Patents

Literature

149 results about "Droplet deposition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

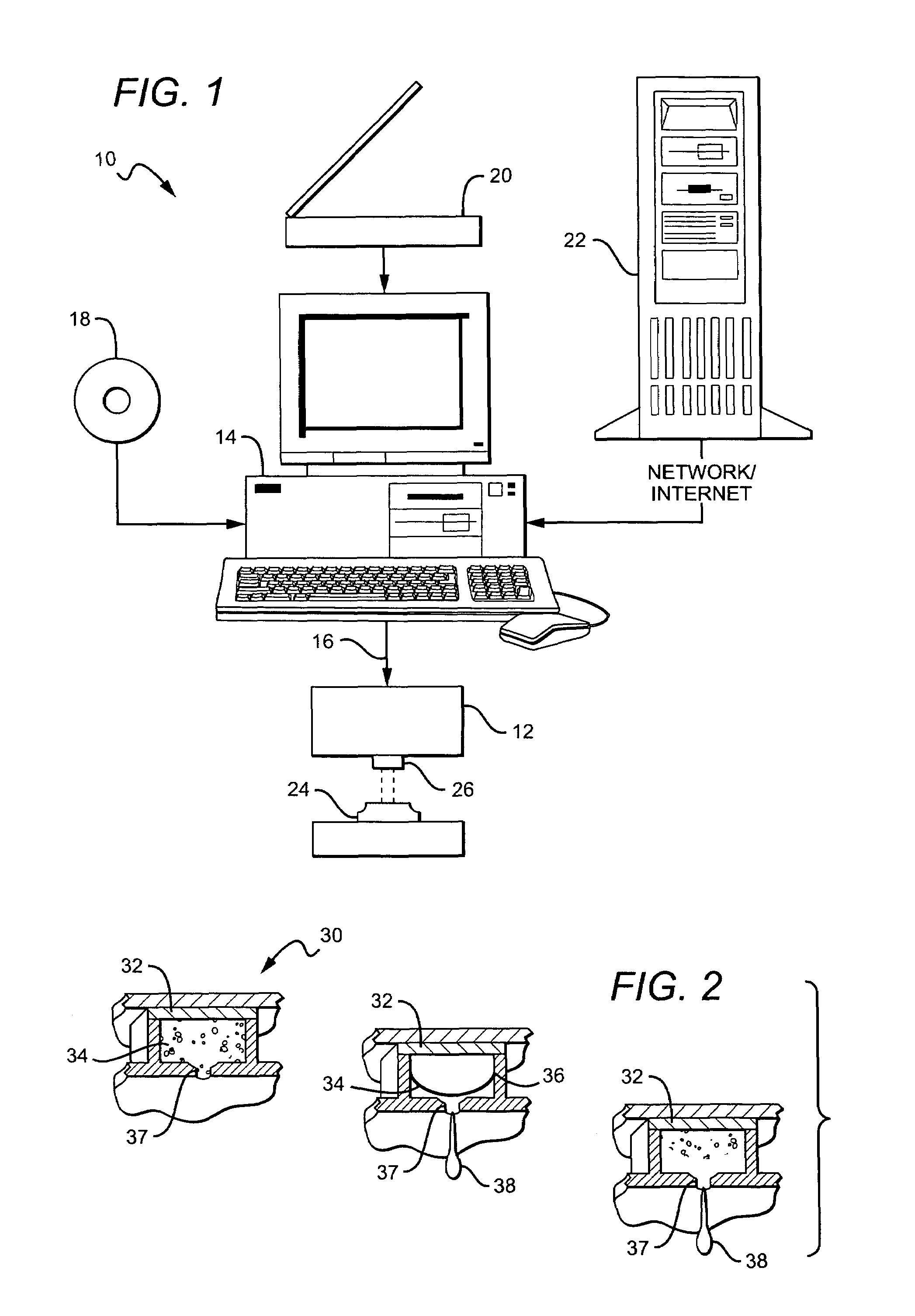

Droplet deposition method for rapid formation of 3-D objects from non-cross-linking reactive polymers

InactiveUS20020111707A13D object support structuresSpecial data processing applicationsThermoplasticControl signal

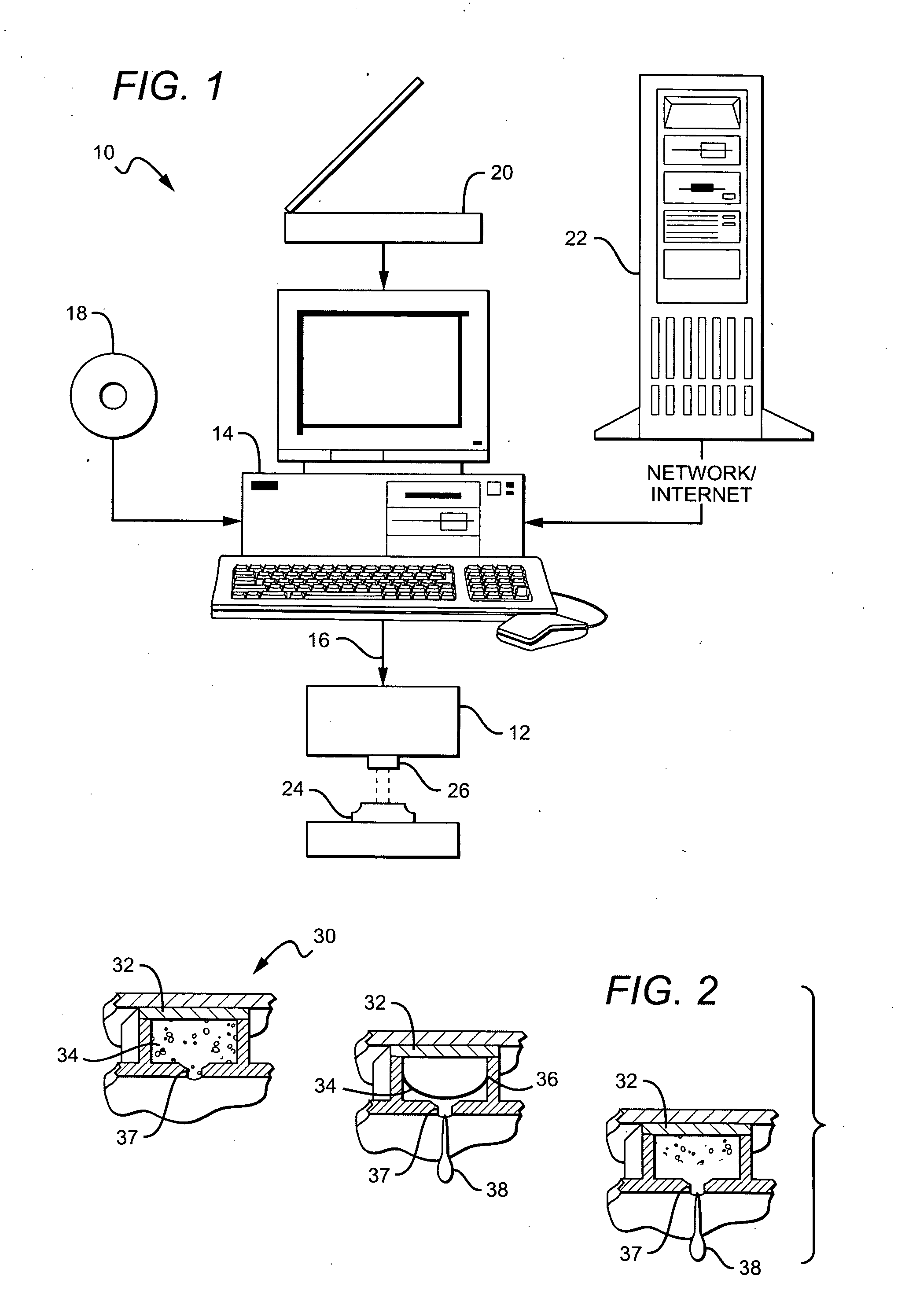

A droplet deposition-based freeform fabrication method for making a three-dimensional object from a design created on a computer, including (a) providing a support member; (b) operating a droplet dispensing head for dispensing droplets of a material composition in a fluent state at a first temperature onto the support member, the material composition including a reactive prepolymer with a melting point above 23° C. and the first temperature being greater than the prepolymer melting point; (c) operating material treatment devices for causing the material composition to rapidly achieve a rigid state in which the material composition is substantially solidified to build up the 3-D object, the material treatment devices also working to convert the reactive prepolymer to a higher molecular weight thermoplastic resin; and (d) operating control devices for generating control signals in response to coordinates of the object design to control the movement of the dispensing head relative to the support member and for controlling the droplet dispensing of the material composition to construct the 3-D object.

Owner:LI ZHIMIN +3

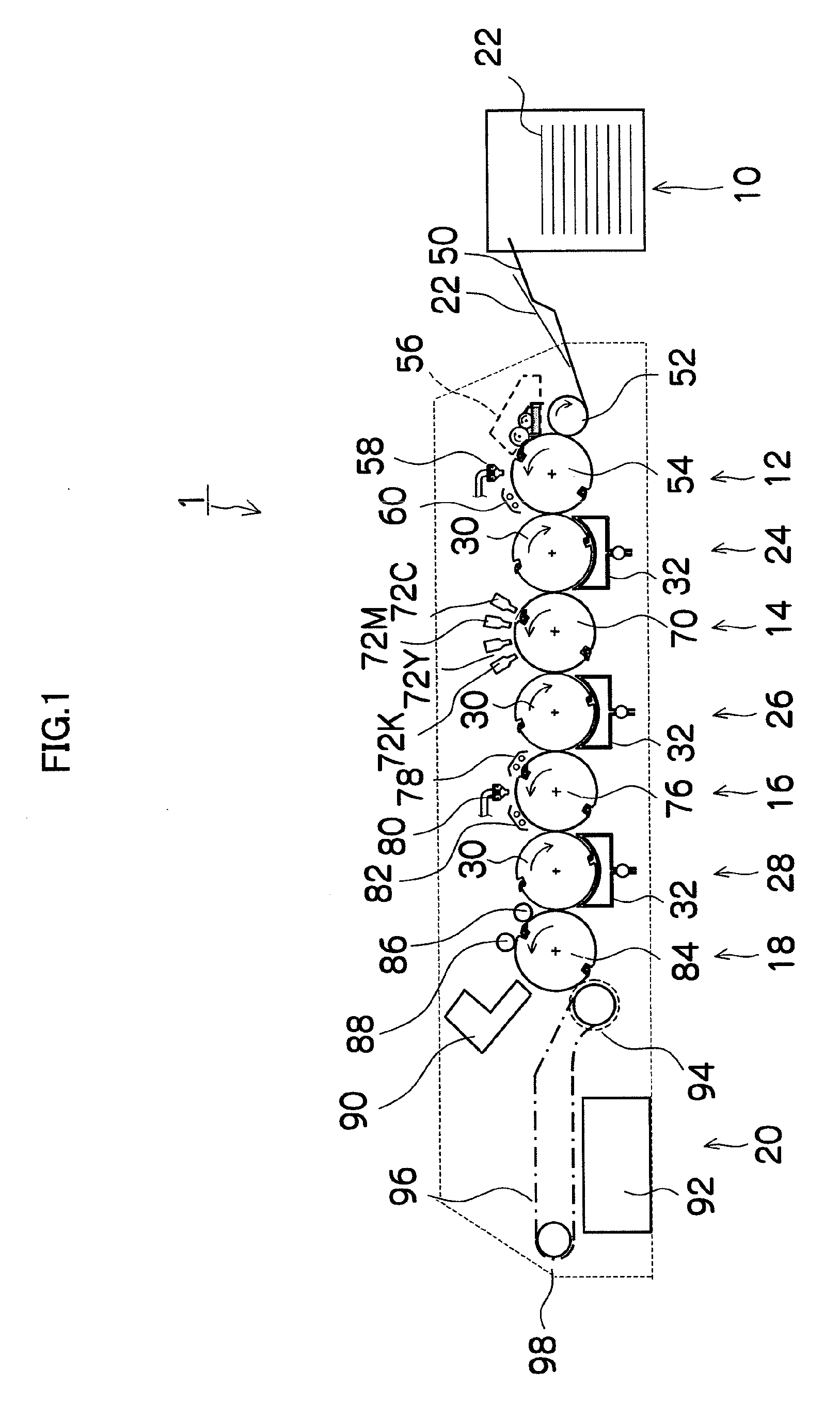

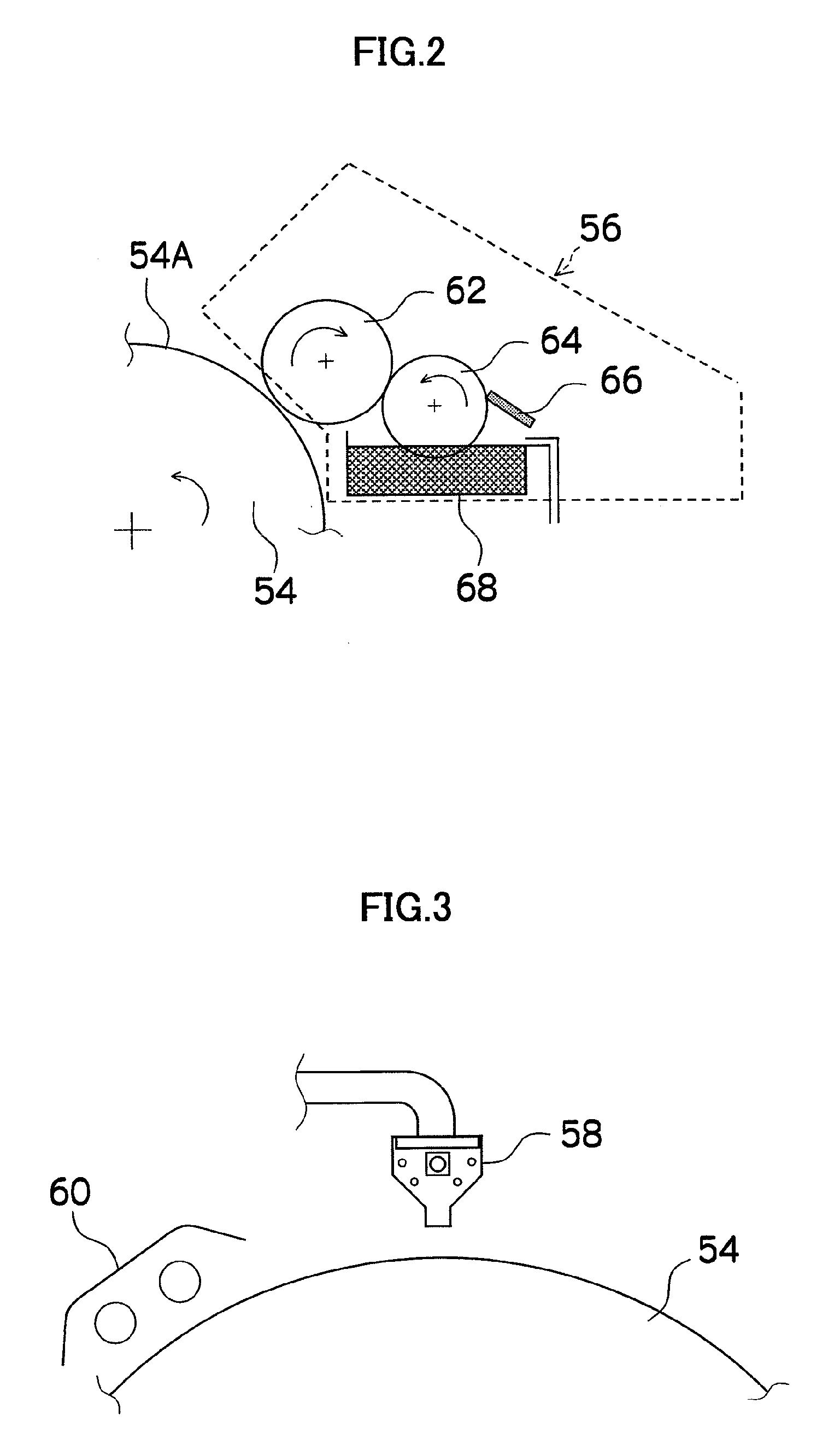

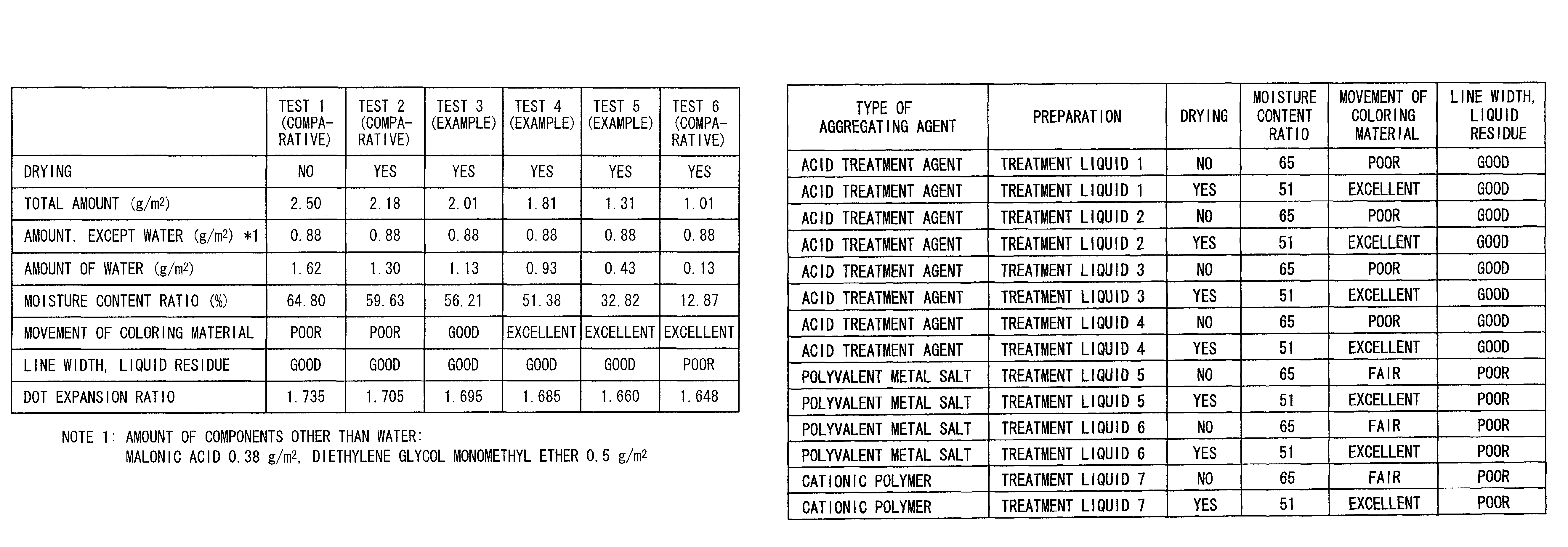

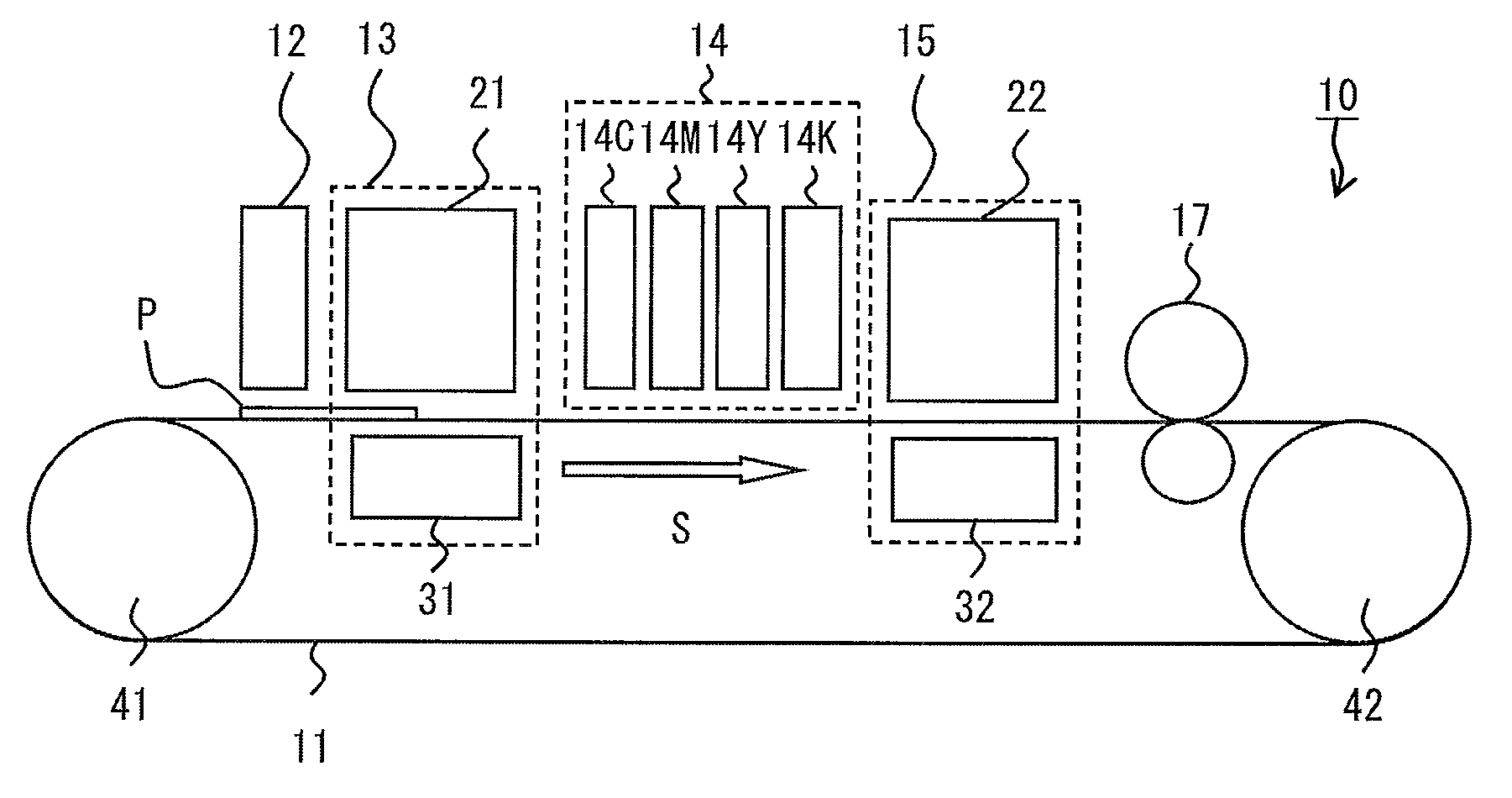

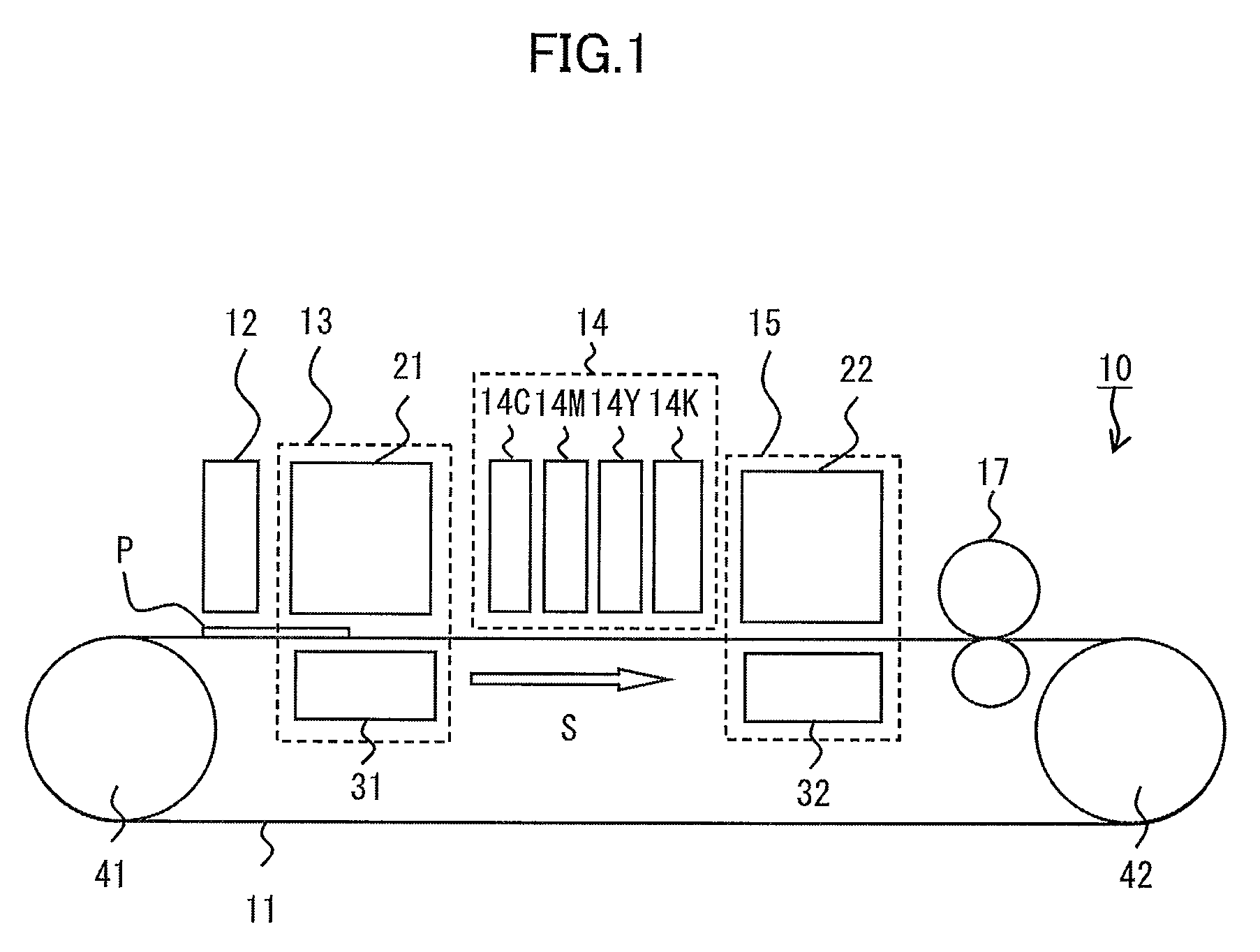

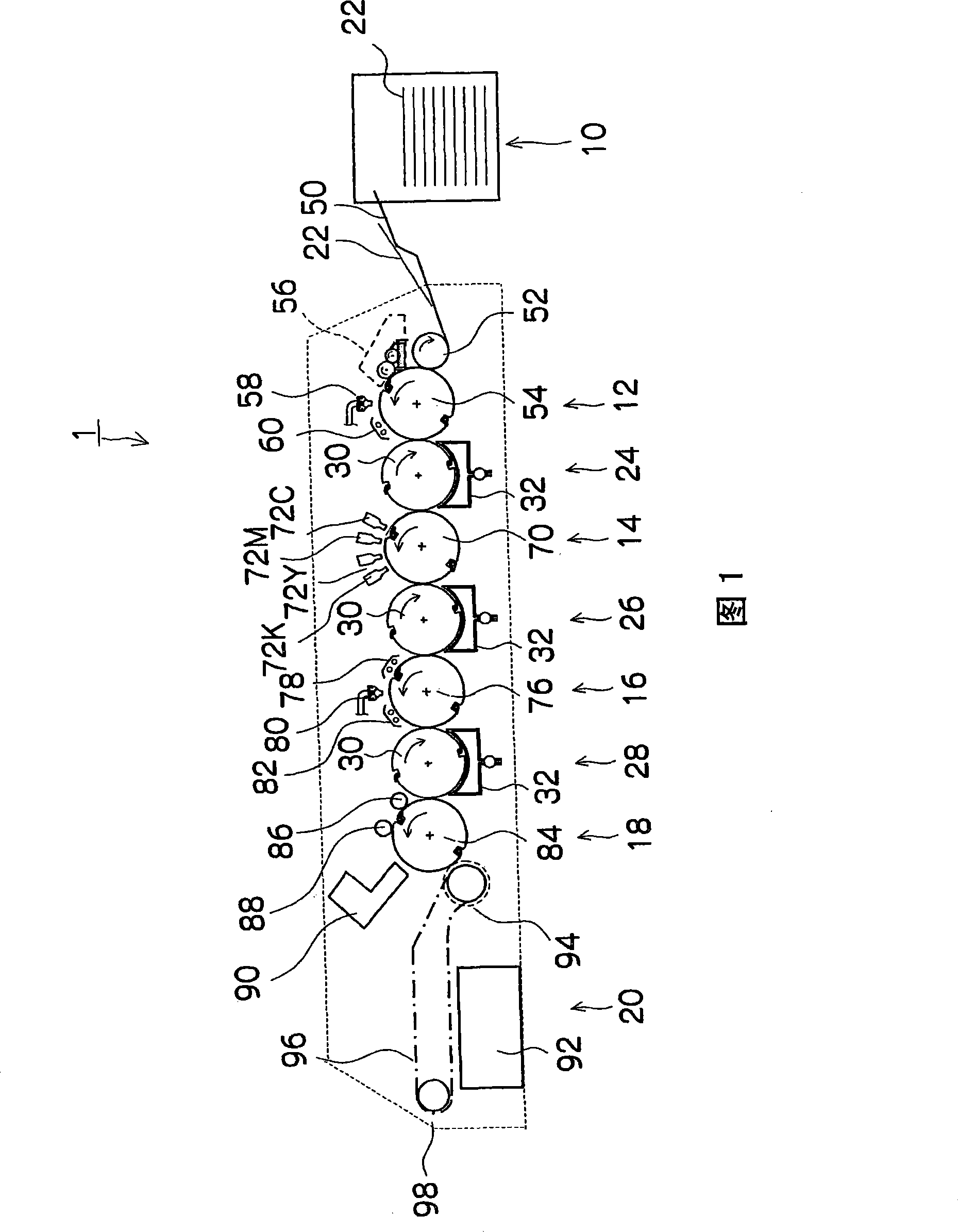

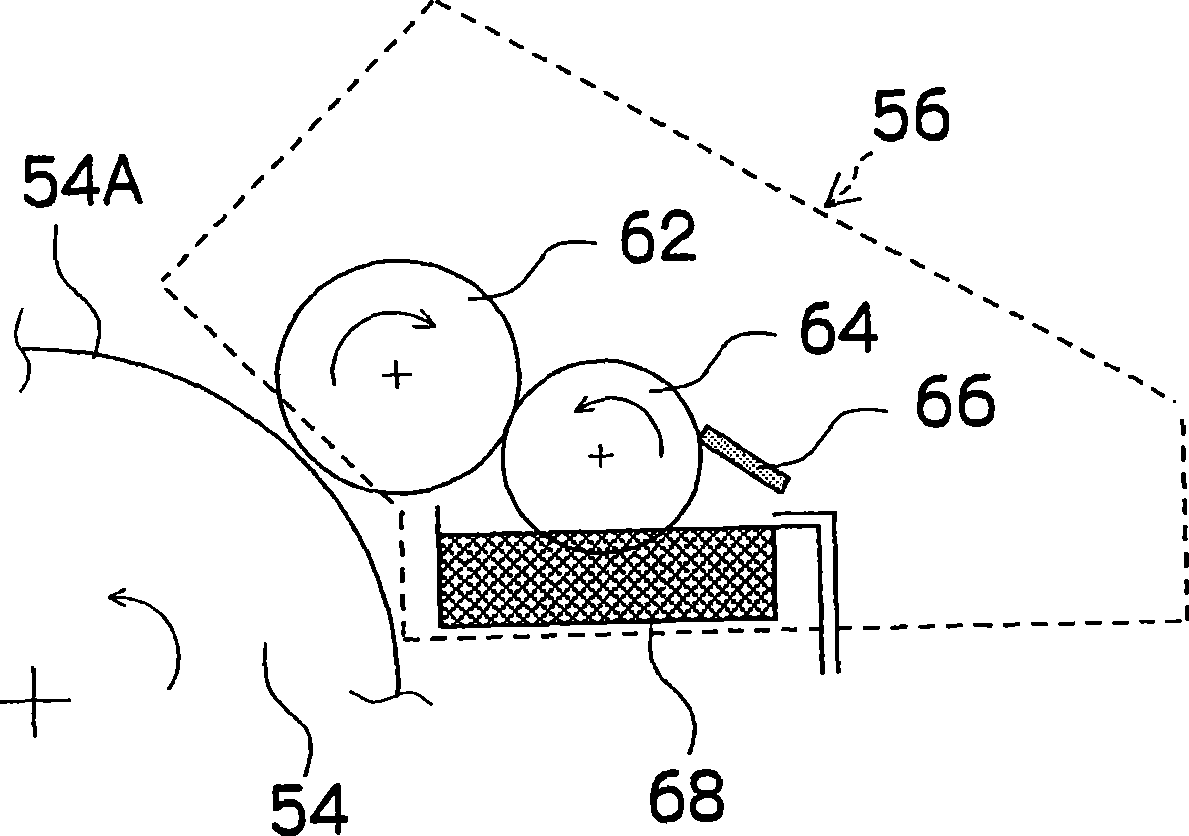

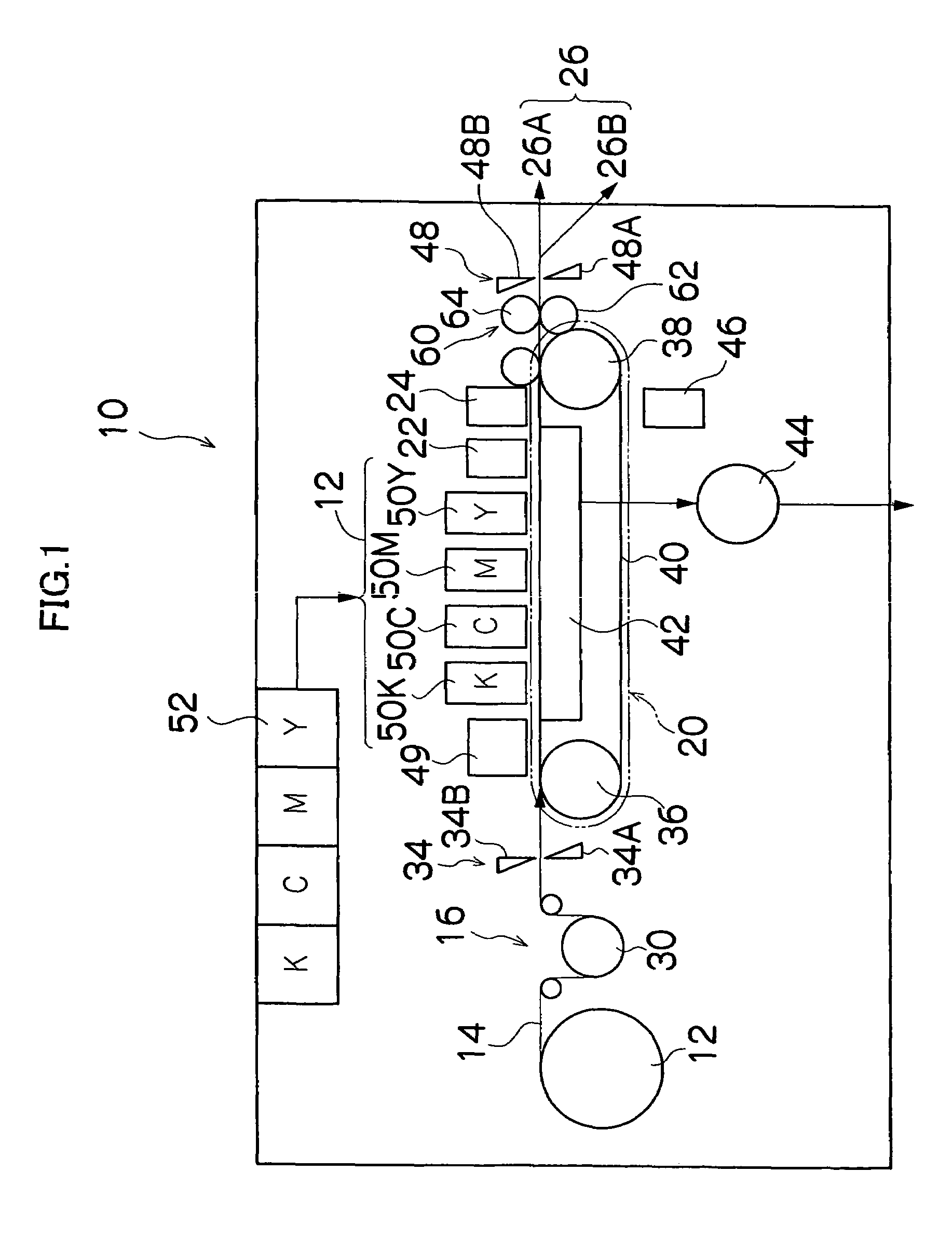

Image forming method and apparatus

ActiveUS20090079784A1High-quality image formationReduce image sizeInking apparatusDuplicating/marking methodsImage formationEngineering

