Patents

Literature

63results about How to "Improve surface reflectivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

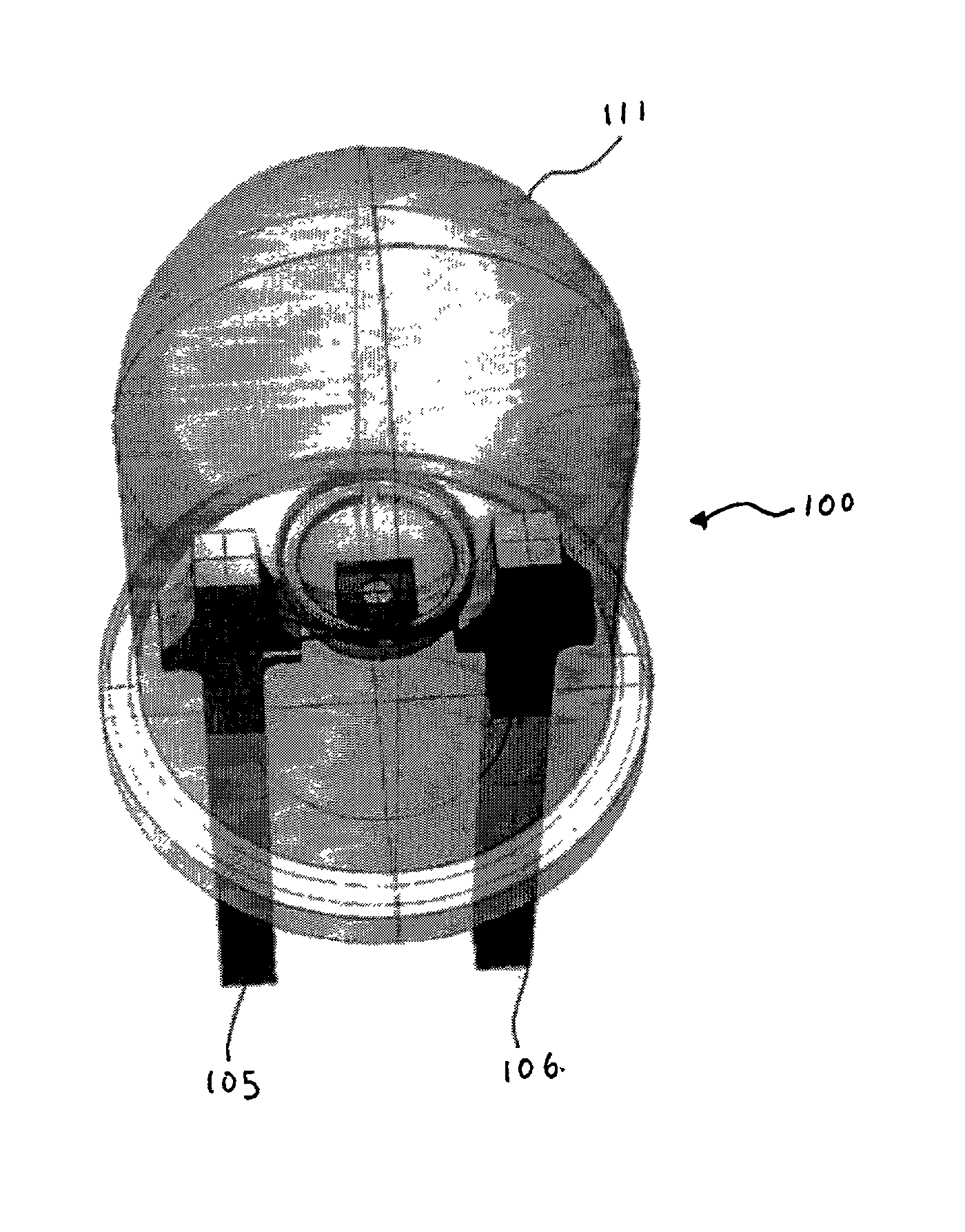

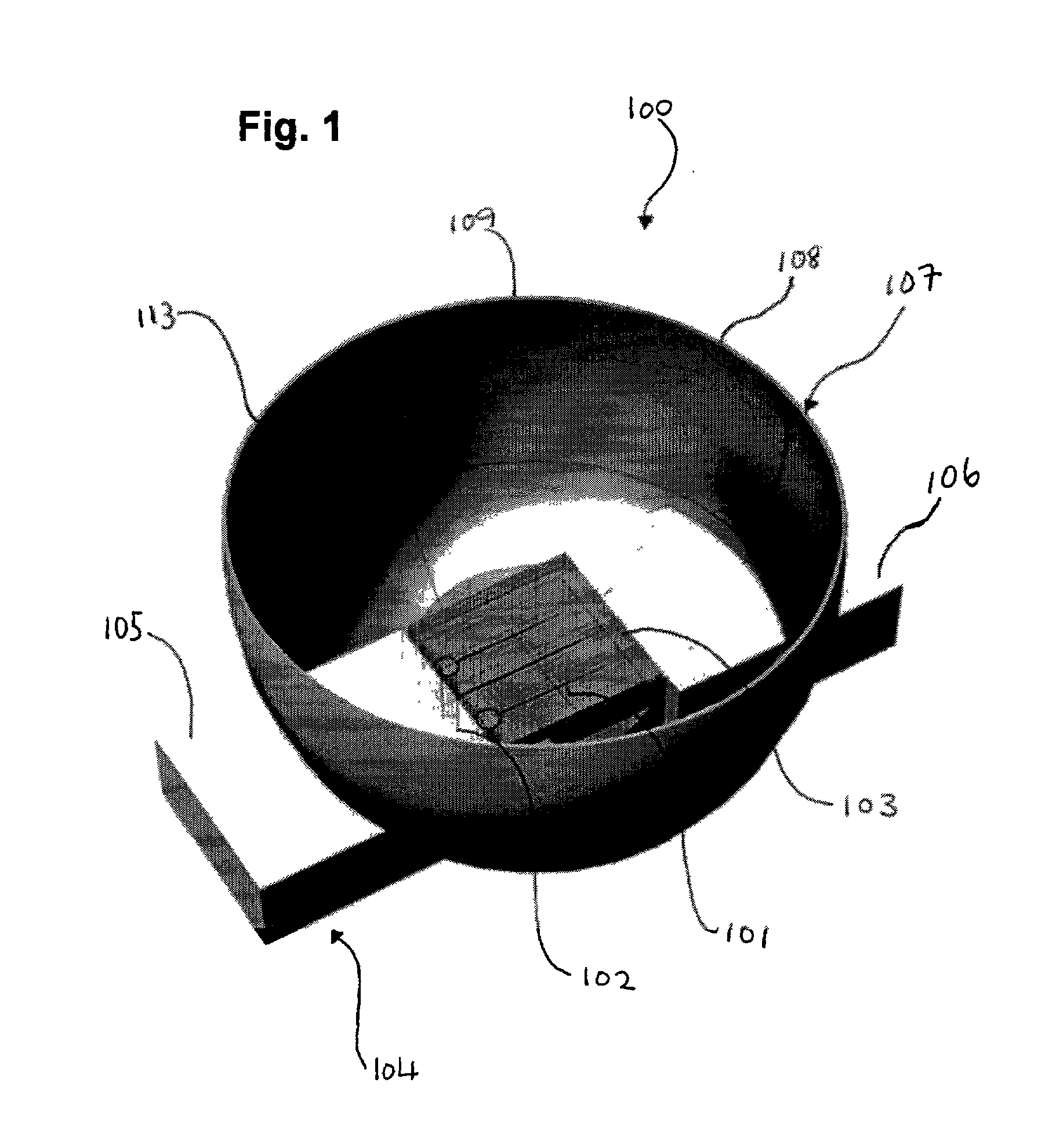

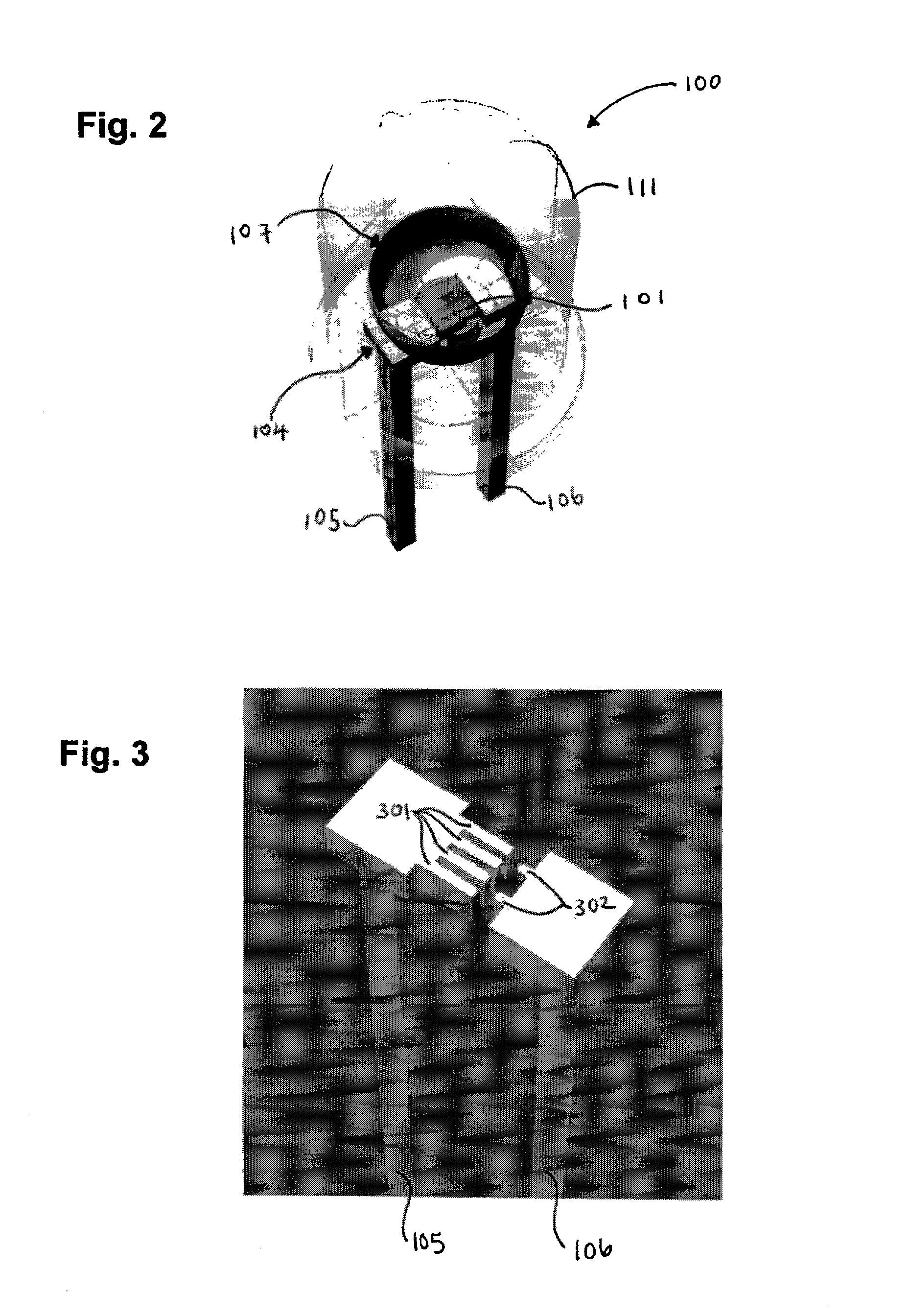

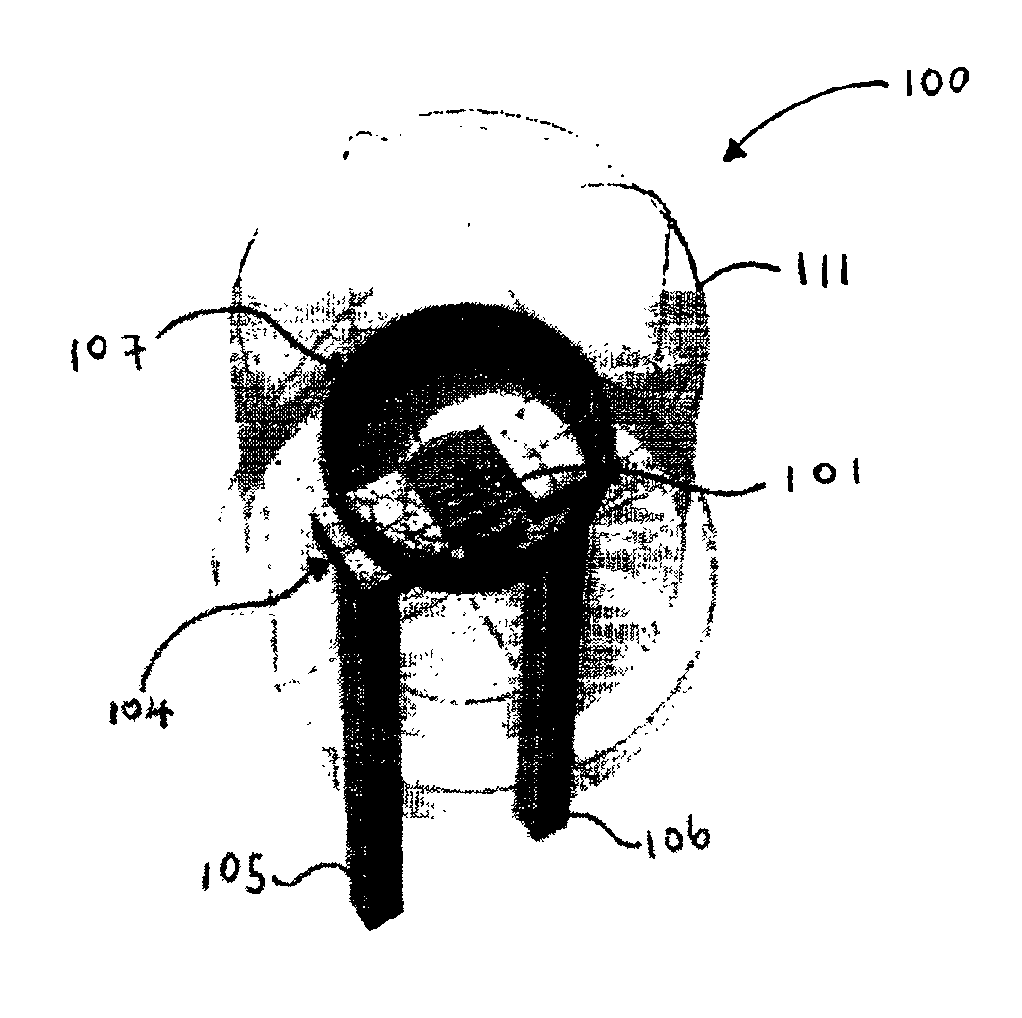

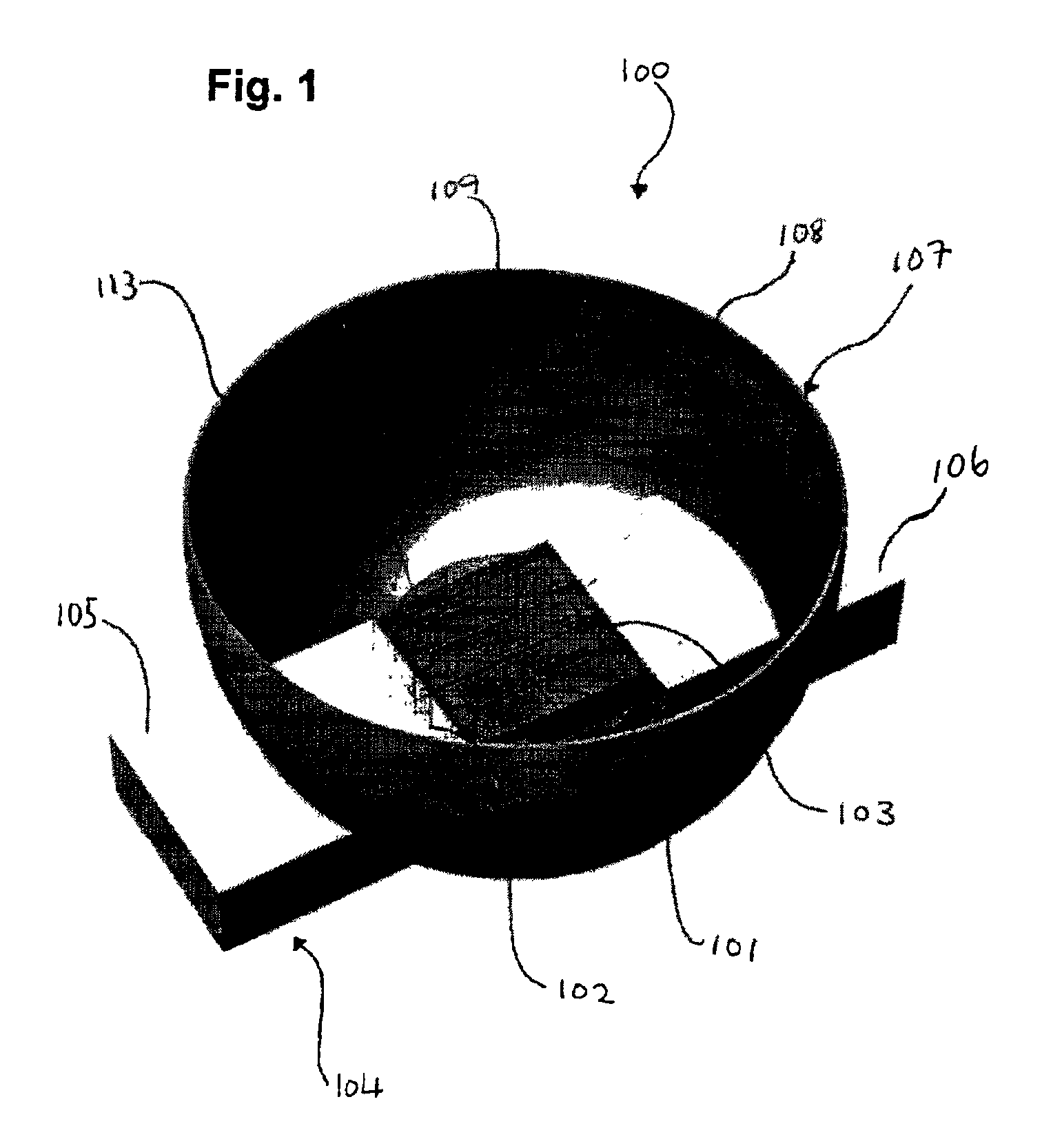

Lighting fixture

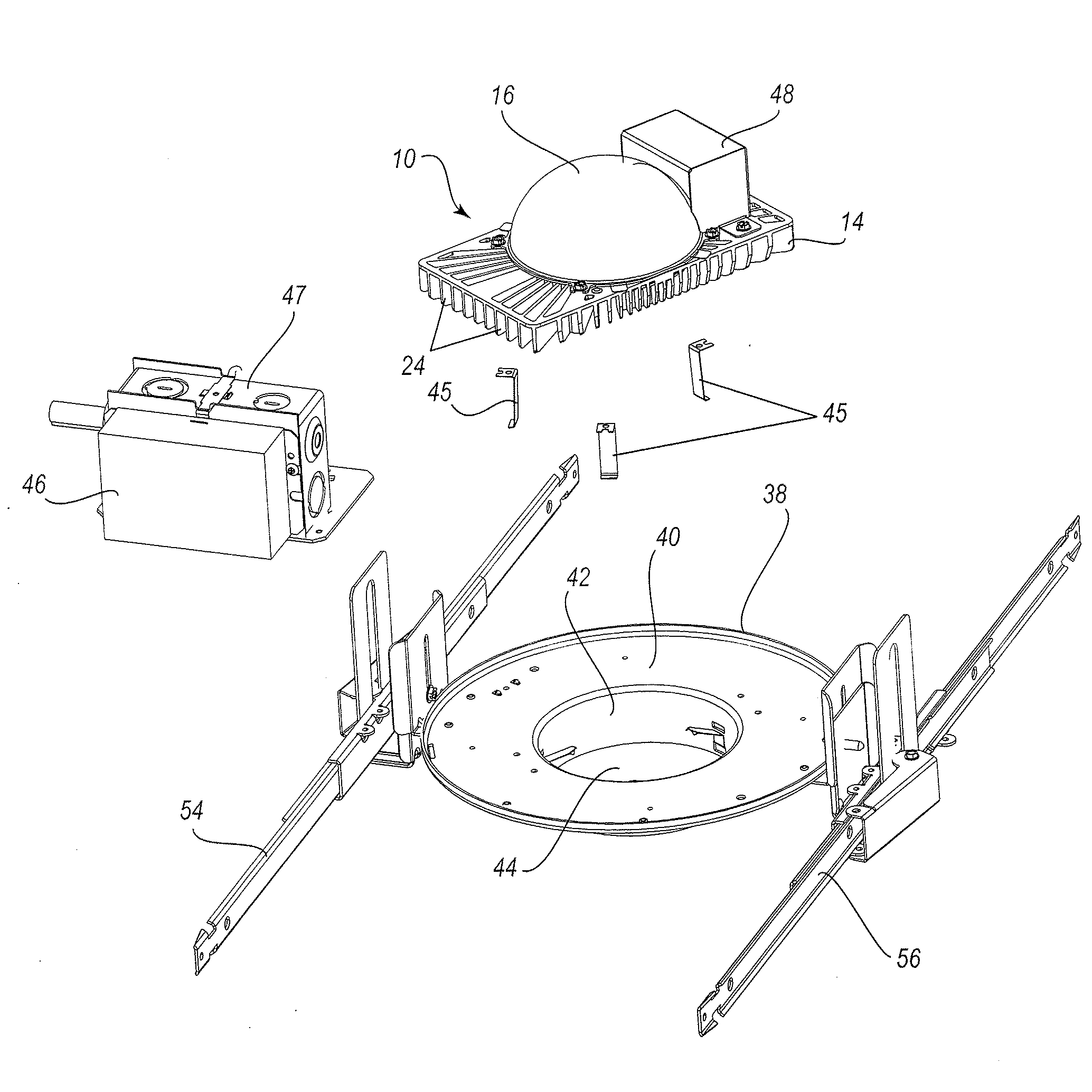

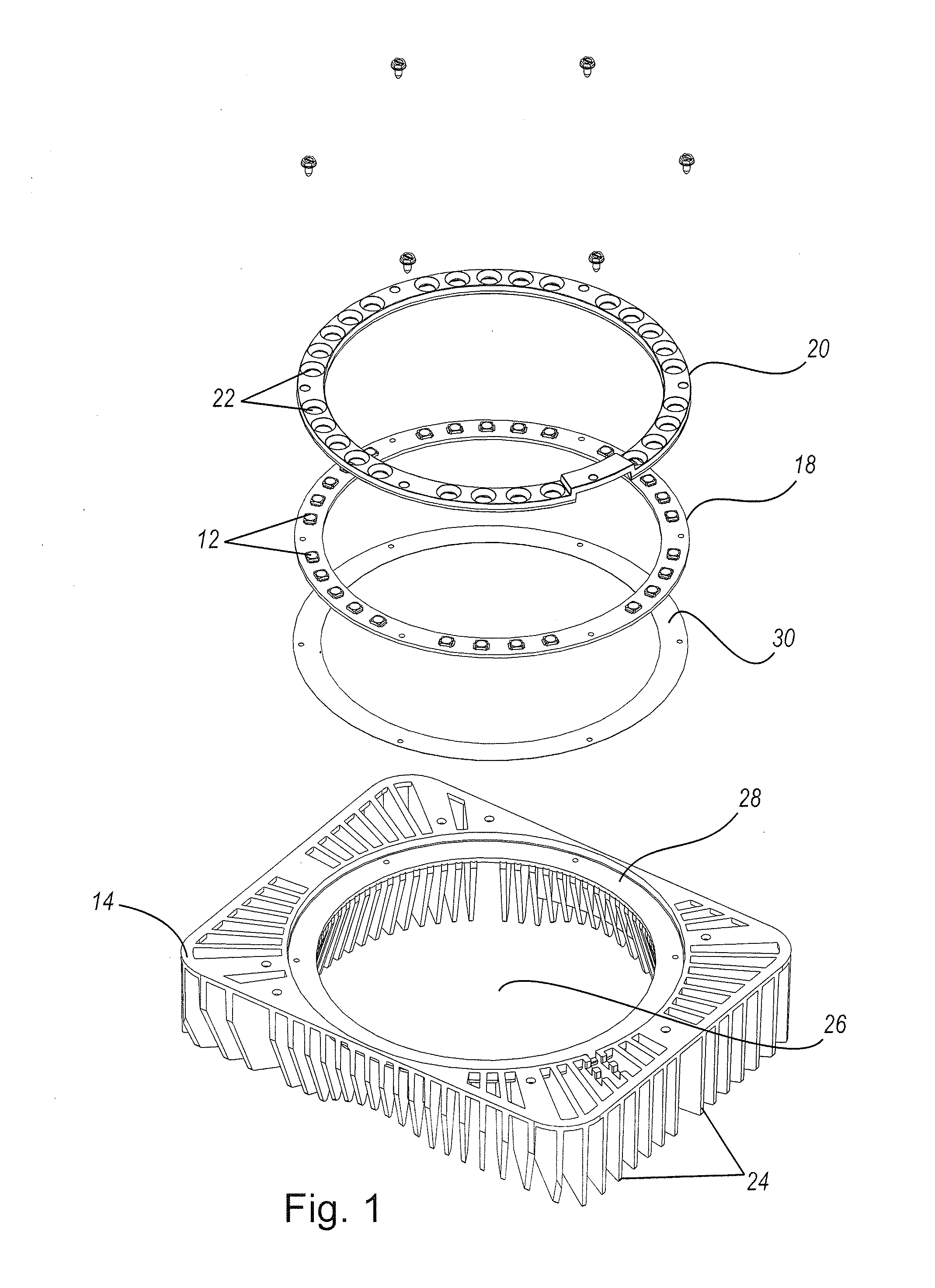

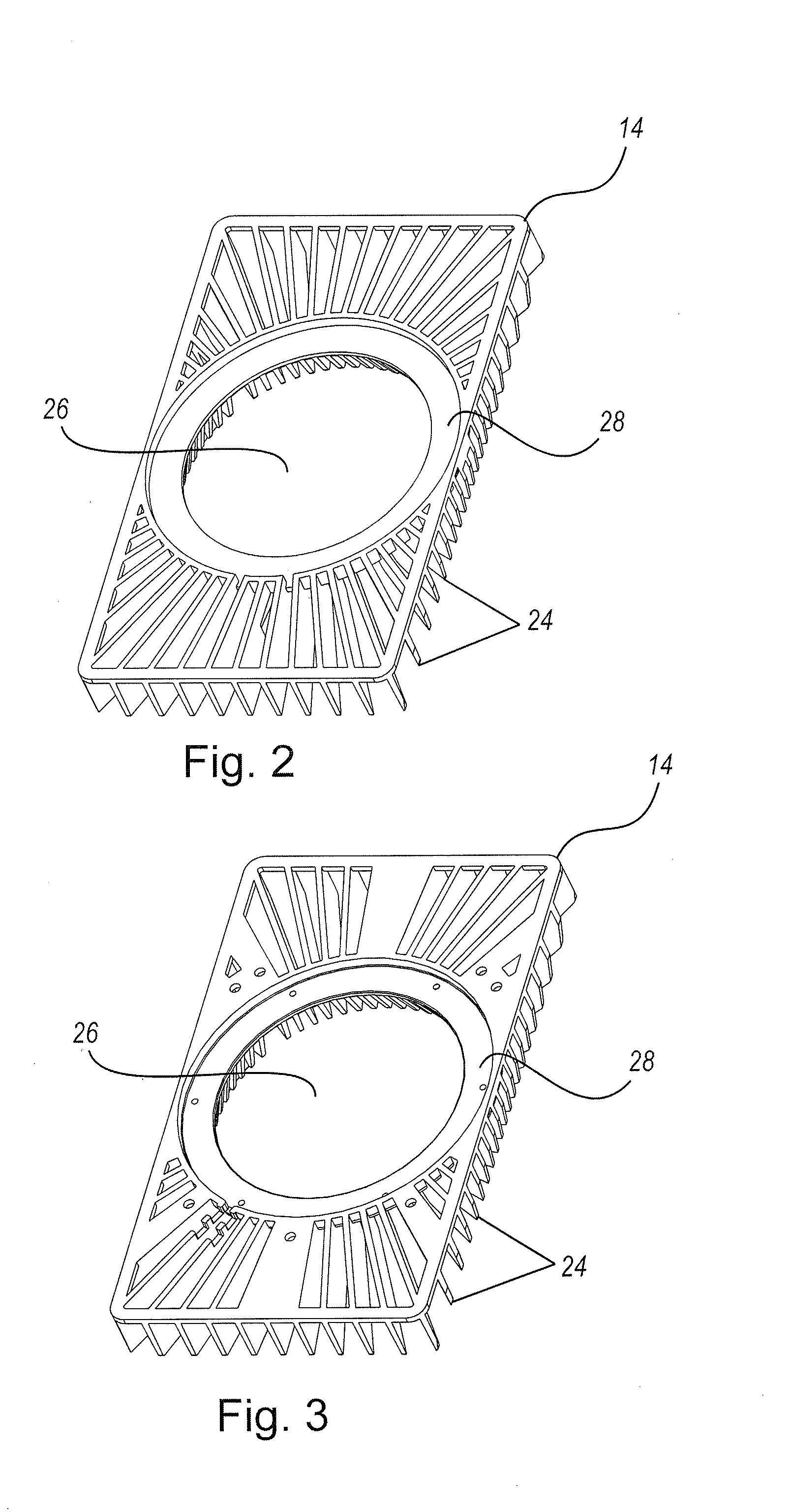

InactiveUS20090290343A1Easy to upgradeImprove surface reflectivityNon-electric lightingPoint-like light sourceModularityEffect light

Embodiments of the invention provide lighting assemblies for installation in lighting fixtures. Lighting assemblies include at least one light source, at least one heat sink, and at least one reflector. Other embodiments of the lighting assembly may also include an outer surface of the reflector comprising a heat sink. In some embodiments, it may be desirable to direct light toward a wall. In those situations, a wall wash trim may be included. The lighting assemblies disclosed herein may be modular and thus replaced without having to uninstall the entire fixture. In some embodiments, a circuit board containing at least one light emitting diode in an existing lighting assembly may be replaced with another circuit board containing light emitting diodes of a different color temperature or a different color.

