Patents

Literature

4342results about How to "Improve assembly accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

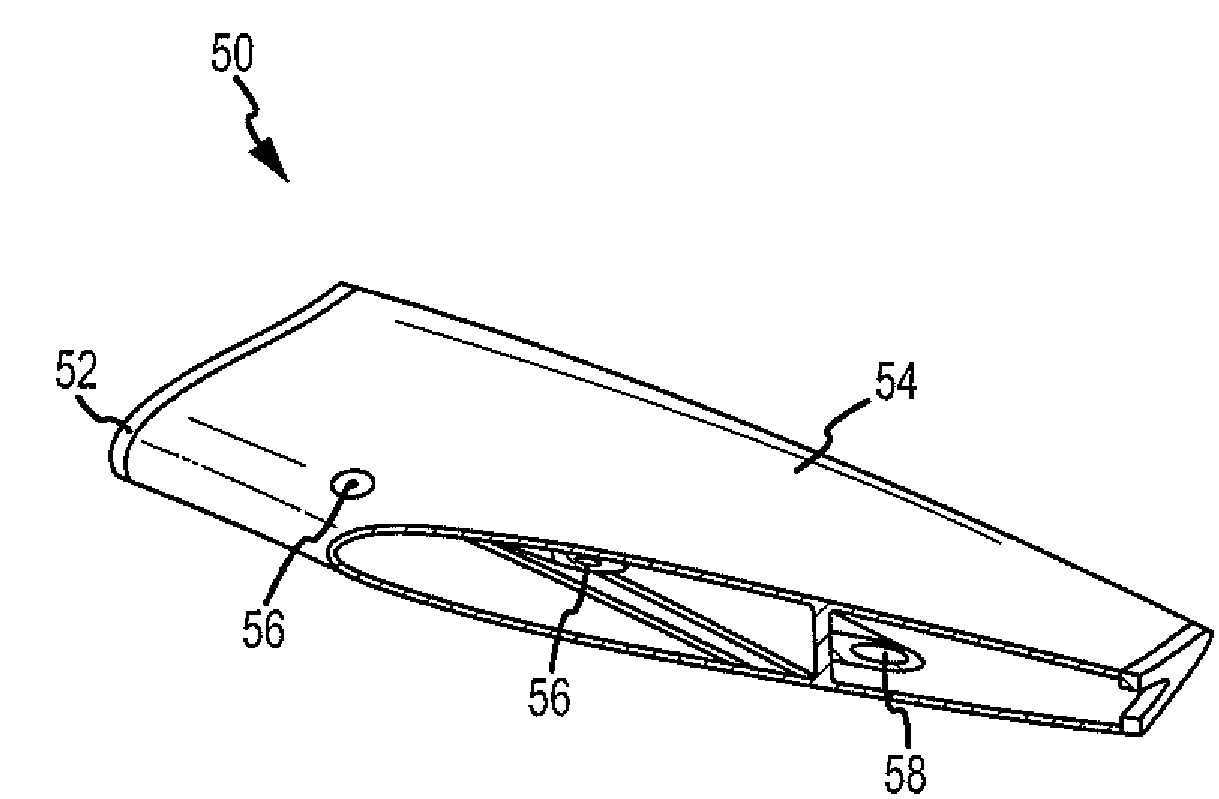

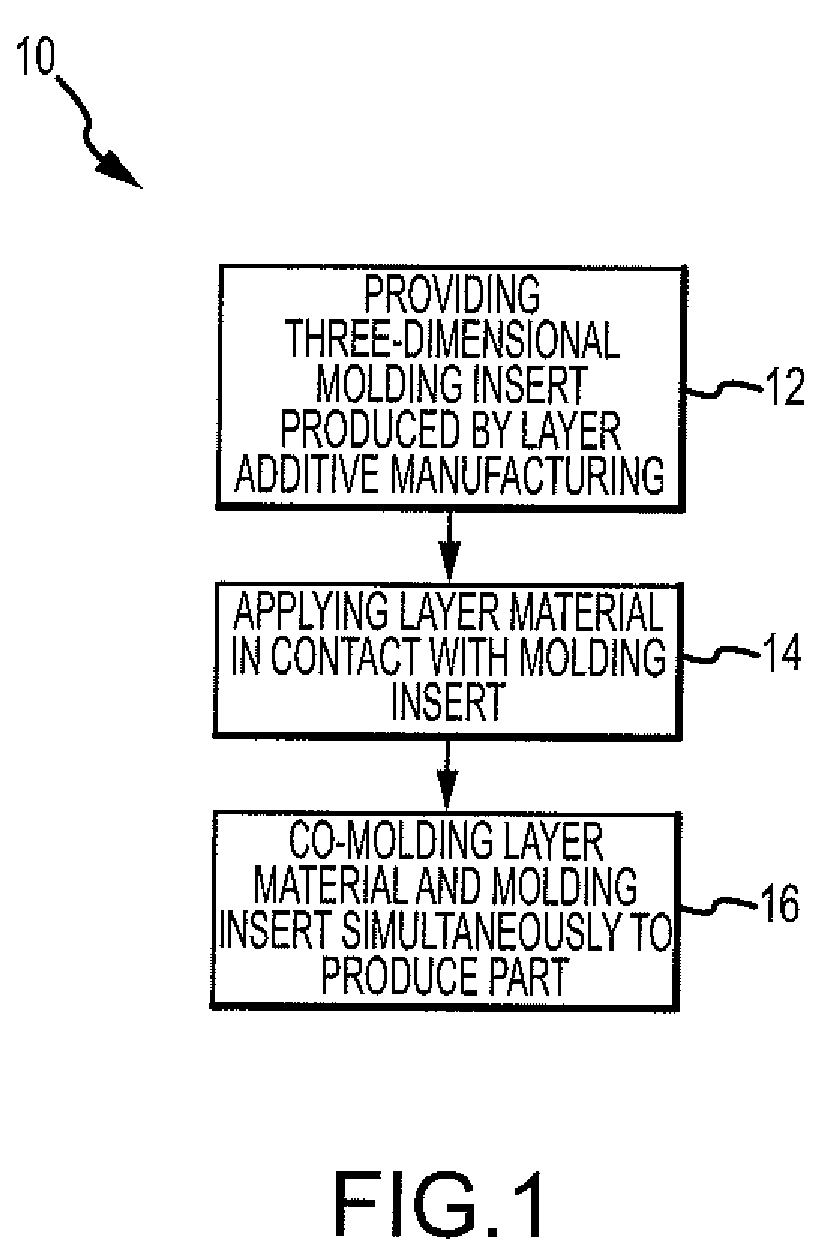

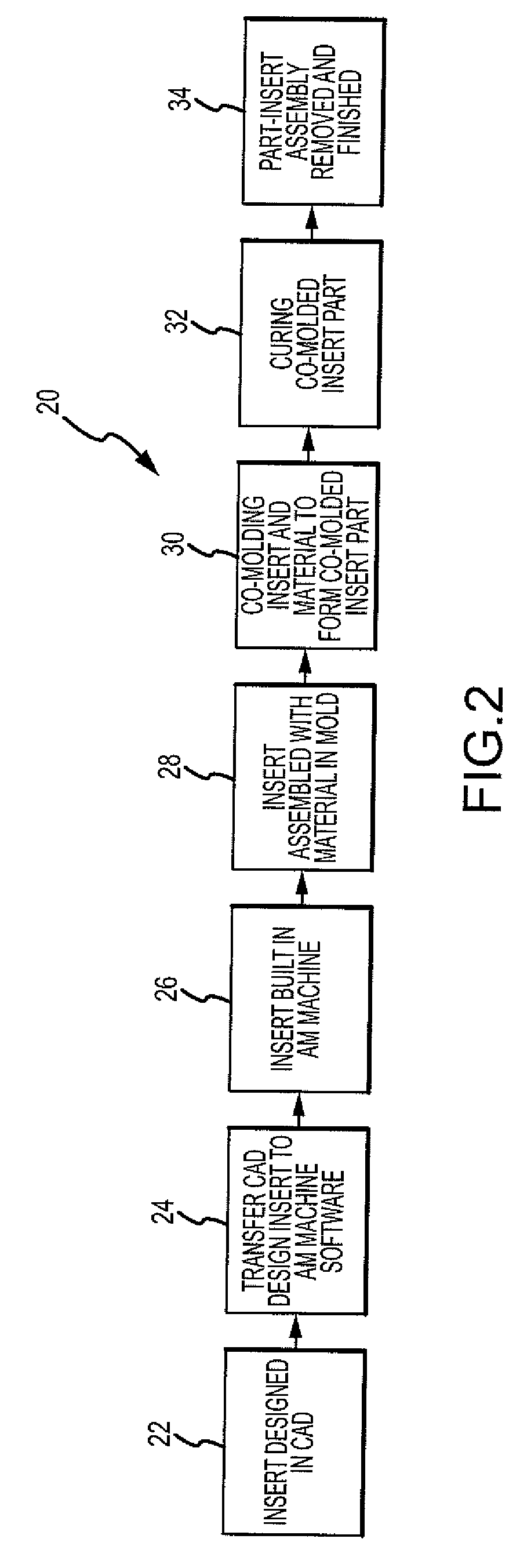

Method of manufacturing co-molded inserts

ActiveUS8383028B2Little costsLittle timeAdditive manufacturing apparatusLamination ancillary operationsMaterials scienceMetal

A method for manufacturing a co-molded insert part for use in composite, plastic, or metal parts is disclosed. The method comprises the step of providing a three-dimensional molding insert produced by a layer additive manufacturing process. The method further comprises the step of applying a layer material in contact with at least a portion of the molding insert. The method further comprises the step of co-molding the layer material and the molding insert simultaneously to produce a co-molded insert part.

Owner:THE BOEING CO

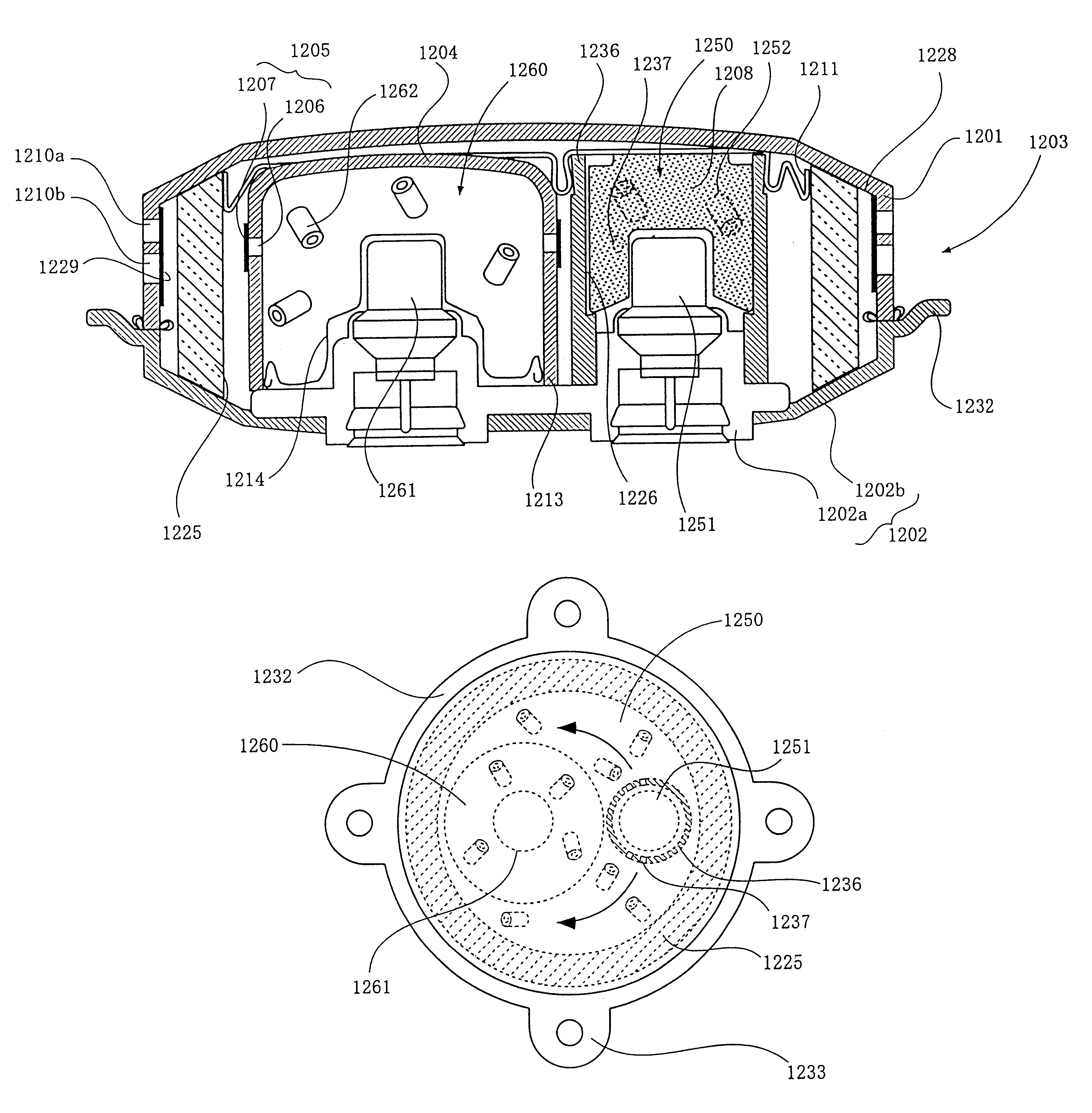

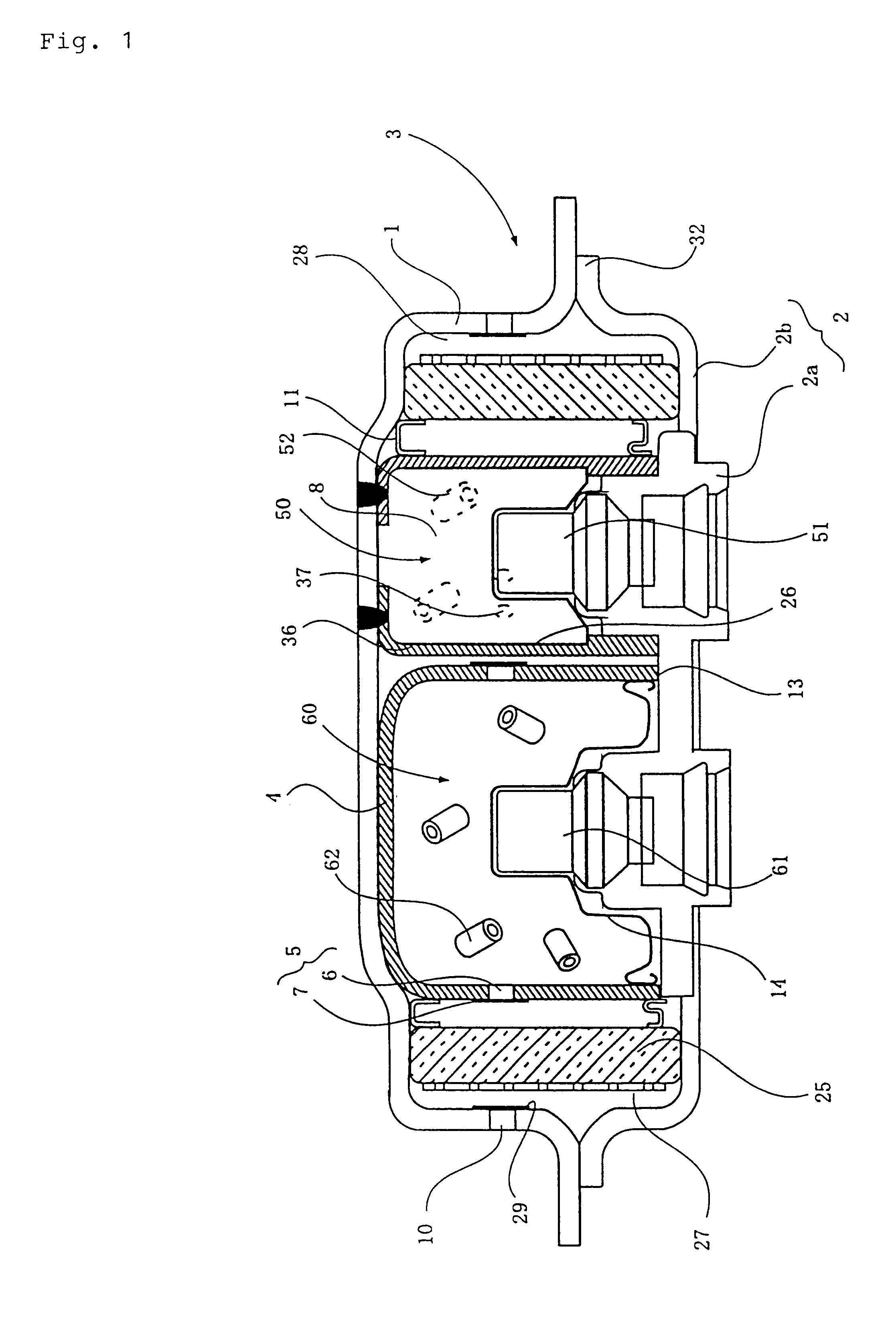

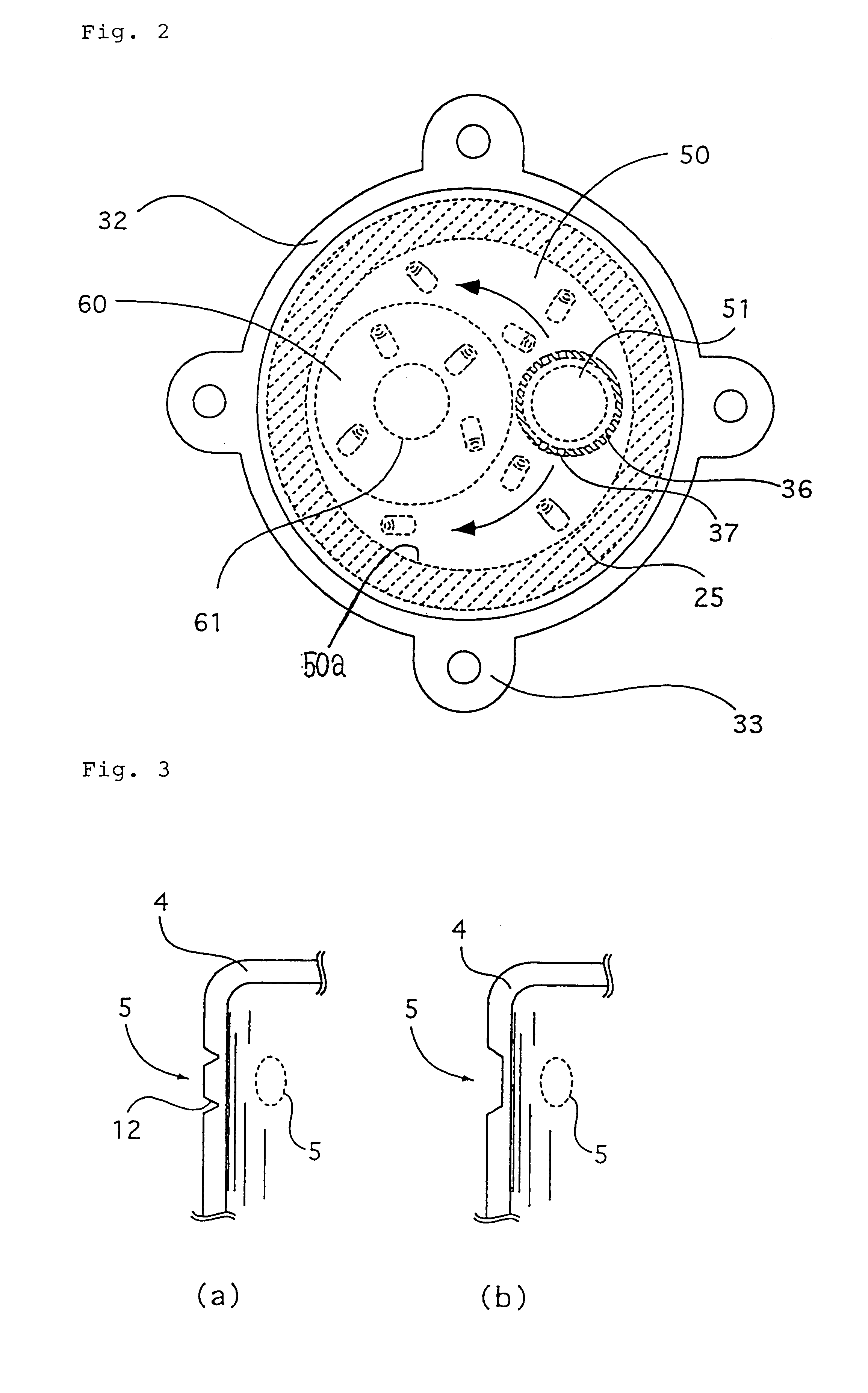

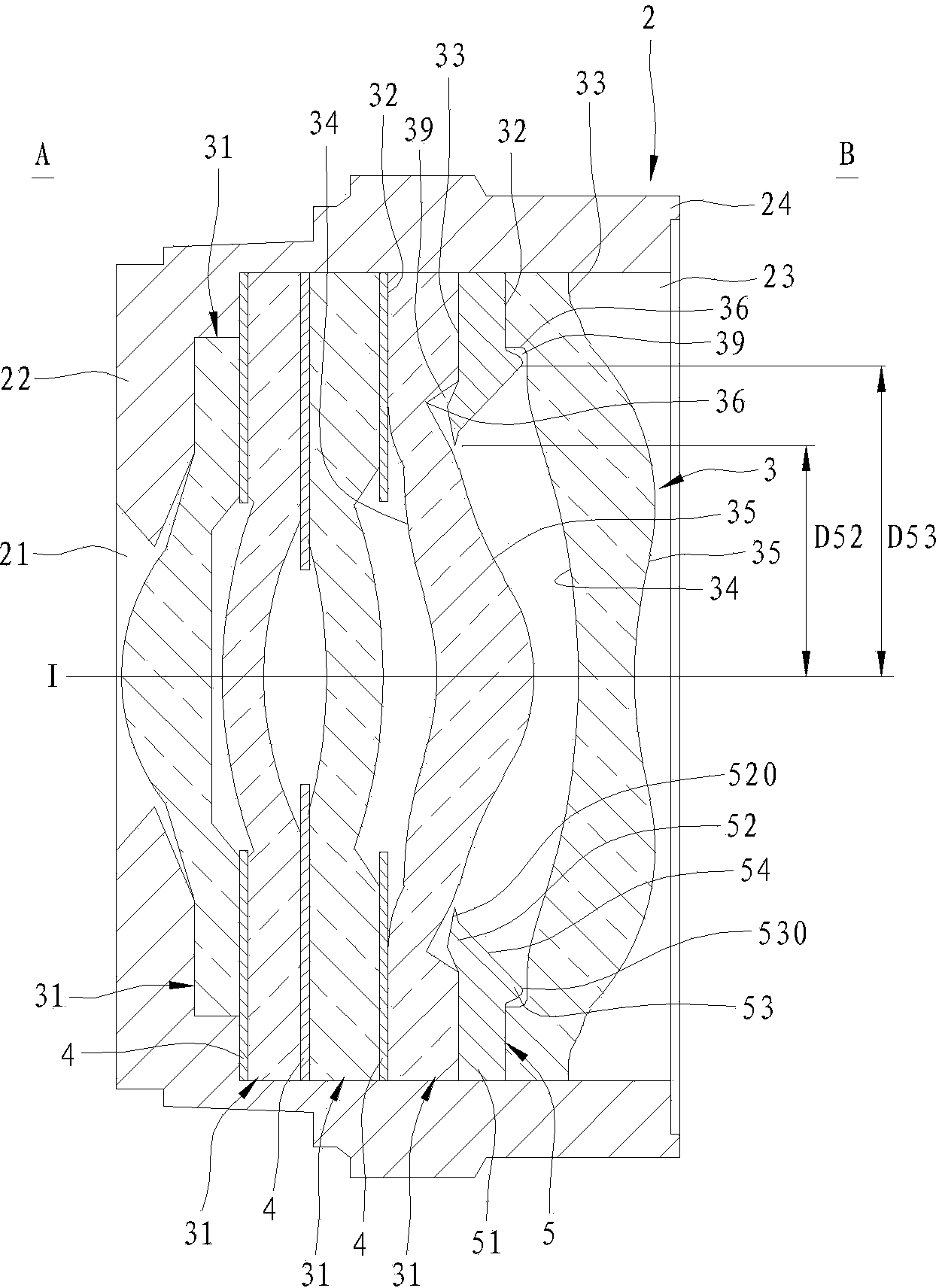

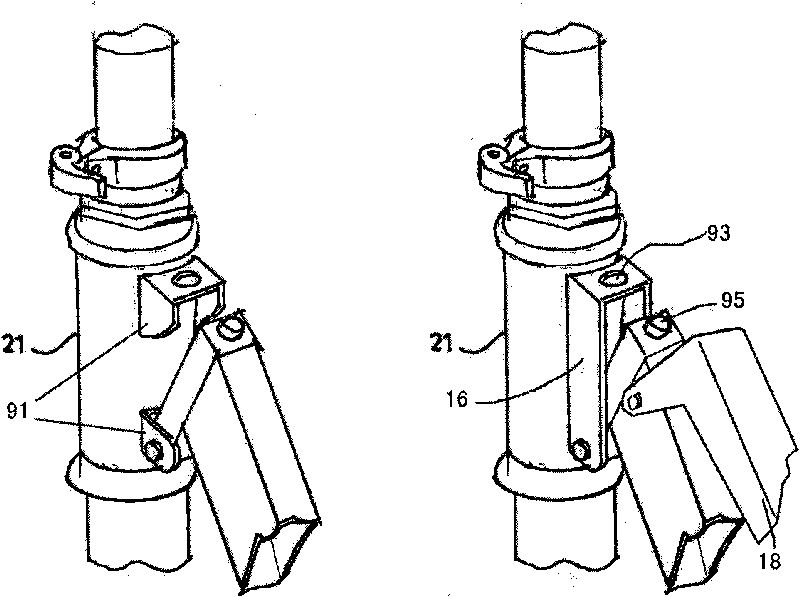

Gas generator for multi-stage air bag and air bag device

InactiveUS6722694B1Reduce sizeShort pass of the activation gas can be effectively avoidedGas treatmentDispersed particle filtrationCombustion chamberEngineering

There is provided a multistage gas generator for an air bag in which the entire size of a container is suppressed, a volume ratio of each combustion chamber can arbitrarily be adjusted. Ignition means 311 are respectively disposed in the combustion chambers 305 and 306 provided in a housing 303. At least one of the combustion chambers is provided inside an inner shell 304 disposed eccentrically with respect to the center axis of the housing 3. The respective ignition means are disposed eccentrically with respect to the center axis of the housing 3. Further, a communication hole which allows mutual communication between the combustion chambers is provided. An automatic ignition material (AIM) which is to be ignited and burnt by a transmitted heat is provided in either one of the combustion chambers. One or both of axial end surfaces of a cylindrical filter means 350 are formed as inclining end surfaces 351 which get narrower in the axial extending direction. A supporting member 353 for supporting the inclining end surfaces 351 of the filter means 350 which is expanded radially by passage of an activation gas is provided in the housing.

Owner:DAICEL CHEM IND LTD

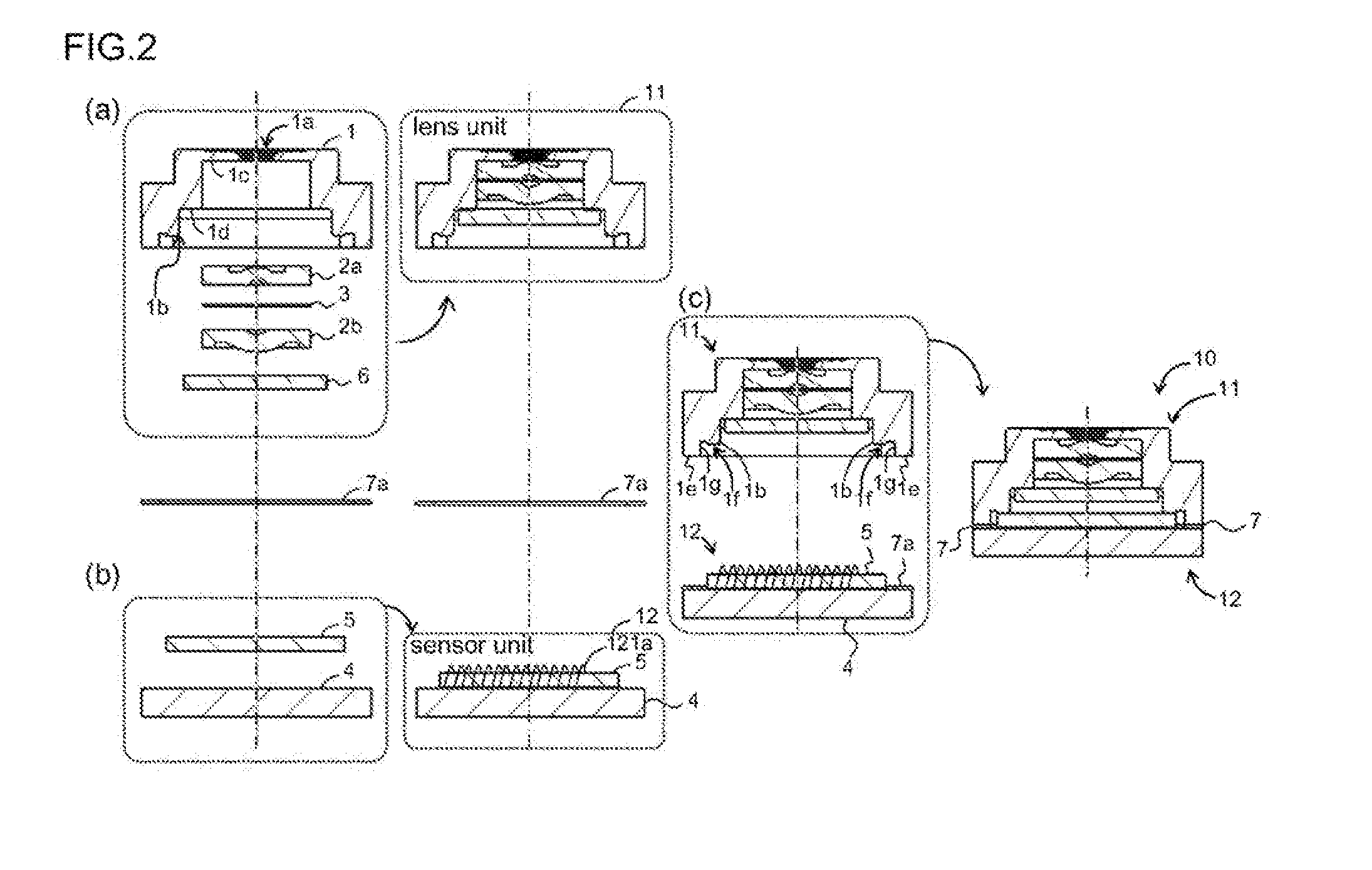

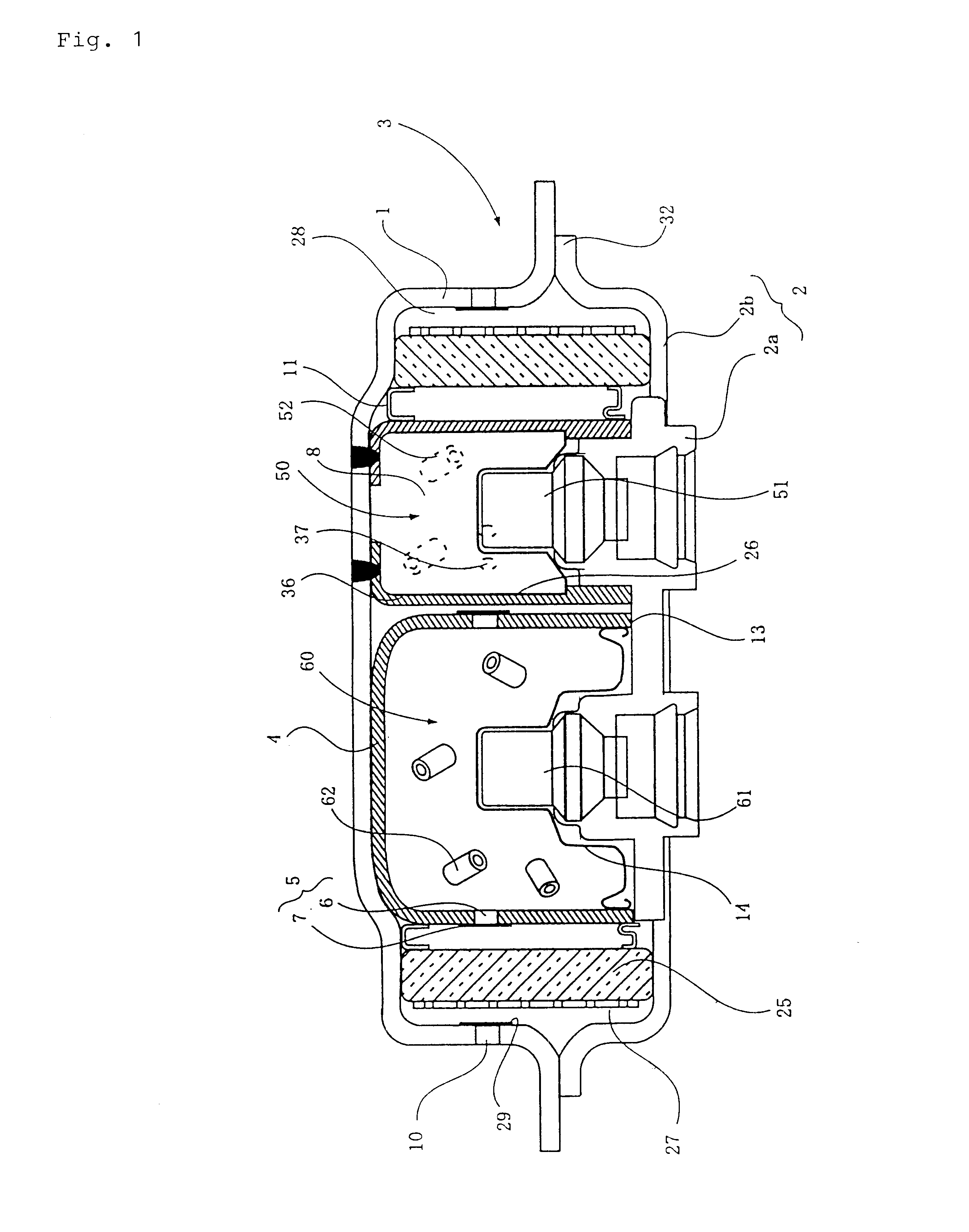

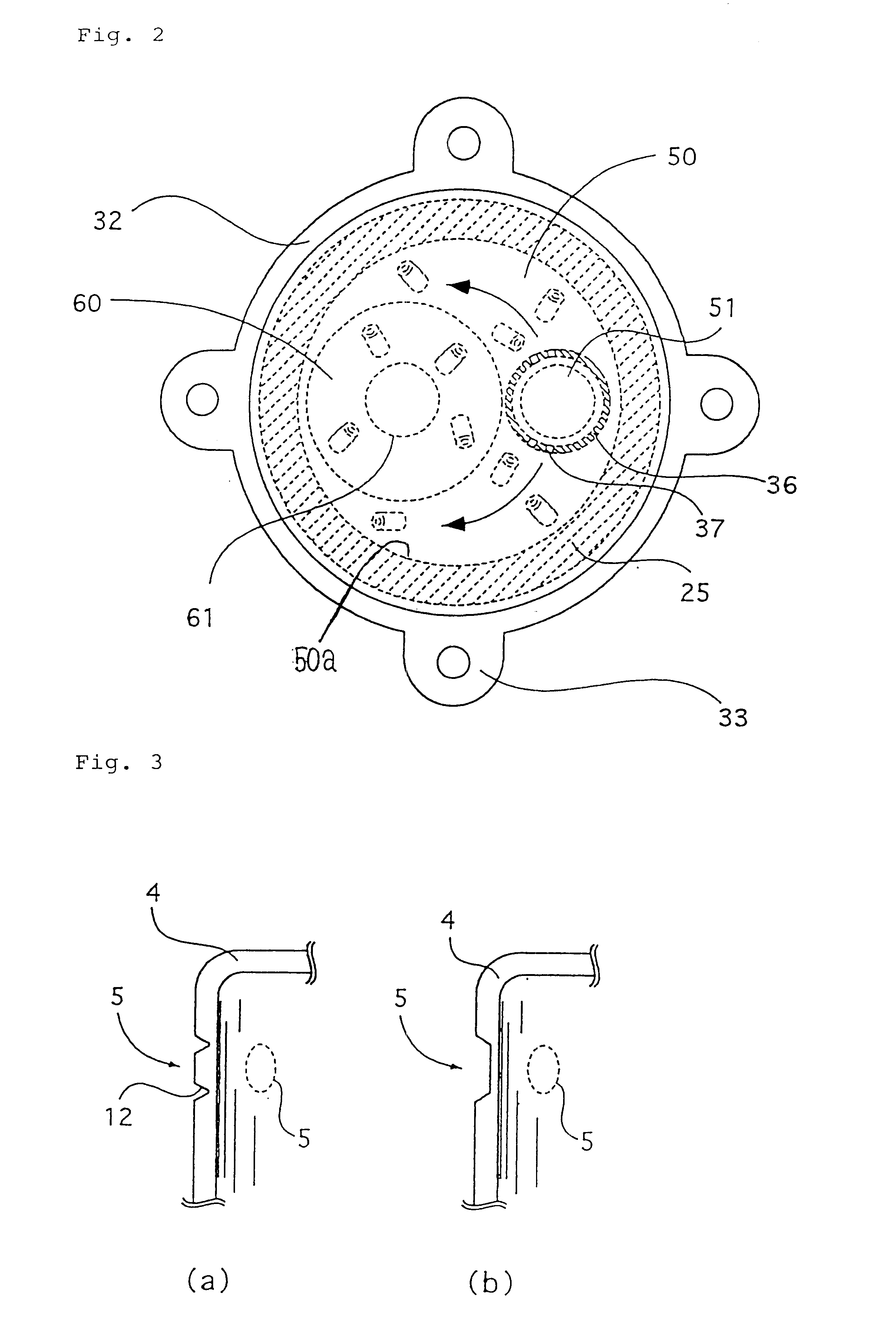

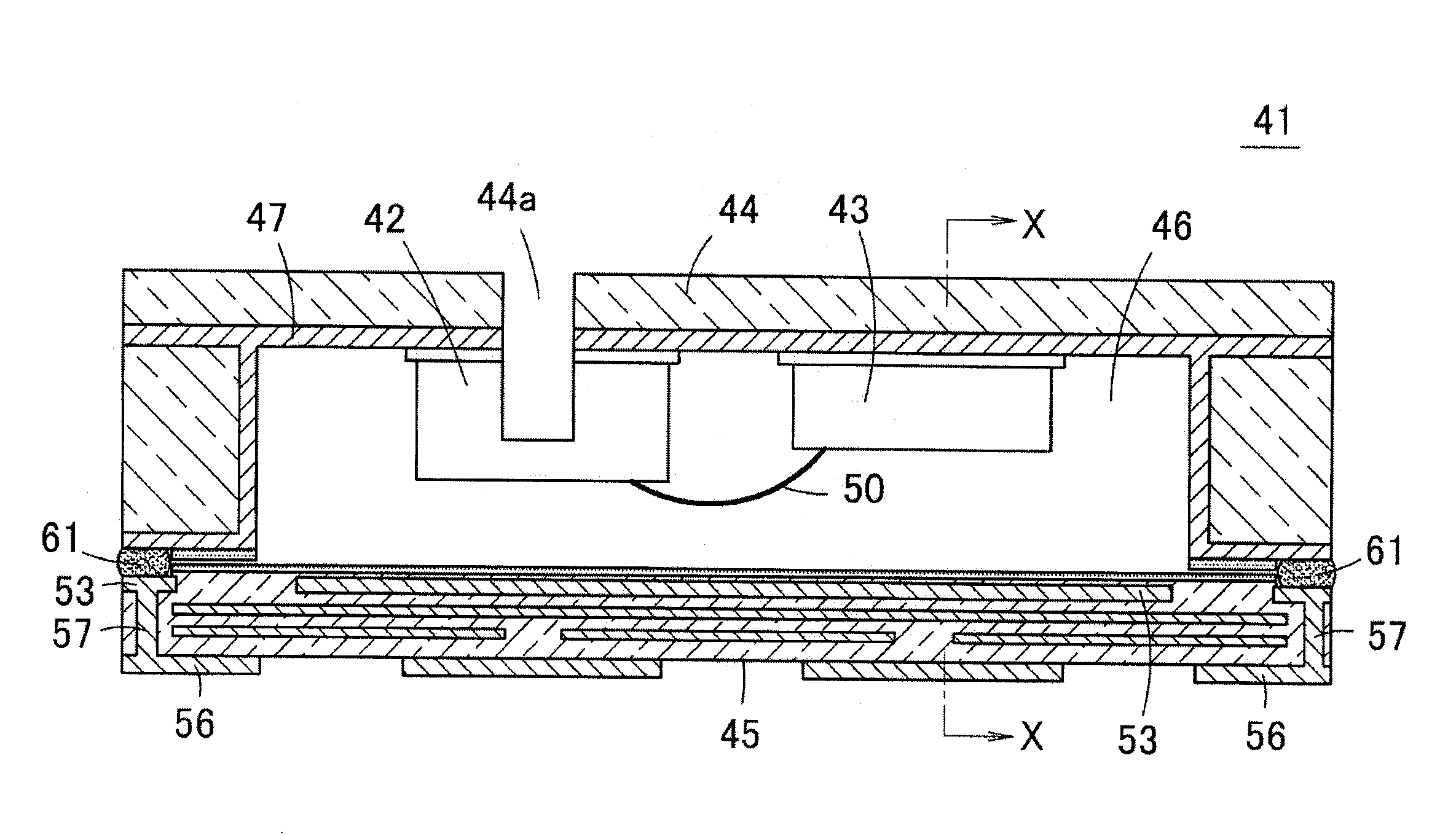

Image capturing module, method for manufacturing the image capturing module, and electronic information device

InactiveUS20090160998A1Improve accuracyFixed and accurateTelevision system detailsLaminationComputer moduleElectronic information

An image capturing module according to the present invention includes a holder member, which accommodates therein a focusing lens for forming an image of a subject light on an image capturing chip attached on a substrate and is attached to the substrate to cover the image capturing chip, where the holder member is directly supported on a surface of the image capturing chip.

