Patents

Literature

12886results about "Cold cathode manufacture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

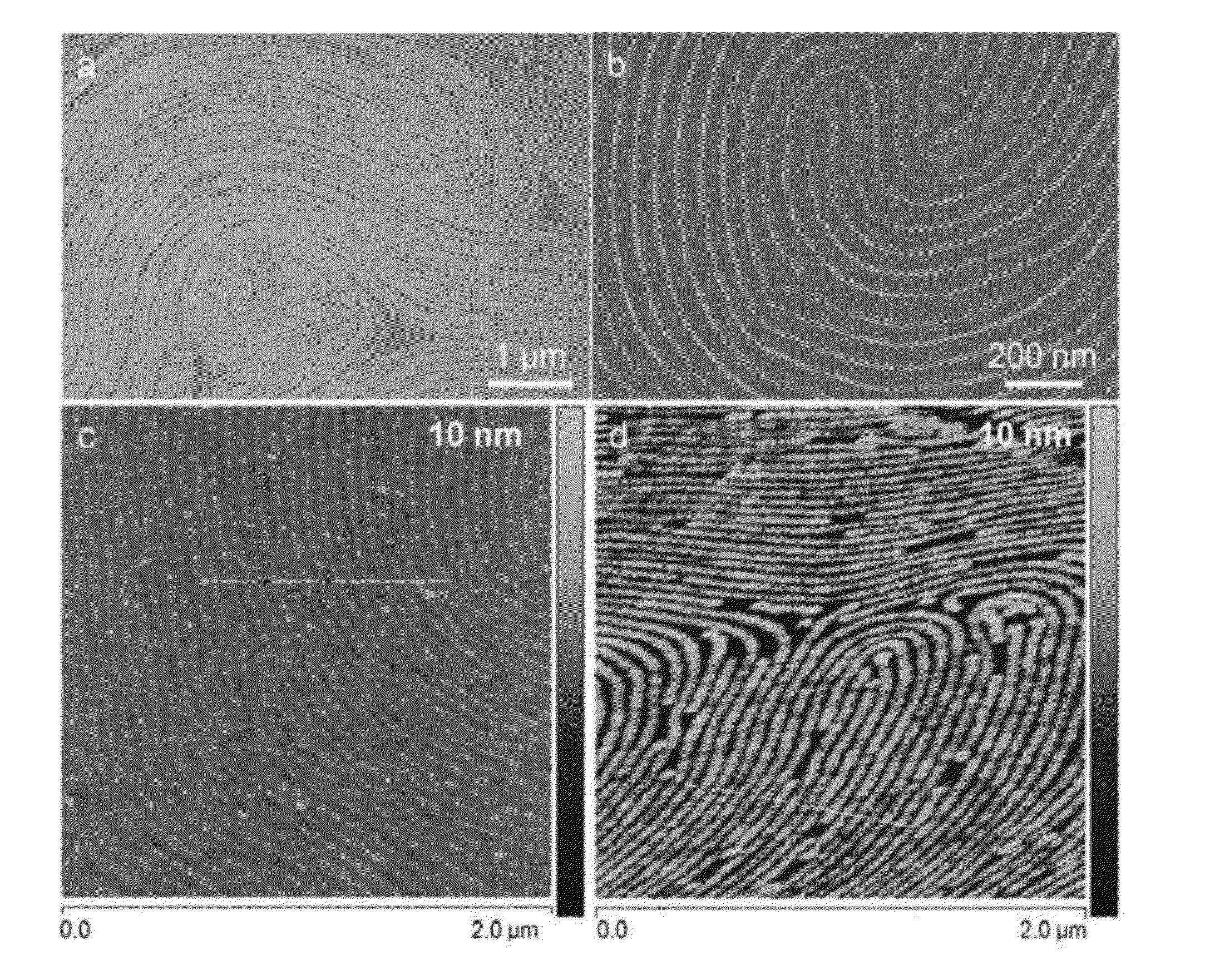

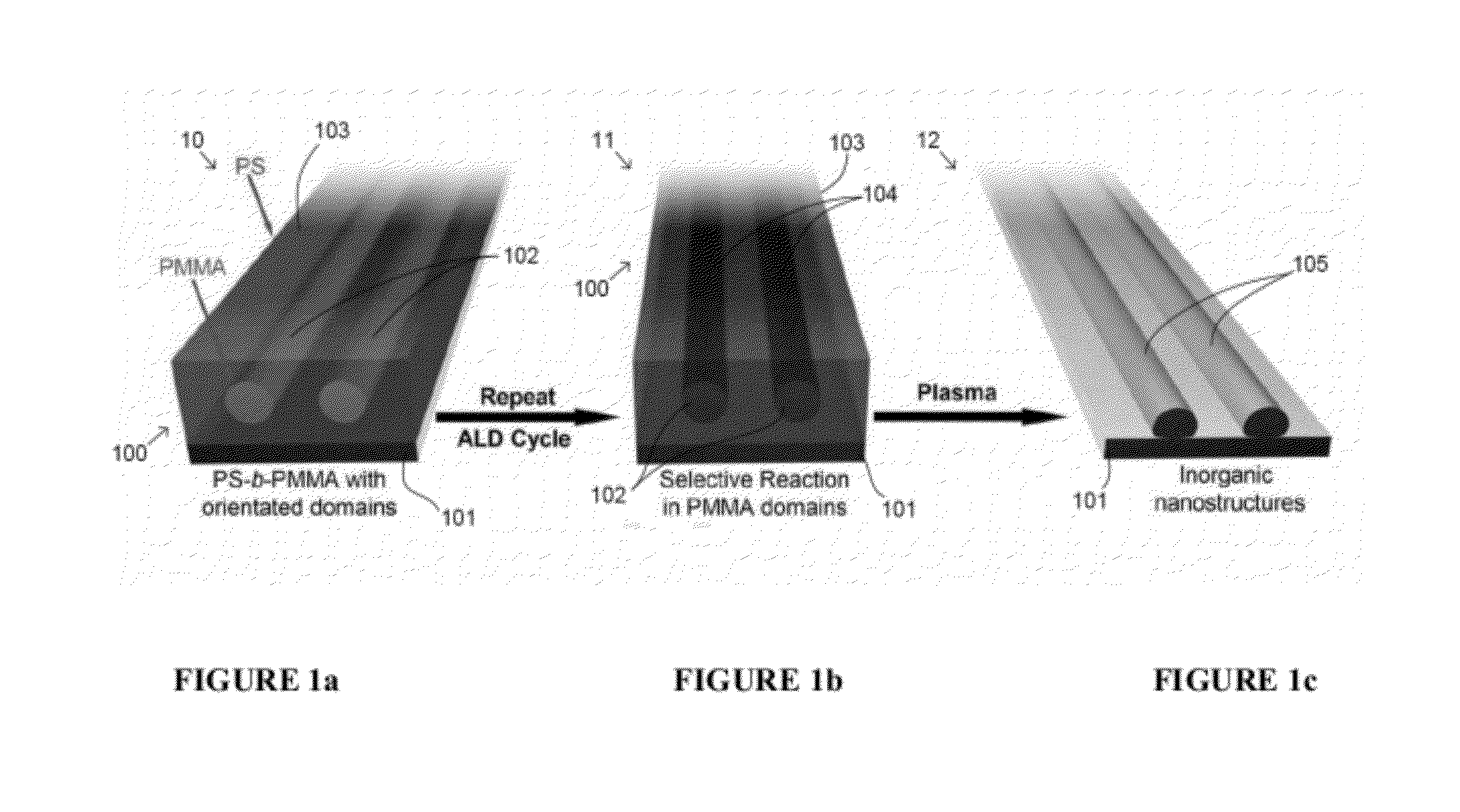

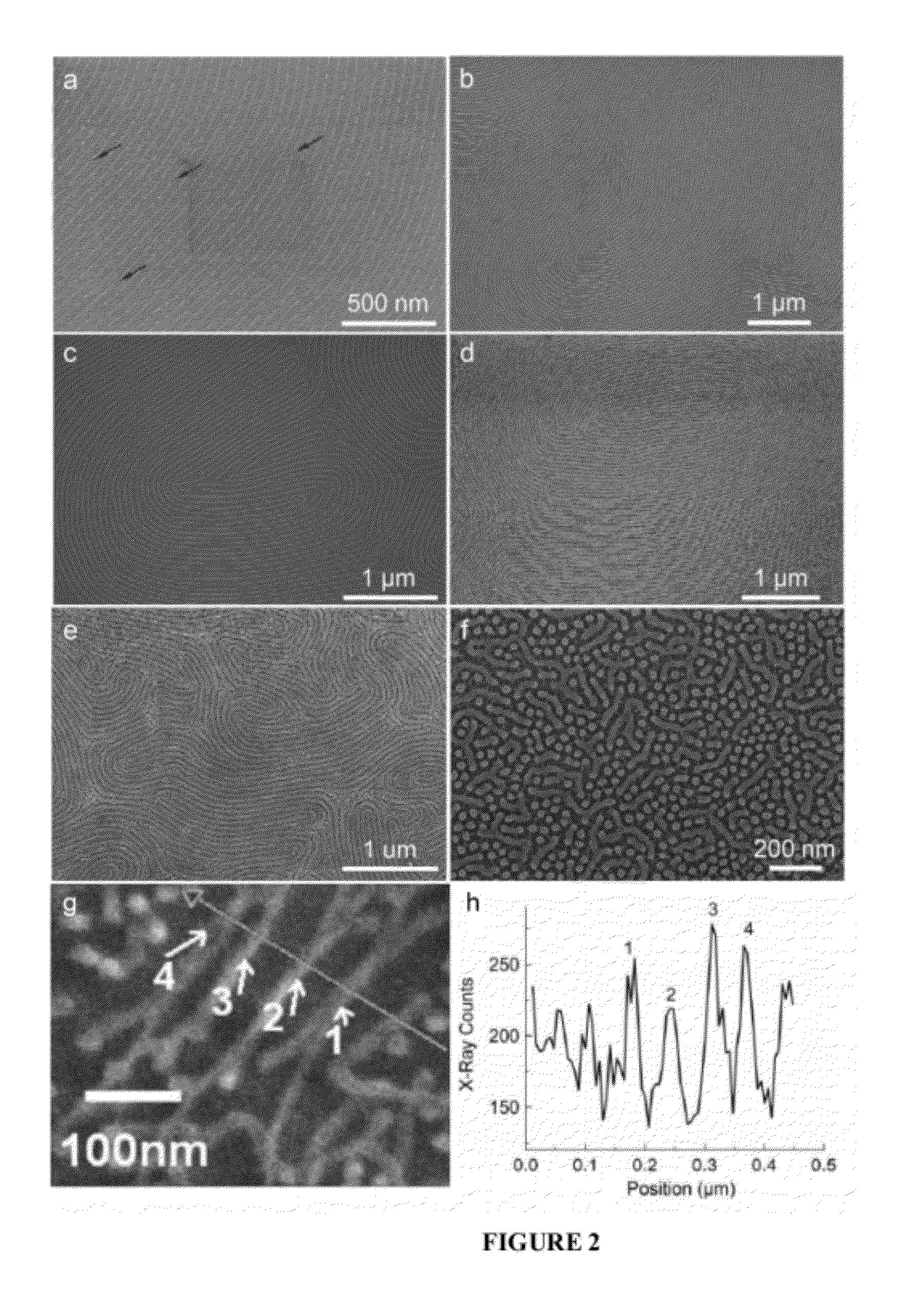

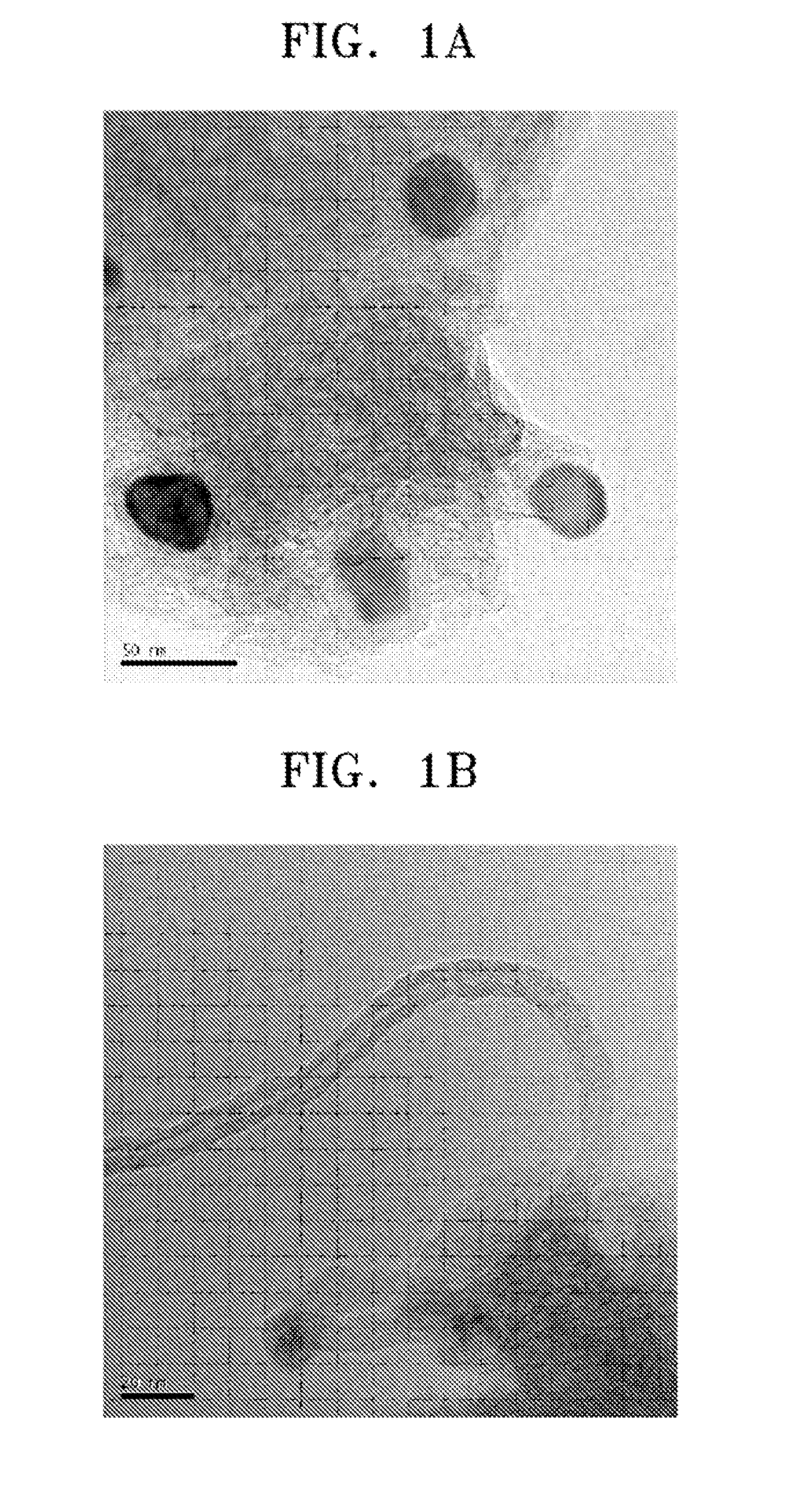

Ordered Nanoscale Domains by Infiltration of Block Copolymers

ActiveUS20120046421A1Low costHighly controllable molecularProgramme controlSolid electrolytesNanostructureAtomic layer deposition

A method of preparing tunable inorganic patterned nanofeatures by infiltration of a block copolymer scaffold having a plurality of self-assembled periodic polymer microdomains. The method may be used sequential infiltration synthesis (SIS), related to atomic layer deposition (ALD). The method includes selecting a metal precursor that is configured to selectively react with the copolymer unit defining the microdomain but is substantially non-reactive with another polymer unit of the copolymer. A tunable inorganic features is selectively formed on the microdomain to form a hybrid organic / inorganic composite material of the metal precursor and a co-reactant. The organic component may be optionally removed to obtain an inorganic feature s with patterned nanostructures defined by the configuration of the microdomain.

Owner:UCHICAGO ARGONNE LLC

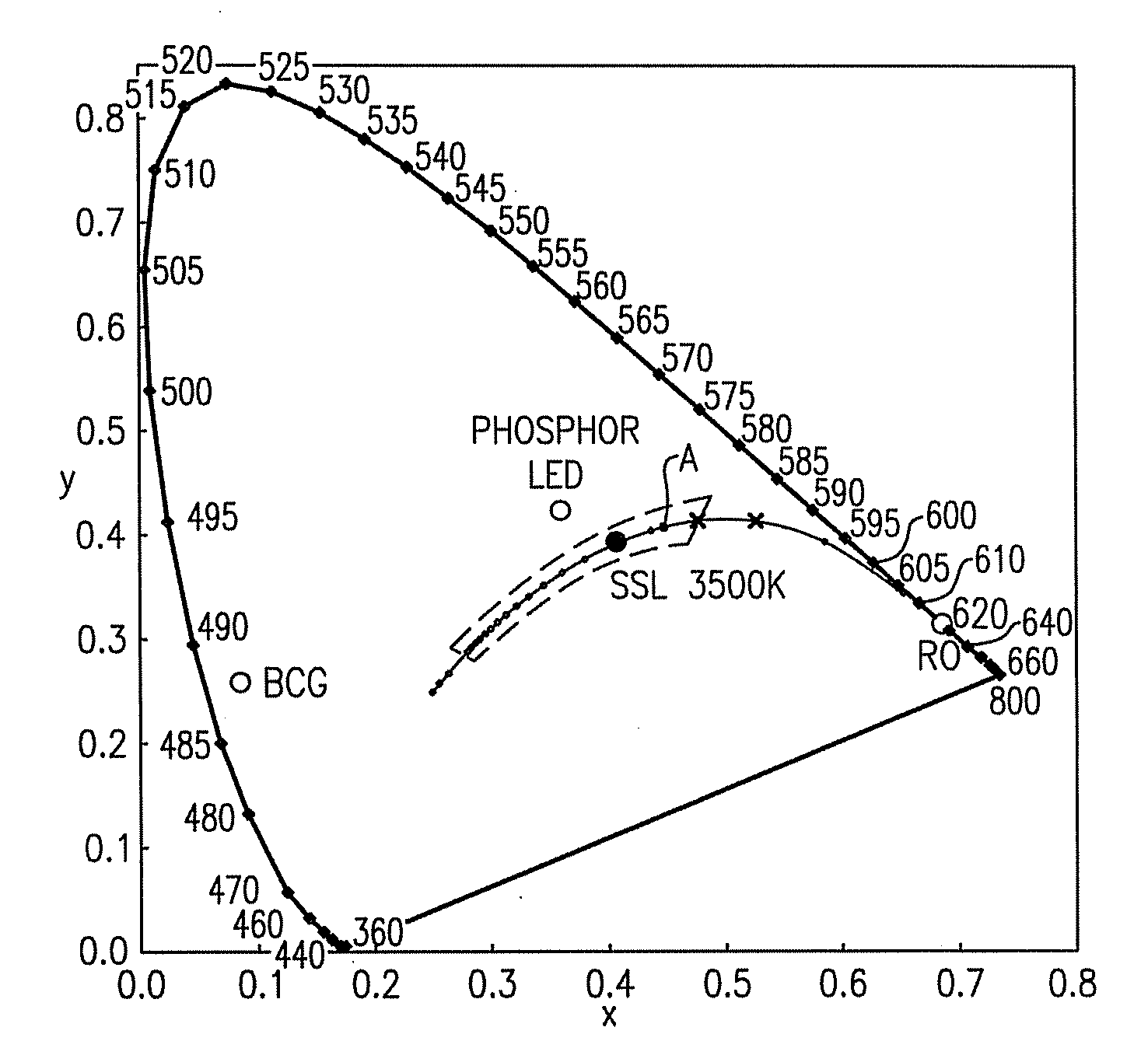

Lighting device and method of making

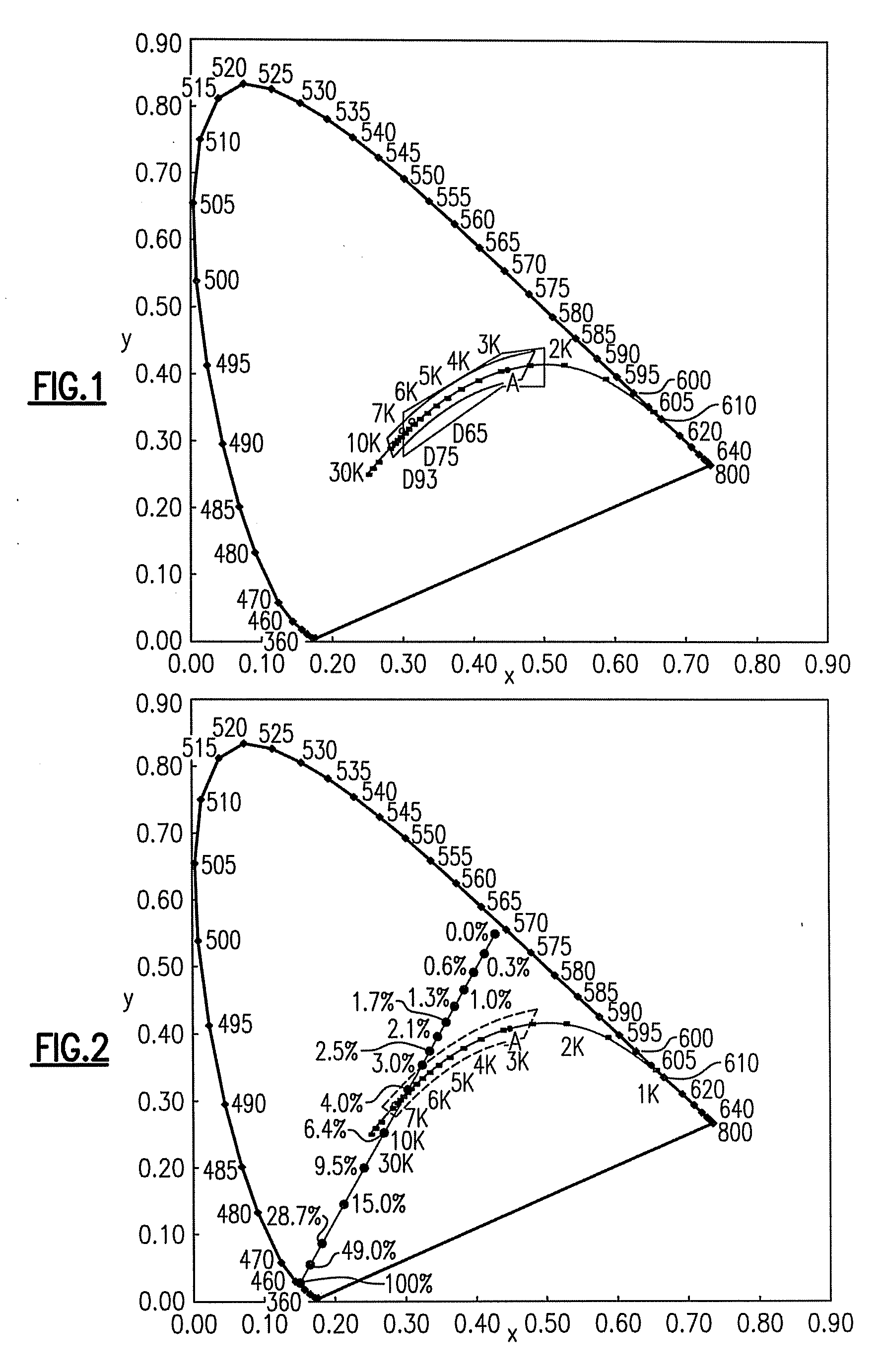

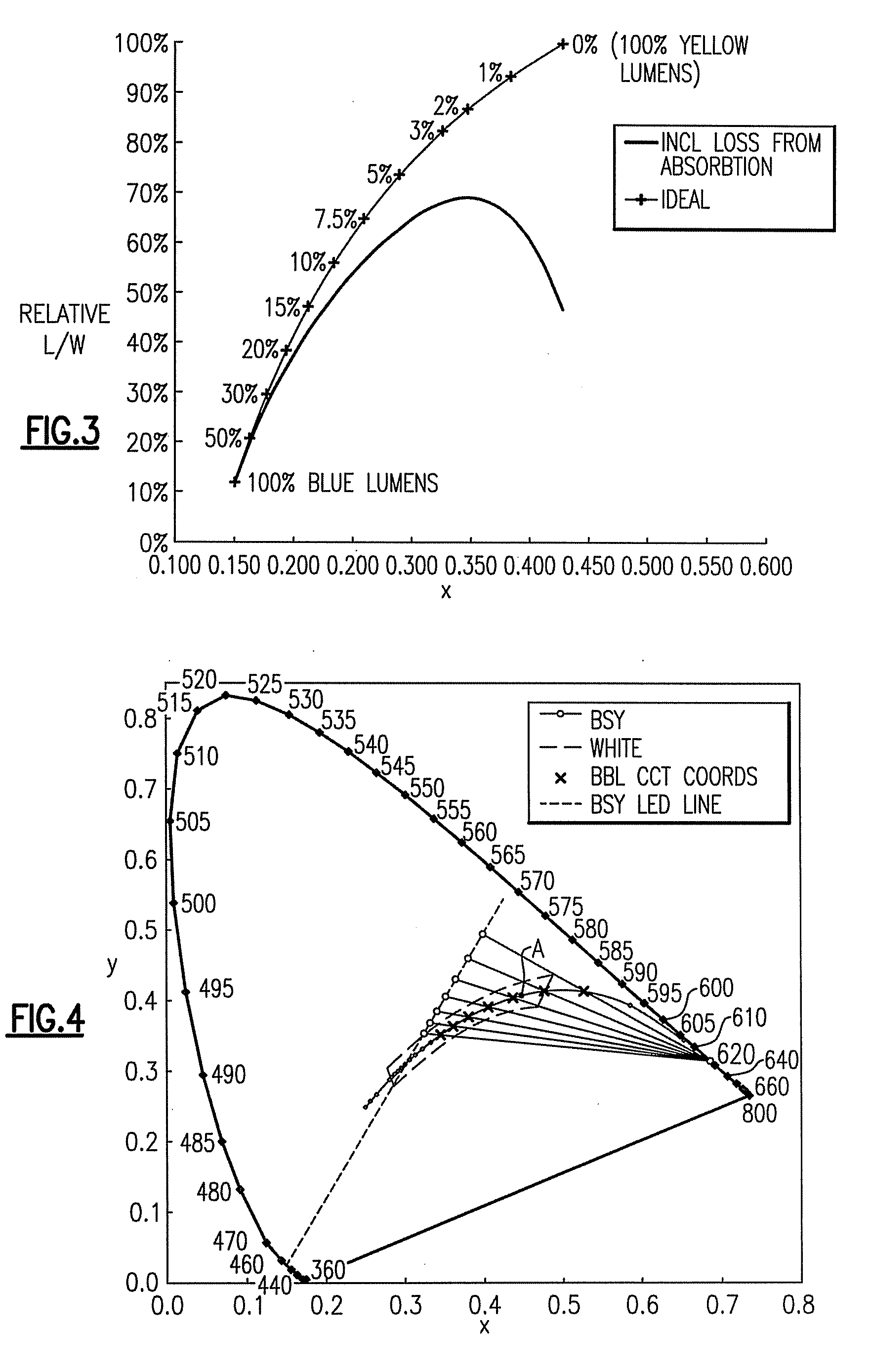

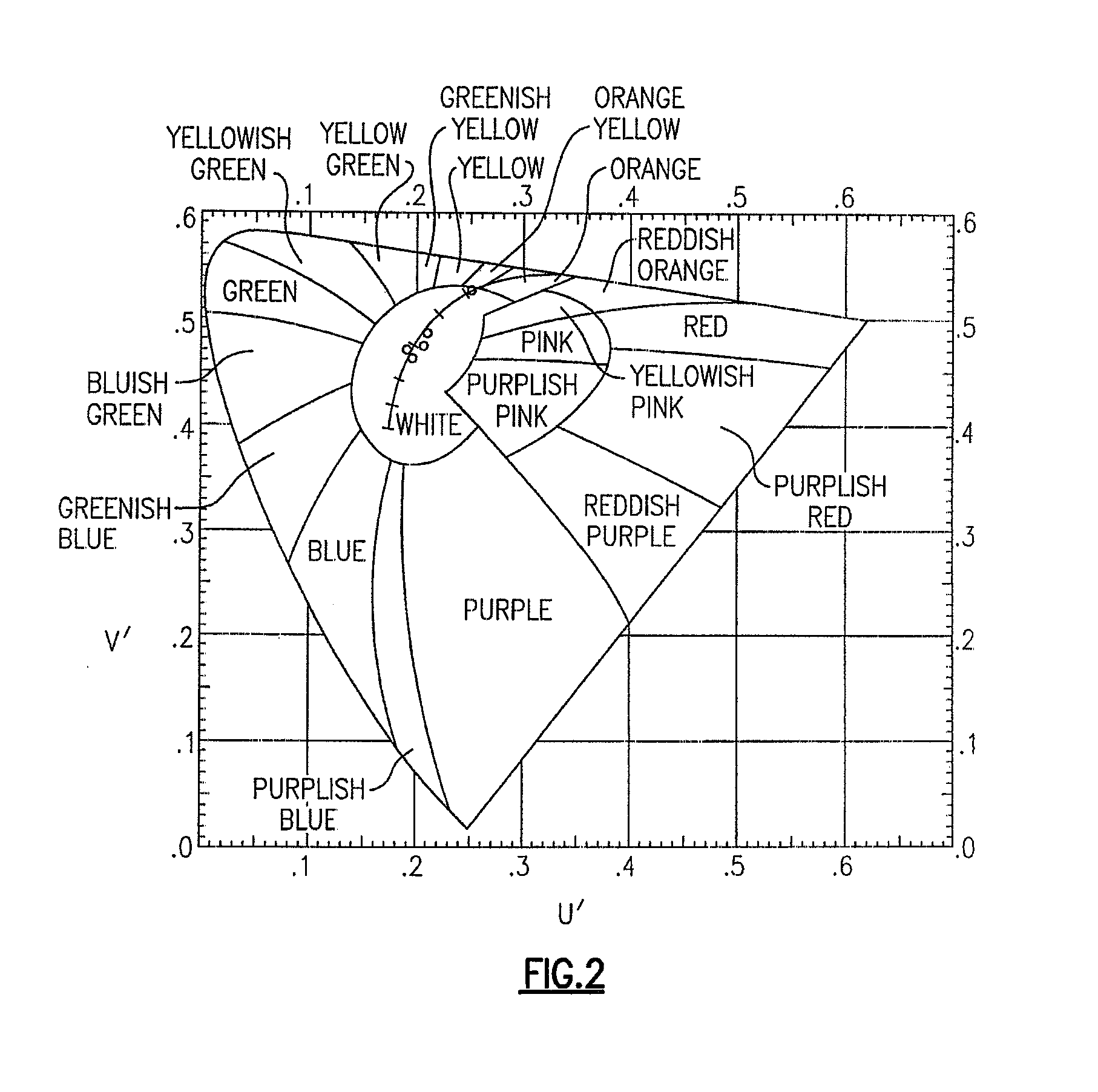

ActiveUS20090184616A1High color rendering indexLight source combinationsDischarge tube luminescnet screensEffect lightLength wave

A lighting device comprising at least one non-white light source, at least a first supplemental light emitter and at least a second supplemental light emitter. The non-white light source(s) is outside an area from 0.01 u′v′ above to below the blackbody locus, and within an area defined by curves between saturated light of wavelength 430-480 nm and 560-580 nm and line segments between saturated light of wavelength 430-580 nm and 480-560 nm. The first supplemental light emitter(s) have dominant emission wavelength of 465-540 nm. The second supplemental light emitter(s) have dominant emission wavelength of 600-640 nm.

Owner:IDEAL IND LIGHTING LLC

Carbon nanotube hybrid system using carbide-derived carbon, a method of making the same, an electron emitter comprising the same, and an electron emission device comprising the electron emitter

InactiveUS20080248310A1Improve uniformityLong life-timeMaterial nanotechnologyNanostructure manufactureHybrid systemHalogen

A carbon nanotube hybrid system includes: a carbide-derived carbon prepared by reacting a carbide compound and a halogen group containing gas to extract elements of the carbide compound except carbons; metals supported on the carbide-derived carbon or remaining in the carbide-derived carbon; and carbon sources from which carbon nanotubes are grown from the carbide-derived carbon. A method of preparing the carbon nanotube hybrid system includes preparing the carbide-derived carbon, extracting elements therefrom, and growing carbon nanotubes from the carbide-derived carbon. The carbon nanotube hybrid system has excellent uniformity and a long lifetime. An electron emitter having improved electron emitting properties can be inexpensively prepared using the carbon nanotube hybrid system compared to conventional carbon nanotubes. An electron emission device having excellent electron emitting properties can be prepared using the electron emitter.

Owner:SAMSUNG SDI CO LTD

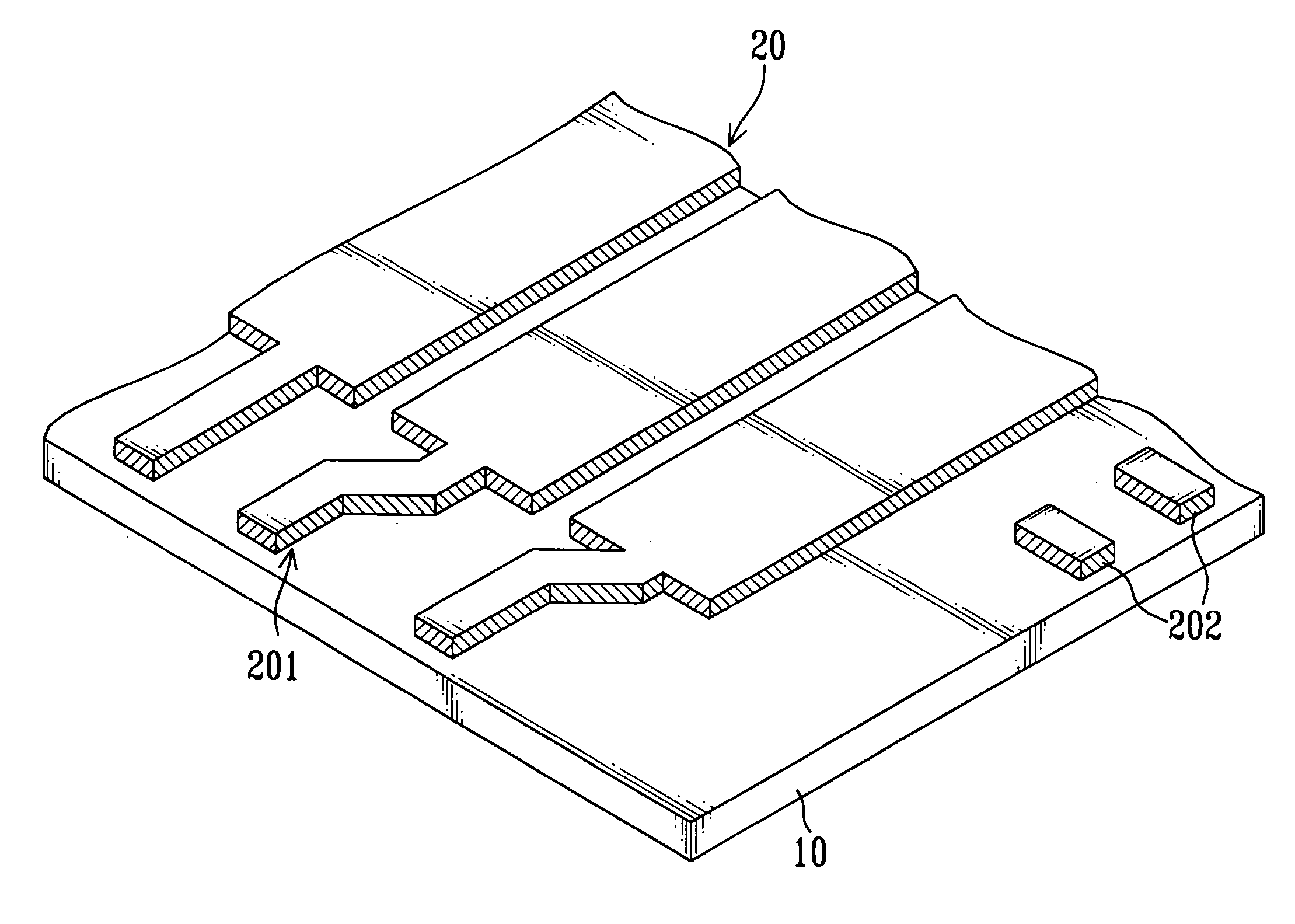

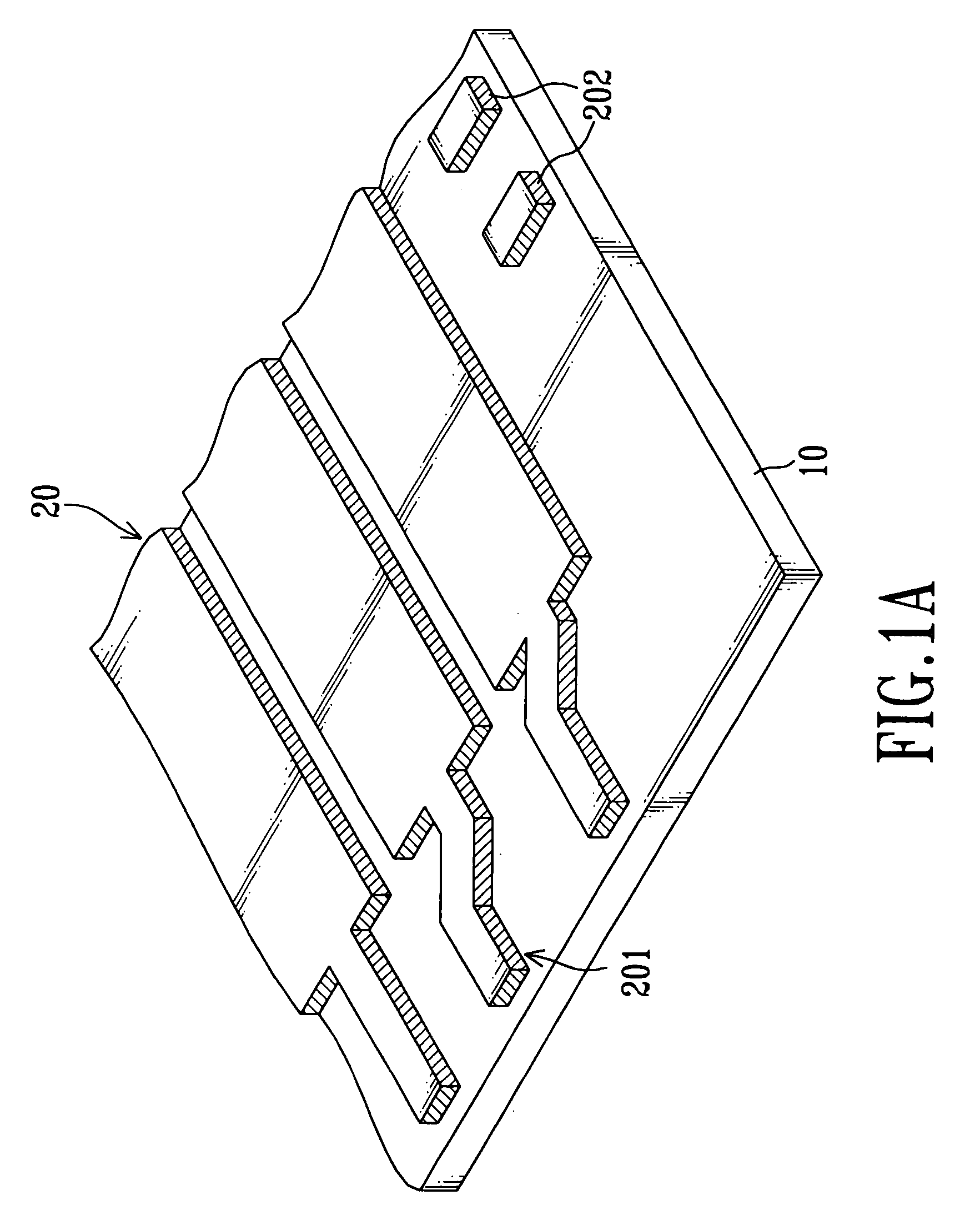

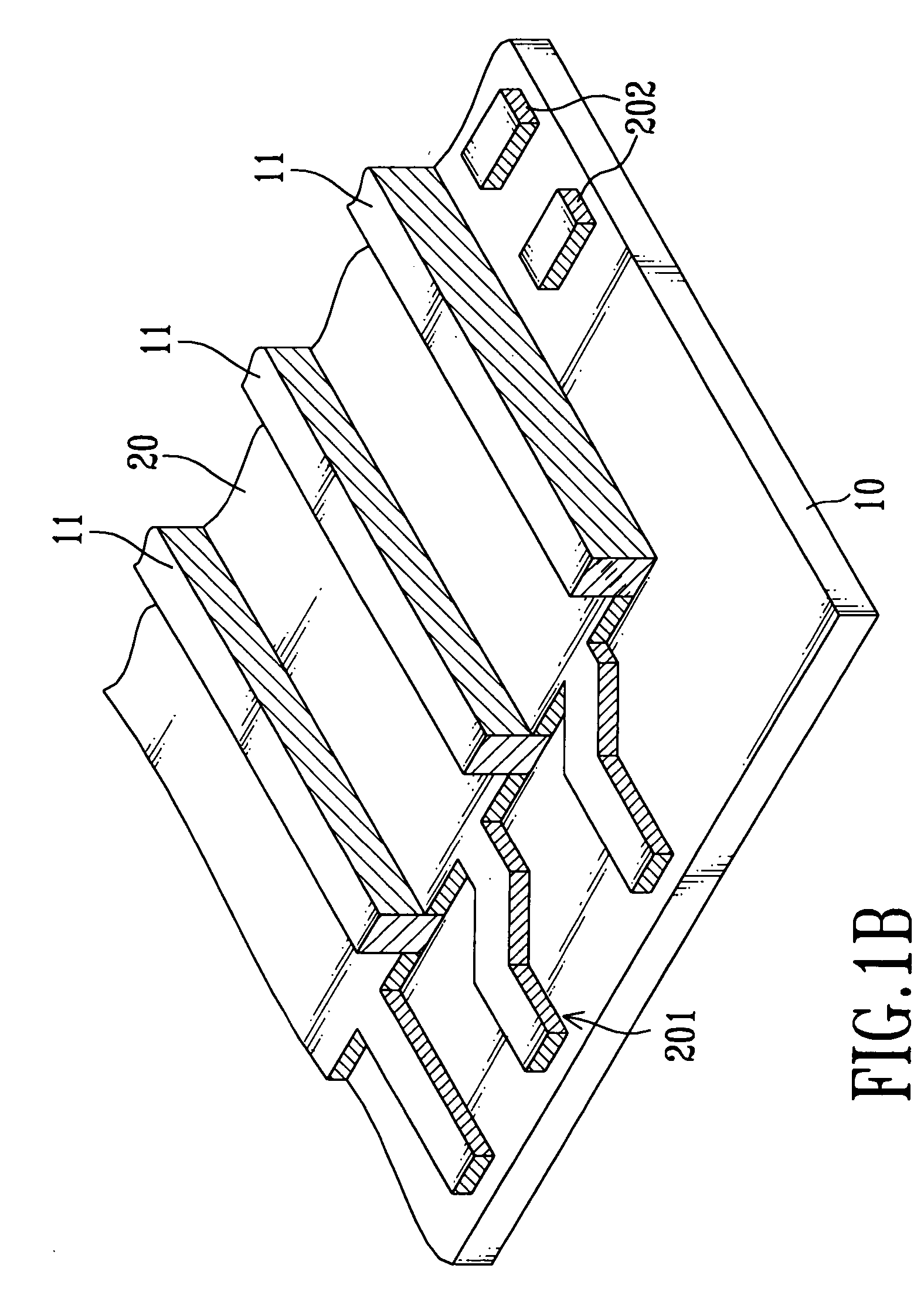

Method and apparatus for filling liquid crystal display (LCD) panels

InactiveUS6055035AElectroluminescent light sourcesVessels or leading-in conductors manufactureLiquid-crystal displayEngineering

A system, apparatus, and method for filling a display panel having first and second plates, with liquid crystal material, includes a nozzle for depositing a layer of liquid crystal material over a surface of a first plate of the panel, a scanning arm, coupled to the nozzle, for uniformly forming the layer of liquid crystal material over the surface of the first plate of the panel, and an attachment mechanism for placing the second plate over the first plate having the liquid crystal material thereover, thereby to form the display panel.

