Patents

Literature

26956results about How to "Improve rigidity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Endoscope having detachable imaging device and method of using

An endoscope assembly with a main imaging device and a first light source is configured to provide a forward view of a body cavity, and further includes a detachable imaging device with an attachment member engageable with the distal end region of the endoscope, a linking member connected to the attachment member, and an imaging element with a second light source, wherein the detachable imaging device provides a retrograde view of the body cavity and the main imaging device. Light interference is reduced by using polarizing filters or by alternating the on / off state of the main imaging device, the first light source, the imaging element and the second light source so that the main imaging device and first light source are on when the imaging element and second light source are off and the main imaging device and first light source are off when the imaging element and second light source are on.

Owner:PSIP LLC

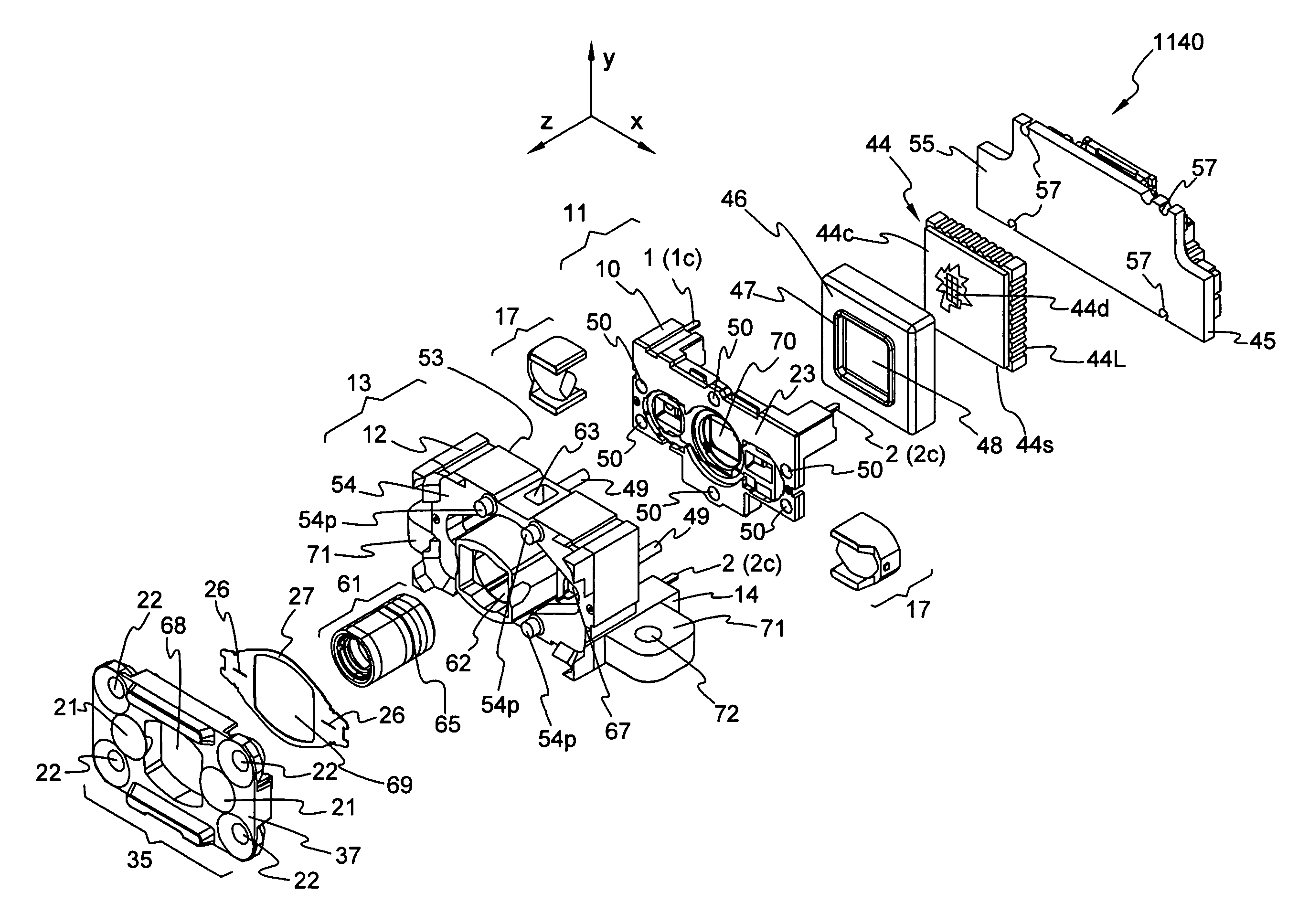

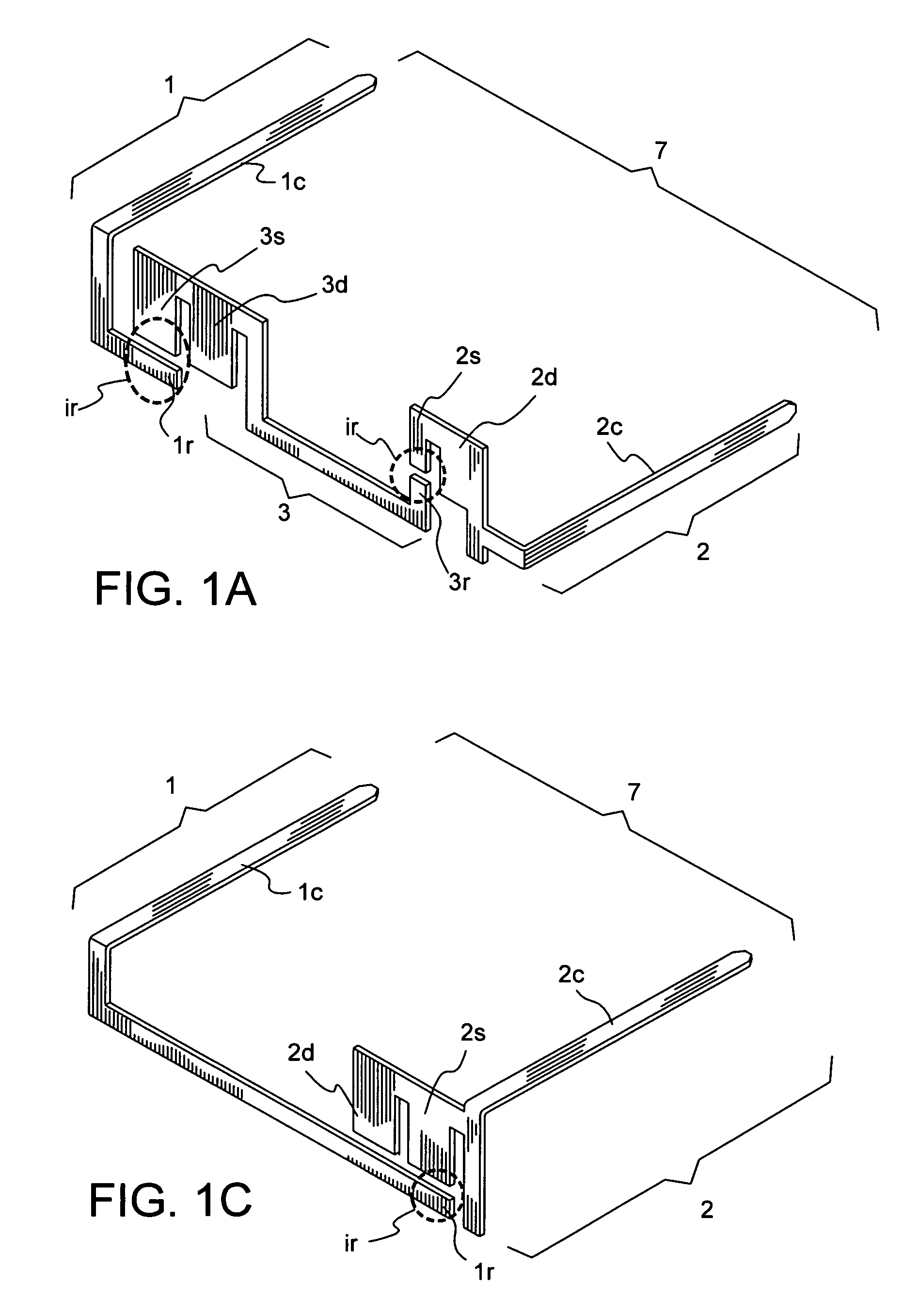

Imaging module having lead frame supported light source or sources

ActiveUS8915444B2Easy to disassembleImprove rigiditySensing by electromagnetic radiationBarcodeEngineering

An imaging module for data collection devices, such as bar code scanners. The module includes an aiming or illumination light source or sources, seated on a support is mounted in a housing. The support is fixed in the housing to provide for its precise placement therein, in a predetermined position.

Owner:HAND HELD PRODS

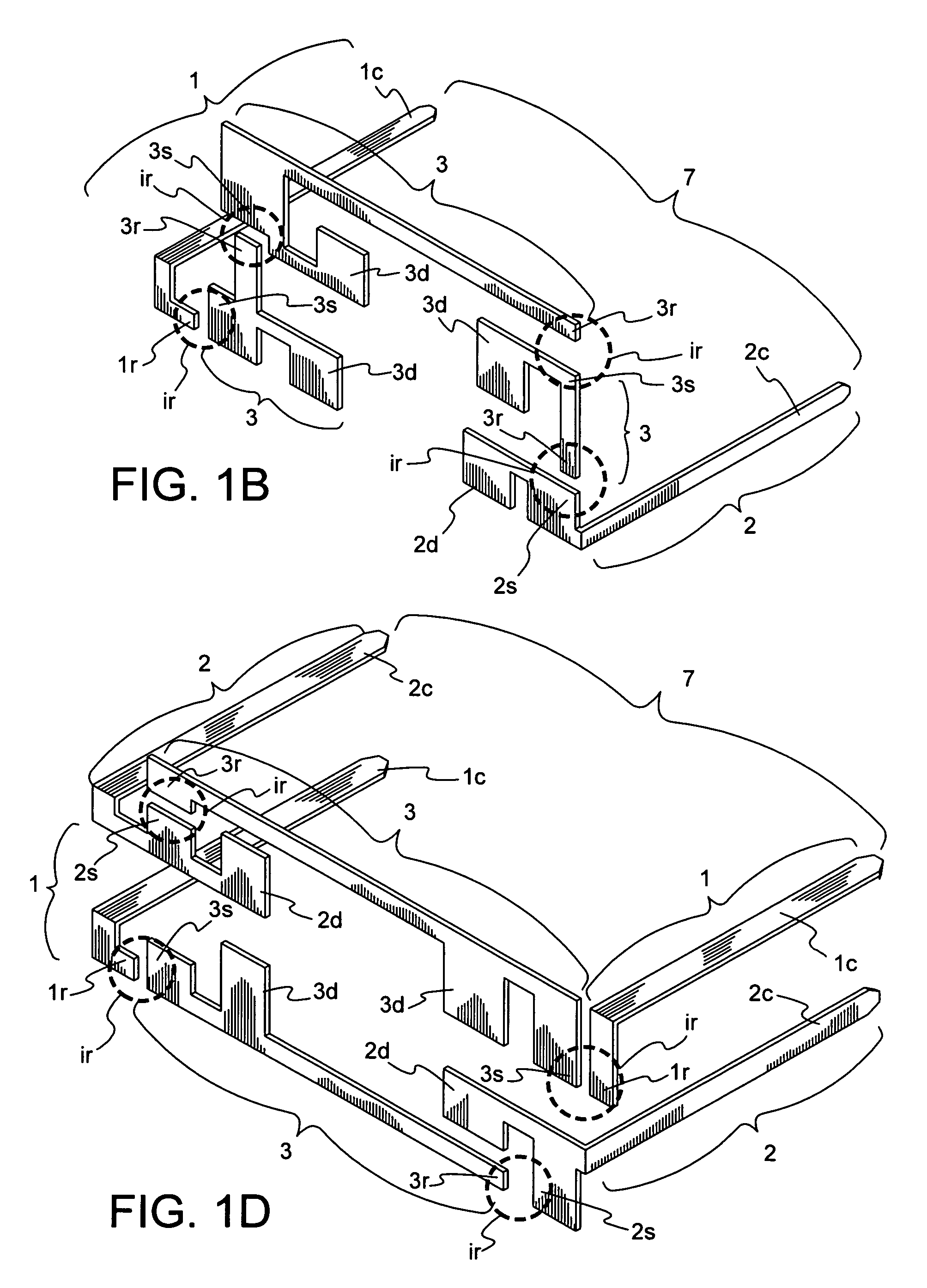

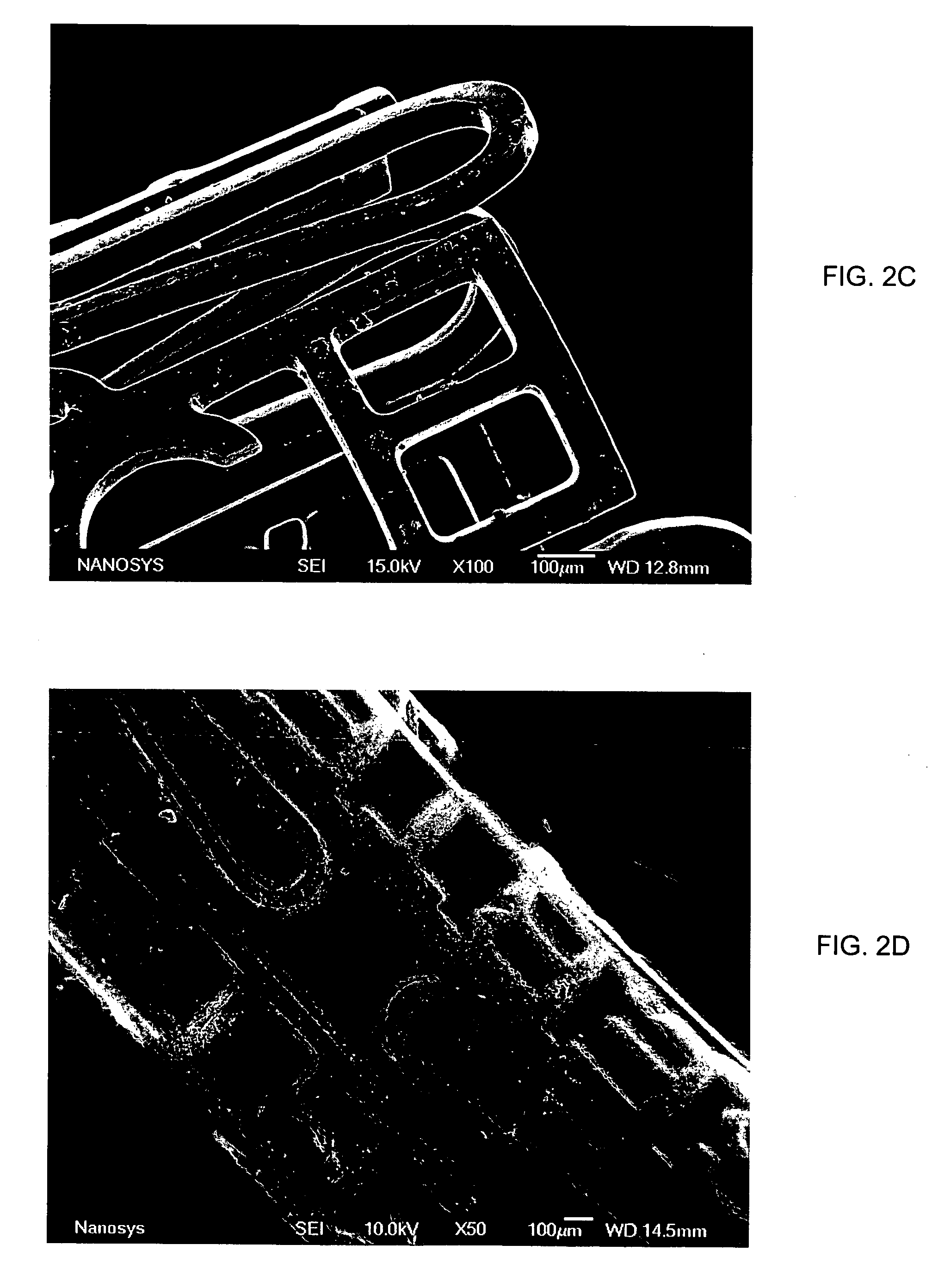

Medical device applications of nanostructured surfaces

InactiveUS20060204738A1Improve adhesionIncrease frictionBiocideMaterial nanotechnologyOsteoblastNanofiber

This invention provides novel nanofiber enhanced surface area substrates and structures comprising such substrates for use in various medical devices, as well as methods and uses for such substrates and medical devices. In one particular embodiment, methods for enhancing cellular functions on a surface of a medical device implant are disclosed which generally comprise providing a medical device implant comprising a plurality of nanofibers (e.g., nanowires) thereon and exposing the medical device implant to cells such as osteoblasts.

Owner:GLO TECH LLC

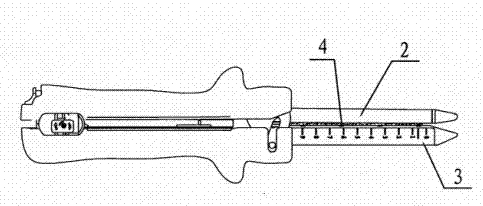

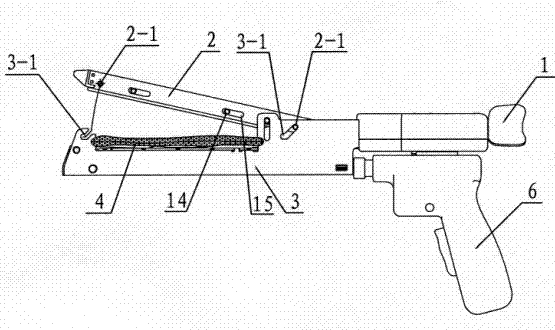

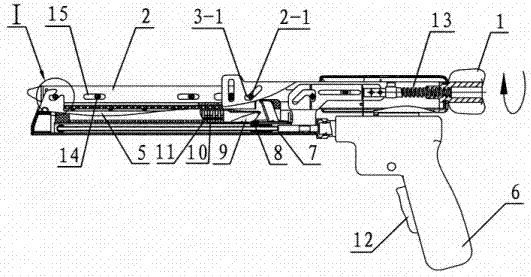

Cutter stapler for surgery

Owner:CHANGZHOU KANGDI MEDICAL STAPLER

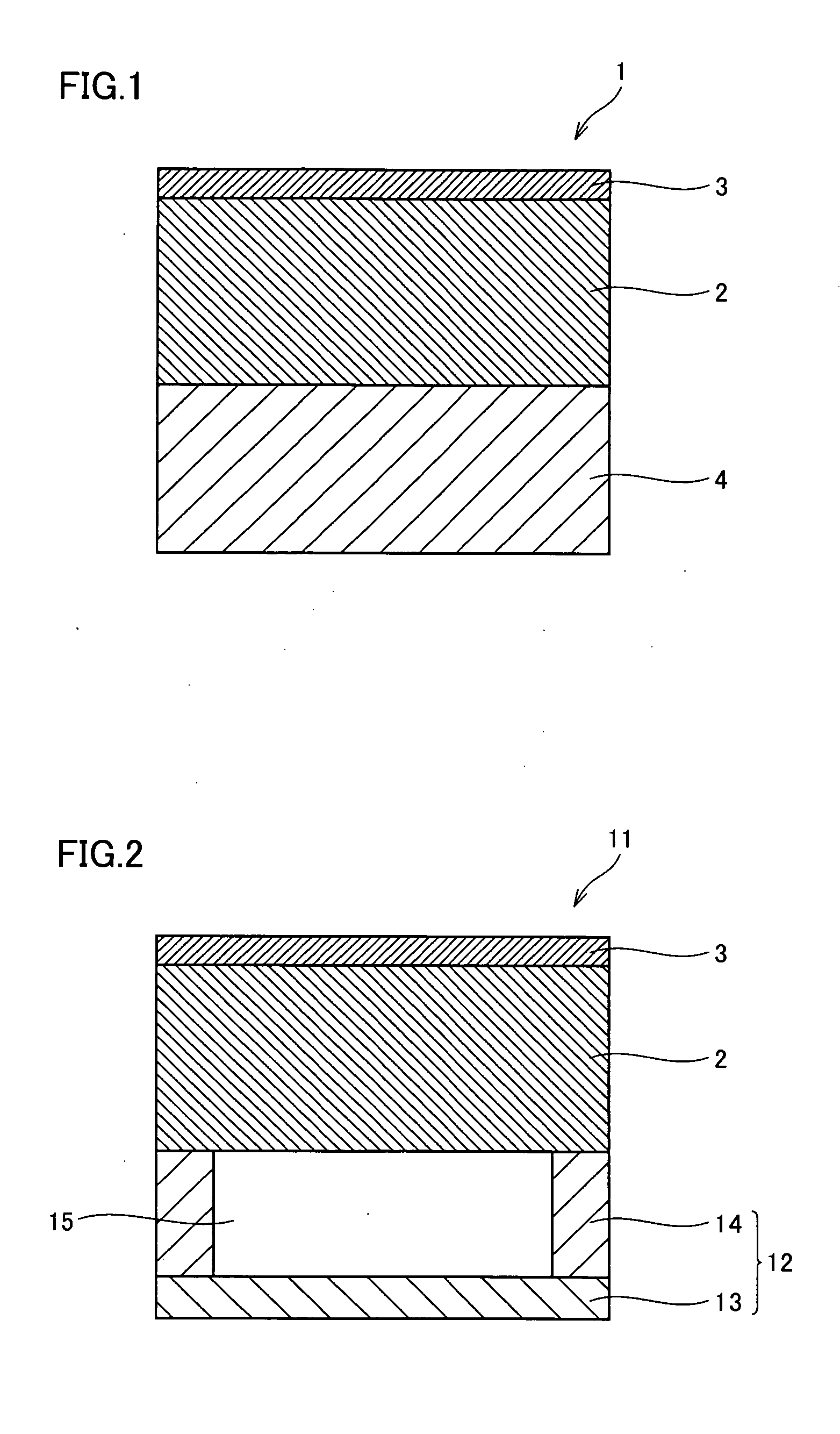

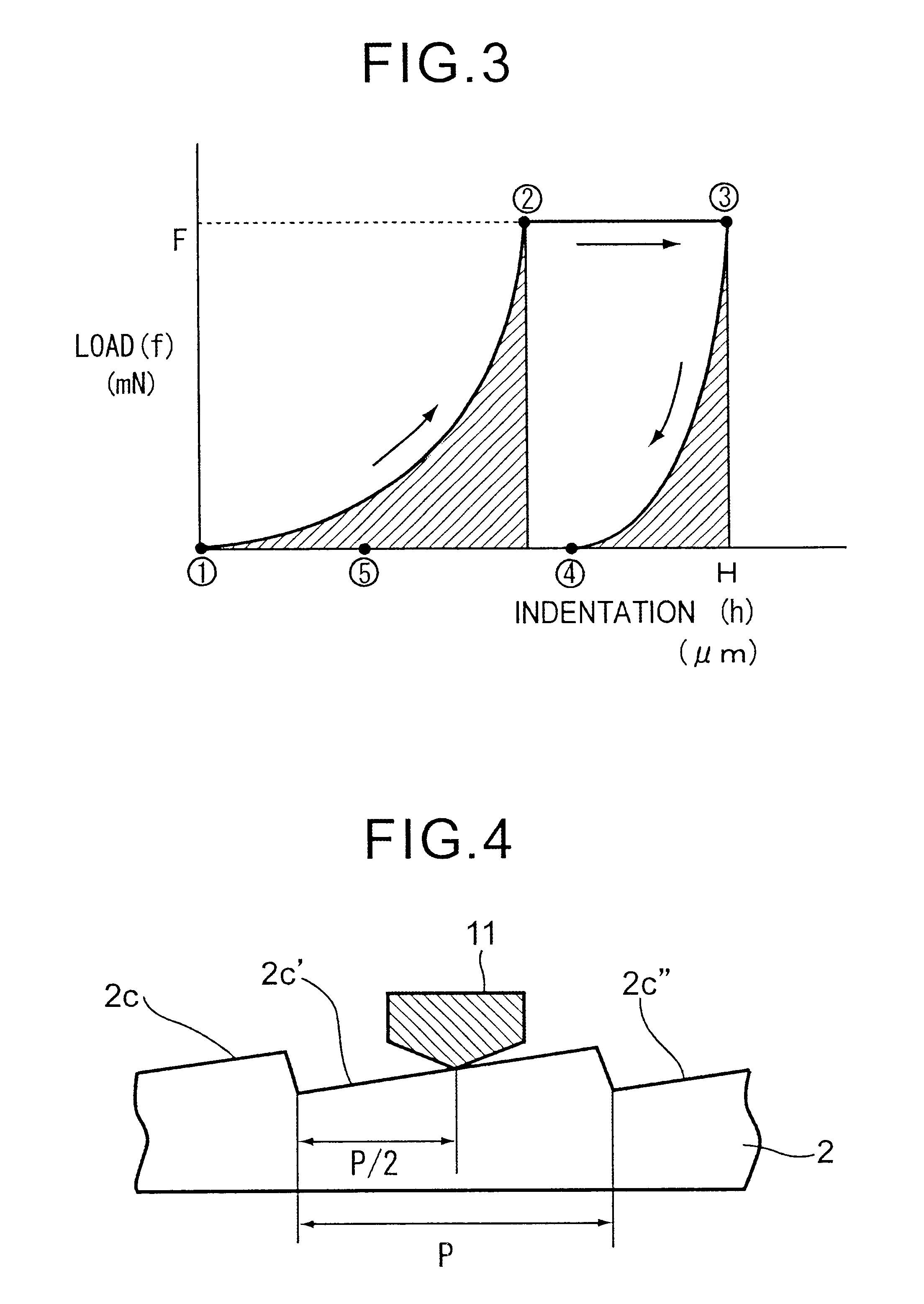

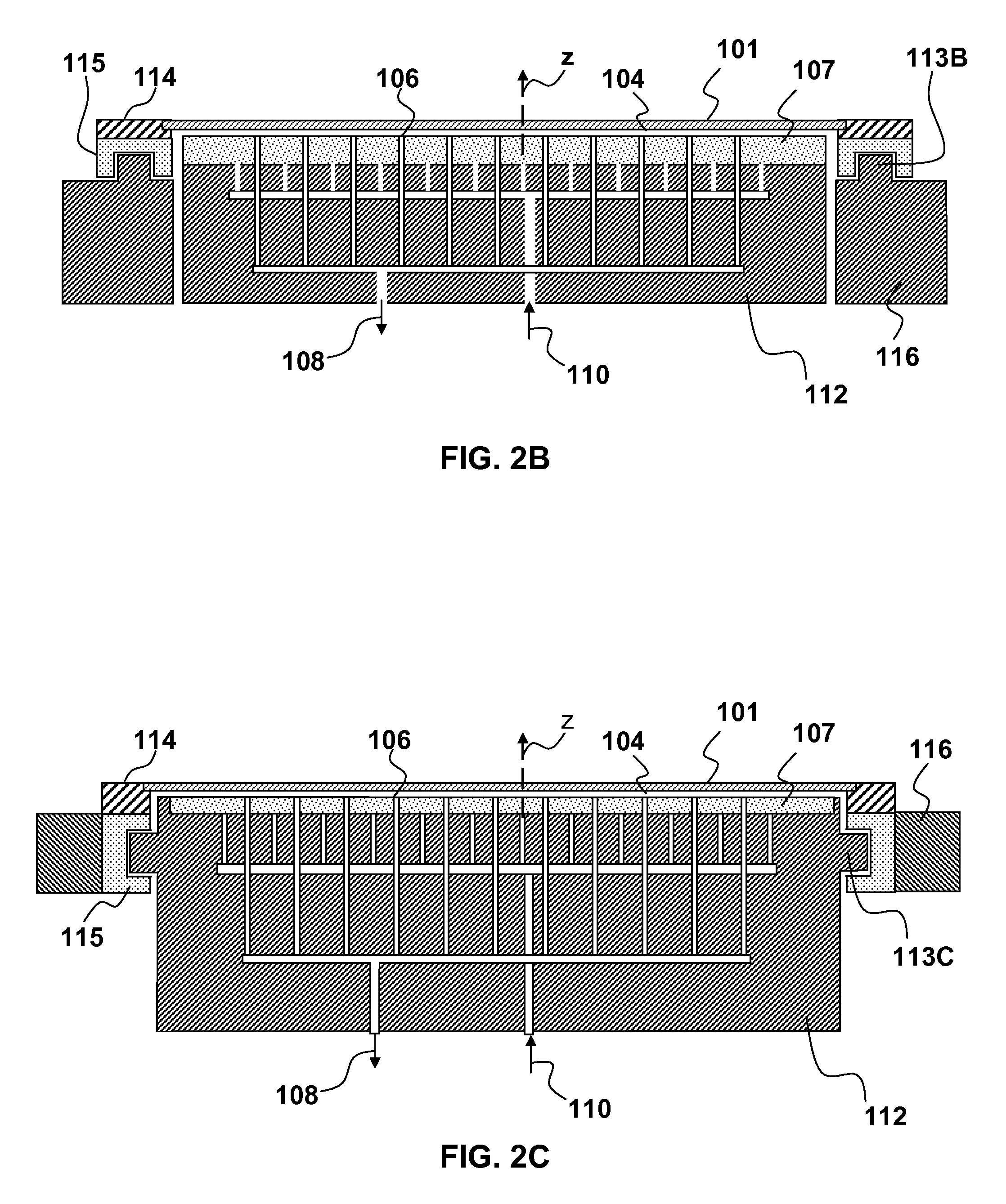

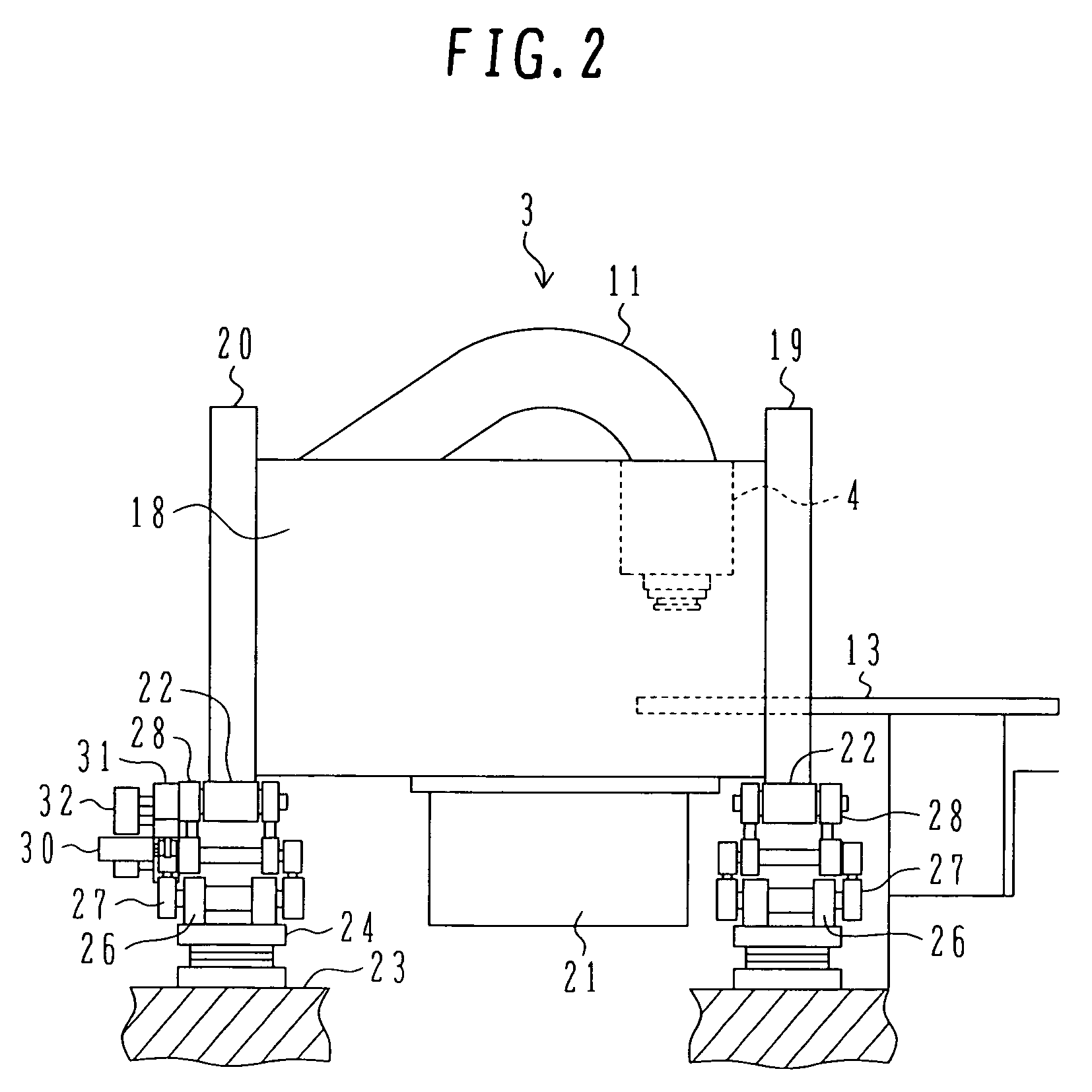

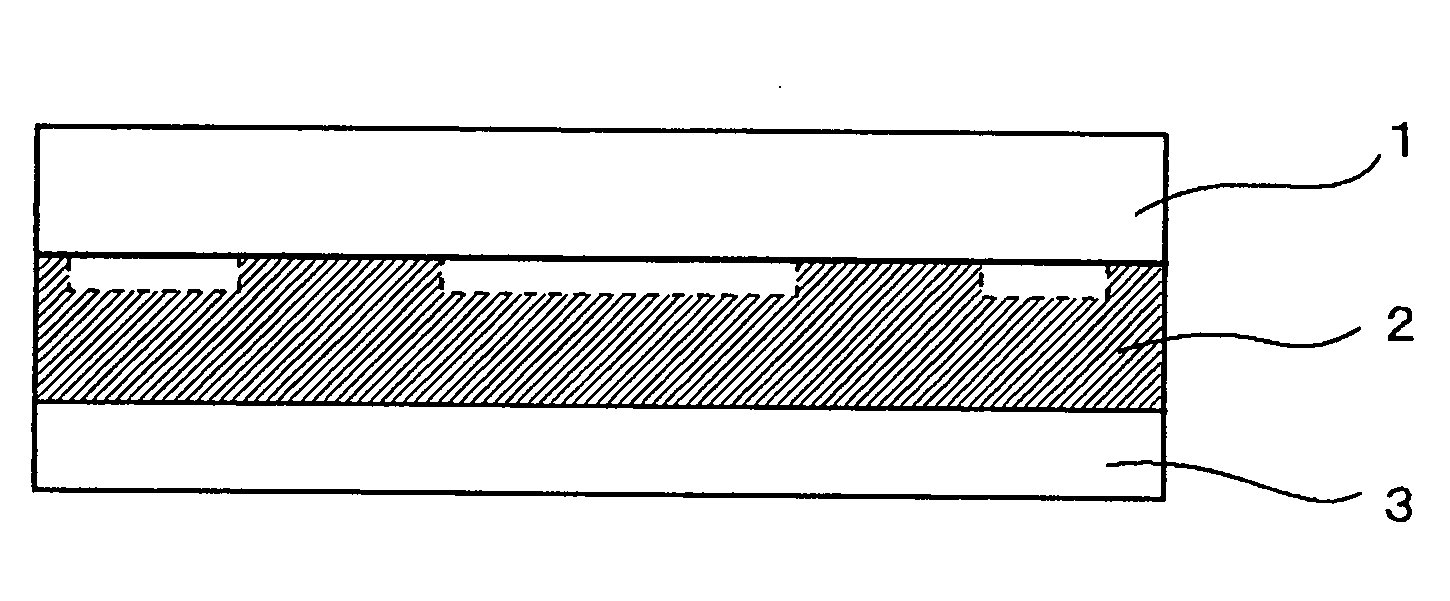

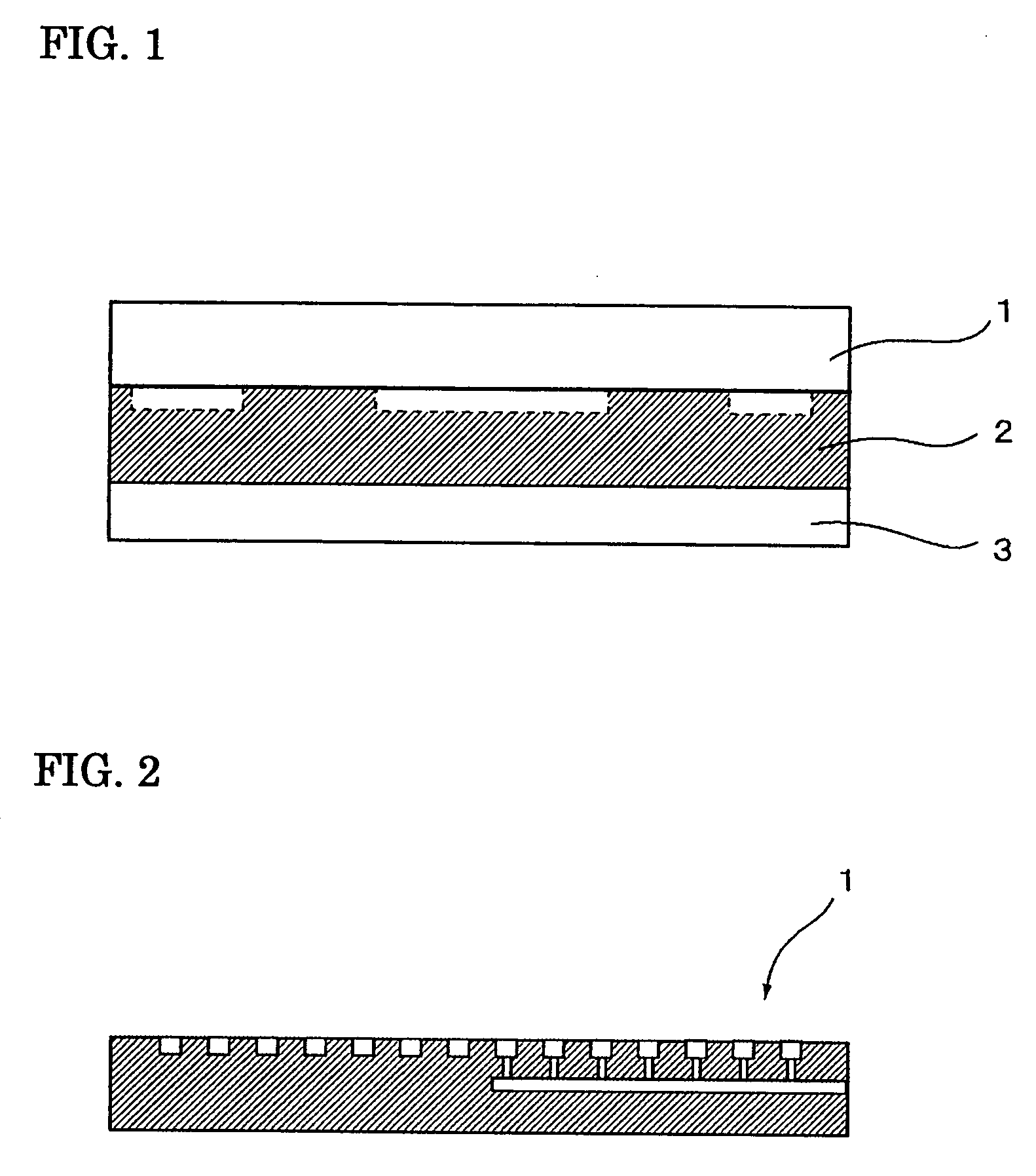

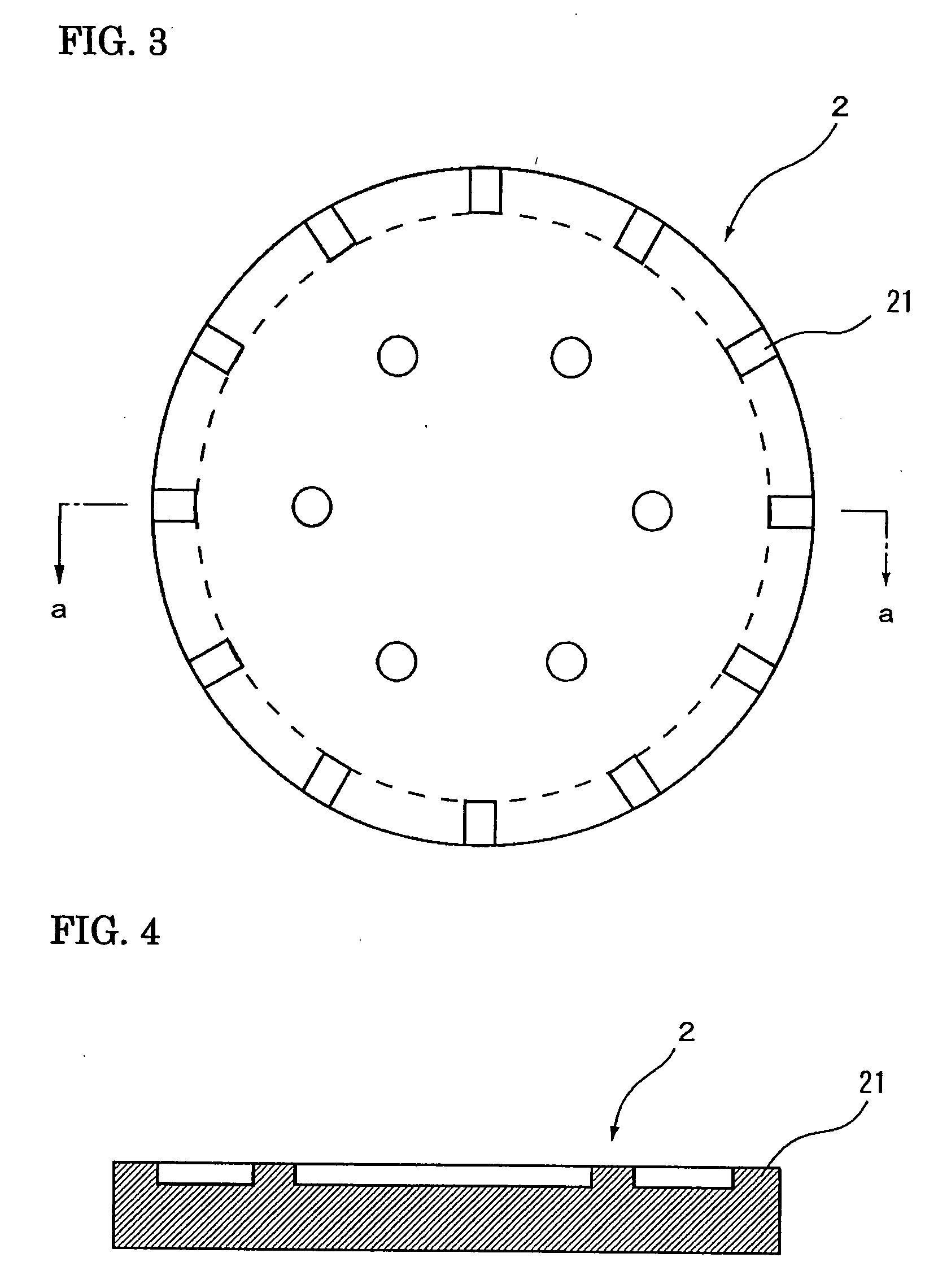

Wafer holder, heater unit used for wafer prober and having wafer holder, and wafer prober

InactiveUS20080211526A1Avoid contact failureAvoid temperature riseSleeve/socket jointsTurning machine accessoriesContact failureSemiconductor chip

By wafer holder including a chuck top for mounting a wafer and a supporter supporting the chuck top and having flatness of at most 0.1 mm, a heater unit for a wafer prober and the wafer prober using the wafer holder, a wafer holder and a wafer prober apparatus hardly deformable even under high load and capable of effectively preventing contact failure, and capable of preventing temperature increase in a driving system when a semiconductor wafer having semiconductor chips with minute circuitry that requires high accuracy is heated can be provided. In the wafer holder of the present invention, the flatness of the supporter is preferably at most 0.05 mm, and more preferably at most 0.01 mm.

