Patents

Literature

519results about How to "Reduce assembly man-hours" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

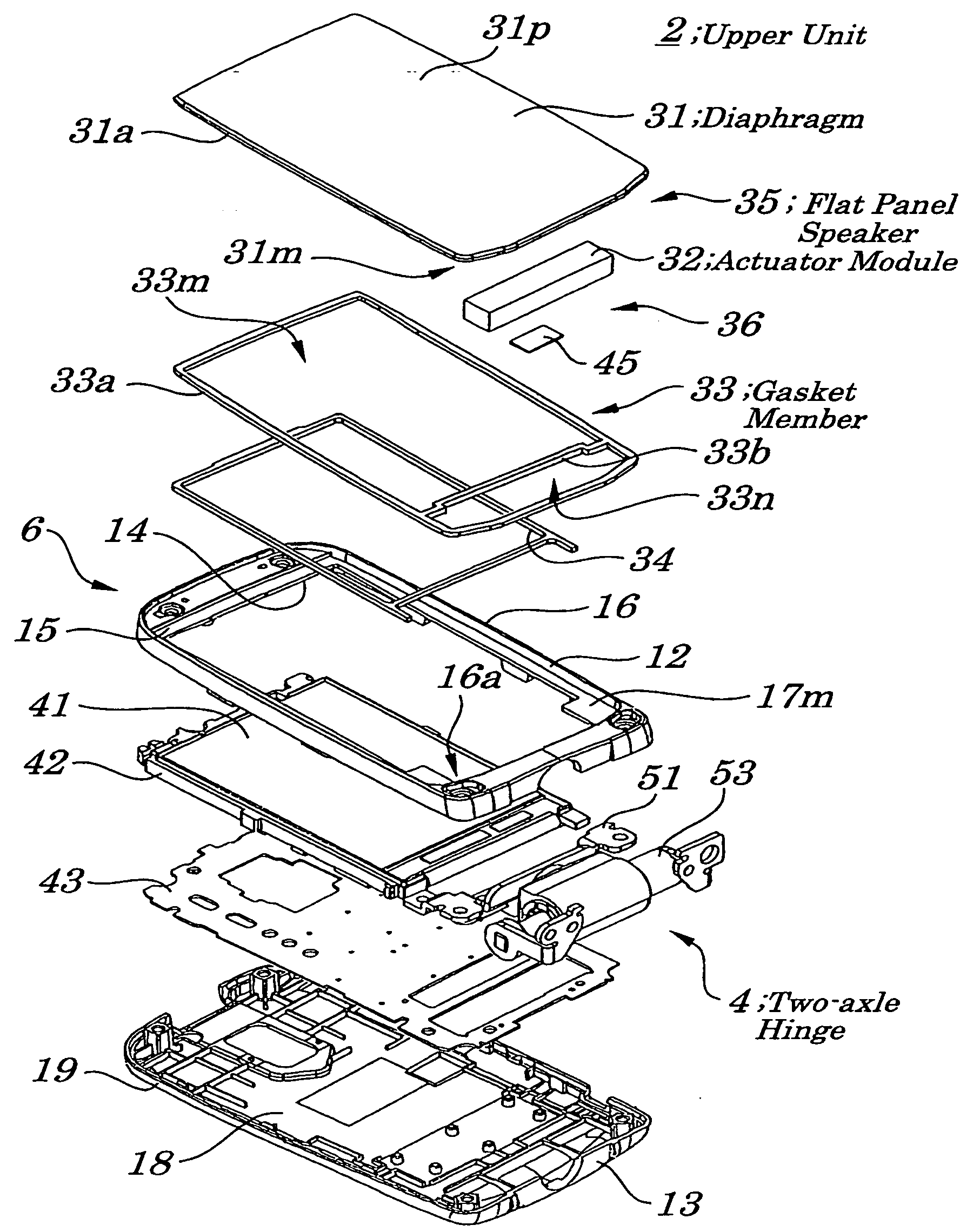

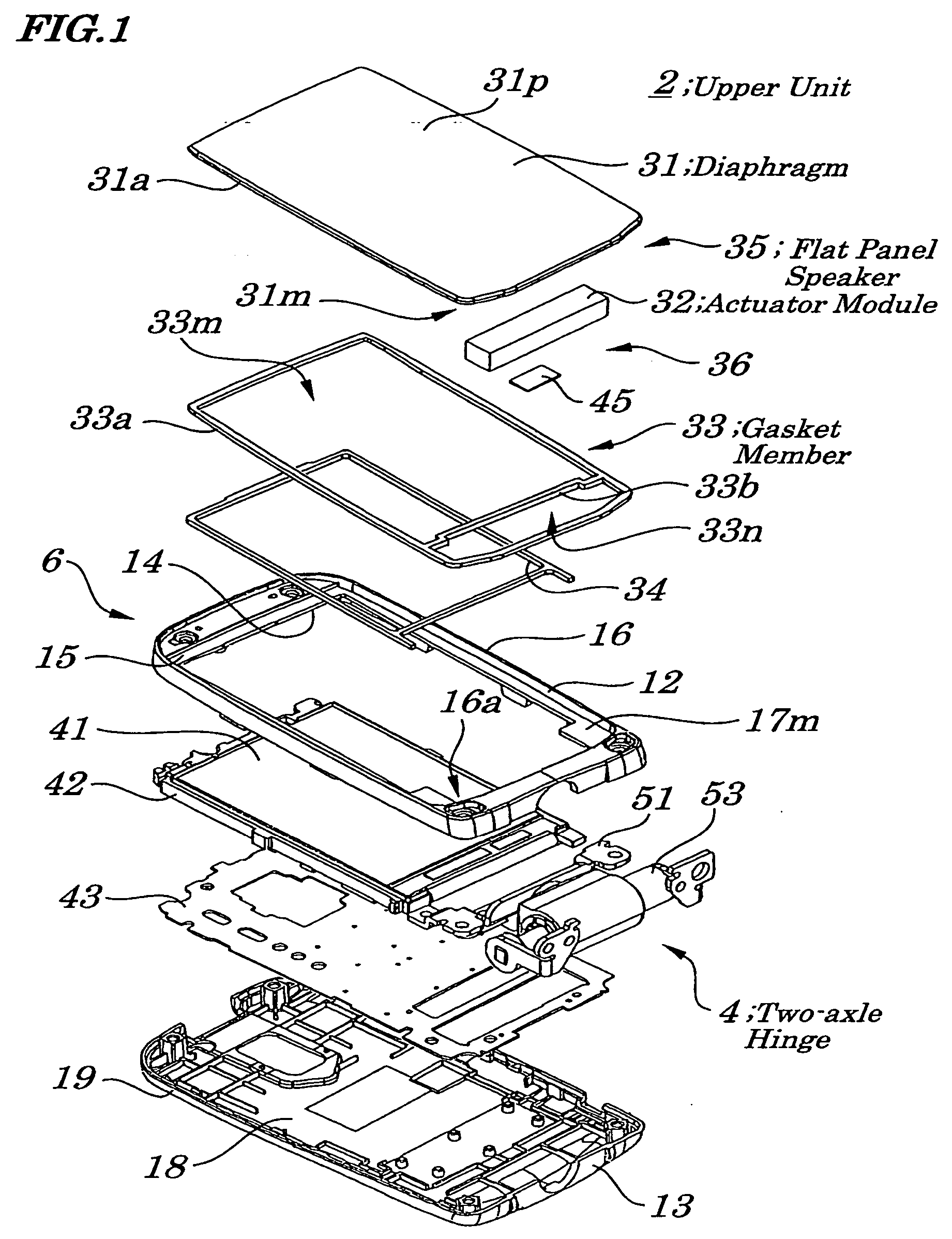

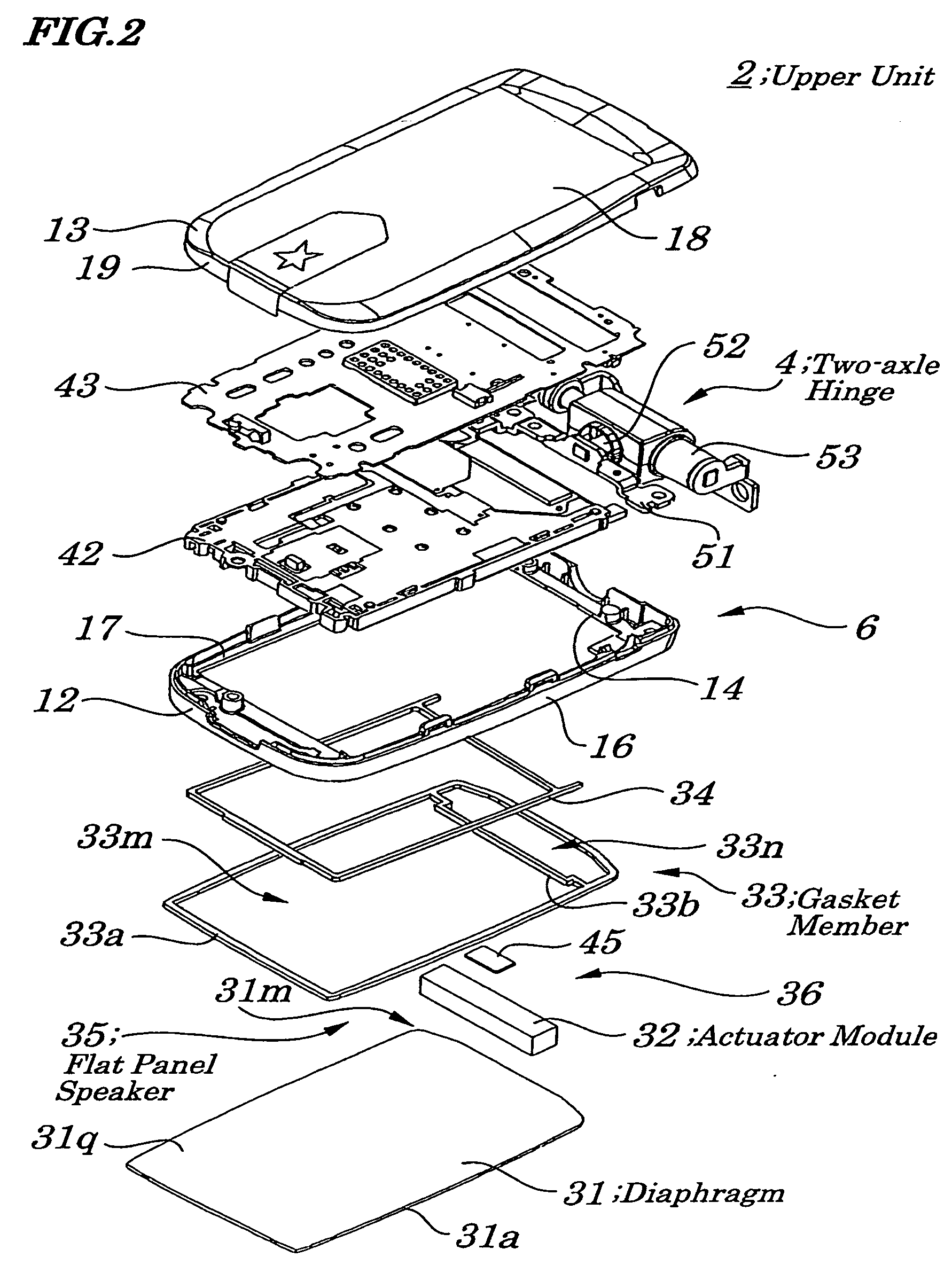

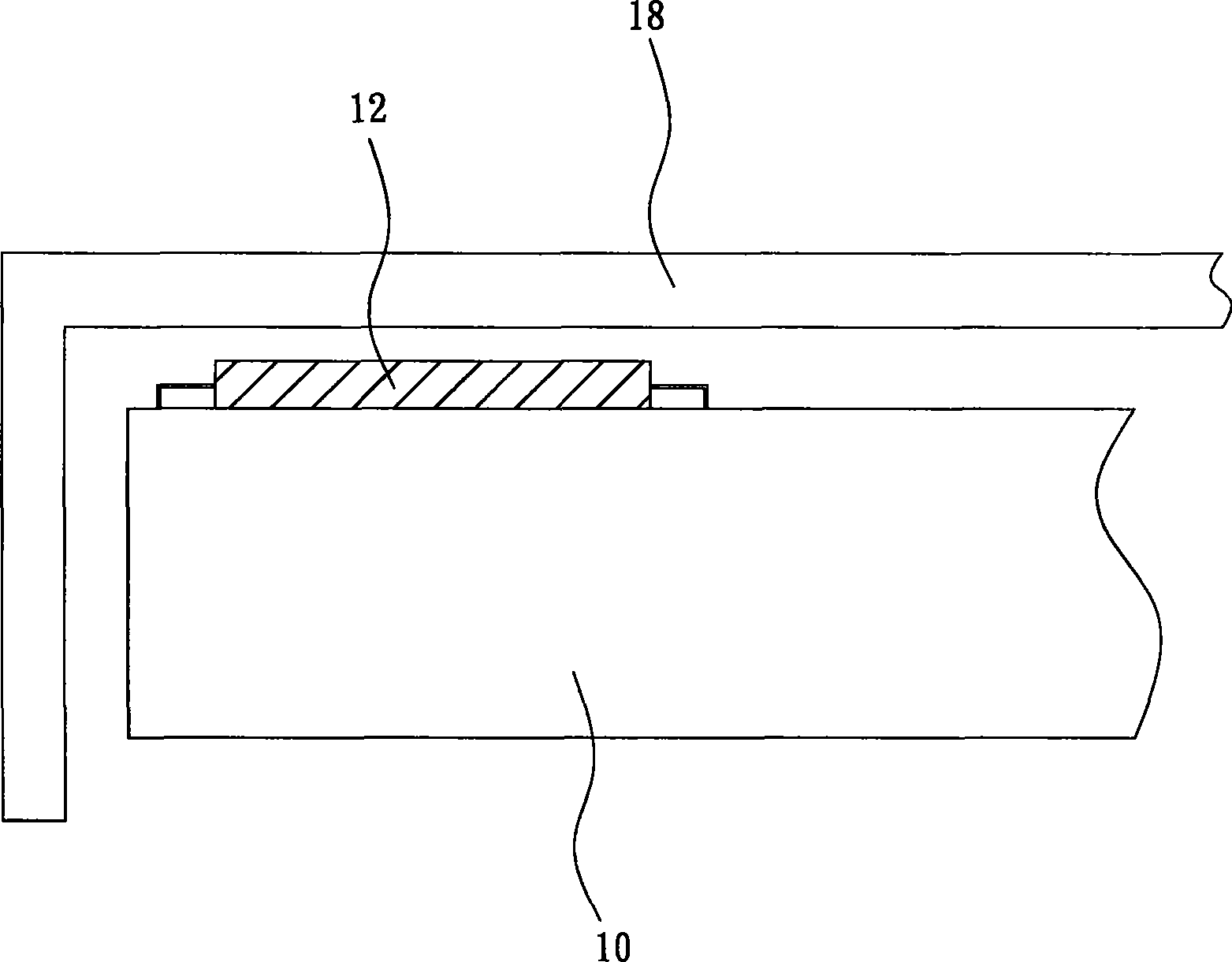

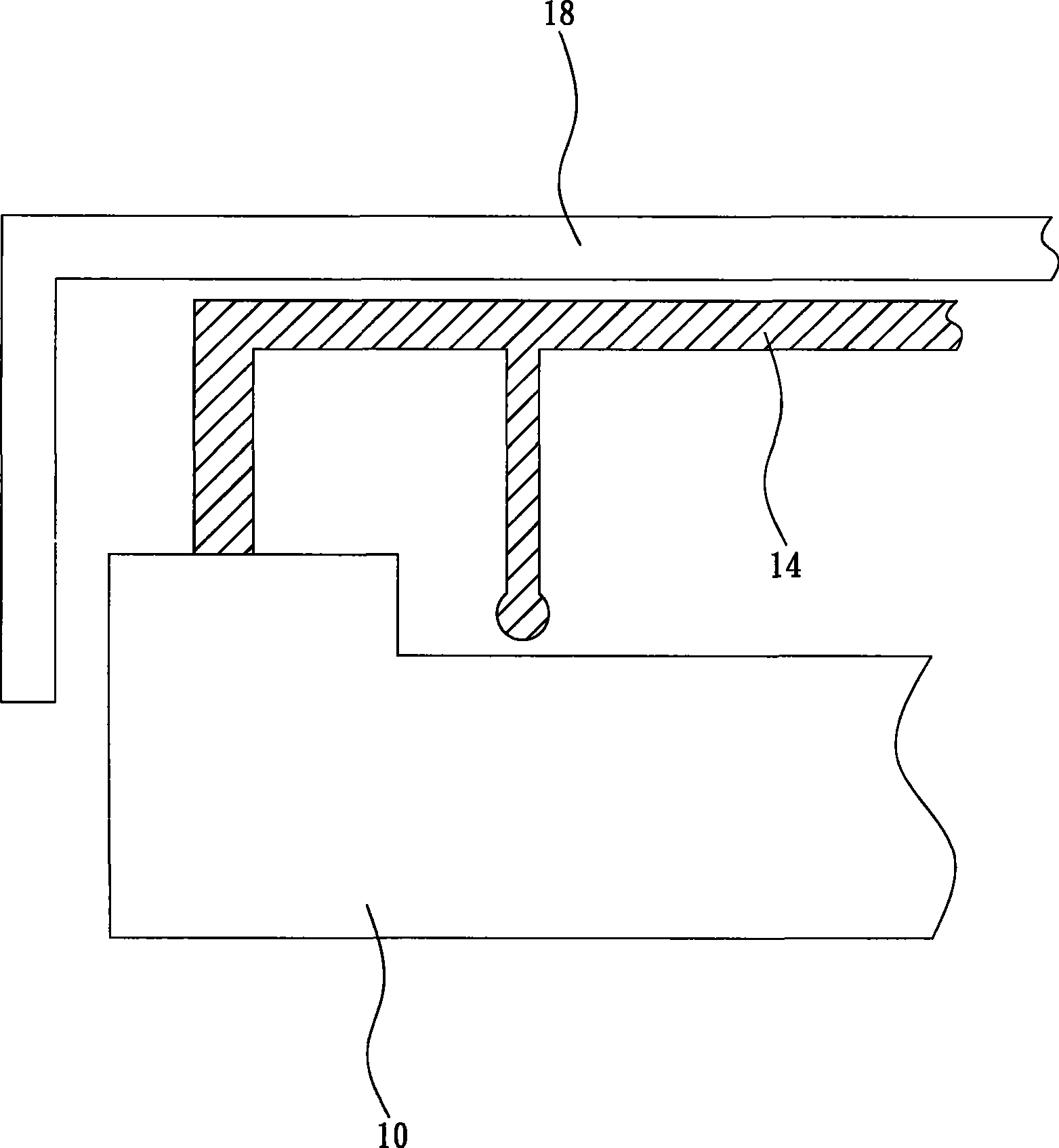

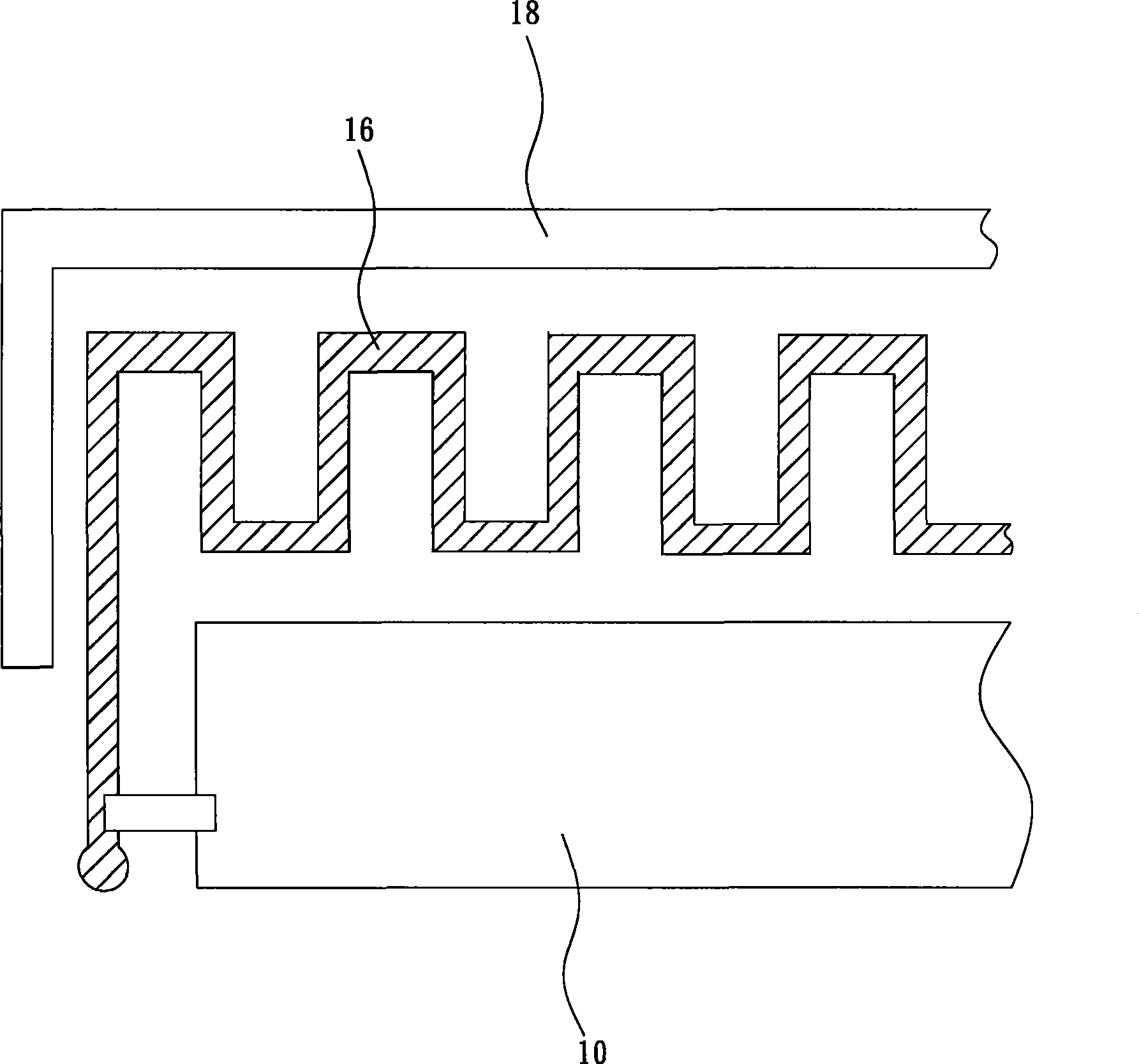

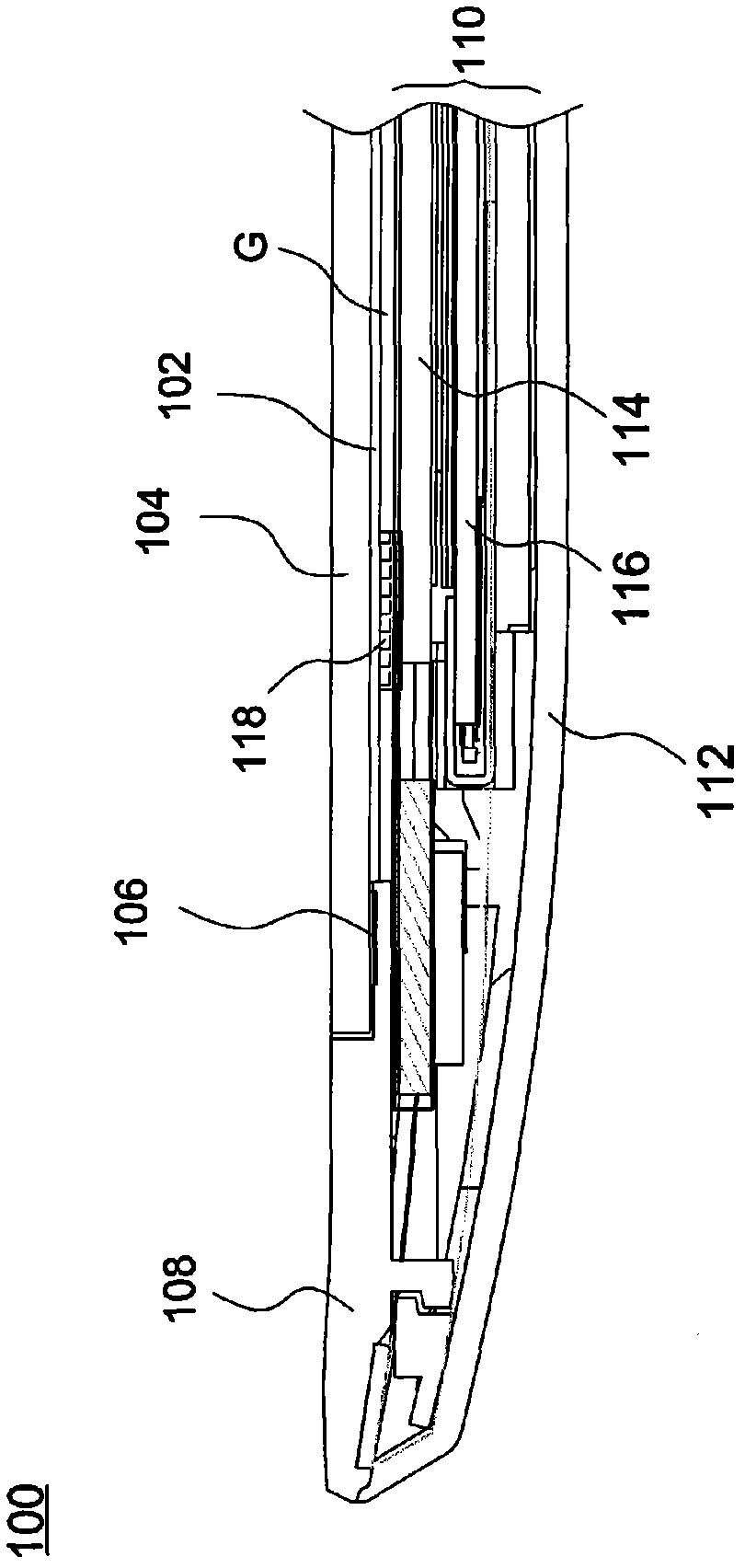

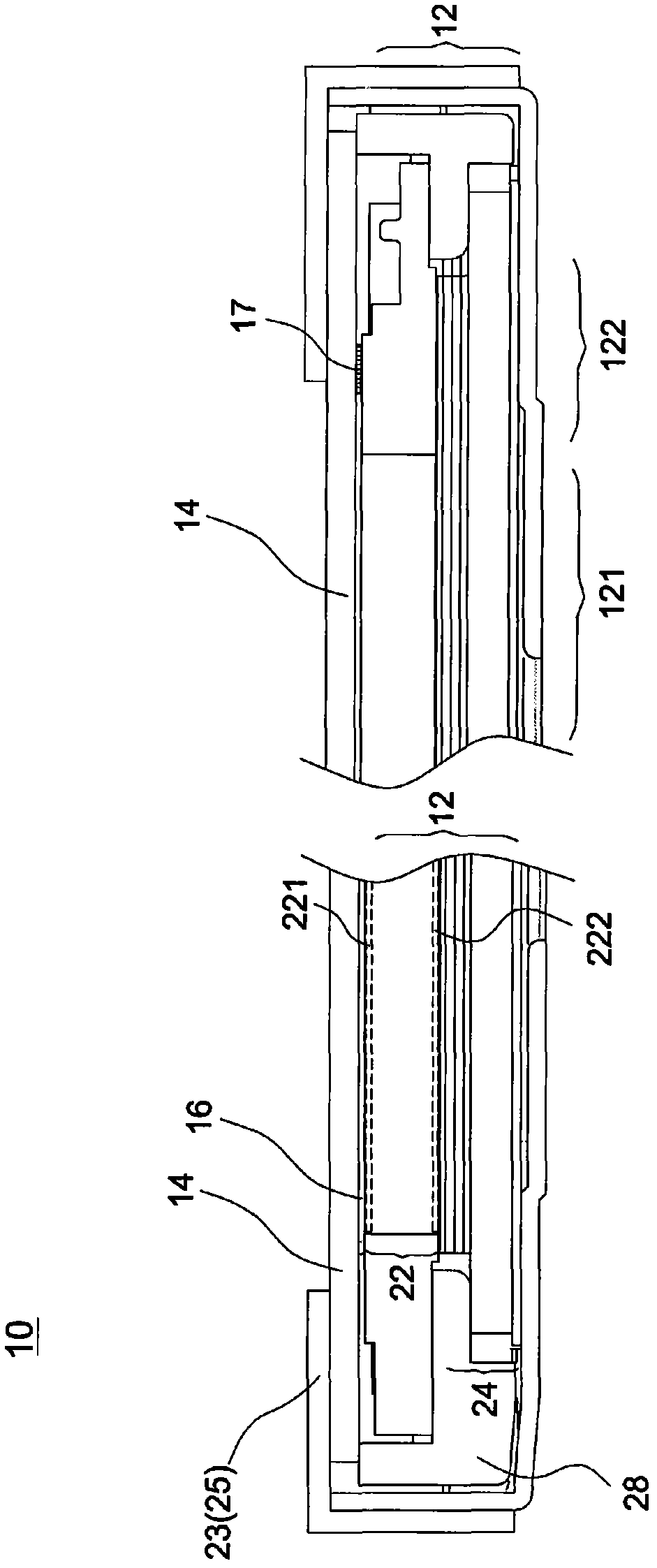

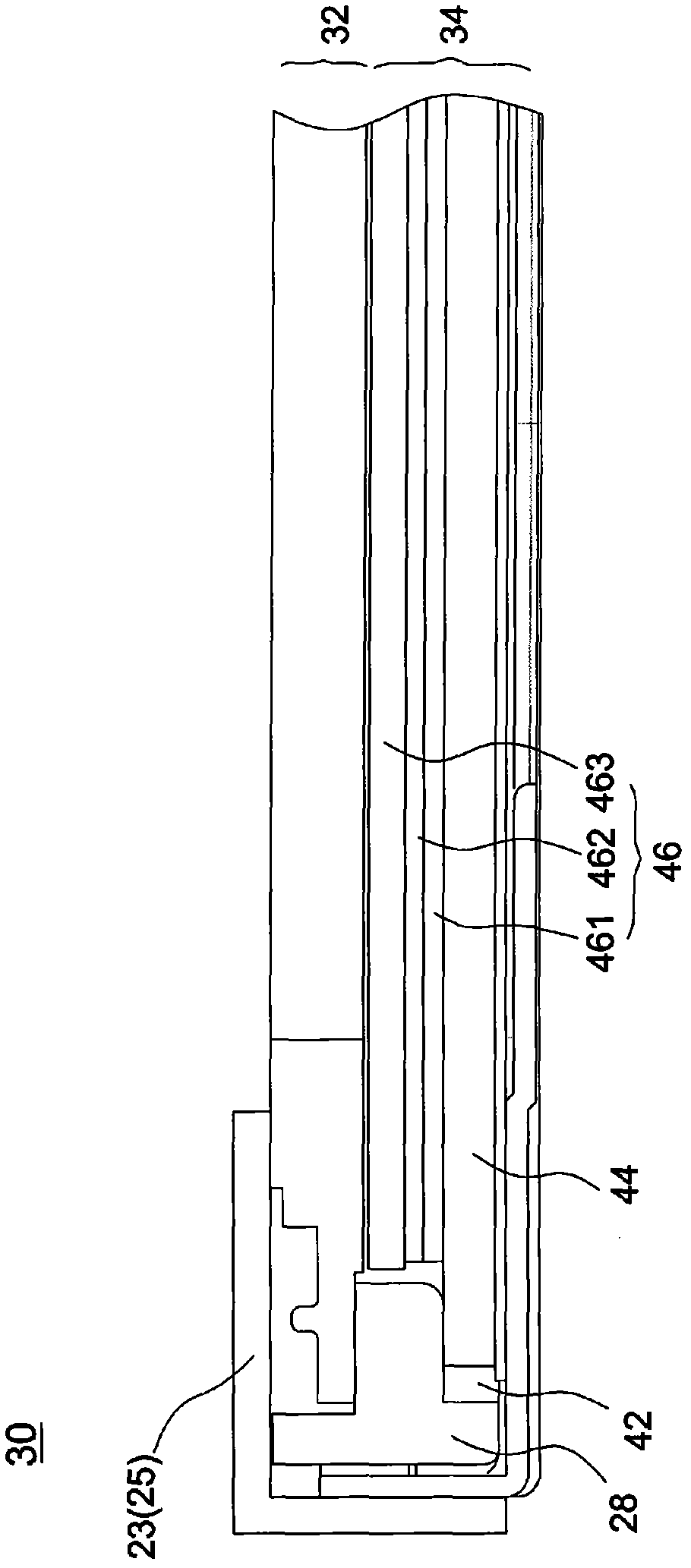

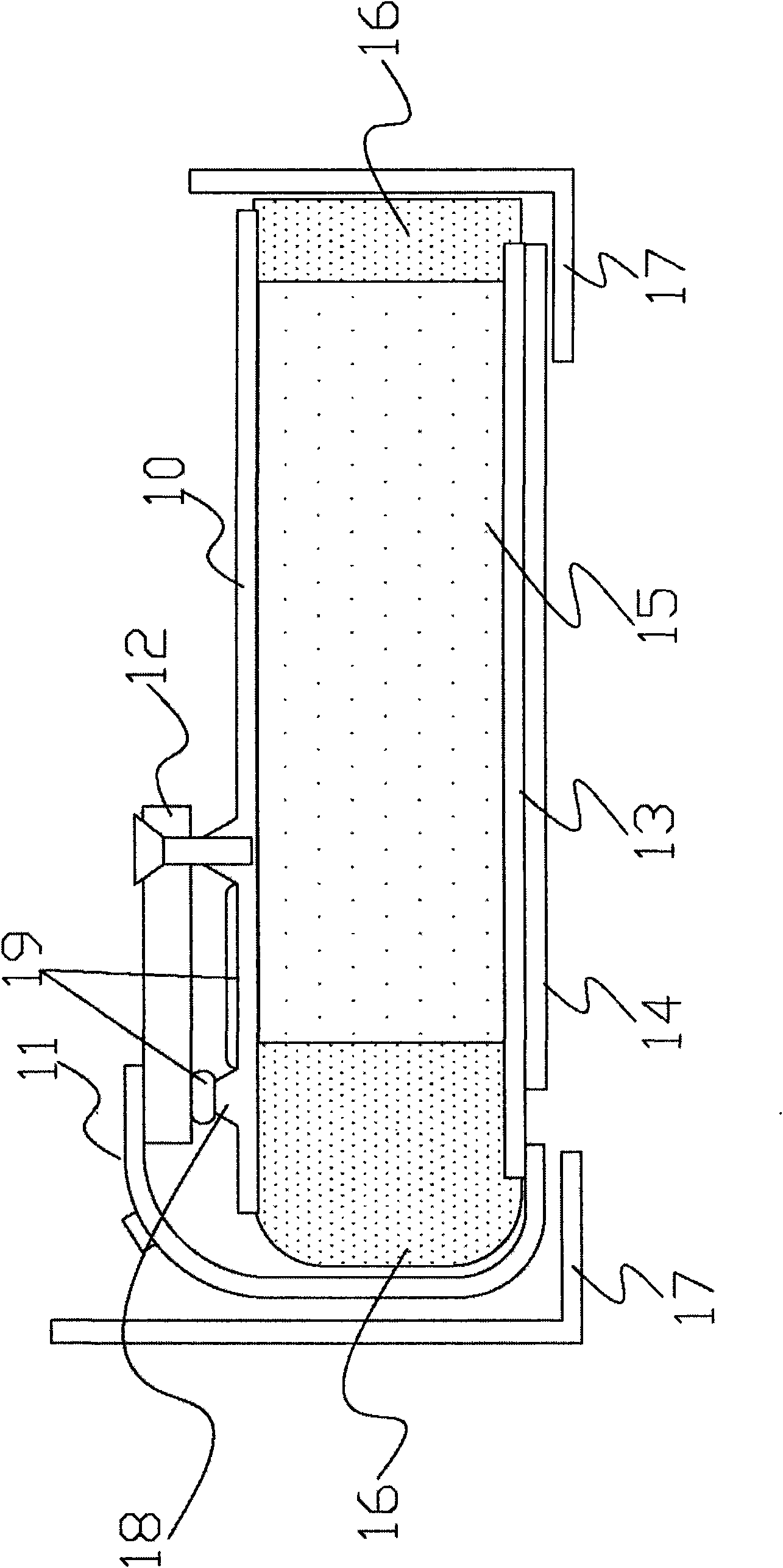

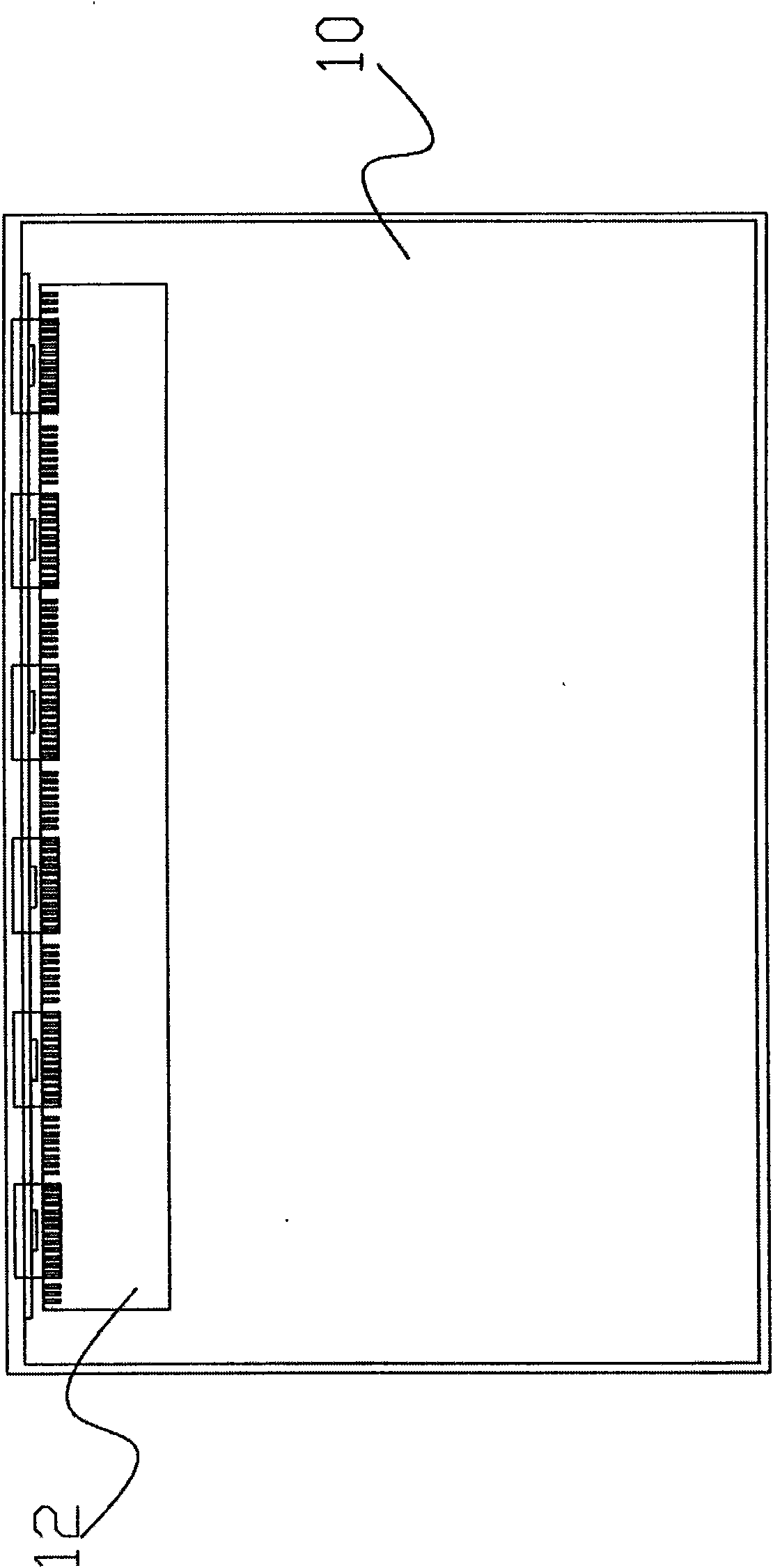

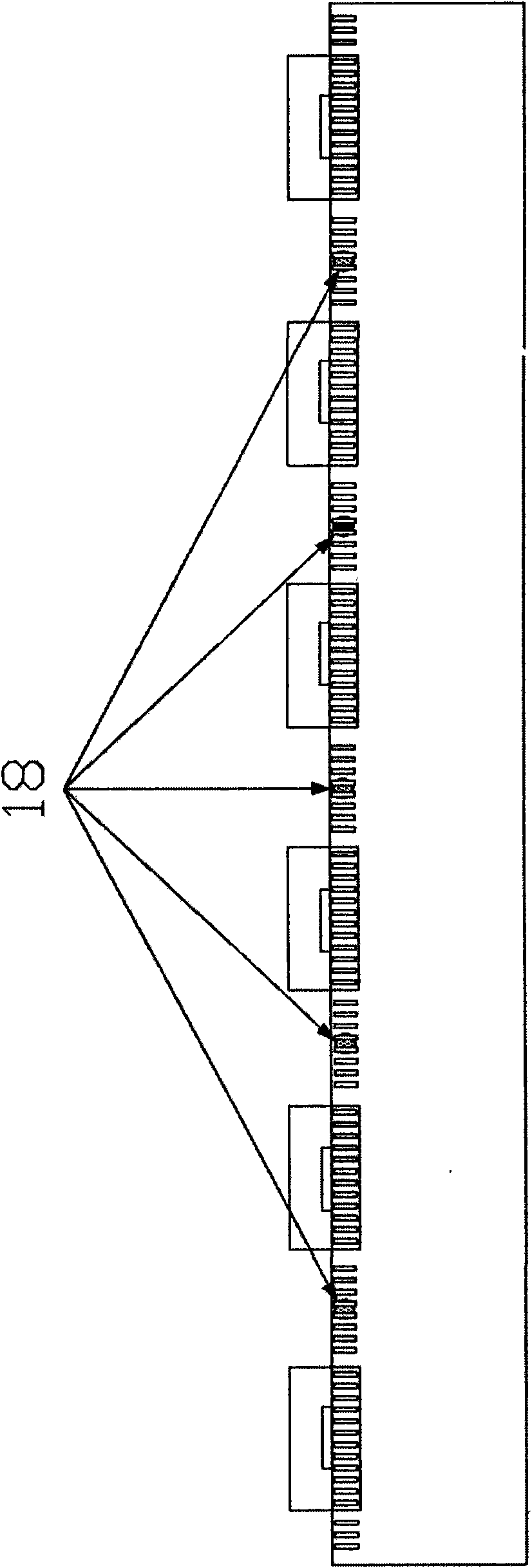

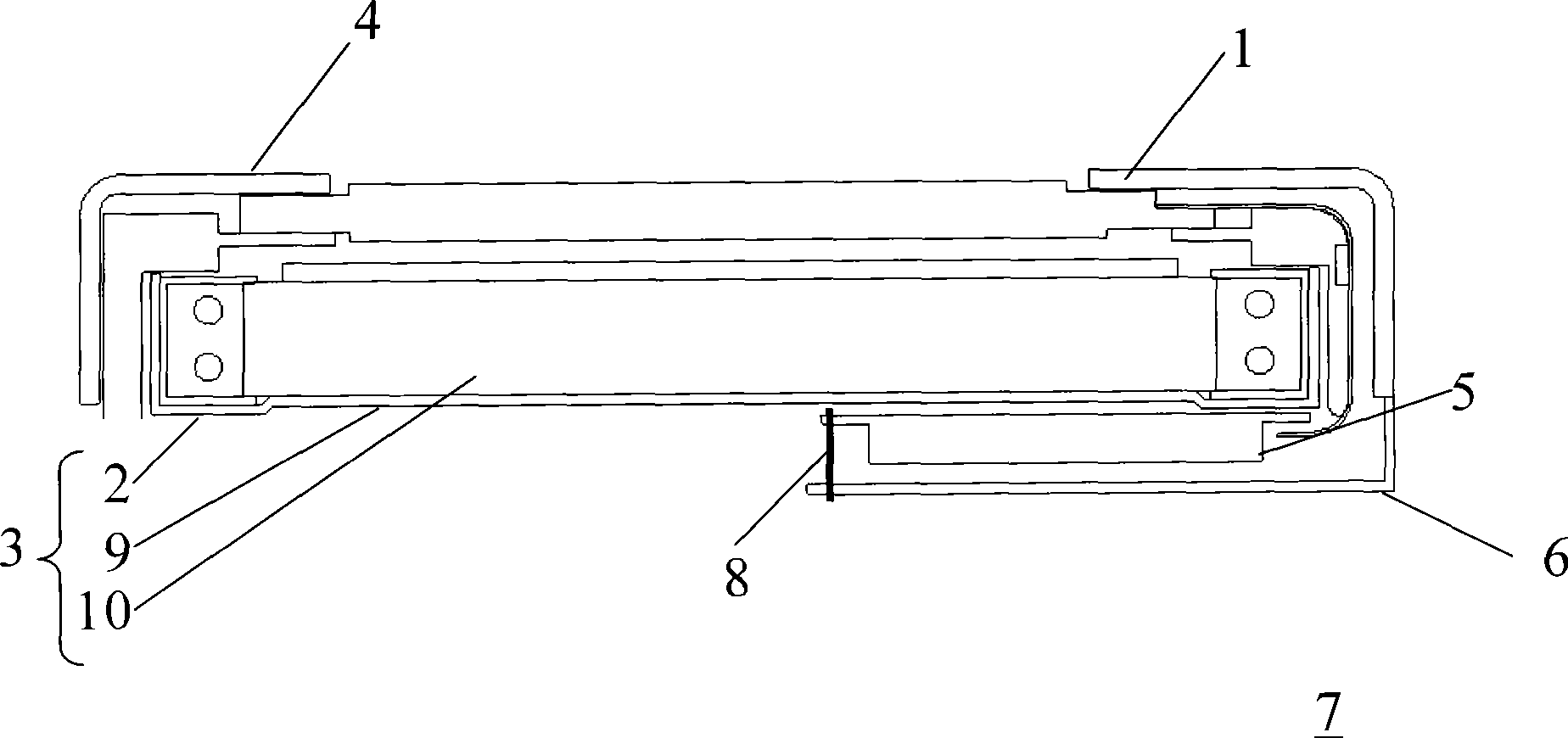

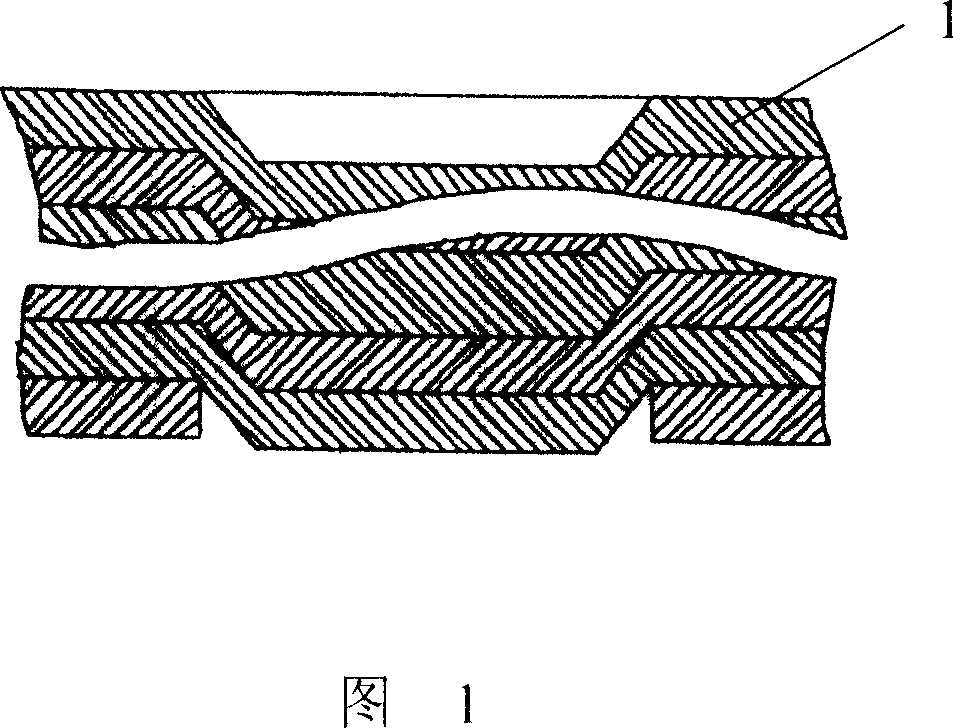

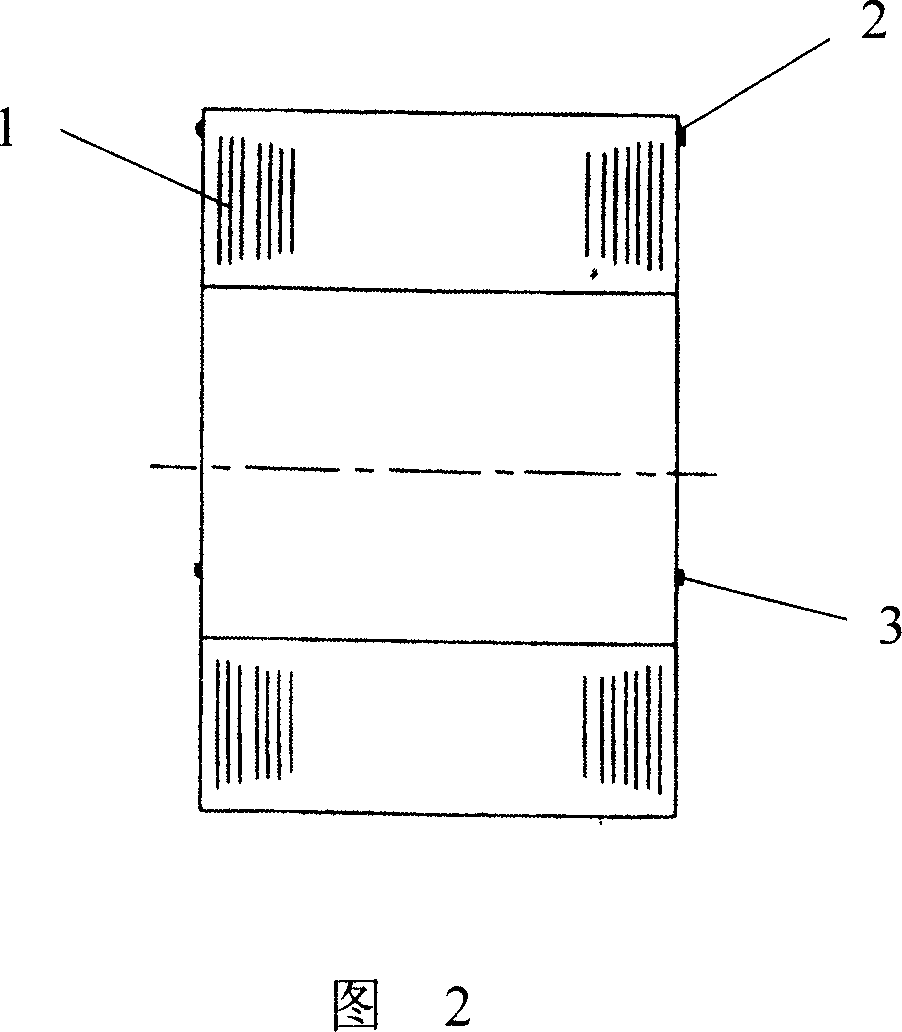

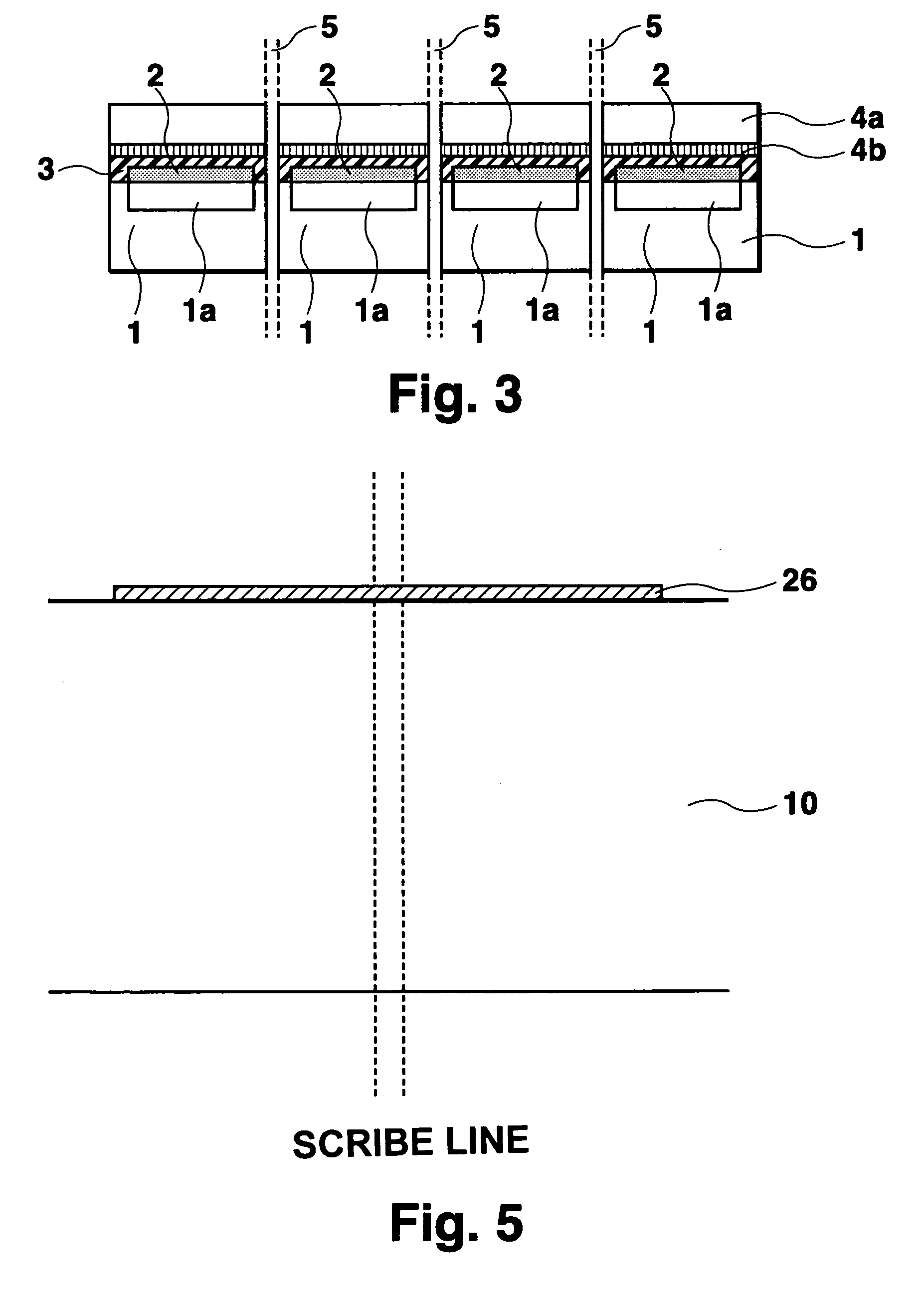

Gasket member, diaphragm, flat panel speaker, method of mounting same flat panel speaker, and method of assembling electronic device

InactiveUS20060140439A1Improve display qualityImprove featuresLoudspeaker transducer fixingPiezoelectric/electrostrictive transducersLiquid-crystal displayEngineering