Owner:AU OPTRONICS CORP

Field emission electron source

InactiveUS6057637AStable and reproducible current-voltage characteristicStraightforward and commercially feasibleElectric discharge tubesLayered productsElectron currentElectron source

A novel field emitter material, field emission electron source, and commercially feasible fabrication method is described. The inventive field emission electron source produces reliable electron currents of up to 400 mA / cm2 at 200 volts. The emitter is robust and the current it produces is not sensitive to variability of vacuum or the distance between the emitter tip and the cathode. The novel emitter has a sharp turn-on near 100 volts.

Owner:RGT UNIV OF CALIFORNIA

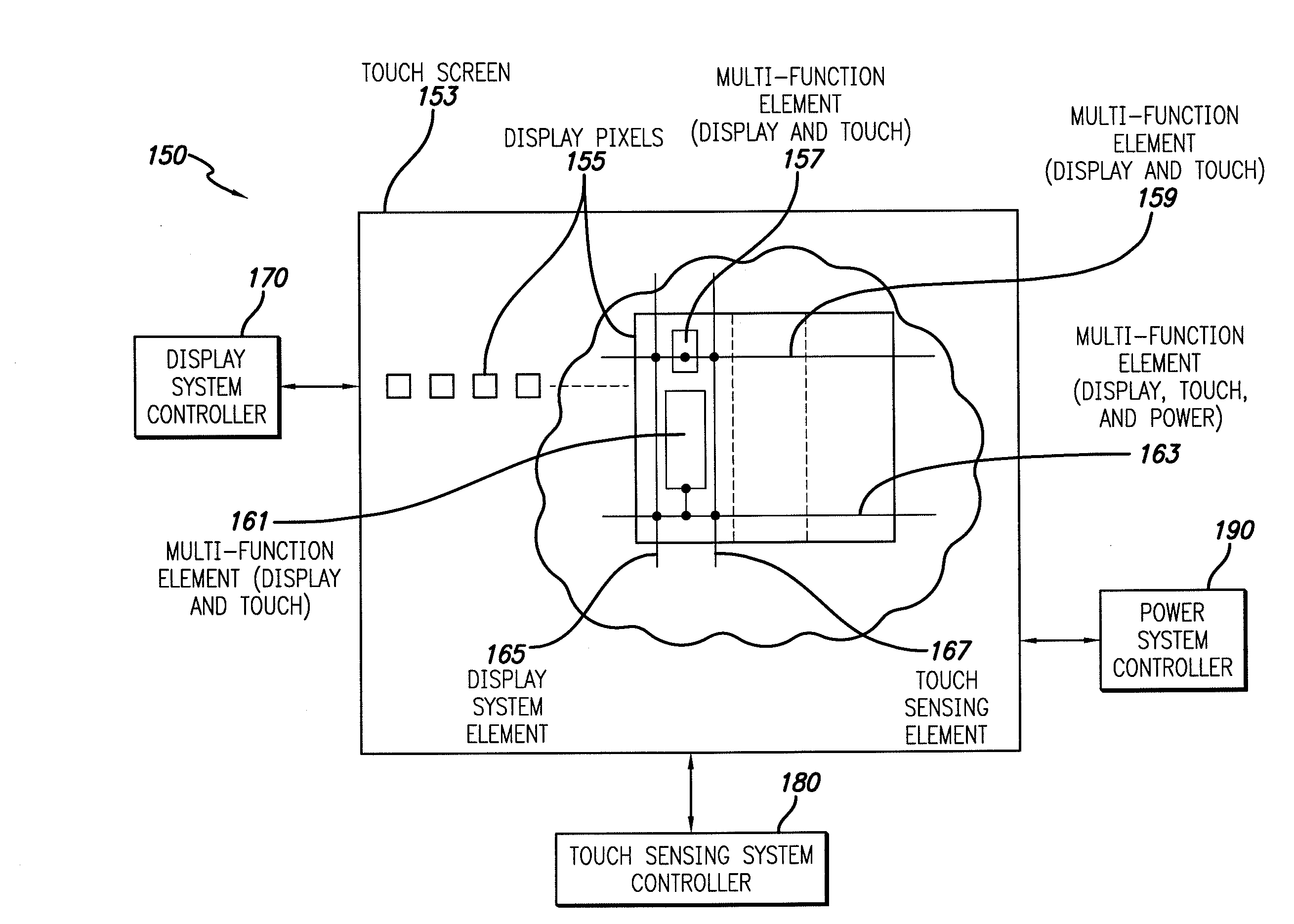

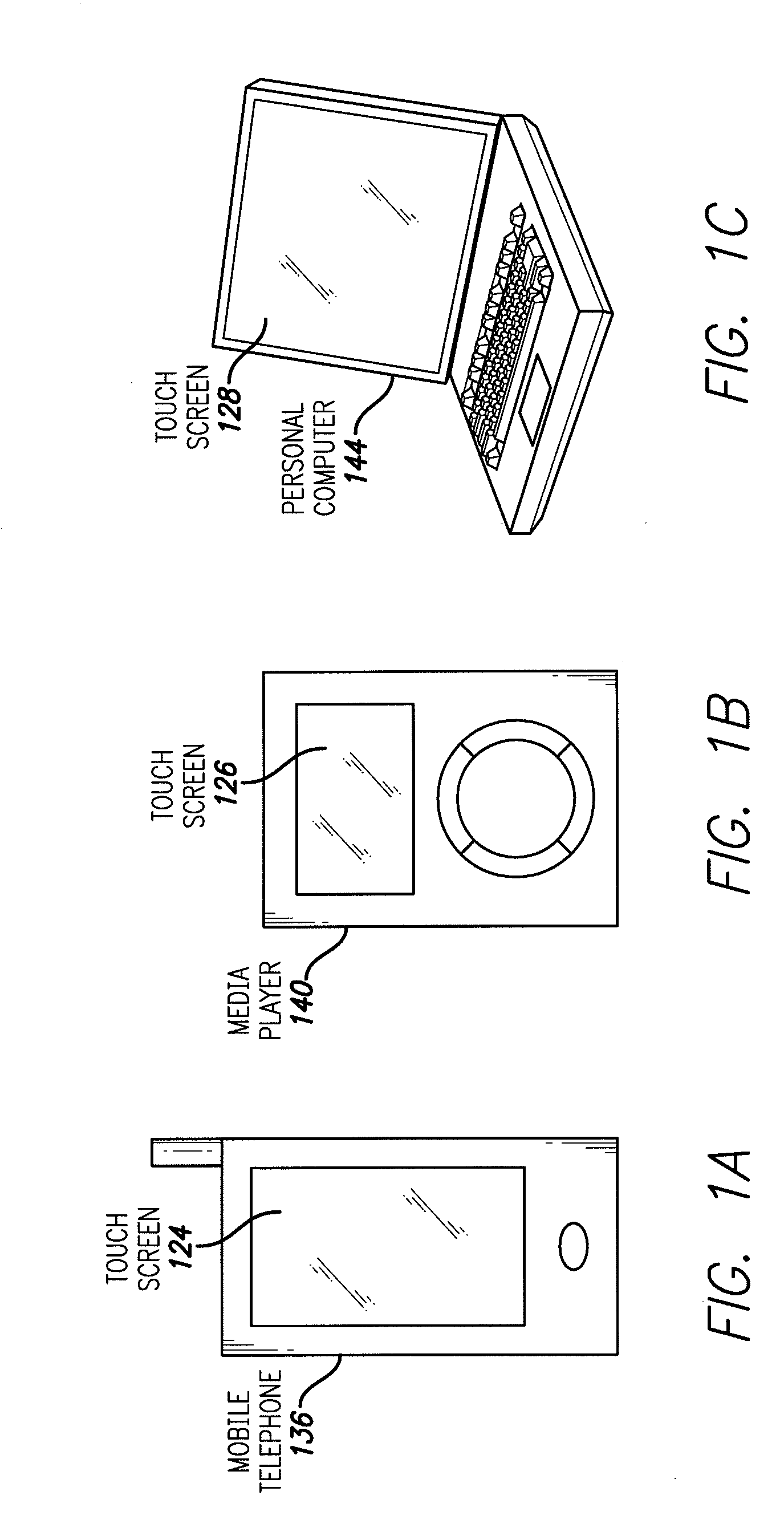

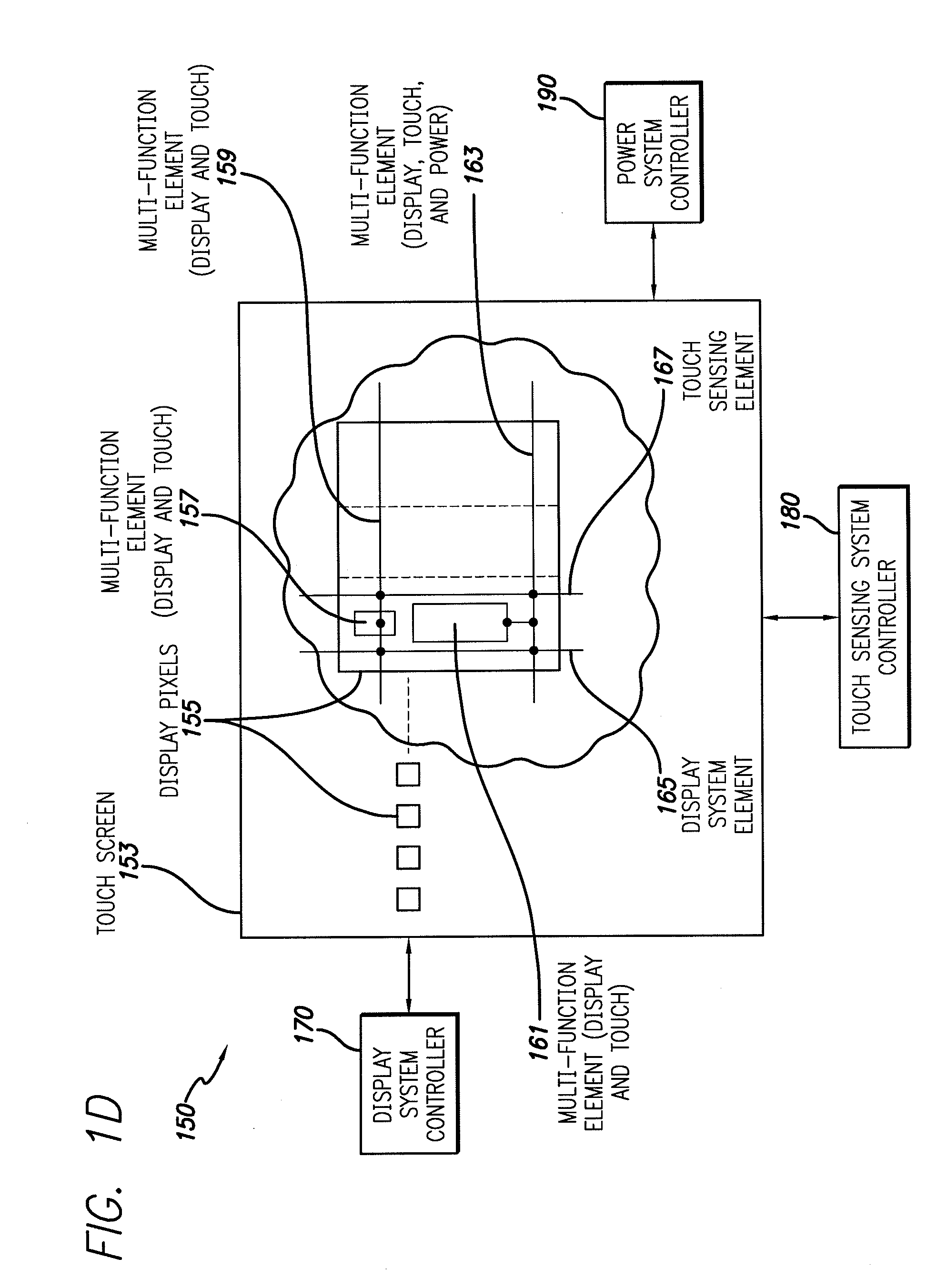

Integrated Touch Screen

ActiveUS20100194697A1Less powerFew partsStatic indicating devicesVessels or leading-in conductors manufactureTouch SensesDisplay device

Displays with touch sensing circuitry integrated into the display pixel stackup are provided. Circuit elements, such as touch signal lines, such as drive lines and sense lines, grounding regions, in the display pixel stackups can be grouped together to form touch sensing circuitry that senses a touch on or near the display. An integrated touch screen can include multi-function circuit elements that can operate as circuitry of the display system to generate an image on the display, and can also form part of a touch sensing system that senses one or more touches on or near the display. The multi-function circuit elements can be, for example, capacitors in display pixels that can be configured to operate as storage capacitors / electrodes, common electrodes, conductive wires / pathways, etc., of the display circuitry in the display system, and that may also be configured to operate as circuit elements of the touch sensing circuitry.

Owner:APPLE INC

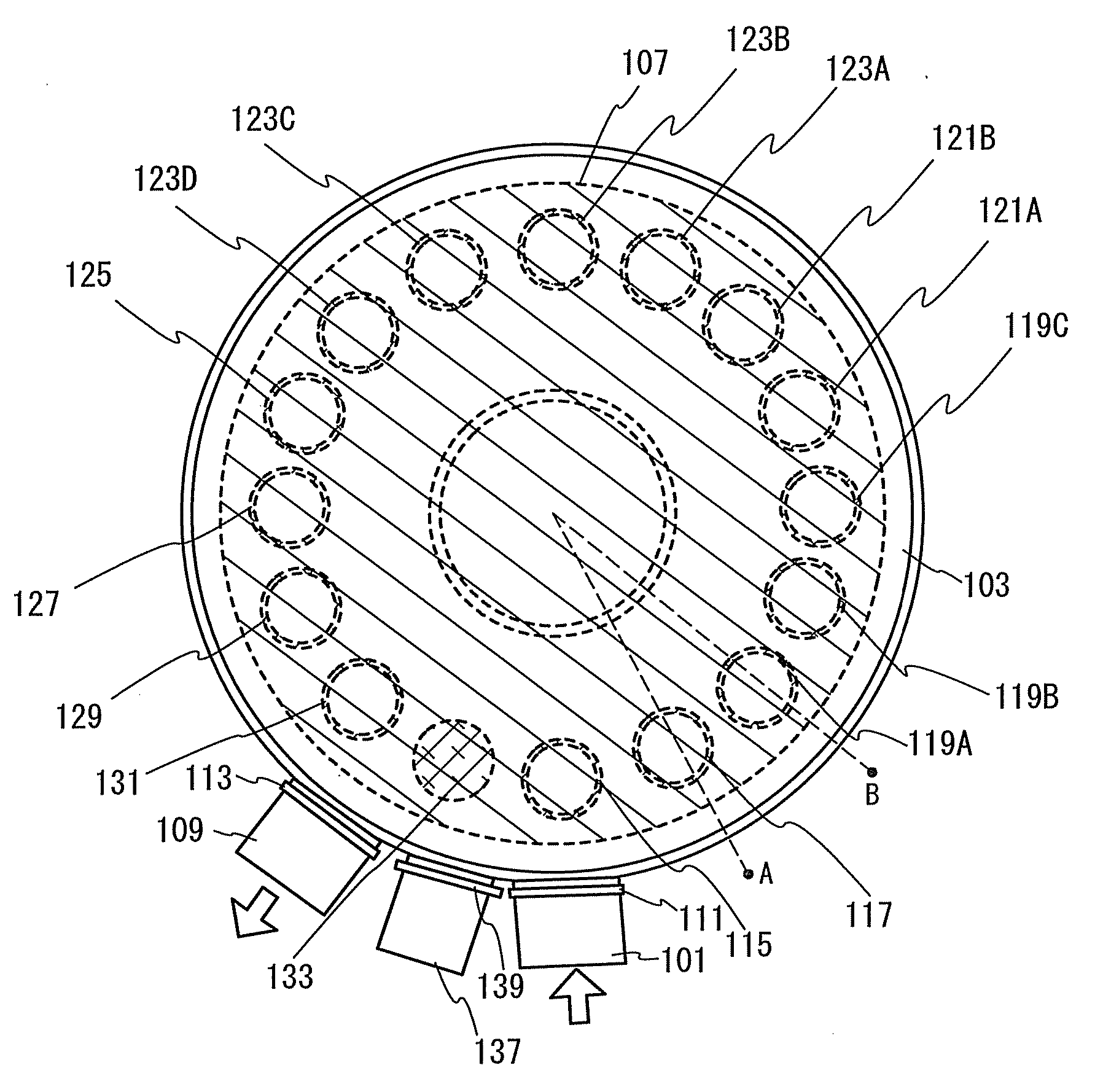

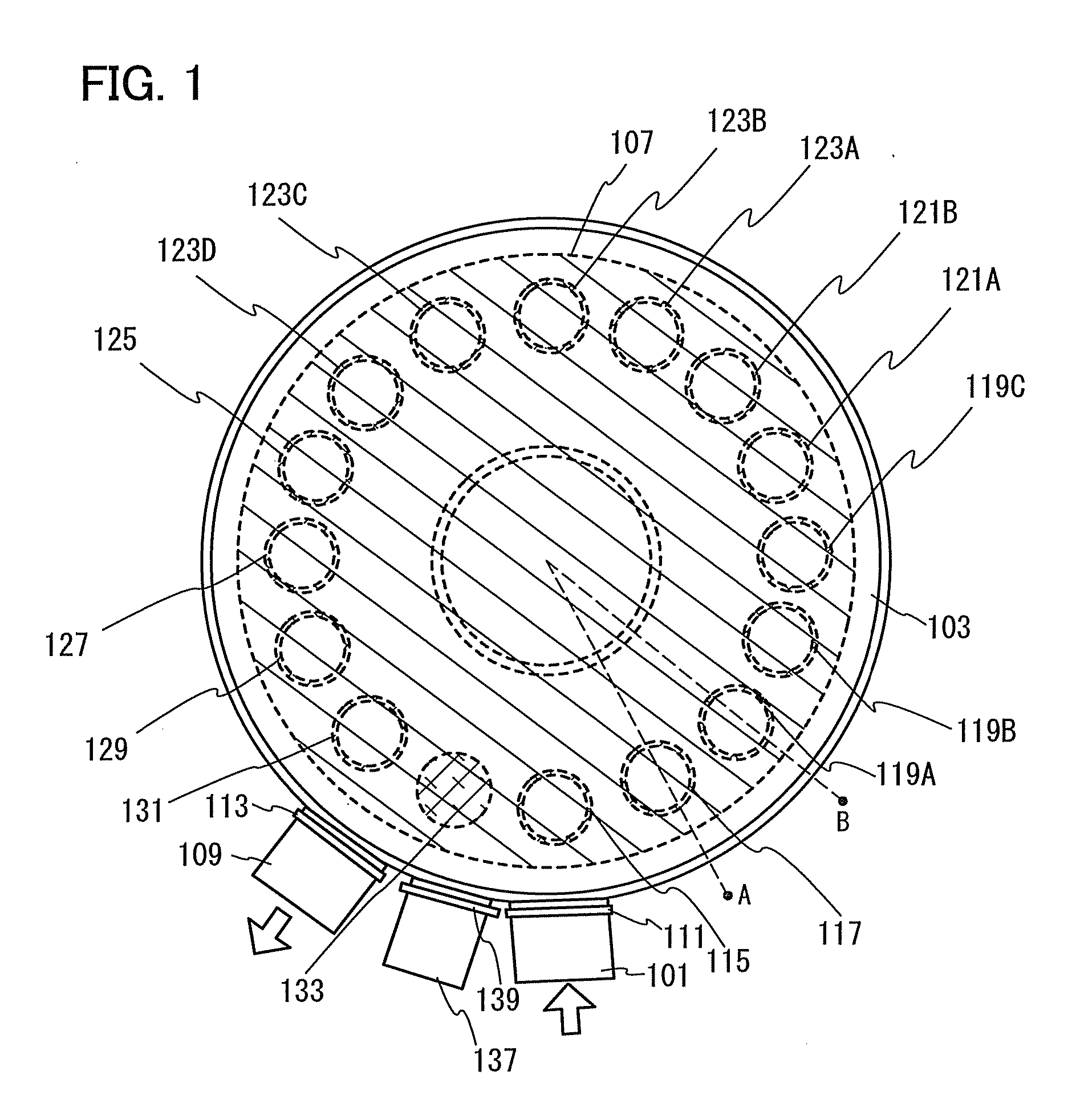

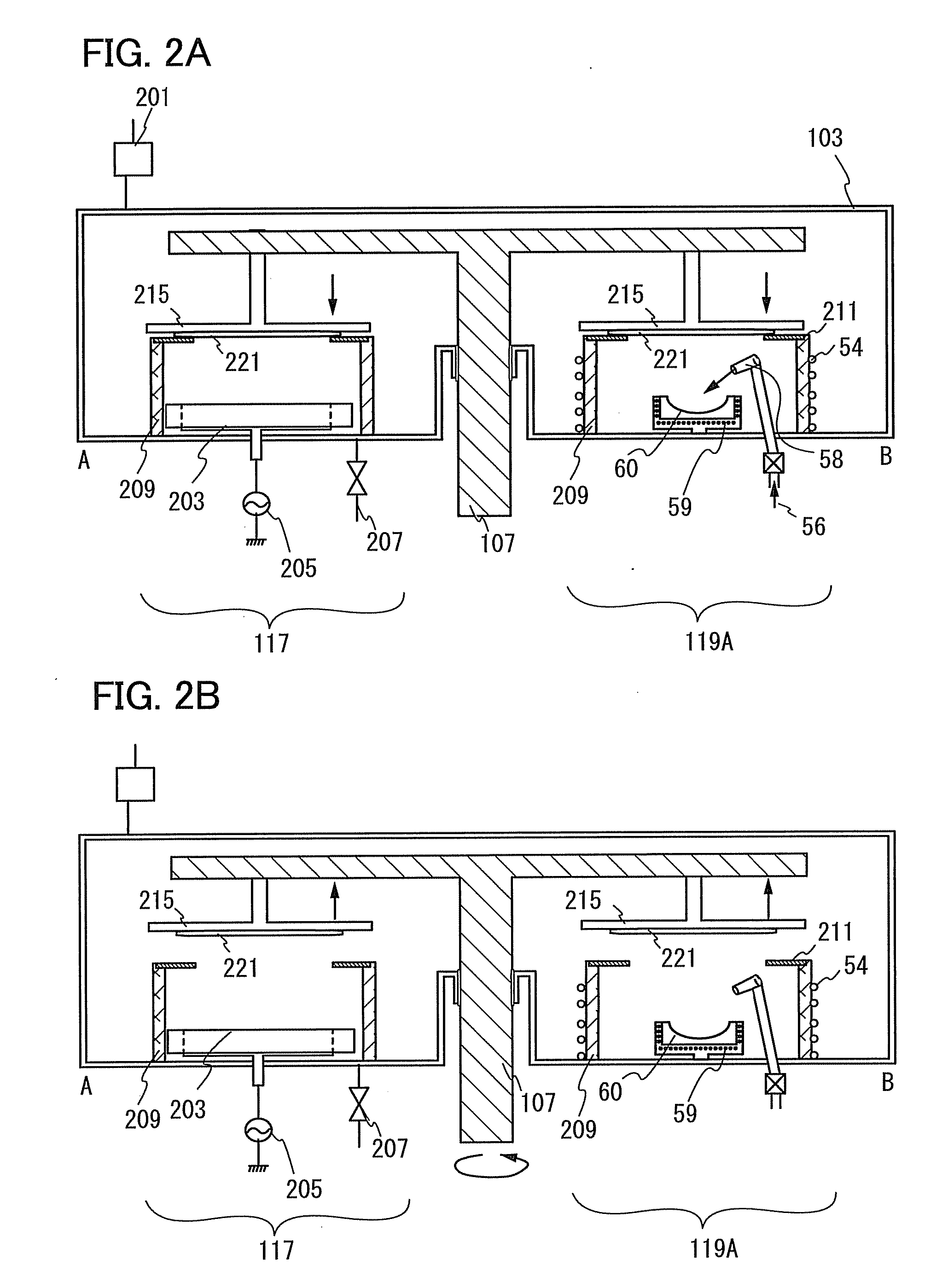

Manufacturing Apparatus and Manufacturing Method of Lighting Device

InactiveUS20100236691A1Improve efficiencyReduce manufacturing costVacuum evaporation coatingSolid-state devicesInter layerManufactured apparatus

A manufacturing apparatus of a lighting device, including a vacuum chamber, an exhaust system by which the vacuum chamber is set to a reduced-pressure state, and a transfer chamber from which a substrate is transferred to the vacuum chamber is provided. The vacuum chamber of the manufacturing apparatus includes a plurality of deposition chambers in which a first electrode, a first light-emitting unit including at least a light-emitting layer, an intermediate layer, a second light-emitting unit including at least a light-emitting layer, a second electrode, a sealing film are formed, and a substrate transfer means by which the substrate is sequentially transferred to the deposition chambers.

Owner:SEMICON ENERGY LAB CO LTD

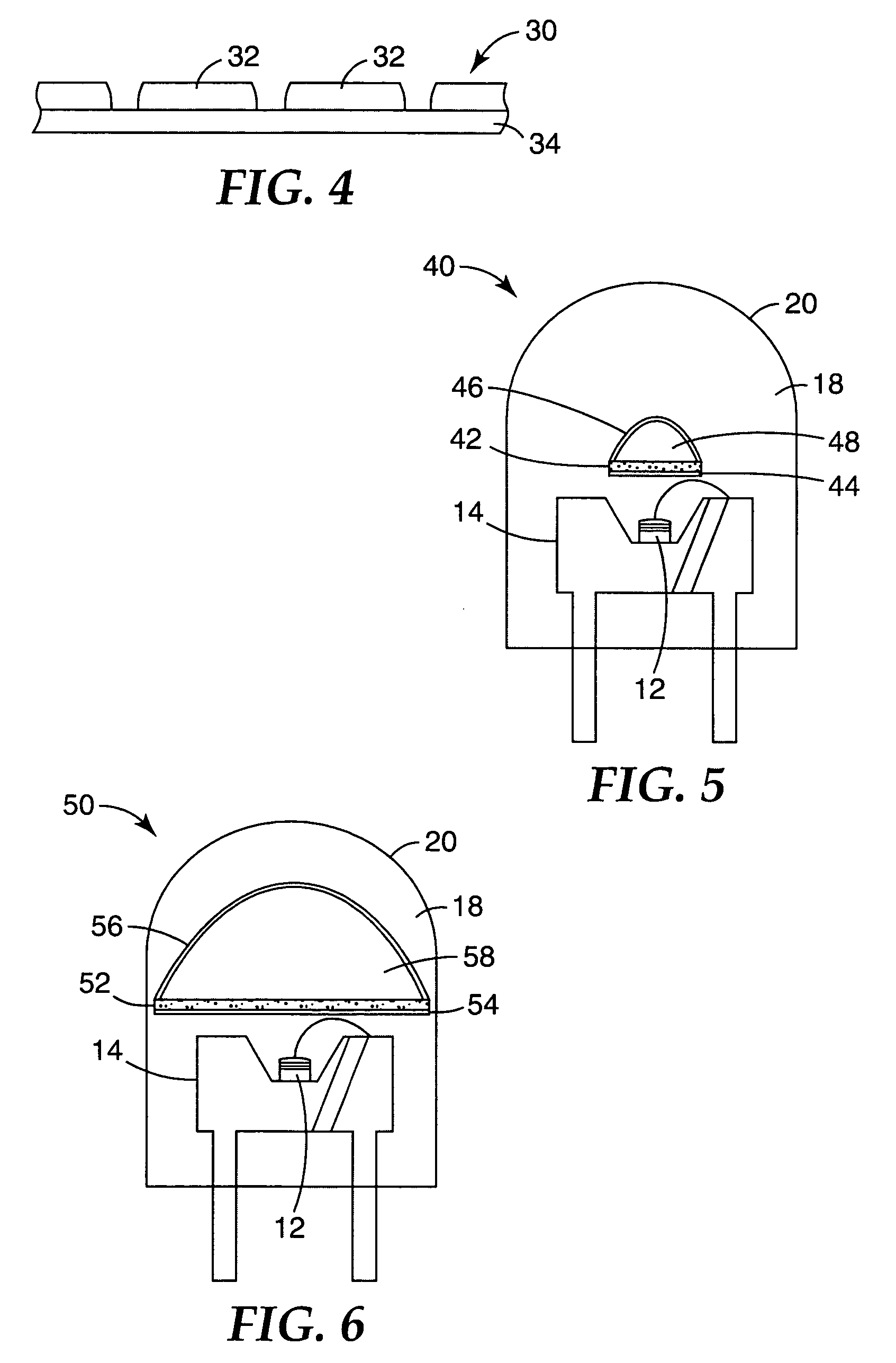

Lighting device and method of making same

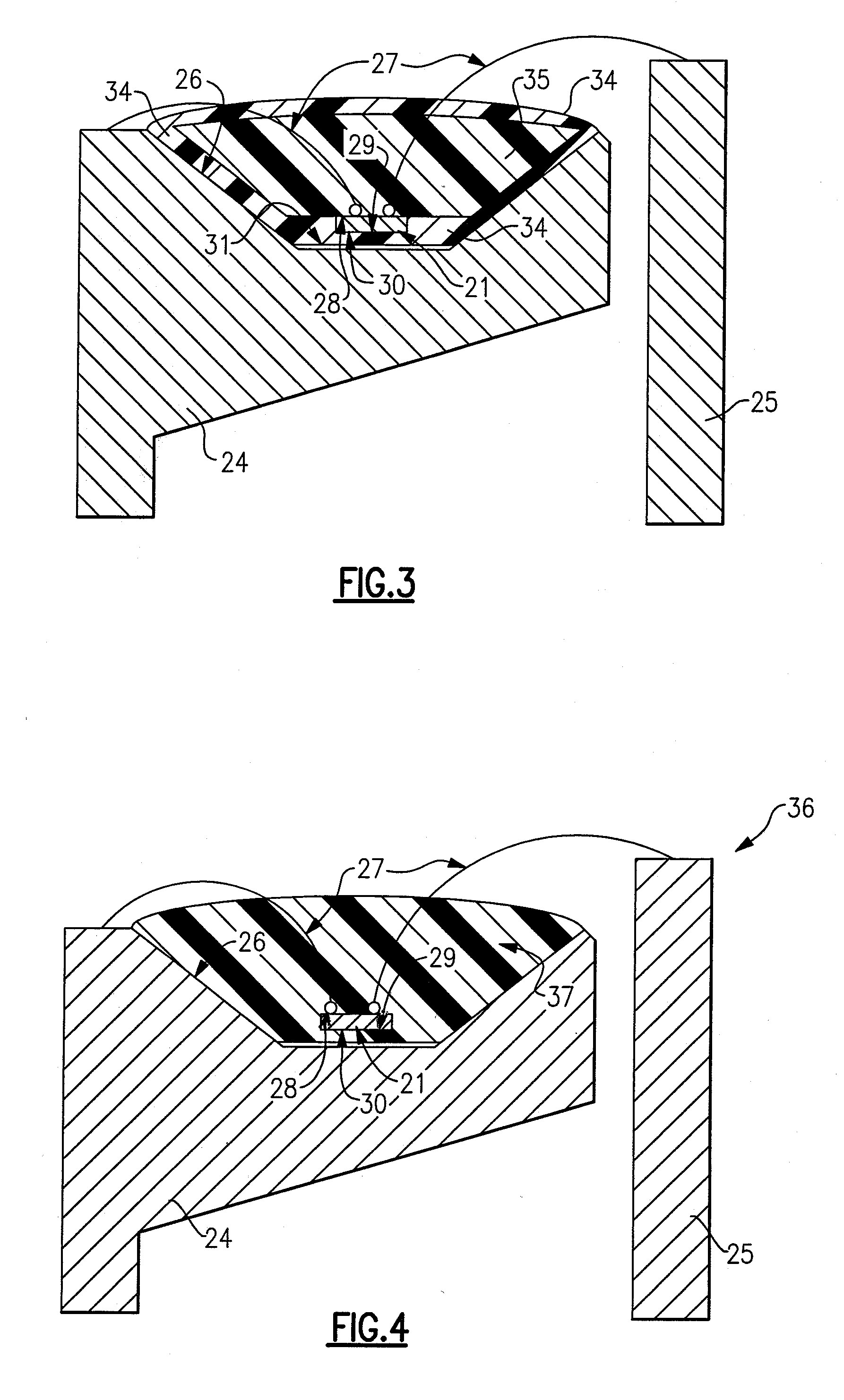

ActiveUS20080089053A1Simple materialReducing performance (intensity)Solid-state devicesVessels or leading-in conductors manufactureEffect lightEngineering

A lighting device comprising a light emitter chip, a reflective cup and a lumiphor positioned between the chip and the cup. Also, a lighting device comprising a light emitter chip, a wire bonded to a first surface of the chip and a lumiphor which faces a second surface of the chip. Also, a lighting device comprising a light emitter chip, and a lumiphor, a first surface of the chip facing a first region of the lumiphor, a second surface of the chip facing a second region of the lumiphor. Also, a lighting device comprising a light emitter chip and first and second lumiphors, a first surface of the chip facing the second lumiphor, a second surface of the chip facing the first lumiphor. Also, methods of making lighting devices.

