Patents

Literature

1074results about How to "Improve forming quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

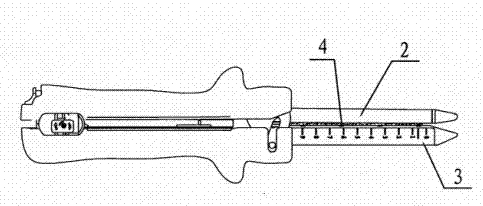

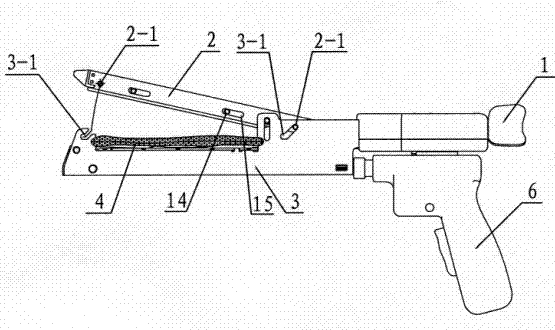

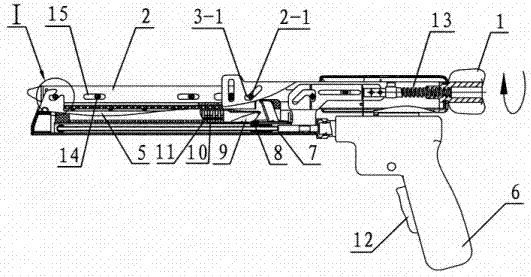

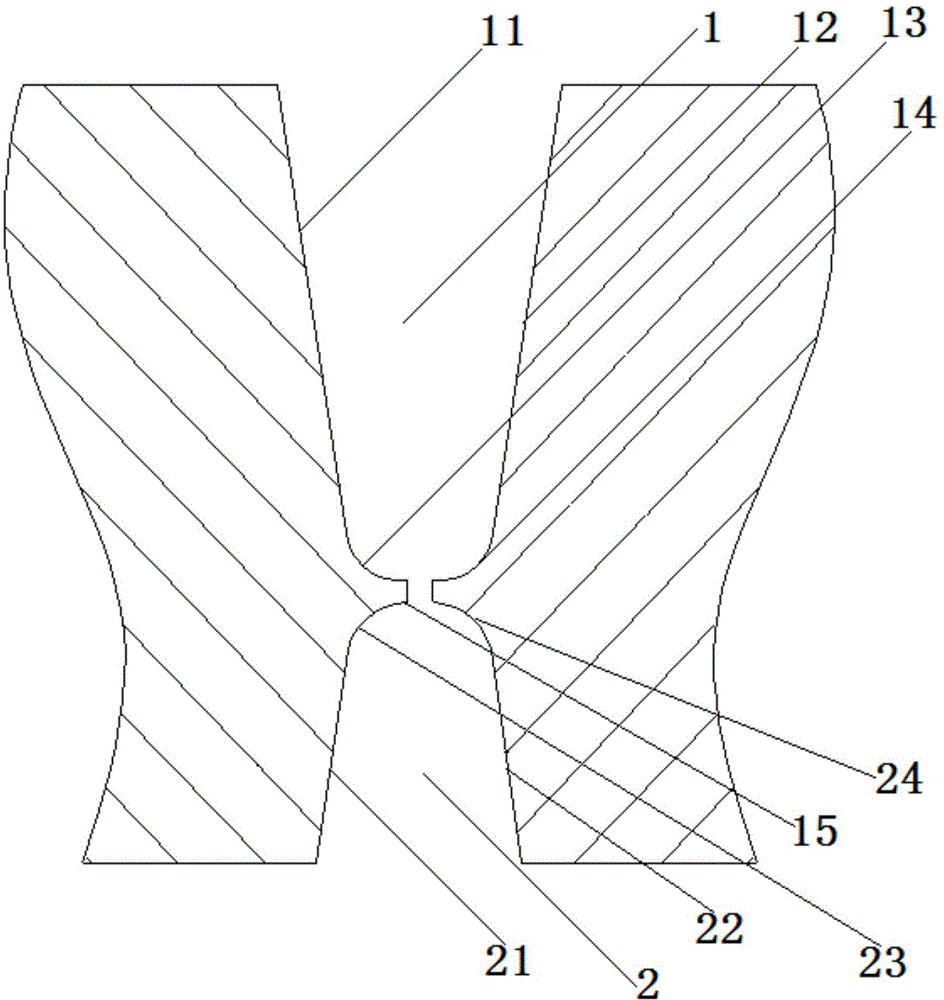

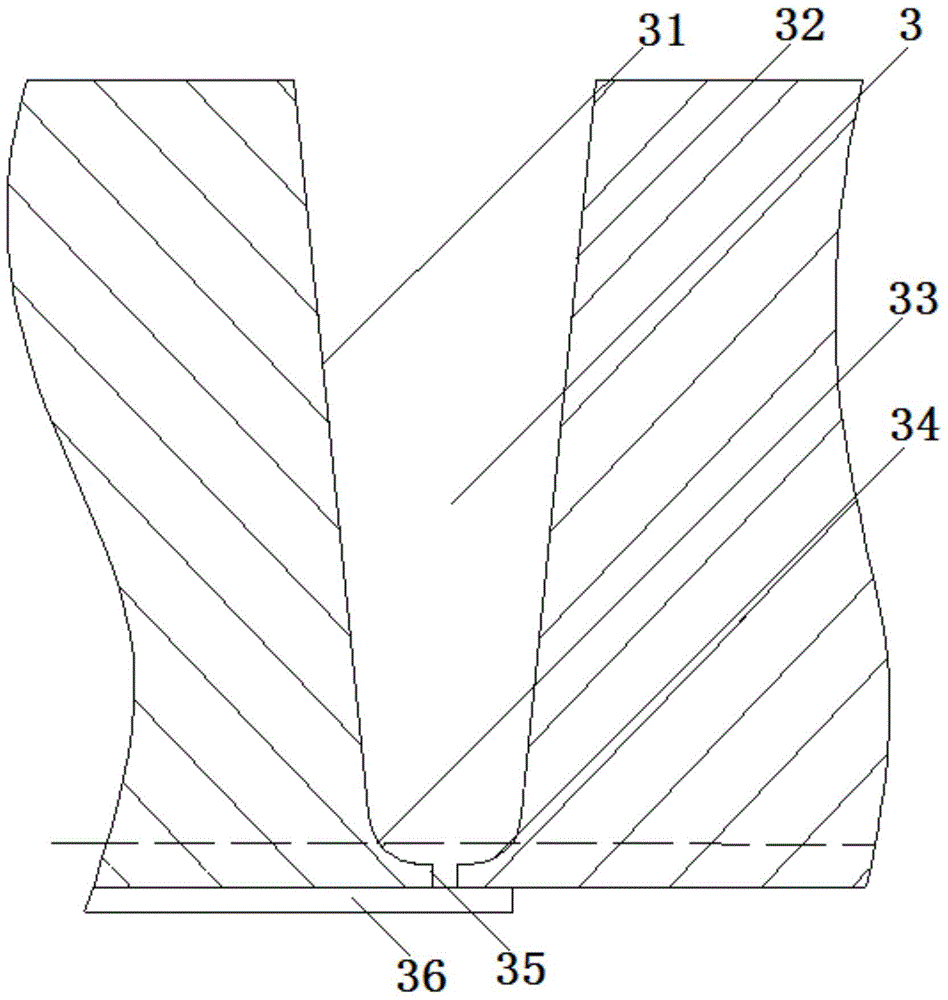

Cutter stapler for surgery

Owner:CHANGZHOU KANGDI MEDICAL STAPLER

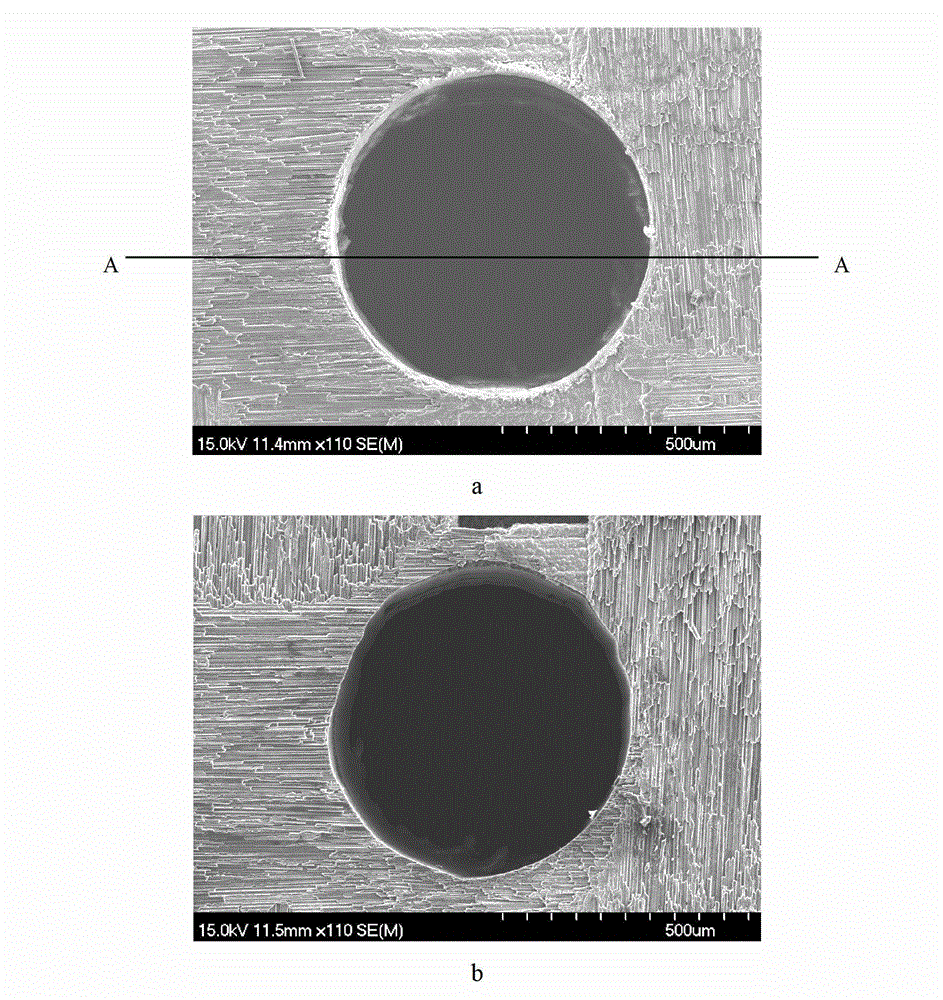

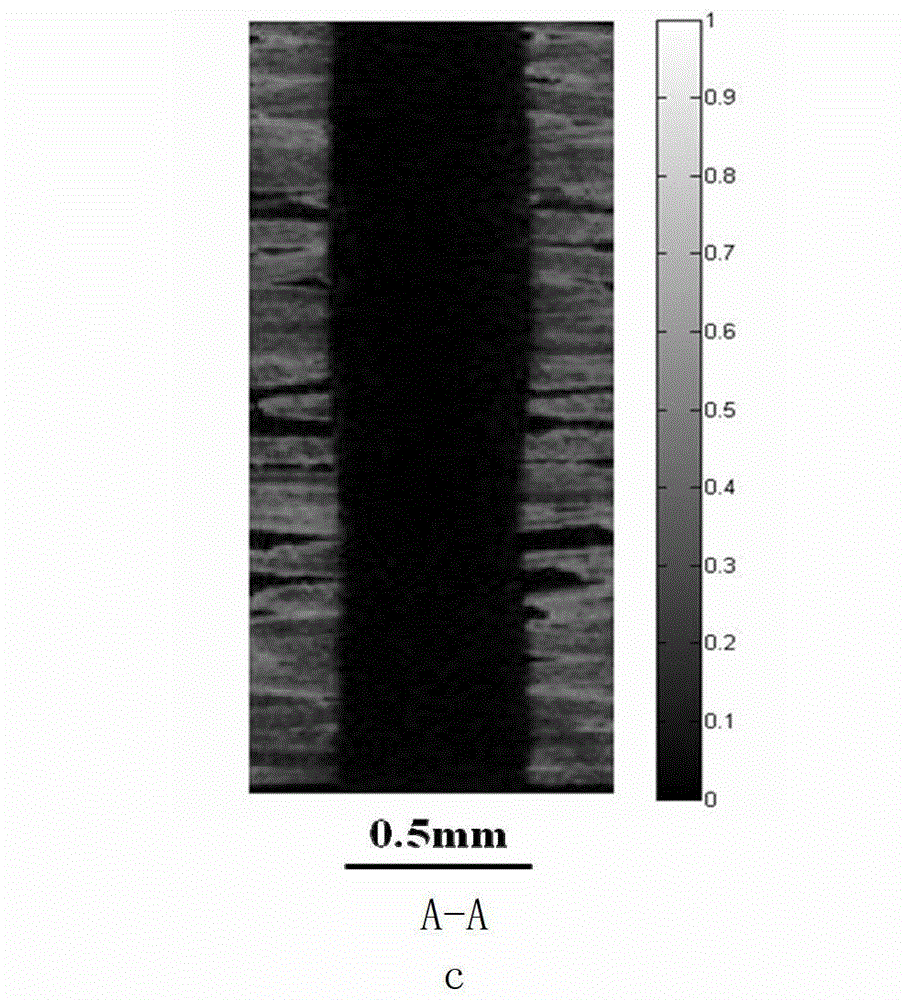

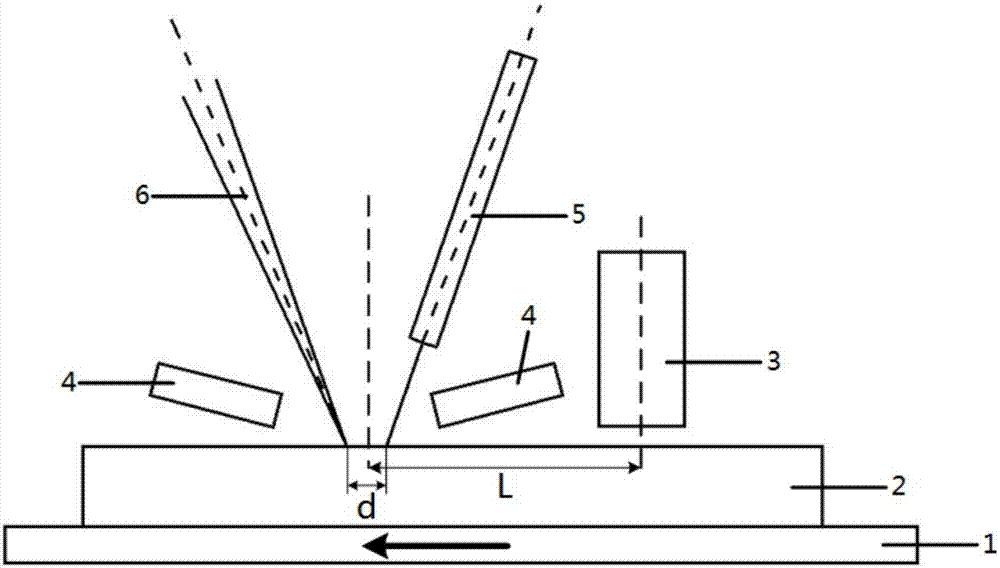

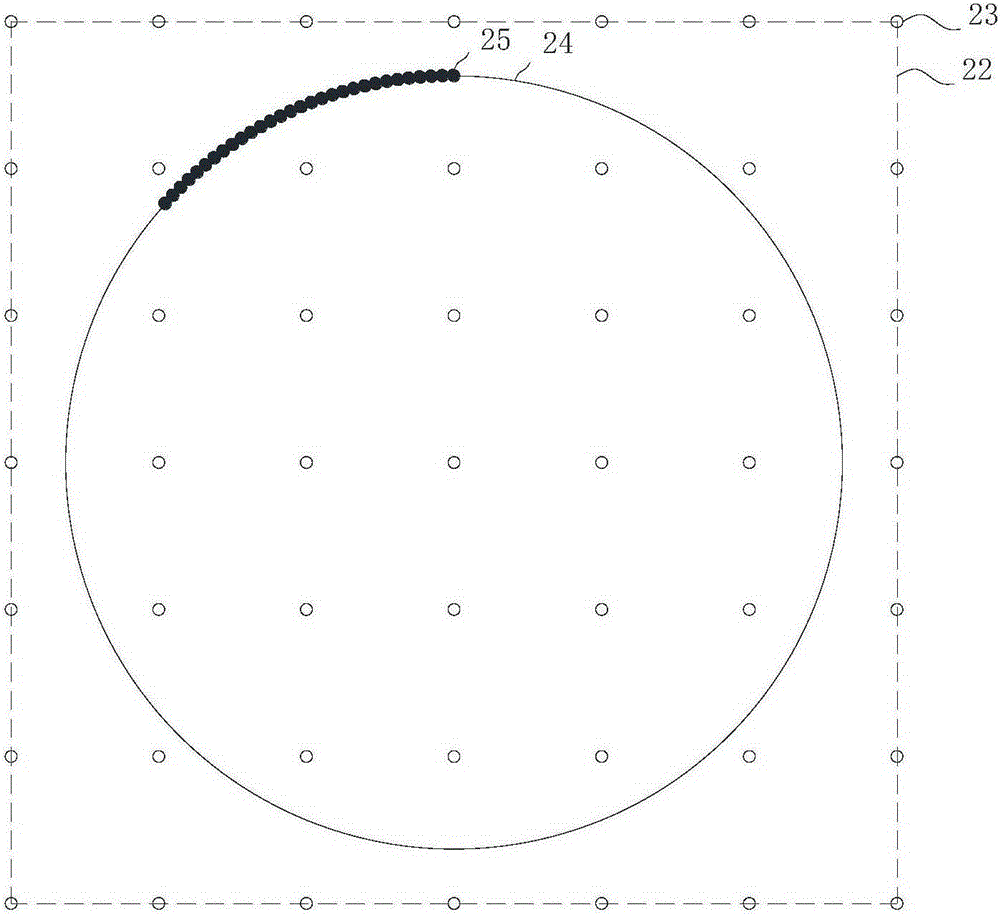

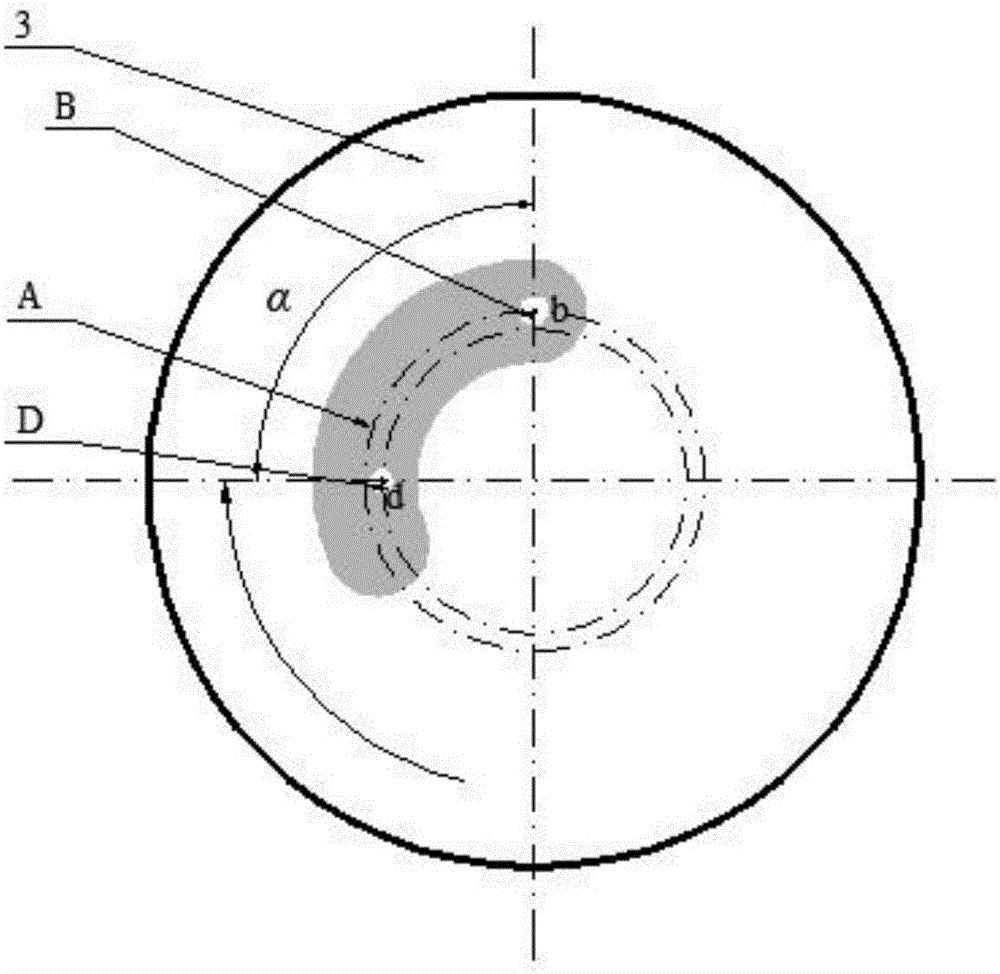

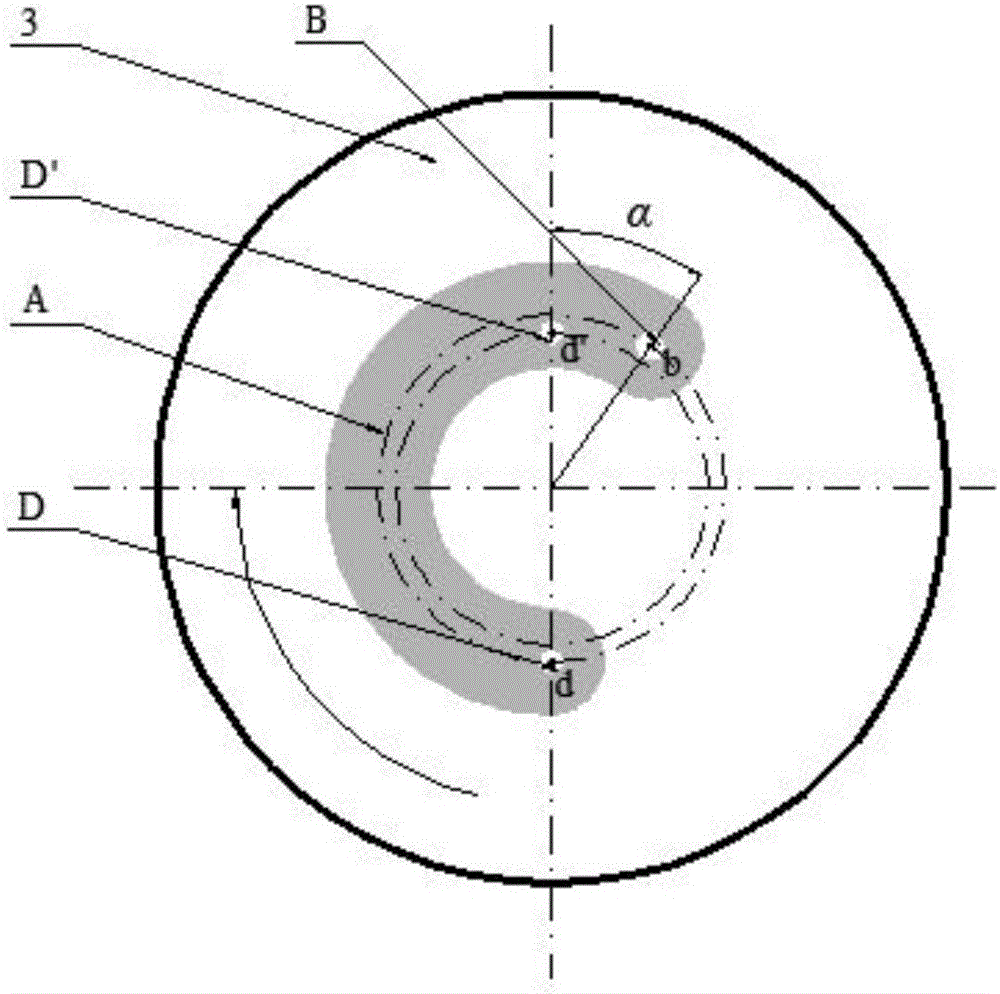

Method for hole machining with picosecond laser

ActiveCN103143841AImprove forming qualityGood processing designabilityLaser beam welding apparatusPicosecond laserOptoelectronics

