Patents

Literature

1199results about "Byproduct vaporization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Treatment of biomass to obtain fermentable sugars

InactiveUS20070031918A1Toxic reductionReduce needBiological substance pretreatmentsByproduct vaporizationFermentable sugarCompound (substance)

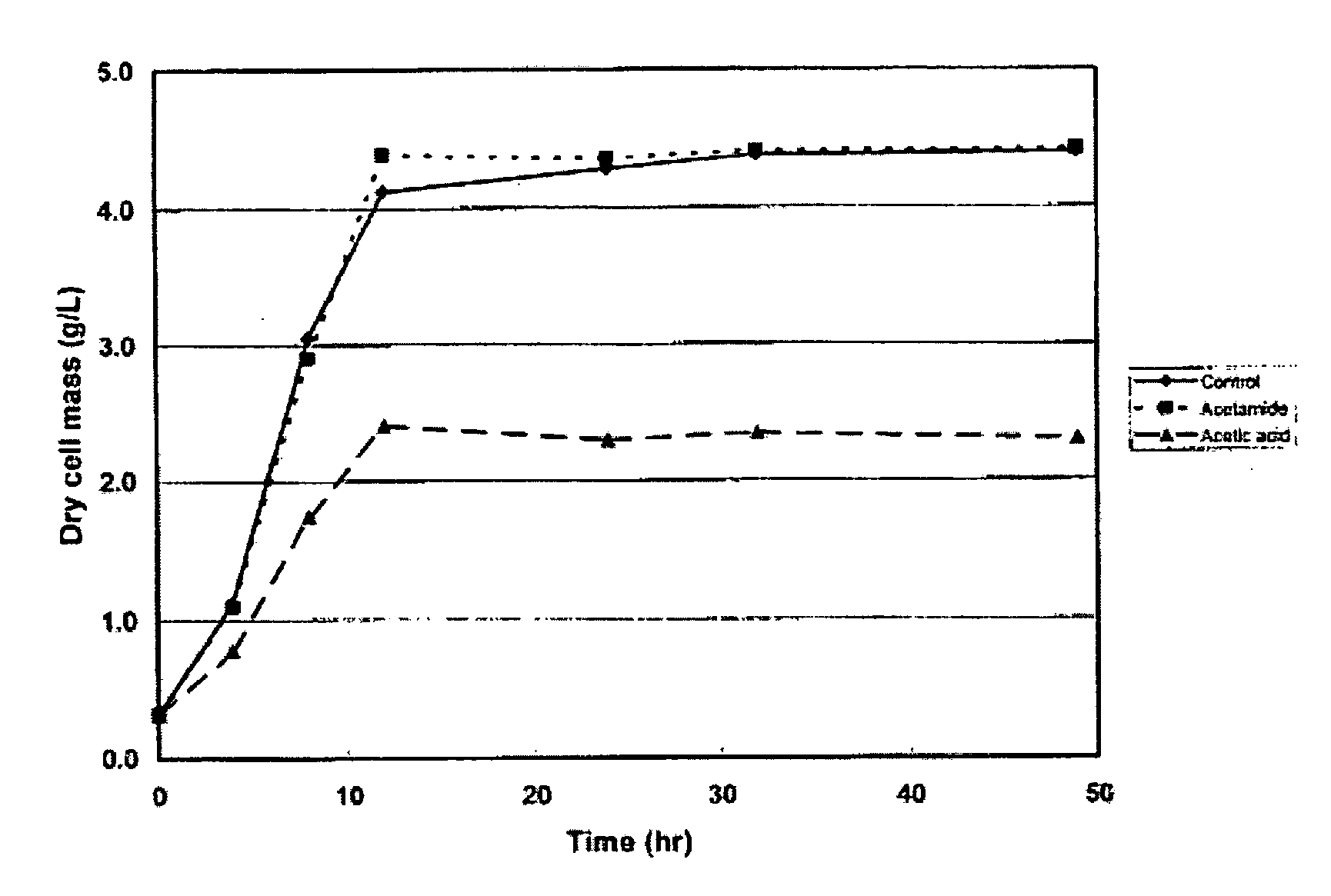

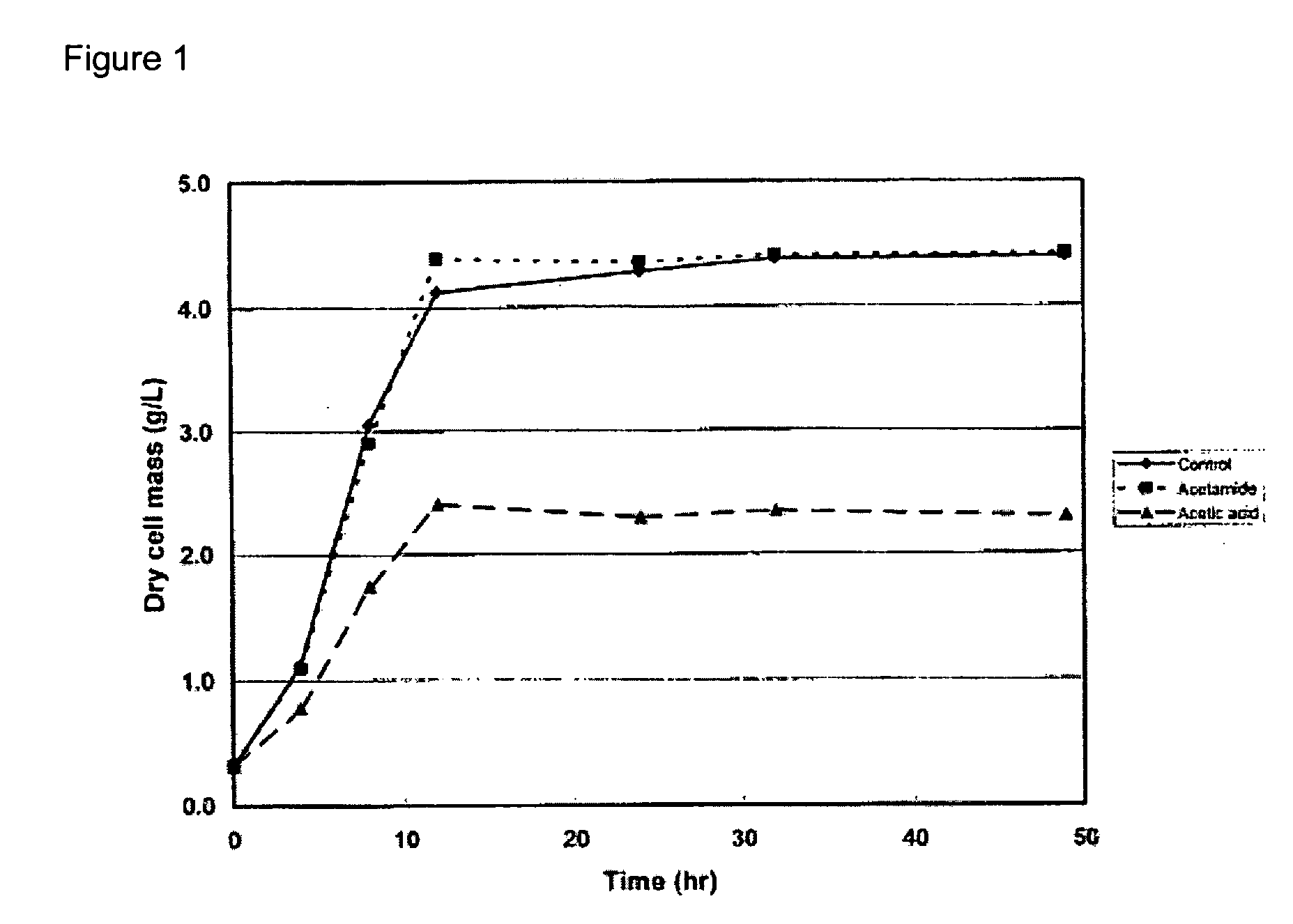

Biomass is pretreated using a low concentration of aqueous ammonia at high biomass concentration. Pretreated biomass is further hydrolyzed with a saccharification enzyme consortium. Fermentable sugars released by saccharification may be utilized for the production of target chemicals by fermentation.

Owner:ALLIANCE FOR SUSTAINABLE ENERGY +1

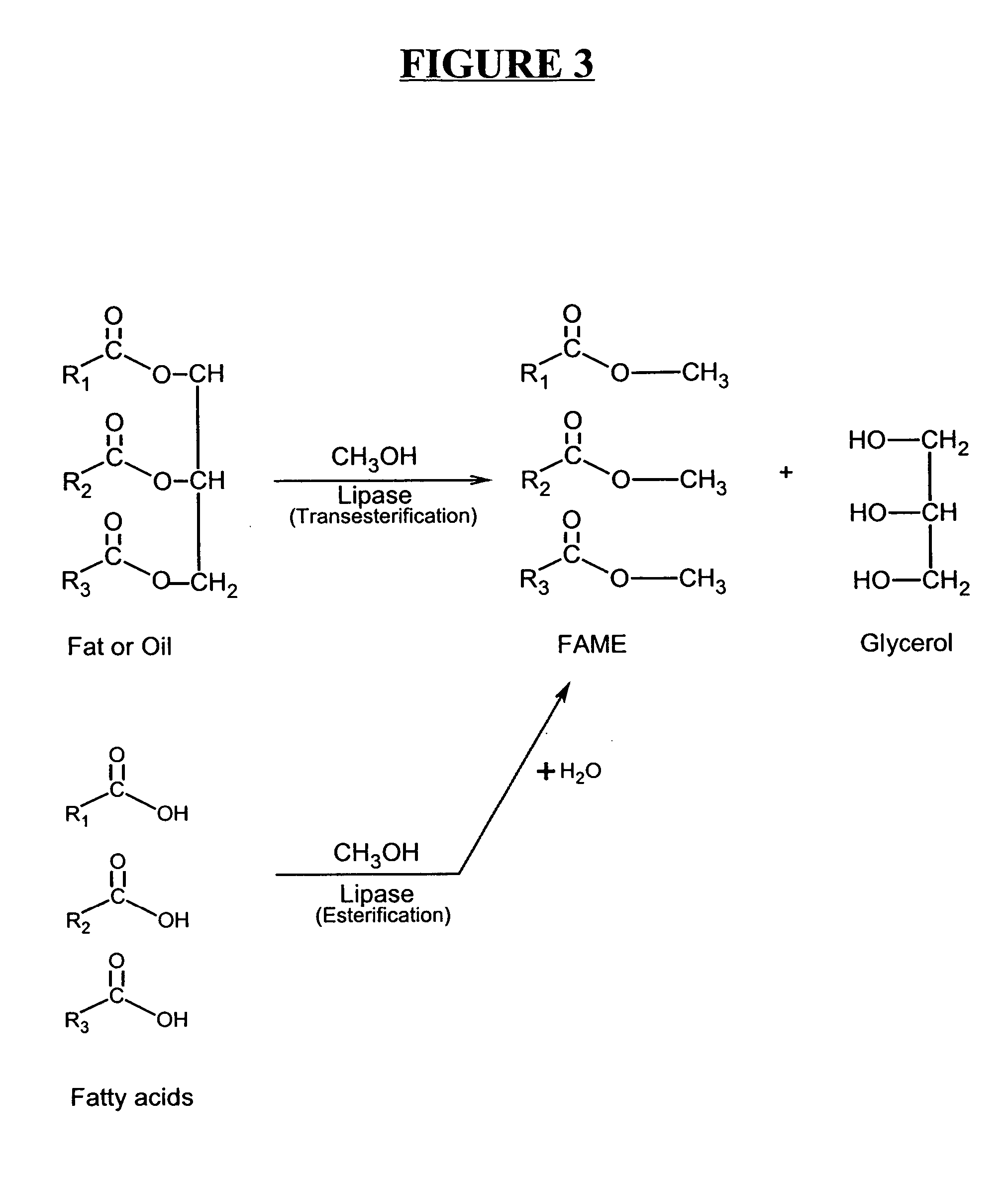

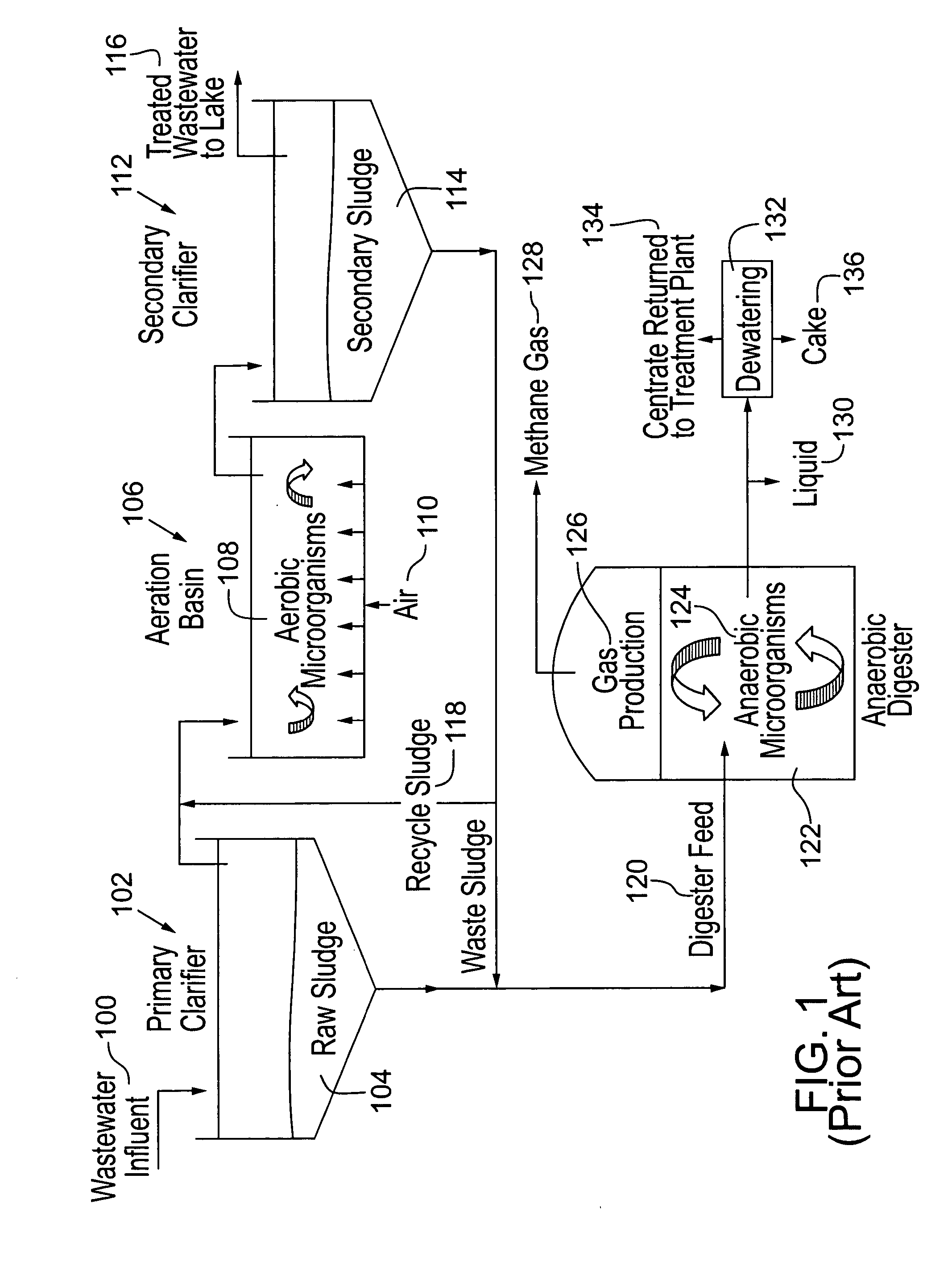

Production of biodiesel and other valuable chemicals from wastewater treatment plant sludges

ActiveUS20050112735A1Reduce the environmentPromote digestionBio-organic fraction processingByproduct vaporizationLipid formationSludge

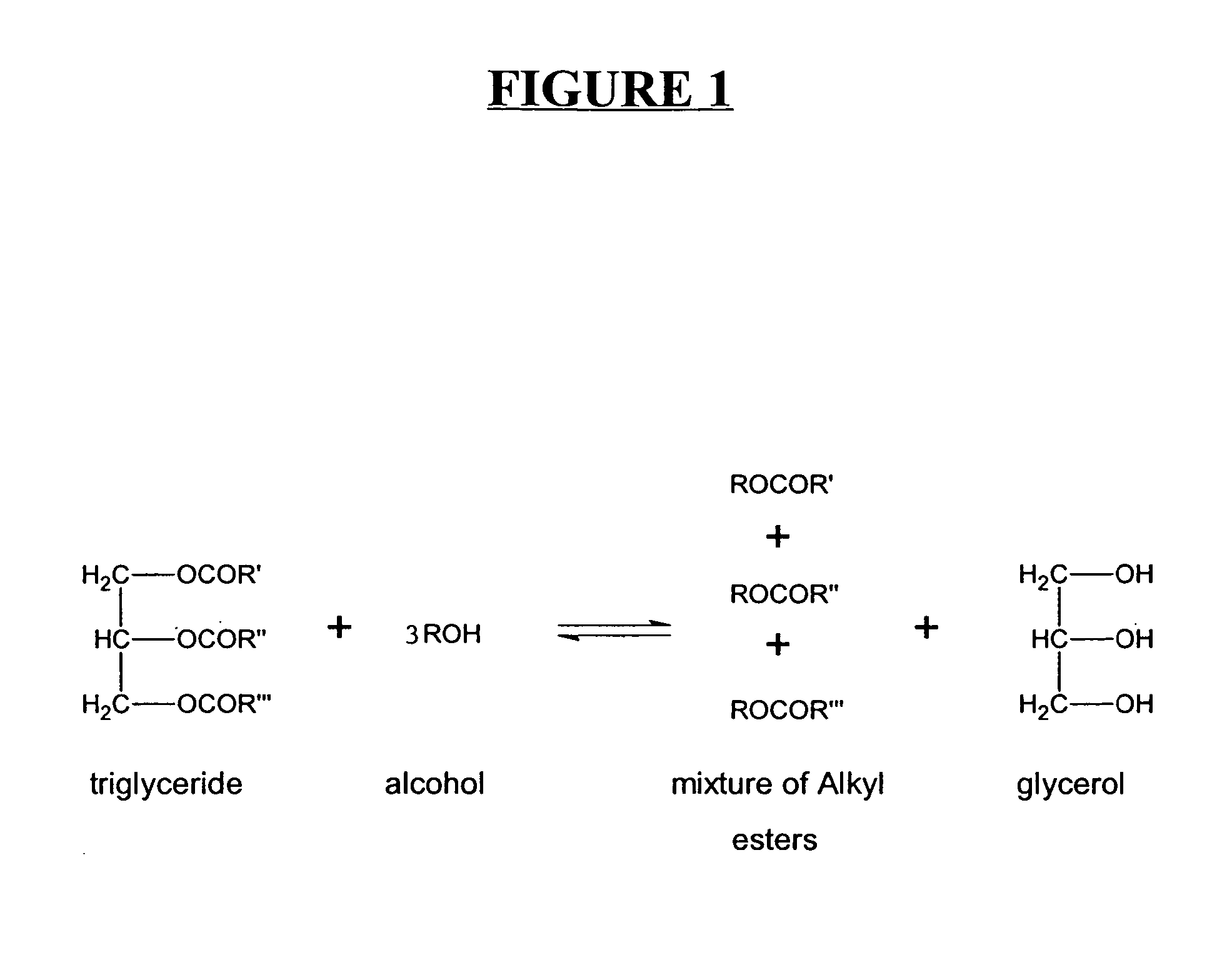

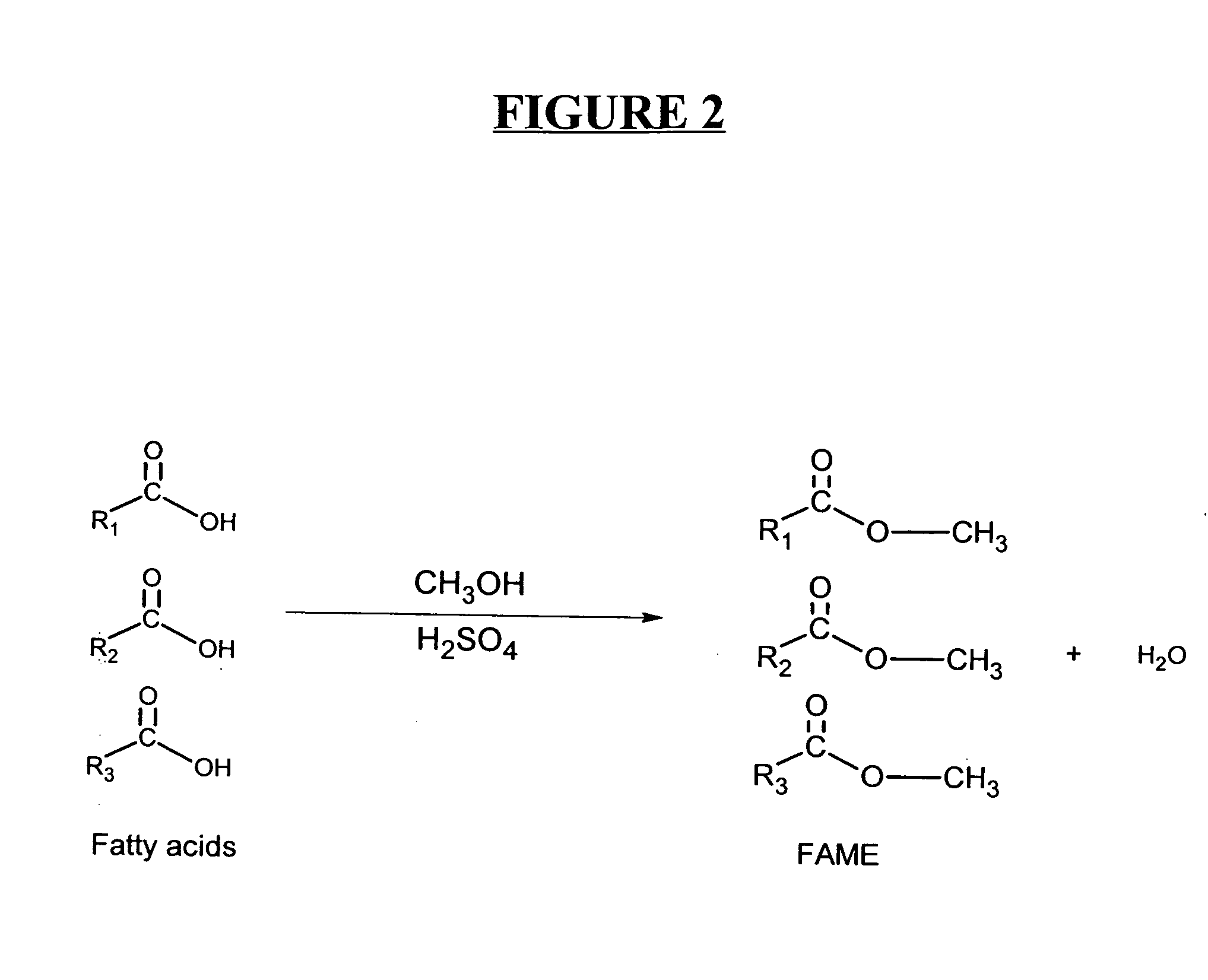

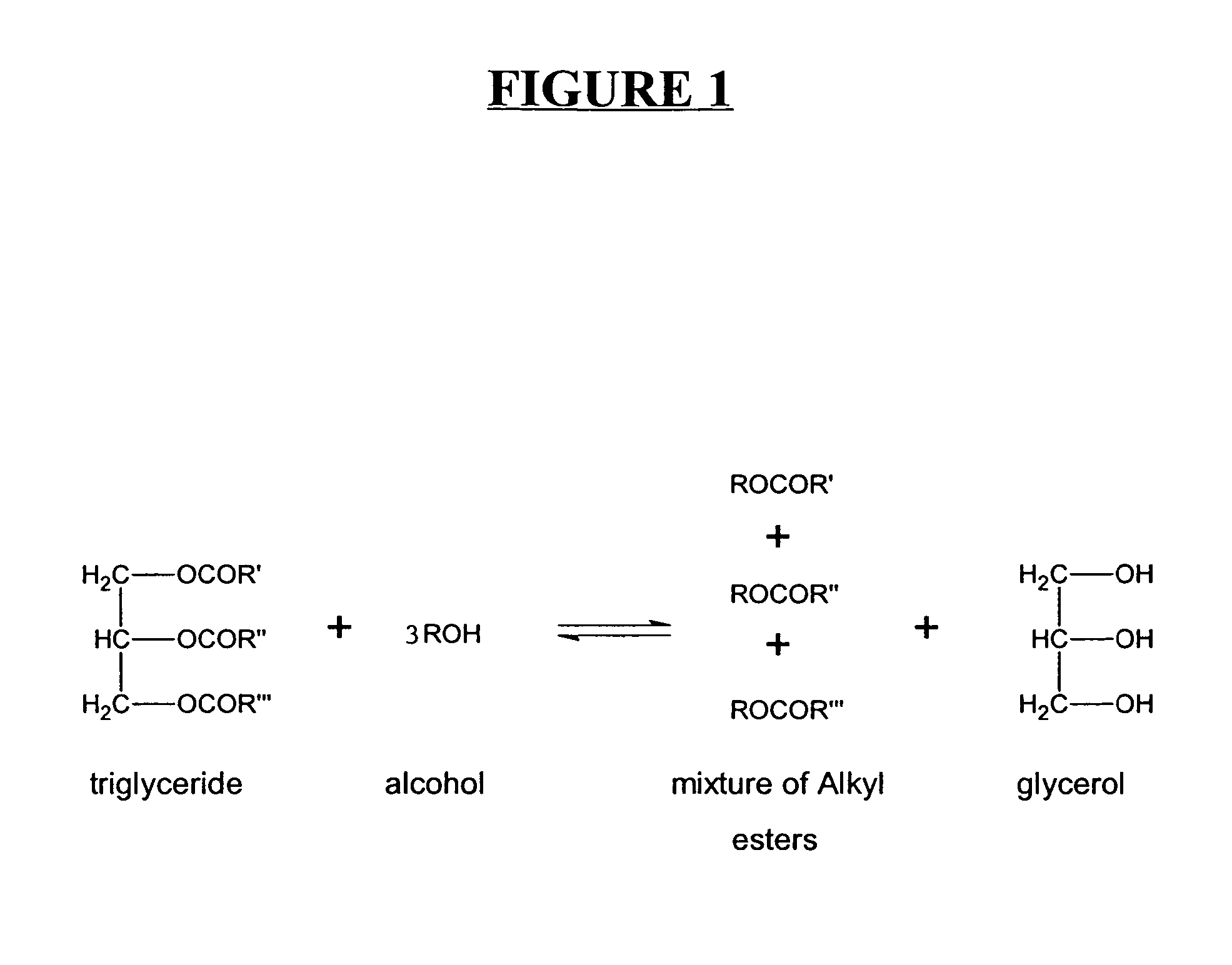

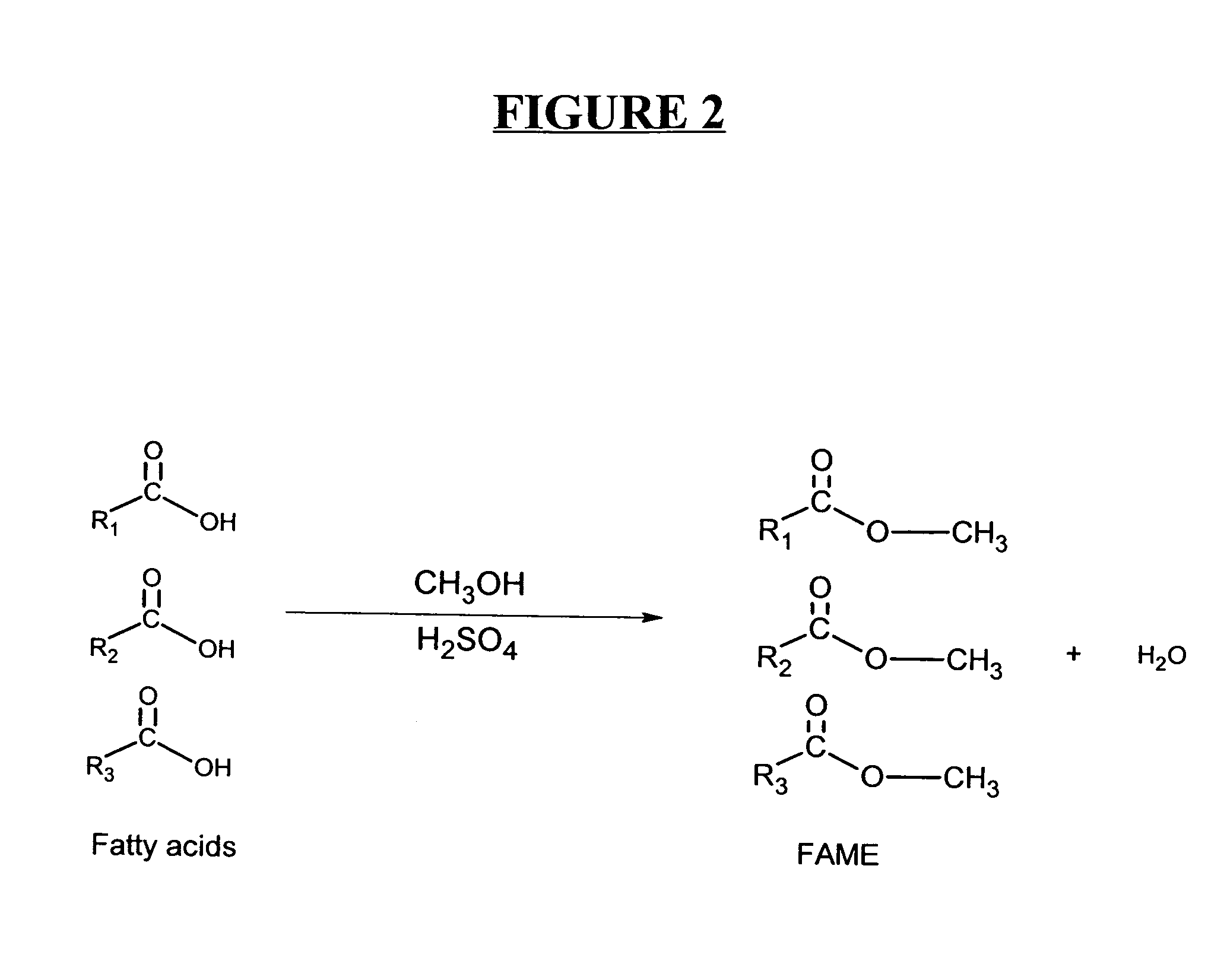

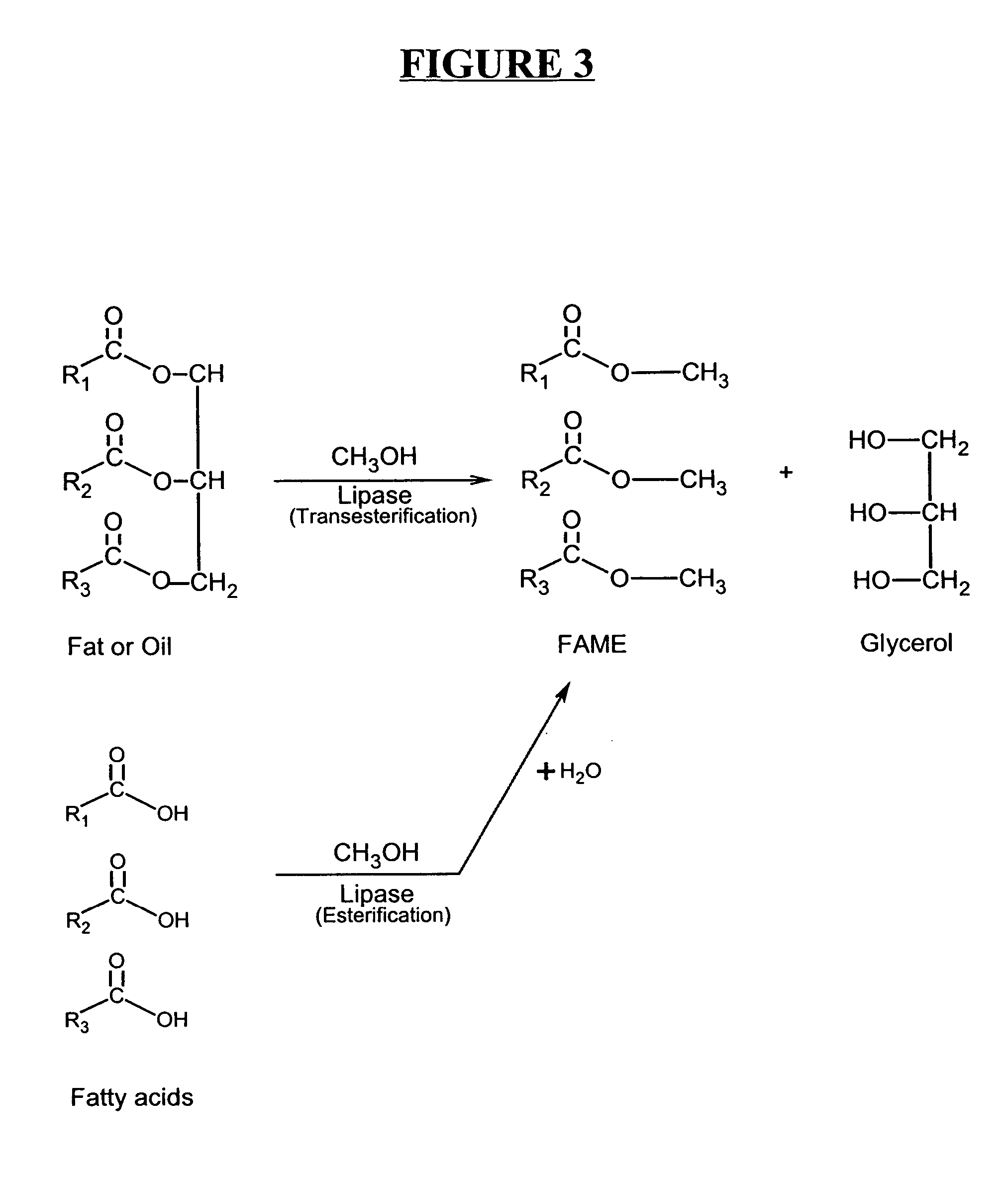

A process for producing biodiesel has been invented by first extracting lipids from the sludges generated during primary and / or biological treatment of municipal, agricultural, and industrial wastewaters using primary, secondary, and tertiary treatments followed by the transesterification of the extracted lipids using transesterification conversion into alcohol-based esters. The resulting products from this process include biodiesel, glycerol, lipid-free proteins, various other useful chemicals and an aqueous-based substrate well suited for optimized digestion within subsequent biological digestion (either aerobic or anaerobic). The lipids extracted from the sludges containing high levels of microorganisms are phospholipids which can also be directly used as lecithin. The extraction of the lipids from the sludges will be performed using chemical extraction techniques with the transesterification of the extracted lipids accomplished using basic, acidic, and / or a combination of the two transesterification techniques.

