Patents

Literature

83results about How to "Short discharge time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

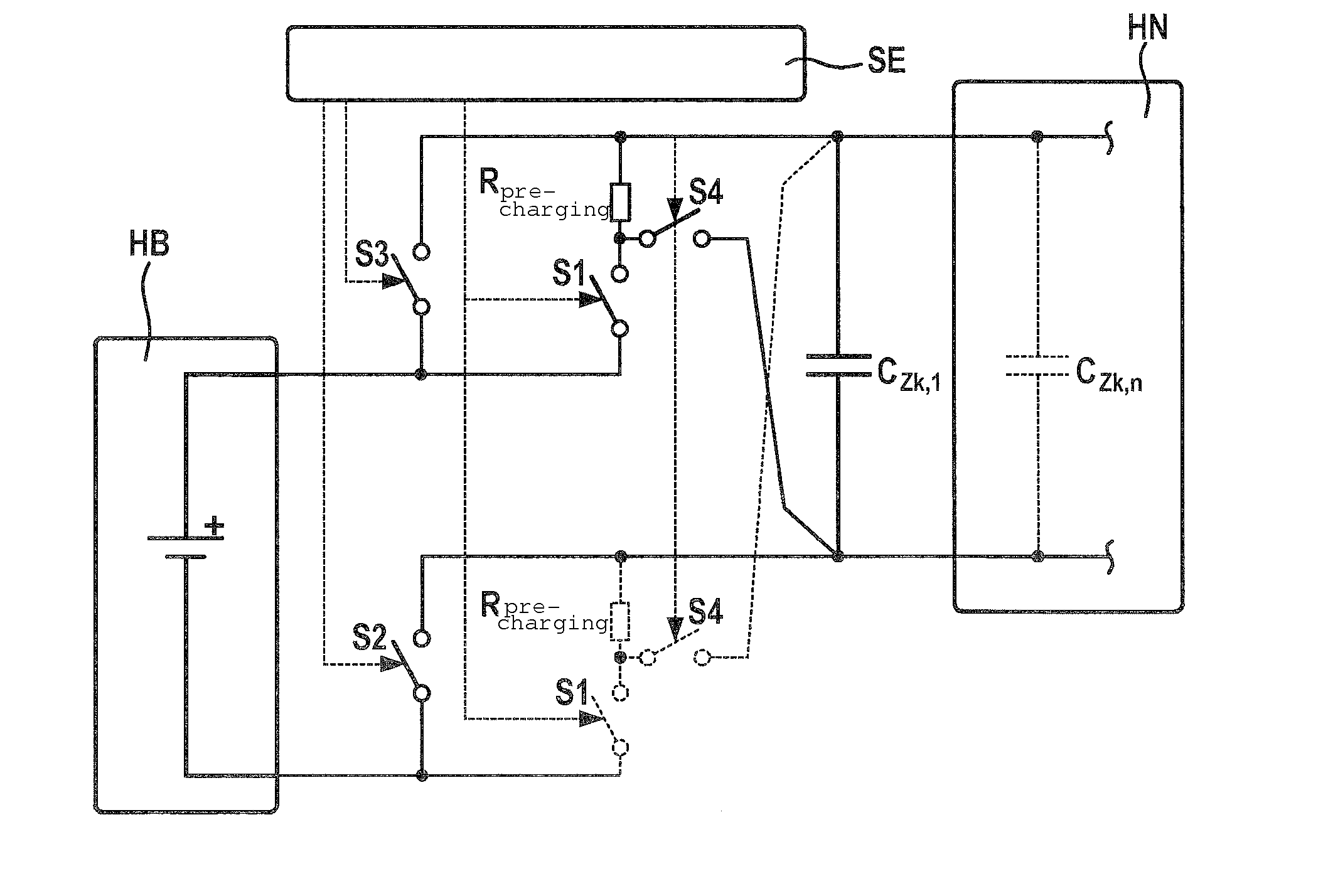

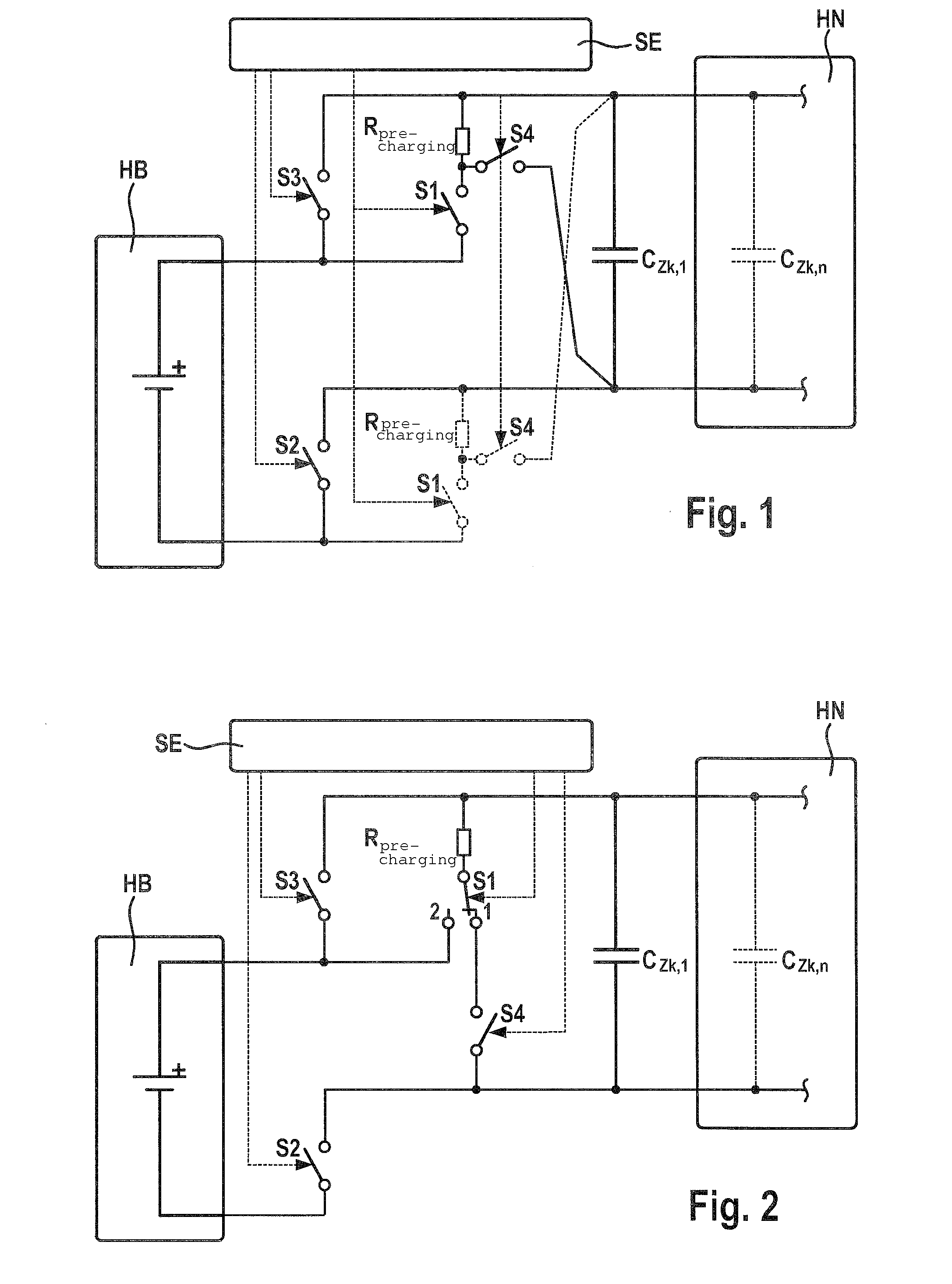

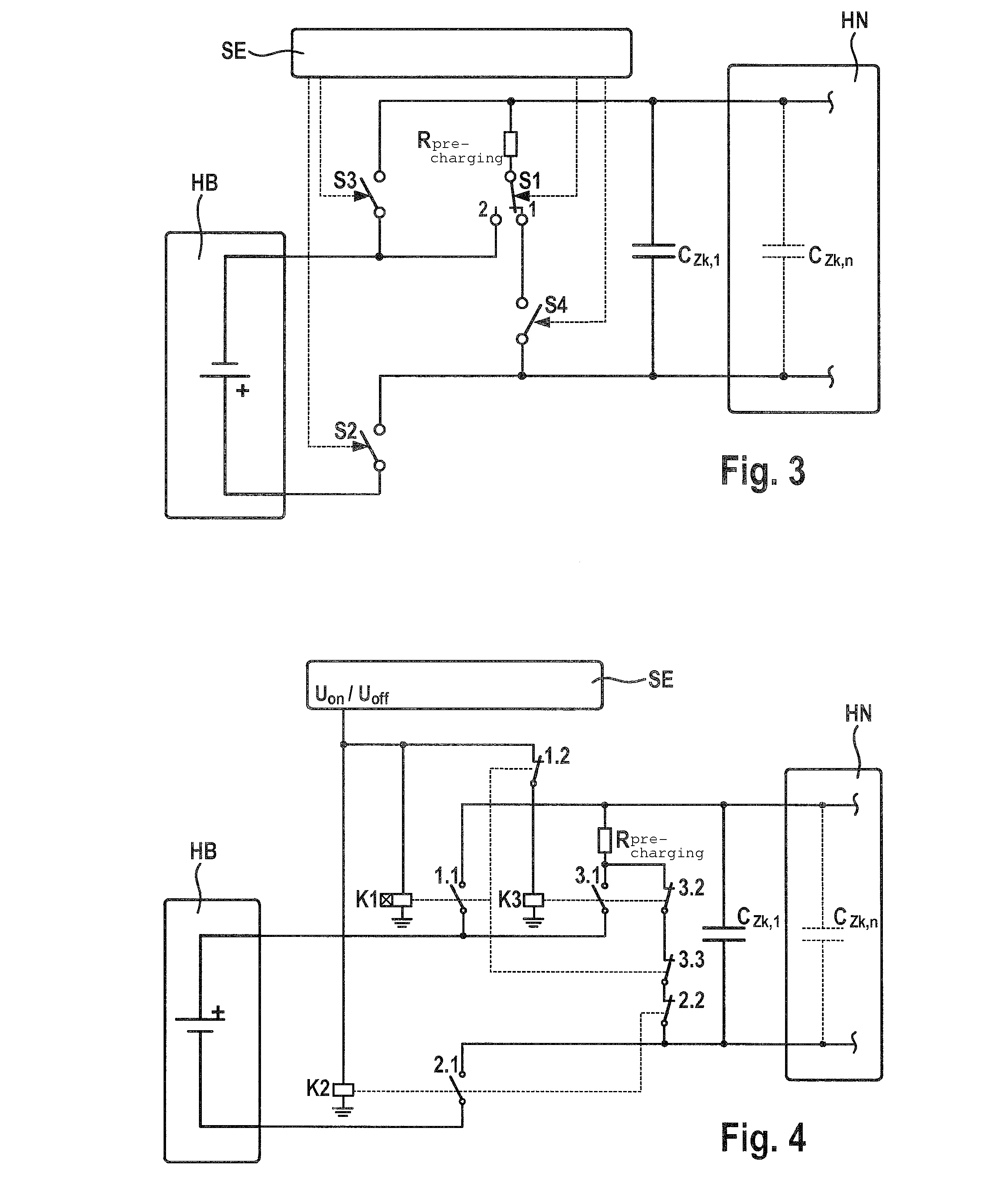

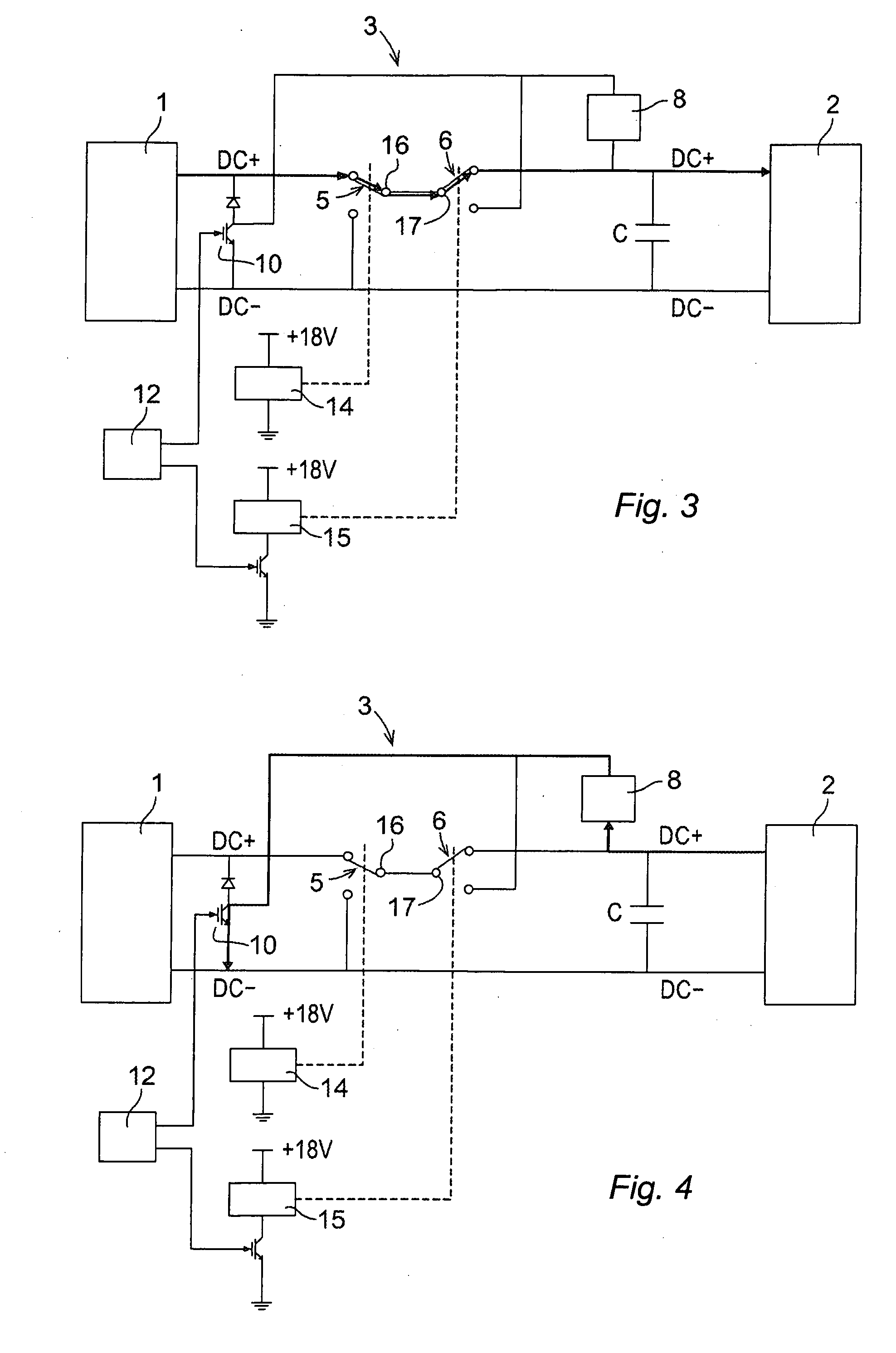

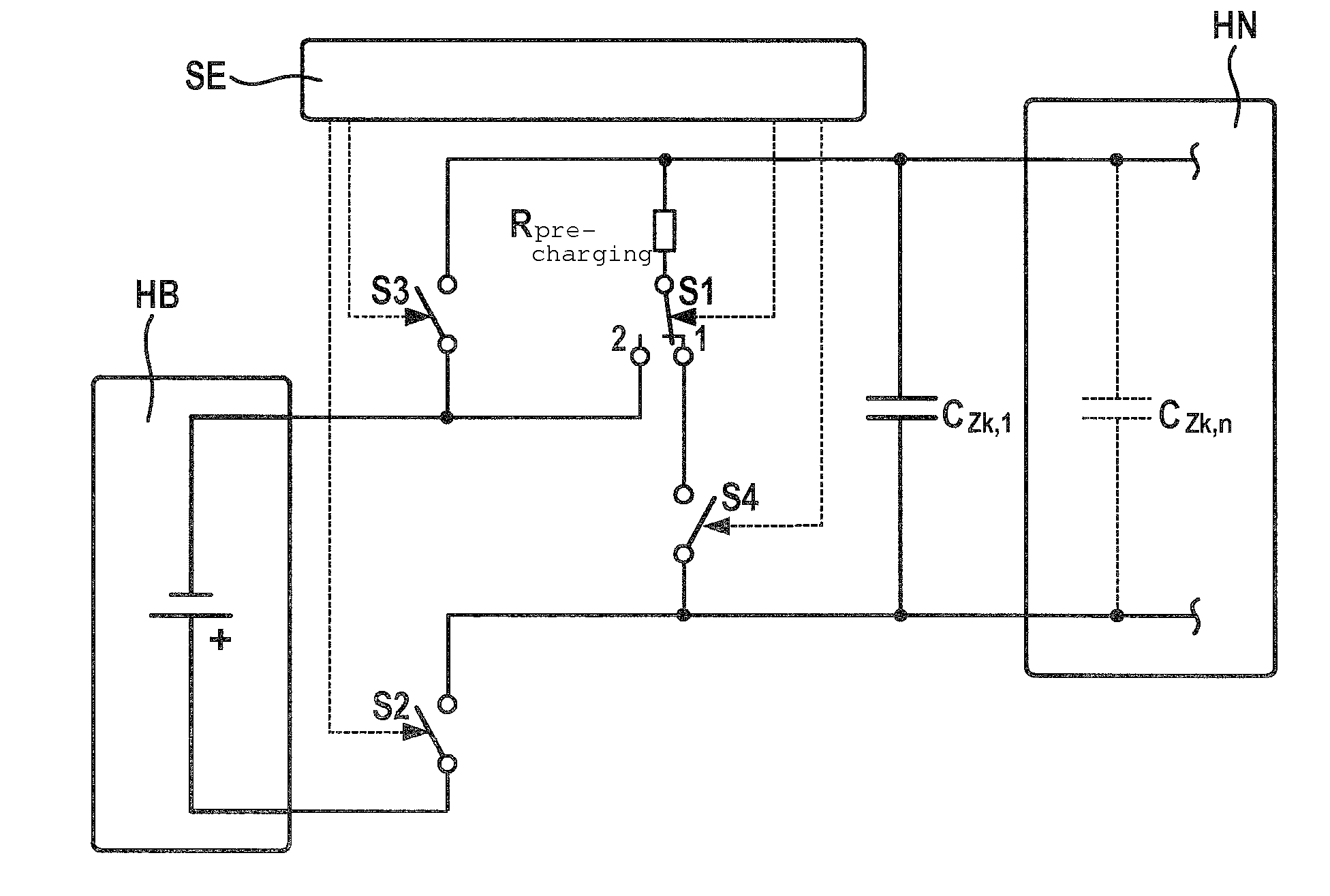

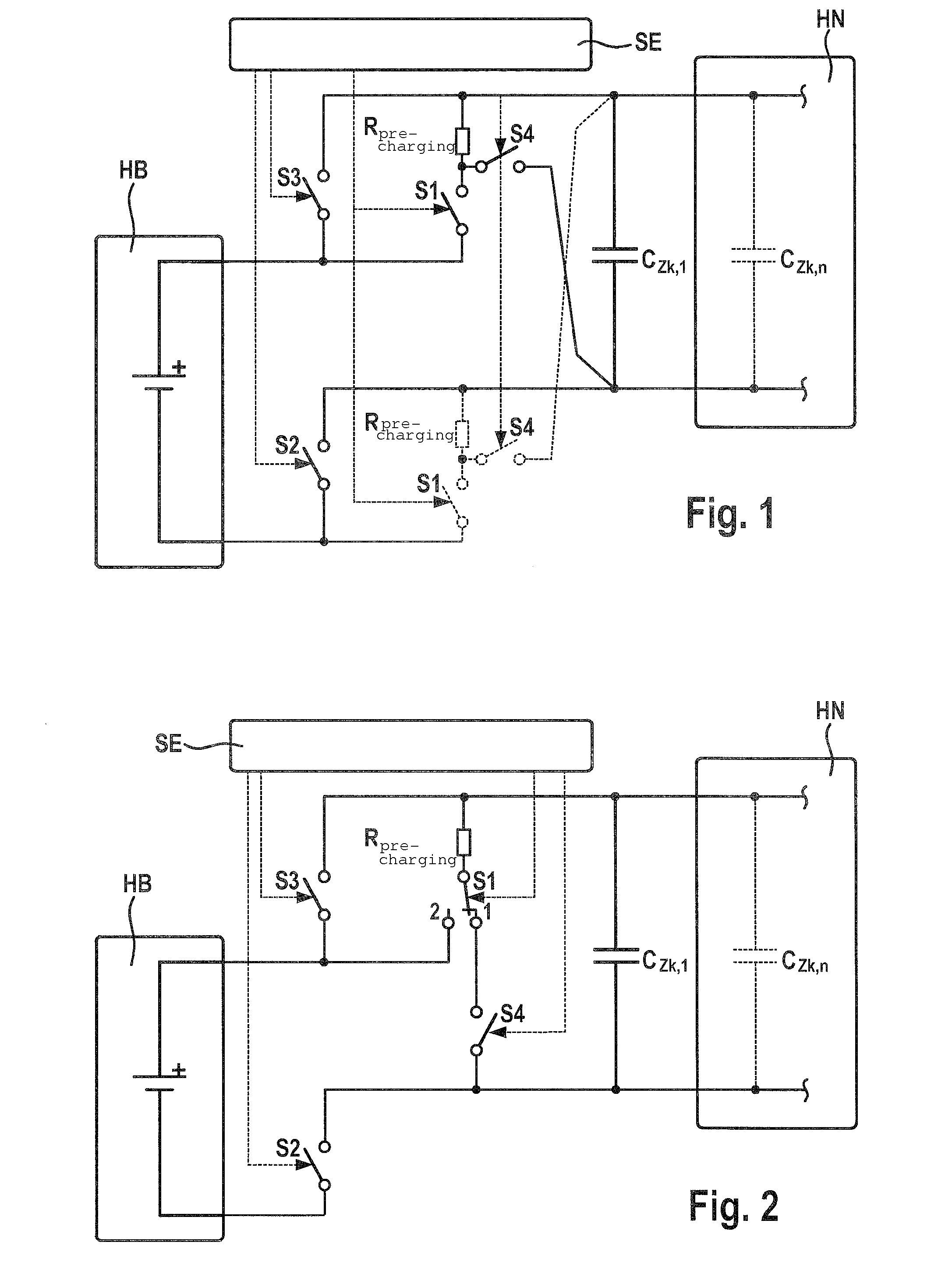

Method and Device for Limiting the Starting Current and for Discharging the DC Voltage Intermediate Circuit

ActiveUS20110006726A1Saving and reducing installation spaceSimple and cost-effective meanHybrid vehiclesBatteries circuit arrangementsContactorCharge and discharge

Methods and associated devices are described for discharging the high-voltage network, particularly a DC voltage intermediate circuit, in which for discharging the capacitors of the high-voltage network, switching devices are used that lie between the capacitors and at least one precharging resistor and a high-voltage battery, and the switching devices are switches having a specifiable positioning of the switching contacts or switching units or relays or contactors, which are switchable with the aid of a control device. The operation of the switching units takes place in such a way that the at least one precharging resistor is used simultaneously for charging and discharging the DC voltage intermediate circuit.

