Patents

Literature

1224 results about "Pyrolytic carbon" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pyrolytic carbon is a material similar to graphite, but with some covalent bonding between its graphene sheets as a result of imperfections in its production. Pyrolytic carbon is man-made and is not thought to be found in nature. Generally it is produced by heating a hydrocarbon nearly to its decomposition temperature, and permitting the graphite to crystallise (pyrolysis). One method is to heat synthetic fibers in a vacuum. Another method is to place seeds on a plate in the very hot gas to collect the graphite coating. It is used in high temperature applications such as missile nose cones, rocket motors, heat shields, laboratory furnaces, in graphite-reinforced plastic, coating nuclear fuel particles, and in biomedical prostheses.

High Capacity Anode Materials for Lithium Ion Batteries

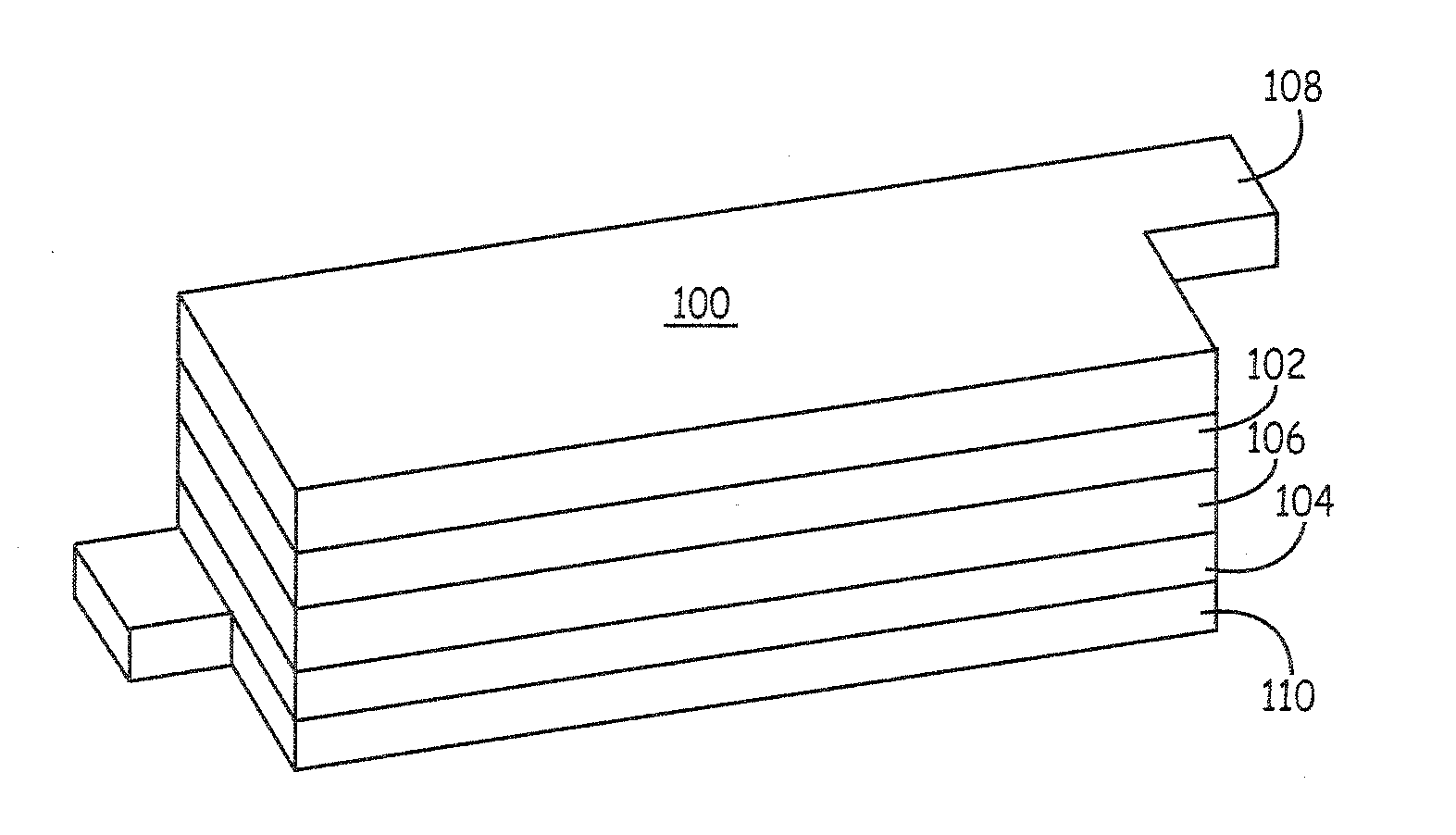

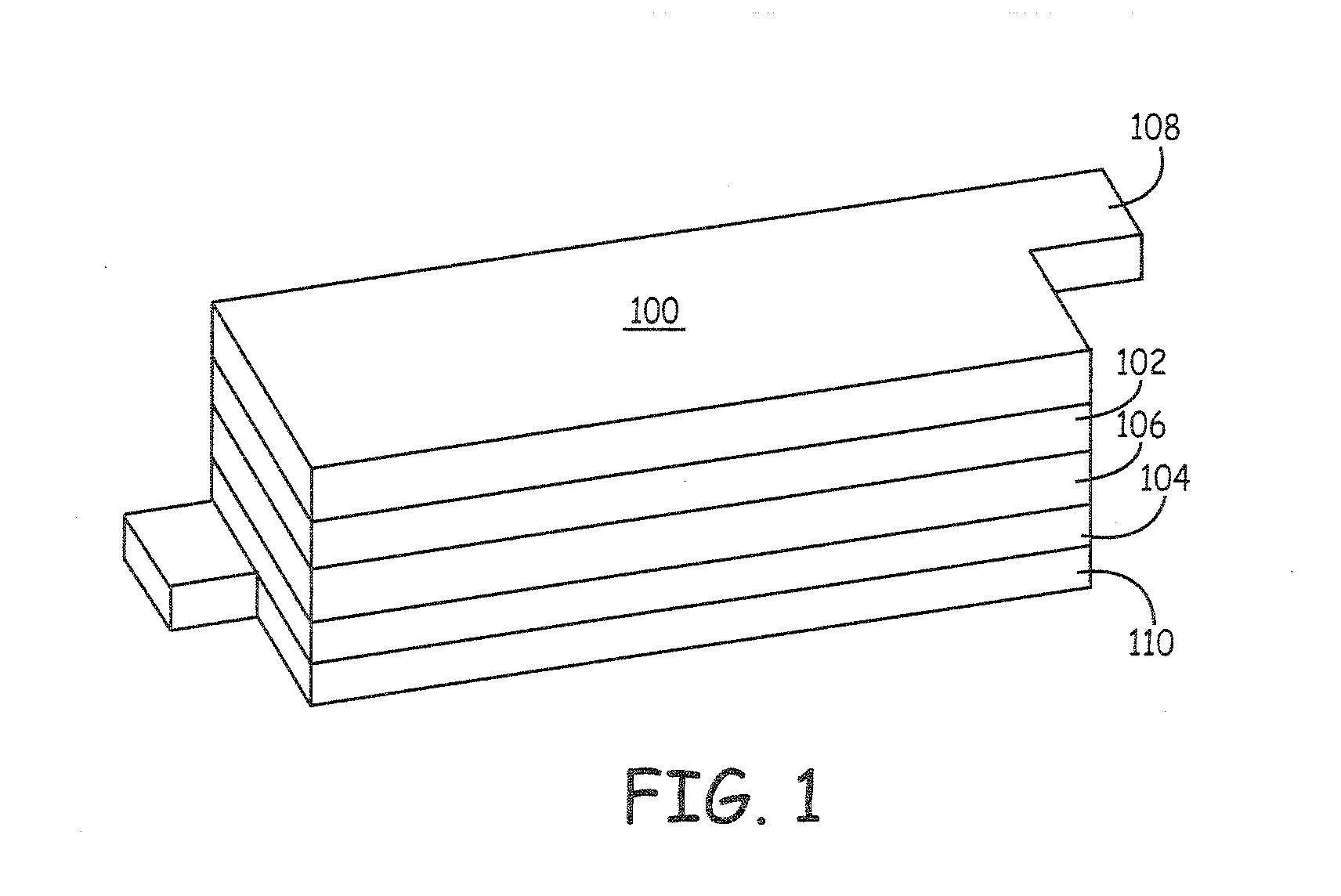

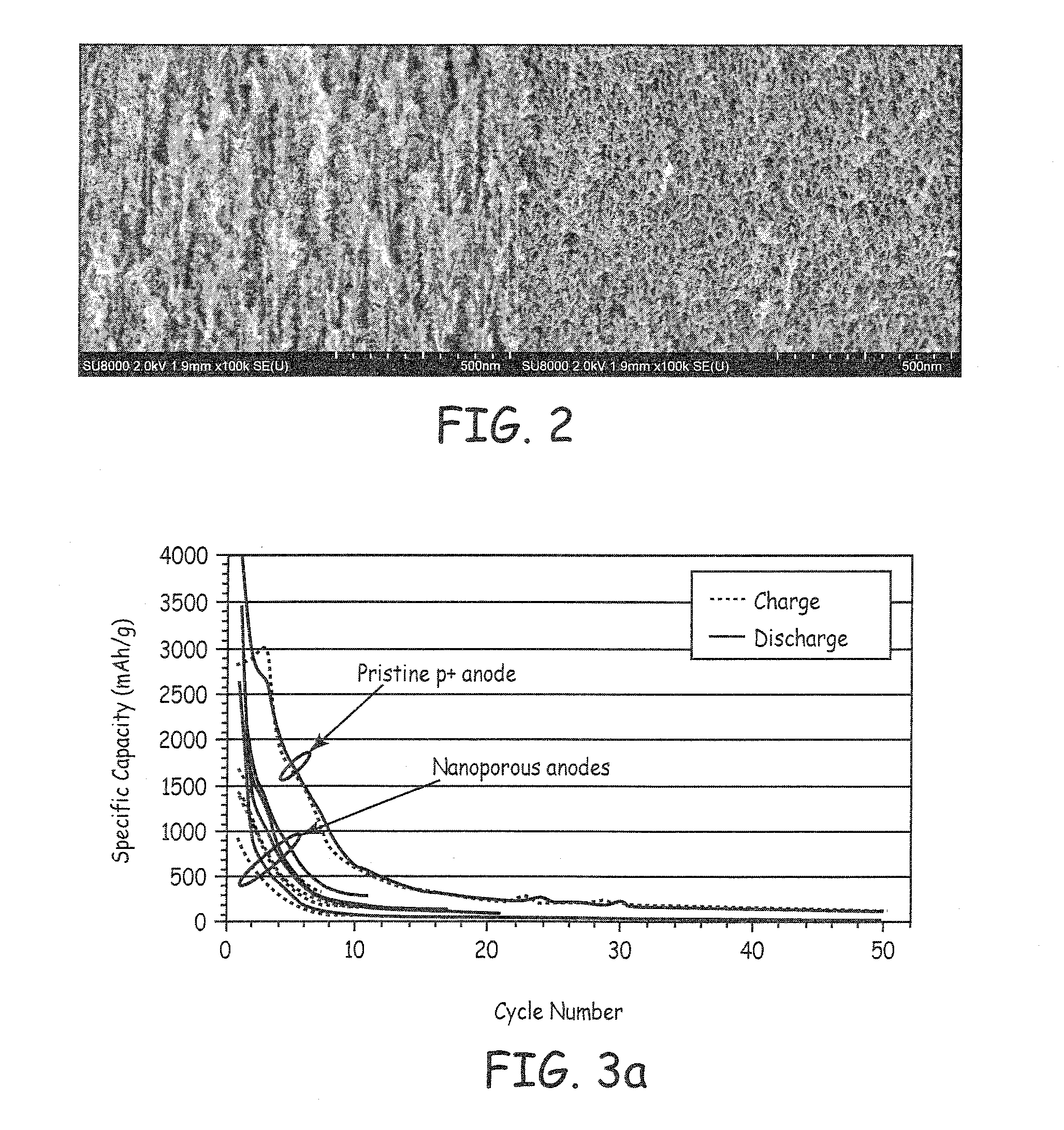

High capacity silicon based anode active materials are described for lithium ion batteries. These materials are shown to be effective in combination with high capacity lithium rich cathode active materials. Supplemental lithium is shown to improve the cycling performance and reduce irreversible capacity loss for at least certain silicon based active materials. In particular silicon based active materials can be formed in composites with electrically conductive coatings, such as pyrolytic carbon coatings or metal coatings, and composites can also be formed with other electrically conductive carbon components, such as carbon nanofibers and carbon nanoparticles. Additional alloys with silicon are explored.