Owner:CREELED INC

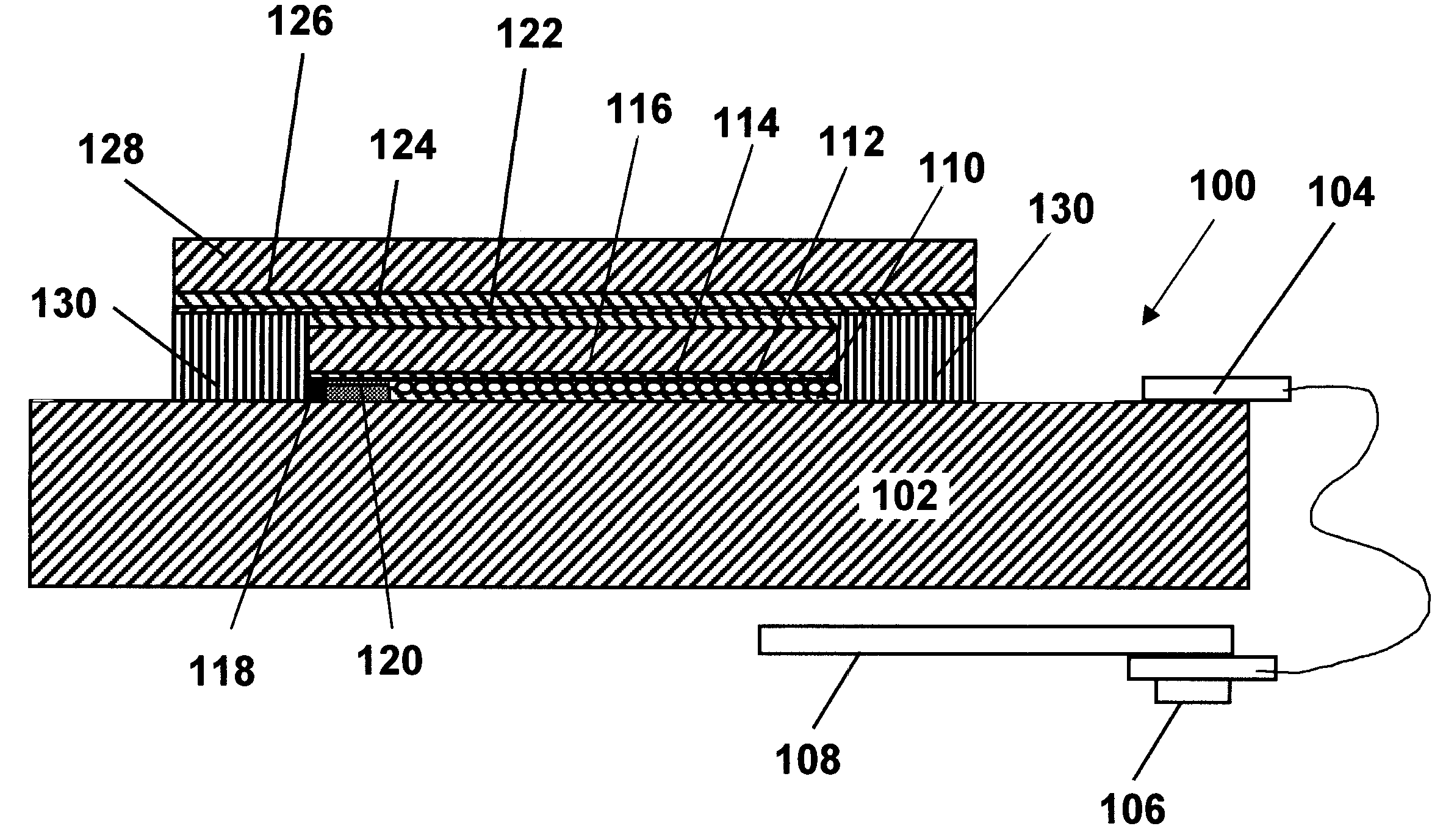

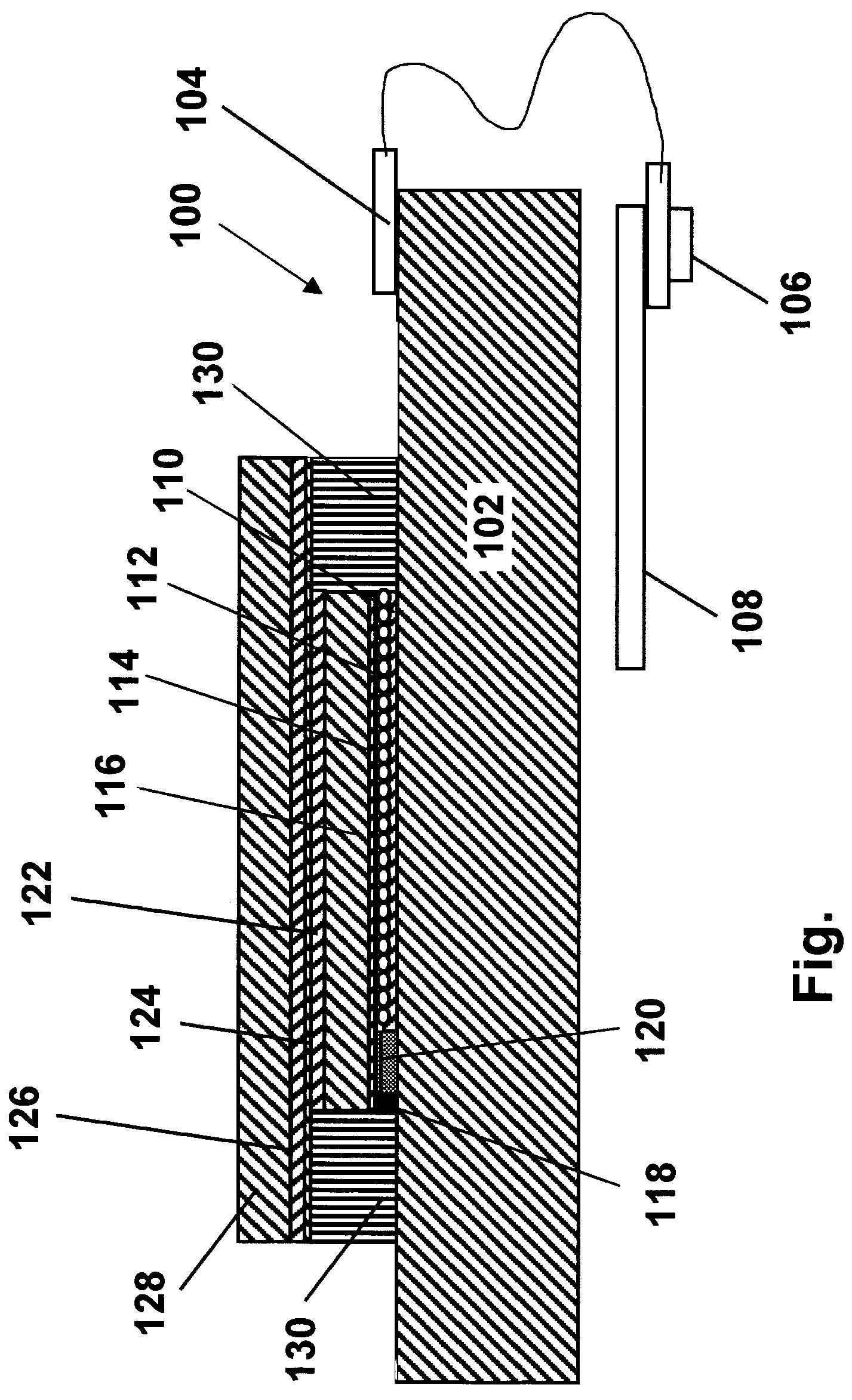

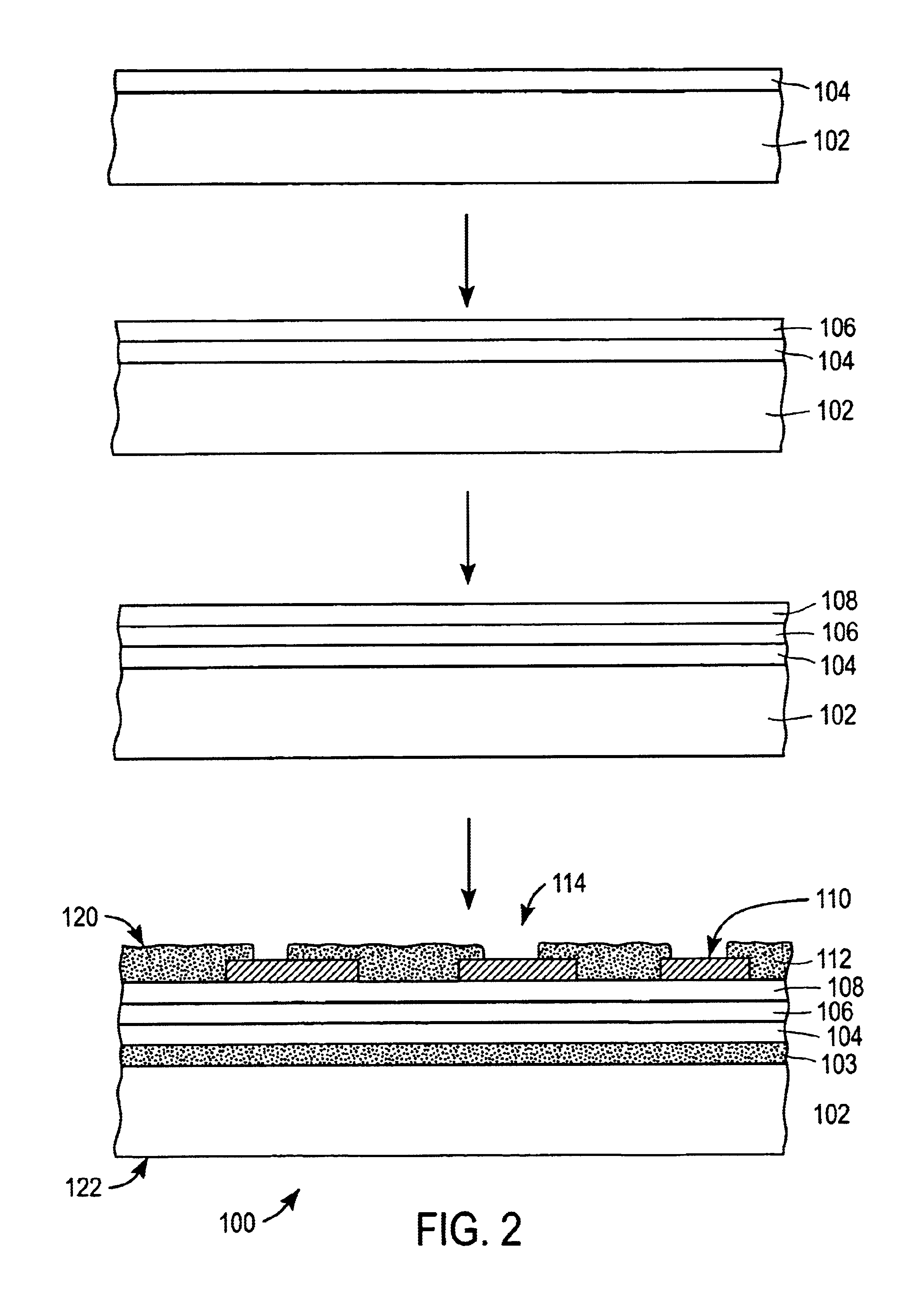

Process for sealing electro-optic displays

An electro-optic display (100) comprising a backplane (102), a layer (112) of electro-optic material and a protective layer (128) capable of absorbing ultra-violet radiation and disposed on the opposed side of the layer (112) of electro-optic material from the backplane (102), is provided with an edge seal (130). The protective layer (128) extends beyond the layer (112) of electro-optic material, thus leaving a peripheral gap between the protective layer (128) and the backplane (102). To form the edge seal (130) an uncured edge sealing material curable by radiation transmitted by the protective layer (128) is placed in the gap and cured by transmitting radiation through the protective layer (128).

Owner:E INK CORPORATION

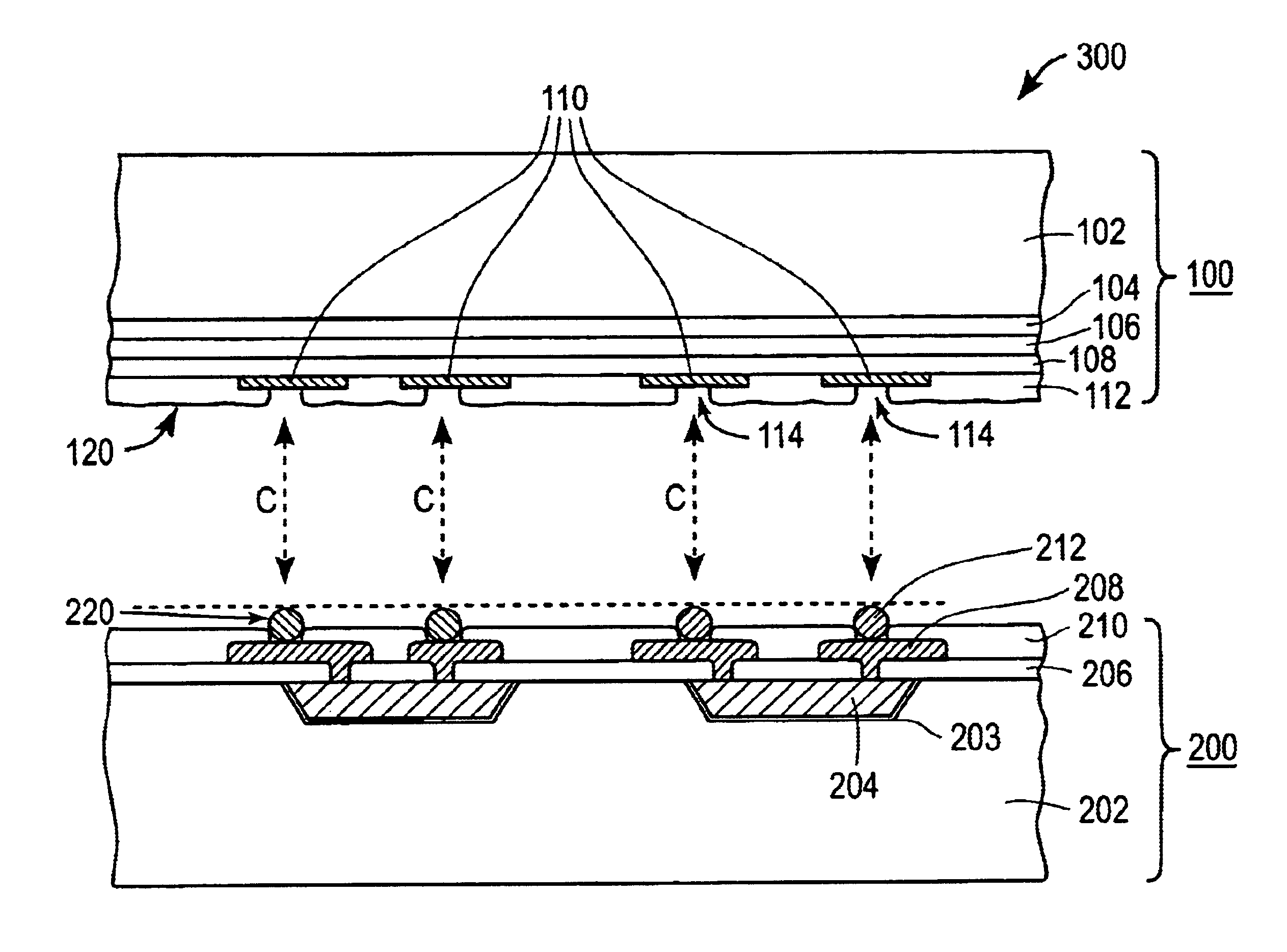

Split-fabrication for light emitting display structures

Methods and apparatuses for fabricating an electroluminescent display structure. A method including coupling a frontplane to a backplane wherein a frontplane top surface laminates to a backplane top surface. The frontplane and the backplane are fabricated separately. A first electrode layer which is transparent is disposed over the frontplane. A display medium which produces electro-optical effects upon a voltage application is disposed over the first electrode. A second electrode layer which is pattered is disposed over the display medium. The second electrode layer includes a plurality of connecting regions. The backplane is electrically active to provide driving signals for the display medium wherein the backplane includes a plurality of output pads to match the plurality of connecting regions.

Owner:RUIZHANG TECH LTD CO

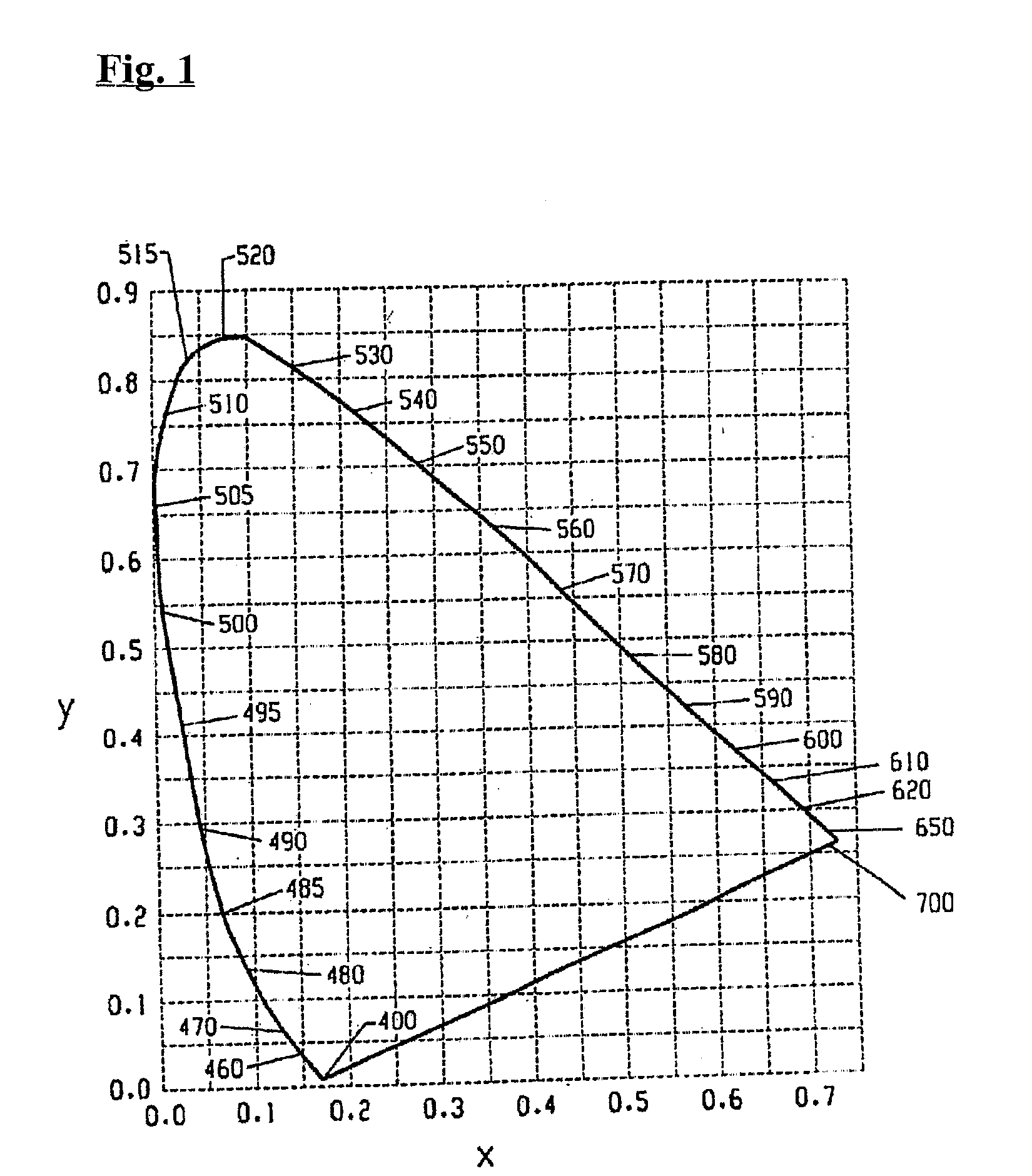

Lighting device and lighting method

ActiveUS20080136313A1Low efficiencyIncreased complexityDischarge tube luminescnet screensPoint-like light sourceEffect lightLight emitter

A lighting device comprising first, second and third groups of solid state light emitters, and first and second groups of lumiphors. A mixture of light emitted from the first group of emitters and the first group of lumiphors has x,y color coordinates within an area defined by coordinates (0.36,0.48), (0.43,0.45), (0.5125,0.4866), and (0.4087,0.5896) (or (0.41,0.455), (0.36,0.48), (0.4087,0.5896), and (0.4788,0.5202)). A mixture of light emitted from the second group of emitters and the second group of lumiphors is within an area defined by (0.32,0.40), (0.36,0.38), (0.30,0.26), and (0.25,0.29). A mixture of light from the first and second groups of emitters and the first and second groups of lumiphors is within an area defined by (0.32,0.40), (0.36,0.48), (0.43,0.45), (0.42,0.42), and (0.36,0.38) (or (0.32,0.40), (0.36,0.38), (0.41,0.455), and (0.36,0.48)). A mixture of light from all of these emitters and lumiphors is within ten MacAdam ellipses of the blackbody locus. Also, methods of lighting.

Owner:IDEAL IND LIGHTING LLC

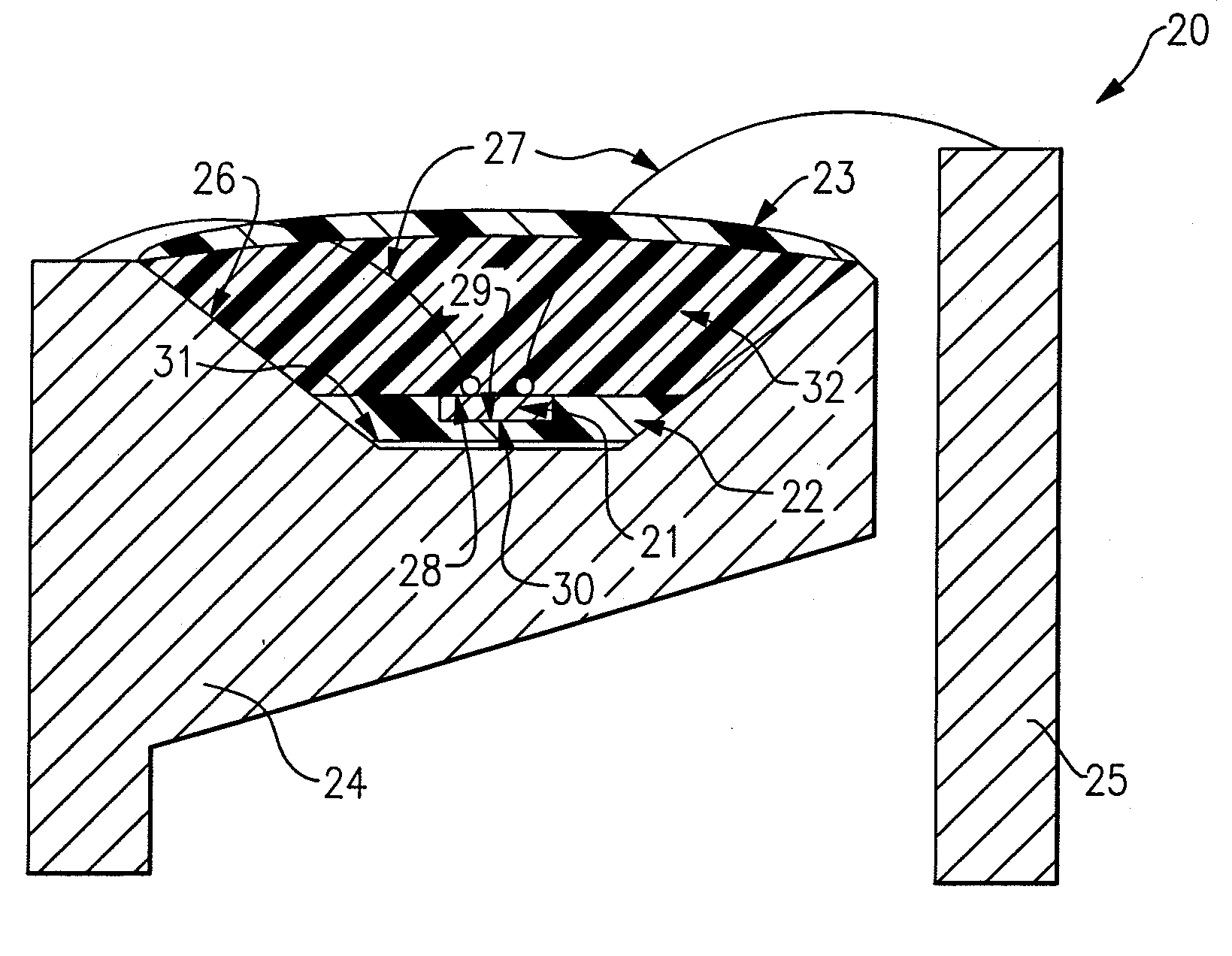

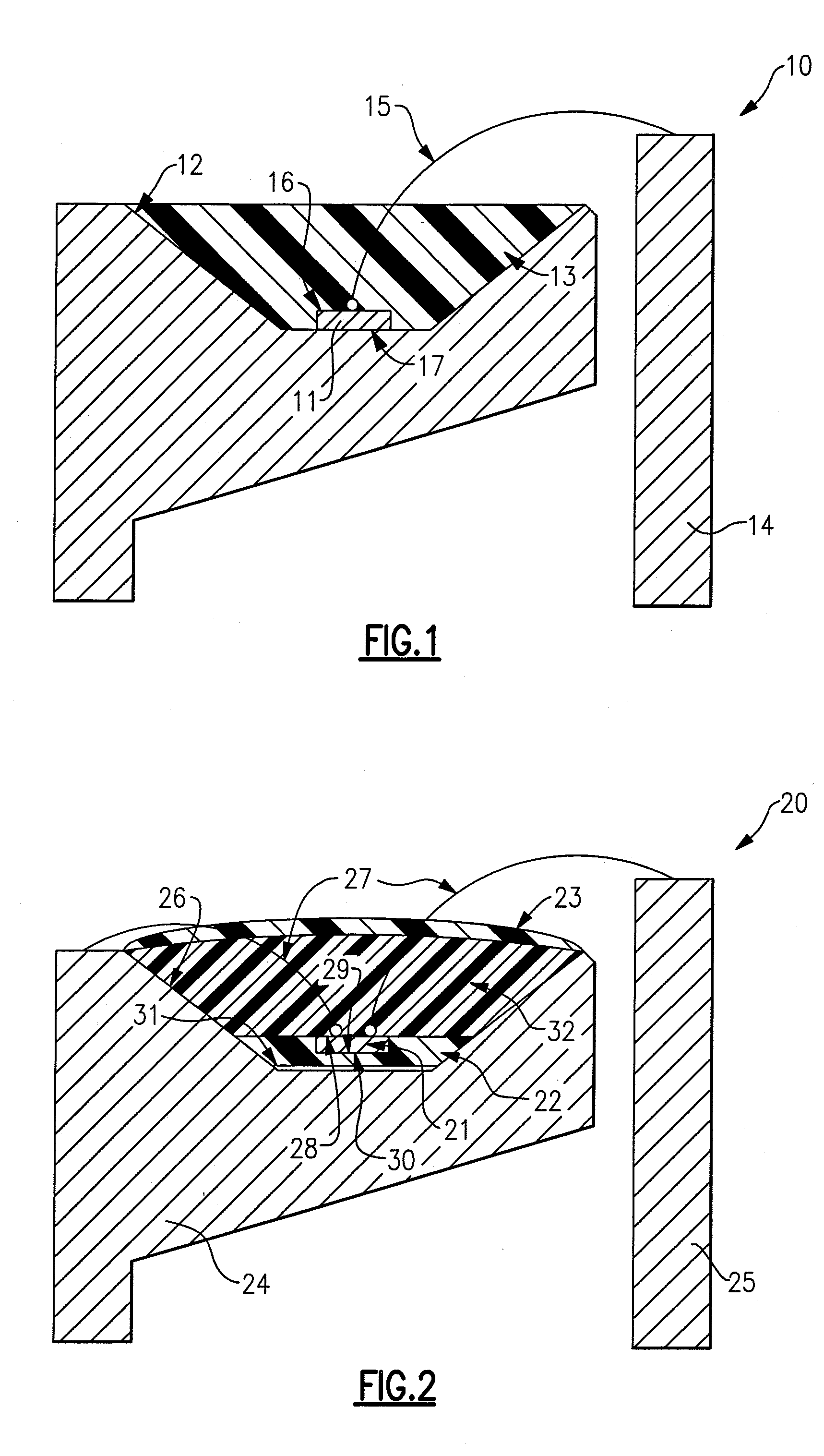

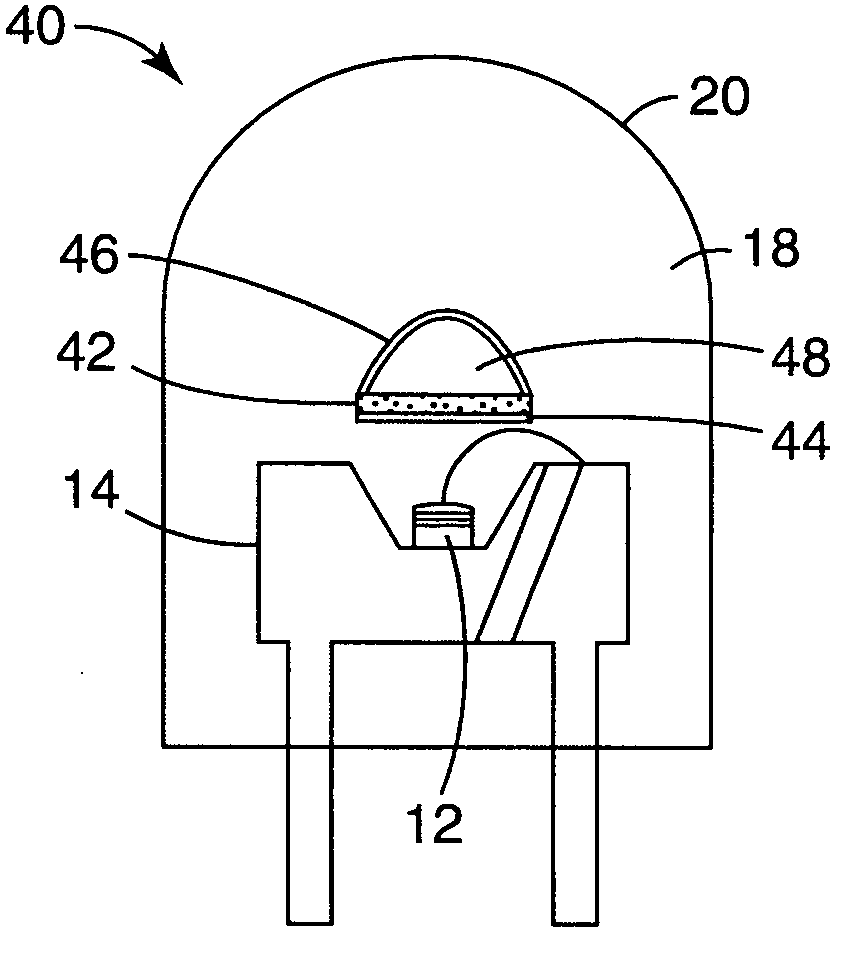

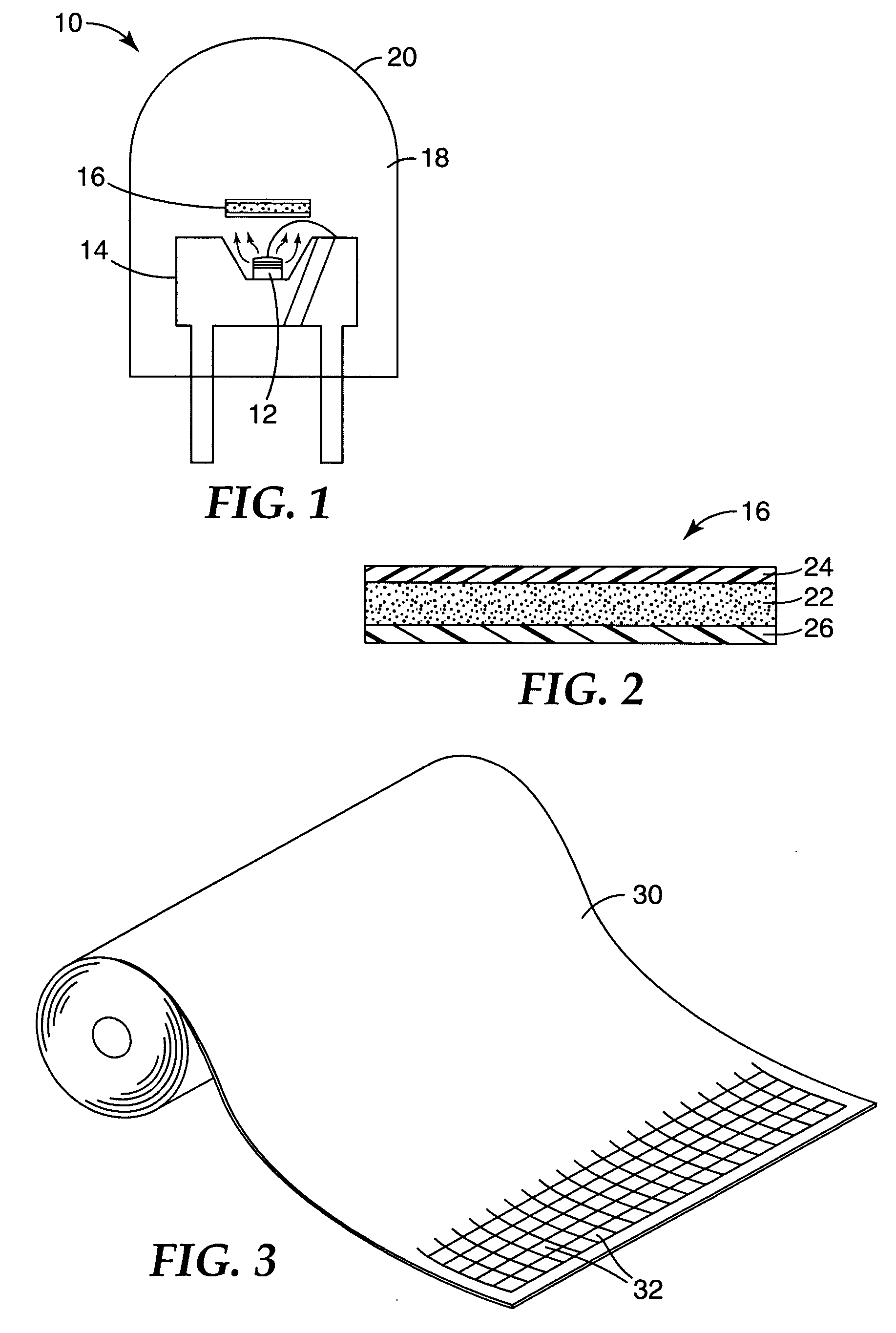

Methods of making phosphor based light sources having an interference reflector

ActiveUS20040116033A1Maintain reflectivityPrevent leakageLayered productsSolid-state devicesPhosphorLight source

A method of manufacturing a light source includes the steps of providing a first flexible sheet comprising a first multilayer interference reflector, providing a carrier film to carry the reflector, dividing the reflector into individual pieces carried by the carrier film, and positioning at least one of the individual pieces proximate an LED capable of emitting light that excites a phosphor material.

Owner:3M INNOVATIVE PROPERTIES CO

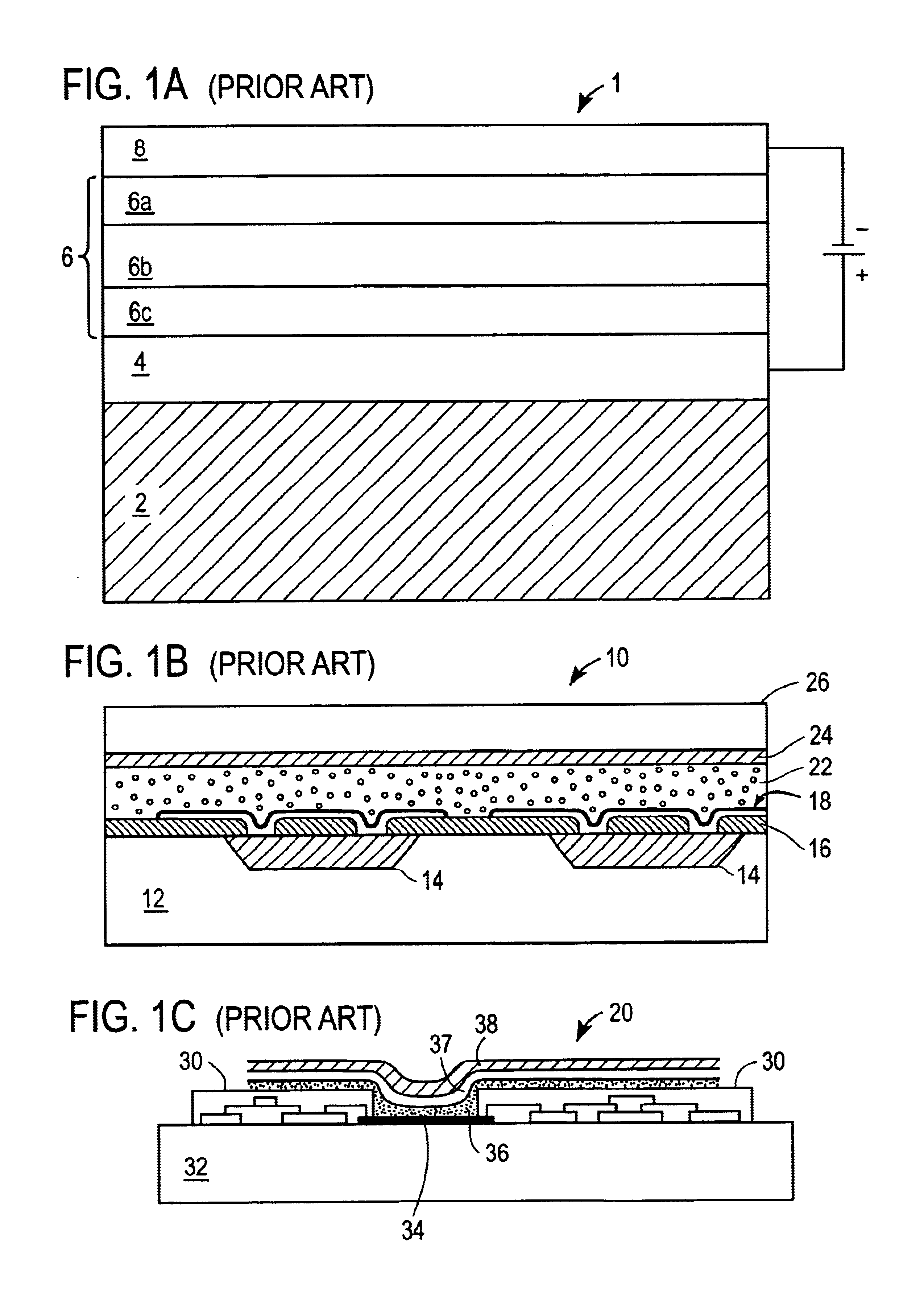

Optical-interference type display panel and method for making the same

InactiveUS20040147198A1Semiconductor/solid-state device manufacturingVessels or leading-in conductors manufactureIndium tin oxideTransparent conducting film

An optical-interference type display panel and a method for making the same are disclosed, wherein the display panel has a substrate on which multiple first conductive optical film stacks, supporting layers and multiple second conductive optical film stacks are formed. The substrate further has a plurality of connecting pads consisting of a transparent conductive film of the first conductive optical film stacks. Since the transparent conductive film is made of indium tin oxide, these connecting pads have the excellent anti-oxidation ability at their surface.

