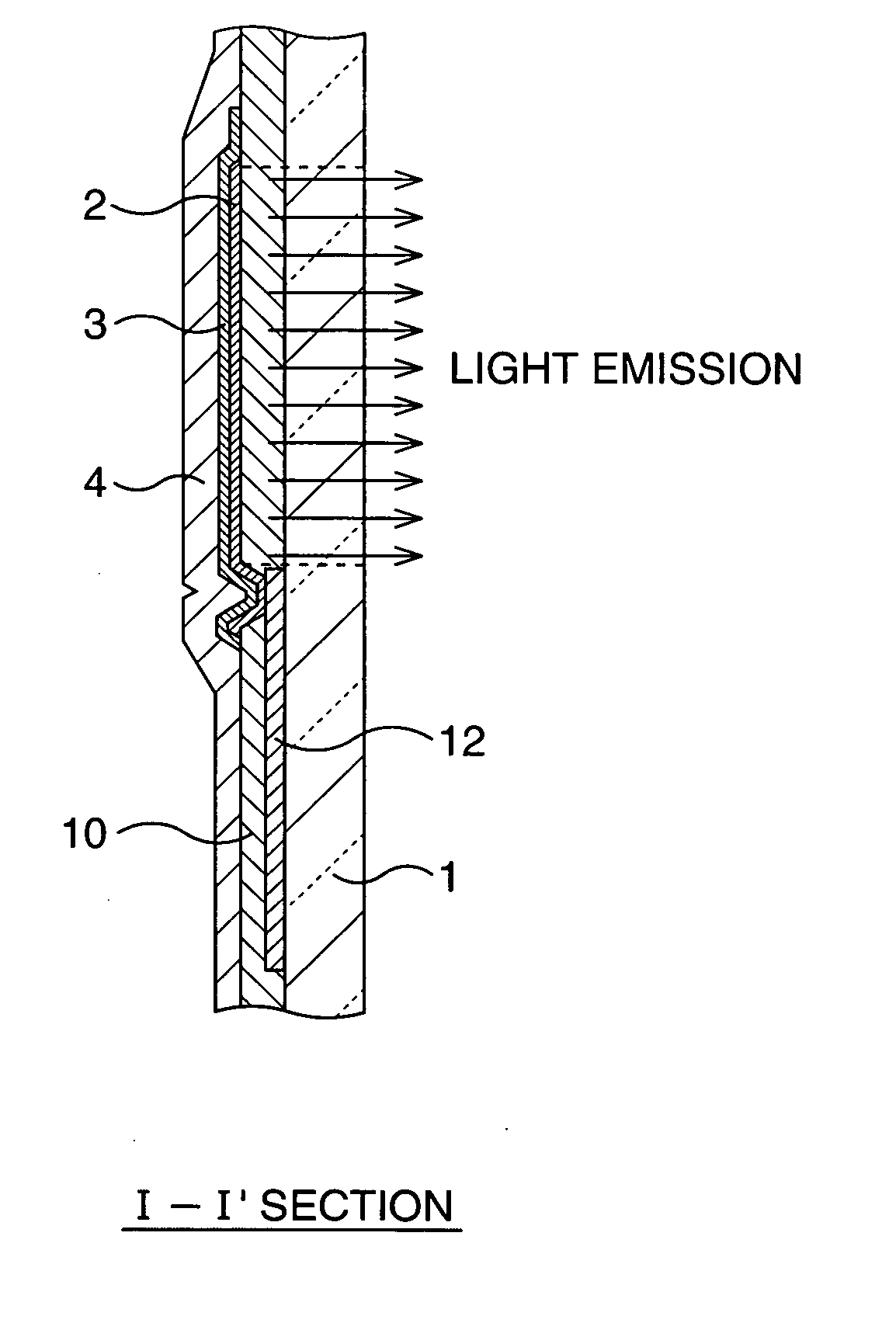

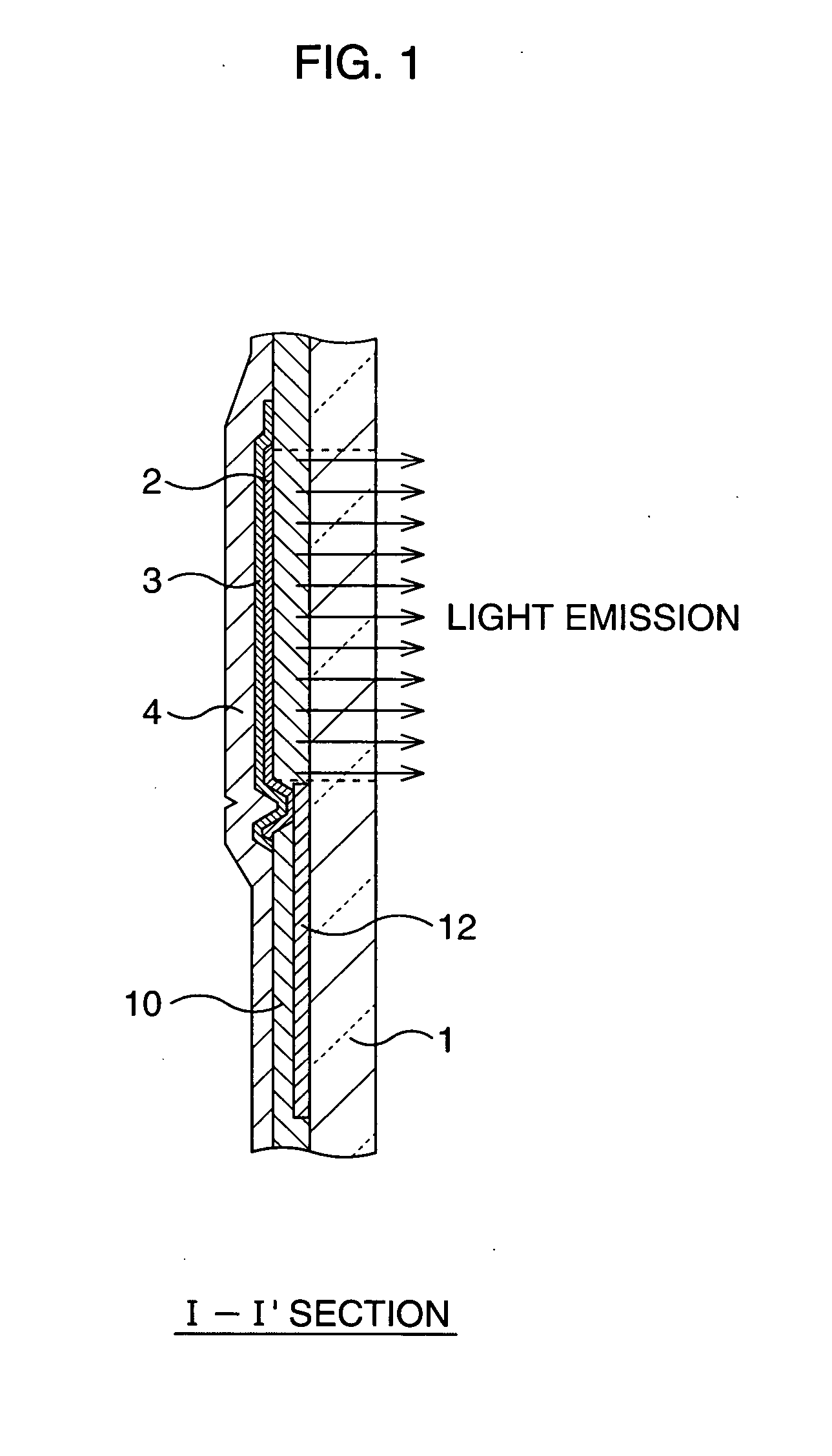

LED device having improved contrast

ActiveUS20090051283A1Discharge tube luminescnet screensLamp detailsLight-emitting diodeOptical microcavity

A light-emitting diode device, including a substrate; and a reflective electrode and a semi-transparent electrode formed over the substrate and an unpatterned white light-emitting layer formed between the reflective electrode and the semi-transparent electrode, the reflective electrode, semi-transparent electrode, and unpatterned white-light-emitting layer forming an optical microcavity, and wherein either the reflective or semi-transparent electrodes is patterned to