Electromagnetic relay

A technology of electromagnetic relays and electromagnets, applied in the direction of electromagnetic relays, relays, detailed information of electromagnetic relays, etc., can solve the problems of insufficient reduction in the number of parts and assembly man-hours, etc., and achieve high rigidity, high production efficiency, and high assembly accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

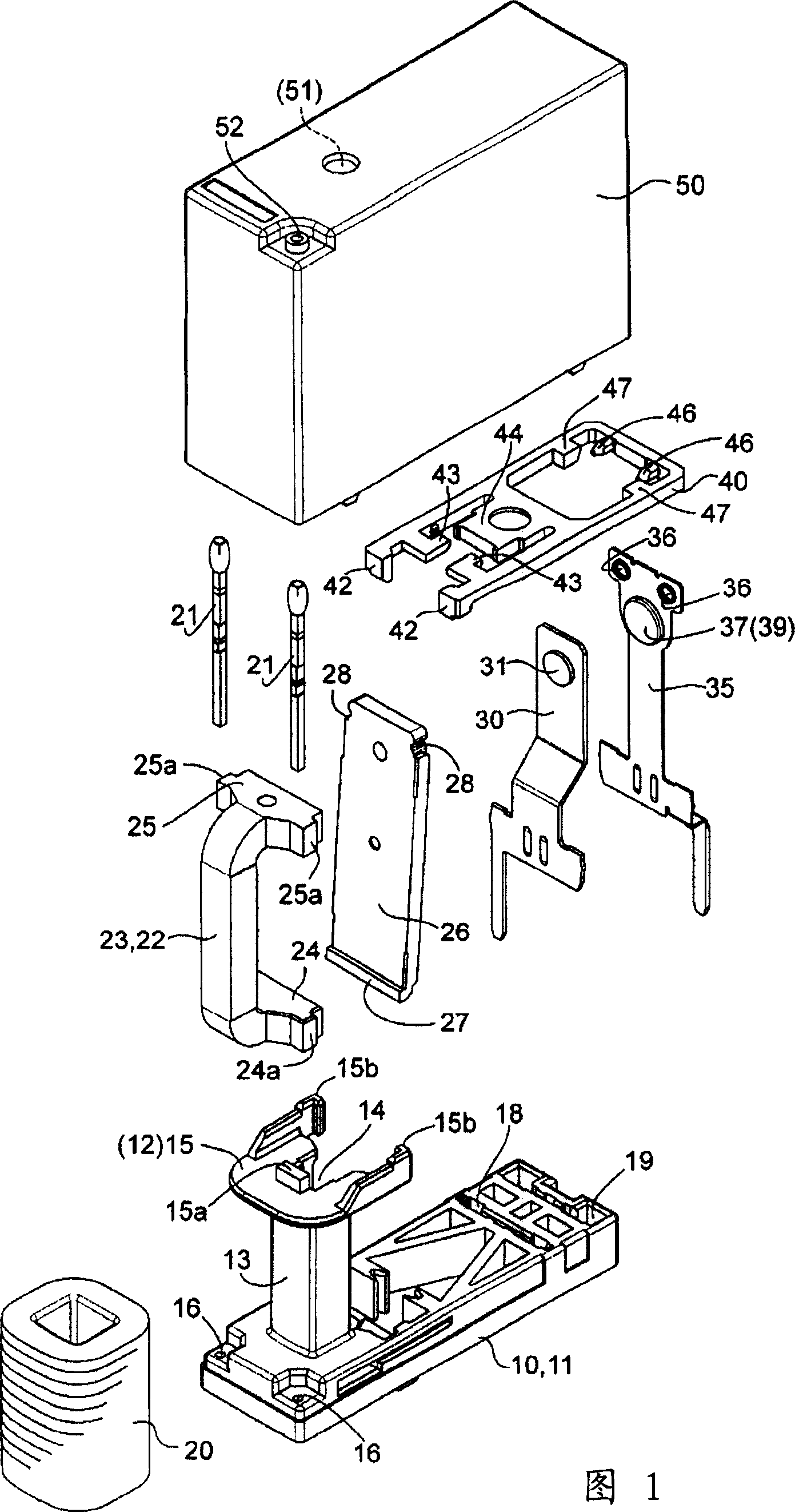

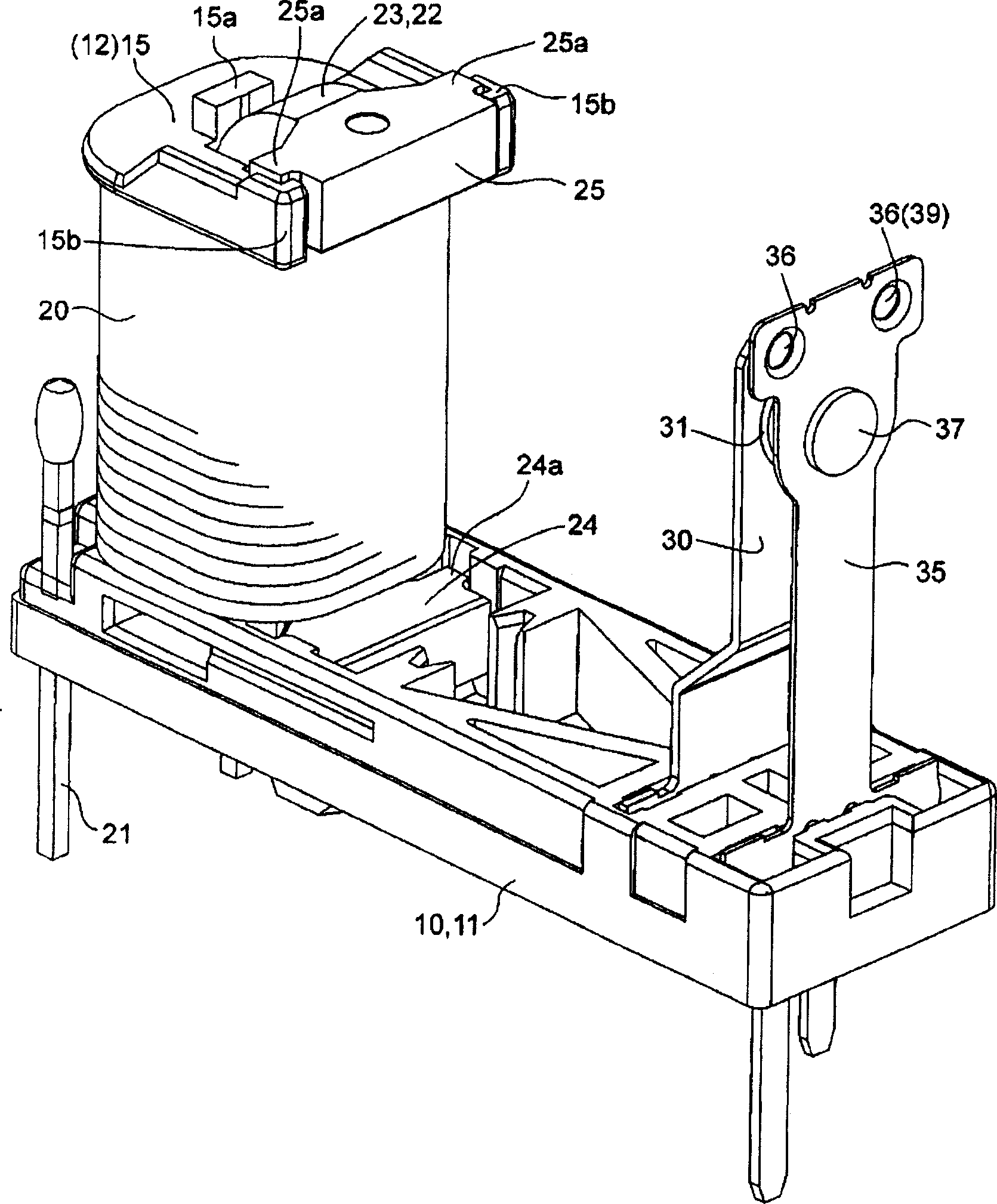

[0034] Embodiments of the electromagnetic relay according to the present invention will be described with reference to FIGS. 1 to 12 .