Owner:SNAPTRACK

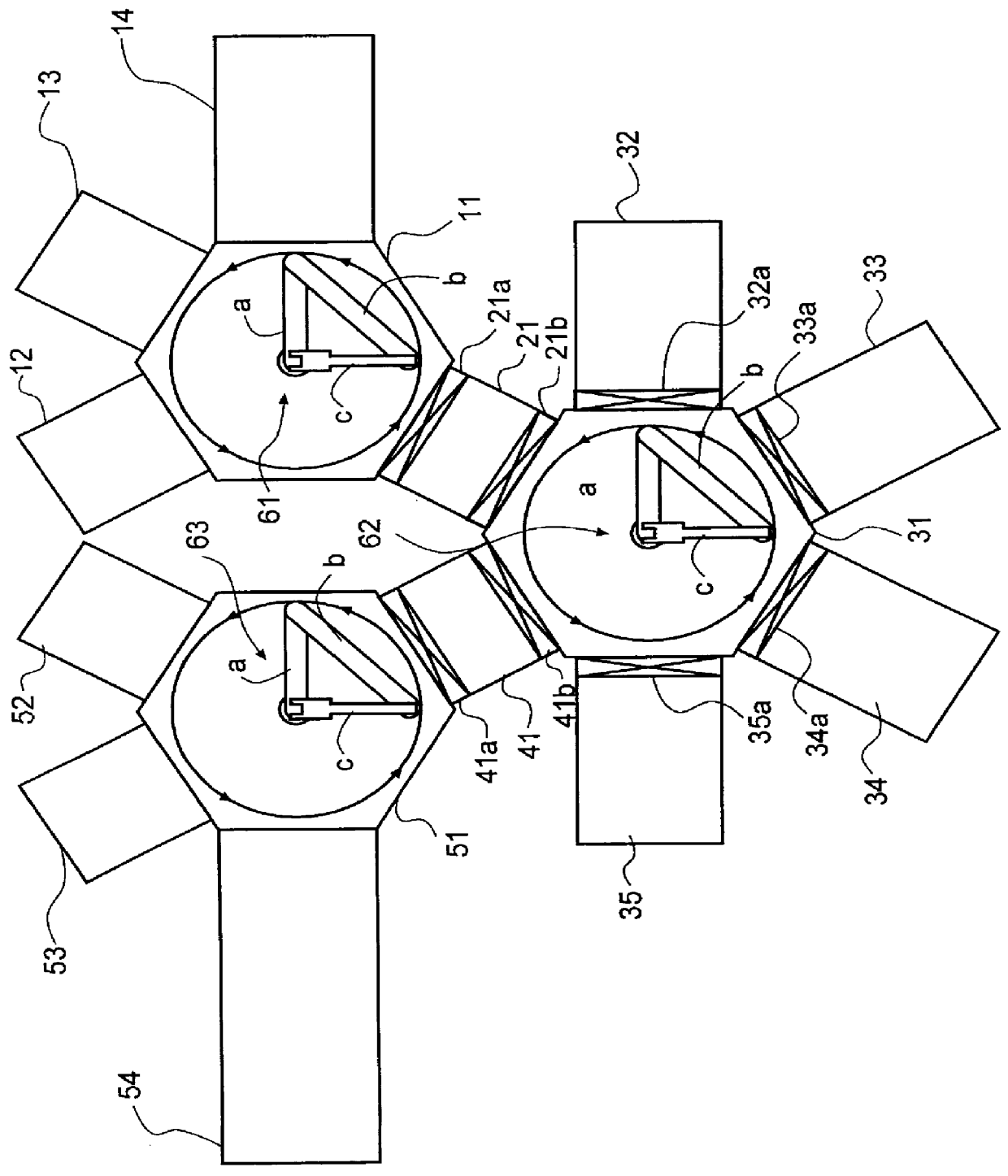

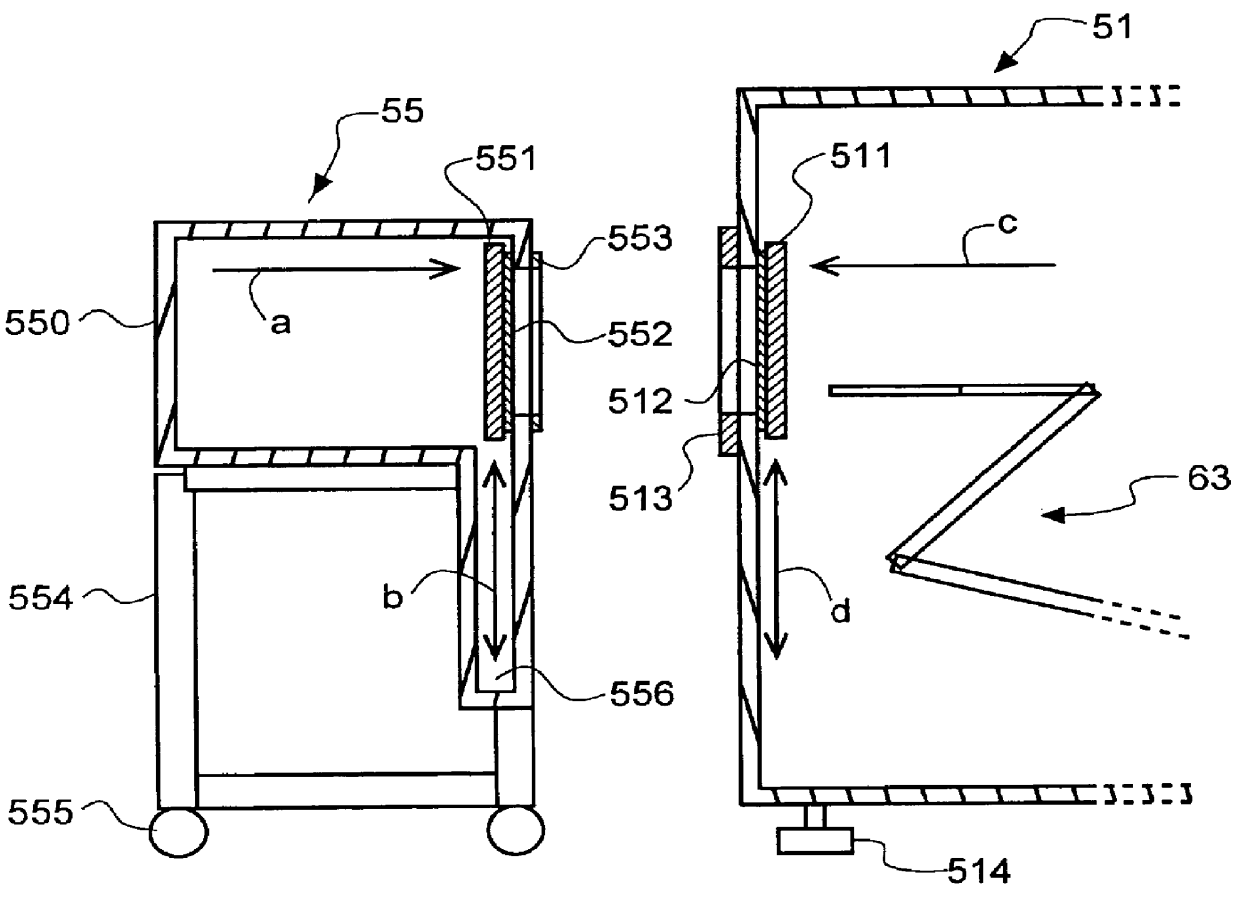

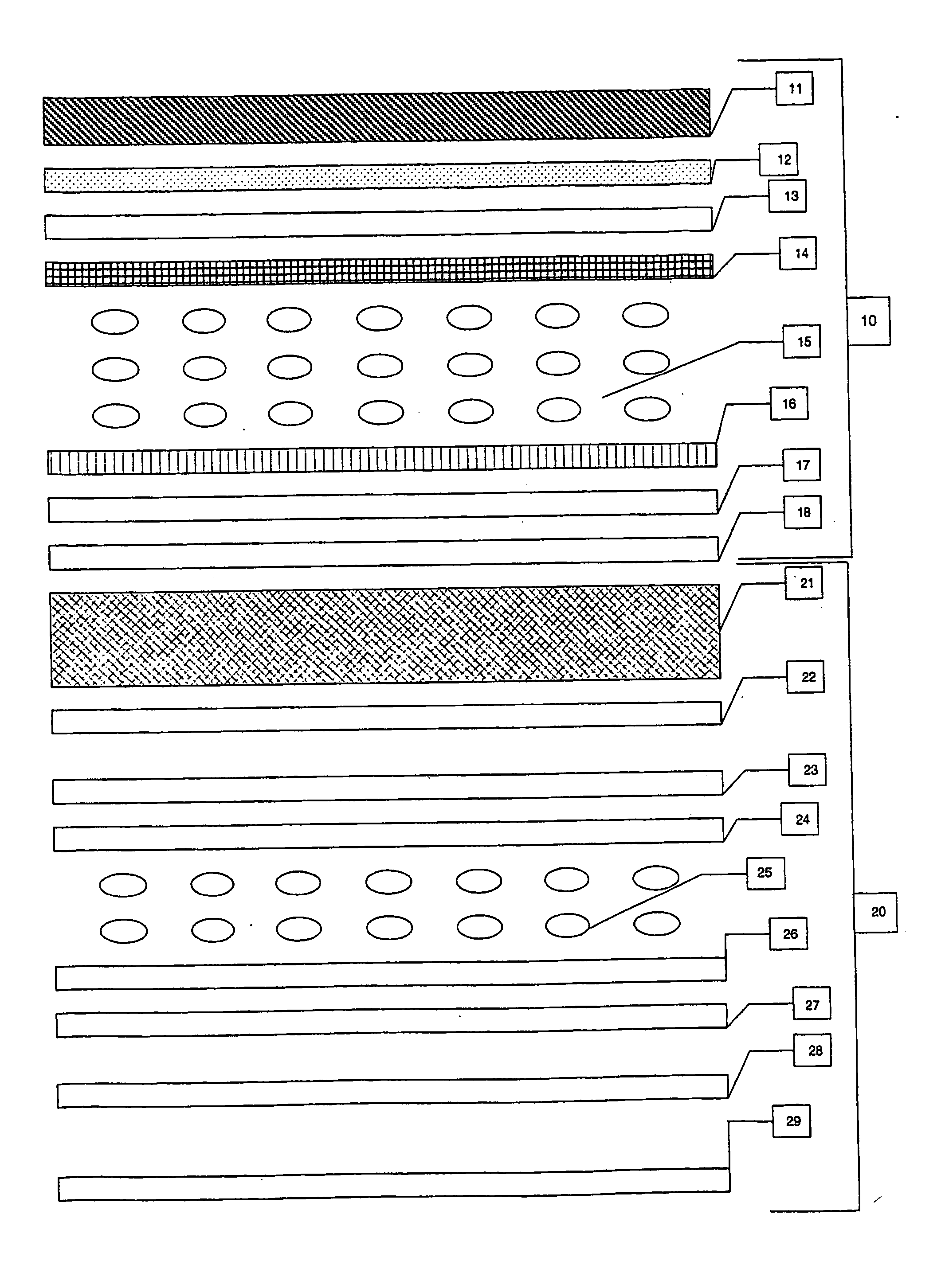

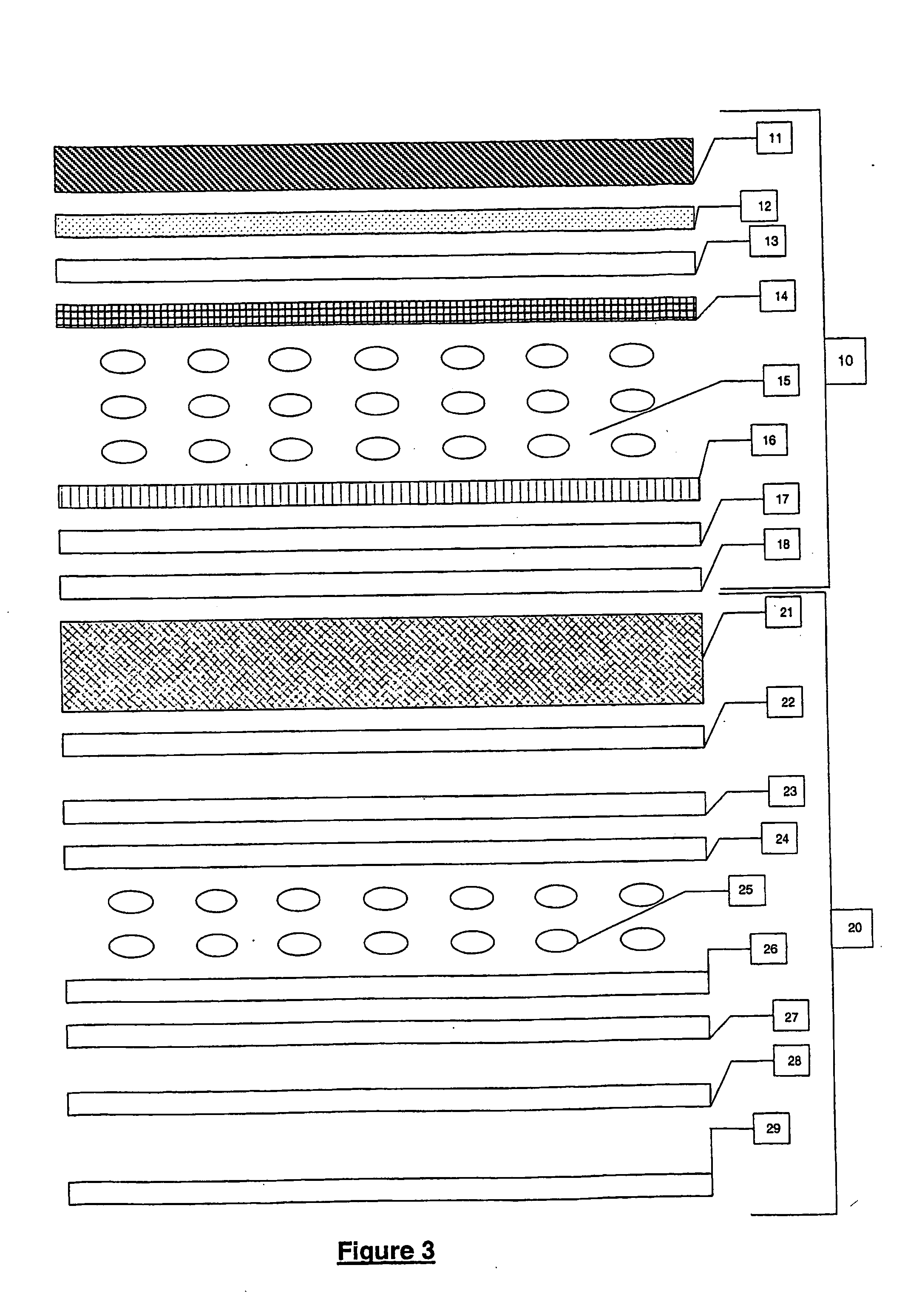

System and process for fabricating an organic electroluminescent display device

InactiveUS6132280ALow costHigh yet stabilized qualityElectroluminescent light sourcesSolid-state devicesEngineeringVacuum delivery

The invention provides an organic EL display device fabrication system comprising a loading side normal-pressure delivery chamber 11 including a first substrate delivery means 61 for delivering a substrate with no film formed thereon, and a loading chamber 21 connected thereto for introducing the substrate from loading side normal-pressure delivery chamber 11 at normal pressure into a vacuum delivery chamber 31 at a vacuum. The vacuum delivery chamber 31 is connected to loading chamber 21 and includes a second substrate delivery means 62 for delivering the substrate in a vacuum, and has one or two or more film formation chambers 32 to 35 connected thereto. The system further comprises an unloading chamber 41 connected thereto for delivering the substrate out of vacuum delivery chamber 31 at a vacuum into an unloading side normal-pressure delivery chamber 51 at normal pressure. The unloading side normal-pressure delivery chamber 51 is connected to unloading chamber 41 and includes a third substrate delivery means 63 for delivering a substrate with films formed thereon. An inert gas atmosphere having a moisture content of up to 100 ppm is maintained in both unloading chamber 41 and unloading side normal-pressure delivery chamber 51 at normal pressure. The invention also provides an organic EL display device fabrication process using this fabrication system.

Owner:FUTABA CORPORATION

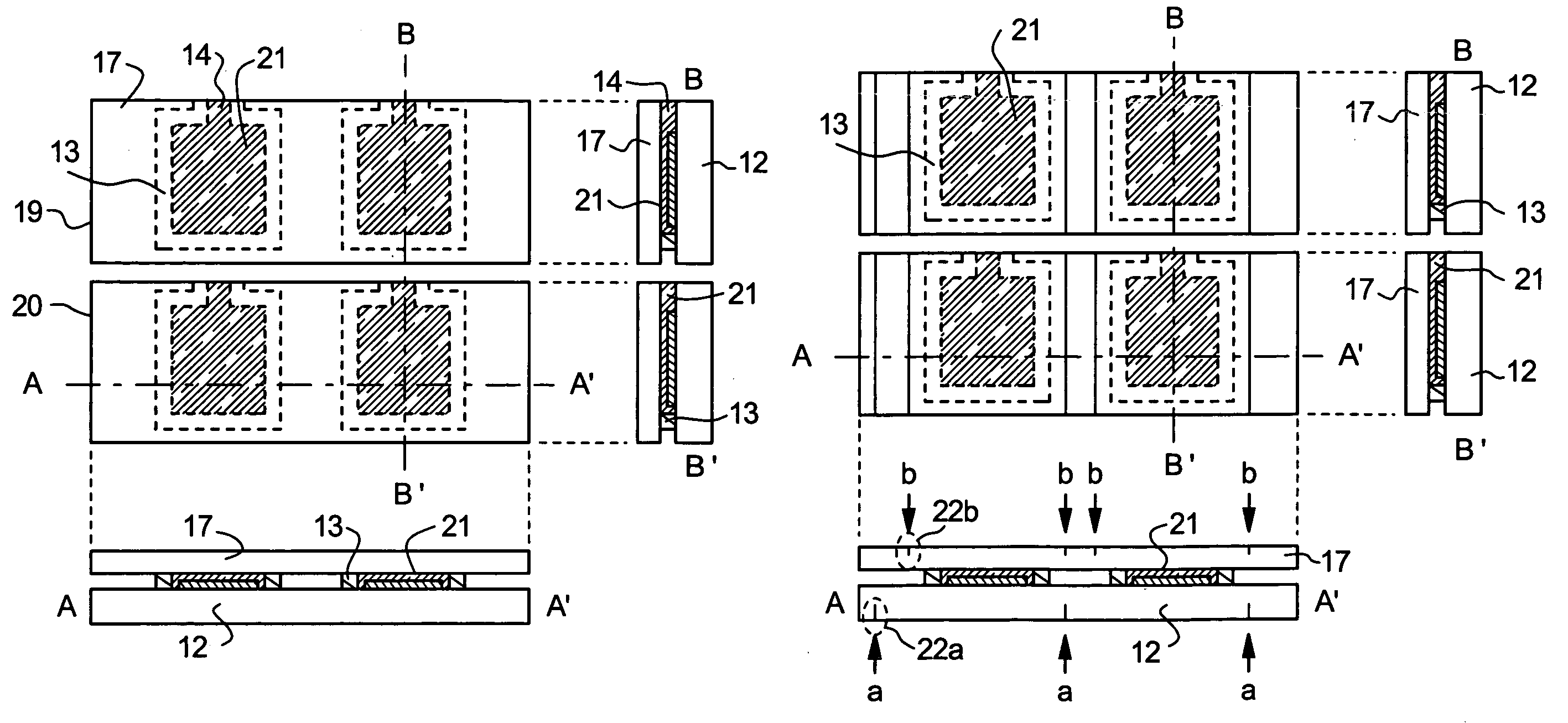

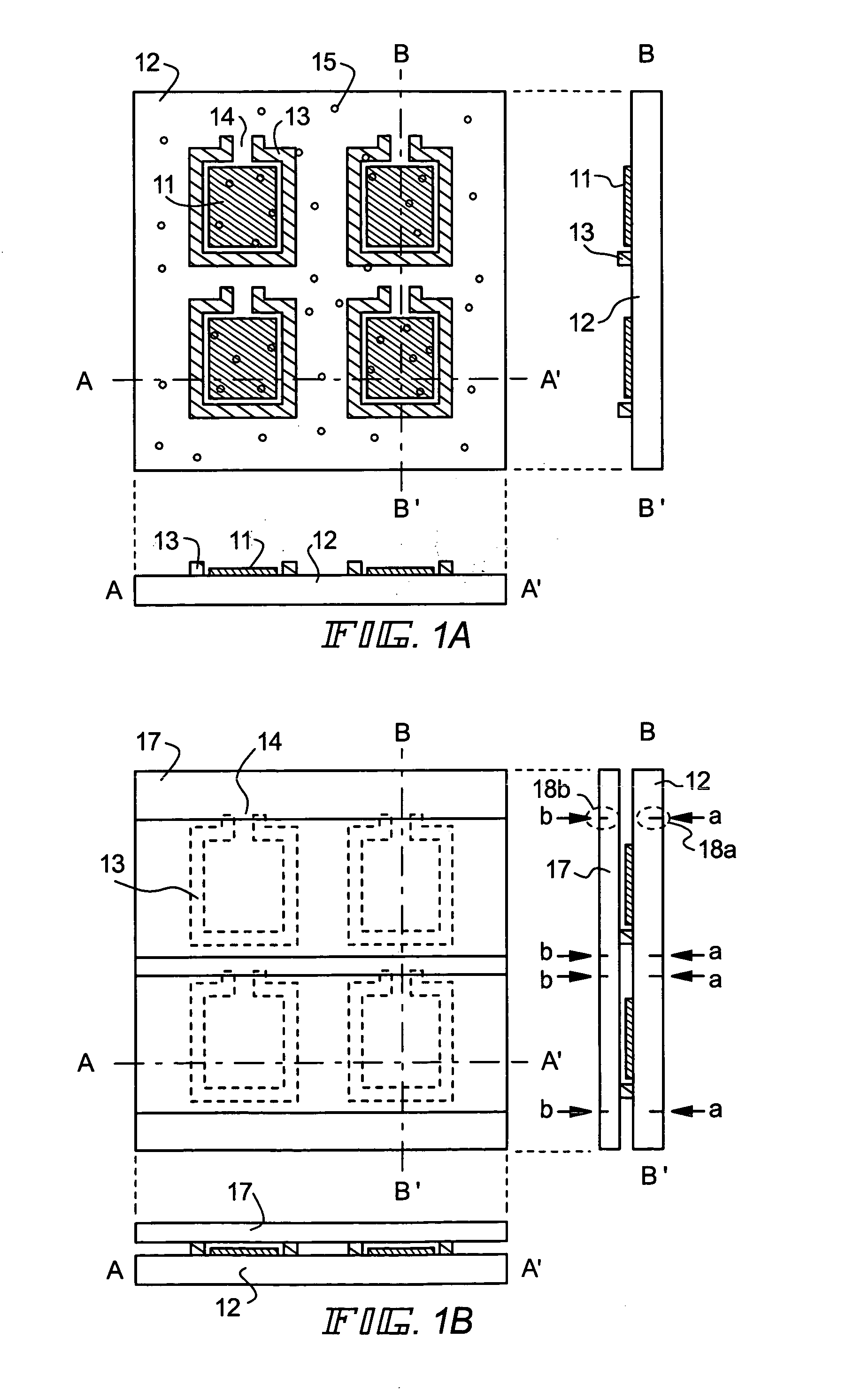

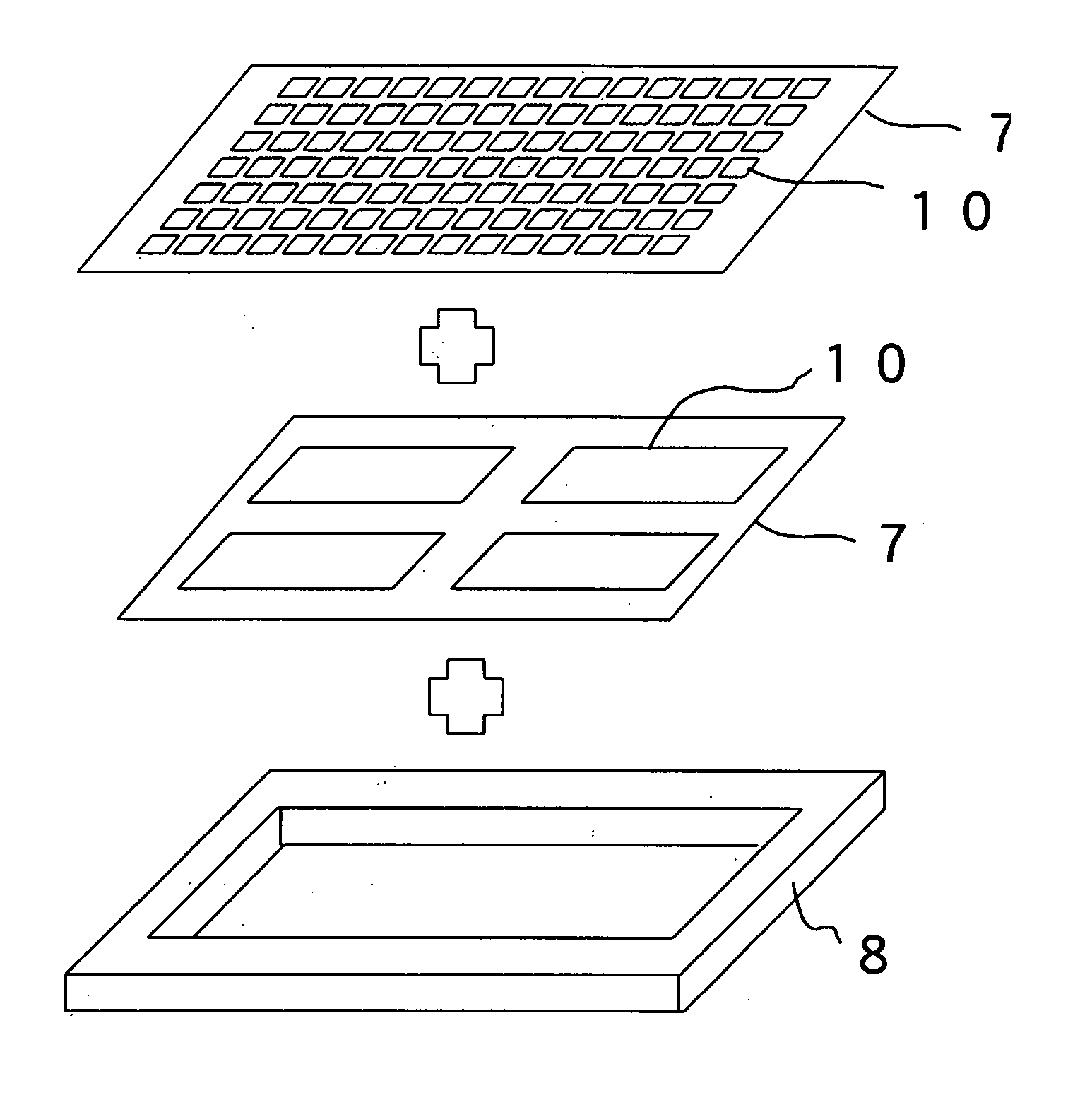

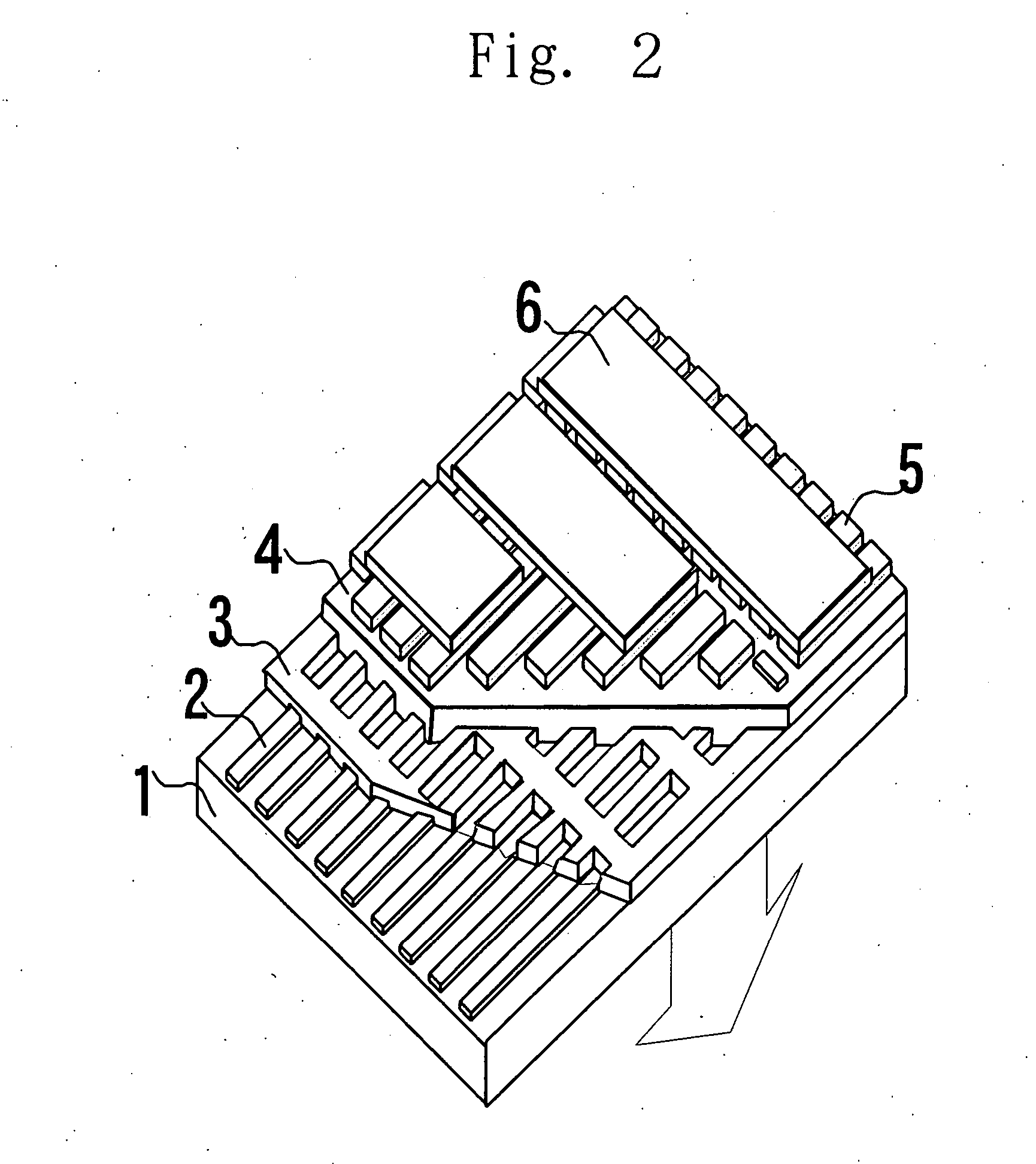

Light emitting device and method of manufacturing the same

ActiveUS7112115B1Improve throughputHigh yieldDischarge tube luminescnet screensElectroluminescent light sourcesManufacturing cost reductionEngineering

Technology to reduce the manufacturing cost of a manufacturing process of a light emitting device is provided. The manufacturing cost of a device using a light emitting element can be reduced by using a multilayout process for forming a plurality of light emitting devices from a large-sized substrate. In particular, an existing line for manufacturing liquid crystal cells can be diverted to a process of encapsulating light emitting elements, which can greatly reduce the manufacturing cost including the investment in plant and equipment.

Owner:SEMICON ENERGY LAB CO LTD

Field emission display and method for fabricating the same

InactiveUS20010004979A1Stable driving voltageUniform characteristicsMaterial nanotechnologyDecorative surface effectsLow voltageCarbon nanotube

Field emission display and method for fabricating the same, the field emission display including a cathode array having a cathode electrode formed on a substrate, insulating layers and carbon nanotube films for use as emitter electrodes formed alternately on the cathode electrode, and a gate electrode formed on the insulating layer, thereby permitting fabrication of a large sized cathode plate at a low cost because the film is formed by screen printing and exposure, which can reduce the cumbersome steps in fabrication of the related art Spindt emitter tip, and both a low voltage and a high voltage FEDs because the carbon nanotube film used as the emitter has a low work function, with an easy and stable electron emission capability.

Owner:LG ELECTRONICS INC

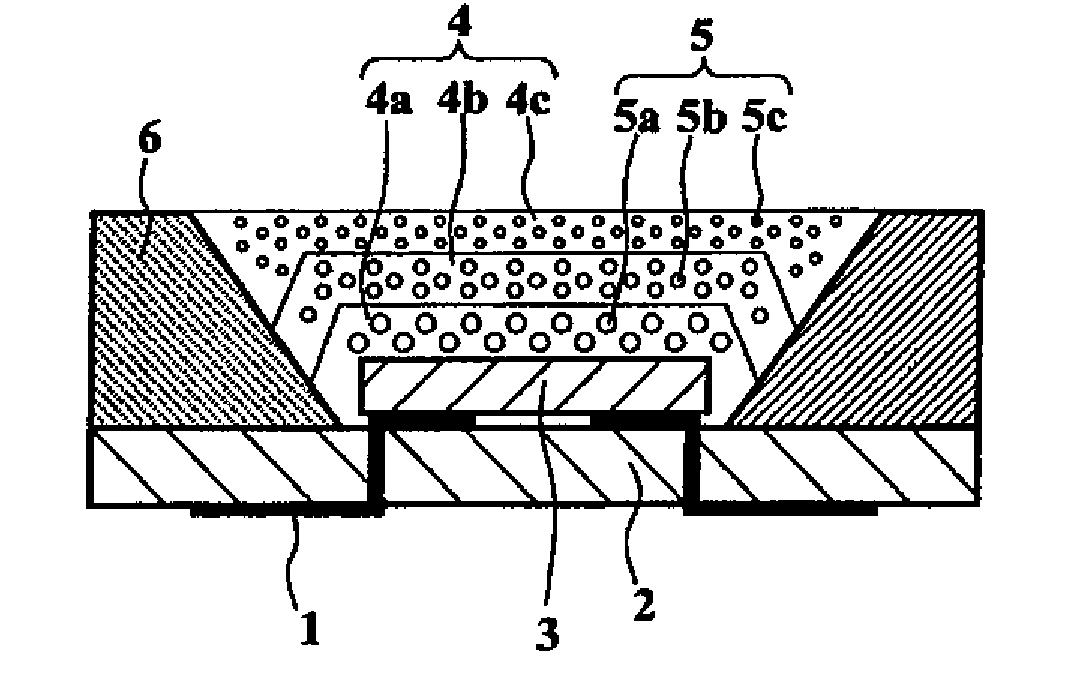

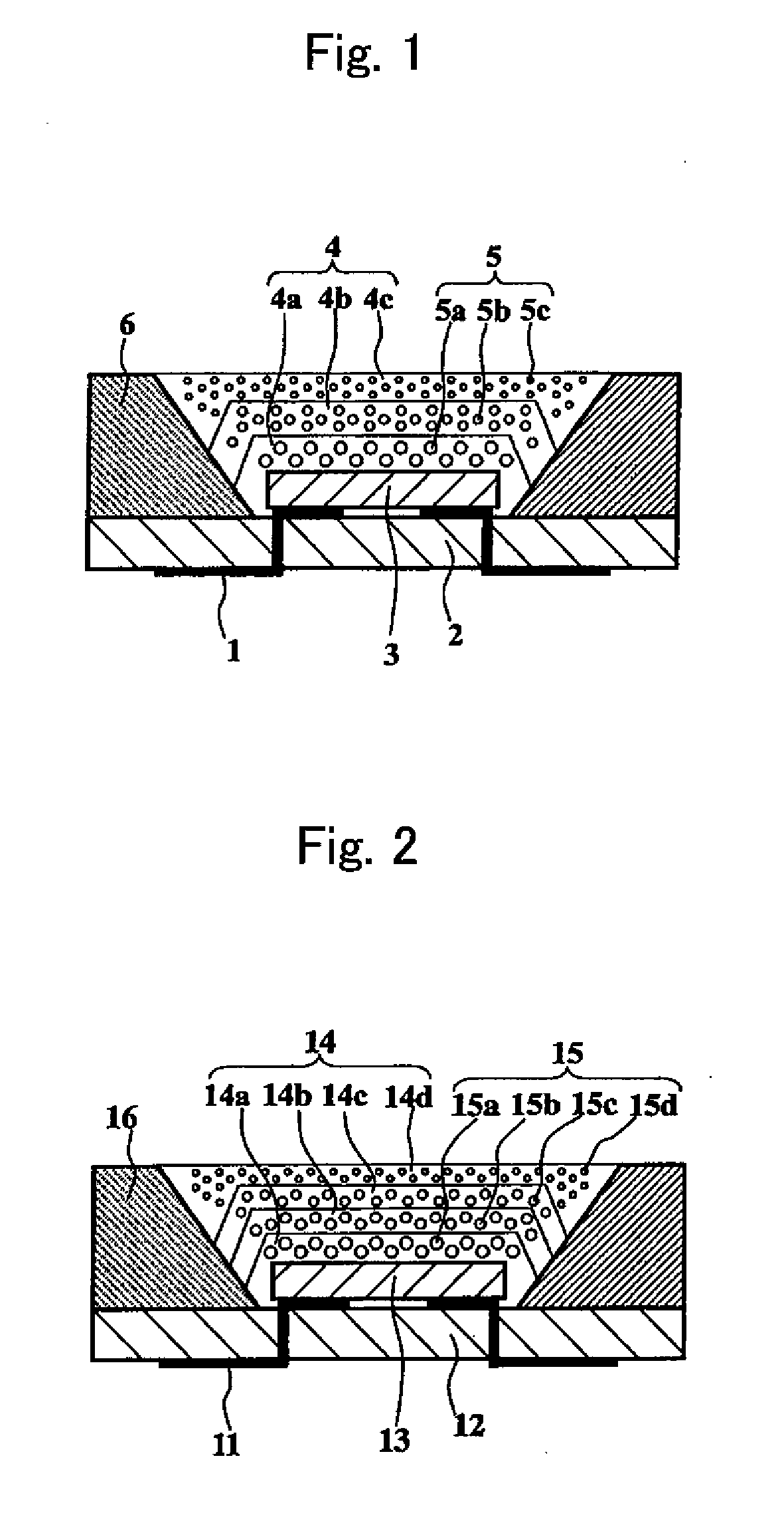

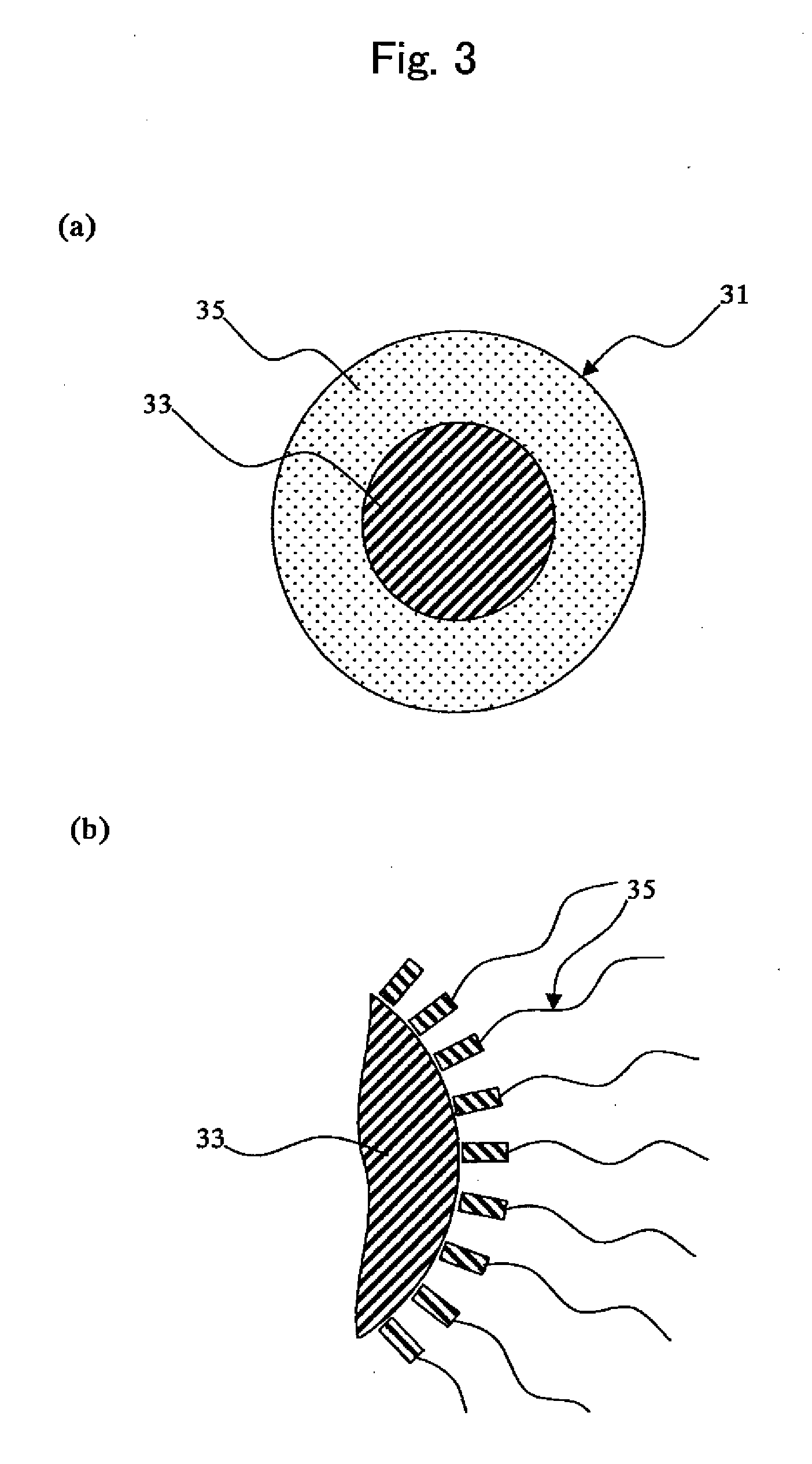

Wavelength Converter, Light-Emitting Device, Method of Producing Wavelength Converter and Method of Producing Light-Emitting Device

InactiveUS20080231170A1Reduce self-quenchingSolve low luminous efficiencyDischarge tube luminescnet screensLamp detailsPhosphorFluorescence

A light-emitting device comprises a light-emitting element 3 that is provided on a substrate 2 and emits excitation light, and a wavelength converter 4 that converts the excitation light into visible light. The visible light is output light. The wavelength converter 4 comprises a plurality of wavelength conversion layers 4a, 4b and 4c which respectively contain, as phosphors, at least one type of semiconductor ultrafine particles having a mean particle size of not more than 20 nm and at least one type of fluorescent substance having a mean particle size of not less than 0.1 μm in a resin matrix. Thereby, self-quenching of phosphors is reduced and high luminous efficiency is attained.