Owner:SHARP KK

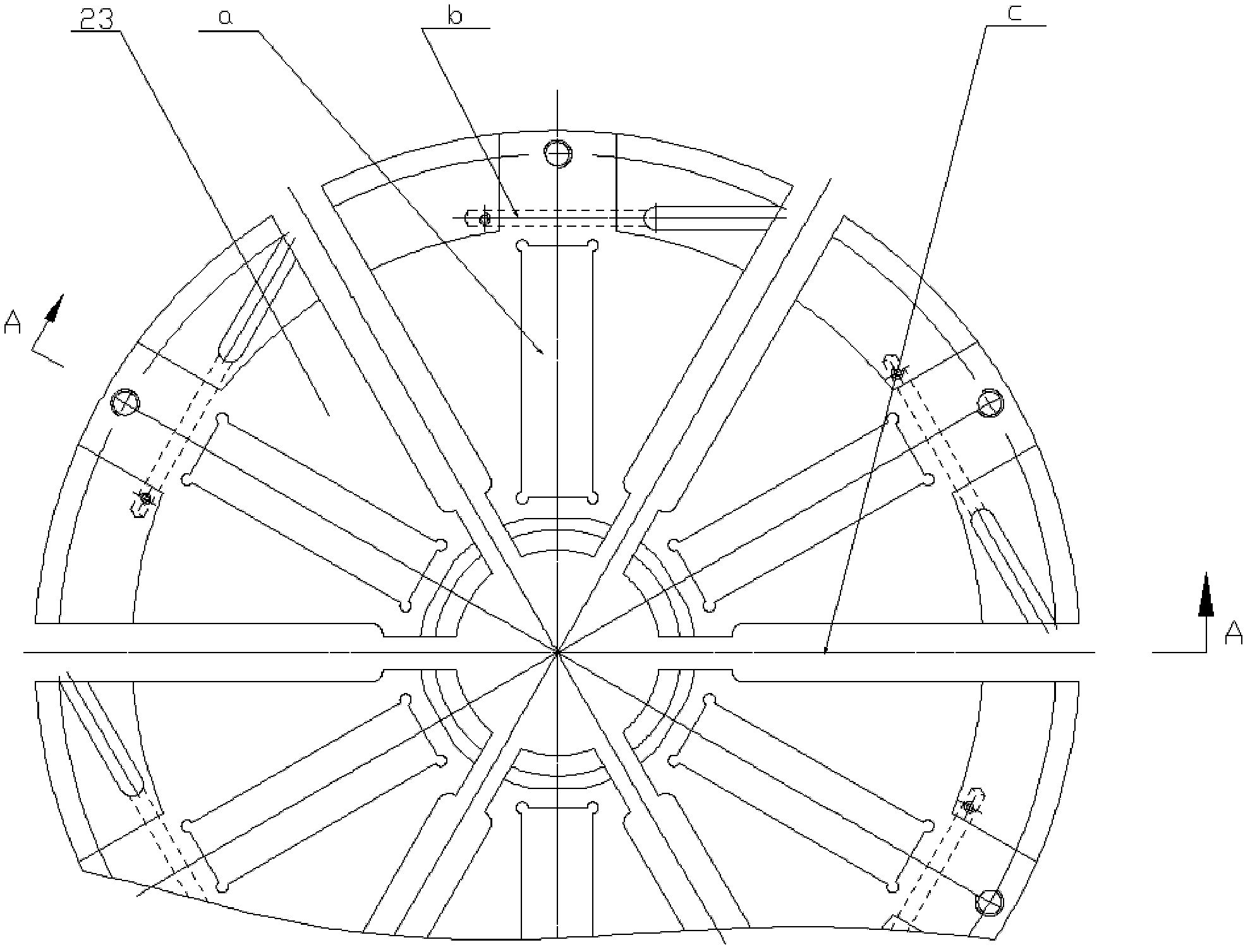

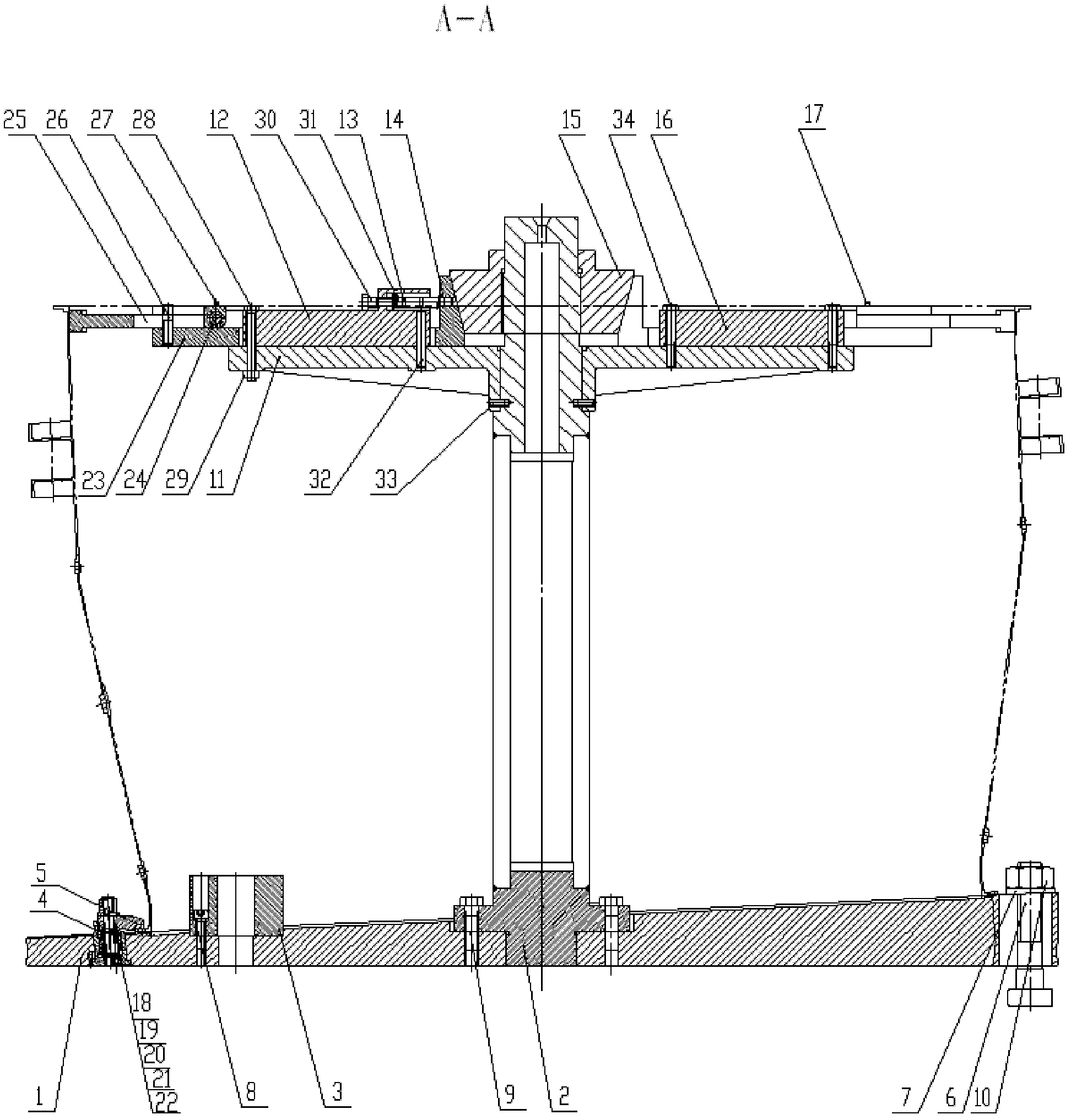

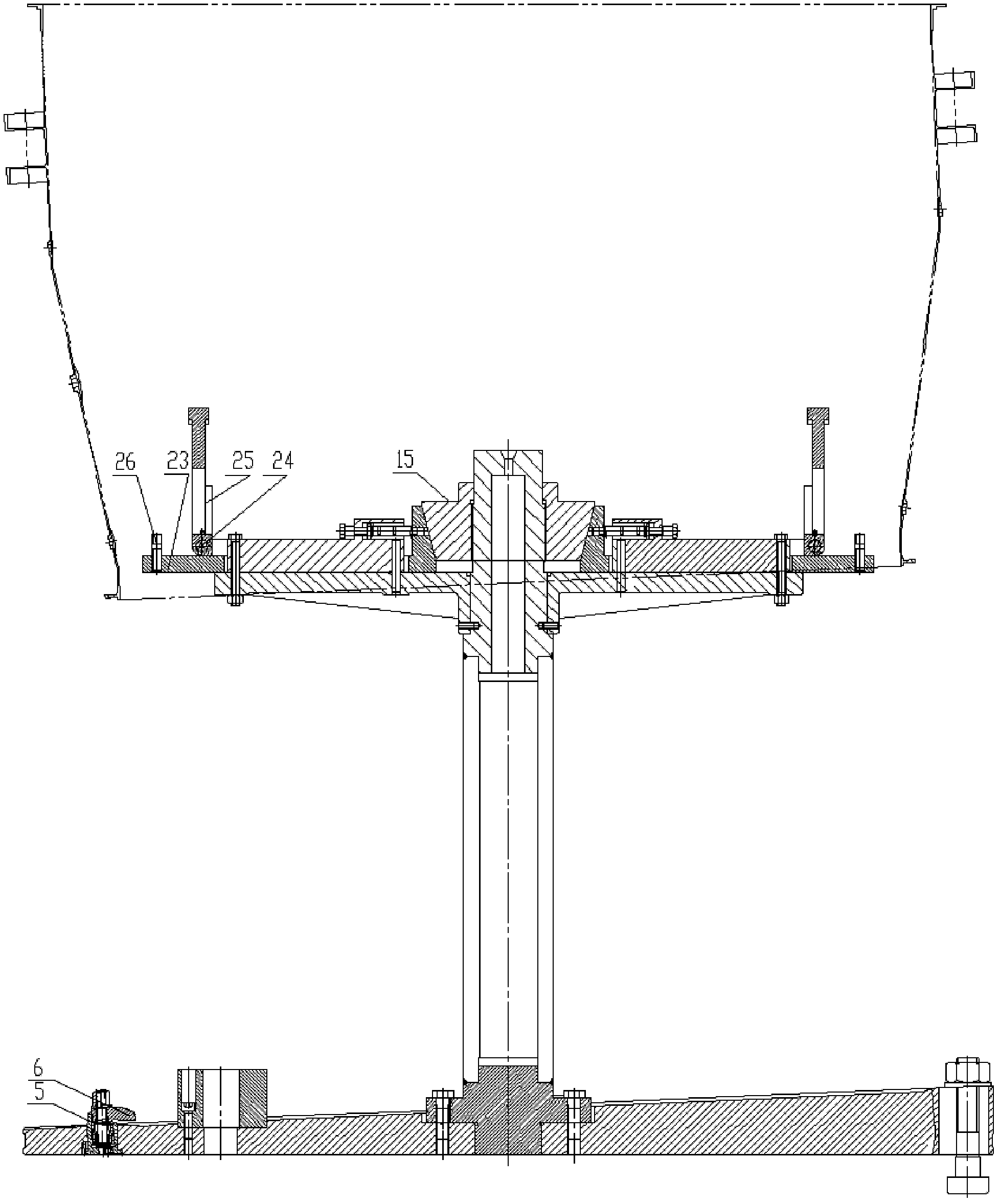

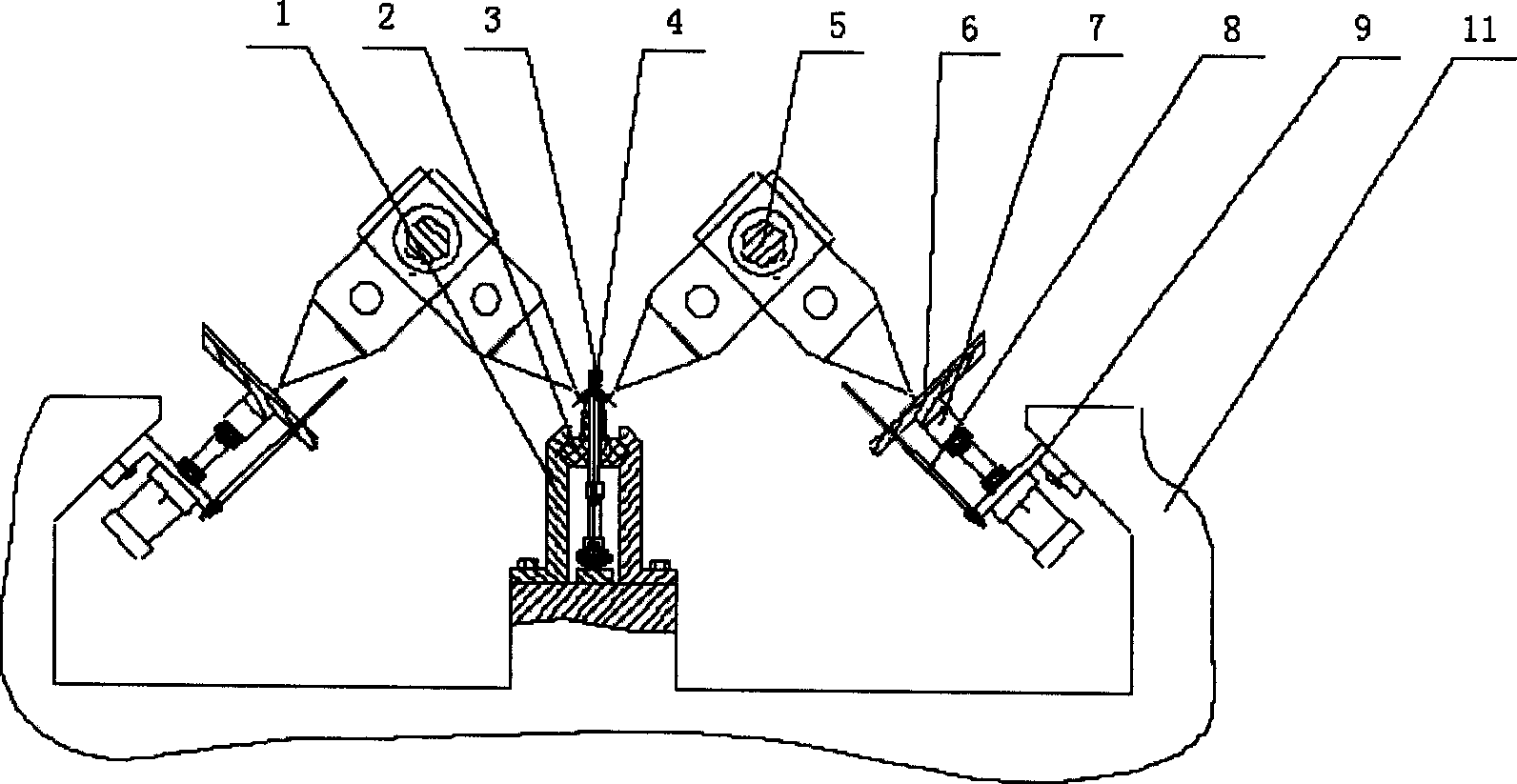

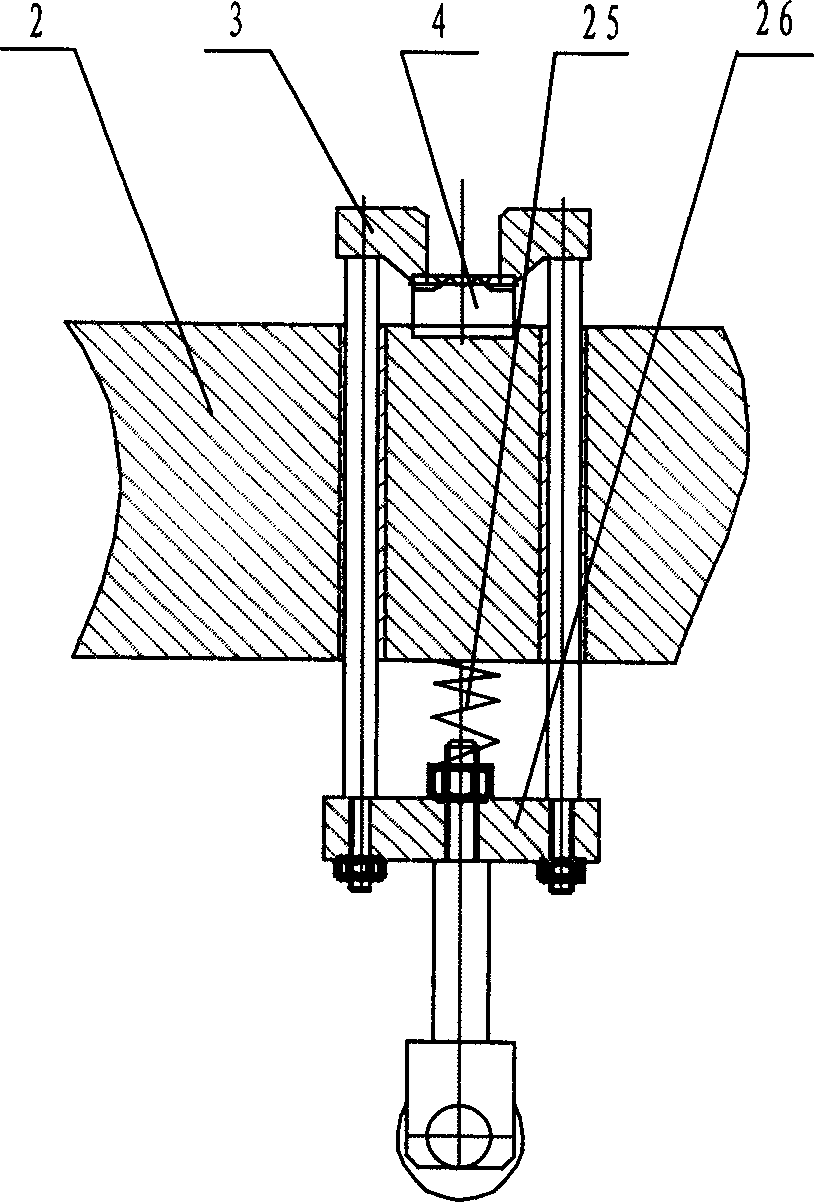

Method for positioning and clamping welding receiver lathing installation edges and device

ActiveCN102423858AImprove assembly accuracyImprove processing efficiencyPositioning apparatusMetal-working holdersBlock structureMachining

The invention provides a method for positioning and clamping welding receiver lathing installation edges and a device. In the method, according to the principle of the same basis, a large and a small installation edge positioning and clamping structures are designed into a whole; expansion of the installation edge on a large-diameter end is realized by adopting a partially rotatable structure; assembly, expansion and co-axis of the large and small installation edges are realized by applying the condition that the same basis is used for a whole clamp; in the whole clamp, the clamp expansion part of a conventional structure is designed into an expansion block structure capable of rotating, locking and releasing; the expansion block structure and a positioning block are matched for realizing positioning and expansion of the installation edges of a part on the large and the small ends; machining requirements of the installation edges are satisfied; the problems of assembly errors and low efficiency of positioning, clamping and aligning processes due to use of a traditional splitting clamp in thin wall welding receiver lathing installation edges are solved; part assembly precision and processing efficiency are enhanced; and a production period is shortened.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

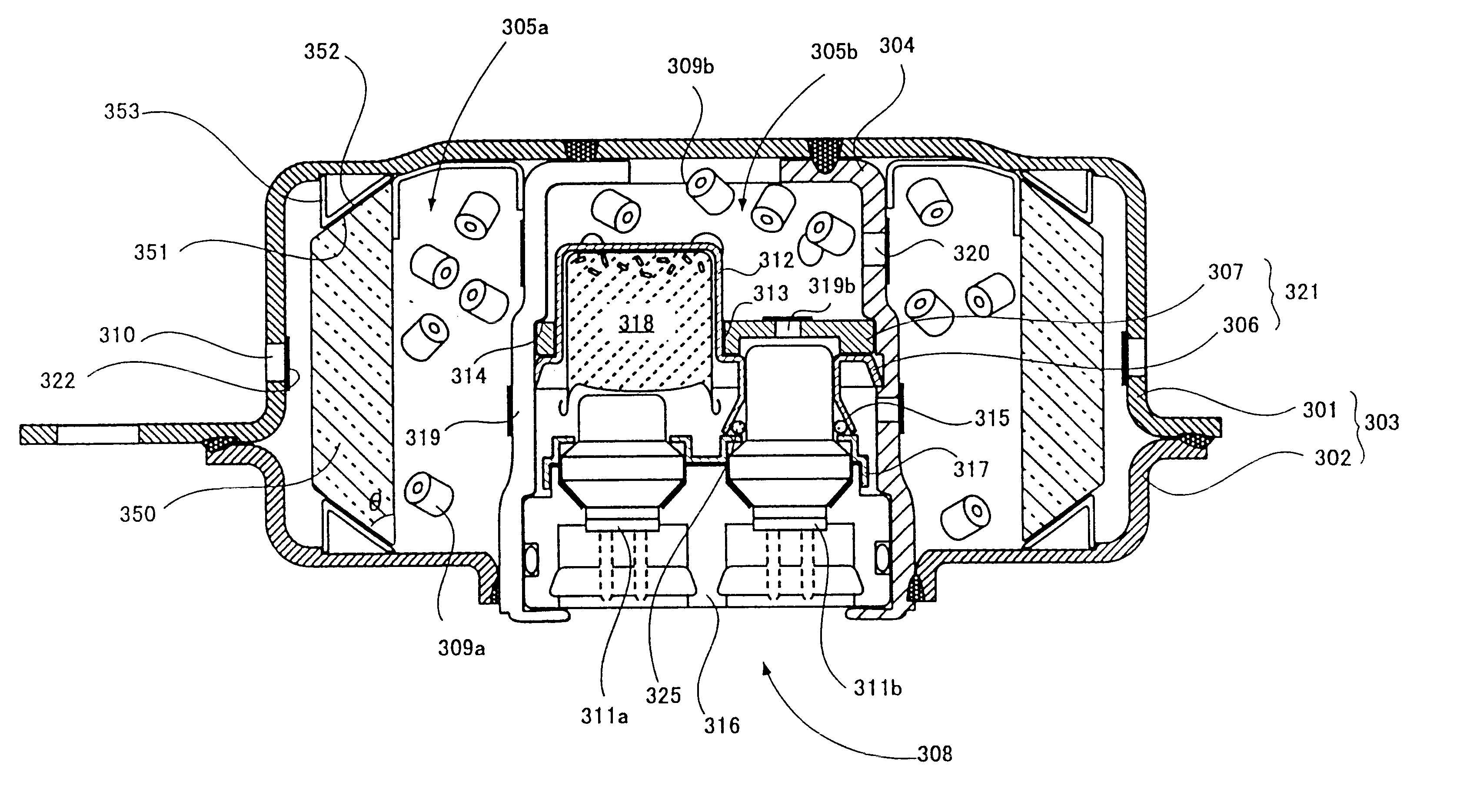

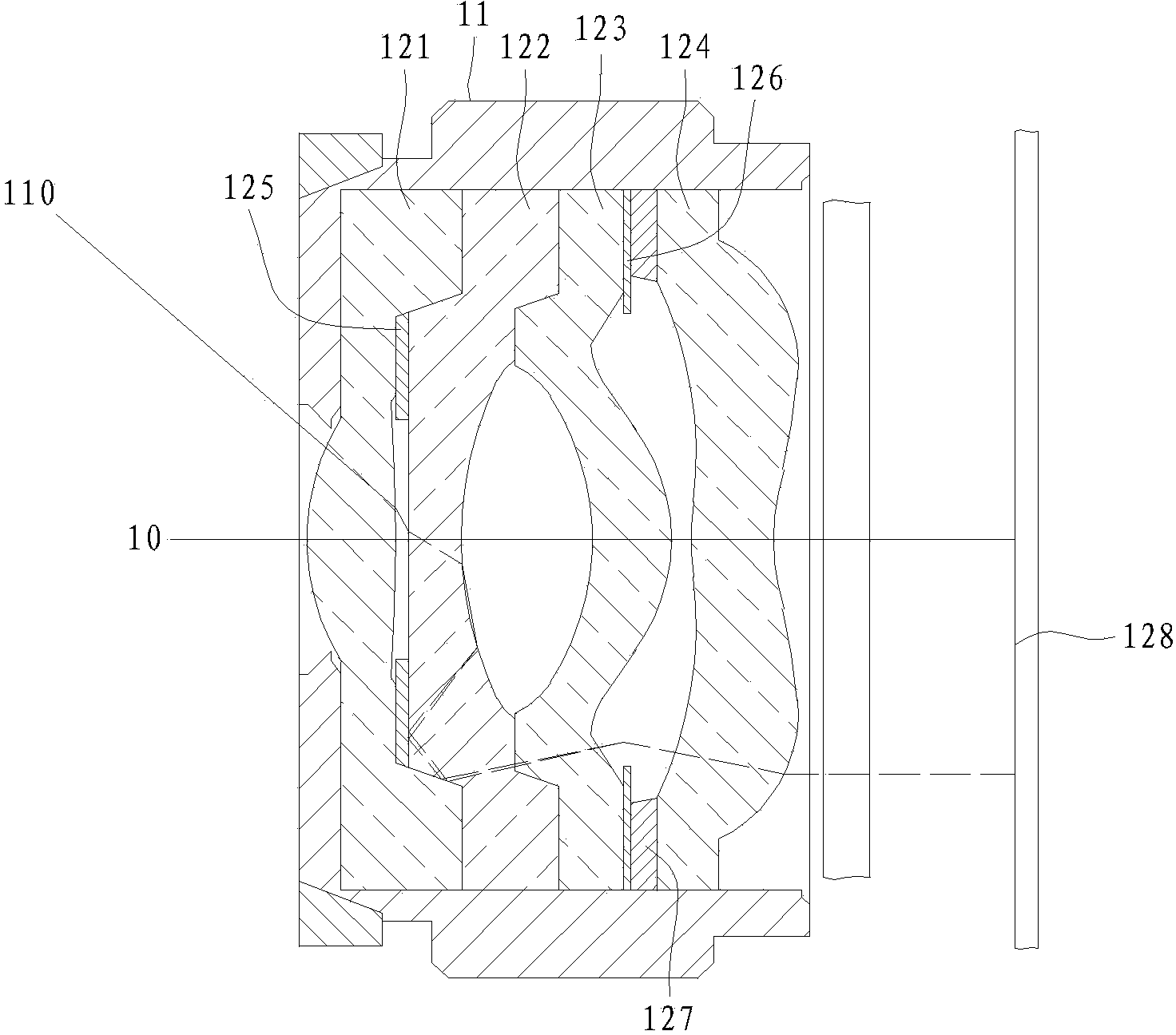

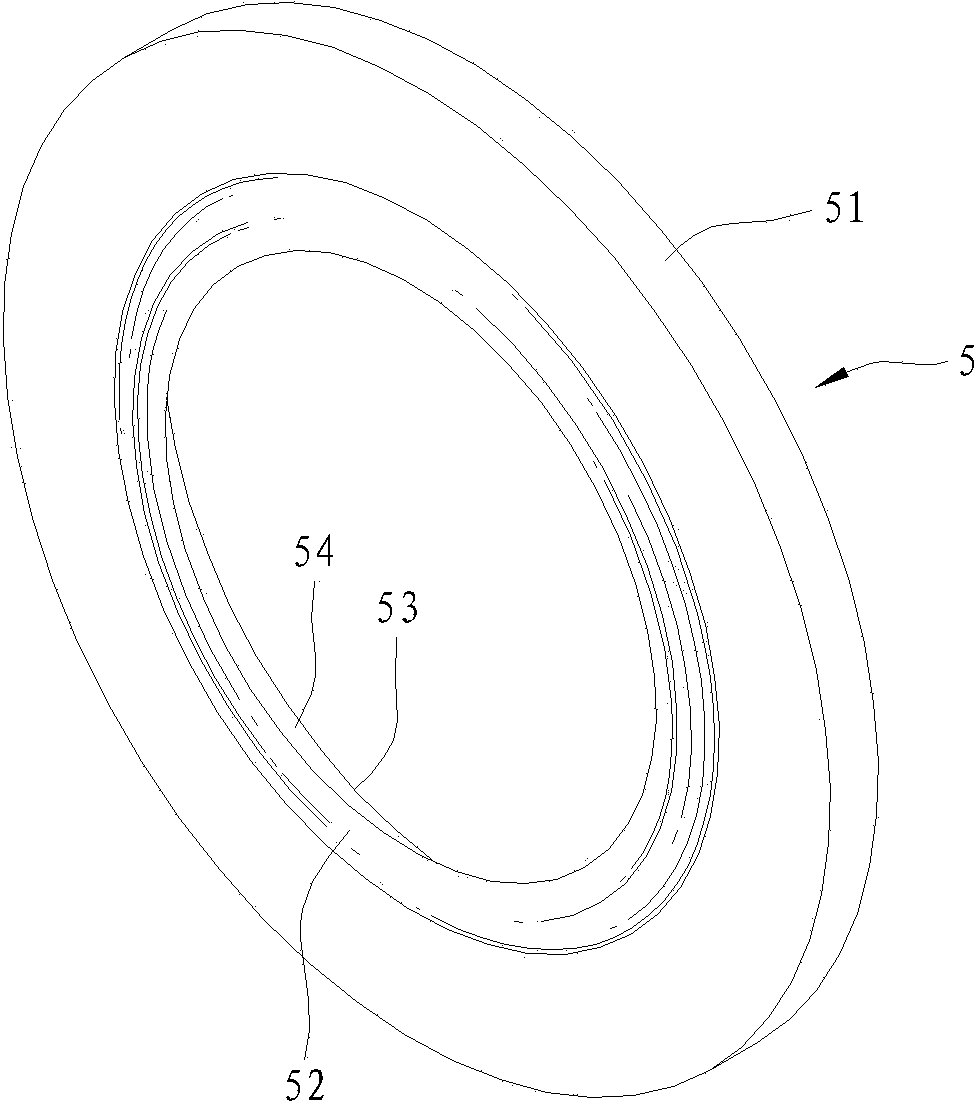

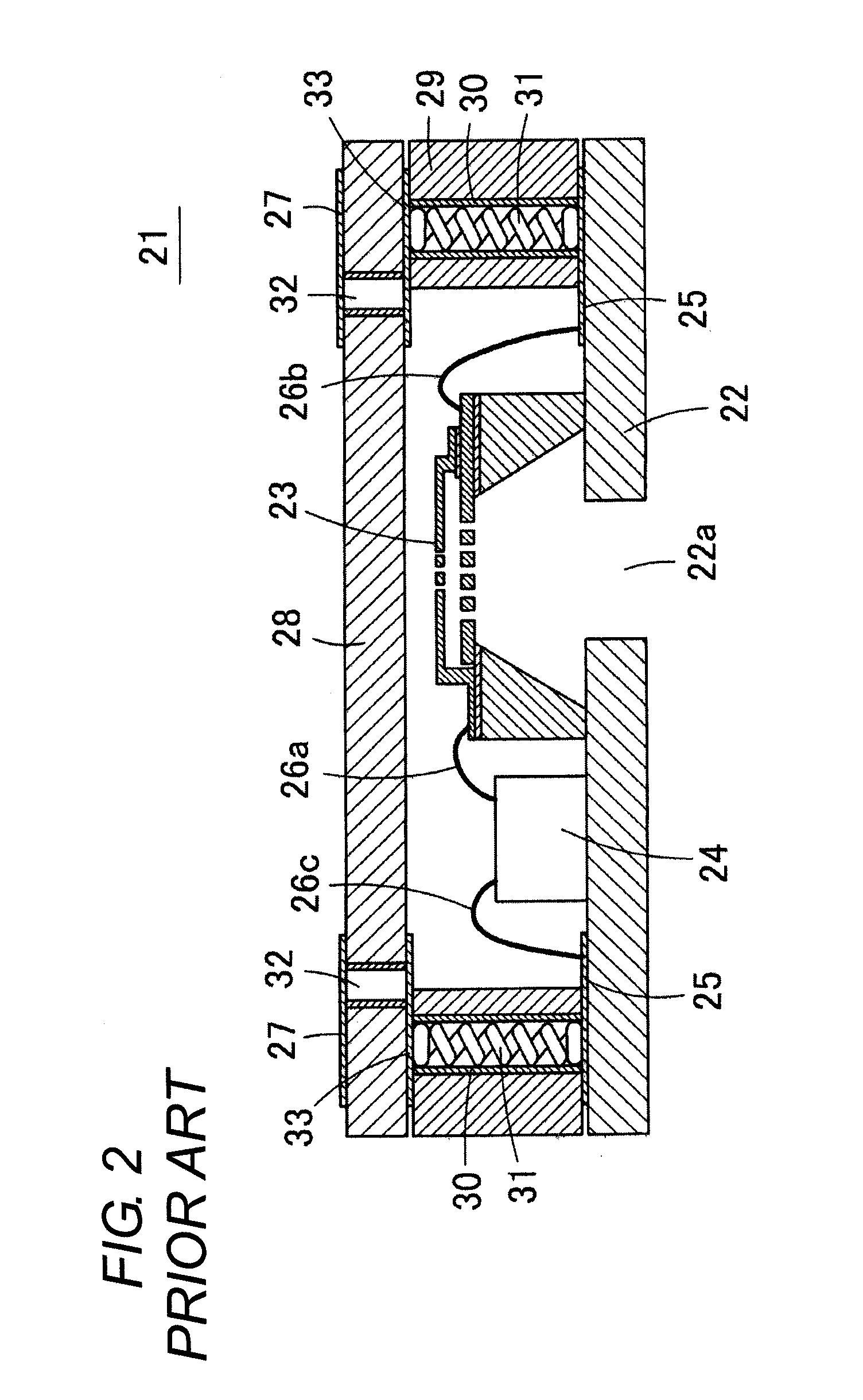

Multistage gas generator for air bag and air bag apparatus

InactiveUS6491321B1Reduce sizeShort pass of the activation gas can be effectively avoidedGas treatmentDispersed particle filtrationCombustionProduct gas

A gas generator for an air bag includes: a housing having top and bottom plates and a cylindrical wall provided between those plates; a cylindrical filter unit, provided inside the housing, at least one end of the filter unit having an inclining end surface such that the length of the filter unit in an axial direction thereof decreases as the distance from a central axis of the filter in a radial direction increases, an outer peripheral surface of the filter unit and an inner surface of the cylindrical wall defining a plenum; and a supporting portion formed inside the housing and having an inclining surface substantially parallel to the inclining end surface of the filter unit. The supporting portion engages with the inclining end surface such that the plenum is maintained even when the filter unit is urged to expand in the radial direction by the combustion gas.