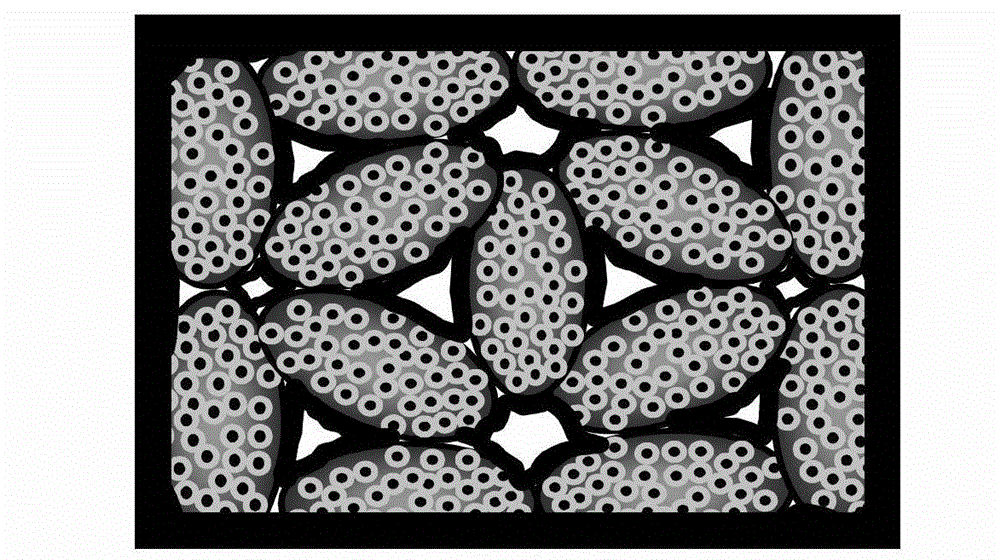

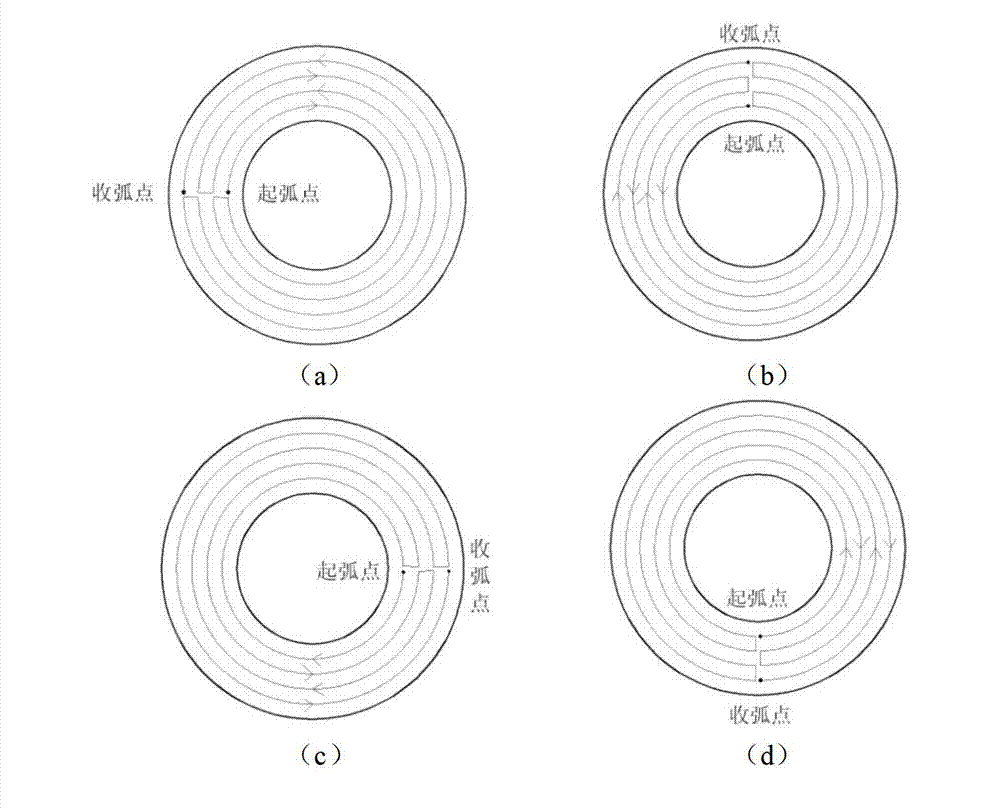

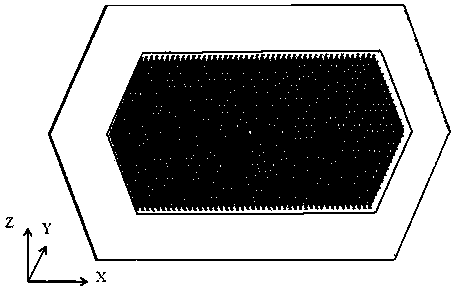

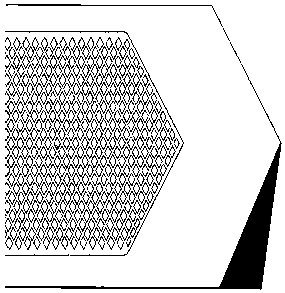

A method for hole machining with picosecond laser realizes hole machining on CMC-SiC (Ceramic Matrix Composite-Silicon Carbide) material according to the characteristics of fiber composite materials and the machining feature that picosecond laser is suitable for various materials due to superhigh peak power of picosecond laser. According to the method, round holes or square holes are machined in the CMC-SiC material layer by layer in a distributed machining mode; the influence of tiny cracks can be ignored during machining; the stability is good; and the method is particularly suitable for mass repeated micro-hole machining. Layer-by-layer machining in a heliciform way is adopted when round holes are machined; and layer-by-layer machining in a linear scanning way is adopted when square holes are machined. The method has the advantages of good stability of the machining technology, strong designability, high precision and the like.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

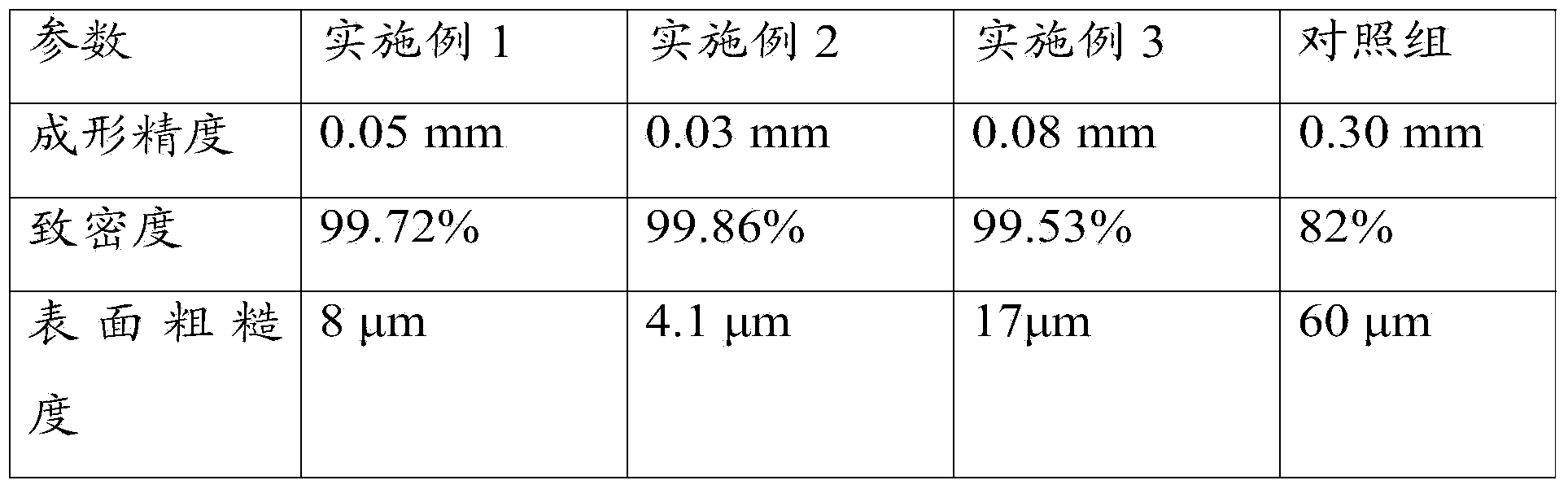

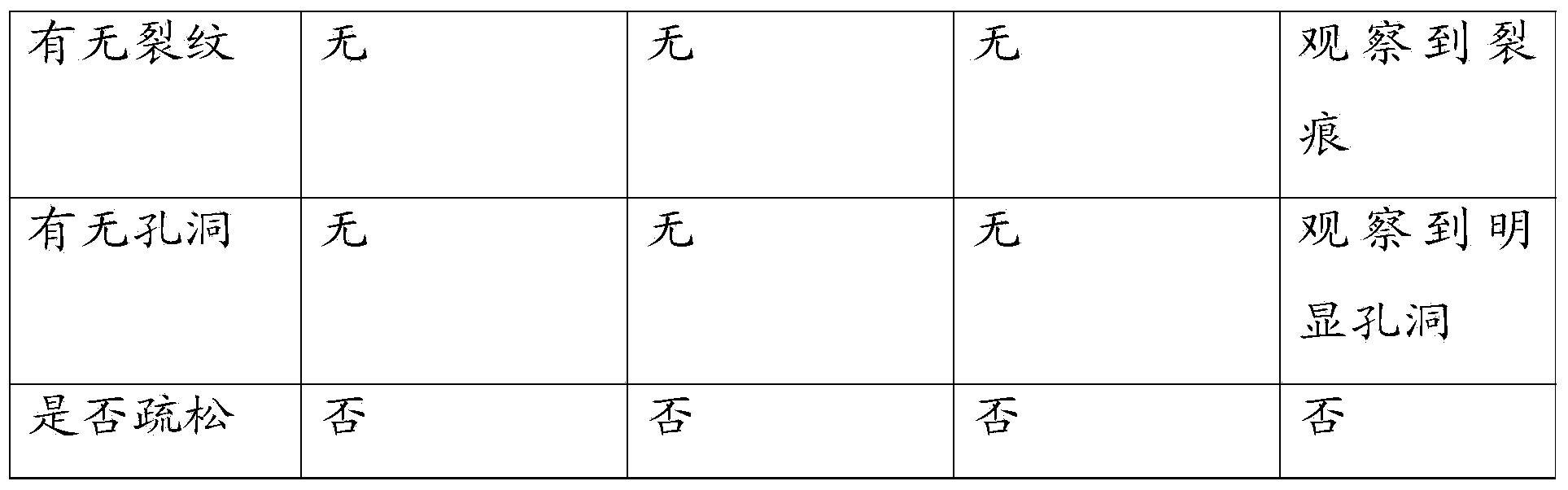

Method for producing titanium alloy artware by adopting selective laser melting

ActiveCN104259459AHigh precisionImprove forming qualityIncreasing energy efficiencySelective laser meltingSelective laser sintering

The invention relates to the field of material preparation, in particular to a method for producing titanium alloy artware by adopting selective laser melting. The method includes the steps: creating two-dimensional slicing data of a part structure to be produced and importing the two-dimensional slicing data into a metal powder laser melting system; setting processing technological parameters of the metal powder laser melting system; taking titanium alloy powder and spreading the titanium alloy powder on the metal powder laser melting system, and sequentially performing laser melting, powder sieving, heat treatment, wire cutting, cleaning, sand blasting, polishing and the like under the protection of inert gas to obtain the titanium alloy artware. According to the method, specific titanium alloy types and specification parameters are selected, and the processing technological parameters of the metal powder laser melting system are optimized for multiple times, so that the produced titanium alloy artware is high in precision, stable in shaping quality, small in distortion, excellent in mechanical property and good in surface smoothness through follow-up processing and has great artistic value.