Owner:KYOCERA CORP

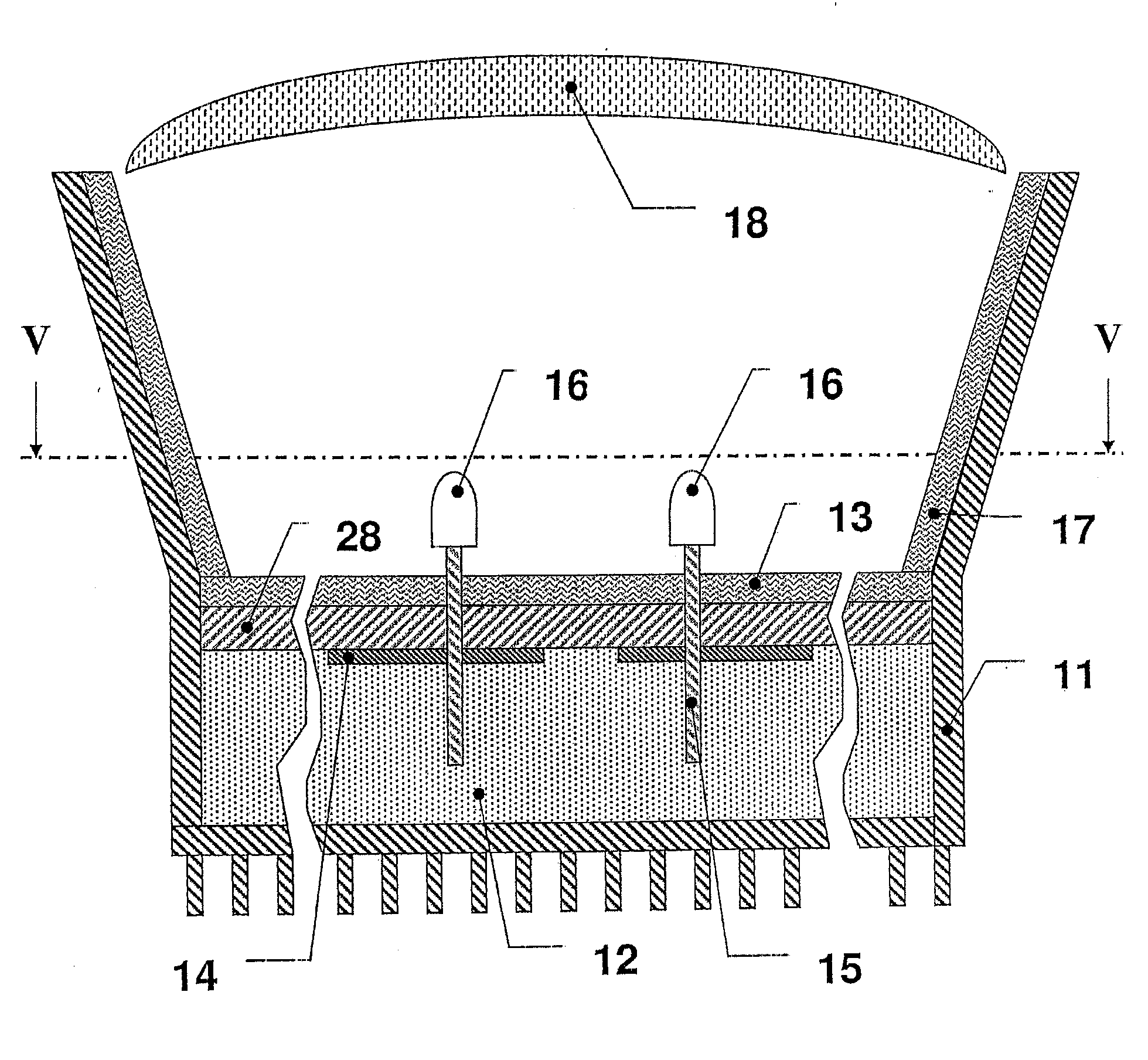

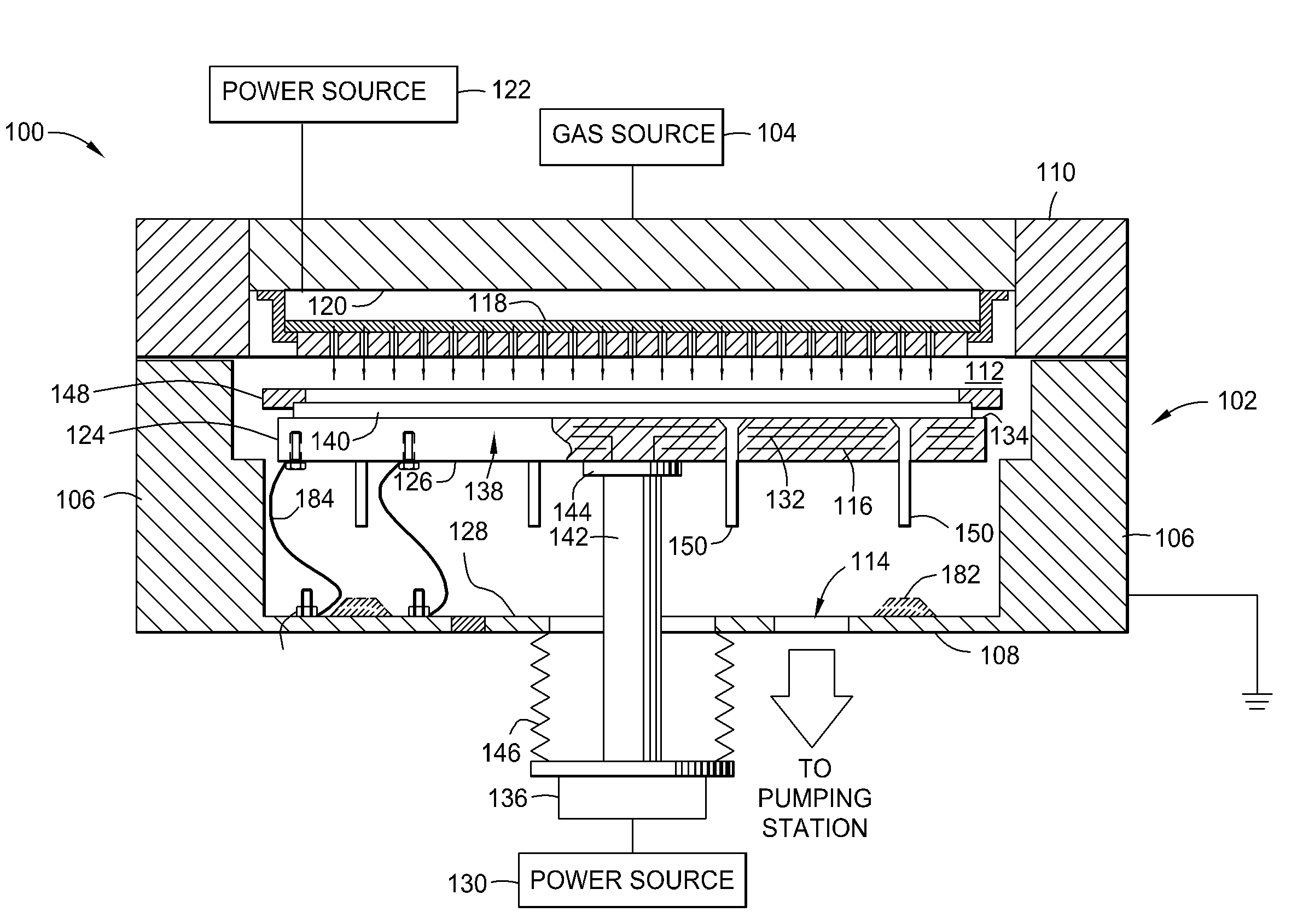

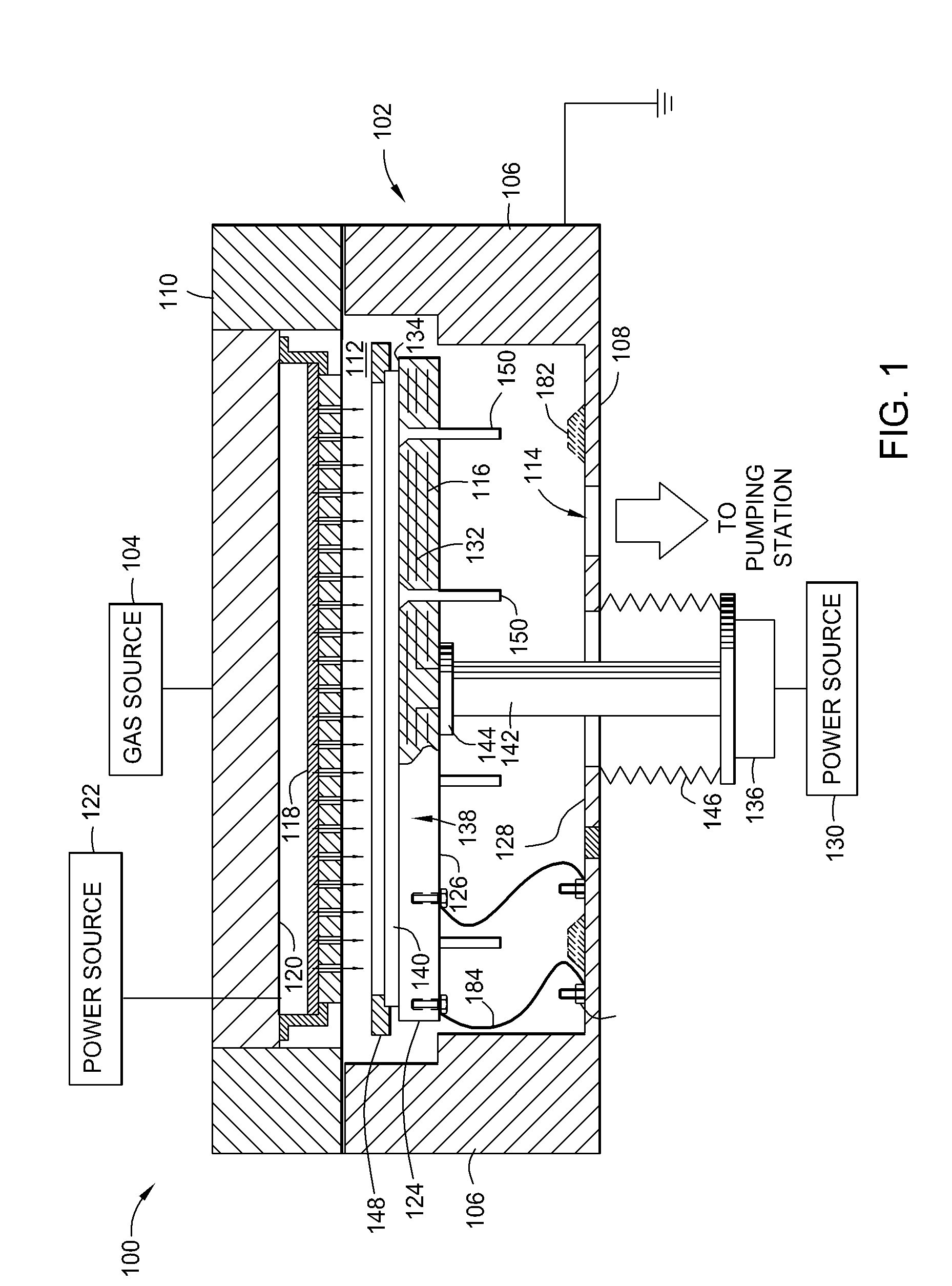

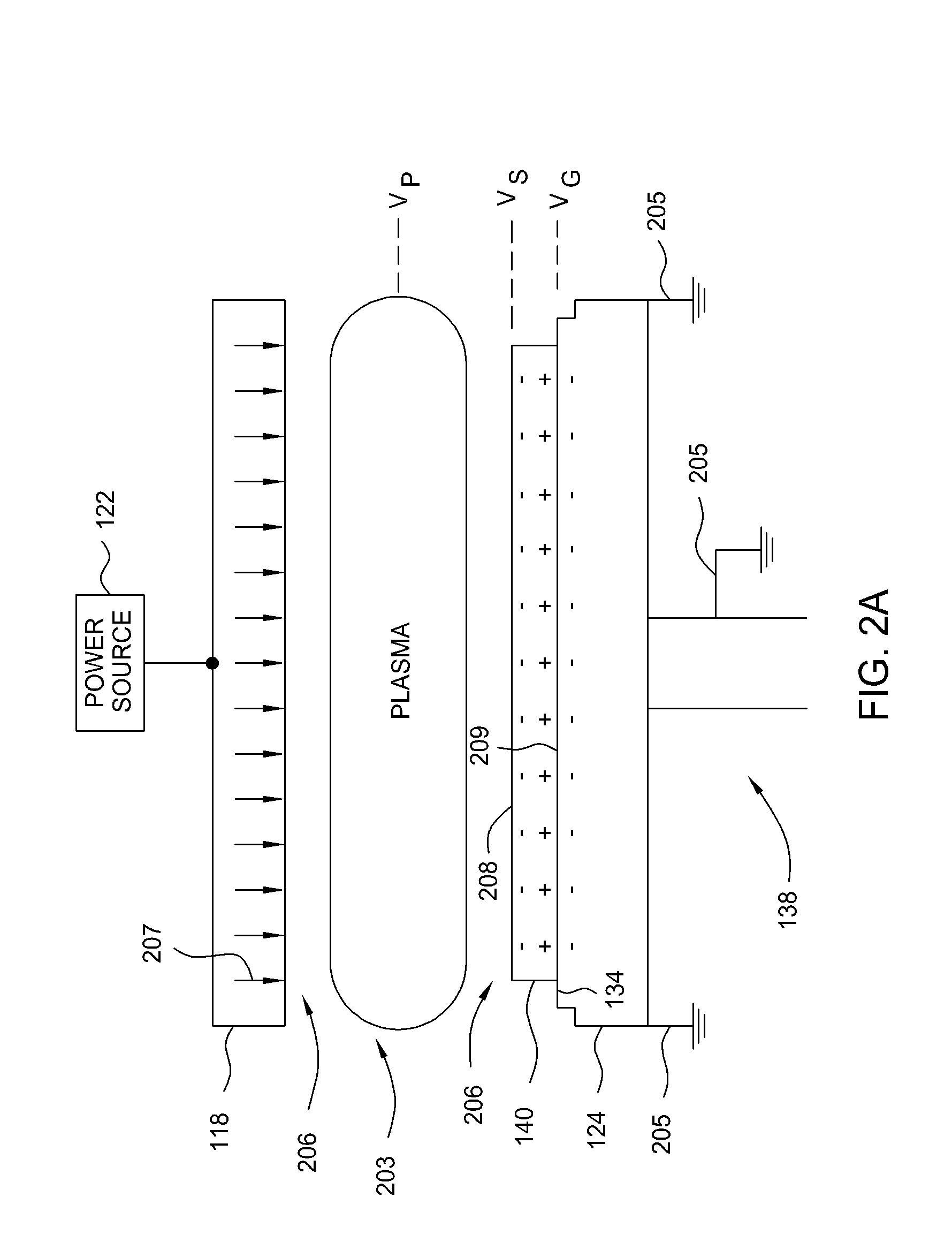

Susceptor with insulative inserts

InactiveUS20080194169A1Reduce arcingElectric discharge tubesSemiconductor/solid-state device manufacturingSusceptorMechanical engineering

A method and apparatus for reducing arcing in a plasma processing system when processing large area substrates which contain one or more holes. In one embodiment of the invention, a substrate support member includes an electrically insulating insert located beneath a hole in an insulating, large area substrate. The insulating insert is made of aluminum oxide, and is located within a hole in the support member such that the insert is disposed beneath a hole in a glass substrate. The substrate support member is made of aluminum with an anodized surface.

