Patents

Literature

2138results about "Material flaws investigation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Temperature sensor, temperature control device, temperature controller and temperature-control method

ActiveUS20080043803A1High measurement accuracyThermometer detailsMechanical apparatusTemperature controlEngineering

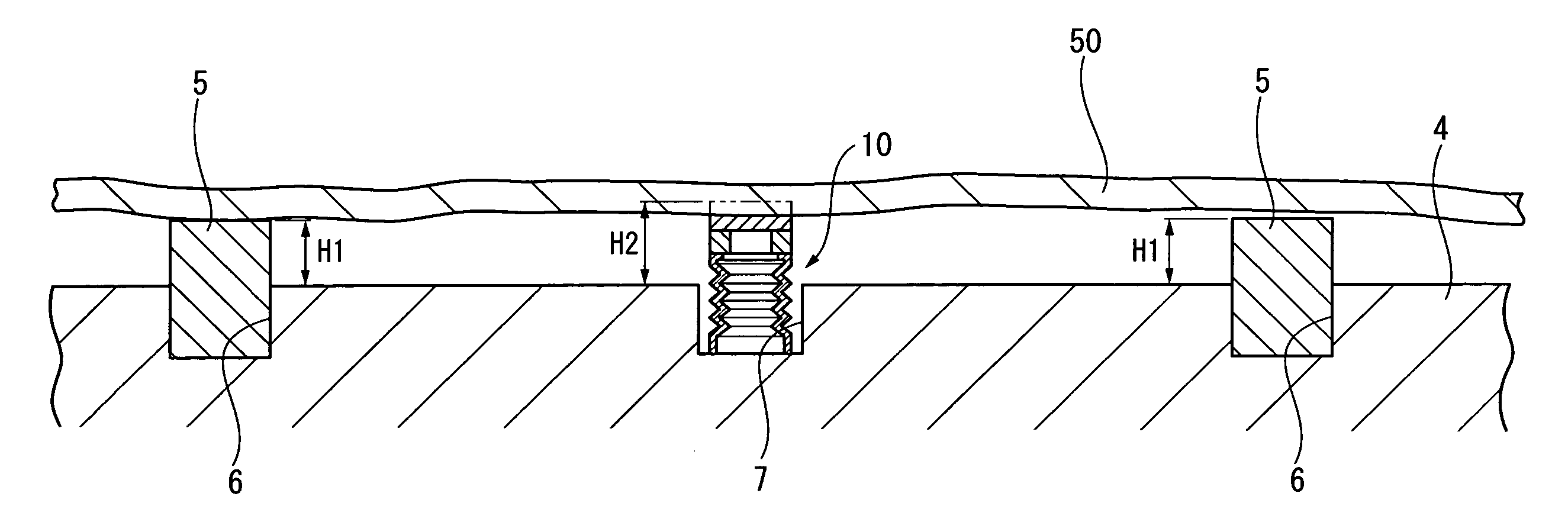

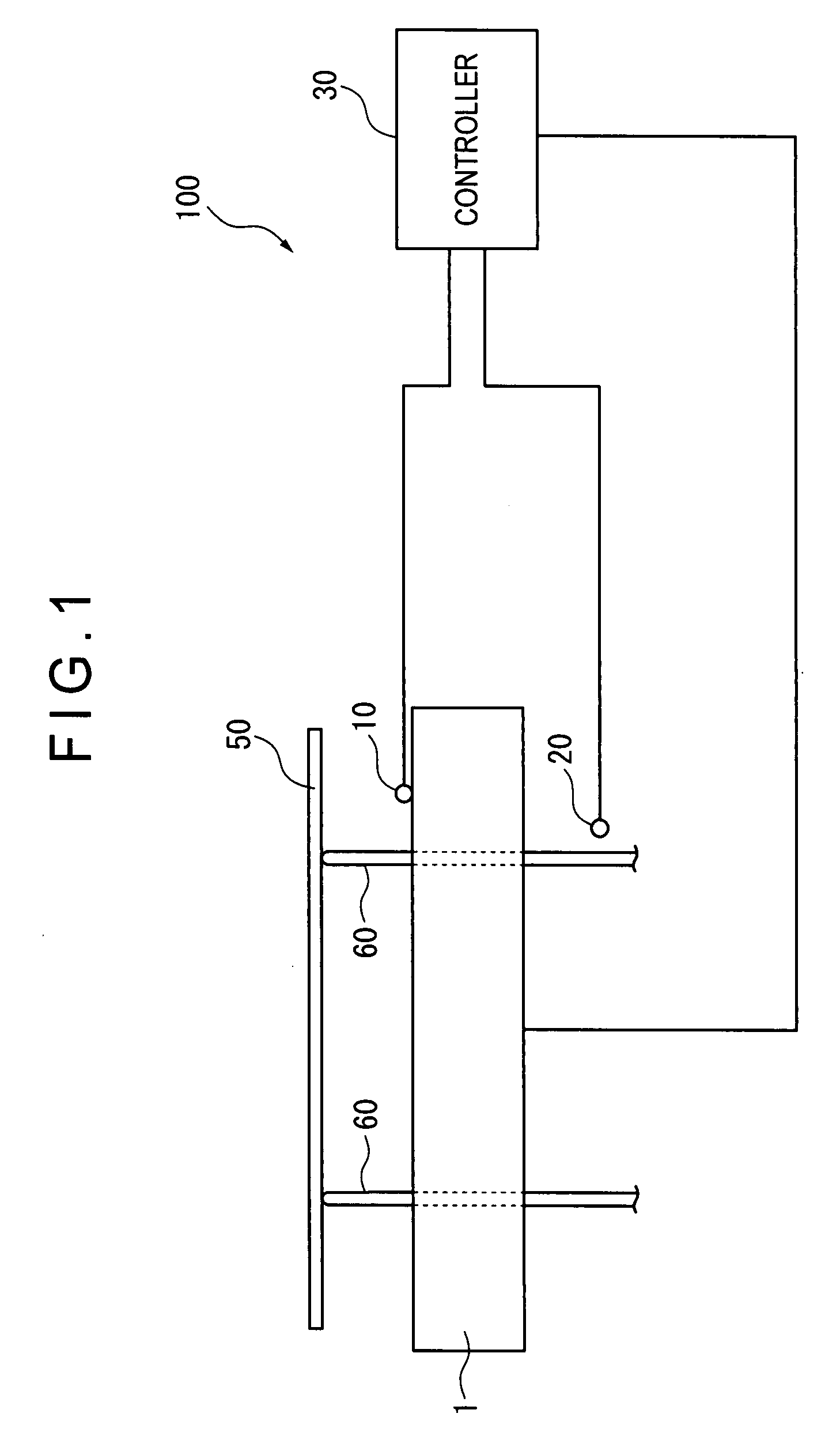

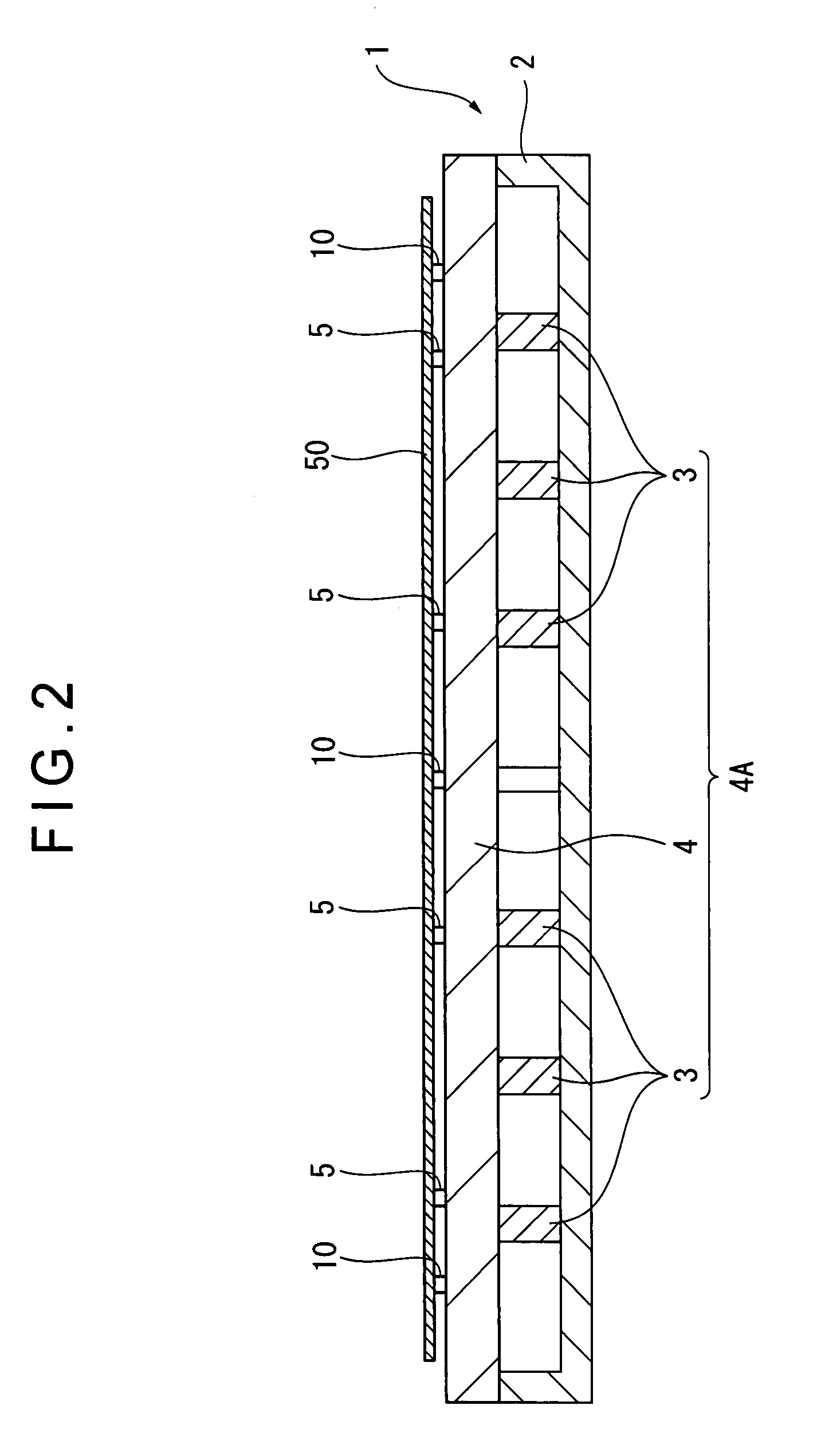

A temperature sensor (10) includes: a temperature-sensing portion for measuring a temperature of an object (50) by contacting the object; and a supporting portion for supporting the temperature-sensing portion from a side opposite to a contact surface, the supporting portion having a space at a portion partially corresponding to the temperature-sensing portion. A temperature controller includes: a temperature control device; the temperature sensor (10) for measuring the temperature by contacting the object (50); and a controller for controlling the temperature control device. The controller includes: a mounting-state judging means for judging a mounting-state of the object (50); a switching means for switching a control gain and a target temperature of the temperature control device based on the judging result; and a control-command generating means for generating a control command based on the control gain, the target temperature and a measurement value of the temperature sensor (10).

Owner:KOMATSU LTD

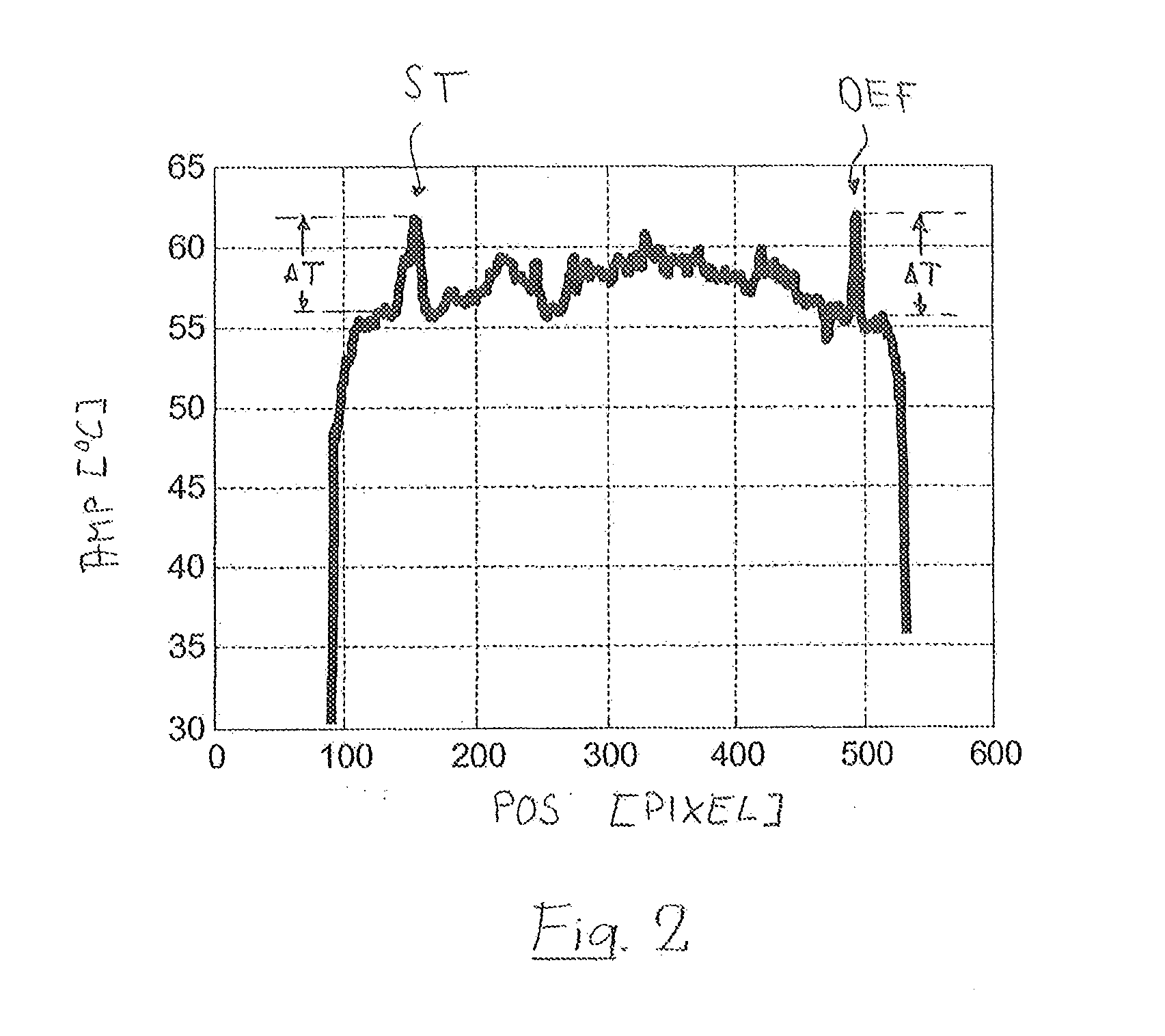

Thermographic Test Method and Testing Device for Carrying Out the Test Method

A thermographic test method locally resolves detection and identification of defects near the surface in a test object. A surface area of the test object is heated up. A series of thermographic images following one after another at a time interval is recorded within a heat propagation phase, each image representing a local temperature distribution in a surface region of the test object recorded by the image. Positionally correctly assigned temperature profiles are determined from the images, each positionally correctly assigned temperature profile being assigned to the same measuring region of the test object surface. Variations over time of temperature values are determined from the temperature profiles for a large number of measuring positions of the measuring region. These variations are evaluated on the basis of at least one evaluation criterion indicative of the heat flow in the measuring region.

Owner:INSTITUT DR FORSTER

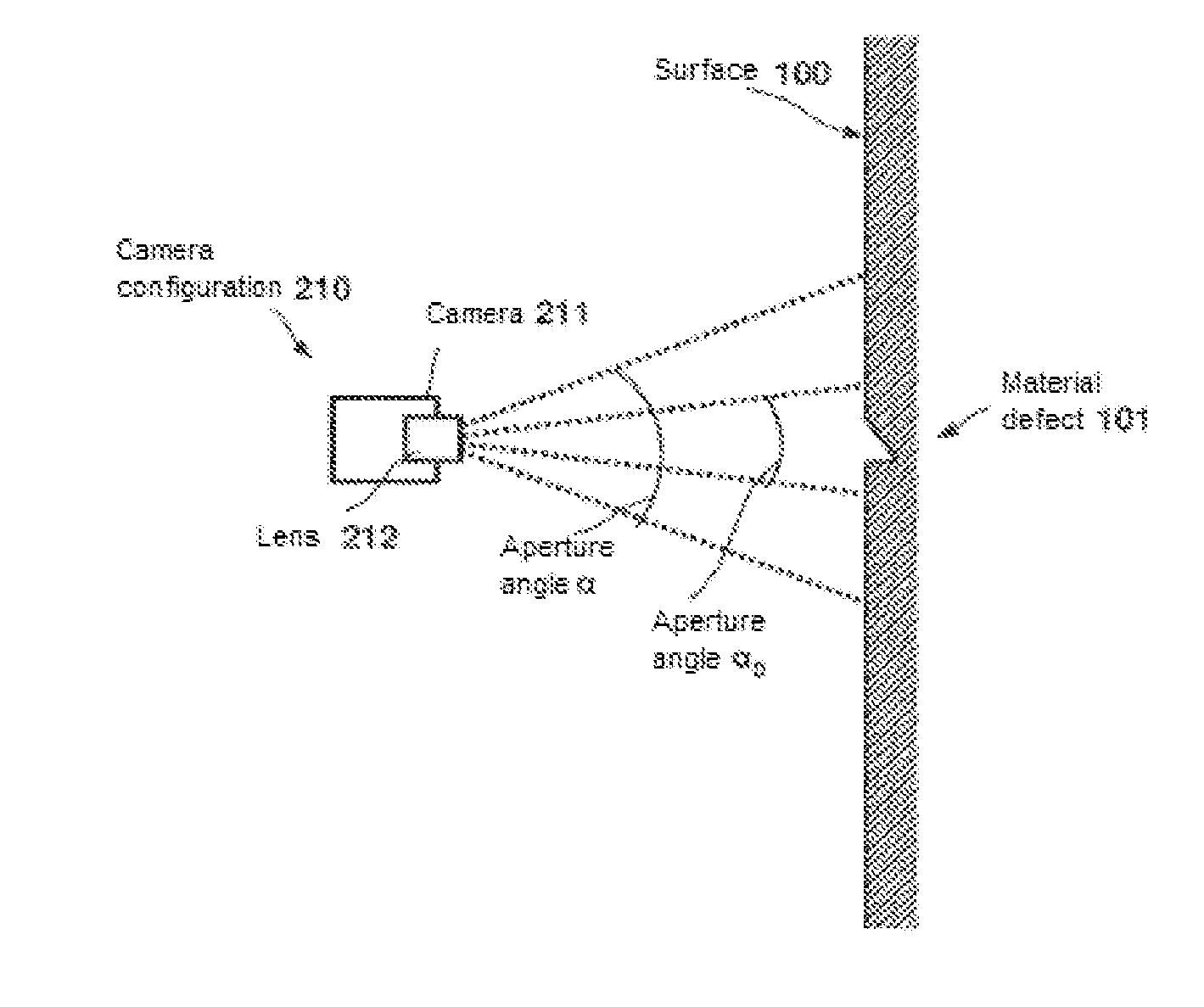

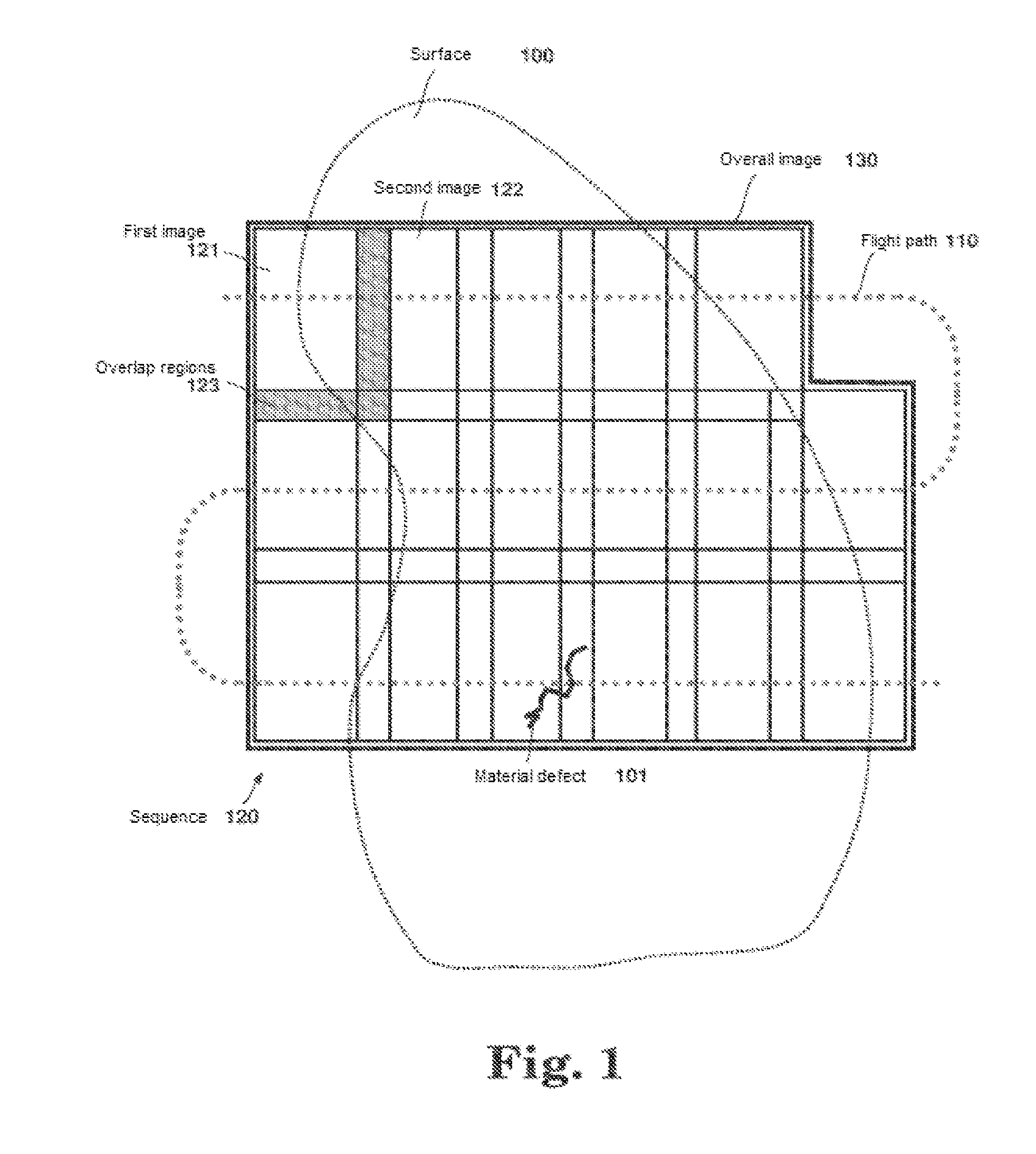

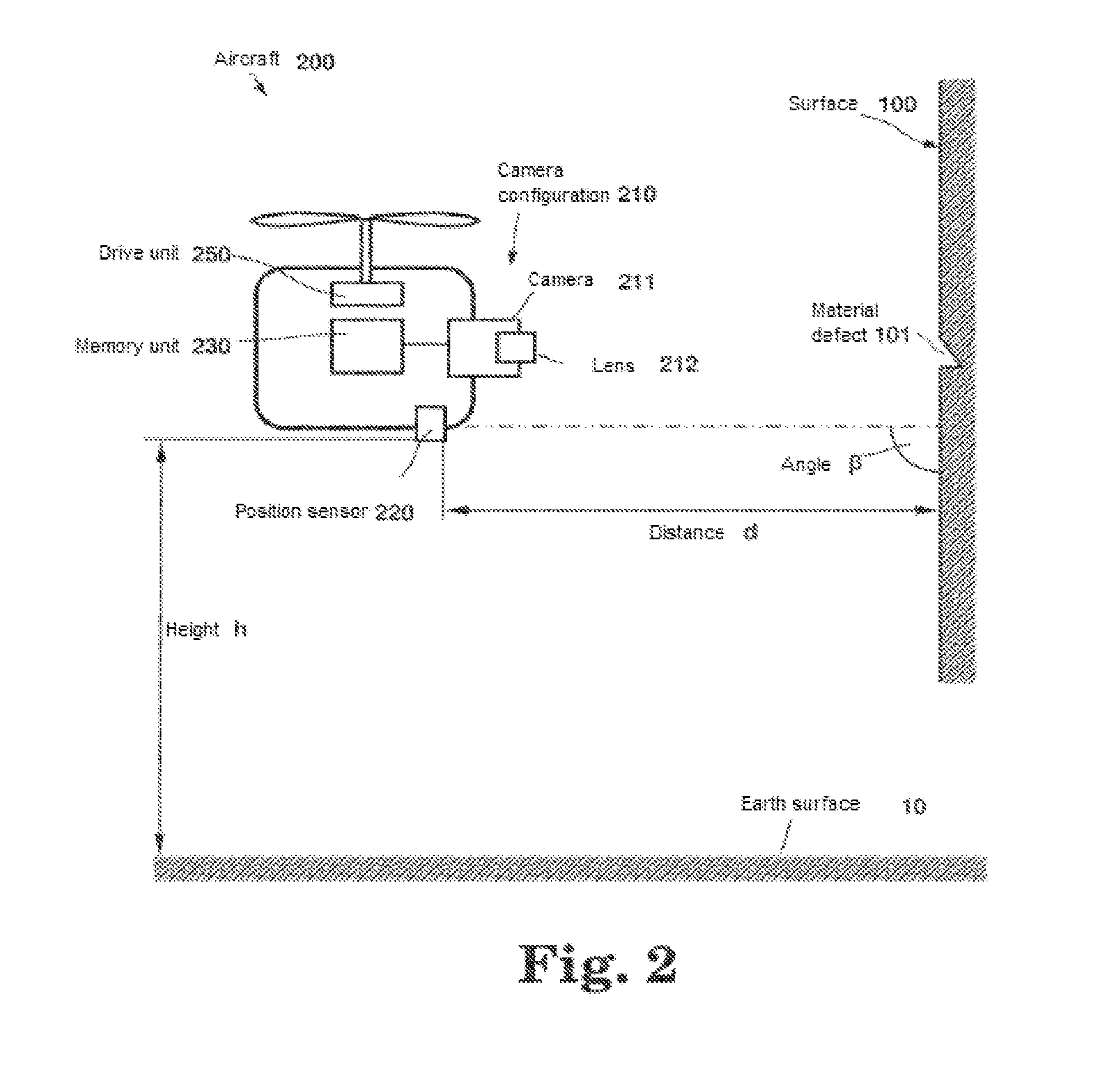

Method and System for Inspecting a Surface Area for Material Defects

ActiveUS20140168420A1Reduce associated effortReduce security risksPicture taking arrangementsColor television detailsMaterial defectEngineering

A camera assembly arranged on an unmanned and autonomously navigating aerial vehicle is employed to inspect a surface area of for material defects. The vehicle is automatically flown to the surface area from a launch site, wherein it can fly around obstacles using automatic obstacle detection and avoidance methods. A relative position of the aerial vehicle with respect to the surface area with the aid of a position sensor is continuously measured and a sequence of images of the surface area is recorded. Between the individual images, the aerial vehicle is moved along a flight path overlapping image details of the surface area. The images of the sequence are composed into an overall image of the surface area to allow for the surface area to be inspected for defects and the location of defects to be ascertained on the basis of the overall image.

Owner:EADS DEUT GMBH

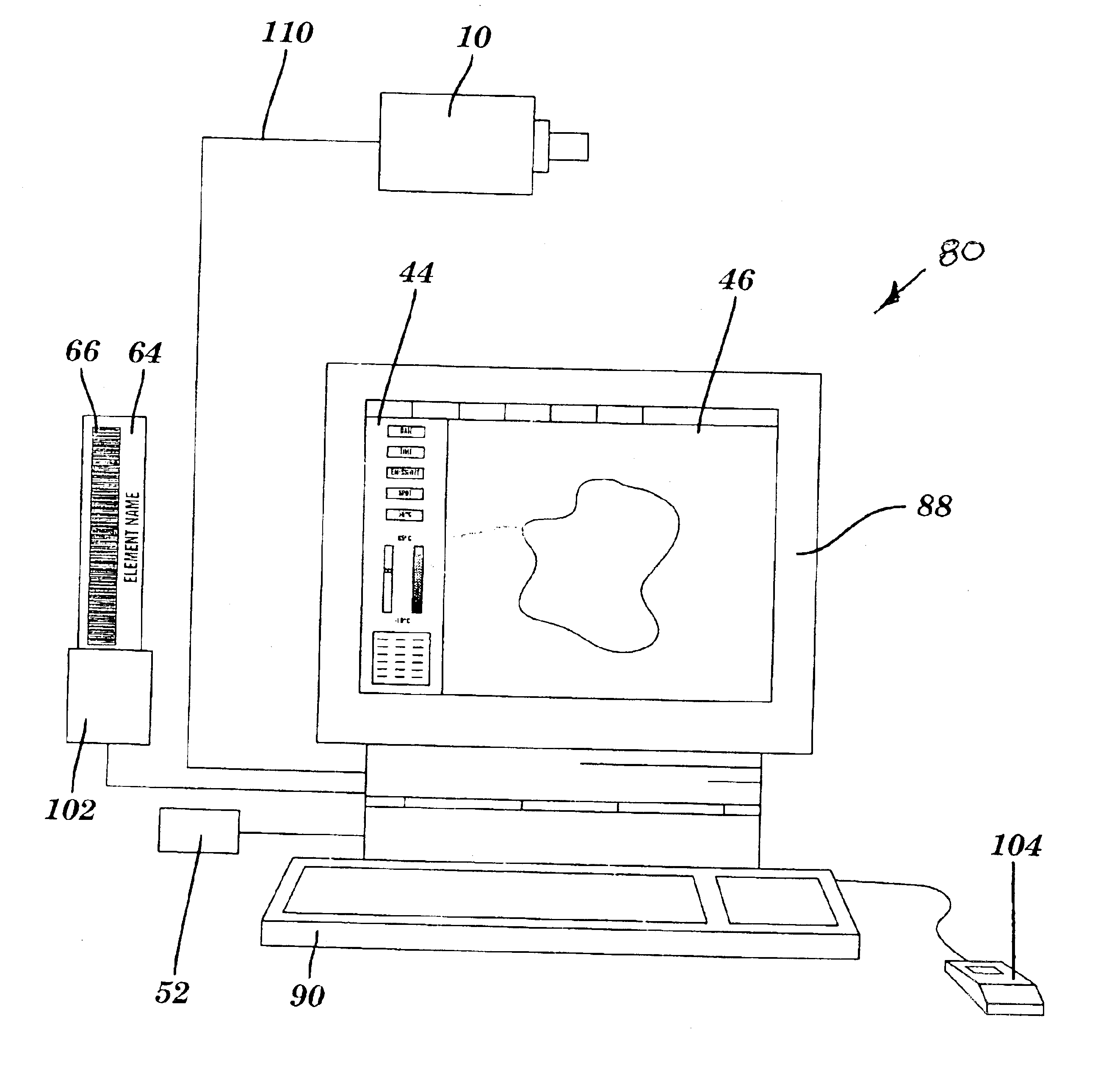

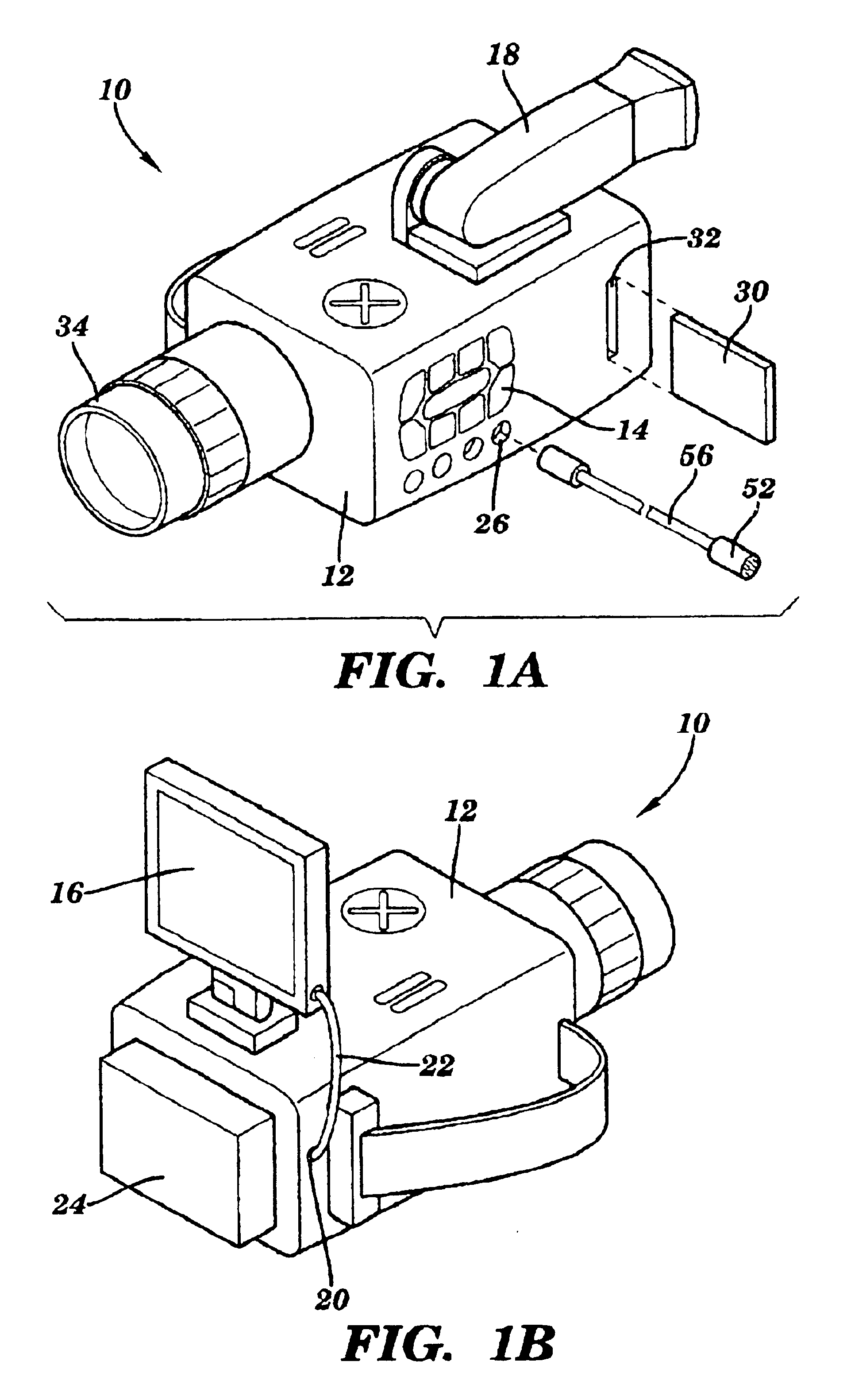

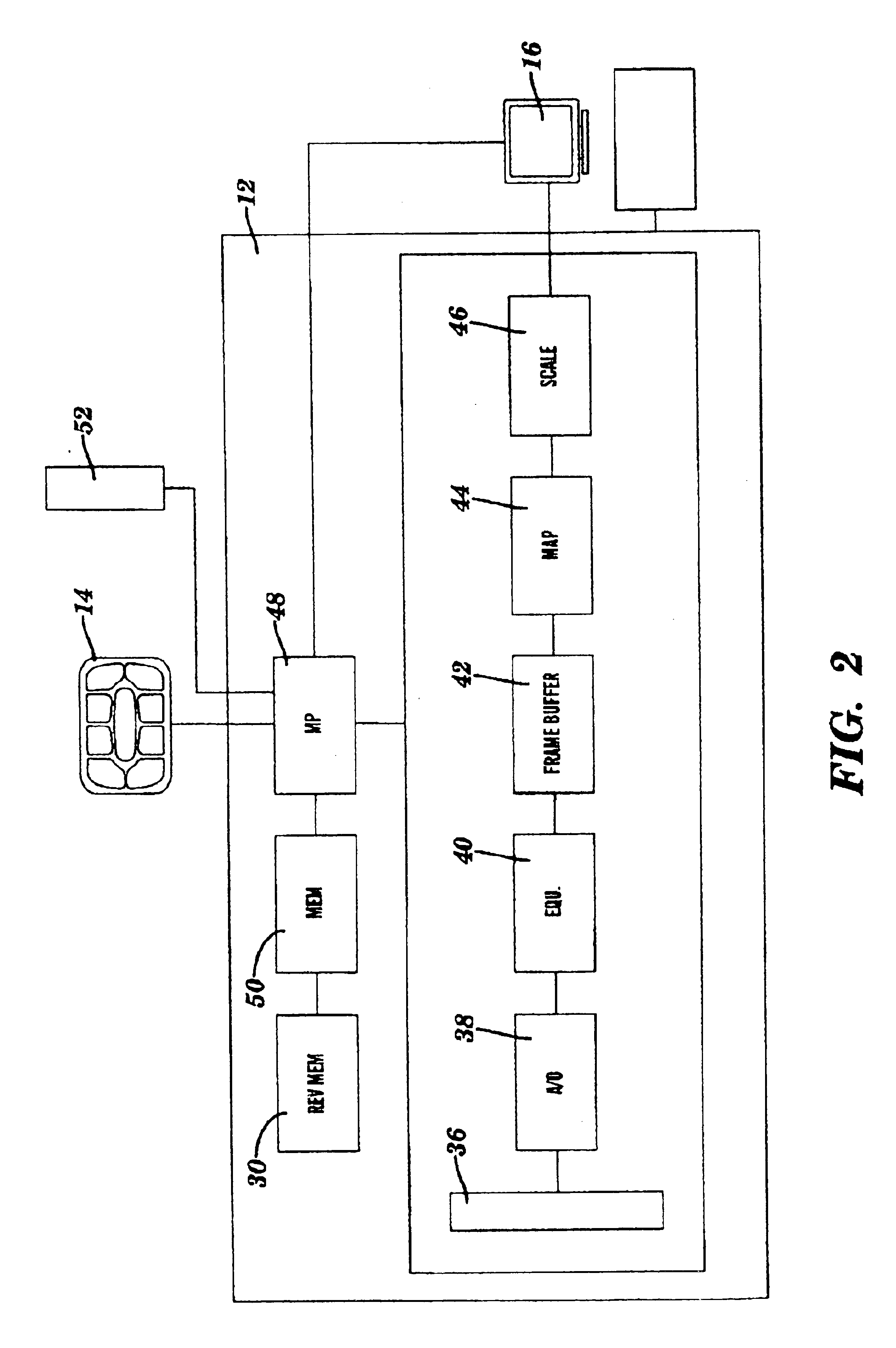

Method and apparatus for barcode selection of themographic survey images

The present invention provides a system and method for capturing video images of elements in a videographic survey, e.g. a thermograph video survey. According to the invention a barcode label having a bar pattern representing a unique identifying name of each element of the survey is associated with each survey element. A video camera system, with a barcode scanner associated therewith, is provided for scanning a barcode associated with a selected element. The selected element is thereby identified to the video camera system. The video camera system recalls data, including the element name, relating to the selected element and displays the data on a display device associated with the video camera system. An operator may review the displayed data and capture a video image of the element with the video camera system. The video image of the selected element may then be stored in a camera memory with the element name associated therewith. In another aspect of the invention, a base computer is provided, with a database program operating thereon, for organizing data fields, including an identifying name field, associated with each element of a survey. Data may be transferred between the video camera system and the base computer for organizing a videographic survey and for analyzing video images of the survey elements.