form a plurality of independently controllable light-emitting elements with at least one light-emitting element having no color filter. Color filters are formed over a side of the semi-transparent electrodes opposite the unpatterned white light-emitting layer in correspondence with the light-emitting elements, the color filters having at least two different colors. Additionally, a reflected-light absorbing layer is located over all of the light-emitting elements.

Owner:GLOBAL OLED TECH

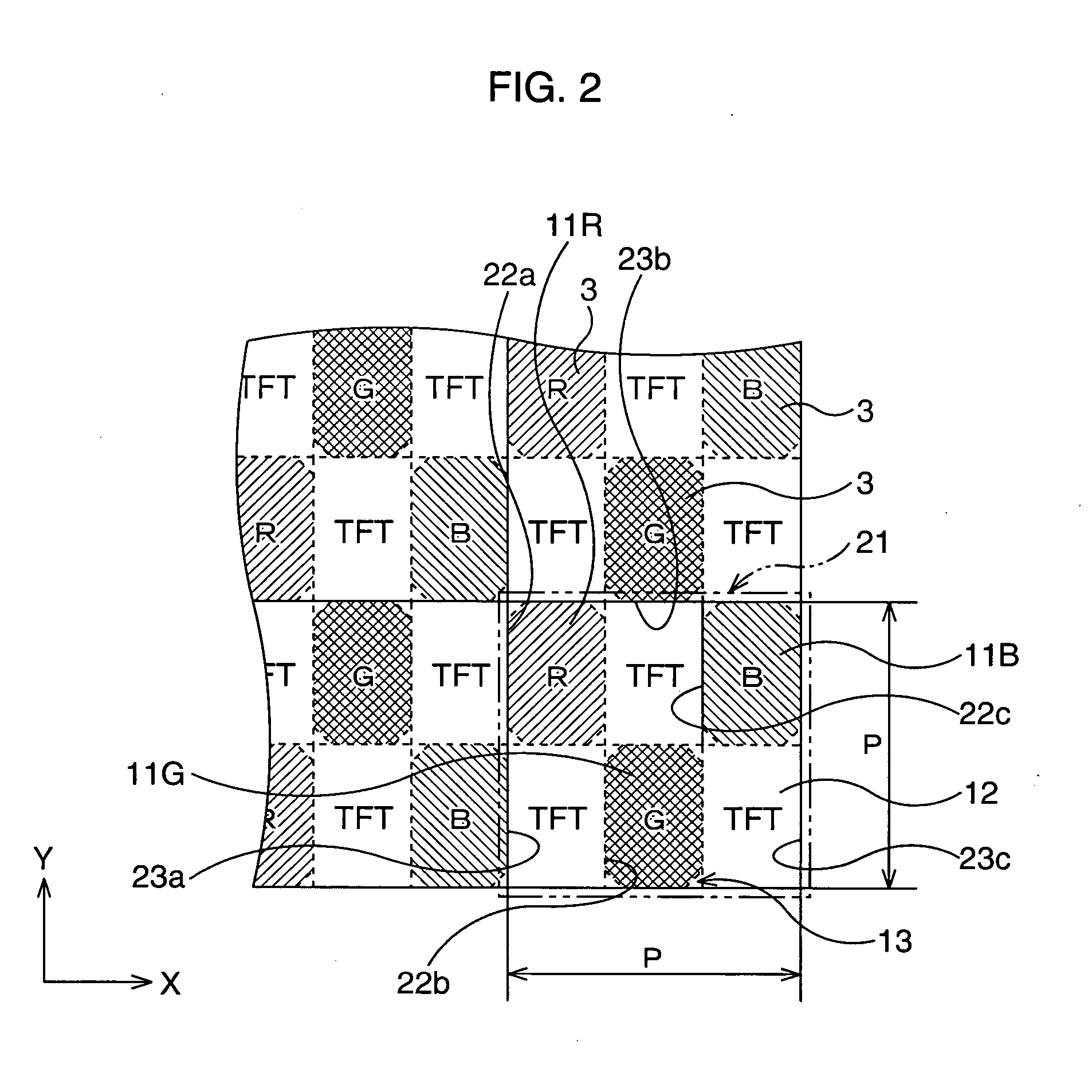

Display device and manufacturing method thereof

InactiveUS20050162079A1Discharge tube luminescnet screensElectroluminescent light sourcesActive matrixImage resolution