Owner:MISSISSPPI STATE UNIV RES & TECH

Integration of alternative feedstreams for biomass treatment and utilization

InactiveUS20070037259A1High solid contentBiological substance pretreatmentsByproduct vaporizationHigh concentrationDry weight

The present invention provides a method for treating biomass composed of integrated feedstocks to produce fermentable sugars. One aspect of the methods described herein includes a pretreatment step wherein biomass is integrated with an alternative feedstream and the resulting integrated feedstock, at relatively high concentrations, is treated with a low concentration of ammonia relative to the dry weight of biomass. In another aspect, a high solids concentration of pretreated biomass is integrated with an alternative feedstream for saccharifiaction.

Owner:SUSTAINABLE TECH CORP +1

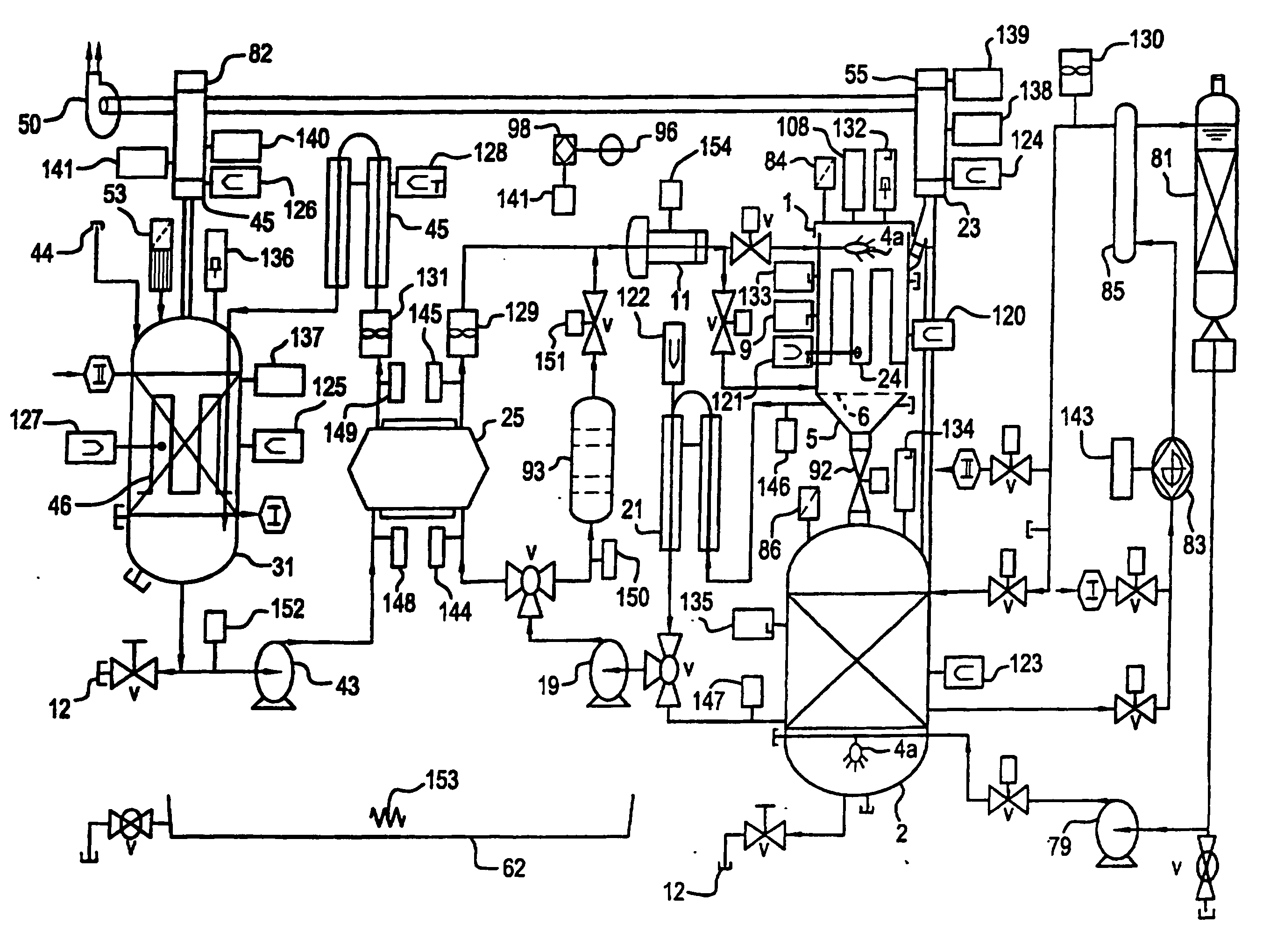

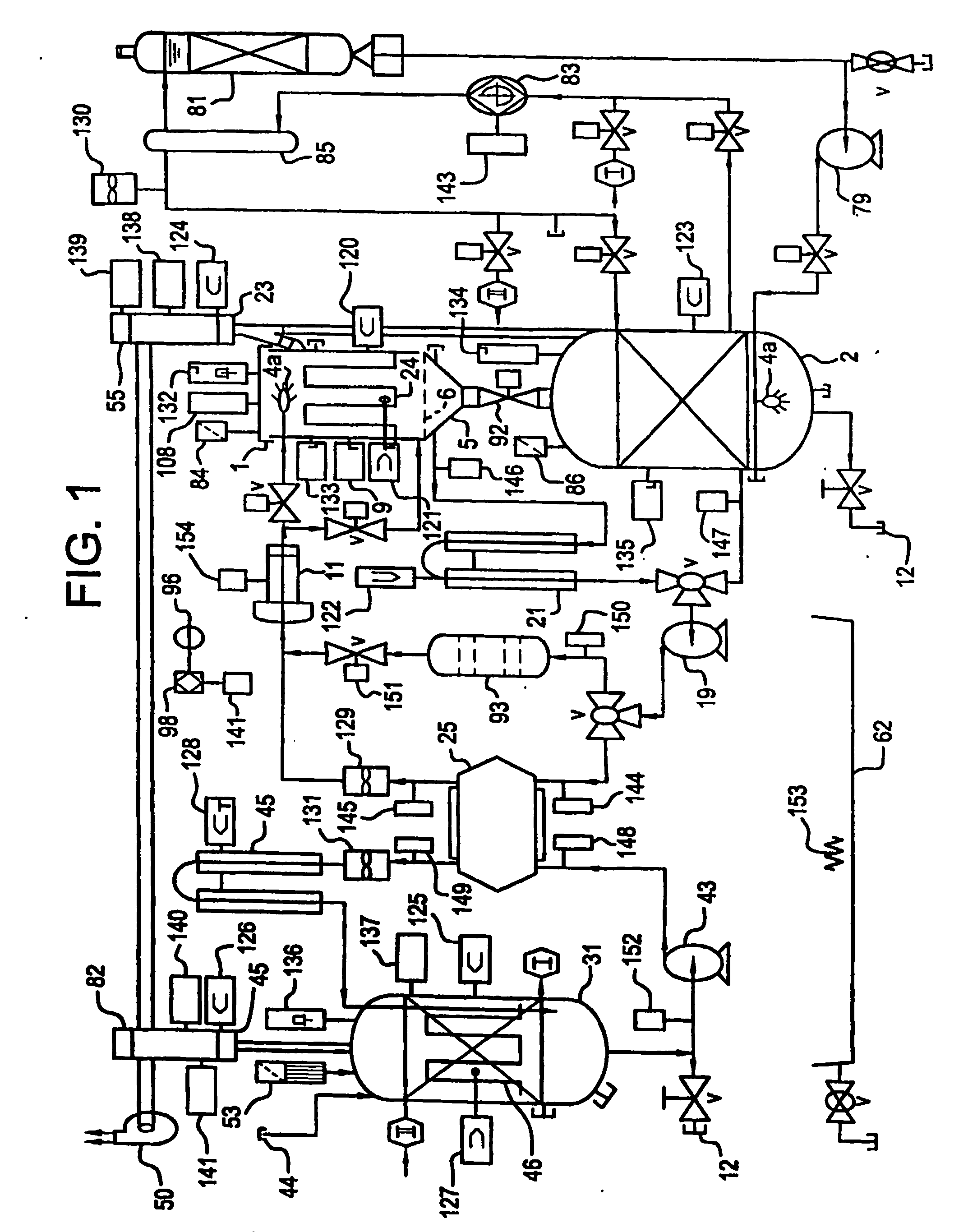

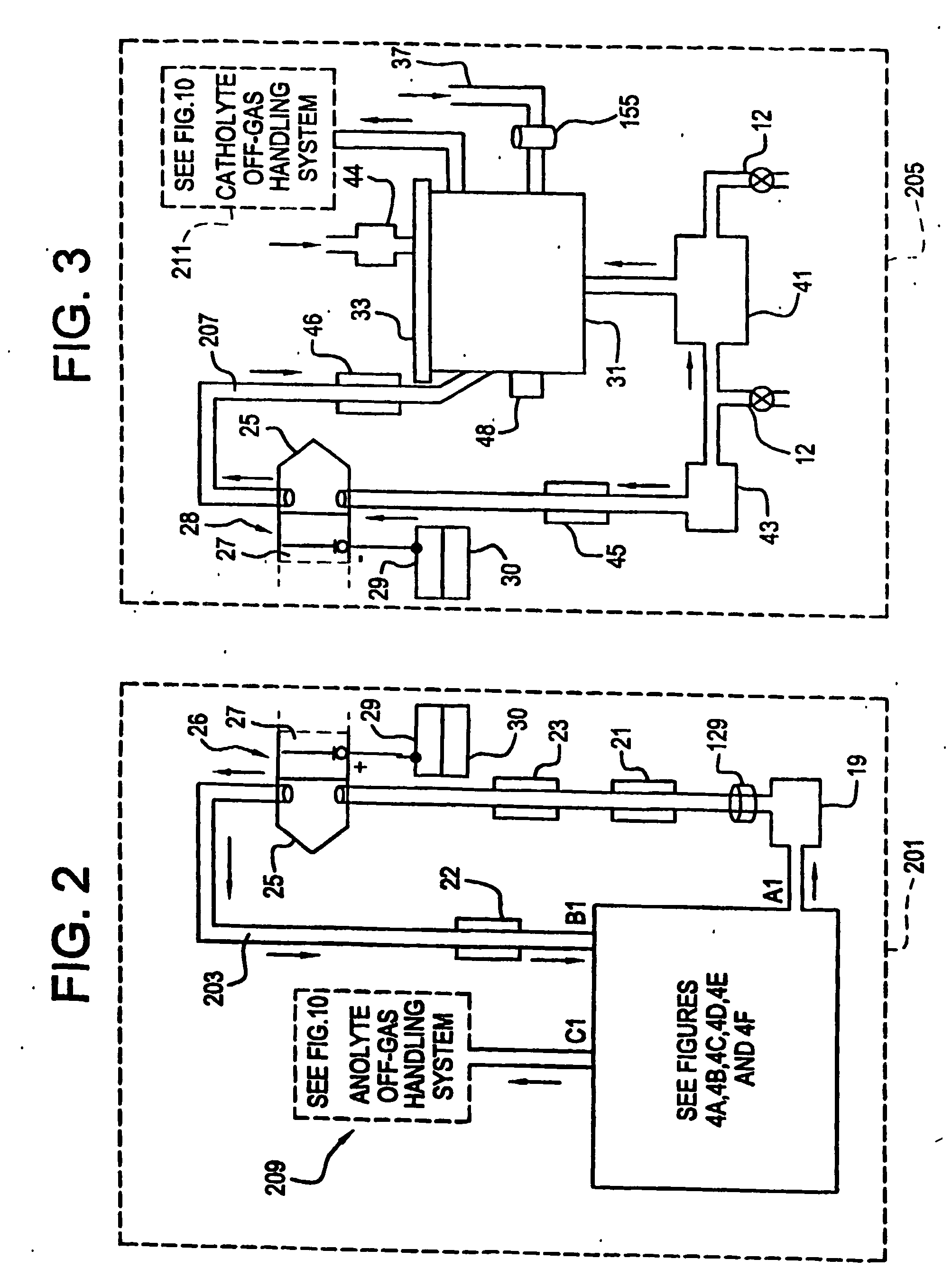

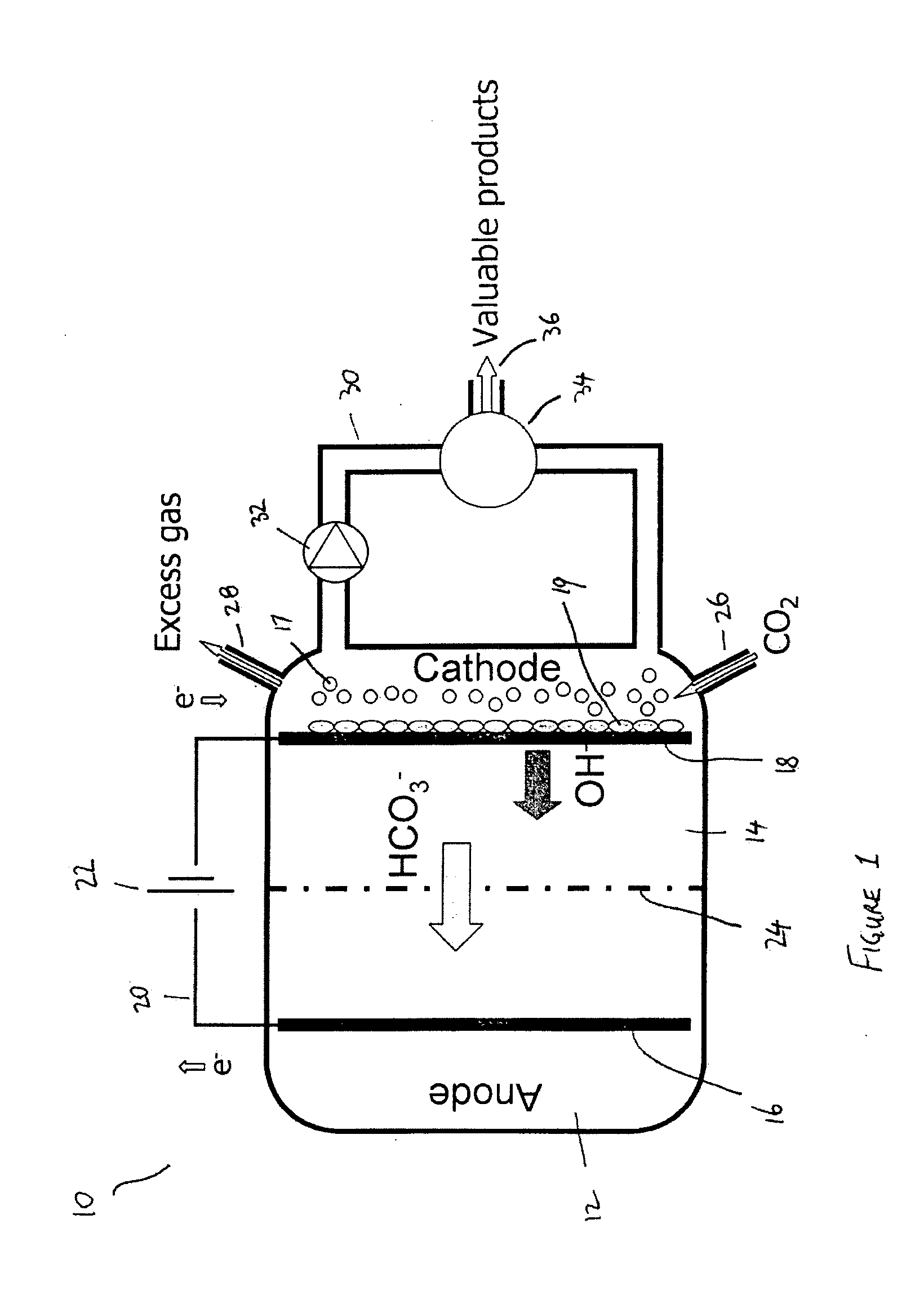

Apparatus and process for mediated electrochemical oxidation of materials

A unique apparatus unique apparatus and process that uses mediated electrochemical oxidation (MEO) for: (1) Destruction of: a) nearly all organic solid, liquid, and gases materials, except fluorinated hydrocarbons; b) all biological solid, liquid, and gases materials; c) and / or dissolution and decontamination (such as cleaning equipment and containers, etc.) of nearly all inorganic solid, liquid, or gas where higher oxidation states exist which includes, but is not limited to, halogenated inorganic compounds (except fluorinated), inorganic pesticides and herbicides, inorganic fertilizers, carbon residues, inorganic carbon compounds, mineral formations, mining tailings, inorganic salts, metals and metal compounds, etc.); and d) combined materials (e.g. a mixture of any of the foregoing with each other); henceforth collectively referred to as materials. (2) Sterilization / disinfection of equipment, glassware, etc., by destroying all existing infectious materials. (3) Dissolution of transuranic / actinide materials and / or destruction of the oxidizable components in the hazardous waste portion of mixed waste. (4) Generation of hydrogen and oxygen from MEO of materials. (5) Alteration of organic, biological, and inorganic materials by MEO to produce other compounds from these materials. The materials are introduced into an apparatus for contacting the materials with an electrolyte containing the oxidized form of one or more reversible redox couples, at least one of which is produced electrochemically by anodic oxidation at the anode of an electrochemical cell. The oxidized forms of any other redox couples present are produced either by similar anodic oxidation or reaction with the oxidized form of other redox couples present and capable of affecting the required redox reaction. The oxidized species of the redox couples oxidize the materials molecules and are themselves converted to their reduced form, whereupon they are reoxidized by either of the aforementioned mechanisms and the redox cycle continues until all oxidizable material species, including intermediate reaction products, have undergone the desired degree of oxidation. The entire process takes place at temperatures between ambient and approximately 100° C. The oxidation process may be enhanced by the addition of reaction enhancements, such as: ultrasonic energy and / or ultraviolet radiation.

Owner:SCIMIST LNC

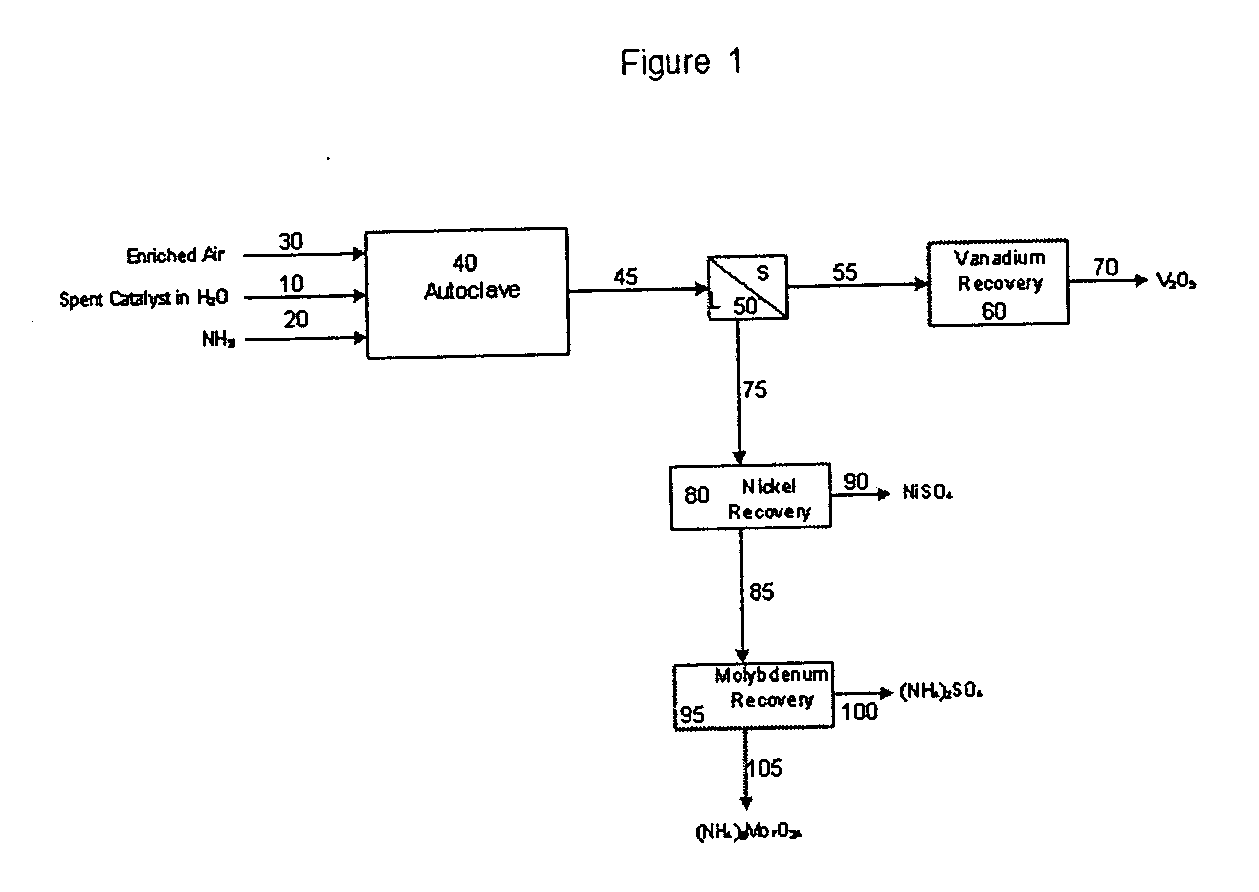

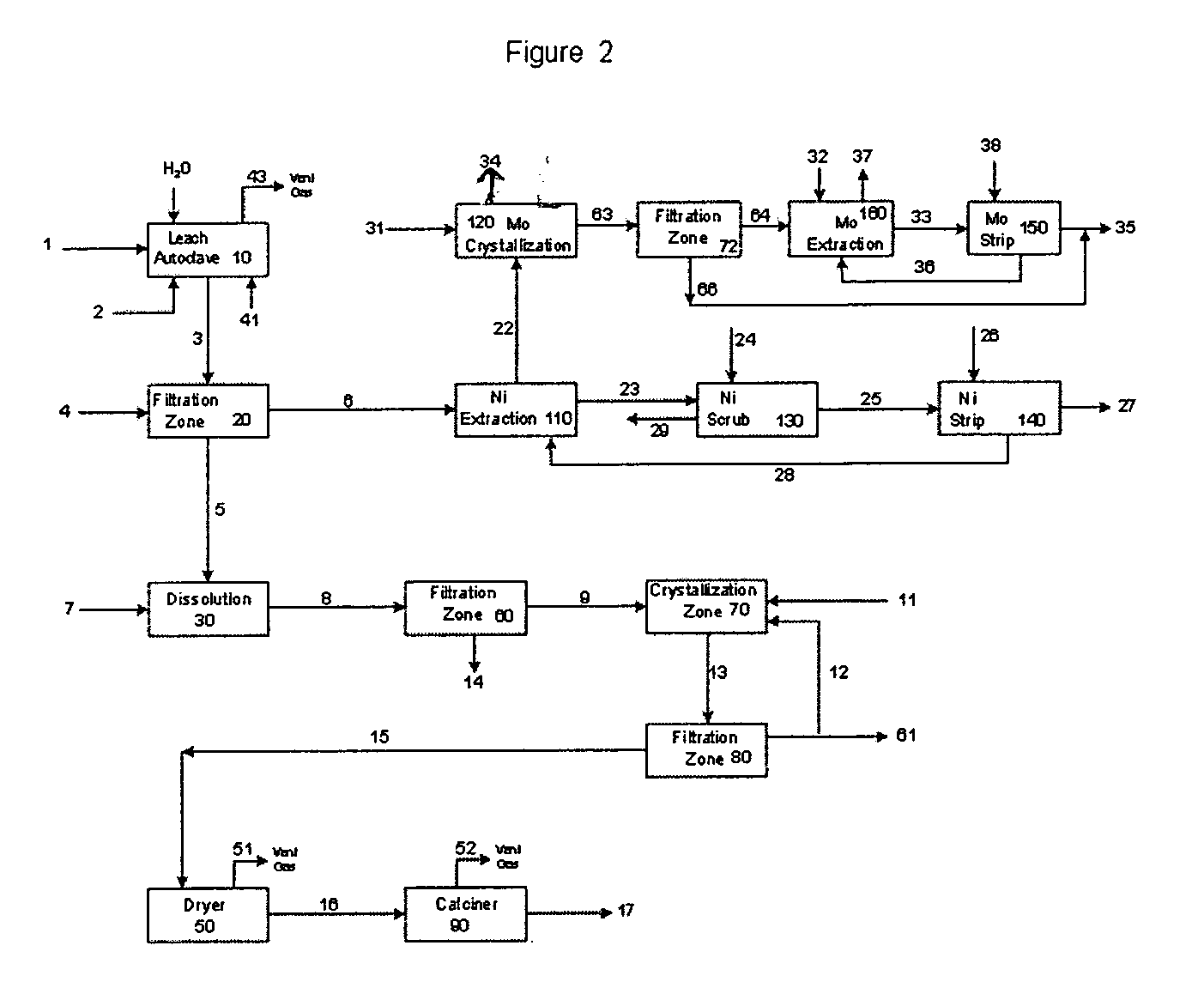

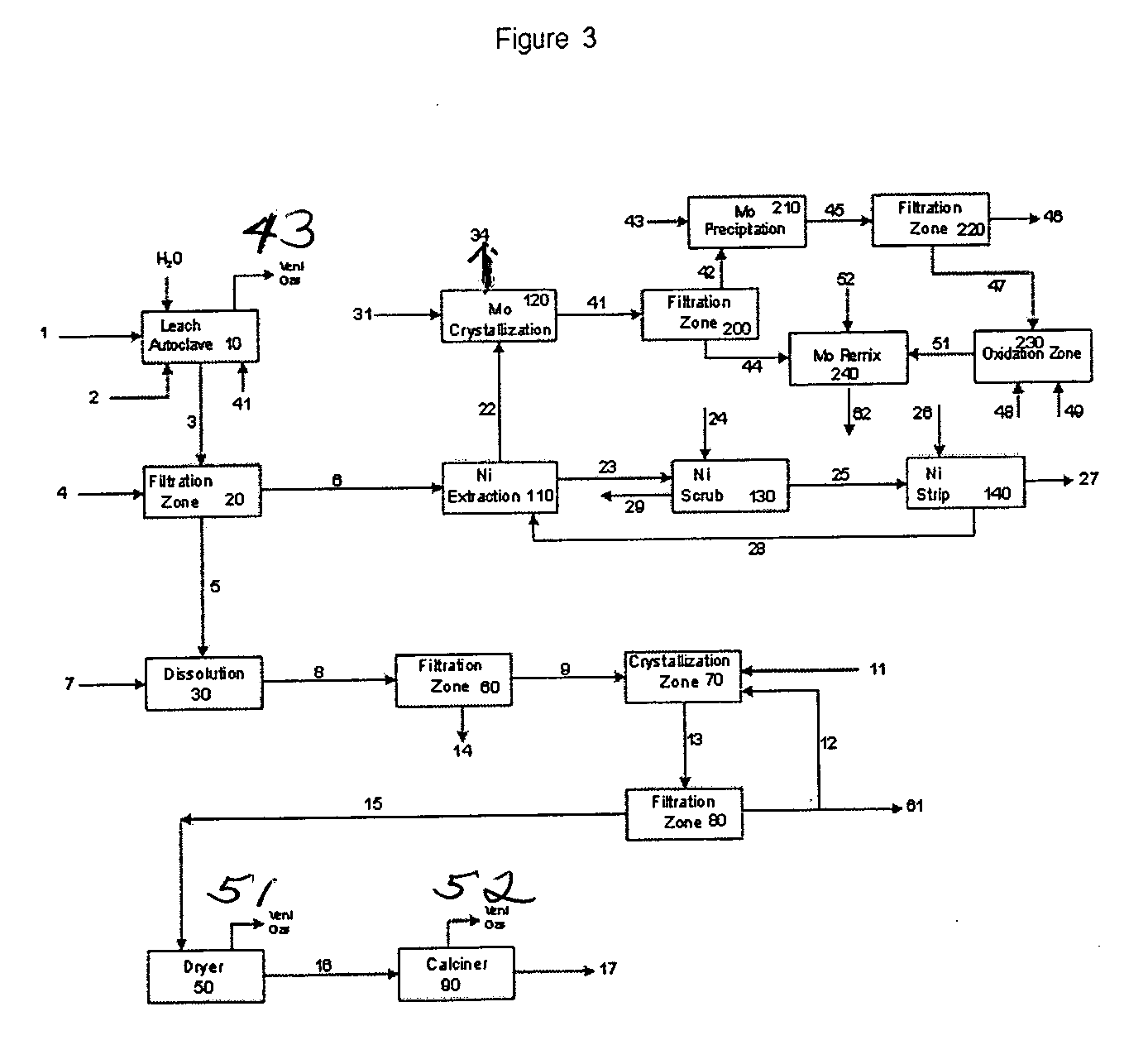

Process for metals recovery from spent catalyst

The process of this invention is directed to the removal of metals from an unsupported spent catalyst. The catalyst is subjected to leaching reactions. Vanadium is removed as a precipitate, while a solution comprising molybdenum and nickel is subjected to further extraction steps for the removal of these metals. Molybdenum may alternately be removed through precipitation.