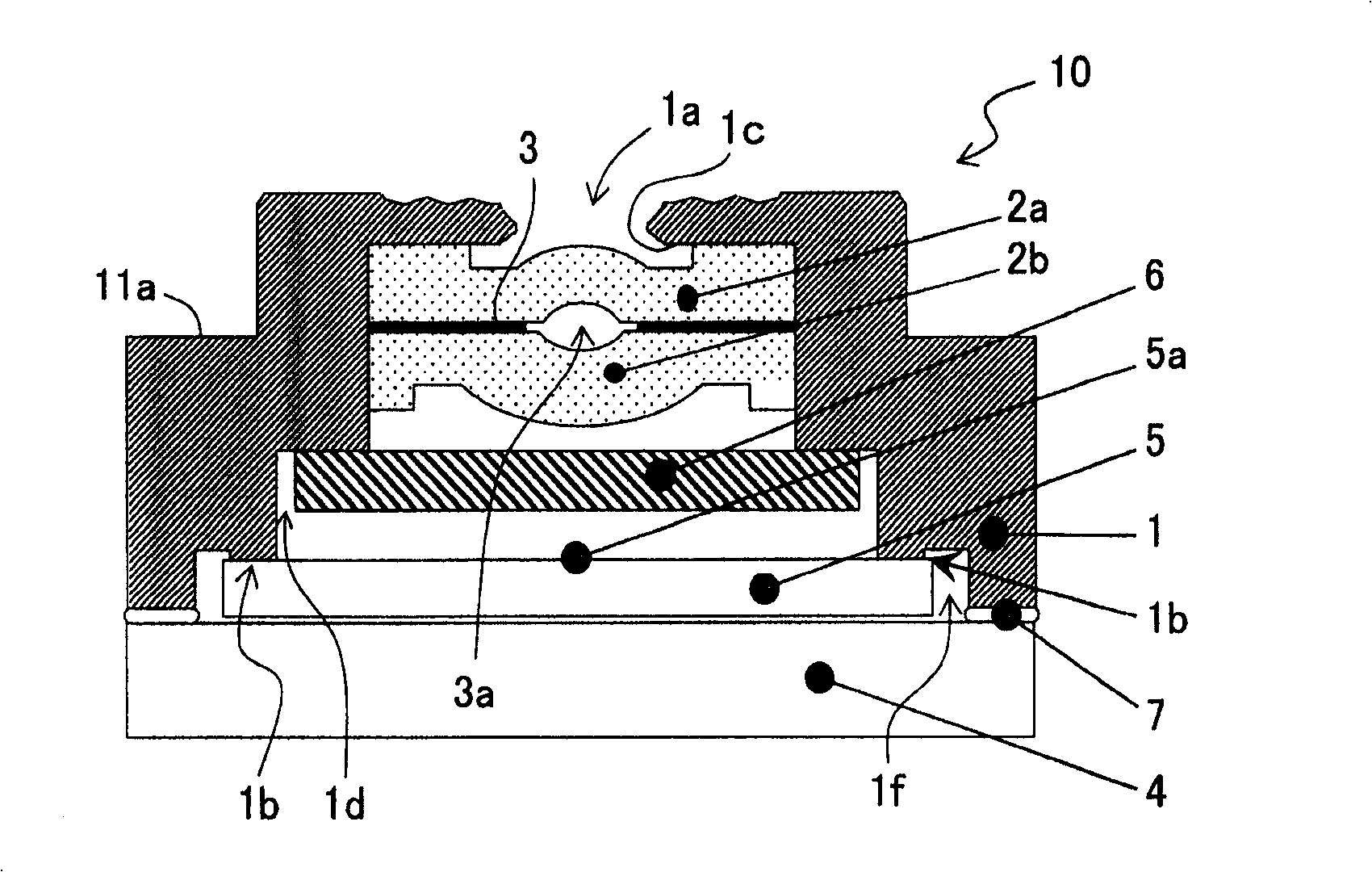

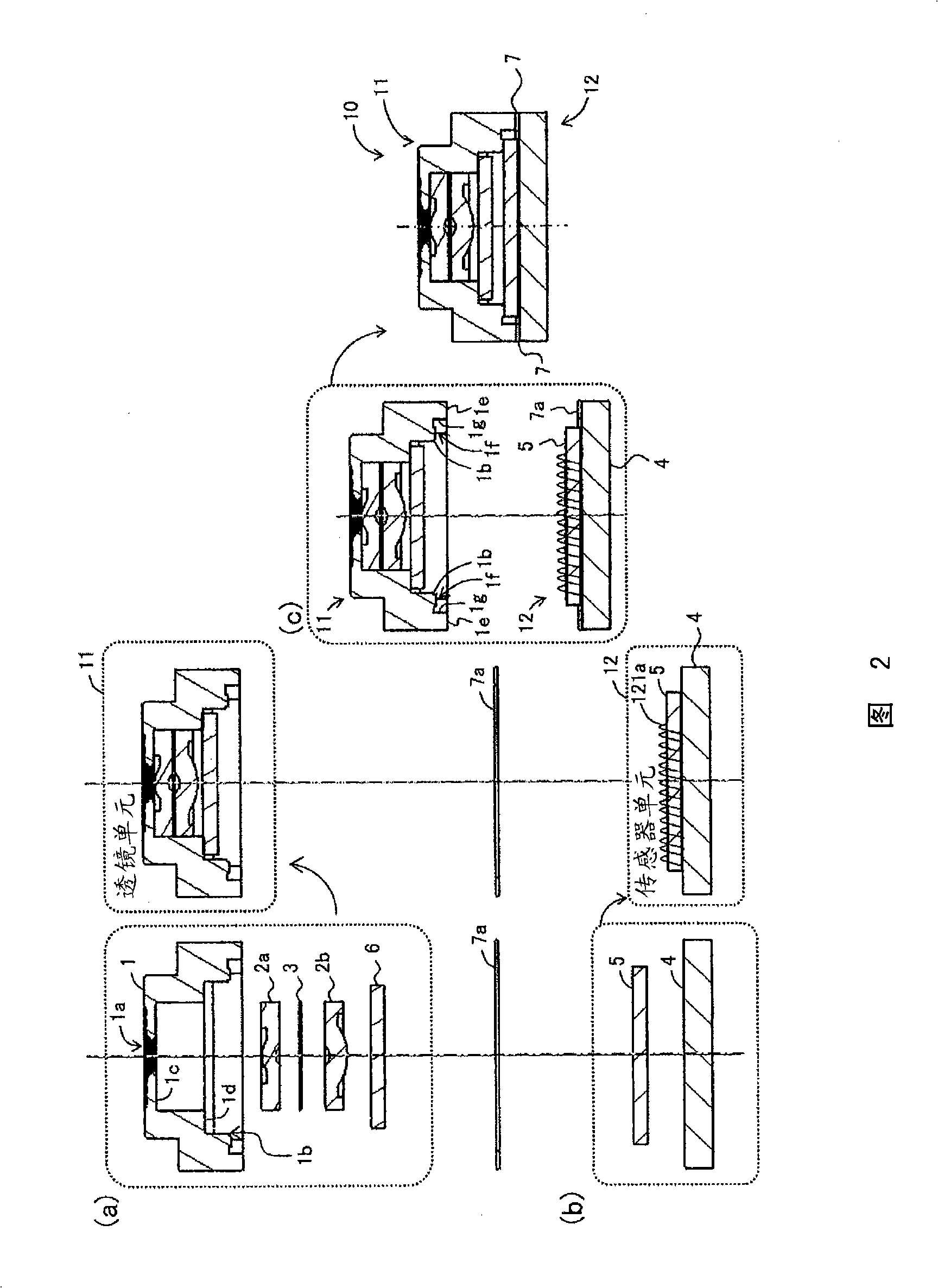

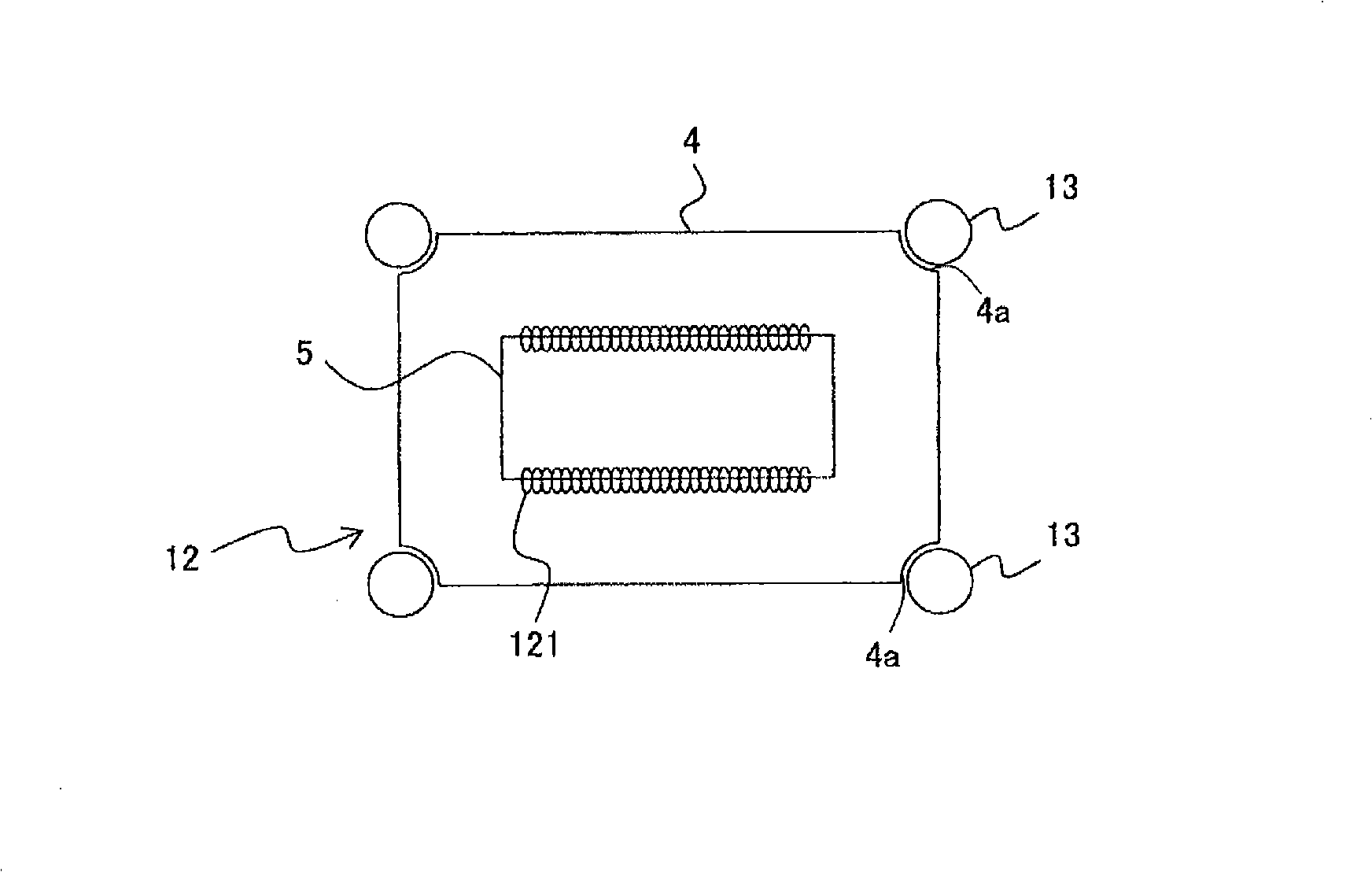

A method of mounting a flat panel speaker is provided which is capable of reliably preventing entry of dust and of shortening assembling time. By bonding a gasket member to a diaphragm, by pasting a separator to a gasket member side opposite to the diaphragm and, by sandwiching the diaphragm and the gasket member from both sides, a gasket-attached diaphragm is fabricated. After peeling off a protecting sheet on a rear side of the gasket-attached diaphragm, the actuator module is bonded to the diaphragm. Then, after peeling the separator from the gasket-attached diaphragm, positioning is performed on the diaphragm and the gasket member is bonded to a putting-face of the front case. The entry of dust into a region corresponding to a liquid crystal display panel is blocked by a partitioning portion of the gasket member.