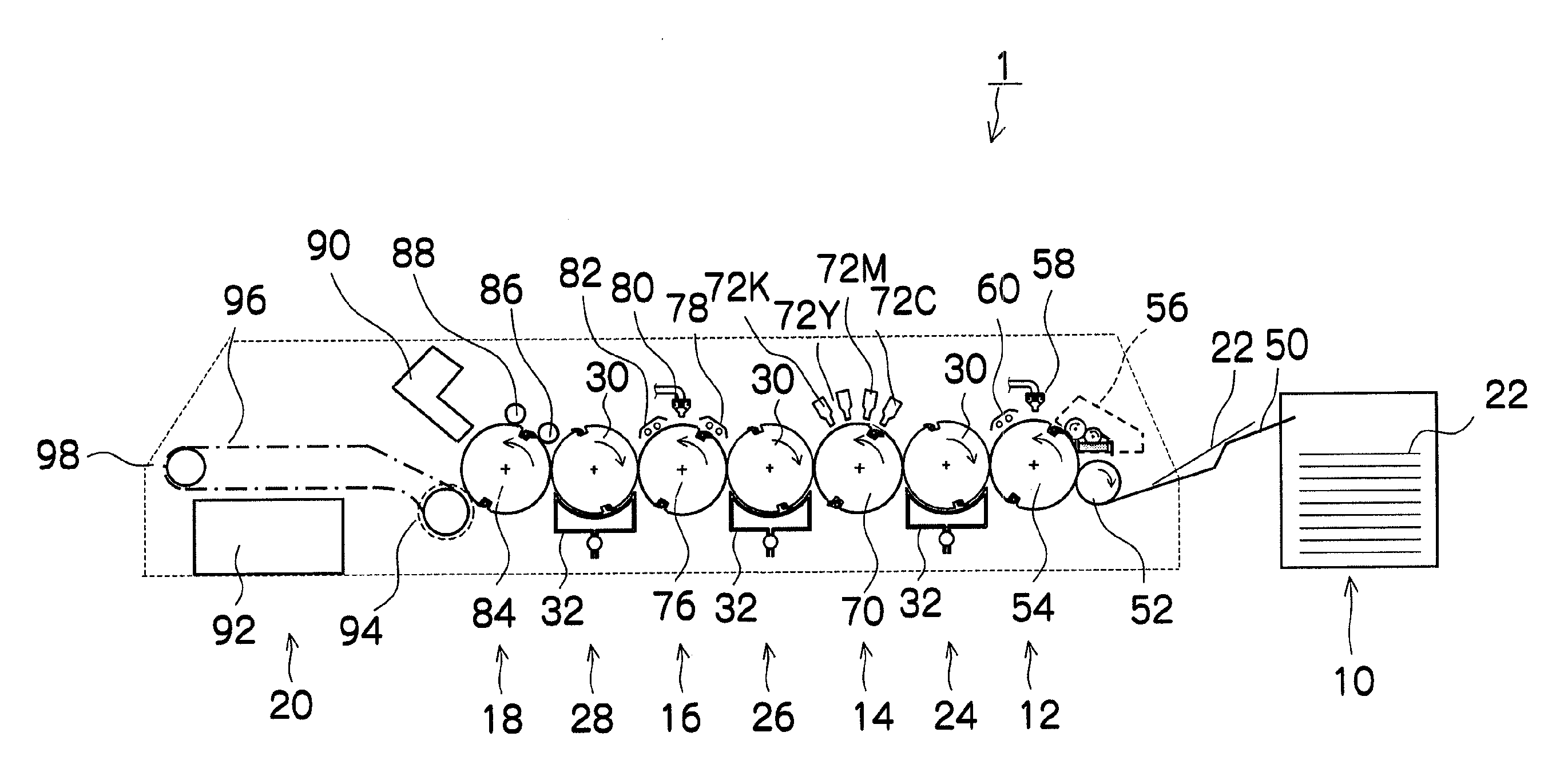

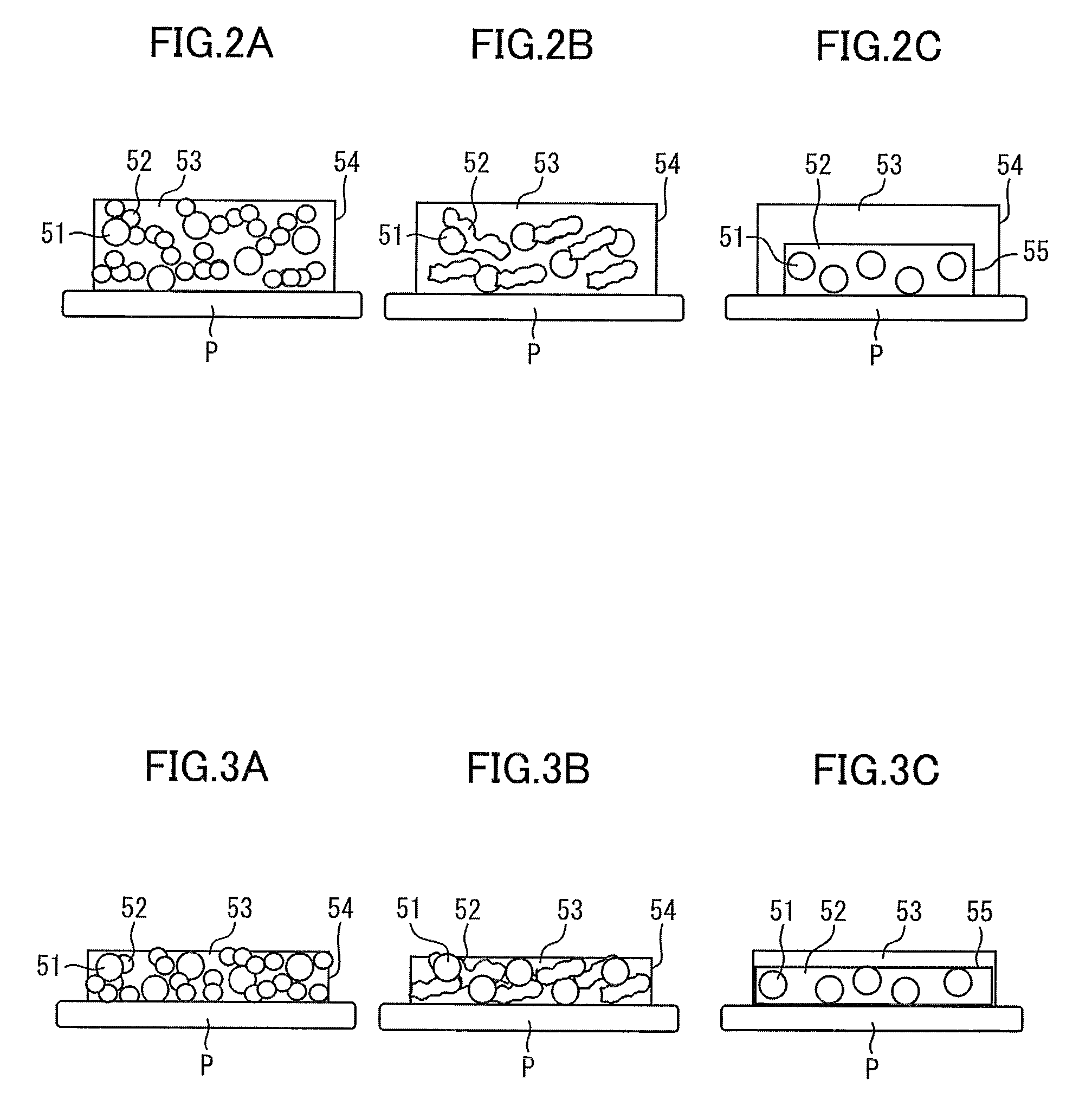

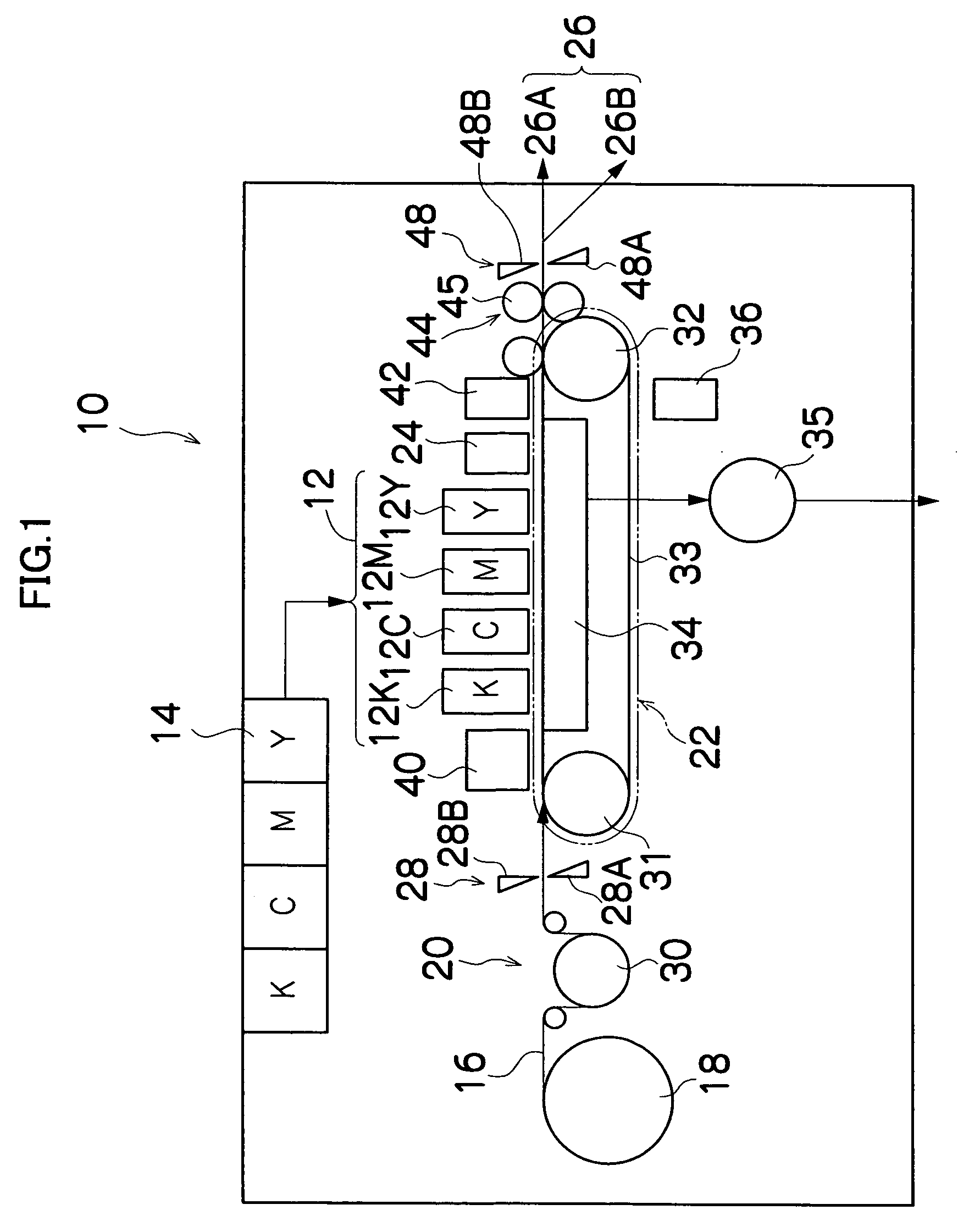

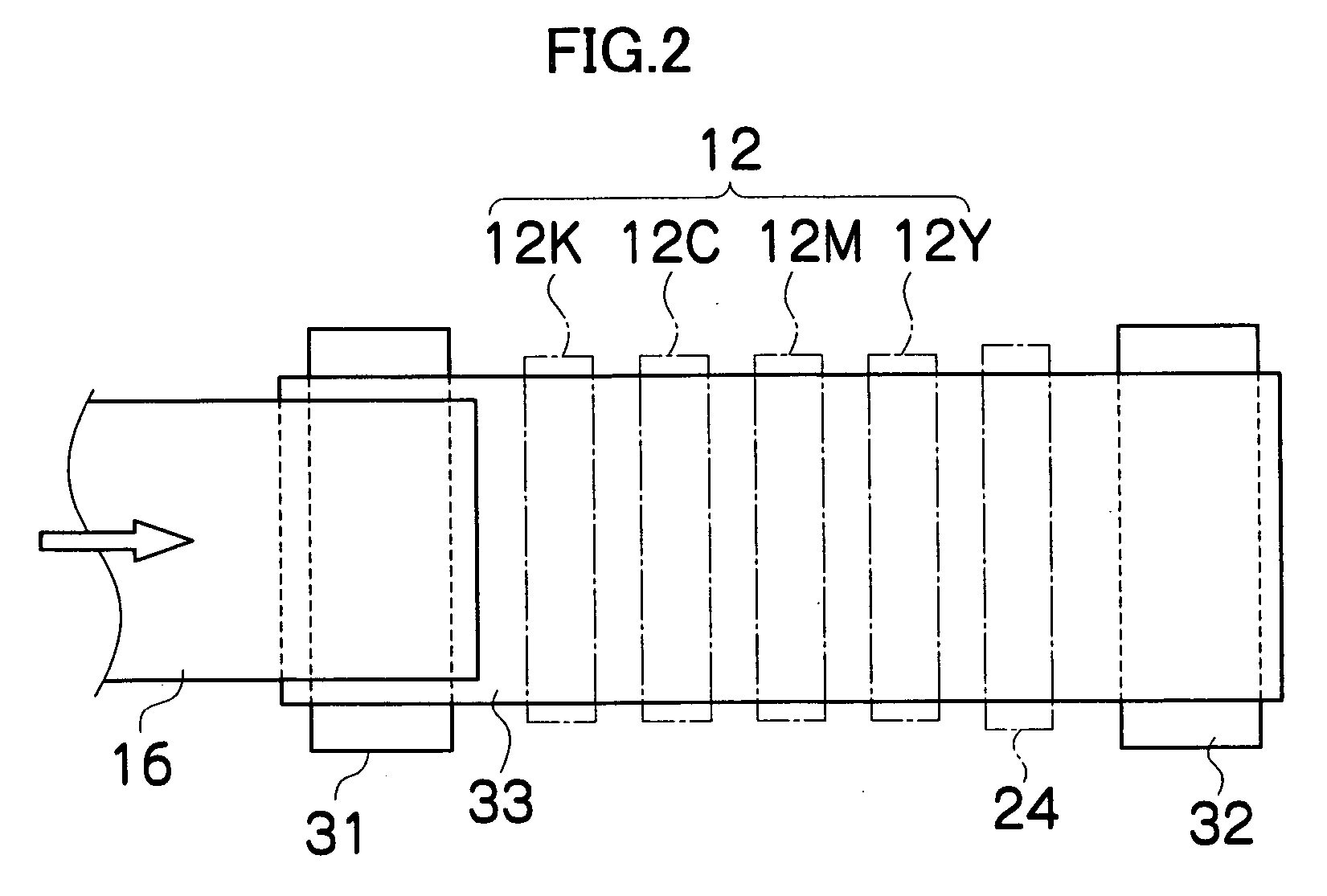

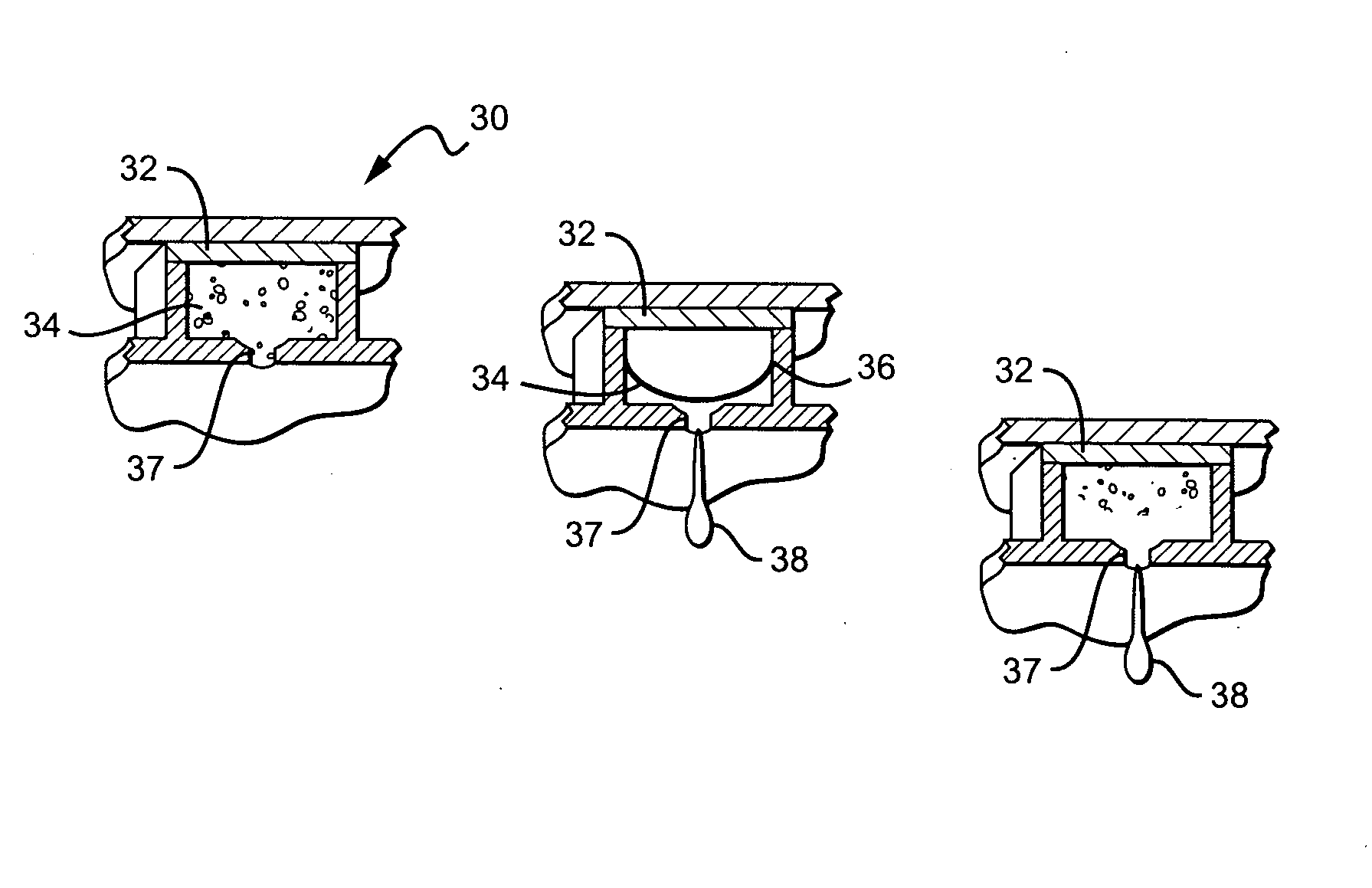

The image forming method is for forming an image on an image formation body by using an ink liquid including a coloring material and an aggregation treatment agent including a component that causes the coloring material to aggregate. The image forming method includes: an aggregation treatment layer formation step of forming, on the image formation body, a semisolid aggregation treatment layer that includes the aggregation treatment agent and has a moisture content ratio not more than 56%; an ink droplet deposition step of ejecting droplets of the ink liquid and depositing the droplets of the ink liquid onto the image formation body where the aggregation treatment layer has been formed; and a solvent removal step of removing a liquid solvent present on the image formation body after the ink droplet deposition step.

