Patents

Literature

8608 results about "Carbide silicon" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Silicon Carbide. Silicon carbide is a man-made abrasive comprised of silica (Si) and carbon (C) with a hardness value second only to naturally occurring diamond. The extreme hardness of silicon carbide makes it an excellent material for abrasive wear applications.

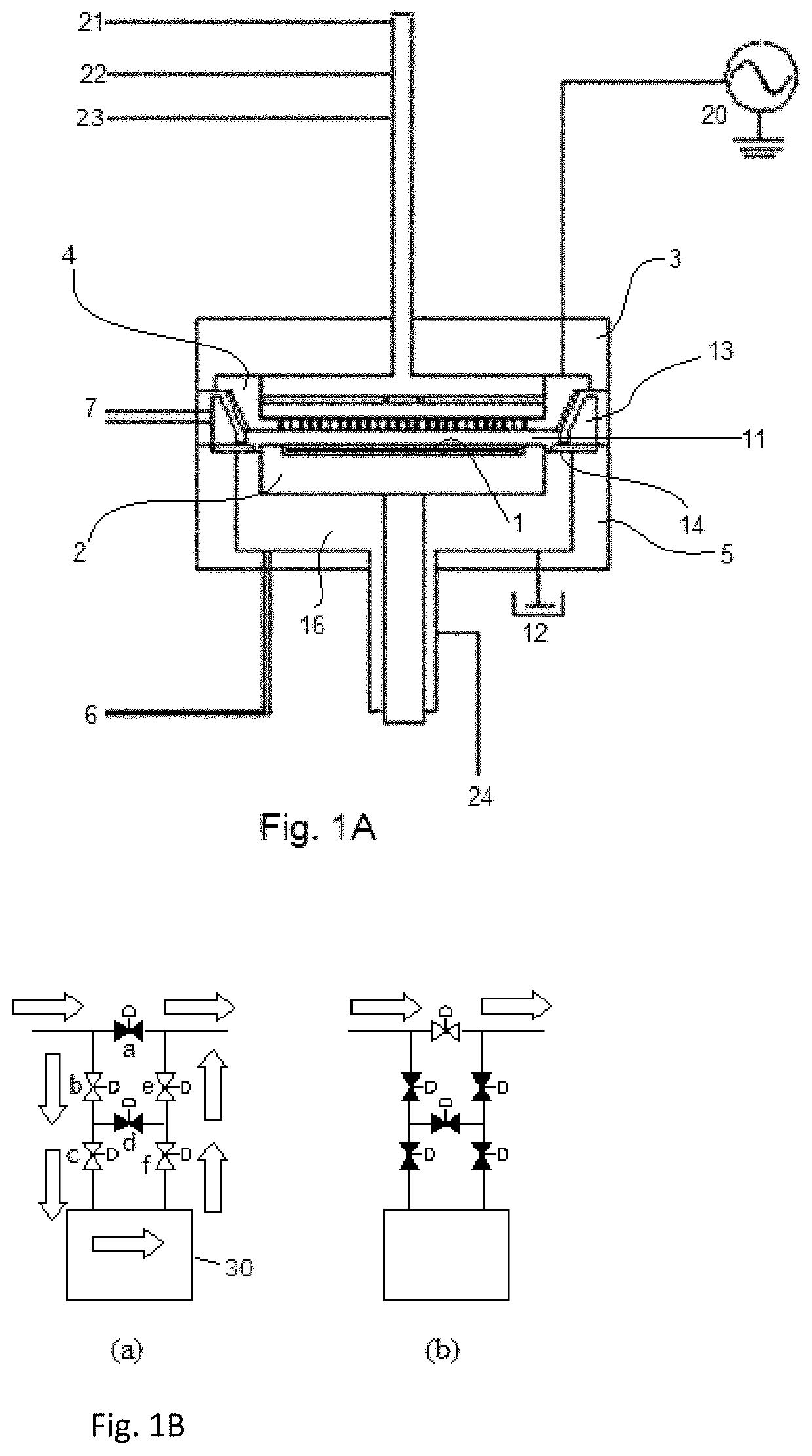

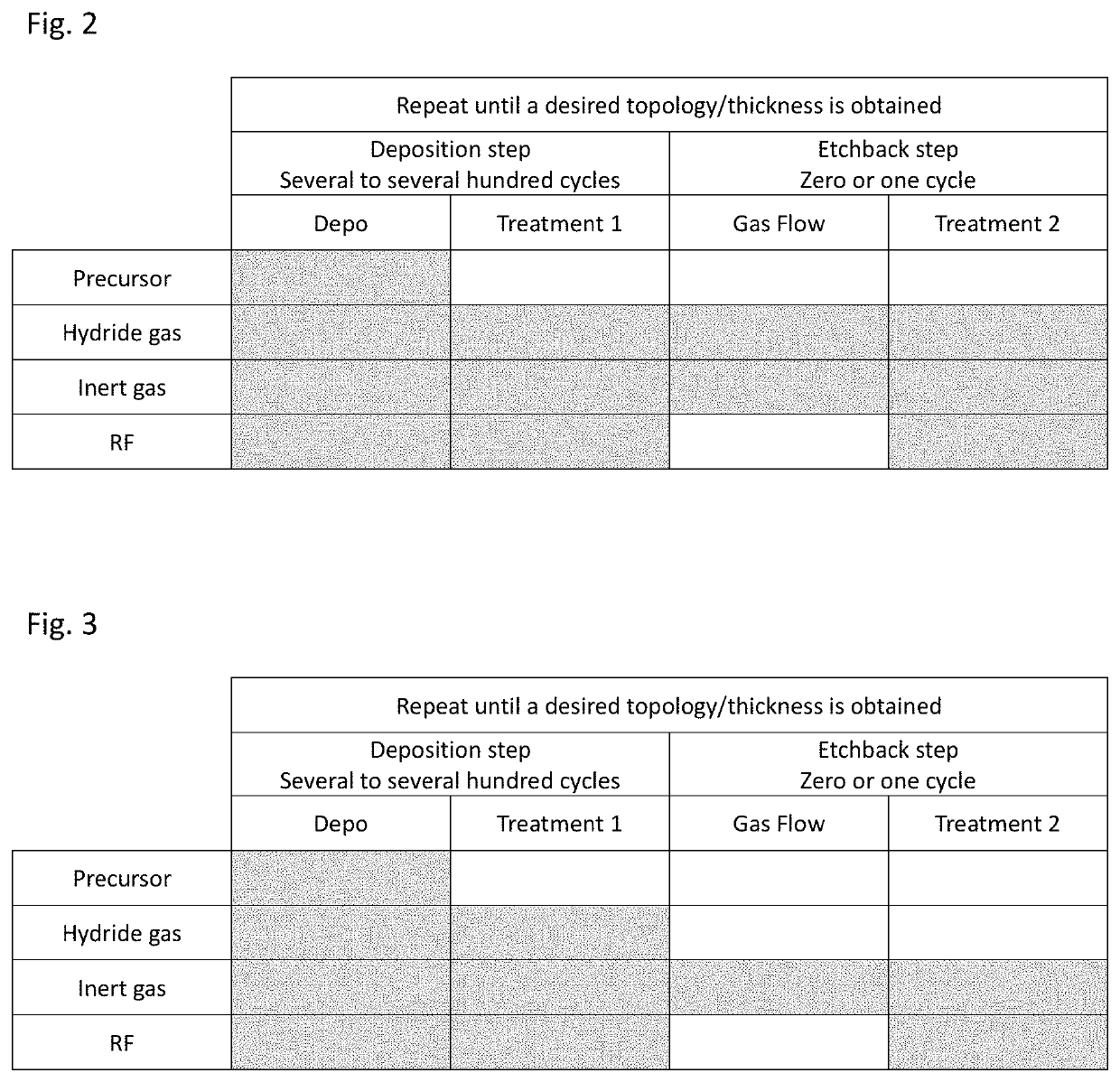

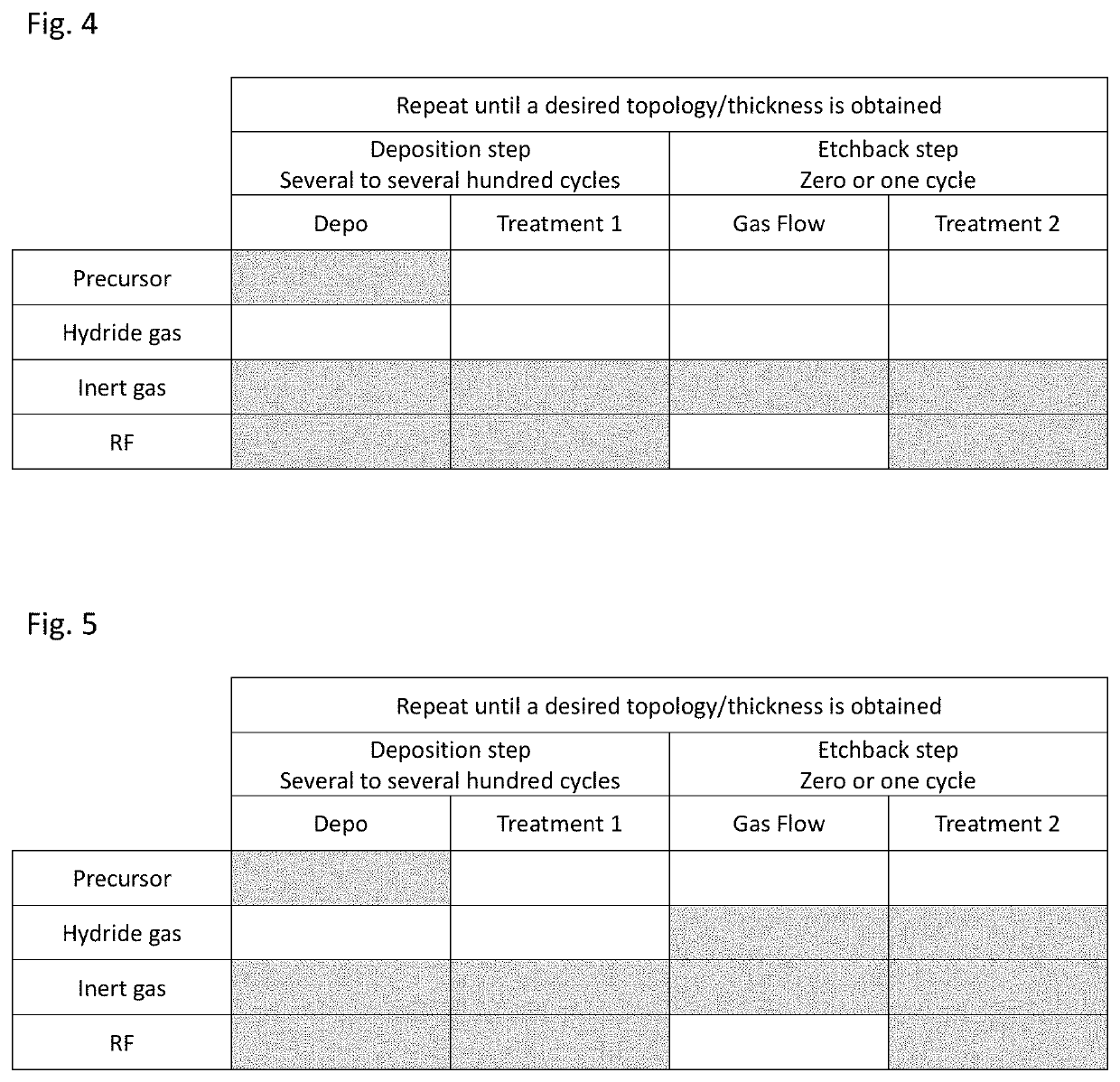

Method of forming conformal silicon carbide film by cyclic CVD

ActiveUS20200118815A1Electric discharge tubesSemiconductor/solid-state device manufacturingCarbide siliconSilanes

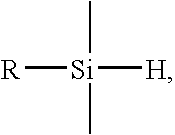

A method of forming, on a substrate having a recess pattern, a silicon carbide film having a reflective index of 2.3 or higher as measured at 633 nm, includes (i) supplying an organosilane precursor in a pulse to a reaction space where the substrate is placed, which precursor has a formula of RSiH3 wherein R is a hydrocarbon-containing moiety including at least one unsaturated bond; (ii) continuously supplying a plasma-generating gas to the reaction space, which plasma-generating gas is selected from the group consisting of inert gases and hydride gases; (iii) continuously applying RF power to the reaction space to generate a plasma which excites the precursor; and (iv) repeating steps (i) through (iii), thereby forming a silicon carbide film on the substrate, which silicon carbide film has a reflective index of 2.3 or higher as measured at 633 nm.

Owner:ASM IP HLDG BV

Method of improving stability in low k barrier layers

InactiveUS20040137756A1Decorative surface effectsSemiconductor/solid-state device detailsHydrogenPhenyl group

A method is provided for processing a substrate including providing a processing gas comprising hydrogen gas and an organosilicon compound comprising a phenyl group to the processing chamber, and reacting the processing gas to deposit a low k silicon carbide barrier layer useful as a barrier layer in damascene or dual damascene applications with low k dielectric materials.

Owner:APPLIED MATERIALS INC

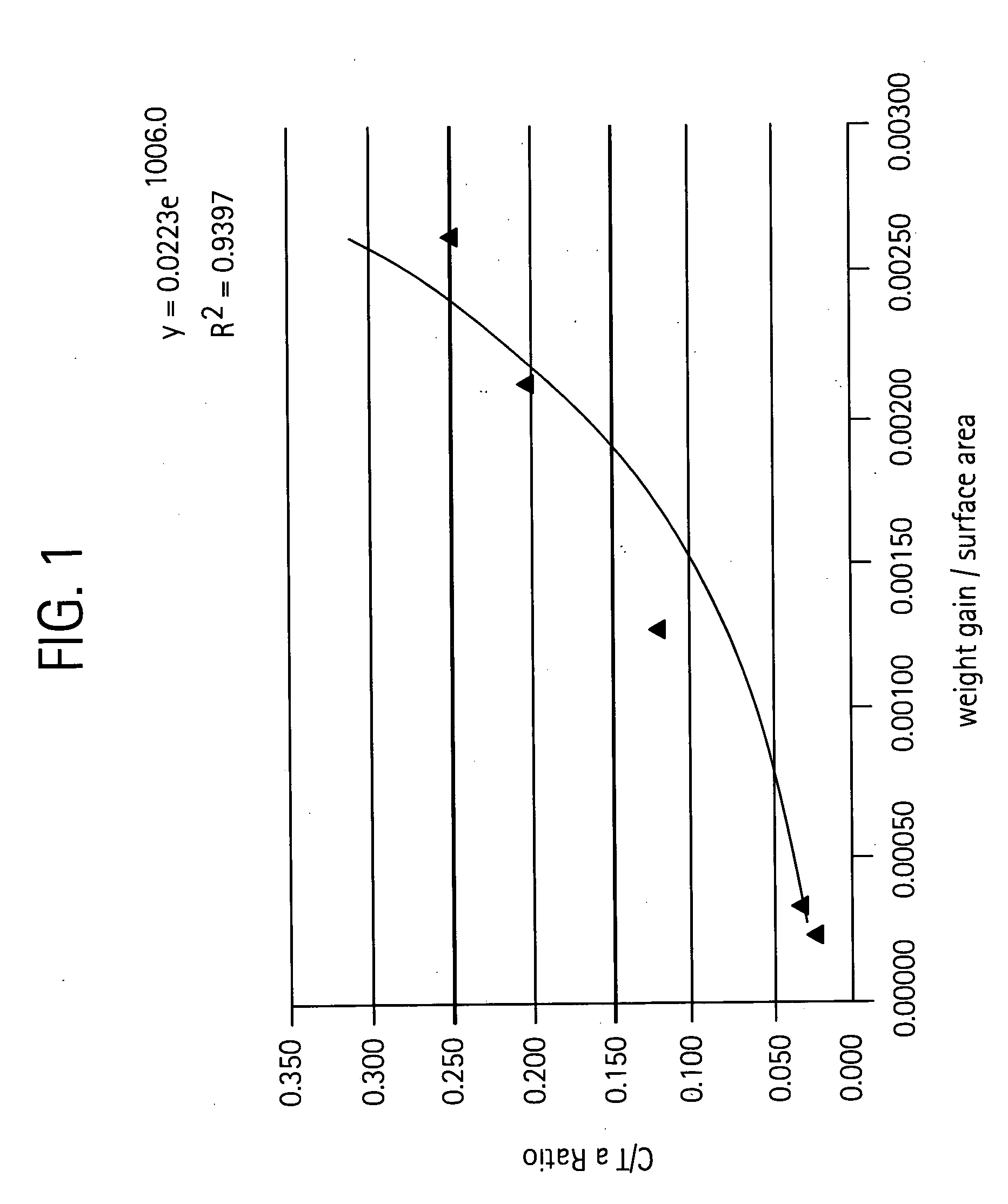

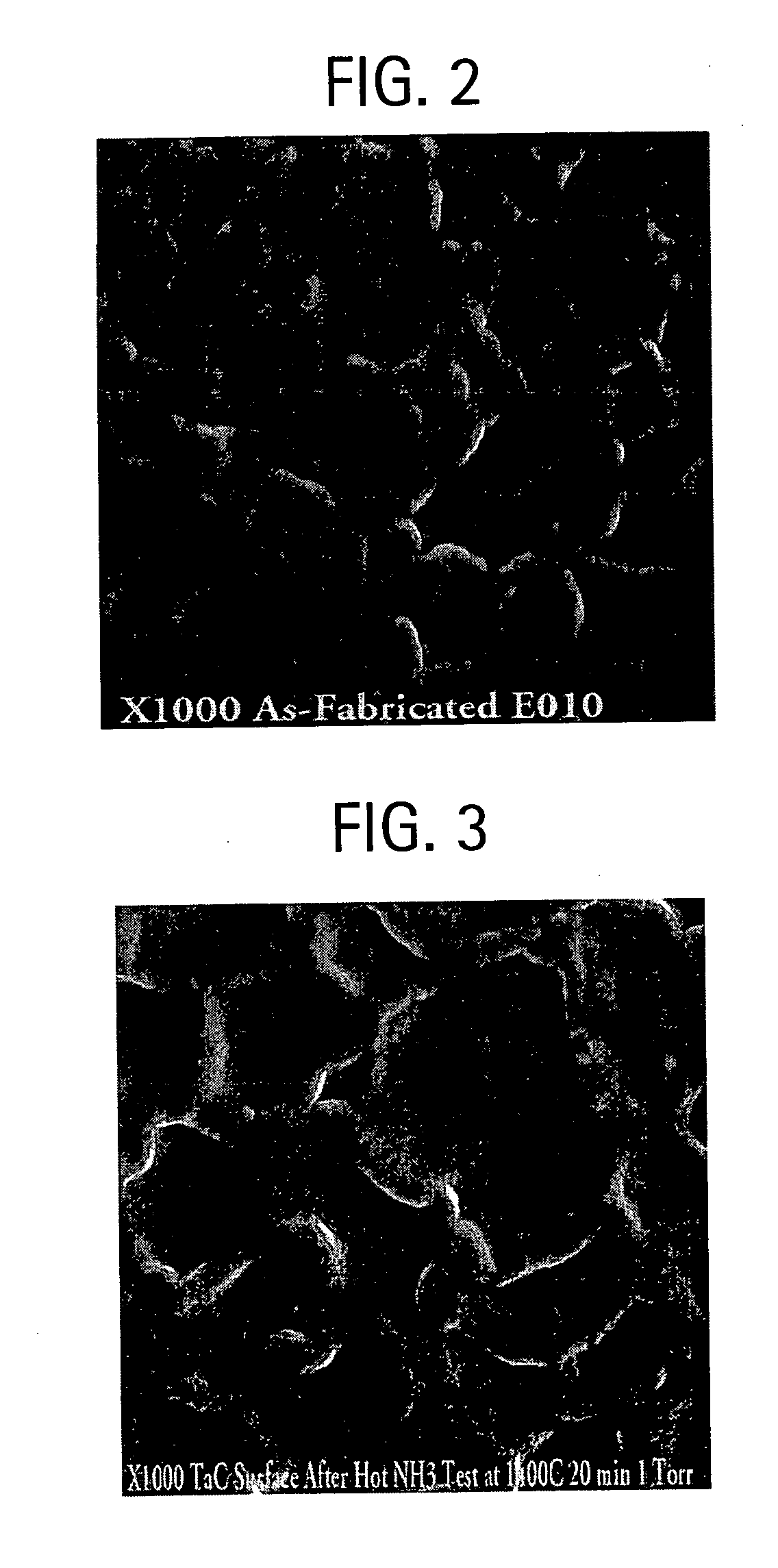

Composite refractory metal carbide coating on a substrate and method for making thereof

InactiveUS20050064247A1Improved corrosion resistance propertyIncreased emissivity insensitivityLiquid surface applicatorsSemiconductor/solid-state device manufacturingBeryllium carbideMagnesium

A composite coating for use on semi-conductor processing components, comprising a refractory metal carbide coating with its surface modified by at least one of: a) a carbon donor source for a stabilized stoichiometry, and b) a layer of nitride, carbonitride or oxynitride of elements selected from a group B, Al, Si, refractory metals, transition metals, rare earth metals which may or may not contain electrically conducting pattern, and wherein the metal carbide is selected from the group consisting of silicon carbide, tantalum carbide, titanium carbide, tungsten carbide, silicon oxycarbide, zirconium carbide, hafnium carbide, lanthanum carbide, vanadium carbide, niobium carbide, magnesium carbide, chromium carbide, molybdenum carbide, beryllium carbide and mixtures thereof. The composite coating is characterized as having an improved corrosion resistance property and little emissivity sensitivity to wavelengths used in optical pyrometry under the normal semi-conductor processing environments.