Owner:ABL IP HLDG

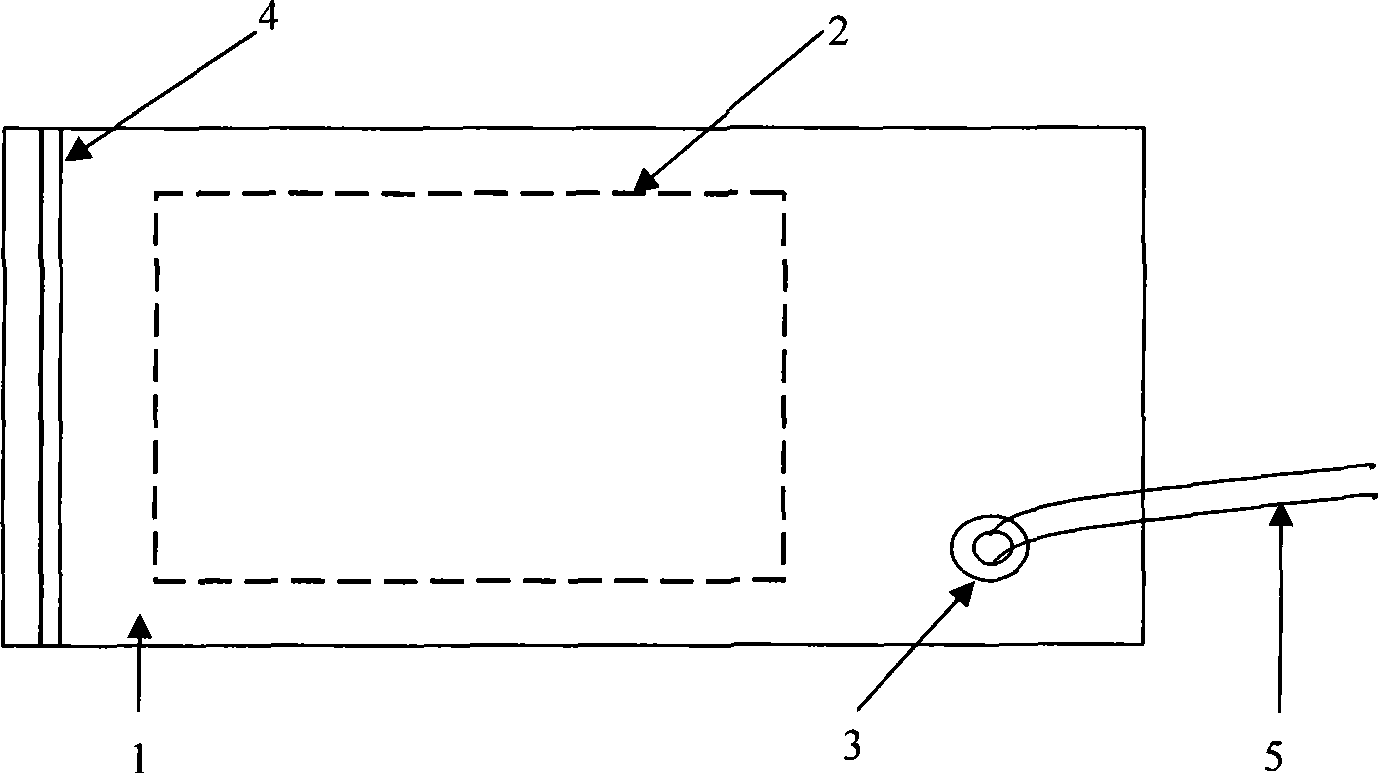

Panel light source for back-lit signs

InactiveUS20080285274A1Easy to installEasy maintenanceNon-electric lightingPoint-like light sourceGraphicsLight guide

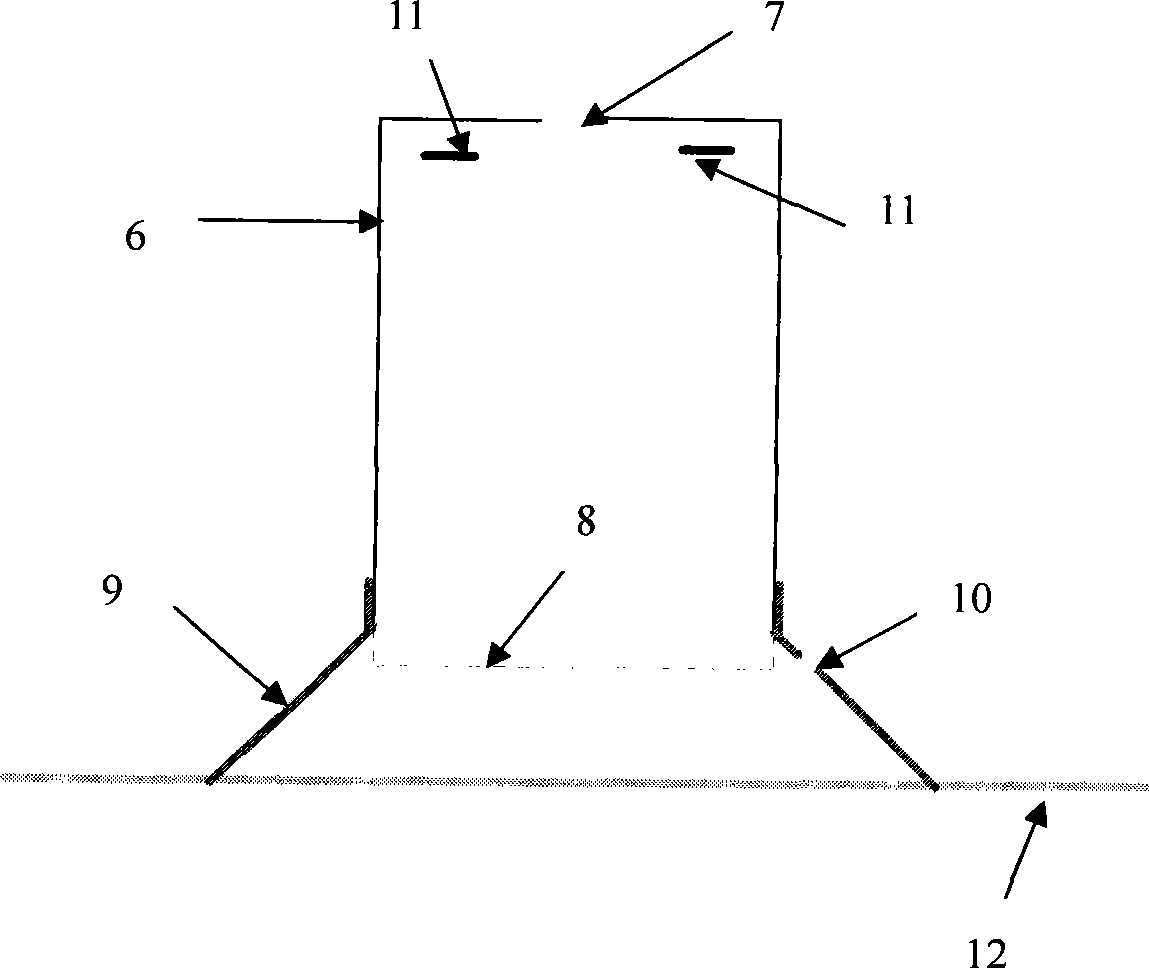

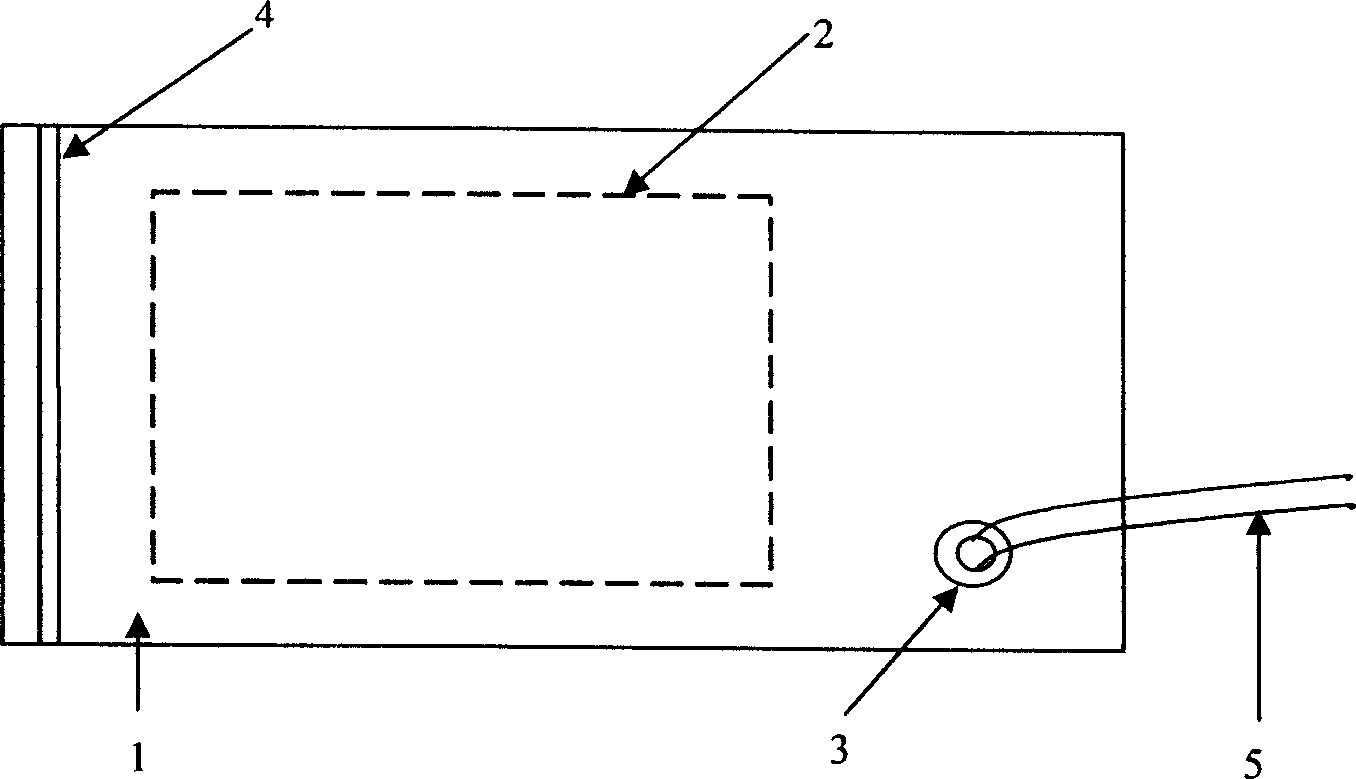

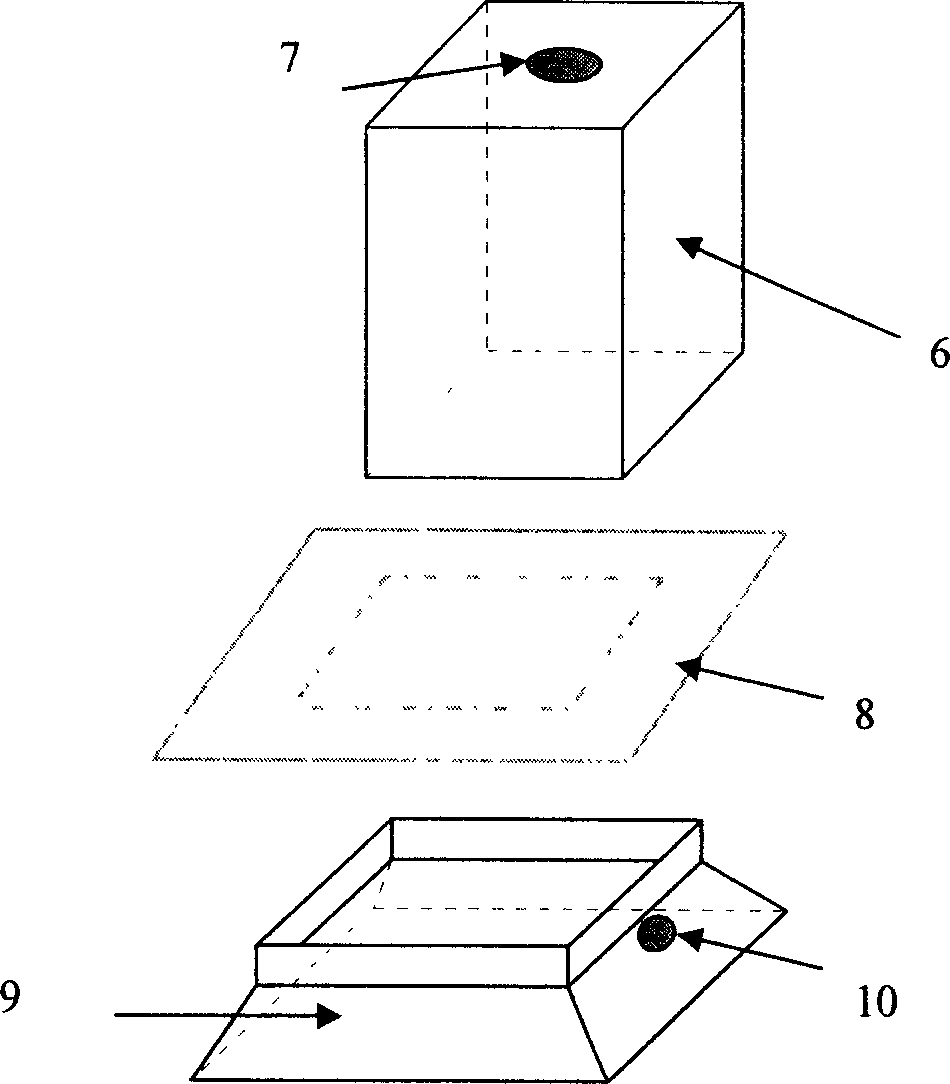

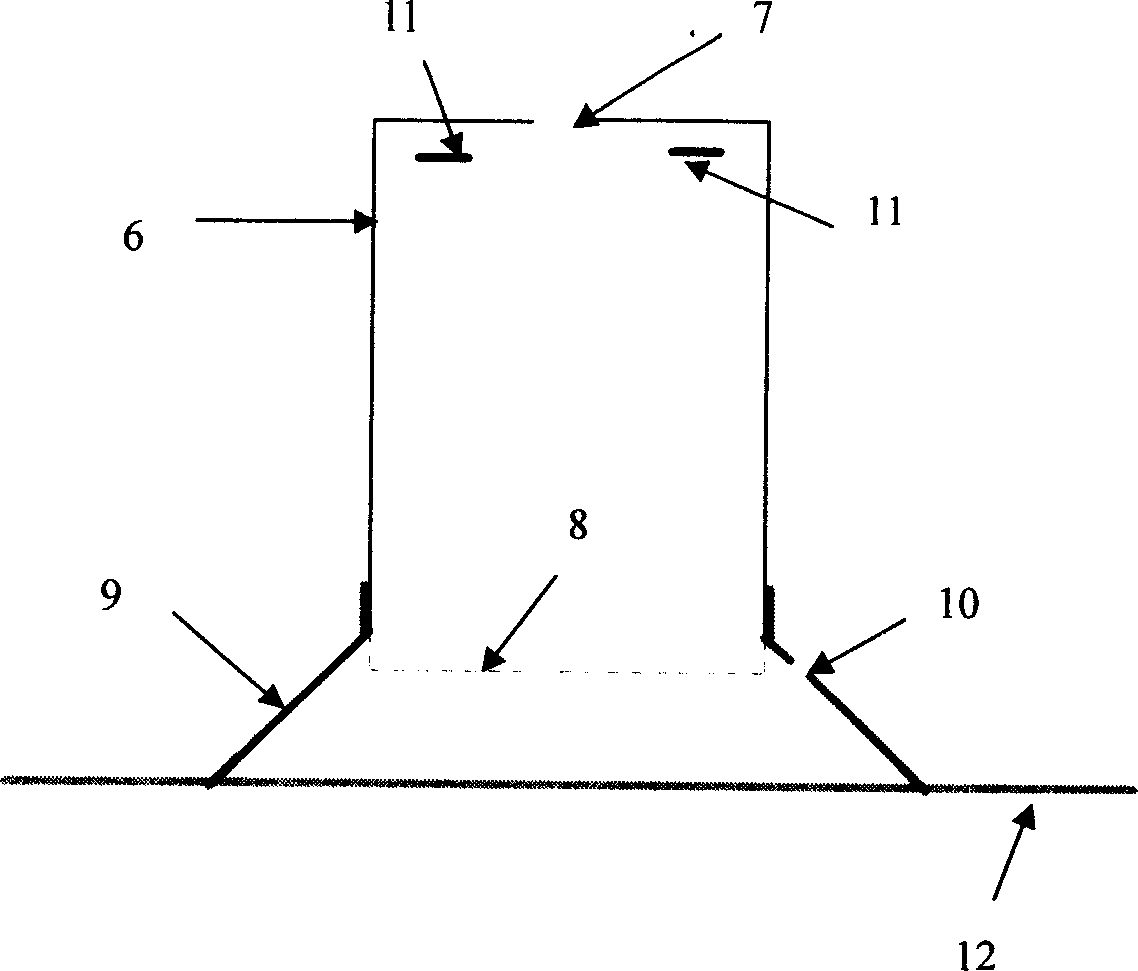

Disclosed herein is an illuminated signboard using a plane light source in which edges of two light guide plates are cut in an inclined form, an opaque plate having high surface reflectivity is inserted between the two light guide plates to optically block the two light guide plates from each other, and the light guide plates and the opaque plate are combined to form a second lighting part. U-shaped frames including LEDs are connected to construct a frame housing and the second lighting part is combined with the frame housing. Light emitted from the LEDs and transmitted in the light guide plates is dispersed by a dispersing mechanism formed on the backsides of the light guide plates using paint, print ink or engraving to transmit the light guide plates and graphics or natural color pictures formed on transparent plates attached to the outer sides of the light guide plates so as to illuminate the graphics or the natural color pictures.

Owner:JUNG HAE RYONG JUNG

Metal piece and method for processing surface of metal piece

ActiveCN101591798AImprove electrochemical uniformityImprove surface roughnessSurface roughnessHigh pressure

The invention relates to a metal piece, the roughness concentration of the surface of the metal piece is 0.02 micron to 0.1 micron, and the reflectivity of the surface is 65 percent to 90 percent. A method for processing the surface of the metal piece is used for obtaining the metal piece by polishing a metal substrate, and the polishing comprises the following steps: polishing pretreatment is carried out to the metal substrate; the metal substrate after the polishing pretreatment is dipped in polishing liquid containing ammonium salt and an addition agent, the metal substrate is put on a positive pole, and a pulse electric field with high frequency and high voltage is applied for plasma body polishing; and the metal piece is obtained after the polished metal substrate is washed and parched. Compared with the traditional polishing method, the method for processing the surface of the metal piece has the advantages that the electrochemistry leveling of the surface of the metal substrate is greatly increased, and the roughness concentration is reduced.

Owner:BYD CO LTD

Polishing solution used for amorphous alloy and polishing method of amorphous alloy

The invention provides a polishing solution used for an amorphous alloy and a polishing method of an amorphous alloy. The polishing solution comprises: a sodium salt, an ammonium salt and a brightener, i.e. ceric sulfate. The polishing method includes plasma polishing to an amorphous alloy. And the plasma polishing method consists of: connecting the amorphous alloy to a positive electrode, and immersing the amorphous alloy into an electrolytic cell containing the polishing solution, and taking the electrolytic cell body as a negative electrode for plasma polishing. The amorphous alloy prepared with the polishing solution provided in the invention and by the plasma polishing method of the invention has a smooth surface and high surface reflectivity.