Each pixel (21) includes a plurality of light emitting regions (11R, 11G, and 11B) corresponding R, G, and B each having an organic EL layer (3), and a plurality of TFT elements (12) provided corresponding to the light emitting regions to control light emission in the respective light emitting regions. The light emitting regions are provided in a zigzag manner and adjacent light emitting regions are kept from contacting one another. Each pixel (21) is divided into six segments (22a to 22c and 23a to 23c), and the light emitting regions are arranged in three segments (22a to 22c) in a zigzag manner. In this way, in a bottom emission type, active matrix organic EL display, a sufficient aperture ratio can efficiently be secured, and pixels can be arranged so that the aperture ratio is hardly a trade off for higher resolution. Therefore, power consumption for obtaining necessary luminance can be reduced, and this can contribute to downsizing of the driving circuit and the device as a whole.

Owner:UDC IRELAND +1

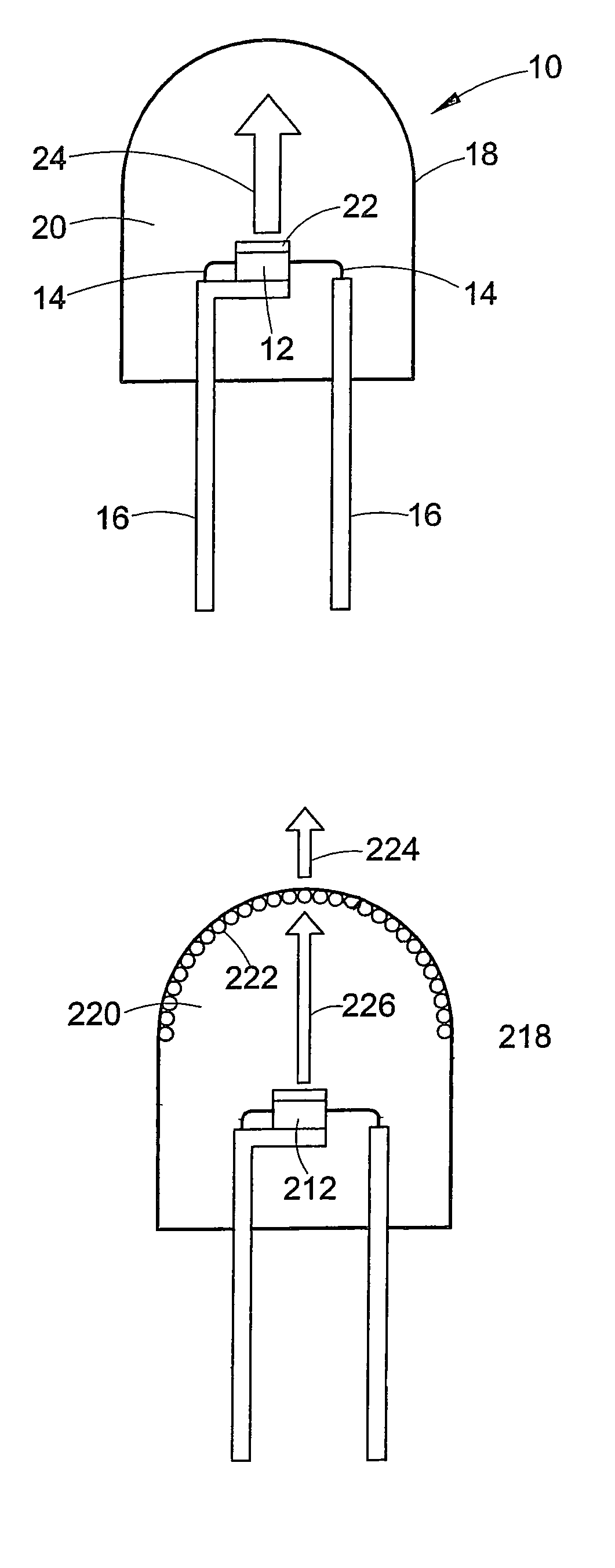

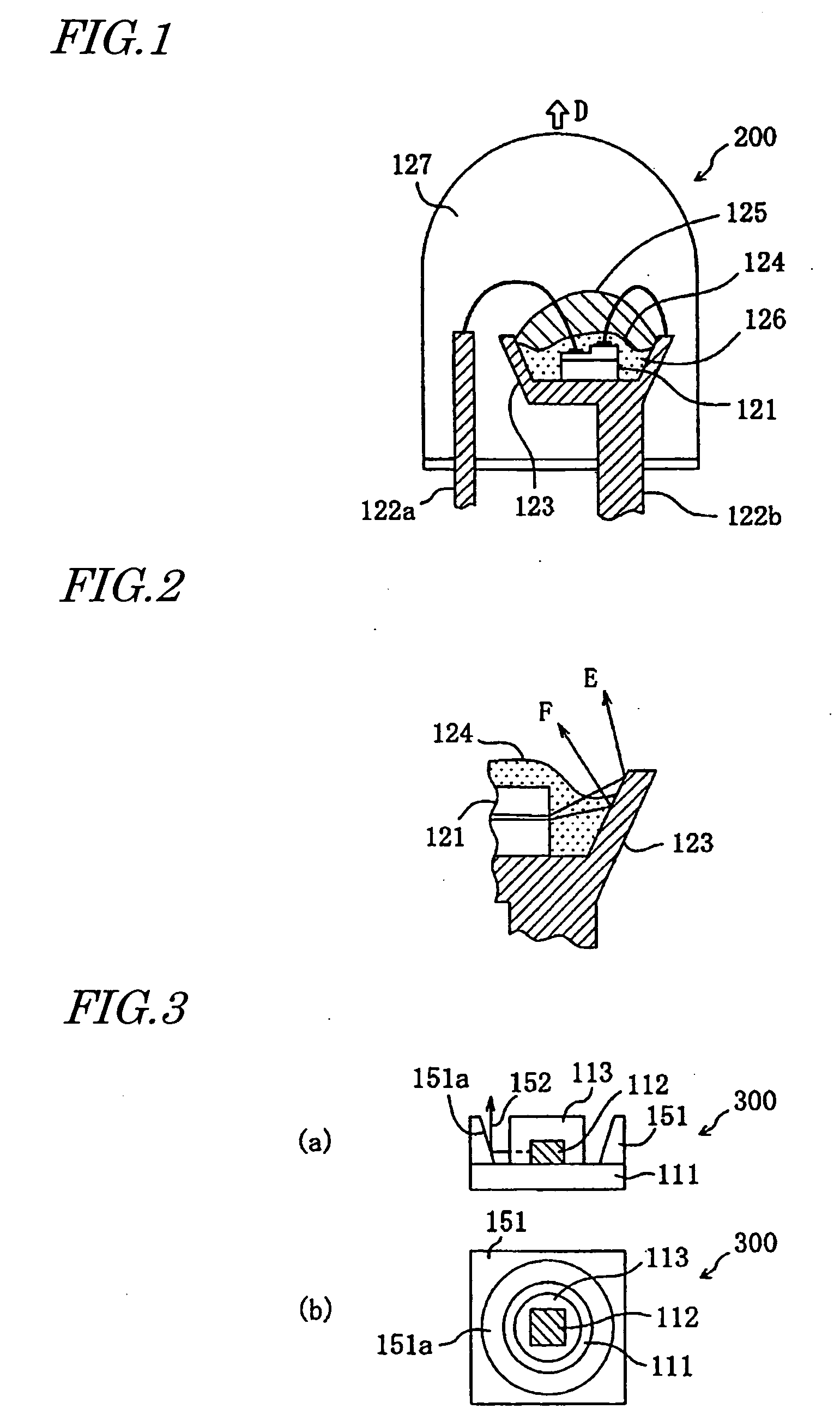

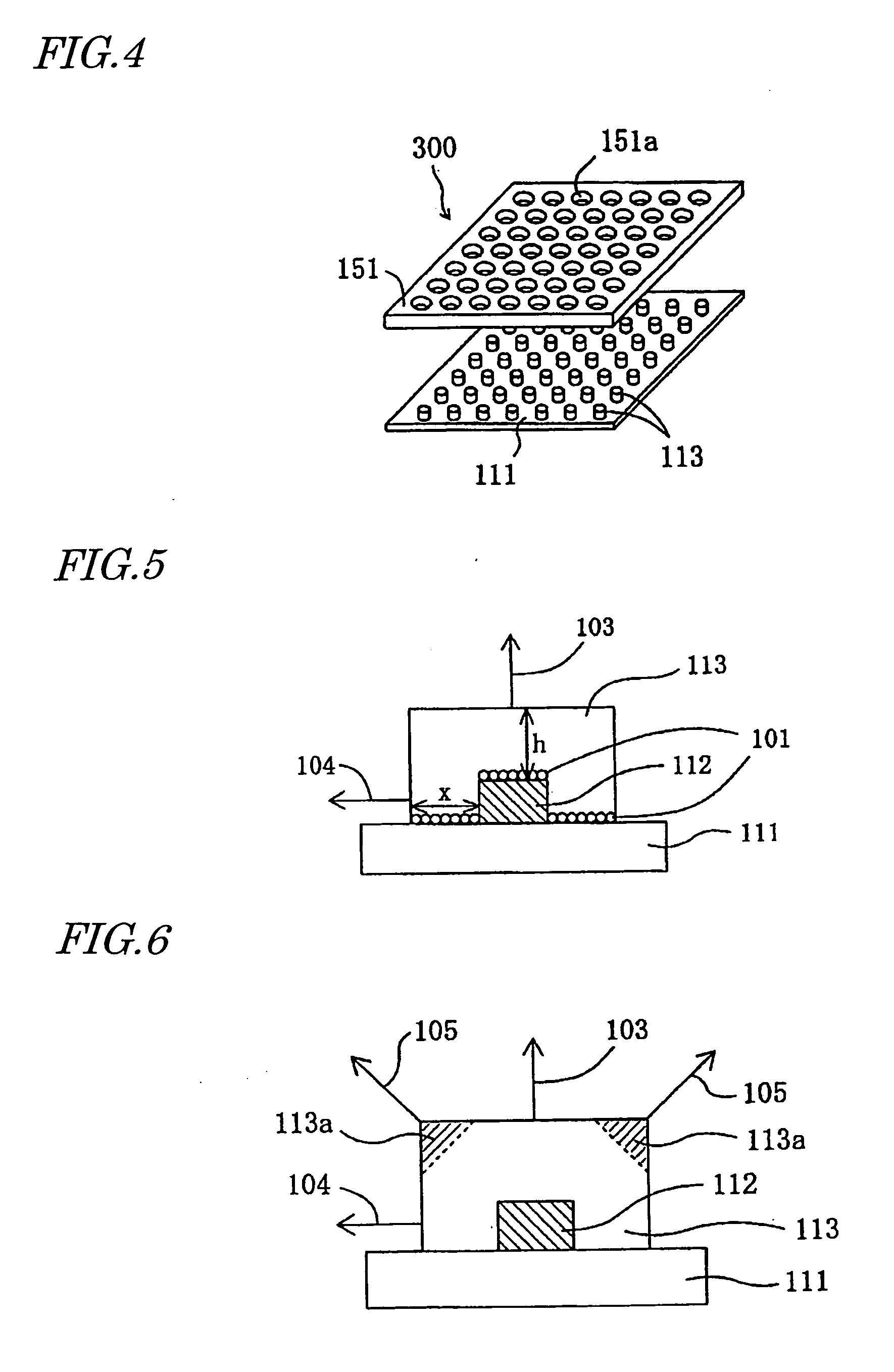

Method for Fabricating Led Illumination Light Source and Led Illumination Light Source