Owner:LENOVO INNOVATIONS LTD HONG KONG

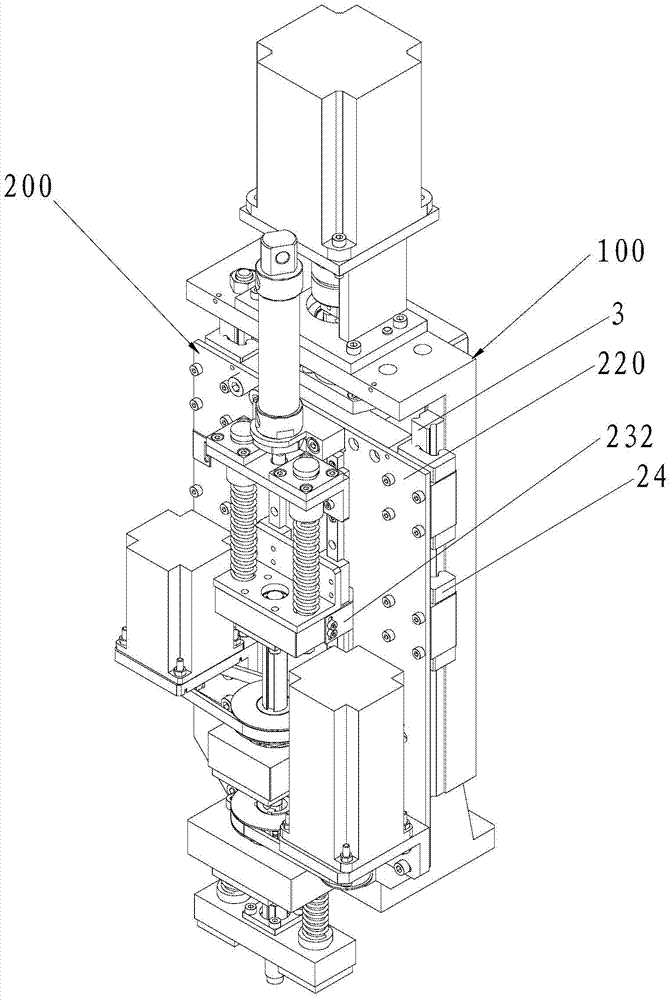

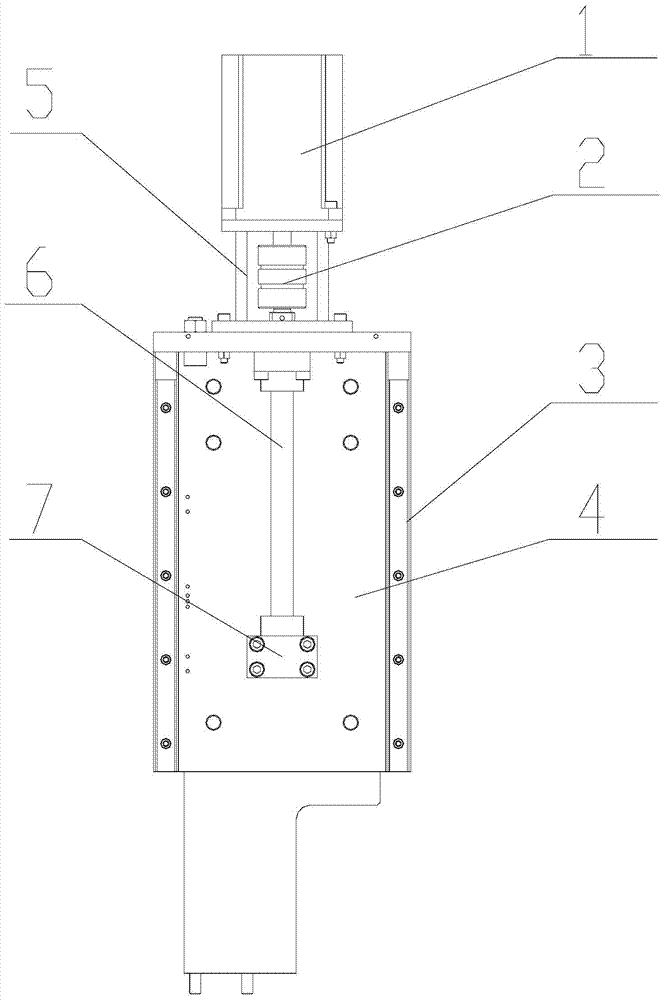

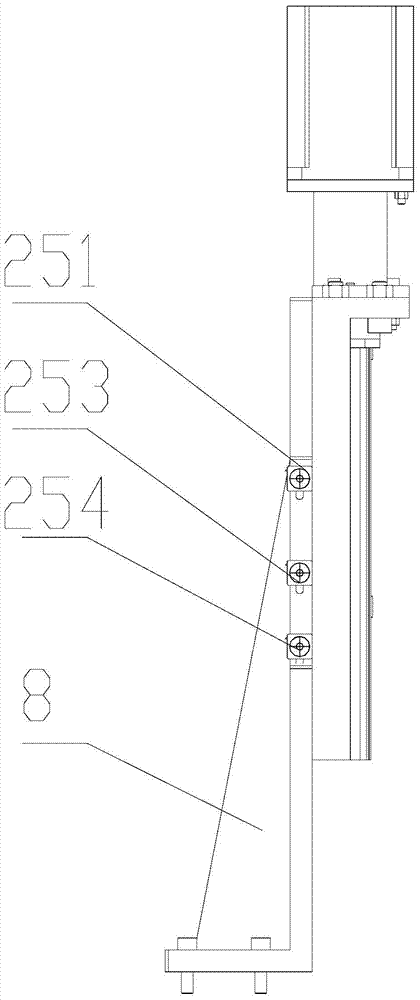

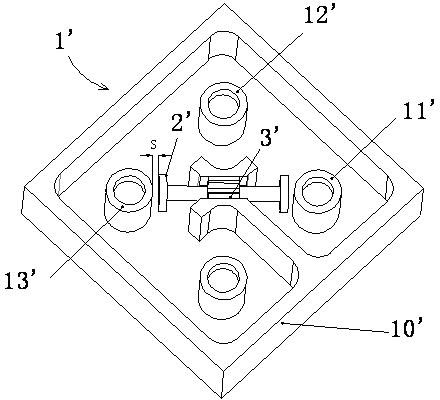

Automatic screw and nut combination locking device

ActiveCN103537892AReduce assembly man-hoursImprove accuracy and efficiencyMetal working apparatusEngineeringSlide plate

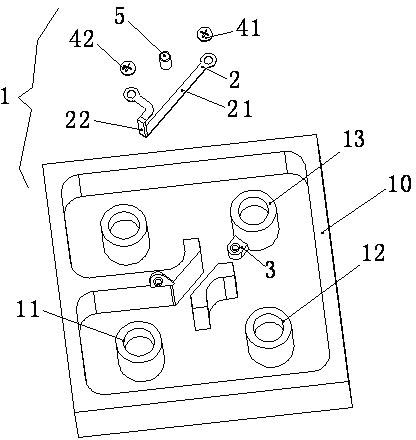

The invention is applicable to the field of assembly technologies for screws and nuts, and discloses an automatic screw and nut combination locking device which comprises a fixing assembly and a sliding assembly. The sliding assembly comprises a sliding plate, the sliding plate is slidably connected to the fixing assembly, and a sliding plate driving assembly is arranged on the fixing assembly; a screw locking assembly and a nut locking assembly are connected onto the sliding plate, the screw locking assembly comprises a screwdriver, a screw rotation driving assembly and an axial driving assembly, the screw rotation driving assembly is used for driving the screwdriver to peripherally rotate, and the axial driving assembly is used for driving the screwdriver to vertically slide; the nut locking assembly comprises a nut locking sleeve and a nut rotation driving assembly, the nut rotation driving assembly is used for driving the nut locking sleeve to rotate, and the screwdriver and the nut locking sleeve are coaxially arranged. The automatic screw and nut combination locking device has the advantages that a screw and a nut can be assembled at one station, so that the product assembly working hours can be greatly reduced, the assembly efficiency and the assembly precision can be improved, the cost can be reduced for an enterprise, and the core competitiveness of the enterprise can be improved.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

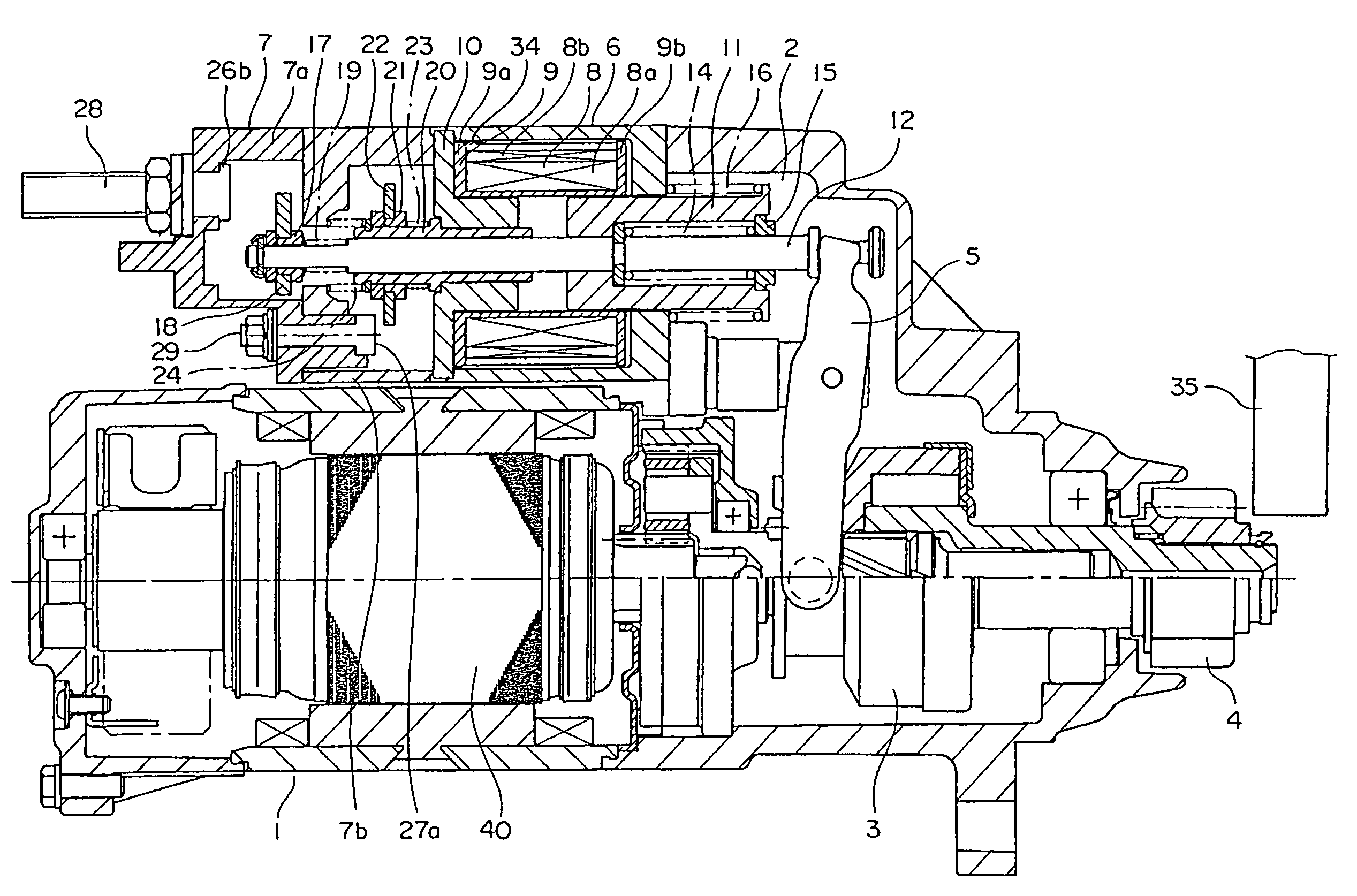

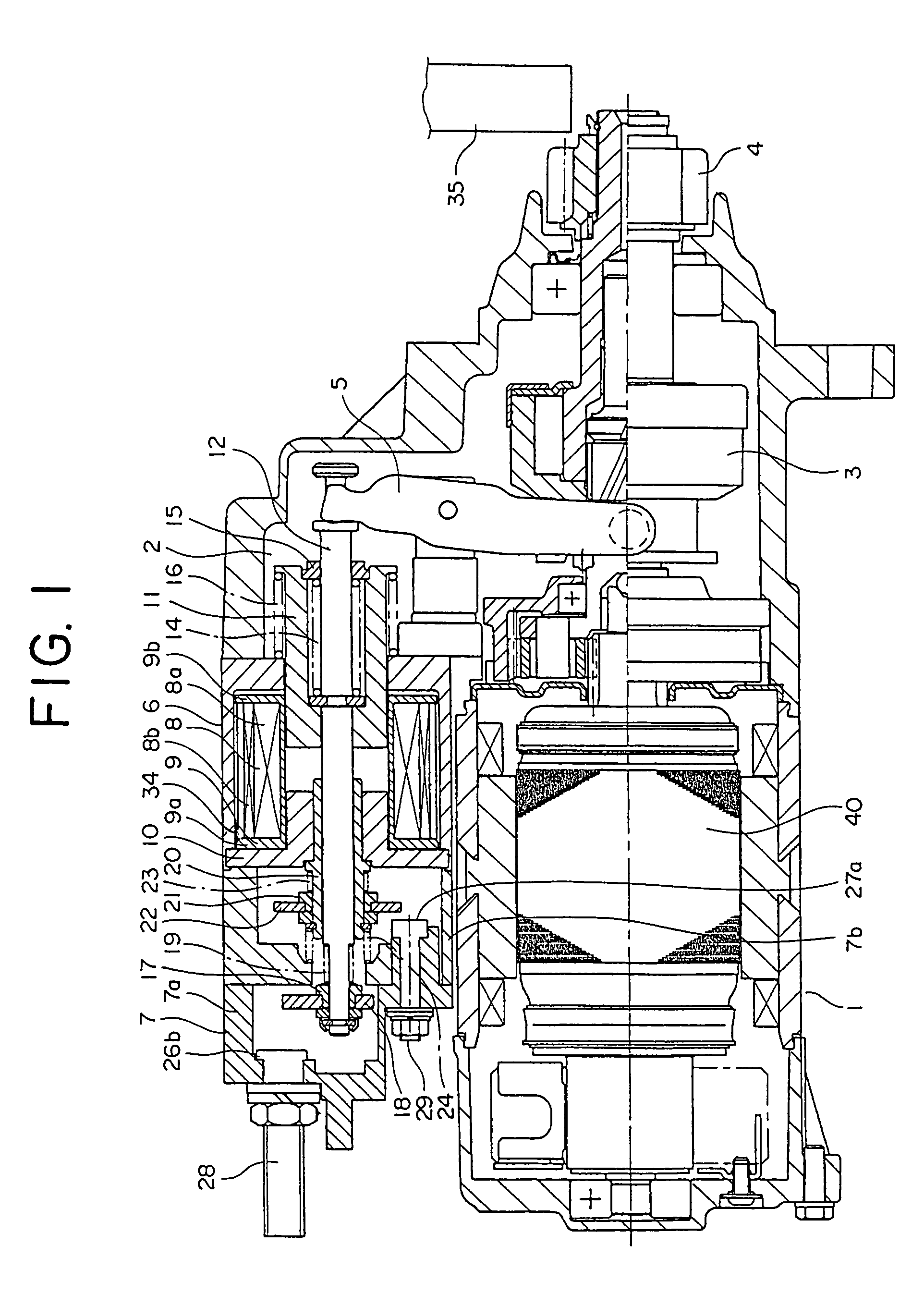

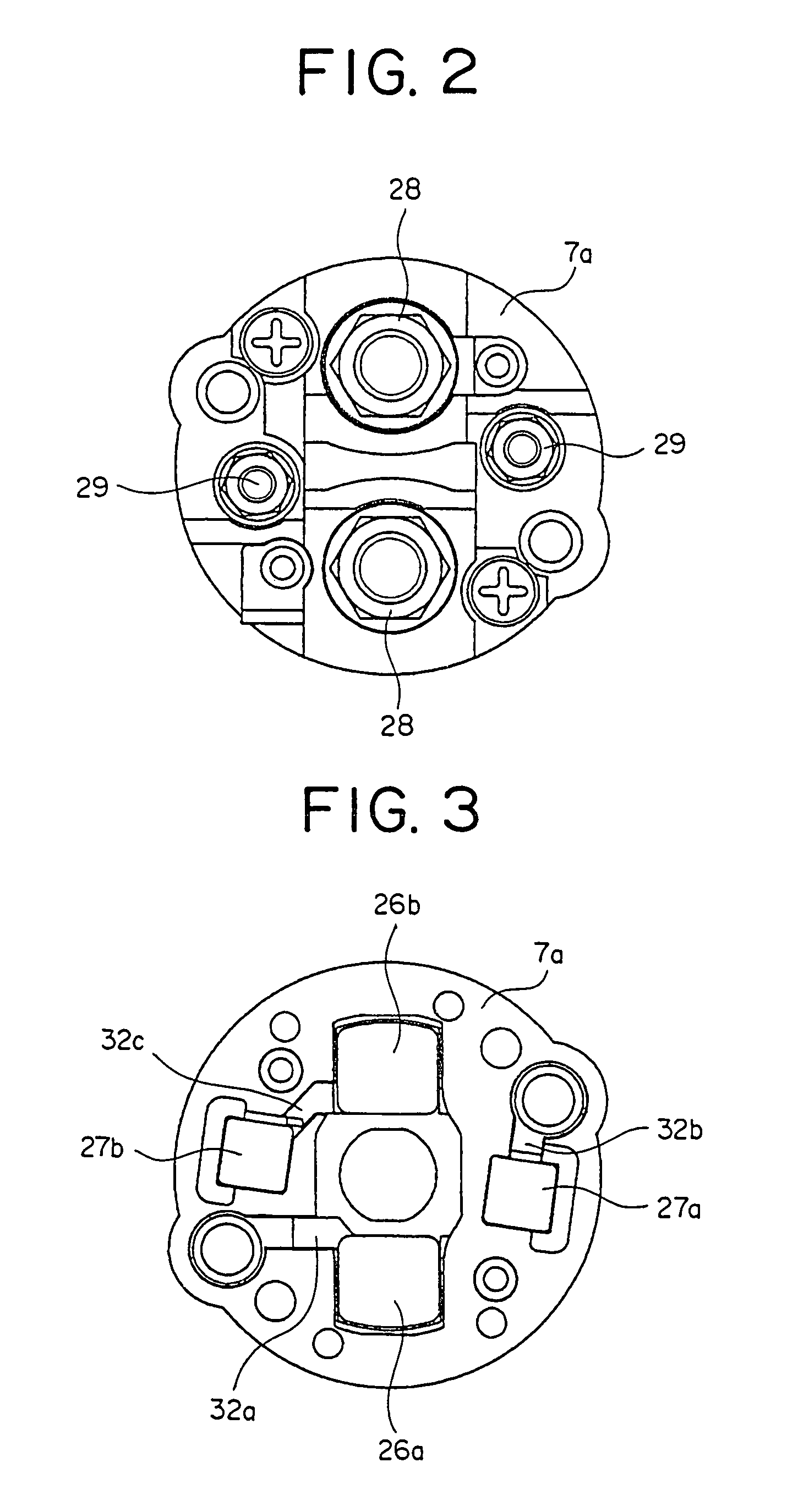

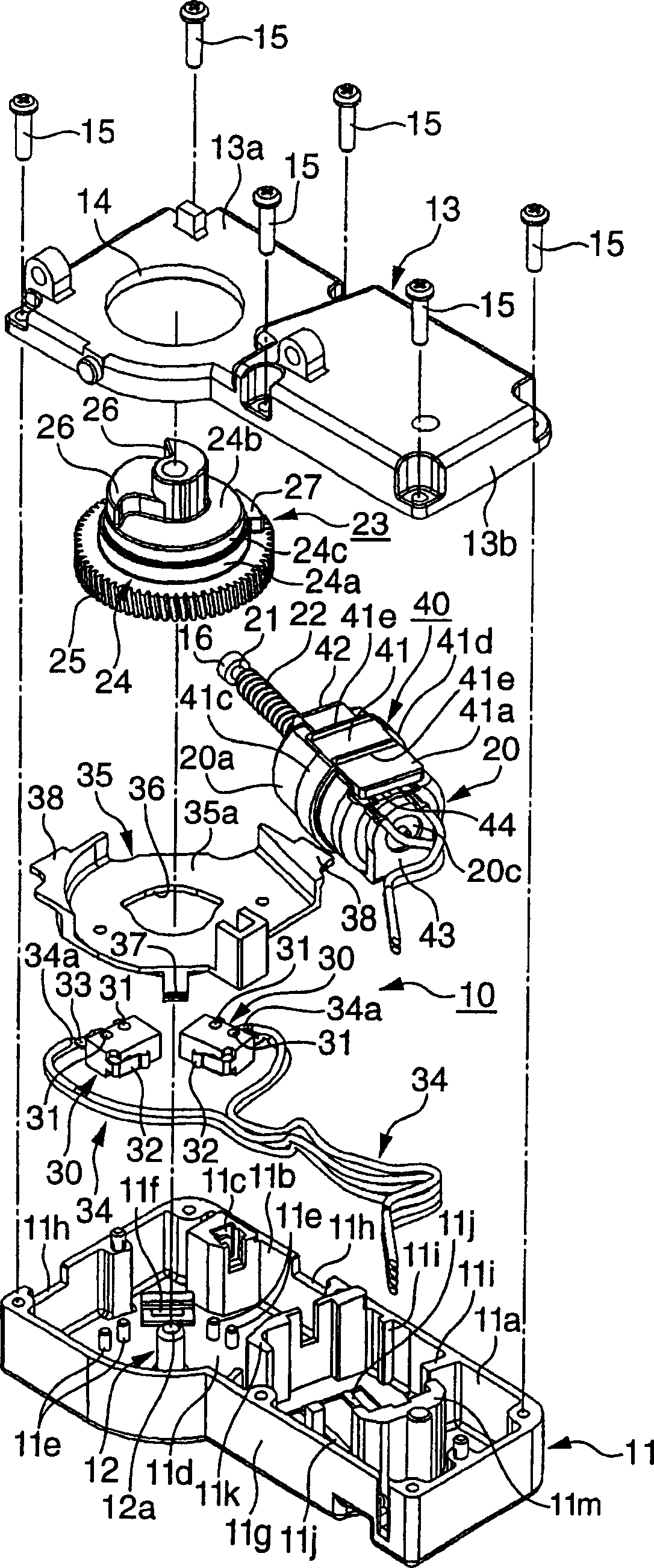

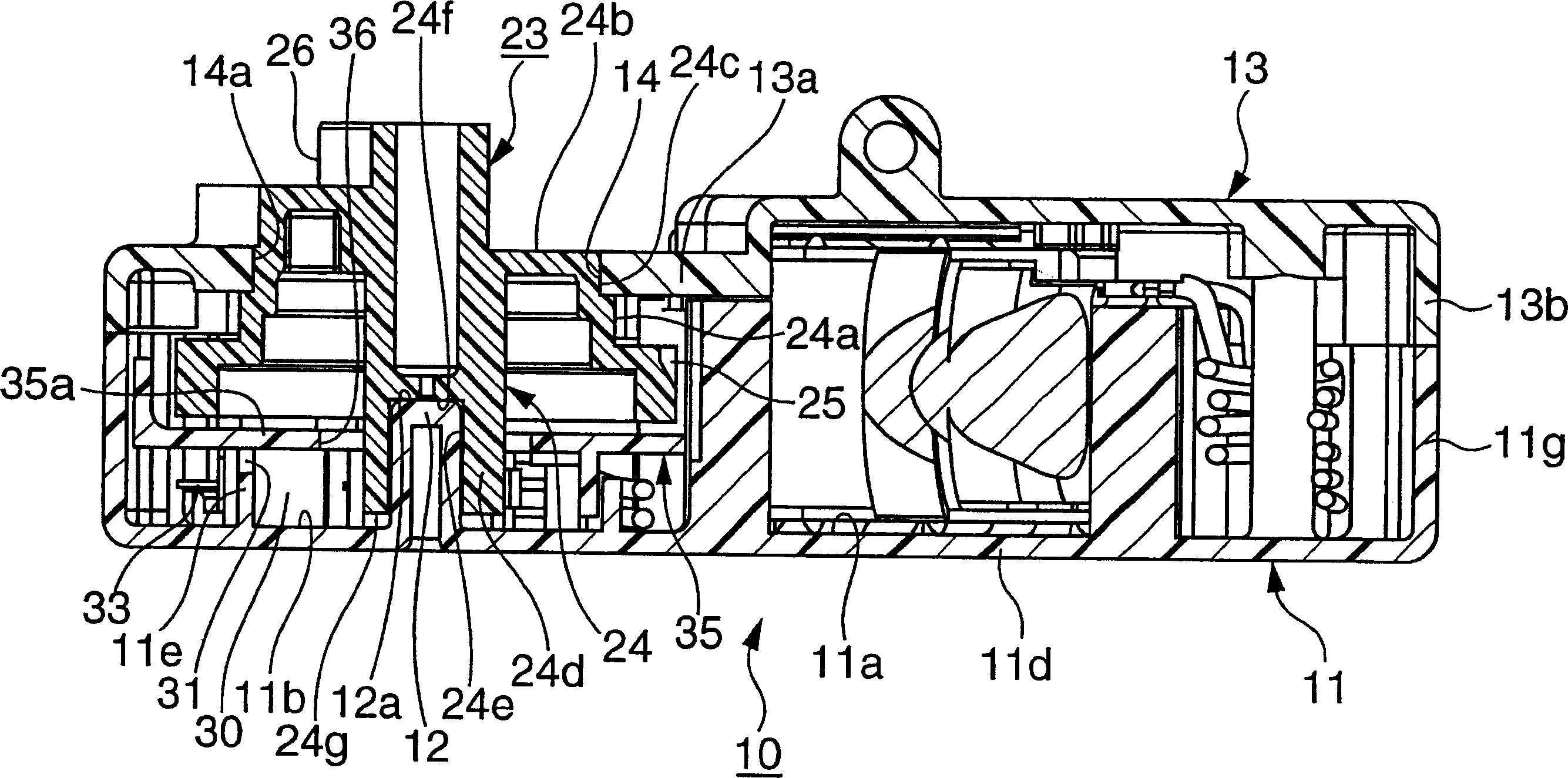

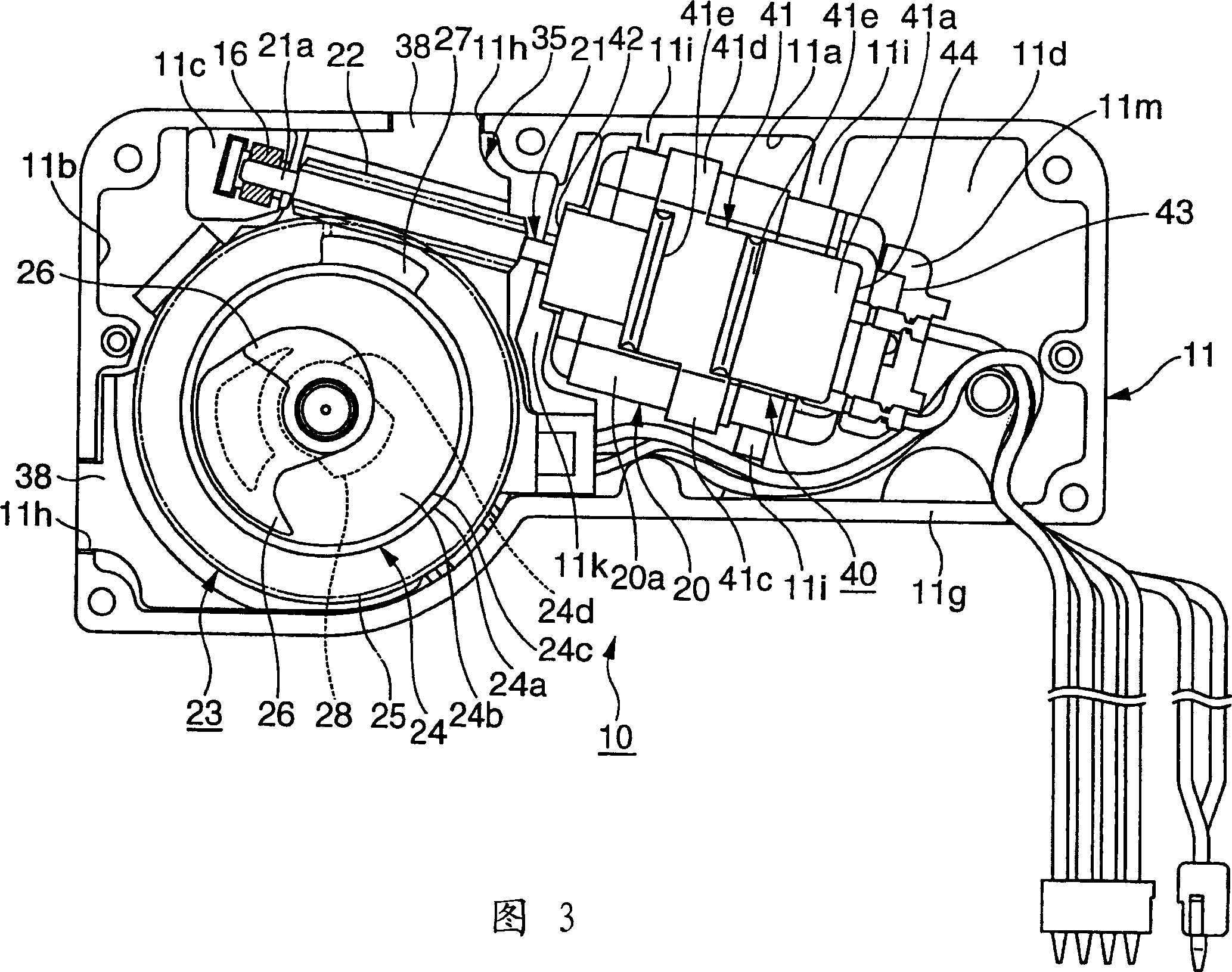

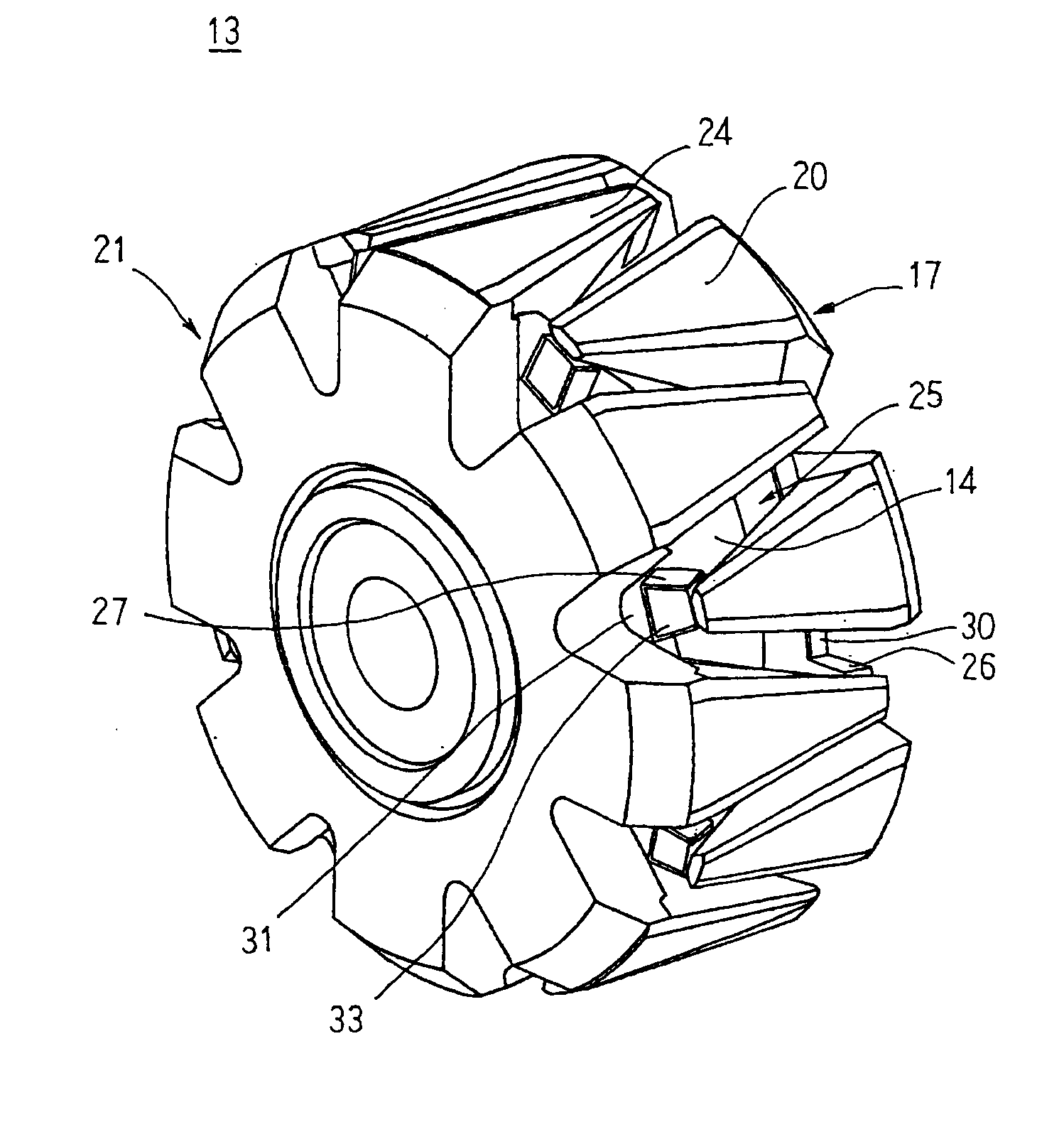

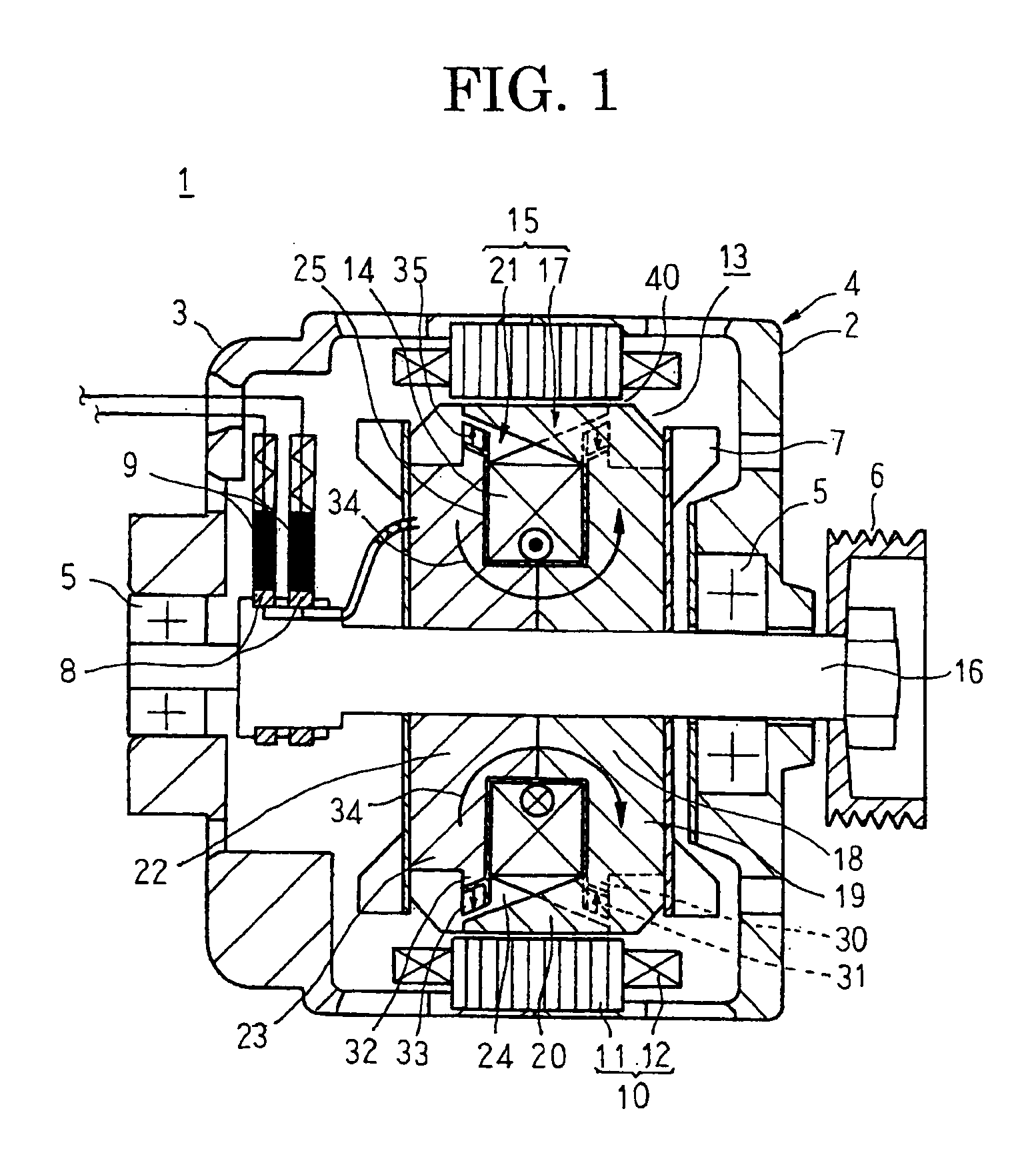

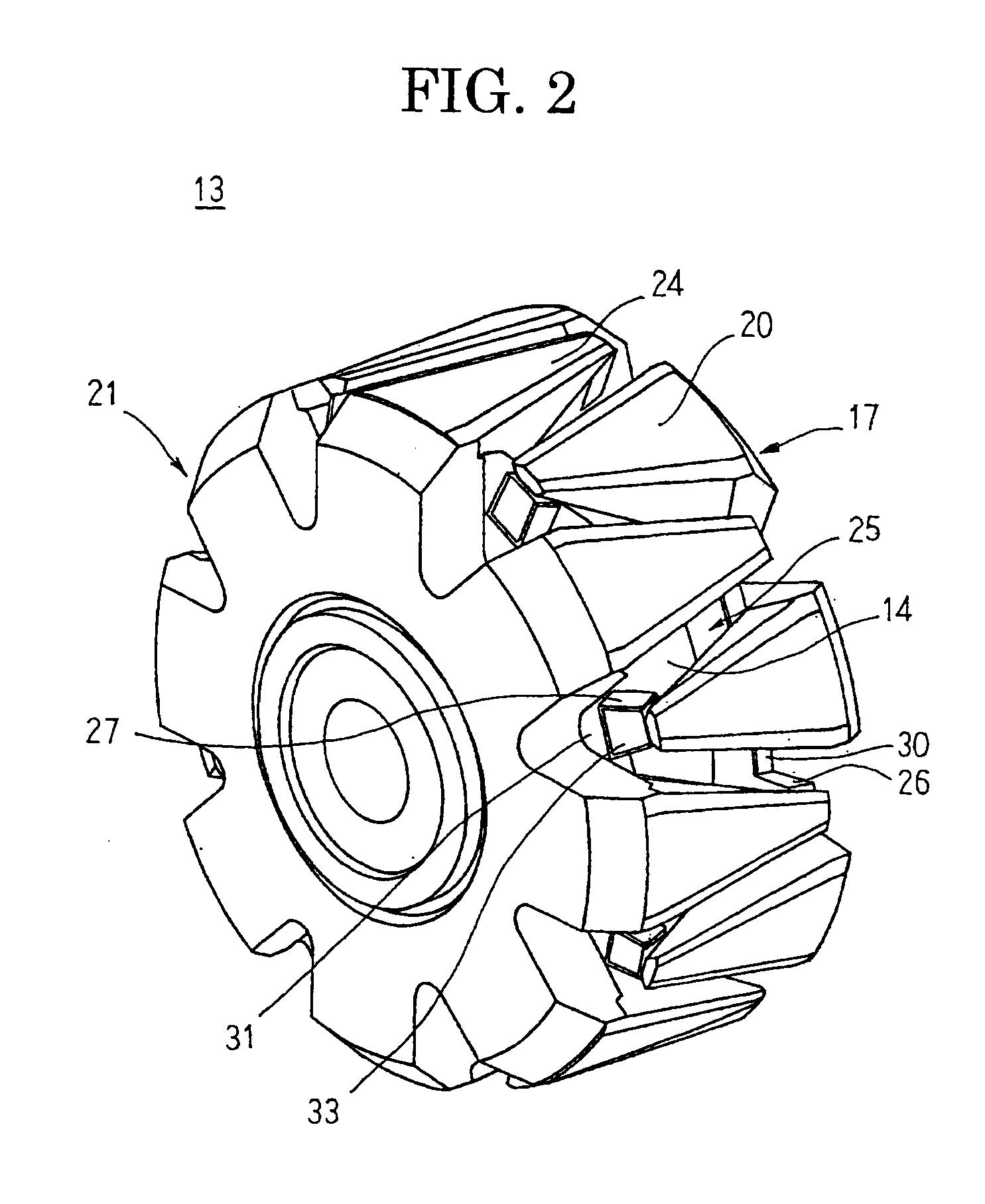

Electromagnetic starter switch

ActiveUS7038564B1Reduce assembly man-hoursPower operated startersEngine controllersElectric machinePinion

An electromagnetic starter switch in which a voltage from a power source is depressed by a resistor and applied to a motor by an auxiliary movable contact coming into contact with a first auxiliary fixed contact and a second auxiliary fixed contact before a pinion gear intermeshes with a ring gear, and the voltage from the power source is subsequently applied to the motor without modification by the main movable contact also coming into contact with a first main fixed contact and a second main fixed contact after the pinion gear intermeshes with the ring gear, wherein: the first main fixed contact, the second main fixed contact, the first auxiliary fixed contact, and the second auxiliary fixed contact are disposed on a main switch cover.

