Patents

Literature

256results about How to "Shorten spin time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sludge-dewatering compound conditioning agent and application method thereof

ActiveCN102381828AAchieve deep dehydrationShorten spin timeSludge treatment by de-watering/drying/thickeningSludge treatment by oxidationPOLYMER SUBSTANCEFenton reagent

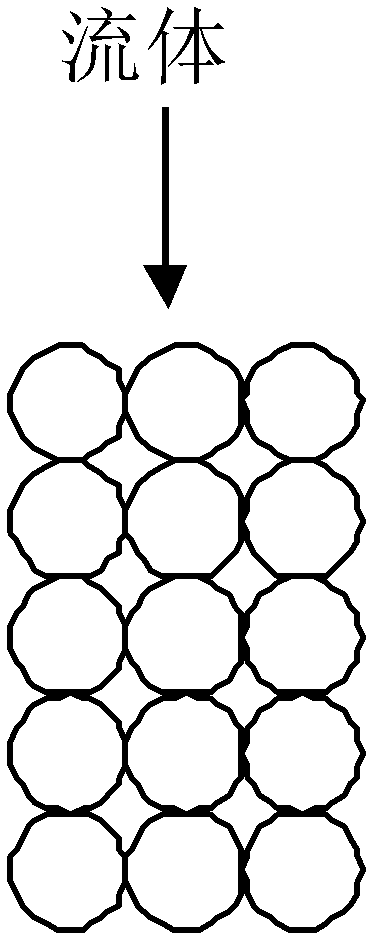

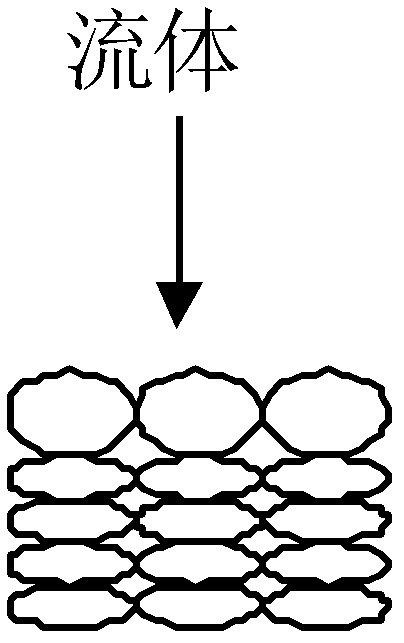

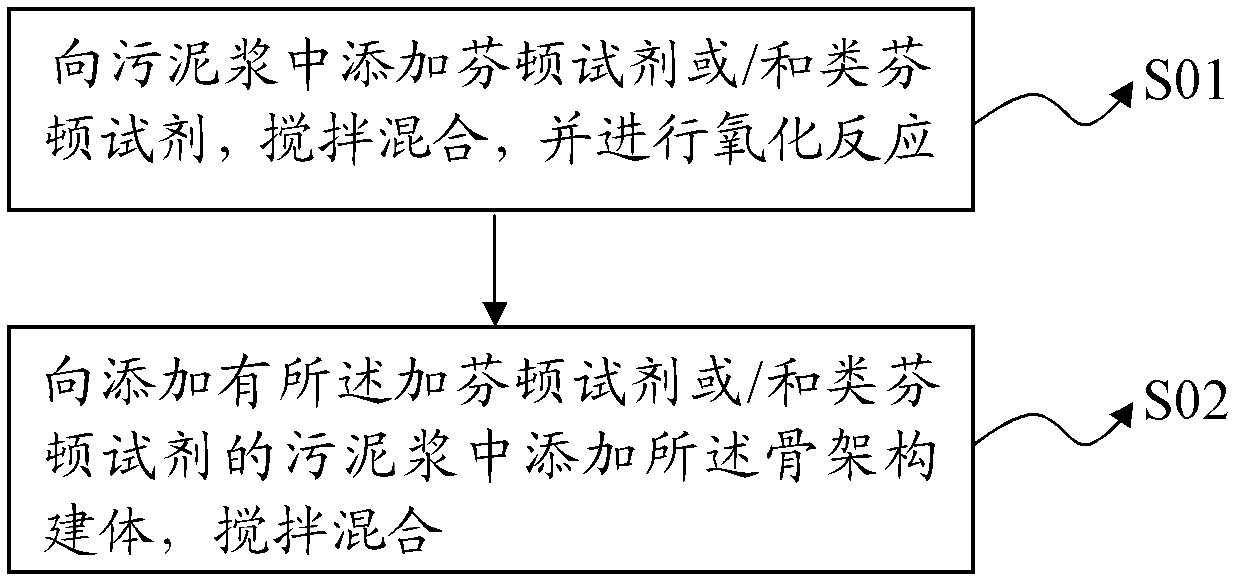

The invention provides a sludge-dewatering compound conditioning agent and an application method thereof. The sludge-dewatering compound conditioning agent comprises a Fenton reagent or / and similar Fenton reagent and a skeleton construct, and the weight ratio of the Fenton reagent or / and similar Fenton reagent and the skeleton construct is 1: (0.05-300); and the skeleton construct adopts a powder body. The application method comprises the following steps: adding the Fenton reagent or / and similar Fenton reagent into sludge slurry, and mixing for oxidation; and adding the skeleton construct into the sludge slurry with the Fenton reagent or / and similar Fenton reagent, and mixing. Due to synergy of the Fenton reagent or / and similar Fenton reagent and the powder type skeleton construct, extracellular polymeric substances in sludge can be destructed effectively, the compressibility of organic substances can be reduced, and the sludge dewatering performance of the sludge-dewatering compound conditioning agent can be improved greatly. The procedures of the application method are simple, the conditions can be controlled easily, the sludge dewatering time can be shortened, and the large-scale treatment of the sludge can be realized.

Owner:UNIVERSTAR SCI & TECH SHENZHEN +1

Former hot blast and latter vacuum microwave combining drying process of producing crisp fruit and vegetable grains

InactiveCN1672531AReduce drying loadReduced moisture removal requirementsFruits/vegetable preservation by dehydrationWater contentFood processing

The present invention is former hot blast and latter vacuum microwave combining drying process of producing fruit and vegetable grains, and belongs to the field of fruit and vegetable food processing technology. The drying process includes the steps of: washing fruit and vegetable material, dicing, scalding to killing enzyme, cooling in flow water, draining, optional fast freezing and defrosting, soaking with seasoning, draining, pre-dewatering with hot blast to obtain semi-finished product with water content of 40-60 %, and final vacuum microwave drying to obtain product with water content of 2-5 %. The said process has the nutritious components and color well maintained, crisp product, short production period, low cost, high product quality and other features.

Owner:JIANGNAN UNIV

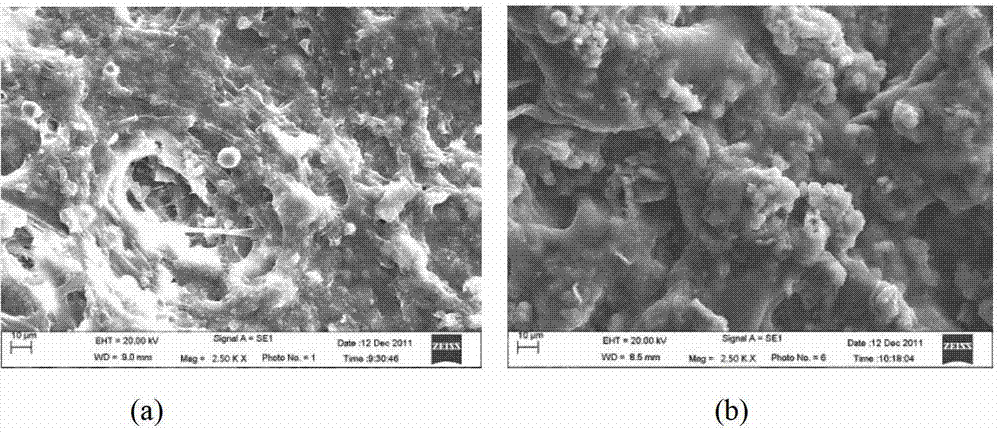

Method for conditioning and dehydrating residual sludge

ActiveCN103030259APromote moisture penetrationImprove dehydration effectSludge treatment by de-watering/drying/thickeningPolymer dissolutionBiological cell

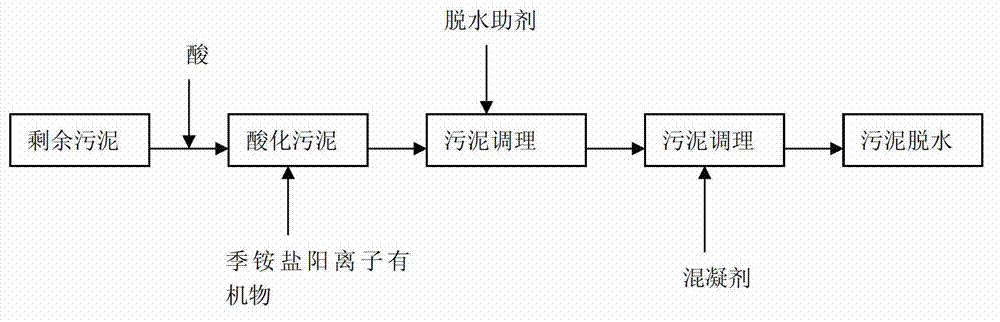

The invention relates to the technical field of residual sludge treatment, in particular to a process method for conditioning and dehydrating residual sludge. The method particularly comprises the following steps: (1) adding acid into the residual sludge to be treated and with the water content of 90 to 95 percent and adjusting until the pH value is between 4.0 and 6.0; (2) adding quaternary ammonium salt cationic organic matters into the conditioned sludge in the step (1) and performing hybrid reaction; (3) adding a dehydration aid into the conditioned sludge in the step (2) and stirring uniformly; and (4) adding coagulant into the conditioned sludge in the step (3) and mechanically dehydrating after mixing and stirring. The extracellular polymers on sludge flocs are stripped and partially hydrolyzed by a chemical conditioning mode, microbial cells are dissolved, a large amount of bound water is released, and the water permeability of the sludge is improved by utilizing the aid, so that the dehydration performance of the sludge is integrally improved, the water content of the sludge is reduced, the dehydration time is shortened and the dehydration cost is reduced.

Owner:北京方兴科创环境科技有限公司

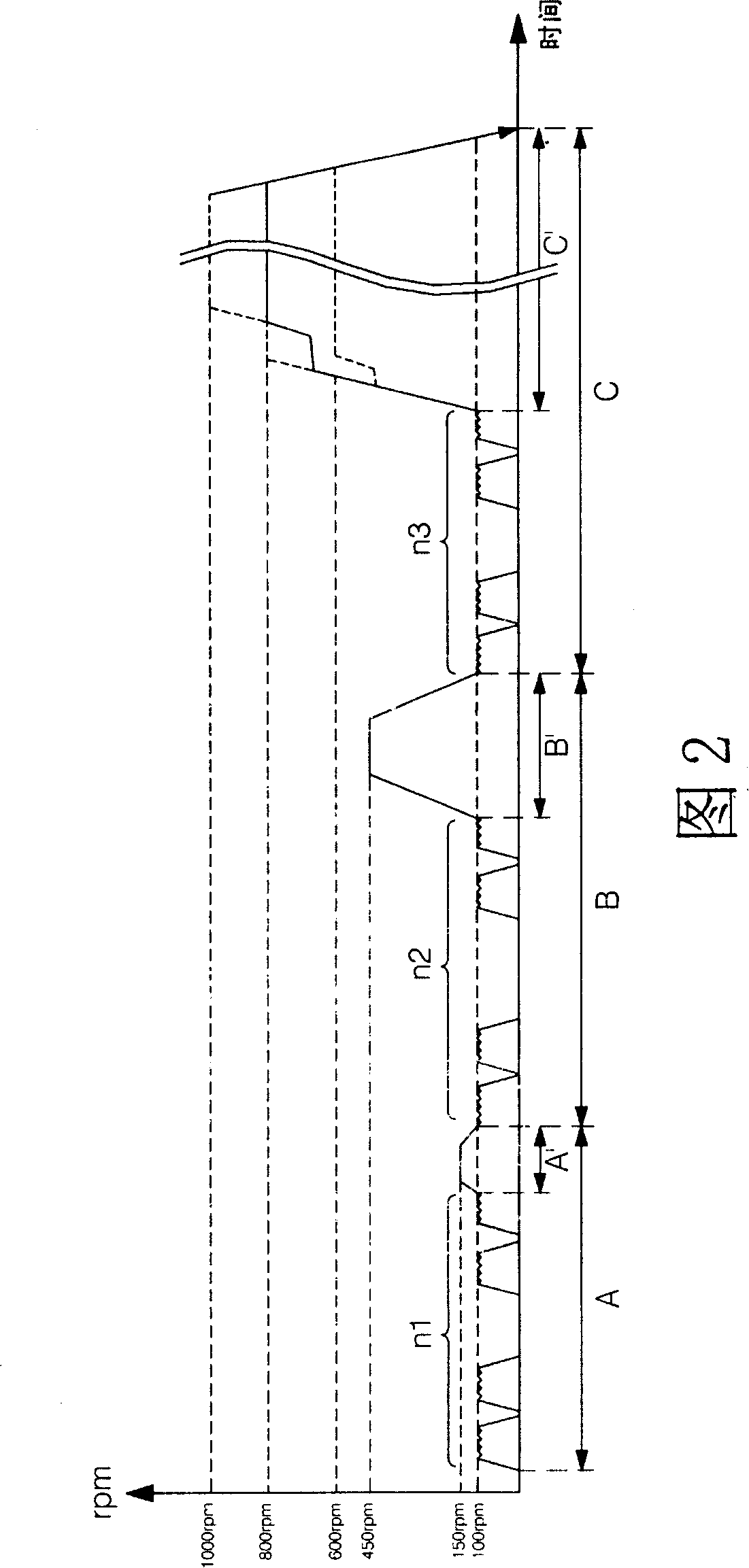

Dewatering control method for roller washing machine

ActiveCN103233340AReduce vibrationReduce noiseControl devices for washing apparatusTextiles and paperLow speedPulp and paper industry

The invention relates to a dewatering control method for a roller washing machine. The dewatering control method includes a distribution detecting step and a dewatering step. The distribution detecting step includes that an eccentric value is divided into a plurality of gears, and during distribution, the gears are tried from low gears to high gears. If an actual eccentric value falls at a certain gear, low-speed dewatering is conducted, after a part of water is removed, an eccentric value is detected, and if the eccentric value still falls at the gear, medium-speed dewatering is conducted, otherwise, distribution is conducted again. Eccentric value detecting is also conducted during medium-speed dewatering, and if gears of an eccentric value are the same, final dewatering is conducted, otherwise, distribution is conducted again. During dewatering, low-speed dewatering and medium-speed dewatering are conducted first, eccentric value detecting is conducted, and final dewatering speed is relevant to the gears, and therefore, vibration of the washing machine can be fully reduced, noise is reduced, and box body collision can be avoided. Load with poor balancing performance is distributed at a high gear, dewatering at the set rotating speed is conducted, distribution detecting time can be effectively reduced, and power consumption and dewatering time can be effectively reduced.

Owner:HISENSE(SHANDONG)REFRIGERATOR CO LTD

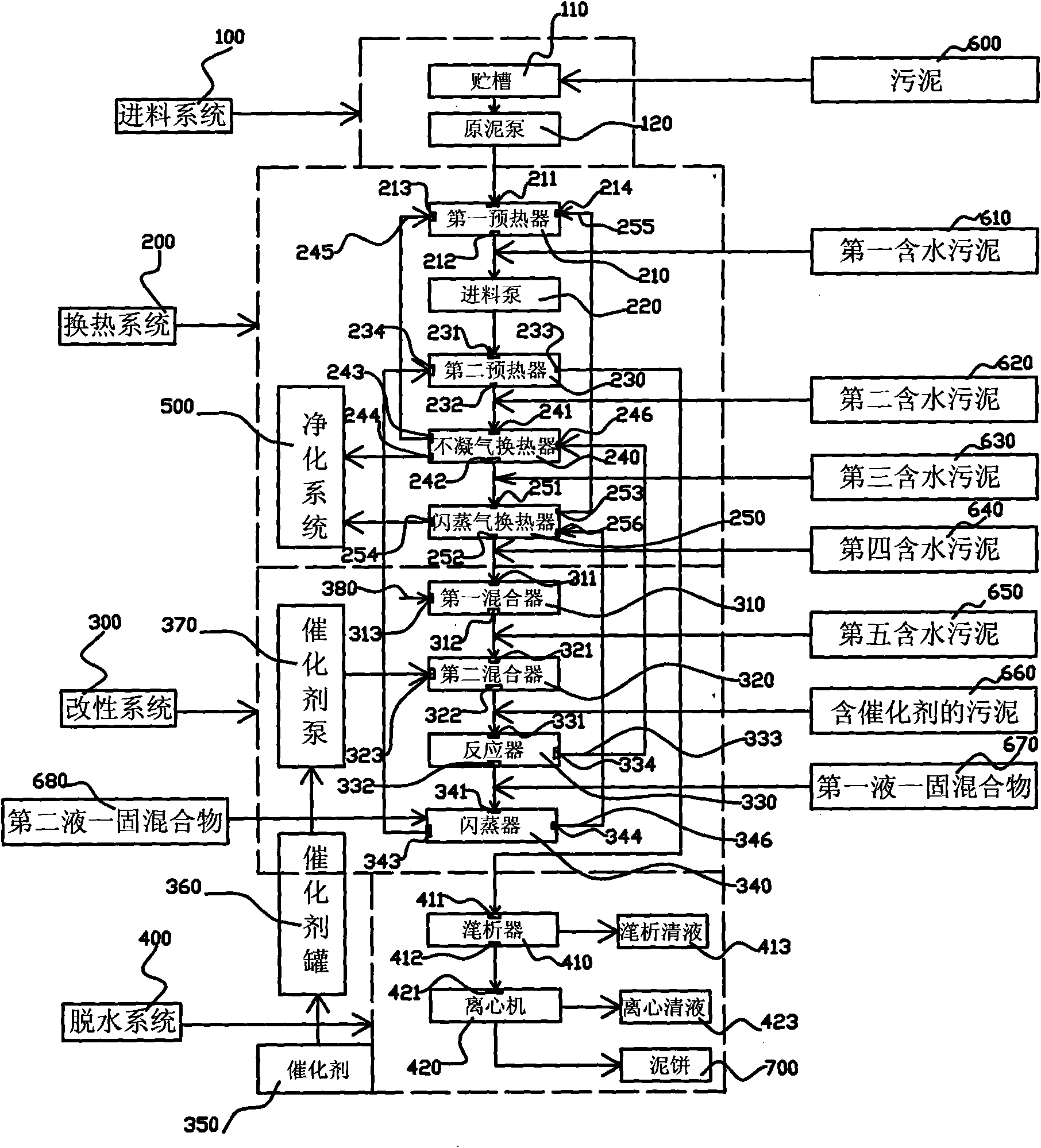

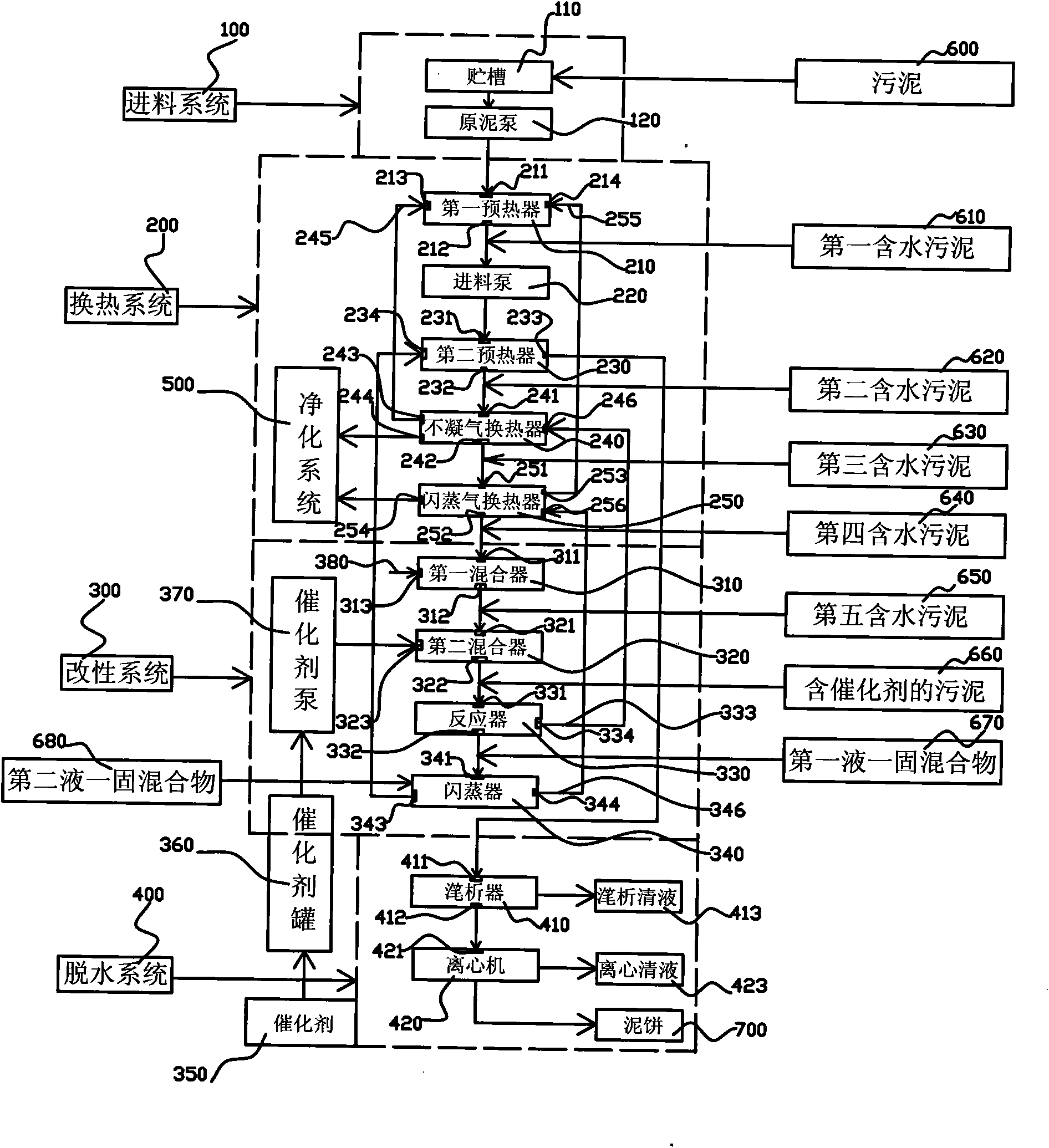

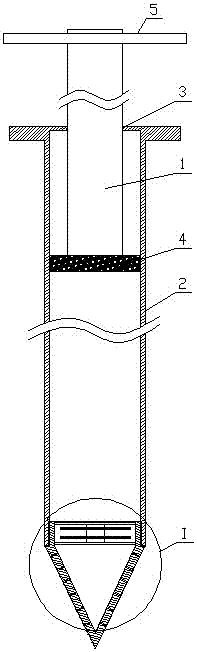

Tubular pyrohydrolysis treatment method and device for sludge

InactiveCN101979349AShorten spin timeEffectively control pH5-7 valueSludge treatment by de-watering/drying/thickeningClimate change adaptationSludgeHydrolysis