Owner:FUJIFILM CORP

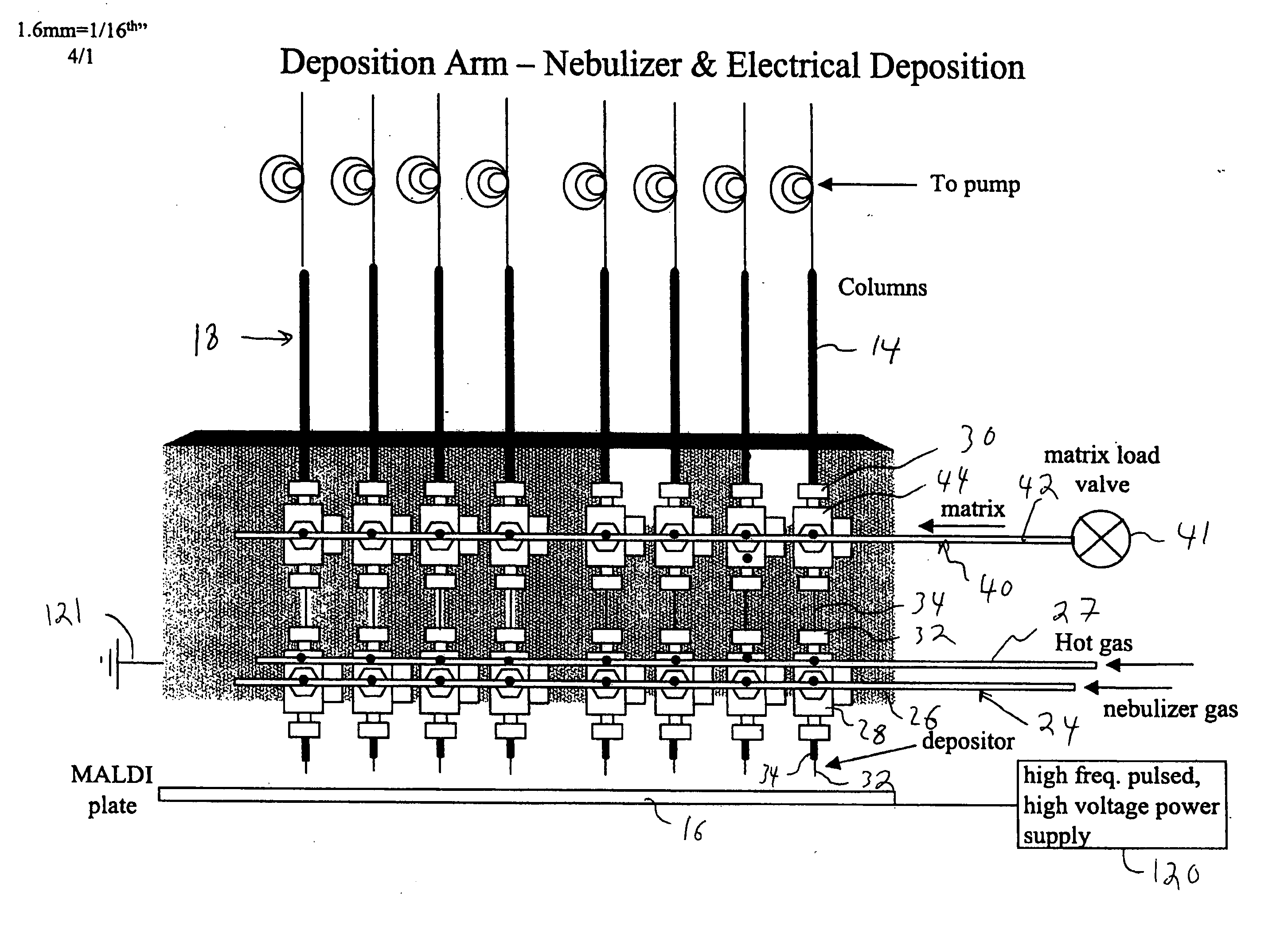

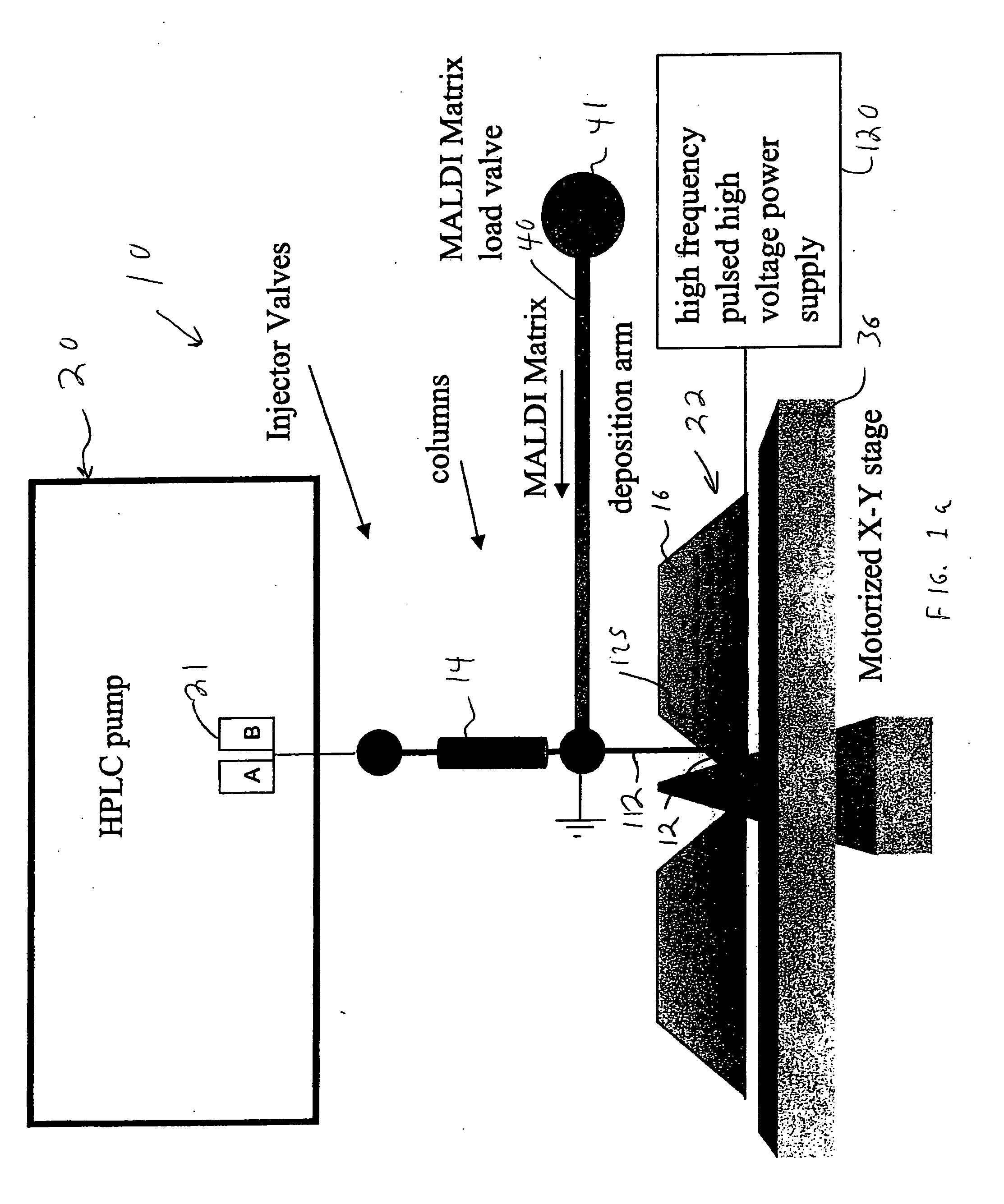

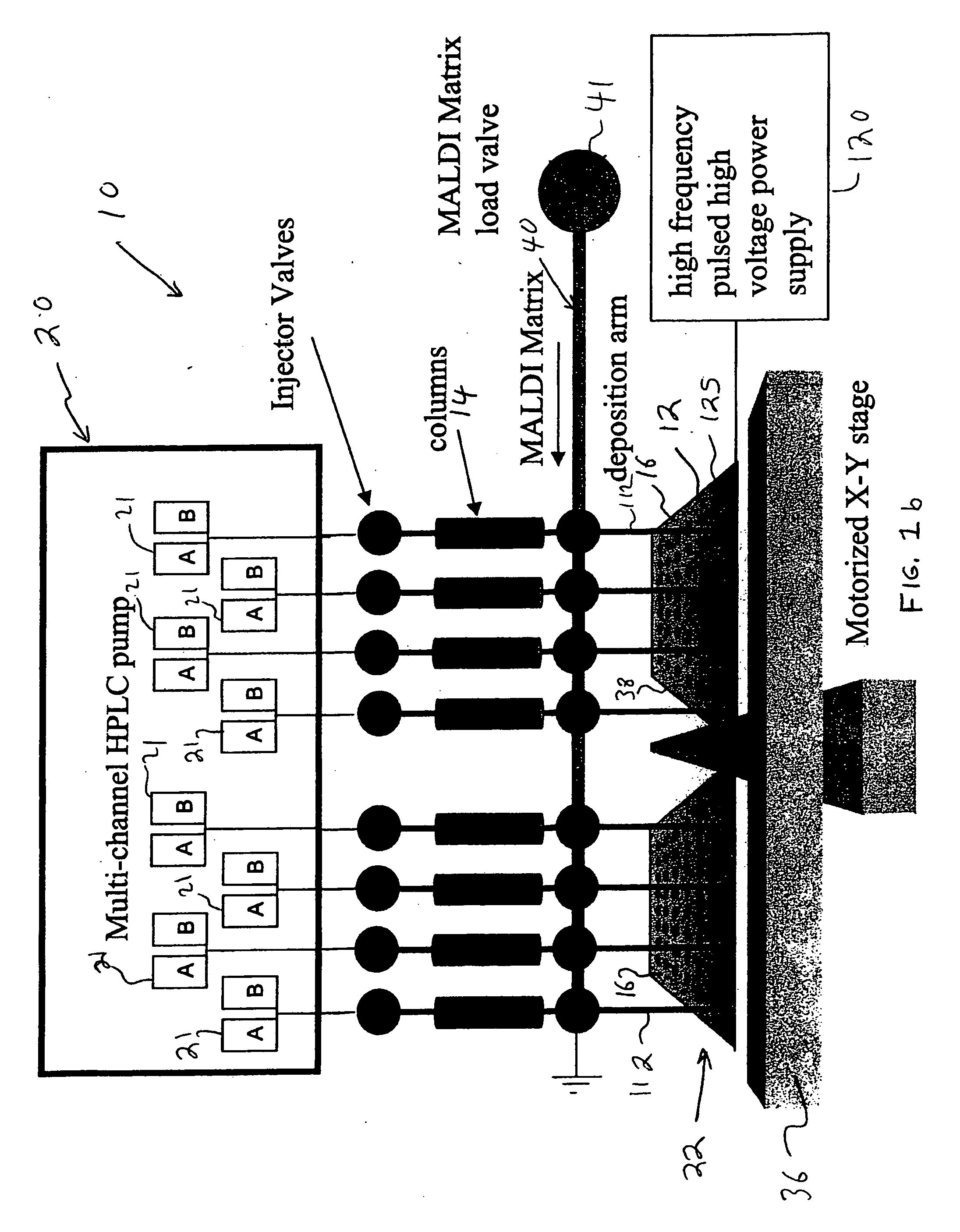

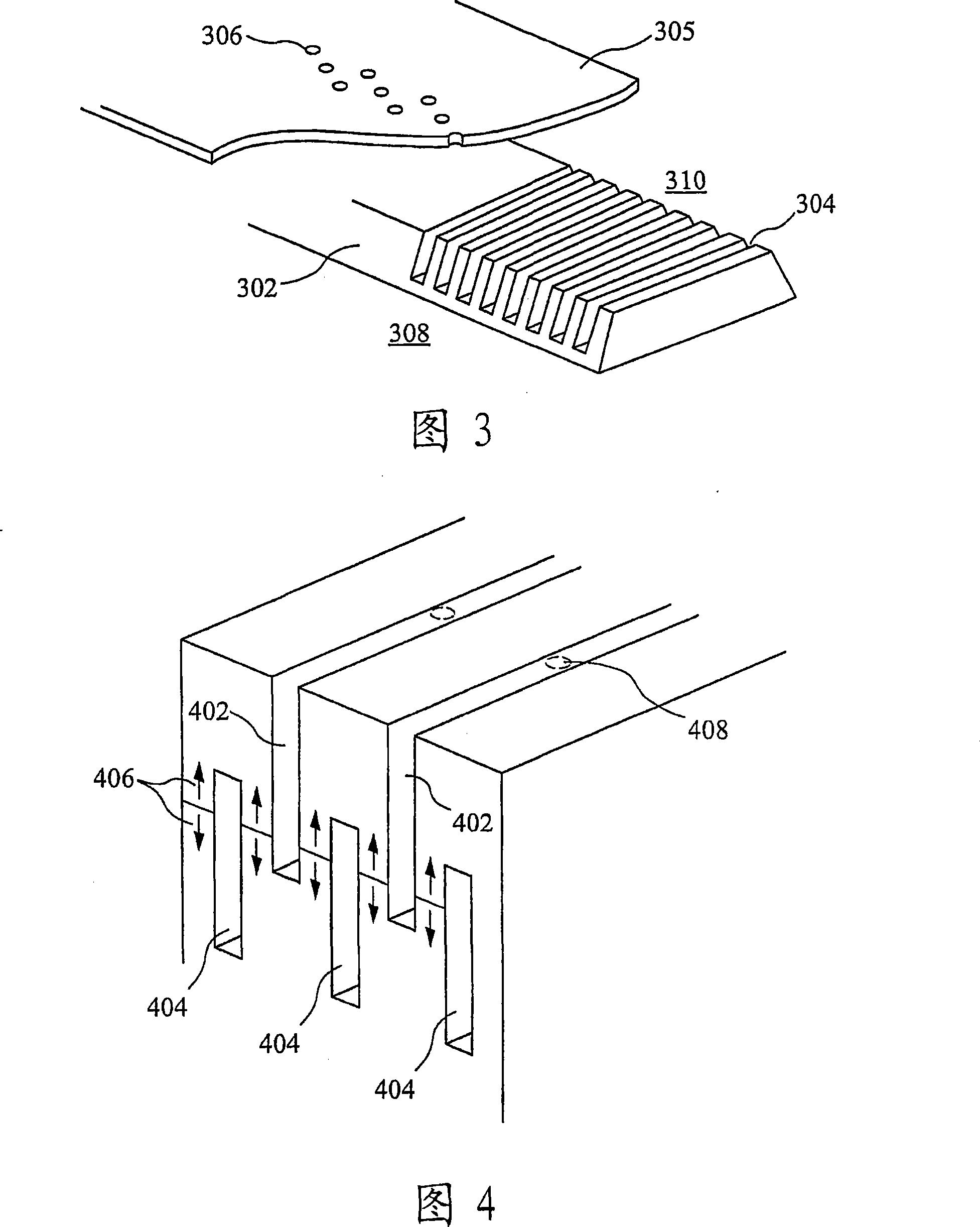

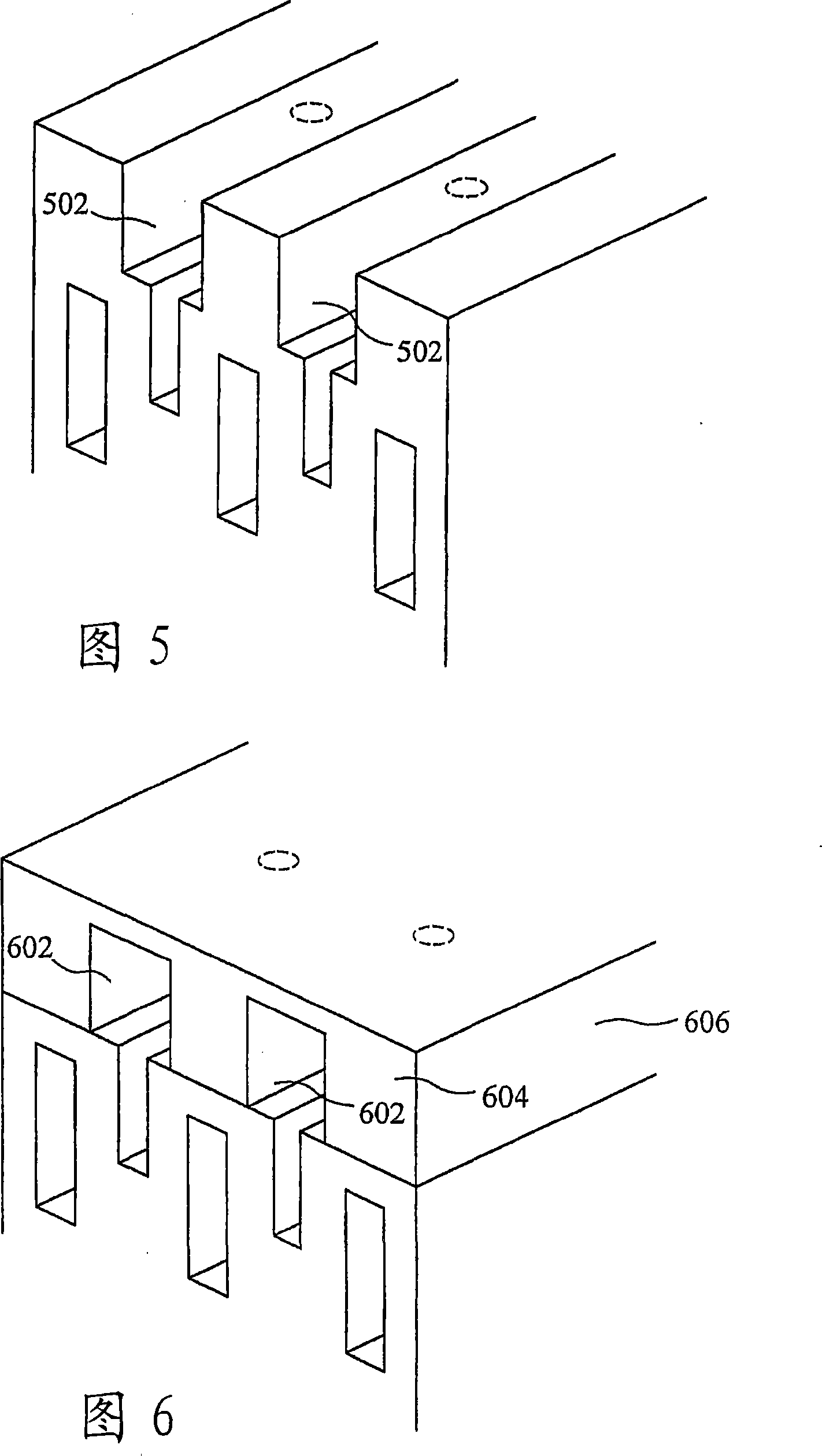

Method and apparatus for sample deposition

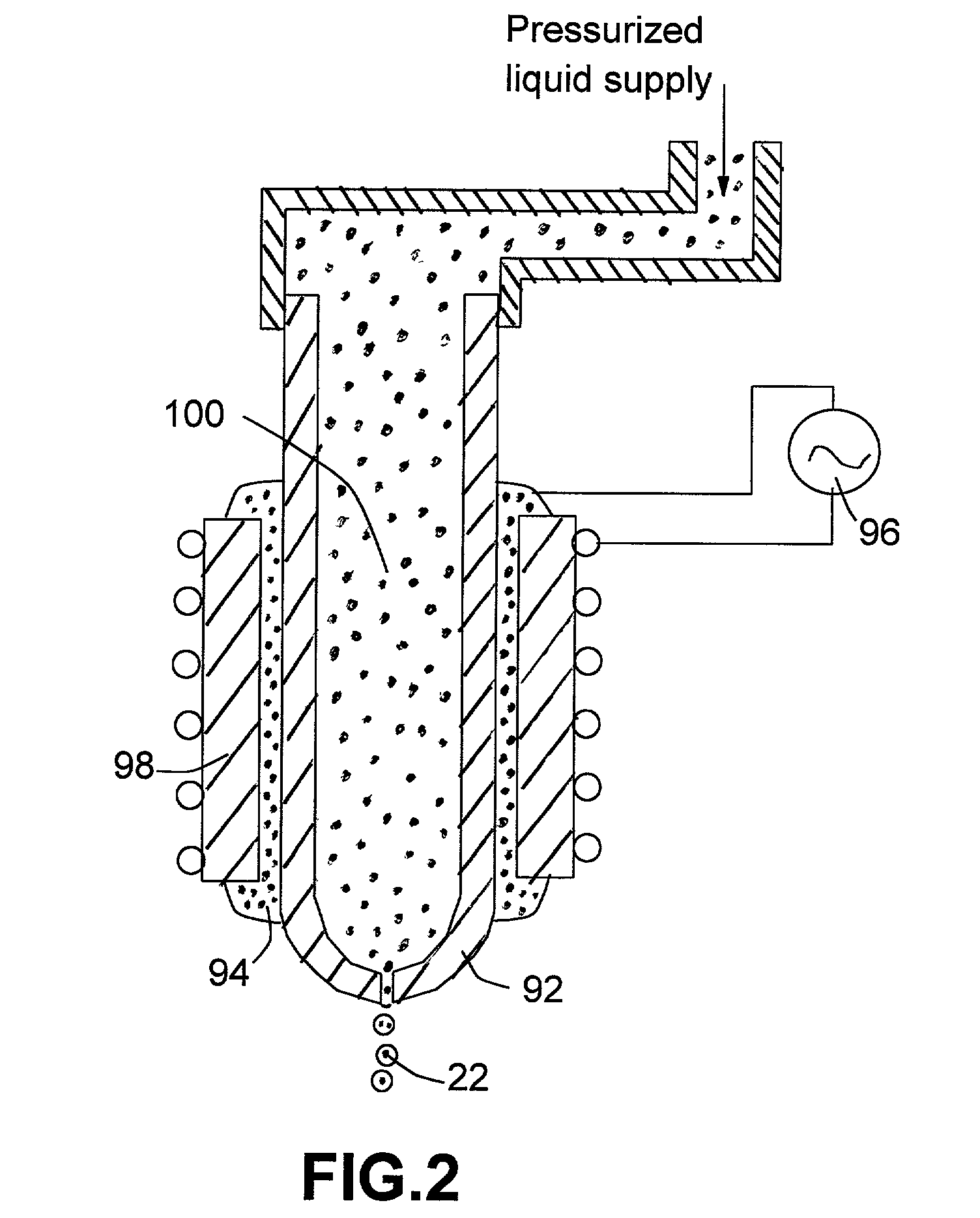

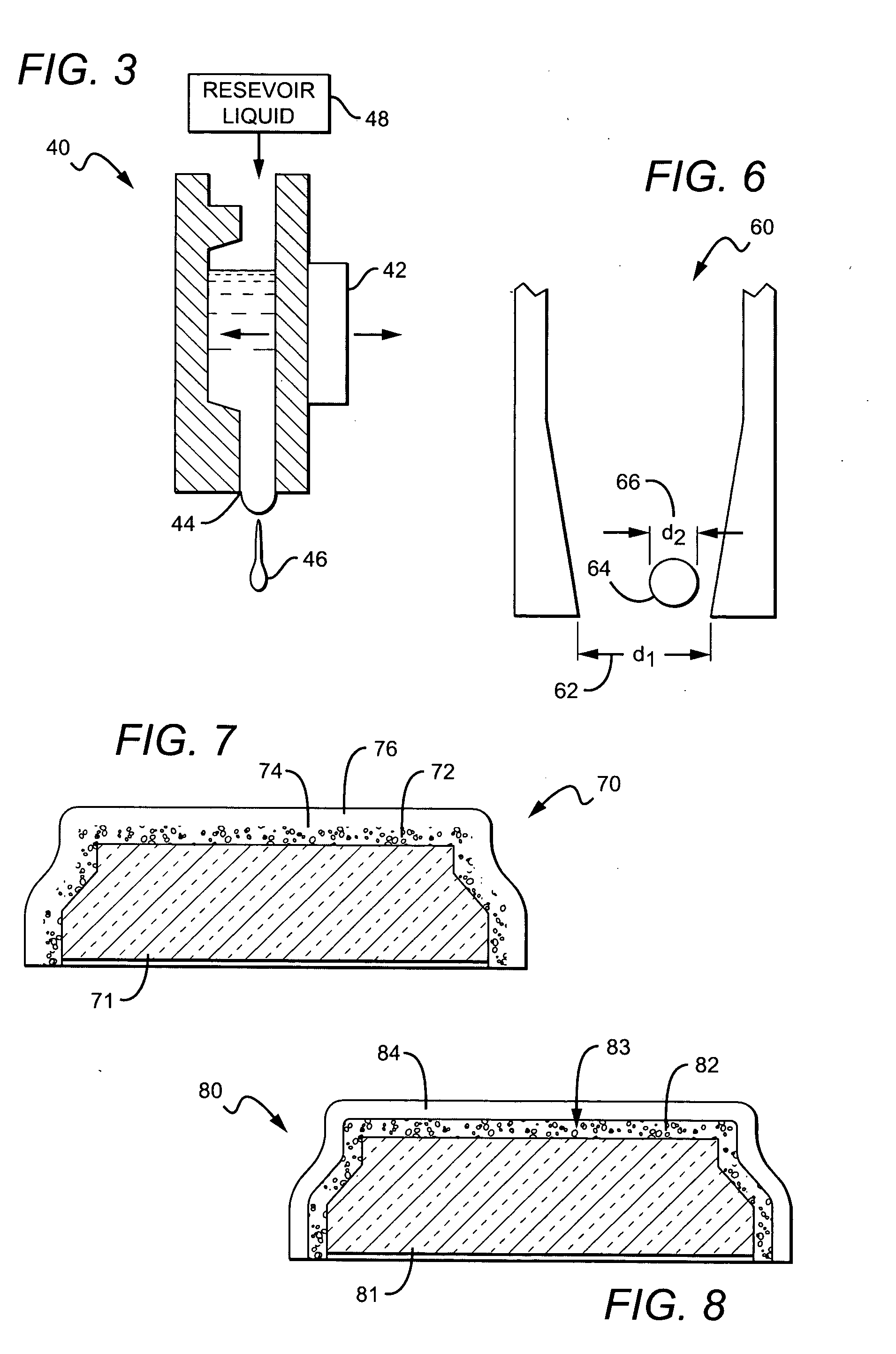

A method and apparatus is disclosed to prepare a sample or a plurality of samples for subsequent analysis. A single sample deposition apparatus, and a multiplexed sample deposition apparatus are shown. The apparatus allows for a system that can provide a high throughput deposition of samples to form chromatograms by discrete droplet deposition or as continuous traces. The system can achieve high resolution digitization by pulsing the fluid emanating from the chromatographs by applying a voltage to the target plate that operates at frequencies equal to or greater than about 10 Hz, and up to and including about 1 KHz. The system also allows for analogue recording (i.e., approaching infinite resolution) by nebulizing the fluid coming from multiple columns and simultaneously collecting it on a target plate as a continuous trace.

Owner:APPLIED BIOSYST CANADA

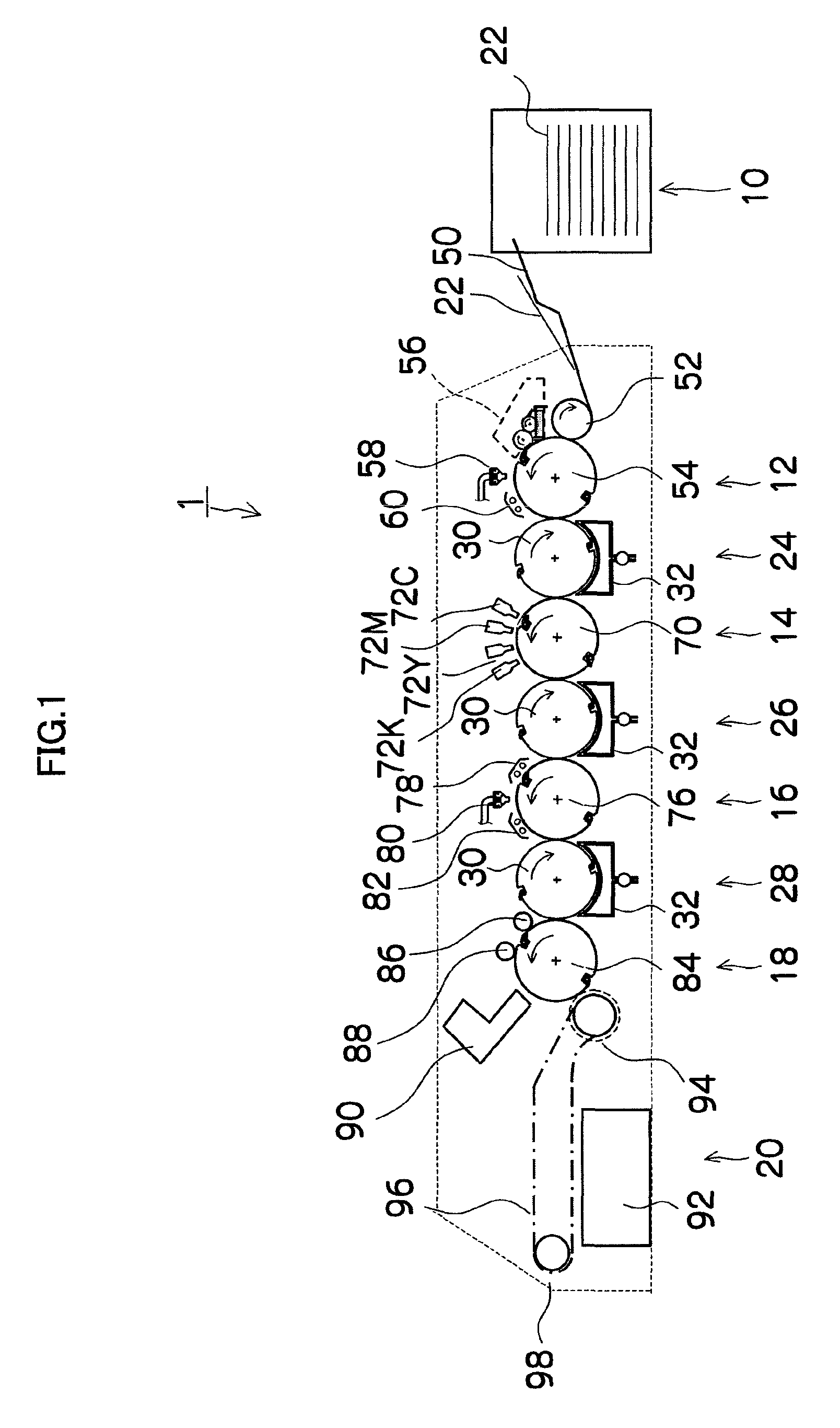

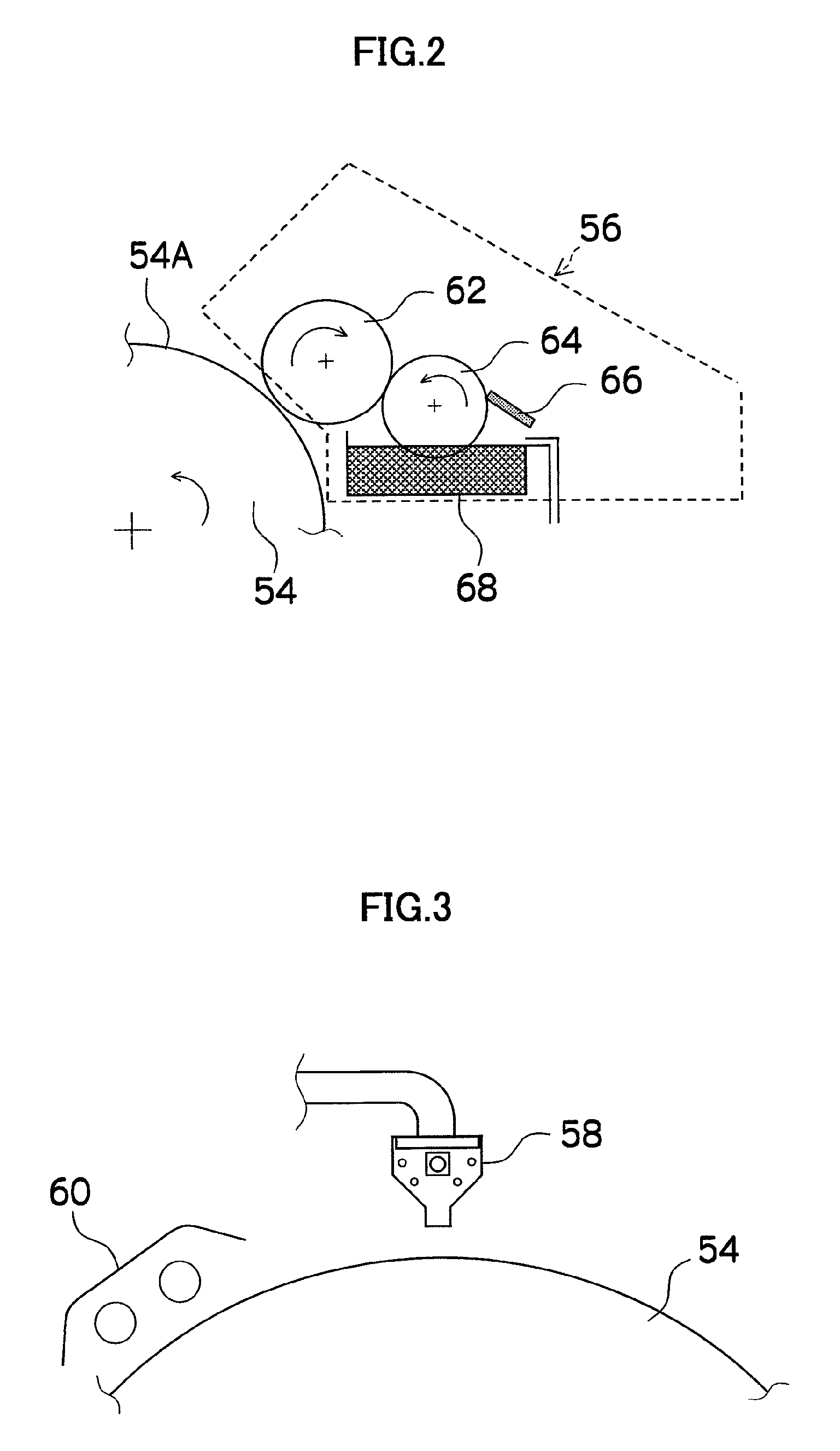

Image forming method and apparatus

ActiveUS8042906B2Inhibit deteriorationAvoid it happening againInking apparatusDuplicating/marking methodsImage formationEngineering

Owner:FUJIFILM CORP

Image forming method and apparatus

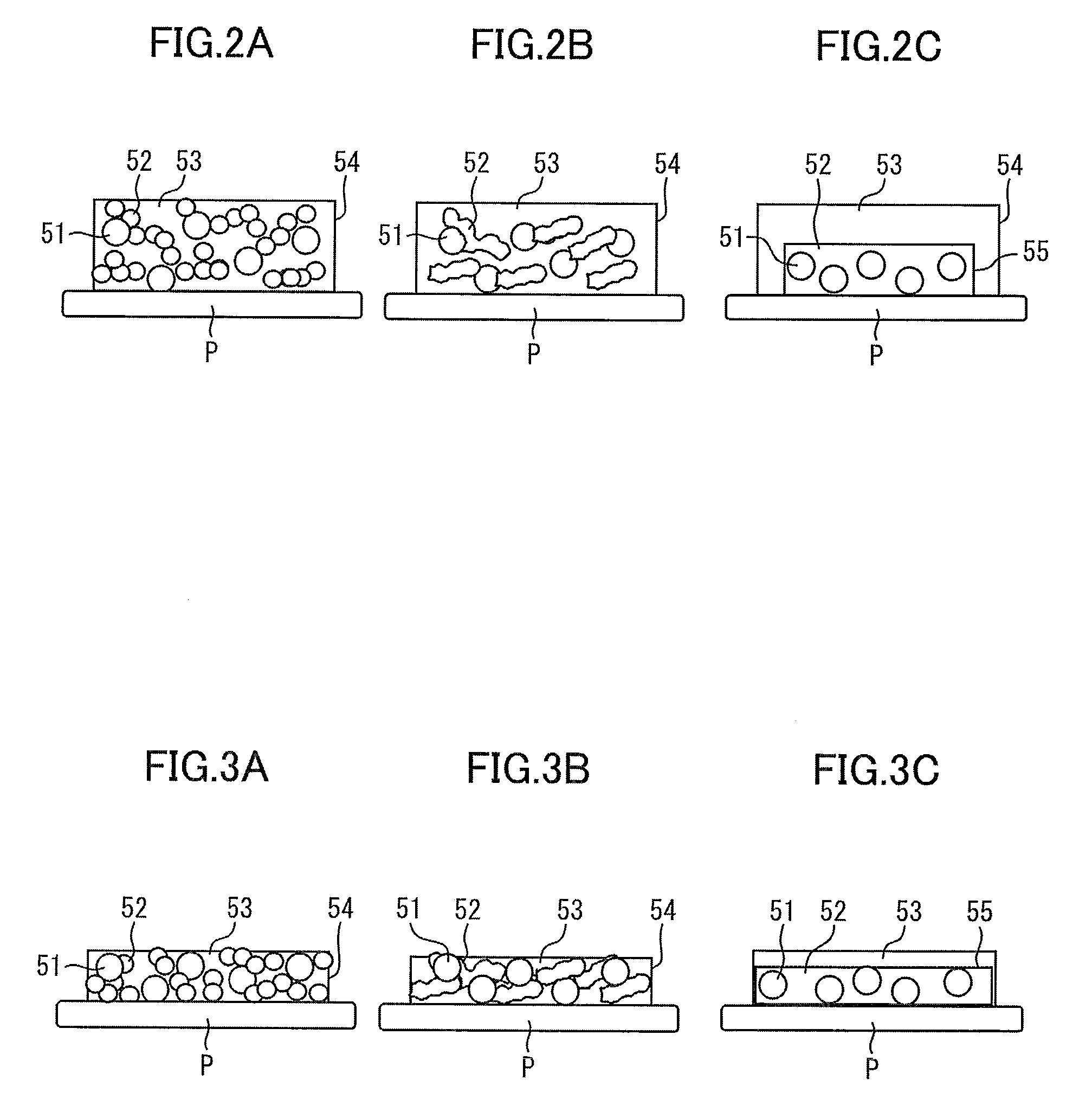

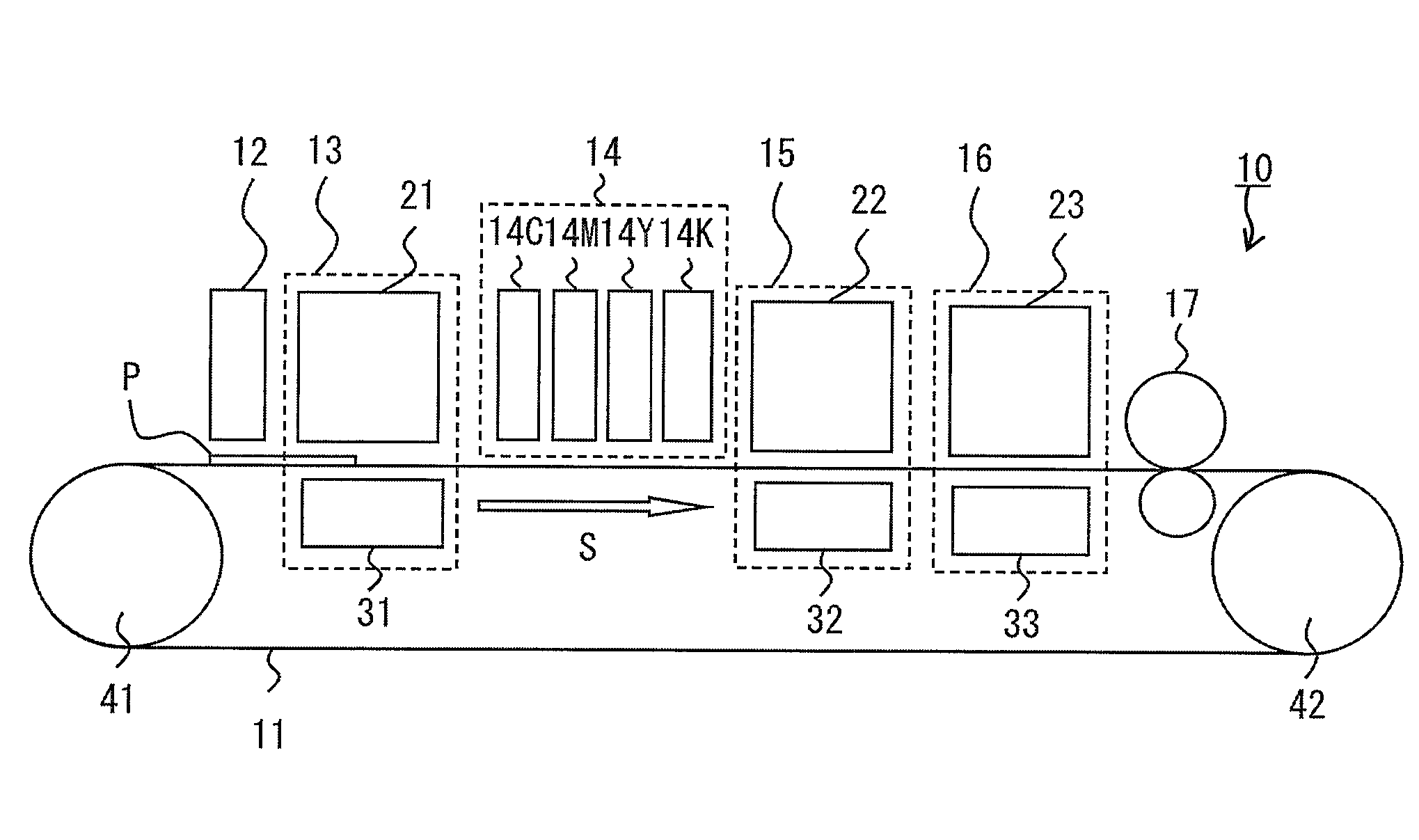

InactiveUS20090244146A1Quality improvementMeasurement apparatus componentsDuplicating/marking methodsSolid massImage formation

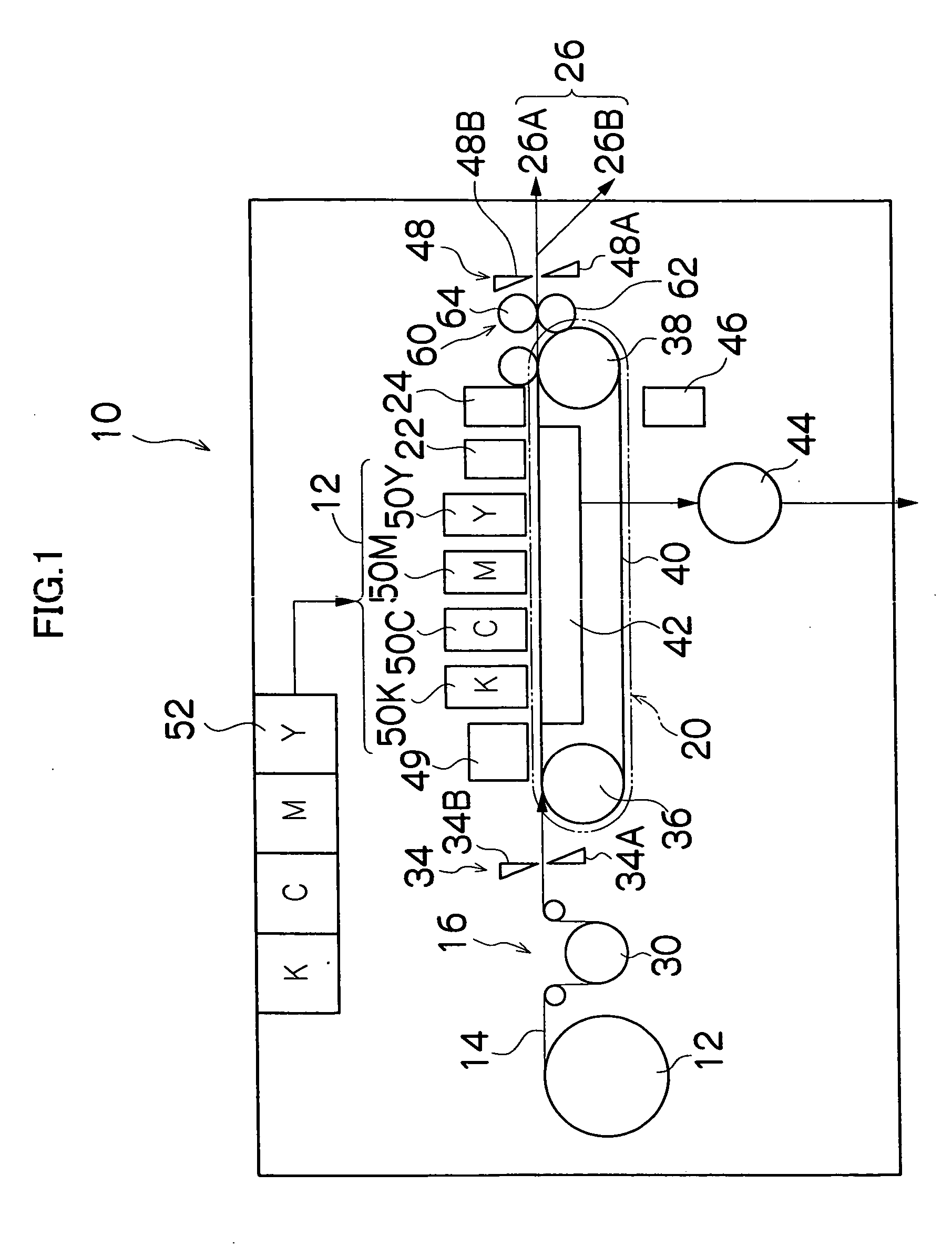

The image forming method forms an image on a medium by using ink and treatment liquid. The ink contains coloring material and thermoplastic resin particles in a solvent, and the treatment liquid contains a component which aggregates the coloring material. The image forming method includes: a treatment liquid deposition step of depositing the treatment liquid onto the medium to form a treatment liquid film on the medium; an ink droplet deposition step of ejecting and depositing droplets of the ink onto the medium to form an ink film on the medium on which the treatment liquid film has been formed; and an ink film drying step of heating and drying the ink film under conditions where T<MFT+20° C. until α declines to a state not higher than 2.0 from a state exceeding 2.0, where T is a surface temperature of the ink film, MFT is a minimum film forming temperature of the thermoplastic resin particles, and a is a solvent content rate of the ink film formed on the medium in the ink droplet deposition step defined as a volume of the solvent per unit surface area in the ink film divided by a volume of solid material per unit surface area in the ink film.