Owner:CHEVROU USA INC

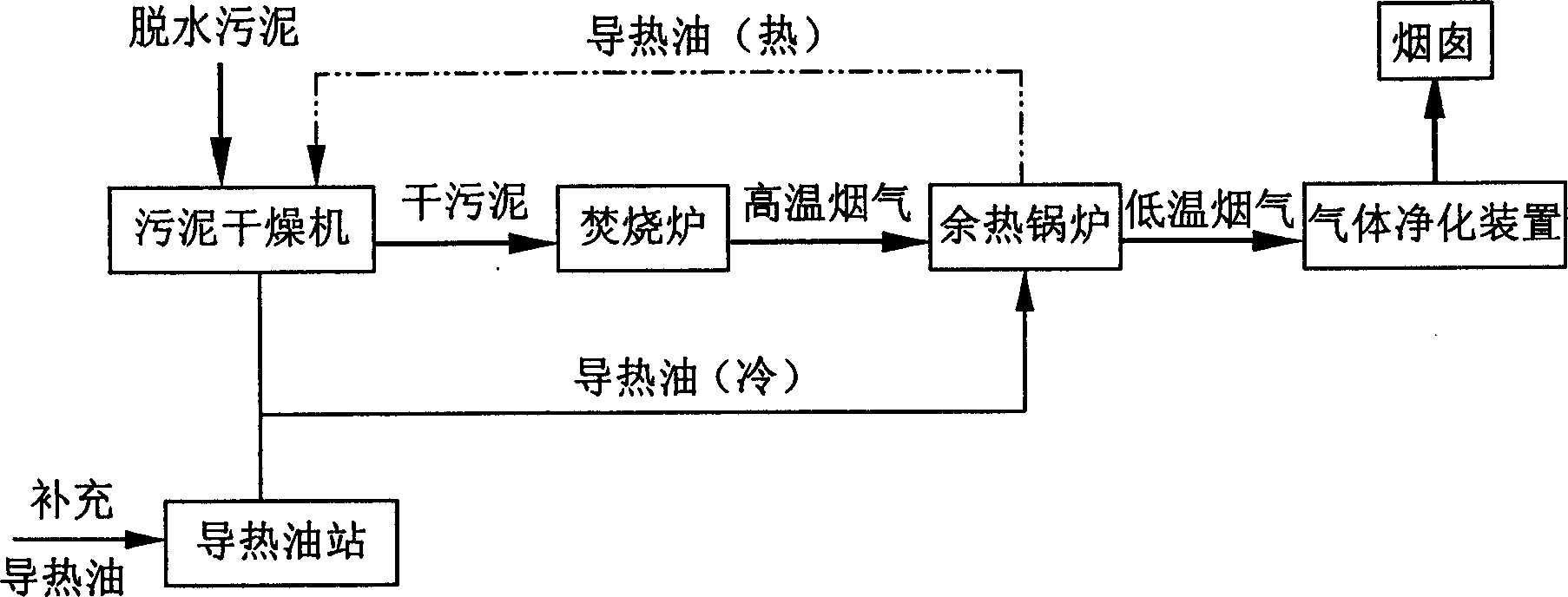

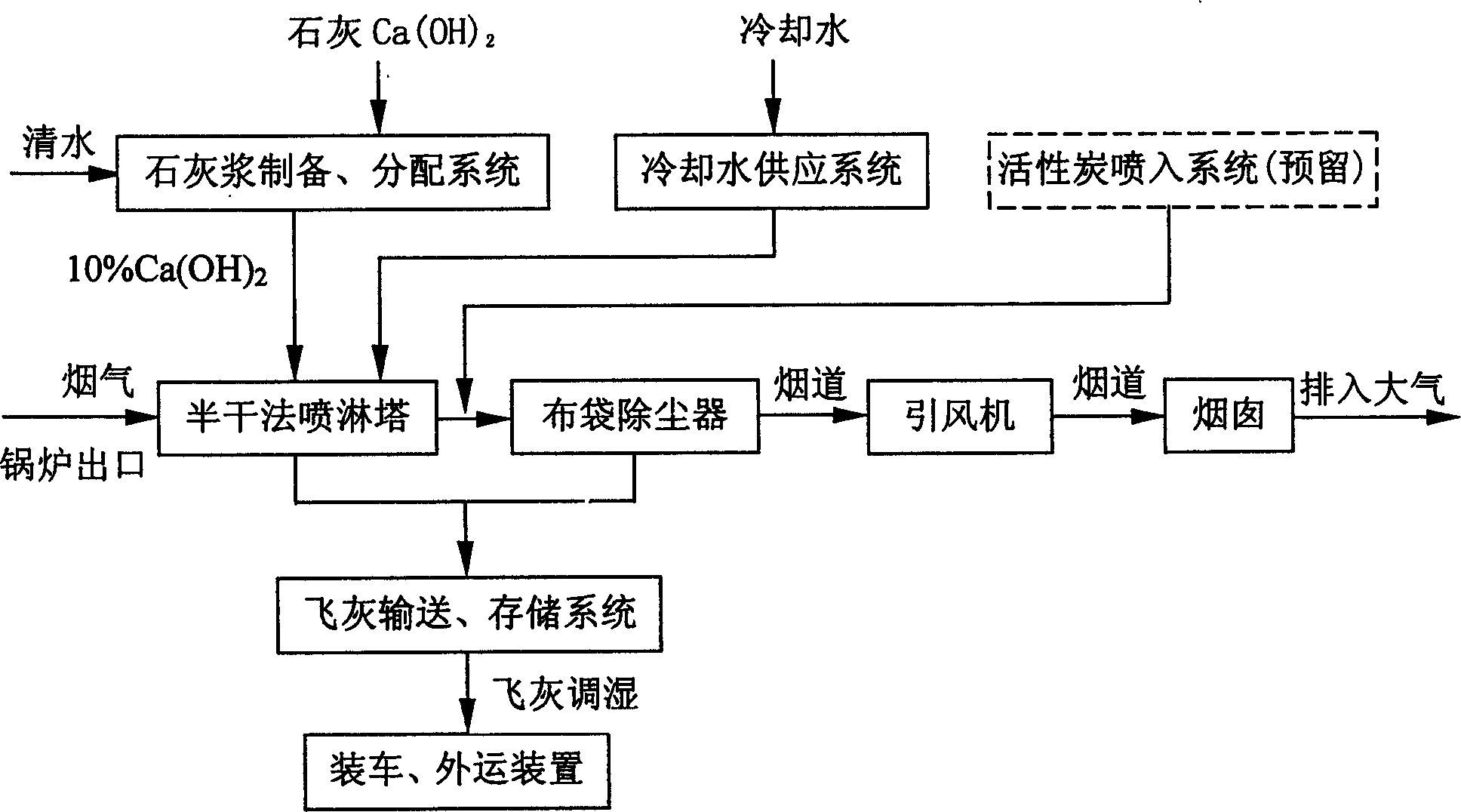

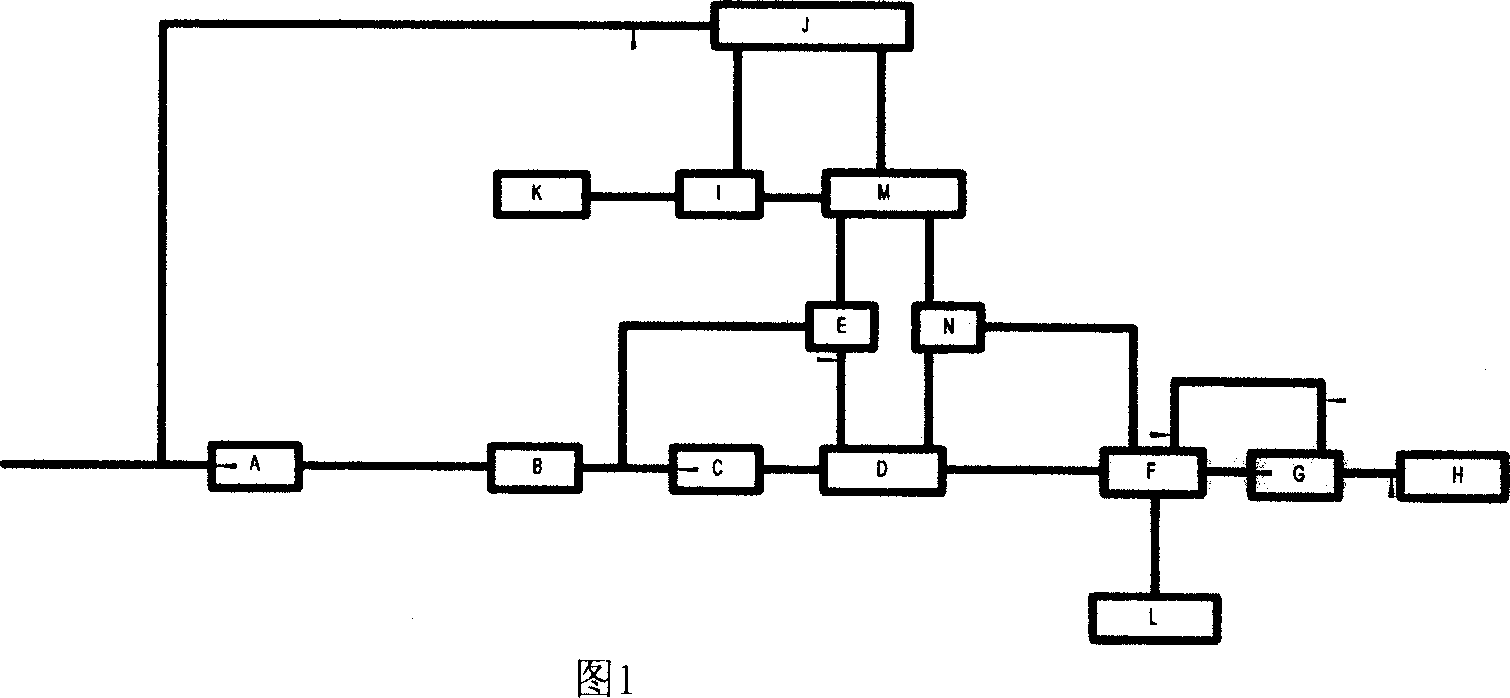

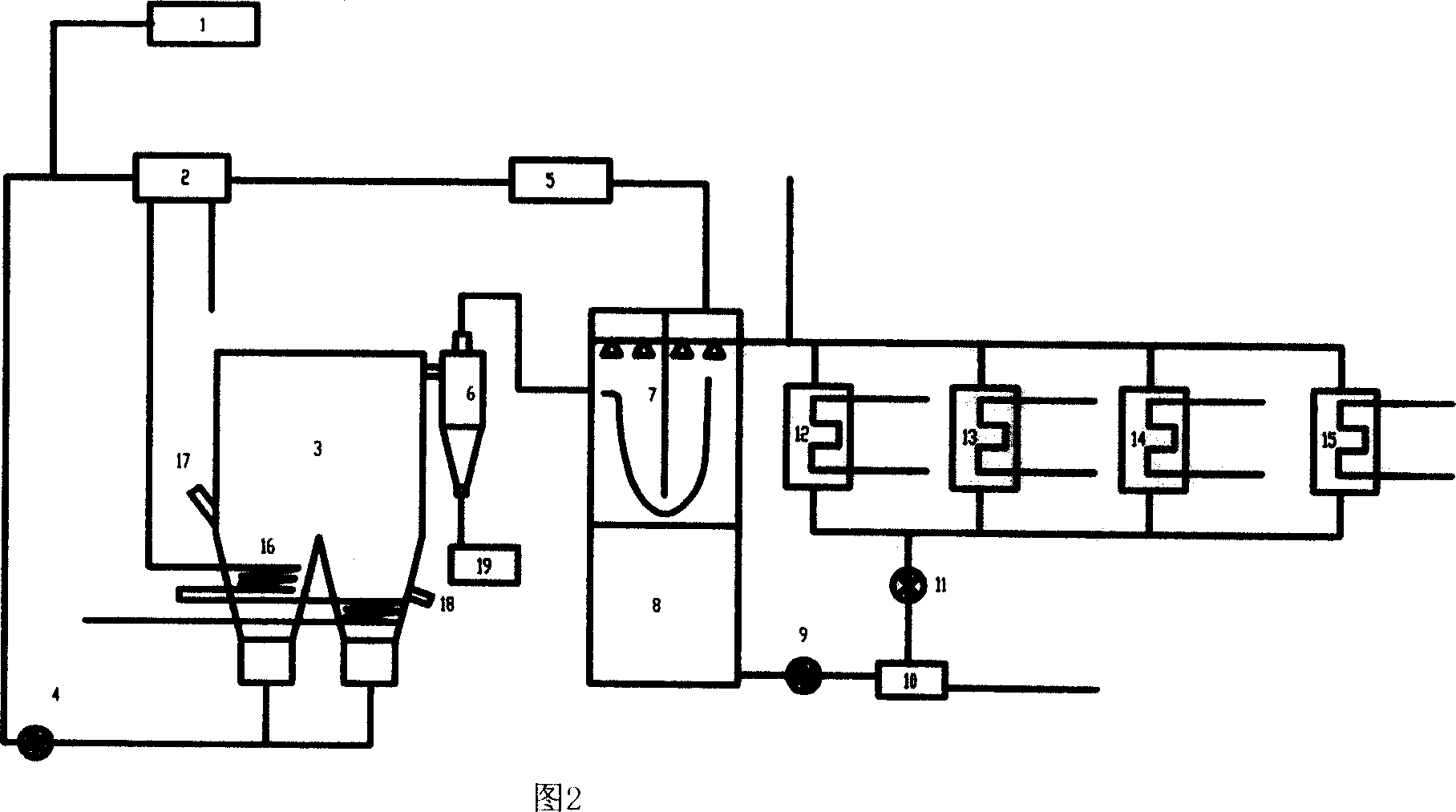

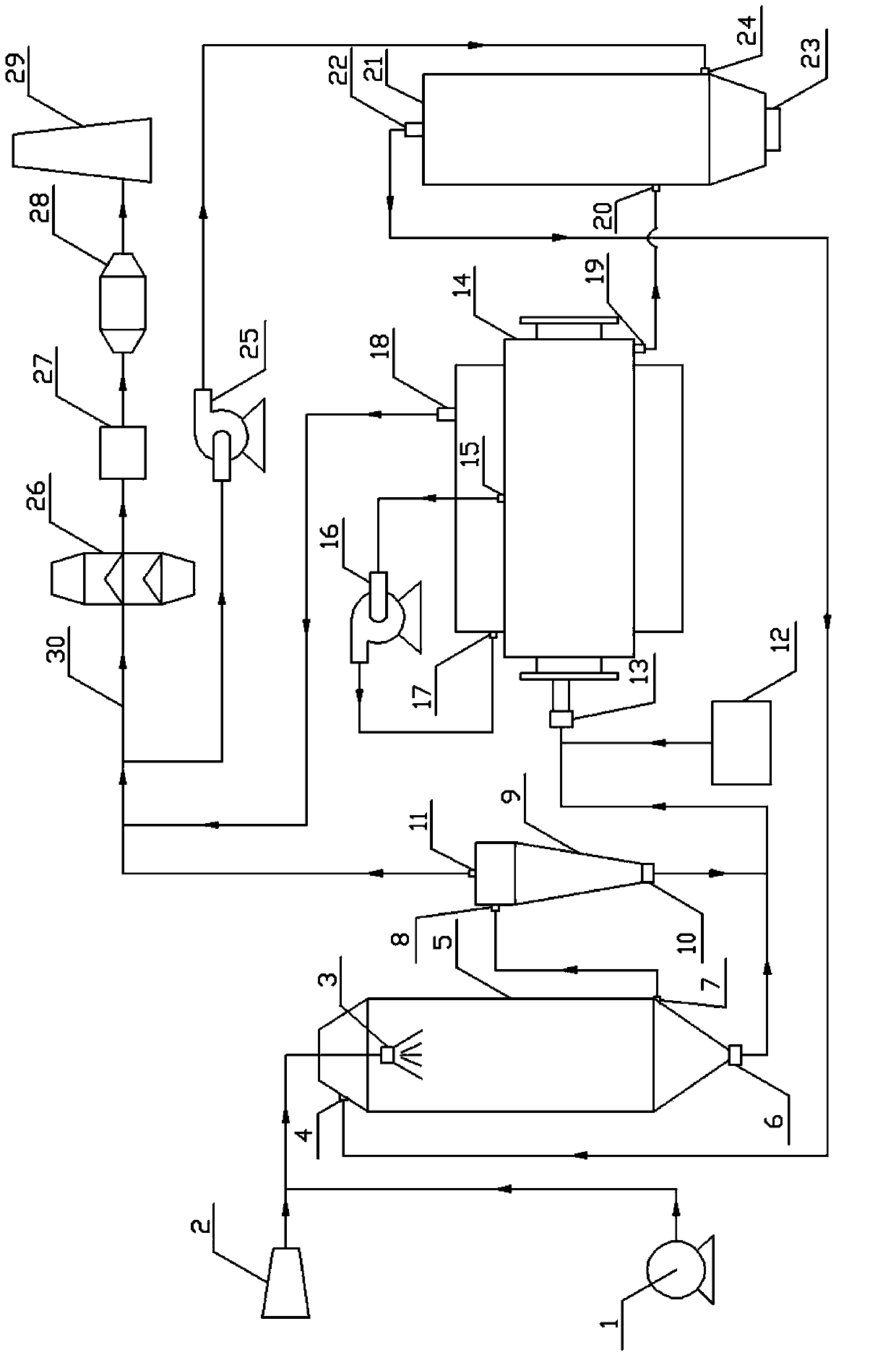

Sludge anhydration and burning process, and its systematic device

ActiveCN1800062ALow investment costLow running costSludge treatment by de-watering/drying/thickeningSludge treatment by oxidationAir preheaterHeat conducting

The invention relates to a sludge drying and burning technique and its system devices, applying to the handling of active sludge in urban sewage treatment plants, its process flows through: wet sludge stock house, measuring bin, sludge mixer, sludge dryer, granular splitter, cooler, drying products storage bin, incinerator, smoke gas cleaning devices, which is characterized by: said incinerator is bubbling fluid bed incinerator with coal economizer, air heater fixed in its end part, high-heat smoke gas generated by burning is used to heat heat-conducting oil and cool air individually, and heat-conducting oil after being heated is transferred to sludge dryer through the circulating pump to dry wet-sludge. The invention is characterized by: take heat-conducting oil as heating medium, use the heat generated by burning dry sludge to heat heat-conducting oil and then dry wet-sludge to make full use of resources; the volume-reducing quantity after drying and burning could reach over 90%; the percentage of desulphurization in incinerator could reach 75% as a result of adopting two stage technology of sulfur removal, and the gross percentage of desulphurization meets national environmental legislation requirements. The invention accomplishes the resources, volume reduction, and innocence of sludge.