Owner:GENERAL ELECTRIC CO

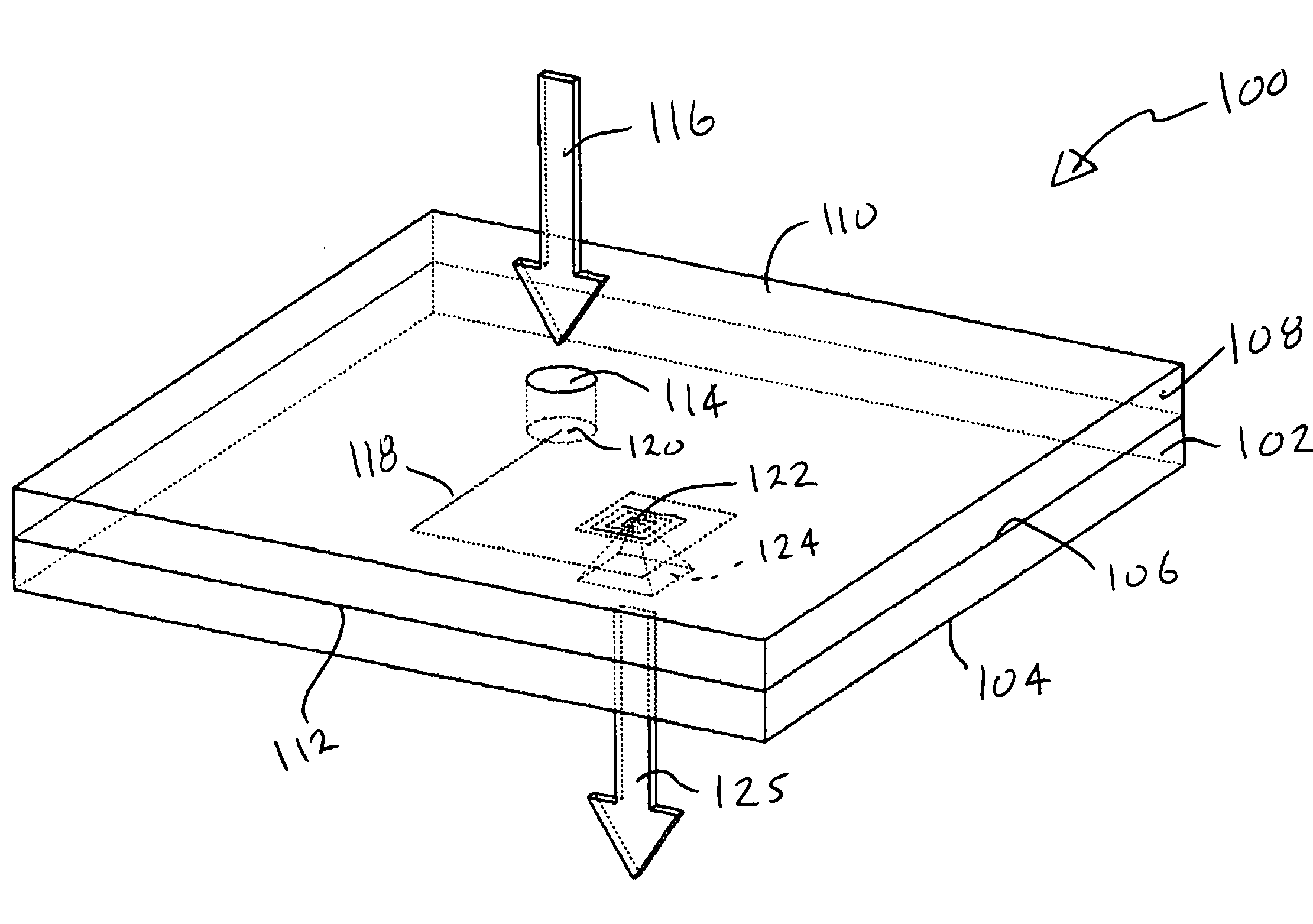

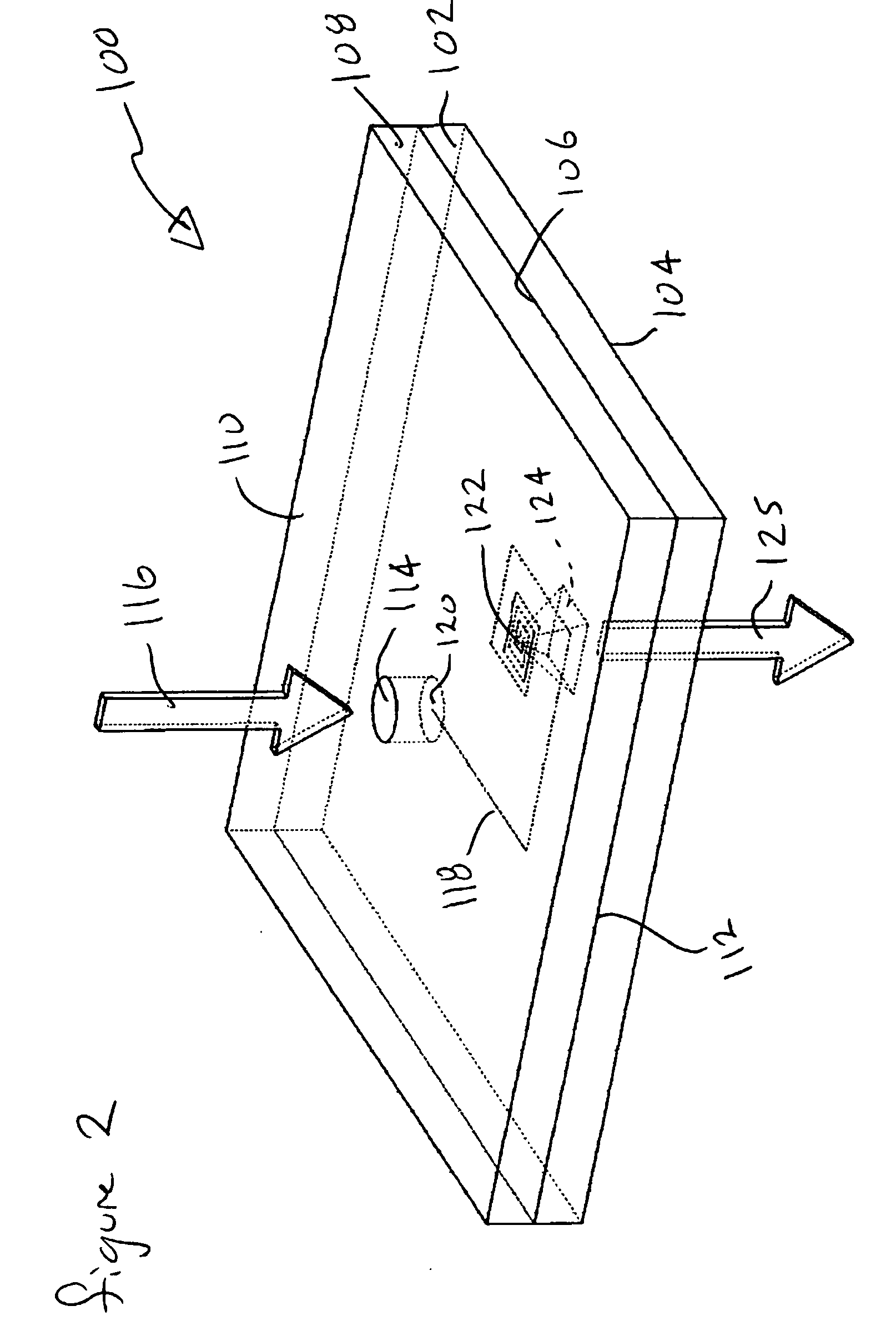

Barrier coating deposition for thin film devices using plasma enhanced chemical vapor deposition process

InactiveUS20080139003A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingSilicon oxideSolar cell

A method to produce barrier coatings (such as nitrides, oxides, carbides) for large area thin film devices such as solar panels or the like using a high frequency plasma enhanced chemical vapor deposition (PECVD) process is presented. The proposed process provides a uniform deposition of barrier coating(s) such as silicon nitride, silicon oxide, silicon carbide (SiNx, SiO2, SiC) at a high deposition rate on thin film devices such as silicon based thin film devices at low temperature. The proposed process deposits uniform barrier coatings (nitrides, oxides, carbides) on large area substrates (about 1 m×0.5 m and larger) at a high frequency (27-81 MHz). Stable plasma maintained over a large area substrate at high frequencies allows high ionization density resulting in high reaction rates at lower temperature.

Owner:NOVASOLAR HLDG

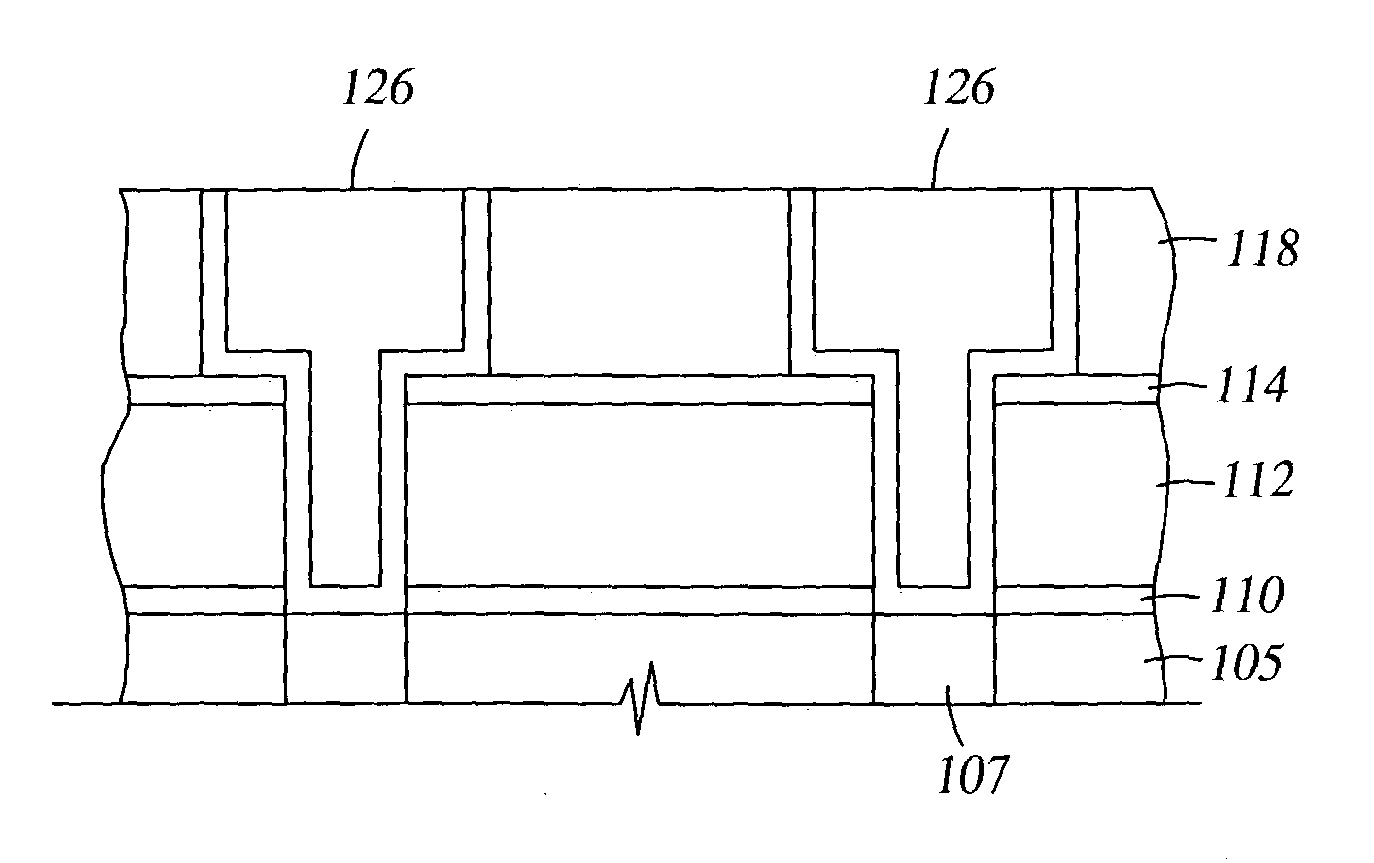

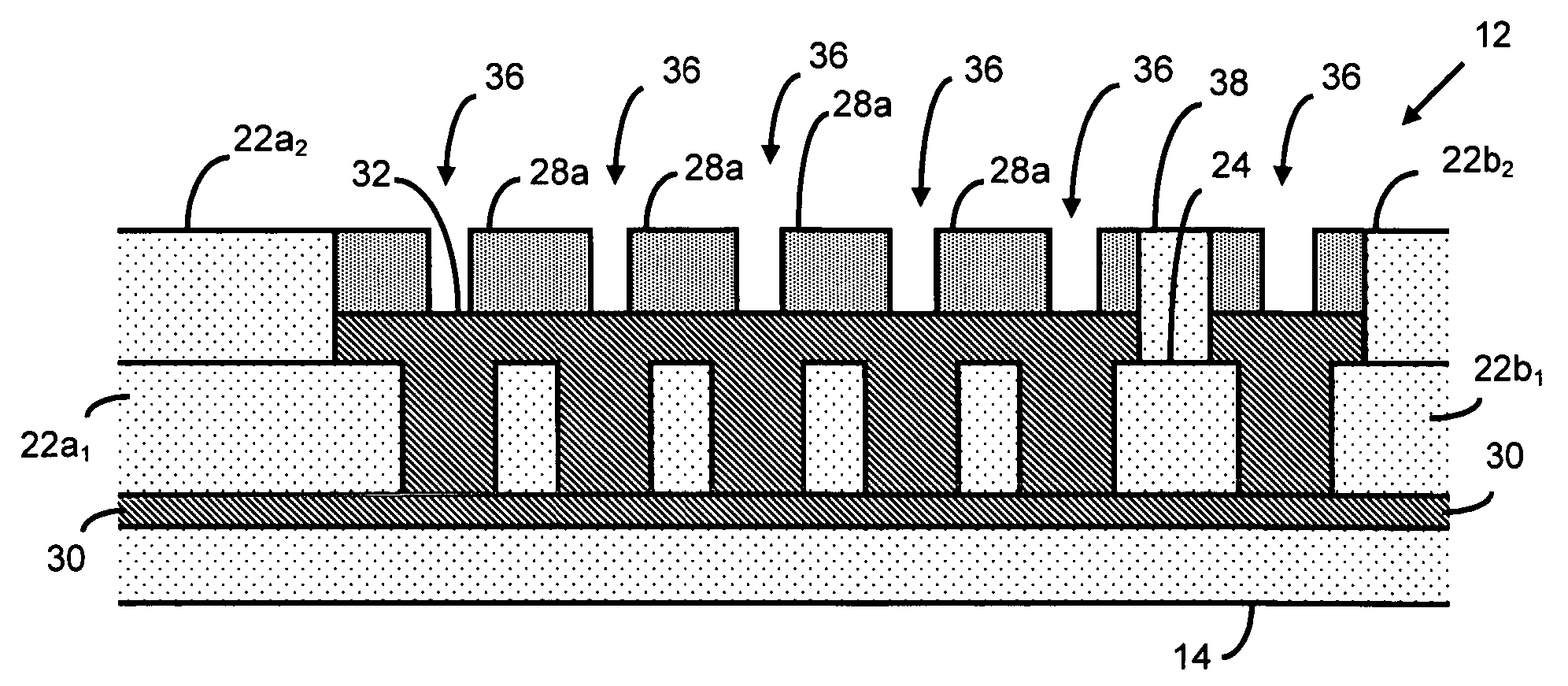

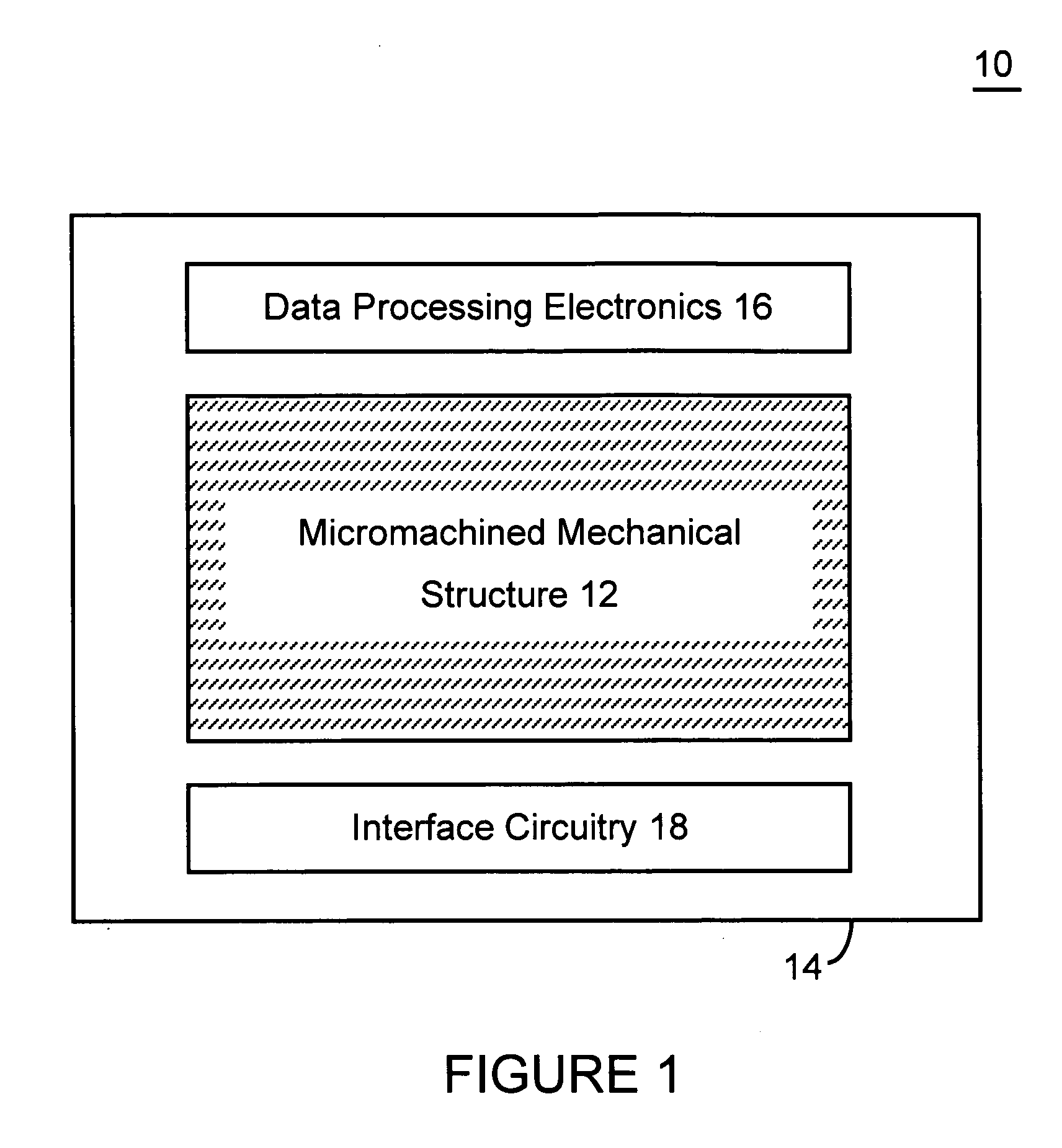

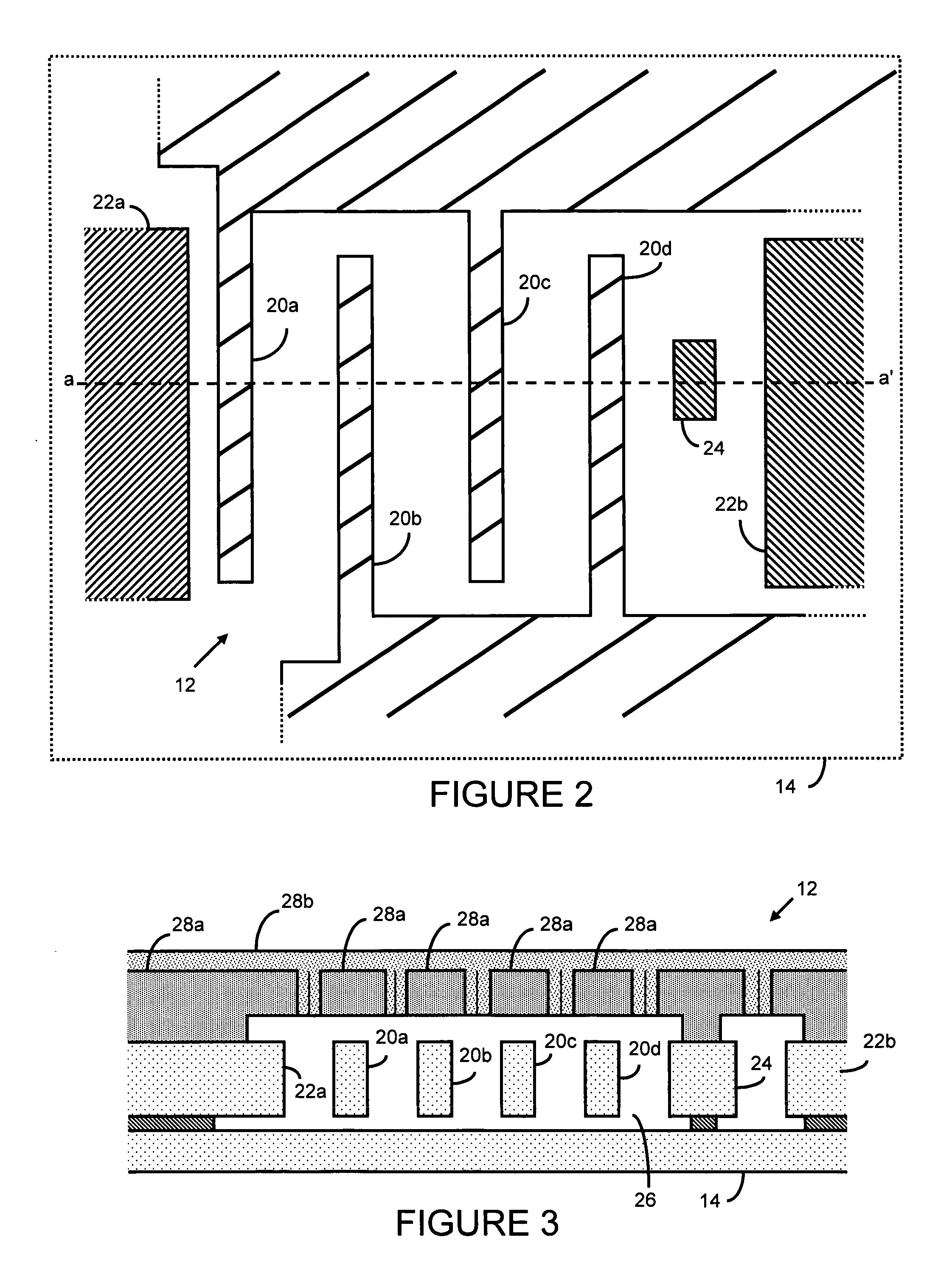

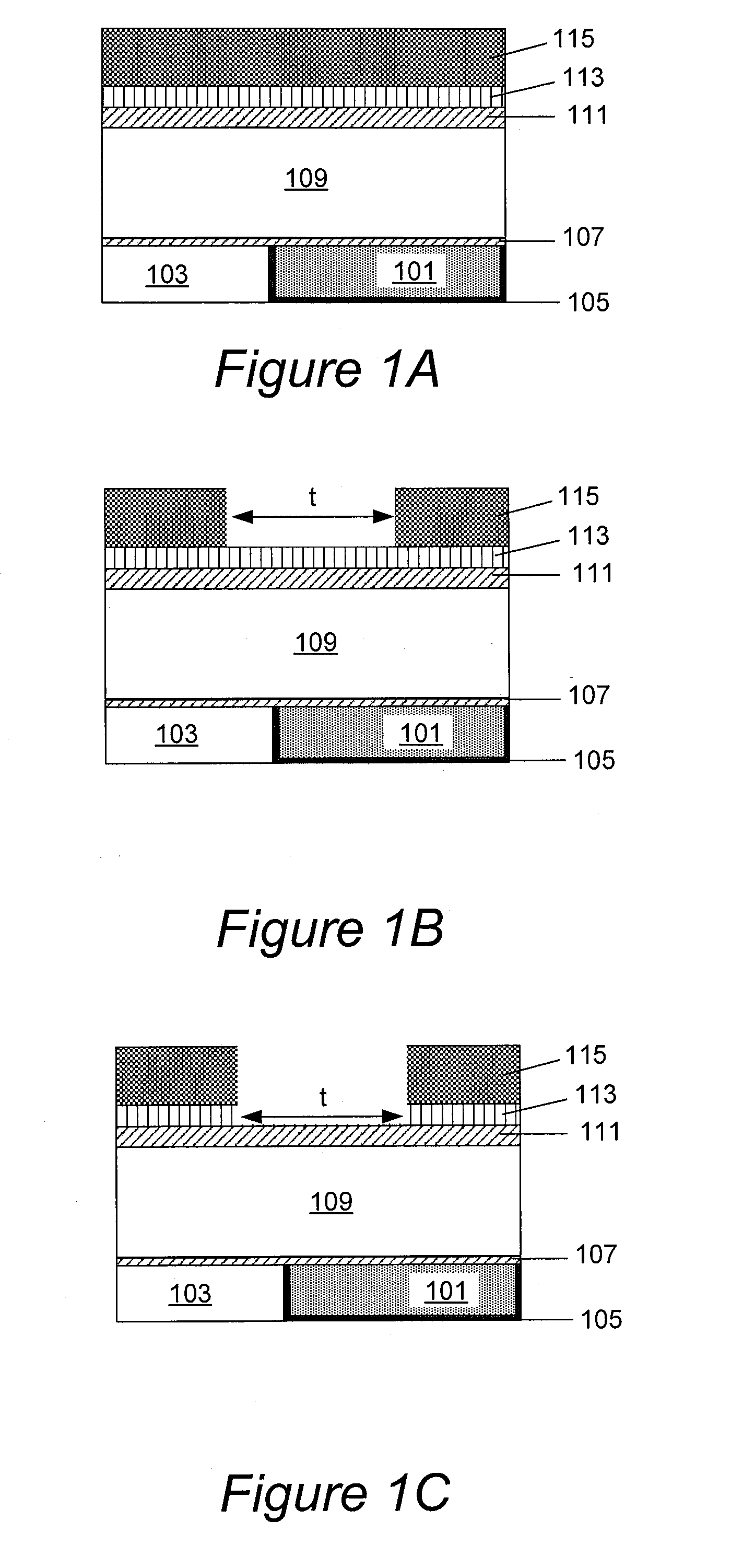

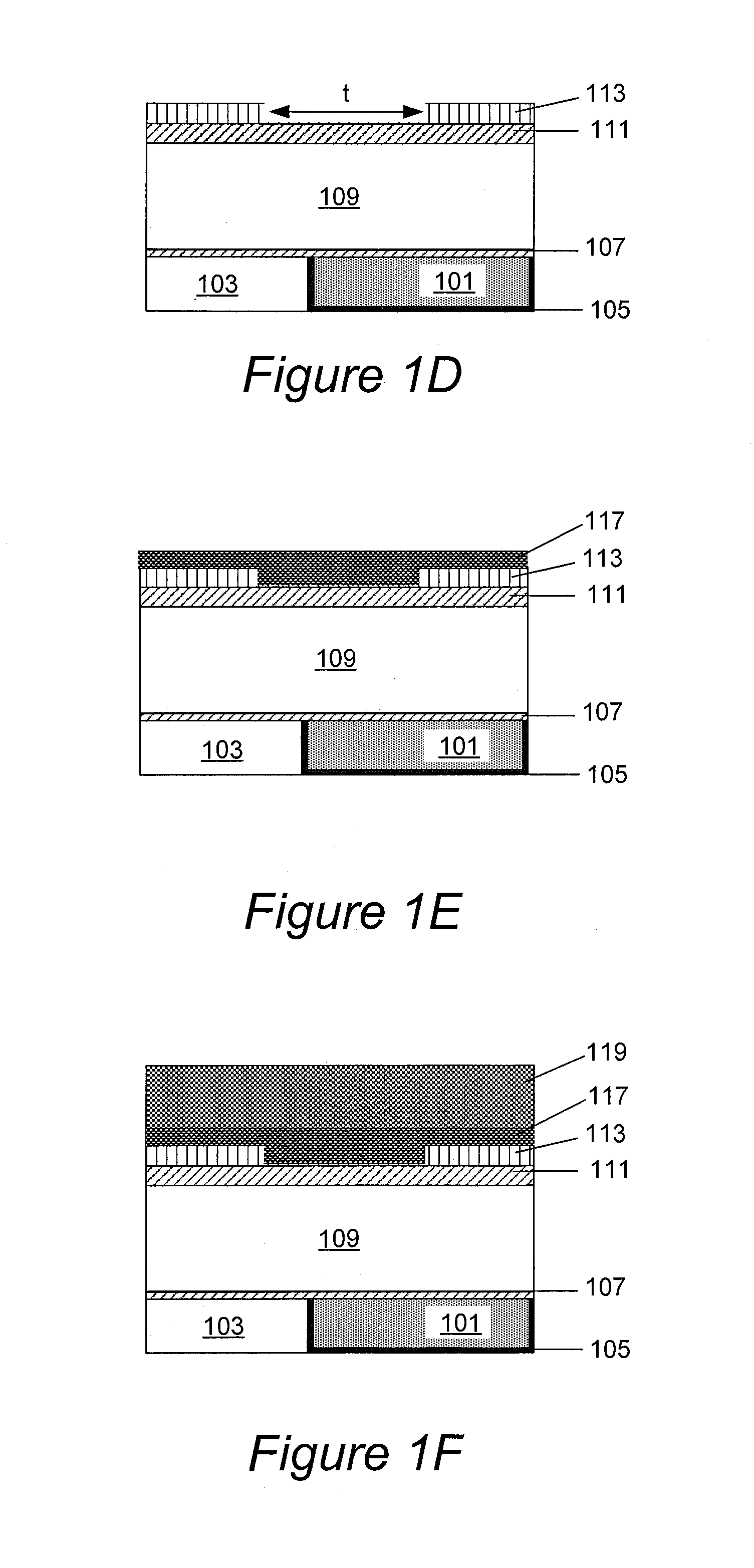

Microelectromechanical systems, and methods for encapsulating and fabricating same