Owner:FUJIFILM CORP

Image forming method and apparatus

InactiveUS8186820B2Quality improvementMeasurement apparatus componentsDuplicating/marking methodsImage formationSolvent

The image forming method forms an image on a medium by using ink and treatment liquid. The ink contains coloring material and thermoplastic resin particles in a solvent, and the treatment liquid contains a component which aggregates the coloring material. The image forming method includes: a treatment liquid deposition step of depositing the treatment liquid onto the medium to form a treatment liquid film on the medium; an ink droplet deposition step of ejecting and depositing droplets of the ink onto the medium to form an ink film on the medium on which the treatment liquid film has been formed; and an ink film drying step of heating and drying the ink film under conditions where T<MFT+20° C. until α declines to a state not higher than 2.0 from a state exceeding 2.0, where T is a surface temperature of the ink film, MFT is a minimum film forming temperature of the thermoplastic resin particles, and α is a solvent content rate of the ink film formed on the medium in the ink droplet deposition step defined as a volume of the solvent per unit surface area in the ink film divided by a volume of solid material per unit surface area in the ink film.

Owner:FUJIFILM CORP

Inkjet recording apparatus and recording method

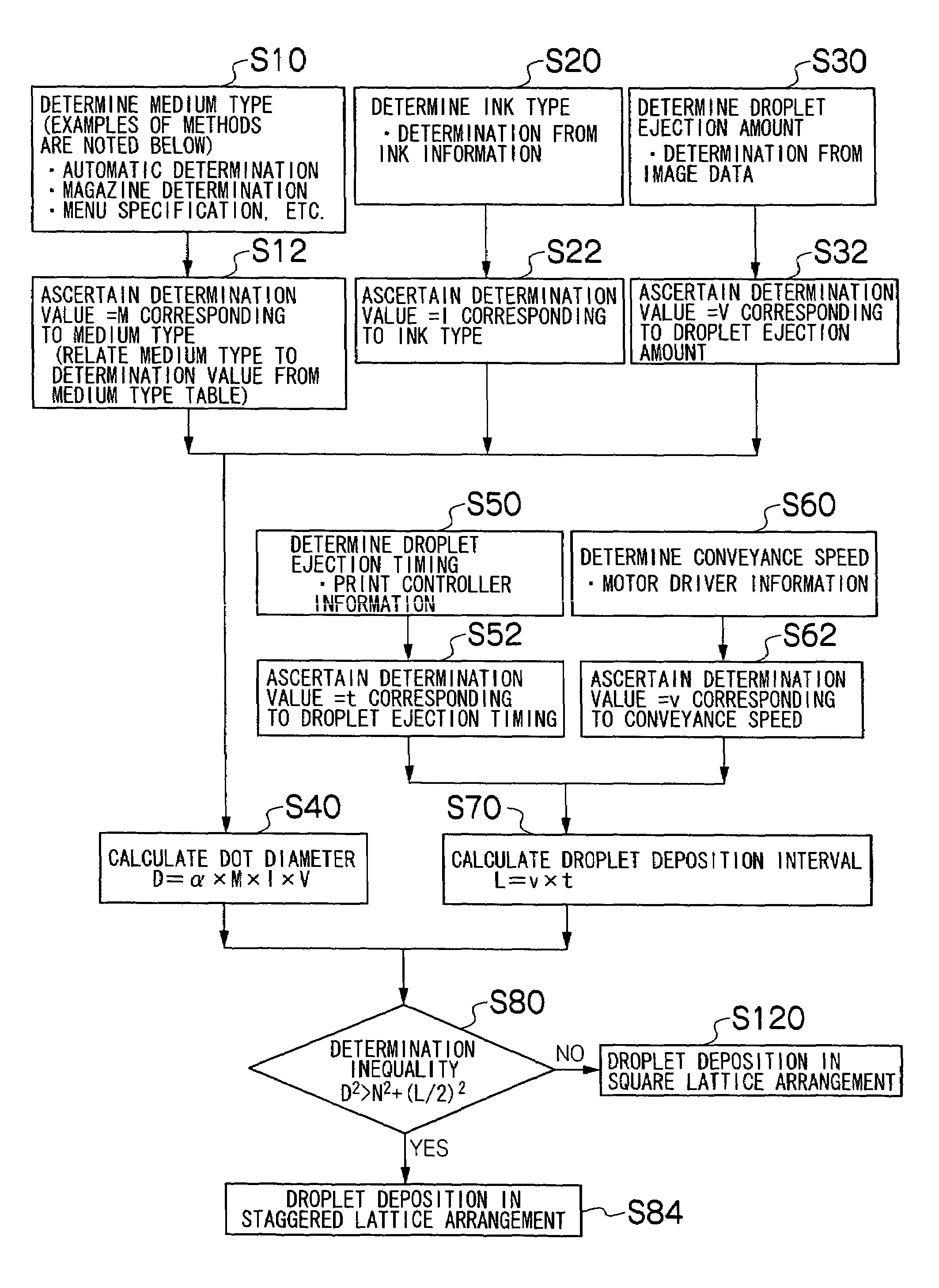

InactiveUS20050057591A1Reduce perceptionReduce control loadOther printing apparatusRecording mediaElectrical and Electronics engineering

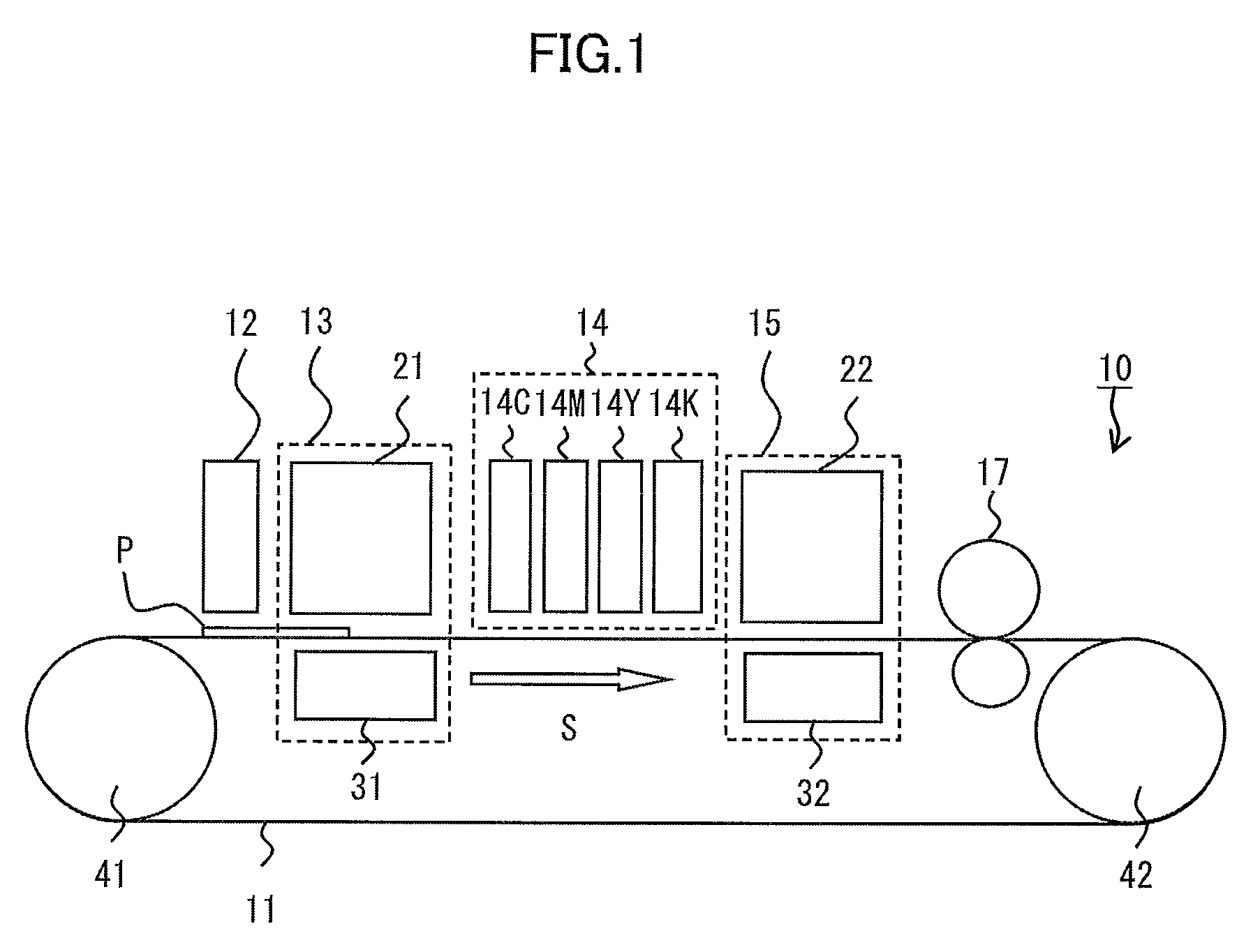

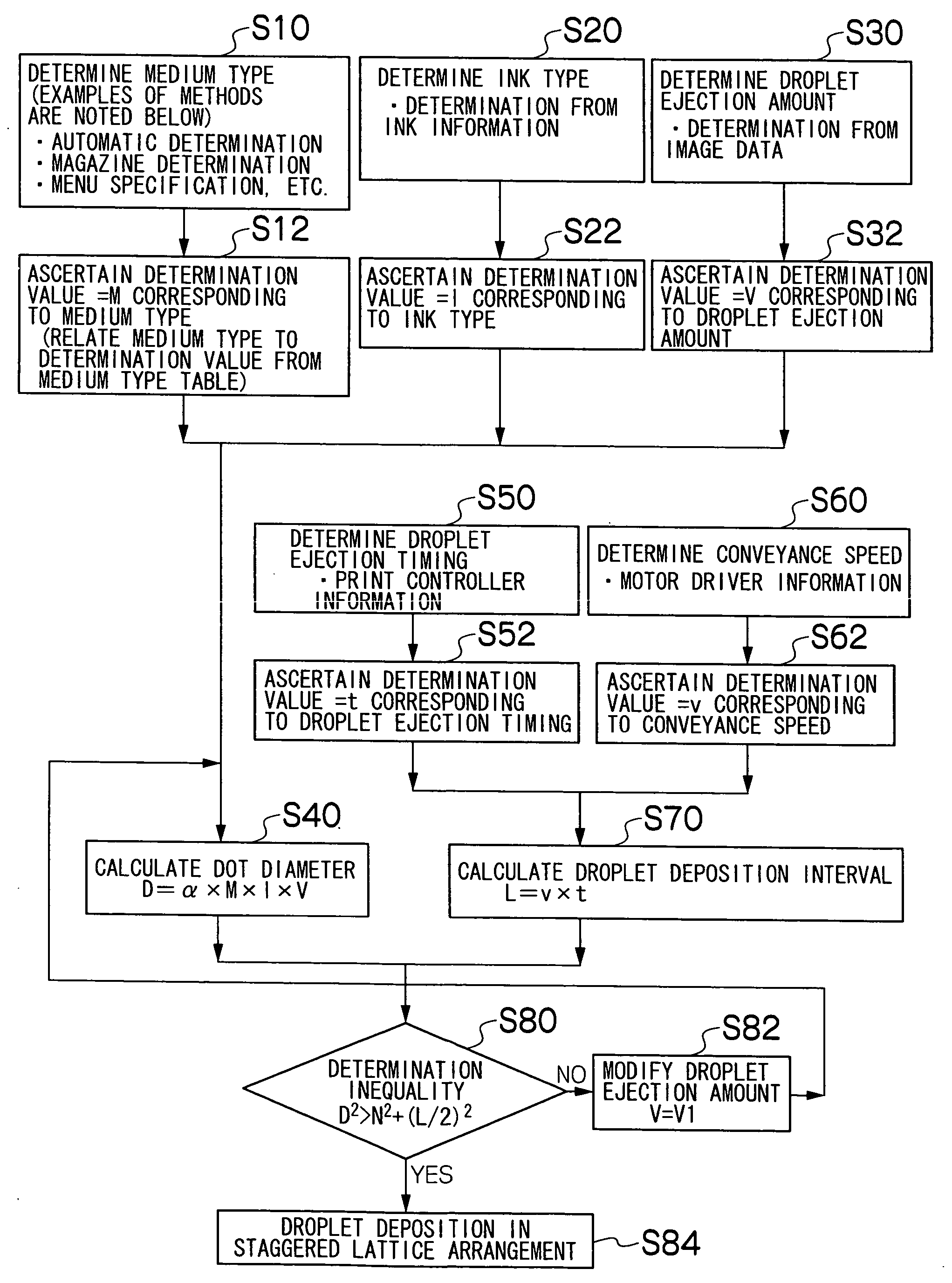

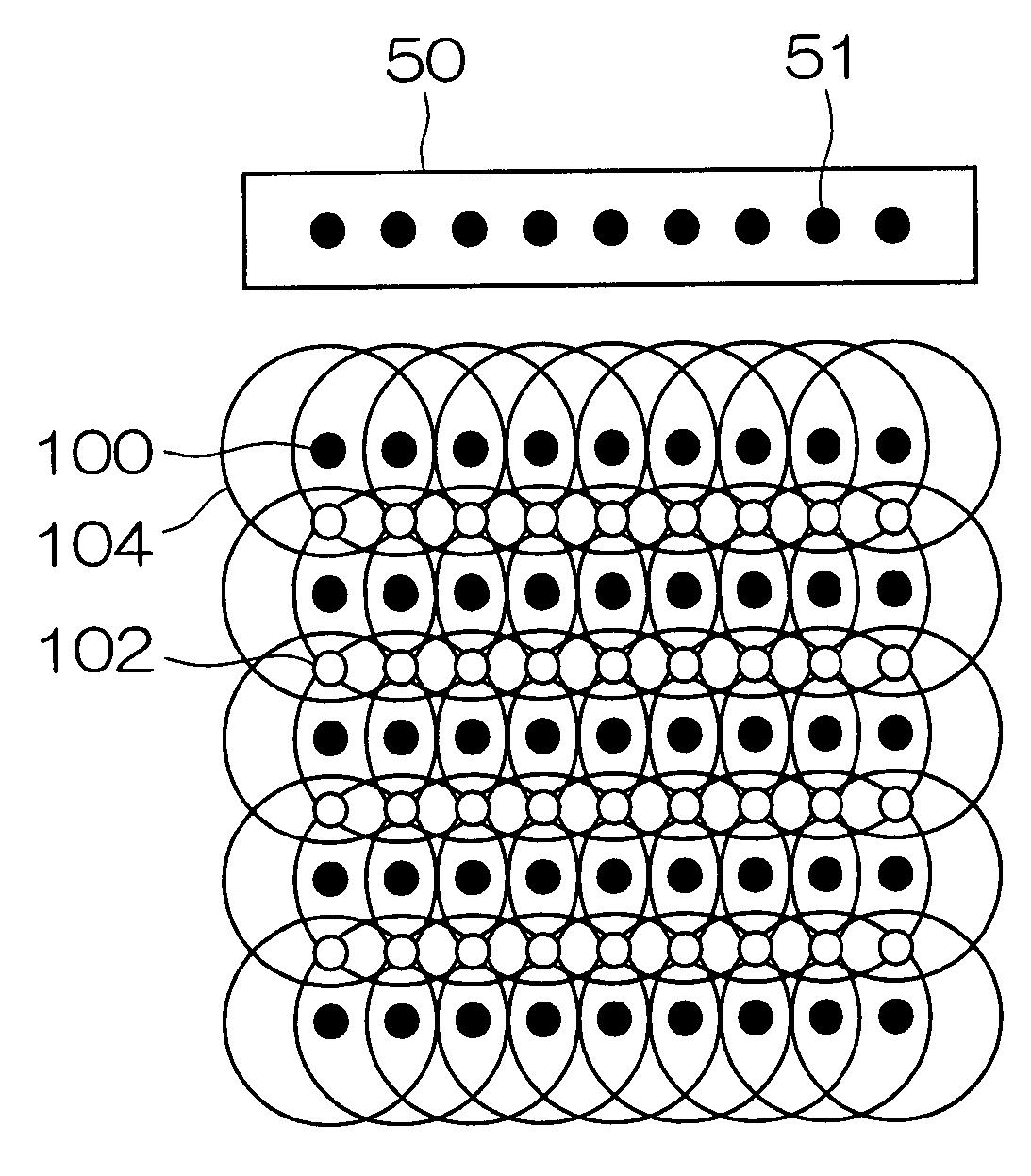

The inkjet recording apparatus comprises: a full line type recording head which includes a plurality of nozzles for discharging ink arranged in a nozzle row across an entire printable width in a main scanning direction; a conveyance device which moves a recording medium and the recording head relatively to each other in a sub-scanning direction substantially orthogonal to the nozzle row provided in the recording head; and a droplet ejection control device which controls a droplet ejection timing of each nozzle, in such a manner that a basic arrangement of droplet deposition points of dots formed on the recording medium by means of ink droplets ejected from the nozzles becomes a staggered lattice arrangement.

