Surface quality control device for three-dimensional (3D) part formed through metal drop printing and control method of surface quality control device

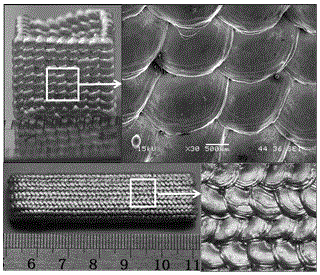

A technology of surface quality and control device, applied in the direction of additive processing, can solve the problems of difficult to meet the technical requirements of parts use, large surface roughness, etc., to reduce interlayer defects and step effects, improve forming quality, reduce fish scales The effect of topography

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1. Tin alloy droplet printing forming part test

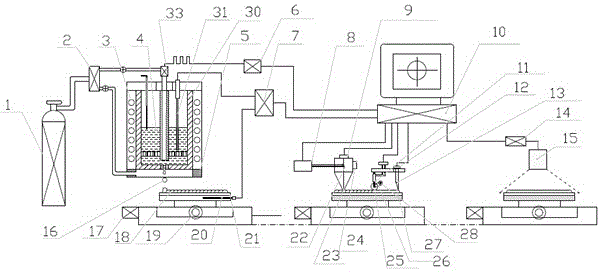

[0022] (1) According to the material properties of the tin alloy droplet, the diameter of the selected deposited droplet is: 200 microns, the thickness of the deposited layer is 150 microns, the selected laser power is 1.5KW, the spot size is 250 microns, and the scanning speed is 5m / s;

[0023] (2) According to the layered data information of the parts, the computer sets the appropriate temperature of the deposition substrate as: 150°C, the injection frequency of metal droplets is 5Hz, the speed of the moving platform is 1mm / s, and deposits a single layer point by point according to the scanning deposition path. level;

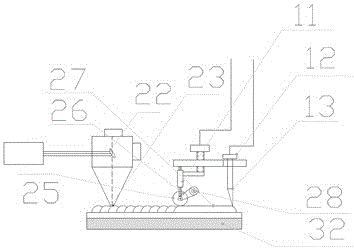

[0024] (3) Move the deposited single layer to the laser cladding area, turn on the laser and set the laser power to 1.5KW and the spot size to 250 microns, and set the appropriate roller cladding depth to 50 microns through the roller height adjuster and a pressure of 0.2MP;

[0025] (4)...

Embodiment 2

[0030] Example 2. Test of Aluminum Alloy Droplet Printing and Forming Parts

[0031] (1) According to the material characteristics of the aluminum alloy droplet, the diameter of the selected deposited droplet is: 300 microns, the thickness of the deposited layer is 250 microns, the selected laser power is 3KW, the spot size is 350 microns, and the scanning speed is 5m / s;

[0032](2) According to the layered data information of the parts, the computer sets the appropriate deposition substrate temperature as: 550°C, the injection frequency of metal droplets is 10Hz, and the speed of the moving platform is 3mm / s, and deposits a single point by point according to the scanning deposition path. level;

[0033] (3) Move the deposited single layer to the laser cladding area, turn on the laser and set the laser power to 3KW and the spot size to 350 microns, and set the appropriate roller cladding depth to 50 microns and The pressure is 0.5MP;

[0034] (4) Control the vibrating mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com