Owner:ROBERT BOSCH GMBH

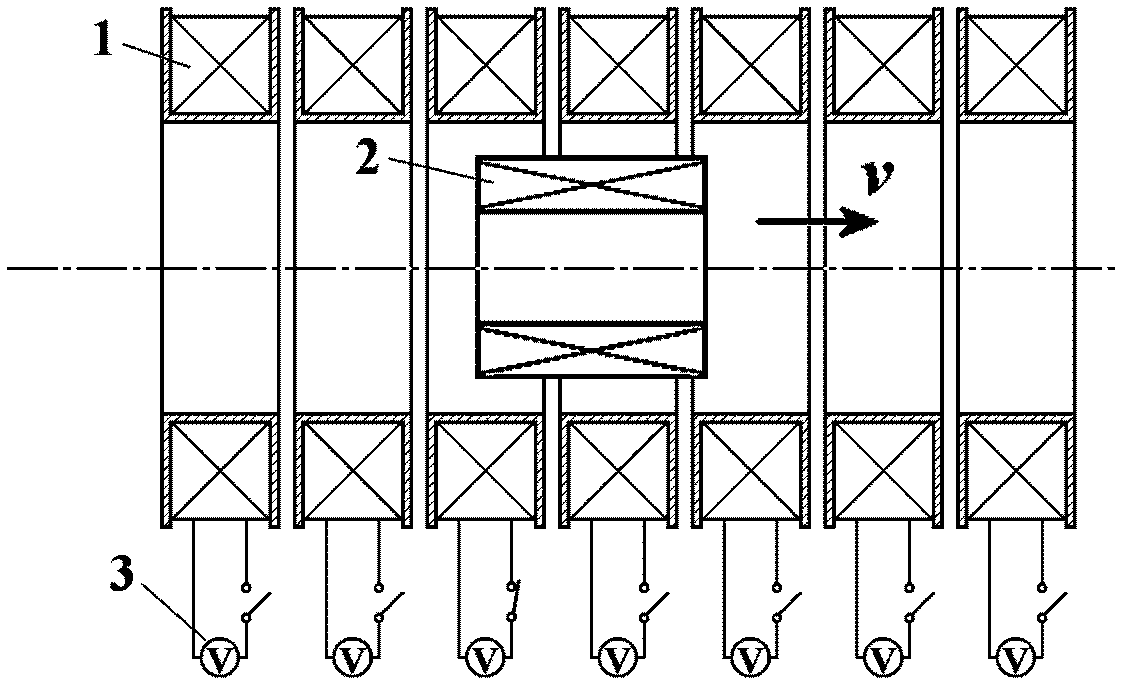

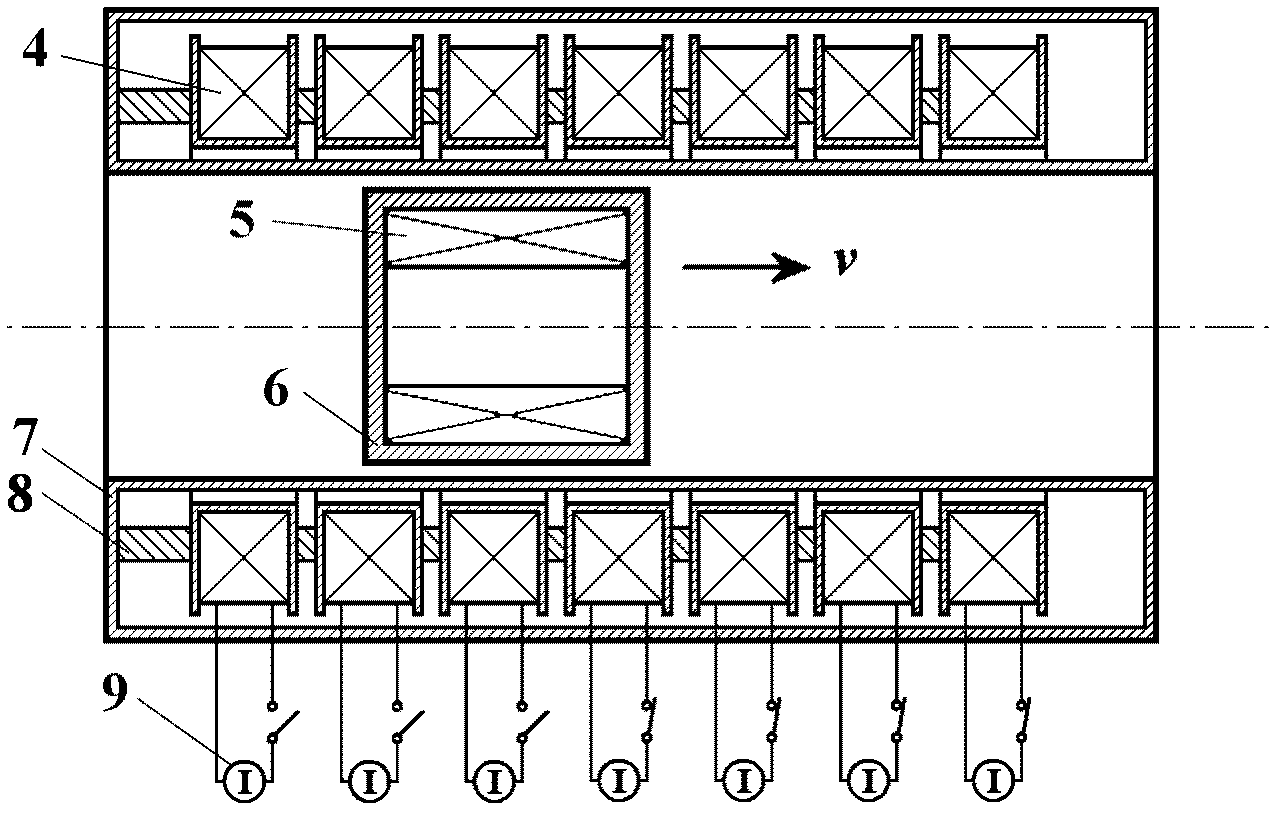

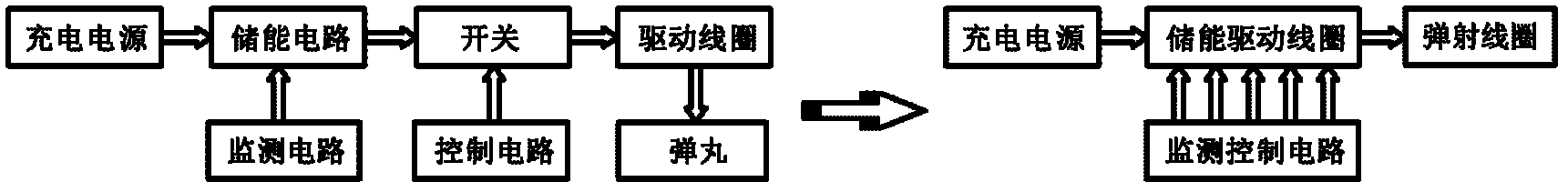

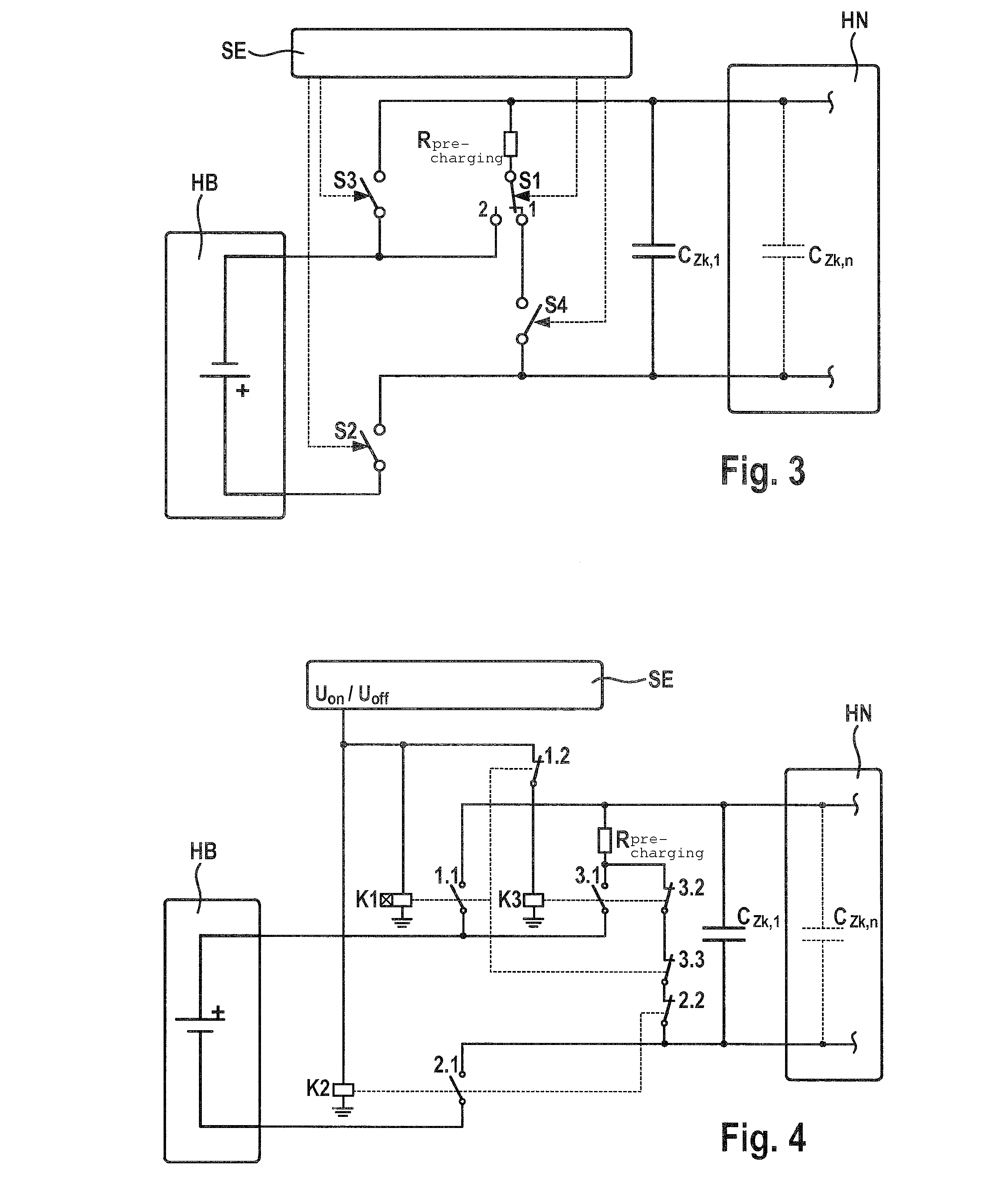

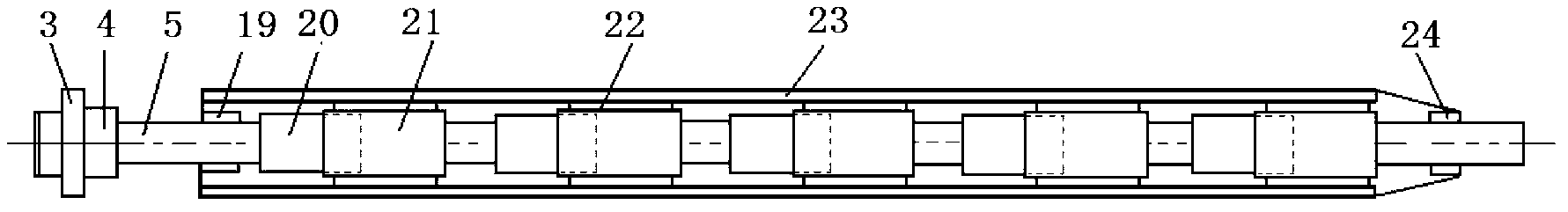

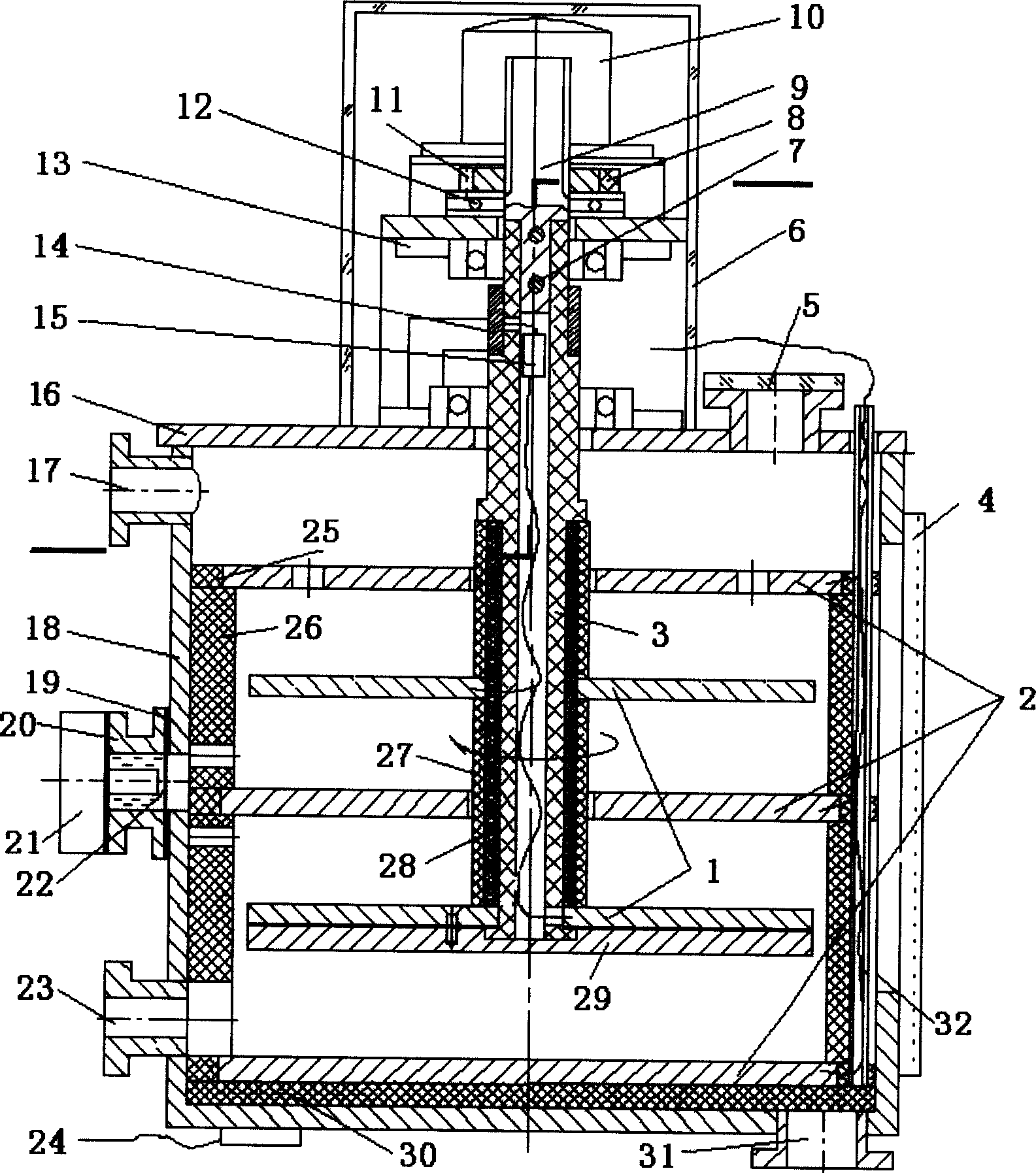

Ejector capable of directly releasing energy by using superconducting magnet

InactiveCN102320380AEnhanced magnetic forceImprove utilization efficiencyLaunching/towing gearSuperconducting CoilsEngineering

The invention provides an ejector capable of directly releasing energy by using a superconducting magnet, belonging to the field of a superconducting technology. The ejector comprises a low-temperature container shell, superconducting drive coils, an armature, a superconducting power supply, a supporting frame and an armature low-temperature container; the low-temperature container shell is a hollow and sealed container and multiple levels of superconducting drive coils are installed on the inner wall of the low-temperature container shell; and the ejection coil is distributed on the axis in a pipeline which is composed of the superconducting drive coils and the low-temperature container shell. The armature can flexibly move on the axis; each level of the superconducting drive coil is equipped with one superconducting power supply or several levels of the superconducting drive coils are equipped with one power supply. The ejector capable of directly releasing energy by using the superconducting magnet has the advantages that: the superconducting energy storage property is directly utilized and the superconducting power supply with smaller power can be used for charging a magnetic field to the superconducting drive coils, so that the electromagnetic drive force is stronger than that of the traditional design scheme which utilizes an impulse power supply to charge the fixed drive coil and is repelled with the armature. In the invention, the conversion process of the energy is simplified and the utilization efficiency of the energy is improved.

Owner:吴春俐

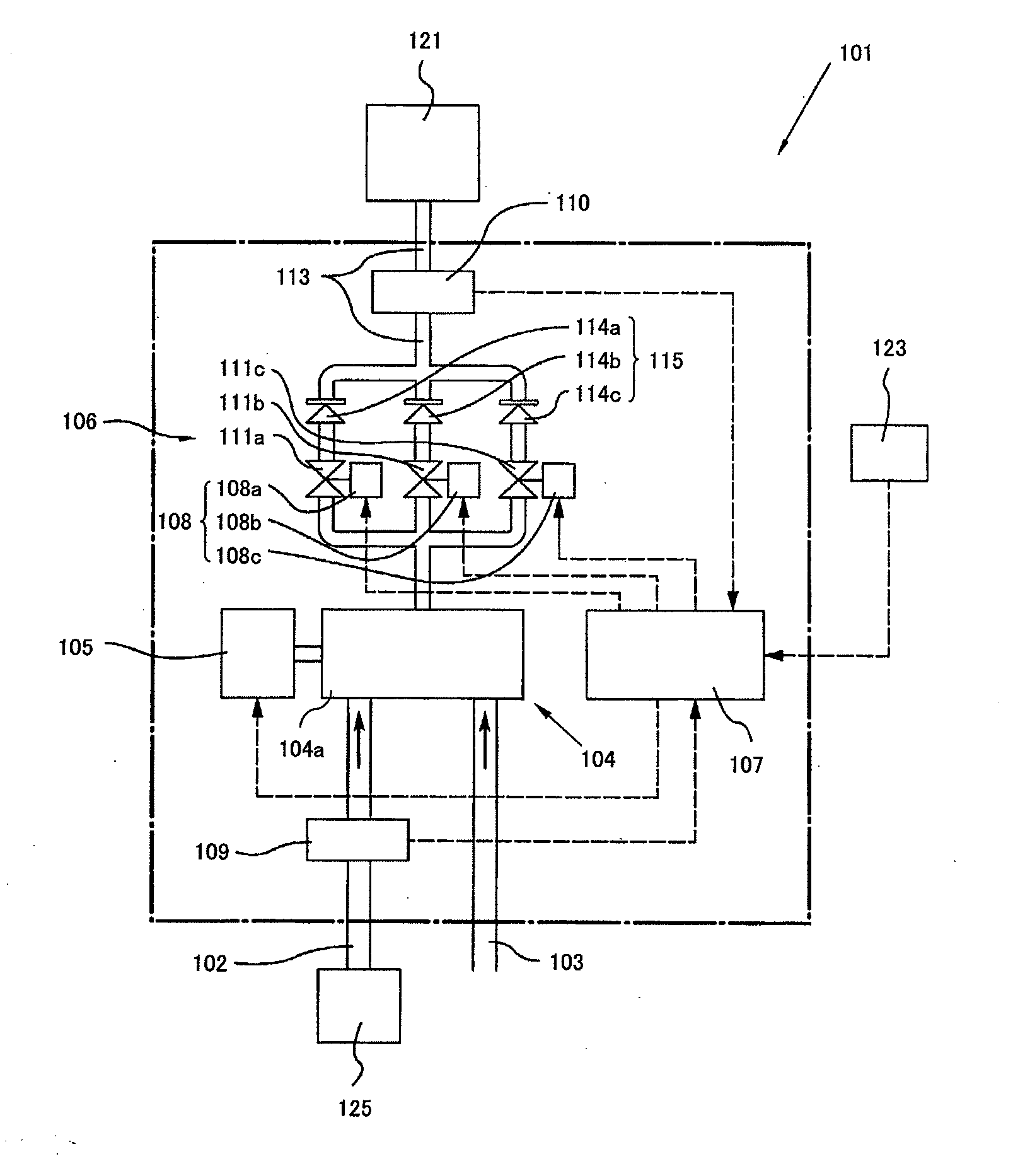

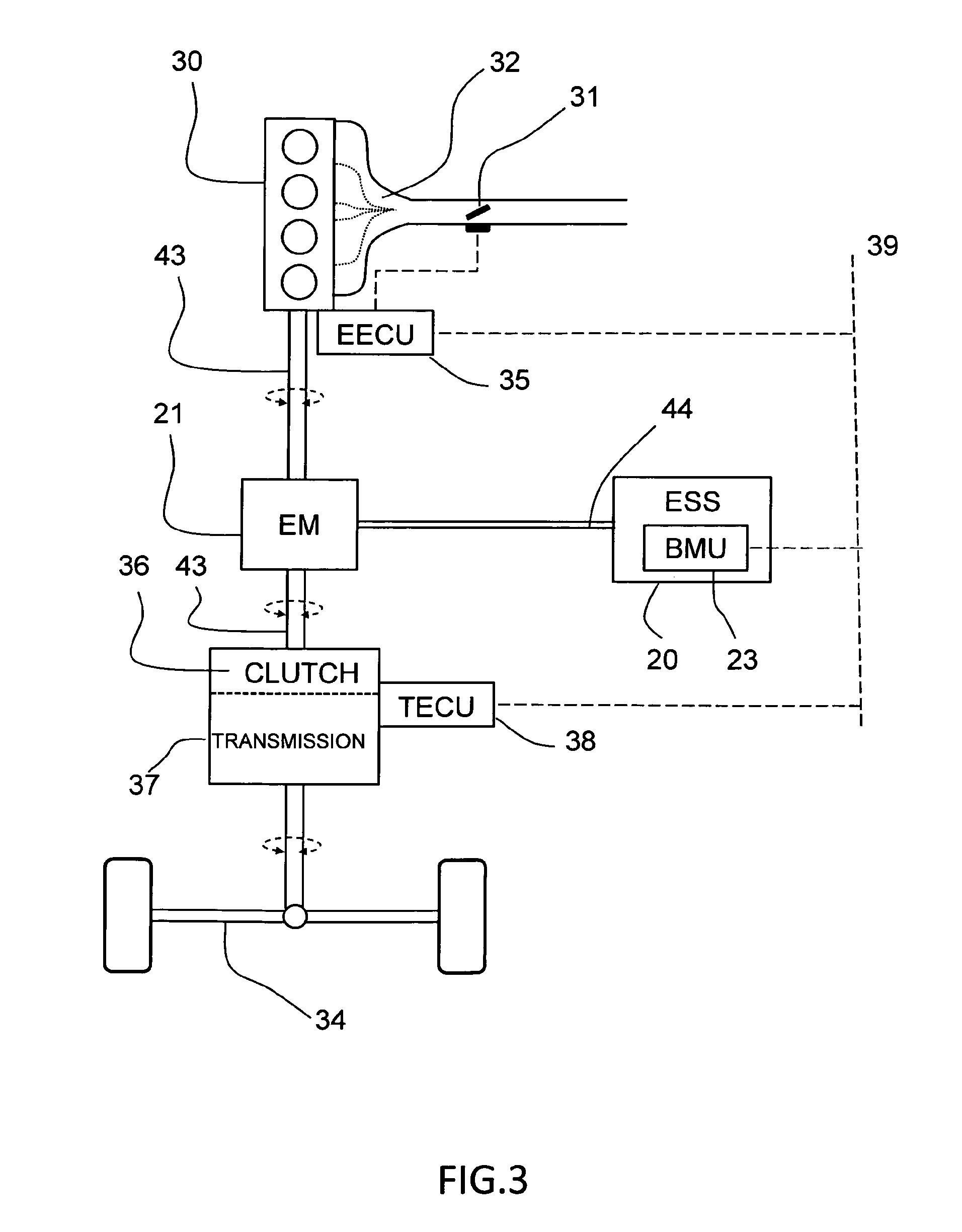

Drive unit

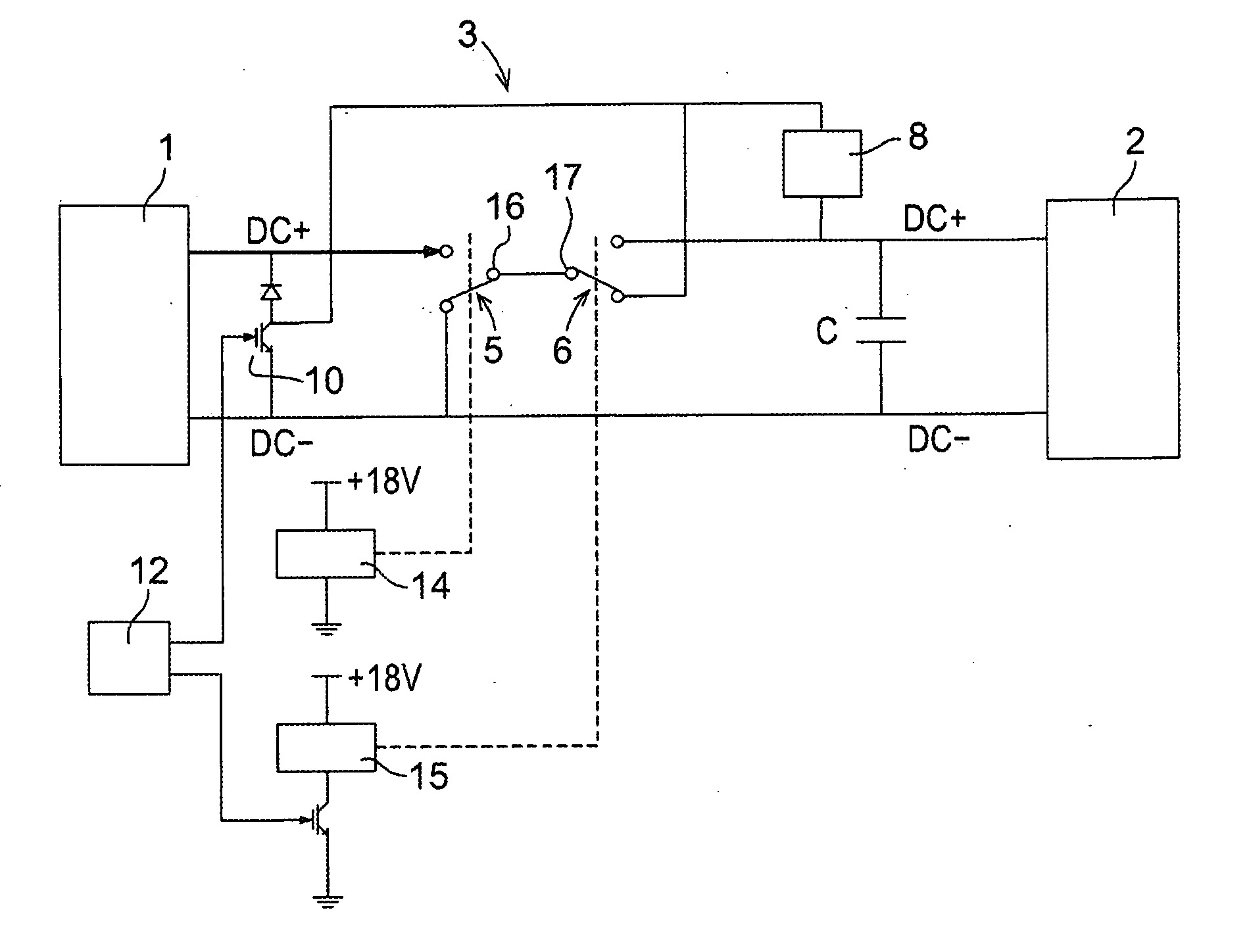

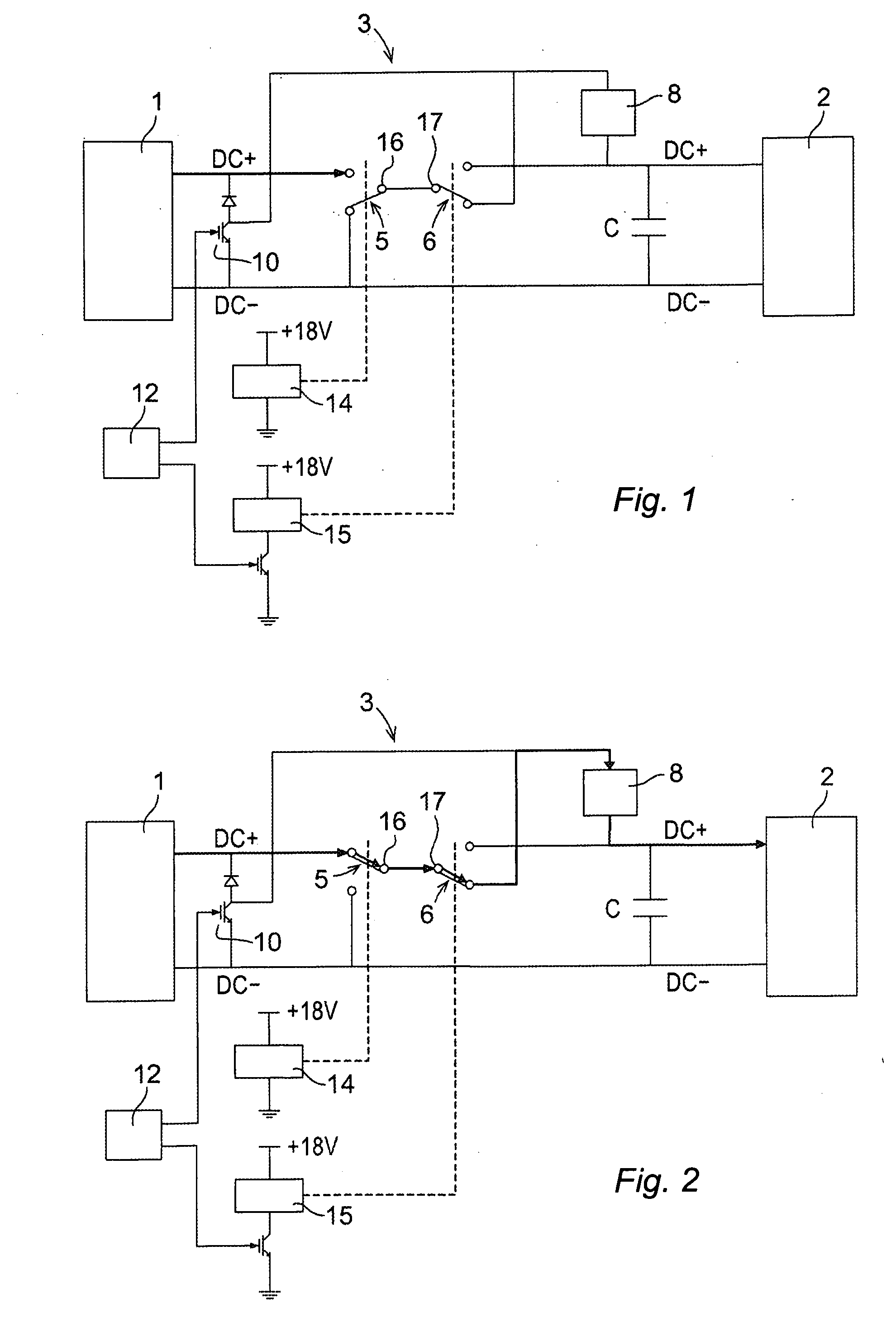

ActiveUS20110127935A1Low costSize savingElectronic commutation motor controlMotor/generator/converter stoppersPower inverterControl power

The present invention relates to a drive unit for at least one electric motor. The drive unit comprises: a control power supply (+18V) for supplying the drive unit with control power, a power source (1) producing direct current to one or more inverters (2), at least one inverter producing current to the motor, an energy storage (C) arranged at the output of the power source for smoothing direct current and storing energy recovered during braking of the motor, and a discharge circuit (8,10) for discharging the energy stored in said energy storage, wherein the discharge circuit includes a power resistor (8) arranged to discharge the energy stored in the energy storage. The drive unit further comprises a first and a second switch (5,6) arranged between the power source and the energy storage, and the switches are arranged such that they are in default positions when there is no control power in the drive unit, and the drive unit is arranged such that the power source is disconnected from the motor and the energy storage is discharged via said power resistor when the switches are in their default positions.