Owner:SUMITOMO ELECTRIC IND LTD

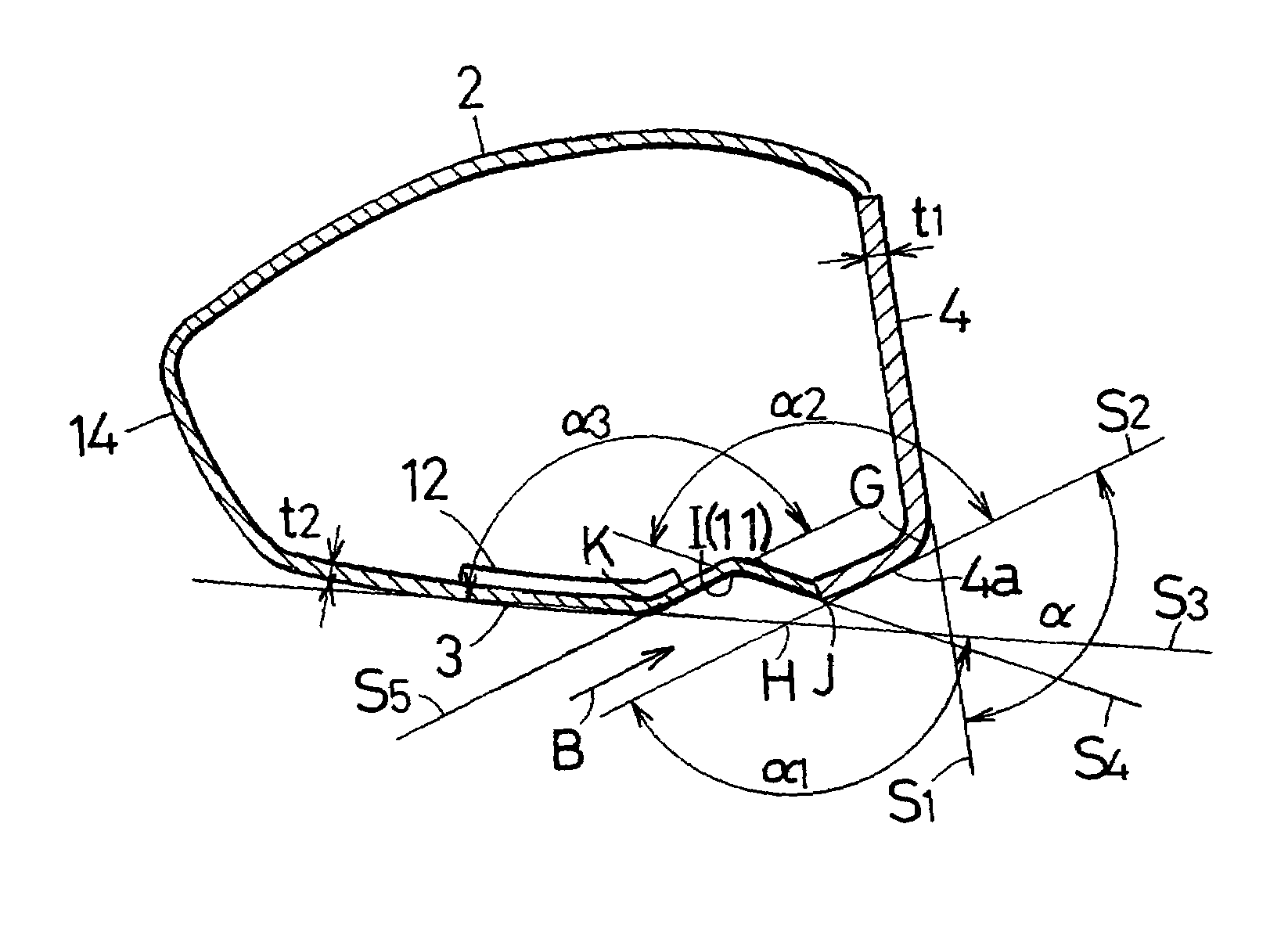

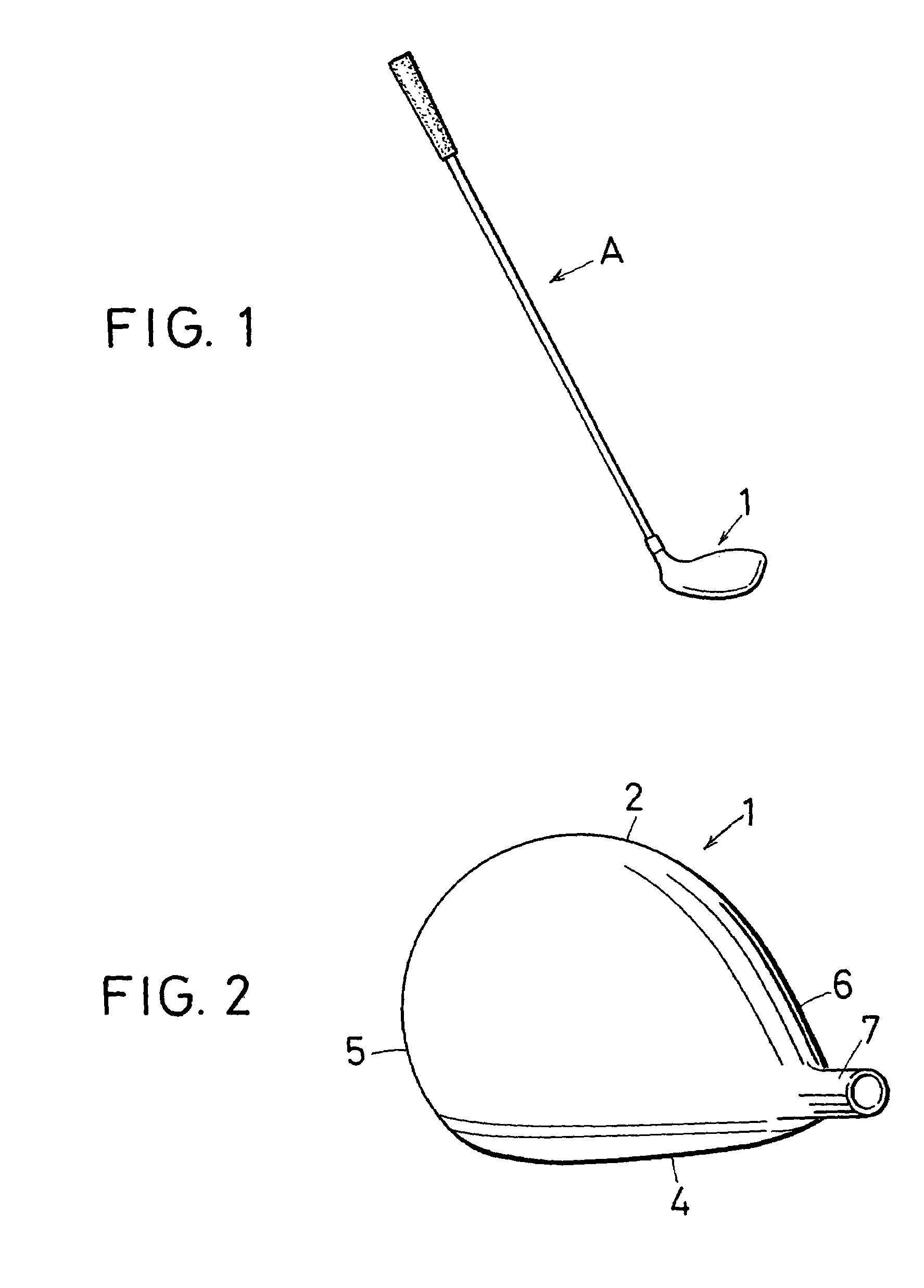

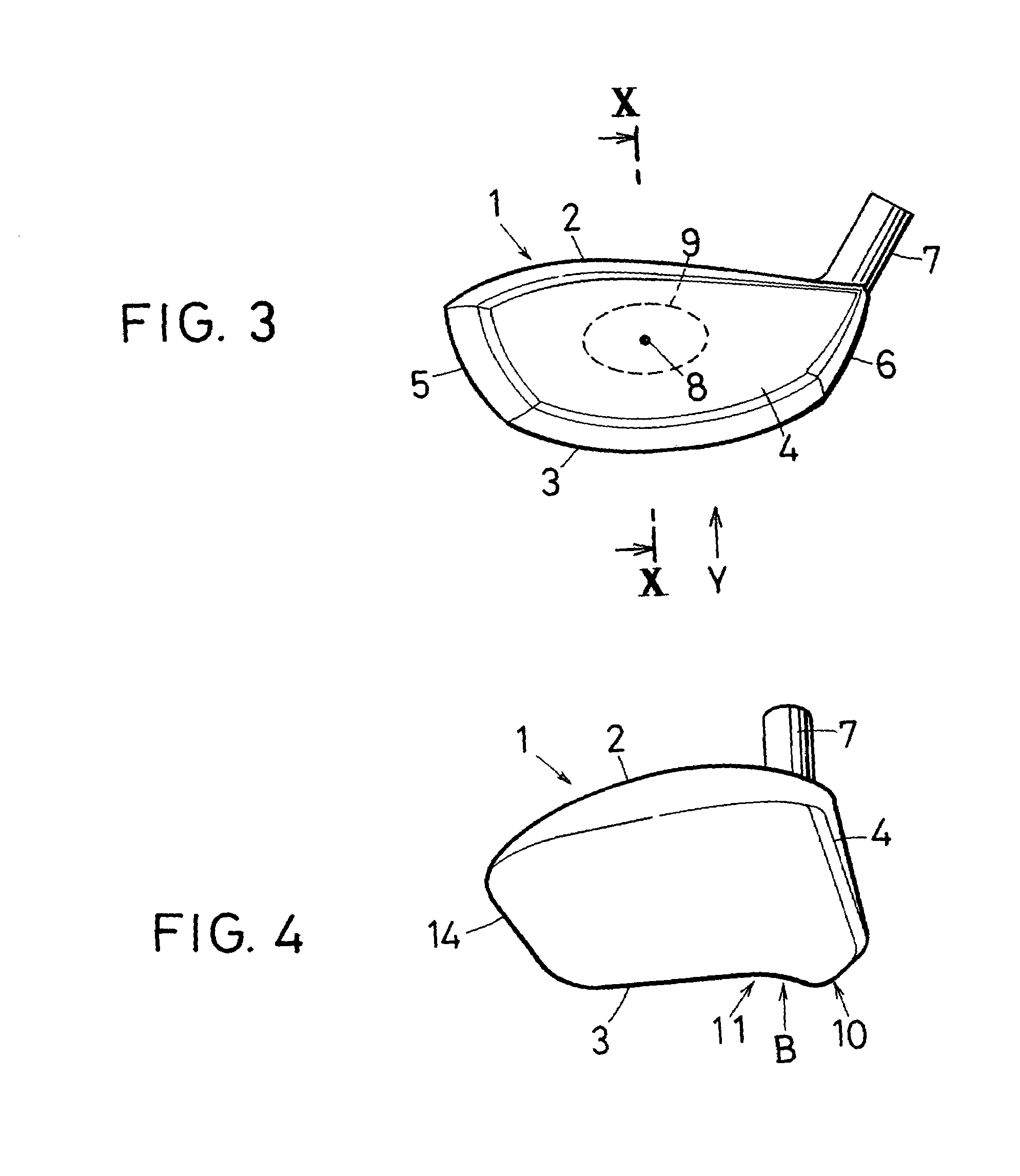

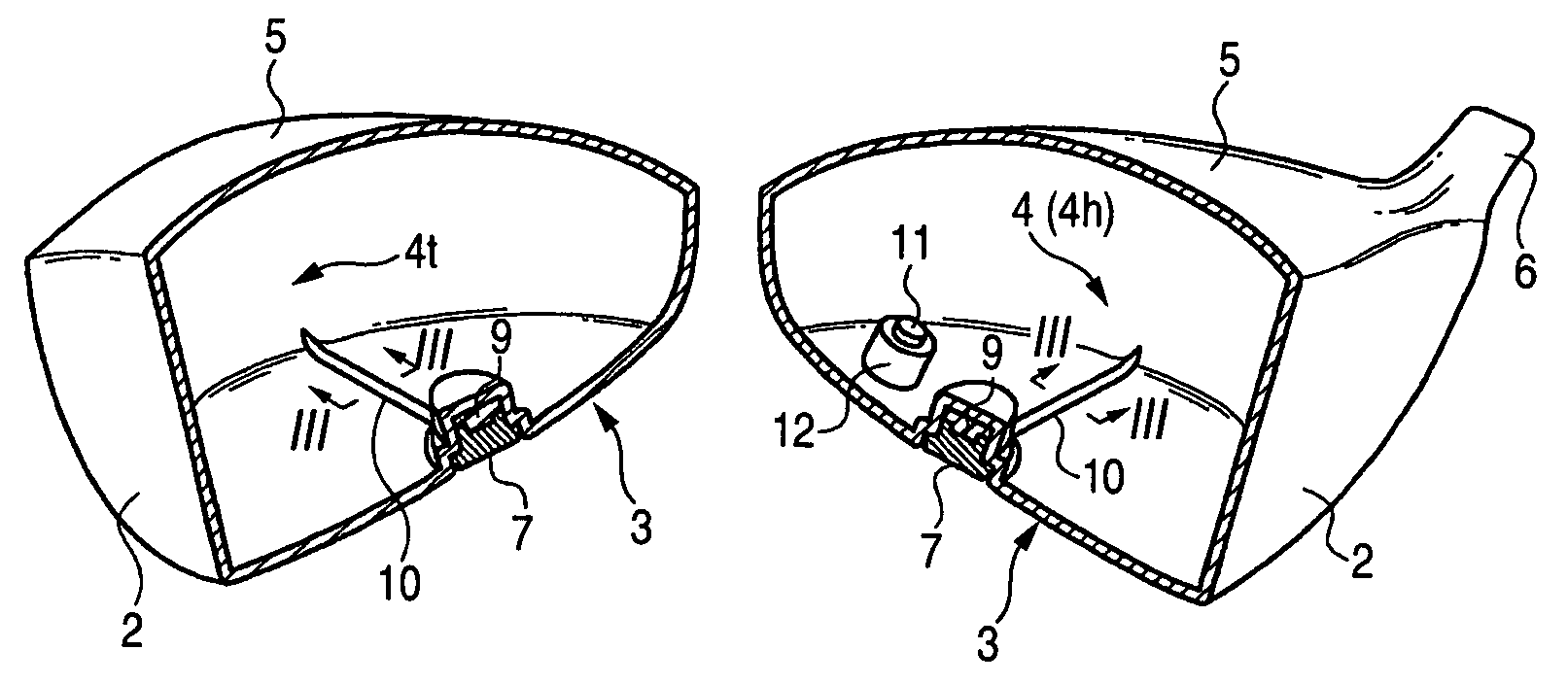

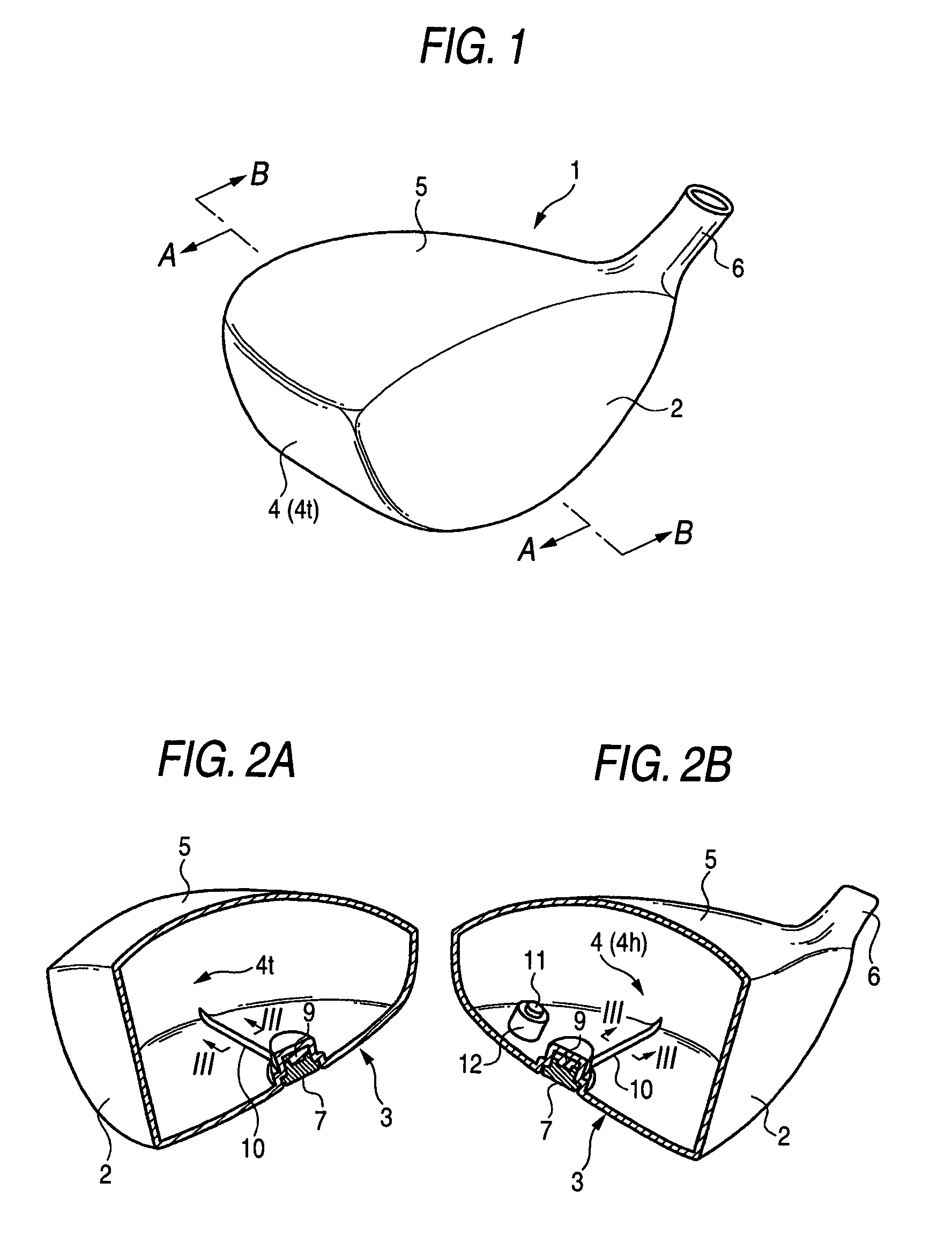

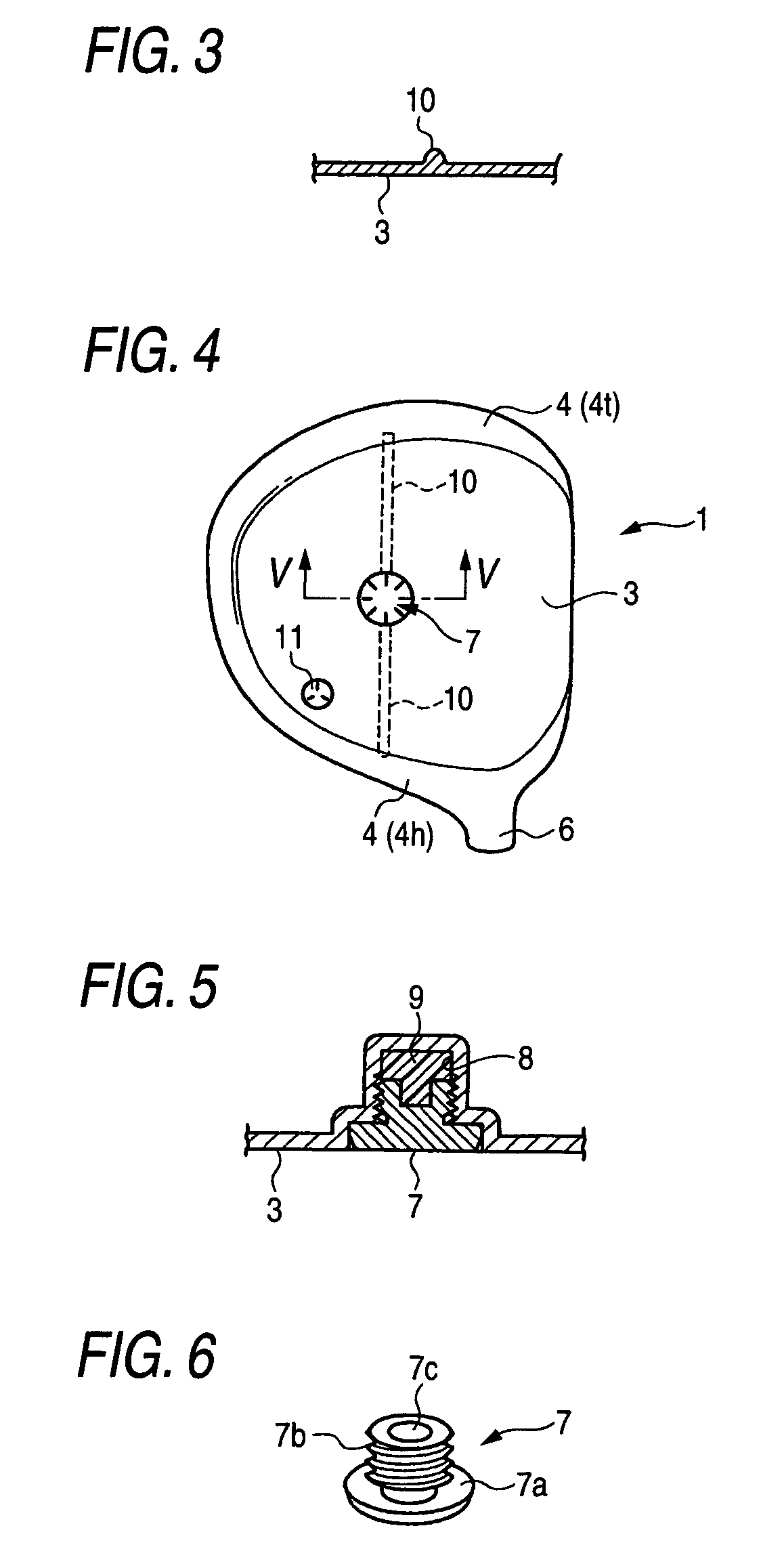

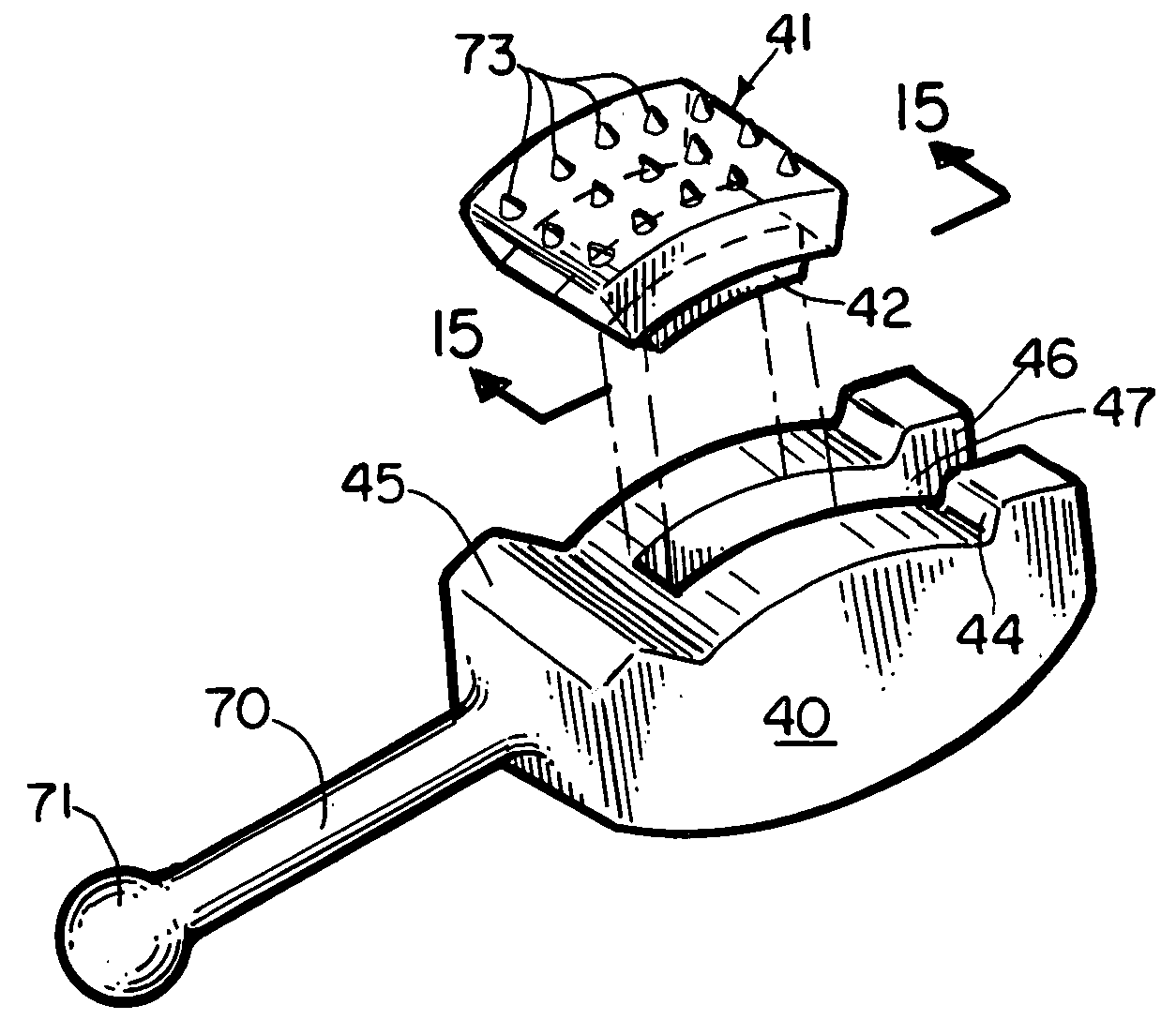

Golf club

In a driver golf head (1) comprising a face (4) having a hitting surface, a sole (3) forming a lower portion, and a crown (5) forming an upper portion, the sole (3) is improved. The sole (3) in the position close to the face (4) was formed into an elastically deformable recess-projection shape, and part of the face (4) was formed into a projecting shape and integrated with the sole (3) to increase rigidity. Using a configuration with increased rigidity and decreased rigidity between the face (4) and sole to obtain an elastically deformable portion and providing a high-rigidity body (12) increased the repulsion force in the lower portion of the face and extended the traveling distance of the golf ball.

Owner:ENDO MFG COMPANY

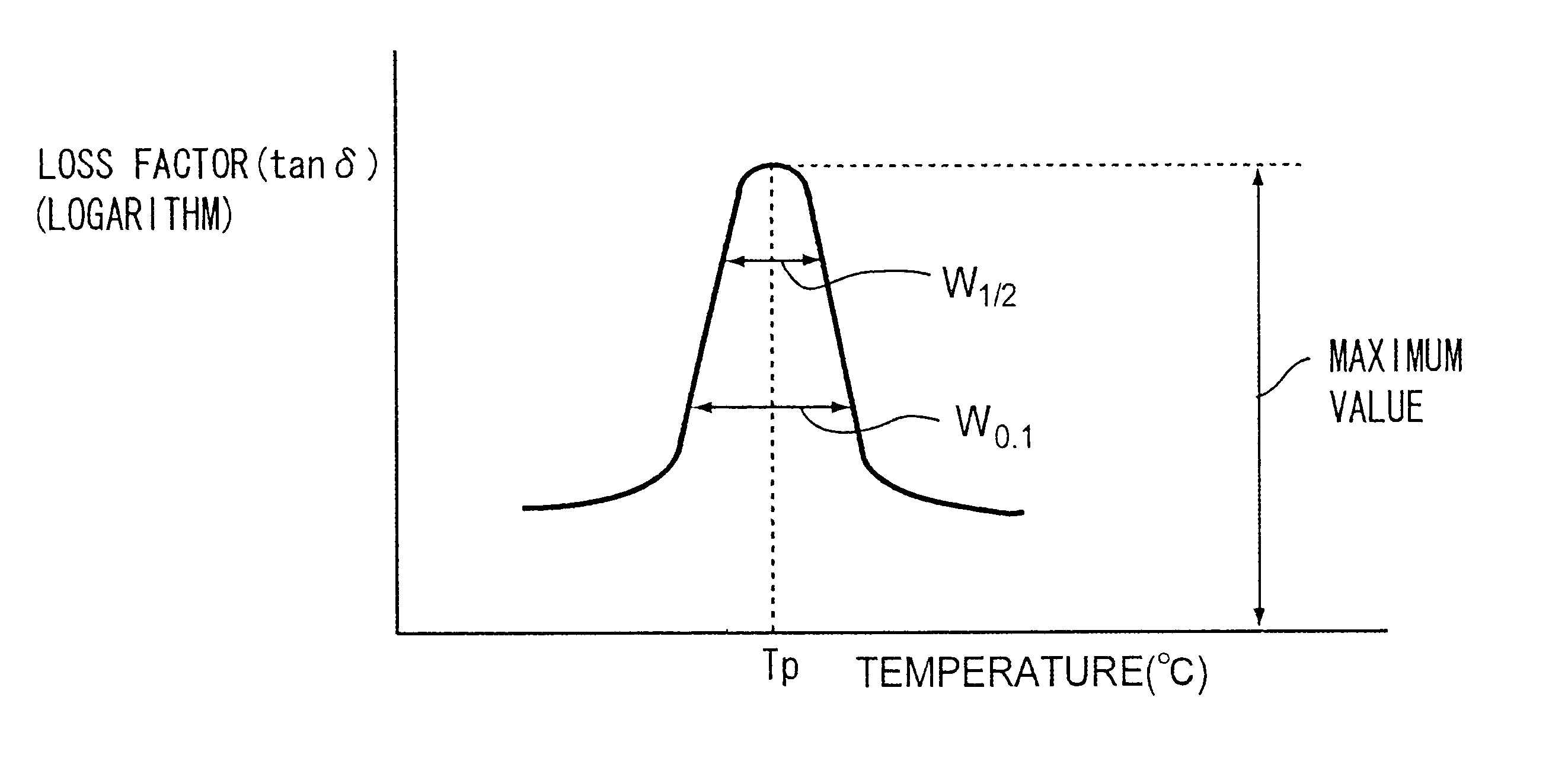

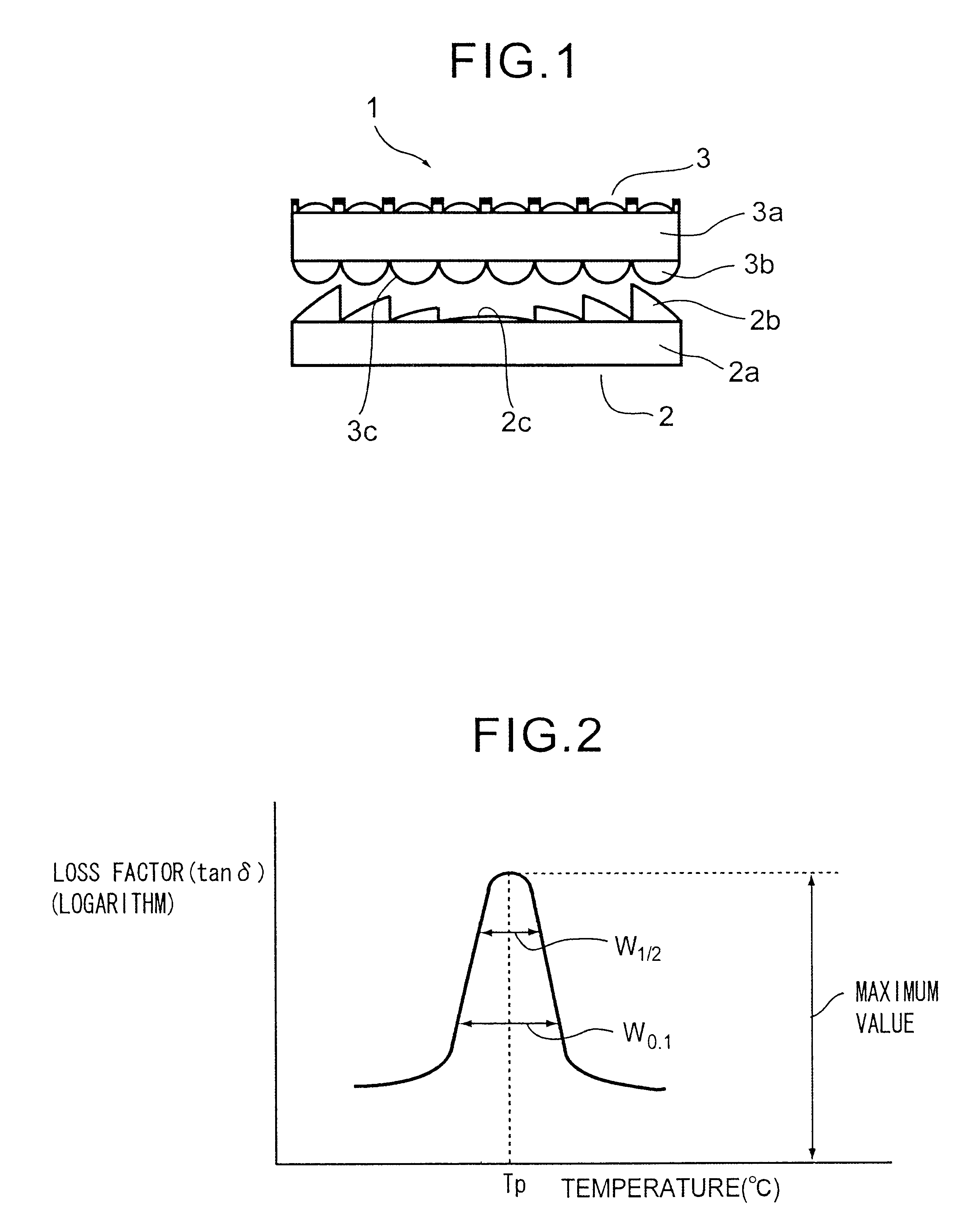

Resin composition for production of optical element, the optical element, and projection screen

InactiveUS6650471B2Increase crosslink densityHigh refractive indexProjectorsOptical articlesTemperature curveProjection screen

A resin composition for production of an optical element being adapted to form the optical element has a characteristics of which, when W1 / 2 (° C.) represents, regarding a crest portion in a loss factor / temperature curve obtained by measuring the loss factor of the resin composition relative to a change in the temperature, the width of the crest portion at the position of ½ of the maximum value of the loss factor in the crest portion temperature range; W0.1 (° C.) represents, regarding the crest portion, the width of the crest portion at the position of 0.1 of the maximum value of the loss factor; and DeltaW (° C.), the difference between the widths of the two crest portions, is set to be DeltaW=W0.1-W1 / 2, the DeltaW is in the range of from 16° C. to 31° C.