Owner:飞而康快速制造科技有限责任公司

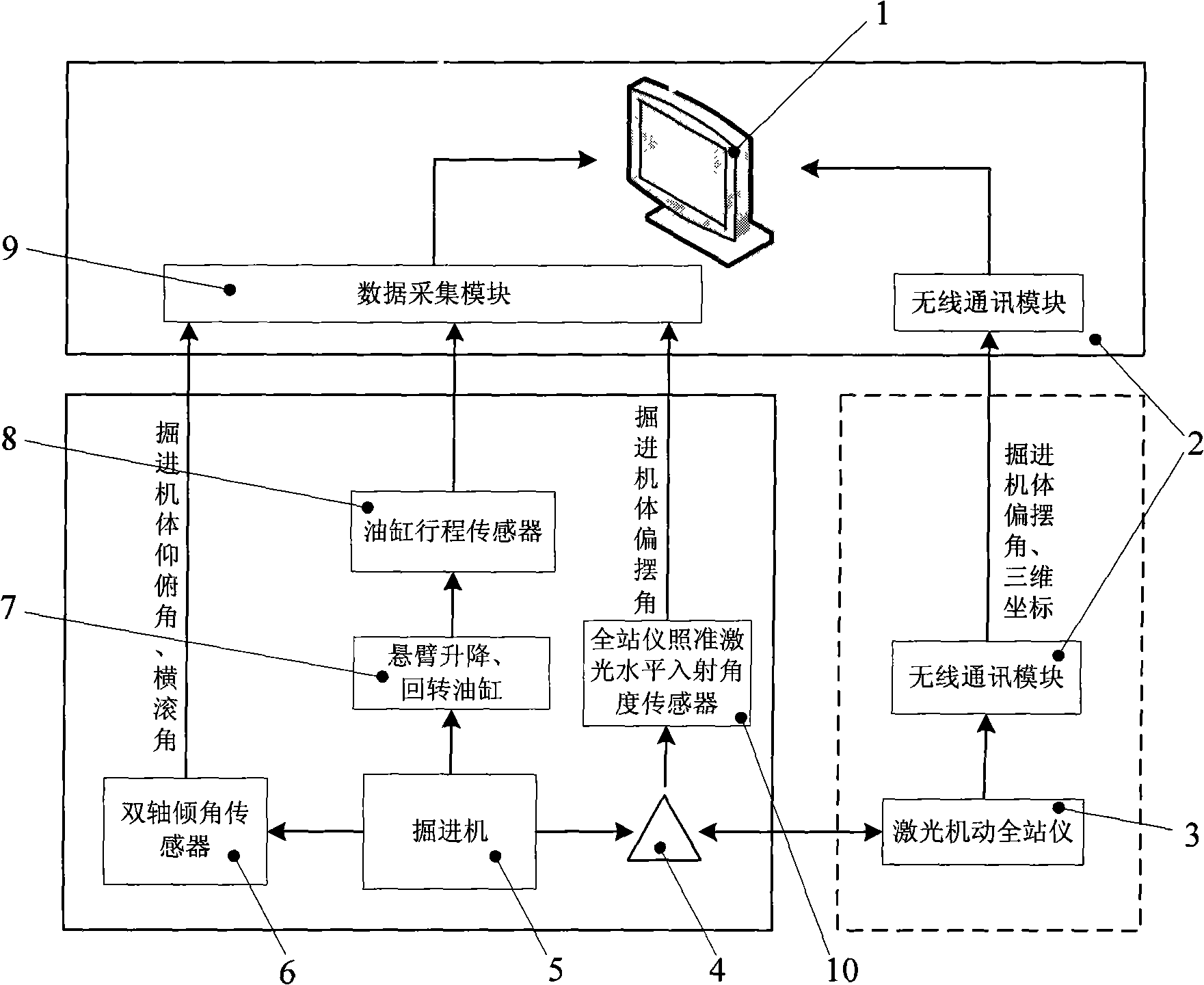

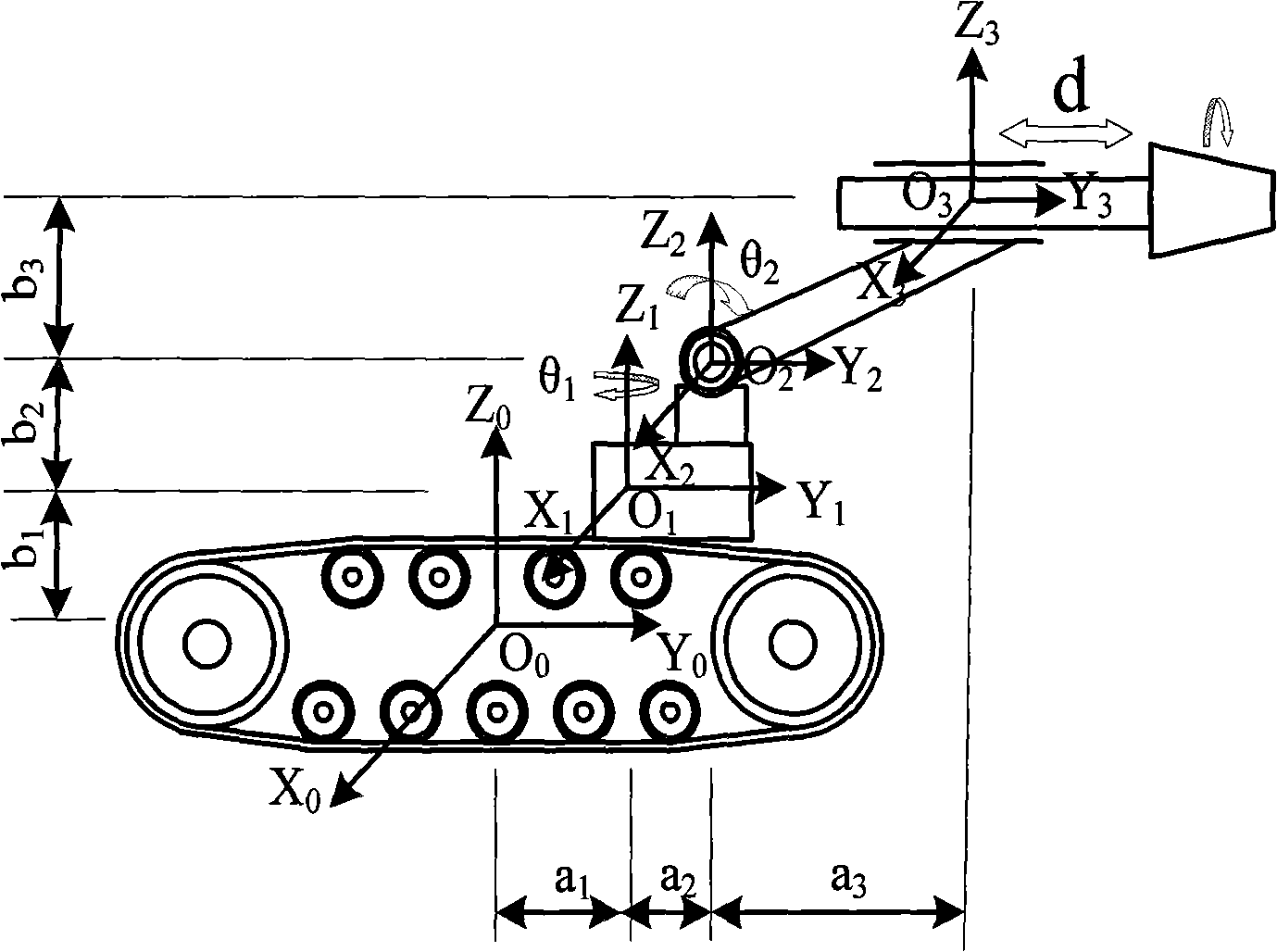

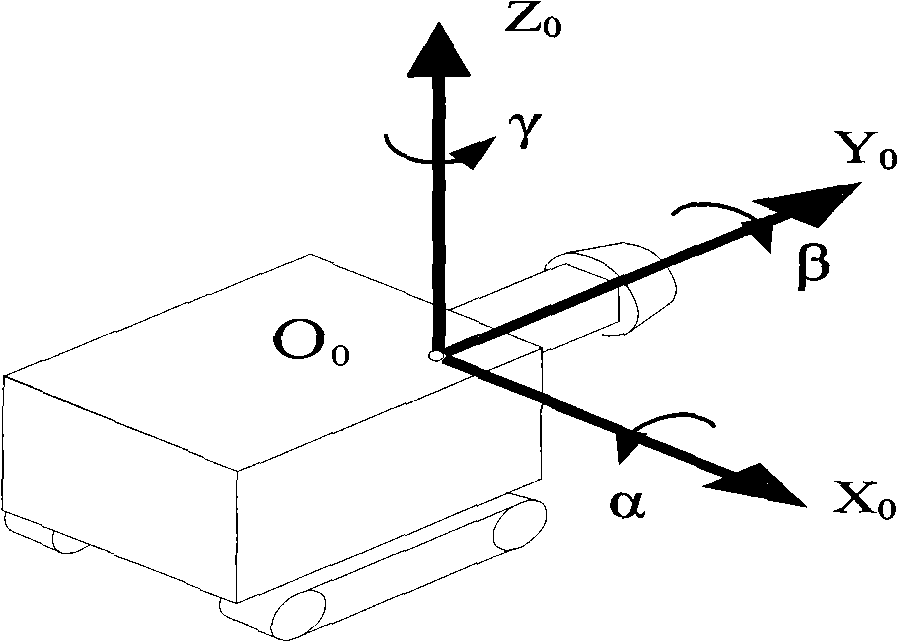

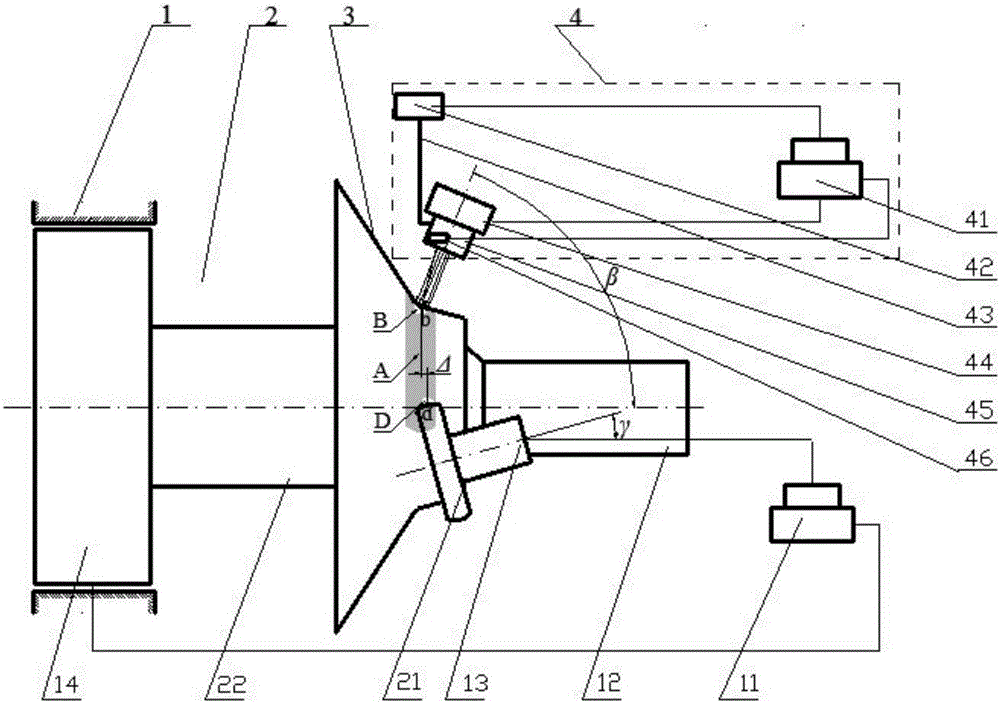

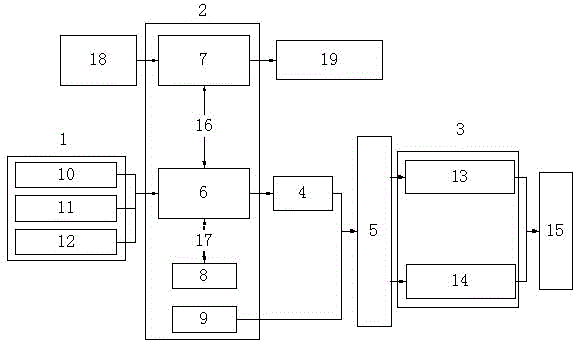

Cantilever driving frame head posture measuring systems and its method

ActiveCN101266134AHigh accuracy of pose measurementReduce labor intensityUsing optical meansCutting machinesTotal stationRolling angle

The invention relates to the measurement system of a cantilever tunneling head pose and the method, which is characterized in that a laser mobile electrical total station is arranged on a formed tunnel wall, and measures the coordinate of the tunneling machine body in the earth coordinate system, a body deflection angle sensor is installed behind a reflector prism, and measures to the deflection angle of the tunneling machine body, a biaxial inclination angle sensor surveys the pitching angle and the roll angle of the tunneling machine body, oil cylinder stroke sensors install in a cantilever lifting oil cylinder, a cantilever revolving oil cylinder and a tunneling head flexible oil cylinder to survey the oil cylinder stroke, a wireless communication module and a data acquisition module transmit the metrical data of the laser mobile electrical total station, the cylinder stroke sensor, the biaxial inclination angle sensor and the body deflection angle sensor to the computer, which gathers, processes, and calculates the pose of the tunneling head relative to the body and the earth coordinate system, so as to realize the surveying of the tunneling head pose. The invention has the advantages of good timeliness, high precision, and suitable for the measurement and the position of the tunneling head pose of a tunneling equipment such as the cantilever tunneling machine.

Owner:SHANXI COKING COAL GROUP +1

Manufacturing method of arc additive of titanium alloy structural part

ActiveCN102962547AImprove forming qualityUniform chemical compositionArc welding apparatusCrystalliteWeld bead

The invention provides a manufacturing method of an arc additive of a titanium alloy structural part. An arc wire feed additive manufacturing method is used to carry out welding of each layer of ring members, i.e., a wire feeder feeds welding wires, the welding wires are melted by a welding gun to weld, and ring welding beads from the inside to the outside are sequentially lapped to form a layer of ring members; and then one thickness of layer of the welding gun is increased, and the welding method is repeated to form another layer of ring members, and so forth; and finally, a plurality of layers of ring members are overlapped to form a titanium alloy structural part. The welding forming part provided by the invention has a fine and uniform grain size and good mechanical properties, and can meet or exceed the level of congruent castings, and the product has a short development cycle and high processing efficiency.