Owner:贵州筑信水务环境产业有限公司

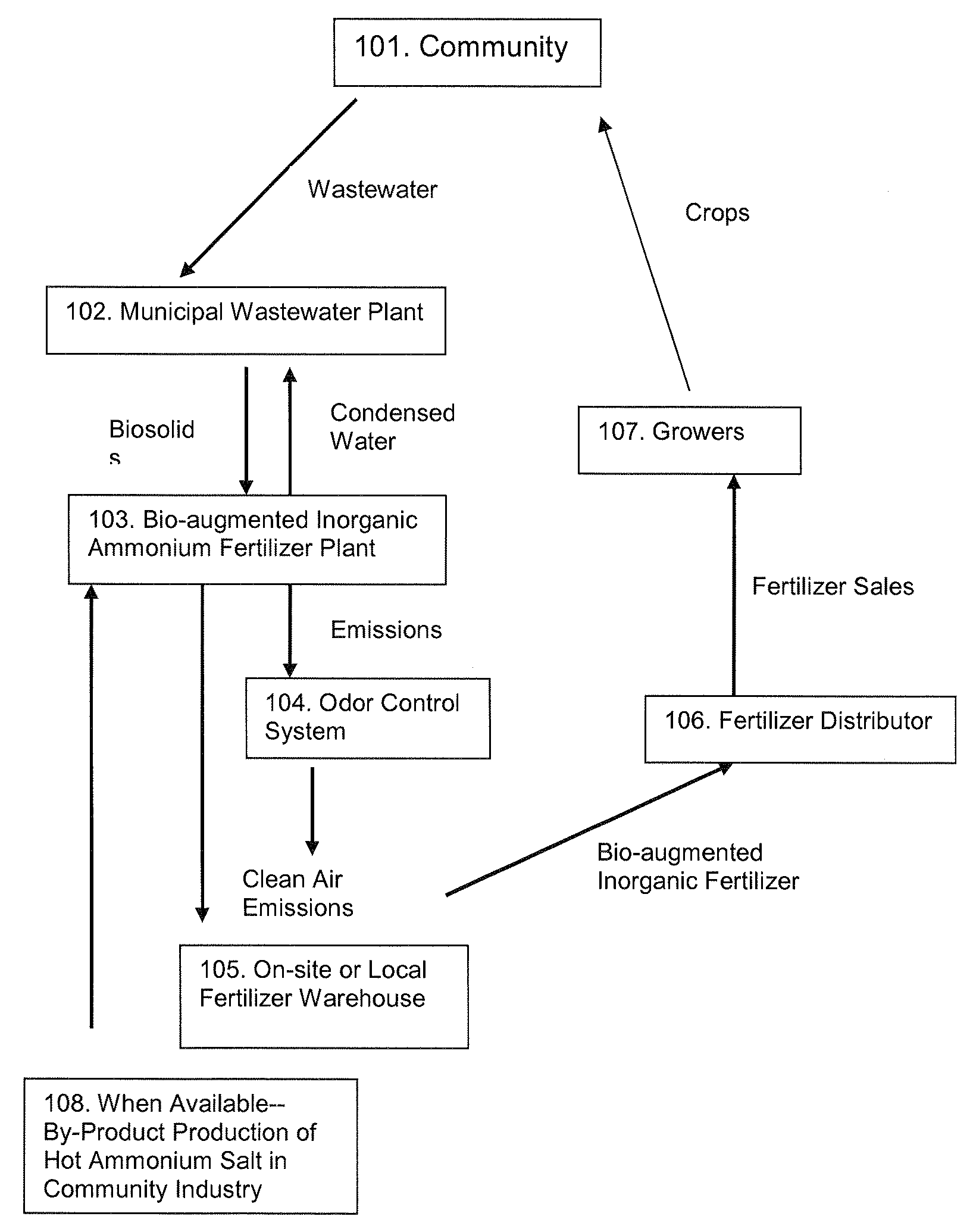

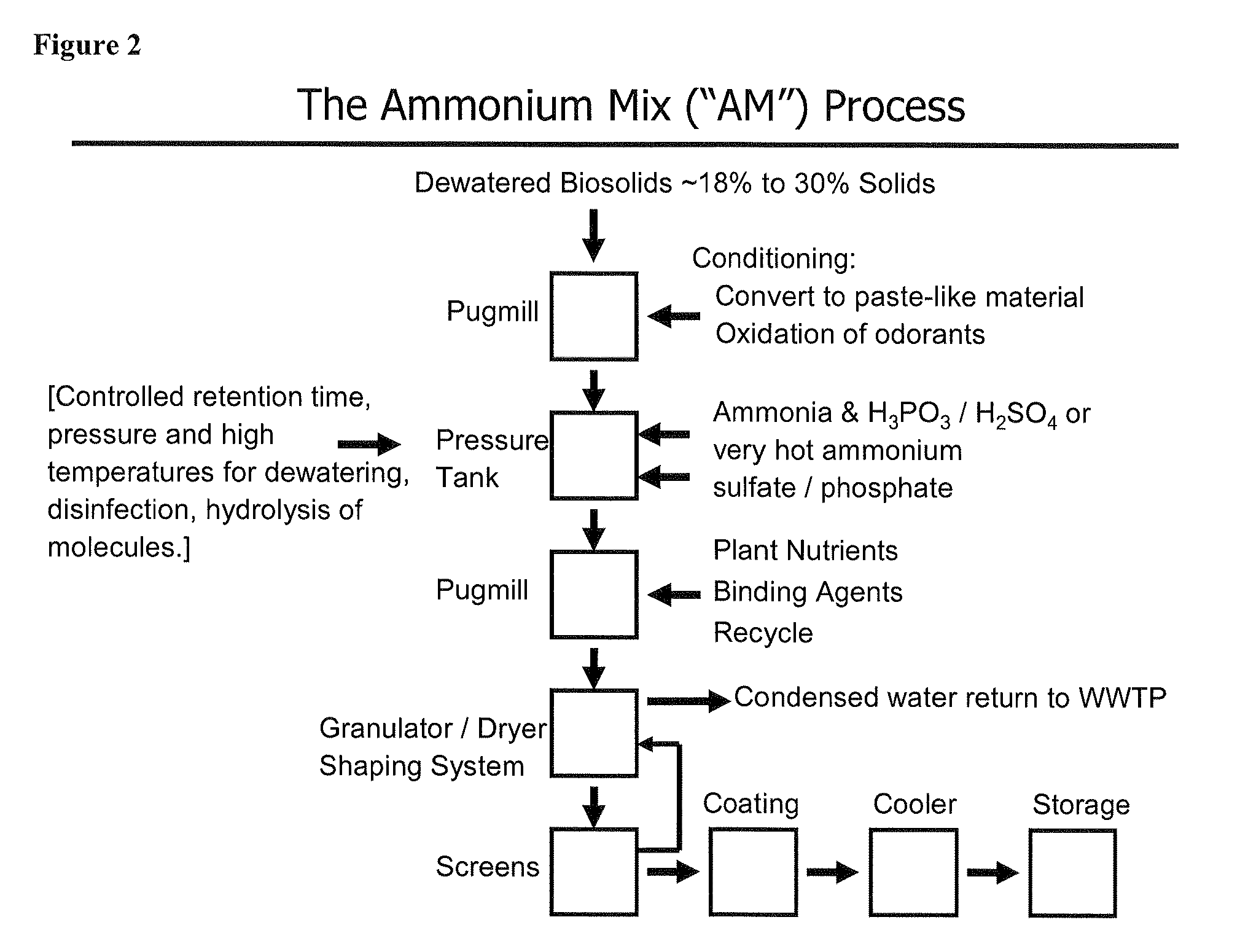

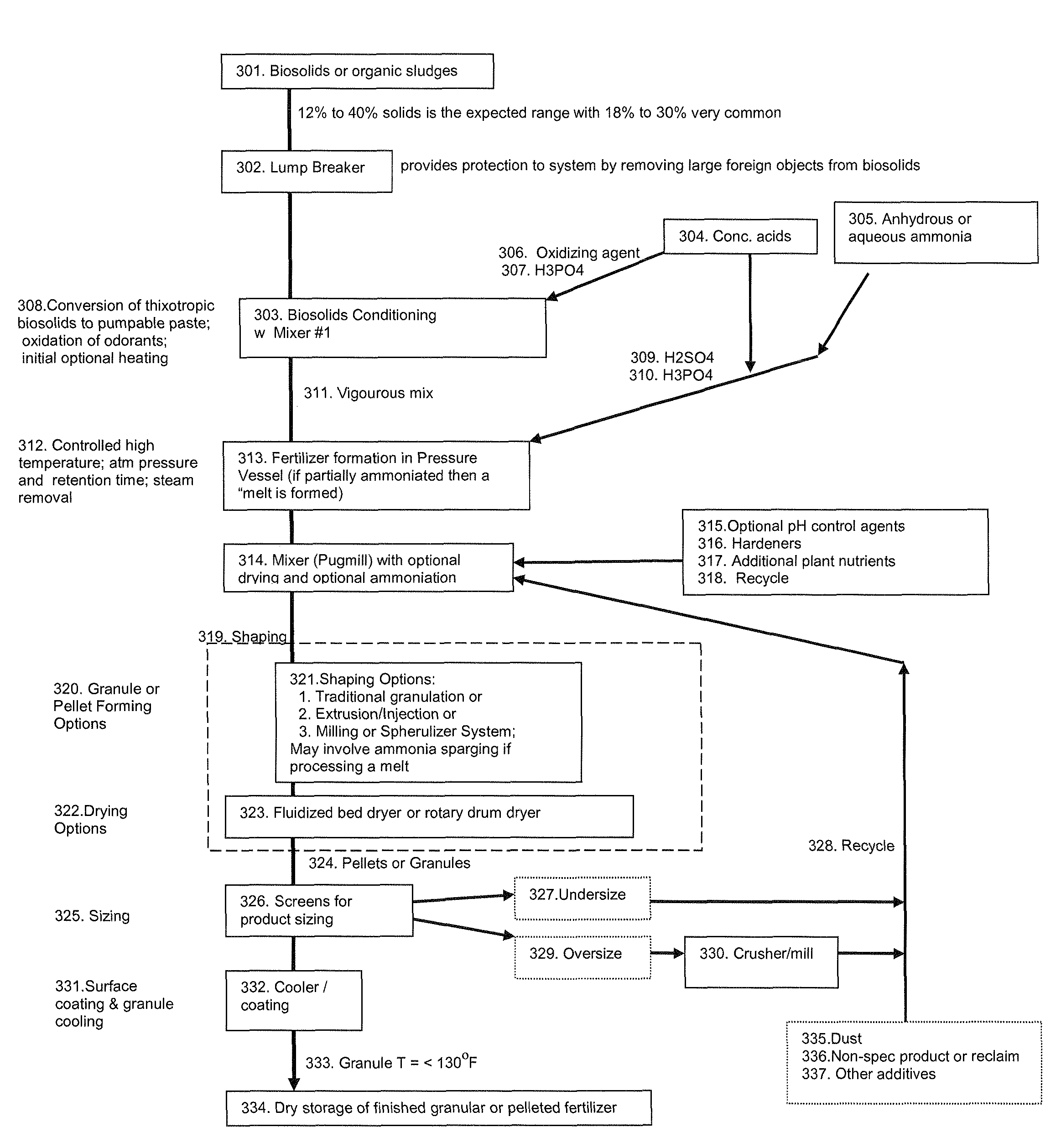

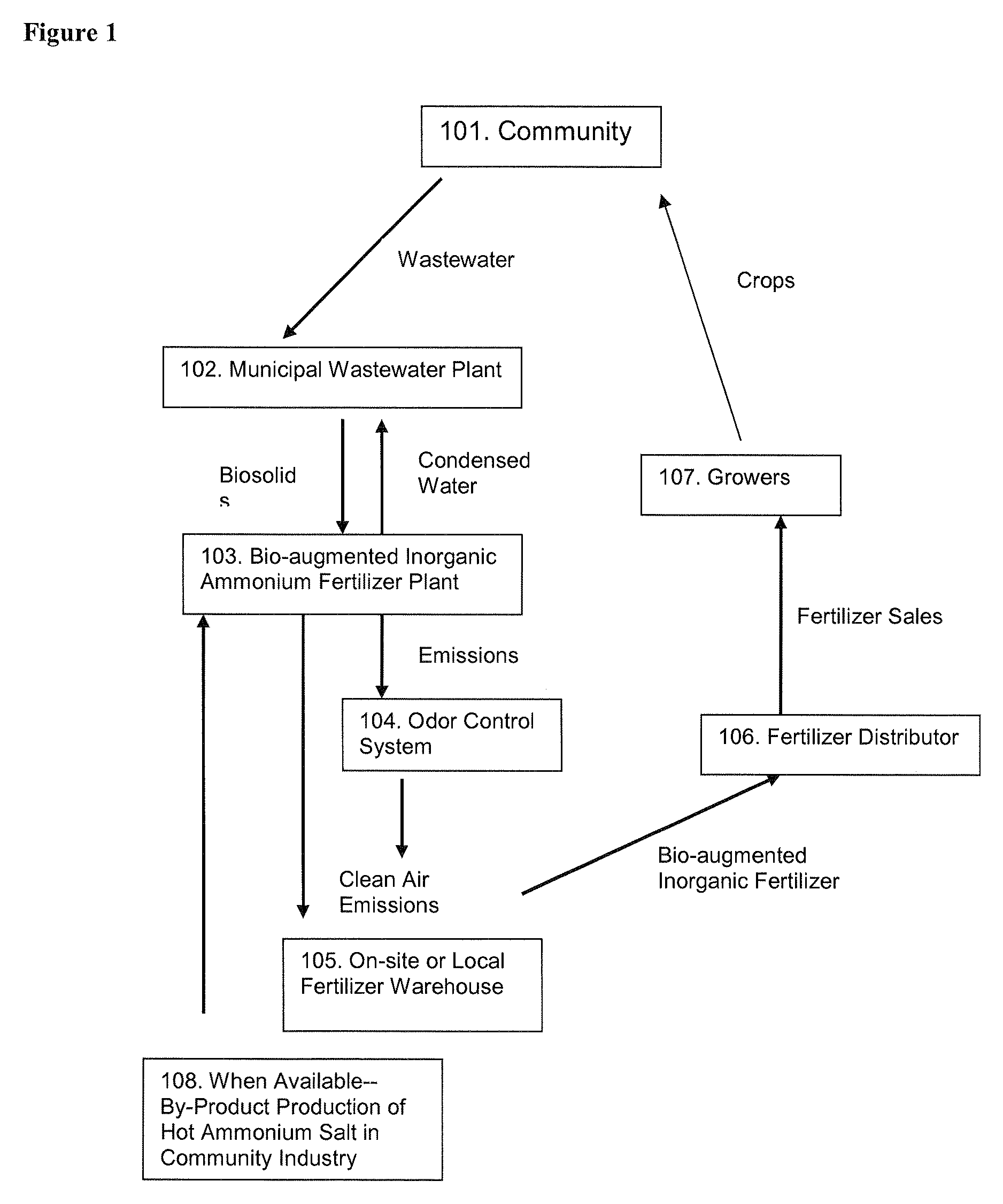

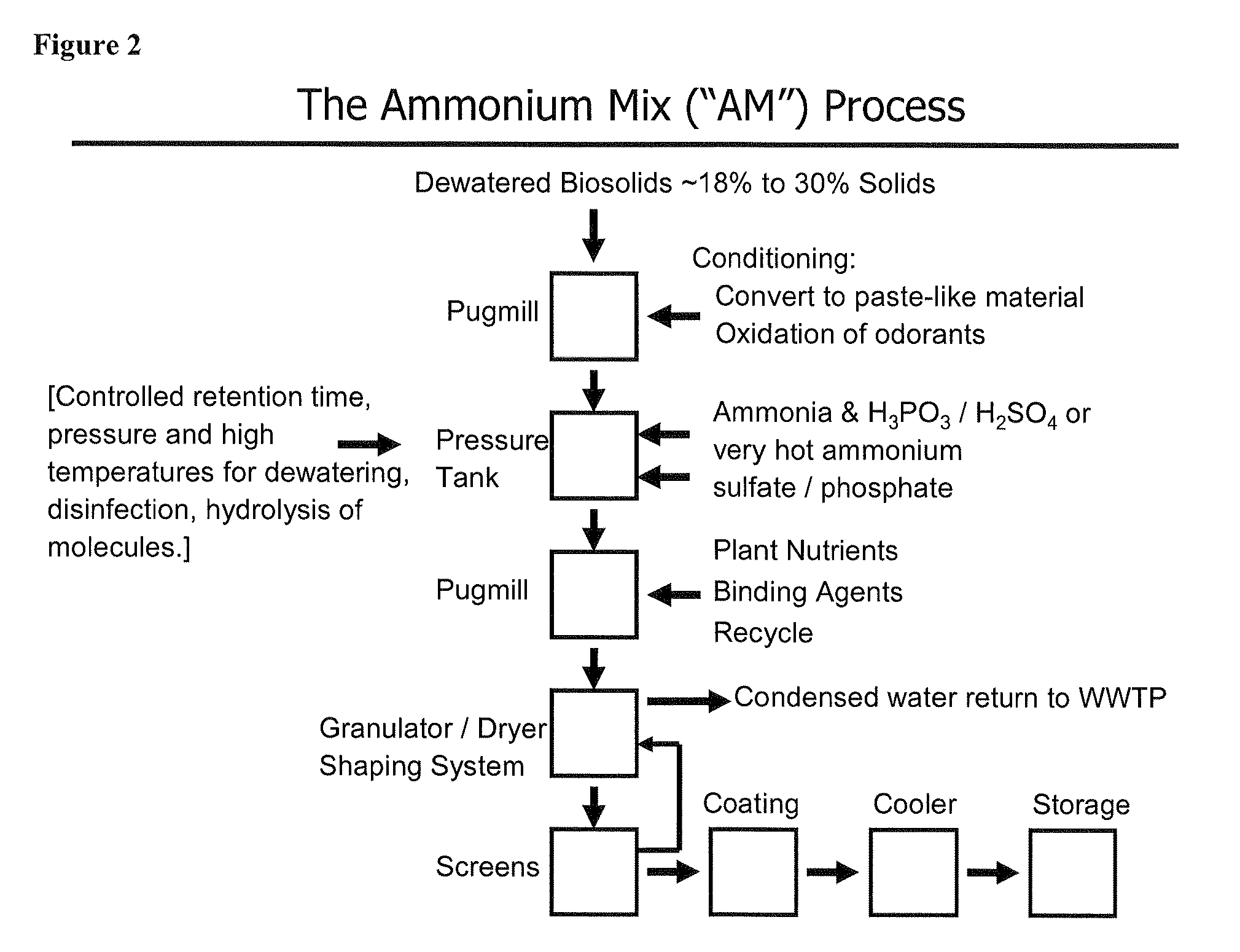

Process for treating sludge and manufacturing bioorganically-augmented high nitrogen-containing inorganic fertilizer

ActiveUS20080230484A1Reduce logisticsReduces liabilityByproduct vaporizationExcrement fertilisersPhosphateRetention time

The invention describes a new method for treating sludge, which can result in the production of high nitrogen organically-augmented inorganic fertilizer that incorporates municipal sludges or biosolids or organic sludges that can compete with traditional fertilizers such as ammonium phosphate, ammonium sulfate and urea on the commodity fertilizer marketplace. The method takes advantage of the thixotropic property of dewatered biosolids or organic sludge to create a pumpable paste-like material from the biosolids or organic sludge that is then treated with an oxidizer to reduce odorant effects and an acid. This mix is then interacted with concentrated sulfuric and or phosphoric acids and an ammonia source or alternatively a hot or molten melt or salt of ammonium sulfate / phosphate to form a fertilizer mix. The present invention controls the heat, atmospheric pressure and retention time of the fertilizer mix in the reaction vessel. When a fertilizer melt is formed ammoniation is subsequently completed by the specific use of vaporized ammonia. The invention can also be an add-on to commercial production of ammonium salts. The fertilizer produced by the present invention contains more than 8 wt. % nitrogen and preferably 15 wt. % nitrogen. The invention is oriented to be tailored to the biosolids production for individual municipal waste treatment plants in order to keep the fertilizer manufacturing plants of the present invention small with a minimization of logistics and liability.

Owner:GENERATE LENDING LLC +1

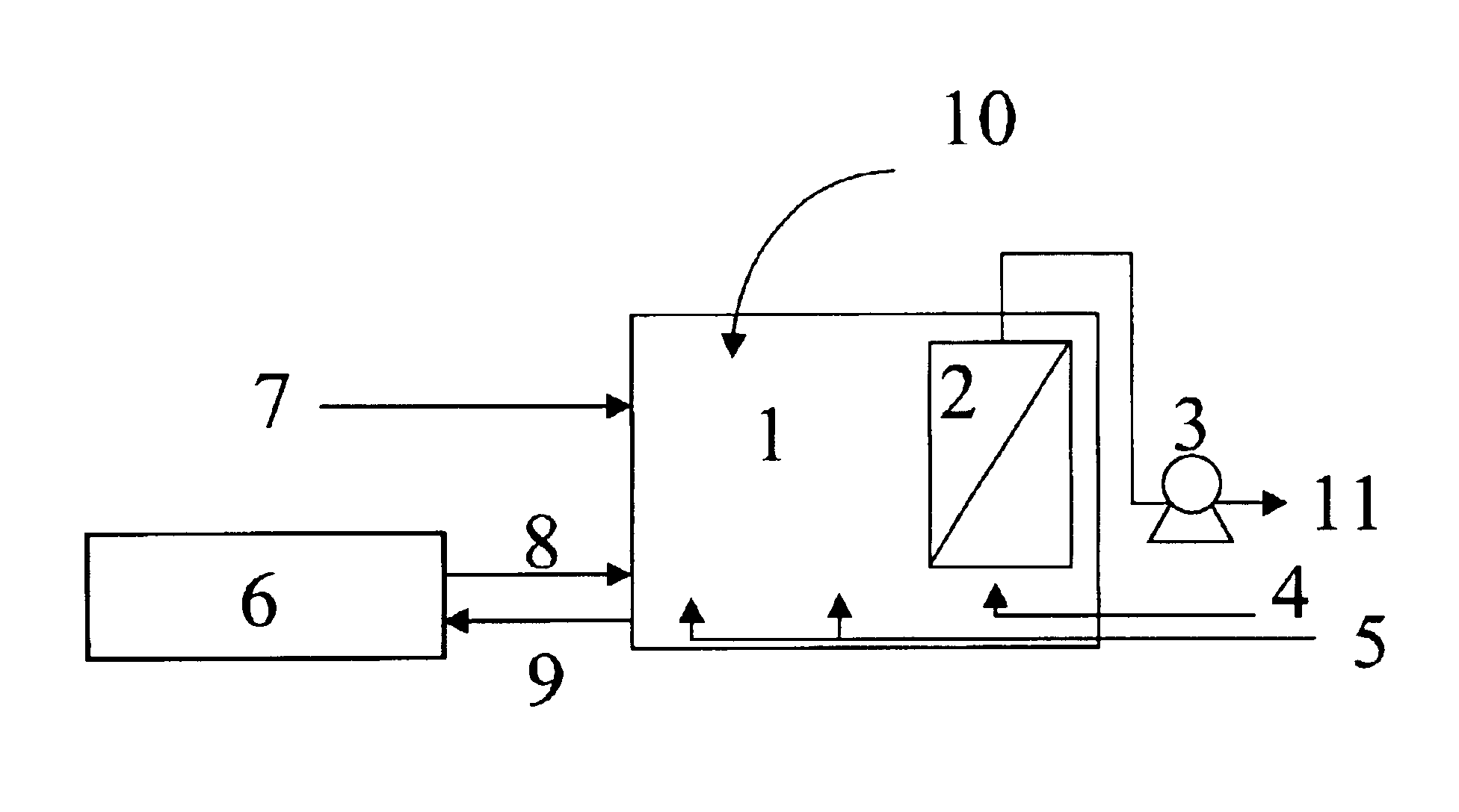

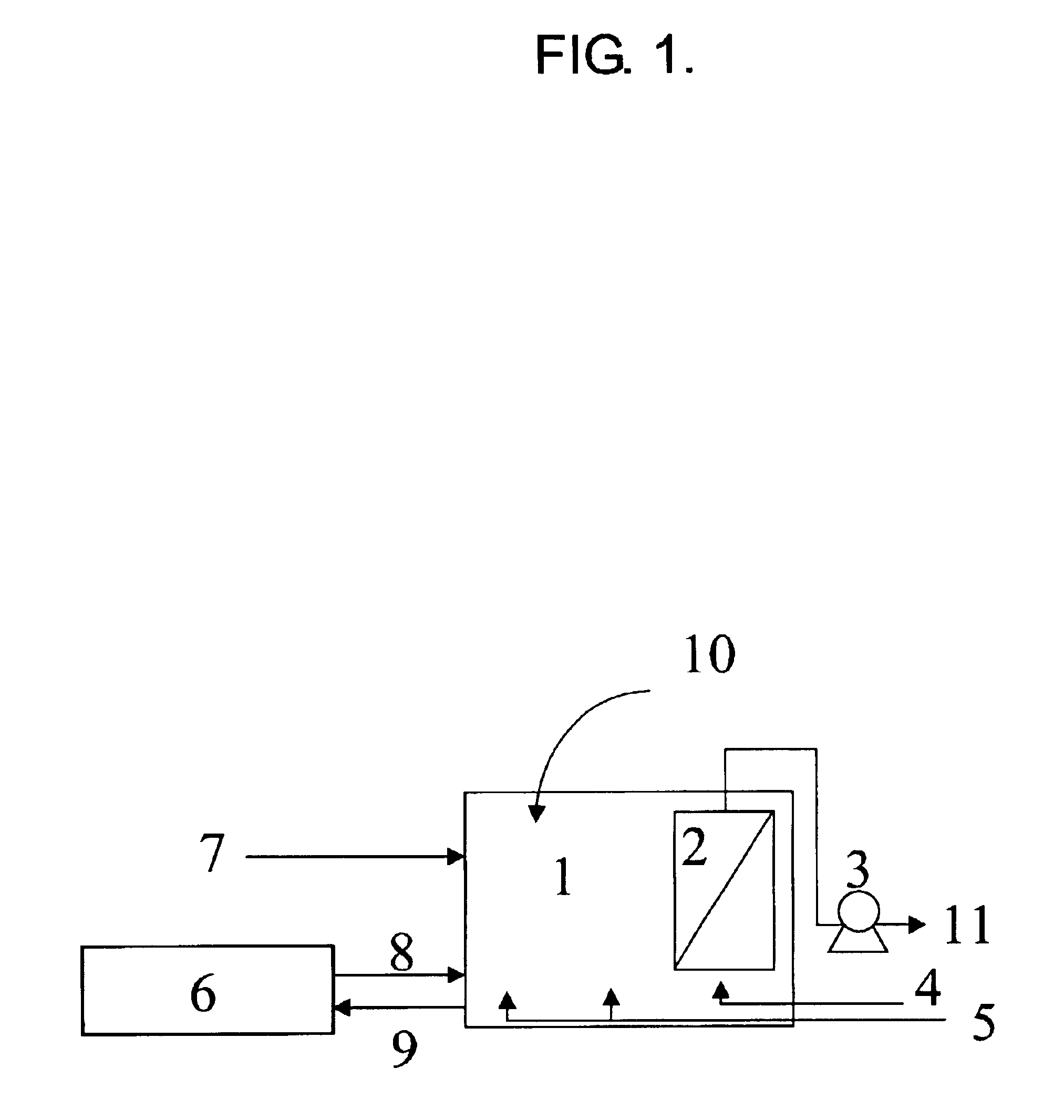

Method of using water soluble polymers in a membrane biological reactor

InactiveUS6926832B2Amount of timeLower cost of capitalMembranesTreatment using aerobic processesMembrane foulingWater soluble

A method of conditioning mixed liquor in a membrane biological reactor comprising adding to the mixed liquor an effective coagulating and flocculating amount of one or more water soluble cationic, amphoteric or zwitterionic polymers, or combination thereof and methods of reducing membrane fouling, enhancing membrane flux and reducing sludge production.

Owner:ECOLAB USA INC

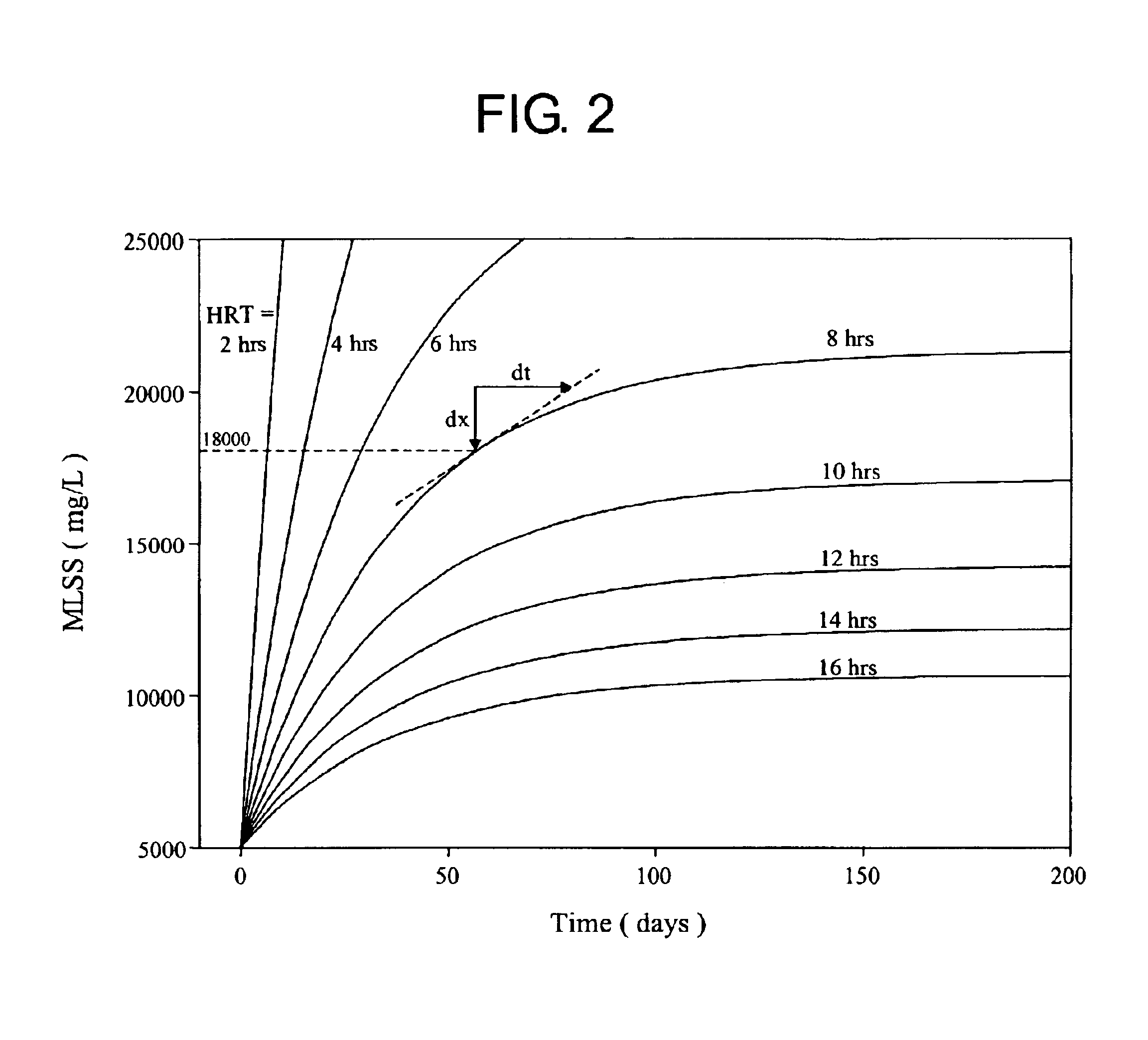

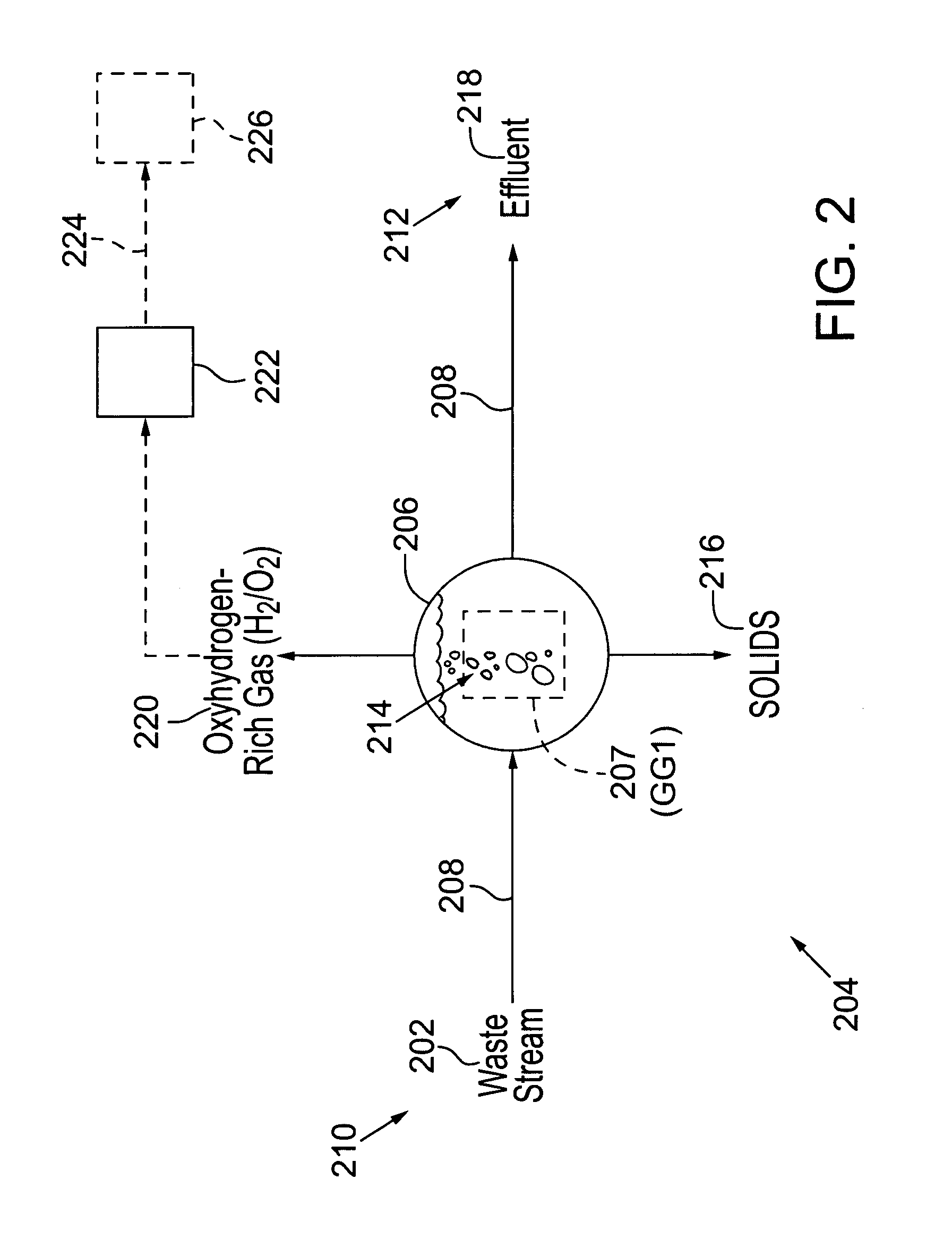

Treatment of a waste stream through production and utilization of oxyhydrogen gas

Methods and systems for treating a waste stream in a waste treatment system involve performing a unit process of the waste treatment system by contacting the waste stream with oxyhydrogen-rich gas generated on-site by an oxyhydrogen gas generator that implements water dissociation technology. In a preferred embodiment, the oxyhydrogen gas generator involves applying a pulsed electrical signal to a series of closely-spaced electrodes that are submerged in the waste stream to produce oxyhydrogen-rich gas from a water component of the waste stream. Operation of the oxyhydrogen gas generator in the waste stream may accomplish one or more unit processes for waste treatment, such as conditioning, stabilization, thickening, and dewatering, among others. At least a portion of the oxyhydrogen-rich gas can be conveyed for a second use in the waste treatment system, such as a source of combustible fuel for incineration or power generation, for example.

Owner:XOGEN TECH

Method and apparatus for converting organic material

ActiveUS20060260186A1Apparatus is enlargedCatalytic crackingByproduct vaporizationHomogeneous catalysisHydrocarbon