InactiveUS20080074032A1Eliminating color unevennessImprove throughputPlanar light sourcesPoint-like light sourcePhosphorFluorescence

An LED lamp according to the present invention includes: at least one LED chip 12 that is mounted on a substrate 11; a phosphor resin portion 13 that covers the LED chip 12; a lens 22 to act on the outgoing light of the phosphor resin portion 13; and an optical diffusion layer (light-transmissive resin portion 20), which is arranged between the phosphor resin portion 13 and the lens 22 and in which particles to scatter the light are dispersed.

Owner:SOVEREIGN PEAK VENTURES LLC

Method of making a glass envelope

InactiveUS20070128967A1Easy to understandElectroluminescent light sourcesSolid-state devicesFritLight beam

A method of minimizing stress in an OLED device laser sealing process using an elongated laser beam. A laser beam having an intensity distribution which decreases as a function of distance from the longitudinal axis of the beam is passed through a mask to create an elongated beam having a length-wise intensity distribution which decreases as a function of distance from the axis of the beam and a substantially constant width-wise intensity distribution. The elongated beam is traversed over a line of frit disposed between two substrates. The tails of the length-wise intensity distribution provide for a slow cool down of the frit as the beam traverses the line of frit.

Owner:CORNING INC

Organic light emitting compound and organic light emitting device comprising the same, and method of manufacturing the organic light emitting device

InactiveUS20080122344A1Improve solubilityImprove thermal stabilityOrganic chemistryDischarge tube luminescnet screensOrganic light emitting deviceHigh color

Provided are an organic light emitting compound represented by Formula 1 below, an organic light emitting device comprising the same, and a method of manufacturing the light emitting device:wherein CY1, CY2, Ar1, R1 and R2 are described in the detailed description of the invention. An organic light emitting device comprising the organic light emitting compound has low turn-on voltage, high efficiency, high color purity and high luminance.