The invention provides a tubular pyrohydrolysis treatment method and device for sludge. The device consists of five main systems, namely a feeding system, a modification system, a dehydration system, a heat exchange system, and a purification system; and by adopting a catalyst injecting mode, the sludge is directly heated with medium pressure steam and is subjected to pyrohydrolysis at medium temperature, the remaining heat in the hydrolysis process is fully recycled, and a liquid-solid mixture is obtained, so not only supports of controllable components are provided for a compound fertilizer, but also a filter cake which is subjected to liquid-solid separation has an adjustable moisture content, namely the moisture content of the raw sludge can be reduced to 40 to 60 percent from about 80 percent. Compared with the prior art, the device has the advantages that: the structure is simple, the device can be continuously and stably operated, the sludge pyrohydrolysis temperature is 210 to 250 DEG C, the reaction time is 10 to 20 minutes, the reduction and harmless treatment of the sludge can be economically, quickly and effectively achieved, the sludge can be treated on a large scale, and a novel approach is provided for the sludge treatment and the energy recycling of equipment.

Owner:安徽合协生态环境科技有限公司

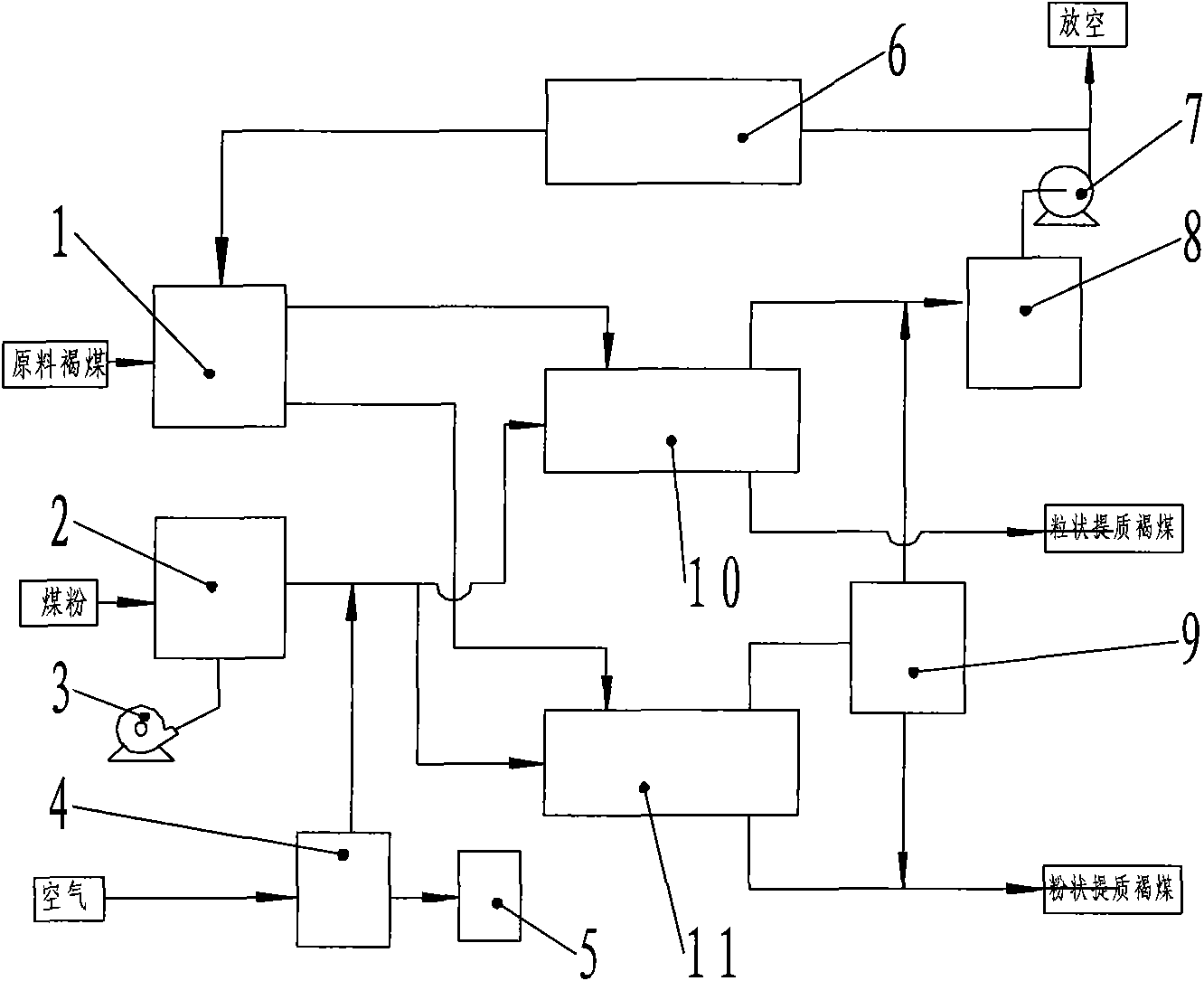

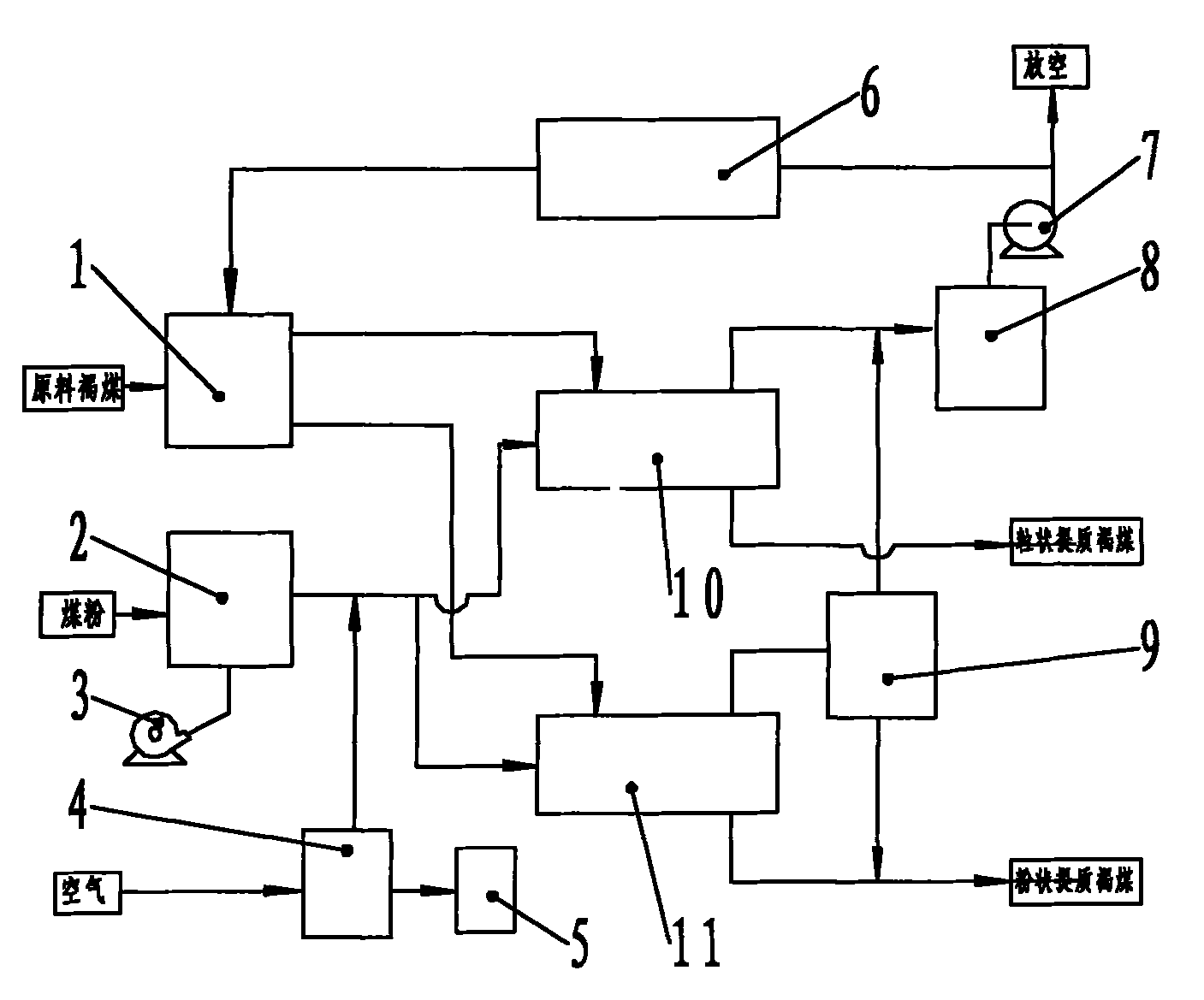

Method and device for drying and quality enhancement of lignite

InactiveCN101776370AImprove qualityIncrease useDrying solid materials with heatDrying machine combinationsLow oxygenCoal

The invention provides a method and a device for the drying and the quality enhancement of lignite. The device comprises a drying / sieving device, a preheating and drying / sieving device, a hot blast heater, a drying drum, a vibration fluidized bed, a cyclone separator, a defogger and a dust remover. The hot blast heater is respectively connected to the drying drum and the vibration fluidized bed, and an outlet of the preheating and drying / sieving device is respectively connected with the drying drum and the vibration fluidized bed. The preheating and drying / sieving device divides the lignite into two stages of big particle diameter and small particle diameter, high-temperature flue gas generated by the hot blast heater is used as a heating medium, the temperature of the flue gas is regulated by the residual low-oxygen gas after oxygen gas is separated by using an air separation system, the drying drum and the vibration fluidized bed are used for producing the quality-enhanced lignite with the big particle diameter and the small particle diameter, different production requirements are met, and part of exhausted tail gas is circularly used for preheating the raw materials of the lignite after being defogged. The invention respectively carries out drying and quality enhancement on the lignite according to the sizes of the particle diameters by grading equipment, eliminates the problem of uneven drying caused by different particle diameters, realizes the effective quality enhancement and the comprehensive utilization of coal resources, and is used for the large-scale process of drying and quality enhancement of the lignite.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Method for improving dehydration performance of sludge through oxidizing organic matters in sludge

ActiveCN104003602AStrong oxidizing propertiesHigh reactivitySludge treatment by de-watering/drying/thickeningSludge treatment by oxidationSludgeSoil organic matter

A method for improving dehydration performance of sludge through oxidizing organic matters in the sludge includes the following steps that (1), mixing dilution or concentration is performed; (2), chemical feeding is performed for oxidization; (3), solid-liquid separation is performed; (4), liquid filtering is performed. The method is simple in progress, conditions are easy to control, the dehydration time for the sludge can be shortened, and the sludge can be treated on a large scale.

Owner:湖南葆华环保科技有限公司

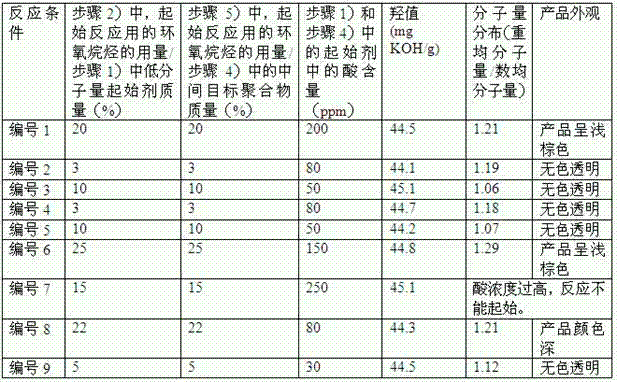

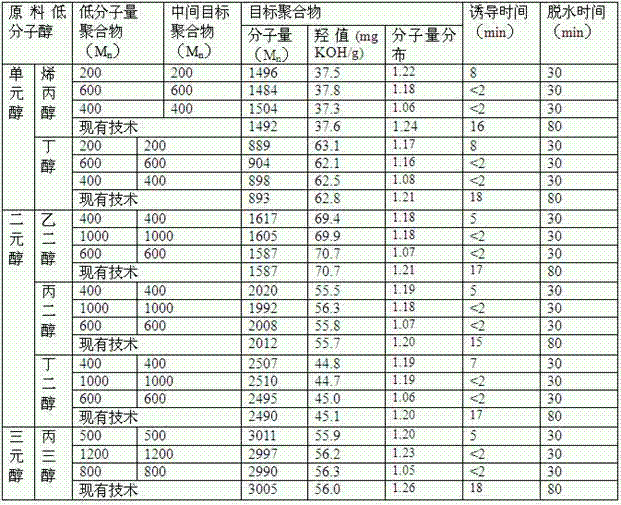

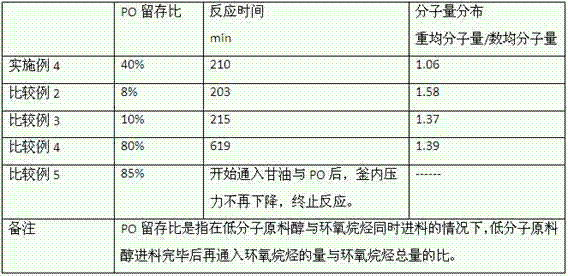

Method for preparing polyether polyol in recycling manner by aid of DMC (double metal cyanide) catalyst

The invention discloses a method for preparing polyether polyol in a recycling manner by the aid of a DMC (double metal cyanide) catalyst. The method includes carrying out polymerization reaction on first low-molecule alcohol and alkylene oxide to obtain polymers with low molecular weights; carrying out reaction on the polymers with the low molecular weights, DMC, acid and alkylene oxide, simultaneously filling the polymers with the low molecular weights with a certain quantity of second low-molecule alcohol used as a raw material to obtain intermediate target polymers; preparing target polymers from a part of the obtained intermediate target polymers and preparing other intermediate target polymers from another part of the obtained intermediate target polymers in a recycling manner. The first low-molecule alcohol is used as a raw material. The polymers with the low molecular weights are used as initiators, the DMC is used as the catalyst, and the acid is used as an auxiliary. The average molecular weight of the intermediate target polymers is identical to the average molecular weight of the polymers with the low molecular weights. The method has the advantages that the polyether polyol can be prepared by the aid of the method in the recycling manner without alkali manufacturing initiators, and accordingly loss of materials and discharge of filter residues and wastewater can be reduced; the DMC catalyst in reaction systems for initial reaction is already activated under the condition that the concentration of the DMC in the target polymers keeps identical, accordingly, the dehydration time and the initiation time can be shortened to a great extent in production procedures, and the utilization efficiency of devices can be improved.

Owner:HUAIAN BUD POLYURETHANE SCI & TECH CO LTD

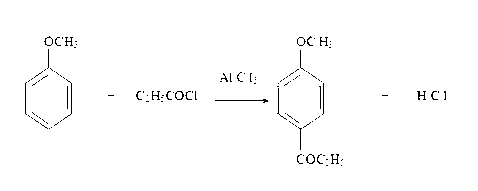

Synthetic method of anethole

InactiveCN103058835AReduce lossesLow costOrganic chemistryOrganic compound preparationSolventSide reaction

The invention discloses a synthetic method of anethole. Anisole and propionyl chloride serve as starting raw materials, are subjected to a friedel-crafts acylation reaction, then are restored through sodium borohydride, and then are catalyzed and dehydrated through organic acid and acid inorganic salt, and finally the anethole is manufactured through rectification. Side reaction is low through the adoption of acylation and reduction, a middle body is not needed to be purified and can be directly put into the next reaction, purification loss and purification cost of the middle body are reduced, yield coefficient is improved, and energy consumption is reduced. A chemical reduction method is utilized to replace a catalytic hydrogenation method, selectivity is high, response speed is fast, side reactions are small in number, and reduction yield coefficient can reach above 98%. Double catalysts are adopted to carry out ordinary pressure low temperature dehydration in dissolvent with a low boiling point, and compared with a negative pressure continuous dehydration method, dehydration time can be shortened by 90%, and the energy consumption is greatly reduced. The total yield coefficient of the method can reach 75%. A product quality index is higher than that of a natural product standard.

