Patents

Literature

266 results about "Material defect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method and System for Inspecting a Surface Area for Material Defects

ActiveUS20140168420A1Reduce associated effortReduce security risksPicture taking arrangementsColor television detailsMaterial defectEngineering

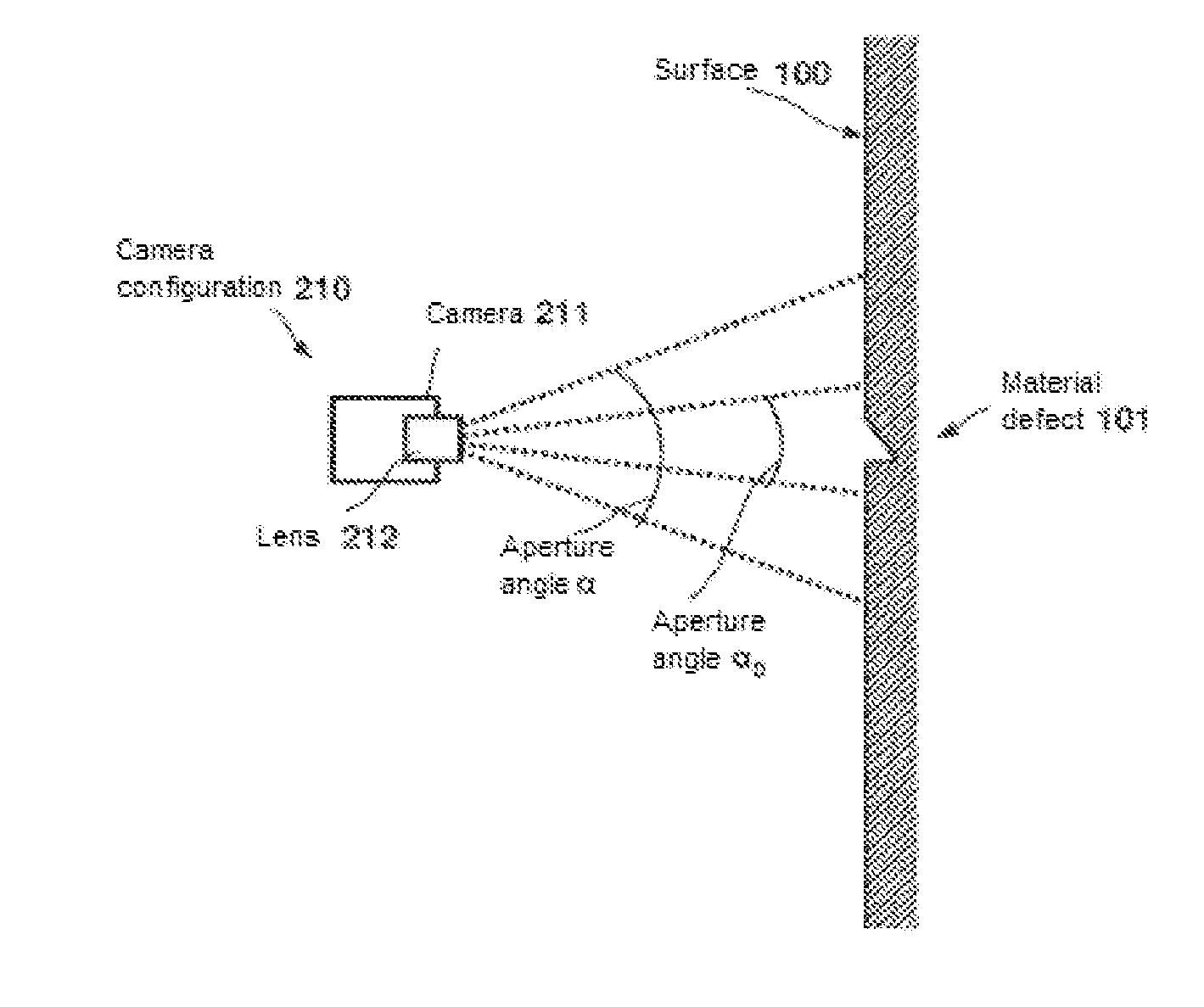

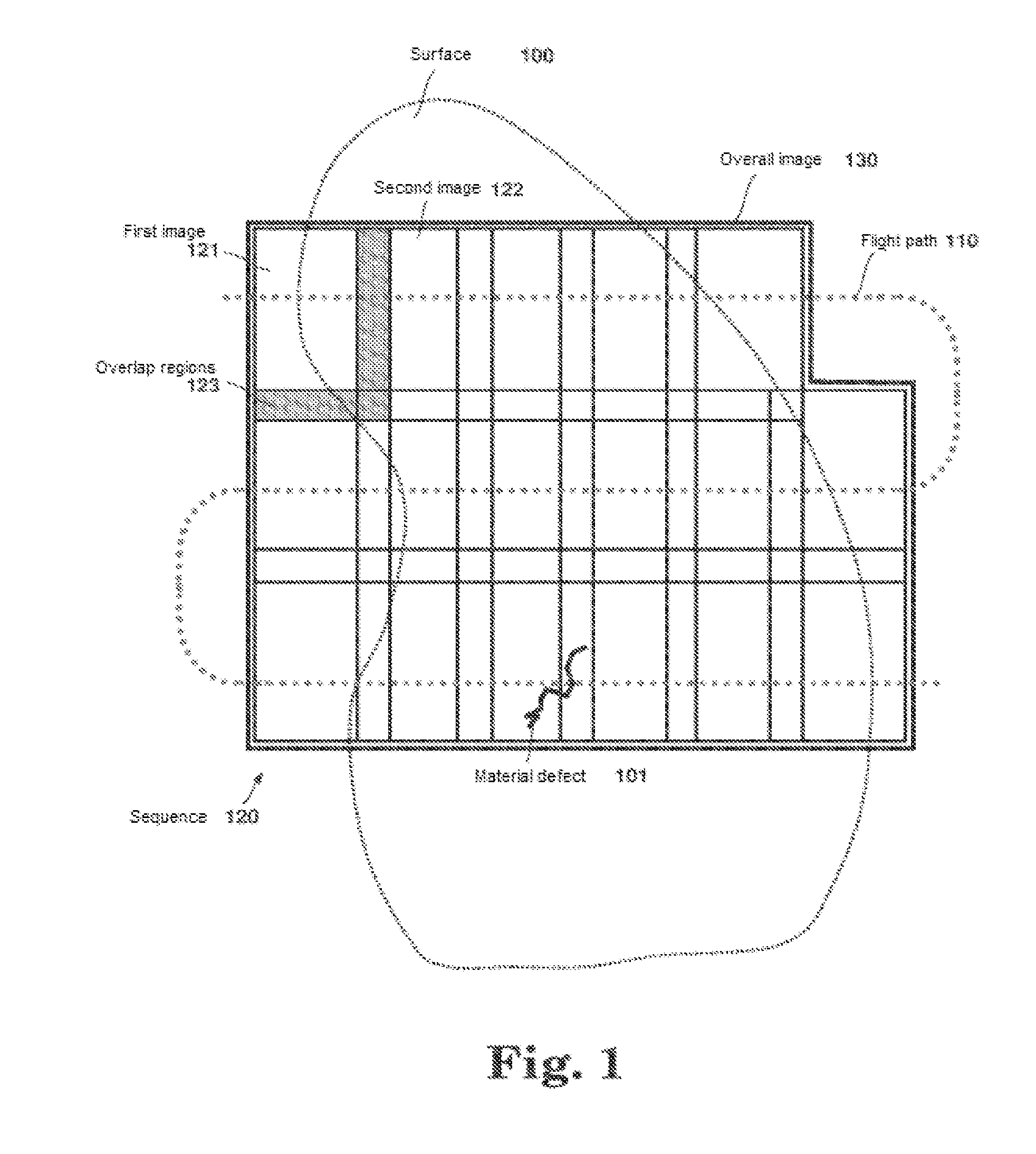

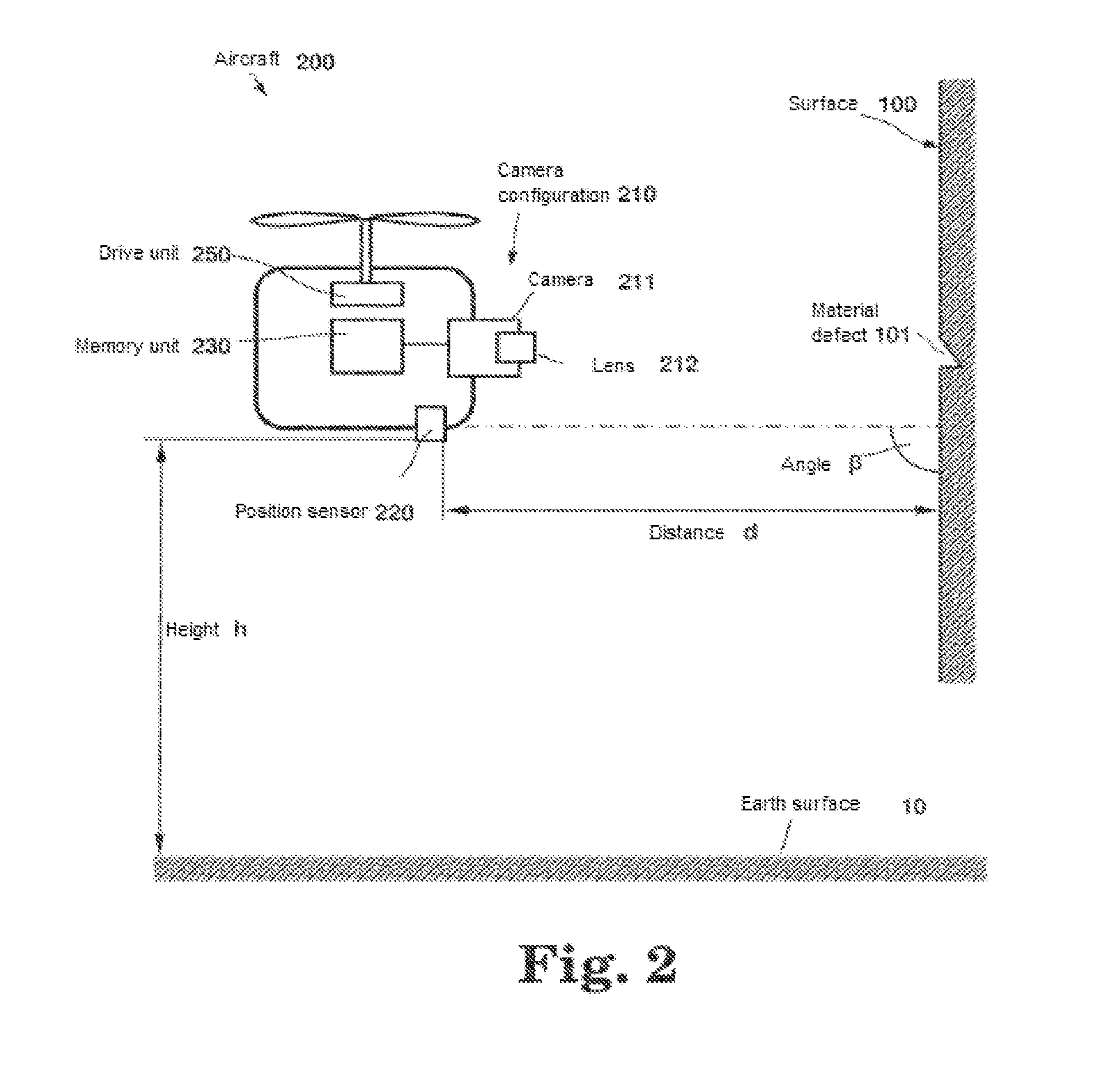

A camera assembly arranged on an unmanned and autonomously navigating aerial vehicle is employed to inspect a surface area of for material defects. The vehicle is automatically flown to the surface area from a launch site, wherein it can fly around obstacles using automatic obstacle detection and avoidance methods. A relative position of the aerial vehicle with respect to the surface area with the aid of a position sensor is continuously measured and a sequence of images of the surface area is recorded. Between the individual images, the aerial vehicle is moved along a flight path overlapping image details of the surface area. The images of the sequence are composed into an overall image of the surface area to allow for the surface area to be inspected for defects and the location of defects to be ascertained on the basis of the overall image.

Owner:EADS DEUT GMBH

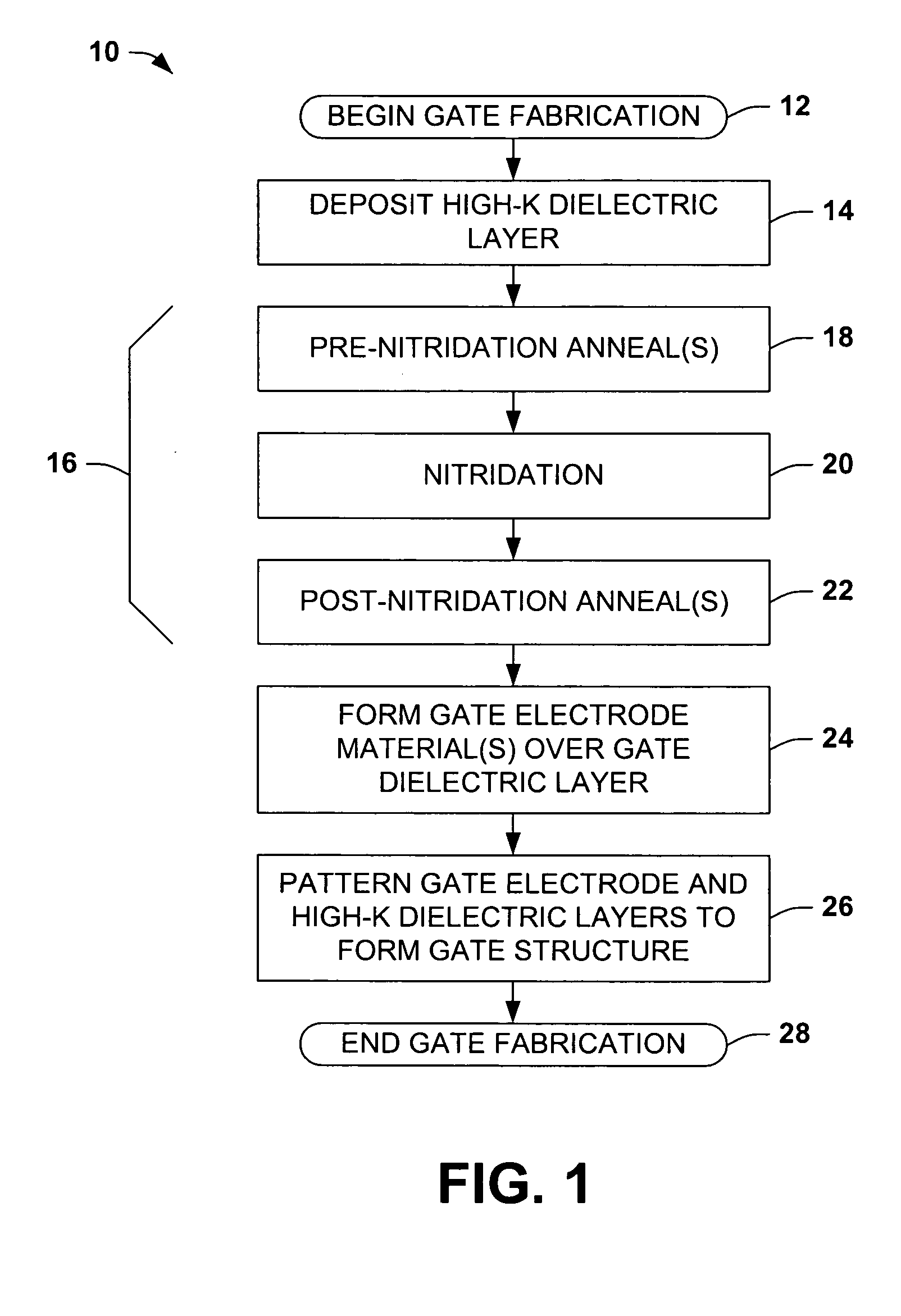

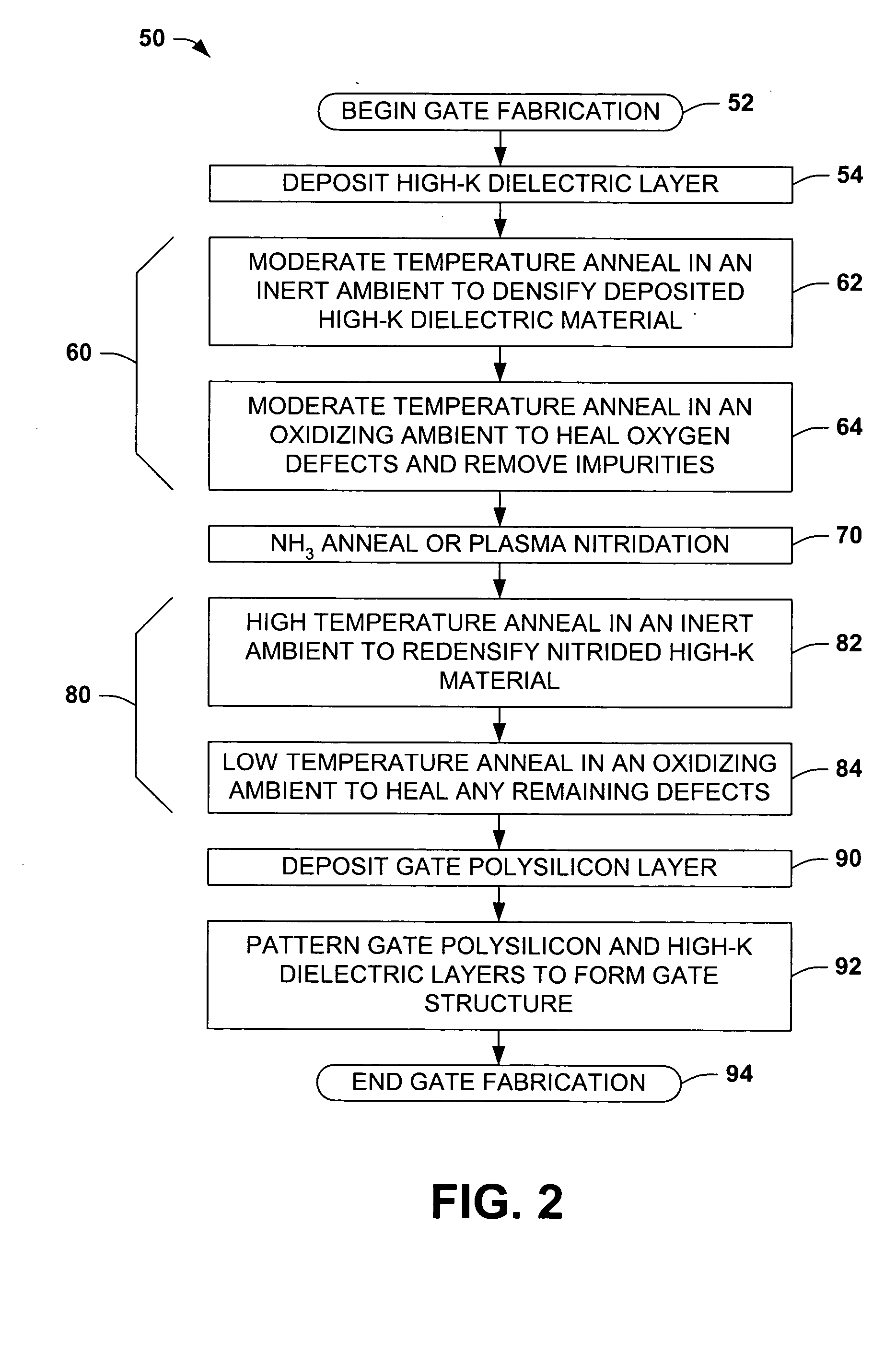

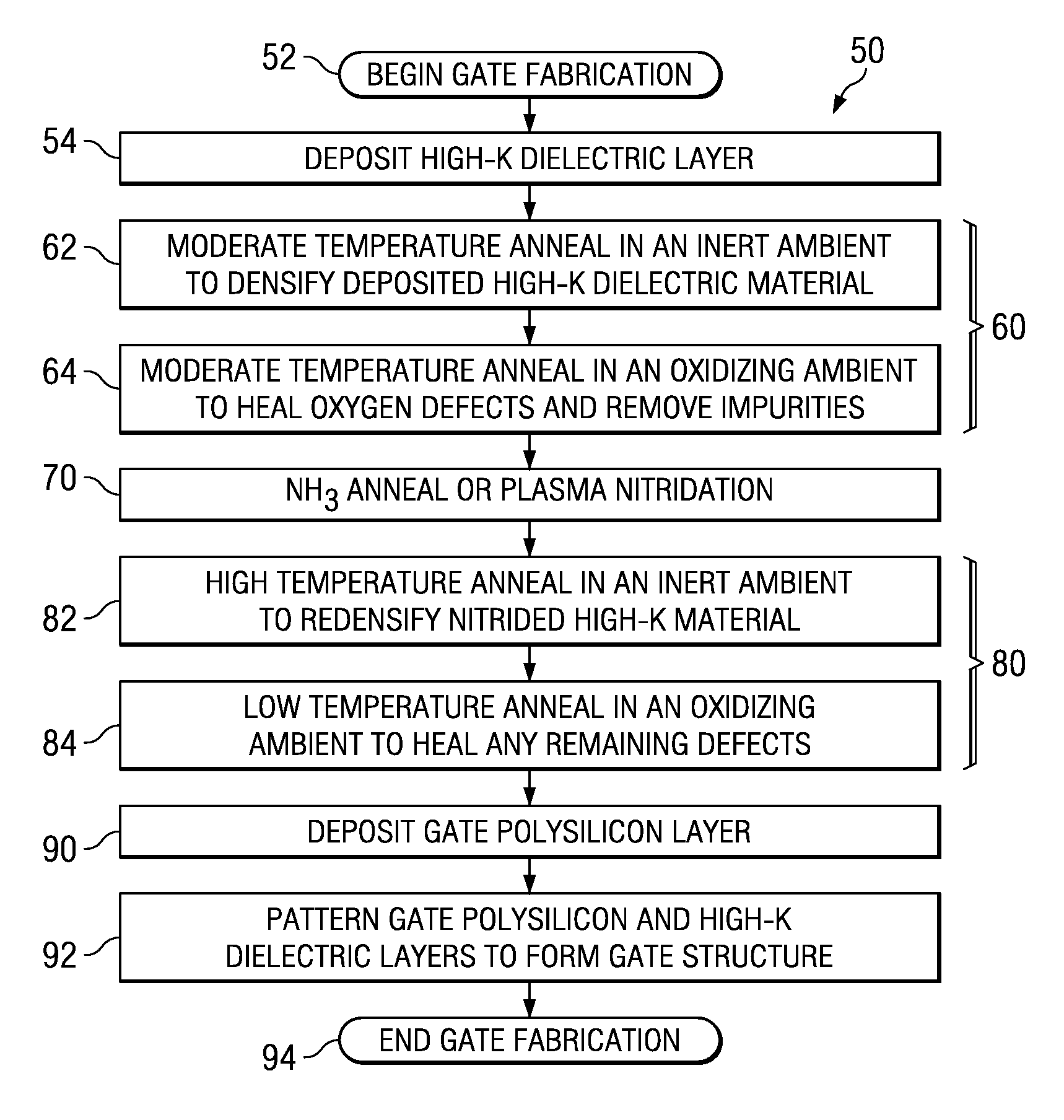

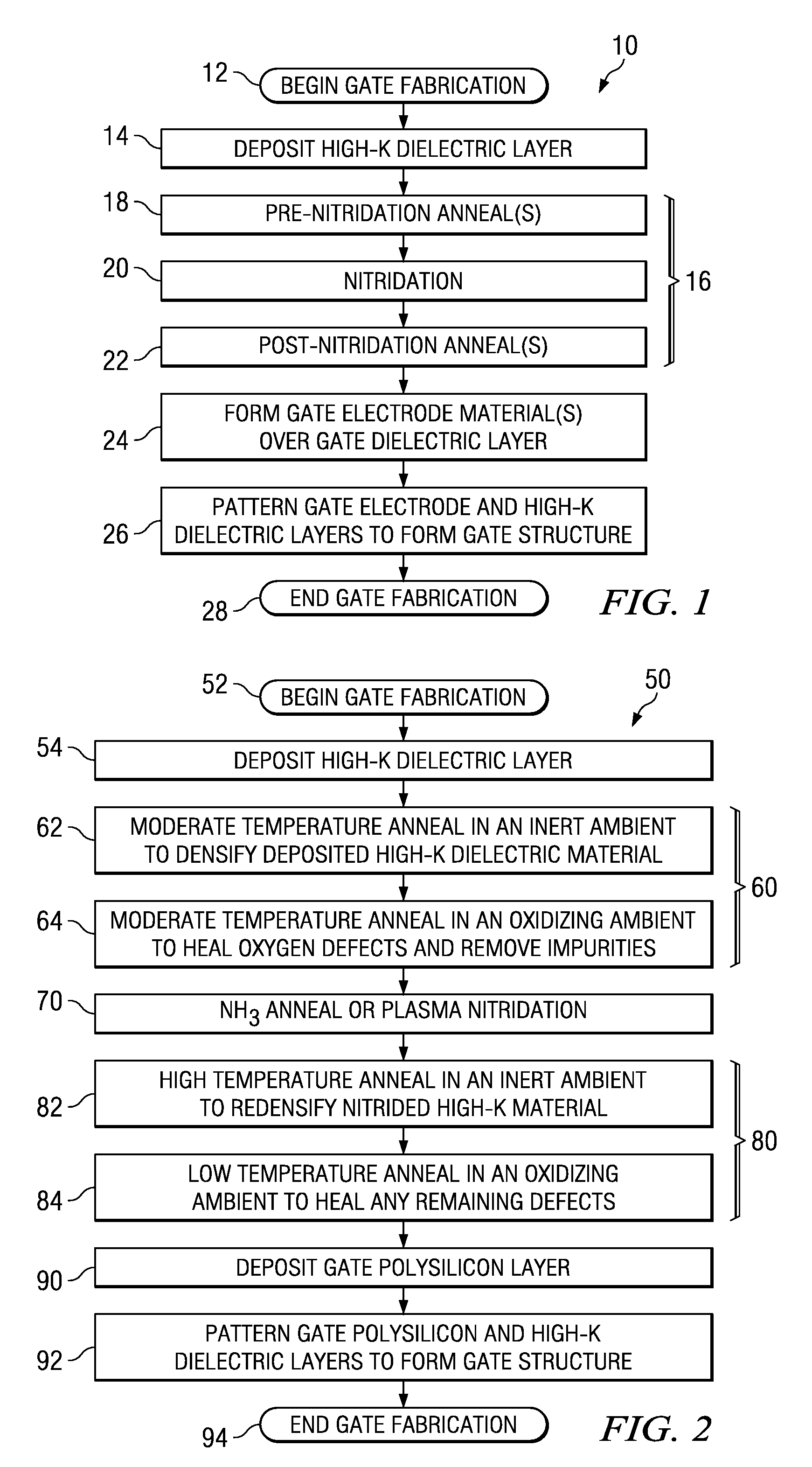

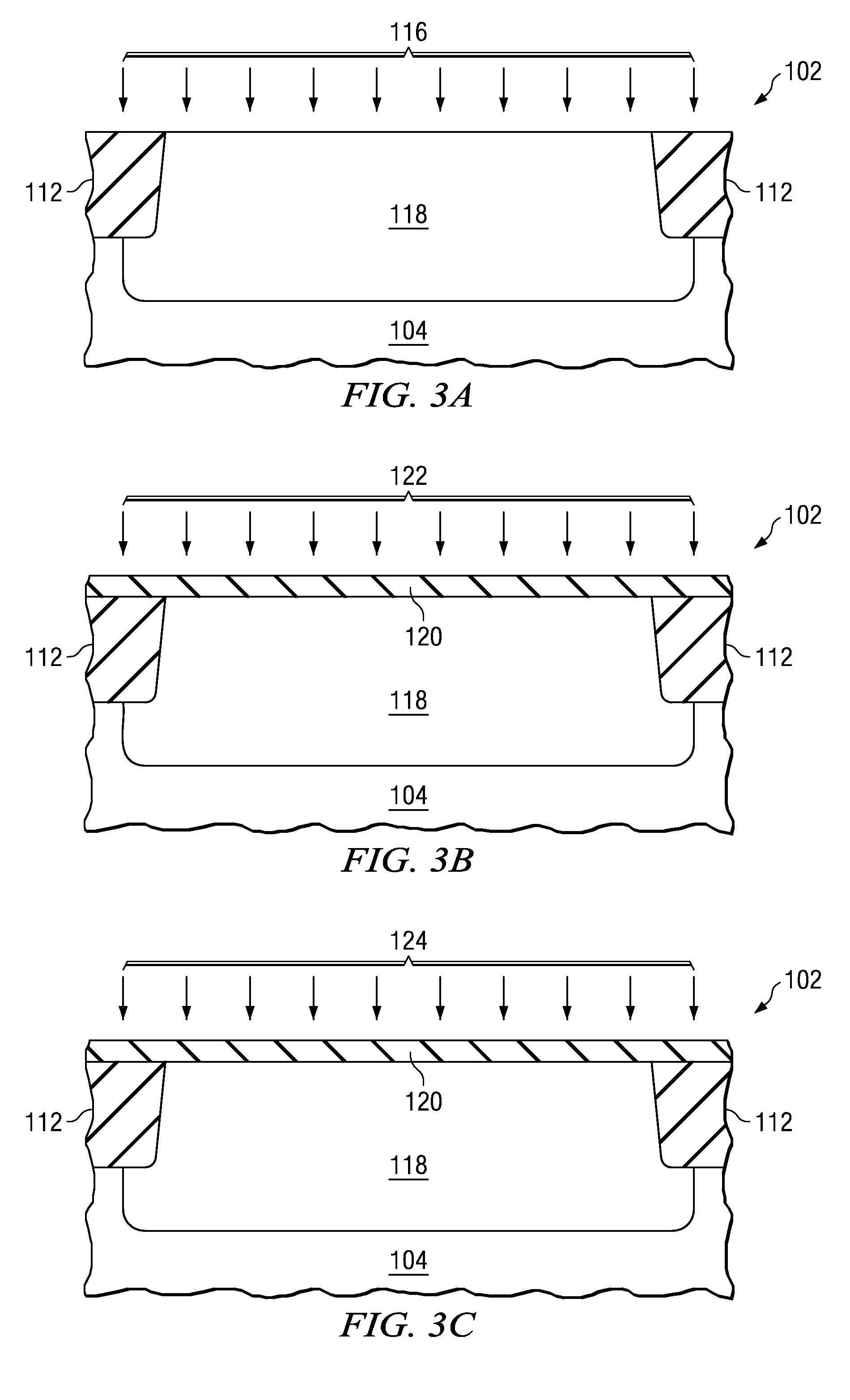

Method for fabricating transistor gate structures and gate dielectrics thereof

ActiveUS20050130442A1Improve thermal stabilitySemiconductor/solid-state device manufacturingSemiconductor devicesMaterial defectGate dielectric