Owner:SAMSUNG DISPLAY CO LTD

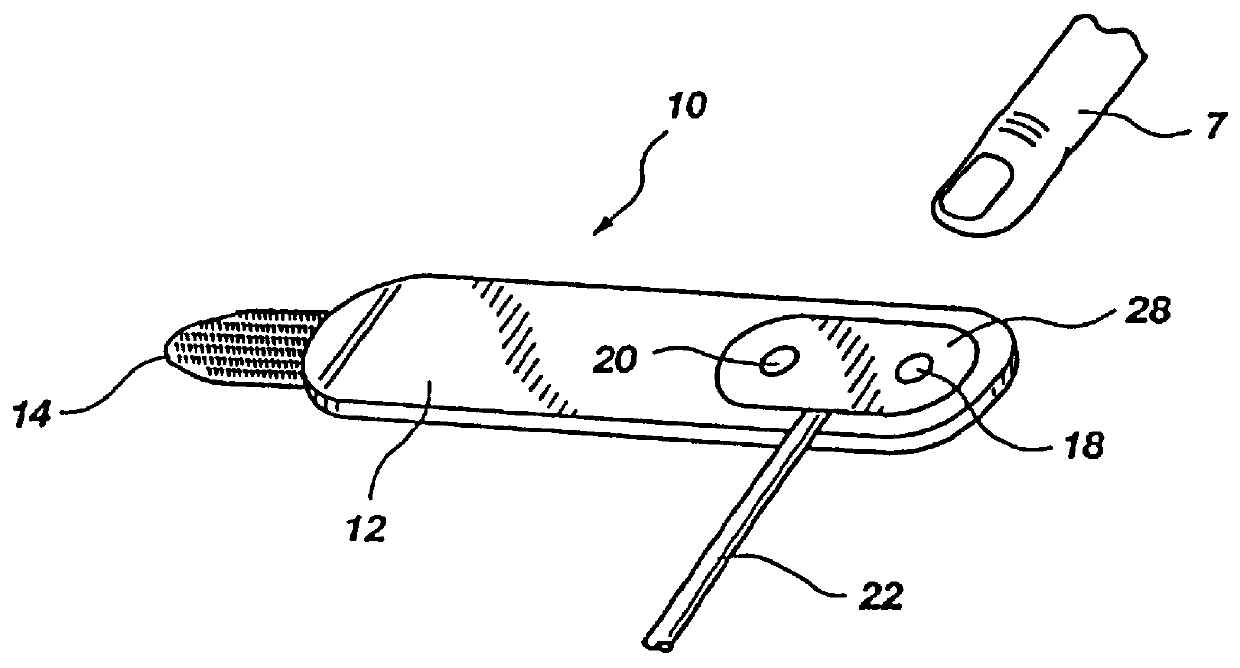

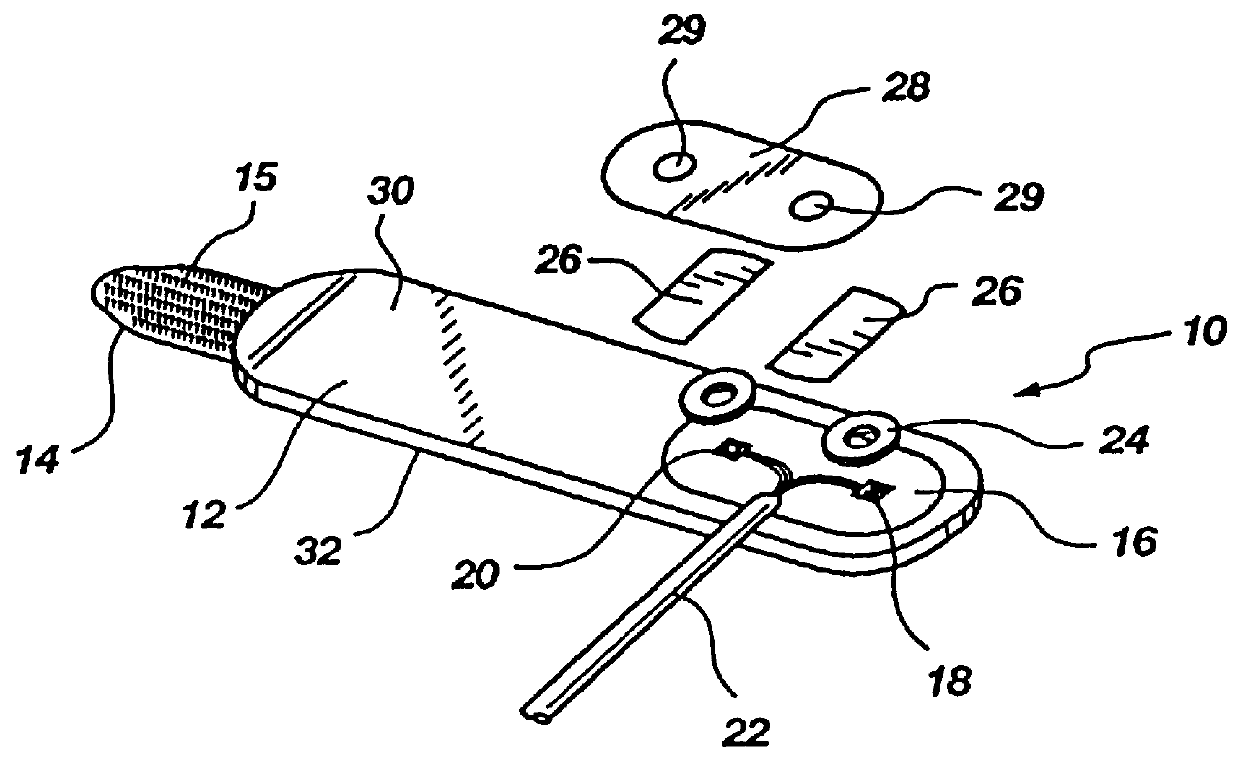

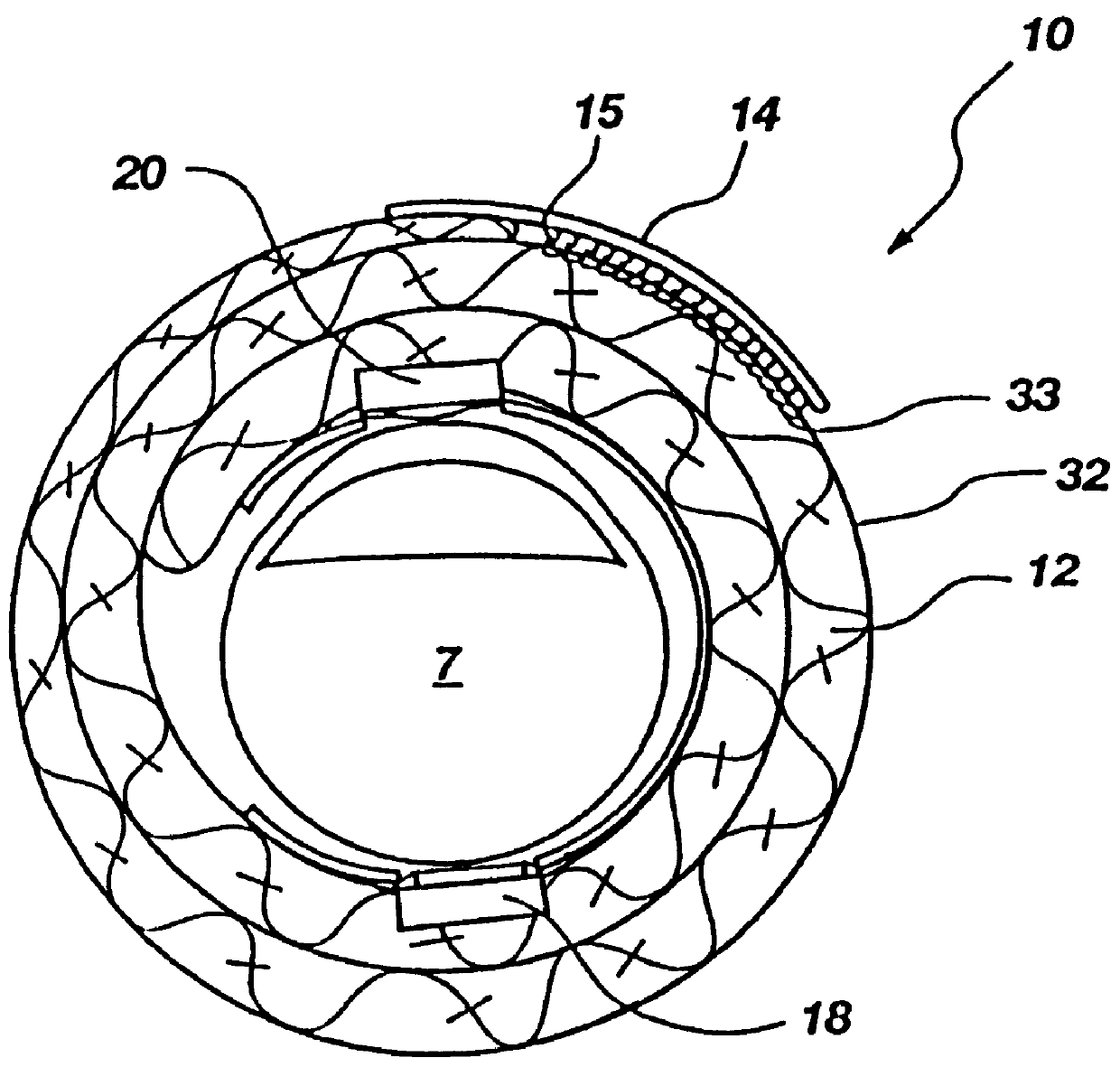

Extended life disposable pulse oximetry sensor and method of making

InactiveUS6149481AReduce manufacturing costVessels or leading-in conductors manufactureSensorsPulse oximetryEngineering

An oximetry sensor comprising a foam wrap member including a fastener, back film mounting member, LED assembly and photodiode connected to a cable, support rings for the LED assembly and photodiode, window film for the LED assembly and photodiode, and a top liner.