ActiveUS20060108652A1Acceleration measurement using interia forcesSemiconductor/solid-state device detailsIntegrated circuitEngineering

There are many inventions described and illustrated herein. In one aspect, the present invention is directed to a MEMS device, and technique of fabricating or manufacturing a MEMS device, having mechanical structures encapsulated in a chamber prior to final packaging. The material that encapsulates the mechanical structures, when deposited, includes one or more of the following attributes: low tensile stress, good step coverage, maintains its integrity when subjected to subsequent processing, does not significantly and / or adversely impact the performance characteristics of the mechanical structures in the chamber (if coated with the material during deposition), and / or facilitates integration with high-performance integrated circuits. In one embodiment, the material that encapsulates the mechanical structures is, for example, silicon (polycrystalline, amorphous or porous, whether doped or undoped), silicon carbide, silicon-germanium, germanium, or gallium-arsenide.

Owner:ROBERT BOSCH GMBH

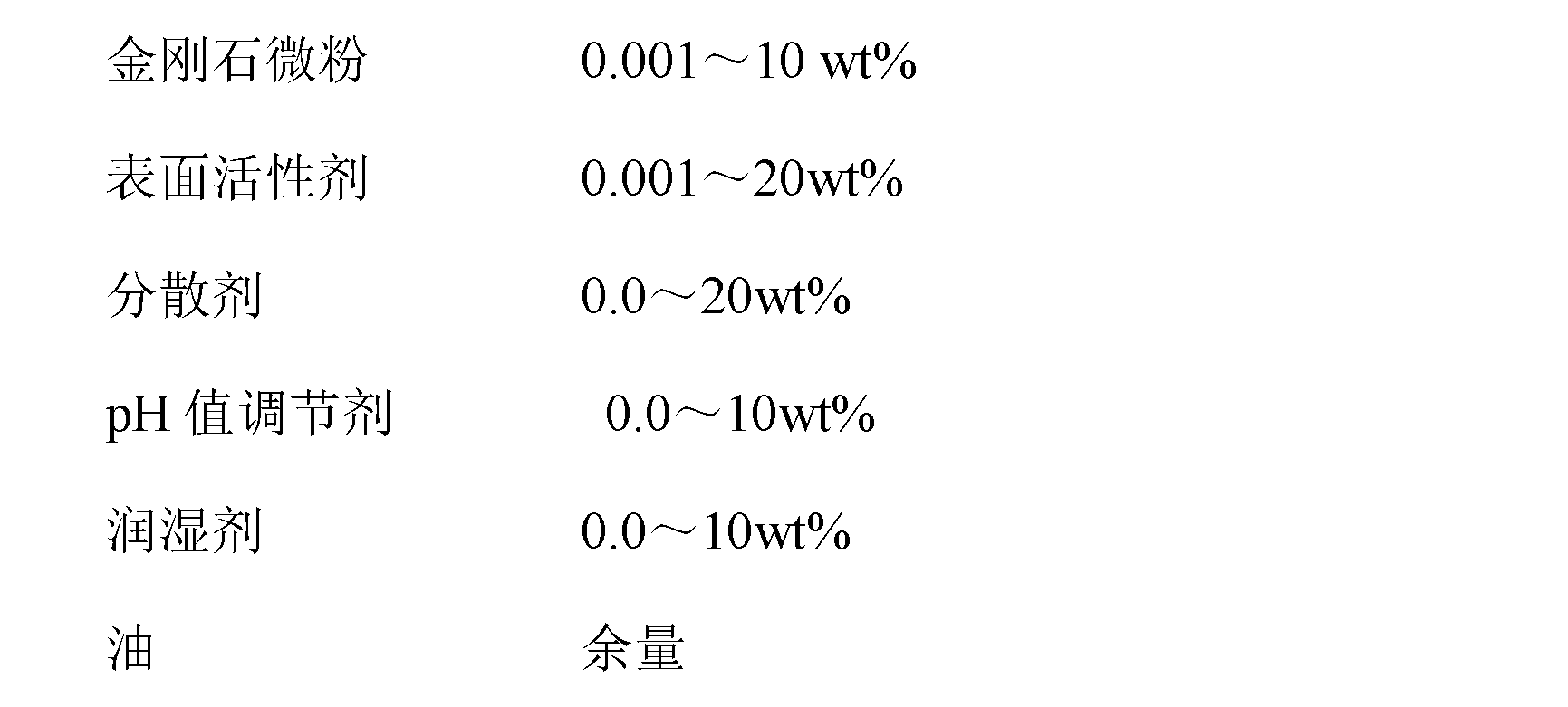

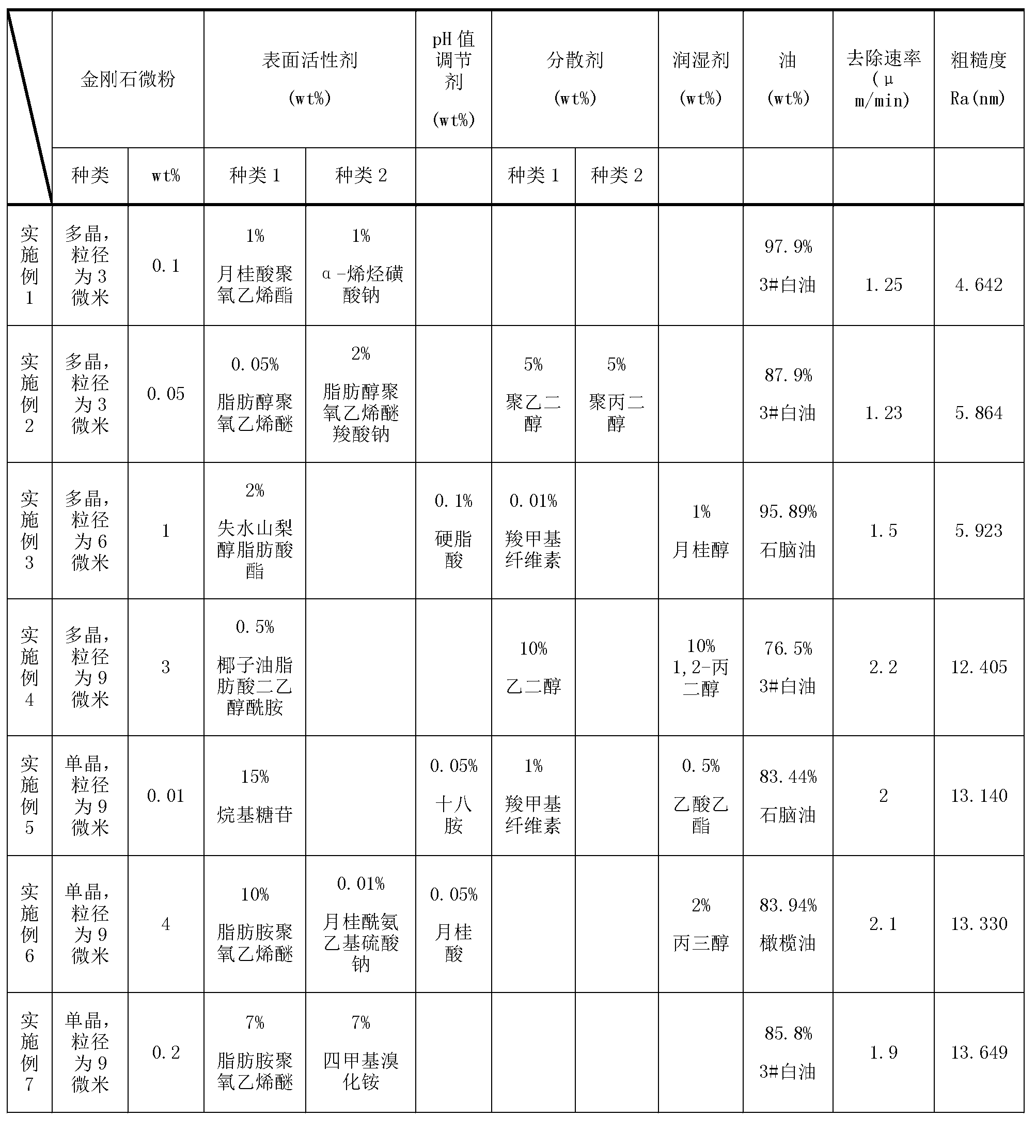

Oily diamond grinding liquid and preparation method thereof

InactiveCN103013345AImprove polishing efficiencyImprove matchPolishing compositions with abrasivesStable stateEnvironmental resistance

The invention discloses an oily diamond grinding liquid and a preparation method thereof, and belongs to the technical field of surface superfine grinding. The grinding liquid comprises the following components by weight percent: 0.001%-10% of diamond micro powder, 0.001%-20% of surface active agent, 0-20% of dispersant, 0-10% of pH value regulator, 0-10% of wetting agent and oil in balancing amount. The oily diamond grinding liquid is mainly applied to surface grinding and polishing of silicon carbide wafers, LED sapphire substrate slices, ceramic, optical fiber, dies, semi-conductor compound wafers and the like. By the use of the oily diamond grinding liquid provided by the invention, the polishing efficiency can be greatly improved; the dispersing performance is good; a uniform and stable state can be kept for a long time; the degree of finish of products polished with the oily diamond grinding liquid is high; the polishing effect is good; no ingredient harmful to human body is contained; the cleaning is easy; and the environmental protection is facilitated.

Owner:TSINGHUA UNIV +2

Method for preparing C/SiC composite material through low-cost fused silicon impregnation method

The invention relates to a method for preparing a C / SiC composite material through a low-cost fused silicon impregnation method, which comprises the following steps: performing calcining pretreatment on a carbon felt or graphite felt at 400-600 temperature; immersing the pretreated carbon felt or graphite felt in a melamine and boric acid solution, thus coating a boron nitride protective layer; immersing in a carbon / silicon carbide slurry water solution, performing impregnation to ensure that pores of the carbon felt or graphite felt are fully filled with carbon / silicon carbide, placing in a sintering furnace, and performing primary fused silicon impregnation treatment at 1600-1800 DEG C; immersing in liquid phenolic resin, and performing carbonization treatment under the protection of an inert atmosphere at 800-1000 DEG C to ensure that all the resin is carbonized; and finally, performing secondary fused silicon impregnation treatment to ensure that carbon produced by carbonization of the resin totally reacts with silicon to generate silicon carbide, thus obtaining the C / SiC composite material. The obtained C / SiC composite material is high in density, low in air pore and free silicon content, and favorable in material strength, toughness and frictional wear performance, and can be used for manufacturing of brake pads.

Owner:山东宝纳新材料有限公司

Short fiber-particle synergetically-reinforced copper-based composite material and preparation method thereof

The invention relates to a copper-based composite material, and particularly relates to a short fiber-particle synergetically-reinforced copper-based composite material which is prepared through powder metallurgy. Short fibers and particles are used as reinforced phases, the content of the short fiber is 0.1-0.1 wt%, and the content of reinforcement particles is 0.1-10 wt%. The short fibers can be carbon nanotubes, carbon nanofibers, ceramic short fibers, and the like, and the particles used as reinforced phases can be aluminum oxide, zirconium oxide, magnesium oxide, titanium dioxide, silicon carbide, titanium carbide, tungsten carbide, silicon nitride, aluminum nitride, titanium nitride, titanium diboride, Ti3SiC2, and the like. The composite material is prepared through the steps of mixing, forming, sintering and processing, and the room temperature and the high temperature strength of the composite material can be increased by more than 3 times in comparison with those of pure copper; the electrical conductivity of the composite material can reach more than 80% of that of pure copper; the thermal conductivity of the composite material can reach more than 70% of that of pure copper; the coefficient of friction of the composite material can be reduced to be below 70% of that of pure copper; and the wear rate of the composite material can be reduced to be below 50% of that of pure copper.

Owner:UNIV OF SCI & TECH BEIJING

Monolithic honeycomb structure made of porous ceramic and use as a particle filter

InactiveUS6582796B1Prevent the evaporation of the waterEasy curingInternal combustion piston enginesSilencing apparatusSodium BentoniteOxygen

A monolithic honeycomb-type structure useful in particular as a particle filter for exhaust gases from diesel engines has a number of passages that empty into the end faces of said monolith, but are alternately open and sealed. The monolith consists of a porous refractory material that comprises: 70 to 97% by mass of alpha and / or beta crystallographic-type silicon carbide that has at least one particle size and preferably at least two particle sizes, and 3 to 30% by mass of at least one bonding ceramic phase in the form of a micronic powder or particles that are obtained by atomization, comprising at least one simple oxide, for example, B2O3, Al2O3, SiO2, MgO, K2O, Li2O, Na2O, CaO, BaO, TiO, ZrO2 and Fe2O3 and / or at least one mixed oxide, for example, the alkaline aluminosilicates (of Li, Na, or K) or alkaline-earth aluminosilicates (of Mg, Ca, Sr or Ba), clays, bentonite, feldspars or other natural silico-aluminous materials. The production of the monolith comprises a calcination stage under an oxygen-containing atmosphere at a temperature up to 1650° C., but less than 1550° C.

Owner:INST FR DU PETROLE

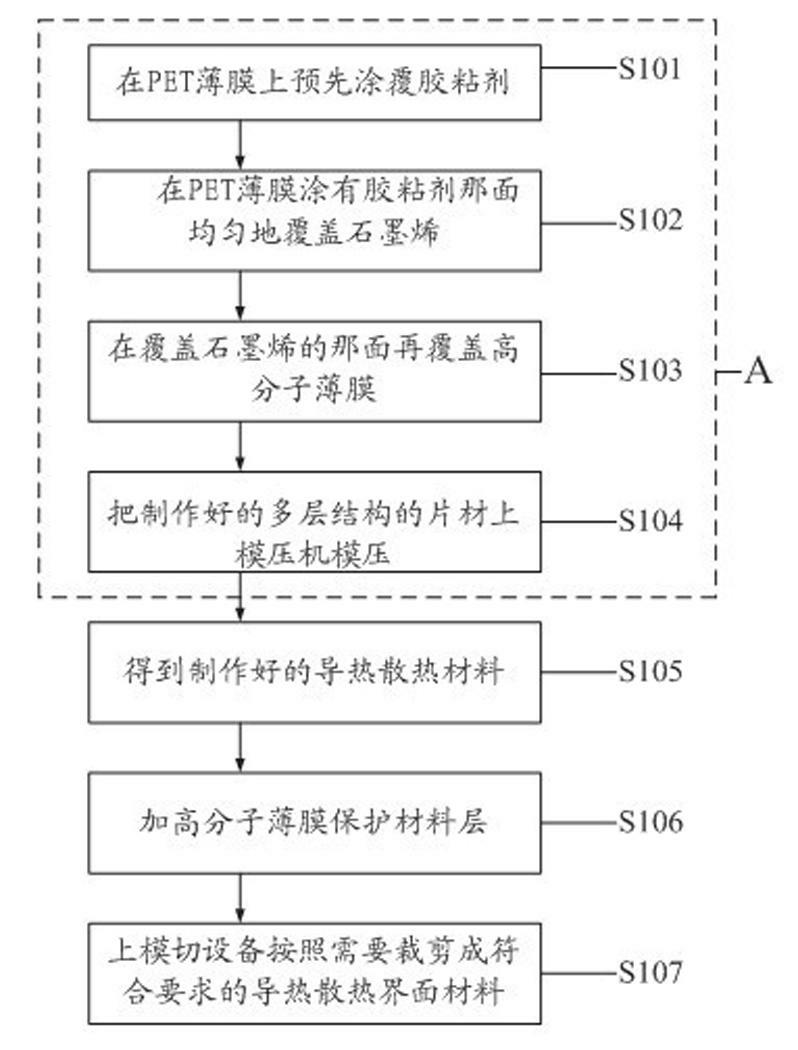

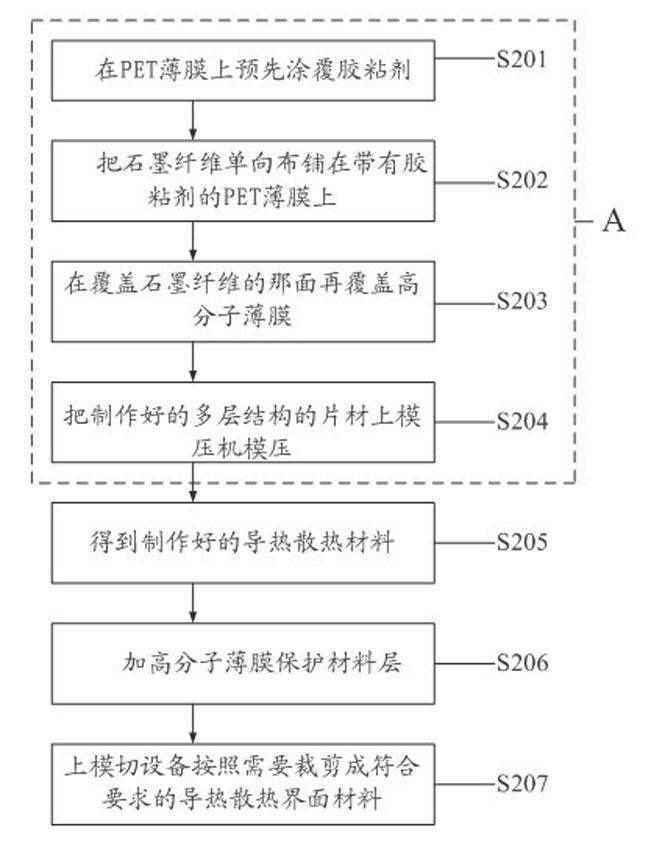

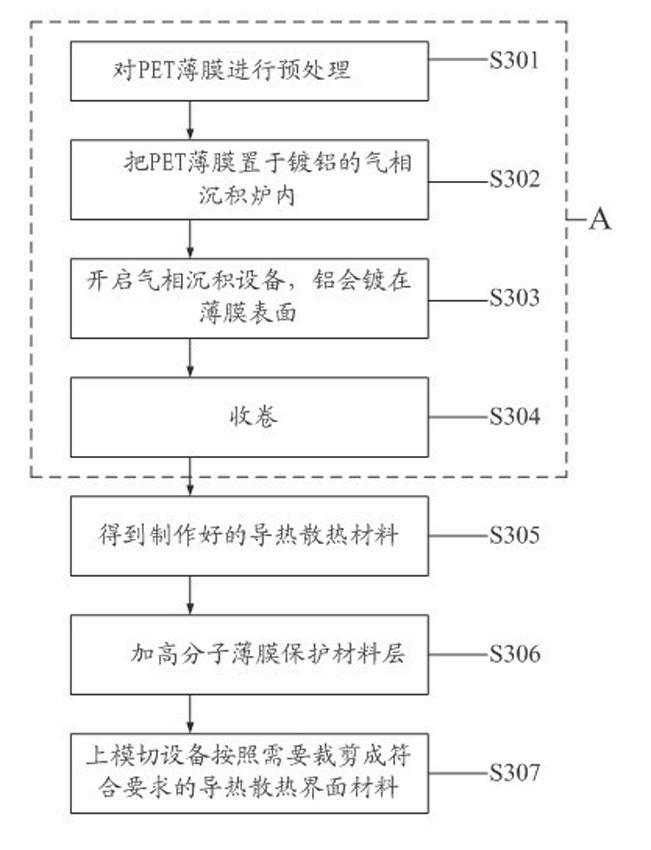

Heat-conduction heat-dissipation interface material and manufacturing method thereof

ActiveCN102651961AReduce volumeThe overall thickness is thinLayered productsCooling/ventilation/heating modificationsMetal fiberCalcium silicate

The invention provides a heat-conduction heat-dissipation interface material and a manufacturing method thereof, wherein the heat-conduction heat-dissipation interface material is applied to the field of heat dissipation of electronic products. The heat-conduction heat-dissipation interface material comprises a heat-conduction heat-dissipation layer and a surface protective material layer, wherein the heat-conduction heat-dissipation layer consists of one or more of graphite, nano graphite, crystalline flake graphite, graphene, pyrolytic carbon, pyrolytic graphite, graphite powder, carbon nano tubes, carbon fibers, graphite fibers, resin, ceramic fibers, quartz fibers, metal fibers, zirconia, boron nitride, silicon nitride, boron carbide, silicon carbide, magnesia powder, metasillicio acid fibers, calcium silicate aluminum fibers, aluminium oxide fibres, copper power, aluminium power, silver power, tungsten power and molybdenum power; and the surface protective material layer is a polymeric membrane. The heat-conduction heat-dissipation interface material manufactured according to the materials and the method provided by the invention has the advantages of effectively improved heat-dissipation performance, small volume, light weight and small thickness, can be used for prolonging the service life of an electronic component, and simultaneously is easy to produce and process.