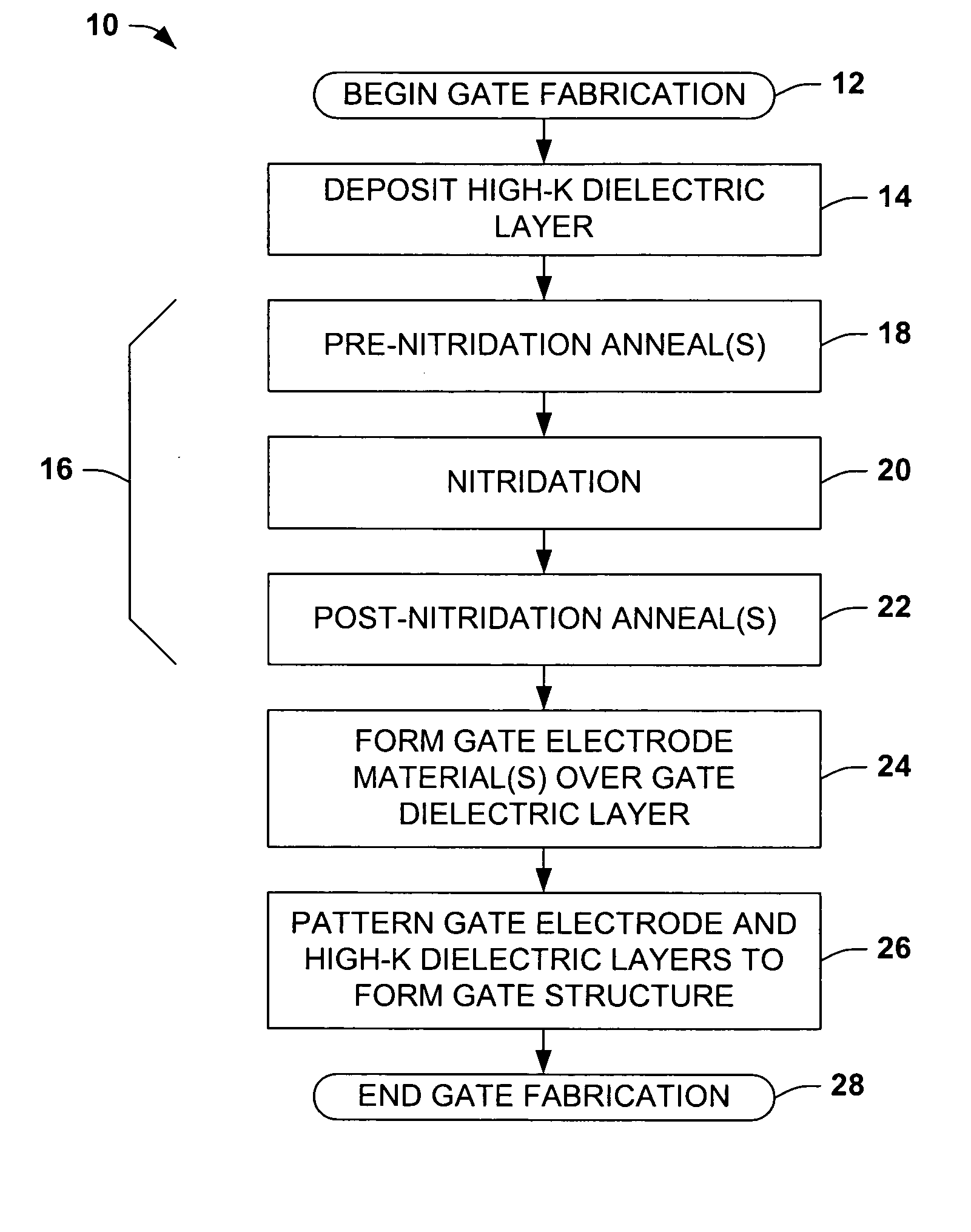

Methods are disclosed for treating deposited gate dielectric materials, in which the deposited dielectric is subjected to one or more non-oxidizing anneals to densify the material, one or more oxidizing anneals to mitigate material defects, and to a nitridation process to introduce nitrogen into the gate dielectric. The annealing may be performed before and / or after the nitridation to mitigate deposition and / or nitridation defects and to densify the material while mitigating formation of unwanted low dielectric constant oxides at the interface between the gate dielectric and the semiconductor substrate.

Owner:TEXAS INSTR INC

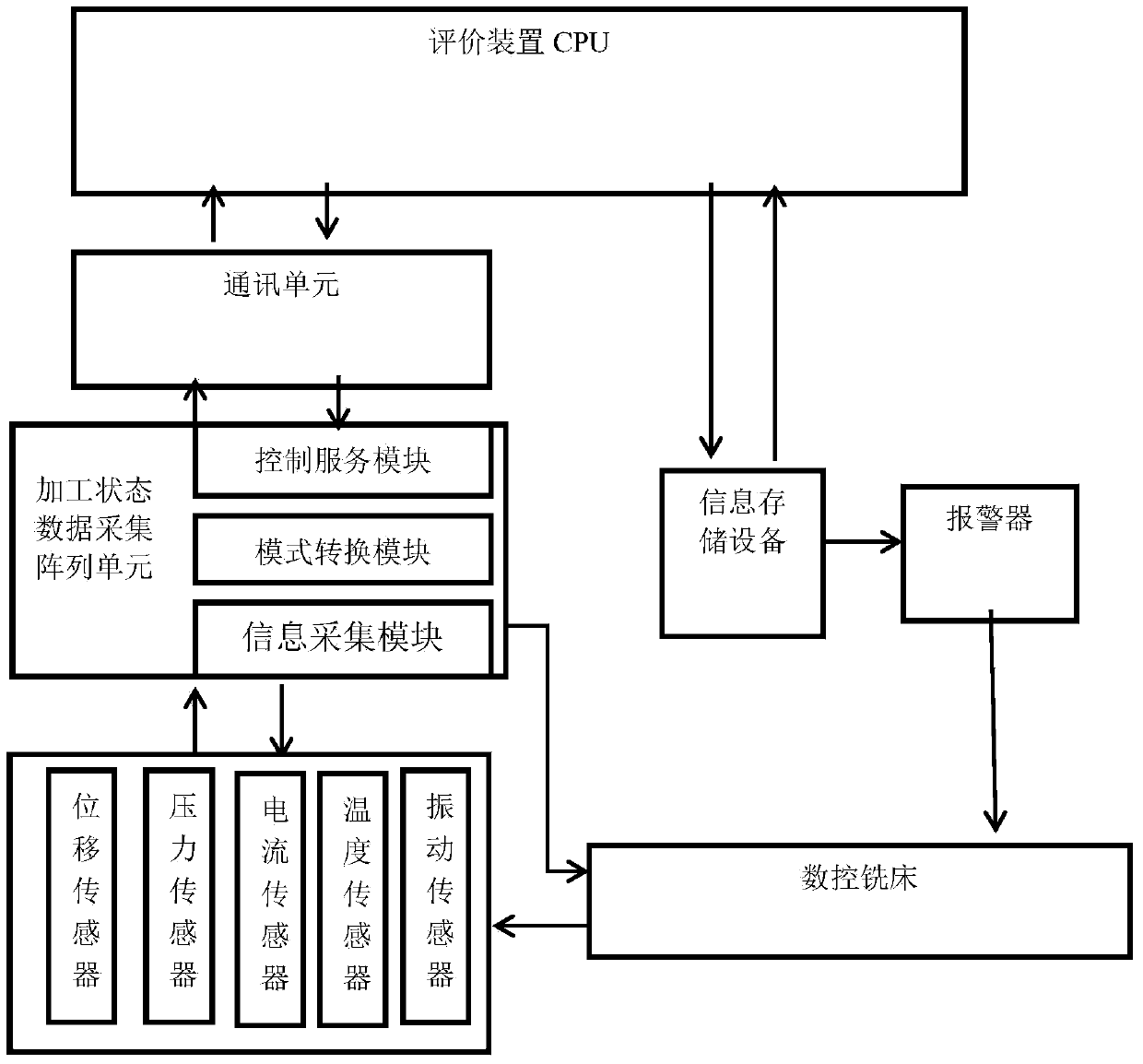

Evaluation device of state information of machining process of numerical control milling machine

InactiveCN103760820AImprove processing qualityImprove efficiencyProgramme controlComputer controlMaterial defectCommunication unit

The invention discloses an evaluation device of state information of the machining process of a numerical control milling machine. A machining state data collecting array device, an information storage device, a numerical control system and the like on a machine tool are connected into a semi-closed-loop control circuit through the evaluation device MCU. A machining state data collecting array collects state data of main shaft currents, feed currents, vibration, machining temperatures and the like in the machining process of the numerical control machine tool and can intelligently identify abnormal states of abrasion and breakage of a cutter, material defects of workpiece blank and the like. A communication unit can achieve real-time connection between the machining state information collecting array and the evaluation device MCU. The evaluation device MCU checks and analyzes collected machining state parameters according to a certain algorithm, generates a check report and guides the information storage device to update the optimal parameter record. Meanwhile, the evaluation device has the prejudgment function, submits alarming when meeting with problems which cannot be dealt with and meanwhile analyzes corresponding error reasons and provides proper solutions. According to the evaluation device of the state information of the machining process of the numerical control milling machine, the machining parameters of the milling machine and the state information of the machining process are checked.

Owner:HUAZHONG UNIV OF SCI & TECH

Method for fabricating transistor gate structures and gate dielectrics thereof

ActiveUS7135361B2Improve thermal stabilitySemiconductor/solid-state device manufacturingSemiconductor devicesMaterial defectGate dielectric

Owner:TEXAS INSTR INC

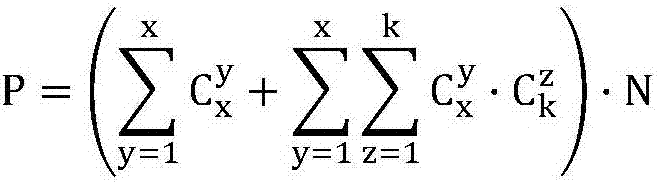

Incremental critical area computation for VLSI yield prediction

InactiveUS6044208ASemiconductor/solid-state device testing/measurementSolid-state devicesMaterial defectLinear approximation

An efficient method to compute critical area for shorts and breaks in rectilinear layouts in Very Large Scale Integrated (VLSI) circuits. The method is incremental and works in the L INFINITY geometry and has three major steps: Compute critical area for rectilinear layouts for both extra material and missing material defects (i.e., shorts and opens) by modeling defects as squares (which corresponds to the L INFINITY metric) instead of circles (Euclidean geometry). Treat the critical region for shorts and opens between any two edges or corners of the layout as a rectangle that grows uniformly as the defect radius increases. This is valid for rectilinear layouts and square defects (L INFINITY metric) . Use an incremental critical area algorithm for shorts and opens, which are computed for rectilinear layouts assuming square defects. Non-rectilinear layouts are approximated, first, by a rectilinear layout using a shape processing tool. The critical area for the rectilinear approximation is computed using the preferred incremental method.

Owner:GLOBALFOUNDRIES INC

Preparation method of complex phase ceramic material containing zirconium boride

InactiveCN102173813AControlling chemical reaction driving forcesControl the severity of the reactionBorideMaterial defect

The invention relates to a preparation method of a complex phase ceramic material containing zirconium boride, relating to a preparation method of ceramic materials and aiming to overcome the material defects of abnormal crystal grain growth, phase clustering, and the like which are caused by difficult control and overhigh partial temperature in the traditional reaction sintering preparation method and solve the problems of tissue uniformity and comprehensive mechanical property of the complex phase ceramic material. The preparation method comprises the following steps of: 1, placing zirconium oxide and a boron-containing compound or a boron-containing composite into a ball mill to form composite powder; 2, drying the composite powder, then crushing, and screening through a sieve of 200 meshes to obtain uniform mixed powder; 3, carrying out mould pressing or cold isostatic pressing on the mixed powder, and then carrying out pressureless sintering, hot pressing sintering or hot isostatic pressing sintering to obtain the complex phase ceramic material containing the zirconium boride. The complex phase ceramic material containing the zirconium boride has uniform crystal grain size and distribution, the fracture toughness of 3.5-7.5 MPa.m<-1 / 2> and the bending strength of 250-700 MPa and can be used in the field of high-temperature resistant structural members and the like.

Owner:HARBIN INST OF TECH

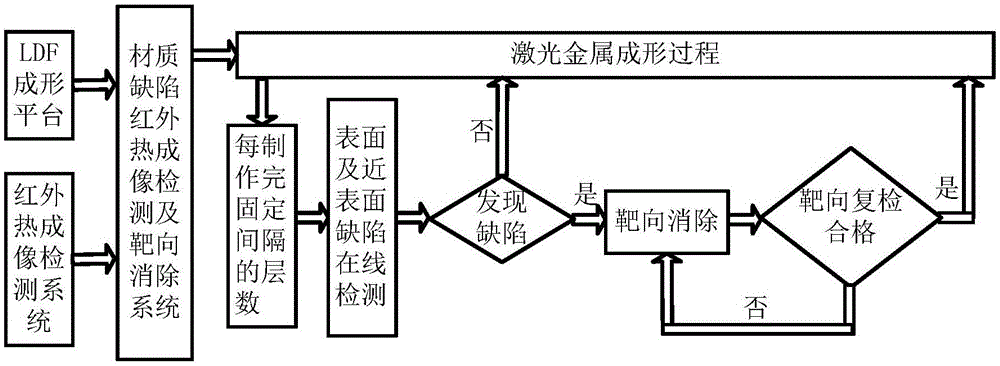

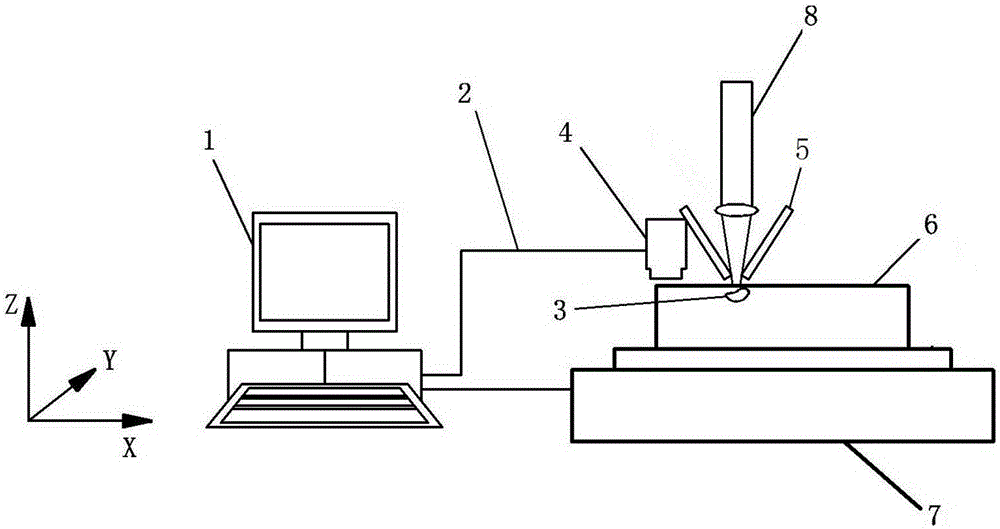

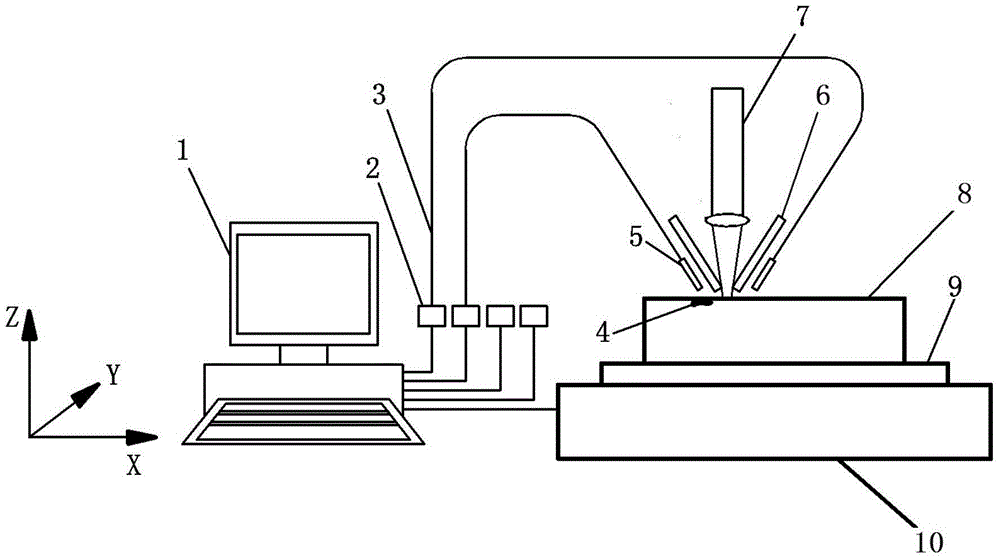

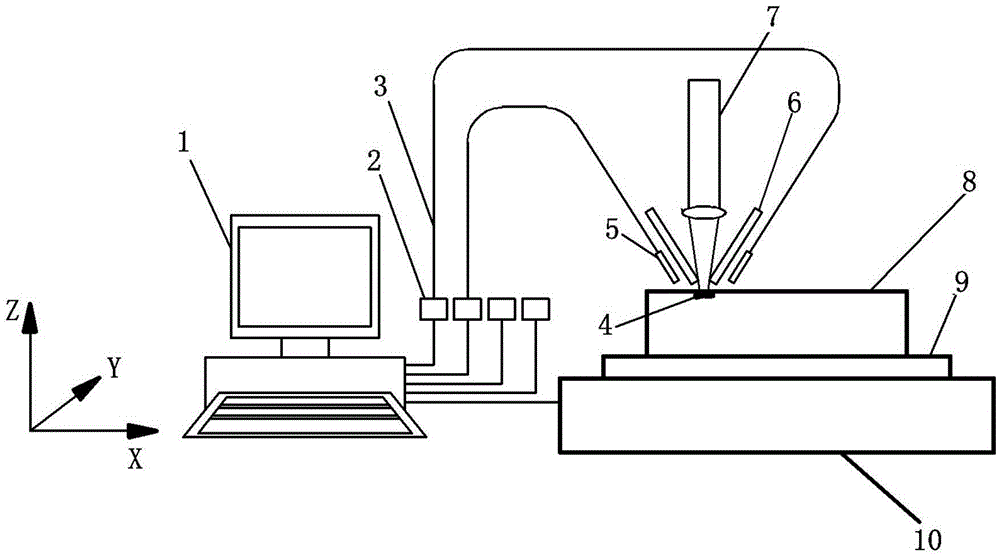

Material defect infrared thermal imaging detection and targeted elimination method in laser metal forming

InactiveCN105044154AResolve detectionSolve the problem of eliminationMaterial flaws investigationCamera lensMaterial defect

The invention discloses a material defect infrared thermal imaging detection and targeted elimination method in laser metal forming. In laser metal forming, after layers with fixed interlayers are produced, a workbench is controlled by a computer to move in the horizontal direction at a constant speed, thus an infrared thermal imaging detection lens can move in the horizontal direction above the imaging plane and carries out non-contact scanning and photo-taking by utilizing the residual heat of metal parts, and then the infrared thermal imaging detection images are analyzed online to calculate the coordinate azimuth of the metal forming plane. The computer control laser beams to target-melt the detected defects so as to eliminate the defects; after laser re-melting, an infrared thermal imaging detector is used to re-examine the metal forming surface to confirm the defect elimination effect. The provided method solves the problems that the defects on micro materials cannot be detected online and eliminated, effectively improves the using performance and service safety of laser formed metal parts, and reduces the risk of fatigue breakage.

Owner:XIAN UNIV OF TECH +2

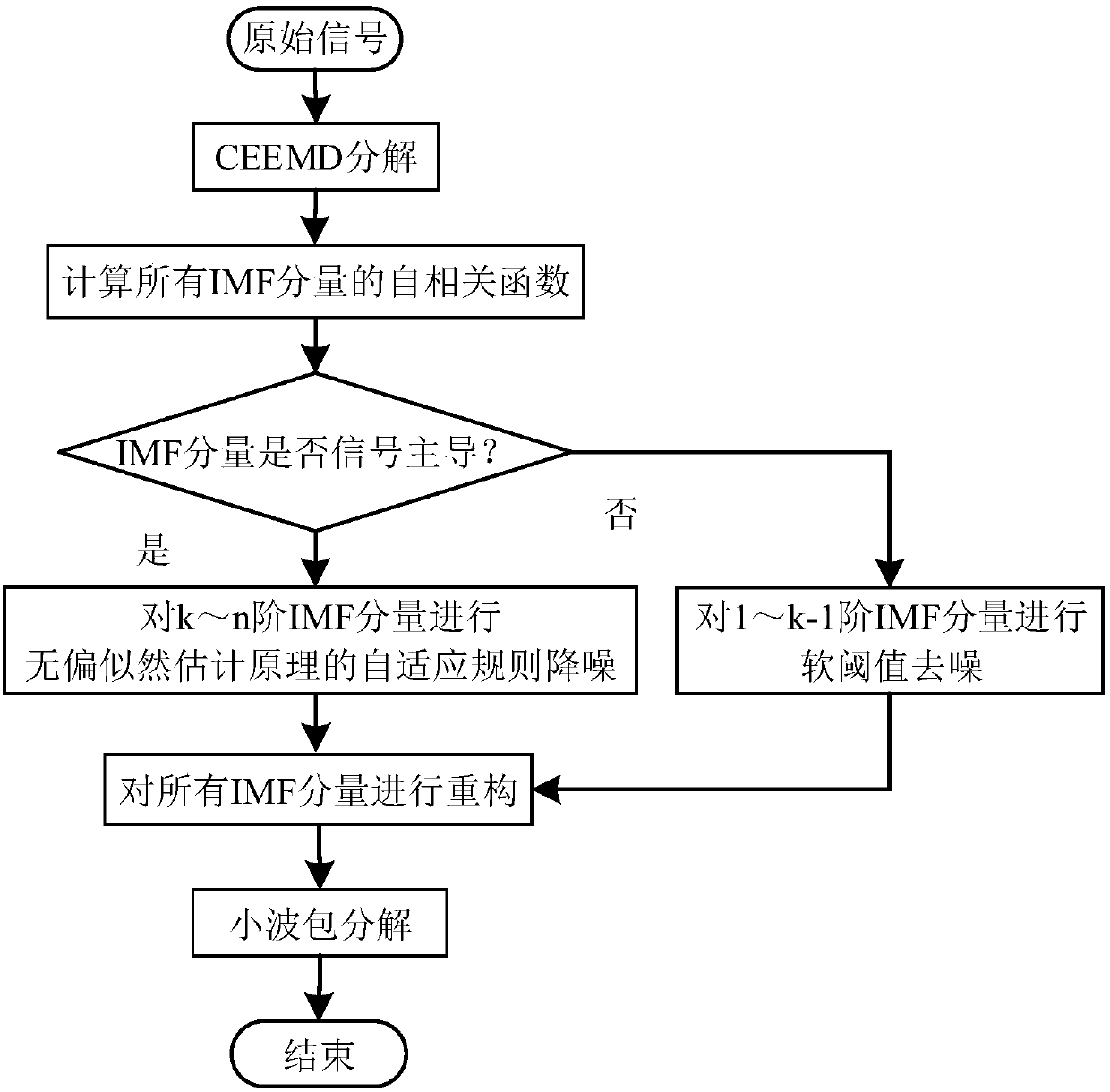

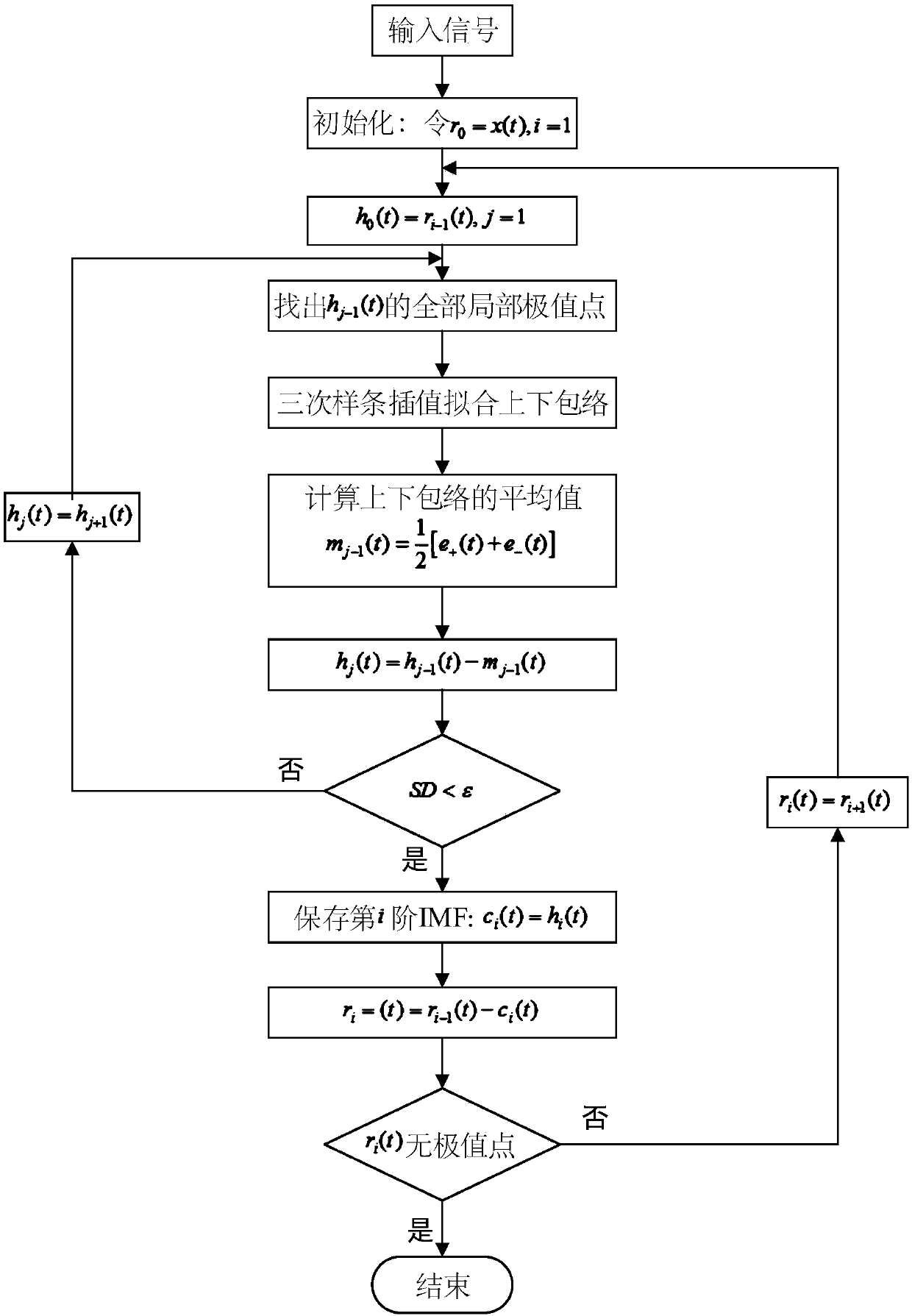

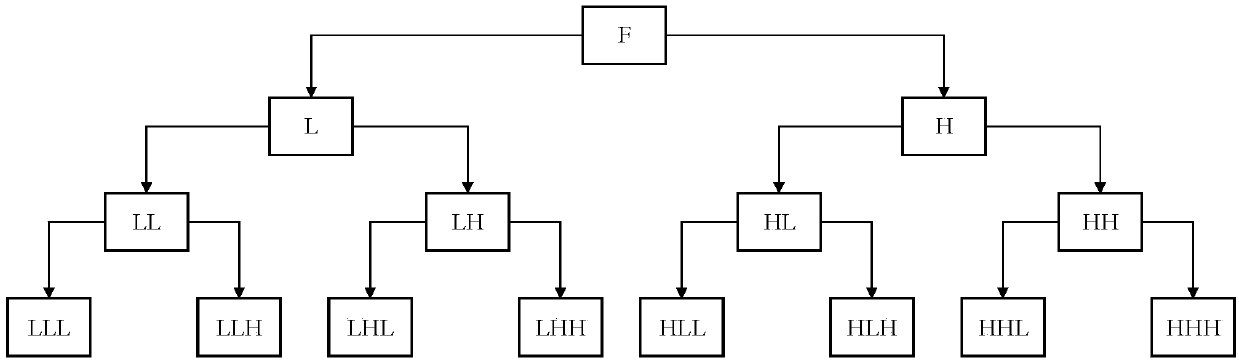

CEEMD and wavelet packet-based ultrasonic signal denoising method

InactiveCN108491355AEffective noise reductionEfficient removalCharacter and pattern recognitionComplex mathematical operationsMaterial defectSonification