Owner:DAICEL CHEM IND LTD

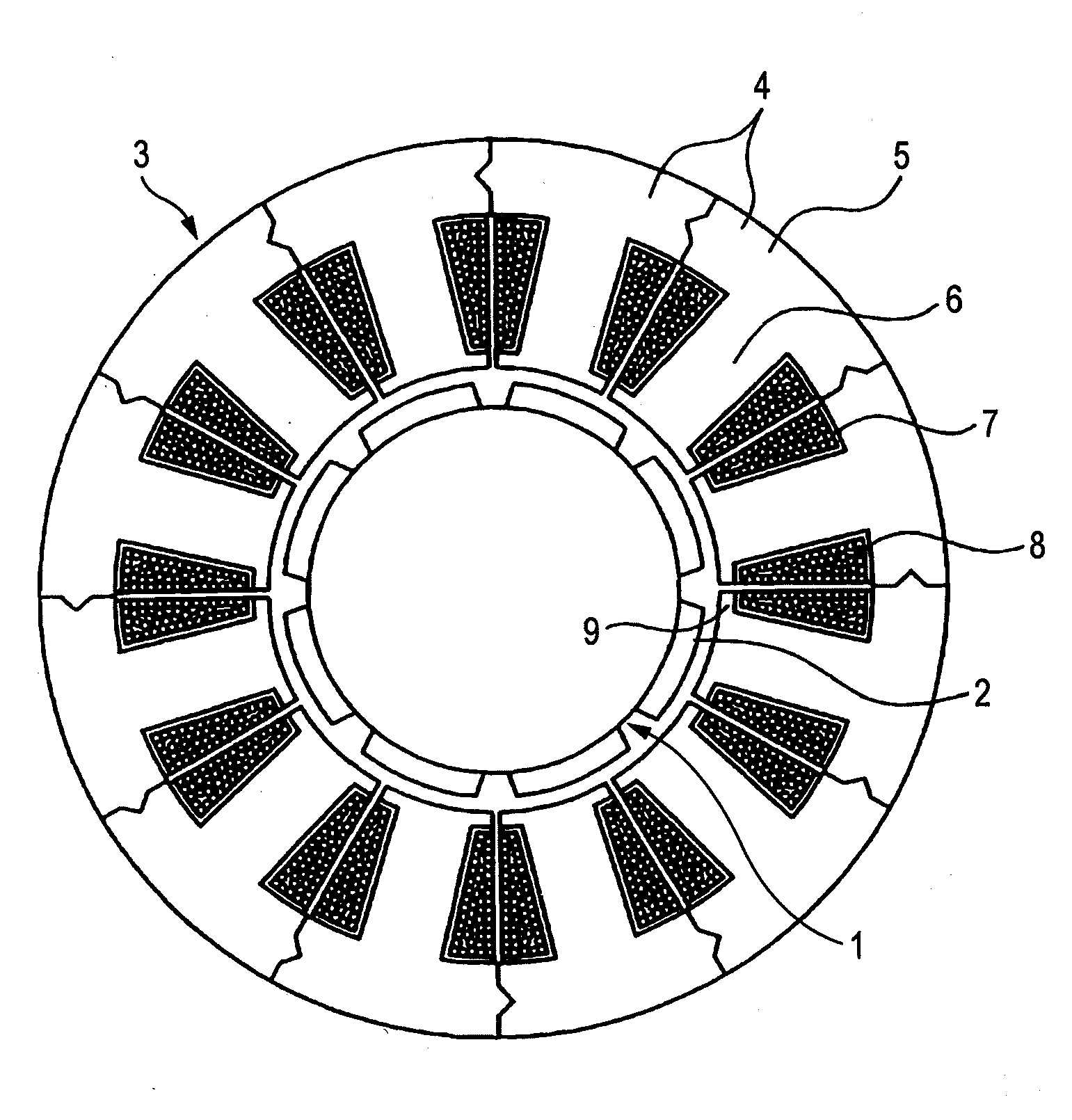

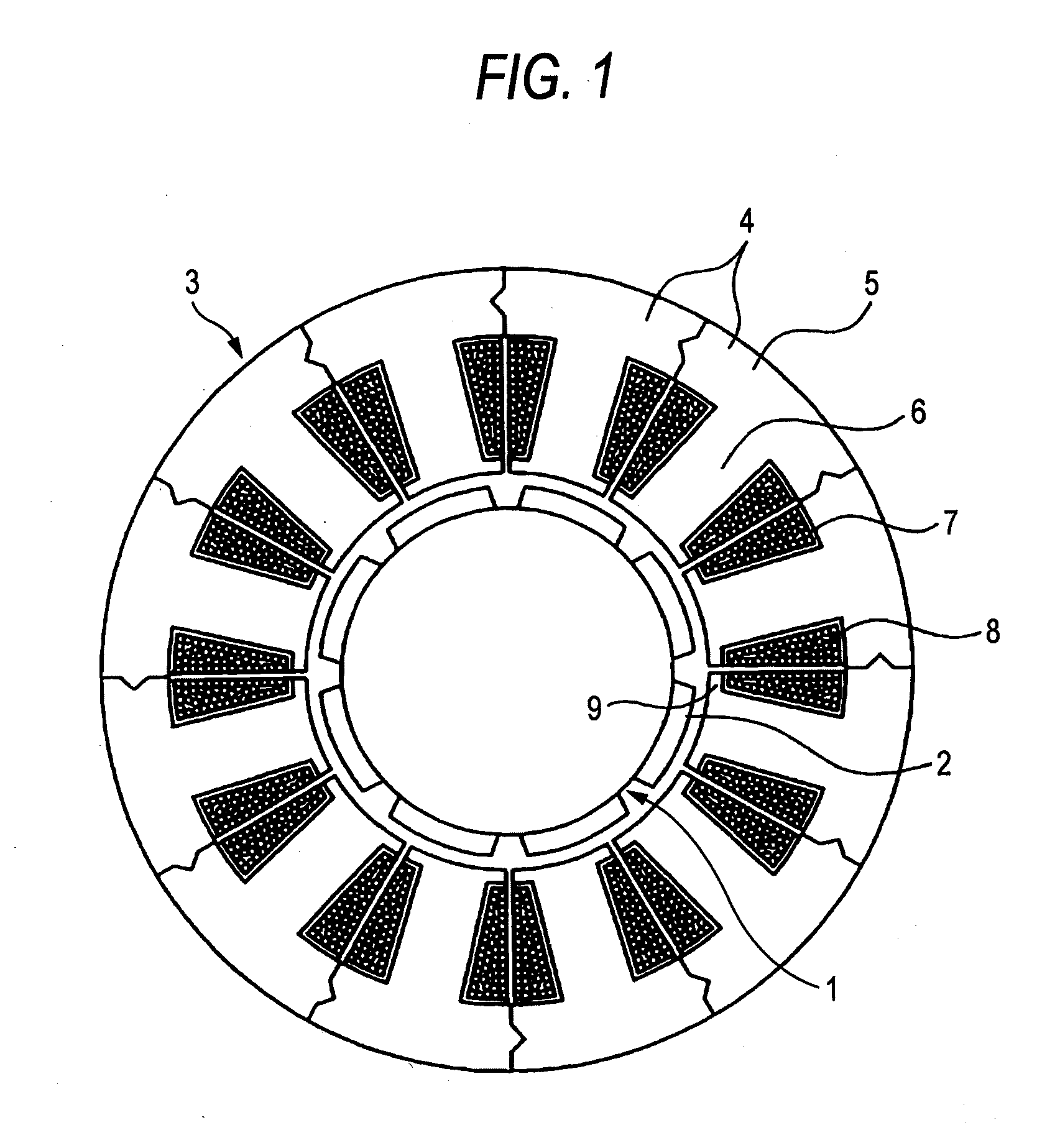

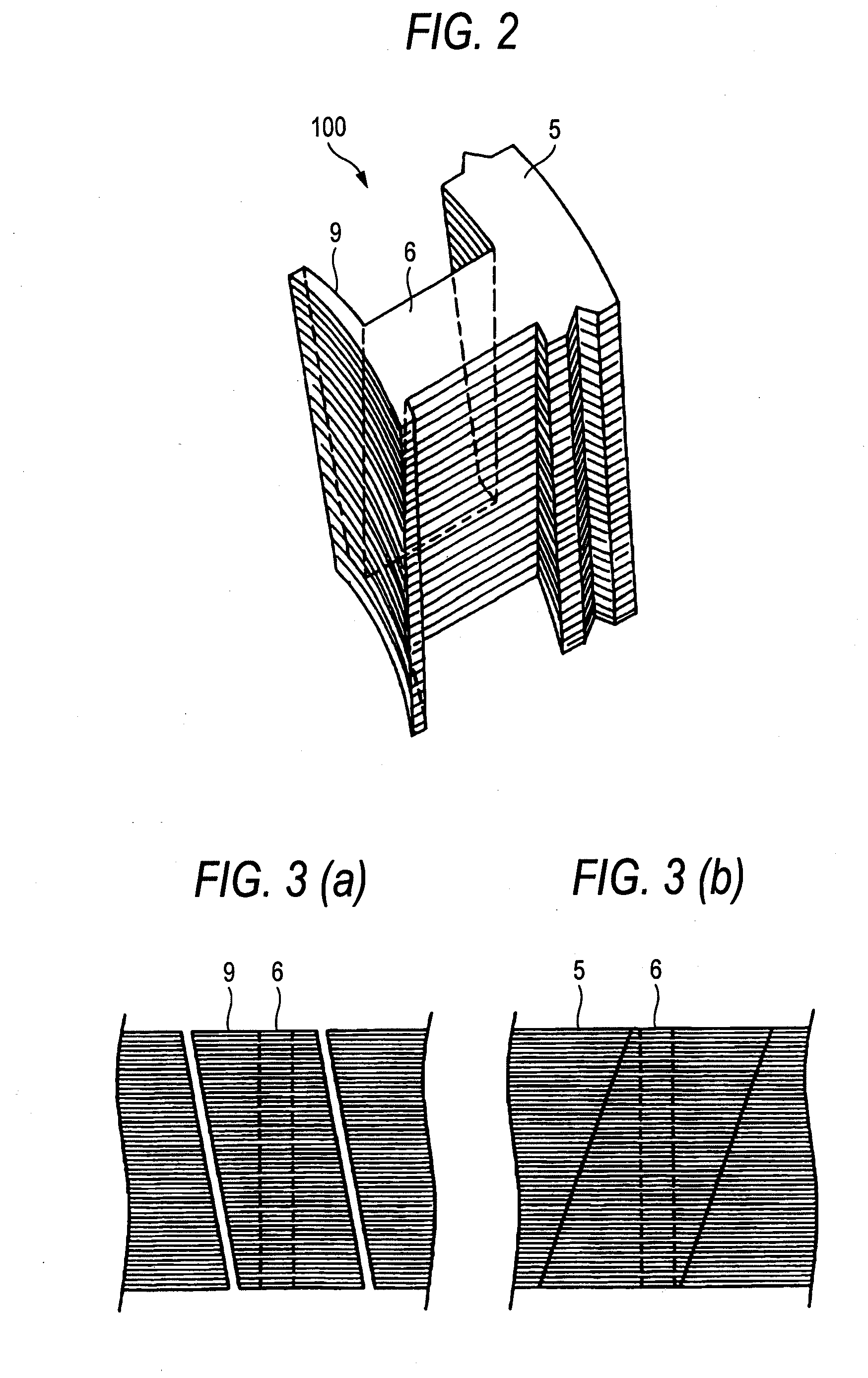

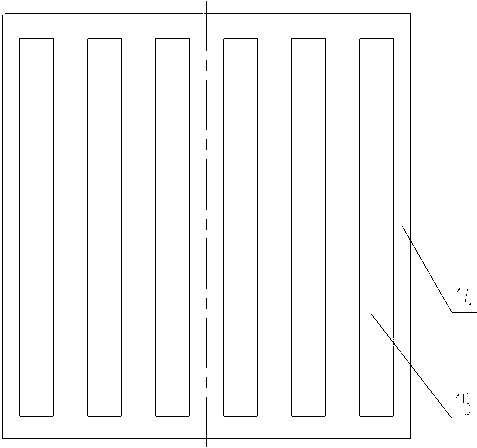

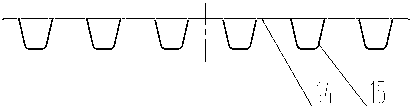

Split cores for motor stator, motor stator, permanent magnet type synchronous motor and punching method by split core punching die

ActiveUS20090026872A1Improve rigidityImprove assembly accuracyMagnetic circuit stationary partsManufacturing stator/rotor bodiesSynchronous motorPunching

Although in a conventional permanent magnet type synchronous motor, cogging torque is reduced by displacing permanent magnets of a rotor in a circumferential direction or displacing a stator core in a circumferential direction, since the skew so produced reduces the output of the motor and moreover the winding work of windings cannot be automated to make the resulting motor highly expensive, split cores are provided which solves those problems and enables the winding work of windings to be automated so as to obtain an inexpensive and high-output motor.There are provided a plurality of split cores (100) made up of laminated iron cores each having formed thereon a tooth (6), and a yoke (5) and a pole piece (9) which are made to connect to the tooth (6) at both ends thereof, and arranged and connected together into an annular shape to make up a stator, characterized in that both ends of the yokes (5) and both ends of the pole pieces (9) are displaced in one circumferential direction by laminated iron core from a top laminated layer to a bottom laminated layer of the iron cores of the split cores.