Owner:SCF TECH AS

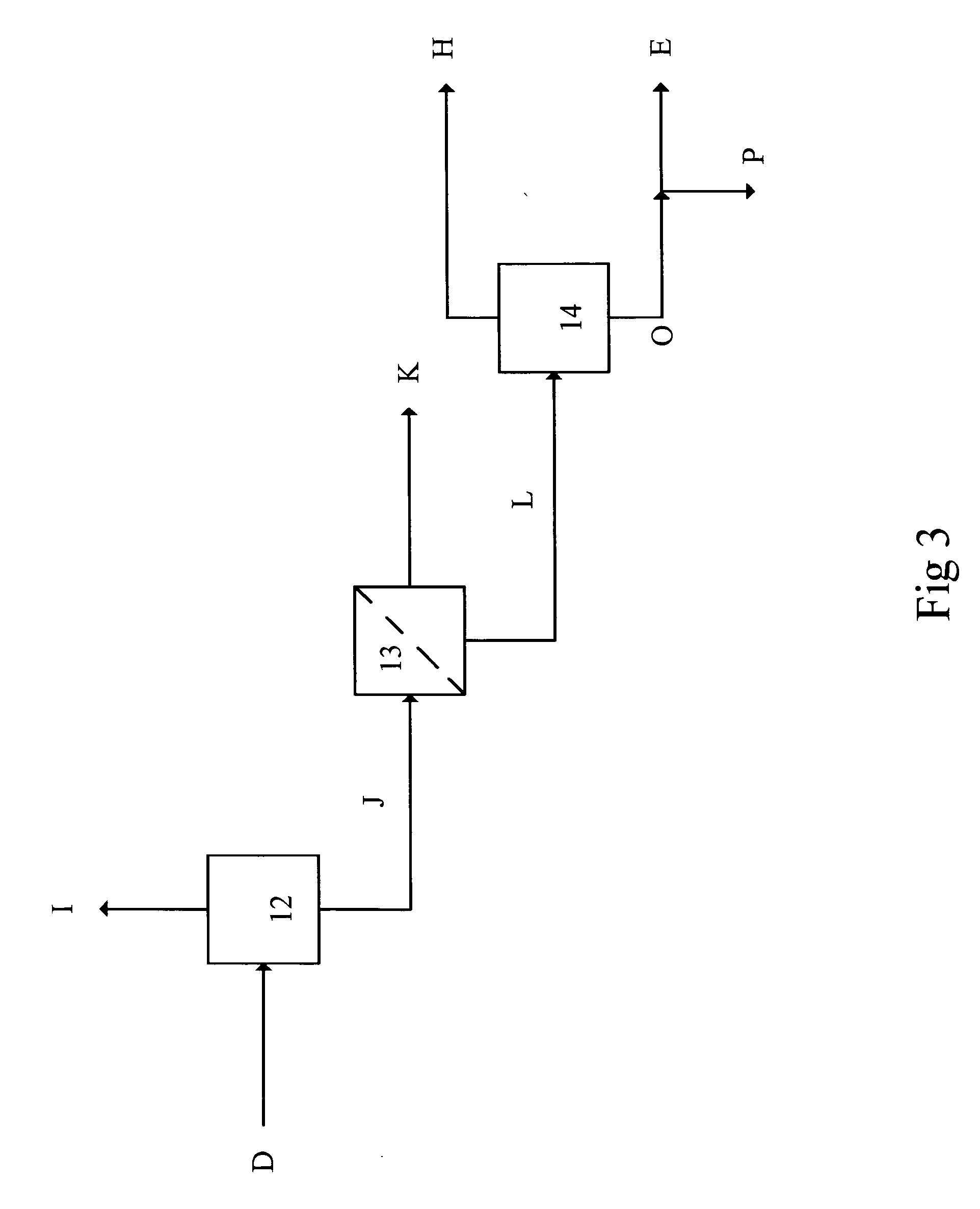

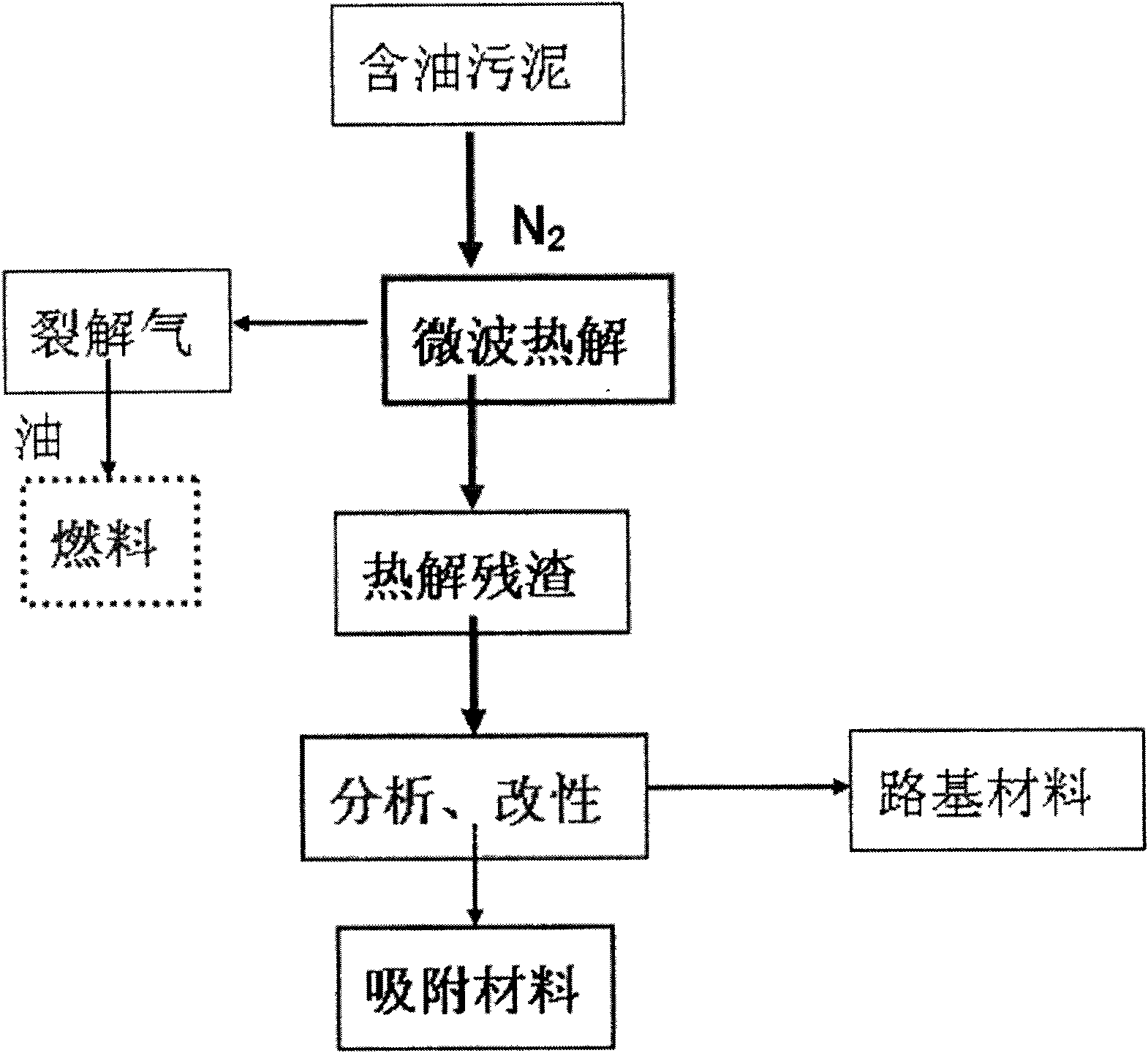

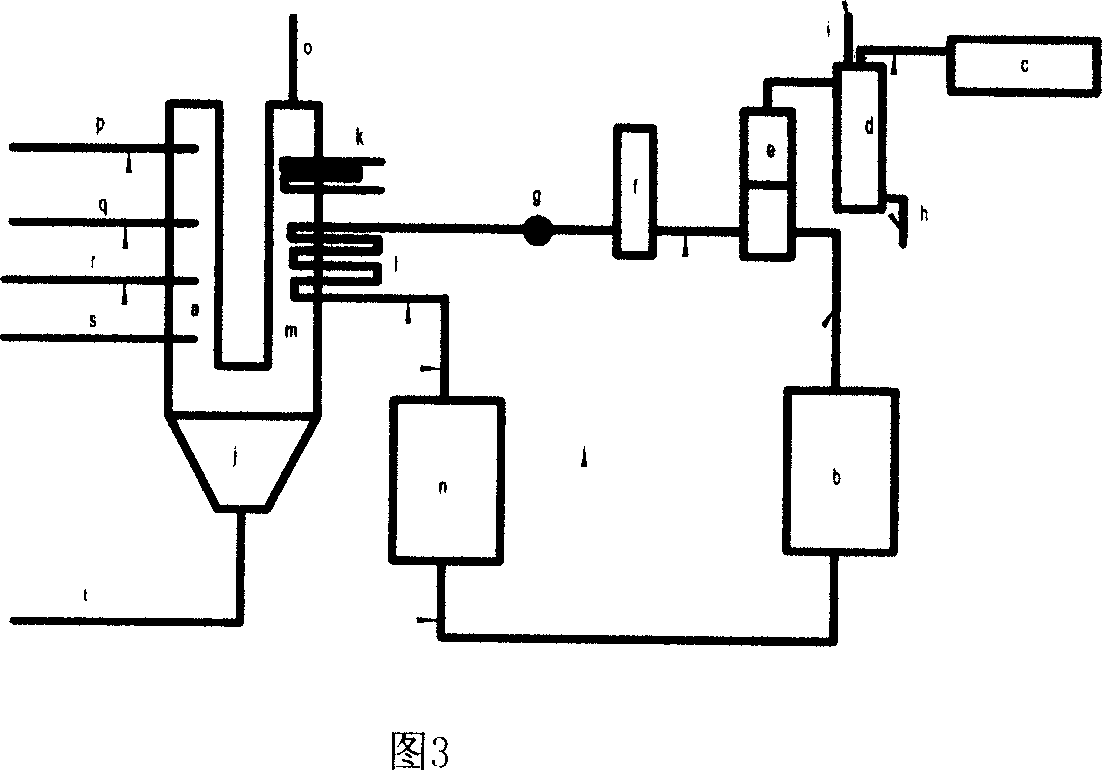

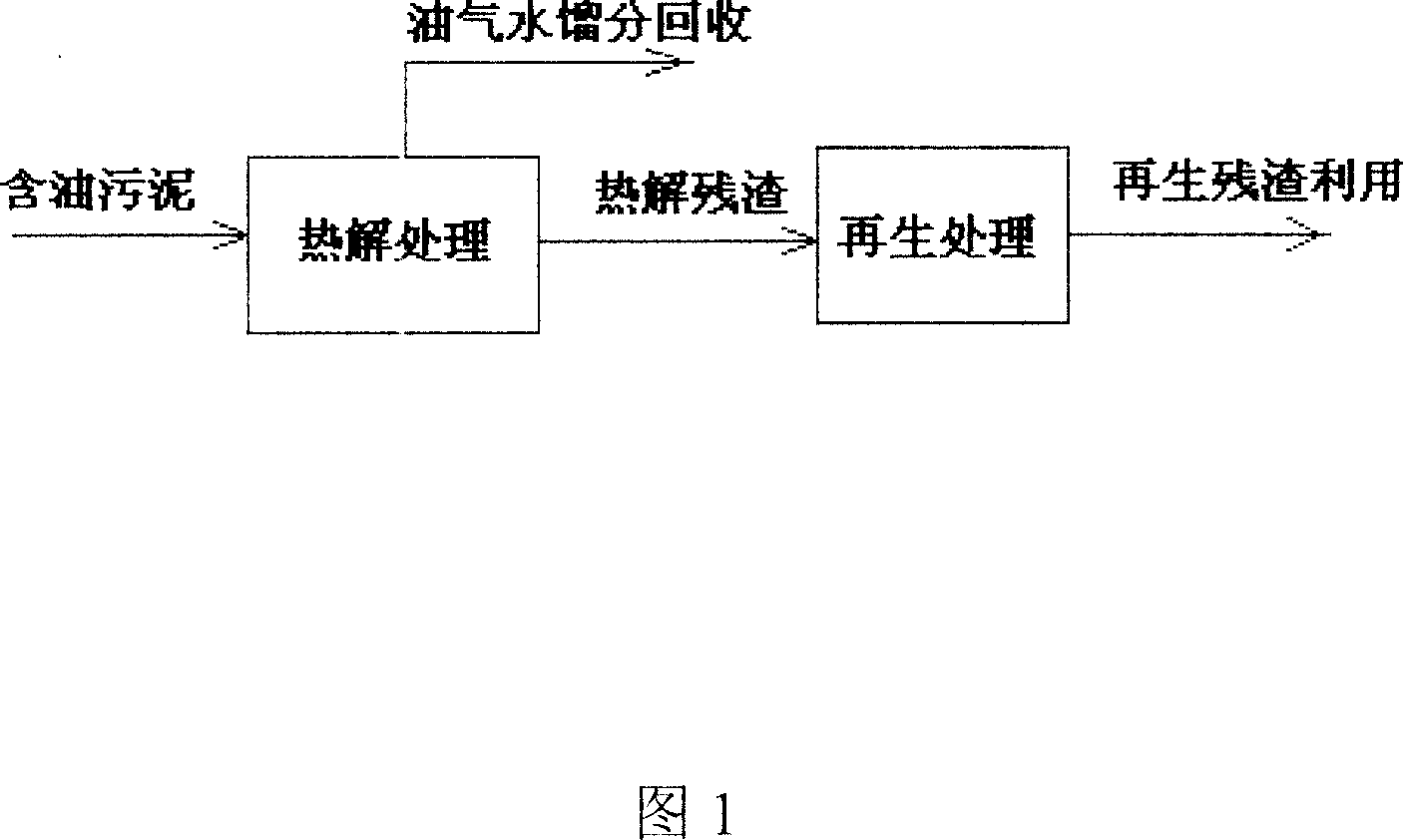

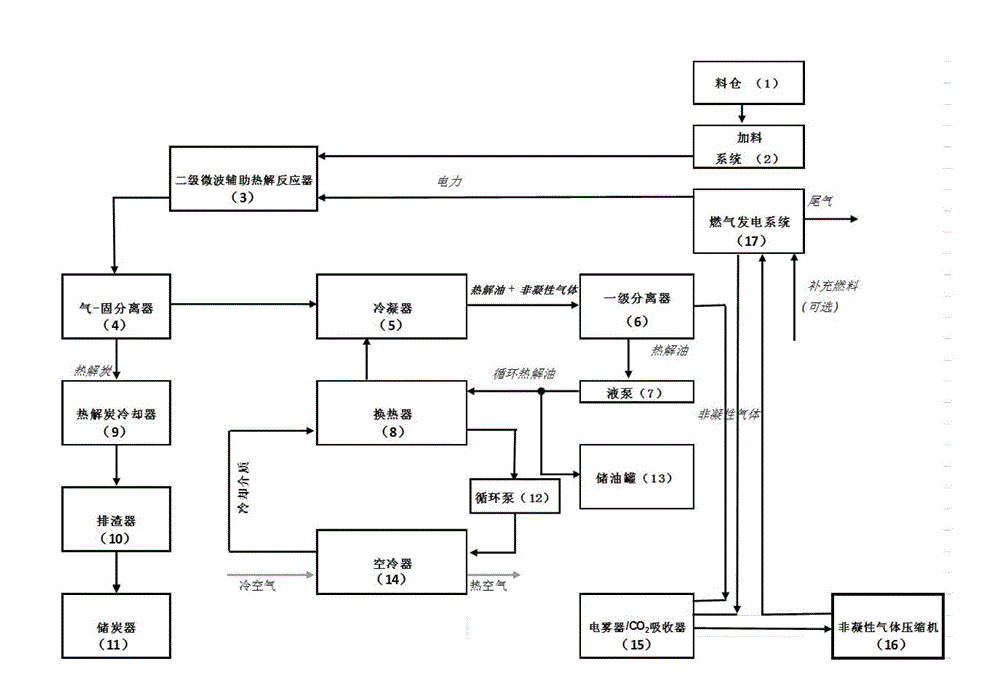

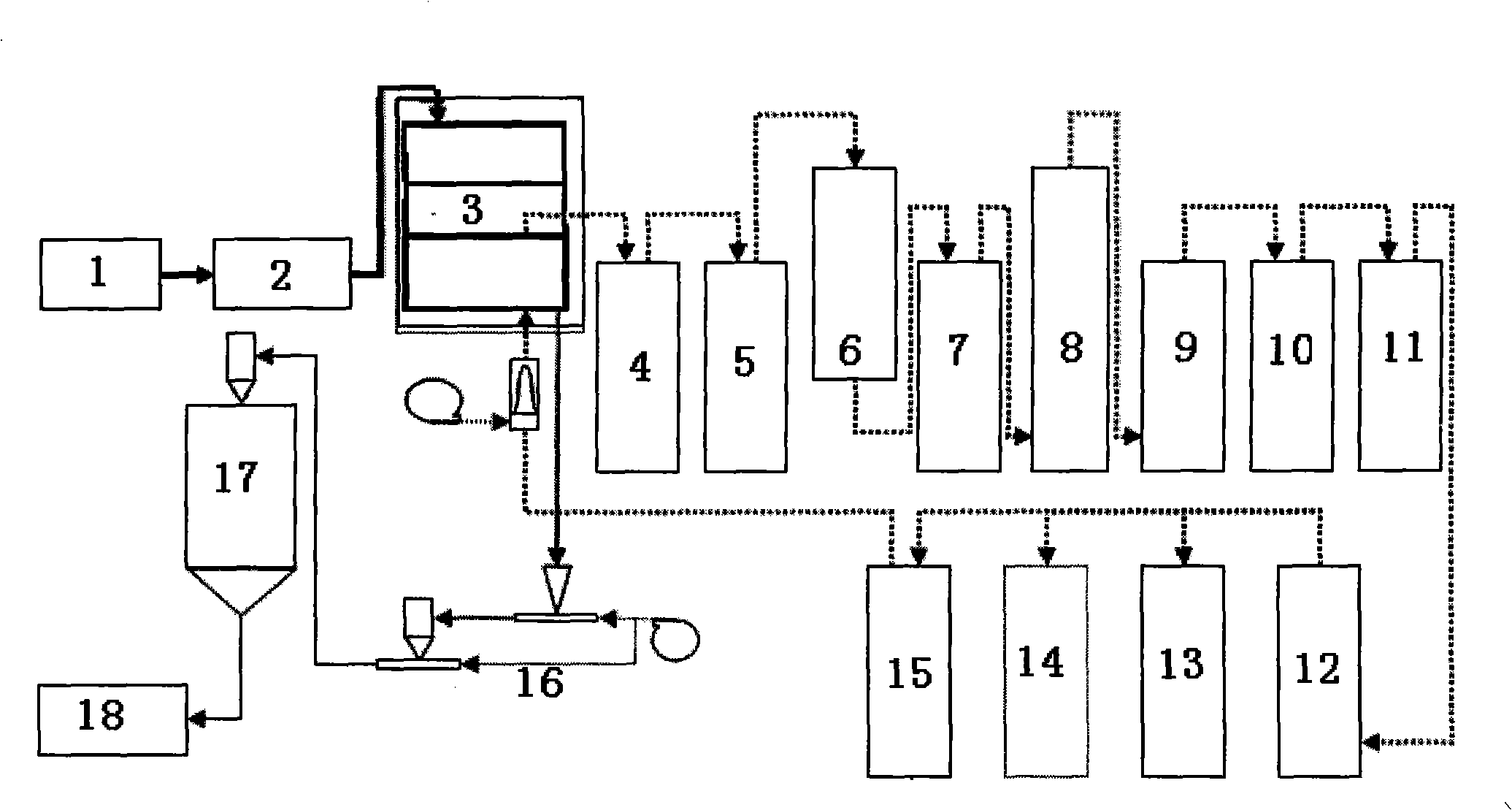

Resourceful treatment method and device for oil-containing sludge in oil fields by microwave pyrolysis

ActiveCN101838094ASolve pollutionAvoid Hazardous Waste Sewage FeesOther chemical processesSludge treatment by pyrolysisMicrowave pyrolysisSludge

The invention discloses a resourceful treatment method and a resourceful treatment device for oil-containing sludge in oil fields by microwave pyrolysis. The oil-containing sludge is conveyed into an enclosed reactor heated by microwaves, and is subjected to pyrolysis treatment at the temperature of between 200 and 900 DEG C; oil, gas and water generated by the pyrolysis treatment are recycled; the residue after the pyrolysis is used as a roadbed material or modified by nitric acid or NaOH alkali; and the modified residue is used as an adsorbing material. After the method and the device are implemented, over 75 percent of crude oil in the oil-containing sludge can be recycled, the pollution fee of 1,000 yuan / t can be saved, the social and economic benefits are obvious, and the method and the device have wide market application prospect.

Owner:CHINA PETROCHEMICAL CORP +2

Production of biodiesel and other valuable chemicals from wastewater treatment plant sludges

ActiveUS7638314B2Reduce the environmentPromote digestionBio-organic fraction processingByproduct vaporizationSludgeFree protein

A process for producing biodiesel has been invented by first extracting lipids from the sludges generated during primary and / or biological treatment of municipal, agricultural, and industrial wastewaters using primary, secondary, and tertiary treatments followed by the transesterification of the extracted lipids using transesterification conversion into alcohol-based esters. The resulting products from this process include biodiesel, glycerol, lipid-free proteins, various other useful chemicals and an aqueous-based substrate well suited for optimized digestion within subsequent biological digestion (either aerobic or anaerobic). The lipids extracted from the sludges containing high levels of microorganisms are phospholipids which can also be directly used as lecithin. The extraction of the lipids from the sludges will be performed using chemical extraction techniques with the transesterification of the extracted lipids accomplished using basic, acidic, and / or a combination of the two transesterification techniques.