Owner:DAI NIPPON PRINTING CO LTD

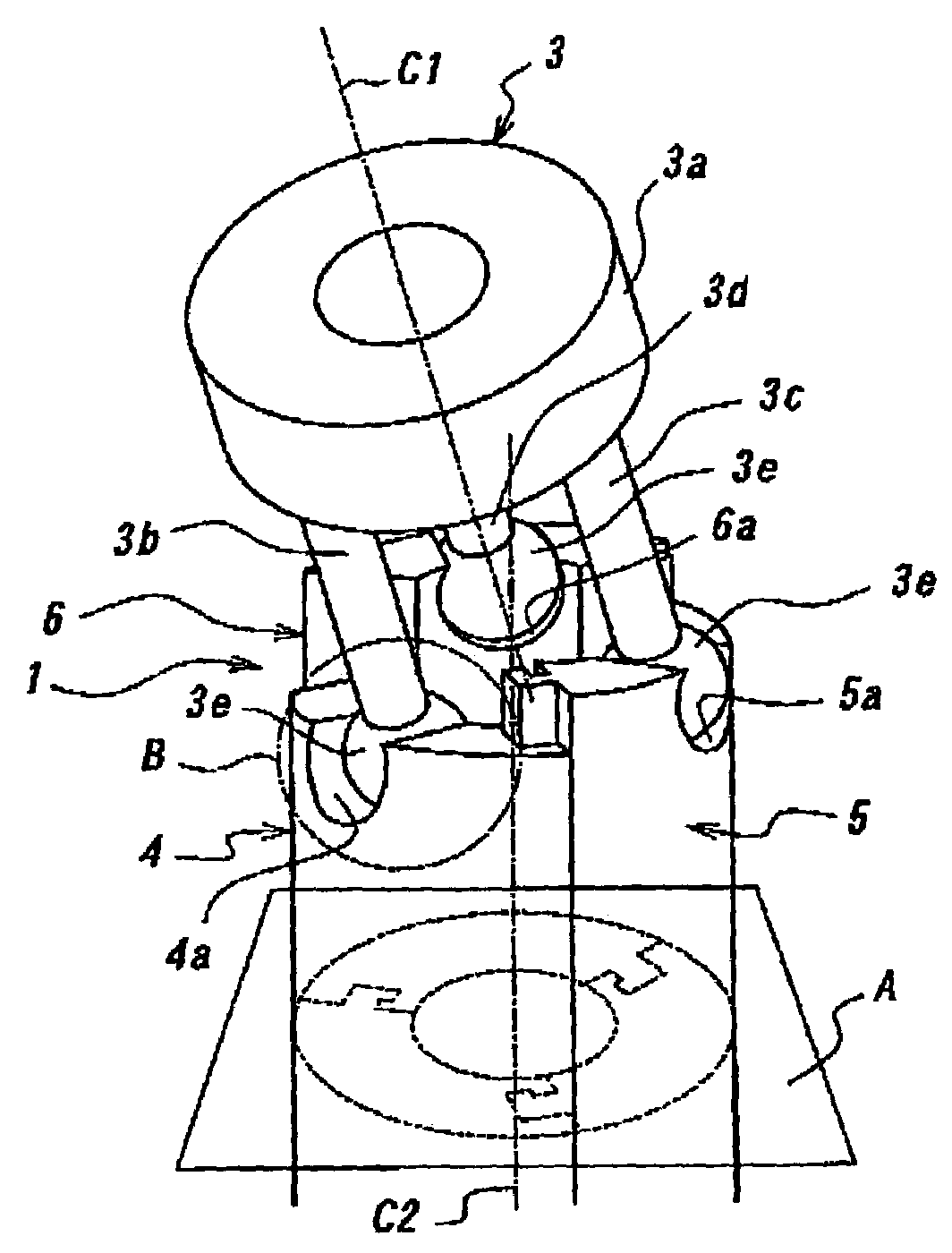

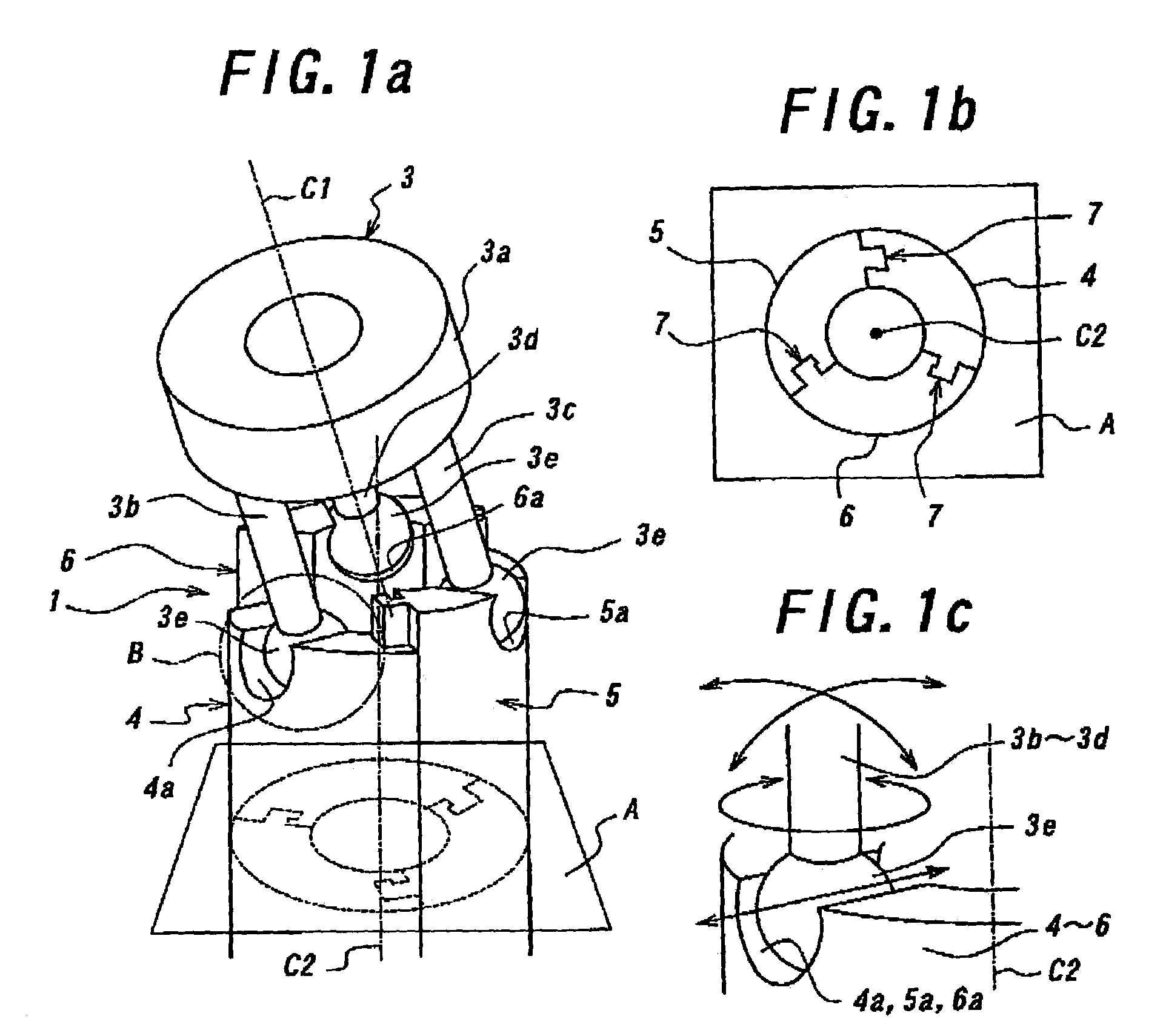

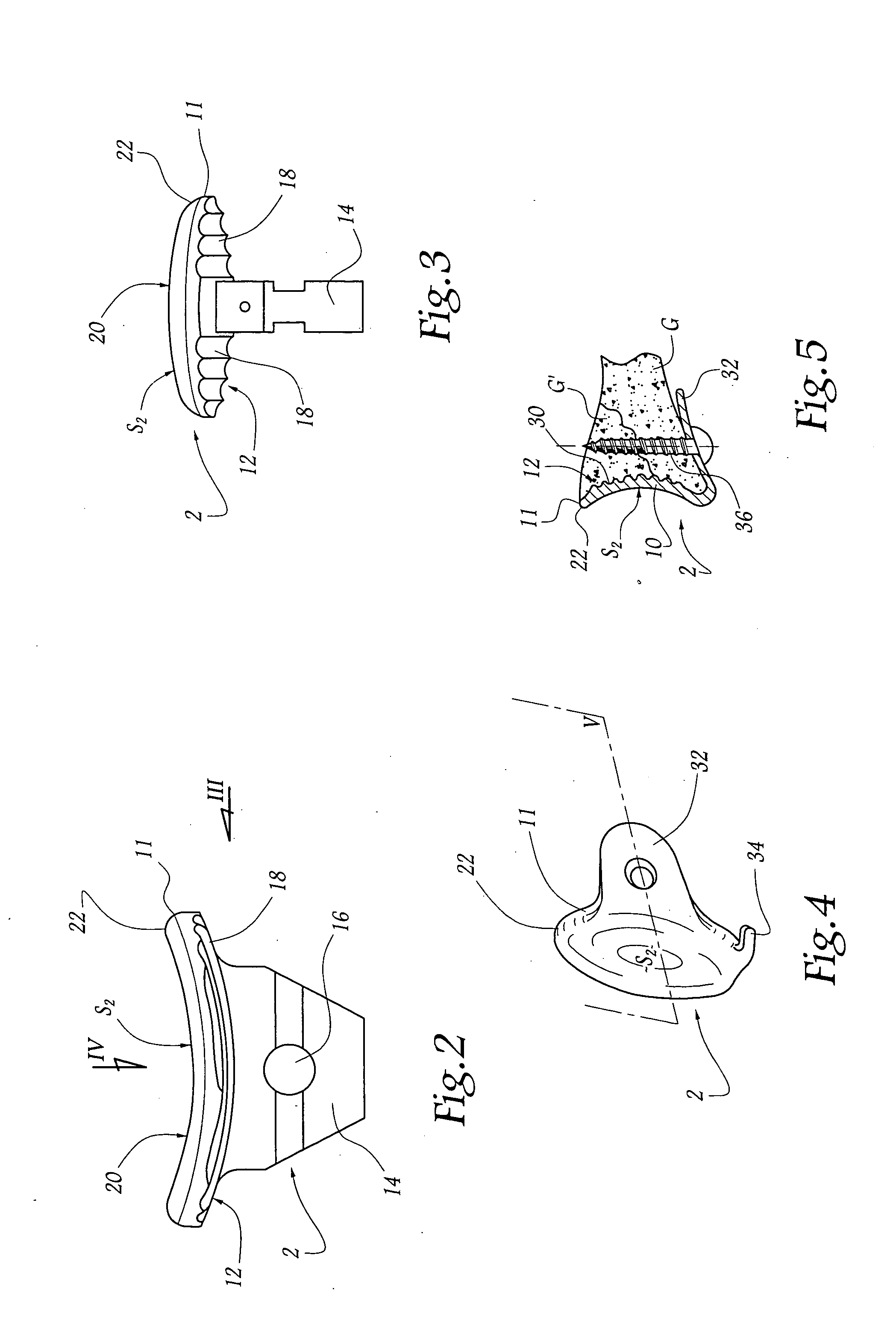

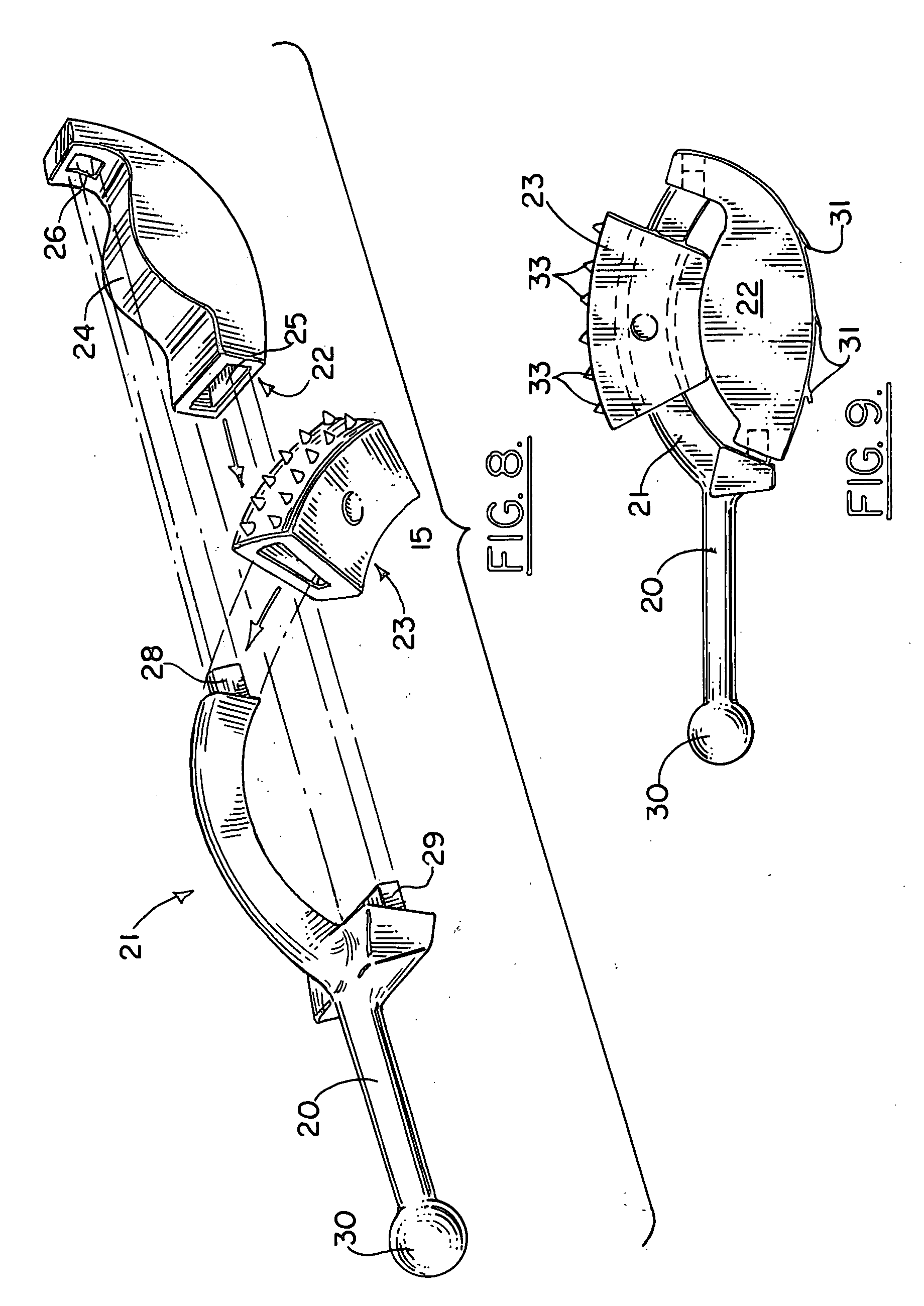

High-rigidity forceps tip assembly for active forceps and active forceps equipped with the same

InactiveUS7273488B2Efficiently transmitHigh rigidityMechanical apparatusJointsLaparoscopic surgeryForceps

Provided is a forceps tip assembly capable of supporting a forceps tip with high rigidity in order to realize a laparoscopic surgery requiring a significant power with the forceps tip, such as an organ removal surgery which has been heretofore difficult to be performed by a robot for medical use. The forceps tip assembly includes: a forceps tip supporting member which has a supporting part for supporting a forceps tip and three leg parts which are disposed at even intervals in a circumferential direction around a central axis line C1 and fixed to the supporting part so as to protrude backward from the supporting part; and three back-and-forth moving members which are disposed at even intervals in a circumferential direction around a predetermined central axis line C2 extending in a front-to-rear direction, which have their front end portions coupled with the three leg pads swingably and slidably in a direction orthogonal to the predetermined central axis line C2 and which are mutually coupled together as relatively movable in the extending direction of central axis line C2.

Owner:THE UNIV OF TOKYO

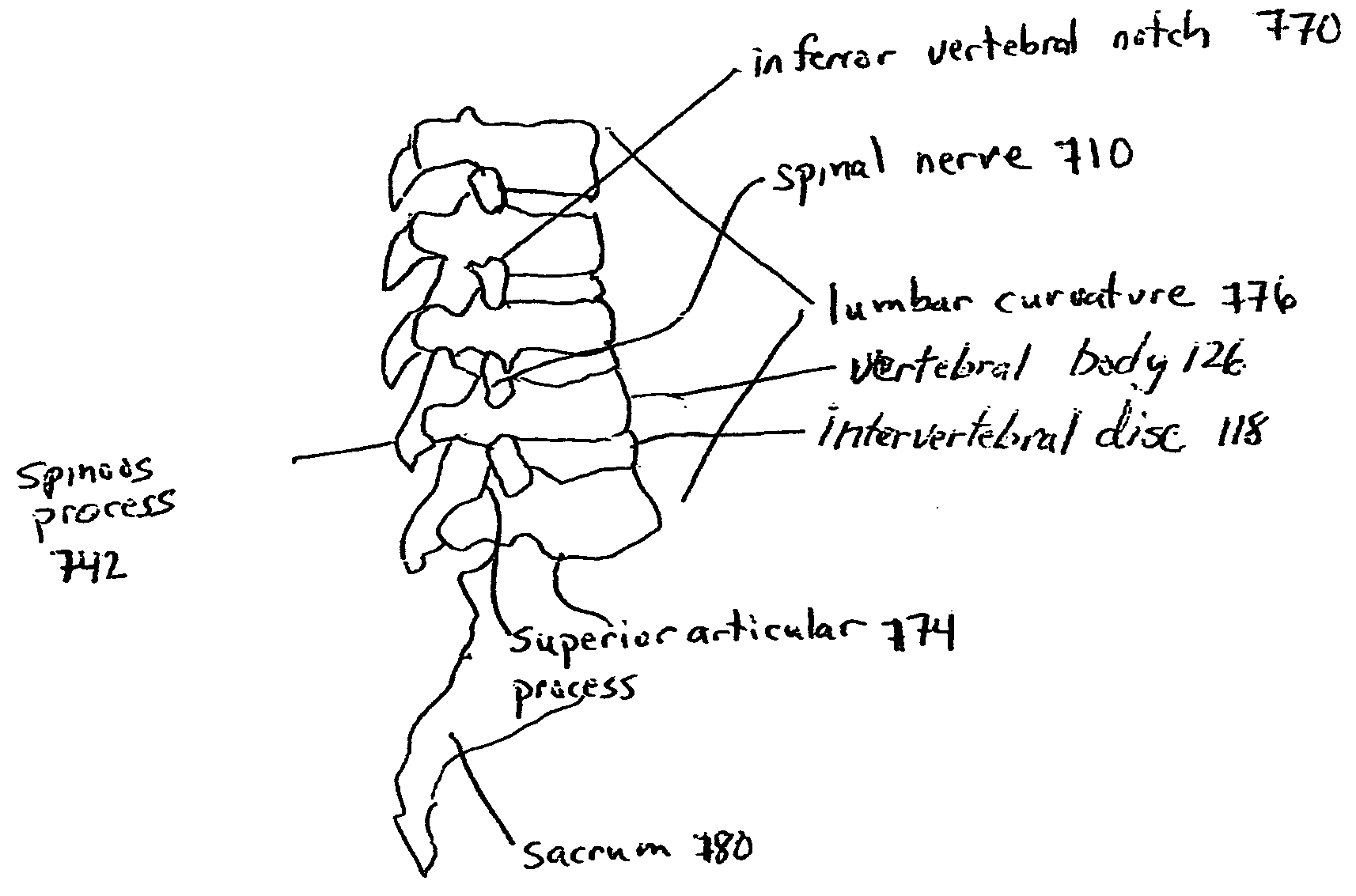

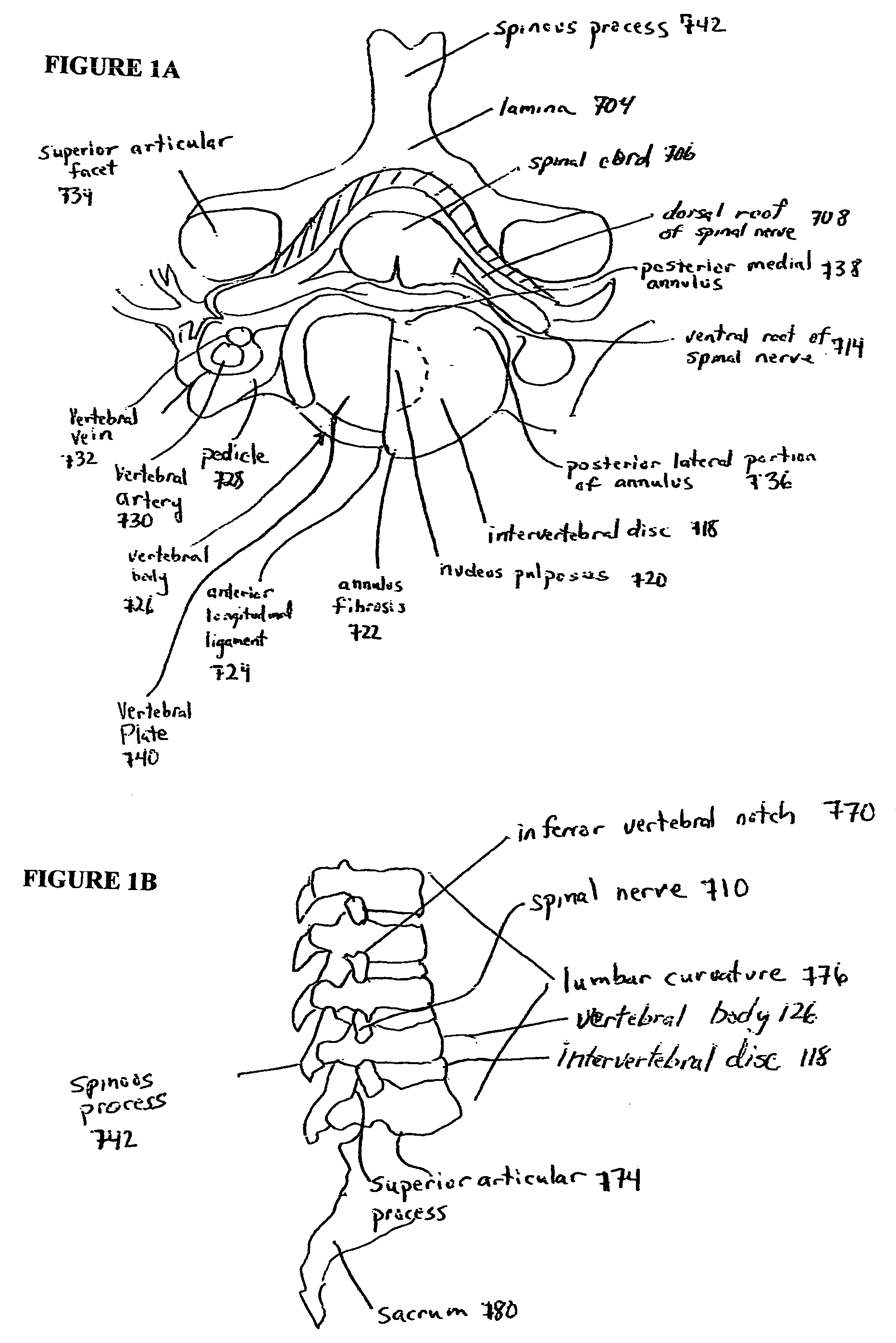

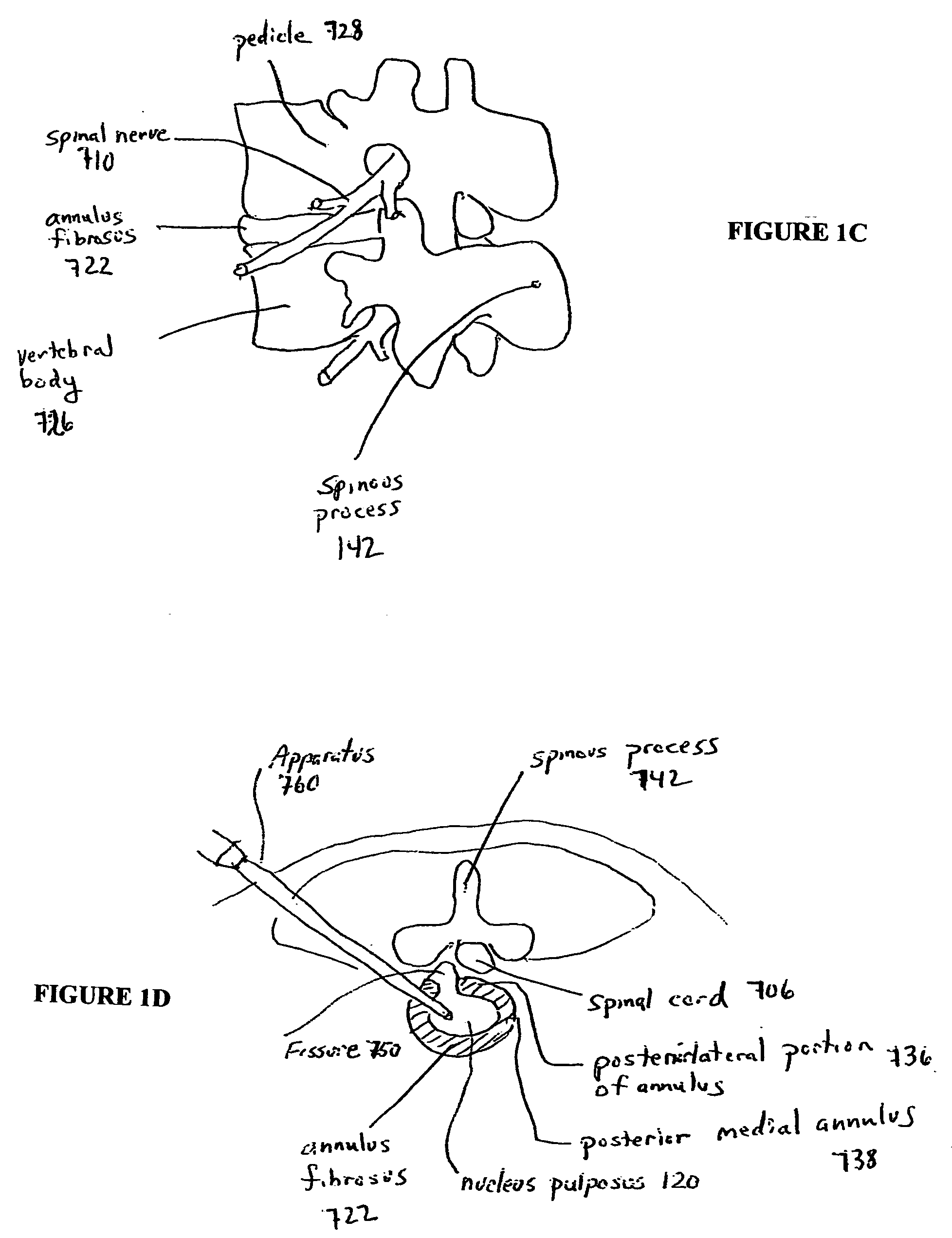

Devices and methods for spine repair

InactiveUS20050070913A1Strengthening intervertebral spaceEasy to operateSurgical furnitureBone implantRepair siteIntervertebral disk

Surgical methods of repairing defects and deficiencies in the spine are disclosed. The methods involve delivering a single part in-situ polymerizing fluid to (i) close a weakened segment or fissure in the annulus fibrosus, (ii) strengthen the annulus, (iii) replace or augment the disc nucleus, or (iv) localize a disc prosthesis. The methods may include placing a delivery conduit adjacent to the repair site and providing a liquid tissue adhesive to bond to and repair a disc defect or deficiency

Owner:PROMETHEAN SURGICAL DEVICES

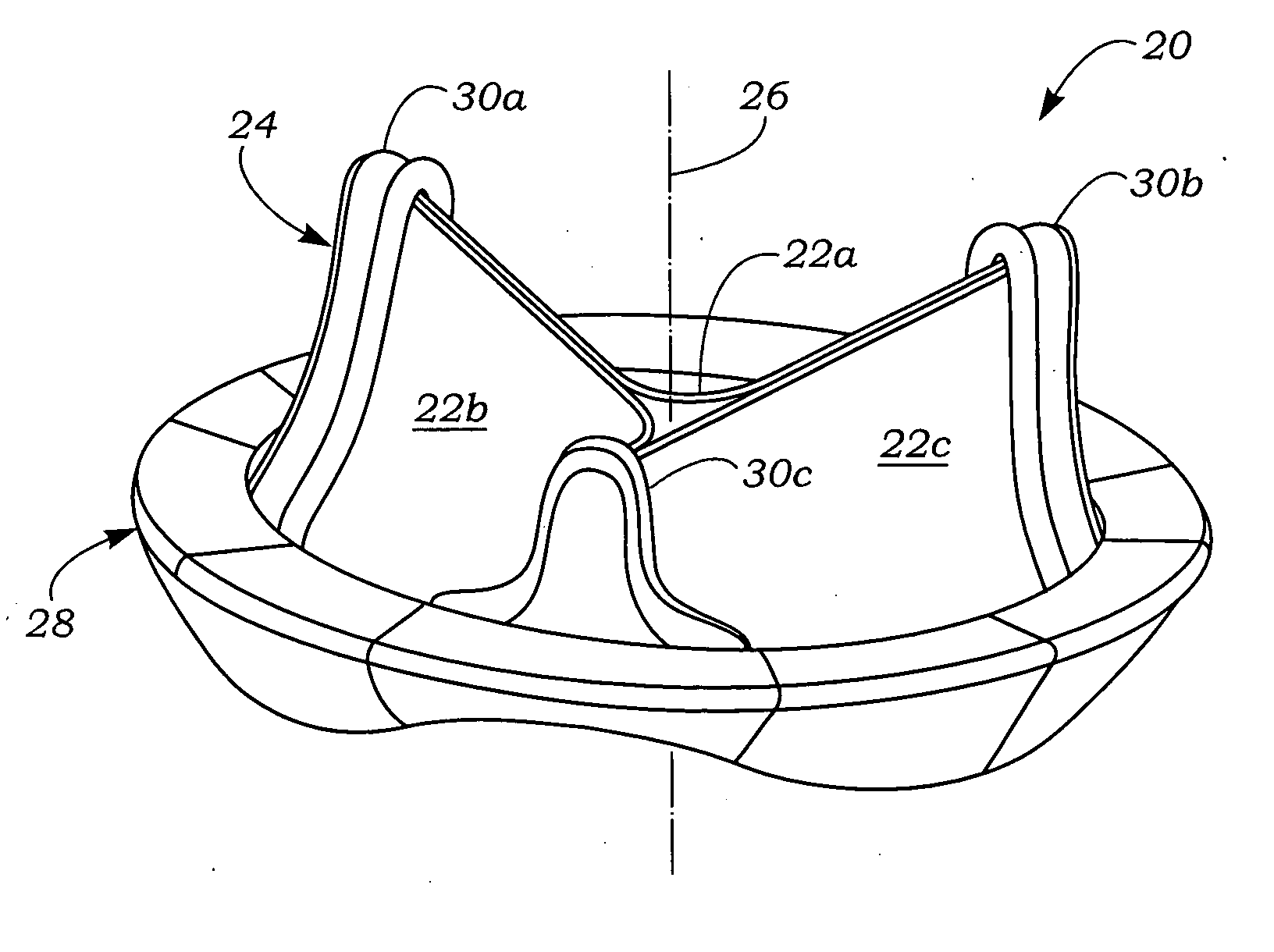

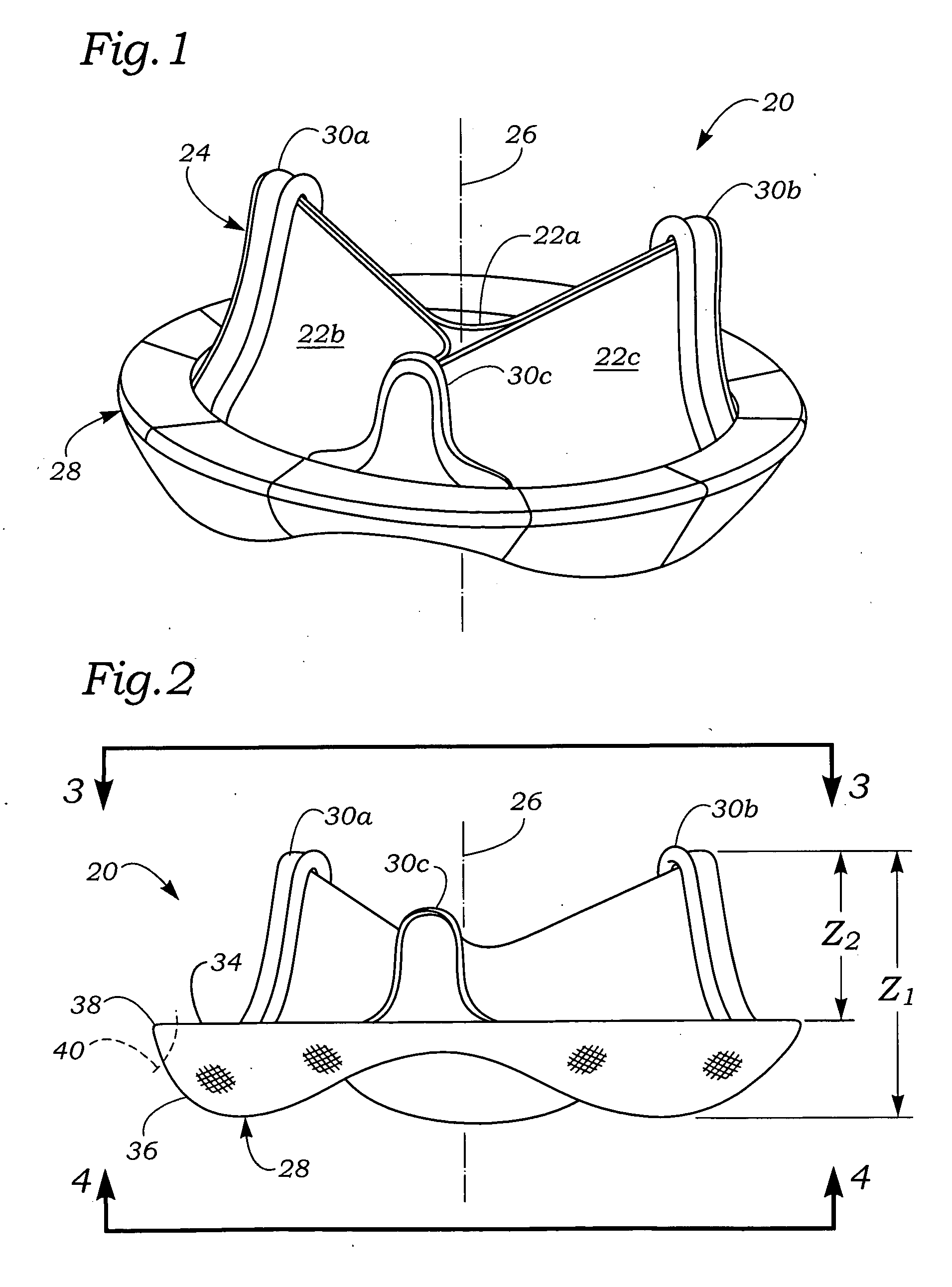

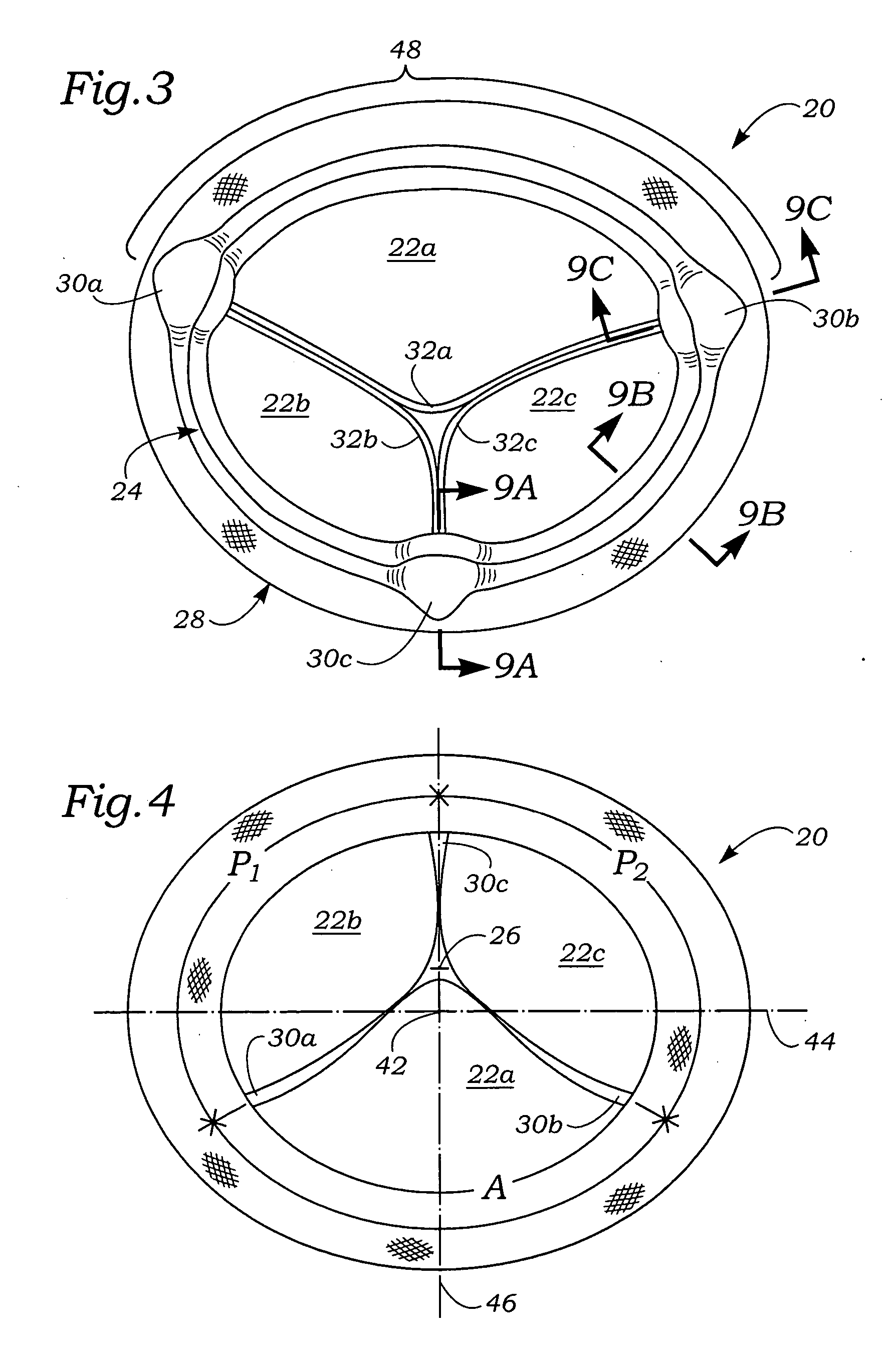

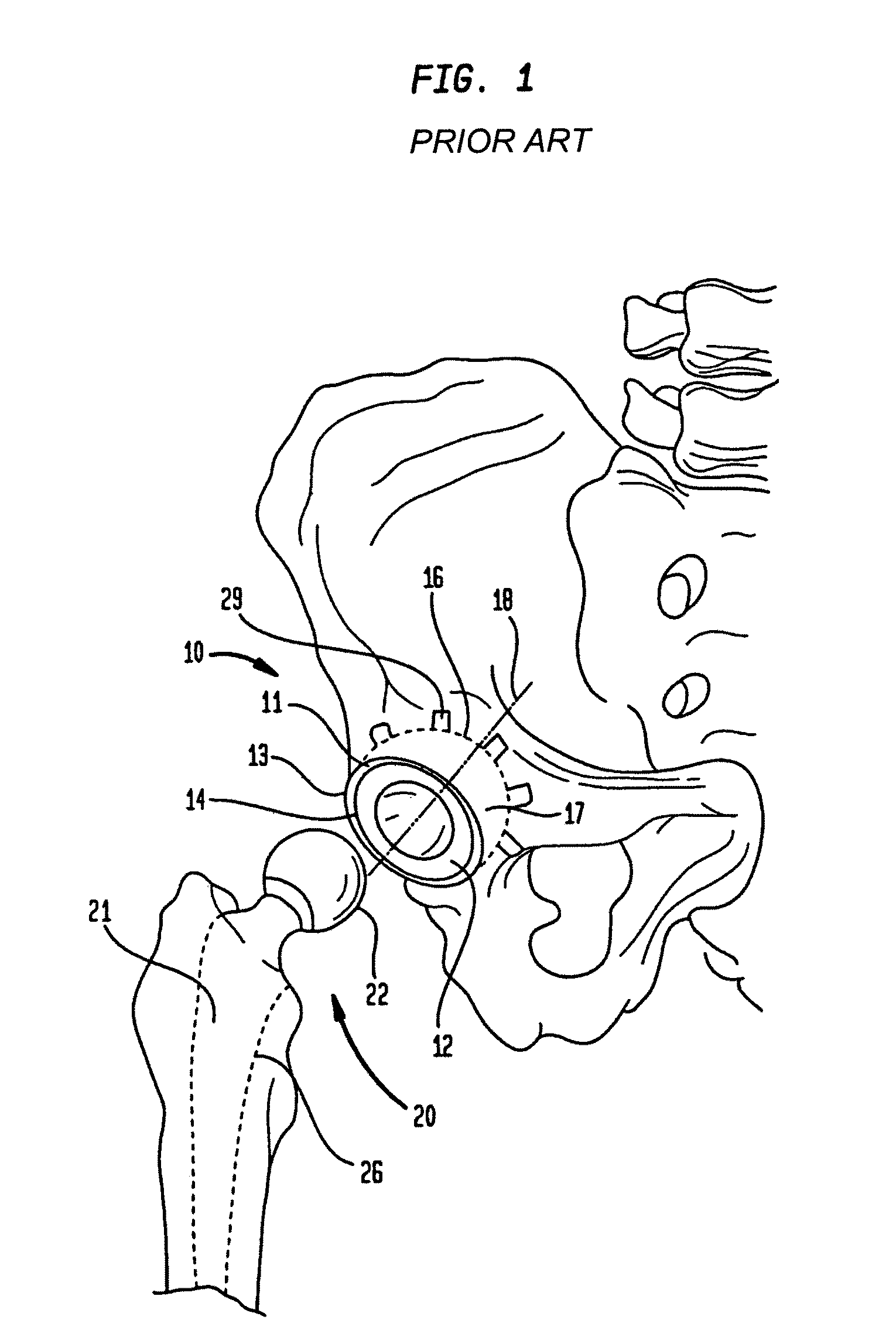

Anatomically approximate prosthetic mitral heart valve

ActiveUS20060293745A1Increase the areaReduce the overall heightAnnuloplasty ringsAnterior leafletMitral annulus

An anatomically approximate prosthetic heart valve includes dissimilar flexible leaflets, dissimilar commissures and / or a non-circular flow orifice. The heart valve may be implanted in the mitral position and have one larger leaflet oriented along the anterior aspect so as to mimic the natural anterior leaflet. Two other smaller leaflets extend around the posterior aspect of the valve. A basic structure providing peripheral support for the leaflets includes two taller commissures on both sides of the larger leaflet, with a third, smaller commissure between the other two leaflets. The larger leaflet may be thicker and / or stronger than the other two leaflets. The base structure defines a flow orifice intended to simulate the shape of the mitral annulus during the systolic phase. For example, the flow orifice may be elliptical. A relatively wide sewing ring has a contoured inflow end and is attached to the base structure in such a way that the valve can be implanted in an intra-atrial position and the taller commissures do not extend too far into the left ventricle, therefore avoiding injury to the ventricle.