Owner:BYD CO LTD

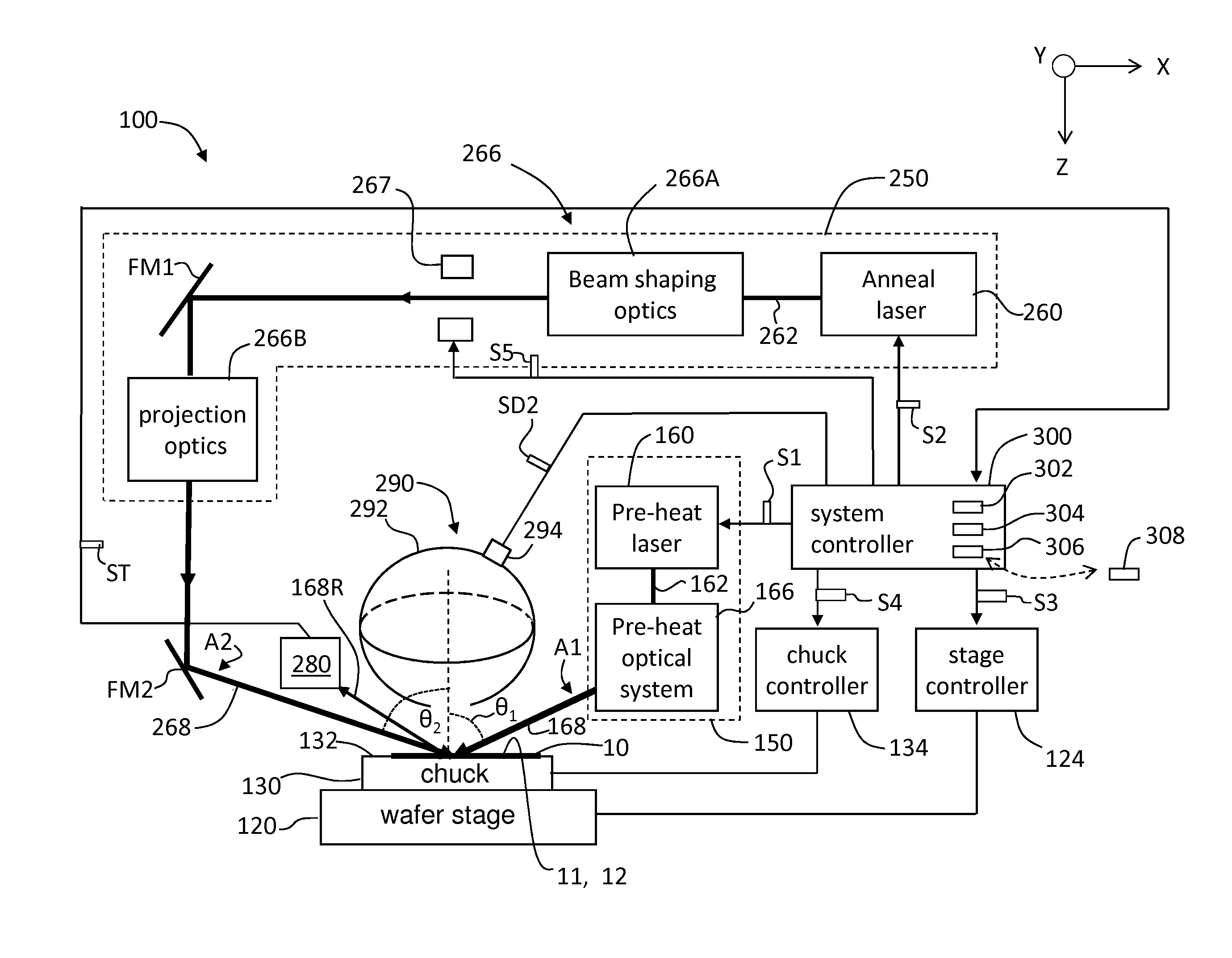

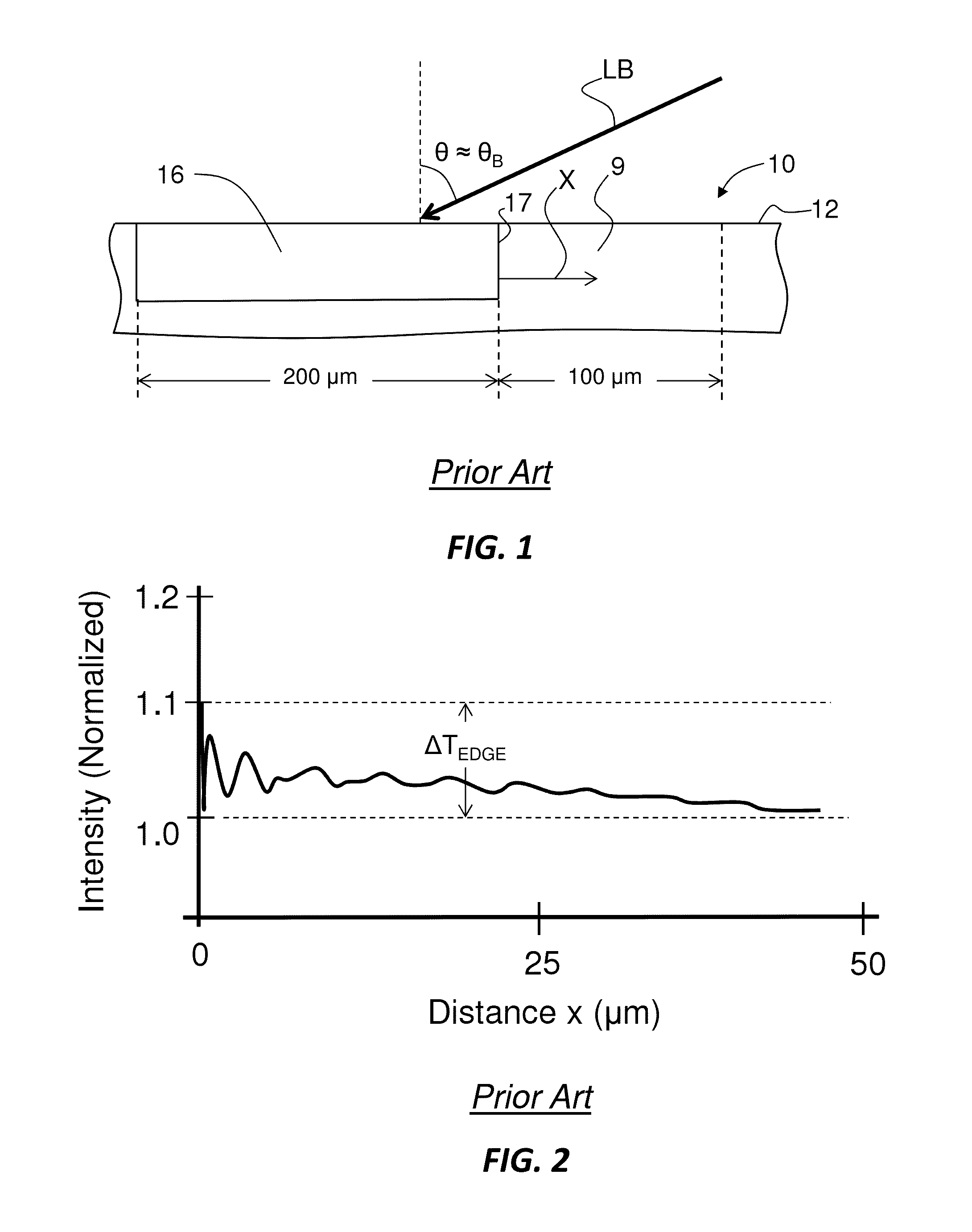

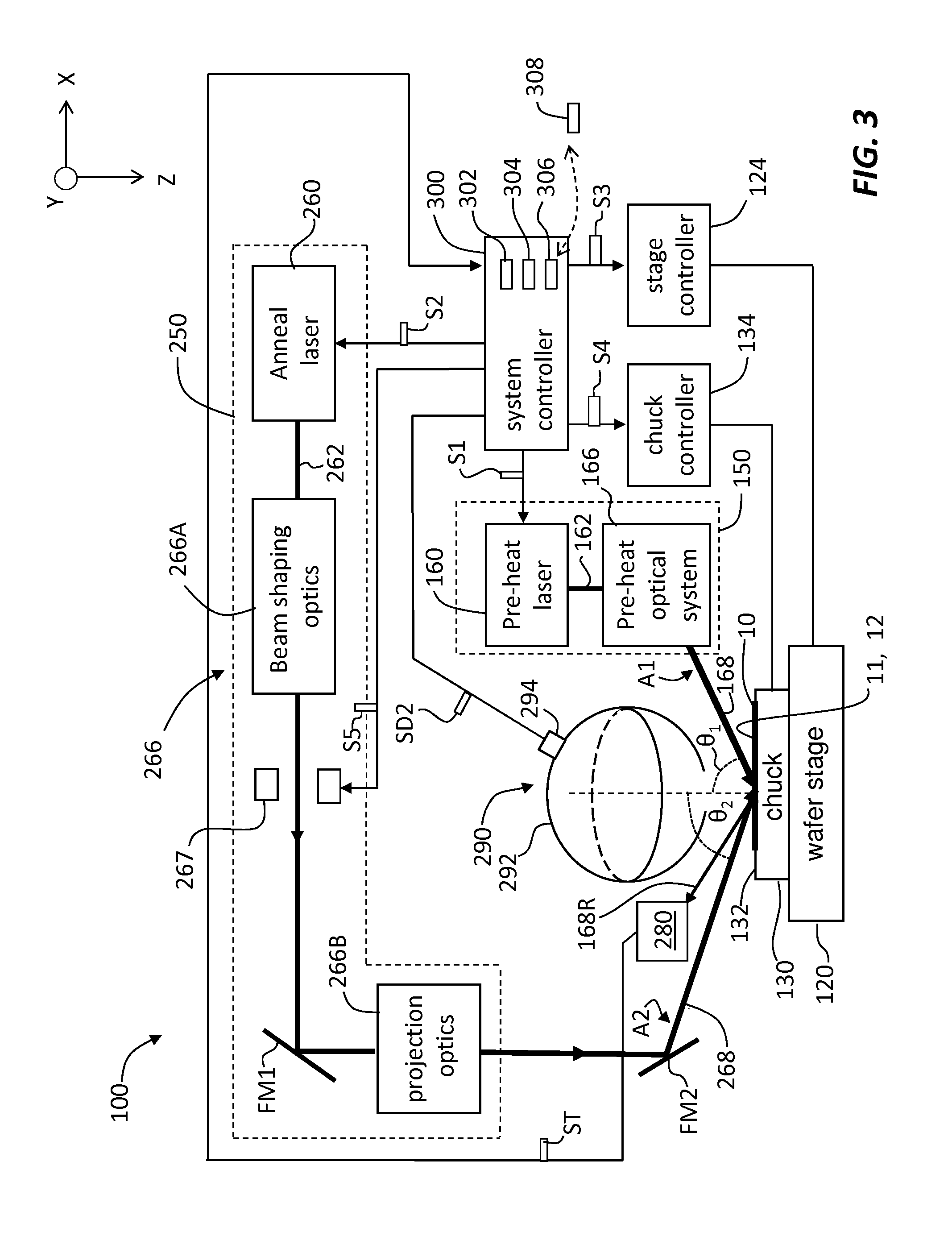

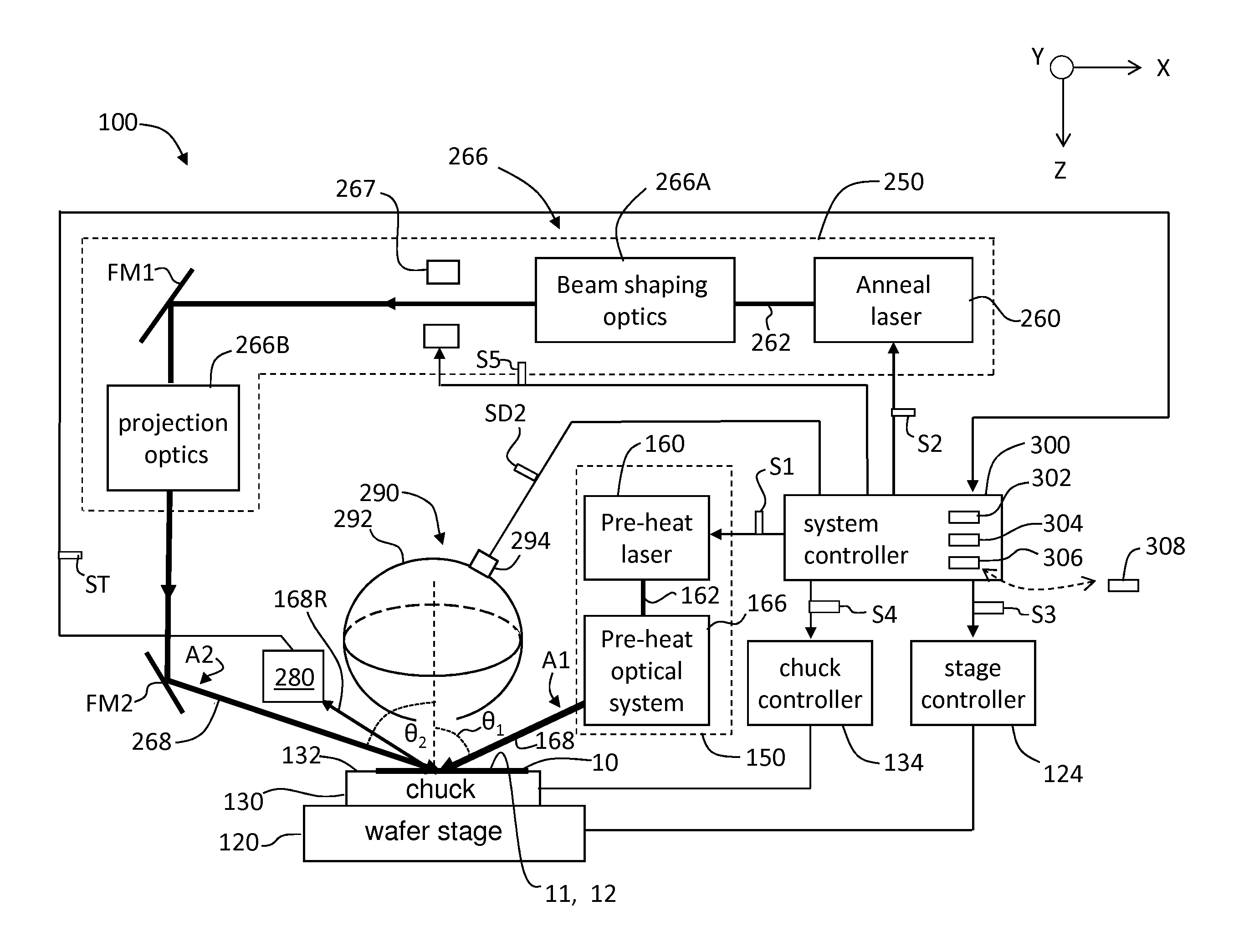

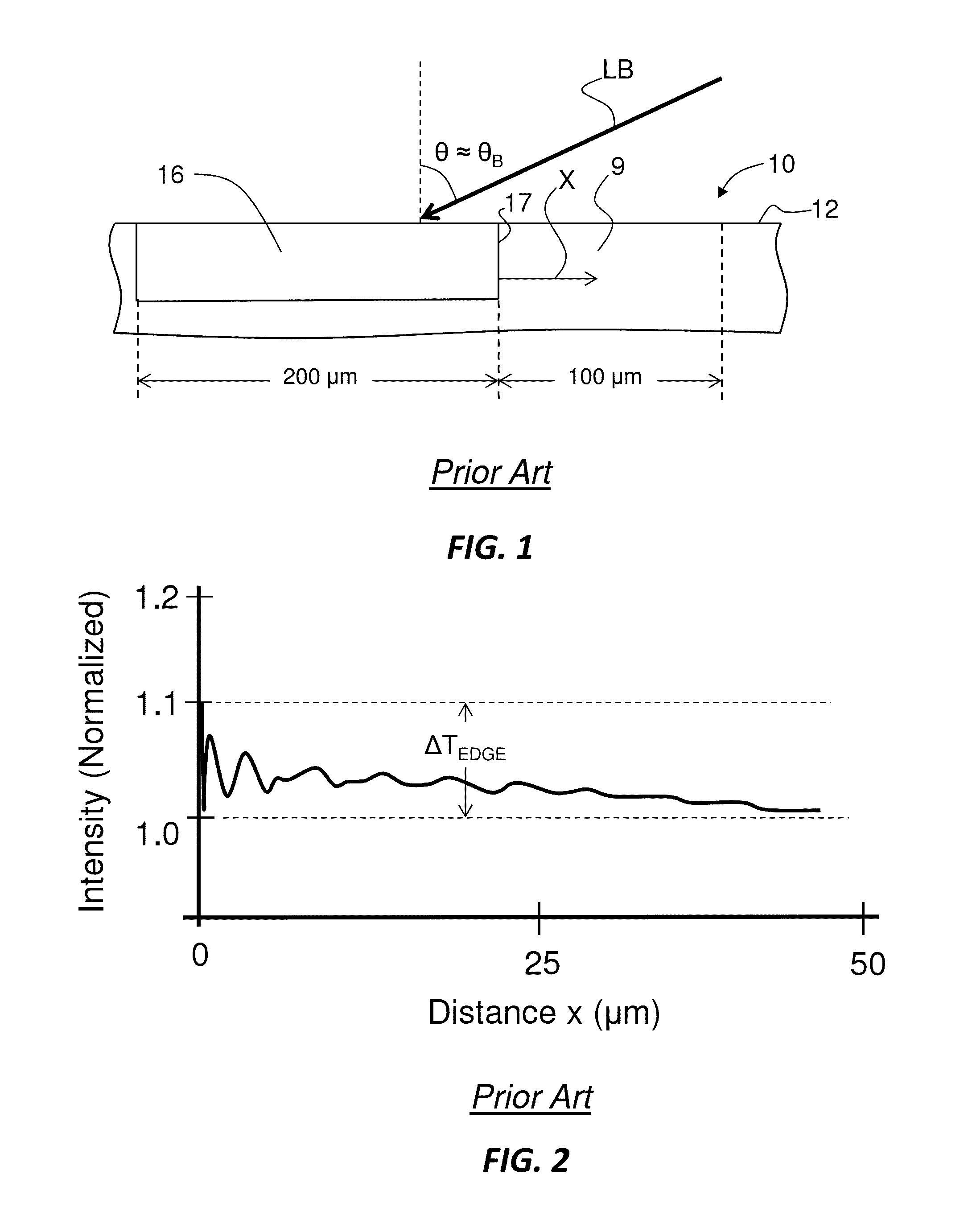

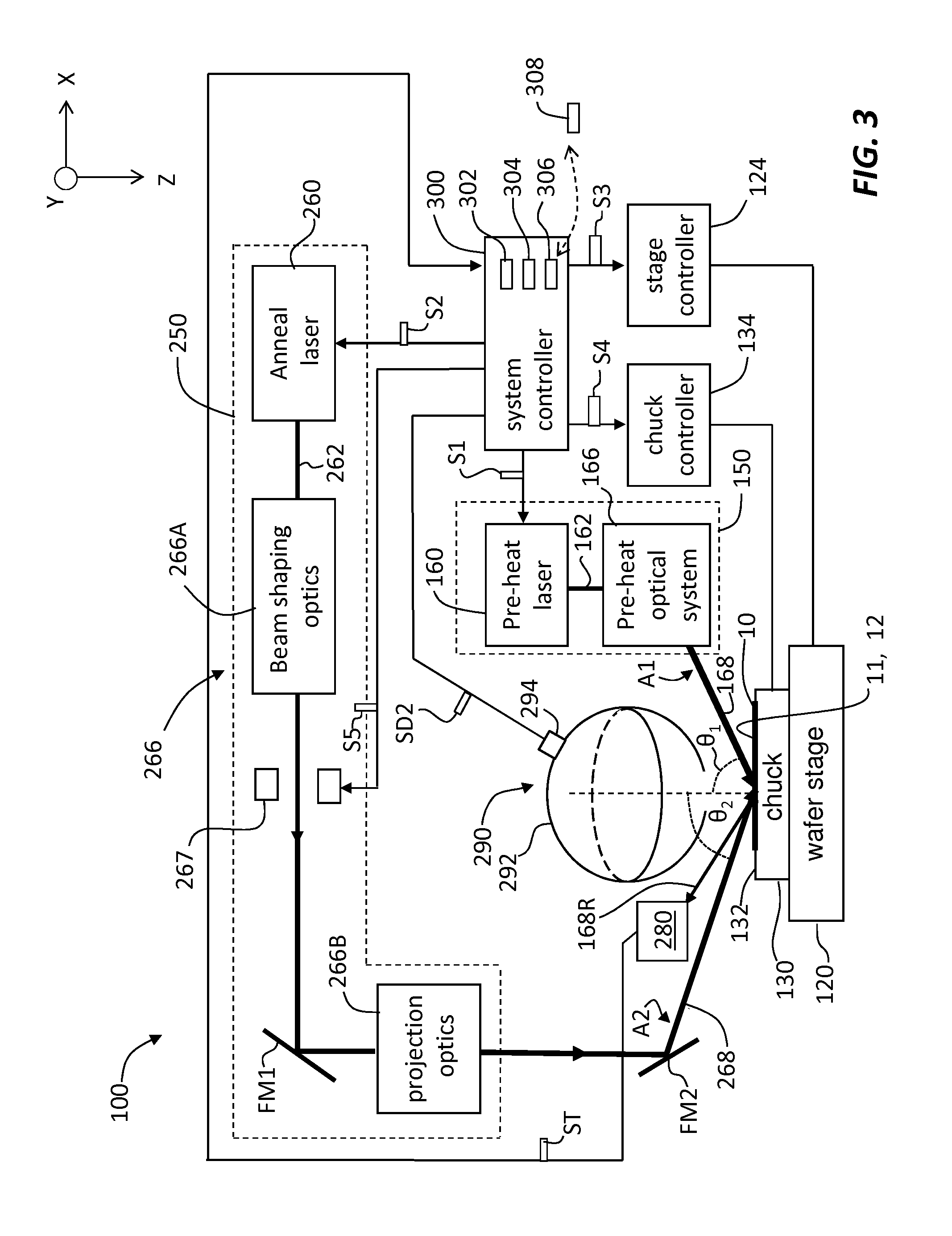

Two-beam laser annealing with improved temperature performance

ActiveUS8546805B2Improve temperature uniformityImprove surface reflectivitySemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsLight beamOptoelectronics

Systems and methods are disclosed for performing laser annealing in a manner that reduces or minimizes wafer surface temperature variations during the laser annealing process. The systems and methods include annealing the wafer surface with first and second laser beams that represent preheat and anneal laser beams having respective first and second intensities. The preheat laser beam brings the wafer surface temperate close to the annealing temperature and the anneal laser beam brings the wafer surface temperature up to the annealing temperature. The anneal laser beam can have a different wavelength, or the same wavelength but different orientation relative to the wafer surface. Reflectivity maps of the wafer surface at the preheat and anneal wavelengths are measured and used to select first and second intensities that ensure good anneal temperature uniformity as a function of wafer position.

Owner:VEECO INSTR

Two-beam laser annealing with improved temperature performance

ActiveUS20130196455A1Improved temperature uniformityImprove temperature uniformitySemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsReflectivityLaser annealing

Systems and methods are disclosed for performing laser annealing in a manner that reduces or minimizes wafer surface temperature variations during the laser annealing process. The systems and methods include annealing the wafer surface with first and second laser beams that represent preheat and anneal laser beams having respective first and second intensities. The preheat laser beam brings the wafer surface temperate close to the annealing temperature and the anneal laser beam brings the wafer surface temperature up to the annealing temperature. The anneal laser beam can have a different wavelength, or the same wavelength but different orientation relative to the wafer surface. Reflectivity maps of the wafer surface at the preheat and anneal wavelengths are measured and used to select first and second intensities that ensure good anneal temperature uniformity as a function of wafer position.

Owner:VEECO INSTR

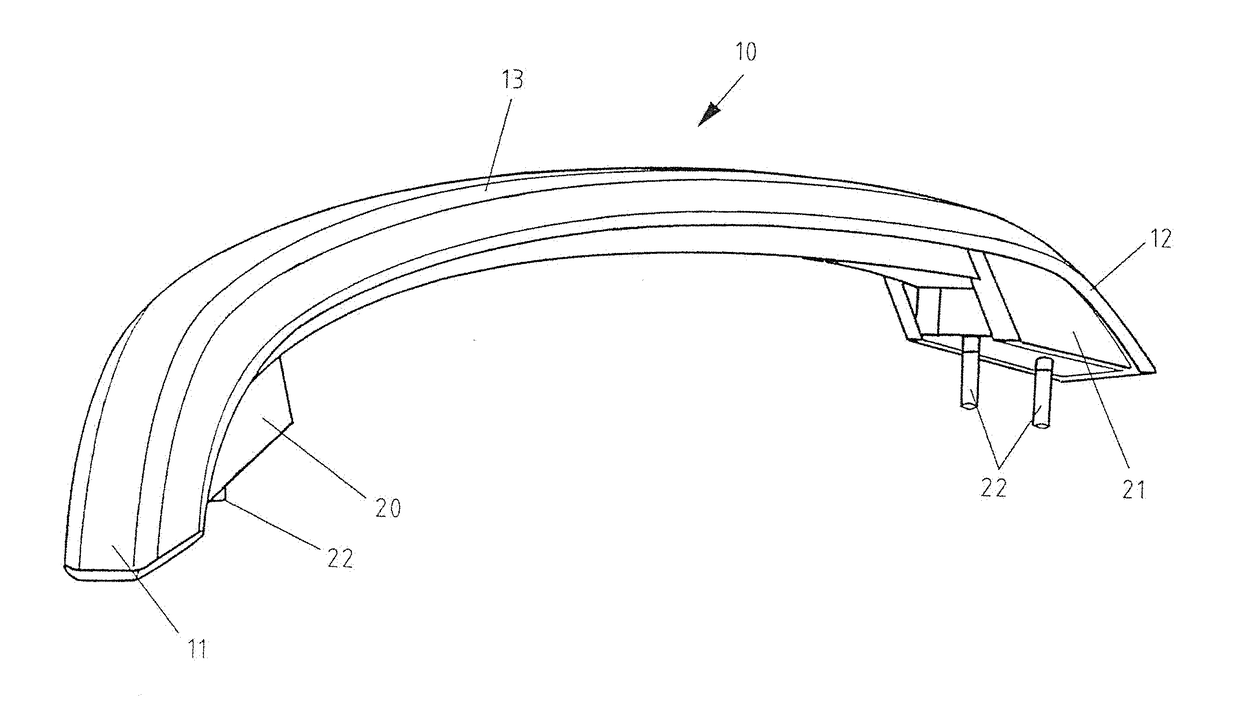

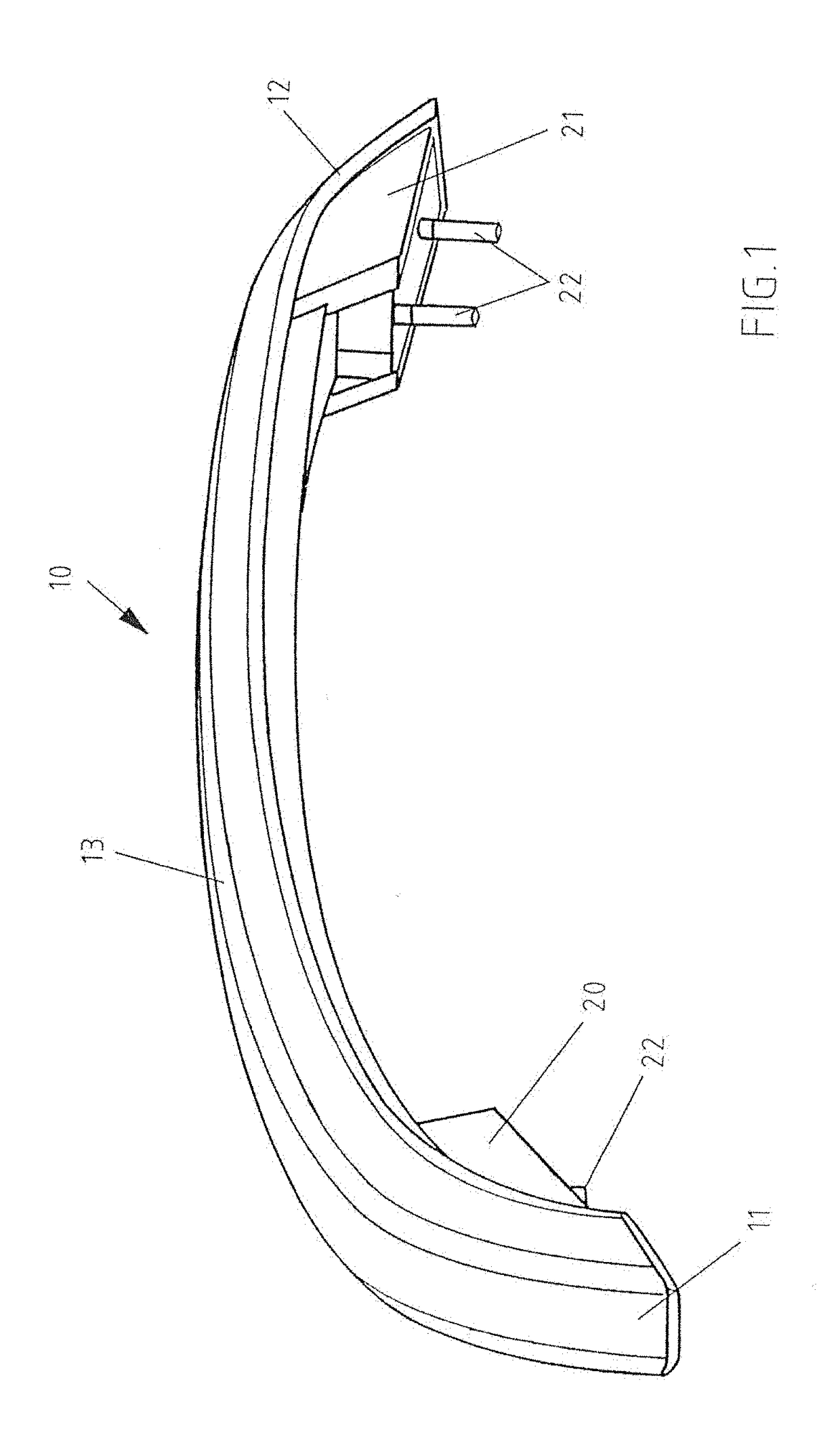

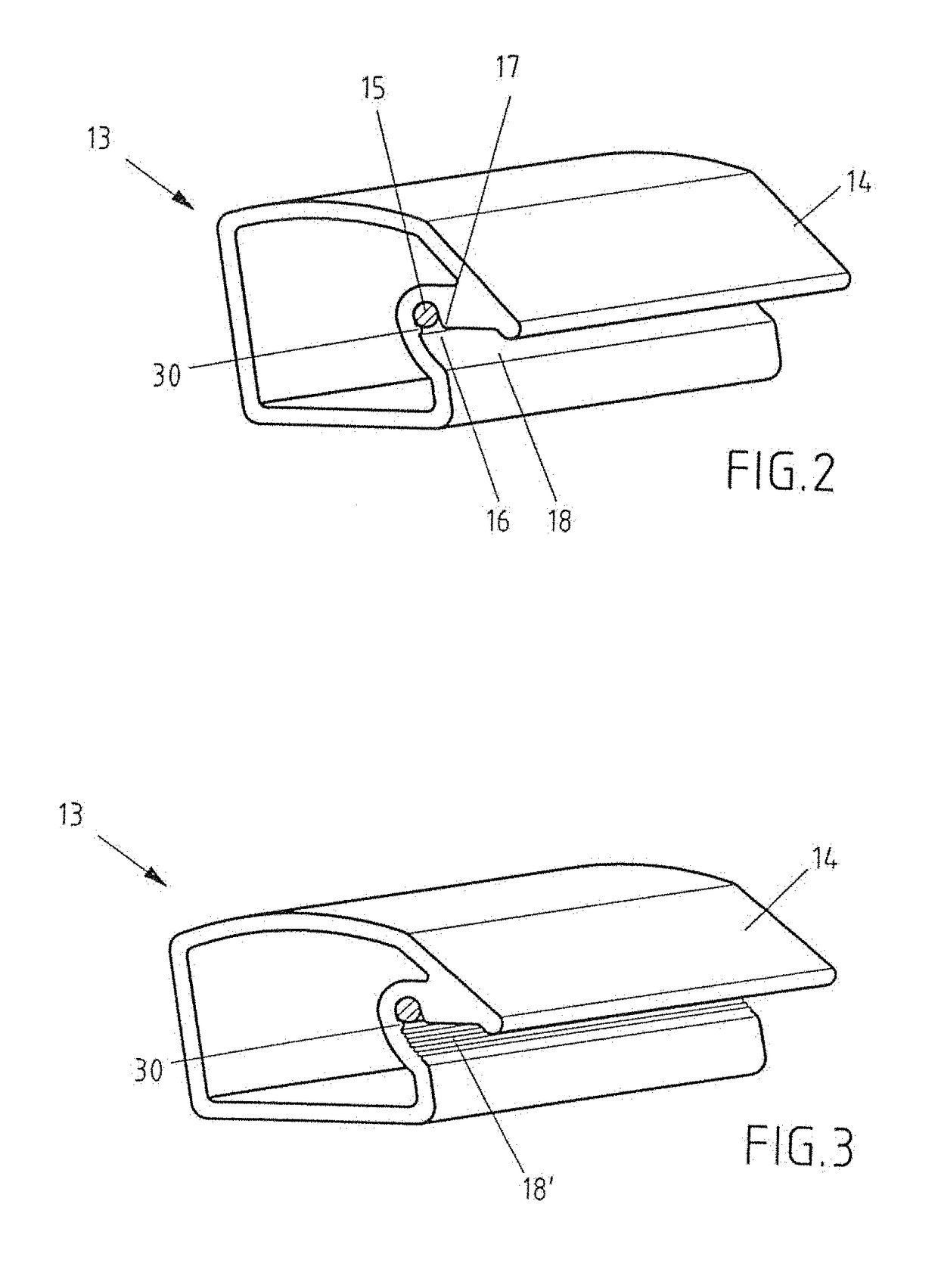

Motor vehicle component

ActiveUS20180172239A1Less sensitiveImprove surface reflectivityVehicle headlampsElectric lightingEffect lightEngineering

A motor vehicle component consisting of a metal profile element and a lighting element. The profile element has a channel extending in the longitudinal direction of the profile with an externally accessible opening extending in the longitudinal direction of the profile. The lighting element serves to produce a strip of light radiating in the longitudinal direction of the profile, and is arranged in the channel of the profile element so as to be concealed behind an outer surface of the profile element so that the radiated light does not arrive directly at the outside, but instead is reflected outward by a reflecting surface of the profile element.