Owner:MITSUBISHI ELECTRIC CORP

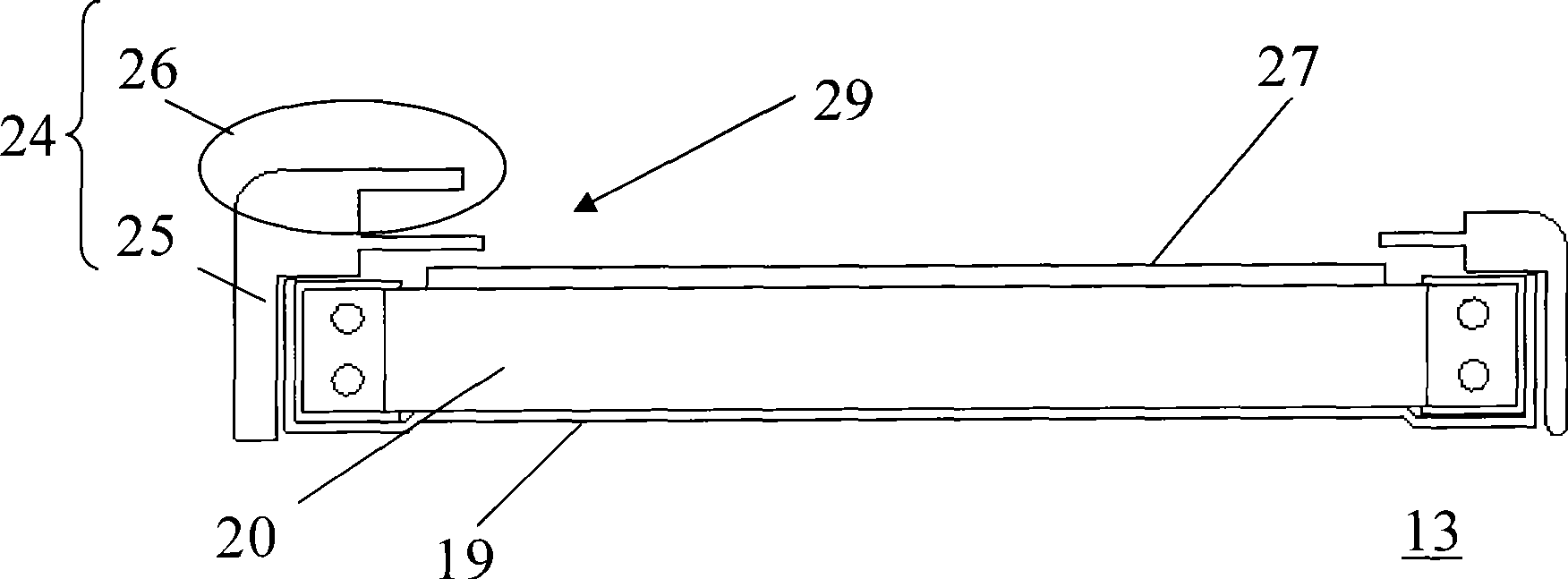

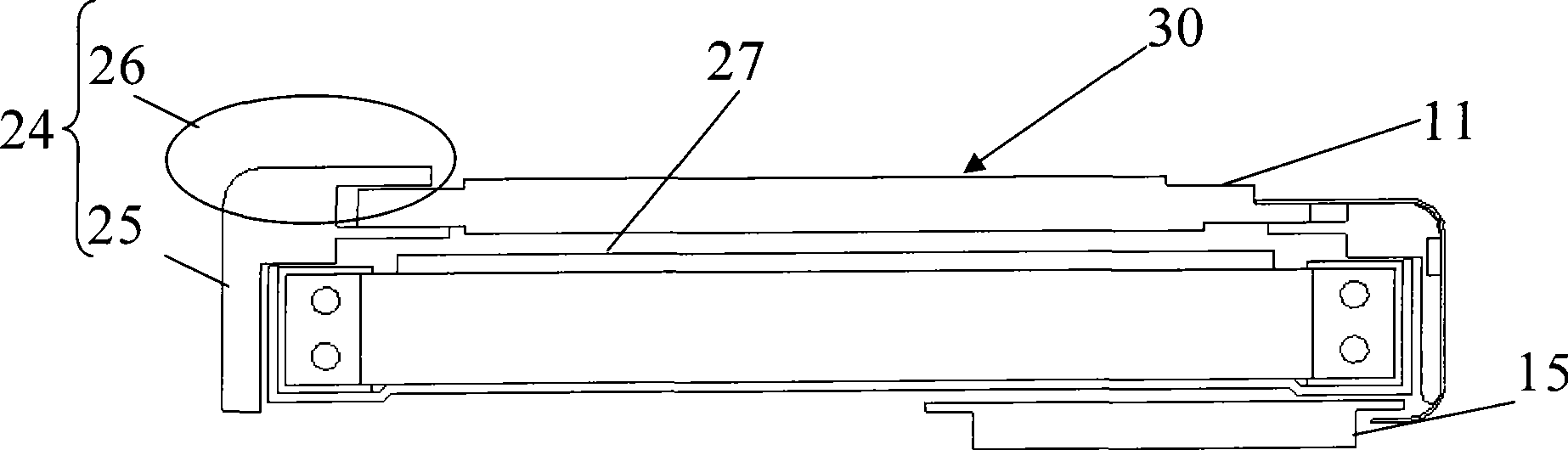

Radio communication device

InactiveCN101431175AImprove functionalityEnhance the ability to send and receive signalsAntenna supports/mountingsRadiating elements structural formsProtection layerCommunication device

A wireless communication device comprises a shell body and an antenna unit. The antenna unit is arranged on the outer surface or the inner surface of the shell body, a protective layer can be selectively covered on the outer surface of the antenna unit, and the protective layer can cover part of the surface of the shell body. Therefore, the antenna which is not arranged on a circuit board can not only save the circuit layout area on the circuit board, but also use the saved layout area as other purposes, and the antenna unit is formed at the shell body, thereby enhancing the effectiveness of transceiving signals of the wireless communication device.

Owner:DELTA ELECTRONICS INC

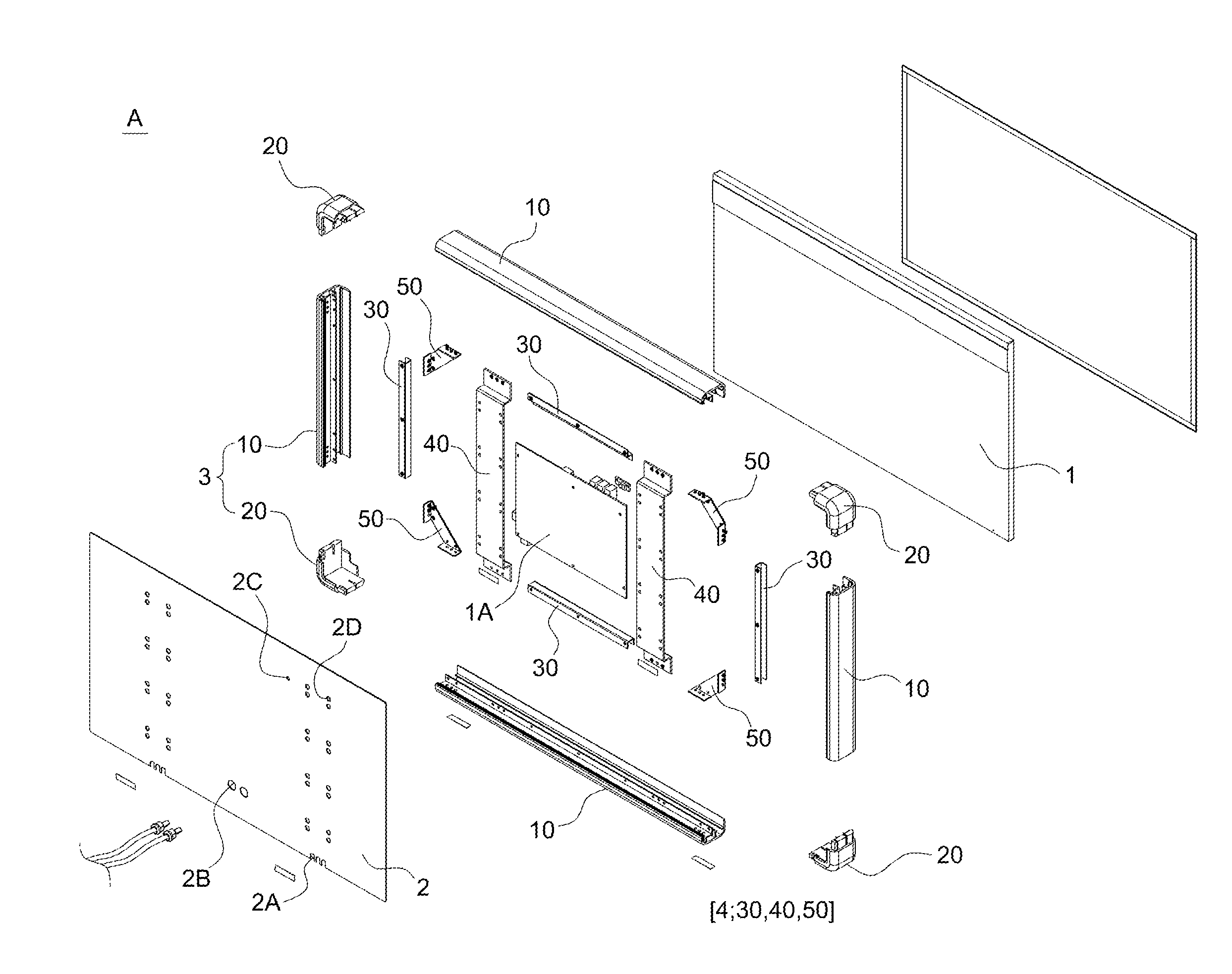

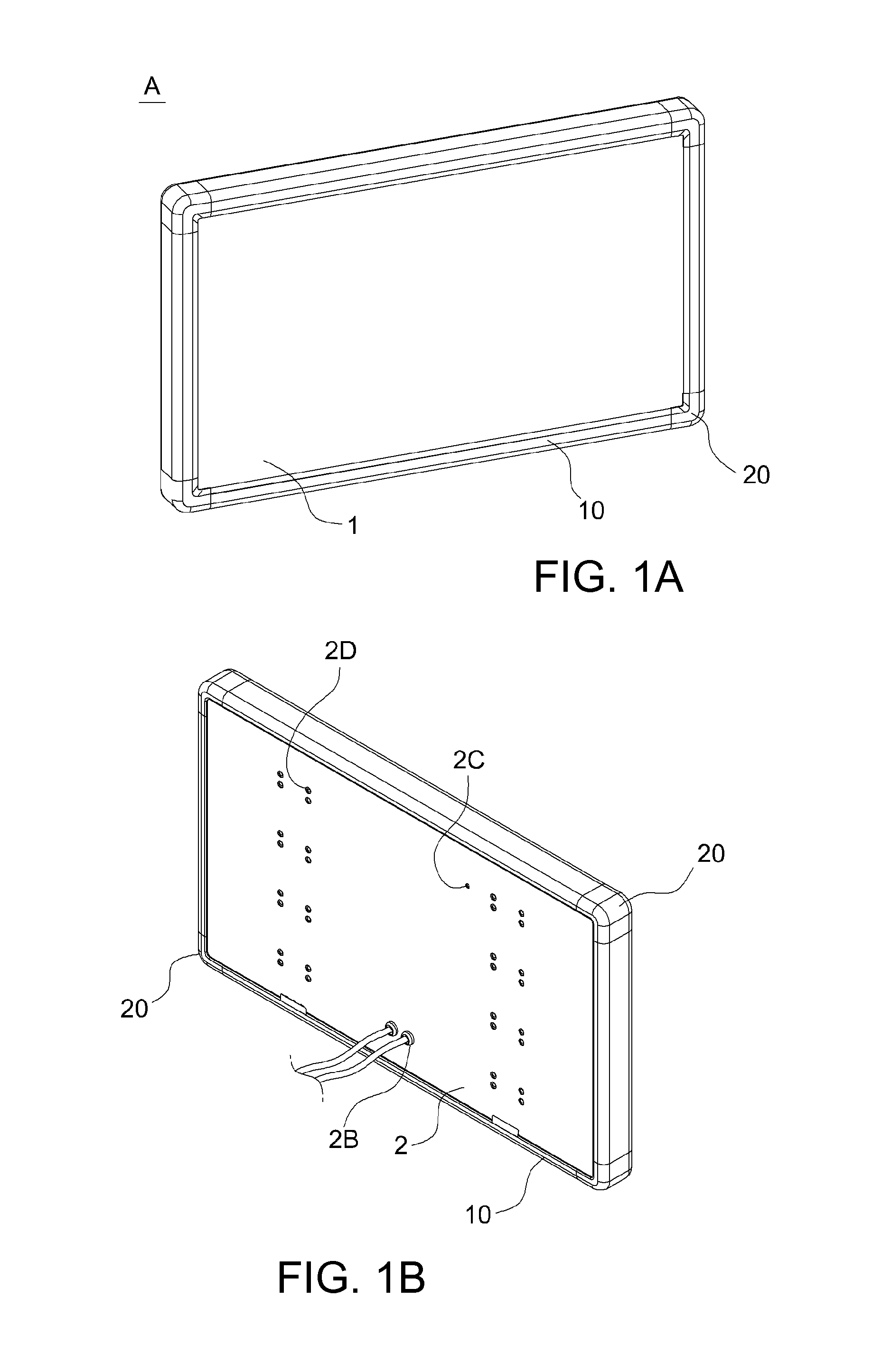

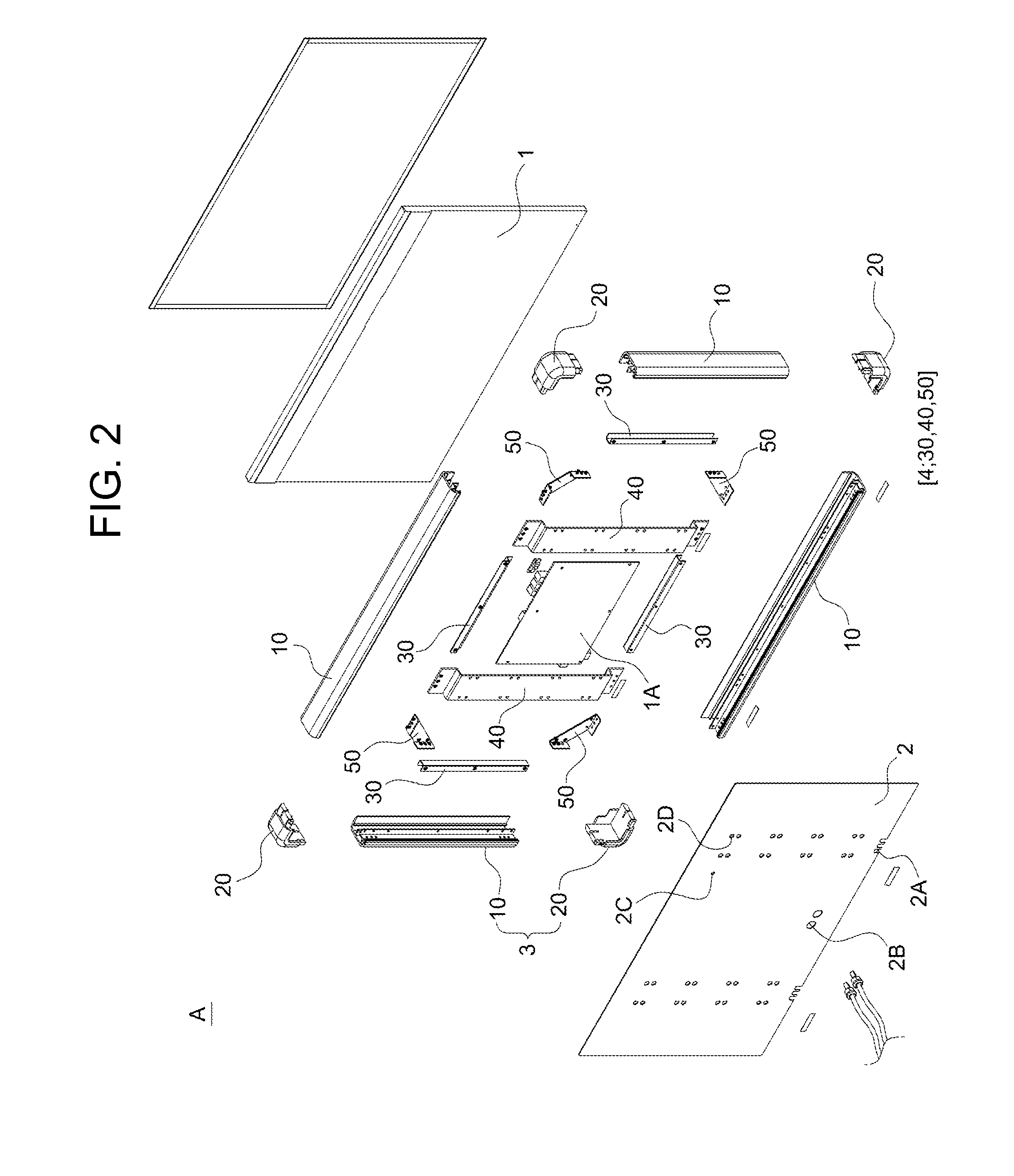

Frame assembly for display panel

ActiveUS20140208626A1Damage to housingReliable couplingPicture framesDomestic mirrorsEngineeringElectrical and Electronics engineering

Disclosed herein is a frame assembly for a display panel. The frame assembly includes a display panel, a rear cover, a housing and an assembling means. The housing includes a plurality of frames which enclose the display panel and the rear cover. Each frame has a sidewall, and a connection member which connects the frames to each other. The assembling means is installed in the housing to provide a closed structure and is provided to ensure coupling force among the display panel, the rear cover and the housing. The assembling means includes a fastening bracket which presses the display panel onto the frames of the housing and fastens the display panel to the frames, a support bracket which supports the rear cover, and an auxiliary bracket which assists connection between the adjacent frames.

Owner:JSLCD

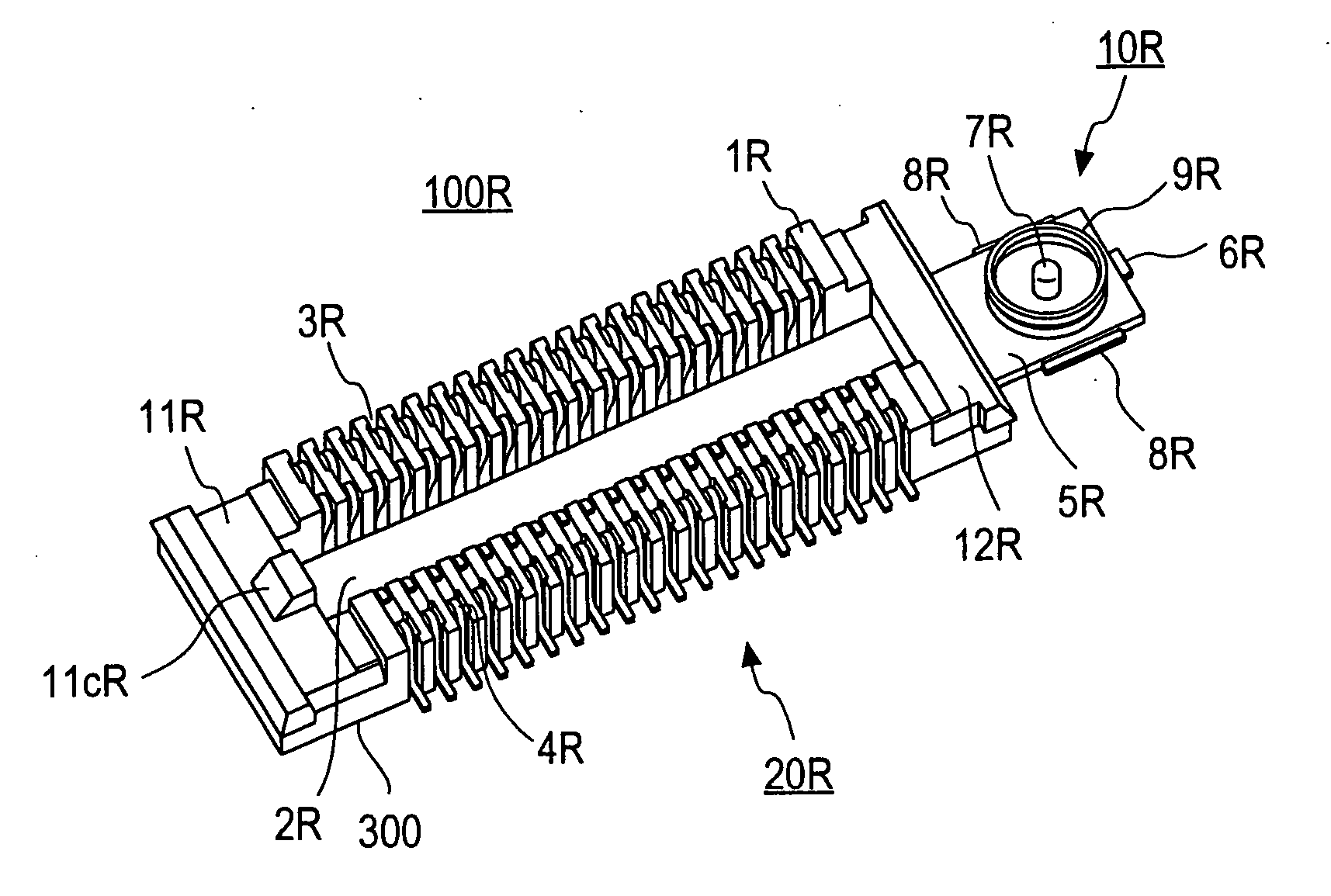

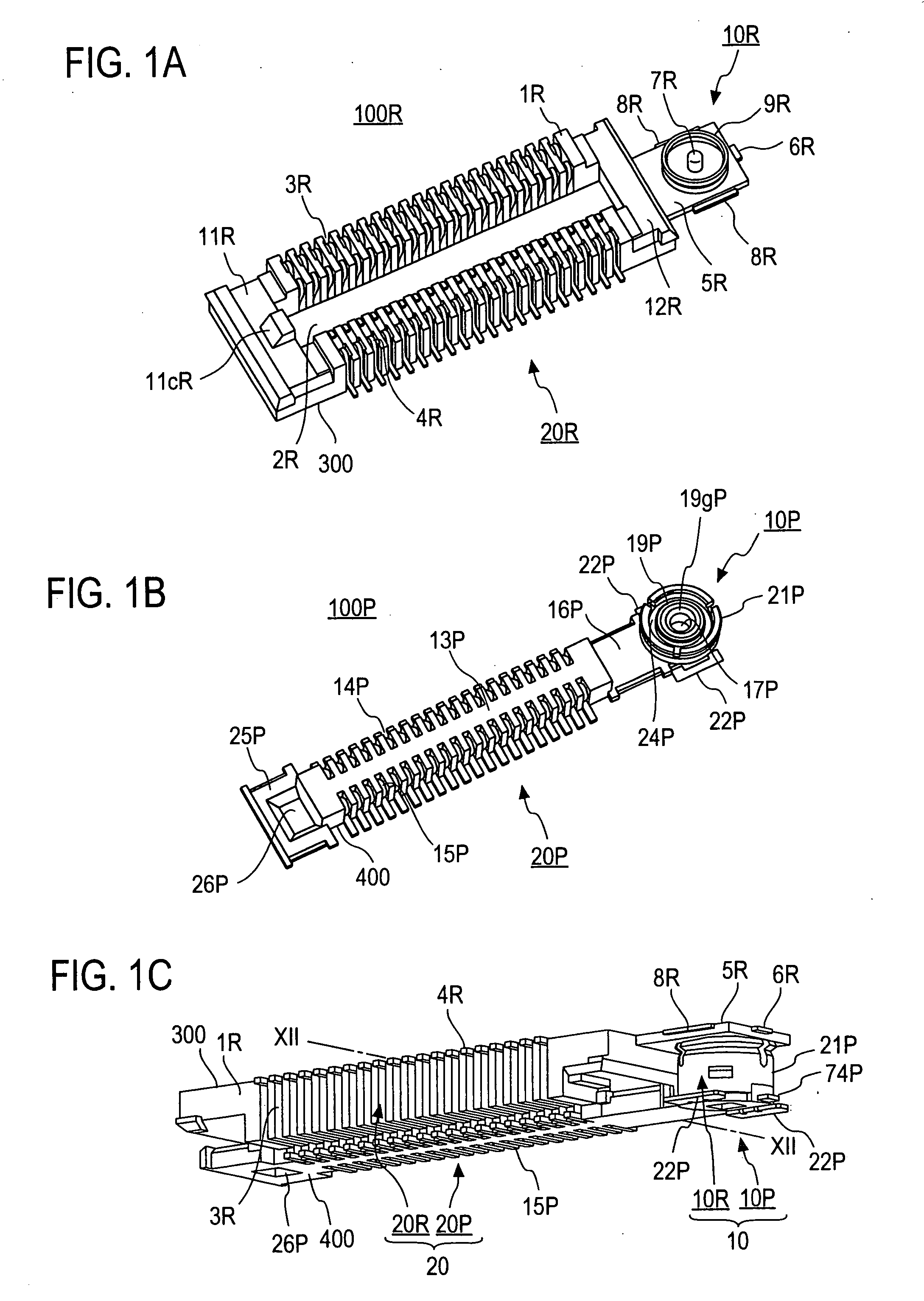

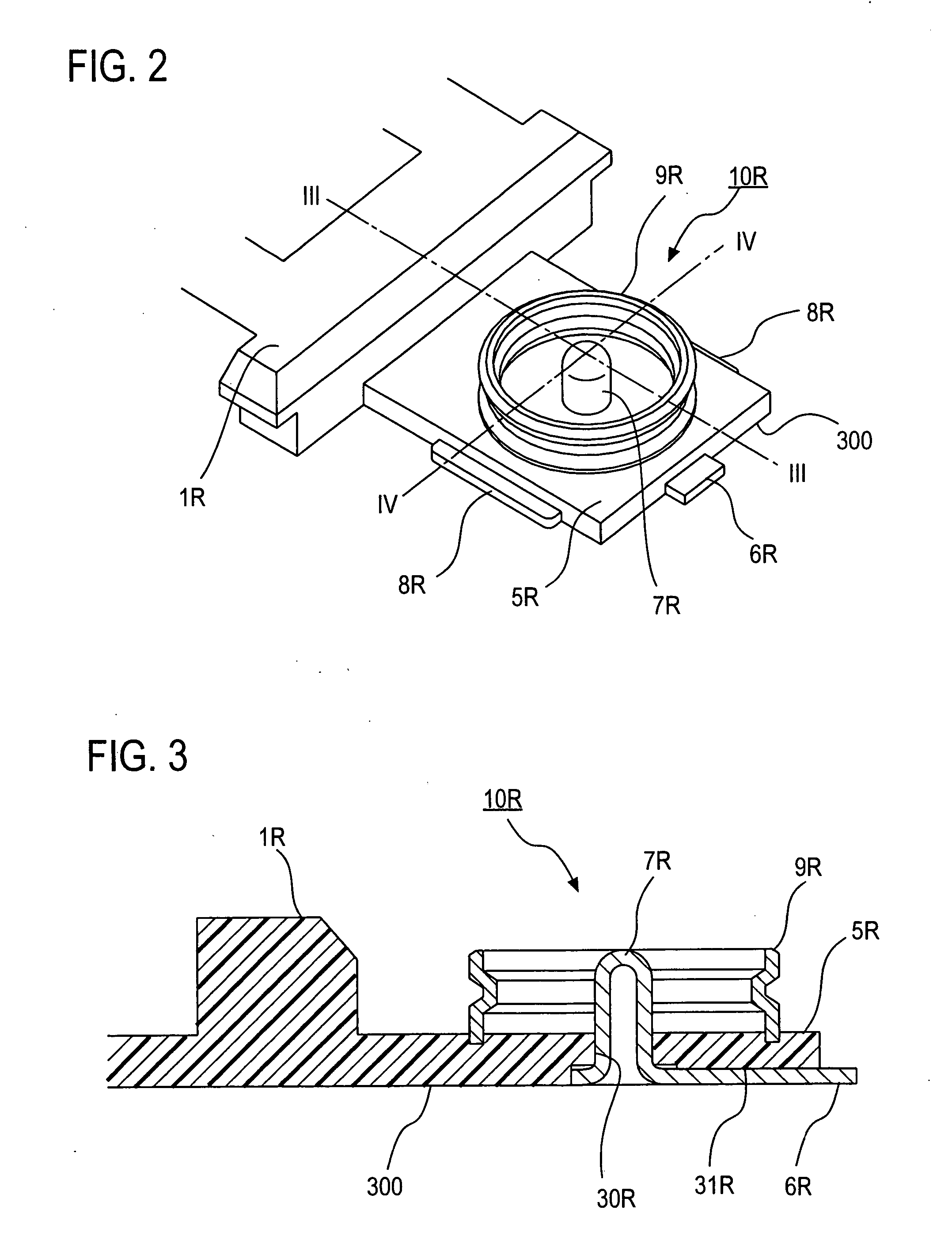

Coaxial connector integrated connector for board connection

InactiveUS20060141811A1Reduce assembly man-hoursLow costElectrically conductive connectionsTwo pole connectionsCharacteristic impedanceMechanical engineering

By forming a coaxial receptacle and a coaxial plug, for which the characteristic impedances have been adjusted, at the respective end portions of a receptacle-side insulating housing and a plug-side body constituting a multi-connector being a parallel connector part, a transmission line has been made possible in which a multi-connector is mated and the signals passing through the coaxial connector at the same time exhibit little reflection and radiation.