Owner:EDWARDS LIFESCIENCES CORP

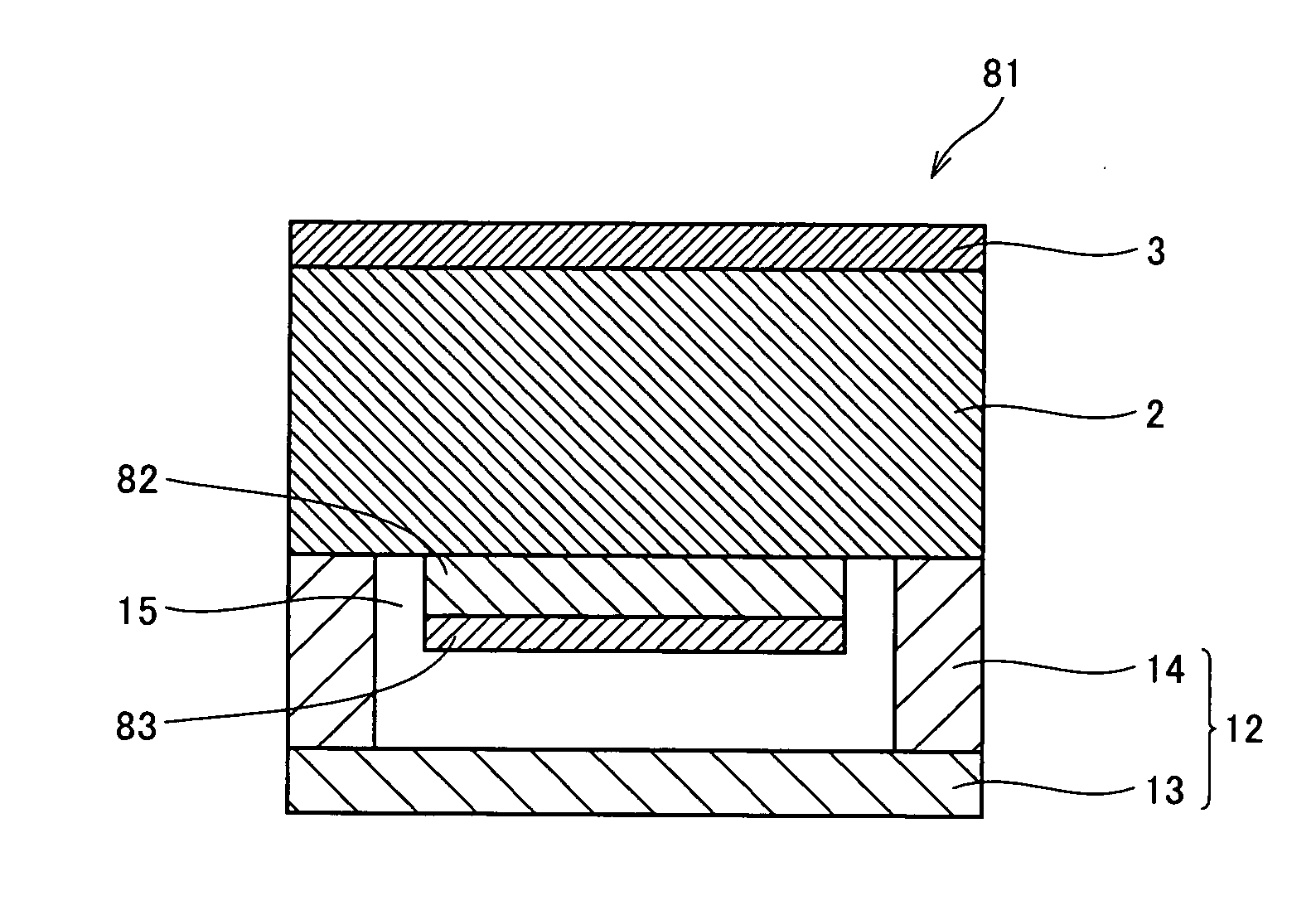

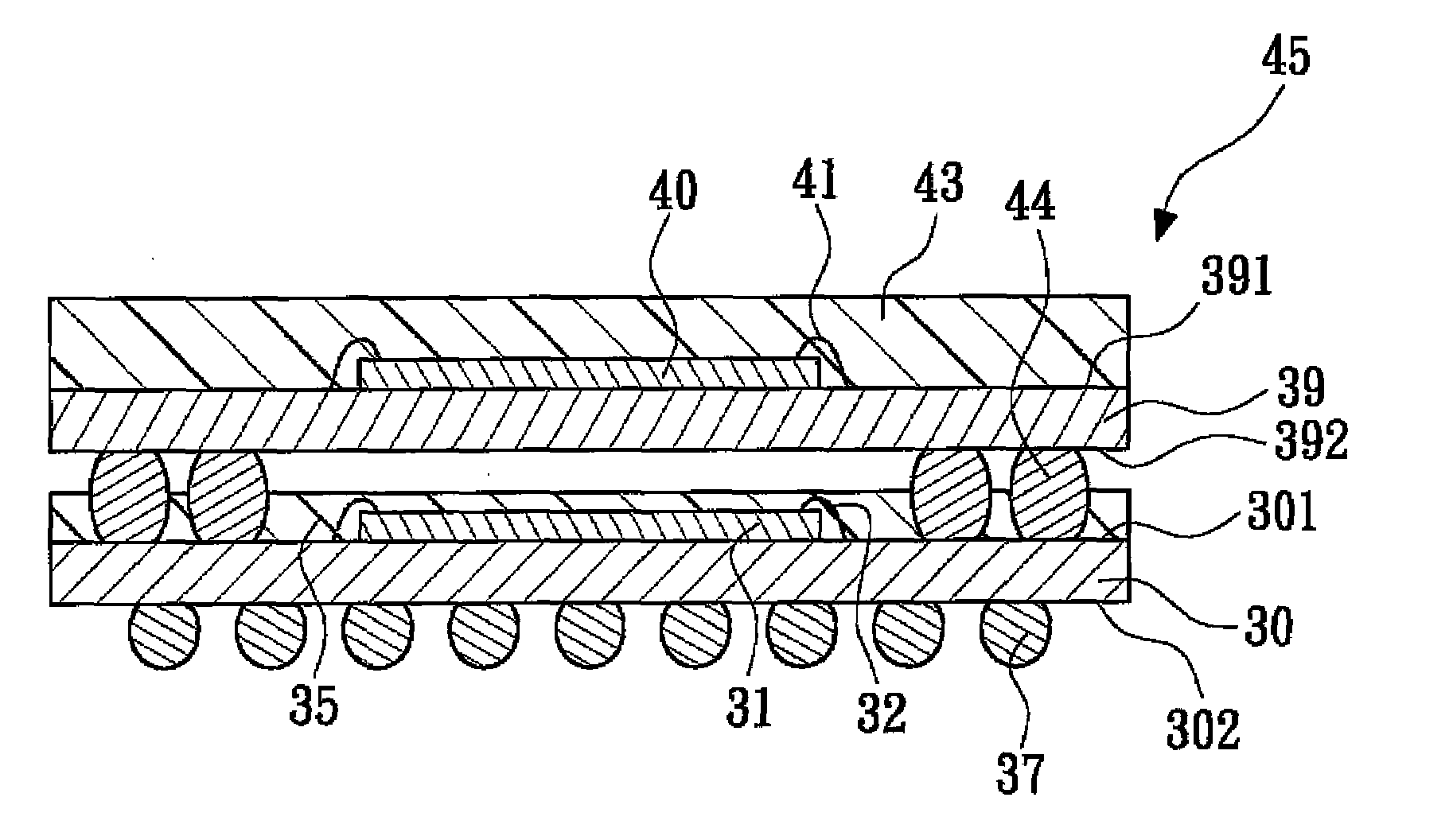

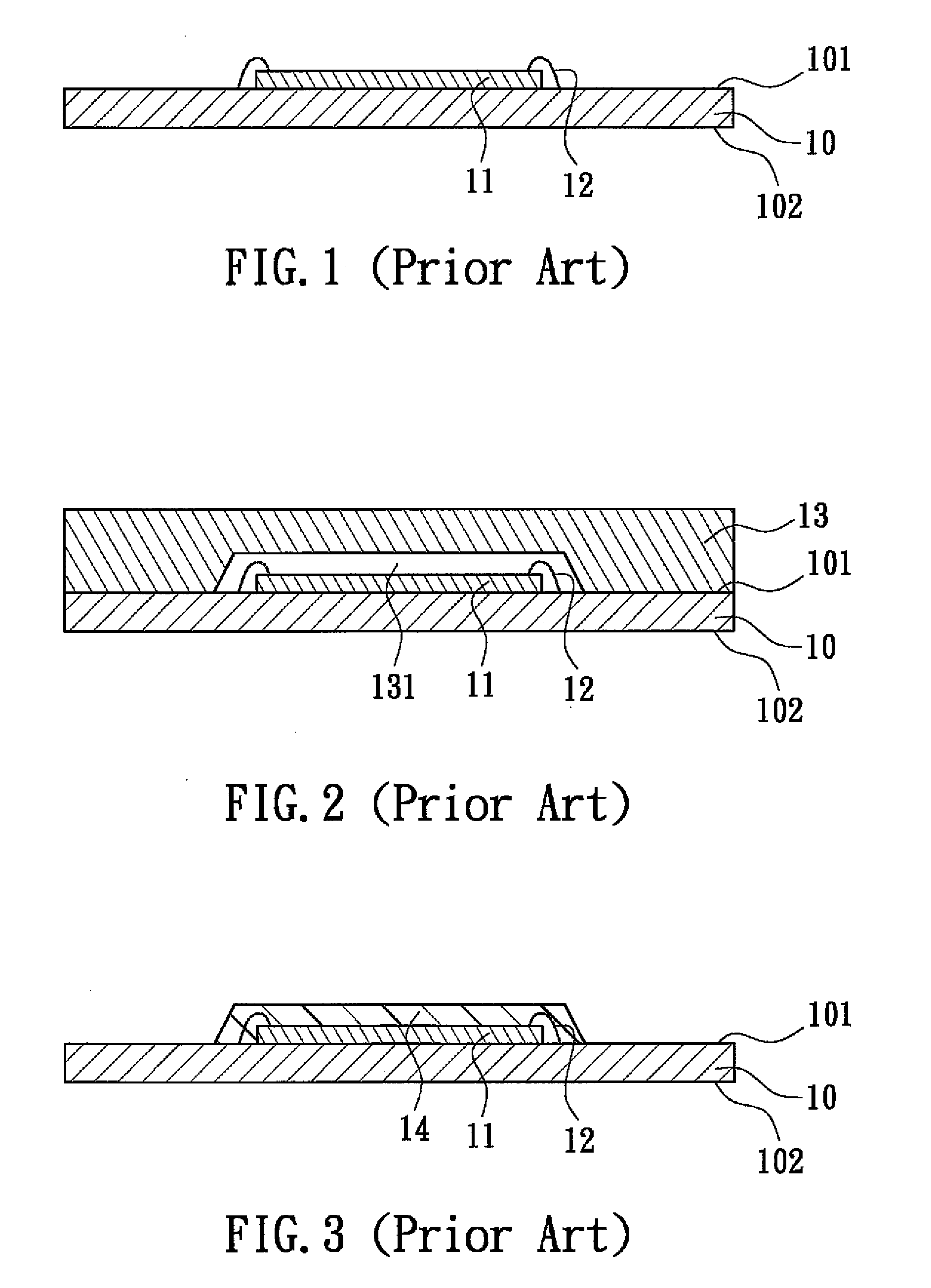

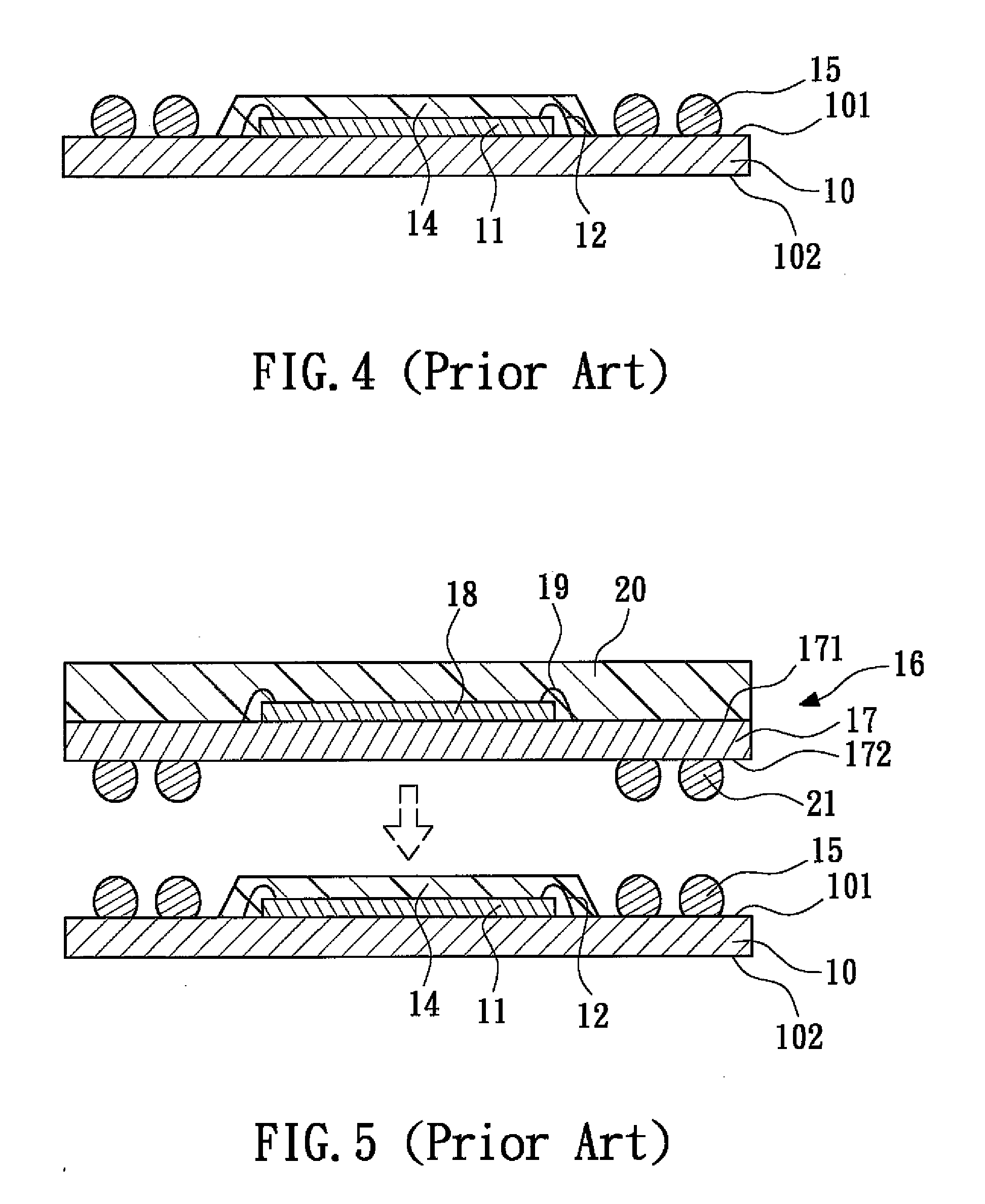

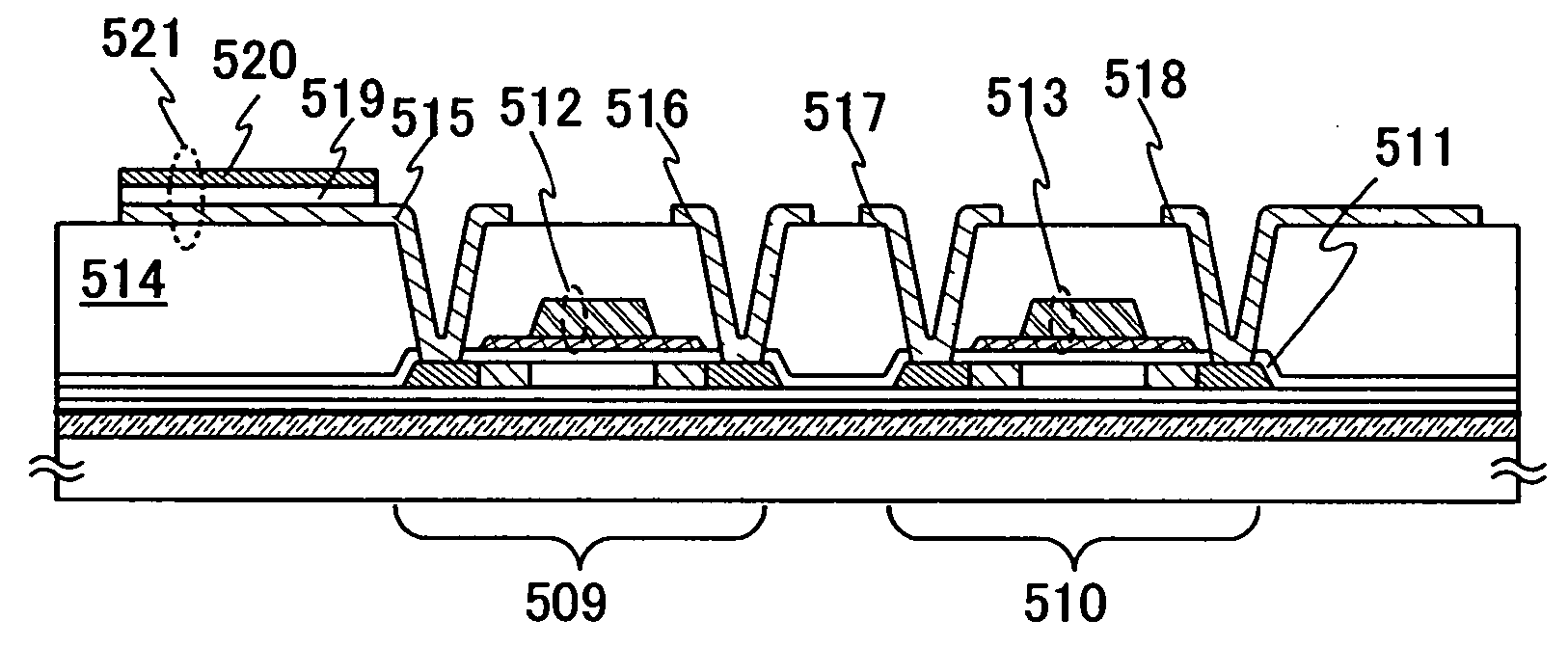

Semiconductor package and the method of making the same

ActiveUS20080230887A1Improve rigiditySemiconductor/solid-state device detailsSolid-state devicesEngineeringElectrical and Electronics engineering

The present invention relates to semiconductor package and the method of making the same. The method of the invention comprises the following steps: (a) providing a first substrate; (b) mounting a first chip onto a surface of the first substrate; (c) forming a plurality of conductive elements on the surface of the first substrate; (d) covering the conductive elements with a mold, the mold having a plurality of cavities accommodating top ends of each of the conductive elements; and (e) forming a first molding compound for encapsulating the surface of the first substrate, the first chip and parts of the conductive elements, wherein the height of the first molding compound is smaller than the height of each of the conductive elements. Thus, the first molding compound encapsulates the entire surface of the first substrate, so that the mold flush of the first molding compound will not occur, and the rigidity of the first substrate is increased.

Owner:ADVANCED SEMICON ENG INC

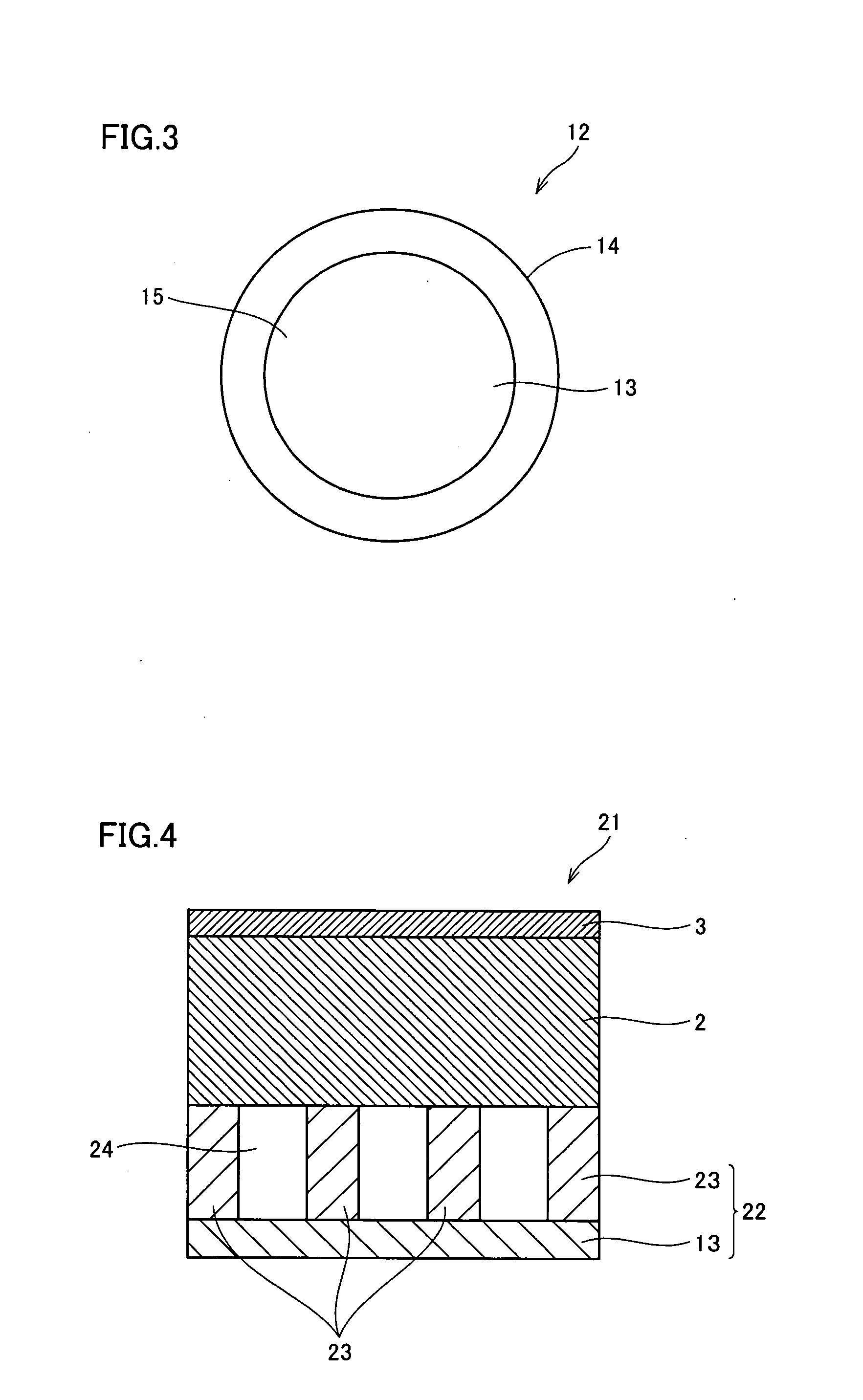

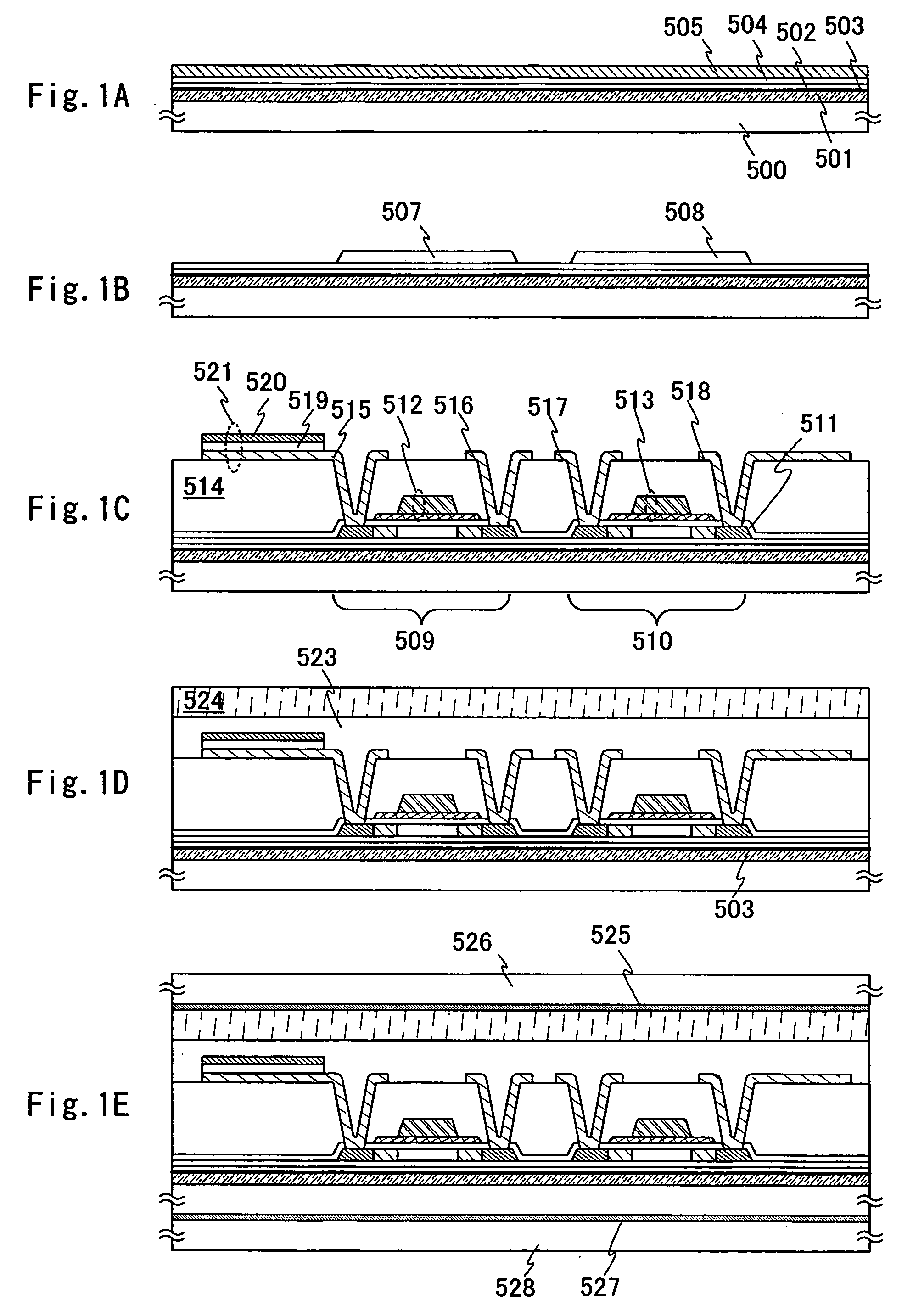

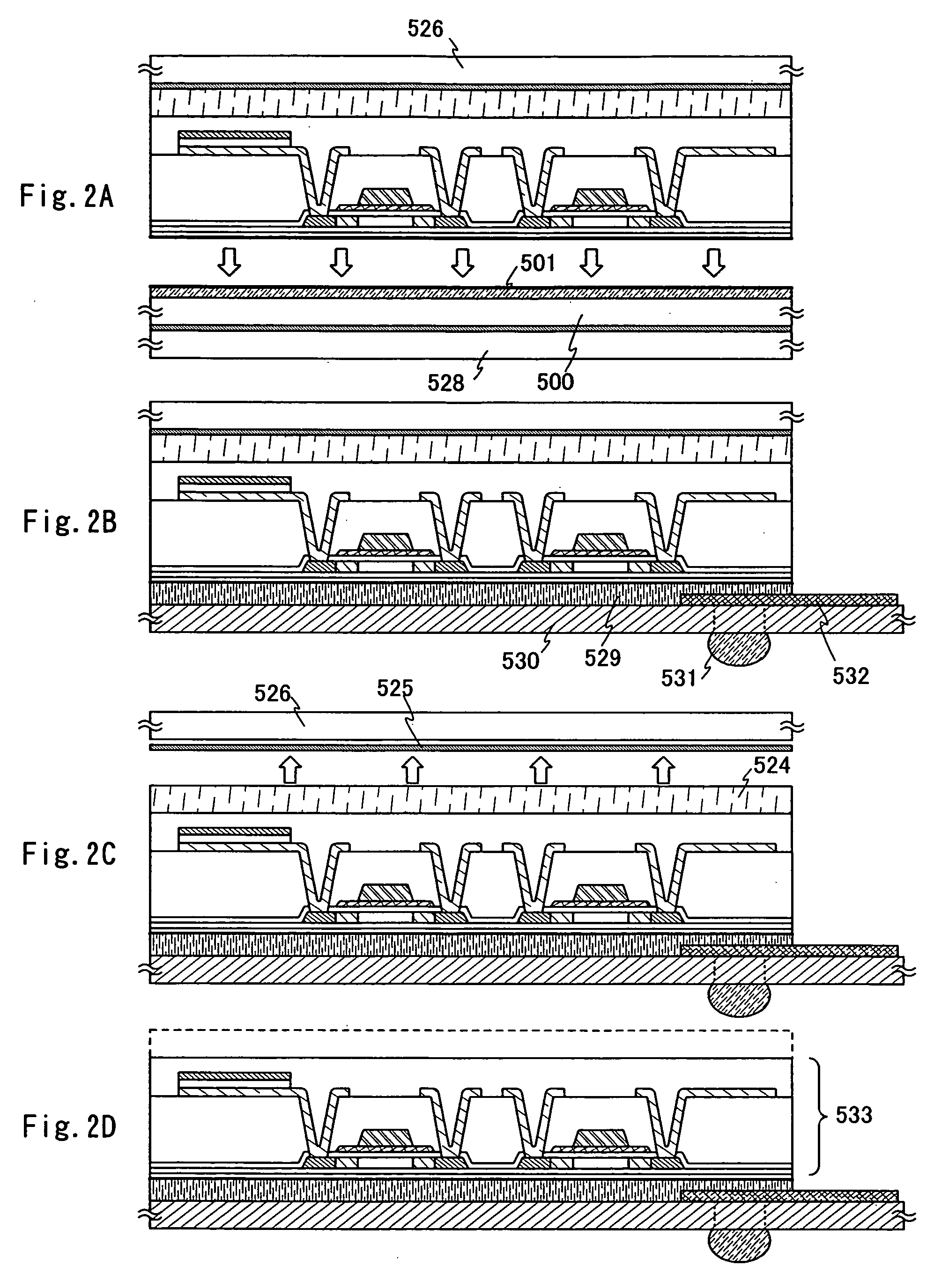

Semiconductor device

InactiveUS20040195572A1Improve rigidityStable separationTransistorSolid-state devicesData rateElectric signal

A semiconductor device which has a high performance integrated circuit formed of an inexpensive glass substrate and capable of processing a large amount of information and operating at higher data rates. The semiconductor device includes semiconductor elements stacked by transferring a semiconductor element formed on a different substrate. A resin film is formed between the stacked semiconductor elements and a metal oxide film is partially formed between the stacked semiconductor elements as well. A first electric signal is converted to an optical signal in a light emitting element electrically connected to one of the stacked semiconductor elements. Meanwhile, the optical signal is converted to a second electric signal in a light receiving element electrically connected to another one of the stacked semiconductor elements.

Owner:SEMICON ENERGY LAB CO LTD

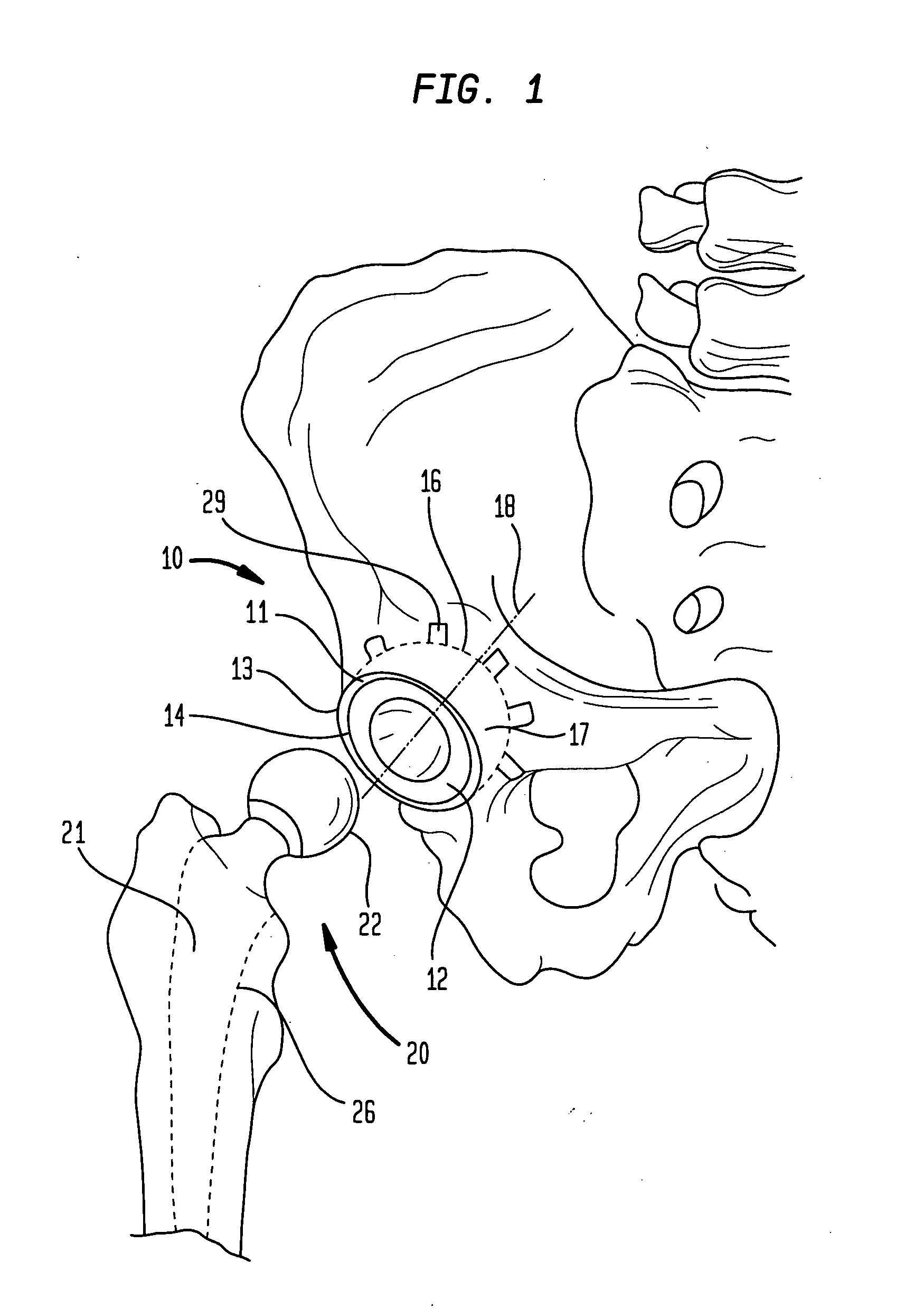

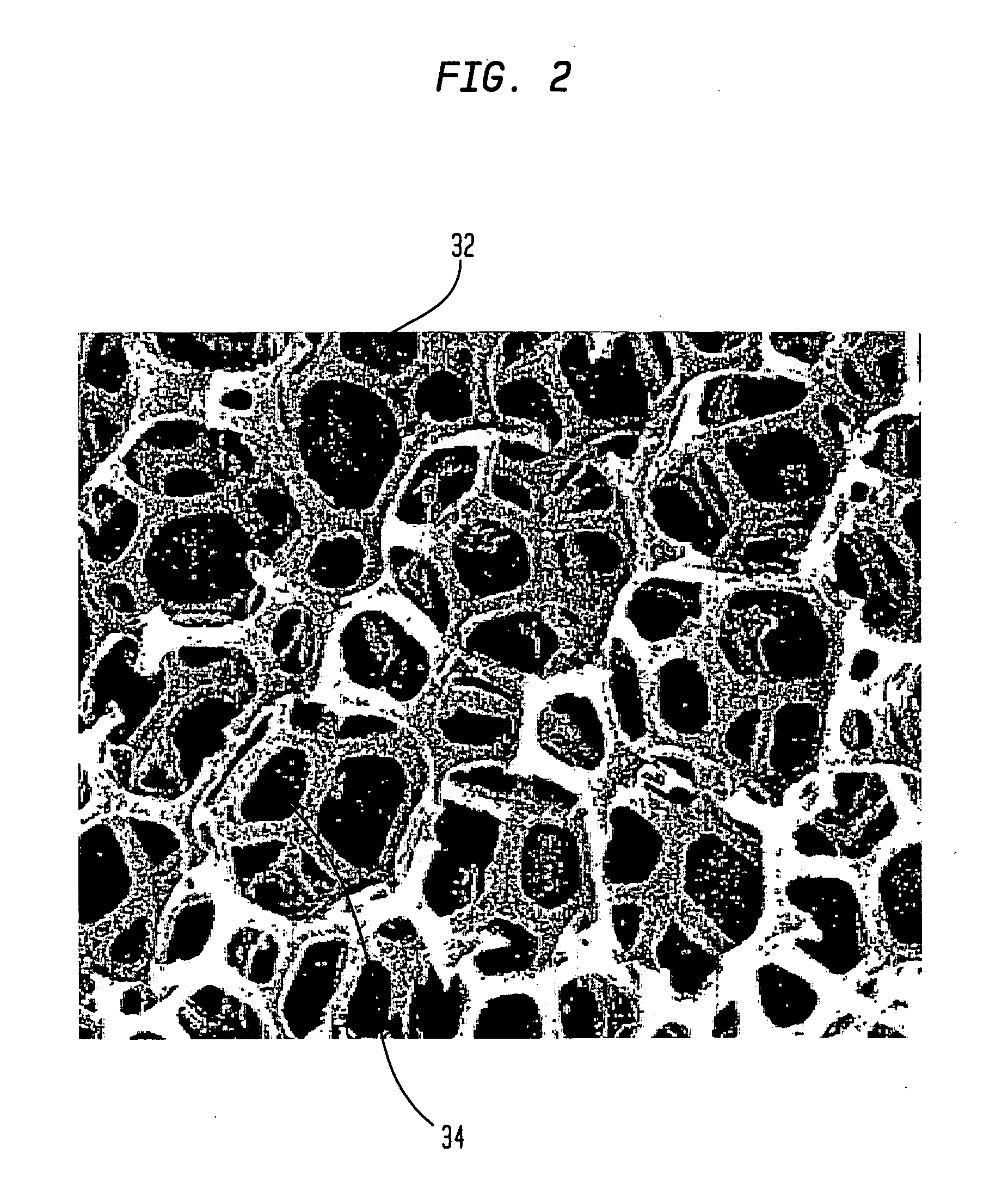

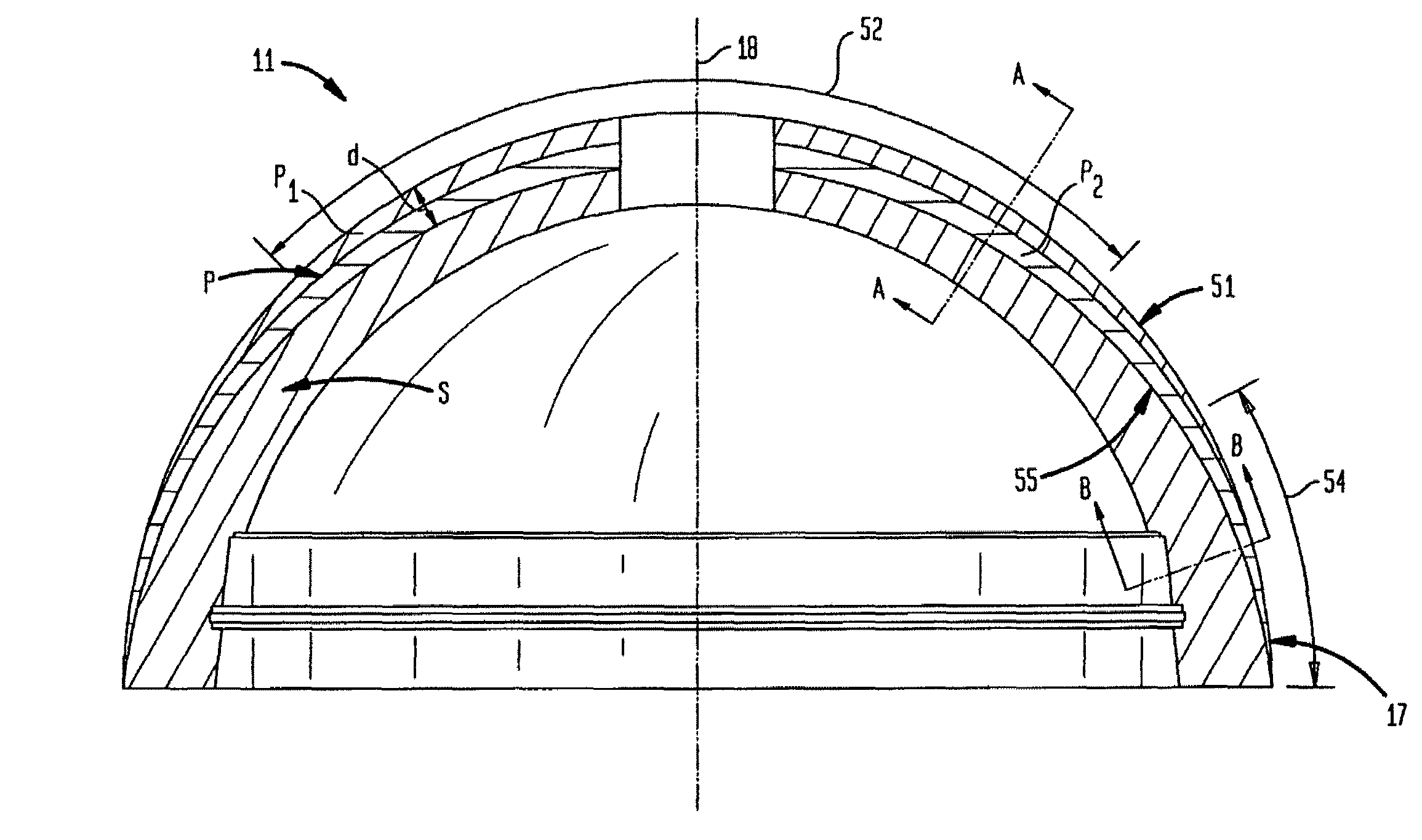

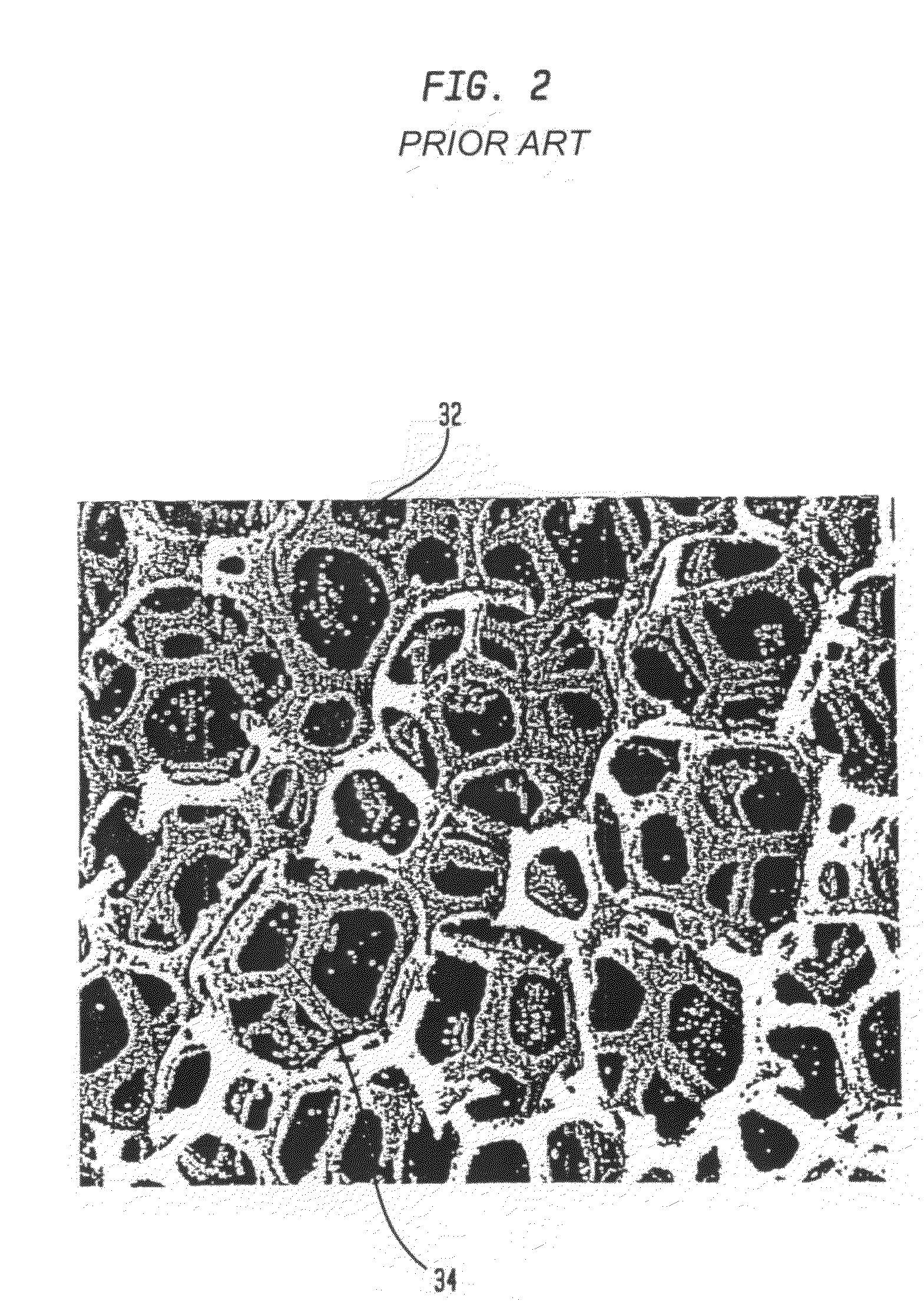

Gradient porous implant

ActiveUS20070150068A1Optimize performanceOptimizes various mechanical and biological requirements of the implants performanceAdditive manufacturing apparatusBone implantPorous metalMedical treatment

An implantable medical device includes a porous metal foam or foam-like structure having pores defined by metal struts or webs wherein the porous structure has directionally controlled pore characteristics. The pore characteristics controlled include one or more of the metal structure porosity, pore size, pore shape, pore size distribution and strut thickness. The pore characteristics may vary in one or more directions throughout the structure. Preferably the pore characteristics are controlled to match the porous metal structure to various mechanical and biological requirements of different regions of the structure in order to optimize aspects of the implants performance and may vary not only over the surface of the porous structure but through the depth of the porous structure. The thickness of the porous metal structure may also be modified to establish a thickness profile that optimizes mechanical and biological requirements of the implants performance. Acetabular cup embodiments of the invention are described. Various methods of manufacturing implants having directionally controlled pore characteristics are described.