Owner:APPLIED MATERIALS INC

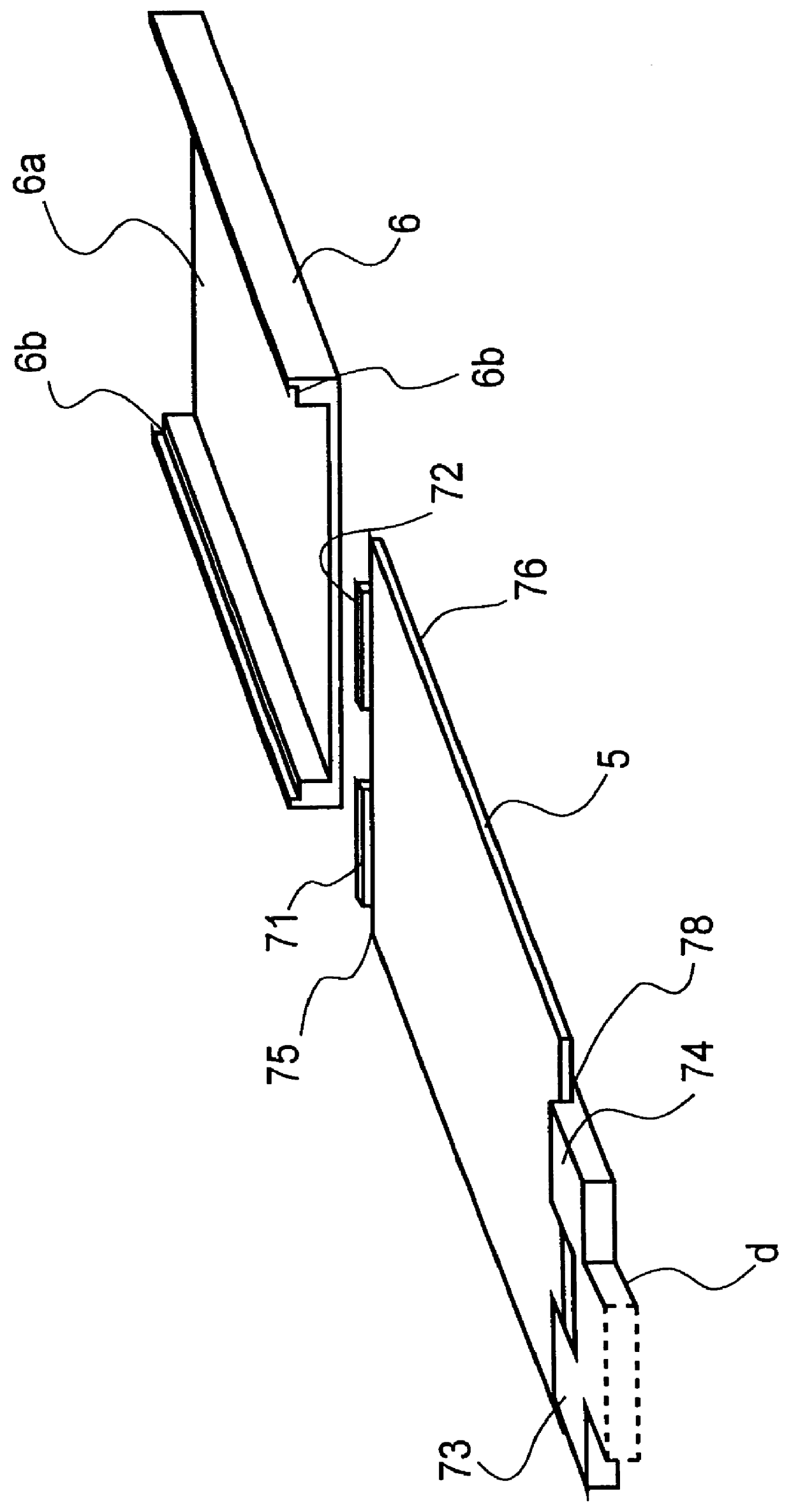

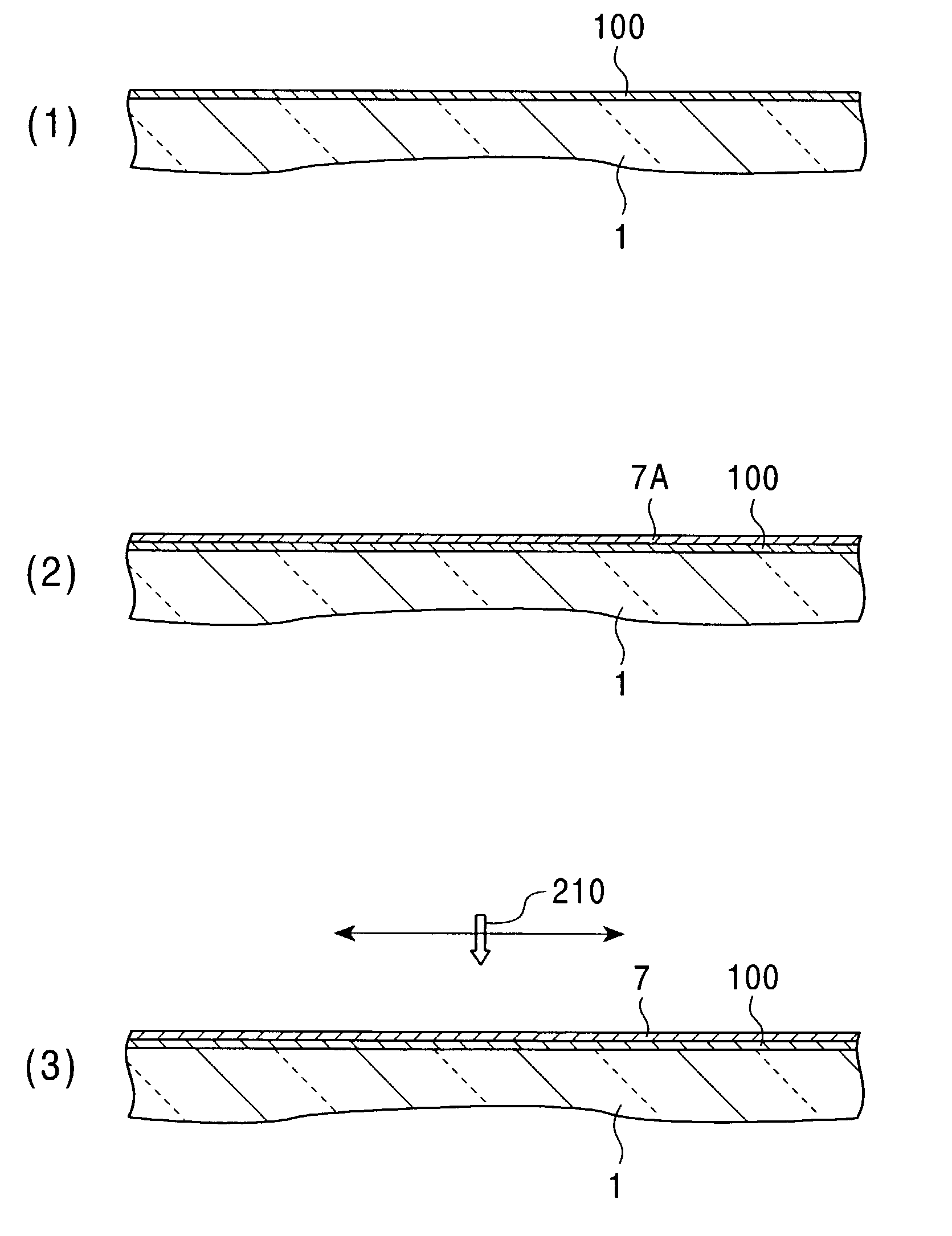

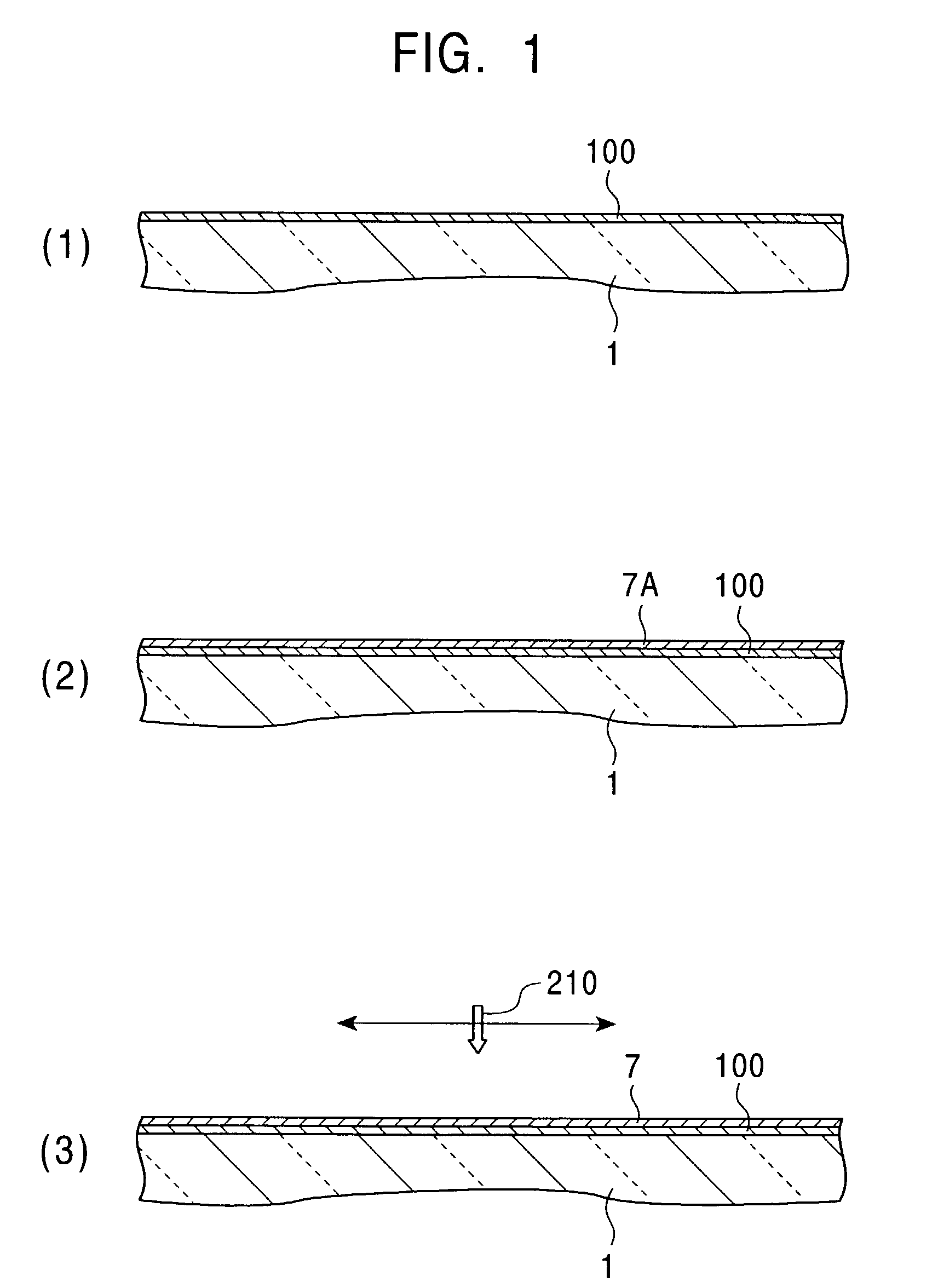

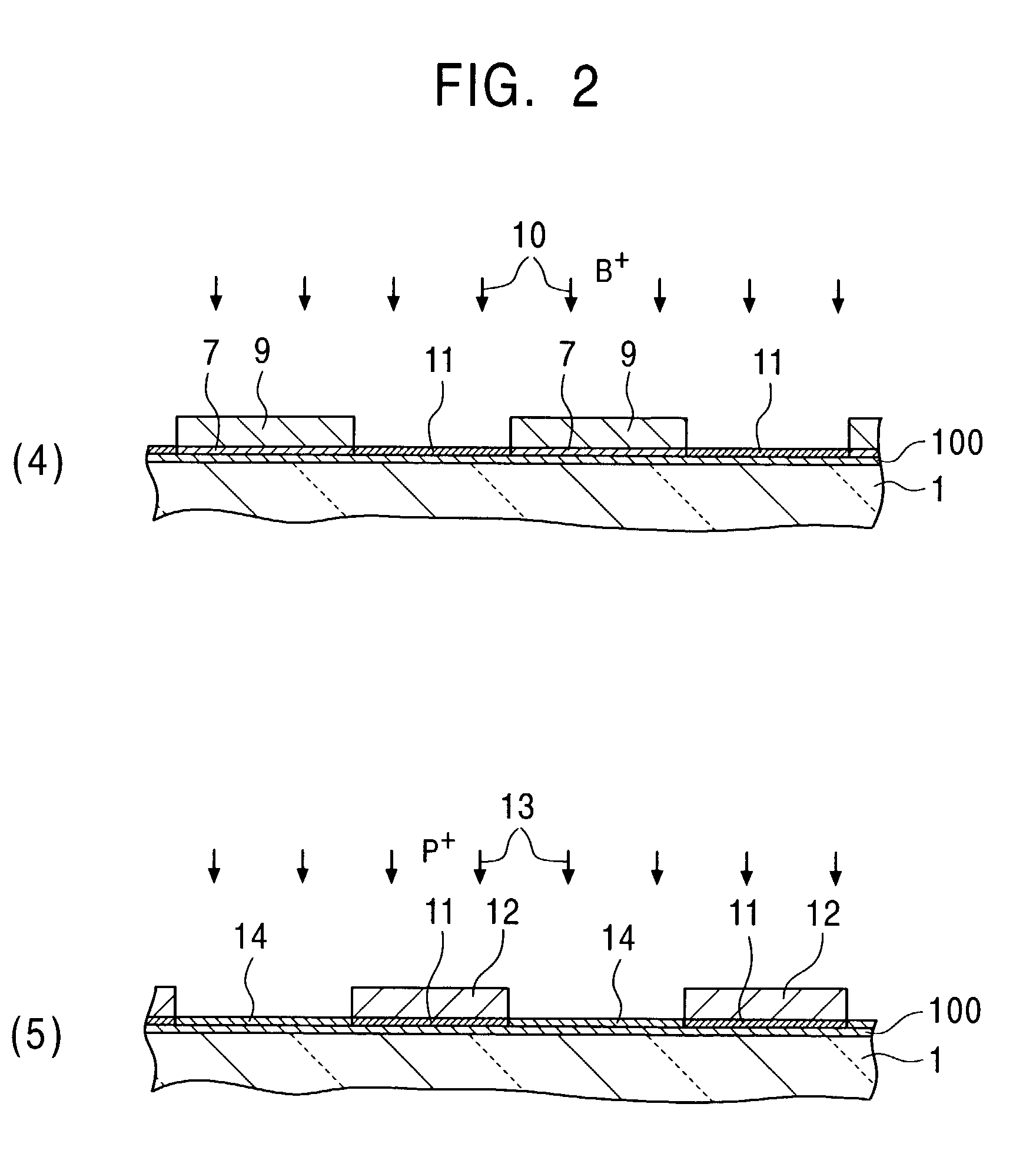

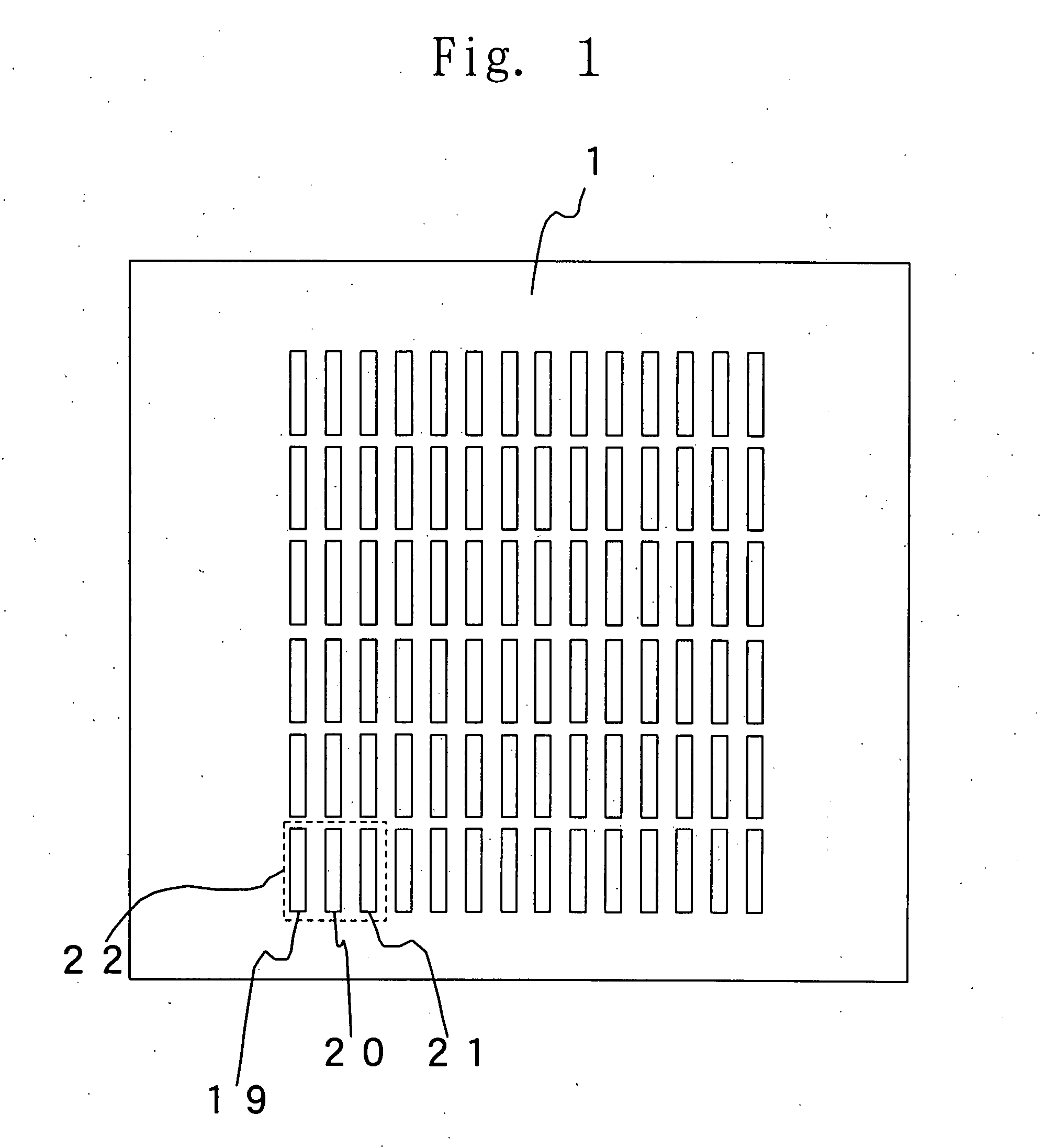

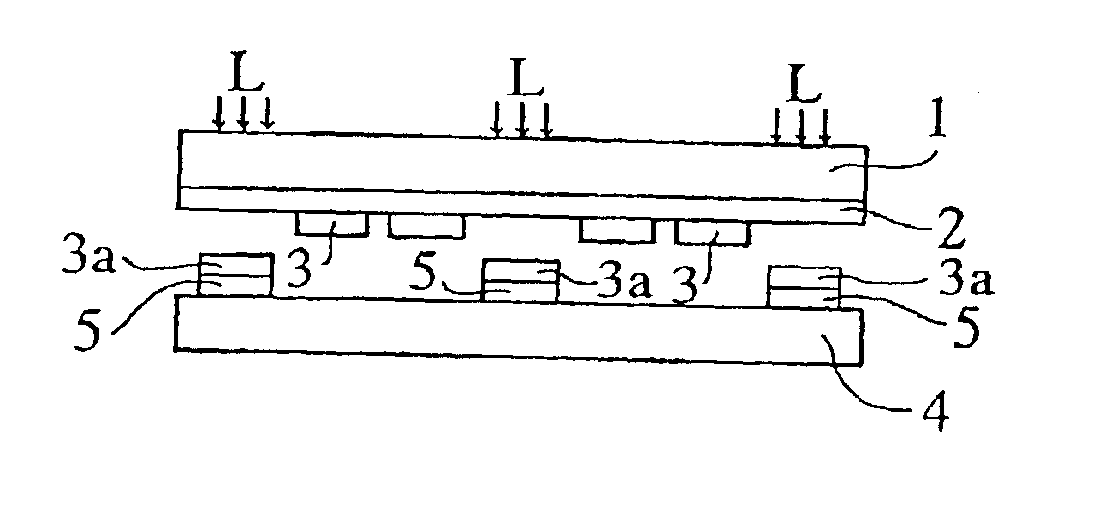

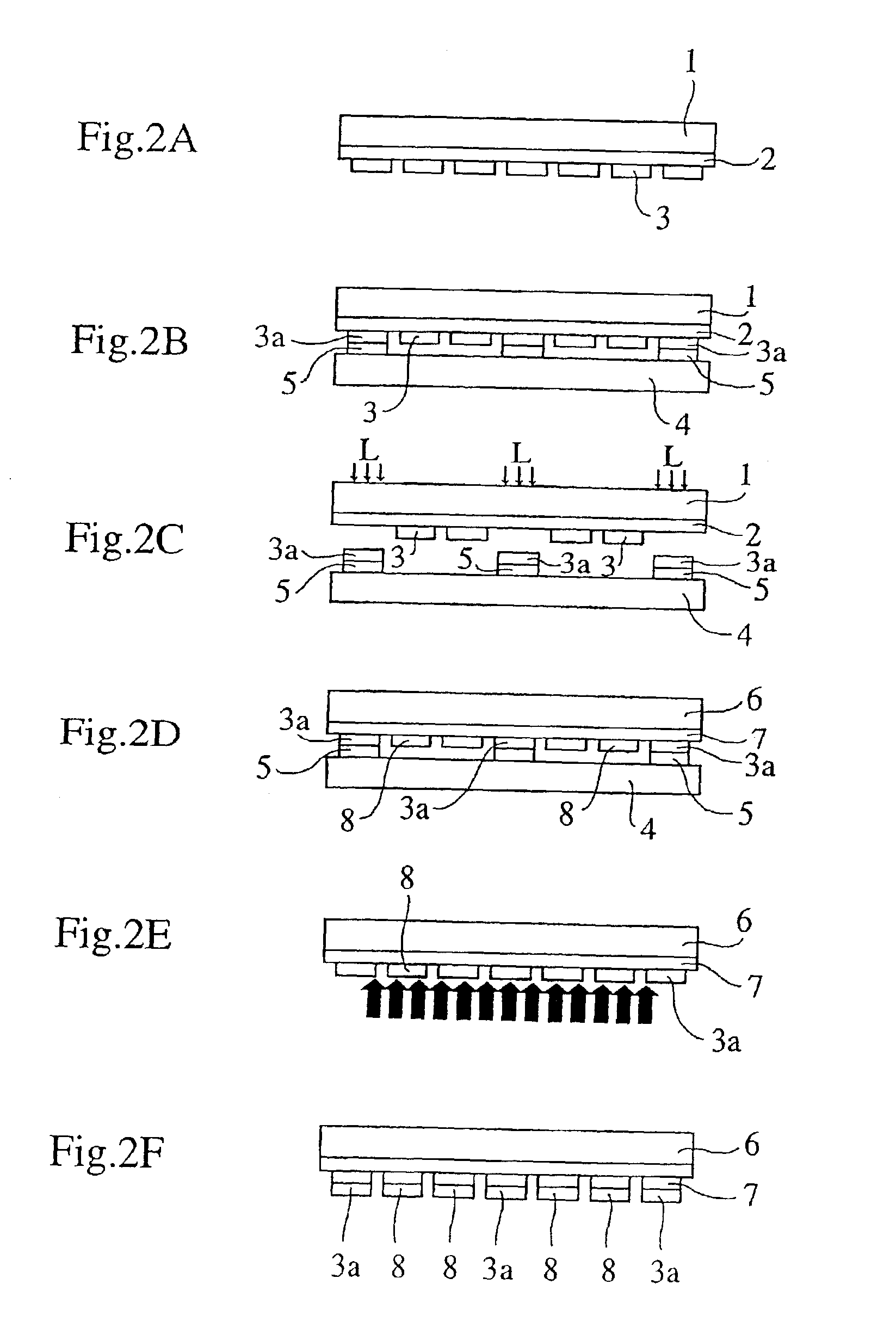

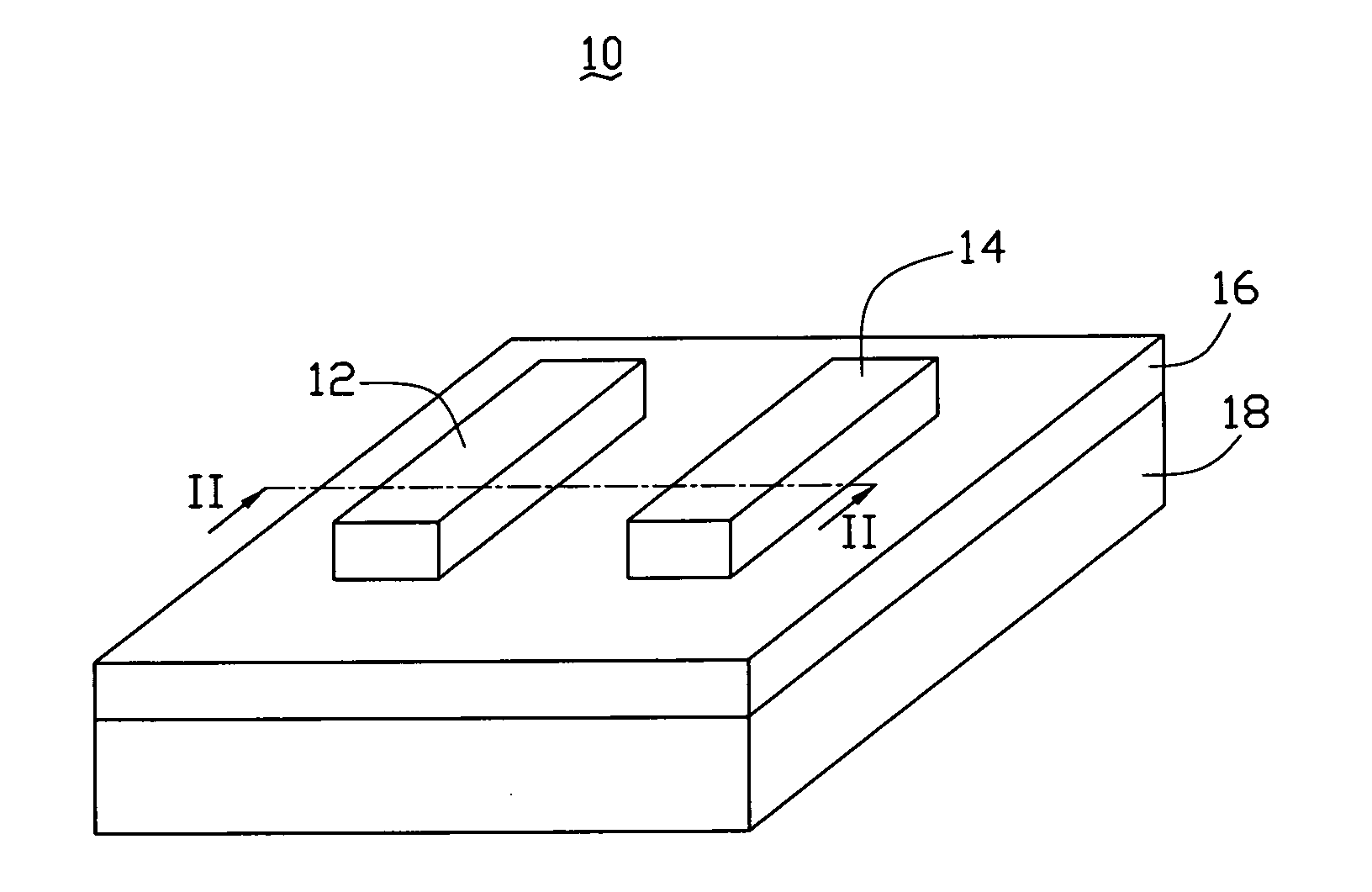

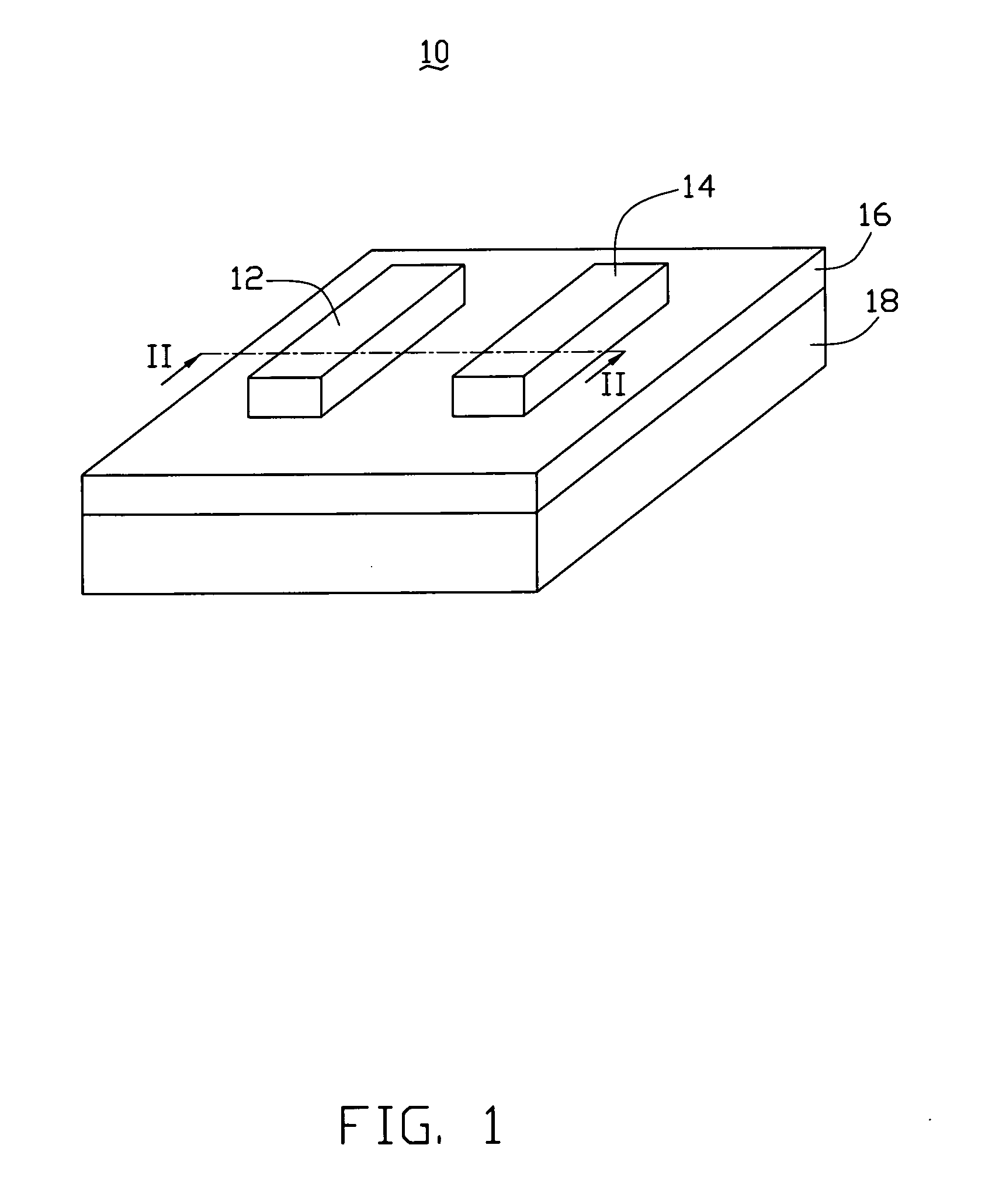

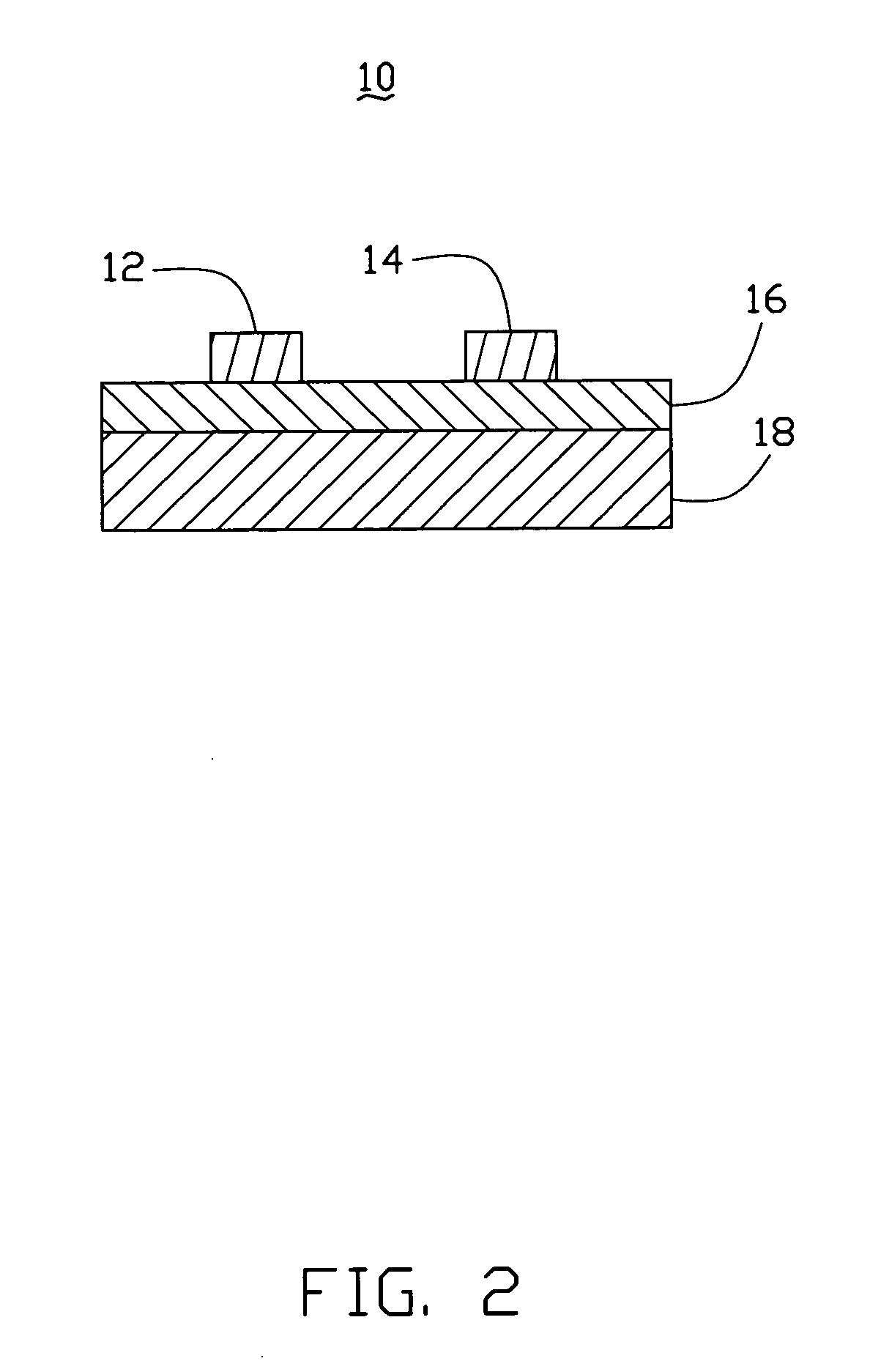

Method for forming thin semiconductor film, method for fabricating semiconductor device, system for executing these methods and electrooptic device

InactiveUS20030148565A1Promote crystallizationEasily realizedTransistorSolid-state devicesMolten stateUltraviolet

The present invention provides a method capable of easily forming a polycrystalline or monocrystalline semiconductor thin film of polycrystalline silicon with a high degree of crystallization and high quality at low cost, and an apparatus for carrying out the method. In a method of forming a polycrystalline (or monocrystalline) semiconductor thin film, a method of manufacturing a semiconductor device and an apparatus for carrying out these methods, in order to form a large-grain polycrystalline (or monocrystalline) semiconductor thin film (7) such as a polycrystalline silicon film with a high degree of crystallization on a substrate (1) or manufacturing a semiconductor device having the polycrystalline (or monocrystalline) semiconductor thin film (7), a low-crystalline semiconductor thin film (7A) is formed on the substrate (1), and then heated in a molten, semi-molten or non-molten state by laser annealing with ultraviolet rays (UV) or / and deep ultraviolet rays (DUV) and cooled to promote crystallization of the low-crystalline semiconductor thin film (7A), obtaining the polycrystalline (or monocrystalline) semiconductor thin film (7).

Owner:SONY CORP

Organic Electroluminescent Device and Manufacturing Method Thereof

InactiveUS20080018236A1Improve display qualityHigh-precision patternLiquid surface applicatorsDischarge tube luminescnet screensOrganic electroluminescenceLight-emitting diode

A highly fine organic electroluminescent device is provided. A method for manufacturing the organic electroluminescent device is provided for patterning a very fine light emitting layer, and a deposition mask is provided to be used in the patterning. For deposition of the light emitting layer, a mask member is provided with apertures (effective apertures) for forming the light emitting layer to be used for light emitting pixel and apertures (dummy apertures) not to be used for forming the light emitting pixel around an area (effective aperture area) separated by the outer edge of a group of the apertures. The light emitting layer is deposited by using the deposition mask.

Owner:TORAY IND INC

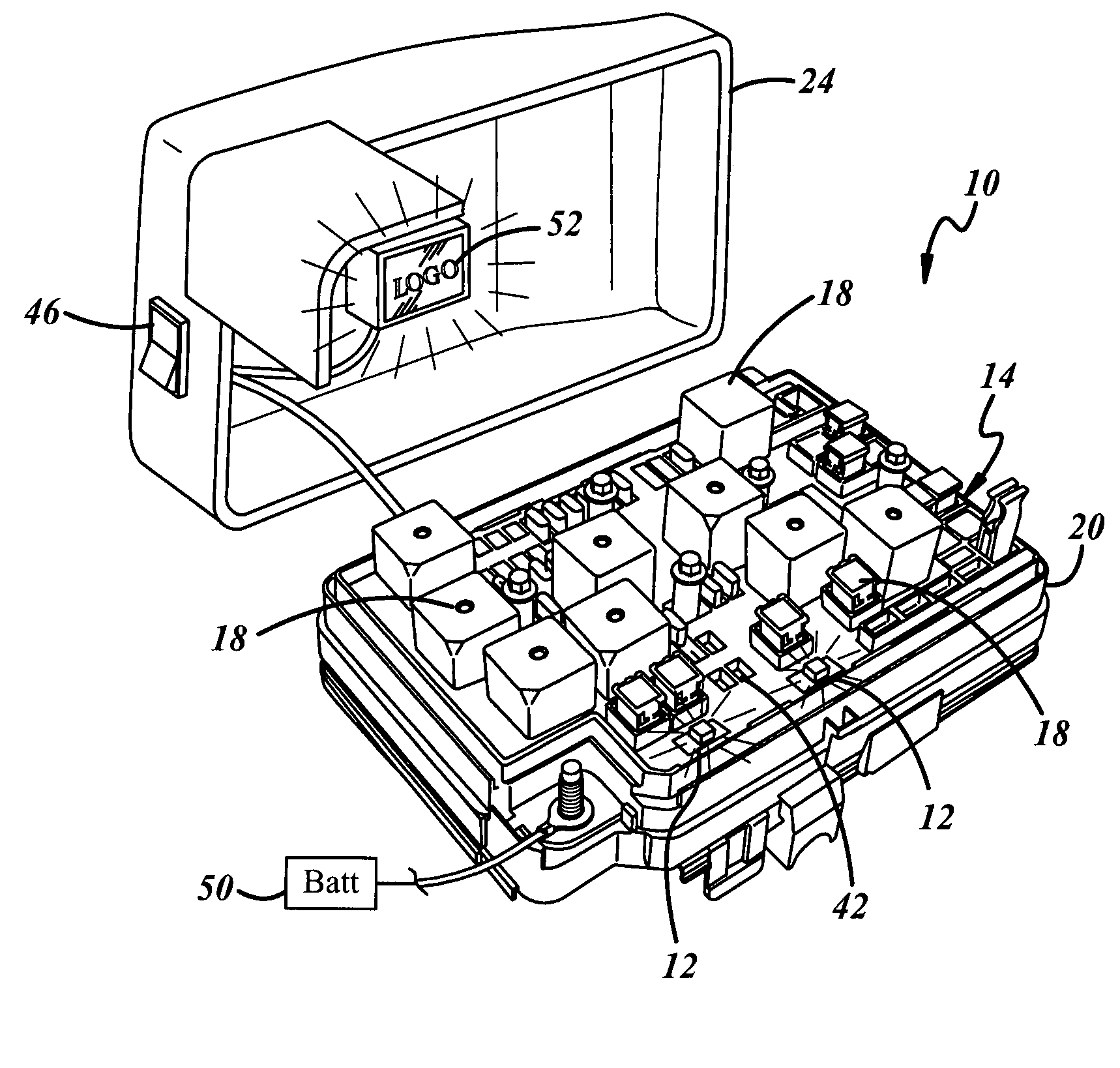

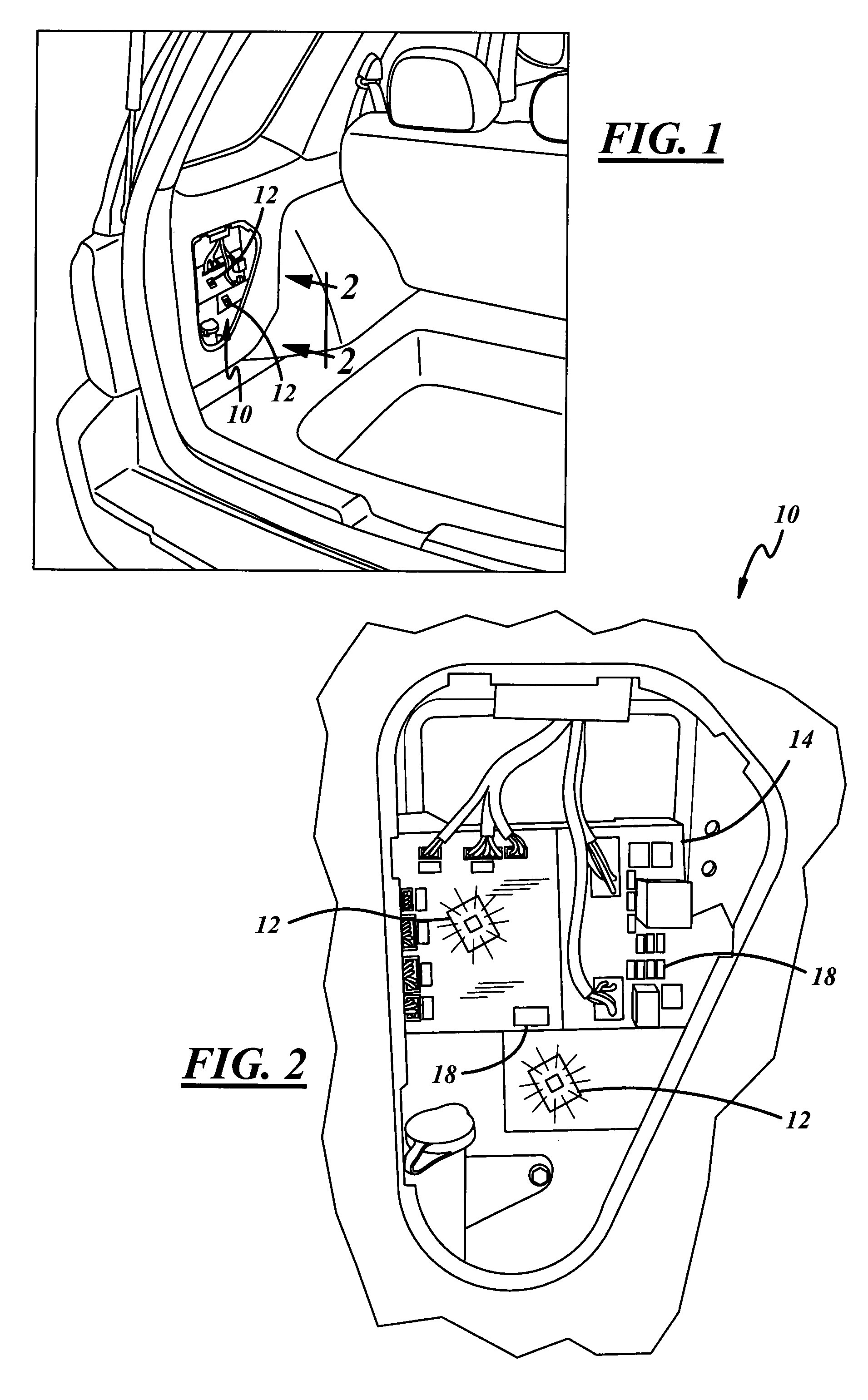

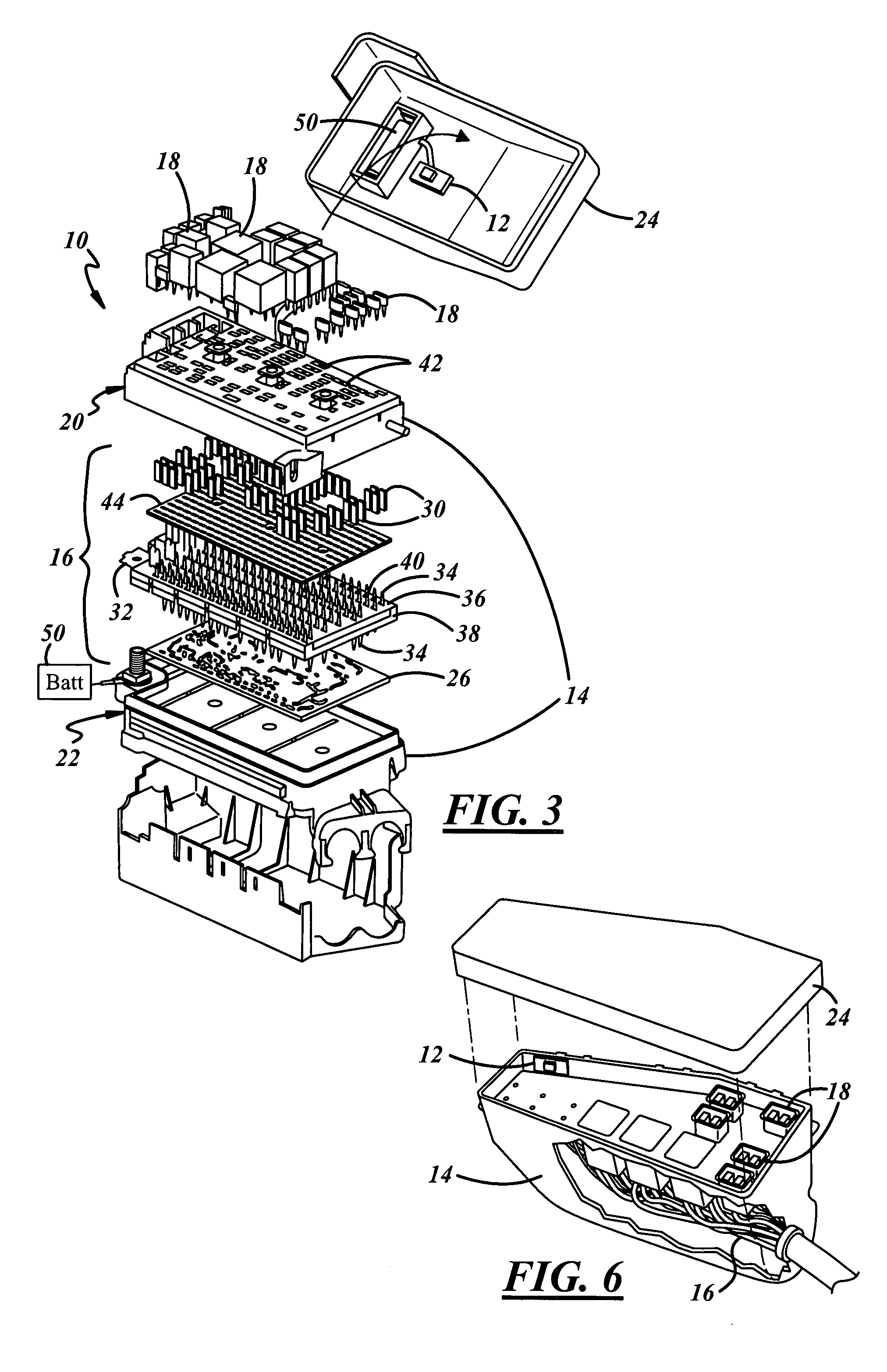

Illuminated electrical center

InactiveUS7635212B2Easy to useElectrically conductive connectionsLighting support devicesEngineeringLight-emitting diode

Owner:APTIV TECH LTD

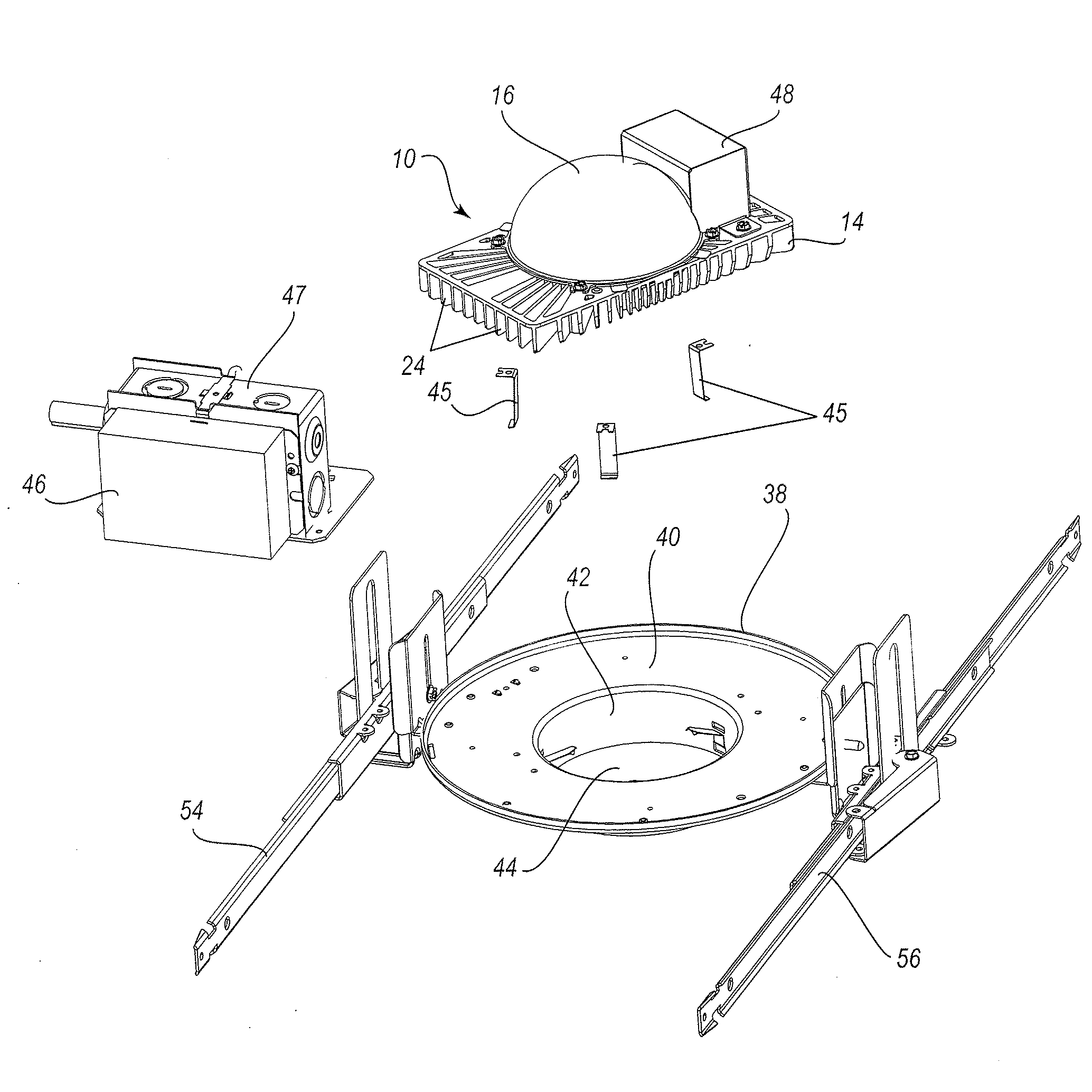

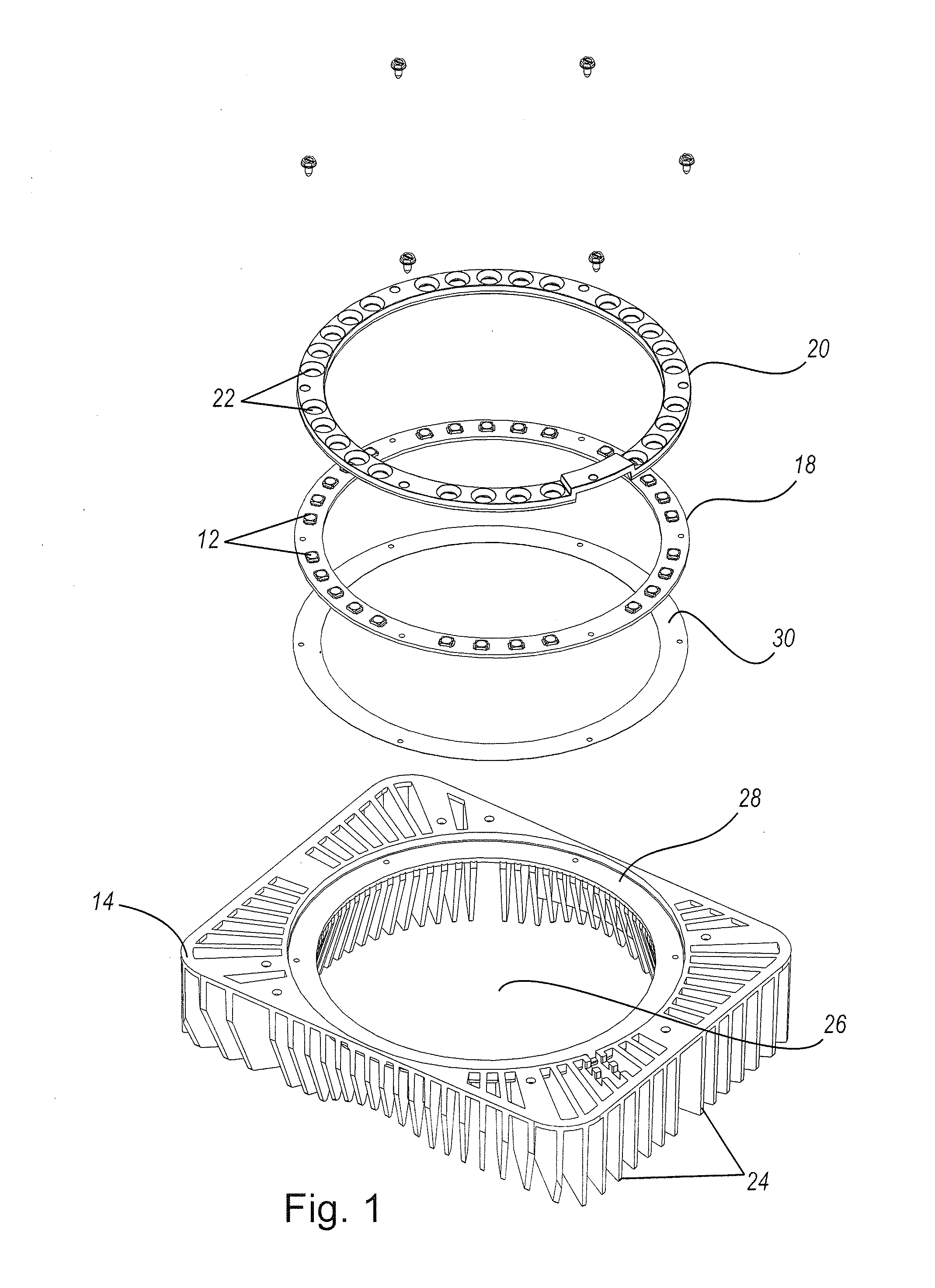

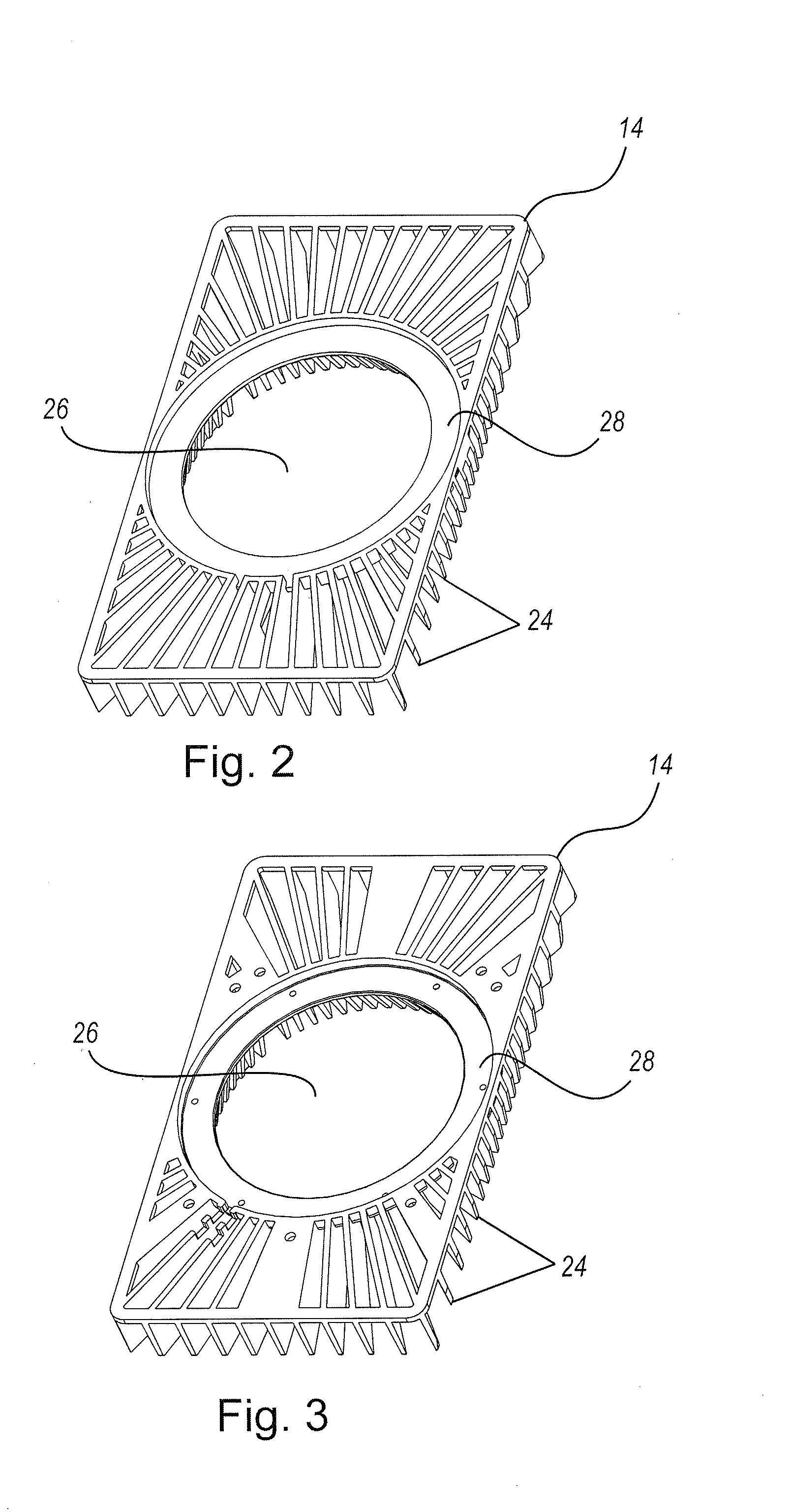

Lighting fixture

InactiveUS20090290343A1Easy to upgradeImprove surface reflectivityNon-electric lightingPoint-like light sourceModularityEffect light

Embodiments of the invention provide lighting assemblies for installation in lighting fixtures. Lighting assemblies include at least one light source, at least one heat sink, and at least one reflector. Other embodiments of the lighting assembly may also include an outer surface of the reflector comprising a heat sink. In some embodiments, it may be desirable to direct light toward a wall. In those situations, a wall wash trim may be included. The lighting assemblies disclosed herein may be modular and thus replaced without having to uninstall the entire fixture. In some embodiments, a circuit board containing at least one light emitting diode in an existing lighting assembly may be replaced with another circuit board containing light emitting diodes of a different color temperature or a different color.