Owner:CAPITAL AEROSPACE MACHINERY +1

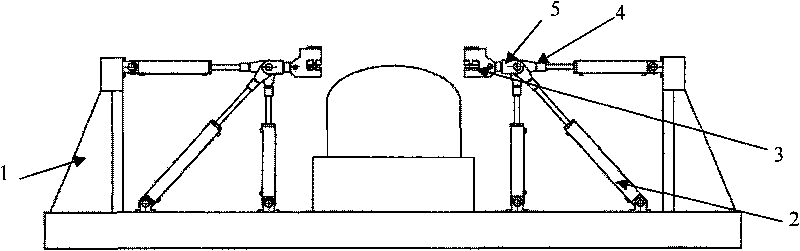

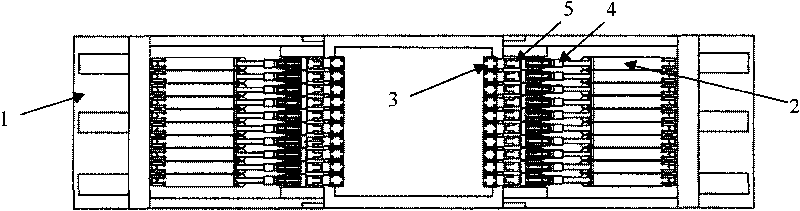

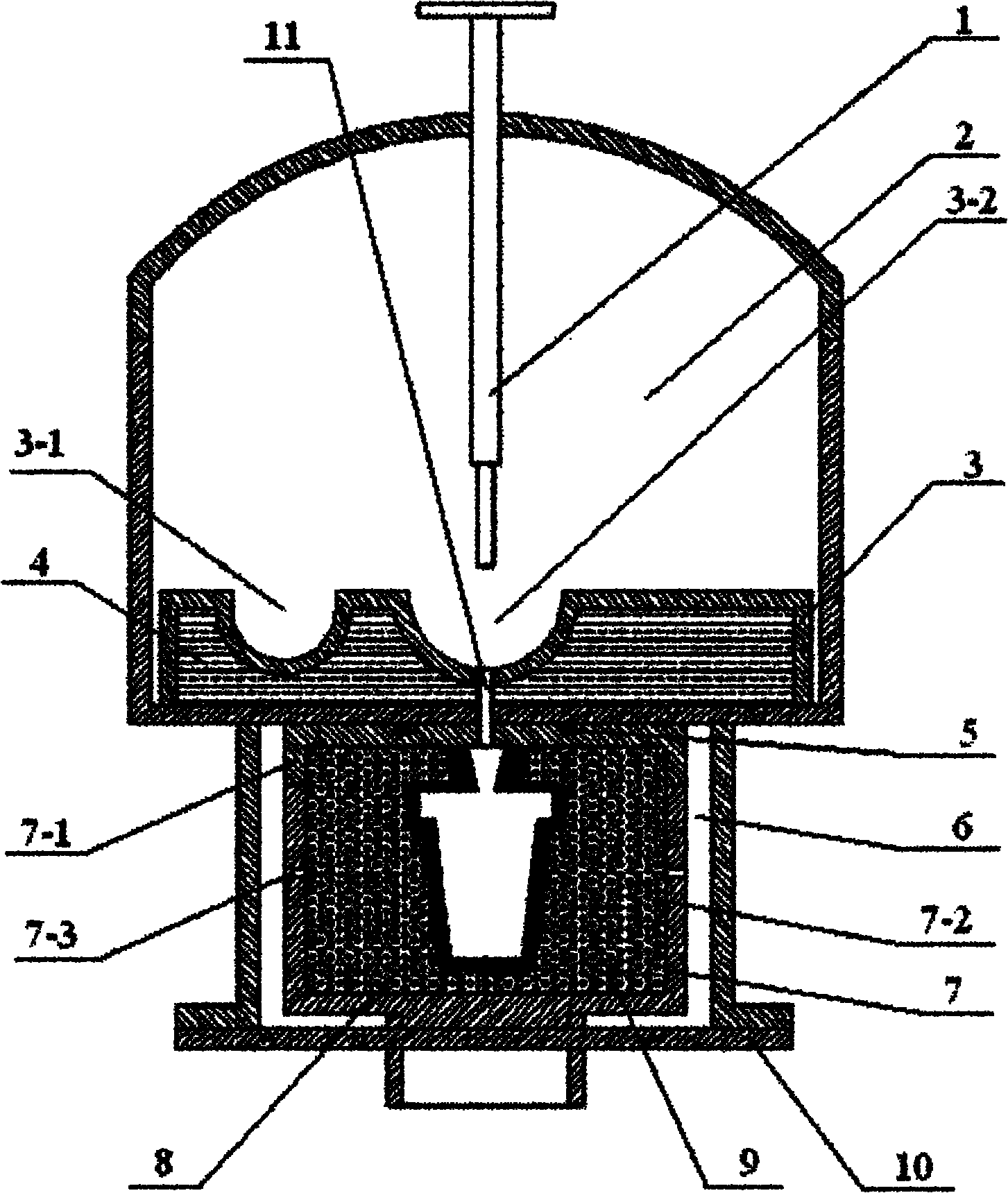

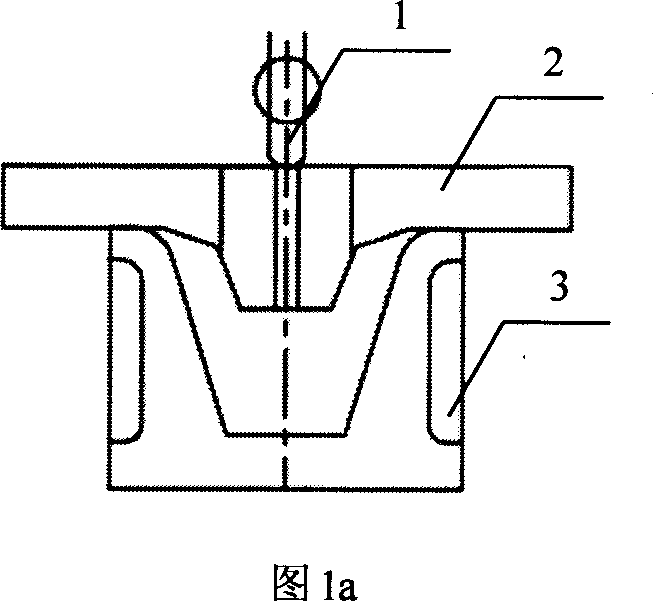

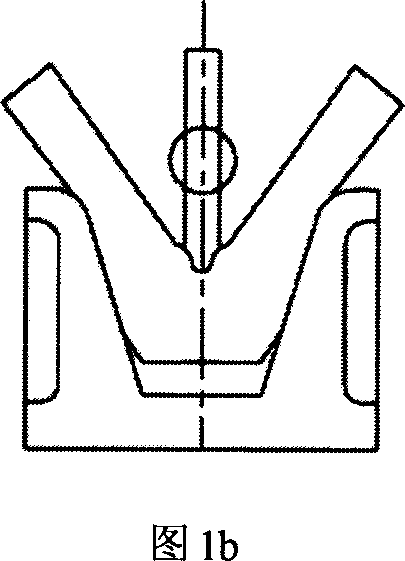

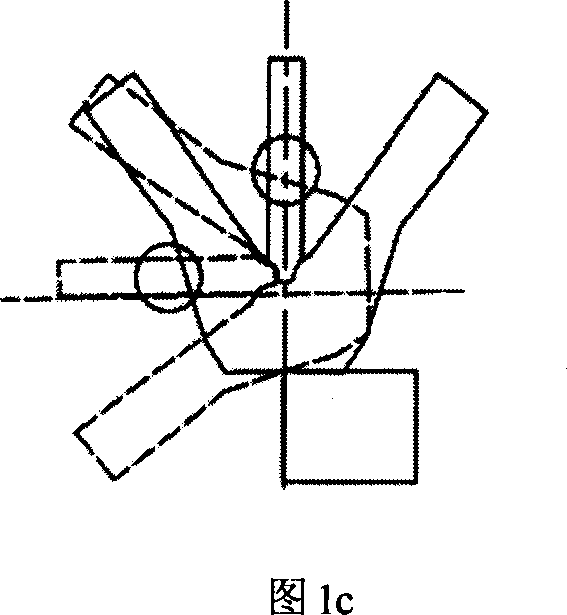

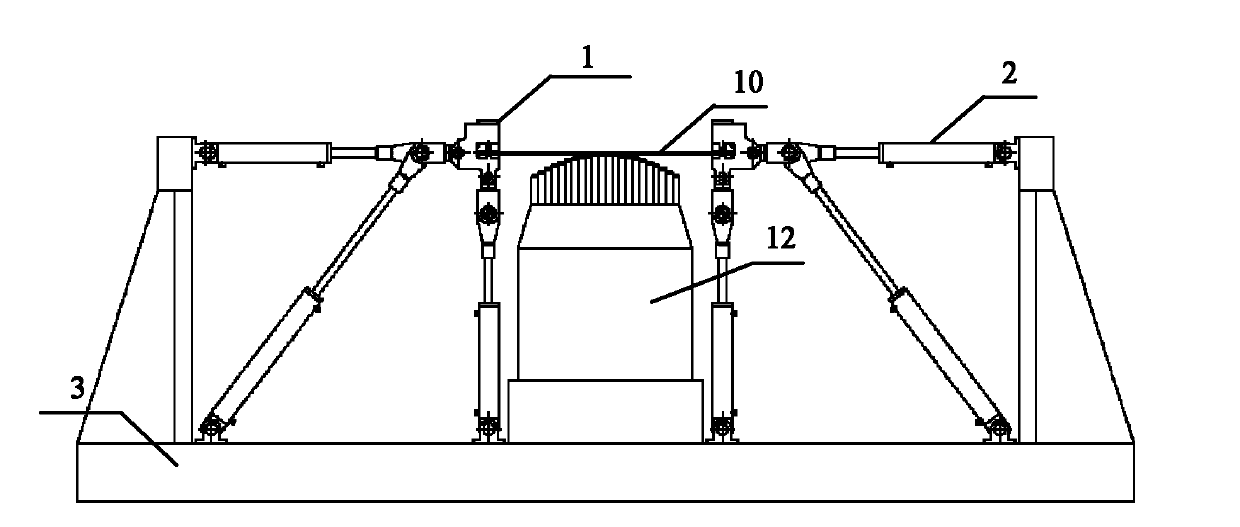

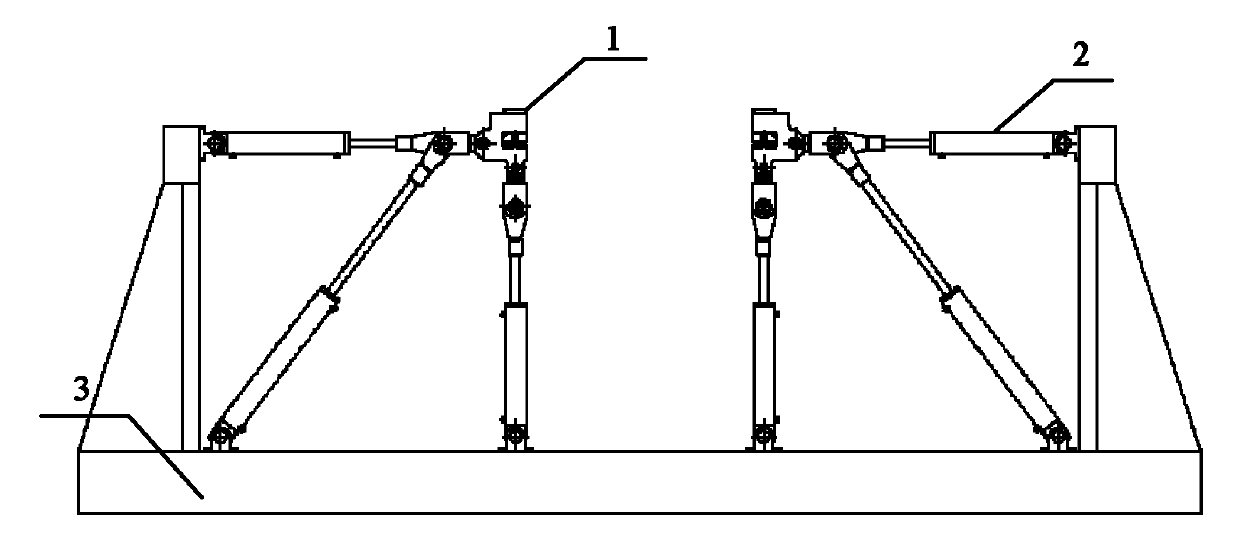

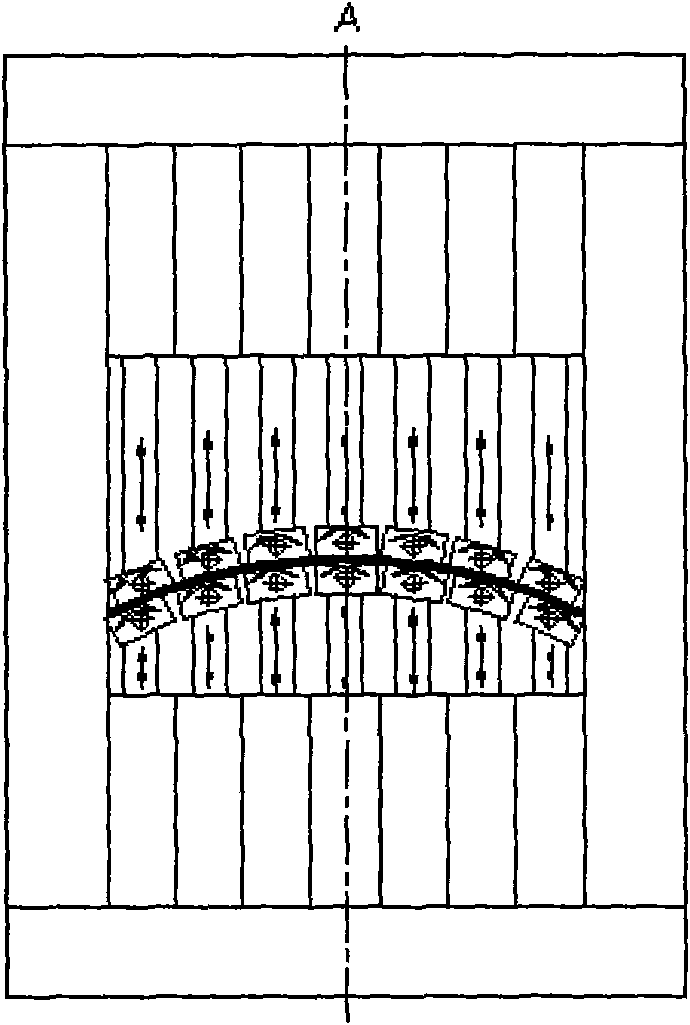

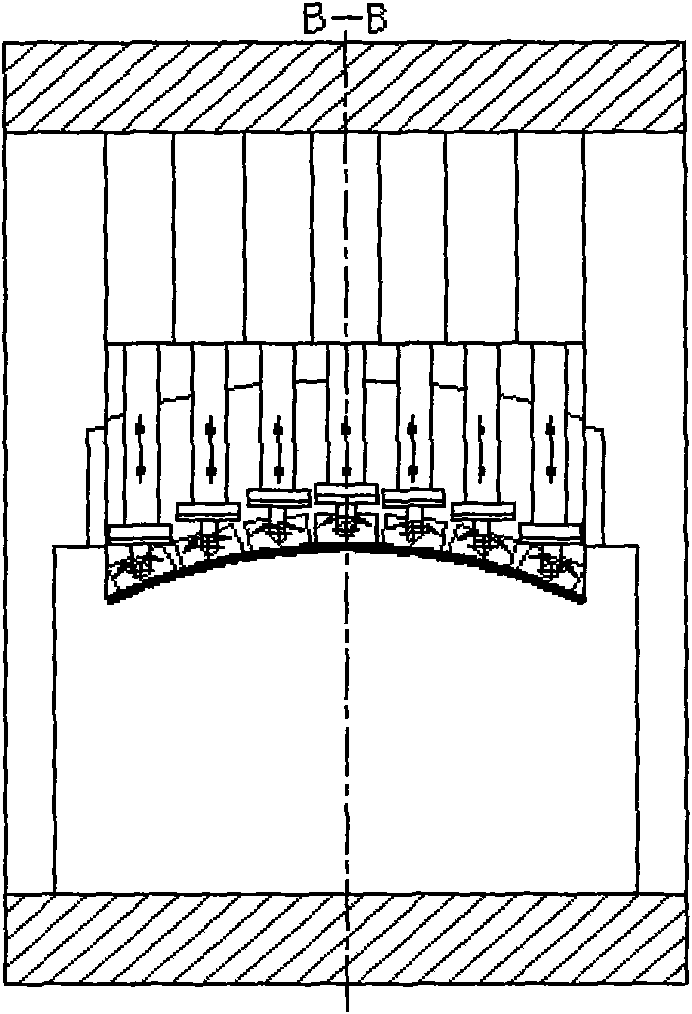

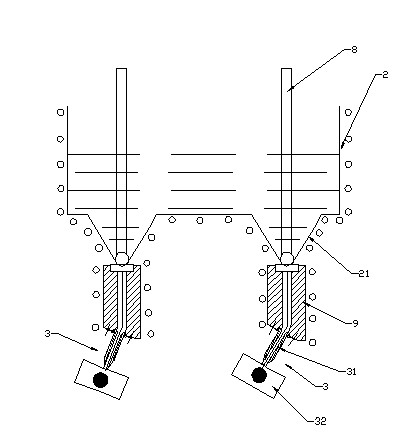

High-flexibility multi-head stretching machine

The invention discloses a high-flexibility multi-head stretching machine, which relates to plastic processing equipment for three-dimensional curved surface forming of sheet parts and belongs to the field of mechanical engineering. The machine aims to make the distribution of the pulling stress and the tension strain of stretched parts more trend to be uniform, improve the stretching quality and the utilization rate of materials, and realize the stretching of curvature parts with larger transverse curvature or certain wave. The machine mainly comprises a main frame (1), material pulling mechanisms, material clamping mechanisms (3) and universal mechanisms (5), wherein a row of a plurality of the material pulling mechanisms, the material clamping mechanisms (3) and the universal mechanisms (5) are arranged on both sides of the main frame (1) respectively; the material pulling mechanisms consist of three hydraulic cylinders (2) respectively, one of the hydraulic cylinders (2) is horizontally arranged, the other hydraulic cylinder (2) is vertically arranged, and the third hydraulic cylinder (2) are slantways arranged; and one end of each of the three hydraulic cylinders (2) is hinged with the main frame (1) respectively, while the other end is jointly connected with the universal mechanism (5) and the material clamping mechanism (3) through a hydraulic cylinder connection body (4) respectively.

Owner:JILIN UNIV

Laser-CMT welding aluminum alloy additive manufacturing method and forming system

PendingCN107283061AImprove stabilityImprove interlayer bonding performanceWelding/soldering/cutting articlesLaser beam welding apparatusSlag (welding)Molten bath

The invention discloses a laser-CMT welding aluminum alloy additive manufacturing method and a forming system. A laser and an electric arc are adopted as a composite heat source, the cold metal short circuiting transfer manner is adopted, and additive manufacturing forming for an aluminum alloy component is achieved. According to the provided laser-CMT welding additive manufacturing method, the problems that in the process of aluminum alloy component manufacturing through laser additive, the required laser power is high, and forming is difficult are solved, the problems that in the traditional process of aluminum alloy manufacturing through electric arc additive, the heat input amount is large, deformation is serious, and a molten bath is prone to overflowing or webbing are solved, and the problem that in the process of aluminum alloy manufacturing through CMT welding additive, incomplete fusion or slag inclusion or the like is likely to happen is solved; and the additive manufacturing method based on the laser-electric arc composite heat source principle is provided for additive manufacturing forming for the aluminum alloy component.

Owner:NAT INST CORP OF ADDITIVE MFG XIAN +1

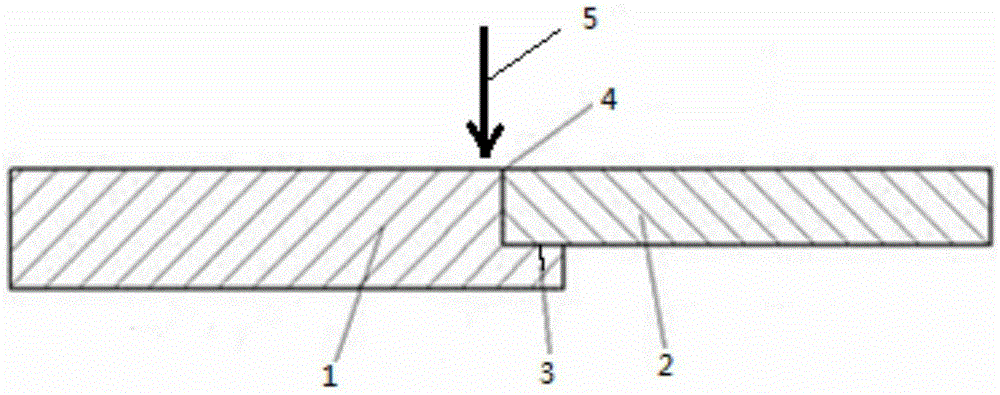

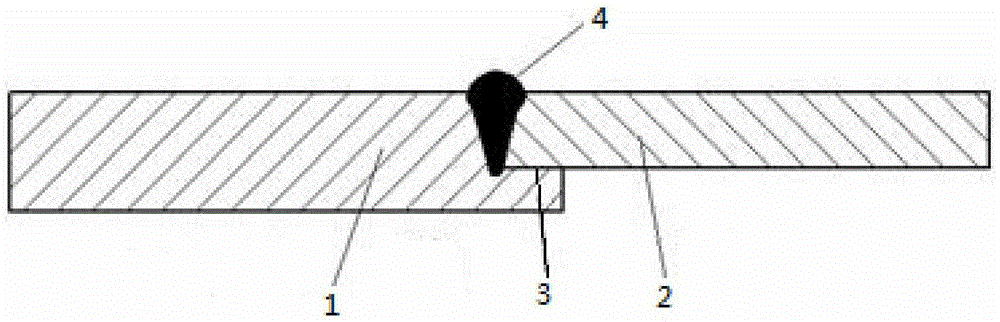

Method and device for laser pulse and electromagnetic pulse composite forming of metal sheet

InactiveCN102125951AMeet the forming requirementsLocality of changeManufacturing technologyEnergy absorption

The invention discloses a method and device for laser pulse and electromagnetic pulse composite forming of a metal sheet and relates to the technical field of processing and manufacturing fastening holes. The head part of an energy absorption rod (10) is a conical surface; a high-power pulse laser outputs an annular laser pulse (8) by means of a light spot regulator (15); the annular laser pulse (8) accommodates the tip part of the conical surface on the head part of the energy absorption rod (10) in a hollow part of a laser beam, and meanwhile, the annular laser pulse (8) is acted on the conical surface on the head part of the energy absorption rod (10) to induce plasma (17) to explode and generate impact waves acted on the internal walls of the fastening holes, so that the fastening holes are strengthened. The method and the device are suitable for strengthening the fastening holes with small diameter; the hollow part of the annular laser pulse (8) keeps away from the tip part of the conical surface of the energy absorption rod (10), so that the energy absorption rod (10) is difficult to damage, which is beneficial to continuously working and achieving a good strengthening effect.

Owner:JIANGSU UNIV

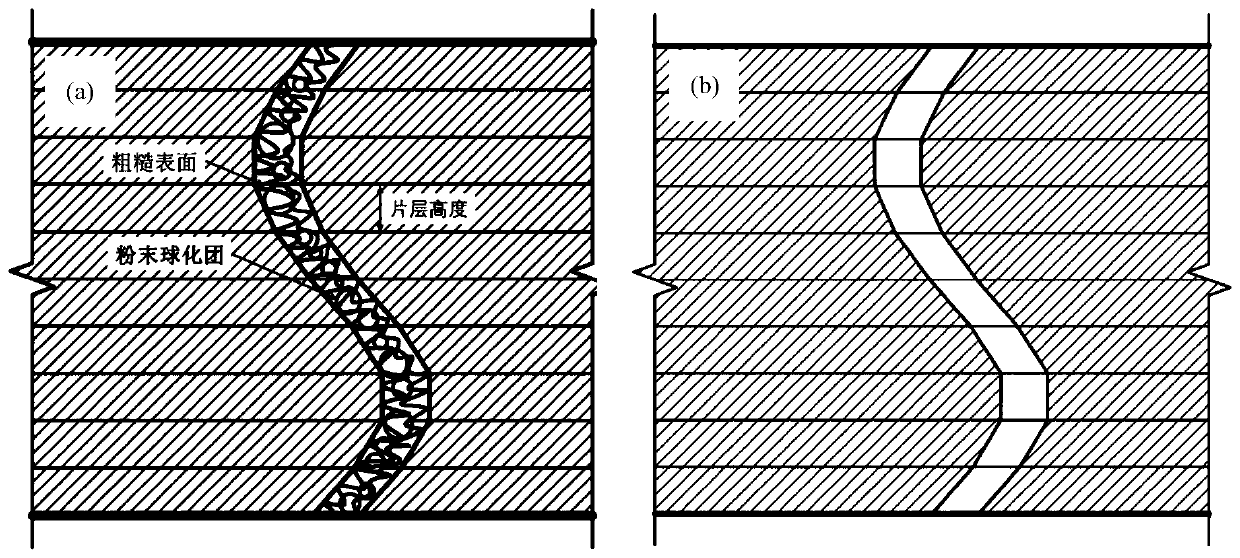

No-mold fusion stacking manufacture method of parts or mold

InactiveCN101362272AReduce or eliminate dropReduce or eliminate droolingWelding/cutting auxillary devicesArc welding apparatusNumerical controlMelting tank

The invention relates to a method for die-free fused deposition modeling of a part or a die, which belongs to the method of die-free modeling, and solves the problems of falling, flowing and collapsing of fusing material in the process of support-free and die-free fused deposition modeling of the existing method. The method comprises the following steps: (1) hierarchy slicing processing is performed to the three-dimensional CAD model of the part or the die; (2) a computer generates numerical control codes required by the shaping of each hierarchy according to the hierarchy slicing data and the characteristics of the slicing size and shape of each hierarchy; and (3) numerically controlled gas-shielded welding arc or laser bean is adopted to fuse and shape the fusing material on the base plate in sequence according to the numerical control codes of each hierarchy, until the requirements on the size and the surface of the part or the die are met; simultaneously, electromagnetic field acting on the fusing material in the melting bath is generated through an electromagnetic device. By adopting the method, the part or the die made of metal, intermetallic compound, metal ceramics, ceramics and functionally gradient material can be quickly obtained with low cost and high quality.

Owner:HUAZHONG UNIV OF SCI & TECH

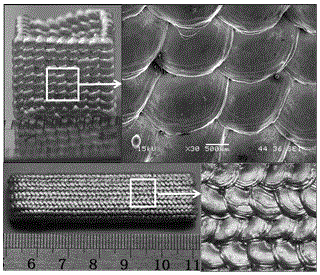

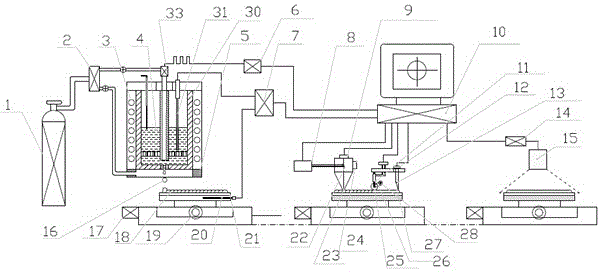

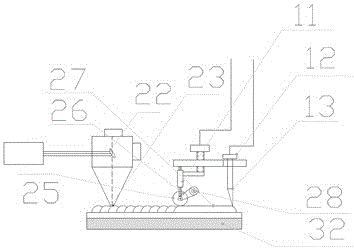

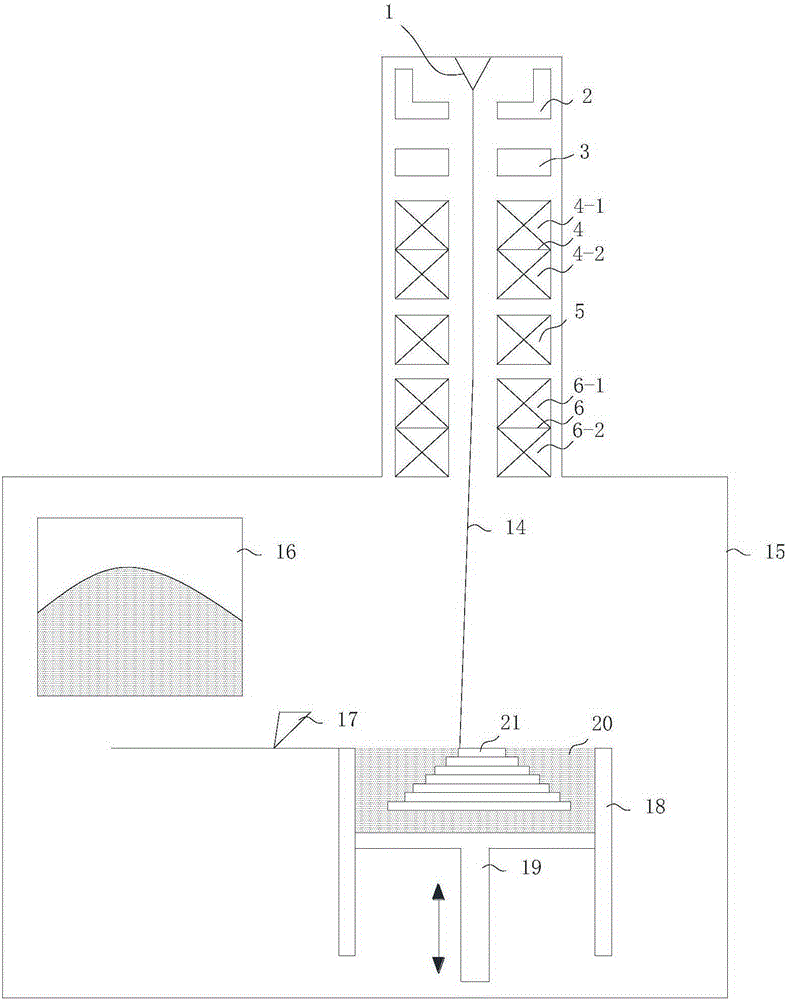

Surface quality control device for three-dimensional (3D) part formed through metal drop printing and control method of surface quality control device

ActiveCN105081325AEliminate the step effectAvoid flattening defectsAdditive manufacturing apparatusImage detectionEngineering

The invention discloses a surface quality control device for a three-dimensional (3D) part formed through metal drop printing and a control method of the surface quality control device. The surface quality control device comprises a computer system, a metal drop spraying head, a laser device, a scanning galvanometer, a galvanometer motor, a movement platform, a deposition base plate, a driving motor, a flat covering roller, a roller motor and a charge-coupled device (CCD) camera. The surface quality control device is characterized by further comprising a laser power regulator, a flat covering roller height adjuster, a base plate temperature control device, a flow edge scraper and the like. According to the surface quality control device, the laser device is used as an energy source, rapid surface fusion covering of a formed layer is achieved through laser beams through the scanning galvanometer, and the flat covering depth and the pressure of the roller are controlled through the flat covering roller height adjuster; in the state that metal drops or melt on the surface layer is not completely solidified, the metal surface which is fusion-covered rapidly is scraped and pressed in a directional mode by controlling the speed of the movement platform and the speed of the flat covering roller, so that secondary spreading and filling of the metal surface are achieved, the formed layer which is scraggly originally is flattened through rolling, and control over the surface quality of the layer is completed; in addition, real-time detection and feedback of the rolling flattening effect are achieved through a CCD image detection system.