Owner:YASKAWA DENKI KK

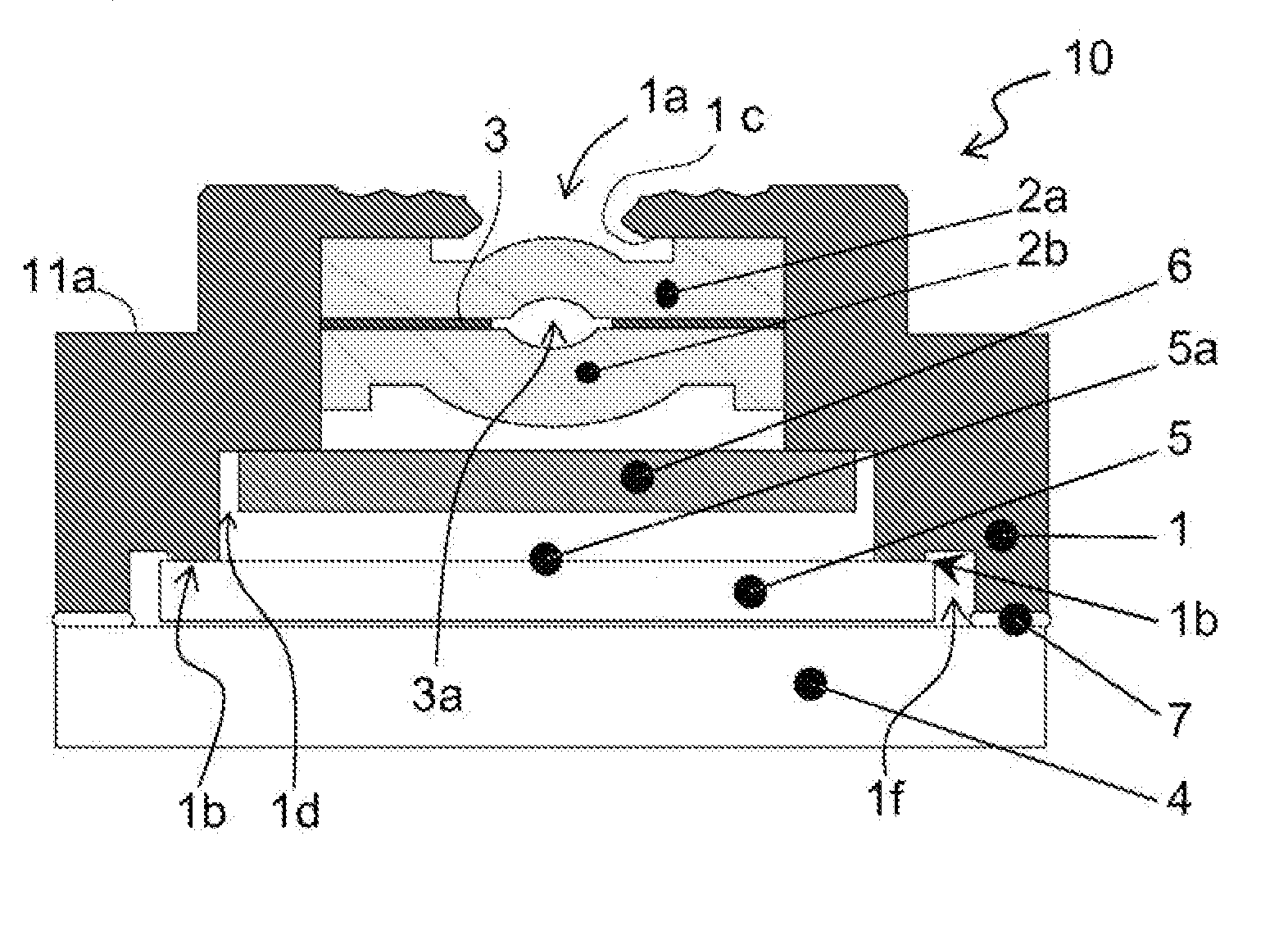

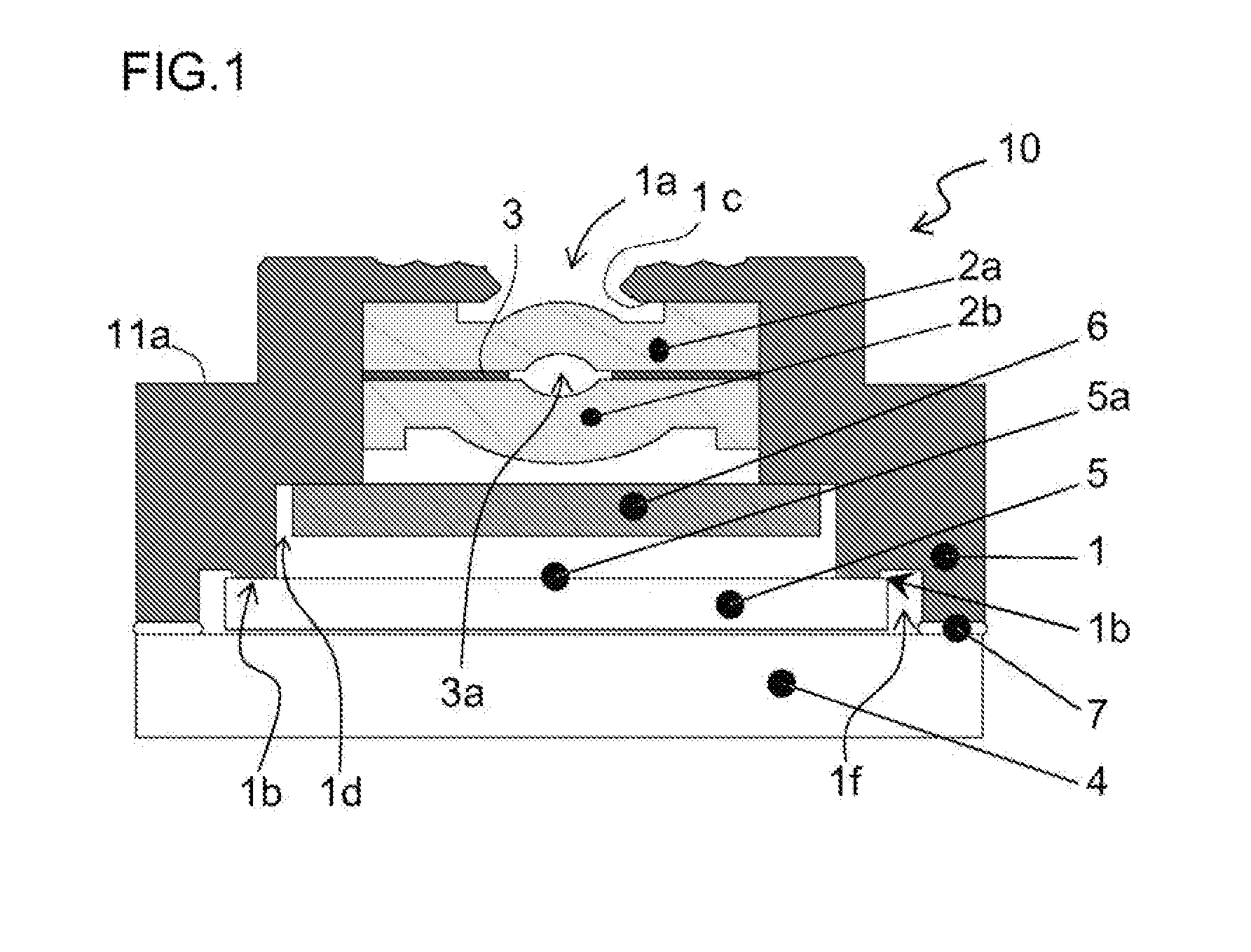

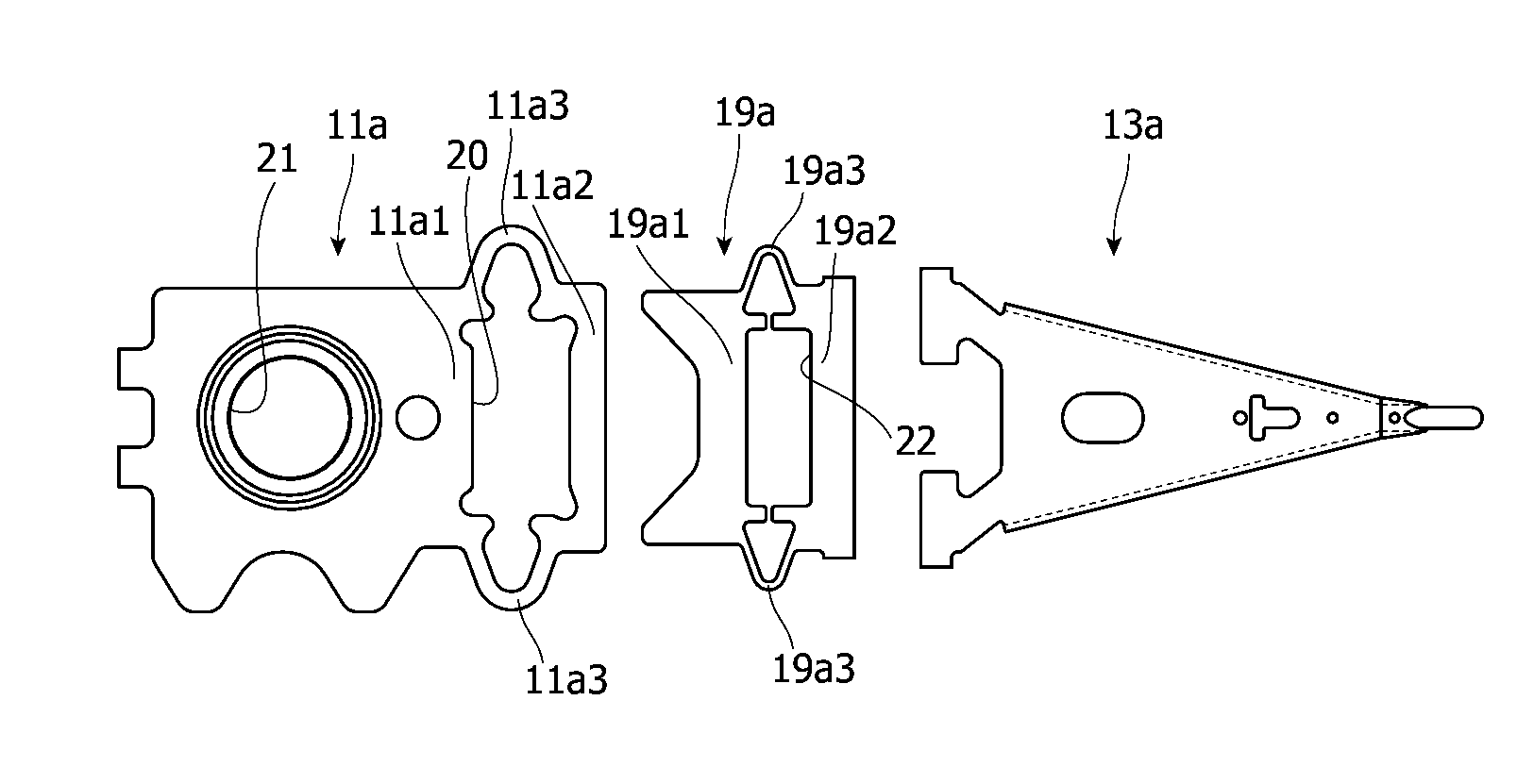

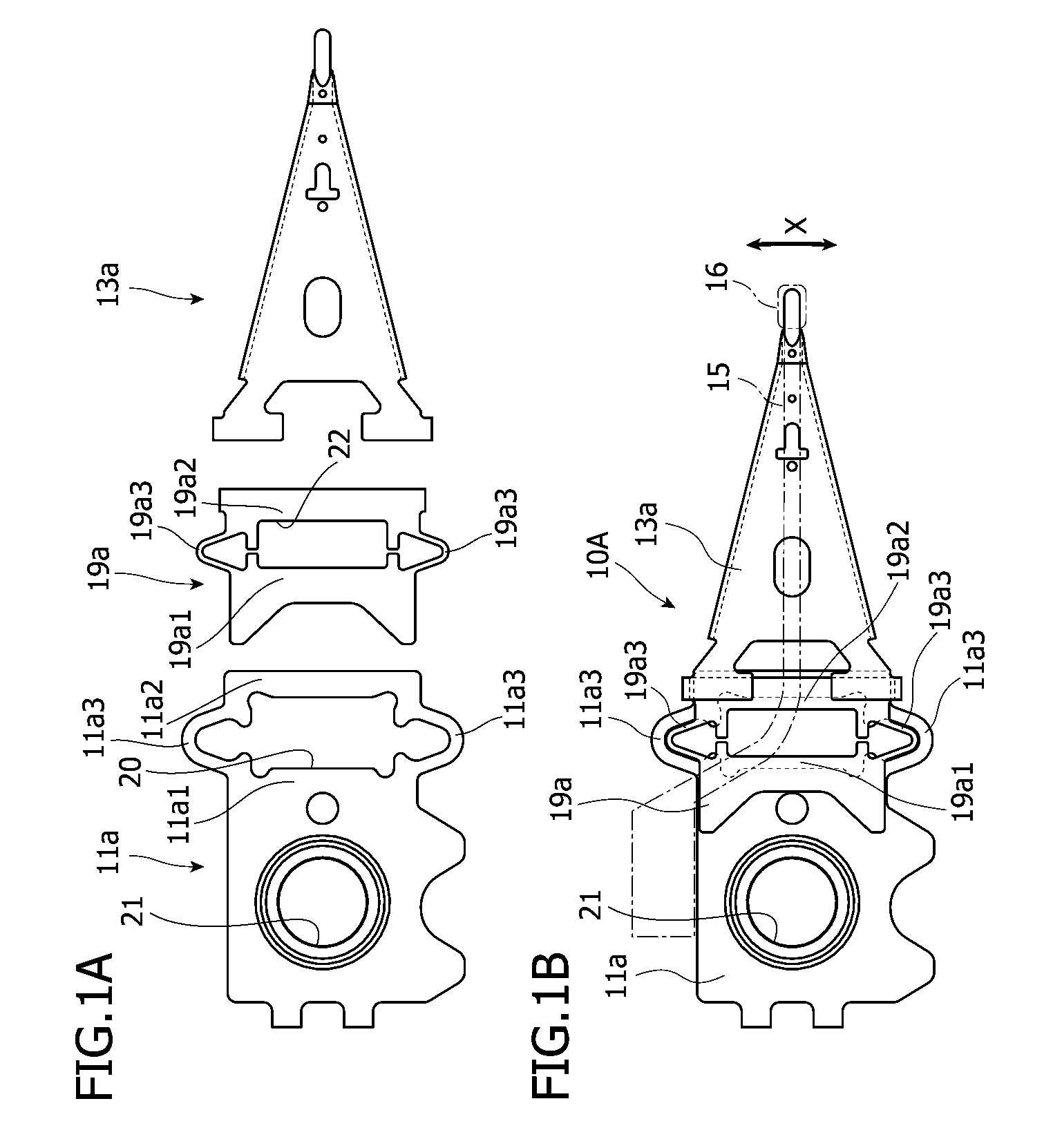

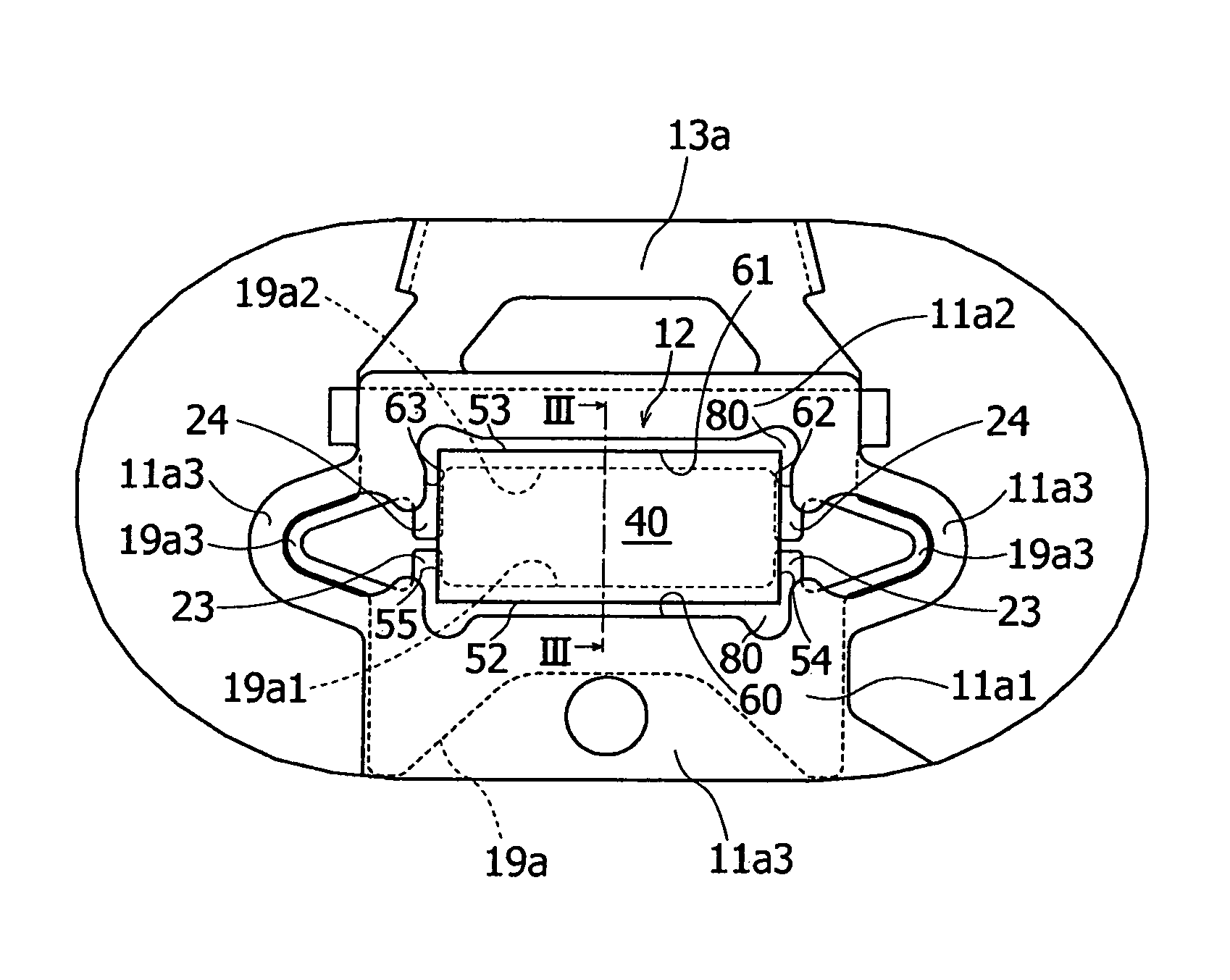

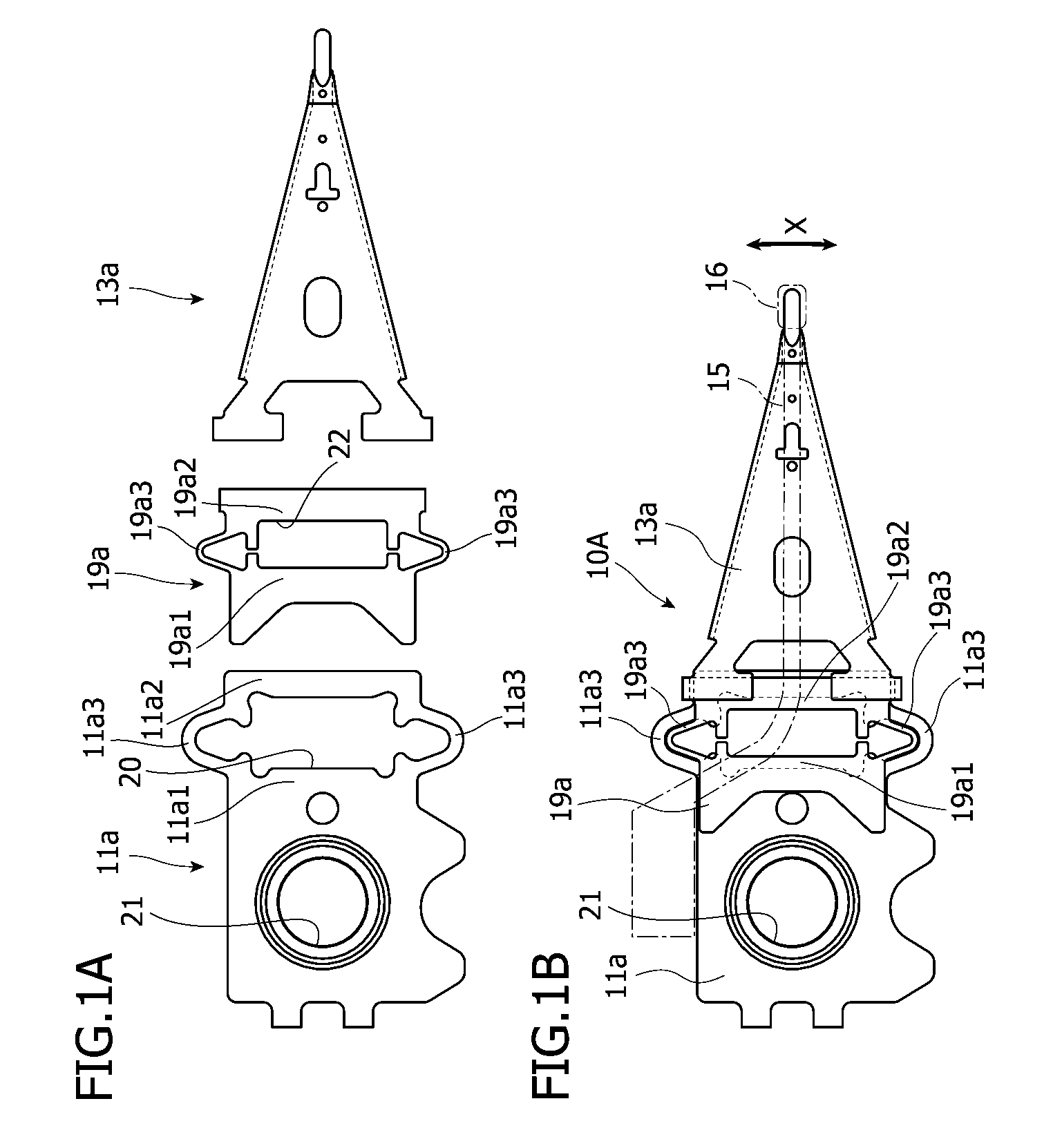

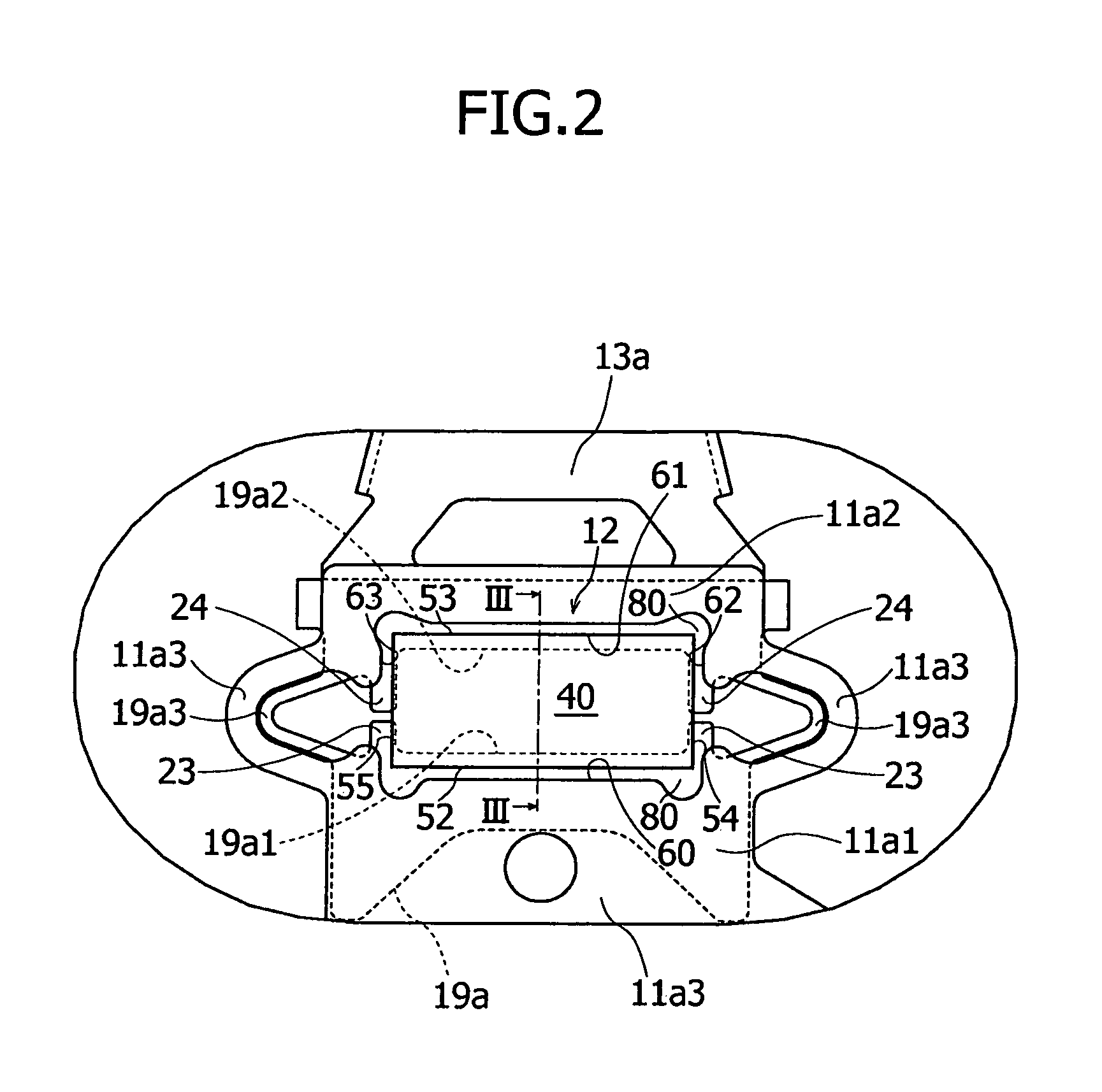

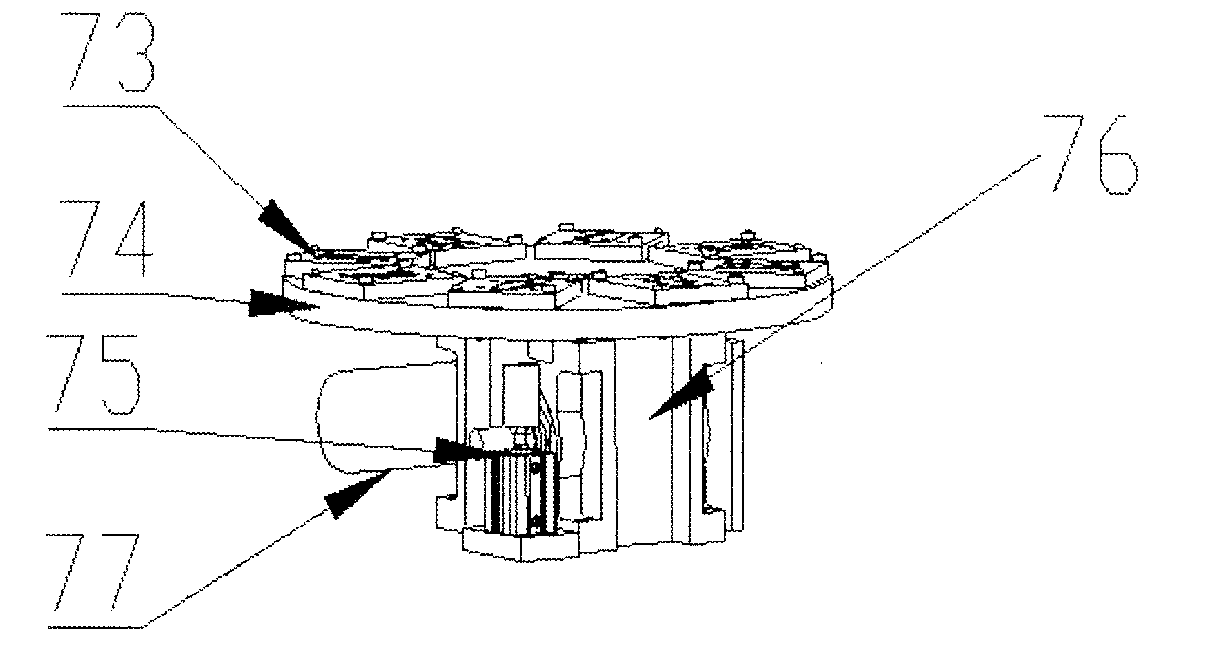

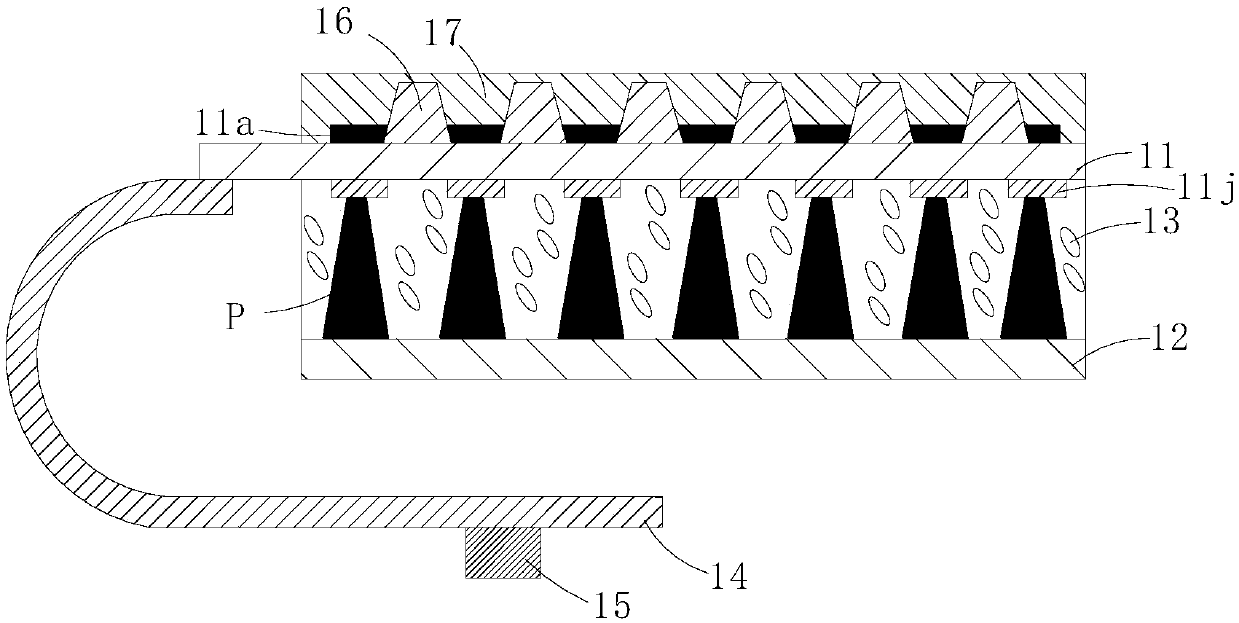

Head suspension

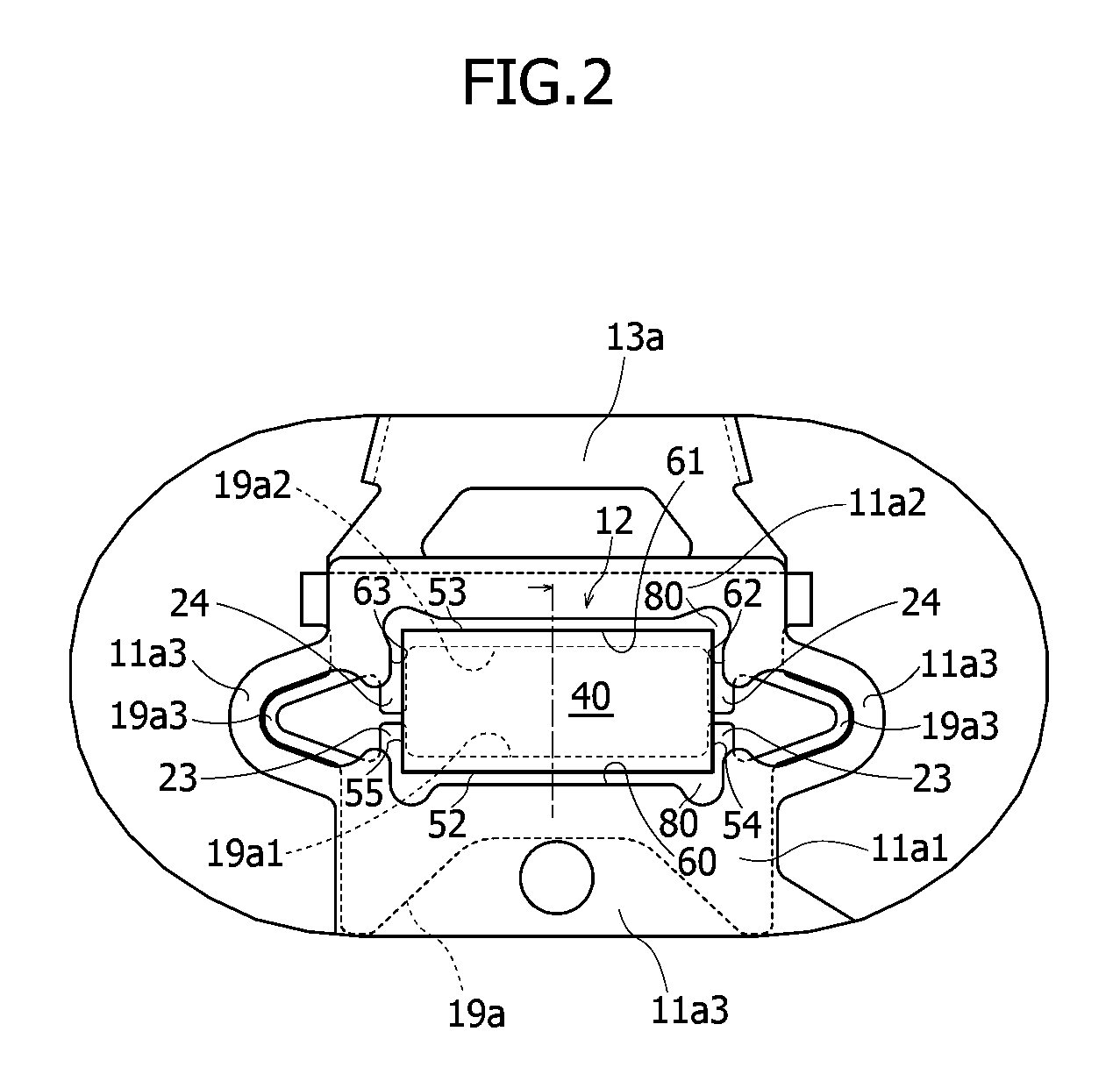

ActiveUS20100208390A1Simple manufacturing processImprove assembly accuracyArm with actuatorsRecord information storageEngineeringMechanical engineering

A head suspension has a base plate 11a, a load beam 13a, and a piezoelectric element 40 that is arranged between the base plate and the load beam and deforms in response to applied power to precisely move a front end of the load beam relative to the base plate. The head suspension includes an opening 20 formed in the base plate and configured to receive the piezoelectric element and a support member 19 joined with the base plate, partly protruding into the opening, and configured to support an electrode 71 of the piezoelectric element. The support member 19 integrally has a base end support 19a1 to support a base end of the electrode, a front end support 19a2 to support a front end of the electrode, and a pair of support links 19a3 to connect the base end support and front end support to each other outside the piezoelectric element. This configuration reduces the number of parts to support the piezoelectric element.

Owner:NHK SPRING CO LTD

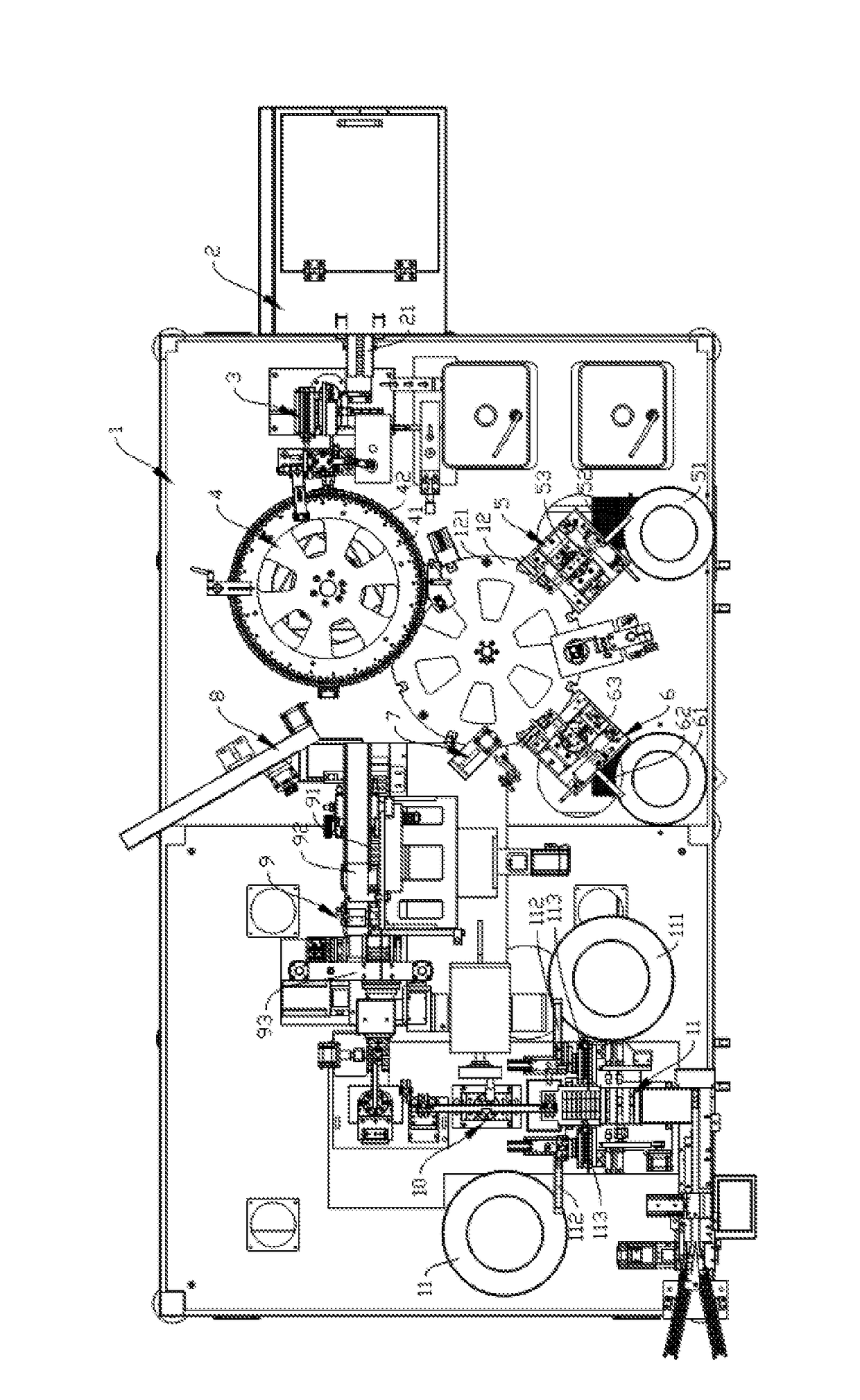

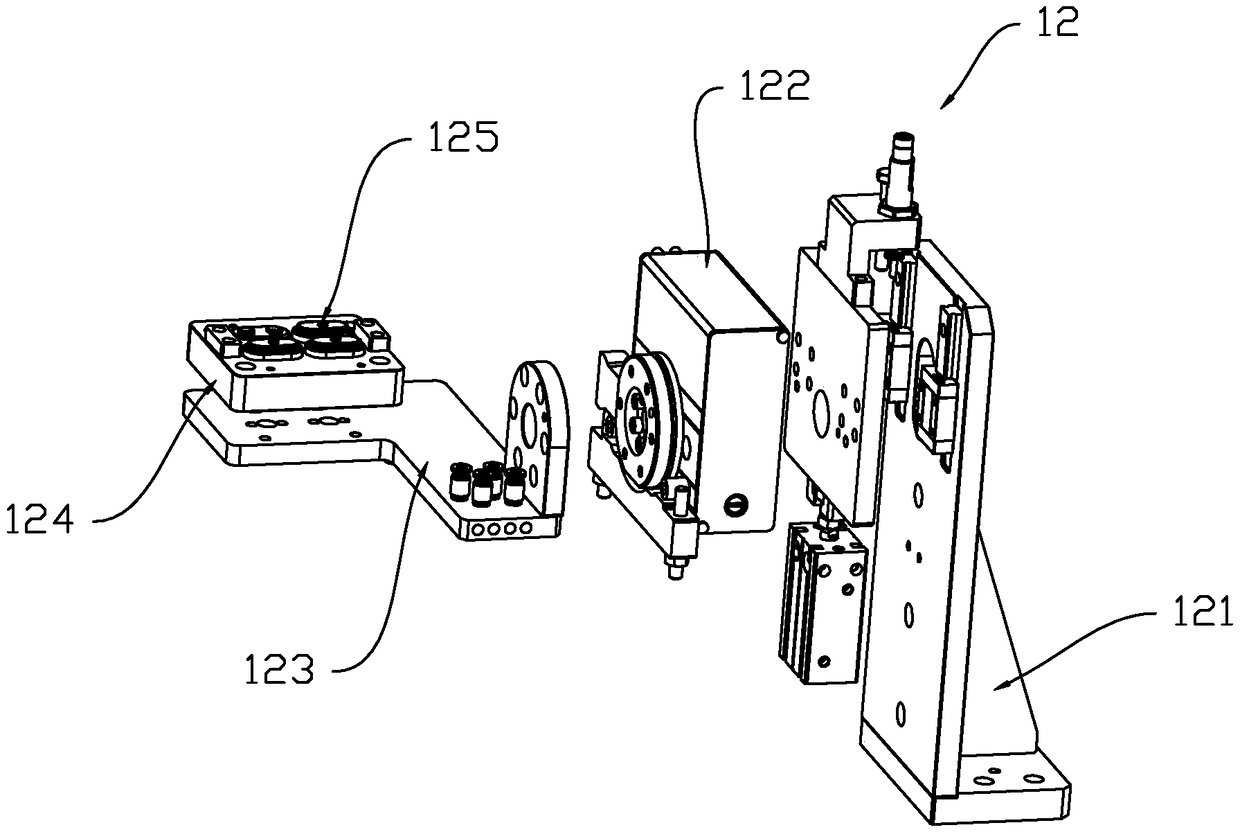

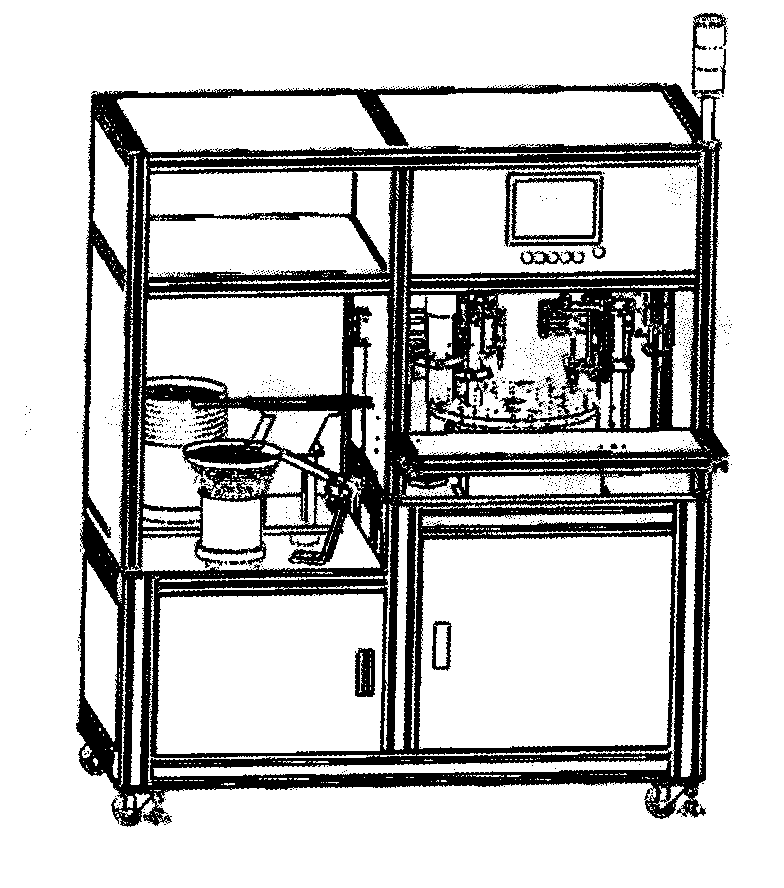

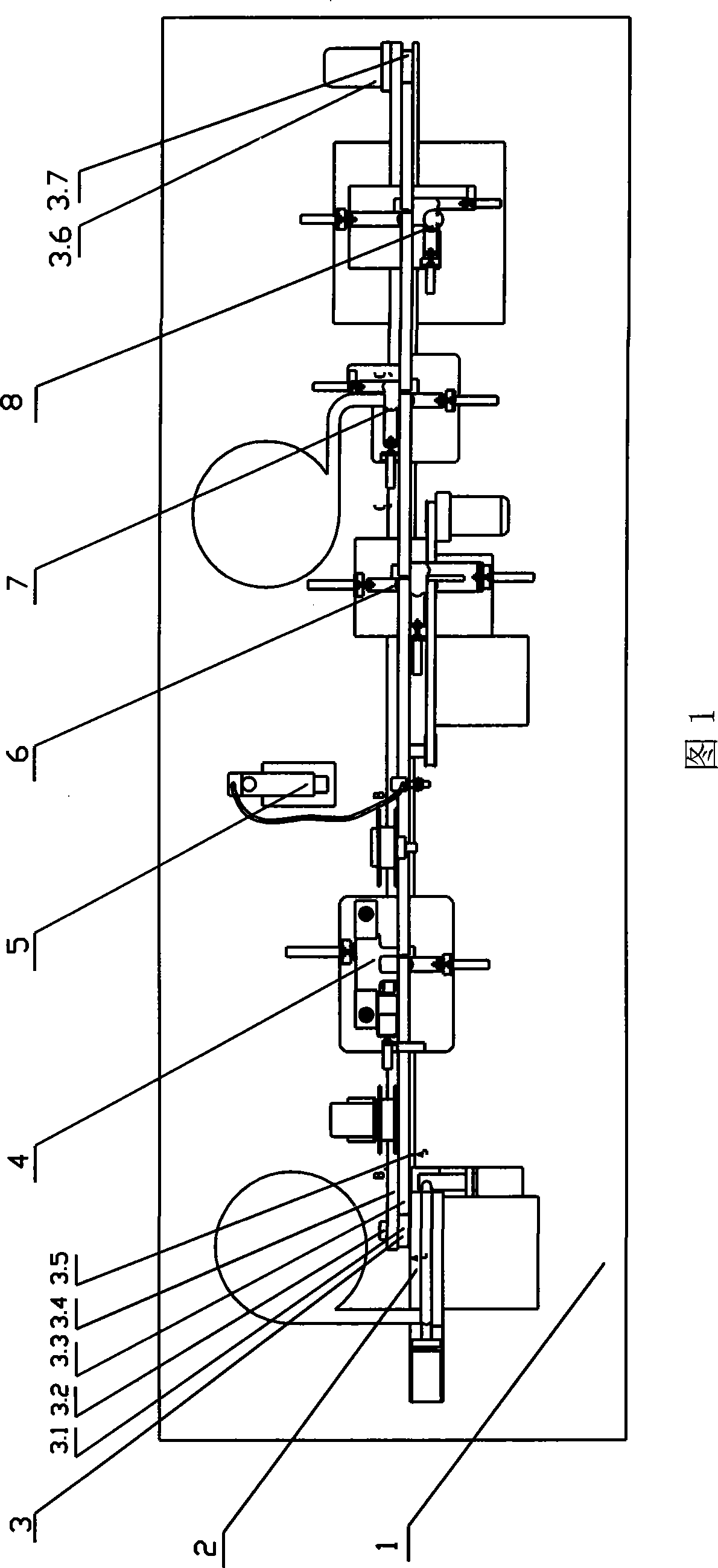

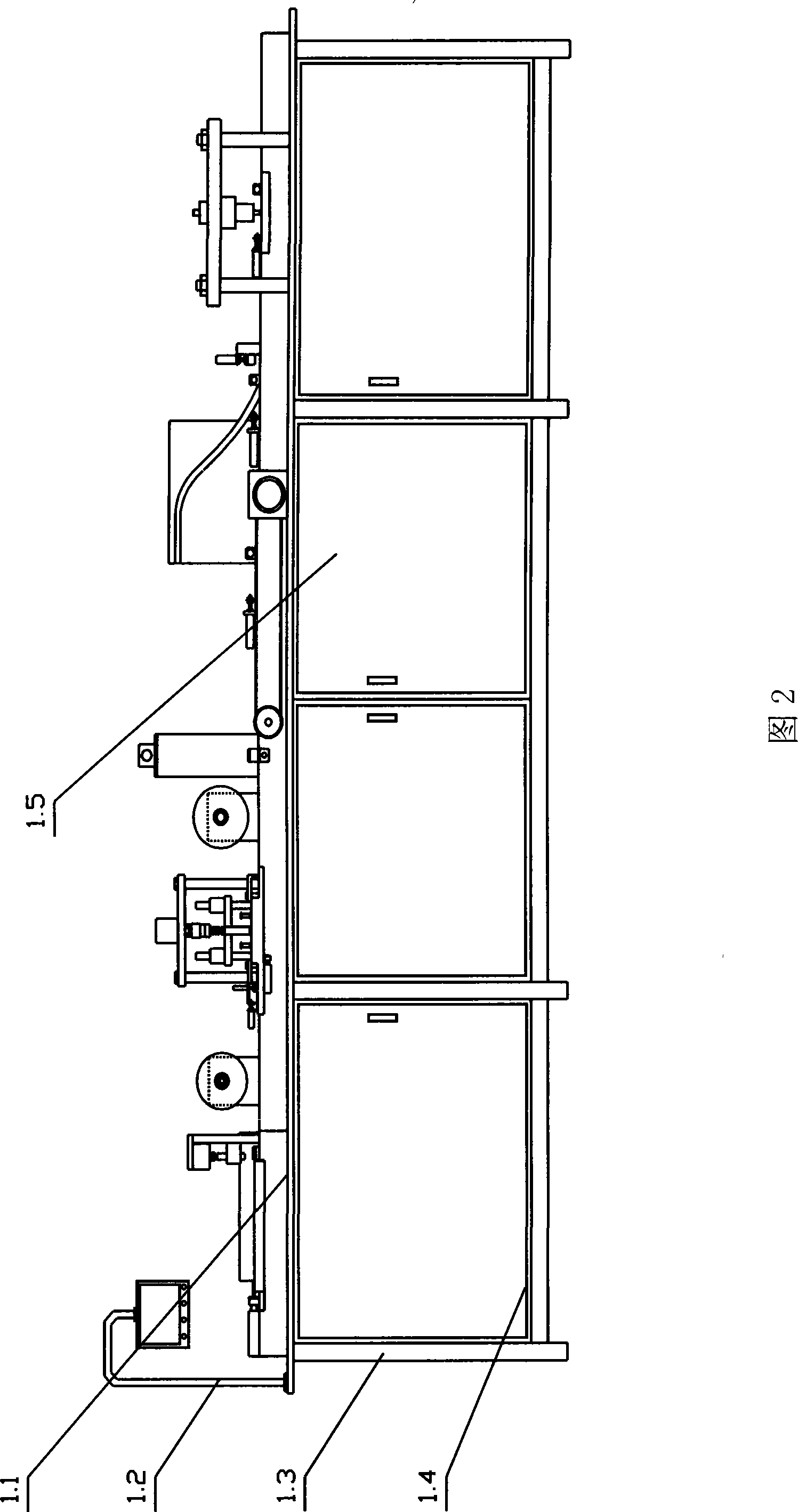

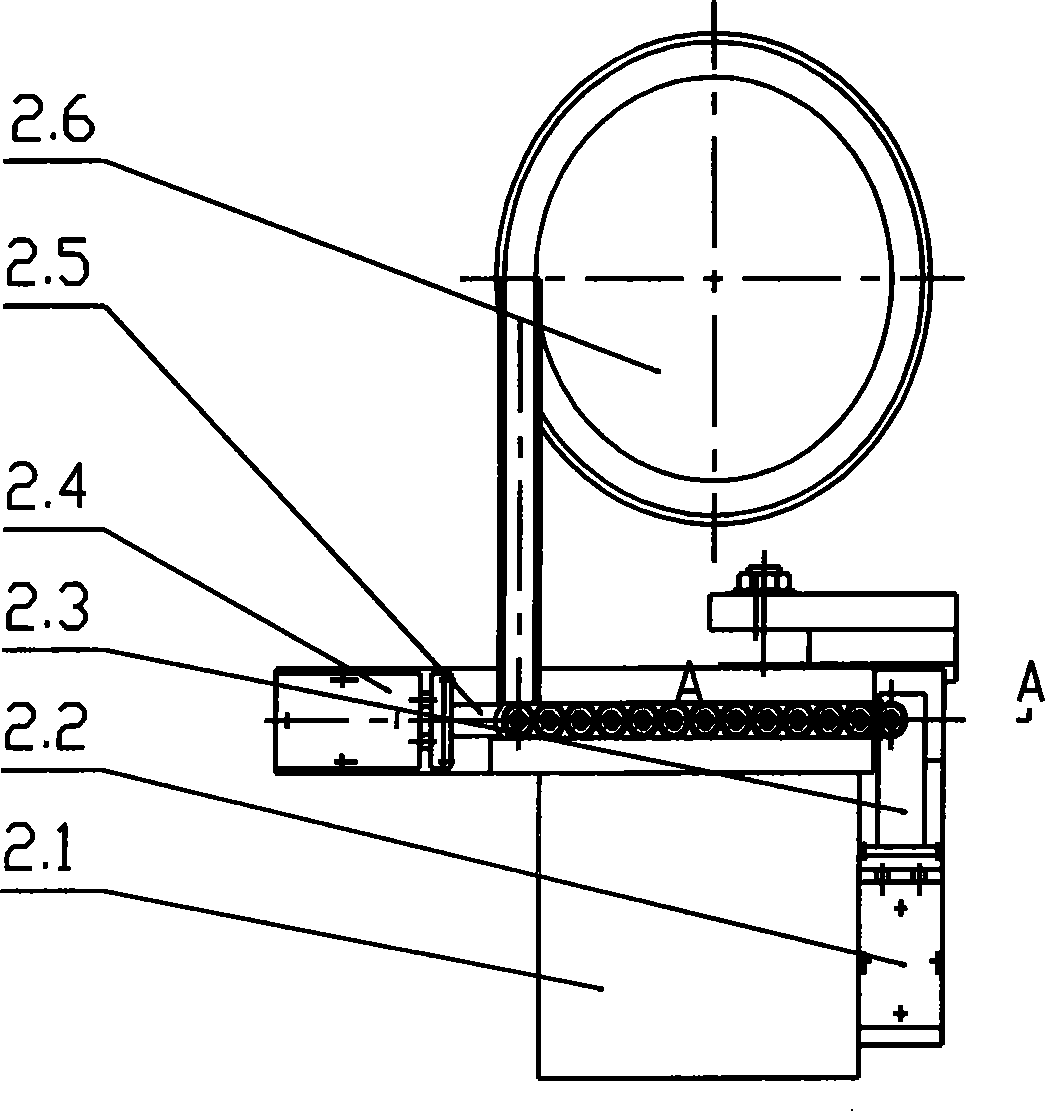

Electronic cigarette atomizer oiling and labeling device

ActiveUS20170196267A1Reduce laborImprove detection qualityAssembly machinesTobacco devicesElectrical resistance and conductanceElectronic cigarette

This disclosure provides oil filling and labeling apparatuses for atomizers of electronic cigarettes, which include a rack provided with a table board. A material pick-up operation position, an oil filling operation position, an assembling operation position, a labeling operation position and a pressing operation position for silicon rubber sleeve are provided on the table board. The oil filling and labeling apparatuses for the atomizers of the electronic cigarettes further include a material loading mechanism, an oil filling mechanism, a mechanism for mounting oil-sealing ring, a mechanism for mounting end cap, an electric resistance detection mechanism, a first material rotation mechanism, a labeling mechanism, a second material rotation mechanism and a mechanism for pressing silicon rubber sleeve. The atomizer of the electronic cigarette is successively conveyed for processing among such mechanisms.

Owner:ZHONGSHAN SHENGYUFENG TRADING CO LTD

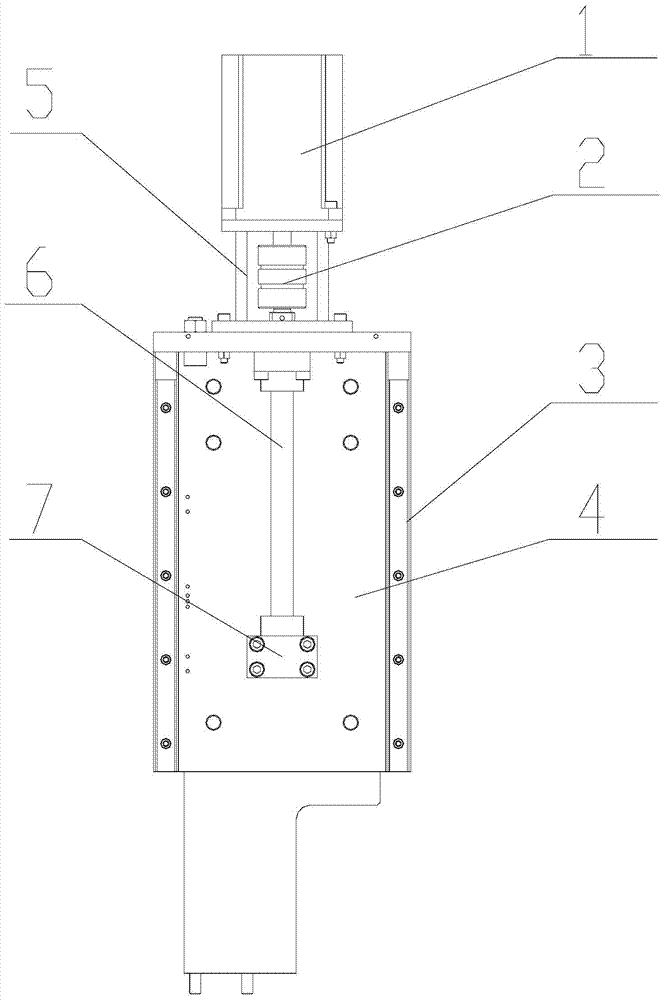

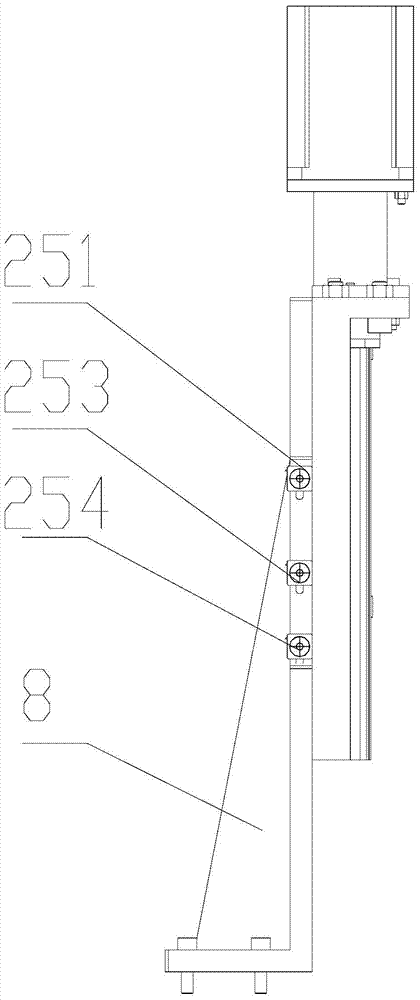

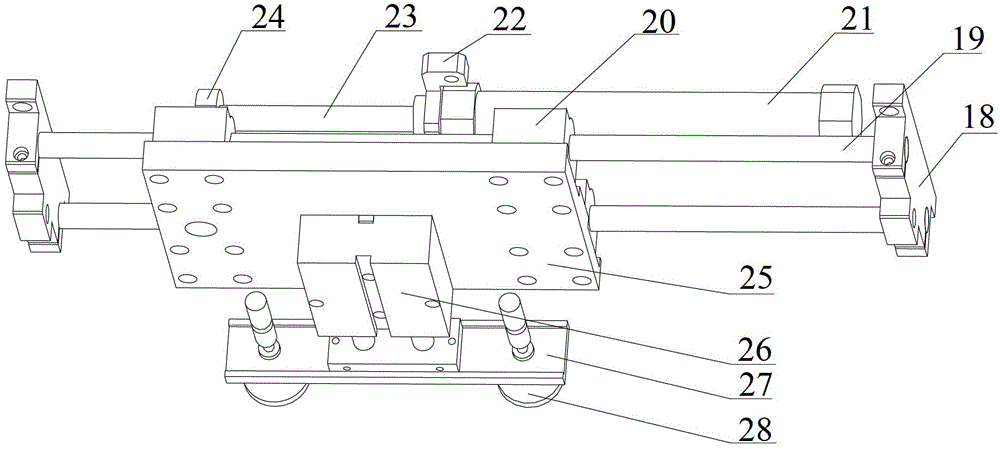

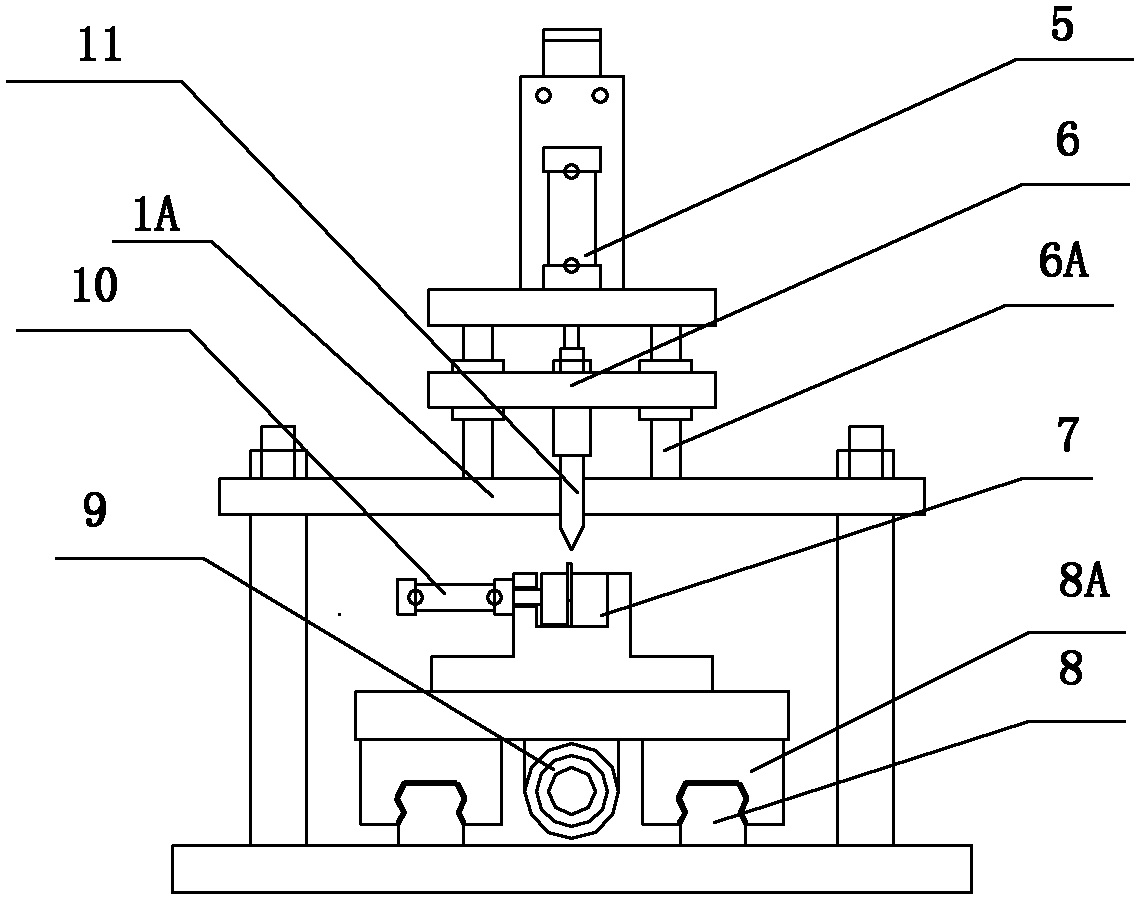

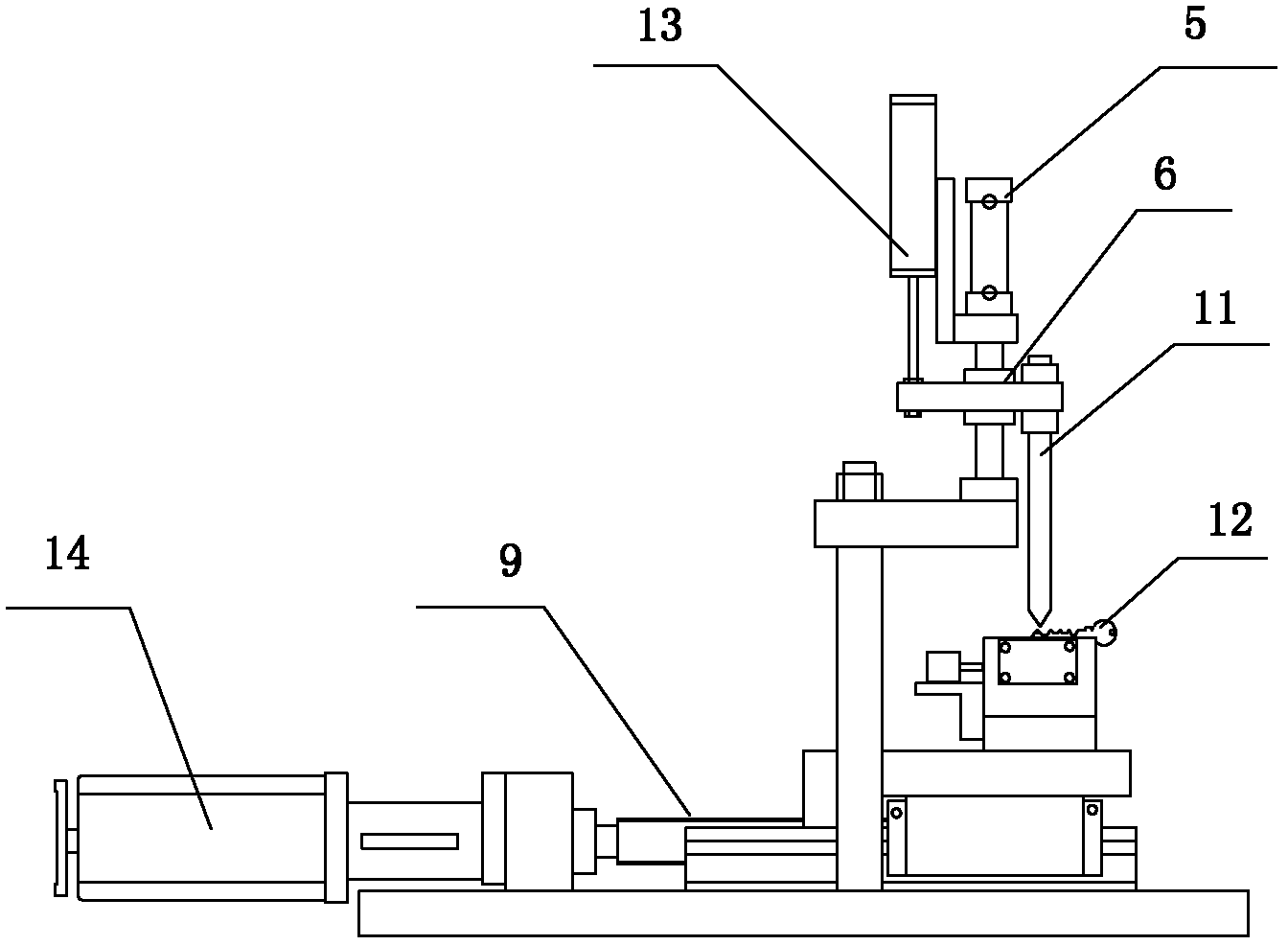

Automatic screw and nut combination locking device

ActiveCN103537892AReduce assembly man-hoursImprove accuracy and efficiencyMetal working apparatusEngineeringSlide plate