Owner:HOSIDEN CORP

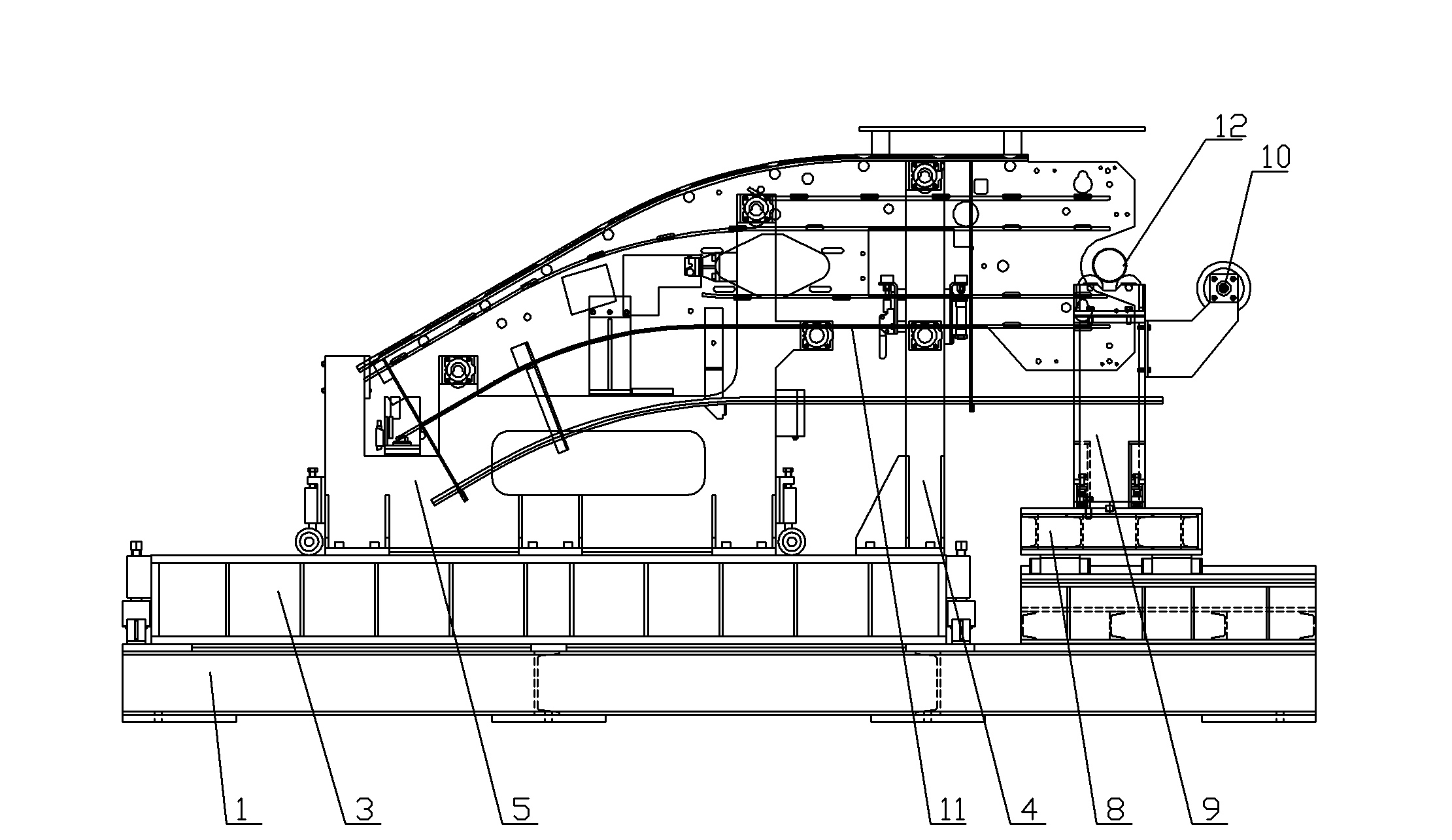

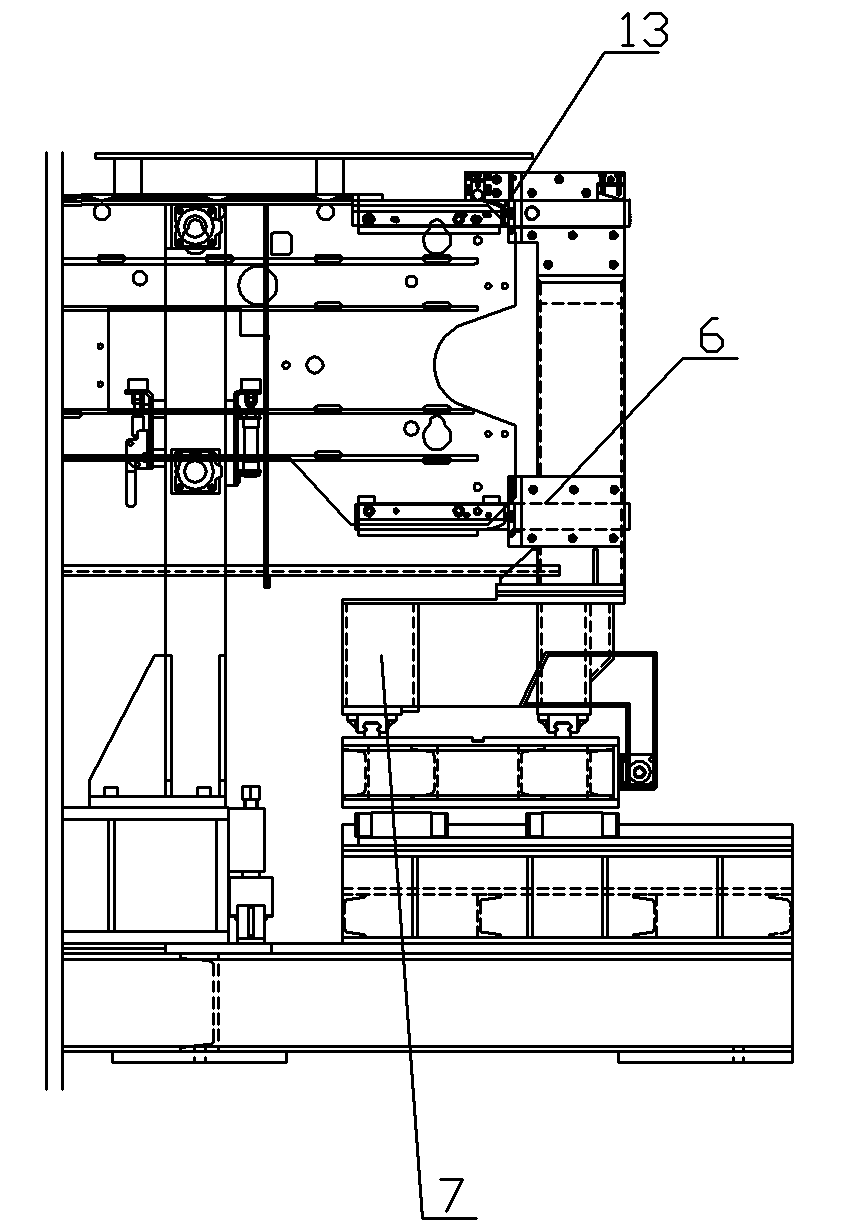

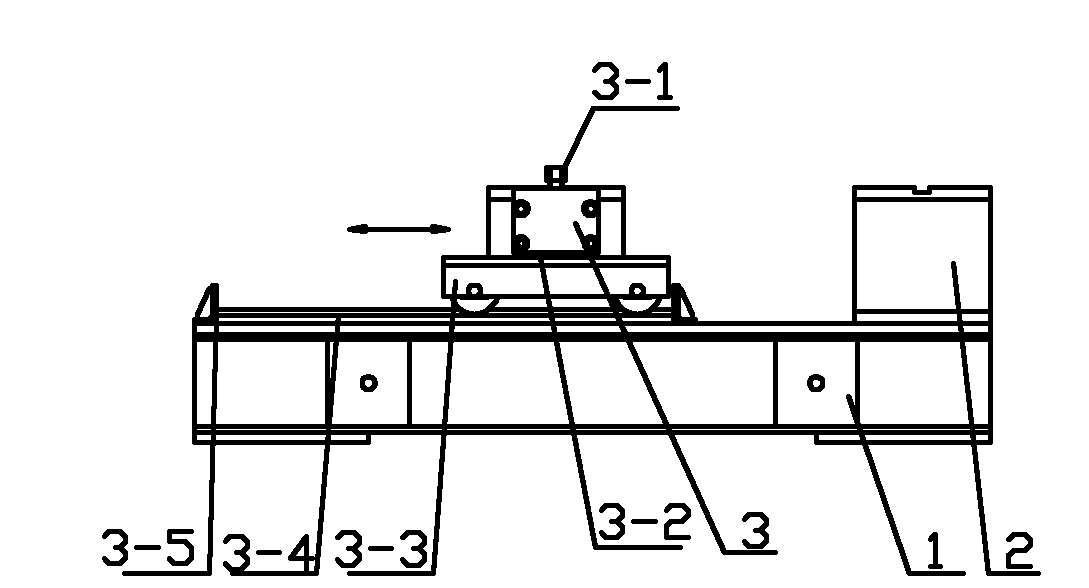

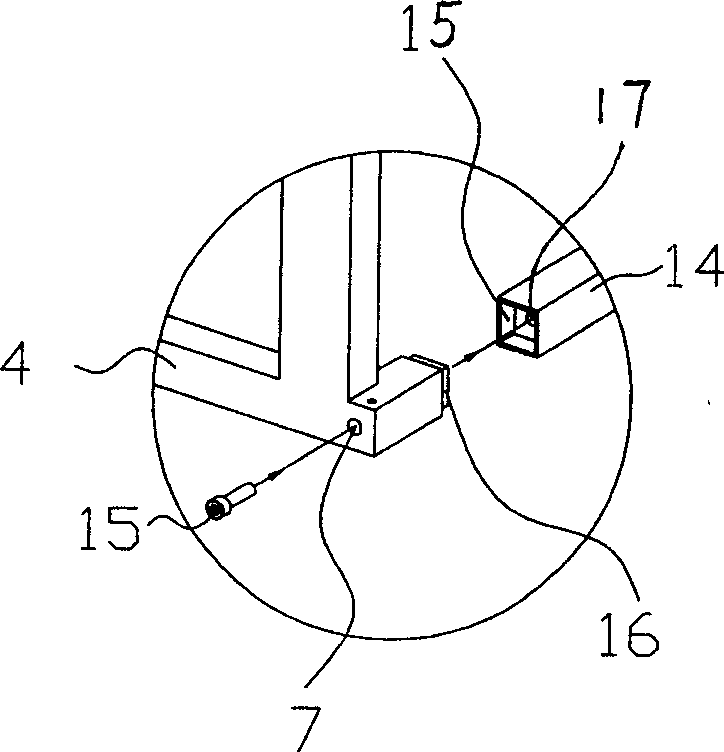

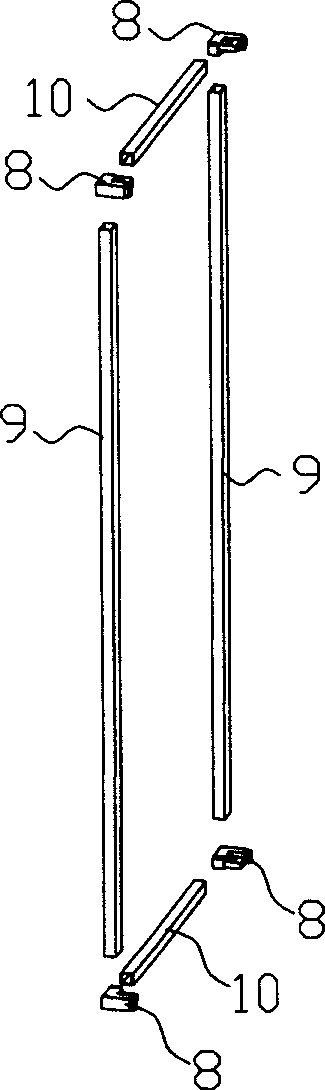

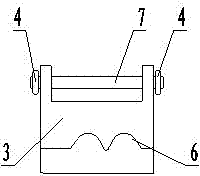

Assembly tooling for double assembly and main drive of head side plate on staircase and assembly method

ActiveCN102632382AReduce spacingLow costWelding/cutting auxillary devicesAssembly machinesAssembly lineEngineering

The invention discloses an assembly tooling for the double assembly and the main drive of a head side plate on a staircase and an assembly method. The tooling comprises a work platform, wherein a fixed reference beam, a beam capable of transversely moving, a main drive lengthways moving dolly are arranged on the work platform, and the two beams are in parallel with each other by moving the beam capable of transversely moving; and a positioning stand column and a positioning wall plate capable of lengthways moving the side plate of the staircase are respectively arranged on the two beams, gaps are remained between the corresponding positioning stand columns and positioning wall plates, and the corresponding positioning wall plates can respectively move along the beams, so that the distances between the corresponding positioning wall plates and the corresponding positioning stand columns are changed; a pair of tangential guide rail arranging seat transverse moving trolleys are distributed on the main drive lengthways moving dolly, and the tangential guide rail is transported to the installing position of the tangential guide rail on the side plate by the dolly; a left / right main drive height positioning device is further arranged on the main drive lengthways moving dolly, and the device is used for positioning the double assembly height position of the center and the side plate of the main drive axis; and a pair of driving axial centering devices is arranged on the main drive height positioning device.

Owner:HANGZHOU XO ELEVATOR

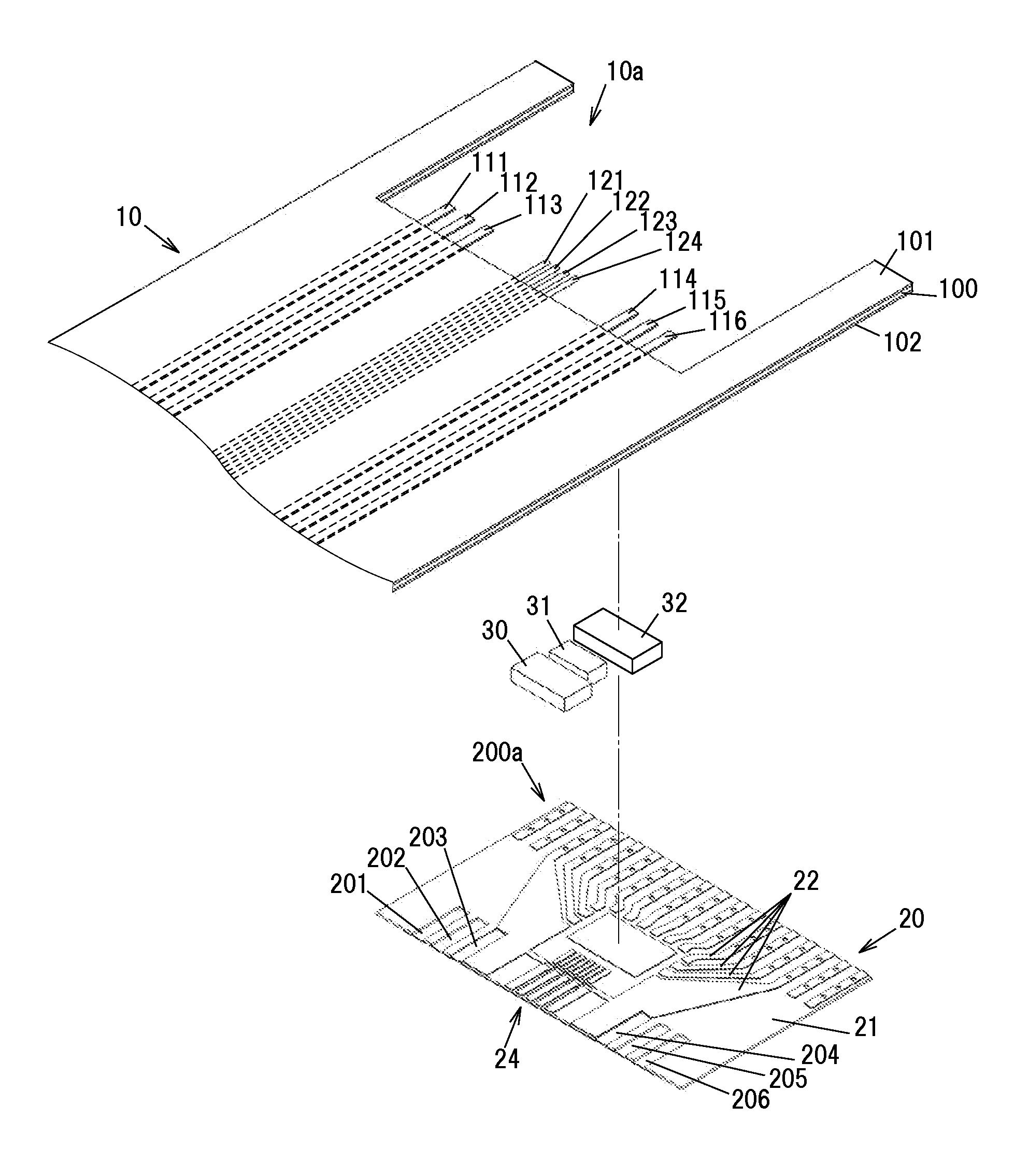

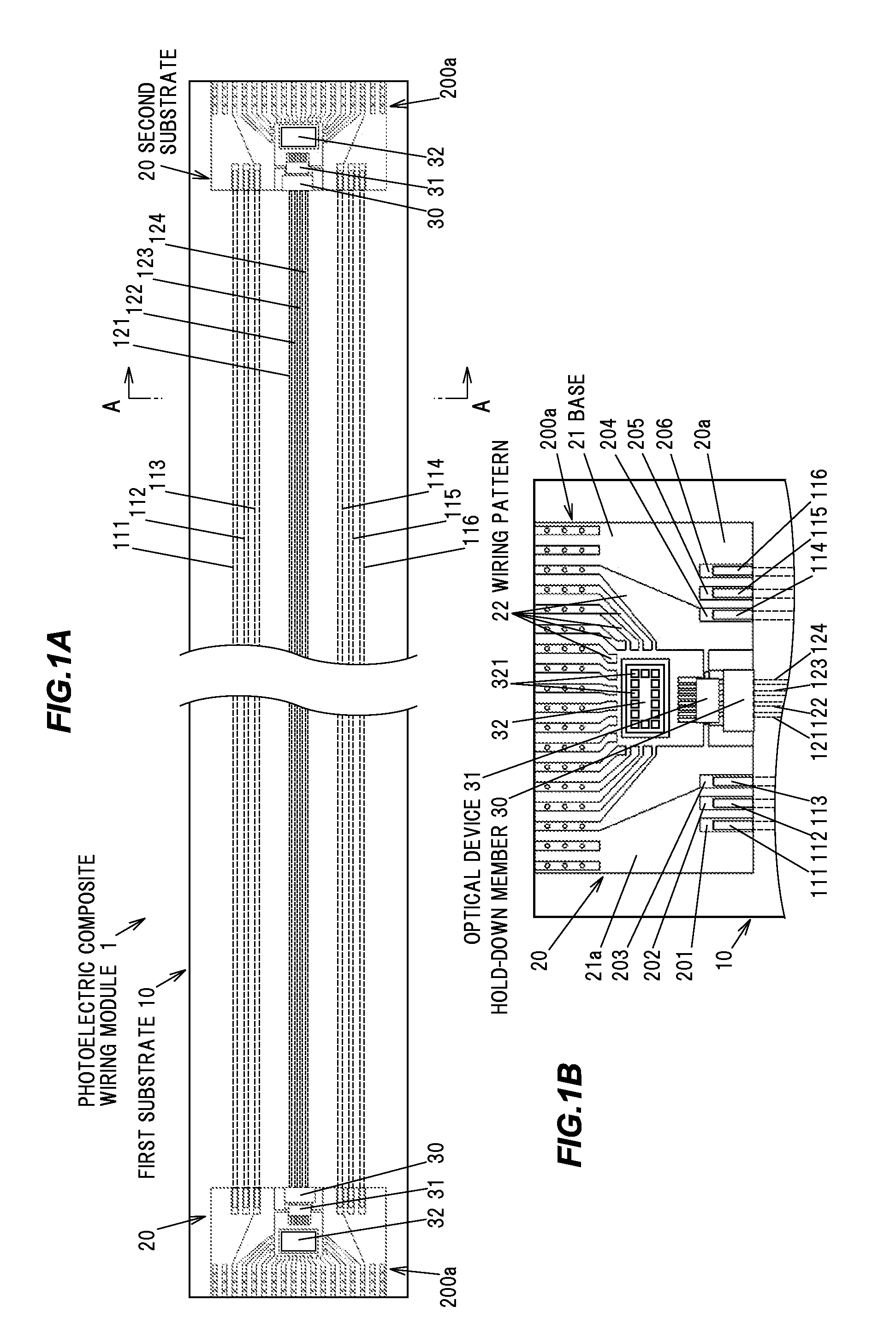

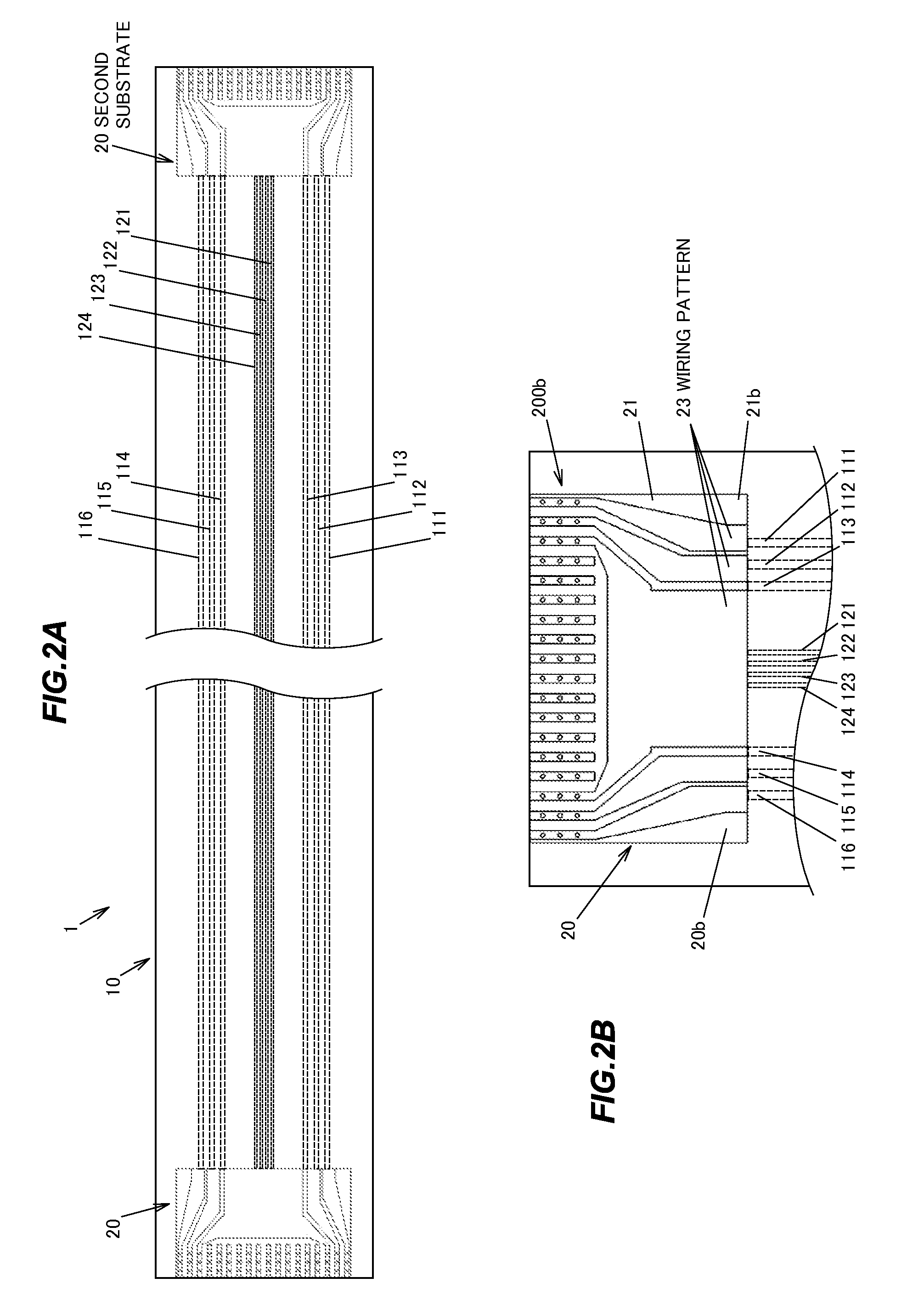

Photoelectric composite wiring module

InactiveUS20130209027A1Increase man-hoursIncreased man-hoursTransparent dielectricsCoupling light guidesEngineeringOptical fiber cable

A photoelectric composite wiring module includes a flexible first substrate including a conductive line and an optical fiber mounted thereon along a longitudinal direction thereof, a second substrate including a recessed portion formed thereon to receive the conductive line and the optical fiber that protrude from an end portion of the first substrate, and an optical device mounted on the second substrate and optically coupled to the optical fiber. The recessed portion includes an opening on a mounting surface side of the second substrate to mount the optical device.

Owner:HITACHI METALS LTD

Lower vehicle-body structure of vehicle

InactiveCN102343939AReduce in quantityReduce assembly man-hoursUnderstructuresVehicle frameEngineering

Owner:MAZDA MOTOR CORP

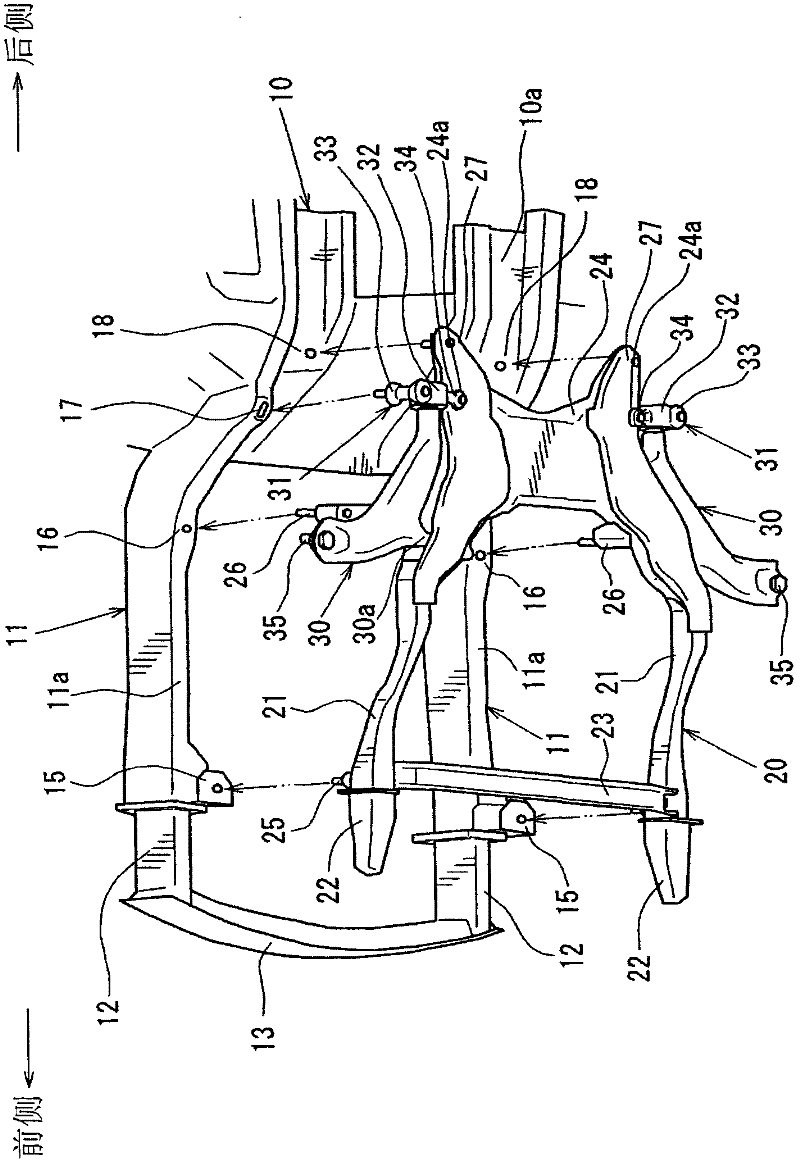

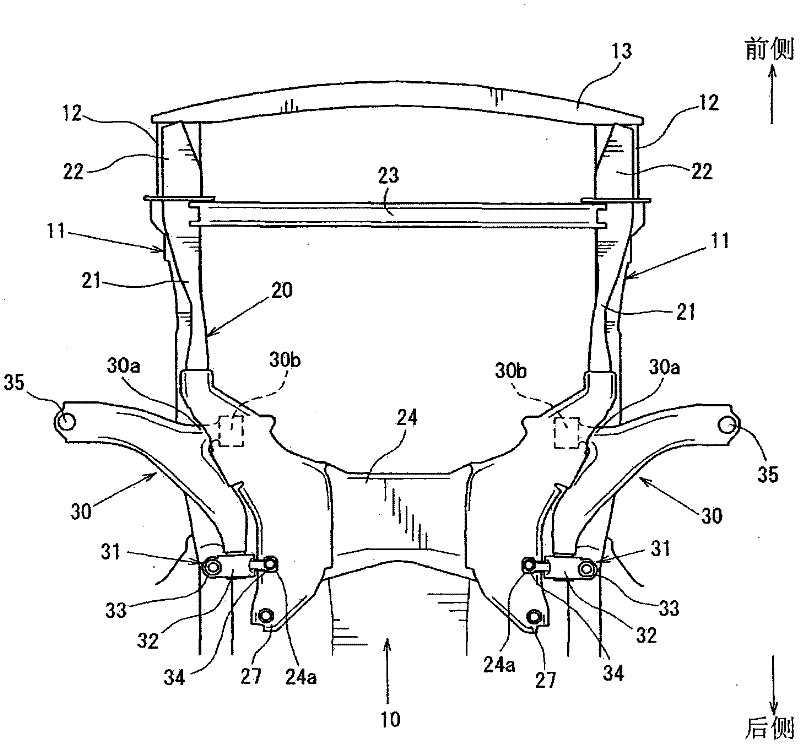

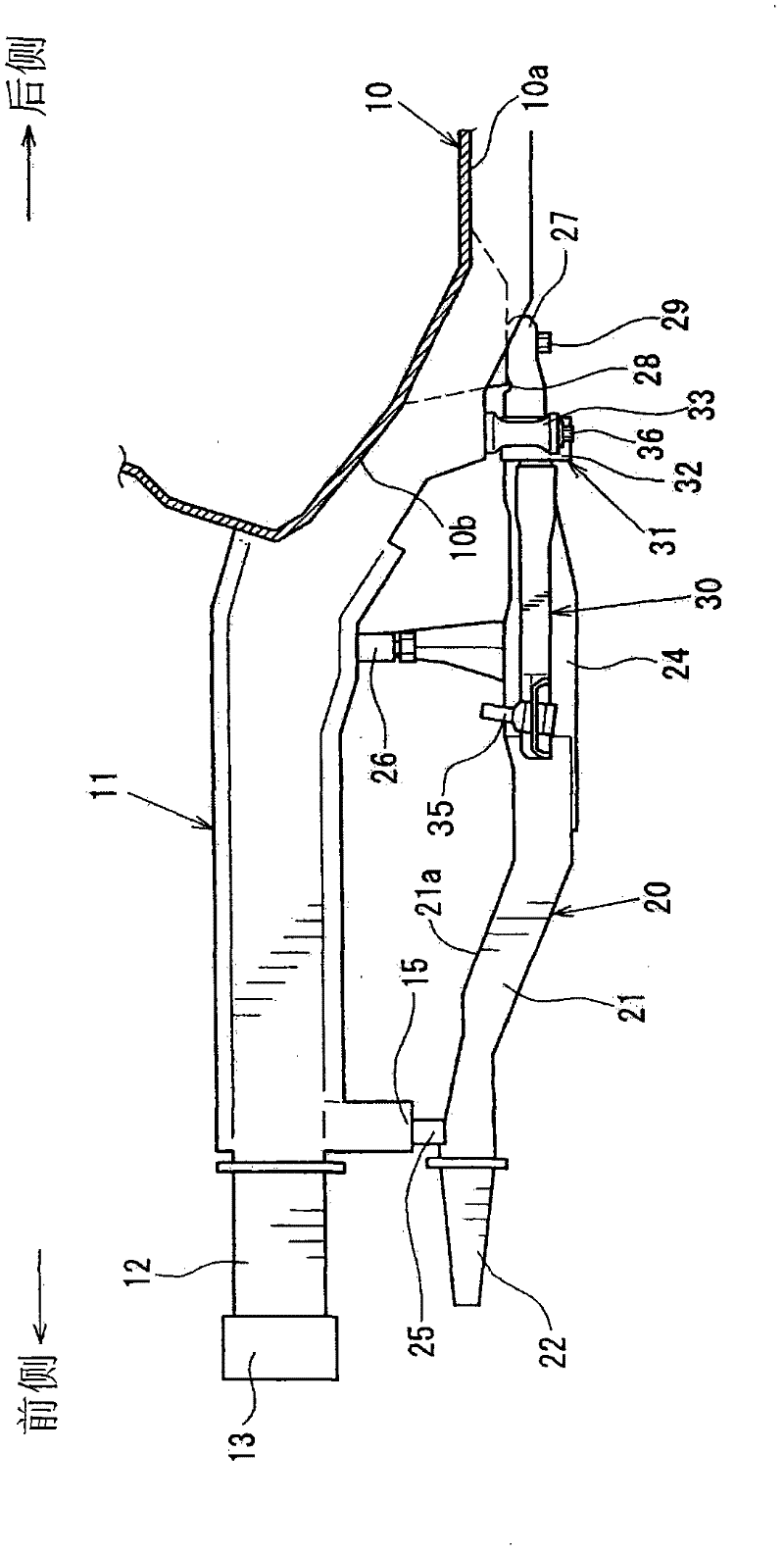

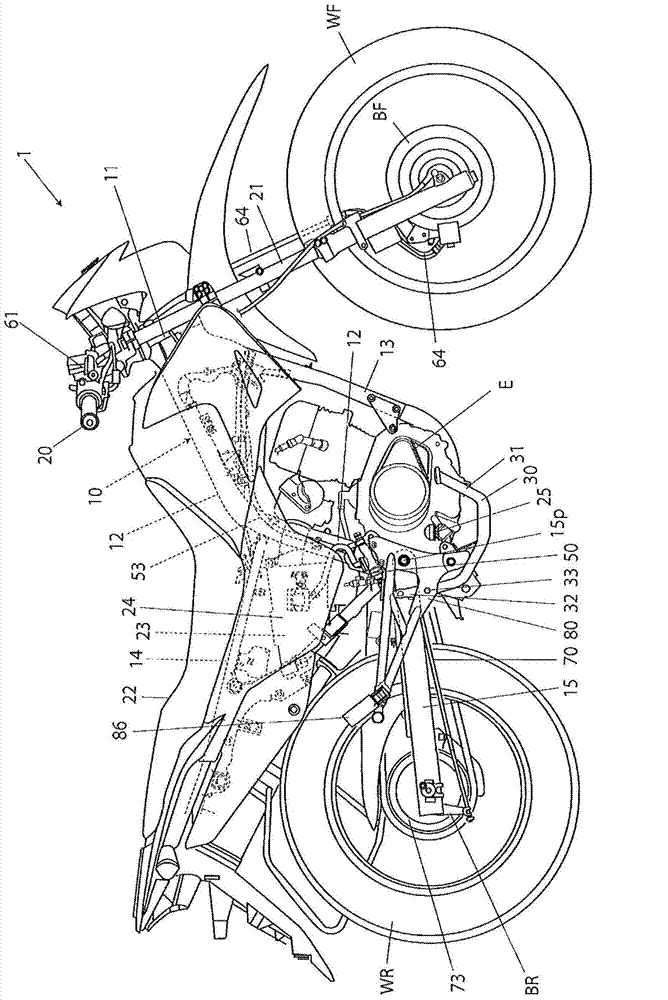

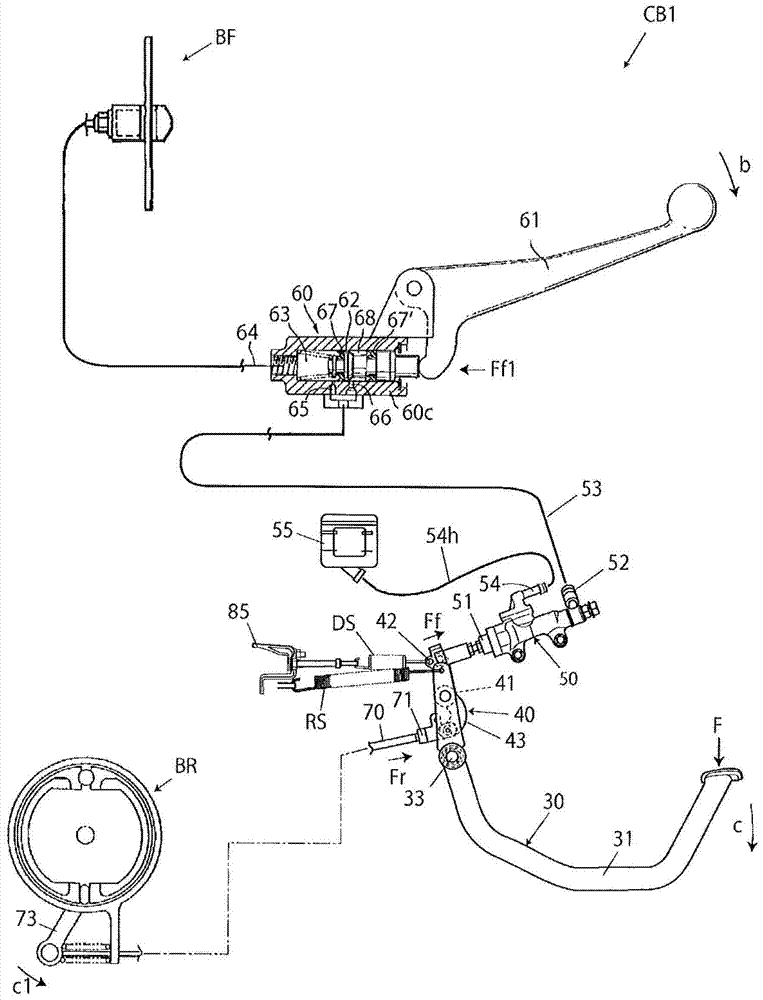

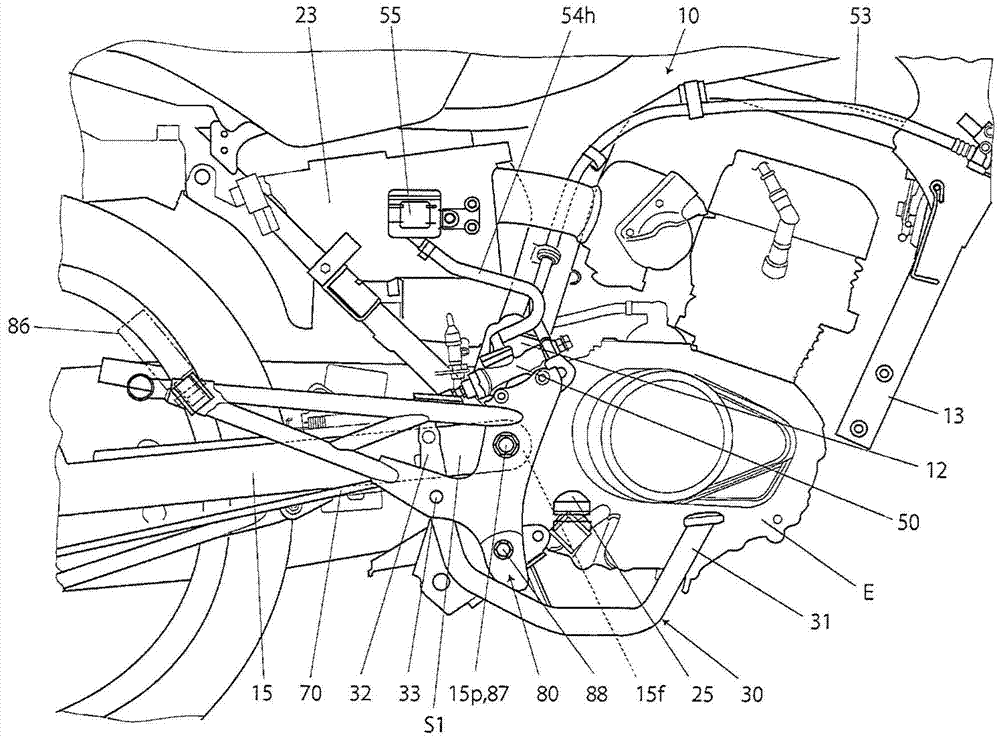

Interlocking brake equipment of saddle form vehicle

ActiveCN103693152AConfiguration impactInhibition effectCycle brakesHydraulic cylinderTransmitted power

The present invention relates to an interlocking brake equipment of a saddle form vehicle, which can properly ensure the rate of a transmitting power forced or transmitting distance of an equalizer relative to an operating force or distance of a brake pedal. The interlocking brake equipment of the saddle form vehicle includes the brake pedal (30), a pedal arm (31) that forward extends with relative to a pedal pivot (33), and a transmitting arm (32) that together rotates with the pedal arm (31) and upward extends relative to the pedal pivot (33). The interlocking brake equipment of the saddle form vehicle also includes the equalizer (40) that is connected with the transmitting arm (32) of the brake pedal (30). One end of the equalizer is connected with a rear transmitting unit (70) that transmits operating power to a rear-wheel brake (BR), the other end of the equalizer is connected with a main hydraulic cylinder (50) that receives the operating power from a front wheel brake (BF). During the observation of side-looking, a swing arm (15p) is provided in such a location: the front of the location is surrounded by a power unit (E), and the rear of the location is surrounded by the transmitting arm (32), the upward side of the location is surrounded by the main hydraulic cylinder (50) and the below side of the location is surrounded by pedal arm (31).