Owner:ABB (SCHWEIZ) AG

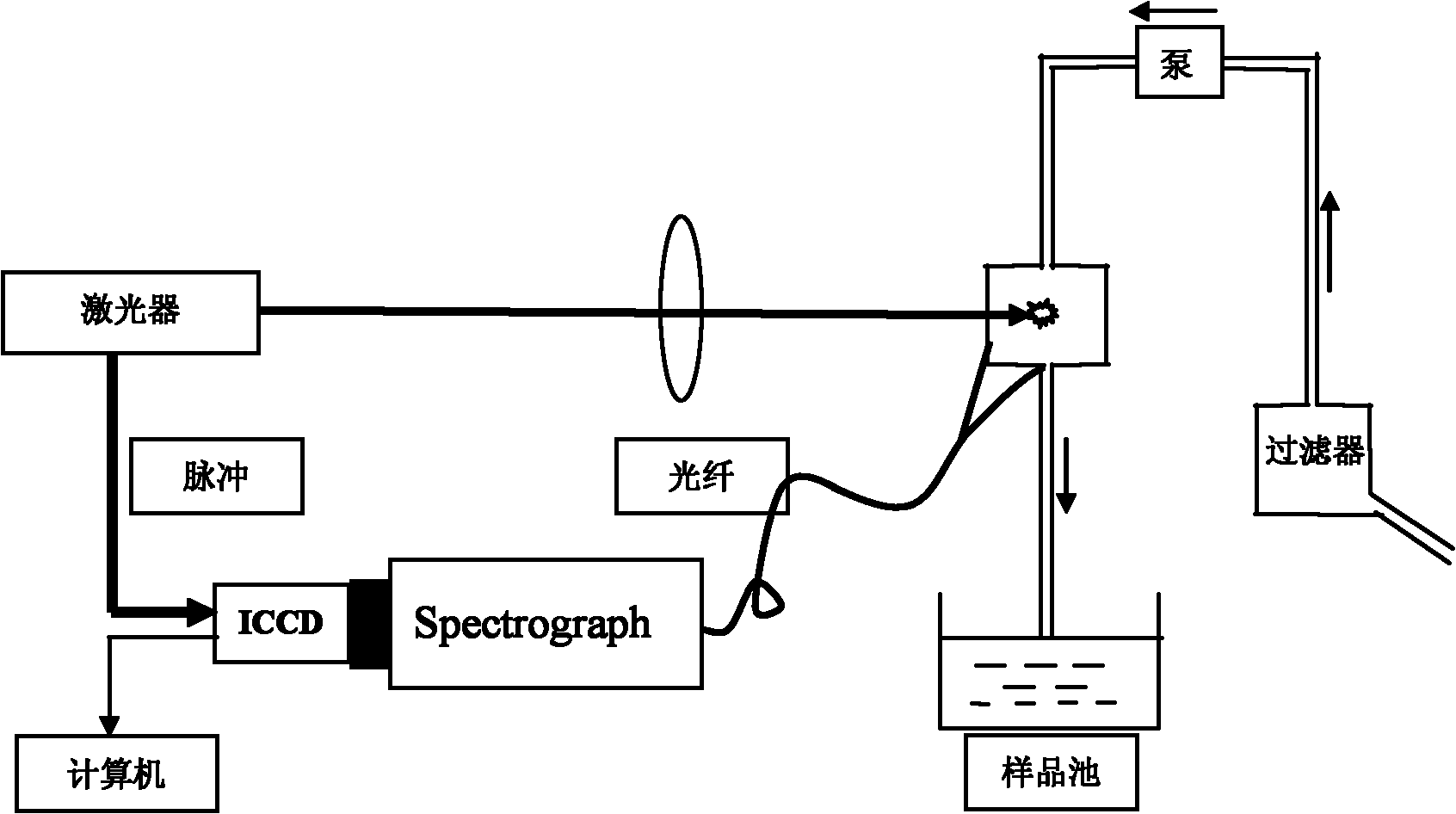

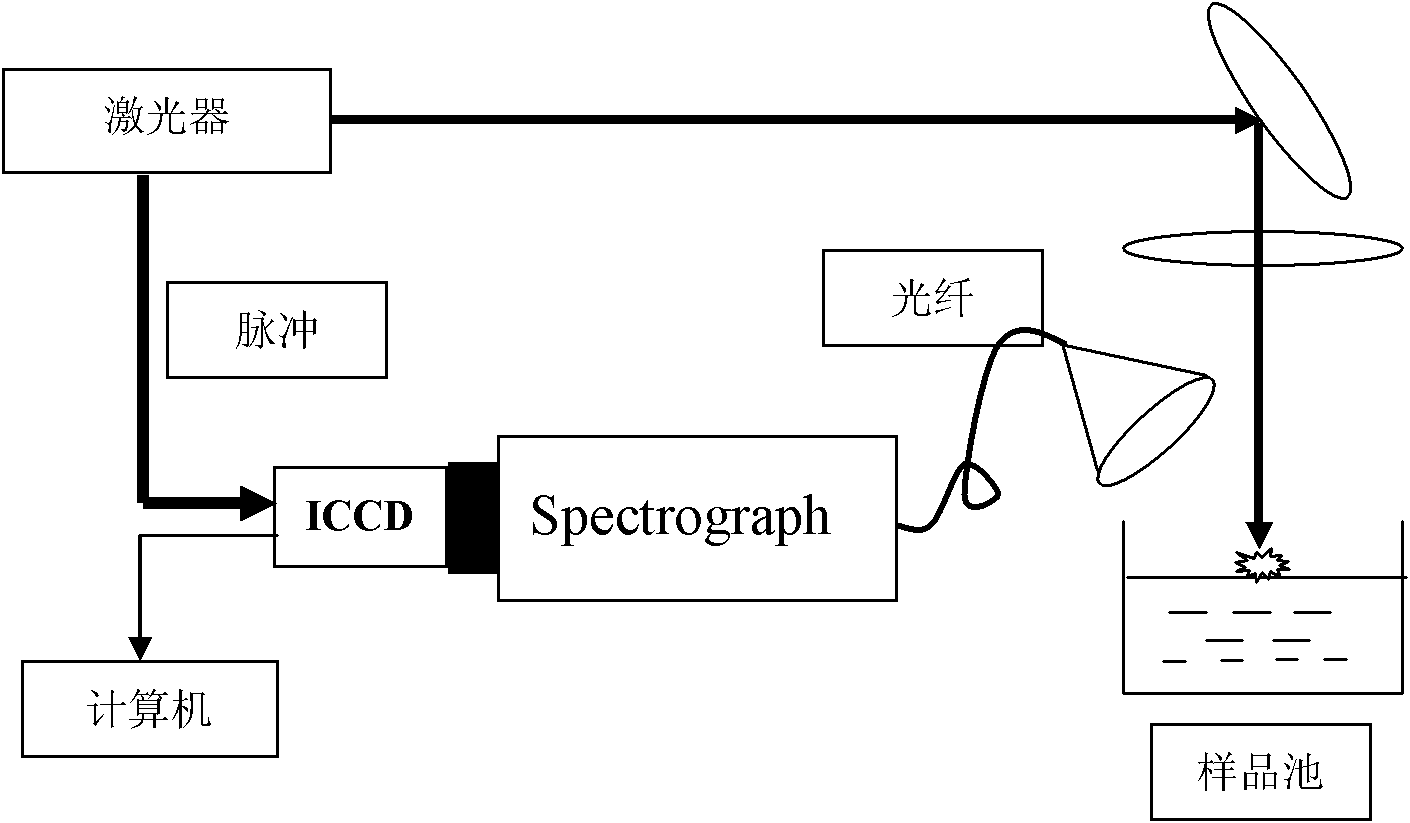

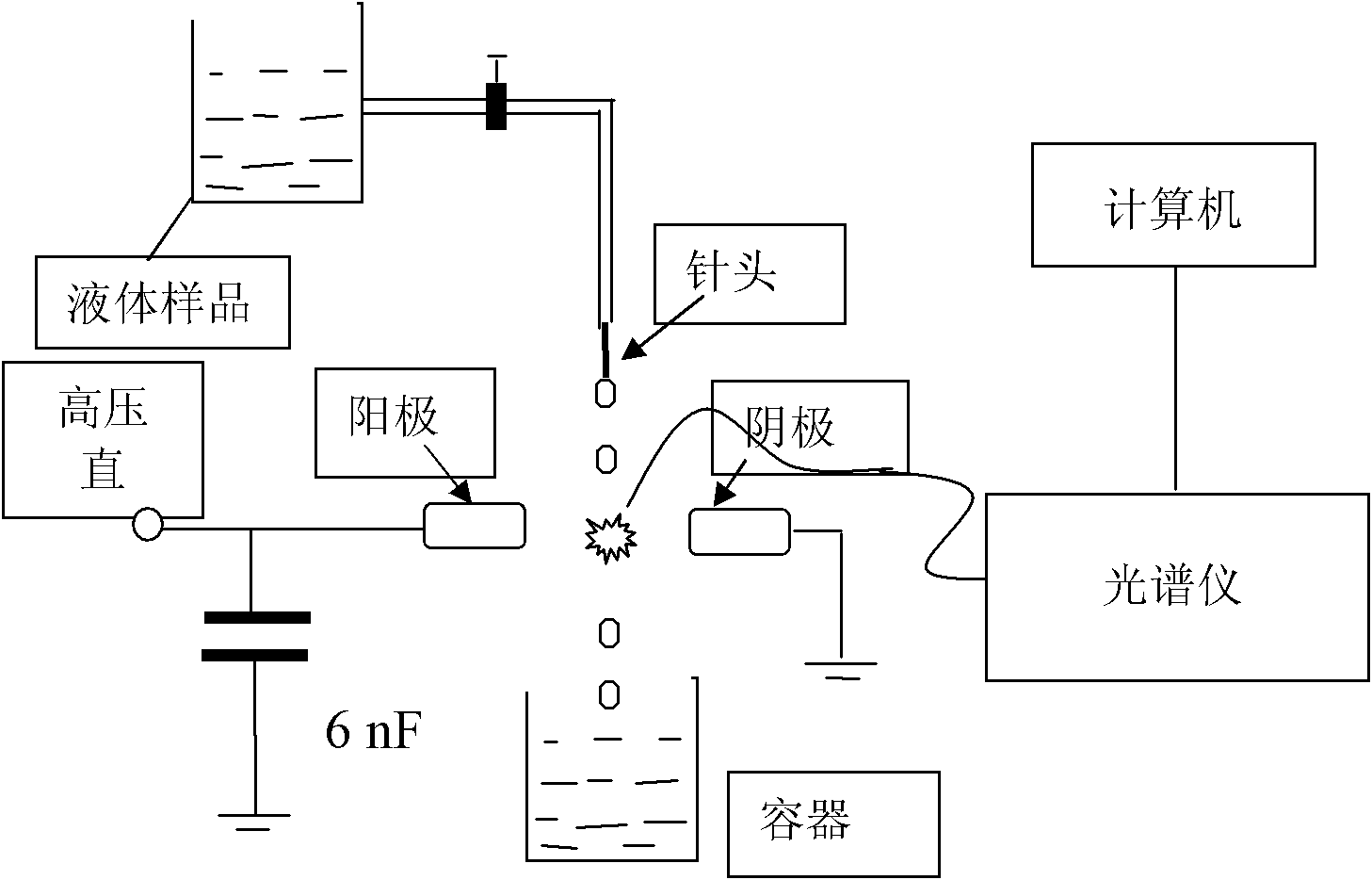

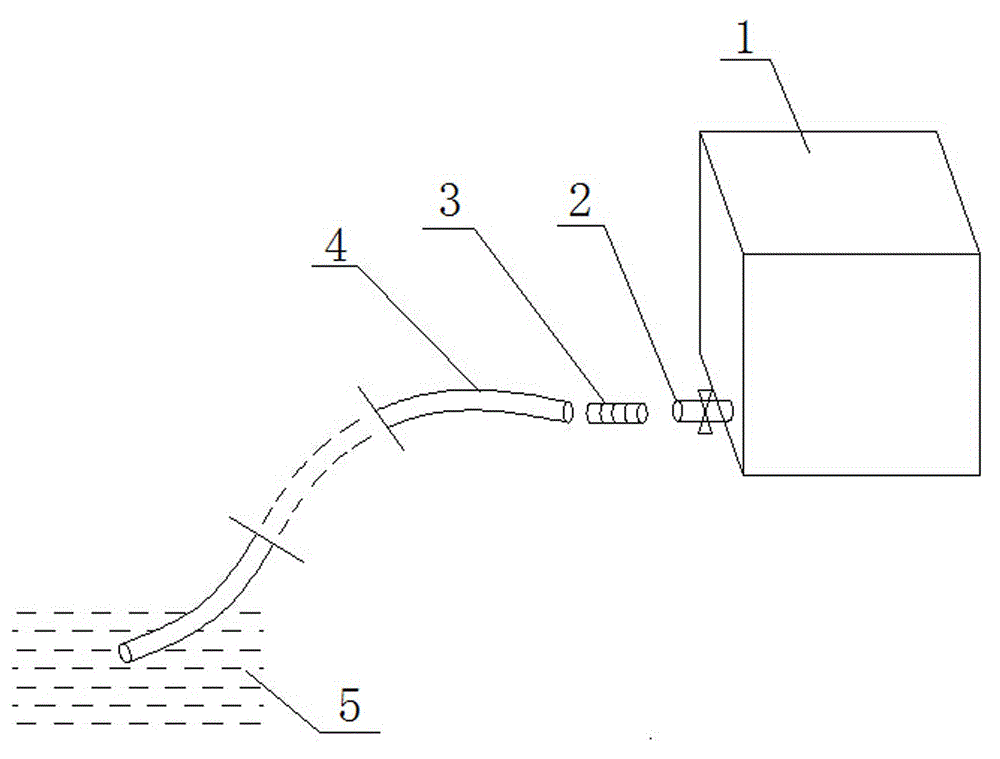

Detecting device and method for contents of elements in solution

InactiveCN102183508AEasy to operateLow costAnalysis by electrical excitationRapid pulseHigh pressure

The invention belongs to the field of a detecting technique for the contents of elements in a solution and particularly relates to a detecting device and method for the content of the elements in the solution by utilizing a high-voltage self-triggering rapid-pulse discharge technique. The detecting device provided by the invention comprises a high-voltage discharge circuit, a liquid sample sampling system and a spectrum detecting system, wherein the high-voltage discharge circuit comprises a discharger which comprises two discharge electrodes; and the liquid sample sampling system comprises a liquid dropper which enables a liquid sample to periodically pass through the gap center between the two discharge electrodes of the discharger. In the invention, a high-voltage self-triggering rapid-pulse discharge plasma spectrometry is used under the premises that complicated equipment does not need to be massively increased and the operation is simple; the heavy metal elements in the liquid are convenient to detect; spectrum signals have good stability; and the method has the potential important application value in the actual detection of water body heavy metal elements.

Owner:ZHEJIANG NORMAL UNIVERSITY

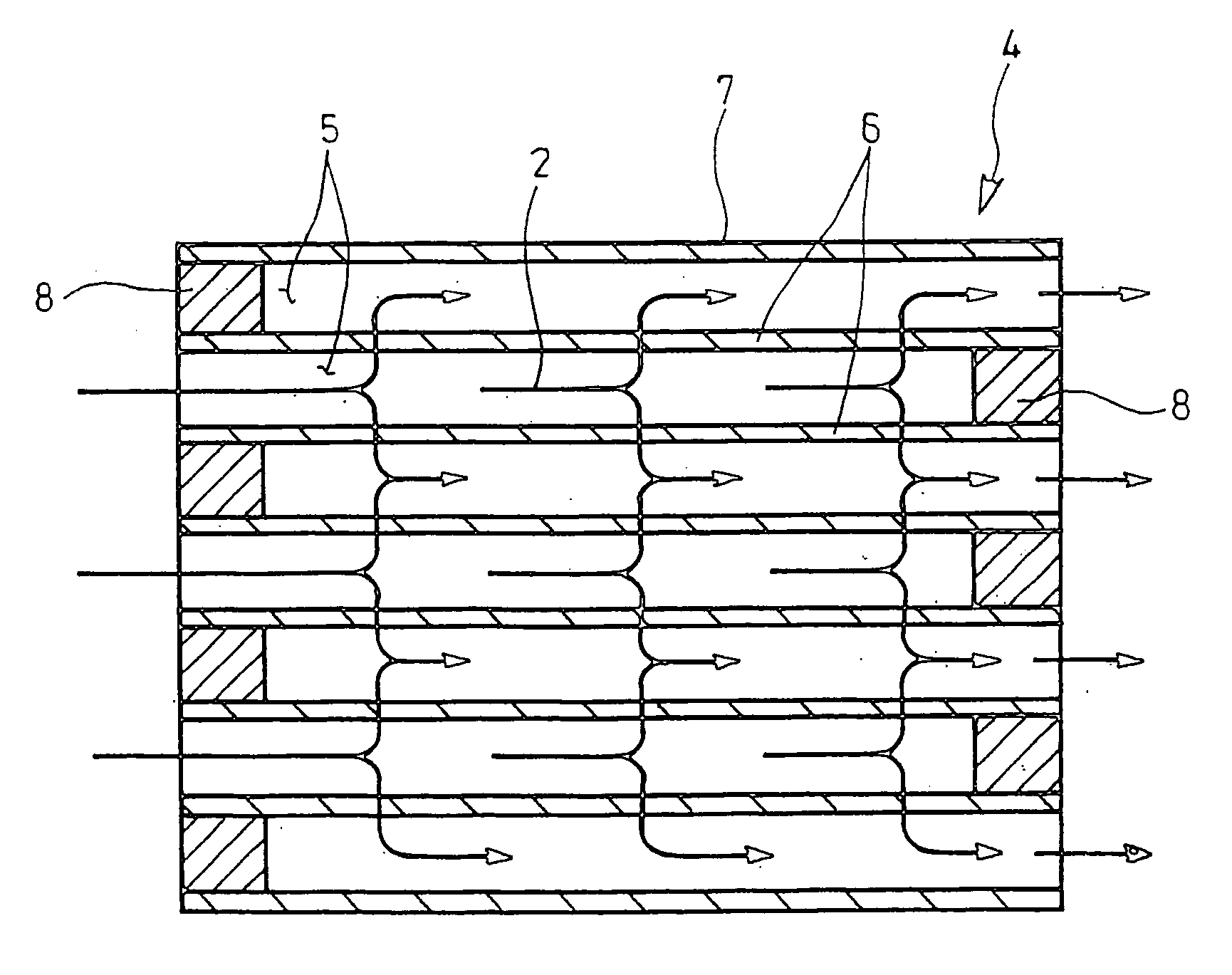

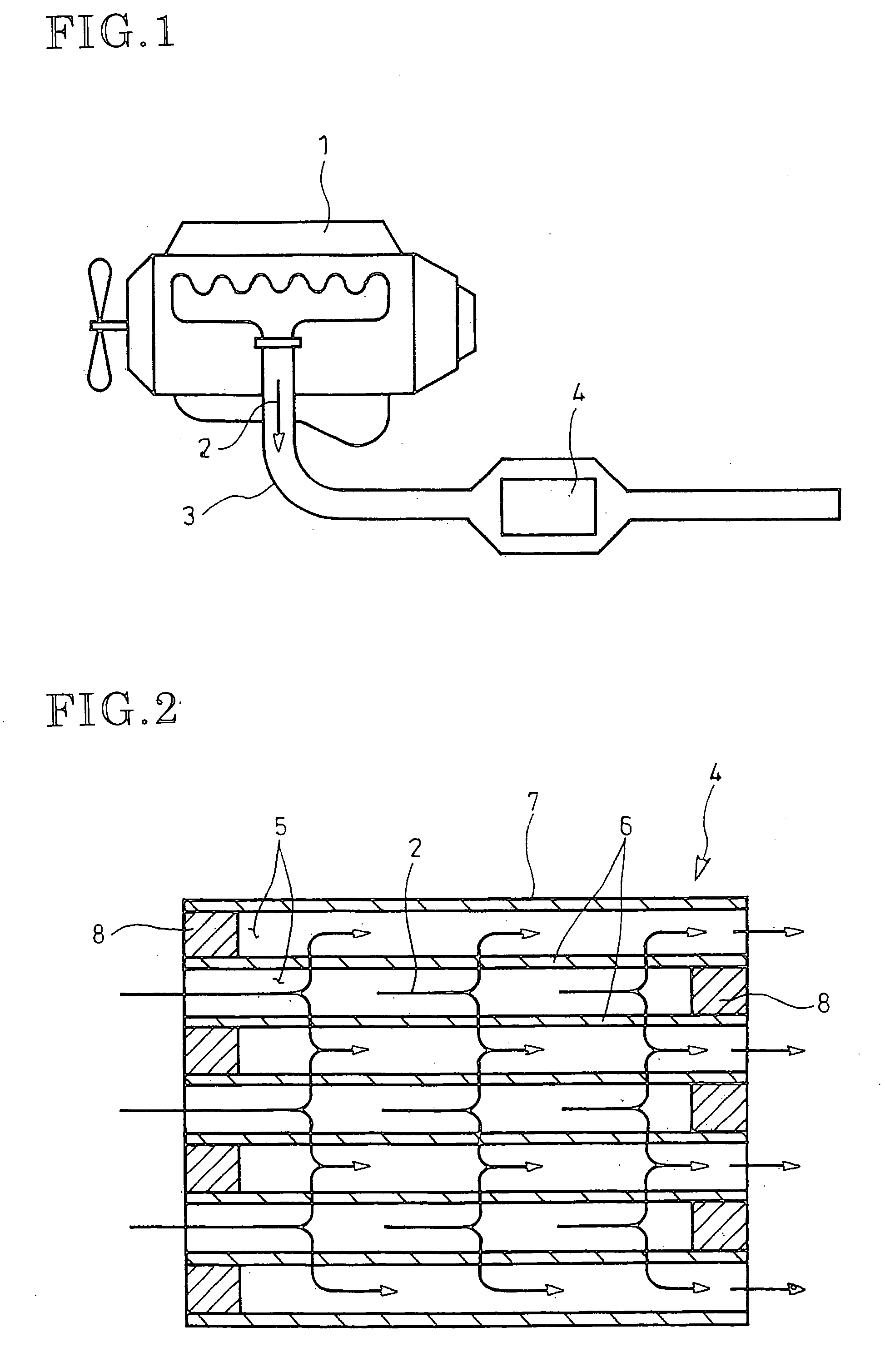

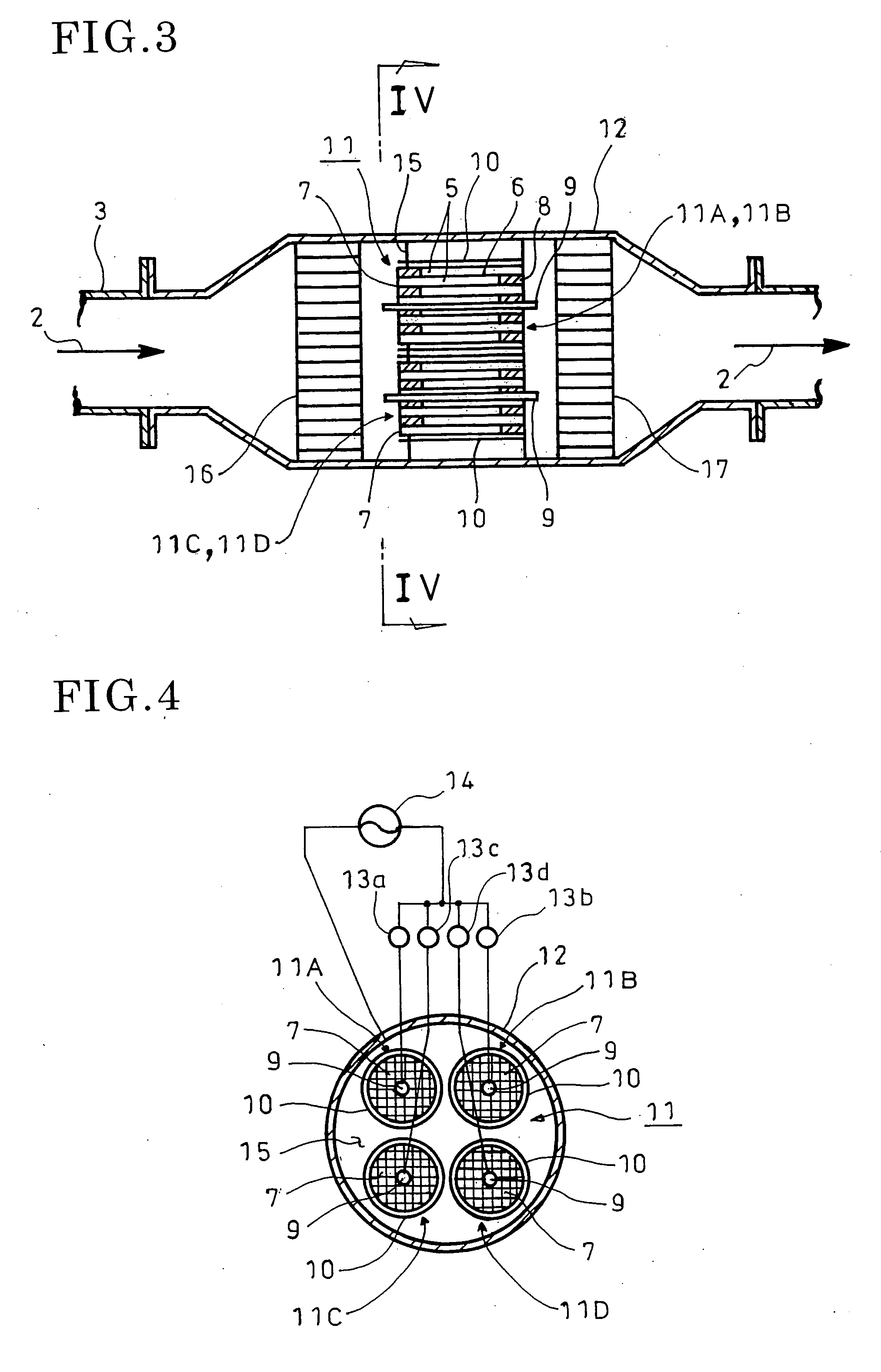

Exhaust gas-purifying device

InactiveUS20070028603A1Reliably burned offShort discharge timeDispersed particle filtrationExhaust apparatusParticulatesCylindrical electrode

Provided is a plasma assisted exhaust emission control device with less electric power consumption and with no harmful gas discharged into atmosphere. A filter body 7 is constituted by porous members through which exhaust gas 2 passes for capturing of particulates in the exhaust gas 2 and is provided with rod-like and cylindrical electrodes 9 and 10 so as to generate plasma in the filter body 7, thereby providing a plasma regenerative particulate filter 11. The particulate filter 11 is accommodated in a filter casing within an exhaust pipe 3. Oxidation catalysts 16 and are arranged respectively upstream and downstream of adjacent to the particular filter 11 in the filter casing 12 so as to obtain heat insulation effect to the particulate filter 11.

Owner:HINO MOTORS LTD

Method and device for limiting the starting current and for discharging the DC voltage intermediate circuit

ActiveUS8729864B2Safe and rapid dischargingSimple and cost-effective meanHybrid vehiclesBatteries circuit arrangementsHigh voltage batteryEngineering

Owner:ROBERT BOSCH GMBH

Comprehensive utilization method for waste lithium ion batteries

ActiveCN105958150AAchieve green recyclingShort discharge timeWaste accumulators reclaimingBattery recyclingCalcium hydroxideLithium electrode

The invention discloses a method for comprehensive utilization of waste lithium ions. Firstly, a resistor is used to perform short-circuit discharge on waste lithium ion batteries; secondly, a liquid conduction hole is opened around the bottom of the waste lithium ion battery with a shell to discharge the internal electrolyte, and the discharged internal The electrolyte is put into the container, and the remaining body including the steel shell and the positive and negative materials is obtained after the electrolyte is discharged; again, by adding LiOH solution to the obtained electrolyte, the dangerous electrolyte can be generated into a stable lithium salt solution , and then further concentrated and purified to obtain LiOH and Li 2 CO 3 ; Then adopt physical methods to separate the steel casing, the positive electrode material lithium cobaltate and the negative electrode material graphite for the remaining body of the gained; finally the positive electrode material lithium cobaltate is sequentially passed through alkali washing, pickling, and sodium carbonate to precipitate cobalt to obtain cobalt carbonate precipitation The obtained cobalt carbonate precipitate is placed in a high-temperature sintering furnace for calcination to obtain cobalt oxide products, thereby realizing green and efficient comprehensive recycling of waste lithium-ion batteries.

Owner:普定县银丰农业科技发展有限公司

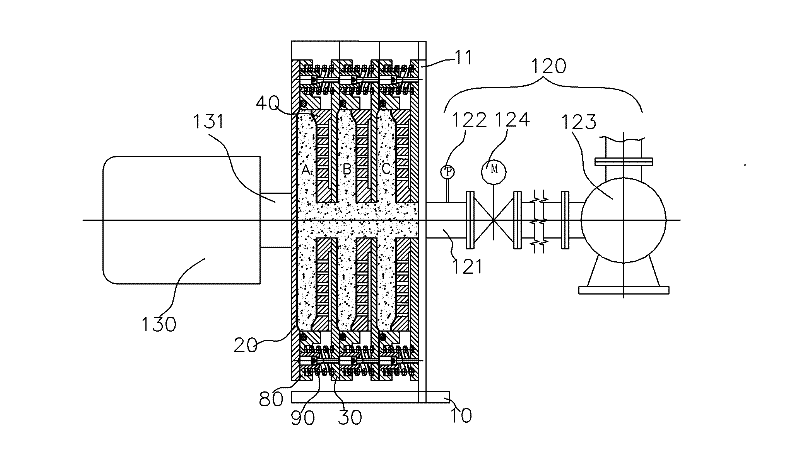

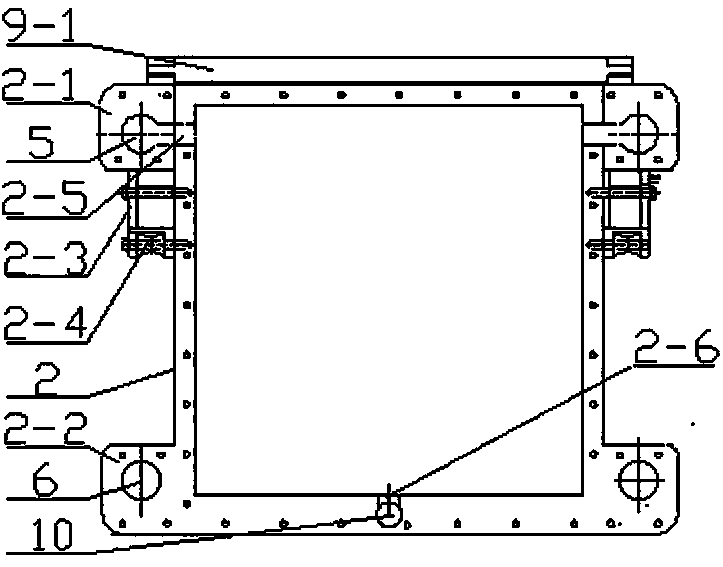

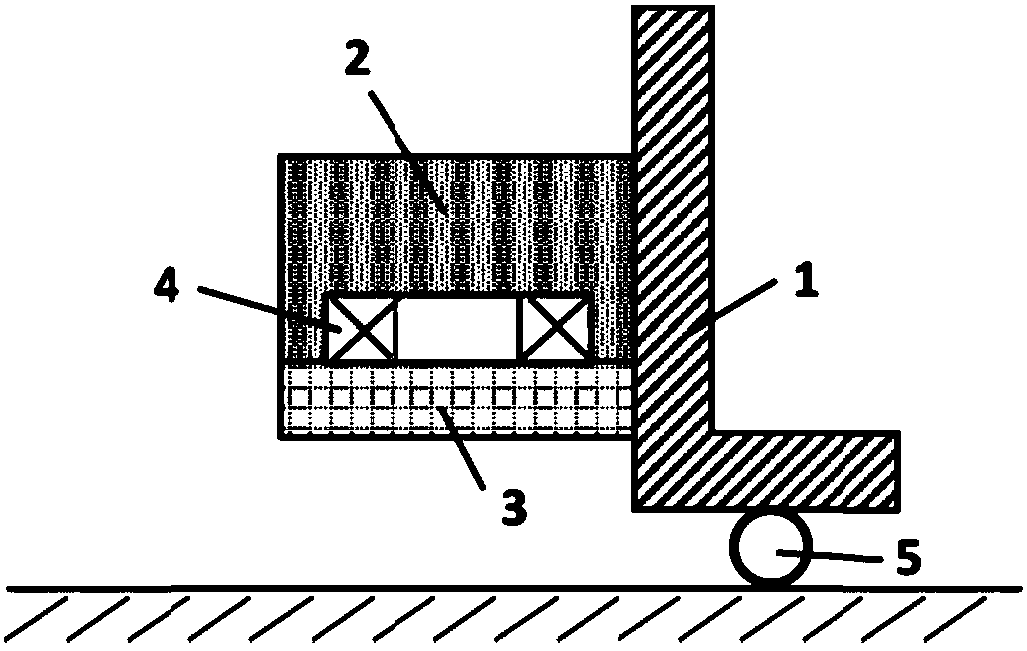

Sludge Dehydrator

ActiveCN102267794AVia short pathShort discharge timeSludge treatment by de-watering/drying/thickeningSludge dewateringExtrusion

The invention discloses a sludge dehydrator, which comprises a frame and a supporting plate connected with the frame; a sludge pumping mechanism and a pressure extrusion mechanism are arranged at two sides of the supporting plate respectively; a frame plate type filter pressing mechanism is arranged between the pressure extrusion mechanism and the connected supporting plate; the filter pressing mechanism comprises a filter pressing unit; a filter plate is arranged in the filter pressing unit; an annular sleeve is sleeved on the peripheral wall of the filter plate; a filter pressing cavity is formed between the filter plate and a front pressing plate; filter cloth is arranged on the surface of the filter plate in the filter pressing cavity; the surface of the filter plate is provided with a filtrate drainage hole; the drainage hole is connected with a drainage passage arranged in the filter plate and extended to the exterior; and the filter plate is interconnected with the surface of arear pressing plate to form a whole, and the middle part of the filter plate is provided with a through hole which is communicated with a pipeline of the sludge pumping mechanism. The sludge dehydrator can improve the filter pressing efficiency and is convenient to control the dryness of mud cakes.