Owner:HOWMEDICA OSTEONICS CORP

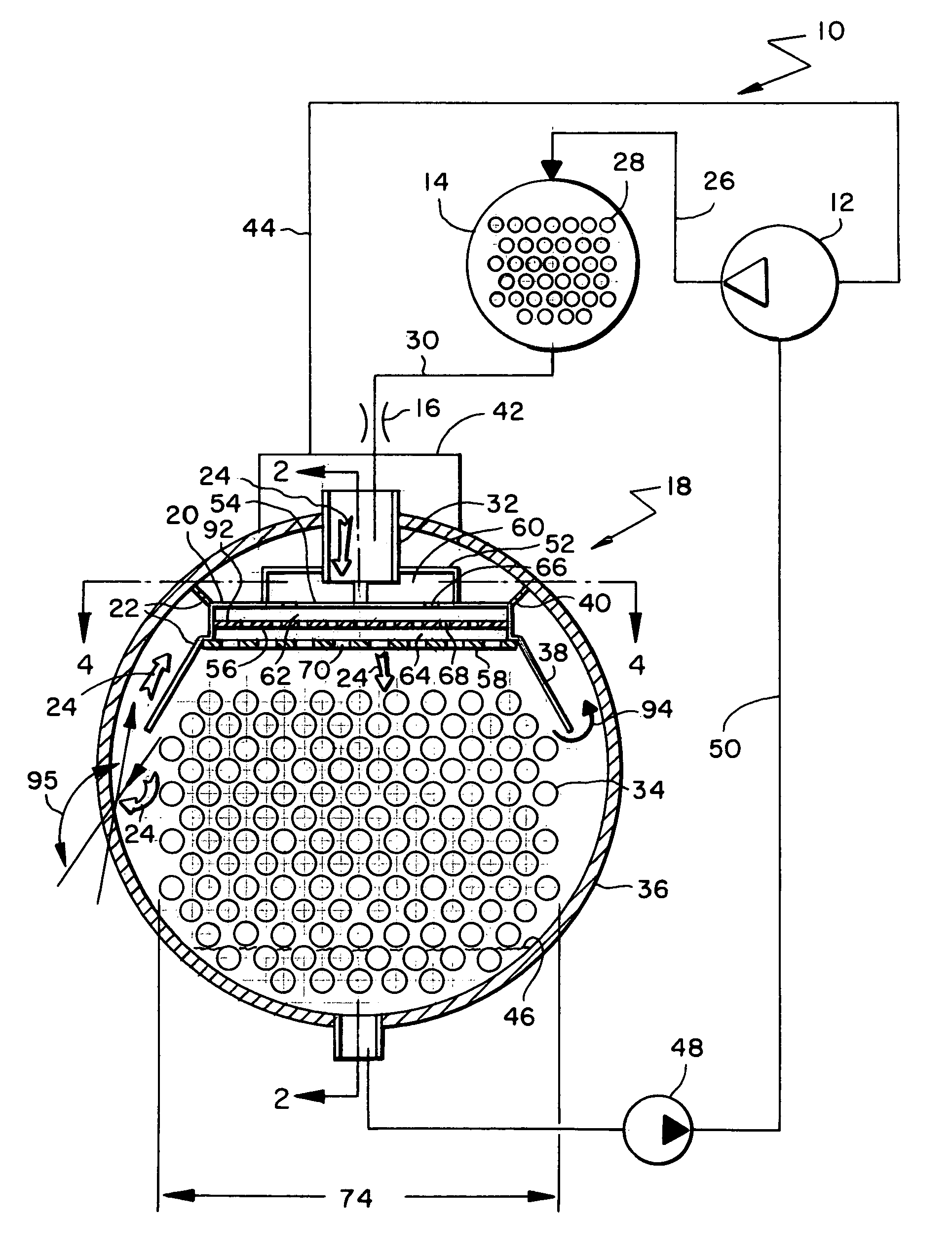

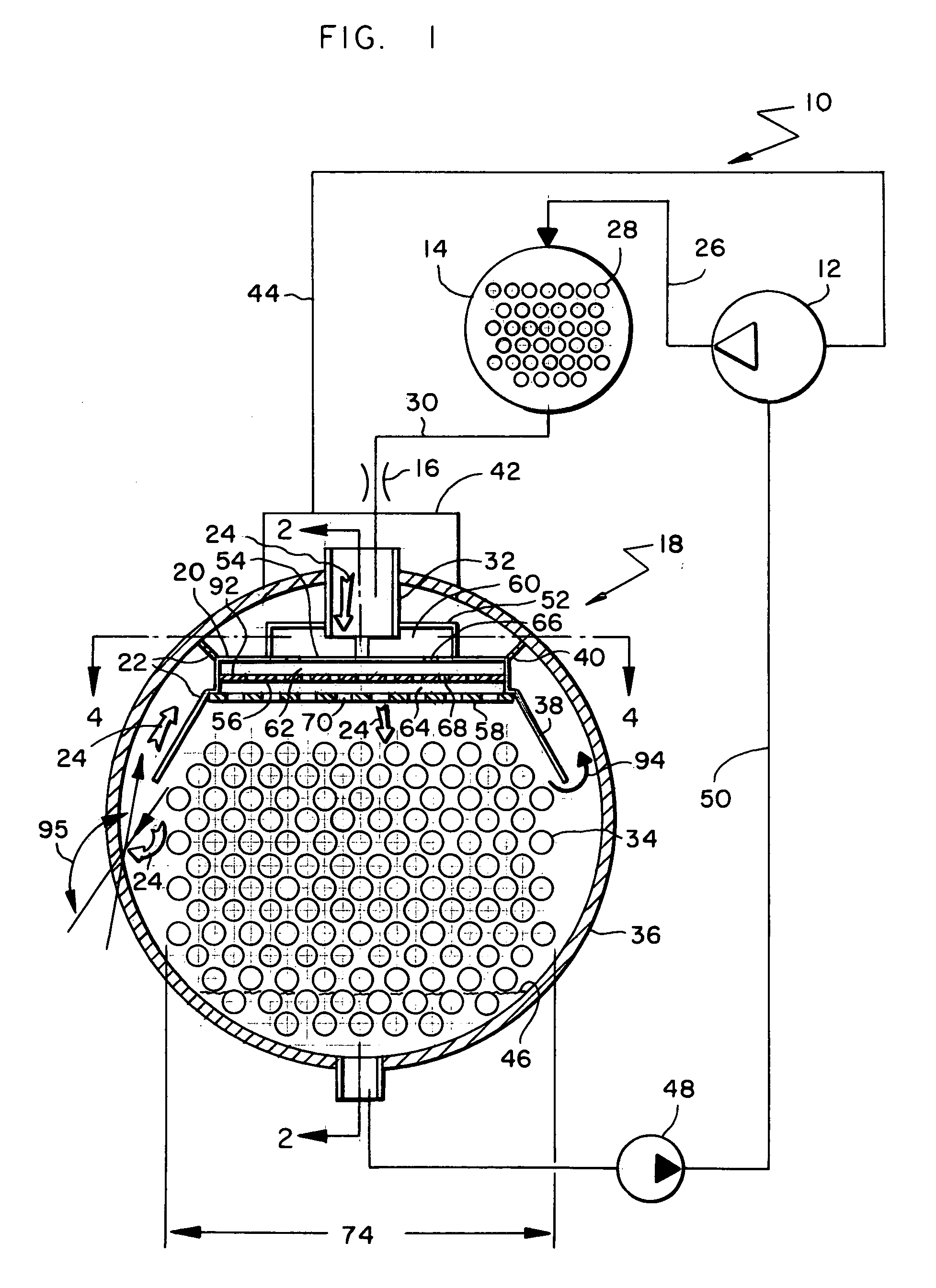

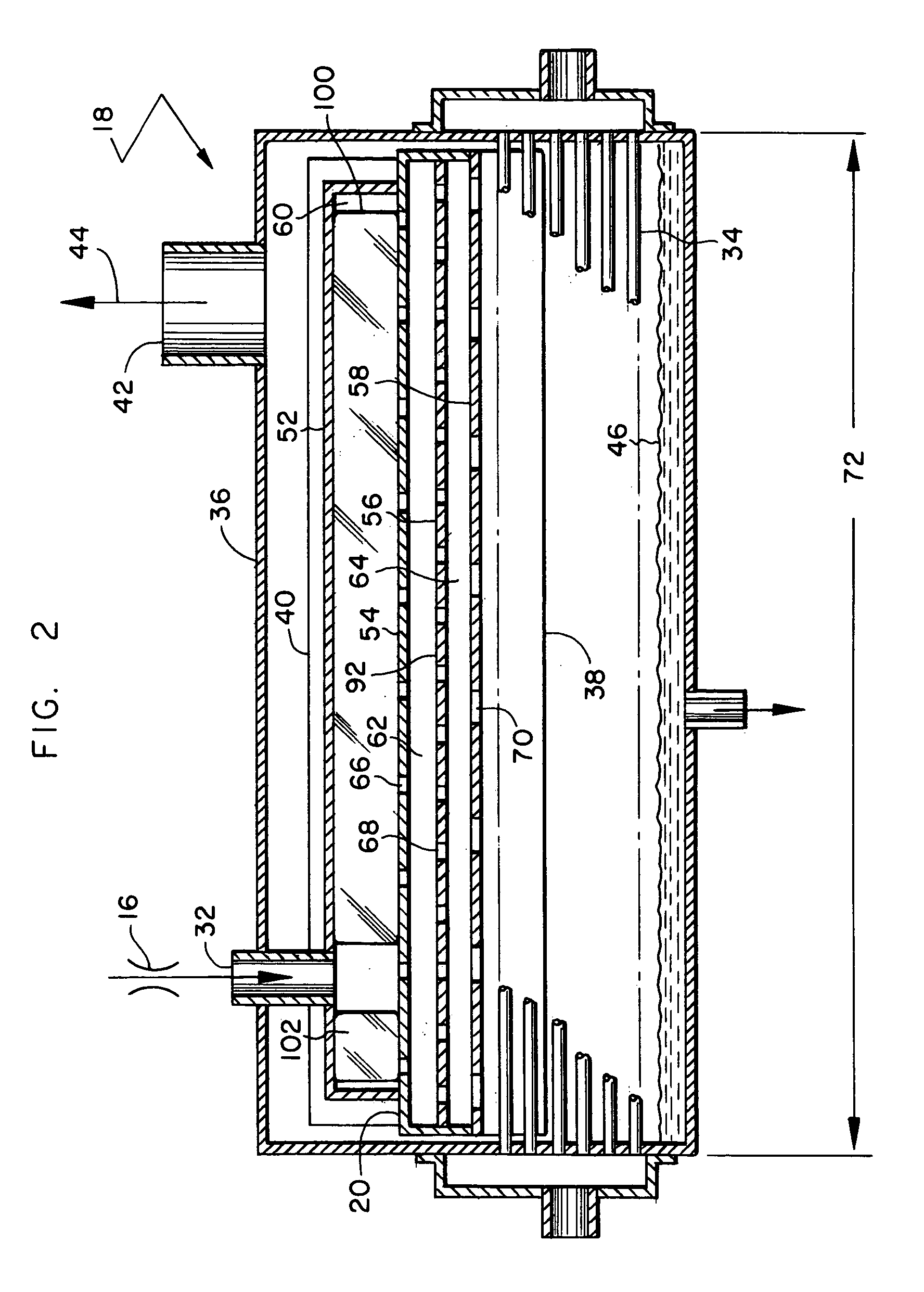

Flow distributor and baffle system for a falling film evaporator

ActiveUS6868695B1Even flow distributionEasy to separateMilk preservationEvaporators/condensersEngineeringRefrigerant

A falling film evaporator includes a flow distributor for uniformly distributing a two-phase refrigerant mixture across a tube bundle. The flow distributor includes a stack of at least three perforated plates each of which are separated by nearly full-width, full-length gaps or chambers. The flow distributor may also include a suction baffle and / or a distributor baffle. The distributor baffle extends downward to provide a hairpin turn past which refrigerant travels before exiting the evaporator. This directional change helps separate liquid from a primarily gaseous refrigerant stream. The suction baffle has various size openings to ensure that the flow rate of refrigerant through the hairpin turn is generally uniform and is maintained low enough to ensure liquid disentrainment over and along the length of the tube bundle within the evaporator.

Owner:TRANE INT INC

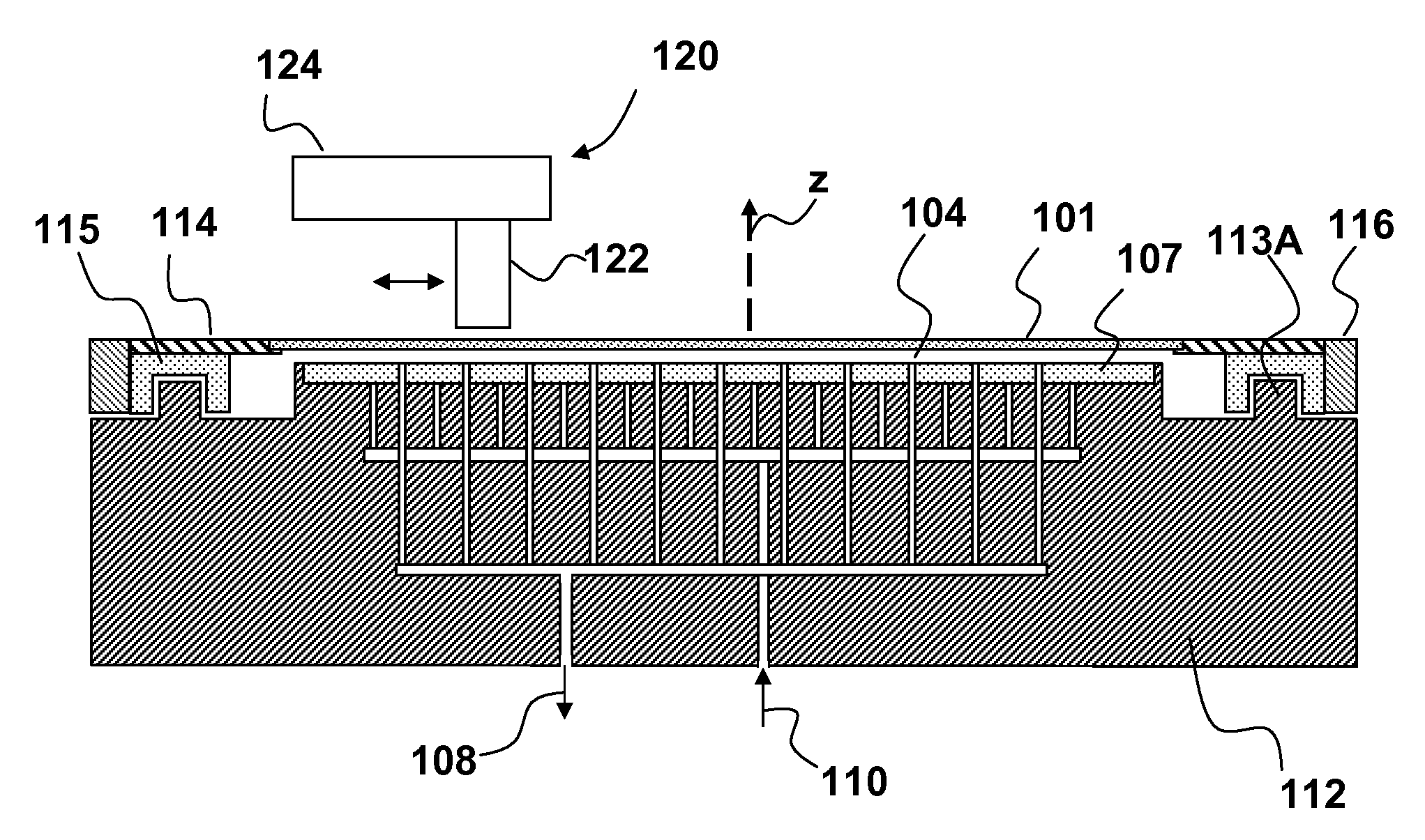

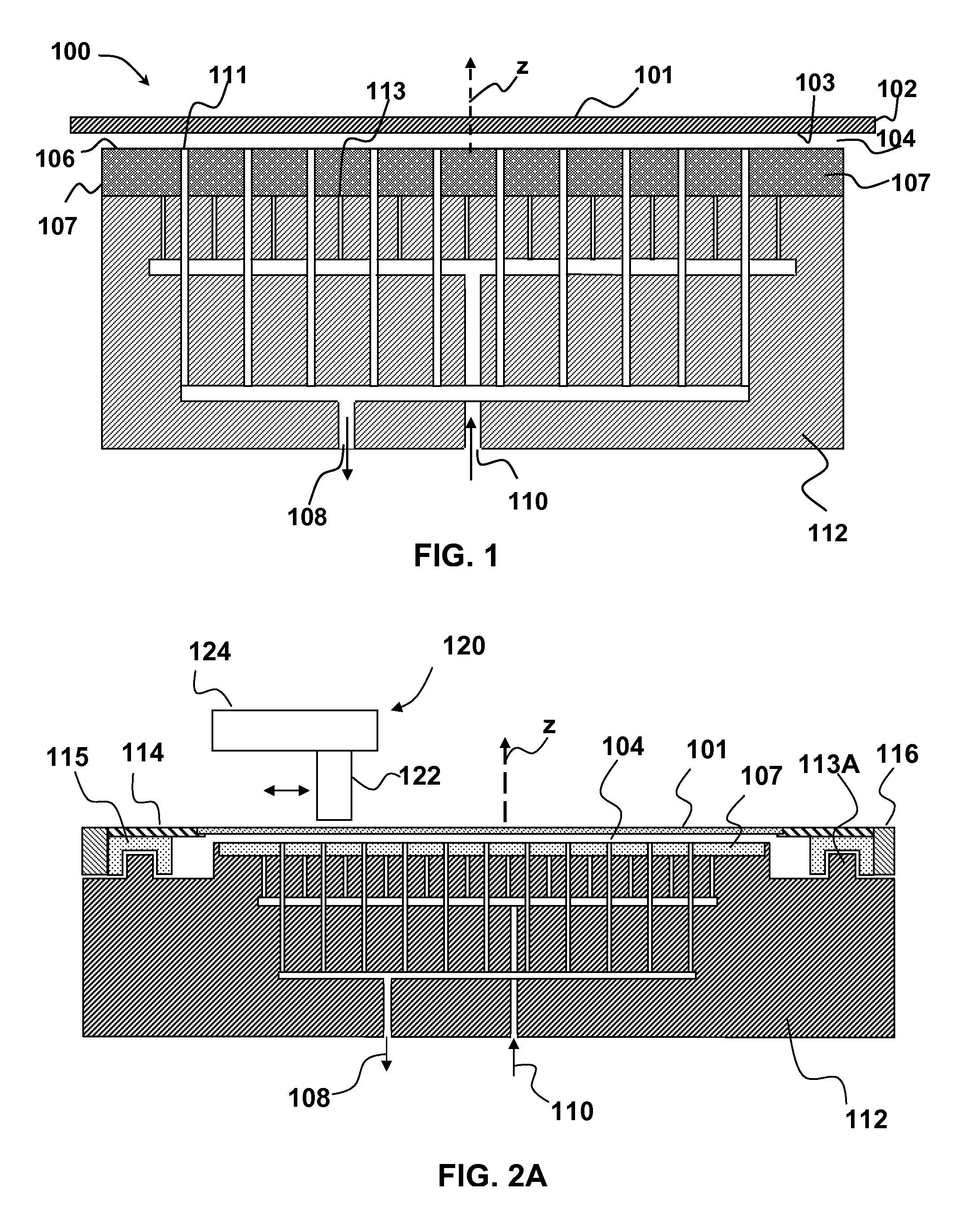

Stabilizing a substrate using a vacuum preload air bearing chuck

ActiveUS20080229811A1Improve rigidityAvoid deformationLinear bearingsGas cushion bearingsAir bearingEngineering

Substrate processing method and apparatus are disclosed. The substrate processing apparatus includes a non-contact air bearing chuck with a vacuum preload.

Owner:KLA TENCOR TECH CORP

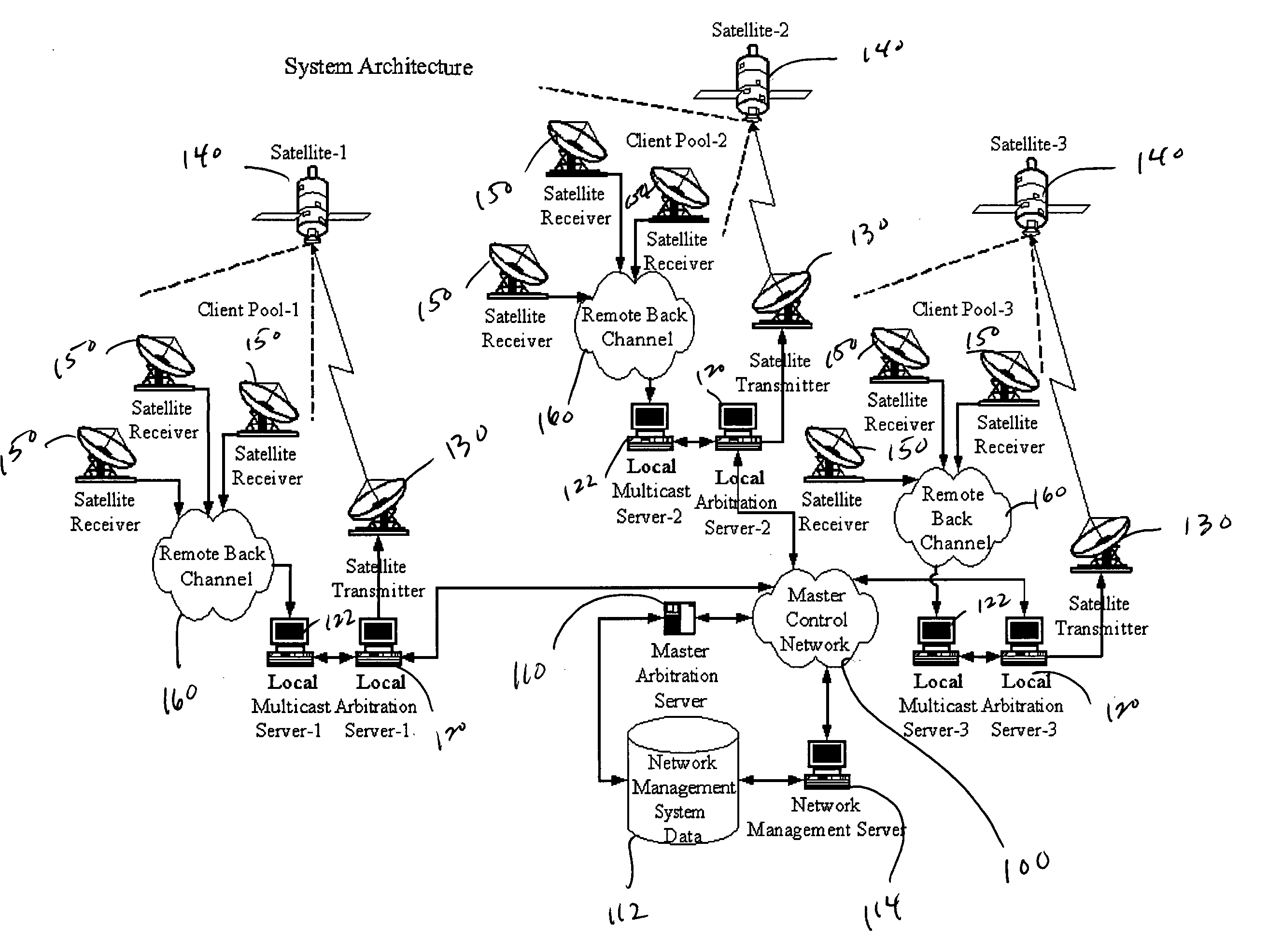

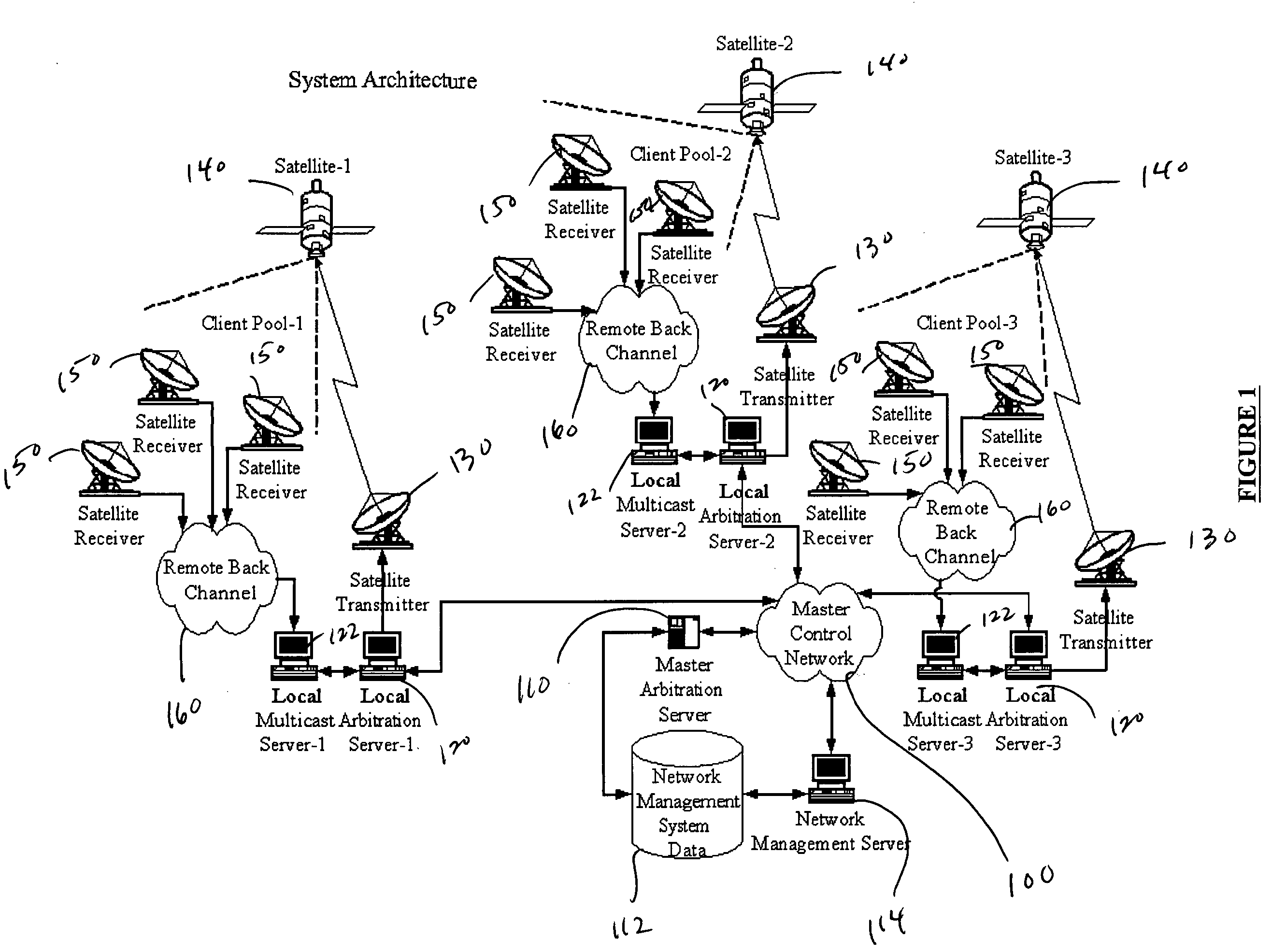

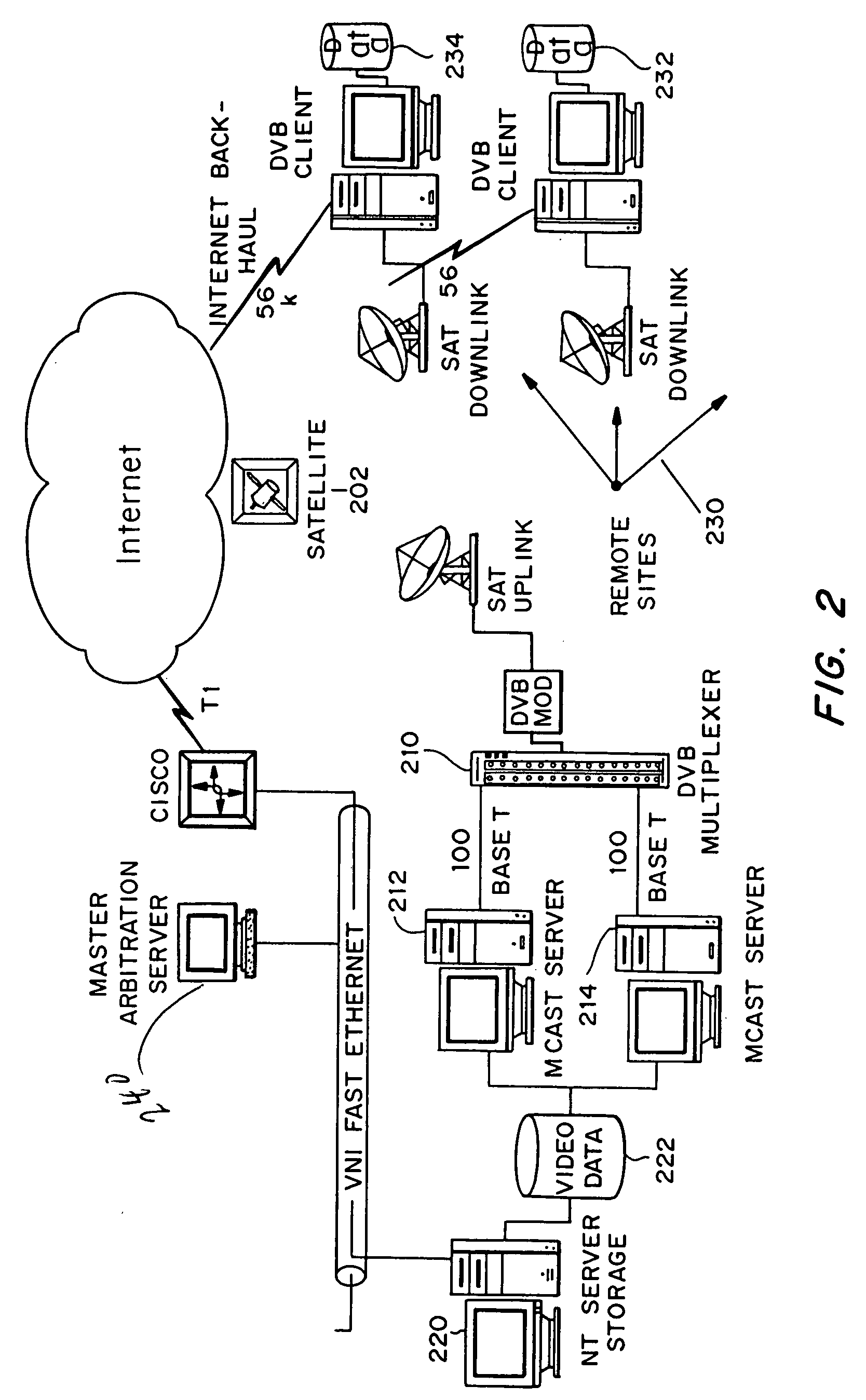

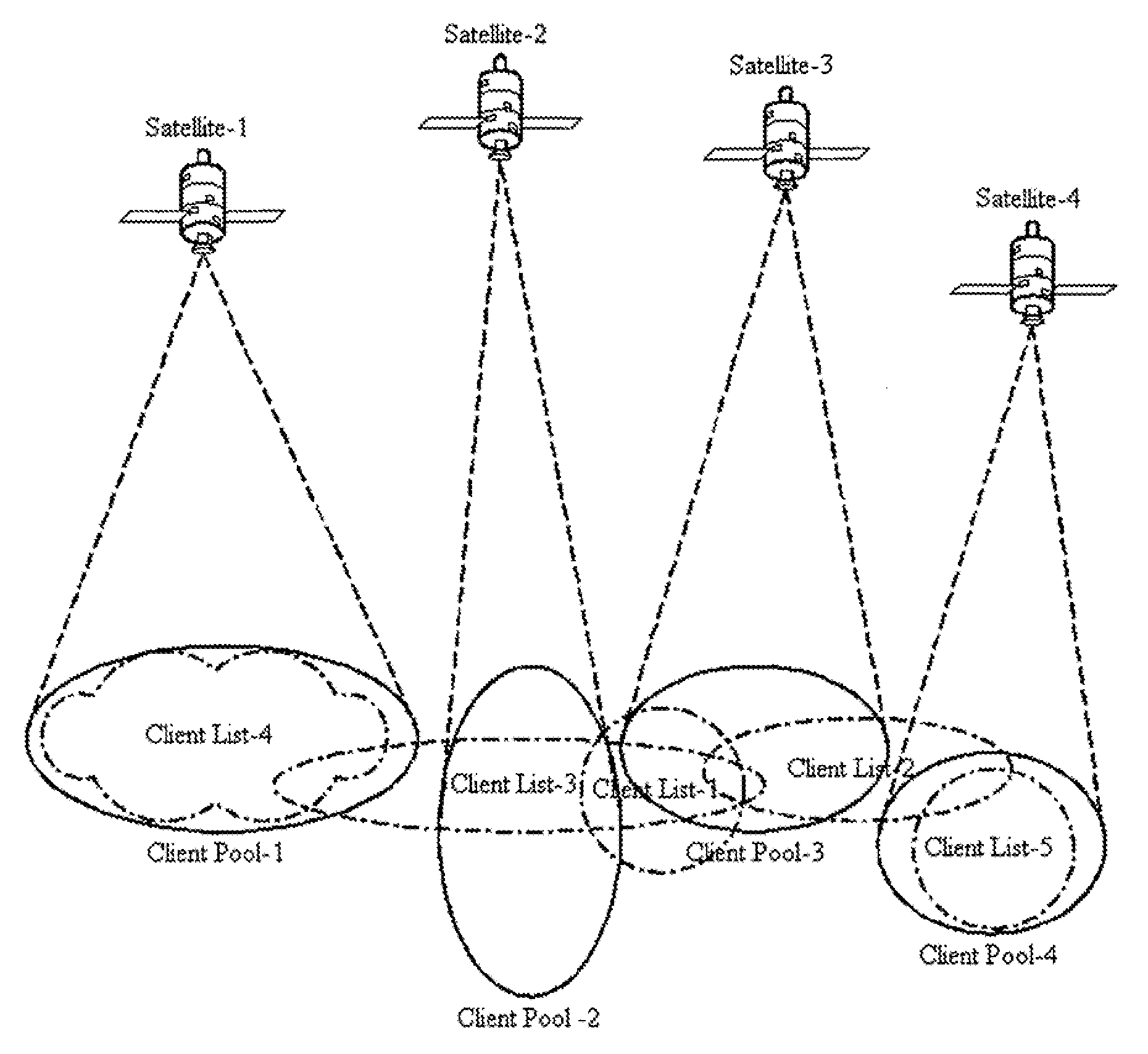

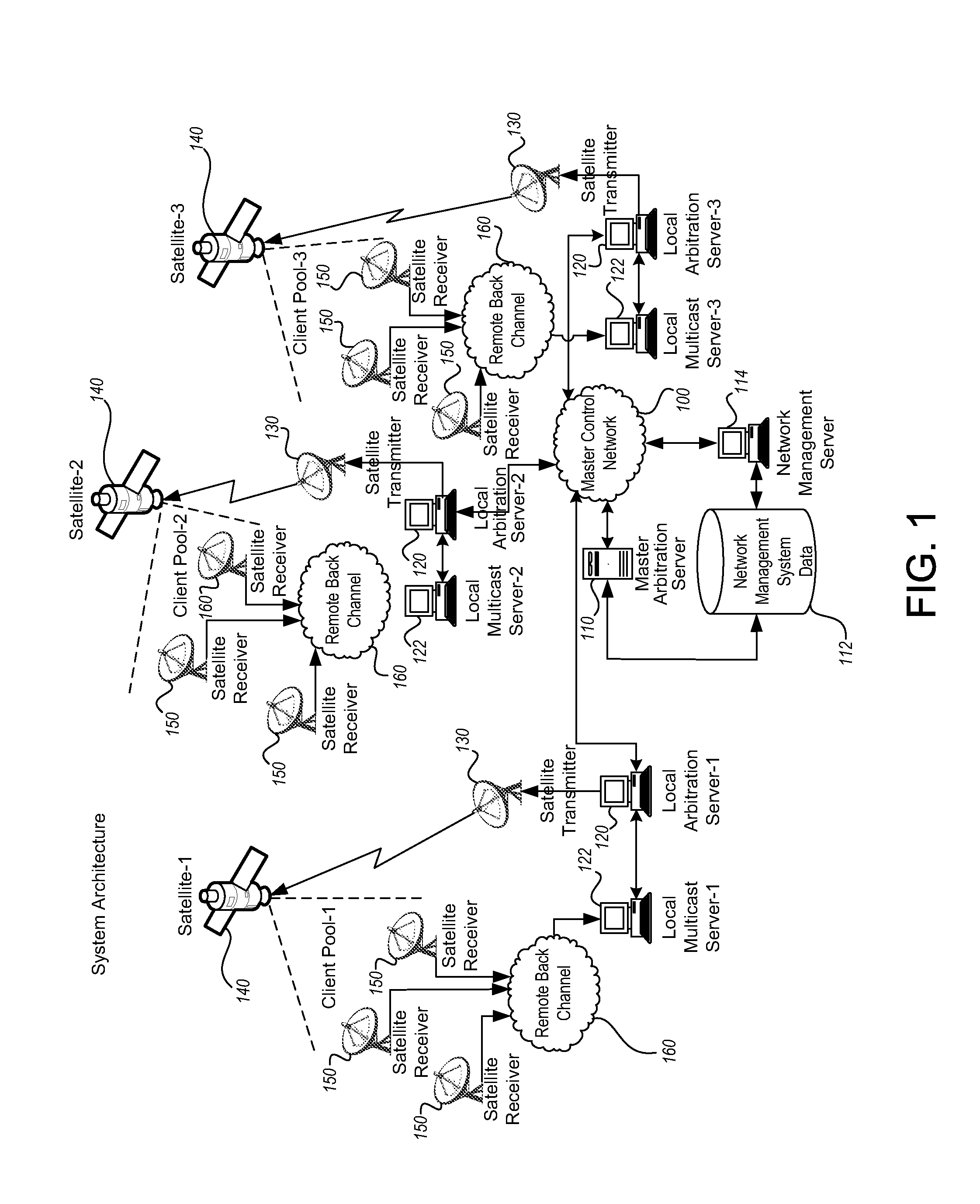

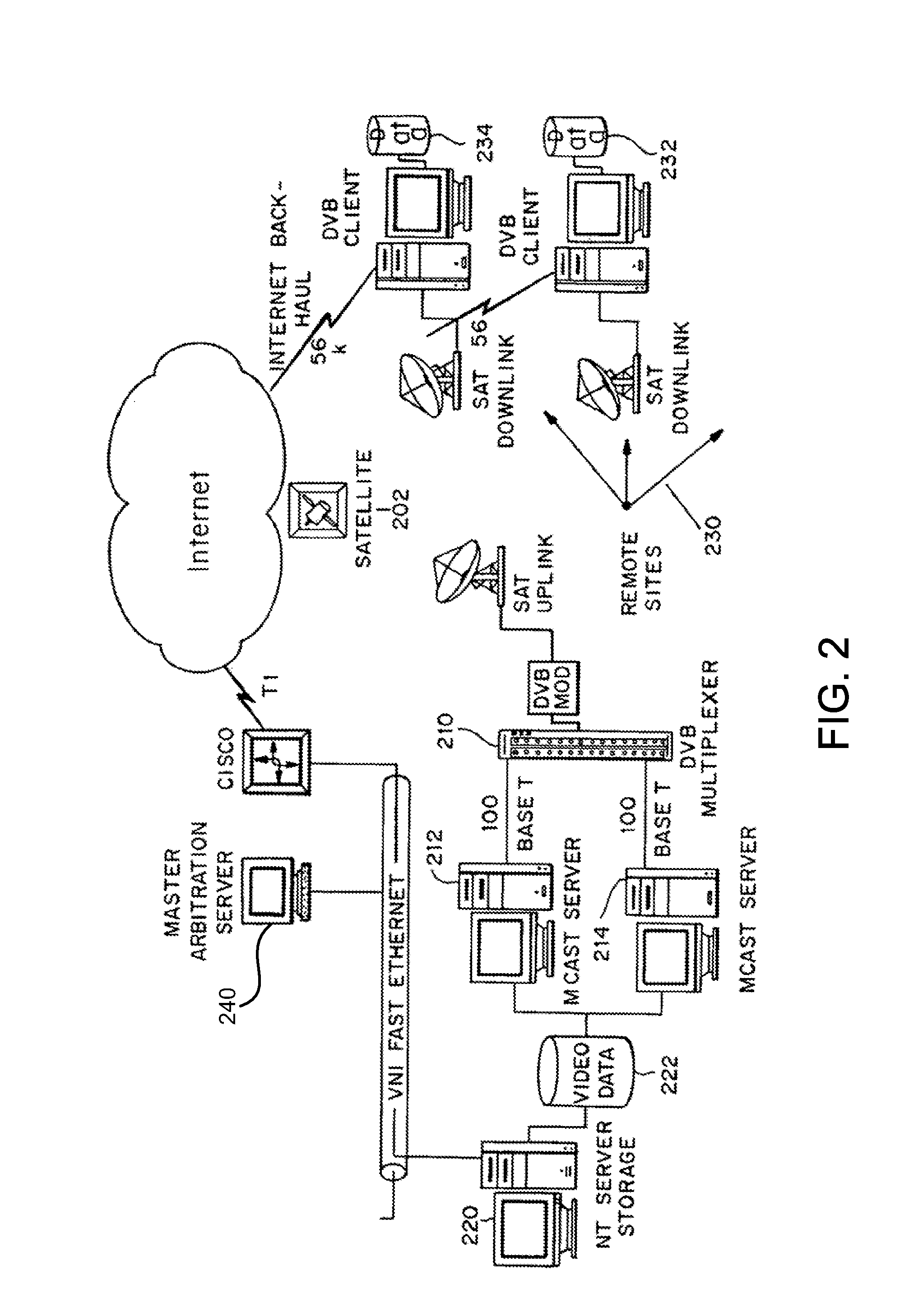

Multicast control systems and methods for dynamic, adaptive time, bandwidth,frequency, and satellite allocations

InactiveUS20050037706A1Improve transmission performanceMaximizing numberBroadcast with distributionNetwork traffic/resource managementControl systemThe Internet

Methods and systems to efficiently share multiple satellites and associated transponders or links among a network of uplinking earth stations are disclosed. An embodiment of this invention uses a terrestrial communications link, such as the Internet, to control access to the transponder or satellite links. Communications over this link may employ a TCP / IP protocol to connect the requesting uplinking earth stations with a centralized controller. This control system creates more efficient use of satellite resources and reduces the overall amount of time needed for transmitting data through the satellite. By reducing the overall amount of time needed for transmitting data, the control system may reduce the cost of using the satellite transponder capacity.