Owner:HONDA MOTOR CO LTD

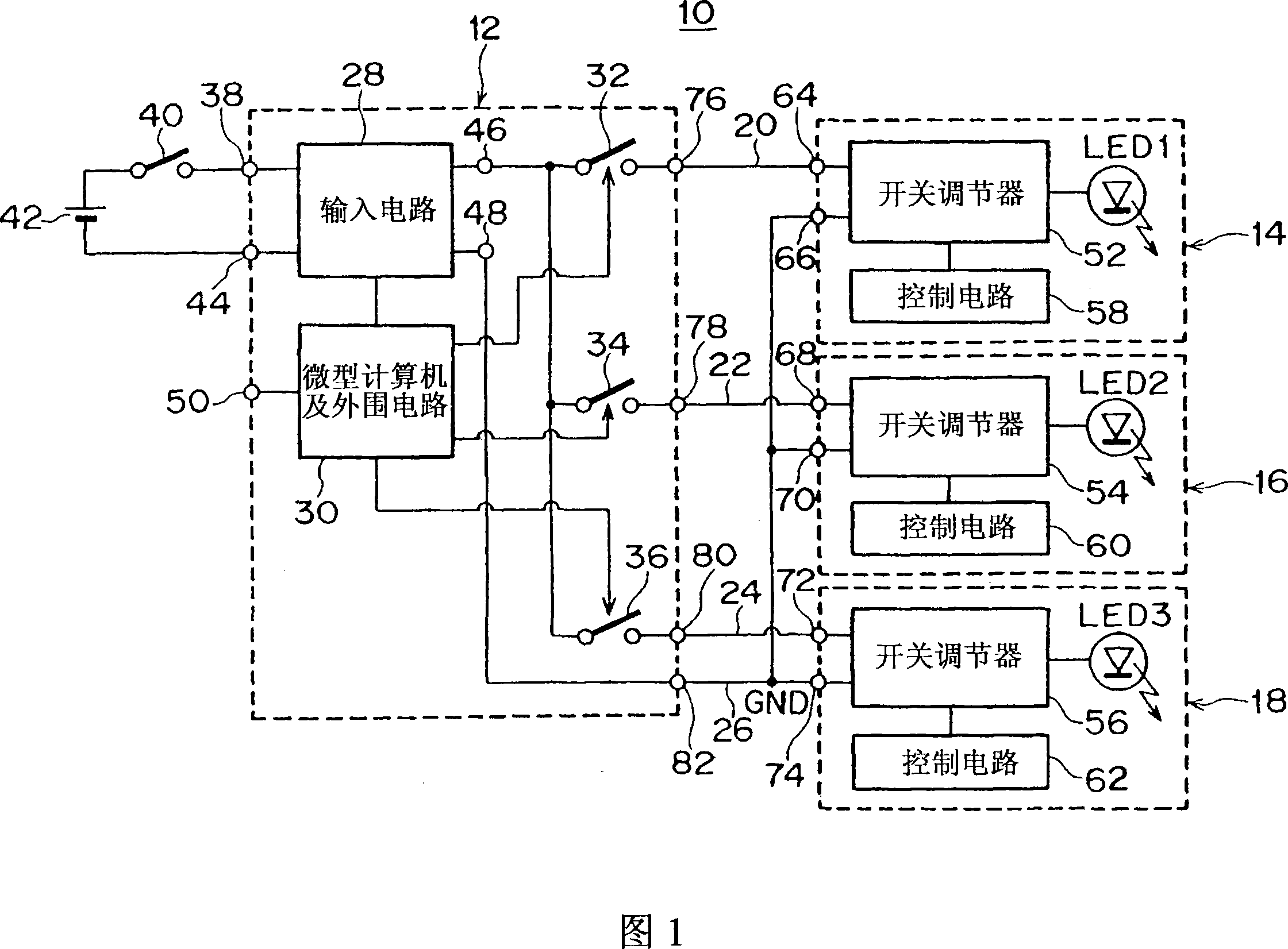

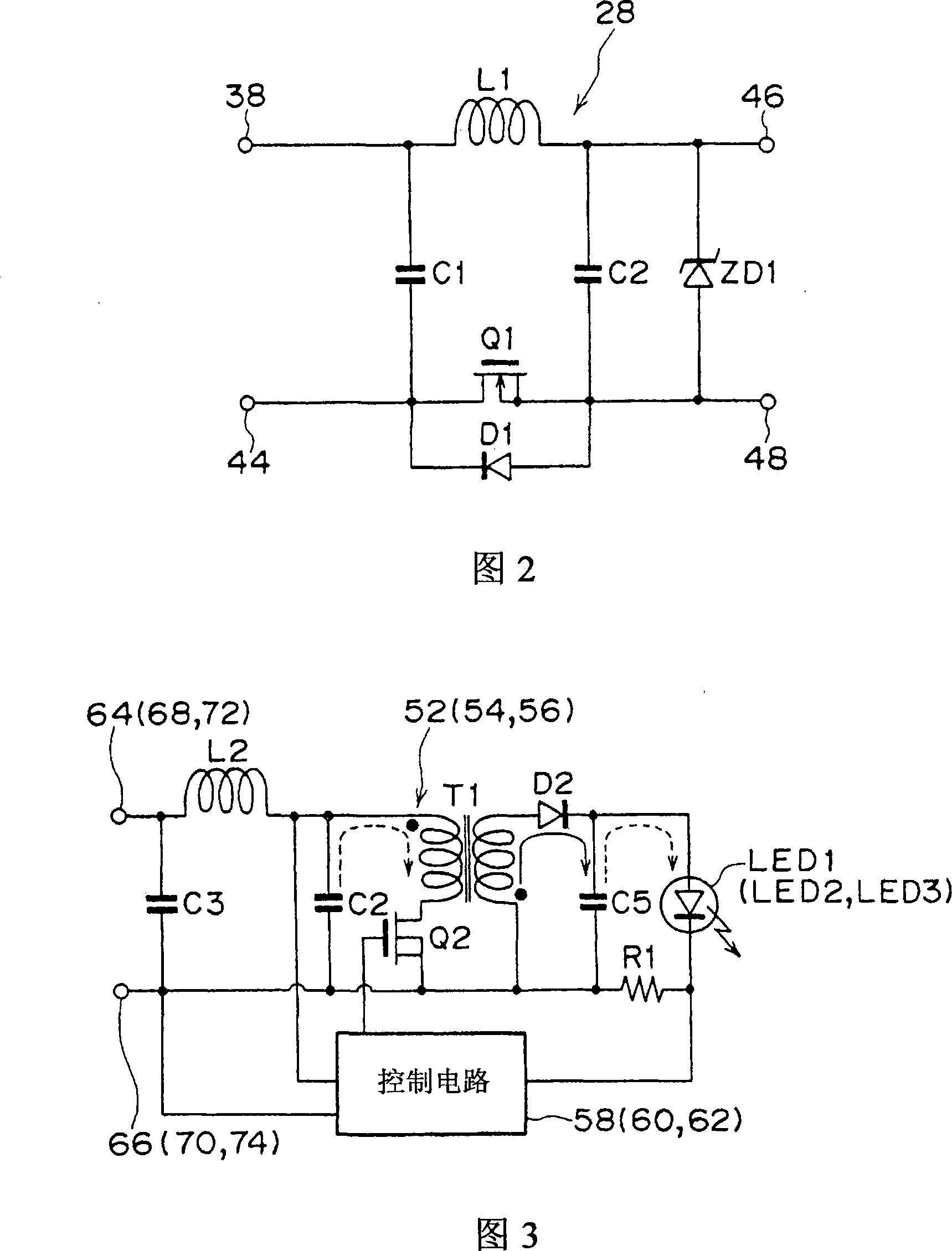

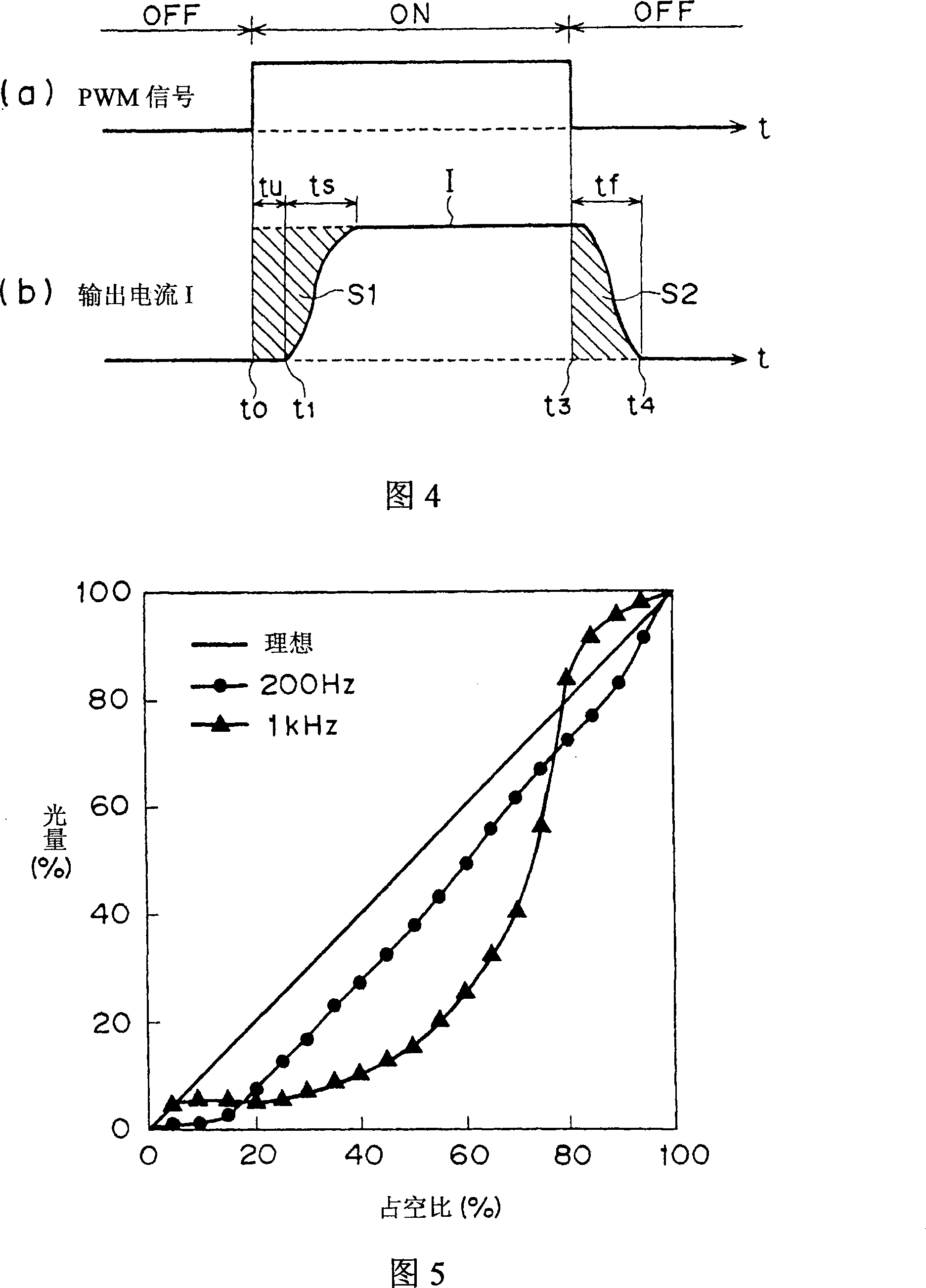

Light emitting device

InactiveCN101247687AReduce assembly man-hoursLow costPoint-like light sourceElectroluminescent light sourcesControl signalEngineering

A light emitting device includes multiple light units each of which includes a semiconductor light source, and a current supply control means for controlling supply of current to the semiconductor light source. A control unit includes a control signal generation means for generating and providing a control signal. The light emitting device also includes switching means for controlling feeding from a DC power source to a corresponding one of the light units in response to the control signal. Each of the switching means is coupled to a corresponding one of the light units through a feed line.

Owner:KOITO MFG CO LTD

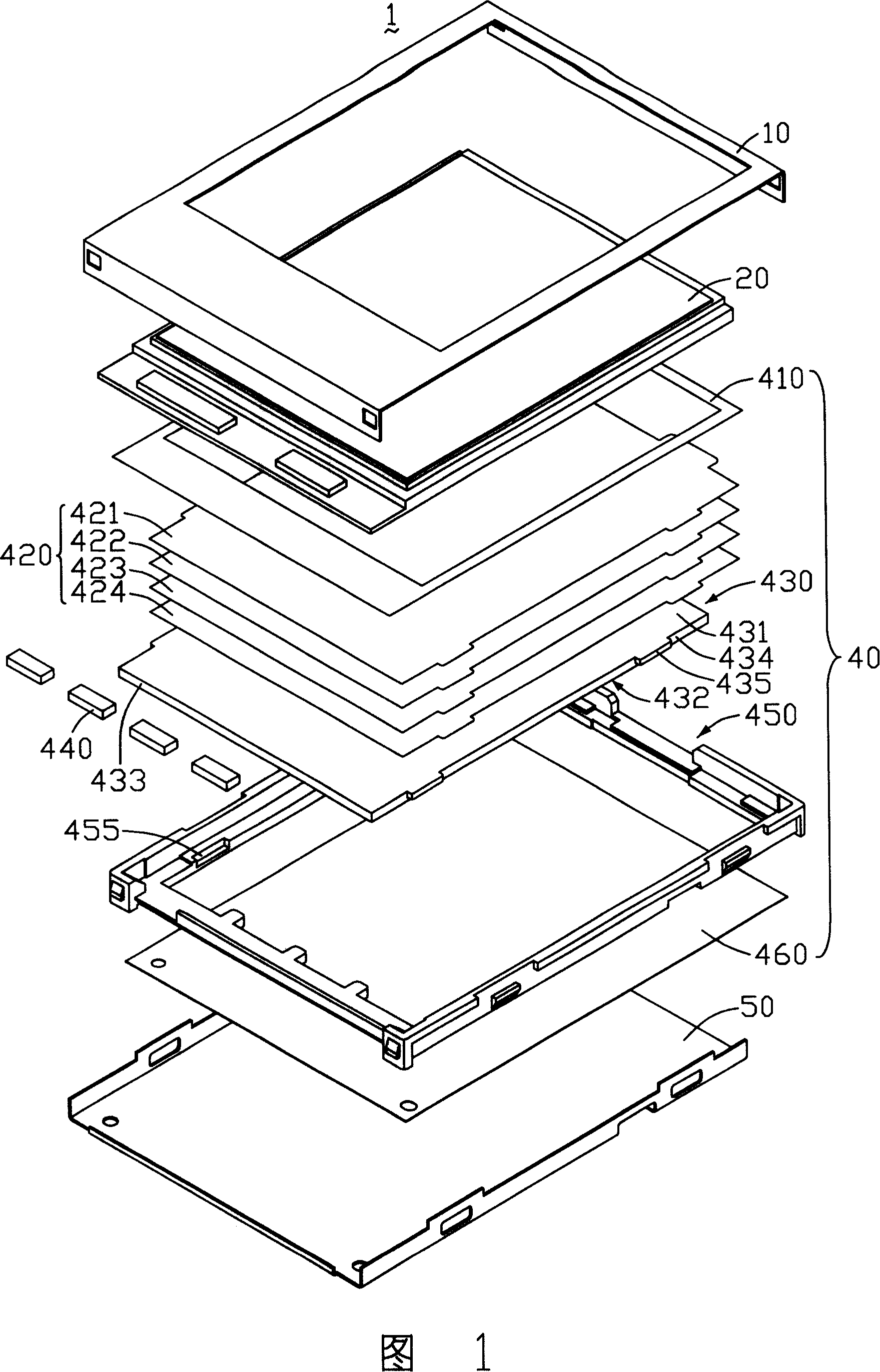

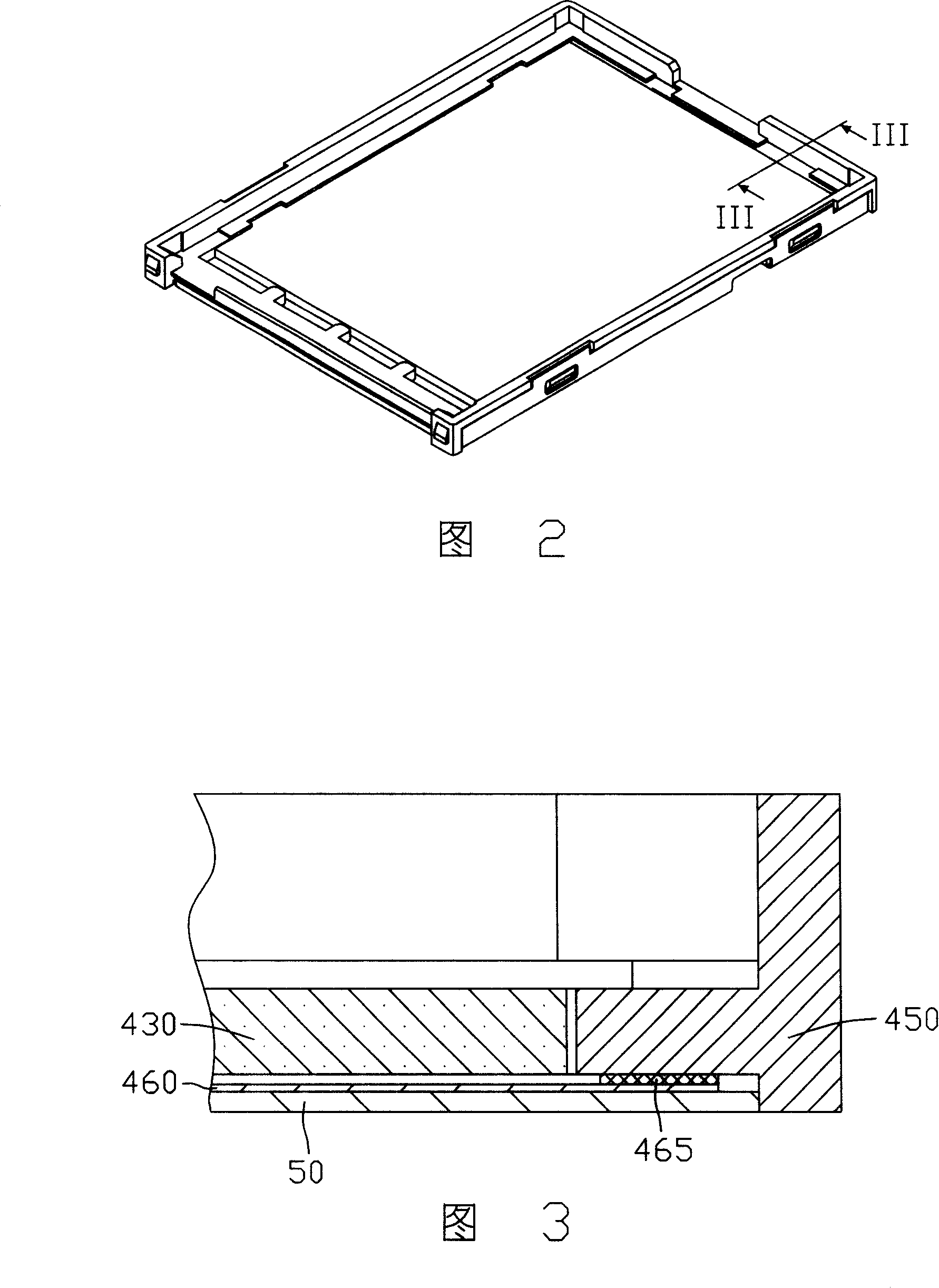

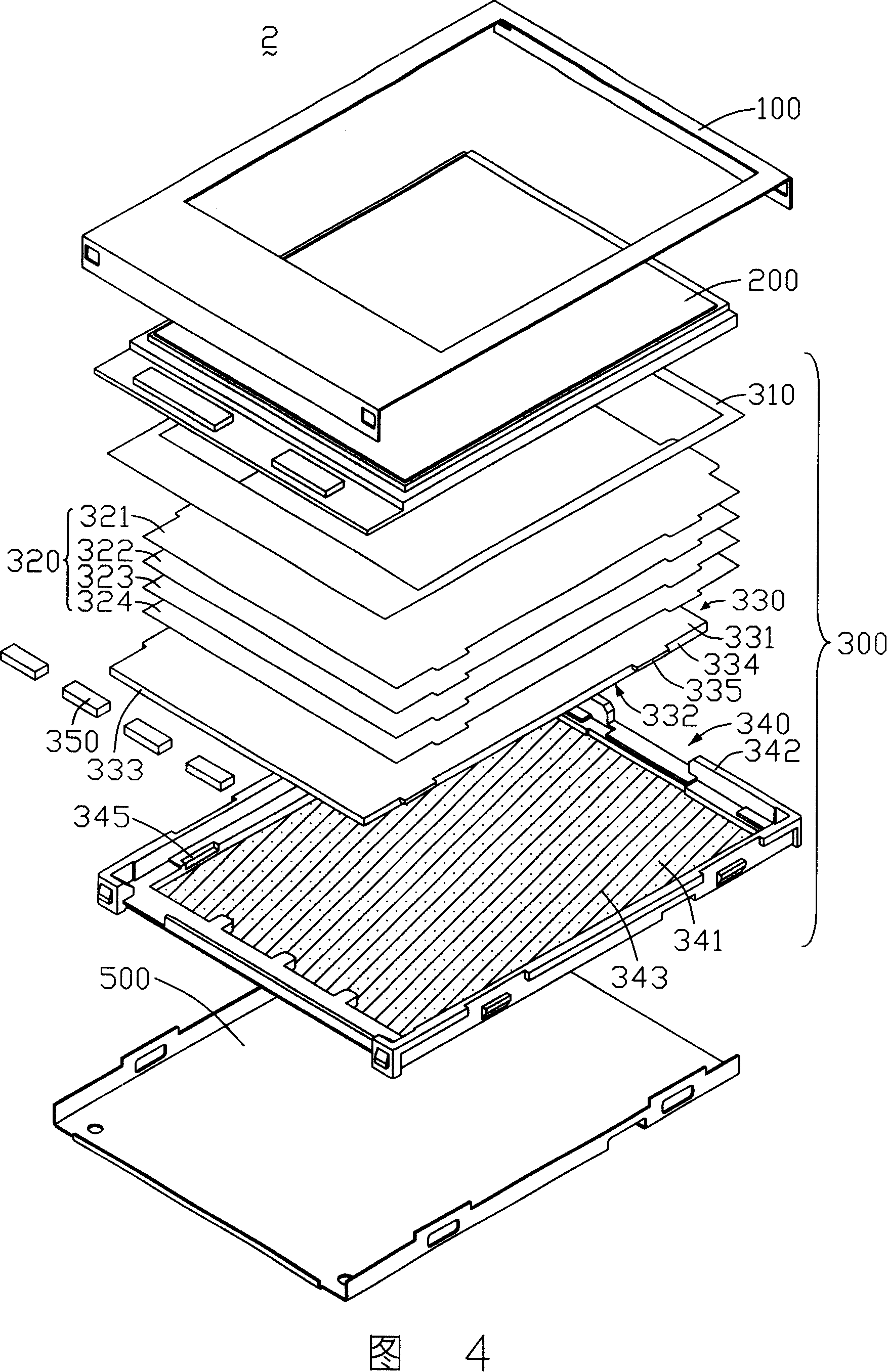

Touch display device

InactiveCN102566808ANot prone to warpingSimplify the assembly processStatic indicating devicesInput/output processes for data processingLiquid-crystal displayTouch Senses

The invention discloses a touch display device which comprises a liquid crystal display module and a touch sensing element, wherein the touch sensing element is attached to one surface of the liquid crystal display module.

Owner:YOUNG LIGHTING TECHNOLOGY INC

Member and structure for fixing core

InactiveCN101405822AReduce the numberMiniaturizationTransformersTransformers/inductances detailsMechanical engineeringMagnetic core

The present invention provides atechnology for reducing sizes, weight and even cost of a reactor by simplifying the core fixing structure of the reactor. A reactor (10) is provided with a case (101) for storing a core (109) and a coil (105). A core fixing member fixes the core (109) in the case (101). The core fixing member is constituted by integrally forming a first spring section (S1), which urges the side surface of the core (109) in the horizontal direction, with a second spring section (S2), which urges the upper surface of the core (109) in the vertical direction. Furthermore, a stopper section (ST), which regulates removal of the core (109) from the inside of the case (101), is integrally formed on a boundary to the second spring section (S2), through a cut (105) to cover a part of the upper surface of the core (109).

Owner:TAMURA KK

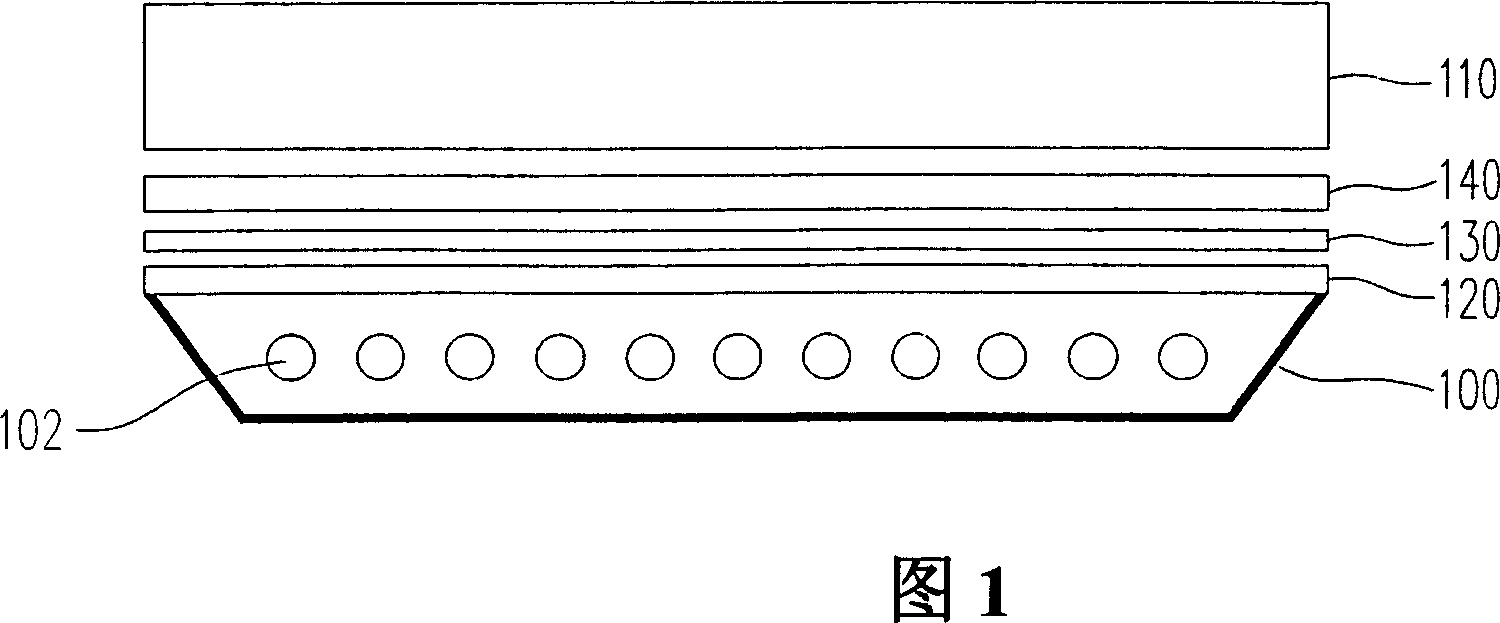

Backlight module group and liquid crystal display device

ActiveCN101149509AAvoid badSimplify the assembly processNon-linear opticsLiquid-crystal displayLight guide

This invention relates to a sort of back-light model and liquid crystal display device which adopts this model. This back-light model consists of a light board and a glue frame which accepts this light board. This light board consists of a out-light face and a underside which corresponds to this out-light face. This glue frame consists of an underside and this underside consists of a reflecting surface which approaches the underside of this light board.