Owner:FUJIFILM CORP

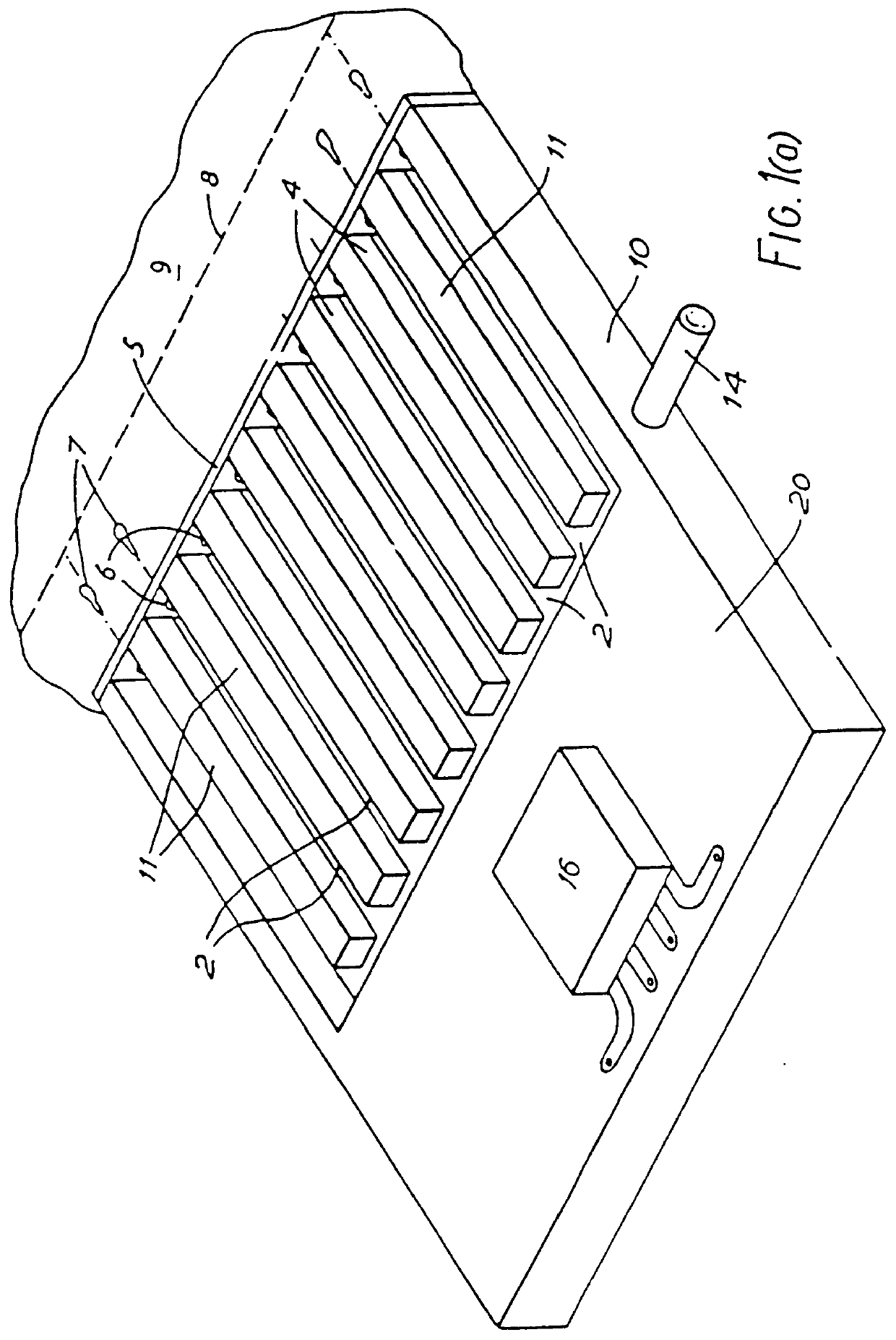

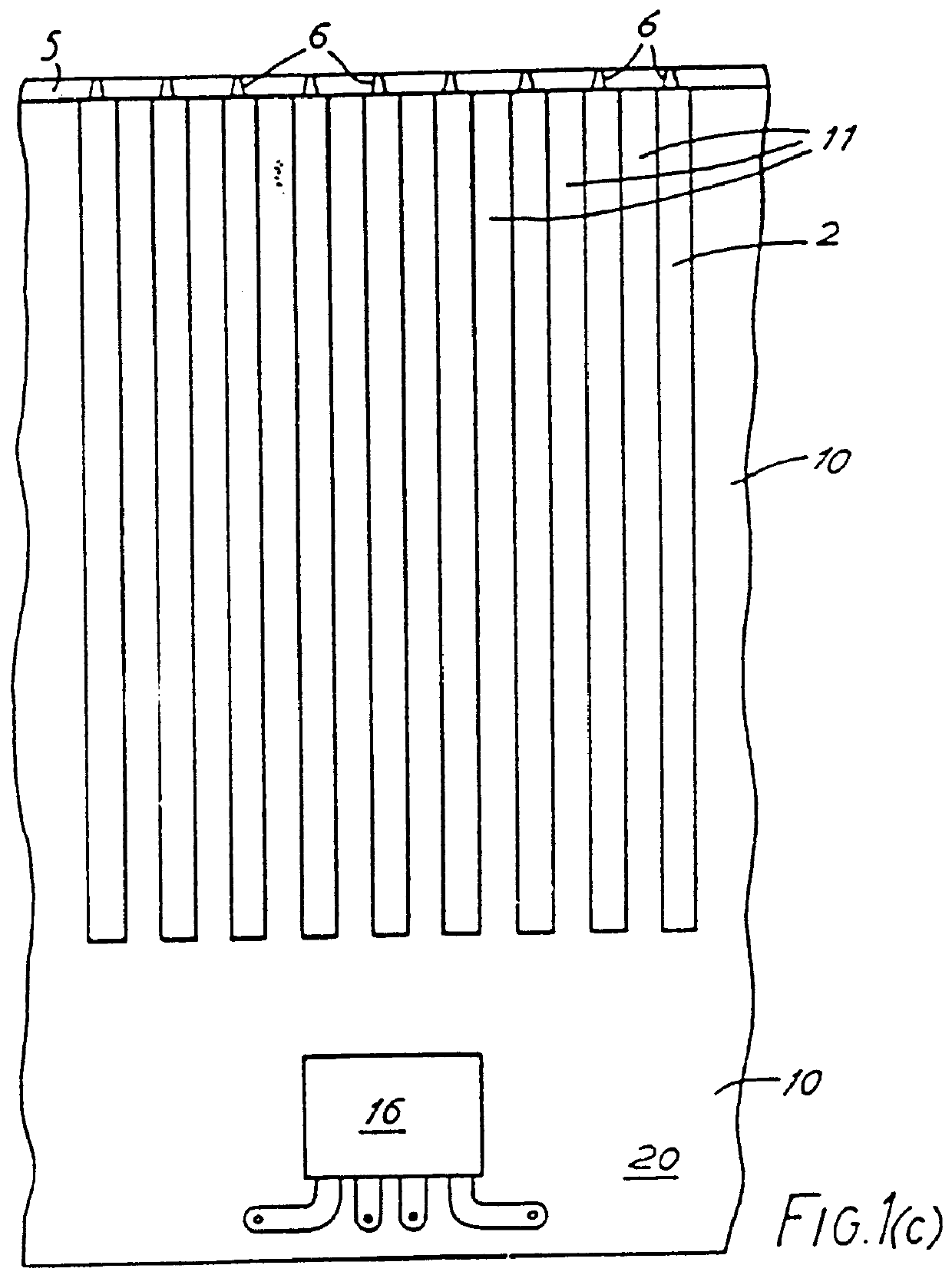

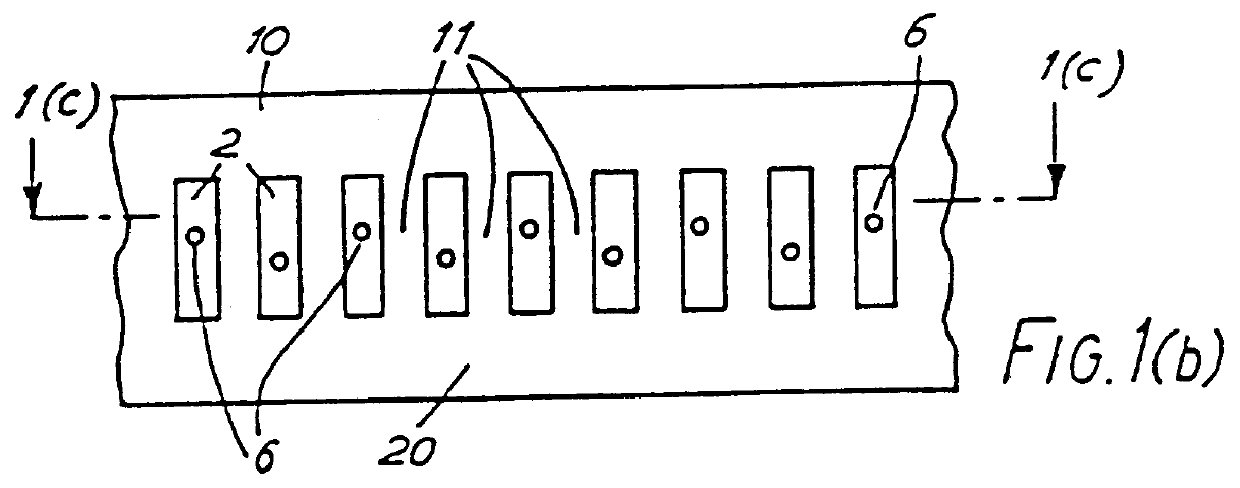

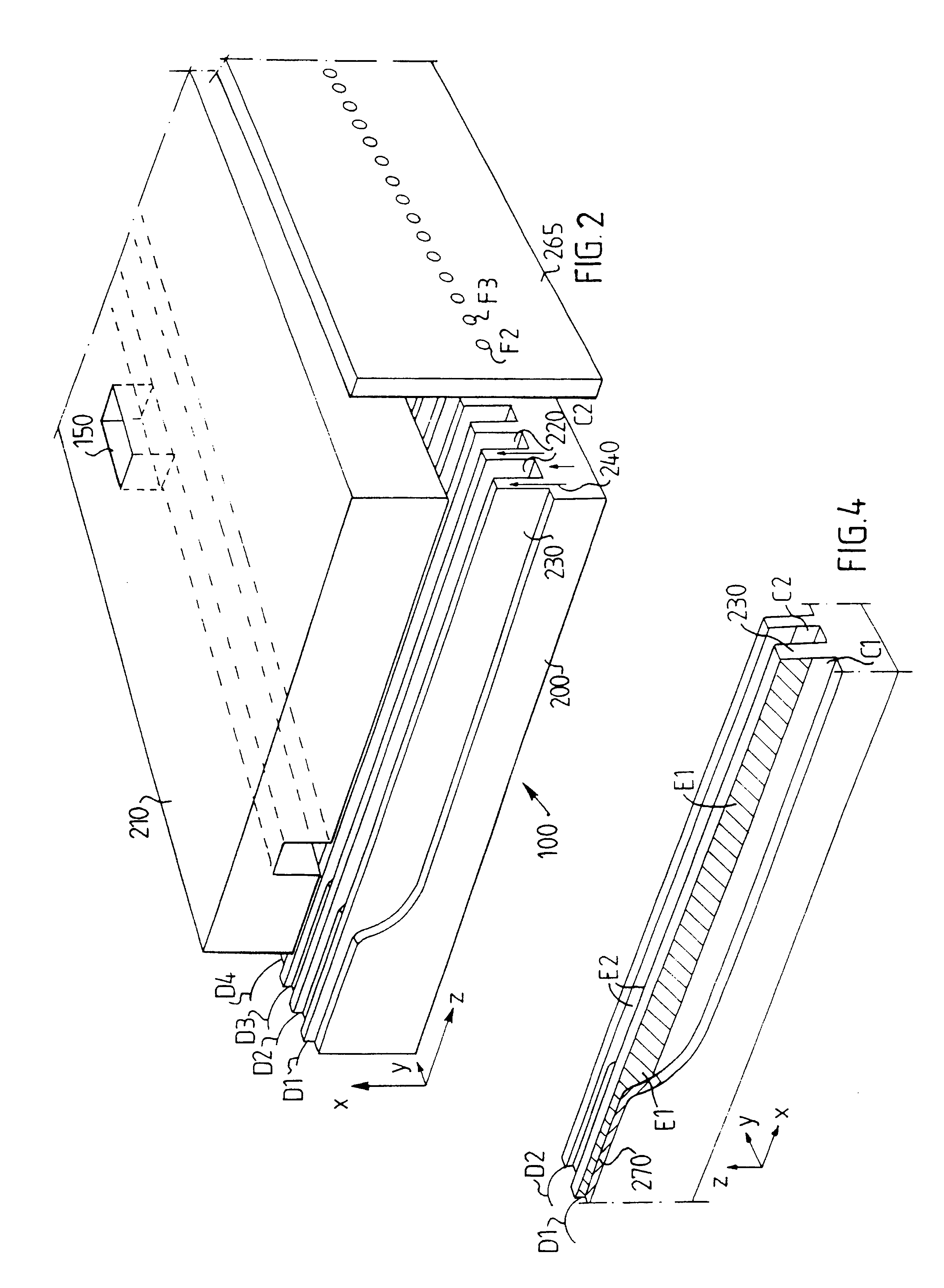

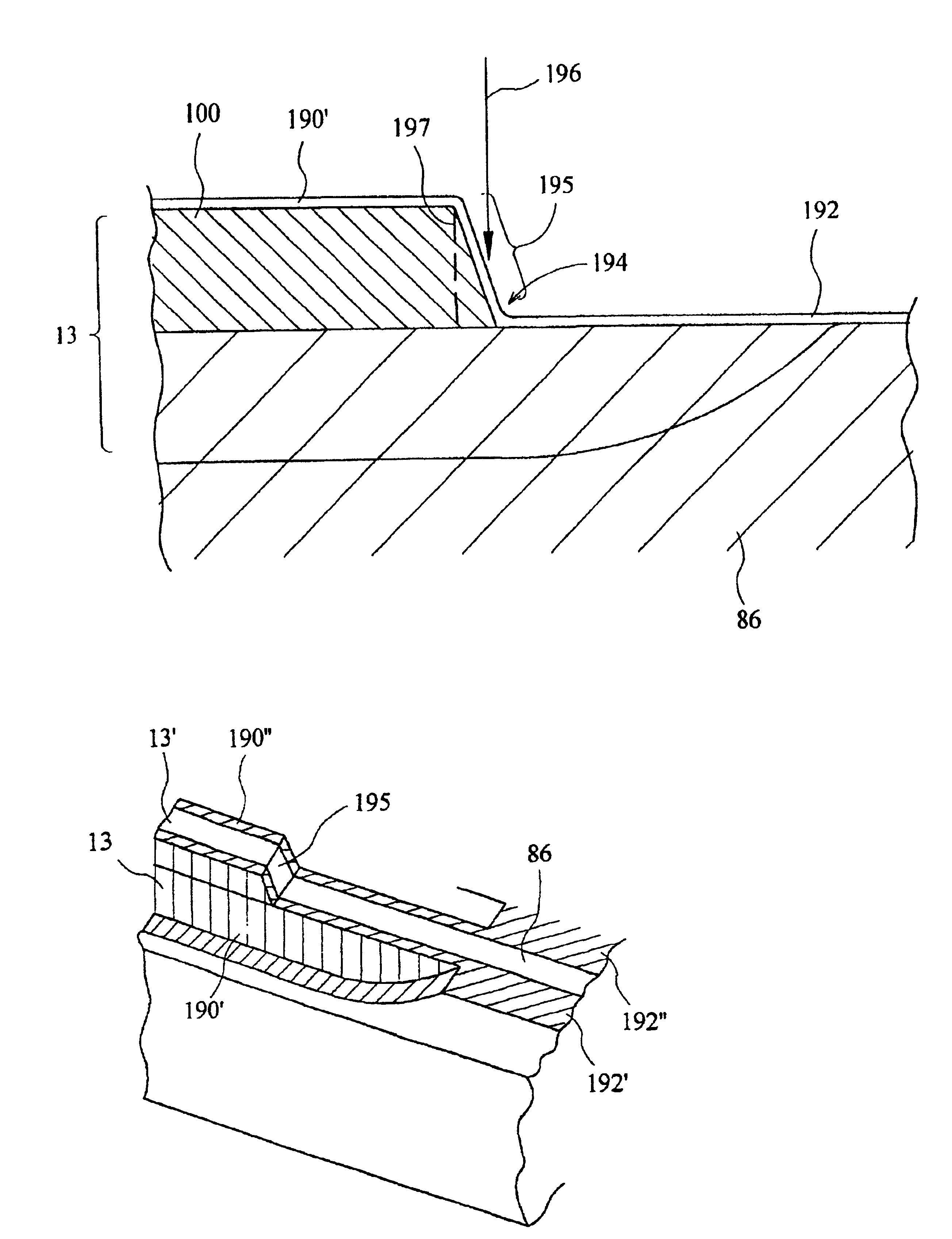

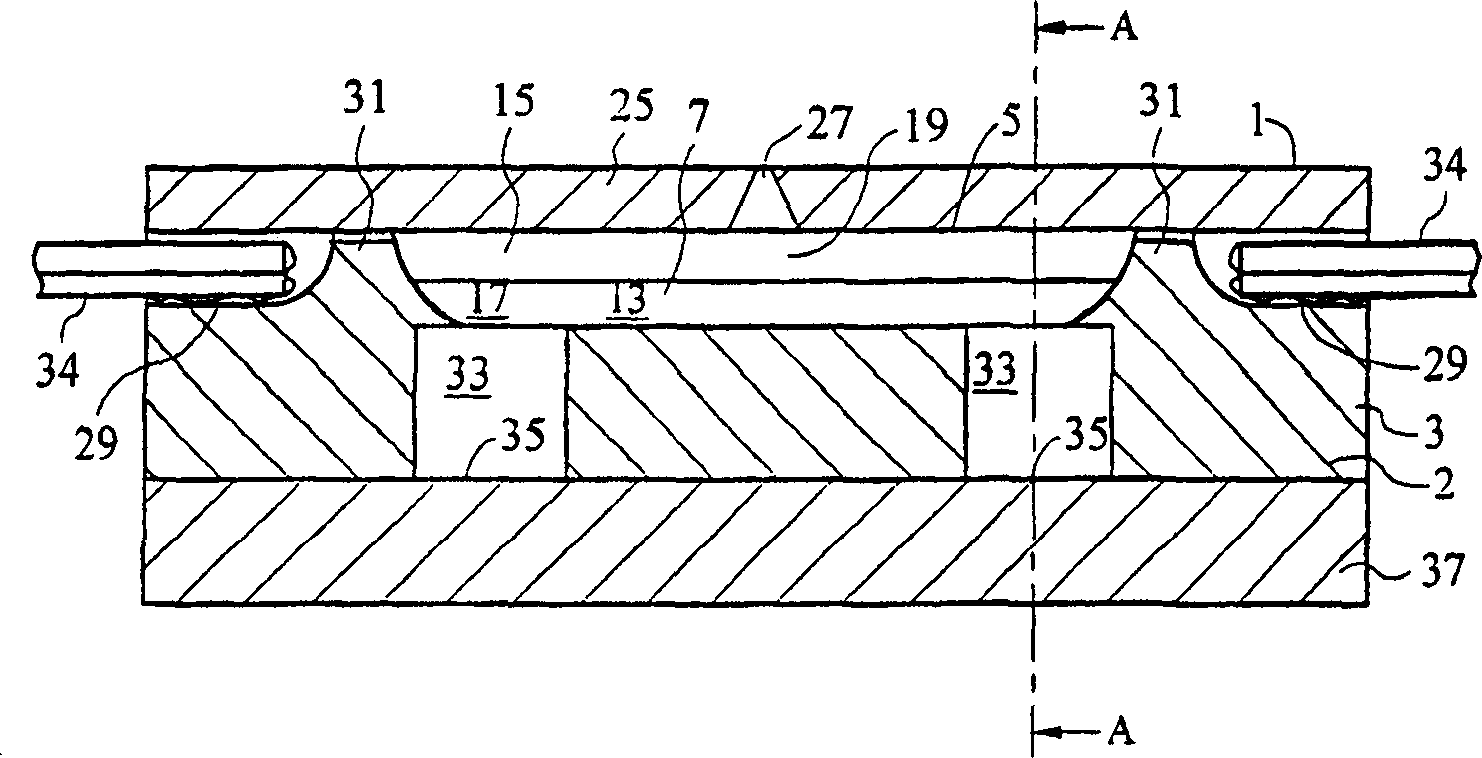

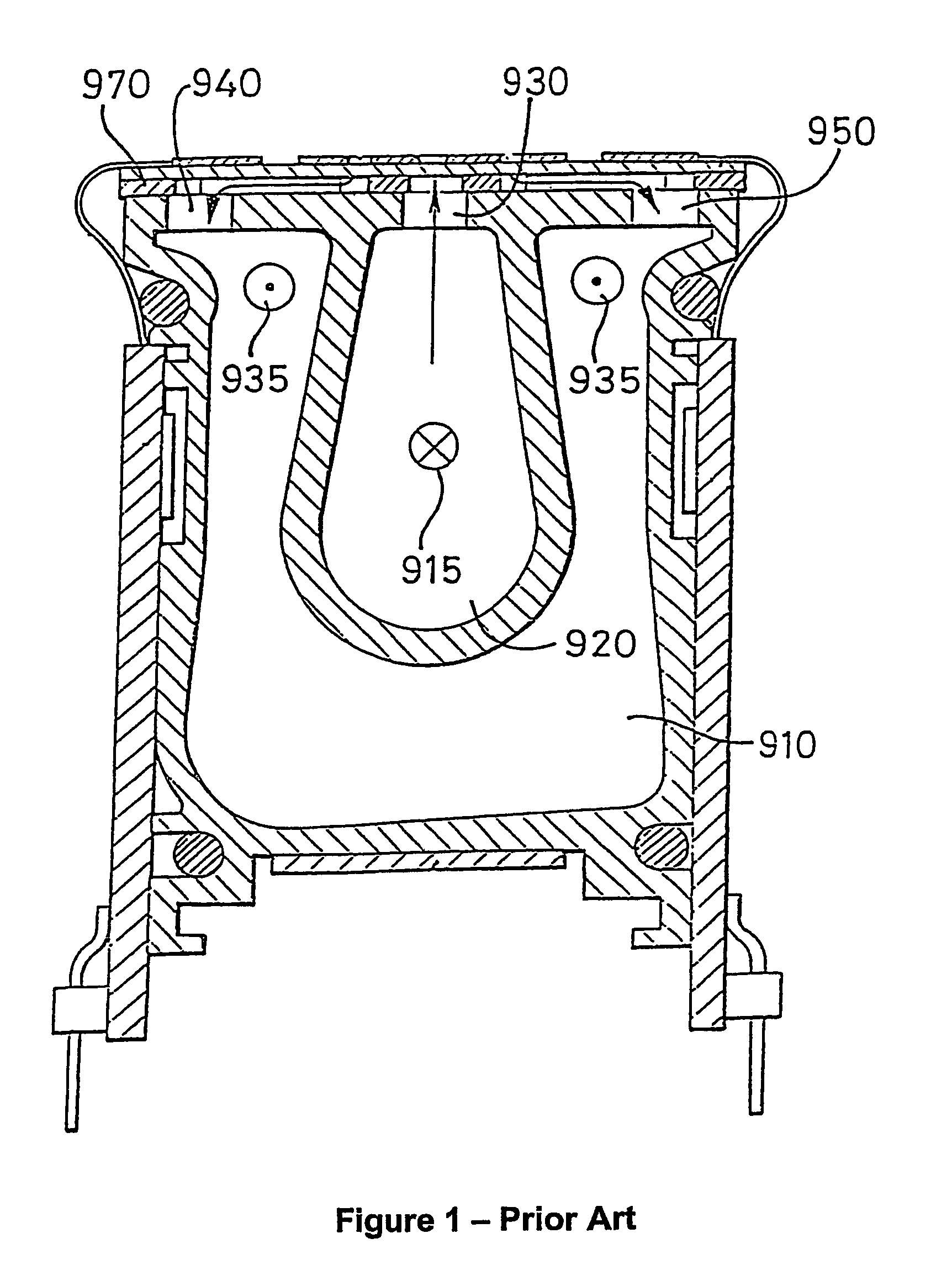

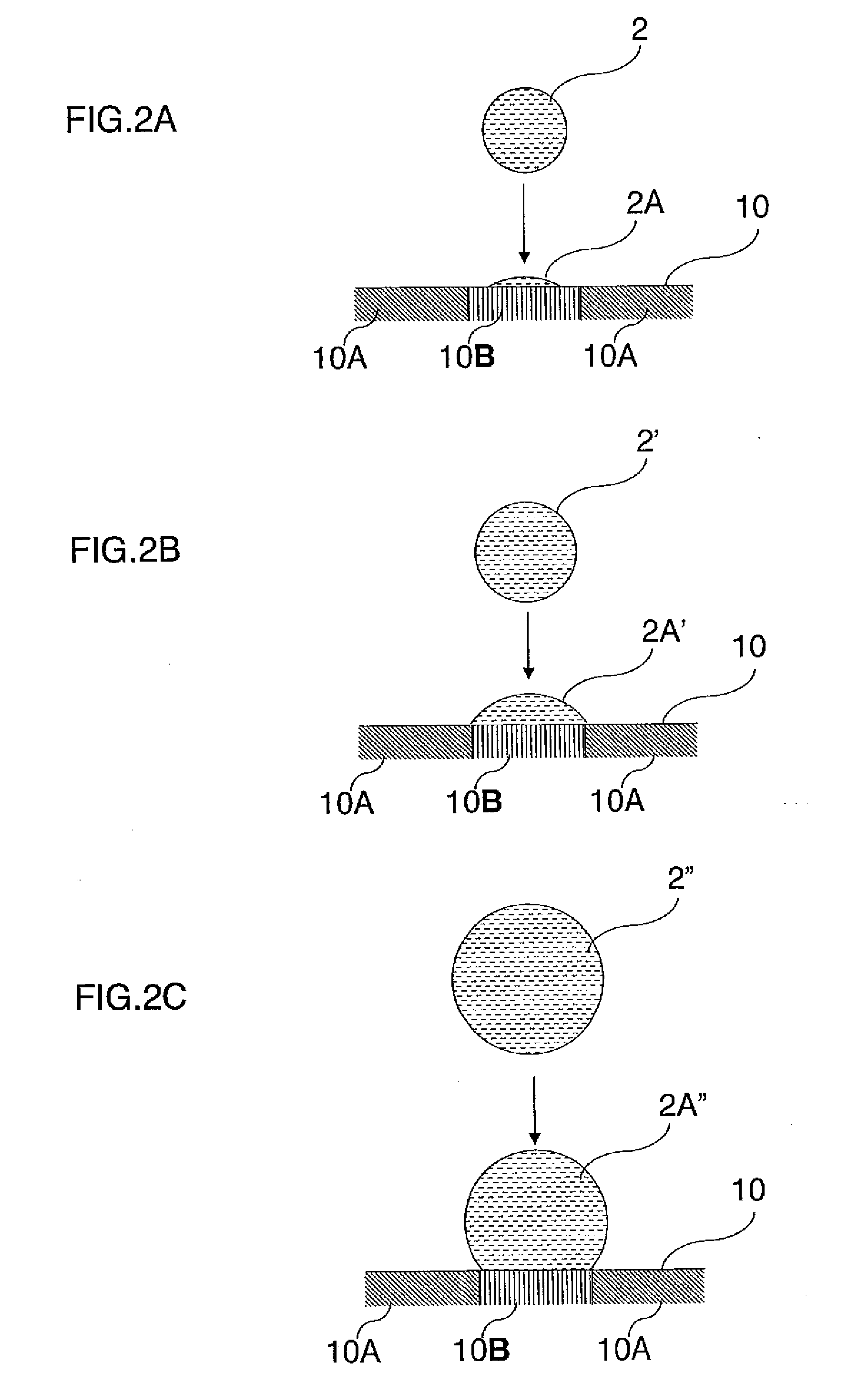

Droplet deposition apparatus

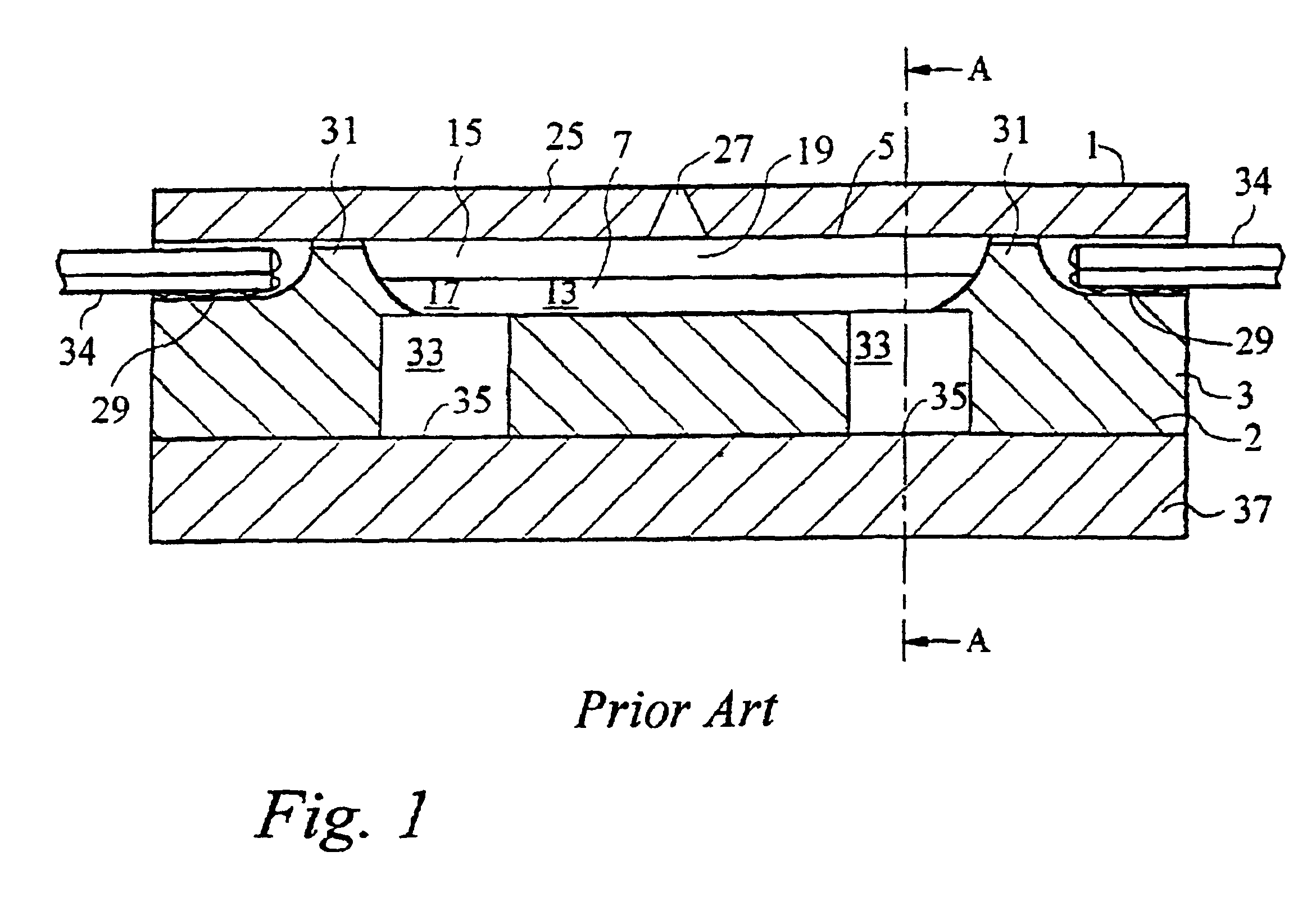

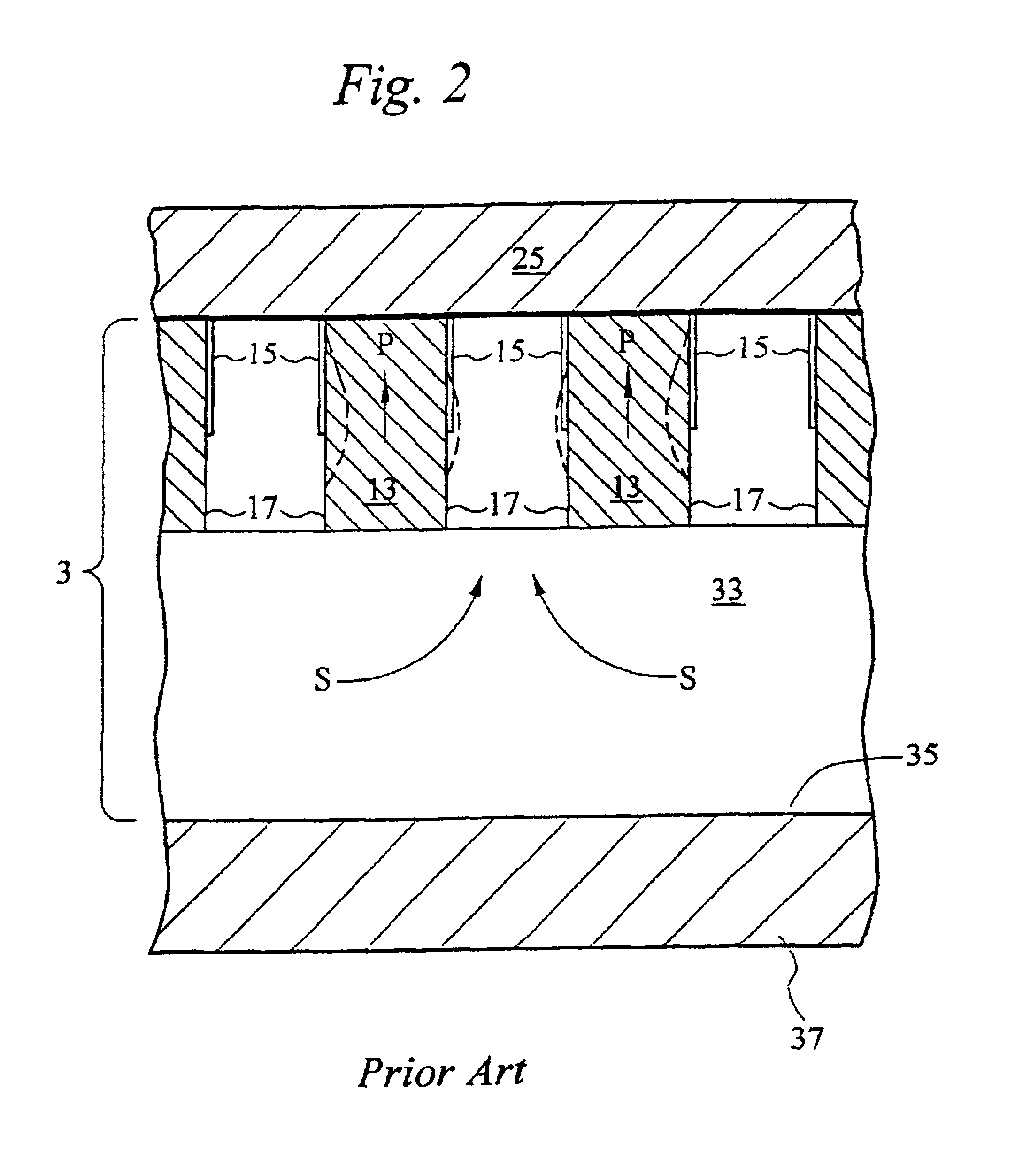

InactiveUSRE36667E1Reduce manufacturing costInking apparatusPiezoelectric/electrostrictive devicesAcoustic wavePiezo electric

A pulsed droplet ink jet printer has relatively long thin ink channels extending in parallel between an ink manifold 13, and a nozzle plate 5 providing a nozzle 6 for each channel. Side walls 11 may be formed substantially entirely of piezo-electric material so as to be displaceable transversely into a selected channel on the application of an electric field. This transverse displacement produces an acoustic wave in the channel which results in the ejection of an ink droplet. The side walls may deflect in shear mode to a cross-section of chevron formation. Usefully, it is arranged that both side walls adjoining the selected channel are displaced inwardly of the channel to cooperate in droplet ejection. Under this arrangement, the channels are assigned alternately to first and second groups of channels, only one group of channels being capable of actuation at any one instant. The nozzles associated with the respective groups of channels may be offset so as to compensate for the time delay in actuation of channels in the first and second groups.

Owner:XAAR TECH LTD

Image forming method and apparatus

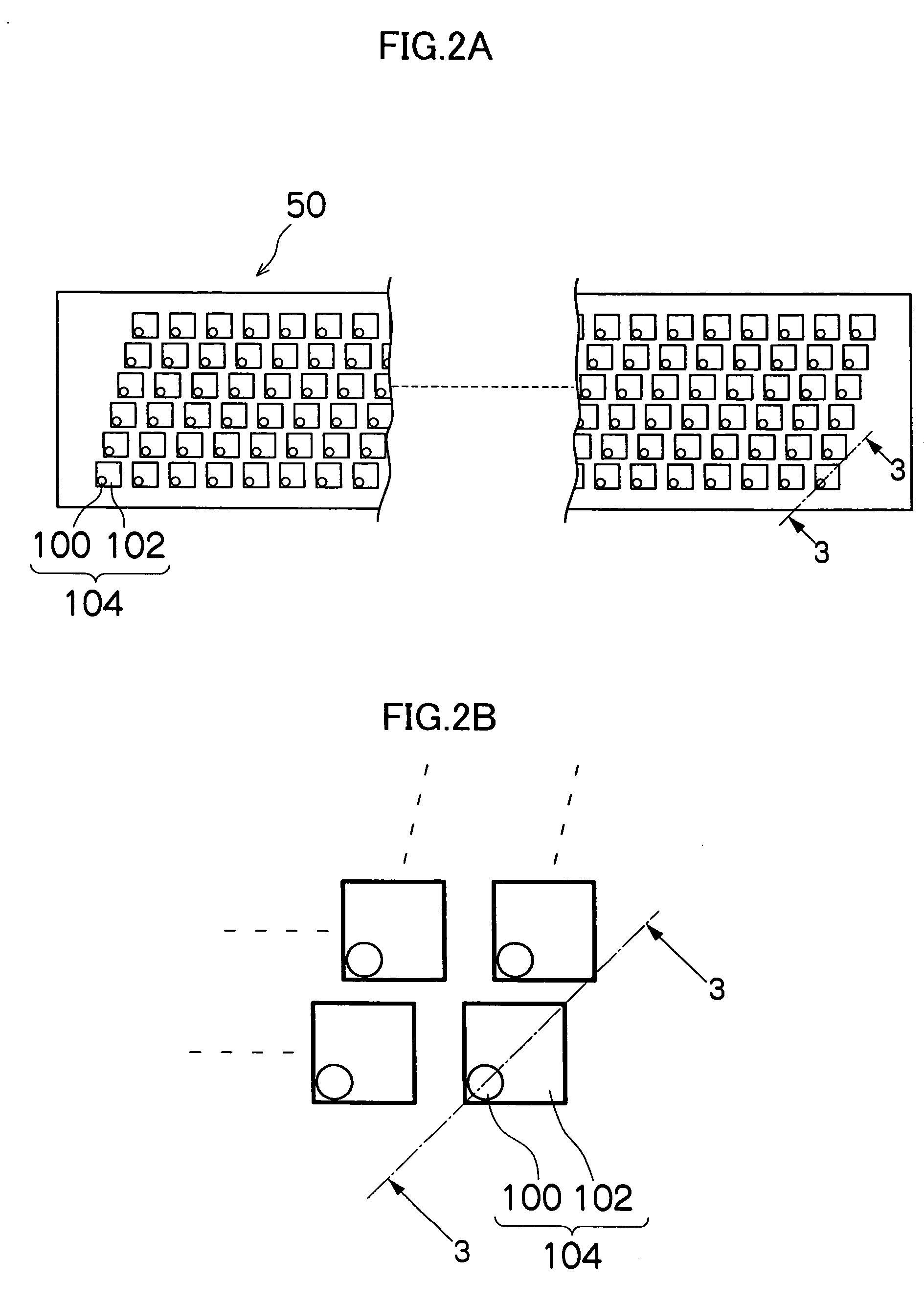

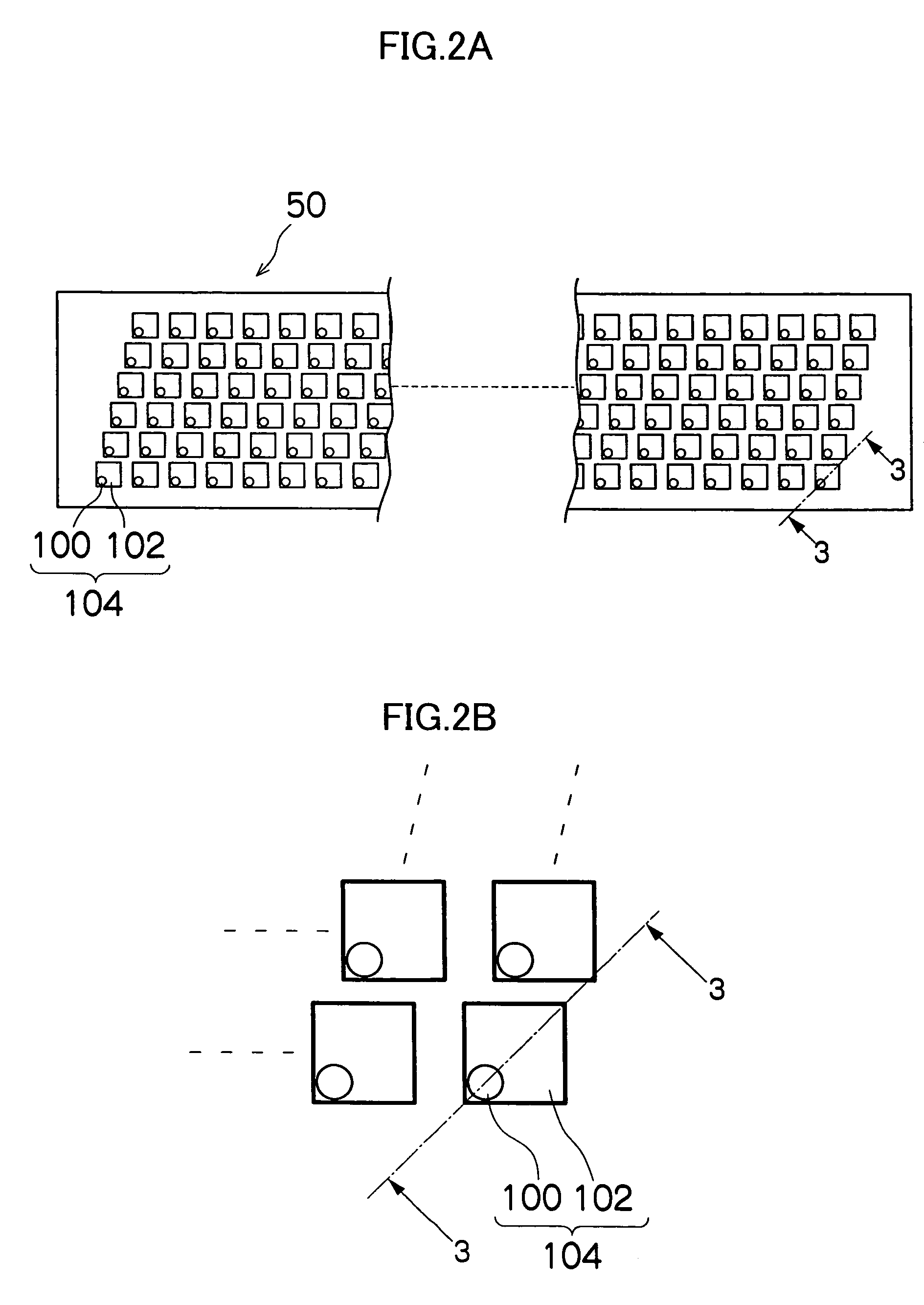

InactiveUS20050253879A1Low perceptibilityReduce perceptionOther printing apparatusImage formationOverlap ratio

The image forming method for forming an image on a recording medium by forming dots on the recording medium by depositing droplets on the recording medium by a recording head having a plurality of nozzles ejecting the droplets while moving the recording head and the recording medium relatively to each other by conveying at least one of the recording head and the recording medium in a relative conveyance direction, wherein the image to be formed is divided into a plurality of regions; a density in each of the plurality of regions is set as a prescribed density so as to form the image; a droplet deposition rate is defined as a ratio of a number of the dots actually formed by depositing the droplets from one of the nozzles within each of the plurality of regions with respect to a maximum number of the dots formable by depositing the droplets from the one of the nozzles within the region; and tonal gradation in the image is represented by means of a collection of the dots based on a dot arrangement specified according to the droplet deposition rate calculated from image data of the image to be formed, the image forming method comprises: a droplet deposition rate calculation step of calculating the droplet deposition rate from the image data; a dot arrangement specification step of specifying a dot arrangement pattern from the droplet deposition rate calculated in the droplet deposition rate calculation step; and a droplet deposition control step of controlling droplet deposition operation performed by the recording head in such a manner that the dot arrangement pattern specified in the dot arrangement specification step is achieved, wherein, in at least one of the plurality of the regions where the droplet deposition rate calculated in the droplet deposition rate calculation step is lower than a maximum droplet deposition rate and is higher than a prescribed reference value, a dot line in a main scanning direction substantially perpendicular to the relative conveyance direction is formed in which the dots are continuously aligned so as to mutually overlap by a prescribed overlap ratio, in accordance with the droplet deposition rate calculated in the droplet deposition rate calculation step.