Owner:安徽省通源环境节能股份有限公司

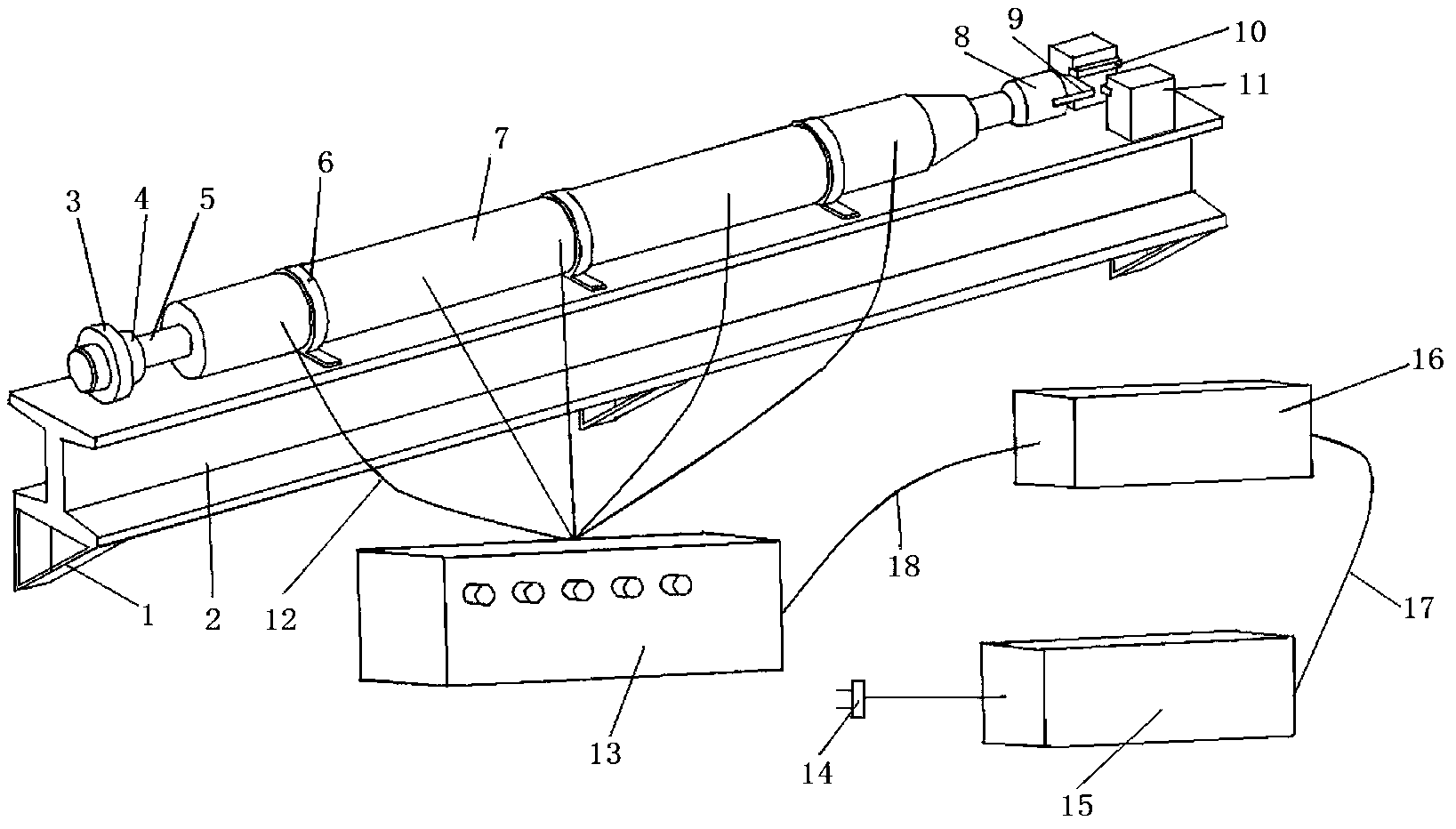

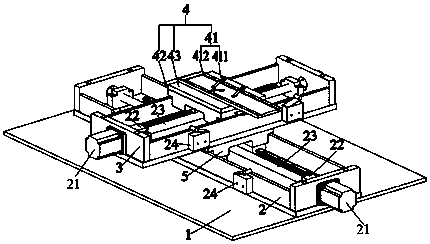

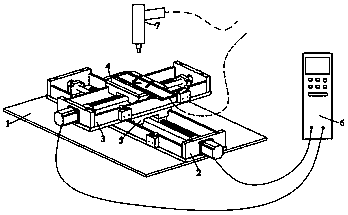

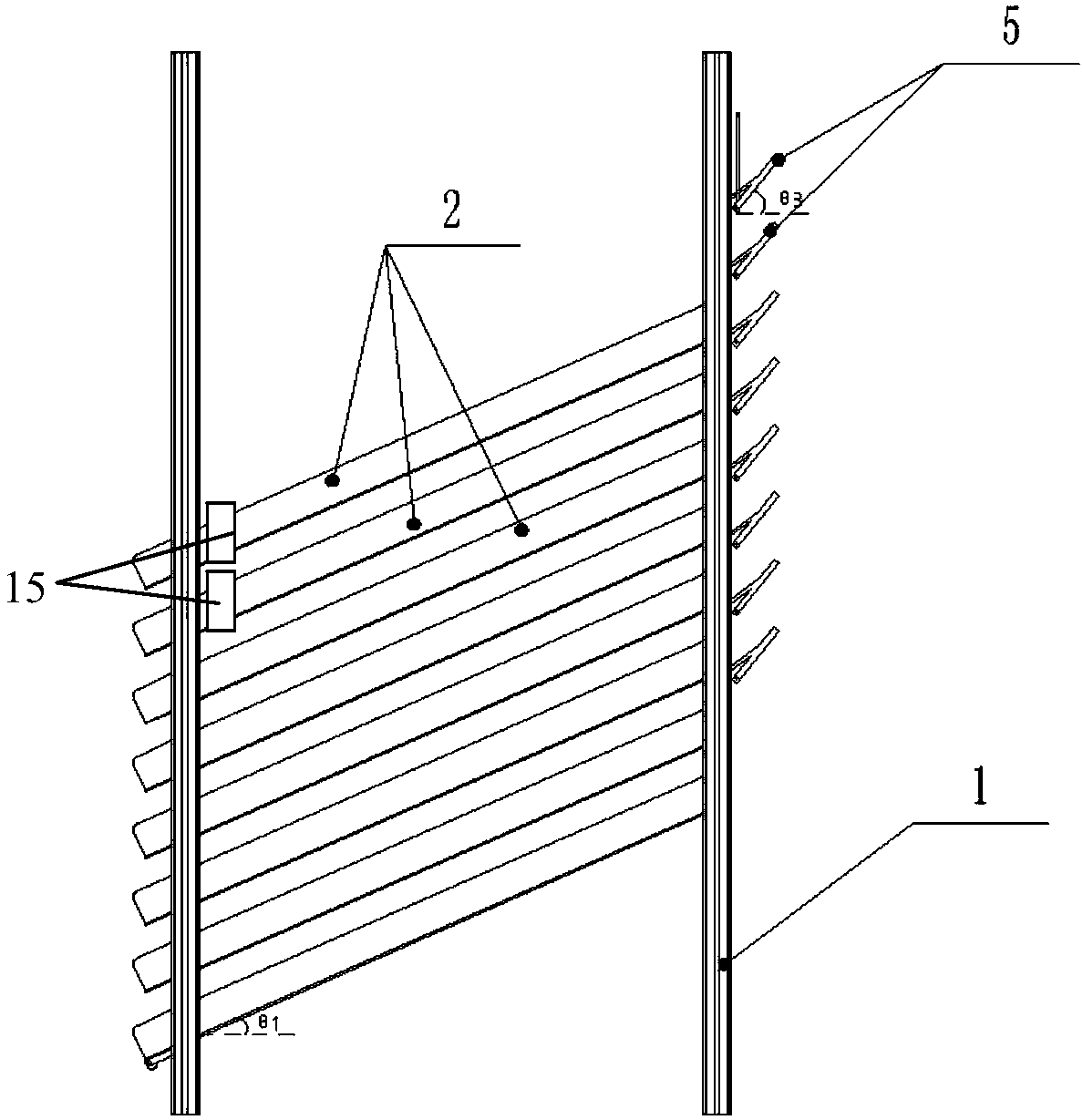

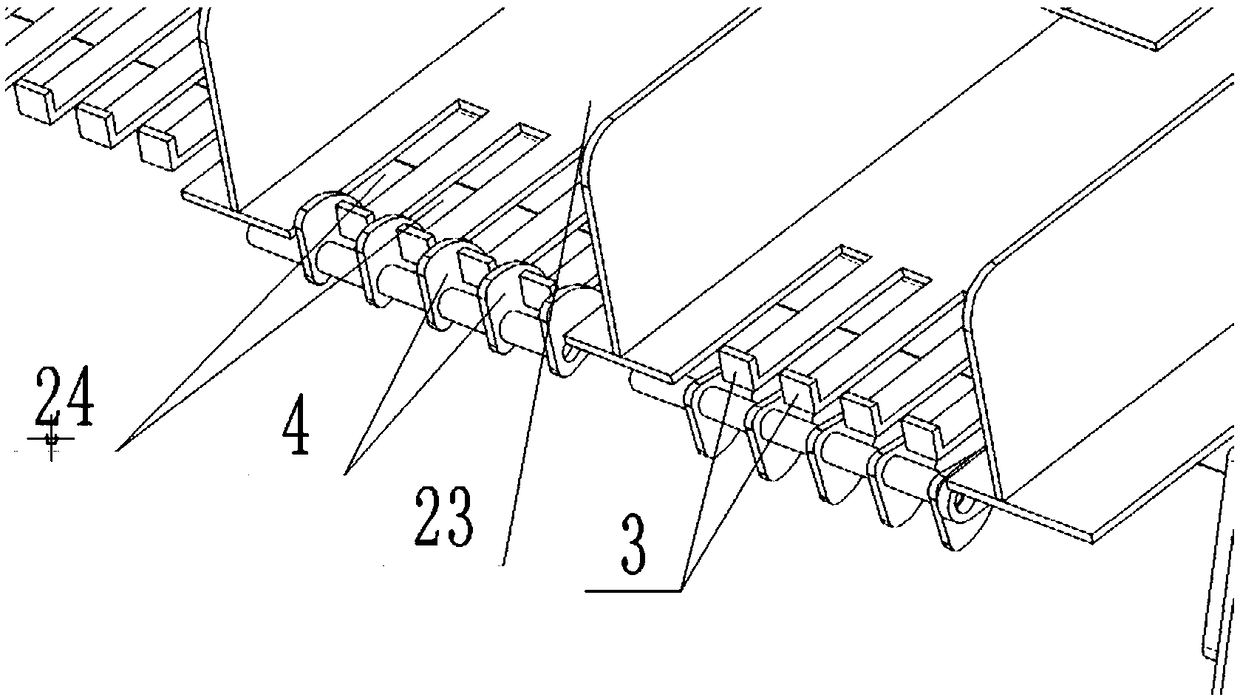

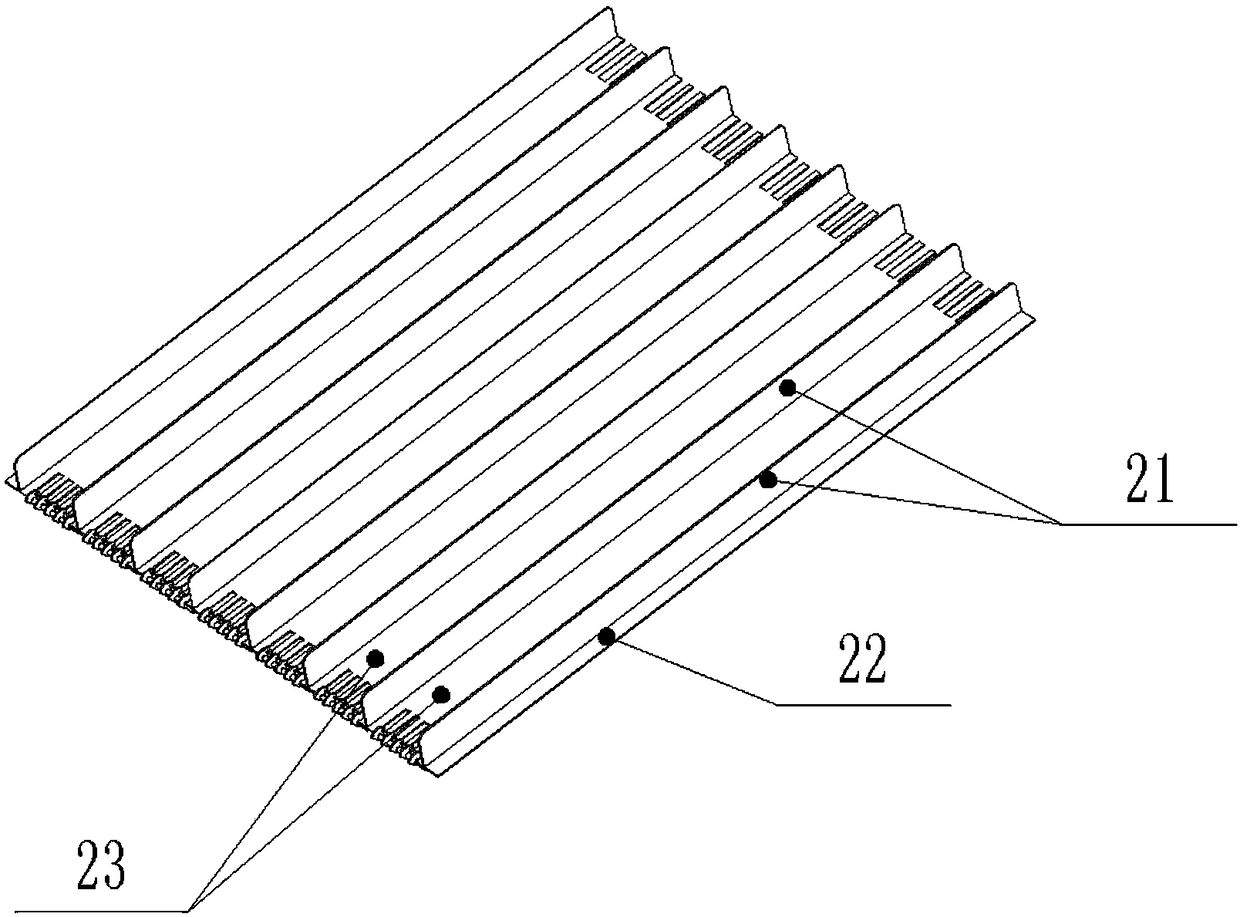

Electromagnetically driven high-speed cutting simulation experimental device

InactiveCN103163038AMeet the requirements of high-speed cutting experimentsWide cutting speed rangeInvestigating machinabilityImaging processingDynamometer

The invention discloses an electromagnetically driven high-speed cutting experimental device which comprises an actuating mechanism, a cutting mechanism and a fixing mechanism, wherein the actuating mechanism is used for producing electromagnetic thrust to drive the cutting mechanism to move at a high speed so as to enable a cutter to cut a workpiece fixed on the fixing mechanism, and the cutter can be rapidly stopped by a cushion and an aluminum alloy end check block on the actuating mechanism. The whole experimental device provided by the invention is constructed based on an electromagnetically driving technology, thus being economical, environment-friendly and good in stability, the experimental device can achieve a very high cutting speed, the cutting speed is adjustable, and a high-speed camera is additionally arranged and can be used for carrying out image processing and analysis on a high-speed cutting process. By matching with instruments such as a laser velocimeter and a dynamometer, the electromagnetically driven high-speed cutting experimental device can meet the requirements of high-speed cutting experiments of various materials.

Owner:SHANDONG UNIV

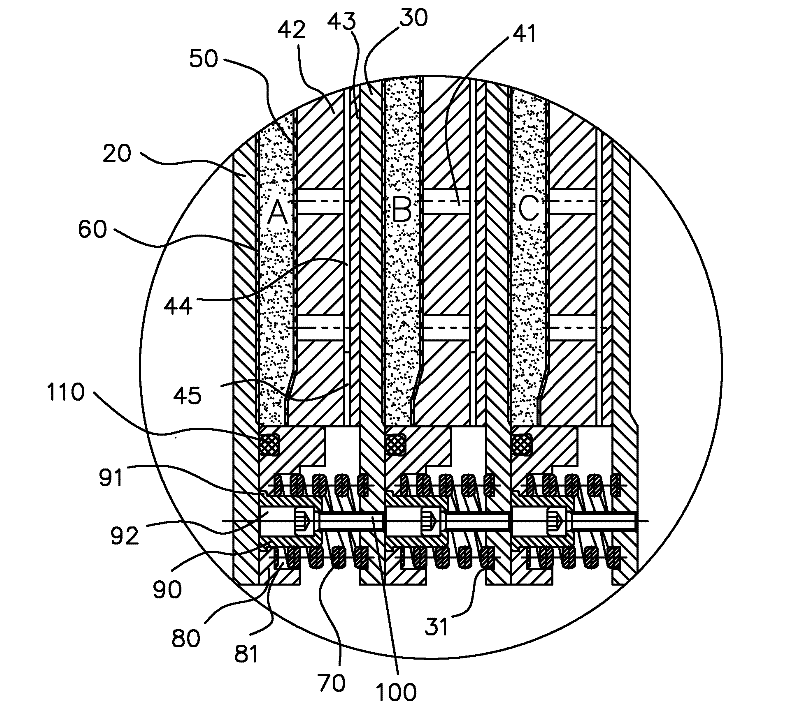

Solid and liquid separator for materials

ActiveCN103657176AImprove stressThe moisture content of solids is reducedFiltration separationPush and pullLocking mechanism

The invention discloses a solid and liquid separator for materials. The solid and liquid separator comprises a frame, press plates, filter plates, a push-and-pull locking mechanism, a filter cloth mechanism, a filter cloth regeneration mechanism and a cleaning mechanism which are arranged on the frame, wherein the press plates and the filter plates are arranged on the frame in a sliding way alternately, and are matched to extrude a material, so that solid and liquid of the material can be separated; the push-and-pull locking mechanism is used for locking, pushing away all the press plates and filter plates, so that solid-liquid separation operation can be performed, or the material can be discharged; the filter cloth mechanism is used for separating solid and liquid of the material when the material is extruded; the filter cloth regeneration mechanism is used for washing to regenerate the filter cloth after the material is discharged; the cleaning mechanism is used for cleaning the material attached to the separator after solid and liquid of the material are separated. The solid and liquid separator has the characteristics of reasonable design, high structure strength, convenience in operation, complete solid and liquid separation, high separation efficiency, convenience in cleaning, long service life, log maintenance frequency, high reliability, strong practicality and the like, and is beneficial for greatly increasing production benefit of enterprises.

Owner:四川宝凯鑫诚环保科技有限公司

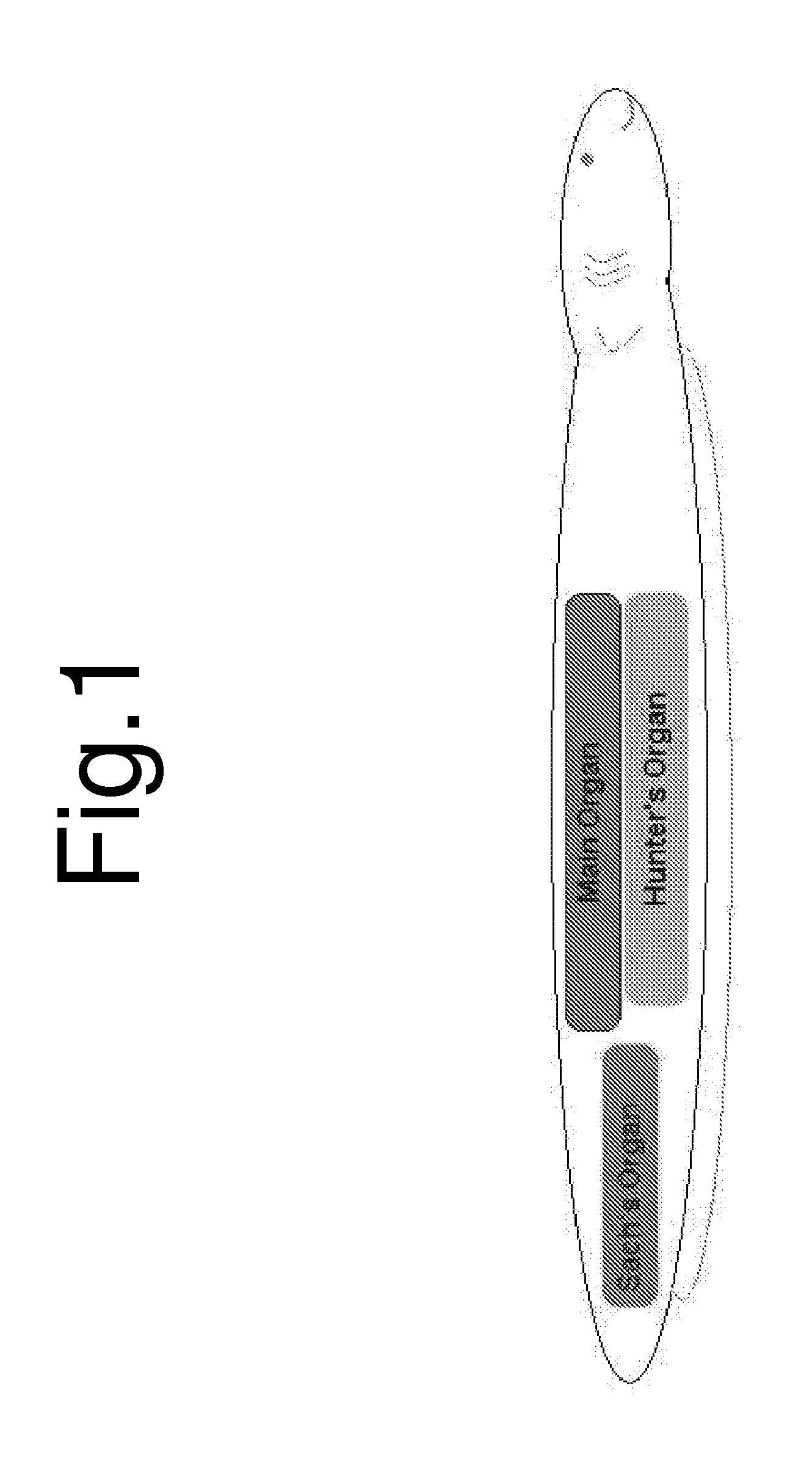

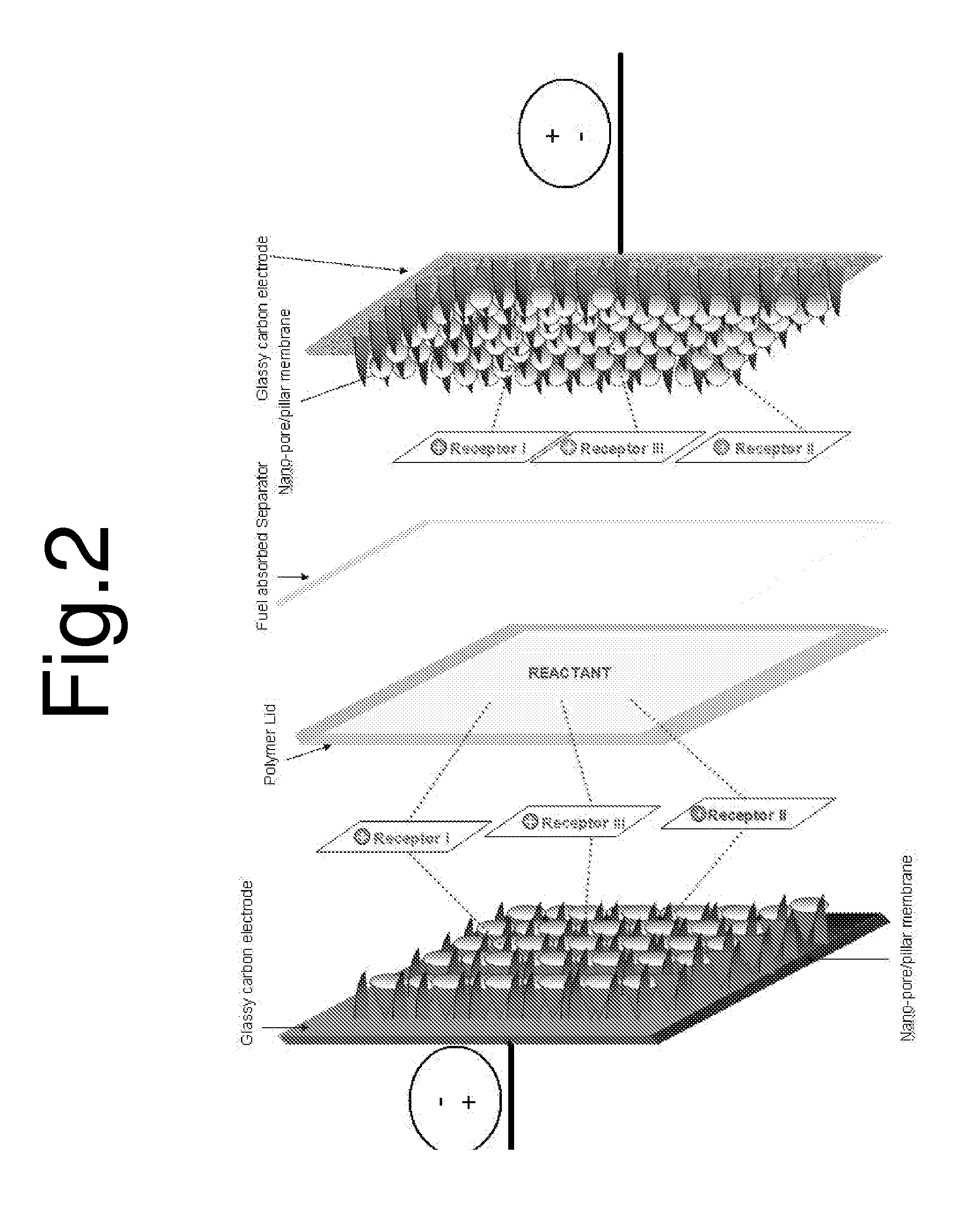

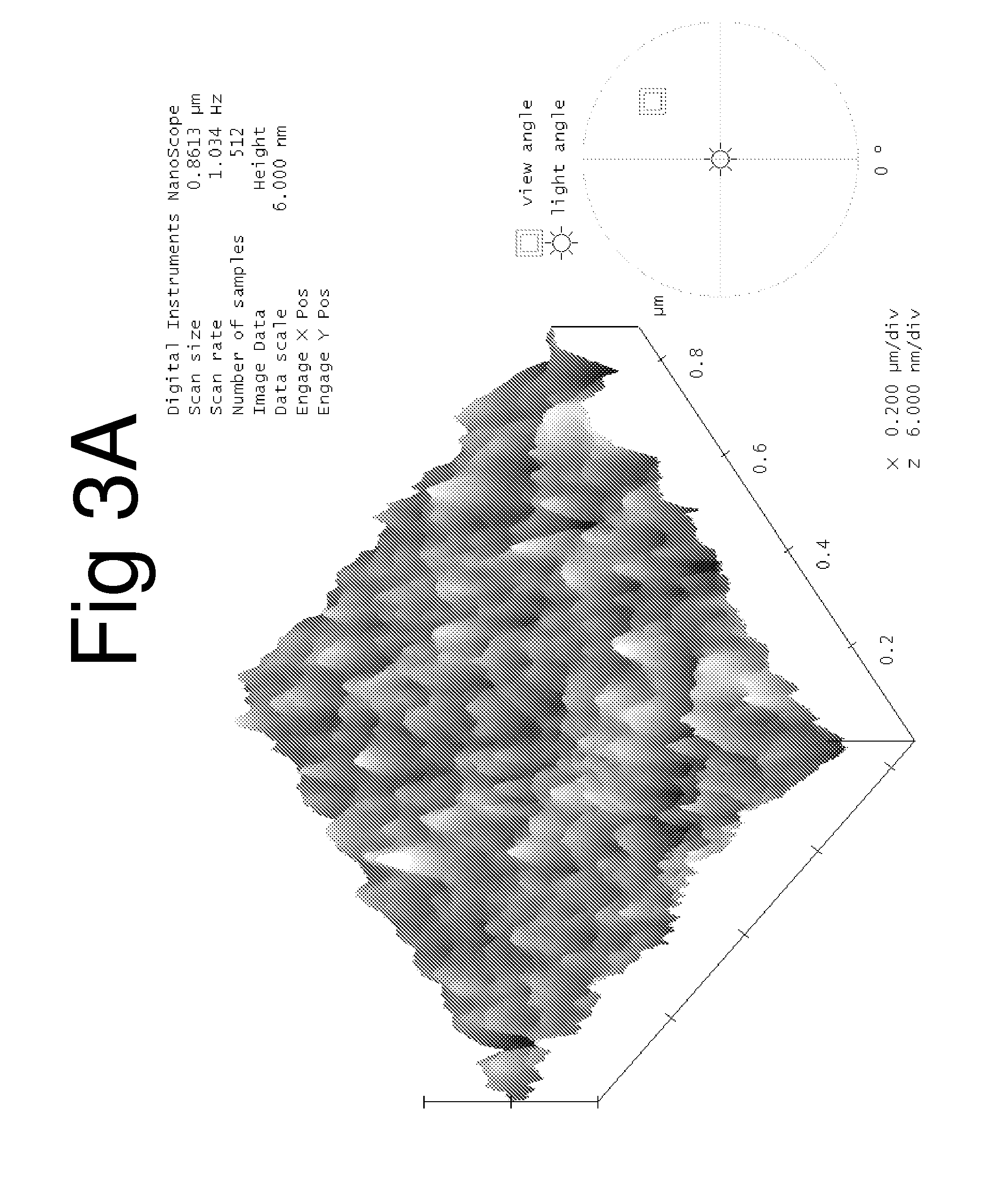

Nanobiomimetic Supercapacitors with High Rate High Energy Storage

ActiveUS20140104751A1Reduce discharge rateShort discharge timeMaterial nanotechnologyHybrid capacitor separatorsHigh rateHigh energy

Nanobiomimetic supercapacitors comprise an “Electron Well” and an “Electron-Dam” Membrane Electrode Assembling (MEA); the “Electron-Well” MEA compromises an electrode comprising a substrate of glassy carbon; a self-assembling membrane comprises a polymer matrix; wherein the polymer matrix is comprised of an electrically conductive copolymer; wherein the copolymer is further comprised of one or more first β-cyclodextrin molecules having at least one or more free acetyl groups; one or more polyethylene glycol molecules; one or more poly(4-vinylpyridine) molecules; and one or more second β-cyclodextrin molecules; the self-assembling membrane having a surface structure comprising one or more nanopores and pillars; the nanopores and pillars are vertically oriented on the substrate to form nanopore and pillar array; the “Electron-Dam” MEA compromises the nanopore / pillar layer sealed with an embedded hydrophobic aromatic substance having a flat lid structure; Wherein the MEA can be as either said positive or negative electrode; wherein the “Electron-Well” also can be either said as positive or negative electrode; separated by a porous insulator wetted by an electrolyte-free and air-independent organic solution; at least two current collectors are at each of the end of the MEAs.