Owner:EXTREME REACH INC +1

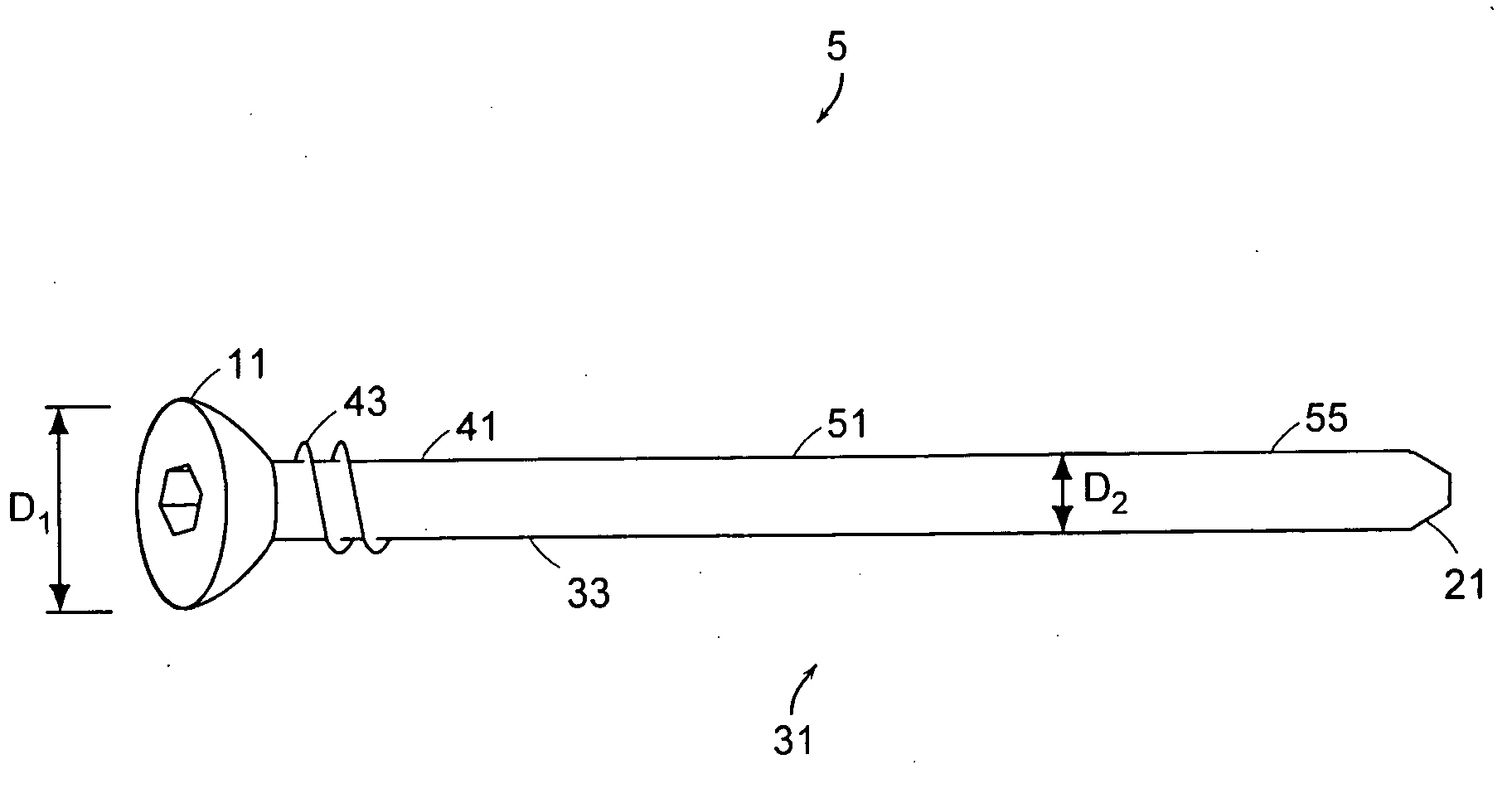

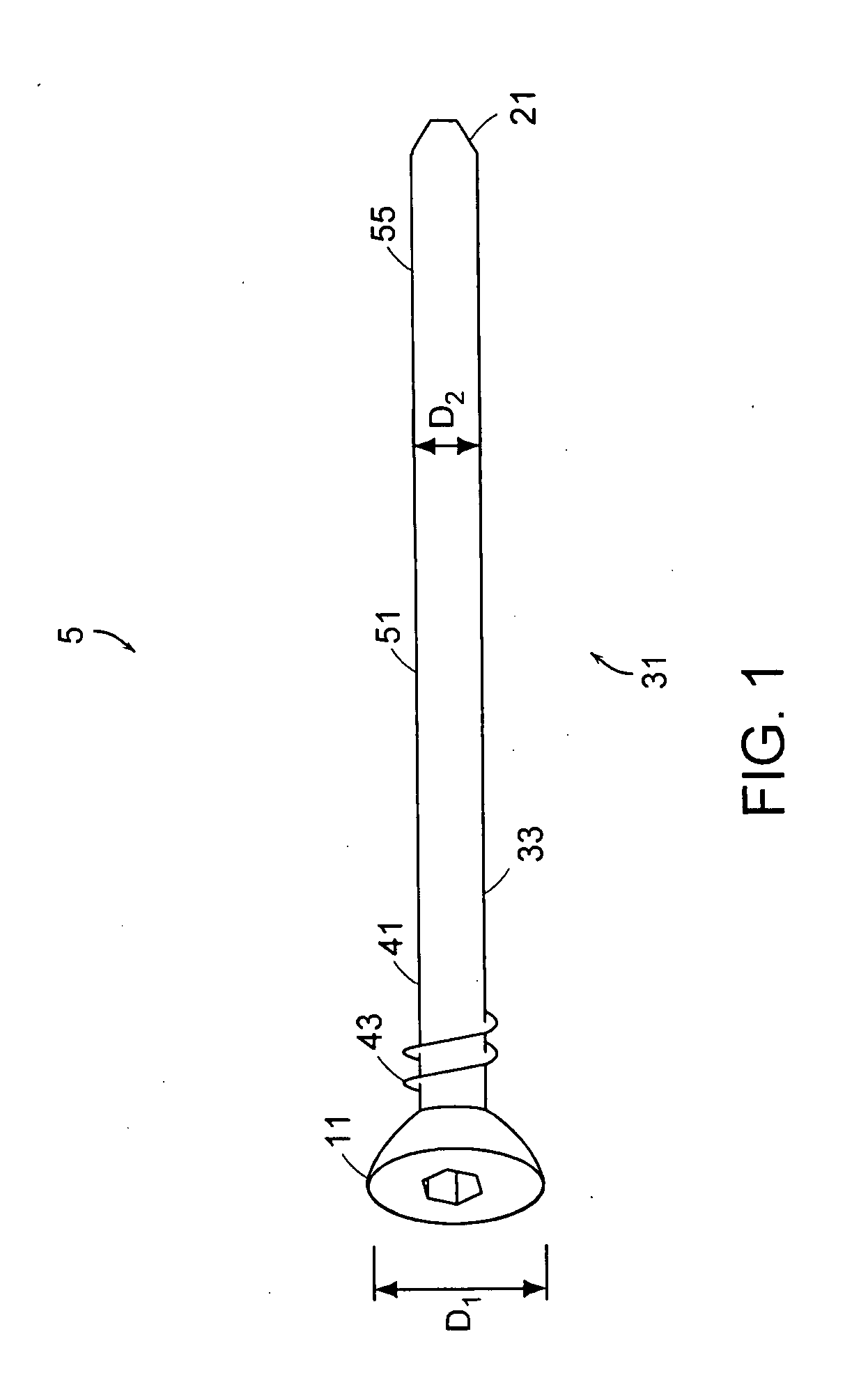

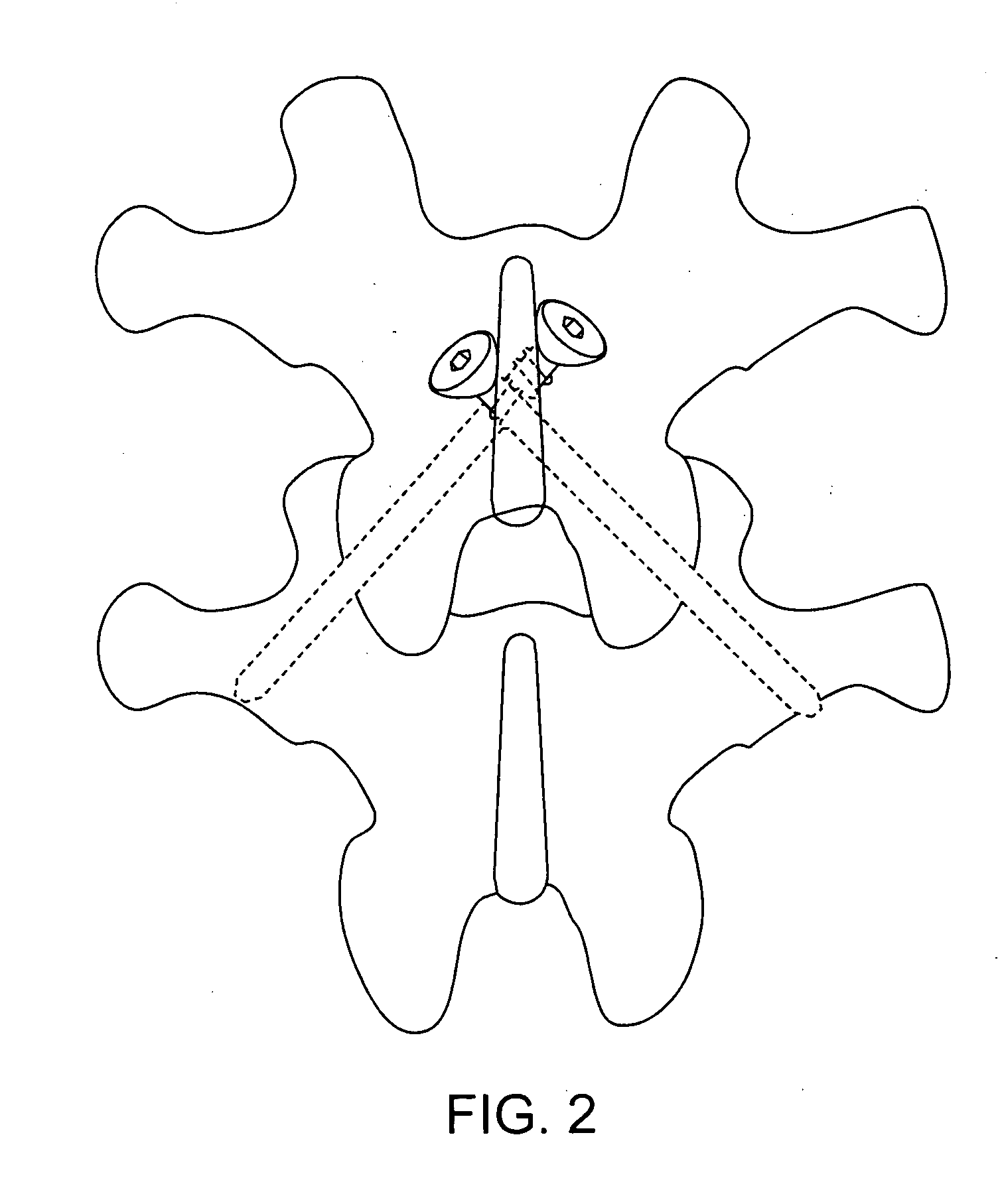

Facet joint fixation system

InactiveUS20050149030A1High stressImprove rigiditySuture equipmentsInternal osteosythesisFacet jointSacroiliac joint

Owner:DEPUY SPINE INC (US)

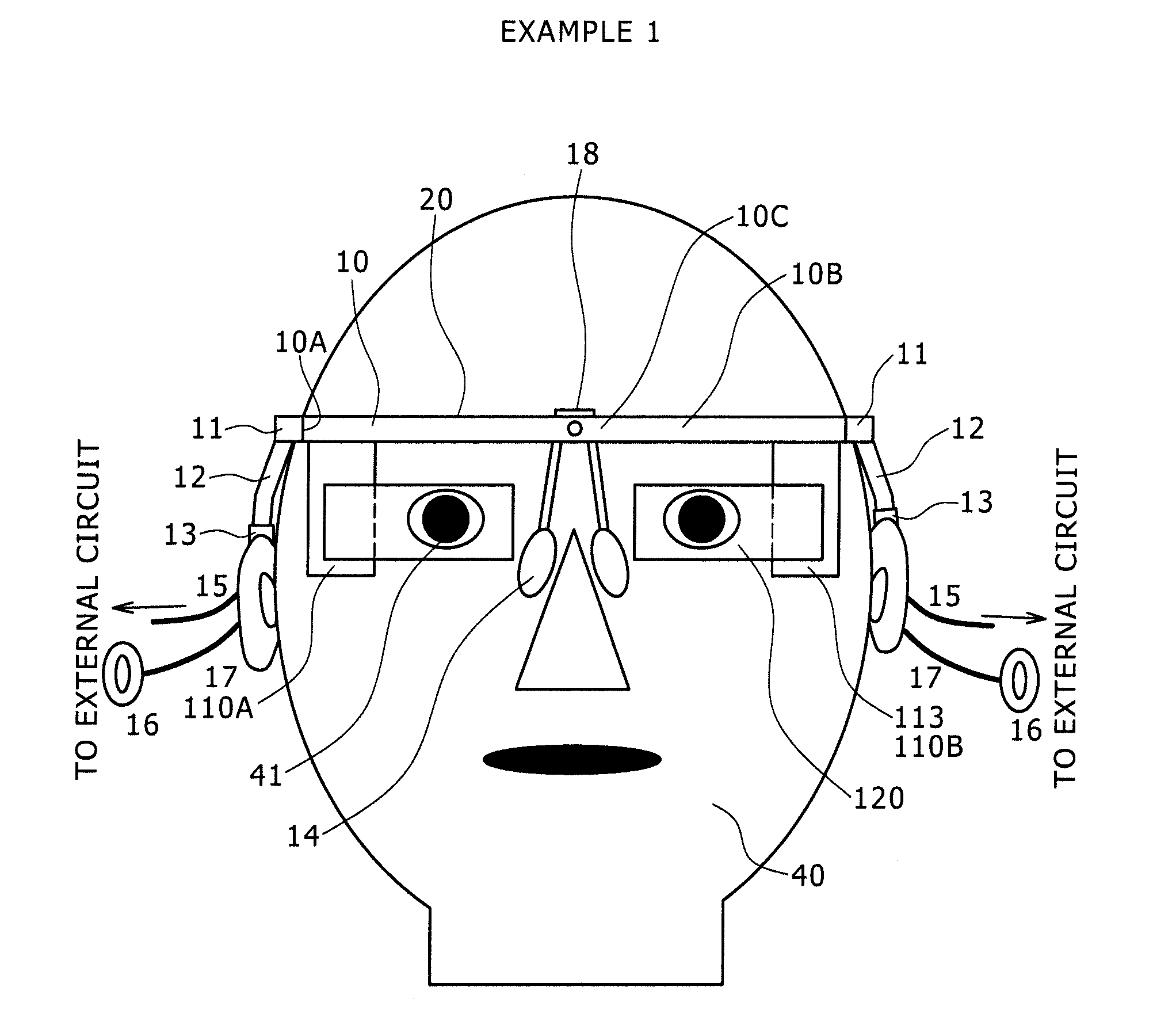

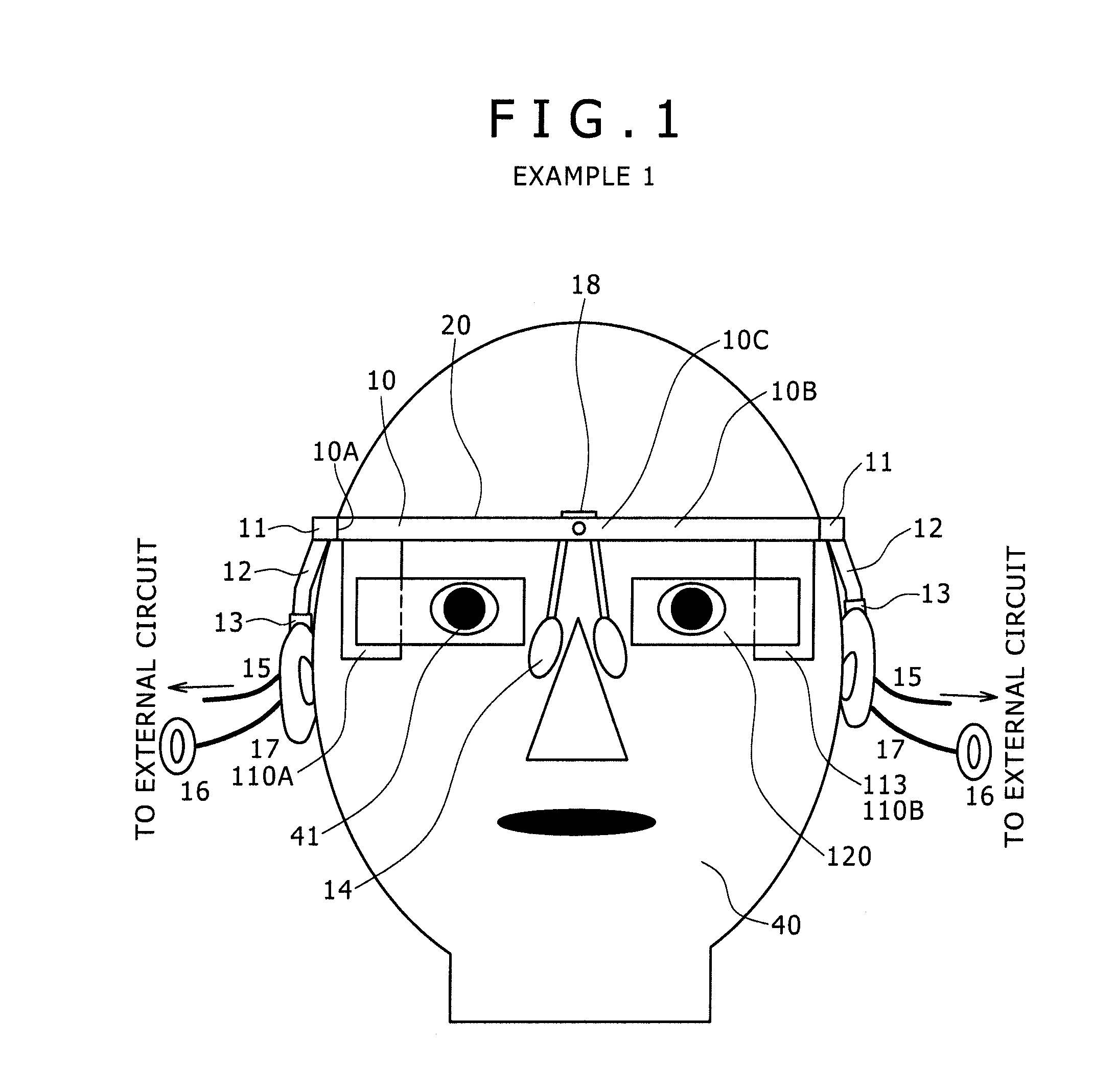

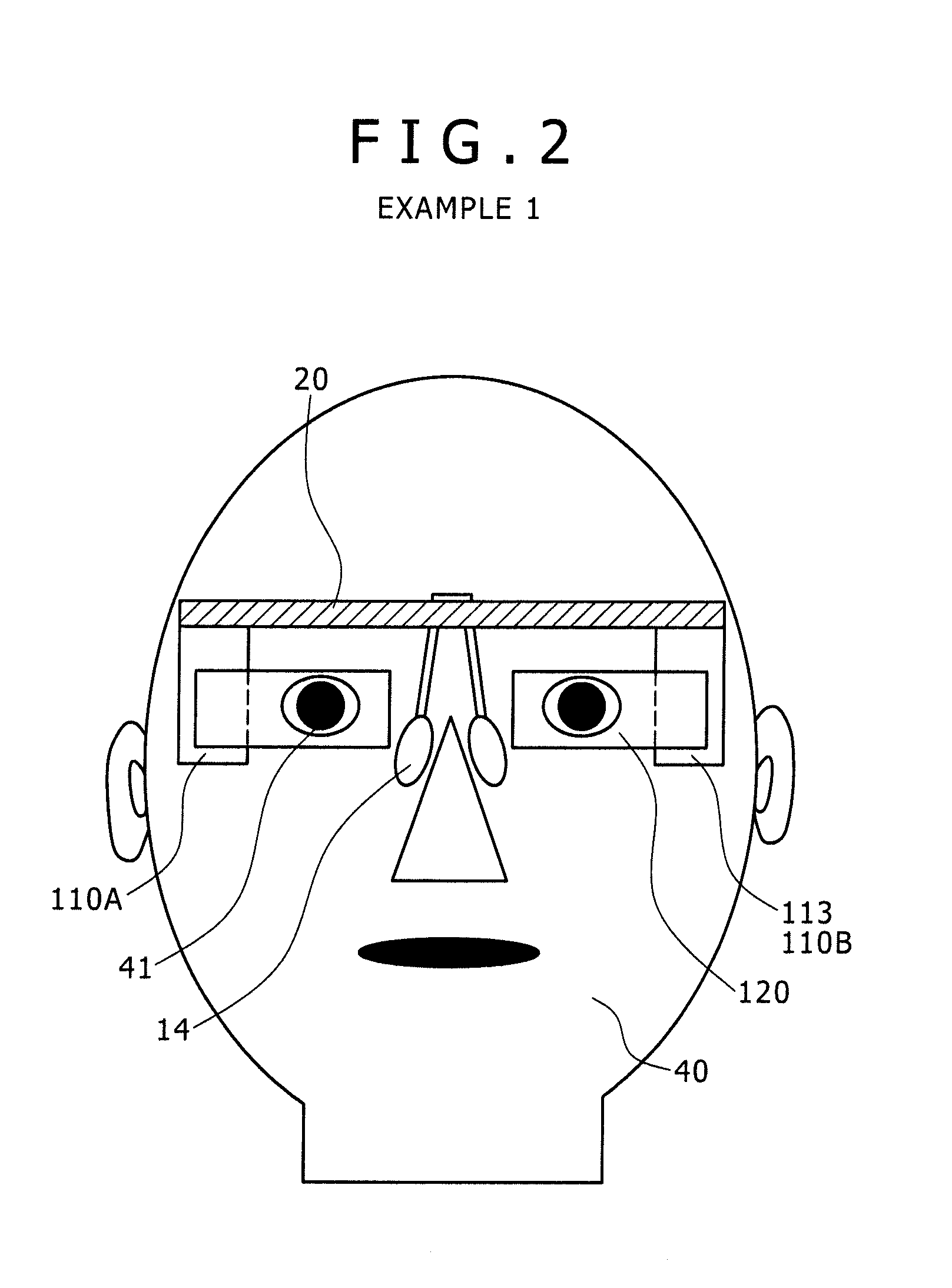

Head mounted display

ActiveUS20100157433A1Increased frame weightIncrease freedomNon-optical adjunctsProjectorsHead worn displayLight guide

Disclosed herein is a head mounted display including: an eyeglasses frame-like frame to be mounted onto an observer's head; and two image display devices, each of the image display devices including an image generating device, and light guide means which is mounted to the image generating device, which as a whole is located on the side of the center of an observer's face relative to the image generating device, on which beams emitted from the image generating device are incident, through which the beams are guided, and from which the beams are emitted toward an observer's pupil.

Owner:SONY CORP

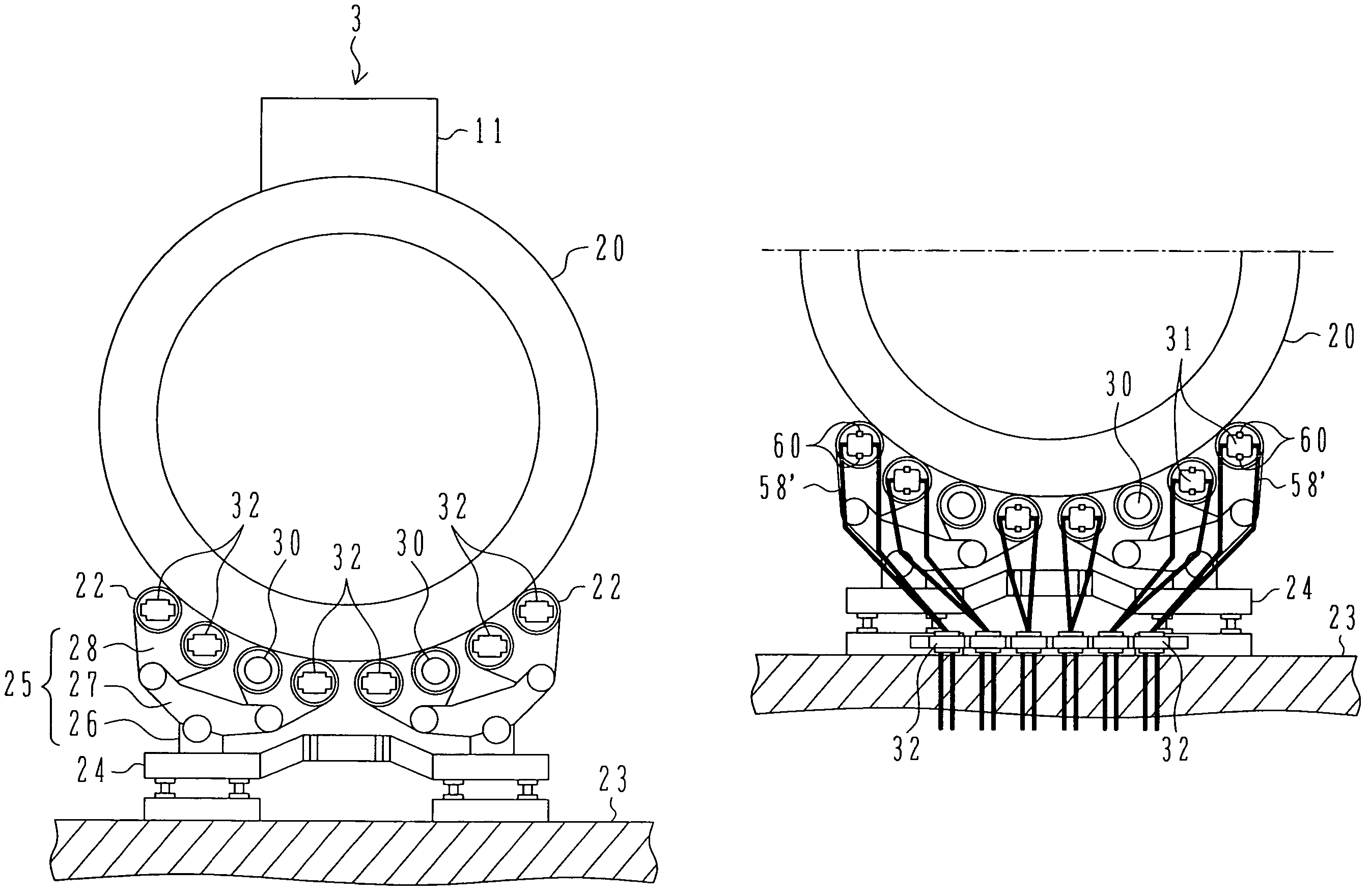

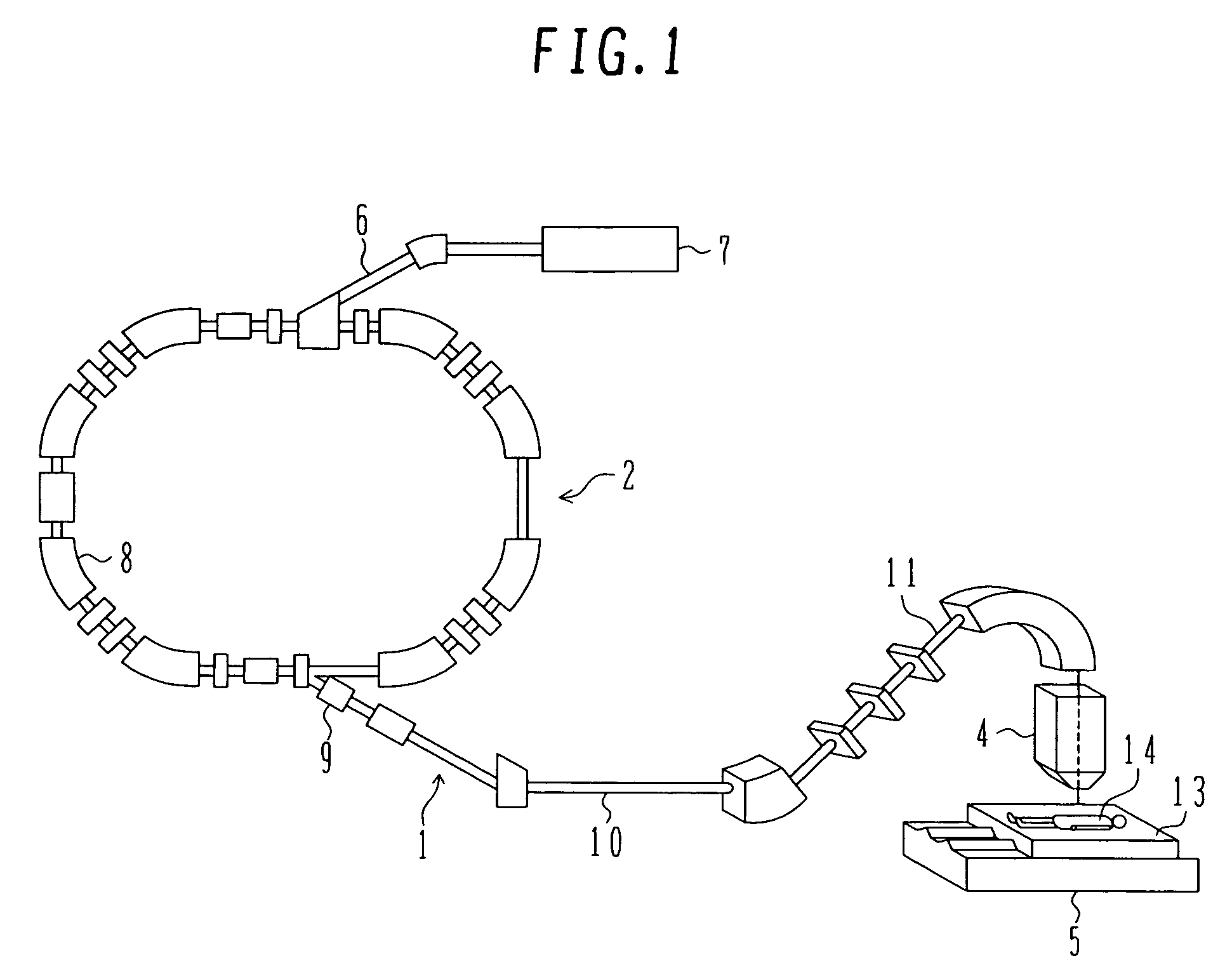

Rotating gantry of particle beam therapy system

ActiveUS7372053B2Improve rigidityVariation can be suppressedThermometer detailsFluid actuated brakesSolenoid valveParticle beam

A rotating gantry includes a link frame for supporting a plurality of rollers which rotatably support the rotating gantry, a brake for releasing a braking force applied to at least one of the rollers upon supply of air and applying the braking force to the one roller upon discharge of air, and a solenoid valve for sealing the supplied air in the brake when closed, and discharging the air from the brake when opened. The solenoid valve is supported by a solenoid valve support member mounted to the link frame such that the solenoid valve is positioned just near the brake. The rotating gantry can be more quickly braked and stopped while maintaining high irradiation accuracy.

Owner:HITACHI LTD +1

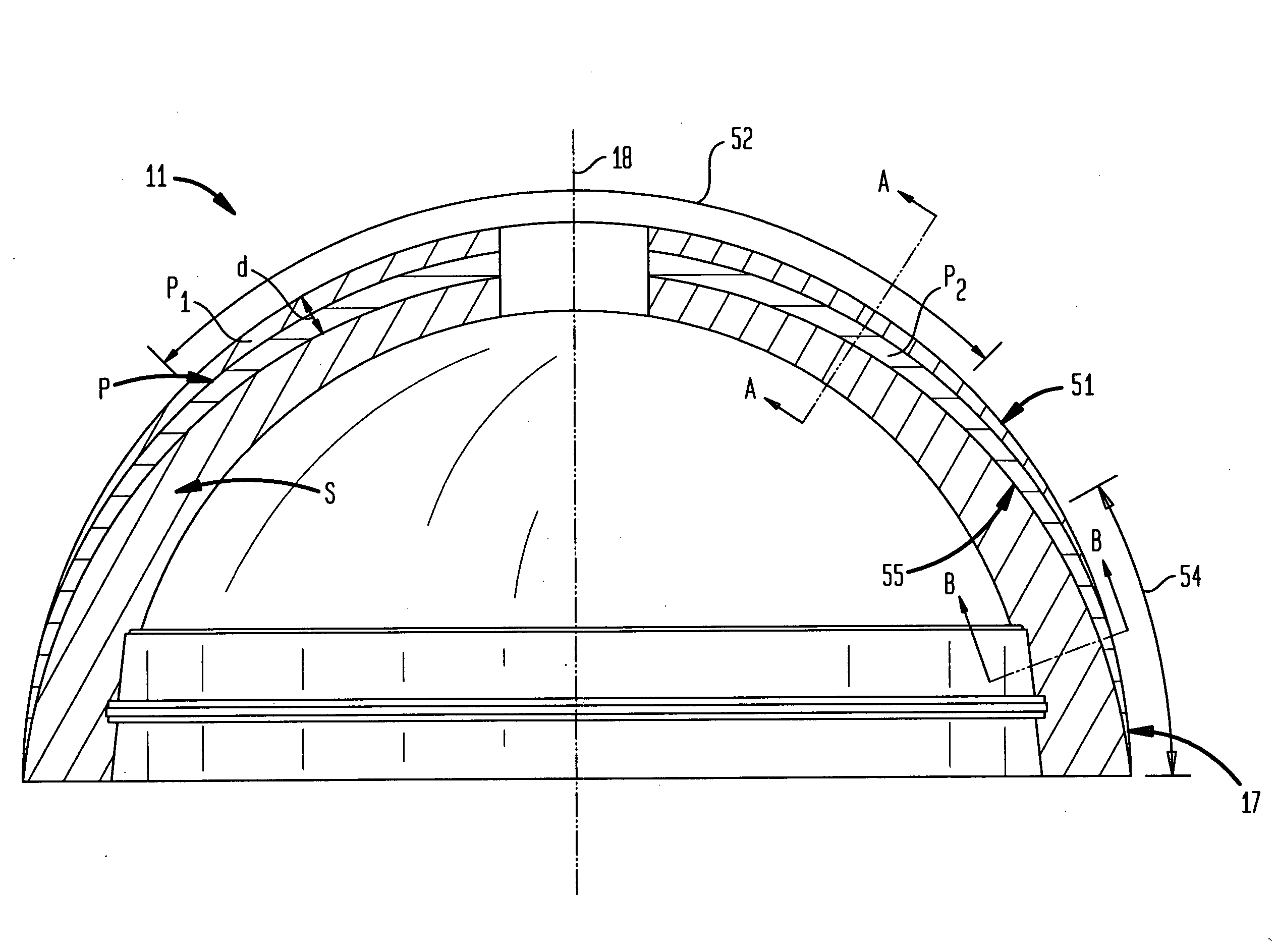

Gradient porous implant

ActiveUS7578851B2Optimizes various mechanical and biological requirements of the implants performanceIncreasing the thicknessAdditive manufacturing apparatusBone implantPorous implantMedical device

An implantable medical device includes a porous metal foam or foam-like structure having pores defined by metal struts or webs wherein the porous structure has directionally controlled pore characteristics. The pore characteristics controlled include one or more of the metal structure porosity, pore size, pore shape, pore size distribution and strut thickness. The pore characteristics may vary in one or more directions throughout the structure. Preferably the pore characteristics are controlled to match the porous metal structure to various mechanical and biological requirements of different regions of the structure in order to optimize aspects of the implants performance and may vary not only over the surface of the porous structure but through the depth of the porous structure. The thickness of the porous metal structure may also be modified to establish a thickness profile that optimizes mechanical and biological requirements of the implants performance. Acetabular cup embodiments of the invention are described. Various methods of manufacturing implants having directionally controlled pore characteristics are described.

Owner:HOWMEDICA OSTEONICS CORP

Wafer holder, and wafer prober provided therewith

InactiveUS20070205788A1Good effectIncrease speedSemiconductor/solid-state device manufacturingHot plates heating arrangementsYoung's modulusEngineering

A wafer holder is provided having high rigidity and an enhanced heat-insulating effect that allow positional accuracy and heating uniformity to be improved, a chip to be rapidly heated and cooled, and the manufacturing cost to be reduced, and a wafer prober apparatus on which the wafer holder is mounted. The wafer holder of the present invention includes a chuck top for mounting a wafer, a support member for supporting the chuck top, and a stand for supporting the support member. The chuck top has a thermal conductivity K1 and a Young's modulus Y1; the support member has a thermal conductivity K2 and a Young's modulus Y2; and the stand has a thermal conductivity K3 and a Young's modulus Y3. K1>K2 and K1>K3; and Y3>Y1 and Y3>Y2.

Owner:SUMITOMO ELECTRIC IND LTD

Golf club head

To provide a golf club head in which a sole portion has a high rigidity. A weight material is mounted near a central part of the sole portion in the fore-to-aft direction, and a rib extends in the toe-to-heel direction. Since the sole portion has high rigidity in the toe-to-heel direction, there is less deformation of the head in the toe-to-heel direction when hitting the ball, thereby suppressing the vibration of the sole portion. An elastic body is filled in a recess portion and closely contacted with the weight material, whereby the vibration of the sole portion is absorbed by the elastic body.