Owner:TELEDYNE FLIR LLC

Pipeline monitoring system

InactiveUS20060225507A1Convenient verificationDetection of fluid at leakage pointVibration measurement in fluidMonitoring systemEngineering

Process and apparatus for sensing possible leaks in a pipeline. The pipeline is monitored continuously by acoustic monitoring means, and acoustic events indicating a possible leak are noted. The pipeline is also equipped with temperature monitoring means, and is monitored for temperature either continuously, periodically or on demand. A leak is deemed probable at any location where there is an acoustic event indicating a possible leak, and at approximately the same time, a temperature difference greater than a pre-chosen amount between that location and adjacent locations

Owner:PURETECH VENTURES

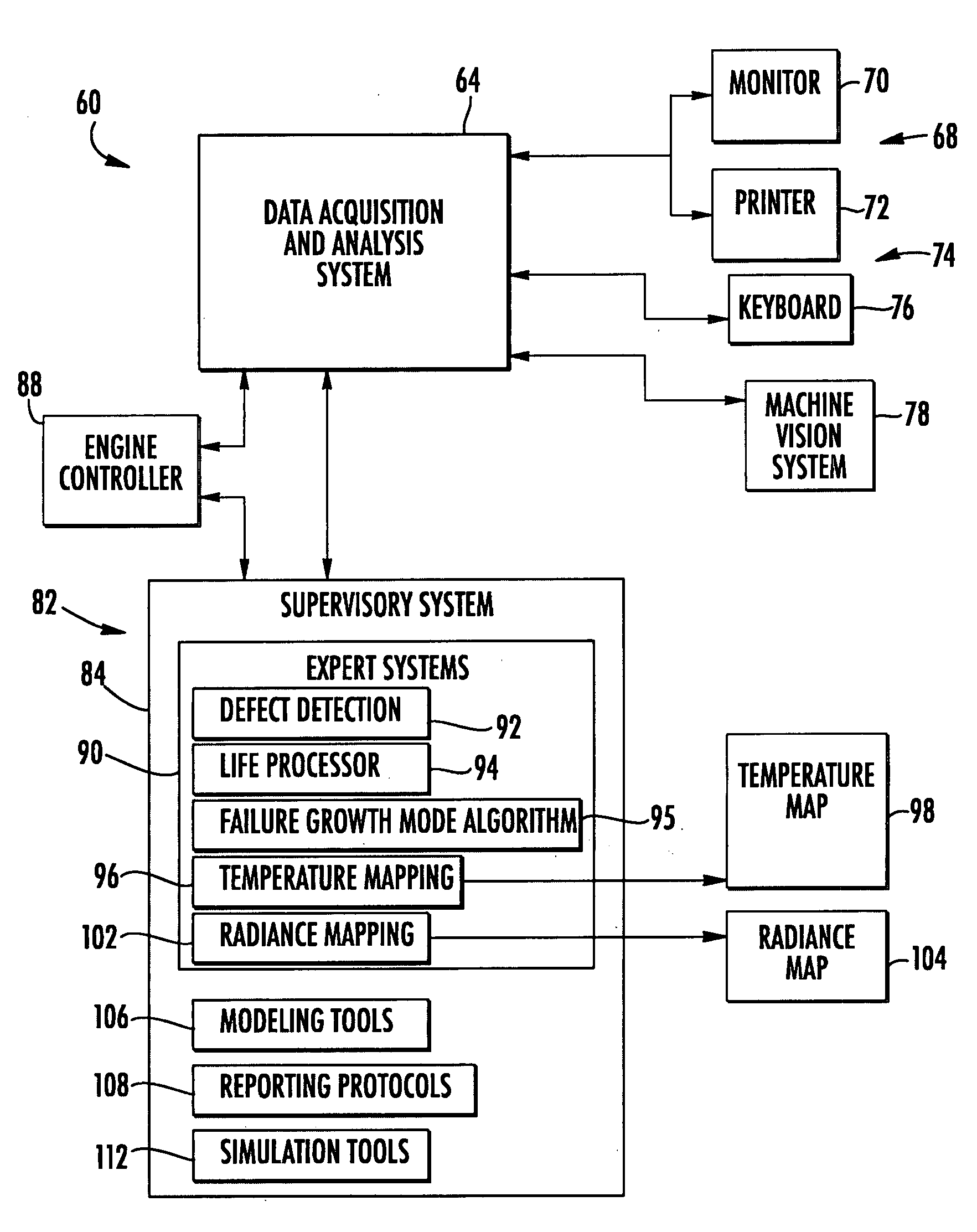

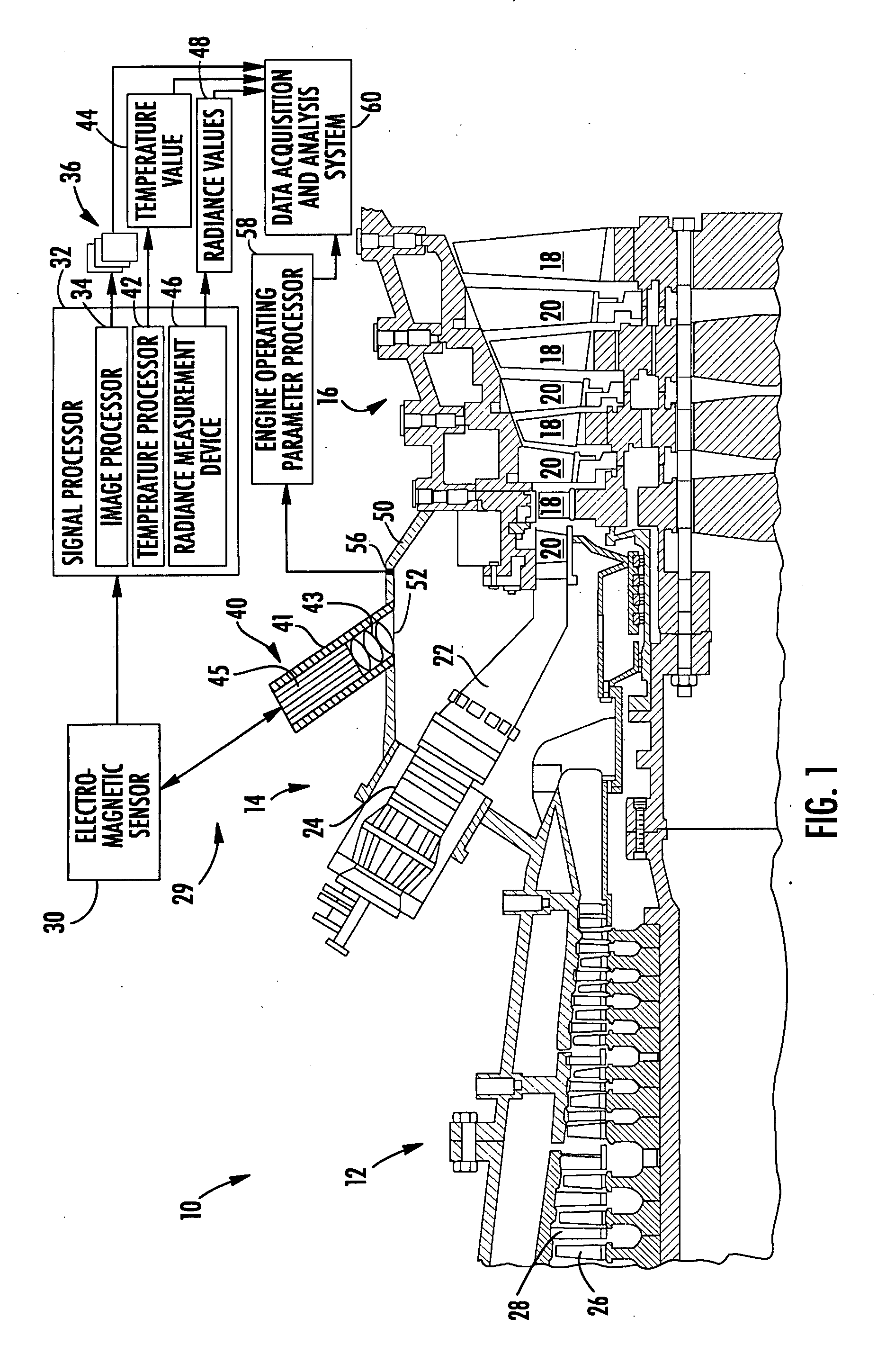

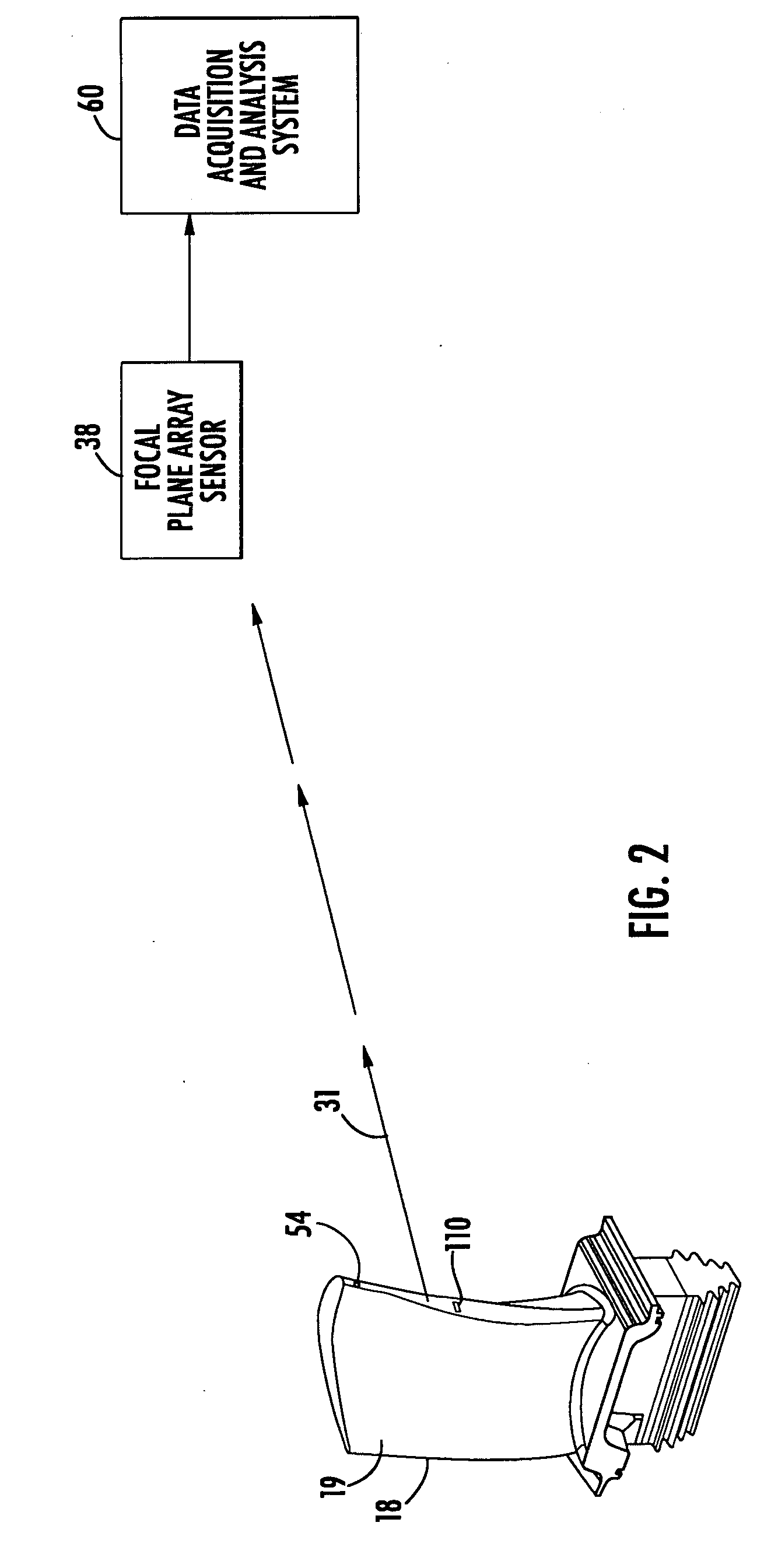

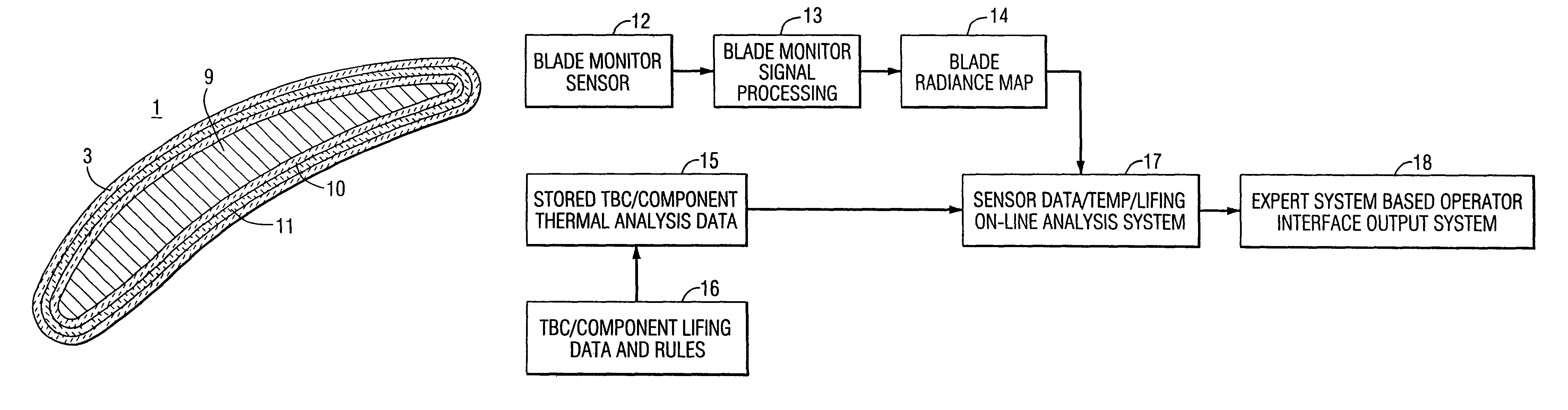

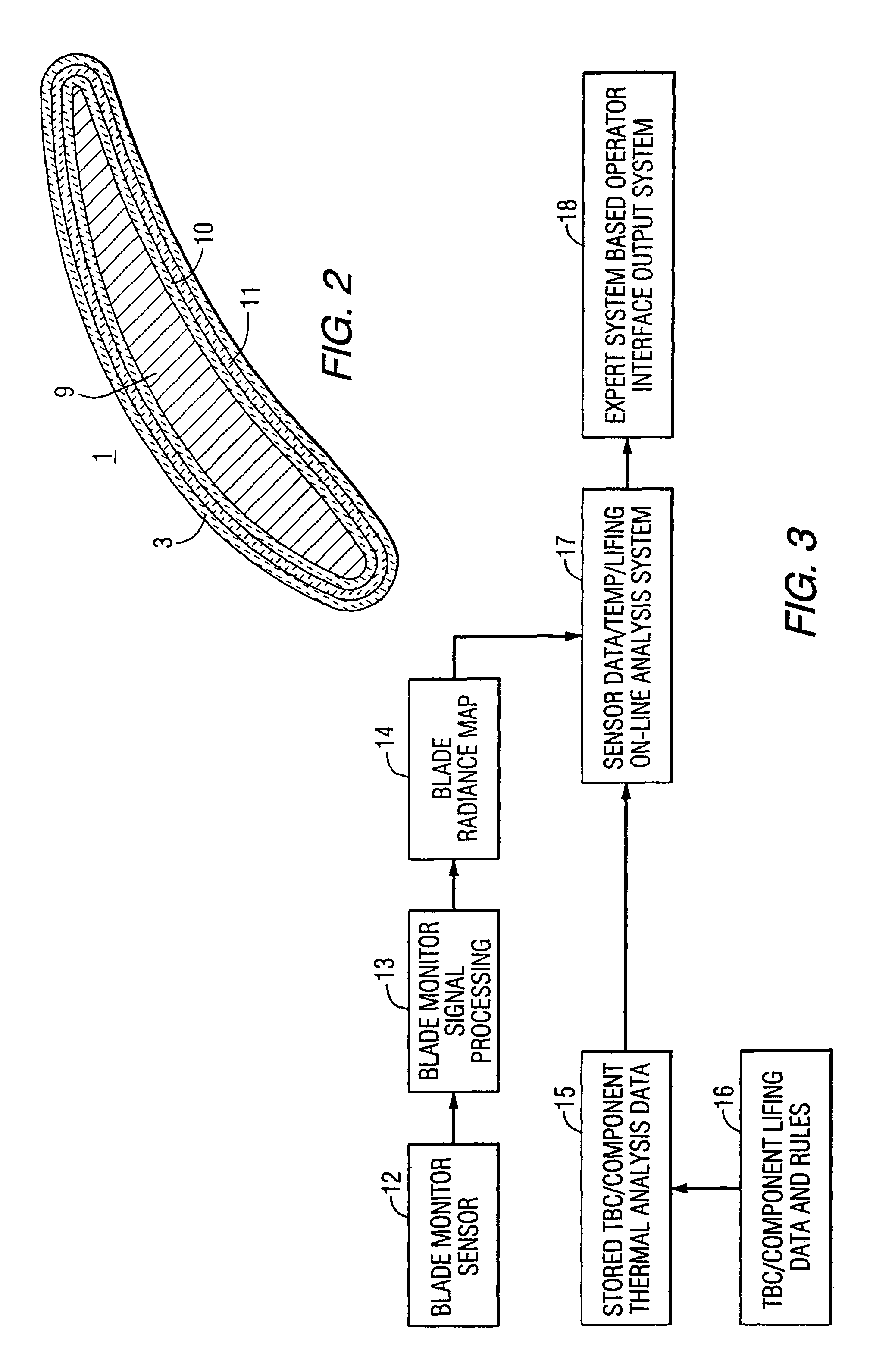

System and method of evaluating uncoated turbine engine components

InactiveUS20080101683A1Gas-turbine engine testingMaterial analysis by optical meansNon destructiveVision based systems

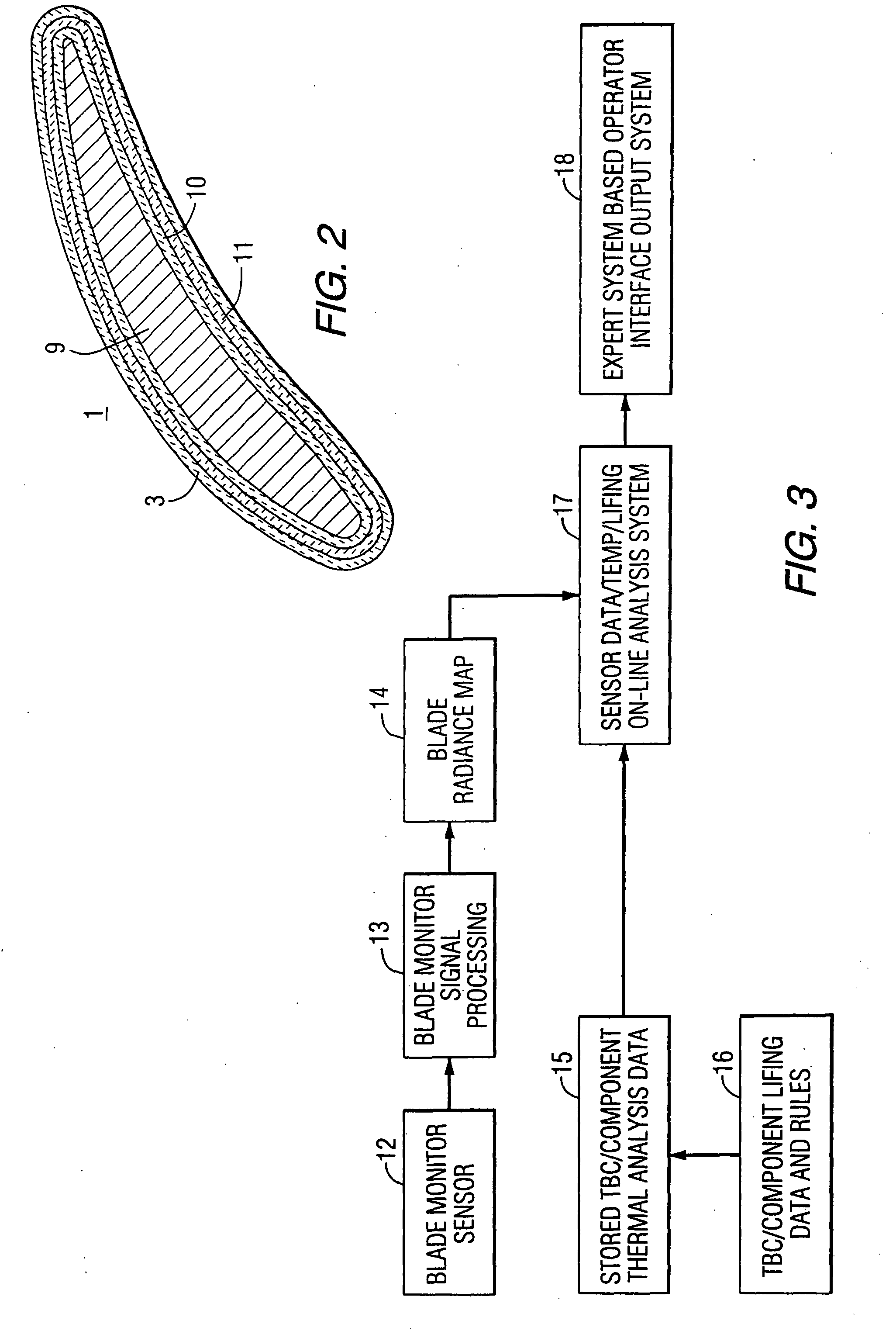

Aspects of the invention are directed to a visual-based system and method for non-destructively evaluating an uncoated turbine engine component. Aspects of the invention are well suited for high speed, high temperature components. Radiant energy emitted from an uncoated turbine engine component can be captured remotely and converted into a useful form, such as a high resolution image of the component. A plurality of images of the component can be captured over time and evaluated to identify failure modes. The system can also measure and map the temperature and / or radiance of the component. The system can facilitate the non-destructive evaluation of uncoated turbine components during engine operation without disassembly of the engine, thereby providing significant time and cost savings. Further, the system presents data to a user with sufficient context that allows an engine operator can evaluate the information with an increased degree of confidence and certainty.