Owner:WKW ENG GMBH

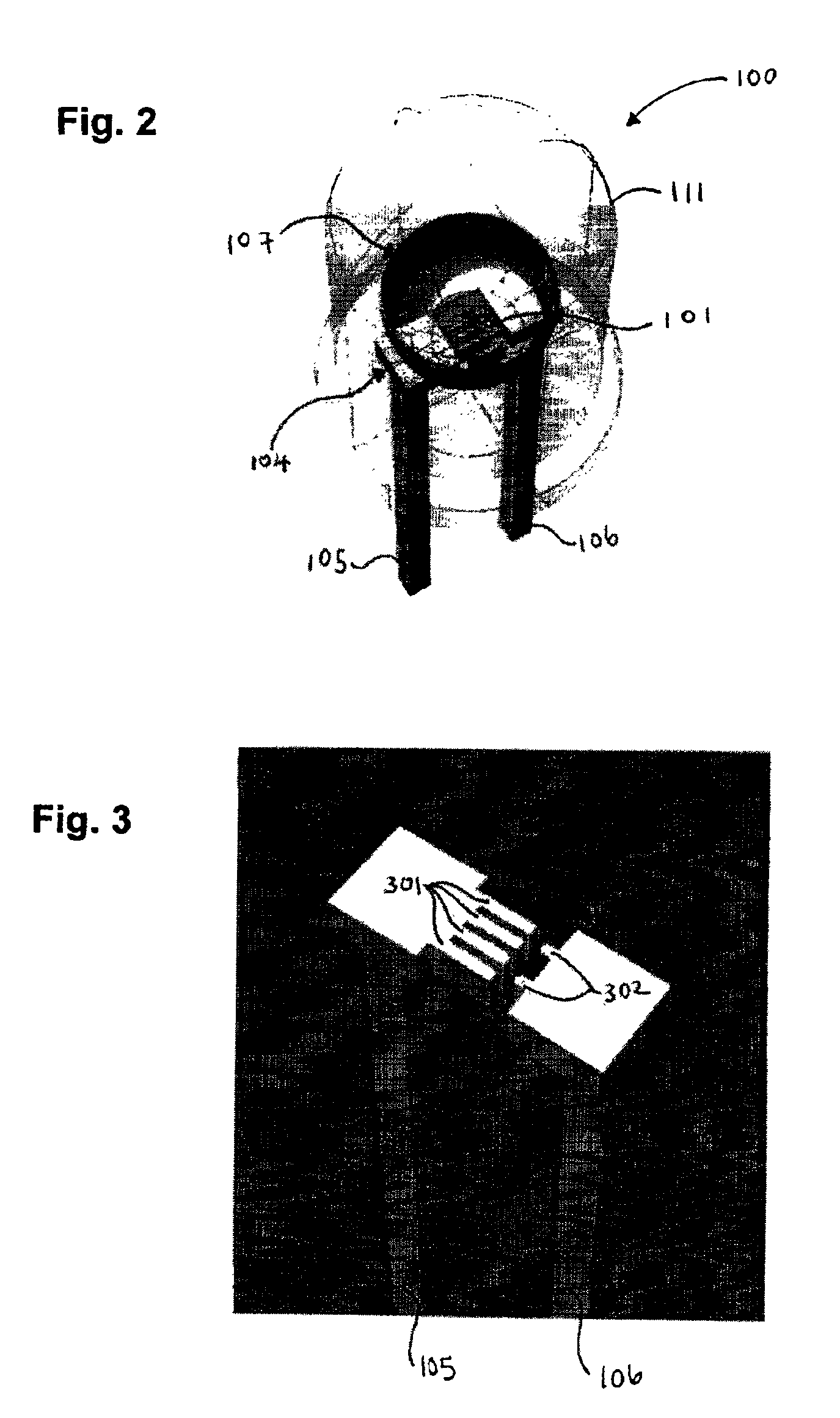

Light-emitting diode with plastic reflector cup

InactiveUS20030001166A1Improve surface reflectivityImprove light outputSolid-state devicesSemiconductor devicesPlastic materialsEngineering

A light-emitting diode comprising a light-emitting diode die, a lead frame, a reflector cup and a dome encapsulating at least the light-emitting diode die and the reflector cup, wherein the reflector cup is made of a plastic material.

Owner:DOCUMENT SECURITY SYST

Magnesium alloy surface treating method and magnesium alloy polished by same

The invention provides a magnesium alloy surface treating method and a magnesium alloy polished by the same. The method is characterized by comprising the following step of: performing plasma polishing on the magnesium alloy, wherein a plasma polishing method comprises the following steps of: connecting the magnesium alloy and an anode; soaking the magnesium alloy into an electrolytic bath which accommodates polishing liquid; taking an electrolytic bath body as a cathode; and performing plasma polishing under an acid condition, wherein the operation voltage of the electrolytic bath is a positive pulse voltage of between 260 and 400 V, an operation temperature is between 65 and 95 DEG C and an operation voltage frequency is between 10 k and 20 kHz. The surface roughness of the magnesium alloy polished by the surface treating method is between 1 and 5 mu m and the surface reflectivity of the magnesium alloy is between 50 and 85 percent. The magnesium alloy prepared by a surface polishing method provided by the invention has a smooth surface and high surface reflectivity.

Owner:BYD CO LTD

Light-emitting diode with plastic reflector cup

InactiveUS6878972B2Improve surface reflectivityImprove light outputSolid-state devicesSemiconductor devicesPlastic materialsEngineering

Owner:DOCUMENT SECURITY SYST

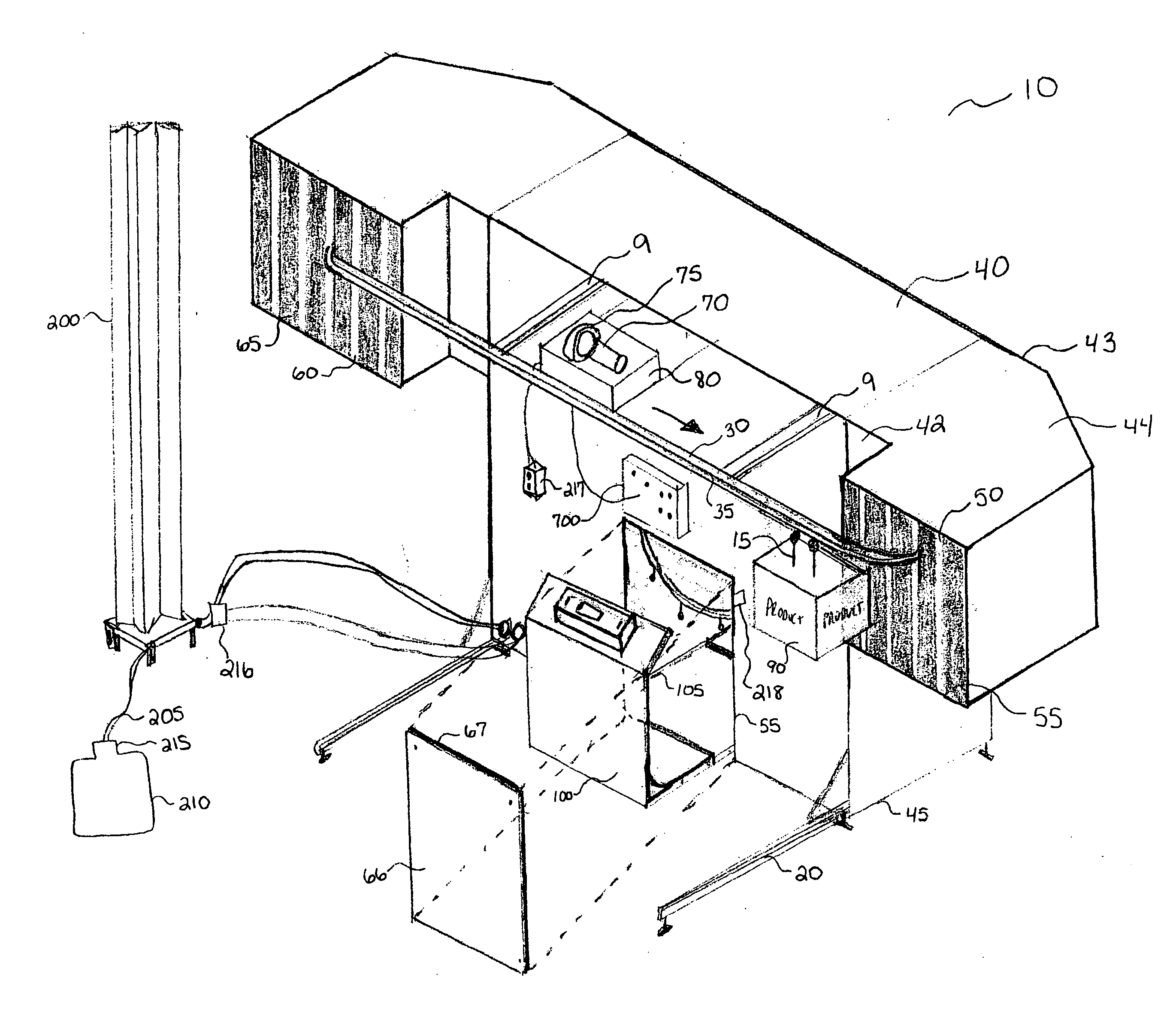

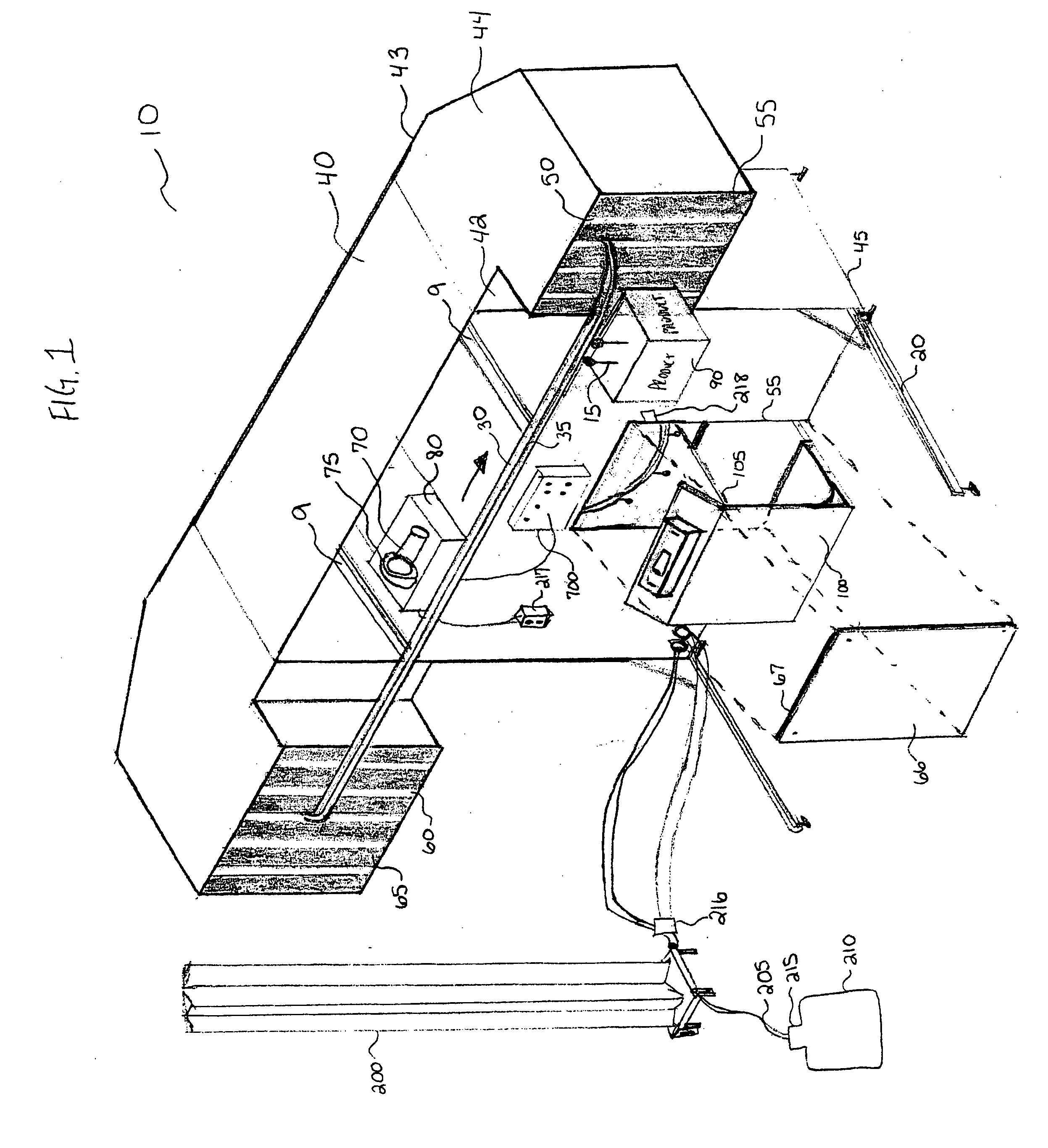

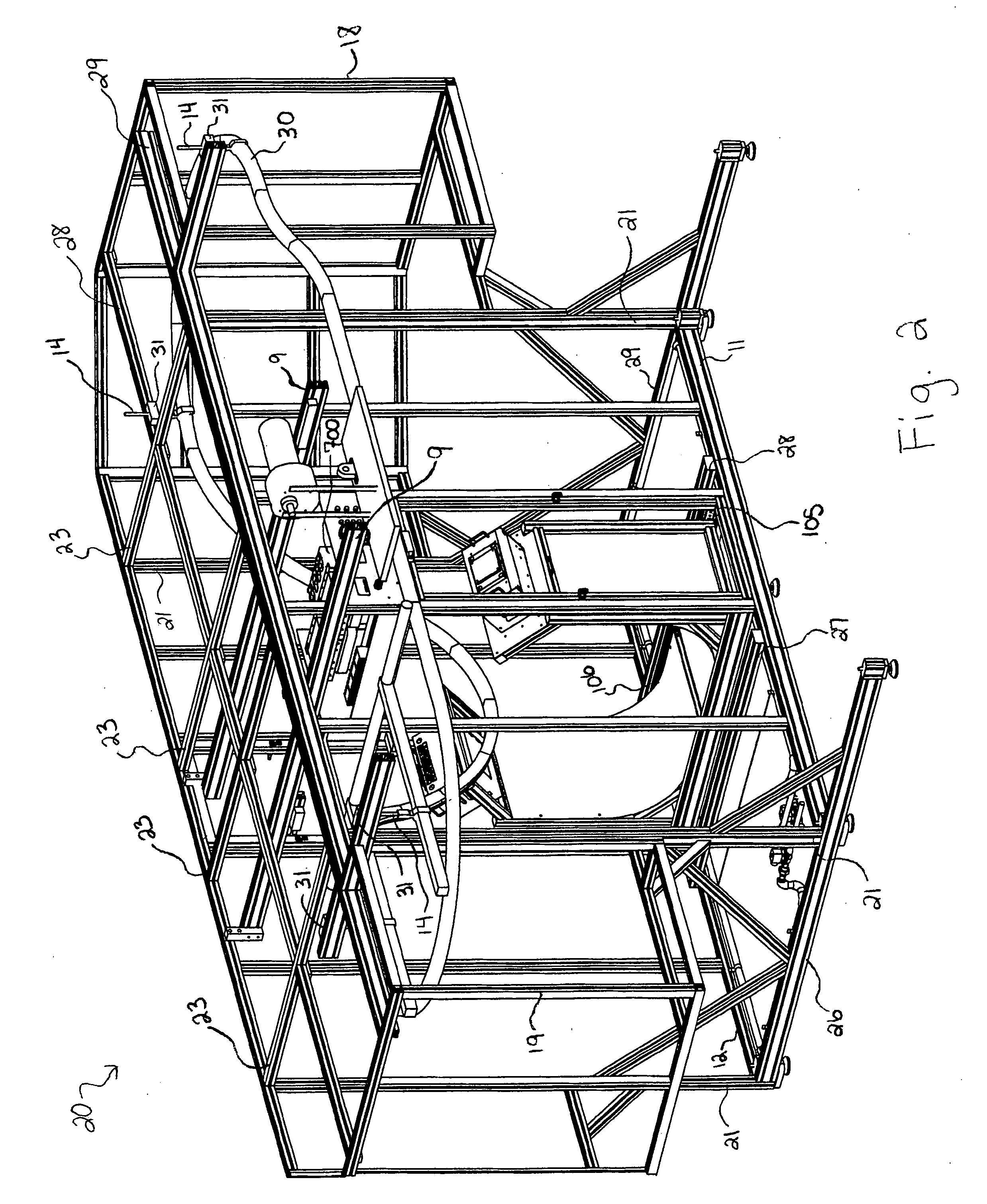

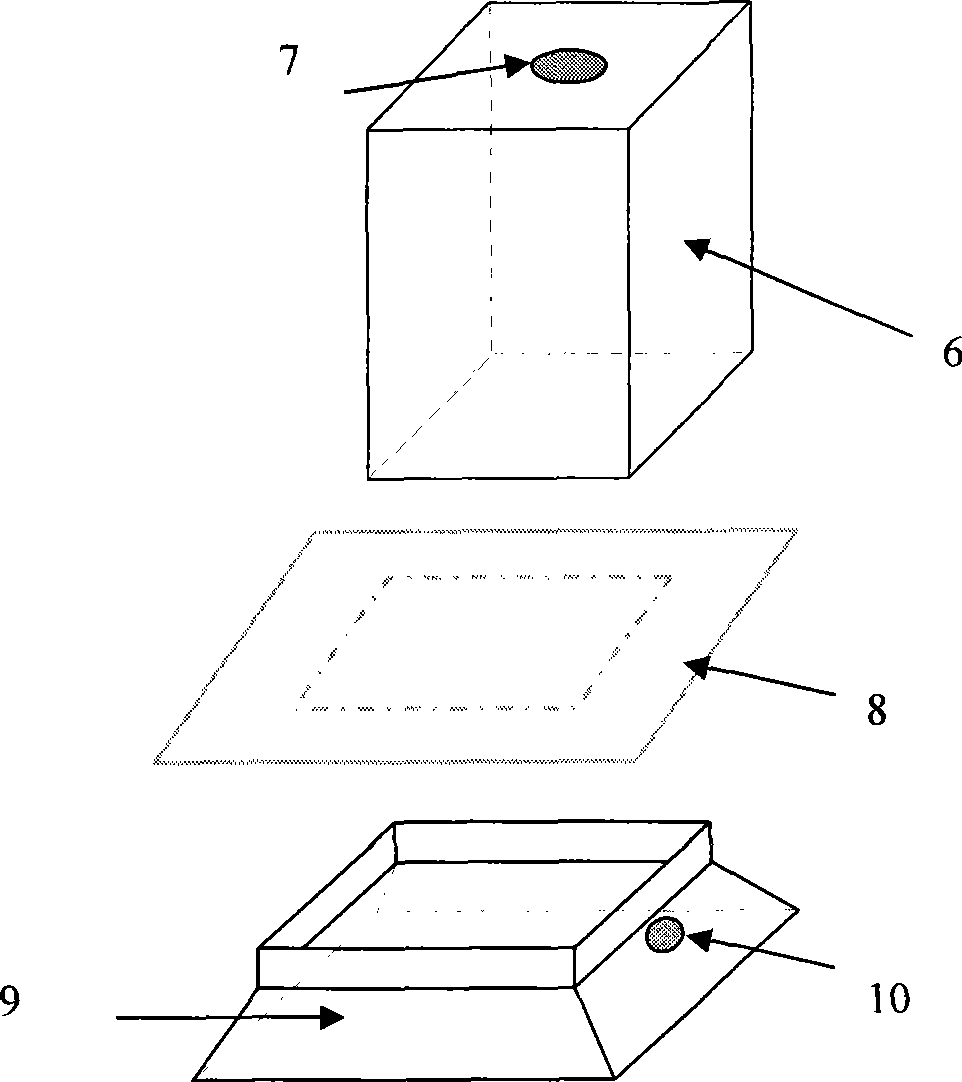

System, apparatus and method for curing of coatings in heavy gas

InactiveUS20060201017A1Increase productionChanged out quickly and easilyDrying solid materials with heatDrying gas arrangementsHexanediol diacrylatePolymer chemistry

A system, apparatus, and method is provided for curing ultraviolet (UV) curable coatings on articles using UV lamps while the article is immersed in an atmosphere of inert gas heavier than air. One example of a UV curable coating includes 35 weight % Laromer™ LR 8987, 20 weight % urethane acrylate hexandioldiacrylate, 38.5 weight % Laromer™ LR 8863, 3.5 weight % polyetheracrylate Iragucure™ 184, 0.5 weight % of a Photoinitiator Lucirin™ TPO, 2 weight % Tinuvin™ 400 and 1.5 weight % UV absorber Tinuvin™ 292. Examples of the inert gas used in the process disclosed include carbon dioxide, nitrogen, argon, hydrocarbon and halogen gases. An example of an apparatus provided by the invention includes a suspended track system; a housing, wherein the housing comprises an internal portion of the suspended track system and a curing chamber having highly reflective surfaces of favorable geometry. Further provided is a plurality of UV lamps, wherein the lamps are disposed on a slidably removable curing caddy system, wherein the slidable curing caddy enables lamp replacement and general interior maintenance of the apparatus. Further provided is an evaporator and alternatively, a vaporizer for providing a heavy gas supply. Further provided is a controller and software to coordinate the functions of the apparatus disclosed.