Owner:CHEN ELLEN T

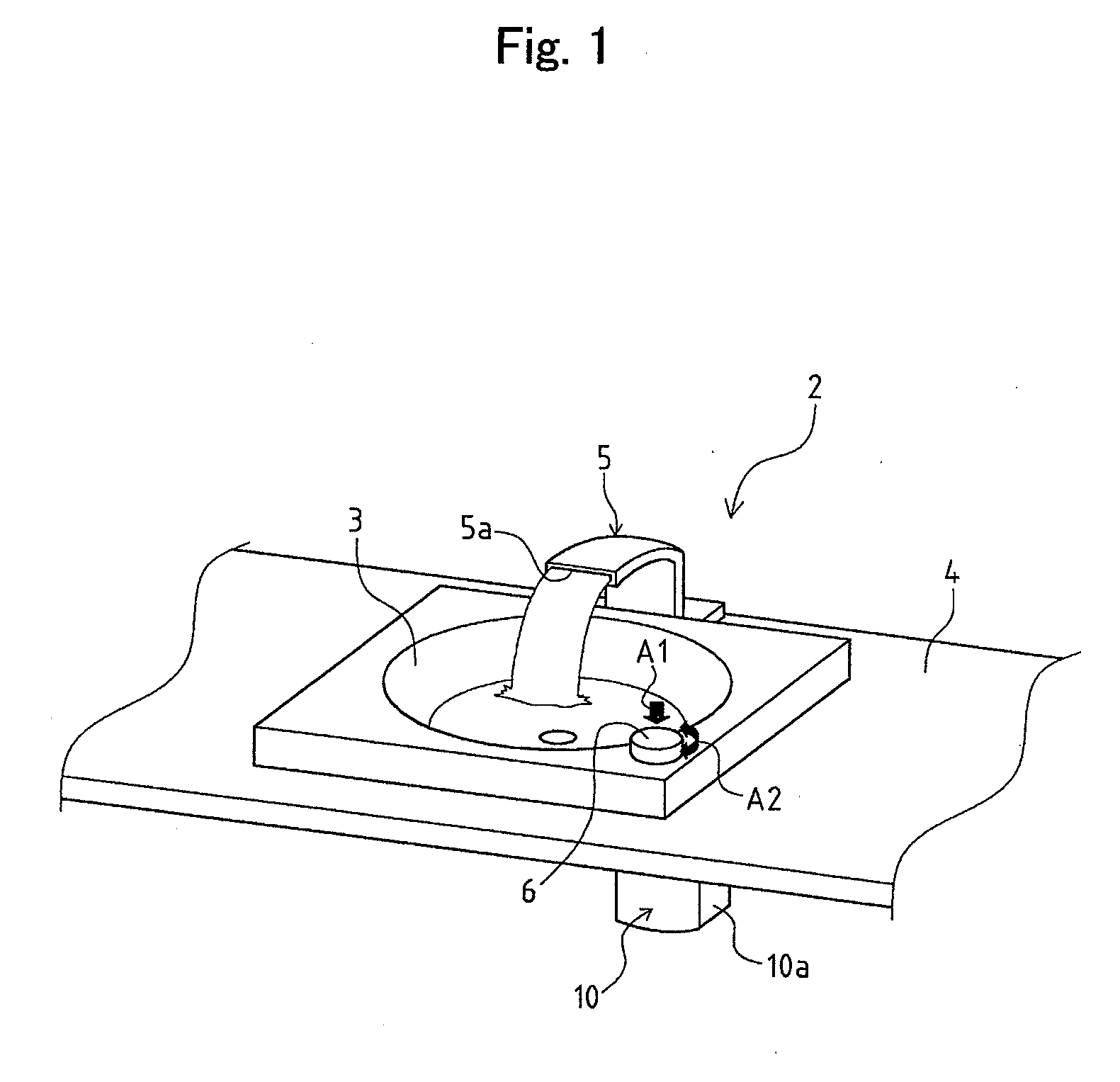

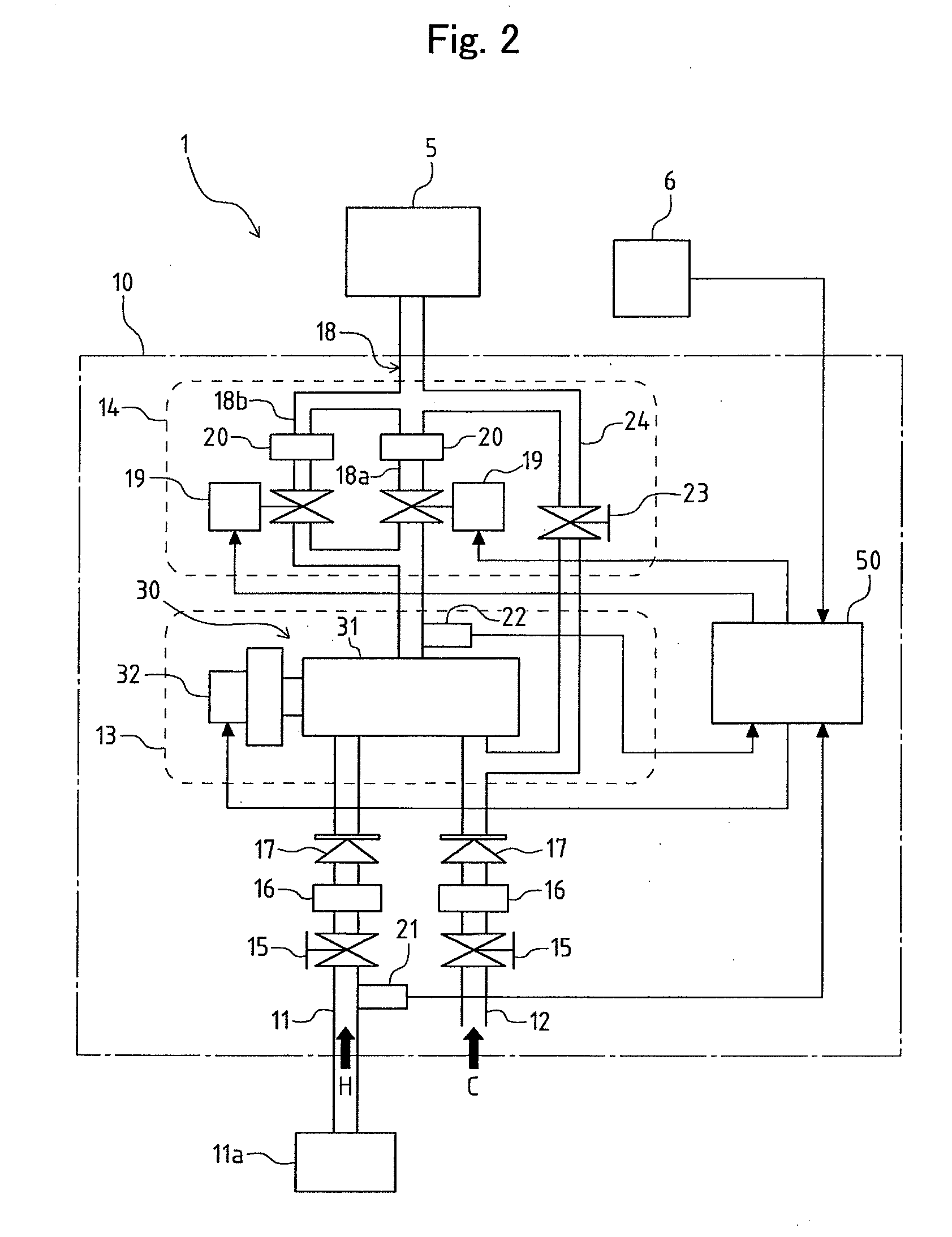

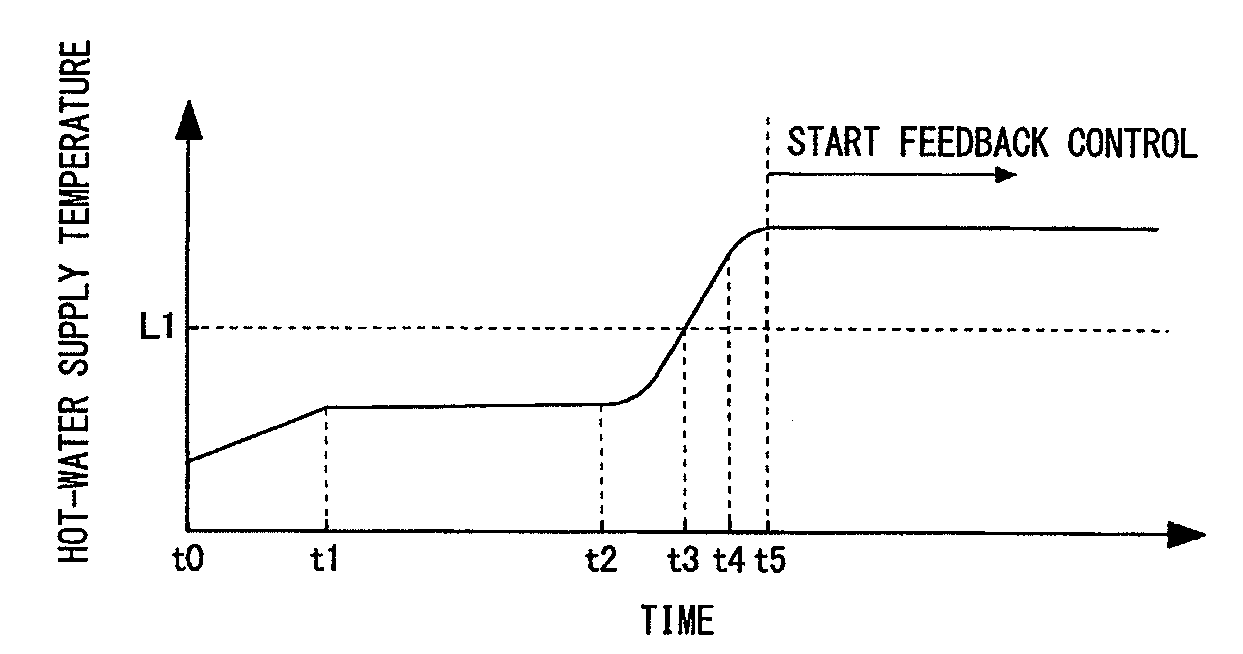

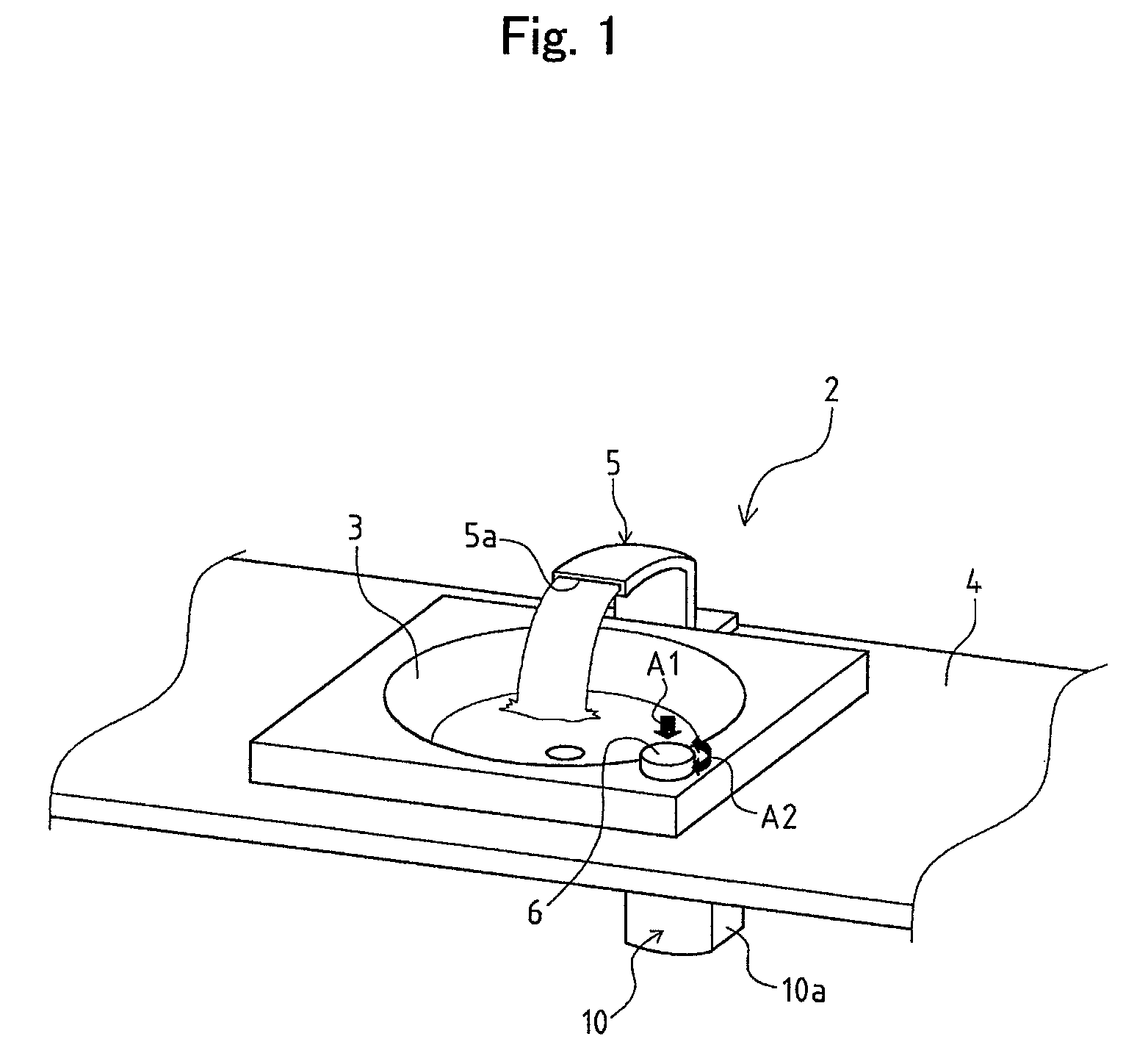

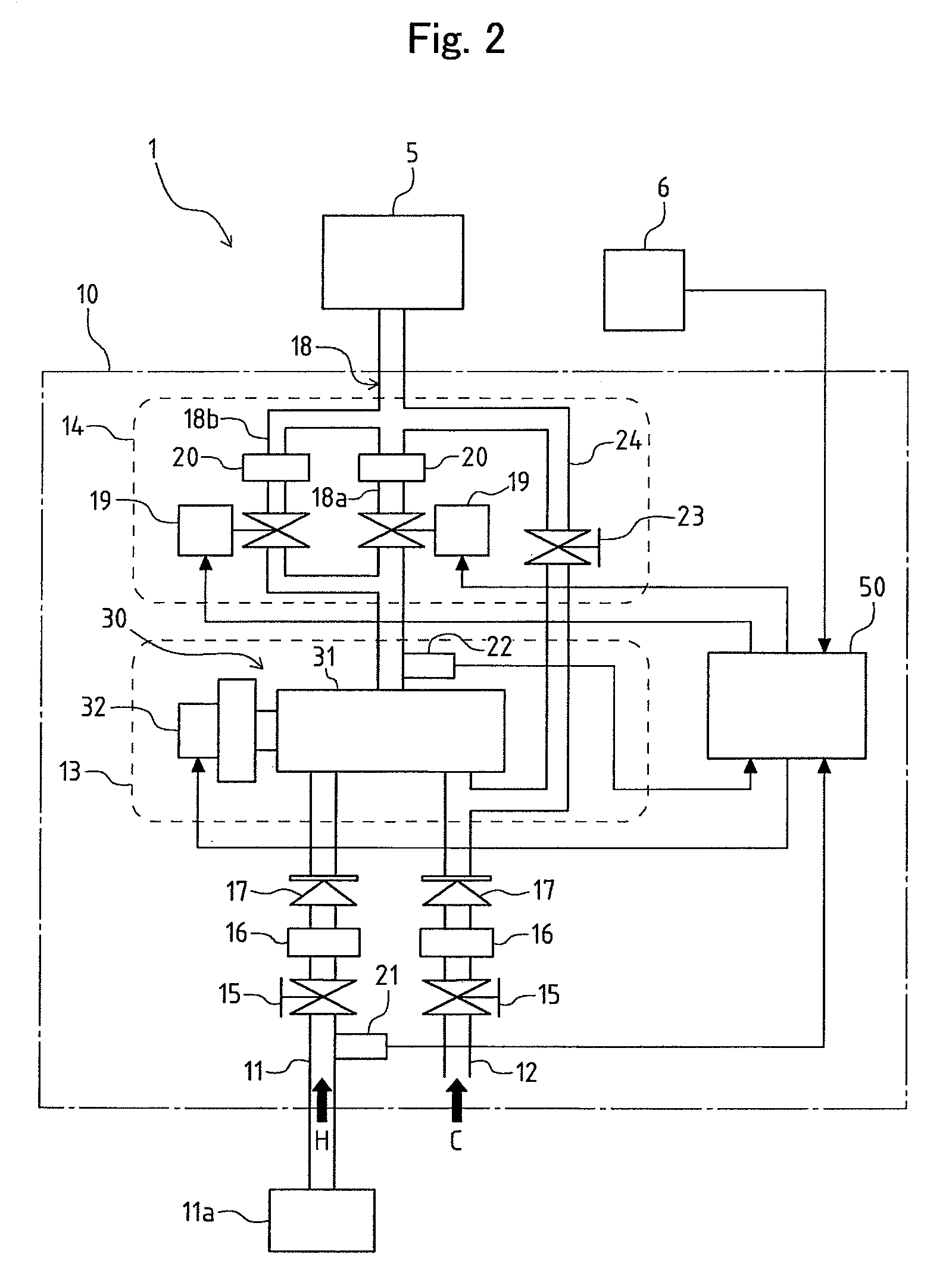

Water-and-hot-water mixing device

InactiveUS20100078491A1Short discharge timeShorten discharge timeTemperature control without auxillary powerOperating means/releasing devices for valvesThermistorFeedback control

A water-and-hot-water mixing device includes a mixing valve unit which mixes hot water and water and discharges mixed water therefrom, an operation part which sets a predetermined temperature, a mixed water thermistor which detects a temperature of mixed water, a hot-water thermistor which detects a temperature of hot water supplied to the mixing valve unit, and a controller which performs a feedback control of a discharge water temperature by controlling the mixing valve unit. The controller starts the feedback control when the controller determines that a change amount of the temperature of the hot water per unit time detected by the hot-water thermistor is not more than a fixed value and the temperature of the hot water detected by the hot-water thermistor is not lower than the predetermined temperature.

Owner:TOTO LTD

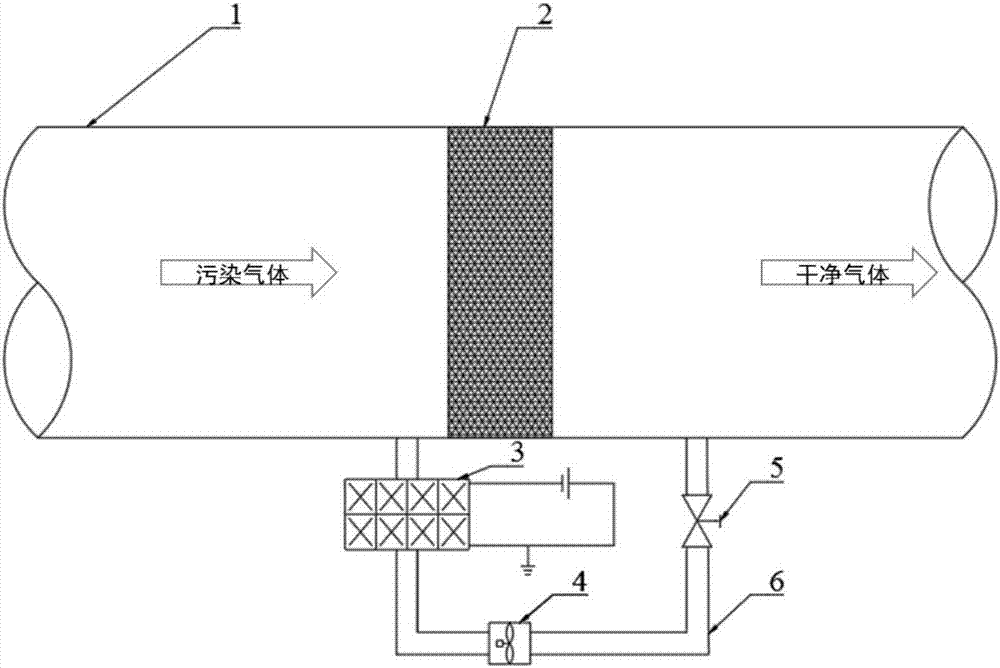

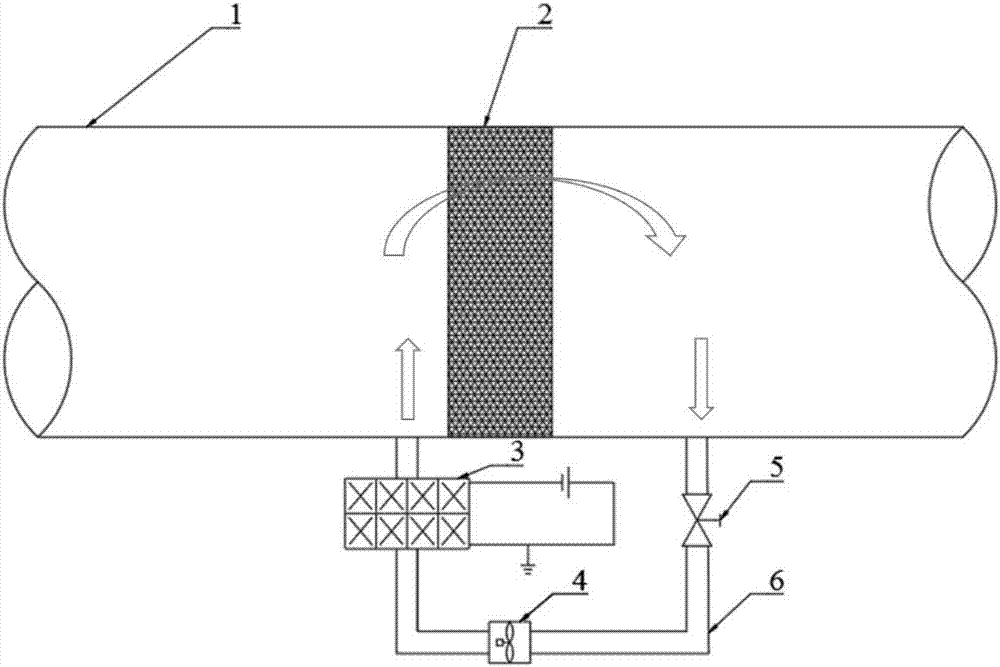

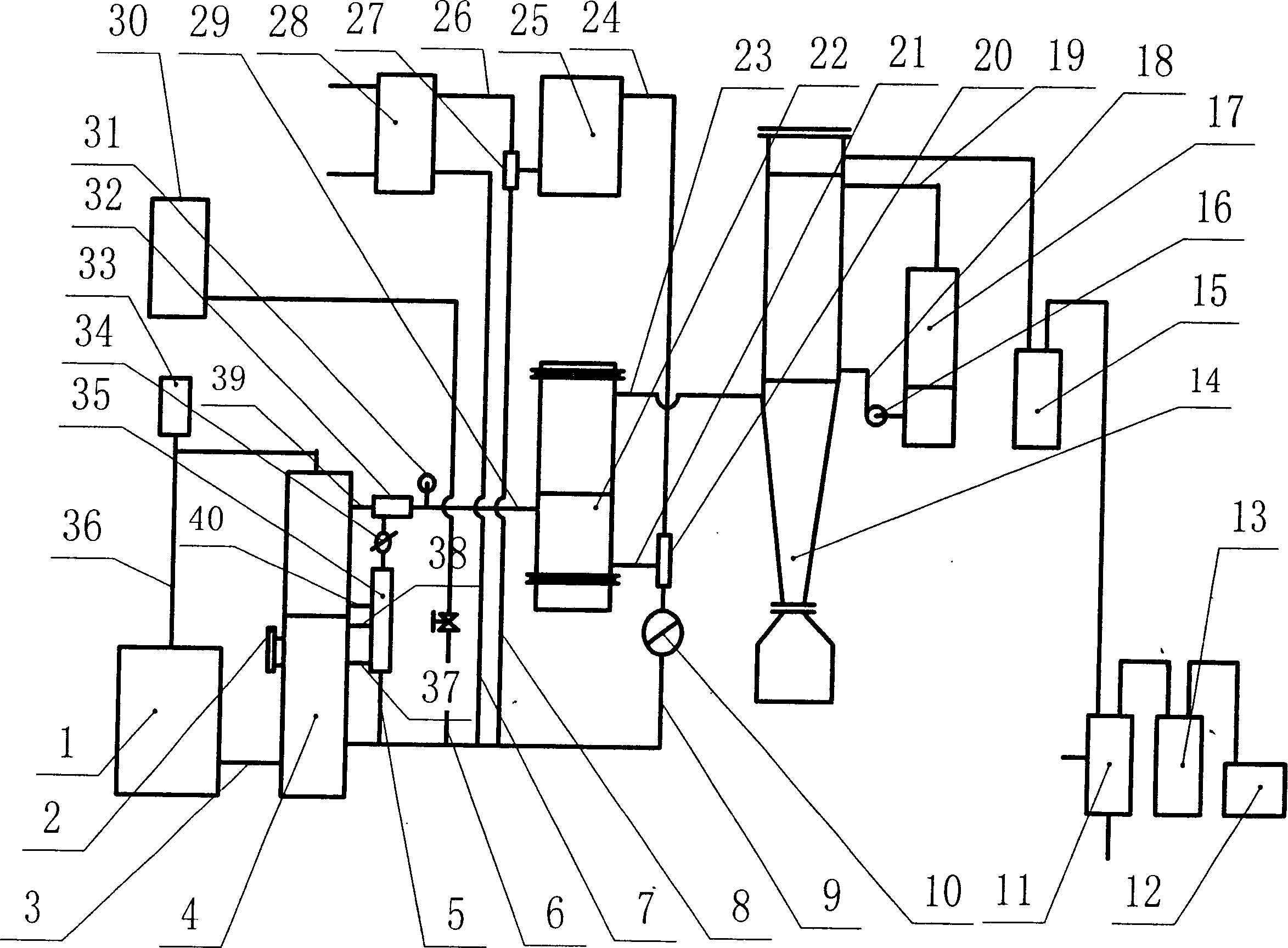

High-efficiency, low-energy-consumption and free-of-secondary-pollution method and device using low-temperature plasma to synergistically catalytically purify indoor volatile organic compounds

ActiveCN107413175AImprove conversion efficiencyReduce energy consumptionGas treatmentDispersed particle separationLow temperature plasmaPollution

The invention discloses a high-efficiency, low-energy-consumption and free-of-secondary-pollution method and device using low-temperature plasma to synergistically catalytically purify indoor volatile organic compounds and belongs to the technical field of indoor air purification. The method is characterized in that an adsorption / catalytic dual-function purification material component located in a main air pipe is utilized to efficiently adsorb and separate the volatile organic compounds in indoor air at normal air speed for a long time in a period when a building starts ventilation and purification; in a period when the building does not start the ventilation and purification, the low-temperature plasma passes the adsorption / catalytic dual-function purification material component in a short time in a circulating manner under a low air speed condition to allow adsorption-state organic matter to be completely oxidized into harmless or low-harm substances; after a low-temperature plasma generator is turned off, circulating gas containing ozone passes the adsorption / catalytic dual-function purification material component in a circulating manner to allow the ozone to be decomposed thoroughly. The method is high in indoor volatile organic matter conversion rate, low in energy consumption and capable of preventing secondary pollutants from being released into the indoor air.