The invention discloses a CEEMD and wavelet packet-based ultrasonic signal denoising method. The method comprises the steps of firstly performing mode decomposition on a signal by utilizing a CEEMD algorithm to obtain a series of intrinsic mode functions and a trend term; secondly performing soft threshold denoising on noise dominant modes in the intrinsic mode functions, and performing adaptive rule denoising of an unbiased risk estimate principle for signal dominant modes; and finally further denoising the signal by utilizing a fine decomposition capability of wavelet packet analysis. According to the CEEMD algorithm, two opposite white noises are added to an original signal, EMD is performed and results are averaged; the end effect and the mode aliasing problem can be effectively eliminated; and the signal is further denoised under the condition of not adding auxiliary noises through wavelet and wavelet packet decomposition. The denoising method has better performance in comparisonwith that of a conventional denoising method. The denoising method can be widely applied to the material defect signal processing.

Owner:NANJING UNIV OF POSTS & TELECOMM

Electronic die cutting material defect detecting implementation method based on machine vision

ActiveCN106770332ARealize the shapeImplement defect identificationOptically investigating flaws/contaminationMaterial defectDimension measurement

The invention discloses an electronic die cutting material defect detecting implementation method based on machine vision. The method comprises the following steps of (a) loading a detection template; (b) transferring a detection object; (c) monitoring through a sensor; (d) capturing an image; (e) identifying an object; (f) processing the image; (g) carrying out binarization processing; (h) carrying out data statistics and detection analysis. The method adopts a non-contact optical sensor system, and adopts a machine to replace human eyes to measure and judge, a system utilizes a CCD (Charge Coupled Device) camera for capturing the image of an objective measuring object, and information such as pixel distribution, brightness and color of the image of the objective measuring object is converted into digital image signals; a project control system operates the signals to extract the characteristics of the measuring object; finally, field equipment is controlled to act according to tolerance and other condition output results so as to meet the core demands on on-line detection of product defects and dimension measurement, so that the measurement precision, the measurement speed, and the reliability under an industrial site environment can be ensured.

Owner:HANGZHOU BYTE INFORMATION TECH CO LTD

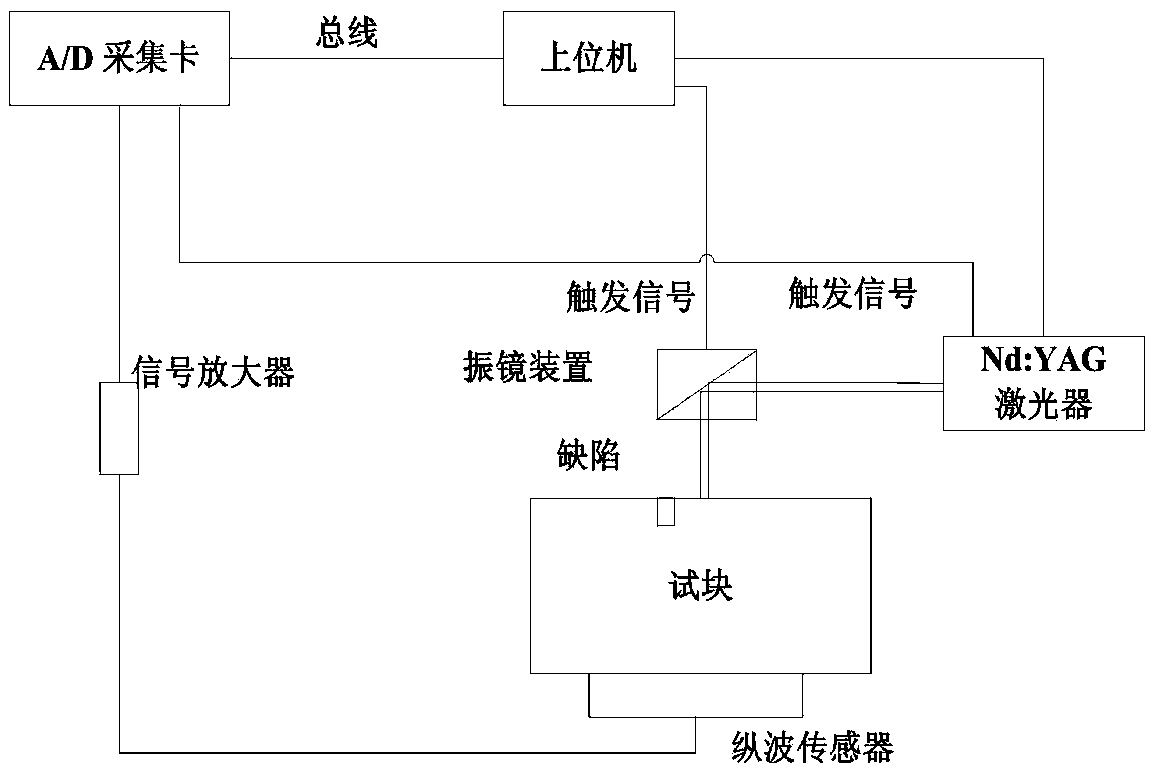

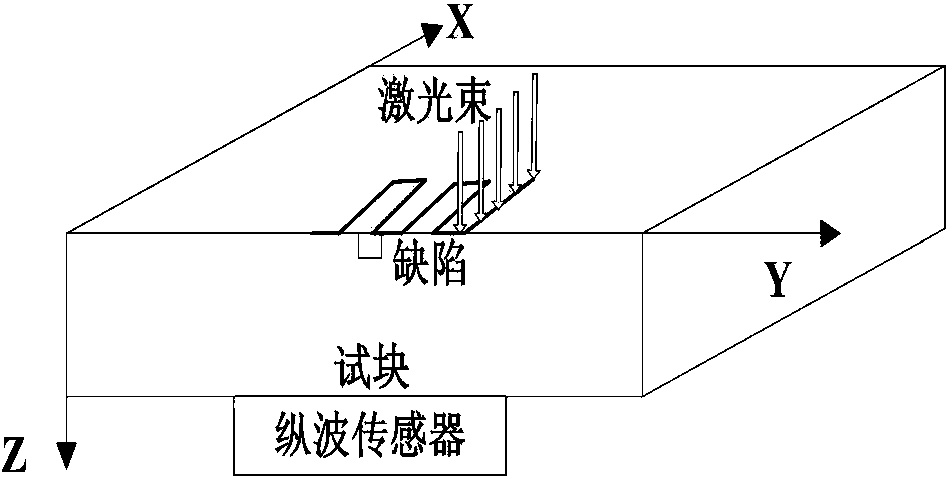

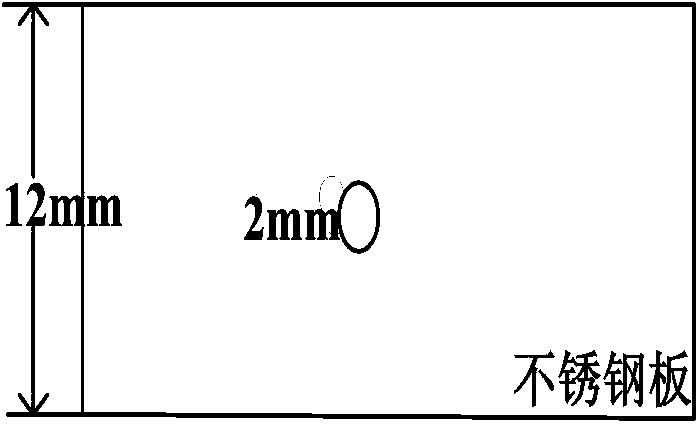

Scanning type laser ultrasonic detection method and system

InactiveCN104345092ABreak through the shortcomings of being unable to carry out quantitative detectionShorten detection timeAnalysing solids using sonic/ultrasonic/infrasonic wavesMaterial defectSonification

The invention discloses a scanning type laser ultrasonic detection method and system. The scanning type laser ultrasonic detection method comprises the following steps: controlling a laser to generate pulse laser beams by using host computer software; performing two-dimensional scanning on a tested material in the horizontal X-Y axis direction by using a galvanometer scanning device; receiving generated longitudinal wave signals by using a longitudinal wave sensor centered at a testing block; amplifying the received longitudinal wave signals, acquiring the generated longitudinal wave signals by using a digital A / D acquisition card, and performing band-pass filtering on acquired ultrasonic signals by using the host computer software; and controlling a scanning moving mirror system to perform two-dimensional scanning imaging on the surface of the material by using a computer control circuit system, and rapidly performing opto-acoustic imaging on the longitudinal wave signals received in the two-dimensional scanning process according to the fact that primary longitudinal wave peak value signals indicating whether the surface of the material has crack defects or not reach the sensor at different moments, thereby achieving rapid quantitative imaging detection on the defects of the detected material. The scanning type laser ultrasonic detection method is small in computer processing data amount, and the material defects can be directly quantitatively detected in a longitudinal wave transmitted image.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

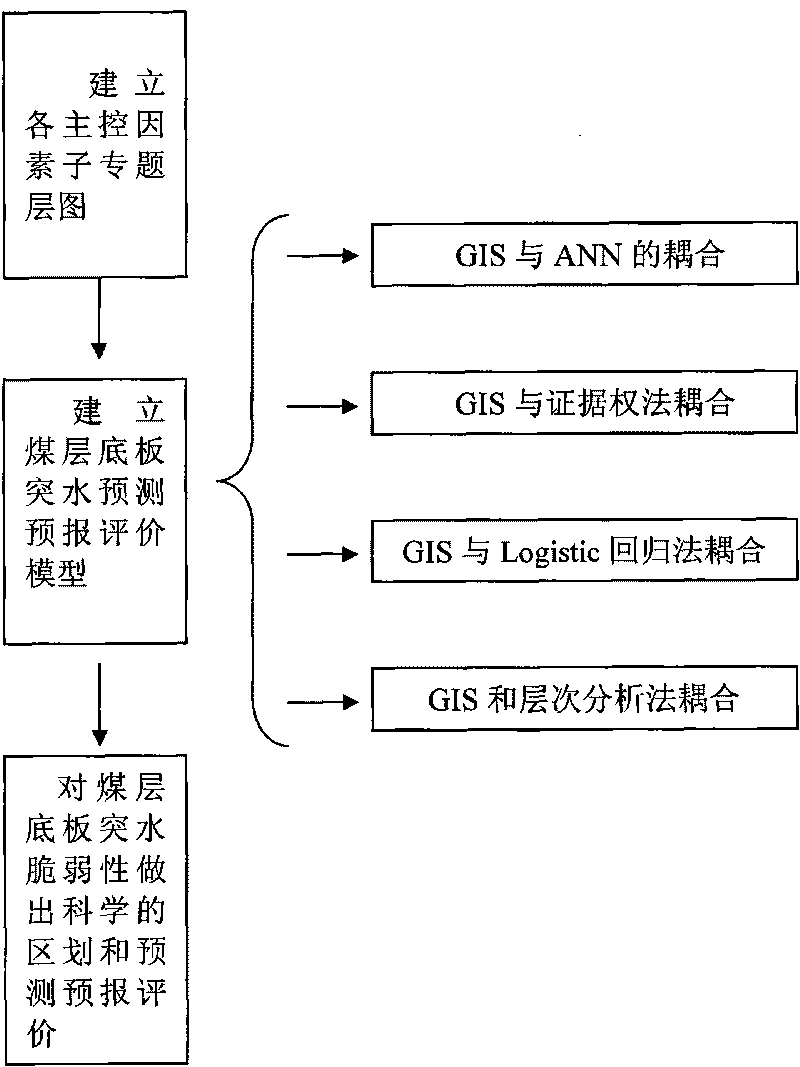

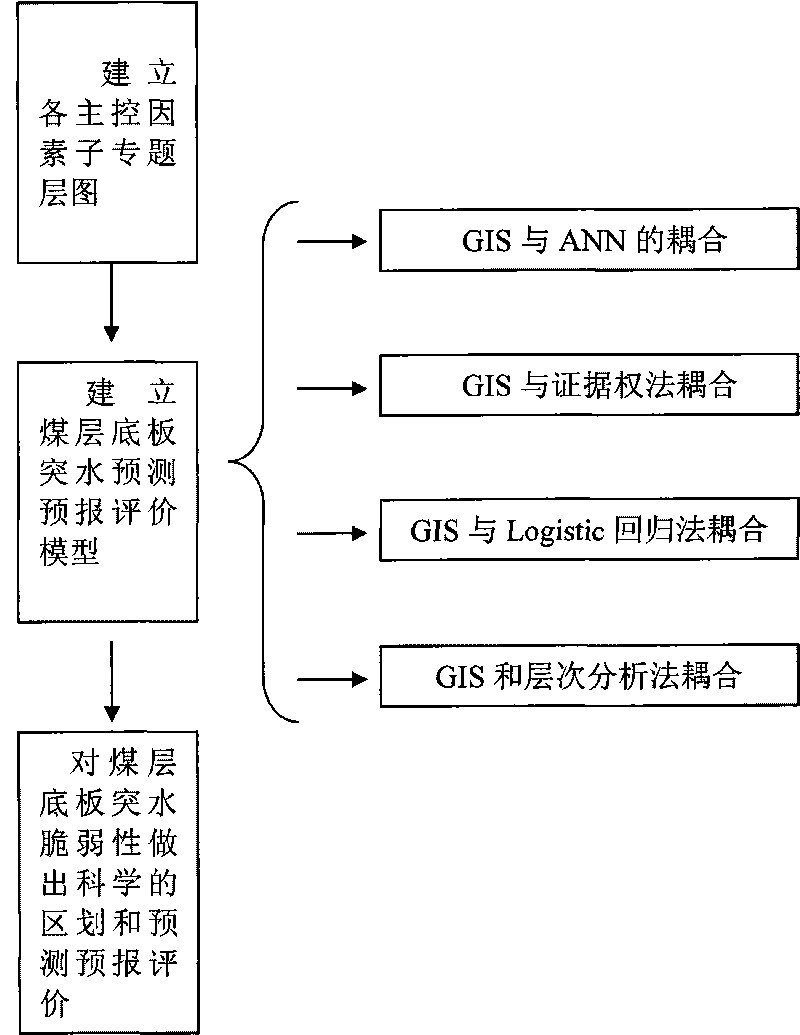

Novel practical method frangibility index method for evaluating seam floor water inrush

InactiveCN101699451ASolve the difficult problem of water inrush prediction and evaluationSpecial data processing applicationsMaterial defectCoupling

The invention relates to a frangibility index method for evaluating seam floor water inrush, which comprises the following steps: determining main control factors of the seam floor water inrush by taking GIS as an operating platform based on a multi-source information fusion theory, and establishing a sub-subject layer diagram for each main control factor through data acquisition, analysis and processing; determining the 'contribution' or the 'weight' of each main control factor to a complex water inrush process and establishing a forecast evaluation model for the seam floor water inrush through the inversion identification or the learning training of the model by applying a multi-source geoscience data composite superposition principle and adopting a modern linear or non-linear mathematical method; and reasonably determining a subarea threshold value of the water inrush frangibility according to the analysis of a frequency histogram of water inrush frangibility indexes calculated by each unit in a research area and finally making a scientific division and a forecast evaluation on the seam floor water inrush frangibility. The method well overcomes the difficulty of the forecast evaluation on the seam floor water inrush, breaks through the restriction by significant deficiencies that the conventional water inrush coefficient method for the seam floor water inrush evaluation can only consider two control factors and has no influence 'weight' concept and the like, and adopts the GIS and the modern non-linear mathematical coupling method to truly depict the non-linear dynamic process of the seam floor water inrush which is controlled by a plurality of factors and has a very complicated formation mechanism.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

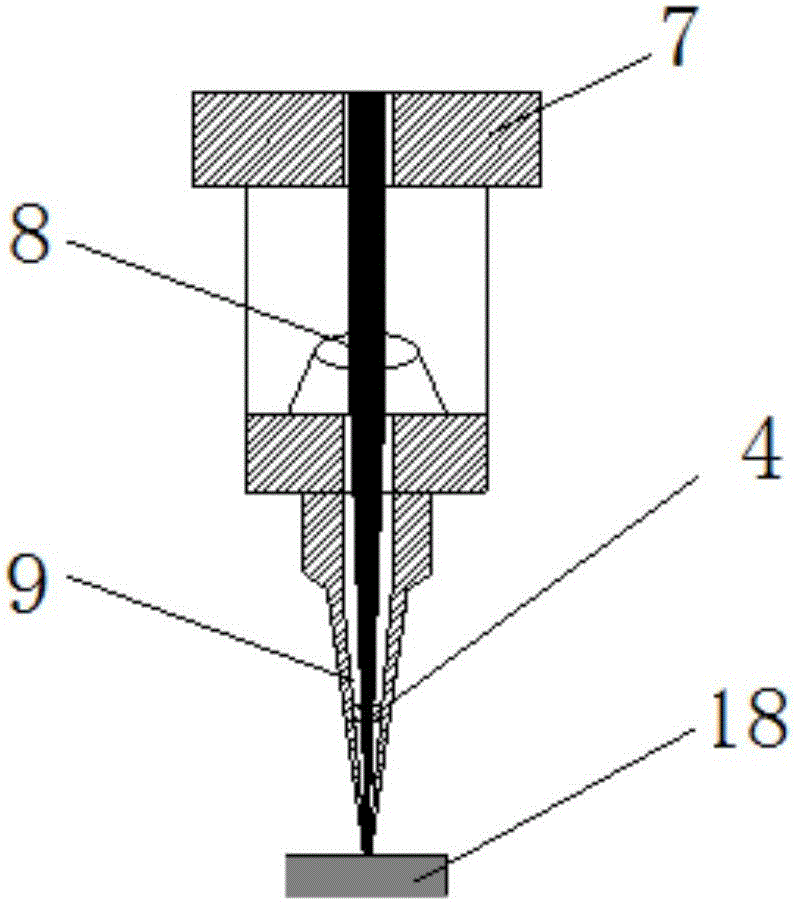

Method and device for coaxial combined machining with tubular electrode discharging and laser irradiation

ActiveCN106424987AImprove processing efficiencyImprove processing localityStress concentrationMaterial defect

The invention provides a method and a device for coaxial combined machining with tubular electrode discharging and laser irradiation, and belongs to the field of non-traditional machining and combined machining. Micro-etching machining is performed on the surface of an insulating high-hardness brittle material by virtue of a coaxial action of cone-shaped tube electrode discharging and laser irradiation, recessive material defects and stress concentration generated by pulsed laser acting on the surface of a workpiece can attract spark discharge to always act on the current area, and meanwhile, the spark discharge changes the surface shape and physico-chemical property of the current area, then nonlinear absorption of the current area on laser energy is improved, a local field enhancement effect is generated, and pulsed laser focused irradiation can accelerate an electrochemical reaction to promote generation of a stable discharge gas film layer on the surface of a hollow tool electrode; and the interactive cooperation of two types of energy achieves fixed-area micro-etching of the insulating high-hardness brittle material, the machining efficiency is significantly improved, and the machining quality is improved.

Owner:JIANGSU UNIV

System and Method of Measuring Defects in Ferromagnetic Materials

ActiveUS20150330946A1Weather/light/corrosion resistanceMaterial analysis by optical meansMaterial defectResidual magnetic field

Owner:CHARLES STARK DRAPER LABORATORY

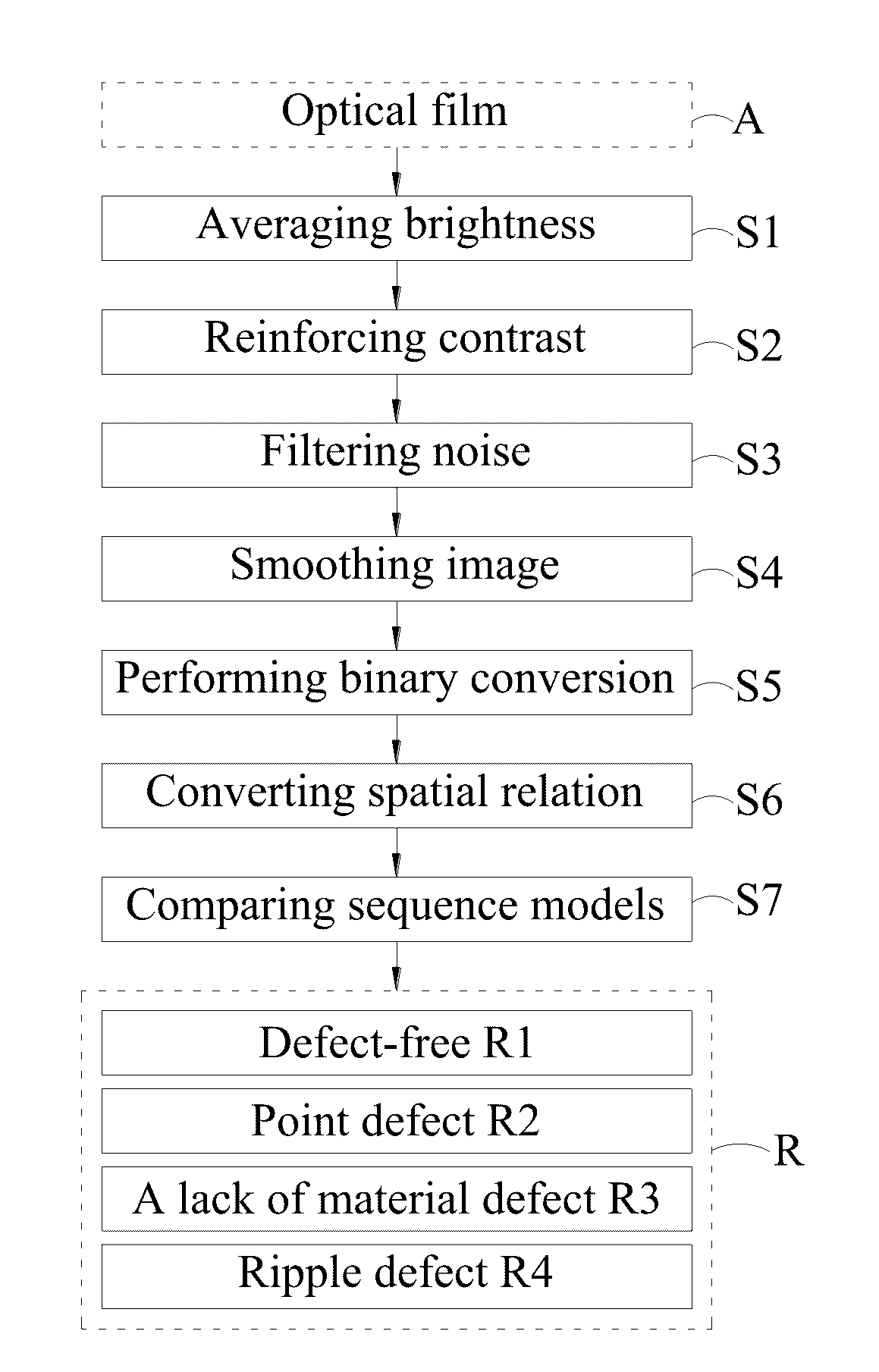

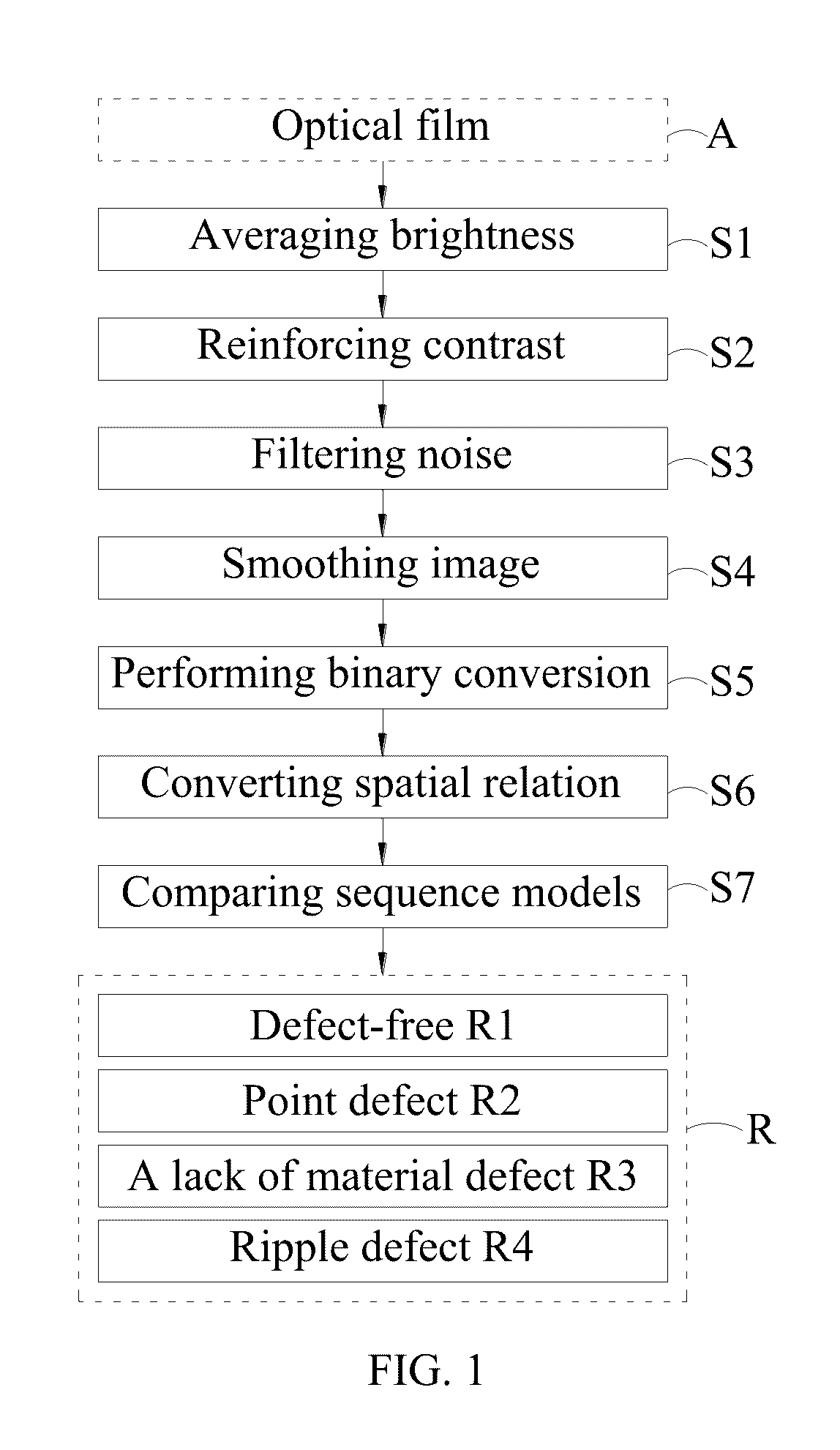

Optical film defect detection method and system thereof

InactiveUS20170004612A1Recognition speed is fastShorten detection timeImage analysisCharacter and pattern recognitionMaterial defectSequence model

An optical defect detection method and a system thereof are disclosed. The detection method includes a process of detecting an image of an optical film by an optical detector. The image is converted into a clean detection image by conducting the following processes: uniforming the brightness, enhancing the contrast, filtering off the noise, smoothing the image and binarizing the image. A relative relation between a pixel and the surrounding pixels of the clean detection image is converted into a spatial relation sequence model. The spatial relation sequence model is compared to the different types of the defect sequence model, so that the defect type of the optical film is identified as a point defect, a lack of material defect or a ripple defect.