Owner:SHANGHAI QI JIE CARBON MATERIALS

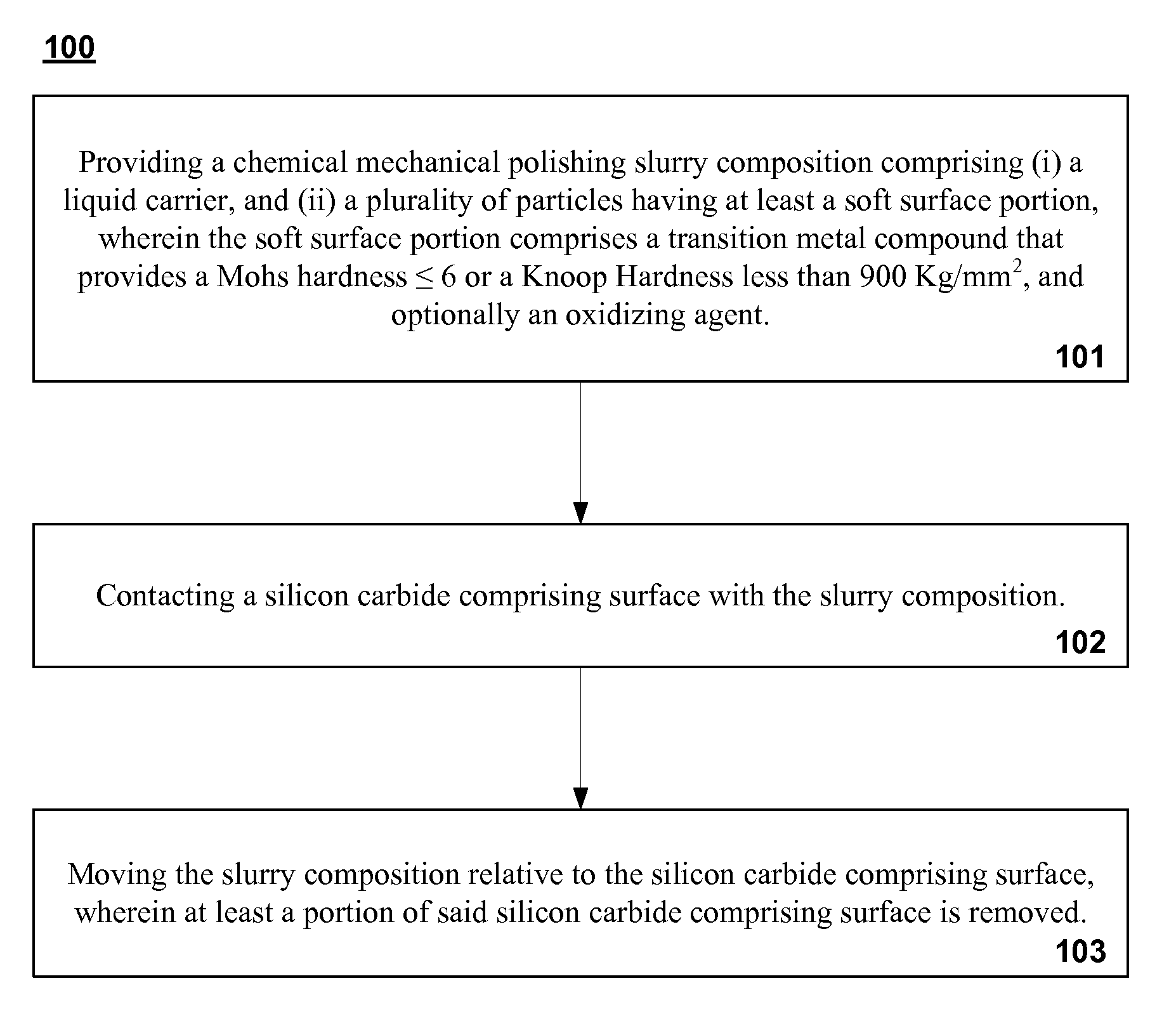

Chemical mechanical polishing of silicon carbide comprising surfaces

ActiveUS20100258528A1High polishing rateReduce sub-surface damageOther chemical processesDecorative surface effectsMohs scale of mineral hardnessSlurry

Slurry compositions and chemically activated CMP methods for polishing a substrate having a silicon carbide surface using such slurries. In such methods, the silicon carbide surface is contacted with a CMP slurry composition that comprises i) a liquid carrier and ii) a plurality of particles having at least a soft surface portion, wherein the soft surface portion includes a transition metal compound that provides a Mohs hardness ≦6, and optionally iii) an oxidizing agent. The oxidizing agent can include a transition metal. The slurry is moved relative to the silicon carbide comprising surface, wherein at least a portion of eth silicon carbide surface is removed.

Owner:ENTEGRIS INC +1

Erosion-resistant components for plasma process chambers

An erosion-resistant article for use as a component in plasma process chamber. The erosion-resistant article comprises a support and an oxide coating comprising yttrium, which is disposed over the support. The support and the oxide coating preferably have material compositions that differ from one another in coefficient of thermal expansion by no more than 5x10<-6> / K. Preferred oxide coating compositions include yttria and yttrium aluminum garnet. Preferred supports include alumina supports and aluminum-silicon carbide supports.

Owner:APPLIED MATERIALS INC

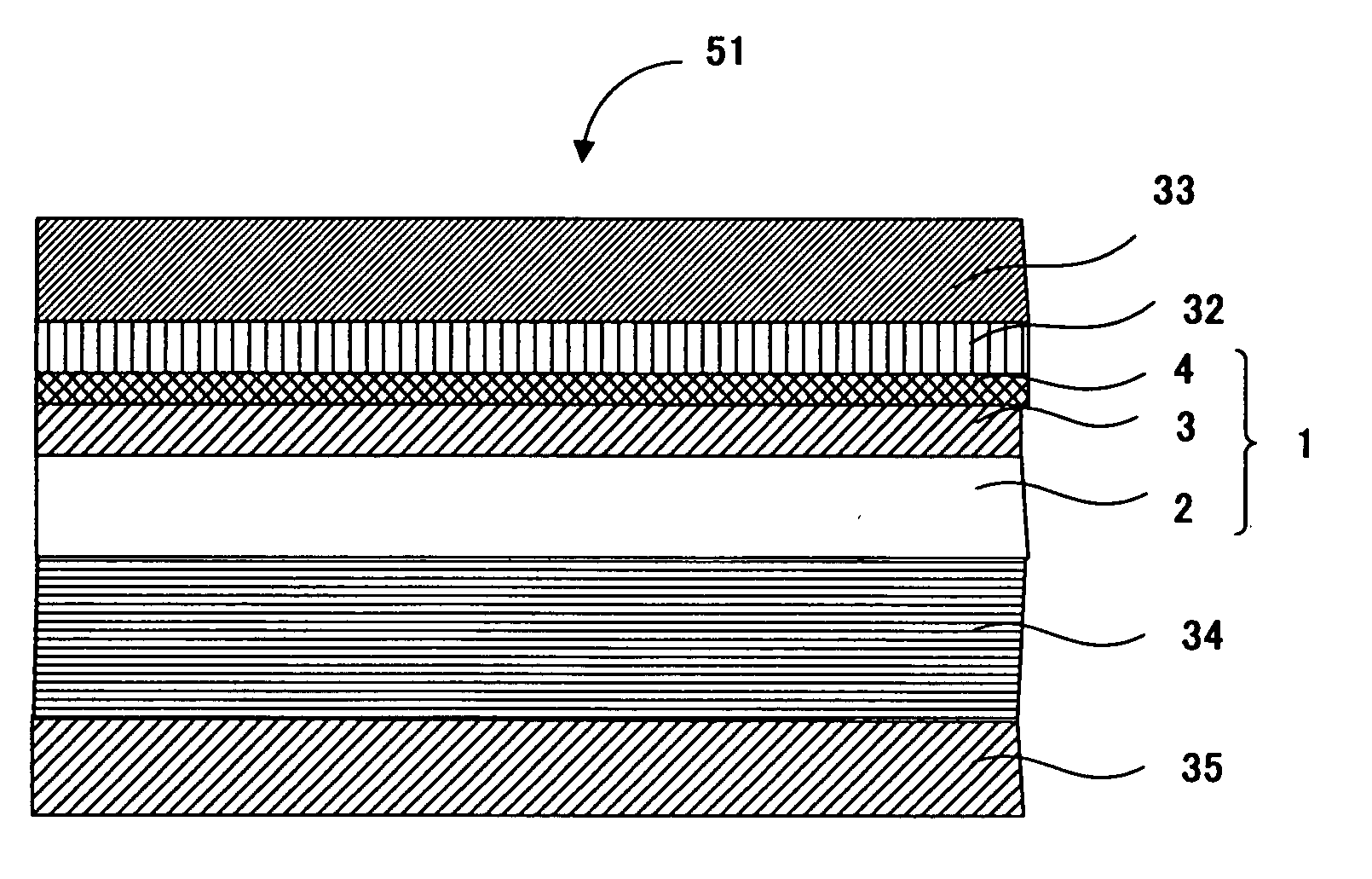

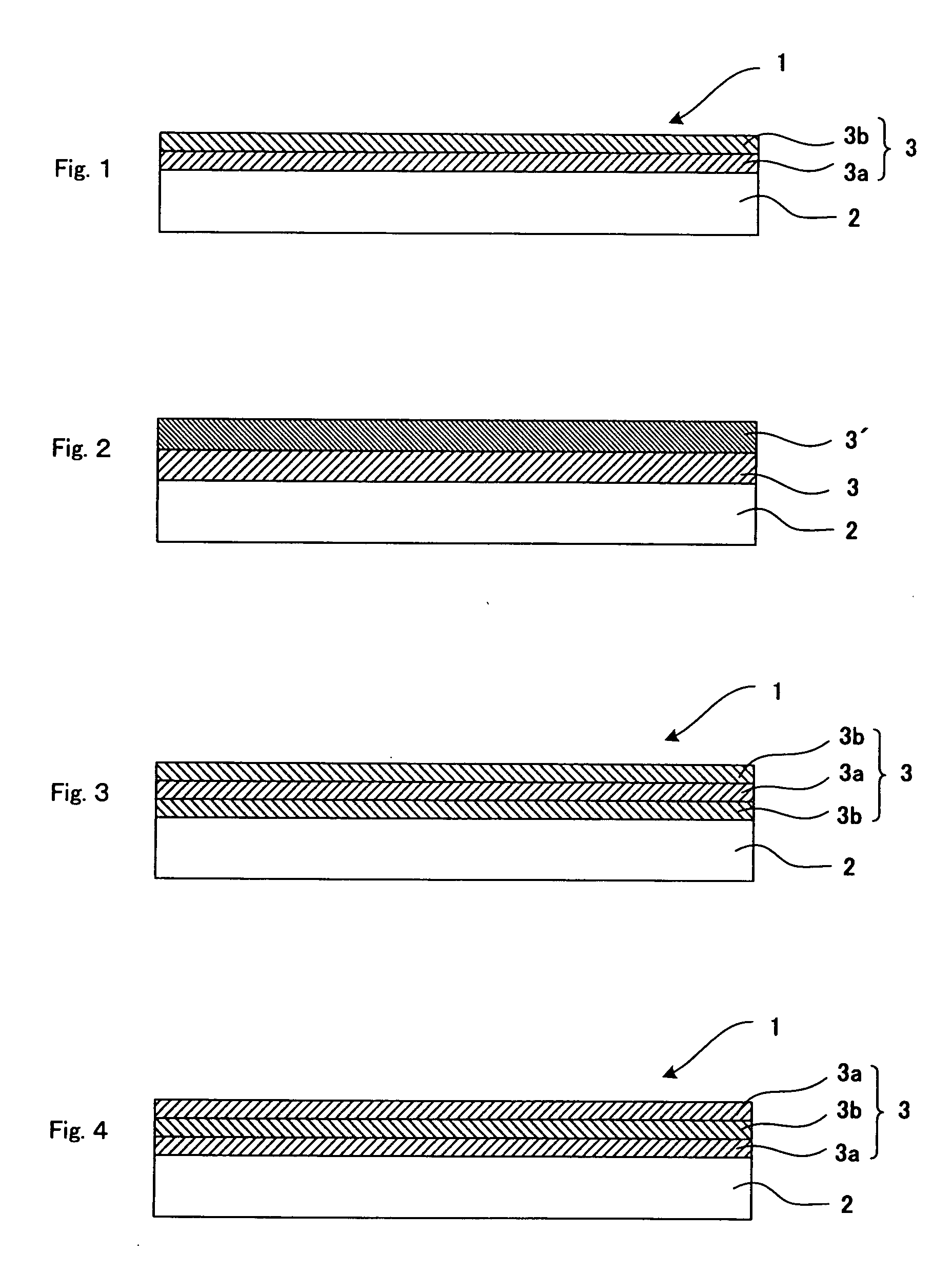

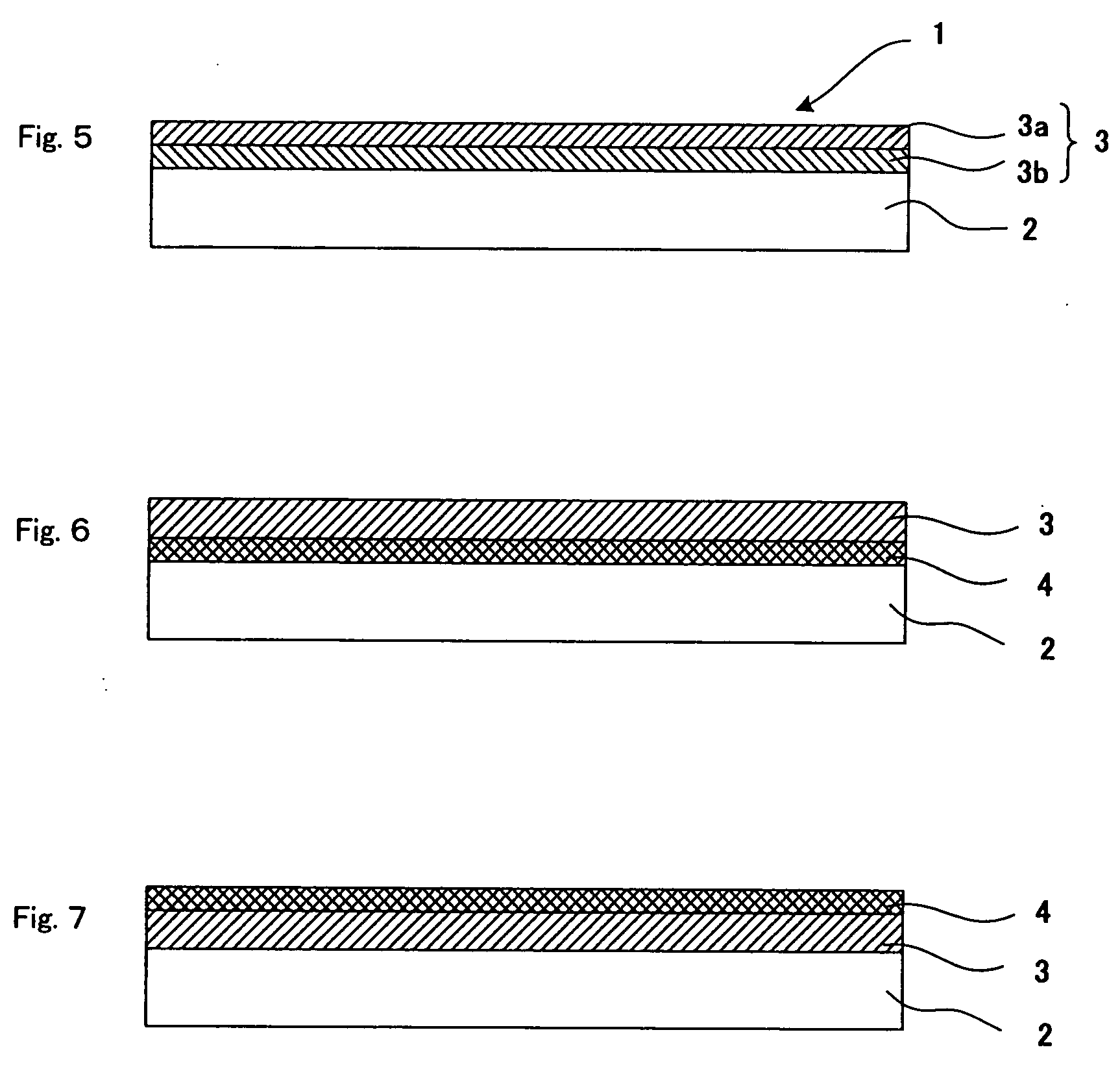

Barrier film

InactiveUS20080050567A1Improve water vapor barrier performanceImprove barrier propertiesNatural mineral layered productsChemical vapor deposition coatingCarbide siliconSilicon oxide

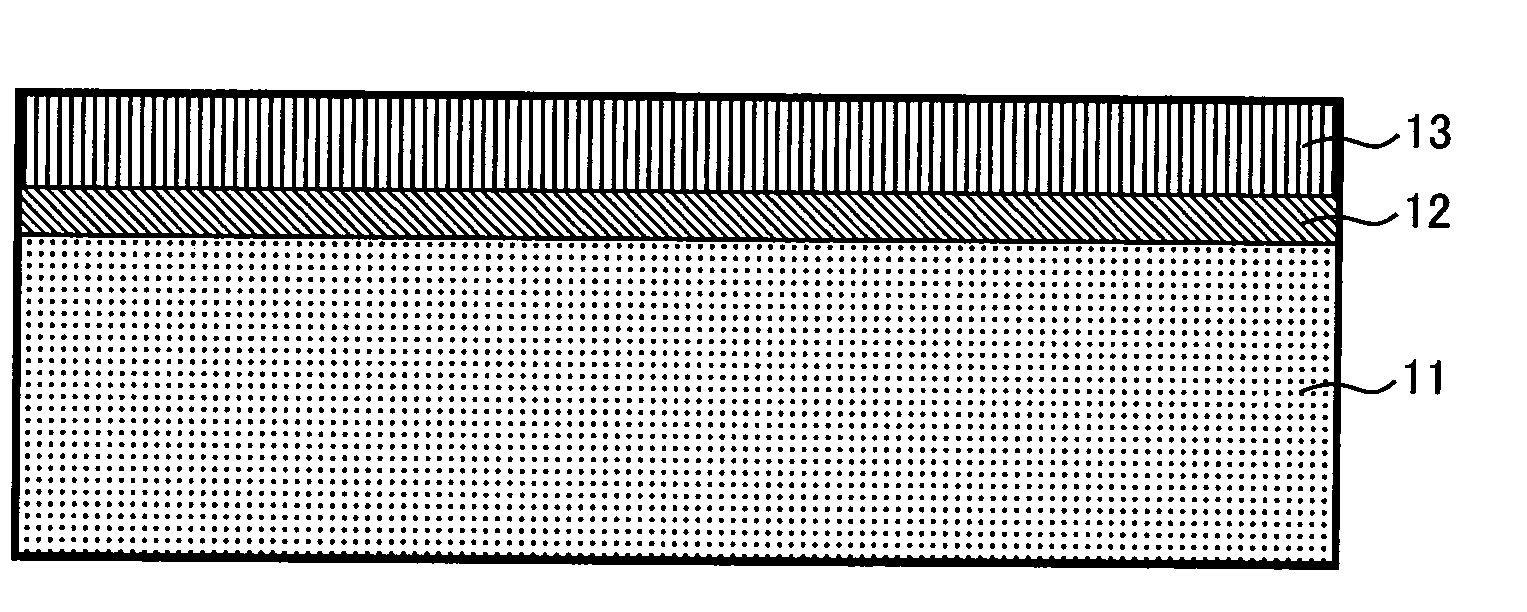

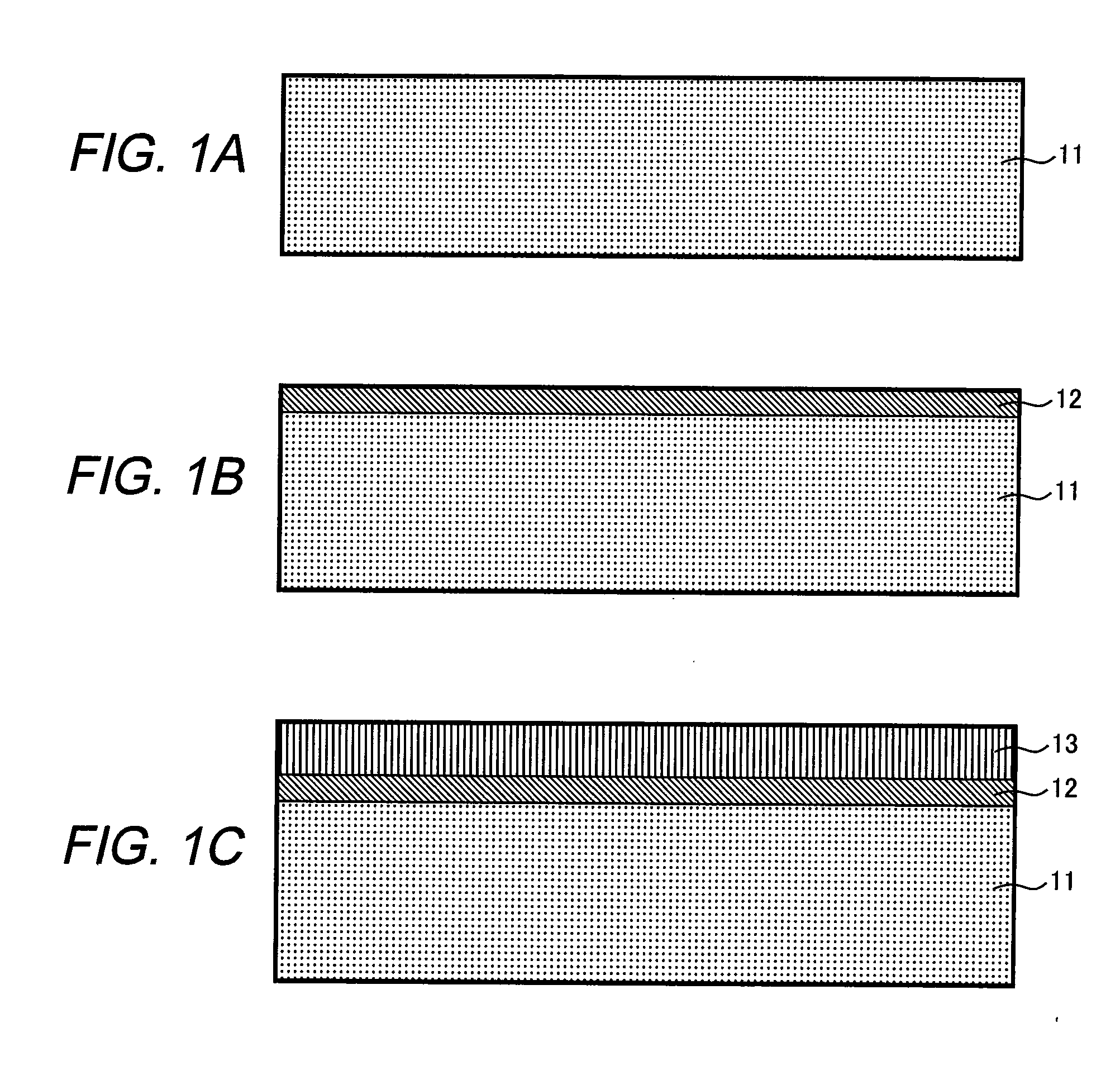

The main object of the present invention is to provide a barrier film having an extremely high barrier property and a good transparency, a laminated material using the above-mentioned barrier film, a packaging container, and an image display medium. The above-mentioned object is achieved by providing a barrier film comprising a base material film and a barrier layer deposited on at least one side surface of the base material film, wherein the barrier layer comprises a water repellent layer and a dense layer, the water repellent layer is a silicon oxide carbide film having the atomic percent of Si:O:C in a range of 100:40 to 120:80 to 160, and the thickness in a range of 2 to 300 nm, and the dense layer is a silicon oxide carbide film having the atomic percent of Si:O:C in a range of 100:100 to 200:5 to 100, and the thickness in a range of 5 to 300 nm.