Owner:BRIDGESTONE SPORTS

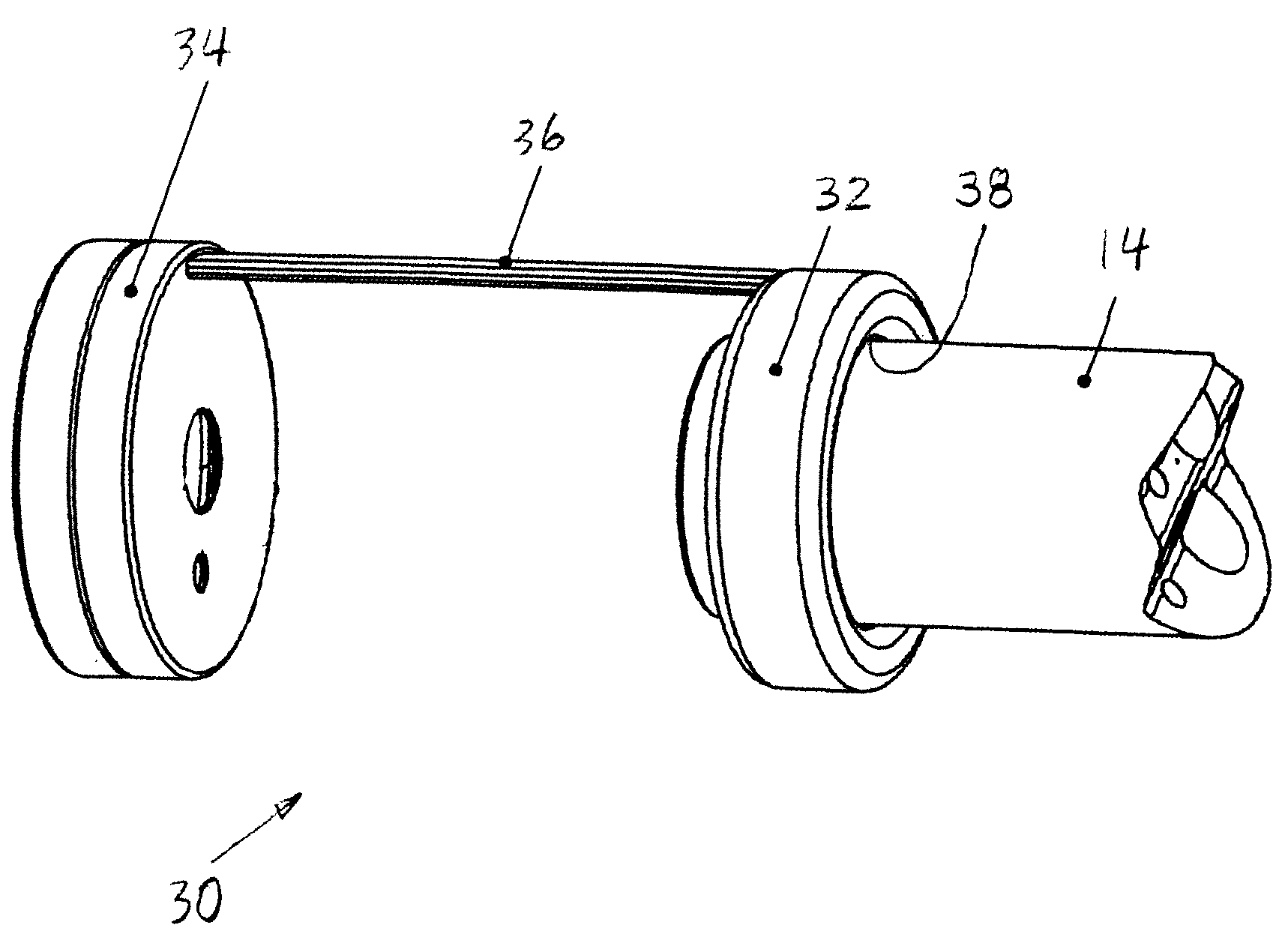

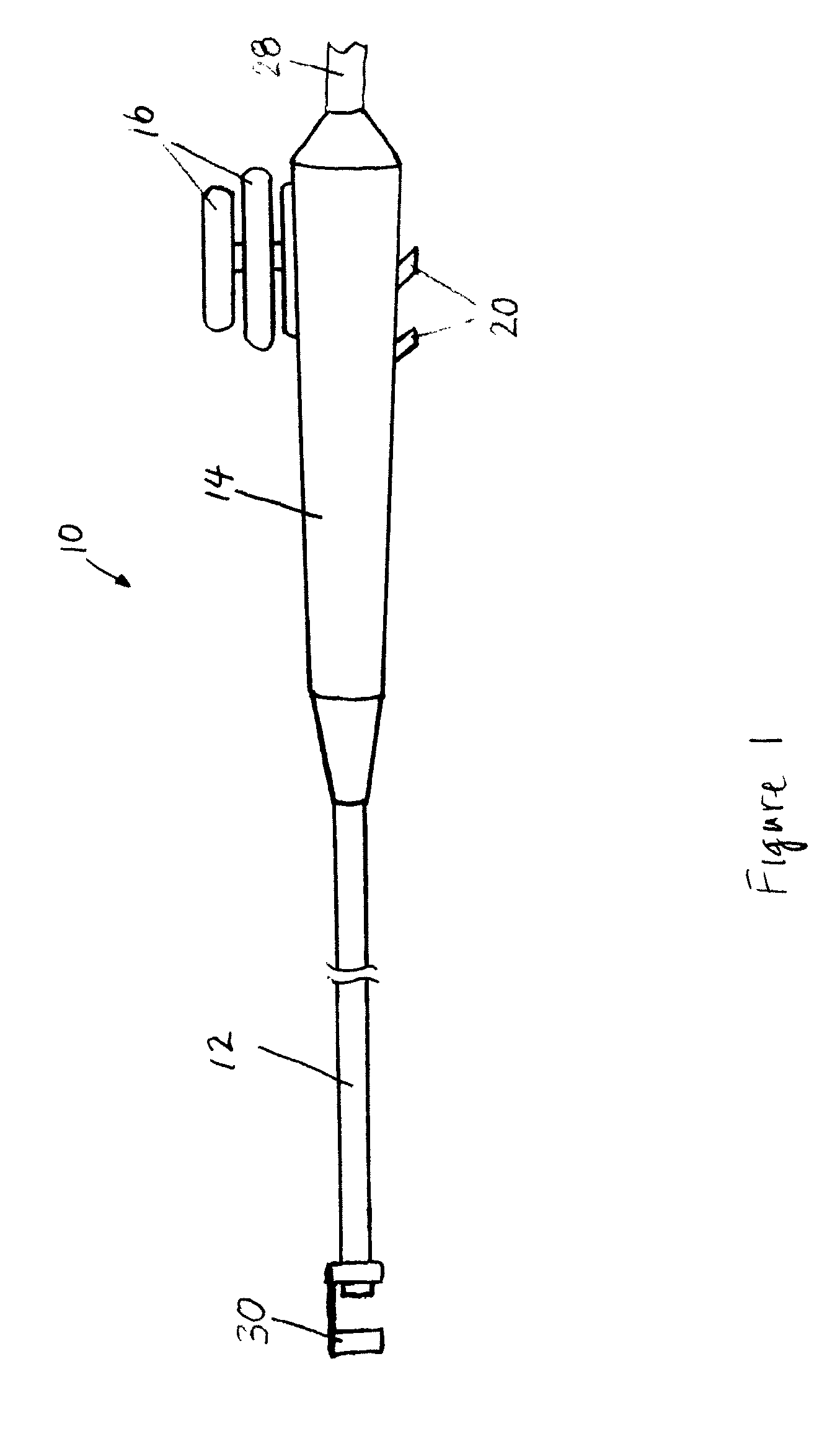

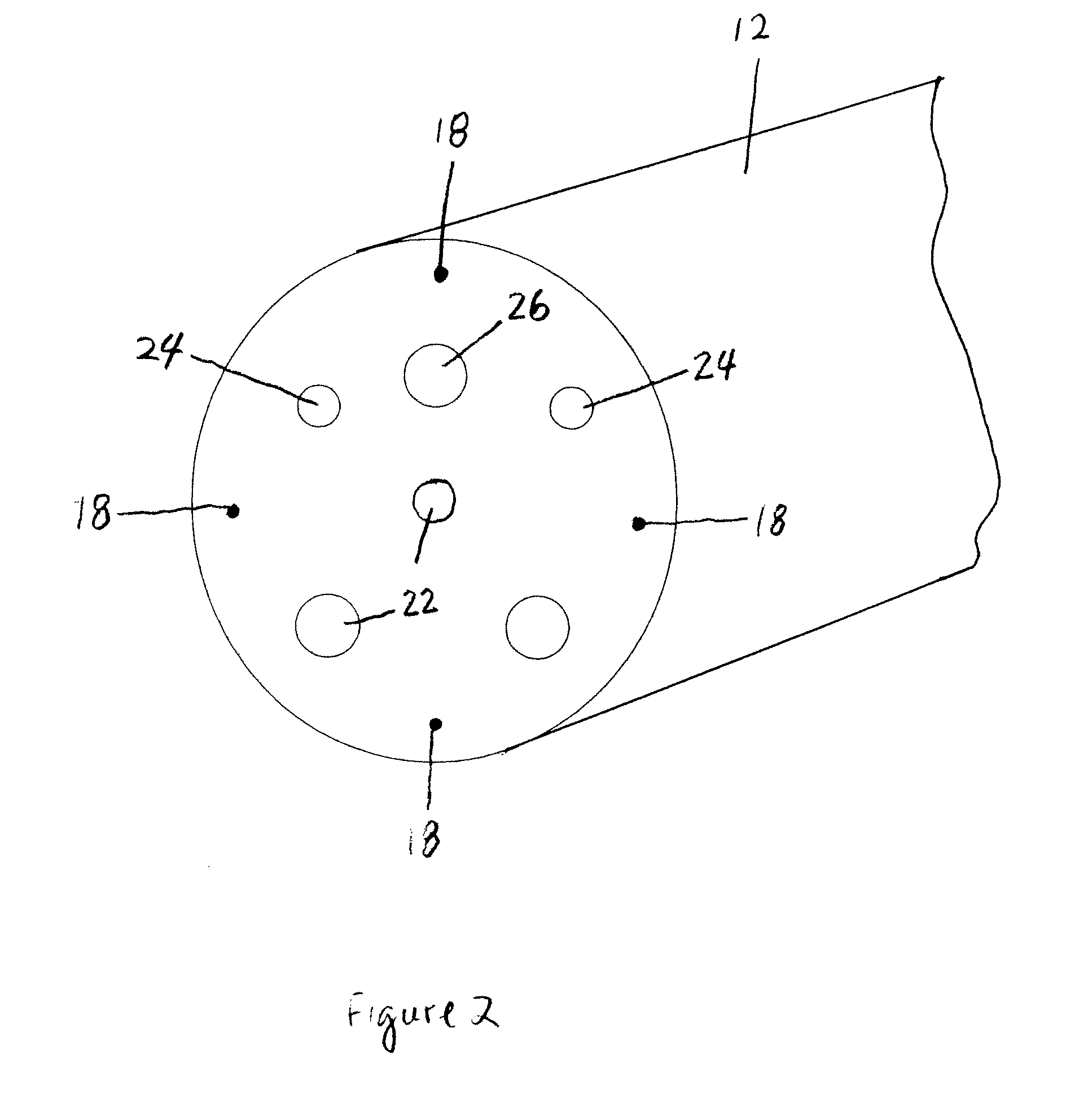

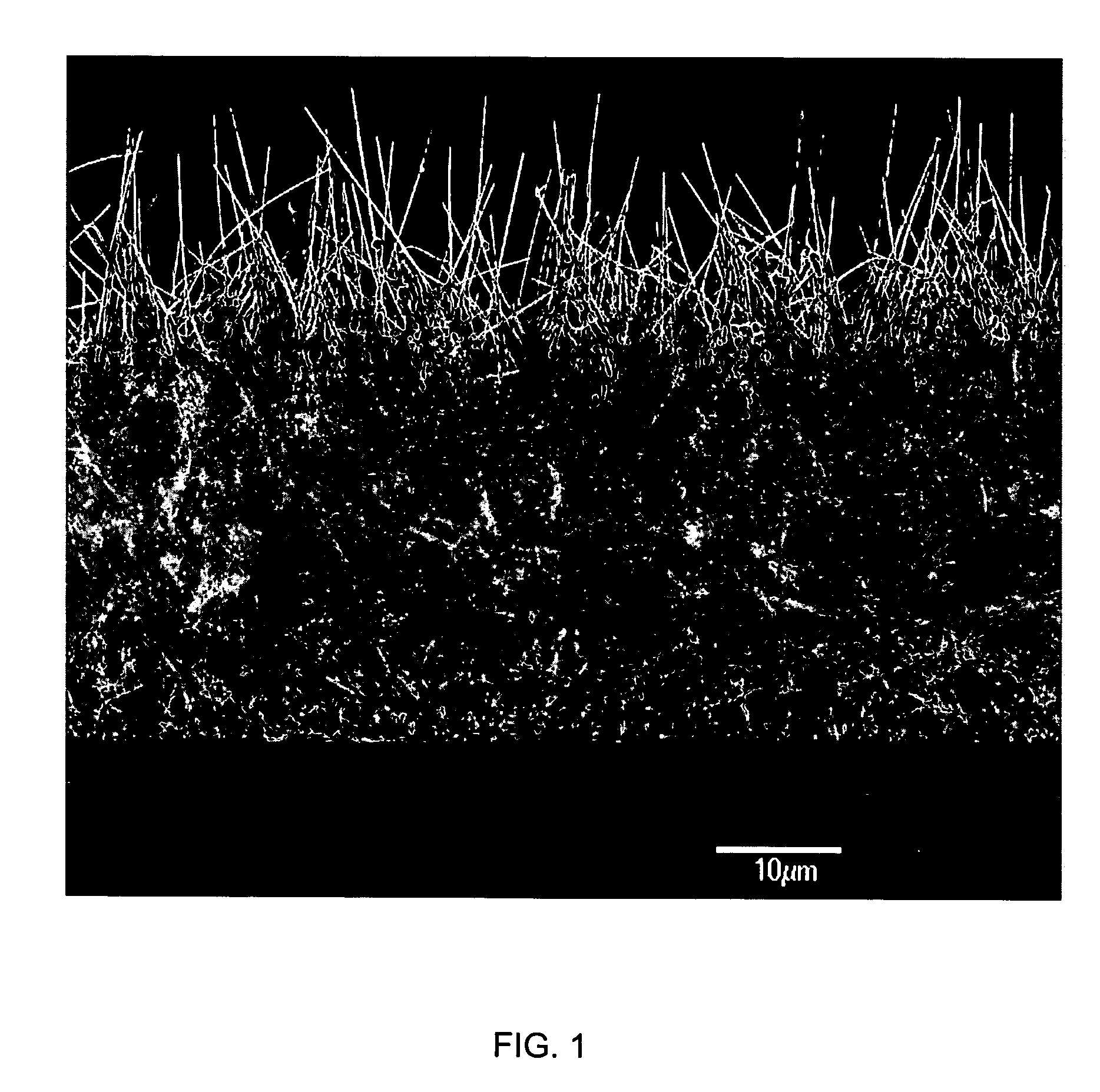

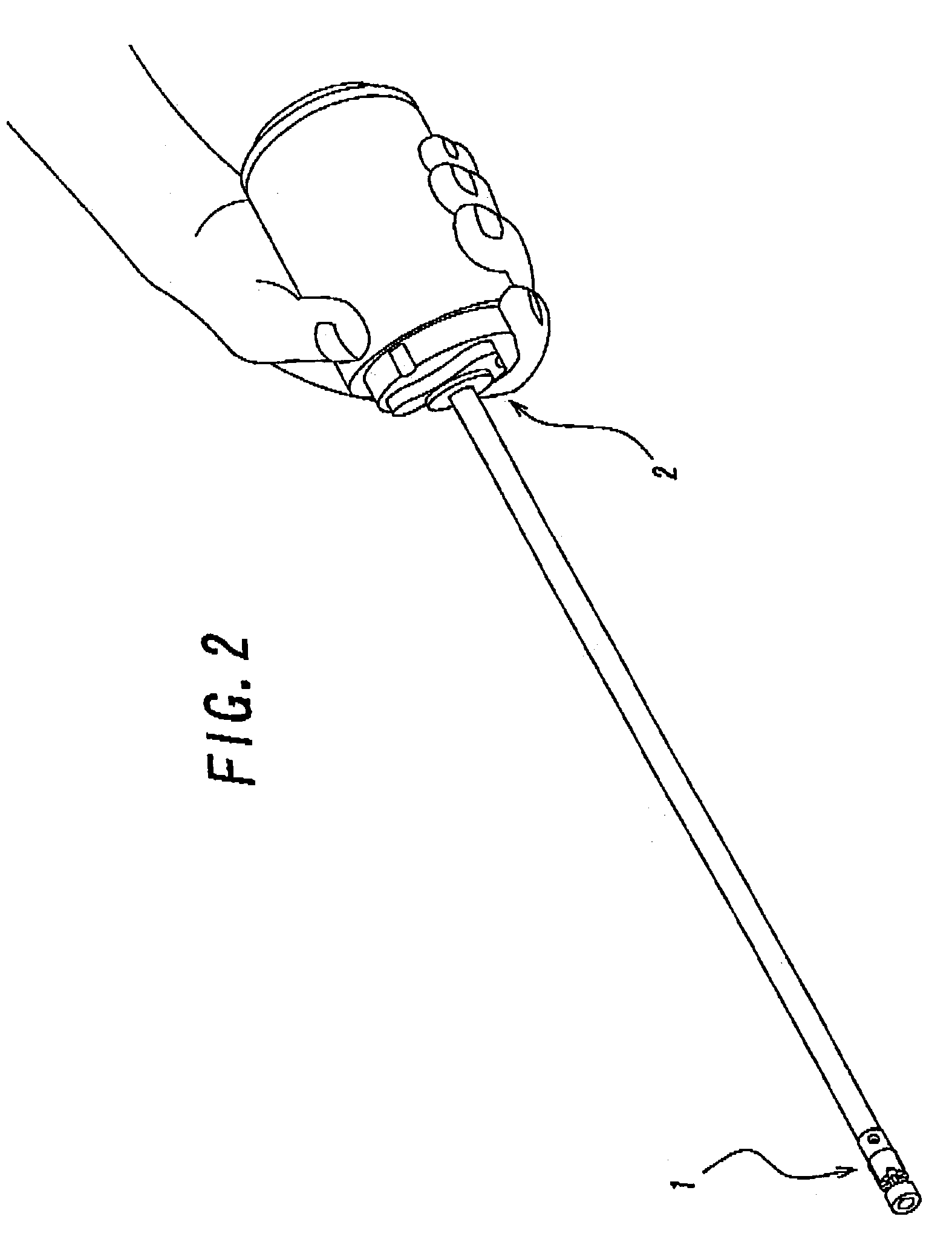

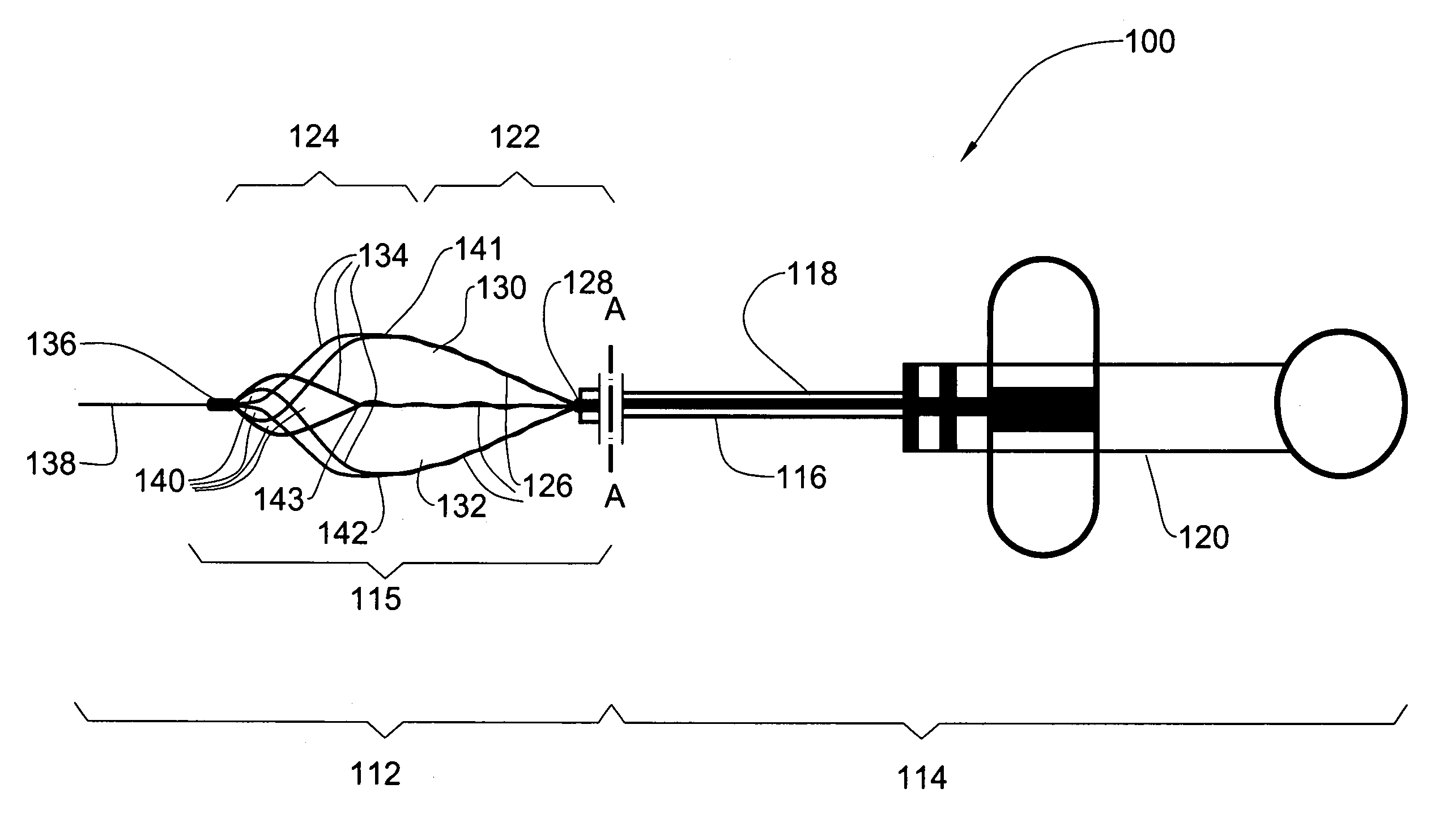

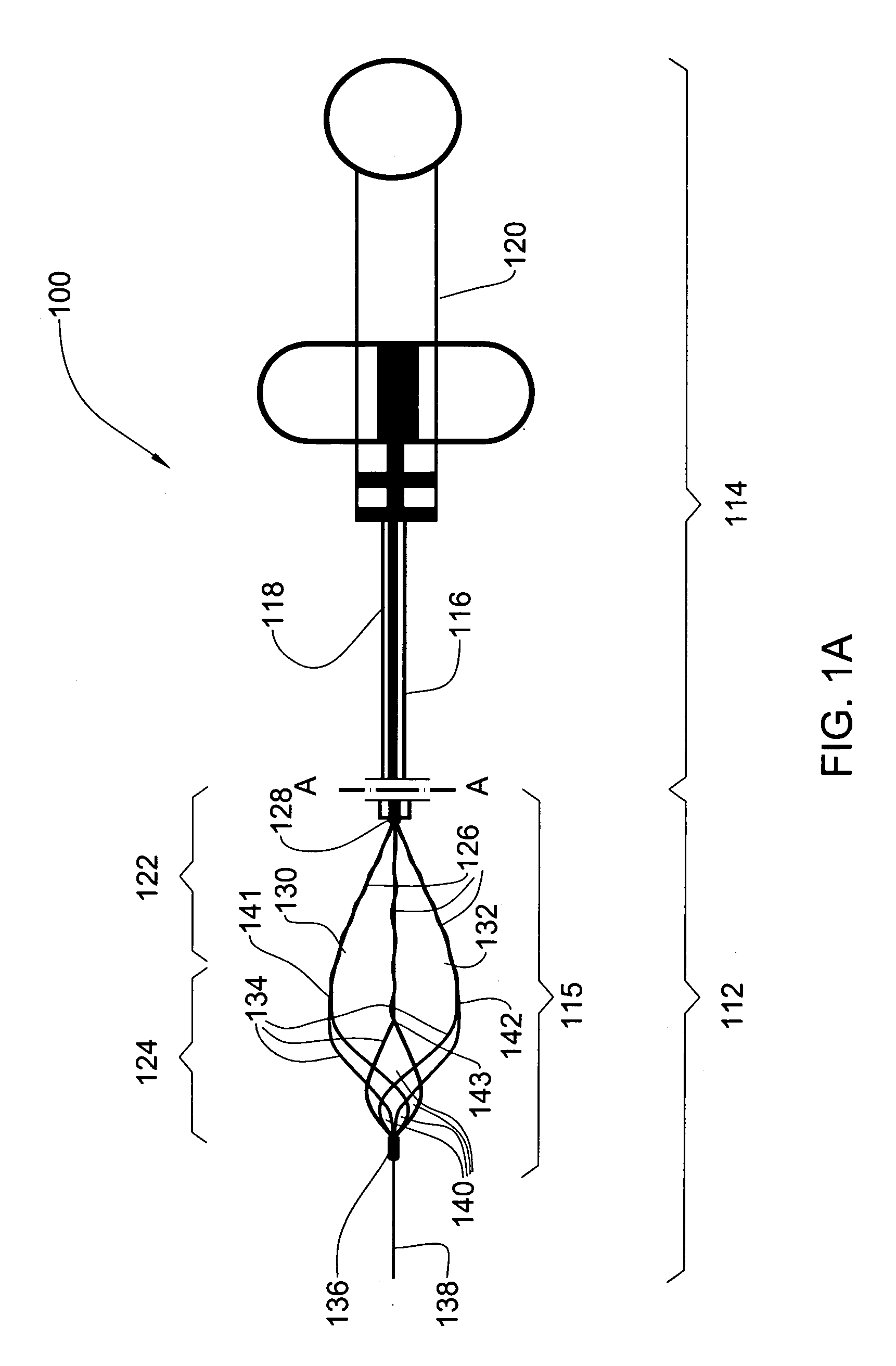

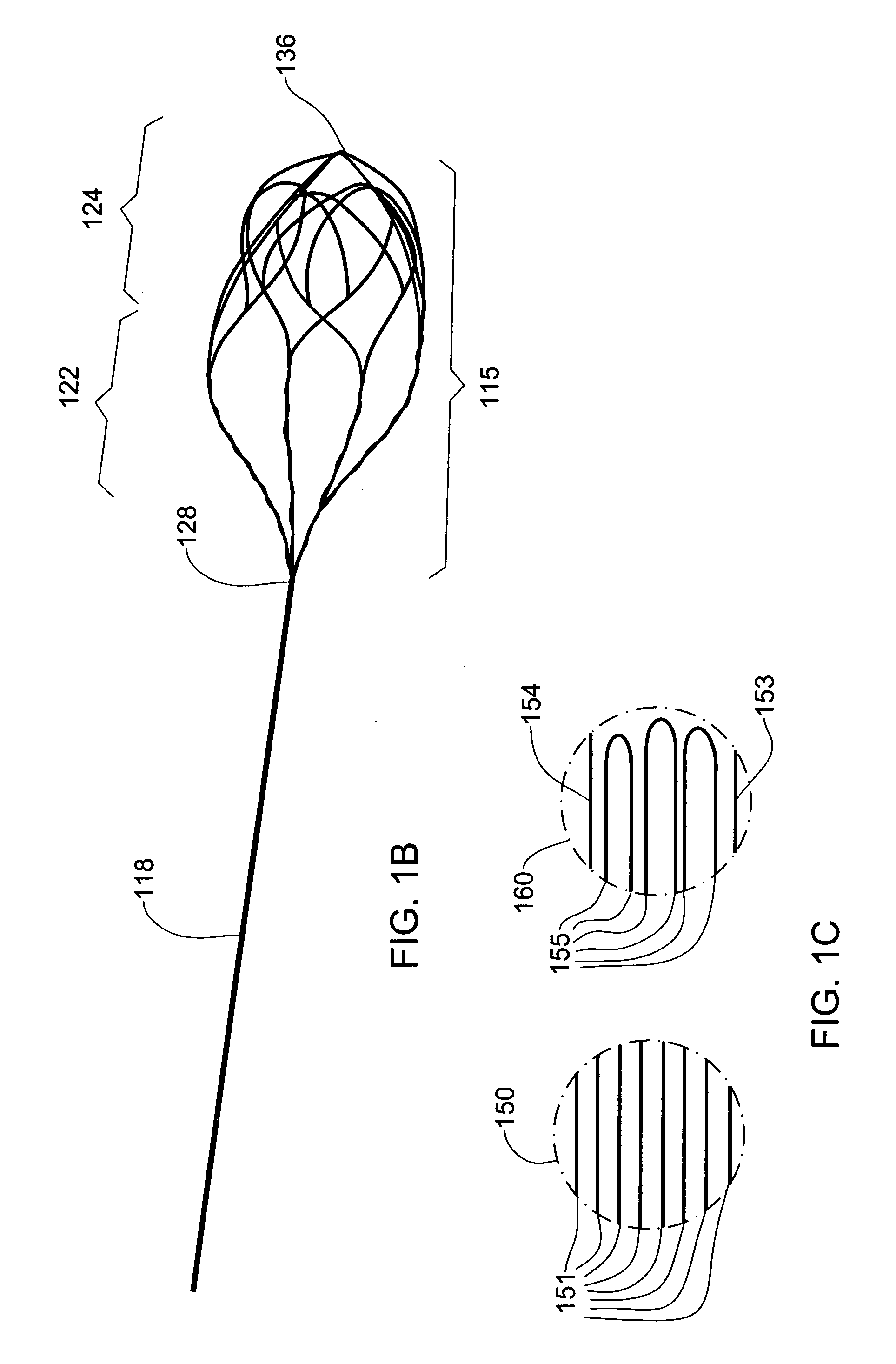

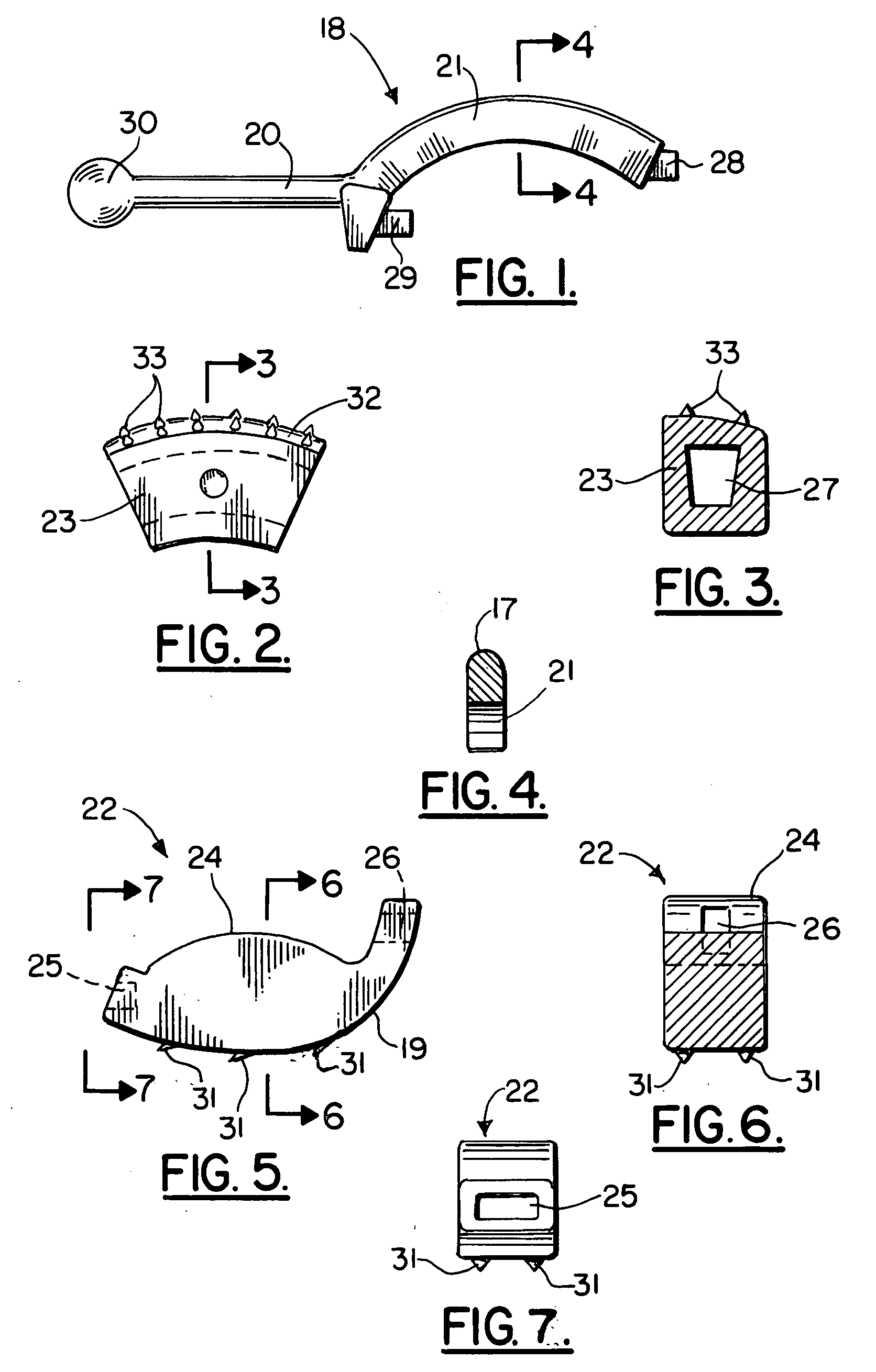

Surgical device for retrieval of foreign objects from a body

A surgical device for removing a foreign object from a body is described. The device includes a retrieval basket for entrapping and retaining the object located in the body, a basket control assembly comprising a tubular sheath adapted to penetrate into the body for reaching the object, and a manipulator for manipulating the basket for extraction the object from the body. The basket comprises a structure having a proximal end and a distal end. The structure is formed by a plurality of filaments fabricated from a single or several wires. The filaments extend from the proximal end towards the distal end. At least a part of the filaments are configured in the form of loops. At least a part of the loops are interlaced so as to define a net at the distal end, and thereby impart structural rigidity and dilatation ability to the basket when opened.

Owner:NORDSON CORP

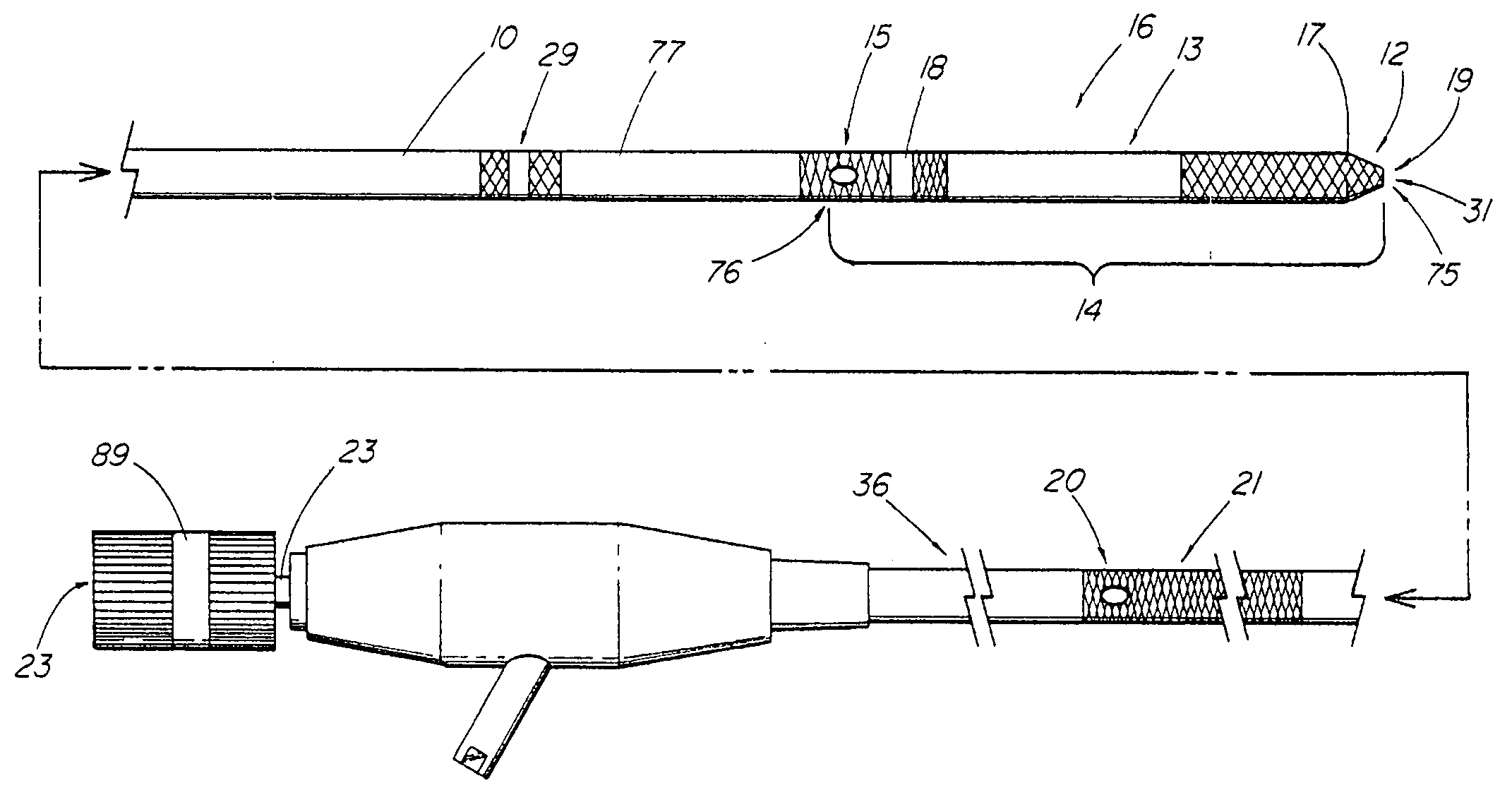

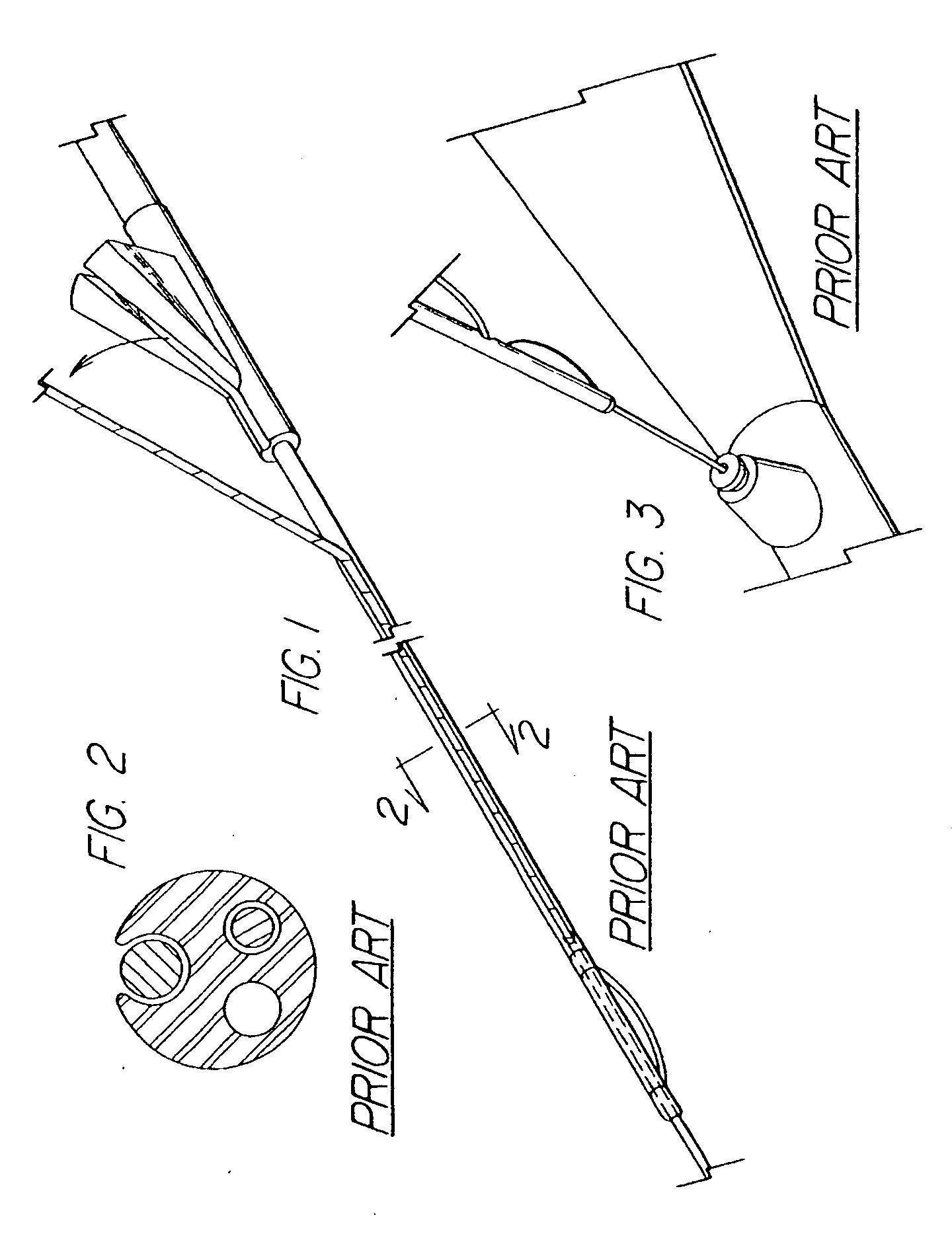

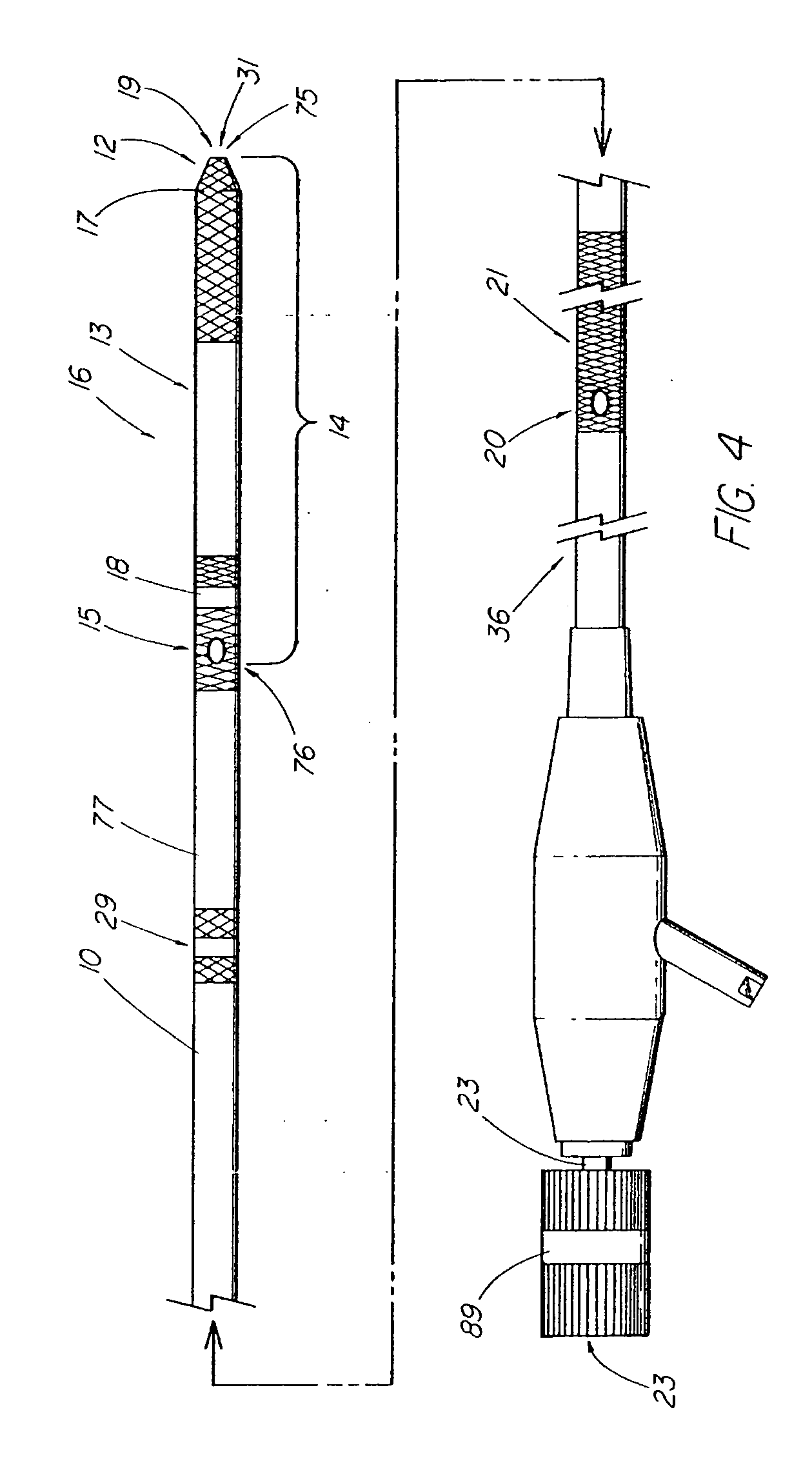

System and method for introducing multiple medical devices

ActiveUS20050059990A1Timely controlSatisfy safety performance requirementsStentsGuide needlesDilatorBiliary tract

A method and apparatus for introducing a first elongate medical device and short wire guide that are coupled together into a work site and remotely disconnecting them within the work site such that a secondary device comprising a catheter member can be introduced over the wire guide to the work site, and / or a second wire guide can be introduced to the work site via a passageway of the primary access device. A separating member may be provided to remotely separate the wire guide from the elongate medical device. A system of indicia, such as radiopaque or viewable markers, permits the operator to monitor the relative alignment of the devices within the work site to determine when uncoupling has occurred. In one example of the method, a wire guide and primary access device (e.g., a sphincterotome) is coupled to the wire guide and introduced via a duodenoscope into the biliary system. After performing a first medical operation, the devices are uncoupled with the wire guide being left within the biliary system such that a secondary access device, such as a balloon, biopsy device, stent delivery catheter, dilator, etc., can be introduced to perform a second medical operation without a traditional over-the-wire exchange being required. In another example of the method, a prosthesis, such as a valve or stent, is placed within the work site coupled to a wire guide which is remotely disconnected within the work site and a secondary device, such as a dilation balloon or second prosthesis, is introduced into the work site after the first delivery system is removed.