Owner:ELLIS GREGORY PAGE +1

Reflective and heat-insulation coating for buildings and preparation method thereof

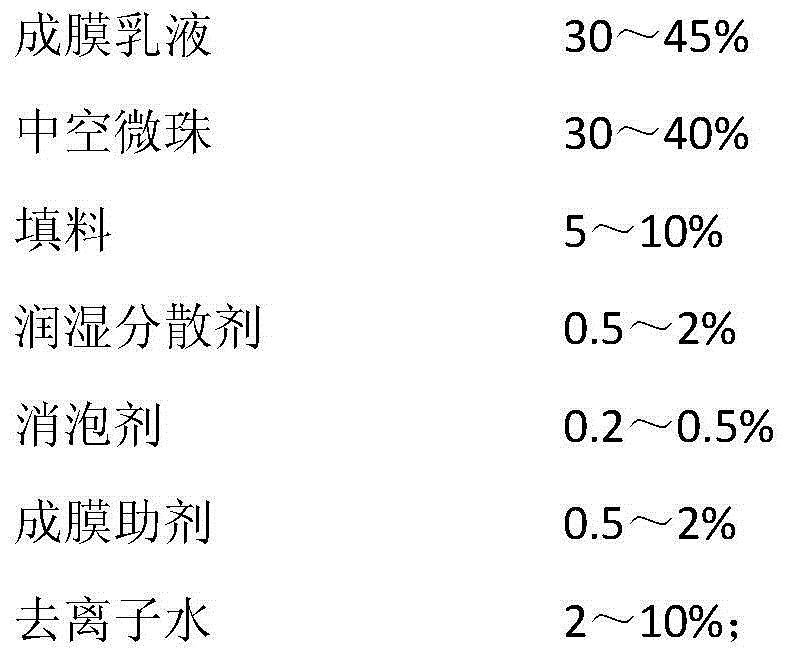

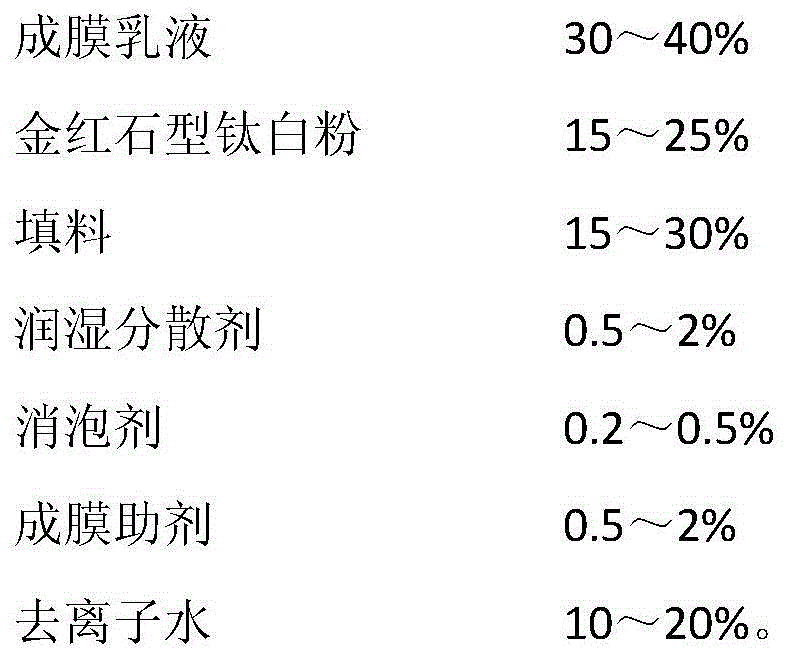

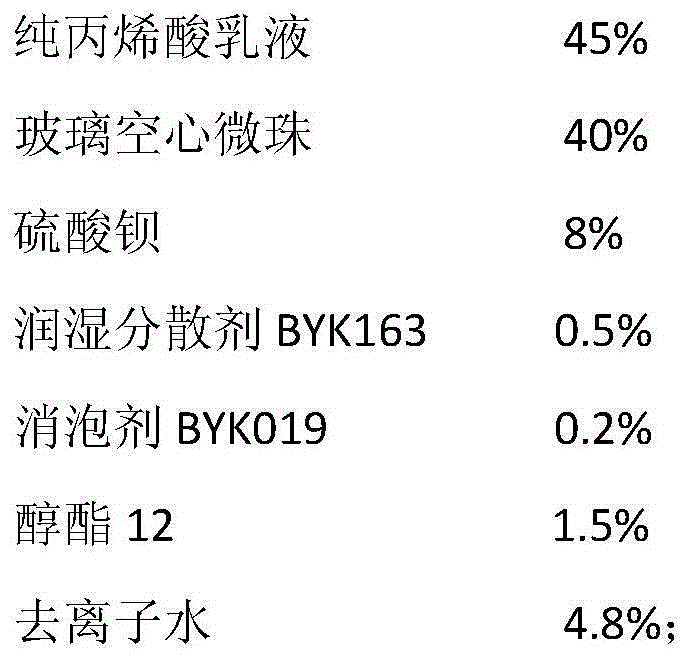

InactiveCN104610829AGood heat insulationEffective insulationReflecting/signal paintsCoated surfaceEmulsion

The invention discloses a reflective and heat-insulation coating for buildings and a preparation method thereof. The reflective and heat-insulation coating for buildings consists of two parts including prime coating and surface coating, wherein the prime coating comprises the following components in percentage by weight: 30-45% of film formation emulsion, 30-40% of hollow microspheres, 5-10% of filler, 0.5-2% of a wetting dispersant, 0.2-0.5% of a defoaming agent, 0.5-2% of a coalescing agent and 2-10% of deionized water; the surface coating comprises the following components in percentage by weight: 30-40% of film formation emulsion, 15-25% of rutile type titanium dioxide, 15-30% of filler, 0.5-2% of a wetting dispersant, 0.2-0.5% of a defoaming agent, 0.5-2% of a coalescing agent and 10-20% of deionized water. According to the reflective and heat-insulation coating for buildings and the preparation method thereof, the prime coating has excellent heat insulation effect, the surface coating has higher sunlight reflectivity, and if the prime coating and the surface coating are combined to be used, the temperature of a coated surface can be remarkably reduced; the reflective and heat-insulation coating has excellent weather, water and stain resistances.

Owner:BEIJING PENGCHUANG WEIYE TECH

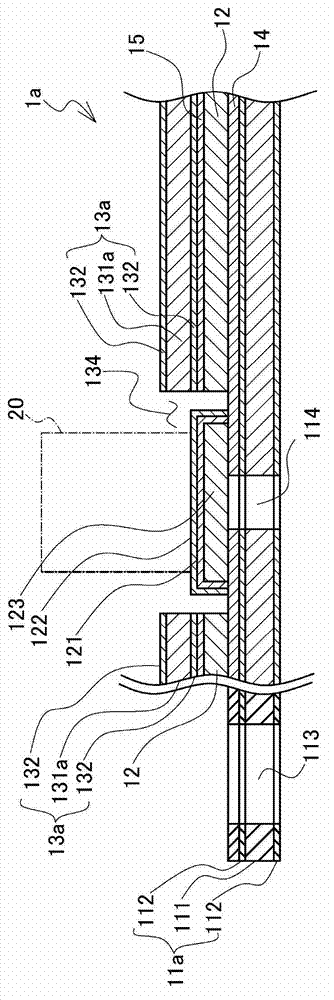

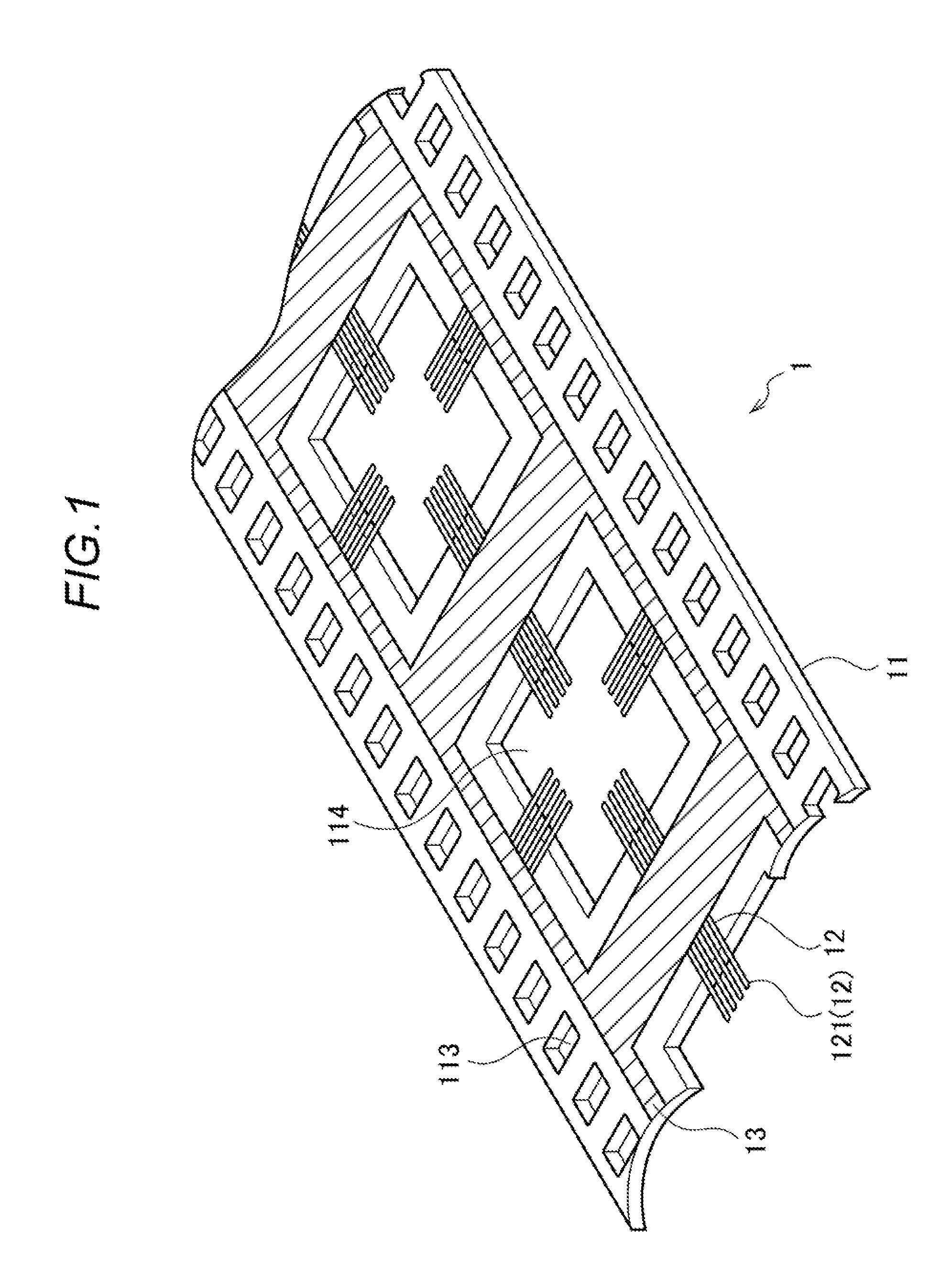

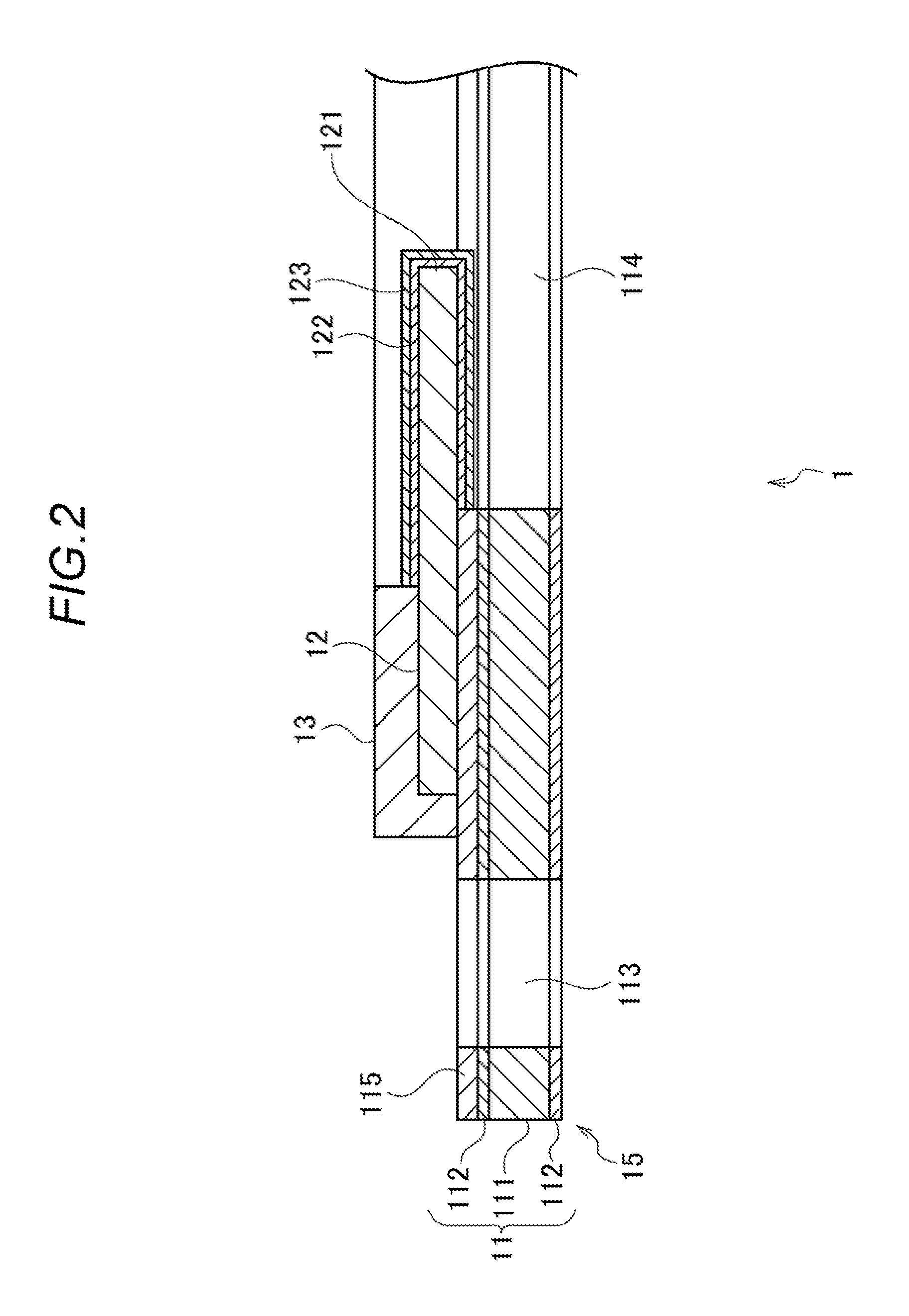

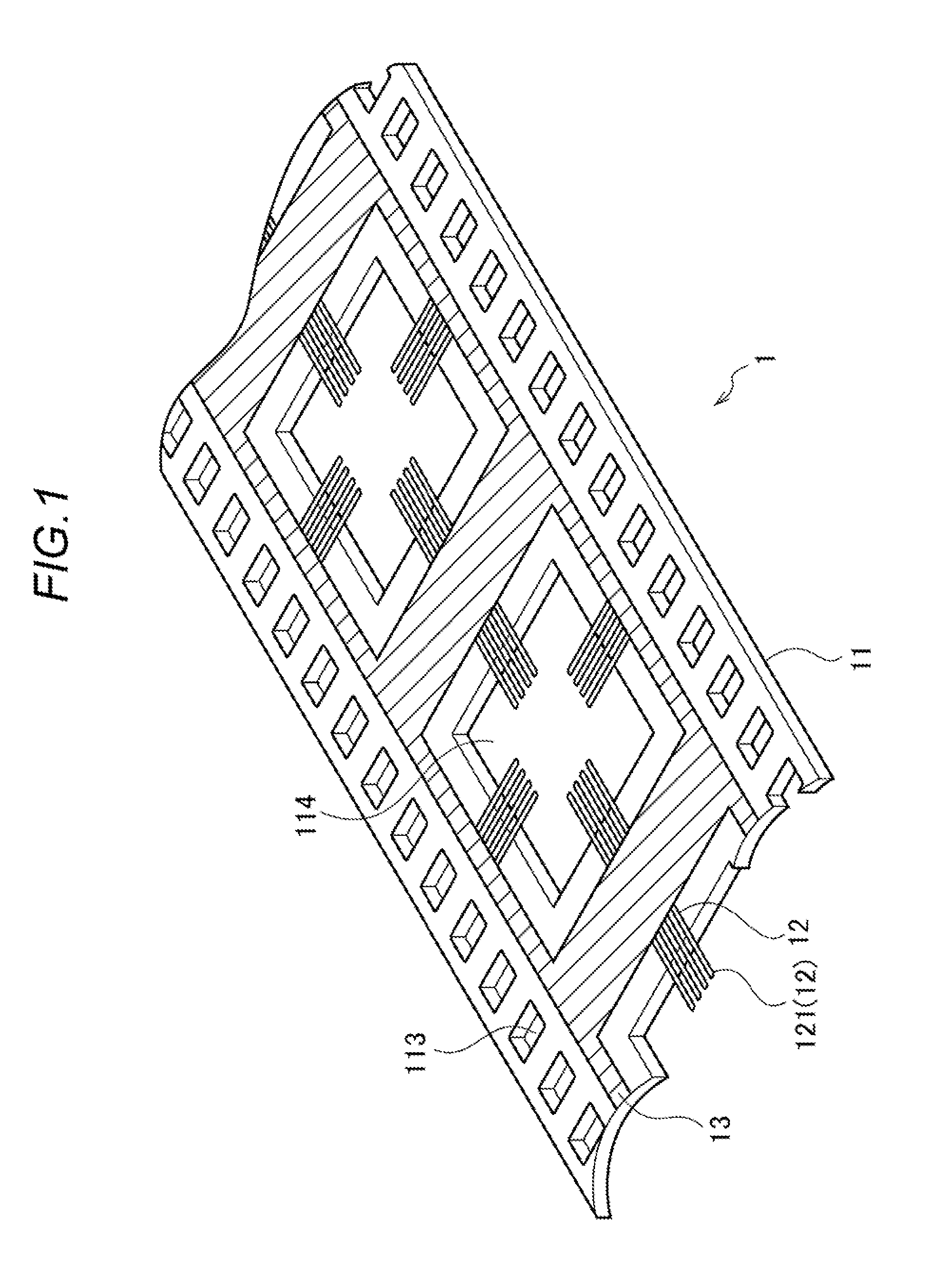

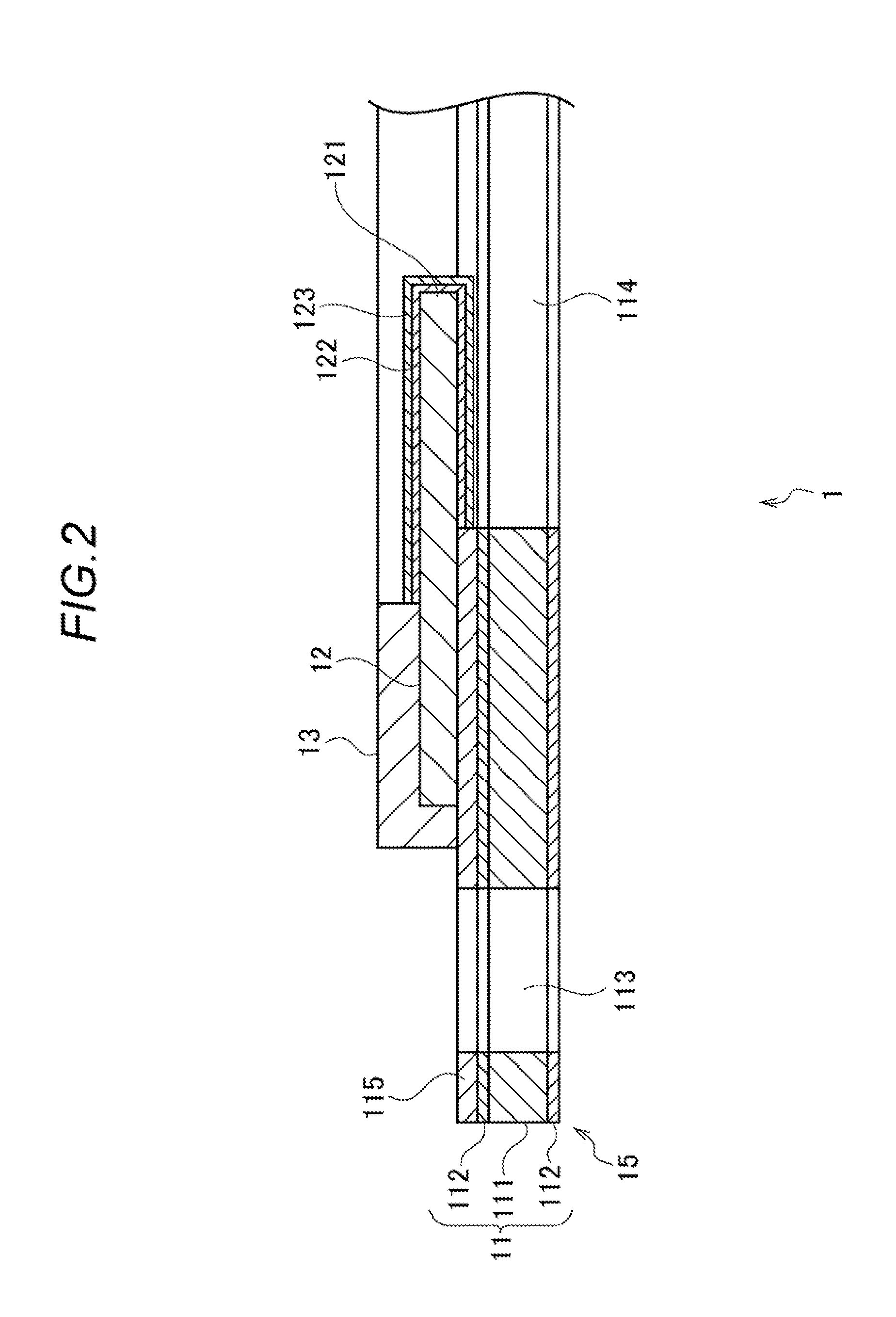

Flexible printed circuit, illumination apparatus, capsule endoscope and vehicle lighting apparatus

InactiveCN103200764AIncrease temperatureEfficient use ofCircuit optical detailsPoint-like light sourceLight equipmentDiffuse reflection

The invention relates to a flexible printed circuit, an illumination apparatus, a capsule endoscope and a vehicle lighting apparatus. The flexible printed circuit for mounting a light emitting element has a base film, a wiring pattern formed on a surface of the base film, and a cover film that covers the base film and the wiring pattern. At least one of the base film and the cover film has a substrate comprising a metal. The cover film has such surface properties as to produce specular reflection or diffuse reflection of light or has a substantially white reflecting film on a surface of the cover film.

Owner:CANON COMPONENTS INC

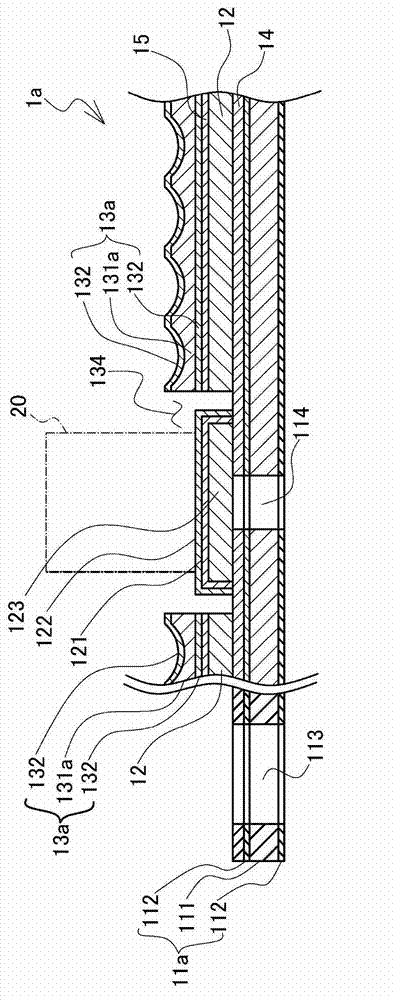

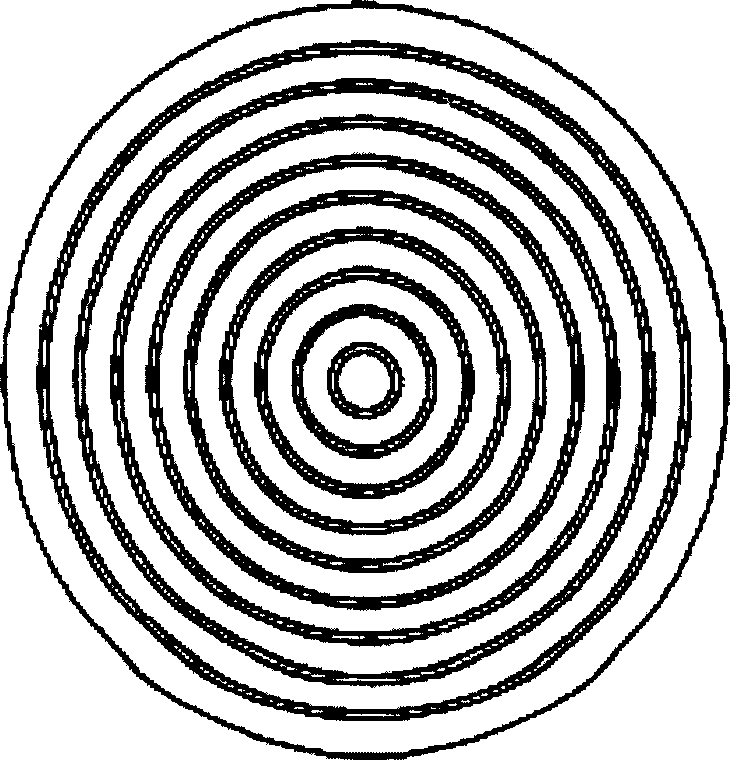

Polishing pad and chemico-mechanical polishing method

InactiveCN101190507AOptimize the extraction processOvercome the defect of low flatness of the wafer surfacePolishing machinesSemiconductor/solid-state device manufacturingWaferPolishing