Owner:DAI NIPPON PRINTING CO LTD

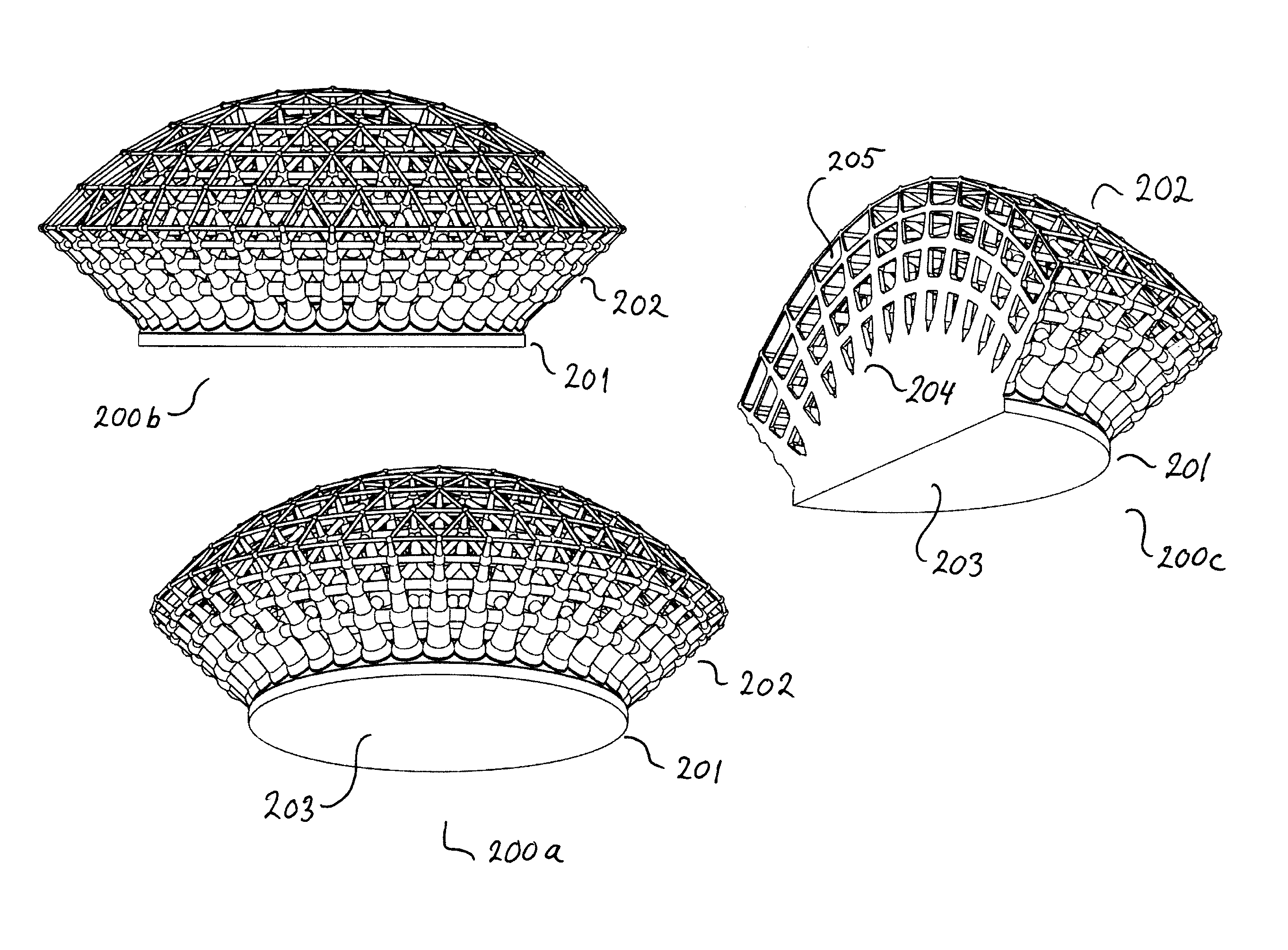

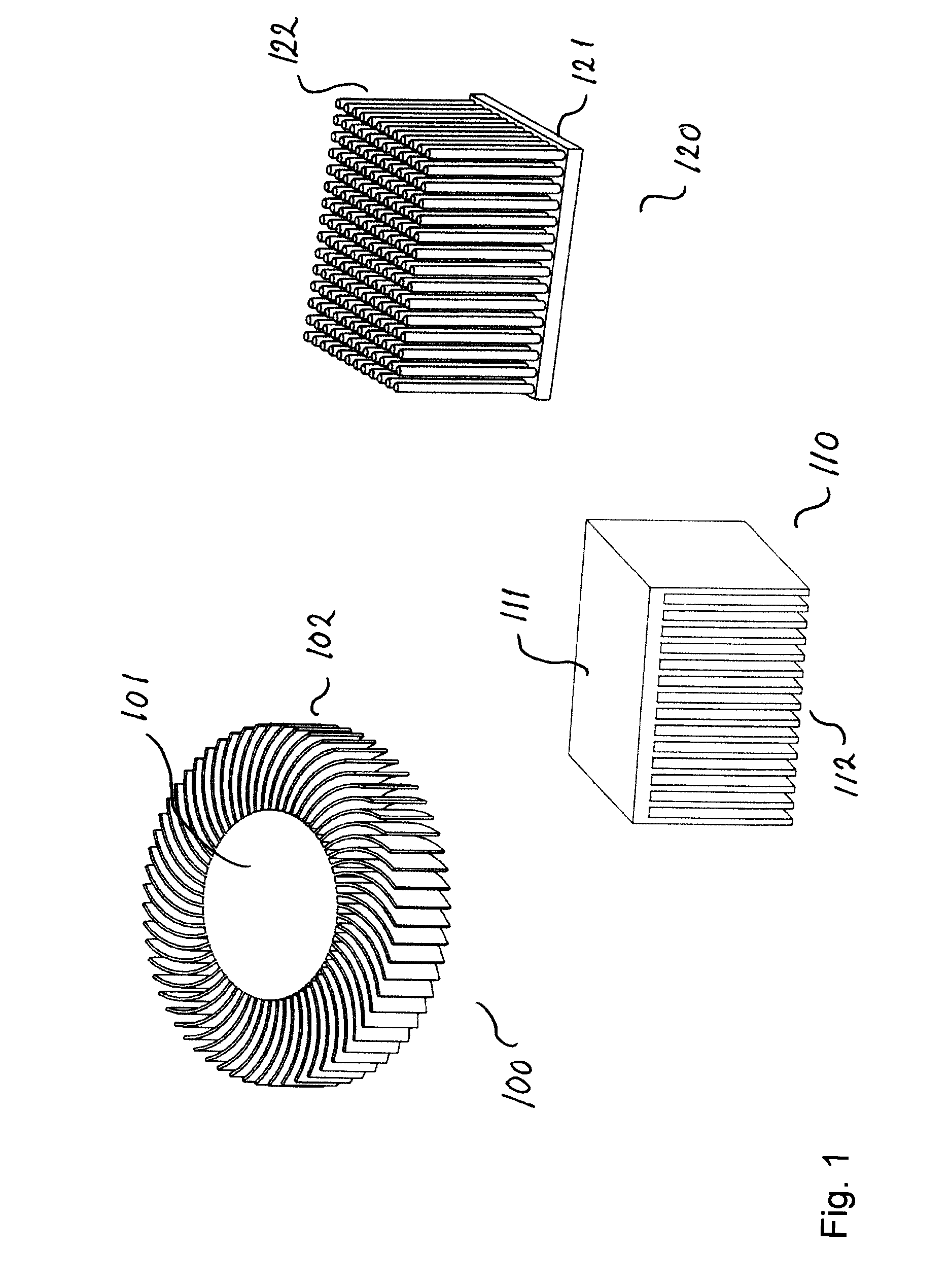

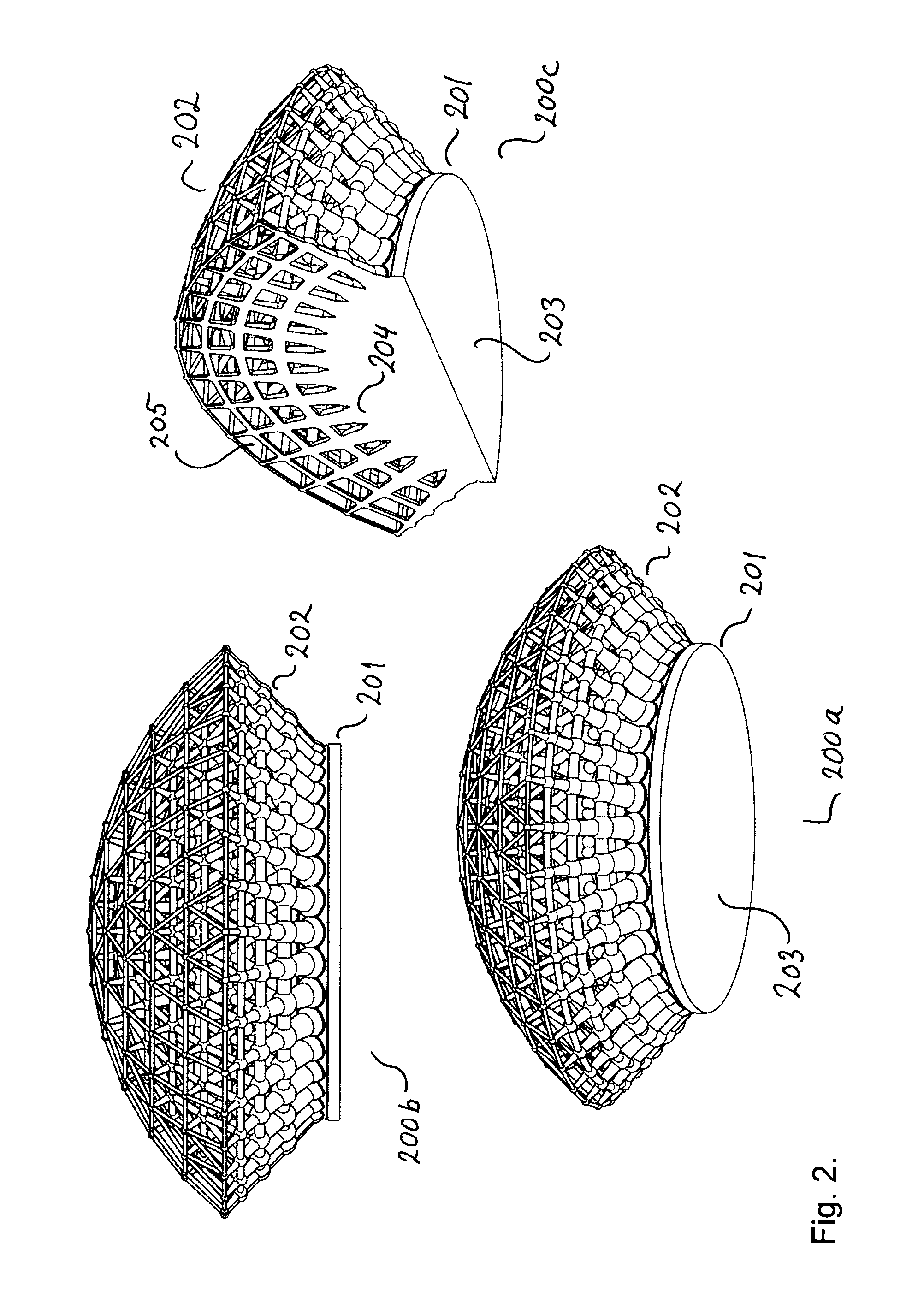

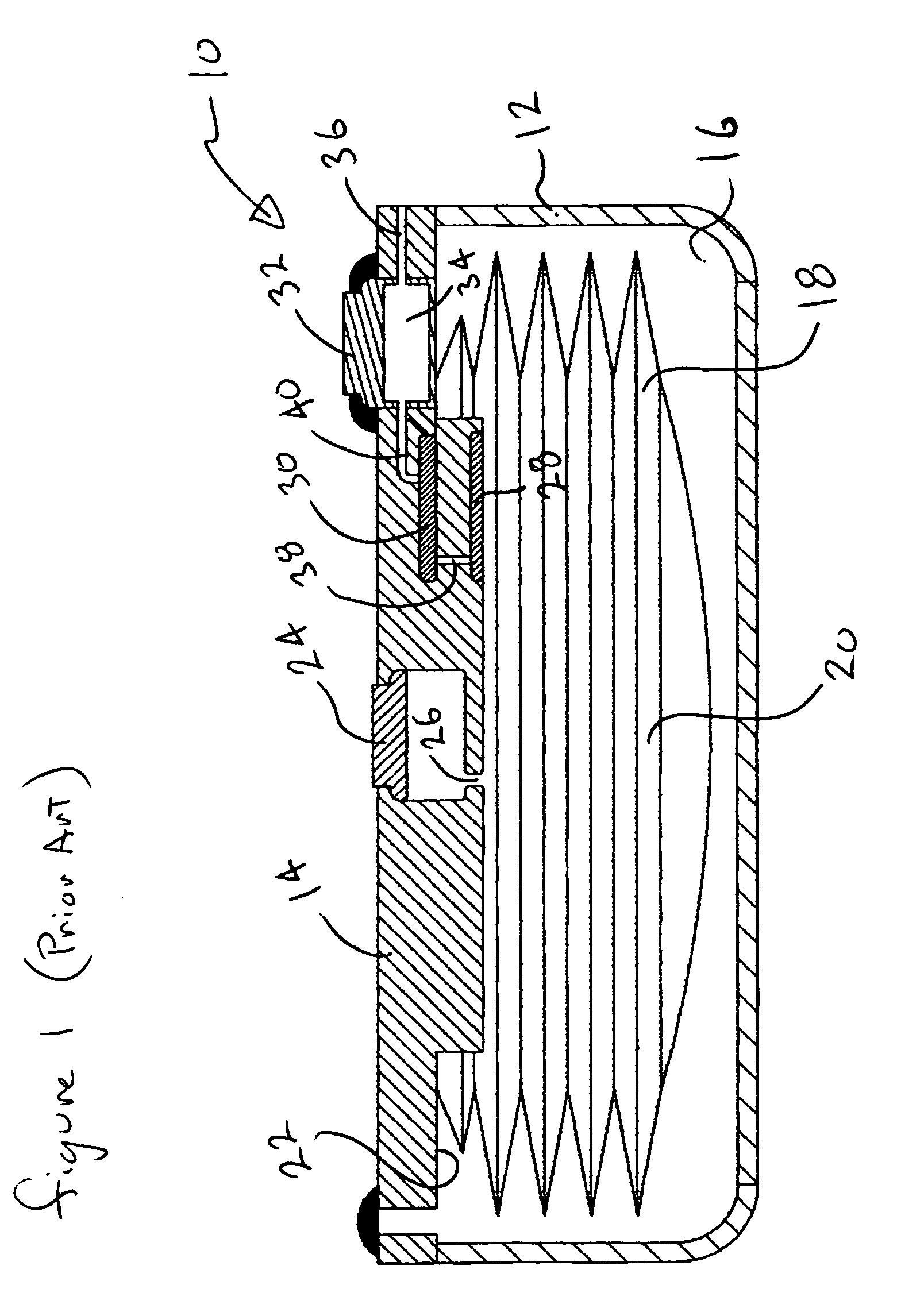

Heat Sink Having a Cooling Structure with Decreasing Structure Density

InactiveUS20160069622A1Increase distanceReduce material densityLighting support devicesDigital data processing detailsSelective laser meltingCarbon nanotube

A heat sink for cooling a heat generating device comprises a body part with a first surface for contacting the heat generating device, and a second surface contacting a cooling part, and the cooling part including a cooling structure. The structure density of the cooling structure decreases with increasing distance to body part. The cooling structure may be a three dimensional structure e.g. a grid or a lattice, but the cooling structure may also be fins projecting or extending from the second surface of the body part. The heat sink can be manufactured using additive manufacturing e.g. selective laser melting process (SLM). The heat sink can be made of metals e.g. aluminum, copper, ceramics e.g. aluminium nitride (AlN), silicon carbide or a composite containing graphite, graphene or carbon nanotubes.

Owner:ALEXIOU & TRYDE HLDG APS

Thermal protective coating

ActiveUS7105047B2Extended shelf lifeReduce weightAlkali metal silicate coatingsPretreated surfacesCalcium silicateSodium Bentonite

A coating, method of coating and substrates coated thereby, wherein the coating contains an inorganic adhesive such as an alkali / alkaline earth metal silicate such as sodium silicate, potassium silicate, calcium silicate, and magnesium silicate; a filler such as a metal oxide for example silicon dioxide, aluminum oxide, titanium dioxide, magnesium oxide, calcium oxide and boron oxide; and one or more emissivity agents such as silicon hexaboride, carbon tetraboride, silicon tetraboride, silicon carbide, molybdenum disilicide, tungsten disilicide, zirconium diboride, cupric chromite, or metallic oxides such as iron oxides, magnesium oxides, manganese oxides, chromium oxides and copper chromium oxides, and derivatives thereof. In a coating solution, an admixture of the coating contains water. A stabilizer such as bentonite, kaolin, magnesium alumina silicon clay, tabular alumina and stabilized zirconium oxide may be added.

Owner:WESSEX

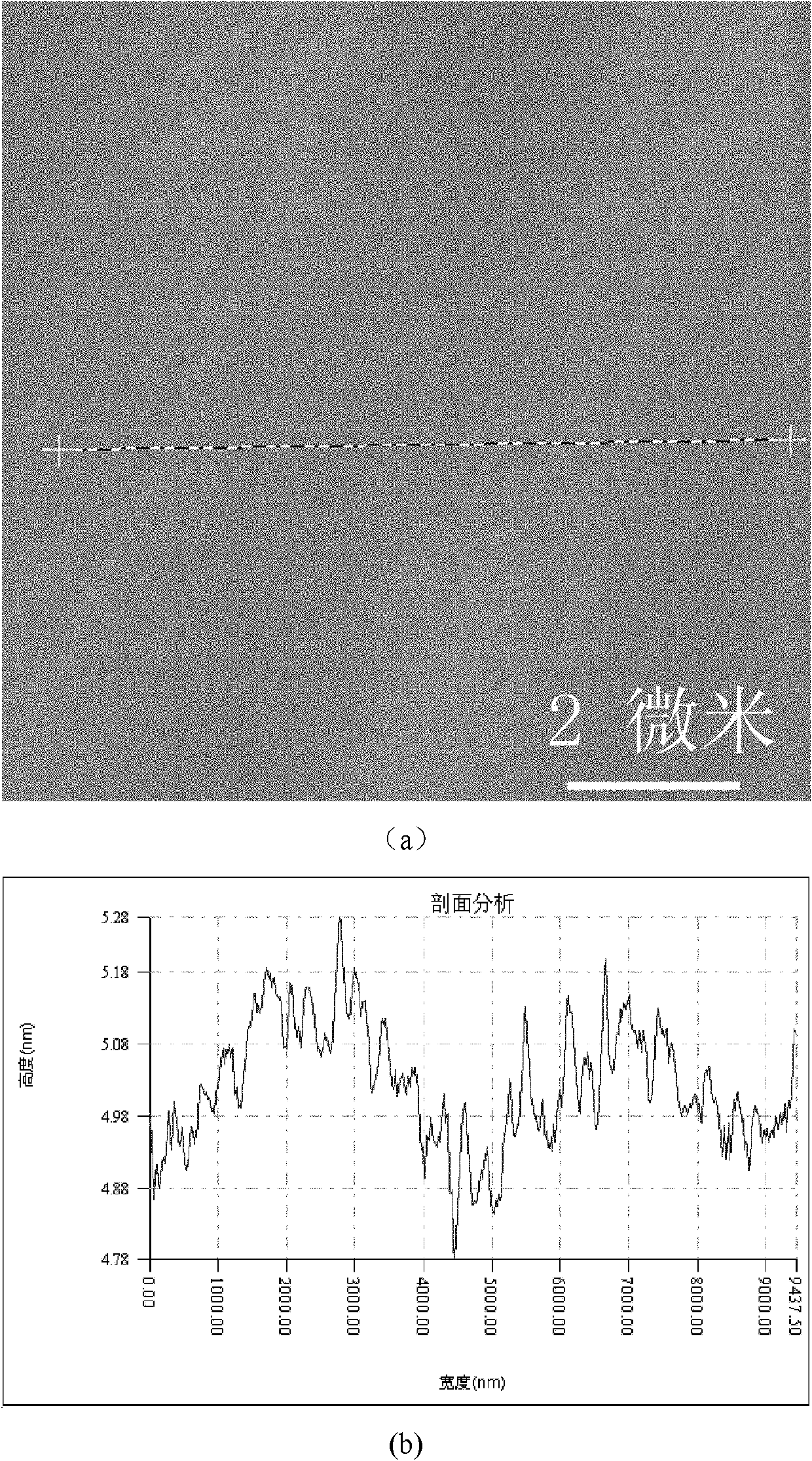

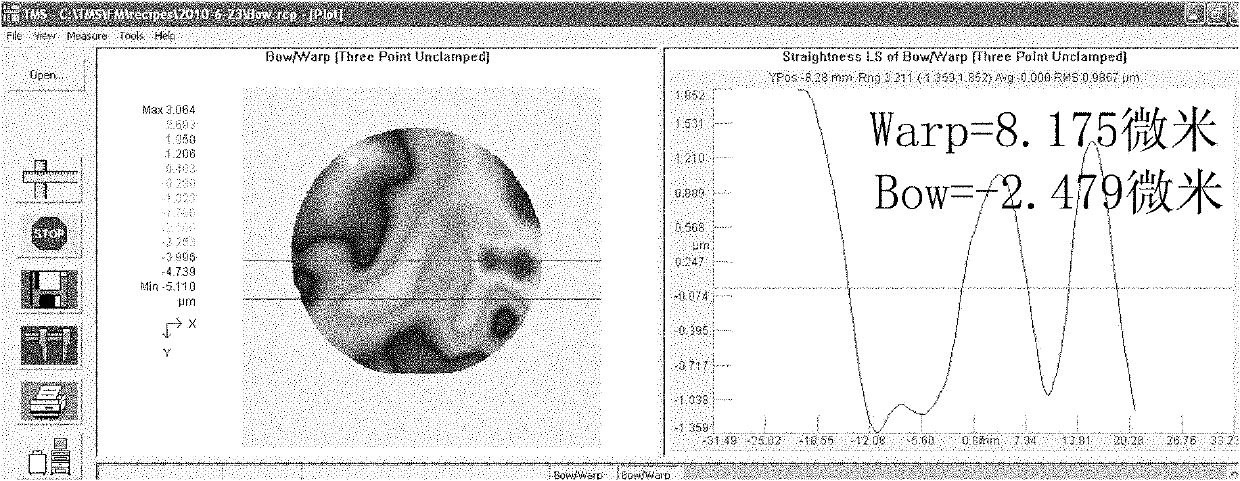

Adjustment method of SiC (silicon carbide) single crystal flatness by wet etching

ActiveCN102569055AWafer Quality ImprovementWafer flatness improvementPolycrystalline material growthAfter-treatment detailsEtchingSingle crystal

The invention provides a method for improving silicon carbide single chip flatness and crystal surfaces by using wet etching. By cleaning, preheating and oxygen-blowing etching silicon carbide single crystal and the like, the method removes dot, line and surface defects on the surfaces of the silicon carbide single crystal and furthest eliminates defects, stress and damaged layers on the surfaces of wafers to a maximum extent, so that the flatness of the silicon carbide wafers can be adjusted to the following parameters: Warp is less than 15mum, absolute Bow is less than 15mum and, and finally the single crystal silicon carbide wafers with high qualities are obtained.