Owner:SIEMENS ENERGY INC

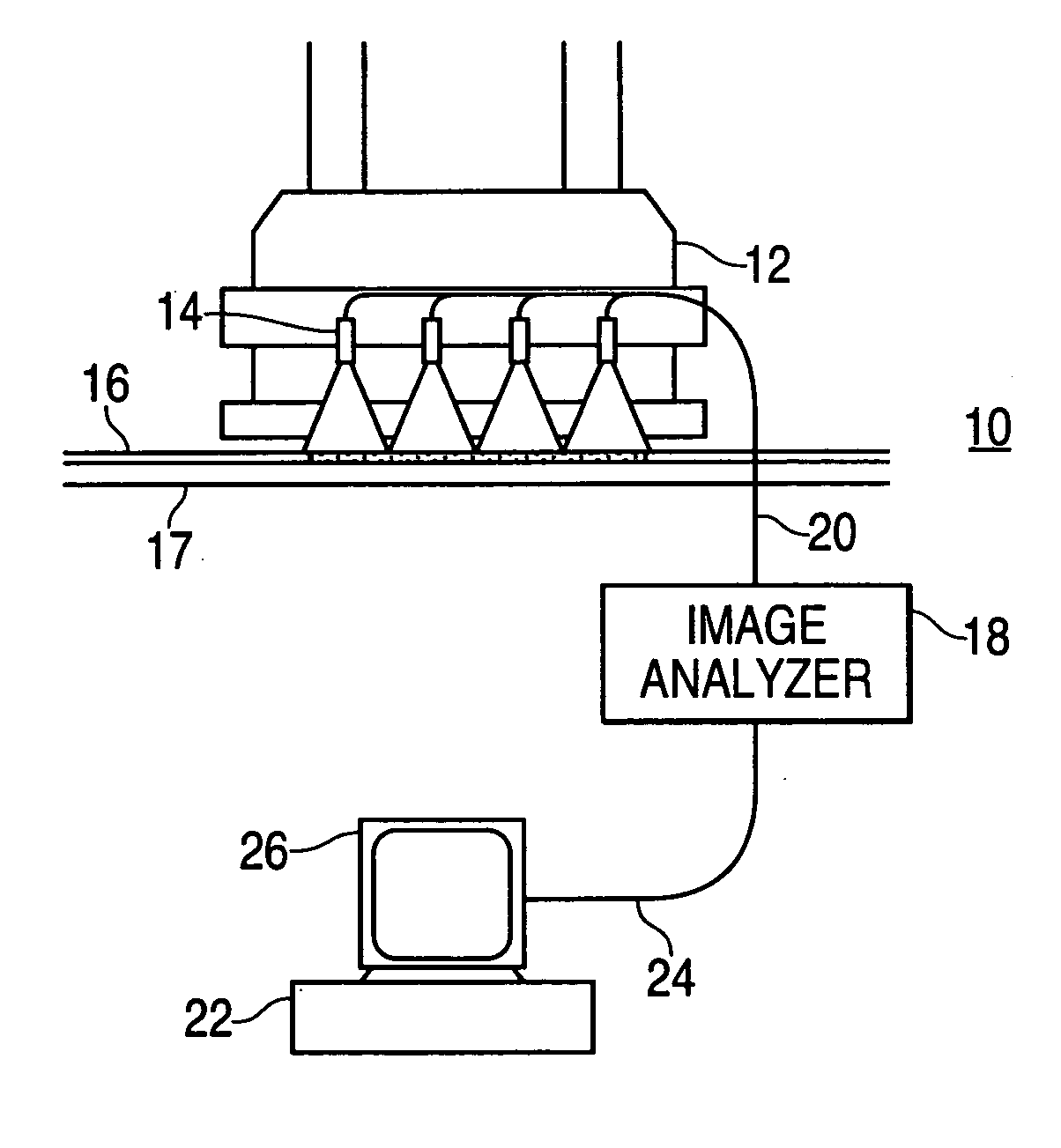

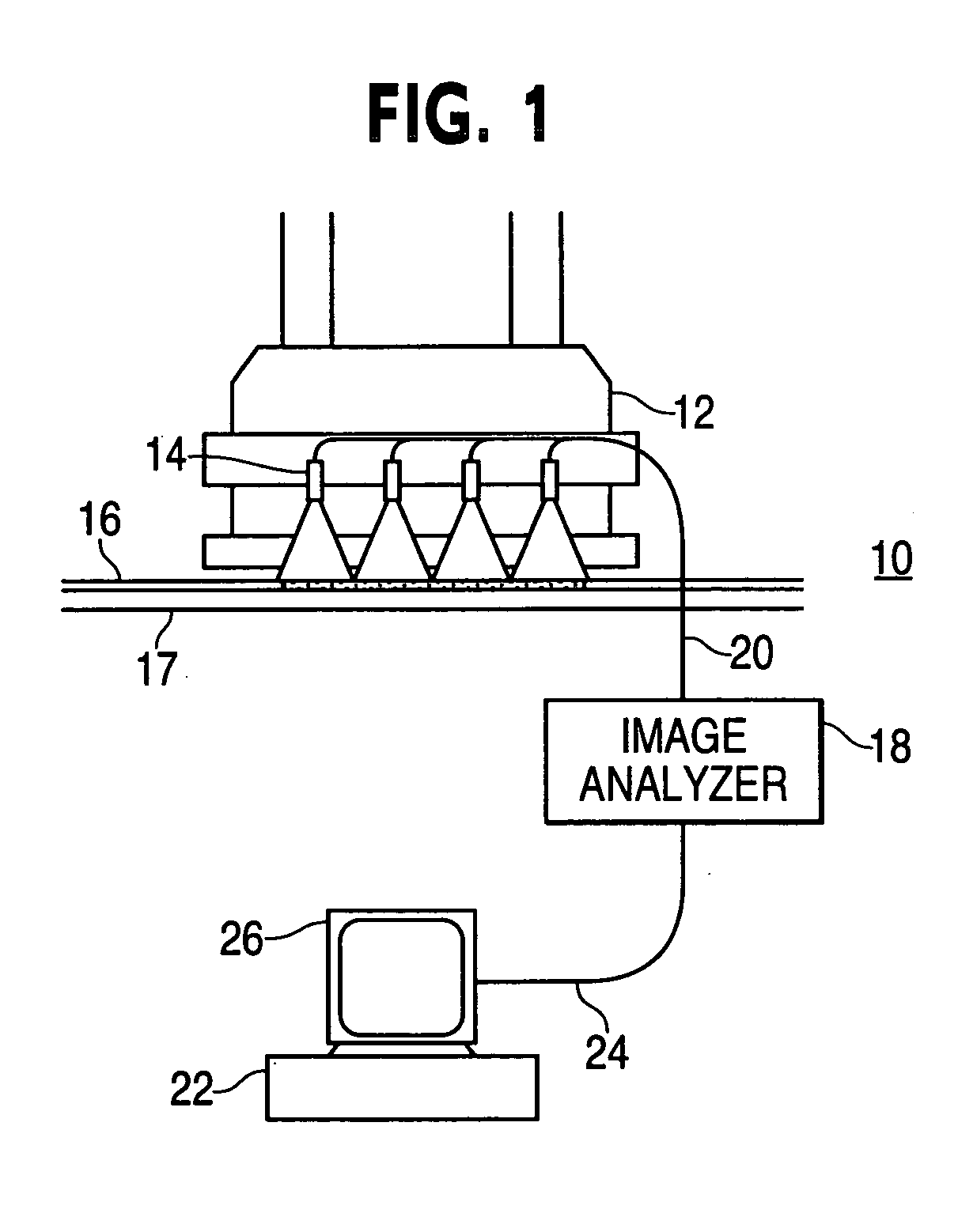

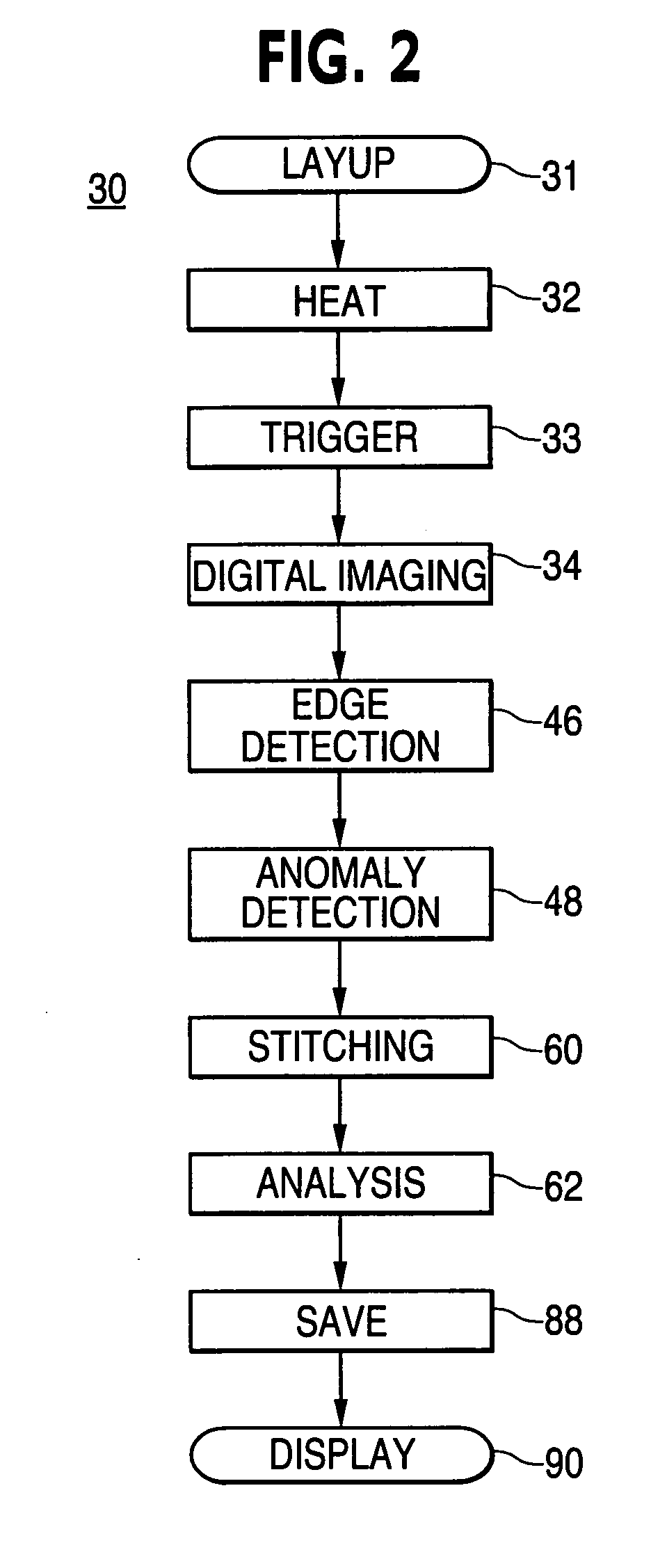

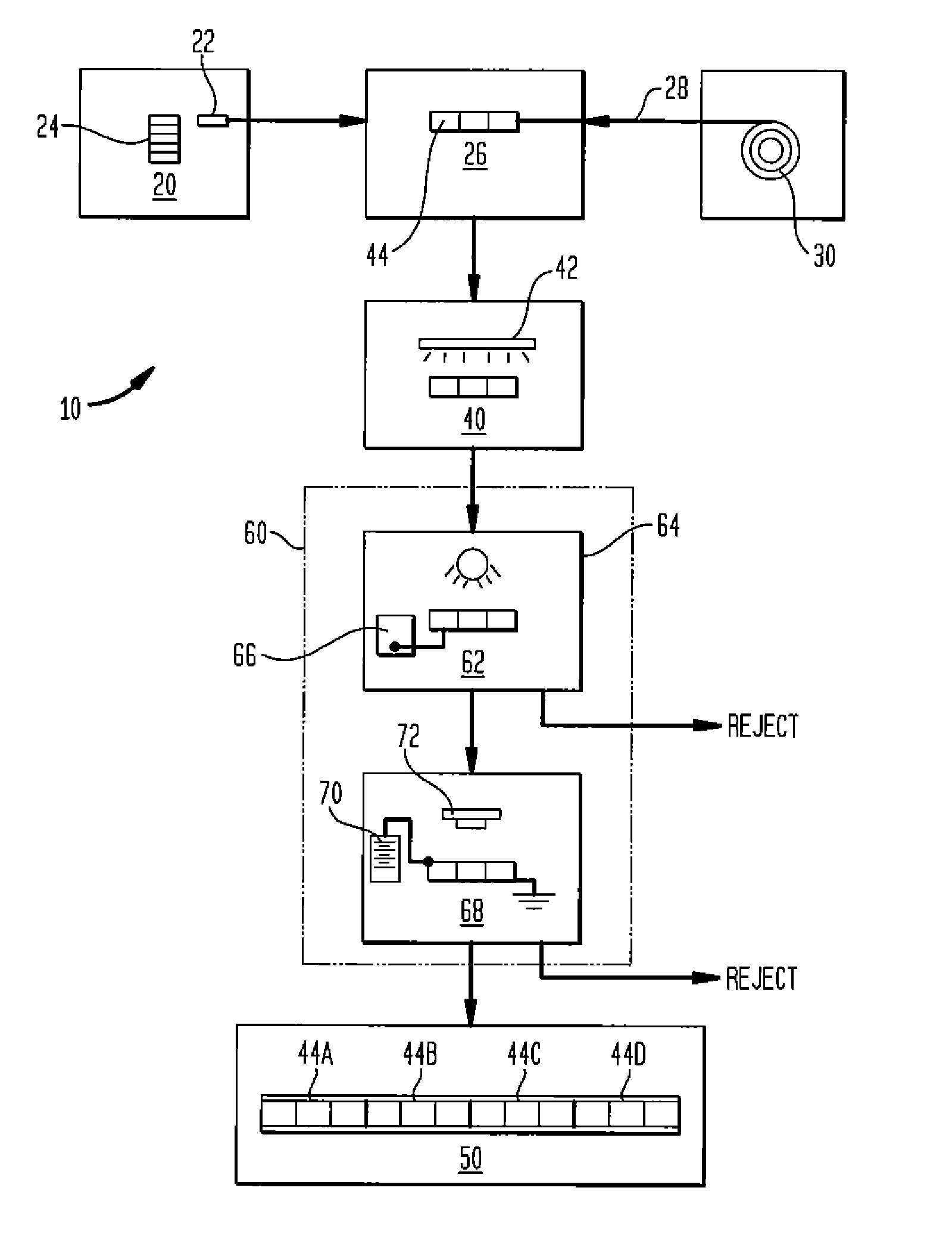

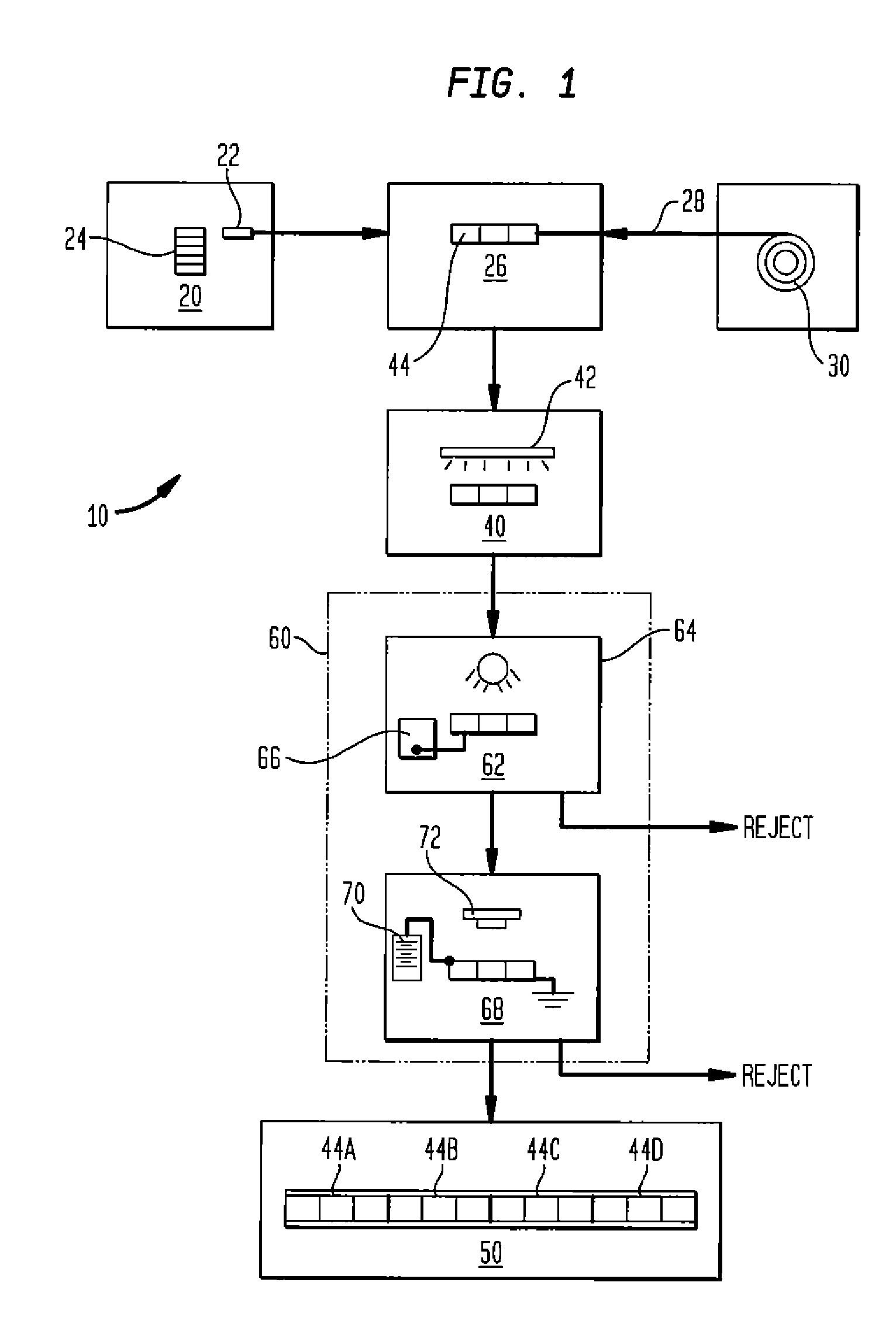

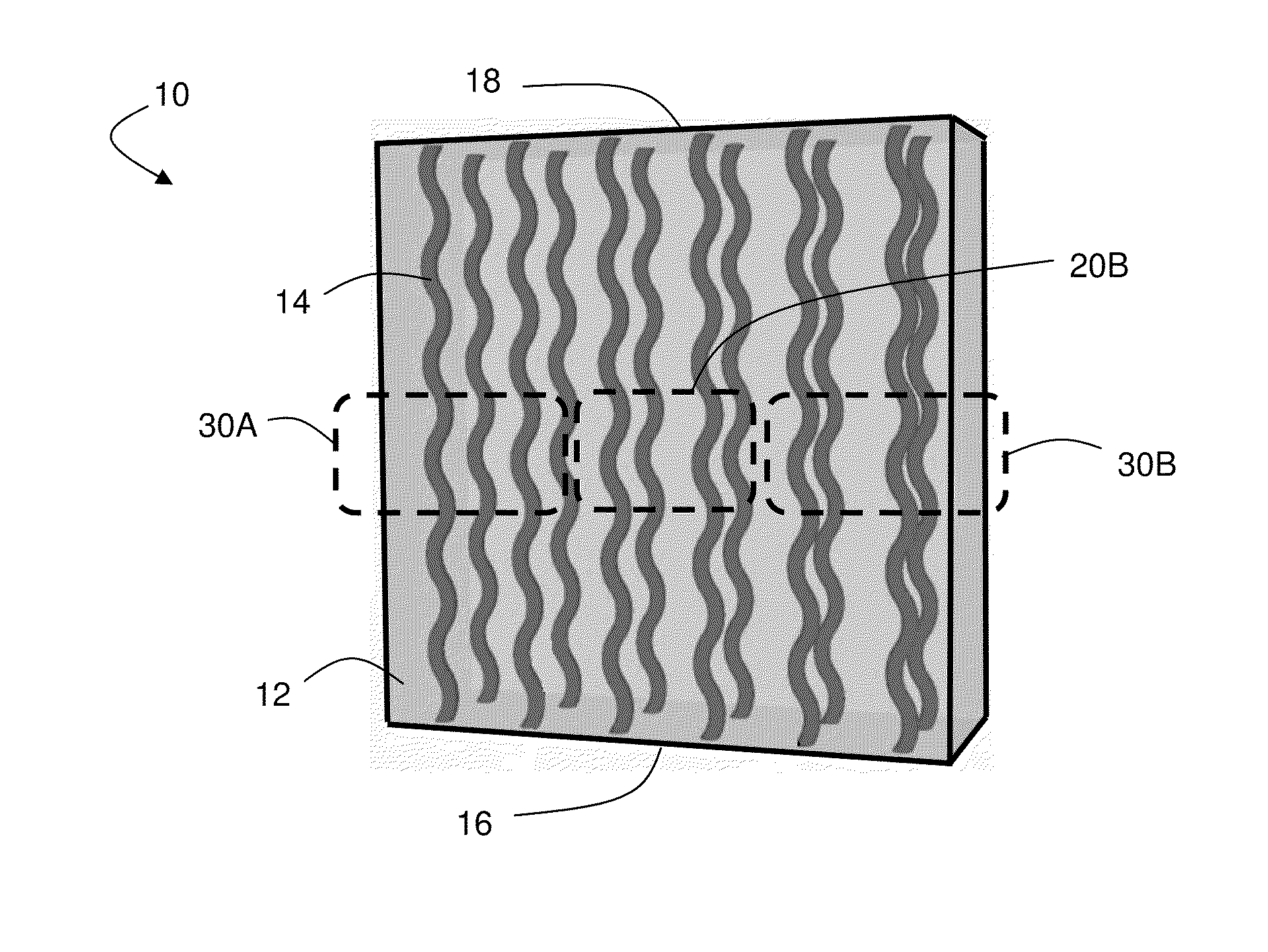

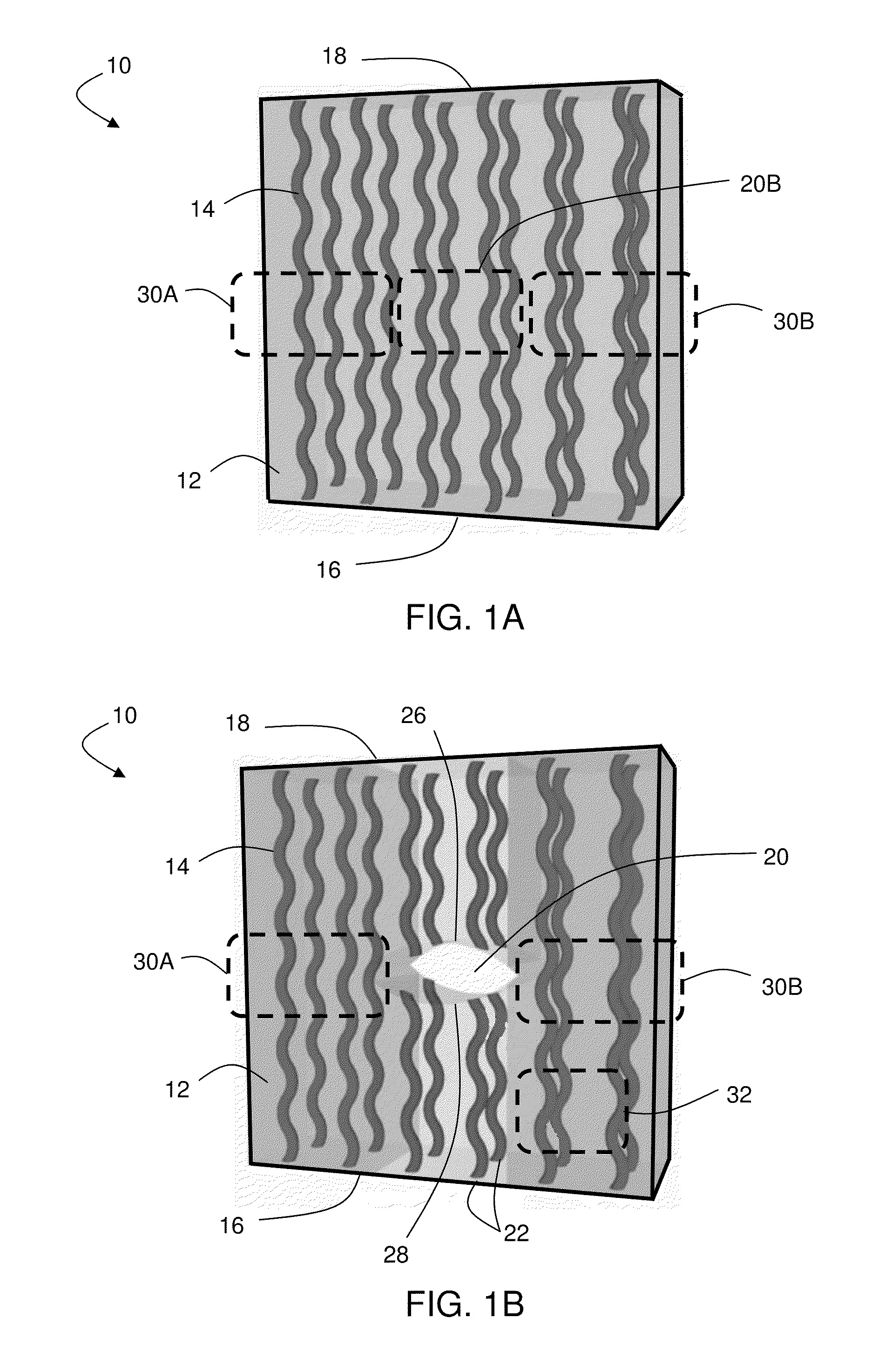

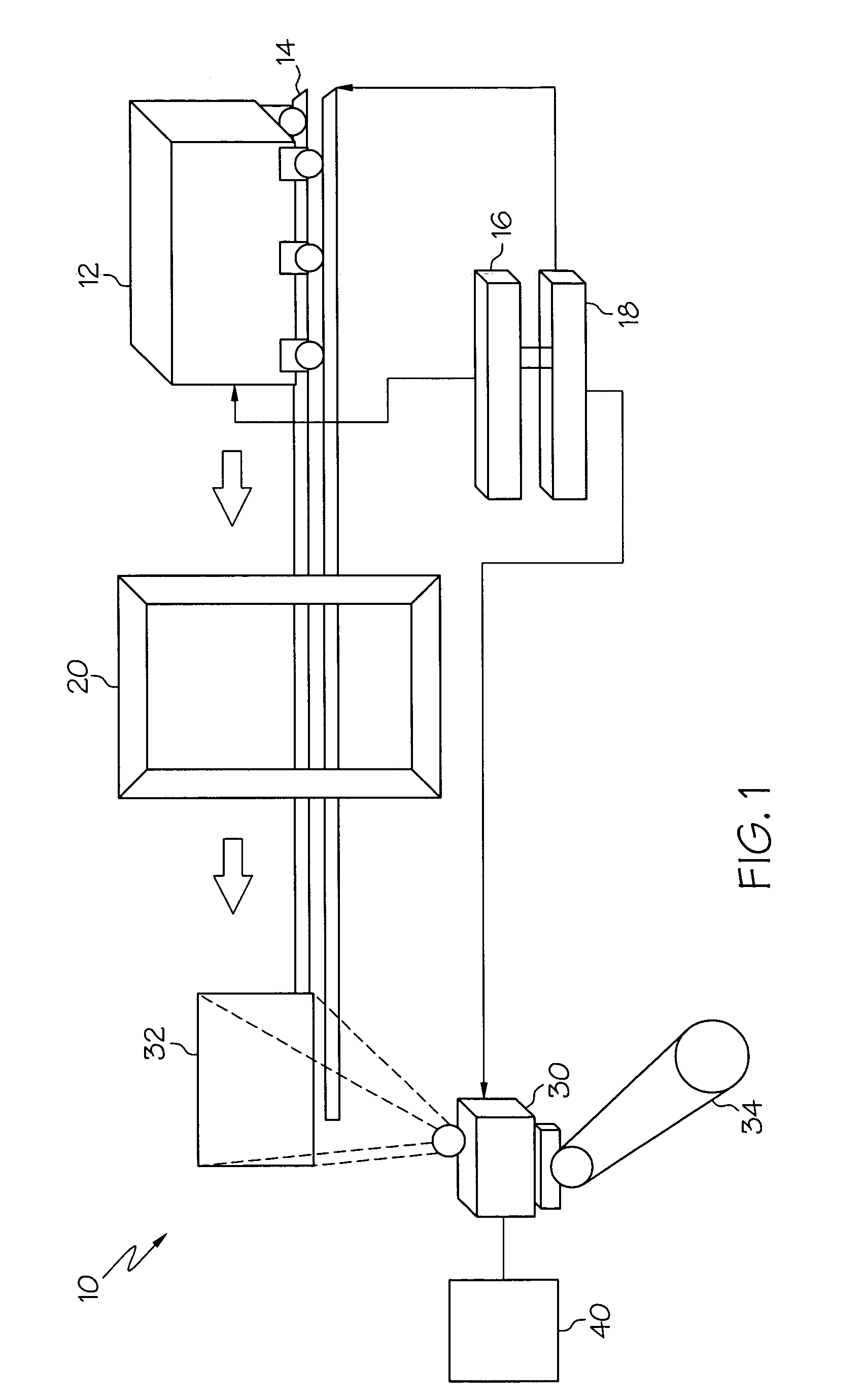

Real-time infrared thermography inspection and control for automated composite material layup

ActiveUS20060191622A1Slight variationImage enhancementRadiation pyrometryComputer visionDigital image data

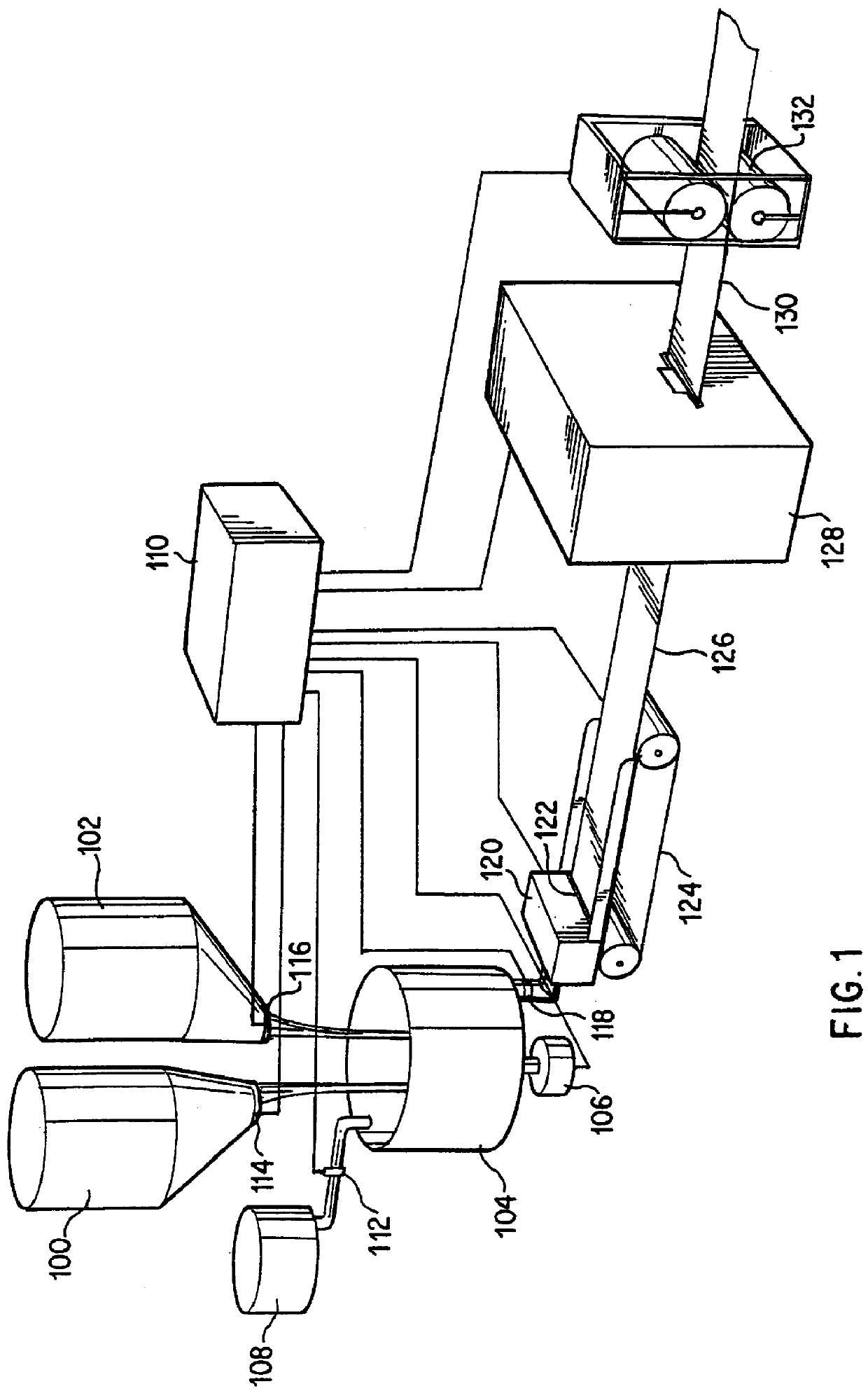

A real-time thermal imaging apparatus and method includes multiple digital infrared cameras mounted to an automated composite material layup device to record digital infrared images of the composite material surface on a real-time basis during a composite material layup process. The digital infrared cameras are triggered periodically to produce digital images of the composite material. The digital image data is sent to an image analyzer which detects edges of and anomalies in the composite material and generates alarm and other process control signals. The image analyzer also aggregates the digital images from the multiple cameras and the digital images recorded over a sequence in time to produce a continuous virtual digital image of the composite material surface. The digital image data and associated analysis results are saved and may be displayed on a real-time basis or at a later time.

Owner:THE BOEING CO

Infrared detection of solar cell defects under forward bias

InactiveUS20050252545A1Low costRadiation pyrometryPhotovoltaic monitoringTest batterySilicon solar cell

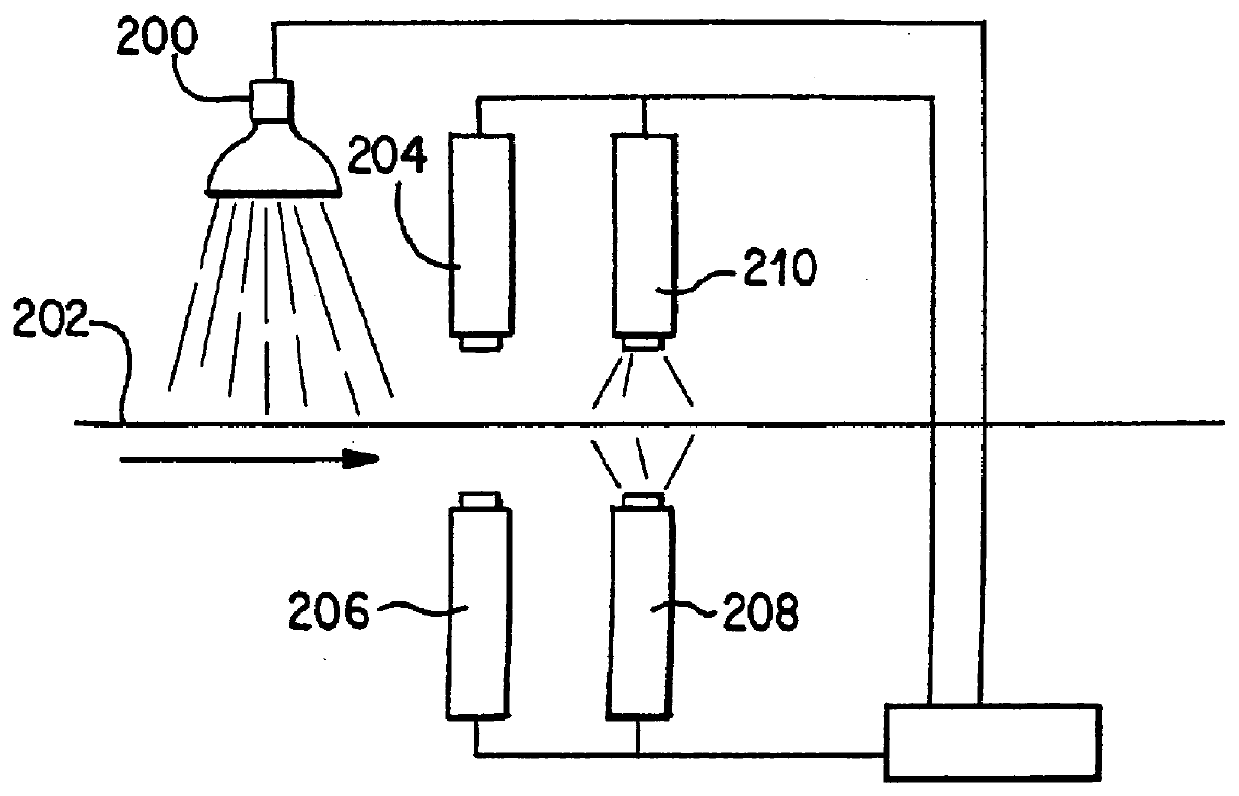

Methods and apparatus are disclosed for detecting solar cell defects by applying a forward-biasing electric current through a silicon solar cell or a group of interconnected solar cells for a short duration and then analyzing the resulting thermal image of each cell with an infrared (IR) camera. The invention is particularly useful in assembling solar cell arrays or modules in which large numbers of cells are to be wired together. Automated module assemblers are disclosed in which the cells (or strings of cells) are tested for defects prior to final module assembly.

Owner:SPIRE

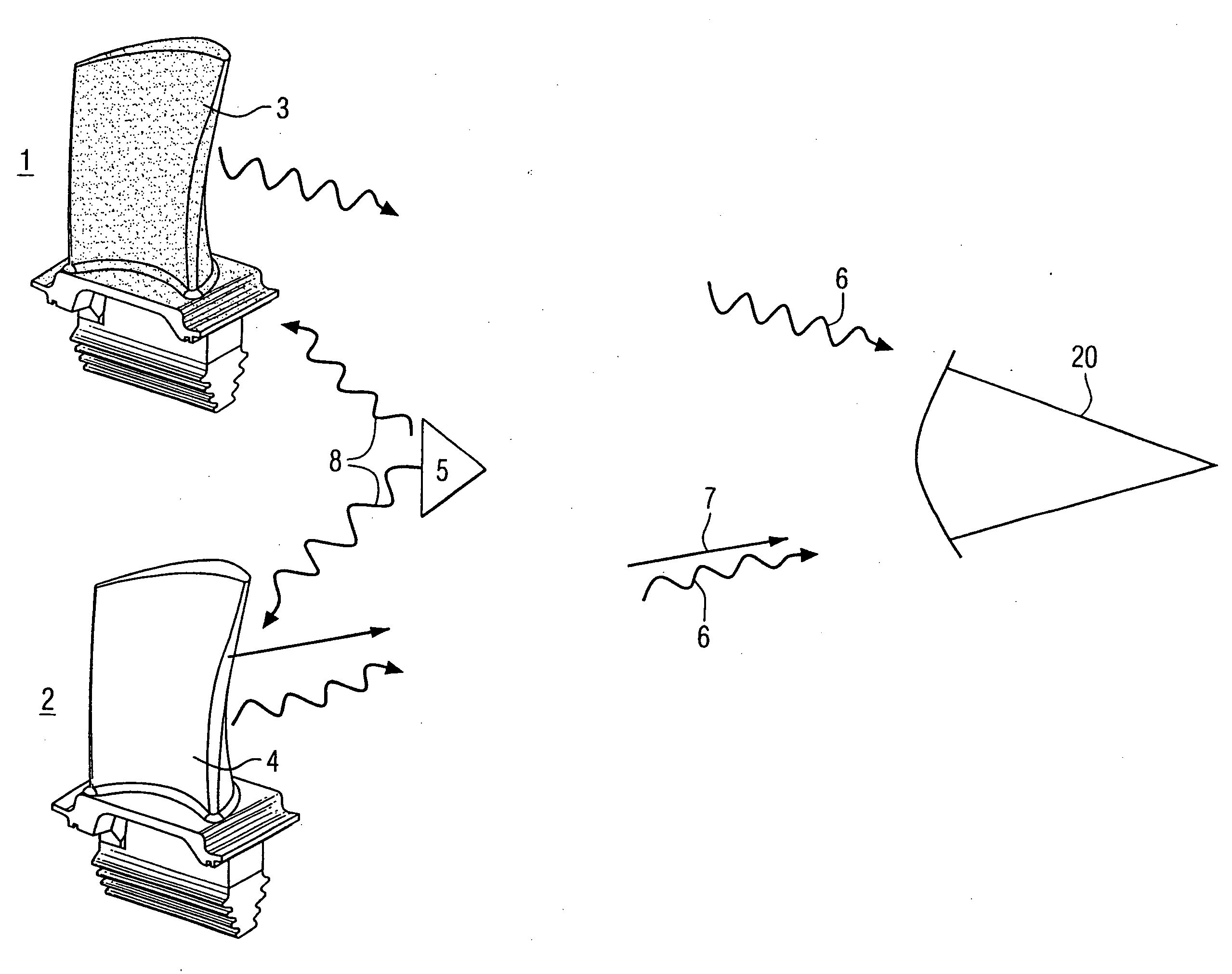

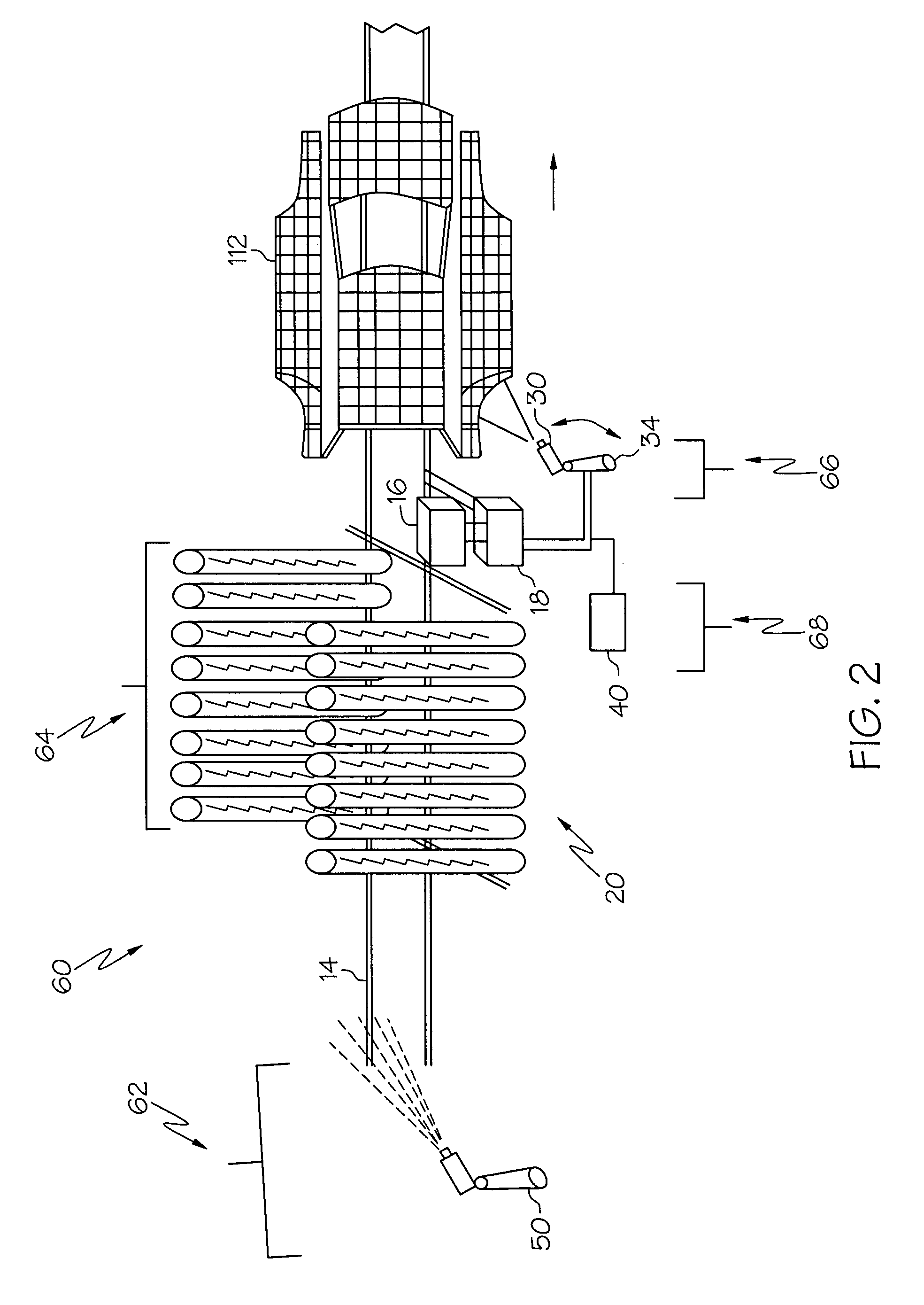

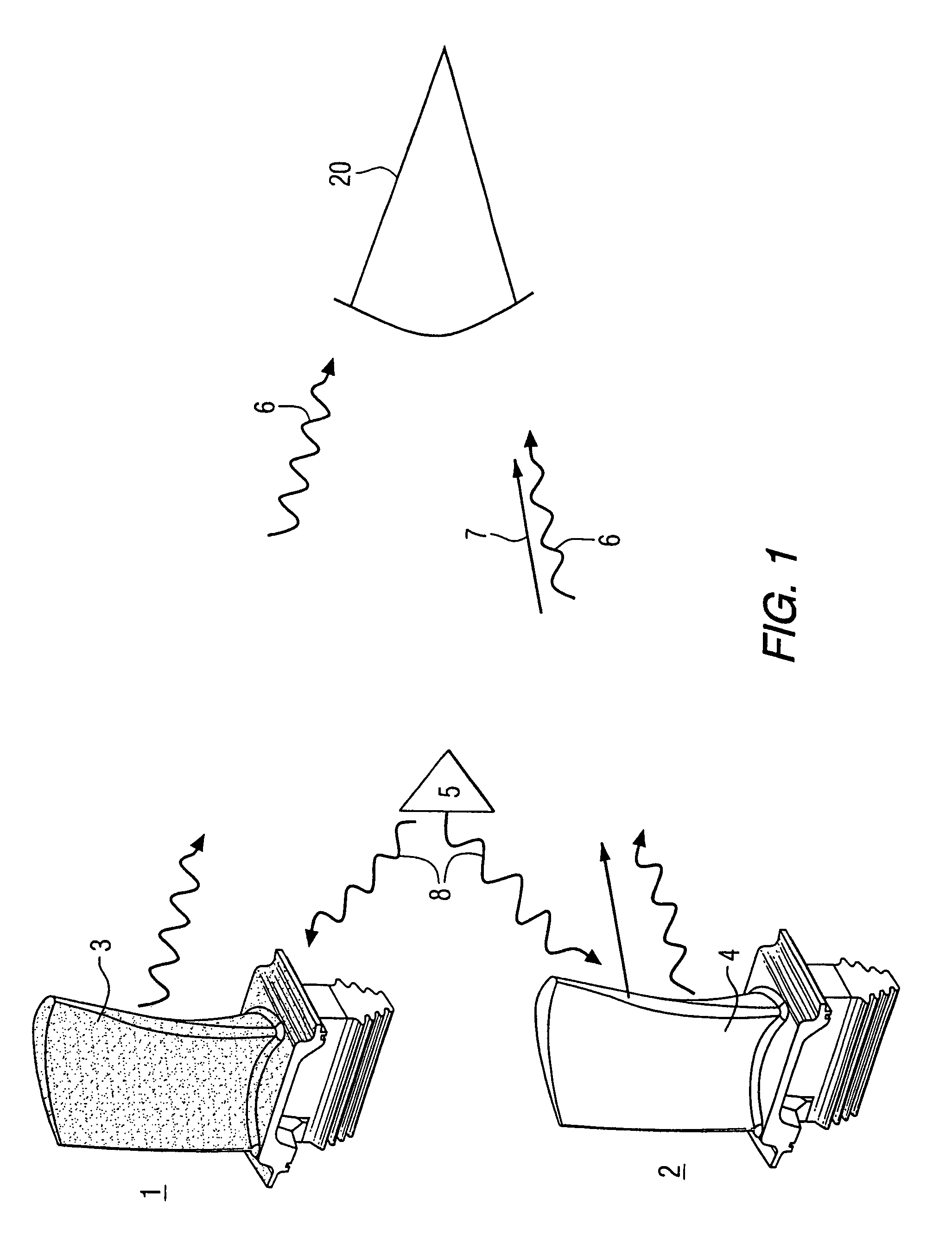

Method and apparatus for measuring on-line failure of turbine thermal barrier coatings

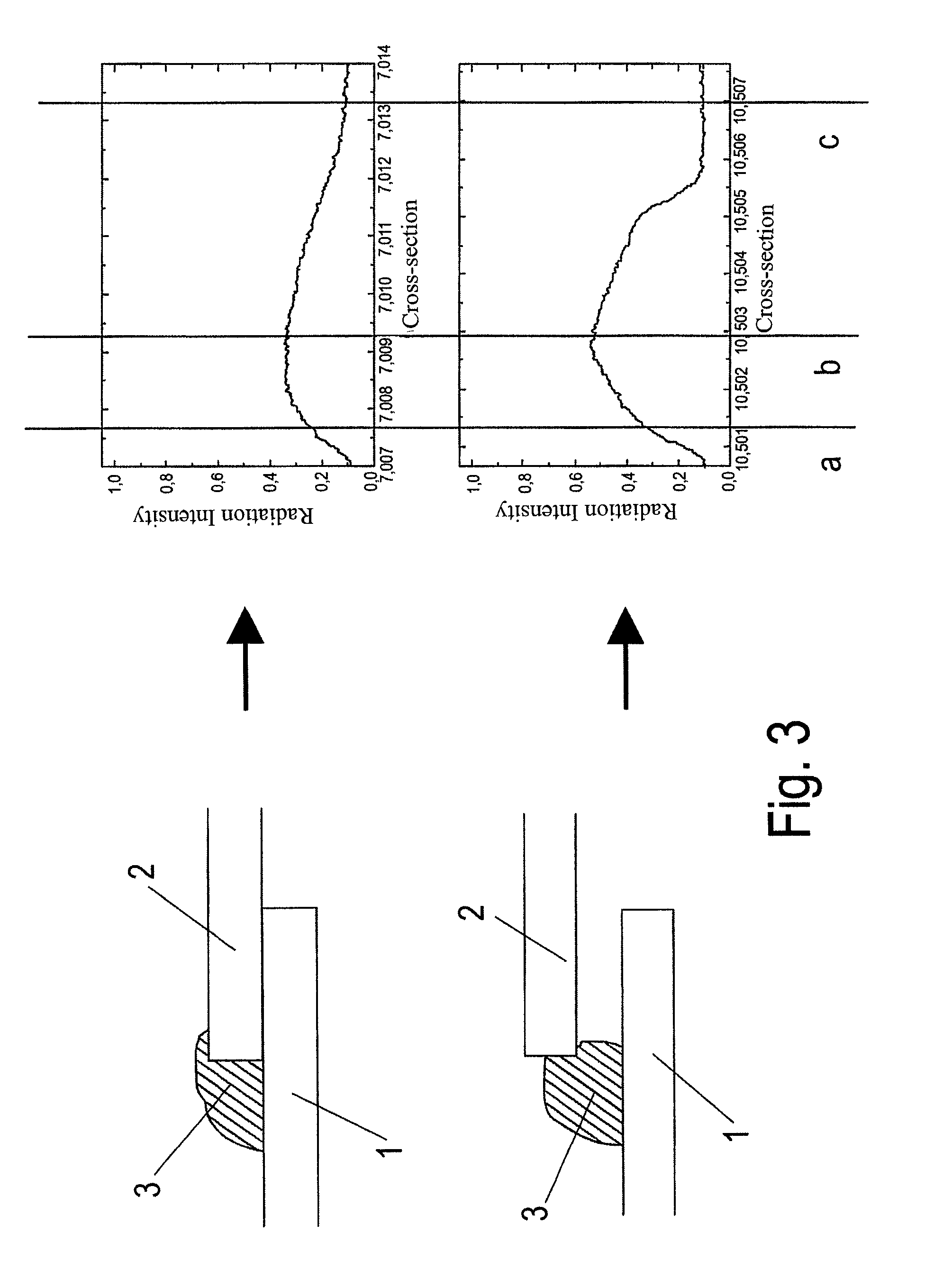

InactiveUS20090312956A1Detect degradationAvoid severe repairThermometer detailsPlug gaugesTurbine bladeEngineering

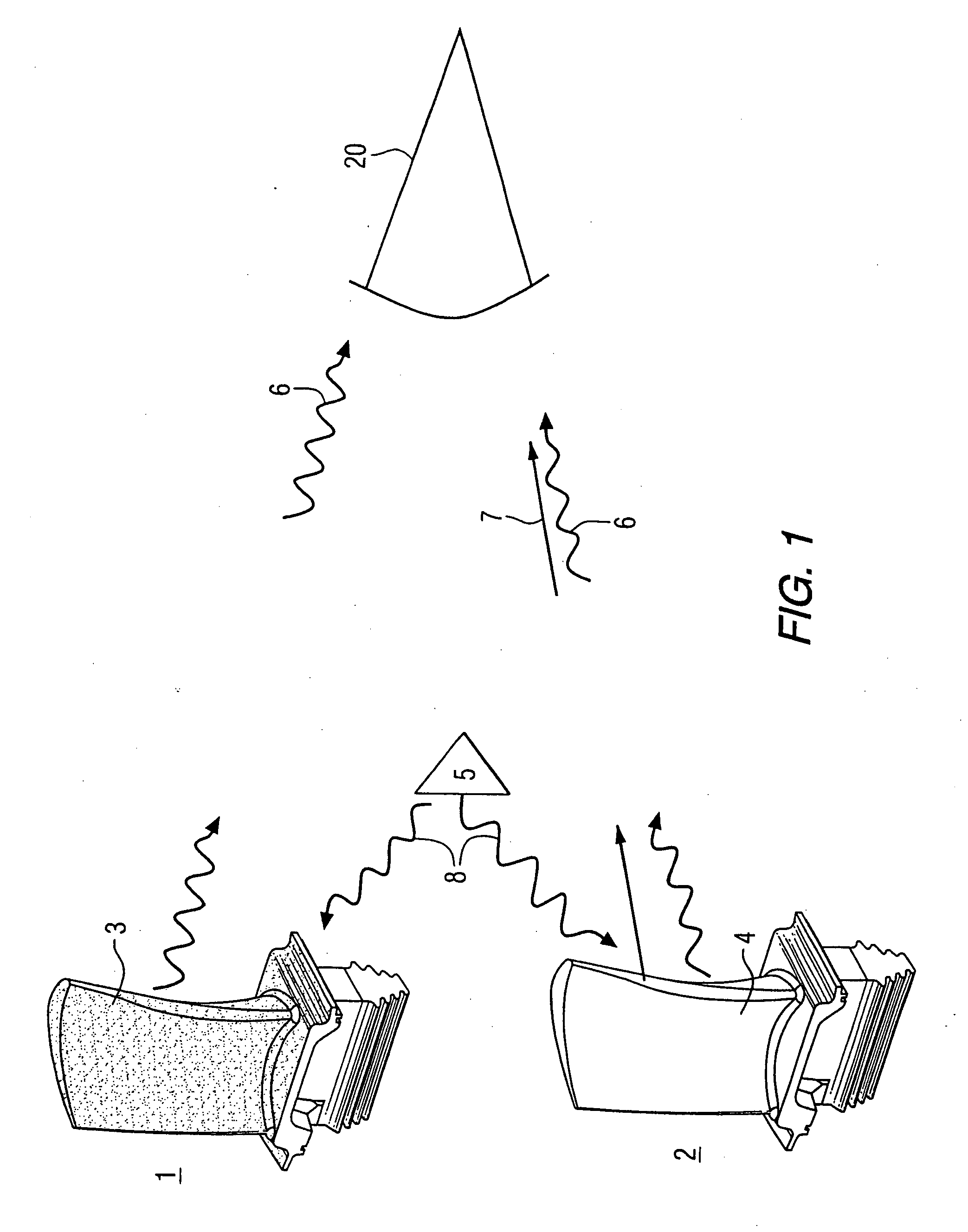

A method of remotely monitoring the radiant energy (6) emitted from a turbine component such as a turbine blade (1) having a low-reflective surface coating (3) which may be undergoing potential degradation is used to determine whether erosion, spallation, delamination, or the like, of the coating (3) is occurring.