Owner:FUJIFILM CORP

Method for coating semiconductor device using droplet deposition

ActiveUS20070161135A1Solid-state devicesSemiconductor/solid-state device manufacturingLiquid mediumDevice material

Owner:CREELED INC

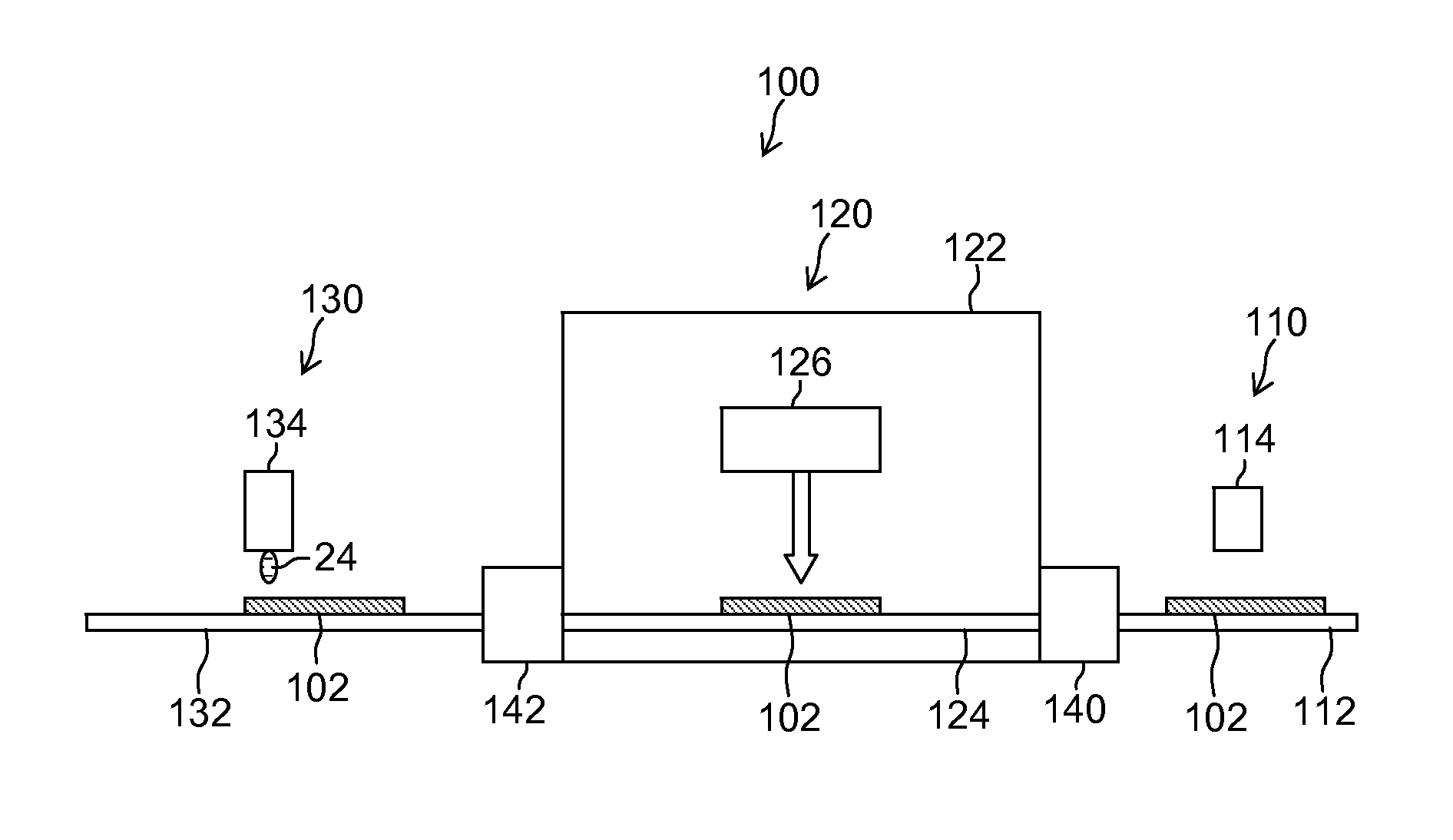

Ink jet printer

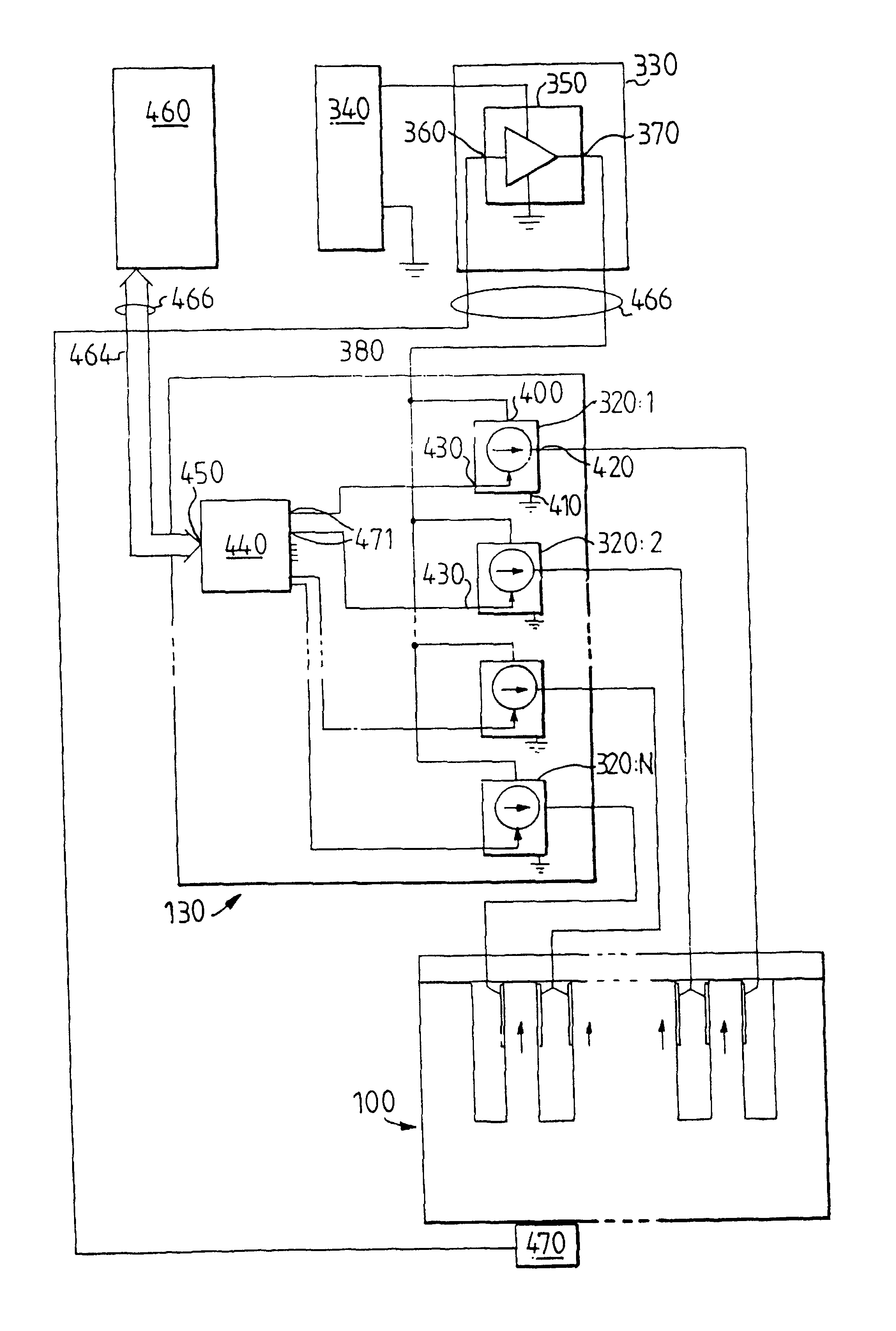

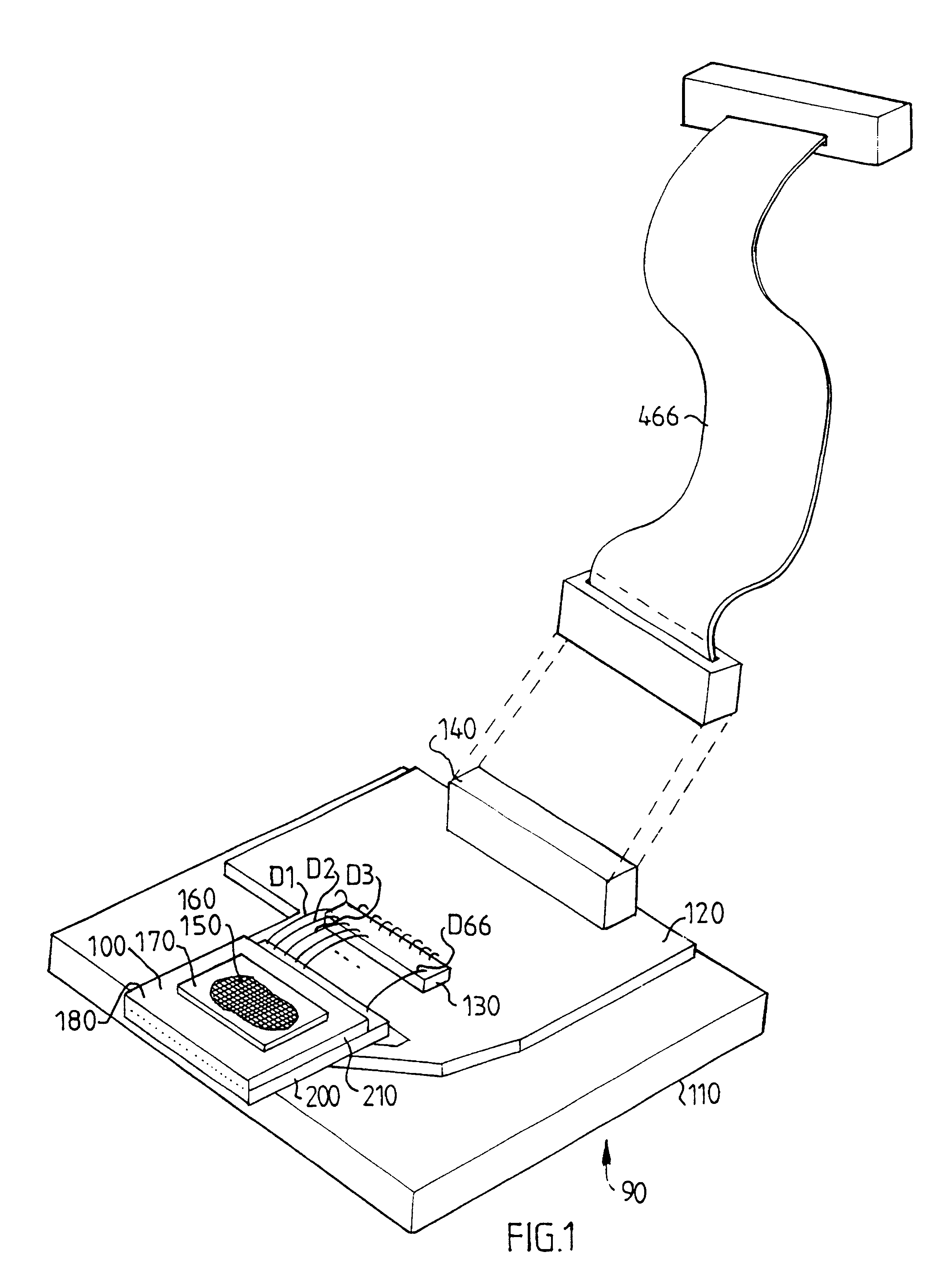

The invention relates to a droplet deposition apparatus including an ink actuator (100) for ejecting ink droplets; a control unit (130) for controlling droplet formation; and power supply means for supplying a drive voltage to the control unit (130); the drive voltage having a voltage amplitude (V100); the control unit (130) having a plurality of drive signal sources (320) for defining the wave forms of said electric signals; means (470) for detecting at least one performance affecting value; and means (490) for generating an amplitude control signal in response to the performance affecting value; and wherein the power supply means (330) comprises means (350) for adjusting the amplitude of the drive voltage in response to the amplitude control signal; said power supply means being separated from said control unit.

Owner:XAARJET

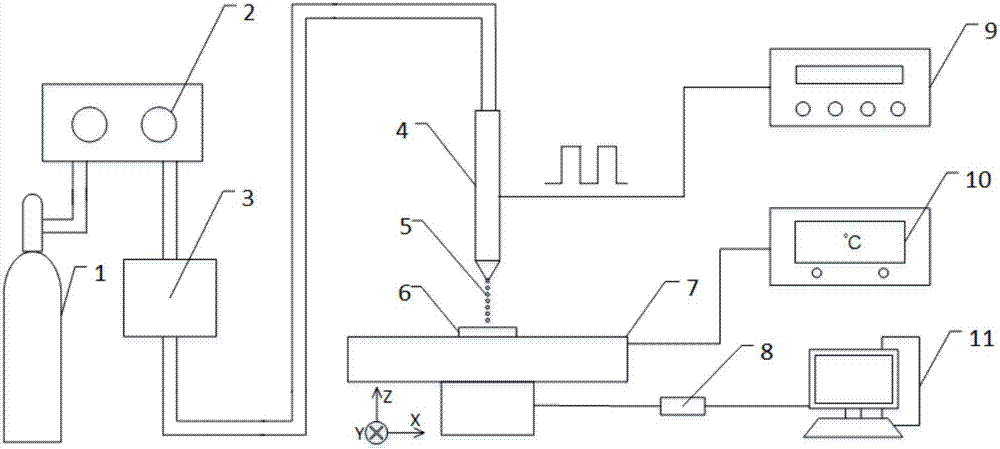

Micro-droplet jetting printing device and method for preparing graphene metamaterial microstructure through device

ActiveCN106891414AFast formingAdditive manufacturing apparatusCeramic shaping apparatusElectricityCvd graphene

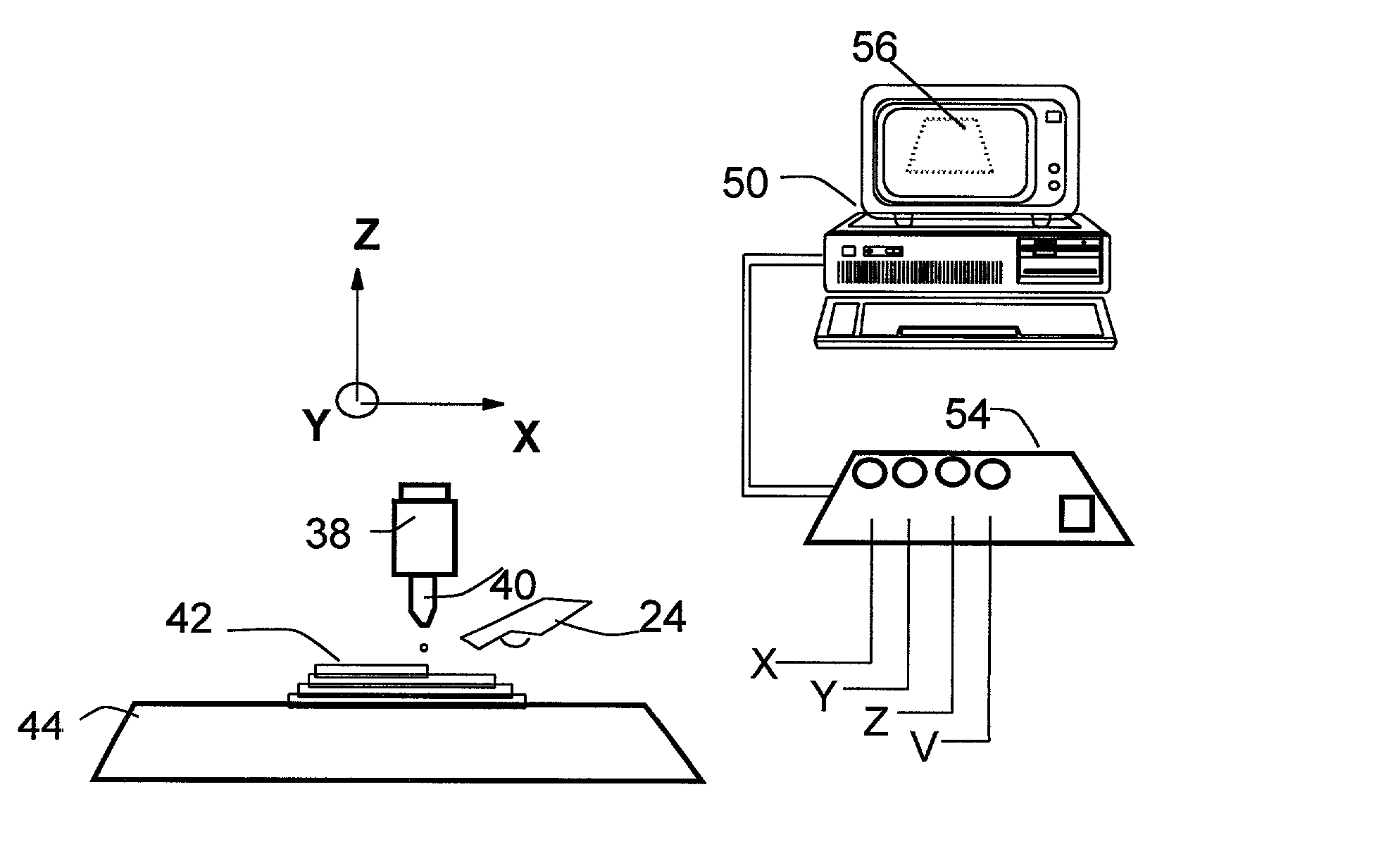

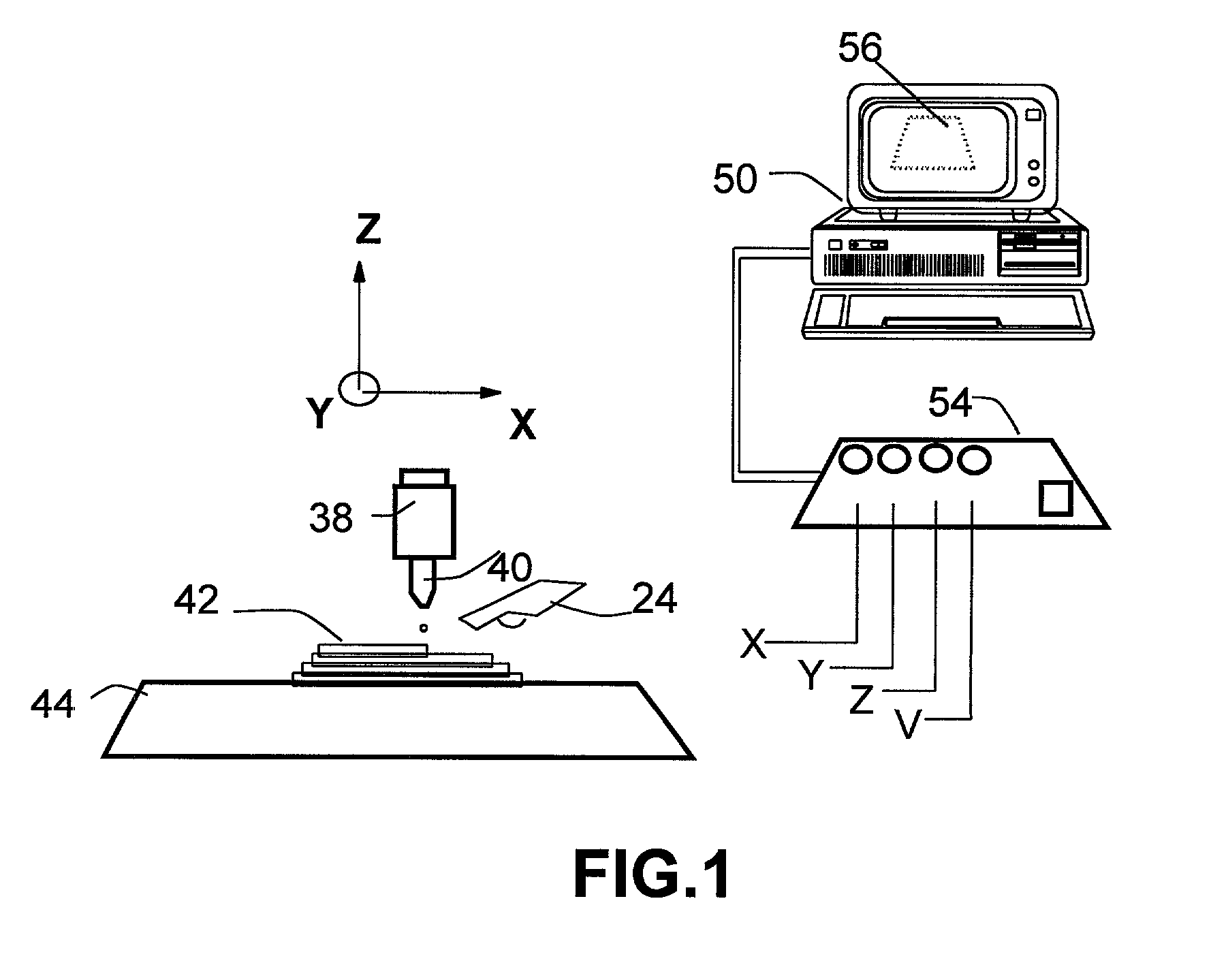

The invention discloses a micro-droplet jetting printing device and a method for preparing a graphene metamaterial microstructure through the device. The micro-droplet jetting printing device and the method are used for solving the technical problem that an existing method for preparing the graphene metamaterial microstructure is complex. According to the technical scheme, the device comprises a nitrogen cylinder, pressure controllers, a liquid accumulator, a piezoelectric micro sprinkler, a microstructure substrate, a three-dimensional associated movement base plate, a three-dimensional associated movement base plate controller, a piezoelectric ceramic driver, a temperature controller and a computer. The method comprises the steps that graphene dispersion liquid is dispersed into picoliter-order uniform graphene micro-droplets through the piezoelectric micro sprinkler, and the liquid droplet diameter and the jetting frequency are adjusted through the piezoelectric ceramic driver; and then the three-dimensional associated movement base plate is controlled through the computer, the accumulation track of the graphene micro-droplets on the substrate is controlled, the graphene microstructure is obtained through point-by-point, line-by-line and layer-by-layer accumulation, meanwhile, the temperature controller is utilized for controlling the evaporation rate and solute migration in the graphene micro-droplet deposition process, and complex graphene metamaterial microstructure patterns are obtained. The method is simple and practicable.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Image forming method and apparatus

The image forming method is for forming an image on an image formation body by using an ink liquid including a coloring material and an aggregation treatment agent including a component that causes the coloring material to aggregate. The image forming method includes: an aggregation treatment layer formation step of forming, on the image formation body, a semisolid aggregation treatment layer that includes the aggregation treatment agent and has a moisture content ratio not more than 56%; an ink droplet deposition step of ejecting droplets of the ink liquid and depositing the droplets of the ink liquid onto the image formation body where the aggregation treatment layer has been formed; and a solvent removal step of removing a liquid solvent present on the image formation body after the ink droplet deposition step.