Owner:BEIJING TIANKE HEDA SEMICON CO LTD

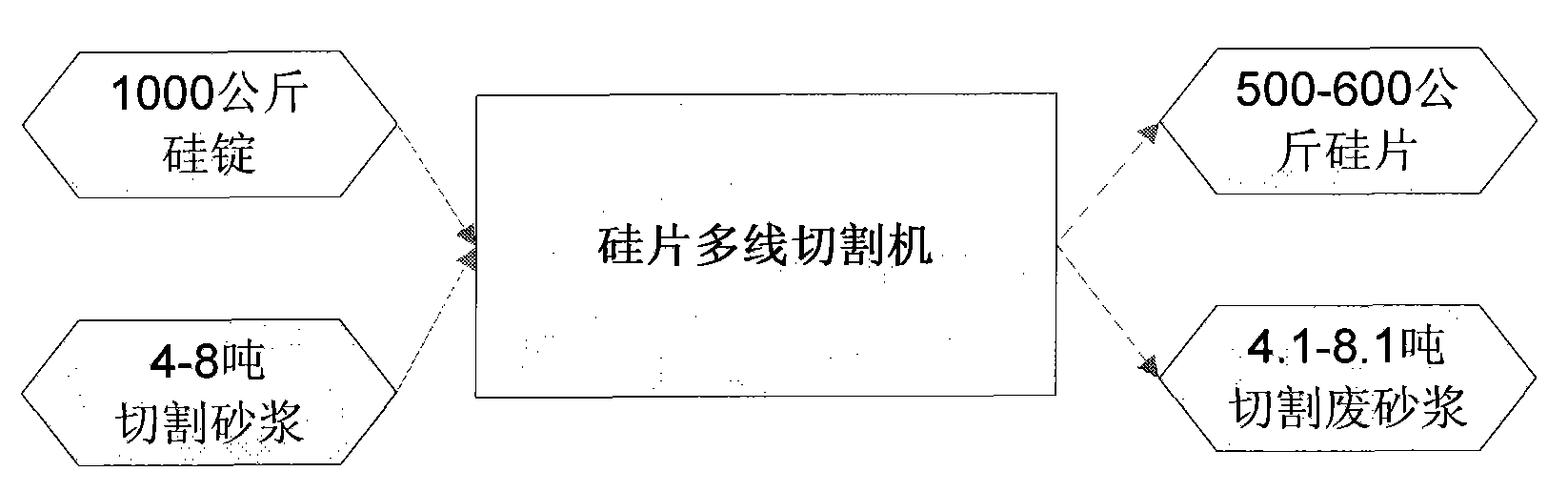

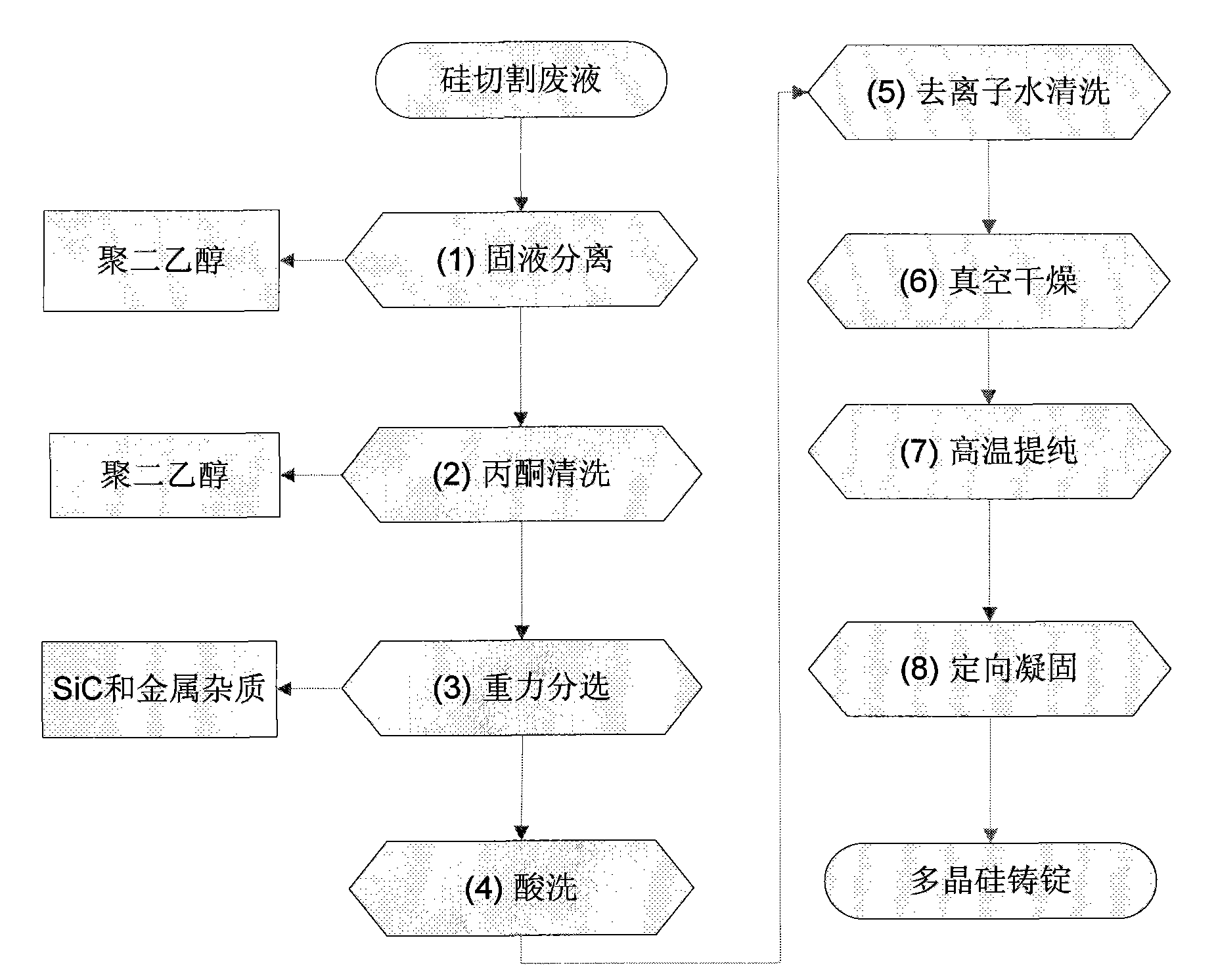

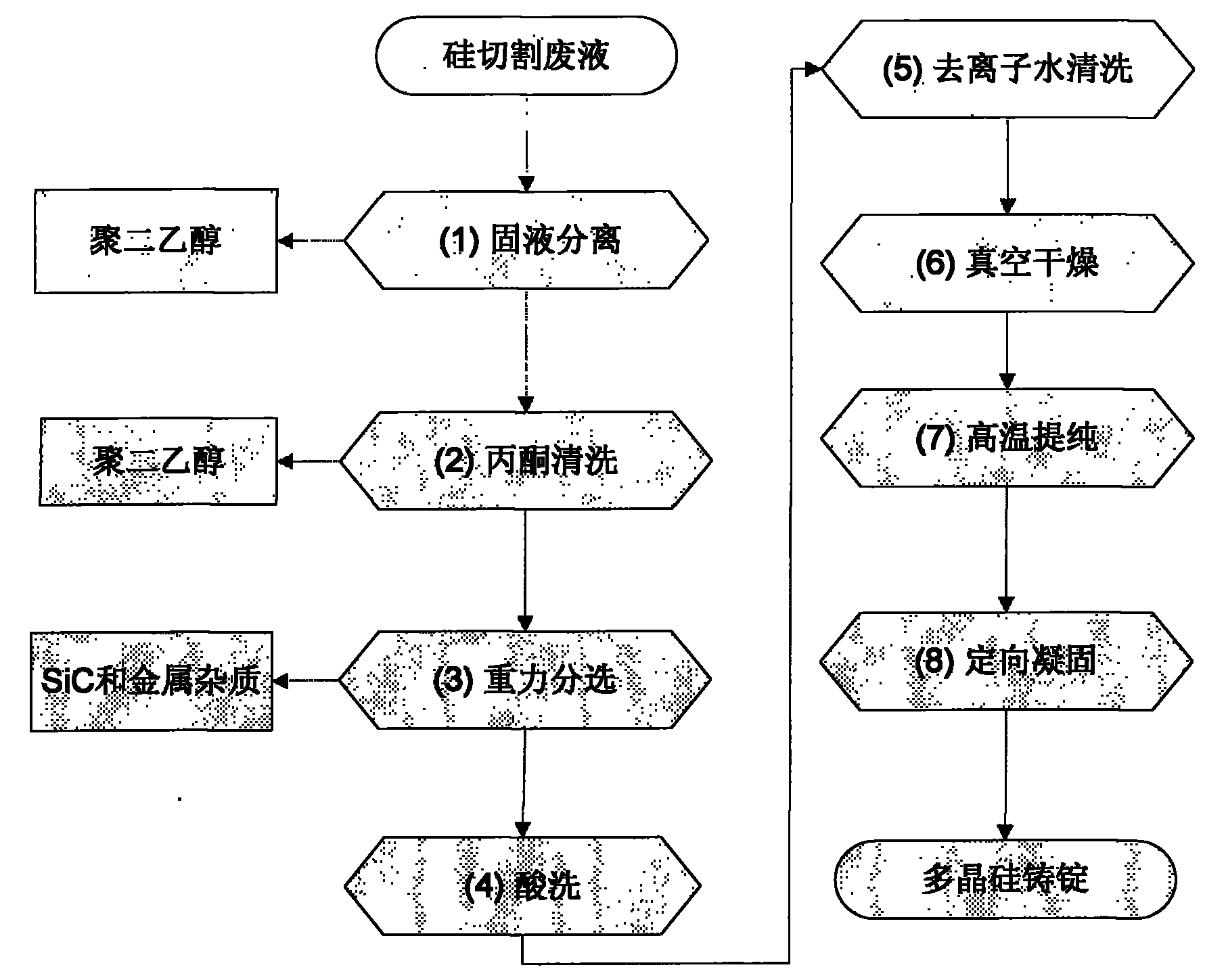

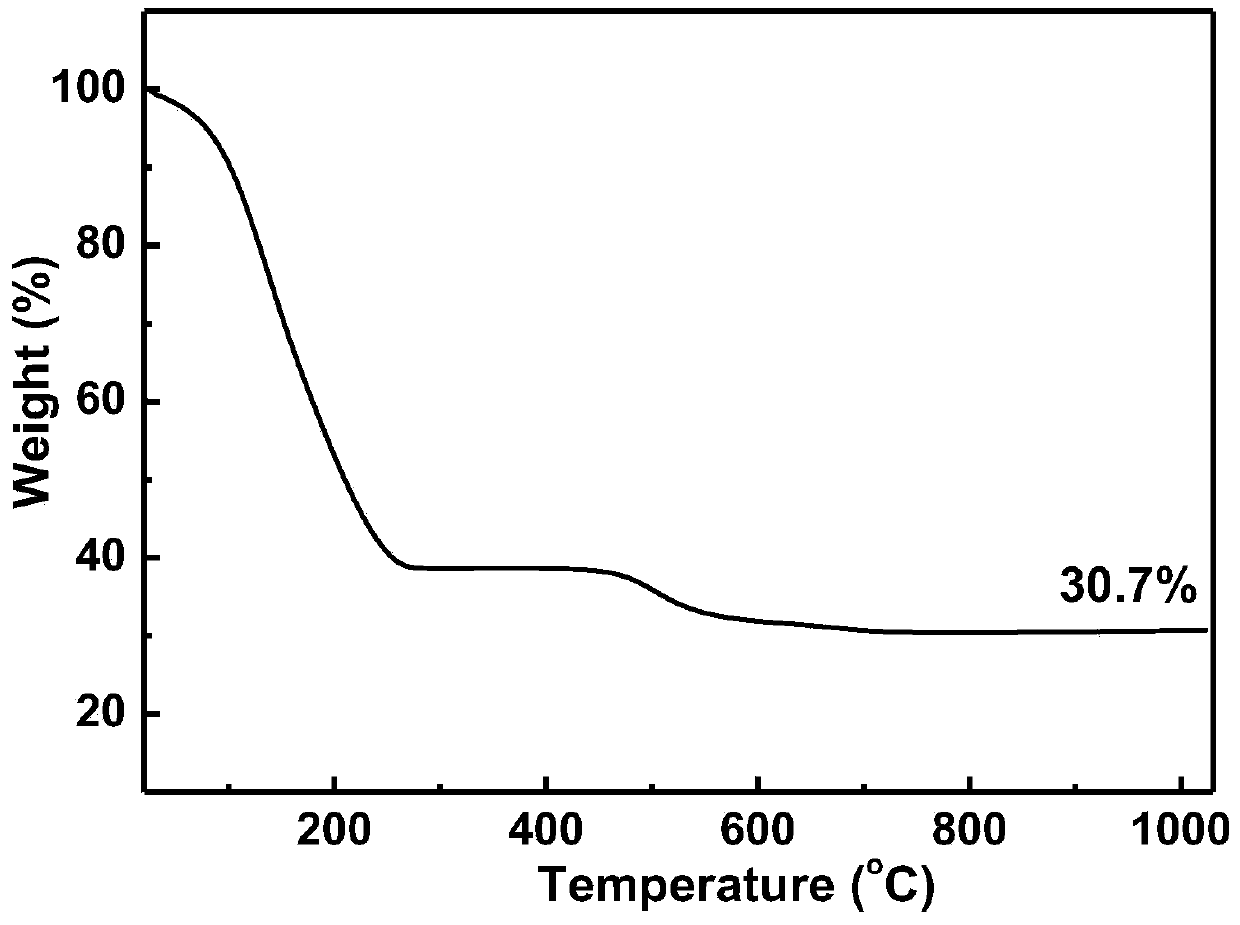

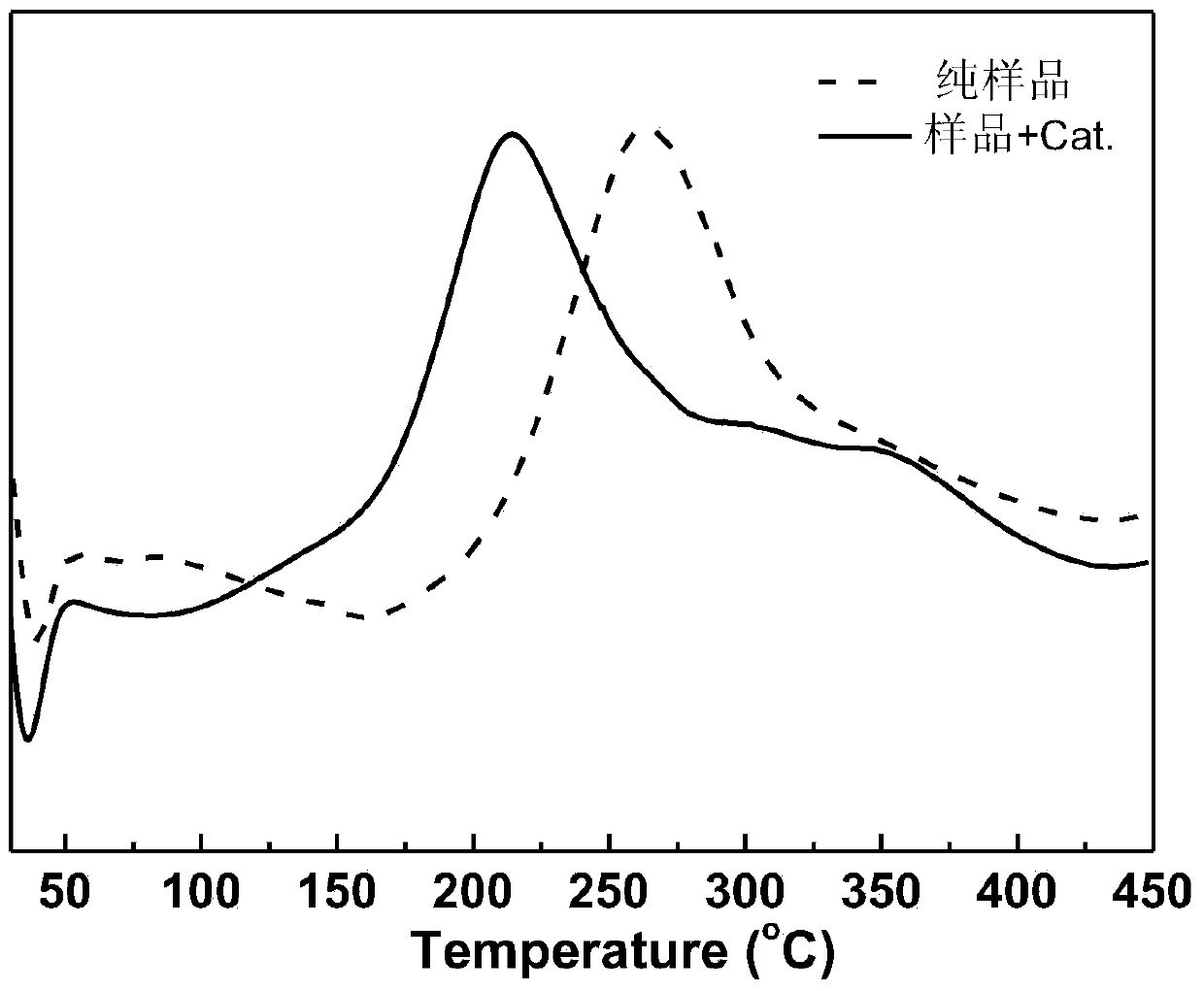

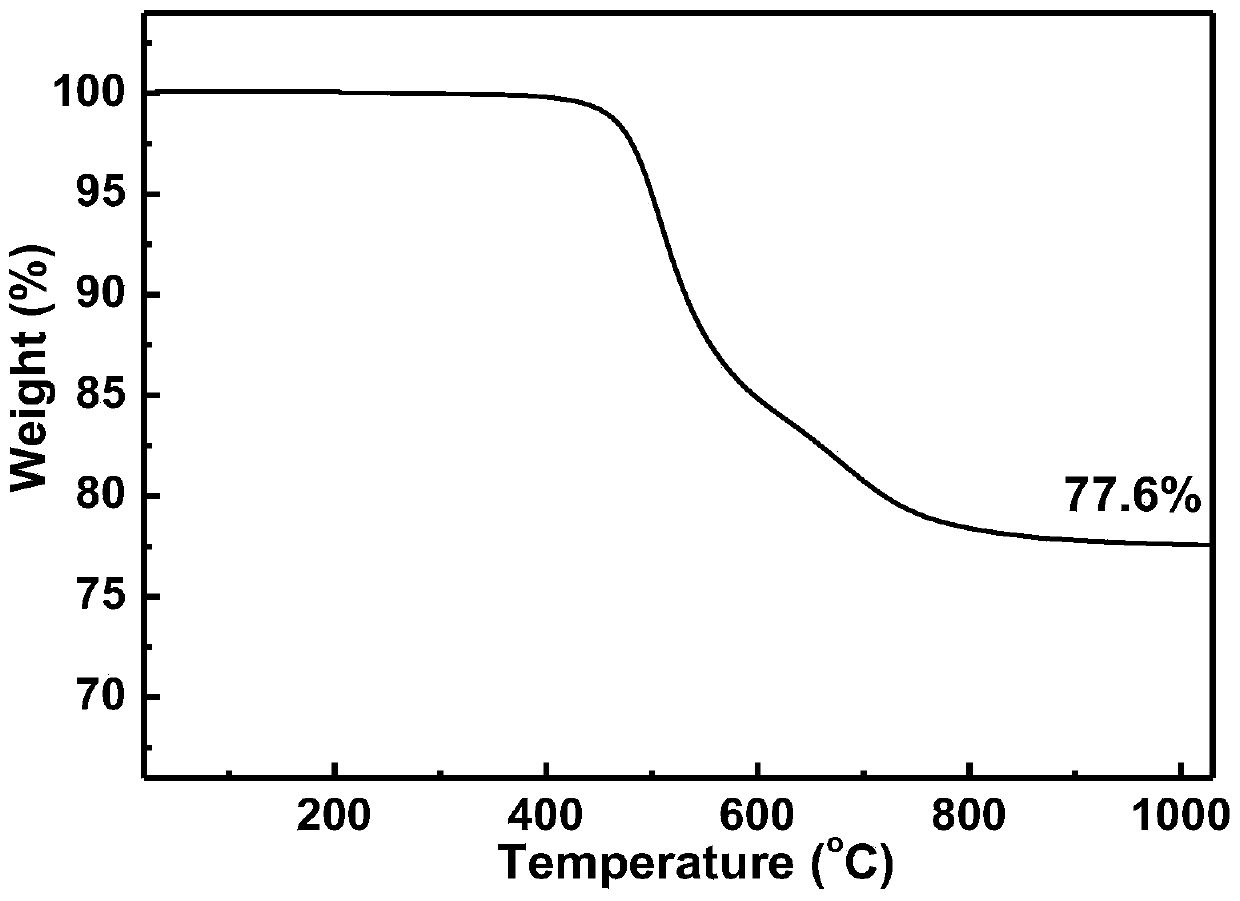

Method for recovering polysilicon ingots, carborundum powder and polyethylene glycol from cutting waste mortar

InactiveCN101792142AHigh yieldMultistage water/sewage treatmentSilicon compoundsPotassiumPolyethylene glycol

The invention discloses a method for recovering polysilicon ingots, carborundum powder and polyethylene glycol from cutting waste mortar. The recovering method comprises the following steps shown as an attached diagram, wherein the high temperature purification comprises the following steps of: mixing the prepared silicon micro powder with a fluxing agent according to the weight ratio of 1: 0.5-5 into lumps, carrying out high temperature treatment in a high temperature vacuum furnace with the treatment temperature range of 1450-1800 DEG C and the treatment time range of 1-10h; and then carrying out directional solidification on melting-state high purity silicon subjected to the high temperature treatment to obtain the polysilicon ingots; wherein the fluxing agent is selected from one or any mixture of silica, alumina, calcium oxide, magnesium oxide, potassium oxide, sodium oxide, calcium fluoride, magnesium fluoride, sodium fluoride, sodium chloride, potassium chloride and calcium chloride. The invention has the advantages that: the yields of carborundum and polyethylene glycol are high and can reach more than 70-80 percent; and the recovered polysilicon ingots reach the purity of 6-7N and completely satisfy of the requirement for preparing silicon slices of silicon solar cell.

Owner:唐康宁

Process for preparing self-sealing silicon carbide ceramic based composite material

The invention relates to a method for manufacturing a self-healing silicon carbide ceramic matrix composite. The method comprises the following steps: preparing fiber preform; filtrating a pyrolytic carbon interface layer by chemical gas phase; carrying out thermal treatment on the interface layer; infiltrating silicon carbide and boron carbide substrate by chemical gas phase alternately; and depositing three silicon carbide coatings by the chemical gas phase. The method has strong designability, simple process and good repeatability. The ceramic matrix composite manufactured by the method has good high temperature resistance and oxidation resistance, has excellent mechanical performance and thermal performance, and can meet the use requirement of a sealing strip / an adjustment sheet, an interior cone and other components of a high thrust-weight ratio aeroengine.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

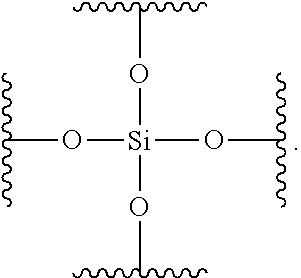

Novel liquid polycarbosilane as well as preparation method and application thereof

The invention discloses novel liquid polycarbosilane which is low in viscosity and high in storage stability and is crosslinkable, a preparation method of novel liquid polycarbosilane, and an application of novel liquid polycarbosilane. Polycarbosilane is prepared by adopting chloromethyl alkoxy silane or mixtures of chloromethyl alkoxy silane as raw materials by virtue of Grignard coupling reaction and reduction reaction, and the structure of polycarbosilane is shown in a formula (I) in the specification. The structure simultaneously contains Si-H bonds and unsaturated bonds such as C=C bonds, can be subjected to self-crosslinking and curing under a certain condition, has relatively high ceramic yield, and can be used as a silicon carbide precursor of a polymer precursor impregnation pyrolysis (PIP) process. Polycarbosilane disclosed by the invention is adjustable in structural composition, good in storage stability, low in viscosity and relatively low in boiling point, and has the utilization potentiality of being used as a silicon carbide ceramic precursor for chemical vapor deposition / chemical vapor infiltration (CVD / CVI). In addition, polycarbosilane can also be used for replacing commonly-used divinyl benzene to serve as a crosslinking agent of solid-state polycarbosilane (PCS).

Owner:淄博市临淄齐泉工贸有限公司

Dedicated pouring material for cement kiln outlet and jetting coal pipe and preparation method thereof

InactiveCN101445379AImprove thermal shock performanceGood alkali resistanceCarbide siliconCement factory

The invention discloses a dedicated pouring material for a cement kiln outlet and a jetting coal pipe, which comprises the following components by the weight percentage: 20 to 30 percent of sintered plate-shaped corundum, 20 to 30 percent of sintered and synthesized mullite, 10 to 15 percent of chrome corundum, 5 to 10 percent of silicon carbide, 3 to 5 percent of silicon carbide superfine powder, 3 to 5 percent of magnesia alumina spinel, 5 to 8 percent of zircon sand, 2 to 5 percent of activated Al2O3 micro powder, 2 to 5 percent of silicon micro powder, 3 to 5 percent of pure calcium aluminate cement, 1 to 2 percent of stainless steel fiber, 5 to 10 percent of synthesized zirconium mullite grinding powder, 0.1 to 0.15 percent of composite additives and 0.01 to 0.1 percent of explosion proof fiber. The invention further discloses a method for preparing the pouring material. The pouring material is applicable to the dry-process cement kiln outlets and the jetting coal pipes in large-scale cement plants and has the advantages of high wear resistance, good anti-stripping resistance and long service life.

