Ejector capable of directly releasing energy by using superconducting magnet

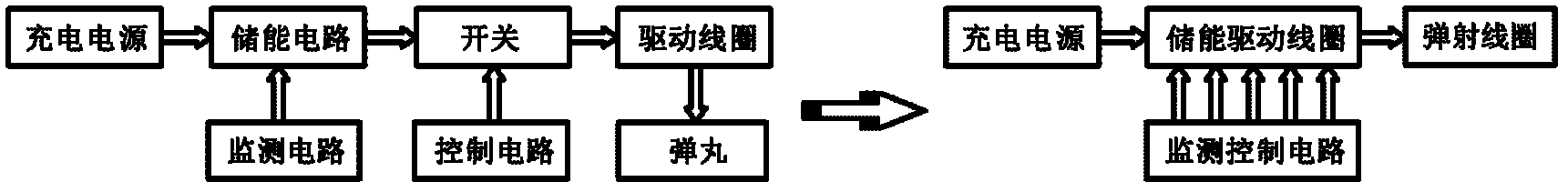

A technology of superconducting magnets and catapults, which is applied in the direction of launching/dragging transmission devices, etc., can solve problems such as no direct drive catapult system solutions, and achieve improved energy utilization efficiency, simplified energy conversion process, and strong electromagnetic driving force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is described in detail in combination with specific embodiments and accompanying drawings.

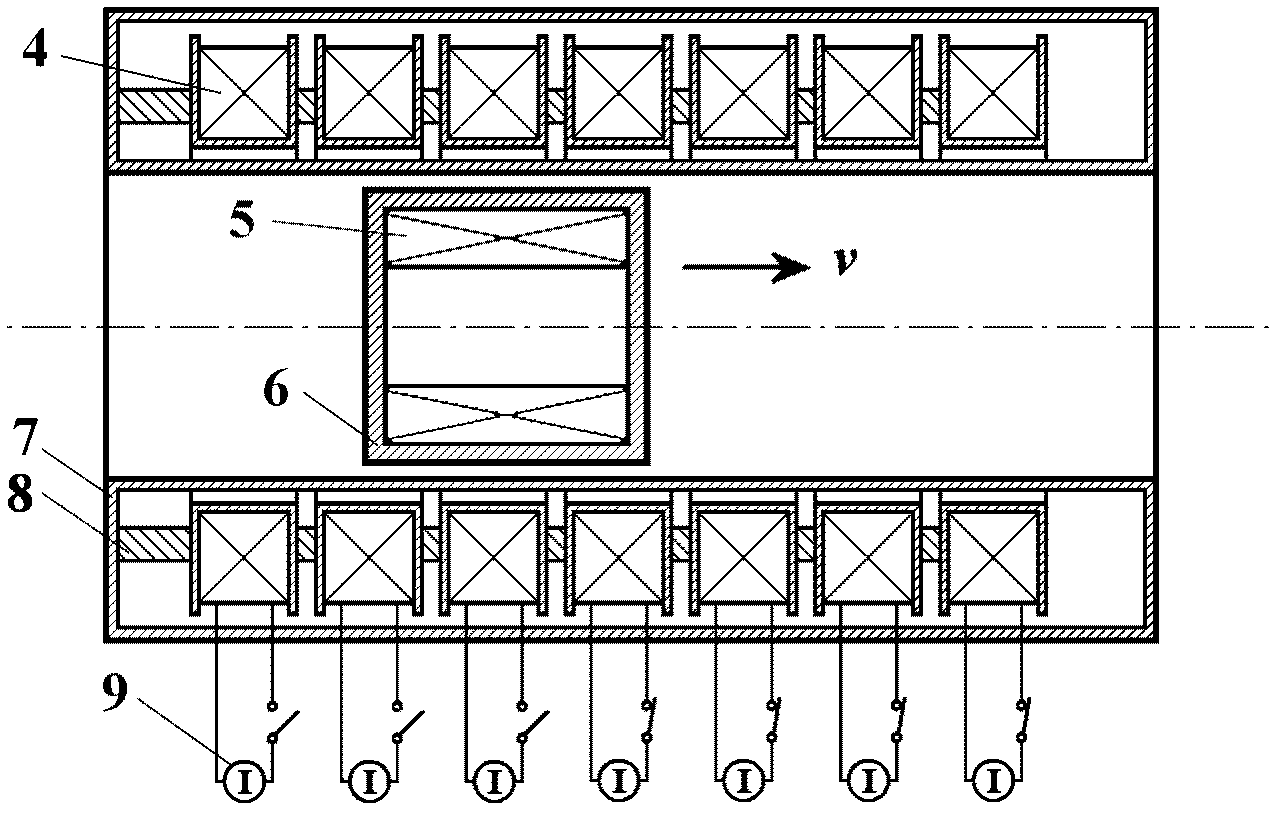

[0023] In the present invention, as figure 2 The superconducting electromagnetic catapult shown. The multistage superconducting driving coils 4 are coaxially arranged in a circular tube shape. Because the force in the working process is very large, there must be strong support between the superconducting drive coils 4 at all levels. Because the superconducting working environment requires low temperature, the outer surface of the superconducting drive coil 4 is surrounded by a shell with relatively high heat insulation requirements—a cryogenic container 7 . A strong supporting structure 8 must also be adopted between the cryogenic container 7 and the superconducting driving coil 4 . Cryogenic liquids such as liquid nitrogen and liquid helium can be used inside the cryogenic container 7 , and a conduction cooling form of a refrigerator can also be used. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com