Owner:YUAN ZE UNIV

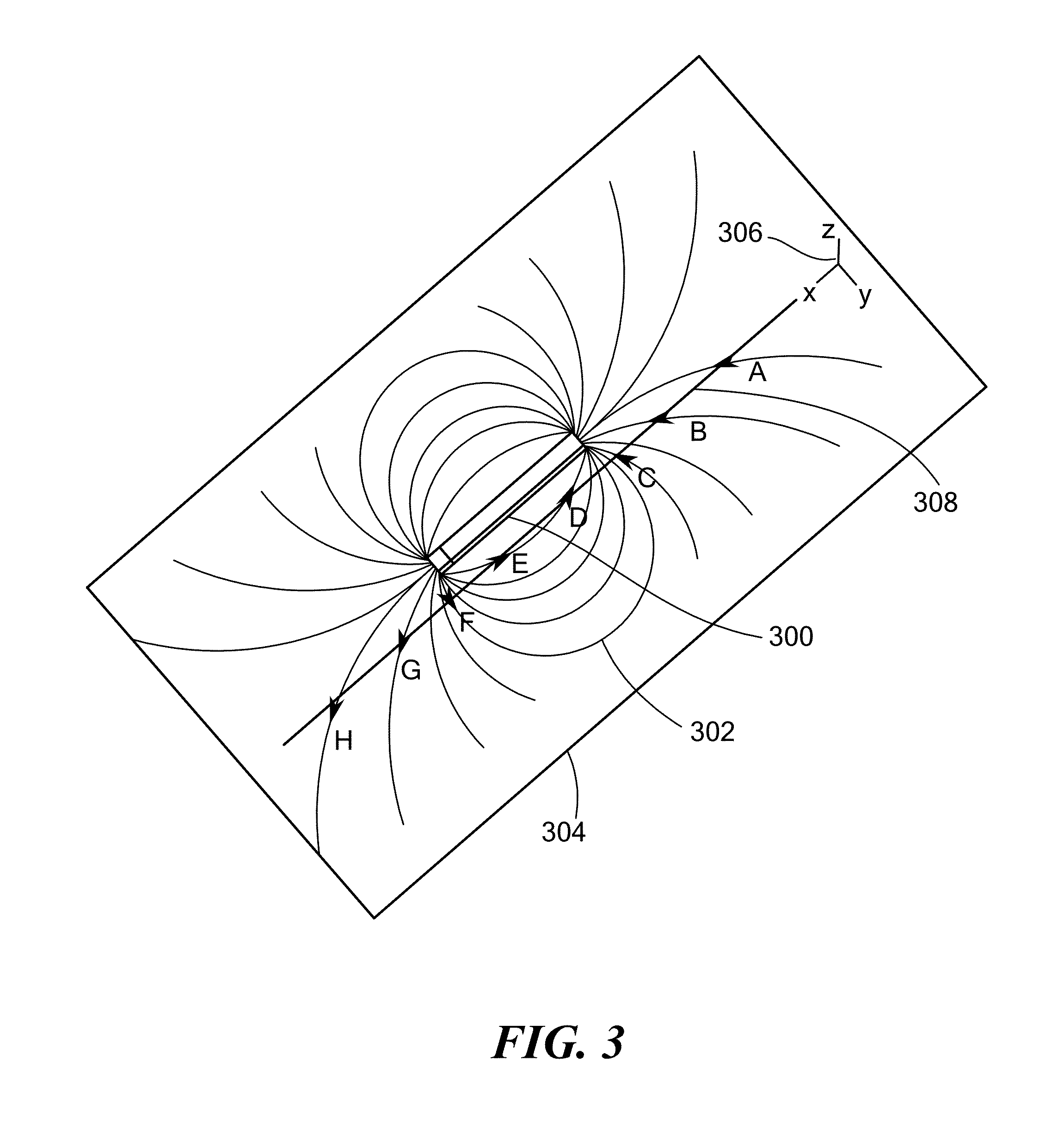

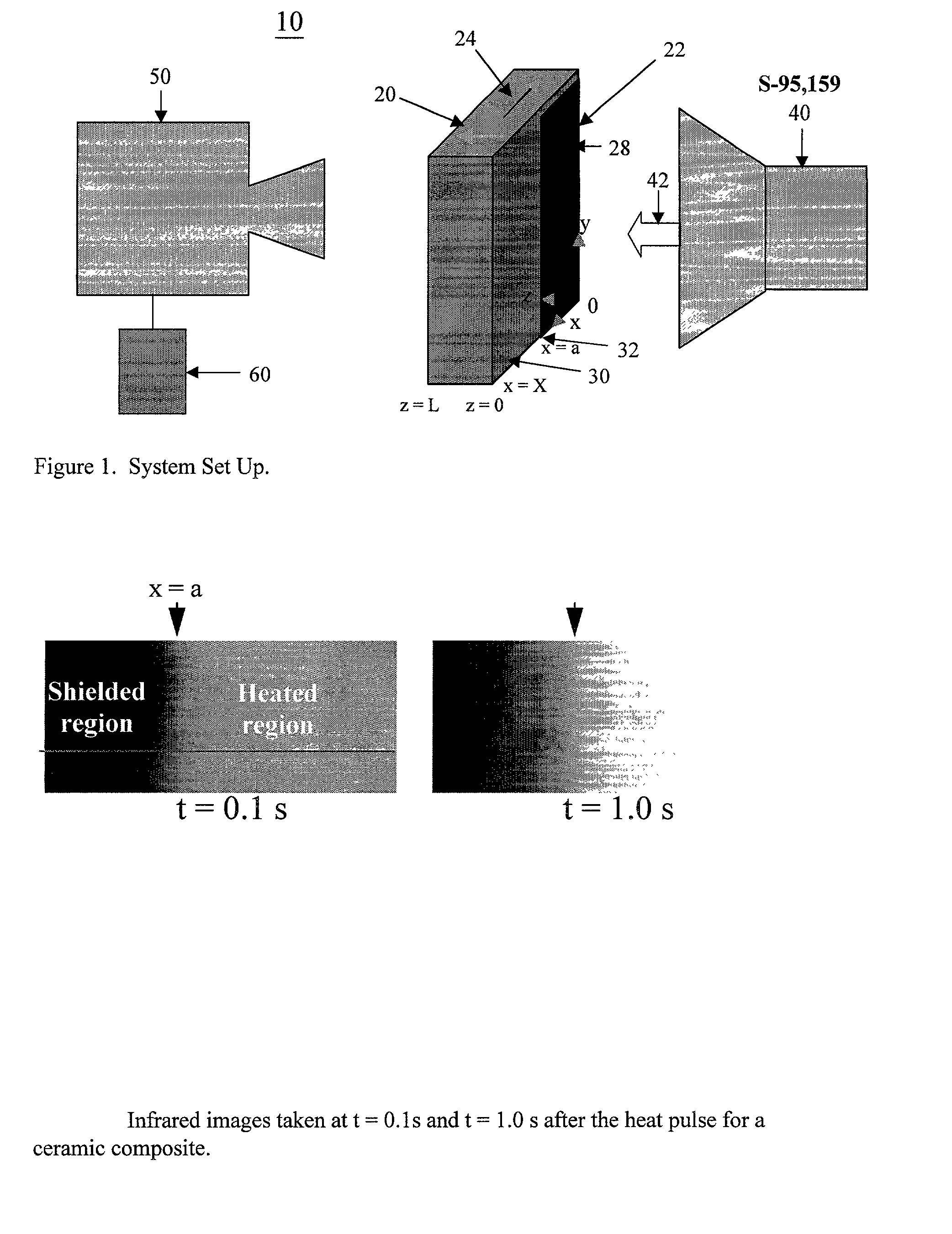

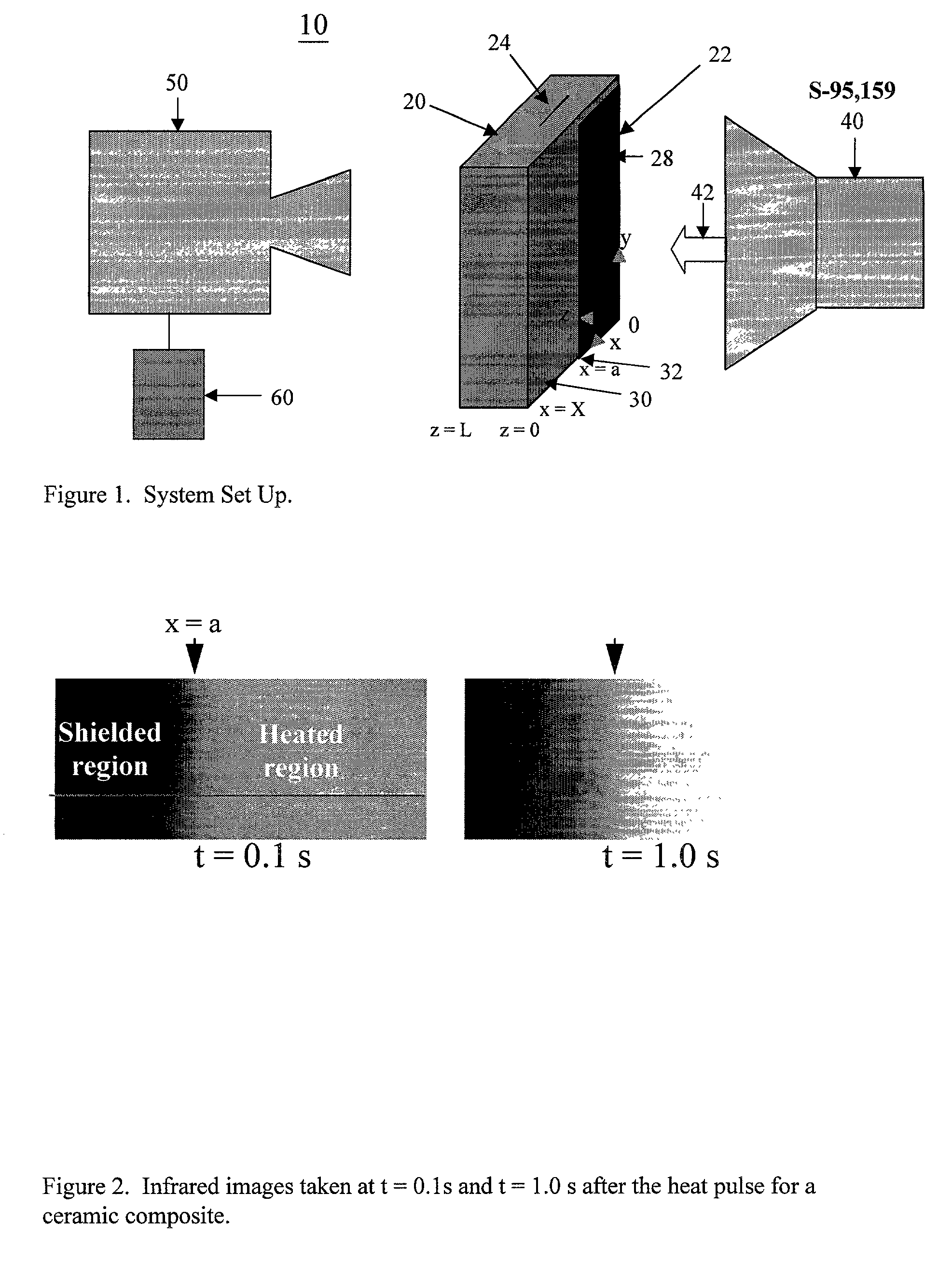

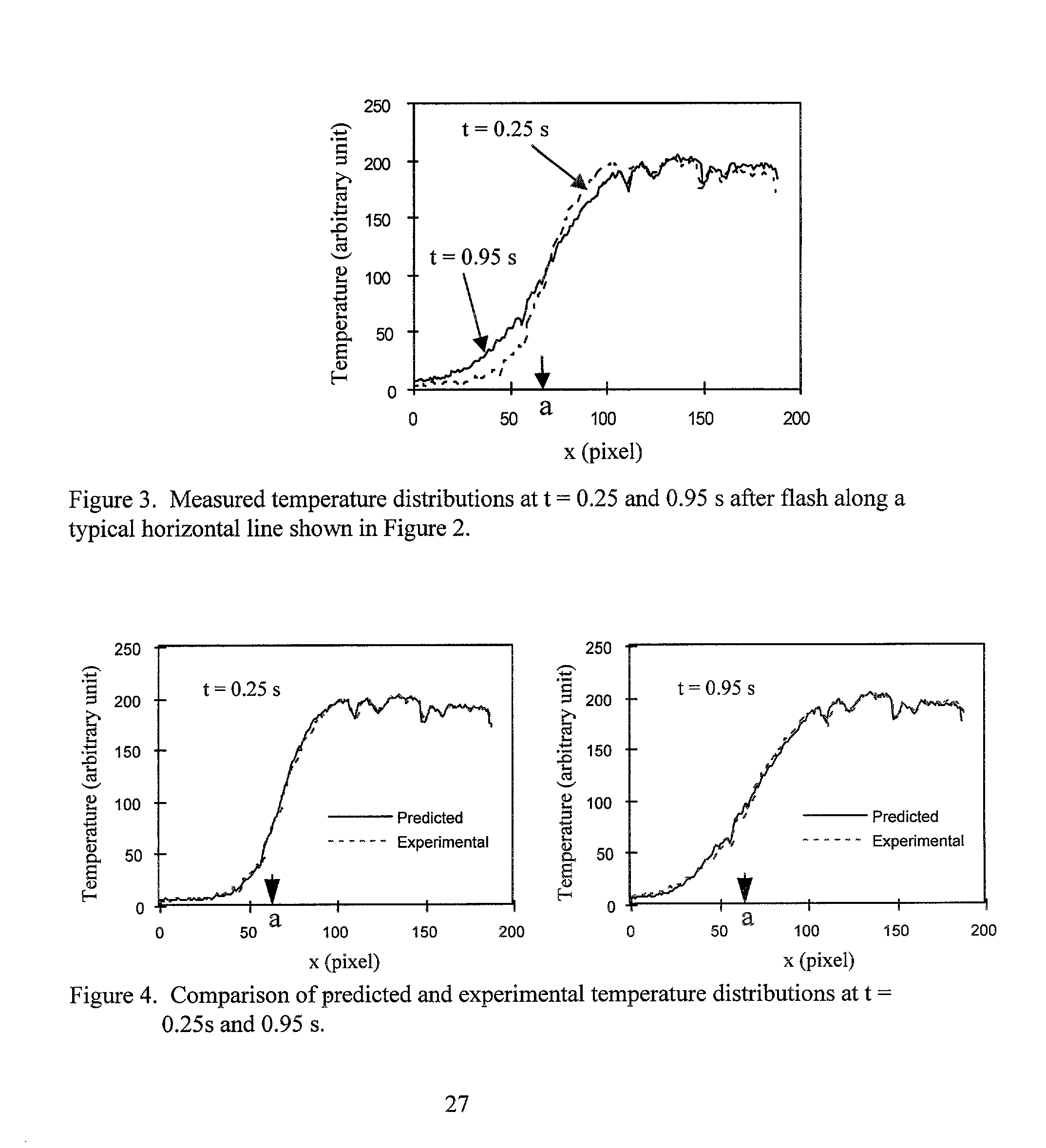

Thermal imaging measurement of lateral diffusivity and non-invasive material defect detection

InactiveUS20020126730A1Accurate methodRadiation pyrometryMaterial heat developmentMaterial defectOrthogonal coordinates

A system and method for determining lateral thermal diffusivity of a material sample using a heat pulse; a sample oriented within an orthogonal coordinate system; an infrared camera; and a computer that has a digital frame grabber, and data acquisition and processing software. The mathematical model used within the data processing software is capable of determining the lateral thermal diffusivity of a sample of finite boundaries. The system and method may also be used as a nondestructive method for detecting and locating cracks within the material sample.