Owner:IONBLOX INC

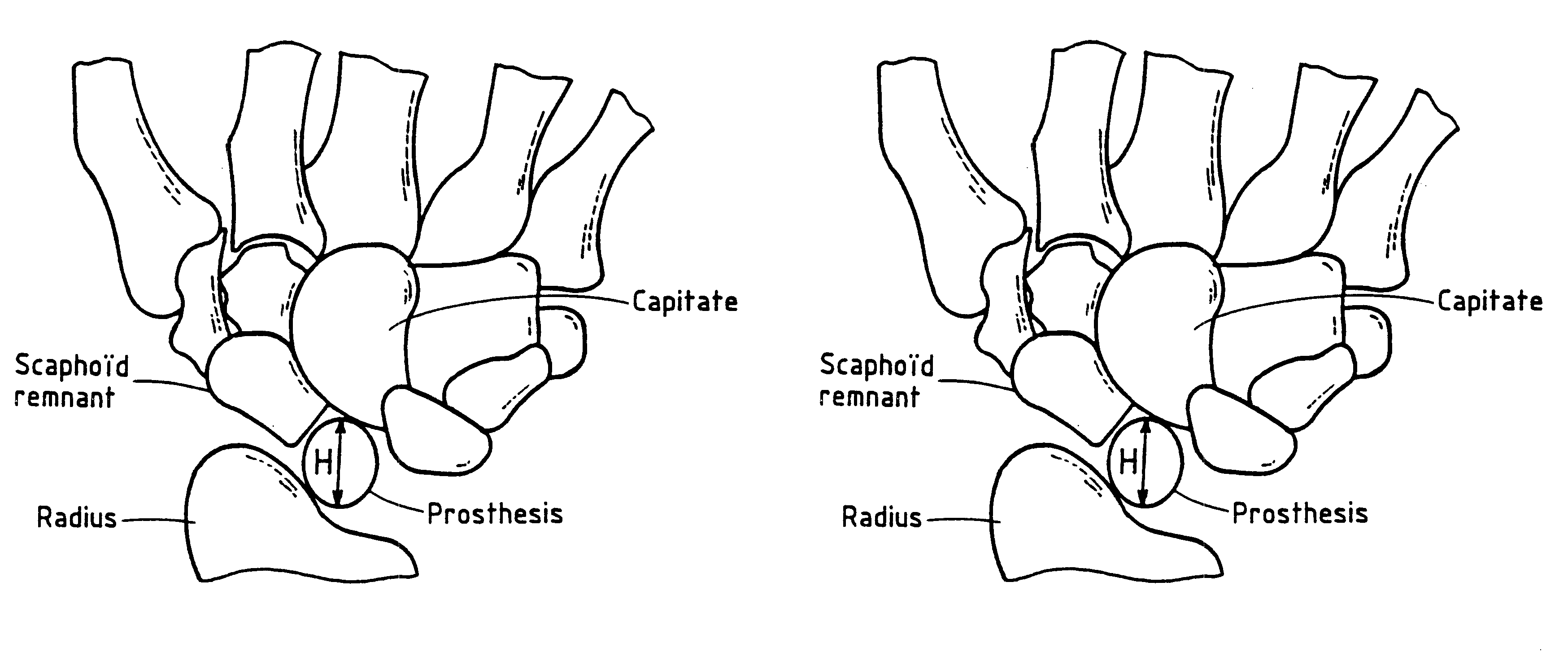

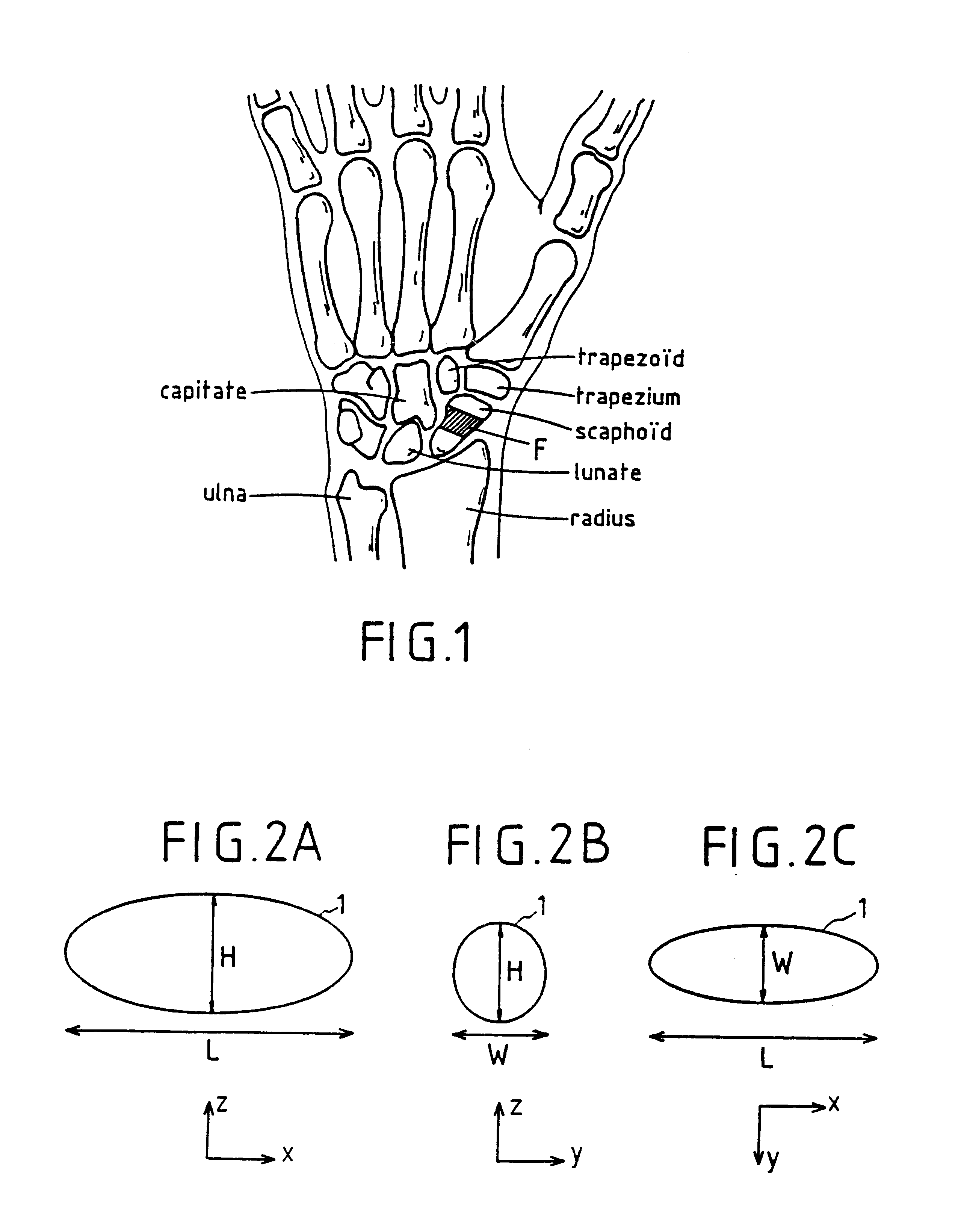

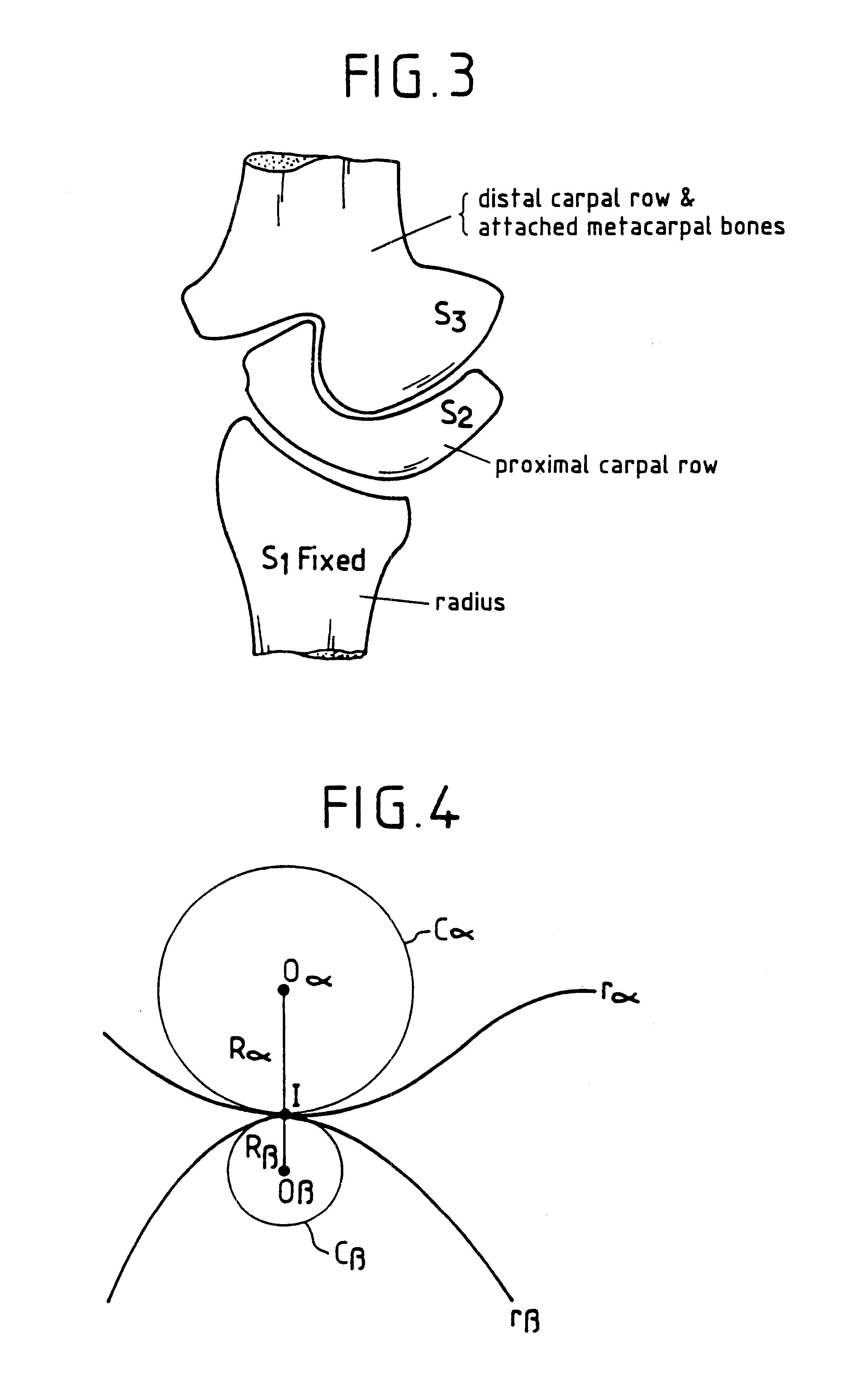

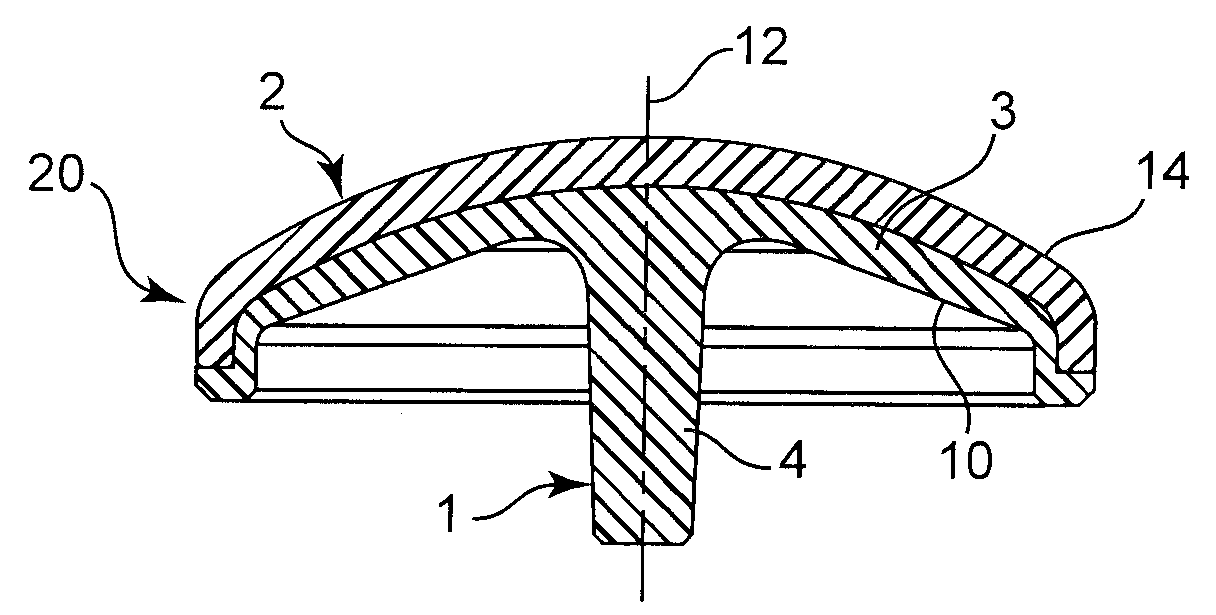

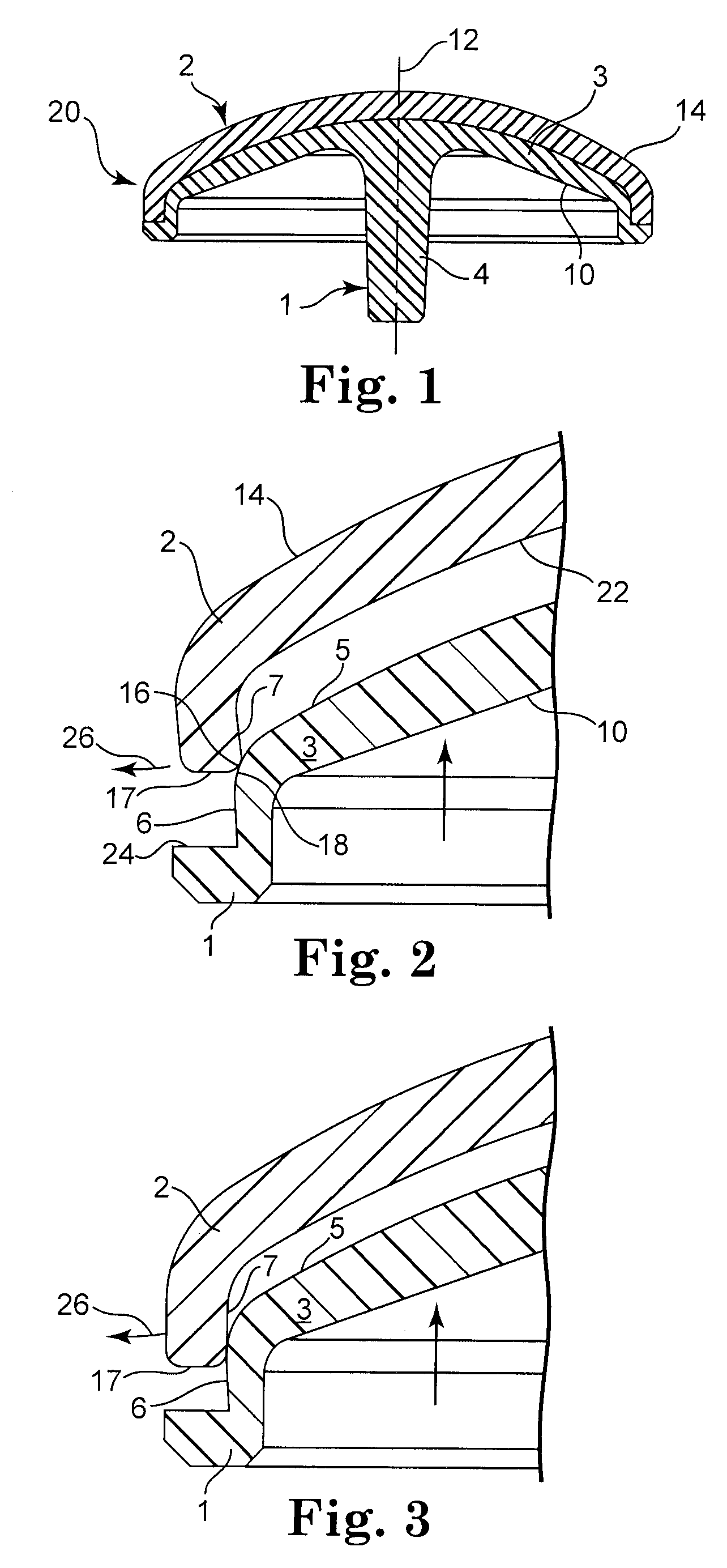

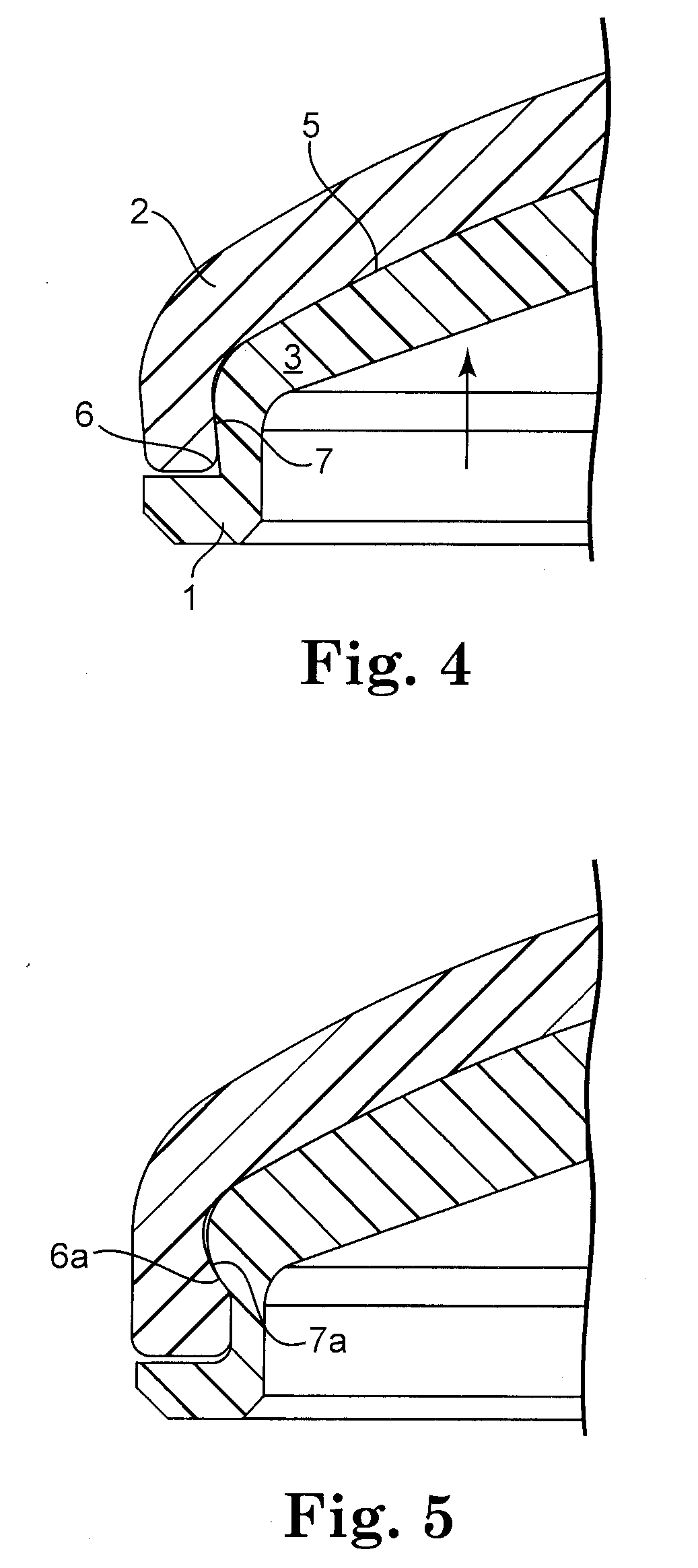

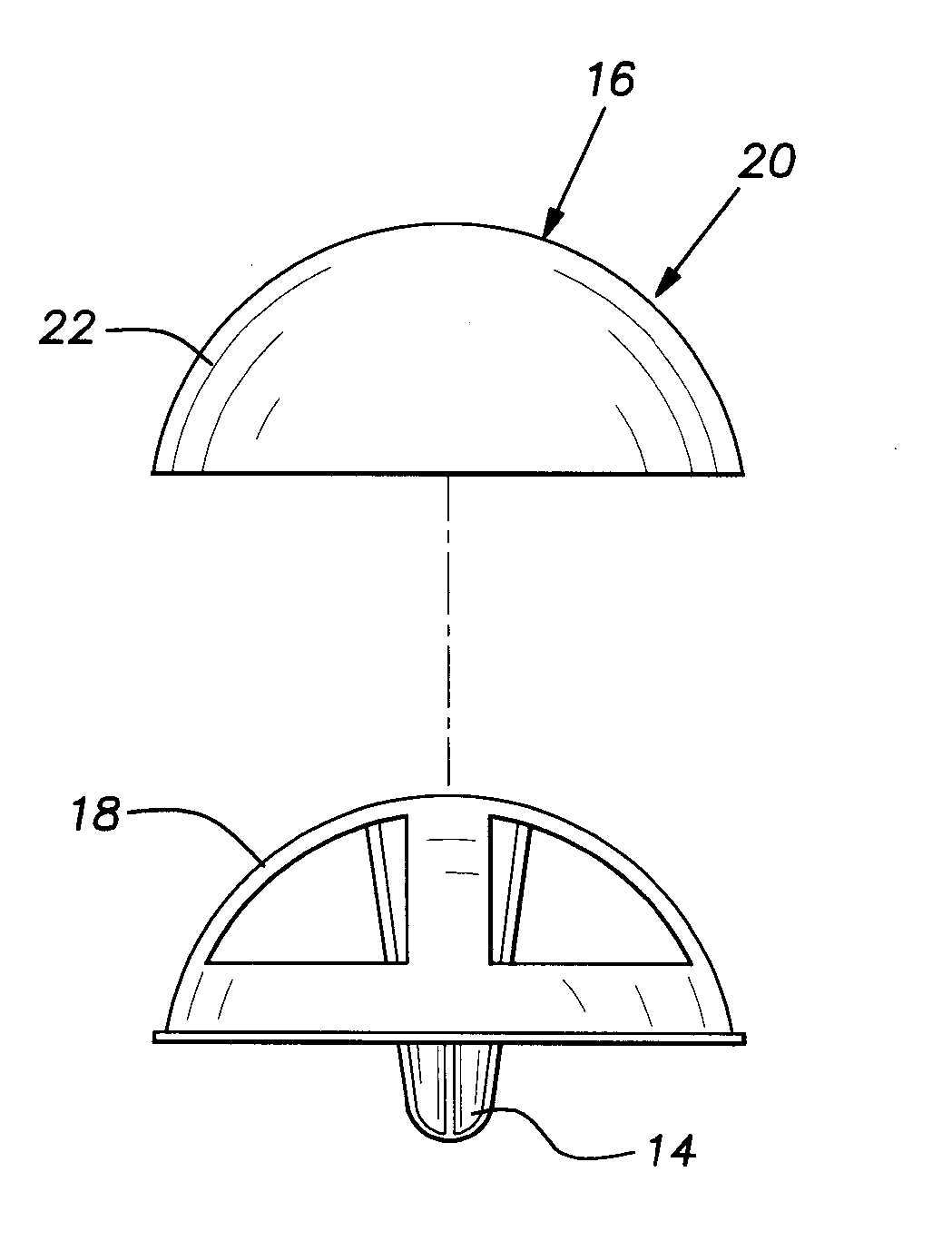

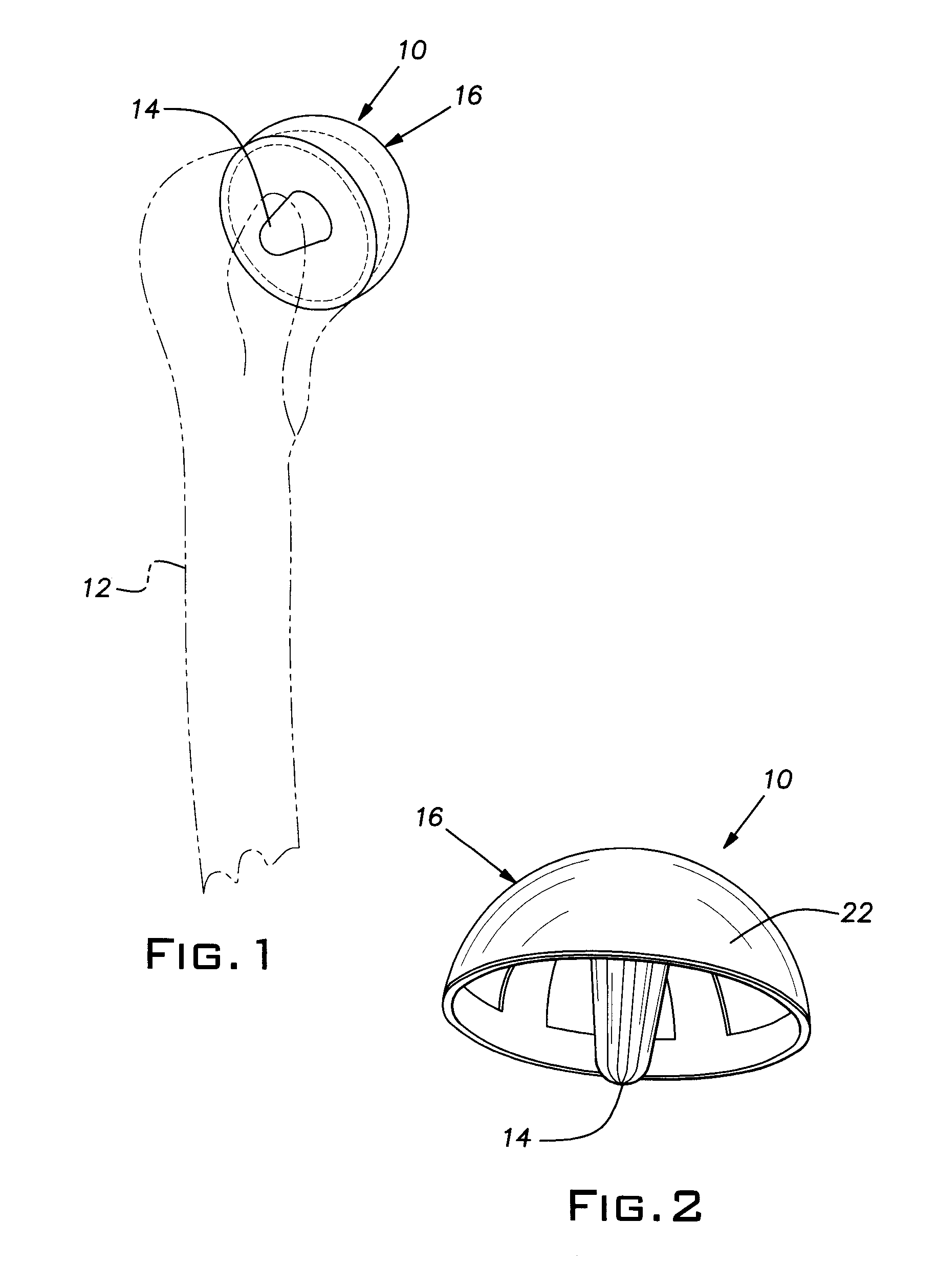

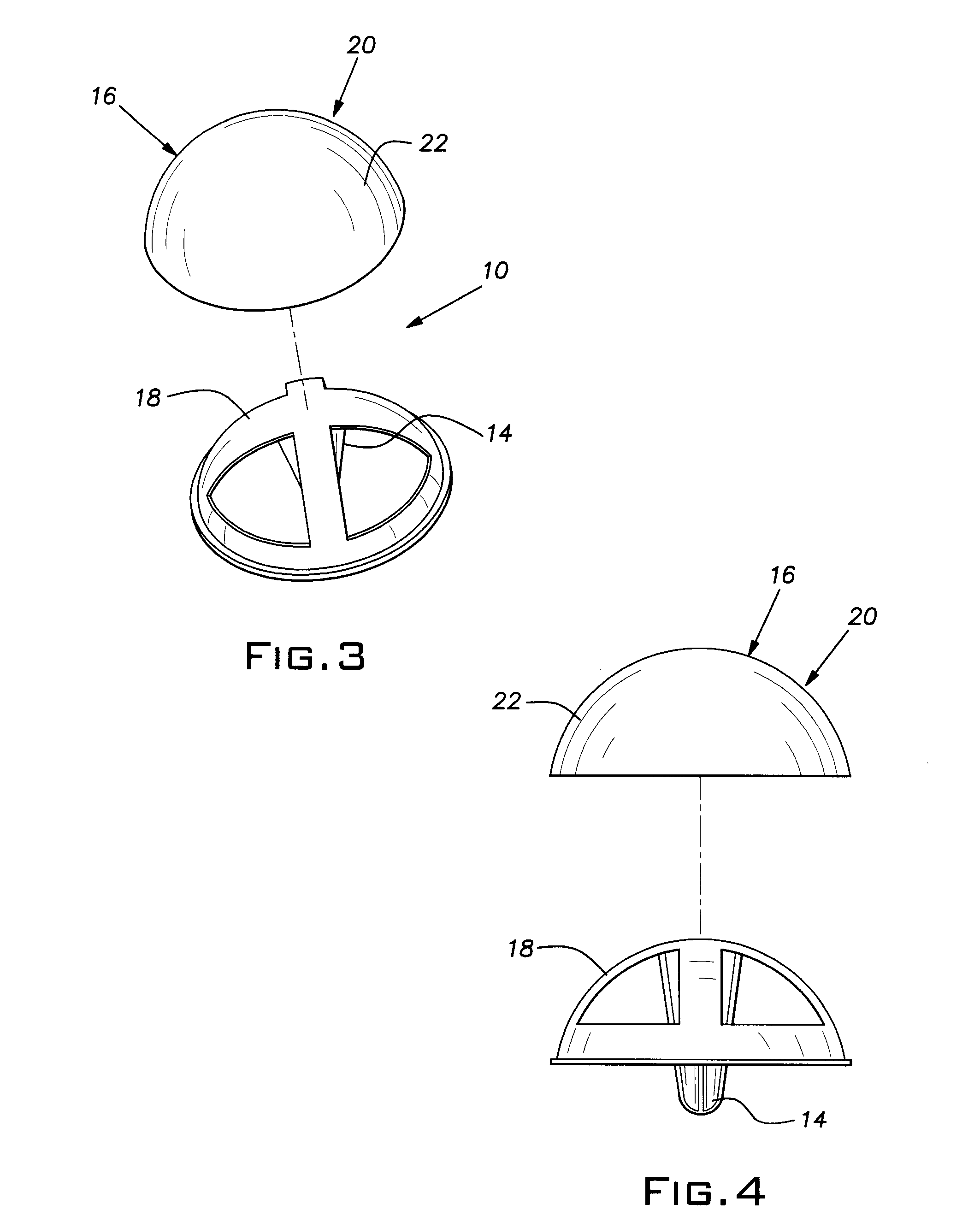

Implant for treating ailments of a joint or a bone

InactiveUS6436146B1Increase coefficient of frictionImprove stabilityFinger jointsWrist jointsDiseasePyrolytic carbon

The implant has at least one contact surface portion, made of pyrolytic carbon, designed to be in mobile contact with at least one bony surface when the implant is implanted in a patient. Furthermore, the implant is free from any attaching means, so that it remains free with respect to the at least one bony surface when implanted in the patient.

Owner:TORNIER SA SAINT ISMIER

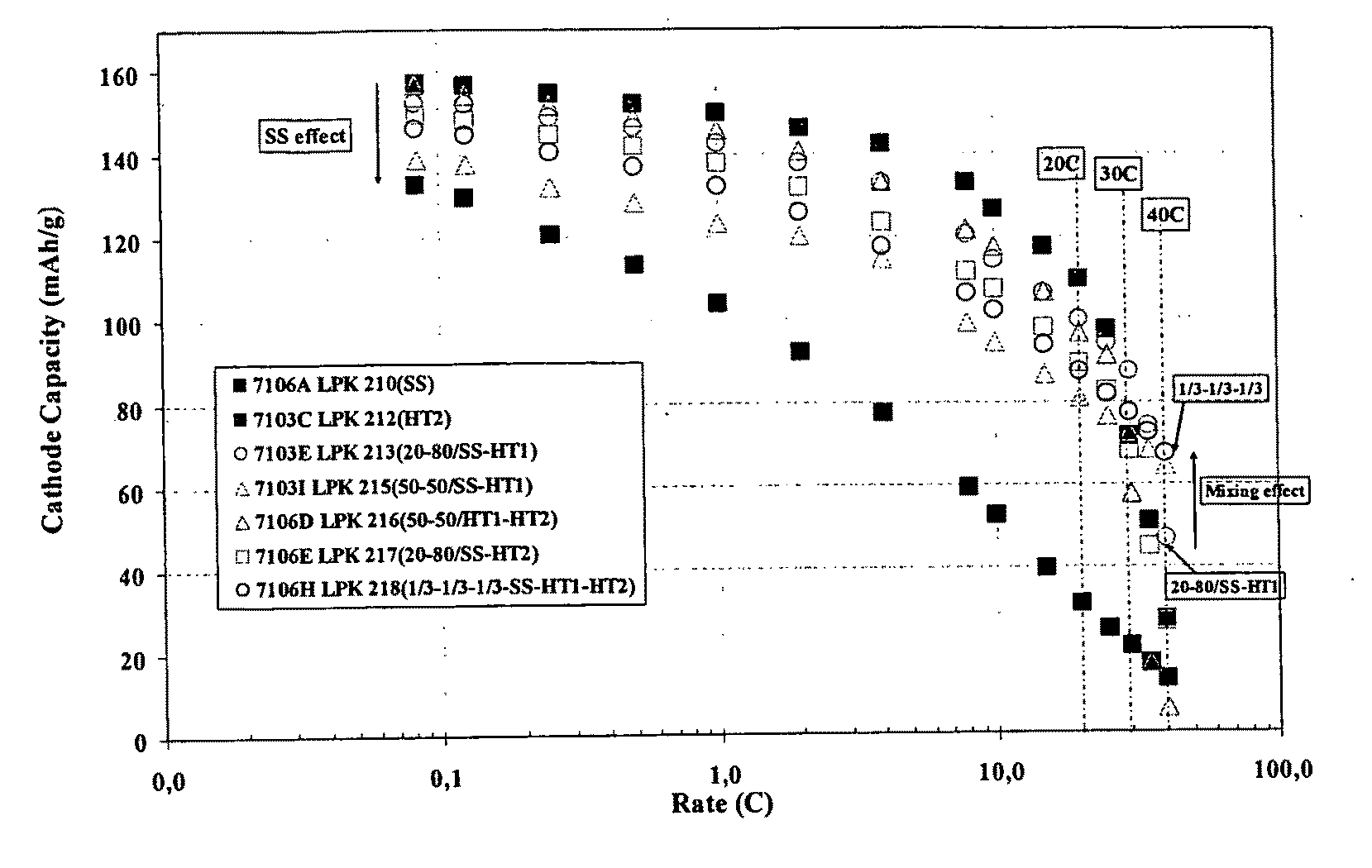

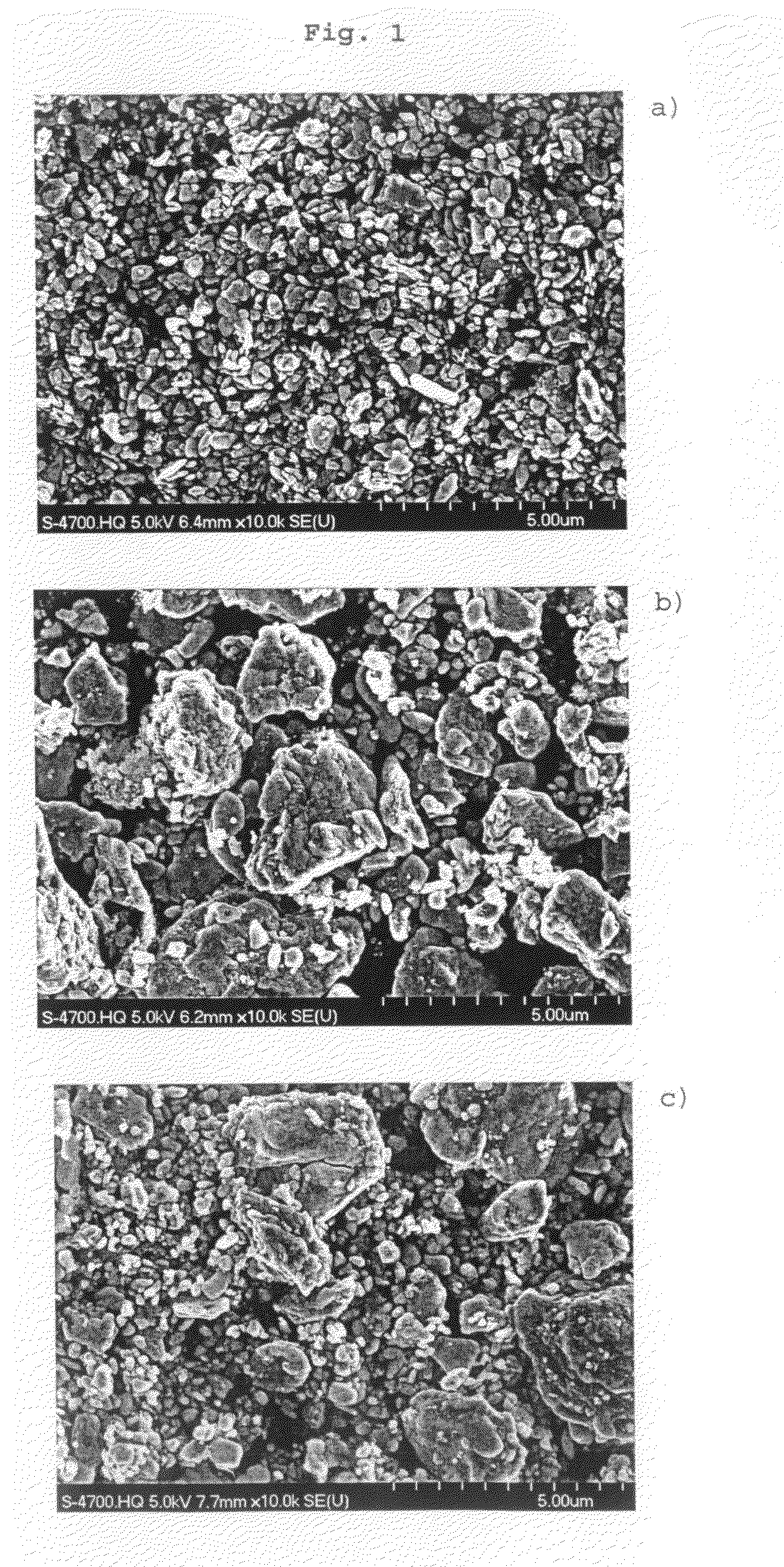

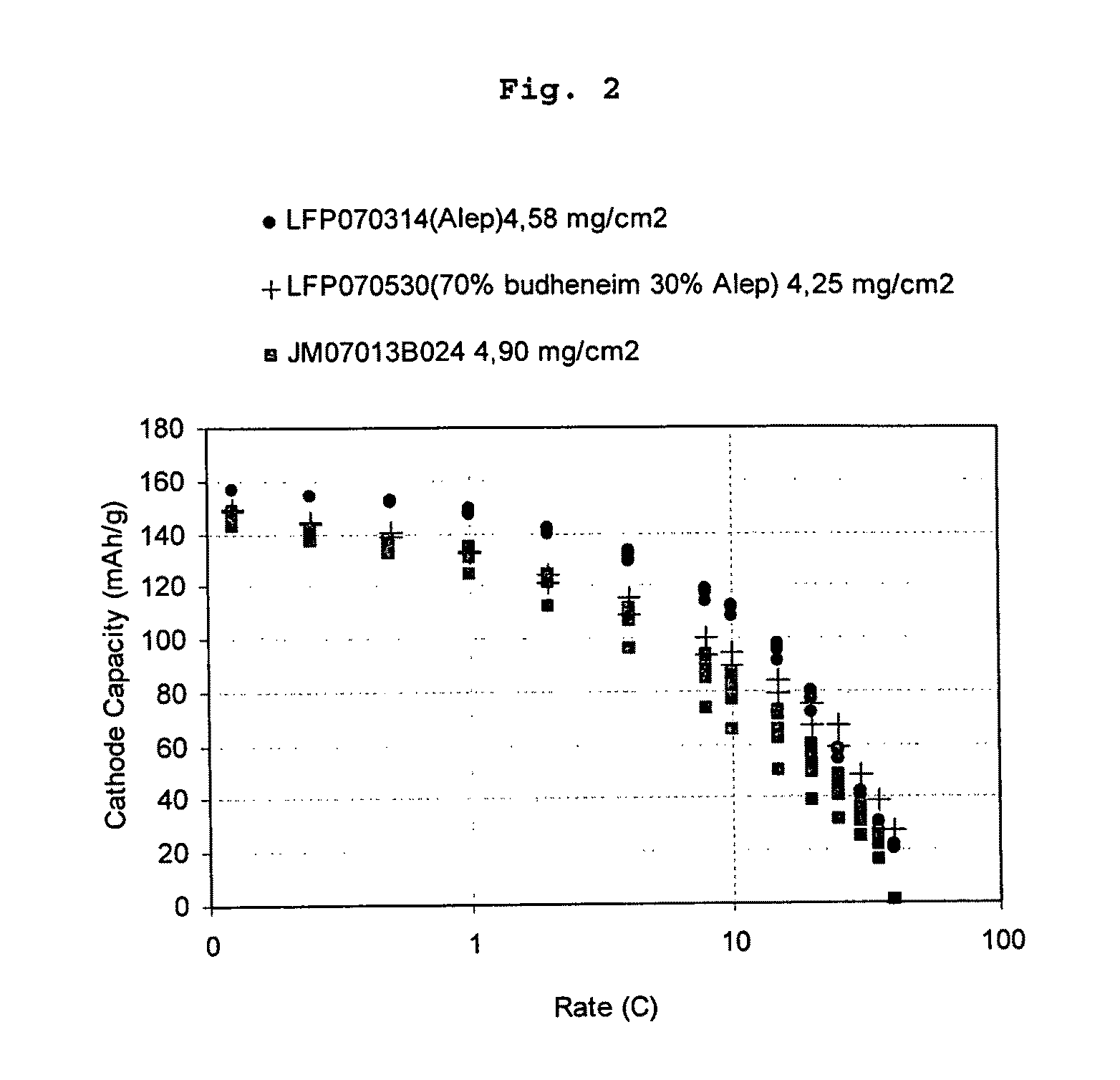

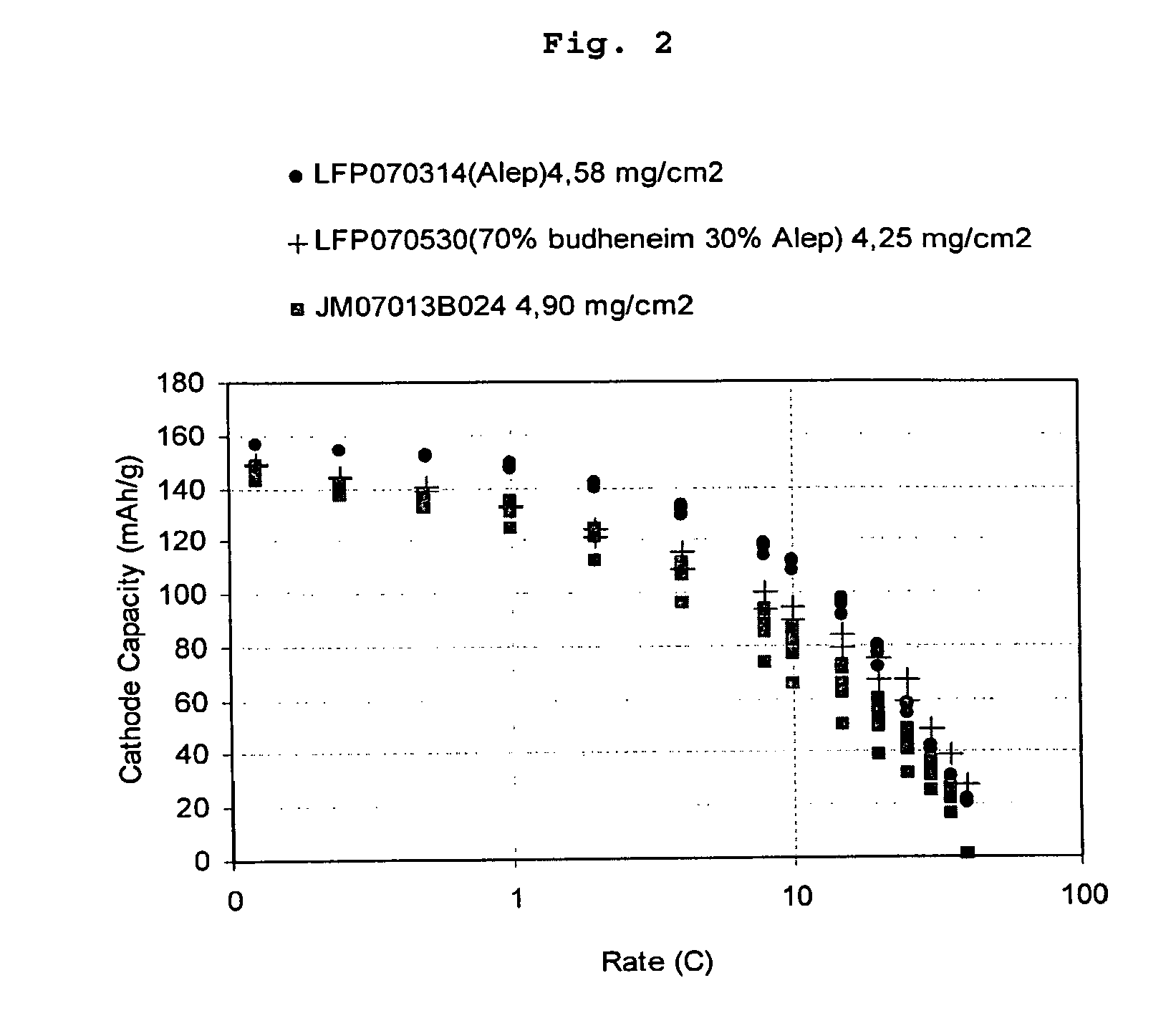

Lithium iron phosphate cathode materials with enhanced energy density and power performance

InactiveUS20090155689A1Powerful performanceHigh discharge ratePhosphatesPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesFiberPhosphate

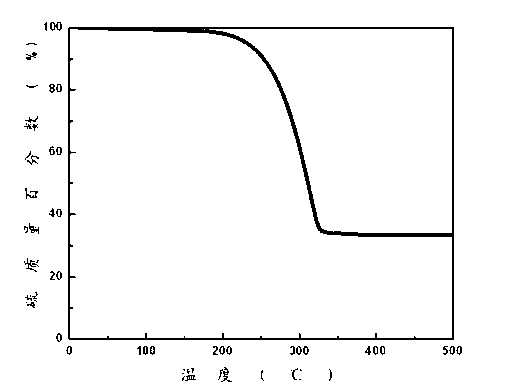

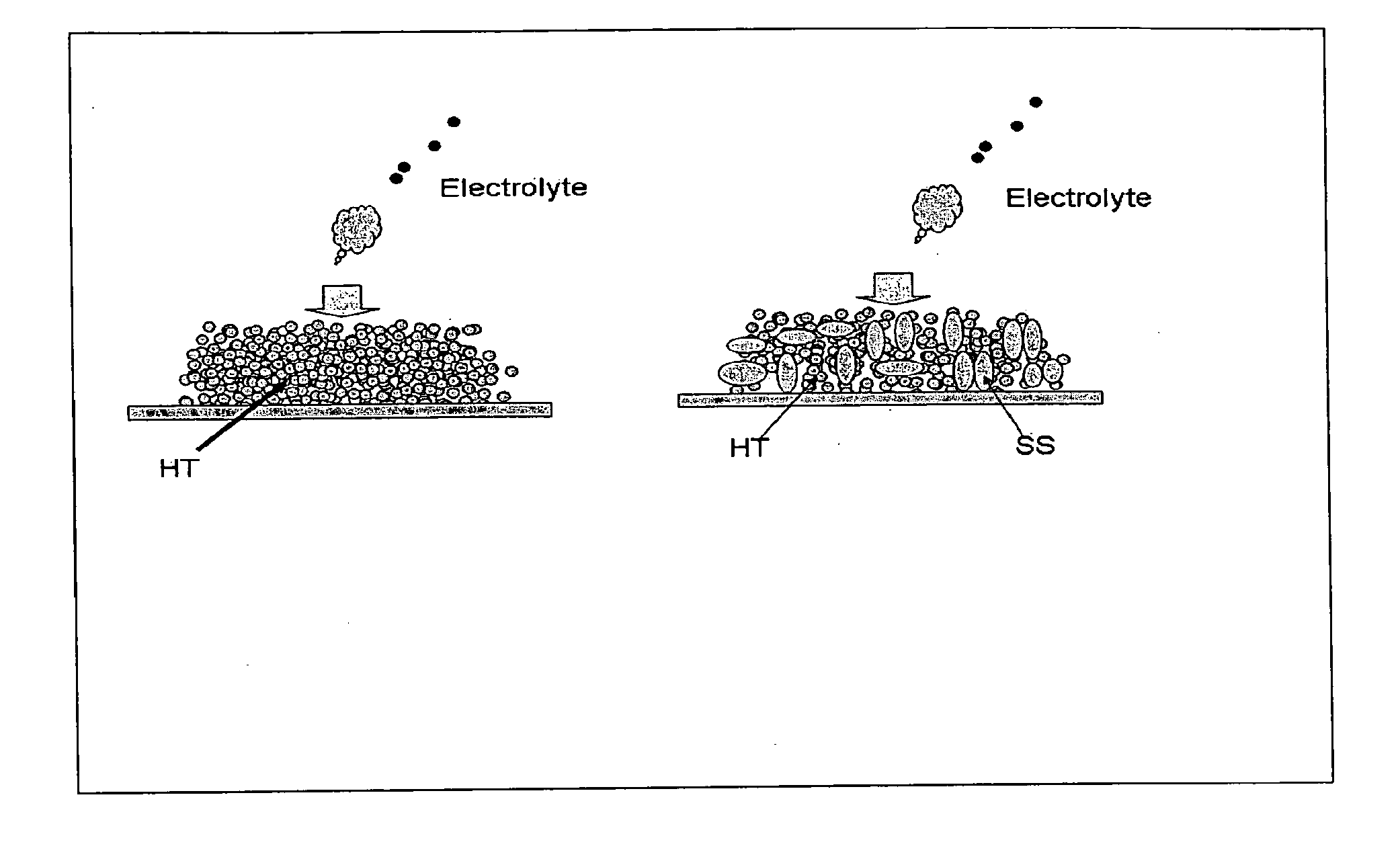

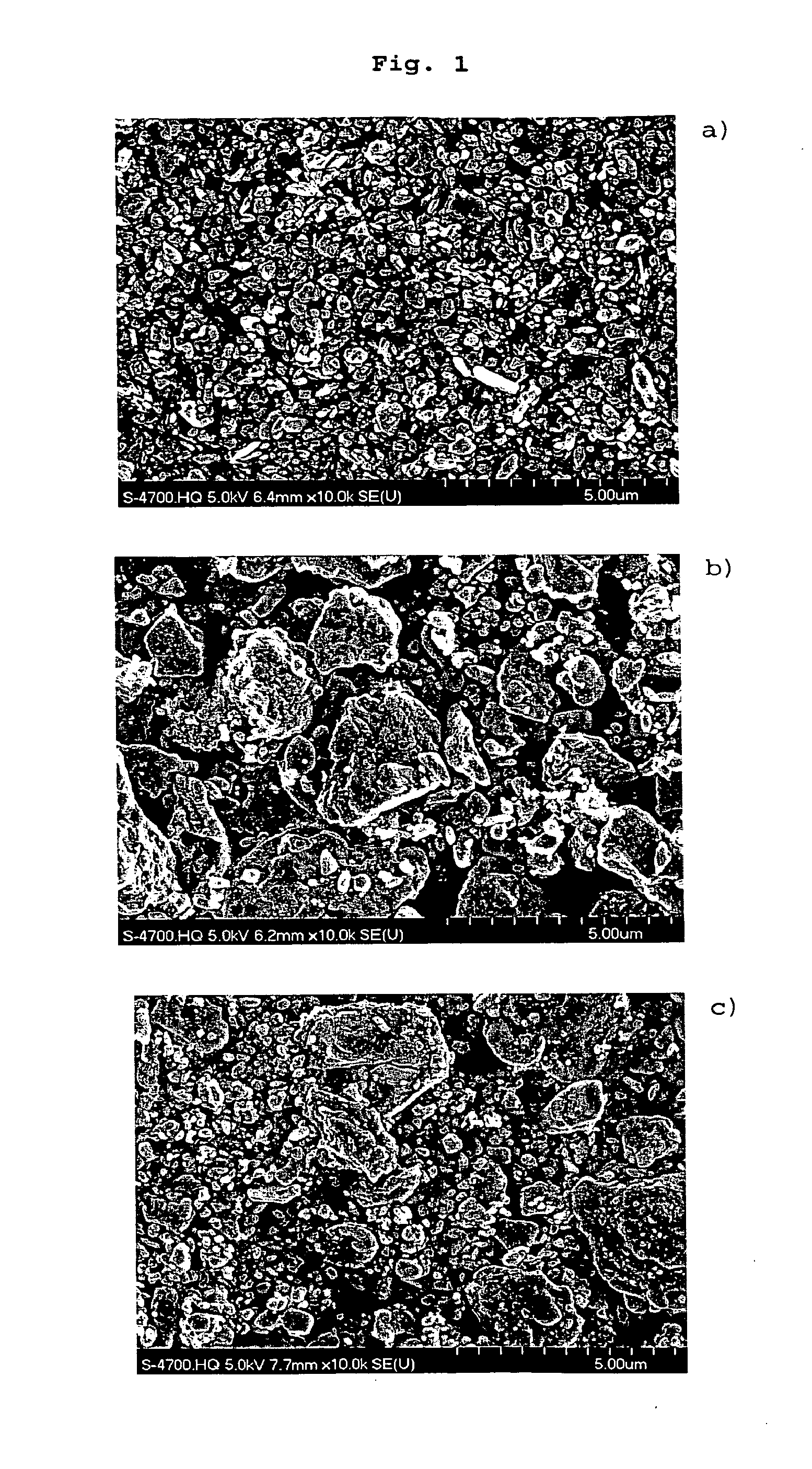

The invention is related to a cathode material comprising particles having a lithium metal phosphate core and a pyrolytic carbon deposit, said particles having a synthetic multimodal particle size distribution comprising at least one fraction of micron size particles and one fraction of submicron size particles, said lithium metal phosphate having formula LiMPO4 wherein M is at least Fe or Mn.Said material is prepared by method comprising the steps of providing starting micron sized particles and starting submicron sized particles of at least one lithium metal phosphate or of precursors of a lithium metal phosphate; mixing by mechanical means said starting particles; making a pyrolytic carbon deposit on the lithium metal phosphate starting particles before or after the mixing step, and on their metal precursor before or after mixing the particles; optionally adding carbon black, graphite powder or fibers to the said lithium metal phosphate particles before the mechanical mixing.

Owner:PHOSTECH LITHIUM

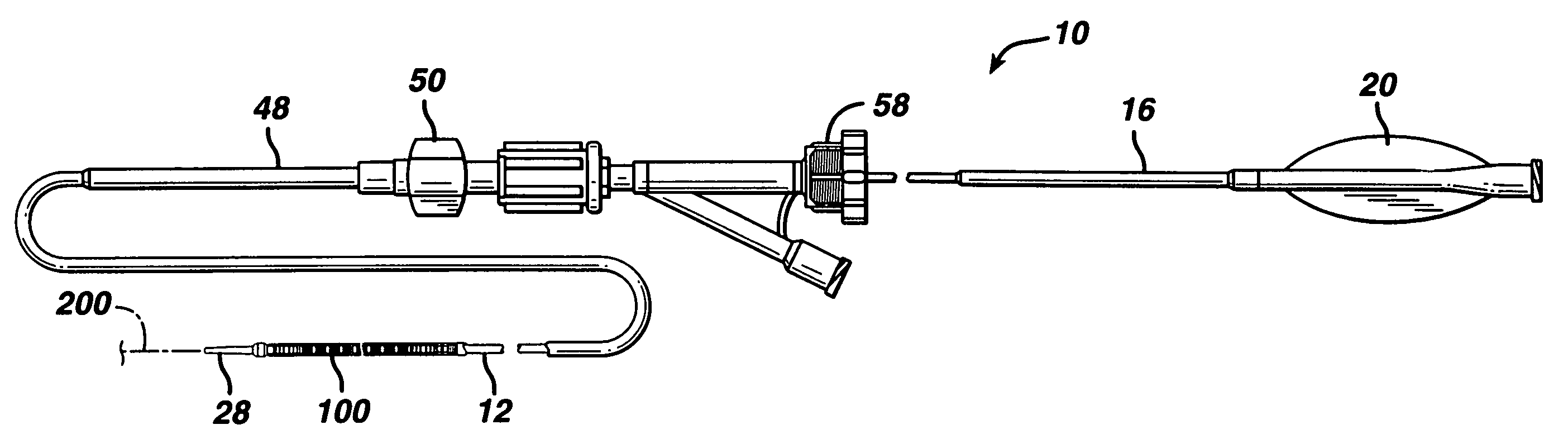

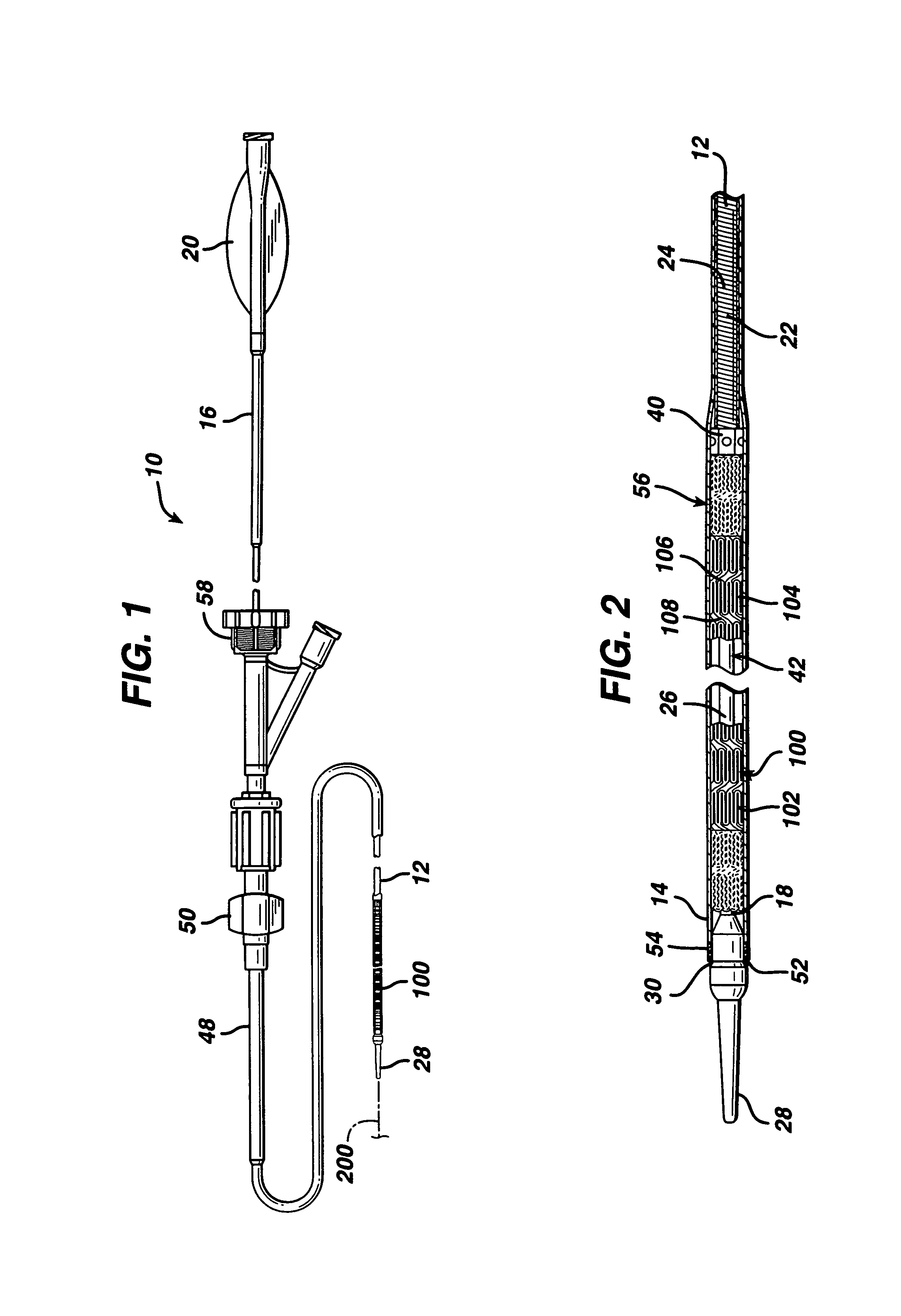

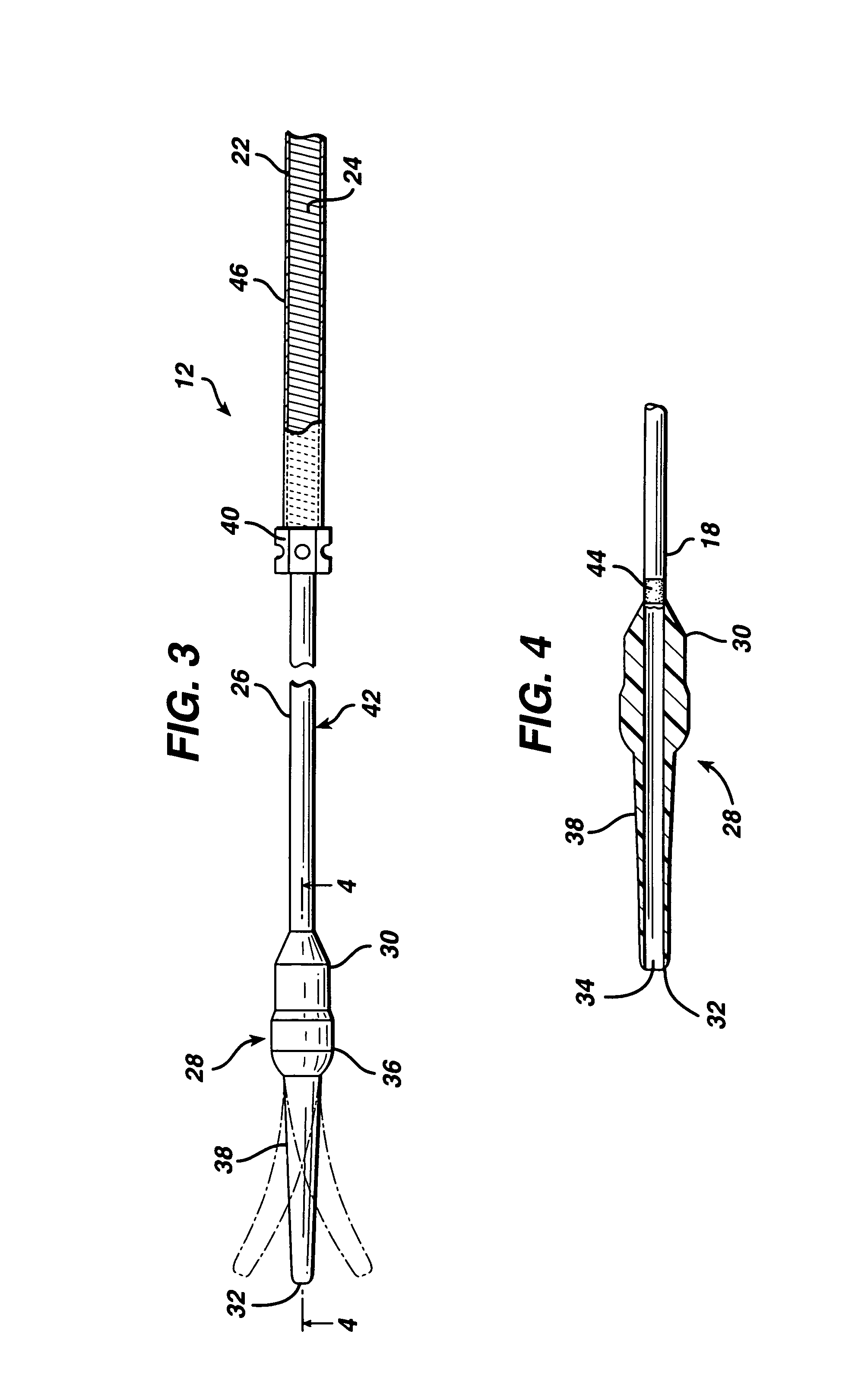

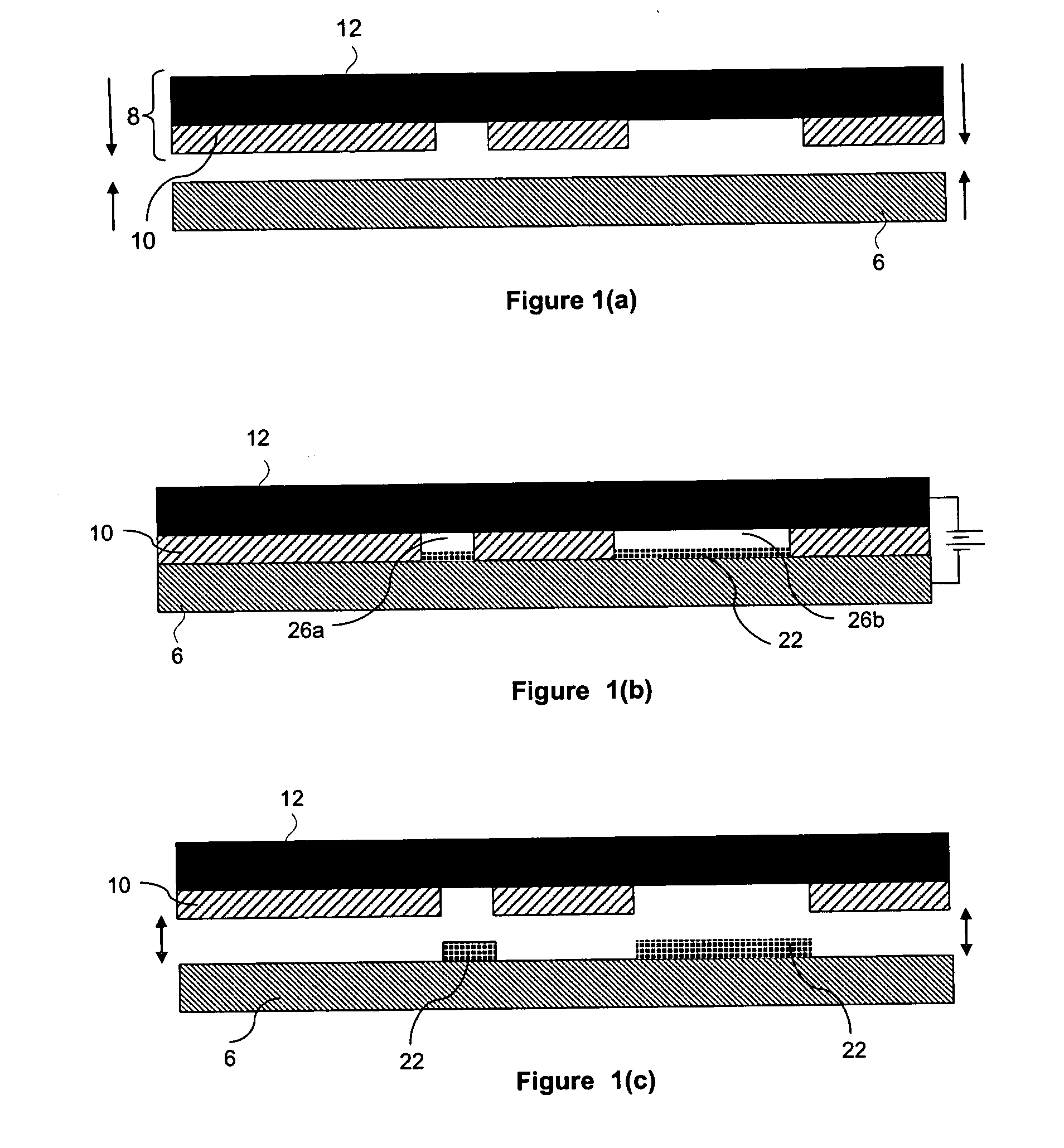

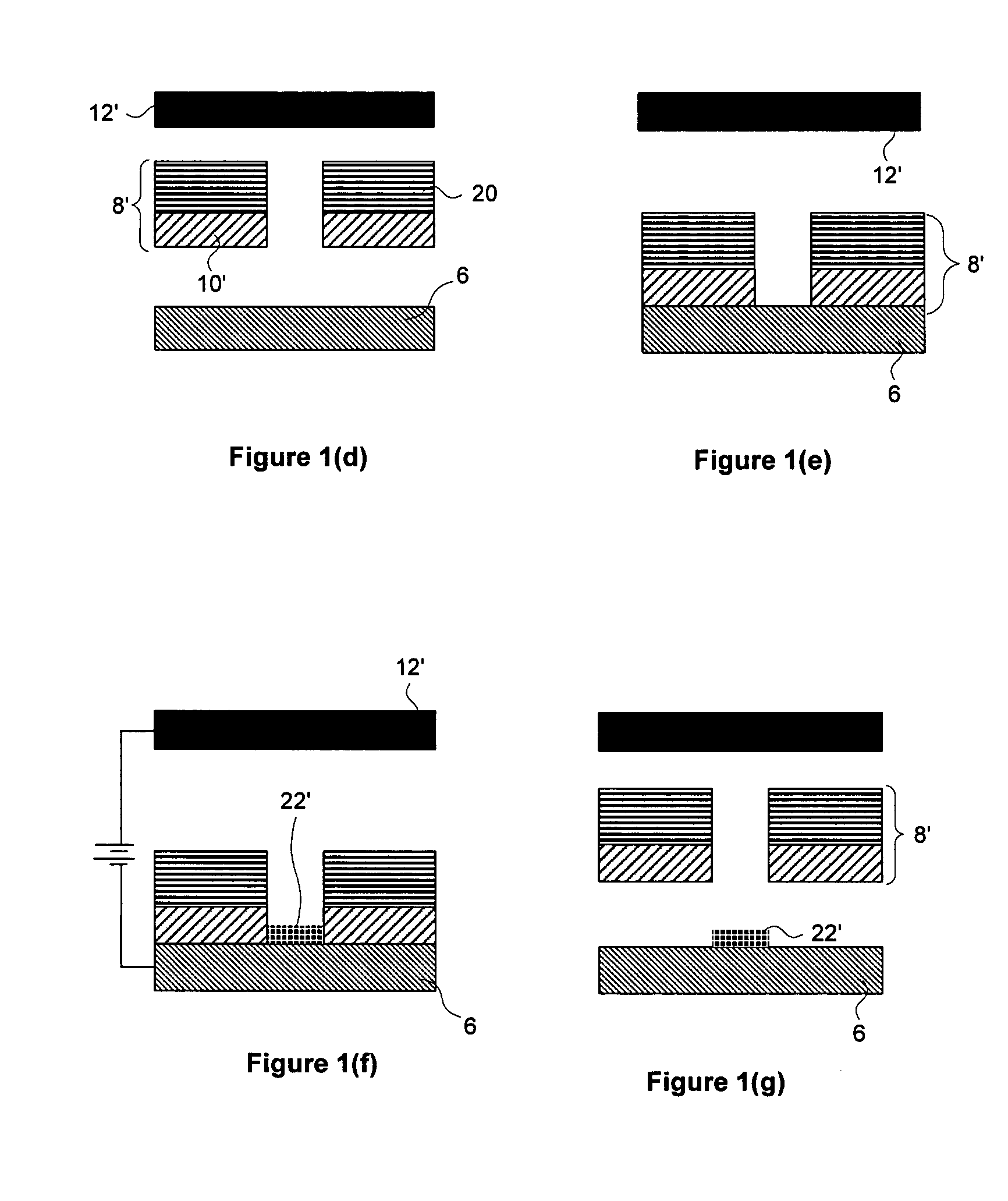

Self-expanding stent delivery system

InactiveUS7169170B2Easy for to accomplish placementAccurate stent deploymentStentsBlood vesselsPyrolytic carbonDelivery system

A self-expanding stent delivery apparatus having a sheath comprising a hard and lubricious coating for the safe, effective and accurate deployment of self-expanding stents. The sheath comprises an inner layer of pyrolytic carbon or other similar substance which prevents the stent from becoming embedded. The inner layer is also lubricious. This combination of properties allows for easier deployment and reduced profile.

Owner:CARDINAL HEALTH SWITZERLAND 515 GMBH

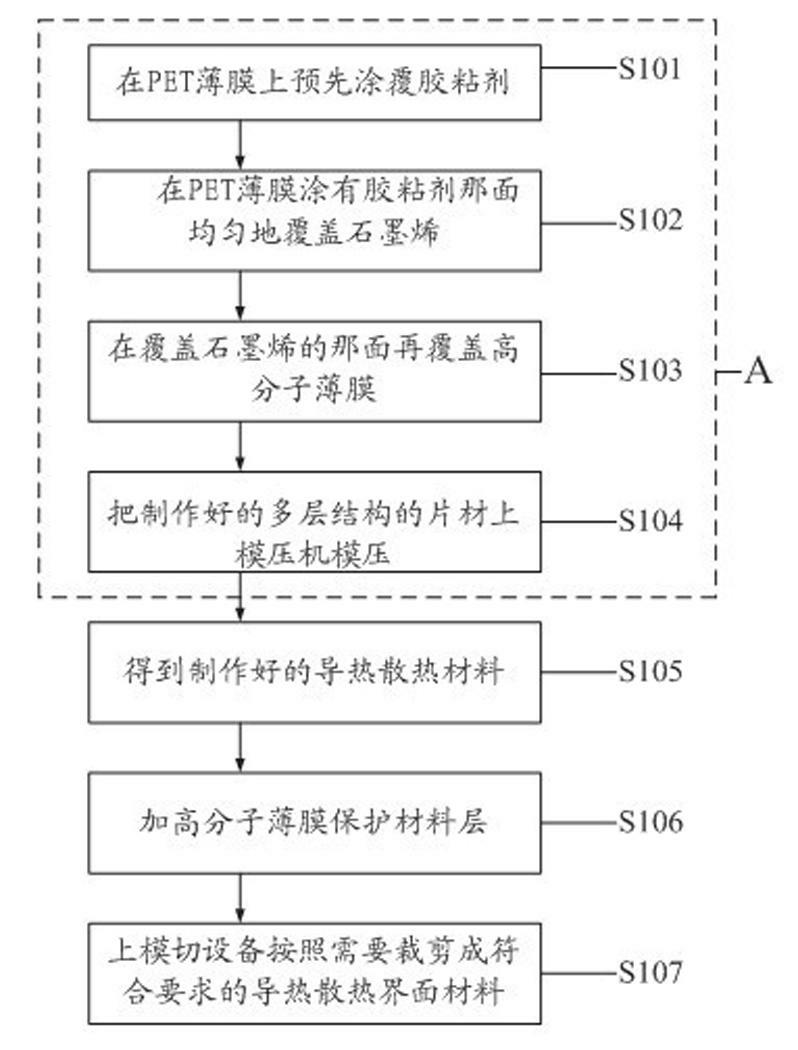

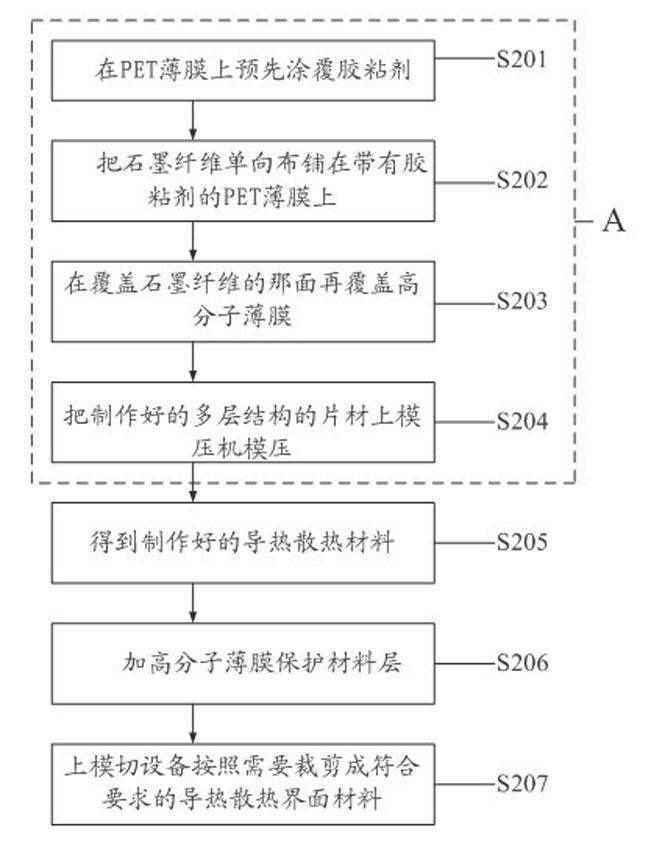

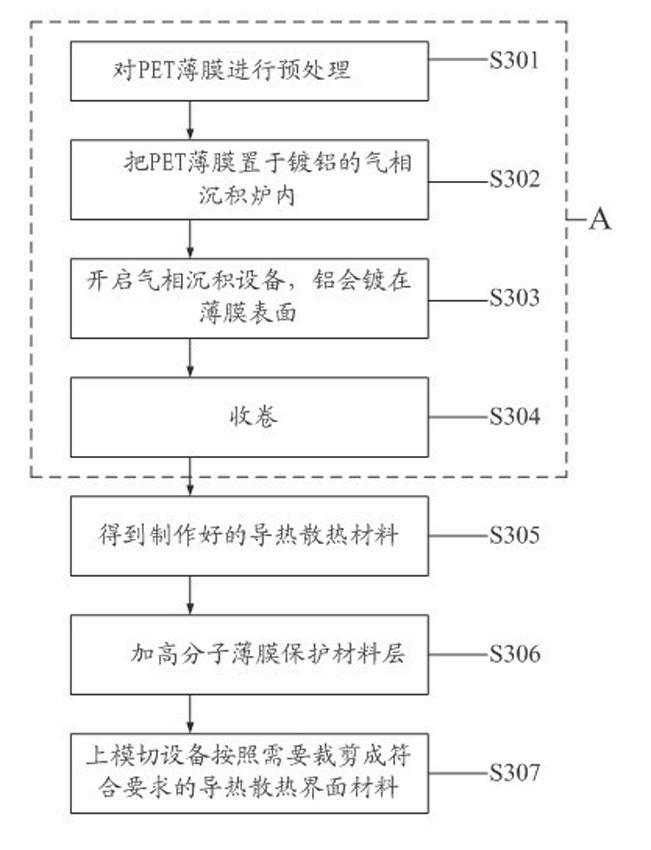

Heat-conduction heat-dissipation interface material and manufacturing method thereof

ActiveCN102651961AReduce volumeThe overall thickness is thinLayered productsCooling/ventilation/heating modificationsMetal fiberCalcium silicate

The invention provides a heat-conduction heat-dissipation interface material and a manufacturing method thereof, wherein the heat-conduction heat-dissipation interface material is applied to the field of heat dissipation of electronic products. The heat-conduction heat-dissipation interface material comprises a heat-conduction heat-dissipation layer and a surface protective material layer, wherein the heat-conduction heat-dissipation layer consists of one or more of graphite, nano graphite, crystalline flake graphite, graphene, pyrolytic carbon, pyrolytic graphite, graphite powder, carbon nano tubes, carbon fibers, graphite fibers, resin, ceramic fibers, quartz fibers, metal fibers, zirconia, boron nitride, silicon nitride, boron carbide, silicon carbide, magnesia powder, metasillicio acid fibers, calcium silicate aluminum fibers, aluminium oxide fibres, copper power, aluminium power, silver power, tungsten power and molybdenum power; and the surface protective material layer is a polymeric membrane. The heat-conduction heat-dissipation interface material manufactured according to the materials and the method provided by the invention has the advantages of effectively improved heat-dissipation performance, small volume, light weight and small thickness, can be used for prolonging the service life of an electronic component, and simultaneously is easy to produce and process.