Owner:XUCHANG UNIV

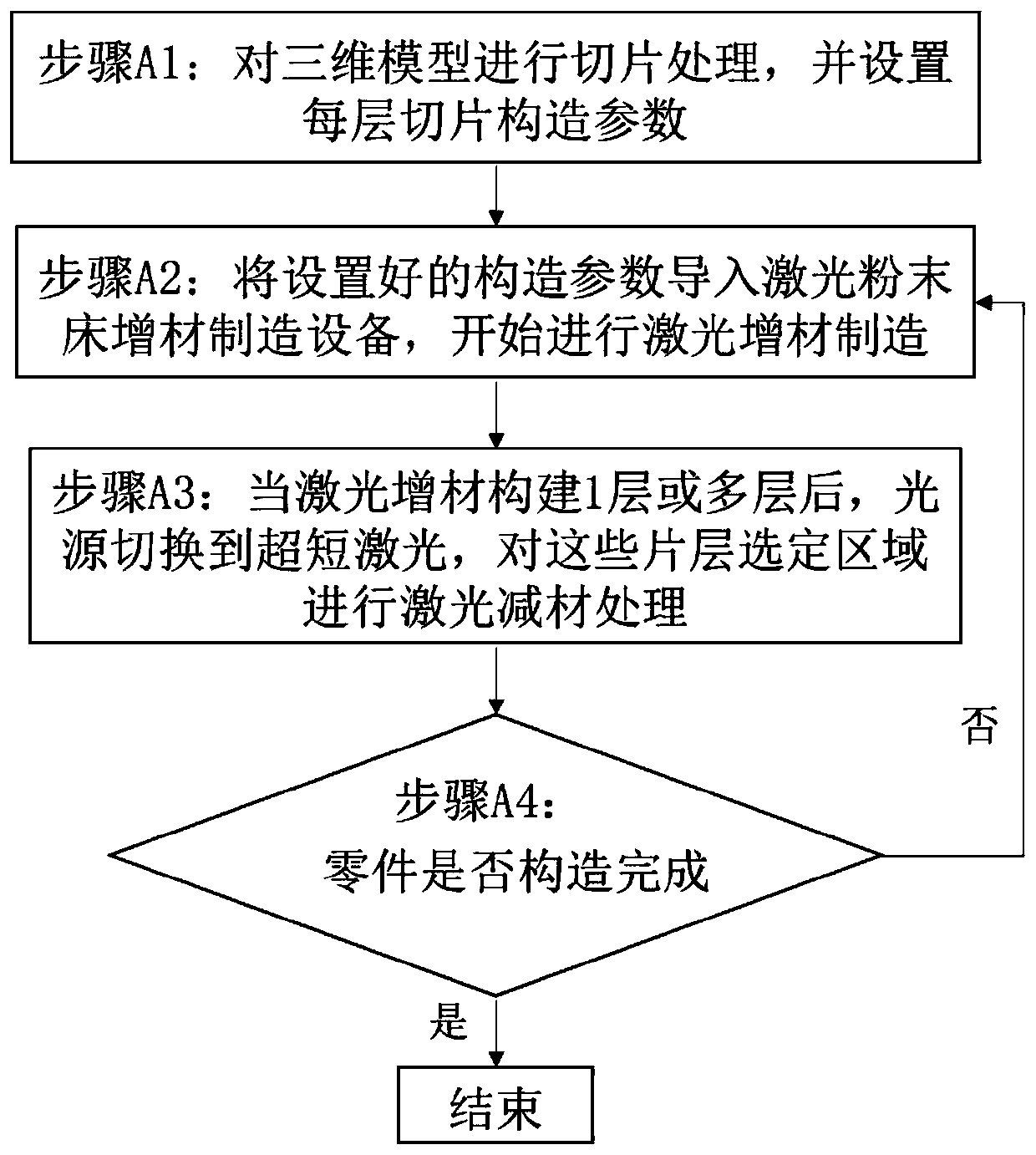

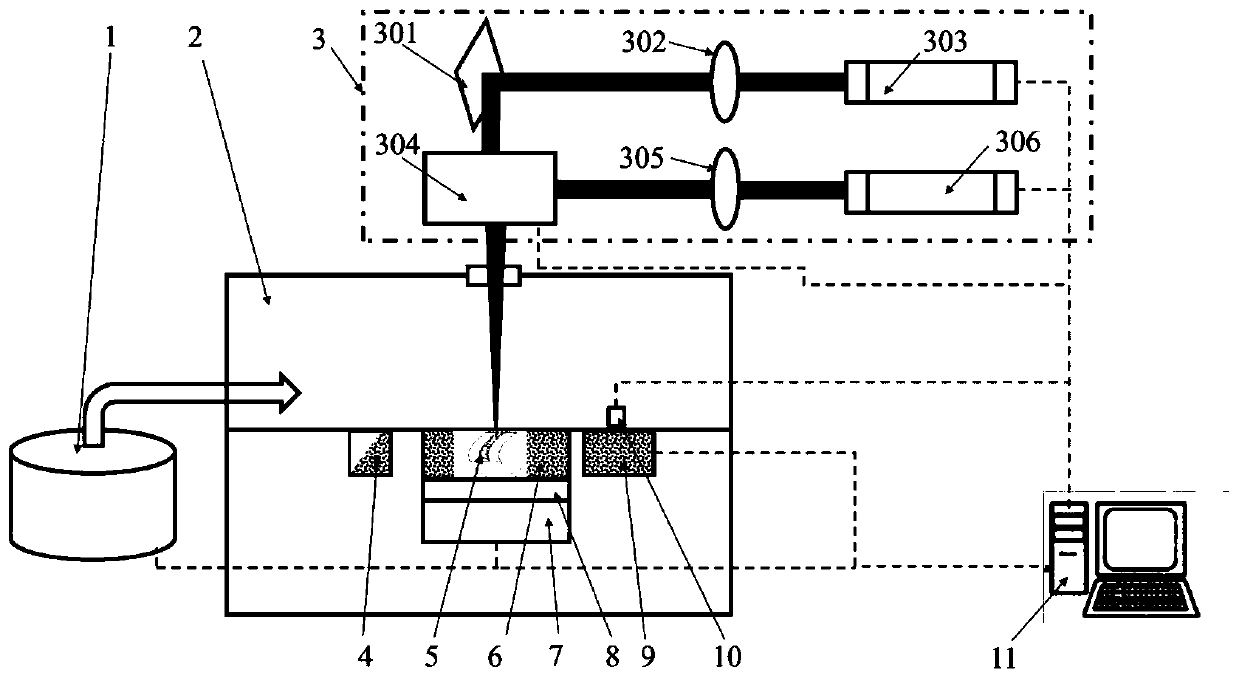

Near-net forming method and device for composite manufacturing fine workpiece based on laser additive manufacturing and subtractive manufacturing

PendingCN110369725AShort duration of actionChange the surface morphologyAdditive manufacturing apparatusIncreasing energy efficiencyFine structureLaser processing

The invention belongs to the field of laser processing, and relates to a near-net forming method and device for composite manufacturing a fine workpiece based on laser additive manufacturing and subtractive manufacturing. According to the method, the construction parameters of a three-dimensional digital-to-layer slicing layer are generated by utilizing software, laser additive manufacturing processing is carried out, and ultrafast pulse laser subtractive manufacturing processing is carried out alternately in the laser additive manufacturing processing process to form a three-dimensional entity. The device comprises a computer control device, a sealing molding chamber, a light path selecting system and an inert protection gas source; during additive manufacturing processing, the computer control device controls the light path selecting system to select the laser emitted by an additive manufacturing laser device and perform laser additive manufacturing processing; and during subtractivemanufacturing processing, the computer control device controls the light path selecting system to select ultrafast pulse lasers emitted by a subtractive manufacturing laser device and perform the ultrafast pulse laser subtractive manufacturing processing. According to the near-net forming method and device, the preparation of complex and fine-structure parts can be completed in a high-precision and integrated manner, the defects that traditional laser additive manufacturing is low in the forming precision, high in roughness and cannot be used for preparing a fine and complex inner cavity areovercome.

Owner:SHANGHAI UNIV OF ENG SCI

Tube bending forming processing device

InactiveCN101147934AImprove memory propertiesIncrease hydrostatic pressureShaping toolsHydraulic cylinderTangential force

The present invention discloses a bending forming processing equipment for pipe material. Said equipment includes the following several portions: bending die clamping die, pressing die, pressurizing plate, circumferential pressure-applying hydraulic cylinder, axial propulsion hydraulic cylinder and bending machine working table. The circumferential pressure-applying hydraulic cylinder pushing rod is rigidly connected with the pressurizing plate, the axial propulsion hydraulic cylinder pushing rod is flexibly connected with the pressing die end portion. The circumferential pressure-applying hydrautic cylinder can be used for driving said pressurizing plate to circumferentially apply pressure to the pipe material, and the axial propulsion hydraulic cylinder can be used for driving pressing die to apply tangential force to the pipe material, the bending die is fixed on the bending machine working table by means of bending centre, and bending die, pressing die and clamping die respectively have the groove fit with the outer diameter of said pipe material, the pressurizing plate is connected with the pressing die by means of dovelail groove, and the pressurizing plate also is connected with the bending machine working table by means of dovetail groove.

Owner:SHANGHAI JIAO TONG UNIV

Shape follow-up support deformation control method for selective laser melting forming of thin-walled part

ActiveCN108372298AEfficient additionAvoid complex and hard-to-remove problemsAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingDeformation control

The invention relates to a shape follow-up support deformation control method for selective laser melting forming of a thin-walled part. On the basis of existing selective laser melting forming support adding, the stress deformation behavior of the large thin-walled structural part in the forming process is analyzed and predicted, according to the molded surface structural characteristics, a design method that different shape follow-up supports are added at different positions is adopted, the problems such as cracking and deformation at the different positions such as the bottom in the selective laser melting forming process are solved through the method of supporting structure shape follow-up adding, the stability in the forming process is effectively improved, and the reliability of thequality of the formed structure part is guaranteed.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

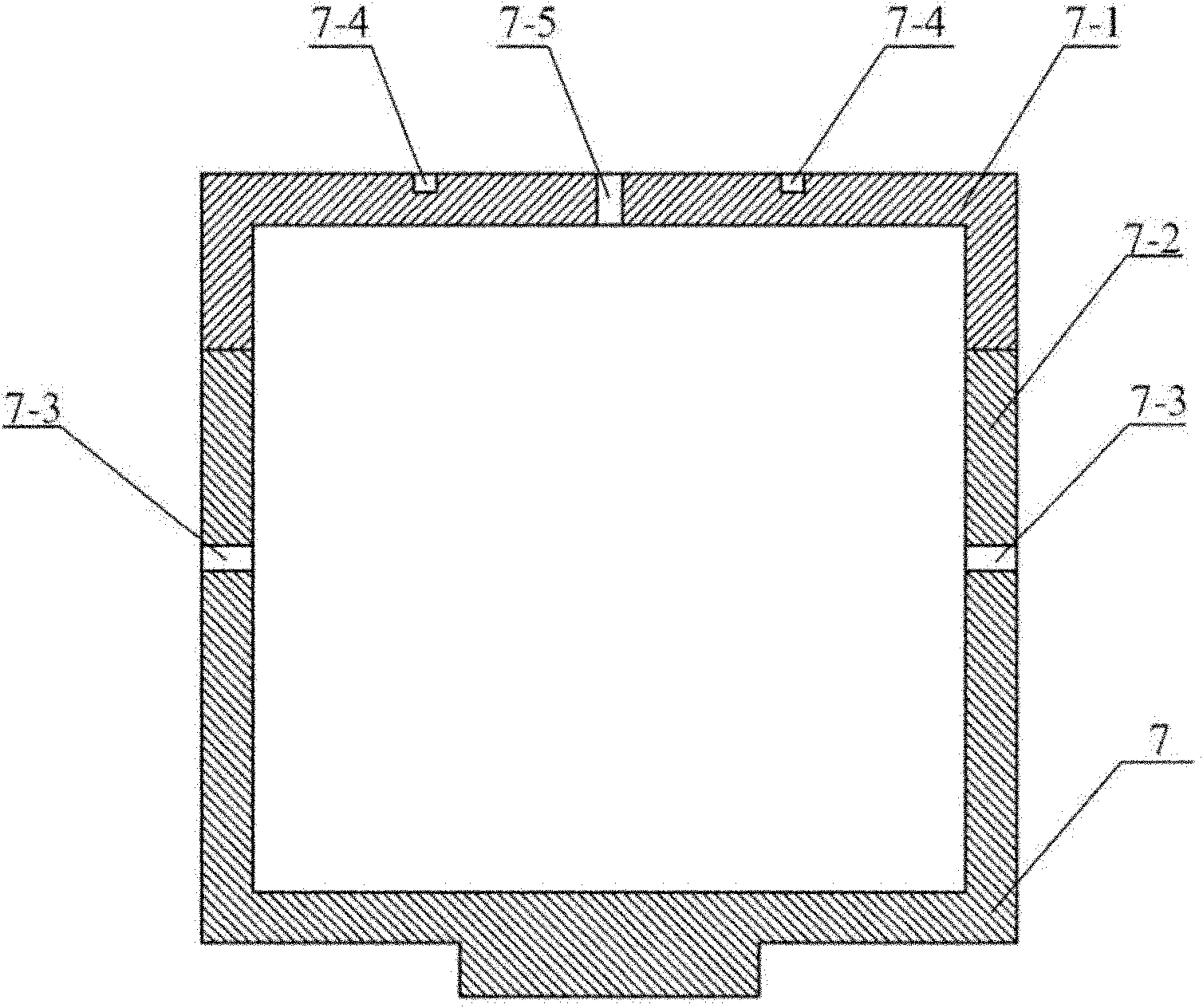

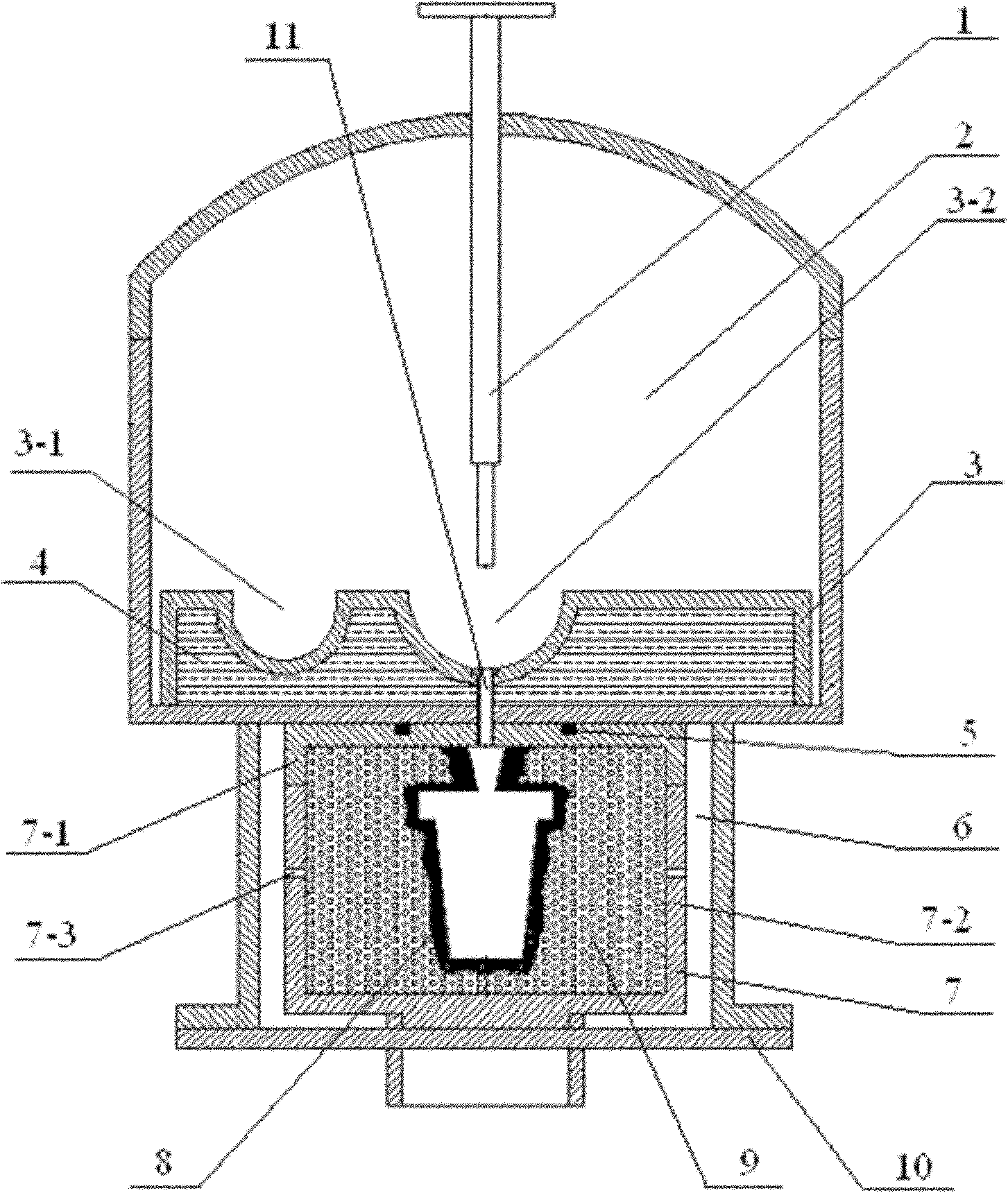

Cast forming method of small titanium alloy or titanium-aluminum alloy complicated casting

InactiveCN102019401AImprove filling abilityImprove efficiencyFoundry mouldsFoundry coresMold fillingIngot

The invention relates to a cast forming method of a small titanium alloy or titanium-aluminum alloy complicated casting, belonging to the casting method of the titanium alloy or titanium-aluminum alloy casting and solving the technical problems that the gravity casting of the traditional titanium alloy member is difficult in smooth mold filling, the centrifugal casting method has complicated process, the material utilization rate is low and the metal bottom-drain type vacuum suction casting method cannot be used for casting and forming thin-walled parts with complicated shapes. The method comprises the steps of: 1. preparing a ventilating shell; 2. preparing a bottom drain type vacuum suction casting container; 3. fixing the shell in the container, fixing the container in a suction casting chamber of a smelting furnace; 4. carrying out electric arc melting on the titanium alloy or titanium-aluminum alloy raw materials to obtain a button ingot; 5. turning the button ingot to a suction casting crucible for smelting to obtain overheating melt; and 6. suction-casting and mold-filling, and cooling to finally obtain the casting. The yield by the method is not less than 90 percent; and the method is a simple near net shape forming method, can be used for preparing a titanium and titanium-aluminum alloy blade, a worm wheel, artware and other small complicated castings.

Owner:HARBIN INST OF TECH

Equipment for bend-forging crank axle toggle of large ship and method for forging the same

ActiveCN1947886AUnder-forecastSimulation is accurateForging/hammering/pressing machinesEngine componentsMarine engineeringIngot

A bending-forging machine for manufacturing the large crankshaft or bellcrank used by ship is composed of upper die with lower arc end, bending lower die, upper and lower flat stocks, and insertion plate with lower arc end. Its forging method includes such steps as upsetting a steel ingot to become a flat square billet, drawing it to become a blank with shoulder, pressing V-shaped die on the middle of blank to form symmetric two V-shaped slots, bending by upper and lower dies, removing the upper and lower dies, inserting the insertion plate for finishing, trimming, and removing insertion plate.

Owner:SHANGHAI HEAVY MACHINERY PLANT +1

Control device and method for achieving wide-range scanning of electron beam and additive manufacturing device

InactiveCN105328187AEliminate astigmatismQuality improvementIncreasing energy efficiencyPower flowAdditive layer manufacturing

The invention discloses a control device and method for achieving wide-range scanning of an electron beam and a additive manufacturing device capable of achieving the wide-range scanning of the electron beam. The control device comprises a negative electrode, a grid electrode, a positive electrode, a focusing coil, a deflecting coil, an anastigmatic coil and a DA converter, wherein the anastigmatic coil is used for generating anastigmatic magnetism which can produce an anastigmatic magnetic field to control the astigmatic degree. According to the control device, the current of the focusing coil can be changed to achieve good focusing of the electron beam; in addition, the current of the anastigmatic coil can be changed to remove astigmatism of the electron beam, and thus beam spots can remain high quality; in addition, the formation quality of electron beam selective melting additive manufacturing (3D printing) can be greatly improved, and particularly the precision and quality of printed large parts can be improved. The control method is high in operability, and enables high-quality scanning of the electron beam in any route and within a wide range.

Owner:QUICKBEAM CO LTD +1

Spinning forming method and device based on laser heating

InactiveCN106424286AImprove heating efficiencyGood process flexibilityShaping toolsProcess equipmentSpinning

The invention discloses a spinning forming method and device based on laser heating. The spinning forming device is characterized by comprising a numerically-controlled spinning machine, spinning process equipment, a laser device, a light guide system, a six-degree-of-freedom robot machining system, a laser machining head, a temperature measuring device and the like. The spinning forming device conducts high-accuracy flexible control over a heating area according to the characteristics of high laser heating speed, accurate and controllable heating parts and temperatures and high degree of freedom and accurate control of the six-degree-of-freedom robot machining system, and spun blanks can be dynamically and locally heated while the spinning process equipment is not heated. The purposes of improving the material spinnability and reducing damage to the spinning machine are achieved. Meanwhile, closed-loop control over the heating temperature and laser output is realized, and realization of production automation is realized. The spinning forming method and device based on laser heating have the advantages of being high in production efficiency, good in process stability, high in forming precision, convenient to operate and the like.