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

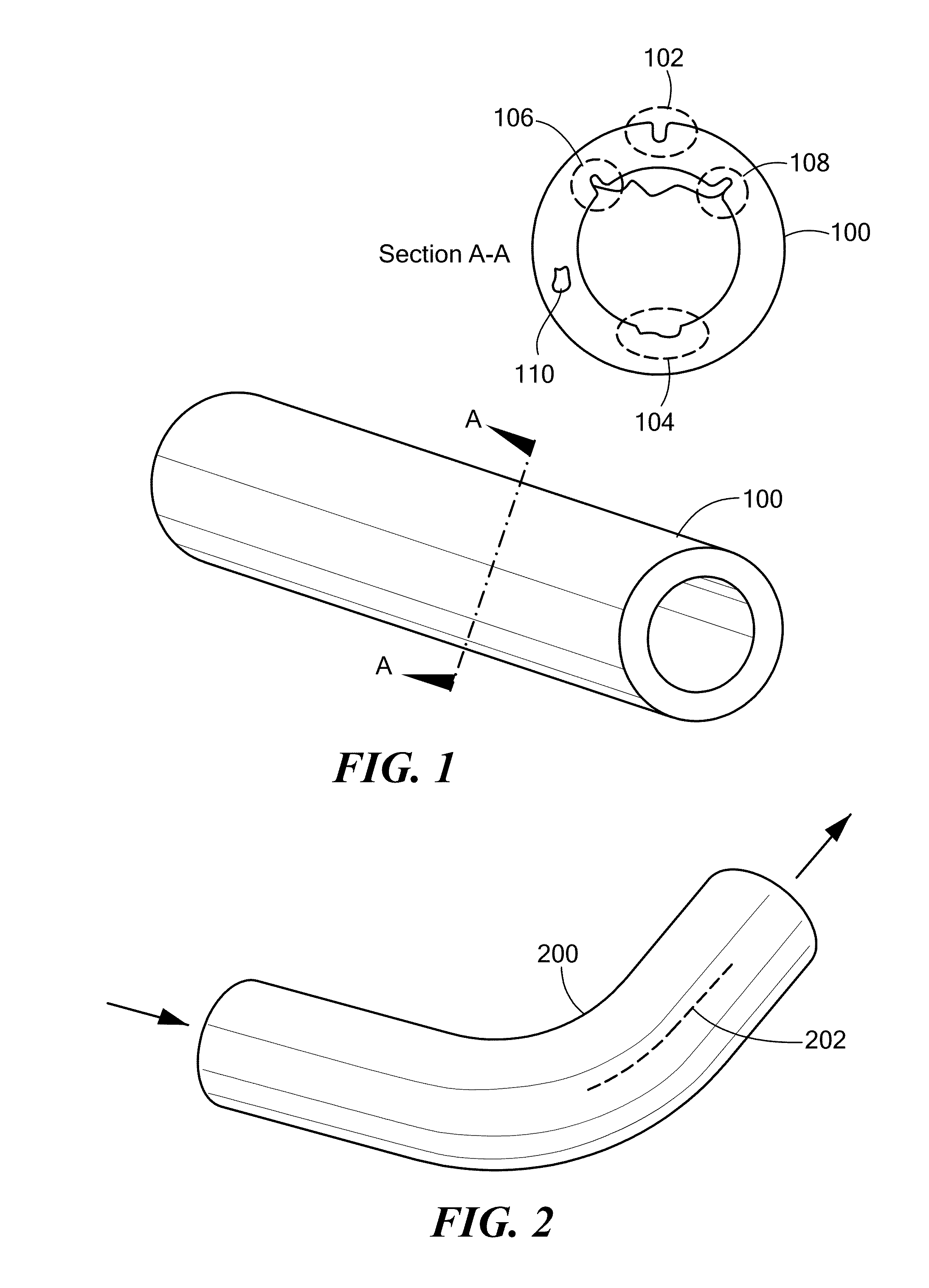

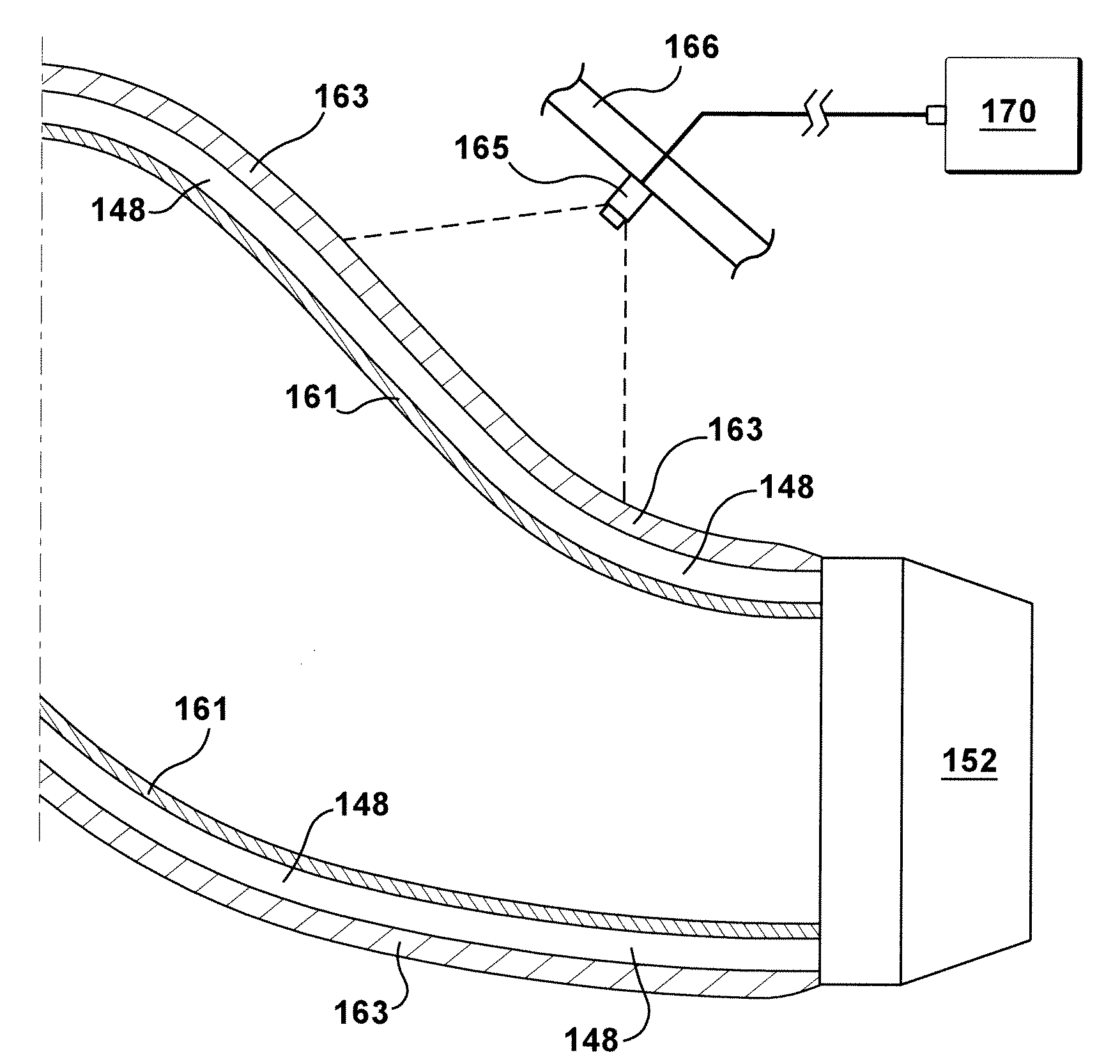

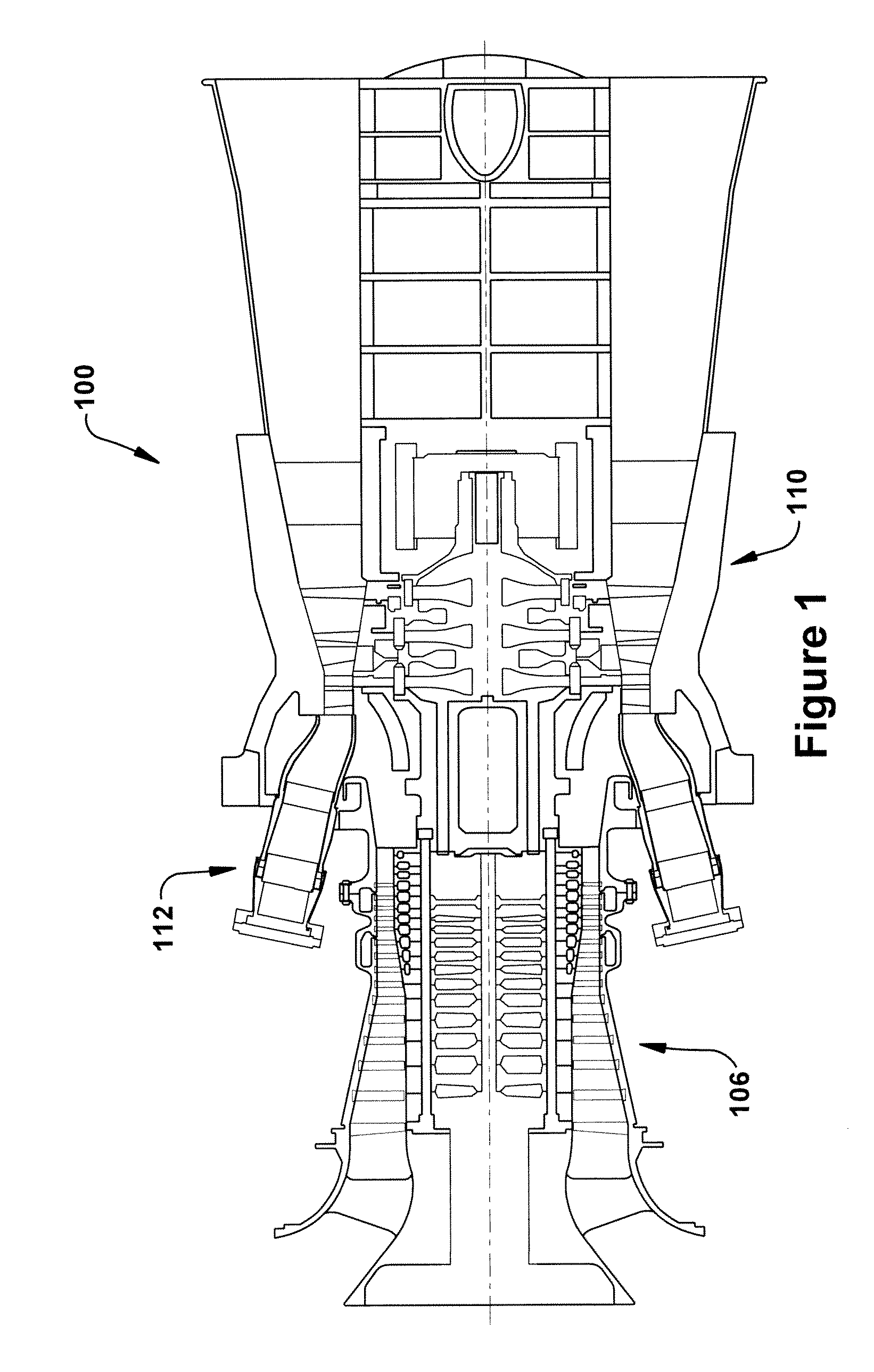

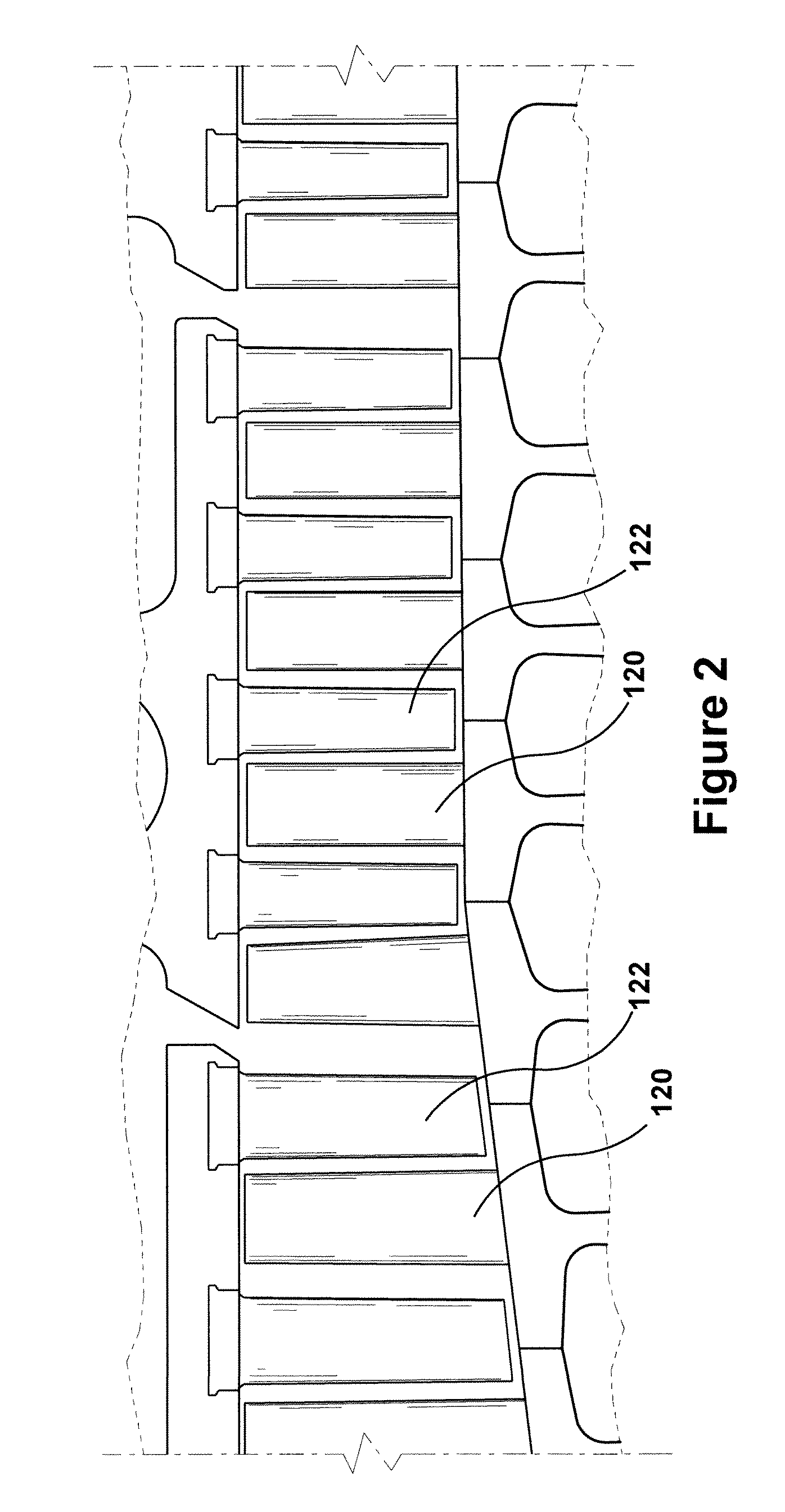

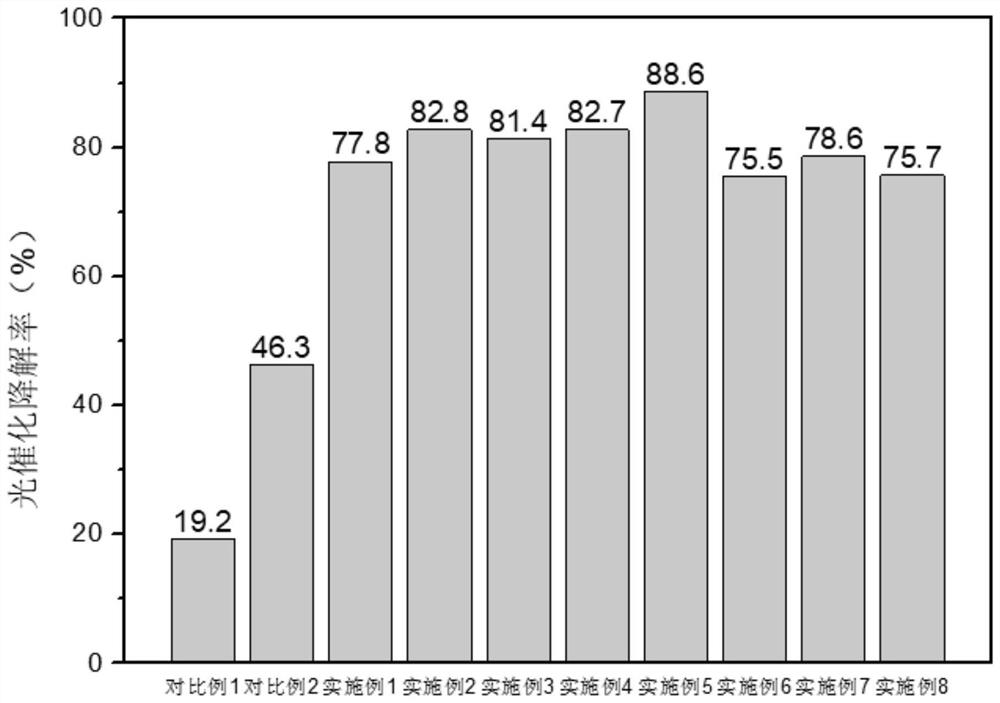

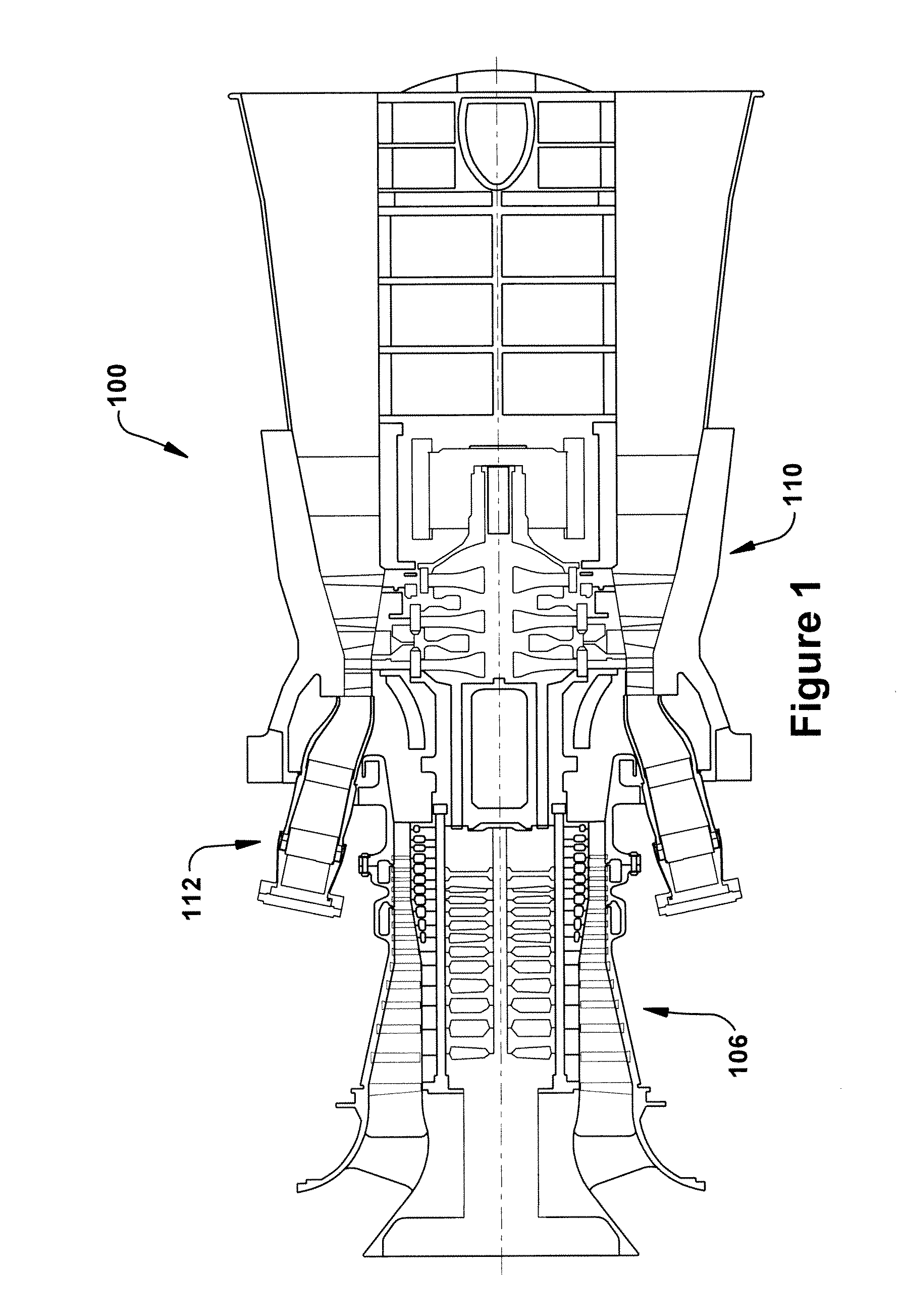

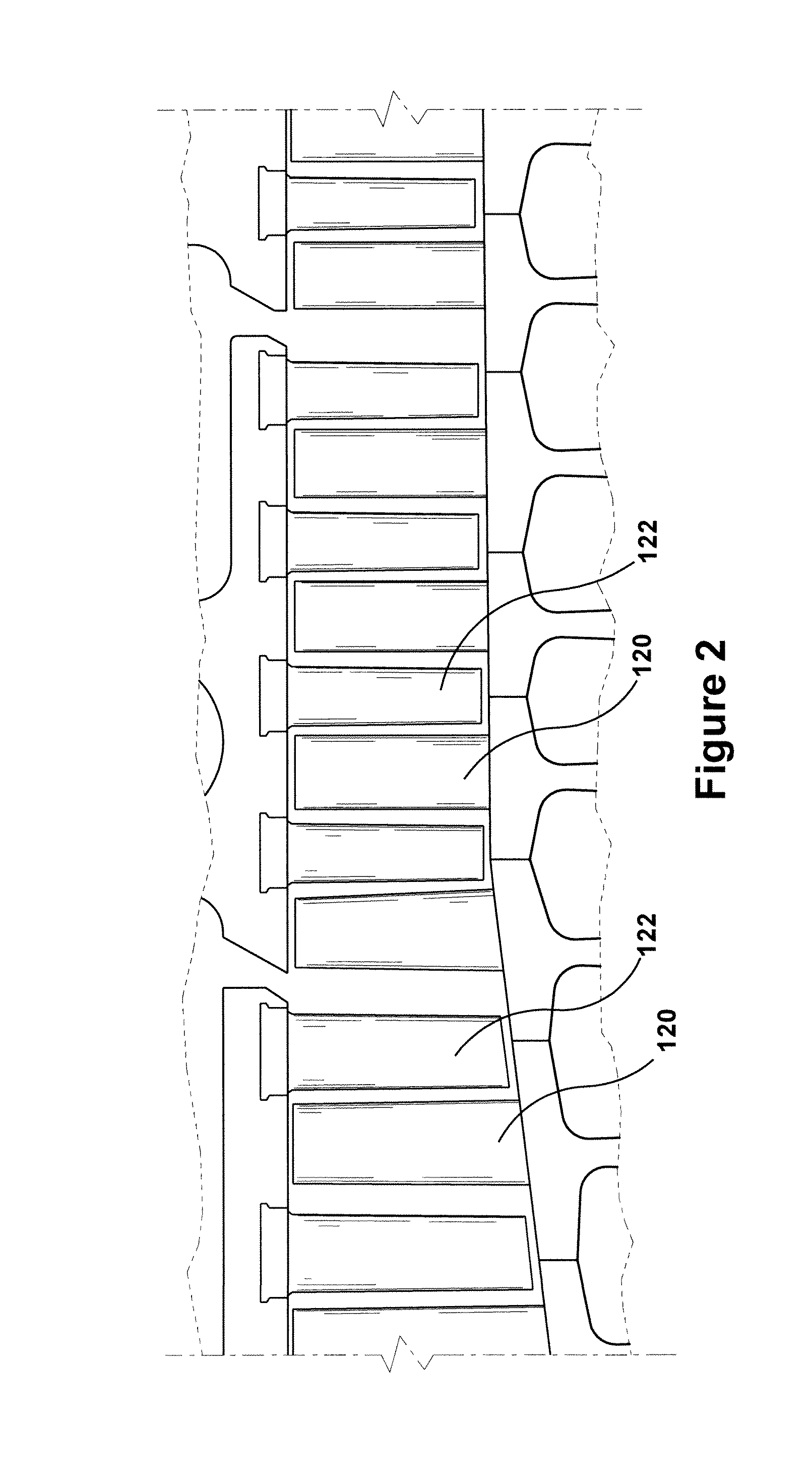

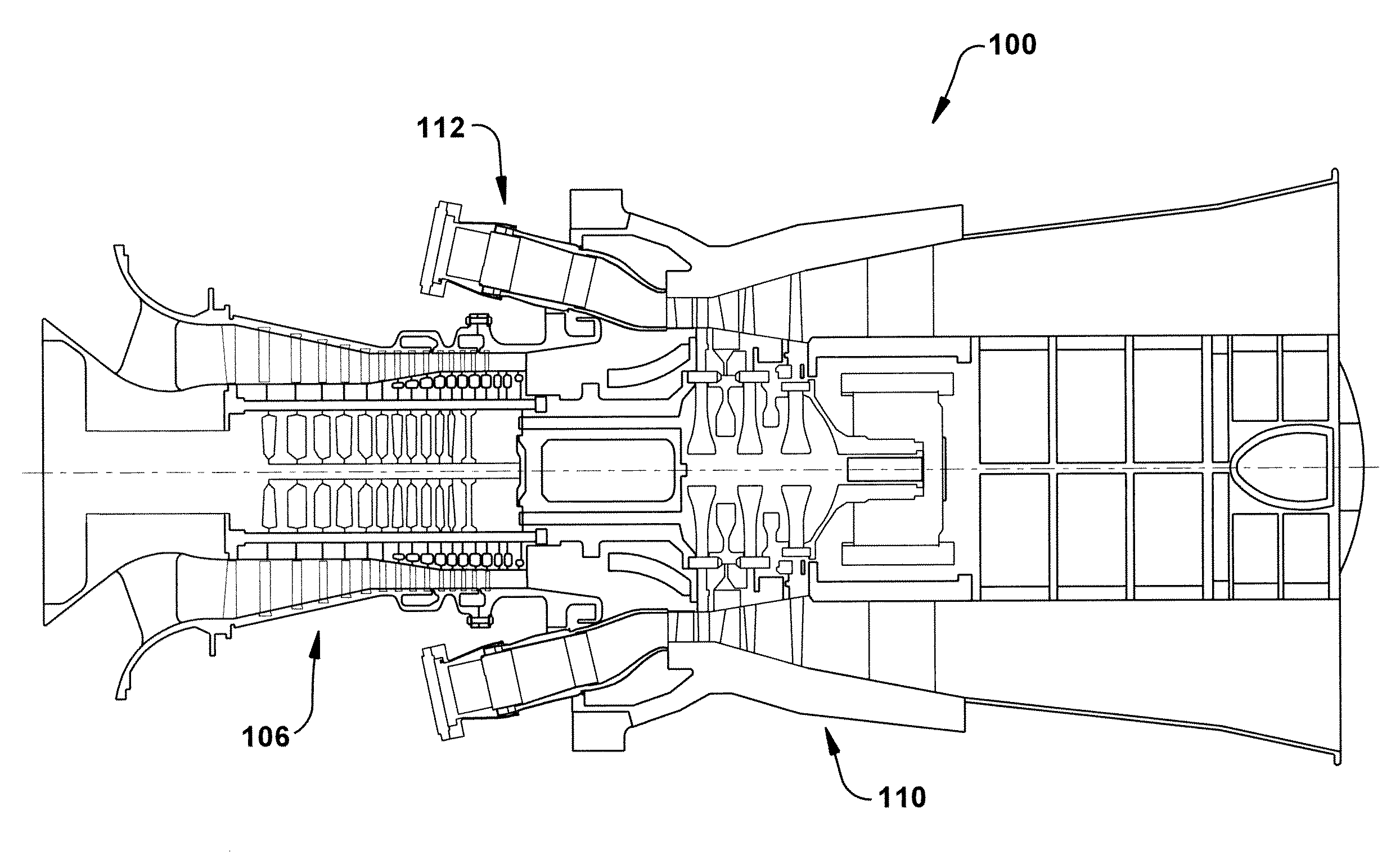

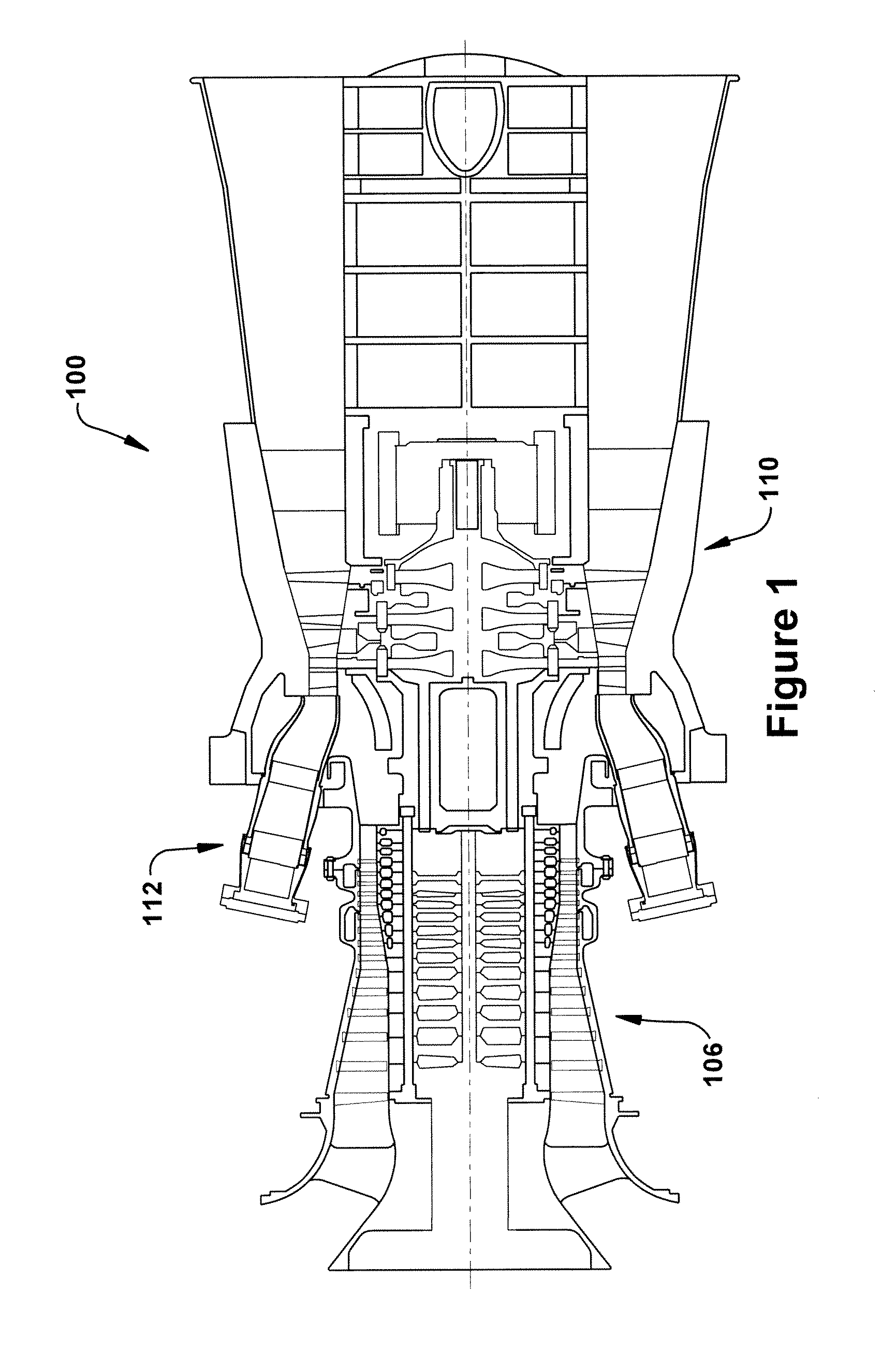

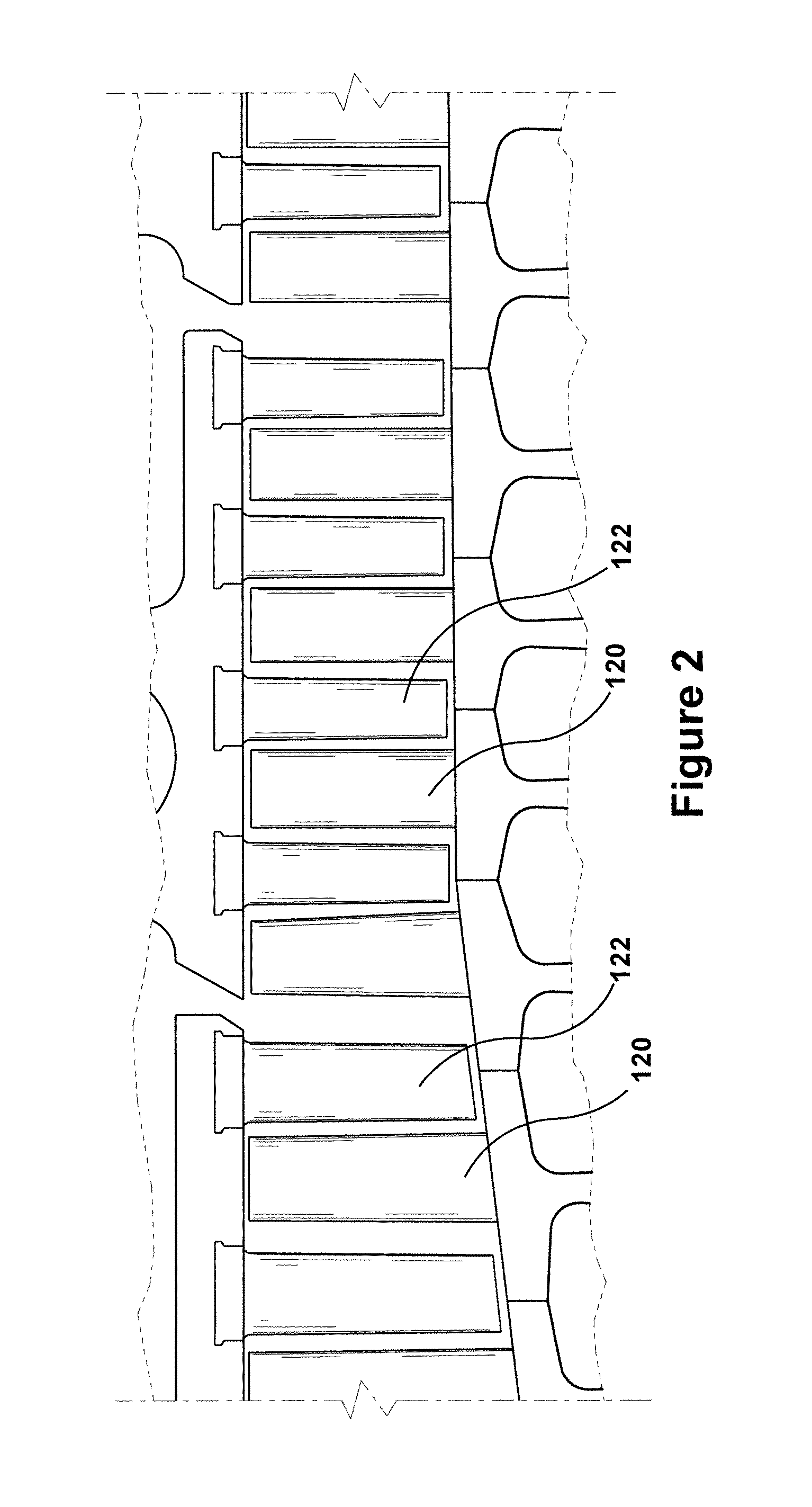

Methods, systems and apparatus for detecting material defects in combustors of combustion turbine engines

A system for detecting defects in a combustion duct of a combustion system of a combustion turbine engine while the combustion turbine engine operates, wherein the combustion duct comprises a hot side, which is exposed to combustion gases and, opposing the hot side, a cold side. In one embodiment, the system comprises: a photodetector aimed at the cold side of the combustion duct, the photodetector being configured to detect a visible change to the cold side of the combustion duct.