Owner:HUAIAN WAN BANG SPICE IND CO LTD +1

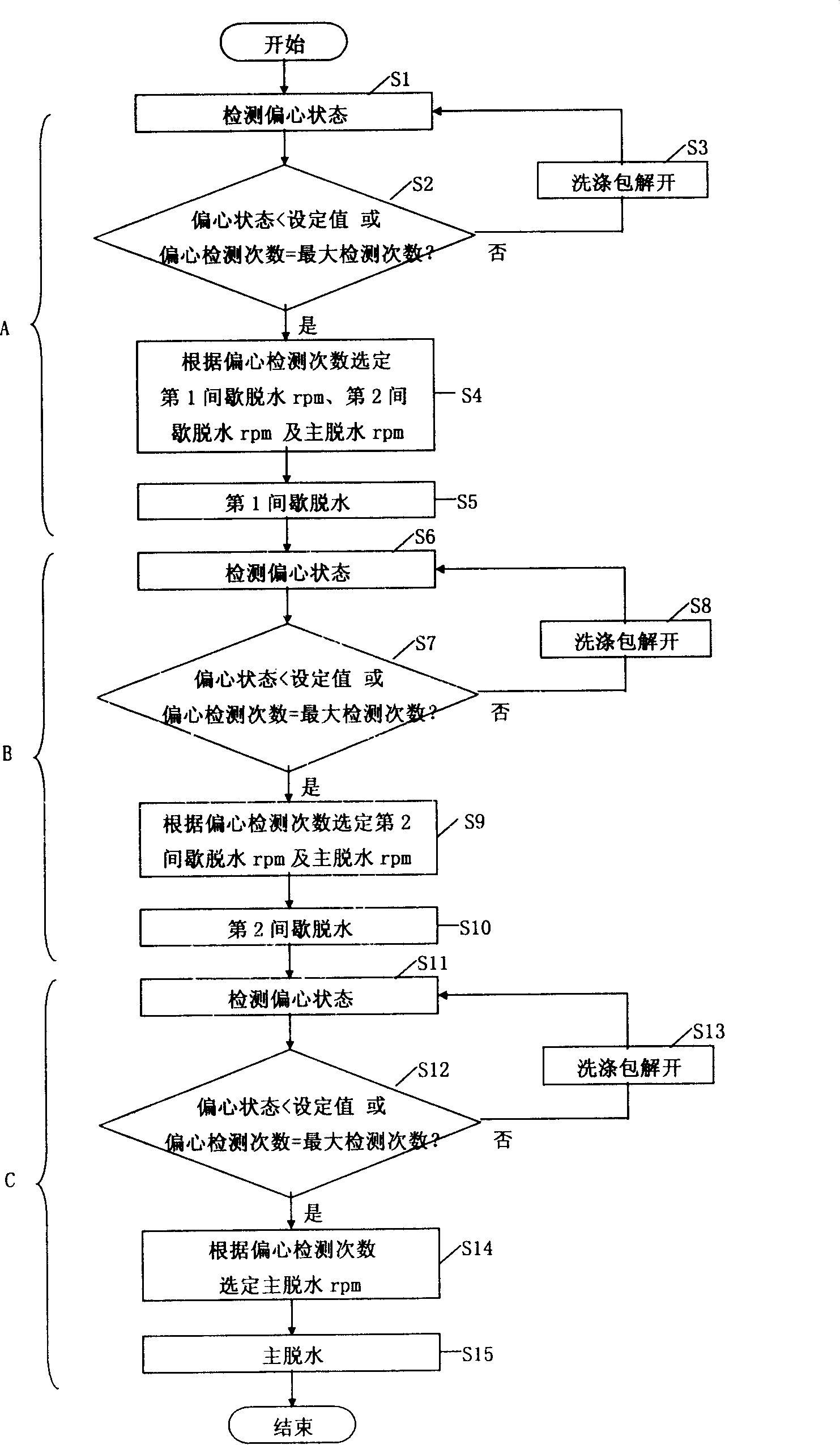

Dewatering control method for washing machine

InactiveCN101173446AEasy dehydration operationShorten spin timeControl devices for washing apparatusTextiles and paperEngineeringDehydration

The invention relates to a dehydration control method for a washing machine, comprising the following steps that: the eccentric state is detected at the dehydration travel of the washing machine, and when the eccentric state is beyond the set value, the operations of unfastening the washing bag and detecting eccentric state are repeatedly processed, and when the eccentric state is within the set value, a first step of a first intermittent dehydration operation is processed; the eccentric state is detected after the first intermittent dehydration operation, and when the eccentric state is beyond the set value, the operations of unfastening the washing bag and detecting eccentric state are repeatedly processed, and when the eccentric state is within the set value, a second step of a second intermittent dehydration operation is processed; the eccentric state is detected after the second intermittent dehydration operation, and when the eccentric state is beyond the set value, the operations of unfastening the washing bag and detecting eccentric state are repeatedly processed, and when the eccentric state is within the set value, a third step of the main dehydration operation is processed. The invention is characterized in that the RPM of each dehydration operation is selected according to the detecting time of eccentric state, and the dehydration operation is processed according to the selected dehydration RPM. The invention has the advantage of shortening the whole dehydration time.

Owner:NANJING LG PANDA APPLIANCES

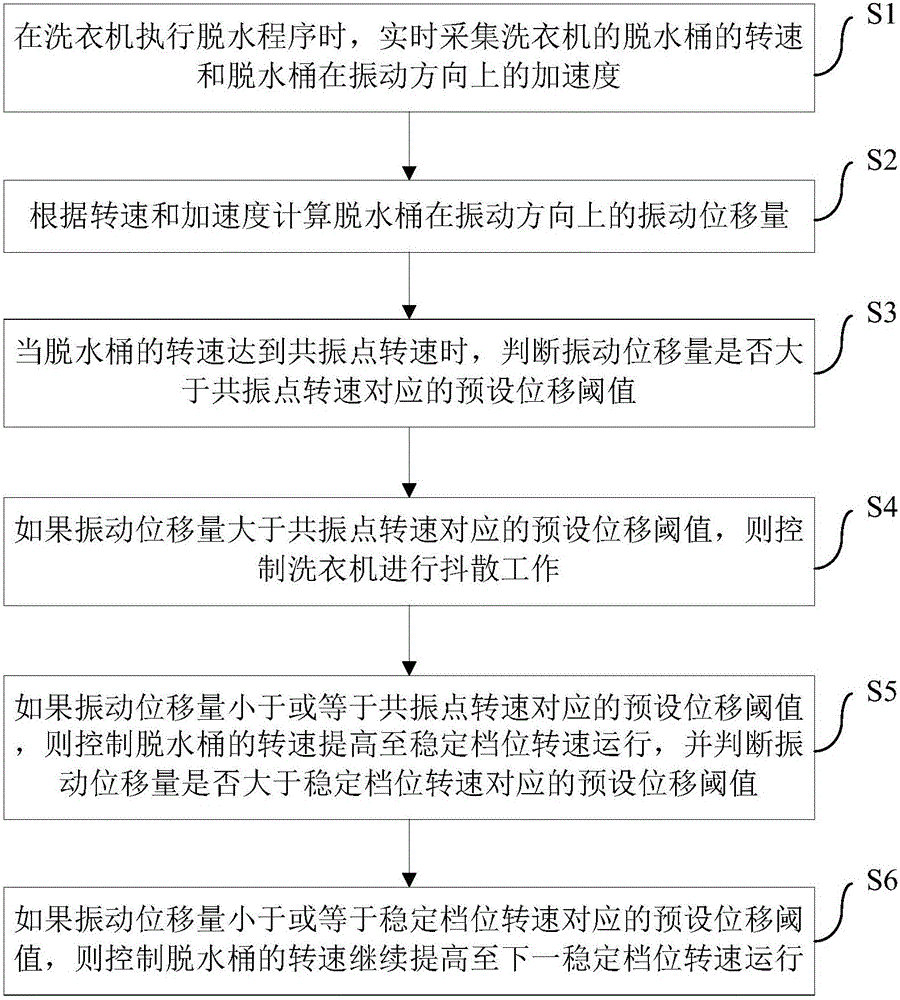

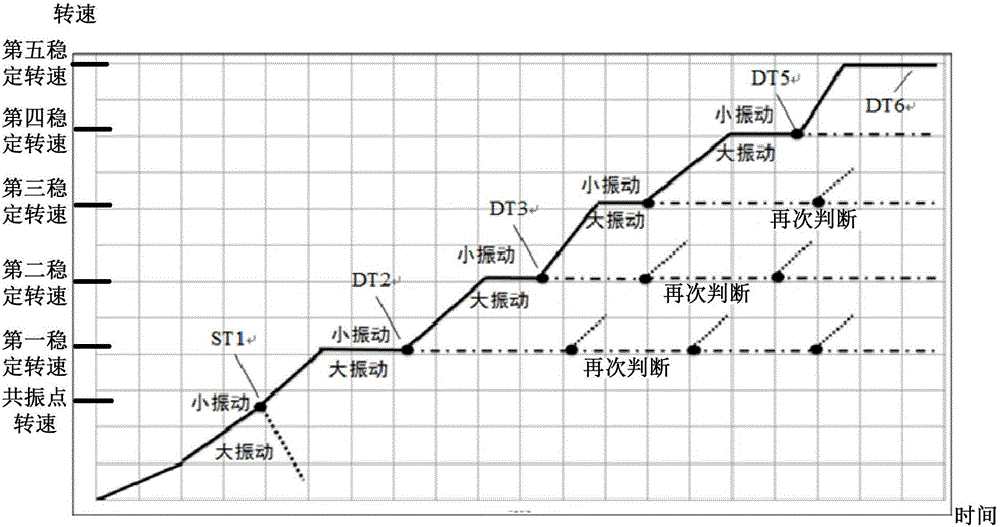

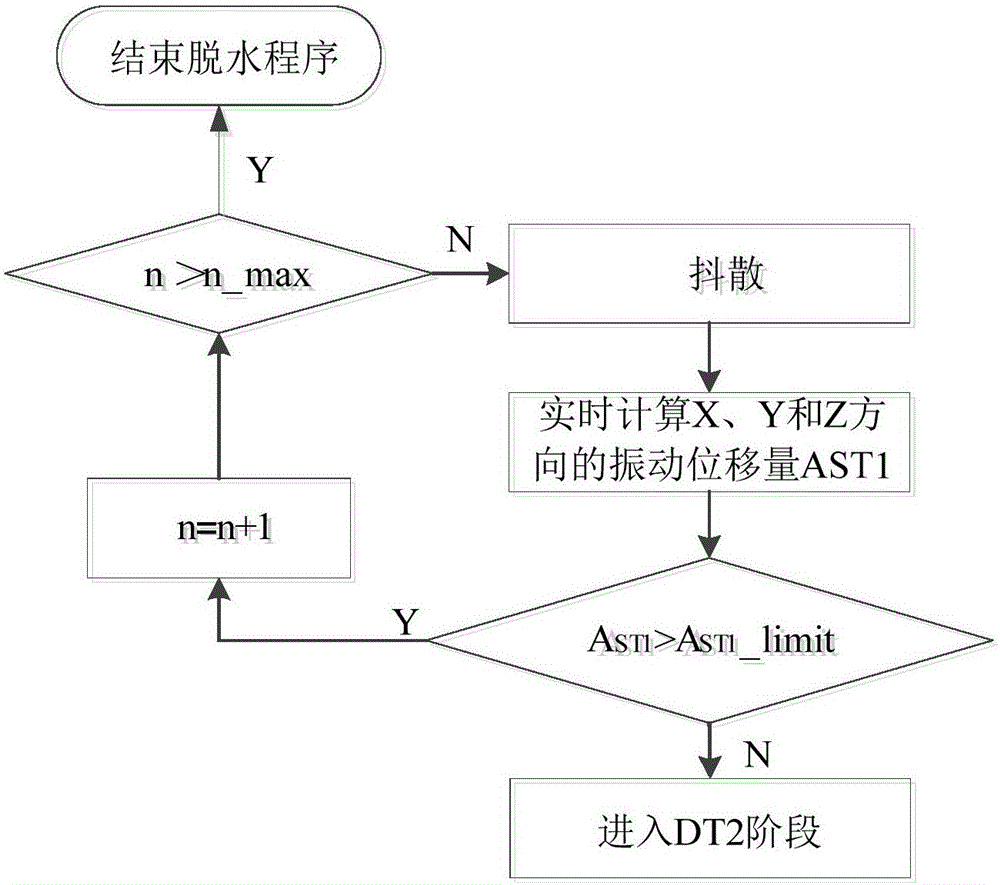

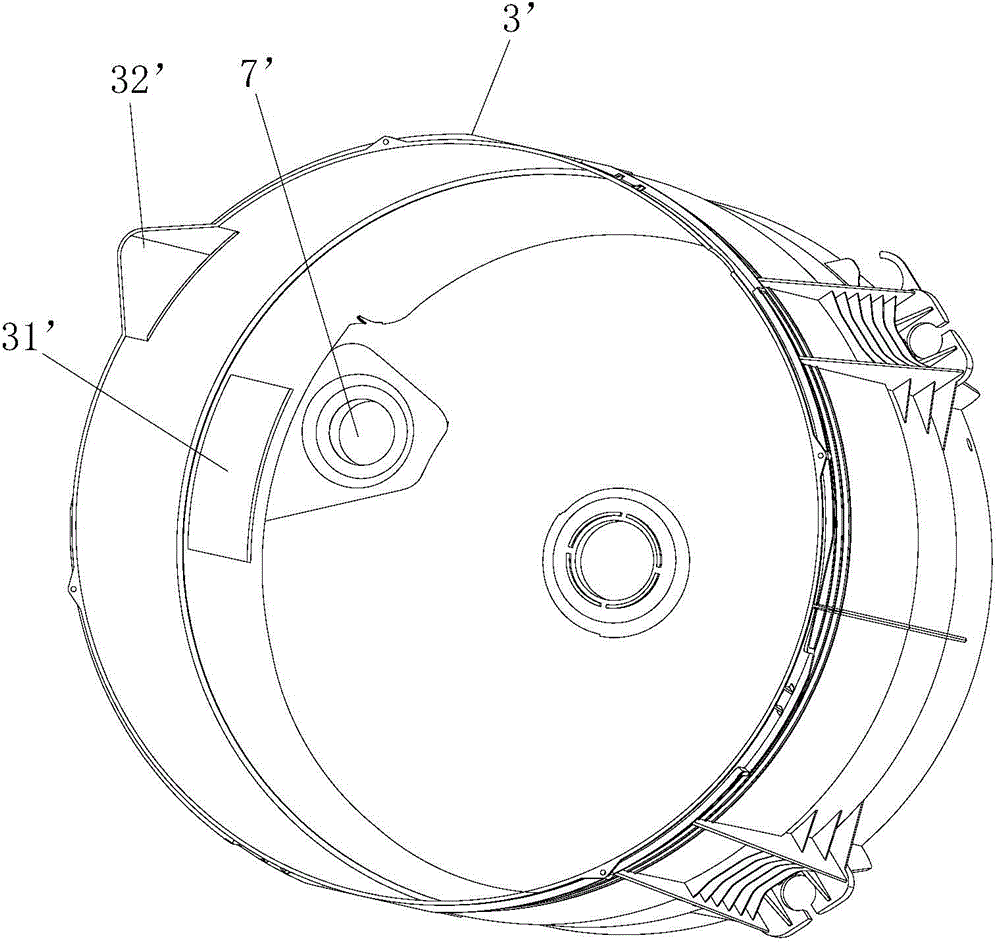

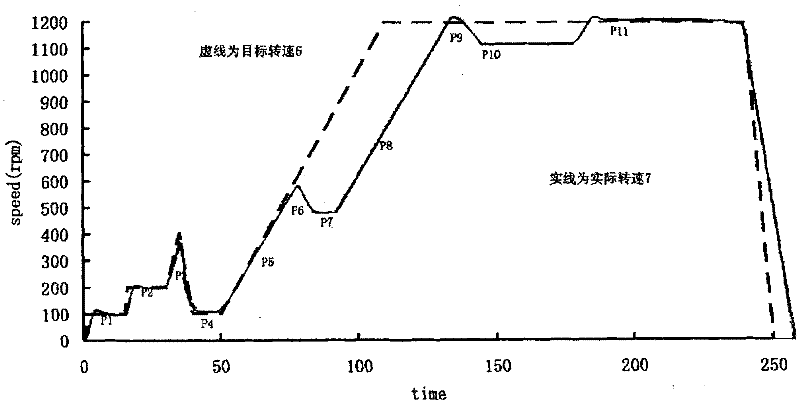

Spin drying control method and device of washing machine and washing machine

ActiveCN105951359AReduce high speed vibrationShorten spin timeControl devices for washing apparatusWashing machine with receptaclesResonance pointProcess engineering

The invention discloses a spin drying control method and device of a washing machine and the washing machine. The method comprises the following steps: when a spin drying procedure is executed, collecting the speed of a spin drying drum and the acceleration of the spin drying drum in the vibration direction in real time; calculating the vibration displacement of the spin drying drum in the vibration direction according to the speed and the acceleration; when the speed of the spin drying drum reaches the resonance point speed, judging whether the vibration displacement is greater than a preset displacement threshold corresponding to the resonance point speed; if so, controlling the washing machine to perform loose shaking work; otherwise, controlling to increase the speed of the spin drying drum to the stable-gear speed, and judging whether the vibration displacement is greater than the preset displacement threshold corresponding to the stable-gear speed; and if the vibration displacement is less than or equal to the preset displacement threshold corresponding to the stable-gear speed, controlling to continuously increase the speed of the spin drying drum to the next stable-gear speed. By adopting the method disclosed by the invention, high-speed vibration of the spin drying drum can be effectively reduced, and the spin drying time is shortened while the spin drying effect is improved.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

Impeller full-automatic washing machine

PendingCN105463790AReduce deliveryAvoid cross infectionOther washing machinesTextiles and paperImpellerWater discharge

The invention discloses an impeller full-automatic washing machine comprising an external barrel, an internal barrel disposed in the external barrel and an impeller disposed in the internal barrel. A drainage port is arranged on the bottom of the external barrel; the washing machine does not have a draining valve; the drainage port of the external barrel is directly communicated with a drain pipe; during washing and rinsing, washing water is only accommodated in the internal barrel and the external barrel contains no washing water; during dehydration, the washing water passes through the external barrel, the external barrel drainage port and the drain pipe from the upper part of the internal barrel and then is directly discharged; during water inlet, water is only charged into the internal barrel; after washing is finished, the internal barrel is driven to rotate at high speed to produce centrifugal force; water in the internal barrel and water in the clothes spirally rise and are discharged out of the external barrel via water discharging holes of the internal barrel; and the water can be directly discharged via the drain pipe. Without the draining valve, assembling technology of the external barrel components can be reduced, installation space of a barrel bottom driving device can be increased and cost can be reduced.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