Owner:JIANGSU UNIV OF TECH

Method for welding heterogenous system aluminum alloy through electron beams

ActiveCN105414733AReduce unevennessImprove performanceWelding/cutting auxillary devicesAuxillary welding devicesSiliconElectron

The invention discloses a method for welding a heterogenous system aluminum alloy through electron beams. Welding base metal is an aluminum-silicon cast aluminum alloy and an aluminum-magnesium wrought aluminum alloy. The method specifically includes the following steps of (1) joint designing, (2) preweld cleaning and assembling, (3) setting of welding parameters of the electron beams, (4) setting of injection positions of the electron beams, (5) welding, (6) modification welding and (7) postwelding cleaning. By means of the method, the welding quality is improved; the welding cost is reduced; meanwhile, the method is free of the special requirement for the environment and does not need special preweld and postwelding treatment; the welding process is easy to implement; the work efficiency is high; the method is quite wide in application prospect.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

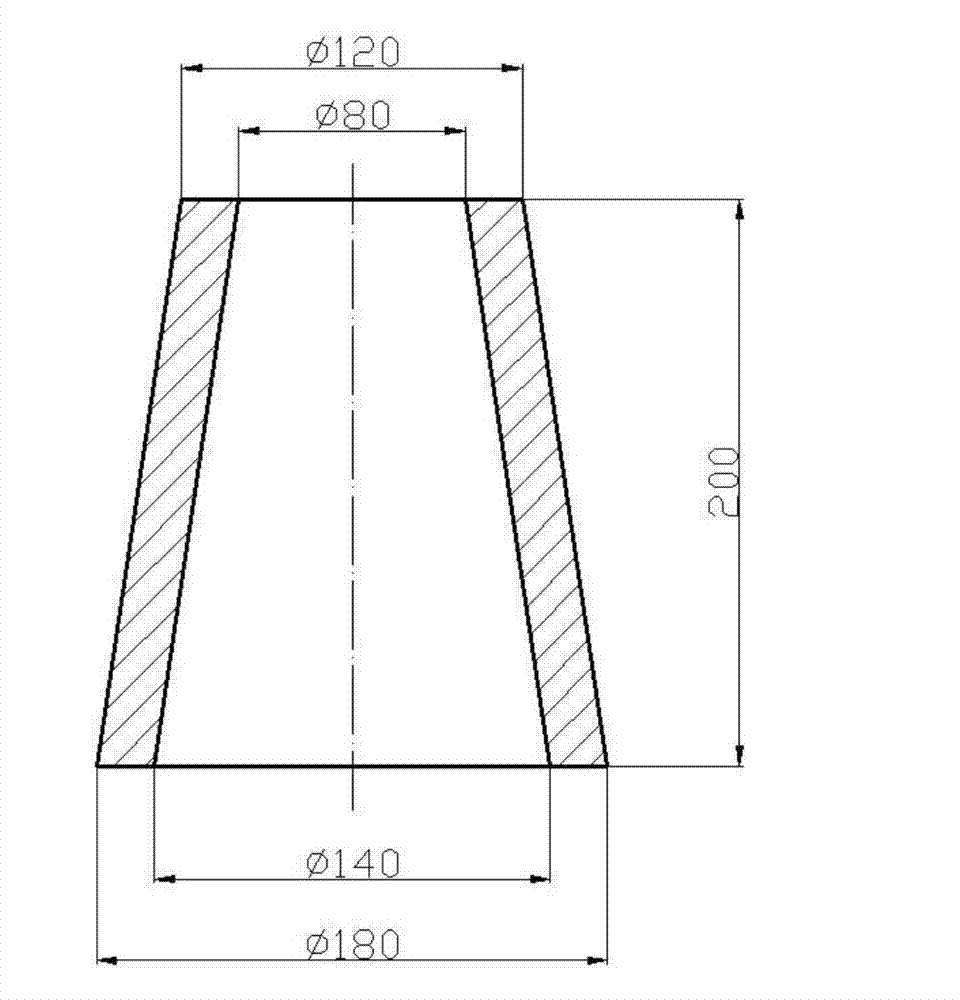

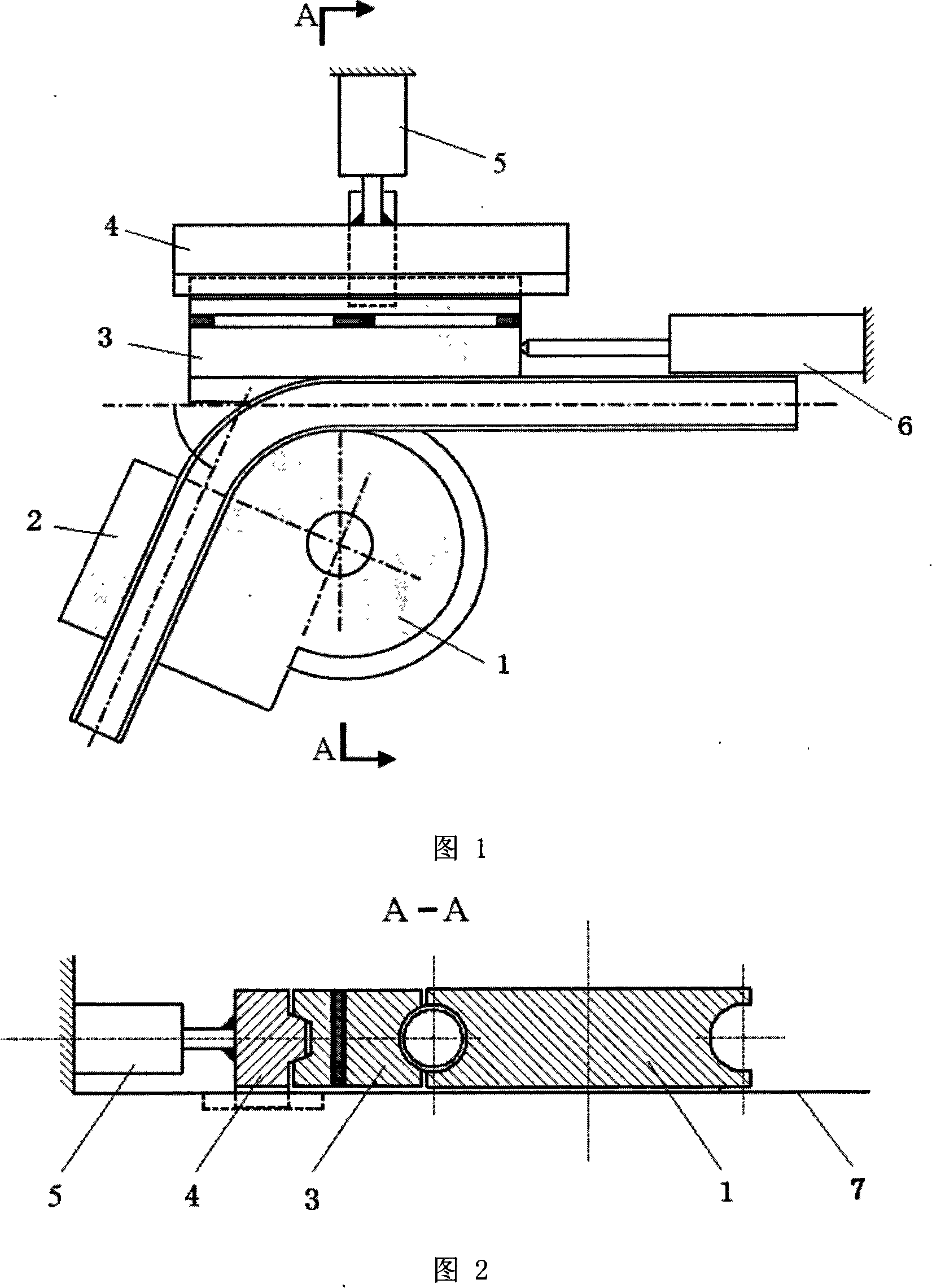

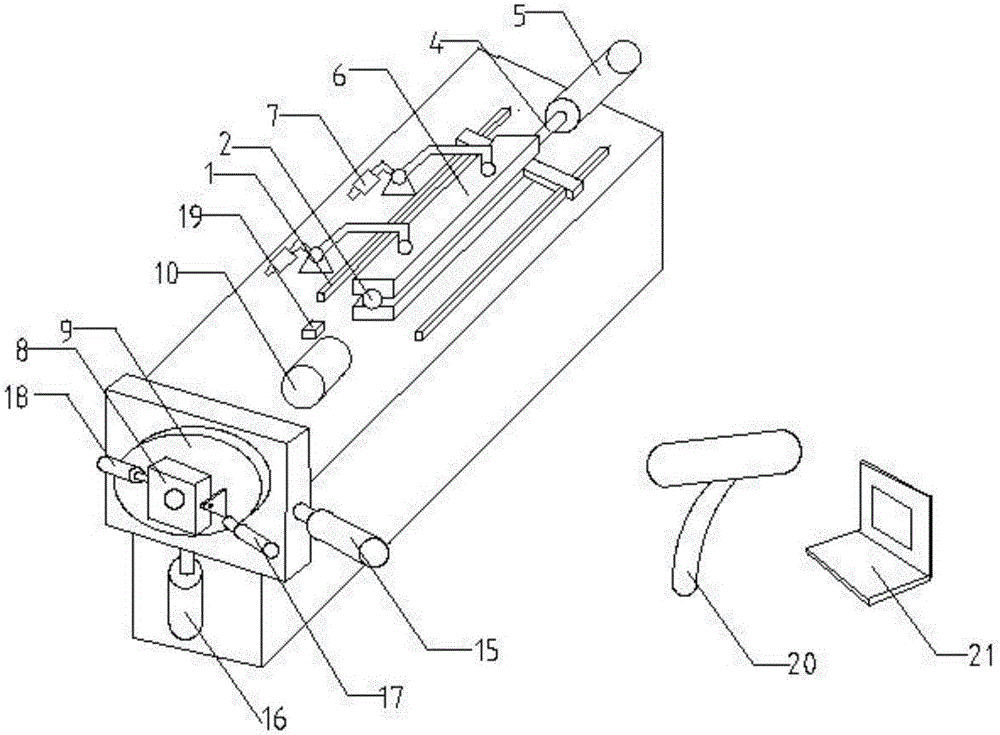

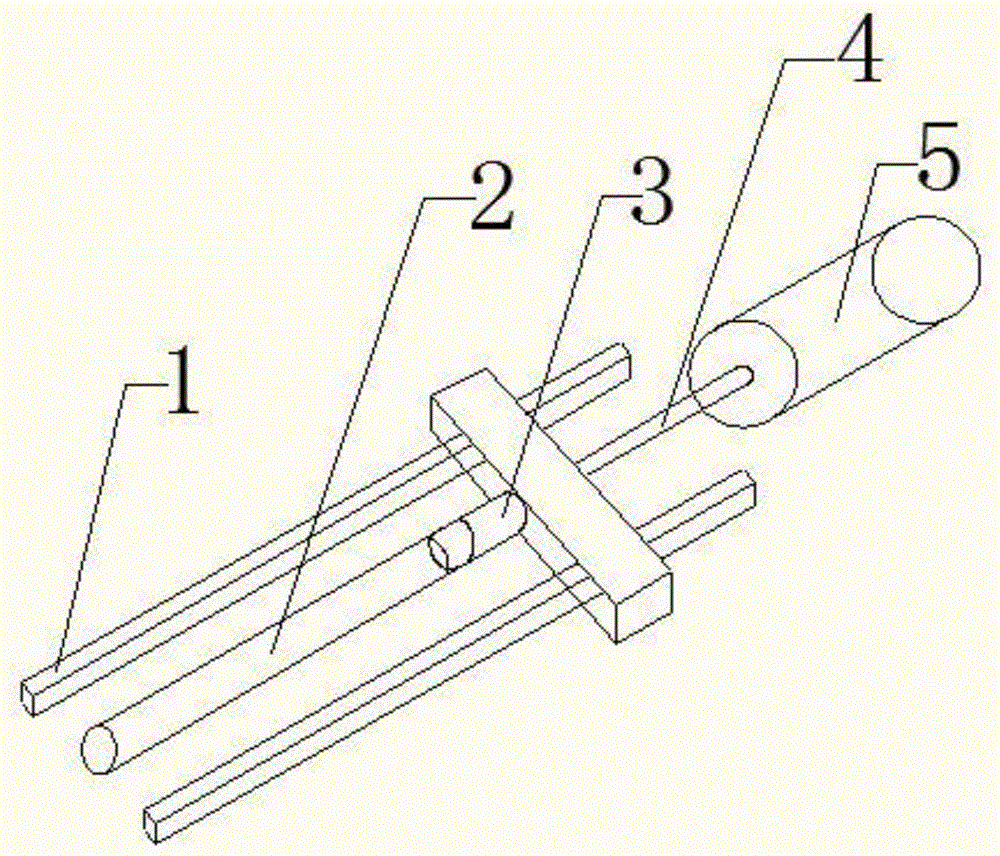

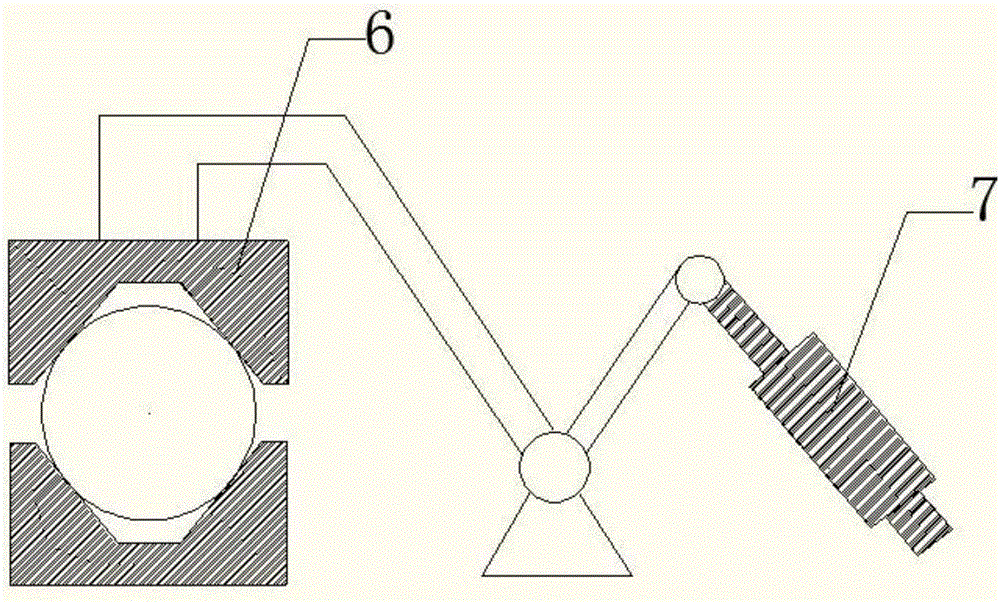

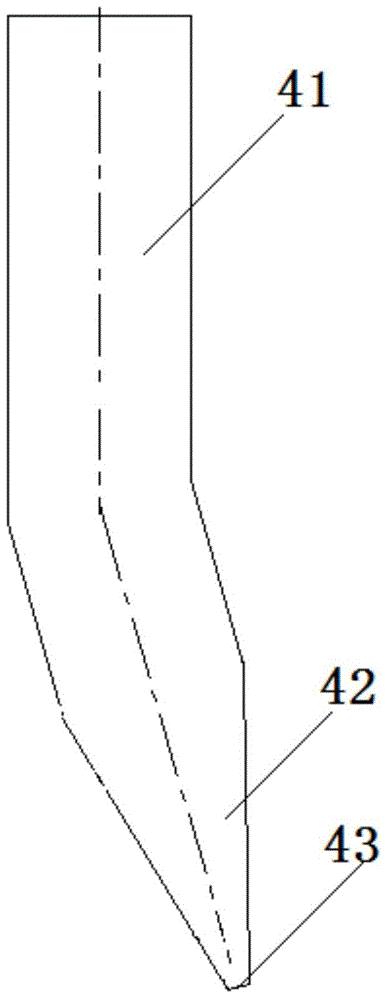

3D free-bending forming method and five-axis free bending device for metal pipes

ActiveCN106475445AImprove forming qualityOvercome pipe section distortionShaping toolsBall screwManipulator

The invention discloses a 3D free-bending forming method and five-axis free bending device for metal pipes. The five-axis free bending device for the metal pipes comprises a pipe pushing module, a pipe axial-movement guiding module, a manipulator bending module, an induction coil heating module, a lubrication module, a reverse scanning module and a measurement module. The pipe pushing module comprises a conical push rod (3), a Z-direction servo motor (5), a ball screw (4) and a linear guide rail (1), and the Z-direction servo motor (5) is used for axial feeding of the pipes. The manipulator bending module comprises an X-direction servo motor (15), a Y-direction servo motor (16), a bending die driving servo motor (18), a bending die holder driving servo motor (17), a bending die (8) and a bending die holder (9). According to the 3D free-bending forming method and five-axis free bending device for the metal pipes, elbow pipes with different bending radii can be formed only by controlling the movement track of the manipulator bending device, and meanwhile since the plane of the bending die can be kept perpendicular to the axes of the pipes in real time, the forming quality of the bent pipes is good.