Owner:SIEMENS ENERGY INC

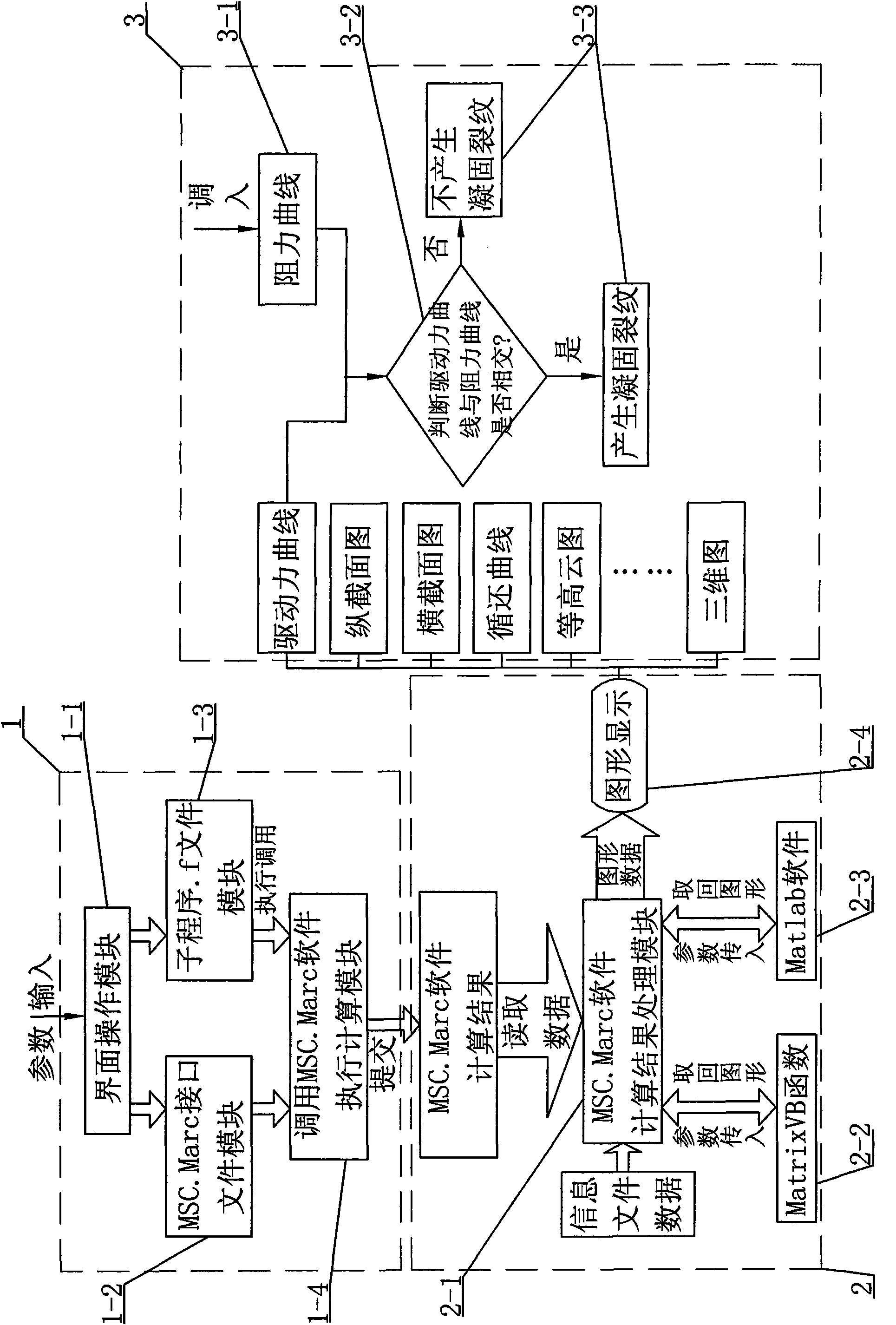

Finite element prediction system for welding and solidifying crack in virtual environment

InactiveCN101571887ASolve many selection difficultiesSolve complexityMaterial flaws investigationSpecial data processing applicationsGraphicsComputational science

The invention provides a finite element prediction system for welding and solidifying a crack in virtual environment, which relates to the technical field of finite element prediction software for welding and solidifying a crack, and the complex simulation and the prediction processes of welding and solidifying a crack are simplified into the simple operation and settings of an interface. A preliminary processing subsystem comprises an interface operating module, an MSC.Marc interface document module, a subprogram.f file module and an invocation MSC.Marc software executing and computing module, and a post processing subsystem comprises a MSC.Marc software computed result processing module, a MatrixVB function module, a Matlab software module and a graphic display module; a solidified crack predicting subsystem comprises a resistivity curve loading module, a judgment module and a result output module. The application of the invention enables a common welding engineering technician to carry out the numerical simulation and prediction for welding and solidifying a crack; the computed result is processed, and the storage space of a result file is decreased; the result file is converted into a file format convenient for graphic display, and the computed results of a temperature field and a stress strain field are visually displayed in a graphic form.

Owner:HARBIN INST OF TECH

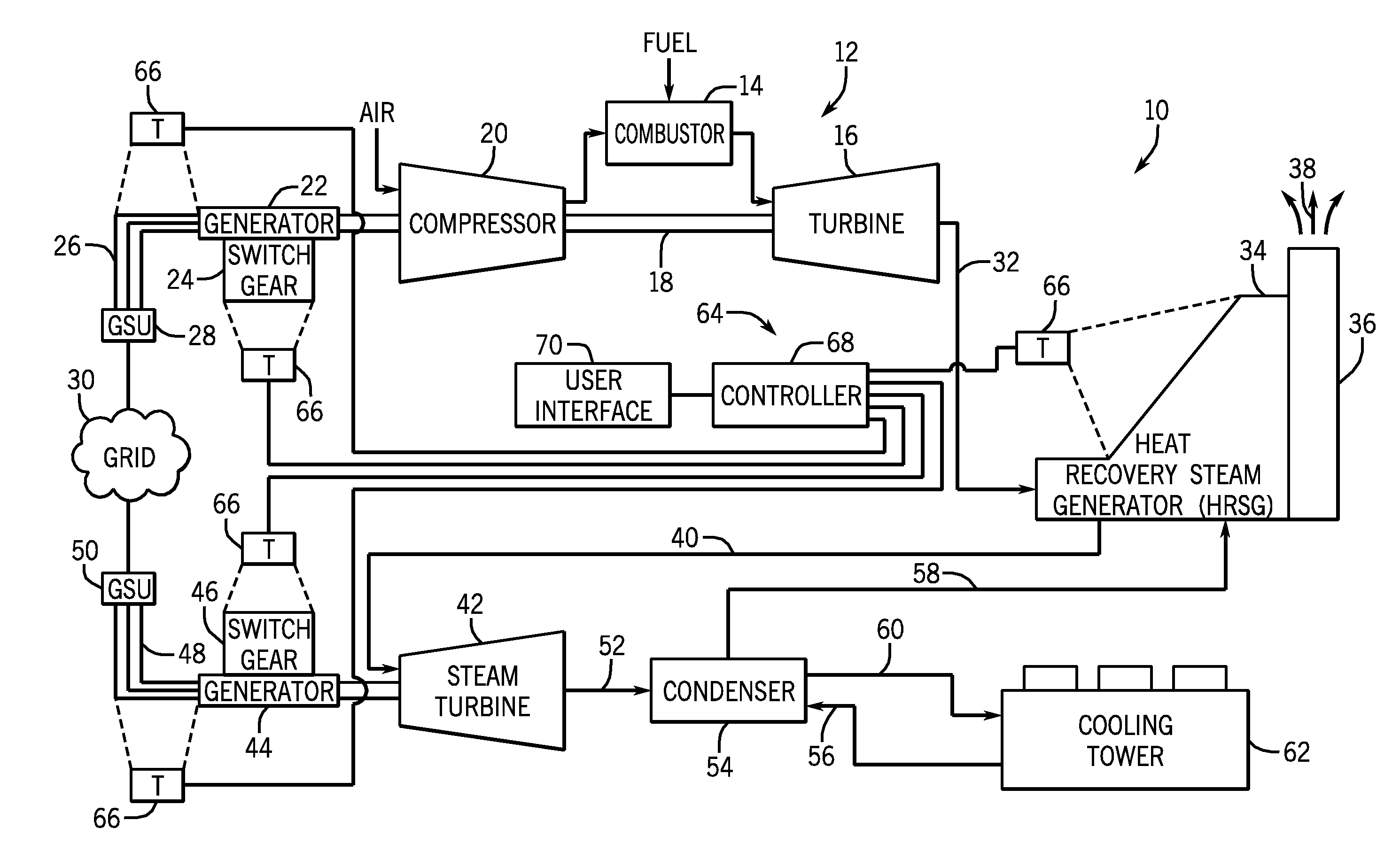

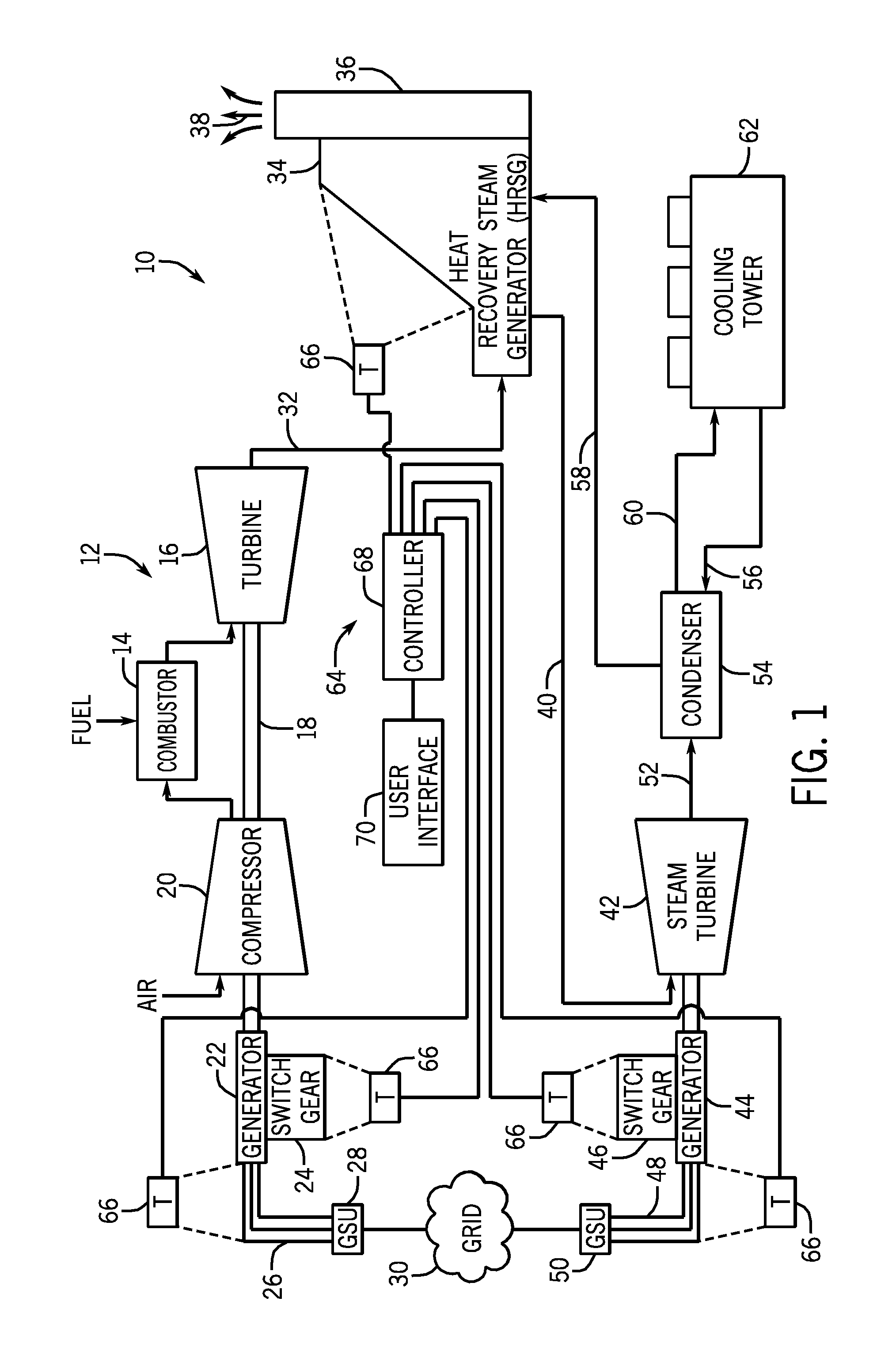

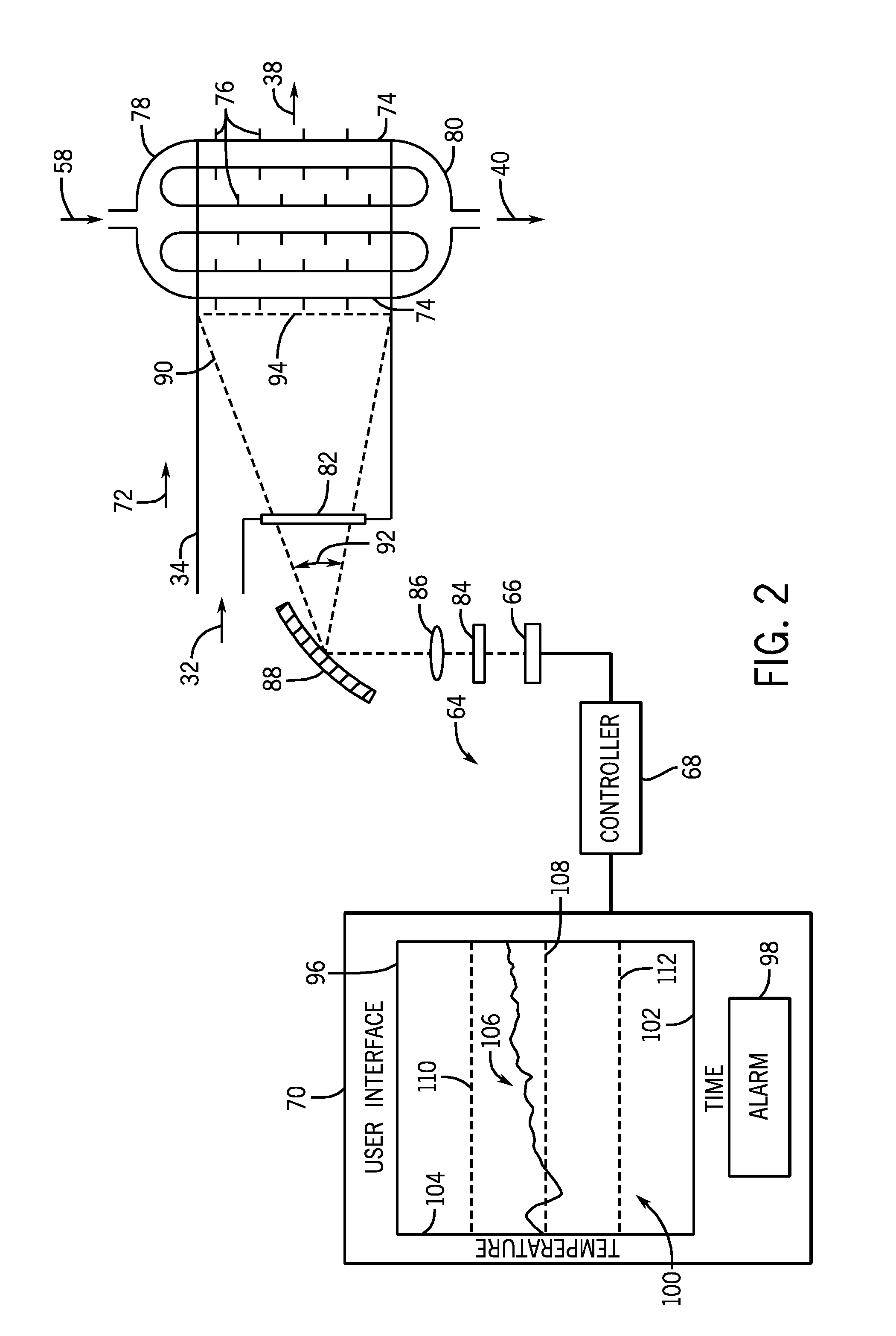

Thermal measurement system for fault detection within a power generation system

InactiveUS20120032810A1Sensing radiation from gases/flamesElectrical testingEngineeringRadiation sensor

A system includes a radiation sensor configured to direct a field of view toward a conduit within a heat recovery steam generator, and to output a signal indicative of a temperature of the conduit. The system also includes a controller communicatively coupled to the radiation sensor. The controller is configured to determine the temperature based on the signal, and to compare the temperature to a threshold value.

Owner:GENERAL ELECTRIC CO

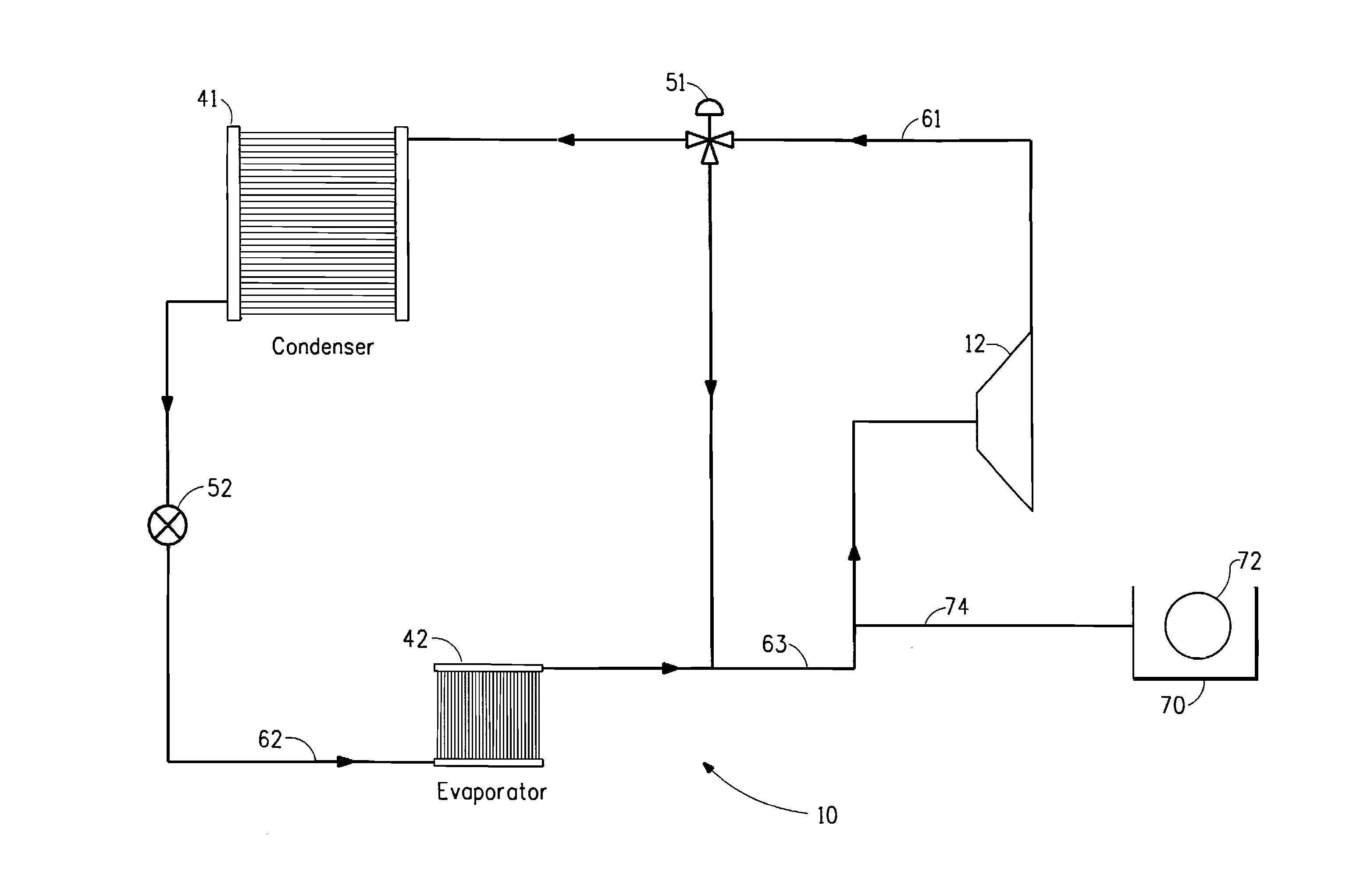

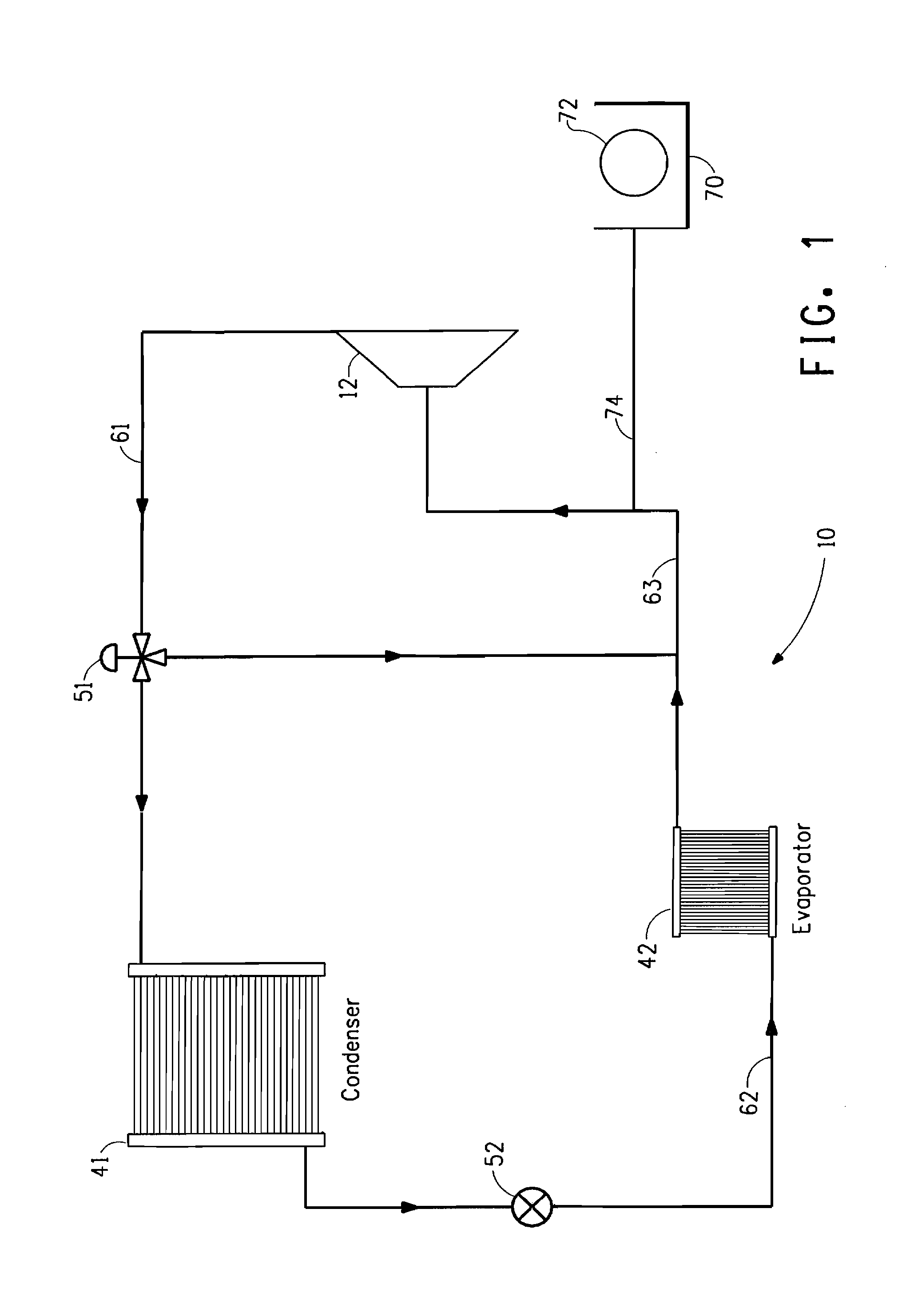

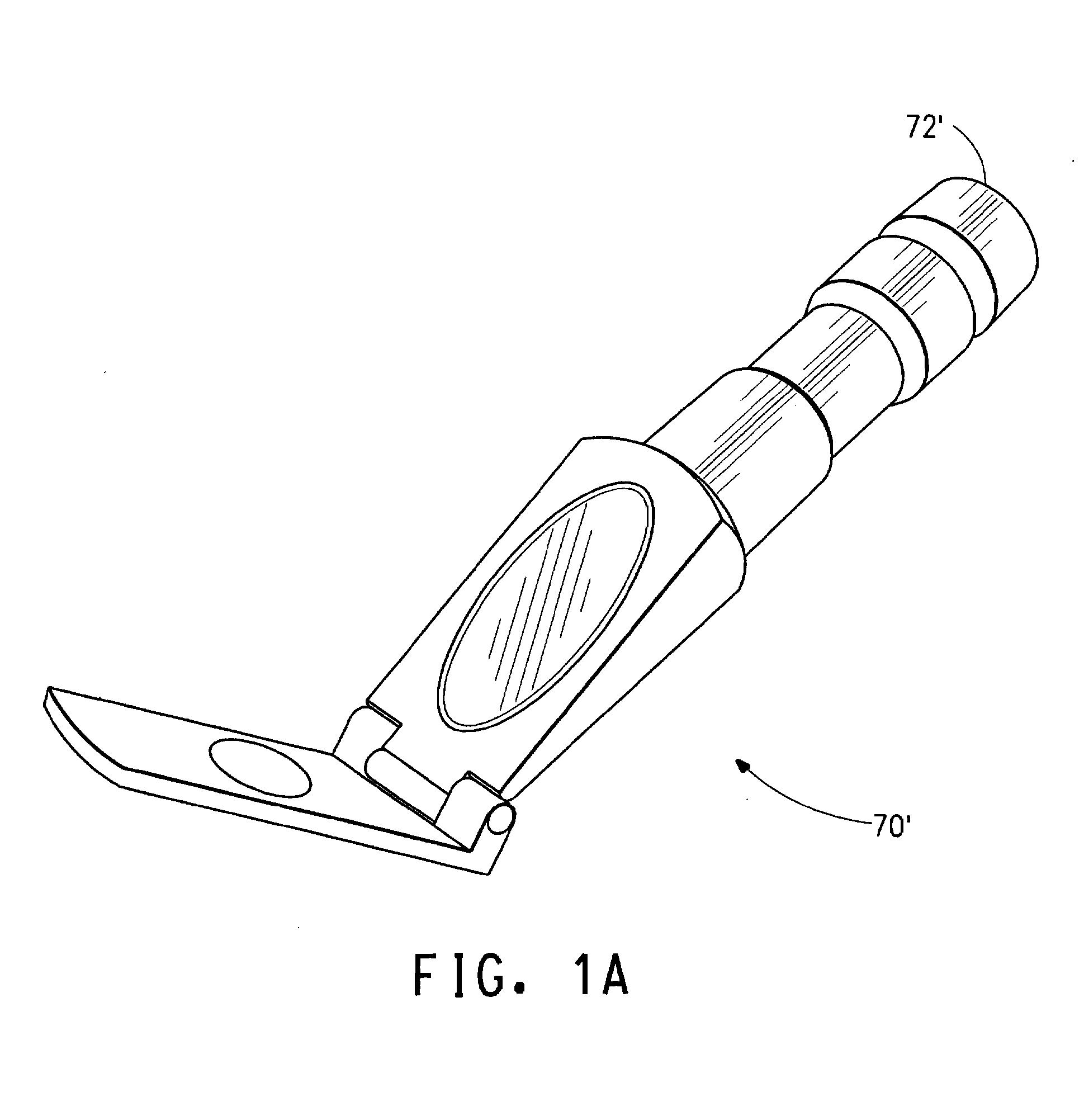

Method of detecting leaks of fluoroolefin compositions and sensors used therefor

InactiveUS20080069177A1Eliminate time and expenseCost effectiveAnalysing fluids using sonic/ultrasonic/infrasonic wavesDetection of fluid at leakage pointPellistorSpectroscopy

Disclosed are a method of detecting a leak of fluoroolefin compositions and sensors used therefor. In particular, the method is particularly useful for detecting a leak of a fluoroolefin refrigerant composition from a cooling system of an automotive vehicle. Such fluoroolefin refrigerant compositions have double bond structures which make them particularly well suited with sensing technologies, including: infrared sensors, UV sensors, NIR sensors, ion mobility or plasma chromatographs, gas chromatography, refractometry, mass spectroscopy, high temperature thick film sensors, thin film field effect sensors, pellistor sensors, Taguchi sensors and quartz microbalance sensors.

Owner:EI DU PONT DE NEMOURS & CO

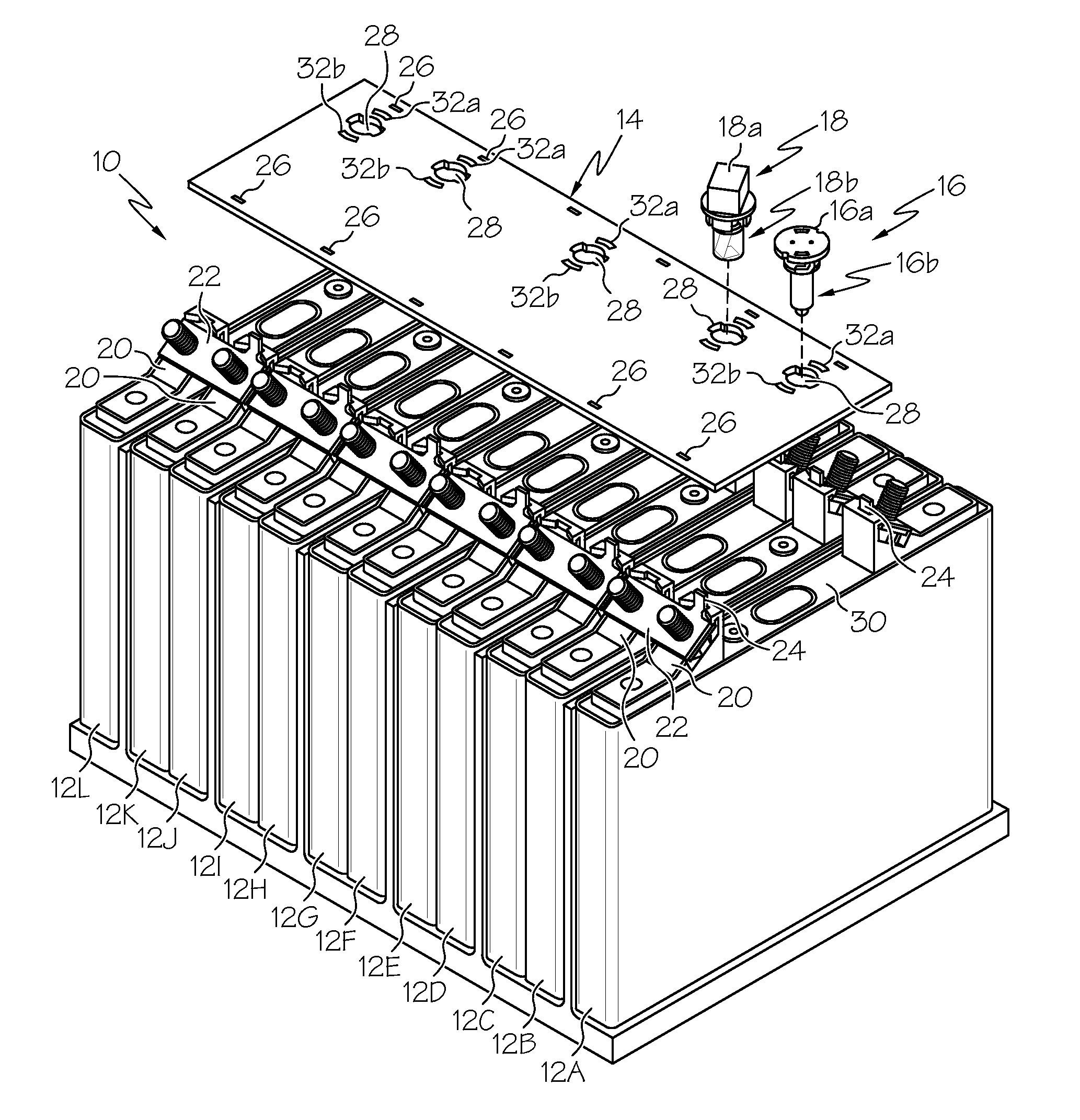

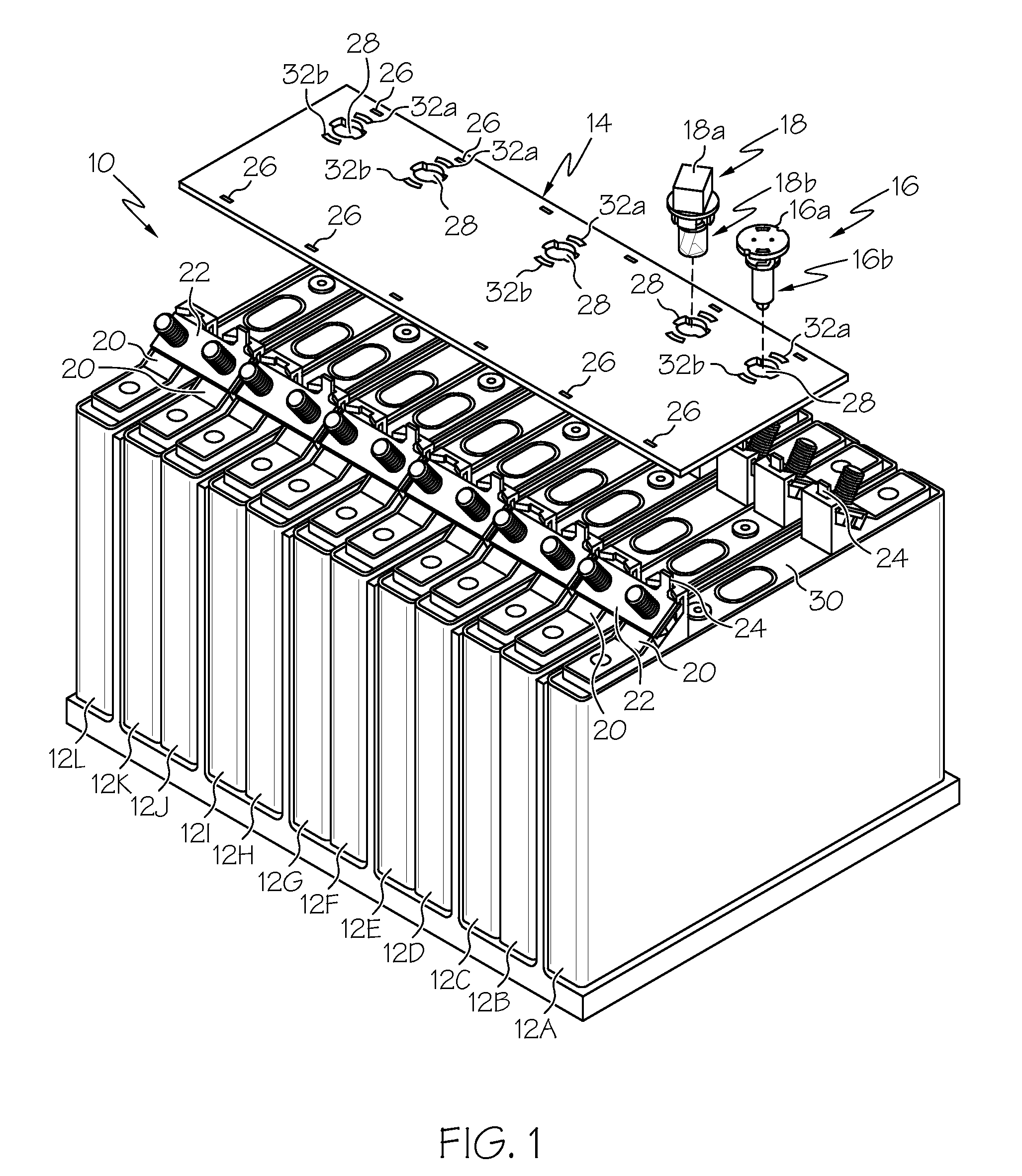

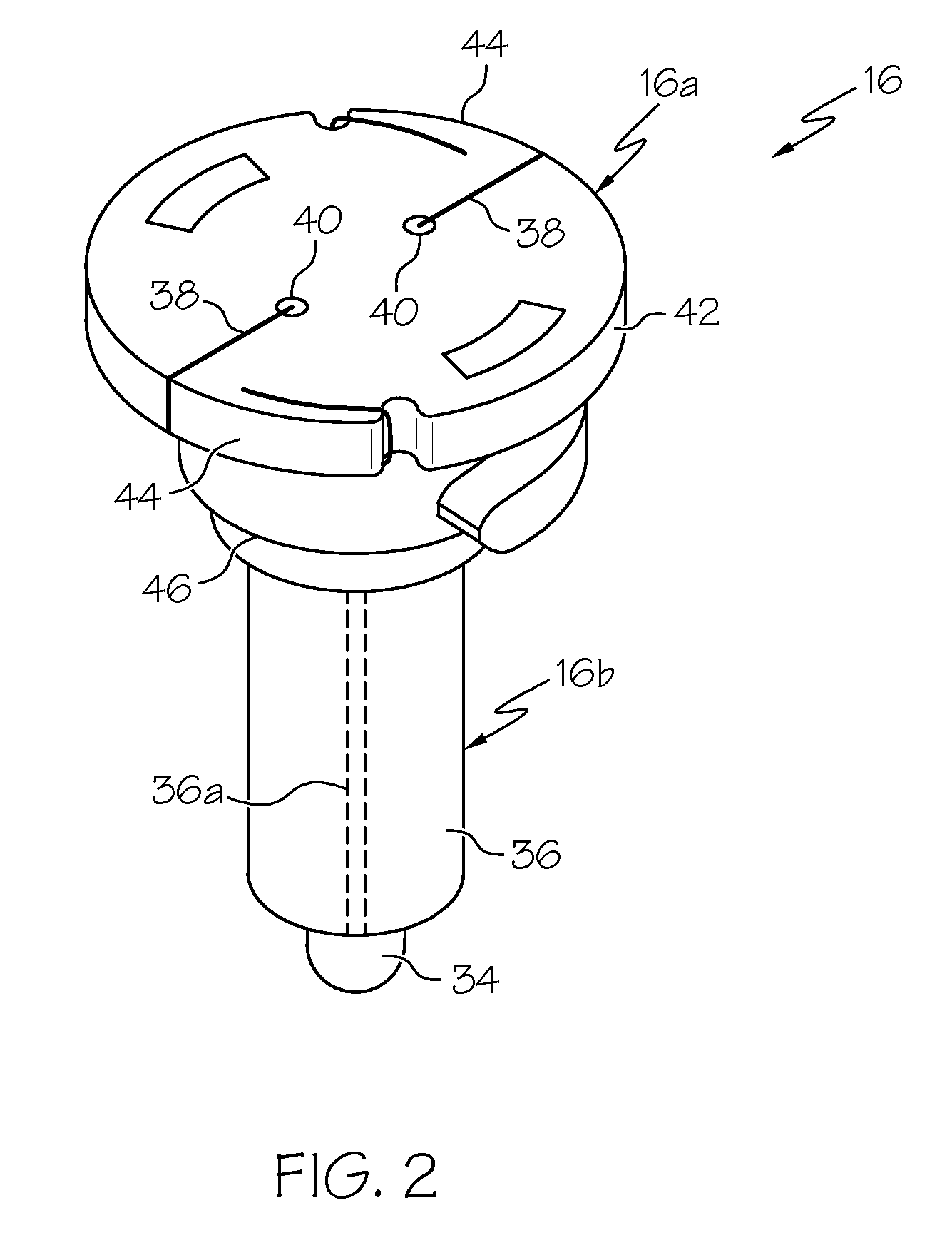

Cell temperature sensing apparatus for a batttery module

A printed circuit board supported over the top surface of a multi-cell battery module for battery cell voltage and temperature monitoring has an array of openings in alignment with selected battery cells for receiving temperature-sensing units that electrically couple with contacts formed on the printed circuit board and resiliently engage the cases of the selected battery cells. Each such temperature-sensing unit includes a printed circuit board mountable lamp socket and a lamp socket insert including a thermistor and a compressible element that maintains the thermistor in thermal proximity to the battery cell case when the temperature-sensing unit is installed in a respective printed circuit board opening.