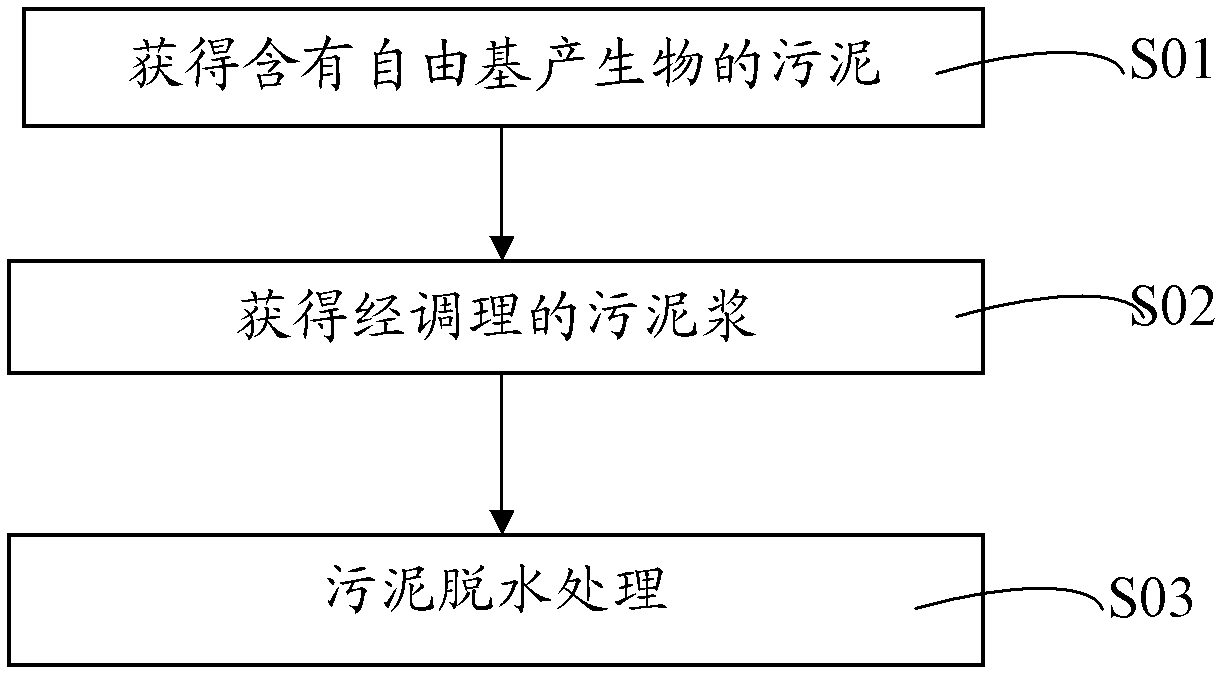

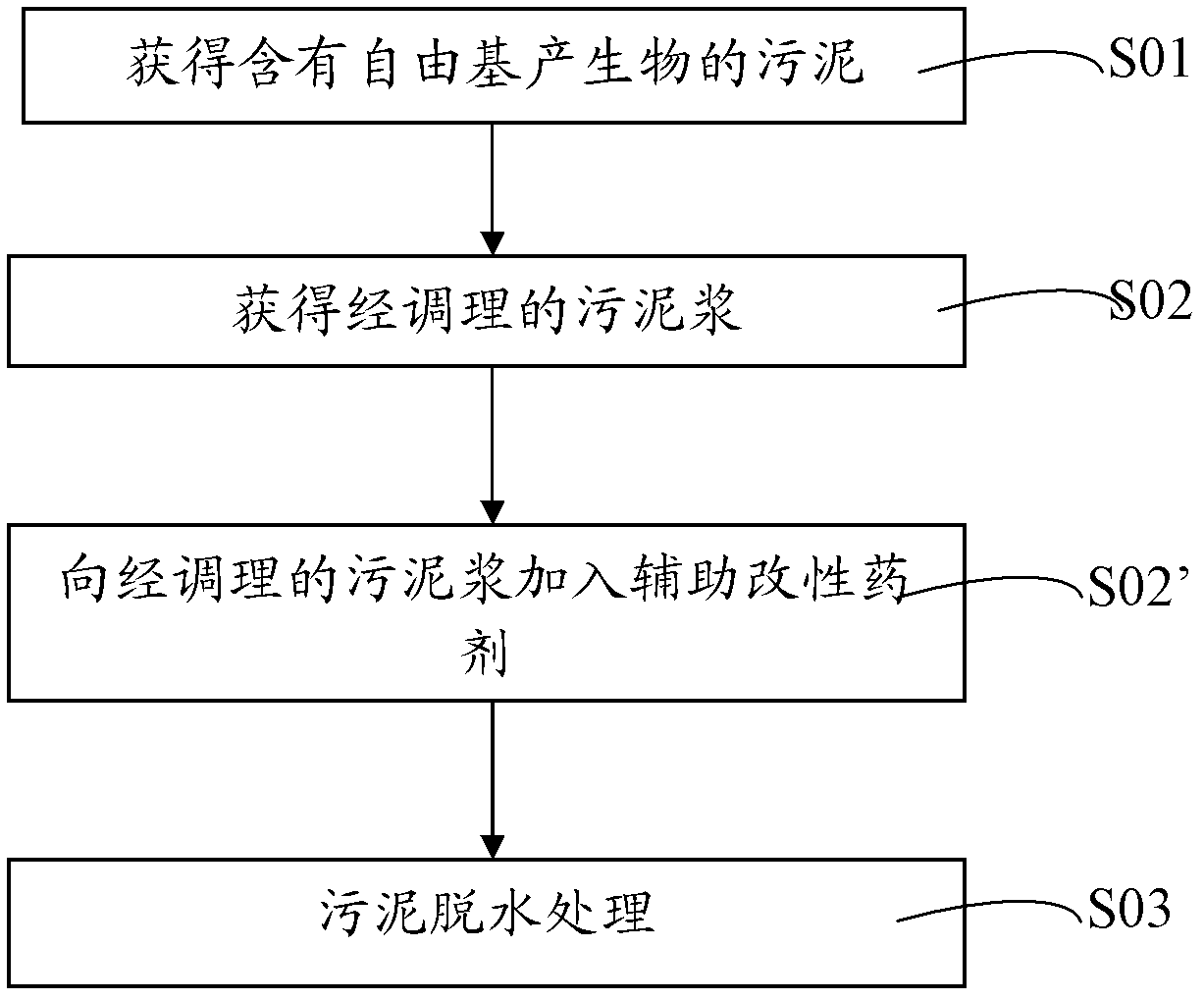

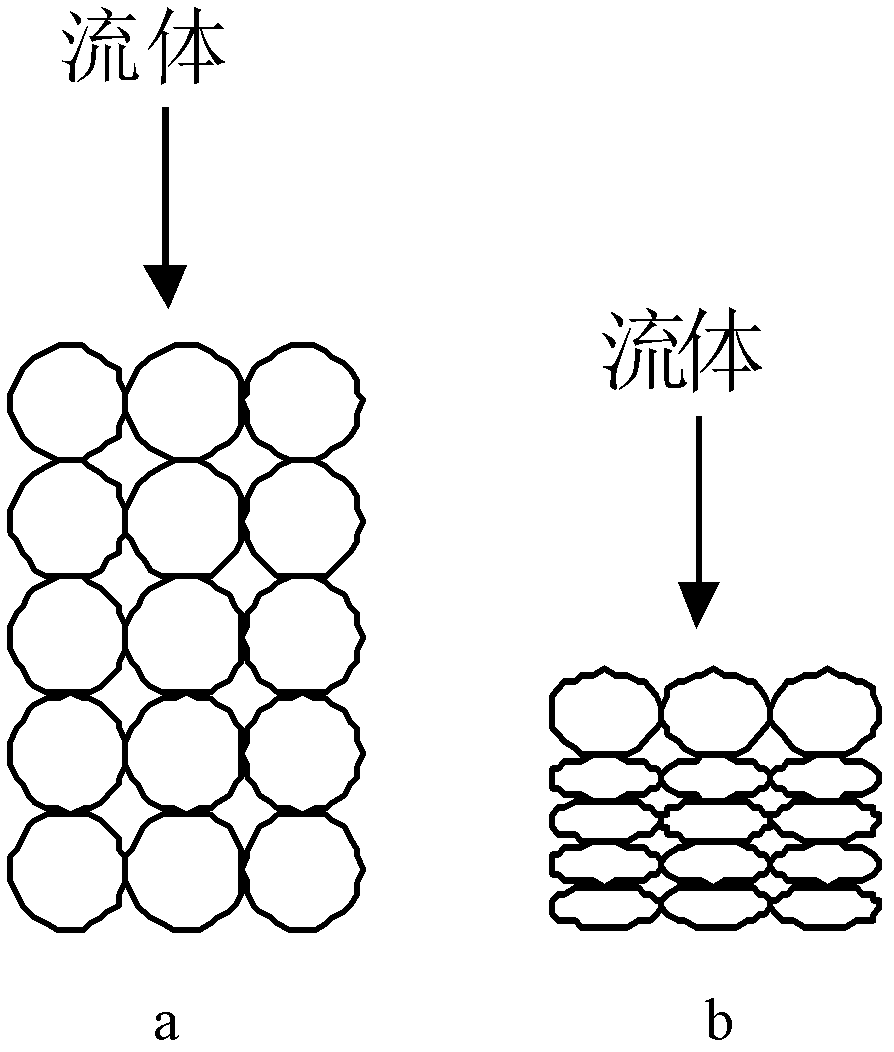

Sludge deep dehydration method

ActiveCN103319066ADeep dehydrationImprove filtering effectSludge treatment by de-watering/drying/thickeningBound waterFiltration

The invention provides a sludge deep dehydration method comprising the following steps: adding 1-10%, based on the dry weight of sludge slurry, of a free radical production into the sludge slurry, and stirring to mix; adding a transition metal salt activator, a magnesium salt activator and / or an aluminum salt activator to the sludge slurry containing the free radical production, carrying out an activation reaction to form active free radicals, and treating by the active free radicals to obtain a conditioned sludge slurry; and dehydrating the conditioned sludge slurry. Through the sludge deep dehydration method, the active free radicals are produced by reacting the transition metal salt, the magnesium salt and / or the aluminum salt and the like with the free radical production, on one hand, can effectively destroy sludge extracellular polymeric substances, alter surface properties of sludge particles, improve the filtration performance of the sludge, and reduce the sludge bound water content; on the other hand, the active free radicals can active ions produced after the completion of the reaction, can be combined with sludge particles, can improve the strength of sludge flocs, are favorable to the sludge dehydration process, so as to realize the sludge deep dehydration.

Owner:UNIVERSTAR SCI & TECH SHENZHEN +1

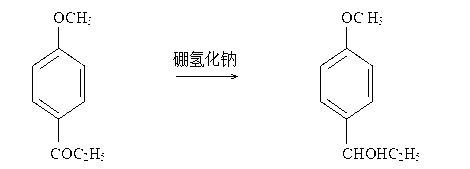

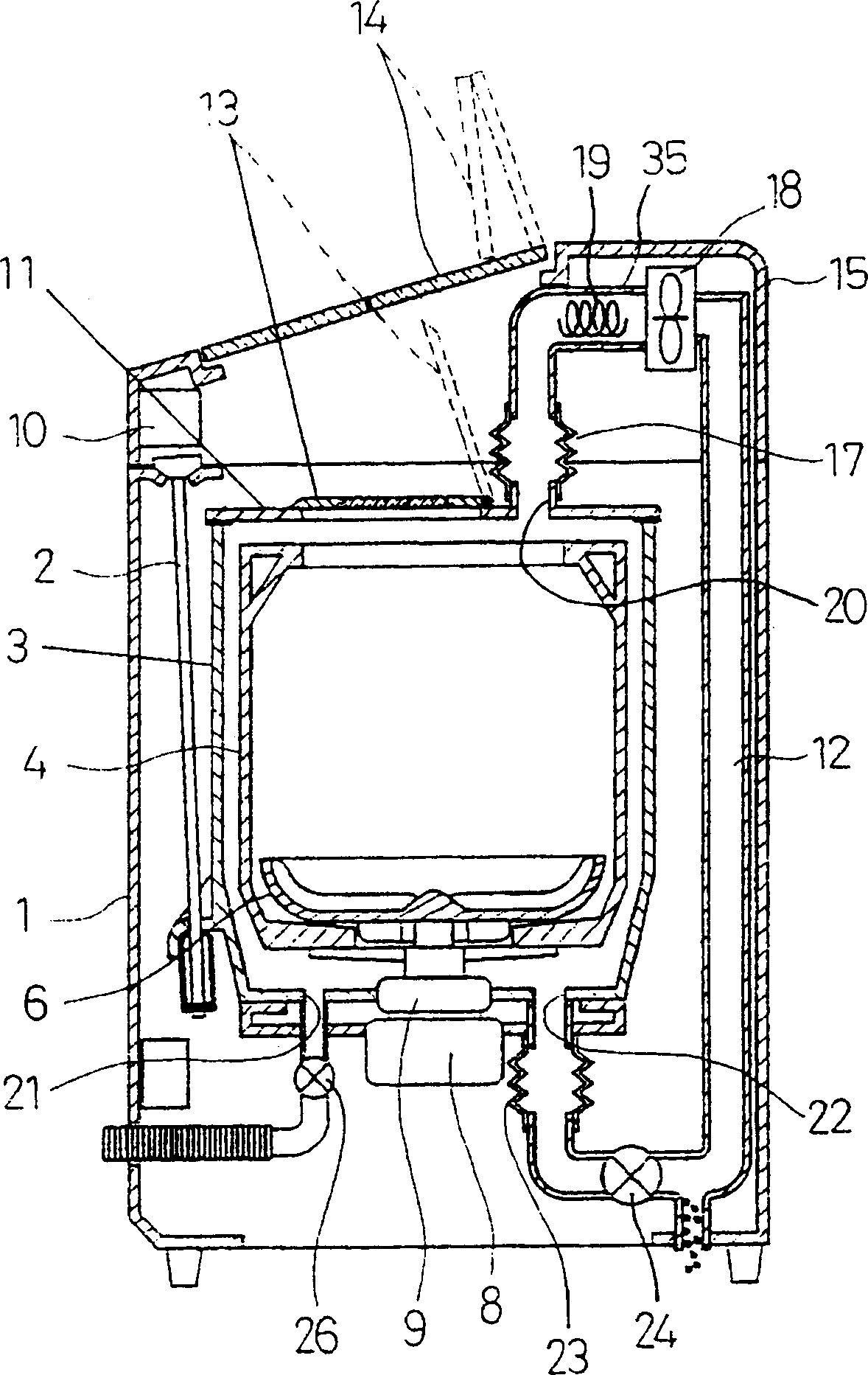

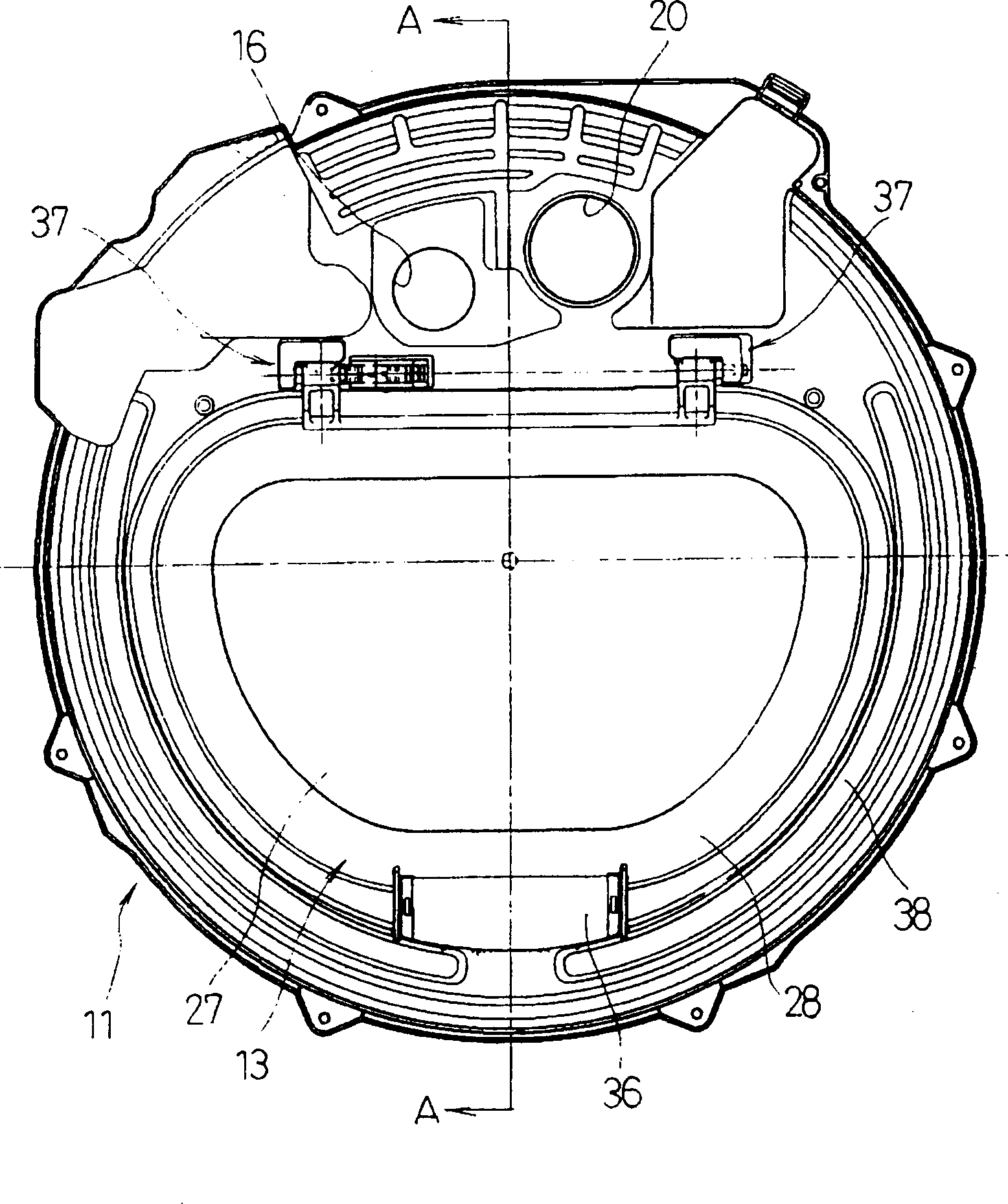

Washing machine with drying device

InactiveCN1537997AIncrease speedShorten spin timeOther washing machinesWashing machine with receptaclesHeat resistanceProcess engineering

Provided is a washing and drying machine by which condition of laundry housed in an inner tub is allowed to be checked during each operation of washing, spin-drying, and drying processes. In the washing and drying machine, an inner cover 13 provided at an outer tub cover 11 for closing the upper opening of an outer tub 3 is formed of a transparent heat resistant resin material, and an outer cover 14 is also formed of a transparent material for readily recognizing the condition of laundry in the inner tub 4 from outside of the washing and drying machine.