Owner:固航科技(常州)有限公司

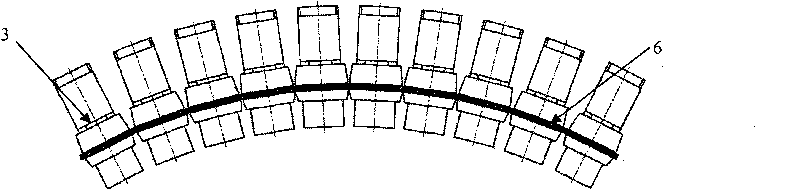

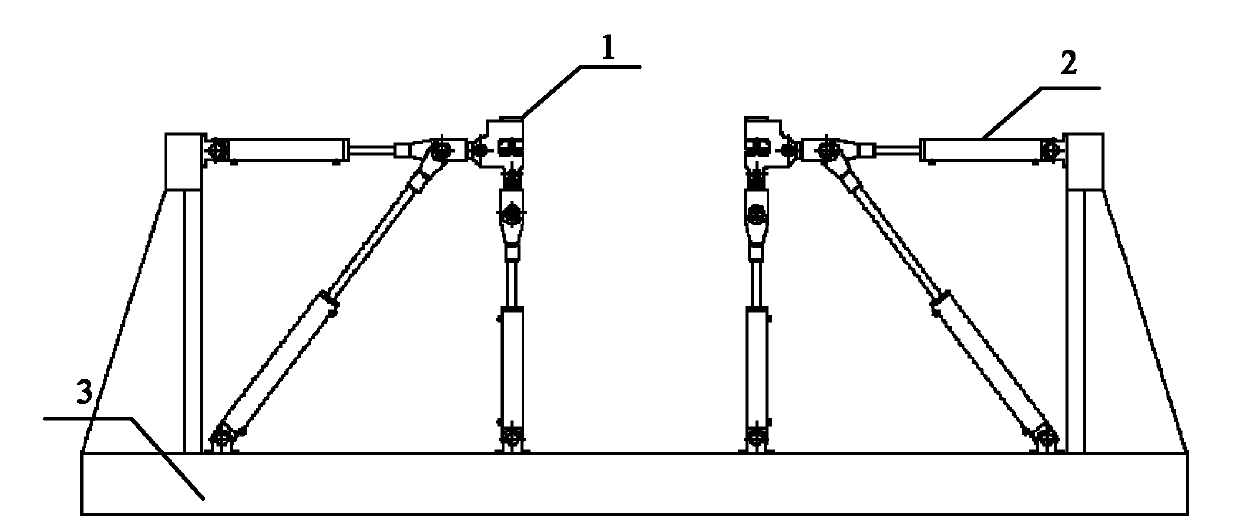

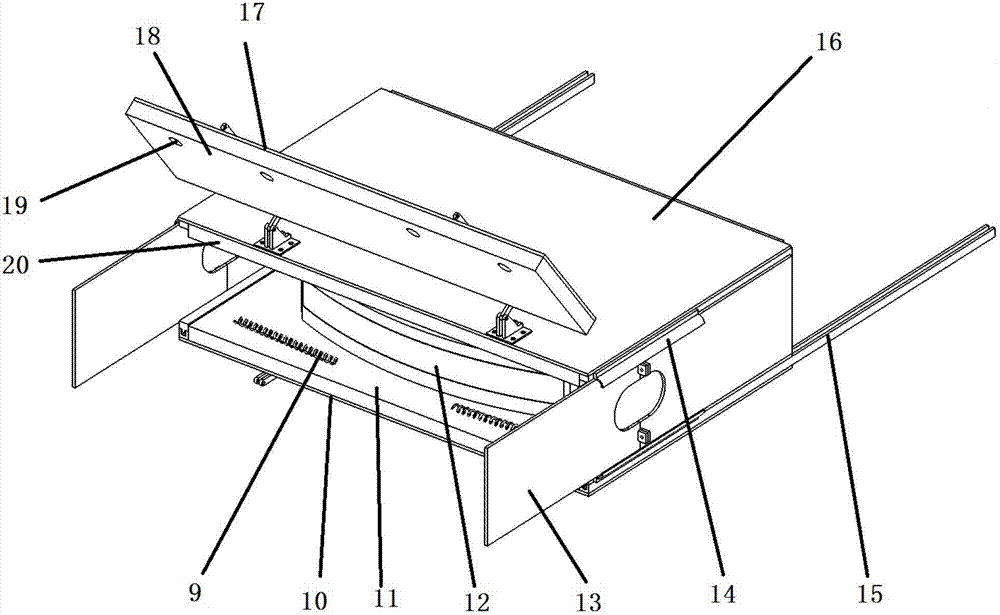

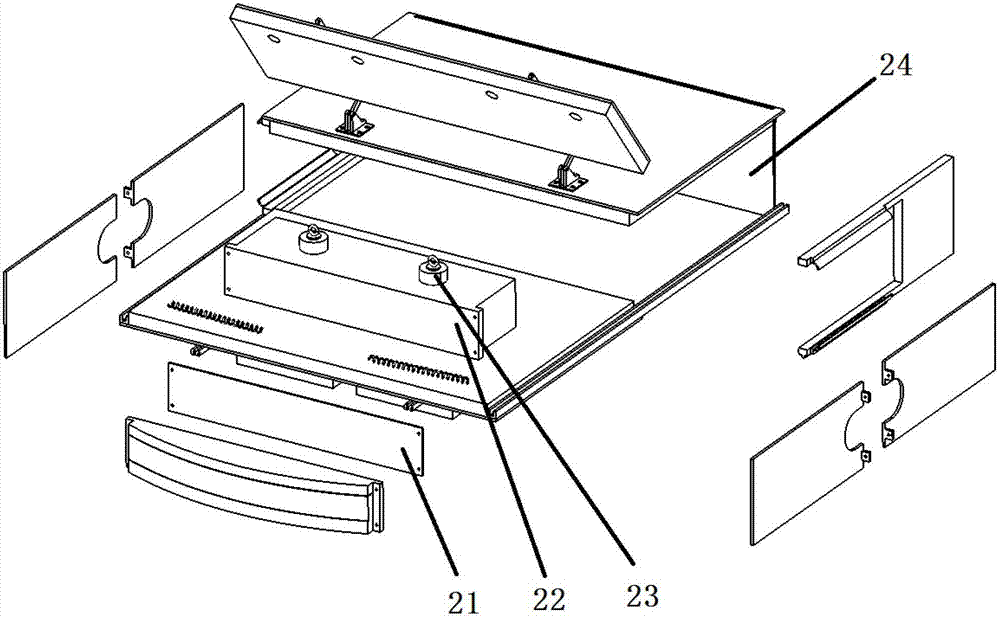

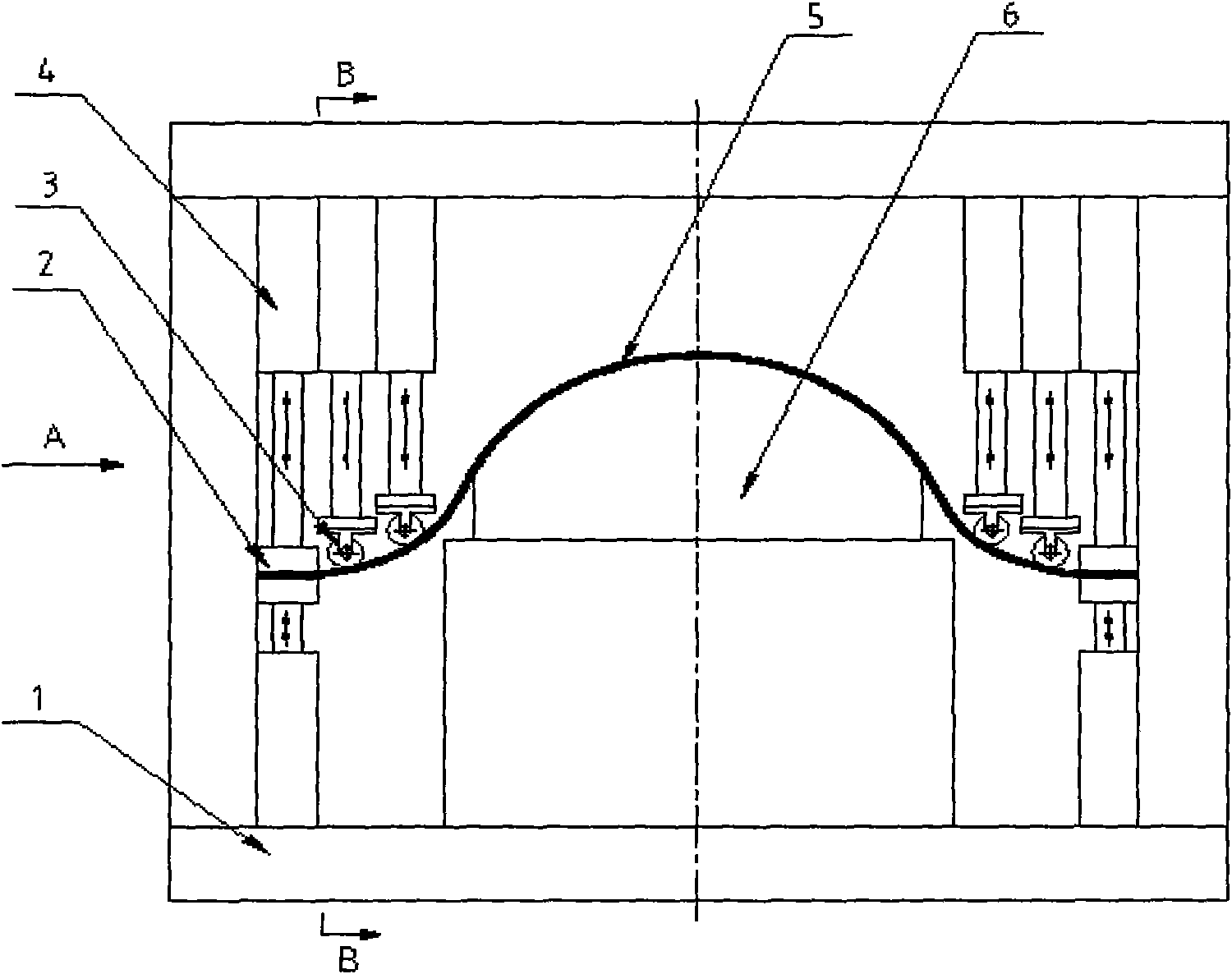

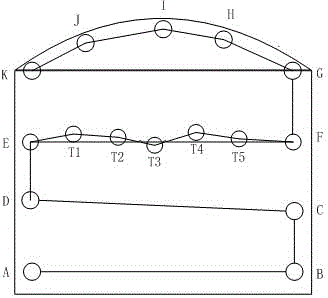

Multiclamp type stretch forming machine

The invention discloses a multiclamp type stretch forming machine and relates to plastic processing equipment for curve forming of plates, belonging to the field of mechanical engineering. The machine mainly comprises clamping mechanisms (1), a stretching mechanism (2) and a stand (3), wherein a row of clamping mechanisms (1) are respectively distributed at both sides of the stand (3); each clamping mechanisms (1) is provided with a lower connecting hole (4) and a rear connecting hole (5); and all the connecting holes are respectively connected with the stretching mechanism (2) by pin shafts or cardan joints. The machine can realize the flexible control of a plurality of clamps, ensure that a workpiece is more easily attached to a die in the stretching process, obviously improve the material utilization ratio of the workpiece and obtain higher workpiece forming effect.

Owner:长春瑞光科技有限公司

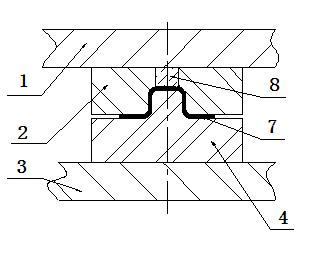

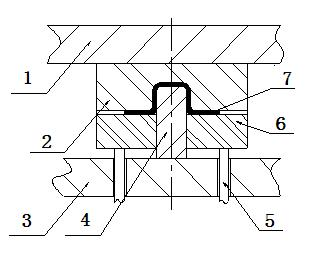

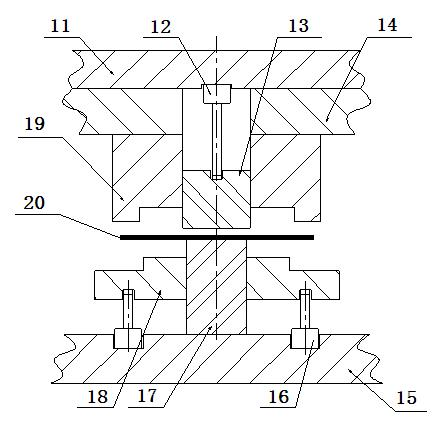

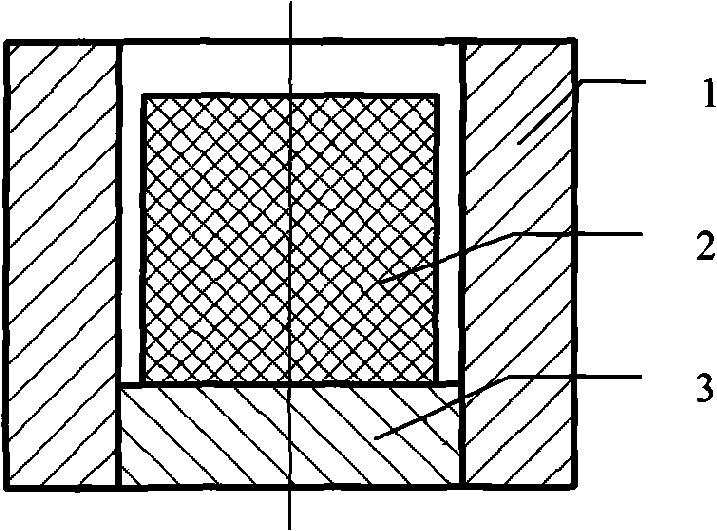

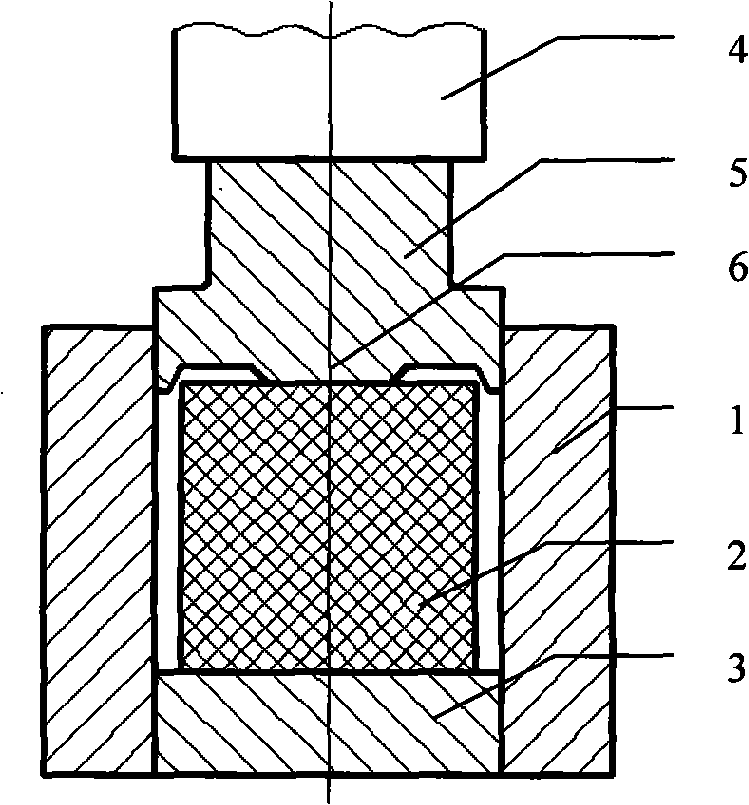

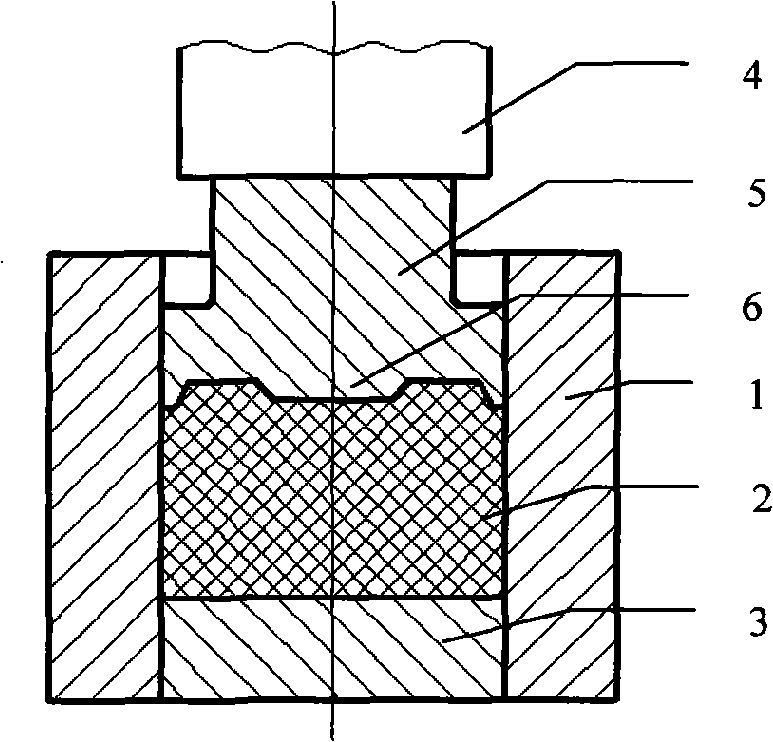

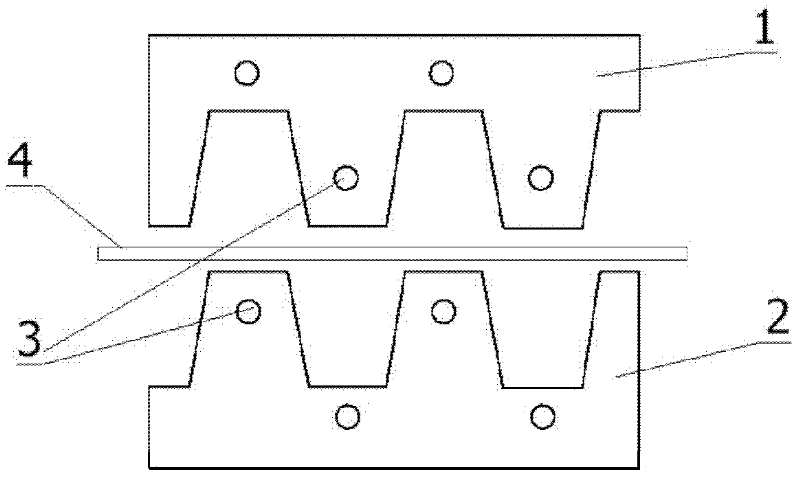

Molding die for processing high-tension plate parts

ActiveCN102310147ASolve molding difficultiesSolve insufficient plastic deformation during moldingShaping toolsEngineeringNitrogen gas

The invention relates to a molding die for processing high-tension plate parts, which comprises an upper die seat (11), a material press core (13), an upper die fixing plate (14), a lower die seat (15), a convex die (17), a material press plate (18) and an upper die knife block (19), wherein the upper die fixing plate (14) is arranged between the upper die seat (11) and the upper die knife block (19), at least one nitrogen spring (12) is arranged between the material press core (3) and the upper die seat (11), at least two nitrogen springs (16) are arranged between the material press plate (18) and the lower die seat (15), a locking unit (21) is manufactured on the material press plate (18) and the upper die knife block (19), a material plate (20) locked between the material press core (13) and the locking unit (21) in molding can be fully stretched for plastic deformation, and the large springback amount after molding is overcome.

Owner:CHERY AUTOMOBILE CO LTD

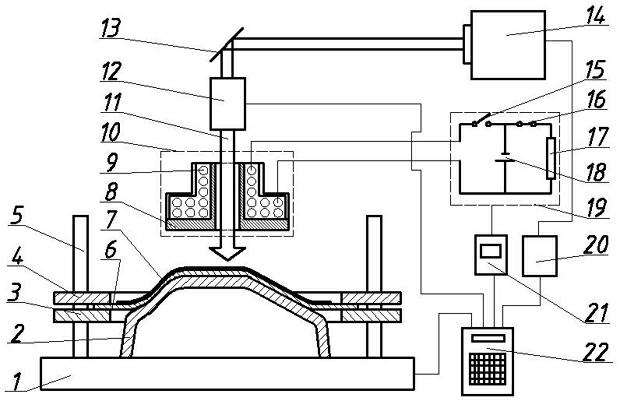

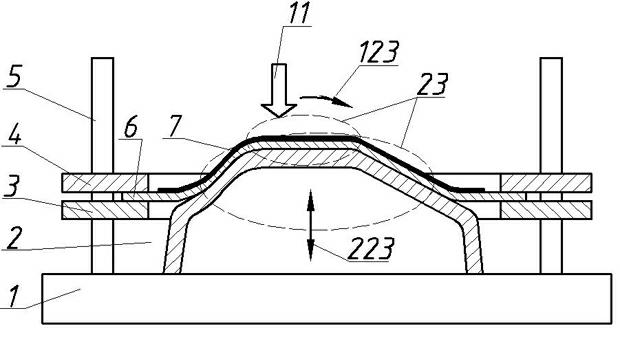

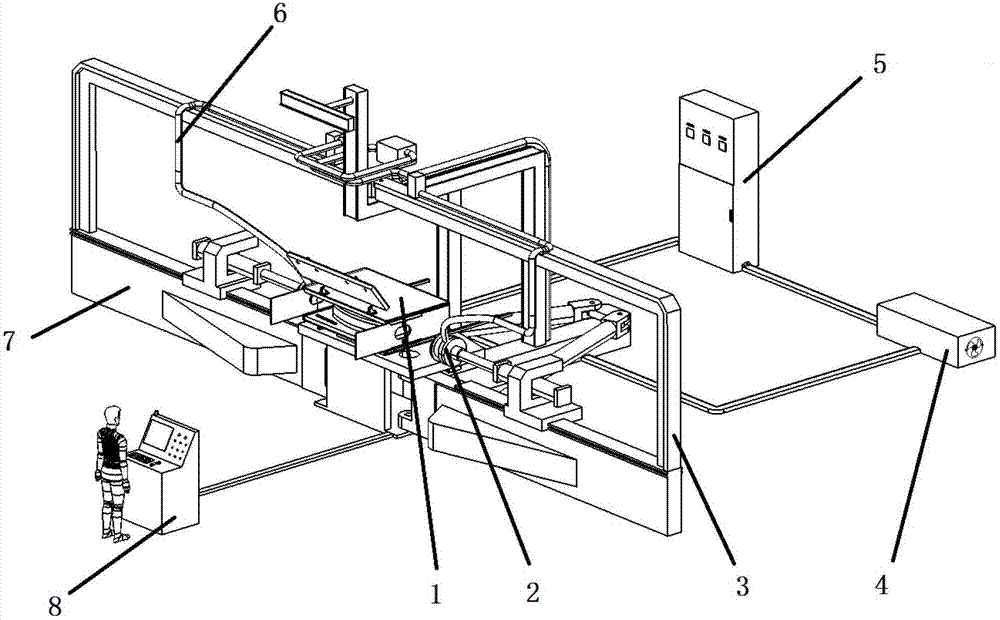

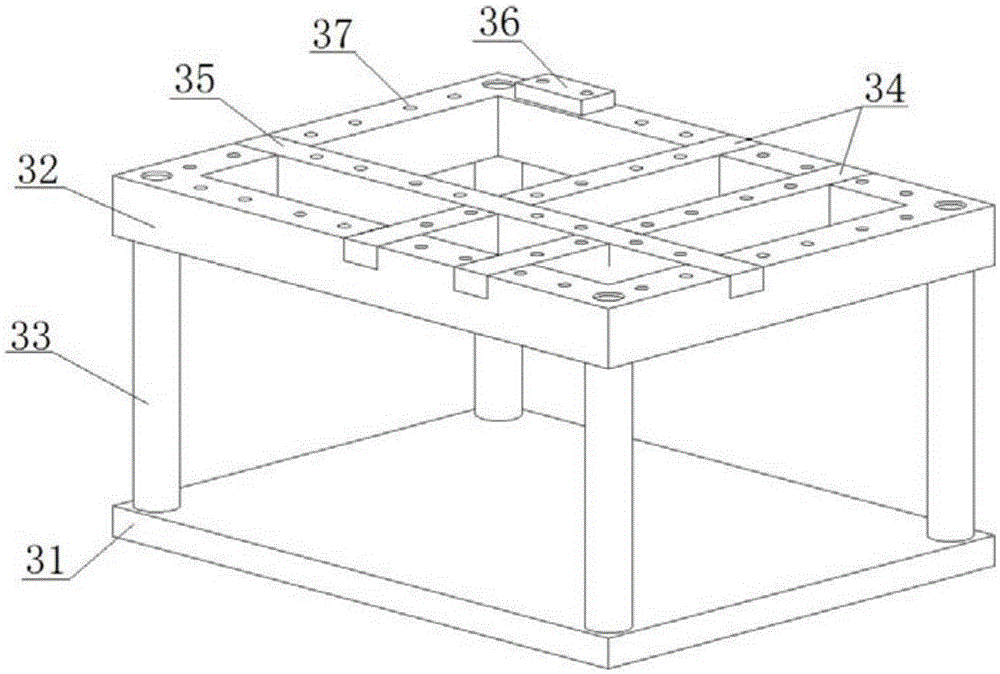

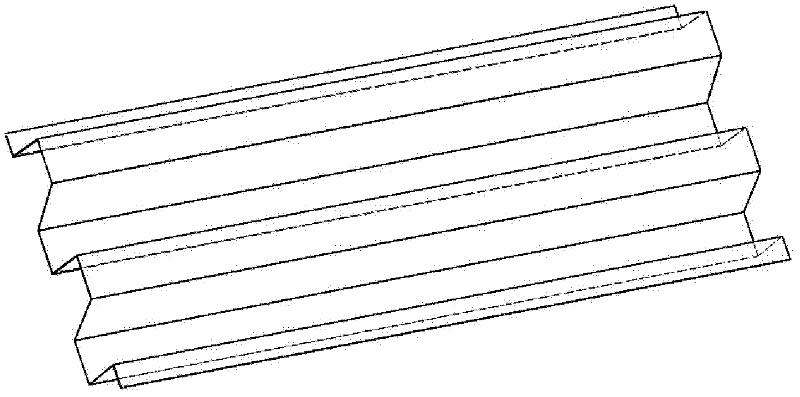

Compound molding tool system for hot stretch bending and creep deformation of section bar and application method of compound molding tool system

The invention relates to a compound molding tool system for hot stretch bending and creep deformation of a section bar. The compound molding tool system comprises a cantilever-type section bar stretch bender, a heating box, a self-resistance heating system, an electric control cabinet and a clamp, wherein the heating box is located on the working table of the middle part of the cantilever-type section bar stretch bender; the electric control cabinet is located in front of the cantilever-type section bar stretch bender and is connected with the cantilever-type section bar stretch bender; the self-resistance heating system is located at the periphery of the tool system; and the clamp is arranged on a cantilever of the cantilever-type section bar stretch bender. An application method of the compound molding tool system for the hot stretch bending and the creep deformation of the section bar comprises six steps. According to the compound molding tool system for the hot stretch bending and the creep deformation of the section bar, the hot stretch bending process of the creep deformation process of the section bar are compounded; the plastic deformation resistance of the section bar is reduced; and the residual stress after the section bar is processed is reduced, and thereby, resilience is reduced, and the molding precision and the structure stability are improved. Compared with products obtained by adopting a traditional stretch bending method, a final product obtained by the compound molding tool system is higher in quality, and the production efficiency is increased.