Owner:INNOCOM TECH SHENZHEN +1

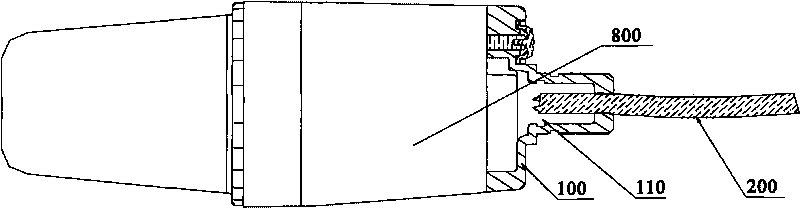

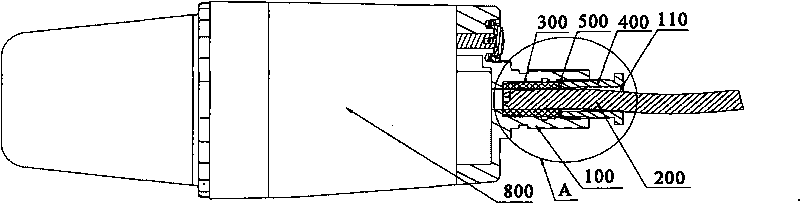

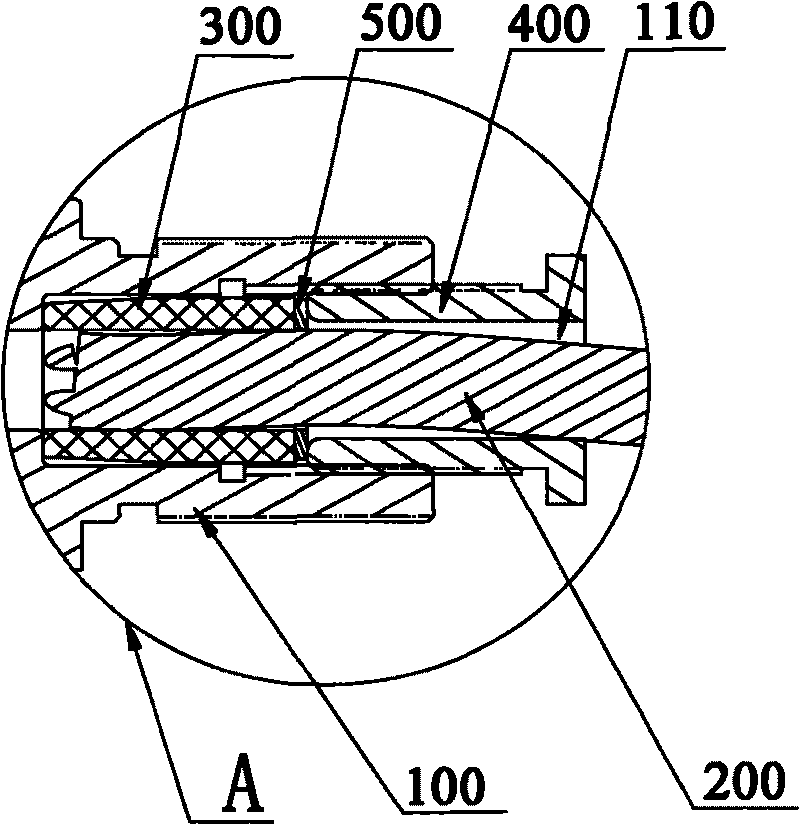

Sealing structure of wire inlet hole and explosion-proof lamp

InactiveCN101709859AImprove securityShort curing timeElectric circuit arrangementsGas-tight/water-tight arrangementsMan-hourEngineering

The invention relates to a sealing structure of a wire inlet hole, which is used for sealing a clearance between a wire inlet hole (110) and a wire cable (200). The sealing structure of the wire inlet hole comprises a filler (300) and a pressing component, wherein the filler (300) is arranged in the wire inlet hole (110), the middle of the filler (300) is provided with a through hole (310), the wire cable (200) penetrates through the filler (300), and the pressing component is arranged at the open end of the wire inlet hole (110) and presses the filler (300) into the wire inlet hole (110) so as to enable the filler (300) to be deformed; one end of the filler (300) contacts with the pressing component, and the other end of the filler (300) supports against the end face of an internal cavity of the wire inlet hole (110). The invention also relates to an explosion-proof lamp adopting the sealing structure of the wire inlet hole. The invention omits a glue sealing process and the curing time of sealing glue, reduces the assembly man-hour, and has more reliable sealing quality by the fixation and the pressing of the pressing component, and simple and easy replacement, and simple operation because the sealing effect can be regulated by regulating the pressing degree of the pressing component.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

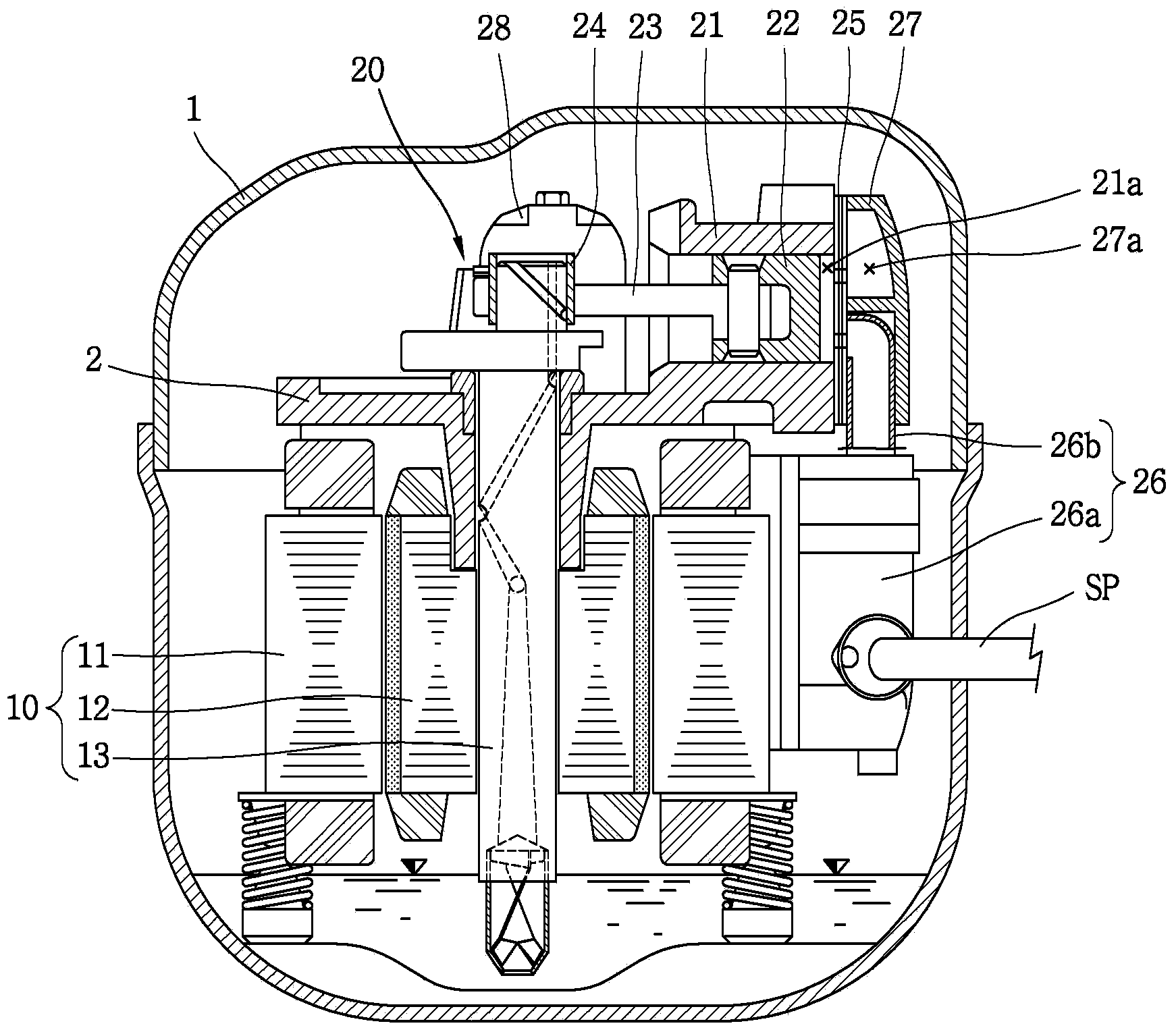

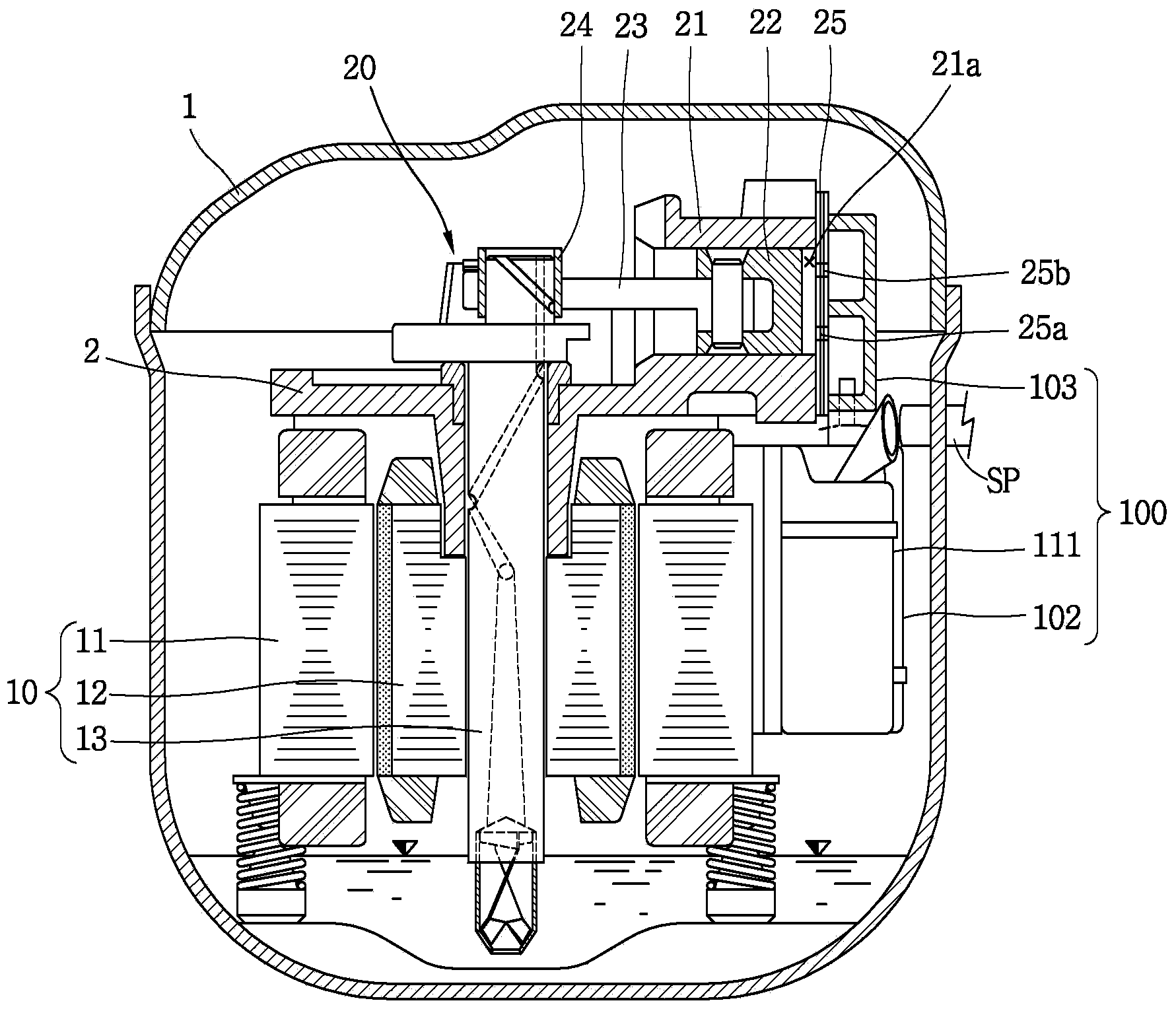

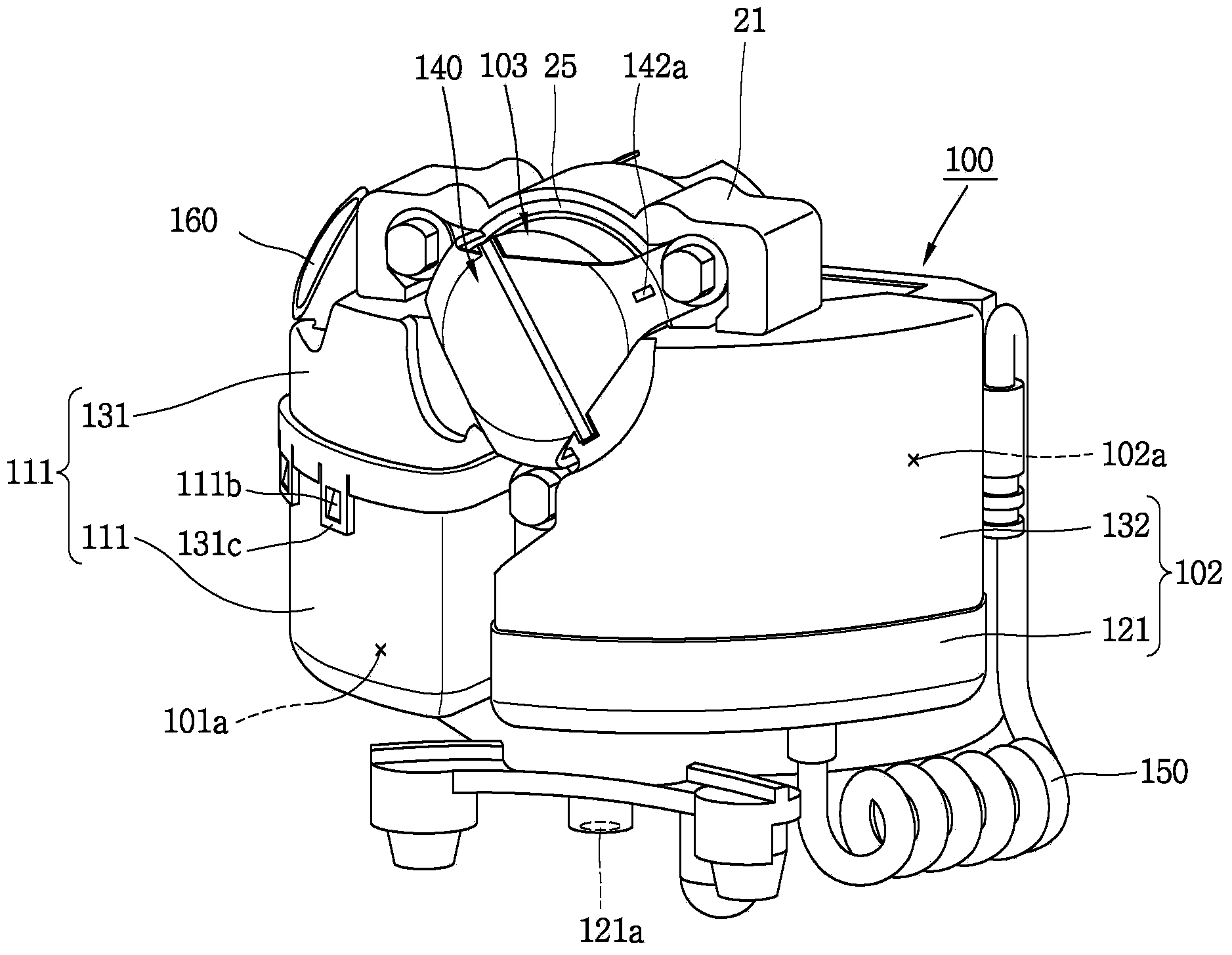

Muffler for compressor and compressor having the same

ActiveCN104121163AImprove performanceReduce the numberPositive displacement pump componentsPositive-displacement liquid enginesNoise removalPlastic materials

In a muffler for a compressor and a compressor having the same according to the present disclosure, an integral formation of a suction noise unit and a discharge noise unit may reduce the number of components for configuring a suction side muffler and a discharge side muffler so as to reduce a leakage of a refrigerant generated at an assembled portion of the muffler and also reduce a suction passage and a discharge passage in length. Also, the division between the suction noise unit and the discharge noise unit may prevent a discharged refrigerant from heating a sucked refrigerant, which may result in a reduction of a suction loss. The formation of the suction noise unit and the discharge noise unit using a plastic material may result in a reduction of fabricating costs. In addition, the structures of the suction side noise space and the discharge side noise space may be simplified and noise removal effect can be increased using the suction chamber and the discharge chamber. This may result in a reduction of an entire size of the muffler and improvement of the noise effect.

Owner:LG ELECTRONICS INC

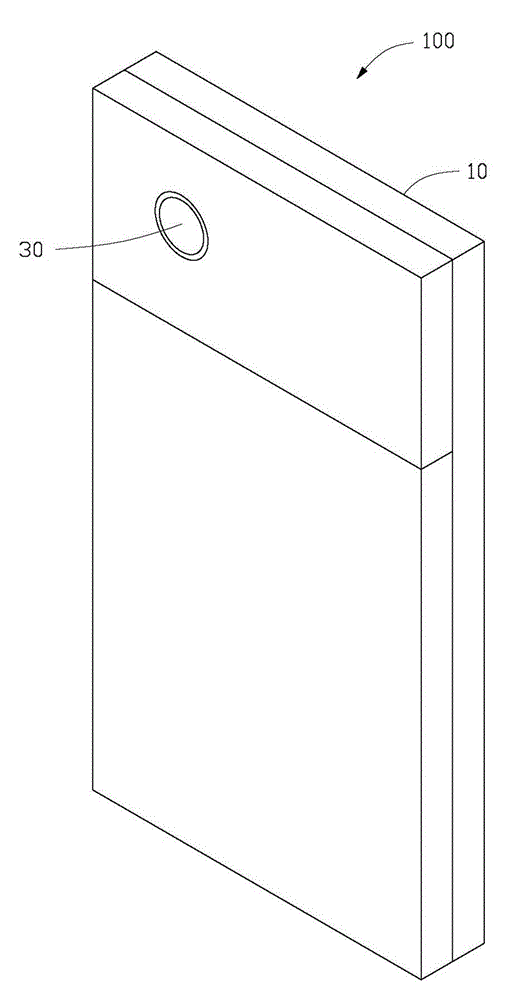

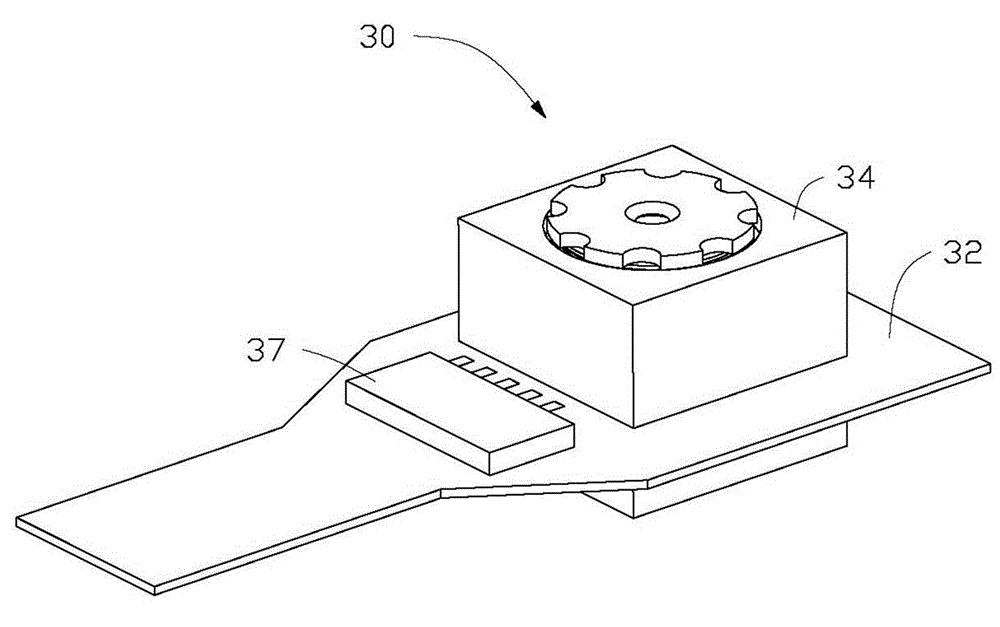

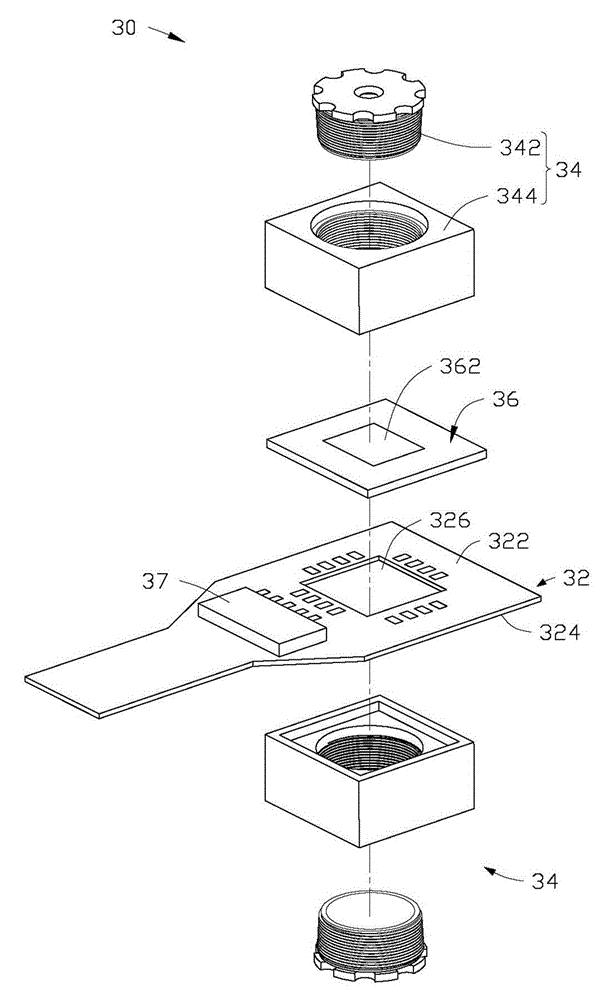

Camera module

InactiveCN106161885AReduce manufacturing costReduce assembly man-hoursTelevision system detailsColor television detailsElectricityCamera lens

The invention provides a camera module. The camera module comprises a circuit board, lens components and a double-sided image sensor, wherein two lens components are provided, the two lens components are electrically connected to the circuit board and are overlapped with the axial line of the circuit board, a through hole is formed in the circuit board, the double-sided image sensor comprises two oppositely arranged photosensitive surfaces, the double-sided image sensor is assembled at the through hole and is located between the two lens components, so that the lens components respectively face to the corresponding photosensitive surfaces of the double-sided image sensor. According to the camera module provided by the invention, the two lens components share one double-sided image sensor and one circuit board, and only one circuit board is connected to a motherboard during assembly, thereby not only improving the production efficiency, but also saving the production cost.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Backboard structure of backlight module

InactiveCN101571644AImprove insulation performanceReduce short circuitLighting support devicesNon-linear opticsEngineeringWorking hours

The invention mainly relates to a backlight module device, in particular to a backboard structure of a backlight module. The backboard structure comprises a framework, a backboard, a driving circuit board, a first fixing element and a second fixing element, wherein the backboard is arranged in the framework and provided with at least one penetrated positioning hole and one positioning part; the driving circuit board is provided with a fixing hole at a position opposite to the positioning part of the backboard; and the first fixing element and the second fixing element respectively correspond to the backboard, the positioning hole and the positioning part of the driving circuit board so as to ensure that the backboard and the driving circuit board are combined and fixed in the framework. The backboard structure can improve the insulating effect of the driving circuit board, reduce the occurrence frequency of short circuit of electronic elements and reduce the cost and assembly working hours.

Owner:CENTURY DISPLAY (SHENZHEN) CO LTD

Back light module unit and display module group

InactiveCN101498863ALow costSavings on Combined ComponentsNon-linear opticsLiquid-crystal displayComputer science

The present invention is applicable to liquid crystal displays and provides a backlight module and a display module thereof. Wherein, the display module comprises a backlight module, a panel and a side cover; the backlight module comprises an upper frame consisting of a main body and the extended part and a backlight element; and a groove between the main body and the extended part accommodates the configuration panel, which is also fixed within the display module by the insertion of the groove and the side cover. The present invention has the advantages of employing the upper frame which combines the design and utility of traditional frontal frame and glue frame and substituting a back cover with a side cover as reformation to save components, reduce assembly time, lower material cost and therefore improve production efficiency.

Owner:CPT DISPLAY TECH SHENZHEN +1

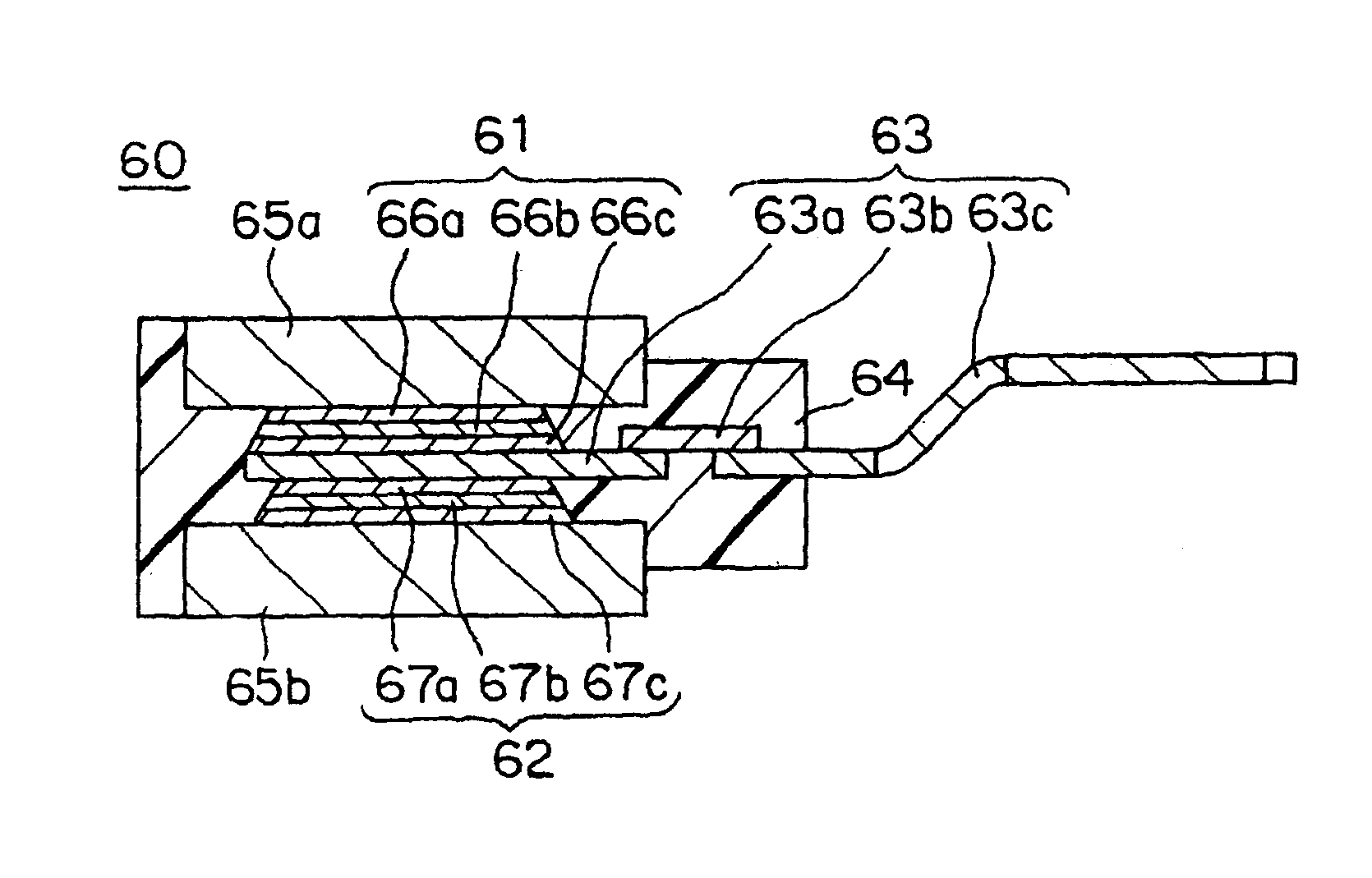

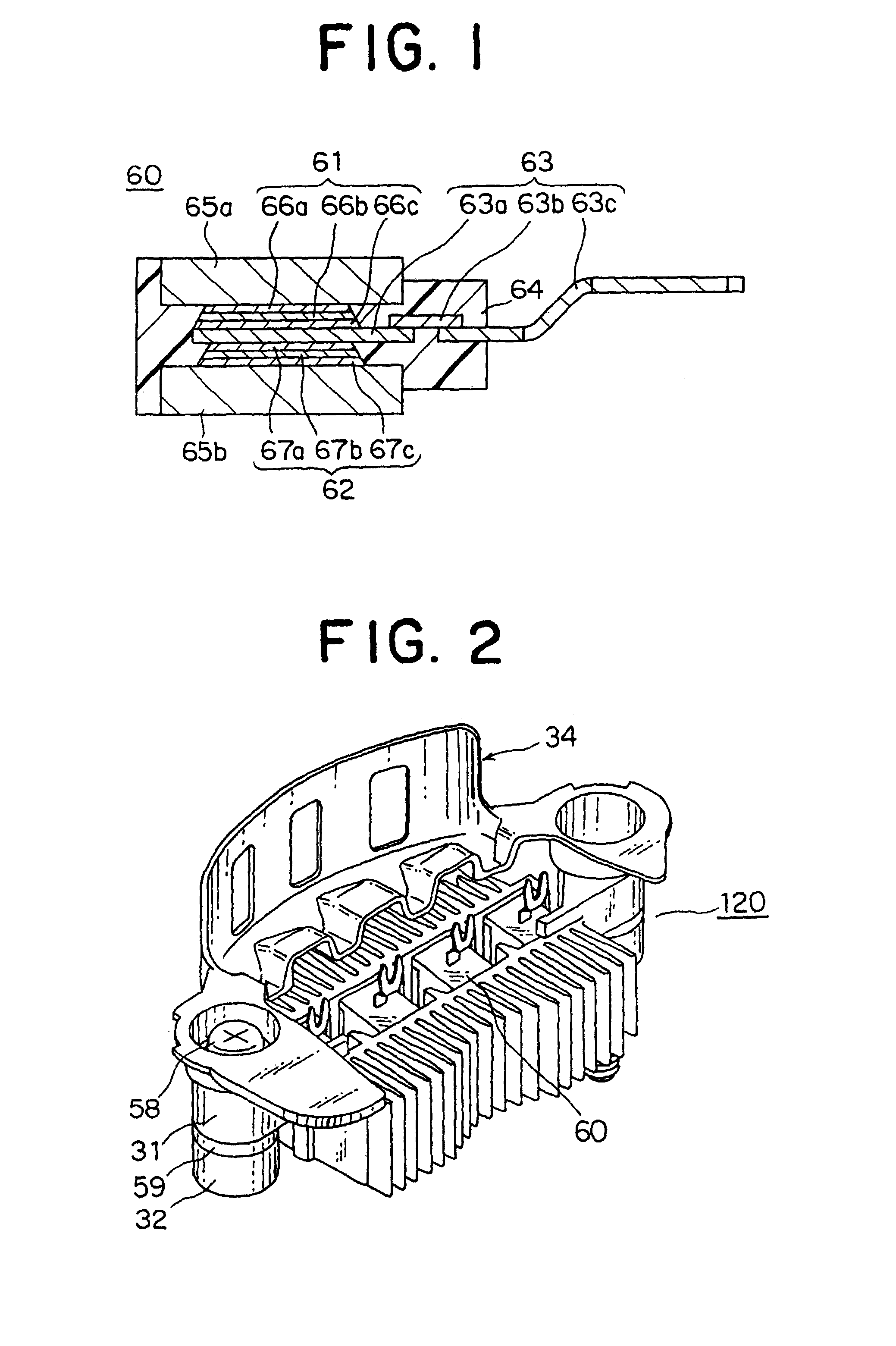

Vehicle AC generator with rectifier diode package disposed between cooling plates

InactiveUS6882069B1Reduce assembly man-hoursAvoid temperature riseSynchronous generatorsSemiconductor/solid-state device detailsRectifier diodesEngineering

A vehicle AC generator having a rectifier unit with cooling plates for the positive-electrode and negative-electrode sides, each having principal planes opposing each other; and a diode package disposed between the cooling plates for the positive-electrode and negative-electrode sides. The diode package has a base for the positive-electrode side formed of a metallic plate and joined to a cathode face of the unidirectionally conducting element for the positive-electrode side; a base for the negative-electrode side formed of a metallic plate and joined to an anode face of the unidirectionally conducting element for the negative-electrode side; and an insulating resin provided so that the unidirectionally conducting elements for the positive-electrode and negative-electrode sides are embedded therein. The end face of the base for the positive-electrode side is joined to the principal plane of the cooling plate for the positive-electrode side while the end face of the base for the negative-electrode side is joined to the principal plane of the cooling plate for the negative-electrode side.

Owner:MITSUBISHI ELECTRIC CORP

Image capturing module, method for manufacturing the image capturing module, and electronic information device

InactiveCN101494721AReduce in quantityFine precisionTelevision system detailsTelevision system scanning detailsElectronic informationImage capture

An image capturing module according to the present invention includes a holder member, which accommodates therein a focusing lens for forming an image of a subject light on an image capturing chip attached on a substrate and is attached to the substrate to cover the image capturing chip, where the holder member is directly supported on a surface of the image capturing chip.