Owner:PANASONIC CORP

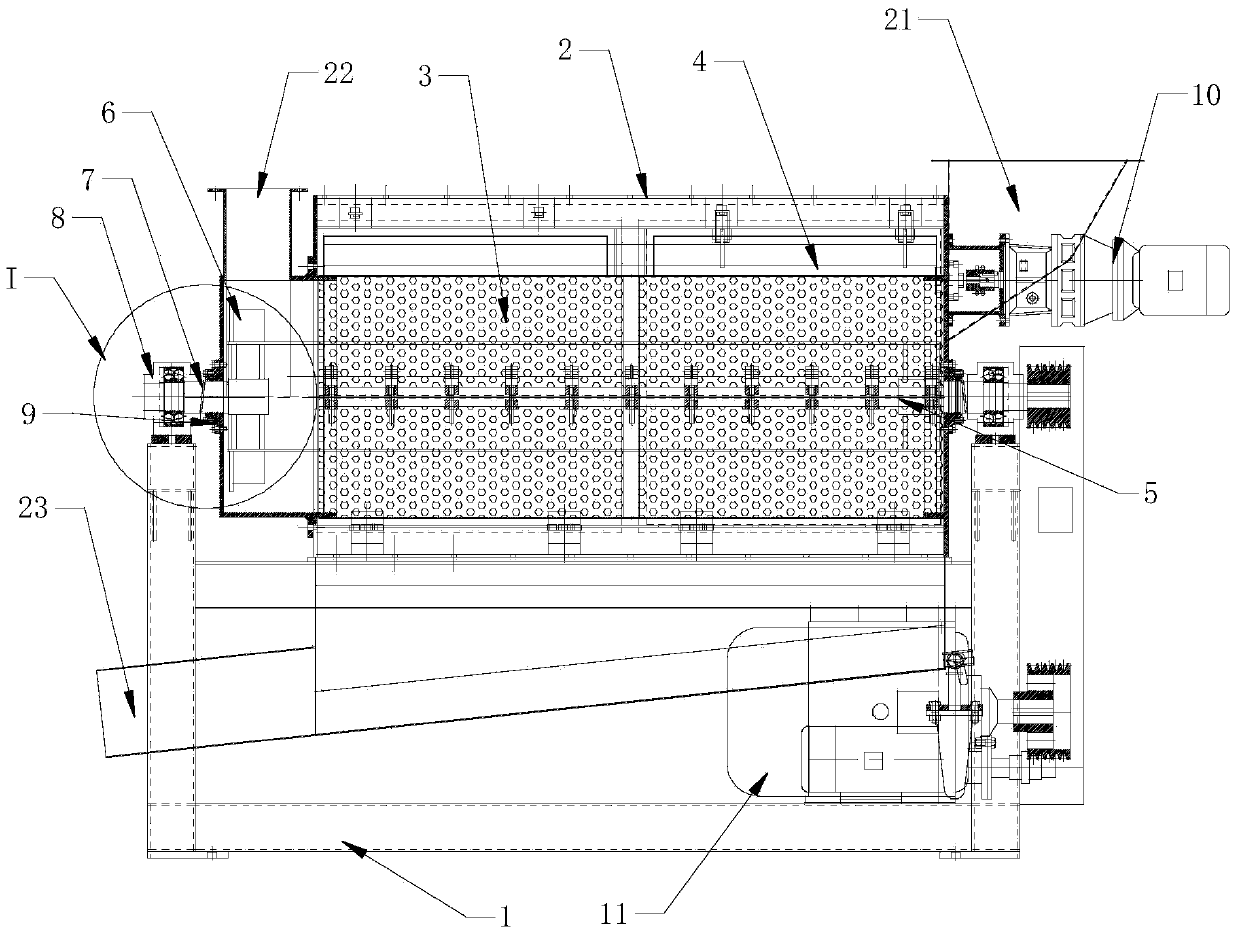

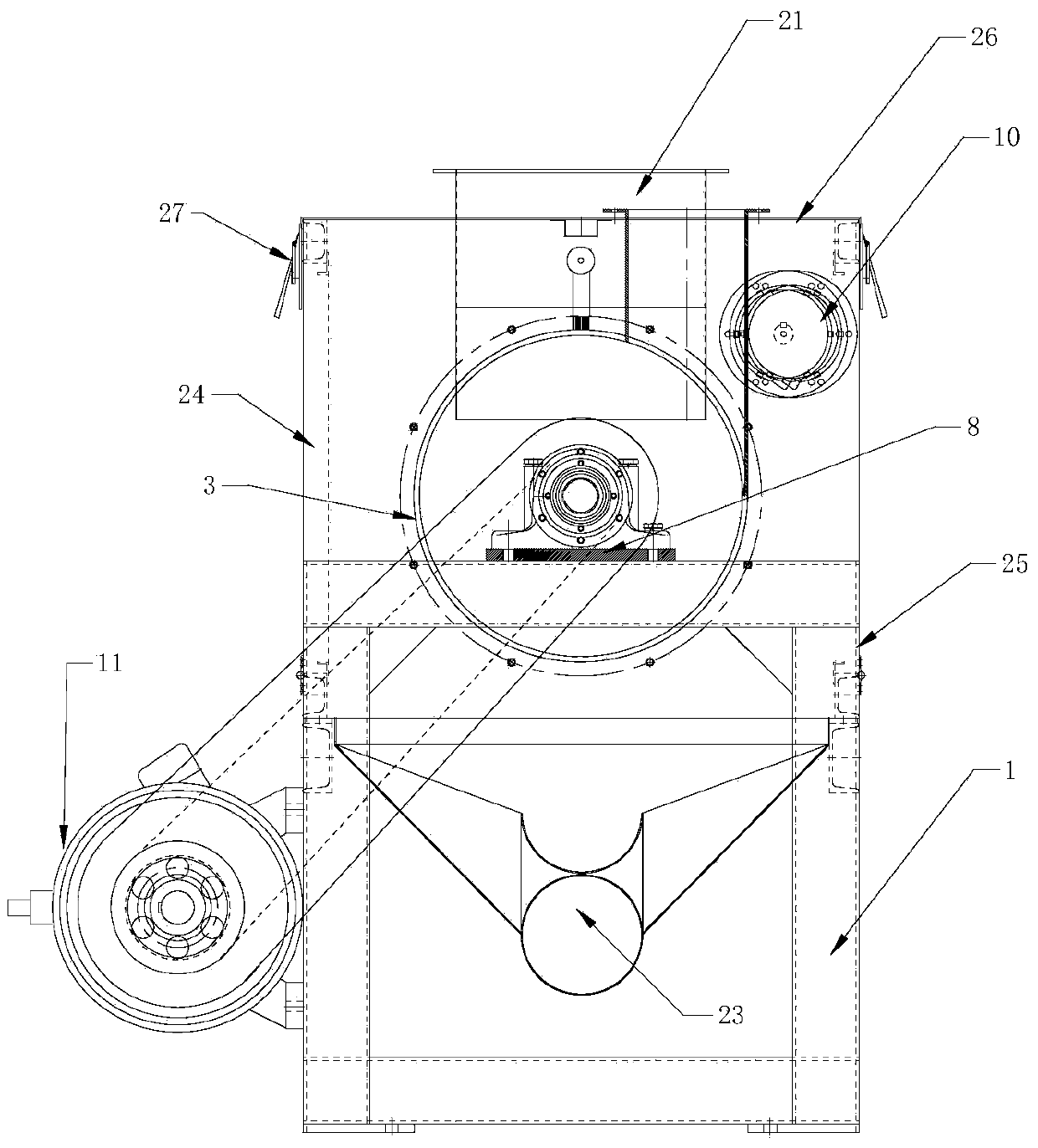

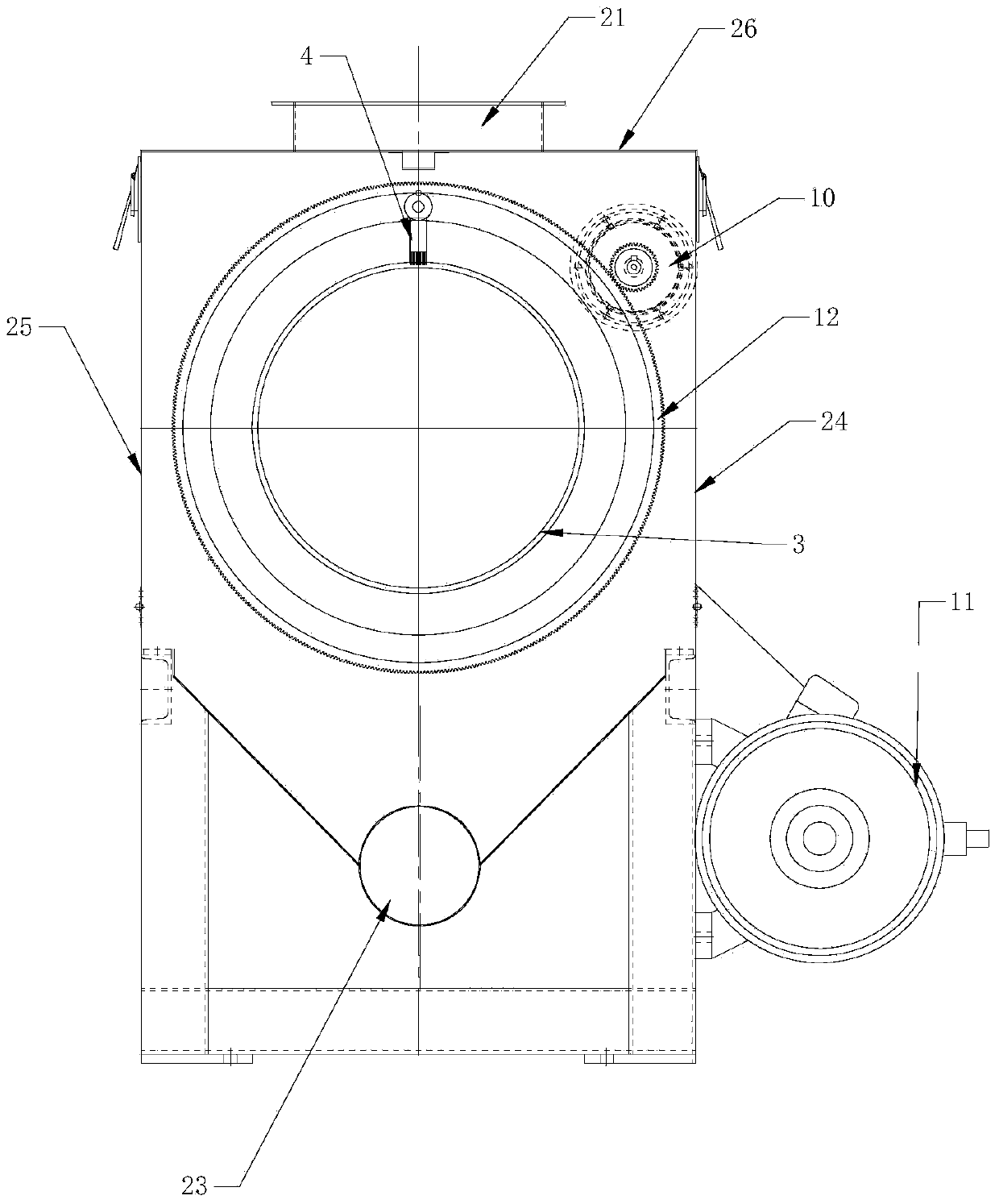

Waste plastic recycling dewatering machine

InactiveCN103438674AGood effectImprove dehydration efficiencySievingScreeningPulp and paper industryEngineering

The invention discloses a waste plastic recycling dehydrater which comprises a base, a machine shell, a screen drum and a main shaft with mixing blades. The bottom of the machine shell is fixed on the base, the screen drum is fixed in the machine shell, and the main shaft is horizontally installed in the center of the screen drum and penetrates through the screen drum and the machine shell. The two ends of the main shaft are fixed on the base through bearing pedestals, sealing devices are arranged at the connecting positions of the two ends of the main shaft and the machine shell respectively, and the main shaft is driven by a main shaft rotation power device to rotate. One end of the machine shell is provided with a feed port communicated with the interior of the screen drum, the other end of the machine shell is provided with a discharge port communicated with the interior of the screen drum, and a water outlet is formed in the bottom of the machine shell. The dewatering machine is reasonable in stress, and the sealing effect between the main shaft and the machine shell is good. In comparison with an existing structure, the main shaft of the dewatering machine is higher in speed, so that the dewatering effect is better.

Owner:ZHANGJIAGANG LIANDA MACHINERY

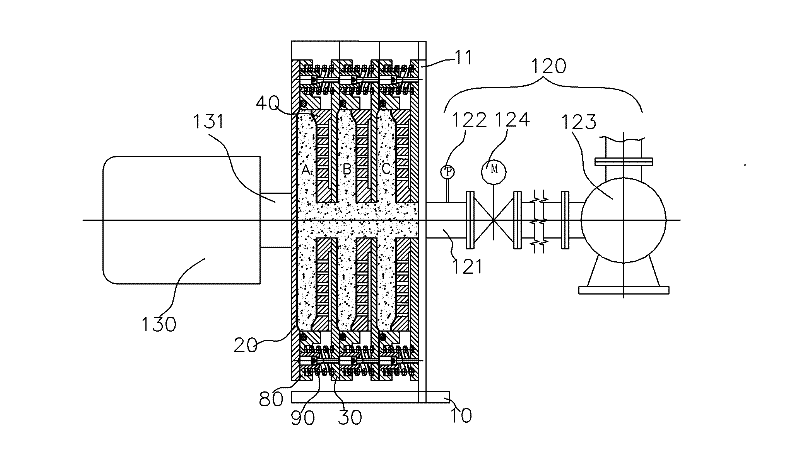

Sludge Dehydrator

ActiveCN102267794AVia short pathShort discharge timeSludge treatment by de-watering/drying/thickeningSludge dewateringExtrusion

The invention discloses a sludge dehydrator, which comprises a frame and a supporting plate connected with the frame; a sludge pumping mechanism and a pressure extrusion mechanism are arranged at two sides of the supporting plate respectively; a frame plate type filter pressing mechanism is arranged between the pressure extrusion mechanism and the connected supporting plate; the filter pressing mechanism comprises a filter pressing unit; a filter plate is arranged in the filter pressing unit; an annular sleeve is sleeved on the peripheral wall of the filter plate; a filter pressing cavity is formed between the filter plate and a front pressing plate; filter cloth is arranged on the surface of the filter plate in the filter pressing cavity; the surface of the filter plate is provided with a filtrate drainage hole; the drainage hole is connected with a drainage passage arranged in the filter plate and extended to the exterior; and the filter plate is interconnected with the surface of arear pressing plate to form a whole, and the middle part of the filter plate is provided with a through hole which is communicated with a pipeline of the sludge pumping mechanism. The sludge dehydrator can improve the filter pressing efficiency and is convenient to control the dryness of mud cakes.

Owner:安徽省通源环境节能股份有限公司

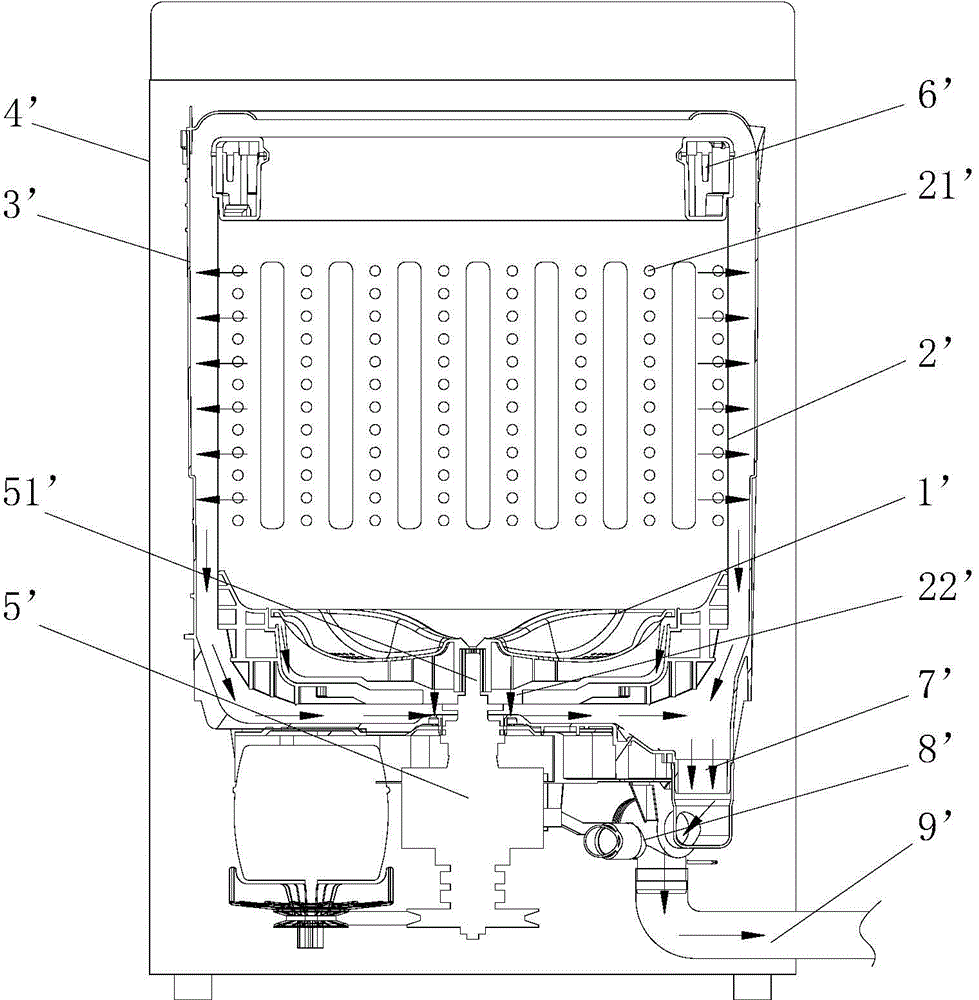

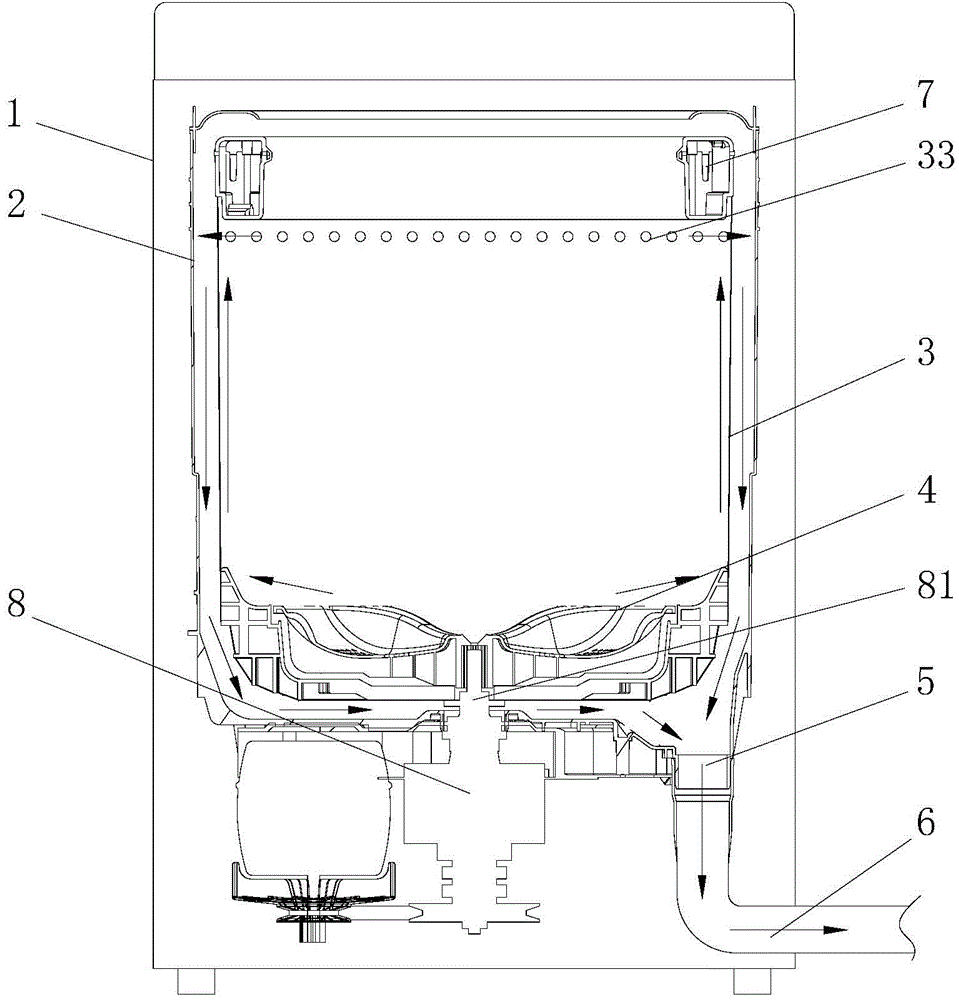

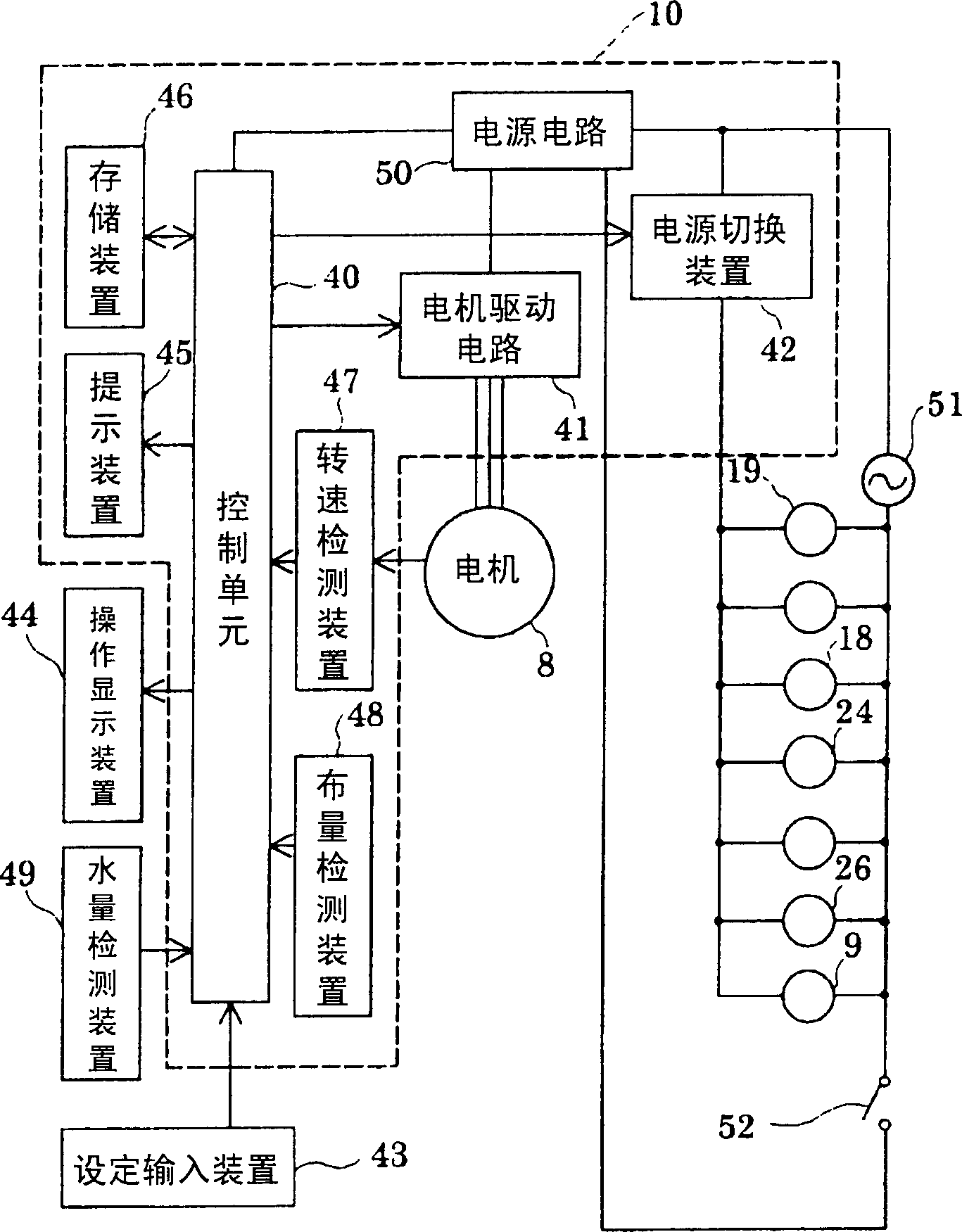

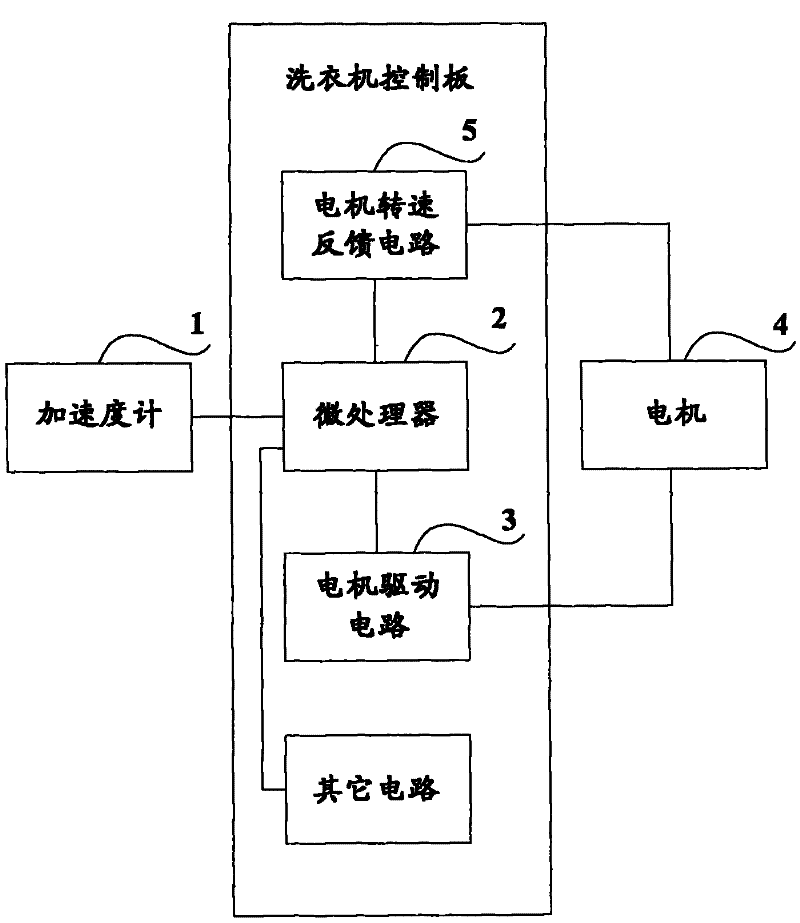

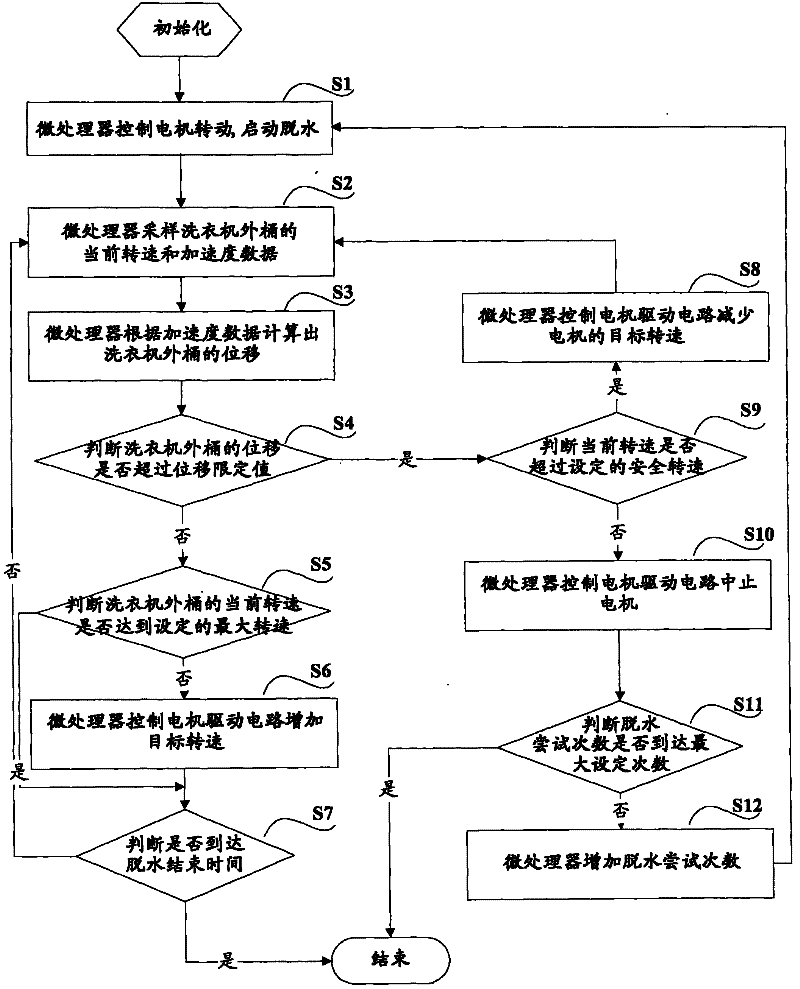

Method and device for controlling dehydration of washing machine

InactiveCN102191660ASolutionSolve the shortcomings of the deviceControl devices for washing apparatusTextiles and paperMotor driveElectric machine