The invention is applicable to the field of assembly technologies for screws and nuts, and discloses an automatic screw and nut combination locking device which comprises a fixing assembly and a sliding assembly. The sliding assembly comprises a sliding plate, the sliding plate is slidably connected to the fixing assembly, and a sliding plate driving assembly is arranged on the fixing assembly; a screw locking assembly and a nut locking assembly are connected onto the sliding plate, the screw locking assembly comprises a screwdriver, a screw rotation driving assembly and an axial driving assembly, the screw rotation driving assembly is used for driving the screwdriver to peripherally rotate, and the axial driving assembly is used for driving the screwdriver to vertically slide; the nut locking assembly comprises a nut locking sleeve and a nut rotation driving assembly, the nut rotation driving assembly is used for driving the nut locking sleeve to rotate, and the screwdriver and the nut locking sleeve are coaxially arranged. The automatic screw and nut combination locking device has the advantages that a screw and a nut can be assembled at one station, so that the product assembly working hours can be greatly reduced, the assembly efficiency and the assembly precision can be improved, the cost can be reduced for an enterprise, and the core competitiveness of the enterprise can be improved.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

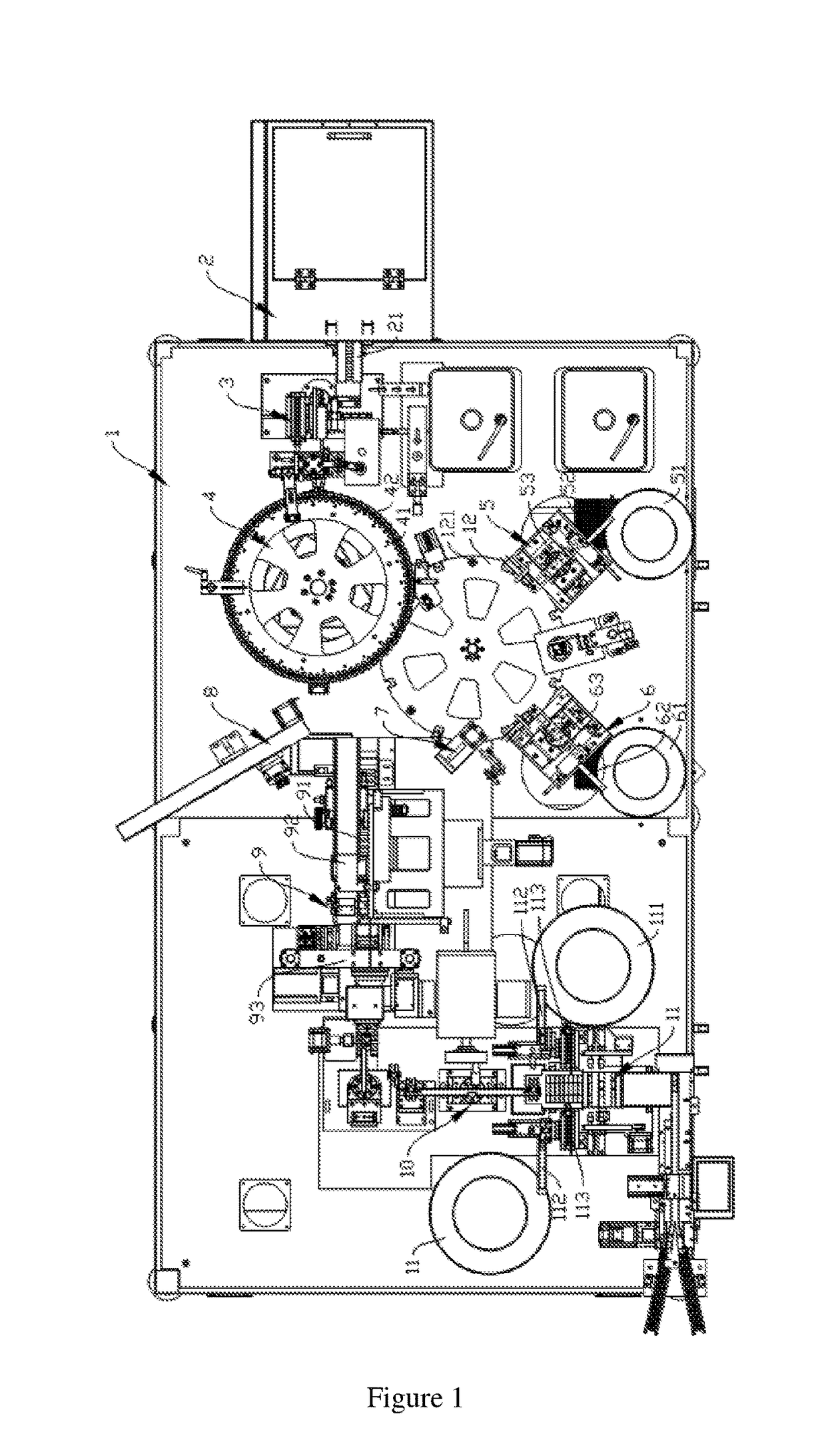

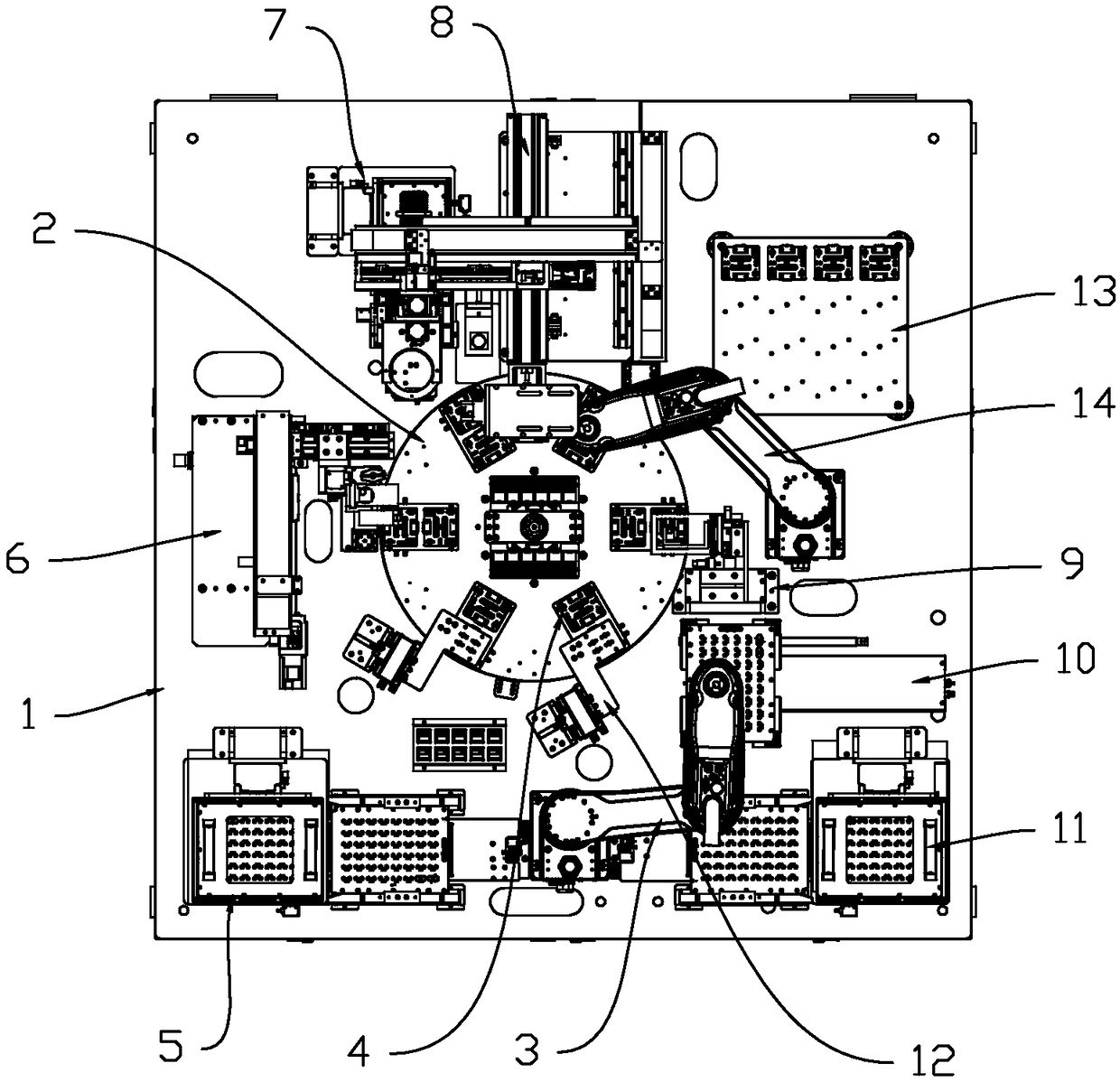

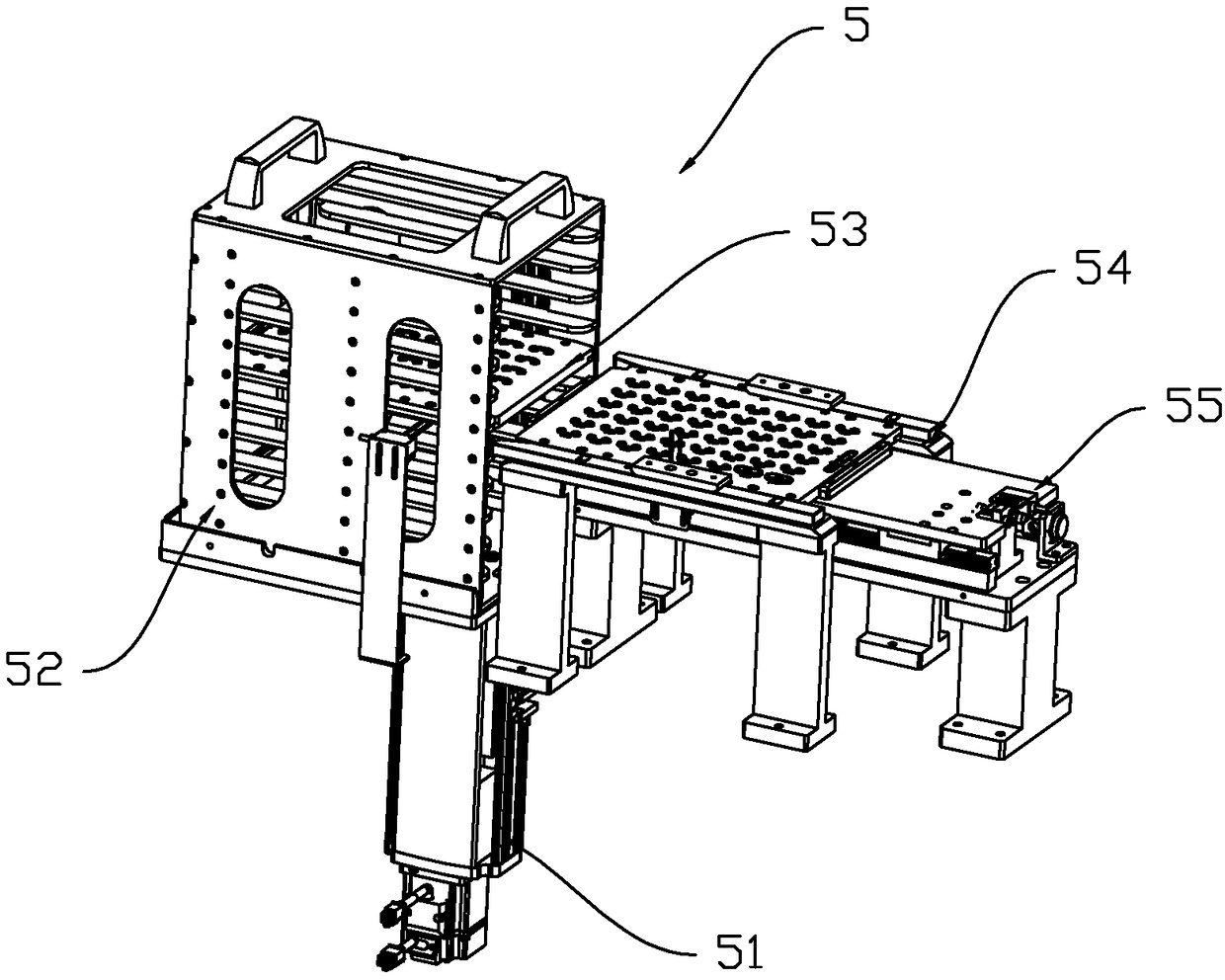

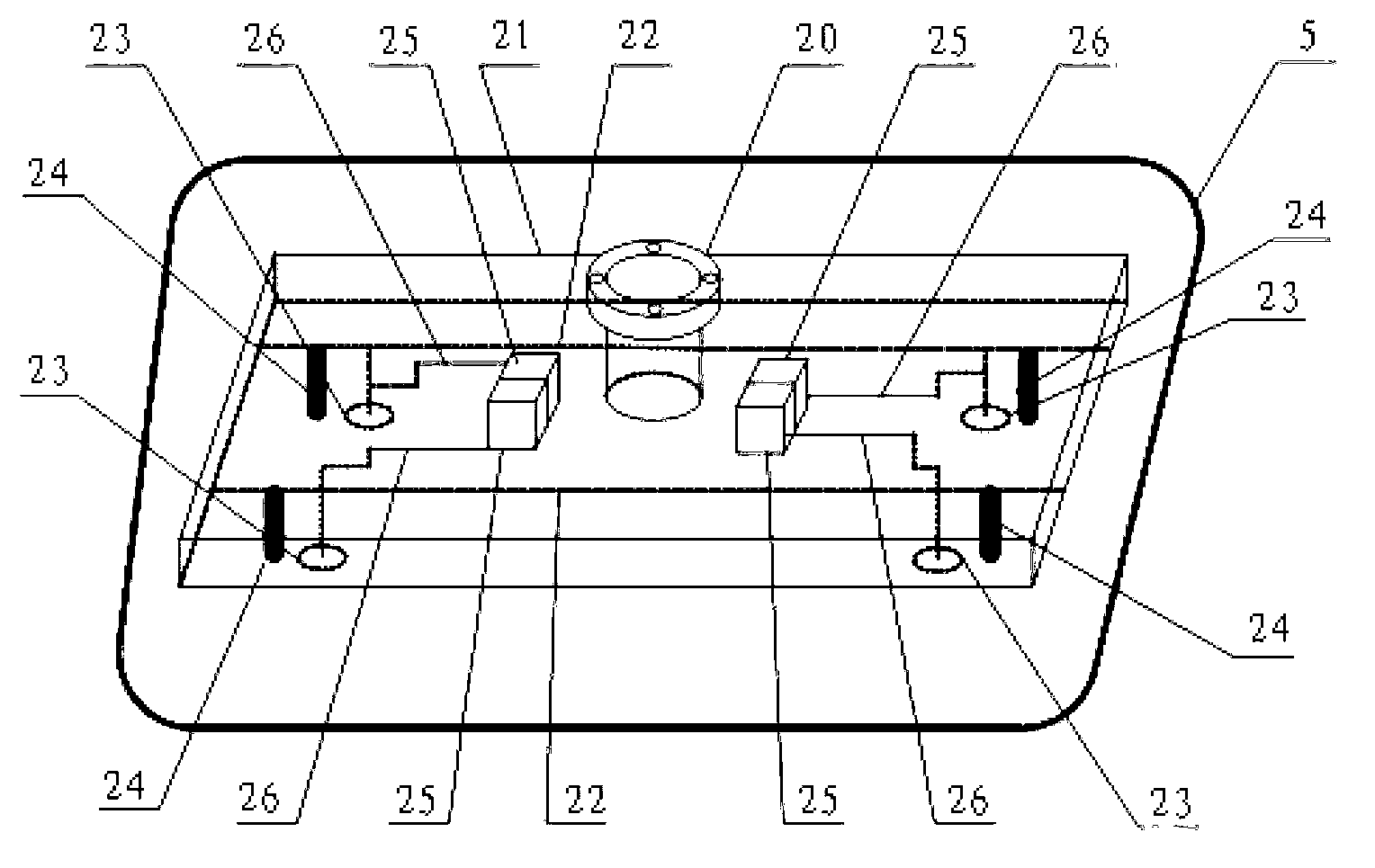

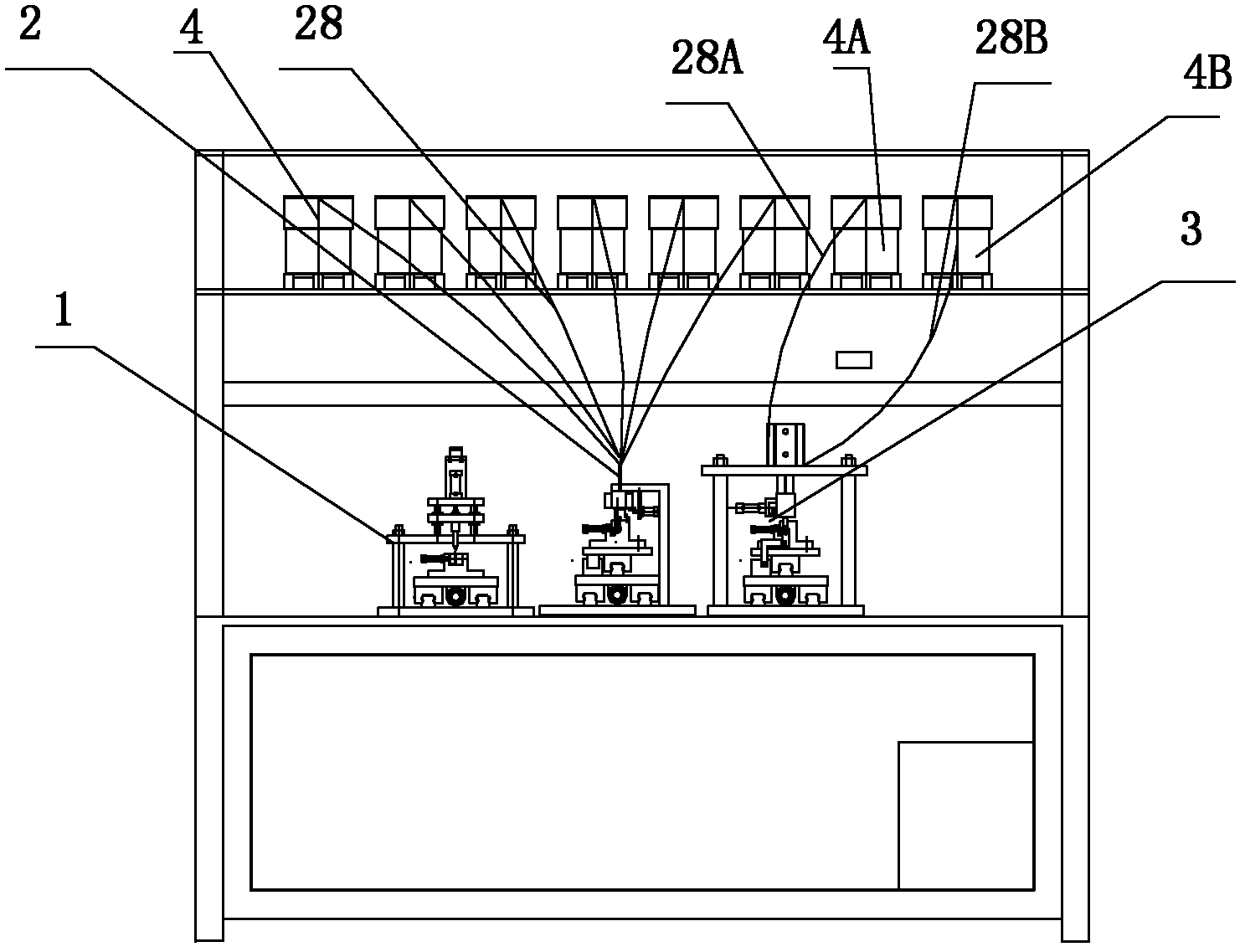

Mobile phone camera LED part automatic assembly machine

PendingCN108857381AImprove assembly efficiencyImprove assembly accuracyMaterial gluingAssembly machinesManipulatorAdhesive

The invention discloses a mobile phone camera LED part automatic assembly machine. The mobile phone camera LED part automatic assembly machine comprises a worktable. The worktable is provided with a rotating disc device and a manipulator arm for feeding and discharging. The rotating disc device is provided with a plurality of auxiliary jigs for placing camera end covers, and a camera end cover feeding device, an adhesive dispensing device, an LED part feeding device, an LED assembly device, a finished product detecting mechanism, a defective product placement area and a finished product discharging device are arranged on the worktable in sequence and surround a rotating disc. A plurality of overturn mechanisms are arranged between the camera end cover feeding device and the rotating disc device. After the camera end covers and LED parts are placed on charging trays, the manipulator arm places the obtained camera end covers on overturn devices, and the overturn devices rotate to overturn the camera end covers and place the camera end covers on the auxiliary jigs; and then through the processes of automatic adhesive dispensing, LED part assembly and the like, and higher assembly efficiency and assembly precision can be achieved. The mobile phone camera LED part automatic assembly machine is used in the field of industrial automation.

Owner:KEYIZHAN INTELLIGENT EQUIP CO LTD +1

Head suspension including integral piezoelectric element electrode support member

ActiveUS8331061B2Simple manufacturing processImprove assembly accuracyTrack finding/aligningArm with actuatorsMechanical engineeringElectrode

Owner:NHK SPRING CO LTD

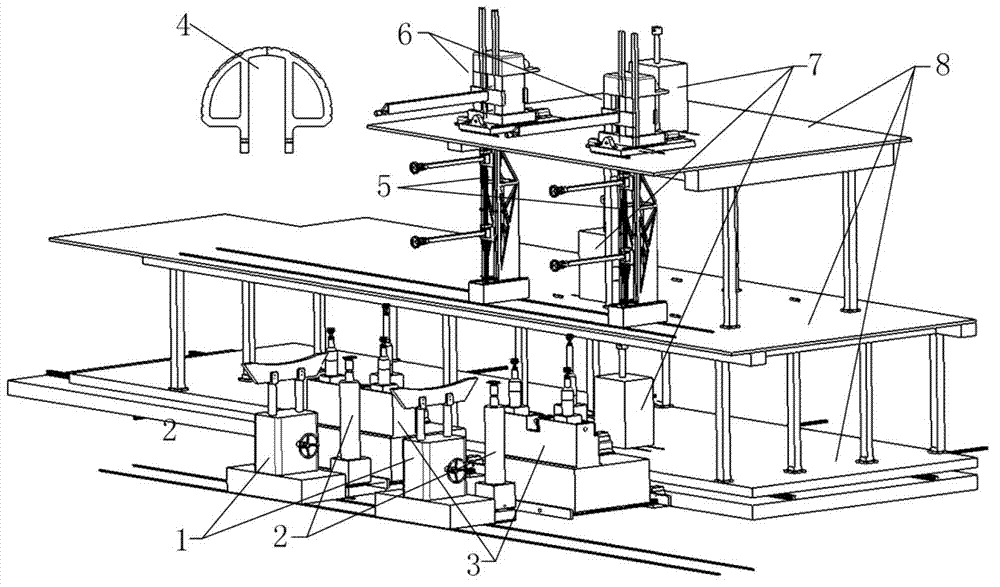

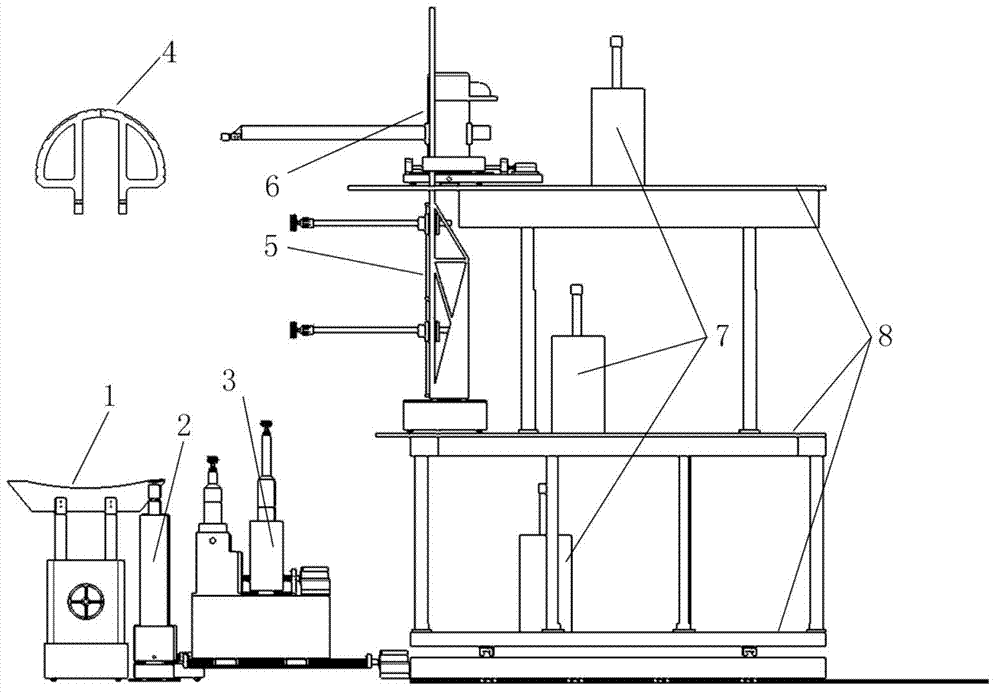

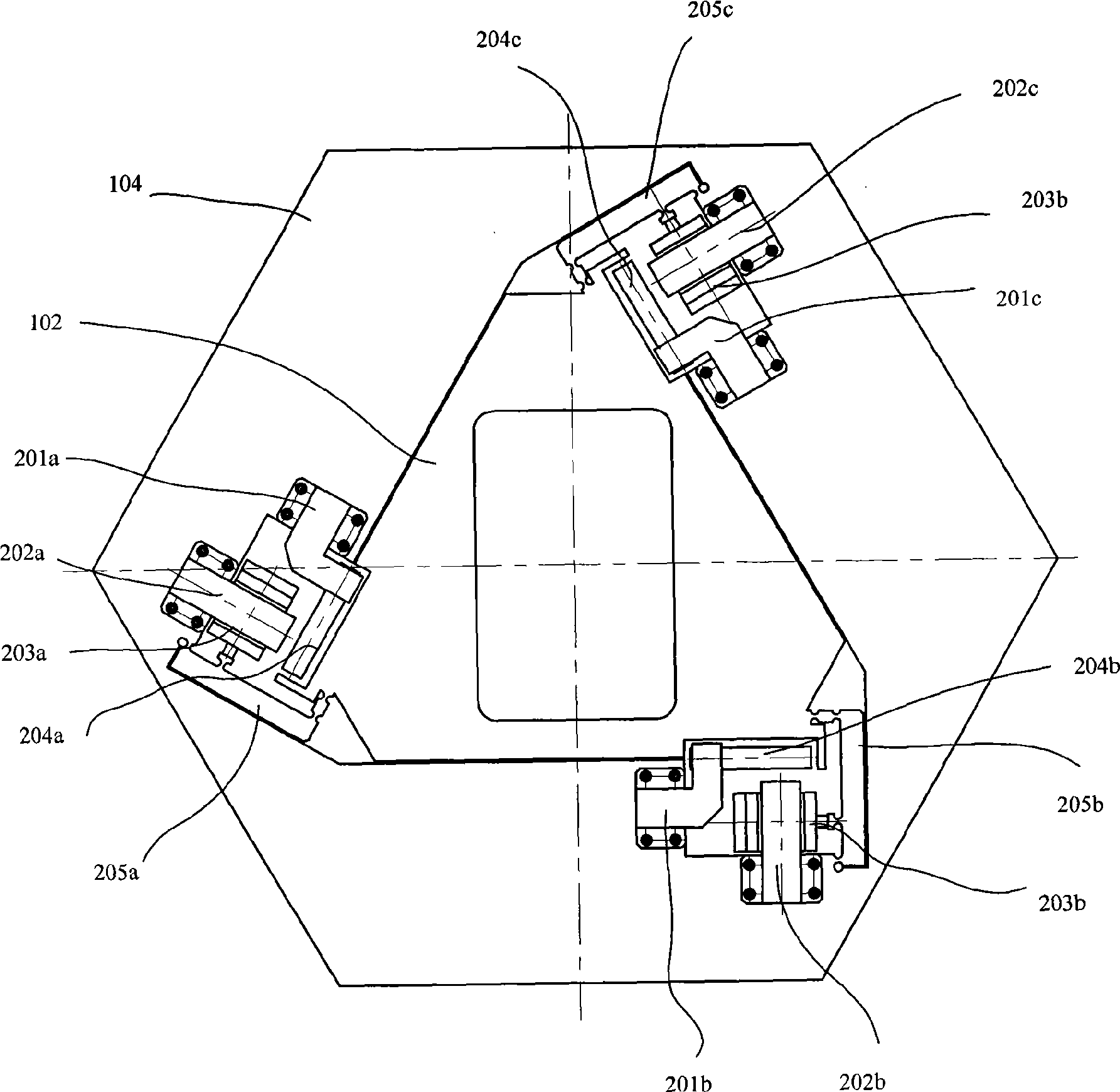

Method and device for folding and flexibly positioning body wallboard

ActiveCN102765489AAchieve six degrees of freedomRealize multi-posture adjustmentAircraft assemblyLaser trackerFuselage

The invention provides a method and a device for folding and flexibly positioning a body wallboard. Due to the method and the tool for folding and flexibly positioning the body wallboard, lots of special clamping boards are not needed and good flexibility is achieved; a positioner clamping mechanism can be adsorbed on a positioning support surface of the wallboard, so that six-freedom-degree and multi-pose regulation of the body wallboard can be achieved; laser trackers distributed on a first layer of working table, a second layer of working table and a third layer of working table can feed back assembling information at real time, thus drastically improving assembly accuracy; the body wallboard is fixed by the adsorption positioning mechanism, thus being simple in assembly and disassembly, reducing manual operation and improving assembly efficiency; and in addition, the method and the device have good generality, so that the method and the device can be suitable for folding process of body wallboard structures with different sizes and satisfy folding requirement of various body wallboards.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

