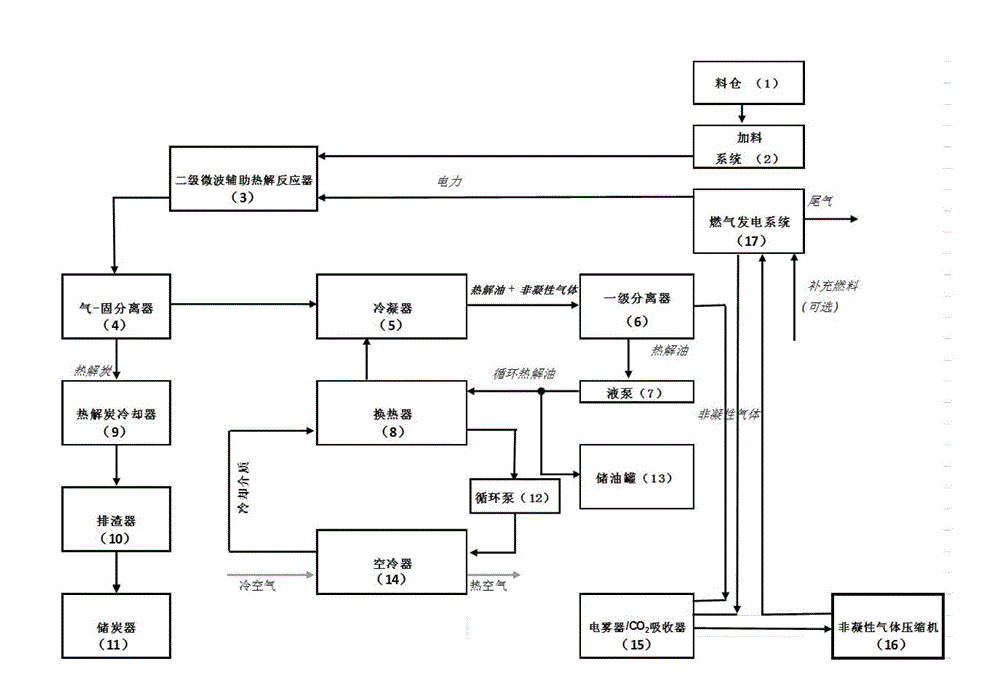

Pyrolysis device and method for in-situ conversion of carbon-containing resources by microwave-assisted pyrolysis

A microwave-assisted and pyrolysis technology, applied in the field of waste recycling equipment, can solve the problems of inconvenient starting and parking, increased energy consumption, long-term preheating, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