Owner:JIANGSU GUOHAO REFRACTORY TECH

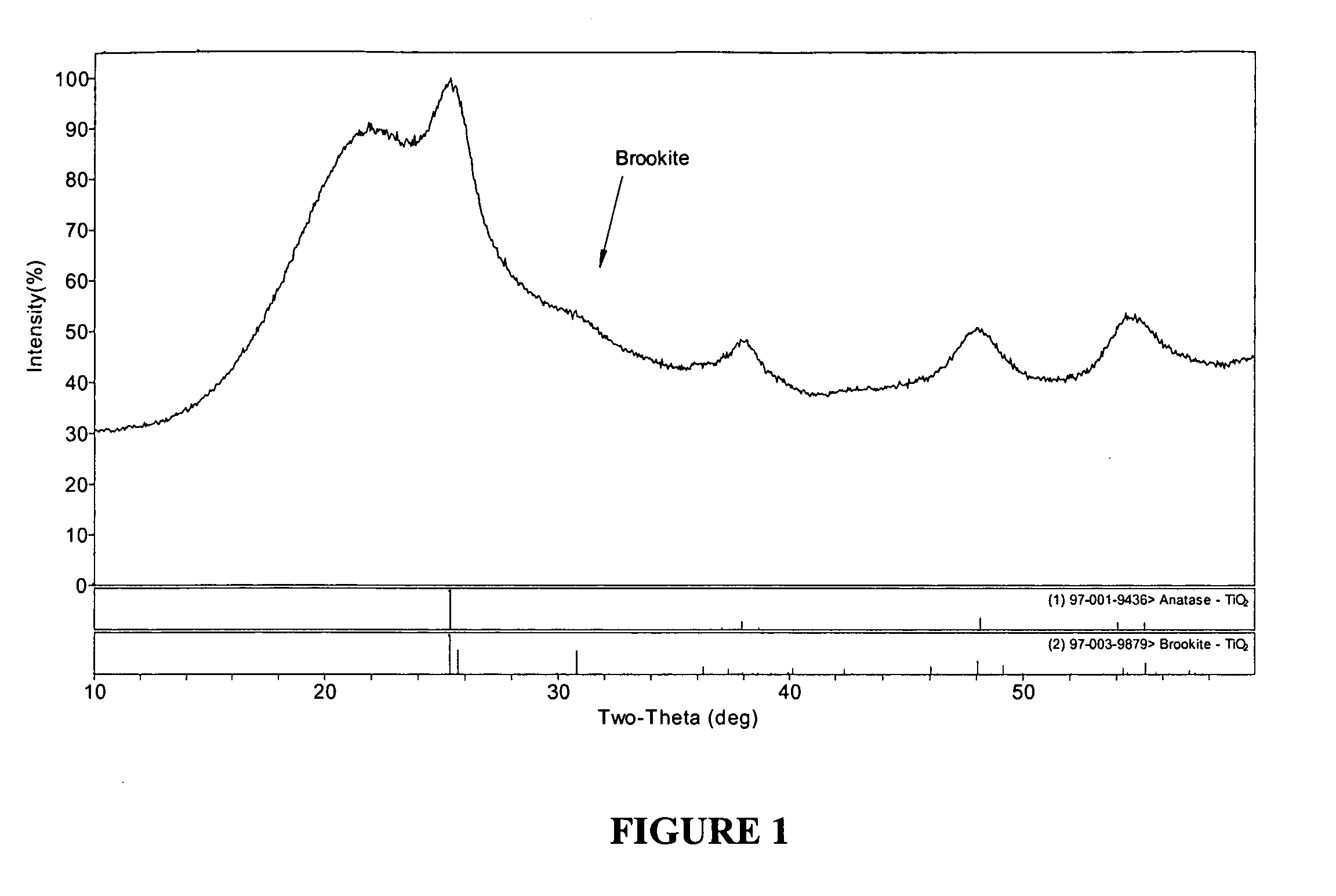

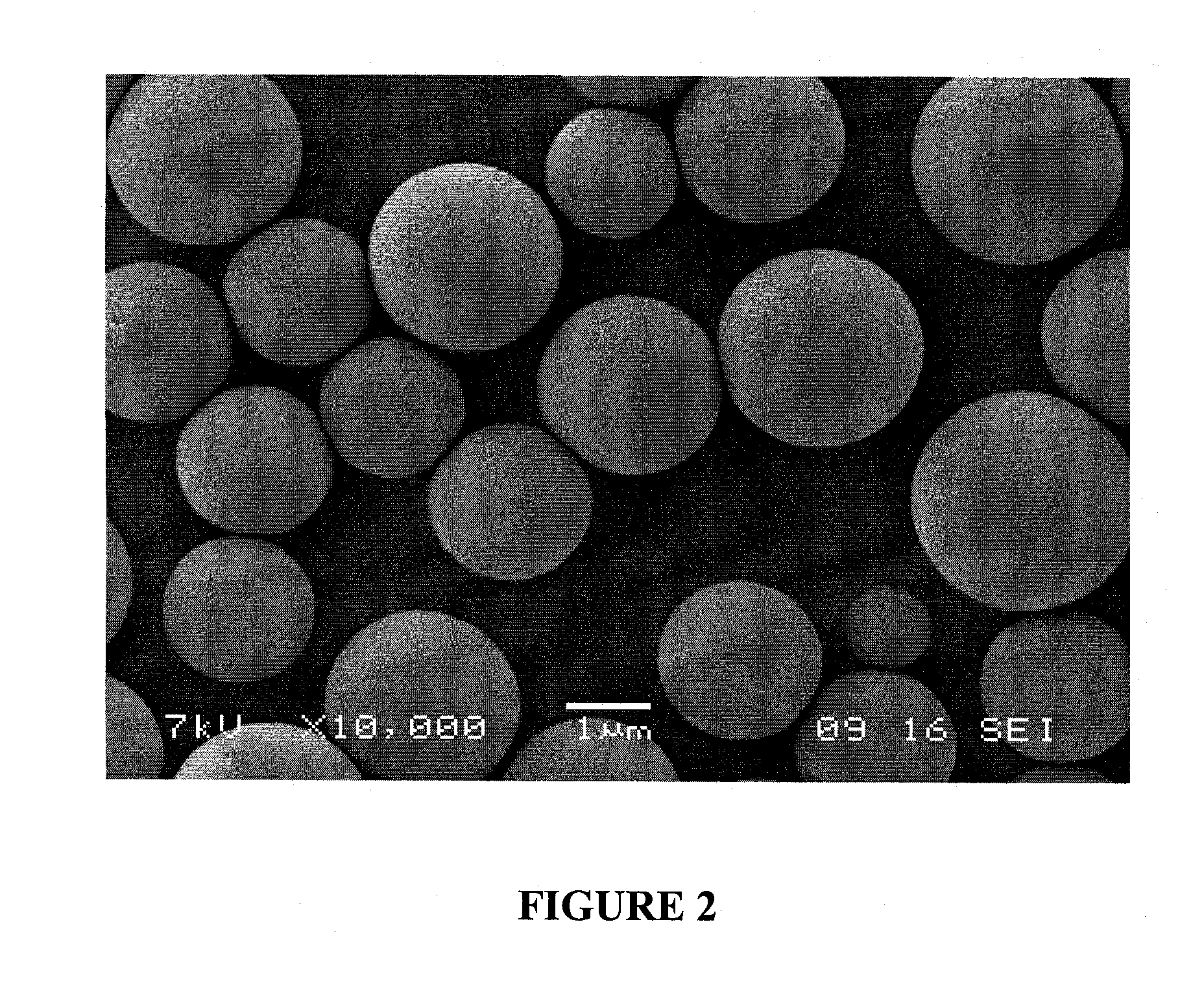

Composite materials containing nanoparticles and their use in chromatography

ActiveUS20110049056A1Increase mechanical strengthImprove thermal propertyIon-exchange process apparatusOther chemical processesChromatographic separationNanoparticle

Novel porous materials comprising nanoparticles, use in chromatographic separations, processes for its preparation, and separations devices containing the chromatographic material are described by the instant invention. In particular, the disclosure describes porous inorganic / organic hybrid particles embedded with nanoparticles selected from oxides or nitrides of the following: silicon carbide, aluminum, diamond, cerium, carbon black, carbon nanotubes, zirconium, barium, cerium, cobalt, copper, europium, gadolinium, iron, nickel, samarium, silicon, silver, titanium, zinc, boron, and mixtures thereof.

Owner:WATERS TECH CORP

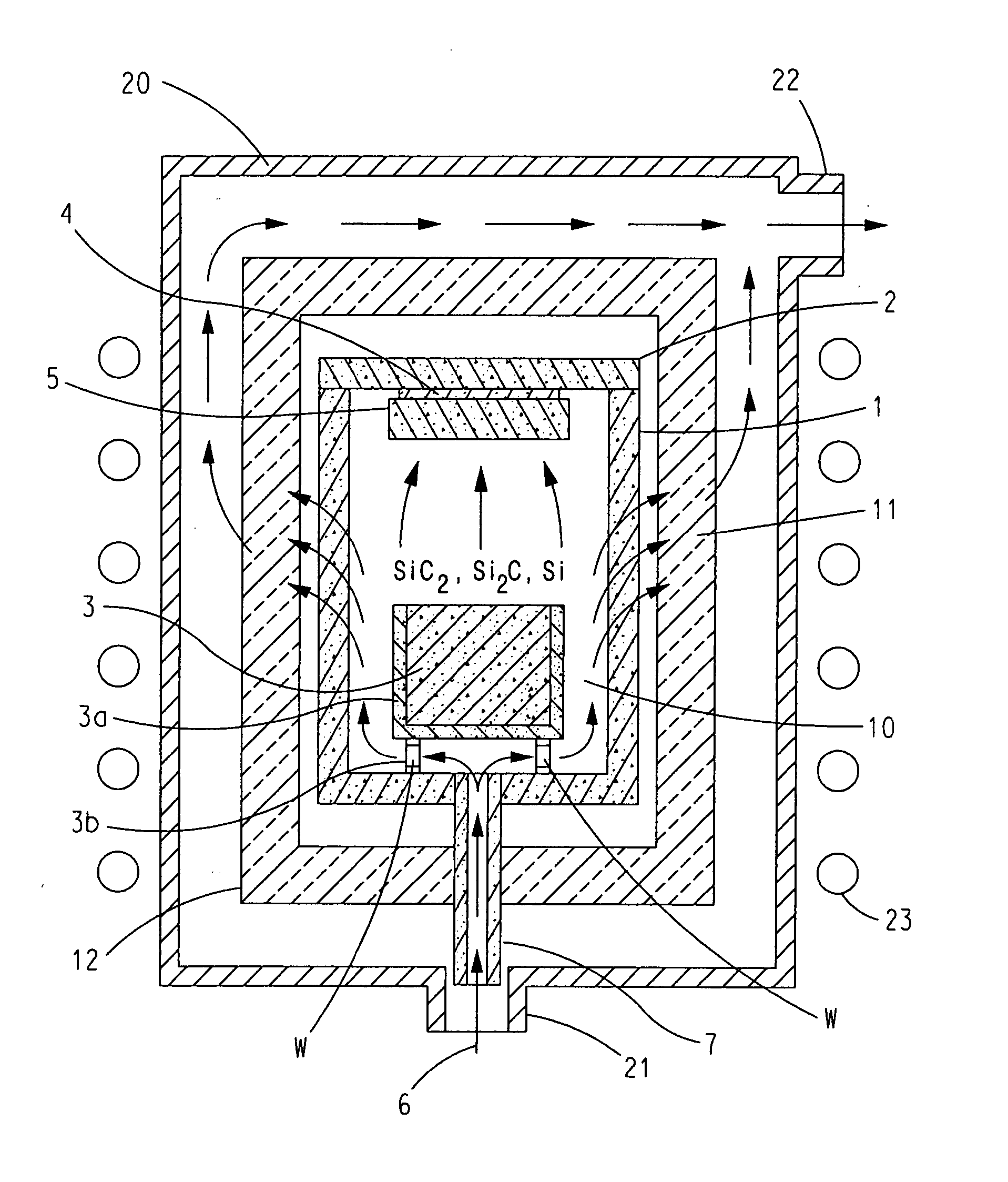

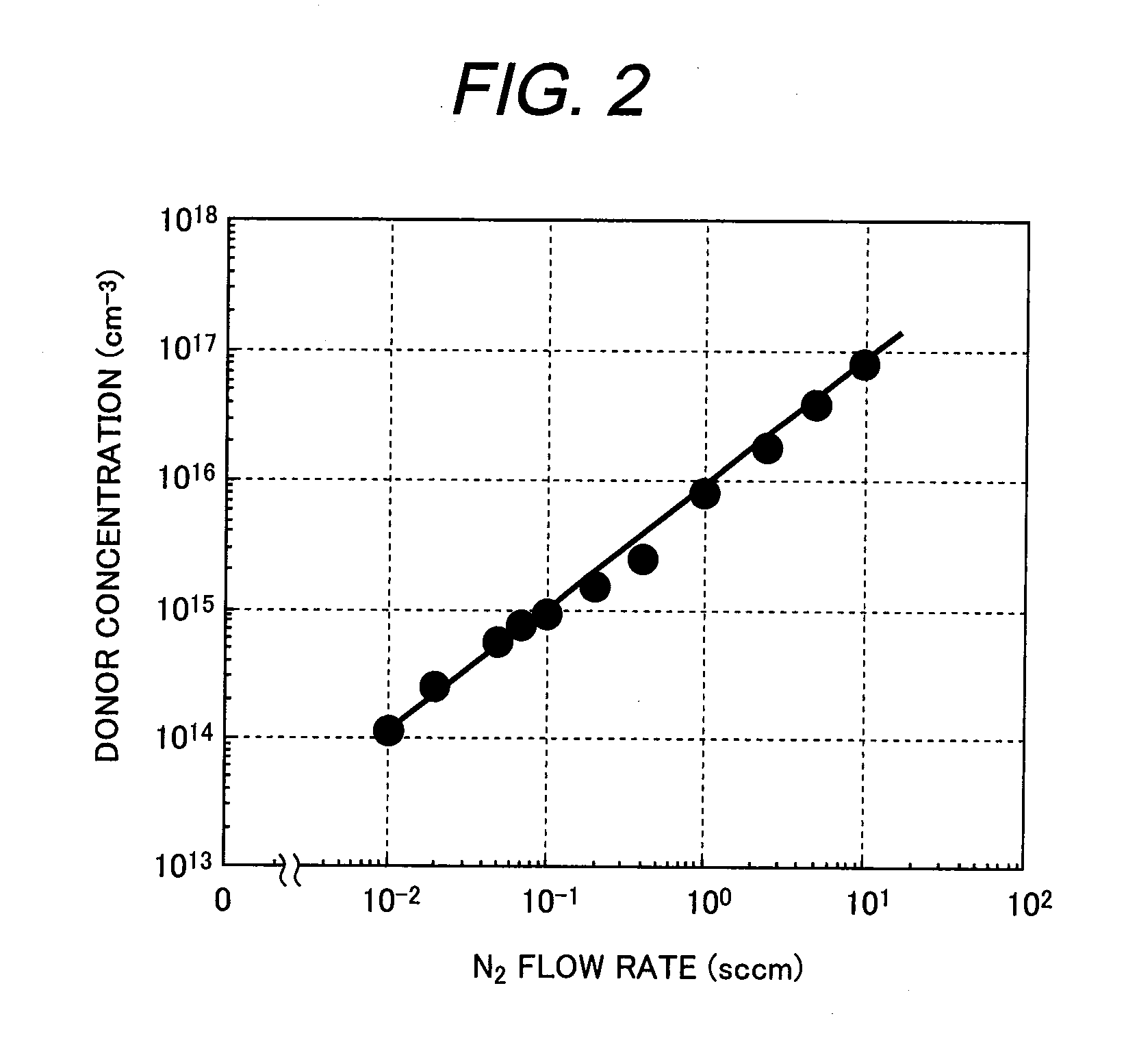

Silicon carbide single crystals with low boron content

ActiveUS20080072817A1Reduce lossesReduce chemical attackPolycrystalline material growthFrom chemically reactive gasesCarbide siliconSource material

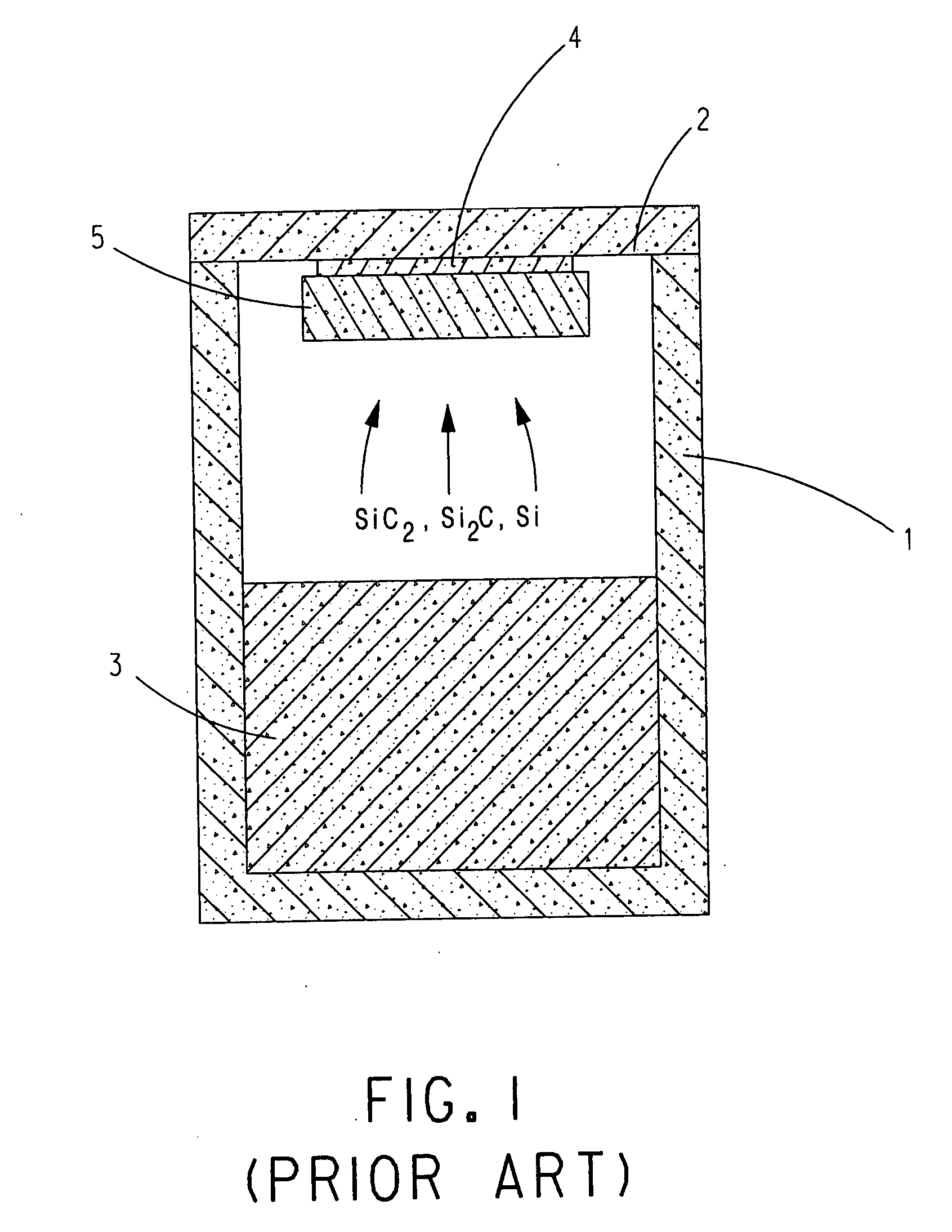

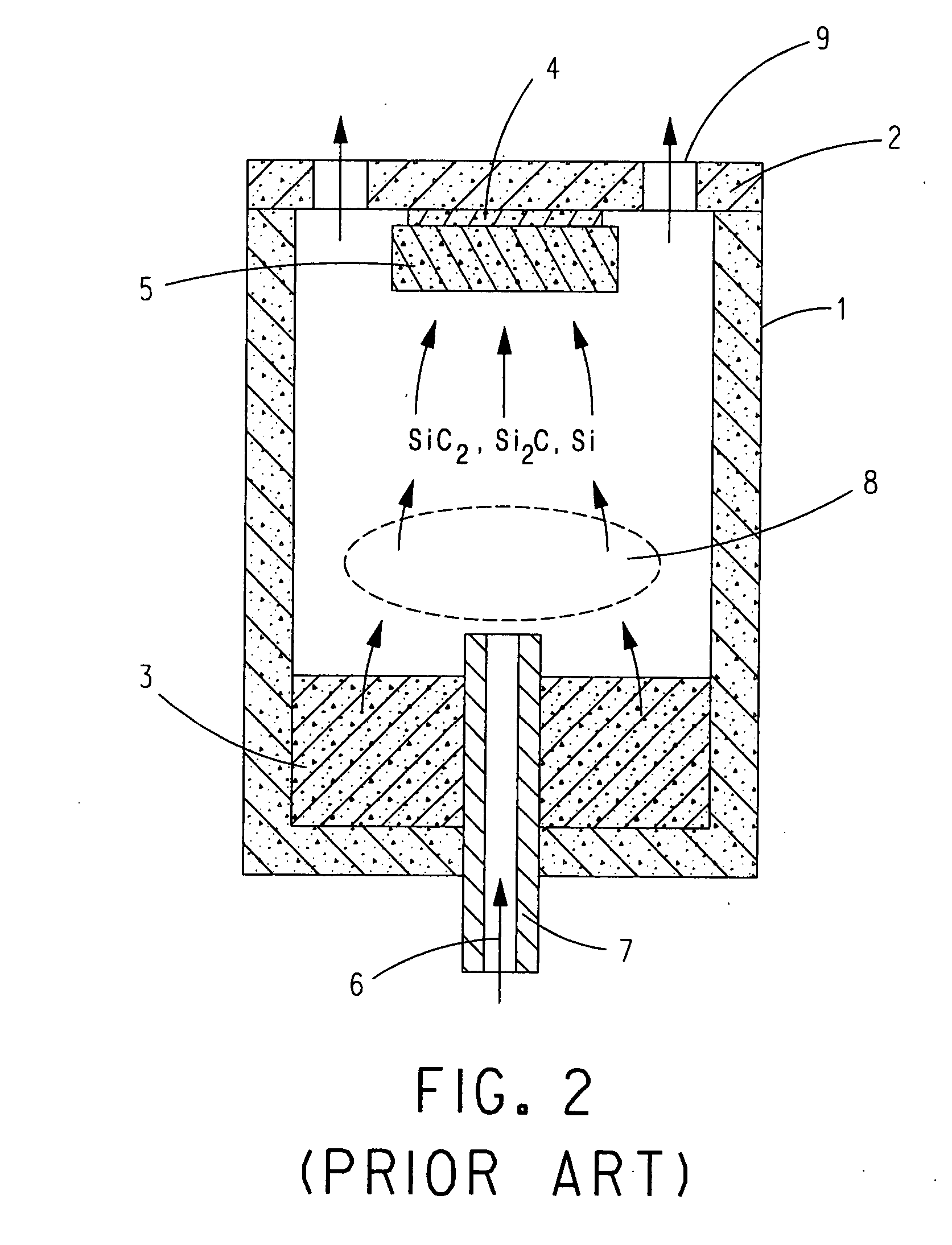

In a crystal growth method, an enclosed growth crucible is provided inside of a growth chamber. The growth crucible has polycrystalline source material and a seed crystal disposed in spaced relation therein. The interior of the growth crucible is heated whereupon a temperature gradient forms between the source material and the seed crystal. The temperature gradient is sufficient to cause the source material to sublimate and be transported to the seed crystal where it precipitates on the seed crystal. A gas mixture is caused to flow into the growth crucible and between the polycrystalline source material and an interior surface of the growth crucible. The gas mixture reacts with an unwanted element in the body of the growth crucible to form a gaseous byproduct which then flows through the body of the growth crucible to the exterior of the growth crucible.