Owner:COOK MEDICAL TECH LLC

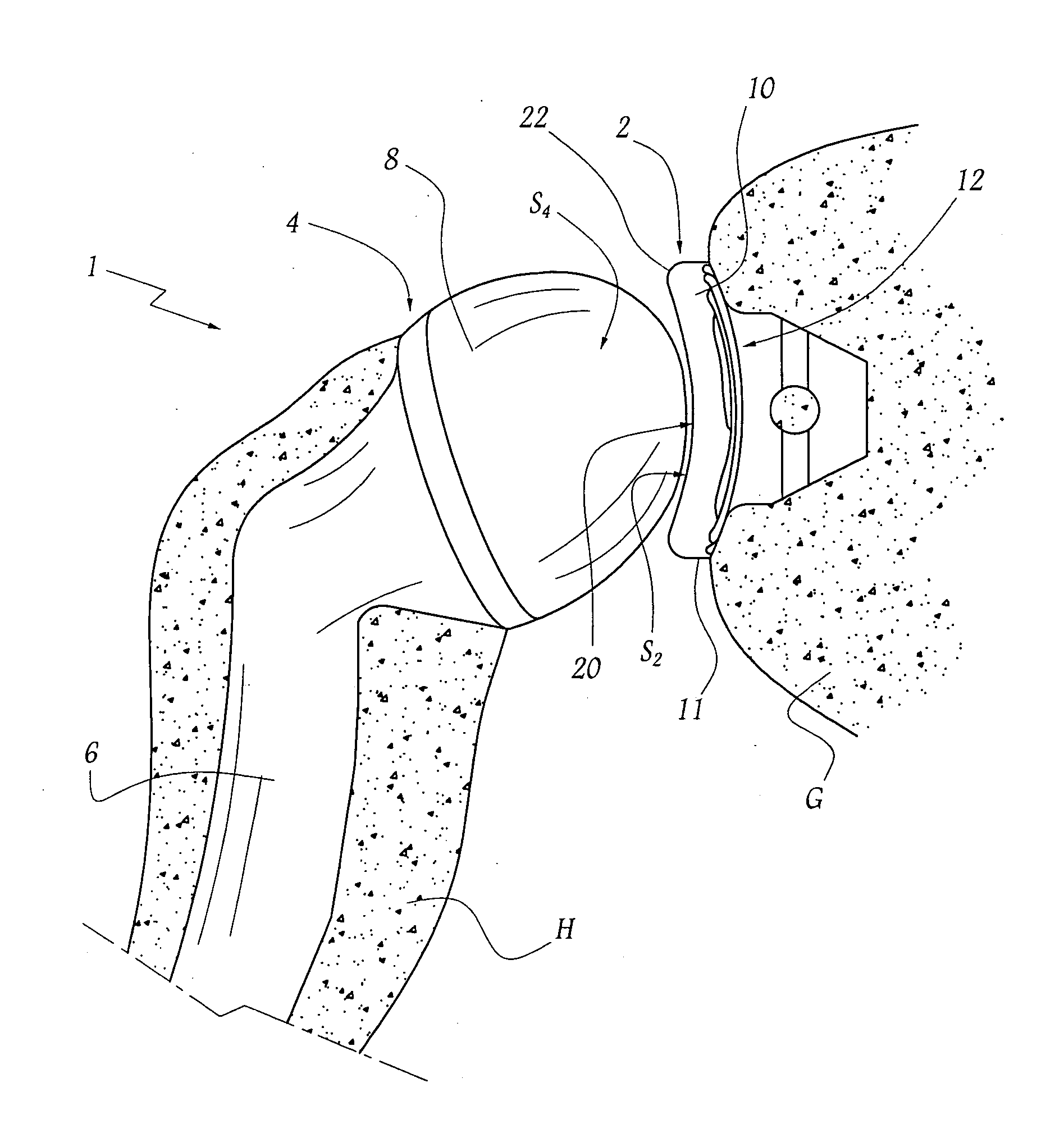

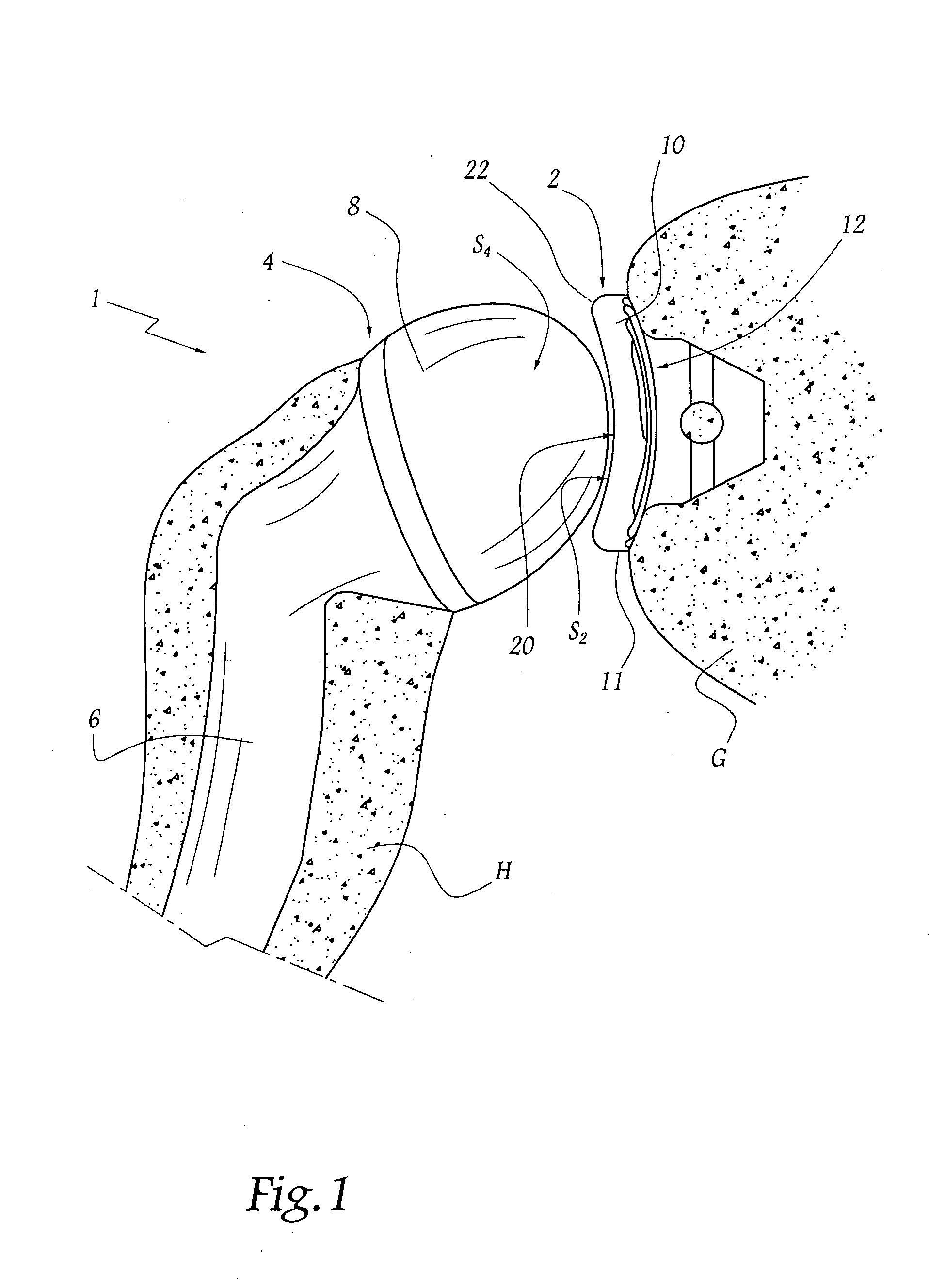

Glenoid component of a shoulder prosthesis and complete shoulder prosthesis incorporating such a component

The glenoid component according to the invention comprises a metal body of which the inner face is adapted to be immobilized on the glenoid cavity of a shoulder and of which the outer face bears a concave articulating surface adapted to cooperate with a humeral component. This articulating surface extends on the periphery by a convex surface forming, at least in part, the edge of the body.

Owner:TORNIER SA SAINT ISMIER

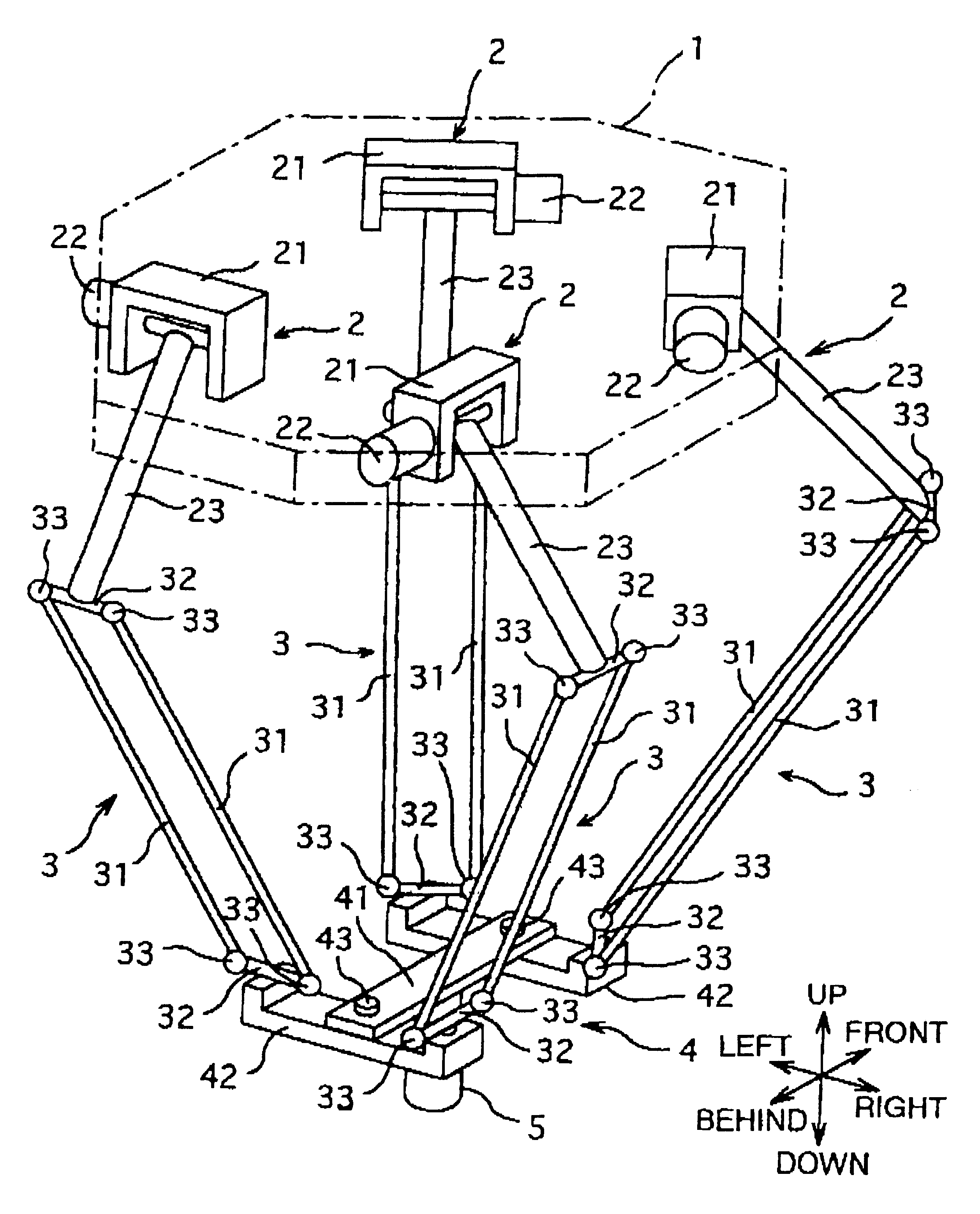

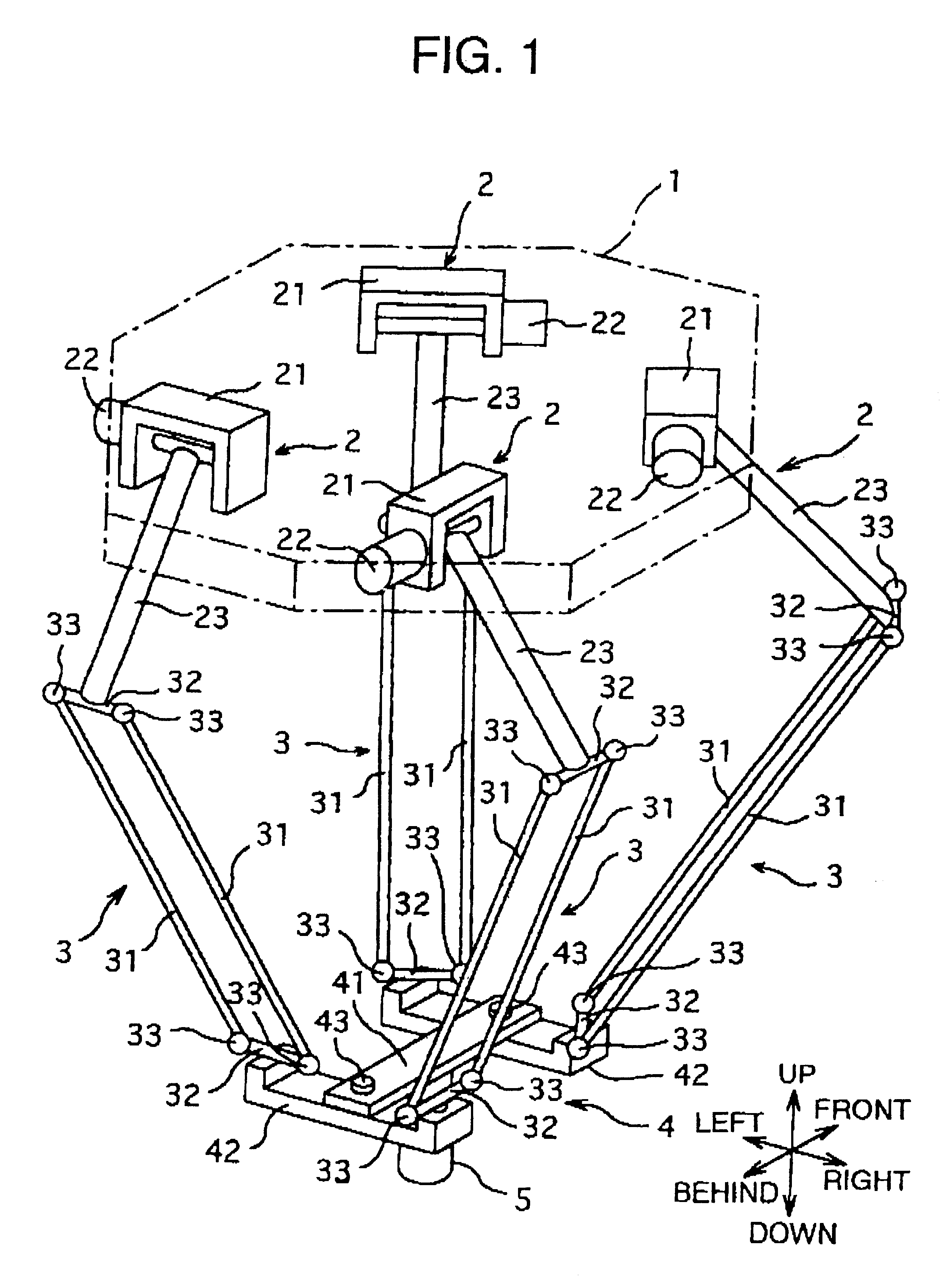

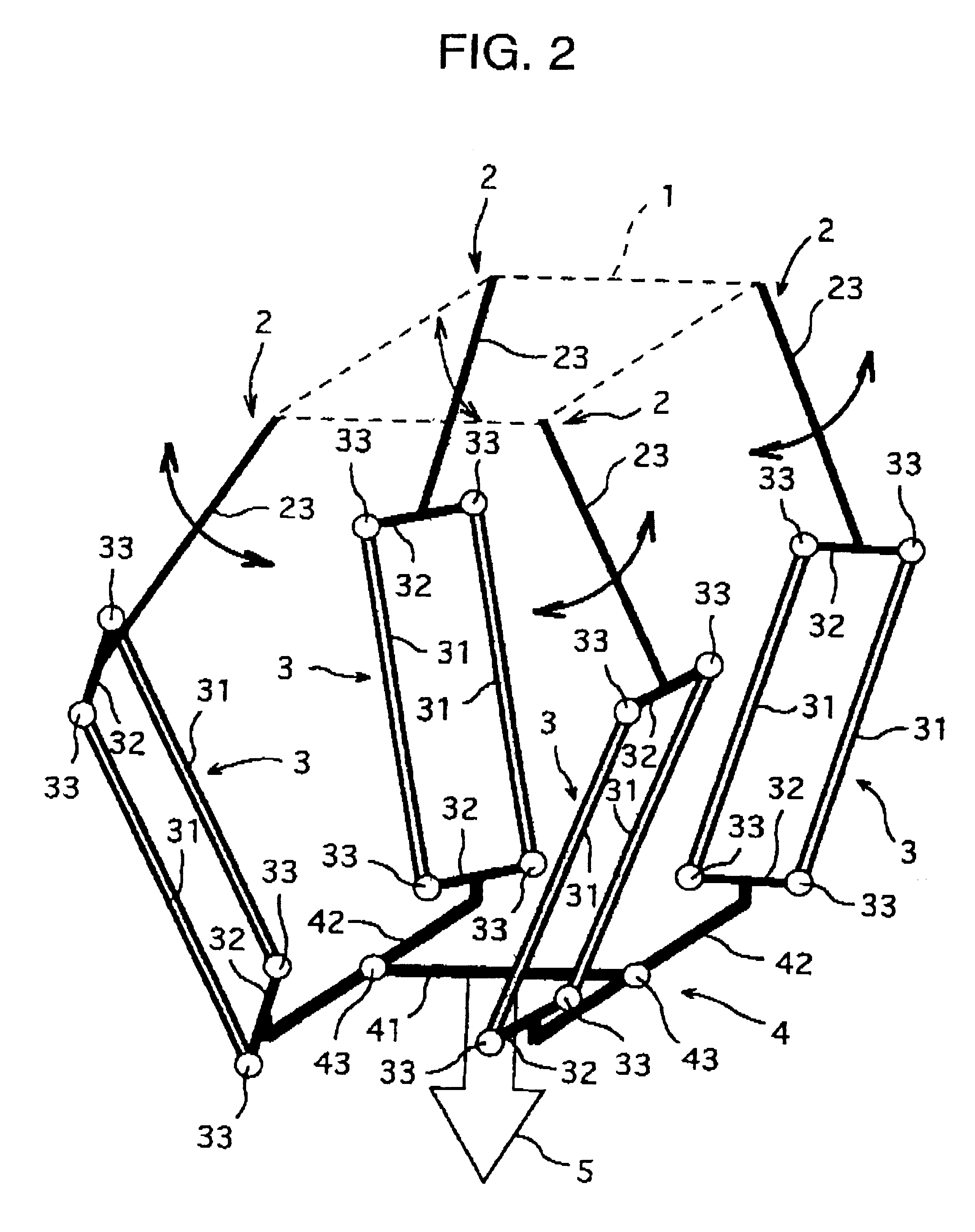

Four-degree-of-freedom parallel robot

InactiveUS6516681B1Improve rigidityImprove accuracyProgramme-controlled manipulatorJointsEngineeringActuator

Owner:PIERROT FRANCOIS +2

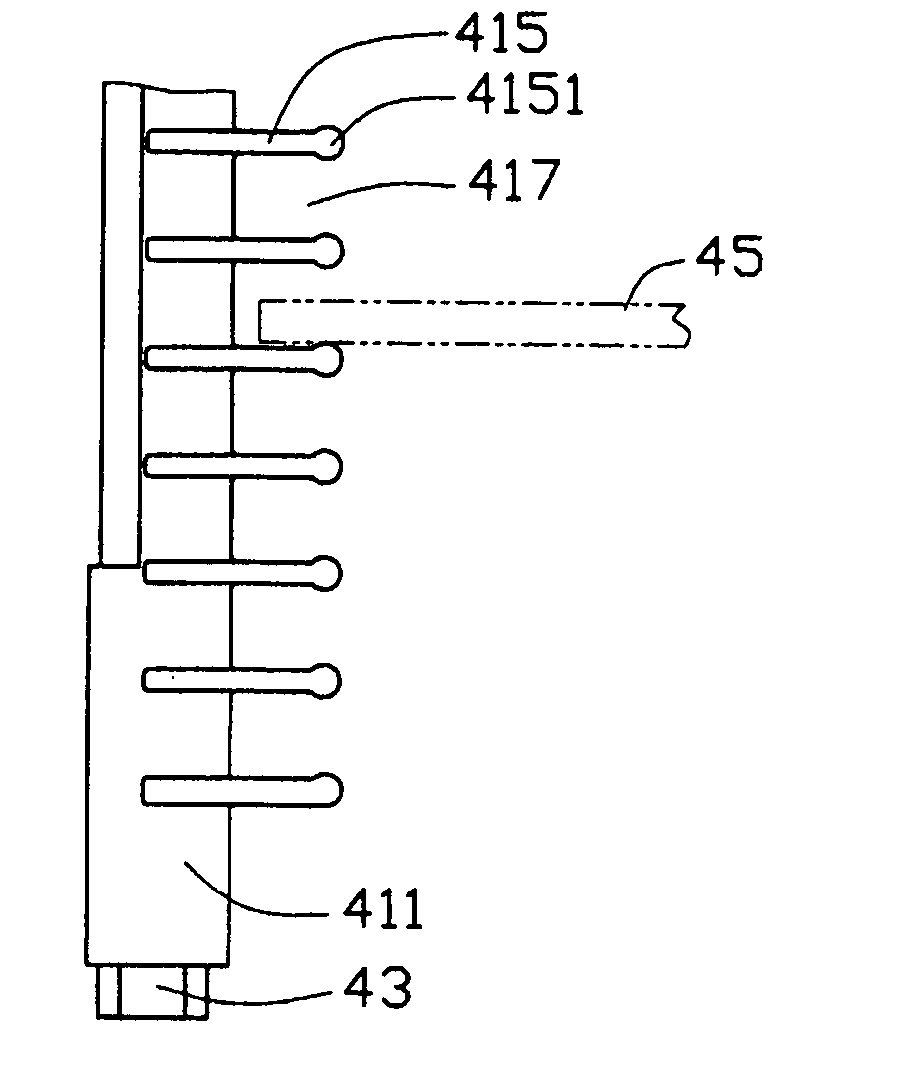

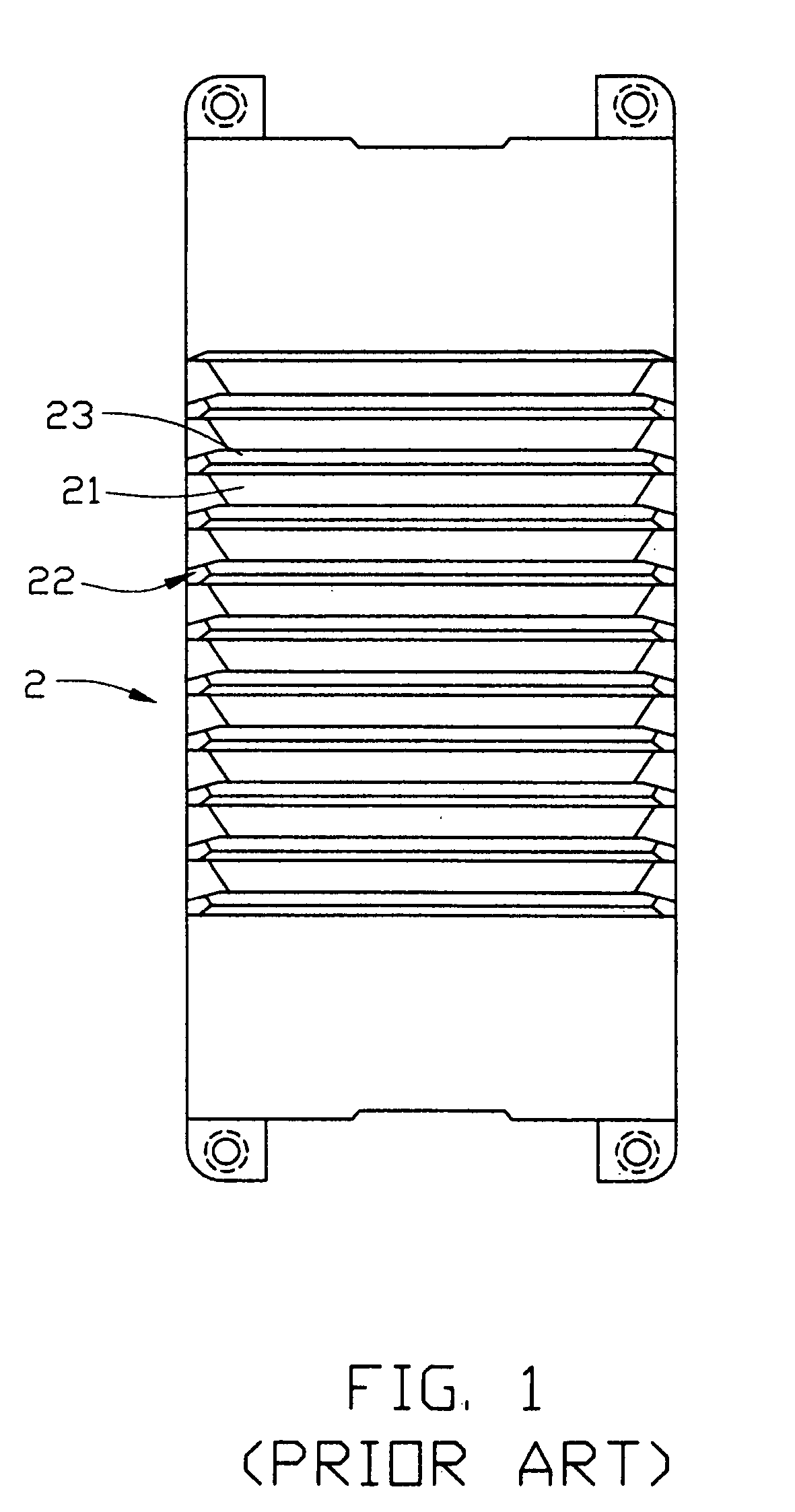

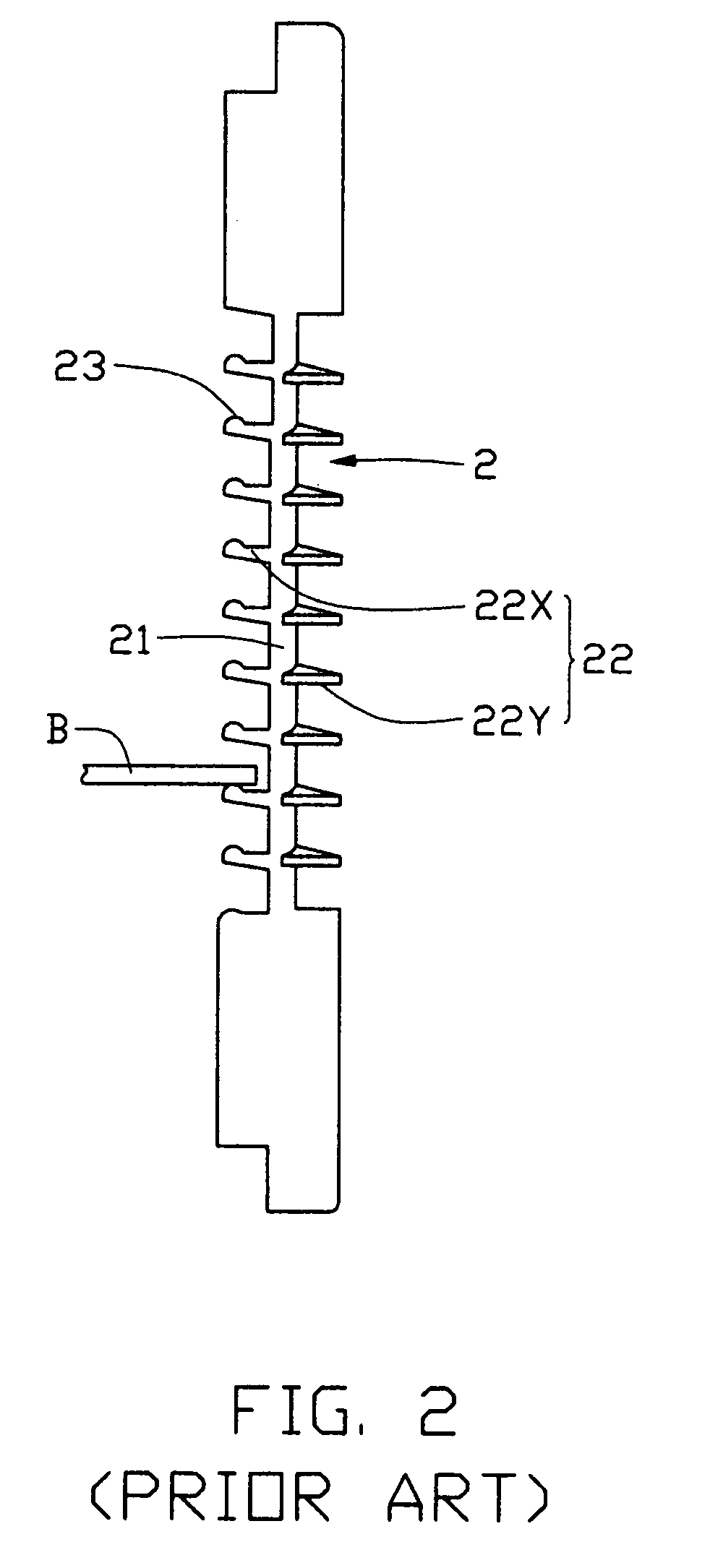

Substrate supporting rod and substrate cassette using the same

InactiveUS20050023231A1Improve rigiditySave materialLiquid surface applicatorsSemiconductor/solid-state device manufacturingEngineeringMechanical engineering

A substrate-supporting rod (4) comprises a resin body (41) and a metal rod (43). The resin body (41) includes a body portion (411) being cylinder-shaped and having a first through hole (413) in a direction of the axis thereof and a number of shelves (415, 415′) arising from said body portion (411) and extending in parallel and inwardly of a cassette (5) at a predetermined pitch. The metal rod (43) is received in the first through hole (413) of the body portion (411) so as to increase the rigidity of the substrate-supporting rob (4). A projection (4151) is defined on the end of each shelf (415, 415′) to support a substrate (45). Further, the body portion (411) is molded from an electrically conductive resin so that not only the cassette (5) can be protected against static discharge but also resin material is saved and cost is decreased.

Owner:FOXSEMICON INTEGRATED TECH INC

Lumbar disc replacement implant for posterior implantation with dynamic spinal stabilization device and method

ActiveUS20080269904A1Resist shorteningReduce frictionInternal osteosythesisDiagnosticsSpinal columnReplacement implant

The invention consists of disc replacement implant for the lumbar spine designed for insertion into the disc space via a posterior approach. The implant can be stabilized in the disc space by connection to the vertebra or can be connected to dynamic spinal stabilization device consisting of interconnected bullets nested in a spring nested in a woven sleeve. By controlling the limits of elongation and compression the device prevents movement beyond normal physiological limits. In the midrange of movement flexibility is allowed. A method for using the dynamic spinal stabilization device is also provided.

Owner:VOORHIES RAND M

Multicast control systems and methods for dynamic, adaptive time, bandwidth,frequency, and satellite allocations

InactiveUS7236738B2Additional satellite capacityOptimize resource allocationNetwork traffic/resource managementNetwork topologiesControl systemThe Internet

Methods and systems to efficiently share multiple satellites and associated transponders or links among a network of uplinking earth stations are disclosed. An embodiment of this invention uses a terrestrial communications link, such as the Internet, to control access to the transponder or satellite links. Communications over this link may employ a TCP / IP protocol to connect the requesting uplinking earth stations with a centralized controller. This control system creates more efficient use of satellite resources and reduces the overall amount of time needed for transmitting data through the satellite. By reducing the overall amount of time needed for transmitting data, the control system may reduce the cost of using the satellite transponder capacity.

Owner:EXTREME REACH INC +1

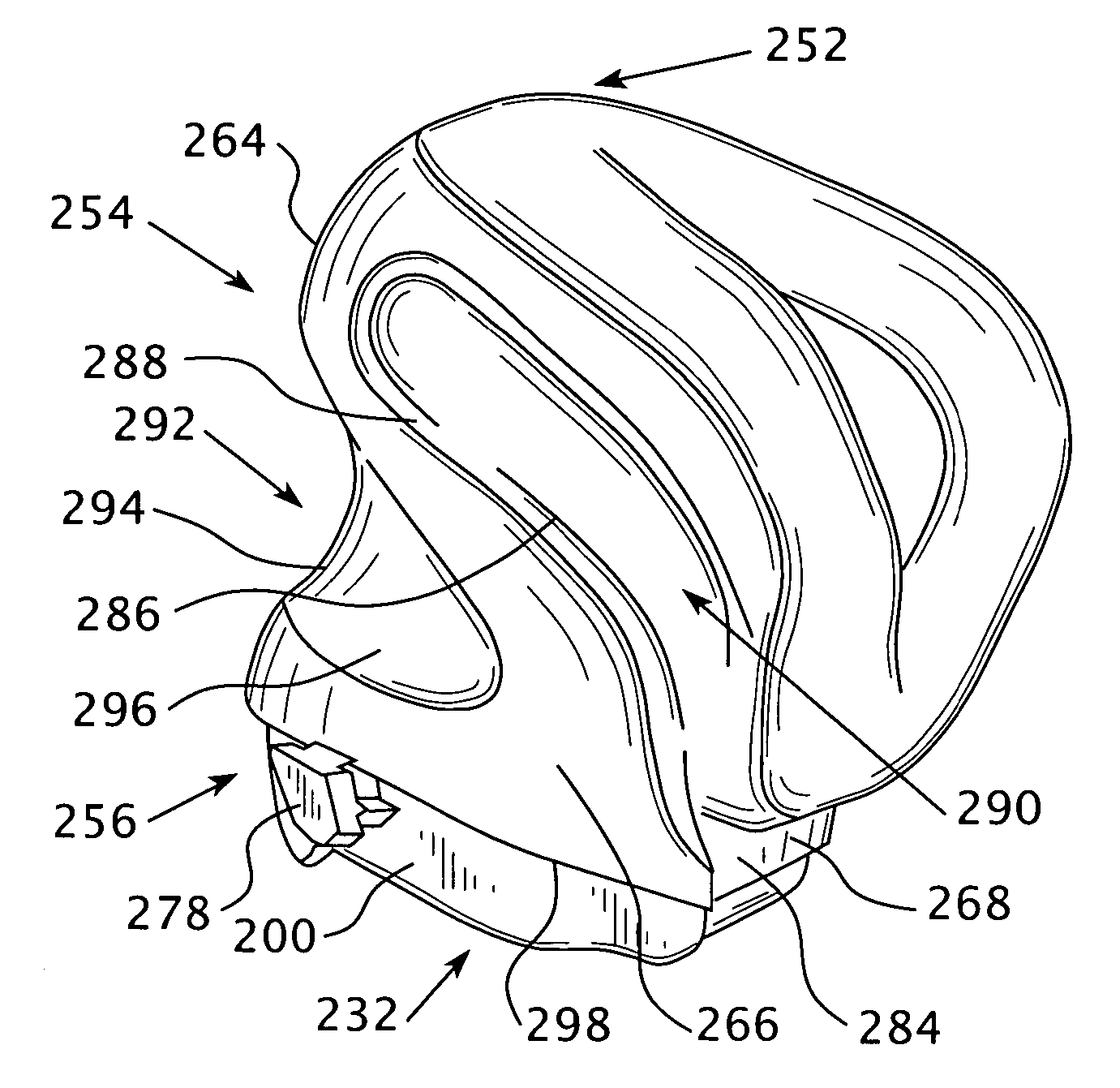

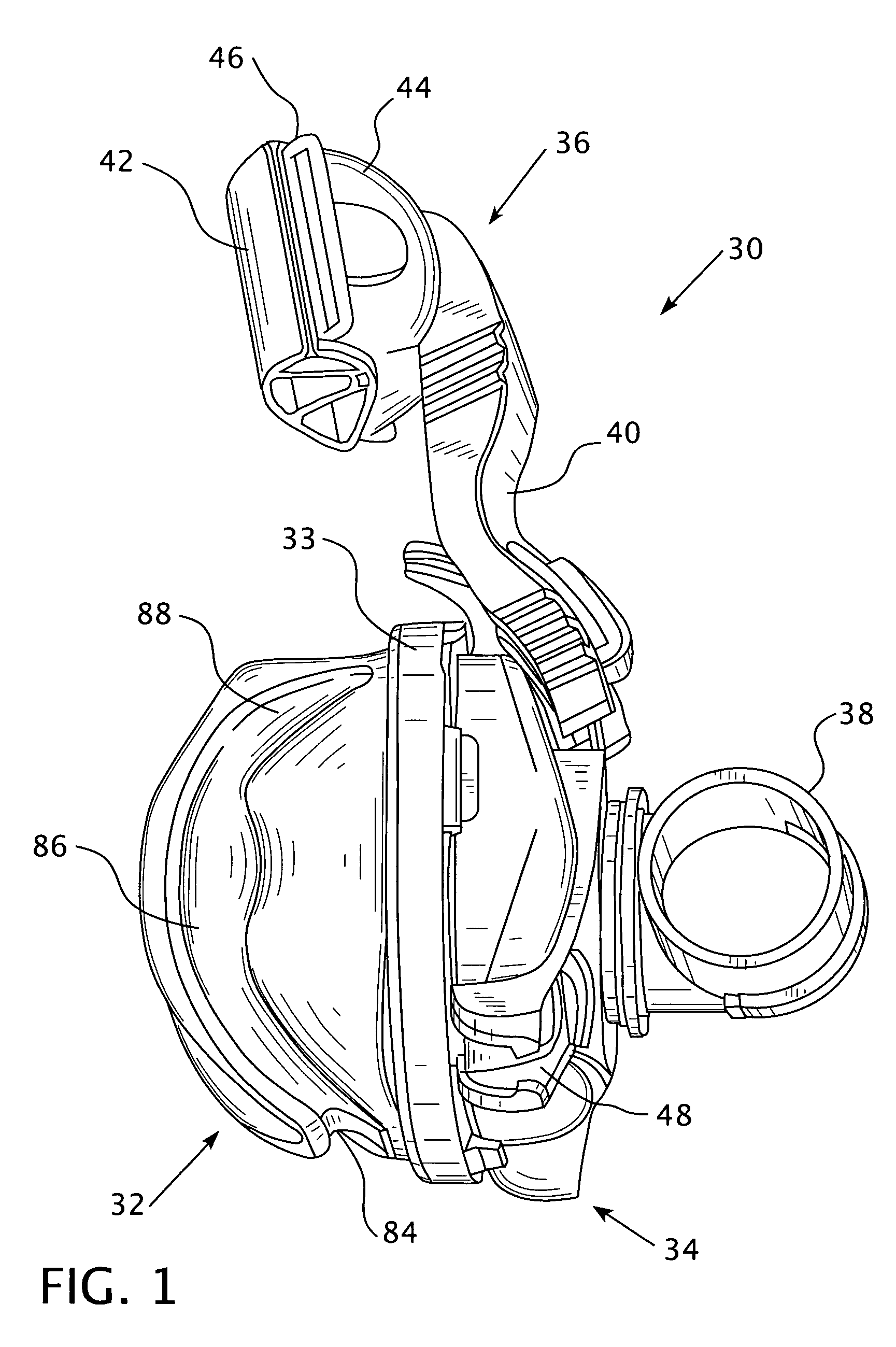

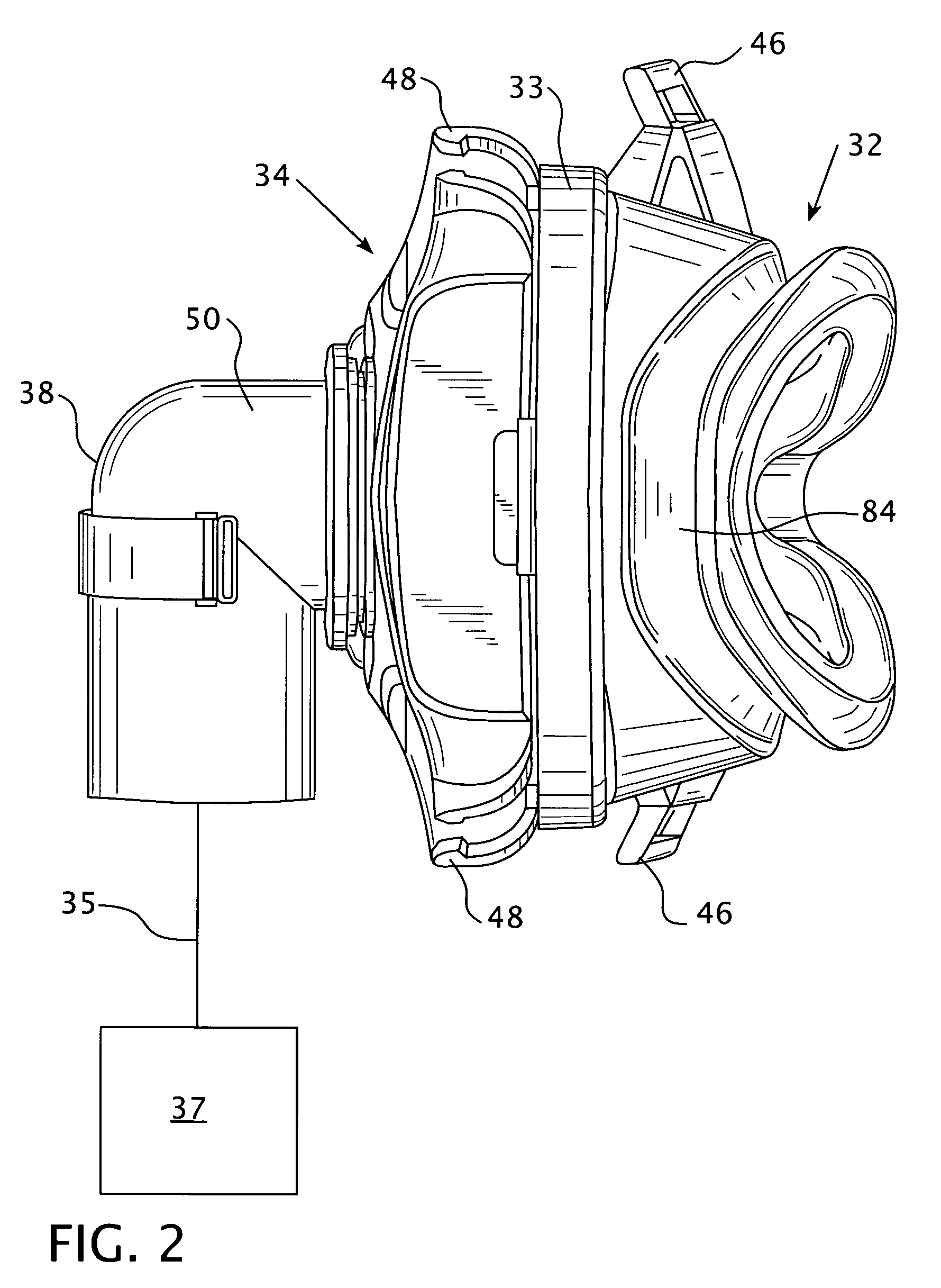

Cushion for a patient interface

ActiveUS7237551B2Comfortable sealAvoid less flexibilityRespiratory masksBreathing masksEngineeringRespiratory mask

A respiratory mask is provided having an outer shell coupled to a cushion for the delivery of a gas to a user. The cushion of the respiratory mask has a pleat and varied wall thicknesses about the device in order to provide varying degrees of flexibility and support about the cushion.

Owner:PHILIPS RS NORTH AMERICA LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com