Owner:BEIHANG UNIV

Hot impact extrusion process and device for large annular barrel type forged piece

ActiveCN101537438ASolve process problemsImprove uniformityExtrusion containersRams/plungersImpact extrusionLubricant

The invention relates to a hot impact extrusion process and a device for a large annular barrel type forged piece, which belongs to the technical field of hot forming of a large hollow forged piece. The process comprises the following steps: firstly, an extrusion cushion is placed on a press platform; secondly, the blanks to be heated are put on the extrusion cushion; thirdly, an extrusion cylinder is sleeved on the extrusion cushion; fourthly, a profiling punch is applied with force so that a mold cavity is filled with the blanks; fifthly, the lubricant is added; sixthly, a solid punch is applied with force so that the blanks are extruded to the set position of the process; seventhly, a hollow punch is sleeved on the solid punch and applied with pressure, so that the blanks are extruded to the set positioned of the process; eighthly, the extrusion cushion is taken out and a bottom flushing drain cap is replaced; and ninthly, the core material at the bottom is flushed out through the hollow punch. The devices required for finishing the process comprise an extrusion cylinder, an extrusion cushion, a profiling punch, a solid punch, a hollow punch, a solid extension rod, a hollow extension rod and a bottom flushing drain cap. The invention solves the difficult problems existing in the large annular barrel forged piece of long process flow of free forging, more forging times and large reverse extrusion molding for die forging and improves the utilization ratio of the material and the molding quality of the forged piece.

Owner:NANJING DEV ADVANCED MFG

Sheet-stretching machine

The invention provides a sheet-stretching machine, relates to a plastic working device for the three-dimensional curved-surface forming of sheet workpieces, and belongs to the field of mechanical engineering. The invention aims to allow pulling pieces to tend to be uniform in the distribution of tensile stress and tension strain, realize the pulling of complex curved-surface workpieces, improve the forming quality of the pulling pieces, improve material utilization rate and reduce the cost for manufacturing pulling devices. This machine mainly comprises a frame (1), a left-side clamping mechanism, a right-side clamping mechanism and a down-pressing mechanism, wherein the frame (1) supports the left-side clamping mechanism, the right-side clamping mechanism and the down-pressing mechanism; each clamping mechanism is divided into an upper part and a lower part; each part has a plurality of clamping devices arranged in a row; and the down-pressing mechanism has a plurality of down-pressing devices arranged in a row or a plurality of rows.

Owner:JILIN UNIV

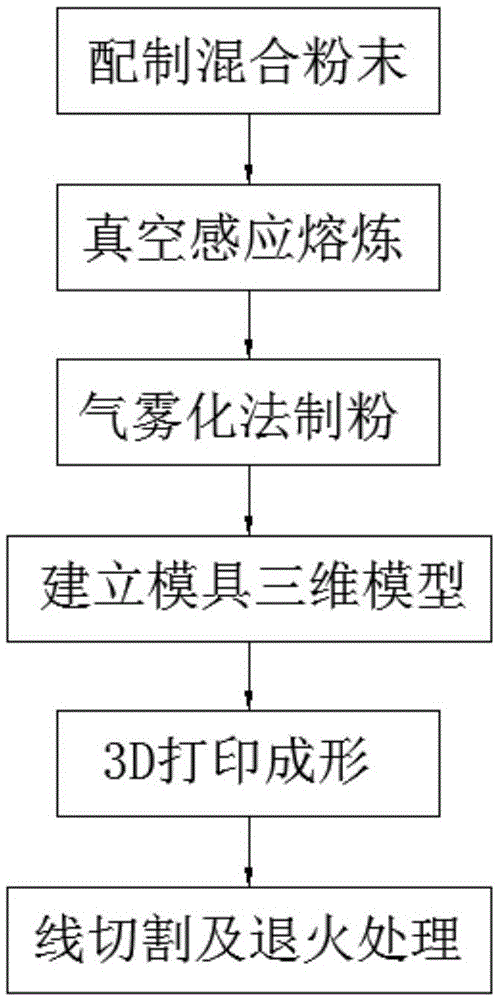

3D printing preparation method for injection mold

InactiveCN105562691AAvoid crackingAdd C elementAdditive manufacturing apparatusIncreasing energy efficiencyPolymer scienceEvaporation

The invention discloses a 3D printing preparation method for an injection mold. The 3D printing preparation method comprises the following steps that 1, mixed powder is prepared, and then vacuum induction melting is carried out, wherein the mixed powder is prepared from, by weight percent, 0.4% to 0.5% of C, 0.7% to 0.75% of Si, 0.35% to 0.45% of Mn, 14% to 15.6% of Cr, 0.25% to 0.35% of V and the balance Fe; 2, an atomization powder preparing method is adopted for preparing the powder; 3, a three-dimensional model is established; 4, the injection mold is formed; and 5, the formed injection mold is separated from a substrate, and then the injection mold is placed in a muffle furnace for annealing to improve the plasticity and toughness of the injection mold. According to the 3D printing preparation method, cracking of mold steel in the 3D printing process can be effectively restrained. Meanwhile, C is added to make up ingredient changes caused by element evaporation and carbonization of the injection mold under the action of lasers.

Owner:HUAZHONG UNIV OF SCI & TECH

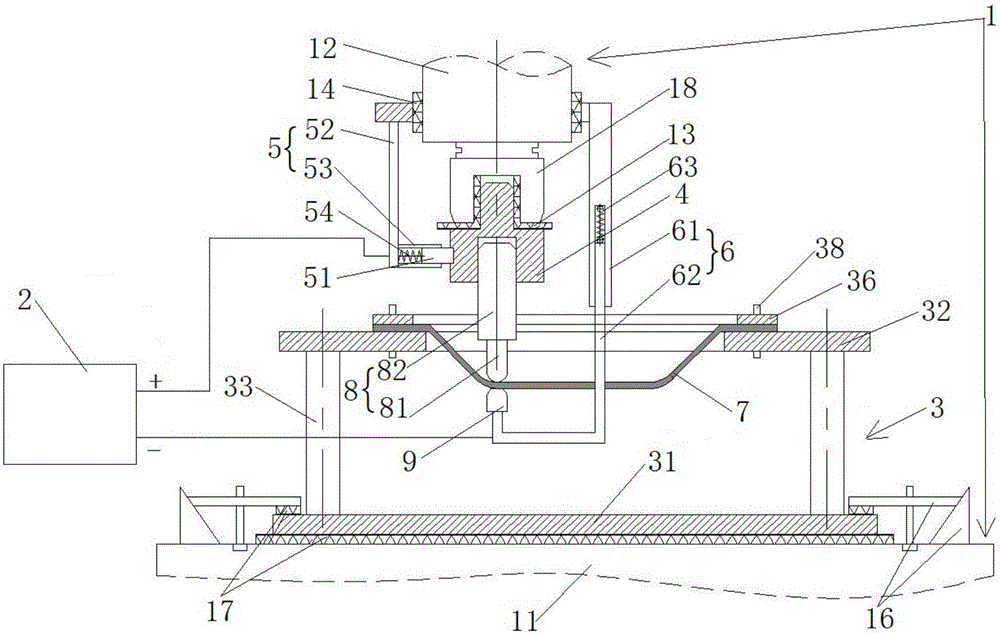

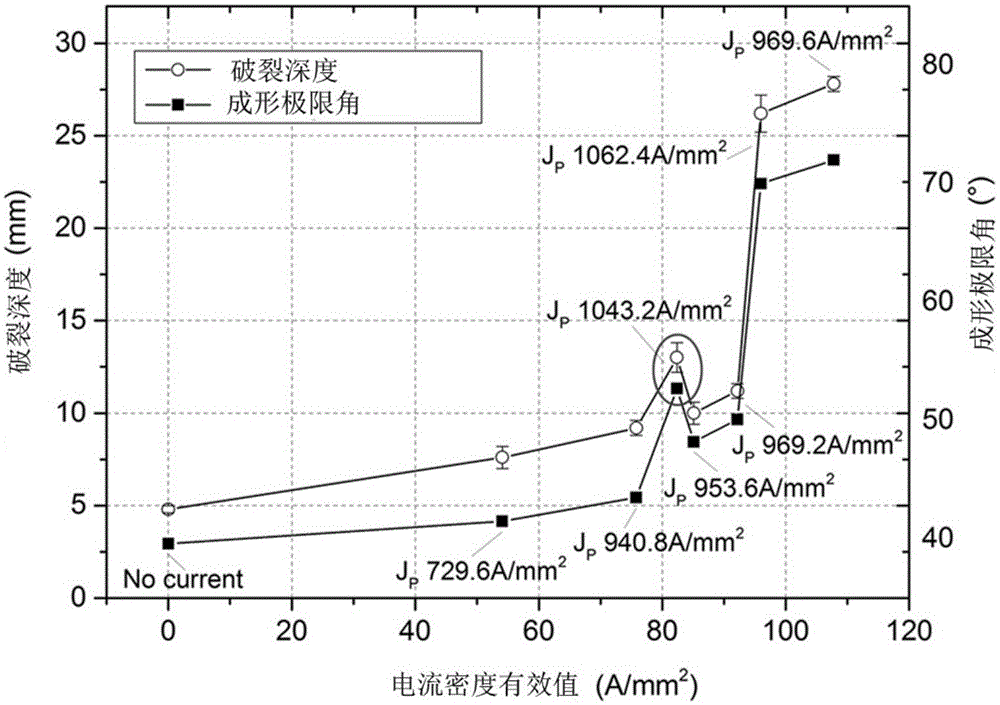

Electroplastic incremental forming device for plate and working method thereof

The invention discloses an electroplastic incremental forming device for a plate and a working method thereof, and belongs to the field of metal processing. The device comprises a machine tool and a pulse power supply, wherein a plate clamping device is fixed on a workbench of the machine tool; a clamping block, an electric brush holder and a retainer are arranged on a main shaft of the machine tool; the clamping block is connected with a tool head used for processing the plate; the electric brush holder is L-shaped, one end of the electric brush holder is fixed on the main shaft, and the other end of the electric brush holder is connected with an electric brush used for being abutted against the clamping block; the retainer is U-shaped, one end of the retainer is fixed on the main shaft, and the other end of the retainer stretches to a place below the plate and is connected with a lower press head used for being abutted against the lower surface of the plate; the tool head faces the lower press head; and the two poles of the pulse power supply are connected with the electric brush and the lower press head respectively. The electroplastic incremental forming device for the plate disclosed by the invention is simple in structure, easy to control, and low in processing cost; the forming accuracy of the plate is high; and the forming limit and the forming quality of the plate are increased and improved.

Owner:山东大学(威海)

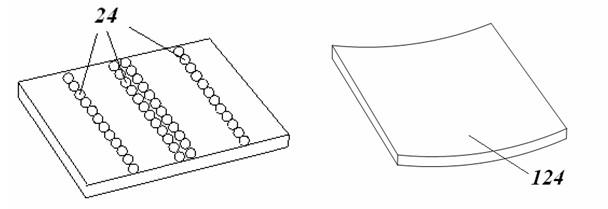

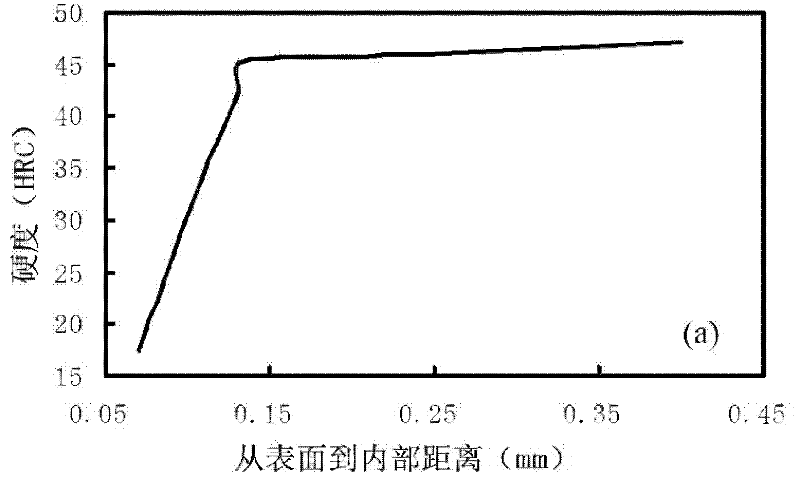

Thermal forming method for multilayer metal composite boards

The invention discloses a thermal forming method for multilayer metal composite boards, comprising the steps of: installing cooling pipelines respectively on an upper mould and a lower mould of a mould; heating a boron alloy steel board for austenite, then sending the red hot board to the mould with the cooling pipeline and placing the mould to a controlled atmosphere protecting heating furnace for hot stamping; controlling the temperature of the heating furnace at 750-800 DEG C; and uniformly cooling and forming at a cooling speed greater than 50 DEG C / s. The hardness test of the sample shows that the hardness of the board prepared by the method increases from the surface to the inside and HRC hardness increases from about 20 to about 50, thus, in the thermal forming process, the test piece is formed and quenched uniformly and controllably. Same distribution trends of strength and hardness of the test piece mean that the metal composite material manufactured by the invention has continuous gradient distribution with low surface hardness and strength and high inner hardness and strength.

Owner:DALIAN UNIV OF TECH

Full-position connecting pipe and safety end circular seam welding method achieved through tungsten electrode inert gas arc welding

ActiveCN104084678AImprove welding efficiencyReduce welding distortionArc welding apparatusWorkpiece edge portionsSpin weldingArchitectural engineering

The invention discloses a full-position connecting pipe and safety end circular seam welding method achieved through tungsten electrode inert gas arc welding. According to the method, nickel base alloy serves as an isolating layer to carry out machining on a connecting pipe and a safety end so that a welding groove can be formed by the connecting pipe and the safety end during assembling, and the welding groove is welded. A plurality of weld beads are welded during welding, the bottom end of a part to be welded is arced during welding, spin welding is carried out along one side of the part to be welded to the top end of the part to be welded, arcing is stopped, the bottom end of the part to be welded is arced again, spin welding is carried out along the other side of the part to be welded to the top end of the part to be welded, and arcing is stopped. When the welding groove is a double-faced U-shaped narrow gap groove, an outer groove is welded but not completely welded, back chipping and complete welding are carried out on an inner groove, and then complete welding is carried out on the outer groove. When the welding groove is a single-faced narrow gap groove, the groove is completely welded, a cushion plate is removed, and back chipping is carried out.

Owner:HARBIN ELECTRIC CORP QINHUANGDAO HEAVY EQUIP

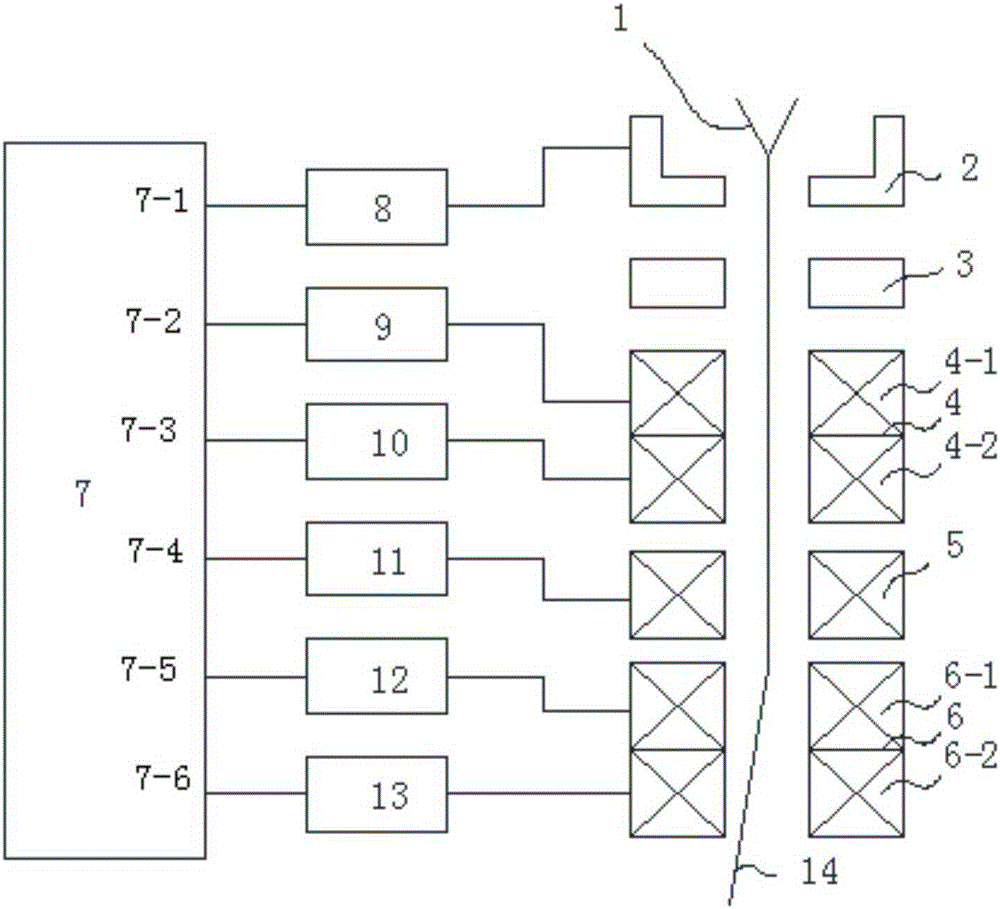

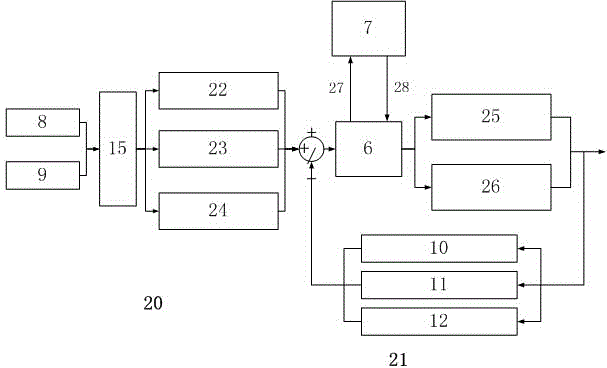

Heading machine memory cutting control system and method thereof

InactiveCN103147756AReduce labor intensityImprove efficiencySlitting machinesAutomatic controlControl function

The invention relates to a heading machine memory cutting control system and a method of the heading machine memory cutting control system. The heading machine memory cutting control system is composed of a detection unit, a control unit, a proportion amplification plate, a load sensitivity type proportion reversal valve group and an execution unit, wherein the control unit comprises a PCC (programmable computer controller), an intelligent operation control panel, a remote controller and a machine body operating handle; and heading machine memory cutting comprises a manual demonstration process and a memory automatic cutting process. The method comprises the following steps that: firstly, a heading machine driver utilizes the remote controller or the machine body operating handle to operate the heading machine to cut once according to a top plate and a bottom plate of a coal seam and the coal rock distribution condition, and an airborne computer control system records information a demonstration path detected by the detection unit; and then the recorded keypoint data is subjected to path matching and intelligent optimization, a control signal is sent to the execution unit according to the path after optimizing, so that a cutting head is automatically controlled to move along a demonstration track, and the memory automatic cutting is performed. The heading machine memory cutting control system is also provided with a boundary control function in the whole memory cutting process, and the tunnel shaping quality when the manual cutting and memory automatic cutting are performed is ensured. The heading machine memory cutting control system and the method of the heading machine memory cutting control system provide a new control means for heading of a coal road boom-type roadheader under the condition with stable surrounding rock of roadway.

Owner:CHINA UNIV OF MINING & TECH (BEIJING) +1

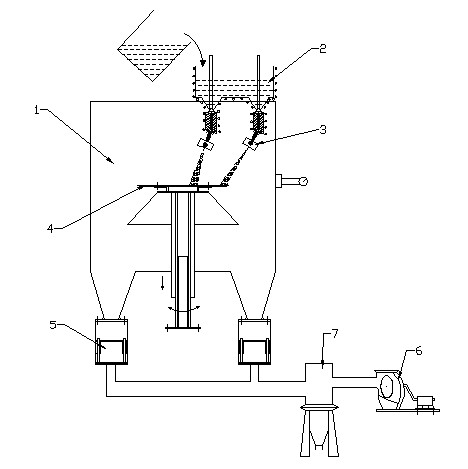

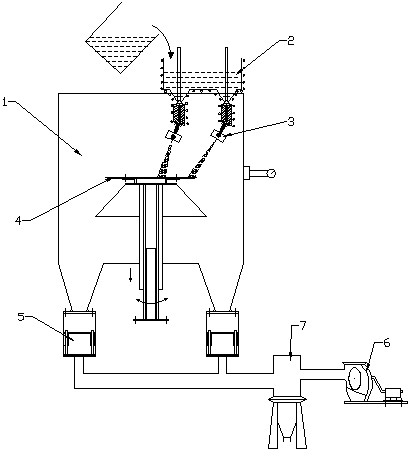

Double-nozzle-scanning inclined spray type cylinder blank injection moulding device

The invention relates to manufacturing equipment of metal materials, in particular to a double-nozzle-scanning inclined spray type cylinder blank injection moulding device. The double-nozzle-scanning inclined spray type cylinder blank injection moulding device comprises a deposition chamber, wherein a ladle used for storing molten metal and atomizing nozzles connected to the bottom of the ladle are arranged at the top of the deposition chamber, and the deposition chamber is internally provided with a rotatable deposition substrate; the deposition substrate is arranged in the center of the deposition chamber and a rotating shaft of the deposition substrate is arranged in a vertical direction, and the atomizing nozzles are arranged above the deposition substrate; and the distances between the two atomizing nozzles and the axial lead of the deposition substrate are different. The injection moulding device provided by the invention has the advantages: the operating stability and the moulding quality of the whole system are improved, and the requirement on the bonding strength of the deposition substrate and a cylinder blank is lower, thus ingot blanks in a larger scale can be conveniently manufactured; the two atomizing nozzles are adopted, and thus a large-diameter ingot blank product can be formed; waste of material and exhaust pollution can be reduced; and optimal moulding technological conditions can be conveniently formed.

Owner:JIANGSU HAORAN SPRAY FORMING ALLOY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com