Owner:GENERAL ELECTRIC CO

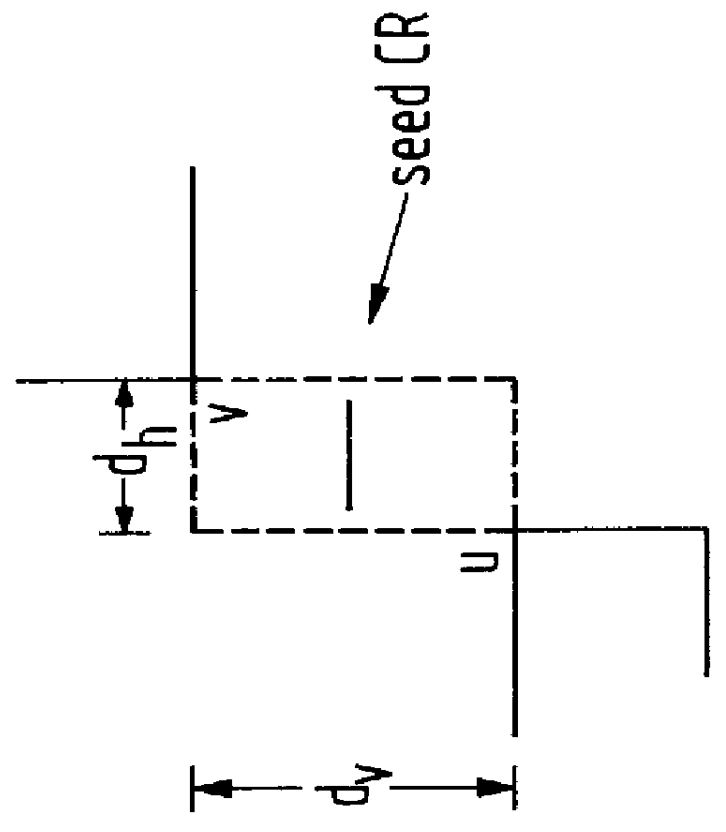

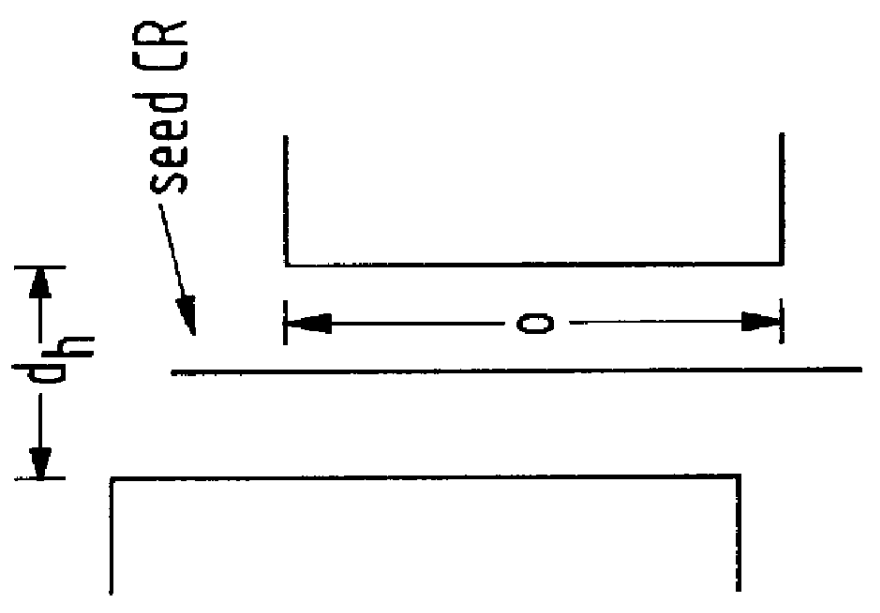

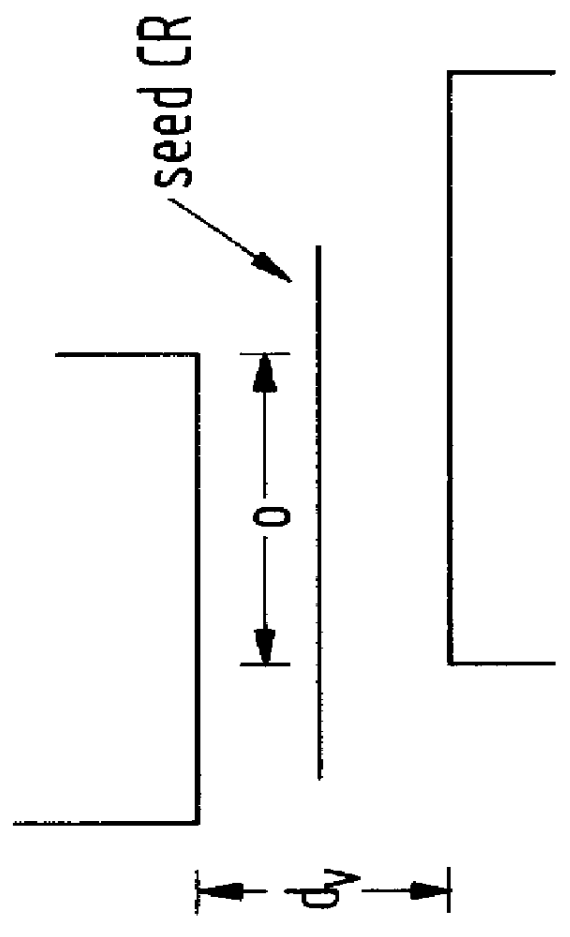

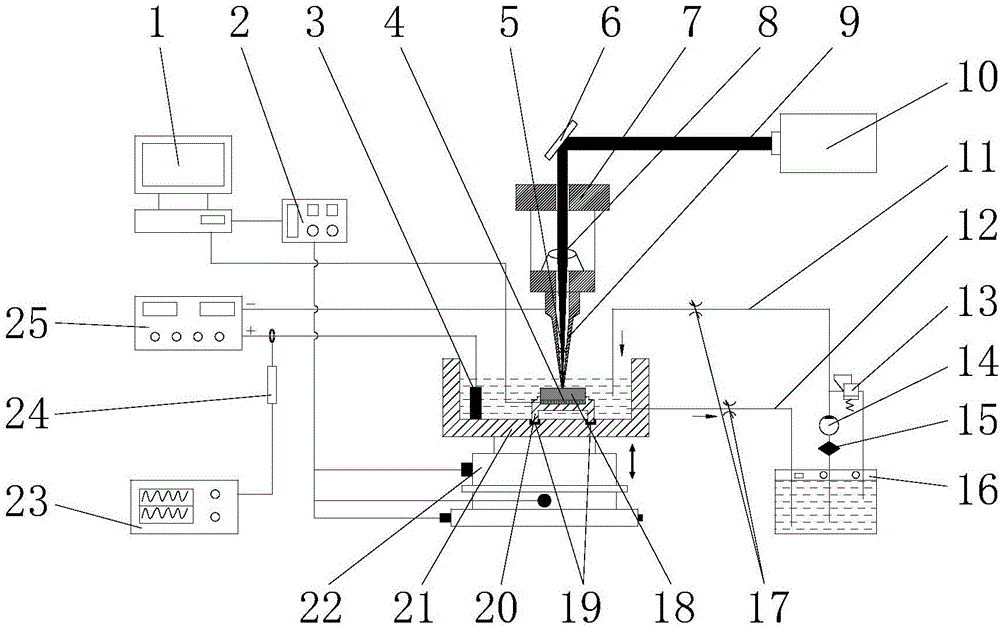

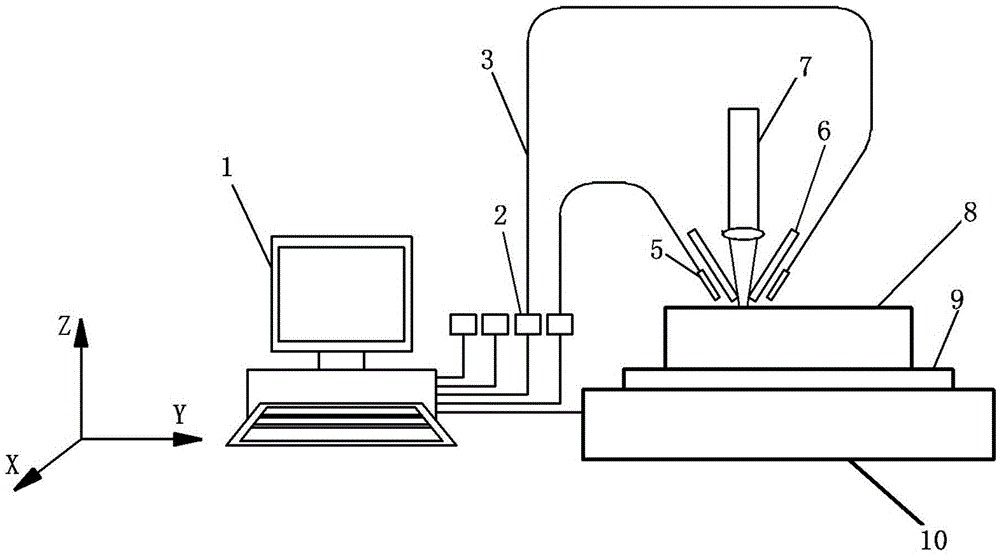

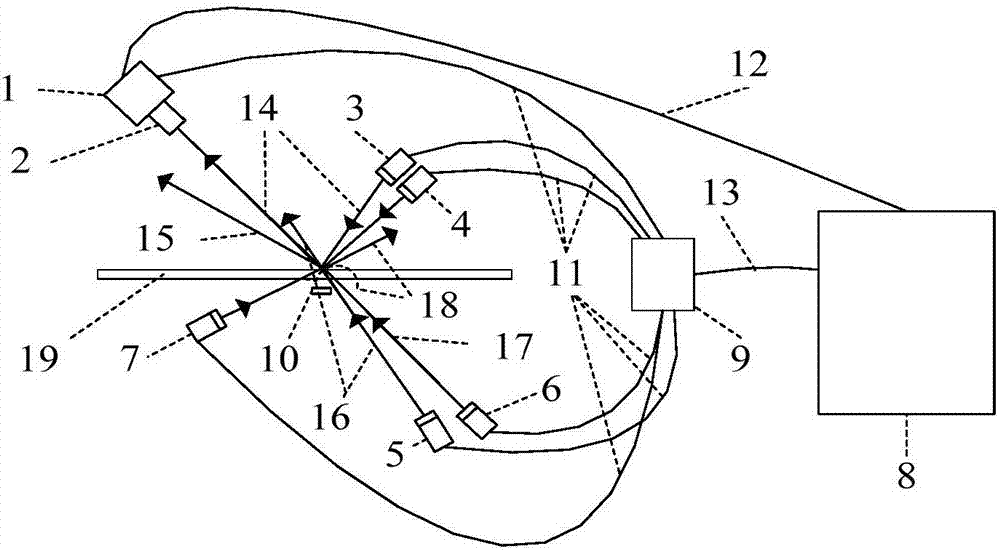

Online detecting and eliminating device and method for melt channel material defects in laser metal forming

InactiveCN105618740AEliminate internal material defectsEasy to useAdditive manufacturing apparatusThermometers using physical/chemical changesMaterial defectMetal forming

The invention discloses an online detecting and eliminating device and method for melt channel material defects in laser metal forming. The device and method are suitable for a laser metal deposition forming process. The device comprises four optical fiber type double-color temperature gauges, and four temperature measuring probes of the optical fiber type double-color temperature gauges are fixed to the left side, the right side, the front side and the back side of a coaxial powder feeding nozzle of a forming system correspondingly; detection aiming points of the four temperature measuring probes are aligned with the left side, the right side, the front side and the back side of a forming scanning laser spot on a forming plane correspondingly, the detection aiming points are away from the center of the laser spot by a certain micro-distance, and the four temperature measuring probes, the coaxial powder feeding nozzle and a laser beam move together; during forming, when the coaxial powder feeding nozzle and the laser beam conduct forming scanning in any one of the -X direction, the X direction, the -Y direction and the Y direction, the temperature measuring probe located at the side opposite to the scanning direction of the coaxial powder feeding nozzle is used for detecting the temperature of the position, away from the laser spot by a certain micro-distance, of a high-temperature melt channel, and when the temperature mutates abnormally, it is judged that the material defects exist in the position, the defect positions are determined, and laser targeted remelting is carried out on the defects.

Owner:XIAN UNIV OF TECH +2

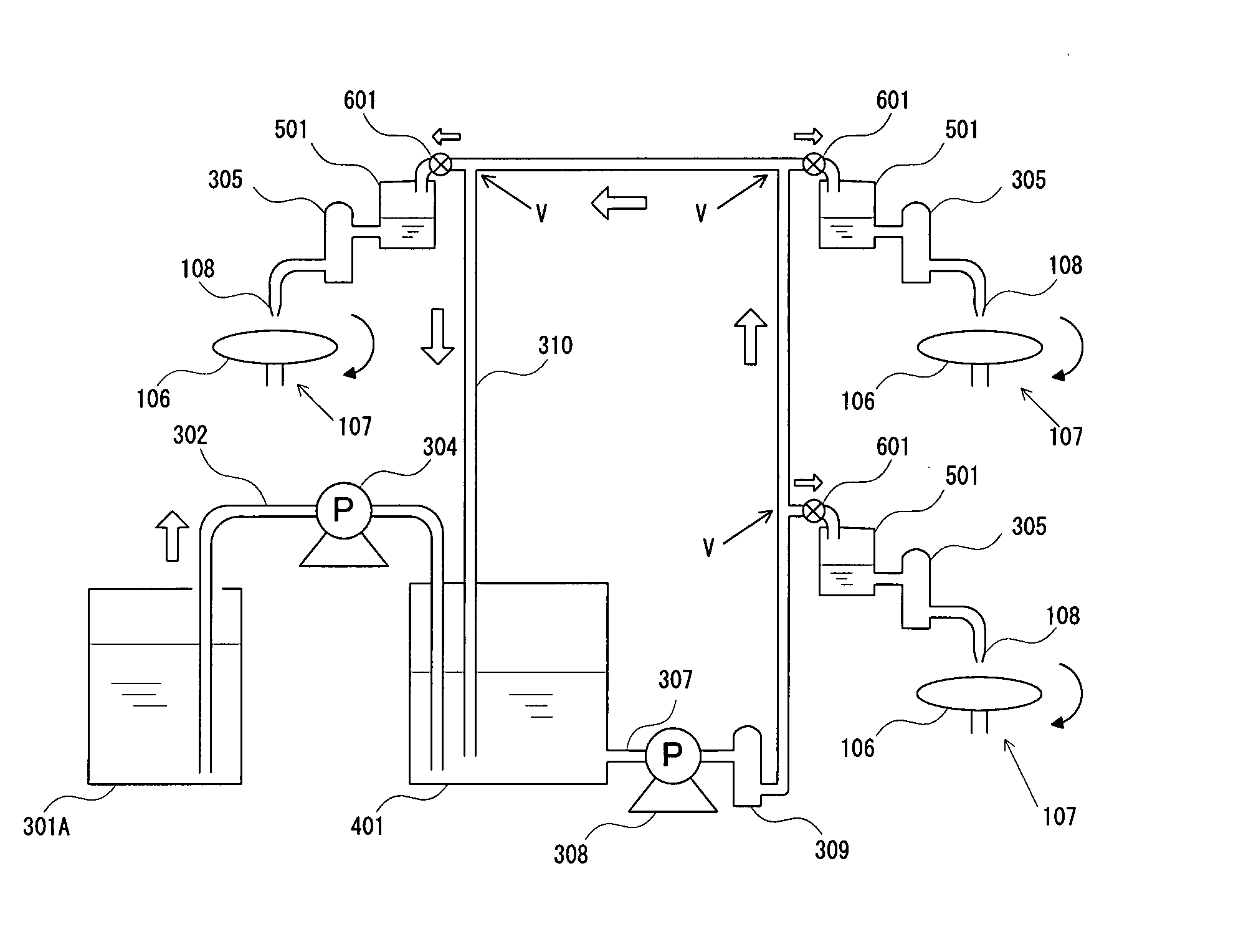

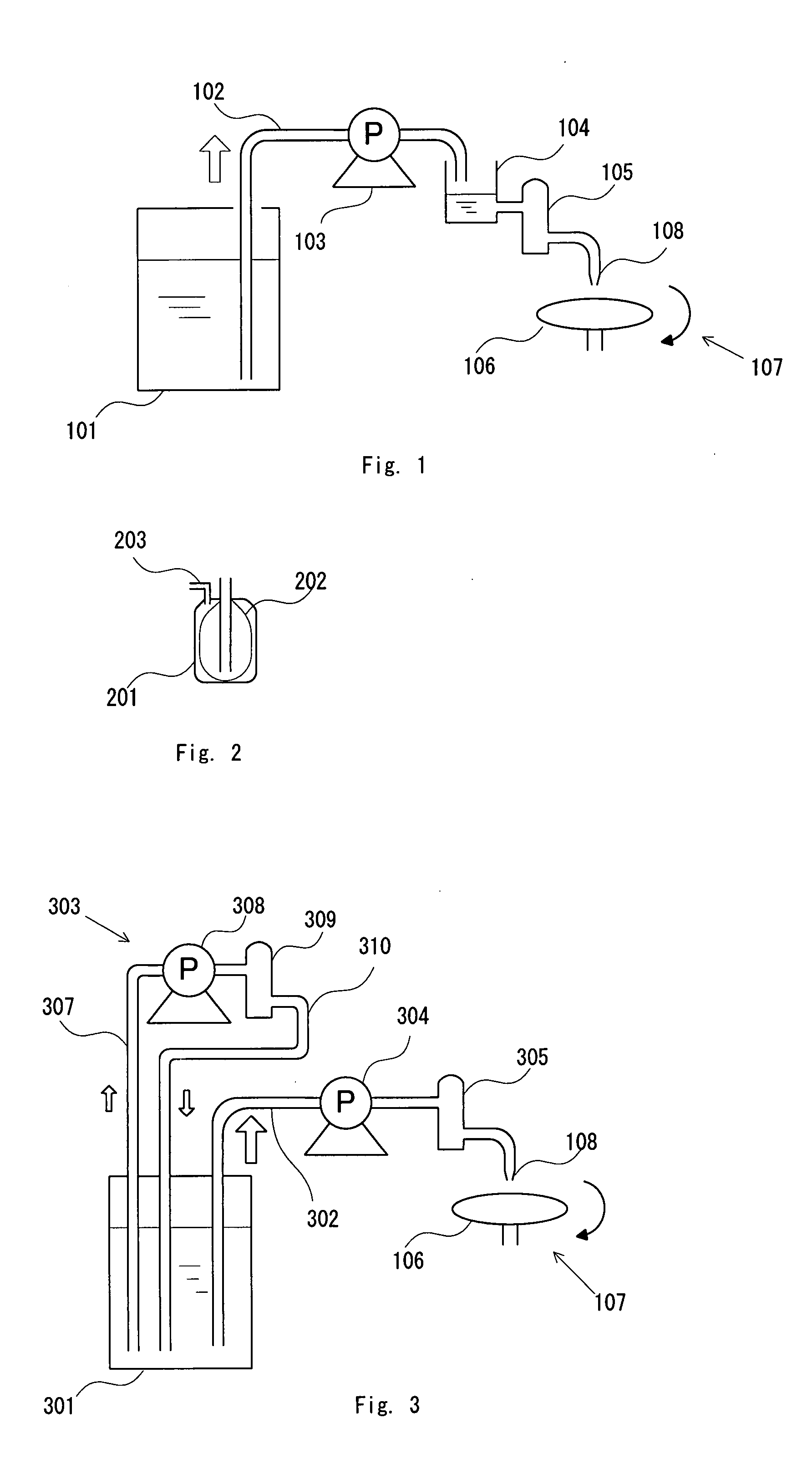

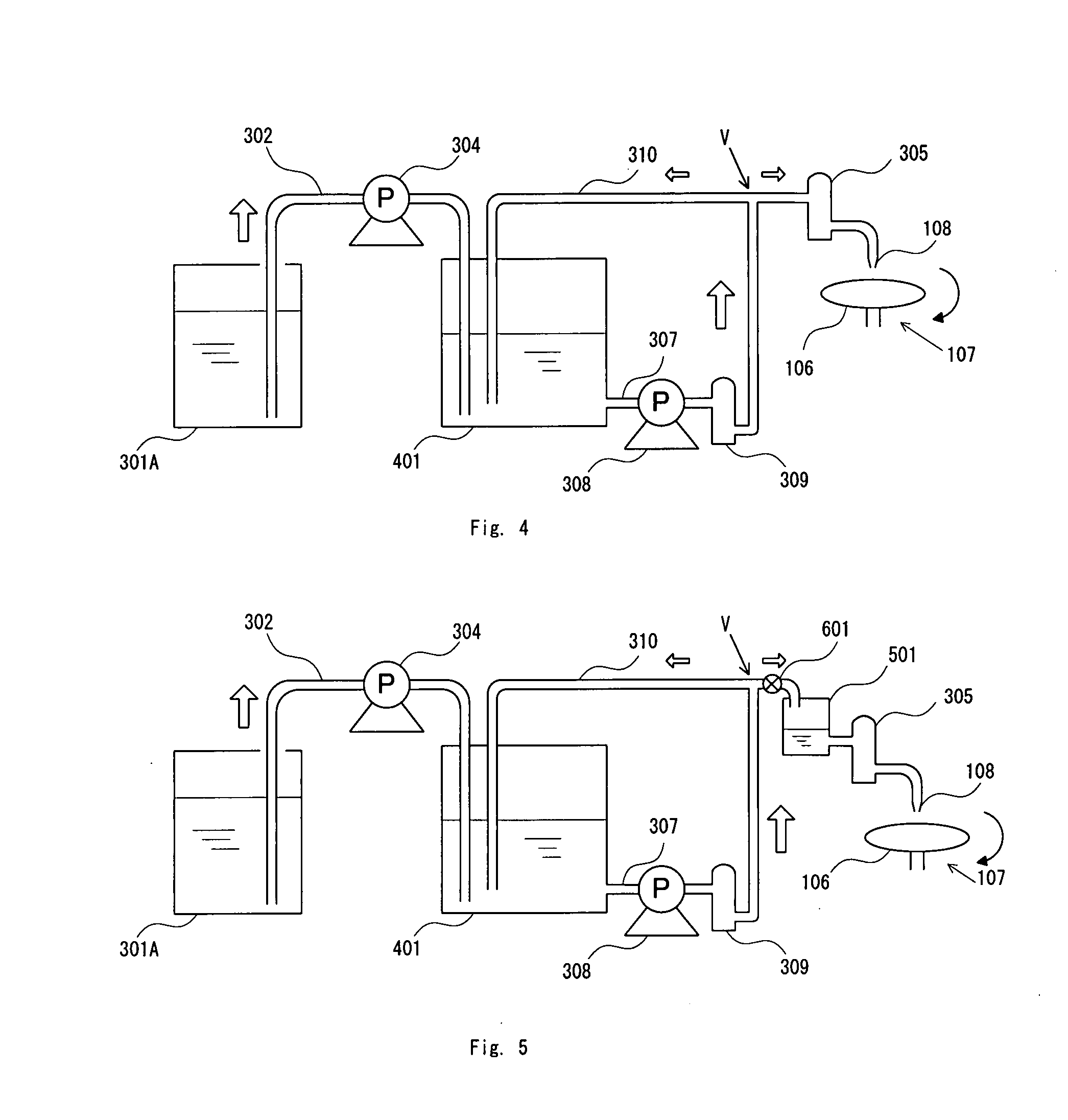

Photoresist Coating Liquid Supplying Apparatus, And Photoresist Coating Liquid Supplying Method And Photoresist Coating Apparatus Using Such Photoresist Coating Liquid Supplying Apparatus

InactiveUS20080087615A1Reduce defectsIncrease productionLiquid separation auxillary apparatusPhotomechanical apparatusResistMaterial defect

This invention provides a photoresist coating liquid supplying apparatus and a photoresist coating liquid supplying method, for supplying a photoresist coating liquid having a low particle content to a photoresist coating apparatus, and a photoresist coating apparatus using such a photoresist coating liquid supplying apparatus, which can realize coating without causing significant defects in a cost-effective manner. The photoresist coating liquid supplying apparatus comprises a buffer vessel for a photoresist coating liquid, a circulation filtering apparatus for drawing a part of the coating liquid from the buffer vessel, filtering the coating liquid, and then returning the filtered coating liquid to the buffer vessel, and a pipe for supplying the coating liquid from the buffer vessel or the circulation apparatus to a coating apparatus. The photoresist coating liquid supplying method uses the photoresist coating liquid supplying apparatus. The photoresist coating apparatus comprises a combination of the coating liquid supplying apparatus with a slit coating apparatus.