Owner:MISSISSPPI STATE UNIV RES & TECH

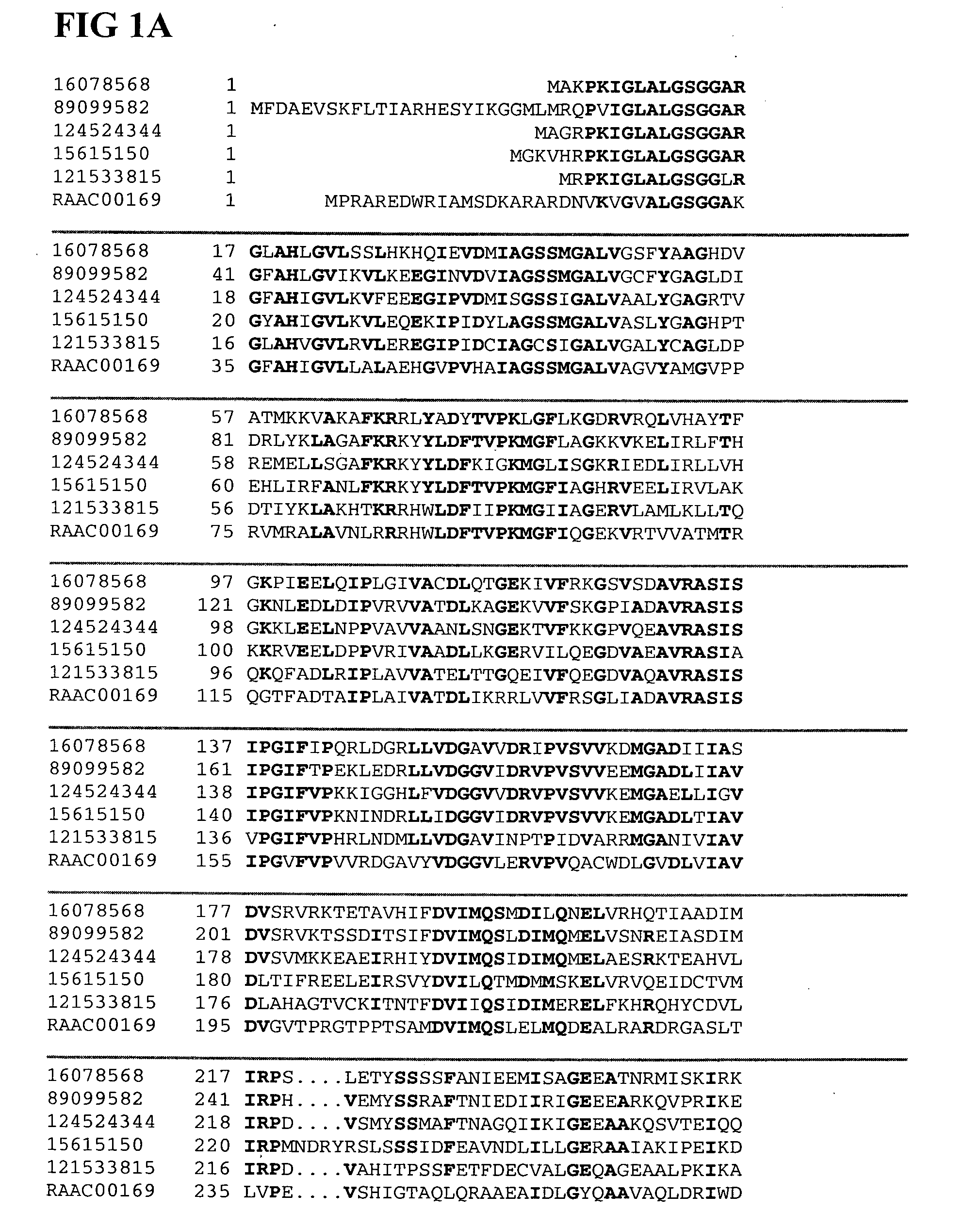

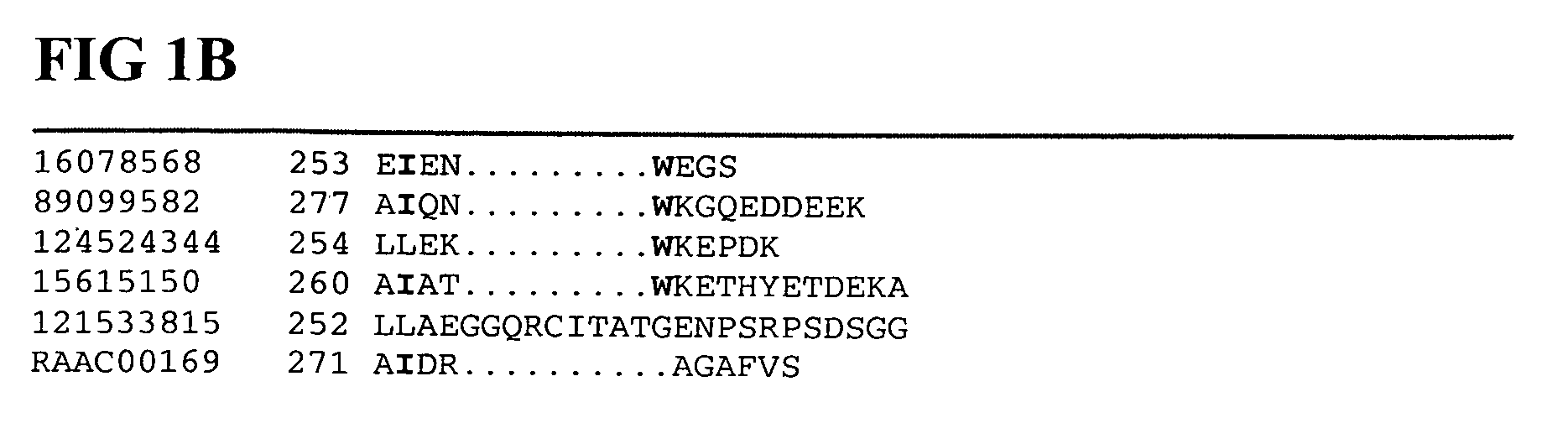

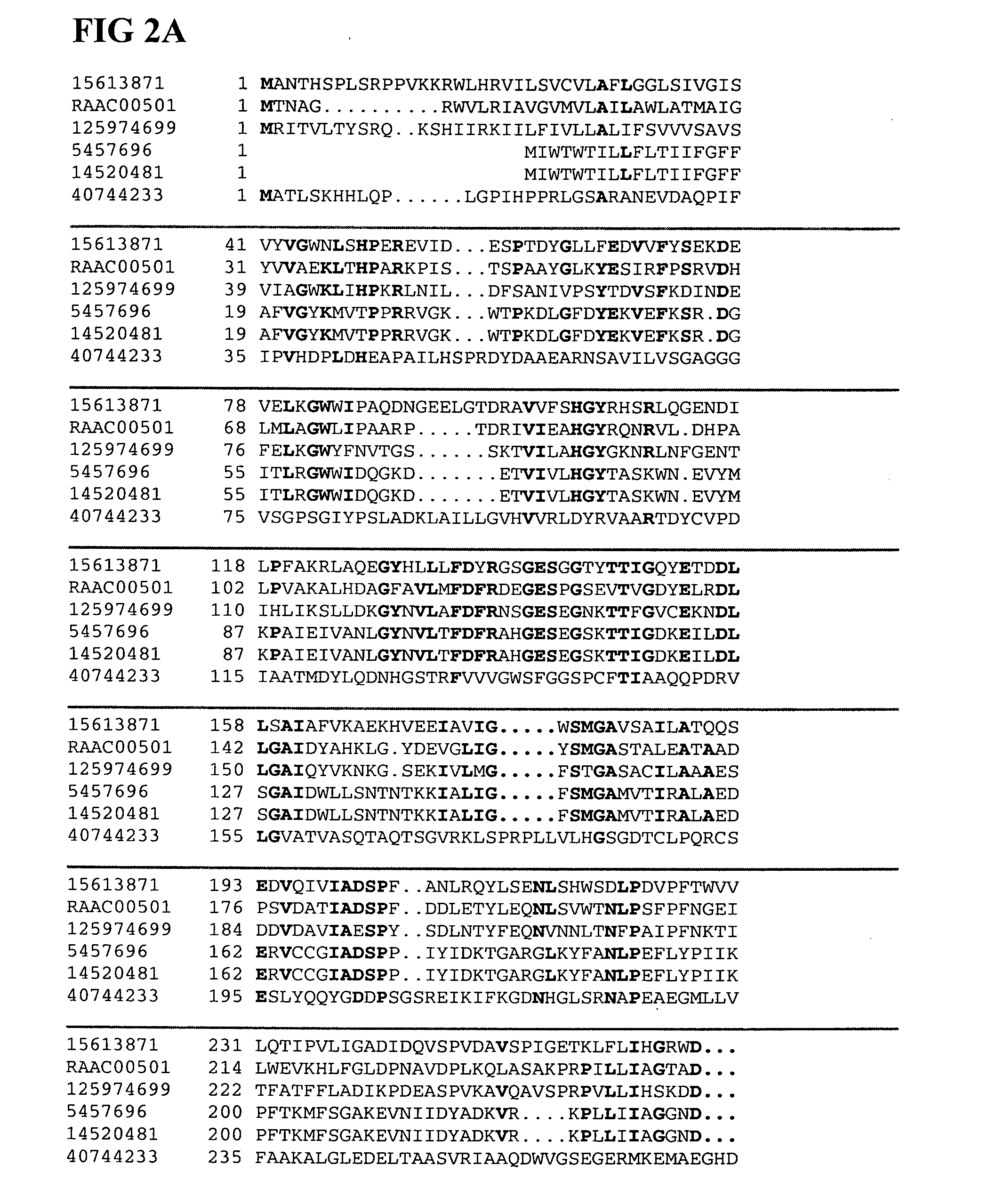

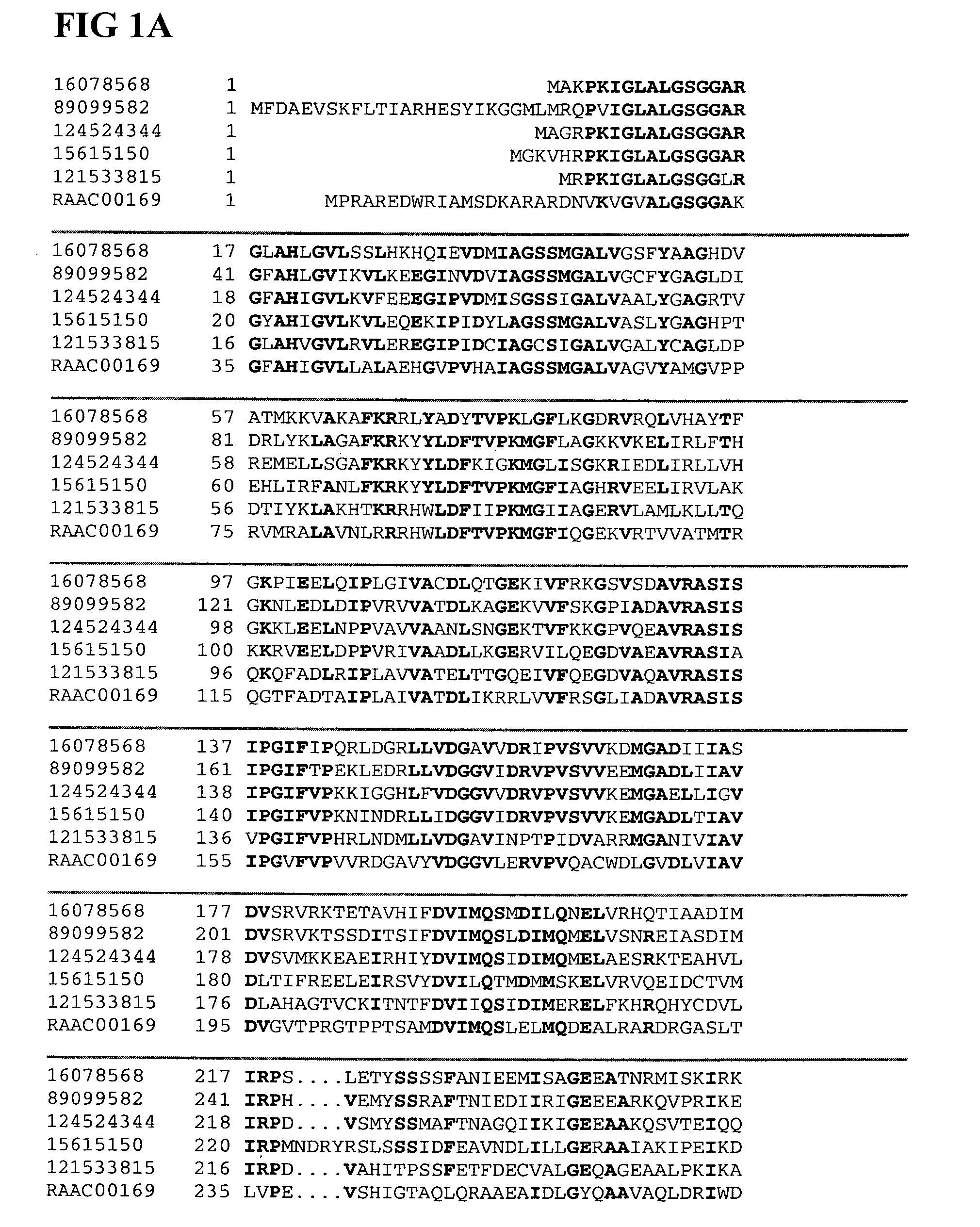

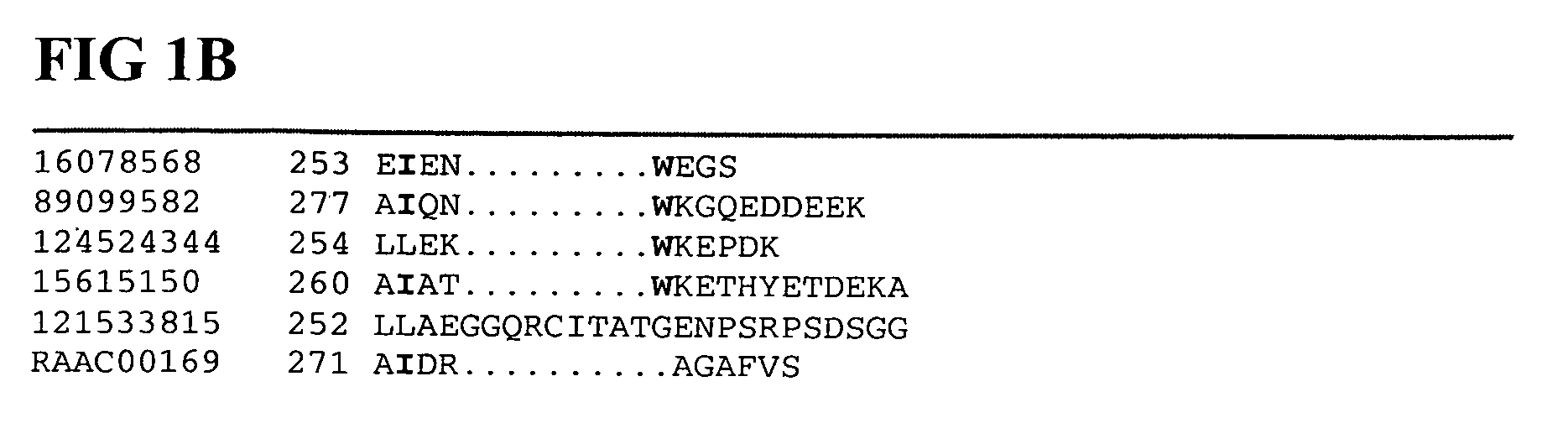

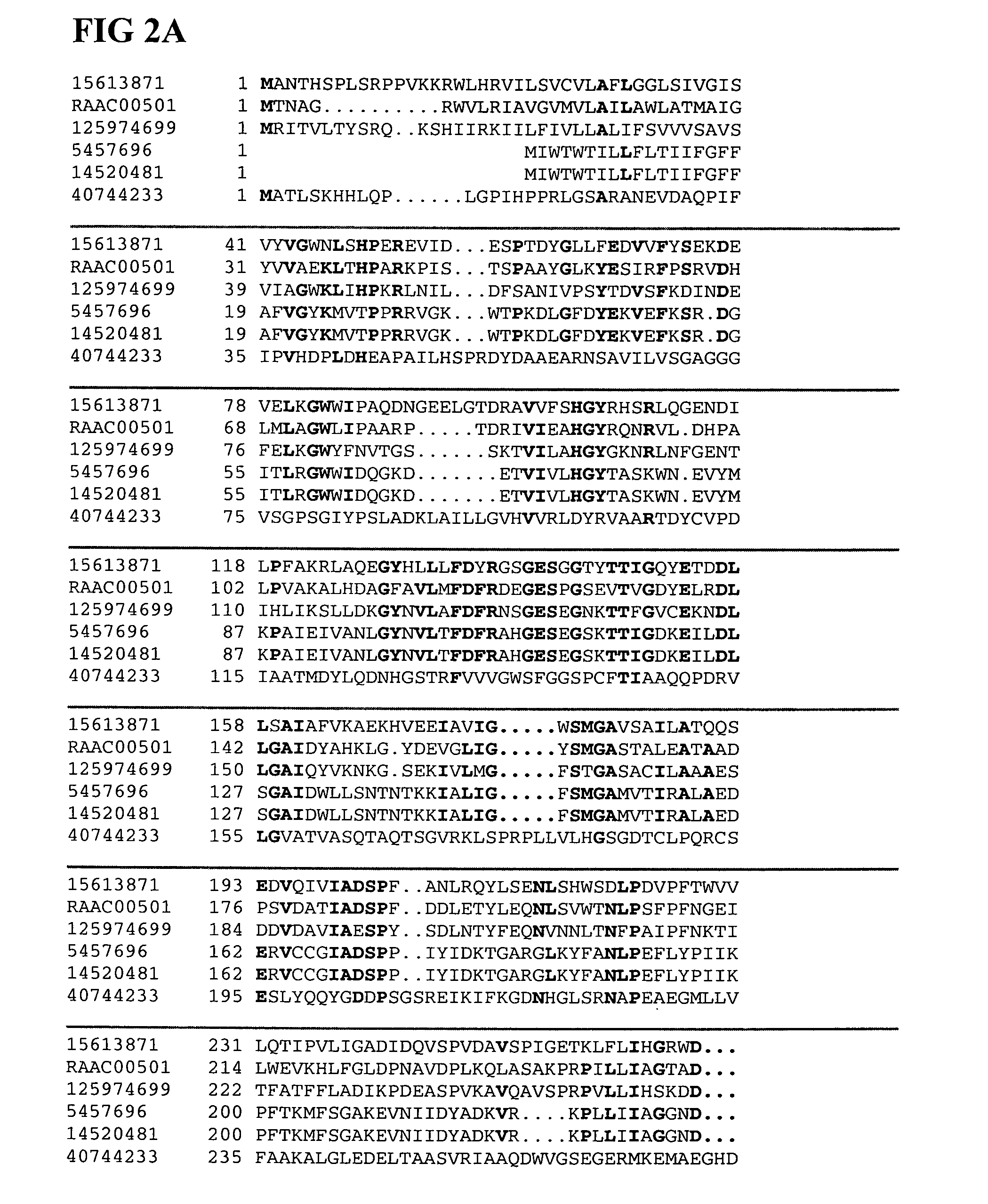

Thermophilic and thermoacidophilic biopolymer-degrading genes and enzymes from alicyclobacillus acidocaldarius and related organisms, methods

Isolated and / or purified polypeptides and nucleic acid sequences encoding polypeptides from Alicyclobacillus acidocaldarius are provided. Further provided are methods of at least partially degrading, cleaving, or removing polysaccharides, lignocellulose, cellulose, hemicellulose, lignin, starch, chitin, polyhydroxybutyrate, heteroxylans, glycosides, xylan-, glucan-, galactan, or mannan-decorating groups using isolated and / or purified polypeptides and nucleic acid sequences encoding polypeptides from Alicyclobacillus acidocaldarius.

Owner:BATTELLE ENERGY ALLIANCE LLC

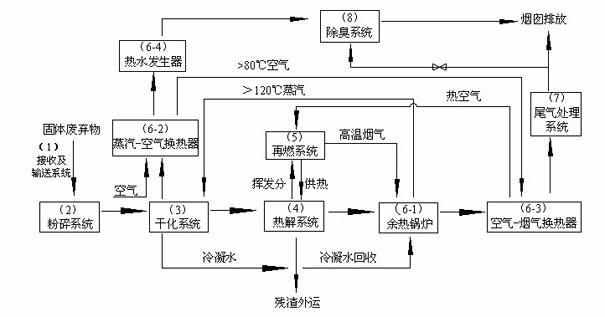

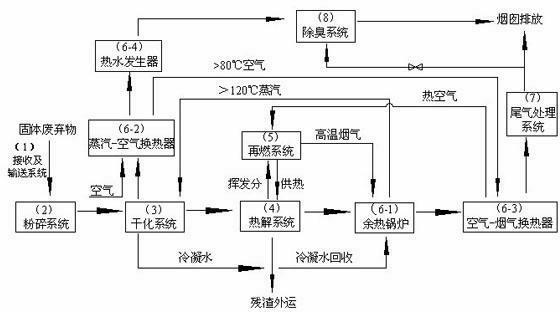

Novel process for pyrolysis of solid wastes

InactiveCN102537973AHas waste heat utilization valueAvoid consumptionSludge treatment by de-watering/drying/thickeningSludge treatment by pyrolysisCombustionRoom temperature

The invention discloses a novel process for pyrolysis of solid wastes. According to the existing pyrolysis technology, the solid wastes with low calorific values and high moisture content are difficult to treat, and effects of being completely harmless, reduced and recycled cannot be achieved. The novel process provided by the invention comprises the following steps of: uniformly crushing the solid wastes by a crushing system and conveying the crushed solid wastes to a drying system to be dried; carrying out the pyrolysis in a pyrolysis system and treating a pyrolyzed product by a re-burning system to provide energy needed by the pyrolysis system; conveying high-temperature smoke into a residual heat boiler to generate saturated vapor with a temperature which is higher than 1000 DEG C; carrying out heat exchange on the vapor by a vapor-air heat exchanger; after raising the temperature of normal-temperature air, conveying the air into the vapor-air heat exchanger to carry out the heat exchange with output smoke of the residual heat boiler; conveying the hot air into the pyrolysis system and carrying out processes of cooling combustion smoke, de-acidifying and removing dust on the smoke of the residual heat boiler through an exhaust gas treatment system; receiving uncondensed gas in condensed odor vapor by the deodorization system, carrying out final treatment on the uncondensed gas and exhausting. According to the invention, the residual heat value of the high-moisture solid wastes is sufficiently utilized and the utilization is not limited by types of the solid wastes, so that the energy source and the operation cost are saved.

Owner:ZHONGCHANG ENVIRONMENT PROTECTION GROUP +1

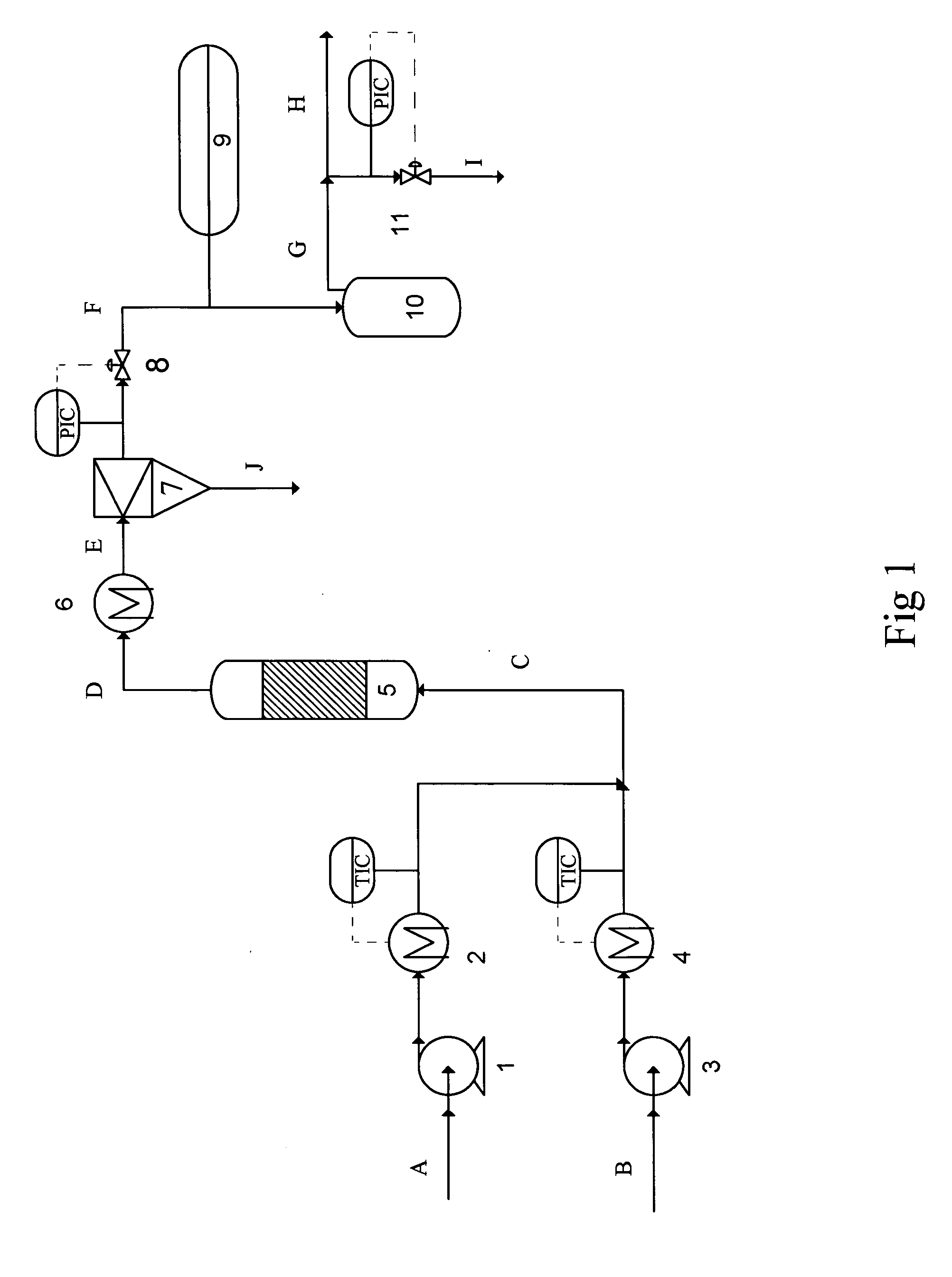

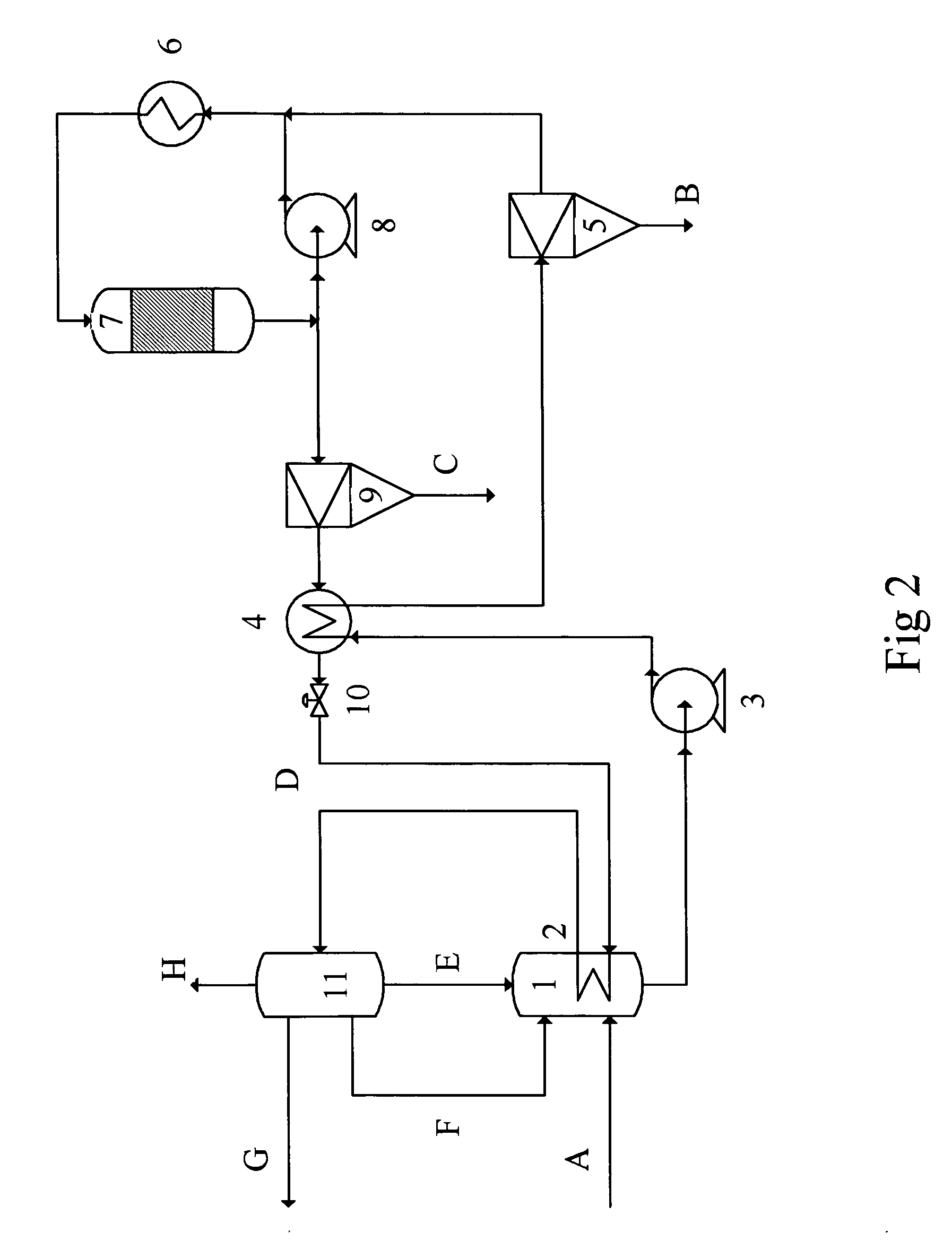

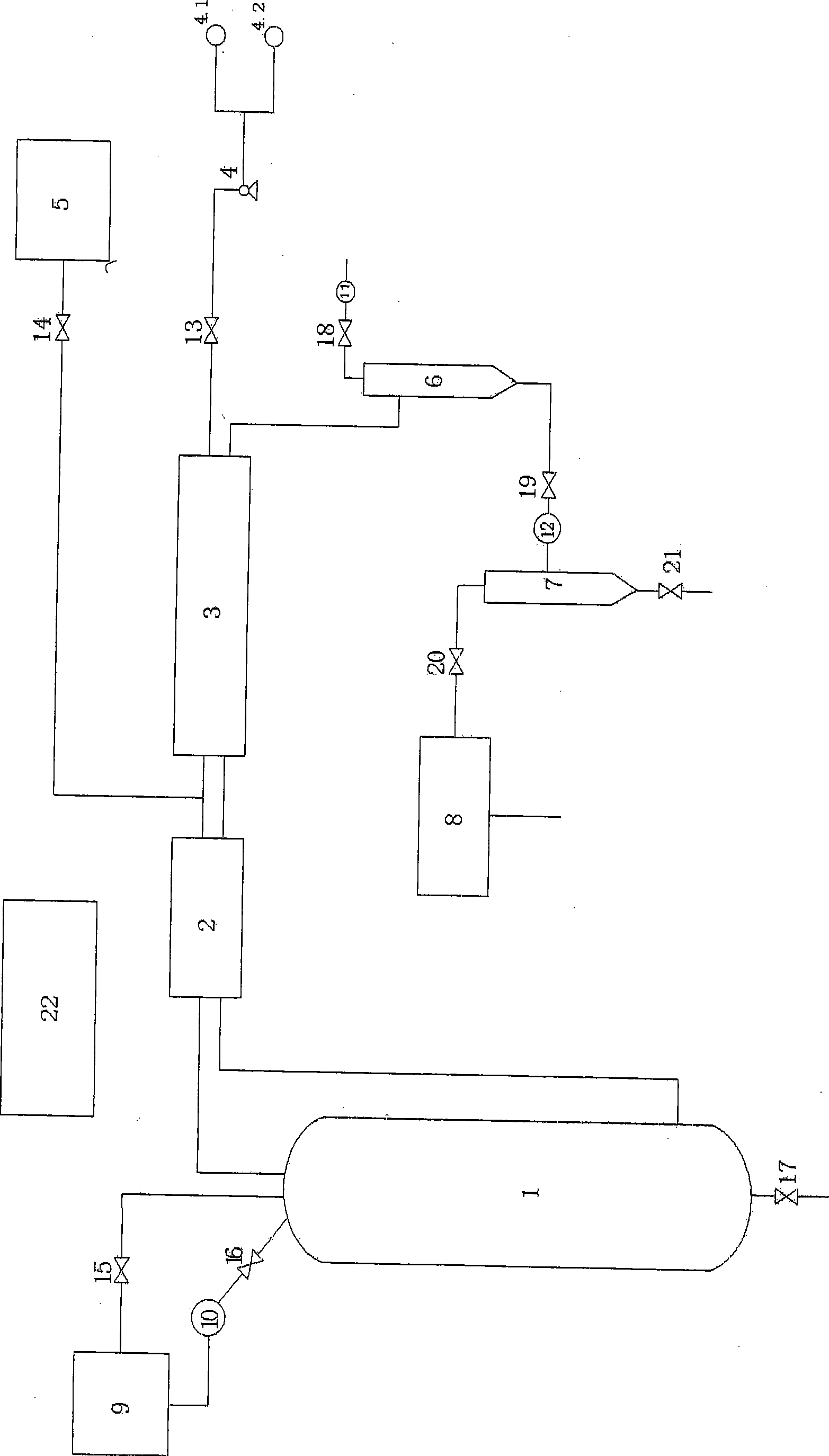

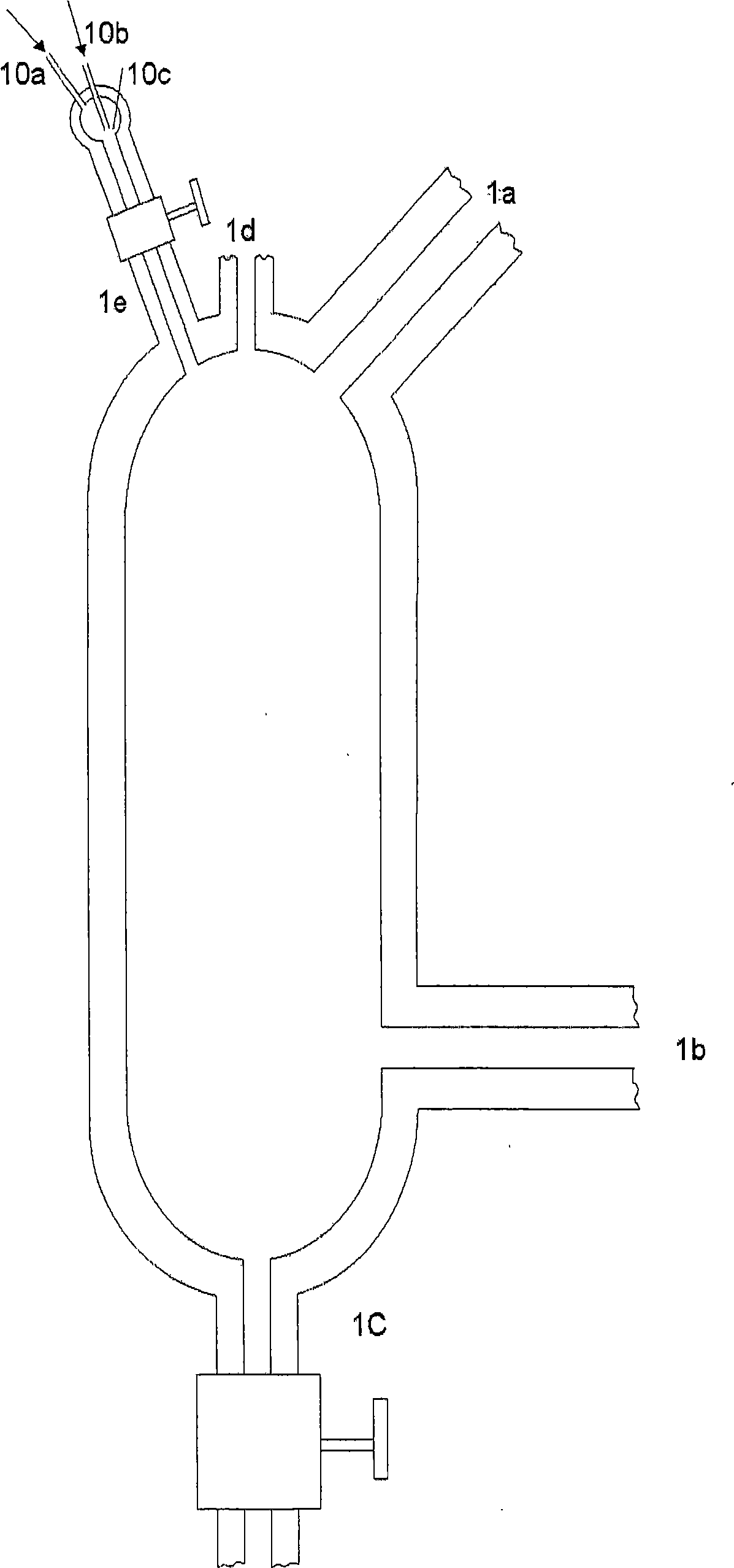

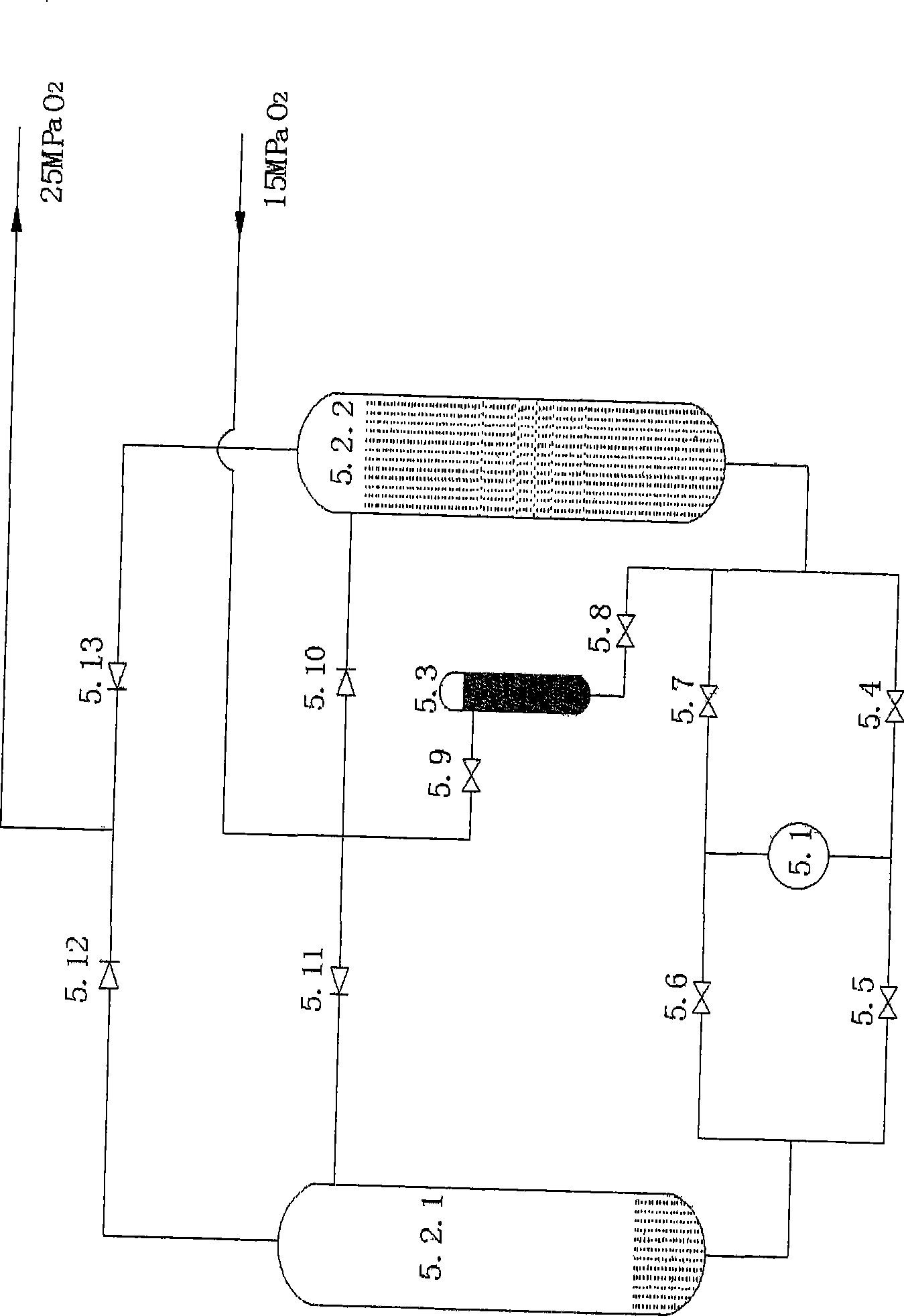

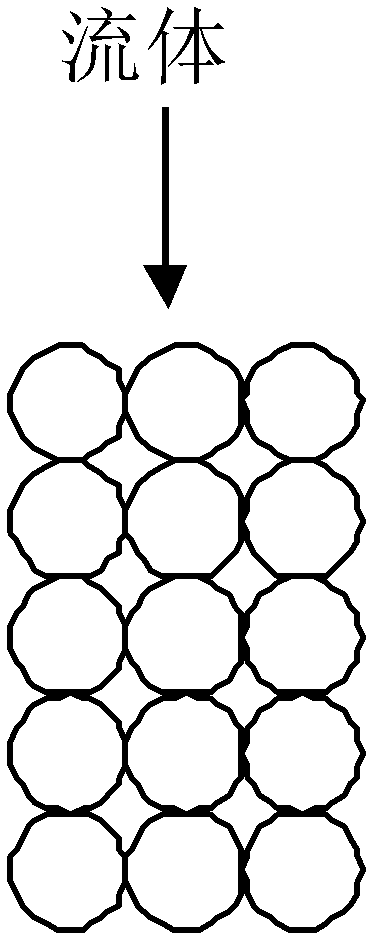

Method and device for oxidizing and treating sewage or sludge containing organic substances by supercritical water

InactiveCN101544419AGuaranteed uptimeReduce construction costsSludge treatment by oxidationByproduct vaporizationCombustionSludge

The invention relates to a method and a device for oxidizing and treating sewage or sludge containing organic substances by supercritical water. The method adopts a combustion reaction furnace, and is characterized in that substance flow of the sewage or the sludge containing the organic substances and oxidant (such as oxygen or hydrogen peroxide and the like) are preheated by a heat exchange device respectively and then enter the combustion reaction furnace, the sewage or the sludge containing the organic substances is oxidized and treated under a supercritical state, the treated substance flow is cooled by the heat exchange device again, then residual gas in the substance flow is separated by adopting a gas-liquid separator, and the lower part of the combustion reaction furnace discharges salt slag through a slag discharging hole and a valve. The method has the advantages of reasonable and practical process, energy conservation and low operation cost.