Owner:DELPHI TECH IP LTD

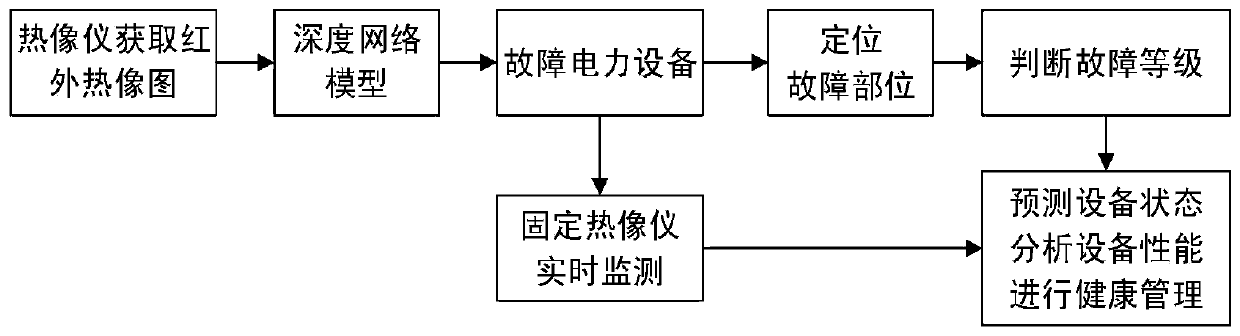

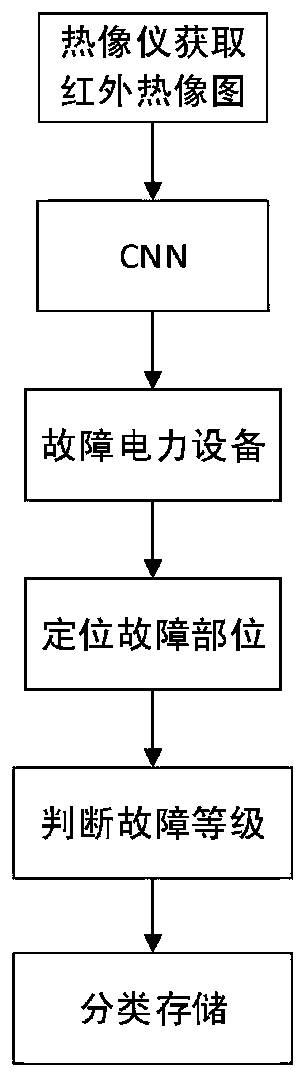

Power equipment infrared image fault positioning, identification and prediction method

ActiveCN110598736AIncreased riskHelps with health managementRadiation pyrometryCharacter and pattern recognitionData setPredictive methods

The invention discloses a power equipment infrared image fault positioning, identification and prediction method. The power equipment infrared image fault positioning, identification and prediction method comprises the following steps: 1) collecting power equipment infrared thermal image data; 2) classifying the infrared images to form a data set; 3) constructing a convolutional neural network model; 4) separating out faulty power equipment; 5) monitoring faulty power equipment in real time, and longitudinally collecting temperature data; 6) positioning a fault part, segmenting the infrared image of the power equipment, and extracting a fault area; 7) diagnosing a fault area, and judging a fault level; 8) predicting an equipment state trend; 9) uniformly outputting and displaying the information; 10) storing the fault level; 11) making four types of infrared image data sets; 12) building a target detection model and training; 13) directly detecting an infrared image of power equipmentto be detected through a target to obtain a fault position and a fault level; 14) repeating the step (5); 15) repeating the step (8); and 16) repeating the step (9) facilitating positioning of the fault position, fault level judgment and prediction of the fault equipment and giving a maintenance suggestion.

Owner:XIAN UNIV OF TECH

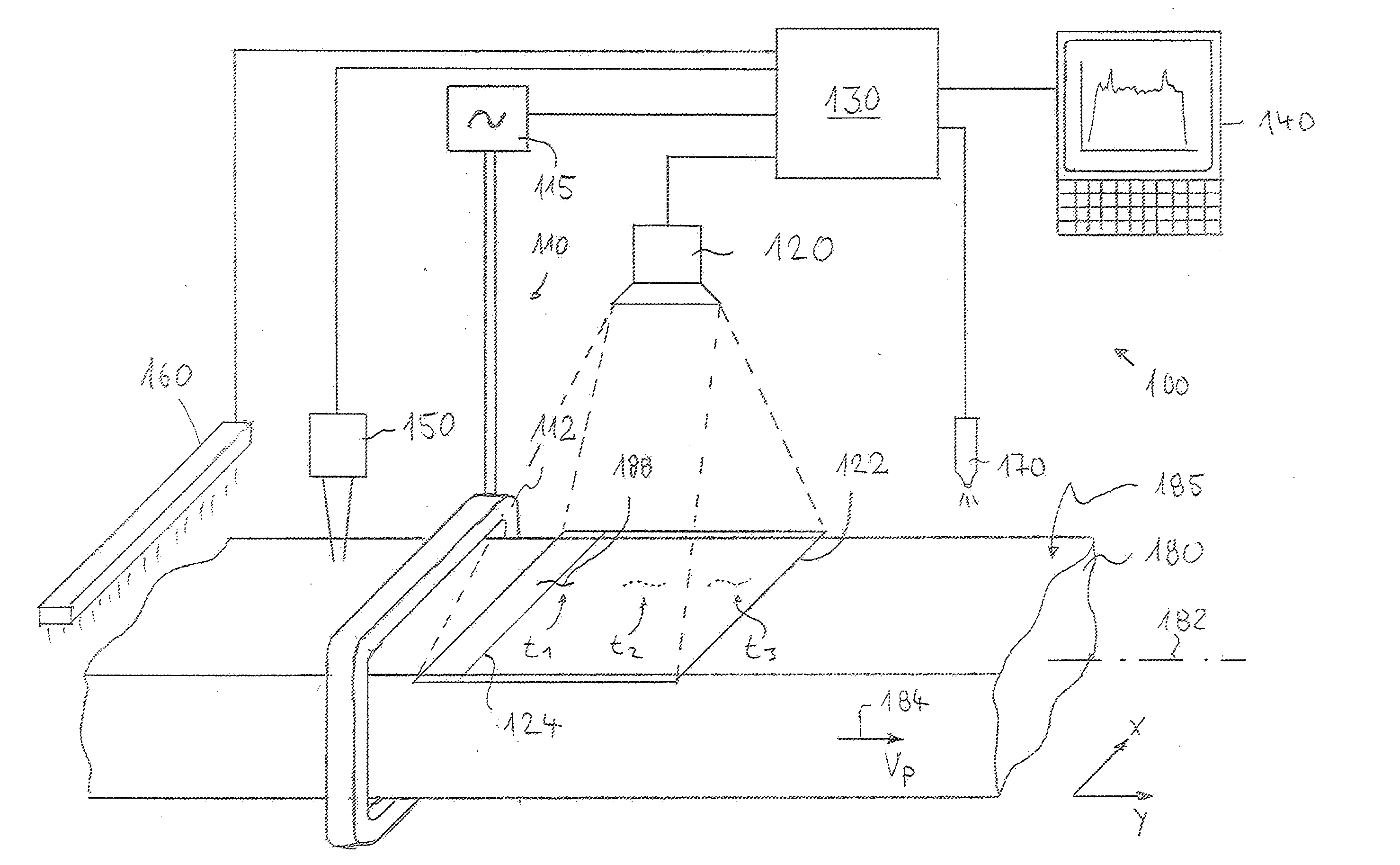

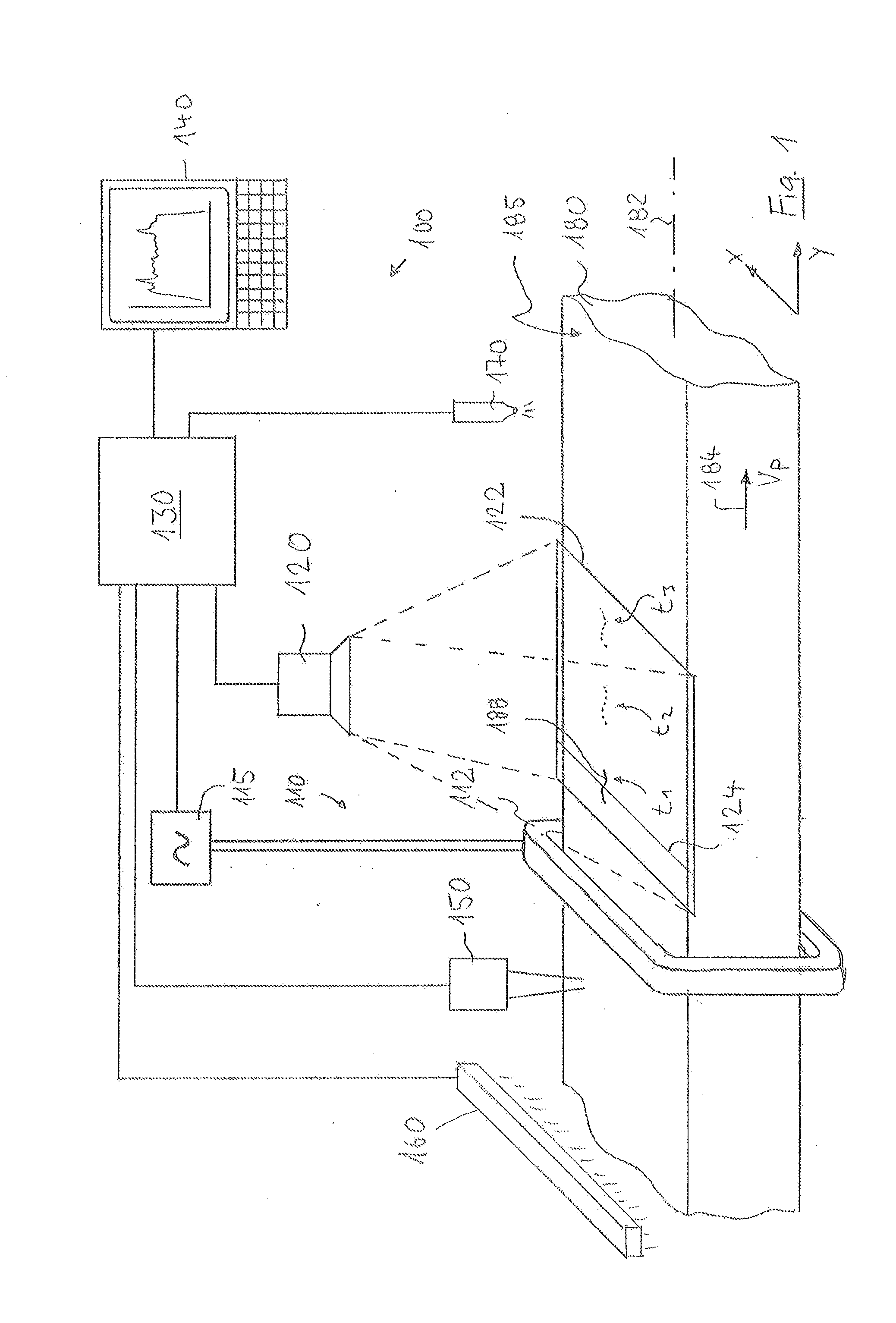

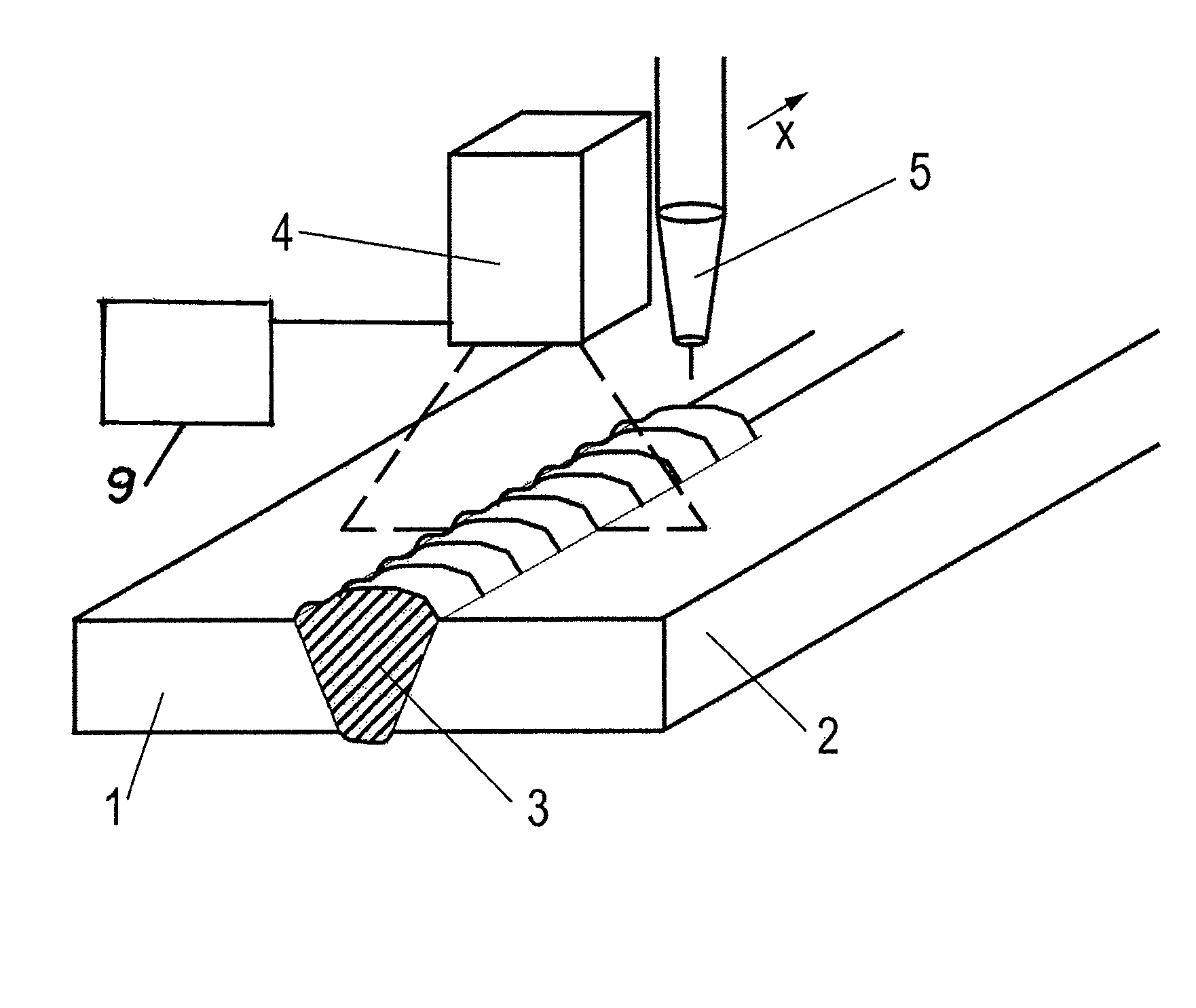

Process control by transient thermography

InactiveUS6013915AEasy to controlGuaranteed high quality outputMaterial flaws investigationOptically investigating flaws/contaminationProcess engineeringThermography

A method and apparatus for detecting, locating, isolating and controlling variations in the manufacturing process by transient thermography. A heat source imparts heat to a surface which is radiated in the infrared region. Infrared sensors are coupled to a processor which tracks the physical characteristics of the sample, and provides feedback to a central process controller to make adjustments to the manufacturing process.

Owner:PHILIP MORRIS PROD SA

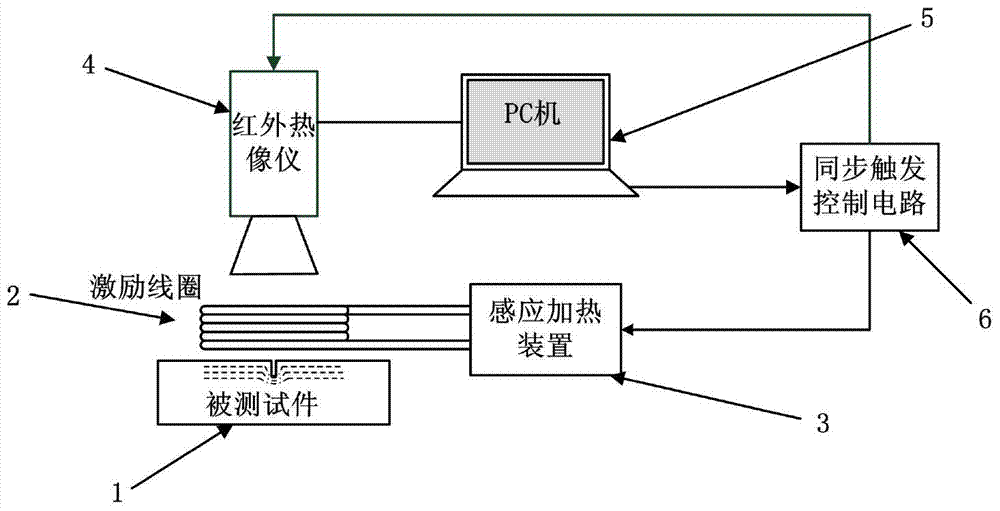

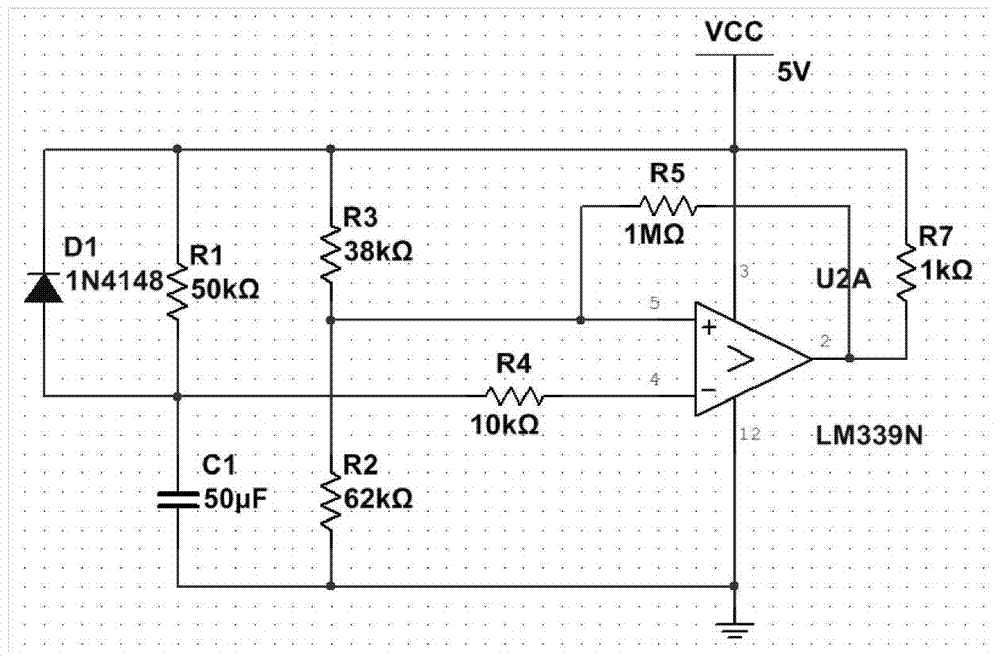

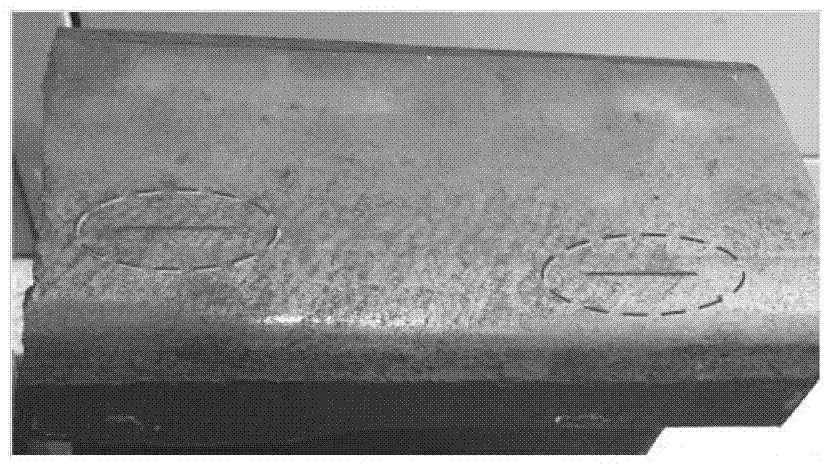

Pulsed eddy current infrared thermal imaging detection system and method for steel rail cracks

InactiveCN104764770AConvenient and intuitive detection meansThe energy of the pulse signal is largeMaterial flaws investigationThermodynamicsImage resolution

The invention discloses a pulsed eddy current infrared thermal imaging detection system and method for steel rail cracks. The system comprises an excitation device, an induction heating device, an infrared thermal imager and a PC, wherein the induction heating device is used for generating a pulse current signal; the pulse current signal is exerted to a tested part through the excitation device; eddy current is induced from the surface of the tested part and a thermal effect is generated, so that the surface temperature distribution changes; the infrared thermal imager is used for recording the surface temperature change process of the tested part and transmitting to the PC to process and analyze. The pulsed eddy current infrared thermal imaging detection system is characterized by also comprising a synchronous trigger control circuit, which is used for synchronously controlling the excitation and recording time of the induction heating device and the infrared thermal imager, so that the heating and cooling processes after complete induction of the tested part are accurately recorded; and the condition that the PC obtains accurate data to analyze and treat is ensured. The pulsed eddy current infrared thermal imaging detection system is high in detection efficiency and high in image resolution ratio; excitation of an excitation source and the infrared thermal imager can be synchronously carried out; and the detection result is not affected by human factors.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

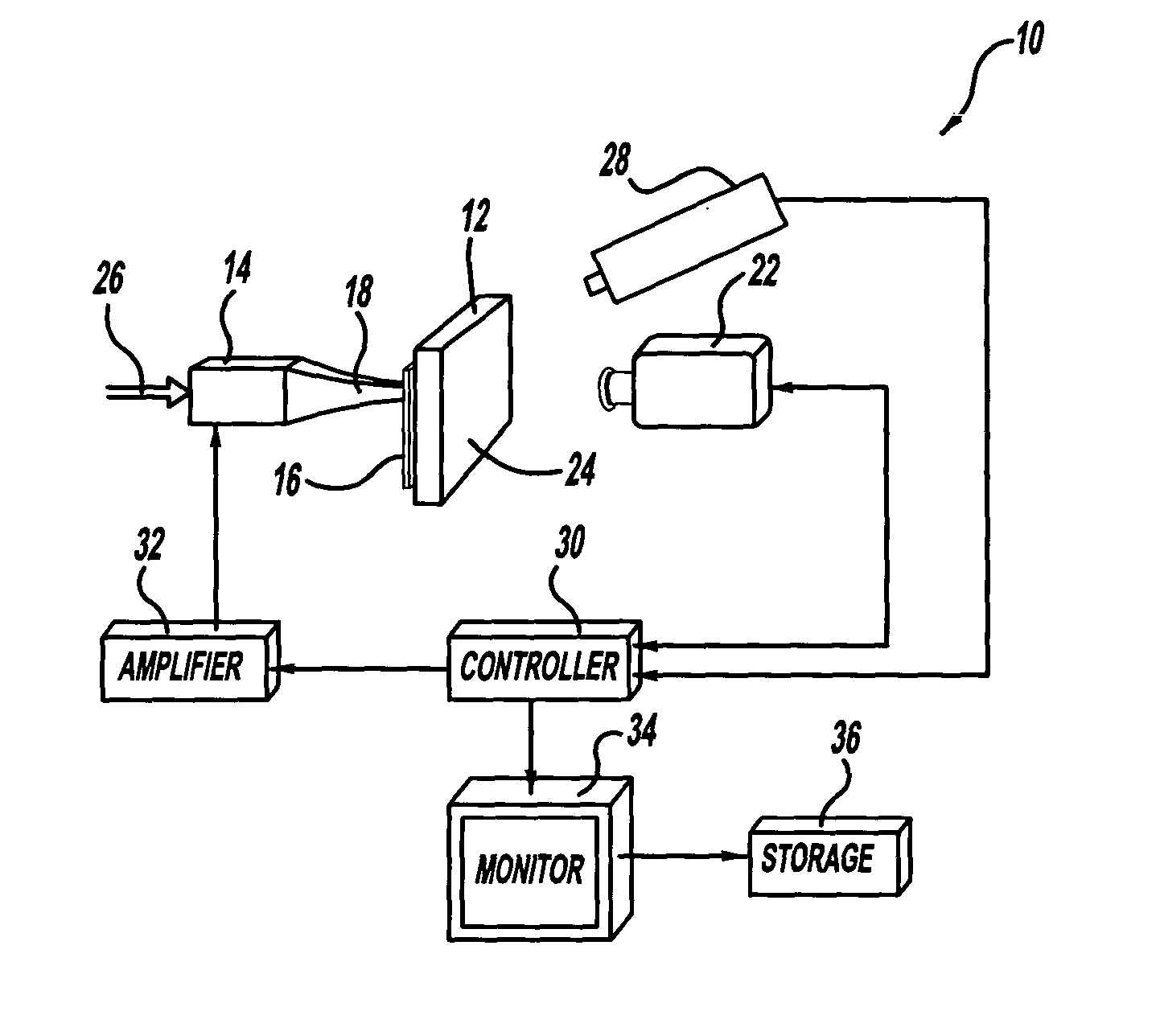

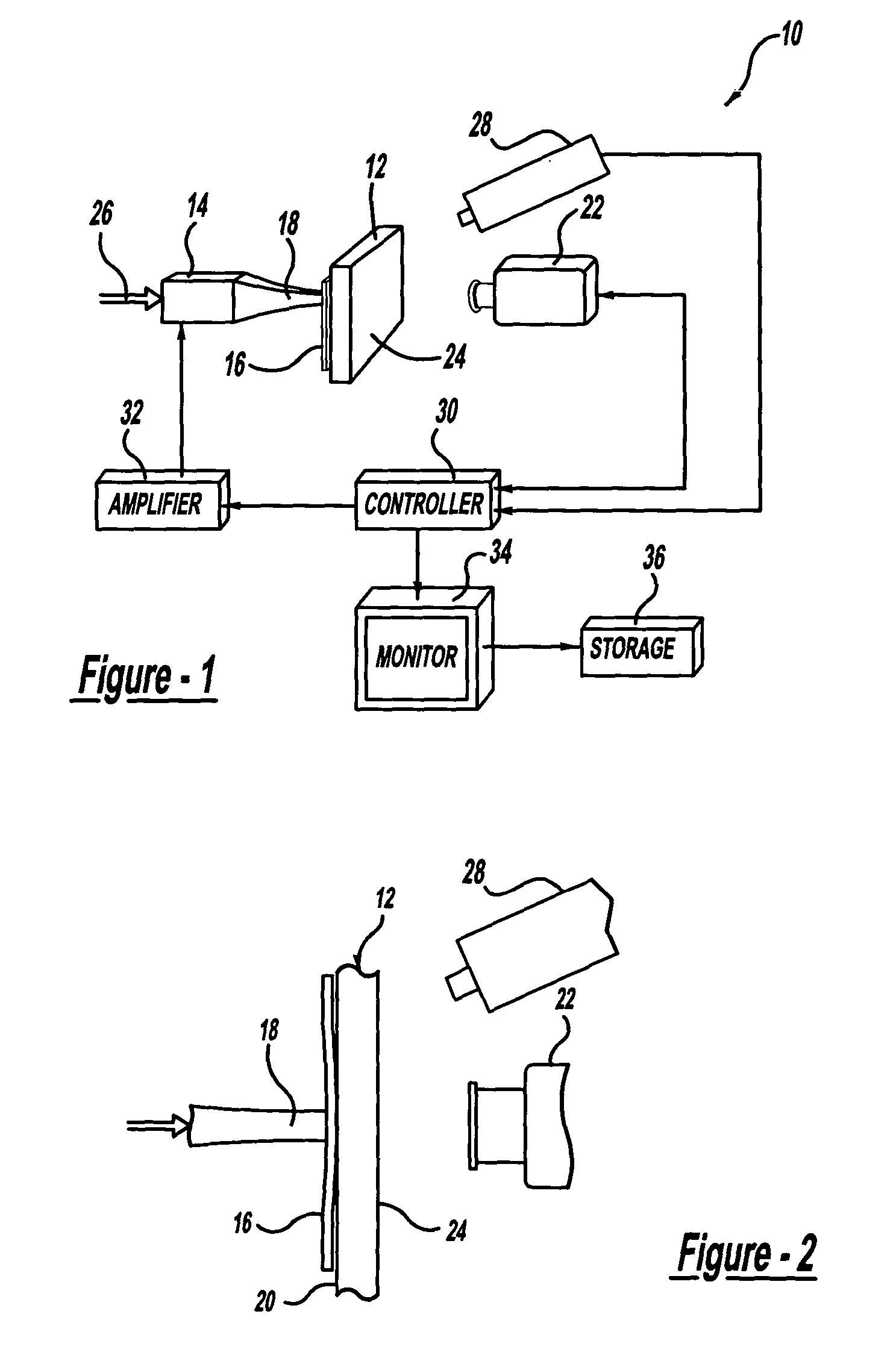

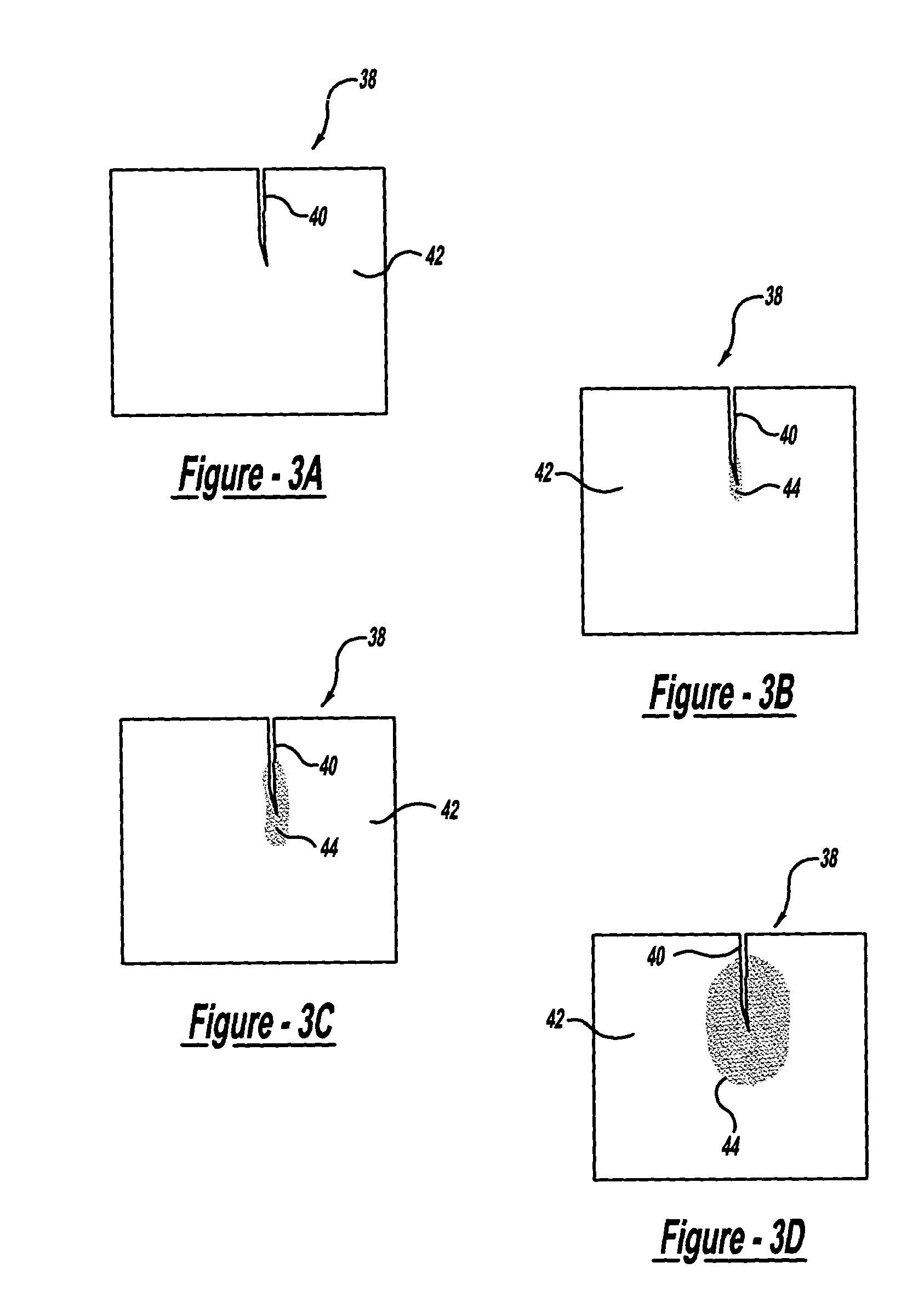

System and method for multiple mode flexible excitation and acoustic chaos in sonic infrared imaging

ActiveUS20040089812A1Analysing solids using sonic/ultrasonic/infrasonic wavesUltrasonic/sonic/infrasonic wave generationThermal energyCamera image

A defect detection system for thermally imaging a structure that has been energized by a sound energy. The system includes a transducer that couples a sound signal into the structure, where the sound signal causes defects in the structure to heat up. In one embodiment, the sound signal has one or more frequencies that are at or near an eigen-mode of the structure. In another embodiment, an on-linear coupling material is positioned between the transducer and the structure to couple the sound energy from the transducer to the structure. A predetermined force is applied to the transducer and a pulse duration and a pulse frequency of the sound signal are selected so that the sound energy induces acoustic chaos in the structure, thus generating increased thermal energy. A thermal imaging camera images the structure when it is heated by the sound signal.

Owner:WAYNE STATE UNIV +1

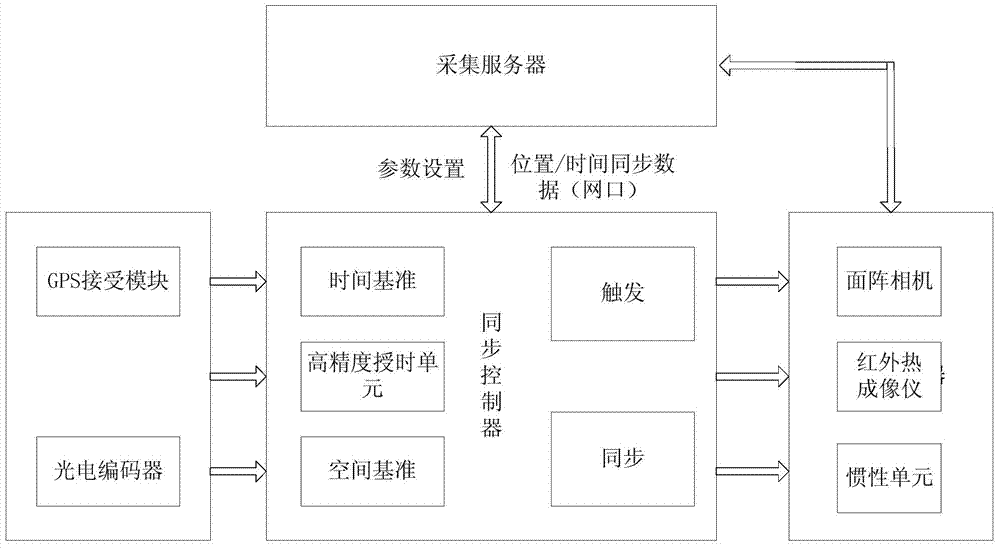

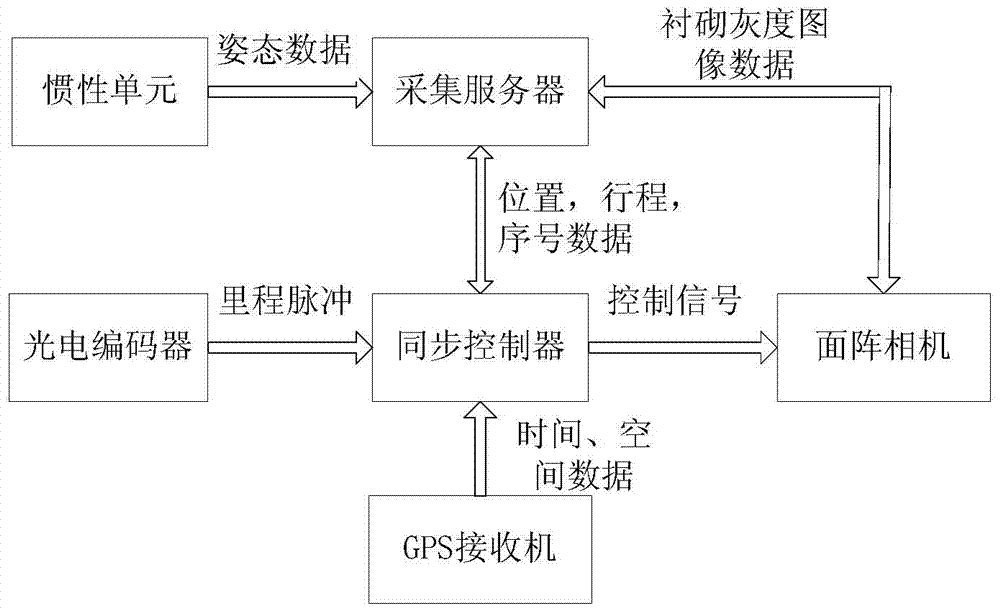

Tunnel lining disease detection device based on infrared temperature field and gray level image

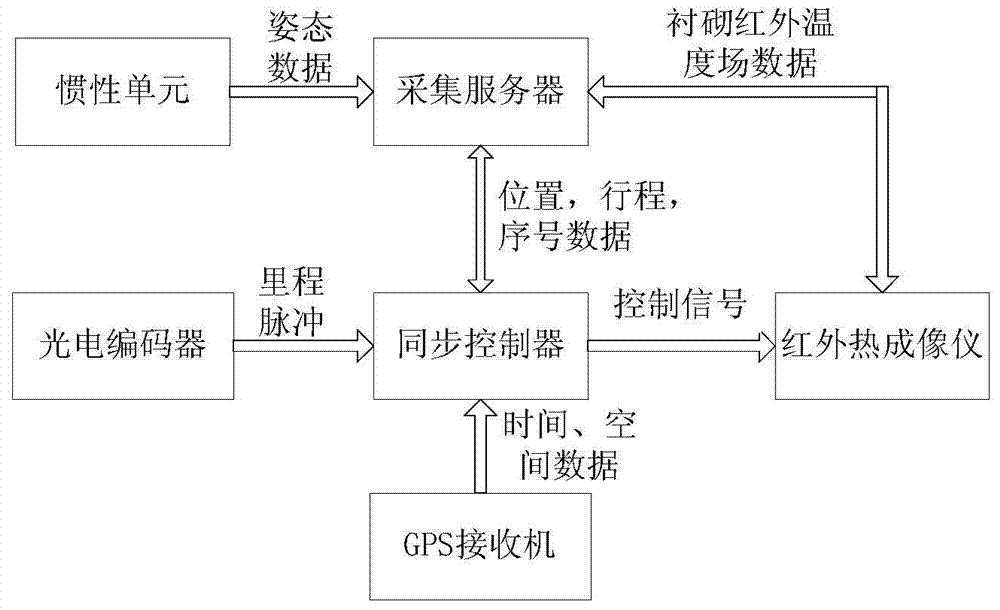

InactiveCN104749187AHigh synchronization accuracyReduce difficultyMaterial flaws investigationOptically investigating flaws/contaminationLight equipmentImaging data

The invention relates to a tunnel lining disease detection device based on an infrared temperature field and a gray level image. The tunnel lining disease detection device comprises a vehicle-mounted mobile platform, illumination equipment, a photoelectric encoder, a GPS (Global Position System) receiver, an inertia unit, a synchronous controller, an area-array camera, an infrared thermal imager, an acquisition server, a display control device and a power supply system; tunnel lining two-dimensional image data, infrared temperature field data and fracture surface deformation data are combined with positioning data of the GPS, the inertia unit and the photoelectric encoder to establish a tunnel model with gray level information, temperature information and fracture surface deformation; and tunnel lining cracks are analyzed, and the length, width and lining leakage water information of the cracks are automatically detected. For the tunnel lining disease detection device, the advantages of infrared temperature field detection and two-dimensional gray level image crack detection are combined so that the detection result is relatively reliable, the speed is rapid and the working efficiency is greatly improved.