Owner:SHANGHAI QI JIE CARBON MATERIALS

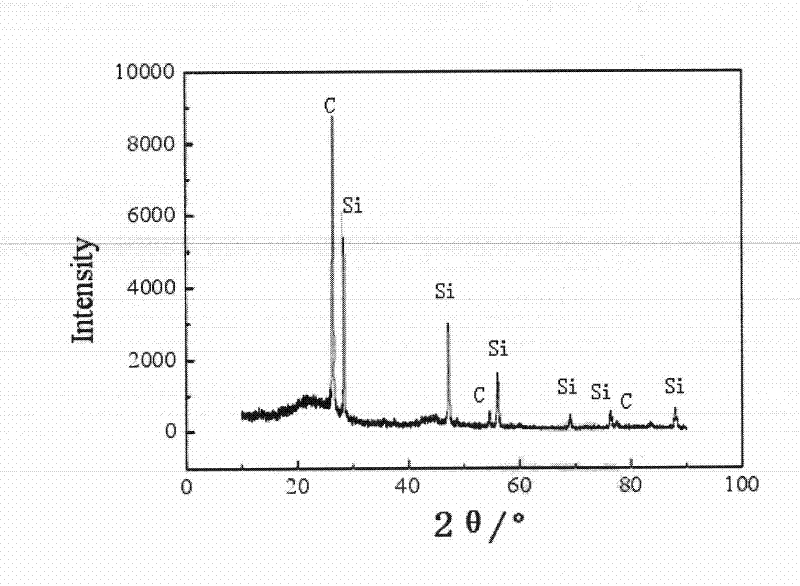

Method for preparing composite material of lithium ion battery cathode, and cathode and battery

ActiveCN101442124AGood lithium intercalation performanceHigh lithium intercalation abilityElectrode manufacturing processesActive material electrodesSlurrySolvent

The invention relates to a method for preparing a composite material for a cathode of a lithium ion battery, and the cathode and the battery which comprise the cathode material. The preparation method comprises: uniformly mixing silicon powder, graphite, pyrolytic carbon precursor and a solvent to prepare slurry, wherein the silicon powder comprises micro-silicon powder and nano-silicon powder, and the weight ratio of the micro-silicon powder and the nano-silicon powder is 2-20:1; and removing the solvent in the slurry, performing primary sintering under the protection of inert gas, performing primary ball grinding, performing secondary sintering under the protection of the inert gas, and performing secondary ball grinding, wherein the temperature of the secondary sintering is higher than that of the primary sintering. The battery made from the composite material for the cathode of the lithium ion battery obtained by the method has good cycling performance and charge and discharge capacity.

Owner:BYD CO LTD

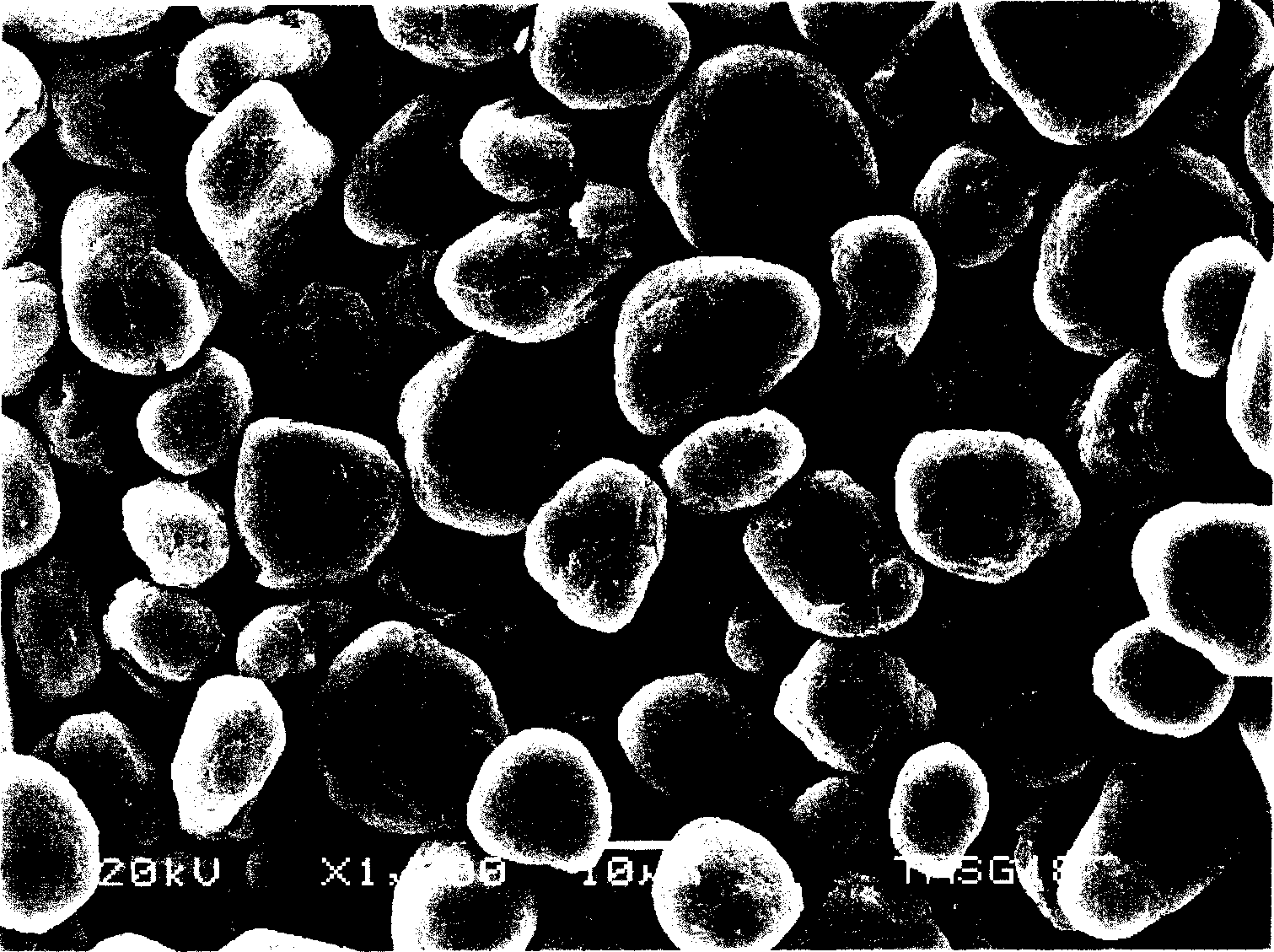

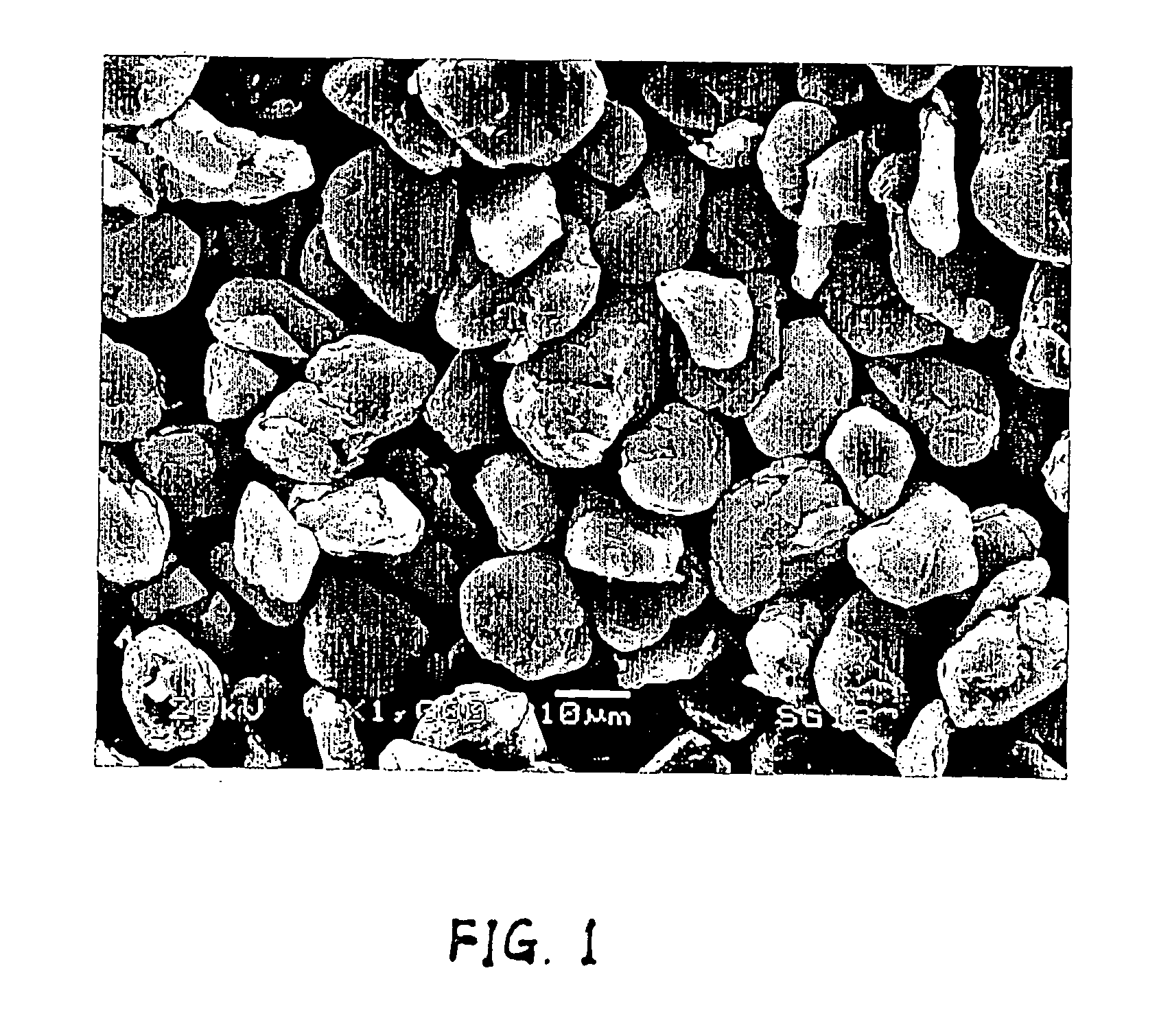

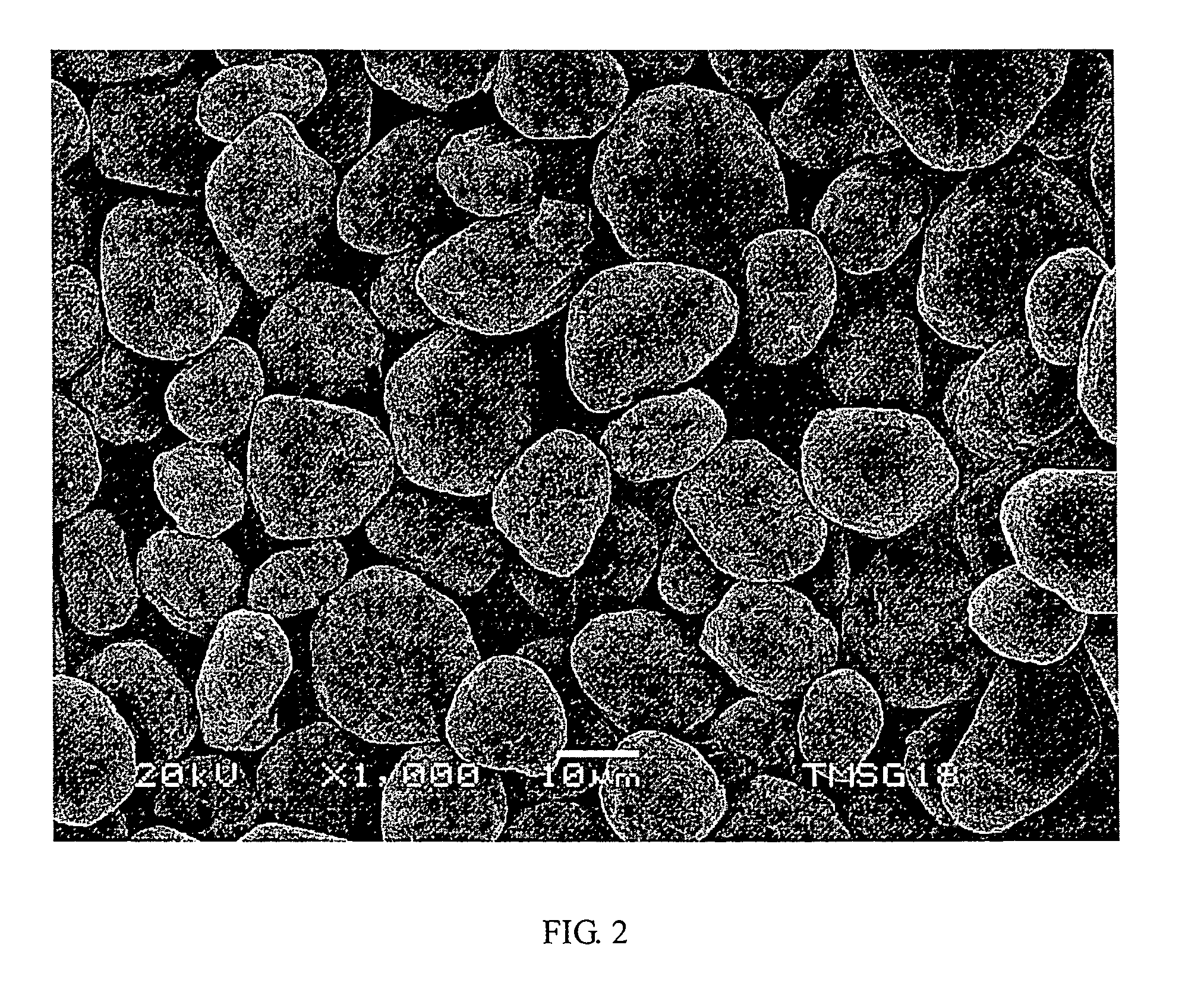

Cathode material of composite carbon in use for lithium ion battery and preparation method

ActiveCN1697215ASimple preparation processEasy to operateElectrode manufacturing processesActive material electrodesLithium-ion batteryMaterials science

The disclosed composite carbon material of negative pole in lithium ion cell is composite graphite including spherical graphite and covering layer, which is pyrolytic carbon of organic matter. Inserted transition metal elements are contained between layers of graphite crystal. Preparation method is as following: crushing graphite, shaping and sphericized, purifying treatment, washing, dewatering and drying, dipped in salt solution doped by transition metal in multivalence, mixed with organic matter, covering treatment, and carbonizing treatment or graphitization treatment. Comparing with prior art, the disclosed material of negative pole possesses advantages of fine capability of embedding lithium and taking off lithium, high cyclical stability, reversible specific capacity larger than 350mAh / g, coulomb efficiency higher than 94% at first cycle, conservation rate for capacity larger than 80% in 500 times of circulation.

Owner:BTR NEW MATERIAL GRP CO LTD

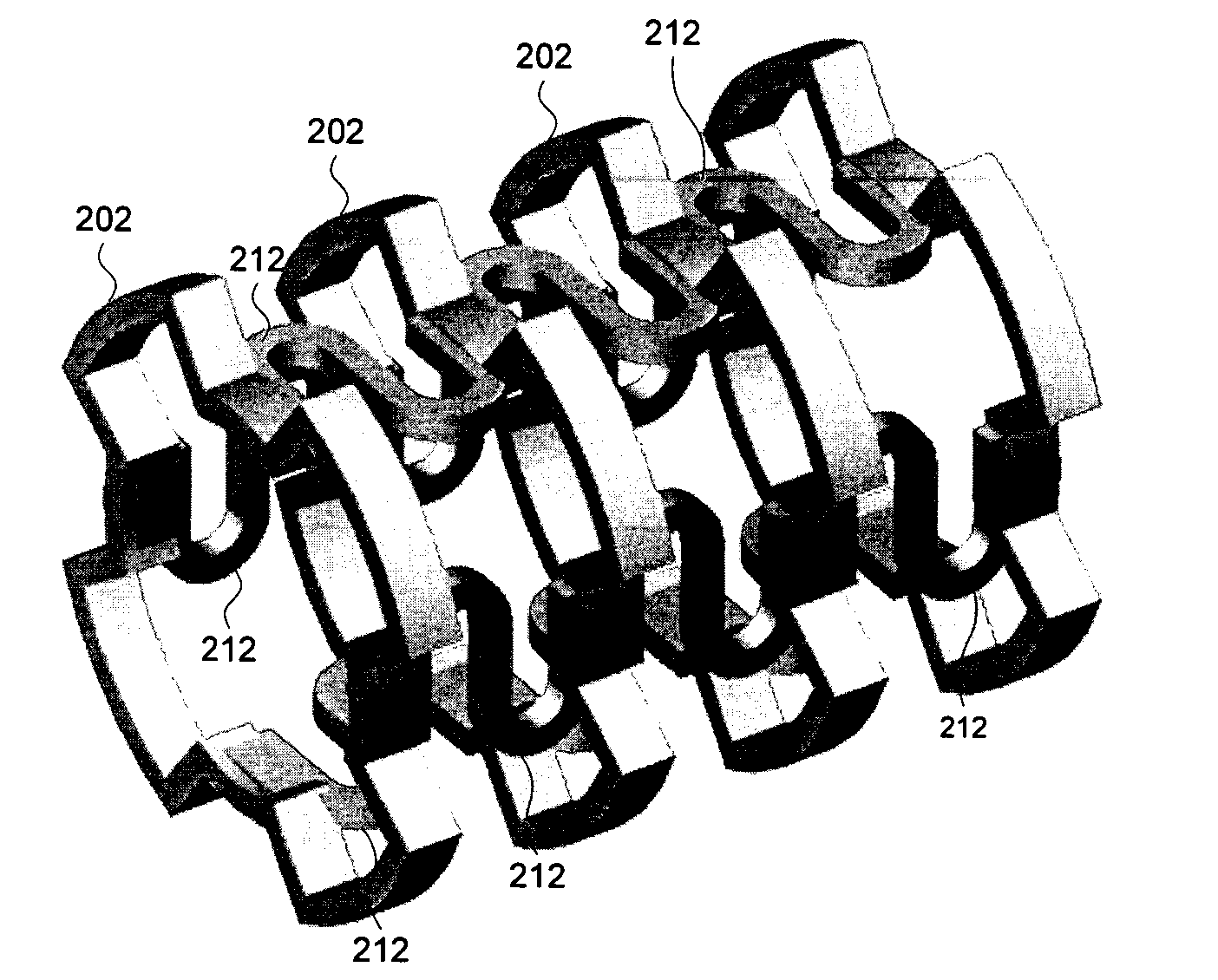

Medical devices and EFAB methods and apparatus for producing them

Various embodiments of the invention present miniature medical devices that may be formed totally or in part using electrochemical fabrication techniques. Sample medical devices include micro-tweezers or forceps, internally expandable stents, bifurcated or side branch stents, drug eluting stents, micro-valves and pumps, rotary ablation devices, electrical ablation devices (e.g. RF devices), micro-staplers, ultrasound catheters, and fluid filters. In some embodiments devices may be made out of a metal material while in other embodiments they may be made from a material (e.g. a polymer) that is molded from an electrochemically fabricated mold. Structural materials may include gold, platinum, silver, stainless steel, titanium or pyrolytic carbon-coated materials such as nickel, copper, and the like.

Owner:MICROFAB

Process for preparing self-sealing silicon carbide ceramic based composite material

The invention relates to a method for manufacturing a self-healing silicon carbide ceramic matrix composite. The method comprises the following steps: preparing fiber preform; filtrating a pyrolytic carbon interface layer by chemical gas phase; carrying out thermal treatment on the interface layer; infiltrating silicon carbide and boron carbide substrate by chemical gas phase alternately; and depositing three silicon carbide coatings by the chemical gas phase. The method has strong designability, simple process and good repeatability. The ceramic matrix composite manufactured by the method has good high temperature resistance and oxidation resistance, has excellent mechanical performance and thermal performance, and can meet the use requirement of a sealing strip / an adjustment sheet, an interior cone and other components of a high thrust-weight ratio aeroengine.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

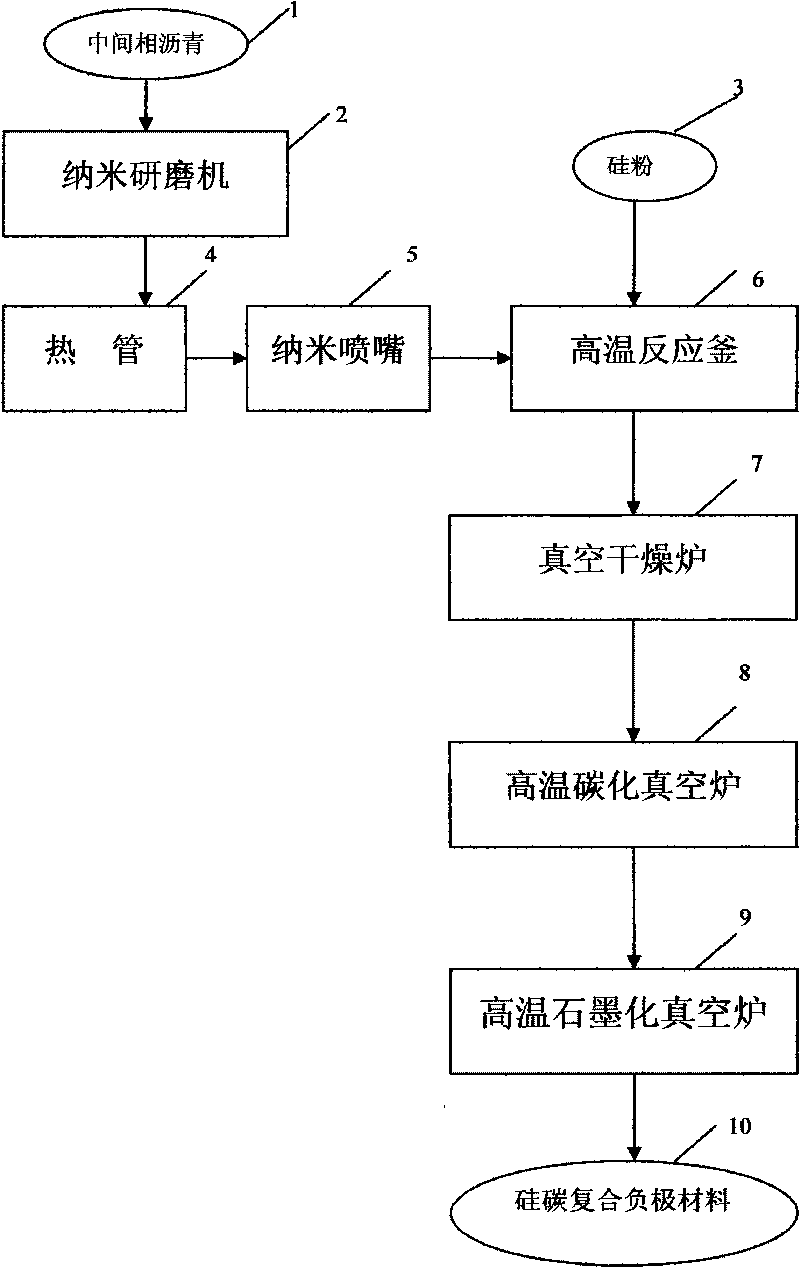

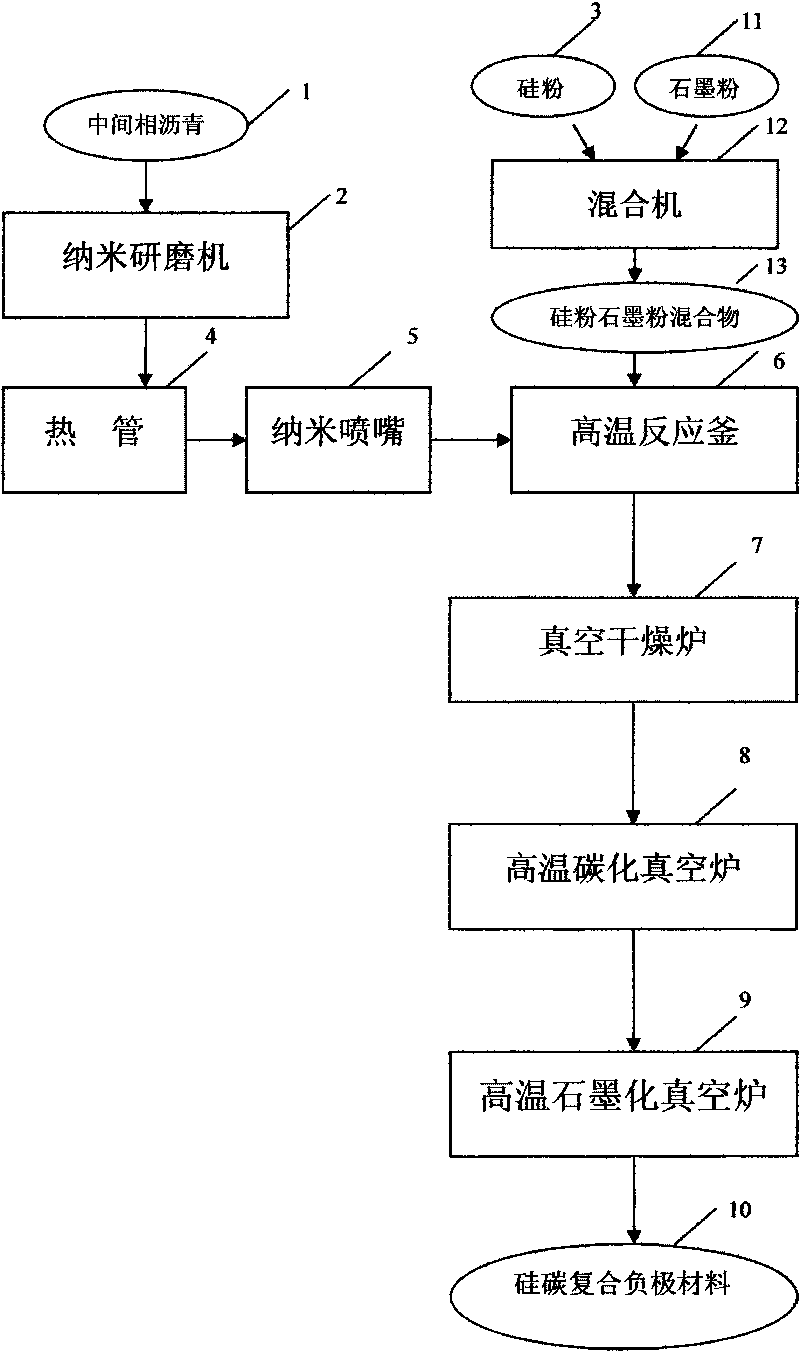

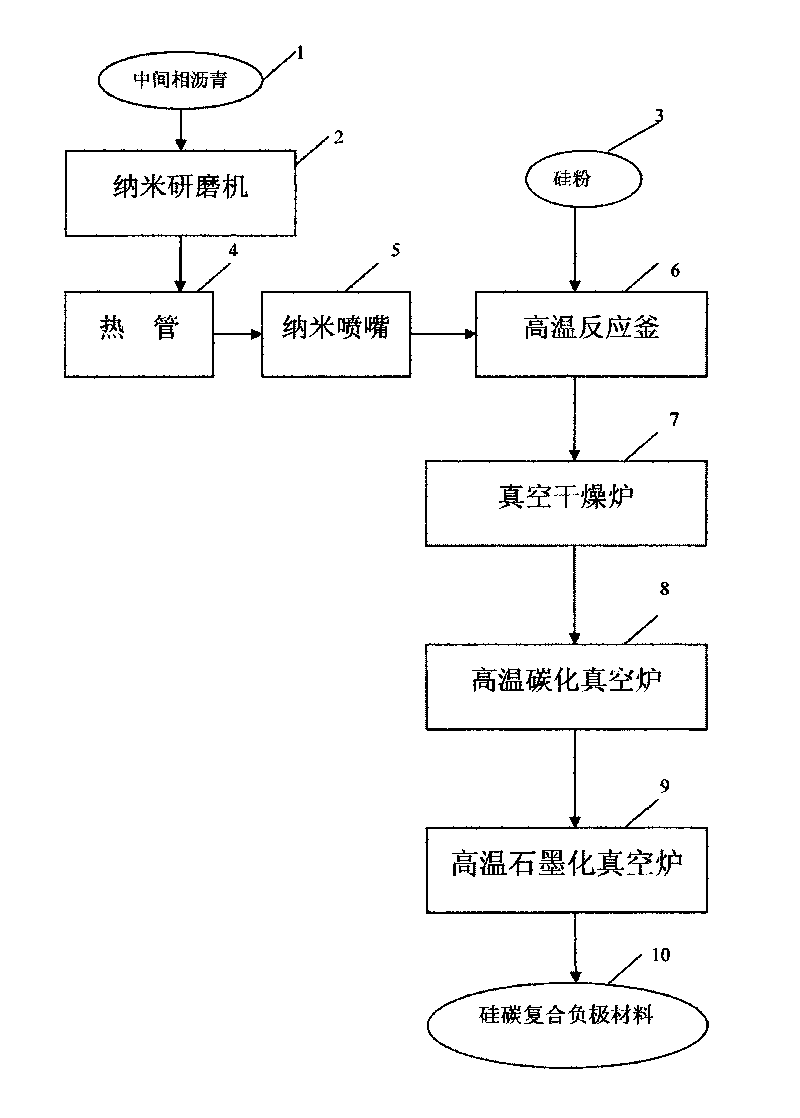

High-energy silicon-carbon composite negative electrode material for lithium ion battery and manufacturing process thereof

InactiveCN101710617AImprove cycle stabilityGive full play to the characteristics of high specific capacityElectrode manufacturing processesCarbon compositesHigh energy

Owner:DALIAN LICHANG NEW MATERIAL CO LTD

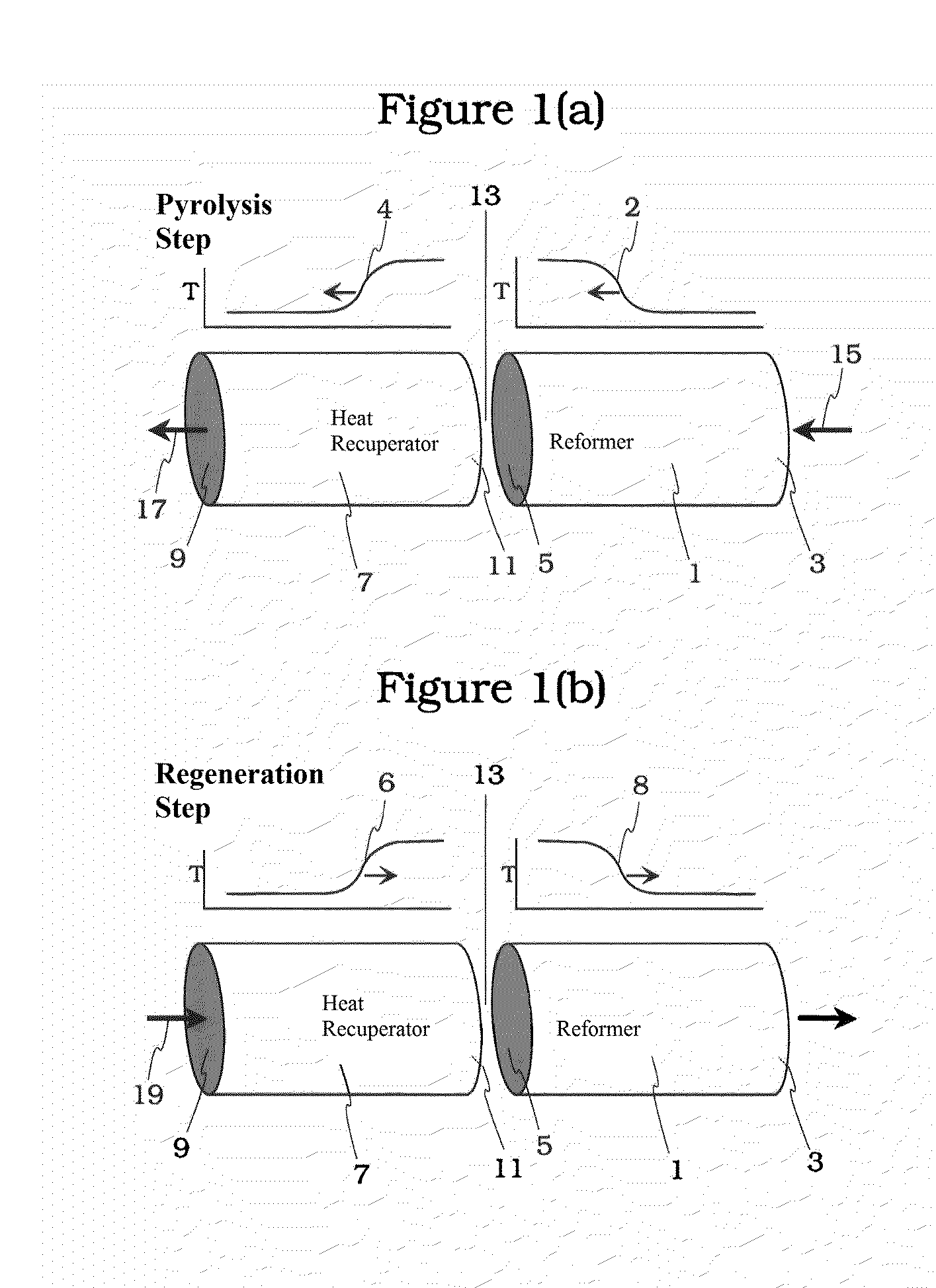

Pyrolysis Reactor Materials and Methods

ActiveUS20100290978A1Reduce corrosionChemical/physical/physico-chemical processesRare earth metal compoundsPorosityReactor system

In one aspect, the invention includes a refractory material for a pyrolysis reactor for pyrolyzing a hydrocarbon feedstock, the refractory material comprising an yttria stabilized zirconia, the refractory material comprising at least 21 wt. % yttria based upon the total weight of the refractory material. In another aspect, this invention includes a method for mitigating carbide corrosion while pyrolyzing a hydrocarbon feedstock at high temperature using a pyrolysis reactor system comprising the steps of: (a) providing a pyrolysis reactor system comprising stabilized zirconia in a heated region of the reactor, the stabilized zirconia including at least 21 wt. % yttria and having porosity of from 5 vol. % to 28 vol. %; (b) heating the heated region to a temperature of at least 1500° C.; and (c) pyrolyzing a hydrocarbon feedstock within the heated region.