Owner:FUJIFILM CORP

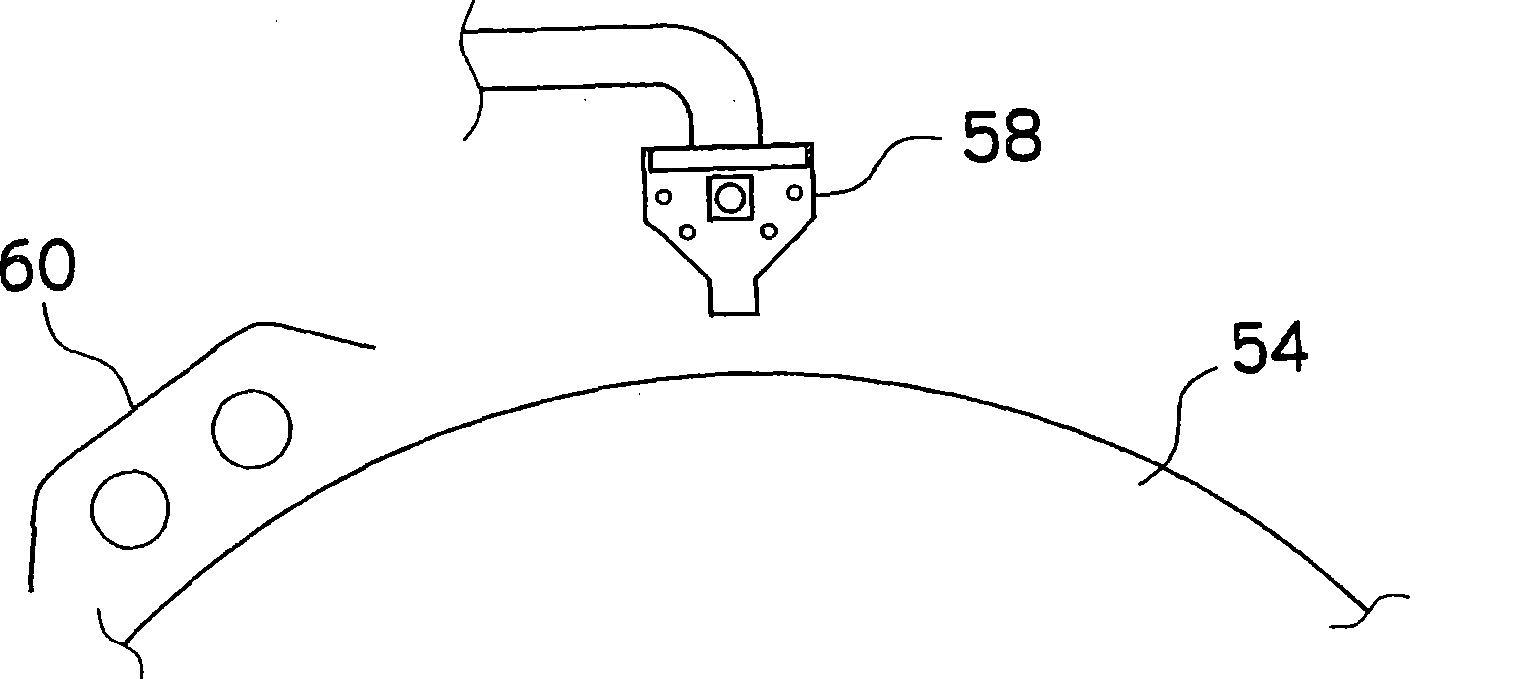

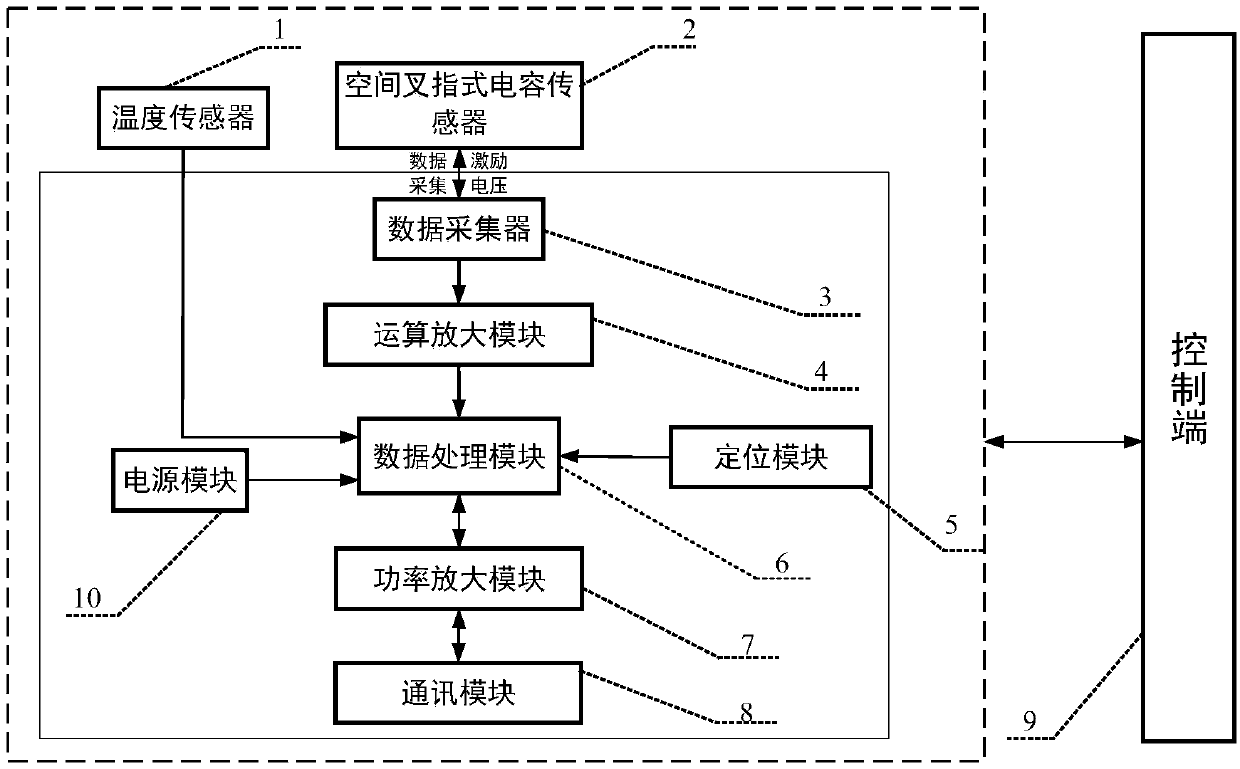

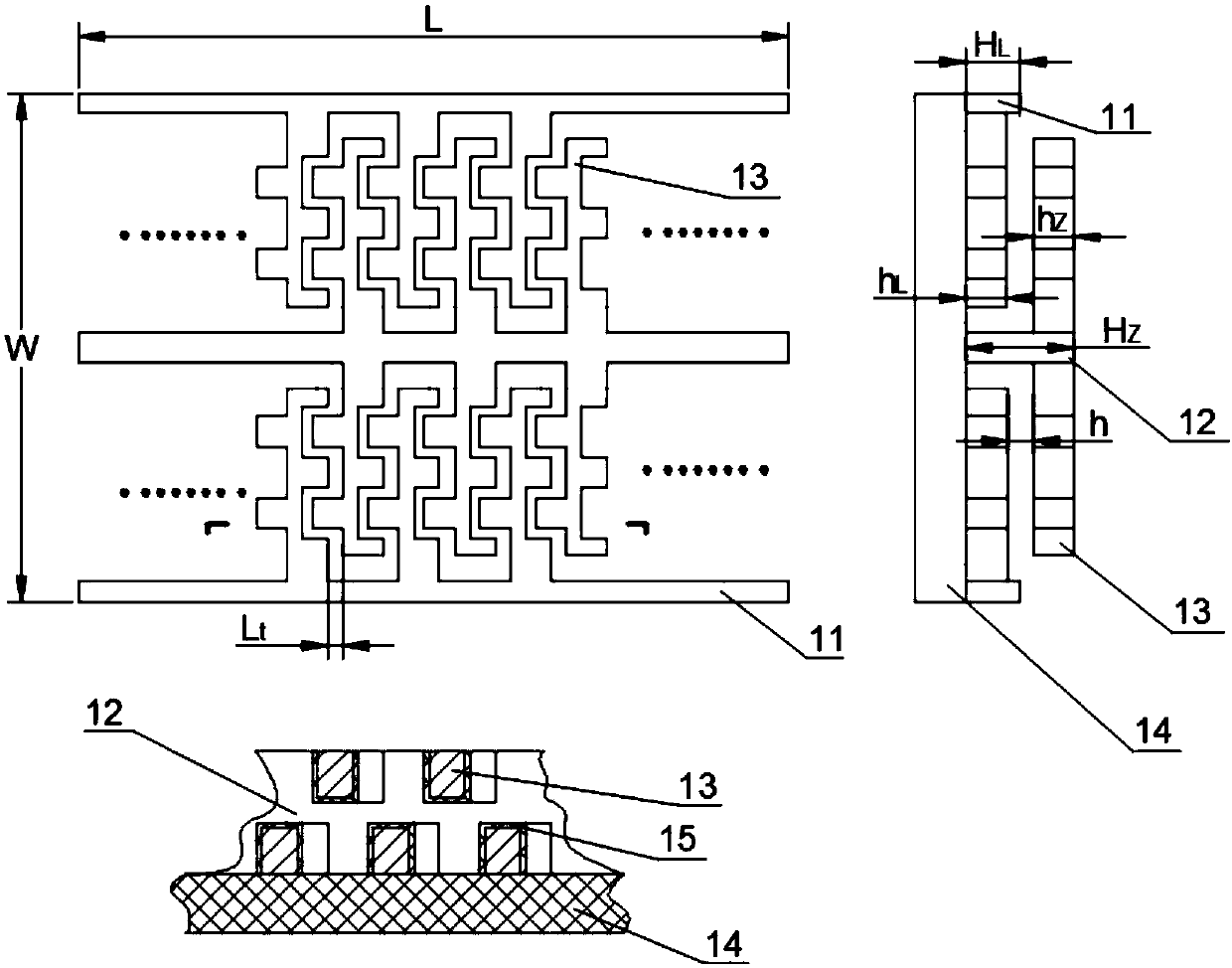

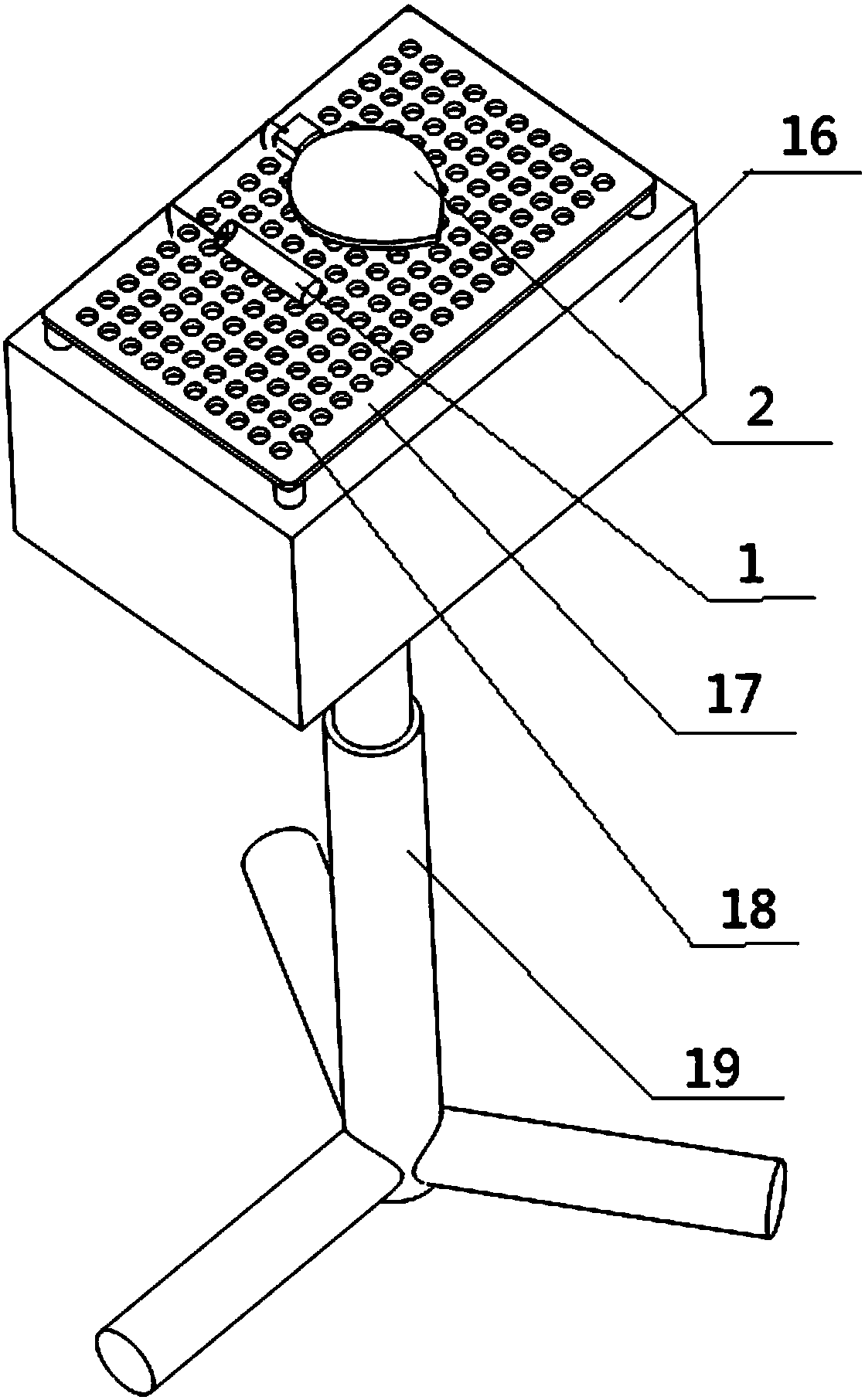

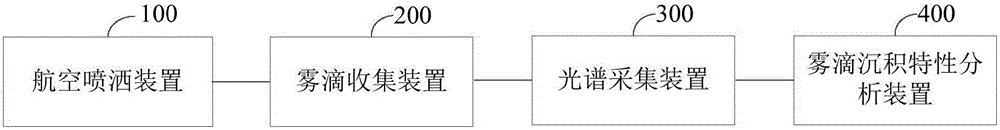

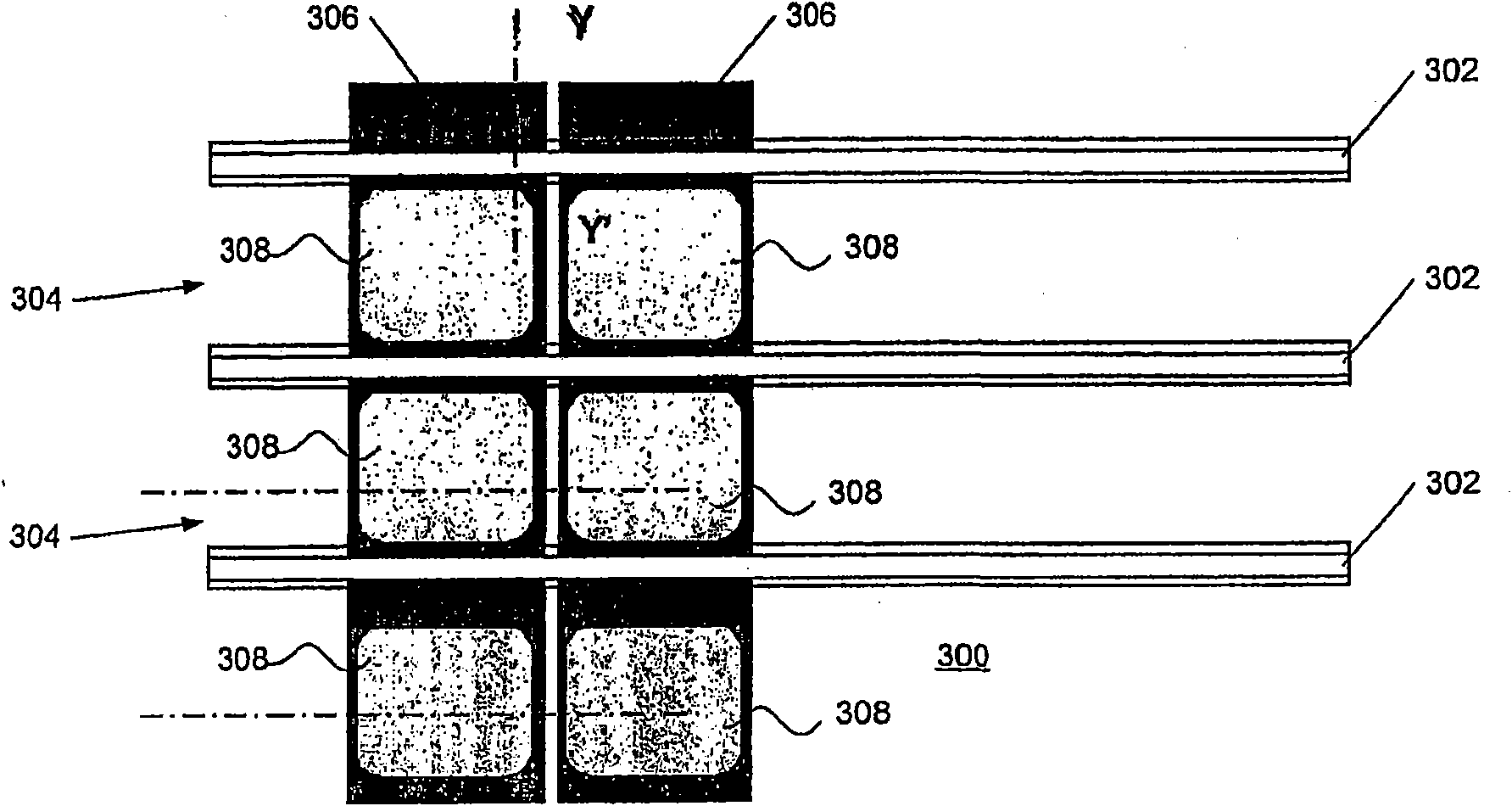

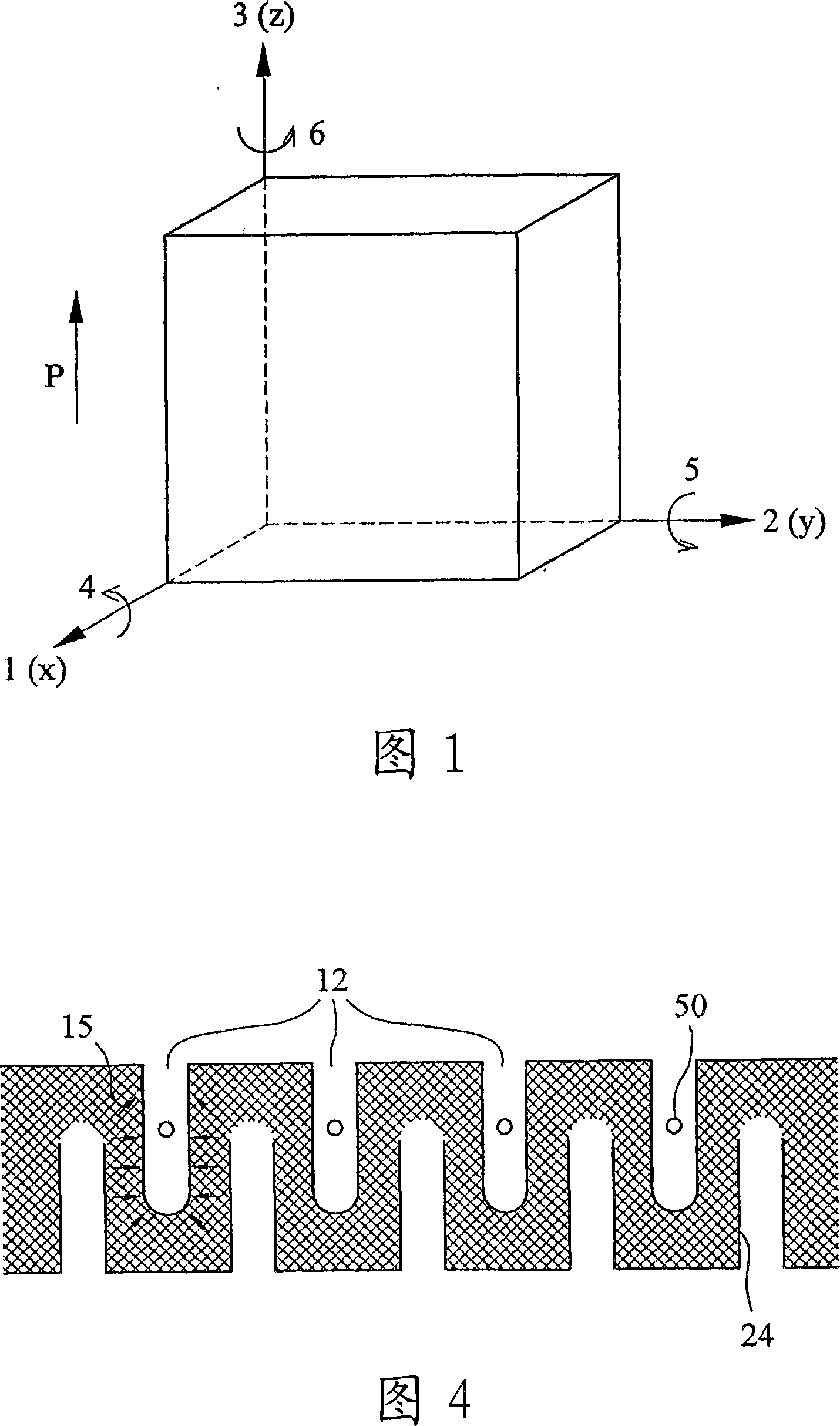

On-line detection system and method for droplet deposition during spraying operation of equipment for plant protection

ActiveCN108469403AImprove detection accuracyEliminate the effects ofLiquid dispersion analysisSpraying apparatusData acquisitionComputer module

The invention discloses an on-line detection system and method for the droplet deposition during spraying operation of equipment for plant protection. The system is composed of a data processing module, a data collector, a temperature sensor, a spatial interdigital capacitance sensor, a communication module, a positioning module, a power supply module, a control end and other parts. The inventionprovides the spatial interdigital capacitance sensor with a three-dimensional structure, and the spatial interdigital capacitance sensor can output voltage data which is in direct proportion to the droplet deposition. The invention provides the specific method and steps for droplet deposition parameter detection. The method comprises the steps that the data processing module of the on-line detection system for the droplet deposition obtains the voltage data through the data collector and processes the voltage data output by the spatial interdigital capacitance sensor, and the voltage data is transmitted to the control end through the communication module. The detection system and method have the function of detecting the droplet deposition parameter during the spraying operation of the equipment for plant protection, and has the advantages of being high in adaptability, quick in response, high in detection precision and the like, and a reliable reference is provided for regulation andcontrol over the spraying operation of the equipment for plant protection.

Owner:JIANGSU UNIV

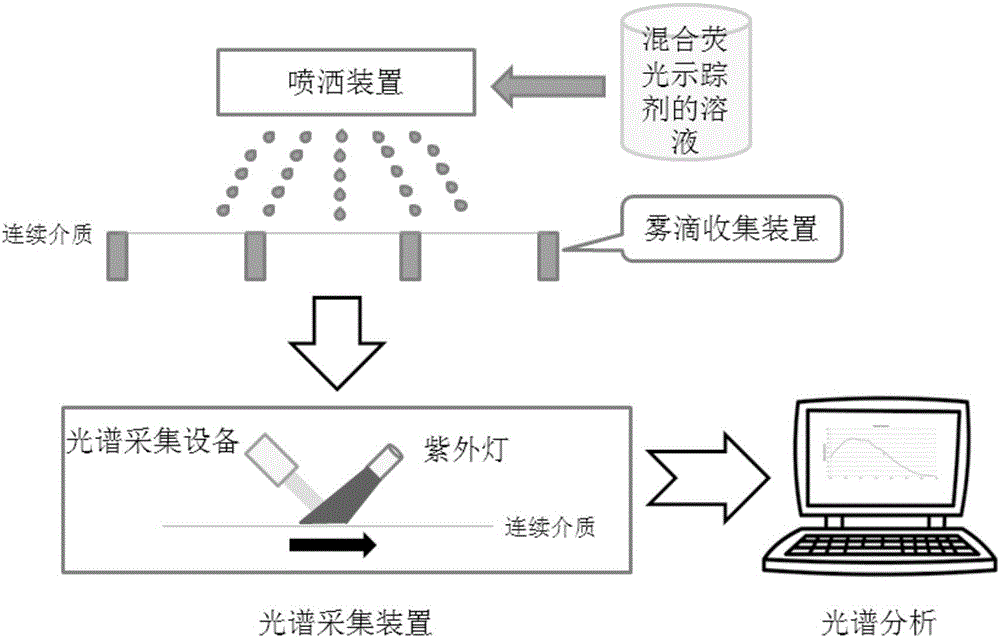

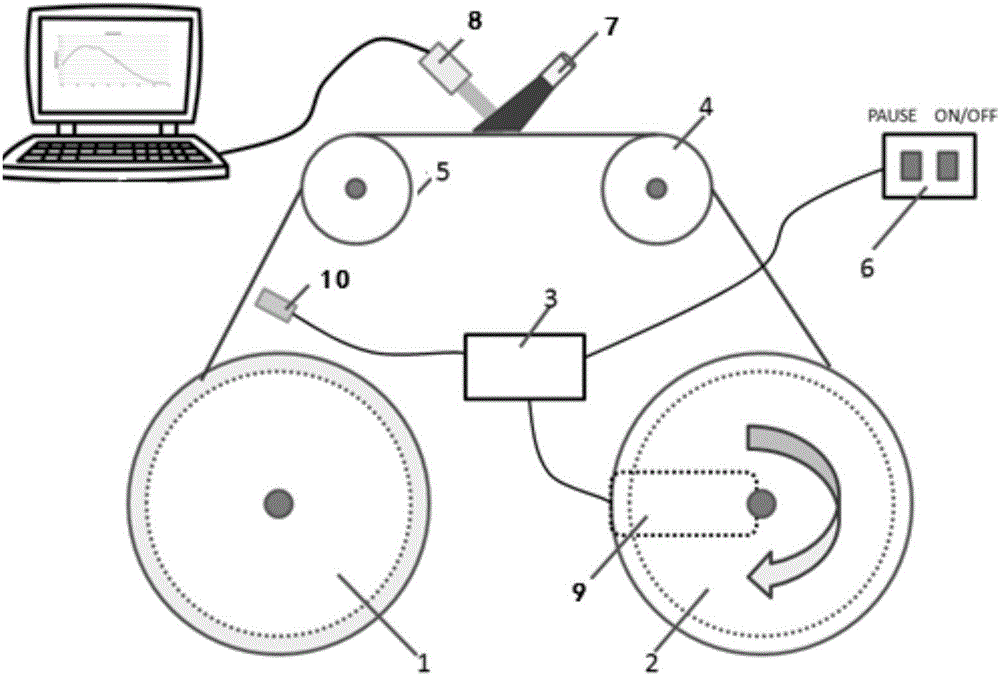

Detection system and method for deposition mass of aerially applied pesticide

ActiveCN106610366AEasy accessSimple detectabilityFluorescence/phosphorescenceAcquisition apparatusBand shape

The invention provides a detection system and method for the deposition mass of an aerially applied pesticide. The detection system comprises an aerial sprinkling apparatus, a droplet collecting apparatus, a spectrum acquisition apparatus and a droplet deposition characteristic analysis apparatus, wherein the aerial sprinkling apparatus is filled with a pesticide application solution mixed with a fluorescent tracer and used for sprinkling the pesticide application solution to a preset area; the droplet collecting apparatus is a rollable continuous band-shaped medium laid in the preset area, having preset width and free of fluorescent effect, and the continuous band-shaped medium is used for collecting the pesticide application solution sprinkled by the aerial sprinkling apparatus; the spectrum acquisition apparatus is used for spectrum acquisition of the continuous band-shaped medium having collected the pesticide application solution; and the droplet deposition characteristic analysis apparatus is used for analyzing spectra acquired by the spectrum acquisition apparatus and calculating the deposition mass of droplet in the preset area. The detection system and method provided by the invention can conveniently acquire the deposition mass of the aerially applied pesticide.

Owner:BEIJING RES CENT OF INTELLIGENT EQUIP FOR AGRI +1

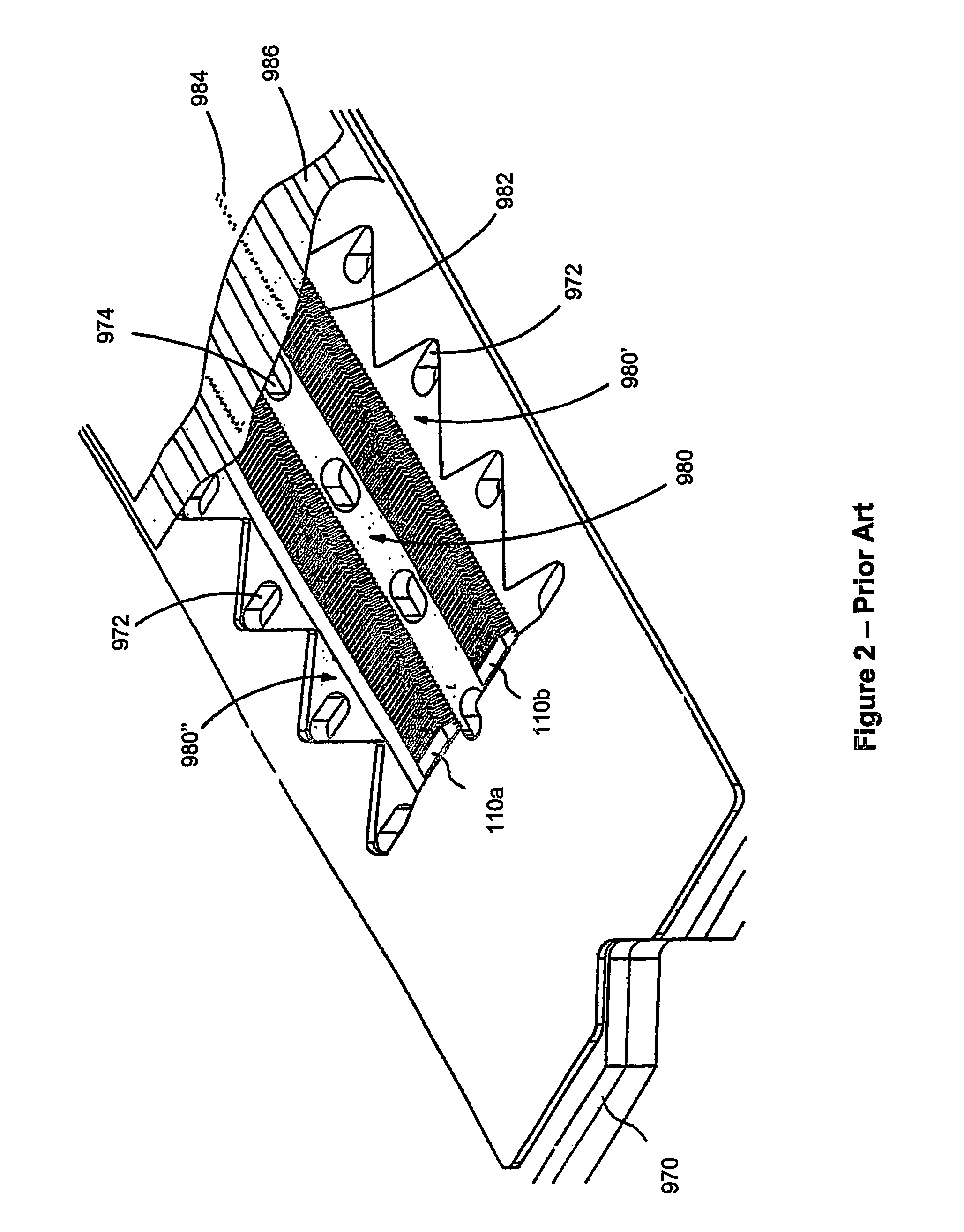

Method of manufacturing a droplet deposition apparatus

InactiveUS6959471B2Effective and reliable electrical connectionInking apparatusWriting implementsElectrical connectionSingle step

A method of manufacturing an ink jet print head includes the steps of bonding a body of piezoelectric material to a base plate and cutting channels into the piezoelectric material to form ink chambers which are actuated by applying voltages to electrodes provided on surfaces of the chambers. The base plate carries IC's which contain the drive circuitry for actuating the ink chambers. To ensure reliable electrical connection between the chamber electrodes and the IC's, the electrodes and conducting tracks on the base plate are formed in a single step by depositing a conductive layer over both the PZT body and the base plate. A step of masking or selective removal of material may be performed to achieve the necessary patterning of the electrodes and tracks.

Owner:XAAR TECH LTD

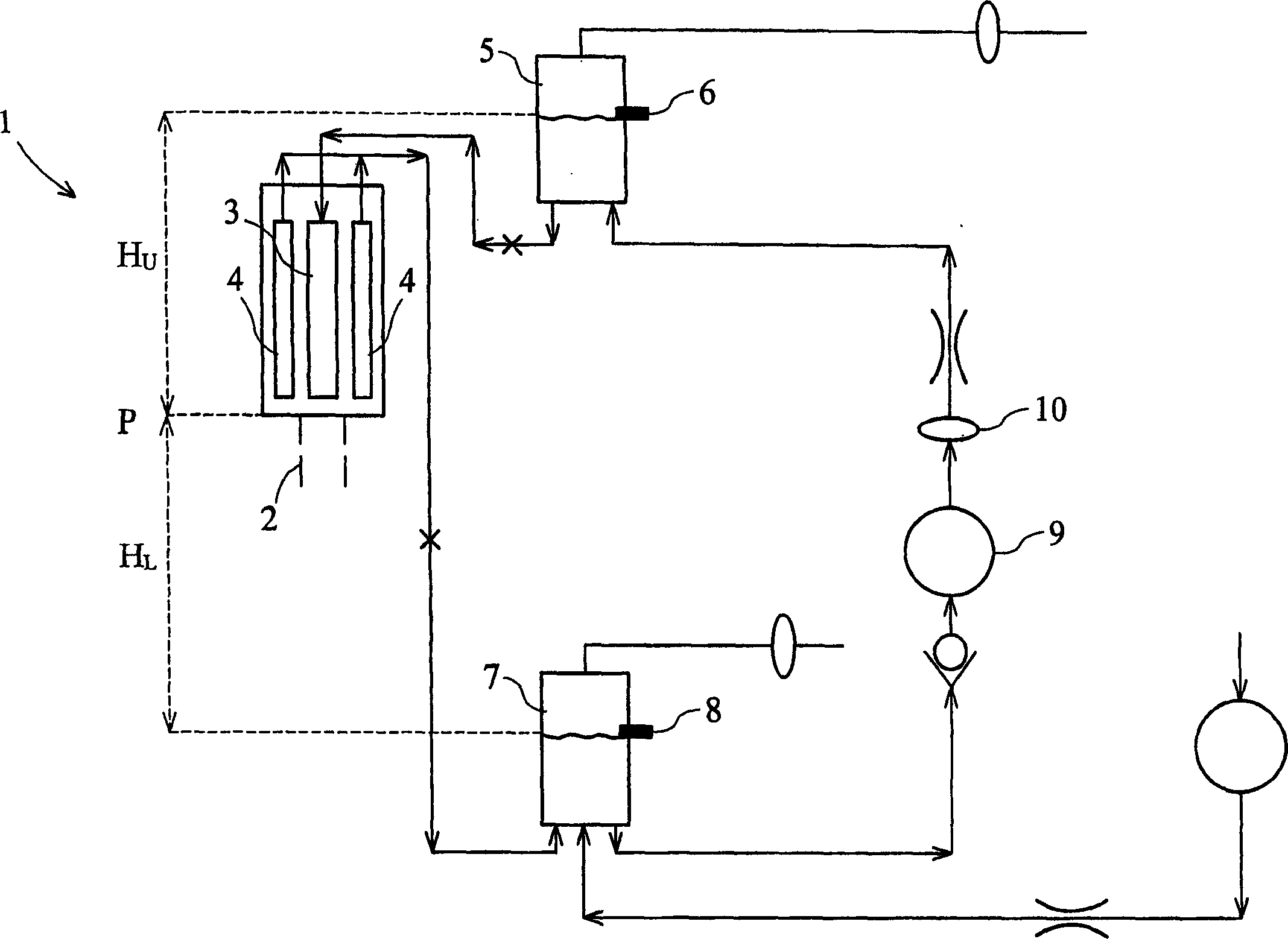

Droplet deposition apparatus

An ink supply system for a droplet deposition apparatus wherein the pressure at the nozzle is controlled by a remote point, said remote point being positioned in parallel with said print head. The flow restrictions in the printhead arm and the pressure control arm of the circuit being selected to achieve this.

Owner:XAAR TECH LTD

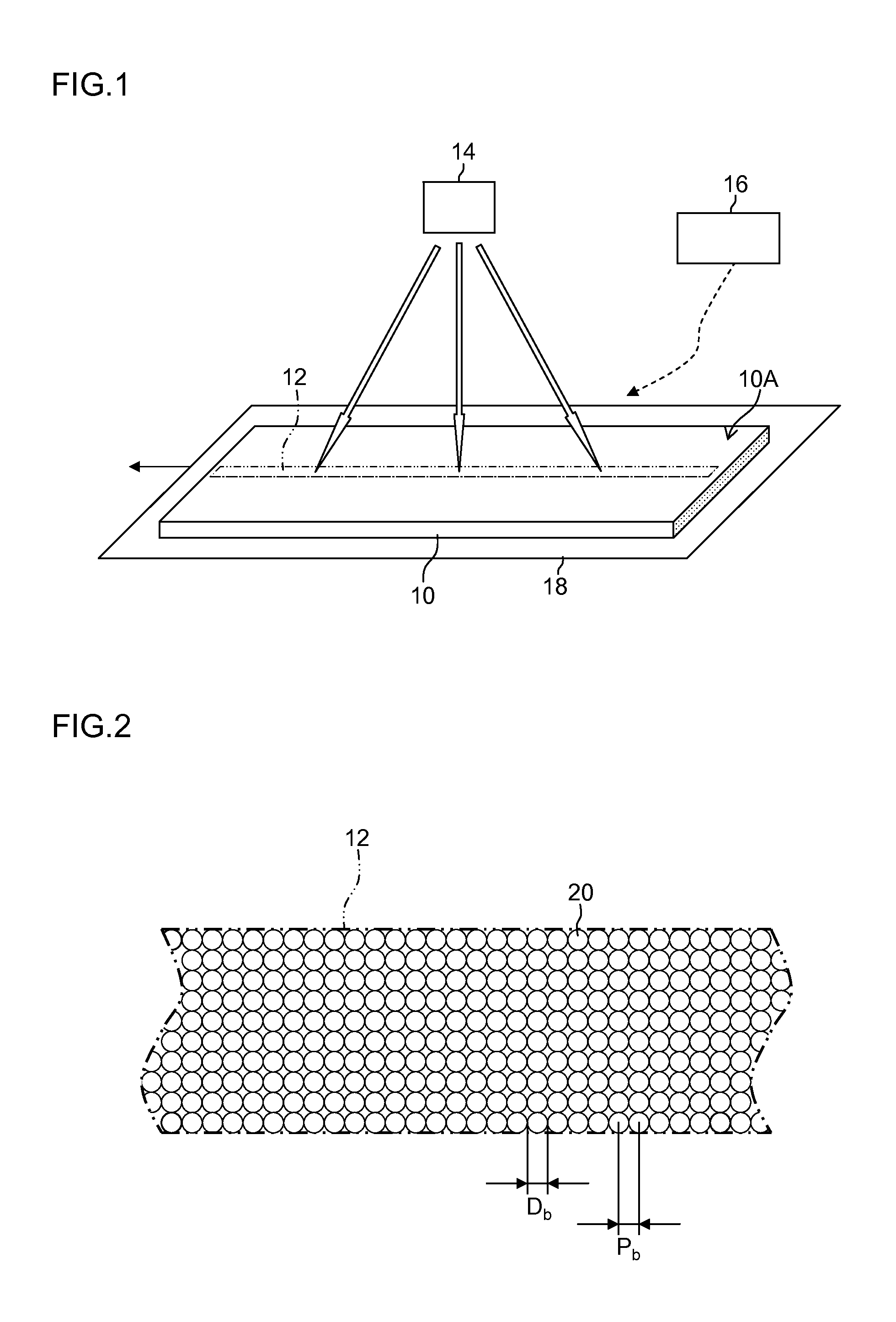

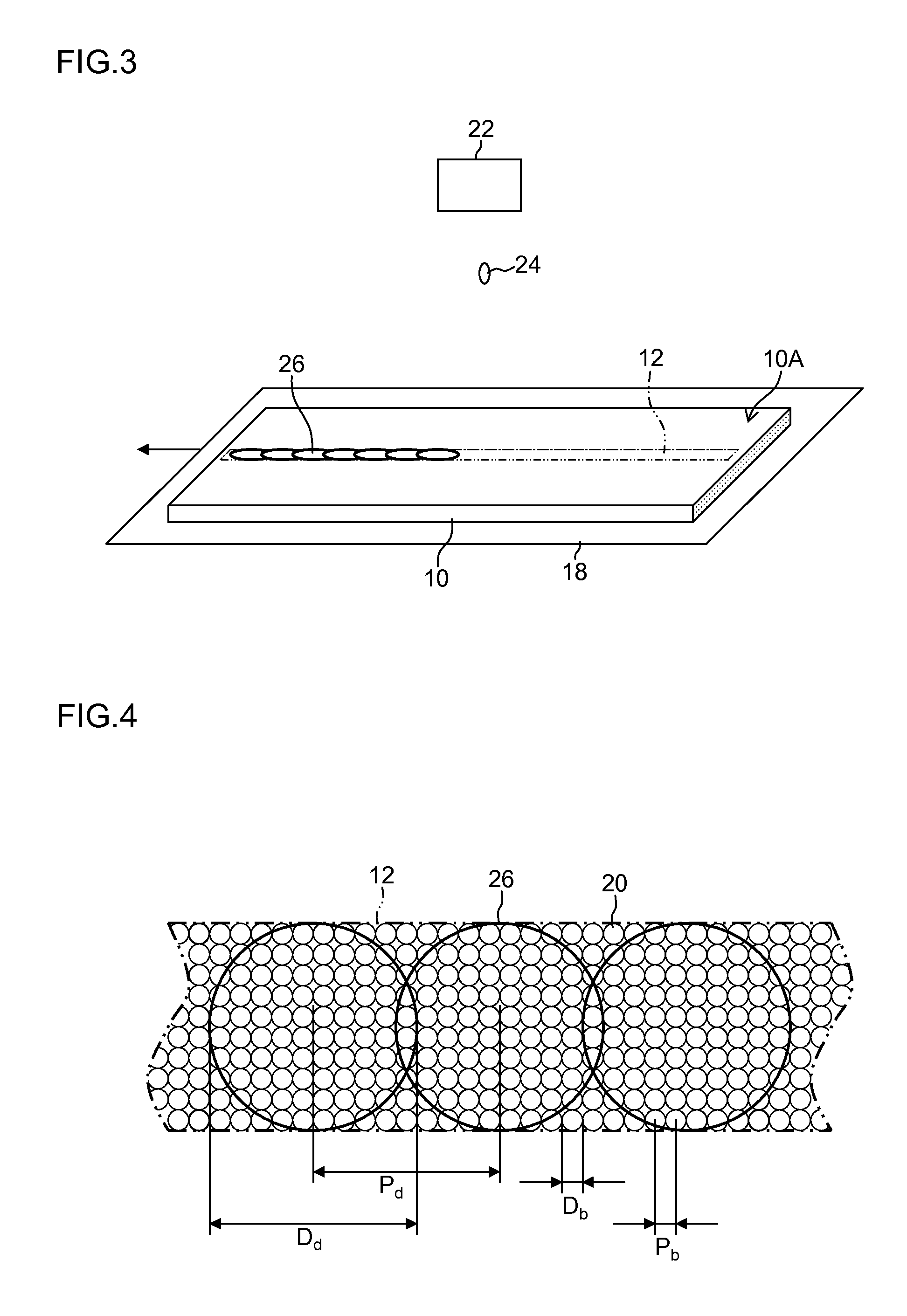

Pattern forming method and pattern forming apparatus

InactiveUS20130201240A1Avoid position deviationImprove pattern qualityPretreated surfacesTypewritersLight beamEngineering

A pattern forming method includes: a modification treatment step of, in accordance with a pattern to be formed on a pattern forming surface of a base body, applying a light beam having a width smaller than a diameter of each of dots to constitute the pattern, onto a treatment target region including at least outer edges on both sides in a width direction of a region where the pattern is to be formed in the pattern forming surface, thereby carrying out modification treatment on the treatment target region; and a droplet deposition step of ejecting and depositing droplets of a functional liquid by an inkjet method onto the region where the pattern is to be formed including the treatment target region where the modification treatment has been carried out.