Owner:楼龙春

Sludge-dewatering compound conditioning agent and application method thereof

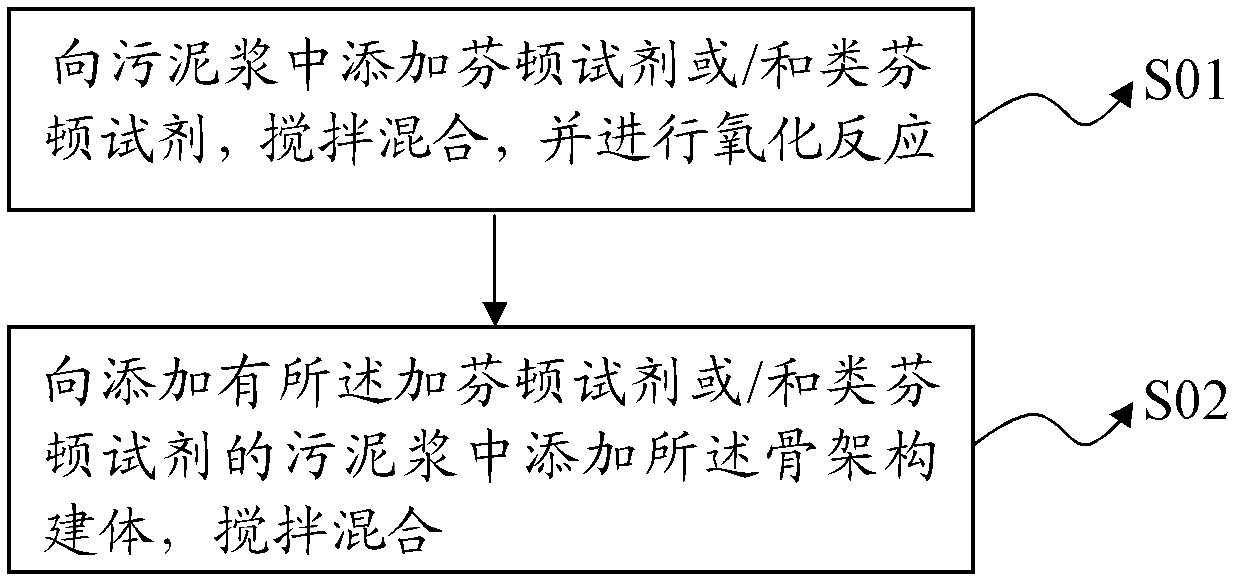

ActiveCN102381828AAchieve deep dehydrationShorten spin timeSludge treatment by de-watering/drying/thickeningSludge treatment by oxidationPOLYMER SUBSTANCEFenton reagent

The invention provides a sludge-dewatering compound conditioning agent and an application method thereof. The sludge-dewatering compound conditioning agent comprises a Fenton reagent or / and similar Fenton reagent and a skeleton construct, and the weight ratio of the Fenton reagent or / and similar Fenton reagent and the skeleton construct is 1: (0.05-300); and the skeleton construct adopts a powder body. The application method comprises the following steps: adding the Fenton reagent or / and similar Fenton reagent into sludge slurry, and mixing for oxidation; and adding the skeleton construct into the sludge slurry with the Fenton reagent or / and similar Fenton reagent, and mixing. Due to synergy of the Fenton reagent or / and similar Fenton reagent and the powder type skeleton construct, extracellular polymeric substances in sludge can be destructed effectively, the compressibility of organic substances can be reduced, and the sludge dewatering performance of the sludge-dewatering compound conditioning agent can be improved greatly. The procedures of the application method are simple, the conditions can be controlled easily, the sludge dewatering time can be shortened, and the large-scale treatment of the sludge can be realized.

Owner:UNIVERSTAR SCI & TECH SHENZHEN +1

Sludge drying and incinerating treatment process

InactiveCN1931753AAvoid pollutionAvoid harmSludge treatment by oxidationByproduct vaporizationChemical compositionSludge

The present invention relates to environmental protection engineering technology, and is especially sludge drying and incinerating treatment process. The present invention has effective utilization of heat energy, no exhaust of harmful gas and bad smell, no exhaust of dangerous clinker, simple structure and high burning efficiency of the sludge incinerating system, no need of auxiliary fuel and other advantages.

Owner:BEIJING CHINA SCI GENERAL ENERGY & ENVIRONMENT CO LTD

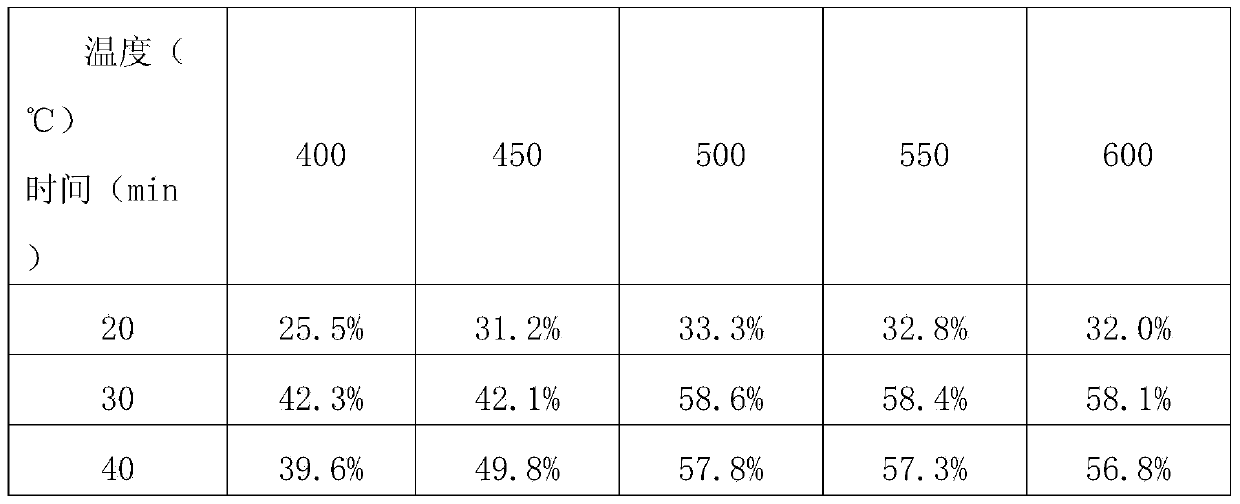

Resource treating method for oil-containing sludge

ActiveCN101113067ASolve pollutionReduce doseSludge treatment by pyrolysisByproduct vaporizationClay mineralsIron salts

The invention relates to a resource processing method for oily sludge. First, the oily sludge is sent to a closed retorting cracking furnace to be pyrolyzed, and the pyrolyzed period is 1-5 hours under 200-600 DEG C, then the oil, gas, and water are recovered. Second, sulfate or hydrochloride is put into the pyrobitumen of sludge containing inorganic aluminum salt or iron salt flocculant according to the chemical equivalent of the aluminum salt or iron salt 1 to 1-1.5 to do acid-soluble processing. The products after the two processes can be reclaimed and used as the flocculant of the sewage processing system, or reclaimed as the concentrating agent of sludge. The pyrobitumen containing mostly clay mineral can be used as decolorizing and absorbing material of waste water and oil, or used as absorbent for lube-oil complementing and refining process. The method used in oilfield gathering transportation and treatment system can realize zero discharge in course of the gathering transportation and treatment, and can effectively solve the pollution problem of the oily sludge and find the automate answer for the oily sludge. Meanwhile, by adopting the method, the cost for the treatment of sewage flocculation and for adding sludge concentration agent can be reduced and the energy material can be reclaimed from sludge and the wastage of oil can be reduced.

Owner:PETROCHINA CO LTD

Process for treating sludge and manufacturing bioorganically-augmented high nitrogen-containing inorganic fertilizer

ActiveUS7947104B2Reduce responsibilityEliminate needByproduct vaporizationExcrement fertilisersRetention timePhosphate

The invention describes a new method for treating sludge, which can result in the production of high nitrogen organically-augmented inorganic fertilizer that incorporates municipal sludges or biosolids or organic sludges that can compete with traditional fertilizers such as ammonium phosphate, ammonium sulfate and urea on the commodity fertilizer marketplace. The method takes advantage of the thixotropic property of dewatered biosolids or organic sludge to create a pumpable paste-like material from the biosolids or organic sludge that is then treated with an oxidizer to reduce odorant effects and an acid. This mix is then interacted with concentrated sulfuric and or phosphoric acids and an ammonia source or alternatively a hot or molten melt or salt of ammonium sulfate / phosphate to form a fertilizer mix. The present invention controls the heat, atmospheric pressure and retention time of the fertilizer mix in the reaction vessel. When a fertilizer melt is formed ammoniation is subsequently completed by the specific use of vaporized ammonia. The invention can also be an add-on to commercial production of ammonium salts. The fertilizer produced by the present invention contains more than 8 wt. % nitrogen and preferably 15 wt. % nitrogen. The invention is oriented to be tailored to the biosolids production for individual municipal waste treatment plants in order to keep the fertilizer manufacturing plants of the present invention small with a minimization of logistics and liability.

Owner:GENERATE LENDING LLC +1

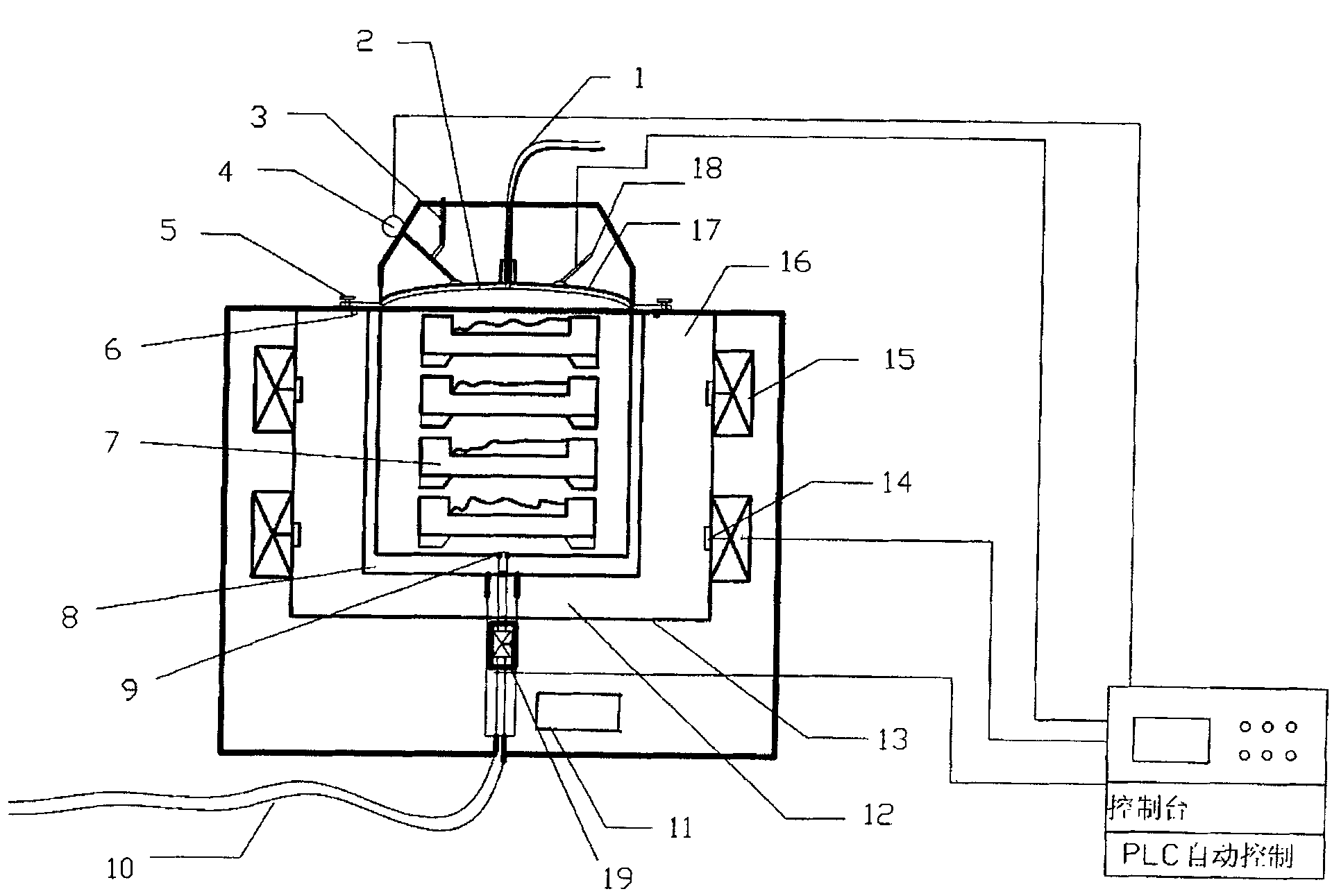

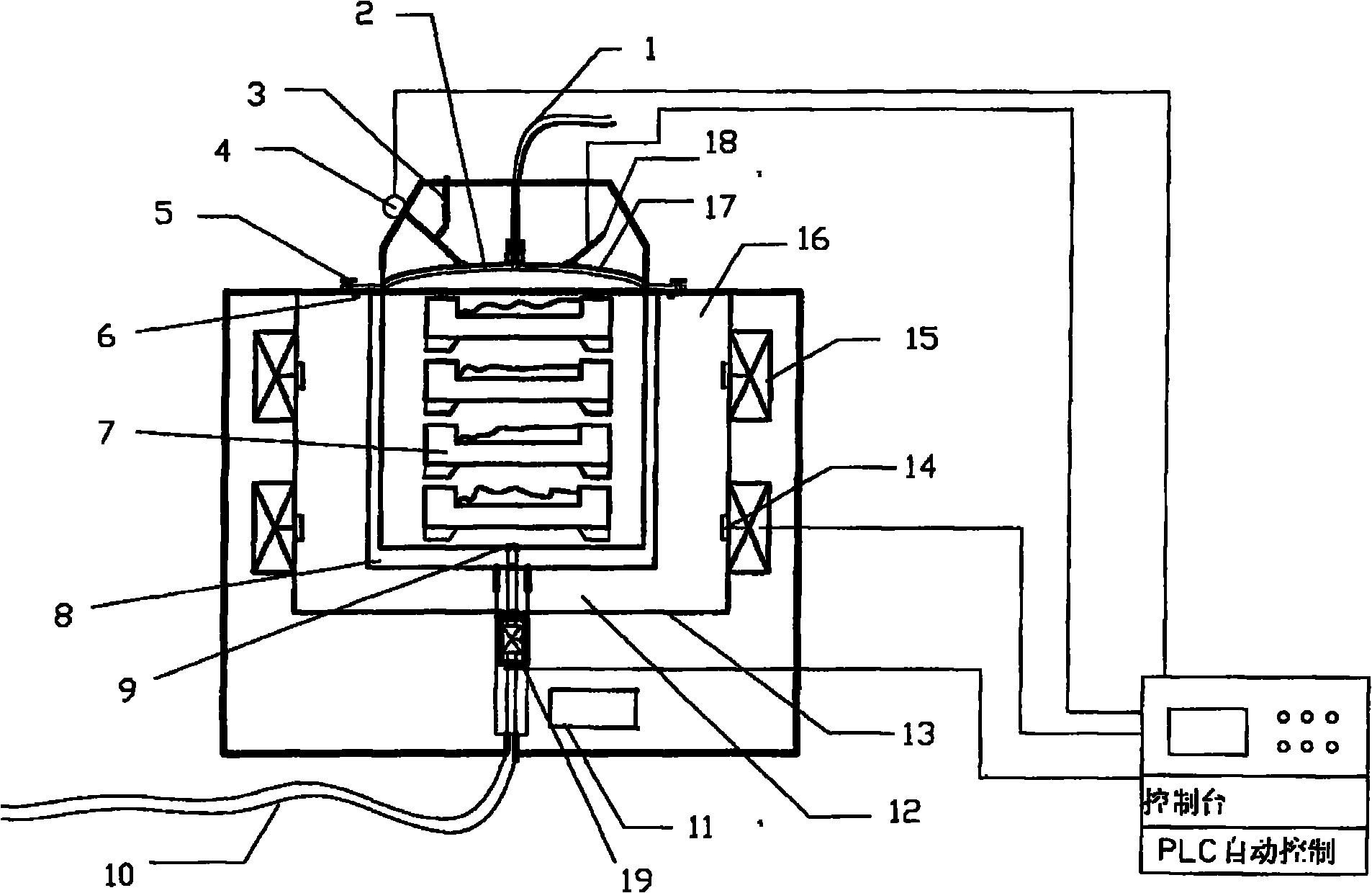

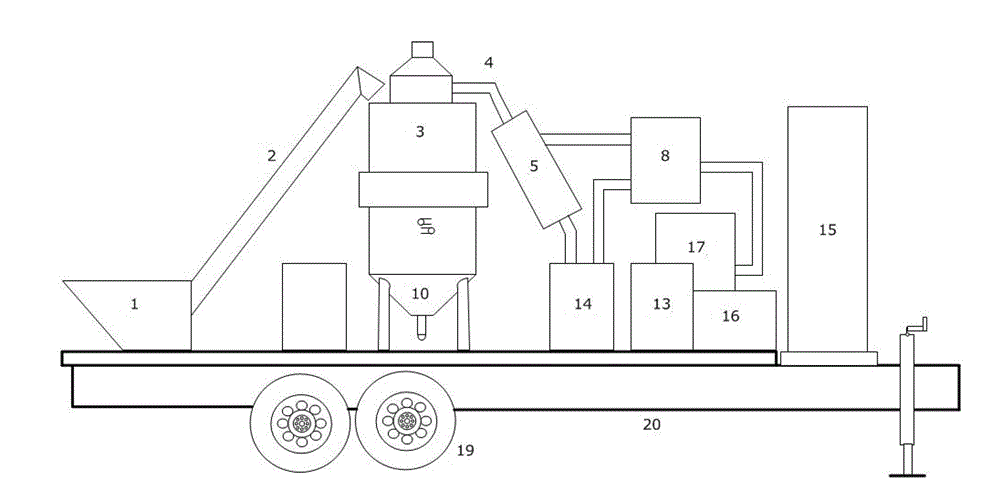

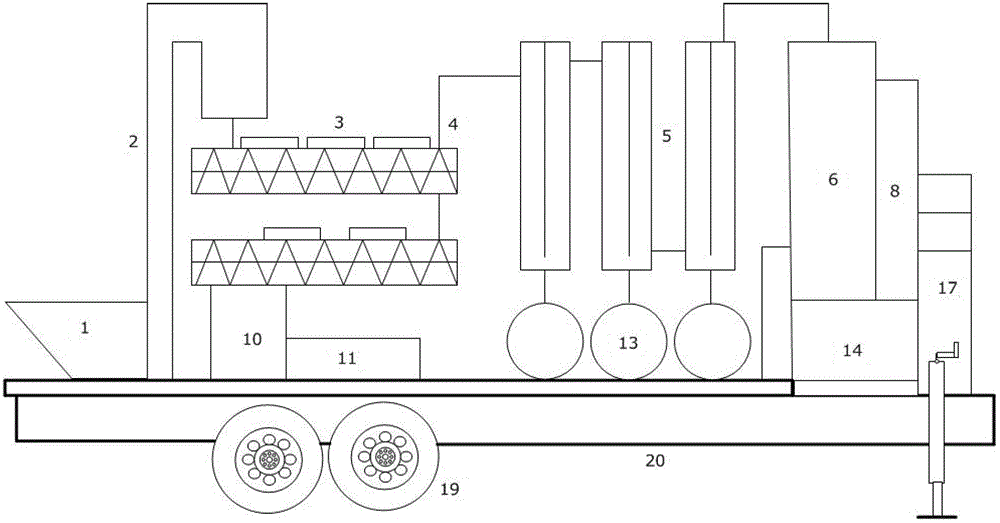

Pyrolysis device and method for in-situ conversion of carbon-containing resources by microwave-assisted pyrolysis

ActiveCN102718383ASolve the difficulty of large-scale collectionSolve the inconvenience of storage and transportationSludge treatment by pyrolysisByproduct vaporizationSlagChar

The invention discloses a pyrolysis device for in-situ conversion of carbon-containing resources by microwave-assisted pyrolysis. The device comprises a microwave-assisted pyrolysis reactor, a solid outlet of the reactor is connected with an inlet of a pyrolytic carbon cooler, an outlet of the pyrolytic carbon cooler is connected with a slag storer through a deslagging machine, a gas outlet of the reactor is connected with an inlet of a condenser through a pipeline, the condenser is provided with a gas-liquid separator, a gas outlet of the condenser is connected with a gas purifier, an outlet of the gas purifier is connected with a gas compressor, a liquid outlet of the condenser is connected with a liquid circulating pump, then one branch of the condenser is connected with an oil storage tank, and the other branch of the condenser is connected back to the condenser through a cooling medium circulating system. The invention further discloses a method for the in-situ conversion of the carbon-containing resources by the microwave-assisted pyrolysis. By the pyrolysis device and the method for the in-situ conversion of the carbon-containing resources by the microwave-assisted pyrolysis, various low-grade carbon-containing resources can be collected, stored and continuously produced at an economic scale.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

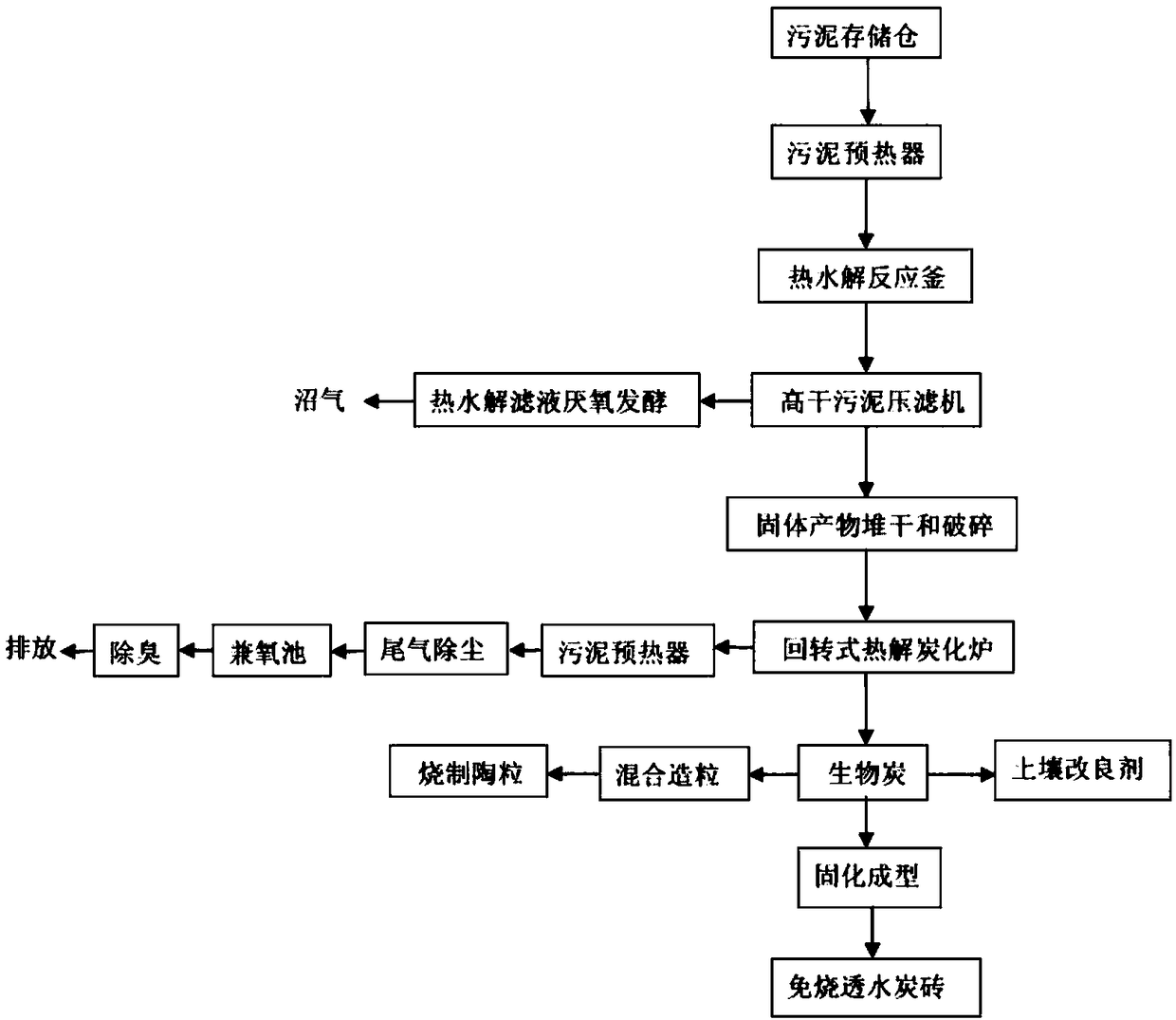

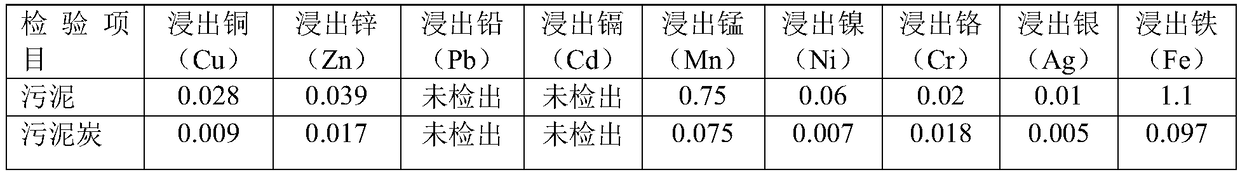

Resource utilization method of sludge based on thermal hydrolysis-pyrolysis carbonization

InactiveCN108423959AImproved Anaerobic Digestion PerformanceImprove dehydration effectWater treatment parameter controlSpecific water treatment objectivesSludgeHigh energy

The invention discloses a resource utilization method of sludge based on thermal hydrolysis-pyrolysis carbonization. The method includes the steps of: (1) transporting dehydrated sludge to a sludge preheater; (2) sending the preheated sludge into a sludge thermal hydrolysis reaction kettle; (3) subjecting the thermal hydrolysis product to solid-liquid separation to obtain thermal hydrolysis filtrate and a solid product; (4) carrying out natural heap drying, crushing, activation and granulation on the solid product successively, then conveying the product to a rotary controllable pyrolysis carbonization furnace by a spiral conveyer, and conducting high-temperature rapid pyrolysis to obtain biochar, tar and high-temperature waste gas, introducing the high-temperature waste gas into the sludge preheater, and subjecting the biochar to resource comprehensive utilization; and (5) subjecting the thermal hydrolysis filtrate to anaerobic fermentation, and using the generated biogas as the fuelof the pyrolysis carbonization furnace. The method provided by the invention overcomes the problems of high energy consumption of the sludge carbonization process and nonstandard resource utilizationmethod of sludge biochar in sewage treatment plants at present, and realizes reduction, stabilization, harmless and resource comprehensive utilization of sludge in sewage treatment plants.

Owner:浙江合泽环境科技有限公司

Oily sludge treatment system and treatment method thereof

PendingCN106746420AGood processing effectEasy to handleWaste water treatment from quariesSievingWater storageSludge

The invention discloses an oily sludge treatment system and a treatment method thereof. The treatment system comprises crushing equipment, a vibrating screen, a precipitation device, an ejector, a high-speed crushing device, a water storage device and separation device for separating oil, water and sludge, wherein the crushing equipment is used for primarily crushing oily sludge and is provided with an oil slick space and a first oil slick outlet which can be opened and closed; the vibration screen is located at the upper part of the precipitation device; the precipitation device is used for precipitating the screened oily sludge; the high-speed crushing device is used for crushing the oily sludge into fine particles; the precipitation device is sequentially connected with the ejector, the high-speed crushing device and the separation equipment; a water outlet of the water storage device is connected with a water inlet of the ejector. The treatment system can be applicable to dewatering of various oily sludges, meanwhile, the oil rate of the oily sludge can be reduced to below 3%, oil can be recovered to the maximal extent and secondary pollution of wastewater is not generated.

Owner:仇霞霞

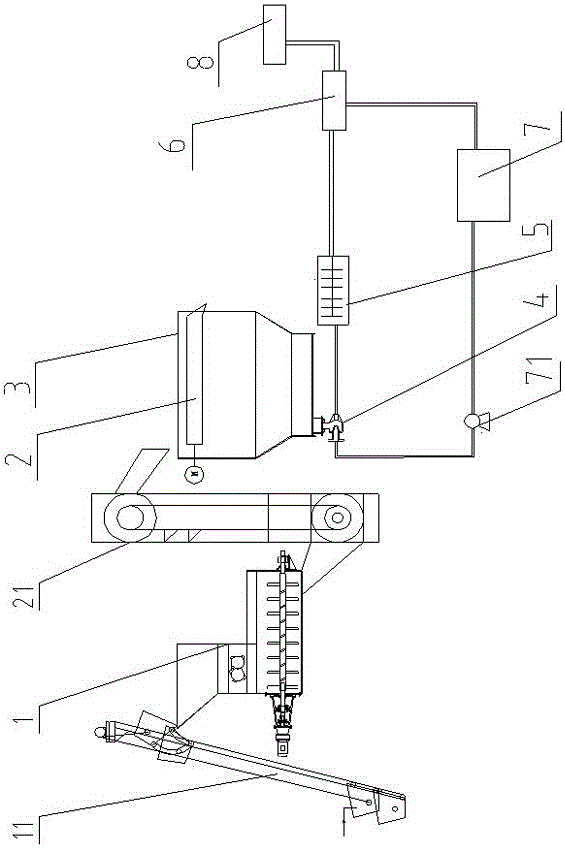

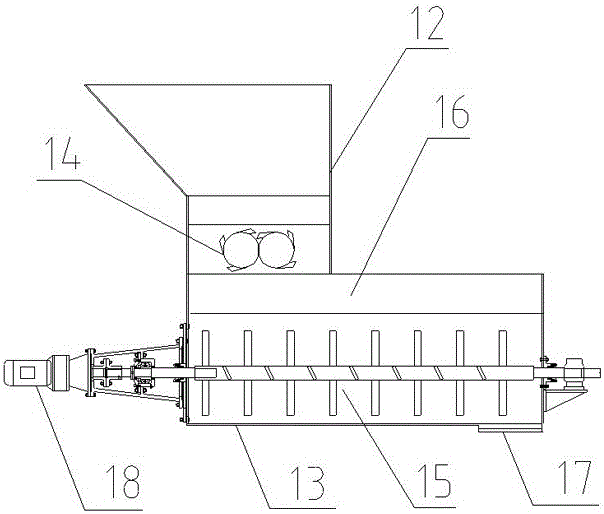

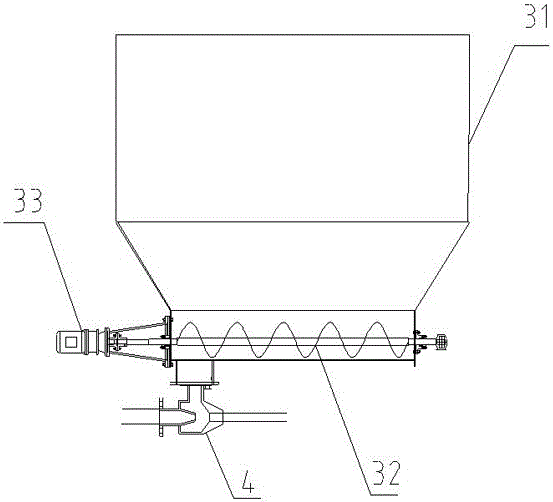

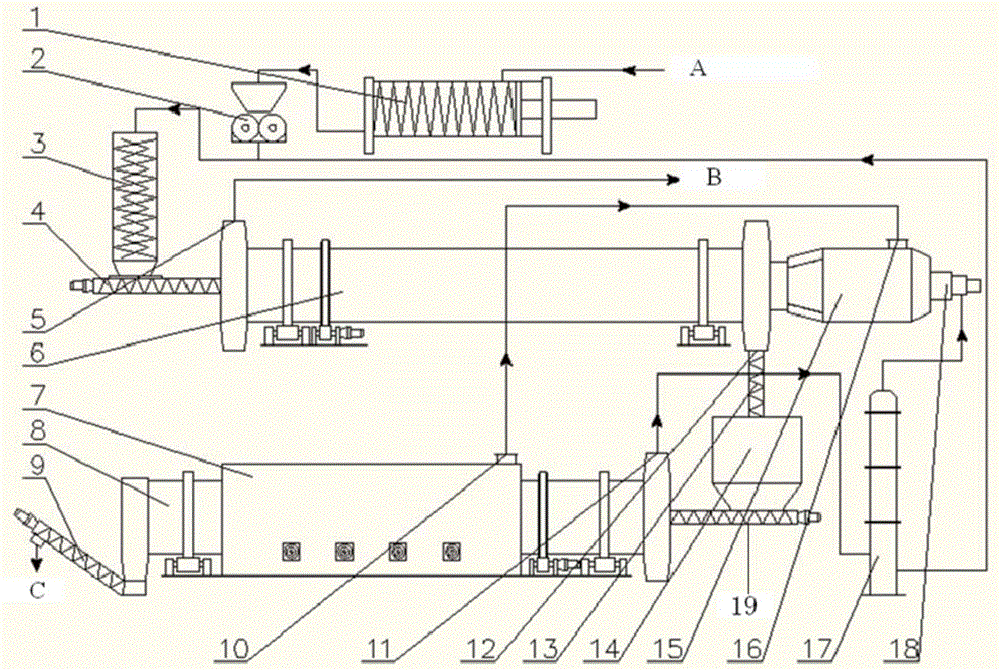

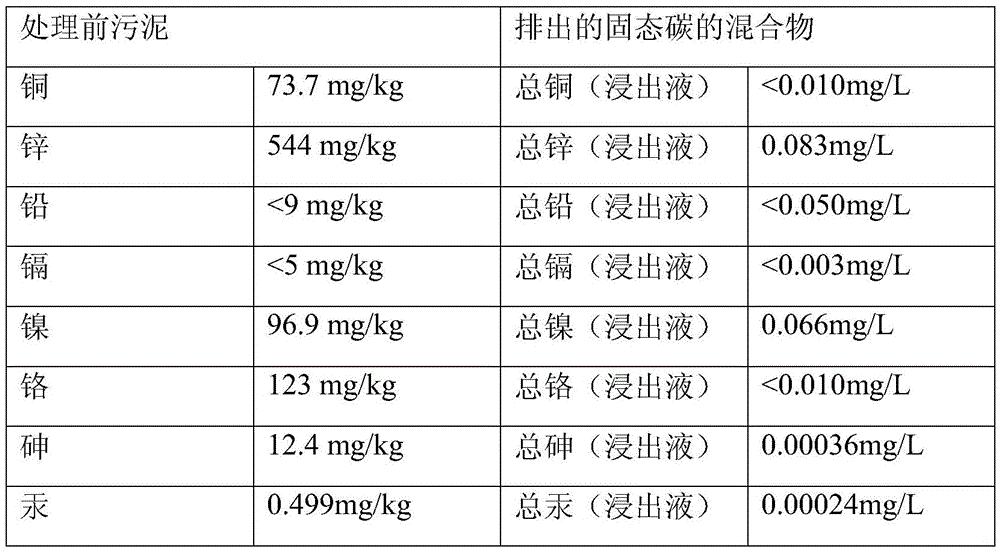

Sludge pyrolysis carbonization technique and device

ActiveCN105601075AStable stateSimple production processSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesSolid carbonWater vapor

The invention discloses a sludge pyrolysis carbonization technique and device. The technique comprises the following steps: sludge is pressed by a press, pulverized by a pulverizer, mixed by a mixer, dried in an internal heating rotary kiln drying machine, sent into a storage bin, and sent into a pyrolysis carbonization furnace; the sludge is subjected to pyrolysis carbonization in the pyrolysis carbonization furnace; the product solid carbon mixture is sent out of the system, and the products vapor and pyrolytic gas enter a separation purification tower to be separated and purified; the purified combustible gas is sent into a combustor and combusted into an internal heating rotary kiln drying machine delivery heat source, and the purified heavy components are sent into the mixture and mixed with the sludge to perform secondary pyrolysis; the flue gas generated by the heating furnace is discharged into a hot-blast furnace to perform secondary ablation; and the exhaust generated by the whole device is discharged by an outlet I of the internal heating rotary kiln drying machine, and is treated and discharged after reaching the standard. The device has the advantages of simple production technique, stable product state and no secondary pollution, and implements the reduction, harmless treatment and recycling of sludge treatment.