Owner:PHILIPS ELECTRONICS NORTH AMERICA +1

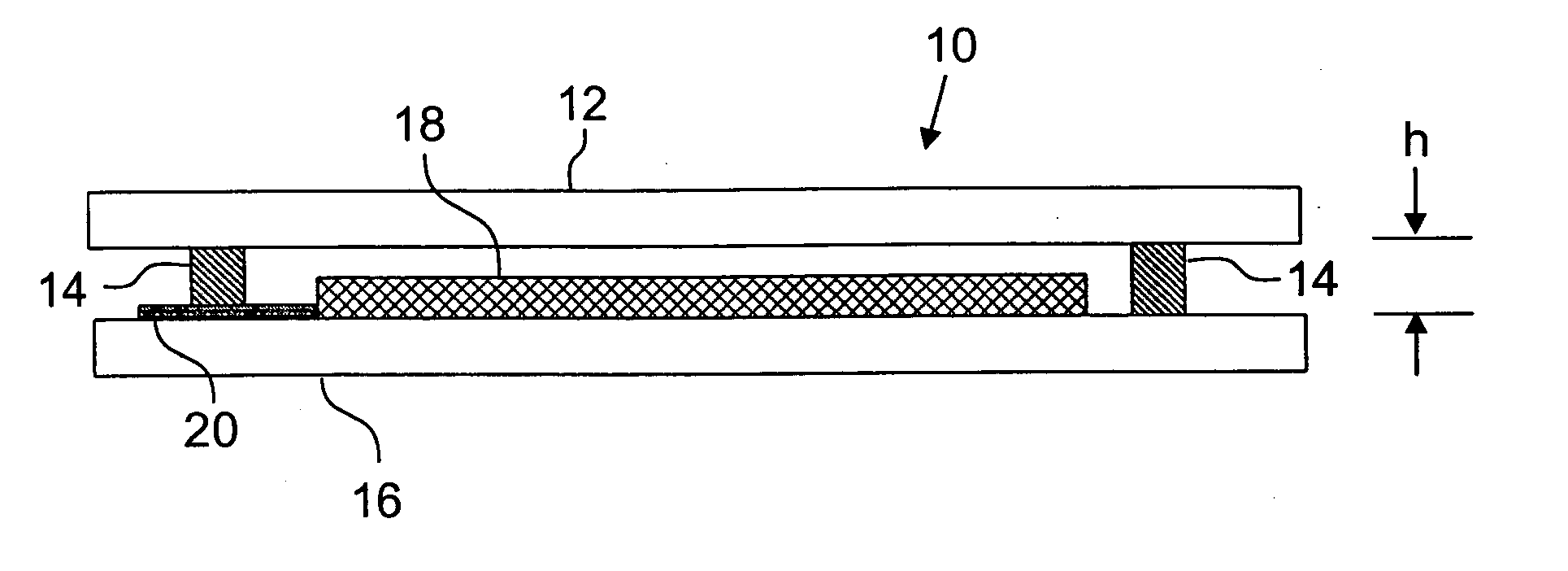

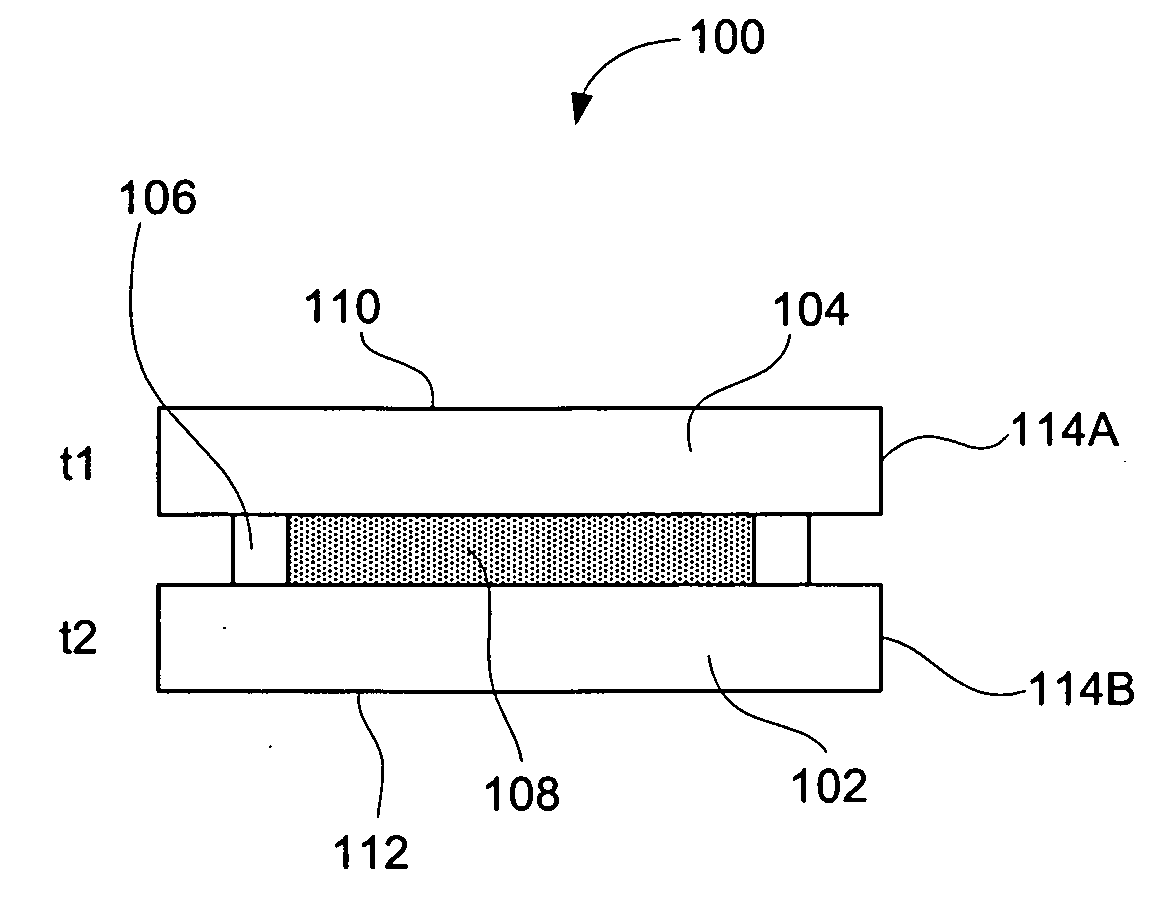

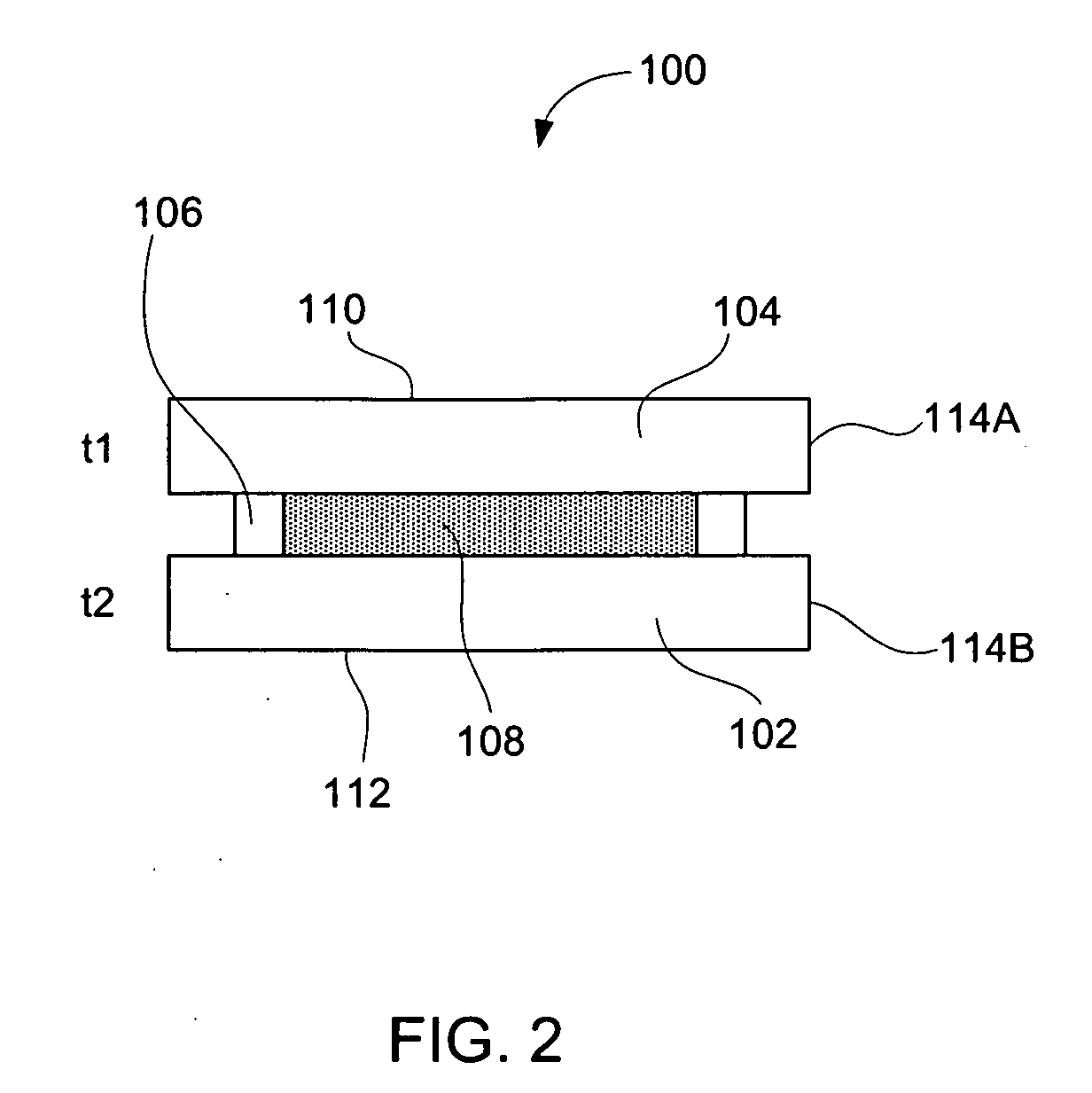

Methods and Systems for Strengthening LCD Modules

InactiveUS20090046240A1High strengthReduce susceptibilityVessels or leading-in conductors manufactureGlass severing apparatusLiquid-crystal displayDisplay device

Systems and methods for improving strength of thin displays, such as Liquid Crystal Display (LCD) displays, are disclosed. In one embodiment, a display can use an asymmetrical arrangement of layers (e.g., glass layers) where one layer is thicker than another layer. Different scribing techniques can also be used in singulating the different layers. The asymmetrical arrangement and / or scribing techniques can facilitate displays that are not only thin but also adequately strong to limit susceptibility to damage.

Owner:APPLE INC

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com