The invention provides a method and a device for controlling dehydration of a washing machine. The method comprises the following steps of: at the starting of the dehydration, acquiring acceleration data; calculating displacement of an outer barrel of the washing machine according to the acquired acceleration data; judging whether the displacement of the outer barrel of the washing machine is greater than a displacement limit value; when the displacement is not greater than the displacement limit value, judging whether the current rotating speed of the outer barrel of the washing machine reaches a set maximum rotating speed, if the current rotating speed of the outer barrel of the washing machine does not reach the set maximum rotating speed, controlling a motor driving circuit to increase a target rotating speed, and if the current rotating speed of the outer barrel of the washing machine reaches the set maximum rotating speed, keeping the current rotating speed until the end of the dehydration; and when the displacement is greater than the displacement limit value, judging whether the current rotating speed is greater than a set safety rotating speed, if the current rotating speed is not greater than the set safety rotating speed, controlling the motor driving circuit to stop a motor, and if the current rotating speed is greater than the set safety rotating speed, controlling the motor driving circuit to decrease the target rotating speed and keeping dehydrating. By the invention, the shortcomings of the conventional method and the conventional device for controlling dehydration of the washing machine can be solved, so that the washing machine can get higher counter balance and dehydration performance.

Owner:DIEHL CONTROLS NANJING

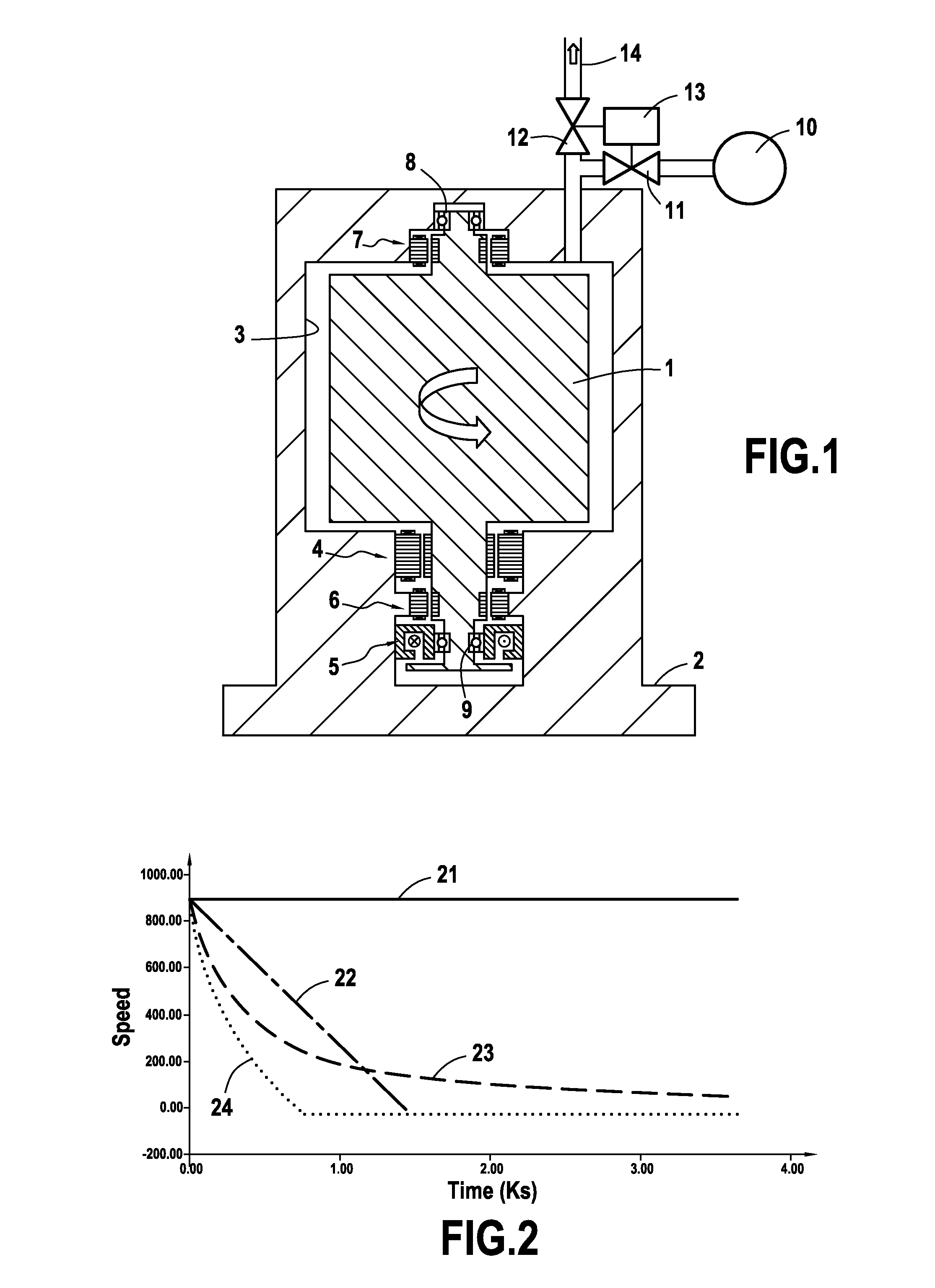

High speed flywheel on magnetic bearings

A high speed energy storage flywheel comprises a rotor which is located in a vacuum chamber provided in a stator housing and is supported by magnetic bearings with respect to the stator housing. A fluid tank used for releasing in a controlled manner, a fluid inside the vacuum chamber and therefore create a braking effect on the rotor by friction.

Owner:SKF MAGNETIC MECHATRONICS

Method for preparing biochar through destructive distillation of oily sludge

ActiveCN108773840ABreak through agricultural restrictionsReduce adverse effectsSludge treatment by de-watering/drying/thickeningOther chemical processesPorositySludge

The invention discloses a method for preparing biochar through destructive distillation of oily sludge, and belongs to the technical field of biochar. The method has the advantages that the oily sludge and biomass materials are utilized as raw materials which are subjected to steps such as drying, activating, destructive distillation, hydrochloric acid soaking and modification to prepare the biochar; the prepared biochar has large specific surface area, high porosity, high fixed proportion of heavy metal and low content of polycyclic aromatic hydrocarbon, and can serve as a heavy-metal ion adsorbent and a soil conditioner.

Owner:SCI RES ACADEMY OF GUANGXI ENVIRONMENTAL PROTECTION

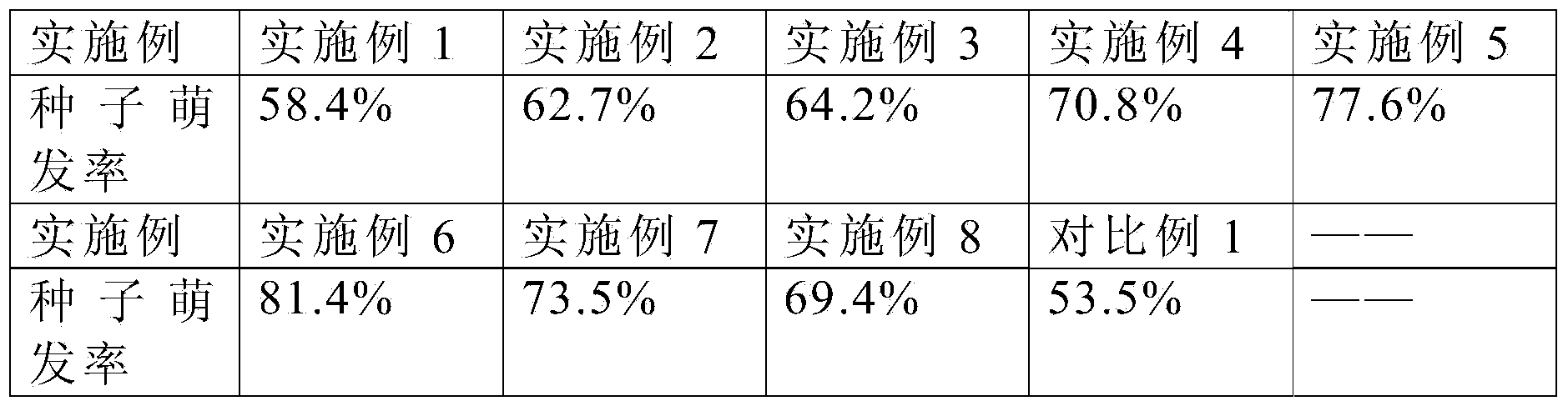

Embedding vitrification ultralow-temperature storage method for bletilla striata seeds

The invention relates to an embedding vitrification ultralow-temperature storage method for bletilla striata seeds. The method comprises the following steps: collecting integral fruit, cleaning, wiping surfaces with ethanol, immersing in ethanol, flushing with sterile water, immersing in a mercuric chloride solution with a concentration of 0.1%, flushing, absorbing water on the fruit surfaces, splitting capsules in a longitudinal direction, and taking out powder-like seeds; pouring seeds into a sodium alginate embedding solution, stirring uniformly, dropwise putting into a calcium ion embedding solution, and putting in a room-temperature environment and forming embedded beads through solidifying; putting the embedded beads into a PVS2 solution and performing dewatering processing for 20-160 min; putting into a refrigeration tube, adding a PVS2 solution, and then putting the refrigeration tube in liquid nitrogen for refrigeration storage; when seeds are needed, taking out the refrigeration tube, unfreezing and removing the PVS2 solution, and washing; and inoculating the washed embedded beads to a solid VW medium for culture, enabling the seed to germinate, and performing domestication transplanting after seedlings grow to have the height of 6-10 cm. The seeds obtained by employing the method are high in germination rate and the cost can be saved.

Owner:RES INST OF SUBTROPICAL FORESTRY CHINESE ACAD OF FORESTRY

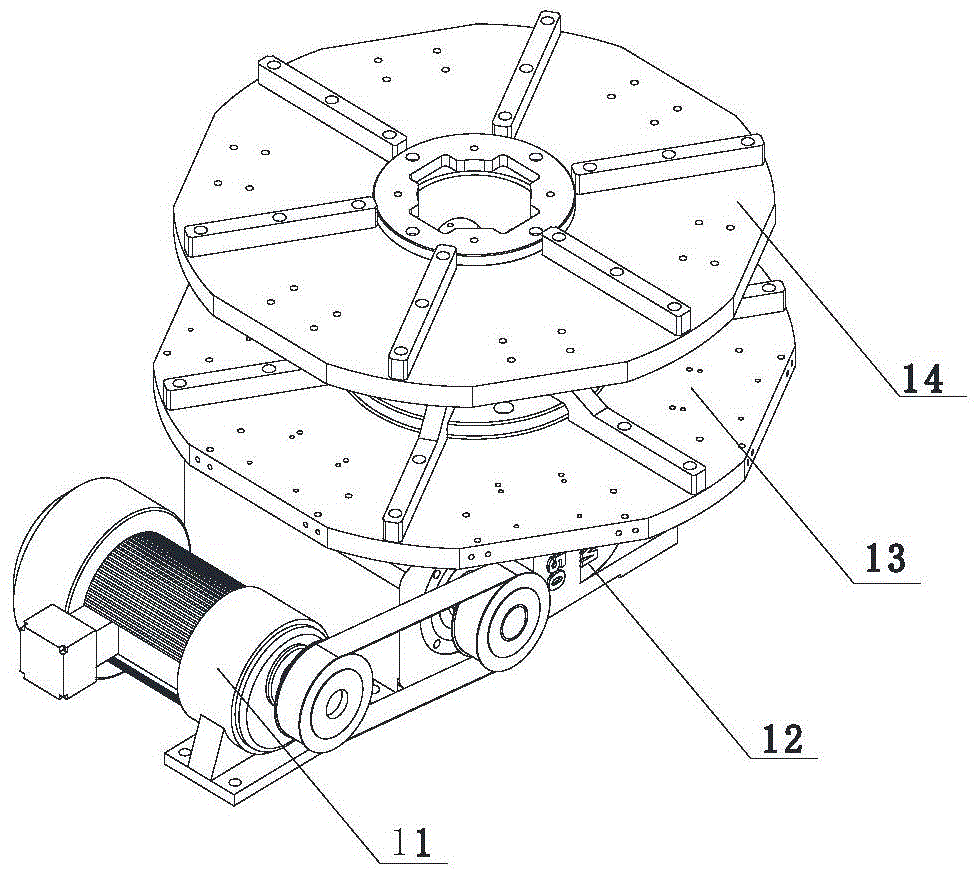

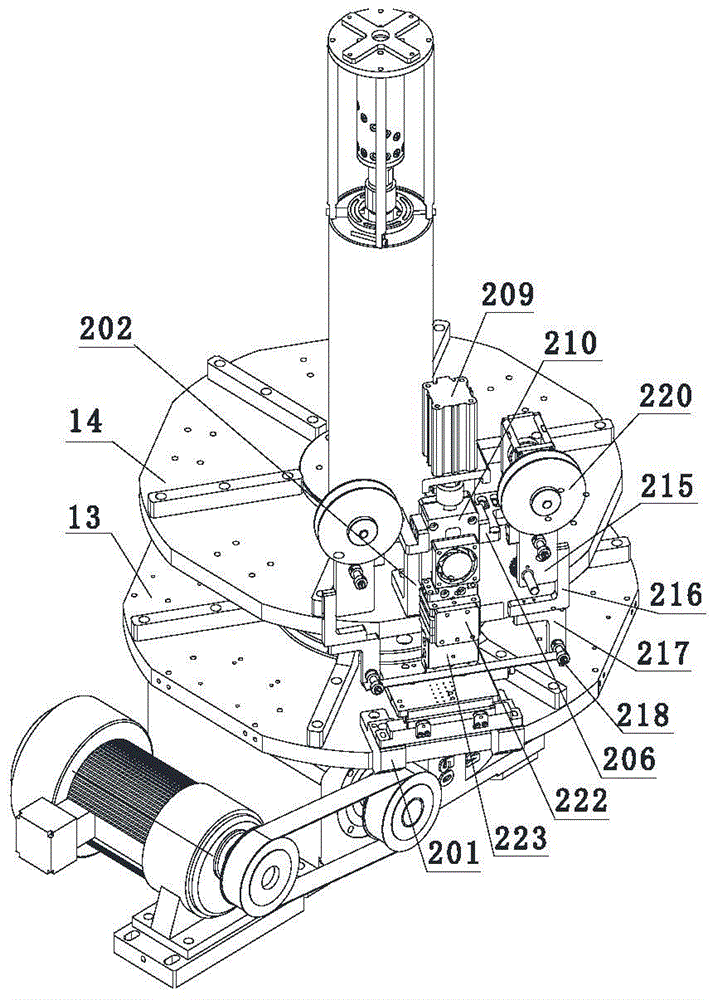

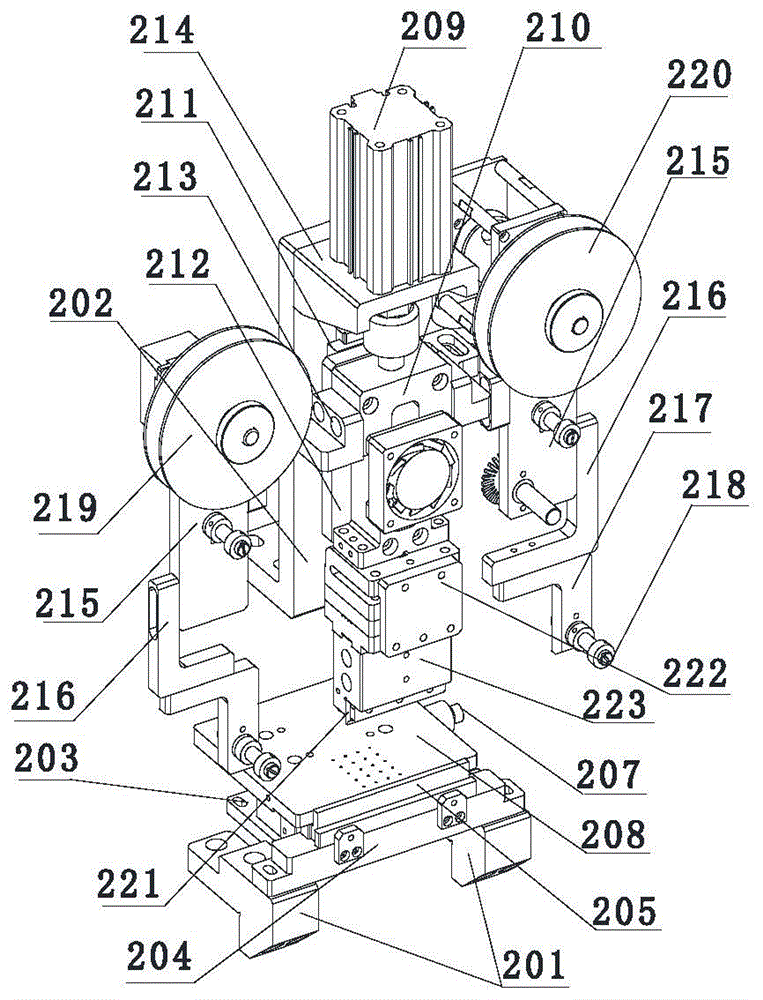

Glass circuit board based FPC (flexible printed circuit) board hot-pressing device, processing system and method

ActiveCN104582305AEfficient crawlingShorten spin timePrinted circuit assemblingAnisotropic conductive filmEngineering

The invention discloses a glass circuit board based FPC (flexible printed circuit) board hot-pressing device, processing system and method. The hot-pressing device comprises a rotating platform capable of rotating intermittently, wherein the rotating platform is provided with two layers of fixing boards which are mutually parallel and can rotate simultaneously, one layer is hot-pressing fixing board used for fixing hot-pressing assemblies, the other layer is a jig fixing board for fixing jig assemblies, the rotating platform is divided into a plurality of station areas, and one hot-pressing assembly and one jig assembly are arranged in each station area; each hot-pressing assembly comprises a lifting control mechanism, a hot-pressing head and a buffering mechanism; a loading platform, a first preset platform, an ACF (anisotropic conductive film) attachment assembly, a second preset platform, the hot-pressing device and an unloading platform are mounted on a mounting platform. The work efficiency of the hot-pressing device can be improved, the area occupied by the equipment can be reduced, and the cost is saved.