Owner:EXXONMOBIL CHEM PAT INC

Composite carbon material of negative electrode in lithuim ion battery and its preparation method

ActiveUS20090136849A1Improve rendering capabilitiesImprove cycle stabilityElectrode manufacturing processesActive material electrodesSpherical shapedSodium-ion battery

A composite carbon material of negative electrode in lithium ion, which is made of composite graphite, includes a spherical graphite and a cover layer, wherein the cover layer is pyrolytic carbon of organic substance. Inserted transition metal elements are contained between layers of graphite crystal. Preparation of the negative electrode includes the steps of: crushing graphite, shaping to form a spherical shape, purifying treatment, washing, dewatering and drying, dipped in salt solution doped by transition metal in multivalence, mixed with organic matter, covering treatment, and carbonizing treatment or graphitization treatment. The negative electrode provides advantages of reversible specific capacity larger than 350 mAh / g, coulomb efficiency higher than 94% at first cycle, conservation rate for capacity larger than 8-% in 500 times of circulation.

Owner:BTR NEW MATERIAL GRP CO LTD

High-capacity silicon-carbon composited anode material, preparation method and application thereof

InactiveCN102637872AOvercoming the low capacity of lithium deintercalationPromote circulationCell electrodesSecondary cellsCarbon compositesPyrolytic carbon

The invention relates to a high-capacity silicon-carbon composited anode material, a preparation method and application thereof, wherein the silicon-carbon composited anode material comprises the following compositions in parts by weight: 1-30 parts of silicon materials, 30-120 parts of carbon materials, and 10-80 parts of pyrolytic carbon. The silicon materials in the silicon-carbon composited anode material disclosed by the invention are uniformly adhered to the surfaces of carbon material particles, and then the outer layers of the carbon material particles are wrapped with the pyrolytic carbon, therefore, the silicon-carbon composited anode material disclosed by the invention has the advantages of lower first irreversible specific capacity, higher specific capacity, excellent cycle performance, low preparation cost and the like; and the first discharge capacity of the silicon-carbon composited anode material is greater than 450 mAh.g<-1> under a 0.2 C discharge ratio, and the retention rate of capacity after 50 cycles is more than 80%.

Owner:天津市贝特瑞新能源材料有限责任公司

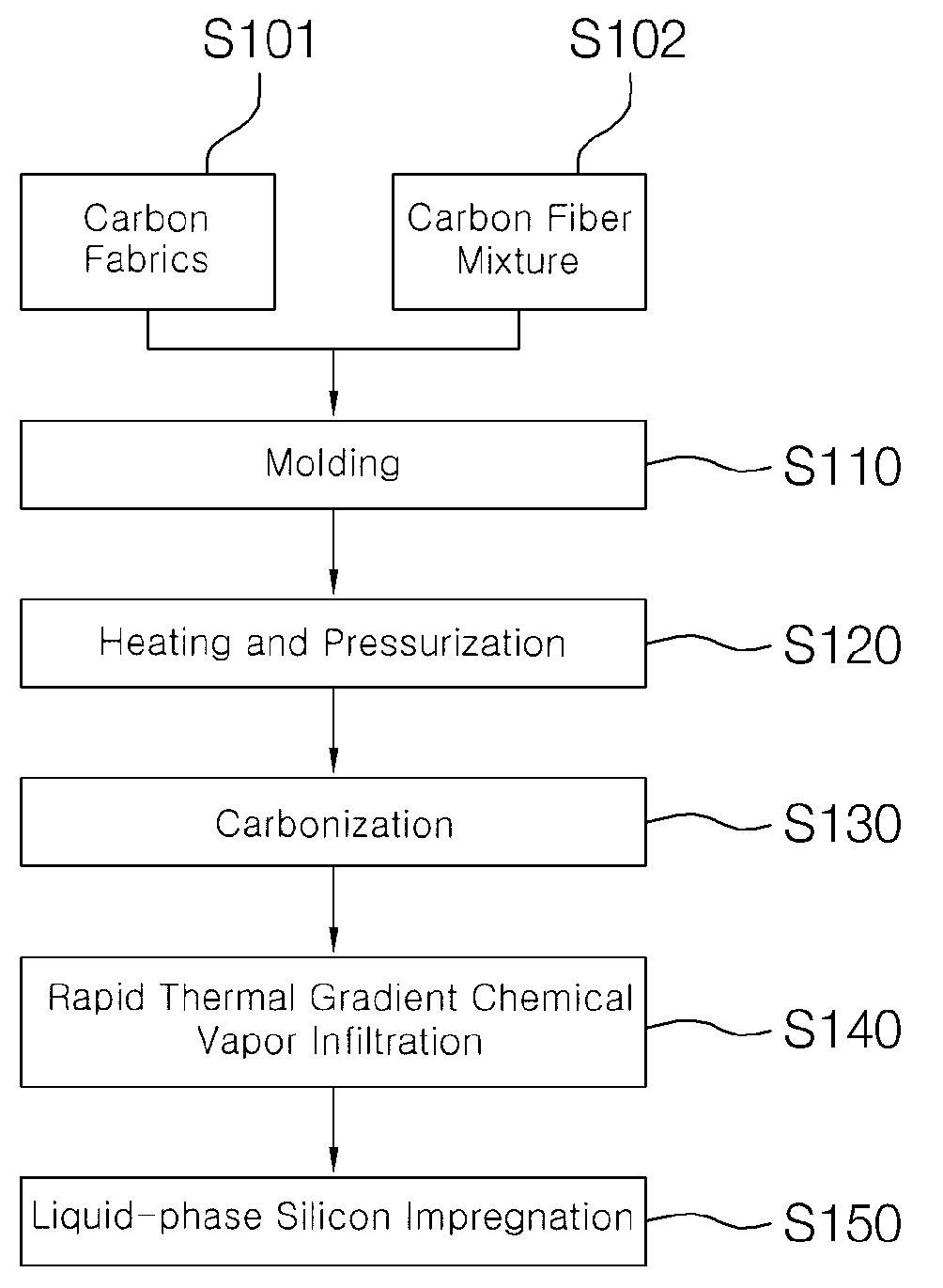

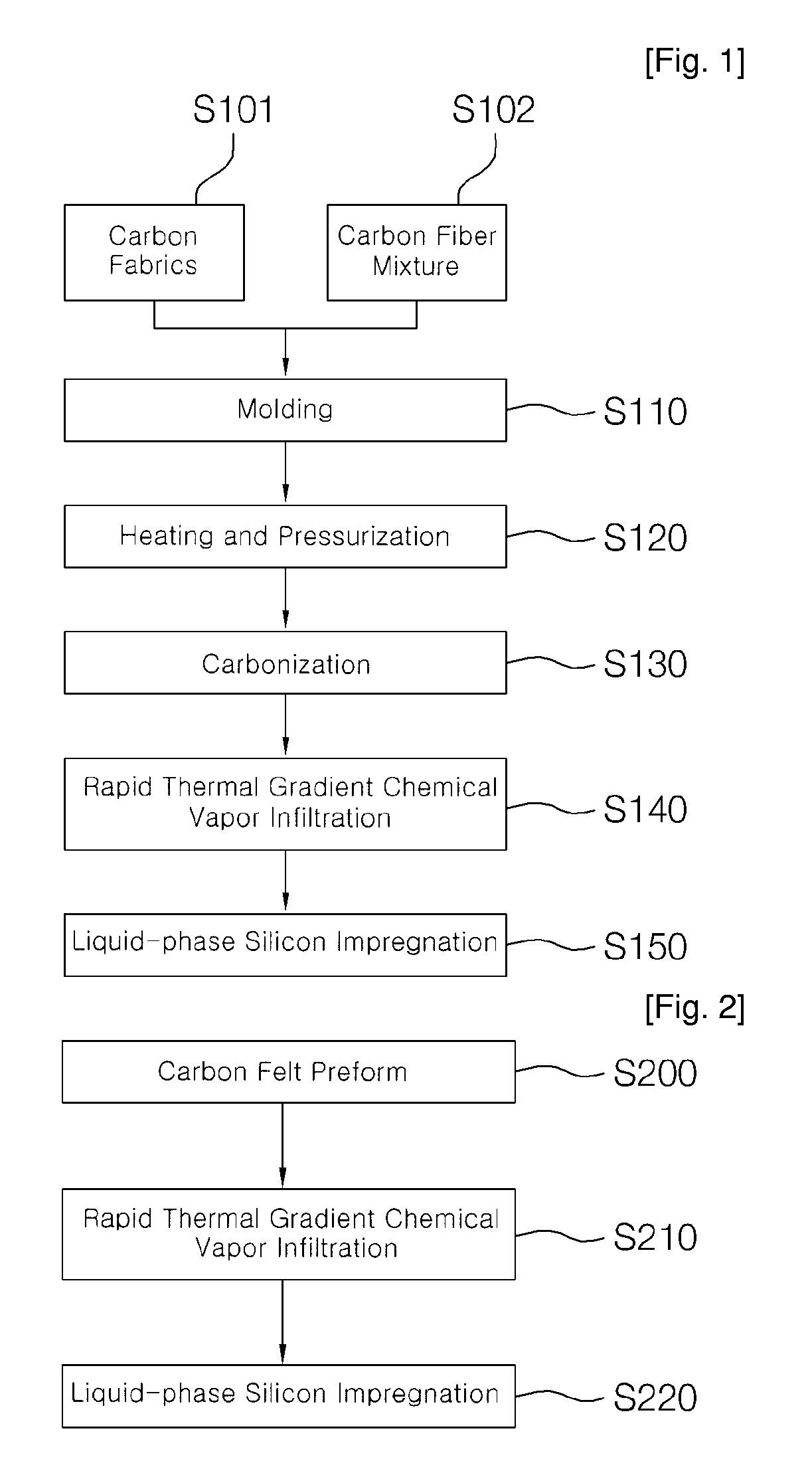

Method of Producing Carbon Fiber Reinforced Ceramic Matrix Composites

InactiveUS20080143005A1Improve propertiesRapid depositionFibre chemical featuresFriction liningCarbon compositesCarbon fibers

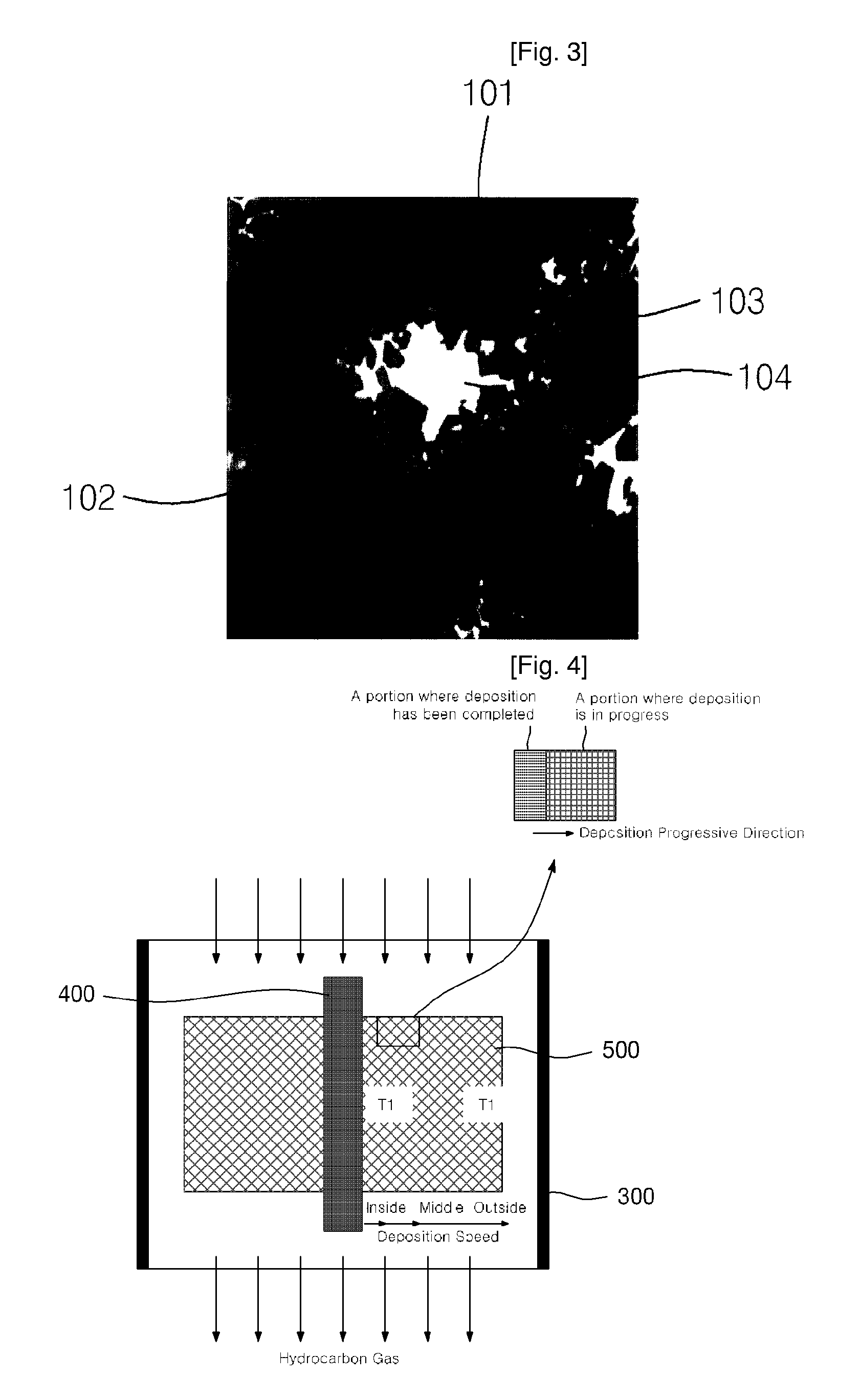

The present invention relates to a method of producing carbon fiber reinforced ceramic matrix composites, the method of producing carbon fiber reinforced ceramic matrix composites according to the present invention is characterized in that the method comprises the steps of: producing a carbon fiber reinforced resin composite that is molded with a mixture in which carbon fibers and polymer precursors containing carbon are mixed; producing a carbon fiber reinforced carbon composite by depositing pyrolytic carbon during a rapid thermal gradient chemical vapor infiltration process while increasing the deposition speed in a direction from the inside to the outside by performing a thermal treatment on said carbon fiber reinforced resin composite at high temperature; and infiltrating liquid-phase silicon into the pores of said carbon fiber reinforced carbon composite. The method of producing carbon fiber reinforced ceramic matrix composites according to the present invention as described above has the effect of improving the properties of carbon fiber reinforced ceramic matrix composites, and it is possible to deposit a pyrolytic carbon layer at a deposition speed 5-10 times faster than other conventional chemical vapor infiltration processes, thereby showing a remarkably improved effect in terms of manufacturing process, time, and cost.

Owner:DACC

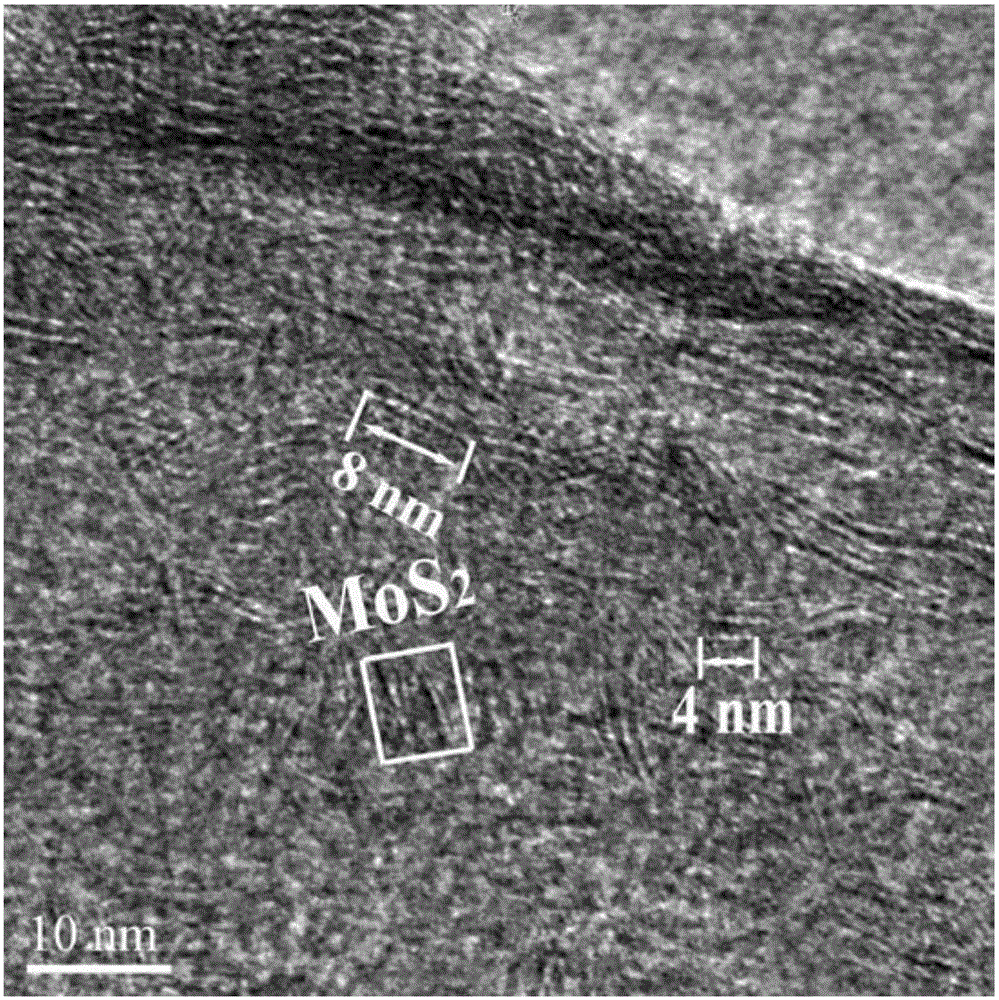

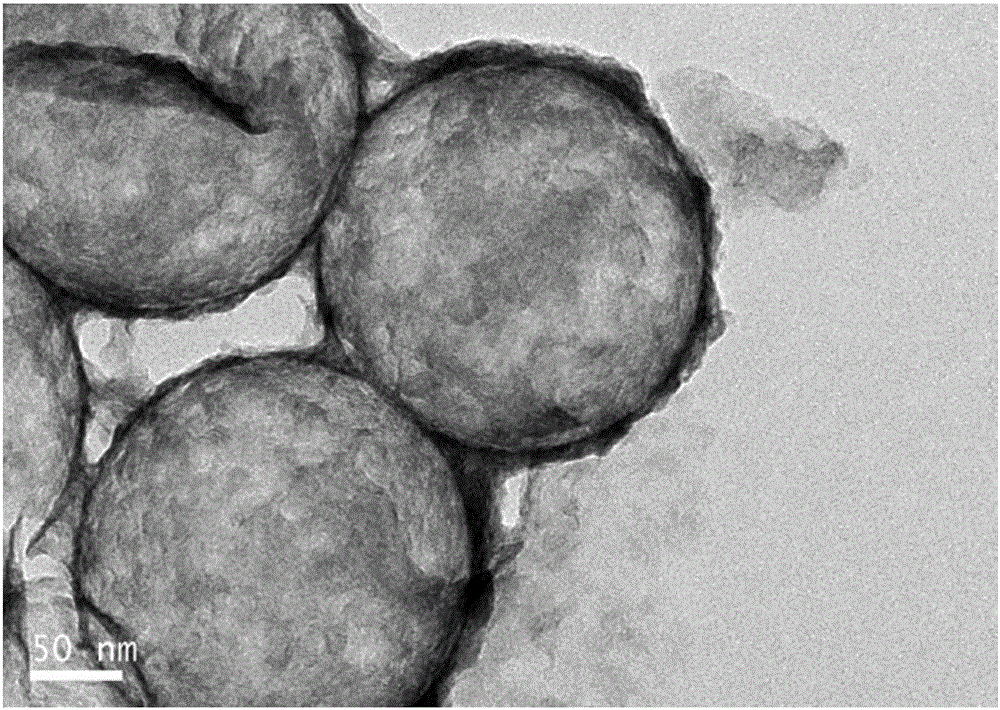

Molybdenum disulfide-carbon hollow ball hybrid material and preparation method thereof

InactiveCN105098151AShorten the transmission distanceImproved magnification performanceCell electrodesSecondary cellsSolventSilicon dioxide

The invention discloses a molybdenum disulfide-carbon hollow ball hybrid material. The molybdenum disulfide-carbon hollow ball hybrid material has a hollow ball structure; and the hybrid material formed by embedding a single layer of molybdenum disulfide nanosheet or a few of layers of molybdenum disulfide nanosheets into a carbon material is a shell layer of the hollow ball. The invention further discloses a preparation method of the molybdenum disulfide-carbon hollow ball hybrid material. The method comprises the following steps: with amino-modified silica particles as a template, coating the template with an organic pyrolytic carbon material and ammonium tetrathiomolybdate through solvothermal reaction; carrying out high-temperature treatment in an inert atmosphere; and finally removing a silicon dioxide template, so as to obtain the molybdenum disulfide-carbon hollow ball hybrid material disclosed by the invention. The initial lithium insertion capacity of the molybdenum disulfide-carbon hollow ball hybrid material disclosed by the invention is close to 1010mAh / g; and the specific capacity can still be kept at 662mAh / g after 40 repeated charge and discharge cycles.