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

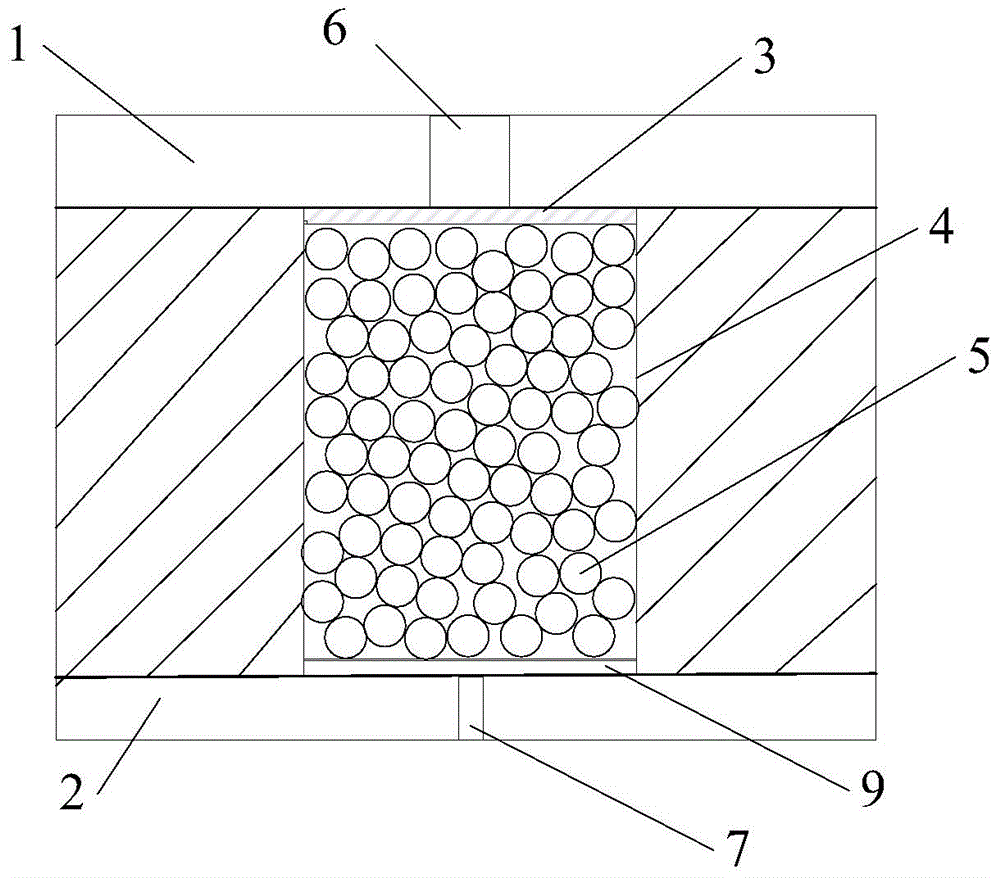

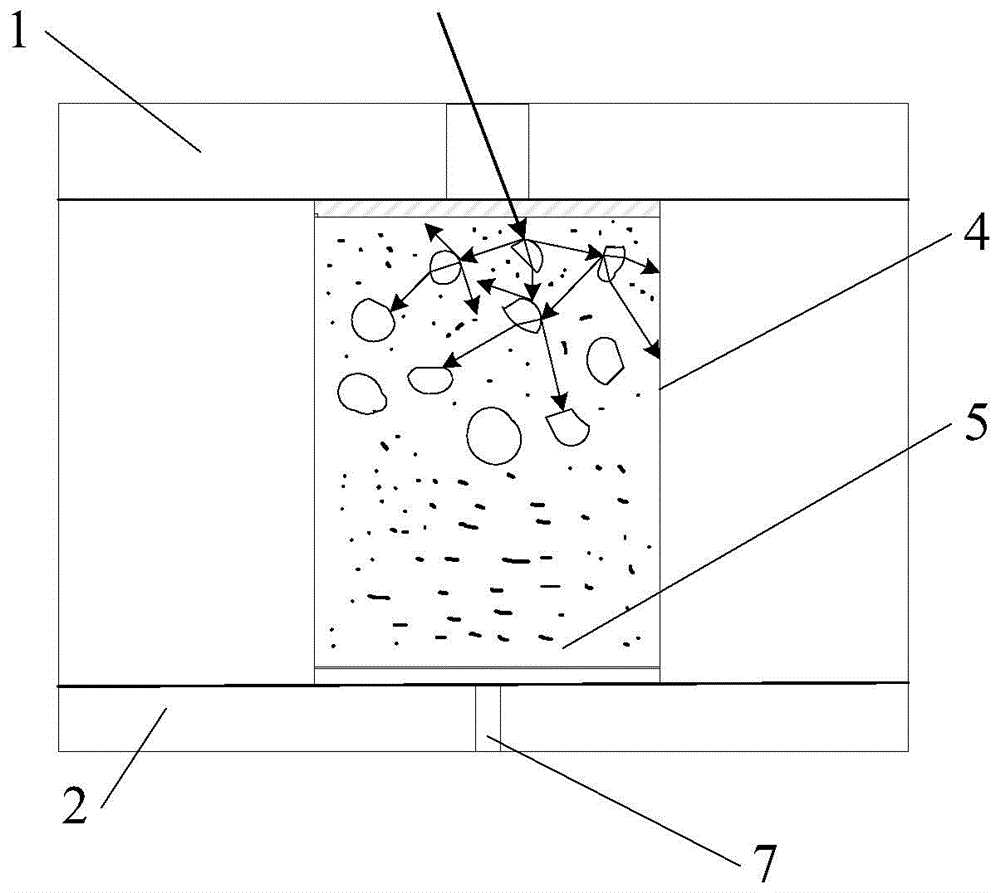

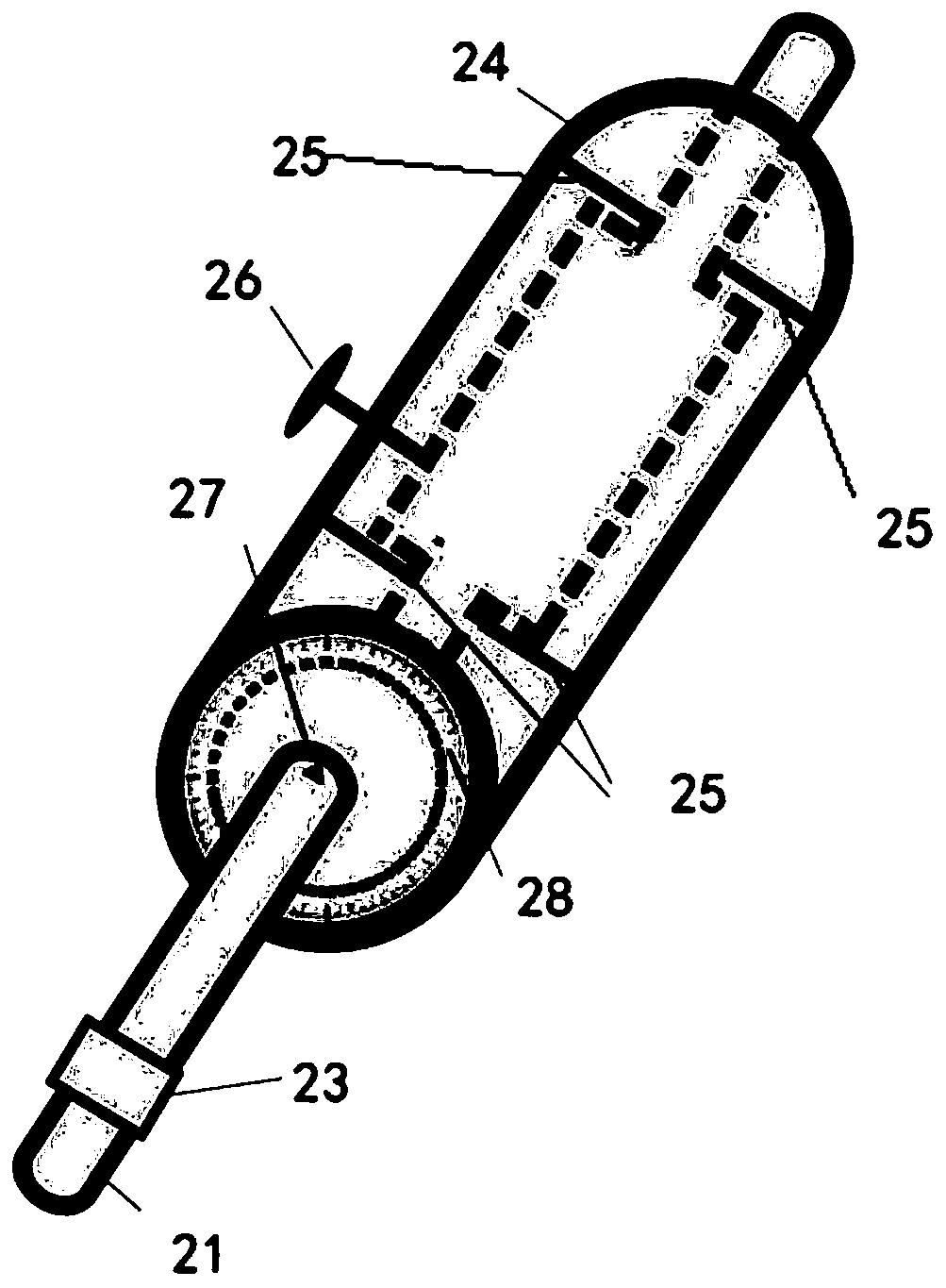

Attenuation sampling device used for large-angle high-energy laser incidence

ActiveCN104019891AGood angle characteristicsImprove the ability to resist laser radiationPhotometryUltrasound attenuationHigh spatial resolution

The invention discloses an attenuation sampling device used for large-angle high-energy laser incidence. The device comprises a front panel, an attenuation unit and a rear panel, wherein a straight laser incidence sampling hole is formed in the front panel, a laser exiting hole is formed in the rear panel, the attenuation unit comprises a front transmission window, a rear transmission window and a cylindrical cavity, the cylindrical cavity is arranged coaxial with the straight sampling hole and the laser exiting hole, and the cylindrical cavity is filled with granular optical volume scattering materials. After being coupled into the attenuation unit through the sampling hole, absorbed through inner walls and the materials, and subjected to volume scattering, lasers are emitted out through the laser exiting hole, laser beam energy can be redistributed in a space within a wide range, and the homogenization effect is achieved; meanwhile, large-angle attenuation sampling can be achieved in the laser oblique incidence, the requirement for substantial attenuation of laser power density can be met, and the device can be used for high-spatial-resolution light intensity detection.

Owner:NORTHWEST INST OF NUCLEAR TECH

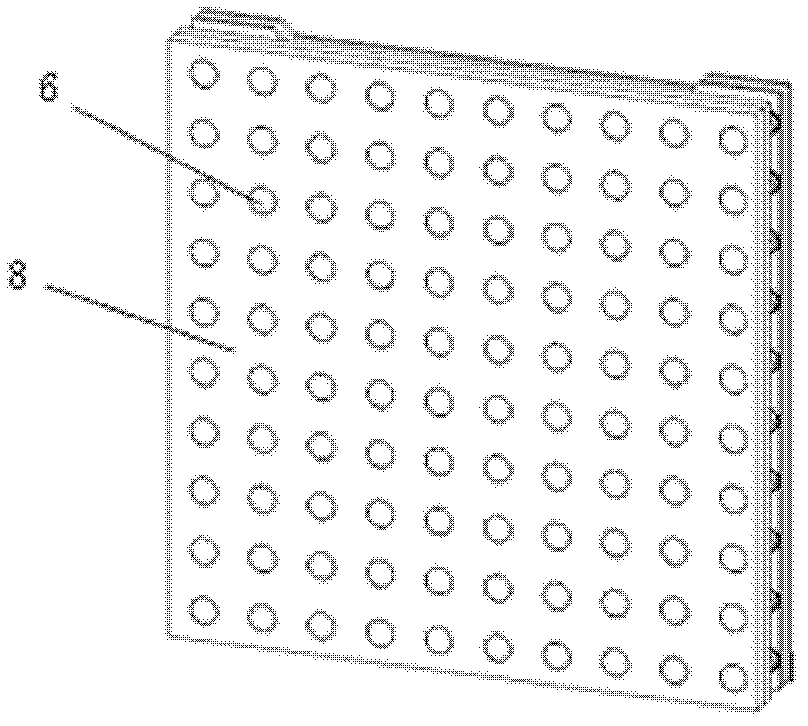

Array attenuator for high-energy laser and manufacturing method thereof

ActiveCN102410875ALow absorption rateAttenuation coefficient unchangedPhotometryMetallic materialsLaser power density

The invention relates to an array attenuator for a high-energy laser and a manufacturing method thereof. The array attenuator comprises a front panel, a rear panel and an array of a plurality of integrating sphere cavities, wherein the front panel and the rear panel are arranged along an incident direction of the laser; each of the integrating sphere cavities is formed by two hemispherical cavities in spliced connection; a laser incident hole and a laser emergent hole are formed on an edge of each of the integrating sphere cavities; the front panel and the rear panel are made of metallic materials; and a diffuse transmission optical window is mounted at the laser incident hole. Compared with the graphite in same size, the array attenuator provided by the invention is low in absorption rate for laser power, thereby being suitable for the attenuation of a medium multiple laser power density. Meanwhile, the diffuse transmission optical window is mounted in front of the laser incident hole, so that the laser passing by the optical window is multi-angularly coupled in the laser incident hole, thereby keeping a basic invariable attenuation coefficient of the attenuator when the laser obliquely incomes within a certain angle scope.

Owner:NORTHWEST INST OF NUCLEAR TECH

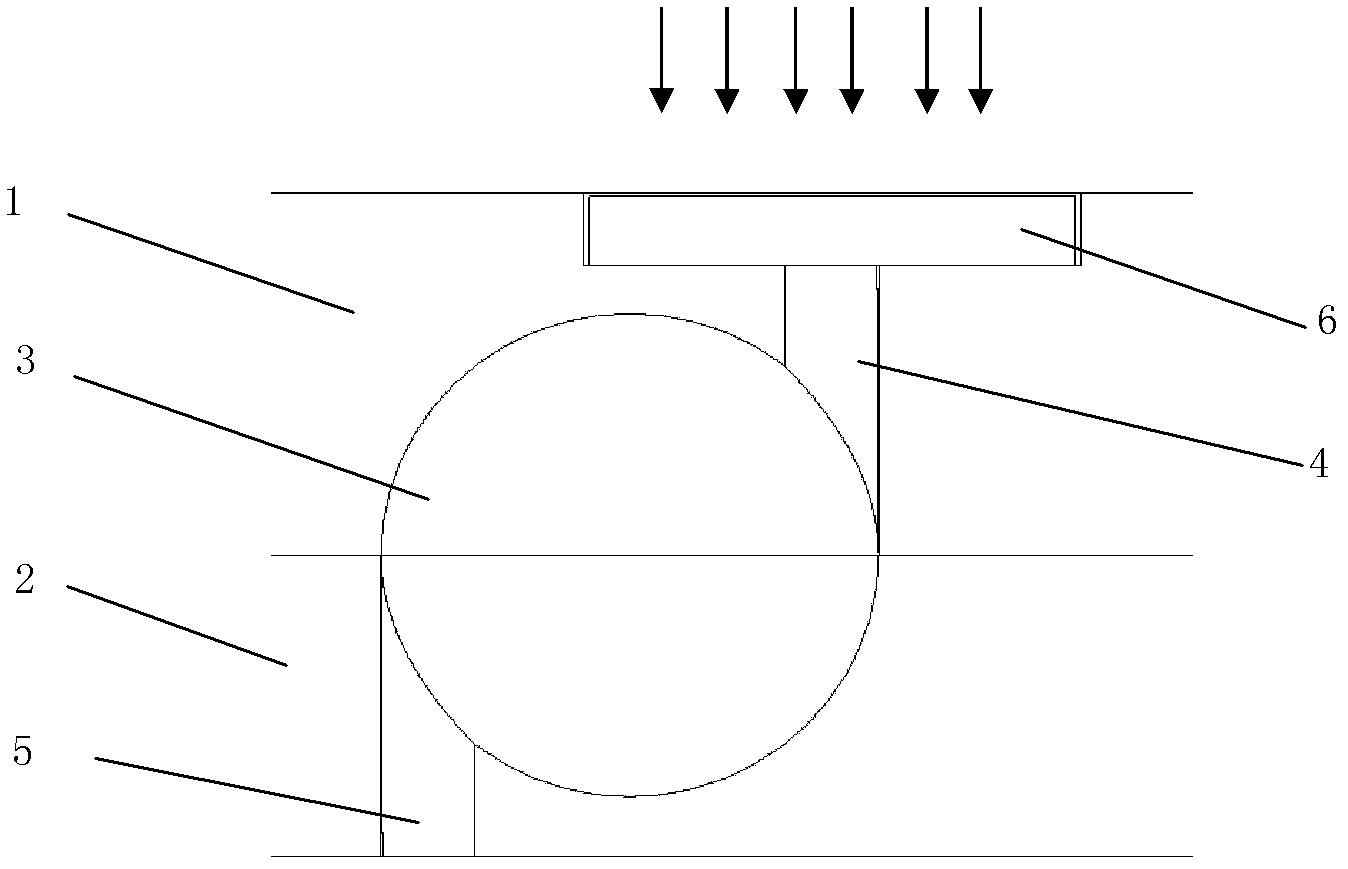

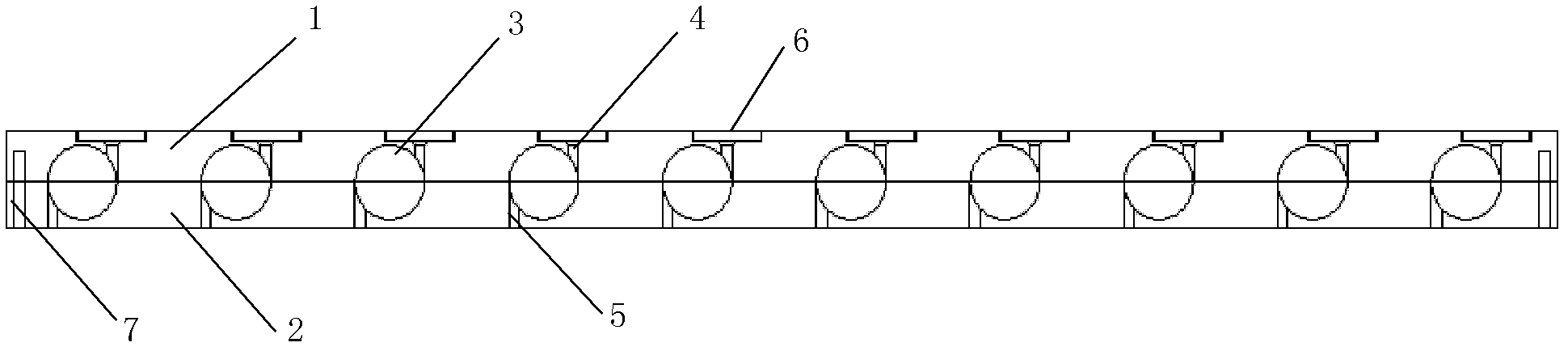

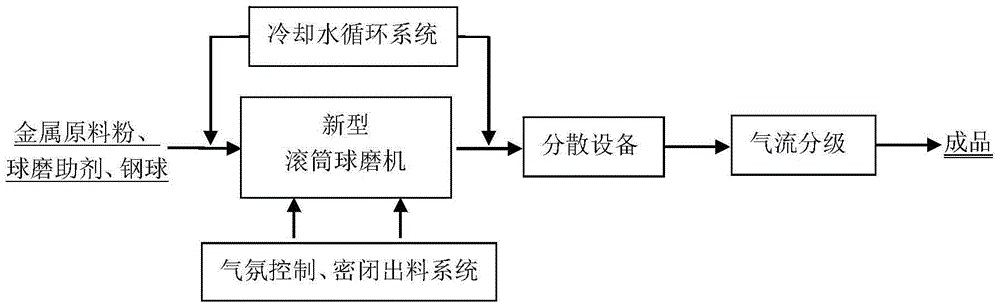

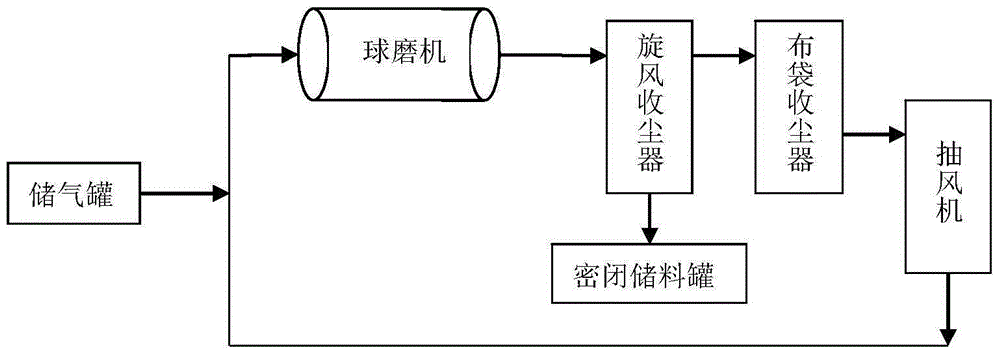

Method and device for preparing flaky metal powder by means of dry ball mill

The invention provides a method for preparing flaky metal powder by means of a dry ball mill. The method comprises the steps that metal raw material powder and ball milling additives are evenly mixed, a mixture and a steel ball are put in a closed novel roller ball mill for ball milling in proportion, the ball milling temperature is controlled through a cooling water circulation system in the ball milling process, and the ball milling atmosphere in a roller is adjusted through a ball milling atmosphere control system; a closed discharging system is adopted for discharging, inert gas of certain pressure is input, an exhaust fan and the ball mill are started, and ground metal powder in the ball mill is blown and sucked out in a blowing and sucking manner; and the metal powder is put in dispersion equipment again to be dispersed, and is graded by airflow grading equipment to obtain finished products. The invention relates to a device for achieving the method. According to the method, the whole process is high in automation degree, no steel ball transfer exists, and the labor intensity and workloads of workers are greatly reduced. In addition, the sealing performance and the cooling effect are good, no dust pollution exists, the phenomena of powder oxidation and spontaneous combustion in the powder discharging process are avoided, the yield is large, and production efficiency is greatly improved.