Owner:刘晓静

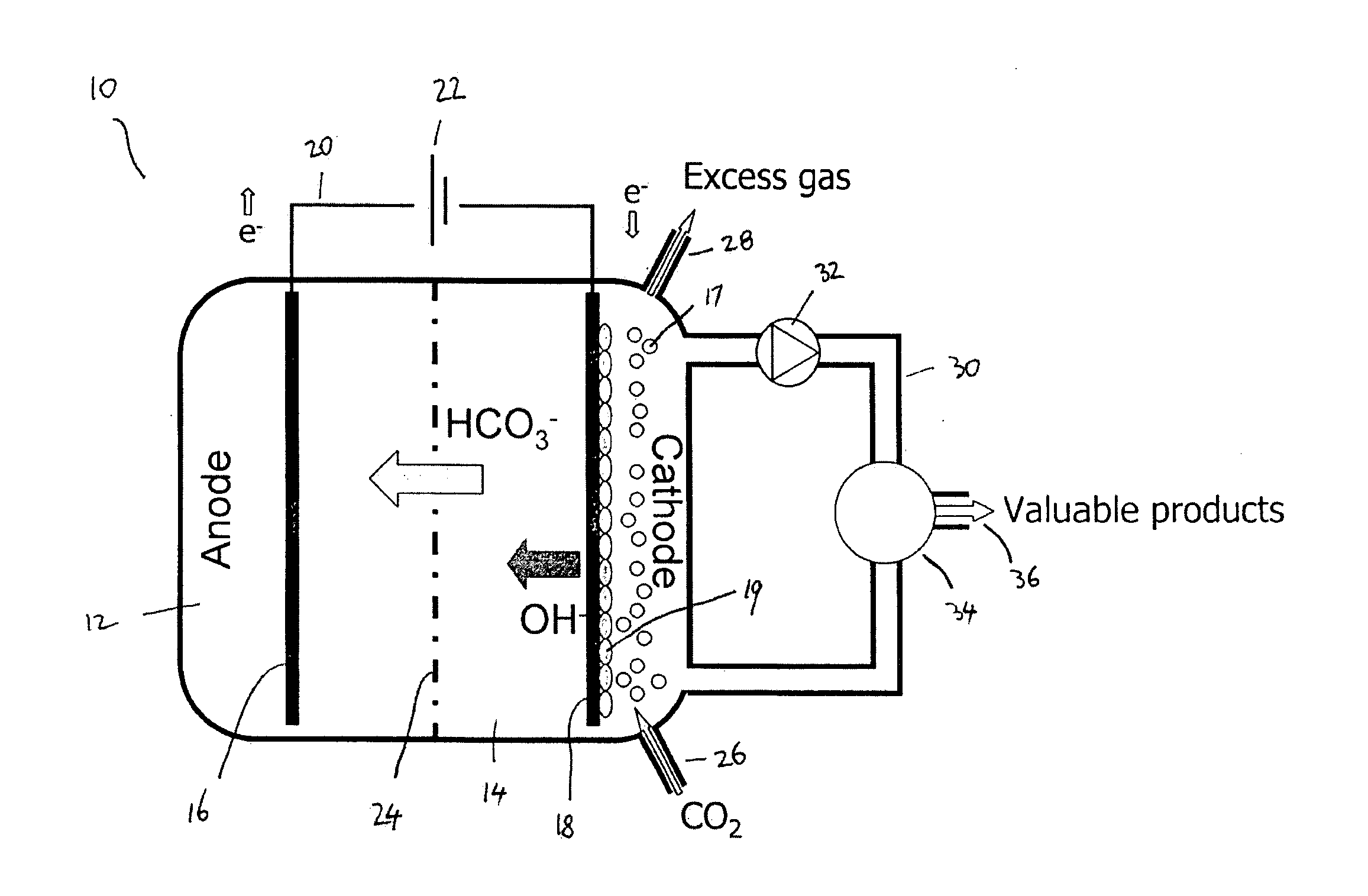

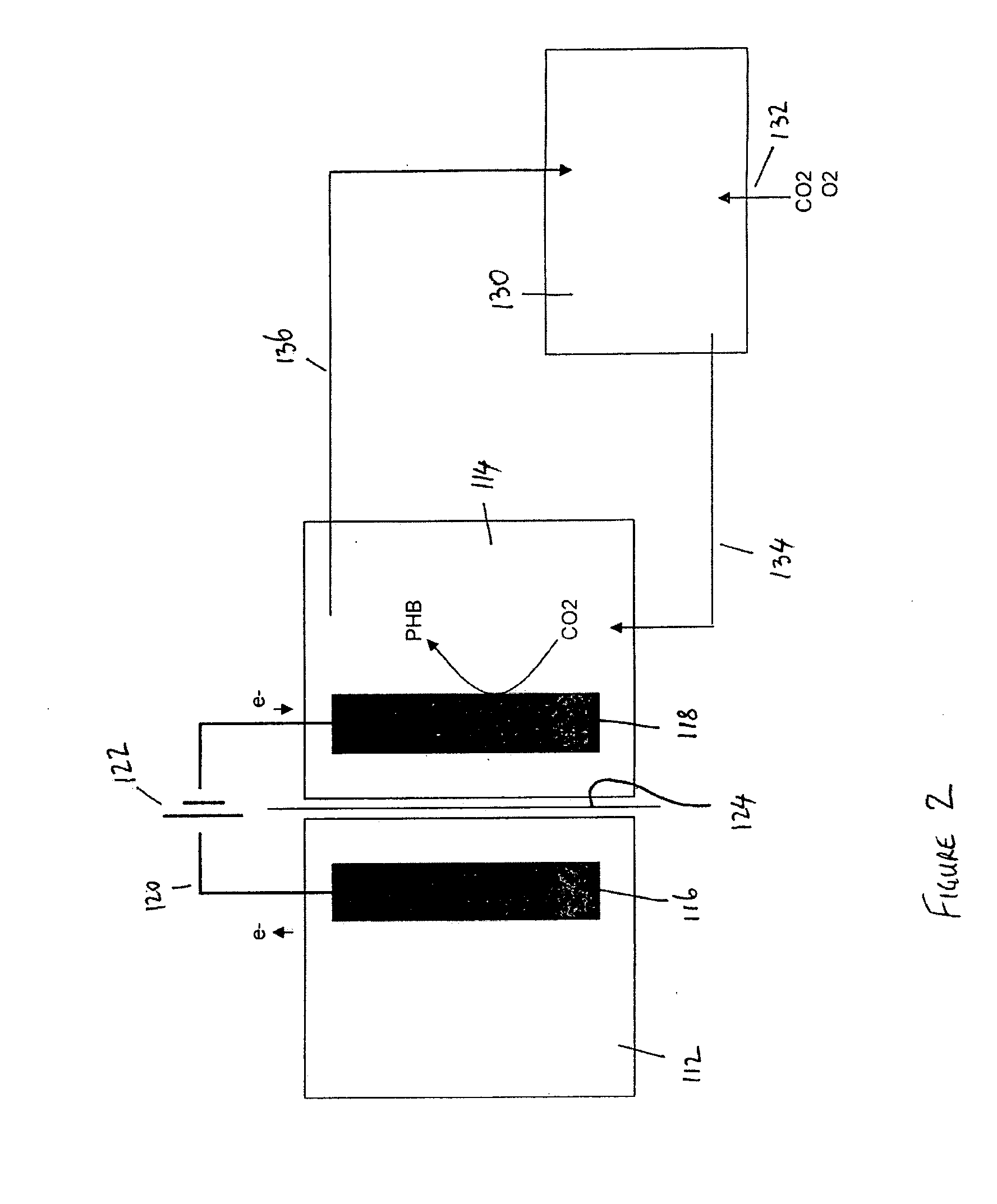

Process for the production of chemicals

InactiveUS20110315560A1Maintain steady stateIncrease ratingsTreatment by combined electrochemical biological processesFinal product manufactureChemical compoundReducing equivalent

A process for producing one or more chemical compounds comprising the steps of providing a bioelectrochemical system having an anode and a cathode separated by a membrane, the anode and the cathode being electrically connected to each other, causing oxidation to occur at the anode and causing reduction to occur at the cathode to thereby produce reducing equivalents at the cathode, providing the reducing equivalents to a culture of microorganisms, and providing carbon dioxide to the culture of microorganisms, whereby the microorganisms produce the one or more chemical compounds, and recovering the one or chemical compounds.

Owner:THE UNIV OF QUEENSLAND

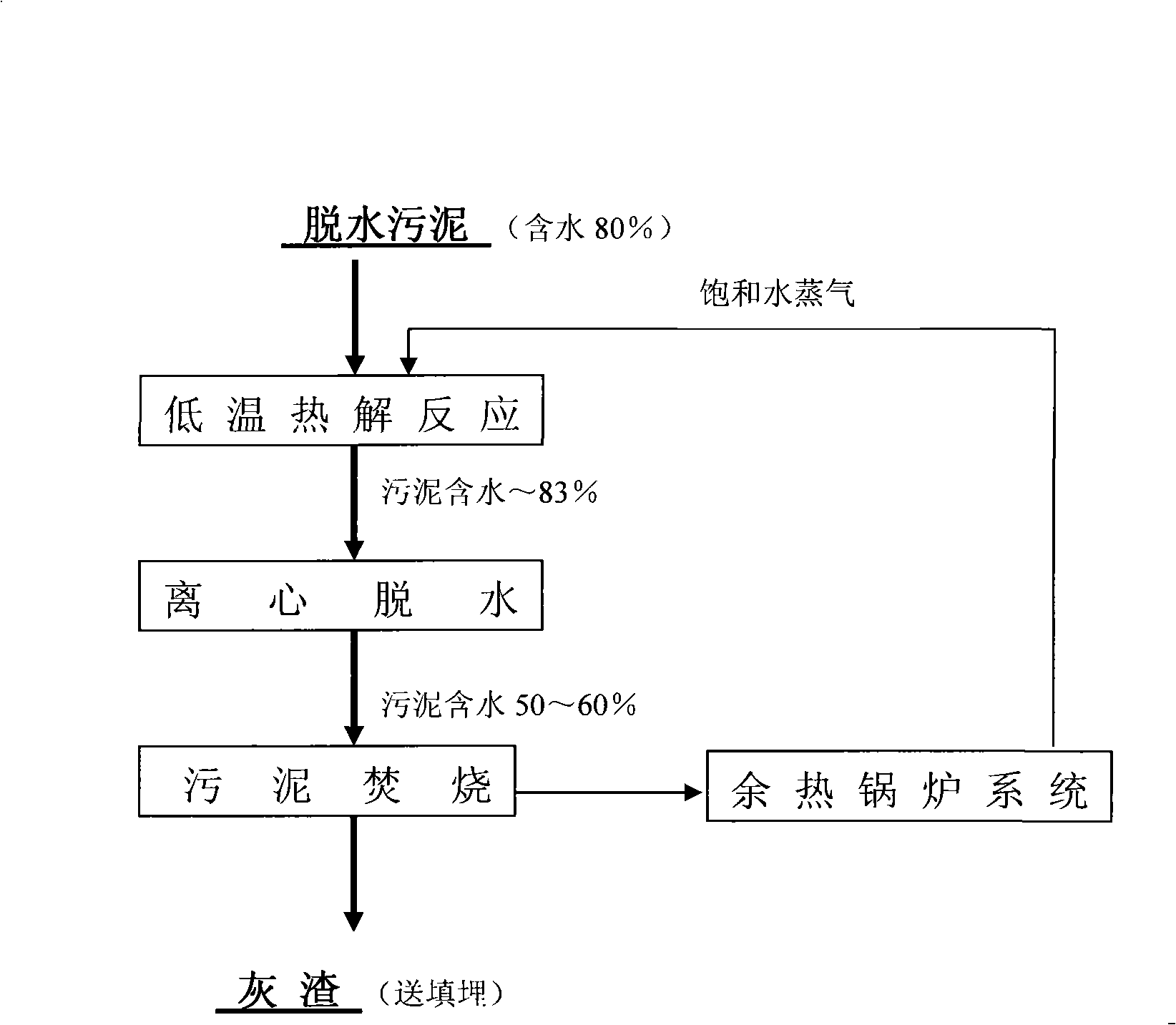

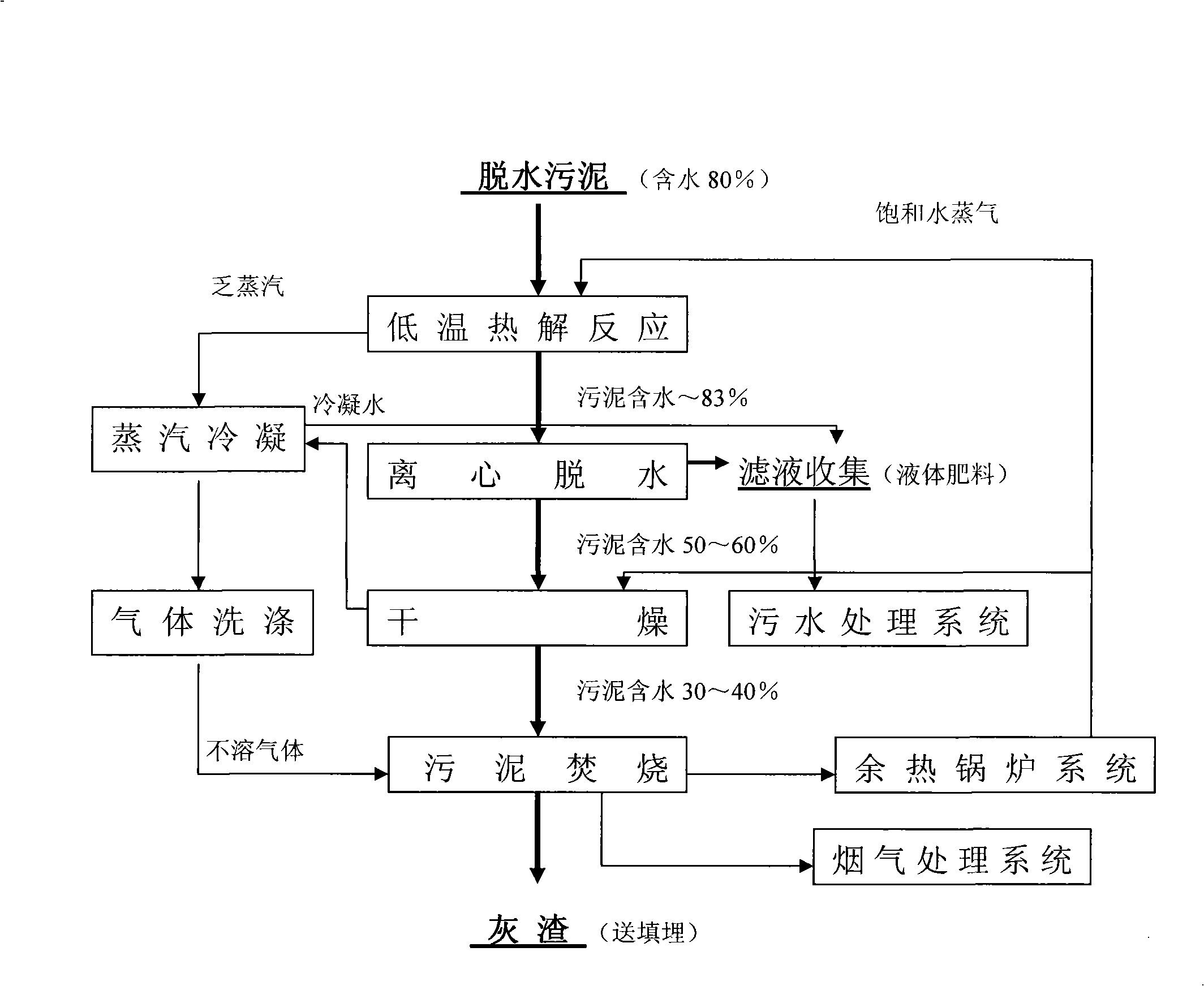

Wet sludge anhydration burning processing system and process

ActiveCN101290121AThoroughly deodorizedHarmlessDrying using combination processesSludge treatment by oxidationSteam condensationResource utilization

The invention relates to a wet sludge drying and incineration processing system. The system comprises a low-temperature pyrolytic reaction device, a centrifuging filtering device, a steam condensation device, a filtrate recovery device and a sludge incineration device; the low-temperature pyrolytic reaction device is used for carrying out low-temperature pyrolytic reaction between wet sludge and saturated steam in order to convert macromolecular organics in the wet sludge into low-molecular organics and destroy a sludge water-holding structure; the centrifuging device is used for carrying out centrifuging filtering to the wet sludge after pyrogenation; the steam condensation device is used for condensing and collecting bled steam converted from saturated steam in the low-temperature pyrolytic reaction device; the filtrate recovery device is used for collecting filtrate produced in the centrifuging device and for collecting condensed fluid from the steam condensation device; the sludge incineration device is used for incinerating semidry sludge after being dehydrated in the centrifuging device and insoluble gas remained in the steam condensation device as fuel. The system also relates to a process for carrying out the processing of wet sludge drying and incineration by adopting the processing system. The system and the process can solve the problem of sludge resource regeneration in a mode of environmental protection, energy conservation, high resource utilization rate and low operating cost.

Owner:SHENZHEN ECO SOLUTION TECH CORP

Resource regeneration processing method and equipment for urban sewage sludge

InactiveCN101318759AReduce lossesAdaptableSludge treatment by oxidationByproduct vaporizationSludgeEnvironmental engineering

The invention discloses a resource treatment method for municipal sludge and equipment thereof. The method comprises the following steps that: the dried sludge is subject to carbonization treatment with a carbonization temperature range of between 450 and 650 DEG C and molded to produce a solid product; carbonization fractions in the carbonization treatment are reclaimed and a condensate is separated off; purified wood coal gas is comprehensively utilized; through a carbonization process adopting a biomass dynamic carbonization and pyrogenation comprehensive treatment technology, feeding, drying, carbonization, carbon generation, the dust removal of wood coal gas, condensation, washing and the separation of various byproducts can be continuously completed; carbonization equipment can realize automatic operation and can carry out resource treatment to biomass; the adopted process has strong adaptability to the variety and humidity of the biomass and has small loss of biomass and high treatment efficiency in the treatment process; as the process adopts a full-closed carbonization furnace, product yield is all products, wherein, the produced wood coal gas is used as fuel for drying, carbonization or power generation, thereby reducing production cost; and the whole system has perfect design and reasonable economical technology.

Owner:谢忠诚 +1

Sludge reduction and recycling treatment device and sludge treatment method

InactiveCN104211274AAchieve recyclingHarmlessSludge treatment by de-watering/drying/thickeningSludge treatment by pyrolysisOxygenCoal pyrolysis

Provided are a sludge reduction and recycling treatment device and a sludge treatment method. The method includes the steps of performing spray drying on dewatered sludge, mixing coal pyrolysis, using pyrolytic carbon incineration ash as a raw building material, recycling pyrolysis oil and pyrolysis gas as supplement energy, performing up-to-standard discharging on flue gas emitted by a pyrolysis furnace after subjecting the flue gas to treatment in a spray tower, a mist removal device and an activated carbon adsorption bed, and supplying an incinerator with low heat of the pyrolysis furnace. The sludge reduction and recycling treatment device and the sludge treatment method have the advantages of being capable of achieving a sludge recycling recovery rate of 95%, a sludge reduction rate of over 96%, a heavy metal solidification rate of 95% and zero emission of pollutants; the generation of harmful gas such as dioxin is inhibited due to fully-enclosed oxygen-free environment pyrolysis and sulfur in coal; residual dioxin can be decomposed by being burnt at the temperature above 950 DEG C so as to ensure no generation and emission of dioxin in an entire reaction process of a system; a mixture of flue gas, low heat, pyrolysis gas and pyrolysis oil can be recycled, so that energy consumption and treatment costs are reduced.

Owner:天津德人生态环境科技集团有限公司

Thermophilic and thermoacidophilic biopolymer-degrading genes and enzymes from alicyclobacillus acidocaldarius and related organisms, methods

Owner:BATTELLE ENERGY ALLIANCE LLC

High-efficiency oil sludge pyrolysis oil making method and system

InactiveCN104261649AReduce moisture contentPrevent deflagrationSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesAtmospheric airOil sludge

The invention discloses a high-efficiency oil sludge pyrolysis oil making method and system and belongs to the technical field of solid waste recycling and environment. Crude oil sludge is subjected to deep drying and breaking treatment by virtue of a two-stage blade-type dryer and then enters a spiral pyrolyzing furnace, and produced pyrolysis gas is subjected to spray cooling to obtain an oil product; noncondensing gas and part of pyrolysis oil which are produced in a drying and pyrolysis process are fed into a burning furnace to be burned, and high temperature smoke produced during burning is used for providing heat for a pyrolysis furnace; smoke at an outlet of a jacket of the pyrolysis furnace passes through a heat conduction oil heat exchanger to recycle waste heat and then is discharged into the air; and the heat conduction oil after being heated provides heat for the blade-type dryer. Therefore, the high-efficiency oil sludge pyrolysis oil making method and system are safe and reliable, drying pyrolysis efficiency is high, the oil product in the sludge can be recycled, gradient utilization of energy is realized, and oil sludge recycling and harmless treatment is realized.

Owner:SOUTHEAST UNIV

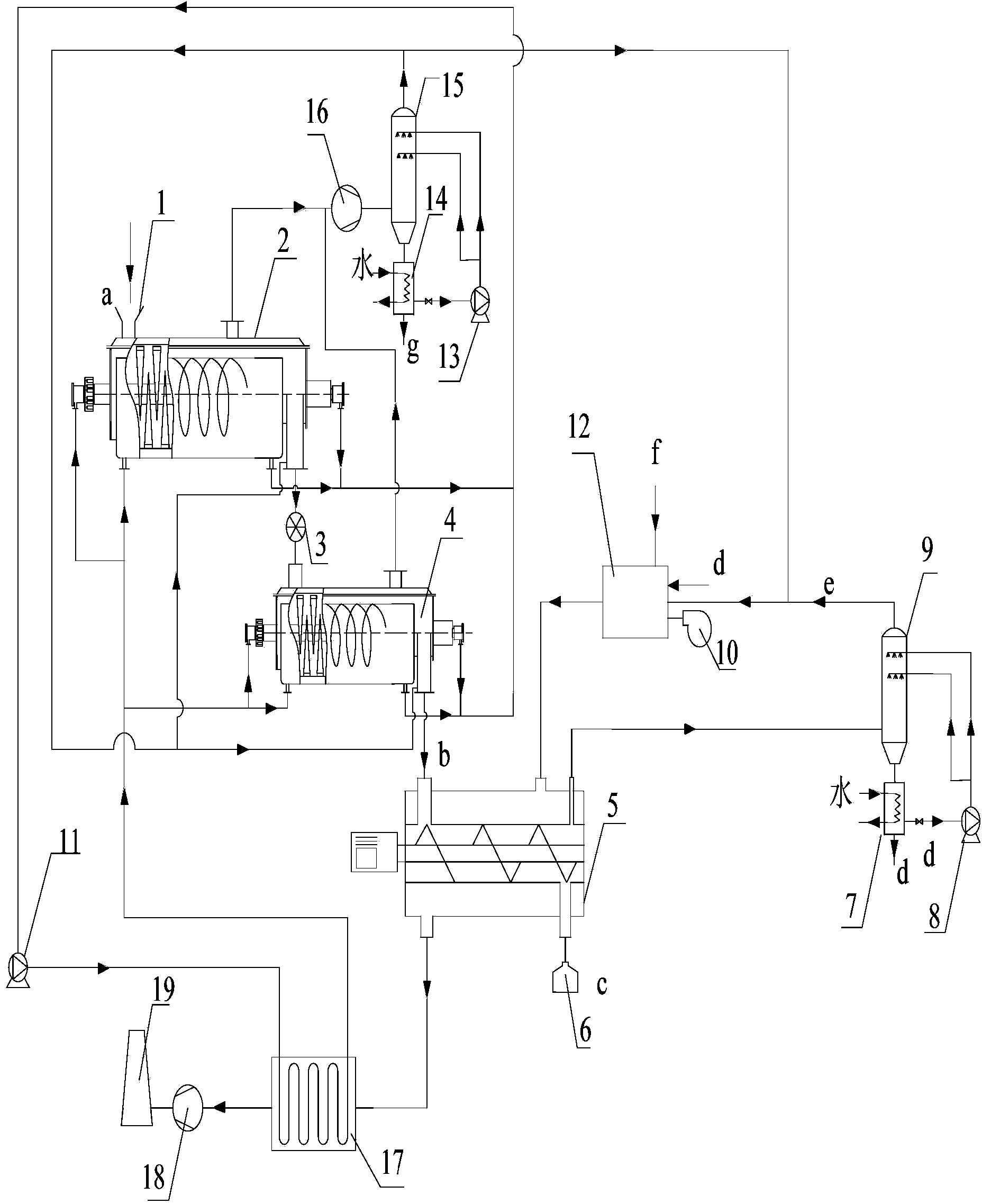

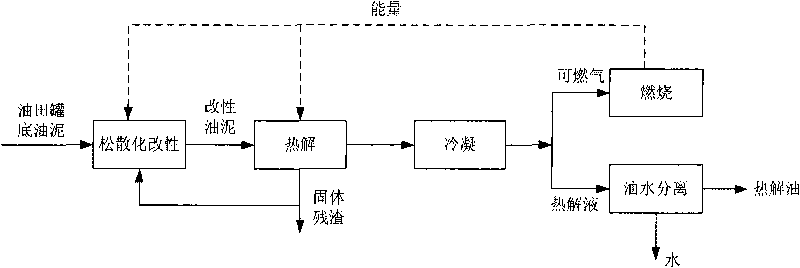

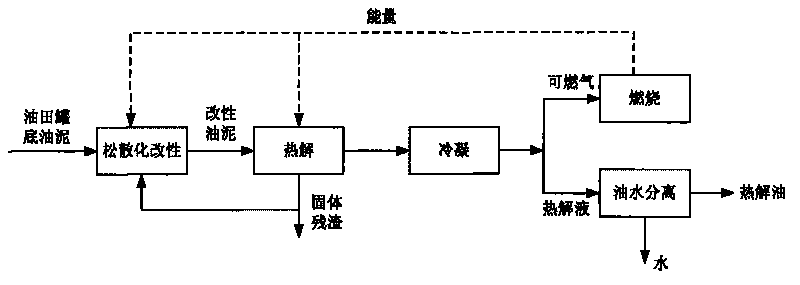

Reclamation treatment method of oil field tank bottom oil sludge

InactiveCN101759339AEnhanced mass transferGuaranteed uptimeSludge treatment by pyrolysisByproduct vaporizationResource recoveryOil field

The invention discloses an oil sludge treatment method which comprises the following steps of: first, carrying out loose modification on oil field tank bottom oil sludge, then carrying out pyrolysis, and obtaining solid residue and gas product; condensing the gas product and obtaining pyrolysis liquid and combustible gas; and carrying out oil-water separation on the pyrolysis liquid, and obtaining pyrolysis oil. The reclamation treatment method of oil field tank bottom oil sludge can effectively recover oil resource in the oil sludge, realizes self-heat-supply of a system and high-efficiency recovery utilization of energy, and achieving the aim of harmless treatment of the oil sludge. Compared with other treatment technologies, the technology has the advantages of stable and reliable operation, high oil resource recovery rate, strong adaptability and low secondary pollution, thus being a reclamation treatment technology of oil field tank bottom oil sludge which is worth popularizing.

Owner:TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com