Owner:SHANGHAI JIAO TONG UNIV

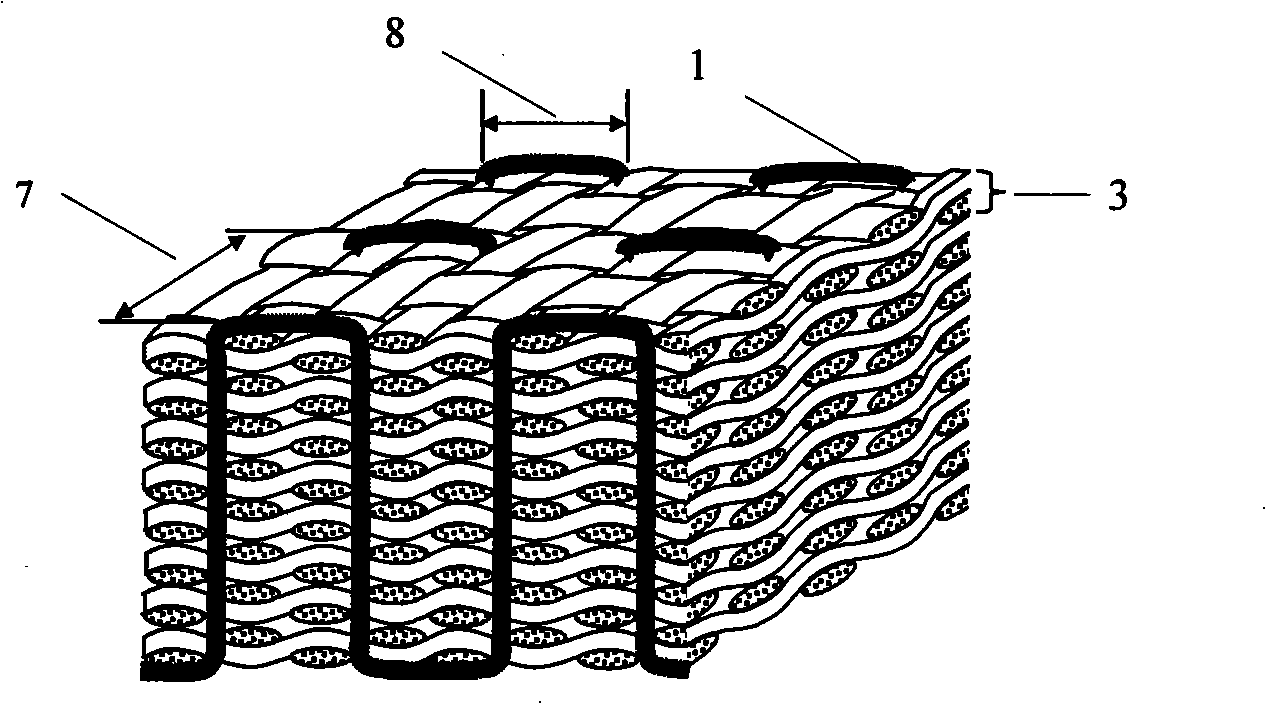

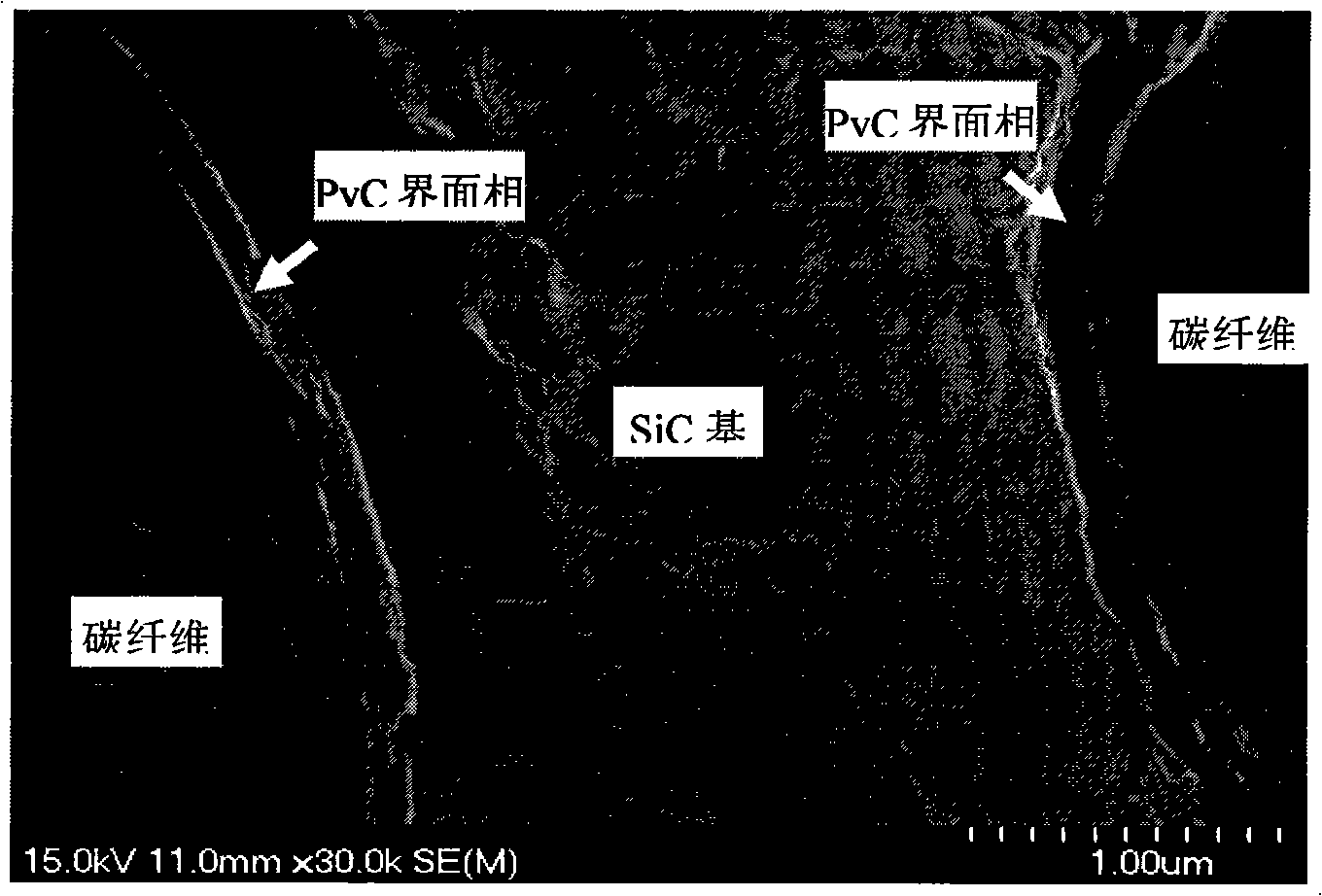

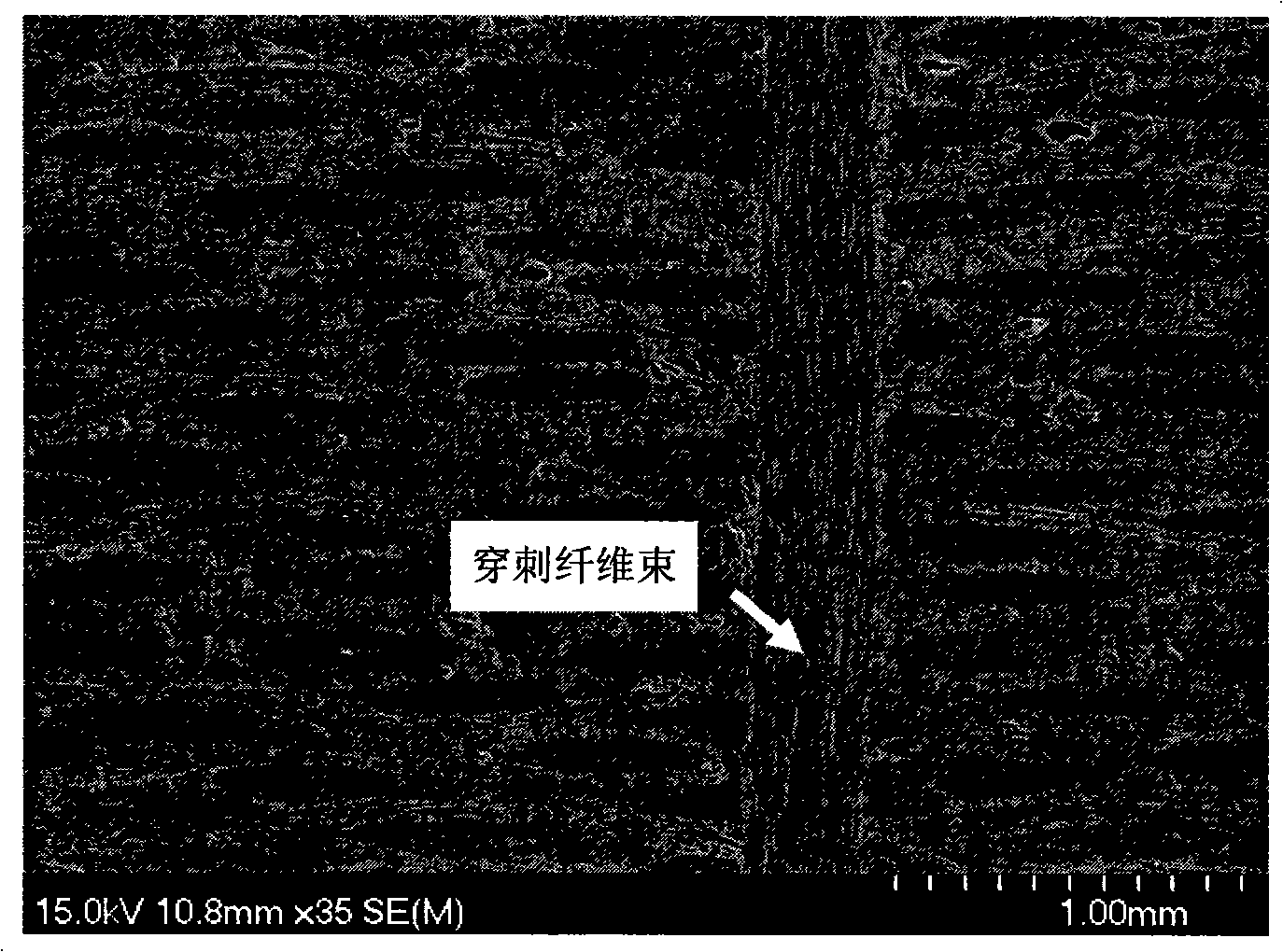

Process for preparing carbon/silicon carbide composite material

ActiveCN101337825AIncreased interlaminar shear strengthHigh tensile strengthInterlaminar shearPyrolytic carbon

The invention discloses a preparation method for a carbon / carborundum composite material. Firstly, carbon fibre is woven into single-layer plain cloth; a plurality of layers of the plain cloth are superposed, and are punctured and stitched with carbon fiber, thus forming a prefabricated carbon fiber body. The prefabricated carbon fiber body is arranged in a vacuum furnace and boiled off as well as pretreated; subsequently, pyrolytic carbon deposits, thus getting the C / C composite material; the multihole C / C composite material is heated; a SiC basal body is impregnated in the treated C / C composite material by adopting the CVI method, thus getting the C / SiC composite material. As the C / SiC composite material is prepared by puncturing and stitching the prefabricated carbon fiber body in combination of the CVI method. The interlaminar shear strength of the C-SiC composite material at 1200 DEG C is increased to 36 to 49MPa from 22 to 24MPa of the prior art; the tensile strength is increased to 275 to 345MPa from 220 to 300MPa of the prior art.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

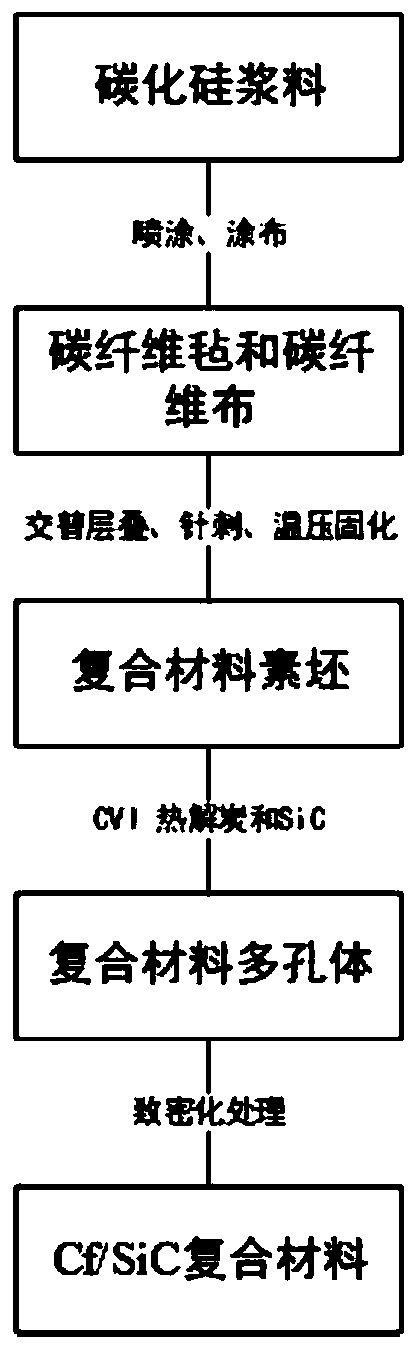

Carbon fiber reinforced silicon carbide ceramic matrix composite material and preparation method thereof

Belonging to the field of new materials, specifically high temperature / high purity, high temperature thermal field / load-bearing, frictional wear, corrosion-resistant materials and antioxidation materials in the fields of solar energy, semiconductors, metallurgy, energy, chemical industry, materials, machinery, transportation, spaceflight and aviation, etc., the invention provides a carbon fiber reinforced silicon carbide ceramic matrix composite material and a preparation method thereof. The preparation method includes: uniformly spraying or coating a silicon carbide slurry on the surfaces ofcarbon fiber felt and carbon fiber cloth, and then conducting alternate laminating, needling, drying and hot pressing curing to obtain a composite green blank; then carrying out carbonization on the composite green blank, and performing alternate infiltration deposition of pyrolytic carbon and silicon carbide on a boundary phase, and finally conducting pyrolytic carbon infiltration deposition anddensification treatment, thus obtaining the carbon fiber reinforced silicon carbide ceramic matrix composite material. The preparation method provided by the invention has the characteristics of shortpreparation period and low preparation cost, and the prepared carbon fiber reinforced silicon carbide ceramic matrix composite material has good uniformity, high strength and reliable performance.

Owner:湖南兴晟新材料科技有限公司

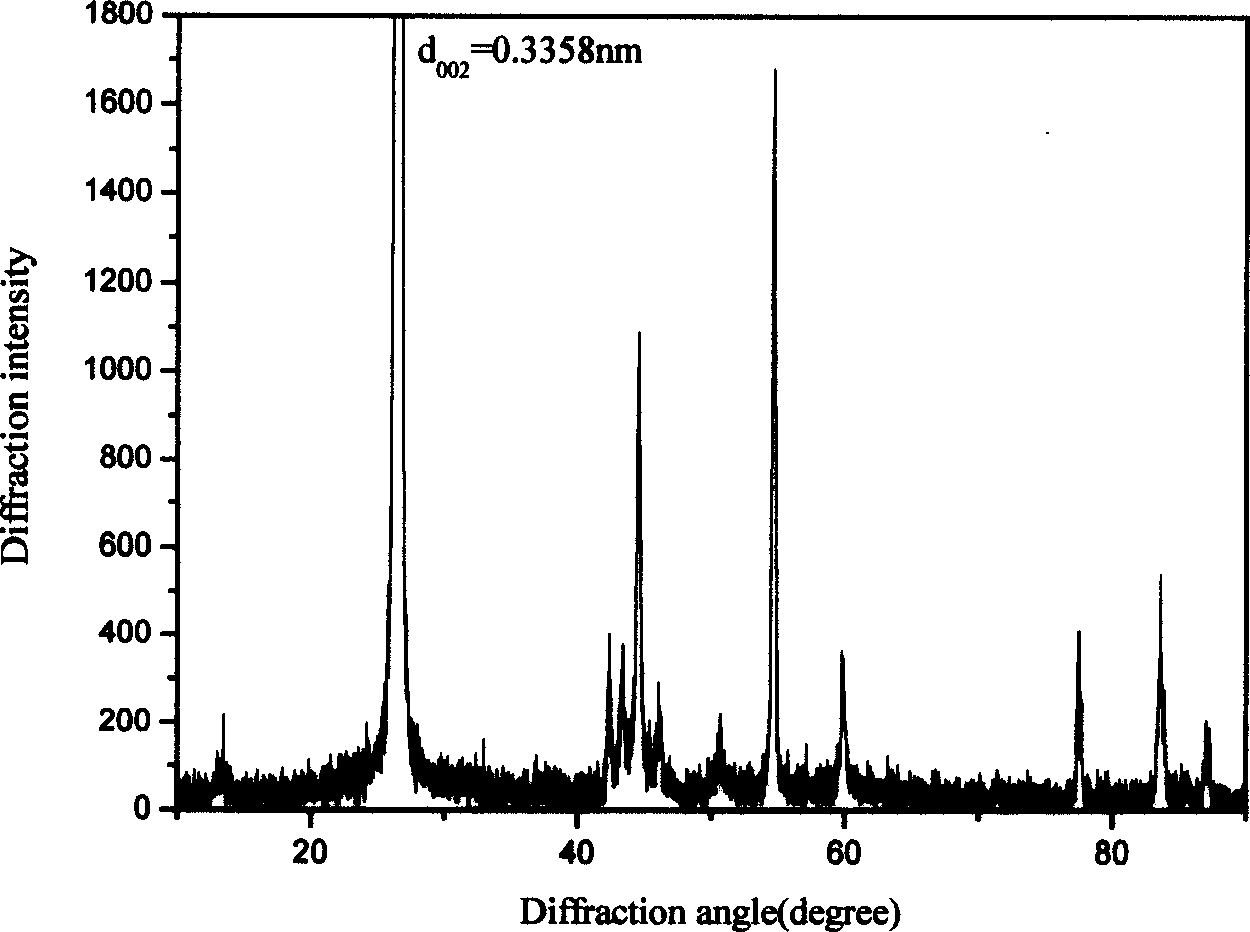

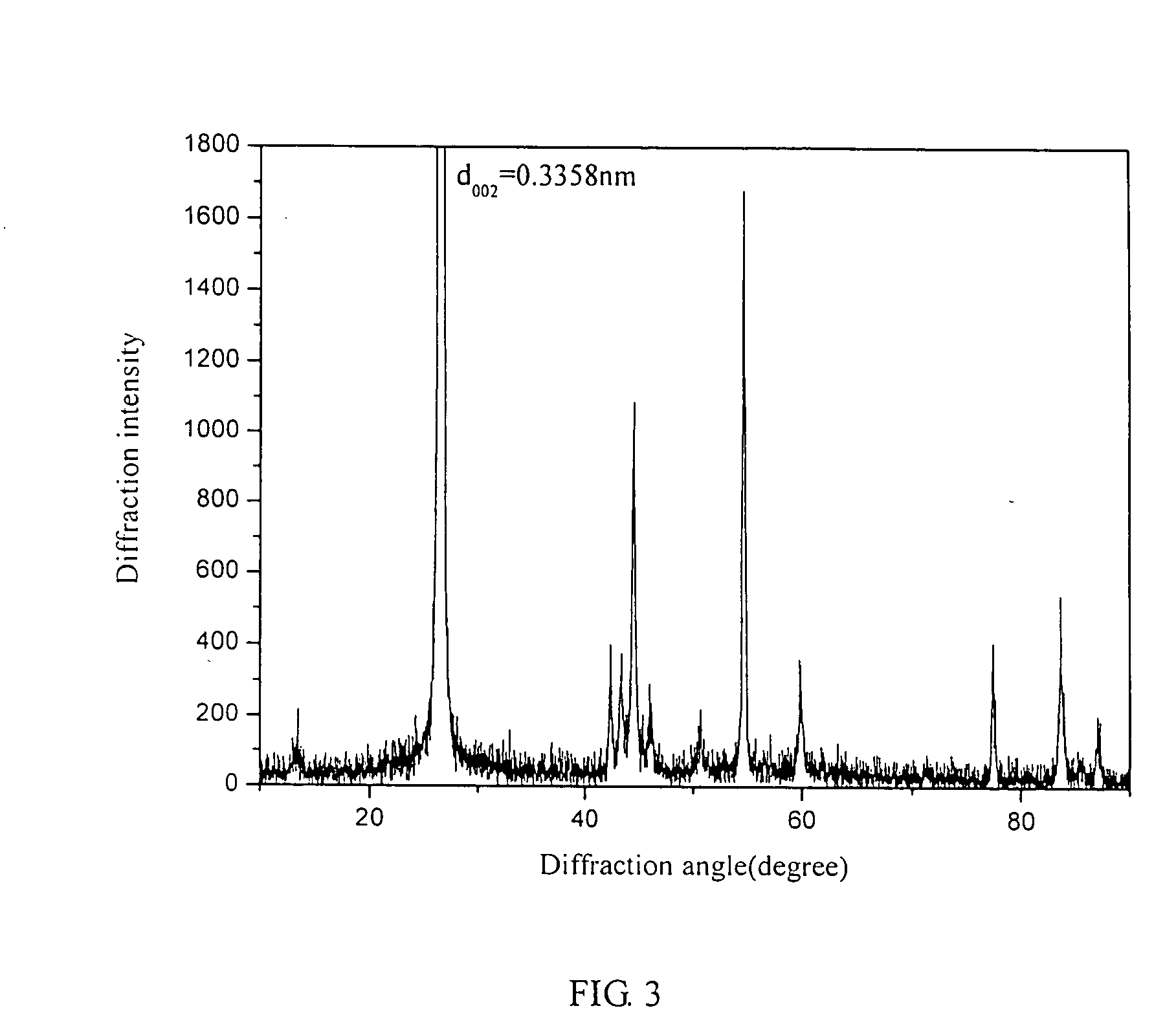

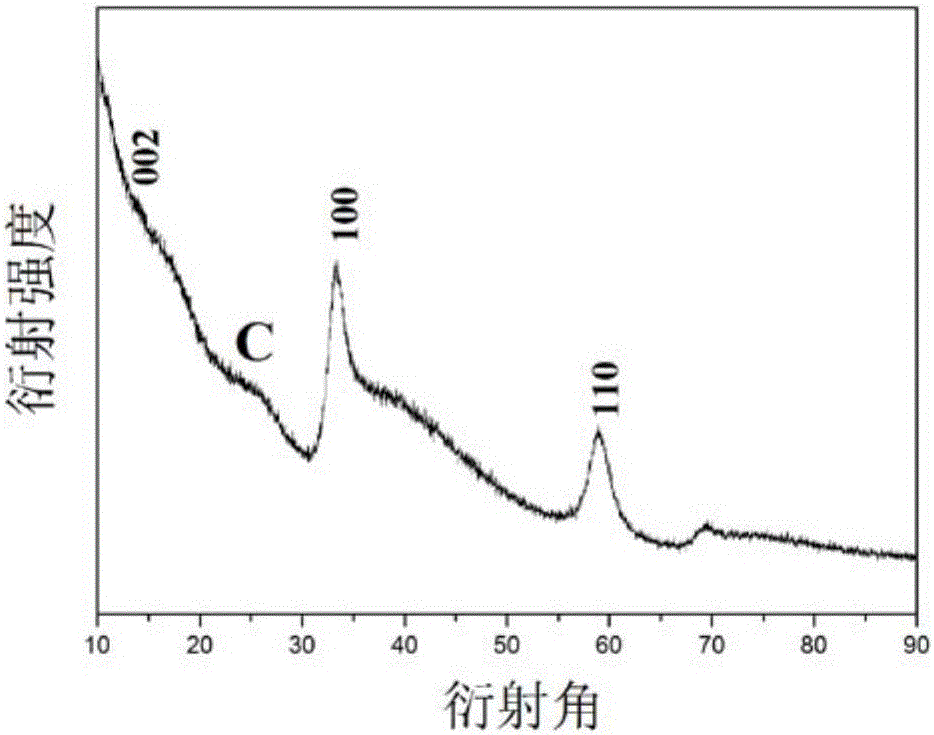

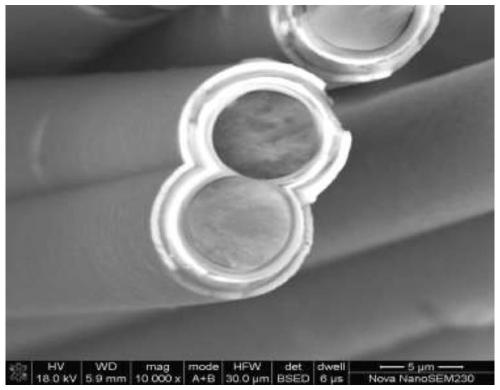

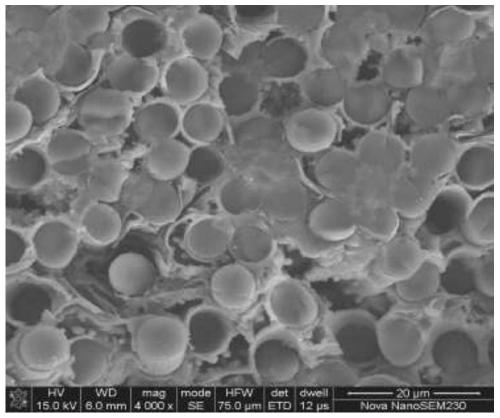

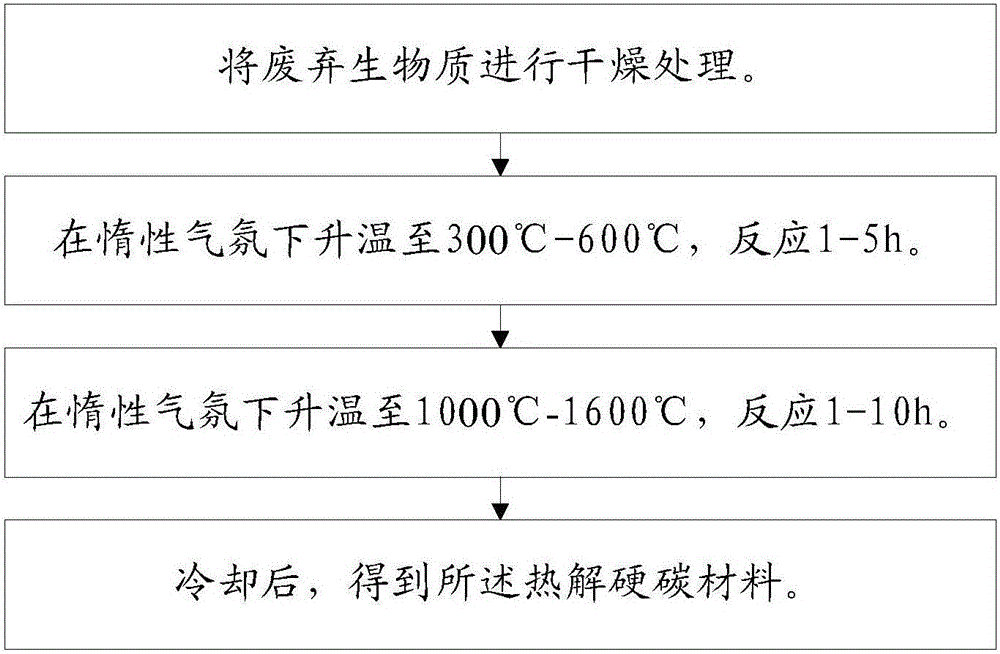

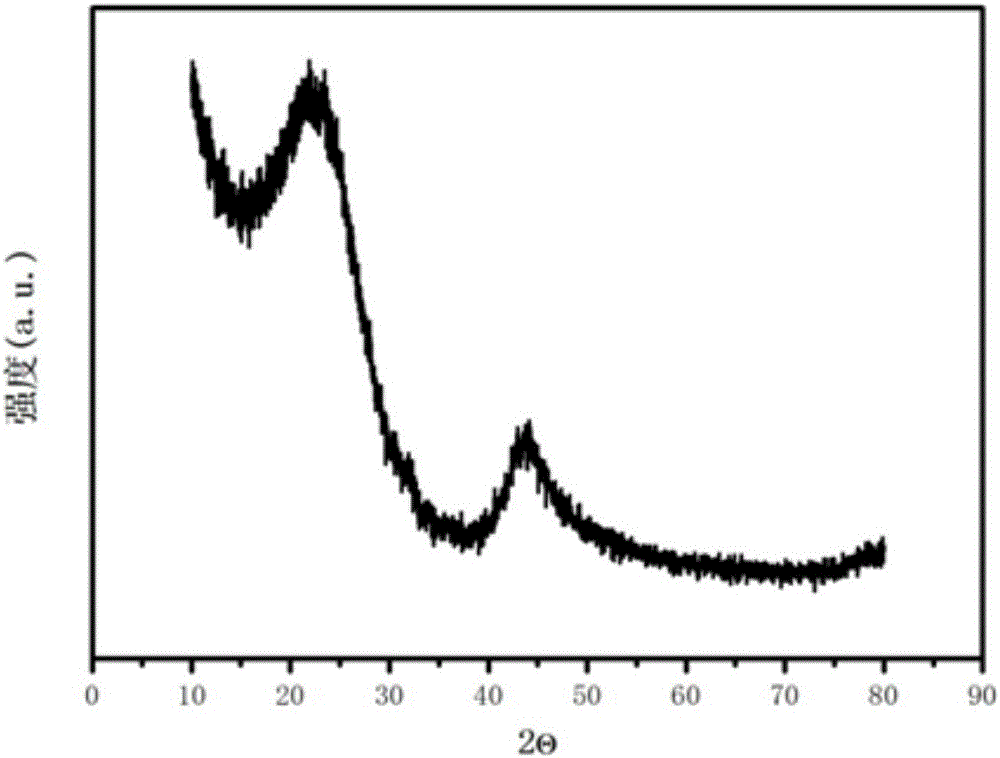

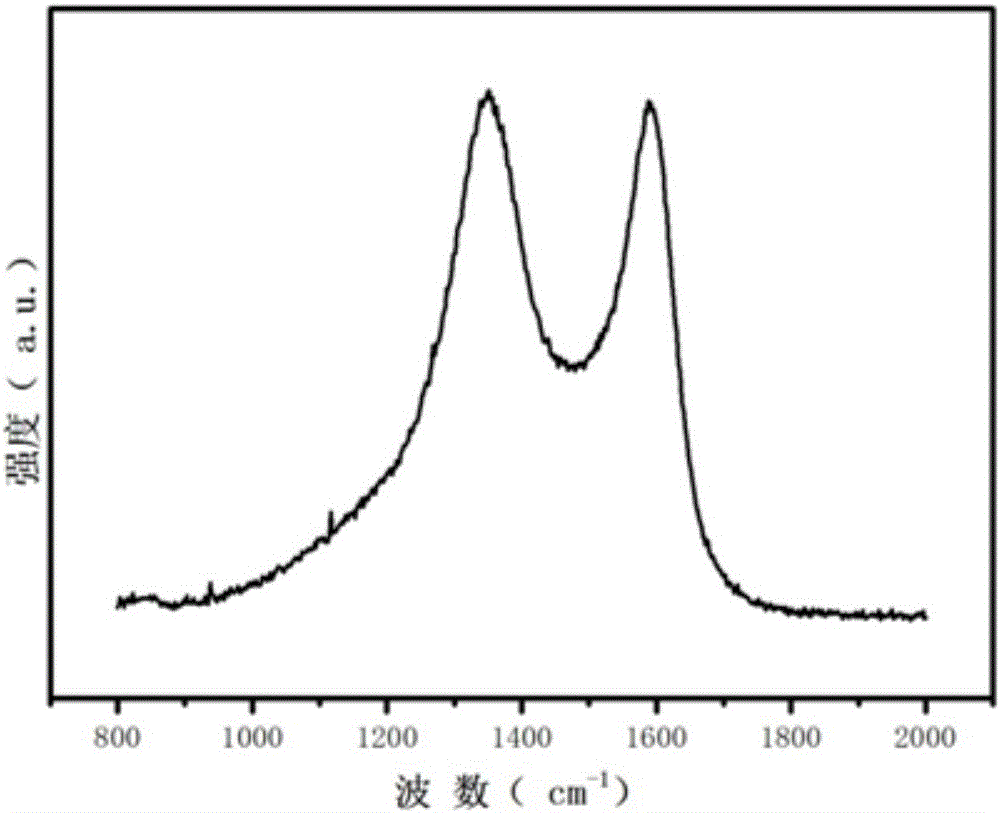

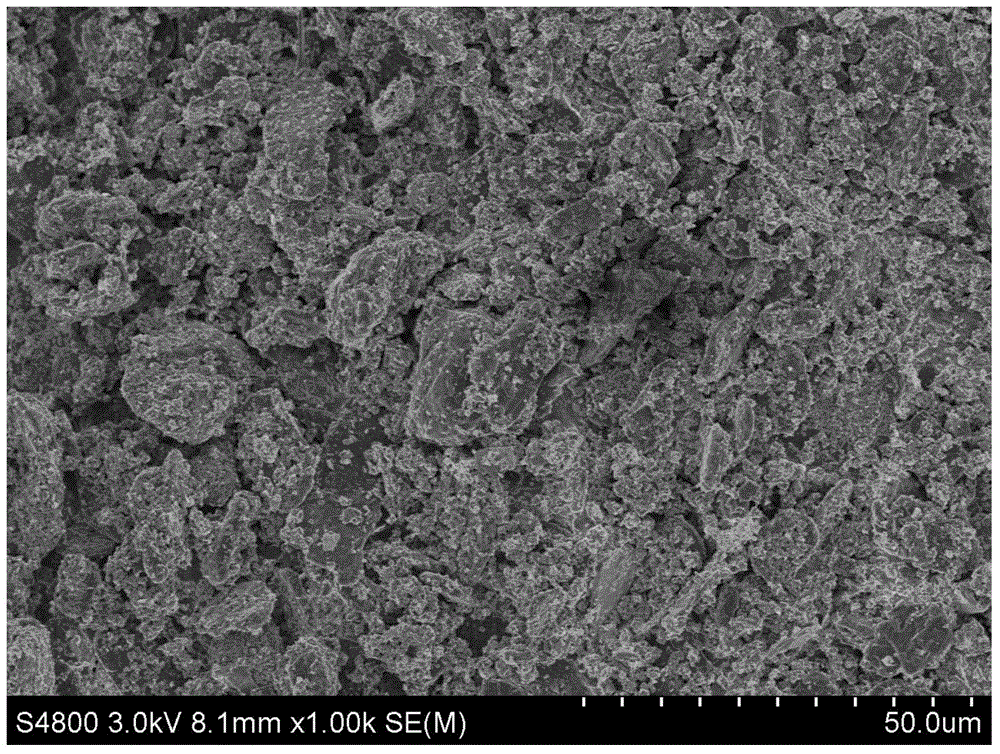

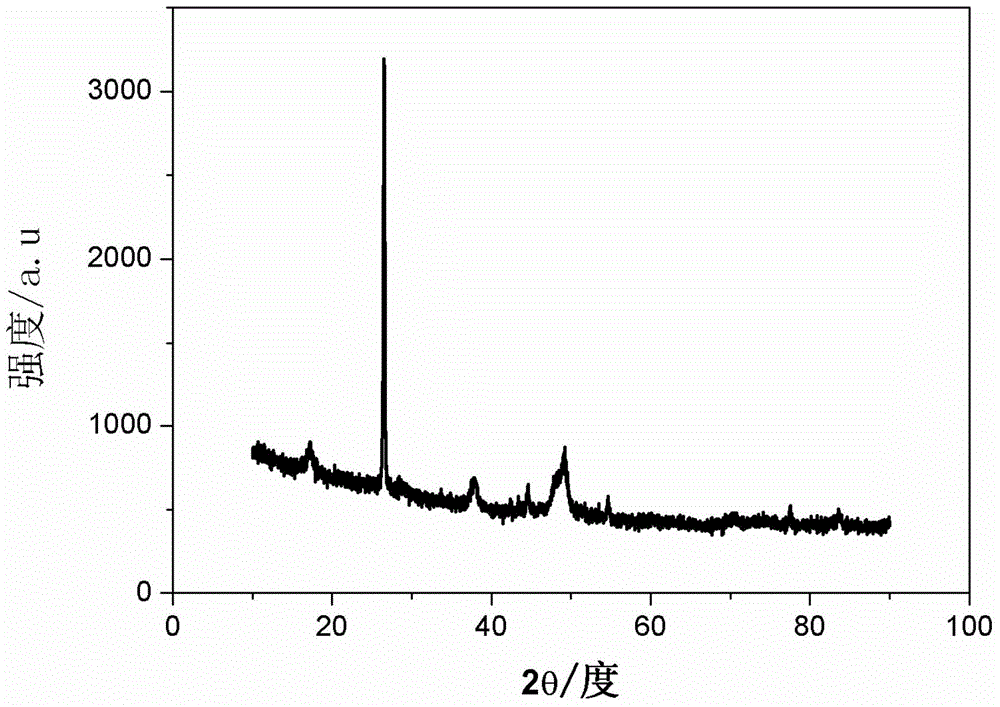

Pyrolytic hard carbon material and application thereof

The invention discloses a pyrolytic hard carbon material. In one embodiment, the material is prepared by the following steps: drying waste biomass; heating to 300-600 DEG C in an inert atmosphere, and carrying out pre-carbonization for 1-5 hours; heating to 1000-1600 DEG C in an inert atmosphere, carbonizing, and pyrolyzing for 1-10 hours; and cooling to obtain the pyrolytic carbon material. The obtained pyrolytic hard carbon material is irregular blocky particles of which the particle size is 1-20 mu m and the average particle size is 5-10 mu m; and the d002 value is 0.38-0.41nm, the Lc value is 1.3-1.5nm, and the La value is 3.7-4.7nm. The pyrolytic hard carbon material has the advantages of simple preparation process, abundant raw material resources and low cost, and is pollution-free green material. The sodium ion secondary battery prepared by using the pyrolytic hard carbon material as the negative electrode active material has the advantages of higher working voltage, higher energy density, high circulation stability and favorable safety performance, and is applicable to large-scale energy storage facilities for solar power generation, wind power generation, intelligent electric network peak shaving, distribution power stations, backup power sources or communication base stations.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