Owner:SHENZHEN NONFEMET TECH

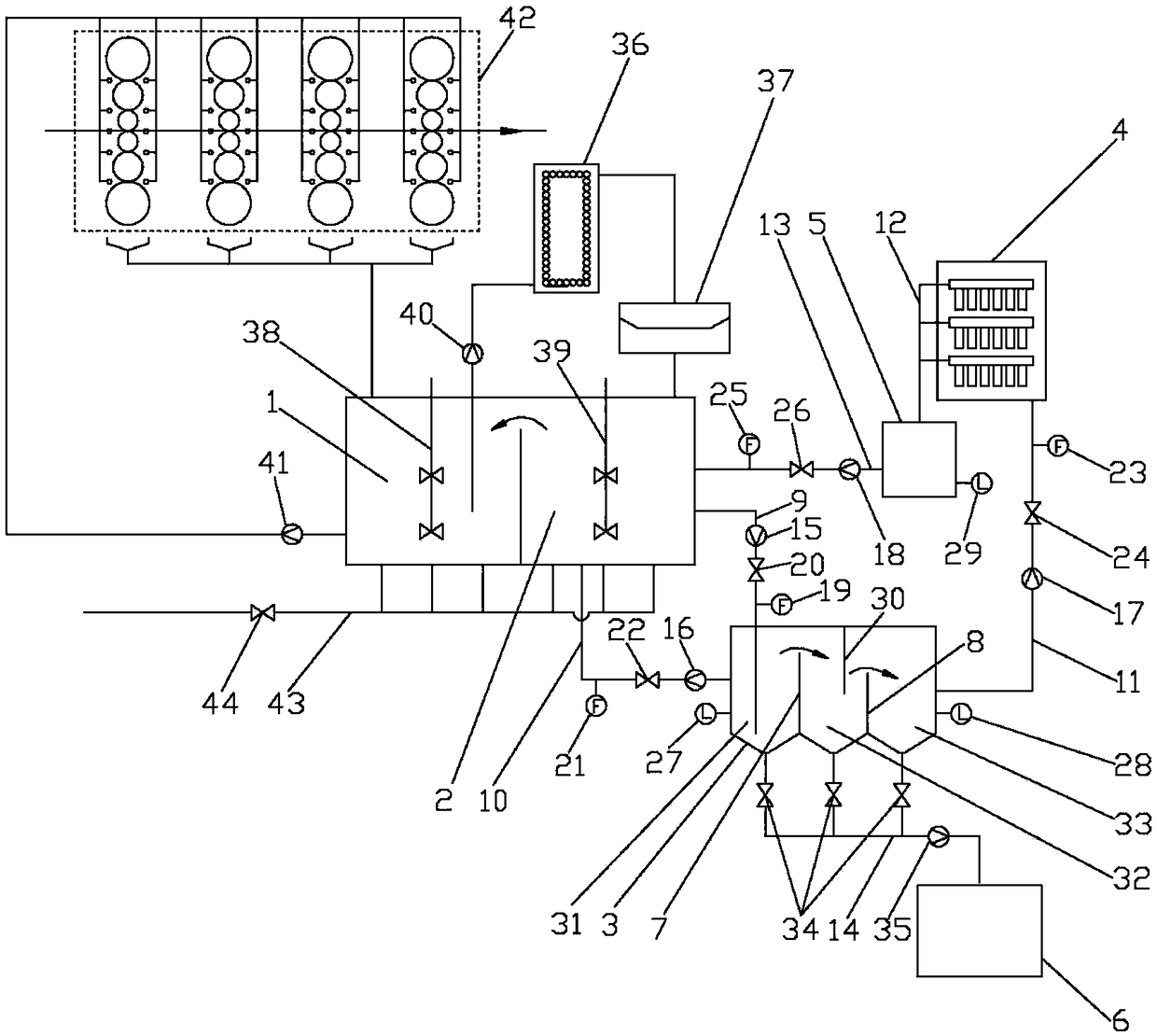

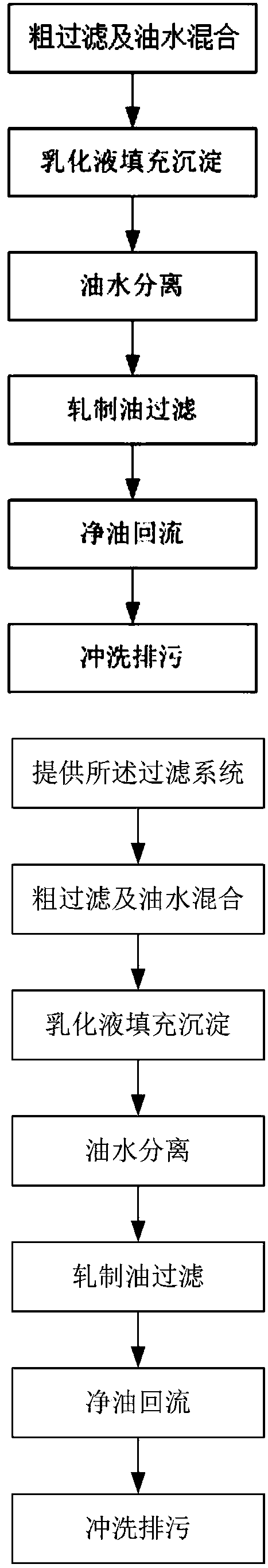

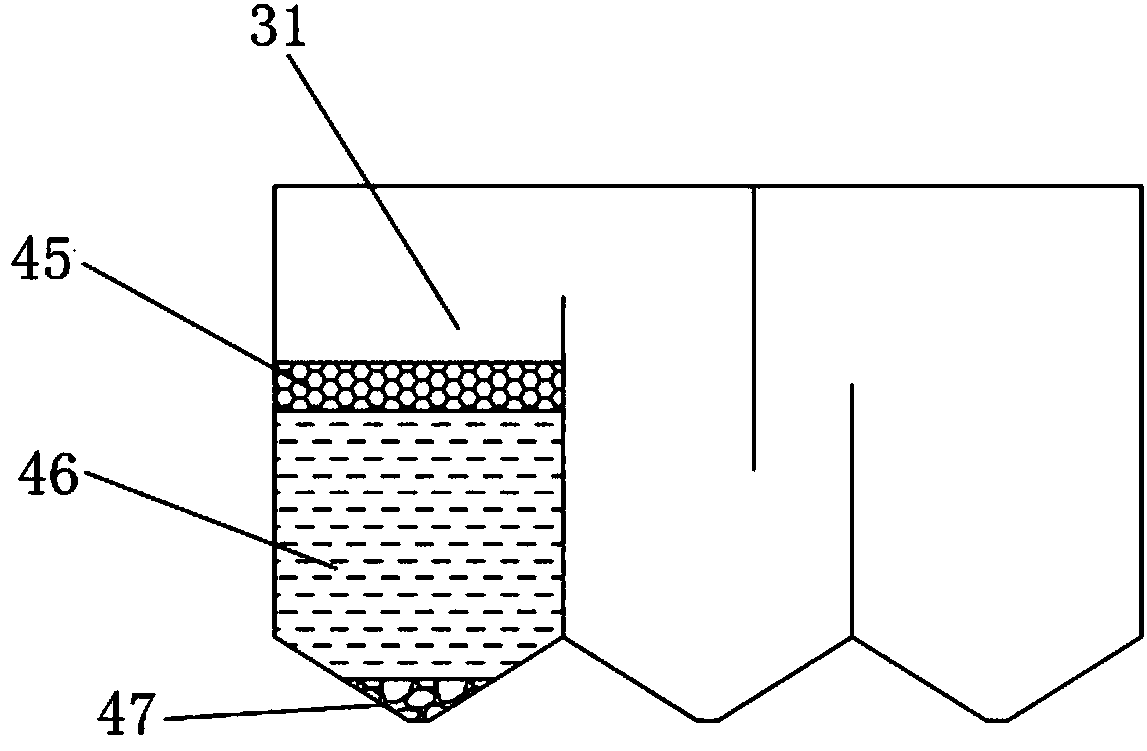

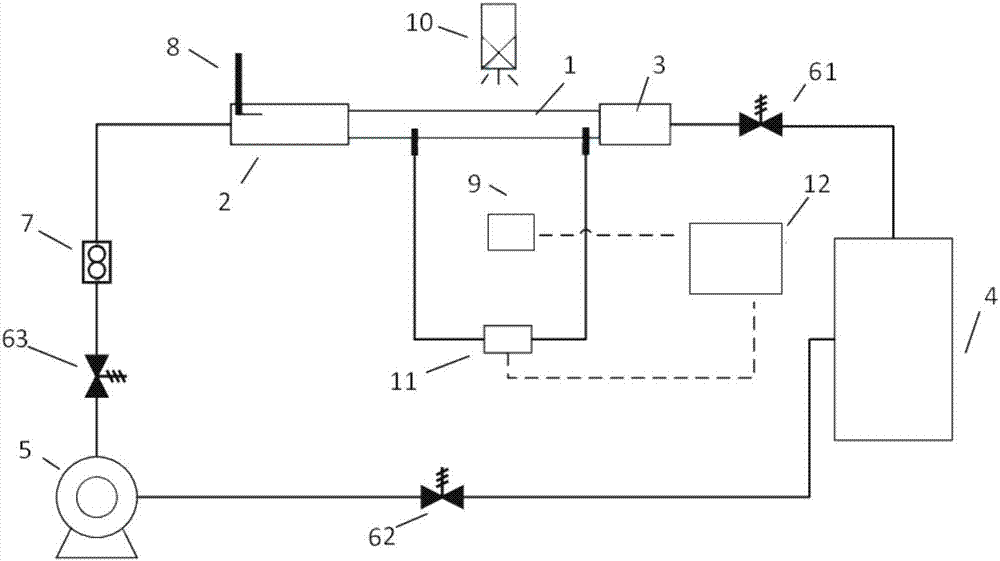

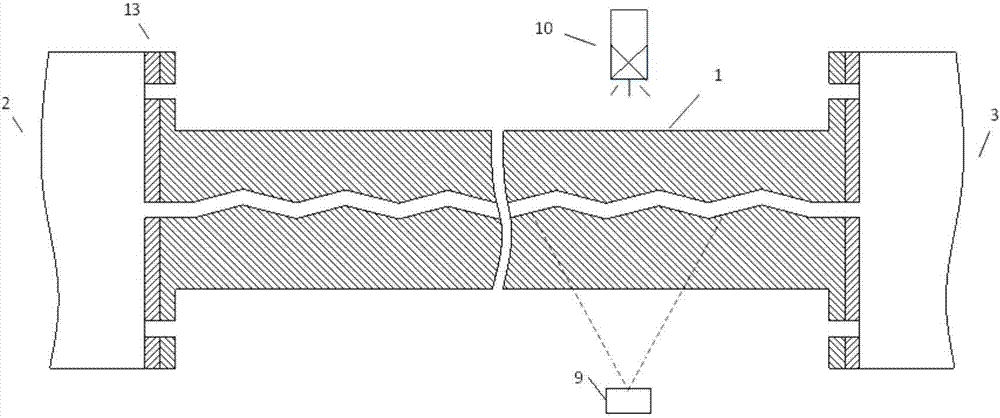

Emulsion filtration system and method for cold continuous rolling of stainless steel

ActiveCN108187402AImprove filtration efficiencyImprove filtering effectFiltration circuitsEmulsionFiltration

The invention discloses an emulsion filtration system for cold continuous rolling of stainless steel. The emulsion filtration system comprises a contaminated emulsion tank, a filtering device, a purified emulsion tank, a standing tank, a rolling oil filter, a purified oil tank and a sewage discharge tank, wherein the bottom part of the contaminated emulsion tank and the bottom part of the purifiedemulsion tank respectively communicate with a compressed air pipeline in a workshop; the purified emulsion tank and the standing tank are in communication; the standing tank and the rolling oil filter are in communication; the rolling oil filter and the purified oil tank are in communication; the purified oil tank and the purified emulsion tank are in communication; the bottom part of the standing tank communicates with the sewage discharge tank; and the interior of the standing tank is provided with a first overflow plate and a second overflow plate. The invention also provides an emulsion filtration method for cold continuous rolling of stainless steel. The invention has the following beneficial effects: the emulsion filtration system and method provided by the invention realize sedimentation of large-sized particles and oil-water separation of an emulsion through arrangement of the standing tank, can filter rolling oil rich in small-sized particular impurities by utilizing the rolling oil filter, can remove 90% or more particular impurities, and have high filtering efficiency and good filtering effect.

Owner:WISDRI ENG & RES INC LTD

Polishing pad and chemico-mechanical polishing method

InactiveCN101190508AOptimize the extraction processOvercome the defect of low flatness of the wafer surfacePolishing machinesSemiconductor/solid-state device manufacturingHigh surfaceEngineering

The invention provides a polishing pad; the polishing surface of the polishing pad is provided with a plane area and a concave / convex area; the plane area is a flat surface with the coarseness less than 20 Mu m used for polishing wafer; the concave / convex area is provided with troughs or holes or the combination of the troughs and holes used for pulling the wafer out of the polishing surface. By adopting the polishing pad provided by the invention, the wafer after chemically and mechanically polished has high surface smoothness; after the polishing is finished, the wafer is moved to the concave / convex area of the polishing pad and the wafer is easy to be pulled out of the surface of the polishing pad.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

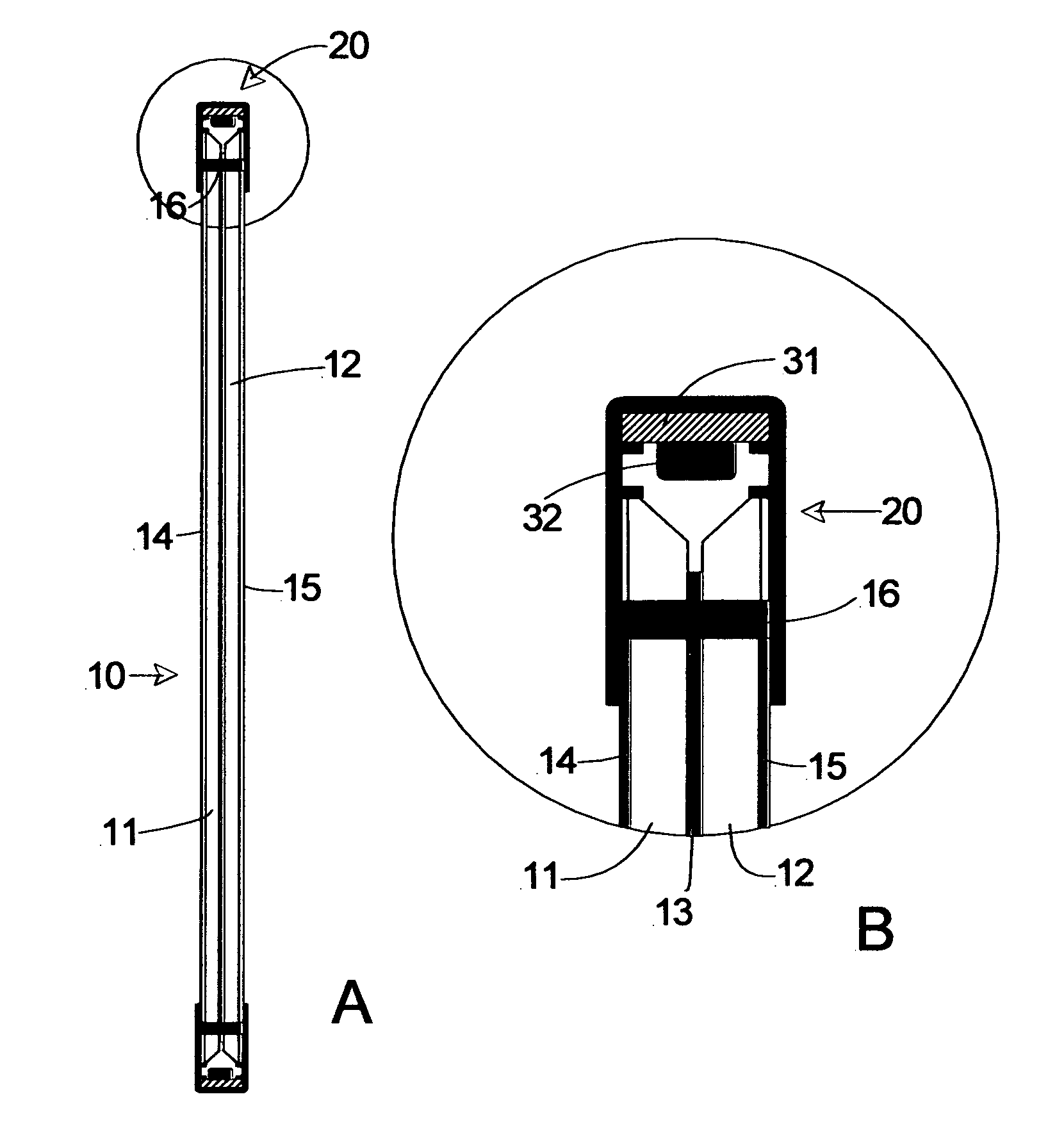

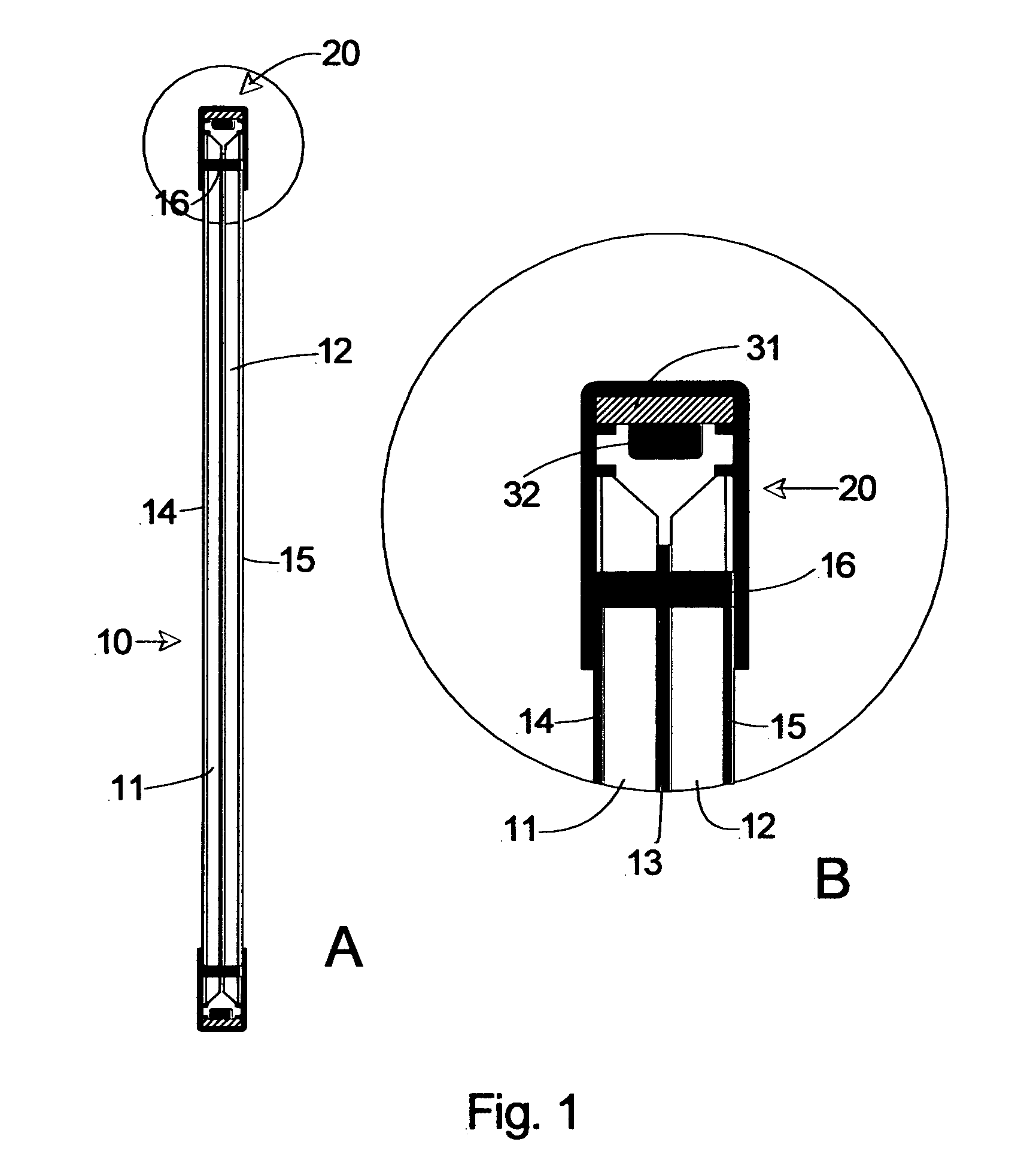

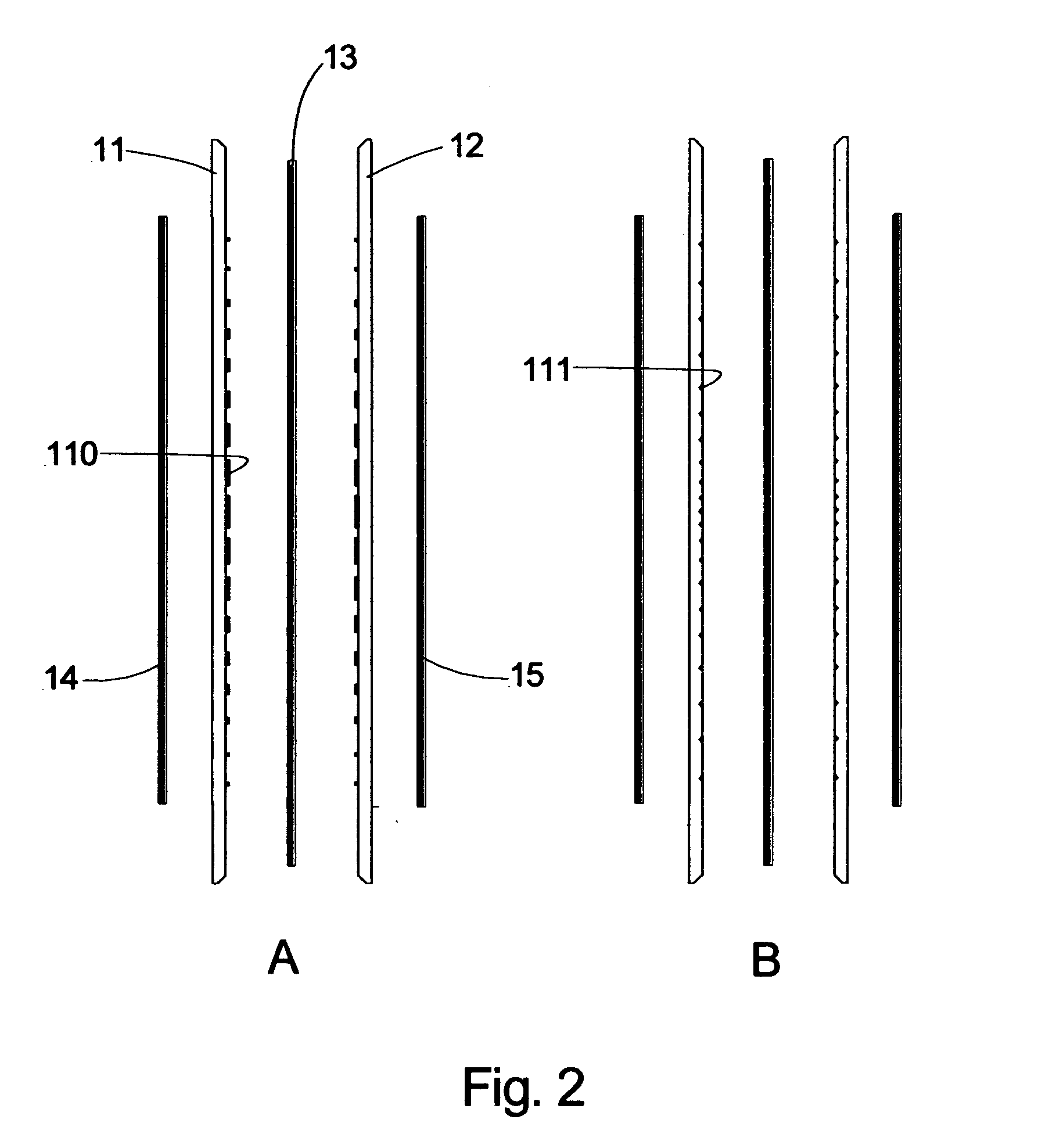

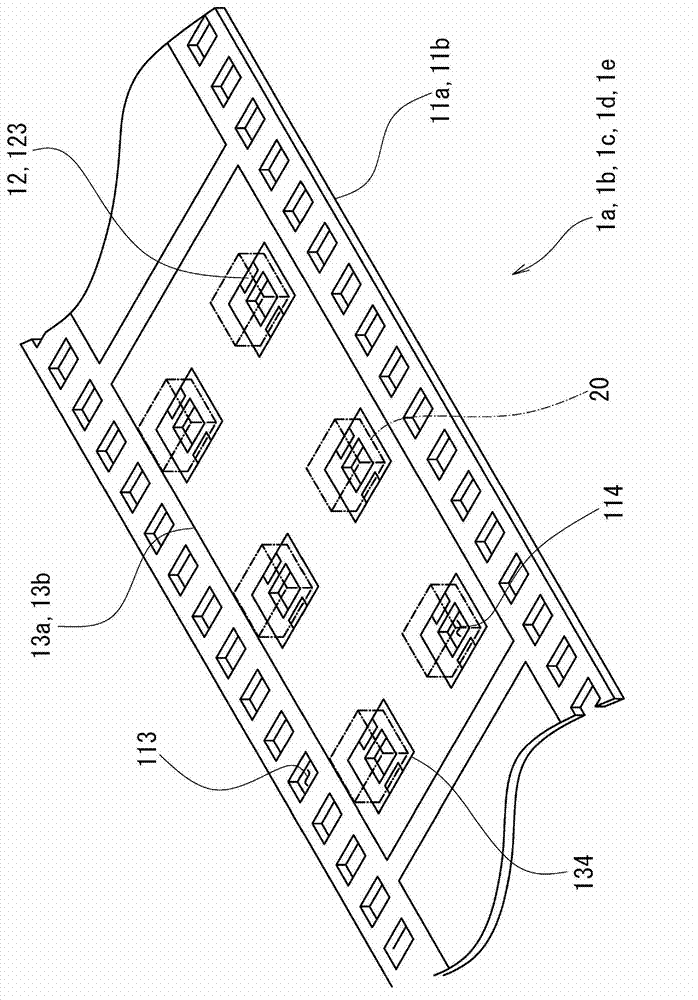

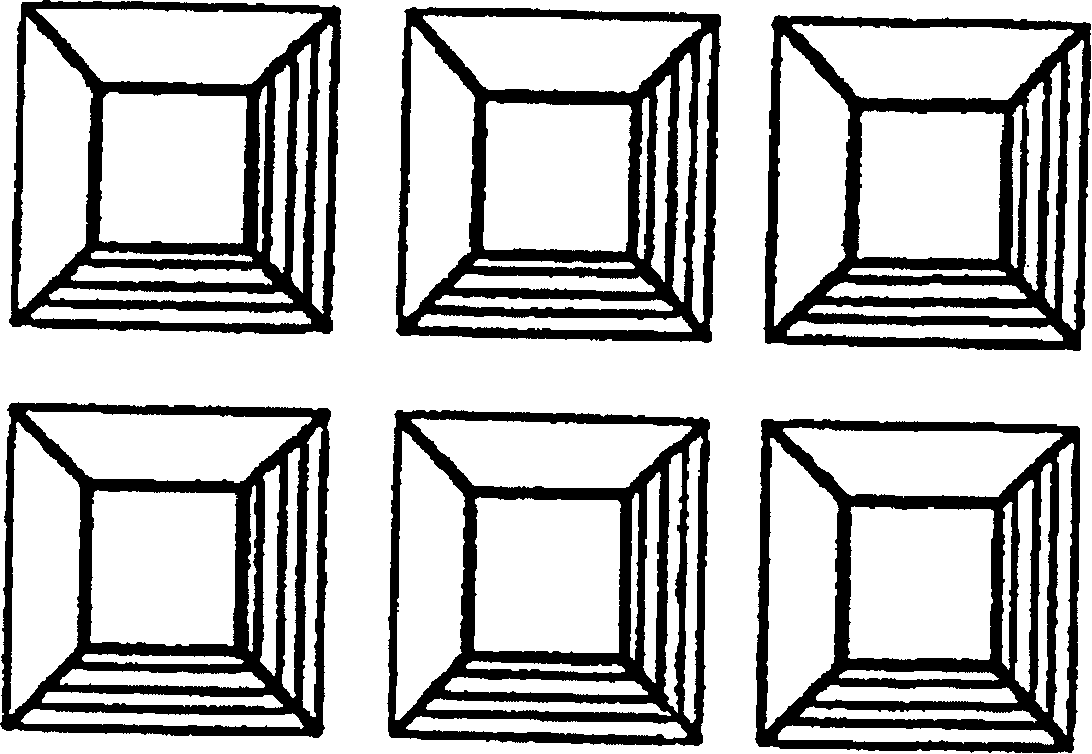

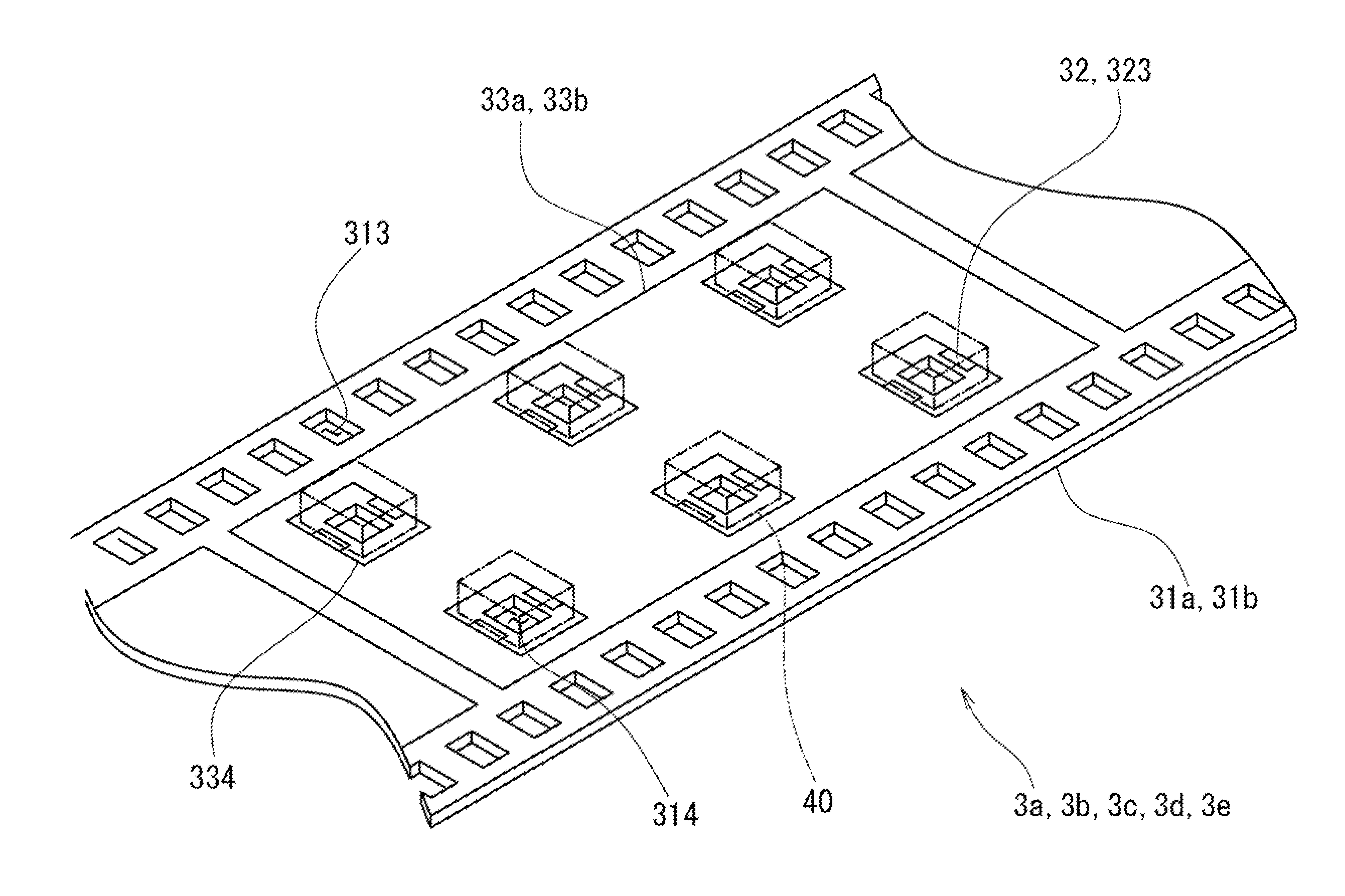

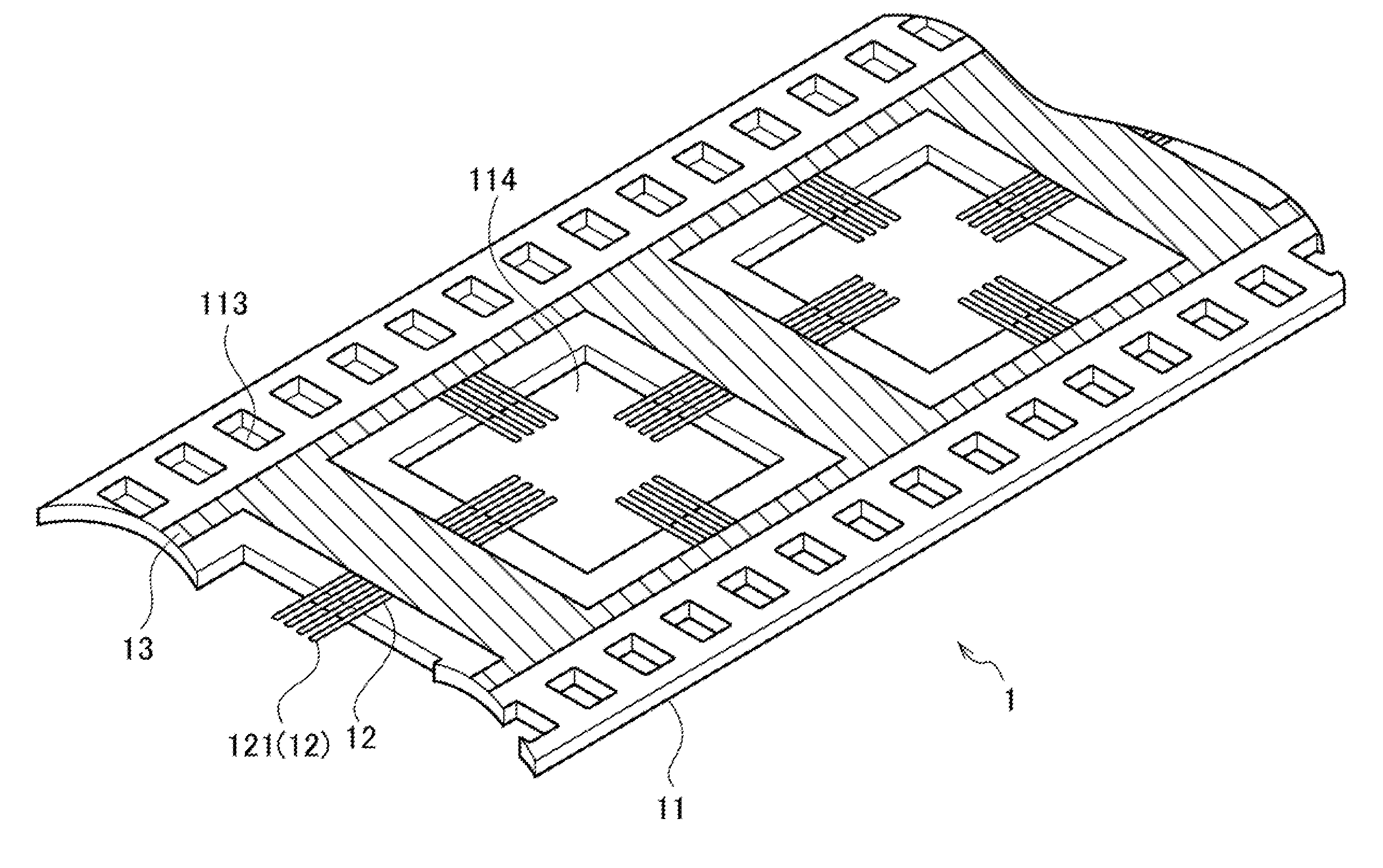

Flexible circuit board for mounting light emitting element, illumination apparatus, and vehicle lighting apparatus

InactiveUS20150292722A1Increase blockingImprove surface reflectivityCircuit bendability/stretchabilityCircuit optical detailsFlexible circuitsEffect light

A flexible circuit board 3a for mounting a light emitting element has base films 31a and 31b, a wiring pattern 32 formed on a surface of the base films 31a and 31b, and the cover films 33a and 33b that covers the base films 31a and 31b and the wiring pattern 32. At least one of the base film and the cover films 33a and 33b have a substrate 331 and 331a comprising a metal. The cover film 33a and 33b have such surface properties as to produce specular reflection or diffuse reflection of light or has substantially white reflecting films 36 and 333 on a surface of the cover film.