Owner:ABL IP HLDG

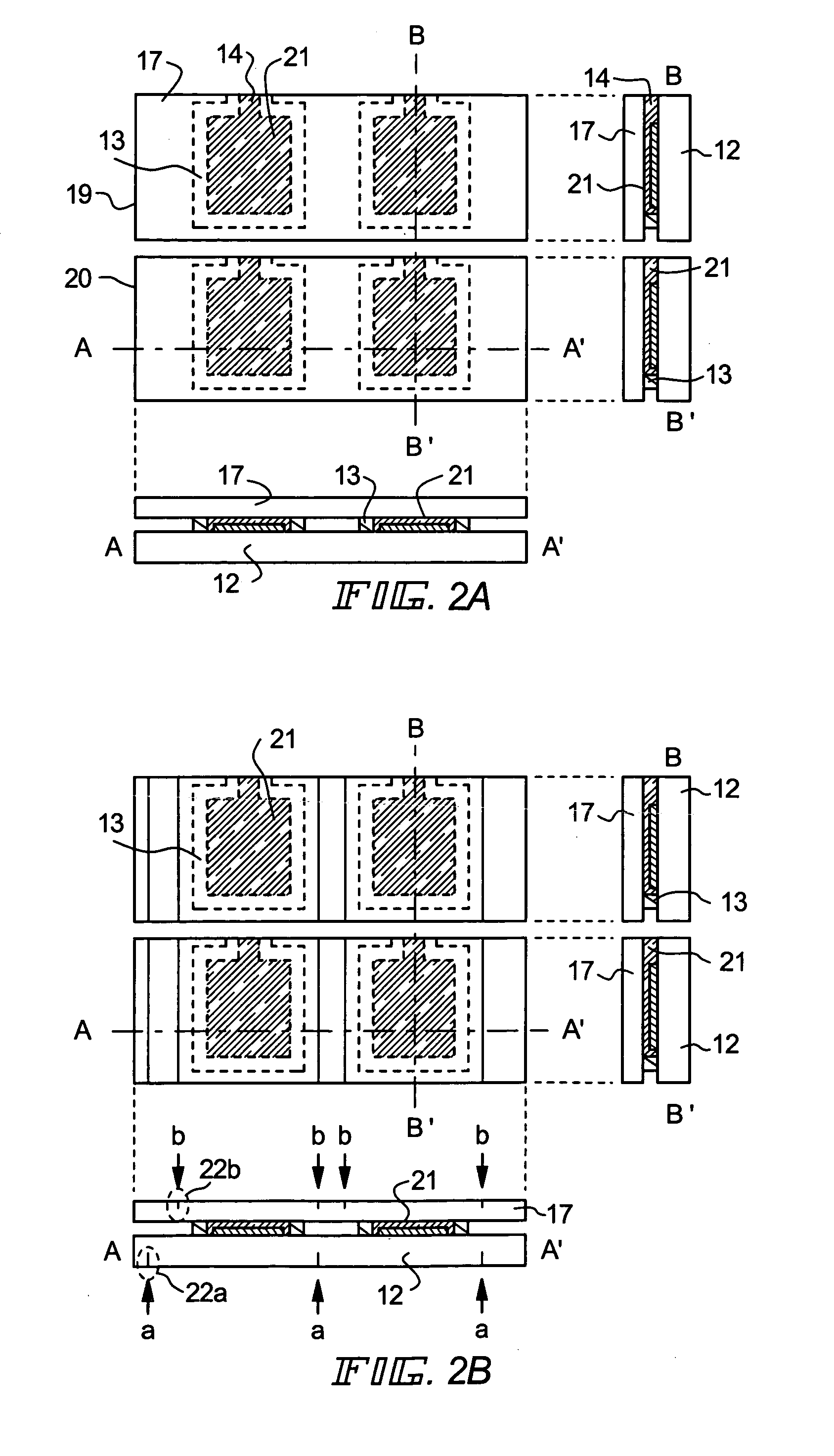

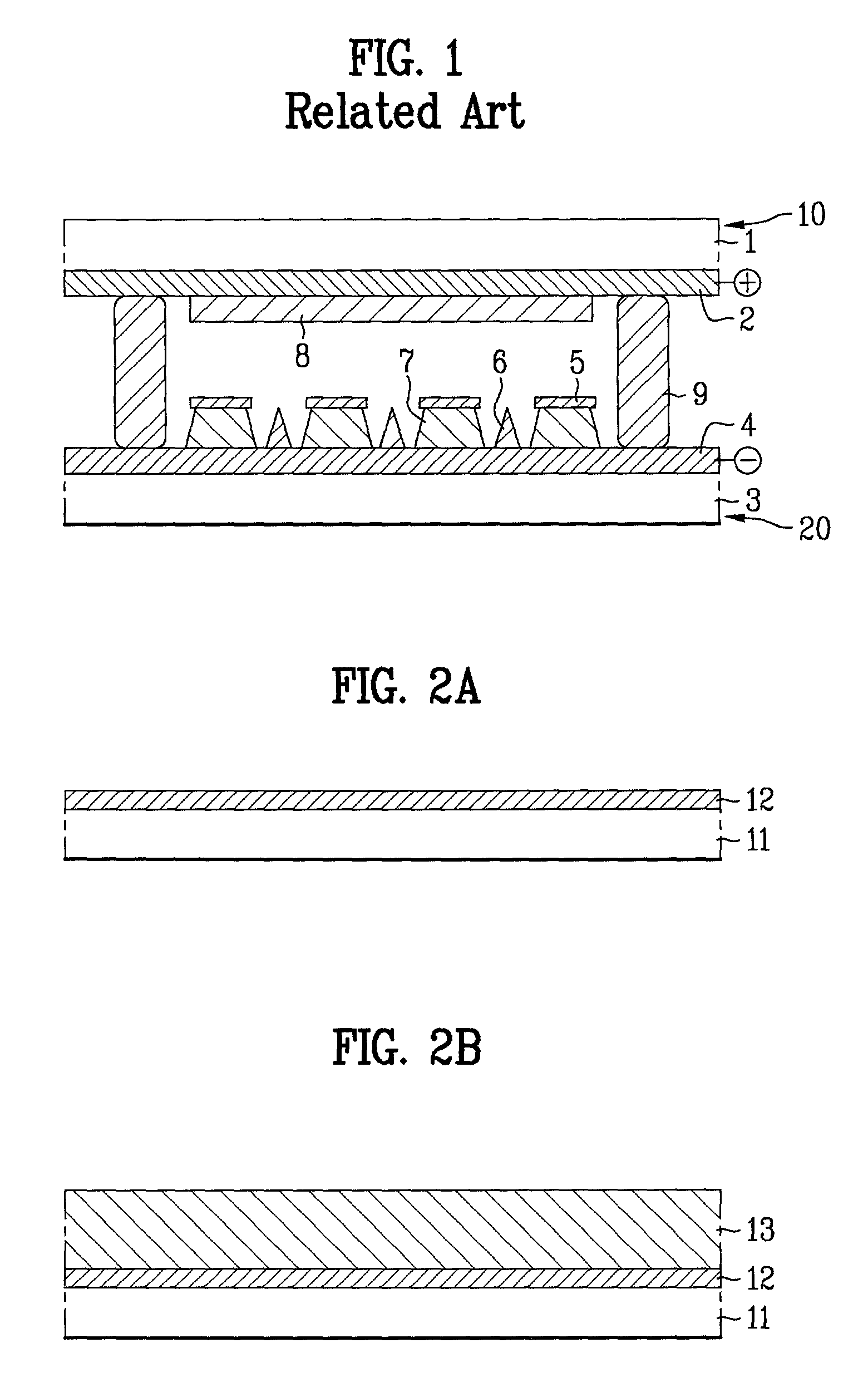

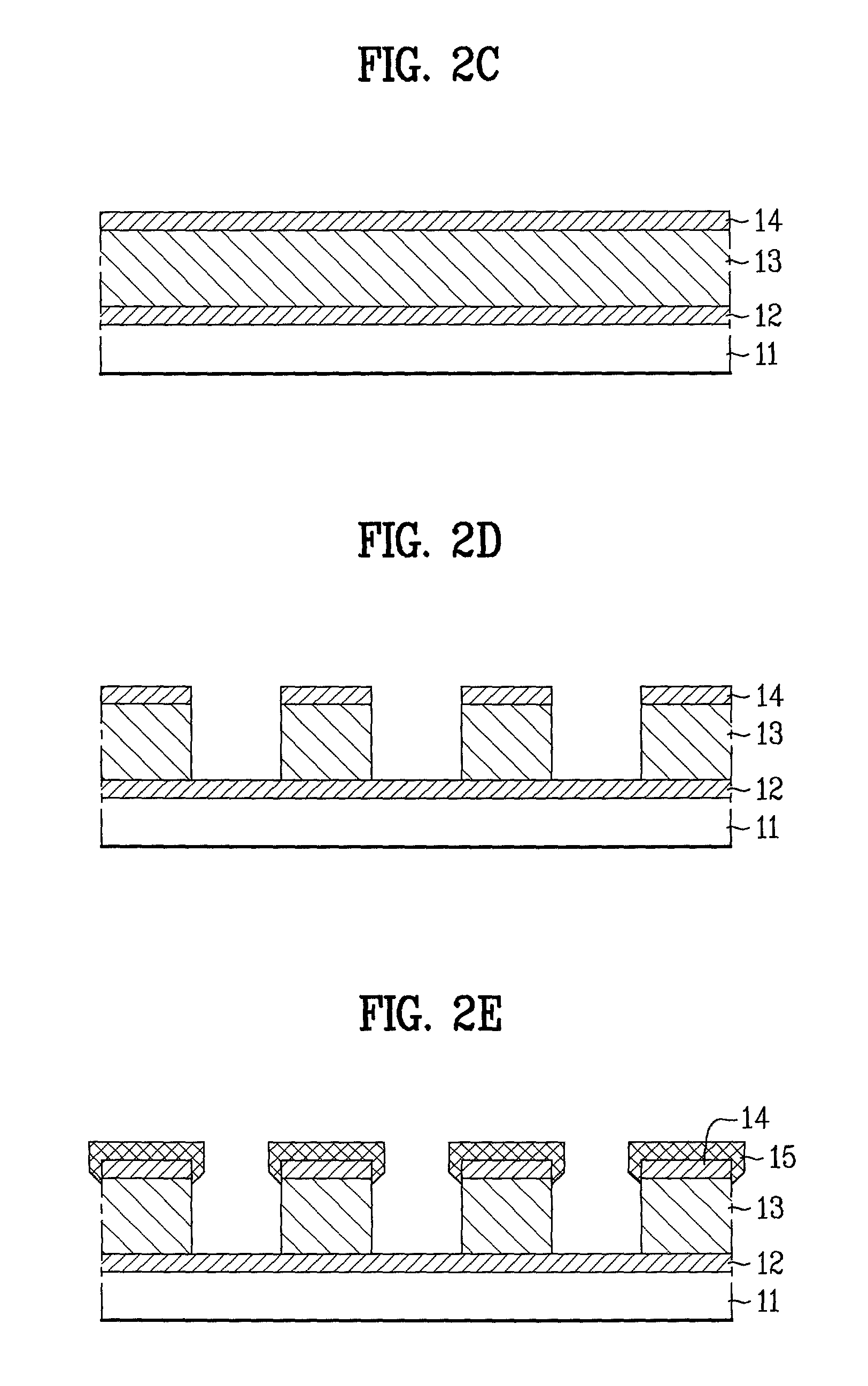

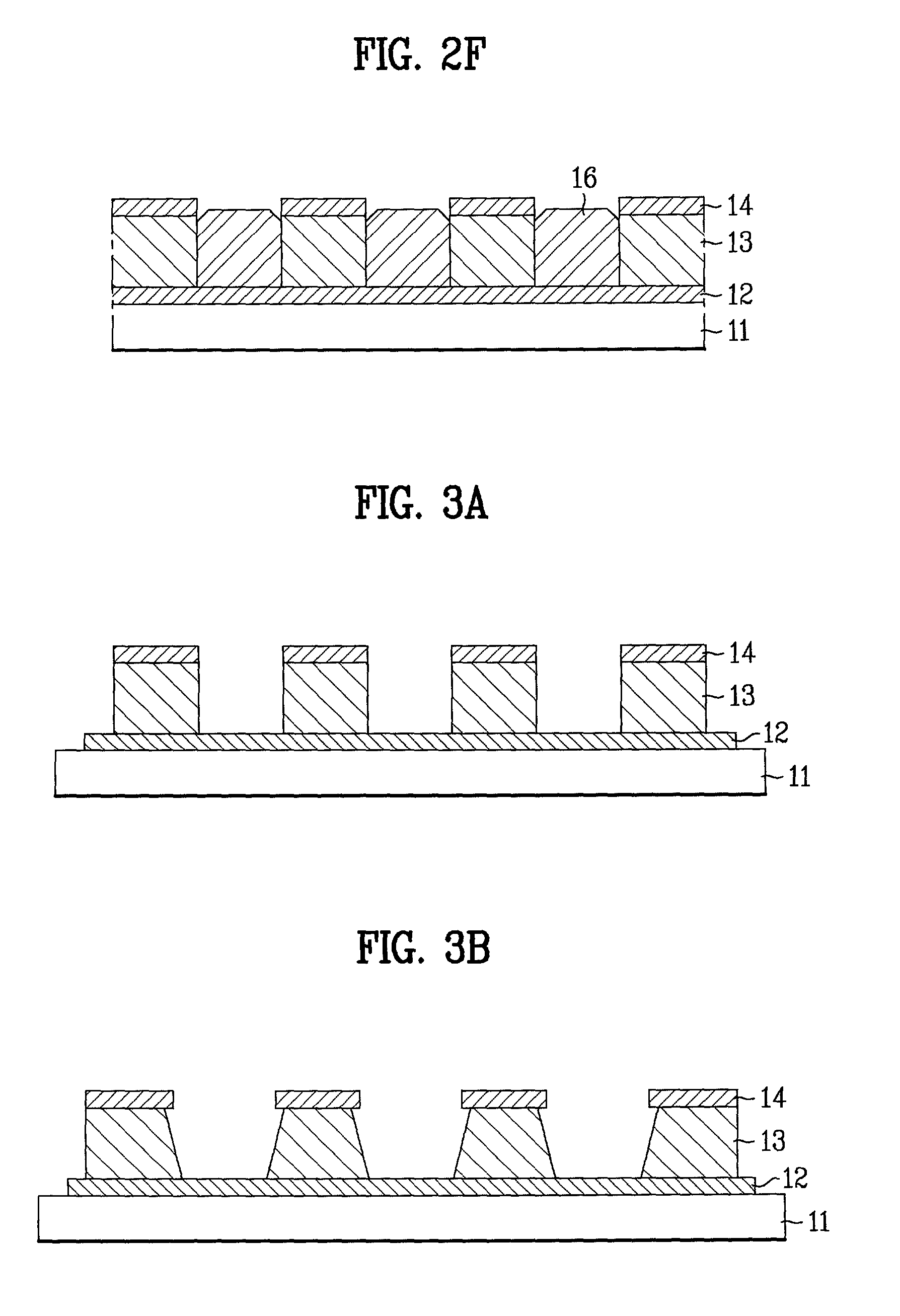

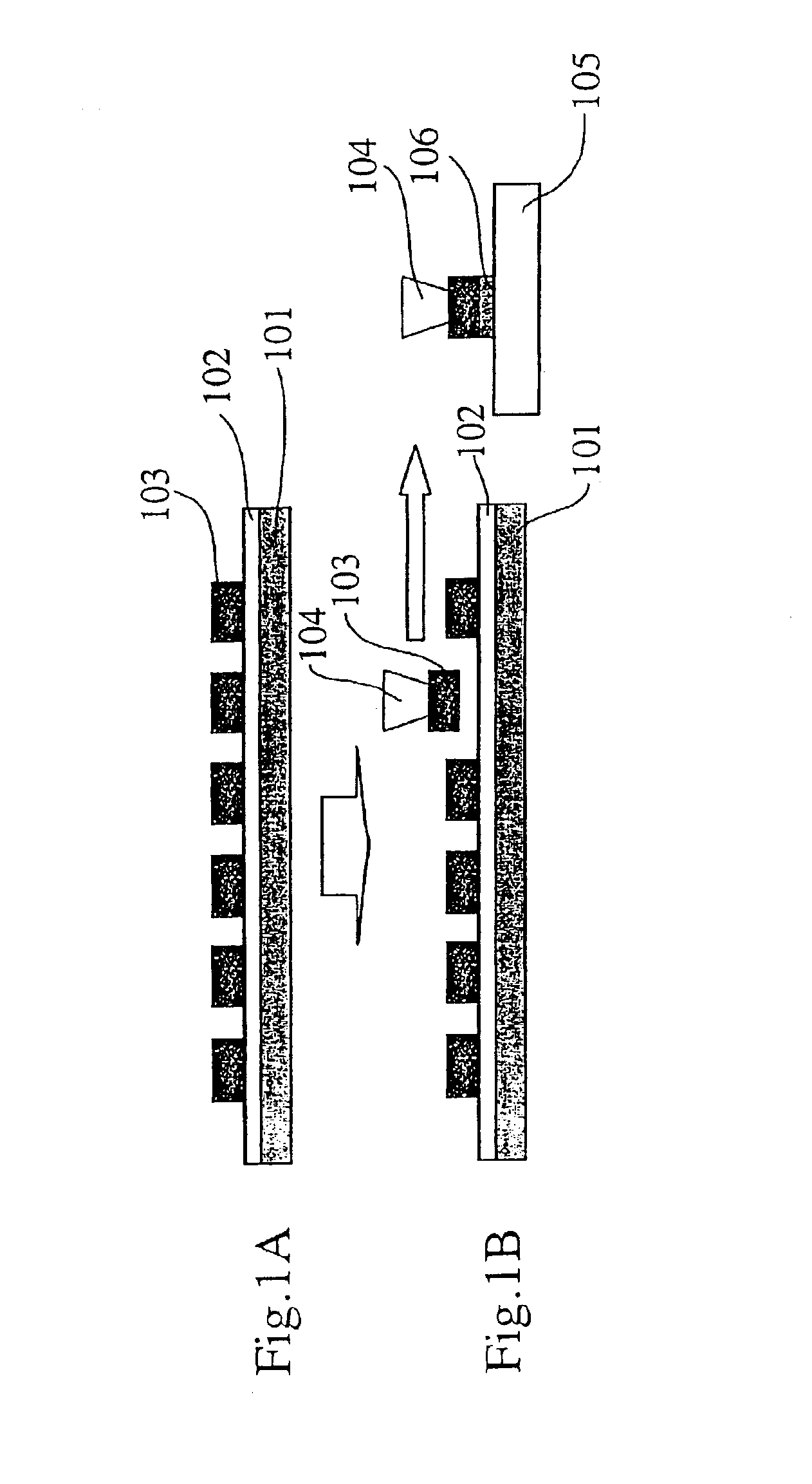

Device transferring method, and device arraying method and image display unit fabricating method using the same

InactiveUS6872635B2Efficiently and accurately transferringEfficiently re-arrayDecorative surface effectsSolid-state devicesIrradiationMaterials science

Owner:XIAMEN SANAN OPTOELECTRONICS CO LTD

Visual display unit illumination

ActiveUS20050062410A1Increased intensityUniform light intensityDischarge tube luminescnet screensElectroluminescent light sourcesPhysicsTransparent display

A method of adapting a visual unit having a first screen (10) in a first focal plant by the addition of one or more at least partially transparent display screens (20) at least partially overlapping said first screen (10) and located in focal planes distinct from said first focal plane, characterised in that an at least partially transparent emissive layer (21) is provided between said first screen (10) and at least one said additional display screen (20).

Owner:APTIV TECH LTD

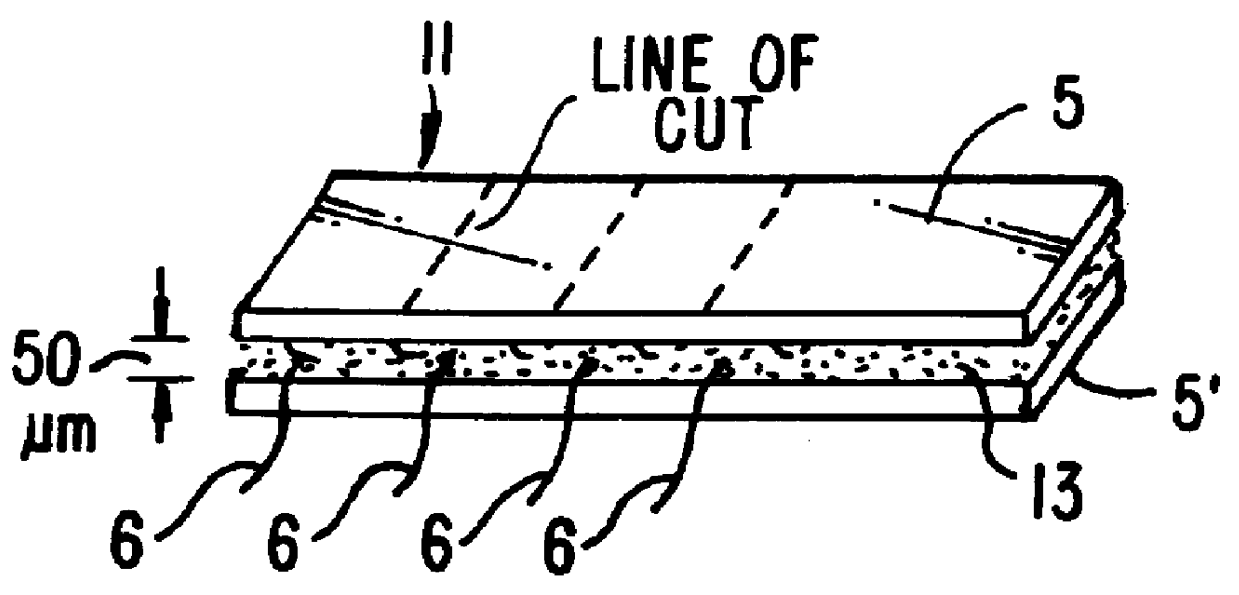

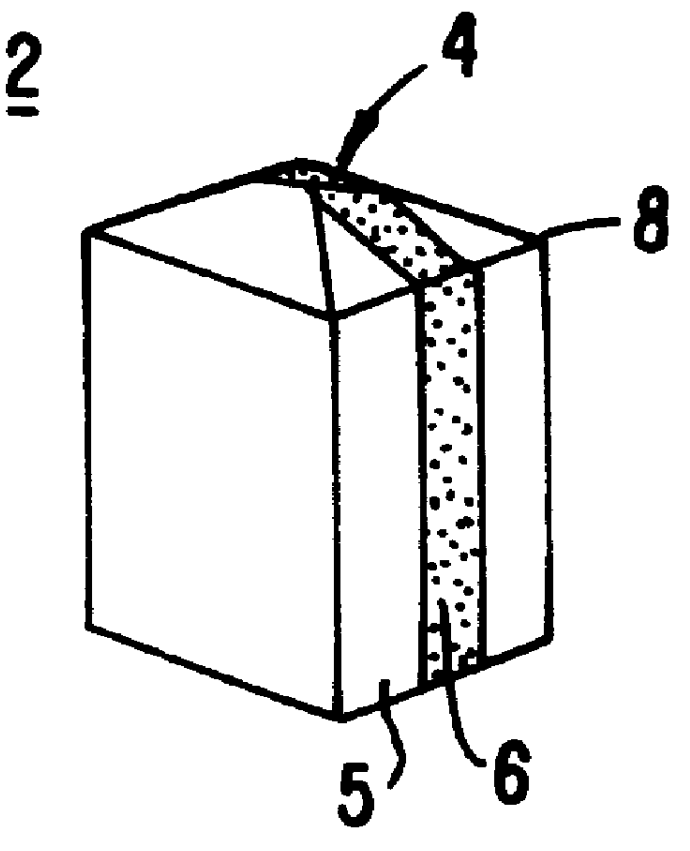

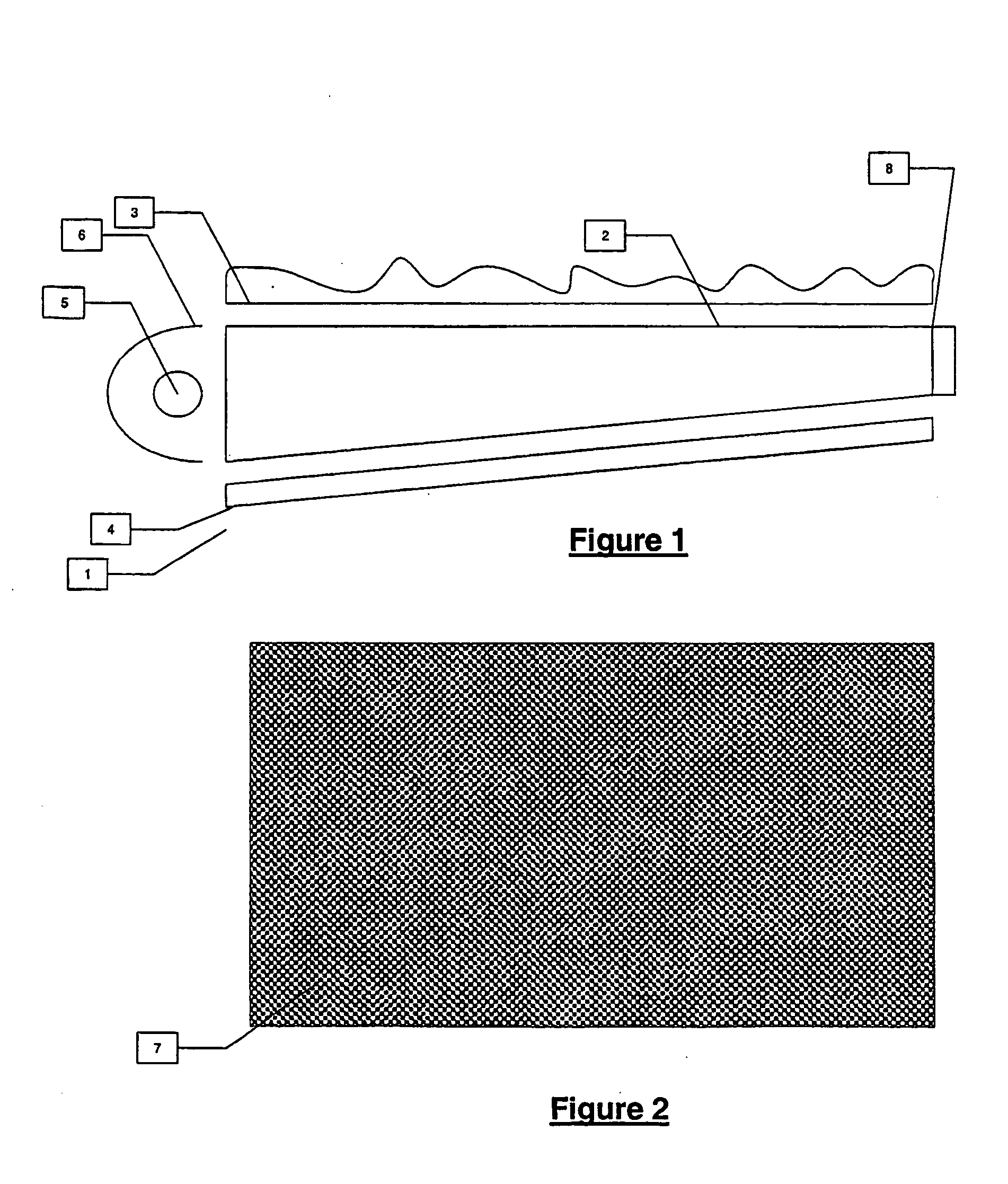

Sheet-shaped heat and light source, method for making the same and method for heating object adopting the same

InactiveUS20090096348A1Efficient use ofNanotechDischarge tube luminescnet screensCarbon nanotubeOptoelectronics

The present invention relates to a sheet-shaped heat and light source. The sheet-shaped heat and light source includes a carbon nanotube film and at least two electrodes. The at least two electrodes are separately disposed on the carbon nanotube film and electrically connected thereto. Moreover, a method for making the sheet-shaped heat and light source and a method for heating an object adopting the same are also included.

Owner:TSINGHUA UNIV +1

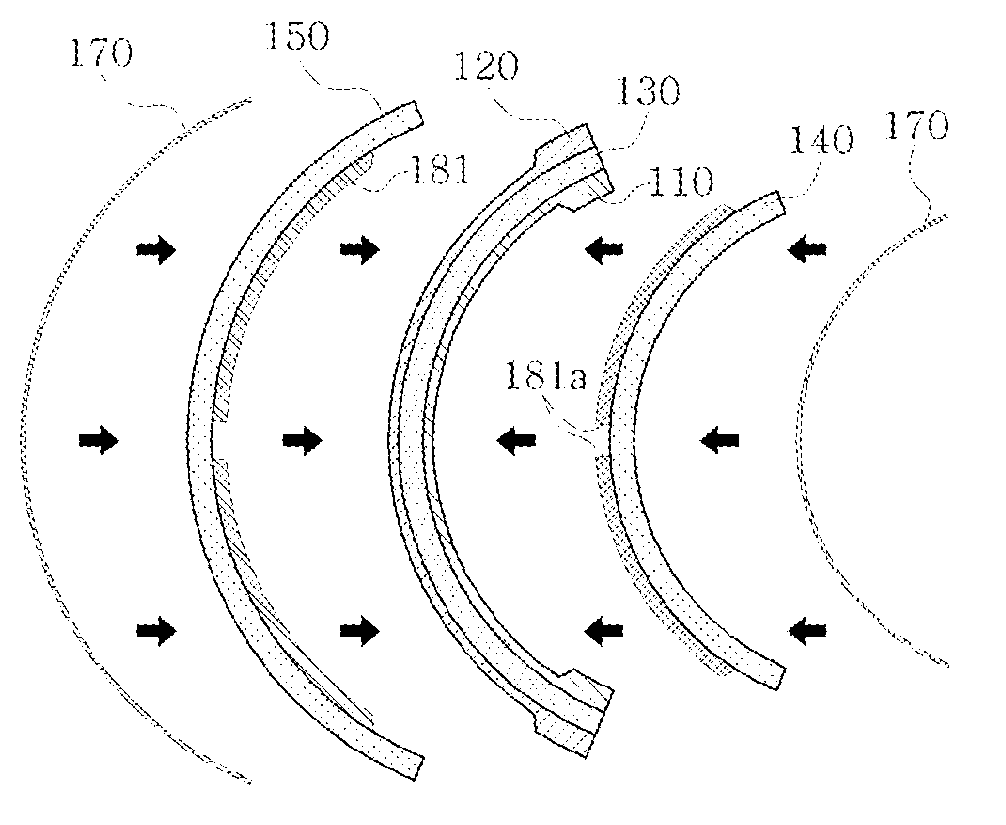

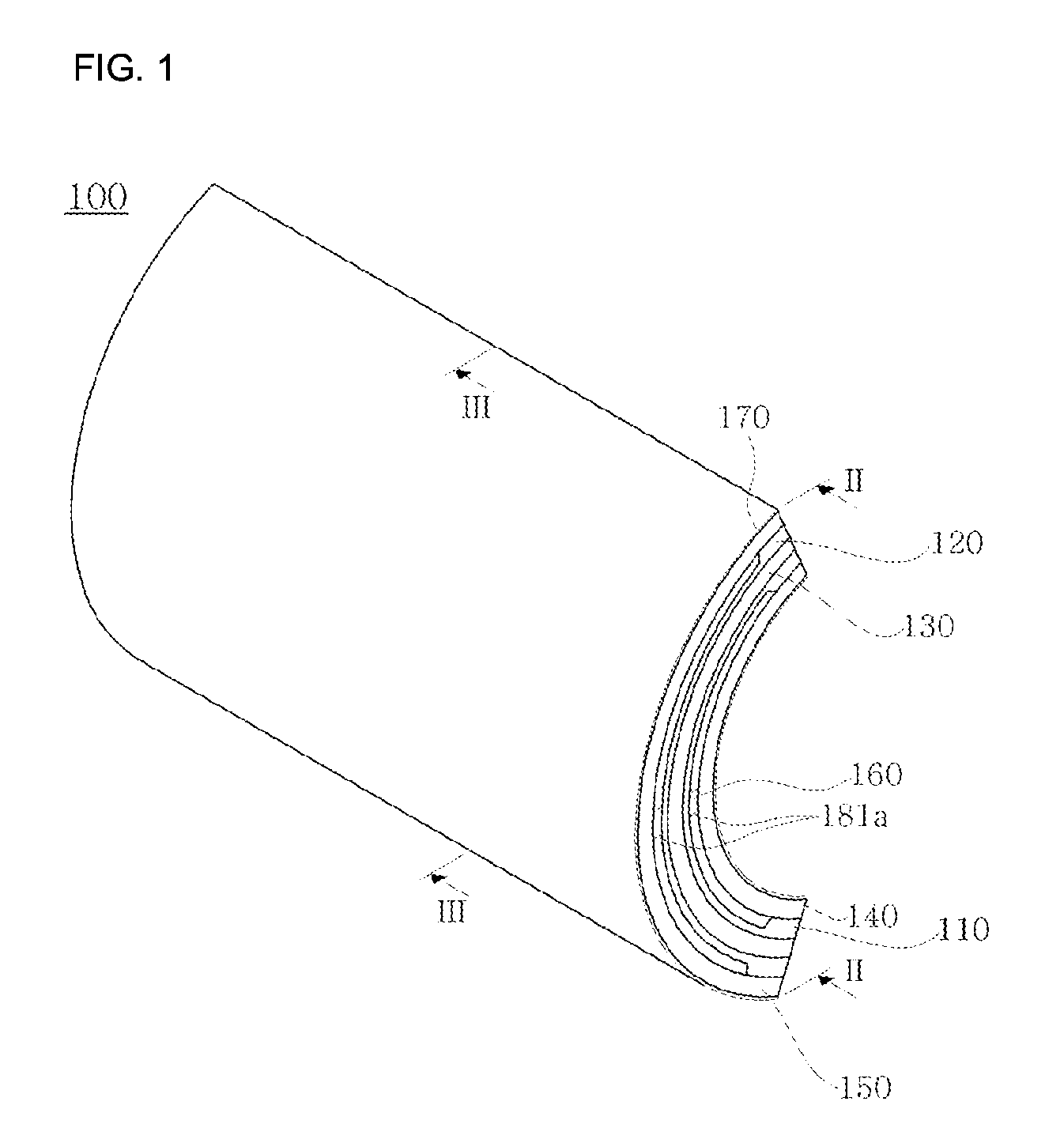

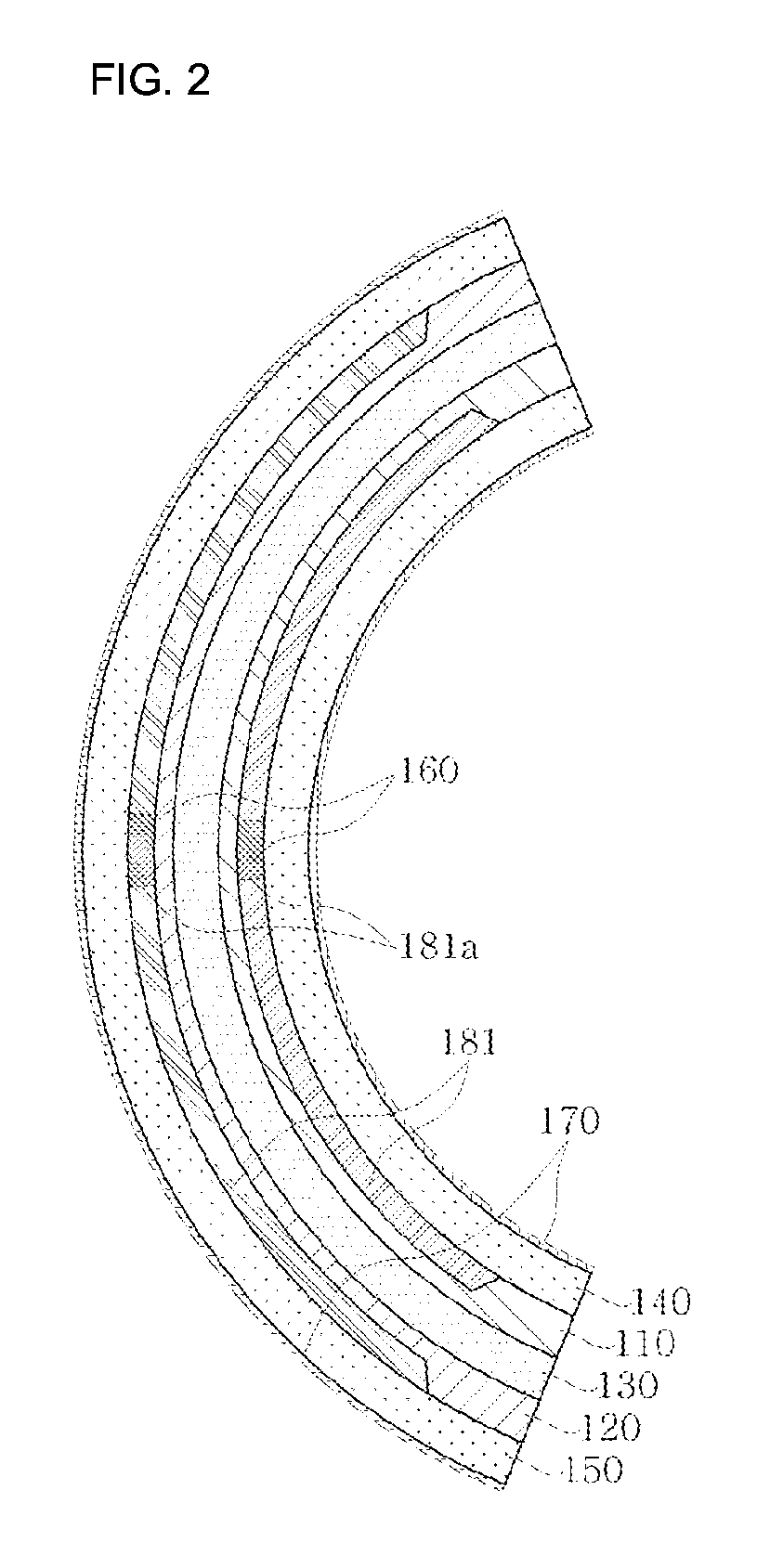

Curved-surface display panel fabrication method, curved-surface display panel using same, and multi-image display device using same

ActiveUS8982545B2Reduce thicknessSimple processDigital data processing detailsVessels or leading-in conductors manufactureSurface displayMulti-image

A curved-surface display panel fabrication method for fabricating a curved-surface display panel using a flat display panel having a first substrate and a second substrate includes: paring partially outer surfaces of the first substrate and the second substrate so as to reduce thicknesses thereof to a predetermined thickness; bending the pared flat display panel to a desired curved shape; attaching a first guide member which has a shape corresponding to the desired curved shape to the first substrate with a predetermined gap from the pared outer surface thereof and attaching a second guide member with has a shape corresponding to the desired curved shape to the second substrate with a predetermined gap from the pared outer surface thereof; and forming light transmitting reinforcing layers respectively in a space between the first guide member and the first substrate and a space between the second guide member and the second substrate.