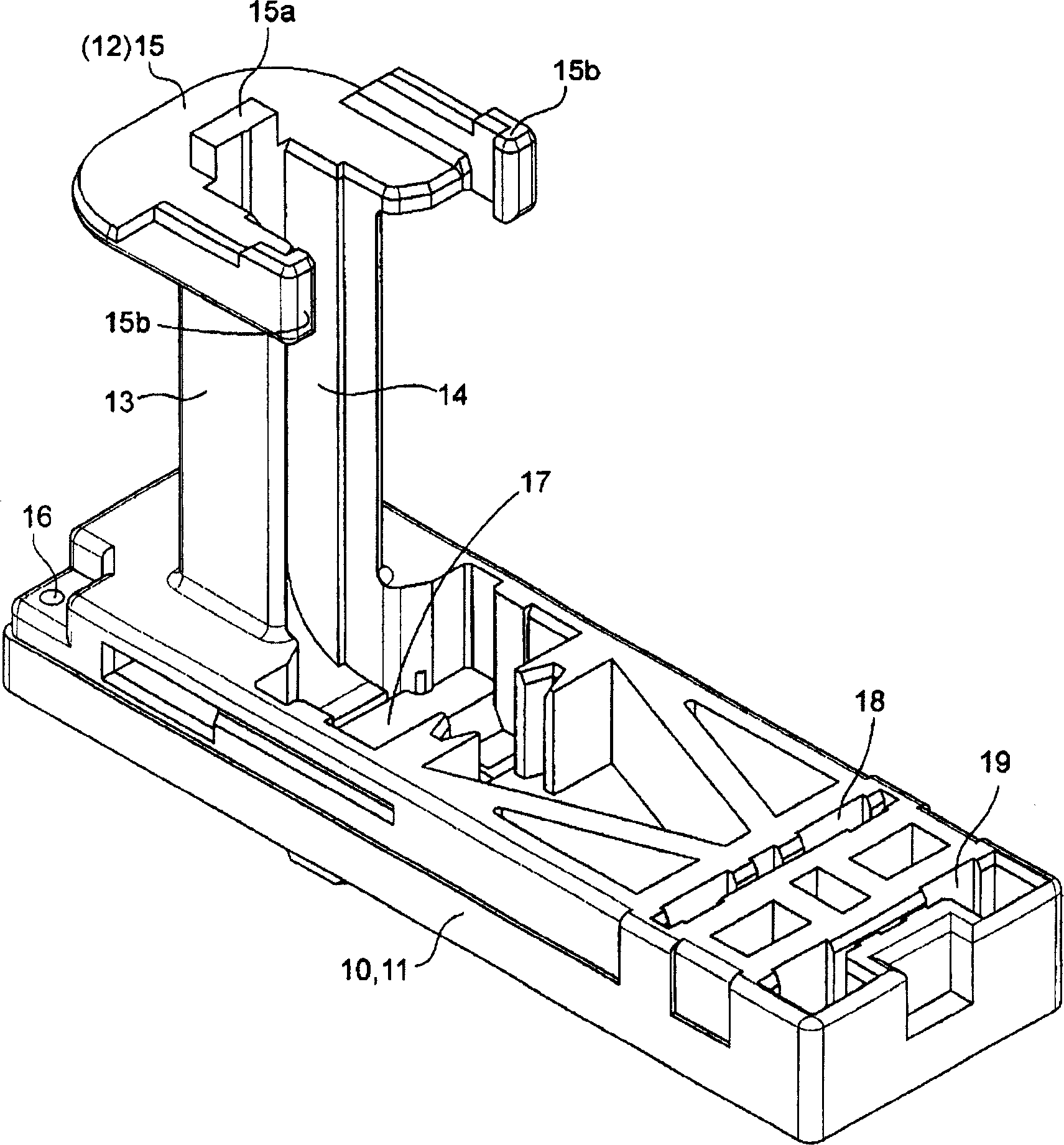

[0035] Figure 1~ Figure 11 As shown, the electromagnetic relay related to the first embodiment assembles the coil 20 and the iron core 22 on the bobbin 13 integrally formed on the upper side of the base 10 to form the electromagnet part 12, and is rotatably supported on the electromagnet part 12. The movable iron piece 26 on the top drives the contact mechanism 39 arranged on the remaining other side above the above-mentioned base 10 through the plug-in 40 to switch on and off the contacts.

[0036] That is, if figure 2 As shown, the above-mentioned base 10 is integrally formed with a bobbin 13 on one side of the upper surface of the base body 11 . The above-mentioned bobbin 13 is vertically formed with an insertion groove 14 capable of inserting the iron core 22 described later, and at the base of the bobbin 13 is provided a recess 17 cap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com