Owner:CANON COMPONENTS INC

Polishing solution used for amorphous alloy and polishing method of amorphous alloy

The invention provides a polishing solution used for an amorphous alloy and a polishing method of an amorphous alloy. The polishing solution comprises: a sodium salt, an ammonium salt and a brightener, i.e. ceric sulfate. The polishing method includes plasma polishing to an amorphous alloy. And the plasma polishing method consists of: connecting the amorphous alloy to a positive electrode, and immersing the amorphous alloy into an electrolytic cell containing the polishing solution, and taking the electrolytic cell body as a negative electrode for plasma polishing. The amorphous alloy prepared with the polishing solution provided in the invention and by the plasma polishing method of the invention has a smooth surface and high surface reflectivity.

Owner:BYD CO LTD

Apparatus for improving absorption rate and emission rate in infrared heat wave nondestructive detection

InactiveCN101368920AImprove surface reflectivityHigh yieldMaterial flaws investigationAviationHigh surface

The invention relates to the infrared thermal wave nondestructive detection techniques, in particular to a device which can improve the surface absorption rate and emissivity of the tested object in the infrared thermal wave nondestructive detection process. The method adopted by the invention is to select a functional membrane with good visible light absorption rate and infrared emissivity in the infrared thermal wave nondestructive detection process to cover the tested object; and the air between the surface of the tested object and the membrane is pumped out to enable the functional membrane to be closely contacted with the tested object. The invention is characterized by improving a flashlight mask based on the existing infrared thermal wave nondestructive detection system so as to achieve the method. The invention causes no pollution and damage to the tested object in the detection process and can improve the visible light absorption rate and infrared emissivity of the tested object so as to greatly improve the infrared thermal wave nondestructive detection result on the object which has high surface reflectivity and can not be treated with spray painting; and the invention is suitable for the infrared thermal wave nondestructive detection of corrosive or precision aerospace and aviation devices.

Owner:CAPITAL NORMAL UNIVERSITY +1

Method for improving photocatalysis function of nano film using optical interference method

InactiveCN101497036AReduce reflectionHigh refractive indexCatalyst activation/preparationDeodrantsRoom temperatureColloid

The invention relates to a method for improving the function of photocatalysis of a nanofilm by the principle of interference of light. The method is to coat a nanometer material with the function of photocatalysis on a substrate material according to a certain optical thickness to prepare the film with a nanometer structure, wherein the nanofilm is made of a single material layer or two materials alternately; and when the nanofilm is coated, the substrate material to be coated makes relative motion with a colloid solution, the coating speed is at about 0.02 to 2.0cm / s, each film is baked for 3 to 20 minutes at a temperature of between 400 and 550 DEG C, and the other layer is coated when the film is cooled to room temperature. The method uses the relative motion of the surface of the colloid solution and the substrate material to achieve film thickness control, and the prepared photocatalyst nanofilm is more useful to prepare a film which sterilizes and degrades harmful gases and has certain requirement on transparency.

Owner:陆晓唯

Method and apparatus for improving absorptivity and emissivity in infrared thermal wave non-destructive testing

InactiveCN1766595AImprove surface reflectivityHigh yieldMaterial flaws investigationAbsorption ratioNon destructive

The invention relates to a method and apparatus for improving the surface absorbing ratio and emissive power during the infrared heat wave nondestructive testing course in the field of infrared heat wave nondestructive test. It is characterized in that it chooses the function thin foil with better light absorbing ratio and emissive power to cover or coat the tested object and uses the method of drafting the air between the tested object surface and the thin foil to make them closed contact with each other during the infrared heat wave nondestructive testing course. The invention provides two apparatus to achieve the method by the size of the tested object.

Owner:CAPITAL NORMAL UNIVERSITY +1

Printed circuit board heat exchanger channel flow field visualization device

InactiveCN107389297AHigh precisionImprove surface reflectivityHydrodynamic testingDifferential pressureComputer module

The invention discloses a printed circuit board heat exchanger channel flow field visualization device comprising a water tank, a tracing particle injector, a front water collecting pipe, a PCHE visual channel module, a rear water collecting pipe, a light source, a CCD camera, a computer and a differential pressure measurement system which is used for detecting pressure drop resistance information of the water before and after the channel in the PCHE visual channel module. Visualization of the printed circuit board heat exchanger fluid channel flow field information can be realized by the device.

Owner:XIAN THERMAL POWER RES INST CO LTD

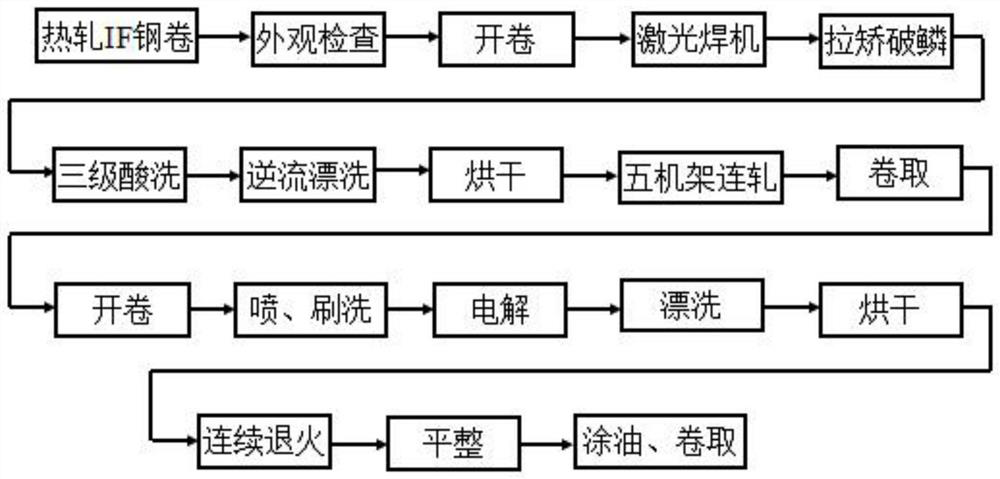

Production method for cold-rolled IF steel with high surface cleanliness

ActiveCN113664037AThe whole production process is mature and stableLow comprehensive manufacturing costProcess efficiency improvementWork cleaning devicesHigh surfaceCorrosion inhibitor

The invention discloses a production method for cold-rolled IF steel with high surface cleanliness. The production method comprises the following steps that 1, a hot-rolled IF steel coil is uncoiled and welded and then is stretched, straightened and subjected to scale breaking; 2, continuous shallow slot turbulence hydrochloric acid pickling is carried out on the strip steel formed by pulling the steel coil open; 3, a pickling corrosion inhibitor is added 12 hours in advance; 4, the strip steel subjected to acid pickling is rinsed and dried; 5, five machine frames carry out continuous rolling, the F1-F4 machine frames adopt small-roughness working rollers for large pressing, and the F5 machine frame adopts a large-roughness working roller for light flattening; 6, the cold and hard steel coil obtained after continuous rolling enters a cleaning unit for powerful cleaning; 7, the strip steel subjected to electrolytic cleaning is rinsed and dried; 8, the surface cleanliness of the strip steel is measured every five coils at an inlet of an outlet loop of the cleaning unit; 9, nitrogen-hydrogen mixed protective gas with the hydrogen concentration of 5-7% is adopted for continuous annealing, flattening, trimming and oiling are carried out, and then coiling is carried out so as to obtain a finished steel coil; The production method has the advantages that the whole production process is mature and stable, and the comprehensive manufacturing cost is low; and the surface reflectivity of the cold-rolled IF strip steel at the outlet of the cleaning section reaches 92% or above.

Owner:SD STEEL RIZHAO CO LTD

Flexible circuit board for mounting light emitting element, illumination apparatus, and vehicle lighting apparatus

ActiveUS20140020935A1Increase productionReduce heat loadCircuit bendability/stretchabilityCircuit optical detailsFlexible circuitsEffect light

A flexible circuit board 3a for mounting a light emitting element has base films 31a and 31b, a wiring pattern 32 formed on a surface of the base films 31a and 31b, and the cover films 33a and 33b that covers the base films 31a and 31b and the wiring pattern 32. At least one of the base film and the cover films 33a and 33b have a substrate 331 and 331a comprising a metal. The cover film 33a and 33b have such surface properties as to produce specular reflection or diffuse reflection of light or has substantially white reflecting films 36 and 333 on a surface of the cover film.

Owner:CANON COMPONENTS INC

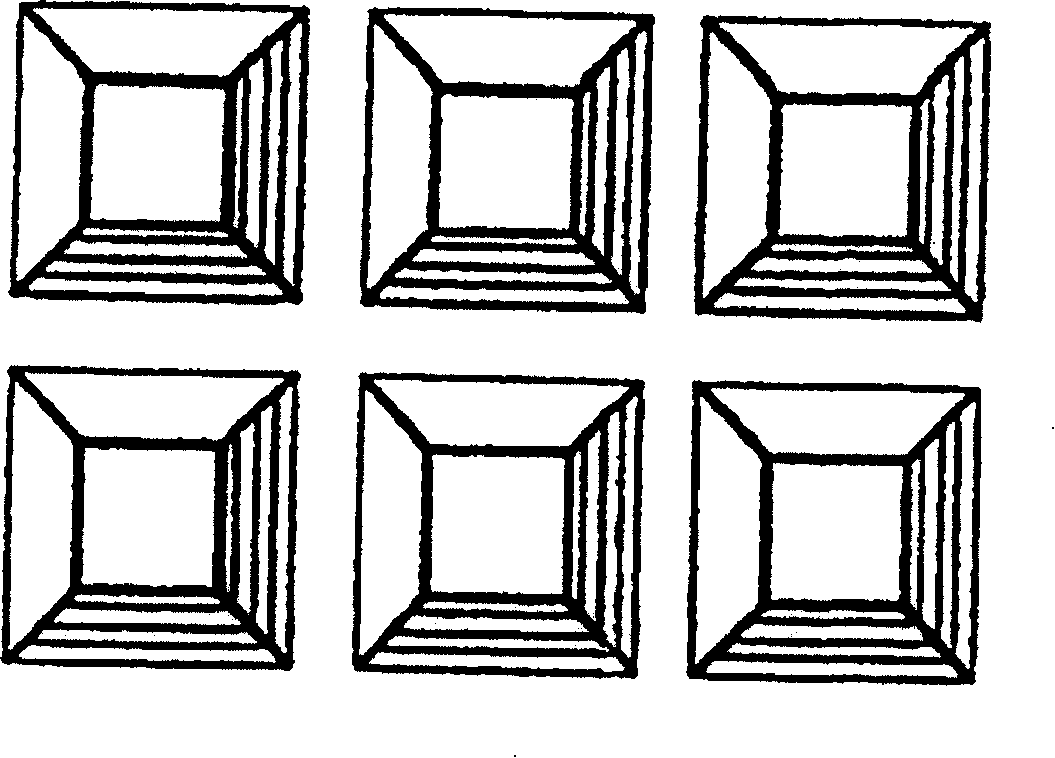

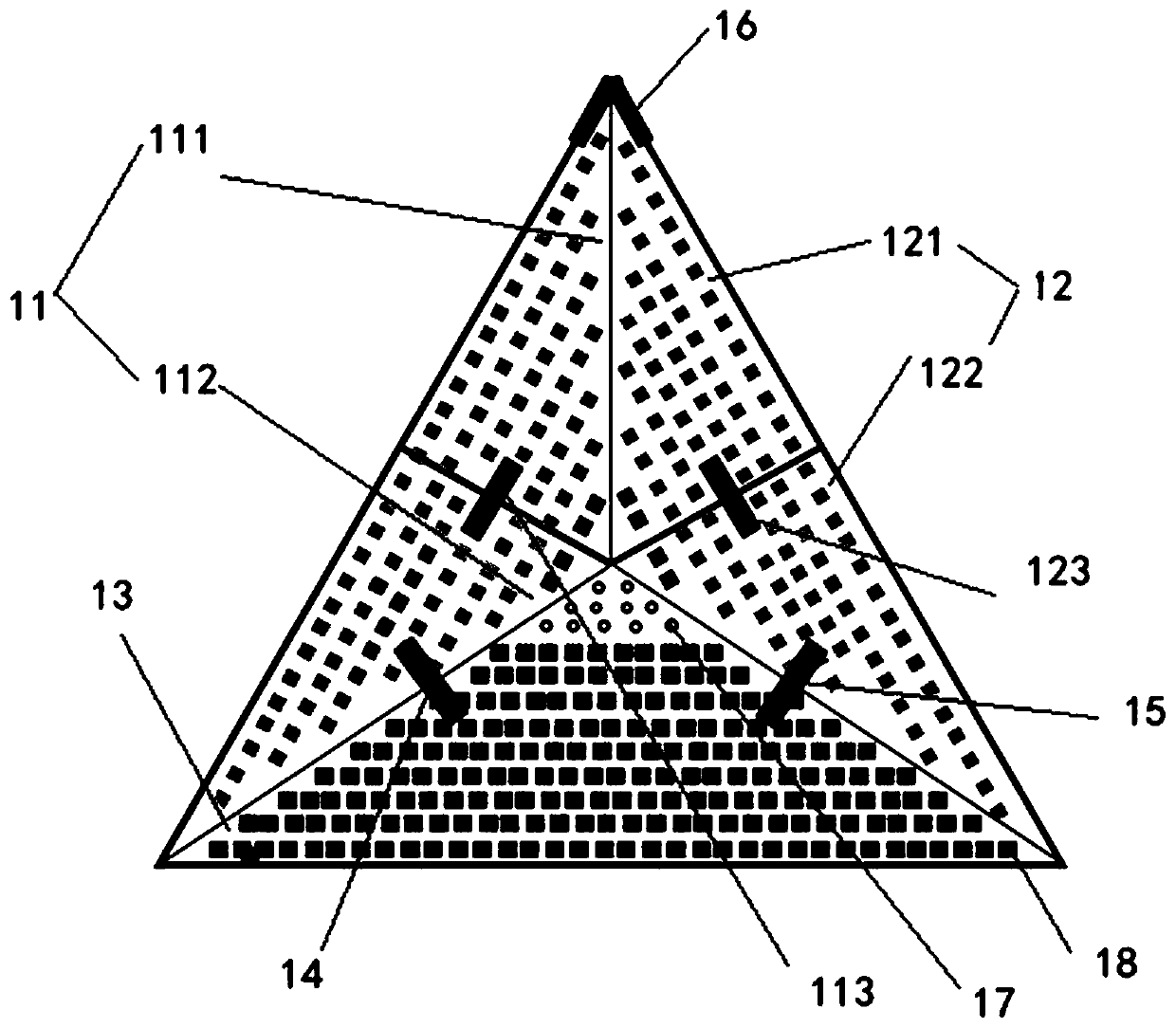

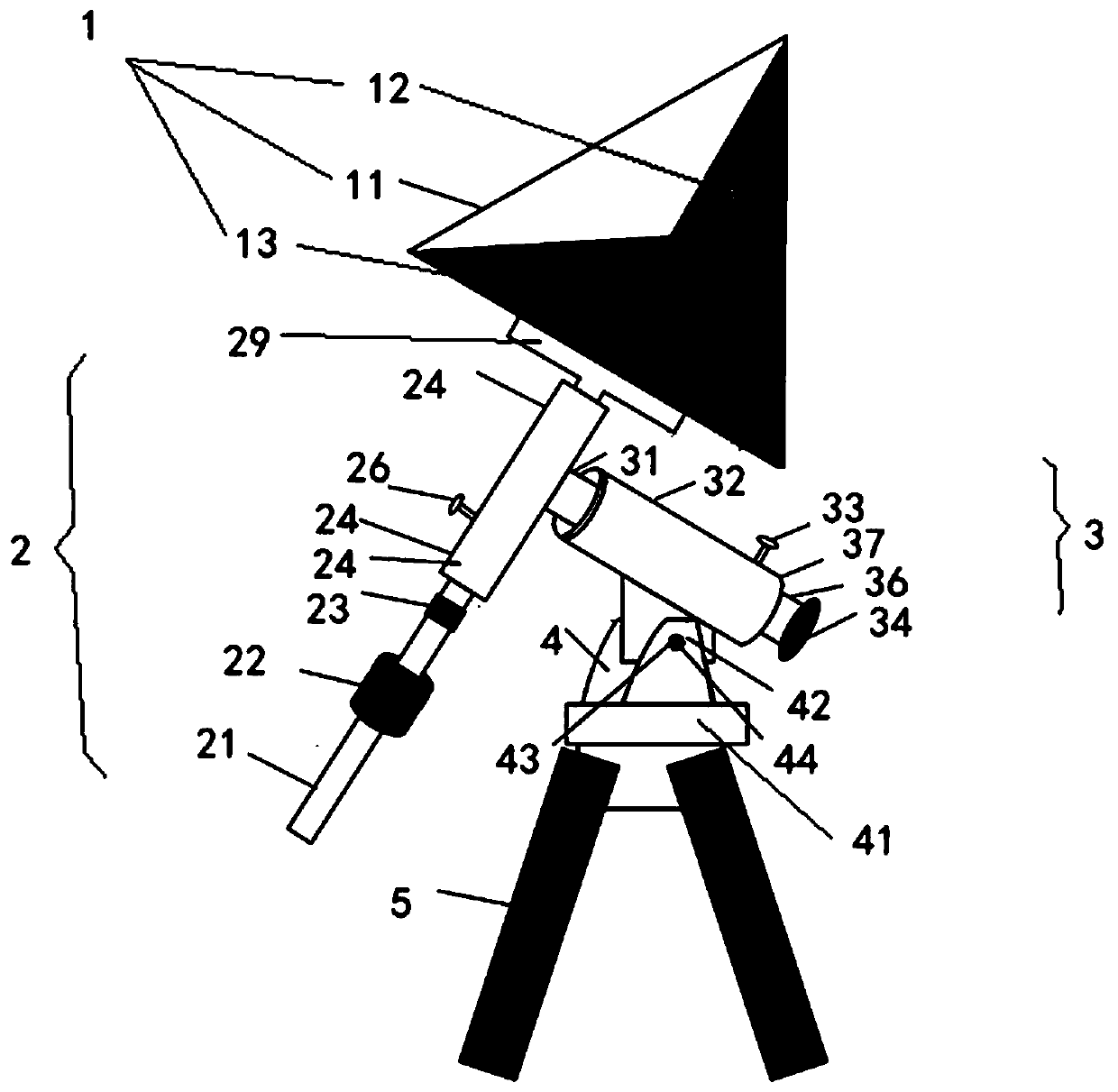

Artificial corner reflector for SAR (synthetic aperture radar) interferometry calibration

ActiveCN109901118AHigh precisionEasy to adjustWave based measurement systemsGround subsidenceSynthetic aperture sonar

The invention relates to an artificial corner reflector for SAR (synthetic aperture radar) interferometry calibration. The artificial corner reflector comprises a corner reflector and a base adjustingdevice. The base adjusting device is connected with the corner reflector, and is used for carrying out multi-directional adjustment on the corner reflector. The corner reflector is a triangular pyramid structure having a folding hinge device; and after observation, the whole corner reflector is folded into a triangle plane through the hinge device. The base adjusting device comprises a longitudinal angle adjusting device, a latitudinal angle adjusting device, a pitch angle adjusting device and a tripod. The tripod is a steel tripod, and serves as a part connecting to the ground. The artificial corner reflector is suitable for calibration for surface deformation monitoring of ground subsidence and ground fracture in a plain area, has the advantages of being detachable, waterproof, high inprecision, easy to adjust and high in reliability and the like, and lays the foundation for the follow-up calibration and surface micro-deformation monitoring work.

Owner:张磊

Environment-friendly high-reflectivity powder coating for lamp cavity .and preparation method thereof

InactiveCN110128908AHigh whitenessImprove reflective effectPowdery paintsEpoxy resin coatingsEpoxyPolyester resin

The invention discloses an environment-friendly high-reflectivity powder coating for a lamp cavity and a preparation method thereof. The environment-friendly high-reflectivity powder coating comprisesthe following components in parts by weight: 25-30 parts of epoxy resin, 25-30 parts of polyester resin, 1-2 parts of a leveling agent, 0.5-1 part of a defoaming agent, 20-25 parts of titanium dioxide, 10-15 parts of precipitated barium sulfate, 3-5 parts of a light-reflective material and 0.05-0.1 part of a pigment. The preparation method of the environment-friendly high-reflectivity powder coating for the lamp cavity comprises the following steps: mixing formula materials, melting, extruding, tabletting, roughly crushing until the crushed grain diameter to a median diameter of 26um+ / -1um, and packaging into a finished product, the finished product is suitable for the lamp cavity, conforms to ROHS instructions and REACH regulations, can manufacture high-gloss and sub-gloss high-reflectivity coatings, and has stable coating and simple production process.

Owner:浙江绿能塑粉科技股份有限公司

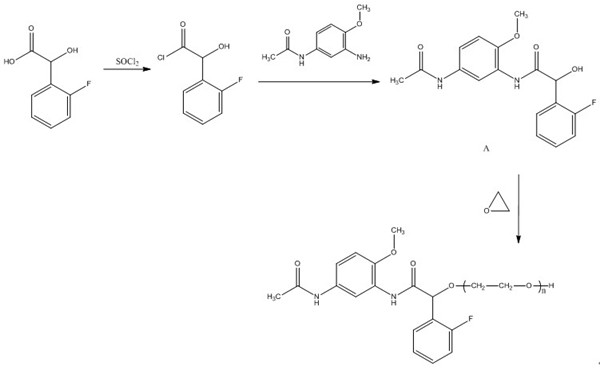

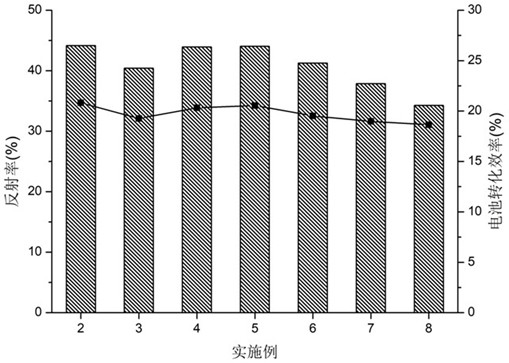

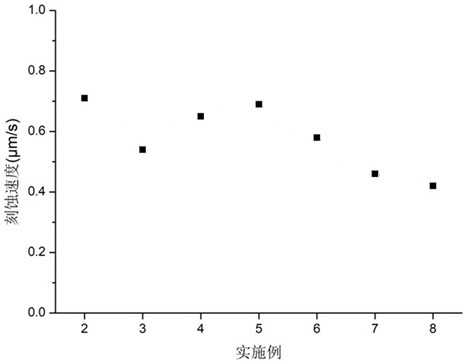

Alkali etching and polishing method for monocrystalline silicon wafer

ActiveCN113980580ASmall amount of thinningPromote absorptionOrganic compound preparationTransportation and packagingActive agentGlycerol

The invention provides an alkali etching and polishing method for a monocrystalline silicon wafer and belongs to the technical field of silicon wafer etching. According to the method, an alkaline polishing solution containing grinding particles, glycerol, an organic amine compound, sodium tartrate, a fluorine-containing nonionic surfactant and sodium tartrate is utilized to perform etching and polishing on monocrystalline silicon through the steps of surface pretreatment, surface etching and polishing, alkali cleaning, acid cleaning, water washing and the like, etching and polishing at the low temperature are achieved, energy consumption is reduced, the etching and polishing effect is good, the silicon wafer thinning amount is low, and the silicon wafer surface reflectivity and the battery conversion efficiency are effectively improved.

Owner:绍兴拓邦新能源股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com