Method of Reclaiming Carbonaceous Materials From Scrap Tires and Products Derived Therefrom

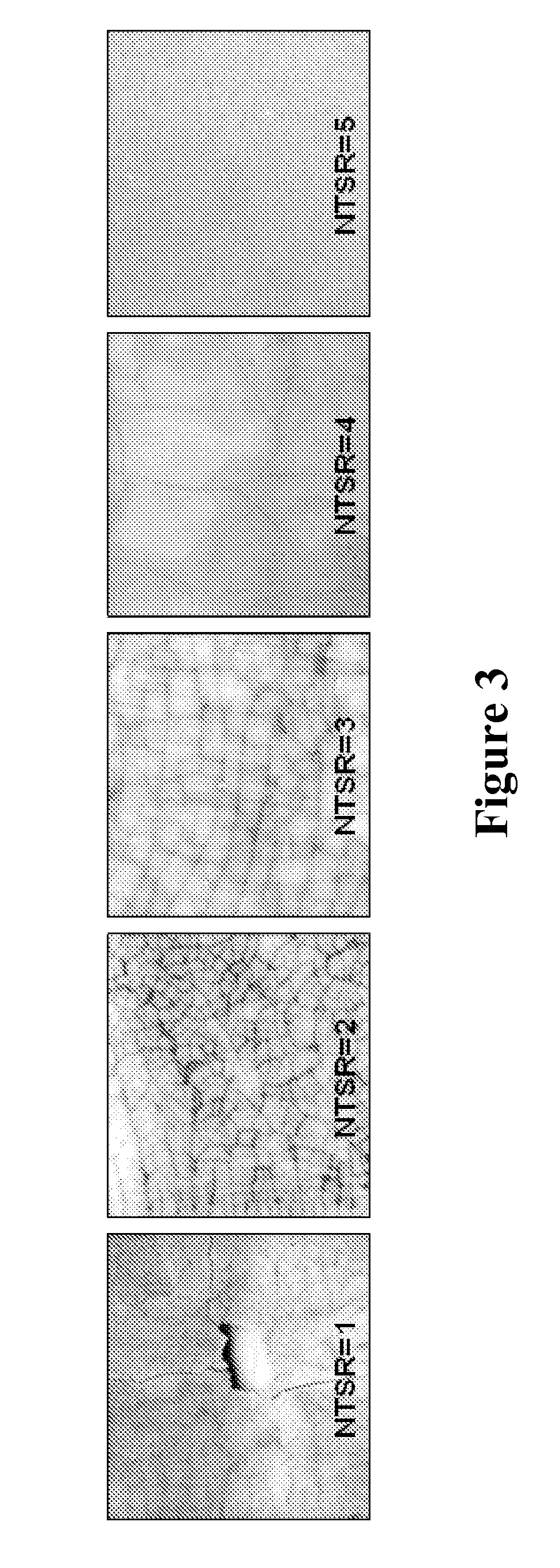

InactiveUS20100249353A1Constant production environmentQuality improvementGaseous chemical processesPressurized chemical processPyrolytic carbonMetal

The invention relates to recycled rubber produced by a process comprising the steps of: a) shredding cleaned rubber tires into shreds less than 2″ long; b) pyrolyzing the shreds in a reaction chamber of a thermal processor in a first anaerobic environment to produce a char; c) drawing off volatile organics from the reaction chamber; c) removing the char from the reaction chamber; d) cooling the char in a second anaerobic environment; e) removing metal and textile components from the char to obtain pyrolytic carbon black; f) milling and sizing the pyrolytic carbon black so obtained into particles of 325 mesh size or smaller; and, g) utilizing the pyrolytic carbon black from the previous step in a polymerization process that produces said recycled rubber. It also relates to the high quality pyrolytic carbon black recovered from this process.

Owner:BERDEKO TECH +1

Preparation method for carbon/carbon-copper composite material

InactiveCN101787504AHigh breaking strengthImprove mechanical propertiesHeating/cooling textile fabricsCross-linkCarbon composites

The invention relates to a preparation method for a carbon / carbon-copper composite material, which belongs to the technical field of special carbon fiber composite materials. The preparation method mainly comprises the following preparation processes: preparation of carbon fiber green bodies; preparation of carbon / carbon preforms; and preparation of the carbon / carbon-copper composite material. The preparation processes comprise the following steps: firstly, cross-linking fibers in a pre-oxidized fiber felt of polyacrylonitrile by using needle-punching; secondly, performing carbonization on the needle-punched pre-oxidized fiber felt to form a carbon fiber needle-punched felt; thirdly, depositing pyrolytic carbon on the surfaces of the carbon fibers by using a chemical vapor infiltration (CVI) process, or densifying the carbon fibers by using a process combining the CVI process and resin impregnation, wherein the carbon fibers are adhered together through the pyrolytic carbon or the pyrolytic carbon and resin carbon to form a porous carbon / carbon composite material preform; and fourthly, performing high-temperature treatment on the porous carbon / carbon composite material preform, and impregnating the solution of copper into the carbon / carbon composite material preform by using a gas pressure infiltration method to obtain the carbon / carbon-copper composite material finally.

Owner:SHANGHAI UNIV

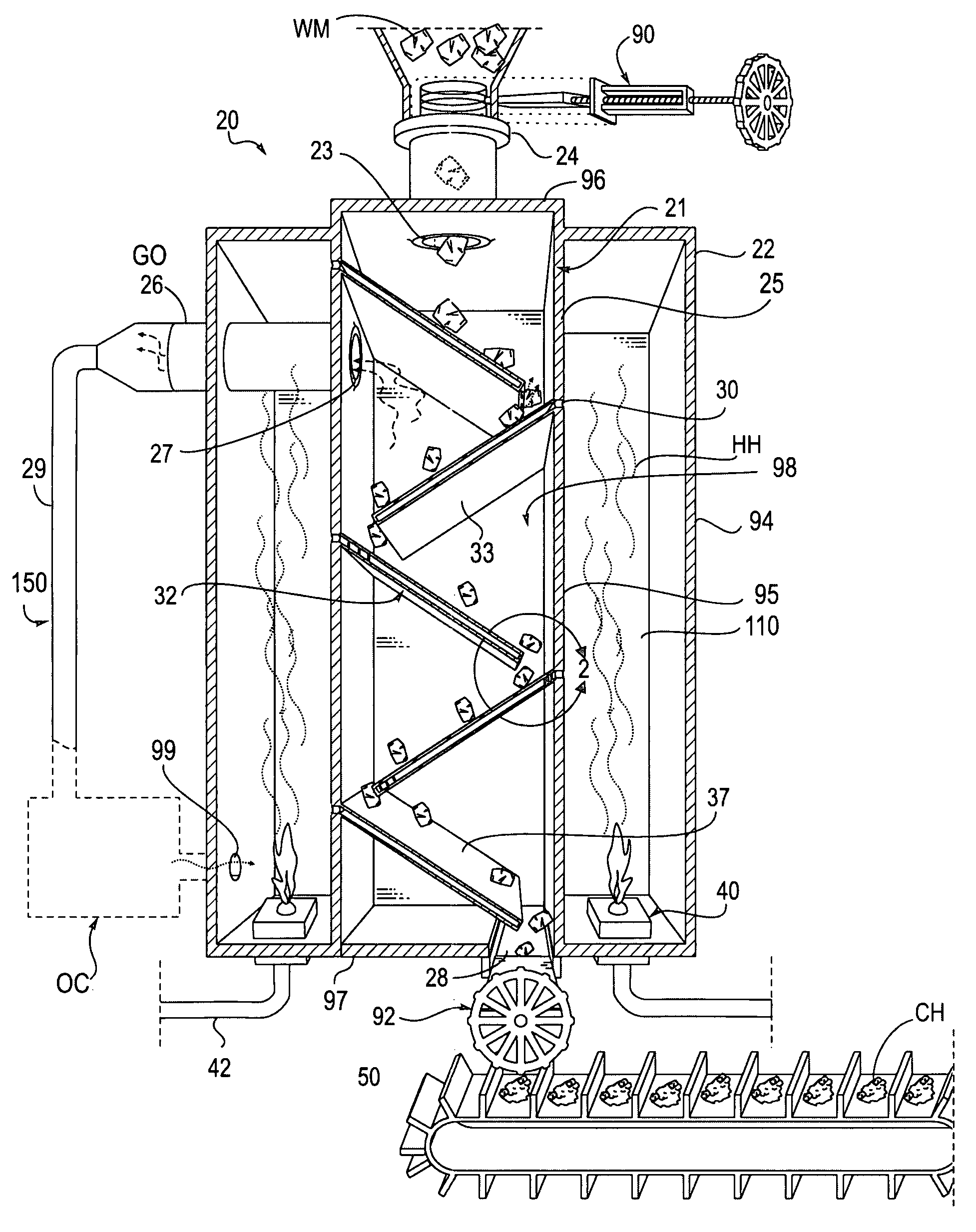

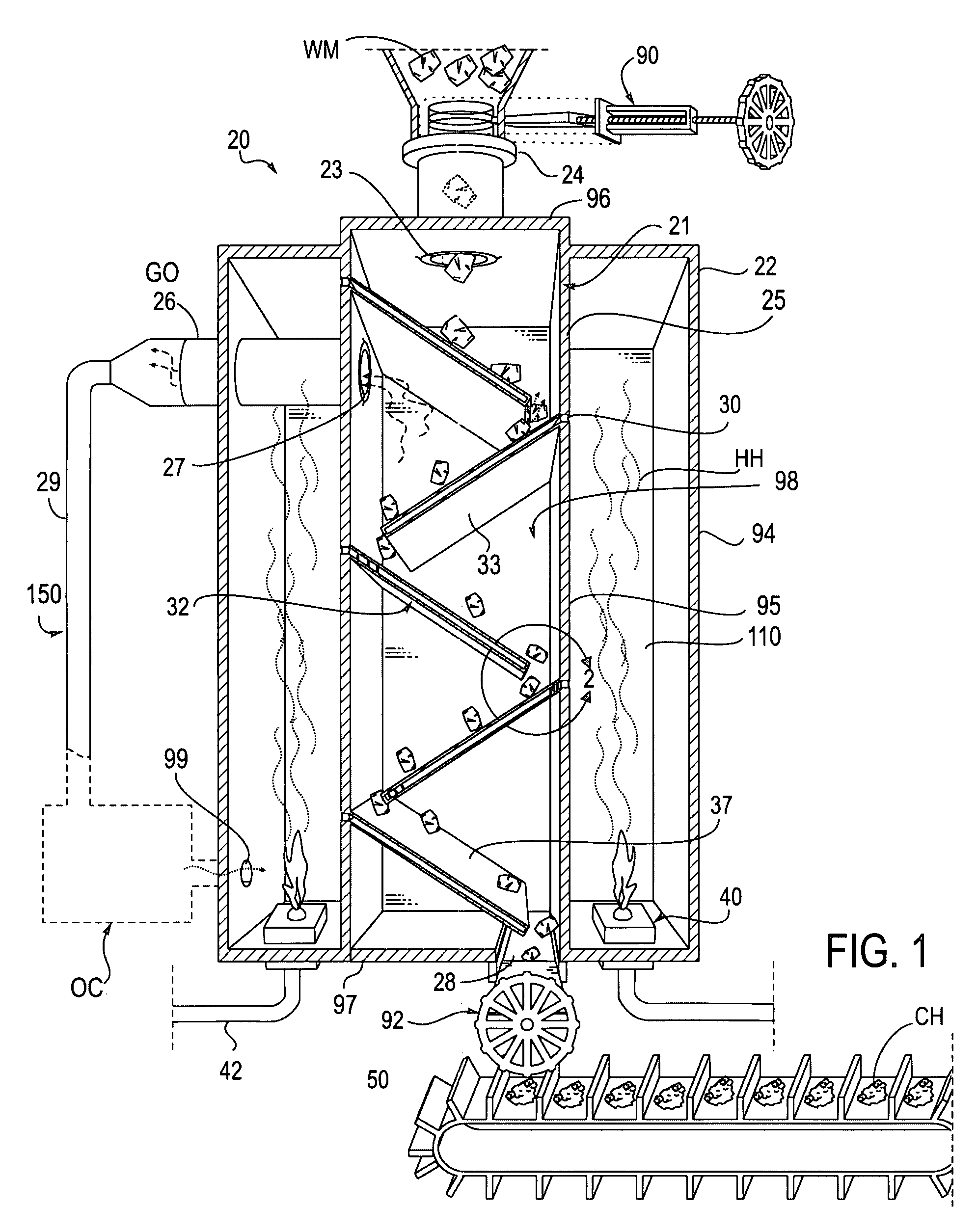

Freefall pyrolytic oven

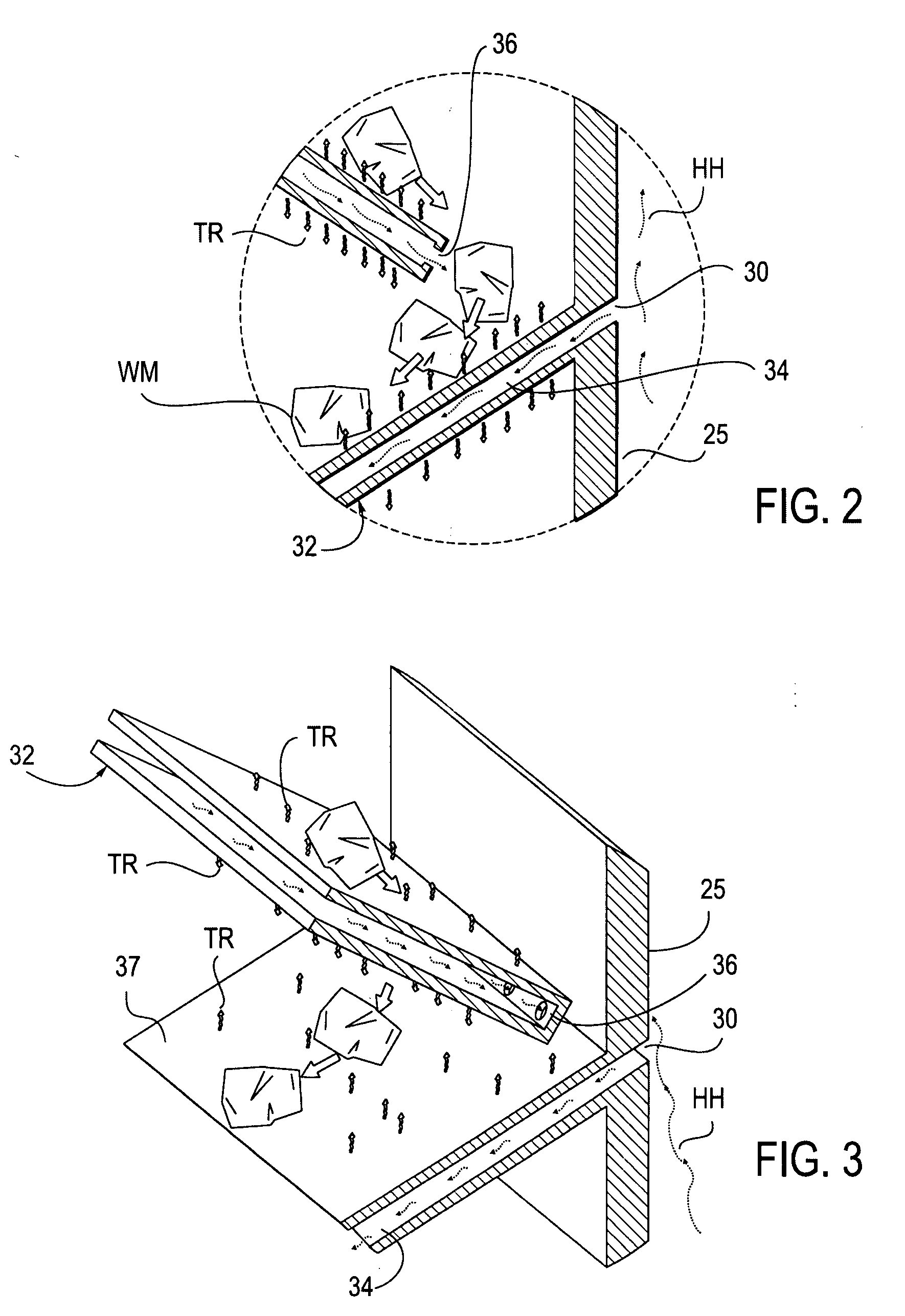

A pyrolysis oven configured for vertical conveyance of material for incineration. The oven makes use of gravity and multiple plates to control the movement of material through the oven chamber. The plates and oven interior are heated in a low oxygen, pressurized environment to effect the decomposition of material as it freefalls down the chamber and makes contact with heated plates. The configuration and angle of declination of plates determines the freefall rate and retention time within the incinerating environment. The decomposition produces char and gas resultants, each of which are carried off through separate exits configured in the oven. The oven may be used as part of a waste management system in connection with a thermal oxidation chamber for the treatment of volatile organic compound gases that are a by-product of the pyrolytic process.

Owner:SIMEKEN

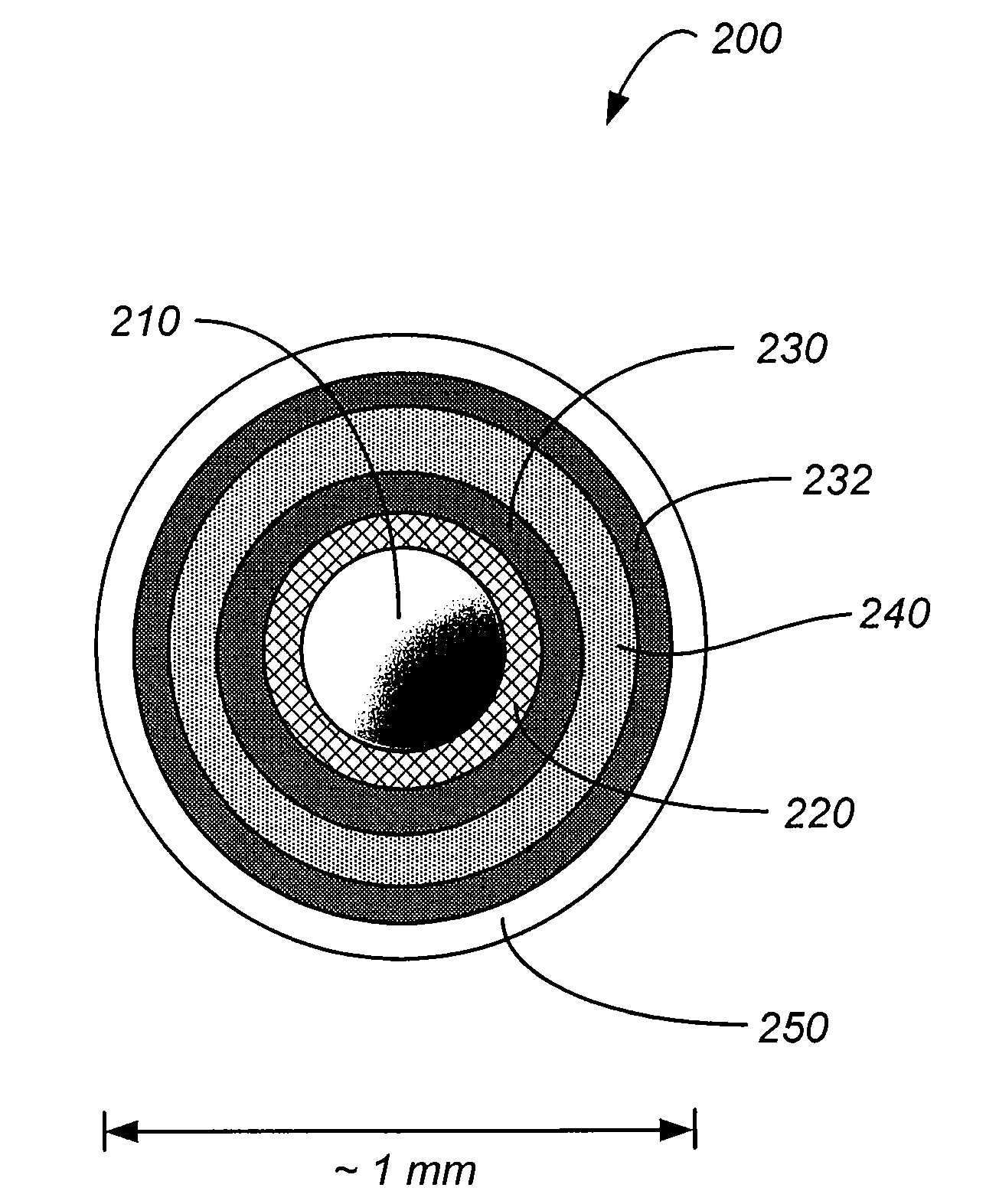

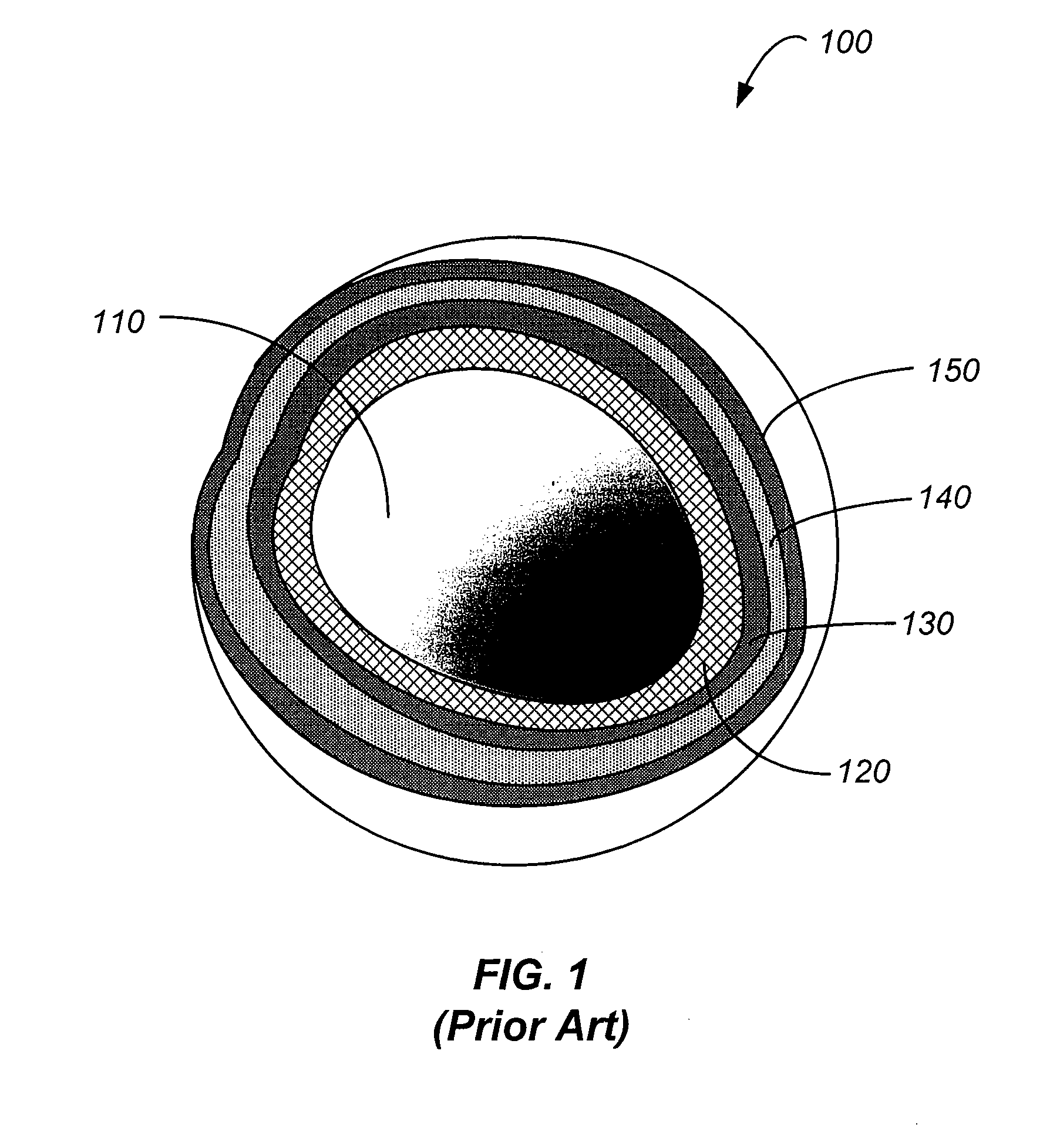

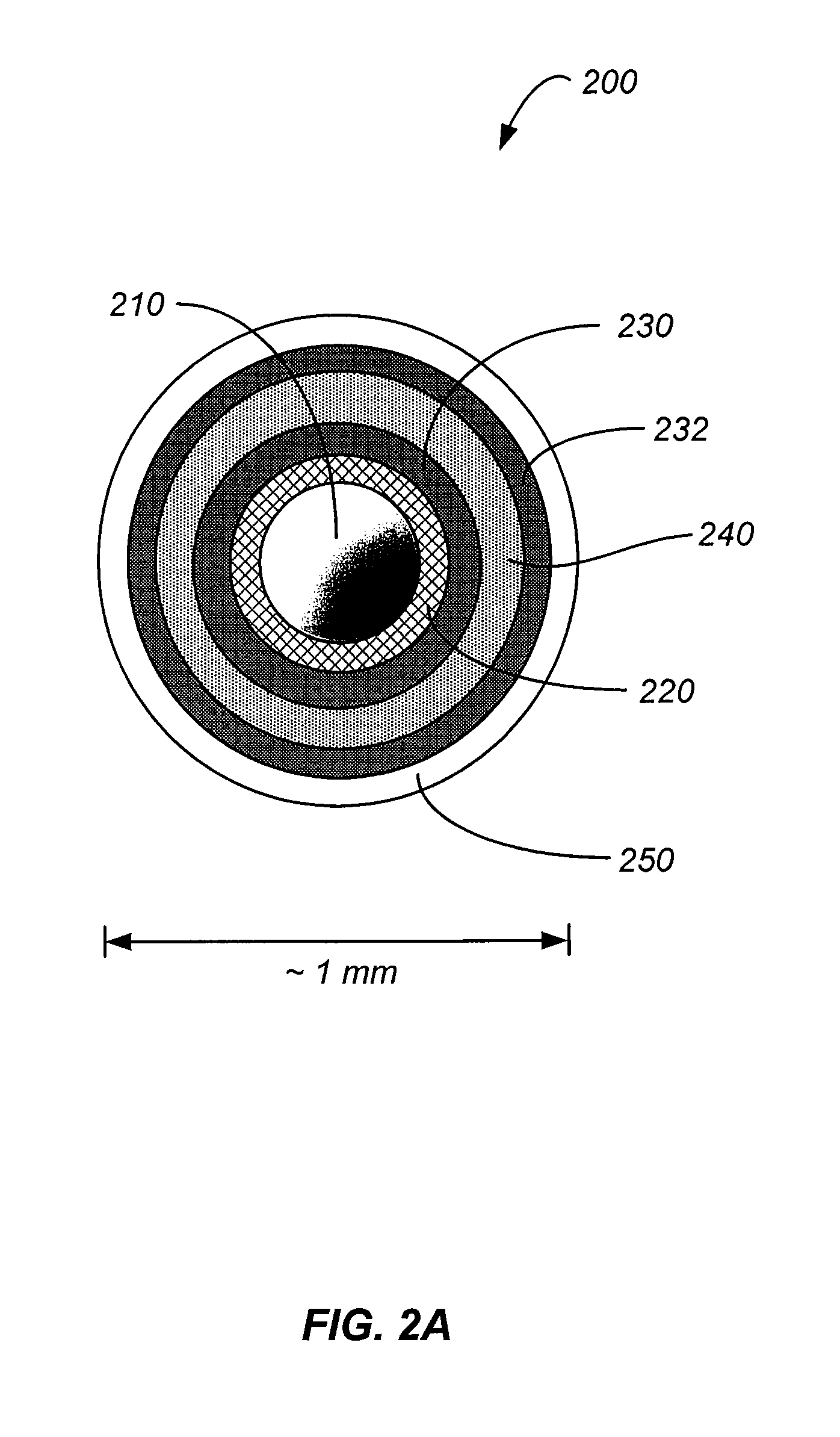

Triso fuel for high burn-up nuclear engine

A fuel particle for use in a fusion-fission nuclear engine includes a fuel kernel and a buffer layer surrounding the fuel kernel. The fuel particle also includes a pyrolytic carbon layer surrounding the buffer layer and a silicon carbide layer surrounding the buffer layer. The silicon carbide is characterized by a stress less than 450 MPa at 95% burn-up. The fuel particle further includes a second pyrolytic carbon layer surrounding the silicon carbide layer.