Owner:WUHAN WUDA ZOYON SCI & TECH

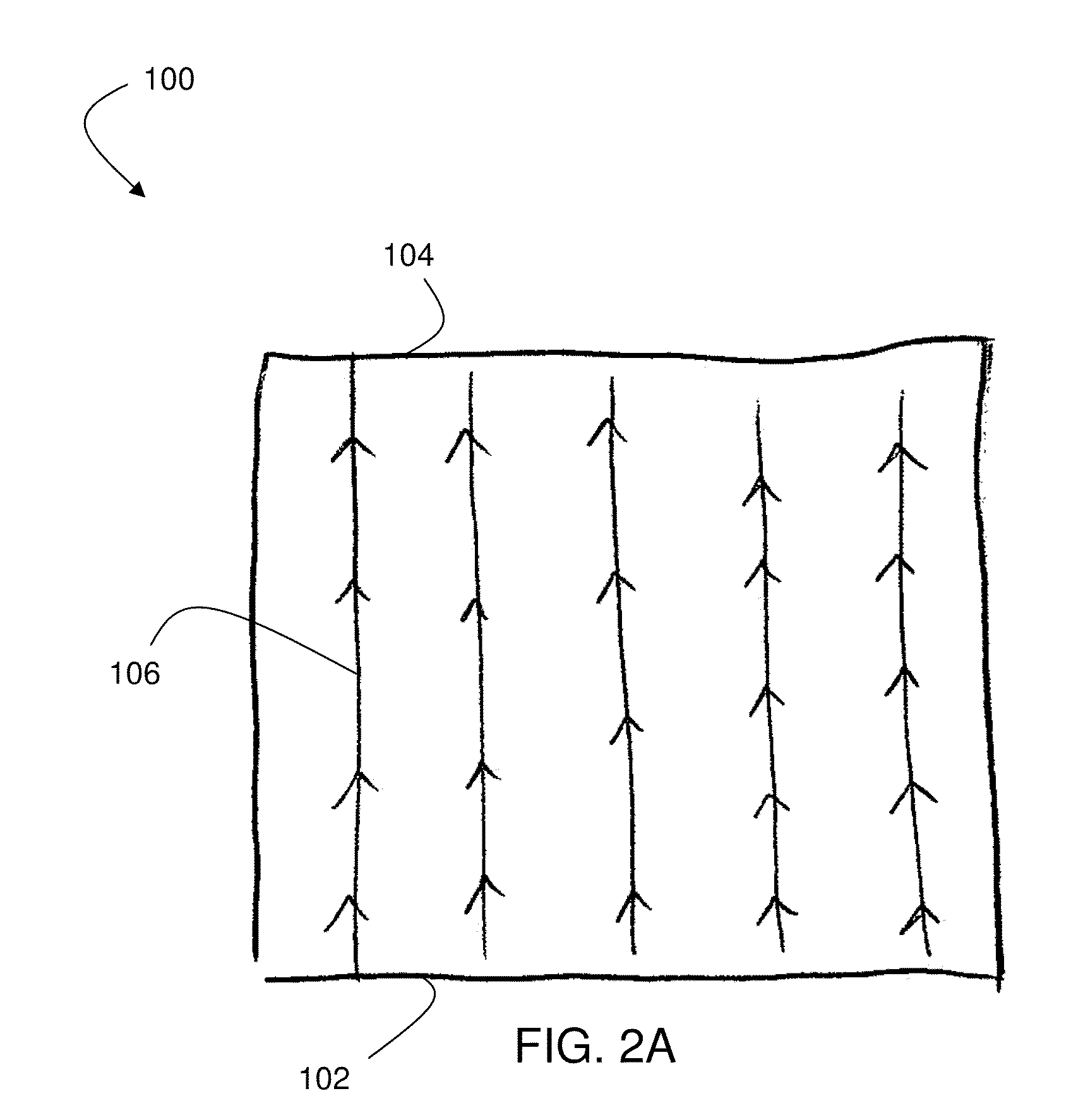

Systems and methods for structural sensing

InactiveUS20110142091A1Thermometer detailsNanosensorsElectrical resistance and conductanceEngineering

Systems and methods related to the determination of one or more mechanical characteristics of a structural element are generally described. In some embodiments, a mechanical characteristic (e.g., a crack, a deformation, an inclusion, etc.) can be determined based at least in part upon the determination of a temperature generated, for example, by passing a current through a network of structures within the structural element. For example, in some embodiments, the structural element can comprise a network of electrically conductive nanostructures and, in some cases, a primary structural material that is not substantially electrically conductive. An electrical current can be passed through the network of electrically conductive nanostructures (e.g., by passing current through an electrical circuit comprising the network of electrically conductive nanostructures). This may result in resistive heating (also known as Joule-effect heating) of the nanostructure network. In some embodiments, a first temperature of the network and / or structural elements can be determined (e.g., via a sensor associated with the electrical circuit). This first temperature can be, in some cases, indicative of a mechanical characteristic of the structural element. In some embodiments, one or more mechanical characteristics of the structural element can be determined based at least in part upon the determination of the first temperature of the structural element.

Owner:MASSACHUSETTS INST OF TECH

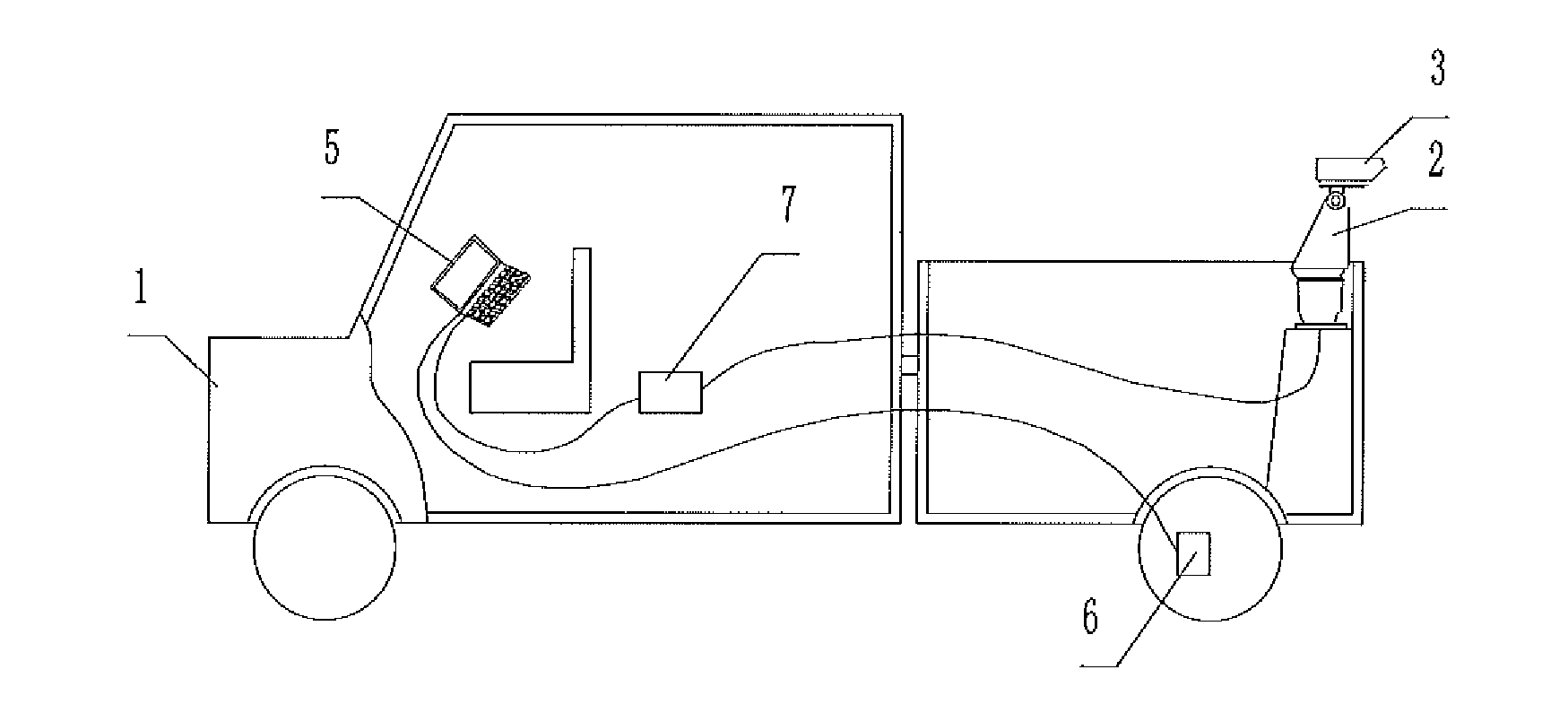

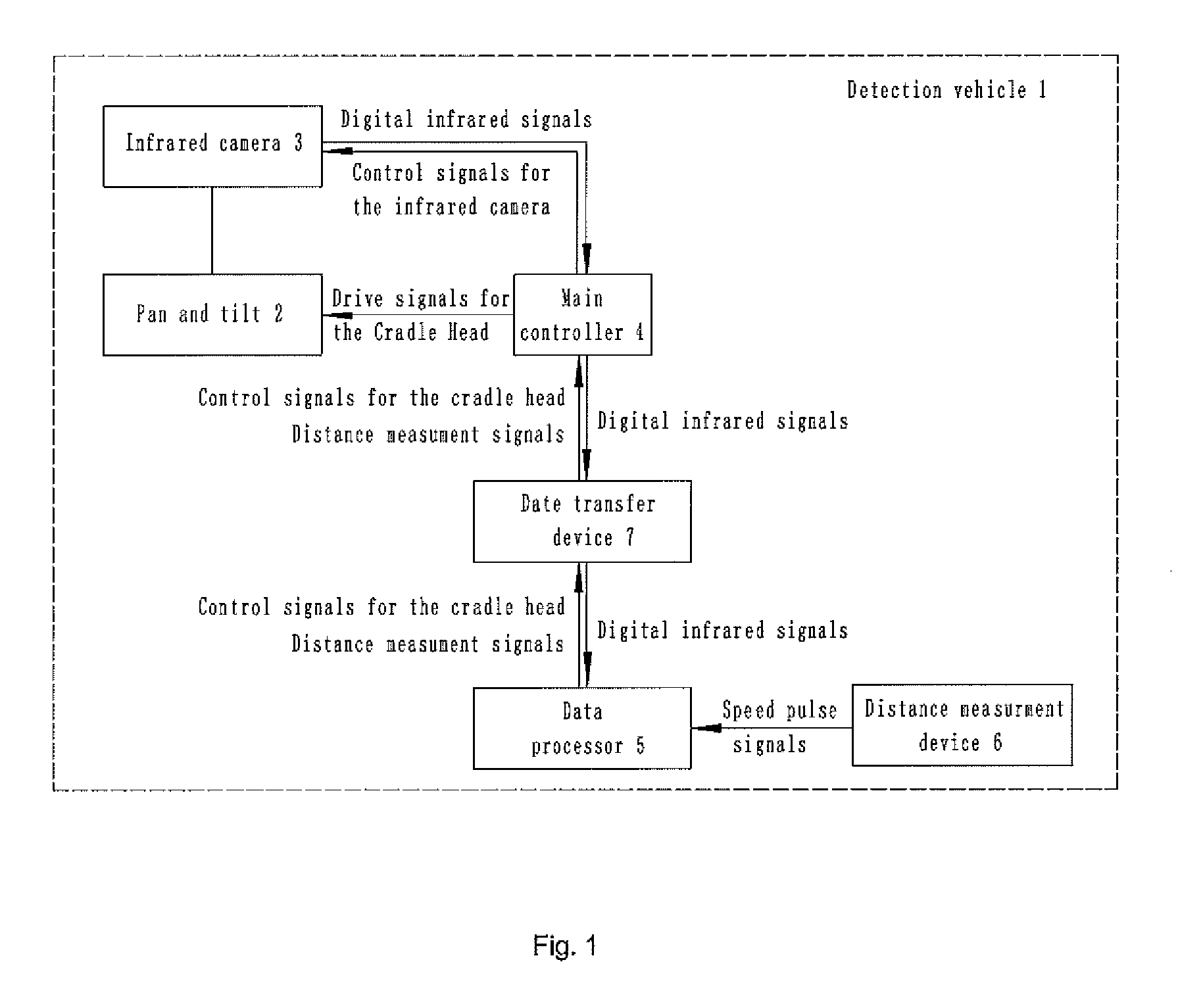

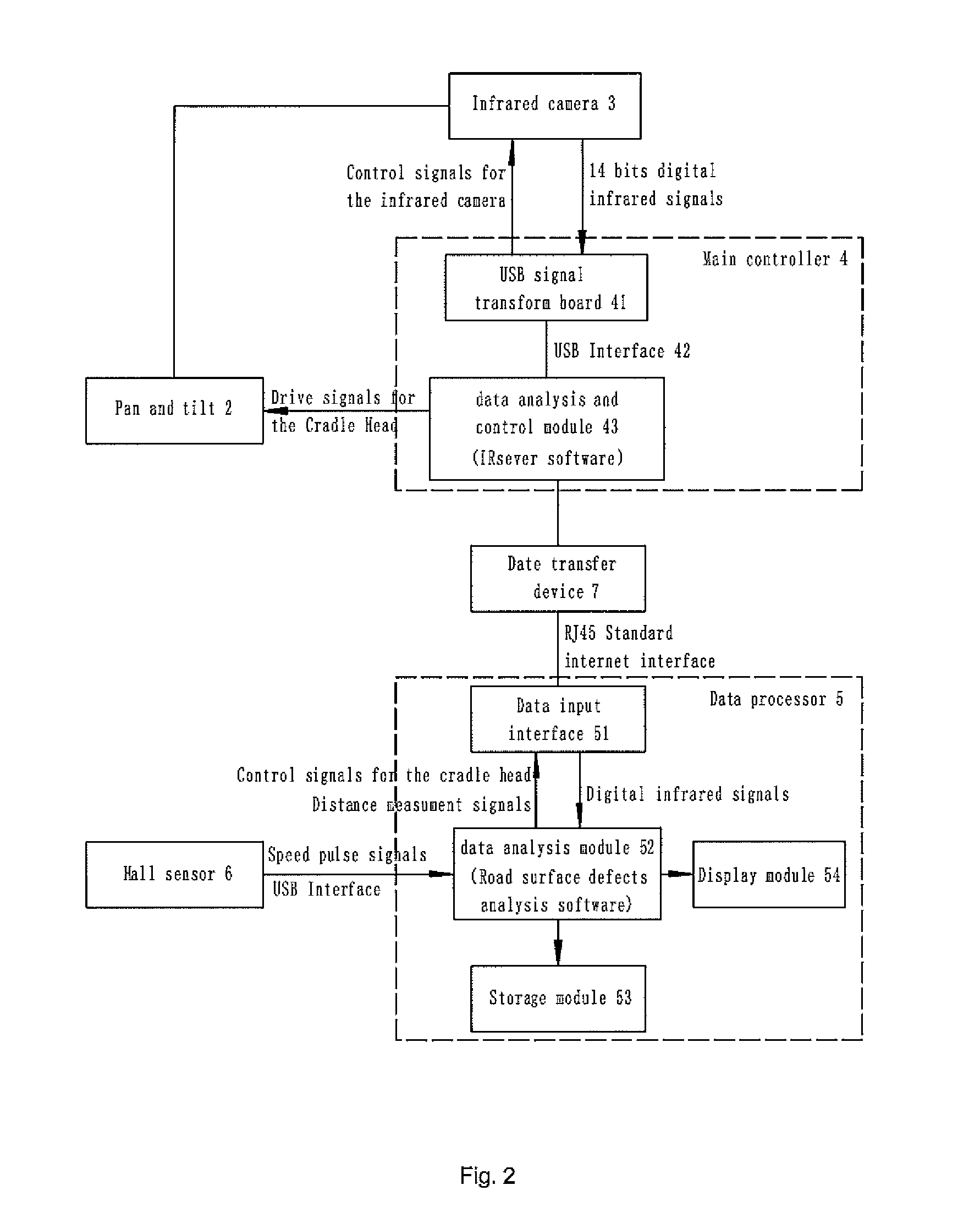

System and method for road surface defects detection

InactiveUS20120218411A1Improves existing maintenance techniqueAccurate timingTelevision system detailsColor television detailsEngineeringRoad surface

A system and method for road surface defects detection based on infrared imaging technology, while the system comprising: a detection vehicle traveling on a detected road surface; a pan and tilt provided on the detection vehicle and rotate horizontally and vertically with respect to the detection vehicle; an infrared camera detachably set on the pan and tilt, which is used to capture infrared thermal images of the detected road surface, and to output inferred thermal image digital signals about the inferred thermal images including temperature values of the detected road surface; a main controller provided on the detection vehicle and connected to the pan and tilt and the infrared camera respectively, which is used to control capture actions of the infrared camera, to control angles of the horizontal and vertical rotations of the pan and tilt, and to transform the infrared thermal image digital signals output from the infrared camera into digital signals to be used in standard network transmission; and a data processor, used to receive the digital infrared signals to be analyzed and processed to determine the type and location of defects on the detected road surface. The system of the present application has excellent operation flexibility and is able to visually display details of the defects.

Owner:GUANGZHOU SAT INFRARED TECH

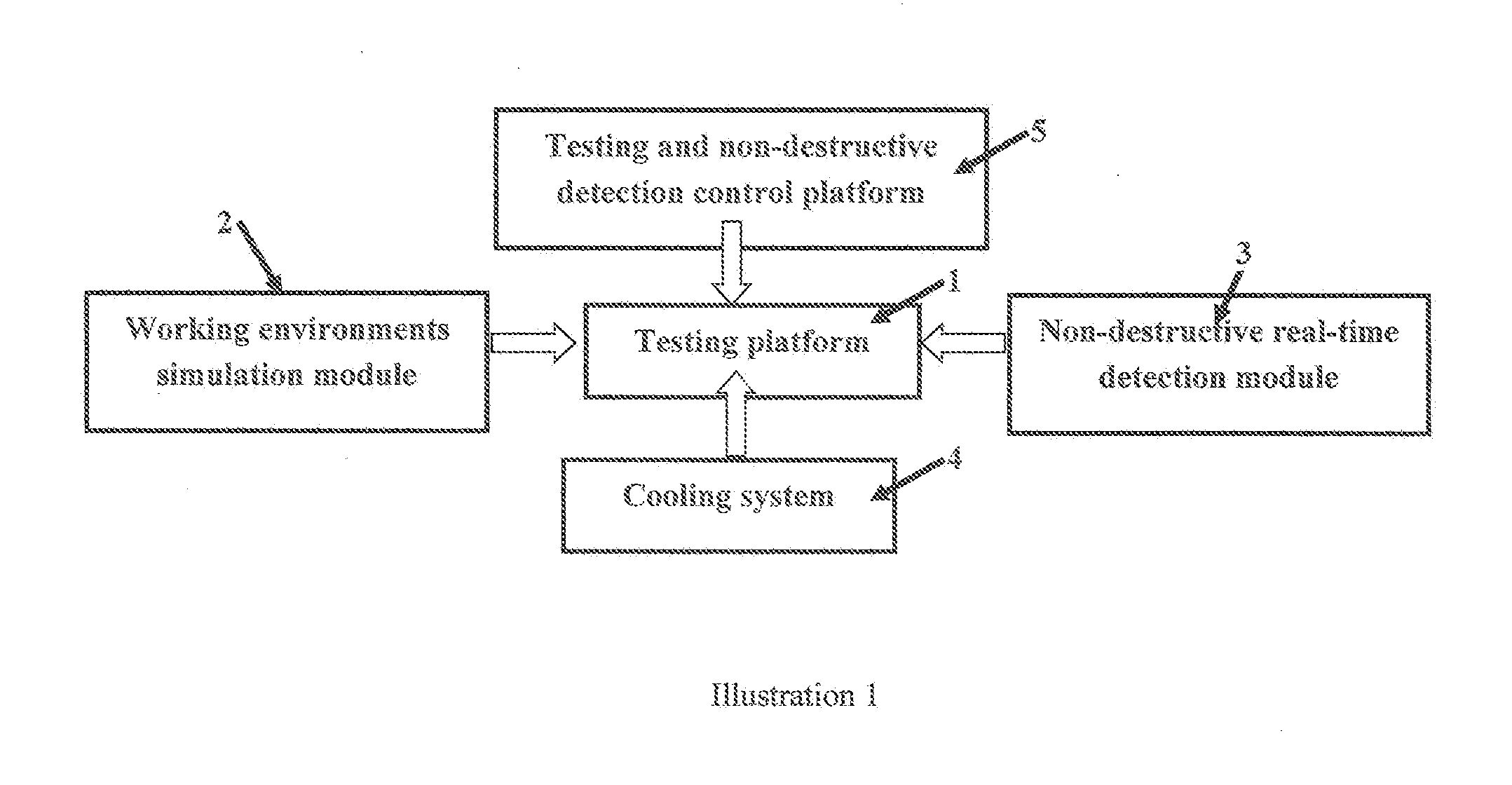

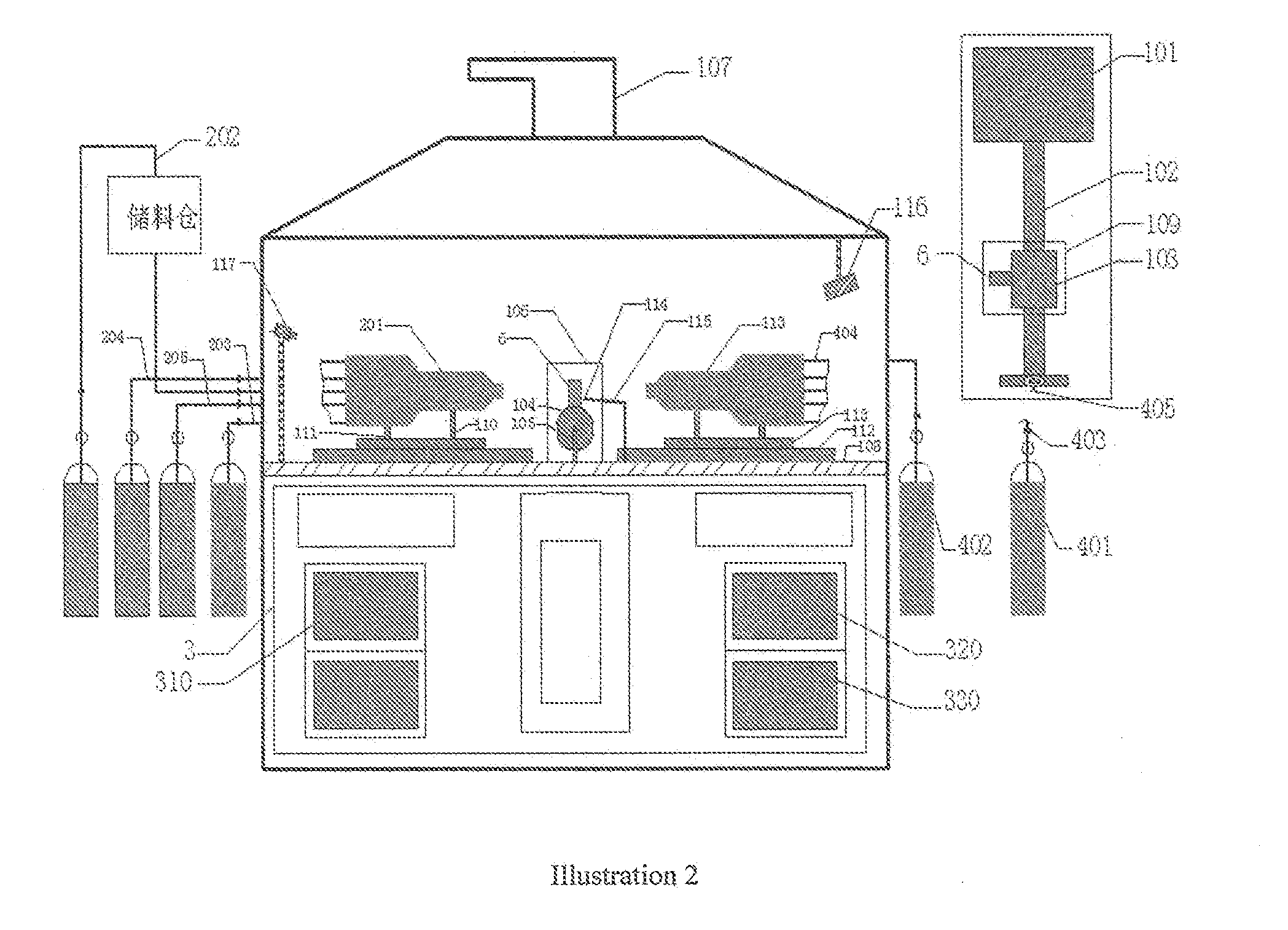

Type of testing equipment for detecting the failure process of thermal barrier coating in a simulted working environment

ActiveUS20150355074A1Better understandingReliable assessmentWeather/light/corrosion resistanceEngine testingSurface oxidationTurbine blade

A type of testing equipment for detecting the failure process of thermal barrier coating in a simulated working environment; it belongs to the field of simulated special working environment equipment. Testing equipment includes testing platform equipped with static or dynamic specimen holding apparatus, simulated module of working environment, real-time detection module, control panel. This invention is capable of simulating a high temperature, erosive, corrosive working environment for thermal barrier coated turbine blade of aero-engines; simulate high speed spinning working environment for thermal coated blade, simulate static working environment for guiding blade; perform real-time testing of temperature field, 3-D displacement field, crack initiation and expansion, surface oxidation, etc. This invention has achieved complete integration of high temperature, erosive, corrosive working environment for thermal barrier coating and complete integration static or dynamic working environment, complete integration of simulated working environment and real-time testing, thus providing a crucial testing platform and reference data to properly understand the failure mechanism of thermal barrier coated blade and to improve relevant designs; strong applicability.

Owner:XIANGTAN UNIV

Systems and methods for inspecting coatings, surfaces and interfaces

InactiveUS7220966B2Efficient detectionMinimization requirementsRadiation pyrometryPretreated surfacesThermodynamicsTemporal change

Owner:TOYOTA MOTOR CO LTD +1

Method and apparatus for measuring on-line failure of turbine thermal barrier coatings

InactiveUS7690840B2Improve efficiencyAvoid maintenanceThermometer detailsPlug gaugesTurbine bladeEngineering

A method of remotely monitoring the radiant energy (6) emitted from a turbine component such as a turbine blade (1) having a low-reflective surface coating (3) which may be undergoing potential degradation is used to determine whether erosion, spallation, delamination, or the like, of the coating (3) is occurring.