Owner:TOVIS

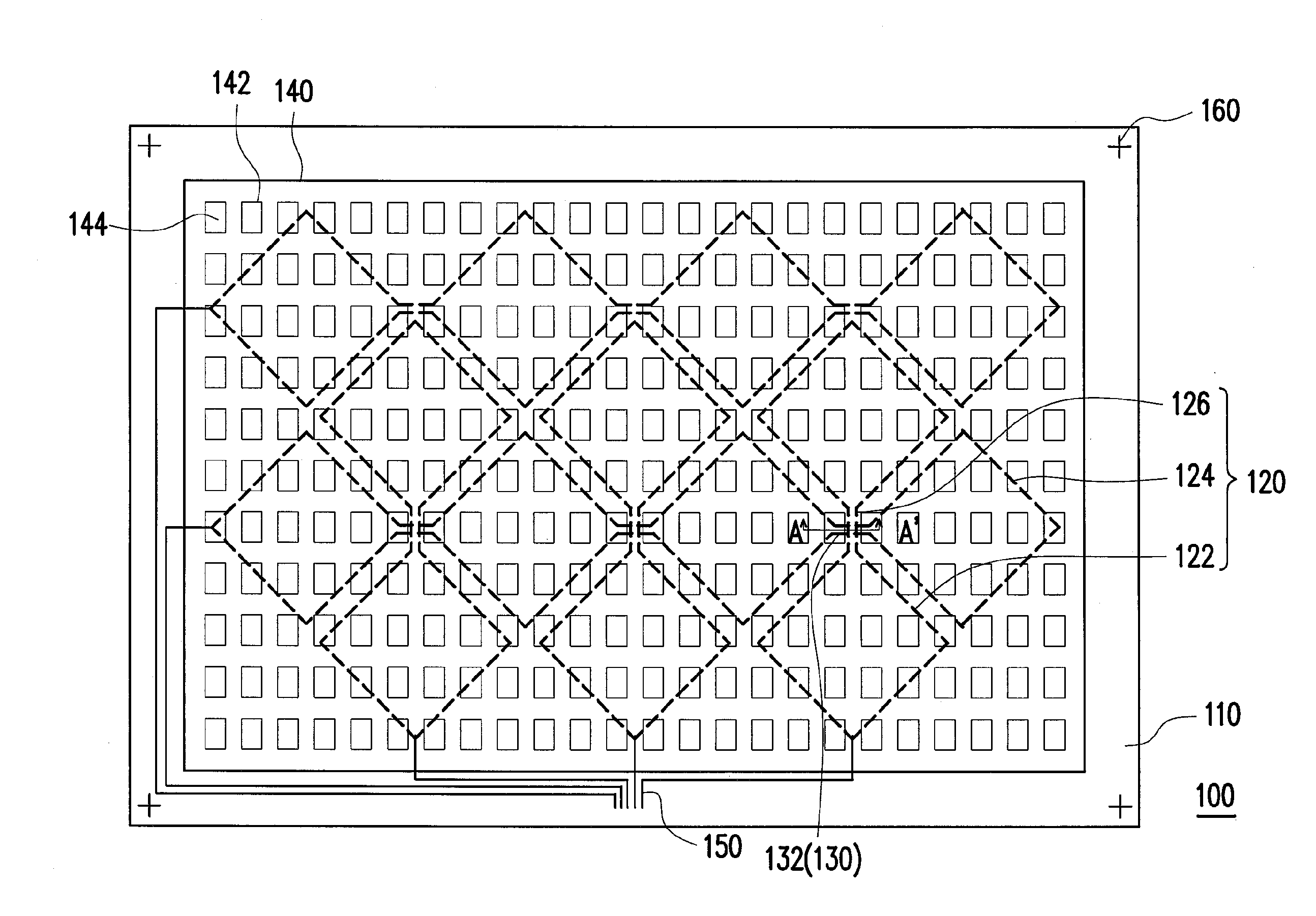

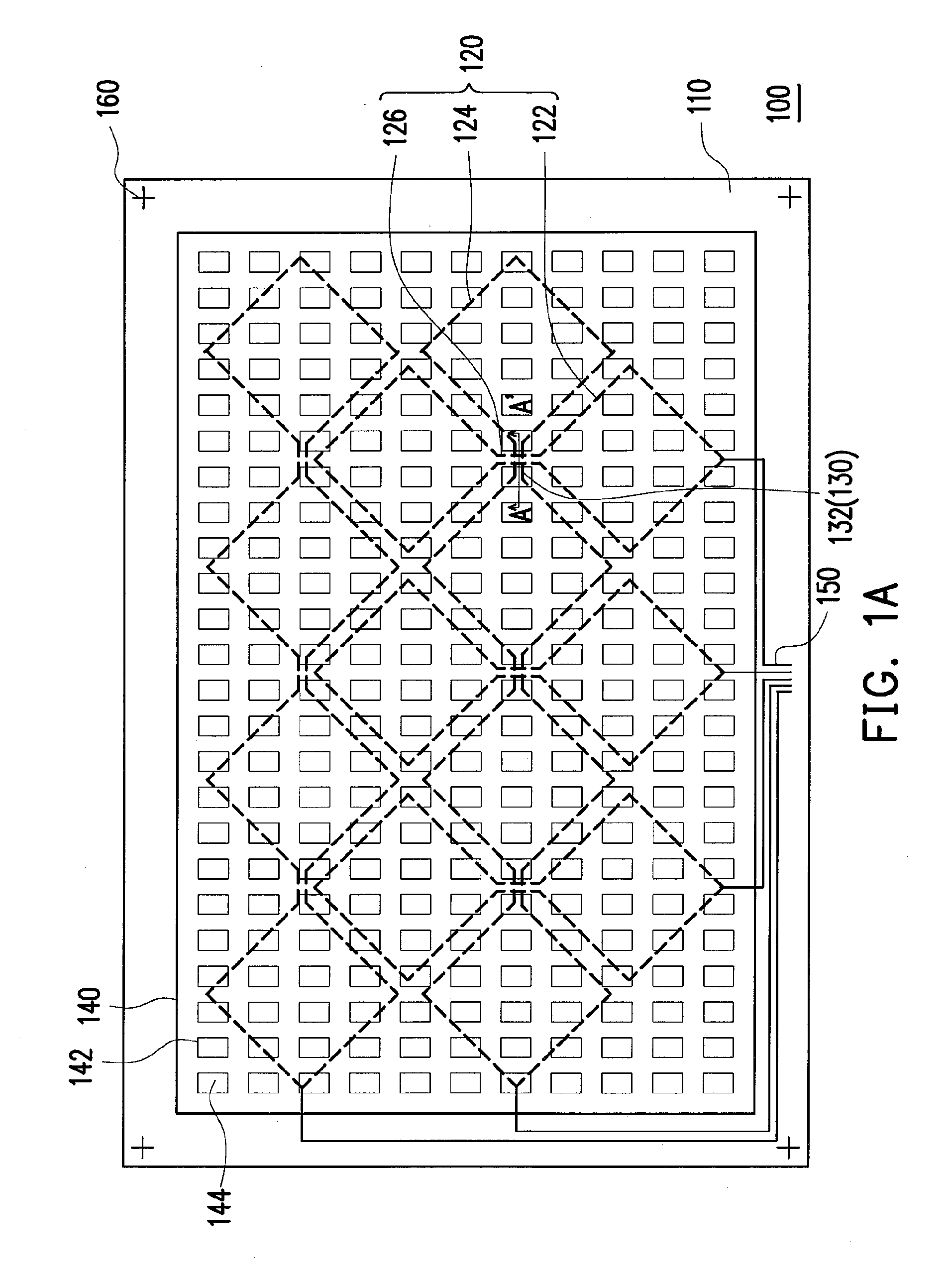

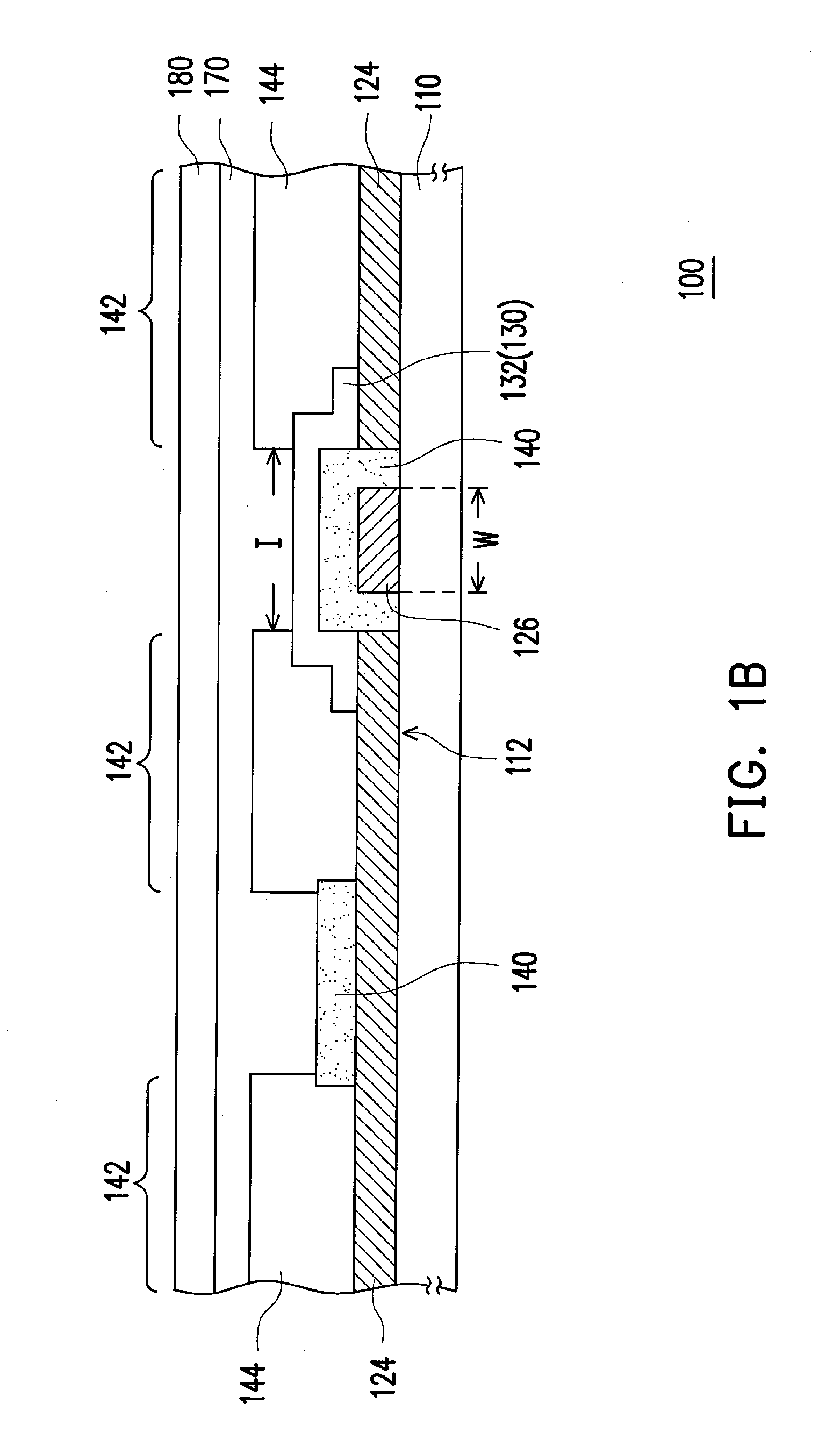

Color filter touch sensing substrate and display panel and manufacturing methods of the same

ActiveUS20100149117A1Small touch sensing areaReduce decreaseVessels or leading-in conductors manufactureNon-linear opticsTouch SensesEngineering

A manufacturing method of a color filter touch sensing substrate is provided. Firstly, a first film is formed on a substrate. The first film includes a plurality of first and second touch sensors and a plurality of first bridge lines for electrically connecting the first touch sensors in the same column. Then, a second film is formed on the substrate. The second film includes a plurality of second bridge lines for electrically connecting the second touch sensors in the same row. Next, a light shielding pattern layer is formed between the first and the second films. The light shielding pattern layer is used to define a plurality of sub-pixel regions on the substrate. Afterward, a plurality of color filter pattern layers is formed in the sub-pixel regions. Furthermore, a color filter touch sensing substrate, a display panel and manufacturing methods thereof are also provided.

Owner:AU OPTRONICS CORP

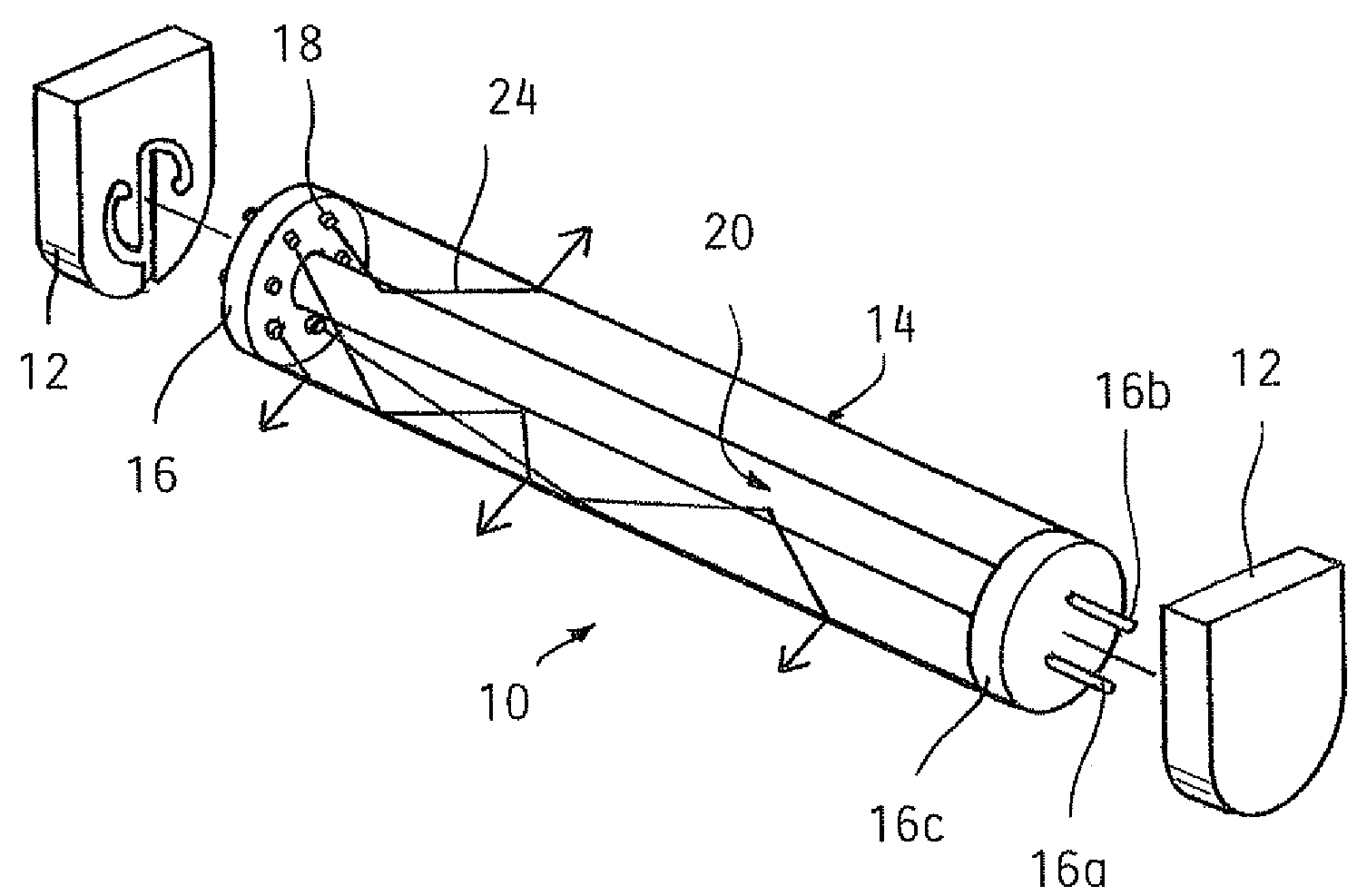

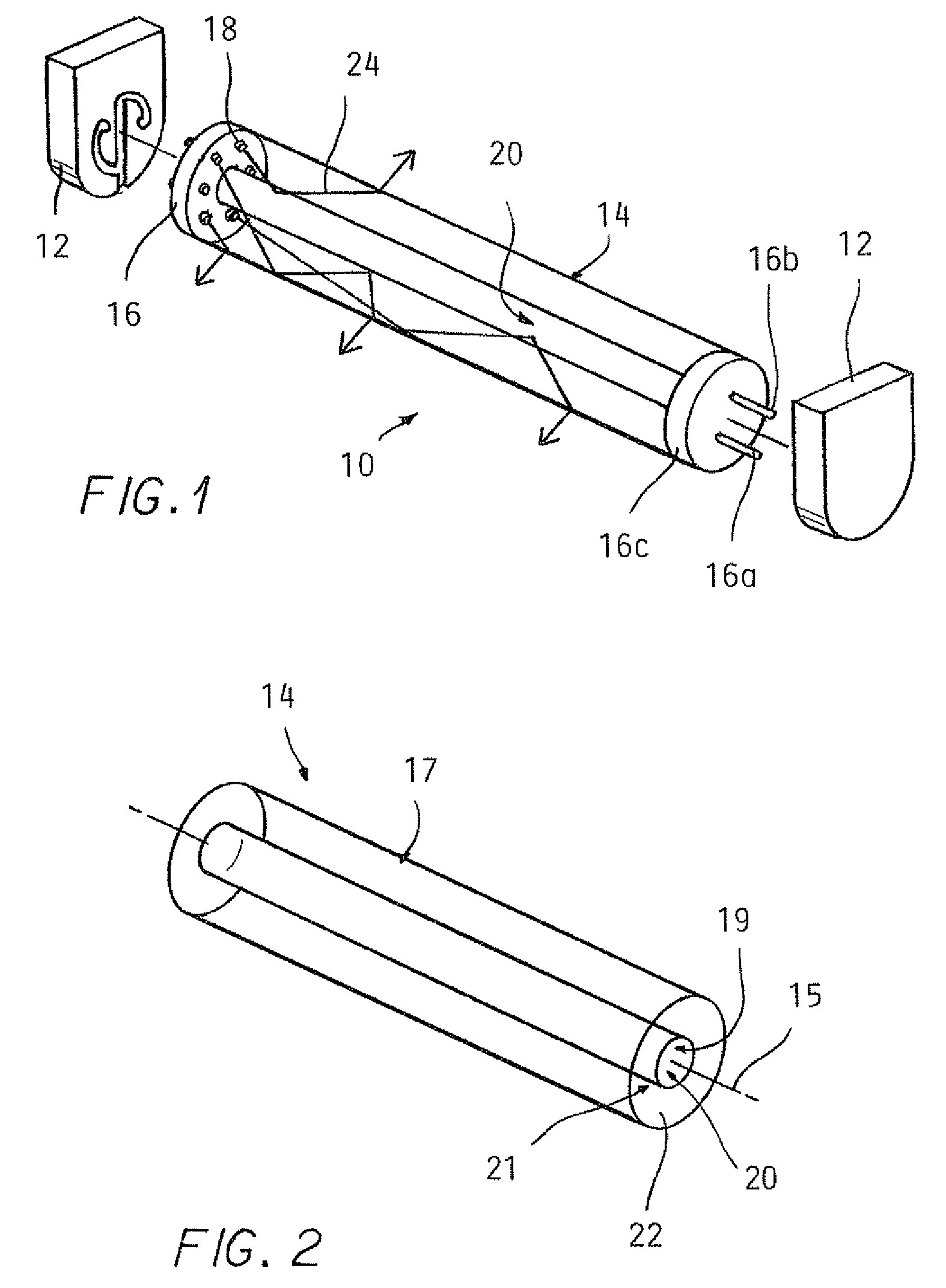

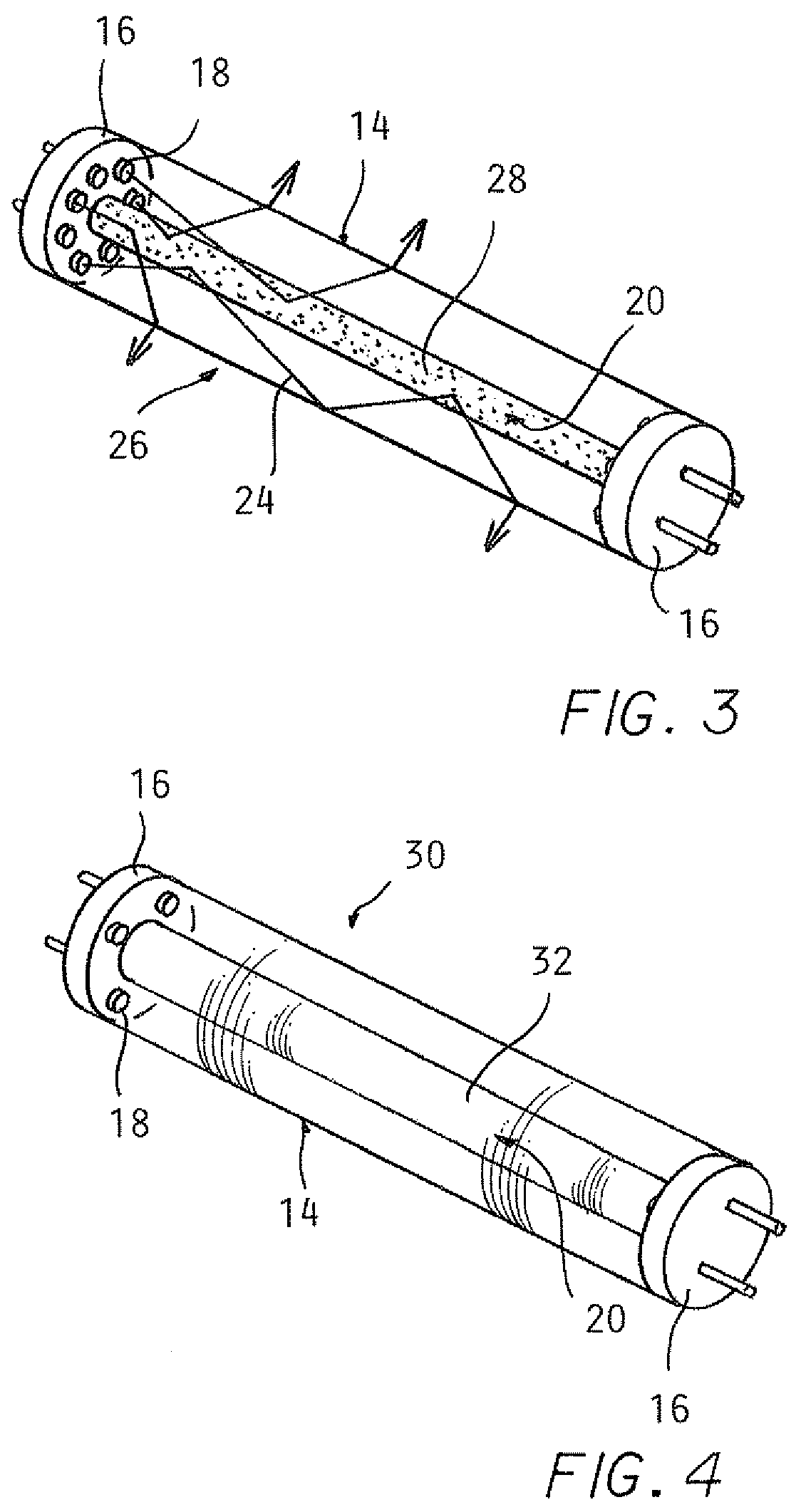

Fluorescent tube replacement having longitudinally oriented LEDs

An LED-based light for replacing a conventional fluorescent tube in a fixture is provided. The LED-based light includes an elongate light transmitting rod defining a bore and at least one LED positioned at one or both ends of the rod and oriented to produce light longitudinally into a portion of the rod radially outward of the bore. At least one connector is physically coupled to an end of the rod and electrically coupled to the at least one LED. The at least one connector is adapted for physical and electrical connection to the fixture. In operation, the directional light produced by the at least one LED is dispersed by way of reflection, refraction, and / or diffusion while traveling longitudinally through the rod to reduce the appearance of bright spots.

Owner:ILUMISYS

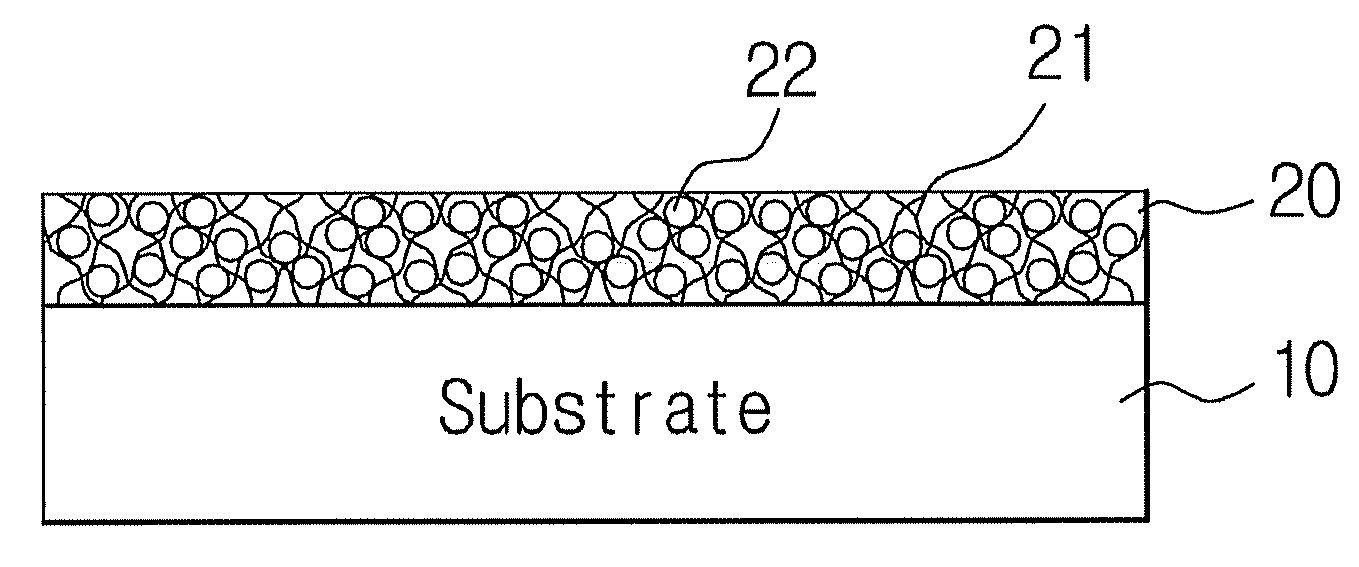

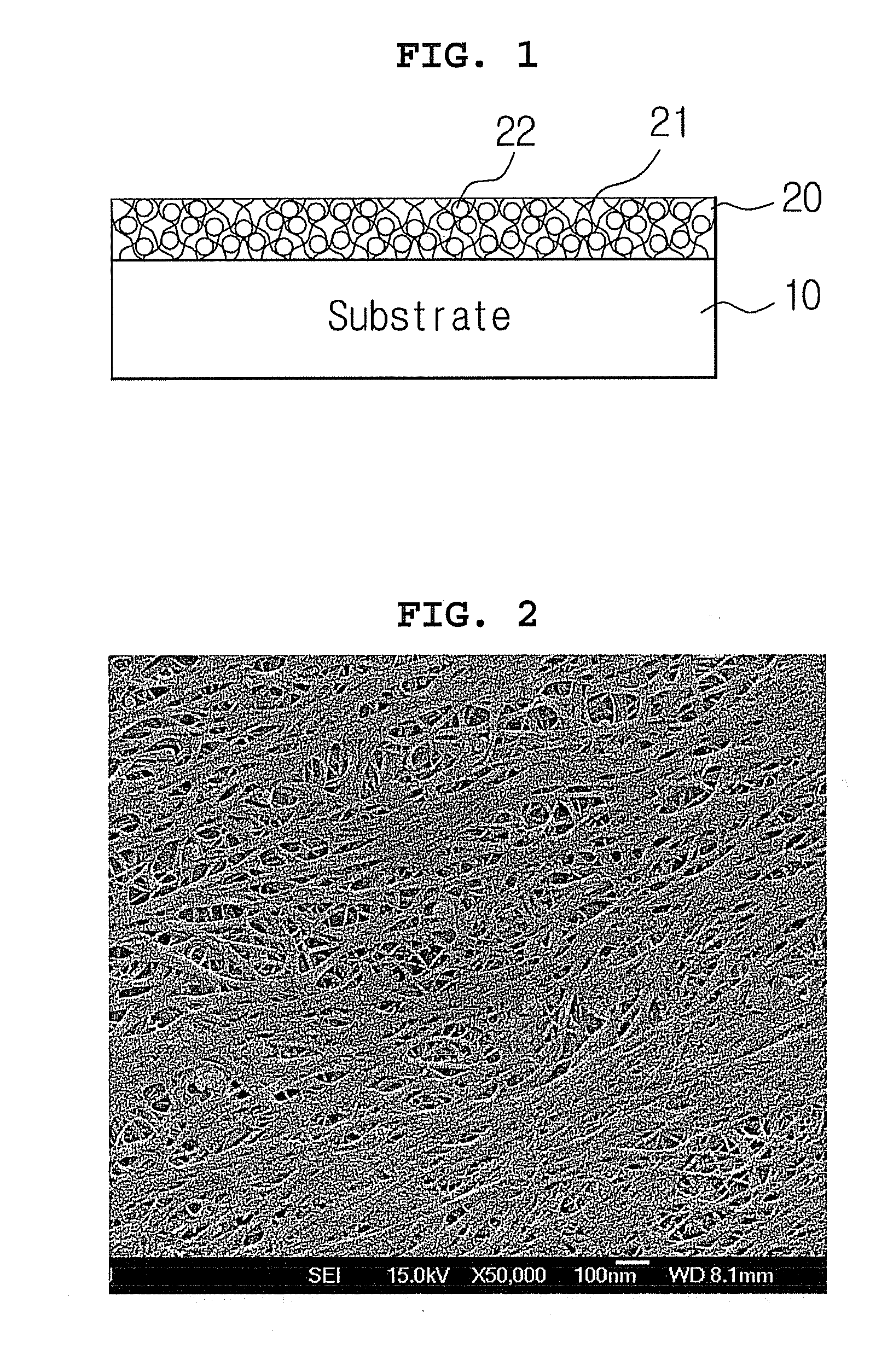

Transparent carbon nanotube electrode using conductive dispersant and production method thereof

ActiveUS20080088219A1Improve conductivityMaterial nanotechnologyConductive layers on insulating-supportsSolar cellTouchscreen

Disclosed is a transparent carbon nanotube (CNT) electrode using a conductive dispersant. The transparent CNT electrode comprises a transparent substrate and a CNT thin film formed on a surface the transparent substrate wherein the CNT thin film is formed of a CNT composition comprising CNTs and a doped dispersant. Further disclosed is a method for producing the transparent CNT electrode.The transparent CNT electrode exhibits excellent conductive properties, can be produced in an economical and simple manner by a room temperature wet process, and can be applied to flexible displays. The transparent CNT electrode can be used to fabricate a variety of devices, including image sensors, solar cells, liquid crystal displays, organic electroluminescence (EL) displays and touch screen panels, that are required to have both light transmission properties and conductive properties.

Owner:SAMSUNG ELECTRONICS CO LTD

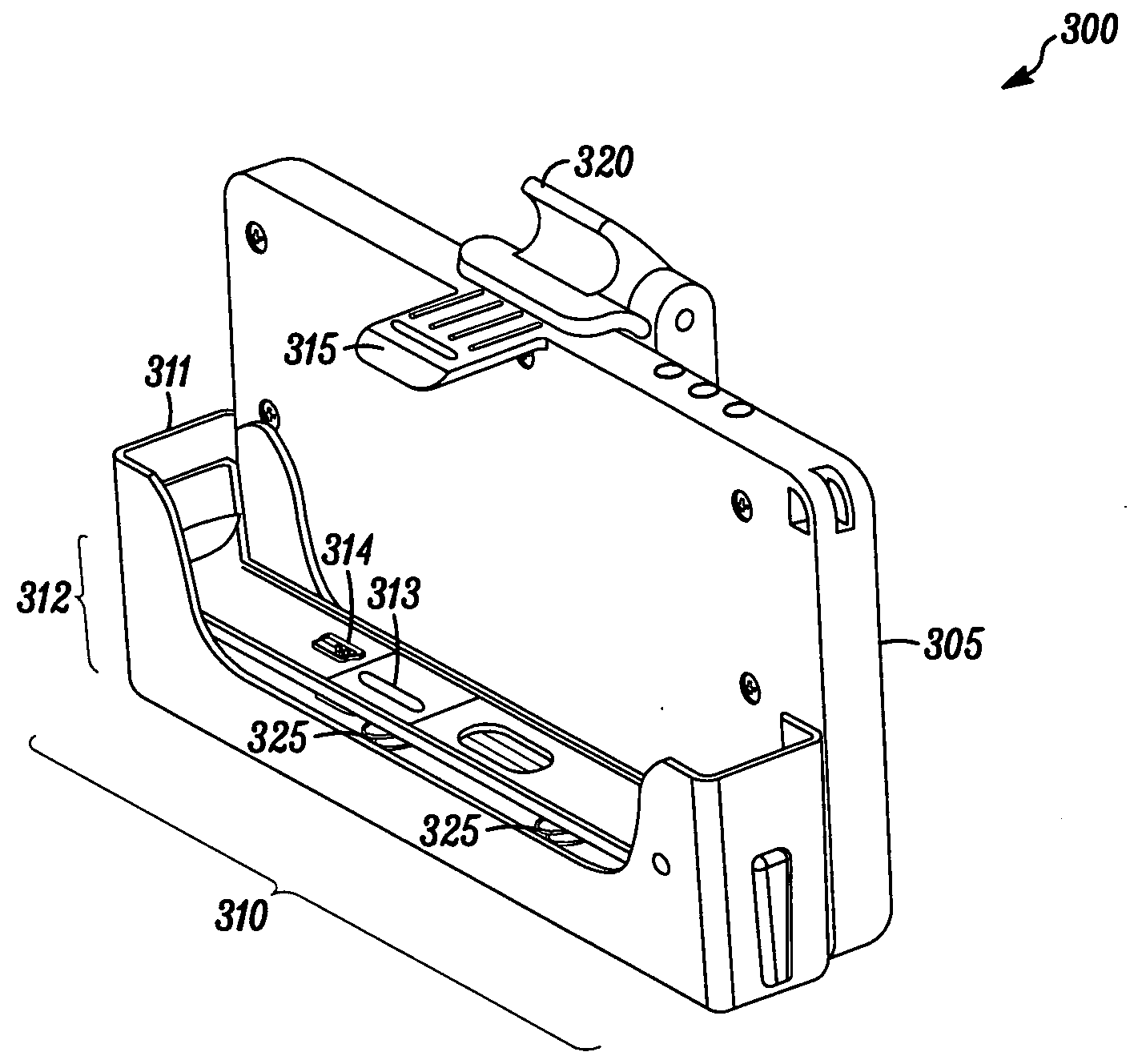

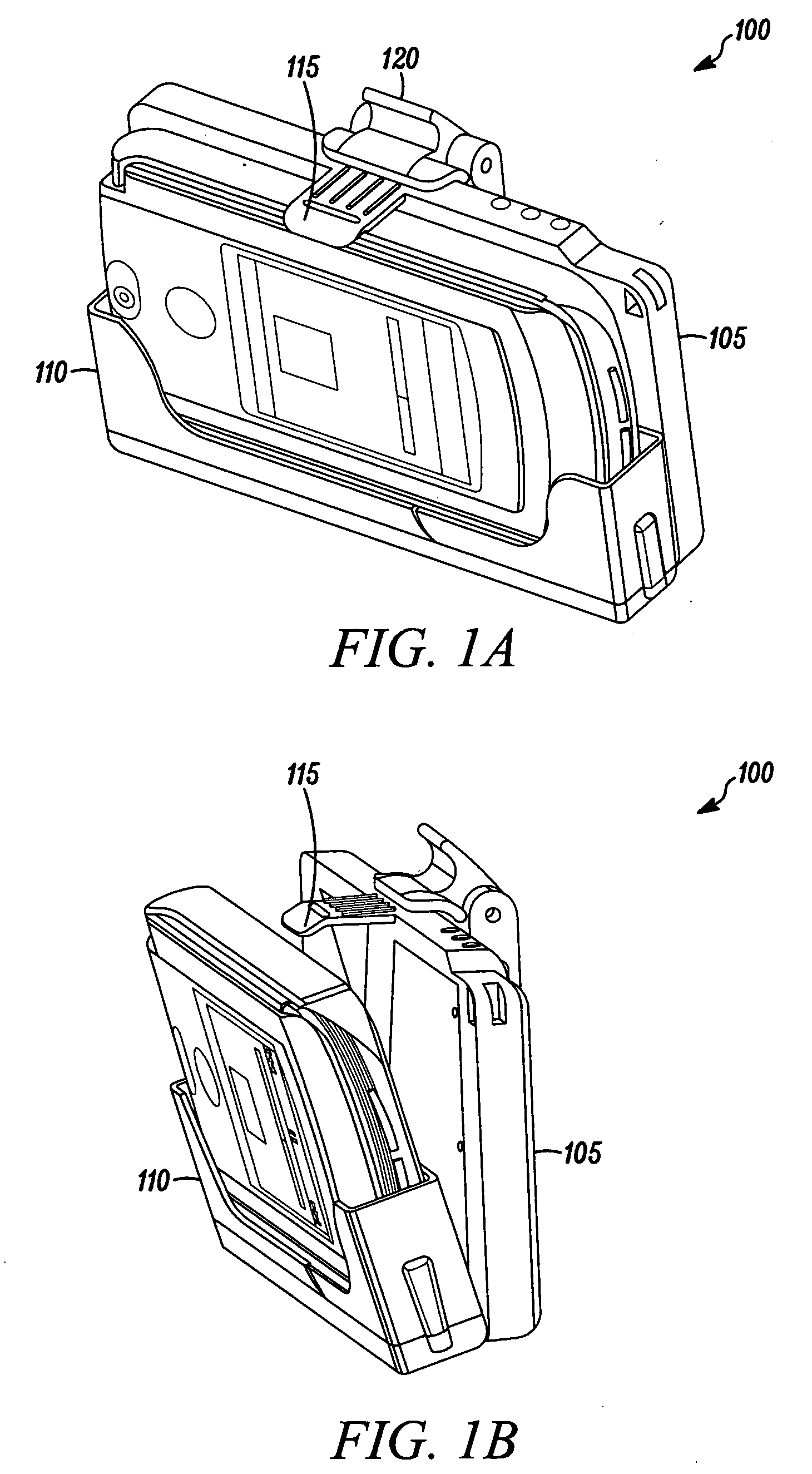

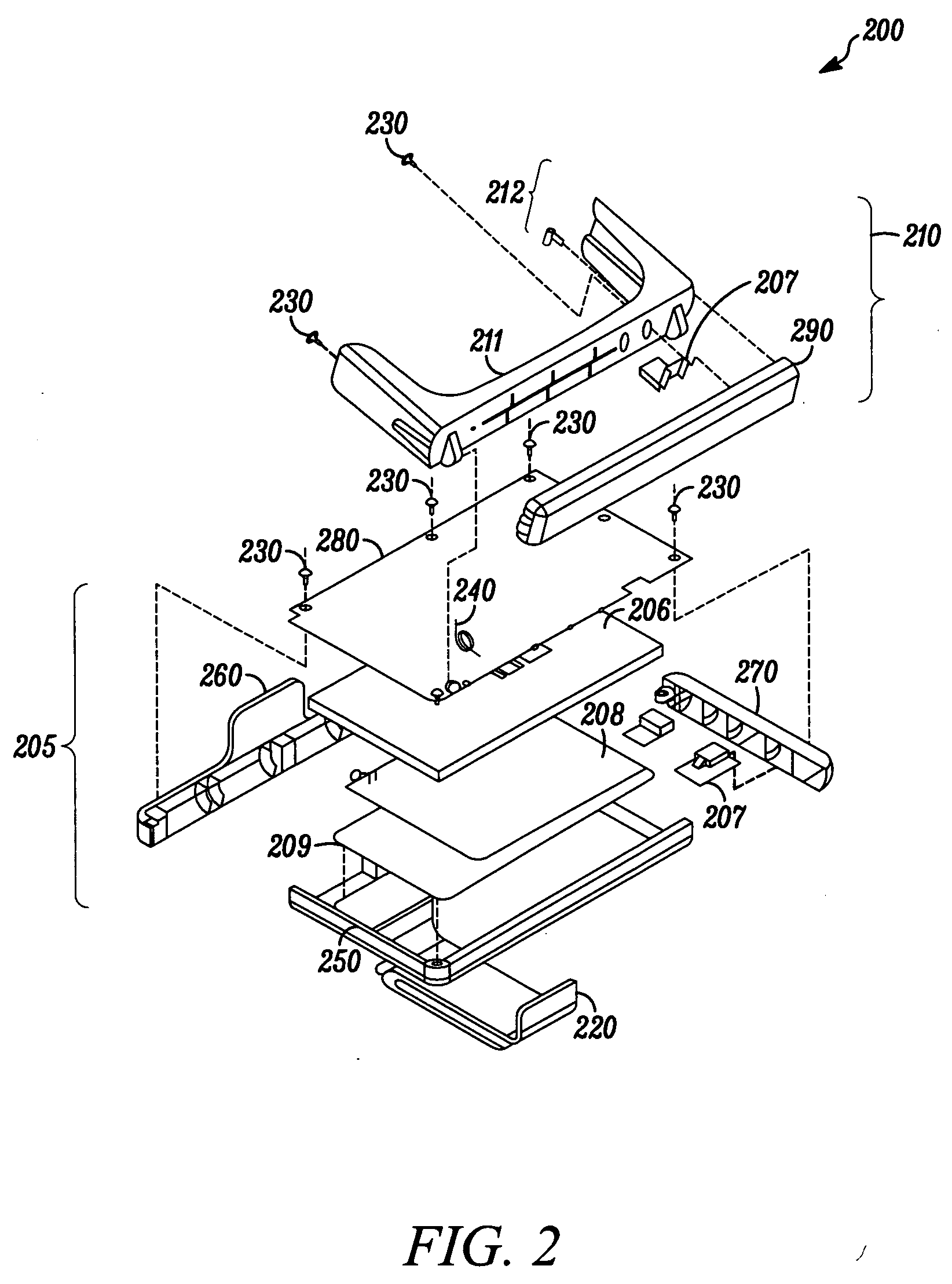

Portable and universal hybrid-charging apparatus for portable electronic devices

InactiveUS20090284216A1Great efficiency in transfer of chargeDifferent batteries chargingVessels or leading-in conductors manufactureEmbedded systemBattery charger

The teachings relate to a power supply that can be used to carry, charge, and power a portable electronic device, as well as be operable by a user while mobile, between or during uses of the portable electronic device. The power supply comprises a modular hybrid-charger assembly operably connected to a device holder. The modular hybrid-charger assembly comprises a rechargeable internal battery connected to a port operable to function as a tetherless connection to a portable electronic device, a power management engine embodied in a computer readable medium, and an untethered solar energy source. The device holder comprises a framework operable to receive, hold, and release the portable electronic device; and an alignment mechanism that facilitates a mating of the portable electronic device with the hybrid-charger assembly. The modular hybrid-charger assembly can comprise a form factor that is interchangeable and operable with each of several different device holder form factors.

Owner:IPOWERUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com