Owner:BEIHANG UNIV

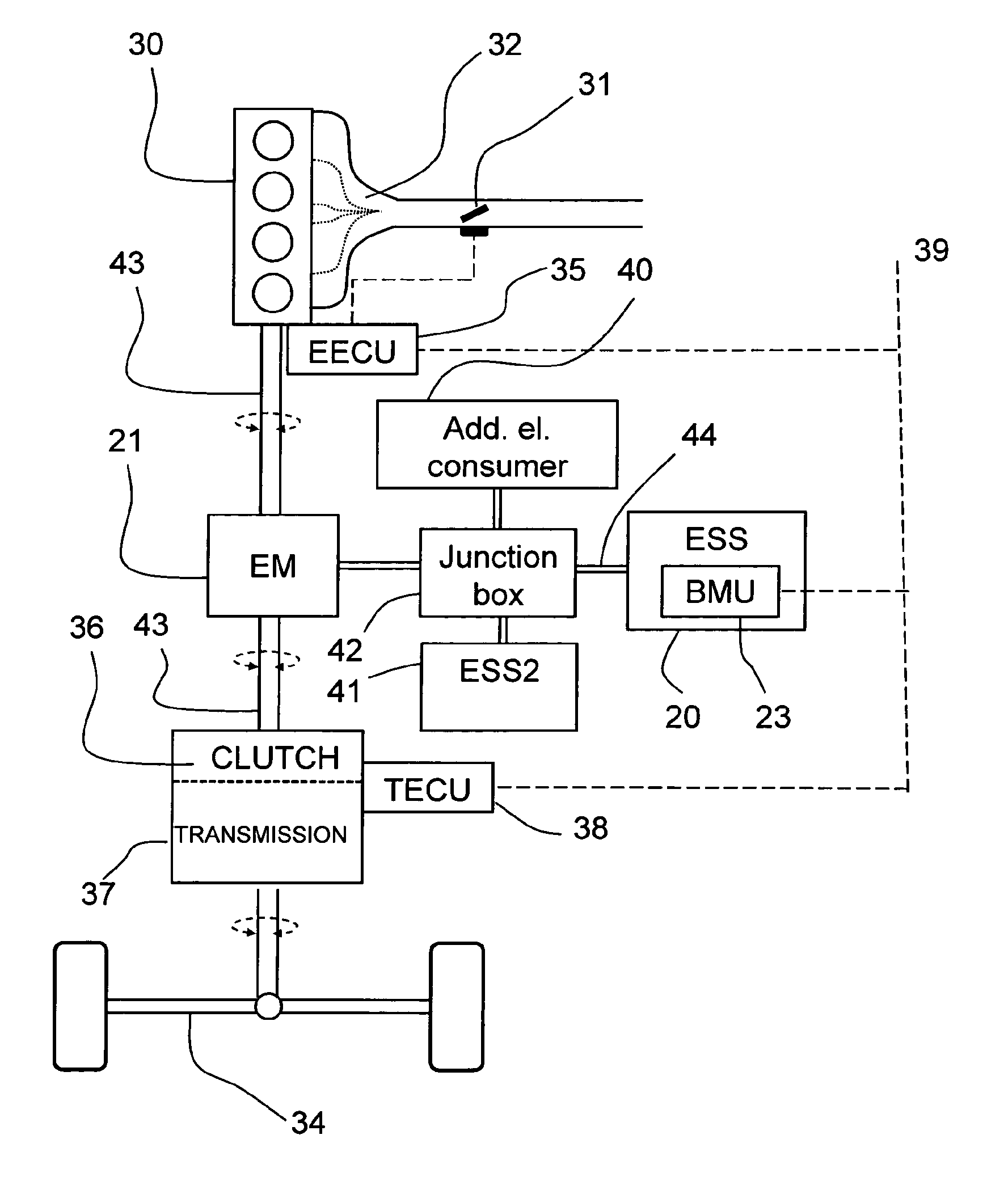

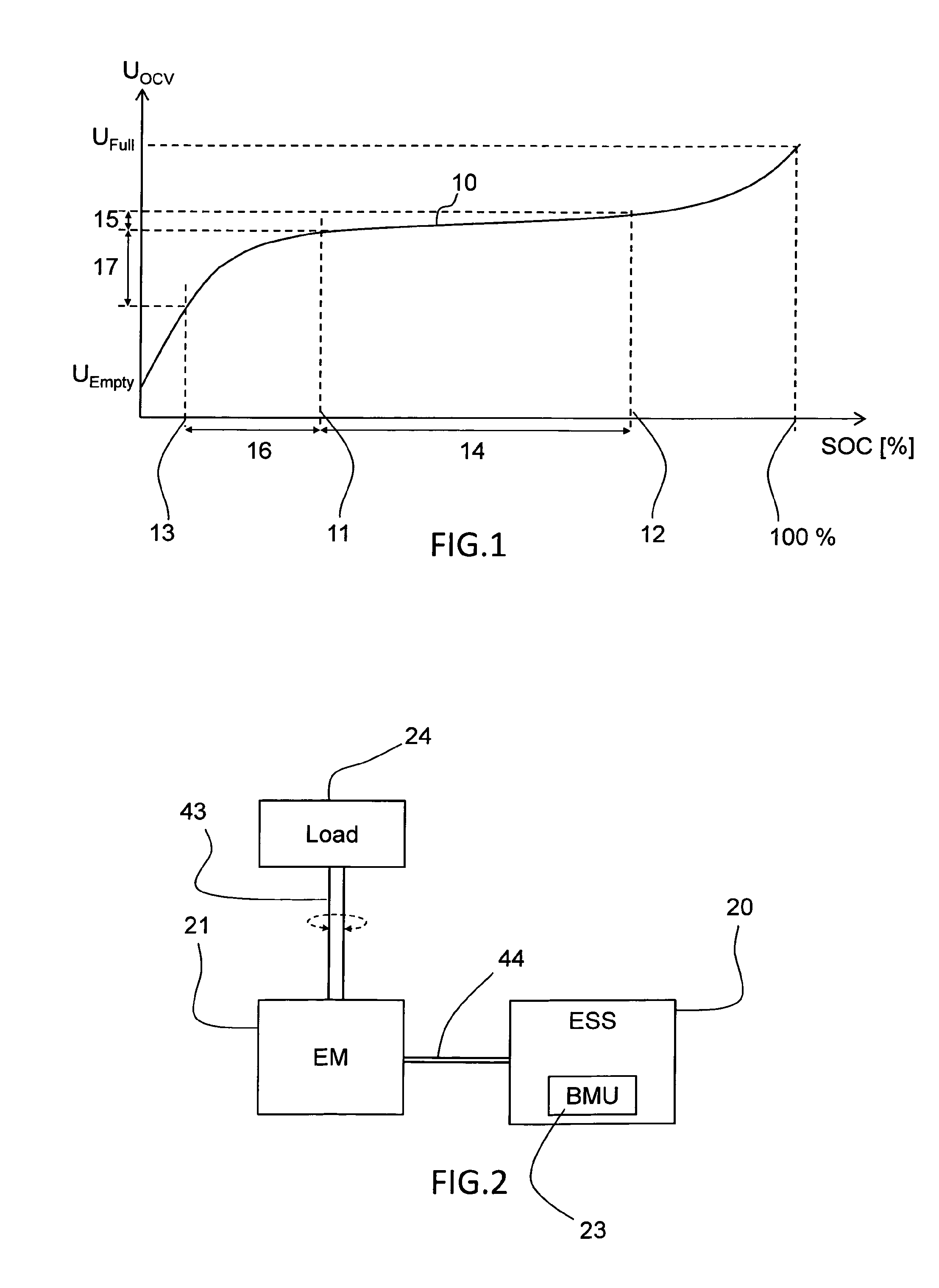

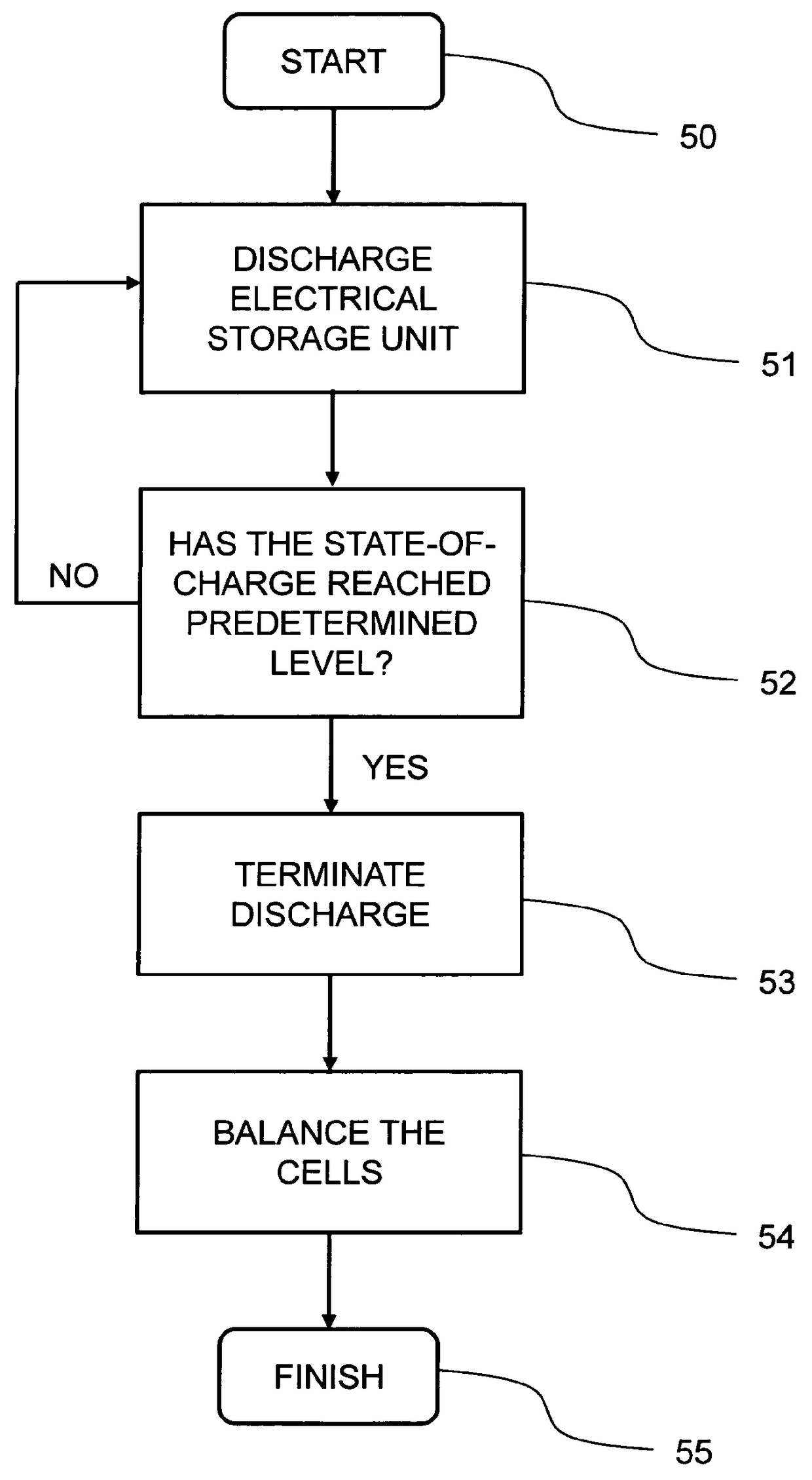

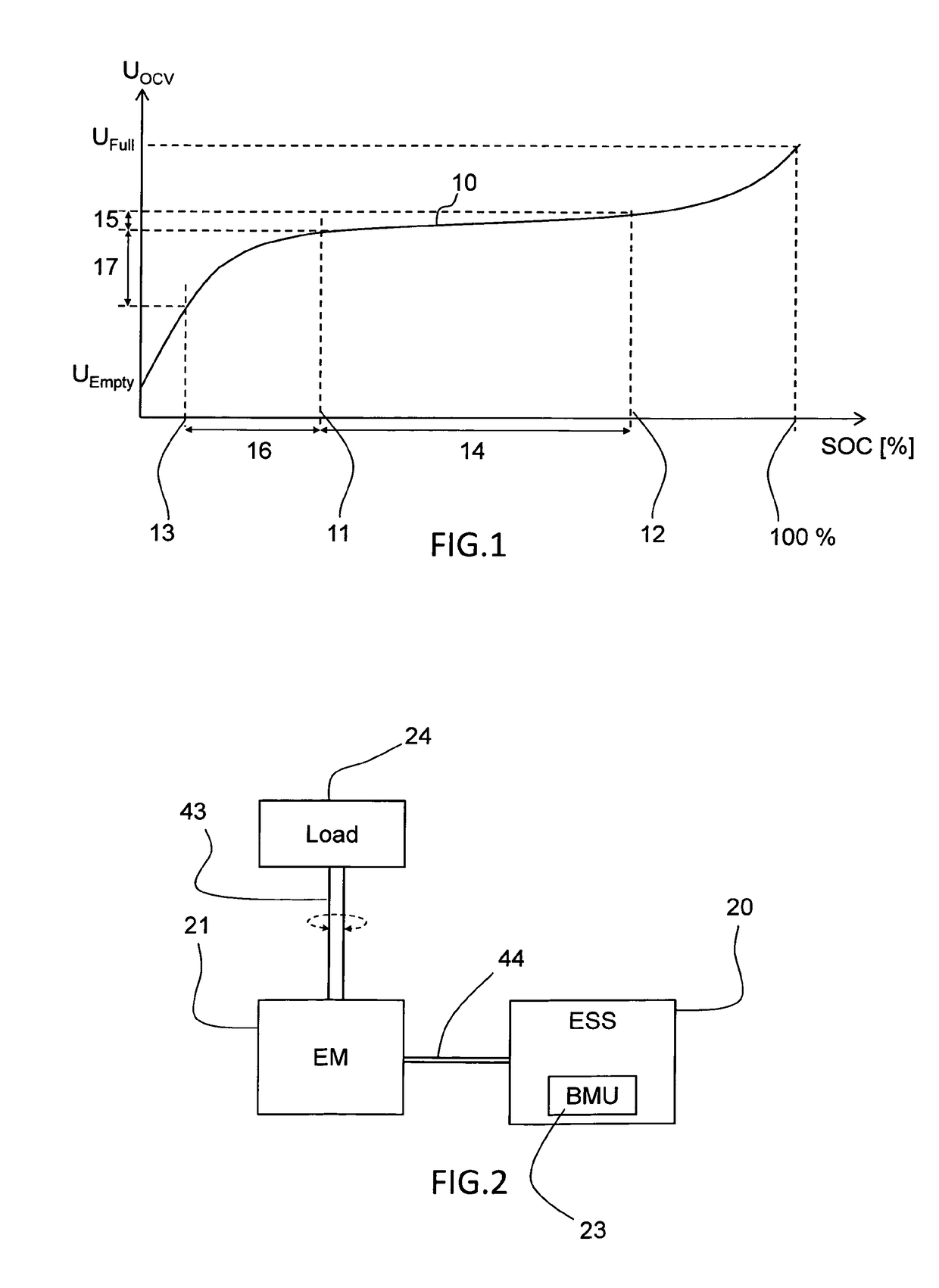

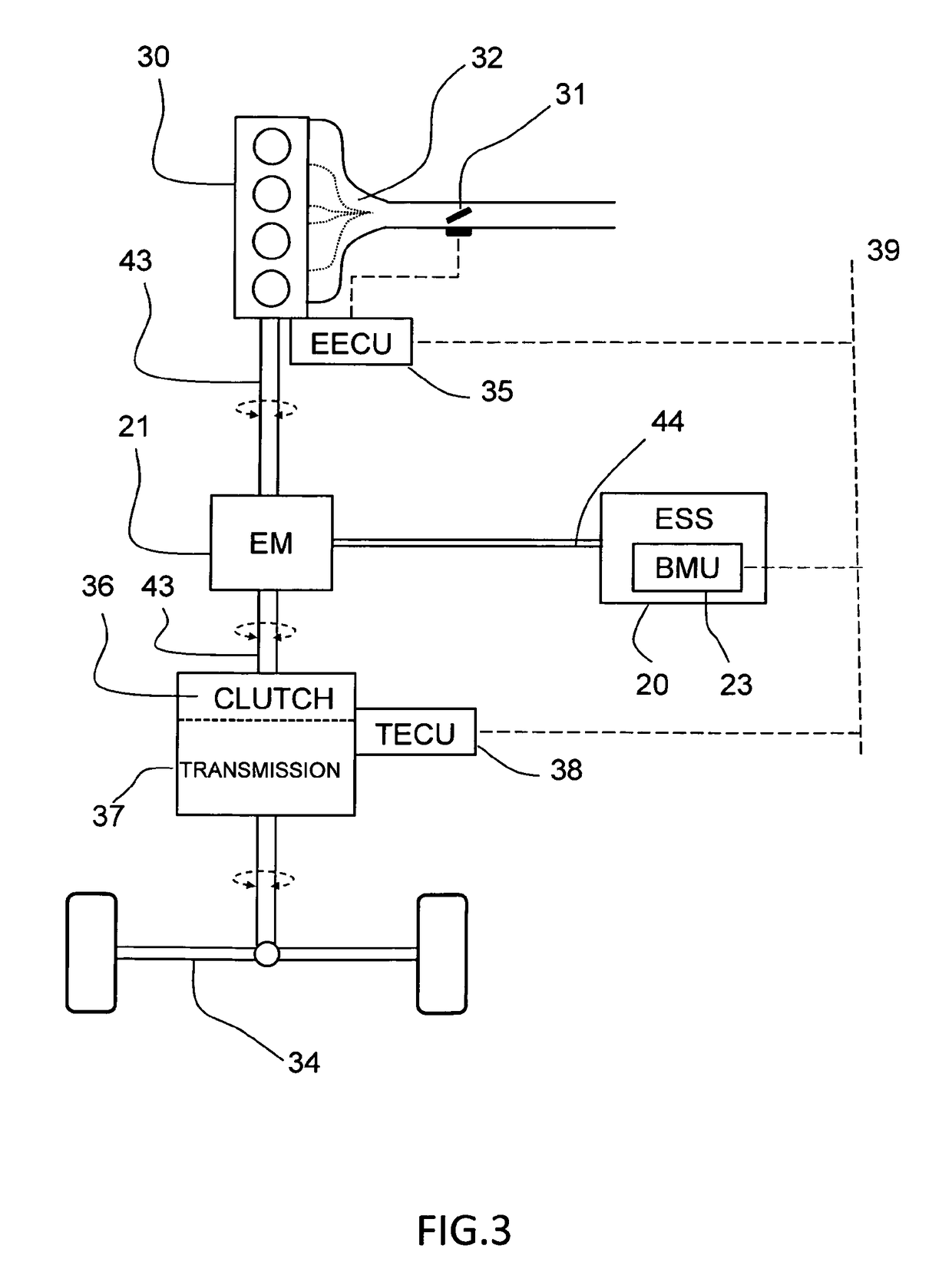

Method for balancing the voltage of battery cel

ActiveUS20160001673A1Fast discharge rateHigh discharge rateCharge equalisation circuitPower to auxillary motorsElectricityElectrical battery

A method is provided for balancing the voltage of multiple series-connected electrochemical cells of an electrical storage system of a hybrid electric vehicle. The method includes discharging the electrical storage system by operating at least one large electrical machine of the vehicle at vehicle standstill until the state of charge of the electrical storage system or the cell having the lowest state of charge has reached a predetermined level, and subsequently balancing the voltage of the cells.

Owner:VOLVO LASTVAGNAR AB

Water-and-hot-water mixing device

InactiveUS8317110B2Short discharge timeShorten discharge timeTemperature control without auxillary powerOperating means/releasing devices for valvesElectrical resistance and conductanceEngineering

A water-and-hot-water mixing device includes a mixing valve unit which mixes hot water and water and discharges mixed water therefrom, an operation part which sets a predetermined temperature, a mixed water thermistor which detects a temperature of mixed water, a hot-water thermistor which detects a temperature of hot water supplied to the mixing valve unit, and a controller which performs a feedback control of a discharge water temperature by controlling the mixing valve unit. The controller starts the feedback control when the controller determines that a change amount of the temperature of the hot water per unit time detected by the hot-water thermistor is not more than a fixed value and the temperature of the hot water detected by the hot-water thermistor is not lower than the predetermined temperature.

Owner:TOTO LTD

Artificial propagating and releasing method for fish fries

ActiveCN105075950AShort discharge timeImprove efficiencyClimate change adaptationPisciculture and aquariaMaterial resourcesFishery

The invention provides an artificial propagating and releasing method for fish fries. The method comprises the steps that 1, preparation before releasing is performed, wherein the fries, a releasing water wagon or water tank and a releasing fish delivery pipeline are selected; 2, the fries are loaded onto a car, wherein before the fries are loaded onto the car, the releasing water wagon or water tank, the fish delivery pipeline and other releasing tools are disinfected, the water addition quality, the oxygenation quality and the water temperature of the releasing water wagon or water tank are controlled, and the fry density is controlled when the fries are loaded onto the car; 3, the fries are released, wherein one end of the fish delivery pipeline is communicated with the releasing water wagon or water tank, and the other end of the fish delivery pipeline is placed into a target releasing sea area for releasing. The running water car is adopted for transportation in the whole releasing process, oxygen charging packaging treatment is not needed, and a ship does not need to be rent; the operation technology is simple, rapid and high in efficiency, damage to the fries is little, the survival rate is high, the labor intensity is low, and a large amount of manpower and financial and material resources are saved.

Owner:MARINE BIOLOGY INST OF SHANDONG PROVINCE

Ramming device and ramming method

The invention discloses a ramming device and a ramming method. The device comprises a rammer, a rammer board, a supporting mechanism and a ramming force generating mechanism, wherein the supporting mechanism is used for providing support for the rammer and the rammer board so as to enable the rammer and the rammer board to freely move on the supporting mechanism; the ramming force generating mechanism comprises a metal channel and / or a liquid channel used for utilizing a first impact force generated by electrified explosion of metal inside the metal channel, a second impact force generated bythe power supply to the liquid, or the gasification explosion generated by electrified the metal in the metal channel, and third impact force generated by reaction of the metal and the liquid are usedas the driving force of the ramming to drive the rammer board to ram the ground; and meanwhile, the rammer moves towards the air under the action of the driving force, and after a certain height is reached, the rammer falls freely, so that the rammer board is driven by the rammer to rammed the ground the second time. According to the device and the method, the ramming device with simple structure, economy, feasibility, convenient construction, remarkable effect, high efficiency, low energy consumption, safe, reliability, free of pollution and wide application range is provided for foundationcompaction.

Owner:HUAZHONG UNIV OF SCI & TECH

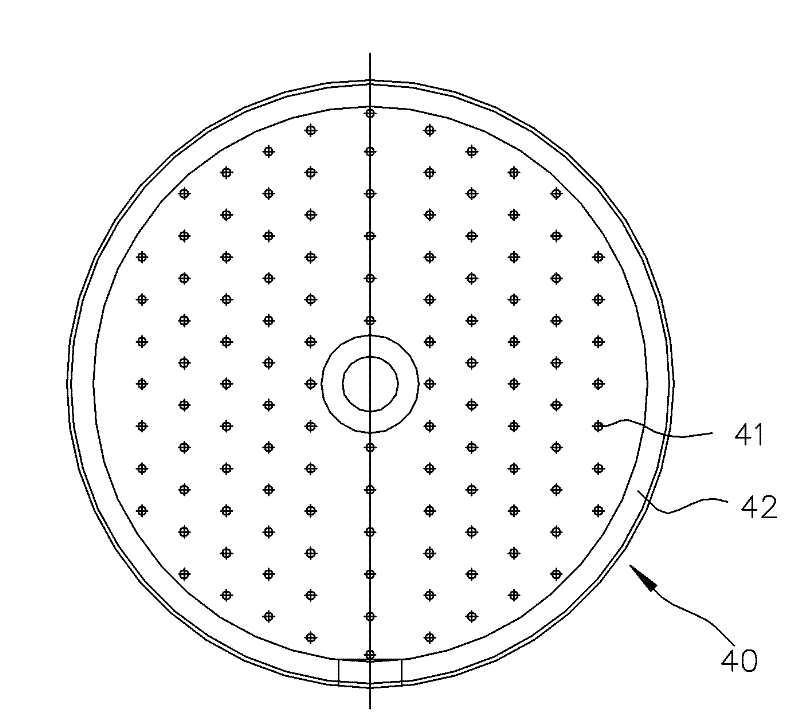

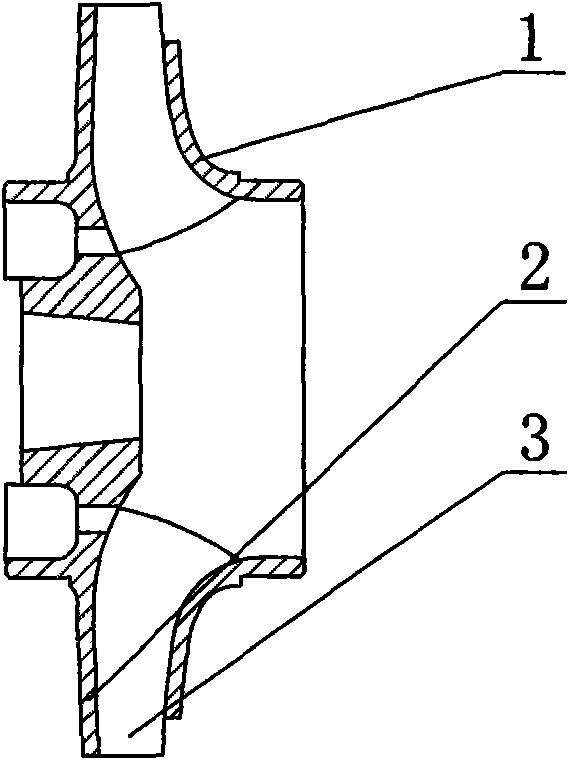

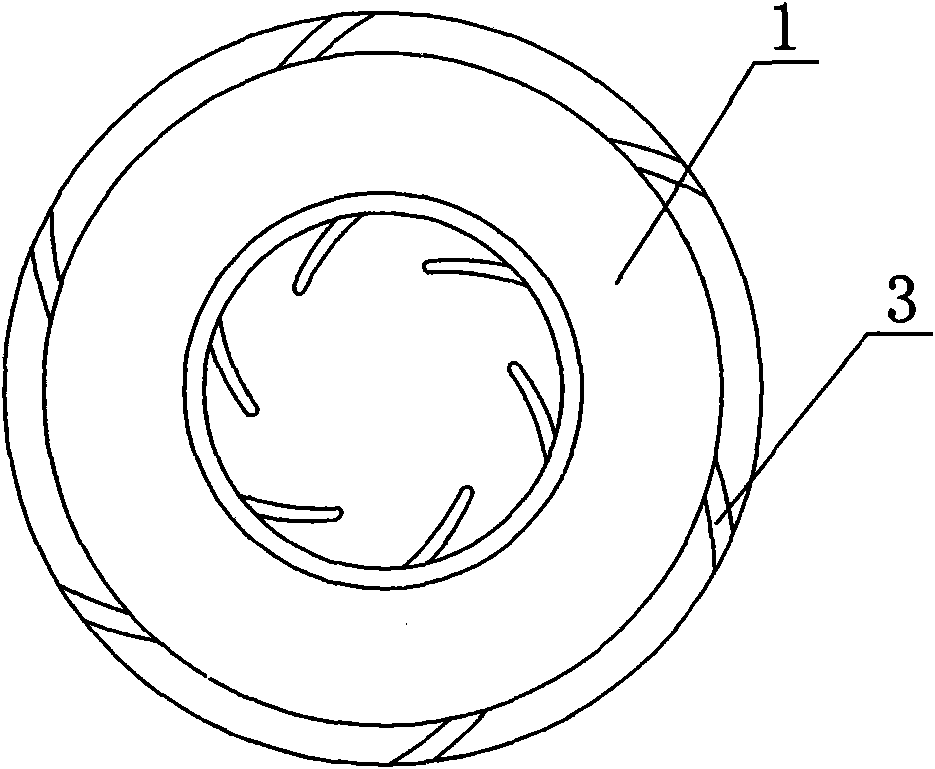

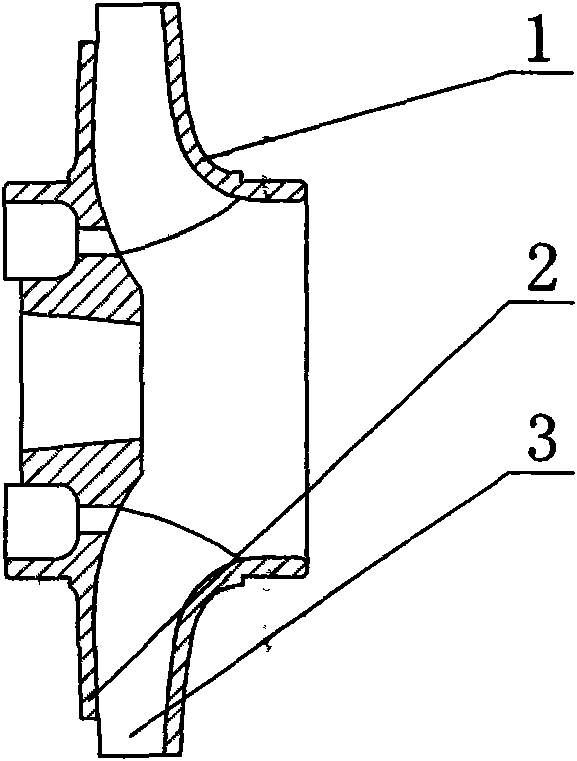

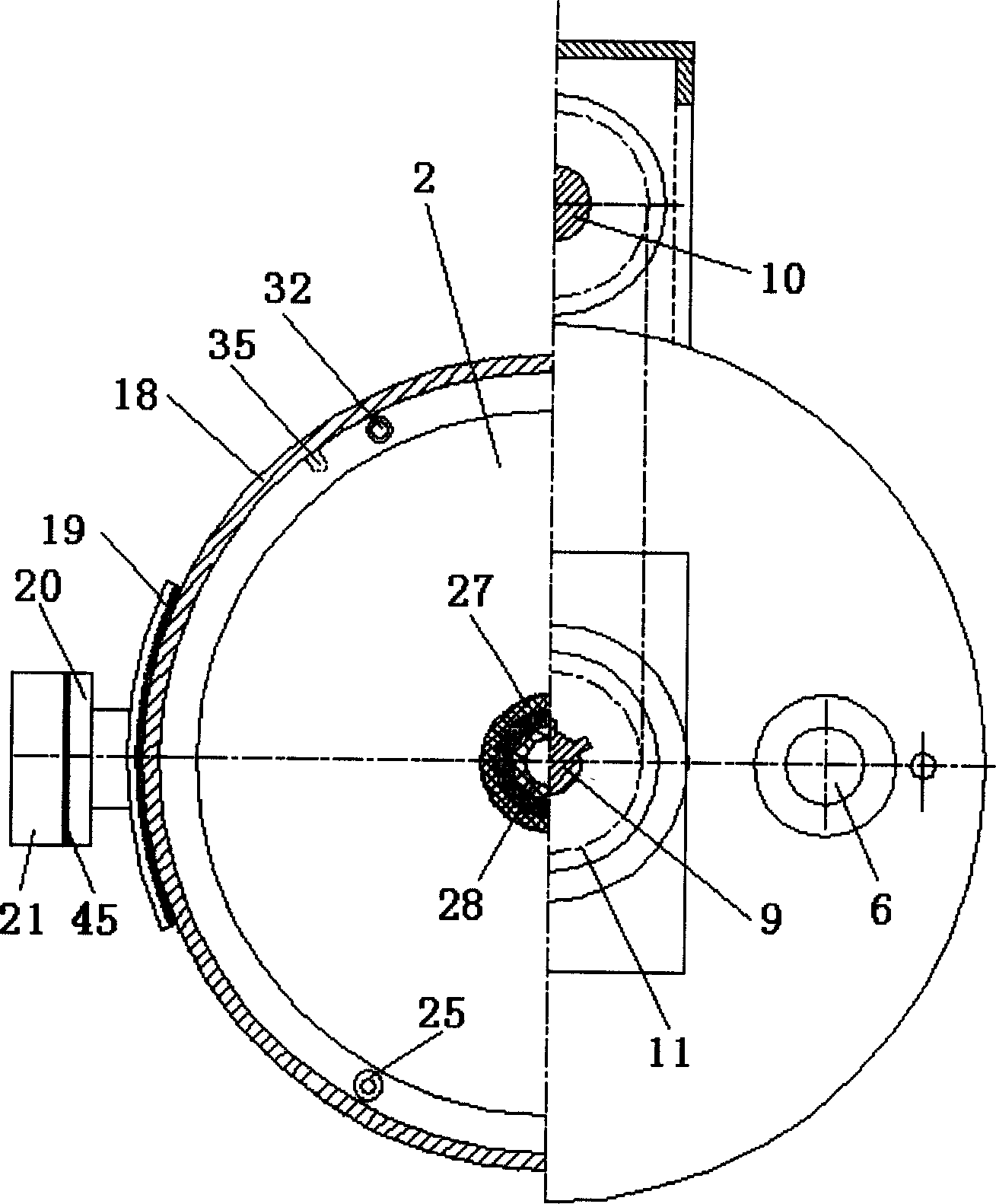

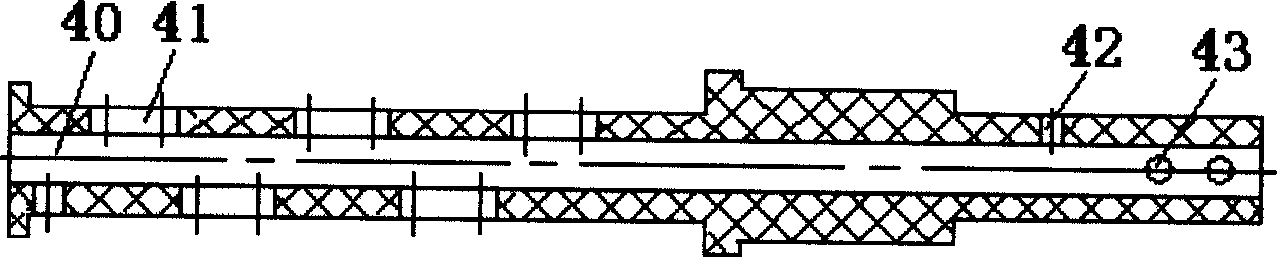

Impeller of externally mixed type self-priming pump

InactiveCN102022374AIncrease contact areaStrong agitationPump componentsPriming pumpAgricultural engineeringFront cover

The invention discloses an impeller of an externally mixed type self-priming pump, relating to pumps. A front cover plate and a rear cover plate are arranged on the impeller, blades are arranged between the front cover plate and the rear cover plate, and annularly cut belts are arranged on the external diameters of the cover plates. As the annularly cut belts are arranged on the external diameters of the cover plates, the blades at the parts of the annularly cut belts are not covered by the cover plates, the blades are exposed, and the contact area of the blades with liquid is large. When the pump starts to work, gas and liquid are well mixed by strong agitation force in the pump, gas discharge time is short, and water is quickly pumped. The impeller is suitable for externally mixed type self-priming pumps.