Owner:MERCK PATENT GMBH

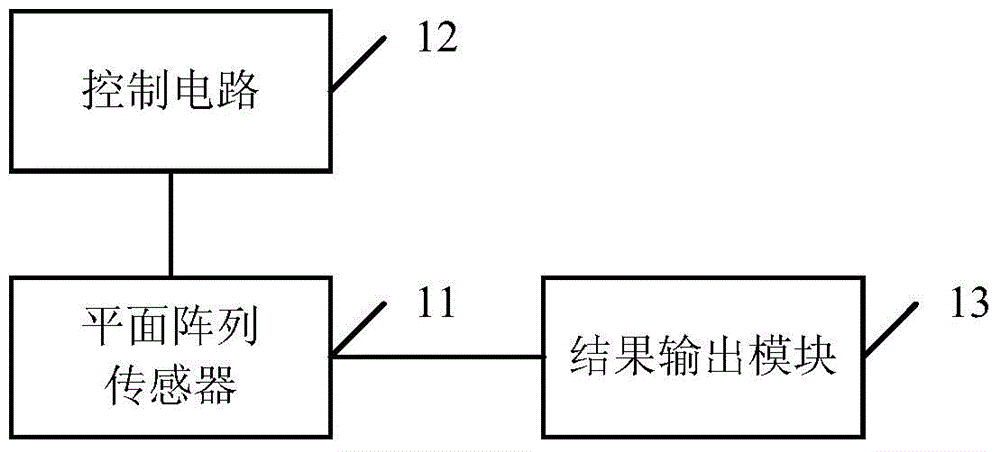

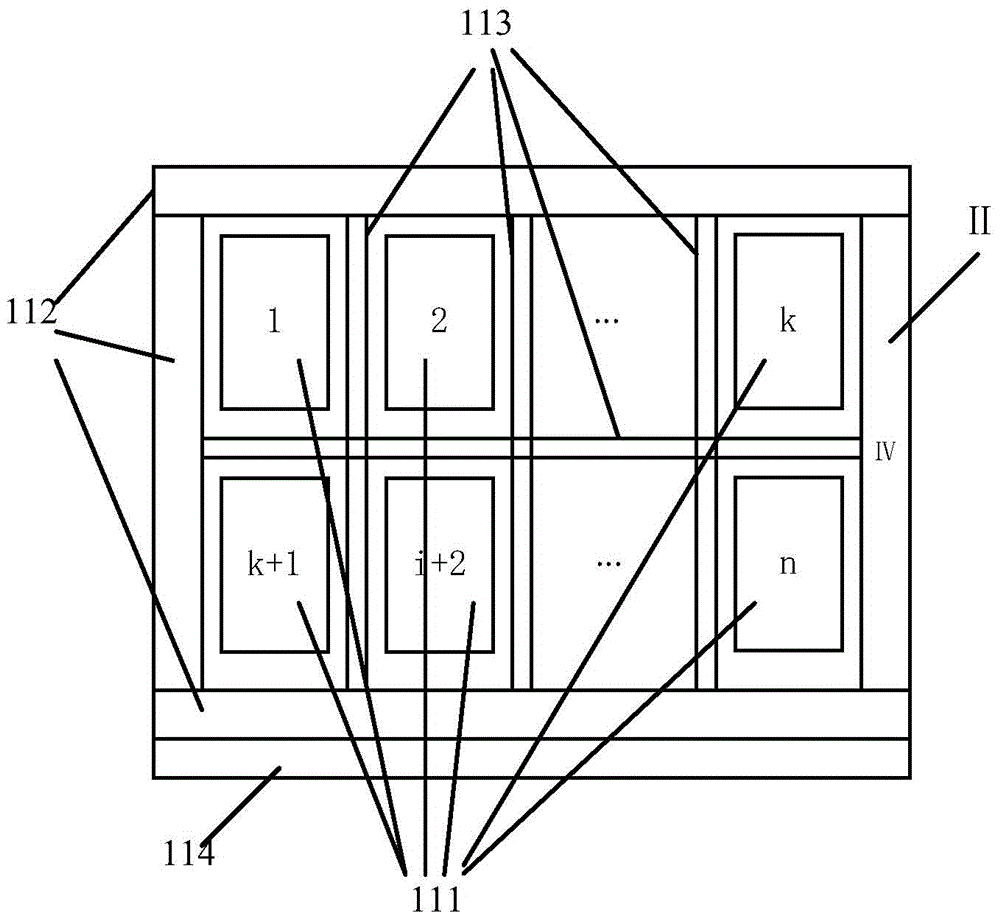

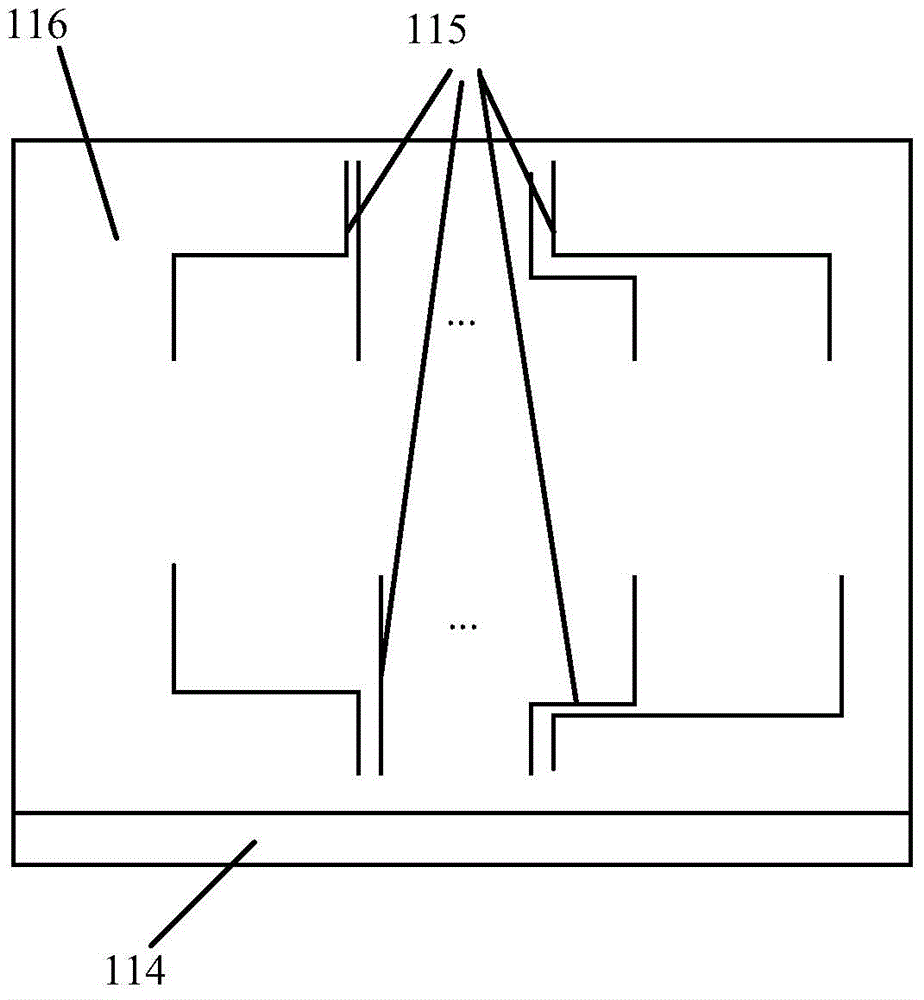

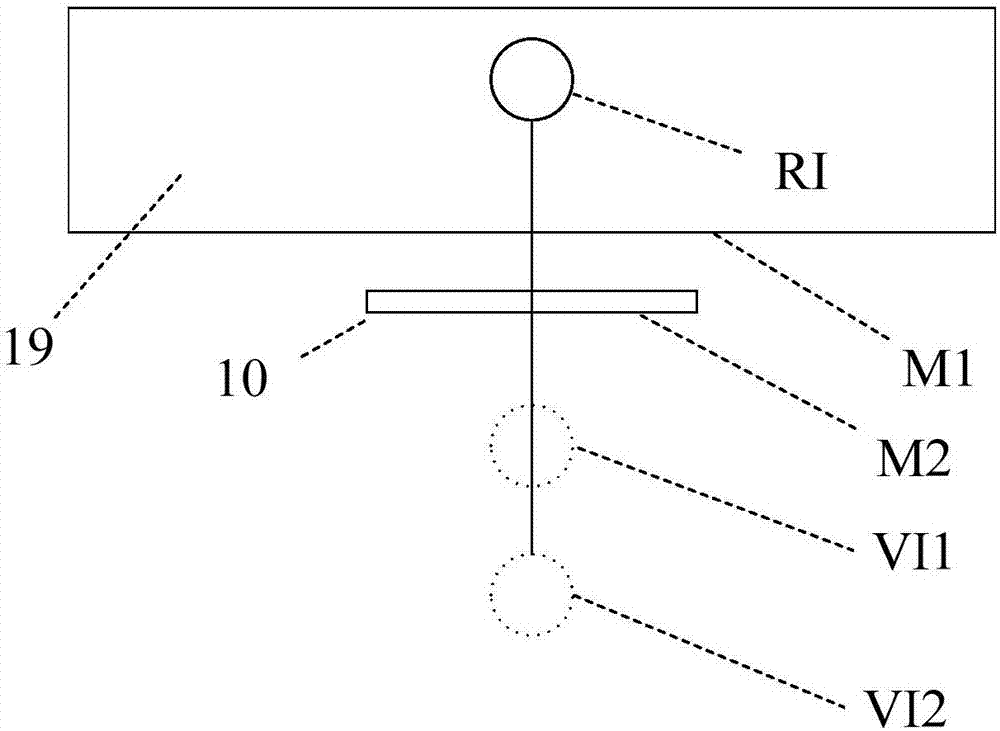

Material defect detector and material defect detection method

The invention discloses a material defect detector and a material defect detection method. The material defect detector comprises a planar array sensor, a control circuit and a result output module, wherein the planar array sensor comprises multiple detection electrodes, an end part shielding electrode, an interstage shielding electrode, a sensor substrate, signal lines and a substrate back surface shielding layer; the control circuit is connected with the multiple detection electrodes for controlling voltage drive on the multiple detection electrodes; the multiple detection electrodes are arranged above the sensor substrate in an array manner, the substrate back surface shielding layer covers the back surface of the sensor substrate, and the signal lines are distributed on the back surface of the sensor substrate; the signal lines are connected with the multiple detection electrodes, are also connected with the result output module, are used for transmitting detection signals to the result output module; the result output module is used for outputting corresponding detection results according to the detection signals. By utilizing the scheme provided by the invention, the nondestructive testing to the interior of a material is realized.

Owner:秦皇岛光宇玻纤制品股份有限公司

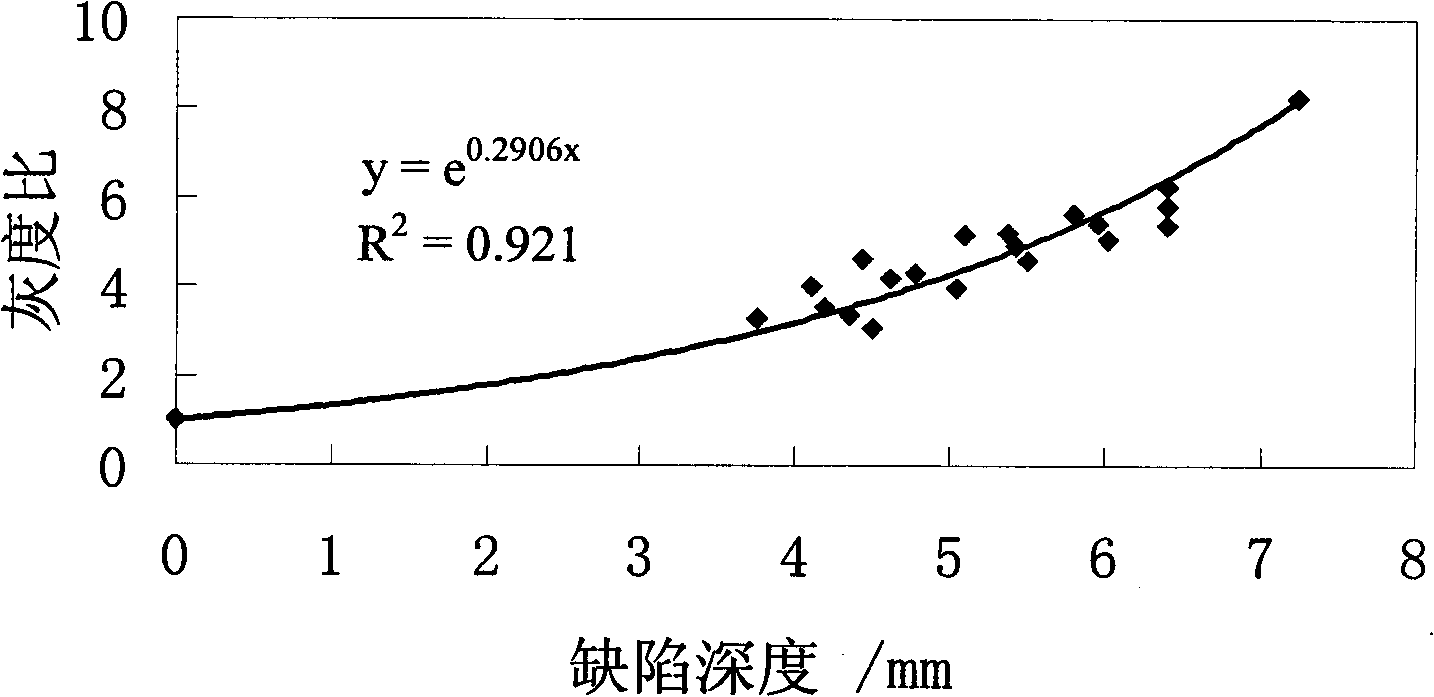

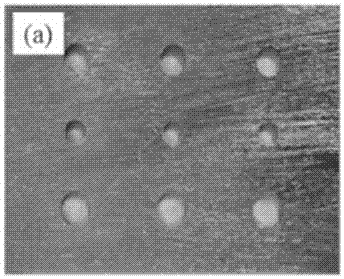

Method for measuring defect thickness in carbon/silicon carbide composite material

InactiveCN101556147AImplement extractionRealize quantitative measurementPreparing sample for investigationUsing wave/particle radiation meansMaterial defectGray level

The invention discloses a method for measuring defect thickness in carbon / silicon carbide composite material, comprising the following steps: a defect material sample, the thickness of which is changed in a way of gradient, is designed and prepared; a measuring sample is photographed by X-ray; a photoplate is scanned to be an electronic picture so that a gray level image thereof is obtained; ratio between the gray level of each defect area of the image and the gray level of no-defect area of the image is obtained by computing in a way of programming so as to establish a calibration function relational expression of the defect depth and the corresponding gray level ratio; and the defect thickness of the same material is computed with the calibration function under the same detecting condition to realize the quantitative measurement of the defect depth. The method conquers the defects of small detecting area, large error, low detecting efficiency, and the like, since the traditional X-ray photographing nondestructive detecting method detects the defect thickness with a nigrometer at one time, establishes the calibration function relationship of the ratio of the material defect thickness, the material defect gray level and the material no-defect gray level, realizes the quantitative measurement of the defect depth of the material, and has high detecting efficiency and higher precision.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

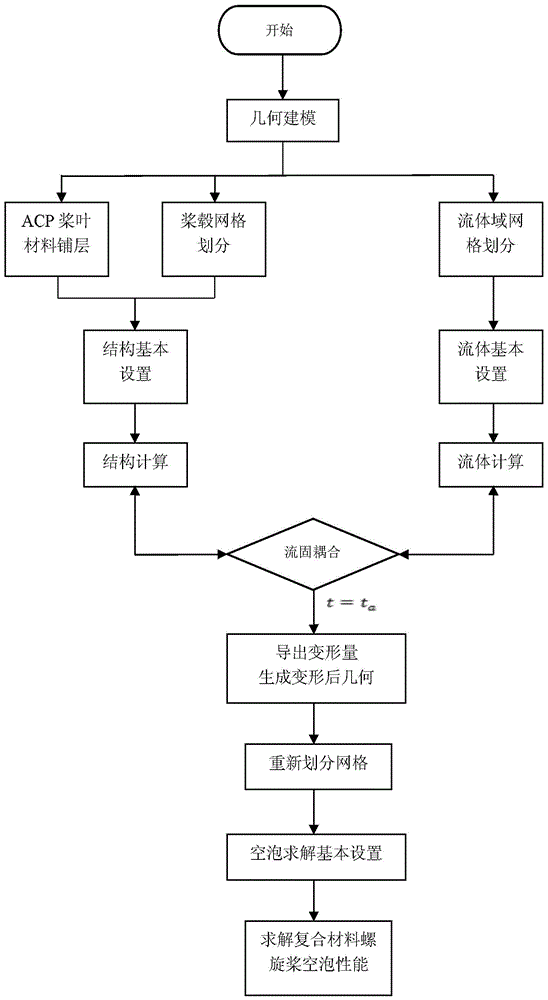

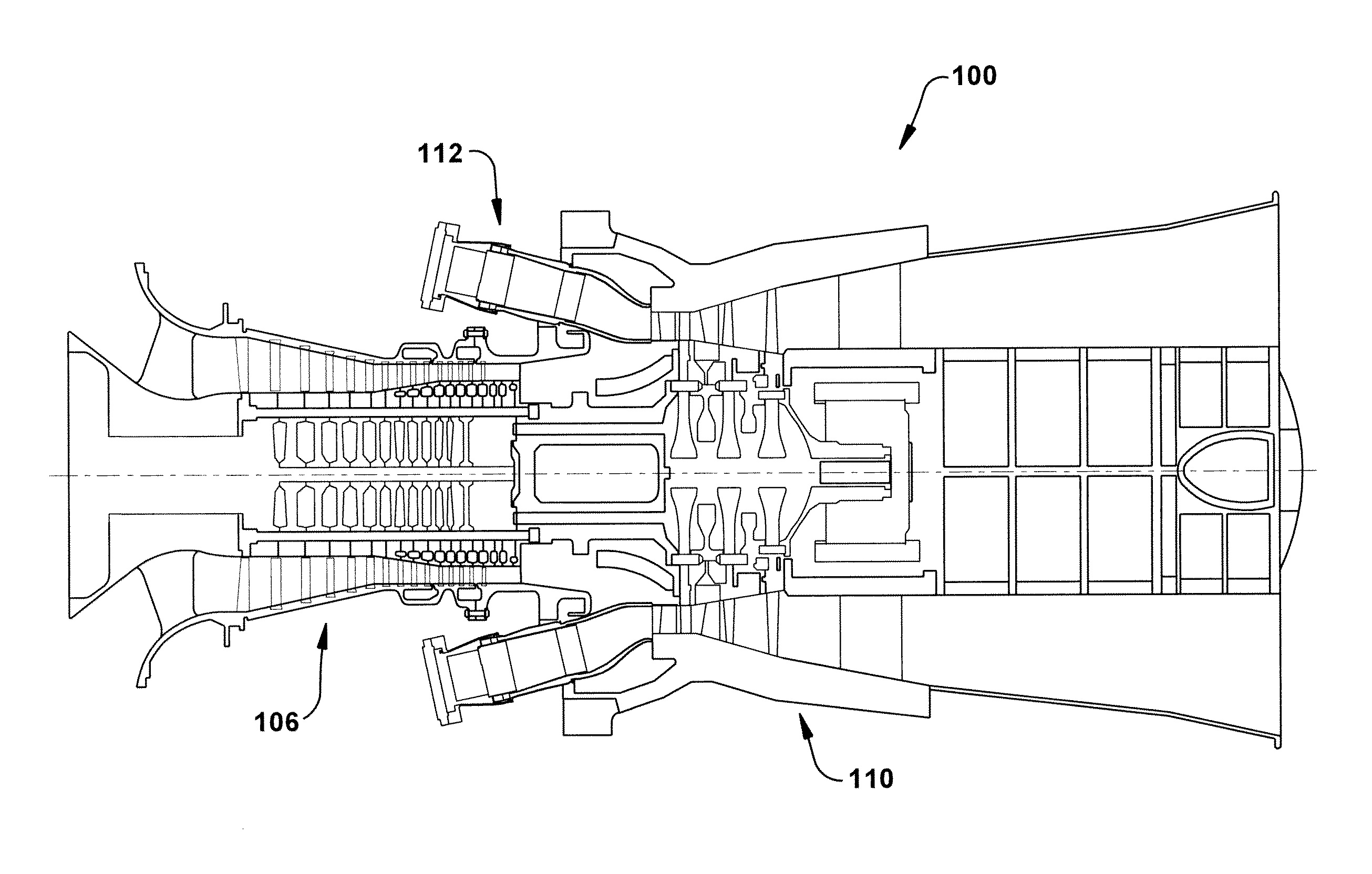

Composite material propeller cavitation performance calculation method

ActiveCN105653781AAvoid affecting propulsion performanceSolve the problem of imperfect research workSustainable transportationDesign optimisation/simulationMaterial defectComposite propeller

A composite propeller cavitation performance calculation method. The present invention relates to a composite material propeller cavitation performance calculation method. In order to solve the problem that due to generation of cavitation, the existing method will affect hydrodynamic performance of propellers, reduce propulsion efficiency, severely affect concealment of vessels, corrode surface materials of the propellers and cause surface material defects, the present invention provides a composite material propeller cavitation performance calculation method. The method comprises: establishing a geometric model; carrying out grid division; carrying out structure and fluid arrangement; carrying out structure and fluid calculation; exporting a deformed geometric model; re-dividing a grid; and carrying out cavitation performance calculation. The method provided by the present invention is applied to the field of propellers.

Owner:HARBIN INST OF TECH

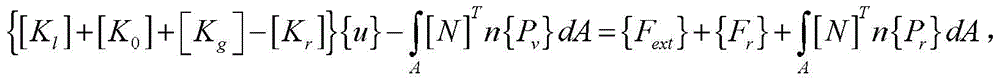

Photocatalyst for efficiently degrading tetracycline under visible light and preparation method and application of photocatalyst

PendingCN112121846AImprove redox abilitySmall specific surface areaWater/sewage treatment by irradiationWater treatment compoundsMaterial defectFreeze-drying

The invention belongs to the field of environmental catalysis, and discloses a photocatalyst for efficiently degrading tetracycline under visible light and a preparation method and application of thephotocatalyst. The preparation method of the photocatalyst comprises the following steps: mixing a nitrogen-containing compound in water, carrying out hydrothermal treatment, cooling, transferring into a culture dish, and carrying out freeze drying treatment to obtain a precursor; and putting the precursor into a closed environment for high-temperature roasting, and naturally cooling to obtain thegraphite-phase carbon nitride photocatalyst for efficiently degrading tetracycline under visible light. According to the preparation method, the raw materials are mixed for hydro-thermal treatment and freeze-drying treatment to obtain the precursor, the graphite-phase carbon nitride obtained through constant-temperature roasting under different conditions has a relatively high specific surface area, and the separation of photo-induced electrons and holes can be effectively promoted through the formation of material defects; therefore, the purpose of efficiently degrading 10 mg / L tetracyclinehydrochloride under visible light is achieved.

Owner:GUANGZHOU UNIVERSITY

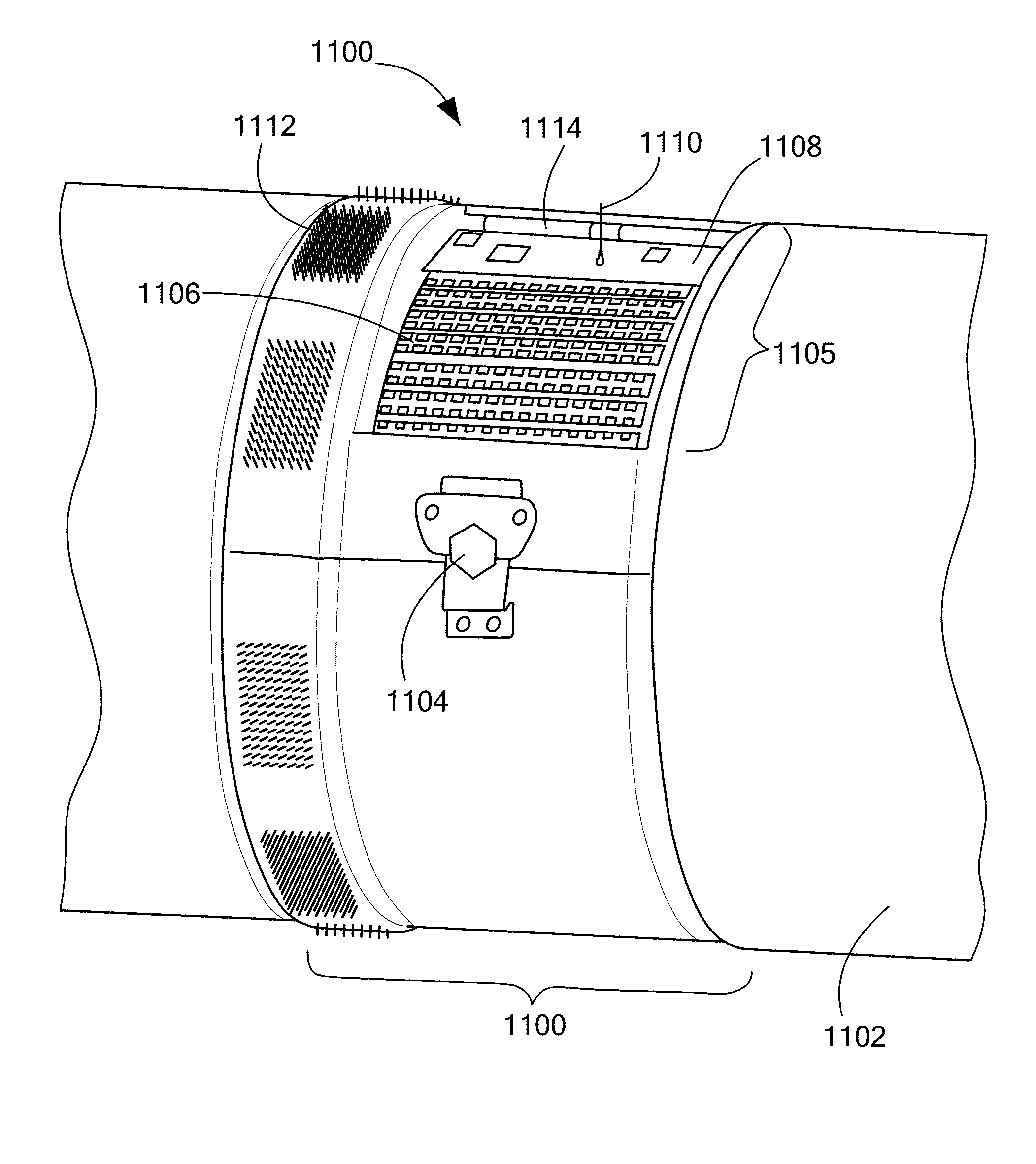

Methods, systems and apparatus for detecting material defects in combustors of combustion turbine engines

InactiveUS20120167664A1Gas-turbine engine testingComponent separationCombustion systemMaterial defect

A system for detecting defects in a combustion duct of a combustion system of a combustion turbine engine while the combustion turbine engine operates, wherein the combustion duct comprises a hot side, which is exposed to combustion gases and, opposing the hot side, a cold side. The system may include: an indicator coating disposed on an outer surface of the combustion duct, the indicator coating comprising a detectable substance; and a gas sensor positioned downstream of the combustor, the gas sensor configured to take a measurement of the amount of the detectable substance in the combustion products of the combustion turbine engine.

Owner:GENERAL ELECTRIC CO

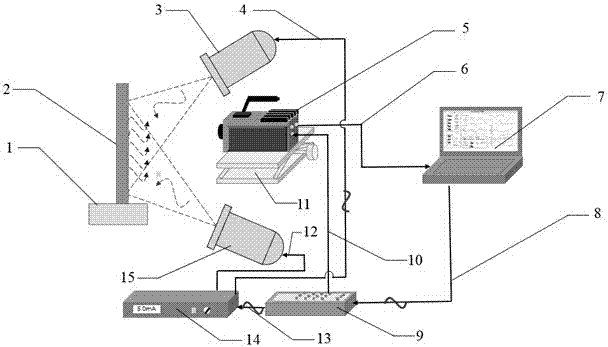

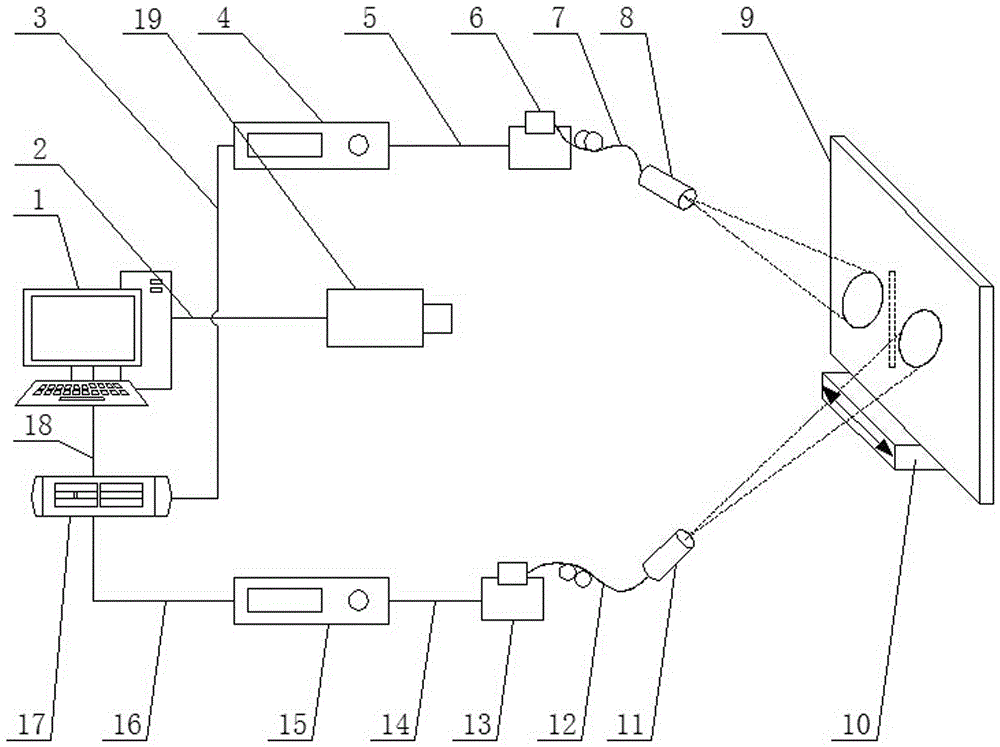

Pulsed excitation-based dynamic thermal chromatography imaging detection system and method

InactiveCN106959319ANot limited by sizeEfficient detectionMaterial flaws investigationMaterial defectData acquisition

The invention discloses a pulsed excitation-based dynamic thermal chromatography imaging detection system and method and belongs to the technical field of imaging detection. The system comprises a mobile station, a first xenon lamp, a first xenon lamp power line, a thermal infrared imager, an Ethernet cable, a computer, a USB data line, a data collection card, a BNC trigger signal line, a vertical lifting platform, a second xenon lamp power line, a BNC data line, a xenon lamp power supply and a second xenon lamp. The pulsed excitation-based dynamic thermal chromatography imaging detection system and method have the advantages that non-destructive and non-contact efficient detection of defects of surfaces and shallow surfaces of a composite material, a metal material, an inorganic nonmetallic material and a synthetic material can be achieved, and meanwhile, the system and the method are not limited by the size of a detected material; lateral heat diffusion of heat flow can be relatively well reduced, thereby improving the signal-to-noise ratio (lightweight) of defect detection; by adopting the xenon lamps as light sources, short-time high power (time 1 / 600s and short-time peak power 4,000W) injection of energy can be ensured; and three-dimensional reconstruction of material defects can be achieved.