Owner:SHENZHEN LIANDE AUTOMATION EQUIP

Furan resin for cast iron and synthesis method thereof

ActiveCN104262560AEmission reductionSolve the pollution problemFoundry mouldsFoundry coresPolymer scienceFurfuryl alcohol

The invention relates to a furan resin for cast iron and a synthesis method thereof. The invention is characterized in that the furan resin is prepared from the following raw materials in parts by weight: 60-80% of furfuryl alcohol, 5-15% of solid formaldehyde, 5-15% of urea, 0.2-1.0% of coupling agent and 5-10% of water. The solid formaldehyde is used instead of liquid formaldehyde in the synthesis process, thereby solving the problem of the sewage generated in the production process of the furan resin for cast iron; and the furan resin for cast iron has the characteristics of high strength, low viscosity, favorable molding-sand property and the like.

Owner:广西兰科资源再生利用有限公司

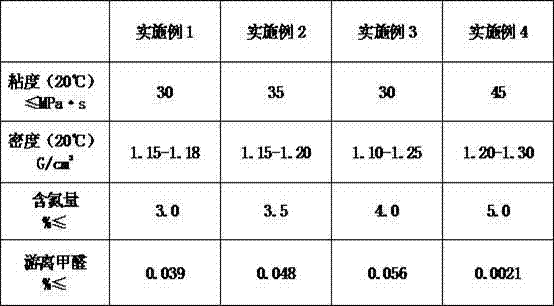

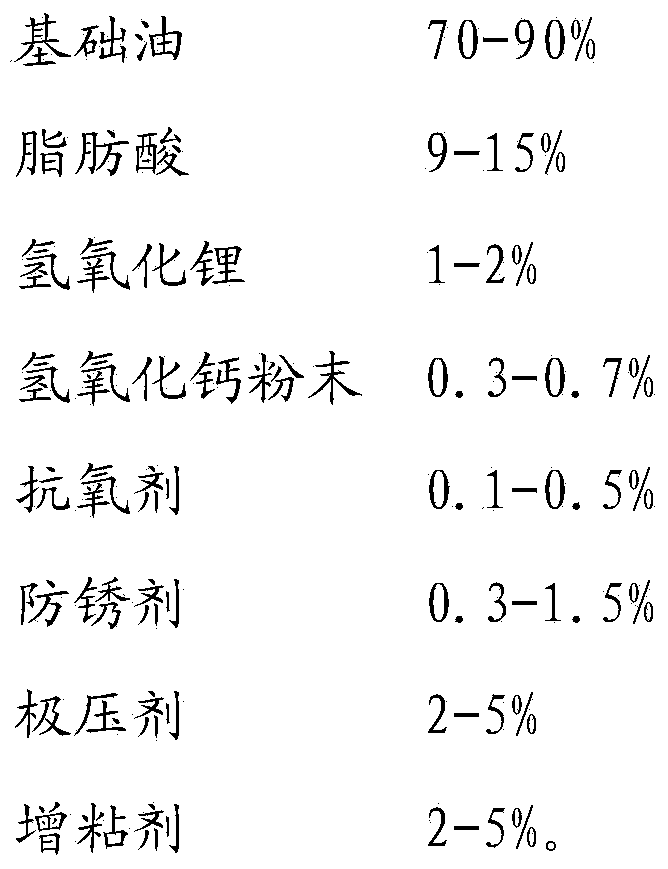

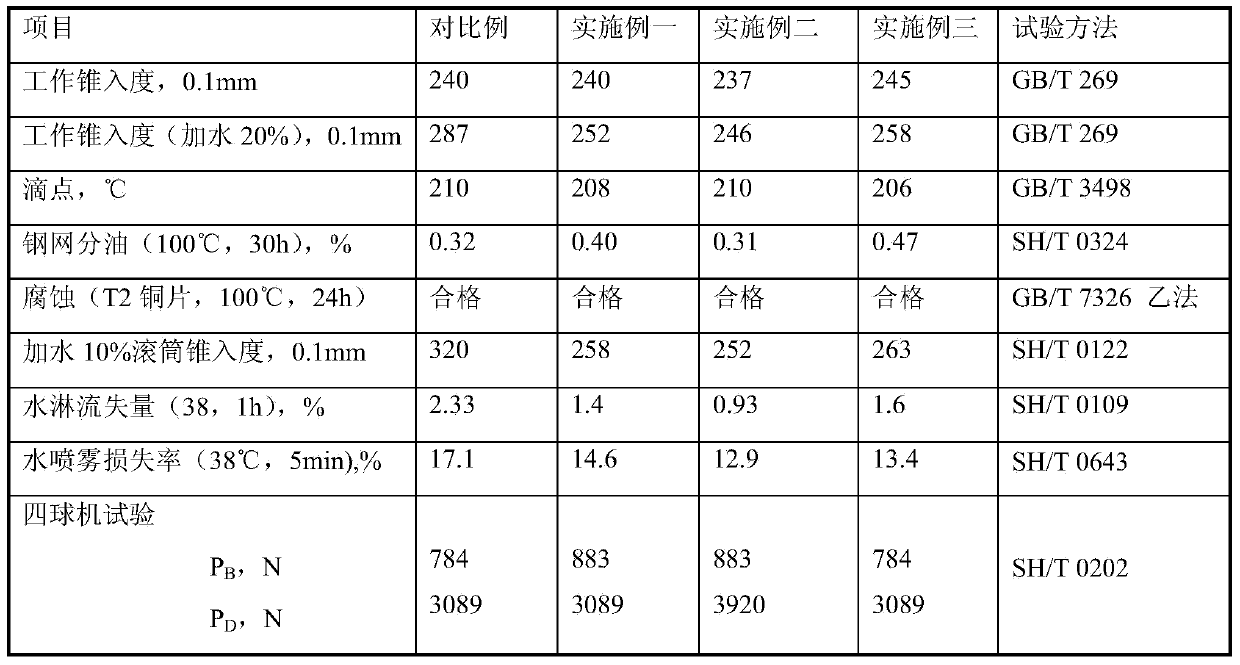

Water-resistant extreme pressure lithium lubricating grease and preparation method thereof

ActiveCN103468357AShorten saponification and dehydration timeDrop point highLubricant compositionLubricationChemistry

The invention relates to lubricating grease and a preparation method thereof, particularly relates to water-resistant extreme pressure lithium lubricating grease and a preparation method thereof, and belongs to the technical field of chemical engineering. The water-resistant extreme pressure lithium lubricating grease comprises the following components by weight percent: 70-90% of base oil, 9-15% of fatty acid, 1-2% of lithium hydrate, 0.3-0.7% of calcium hydroxide powder, 0.1-0.5% of antioxidant, 0.3-1.5% of antirust agent, 2-5% of extreme pressure agent and 2-5% of tackifier. The water-resistant extreme pressure lithium lubricating grease has the beneficial effects that the condition that the water-resistant extreme pressure lithium lubricating grease product has a high dropping point and good shear stability under a general condition is ensured; the product has excellent water-resistance, so that less loss in washing of a lot of water is ensured; the water-resistant extreme pressure lithium lubricating grease can work in the presence of water, is not easily softened to run off, and is good in mechanical stability; the product has excellent anti-rust property and extreme pressure anti-wear property; excellent lubrication of heavy duty equipment under a humid condition can be improved; the lubricating surface is prevented from being rusted.

Owner:JIANGSU LOPALTECH

Method for shortening processing time of microwave freezing drying of fruit or vegetable powder by utilizing dielectric core

InactiveCN1868321AShorten spin timeImprove qualityFood preservationFood preparationMicrowaveFreeze-drying

A dielectric core method for shortening the time taken by microwave freeze-drying of fruit-vegetable powder includes such steps as choosing raw materials, conventional pre-treating, slicing, beating, adding the high-dielectric-constant titanium oxide ceramic nano-particles, amino acid and sugar or salt to form dielectric cores, quick freezing, microwave vacuum freeze-drying, and pulverizing. It features less loss of nutrients.

Owner:JIANGNAN UNIV

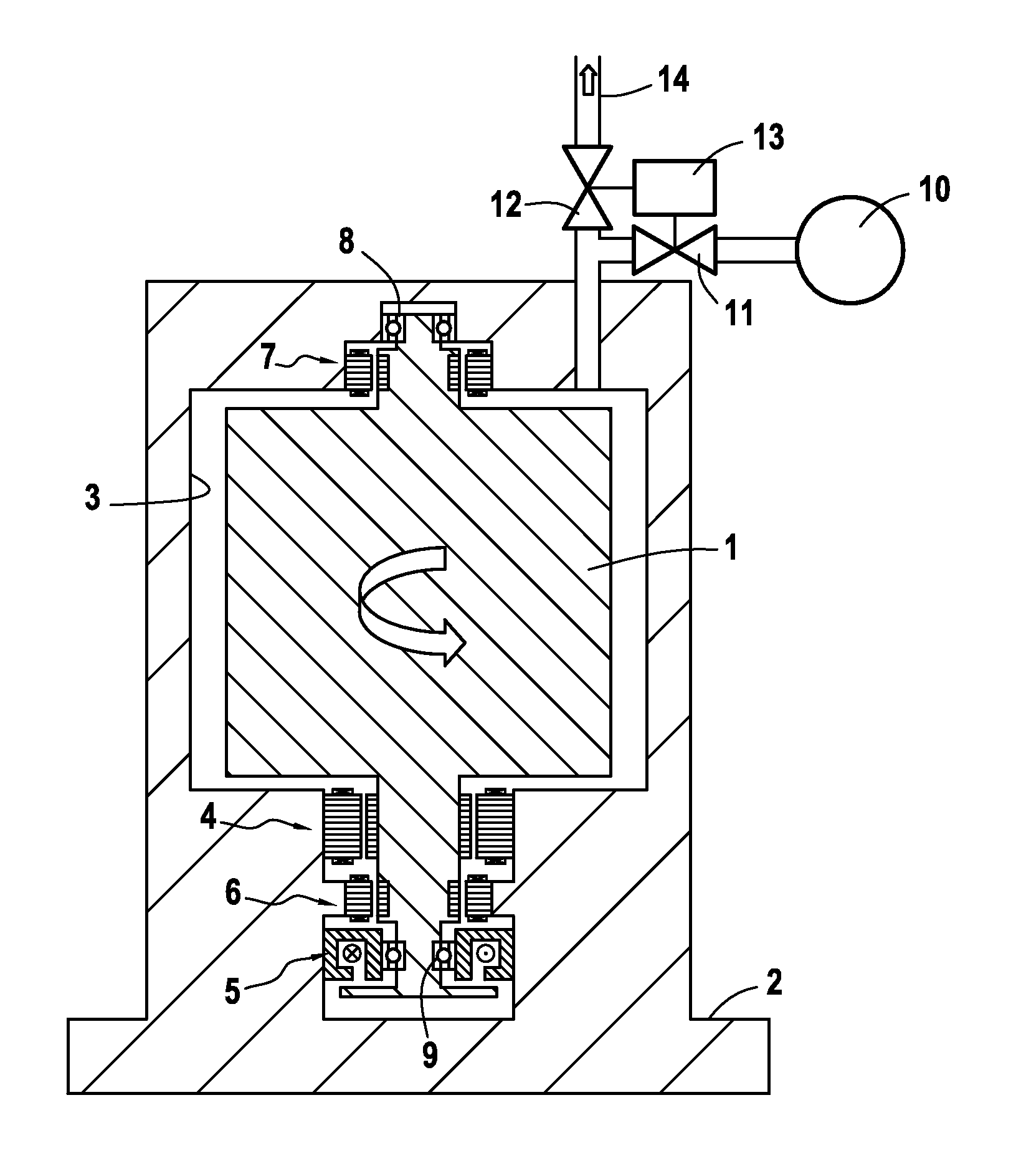

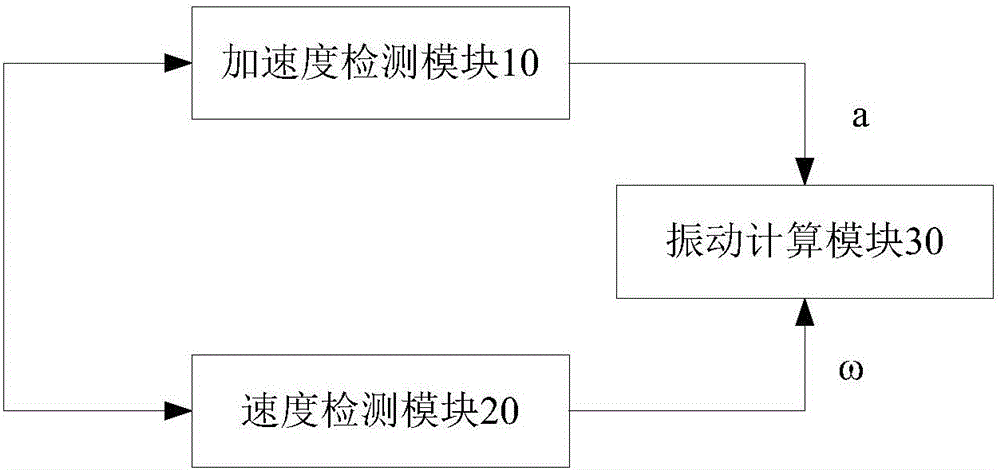

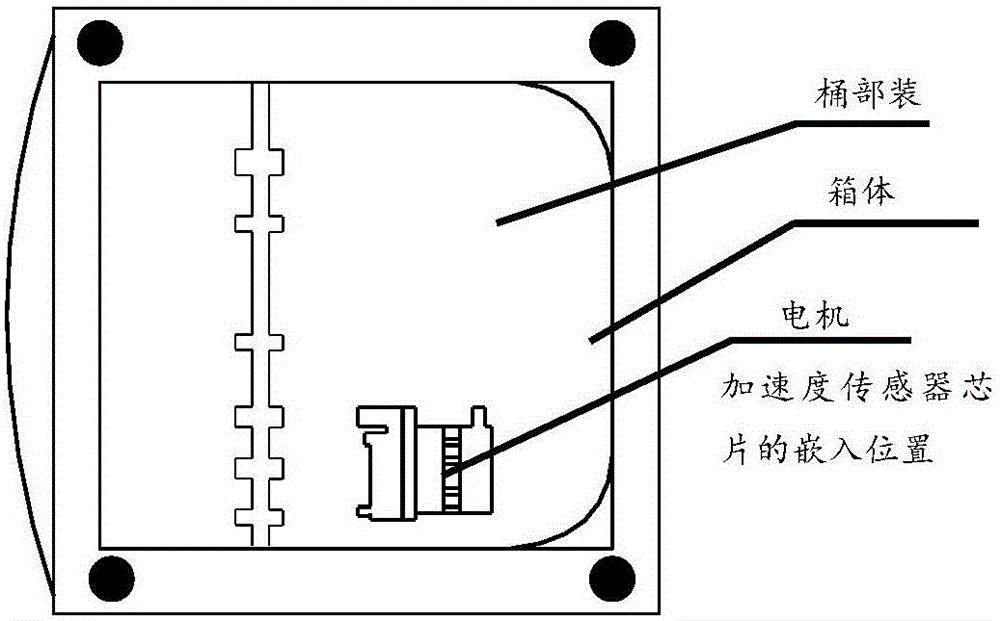

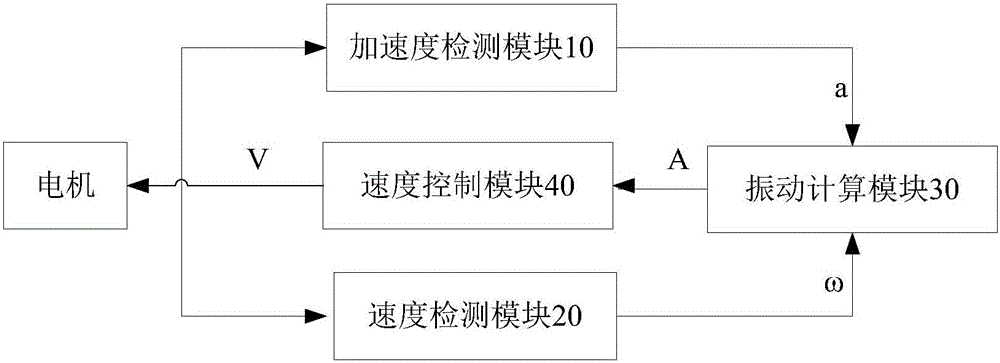

Washing machine and dehydration vibration detecting device and method thereof

InactiveCN105937135AShorten spin timeReduce high speed vibrationOther washing machinesControl devices for washing apparatusVibration accelerationEngineering

The invention discloses a washing machine and a dehydration vibration detecting device and method thereof. The dehydration vibration detecting device comprises an accelerated speed detecting module arranged on a motor of the washing machine and used for detecting the dehydration vibration accelerated speed of the washing machine, a speed detecting module used for detecting the rotating speed of a dehydration tub of the washing machine, and a vibration calculating module. The vibration calculating module is connected with the accelerated speed detecting module and the speed detecting module, used for calculating the vibration displacement of the washing machine according to the vibration accelerated speed and the rotating speed so as to obtain the vibration situation of the washing machine. By means of the device, the vibration displacement of the washing machine can be calculated according to the vibration accelerated speed and the rotating speed of the dehydration tub of the washing machine during dehydration, the vibration situation of the washing machine is obtained, the washing machine selects the next dehydration action according to the vibration situation, and therefore the purposes of shortening dehydration time and reducing high-speed vibration are achieved.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