Owner:山东壮发泵业股份有限公司

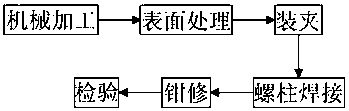

Method for welding combustor liner and tile pads of aeroengine

ActiveCN108500428AReduce the amount of cuttingSmall thermal deformationArc welding apparatusAviationEngineering

The invention relates to the technical field of aeroengines, in particular to a method for welding a combustor liner and tile pads of an aeroengine. The method for welding the combustor liner and thetile pads of the aeroengine comprises floating tile blocks and studs, and the floating tile blocks and the studs use forging pieces as raw materials, and the welding technological steps of the floating tile blocks and the studs are as follows: (1) machining; (2) surface treatment; (3) clamping; (4) stud welding; (5) gripping and repairing; and (6) inspection. By adopting the method disclosed by the invention, the studs are welded to the floating tile blocks by adopting a argon arc welding way, and the verticality deviation of the studs is larger; meanwhile, the phenomenon of incomplete fusionin a central area on which the studs are connected with the floating tile blocks possibly occurs so as to affect the welding strength and low welding and positioning precision of the studs; by adopting an overall machining way, the metal cutting quantity is large, so that a material utilization ratio of the materials is low, and a machining period is long; and moreover, in a machining and cuttingprocess, high-temperature cutting heat deformation easily occurs, and a destressing heat treatment procedures are required after machining, so that the problems of the production cost and the periodsare further increased.

Owner:广汉天空动力机械有限责任公司

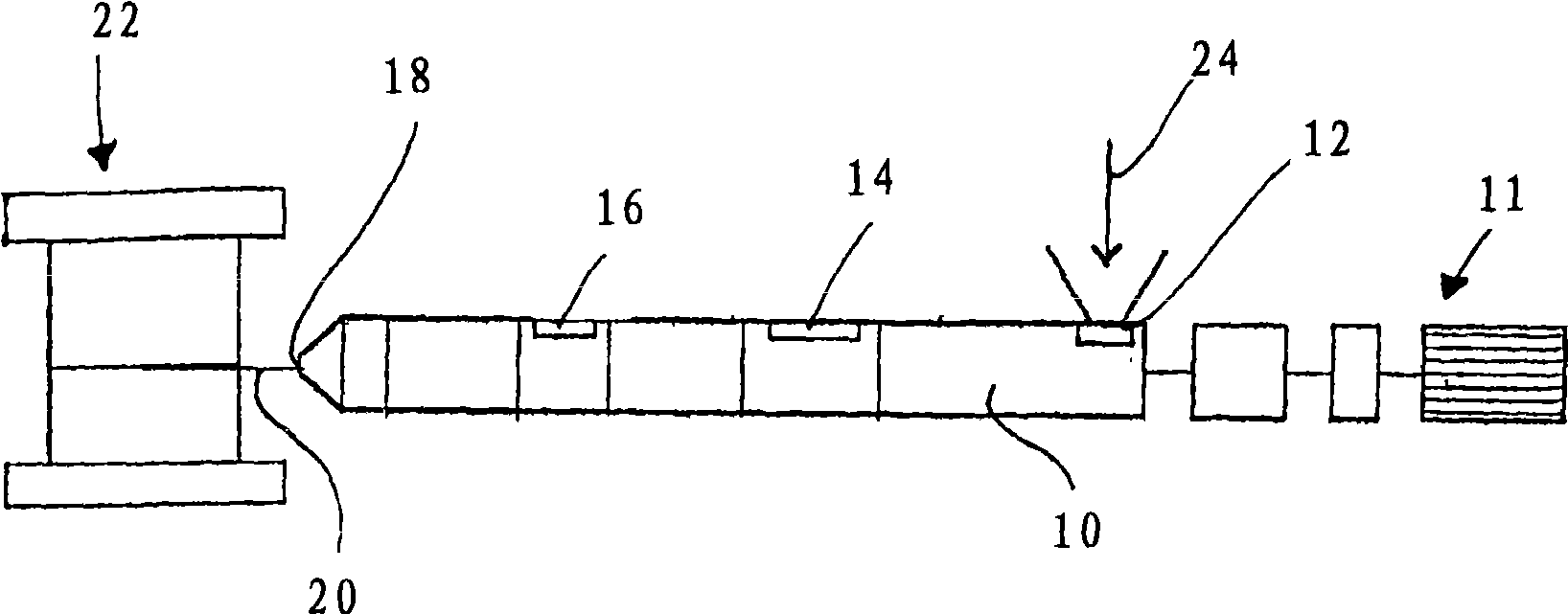

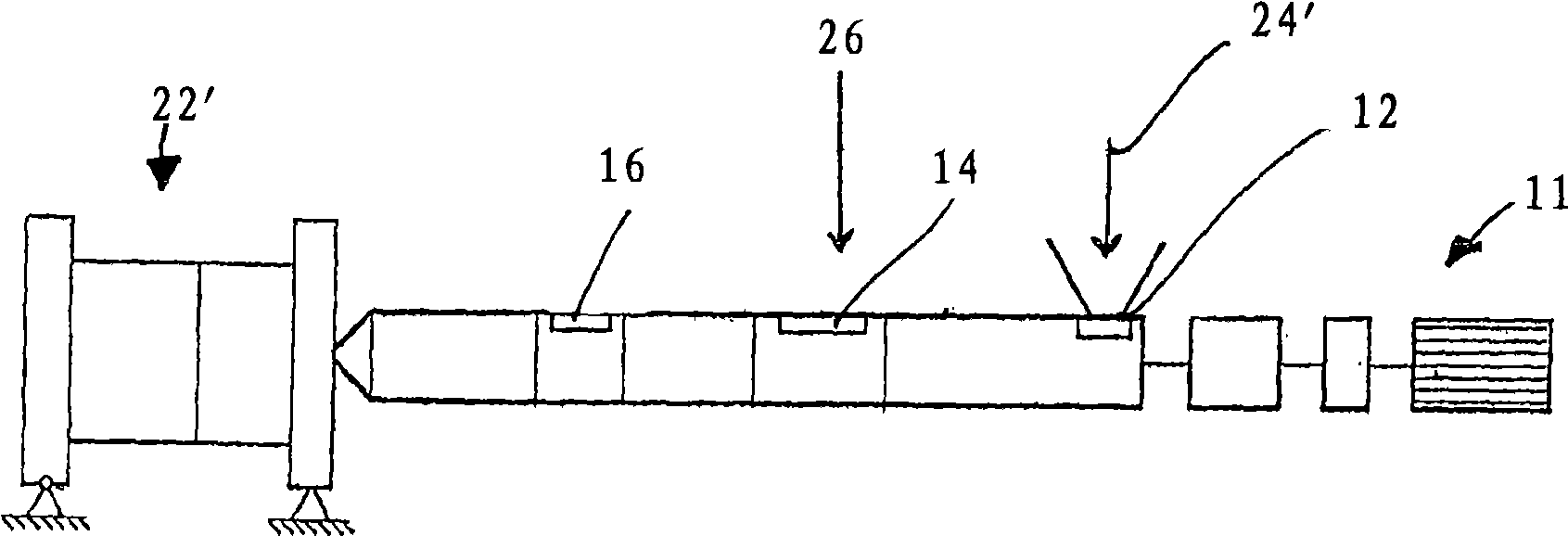

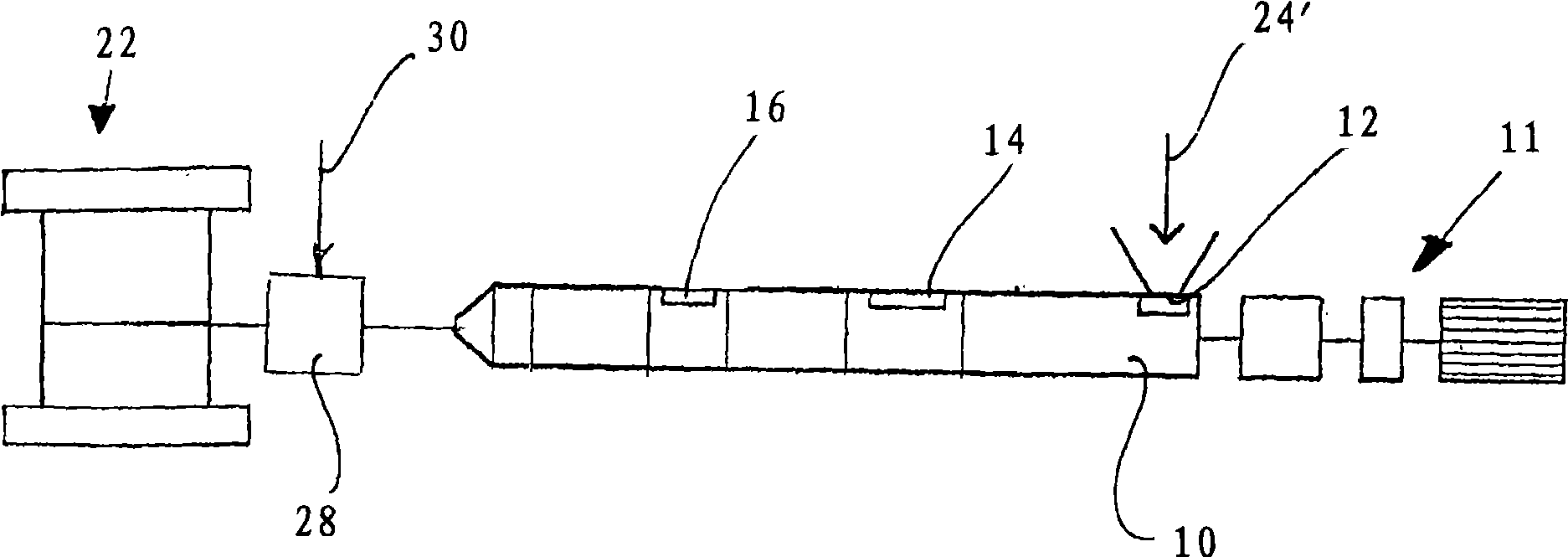

Device and method for processing thermosetting plastics

The present invention relates to a method for processing thermosetting plastics, particularly thermosetting polyurethane, as well as a device for performing such a method. The device comprises an extruder device (10) having a cylinder, in which an extruder screw is received in a rotating manner, wherein the cylinder has at least one inlet opening (12, 14, 16) and one outlet opening (18), and that at least one inlet opening (12) of the cylinder is provided for filling the plastic material into the cylinder, as well as a tool (22), into which, or by means of which the material discharged by the extruder device can be guided in or through. According to the invention the device is characterized in that at least one inlet opening (12, 14, 16) is configured for the feeding of at least one cross-linked or reactive component of a thermosetting plastic.

Owner:KRAUSSMAFFEI TECH GMBH

Method for balancing the voltage of battery cells

ActiveUS9868360B2Increase powerShort discharge timeCharge equalisation circuitPower to auxillary motorsElectricityElectric machinery

A method is provided for balancing the voltage of multiple series-connected electrochemical cells of an electrical storage system of a hybrid electric vehicle. The method includes discharging the electrical storage system by operating at least one large electrical machine of the vehicle at vehicle standstill until the state of charge of the electrical storage system or the cell having the lowest state of charge has reached a predetermined level, and subsequently balancing the voltage of the cells.

Owner:VOLVO LASTVAGNAR AB

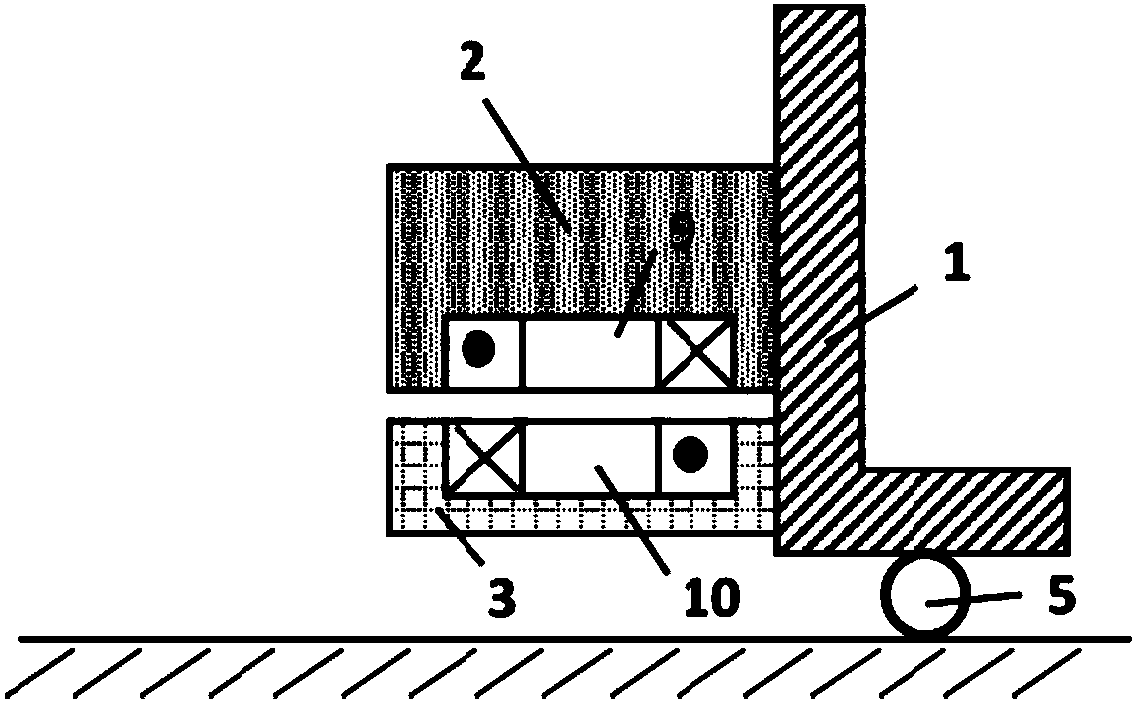

Discharge structure

ActiveCN108113887ASlow and steady slideImprove general performanceOral administration deviceCamElectrical and Electronics engineering

The invention relates to a discharge structure comprising a bracket; at least one slideway, a blocking part and at least one cam and / or at least one eccentric wheel, wherein the at least one slidewayis slantly mounted on the bracket and used for supporting a to-be-conveyed article and enabling the to-be-conveyed article to slide down by means of its own gravity; the blocking part is disposed at the bottom end of the slideway and used for preventing the to-be-conveyed article from further sliding down; and the at least one cam and / or the at least one eccentric wheel are / is disposed at the bottom end of the slideway and used for jacking up the to-be-conveyed article by rotation, so that the to-be-conveyed article crosses across the blocking part to continue to slide down. The discharge structure can ensure medicine boxes are output one by one quickly and accurately.

Owner:SOLEE WUHAN SCI & TECH

Coaction type food biochemical treating equipment

InactiveCN1623447AKeep the flavorKeep the tasteFood preservationLavatory sanitoryBiochemical engineeringHigh energy

A pulse discharge and ultrasonic wave cooperative biochemical process for the food, medicine, chemicals, etc is prepared of a high-energy instantaneous sterilizing, separating and extracting unit, a low-energy gene extracting, inducing and fusing biofermentor, a sewage treating unit, and a discharge unit with rotary positive and negative electrodes. Its advantages are compact structure and high sterilizing effect.

Owner:JIANGNAN UNIV

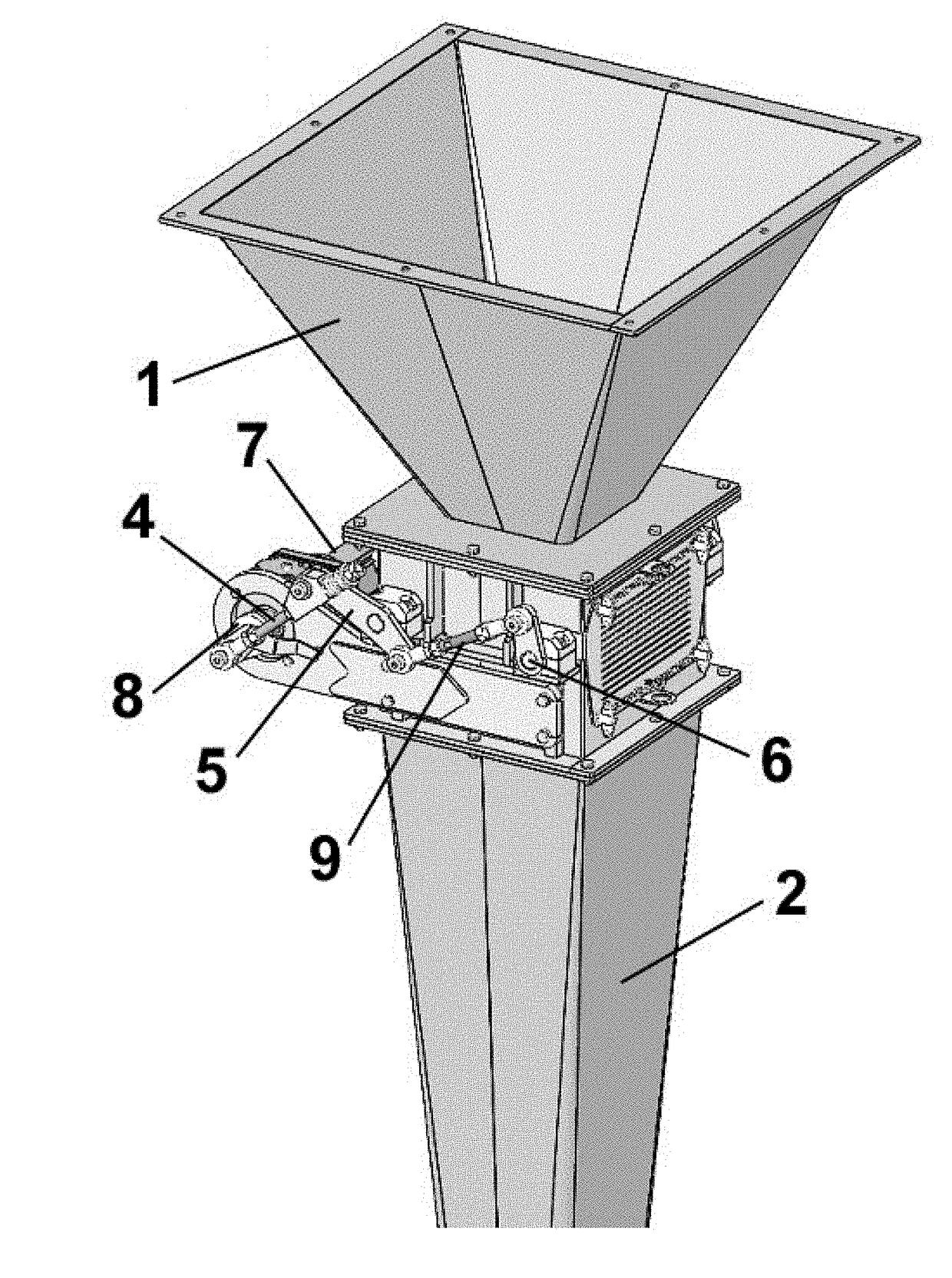

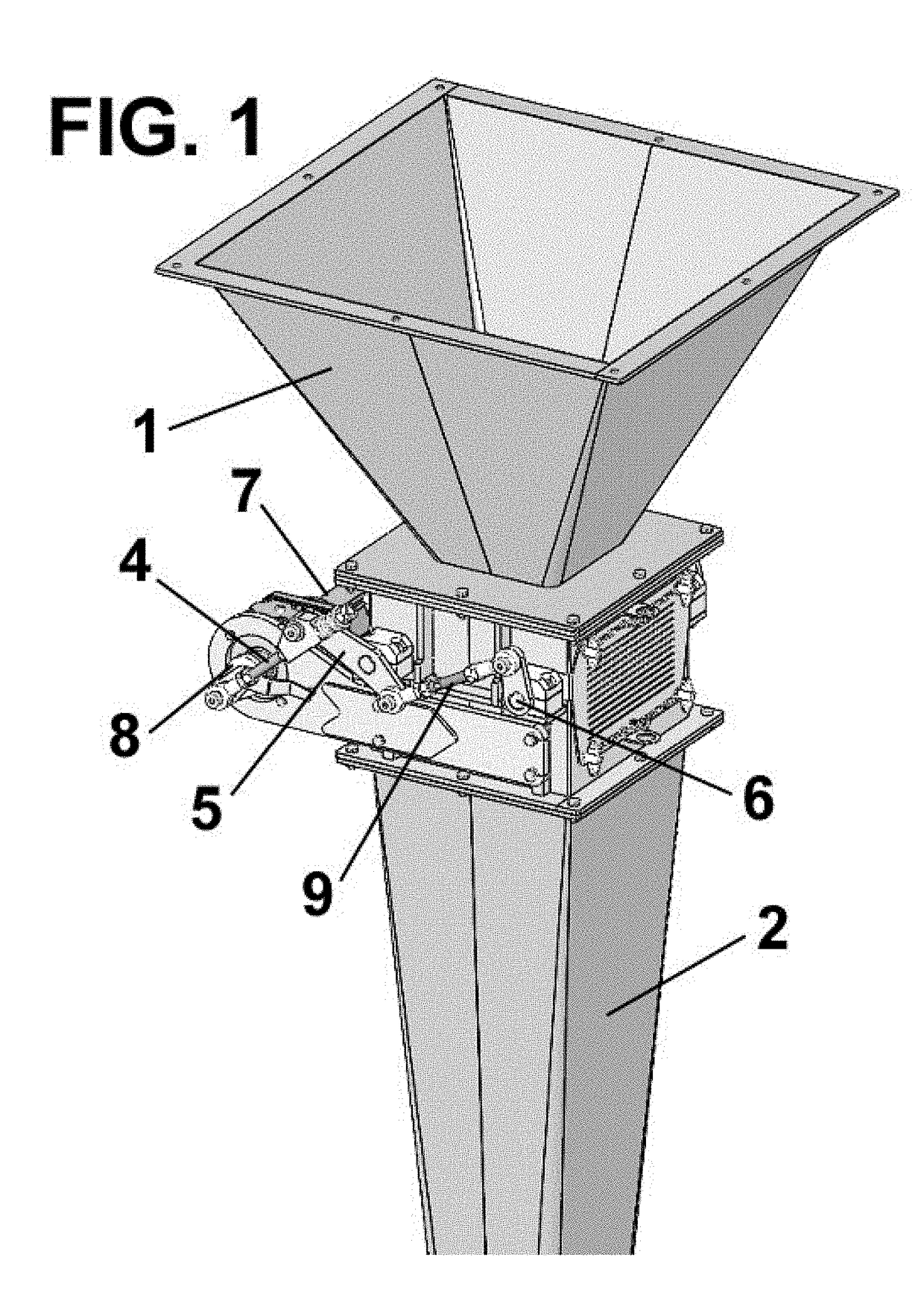

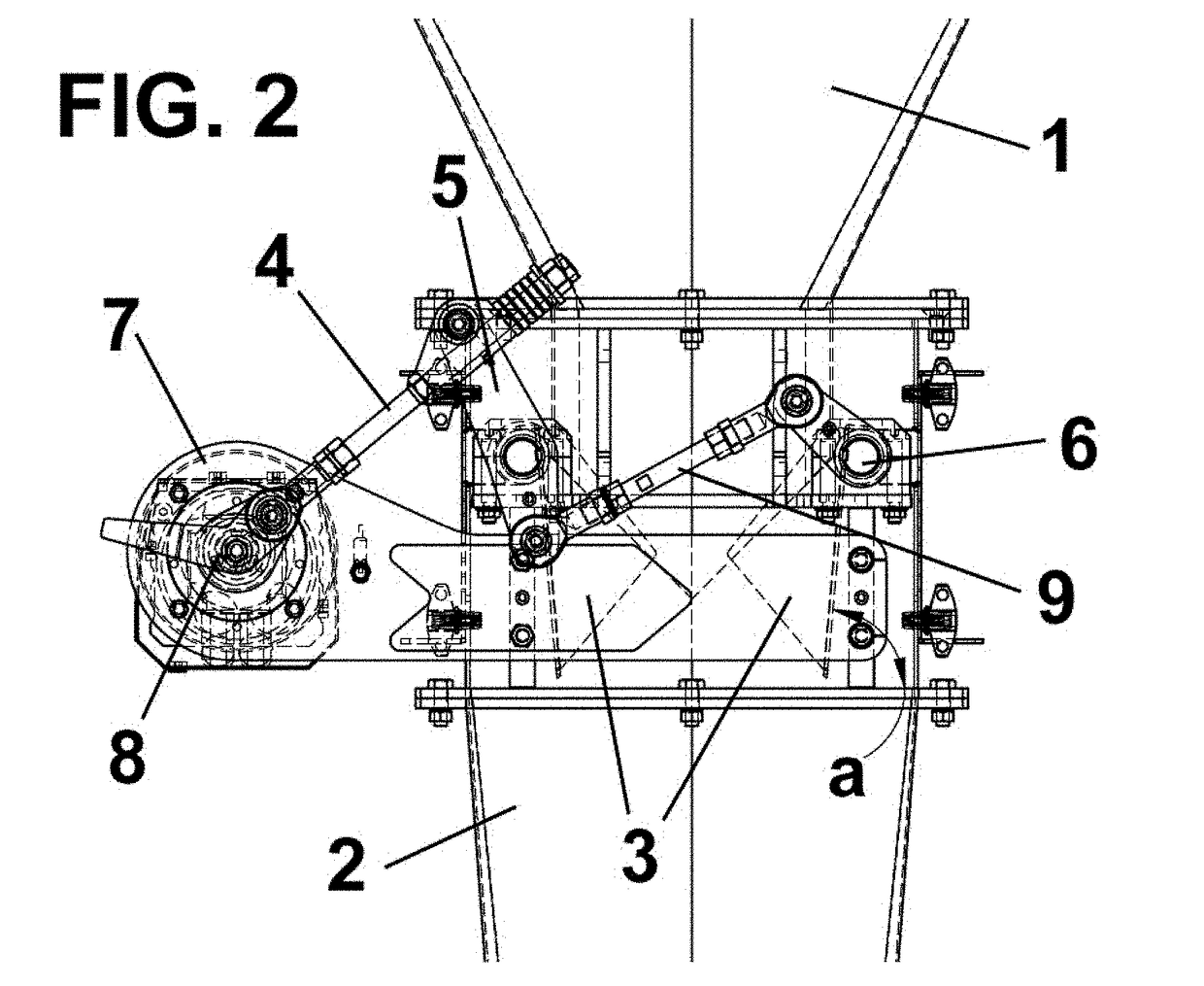

Product discharge control device for a form-fill-seal machine

ActiveUS20180141690A1Short timeShort discharge timeSolid materialPackaging automatic controlElectric machineryEngineering

The invention relates to a discharge control device, comprising a hopper (1) receiving a metered product amount where it is deposited, discharge control elements (3) movable between a closed position and an open position by driving means, and a fill tube (2) connecting the discharge control device with a fill nozzle of the form-fill-seal machine whereby a bag is filled with product, wherein the driving means of the discharge control elements (3) comprise a motor (7) driving the movement of one of the discharge control elements (3), and a synchronizing connecting rod (9) synchronizing the movement of the discharge control element (3) driven by the motor (7) with the other discharge control element (3).The invention allows filling bags reliably and more quickly.

Owner:PAYPER

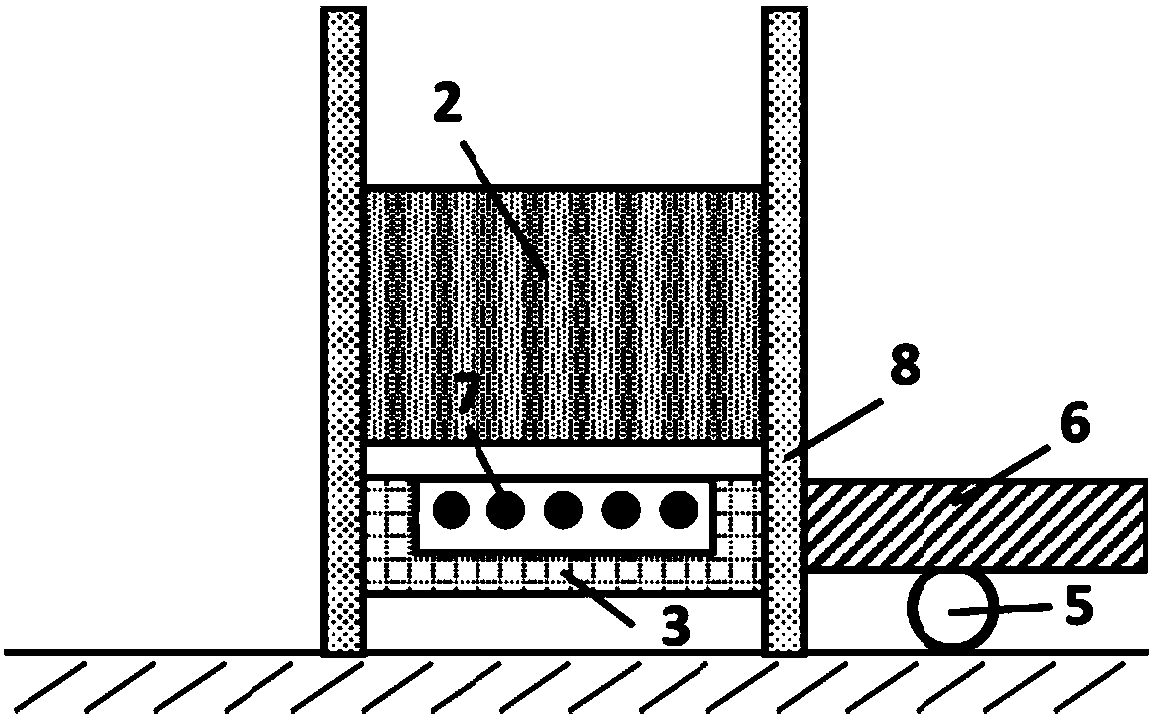

Tunnel construction ventilation method through pressing and extracting combination of airtight cavern

InactiveCN106285759AShort discharge timeImprove ventilationMining devicesTunnel/mines ventillationFresh airEngineering

The invention relates to a ventilation method for tunnel construction. The problems that smoke exhaust time is long and the ventilation effect is poor during tunnel construction at present are main solved. Firstly, a press-in type ventilator and an extracting exhaust type ventilator are mounted at a tunnel portal, a retractable shielding gate is arranged on a secondary lining trolley close to a tunnel, an air pressing pipe of the press-in type ventilator and an exhaust pipe of the extracting exhaust type ventilator extend into an airtight cavern between the shielding gate and a tunnel face through the shielding gate, the shielding gate is closed before tunnel blasting, and smoke produced through blasting is sealed in the airtight cavern between the shielding gate and the tunnel face; then the extracting exhaust type ventilator is started, dirt air is exhausted out of the cavern, and meanwhile fresh air outside the cavern is pressed into the airtight cavern between the shielding gate and the tunnel face through the press-in type ventilator; and after the air quality of the airtight cavern reaches the requirement, the shielding gate is opened, and then the tunnel construction operation is conducted. The method has the advantages that the dirt air exhaust time is short, and the ventilation effect is good.