Owner:UNKNOWN

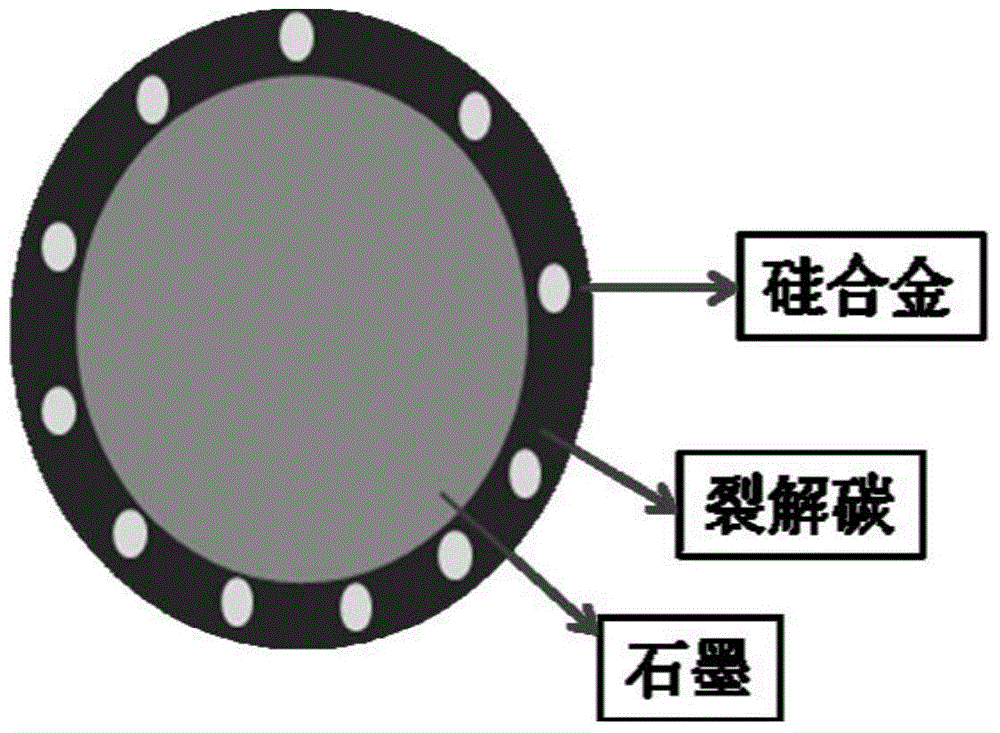

Silicon alloy composite anode material, preparation method and lithium ion battery

ActiveCN104617269AIncrease capacityStable structureCell electrodesSecondary cellsSilicon alloyGraphite

The invention discloses a silicon alloy composite anode material and a preparation method thereof as well as a lithium ion battery employing the anode material. An inner core of the anode material comprises graphite and silicon alloy applied to the surface of the graphite, and a shell is a pyrolytic carbon layer. The silicon alloy anode material with a core-shell structure is prepared in combination with nanocomposite, surface modification and coating modification technologies. The silicon alloy composite anode material is high in compaction density, good in processing performance, high in conductivity, high in first efficiency (more than 90%) and excellent in cyclic stability (400-time cyclic capacity retention rate is more than 92%); the preparation process of the anode material provided by the invention is simple, environment-friendly and pollution-free, and raw materials are low in cost.

Owner:DINGYUAN NEW ENERGY TECH CO LTD

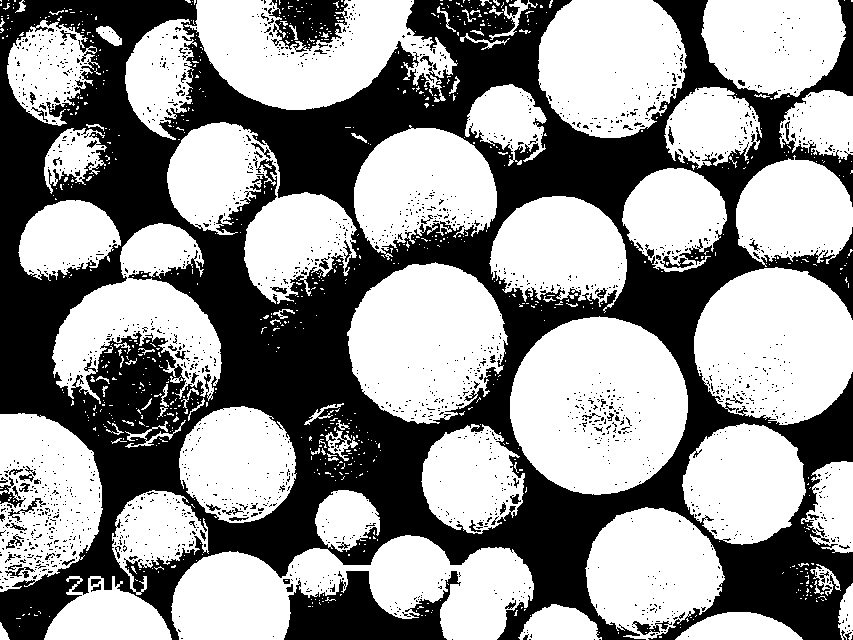

Preparation method for nitrogen-doped porous carbon sphere-sulfur composite positive material

The invention discloses a preparation method for a nitrogen-doped porous carbon sphere-sulfur composite positive material. The preparation method comprises the following steps of: performing spray pyrolysis on a nitrogen-containing carbon source, silica sol and de-ionized water to obtain a spherical nitrogen-doped pyrolytic carbon-silicon dioxide composite, adding the composite into excessive hydrofluoric acid for reaction, and washing and drying the reactants to obtain nitrogen-doped porous carbon spheres; and adding a sulfosalt solution into the nitrogen-doped porous carbon spheres under a vacuum condition, adding glycerin, which is taken as a dispersing agent, into the carbon spheres, adding an acid solution to the carbon spheres under magnetic stirring, and filtering and washing the mixture, and performing vacuum drying on the washed mixture to obtain the nitrogen-doped porous carbon sphere-sulfur composite positive material. The sulfur content of the prepared composite material is 50 to 90 percent, sulfur particles are more uniformly distributed in porous structures of the porous carbon spheres, and carbon and sulfur particles are more closely bound. The material is high in mechanical stability, specific discharge capacity and cycle performance. The method is simple in process, easy to operate, pollution-free and suitable for industrial implementation and batch production.

Owner:SHENZHEN RES INST CENT SOUTH UNIV

Application and preparation method of nanometer Fe(0)-porous sludge carbon material

InactiveCN106076256AGood dechlorination and detoxification effectSolve pollutionOther chemical processesWaste water treatment from textile industryToxicity reductionIron salts

The invention discloses a preparation method of a nanometer Fe(0)-porous sludge carbon material. The method includes: taking iron salt as an iron source of nanometer Fe(0), taking sludge as a precursor for thermal reduction of porous carbon and iron salt, taking an organic matter capable of generating a great quantity of gas by thermal decomposition at 300-500 DEG C as a pore forming agent, taking waste organics as a carbon regulating agent (in order to solve the problem of difference of organic carbon composition of sludge different in source), taking water as a harmonizing agent, and performing pyrolysis carbonization and thermal reduction at 500-900 DEG C to obtain the nanometer Fe(0)-porous sludge carbon material being 0.01-100micron in pore diameter, wherein Fe(0) average particle size is 30-80mm. The nanometer Fe(0)-porous sludge carbon material is effective in dechlorination and toxicity reduction and has a promising application prospect in various environmental pollution control fields including dehalogenation reduction, soil remediation, heavy metal wastewater treatment, printing and dyeing wastewater treatment and / or anaerobic wastewater treatment and the like, and sludge recycling and 'using waste to treat waste' are realized.

Owner:SUN YAT SEN UNIV

Lithium Iron Phosphate Cathode Materials With Enhanced Energy Density And Power Performance

The invention is related to a cathode material comprising particles having a lithium metal phosphate core and a pyrolytic carbon deposit, said particles having a synthetic multimodal particle size distribution comprising at least one fraction of micron size particles and one fraction of submicron size particles, said lithium metal phosphate having formula LiMPO4 wherein M is at least Fe or Mn.Said material is prepared by method comprising the steps of providing starting micron sized particles and starting submicron sized particles of at least one lithium metal phosphate or of precursors of a lithium metal phosphate; mixing by mechanical means said starting particles; making a pyrolytic carbon deposit on the lithium metal phosphate starting particles before or after the mixing step, and on their metal precursor before or after mixing the particles; optionally adding carbon black, graphite powder or fibers to the said lithium metal phosphate particles before the mechanical mixing.

Owner:CLARIANT (CANADA) INC

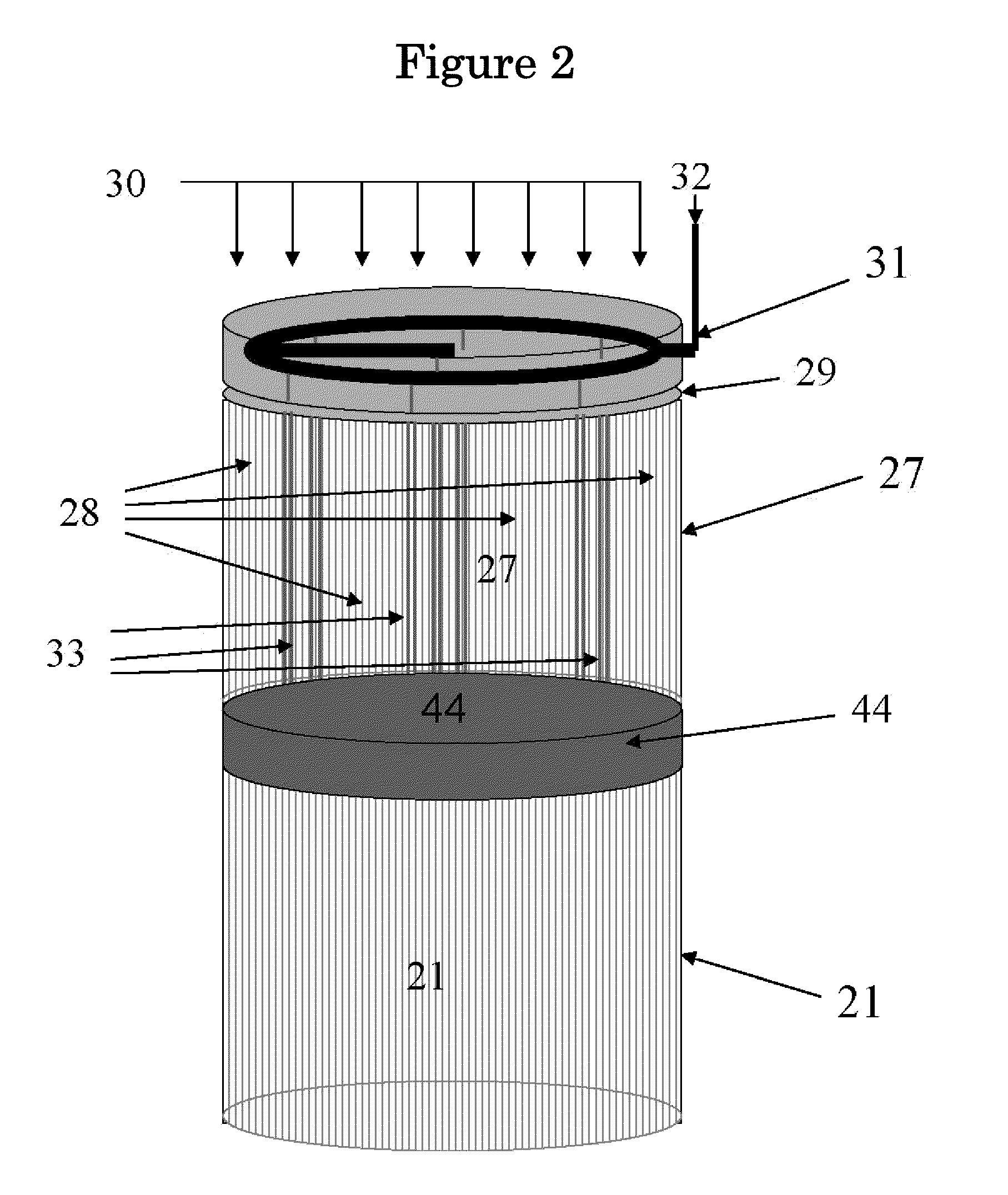

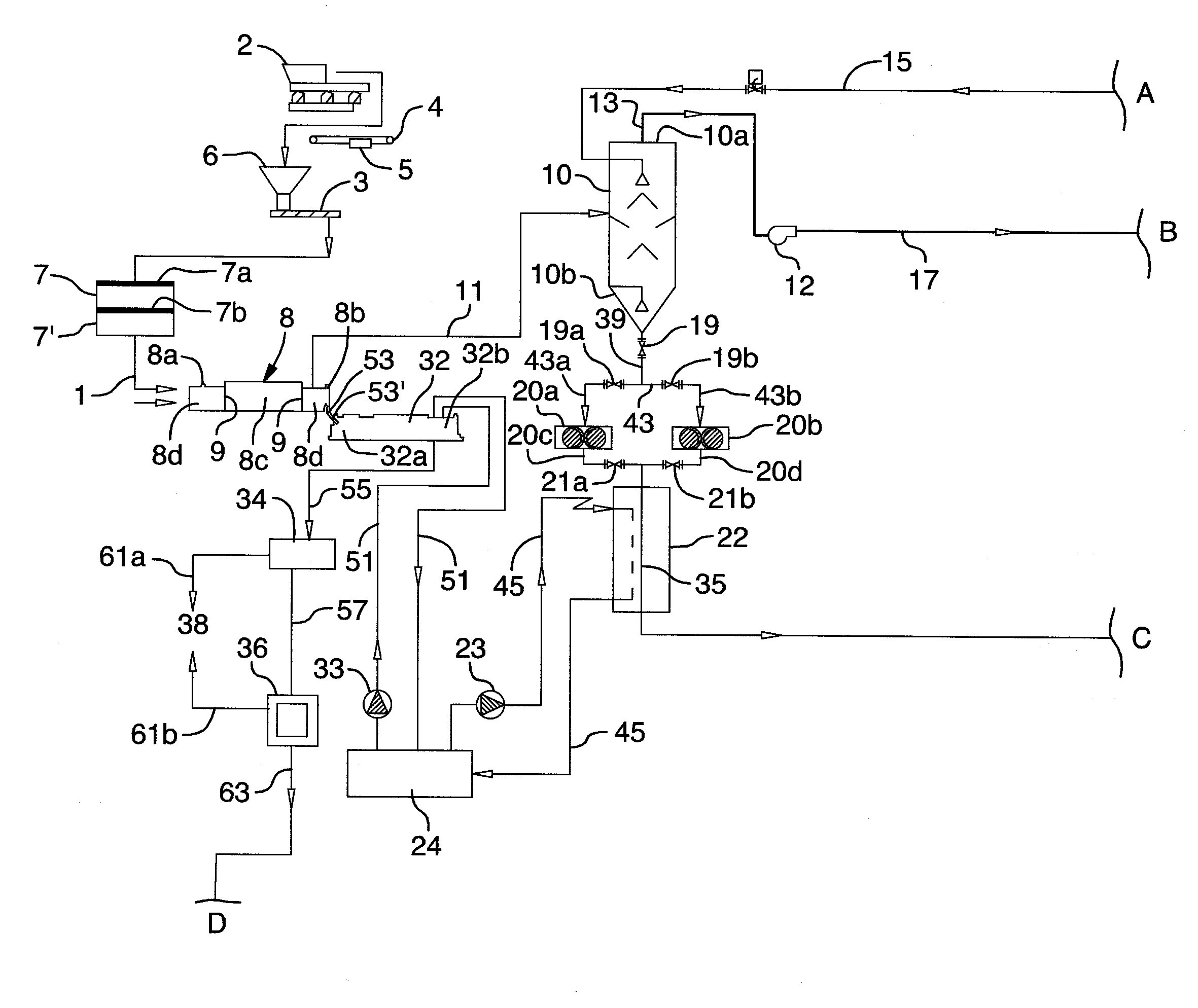

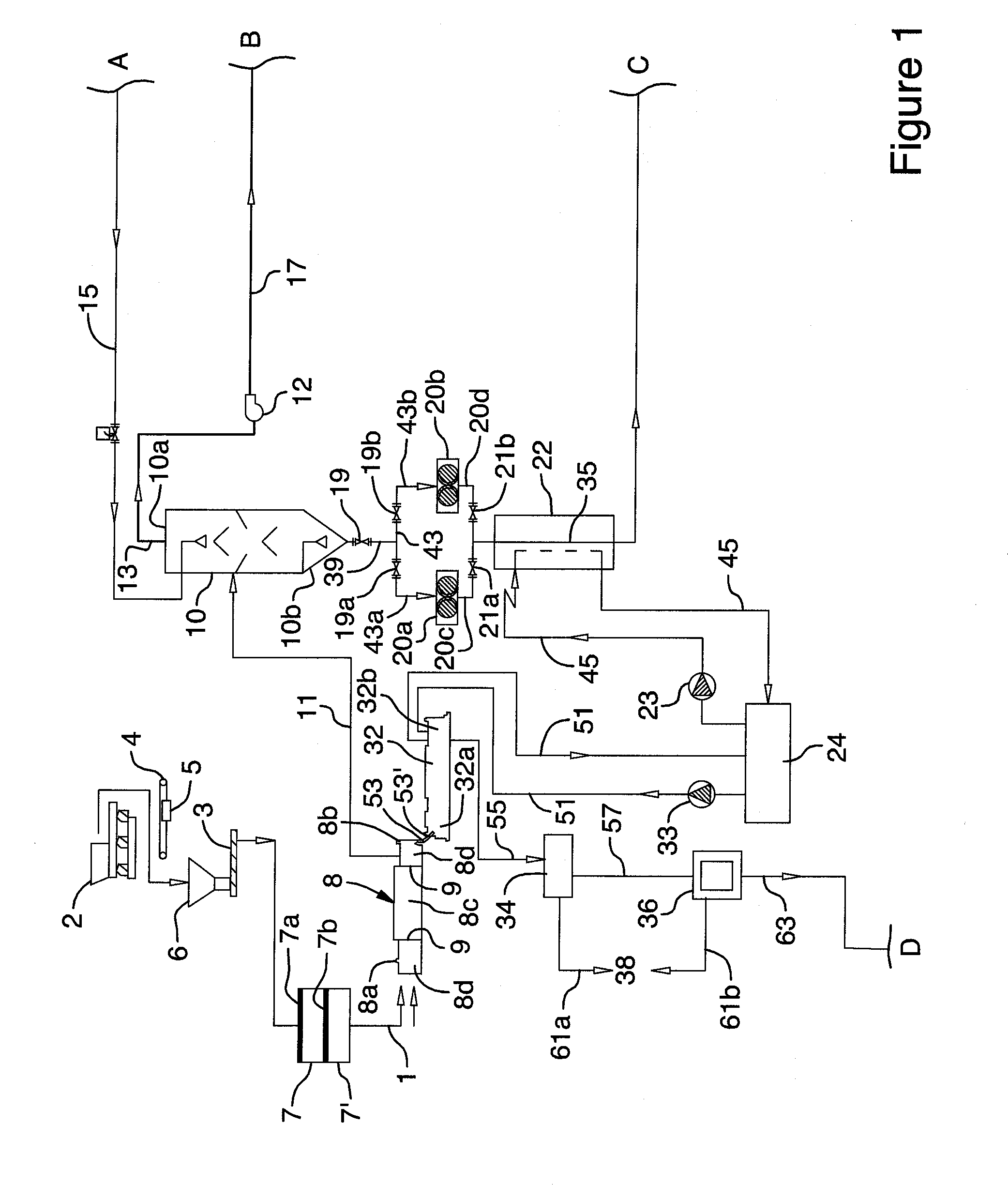

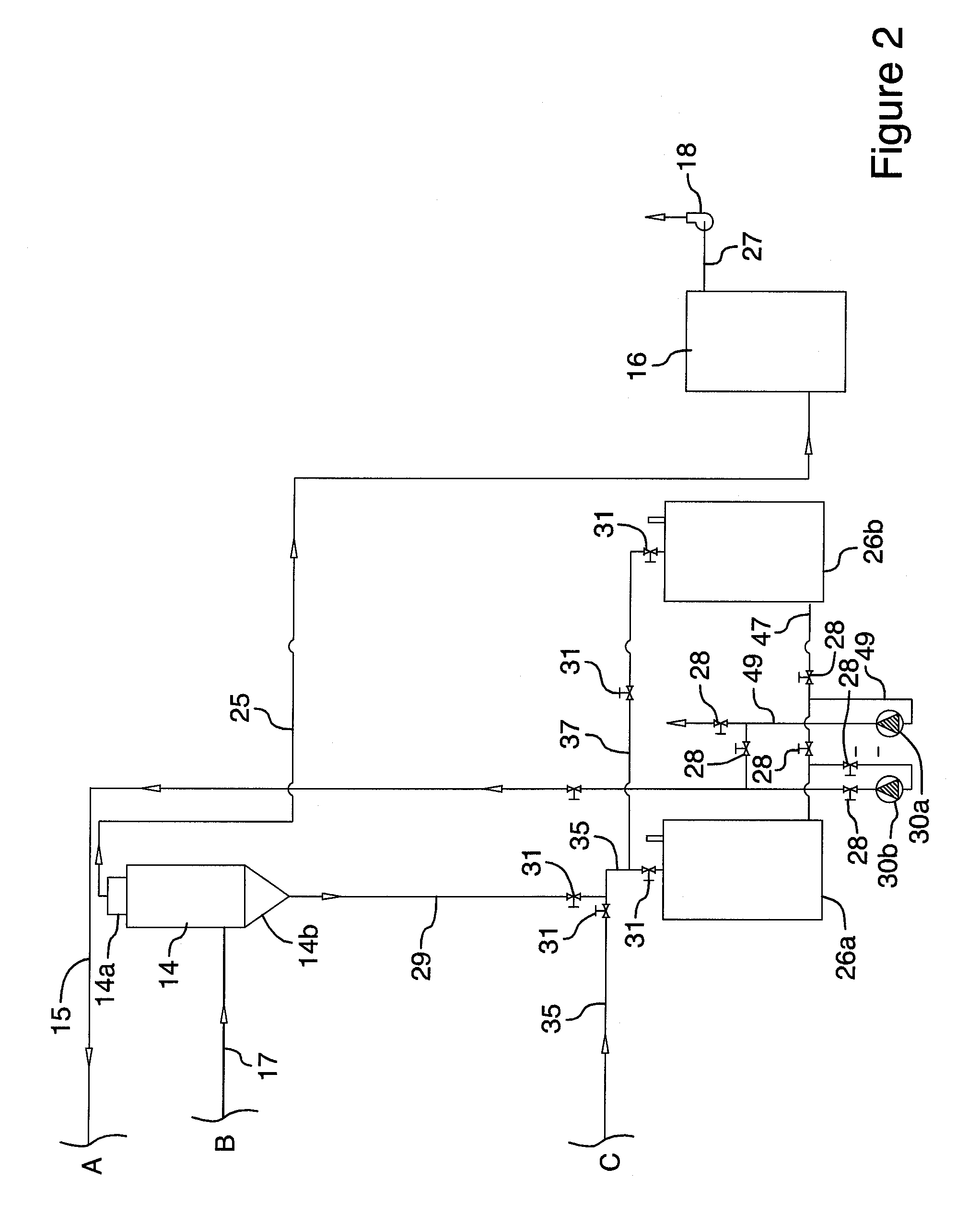

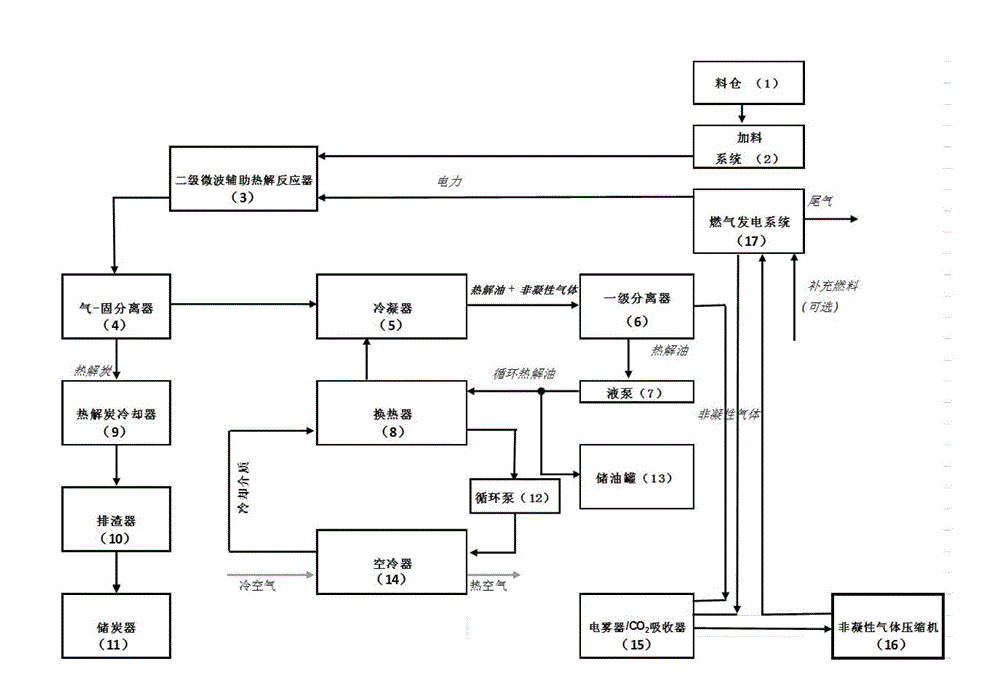

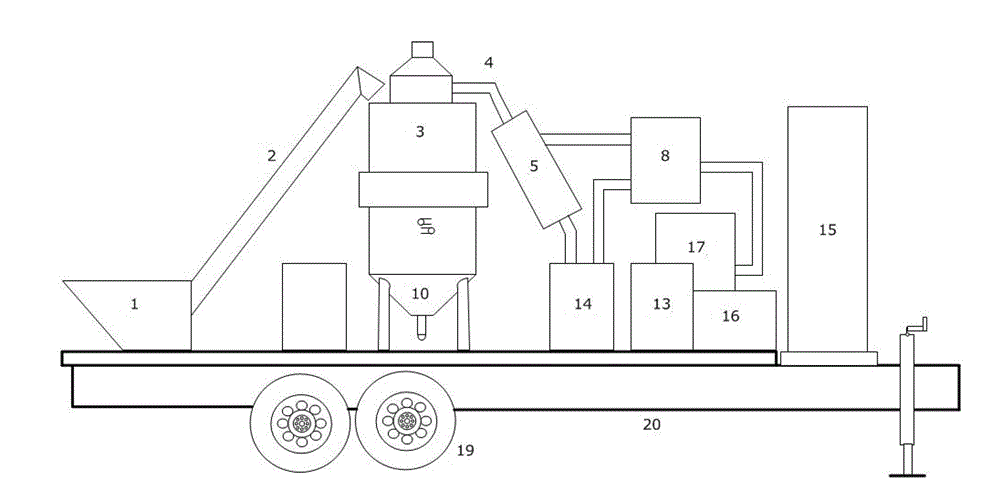

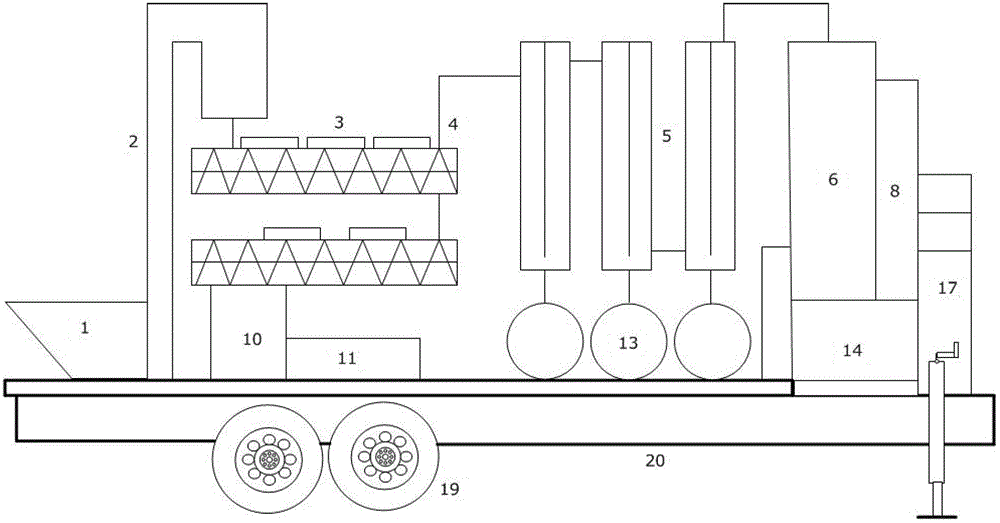

Pyrolysis device and method for in-situ conversion of carbon-containing resources by microwave-assisted pyrolysis

ActiveCN102718383ASolve the difficulty of large-scale collectionSolve the inconvenience of storage and transportationSludge treatment by pyrolysisByproduct vaporizationSlagChar

The invention discloses a pyrolysis device for in-situ conversion of carbon-containing resources by microwave-assisted pyrolysis. The device comprises a microwave-assisted pyrolysis reactor, a solid outlet of the reactor is connected with an inlet of a pyrolytic carbon cooler, an outlet of the pyrolytic carbon cooler is connected with a slag storer through a deslagging machine, a gas outlet of the reactor is connected with an inlet of a condenser through a pipeline, the condenser is provided with a gas-liquid separator, a gas outlet of the condenser is connected with a gas purifier, an outlet of the gas purifier is connected with a gas compressor, a liquid outlet of the condenser is connected with a liquid circulating pump, then one branch of the condenser is connected with an oil storage tank, and the other branch of the condenser is connected back to the condenser through a cooling medium circulating system. The invention further discloses a method for the in-situ conversion of the carbon-containing resources by the microwave-assisted pyrolysis. By the pyrolysis device and the method for the in-situ conversion of the carbon-containing resources by the microwave-assisted pyrolysis, various low-grade carbon-containing resources can be collected, stored and continuously produced at an economic scale.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

Method and assembly of a pyrolytic carbon component attached to another component

Owner:TORNIER SA SAINT ISMIER

SiCf/SiC ceramic-based composite material with composite interfaces

InactiveCN107540400AIncrease temperatureGood toughening effectAntioxidant capacityOxidation resistant

A SiCf / SiC ceramic-based composite material with composite interfaces is characterized by comprising CVD-SiC coating, a PIP-SiC matrix, the composite interfaces and SiC fiber, wherein the CVD-SiC coating is silicon carbide coating prepared through a chemical vapor deposition method, and has the thickness of 100-500 microns; the composite interfaces are formed by alternately and periodically overlapping any two or three of a BN interface, a ZrO2 interface, an LaPO4 interface and an SiC interface, and the cycle period frequency is 3-5 times; the PIP-SiC matrix is silicon carbide formed through in-situ pyrolysis of polycarbosilane; the SiC fiber accounts for 40-60% of the composite material by volume, a pyrolytic carbon layer with the thickness of 5-20 nanometers is formed on the surface thereof. A preparation method comprises the following steps: preparing multiple layers of composite interfaces on the surface of the silicon carbide fiber by different preparation processes, then fillingthe SiC matrix by a PIP method, and finally preparing the surface SiC coating by a CVD method. The SiCf / SiC ceramic-based composite material prepared through the preparation method provided by the invention is high in toughness and strong in antioxidant capacity, and the preparation process is simple.

Owner:SUZHOU HONGJIU AVIATION THERMAL MATERIALS TECH CO LTD

Orthopedic Implants Coated with Pyrolytic Carbon

InactiveUS20070156250A1Resistance to frictionResistant to wearImpression capsBone implantGas phaseTitanium

An orthopedic implant having a metal substrate with an articulating surface includes a coating for the articulating surface made of pyrolytic carbon. Typically, the substrate is made of a metal such as titanium or stainless steel, or alloys thereof. The pyrolytic carbon coating preferably is applied by vapor deposition.

Owner:SEITZ WILLIAM H JR +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com