Owner:SHARP KK

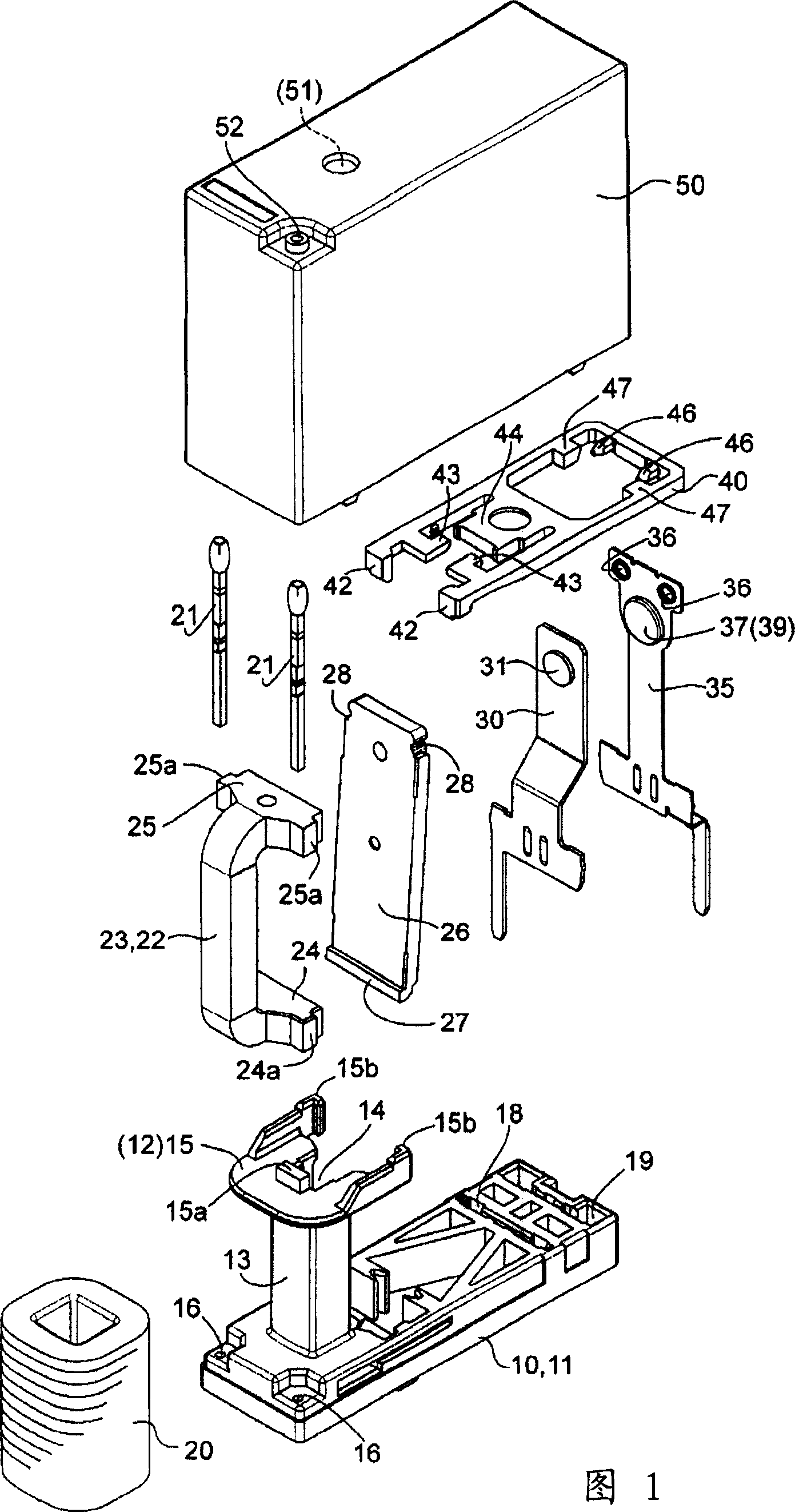

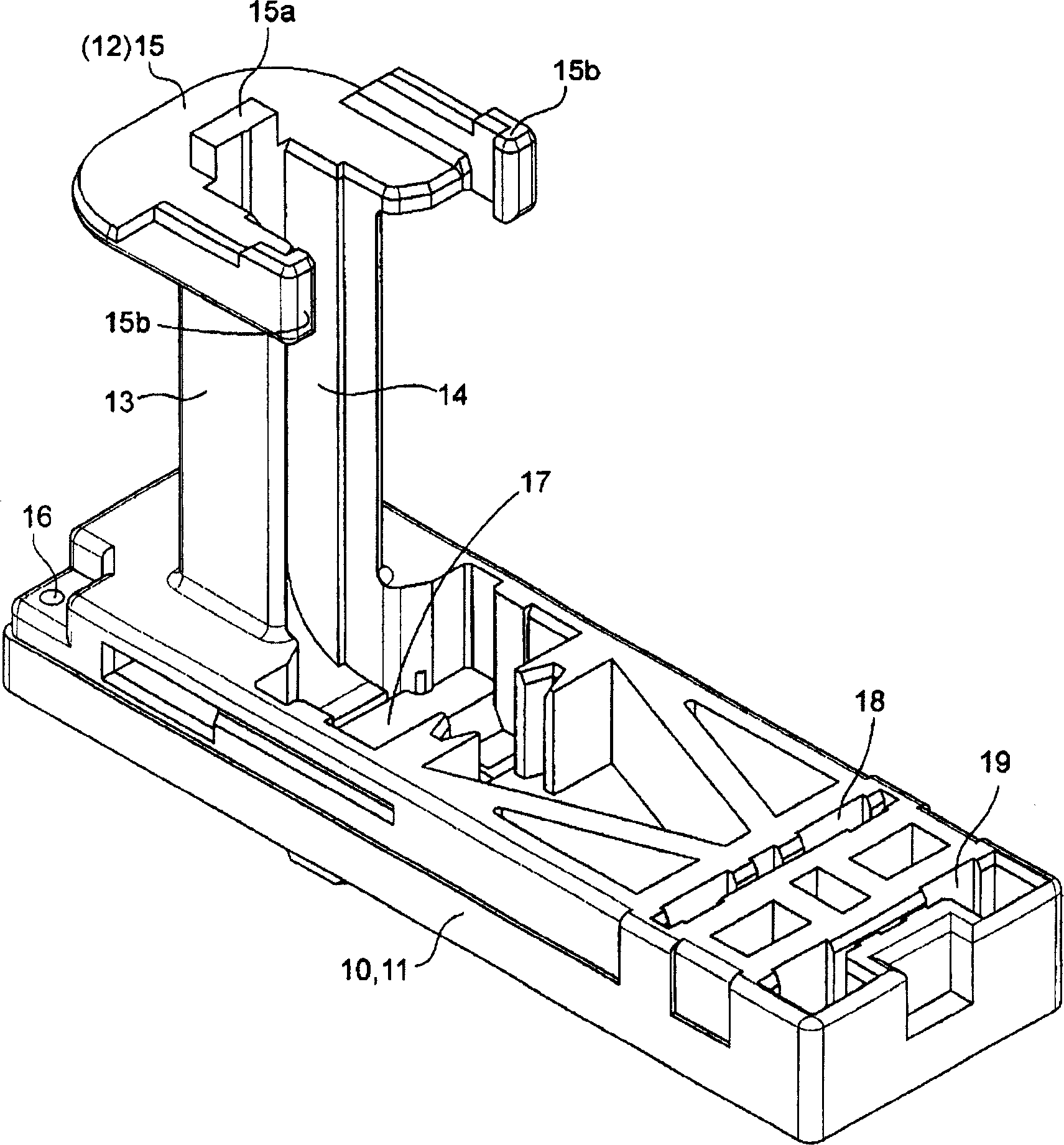

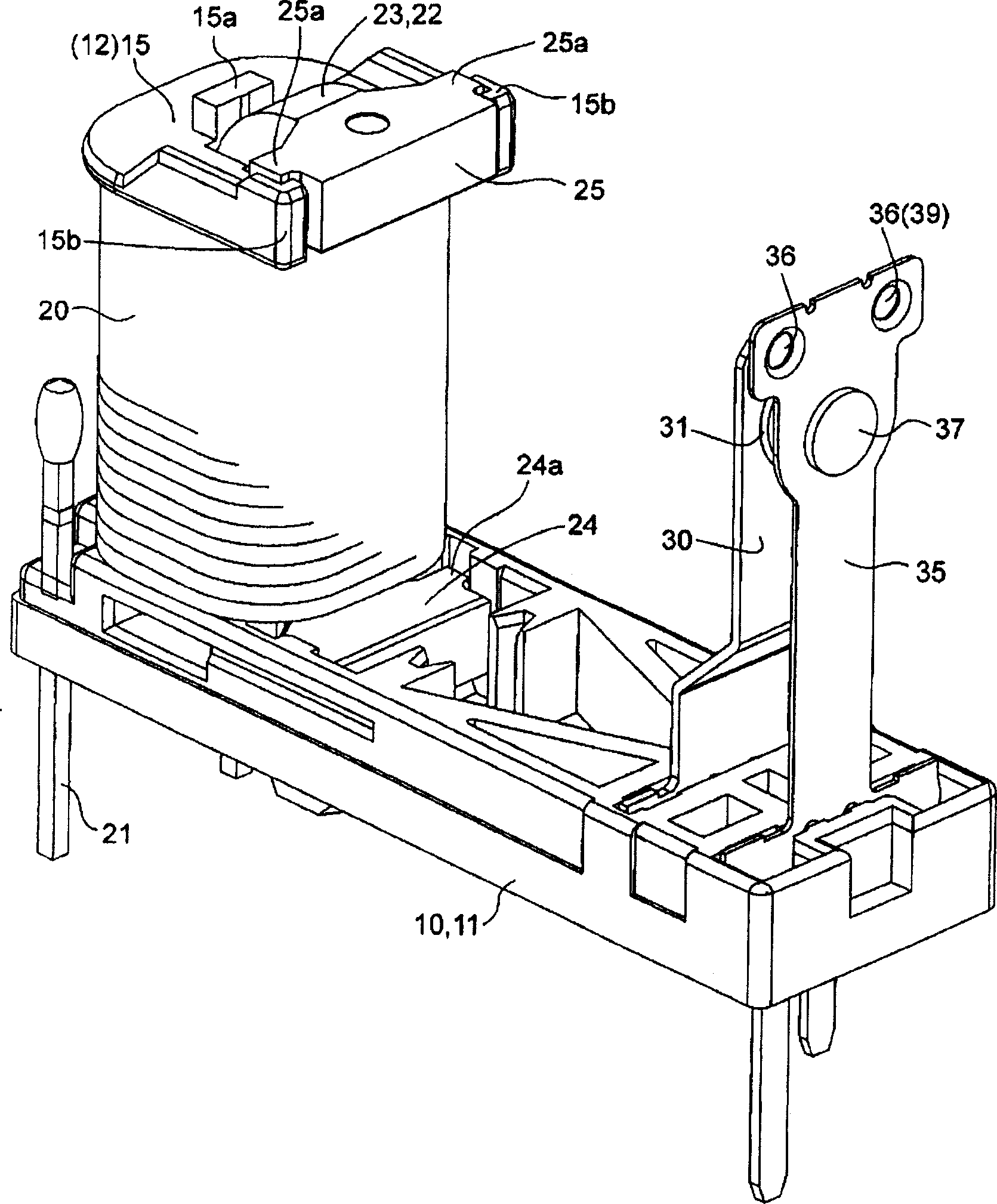

Electromagnetic relay

ActiveCN1677600AFew partsReduce assembly man-hoursElectromagnetic relay detailsMagnetic polesEngineering

The invention provides an electromagnetic relay having a small number of components and a few assembly man-hours. The shaft part 27, provided at the lower end part of a movable iron member 26, is engaged with a recessed part for positioning provided at the base part of a spool 13, and the shaft part 27 of the movable iron member 26 is prevented from pulling off, capable of rotation by the magnetic pole section 24 positioned at the lower end part of the iron core 22 assembled at the spool 13.

Owner:ORMON CORP

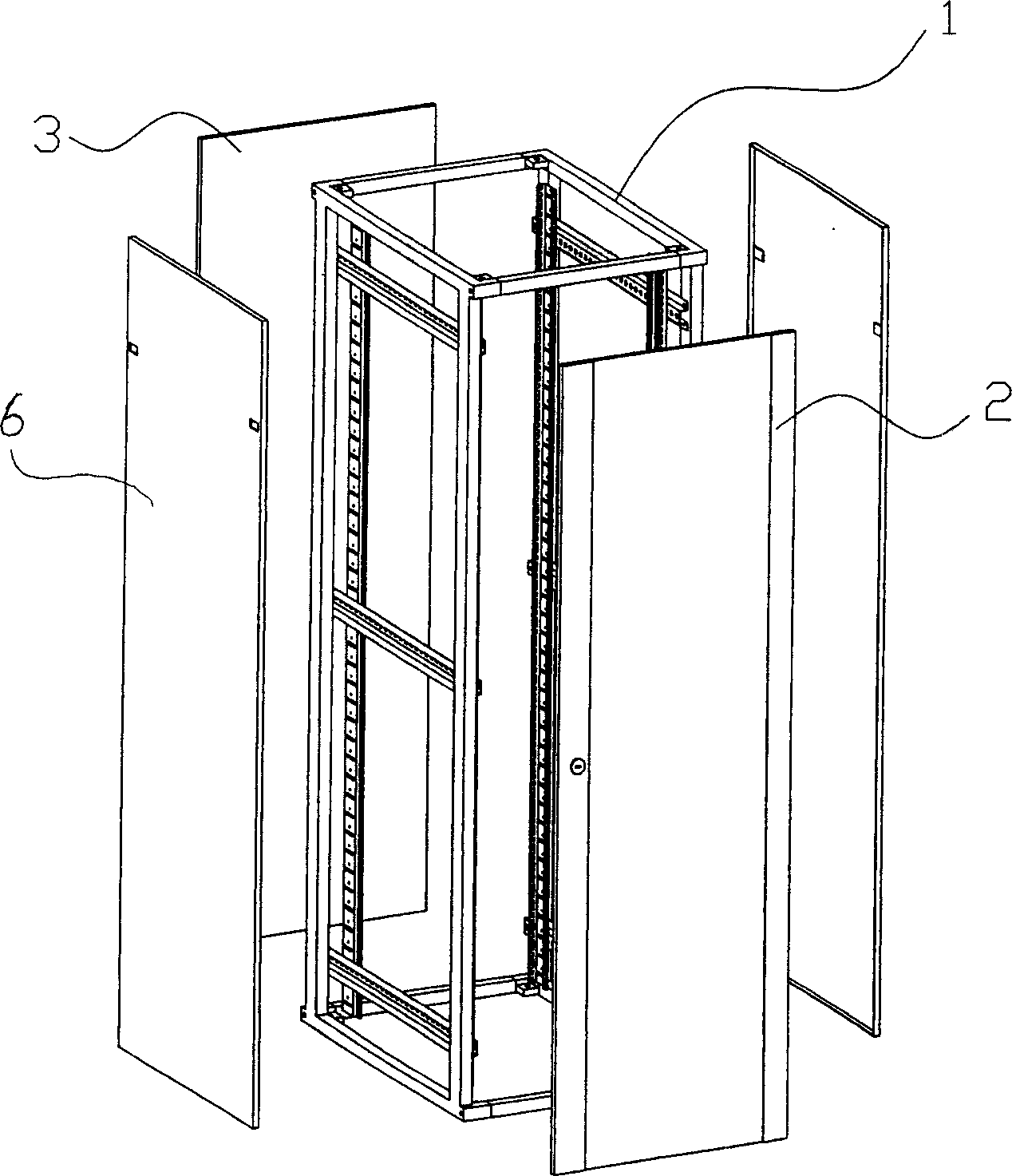

Fast assembled machine cabinet

InactiveCN1668169ARapid assembly prototypingReduce in quantityCasings/cabinets/drawers detailsInstrument housingEngineeringBackplane

A quickly assembled cabinet includes a frame, a door, back plates and screws characterizing that the frame is composed of two surrounding frames, four connection bars connected by eight screws, the surrounding frame component is composed of surrounding frames and door plate, bars and assembly strips preset on it, four corners of the corresponding side of the frames are set with inserted plugs matched to the sag holes of the connecting bats, four corners of the frame sides are corresponding to the inserted plug positions, which are set with stepped through holes for guiding in screws and fastening, both ends of the connecting bars are set with sag holes matched with the inserted plugs, bottom of the holes are set with screw holes corresponding to the stepped through holes.

Owner:SHENZHEN TOTEN COMM TECH

New method for assembling motor stator core

InactiveCN1921271ASmall changes in electrical propertiesReduce the impactManufacturing stator/rotor bodiesEngineeringHigh pressure

The invention relates to a method for assembling iron core of motor stator. Wherein, it comprises: layering iron core plates and positioning them with module to align the inner diameter and outer round; coating insulated dope around the iron core as adhesive to adhere and shape the iron core; compressing the two ends of iron core at high temperature and high pressure. The invention can realize small seam, high connecting strength, non burr, high linearity, and improve the motor property.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

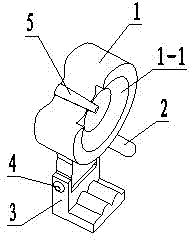

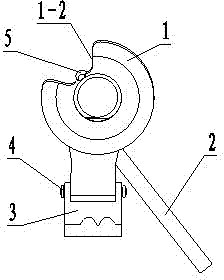

Engine timing system assembling tool

ActiveCN102773818AReduce assembly man-hoursGuarantee normal production cycleWork holdersEngineeringTiming system

The invention discloses an engine timing system assembling tool, which is used for regulating the engine timing position. The engine timing system assembling tool consists of a camshaft timing chain wheel regulation device and a crankshaft timing chain wheel regulation device, wherein the camshaft timing chain wheel regulation device comprises a camshaft timing chain wheel regulation device body, a locking seat, a stop pin and a draw bar; the camshaft timing chain wheel regulation device body is in a disk-shaped structure; the excircle surface of the camshaft timing chain wheel regulation device body is provided with a stop pin avoidance slot; the stop pin is installed on the bottom of the stop pin avoidance slot; the working end surface of the camshaft timing chain wheel regulation device is provided with a ladder groove structure; the ladder groove structure is matched with a hub of a camshaft timing chain wheel; one end of the draw bar is fixedly assembled with the camshaft timing chain wheel regulation device body; and the locking seat is hinged with the camshaft timing chain wheel regulation device body. The engine timing system assembling tool disclosed by the invention has the advantages of simpleness in operation, stable performance and strong popularity and is suitable for assembling protection line bodies for engines of various machine types.

Owner:BAODING WEIYI AUTOMOBILE CO LTD

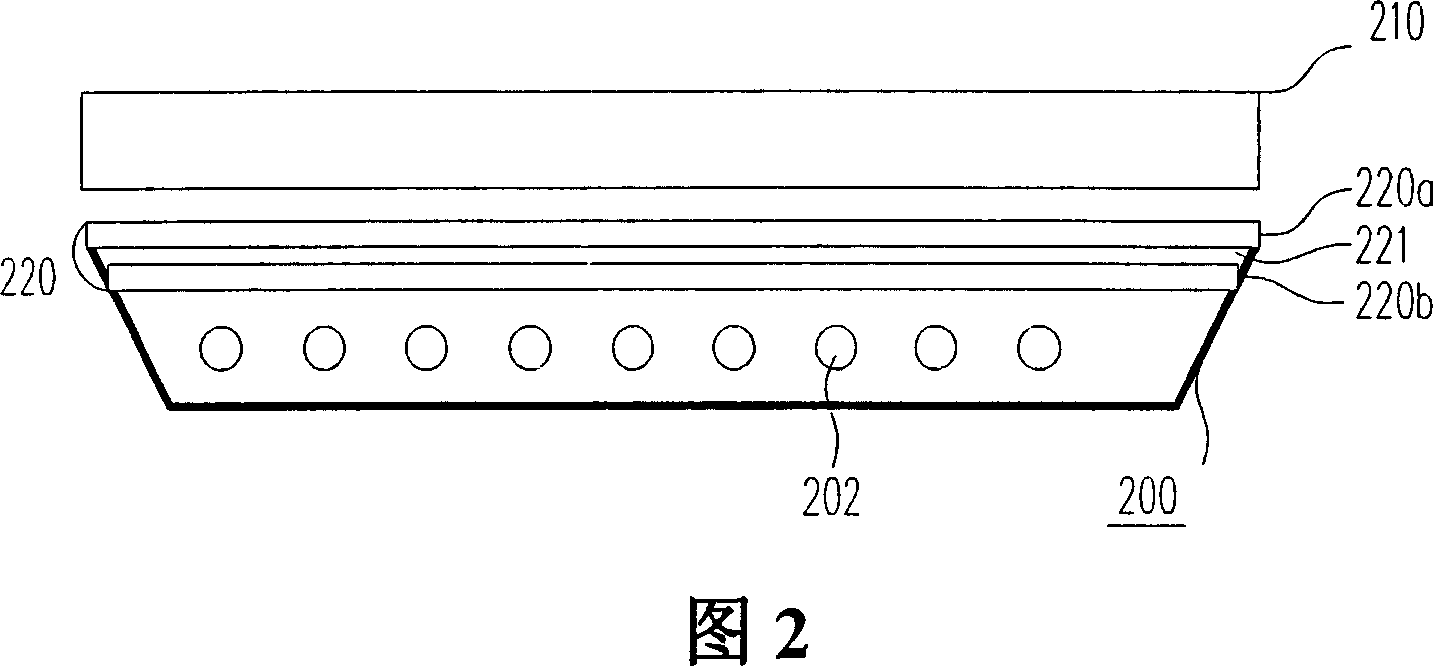

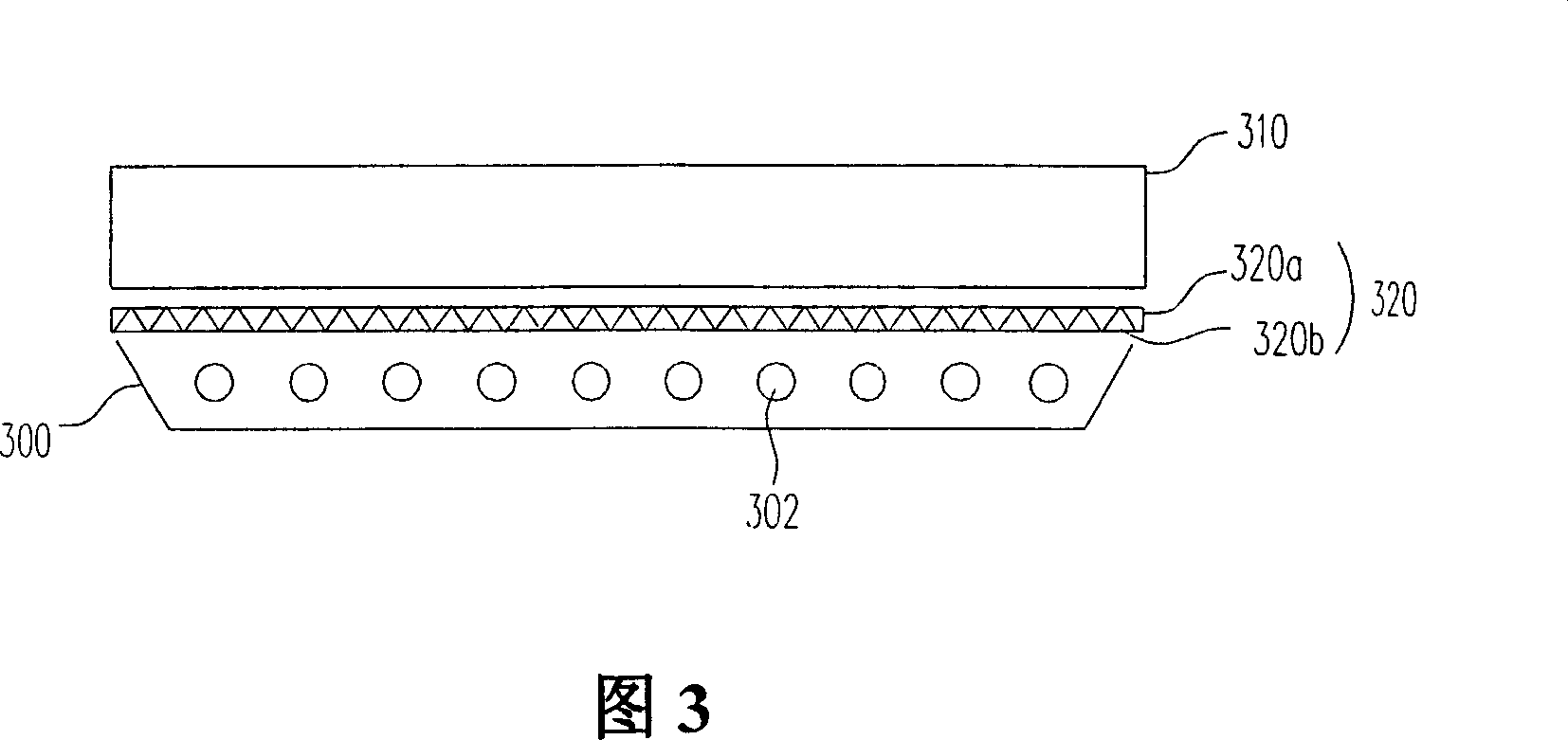

Plane display device and light gathering type diffusing plate therefor

ActiveCN1991512AGood optical performanceReduce the numberDiffusing elementsNon-linear opticsLiquid-crystal displayRefractive index

A plain display is disclosed that consists of backlight module, liquid crystal display panel, and spot-light type diffusing board. The liquid crystal display panel is mounted above the backlight module; the spot-light type diffusing board is located between the backlight module and liquid crystal display panel, and the spot-light type diffusing board includes the first diffusing layer and the second diffusing layer, the first diffusing layer closes to the configuration of liquid crystal display panel, and the second diffusing layer closes to the configuration of the first diffusing layer, and the first and second diffusing layer have different refractive index, permeability, and fog value, and that can make the display reach the optimal optical performance.

Owner:HANNSTAR DISPLAY CORPORATION

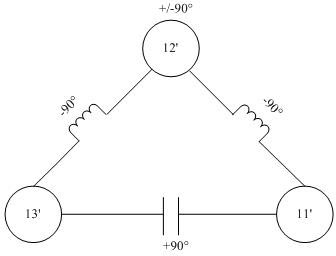

Cavity filter, duplexer, combiner and transmission zero frequency debugging method for cavity filter

The embodiment of the invention provides a cavity filter, which comprises a cavity, a first resonator, a second resonator, a third resonator, a main transmission path, a secondary transmission path and a coupling jumper, wherein the first, second and third resonators are sequentially arranged in the cavity; the main transmission path is led to the third resonator from the first resonator through the second resonator; the secondary transmission path is led to the third resonator from the first resonator; the coupling jumper is arranged between the first and third resonators along the secondary transmission path; and one end of the coupling jumper is assembled on the third resonator, and the other end of the coupling jumper is assembled on the cavity. The cavity filter is easy to assemble, so that work hours for assembly are reduced, requirements for the skills of an assembly operator are greatly lowered, and the error probability of the assembly operator is reduced. Moreover, the coupling jumper is formed by stamping a metal plate, so that the cavity filter is high in consistency and low in cost, the production cost and raw material purchasing cost of the product can be lowered by about 40 percent particularly in batch production compared with those of the conventional transmission zero structure, and the market competitiveness of the product is greatly improved.

Owner:吴芬

Method for manufacturing a solid-state image sensing device, such as a CCD

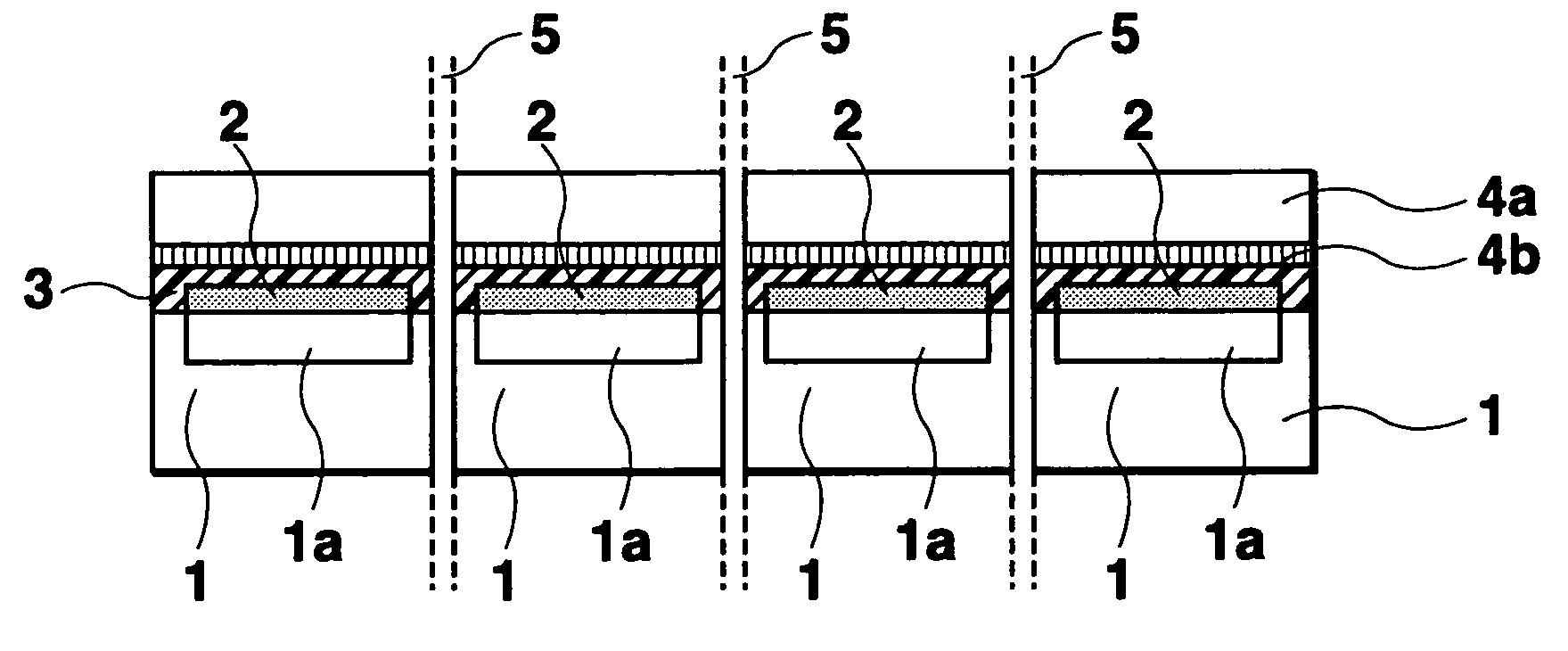

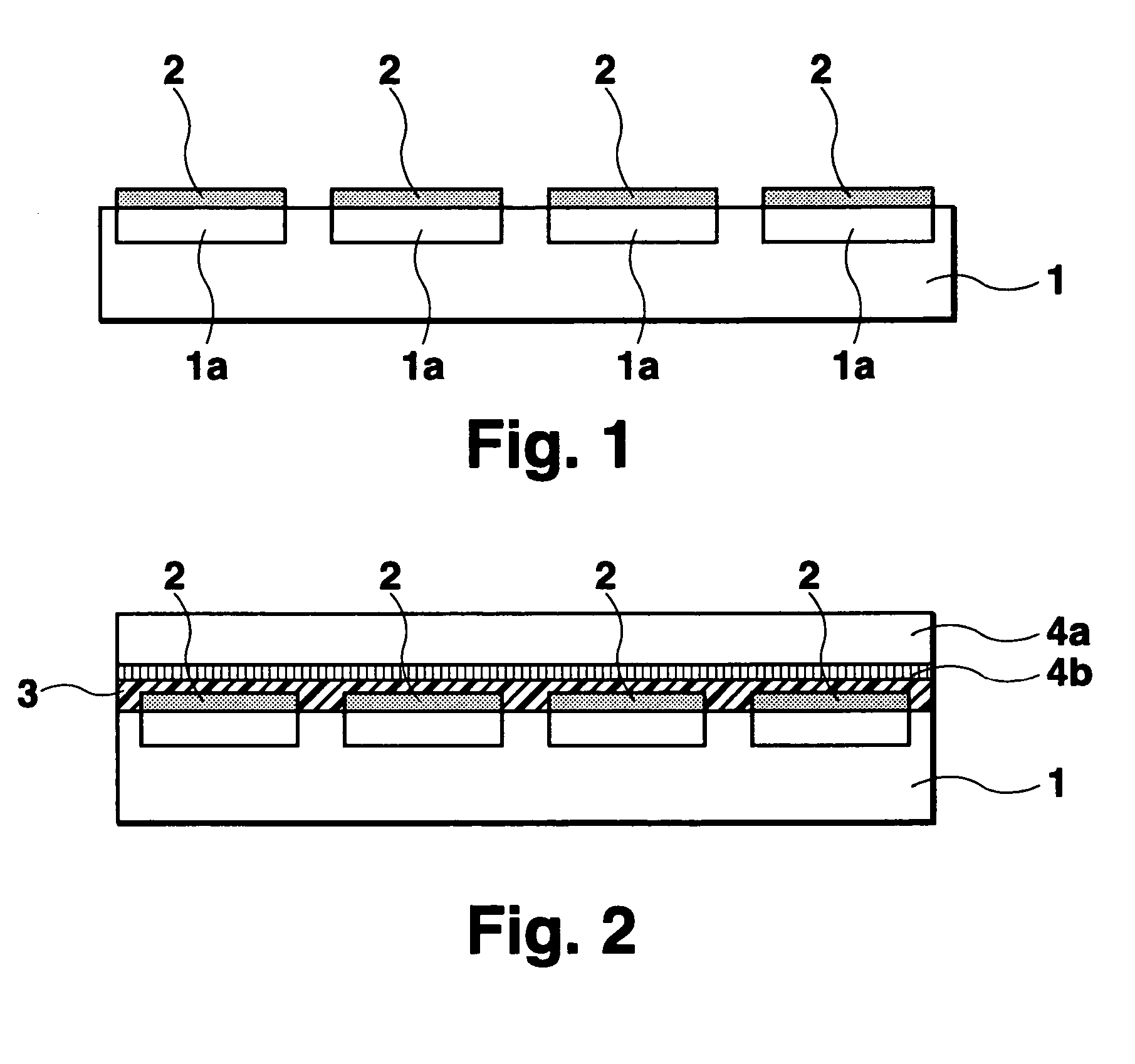

ActiveUS7316937B2Reduce assembly man-hoursEasy to assembleTelevision system detailsSolid-state devicesInfrared cut-off filterEpoxy adhesive

Light detecting elements are formed in areas marked off by scribe lines on a semiconductor substrate, and color filters are deposited in such a manner as to cover the formed areas of the light detecting elements, and then an infrared cut-off filter, on which an infrared reflecting film is vapor-deposited in such a manner as to cover the formed areas of the light detecting elements, is firmly fixed to the surface of the semiconductor substrate through the interposition of a translucent resin layer, such as an epoxy adhesive, to thereby form a multilayered structure, and this multilayered structure is diced along scribe lines.

Owner:SEMICON COMPONENTS IND LLC

Actuator device

InactiveCN1822476AReliable supportReduce assembly man-hoursMechanical energy handlingGearing detailsGear driveDrive shaft

The actuator device includes: a case having a motor housing unit and a gear housing unit; a motor housed in the motor housing unit; and an output gear rotatably housed in the gear housing unit of the case, the output gear driven to rotate by the driving shaft of the motor; the actuator device supporting the motor in a floatable fashion within the motor housing unit via an elastic element; characterized in that the elastic element includes a main body floating part for holding the motor main body of the motor and a pair of bearing floating parts for holding the bearings in front and rear of the driving shaft of the motor and that the main body floating part and the pair of bearing floating parts are integrally formed by way of an elastic element.

Owner:MITSUBA CORP

Dynamoelectric machine

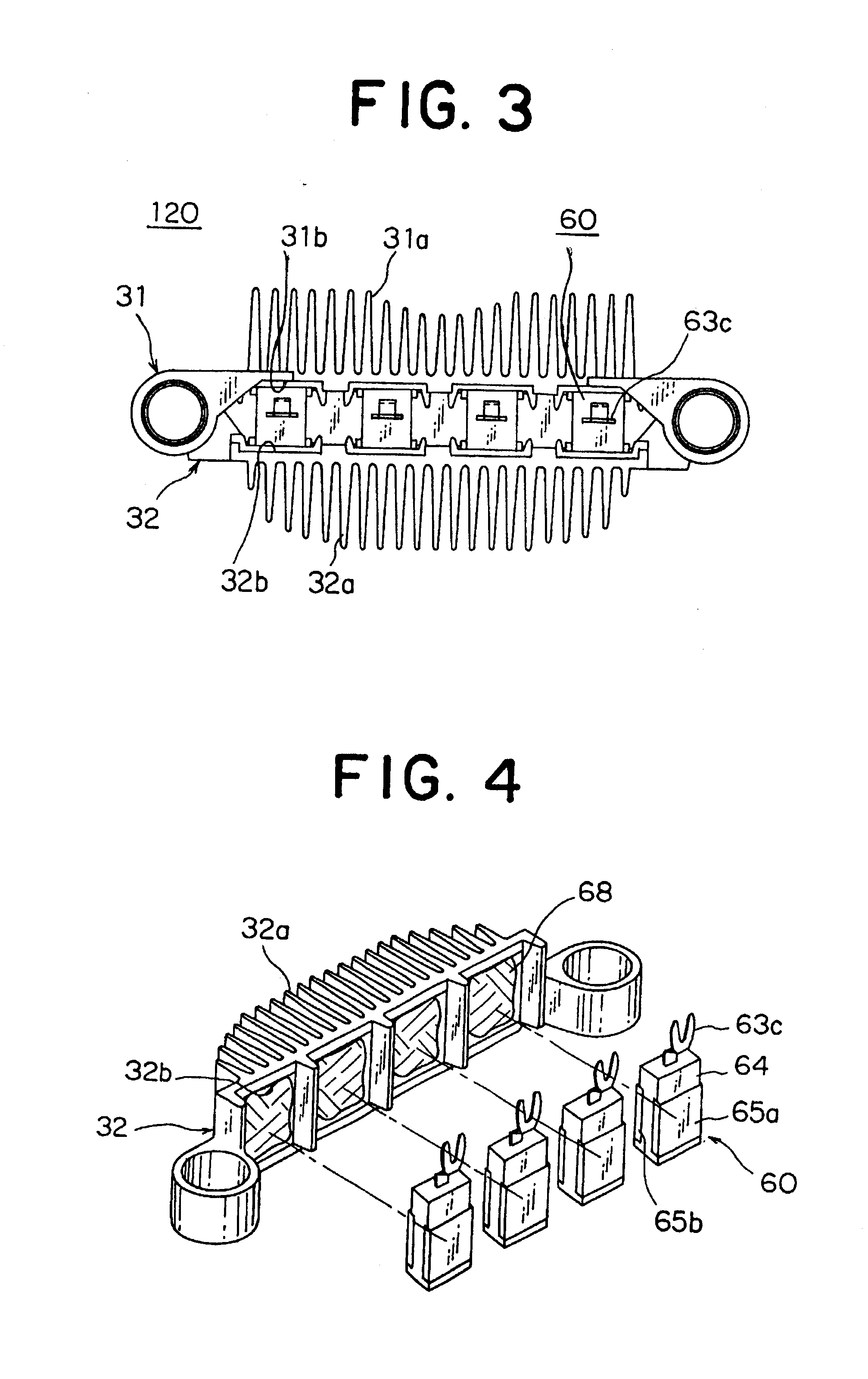

ActiveUS20100207476A1Reduce assembly man-hoursEasy to assembleSynchronous generatorsWindingsBobbinMagnetic poles

A dynamoelectric machine includes first and second magnet seat portions disposed to project from portions of first and second yoke portions that face respective inner circumferential surfaces near tip ends of second and first claw-shaped magnetic pole portions, and magnet housing portions disposed integrally to extend axially outward from outer circumferential portions of a pair of flange portions of a bobbin, extend near the first and second yoke portions that face the inner circumferential surfaces near the tip ends of the first and second claw-shaped magnetic pole portions, and be held by the first and second magnet seat portions. First and second permanent magnets are housed and held in the first and second magnet housing portions, are disposed to face the inner circumferential surfaces near the tip ends of the second and first claw-shaped magnetic pole portions, and the first and second permanent magnets are respectively magnetically oriented in a reverse direction to a direction of a magnetic field that the field coil produces.

Owner:MITSUBISHI ELECTRIC CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com