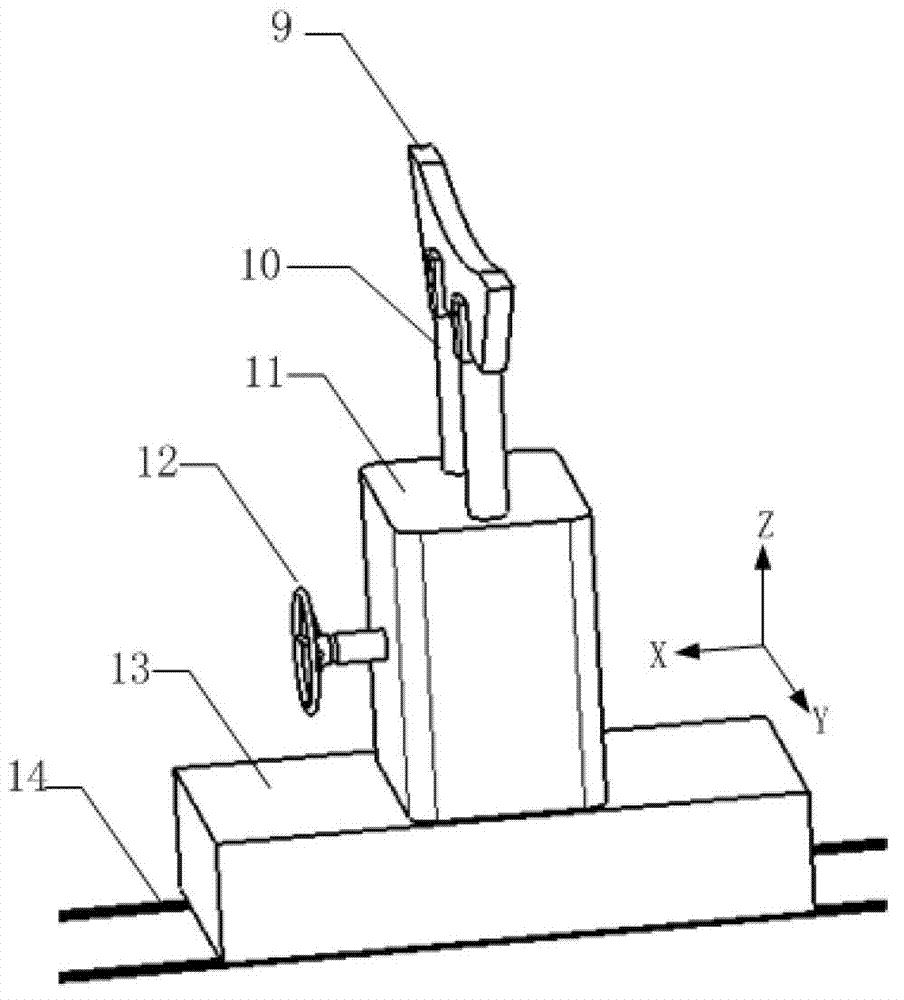

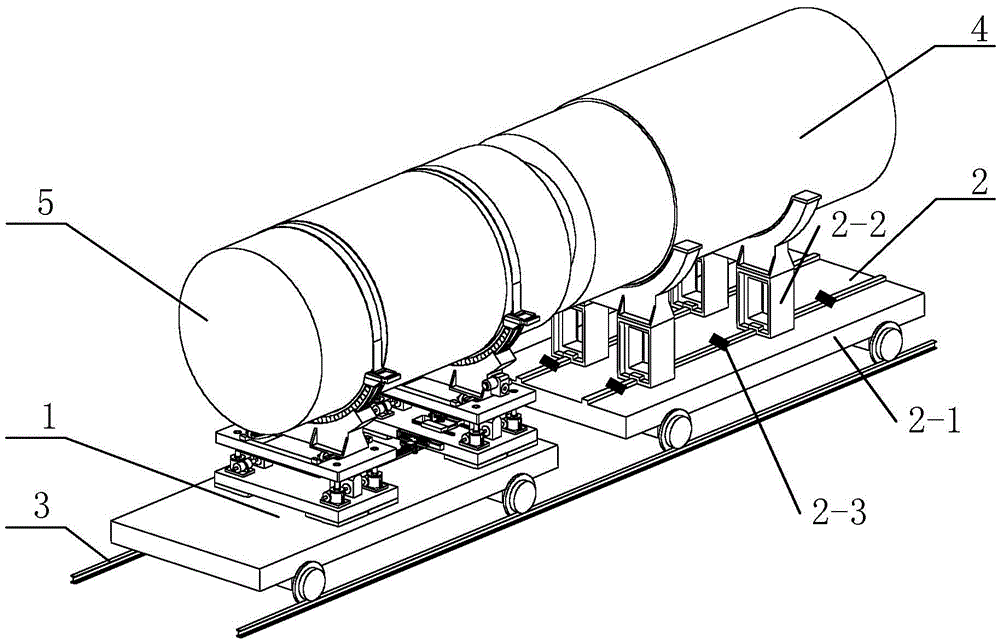

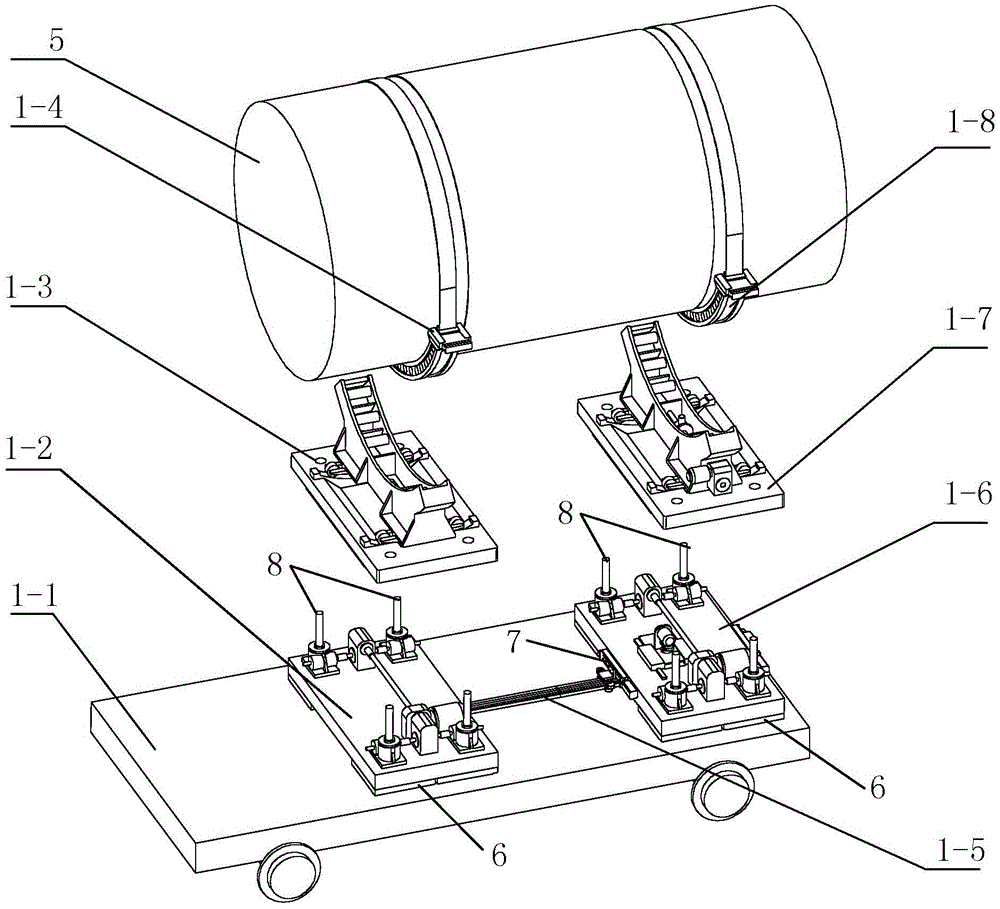

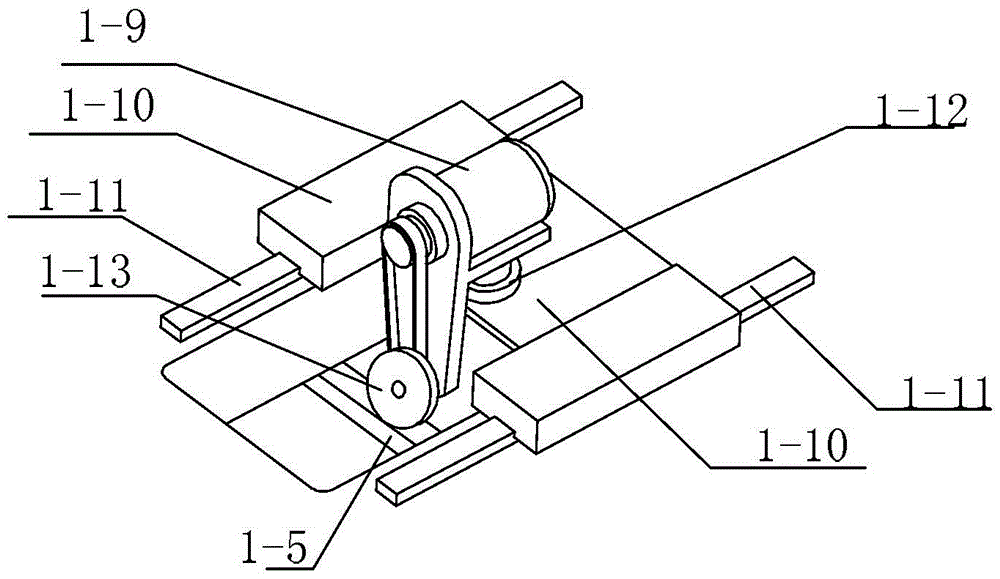

Air-floating type flexible assembly butt-joint system

ActiveCN105619049AImprove assembly efficiencyImprove assembly qualityMetal working apparatusButt jointEngineering

The invention relates to an air-floating type flexible assembly butt-joint system, which relates to the technical field of flexible assembly, and aims at solving problems of low assembling precision, inferior efficiency and inferior flexibility of traditional large-scale cabin section type products. The air-floating type flexible assembly butt-joint system comprises a driving assembly butt-joint vehicle, a driven assembly butt-joint vehicle and a rail, wherein the driving assembly butt-joint vehicle and the driven assembly butt-joint vehicle slide along the same rail; the driven assembly butt-joint vehicle is used for lifting a driven butt-joint cabin section; the driving assembly butt-joint vehicle is used for lifting a driving butt-joint cabin section and controlling the driving butt-joint cabin section to move for butt joint along the extending direction of the rail, move along the direction vertical to the extending direction of the rail, vertically move along the longitudinal direction, rotate in a yawing form, rotate in a pitching form and rotate in a rolling form, so that the butt joint between the driving butt-joint cabin section and the driven butt-joint cabin section lifted on the driven assembly butt-joint vehicle is realized; the driving assembly butt-joint vehicle is used for lifting the driving butt-joint cabin section in an air-floating form. The air-floating type flexible assembly butt joint system is mainly used for fine butt-jointing of large-scale cabin section type products.

Owner:HARBIN INST OF TECH

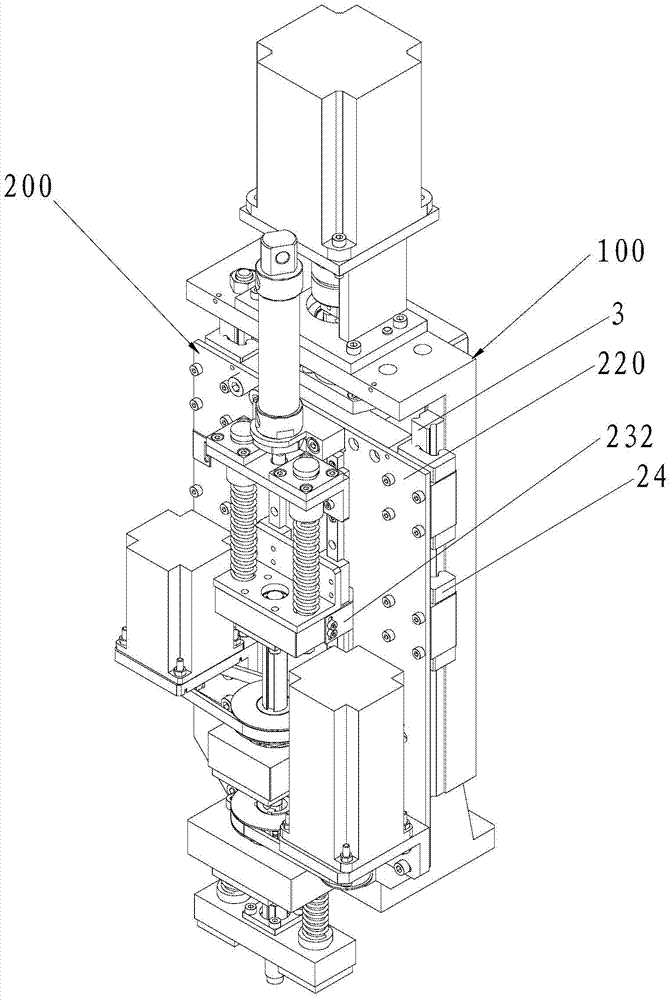

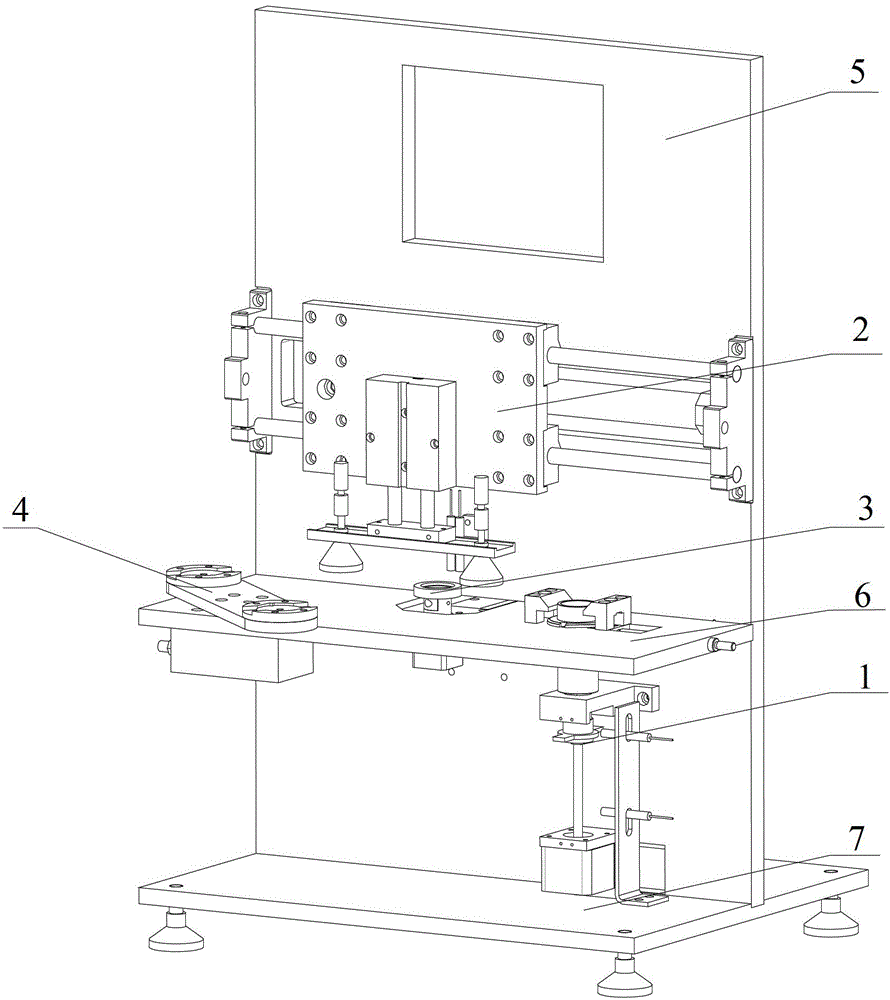

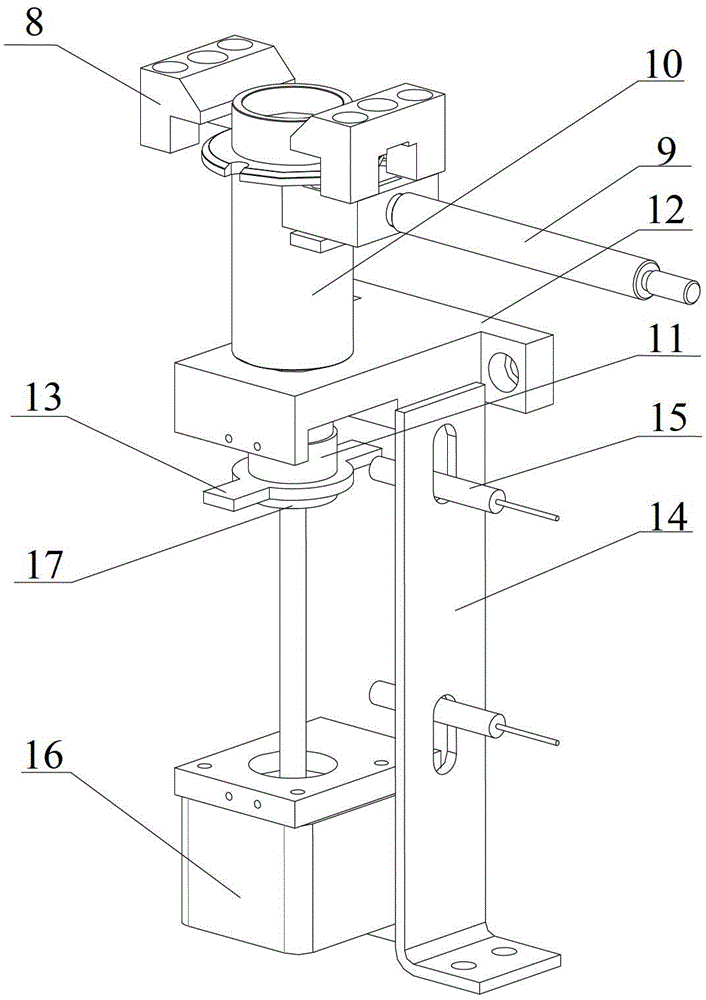

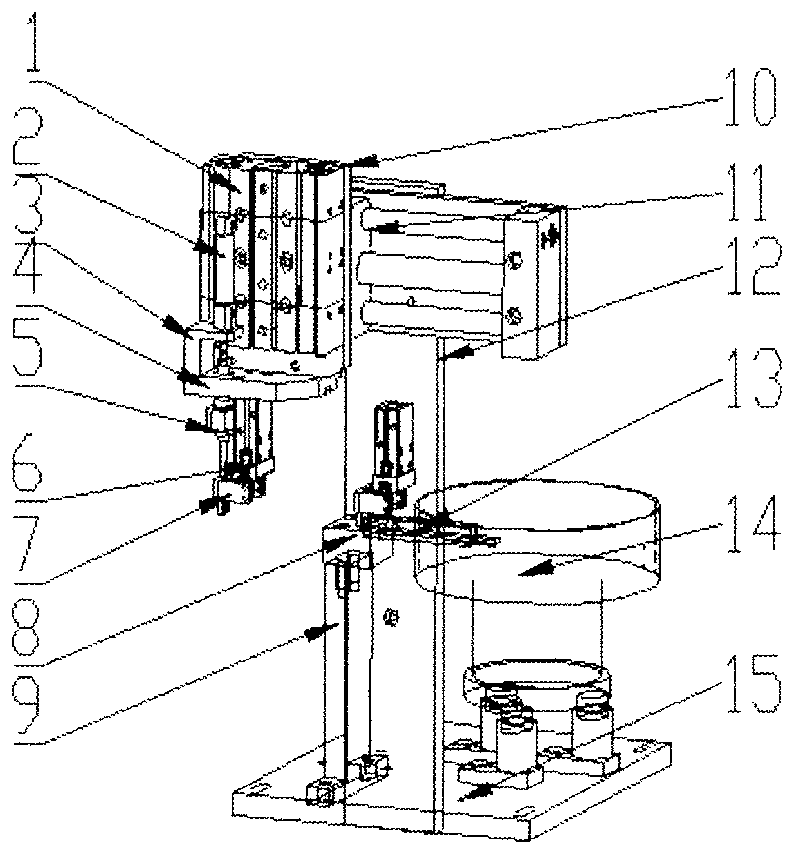

Automatic aligning assembling system of parts

ActiveCN103056635AImprove assembly efficiency and assembly accuracyImprove work efficiencyMetal working apparatusEngineeringMechanical engineering

The invention discloses an automatic aligning assembling system of parts. The automatic aligning assembling system comprises a vertically arranged support, a material feeding device, a position detection adjusting device, an assembling device and a material moving device, wherein the material feeding device is used for conveying the parts to a designated position; the position detection adjusting device comprises a sliding mechanism horizontally installed on the support, a rotary detection table installed on the sliding mechanism and a position detection photoelectric switch, and the position detection photoelectric switch is used for detecting the positions of the parts on the rotary detection table and emitting aligning control signals to the rotary detection table; the assembling device comprises a rotary bearing plate and a die plate arranged at the end of the rotary bearing plate; and the material moving device is used for conveying the parts to the rotary detection table from the designated position and conveying the aligned parts on the rotary detection table to the die plate. The automatic aligning assembling system of parts replaces manual operation, achieves automatic detection and adjusting of part position, improves assembling accuracy and efficiency, accordingly improves production efficiency and reduces production cost of the parts.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Automatic assembly machine for cooling fins and transistors

InactiveCN103317321AImprove work efficiencyReduce manufacturing costMetal working apparatusLocking mechanismEngineering

The invention discloses an automatic assembly machine for cooling fins and transistors. The automatic assembly machine comprises a workbench, a multi-station rotary table mechanism adopting a cam indexer, an automatic screw locking mechanism, an automatic nut feeding mechanism, an automatic crystal feeding mechanism, an automatic glue printing mechanism and an automatic blanking mechanism. The automatic assembly machine is characterized in that circulation of tooling is achieved through a multi-station index plate, and different products are produced only through replacing the tooling. Manual arrangement of the cooling fins, automatic feeding of nuts and crystals, automatic glue printing, automatic locking of screws and automatic blanking can be achieved. The automatic assembly machine has the advantages that the structure is stable, the production efficiency is high, the labor intensity is greatly reduced, and the production efficiency is improved.

Owner:SUZHOU ASILAN AUTOMATION SCI & TECH

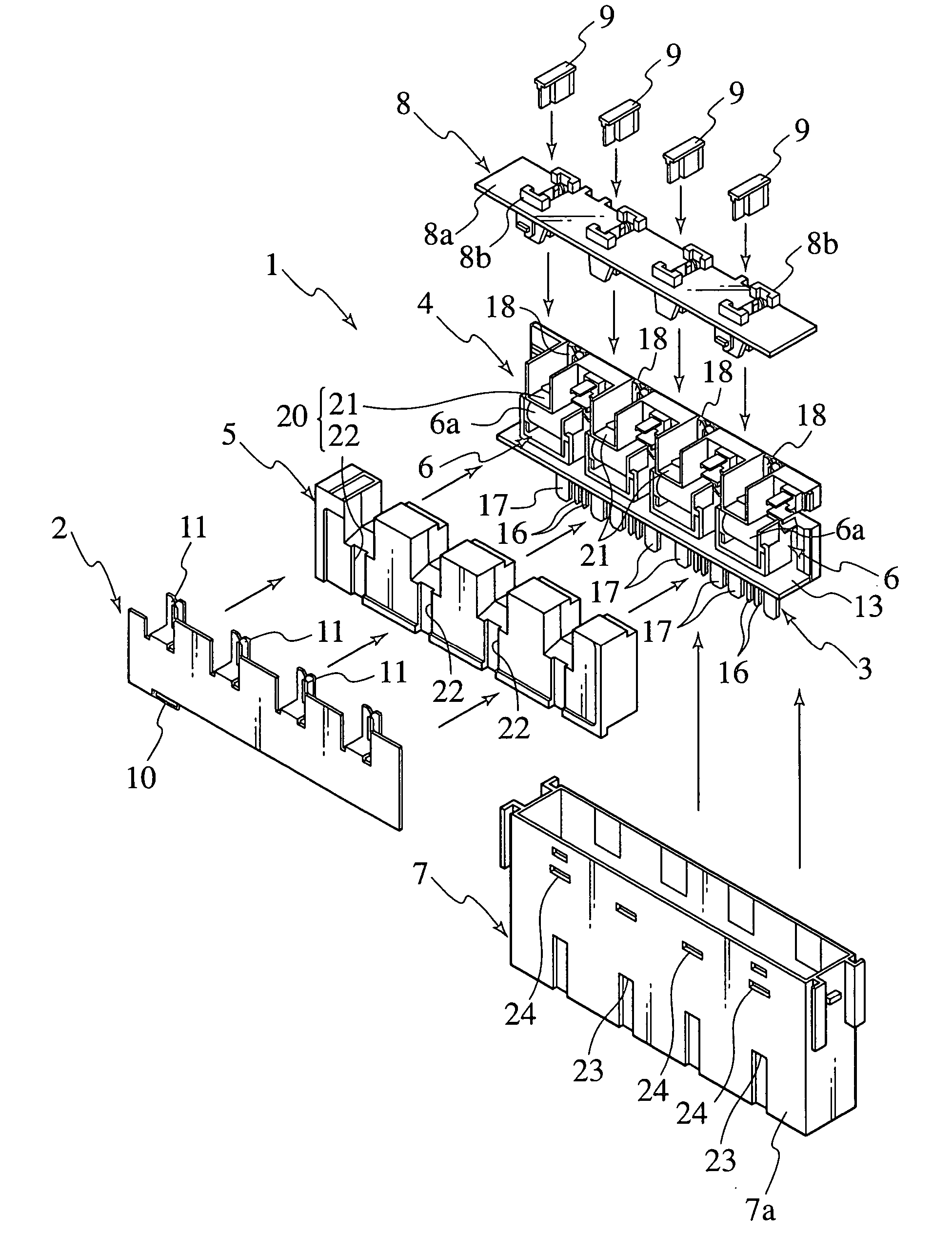

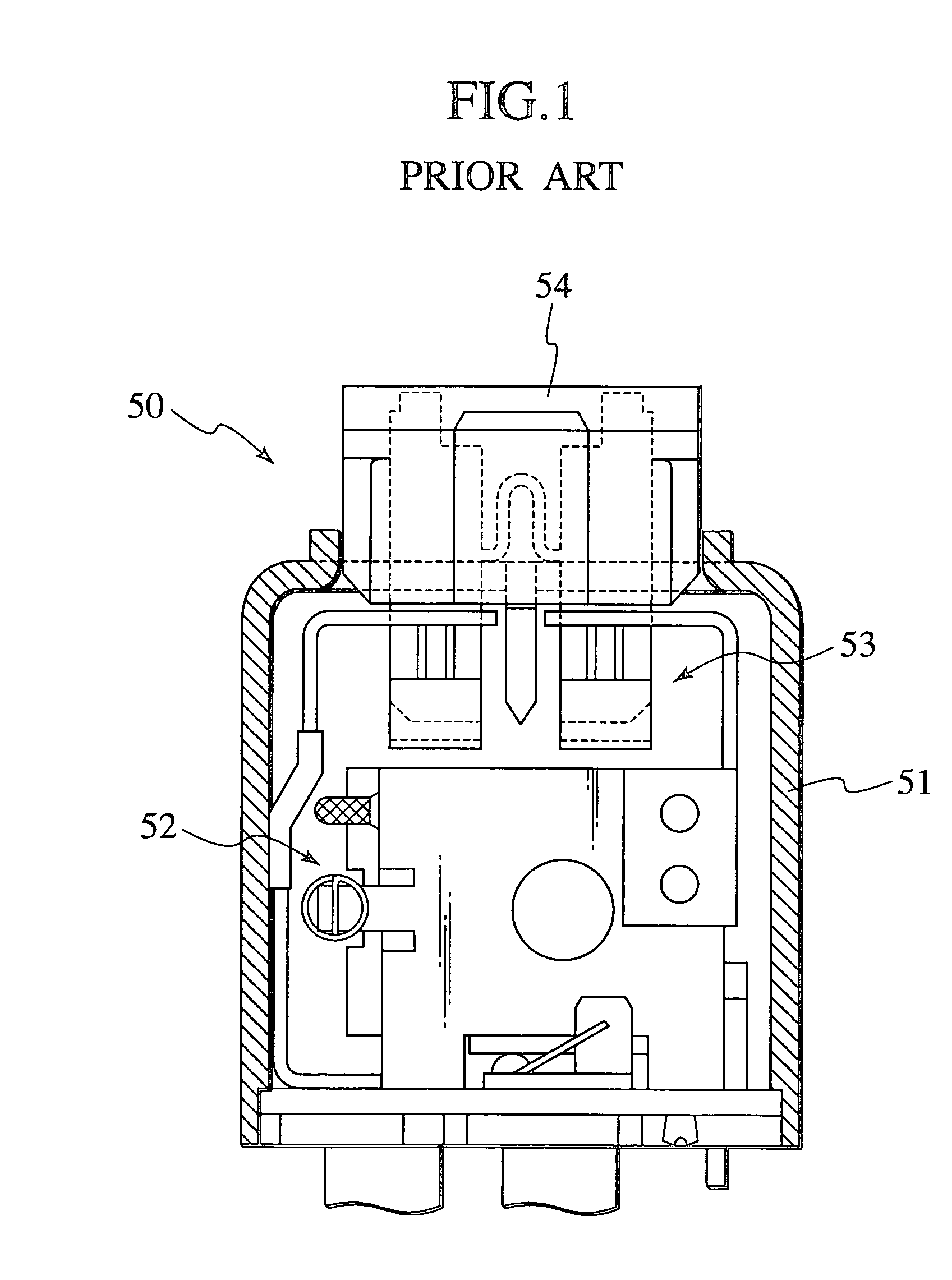

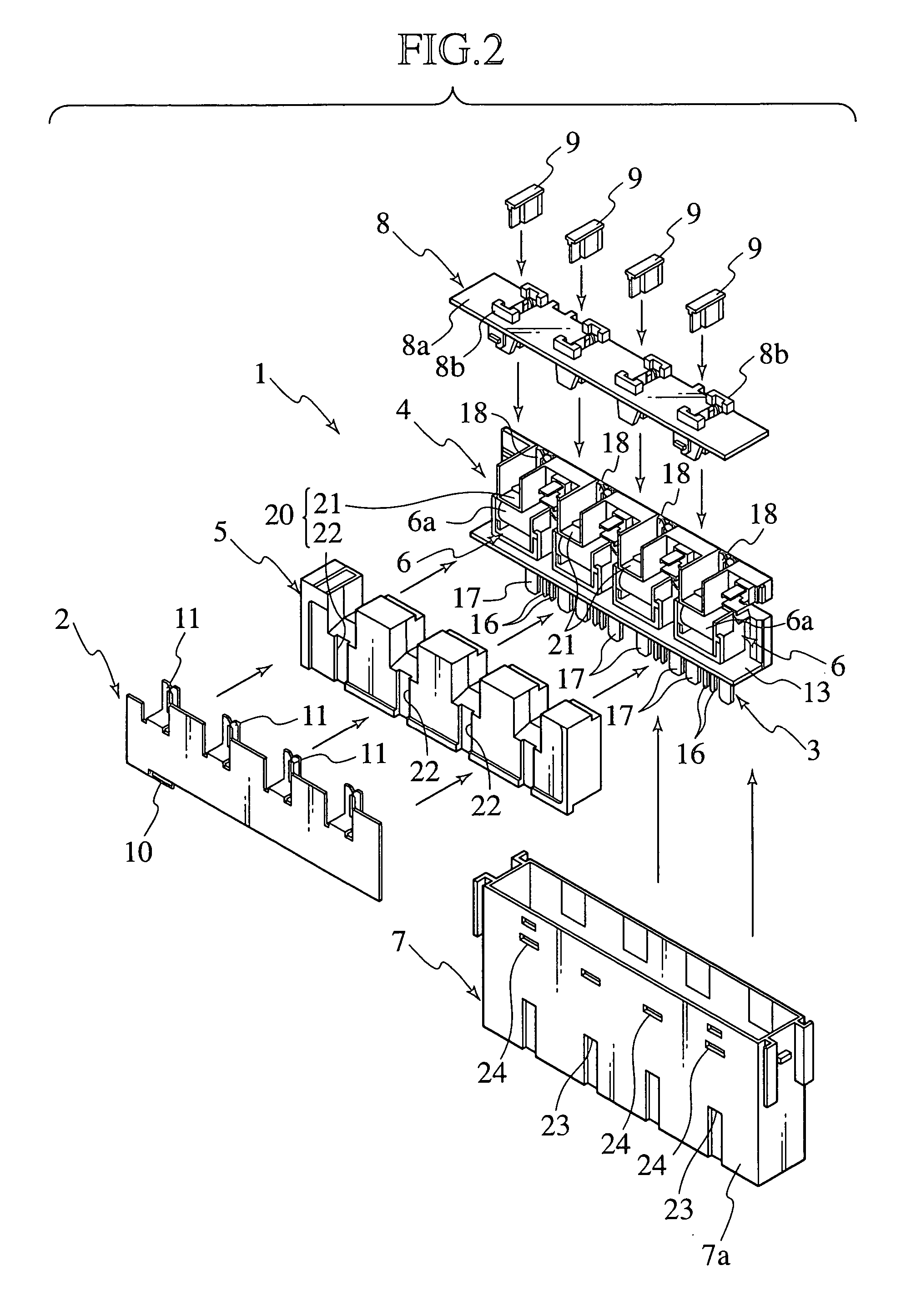

Electrical junction box

ActiveUS20040214458A1Easily and securely assembledAssembling accuracyCouplings bases/casesElectric switchesElectrical junctionEngineering

A relay part is housed in a case, a fuse mounting part is provided above the relay part in the case and a fuse is attached / detached to / from the fuse mounting part from above the case. In the case, provided are an internal cover and a bus bar supporting resin body, which cover the periphery of the relay part. A drainage channel is provided in outer surfaces of the internal cover and the bus bar supporting resin body. In addition, a drainage hole which drains water flowing through the drainage channel to the outside of the case is provided in the case. The drainage channel includes an upper groove which is formed in an upper surface of the bus bar supporting resin body and has an inclined surface on its bottom and a side groove which is communicated with a lowest portion of the inclined surface of the upper groove and is formed on a side of the internal cover.

Owner:ANDEN CO LTD 50

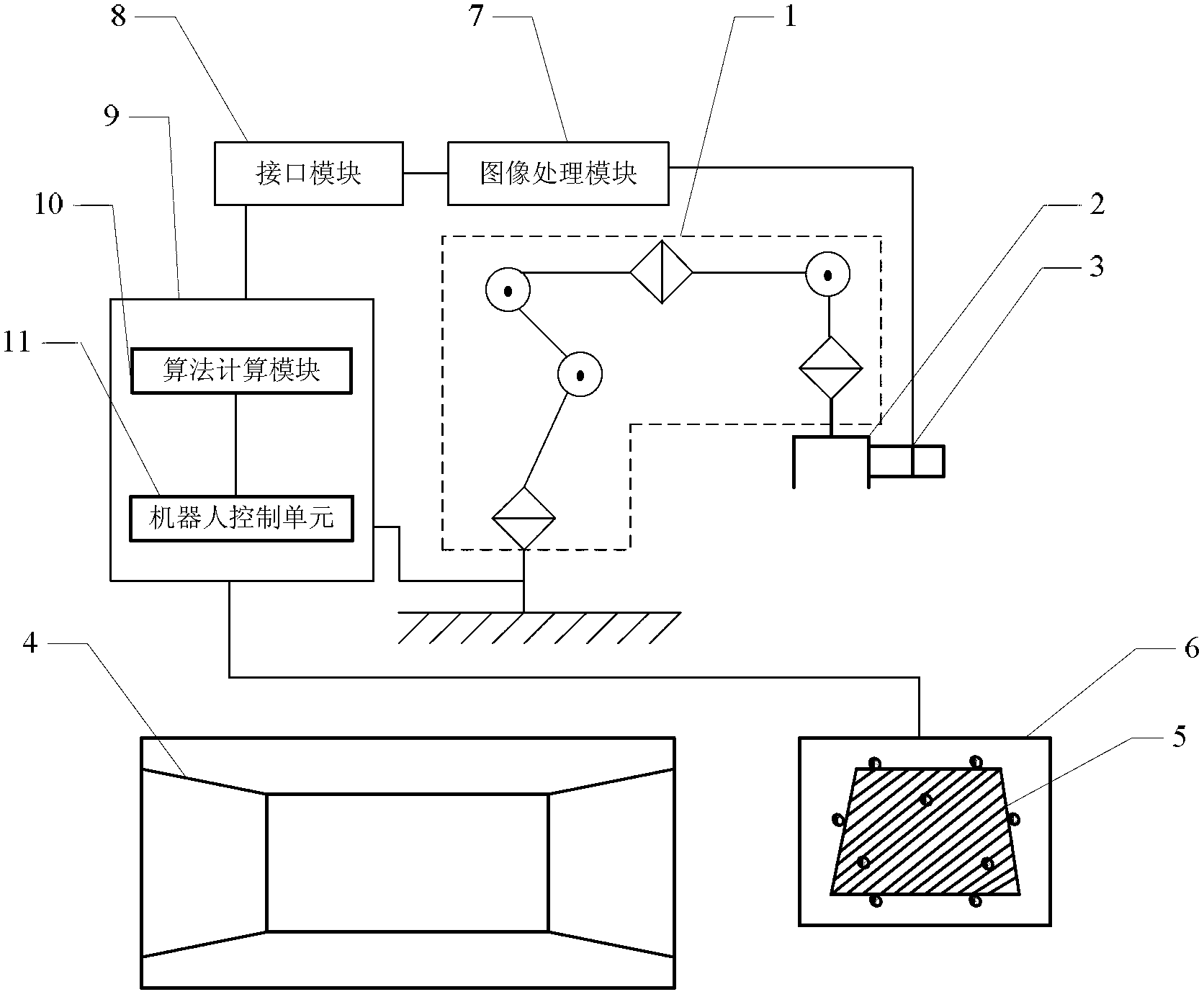

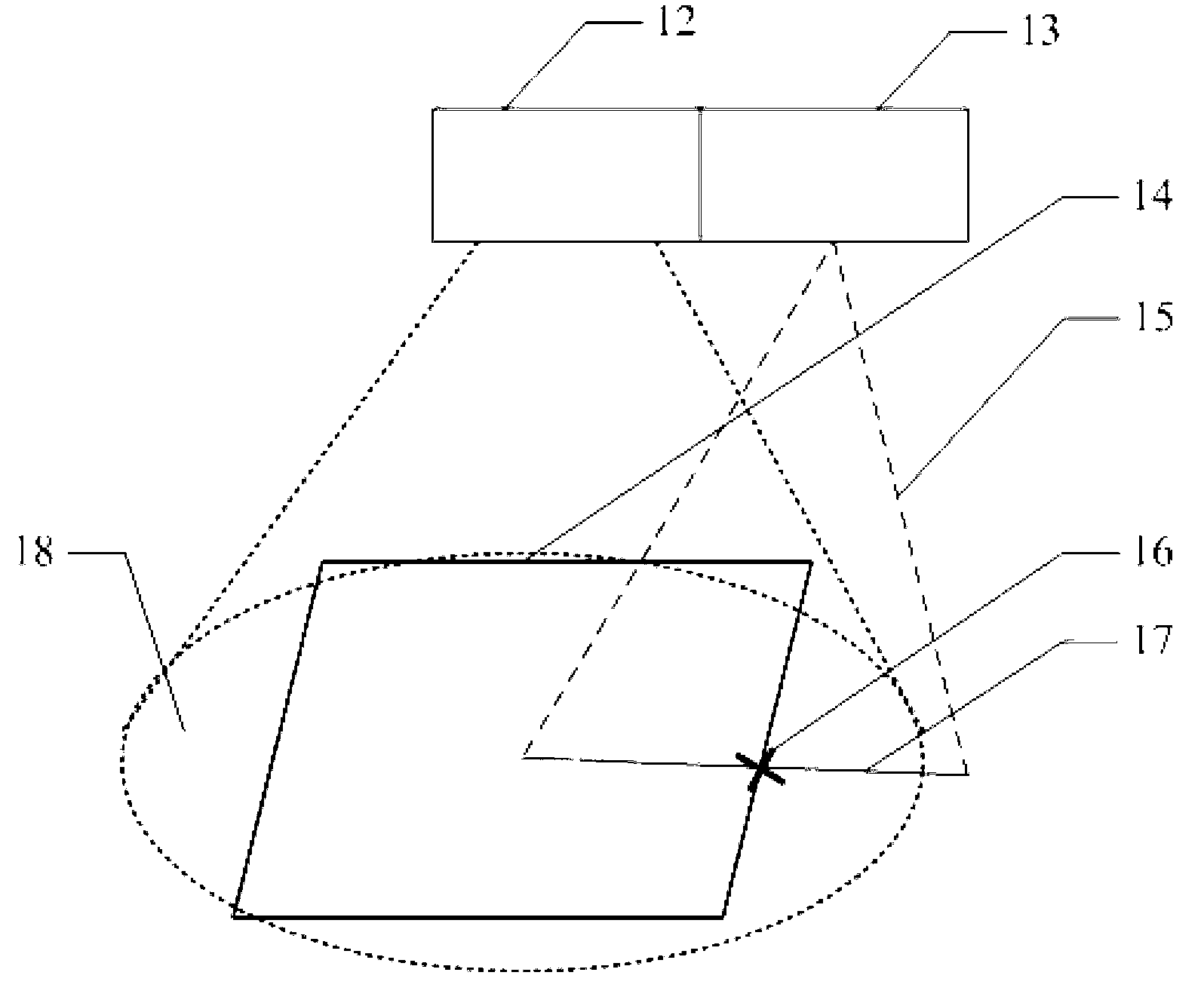

Automatic assembling system and method for vehicle windshield glass

ActiveCN103264738AHigh degree of automationImprove consistencyManipulatorVehiclesRobot handMachine vision

The invention discloses an automatic assembling system for vehicle windshield glass. The automatic assembling system comprises a robot control cabinet, a robot module, a robot hand-gripping module, a vision detection module, a glass centering module and a detected vehicle window frame. The invention also discloses an automatic assembling method for the vehicle windshield glass. The method comprises the following processes of: positioning the windshield glass; detecting the spatial position of the vehicle window frame to obtain a coordinate system (O-xyz) of the spatial position of the vehicle window frame; comparing the coordinate system of the spatial position of the vehicle window frame with the coordinate system of the spatial position of the vehicle window frame at a reference position; computing deviation between the coordinate system of the spatial position of the vehicle window frame and the coordinate system of the spatial position of the vehicle window frame at the reference position; gripping the positioned windshield glass; moving the windshield glass to an installation position according to a standard moving trajectory; and performing deviation compensation on the installation position, and then installing the windshield glass on the vehicle window frame. The assembling system and the assembling method are based on machine vision, manual intervention is completely avoided, and the automation level of assembling of the vehicle windshield glass is improved.