Owner:II VI DELAWARE INC

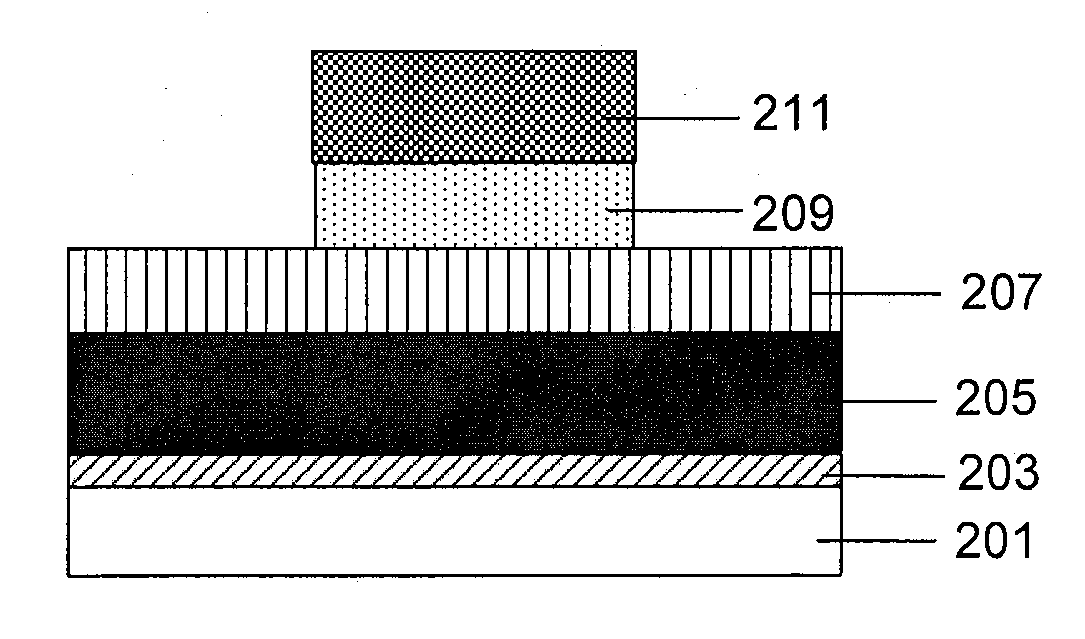

Silicon carbide semiconductor substrate and silicon carbide semiconductor device by using thereof

InactiveUS20090085044A1Reducing basal plane dislocation densityImprove conversion efficiencySemiconductor/solid-state device manufacturingSemiconductor devicesSingle crystalDislocation

A manufacturing method is provided for a silicon carbide semiconductor substrate adapted for reduced basal plane dislocations in a silicon carbide epitaxial layer. Between a silicon carbide epitaxial layer for device fabrication (i.e., a drift layer) and a base substrate formed of a silicon carbide single-crystal wafer, a highly efficient dislocation conversion layer through which any basal plane dislocations in the silicon carbide single-crystal wafer are converted into threading edge dislocations very efficiently when the dislocations propagate into the layer epitaxially grown is provided by epitaxial growth. Assigning to the dislocation conversion layer a donor concentration lower than that of the drift layer, therefore, allows the above conversion of a larger number of basal plane dislocations than the case where the drift layer exists alone (without the dislocation conversion layer).

Owner:HITACHI CABLE

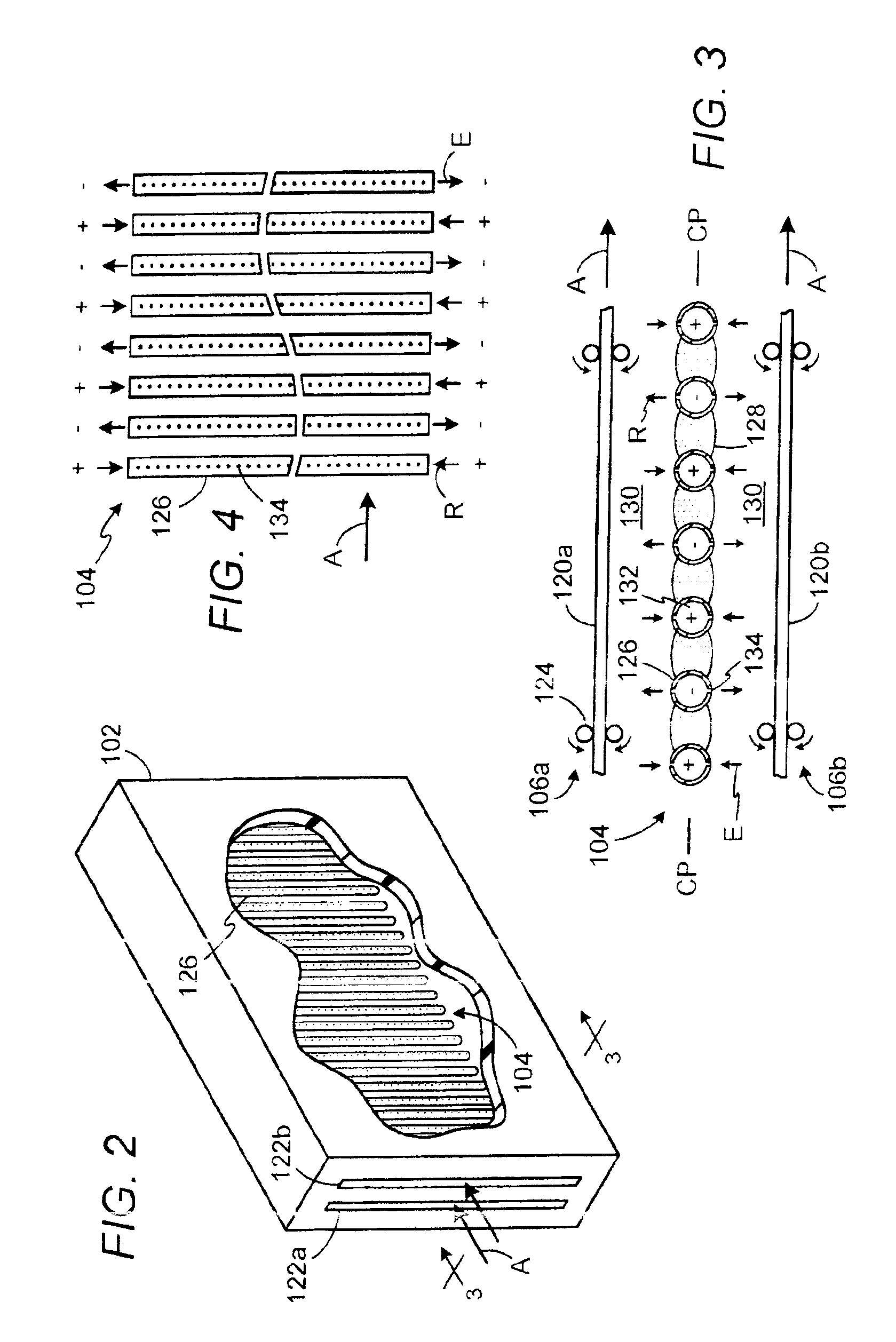

Hardmask materials

ActiveUS20110135557A1Poor pattern alignmentReduce stressLiquid surface applicatorsElectric discharge tubesMaterials sciencePost treatment

Hardmask films having high hardness and low stress are provided. In some embodiments a film has a stress of between about −600 MPa and 600 MPa and hardness of at least about 12 GPa. In some embodiments, a hardmask film is prepared by depositing multiple sub-layers of doped or undoped silicon carbide using multiple densifying plasma post-treatments in a PECVD process chamber. In some embodiments, a hardmask film includes a high-hardness boron-containing film selected from the group consisting of SixByCz, SixByNz, SixByCzNw, BxCy, and BxNy. In some embodiments, a hardmask film includes a germanium-rich GeNx material comprising at least about 60 atomic % of germanium. These hardmasks can be used in a number of back-end and front-end processing schemes in integrated circuit fabrication.

Owner:NOVELLUS SYSTEMS

Recovery processing method of silicon slice cut waste mortar

The invention relates to a recovery processing method of silicon slice cut waste mortar, comprising the following steps: (1) separating solid-liquid components in the silicon slice cut waste mortar; (2) further recovering the remained cutting liquid component in a solid; (3) separating silicon powder and silicon carbide through water flow flotation; (4) recovering the silicon powder; (5) recovering the silicon carbide; (6) coarsely filtering, finely filtering, decoloring, vacuum distilling and dehydrating the recovered cutting liquid, and adding component with corresponding amount for secondary filter. The method can get various recovered products, such as silicon carbide micro powder, cutting liquid and silicon powder, has high recovery rate and recovery profit and can save the cost of the mortar by at least 40 percent; meanwhile, the invention effectively solves the problem of possible secondary pollution caused by single recovery; the cutting function of recovered and treated silicon carbide micro powder is recovered again, thereby changing waste into wealth, realizing the resource reutilization in true sense, and promoting the development of recycling economy; and the method basically realizes the zero emission of waste liquid by reutilizing the treated waste water after combining a sewage treatment process, thereby being beneficial to environment protection.

Owner:HENAN XINDAXIN SCI & TECH

Ceramic-rich composite armor, and methods for making same

InactiveUS7104177B1Reduce manufacturing costHighly dimensionally accurate shaped articleCeramic layered productsArmour platesReaction bonded silicon carbideGrain growth

Silicon infiltration technology, e.g., siliconizing or reaction-bonding, is used to produce ceramic-rich composite bodies having utility as ballistic armor. In the main embodiment of the invention, the ballistic armor includes a reaction-bonded silicon carbide body (RBSC). Good ballistic performance can be advanced by loading the porous mass or preform to be infiltrated to a high degree with one or more hard fillers, and by limiting the size of the morphological features making up the composite body. This control of “grain size” can be accomplished by controlling the size of the largest particles making up the porous mass to be infiltrated, but also of importance is controlling the processing conditions, particularly by controlling the factors that cause grain growth, coarsening of microstructure, and / or grain coalescence.

Owner:II VI DELAWARE INC

High-temperature (800 DEG C) wear-resistant paint and preparation method thereof

The invention discloses high-temperature (800 DEG C) wear-resistant paint and a preparation method thereof. The high-temperature wear-resistant paint comprises a component 1 and a component 2, wherein the component 1 is prepared by mixing a component A and a component B; the component A in the component 1 comprises the following components: black silicon carbide, fine-grain aluminum oxide, dispersing agent, zinc oxide, modified epoxy resin, flatting agent and an auxiliary material; the component B in the component 1 comprises the following components: organic silicon modified epoxy resin, a filler, antimony trioxide, film-forming assistant and thickener; and the component 2 is curing agent and coupling agent. The high-temperature (800 DEG C) wear-resistant paint is prepared by the following steps: mixing the component A and the component B in the component 1, and curing the component 1 with the component 2. The high-temperature wear-resistant paint is prepared by compounding the double components, has excellent high temperature resistance and wear resistance, and also has the fine properties of favorable hardness, high heat stability, ductility, workability and the like. The invention also designs the method for preparing the high-temperature wear-resistant paint. The preparation method is simple and low in cost.

Owner:JIANGSU XIN AN NEW MATERIALS TECH

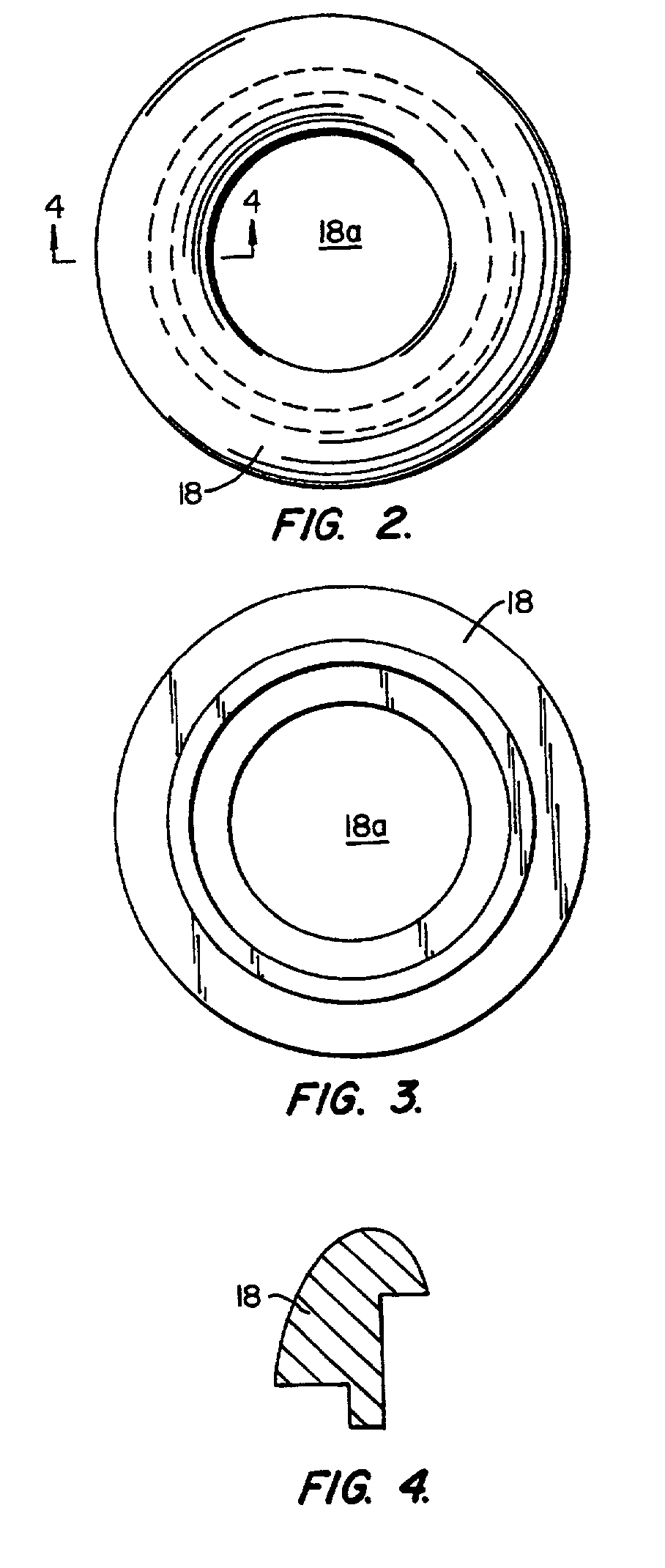

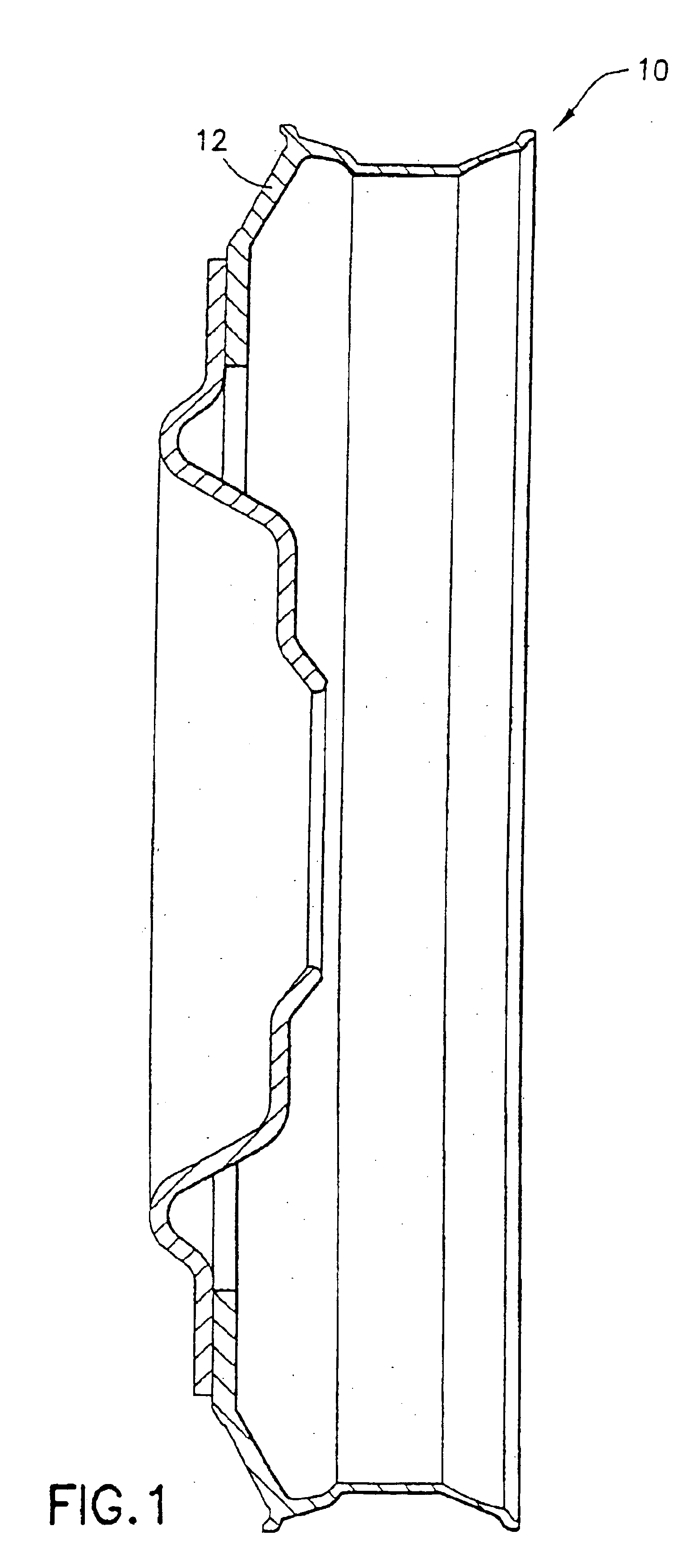

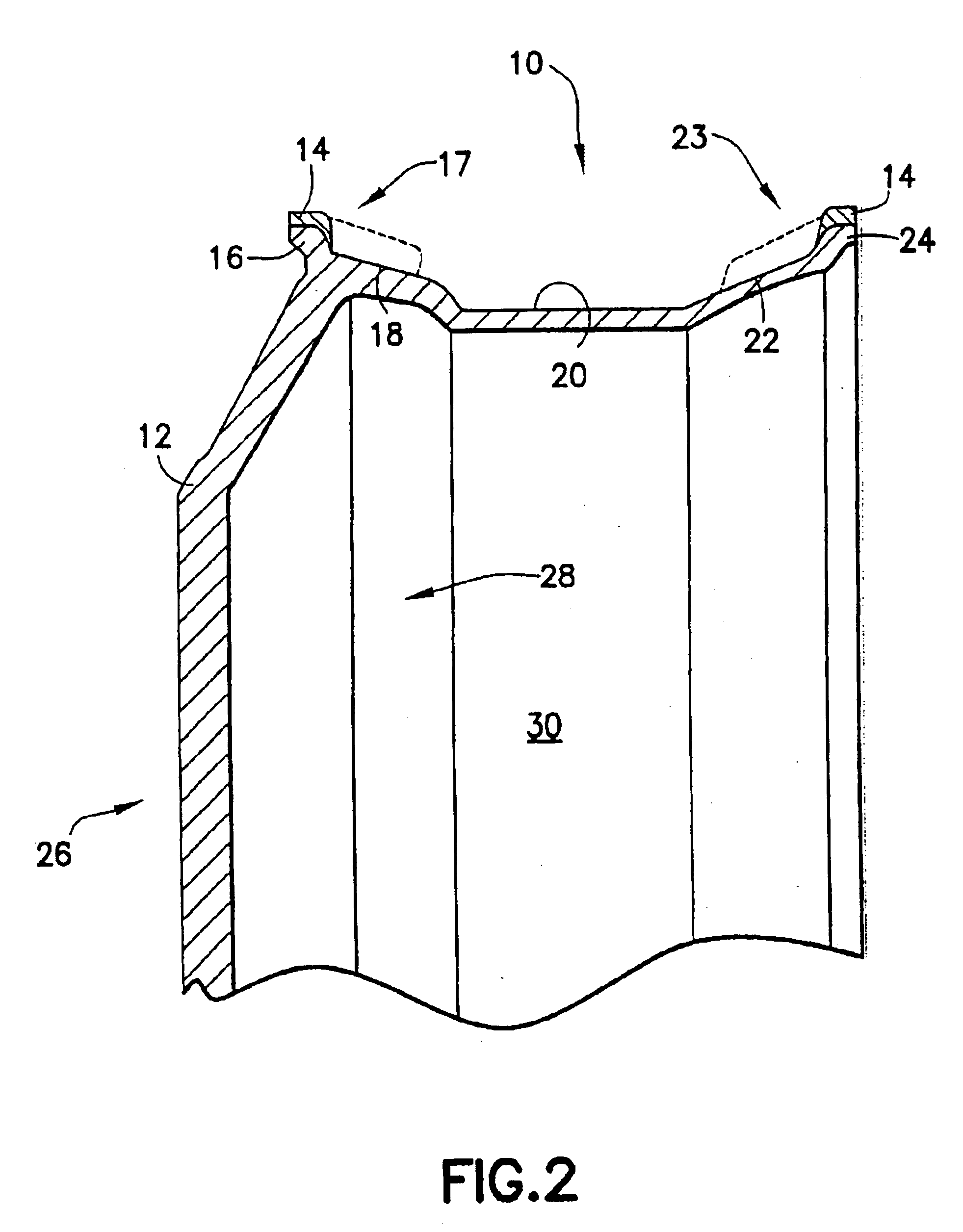

Coated vehicle wheel and method

InactiveUS6872425B2Improve wear conditionsIncrease resistanceMolten spray coatingRimsTire beadThermal spraying

A method of coating a vehicle wheel to increase wear and corrosion resistance of the vehicle wheel, includes the steps of providing a vehicle wheel and applying a wear and corrosion resistant coating onto a surface of the vehicle wheel. The coating is applied to at least a tire bead retaining flange of the vehicle wheel. The coating is of particular use with vehicle wheels made of forged aluminum. The coating is selected from tungsten carbide, optionally including cobalt or chrome, a nickel-based superalloy, aluminum and silicon carbide, or stainless steel.The coating is typically applied to a thickness of about 0.004-0.01 inch. The surface of the vehicle wheel may be prepared by mechanically abrading the surface or chemically etching the surface of the vehicle wheel. The coating may be applied by cold spraying, thermal spraying, or triboelectric discharge kinetic spraying and other similar processes.

Owner:ARCONIC INC

Method for preparing environment-friendly water permeable bricks by using iron tailings

InactiveCN103204698AImprove performanceSimple production processCeramicwareCarbide siliconCompressive resistance

The invention discloses a method for preparing environment-friendly water permeable bricks by using iron tailings, belonging to the field of comprehensive utilization of iron tailing resources and construction ceramic materials. The method is characterized in that through taking iron tailings as basic aggregates and introducing a certain amount of waste broken glass, an environment-friendly water permeable brick with excellent performance is prepared. The method comprises the following process steps of raw material crushing, ball milling, material dispensing, mixing, drying, molding, sintering, cutting and grinding. The dispensed material comprises the following ingredients in percentage by weight: 30-60% of iron tailings powder, 5-15% waste glass powder, 15-30% of clay, 15-24% of quartz, 5-15% of potash feldspar, and 0.25-1.5% of silicon carbide. The prepared water permeable brick is high in compressive strength, good in abrasion resistance and excellent in water permeability, and accords with national related standards of water permeable bricks, therefore, the method creates a new way for the high-technology and high value-added application of iron tailing resources.

Owner:UNIV OF SCI & TECH BEIJING +2

Fluidic capillary chip for regulating drug flow rates of infusion pumps

InactiveUS20090326517A1Avoid erosionValve arrangementsSynthetic resin layered productsDrugs solutionInfusion pump

An erosion-resistant capillary chip for use with in an infusion pump that is made from a silicon substrate having a first surface that includes a micro groove etched therein and a glass plate laminated to the first surface. The glass plate covers the micro groove so that a micro fluid conduit is created. The glass plate includes an inlet bore that connects with the micro fluid conduit and the silicon substrate includes an outlet bore that connects with the micro fluid conduit so that a drug solution entering the inlet bore from the infusion pump may pass through the micro fluid conduit at a restricted flow rate to the outlet bore and thereafter to a target site of a patient. The micro groove includes a passivation layer made from silicon nitride or silicon carbide that protects the micro groove against erosion from passing fluids having high basic or high acidic pH levels. A method for making the capillary chip is disclosed, as well as an infusion pump incorporating the improved capillary chip.

Owner:CODMAN NEURO SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com