Owner:SIEMENS ENERGY INC

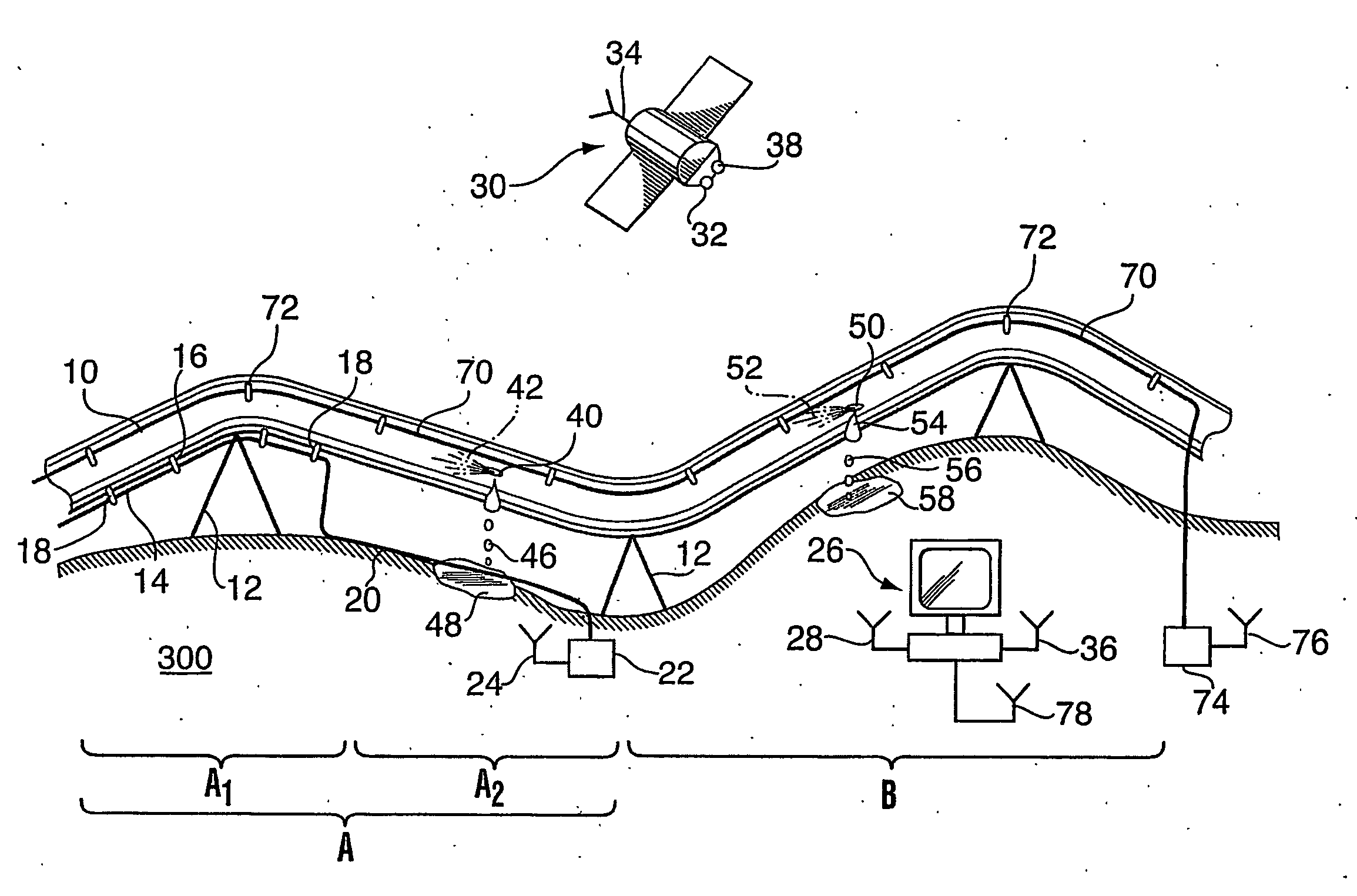

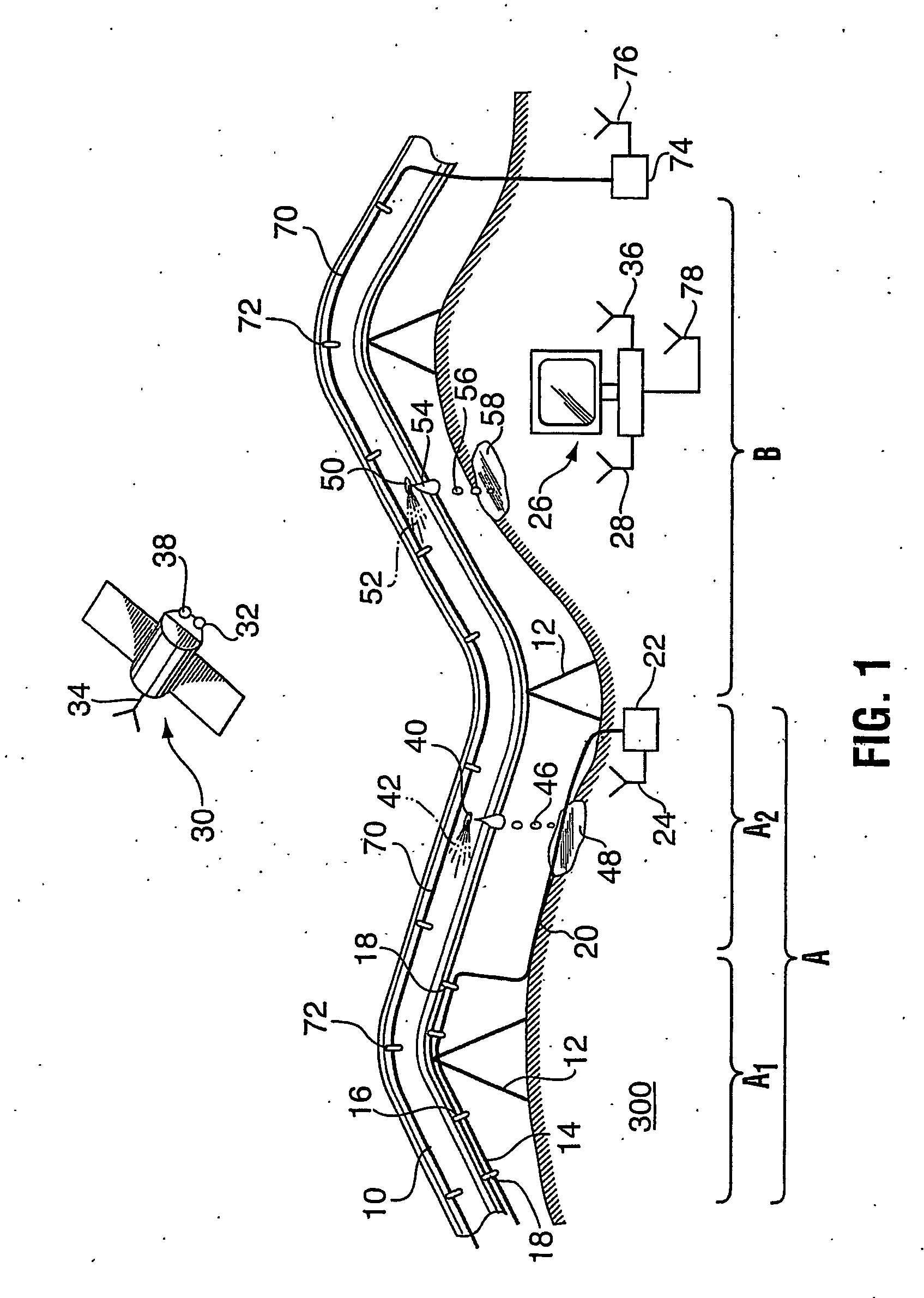

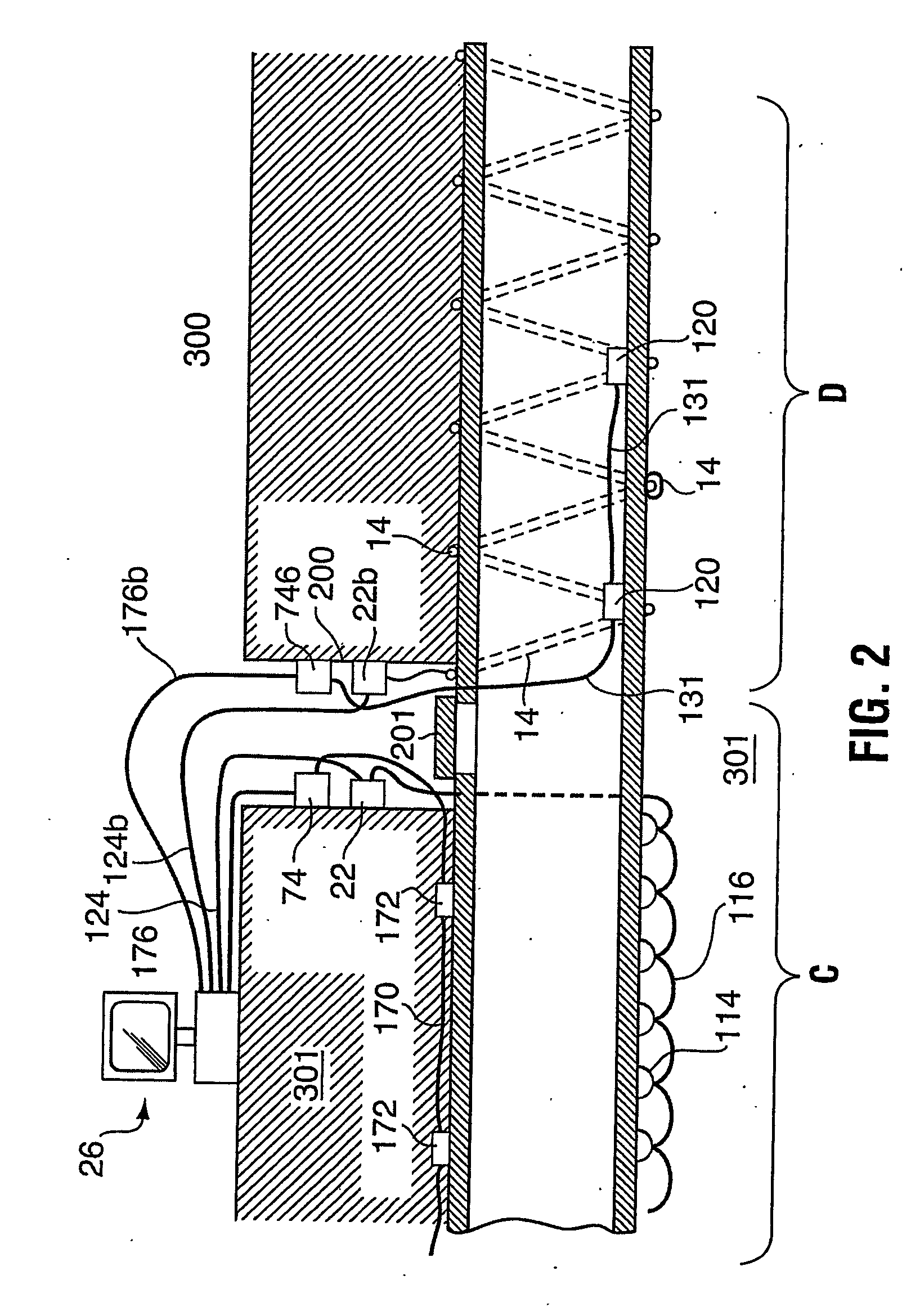

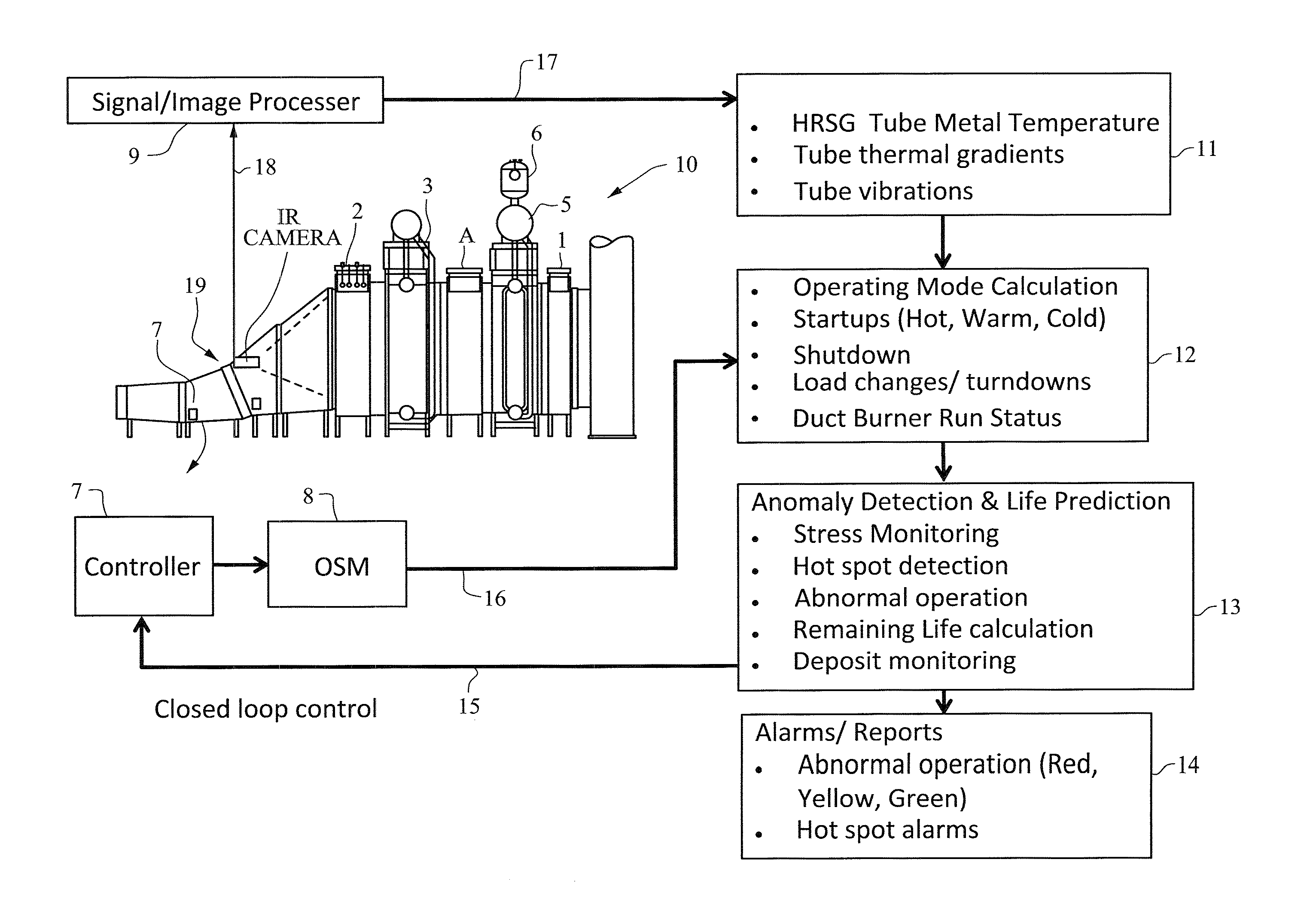

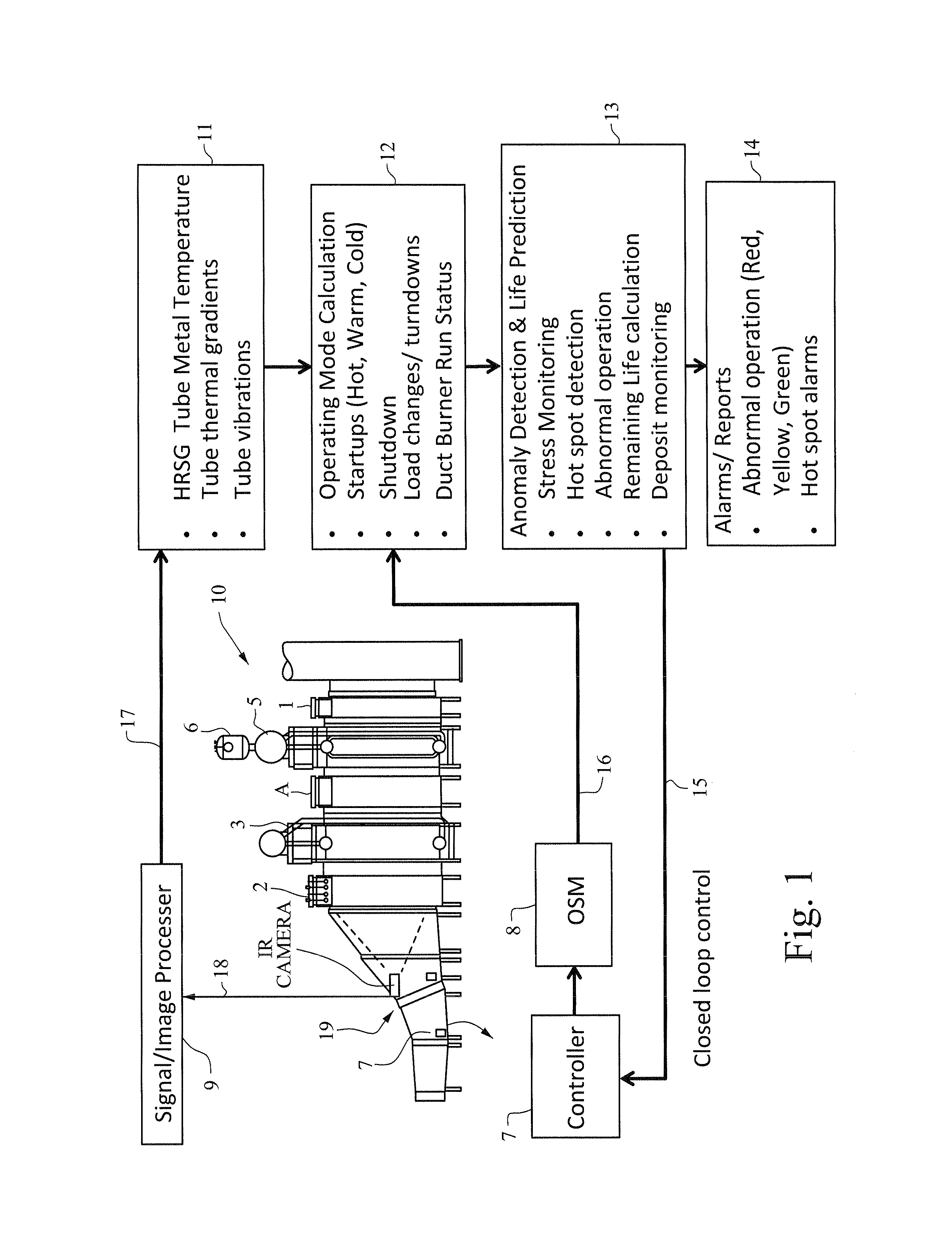

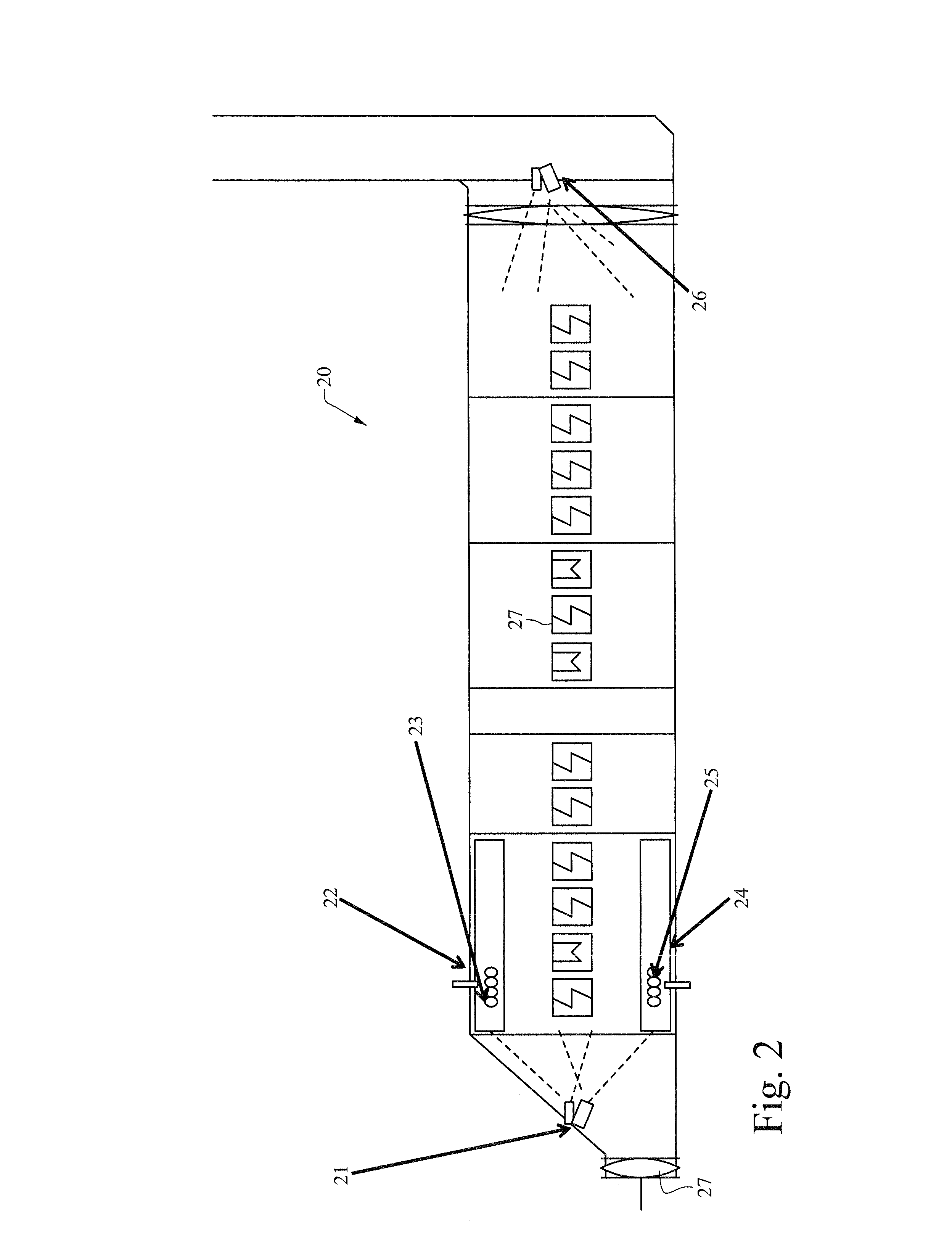

Continuous infrared thermography monitoring and life management system for heat recovery steam generators

ActiveUS20130176418A1Improve reliabilityReduce downtimeTelevision system detailsColor television detailsEngineeringThermography

A method for continuously monitoring the working condition of a heat recovery steam generator (“HRSG”) using infrared thermography, comprising the steps of identifying target locations inside the HRSG, positioning one or more infrared cameras to continuously monitor and record the temperature at each target location, generating continuous thermographic images corresponding to selected components and locations at each target locations, comparing the continuous thermographic images to corresponding, stored base line images and generating a set of comparative data reports in real time for each target location in order to predict the life span or potential failure of HRSG components.

Owner:GENERAL ELECTRIC CO

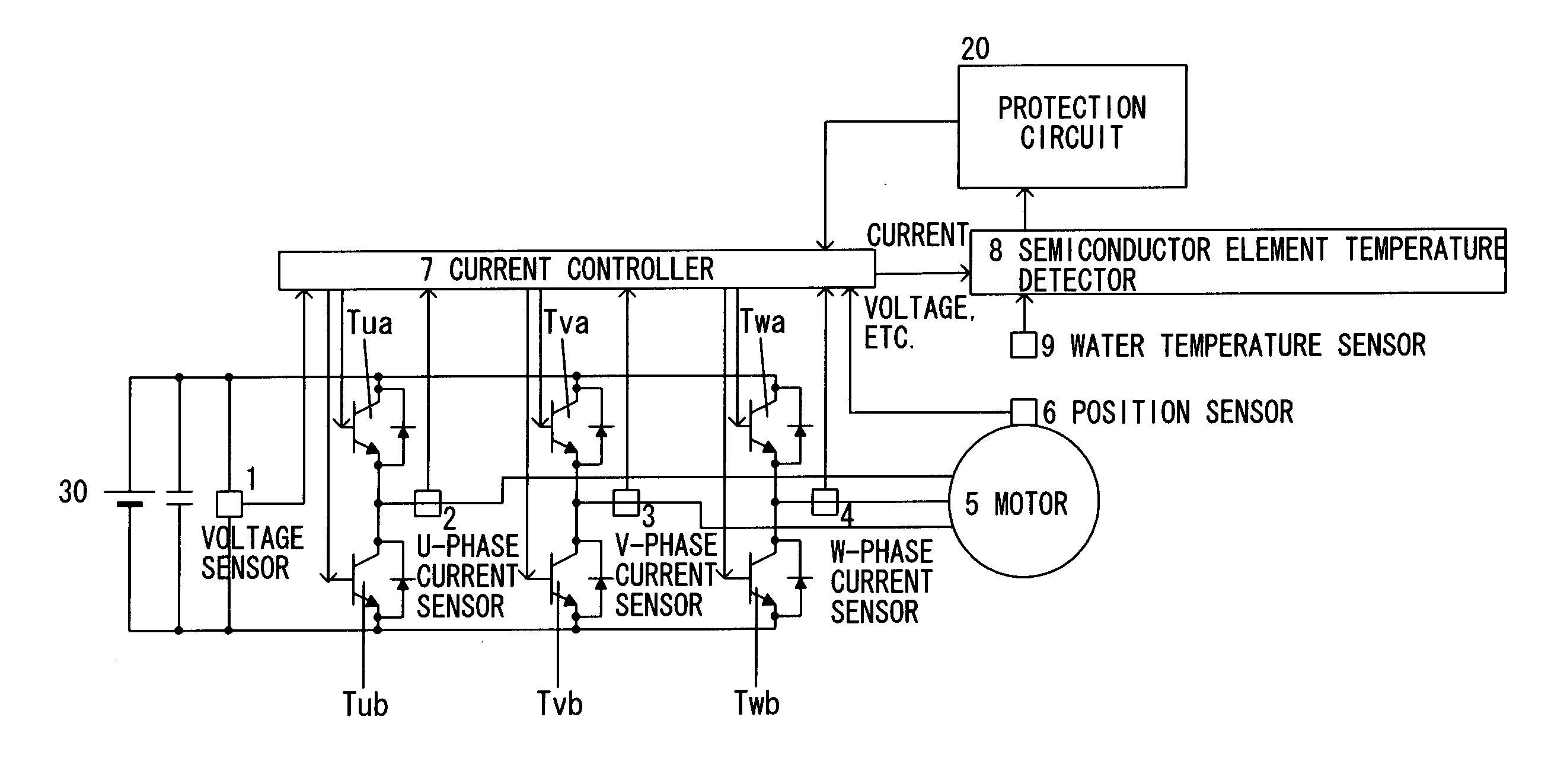

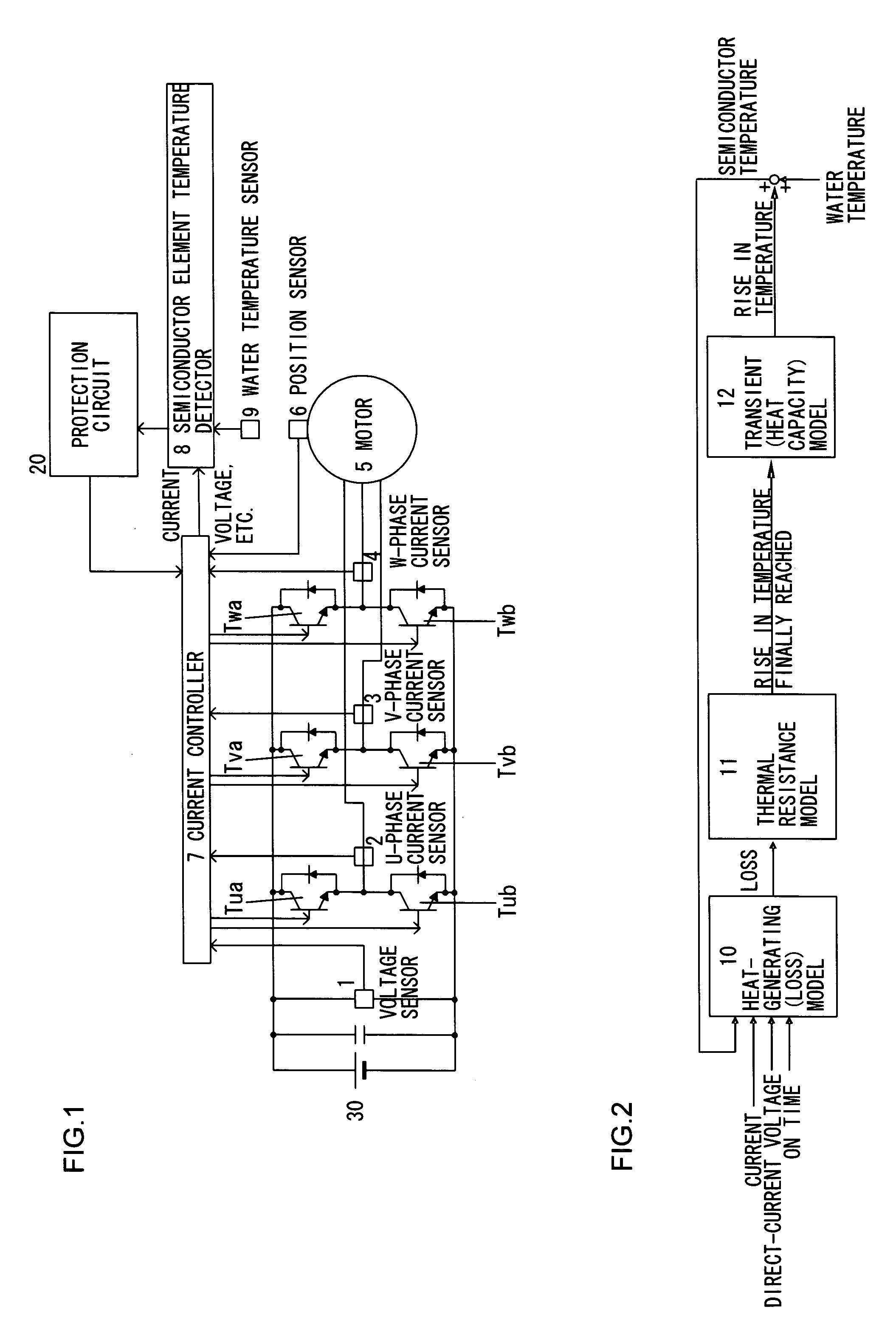

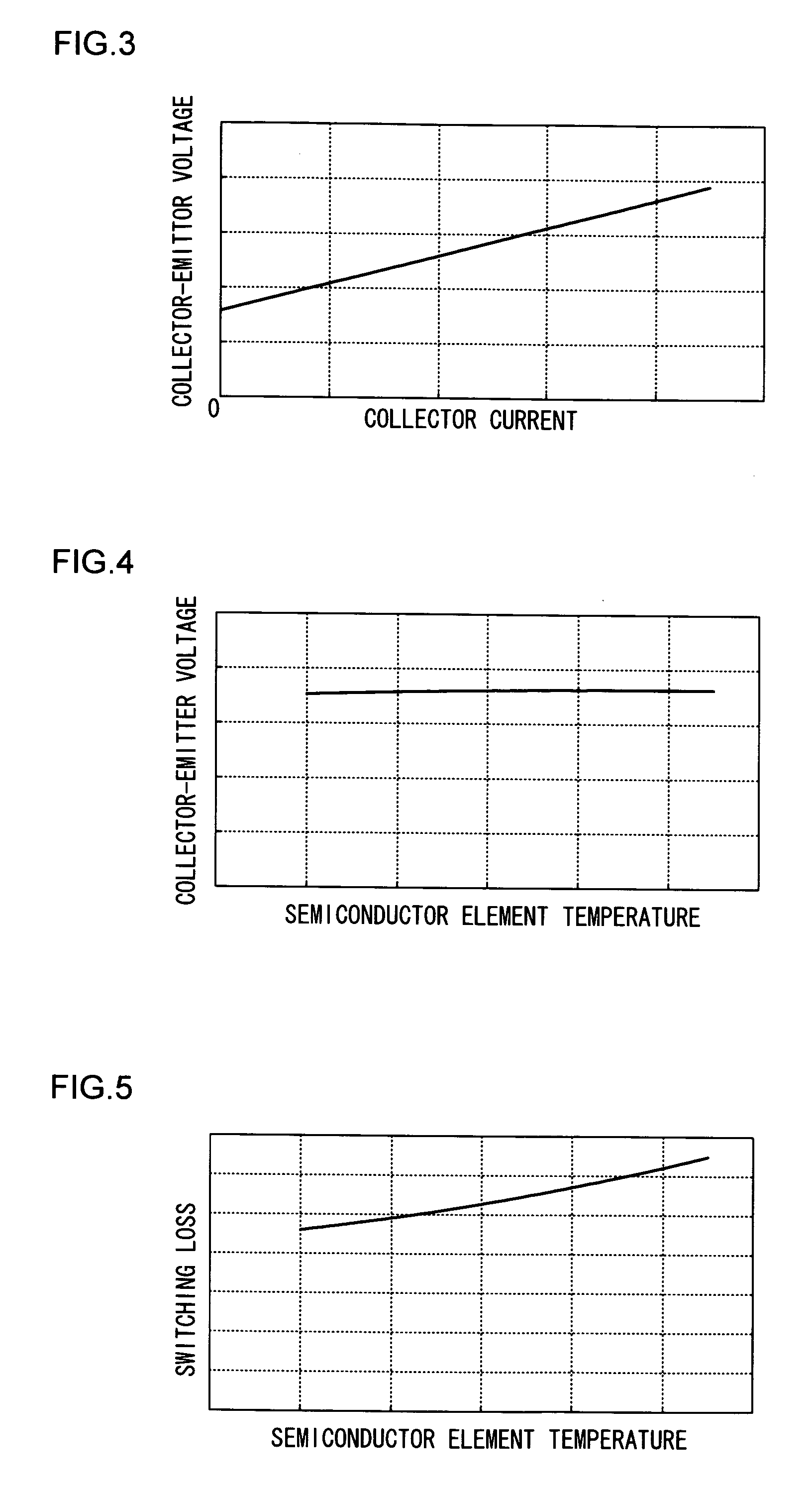

Temperature detection device, temperature detection method, and computer-readable computer program product containing temperature detection program

InactiveUS20050204761A1Increase costIncrease in sizeThermometer detailsThermometers using electric/magnetic elementsTemperature differenceEngineering

Heating value P[W] generated at an IGBT is calculated, and a temperature difference ΔT′j [° C.] between a temperature Tw [° C.] of cooling water circulating in a cooling system and a temperature Tj [° C.] of an IGBT is calculated based on thermal resistance R [° C. / W] of the cooling system. A temperature rise ΔTj [° C.] with transient influences eliminated is then calculated based on the calculated temperature difference ΔT′j [° C.], and the temperature Tj [° C.] (=Tw [° C.]+ΔTj [° C.]) of the IGBT is calculated.

Owner:NISSAN MOTOR CO LTD

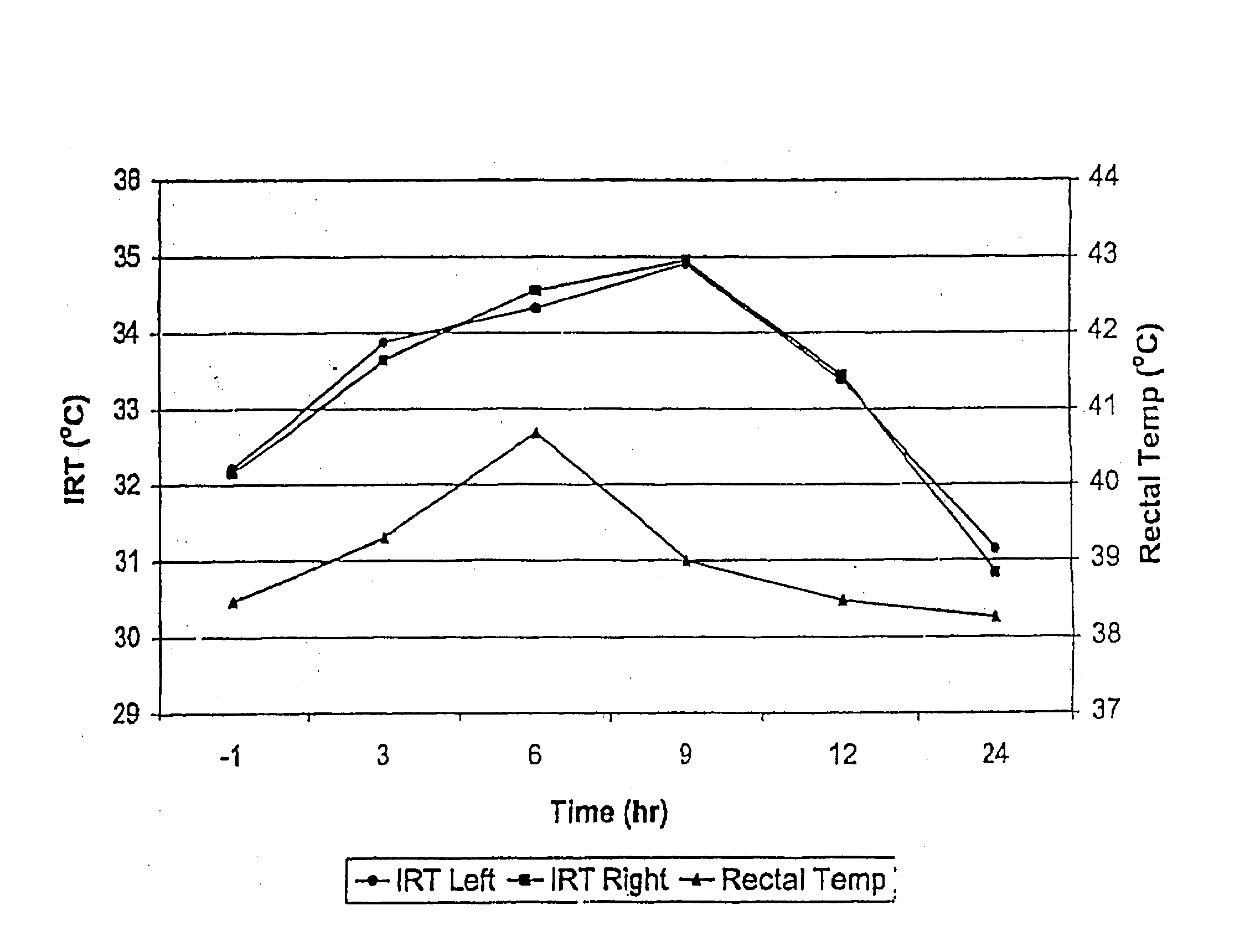

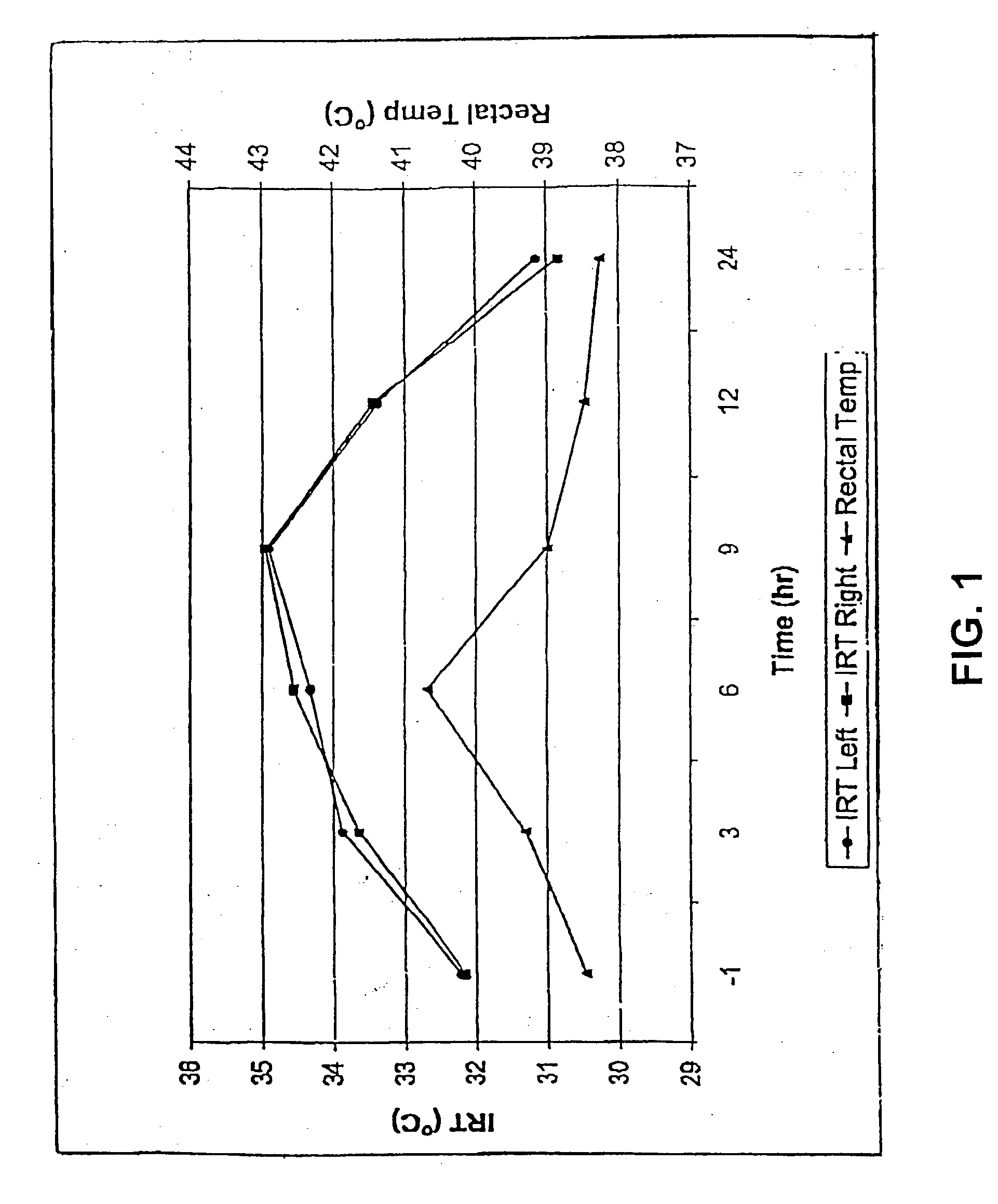

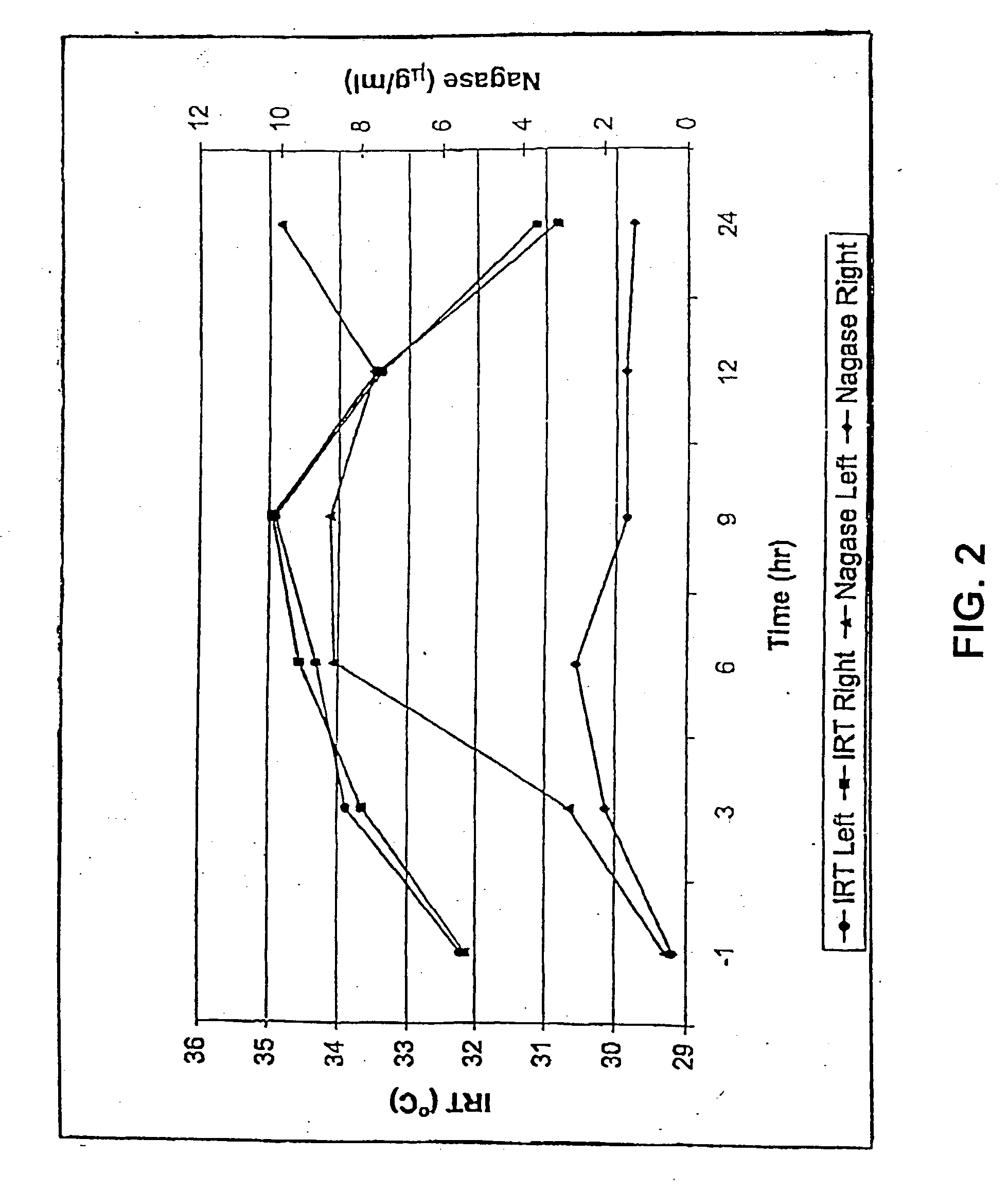

Early detection of inflammation and infection using infrared thermography

InactiveUS20040019269A1Clinically significantMaterial flaws investigationDiagnostic recording/measuringDiseaseAnimal use

The present invention provides a method for the detection of inflammation in animals using infrared thermography. The invention also provides a method for the detection of diseases or disorders that induce inflammation using infrared thermography. The present invention further provides a method for the detection of infections in animals using infrared thermography.