Owner:SHANGHAI FANUC ROBOTICS

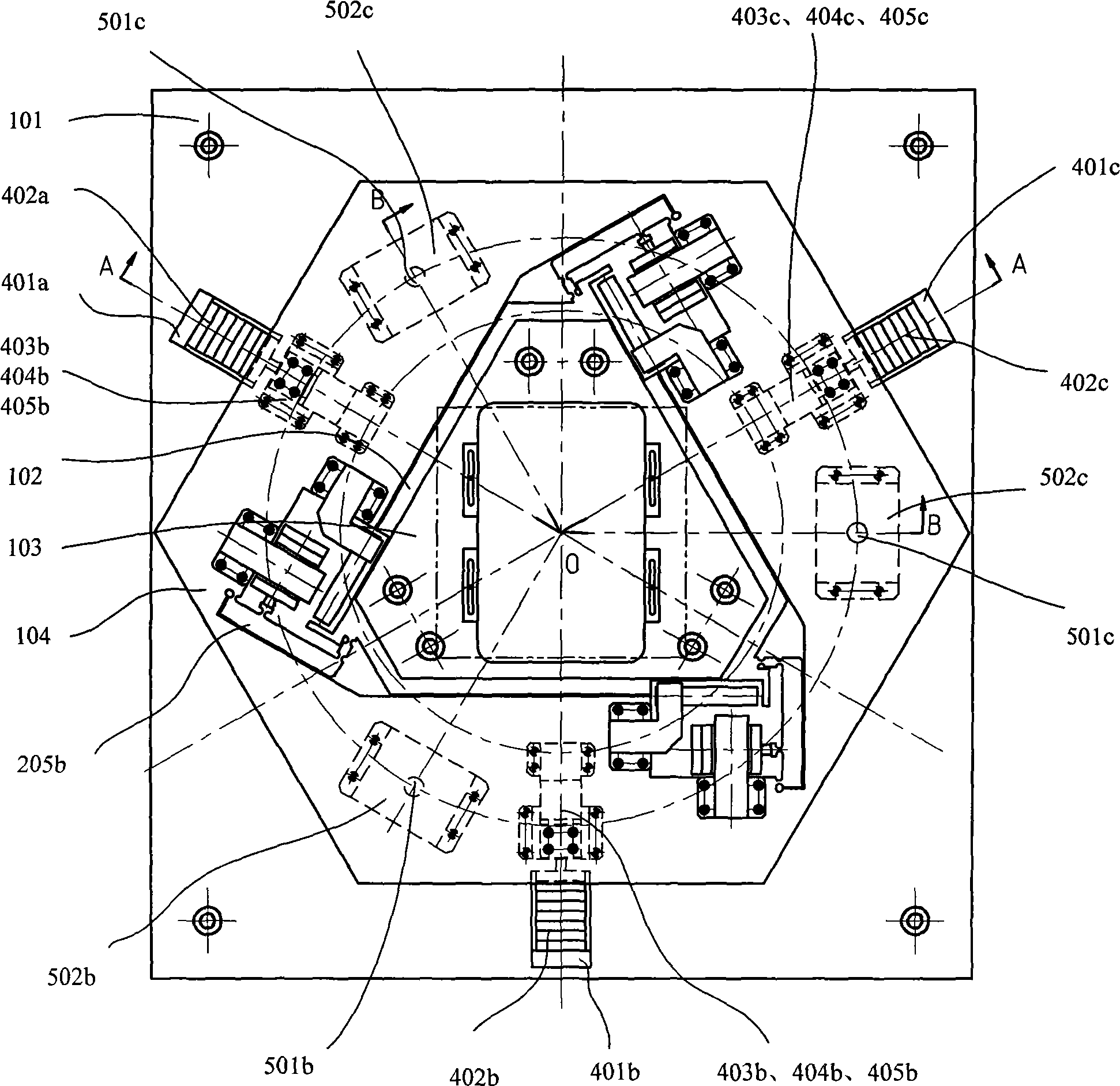

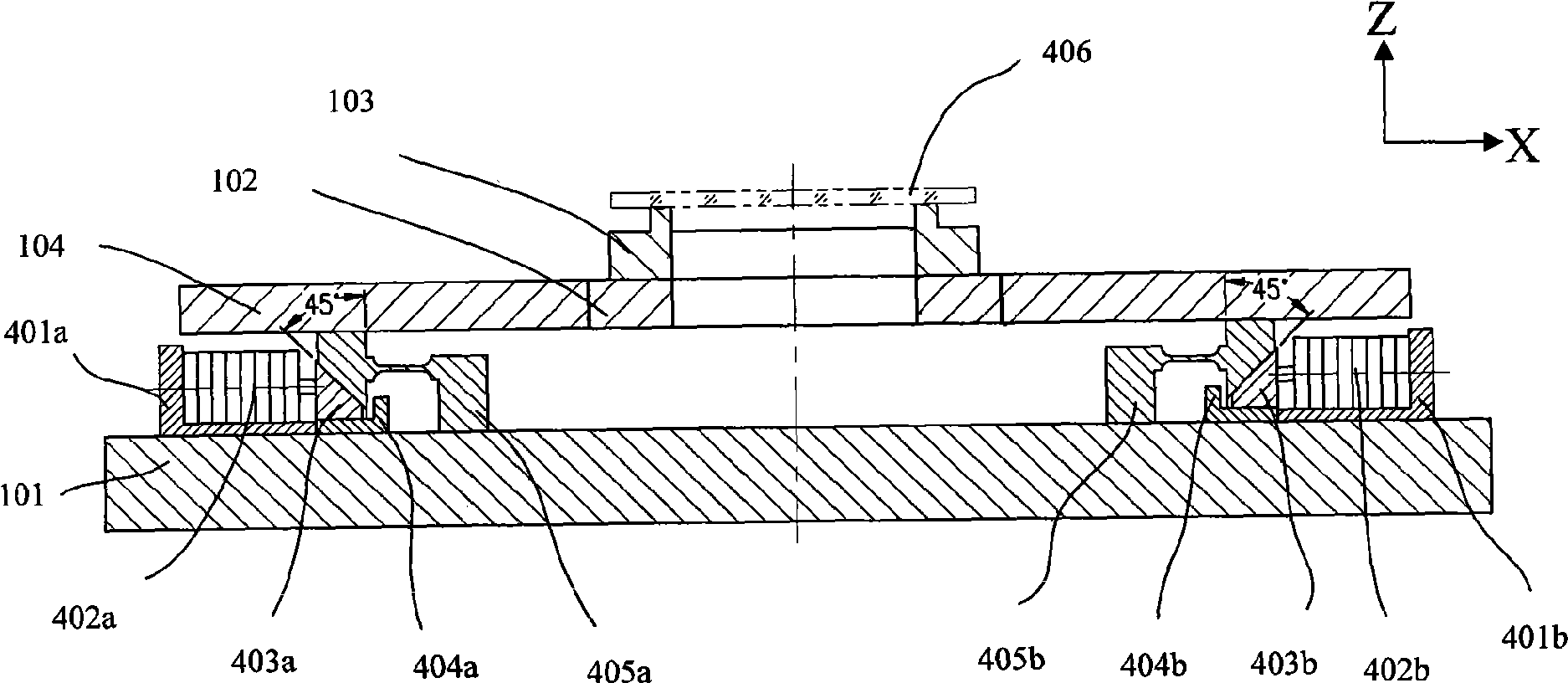

Precise positioning platform with six freedom of motion

ActiveCN101488371ASimple structureReduce manufacturing difficultyInstrument housingEngineeringStructural engineering

The invention provides a 6 degree of freedom precision positioning platform which is used for bearing objects and adjusting the position of a suction bed plate within the scope of the 6 degree of freedom. The 6 degree of freedom precision positioning platform comprises a horizontal adjustment platform and a vertical adjustment platform, wherein, the horizontal adjustment platform can be used for adjusting the position of the suction bed in the directions of an X axis, a Y axis and a Theta z axis, comprising a horizontal output platform which is fixedly connected with the suction bed and is used for bearing the suction bed, three groups of revolute pair flexible articulated mechanisms which are distributed evenly along a circumference and a horizontal base which is connected with the horizontal output platform by the revolute pair flexible articulated mechanisms. The vertical adjustment platform comprises three groups of adjustment mechanisms which are evenly distributed along the circumference and are used for adjusting the position of the suction bed in the directions of a Z axis, a Theta X axis and a Theta y axis. In the invention, the horizontal adjustment platform and the vertical adjustment platform are connected only by a cuniform mechanism and a vertical flexible spring, thus simplifying the structure of the positioning platform, reducing manufacturing difficulty and improving assembly accuracy.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

Imaging lens capable of eliminating stray light

The invention relates to an optical imaging lens capable of being applied to a lens module for image shooting and picture recording. The imaging lens capable of eliminating stray light comprises a lens cone, an imaging unit arranged in the lens cone and a shading assembly arranged in the imaging unit. The shading assembly comprises a fixing portion arranged on the imaging unit in a clamping mode, an object side protruding portion and an image side protruding portion, the object side protruding portion protrudes from the inner periphery, close to an object side, of the fixing portion, extends inwards in a tilted mode and ends at a tail end edge, and the image side protruding portion protrudes from the inner periphery, close to an image side, of the fixing portion, extends inwards in a tilted mode and ends at a tail end edge. The fixing portion of the shading assembly enables the shading assembly to be located and assembled easily, so that good assembly accuracy can be maintained; the object side protruding portion and the image side protruding portion can effectively eliminate the stray light so as to reduce unnecessary influences of the stray light during imaging. The imaging lens has higher imaging quality.

Owner:GENIUS ELECTRONICS OPTICAL XIAMEN

Automatic assembling mechanism for long tail clamp

InactiveCN1748934AReduce the problem of small size and difficult structure layoutSolve tangled puzzlesAssembly machinesManufacturing linePiston rod

The automatic assembling mechanism for long tail clamp includes work stable, clamp locating and conveying mechanism, handle locating and conveying mechanism, handle assembling mechanism, and electric controller for controlling the clamp locating and conveying mechanism, the handle locating and conveying mechanism and the handle assembling mechanism. The handle assembling mechanism includes spline shaft connected to the oscillating cylinder, right and left mechanical claws to form clamp, and clamping cylinder with end cap and piston rod connected separately to the left mechanical claw and the right mechanical claw. The present invention has high work efficiency, low production cost, high assembling precision and other advantages.

Owner:ZHEJIANG UNIV OF TECH

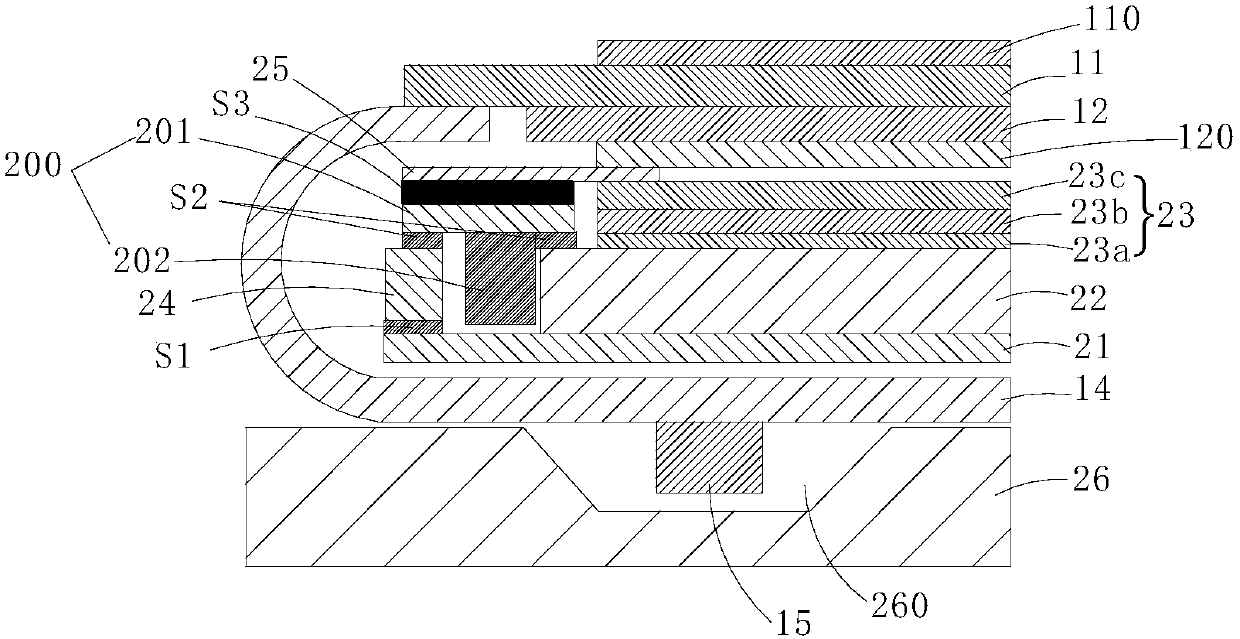

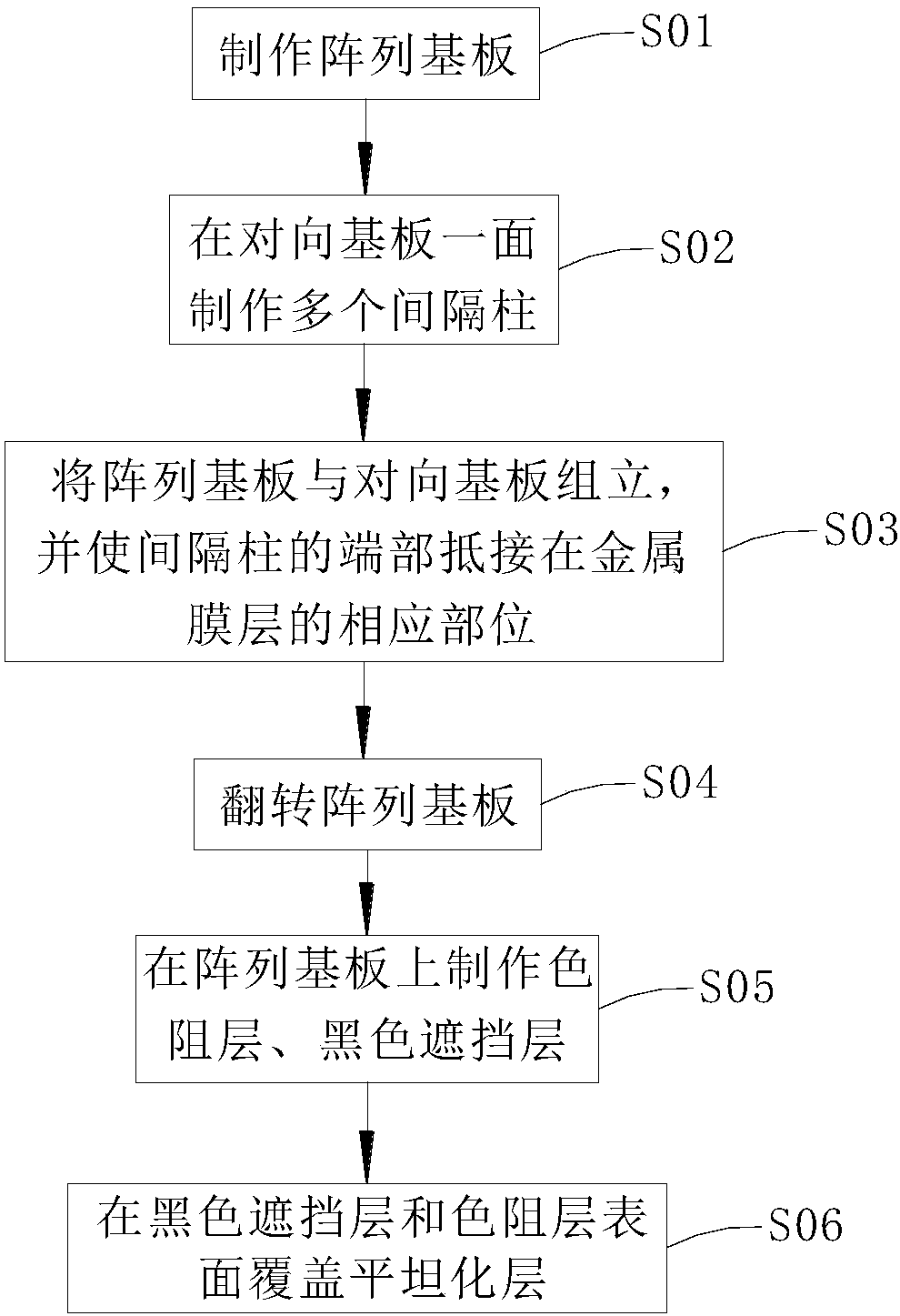

Narrow frame display panel, manufacturing method thereof and display device

InactiveCN107589579ARealize the assembly processReduce border widthStatic indicating devicesFinal product manufactureFlexible circuitsDisplay device

The invention discloses a narrow frame display panel and a manufacturing method thereof. The narrow frame display panel comprises an array substrate, a counter-direction substrate, liquid crystals, aflexible circuit board and a driving chip, wherein the part between the array substrate and the counter-direction substrate is filled with the liquid crystals, the side at which the array substrate ispositioned is a light emitting surface, and one end of the array substrate is a binding end; one end of flexible circuit board is bound to the surface, the binding end, which faces to the counter-direction substrate, and the other end of the flexible circuit is bound with the driving chip; the surface, facing to the counter-direction substrate, of the array substrate is provided with a metal filmlayer with hollow patterns, and a plurality of spacing pillars are convexly arranged on the surface, facing to the array substrate, of the counter-direction substrate, and extend to prop against themetal film layer. According to the display panel provided by the invention, the flexible circuit board cannot be seen from the outer side, so that the width of a narrow frame is narrowed, and the screen occupying ratio is increased; meanwhile, through the propping of the spacing pillars and the corresponding part of the hollow patterns of the metal film layer at the inner side of the array substrate, the assembly process of the substrates of the display panel can be realized by assistance, and the assembly precision is increased.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

Semiconductor device and microphone

ActiveUS20110222717A1Process of wire is facilitatedEasy to assemblePiezoelectric/electrostrictive microphonesSemiconductor/solid-state device detailsPower semiconductor deviceDevice material

The semiconductor device has a simplified structure which includes a package structure in which a member for mounting a semiconductor element is separate from a member including a signal input / output unit. A microphone package is configured with a cover and a substrate. A microphone chip and a circuit element are adhered and fixed to a top surface of a recess formed in the cover. A plurality of bonding pads are arranged on the lower surface of the cover on the outer side of the recess. A bonding wire is connected to the circuit element and the bonding pad. The substrate includes a signal input / output terminal serving as the signal input / output unit, and a connection electrode, conducted with the signal input / output terminal, is arranged facing the bonding pad on the upper surface of the substrate. The substrate, cover, connection electrode, and bonding pad are joined with a conductive member.

Owner:MMI SEMICON CO LTD

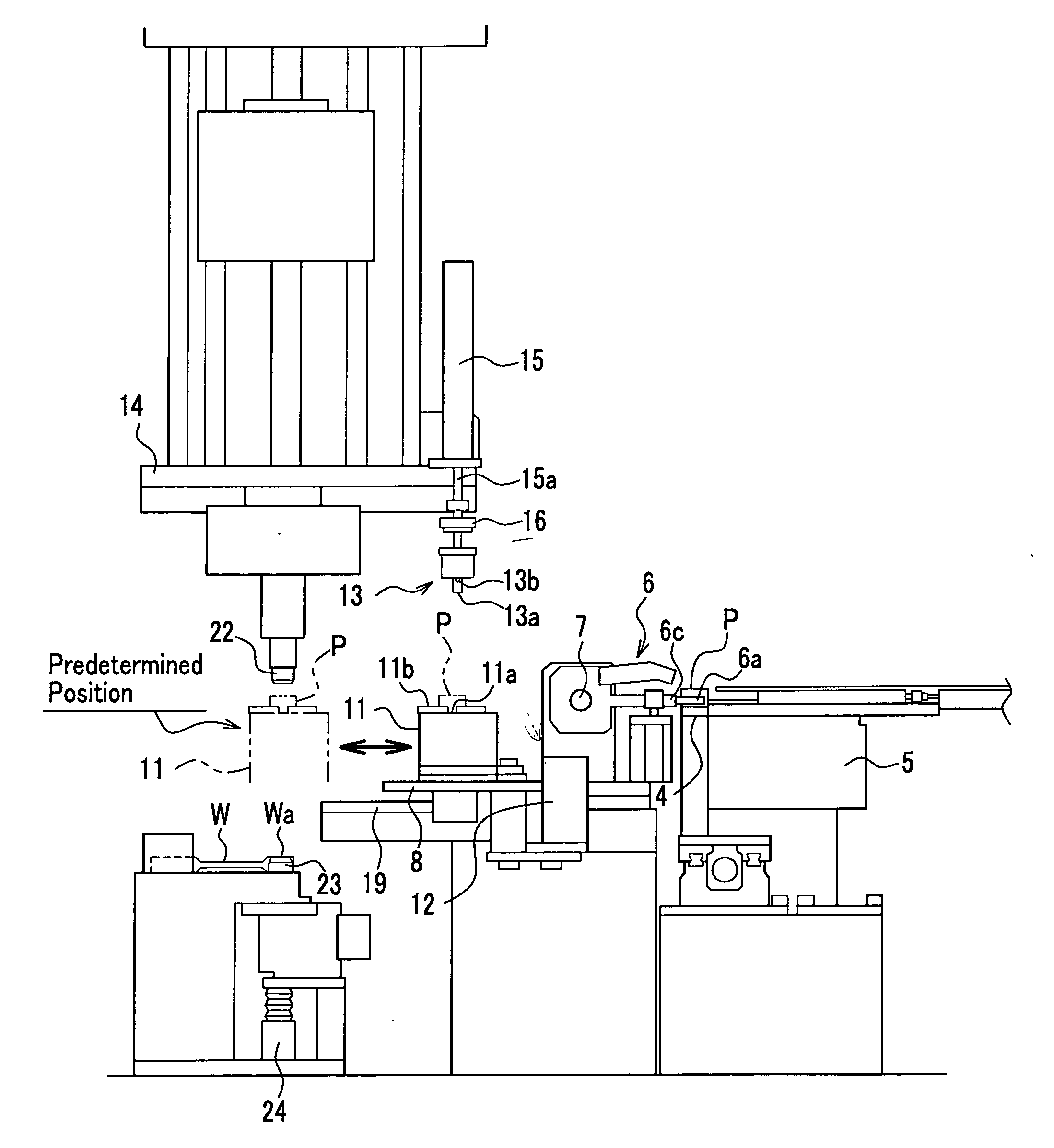

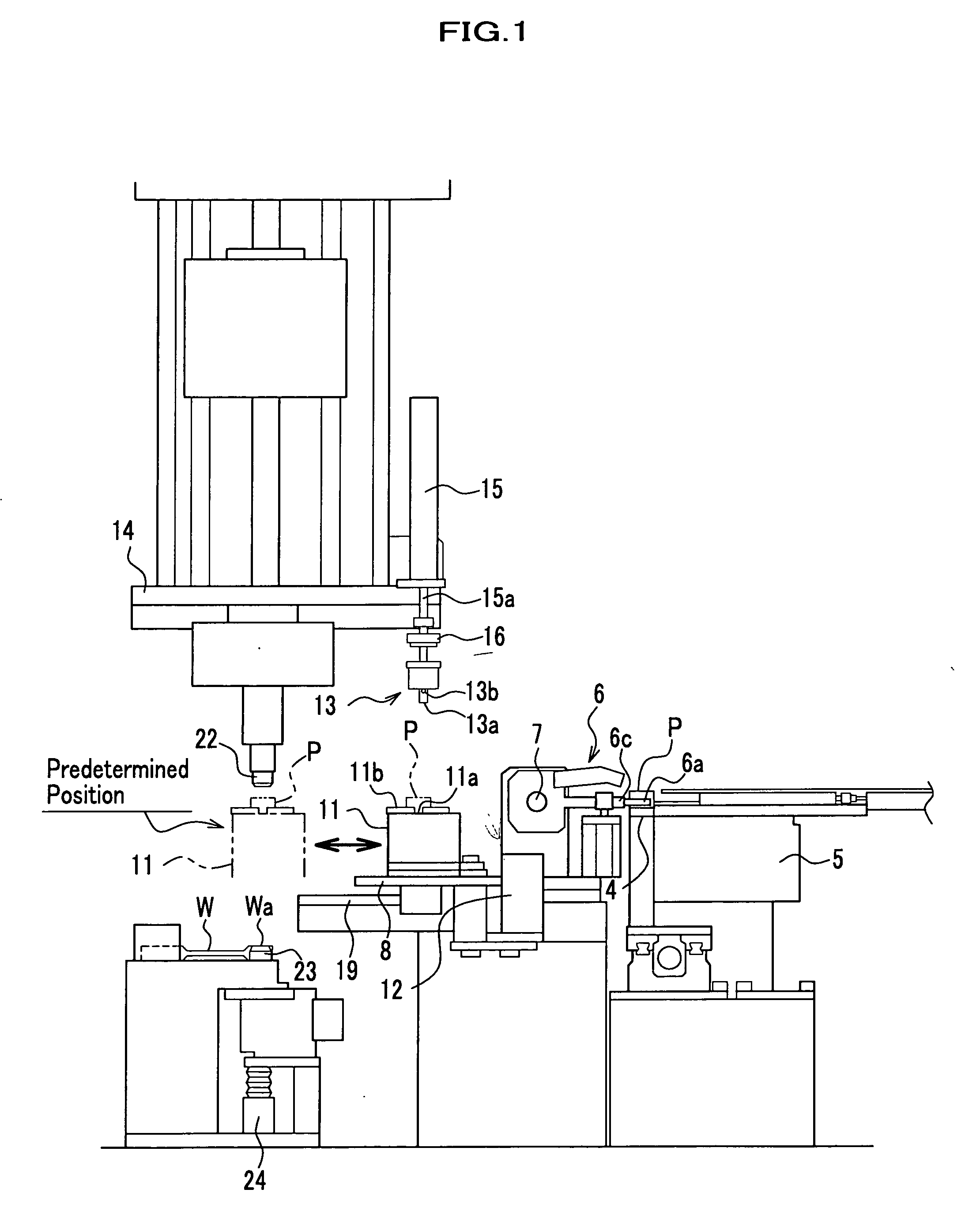

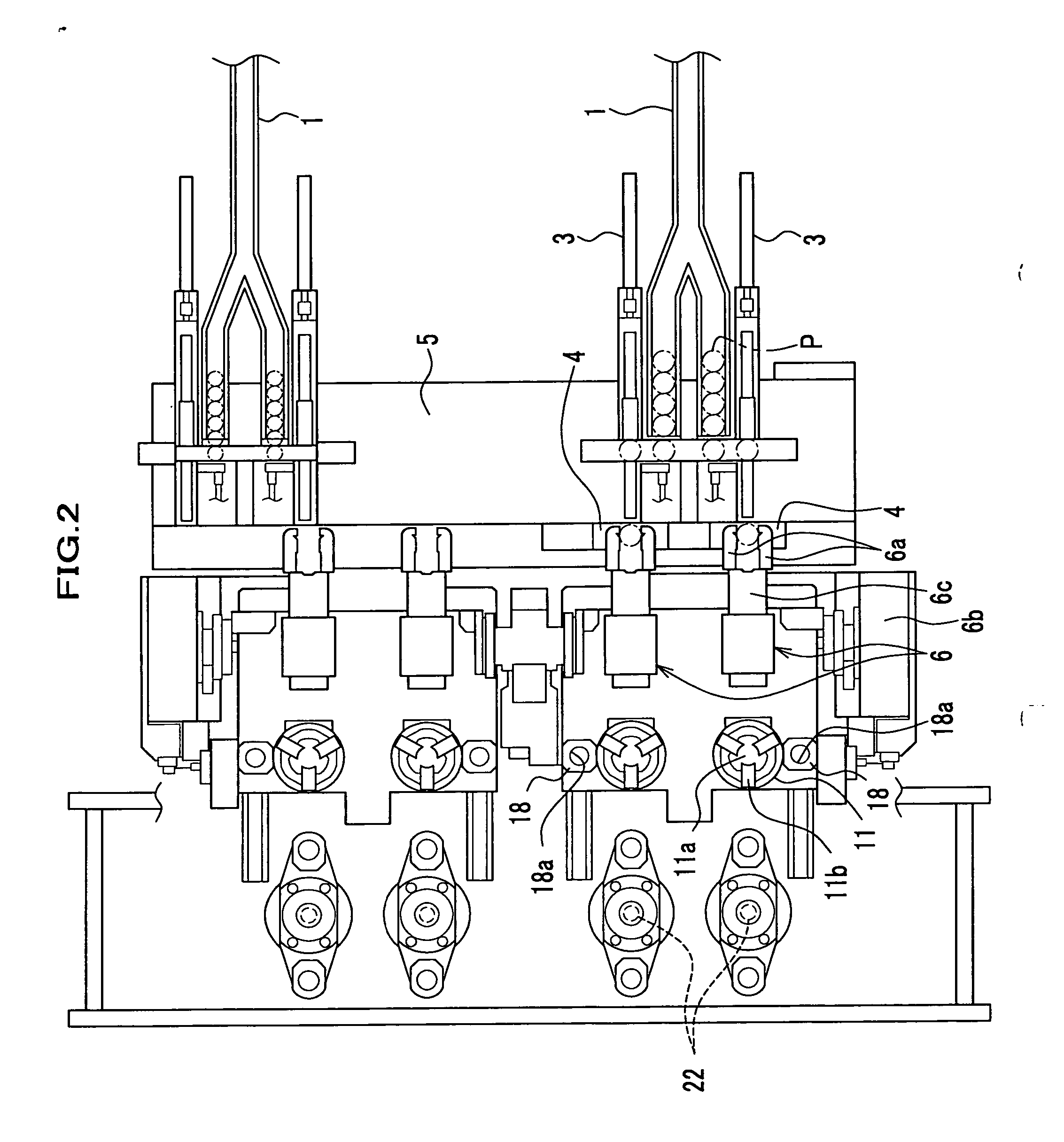

Apparatus for supplying and press-fitting part to work

InactiveUS20070056161A1Improve assembly accuracySimple structureAutomatic control devicesAssembly machinesEngineeringStops device

Owner:HONDA MOTOR CO LTD +1

Button cell battery production line

InactiveCN101252194AAdvanced technologyEasy to controlFinal product manufactureNon-aqueous electrolyte cellsProduction lineLithium

The invention relates to a button cell production line, being characterized in comprising a rack component, a lithium chip loading mechanism, a paper cutting mechanism, a filling mechanism, a manganese chip loading mechanism, an anode case loading mechanism, a sealing mechanism, a main transmission mechanism, a pneumatic control system and an electrical apparatus control system as well as a control program; the rack component comprises a large worktable and a rack fastened on the lower surface of the large worktable, a lower base plate of the rack is arranged on a lower beam of the rack, a control cabinet is arranged on the upper part of the lower base plate of the rack; the lithium chip loading mechanism, the main transmission mechanism, the paper cutting mechanism, the filling mechanism, the manganese chip loading mechanism, the anode case loading mechanism and the sealing mechanism are arranged on the large worktable in turn; the pneumatic control system is arranged on the lower base plate of the rack; the electrical apparatus control system and the control program are arranged inside the control cabinet; a touch screen support is vertically arranged on the upper surface of the large worktable close to one end of the lithium chip loading mechanism.

Owner:TIANJIN POLYTECHNIC UNIV

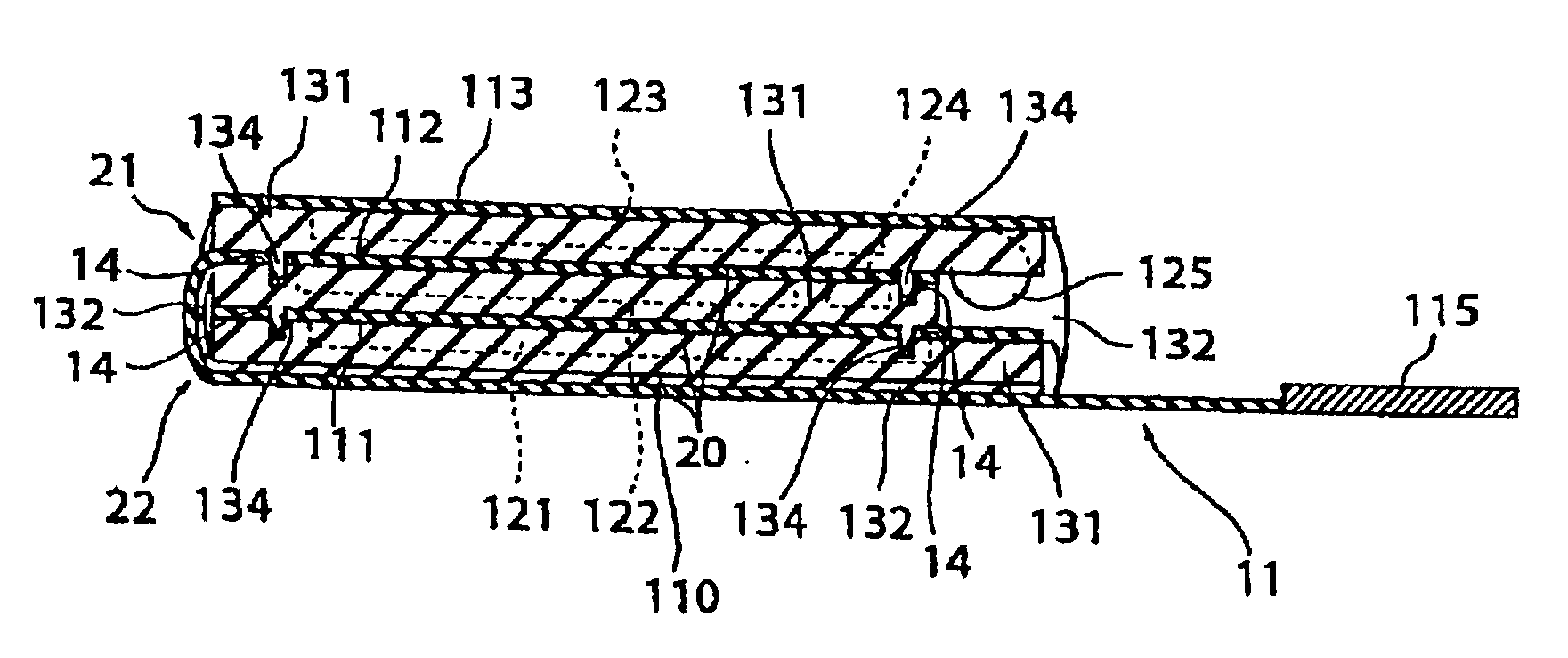

Semiconductor device

InactiveUS20020167081A1Help positioningImprove assembly accuracyPrinted circuit detailsSemiconductor/solid-state device detailsFlexible circuitsEngineering

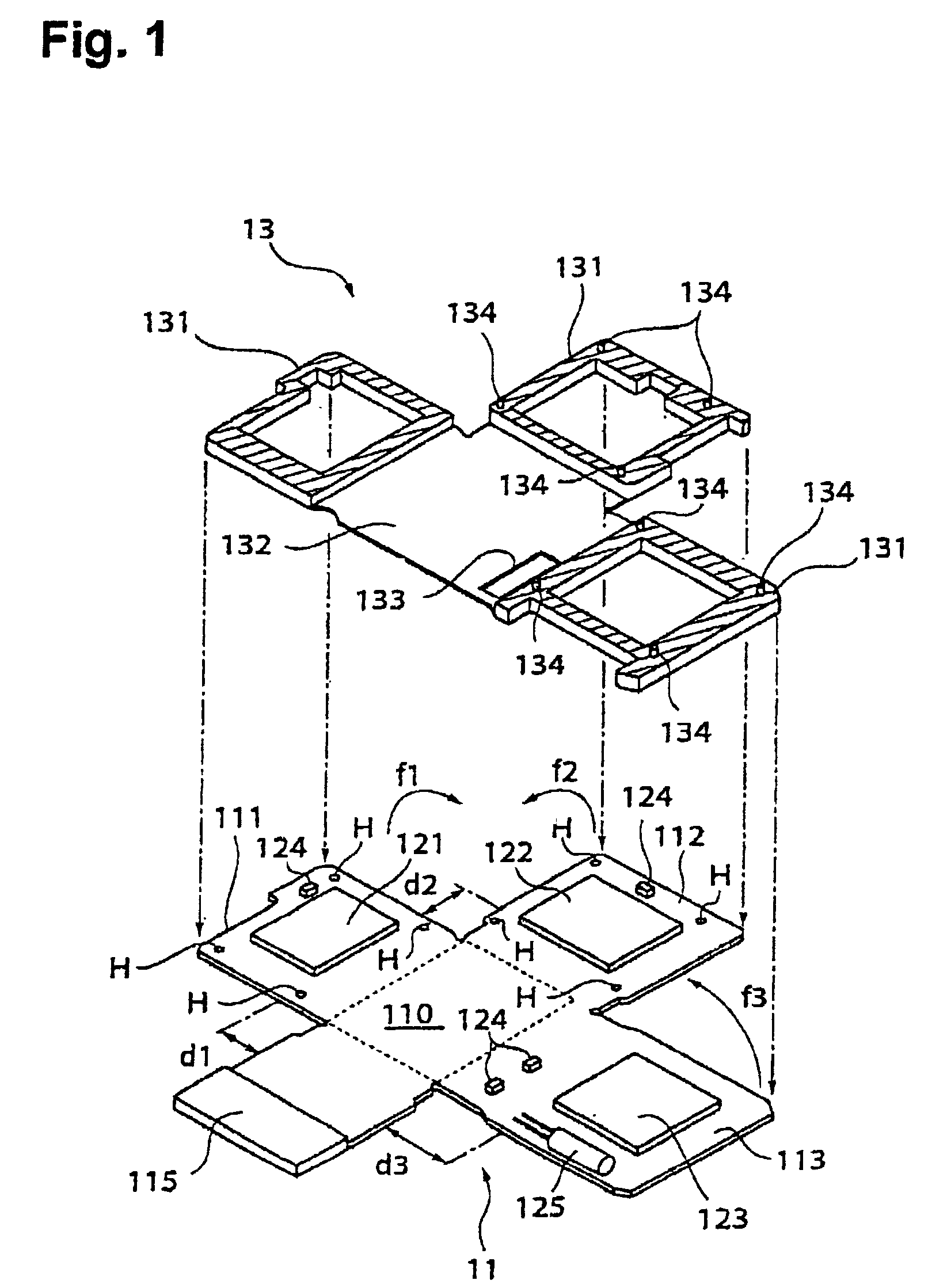

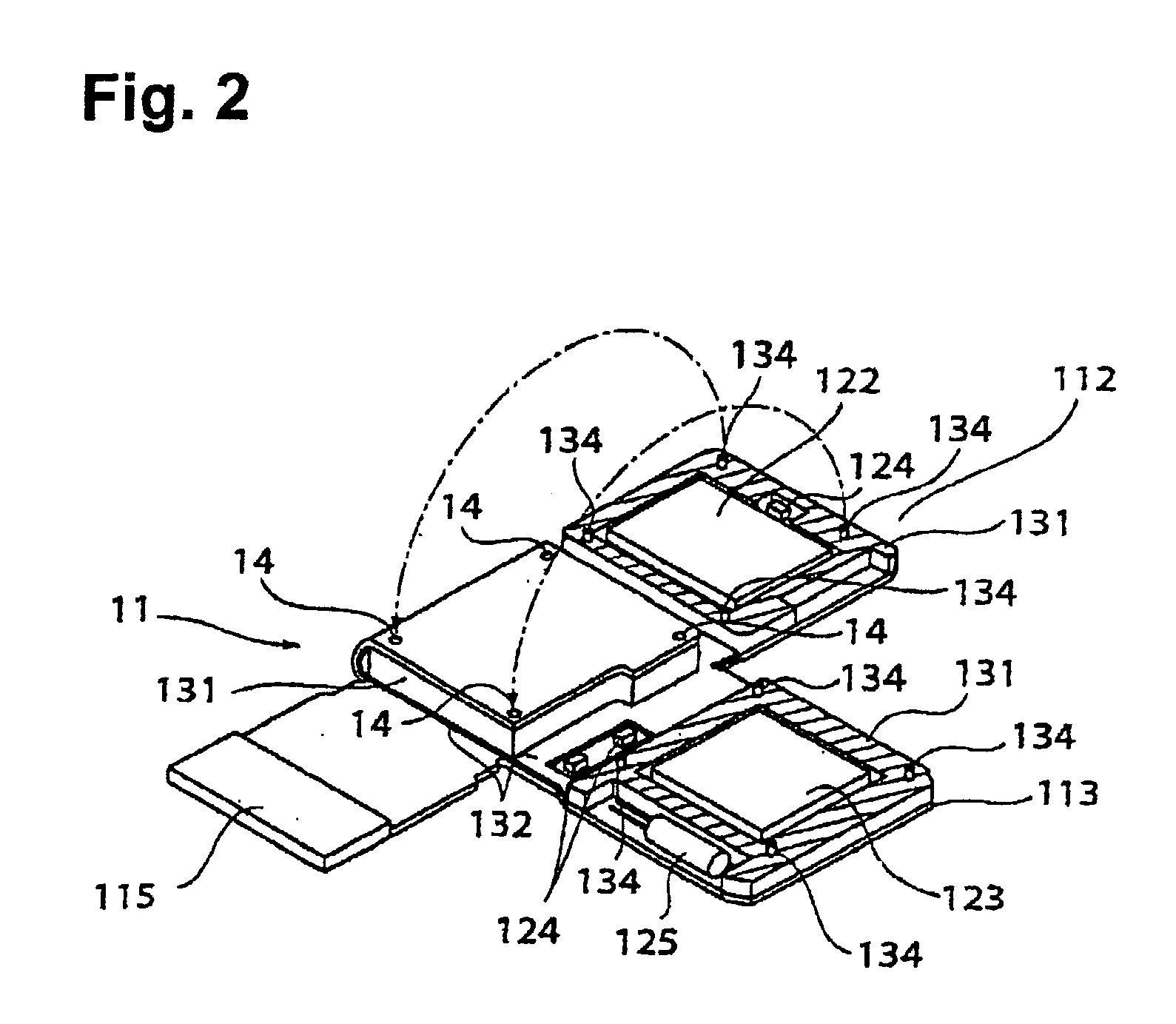

To provide a semiconductor device with a three-dimensional mounting module using a flexible circuit substrate which is easy to assemble a three-dimensional structure and is excellent in the workability in repair work (or re-work). [MEANS FOR SOLUTION] A flexible circuit substrate 11 has mounting regions 111, 112 and 113 on which electronic components 121, 122 and 123 are mainly mounted, respectively, and other electronic components 124 and 125 are also mounted. The flexible circuit substrate 11 is structured in such a manner that the mounting regions 111~113 are folded on top of the other over the base region 110 in a predetermined order (f1~f3). An integrated spacer 13 has thick regions 131 and thin regions 132, and is superposed and affixed to the flexible circuit substrate 11 as indicated by arrows with broken lines, and supports the electronic components 121~125 stacked in layers. Fixing bosses 134 and aperture sections 14 to be coupled therewith are provided to facilitate positioning.