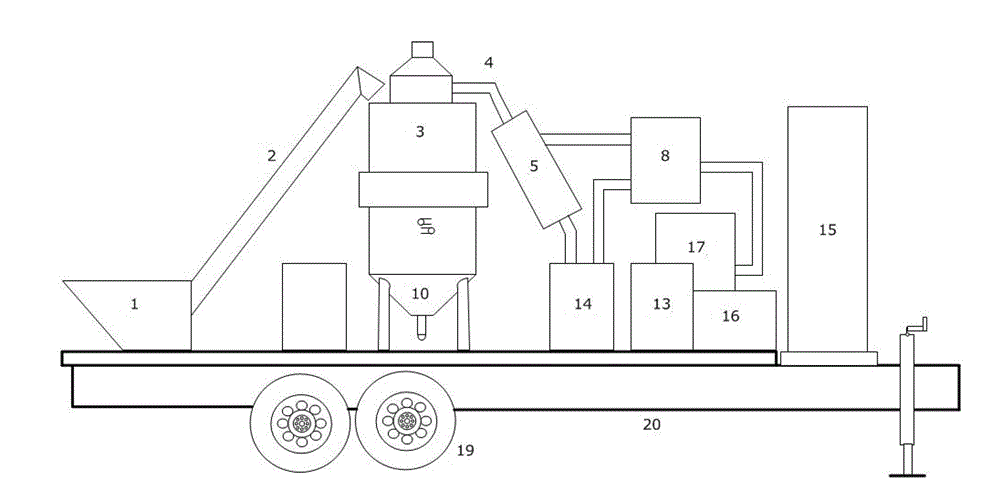

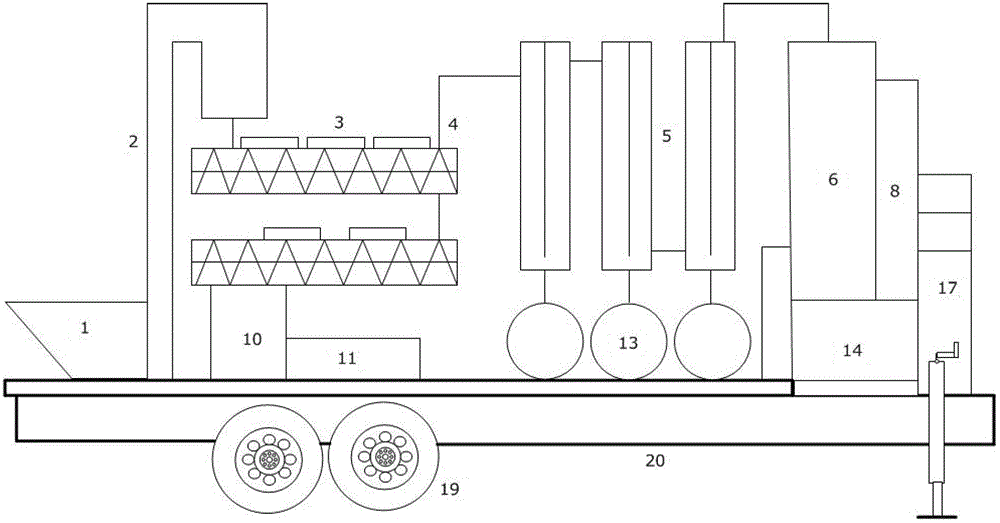

[0141] Example 1: Microwave-assisted pyrolysis of corn stalks

[0142] Put the pyrolysis device on an agricultural trailer, enter the corn stalk drying site, and send the collected 1200 kg corn stalks to the slicer for slicing. The particles are sent to the silo by the crawler conveyor through the bucket elevator, and then enter the microwave-assisted pyrolysis reactor; in the microwave-assisted pyrolysis reactor, the corn straw particles are absorbed by the microwave magnetron and transmitted through the waveguide Rapid heating and pyrolysis after microwave energy;

[0143] The generated condensable steam, together with other gases and solid particles (pyrolysis semi-coke), enters the solid outlet of the microwave-assisted pyrolysis reactor through the cyclone separator, and enters the semi-coke ash hopper (that is, the pyrolysis carbon cooler 9) for cooling A part of the semi-coke is removed from the system through the slag storage device 11 as a by-product or molded in sit...

Embodiment 2

[0146] Example 2: Microwave-assisted pyrolysis of dry branches and leaves

[0147] Put the pyrolysis device on a small trailer, enter the forest site, and send 1,800 kg of dry branches and leaves collected into a small granule molding machine to be pressed into granules. ; The particles that meet the requirements are sent into the silo through the bucket elevator, and then enter the microwave-assisted pyrolysis reactor; Rapid heating and pyrolysis after microwave energy;

[0148] The generated condensable steam, together with other gases and solid particles (pyrolysis semi-coke), passes through the gas-solid separator 4 and enters the solid outlet of the microwave-assisted pyrolysis reactor, and enters the semi-coke ash hopper (that is, the pyrolysis carbon cooler 9 ) cooling, a part of semi-coke is removed from the system through the slag storage device 11 as a by-product or formed in situ to make a lump charcoal product; the other part of semi-coke is used as a microwave ab...

Embodiment 3

[0151] Example 3: Microwave-assisted pyrolysis of waste tires

[0152] A certain number of waste tires are processed by a slicer and a wire stripper to form waste tire particles. The characteristic size of the waste tire particles is not greater than 20mm; the waste tire particles are sent to a mobile pyrolysis device, and the feeding rate and microwave-assisted heating are controlled. The power of the pyrolysis reactor is used to collect pyrolysis semi-coke (carbon black) and pyrolysis oil. The relationship between the product yield and the power used in the test is shown in the table below:

[0153]

[0154] Instructions: Keep feed rate the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| power | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com