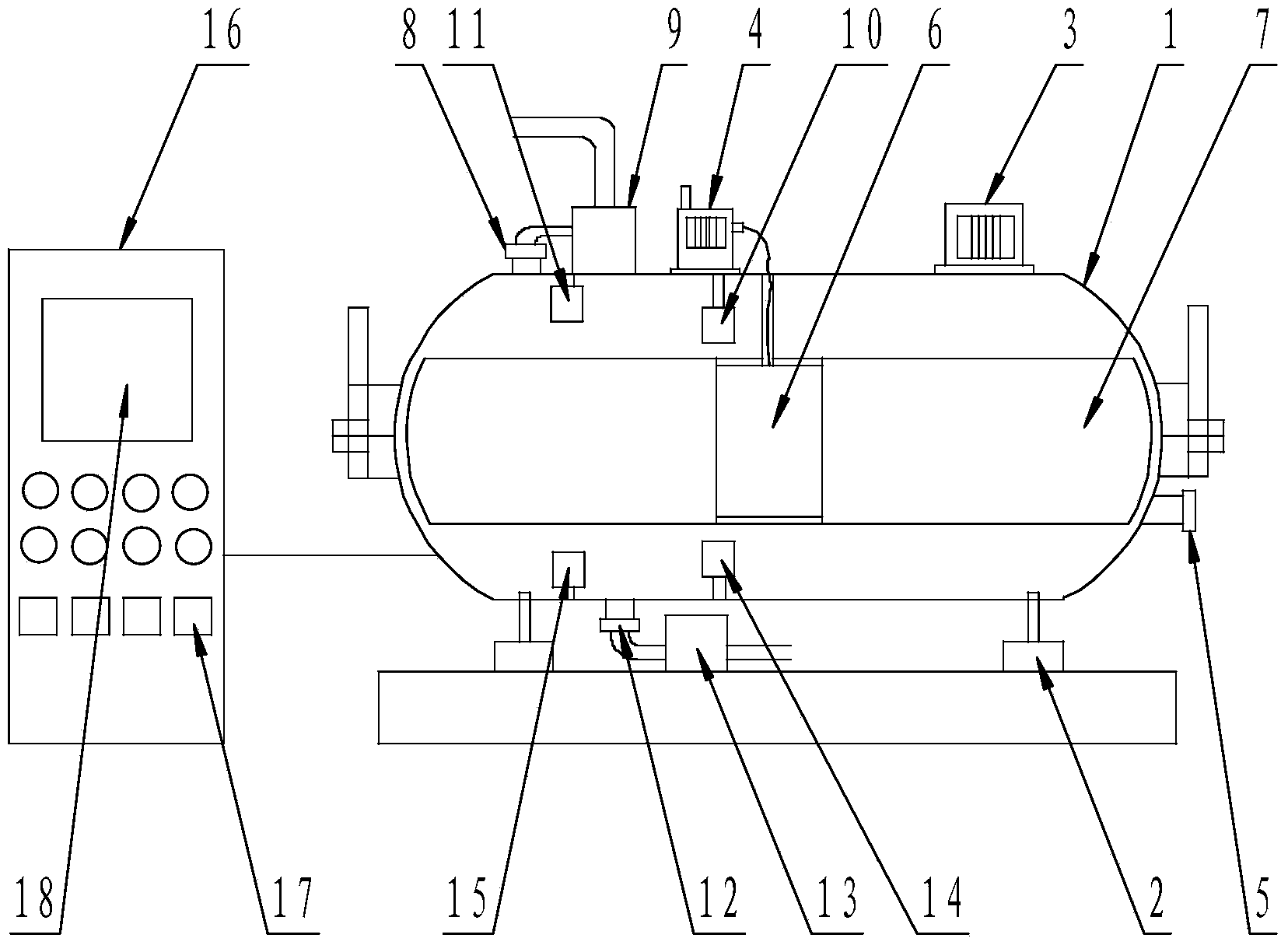

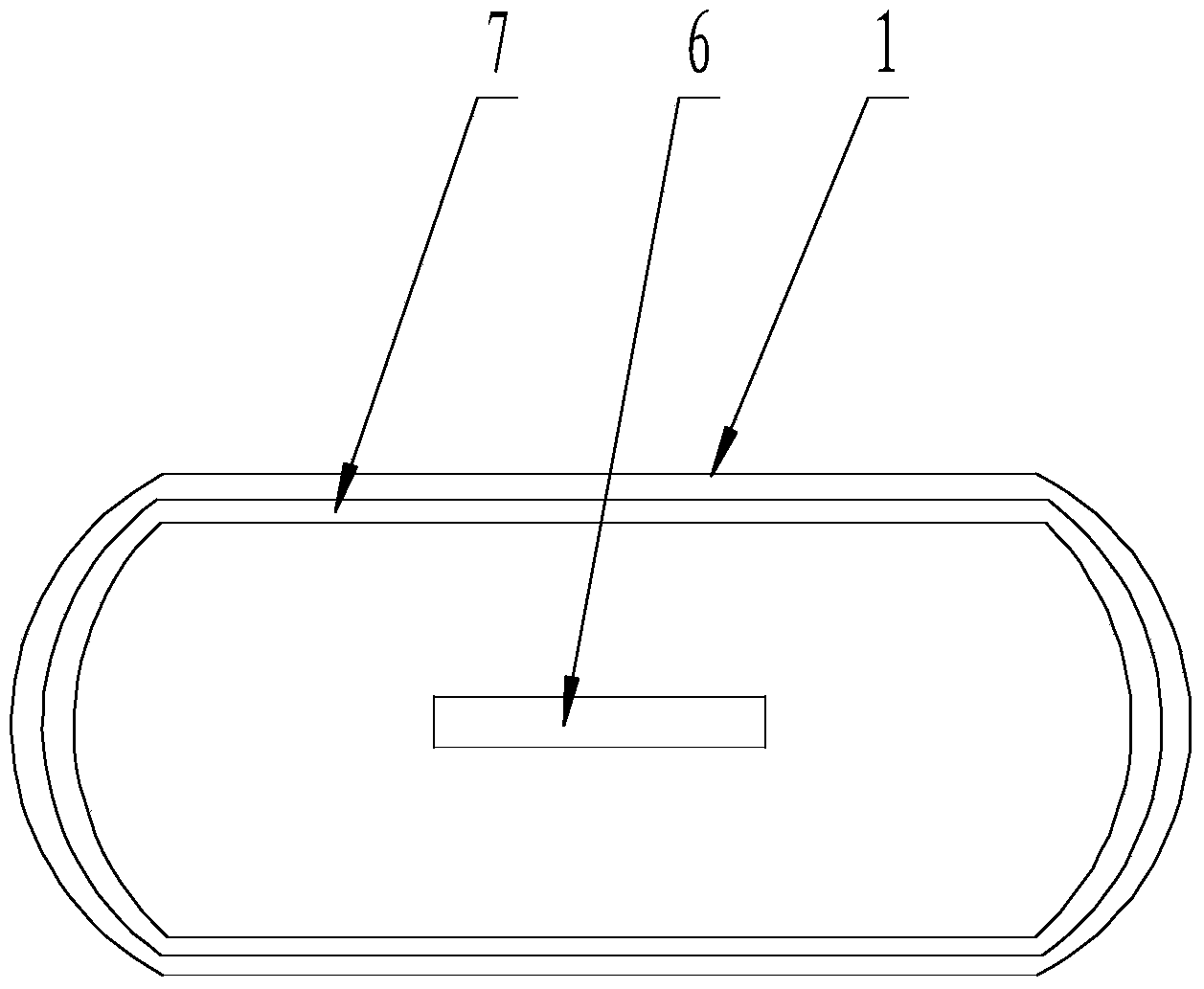

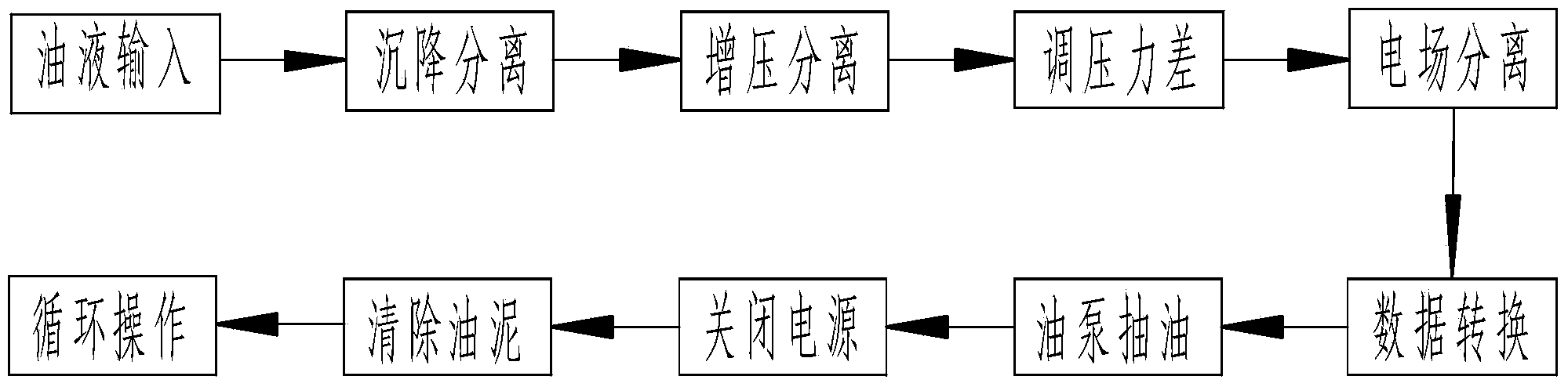

Operation method of electrostatic field oil-water separation system

ActiveCN103446780AShorten spin timeSpatial expansion of the electric fieldLiquid separation by electricityTransformerField separation

The invention relates to an operation method of an electrostatic field oil-water separation system. The electrostatic field oil-water separation system comprises an oil-water separation tank, a support, a press machine, a transformer, a degassed oil input port, an anode electrode plate, an annular cathode electrode plate, an oil outlet, an oil pumping pump, an upper pressure sensor, an upper dielectric constant sensor, an oil mud outlet, an oil mud pumping pump, a lower pressure sensor, a lower dielectric constant sensor, a control cabinet, an adapter module and a central computer. The operation method of the electrostatic field oil-water separation system has the advantages that the problems that crude oil dehydration rate is low, massive oil is contained in discharged water and energy consumption is high are solved, so that space of an electrostatic field is expanded, dehydration time of crude oil in the electrostatic field is shortened, dehydration efficiency is effectively improved, operation power consumption is reduced, production cost is reduced, energy conservation and environmental protection are achieved, height of an emulsion layer is effectively reduced, oil contained in the discharged water is reduced, sewage treatment cost and environmental protection pressure are reduced, structure is simple, operation is convenient, design thought is simple, an electrostatic field separation effect is good, and the operation method of the electrostatic field oil-water separation system is applicable to popularization and application.

Owner:LUOYANG RUIMING PETROCHEM TECH

Method for preparing tuber pickled vegetables through three-stage air-drying multi-section ultra-high-pressure and positive-negative high-pressure permeation technology

ActiveCN103610005ALow costReduce usageClimate change adaptationUltra high pressure food processesUltra high pressureThree stage

The invention discloses a method for preparing tuber pickled vegetables through a three-stage air-drying multi-section ultra-high-pressure and positive-negative high-pressure permeation technology. The method comprises the following steps: performing three-stage air-drying on tuber vegetables; storing dehydrated tuber vegetables in a freezer of -18 DEG C for 10-12 months; during production, performing repeated permeation on the frozen tuber vegetables and a pickled vegetable fermenting solution under the positive-negative high-pressure condition, and performing permeation under the multi-section ultra-high-pressure condition to obtain the tuber pickled vegetables. According to the method, the usage amount of salt is reduced, the dehydrating time is greatly shortened, and the storage time of the dehydrated vegetables is prolonged.

Owner:XIHUA UNIV

Preparation method of electronic grade hydrogenated pyromellitic dianhydride

The invention discloses a preparation method of electronic grade hydrogenated pyromellitic dianhydride. The method comprises the following steps: adding commercially available pyromellitic dianhydride with the purity greater than or equal to 98.0%, deionized water and a noble metal catalyst into an autoclave; feeding hydrogen into the autoclave and simultaneously carrying out a hydrolysis reaction and a catalytic hydrogenation reaction; carrying out aftertreatment after the reactions so as to obtain crude hydrogenated pyromellitic dianhydride; decoloring and refining crude hydrogenated pyromellitic dianhydride with deionized water and activated carbon so as to obtain hydrogenated pyromellitic dianhydride with the purity greater than or equal to 99.5%; finally, carrying out a dehydration reaction on hydrogenated pyromellitic dianhydride by using acetic anhydride so as to obtain electronic grade hydrogenated pyromellitic dianhydride with the purity greater than or equal to 99.85%. According to the method, the purity of prepared hydrogenated pyromellitic dianhydride can reach above 99.85%, and the content of single metal ions (such as sodium, potassium, calcium, iron, copper, aluminum and the like) in prepared hydrogenated pyromellitic dianhydride is respectively less than 1ppm. Thus, electronic grade hydrogenated pyromellitic dianhydride can be widely applied to the field of photoelectronics, micro-electronics and other high and new technologies.

Owner:CHANGZHOU SUNLIGHT PHARMA

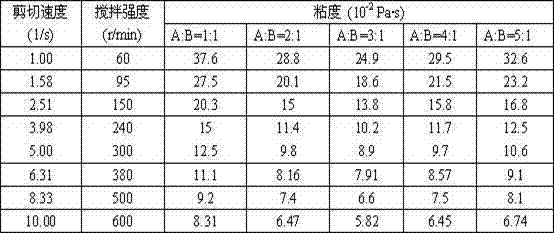

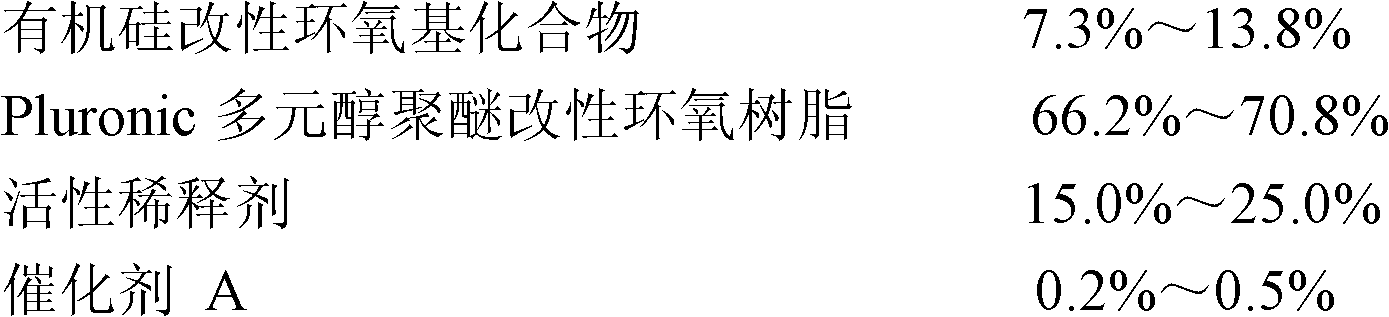

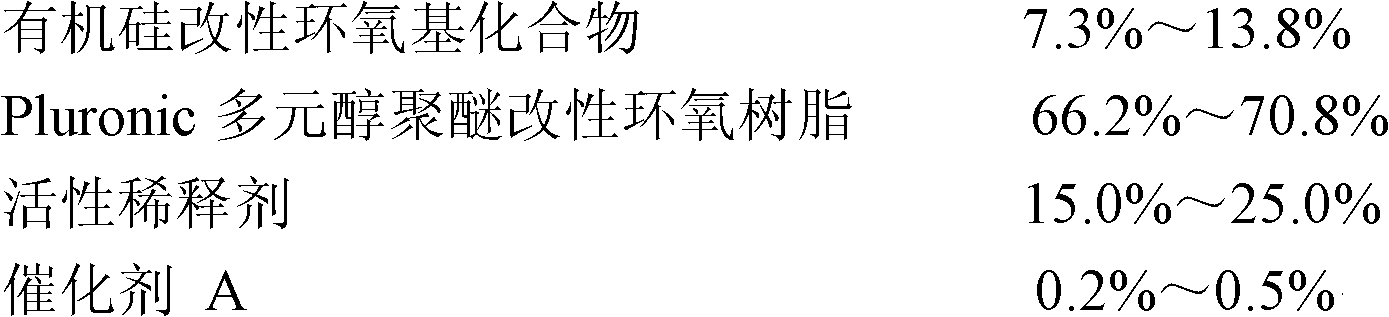

Solvent-free epoxy resin as plugging material, and preparation method and application of the solvent-free epoxy resin

The invention discloses a solvent-free epoxy resin as a plugging material and a preparation method and application of the solvent-free epoxy resin. The material is prepared from part A and part B at a ratio of 4:1 to 20:1 by weight, wherein the part A contains the following components by weight: 7.3-13.8% of organic silicon modified epoxy compound, 66.2-70.8% of Pluronic polyol polyether-modified epoxy resin, 15.0-25.0% of a reactive diluent, and 0.2-0.5% of a catalyst A, and part B contains the following components by weight: 99.0-99.7% of modified phenolic amine, 0.2-0.5% of a silicane coupling agent and 0.1-0.5% a catalyst B. According to the invention, reaction between benzyl glycidyl ether and hydroxyl silicone oil is utilized, so that the molecular weight of the reaction product is reduced, the viscosity is reduced, and the surface tension of the product is small for plugging effect. In addition, reaction between Pluronic polyol polyether and epoxy resin is adopted to improve the elasticity of a consolidating body and increase the surface activity of the system for water repelling effect. The solvent-free epoxy resin as the plugging material can be applied to engineering parts with visible water.

Owner:GUANGZHOU CHEM GROUTING CO LTD CAS

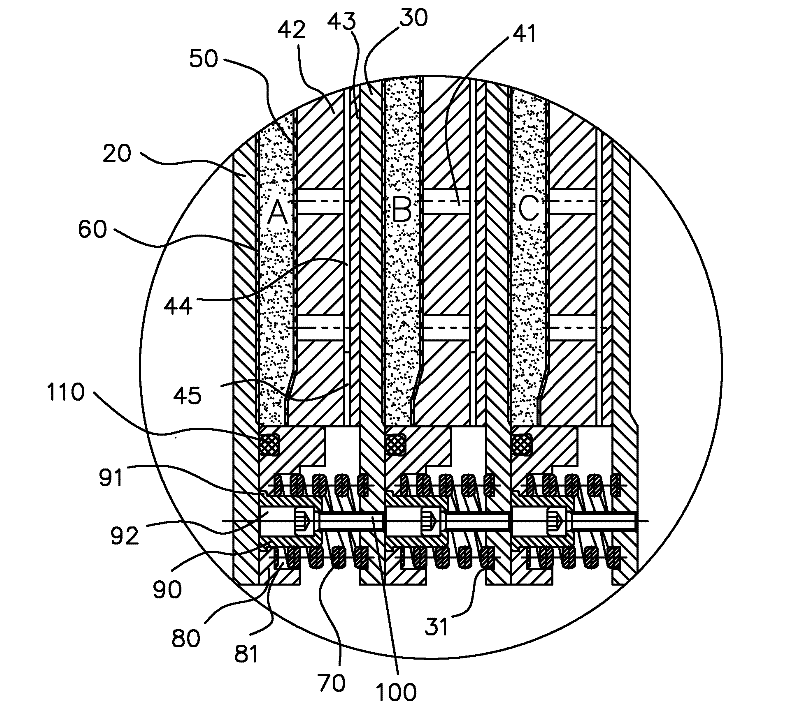

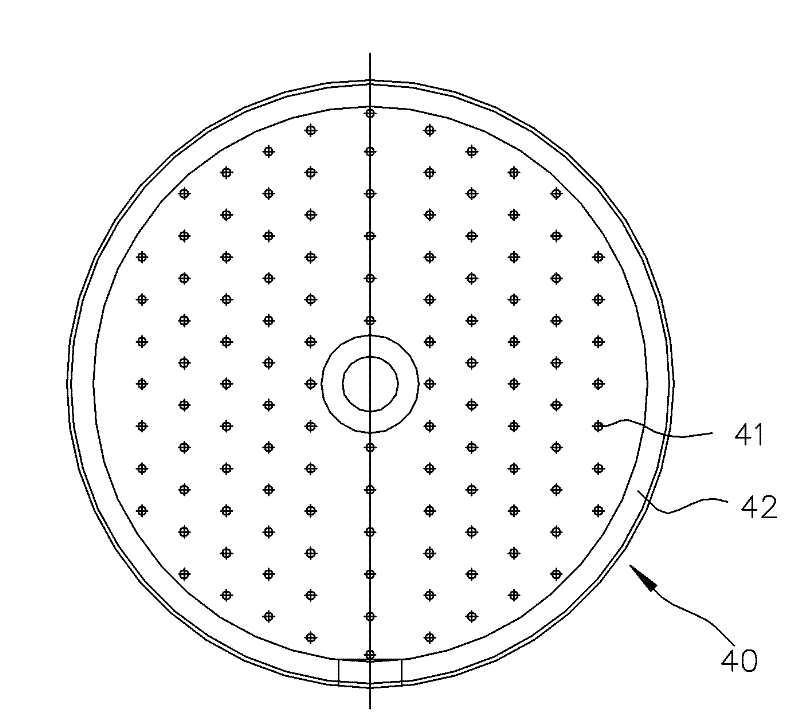

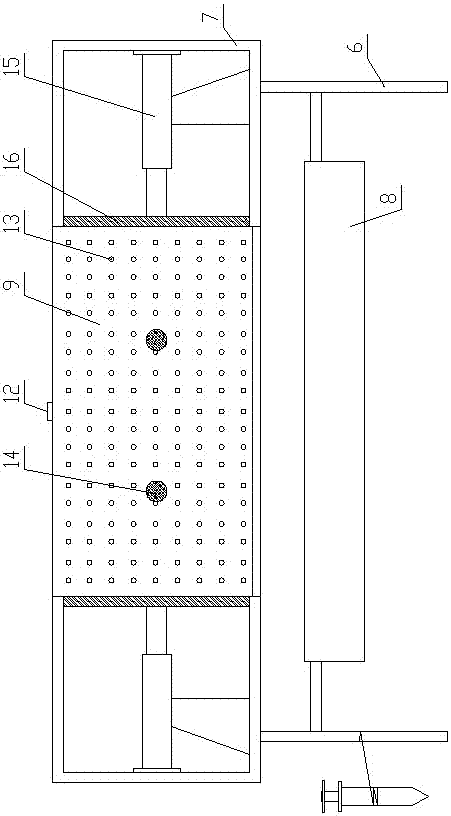

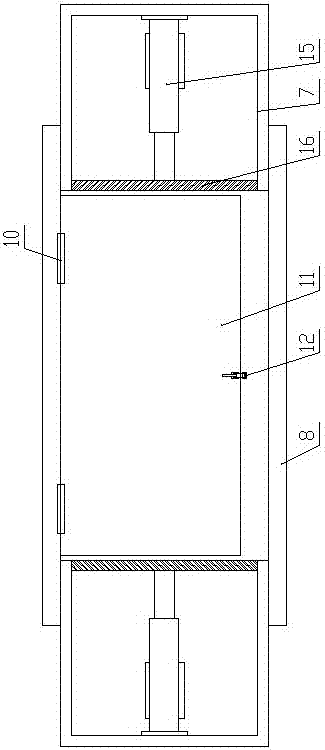

Transfer-electron type electroosmosis-advanced oxidation sludge dewatering system and dewatering method thereof

ActiveCN106904803AReduce moisture contentImprove uniformitySludge treatment by oxidationWater/sewage treatment apparatusConvertersProcess engineering

A transfer-electron type electroosmosis-advanced oxidation sludge dewatering system and a dewatering method thereof are disclosed. The system of the invention comprises a power supply, a positive and negative convertor and an underframe. A mounting rack is arranged above the underframe. An electroosmosis liquid collecting bin which is positioned below the mounting rack is installed on the underframe. A rectangular electroosmosis reactor is installed on the mounting rack. The mounting rack is connected to a dosing injection device through a rope. The length direction of the electroosmosis reactor is the horizontal direction. Width and length of the electroosmosis liquid collecting bin are both greater than width and length of the electroosmosis reactor. The left side and right side of the electroosmosis reactor are both opened. The top of the electroosmosis reactor is provided with a sludge opening, the rear side of which is hinged to a cover plate through a hinge. The front side of the cover plate is connected to the top wall of the electroosmosis reactor through a buckle. In conclusion, sludge is dewatered through combination of electroosmosis and advanced oxidation without addition of lots of advanced oxidizing agents, heavy metal pollution will not be caused due to excessive corrosion of a plate electrode, and the technological process is simple.

Owner:HENAN INST OF ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com