Owner:SEIKO EPSON CORP

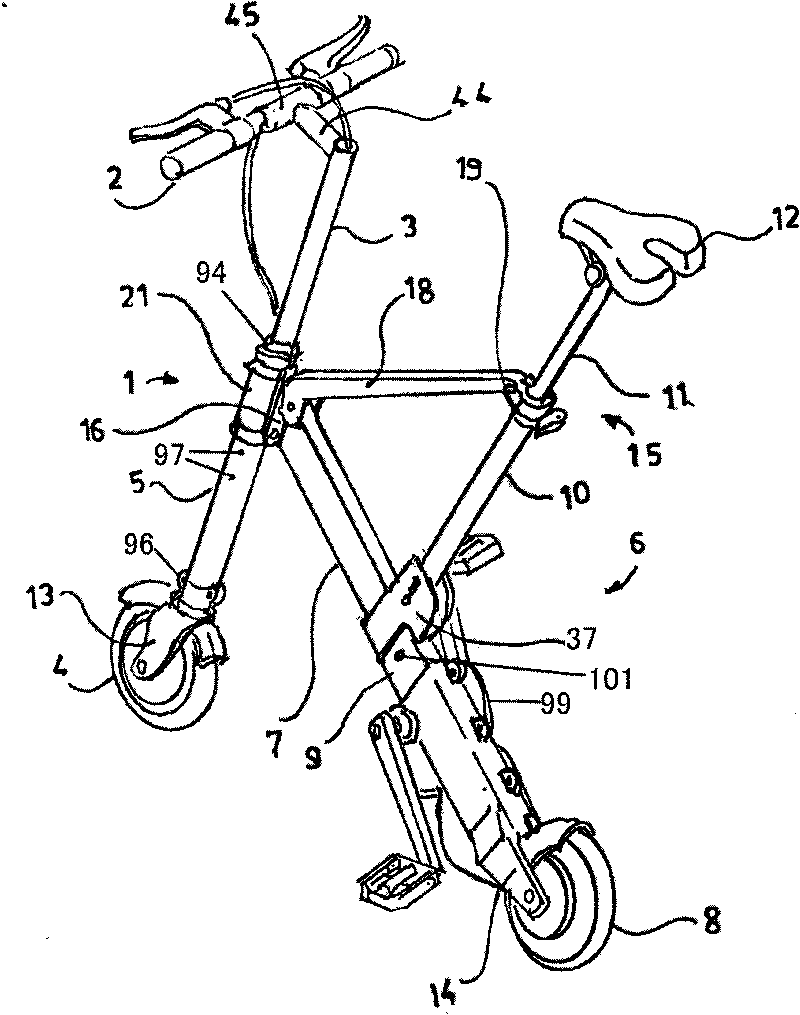

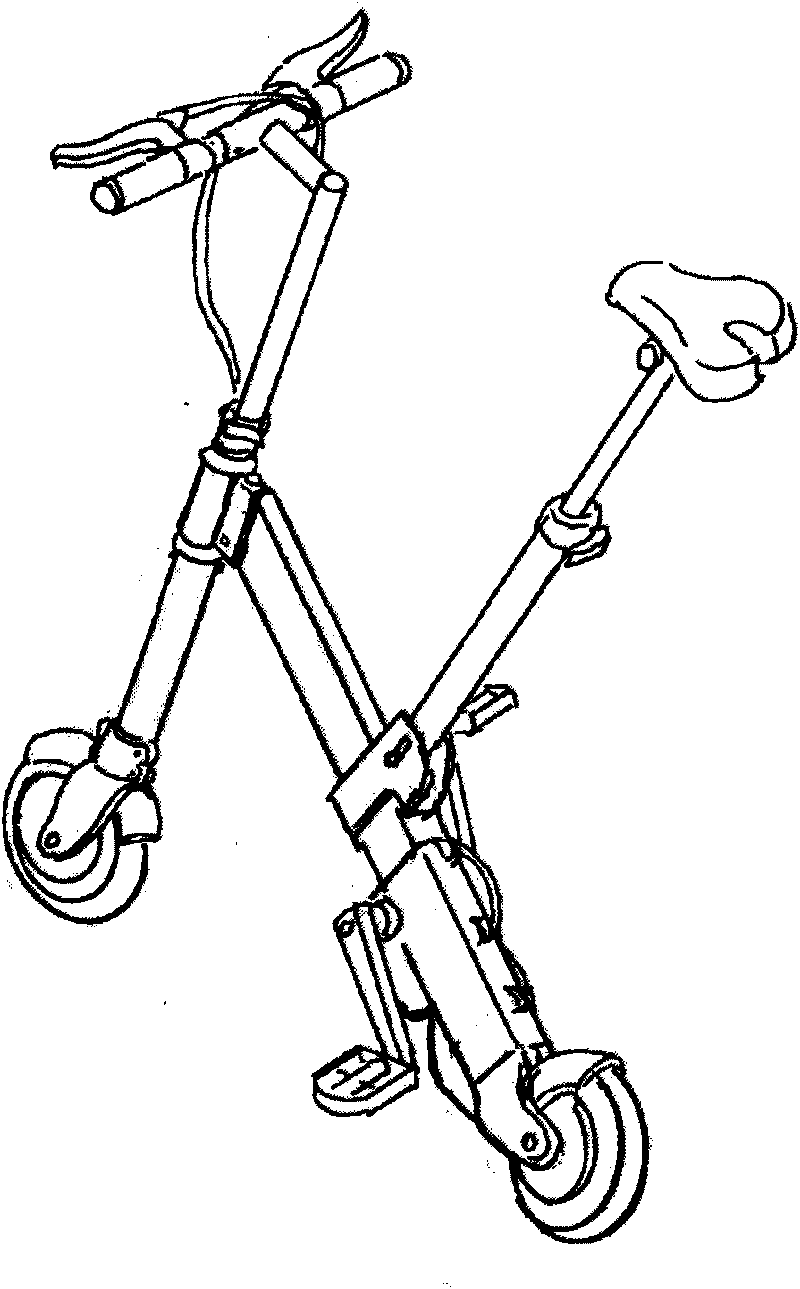

Portable folding bicycle

The invention relates to a portable folding bicycle. Frame connecting rods are reduced to the maximum by a telescopic pipe body nested on a frame and pivot folding, and thereby frame pipe fittings can be rapidly shortened by about half the size; the front wheel and the rear wheel are placed together in parallel after the frame is folded, thereby also reducing the size of the bicycle body to the greatest extent and saving materials and the manufacture cost. The transmission ratio is increased by a multiplying gear configured on the bicycle, thereby enabling minor-diameter wheels used by the bicycle to reach the running speed of big wheels; handle bars and foot pedals can be folded, the folding dimension of the bicycle is about 60*20*10 cm, and the weight is about 5kg, therefore, the bicycle can be carried in a hand bag or a packsack.

Owner:SOUTHWEST JIAOTONG UNIV

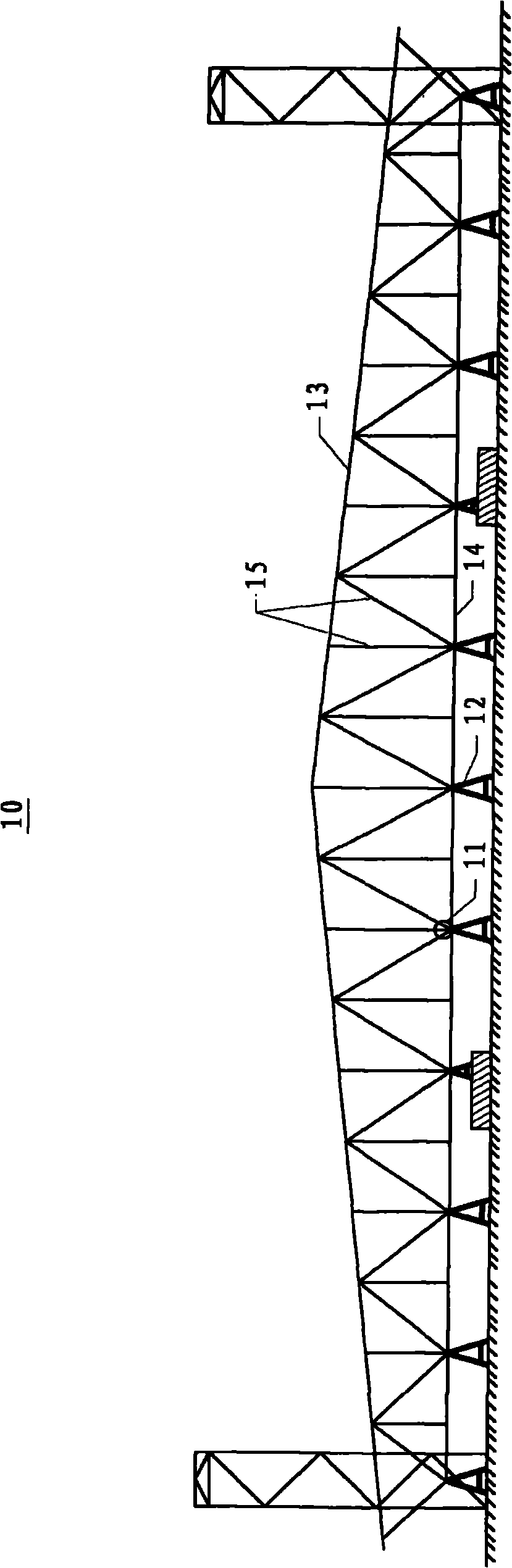

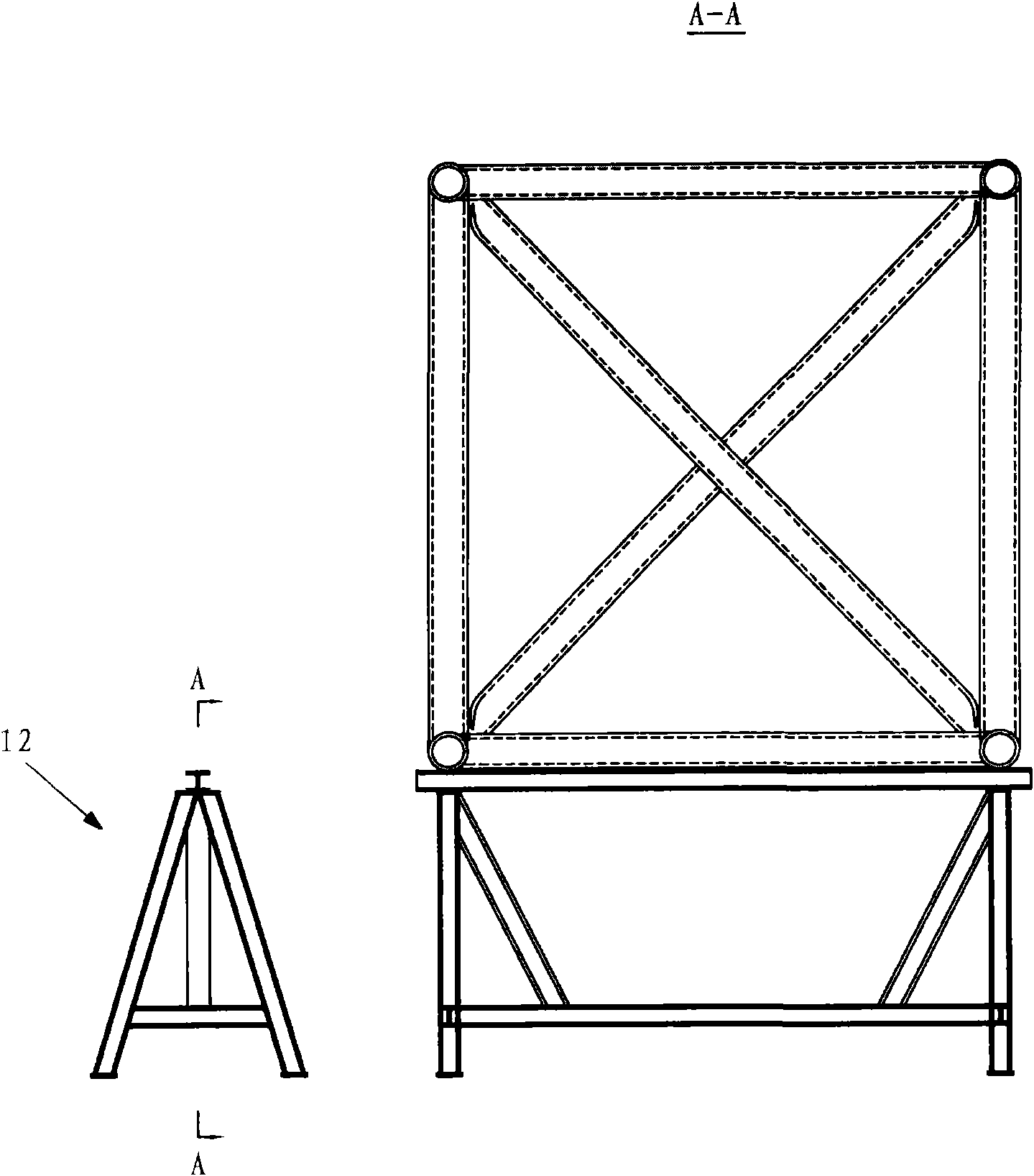

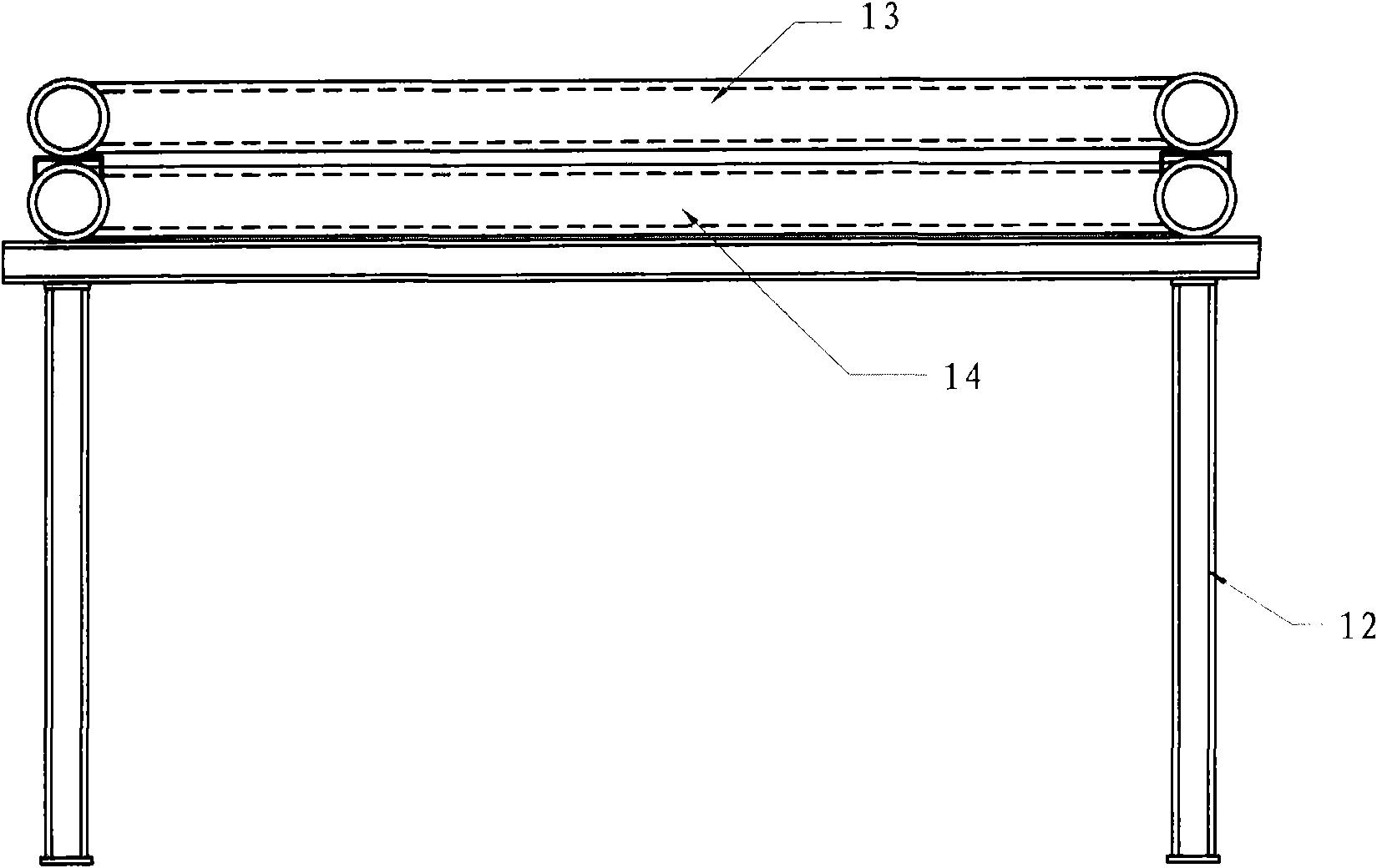

Enormous-span steel tube house truss assembling construction method

The invention provides an enormous-span steel tube house truss assembling construction method which comprises the following steps: step one: an assembling platform is arranged at a node of a truss; step two: firstly, a bottom cord plane truss is assembled; after the assembling of the bottom cord plane truss is completed and passes the inspection, an upper chord plane truss assembly is carried out at the upper part of the bottom cord plane truss; after the assembling of the upper chord plane truss assembly is completed and passes the inspection, the upper chord plane truss is welded; step three: after the upper chord plane truss is welded, the upper chord plane truss is wholly lifted in the air; and after the upper chord plane truss is lift, the bottom cord plane truss is welded; step four: the bottom cord plane truss is arched nearby each node by using a lifting jack; step five: member bars between the upper chord plane truss and the bottom cord plane truss are assembled, the assembling of the member bars between the upper chord plane truss and the bottom cord plane truss is carried out in the air, and an assembling sequence is as follows: upright rods are firstly installed and then slanting poles are installed.

Owner:PANGANG GRP ENG TECH +1

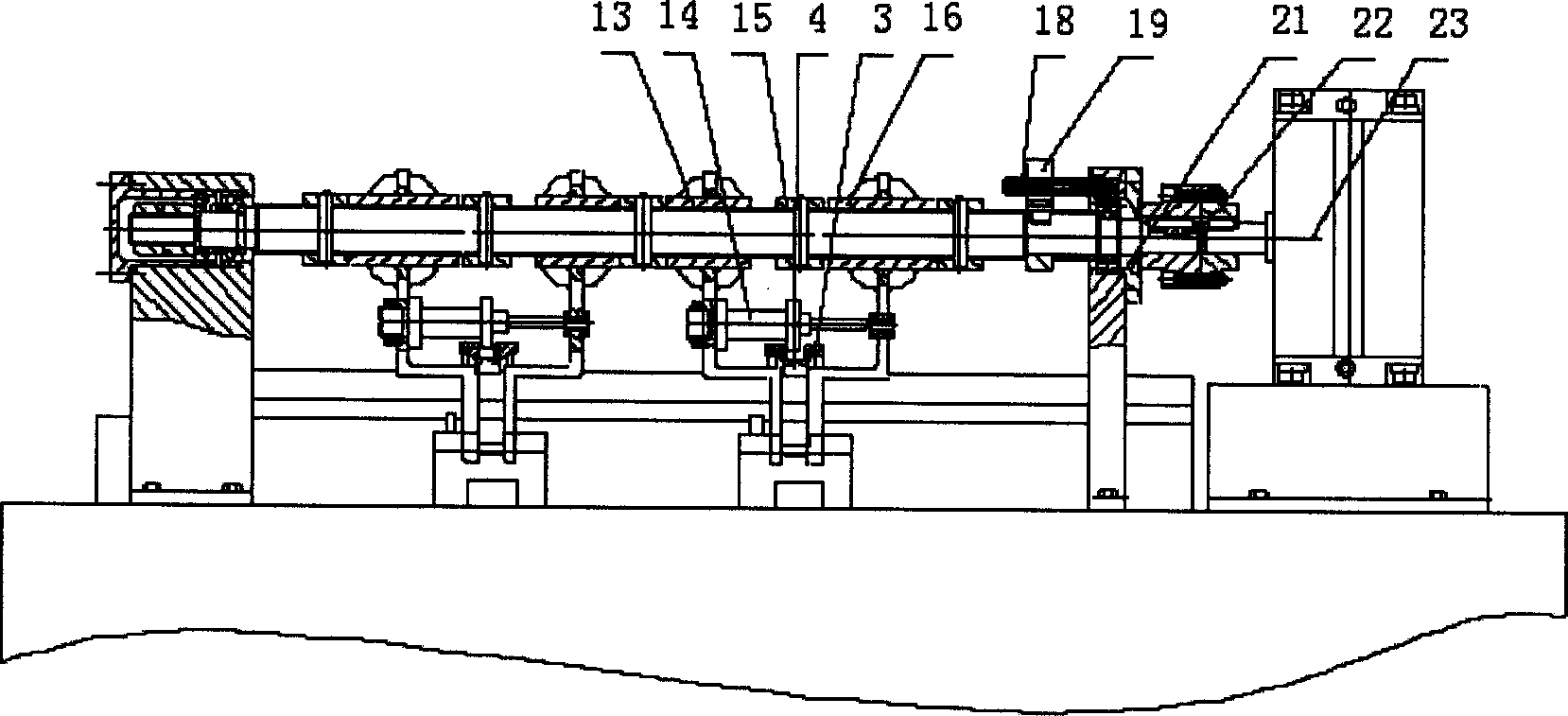

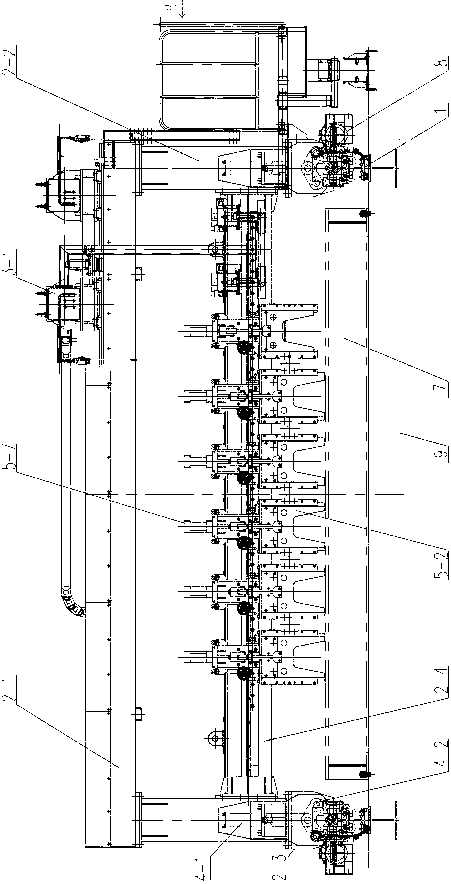

Automatic assembling and tack welding system for U-shaped rib plate units

ActiveCN103008933AImprove assembly accuracyHigh automatic assembly production efficiencyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringRobot welding

The invention discloses an automatic assembling and tack welding system for U-shaped rib plate units, which comprises a pair of parallel rails and a gantry, the gantry can move on the rails, and an assembling platform is laid between the two rails; the gantry comprises an upper crossbeam, a lower crossbeam, four uprights and two traveling beams, the upper crossbeam and the lower crossbeam are respectively fixed between the two front uprights, and one gantry-traveling mechanism is respectively arranged on the bottom of each of the two traveling beams; a movable welding system is arranged on the upper crossbeam; and a movable two-dimensional adjustable positioning and pressing system is arranged on the lower crossbeam. Because the two-dimensional adjustable positioning and pressing system is combined with a polishing and dedusting system and the robotic welding system, the polishing and dedusting of the area to be welded of the U-shaped rib plate units, the positioning and pressing of U-shaped ribs and robotic tack welding can be full-automatically controlled together, and the automatic assembling and tack welding system has the advantages that the assembly precision of the U-shaped ribs of orthotropic bridge plate units is high, the automatic assembly and production efficiency is high, and the quality of welding lines is stable.

Owner:CHINA RAILWAY SHANQIAO GRP CO LTD

Automatic assembly equipment for spring lock

ActiveCN102248398ANovel structureHigh degree of automationAssembly machinesEngineeringIdentification device

The invention relates to assembly equipment for lockset, in particular to automatic assembly equipment for a spring lock. The automatic assembly equipment comprises a machine frame and a microcomputer controller, wherein a spring feed disc, a mechanical spring feed disc, a spring sealing feed disc, a key bit identification device, a spring swinging device and a mechanical spring sealing installation device are arranged on the machine frame, wherein the key bit identification device, the spring swinging device and the mechanical spring sealing installation device are connected with the microcomputer controller respectively; the spring feed disc is connected with the spring swinging device; and the mechanical spring feed disc and the spring sealing feed disc are connected with the mechanical spring sealing installation device. The automatic assembly equipment for the spring lock has the advantages of novel structure, high automaticity and high assembly efficiency and assembly accuracy.

Owner:JINHUA KETE PRECISION MACHINERY

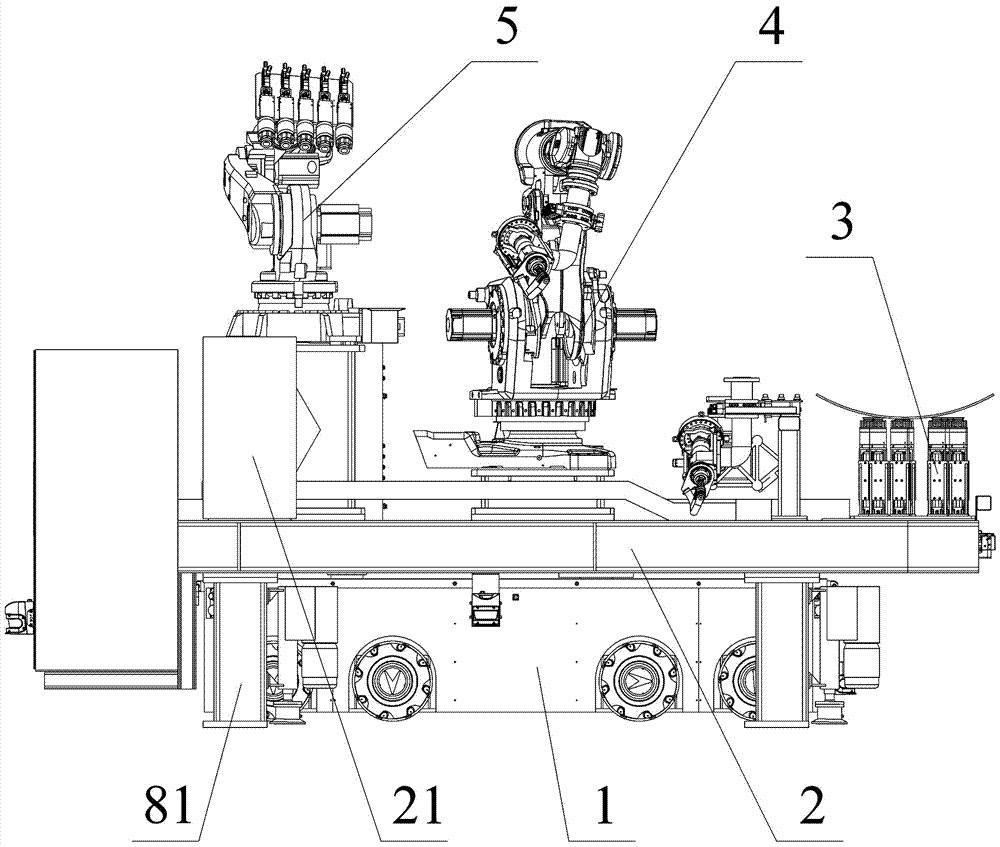

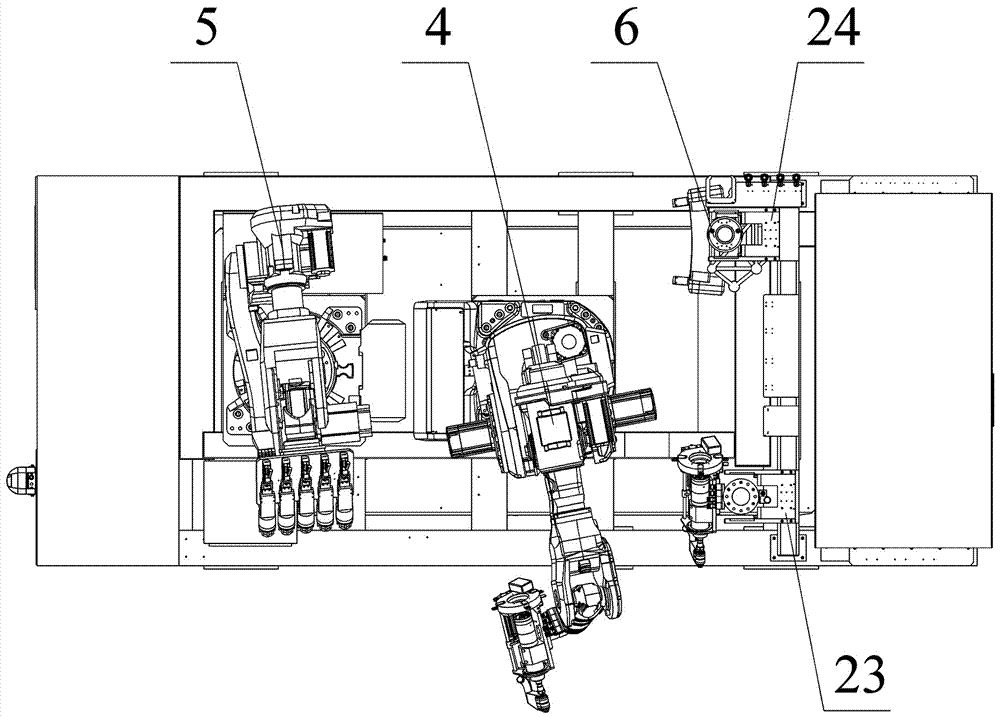

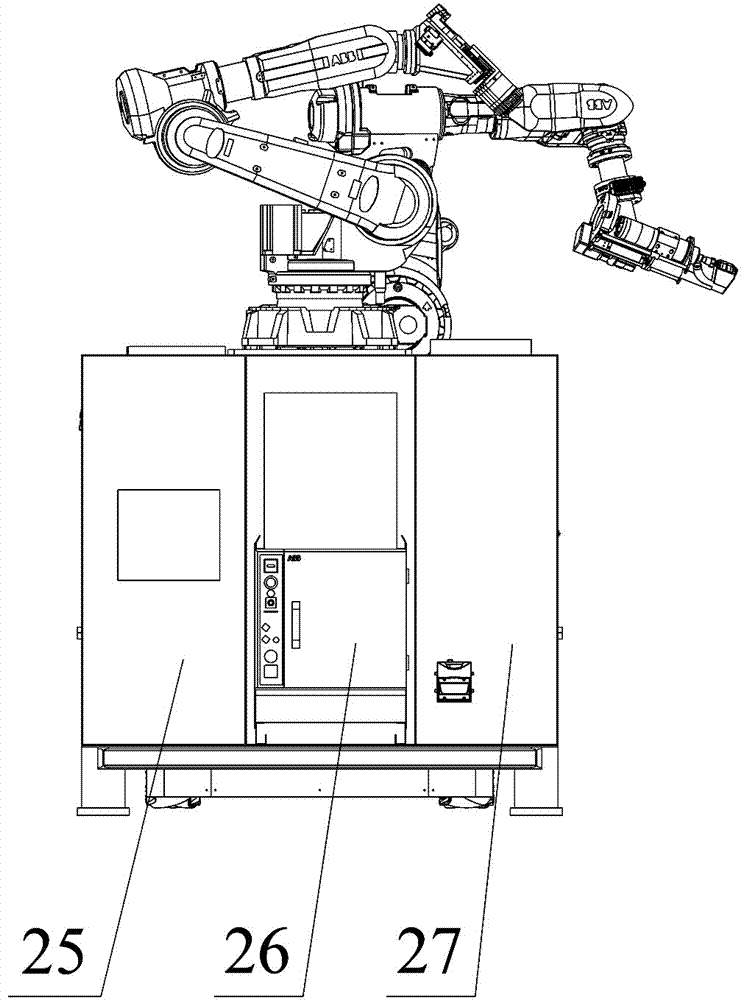

Efficient and high-precise robot automatic milling system in digital assembly process of airplane

ActiveCN107253084AImprove reliabilityImprove assembly accuracyPositioning apparatusManipulatorAutomatic controlAirplane

The invention provides an efficient and high-precise robot automatic milling system in the digital assembly process of an airplane. The system is characterized in that the system comprises a robot off-line programming and simulation system, a robot automatic control system, an AGV, a working platform arranged on the AGV, a flexible positioning tool system arranged on the working platform, a machining system, an auxiliary clamping system and a measuring system; the machining system comprises a machining robot and a machining tail end actuator connected with the machining robot, and the auxiliary clamping system comprises an auxiliary clamping robot and an auxiliary clamping tail end actuator connected with the auxiliary clamping robot; and machining objects of the robot automatic milling system comprise airplane large parts and airplane small parts. According to the efficient and high-precise robot automatic milling system in the digital assembly process of the airplane, robot automatic milling is adopted to replace manual work to grind the assembly allowance of the airplane, the problems that in the assembly process, the allowance is uneven in grinding, difficult to repair, low in working efficiency and the like are solved, the assembly precision and efficiency of the airplane are promoted, the labor intensity of workers is relieved, and physical and psychological health of the workers are guaranteed.

Owner:上海昂恒航空自动化装备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com