Owner:CHINA RAILWAY 19TH BUREAU GRP 1ST ENG

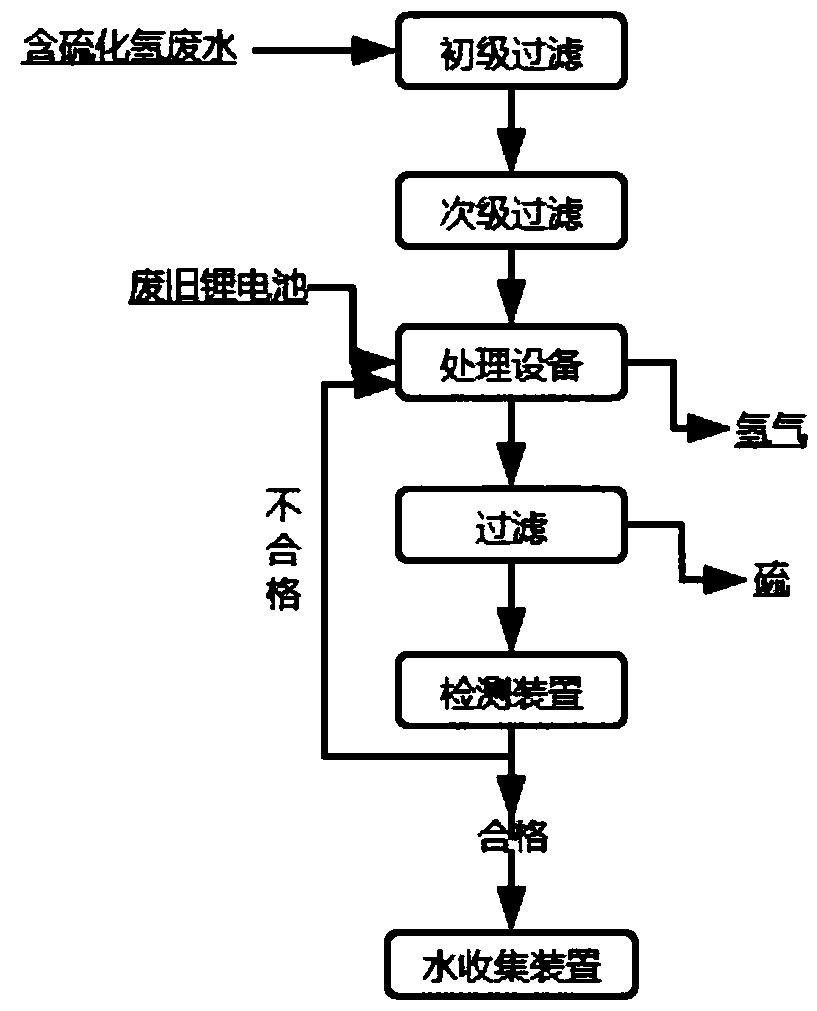

Combined treatment method of electric discharge of waste battery and desulfuration of waste water containing sulfur

ActiveCN110386700ARealize hydrogen productionAchieve sulfur fixationWater contaminantsTreatment involving filtrationElectric dischargeIndustrial waste water

The invention relates to the field of waste water and waste battery combined treatment, and particularly discloses a combined treatment method of electric discharge of a waste battery and desulfuration of waste water containing sulfur. The combined treatment includes the following steps that a battery group of a waste lithium ion battery or a battery monomer obtained by disassembling is placed inthe waste water containing the sulfur for electric discharge; the battery group or battery monomer after the electric discharge is conducted is separated, and water after desulfurization treatment isconducted is discharged; and the waste water containing the sulfur contains at least one H2S, HS- and S2-. According to the combined treatment method, full use of surplus energy in a waste lithium battery is achieved, cleaning is efficient, the disadvantages of the traditional treatment method of hydrogen sulfide in industrial waste water are overcome, and the combined treatment method is simple,practical, economic and feasible, and is suitable for industrial production.

Owner:CENT SOUTH UNIV

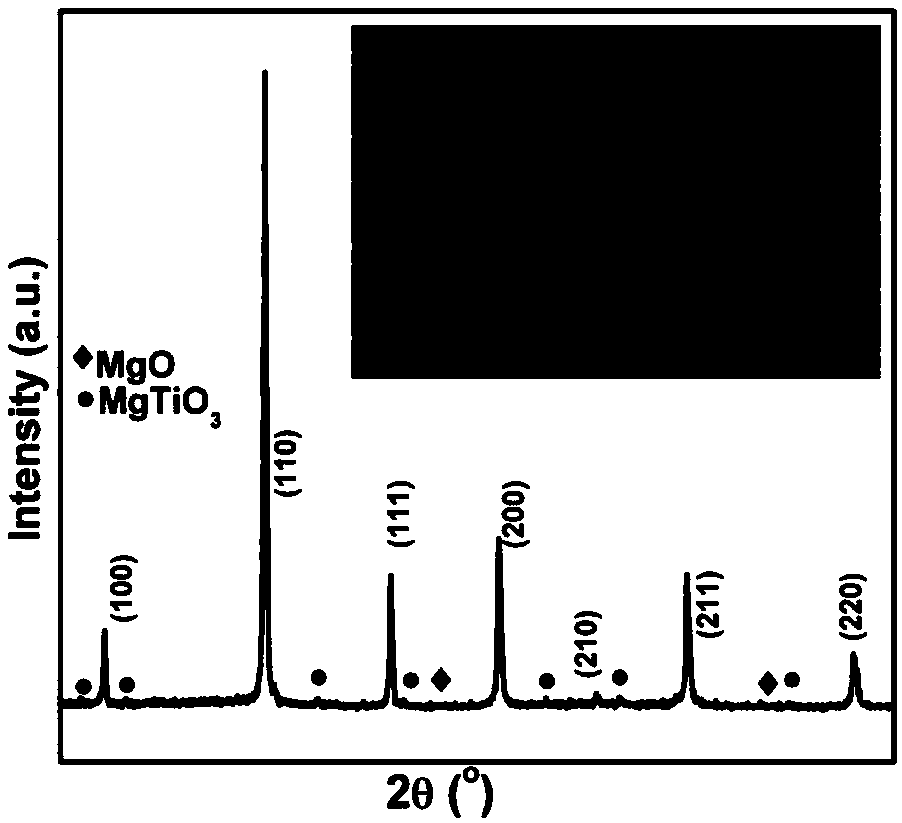

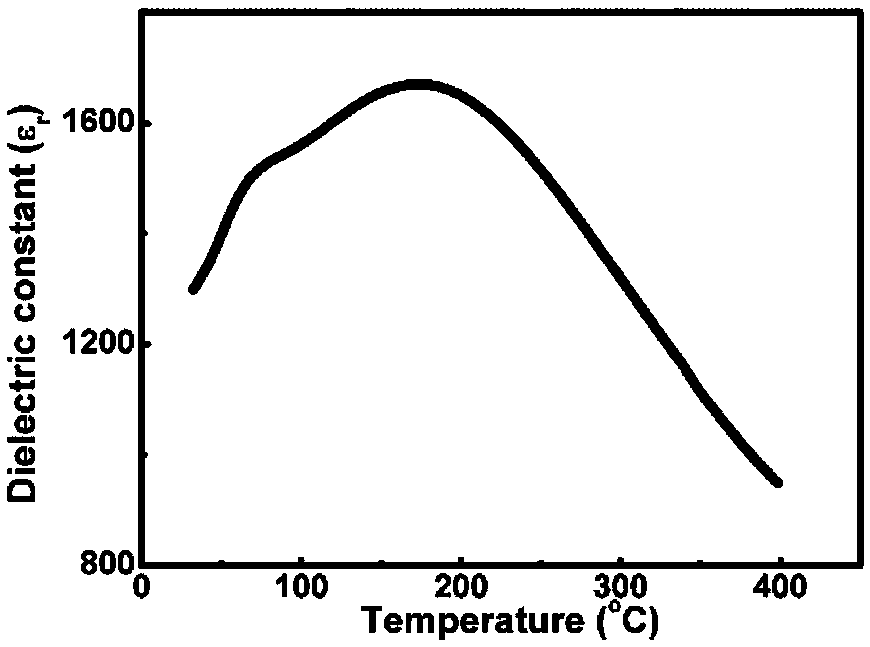

Composite material with high energy storage density and charge-discharge performance, and preparation method of composite material

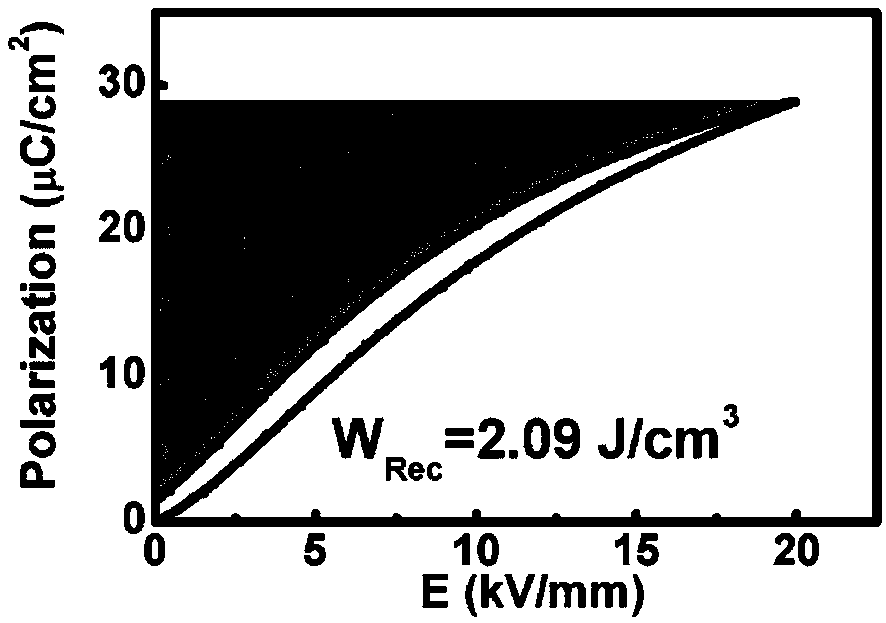

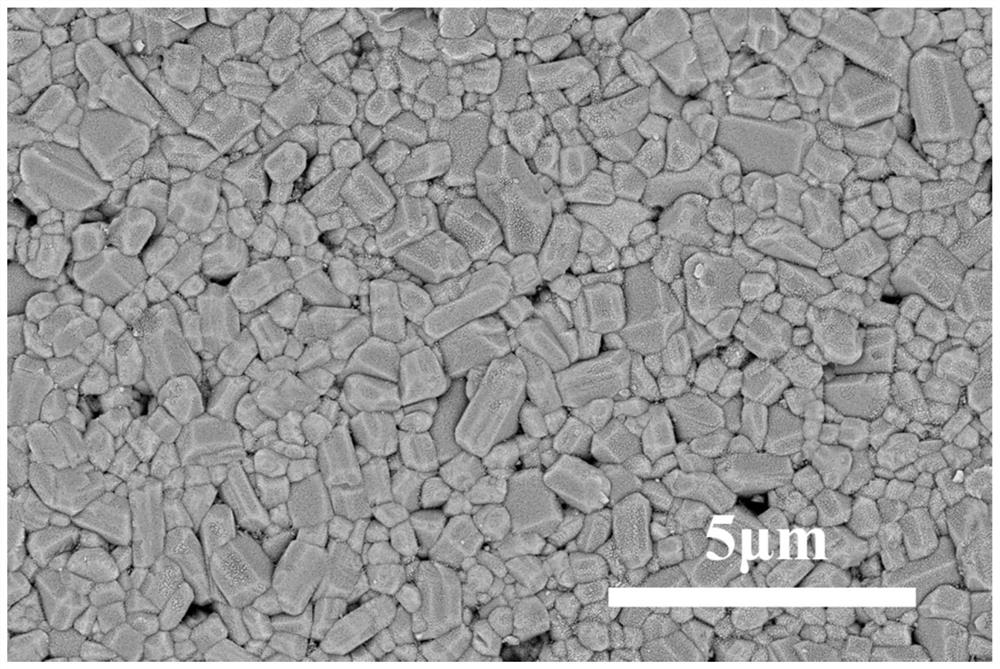

ActiveCN109320236AImprove temperature stabilityHigh energy storage densityFixed capacitor dielectricHigh energyCharge discharge

The invention relates to a composite material with high energy storage density and charge-discharge performance, and a preparation method of the composite material. The chemical formula of the composite material is (Bi0.32Sr0.42Na0.2[square]0.06)TiO3 / MgO, wherein [square] refers to a vacancy. Compared with the prior art, the composite material is lead-free and is an environment-friendly material;compared with antiferroelectric materials and other relaxant materials, a system disclosed by the invention has a large energy storage density (the energy storage density is 2.09 J / cm<3>), has the charge-discharge performance (the current density is 1671 A / cm<2>, and the power density is 150 MW / cm<3>), and has very short discharge time (0.15 mus). Particularly, the energy storage density and charge-discharge performance of the material are excellent in temperature stability. The excellent properties are beneficial to the application in pulsed capacitors, especially at high temperatures.

Owner:TONGJI UNIV

Bismuth strontium titanate-based lead-free ceramic material for efficient capacitor and preparation method of ceramic material

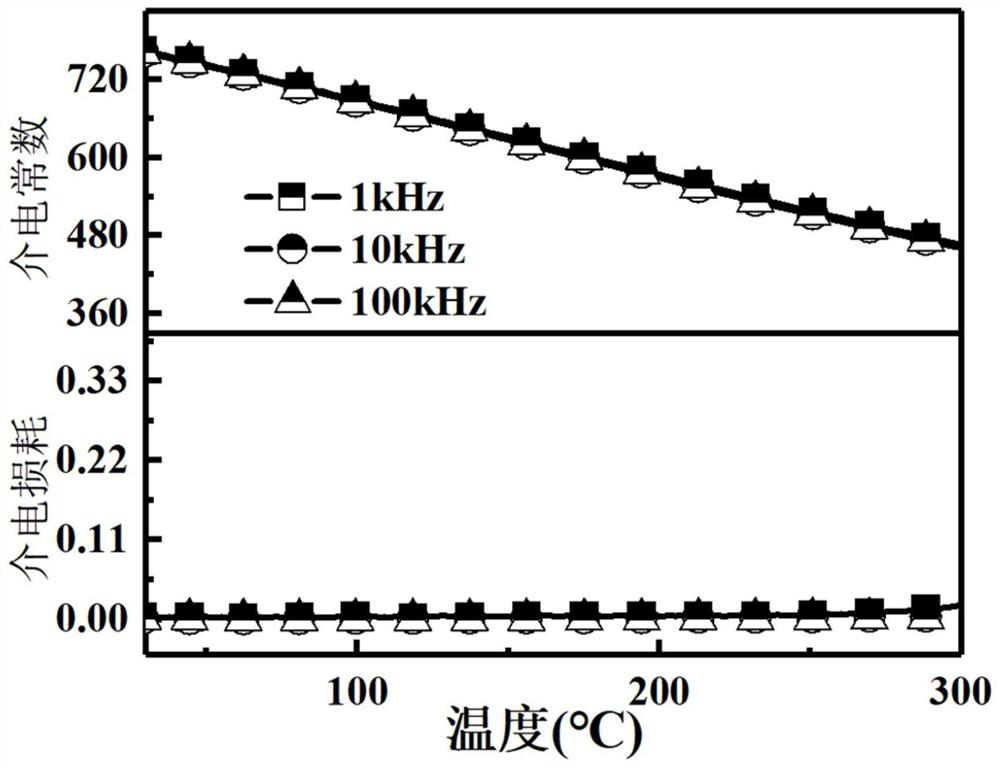

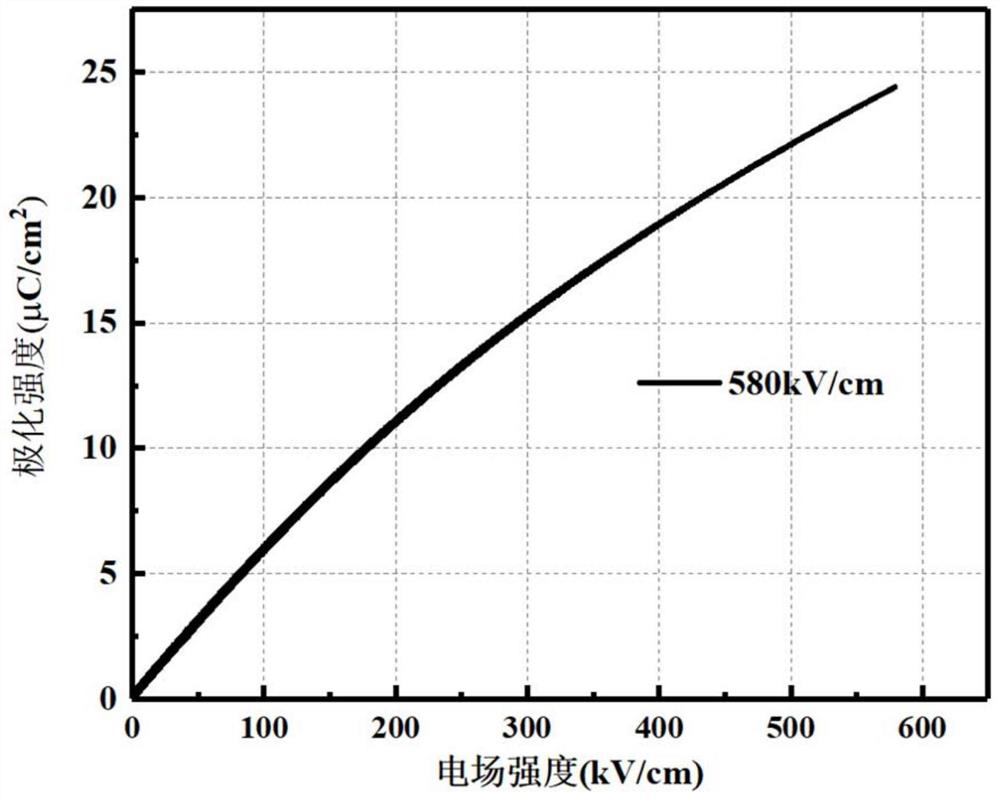

ActiveCN112919903AHigh energy storage densityImprove efficiencyFixed capacitor dielectricStrontium titanateComposite ceramic

The invention relates to a bismuth strontium titanate-based lead-free ceramic material for a high-efficiency capacitor and a preparation method of the ceramic material, and belongs to the field of electric energy storage materials. A solid-phase synthesis method is adopted, on the basis of a relaxor ferroelectric material Sr0.7Bi0.2TiO3, Nb and Ni heterovalent elements in a certain molar ratio are doped into the B site of a perovskite structure to increase the charge disorder of the perovskite structure, the novel composite ceramic is obtained, the chemical formula of the novel composite ceramic is (1-x)Sr0.7Bi0.2TiO3-xBi(Ni2 / 3Nb1 / 3)O3, and x is larger than or equal to 0 and smaller than or equal to 0.15. The main performance parameters of the energy storage ceramic material obtained by the invention can recover the energy storage density Wrec which reaches 4.19-5.98 J / cm<3>, and the energy storage efficiency eta reaches up to 92.6-98.6%. The method is simple in technological process, suitable for industrial production and capable of meeting the current lead-free and environment-friendly requirements.

Owner:HANGZHOU DIANZI UNIV

Coupling type heating method for preparing pyrogallic acid

InactiveCN1733671AIncrease the heating areaIncrease productivityOrganic chemistryOrganic compound preparationGallic acid esterPhysical chemistry

The invention discloses a process for preparing pyrogallol through coupled heating, which comprises using gallic acid as raw material, carrying out intermittent process flows including drying, sublimation, cooling down crystallization and vacuum decarboxylation with a totally coupled heating system and a semi-coupled cooling system, thus the pyrogallic acid can be crystallized and separated.

Owner:保廷荣

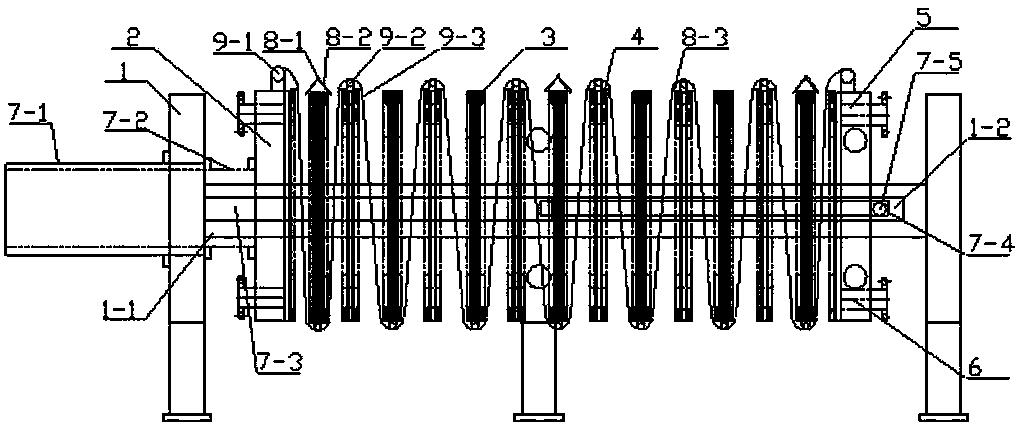

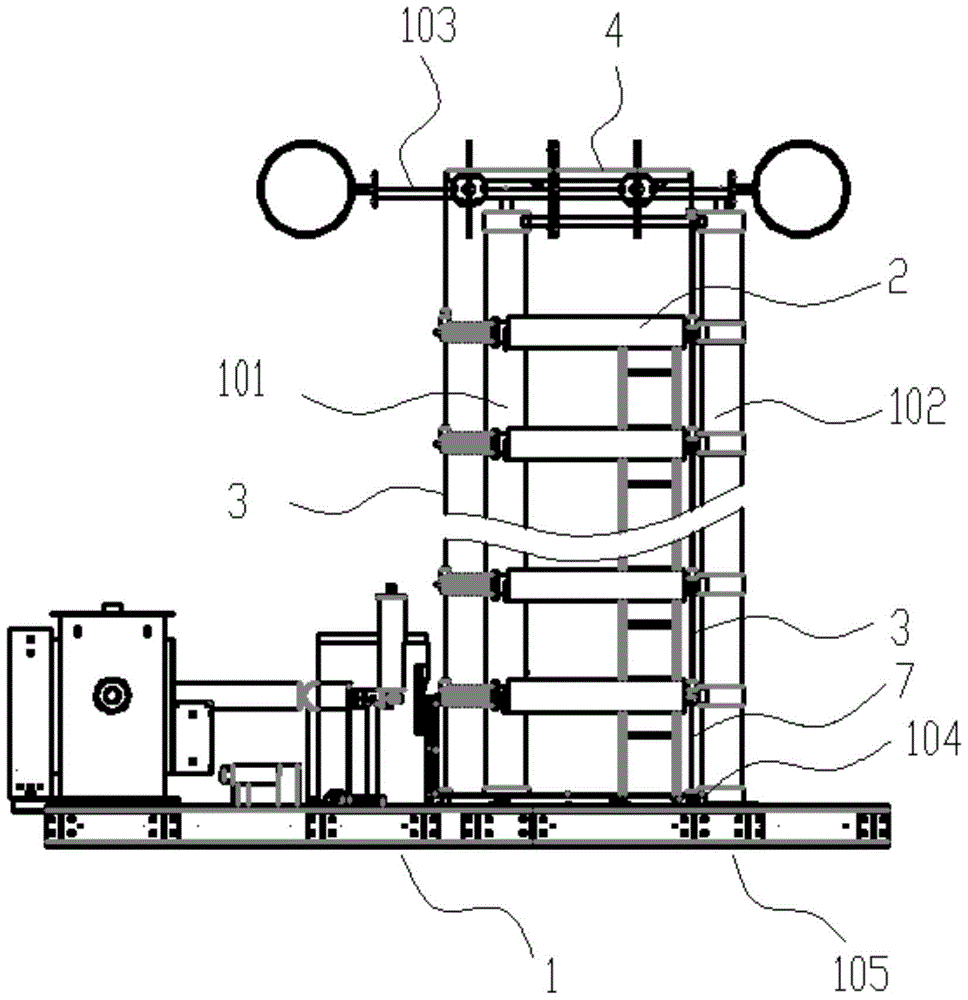

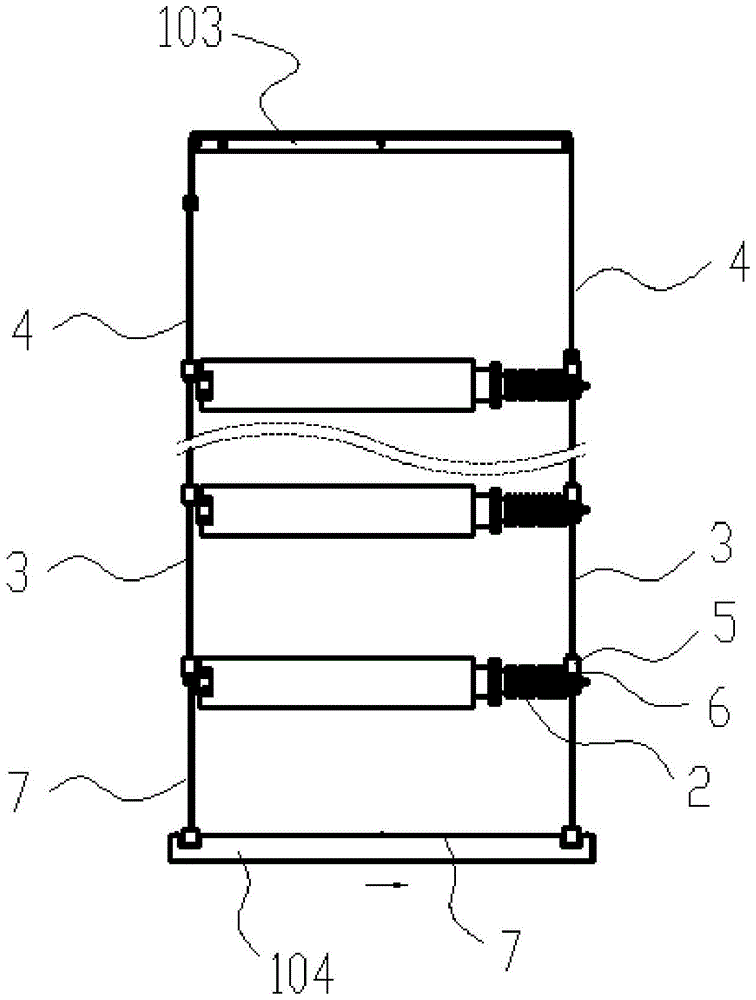

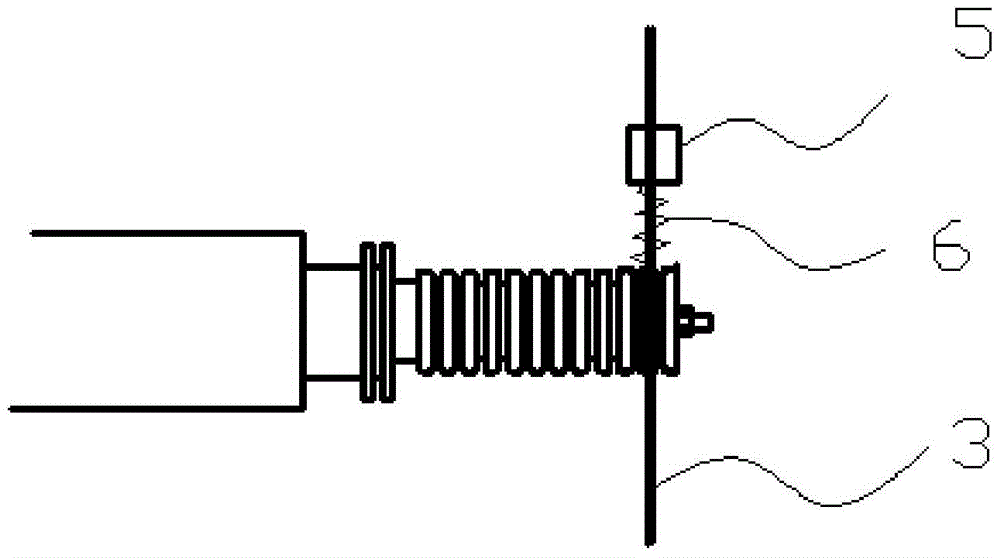

Impulse voltage generator

InactiveCN105044410AShort discharge timeStable and reliable structure operationTesting dielectric strengthElectrical measurement instrument detailsVoltage generatorCapacitance

The invention provides an impulse voltage generator. The generator comprises a rack, a capacitor, an insulation pull rod, an insulation synchronization belt and a discharge apparatus. The rack comprises a base plate 105, an insulation support column, an insulation crossbeam 103 and a conductive seat. The discharge apparatus comprises a metal block, a conductive tension spring and a conductive belt. During charging, capacitors, the capacitor and the conductive belt, the capacitor and the conductive seat and the like are disconnected so as to realize the charging. During discharging, the insulation synchronization belt moves so as to drive the insulation pull rod to move and drive the metal block to move. When the metal block moves to an adjacent capacitor pole, a loop is formed between all the capacitors and the conductive seat so that positive and negative electrode discharge of the capacitors and discharge to the ground are realized. Discharge time of the impulse voltage generator is short and structure operation is stable and reliable.

Owner:WUHAN HUAGAO H V EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com