Owner:SCHAEFER ALLAN L +3

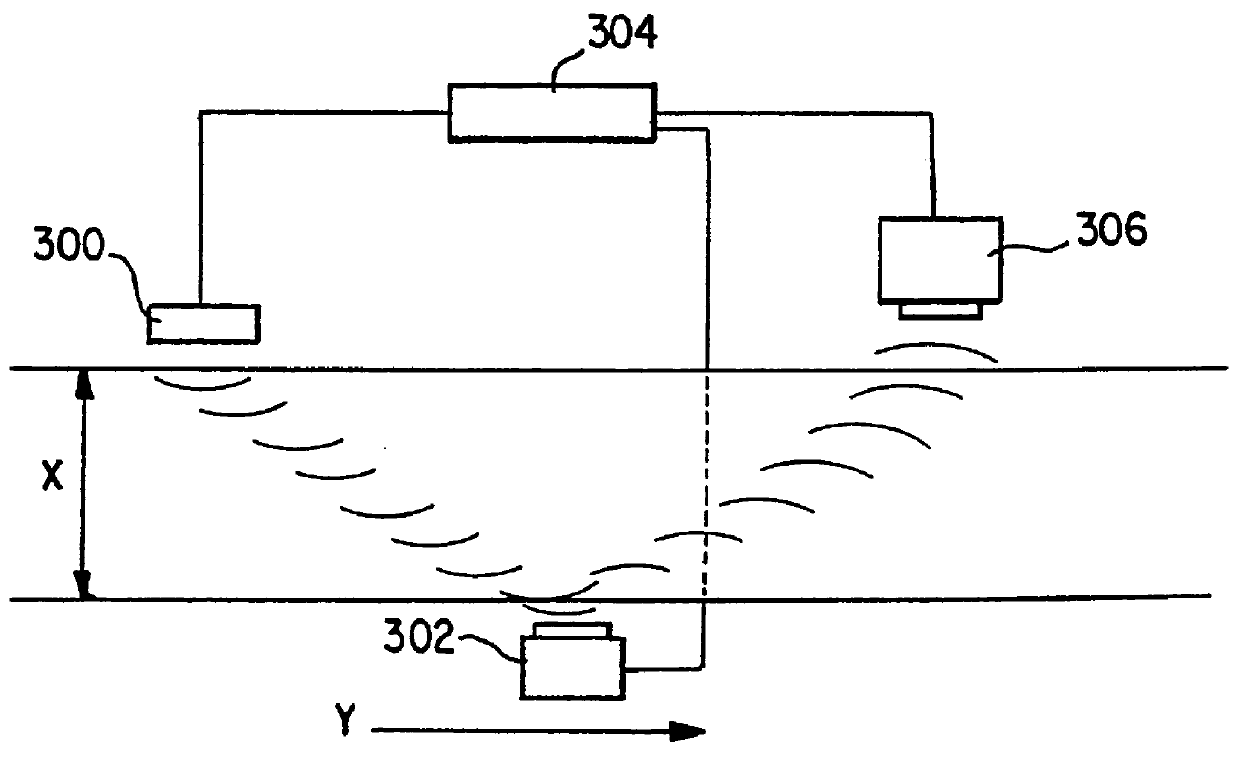

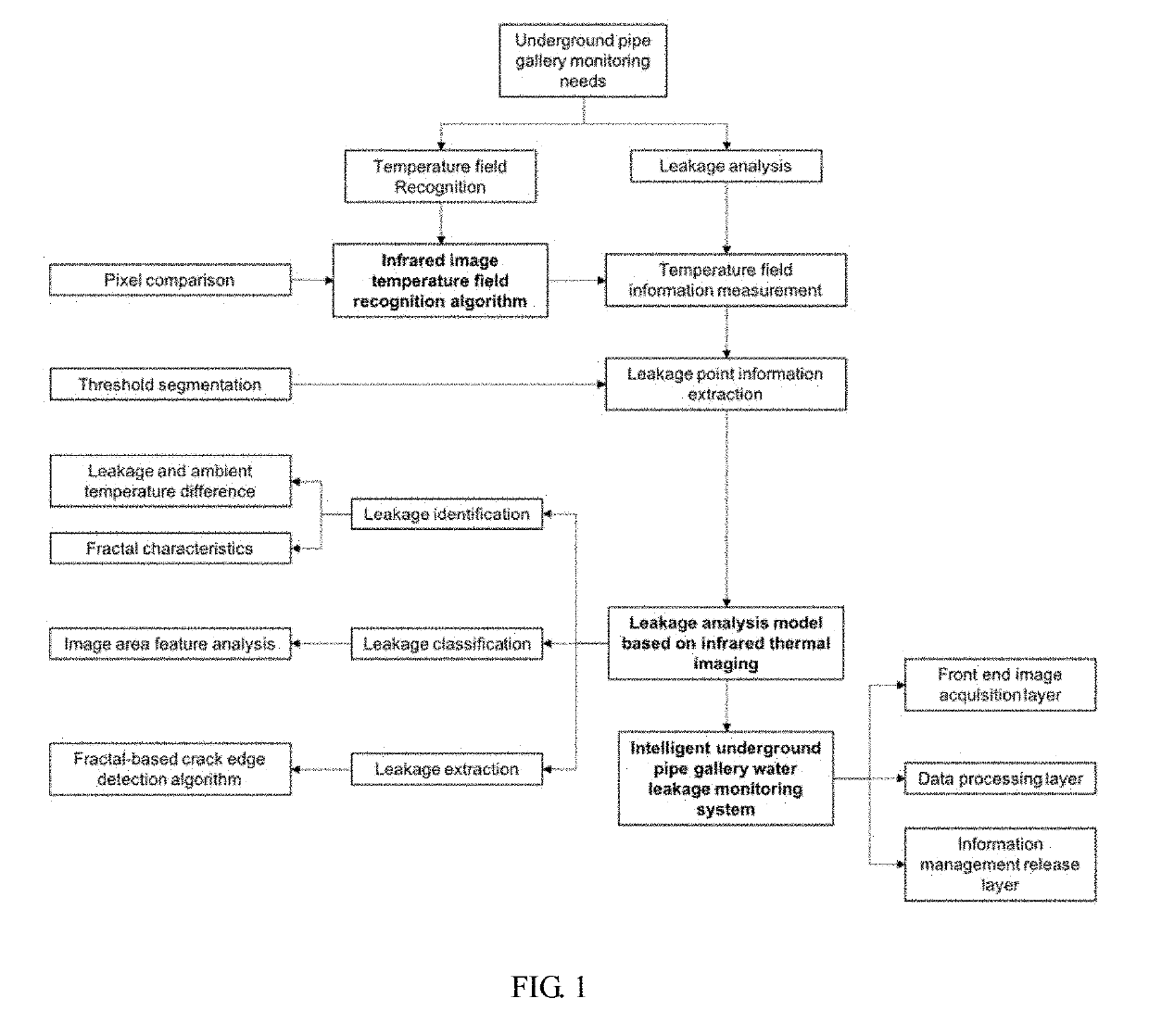

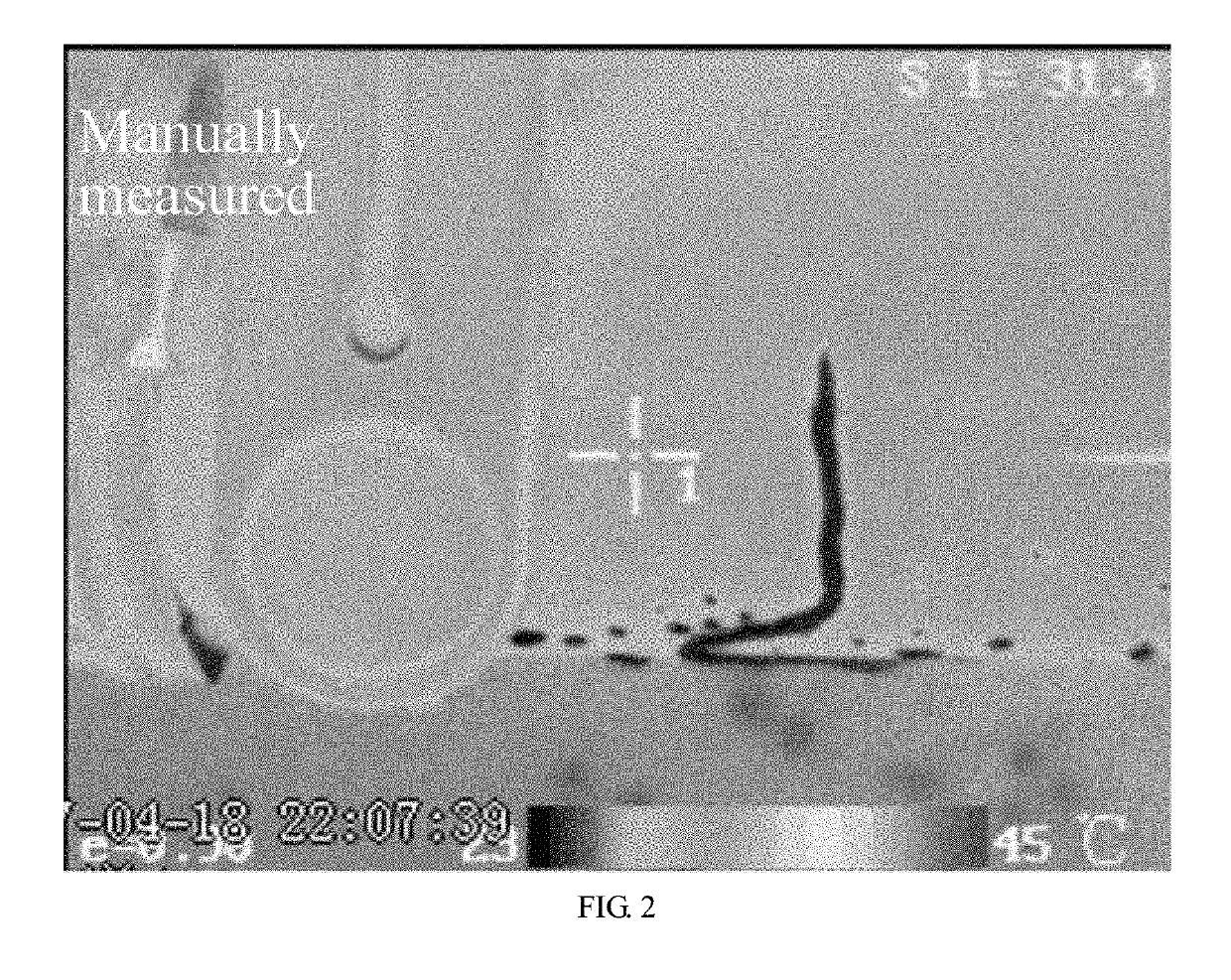

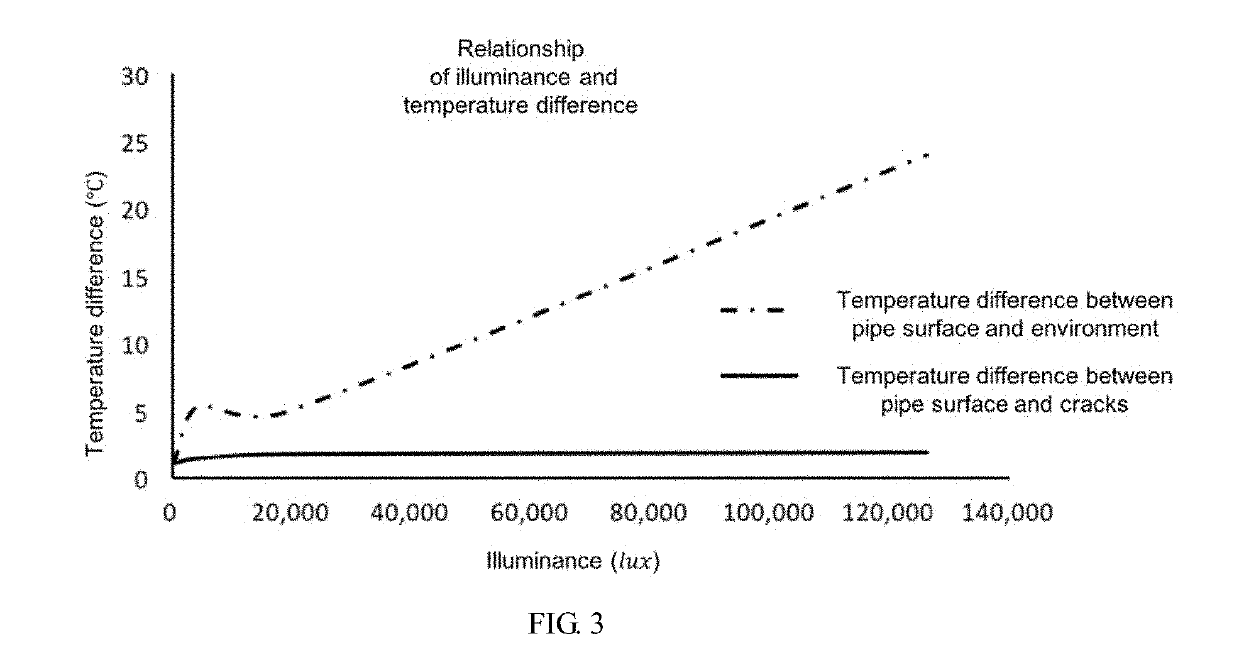

Method for leakage detection of underground pipeline corridor based on dynamic infrared thermal image processing

ActiveUS20190331301A1Little informationReduce contrastIn situ pavingsMaterial strength using tensile/compressive forcesEngineeringThermal image processing

Owner:DU YUCHUAN

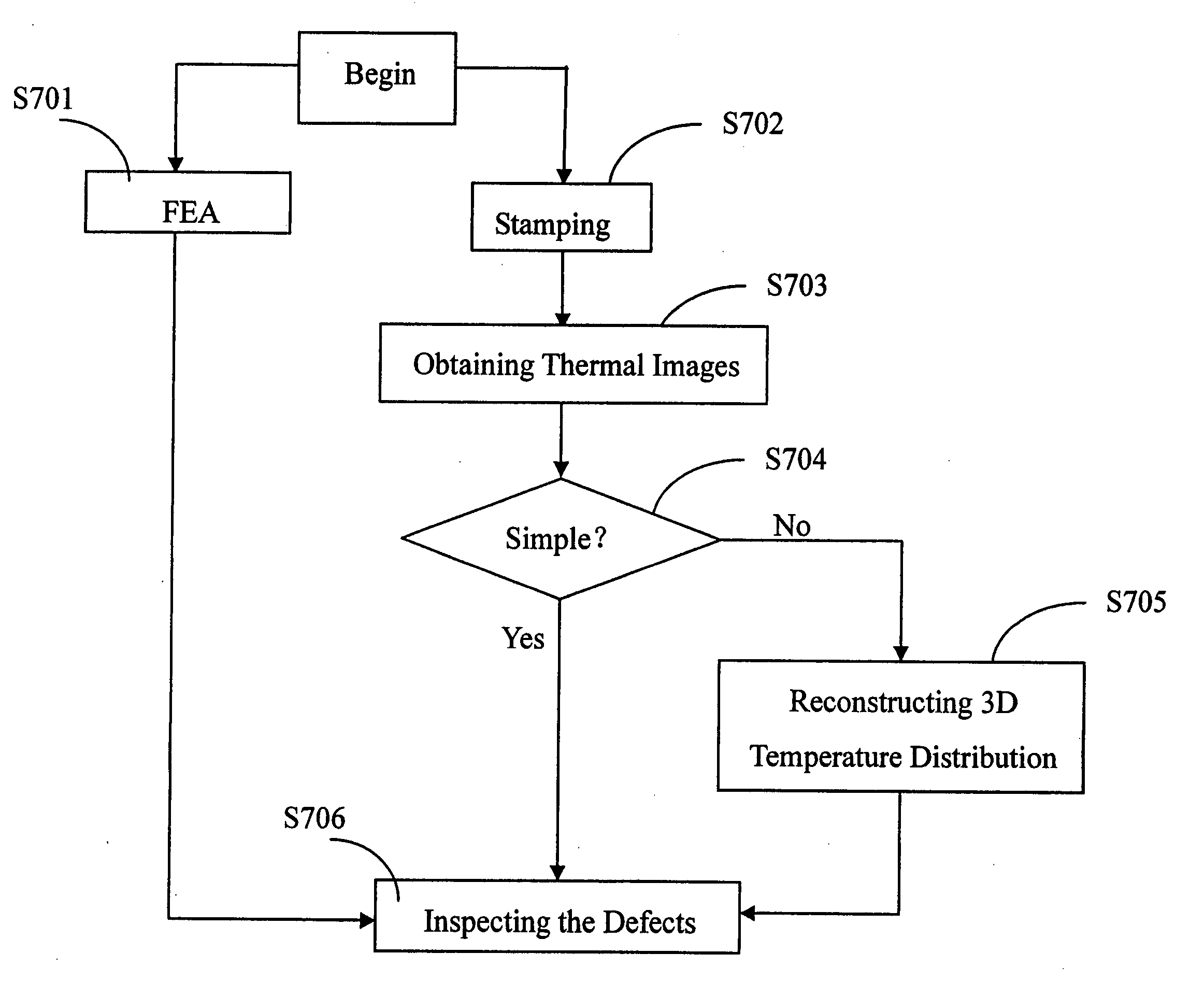

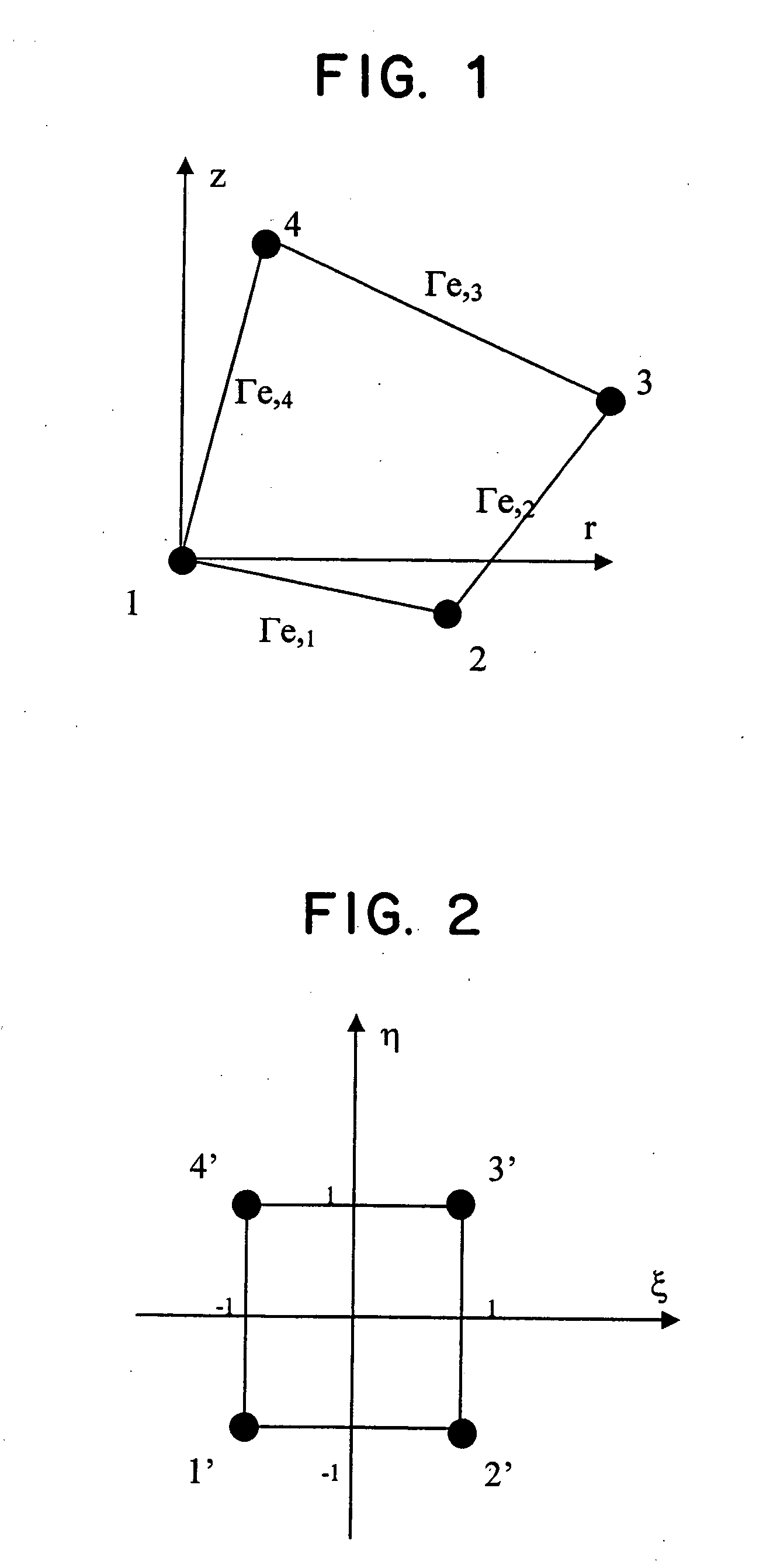

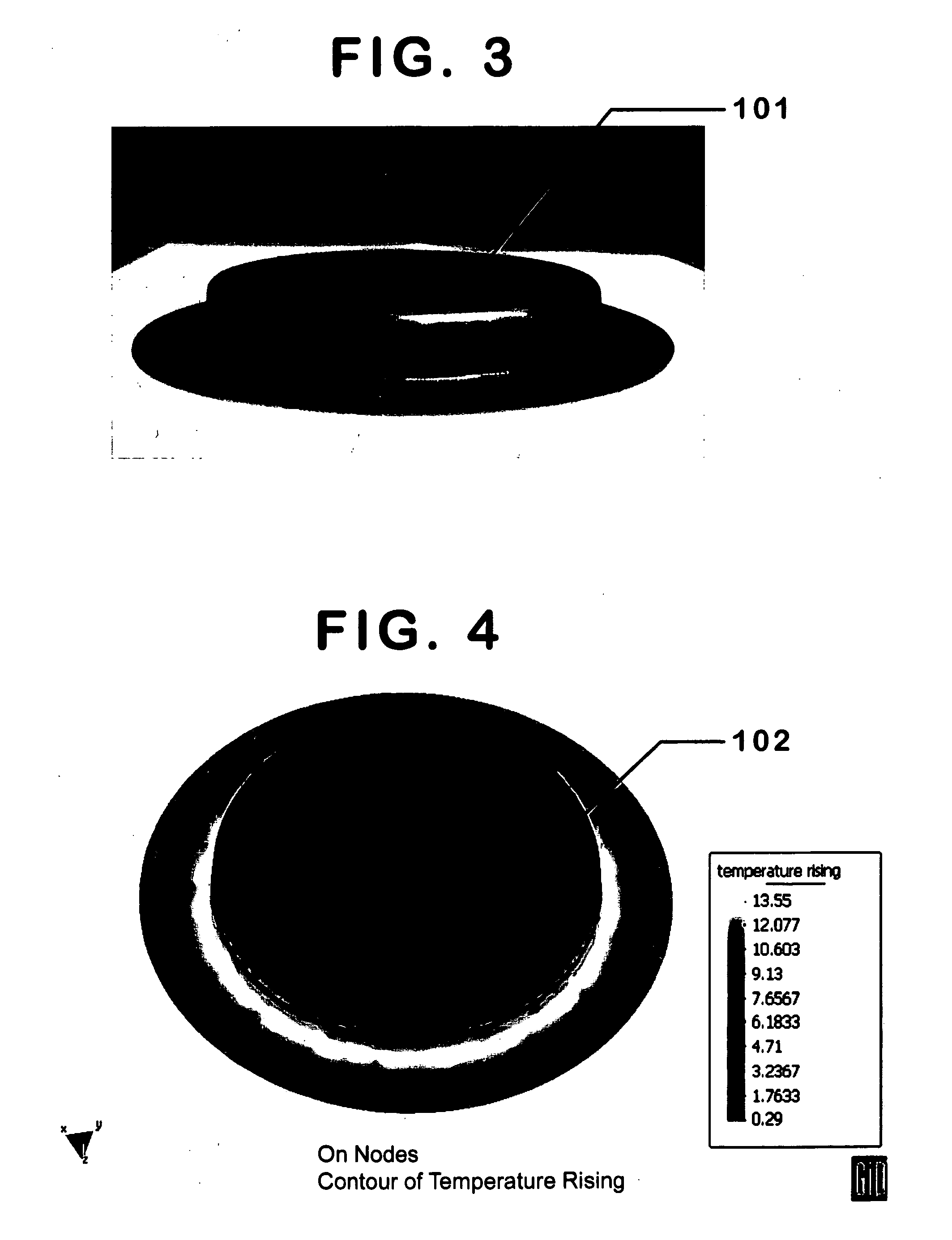

Method and apparatus for inspecting an object after stamping

InactiveUS20060222237A1Character and pattern recognitionMaterial flaws investigationStamping processComputer science

A method and apparatus for inspecting an object after stamping is described. The method and apparatus comprises determining a temperature distribution of an object after stamping; obtaining one or more thermal images of the object after stamping; and comparing the determined temperature distribution with the obtained thermal images so as to identify defects existing in the object after stamping, in which the difference between the temperature distribution and the thermal images indicates the presence of defects in the object. The method and apparatus can therefore inspect and analysis problems of the object occurred during the stamping process.

Owner:THE CHINESE UNIVERSITY OF HONG KONG +1

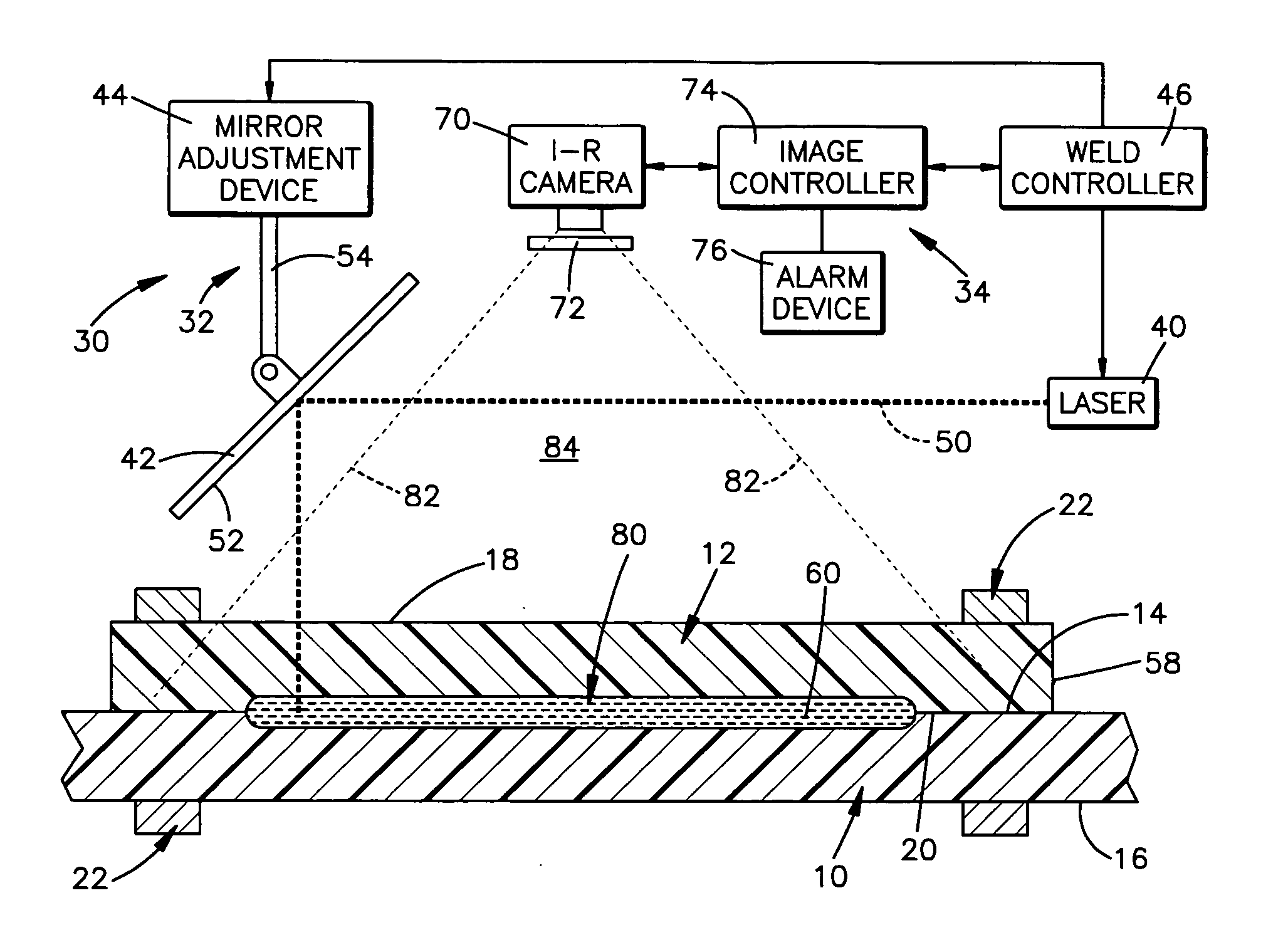

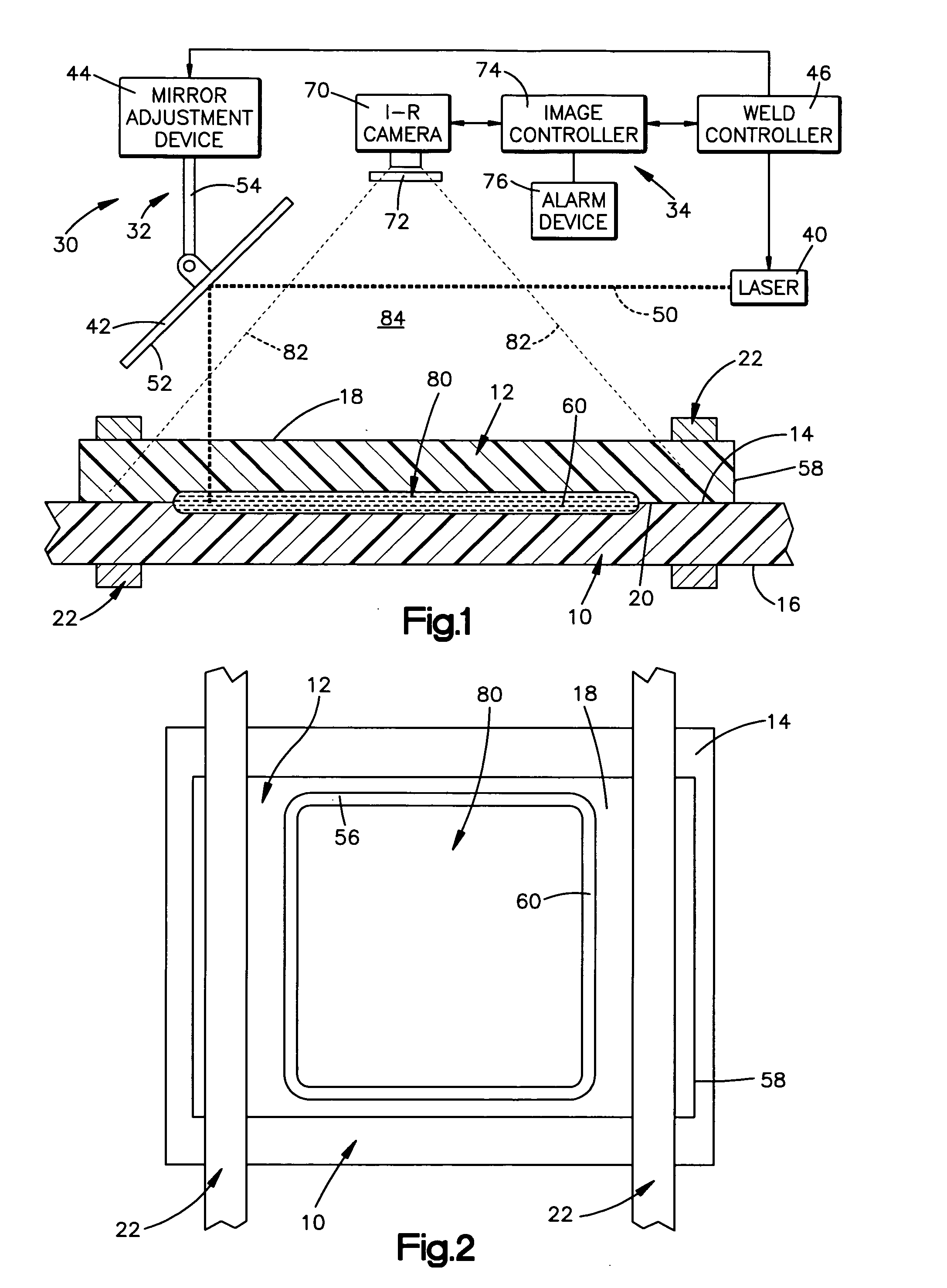

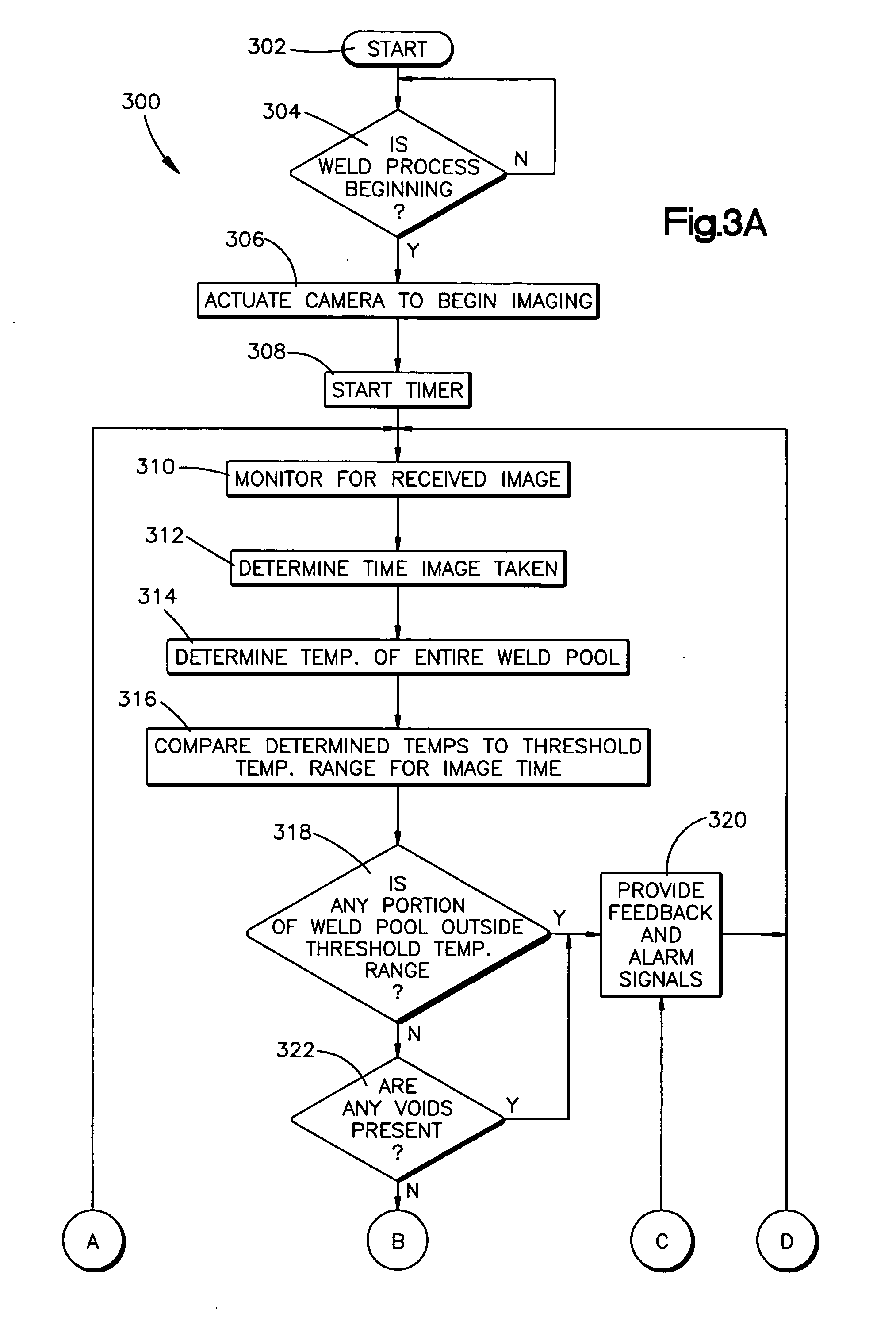

Method for monitoring quality of a transmissive laser weld

InactiveUS20050169346A1Forming accuratelyRadiation pyrometryMaterial flaws investigationEngineeringLaser

A method for monitoring quality of a weld (56) being formed between first and second pieces of material (10 and 12) includes the steps of obtaining a thermal image of the weld (56) being formed by collecting infrared radiation passing through the second piece of material (12); and analyzing the obtained thermal image for characteristics indicative of a properly formed weld (56).

Owner:TRW AUTOMOTIVE US LLC

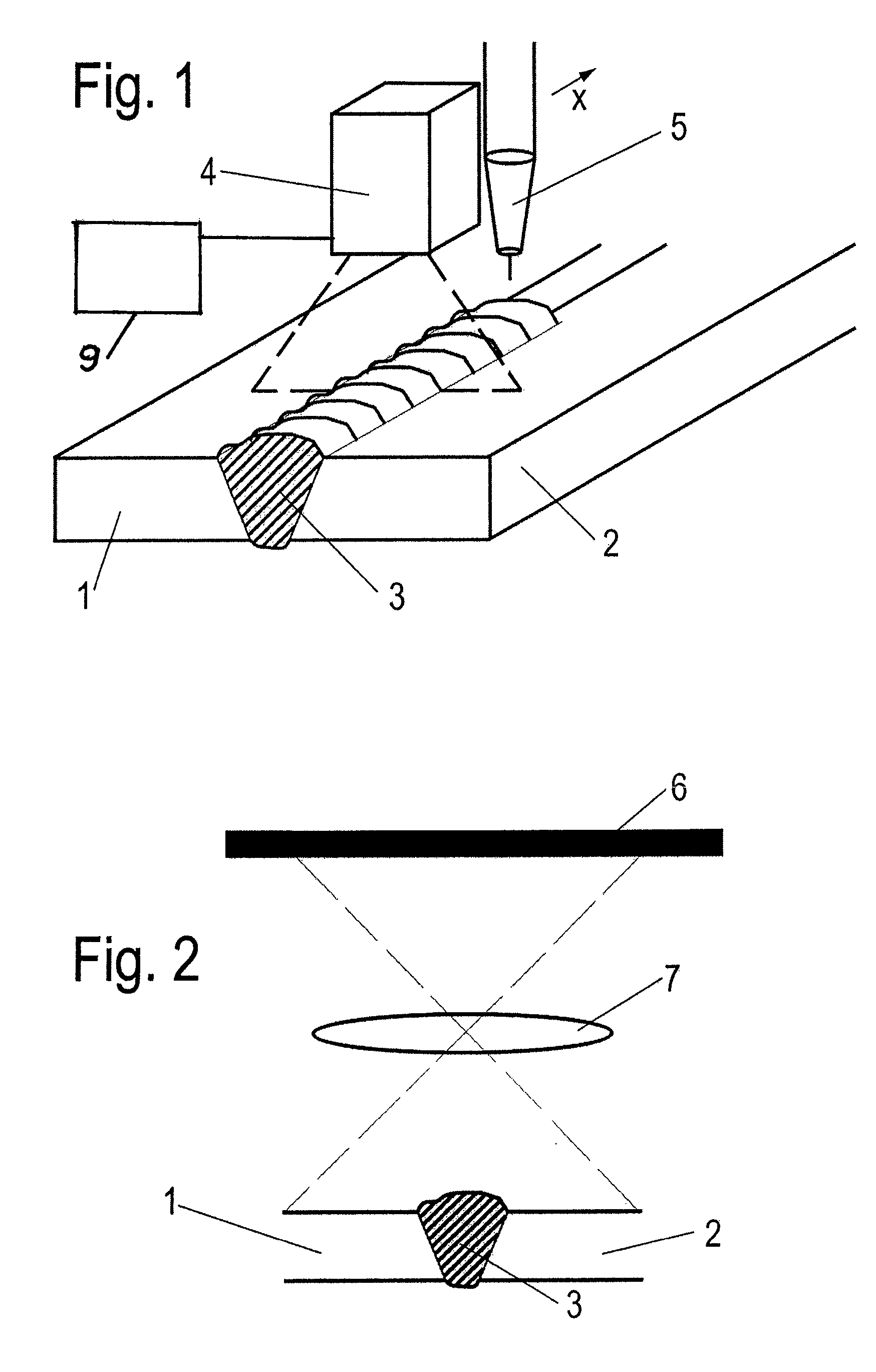

Process and system for the nondestructive quality determination of a weld seam, and a welding device

A process for the non-destructive determination of the quality of a weld seam, the process steps comprising: providing a first and a second component; connecting the first and second components by a weld seam produced by a welding operation; and measuring a surface temperature of the weld seam and surface temperatures of areas of the first and second components adjacent to the weld seam that were heated by the welding operation. A system for carrying out the process for the non-destructive determination of the quality of a weld seam, the system comprising: a measuring device, an analyzing unit, and a welding device.

Owner:BENTELER AUTOMOBILTECHNIK GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com