Owner:HARBIN INST OF TECH

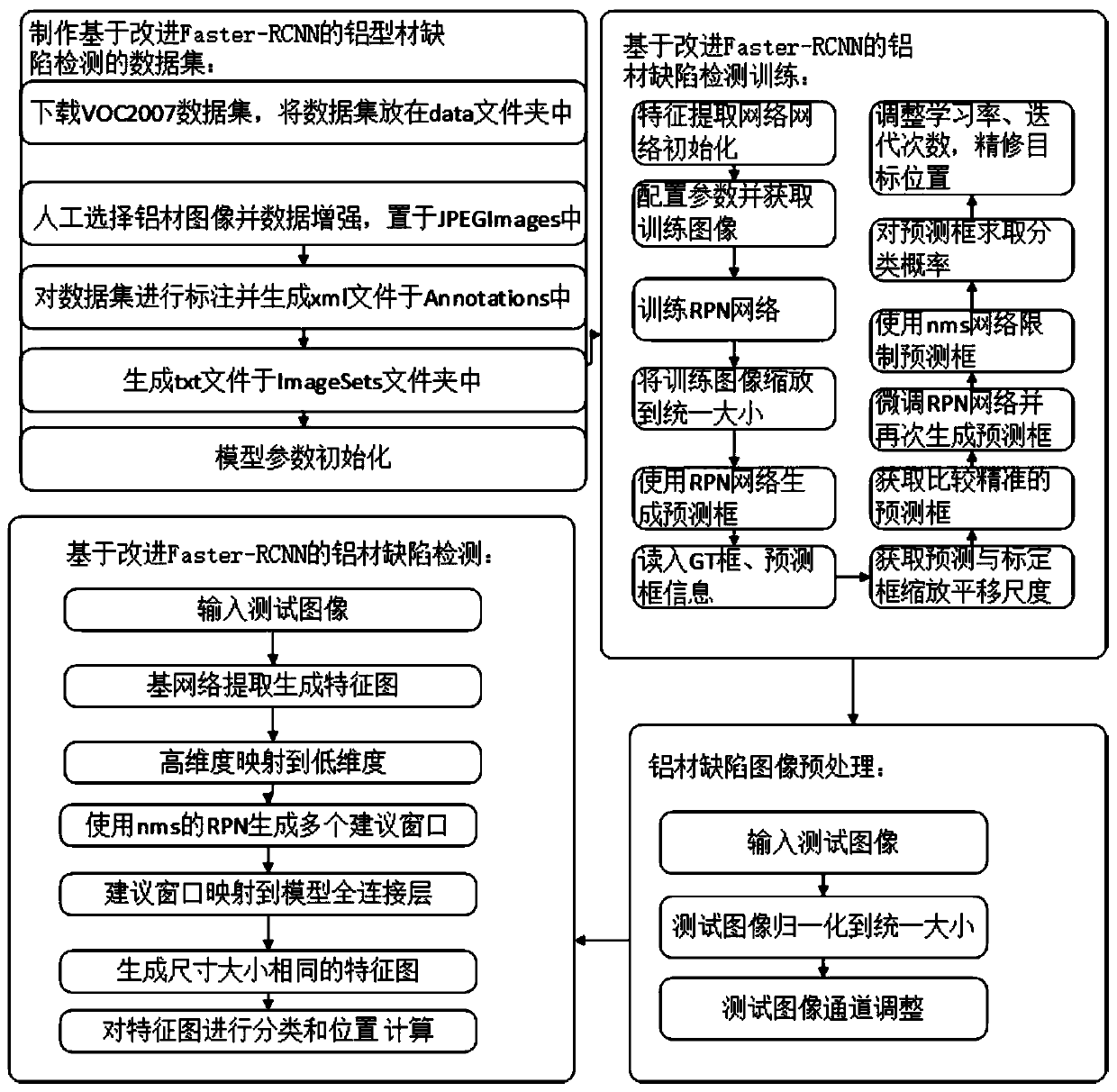

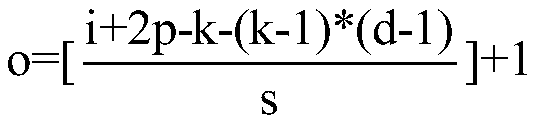

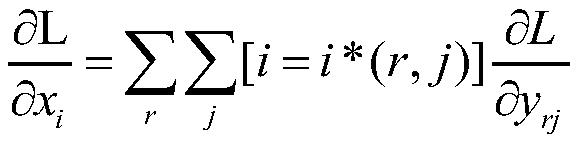

Aluminum profile defect detection method based on improved Faster-RCNN

InactiveCN110853015AEasy to detectImprove applicabilityImage enhancementImage analysisMaterial defectData set

The invention discloses an aluminum profile defect detection method based on an improved Faster-RCNN. The method comprises the steps of selecting a plurality of aluminum material defect images, performing data enhancement for a distribution imbalance phenomenon of a data set to set parameters of a Faster-RCNN model; the aluminum profile defect detection method comprising the steps of preprocessingan aluminum profile defect image, training a defect data set on a Faster-RCNN network, storing a final detection model, and detecting aluminum profile defect data by utilizing the trained improved Faster-RCNN model. The improvement points of the method on a Faster-RCNN model are as follows: 1, optimization is performed by adopting a feature pyramid method aiming at an extreme length-width ratio phenomenon of aluminum profile defects; 2, for the phenomenon that the defect shape is irregular, more defect shapes are learned by adopting deformation convolution; 3, for the phenomenon of feature loss of the small target in the feature extraction process, improving the survival rate of target defect features in a high-level network by adopting hole convolution; and 4, aiming at the phenomenon ofinaccurate positioning of small defects, more accurate positioning information is obtained by adopting an ROI Pooling method.

Owner:CHINA JILIANG UNIV

Transparent material defect detection system and method

PendingCN107957425AImprove the detection rateEasy to identifyMaterial analysis by optical meansMaterial defectTime-sharing

The invention discloses a transparent material defect detection system and method. The system comprises at least one detection unit, at least one face mirror imaging assembly, a transmitting device, acontroller and a processor, wherein each detection unit comprises an imaging device and a combined light source, the imaging device is used for imaging scanning of a transparent material; the combined light source is used for providing multiple illumination modes; the at least one face mirror imaging assembly is used for virtual imaging of defects of a transparent material; the transmitting device is used for promoting relative movement of the transparent material between the at least one detection unit; the controller is used for controlling time division switching of various illumination modes and image acquisition of the imaging device; the processor is in communication connection with the controller and the at least one imaging device. Multichannel image acquisition of the defects ofthe transparent material is realized; compared with existing defect detection systems, the transparent material defect detection system greatly increases the amount of information of image acquisition, improves the accuracy and the precision of defect information and increases the detection rate and the recognition rate of defects of the transparent material, and following specific three-dimensional position analysis of and variety analysis of product defects are facilitated.

Owner:湖南科创信息技术股份有限公司

Methods, systems and apparatus for detecting material defects in combustors of combustion turbine engines

InactiveUS20120169326A1Continuous combustion chamberResistance/reactance/impedenceCold sideMaterial defect

A system for detecting defects in a combustion duct of a combustion system of a combustion turbine engine while the combustion turbine engine operates, wherein the combustion duct comprises a hot side, which is exposed to combustion gases and, opposing the hot side, a cold side. The system may include: an indicator coating disposed on the cold side of the combustion duct; and a proximity sensor positioned in proximity to the combustion duct and configured to detect a distance between the position of the proximity sensor and the cold side of the combustion duct.

Owner:GENERAL ELECTRIC CO

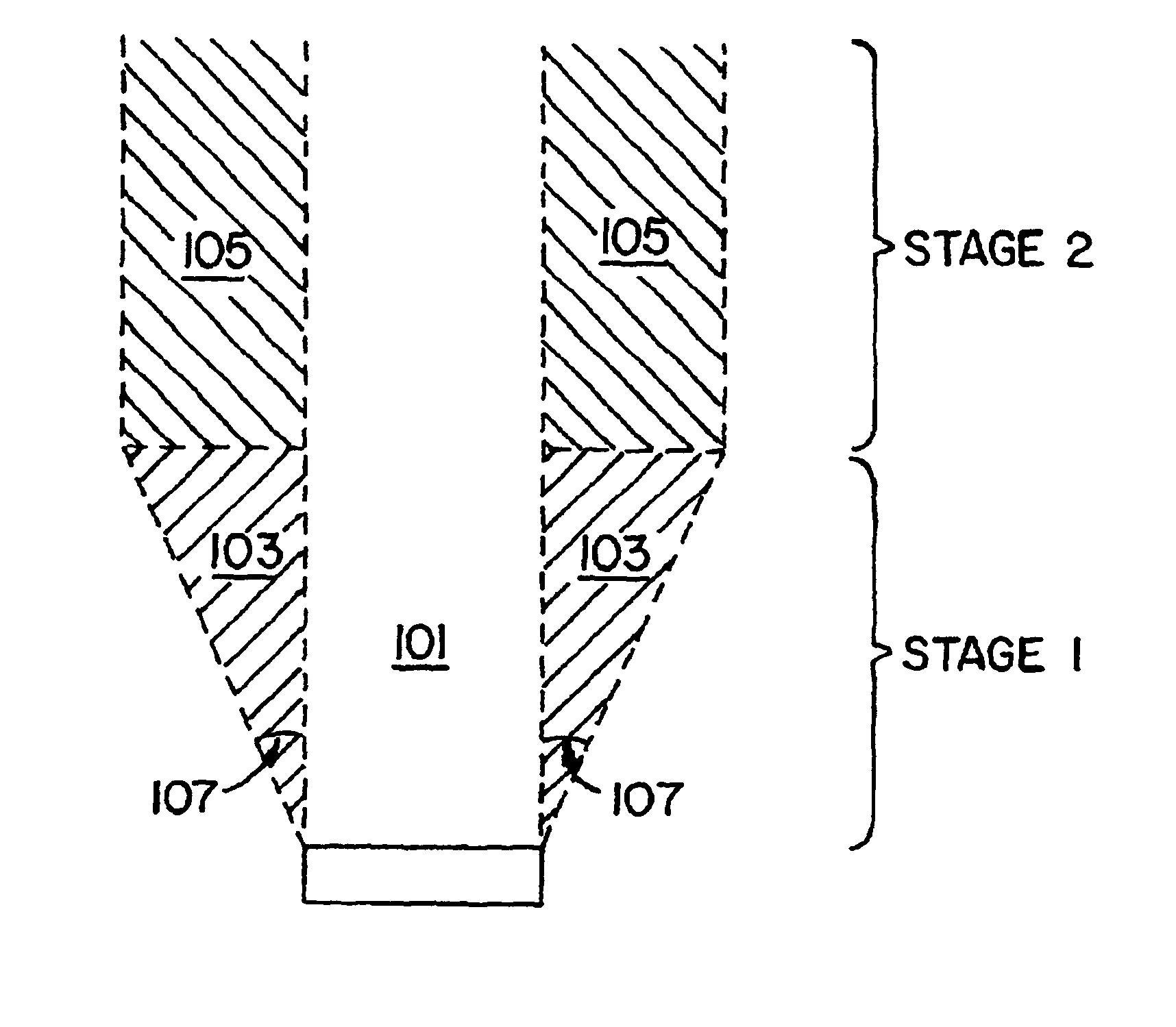

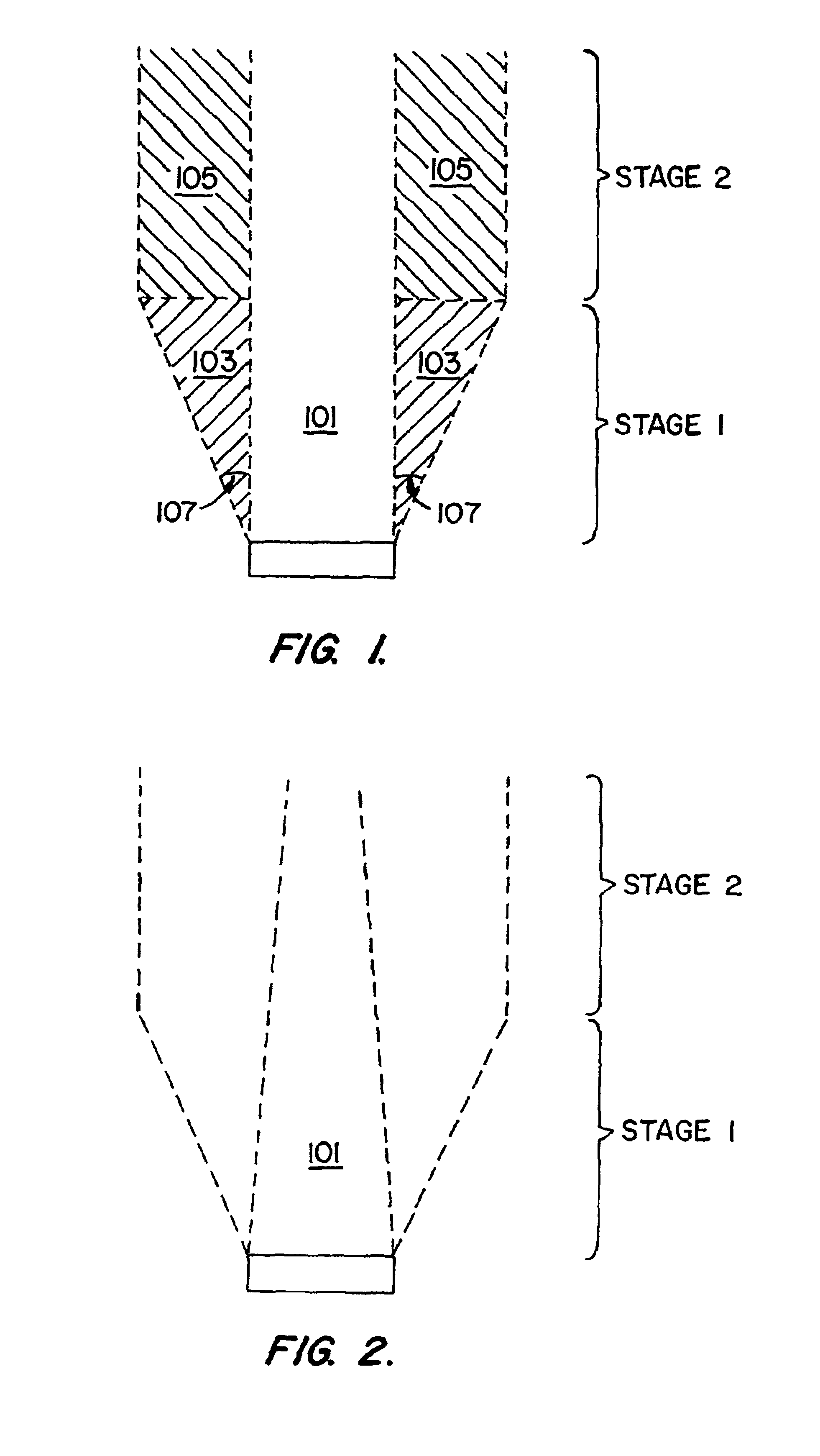

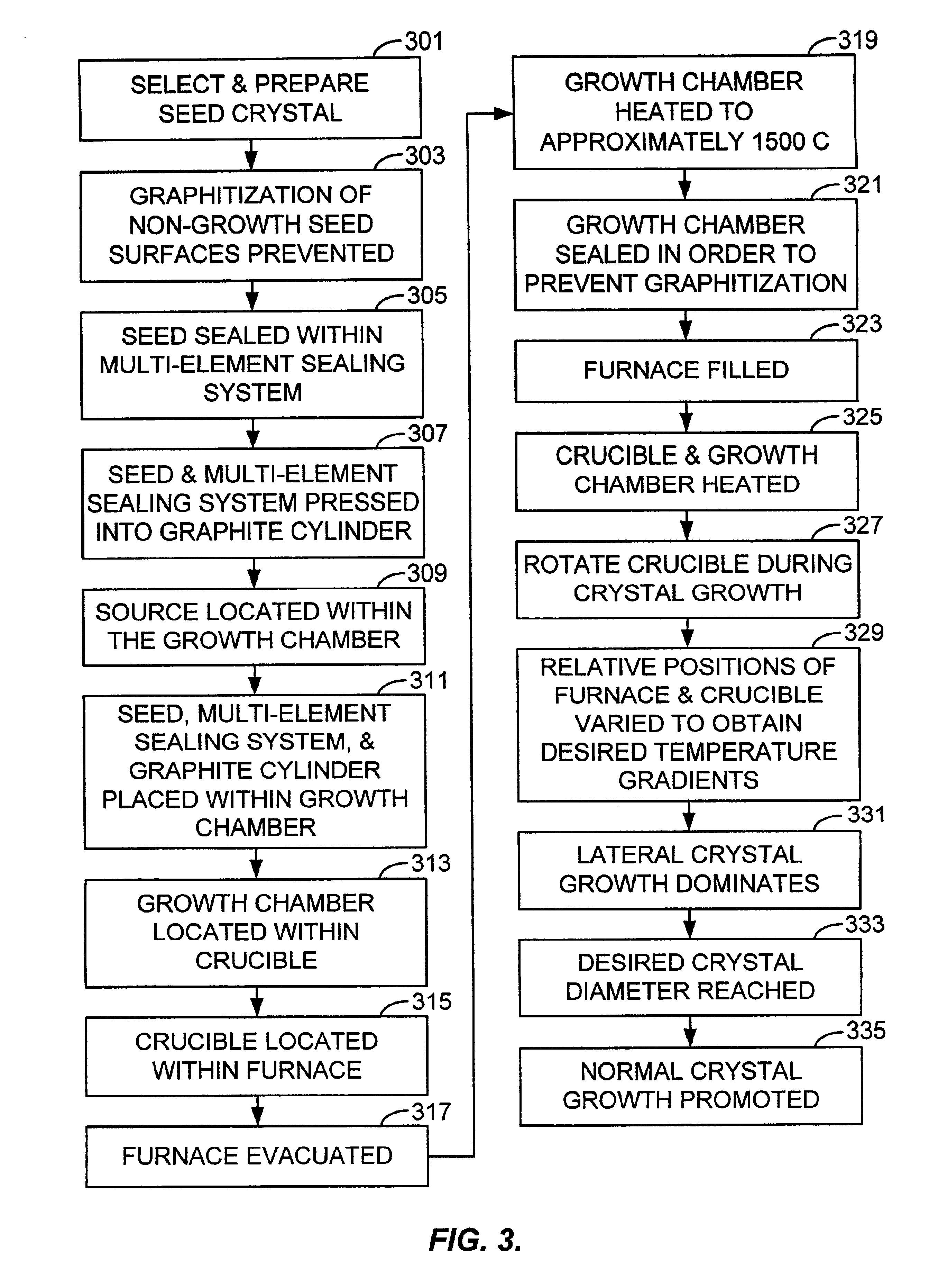

Apparatus for growing low defect density silicon carbide

InactiveUS6863728B2Reduce defect densityReduce generationAfter-treatment apparatusPolycrystalline material growthCarbide siliconMaterial defect

A low defect (e.g., dislocation and micropipe) density silicon carbide (SiC) is provided as well as an apparatus and method for growing the same. The SiC crystal, grown using sublimation techniques, is preferably divided into two stages of growth. During the first stage of growth, the crystal grows in a normal direction while simultaneously expanding laterally. Although dislocations and other material defects may propagate within the axially grown material, defect propagation and generation in the laterally grown material are substantially reduced, if not altogether eliminated. After the crystal has expanded to the desired diameter, the second stage of growth begins in which lateral growth is suppressed and normal growth is enhanced. A substantially reduced defect density is maintained within the axially grown material that is based on the laterally grown first stage material.

Owner:THE FOX GROUP

Infrared coherent thermal wave imaging system and detection method based on system

ActiveCN106404835AOvercome the disadvantage of insensitivity to tiny defect detectionImprove defect effectMaterial flaws investigationMaterial defectSignal-to-noise ratio (imaging)

An infrared coherent thermal wave imaging system and a detection method based on the system belong to the field of infrared imaging nondestructive detection. Two signal output ends of a computer are connected with signal input ends of an infrared thermal imager and a function generator correspondingly; two signal output ends of the function generator are connected with signal input ends of a first laser power supply and a second laser power supply correspondingly; current output ends of the first laser power supply and the second laser power supply are connected with current input ends of a first laser and a second laser correspondingly; laser output ends of the first laser and the second laser are connected with laser input ends of a first collimating mirror and a second collimating mirror correspondingly; and a moving platform is arranged in front of the first collimating mirror and the second collimating mirror. A tiny defect of a detected test piece is detected by a double-beam coherent laser coherent subtraction principle, the disadvantage that the traditional detection method is insensitive on tiny defect detection is overcome, and the signal to noise ratio of detecting a material defect by infrared thermal wave is greatly increased by a coherent excitation loading mode.

Owner:HARBIN INST OF TECH

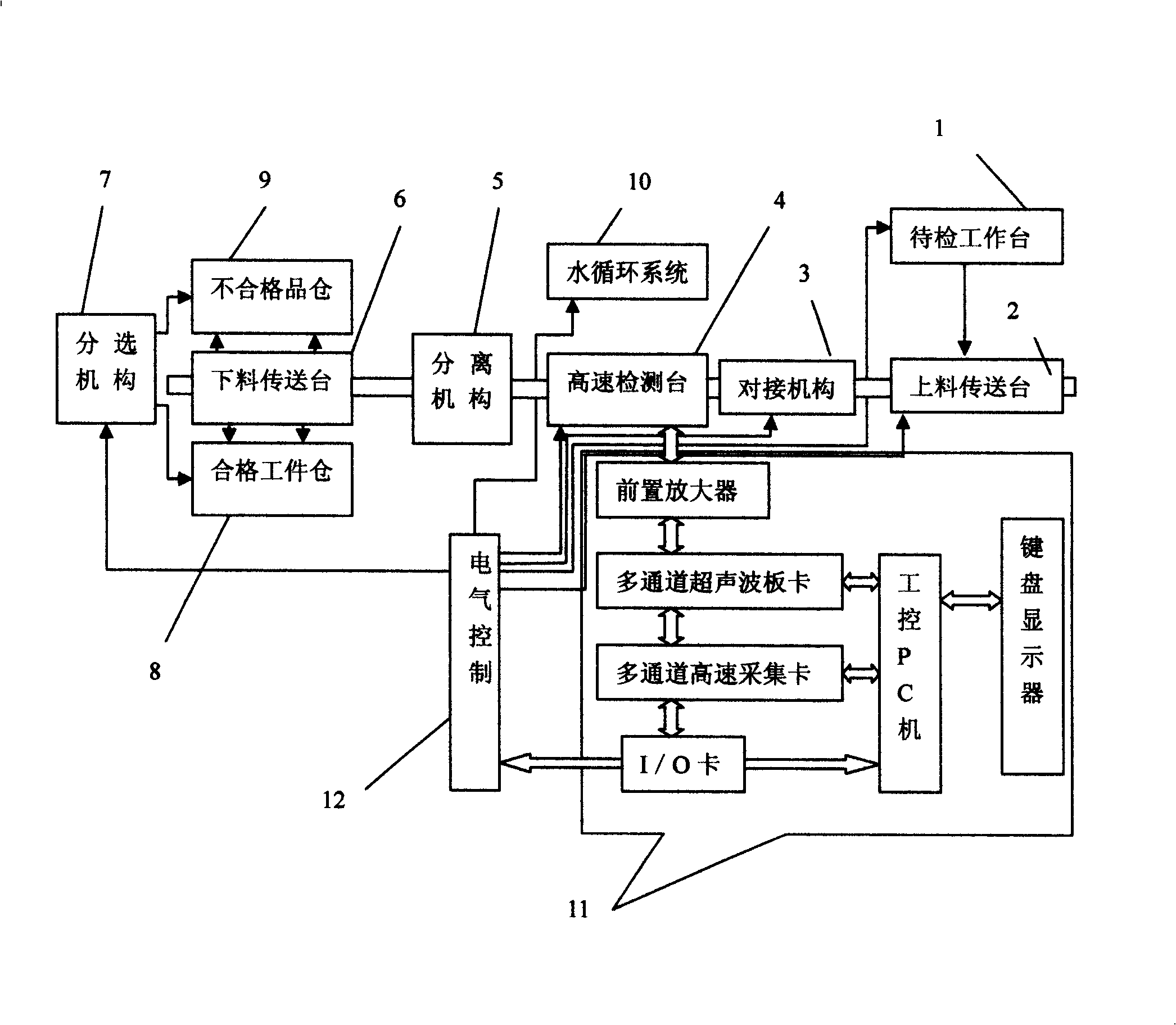

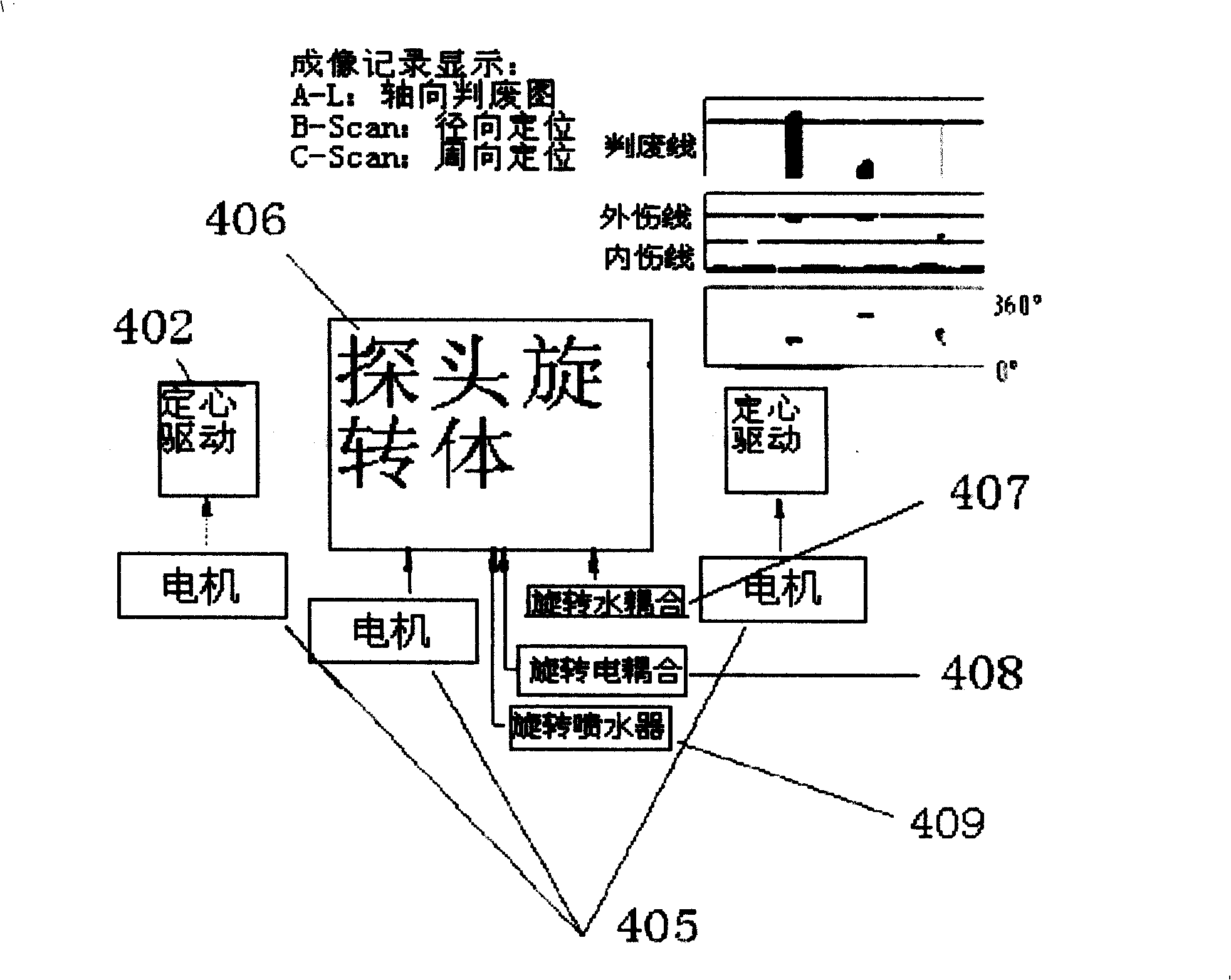

Digital image-forming tube bar material defect nondestructive flaw detection system

InactiveCN101308153ALow skill level requiredShort analysis timeAnalysing solids using sonic/ultrasonic/infrasonic wavesGraphicsMaterial defect

Disclosed is a detection system for nondestructive flaw detection of digital imaging tube bars, which is characterized that: the detection system for nondestructive flaw detection of digital imaging tube bars comprises a table for workpiece to be detected (1), a loading conveyer table (2), a docking mechanism (3), a high-speed detecting table (4), a disengaging mechanism (5), an unloading conveyer table (6), a separating mechanism (7), a qualified workpiece storehouse (8), an unqualified workpiece storehouse (9), a water circulation system (10), a nondestructive testing instrument system (11) and an electric control system (12). The detection system has the advantages that the sizes and locations of defects can be displayed directly according to the detection records, the conclusion can be made by simple analysis and interpretation of the displayed graphics and data, the time needed for analysis is short, and the requirements to the technical level of analysts are not high.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com