Owner:FUJIFILM CORP

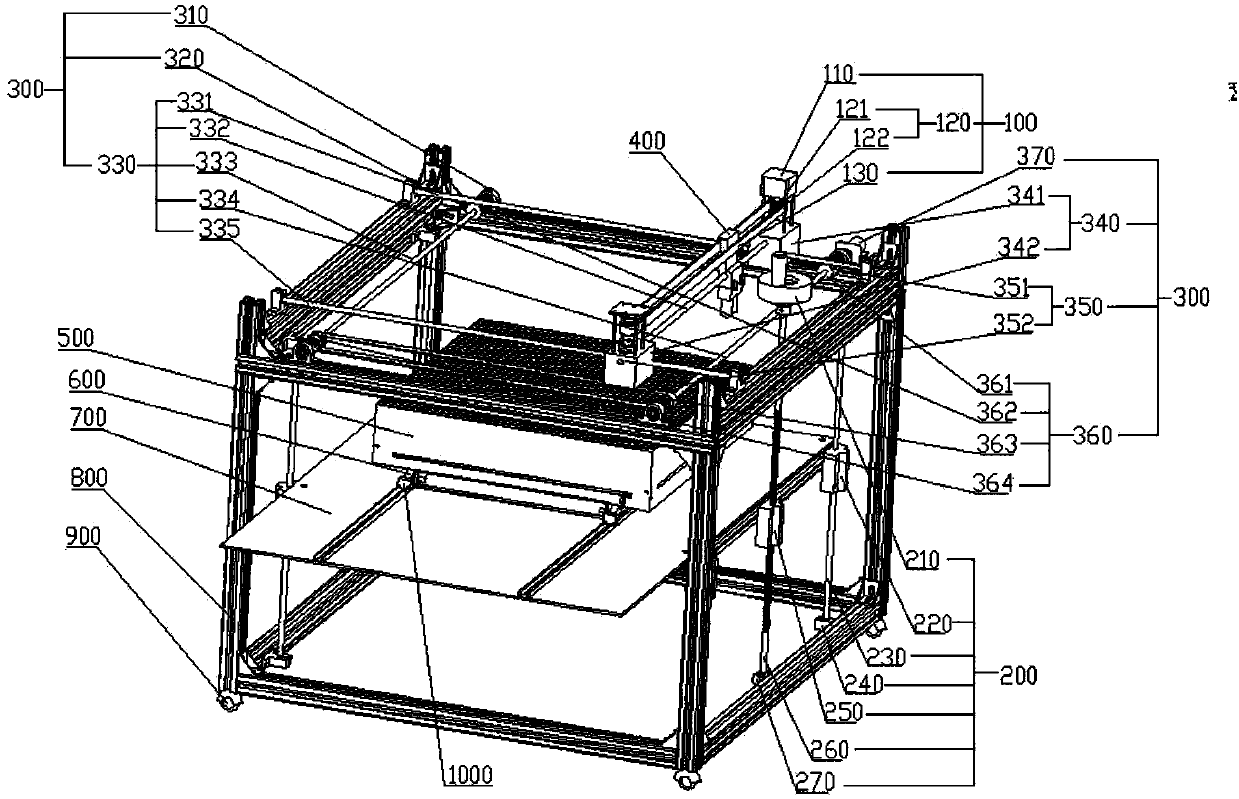

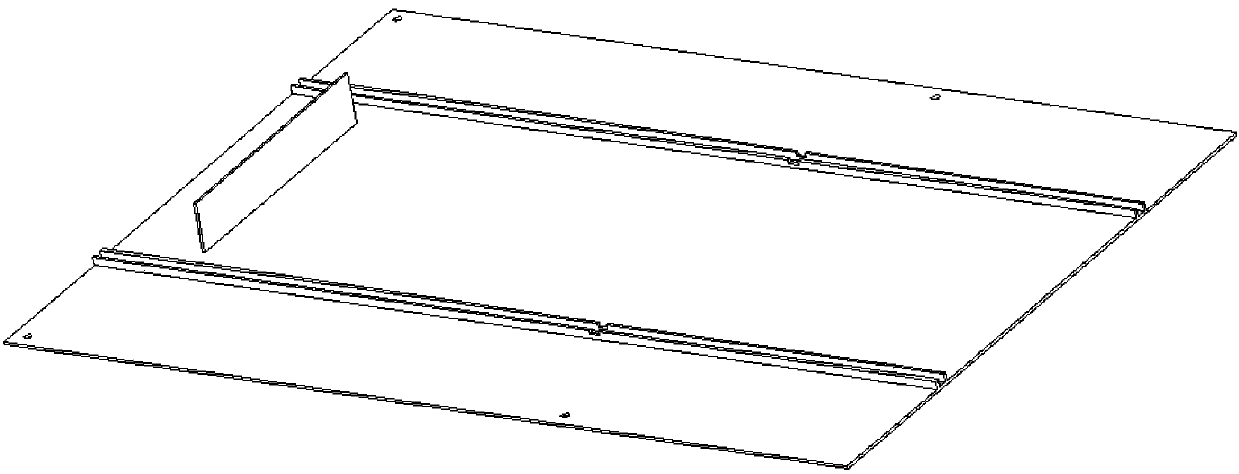

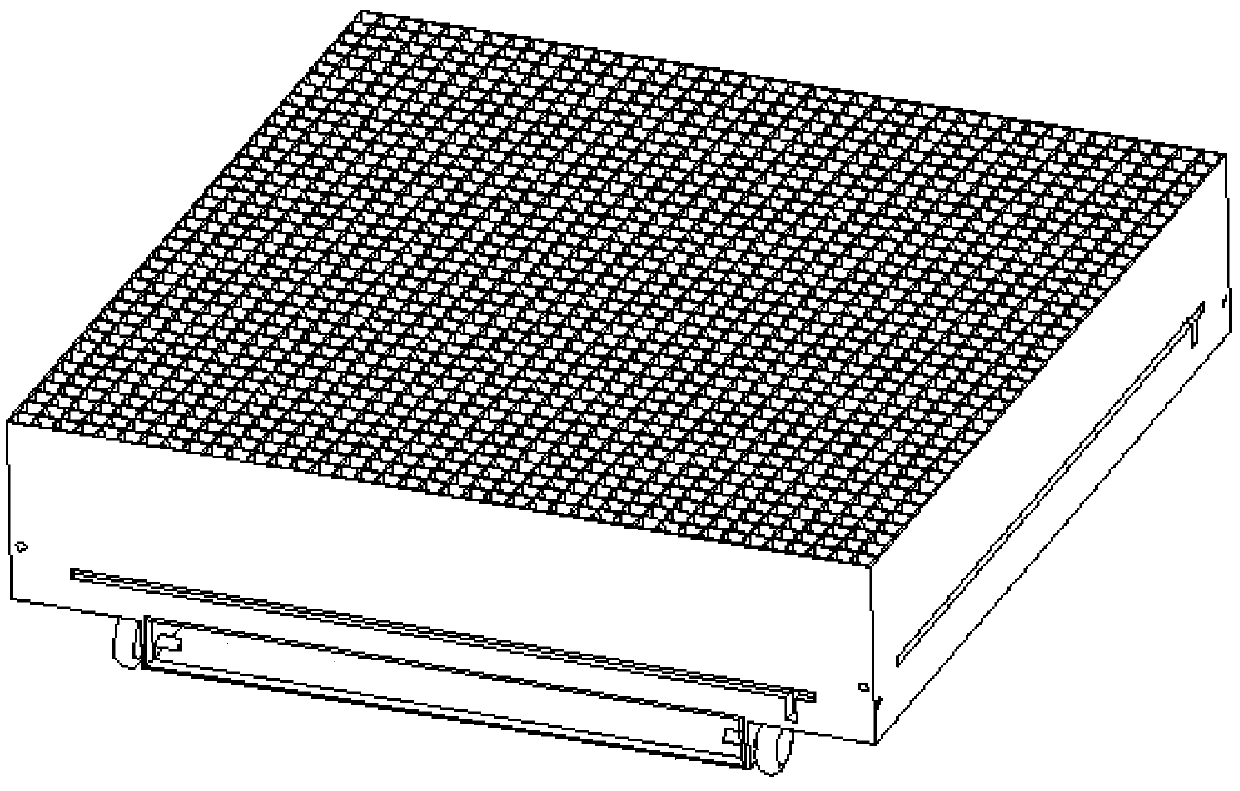

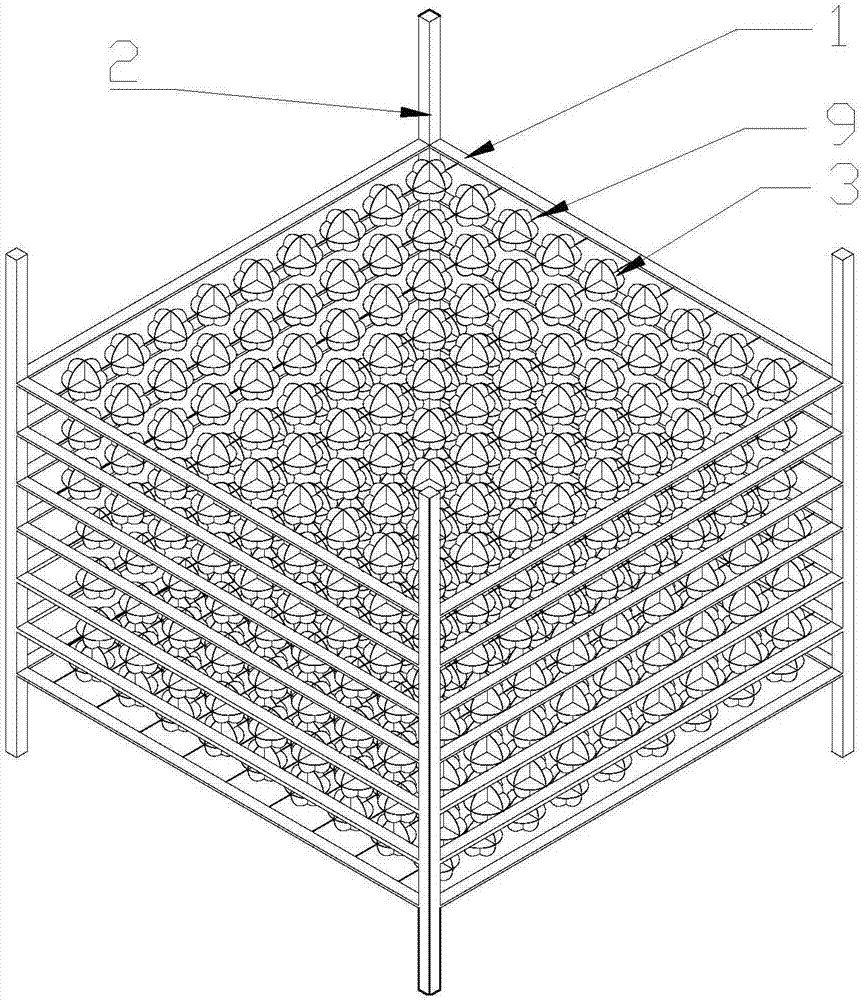

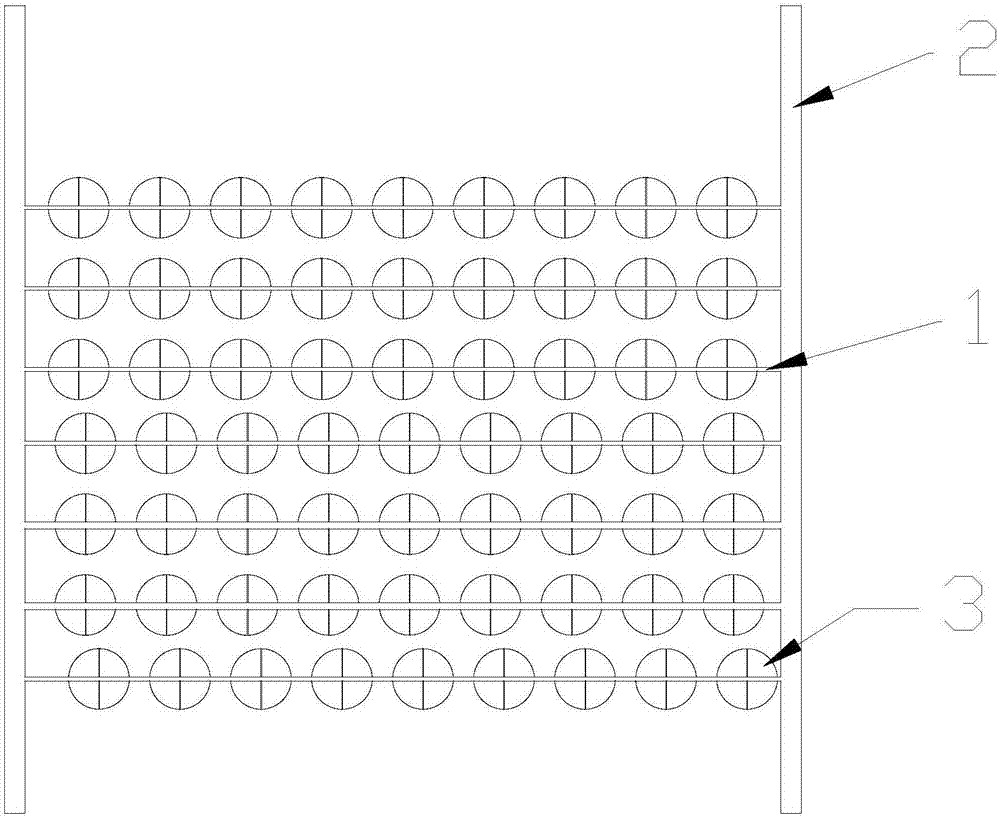

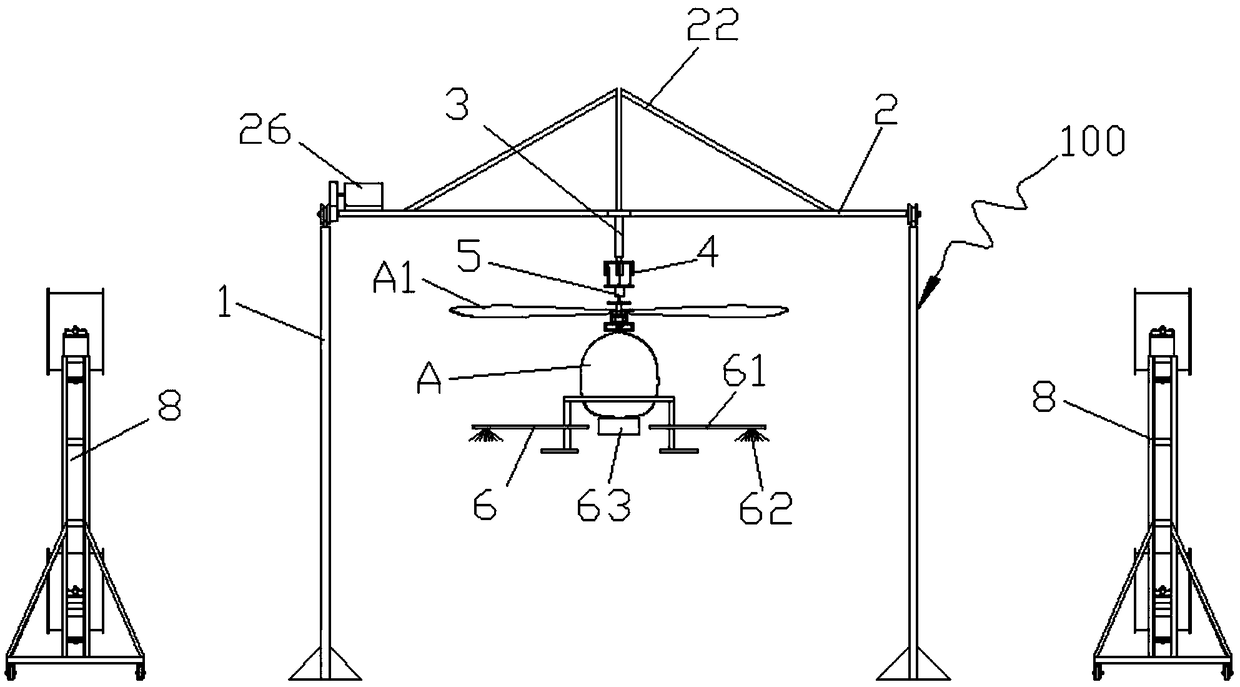

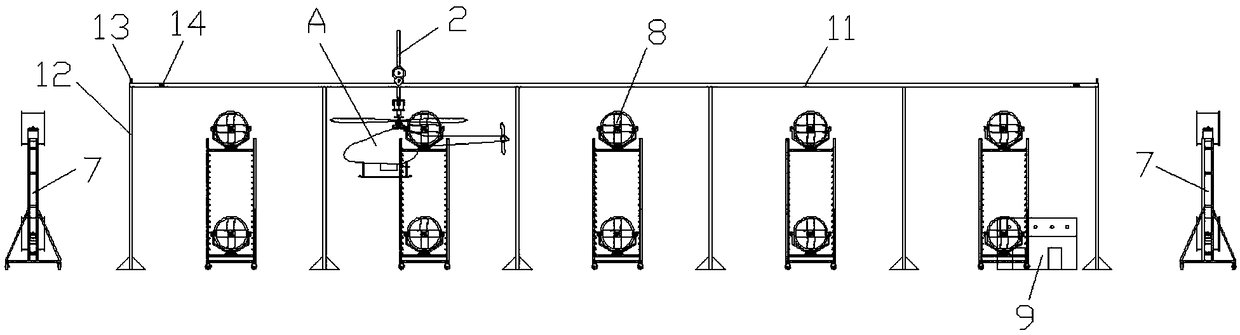

Device and method for detecting spray droplet deposition uniformity of agricultural drone

The invention relates to a device and method for detecting spray droplet deposition uniformity of an agricultural drone. The device comprises one machine frame, an X-directional movement mechanism, aY-directional movement mechanism, a Z-directional movement mechanism, an objective table, a laser ranging module, an array cavity tray container and the other machine frame; in the field of pesticidespraying, the flight height and speed of the drone and the influence of a rotor wing wind field on drifting and depositing of droplets in air can be researched indoors by adopting the detecting deviceand a spray droplet deposition uniformity detecting method provided by the invention; moreover, test space can be saved, and the device and the method have the characteristics of rapidness and intuitiveness.

Owner:SOUTH CHINA AGRI UNIV

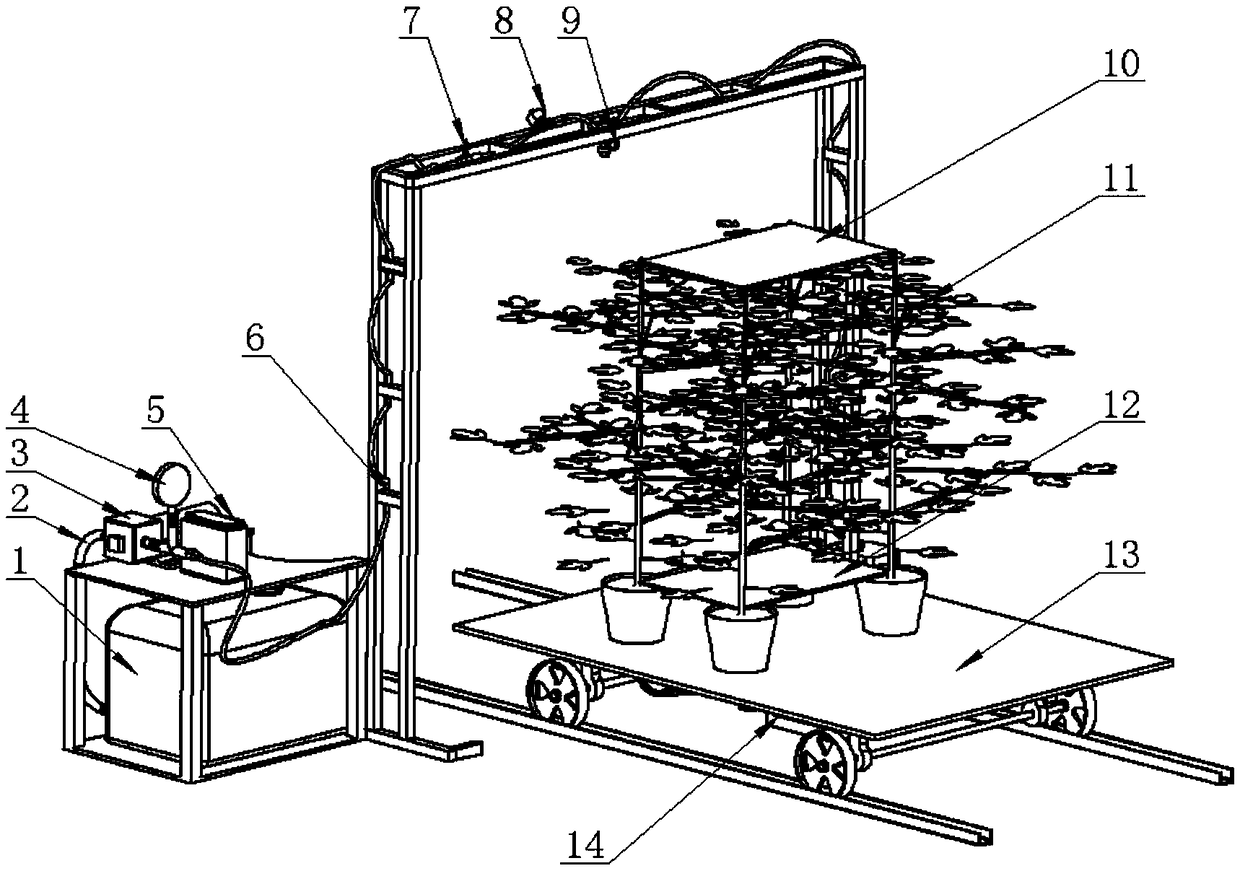

Method for measuring and evaluating spatial droplet deposition based on plant canopy porosity

ActiveCN109490158AAccurate droplet volumeOvercoming the drawbacks of inaccurate dataPermeability/surface area analysisPorosityStatistical analysis

The invention relates to a method for measuring and evaluating spatial droplet deposition based on plant canopy porosity. According to the method, a plant canopy is divided into plural layers, separators are arranged between adjacent layers; water sensitive paper is placed uniformly on the separators as much as possible; a plant runs through a spray frame with constant flow rate at a fixed speed,the deposition data of the water sensitive paper is calculated and analyzed to obtain the deposition of droplets in unit area; the deposition is multiplied with the areas of the separators to obtain the total deposition of the n separator, which is penetration in the n layer of the plant canopy, and the difference of deposition between the (n-1) separator and the n separator is the deposition of the n plant canopy, which reflects the deposition situation of the droplets in the n plant canopy, and the percentage of the total deposition of the n separator in the total deposition of the (n-1) separator reflects the penetration situation of the droplets in the plant canopy, and the relationship of the porosity and deposition percentage of each layer can be obtained by utilizing Gaussian process regression, and important accordance is provided to research of penetration and deposition distribution of droplets inside the plant canopy.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

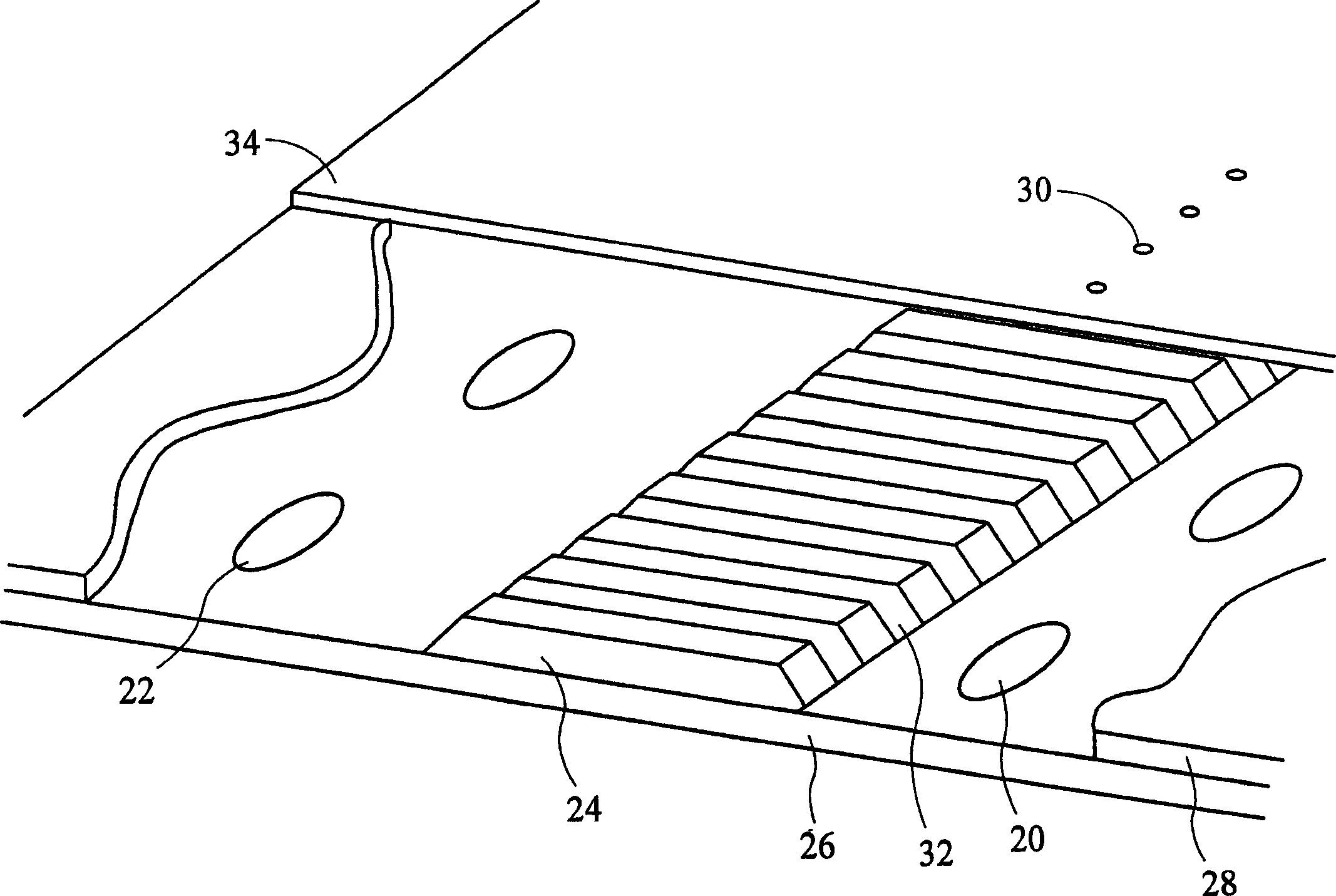

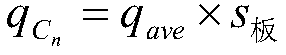

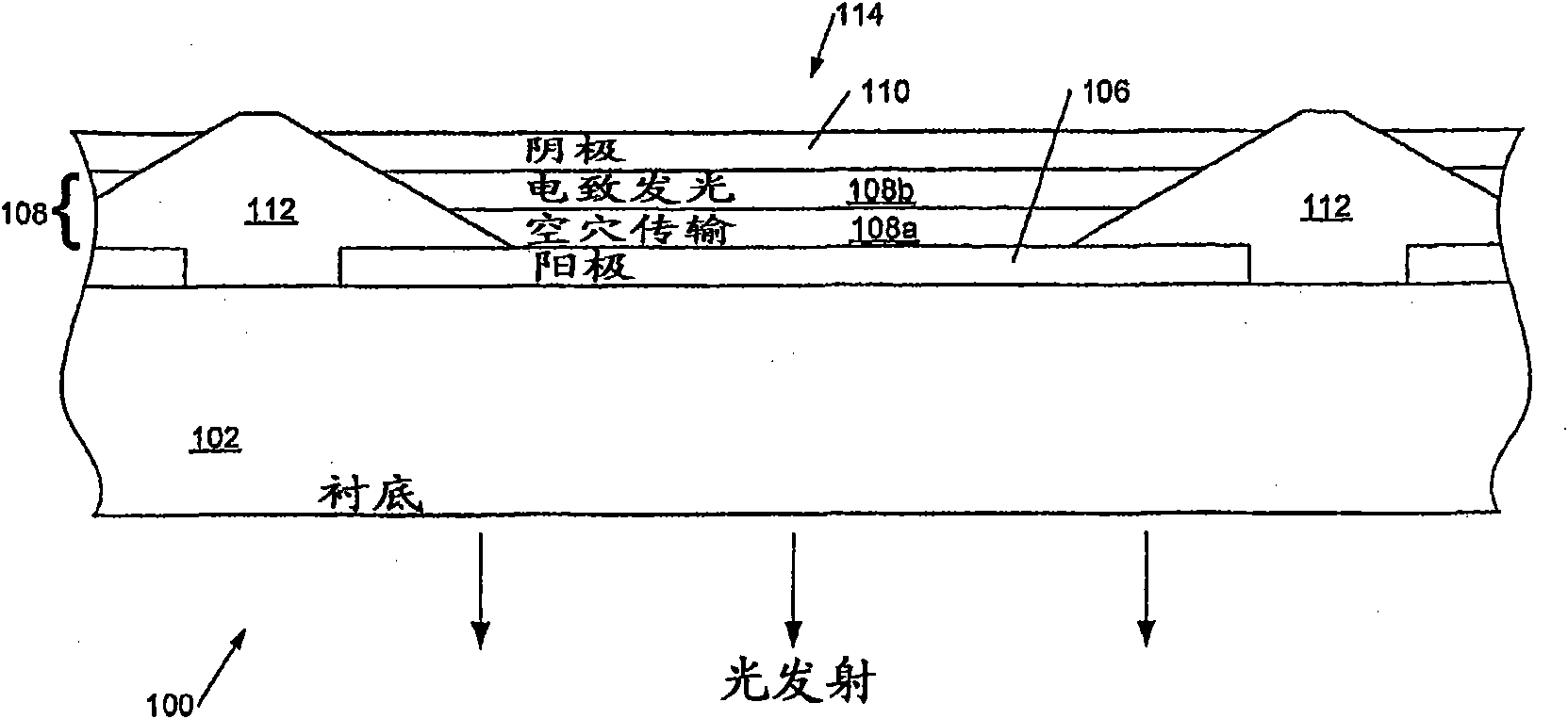

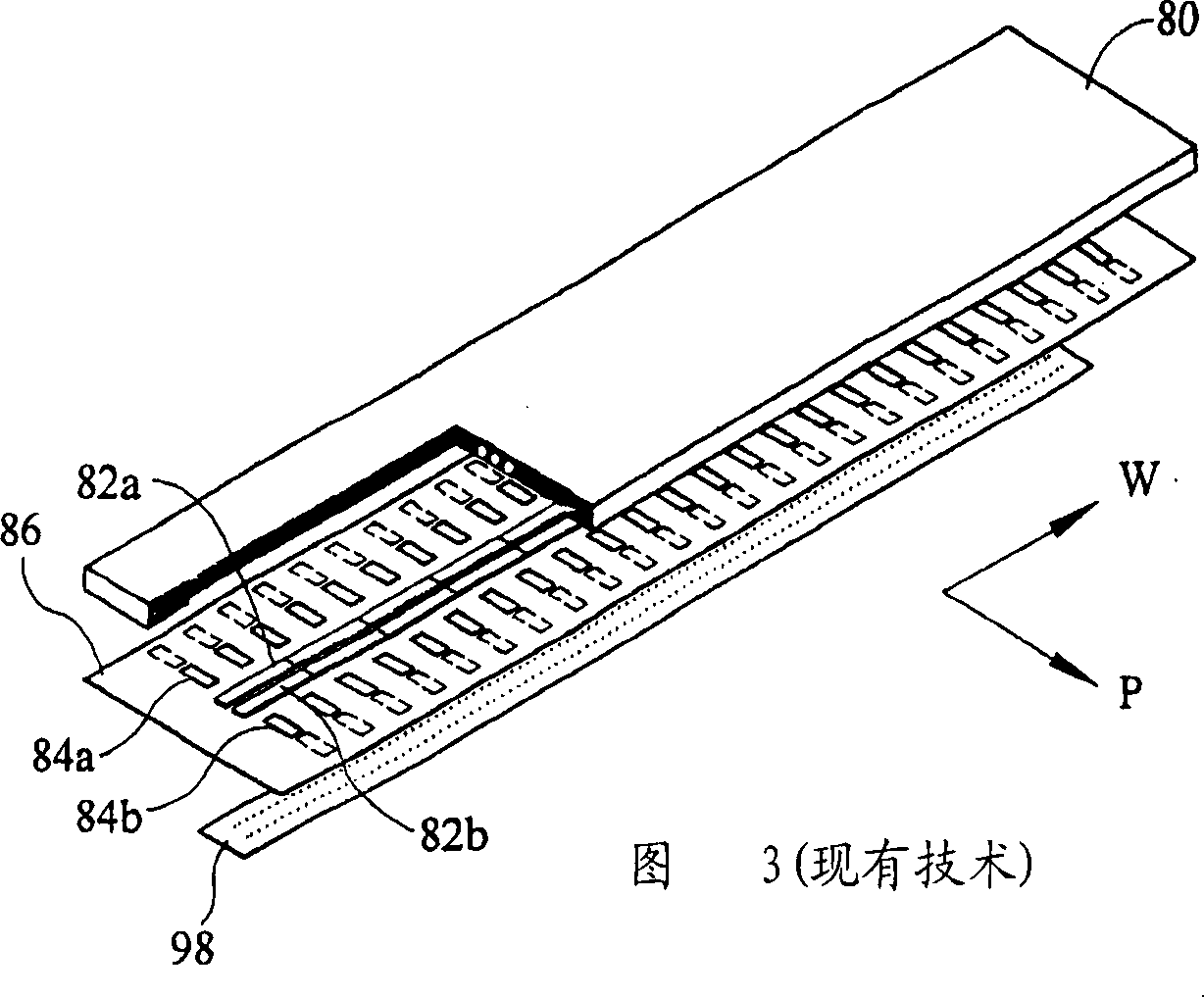

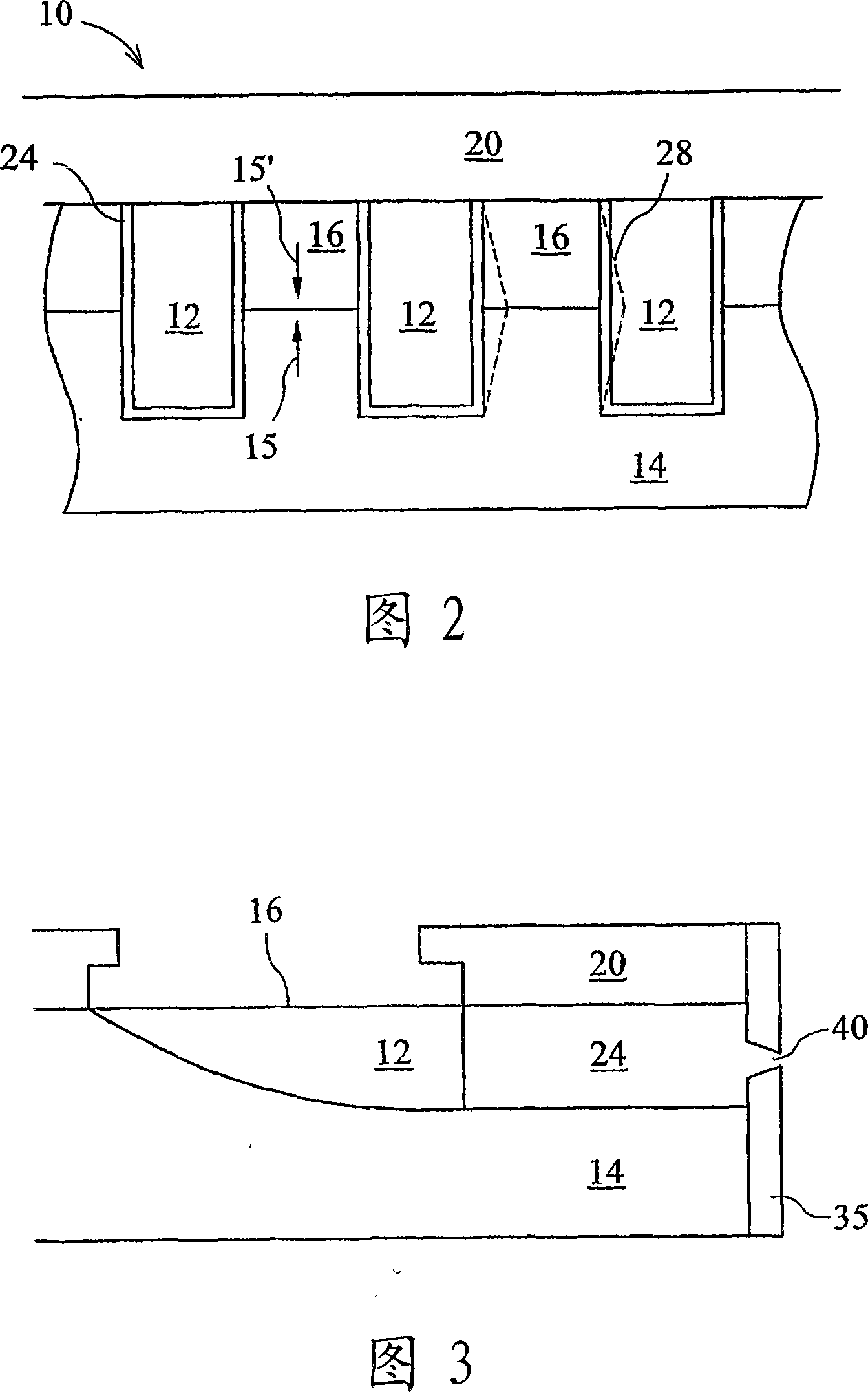

Molecular electronic device fabrication methods and structures

ActiveCN101529597AReduced Tape SeamsLess quantitySolid-state devicesSemiconductor devicesCharge injectionEngineering

This invention generally relates to improved methods of fabricating molecular electronic devices, in particular organic electronic devices such as organic light emitting diodes (OLEDs) by droplet deposition techniques such as ink jet printing. The invention also relates to molecular device substrates fabricated by and / or use in such methods. We describe an optical or optoelectronic device comprising a substrate and a plurality of discrete bank structures disposed on the substrate, wherein: each bank structure defines the perimeter of at least one well; one or more of a charge transporting, charge injecting, light-filtering and light-emitting material is disposed in the well; and at least one bank structure defines the perimeter of at least one well and does not extend to the perimeter of any adjacent well. Thus in embodiments no part of said perimeter defines the bank of more than one well.

Owner:CAMBRIDGE DISPLAY TECH LTD

Droplet deposition apparatus

A method of manufacturing an ink jet print head includes the steps of bonding a body of piezoelectric material to a base plate and cutting channels into the piezoelectric material to form ink chambers which are actuated by applying voltages to electrodes provided on surfaces of the chambers. The base plate carries IC's which contain the drive circuitry for actuating the ink chambers. To ensure reliable electrical connection between the chamber electrodes and the IC's, the electrodes and conducting tracks on the base plate are formed in a single step by depositing a conductive layer over both the PZT body and the base plate. A step of masking or selective removal of material may be performed to achieve the necessary patterning of the electrodes and tracks.

Owner:XAAR TECH LTD

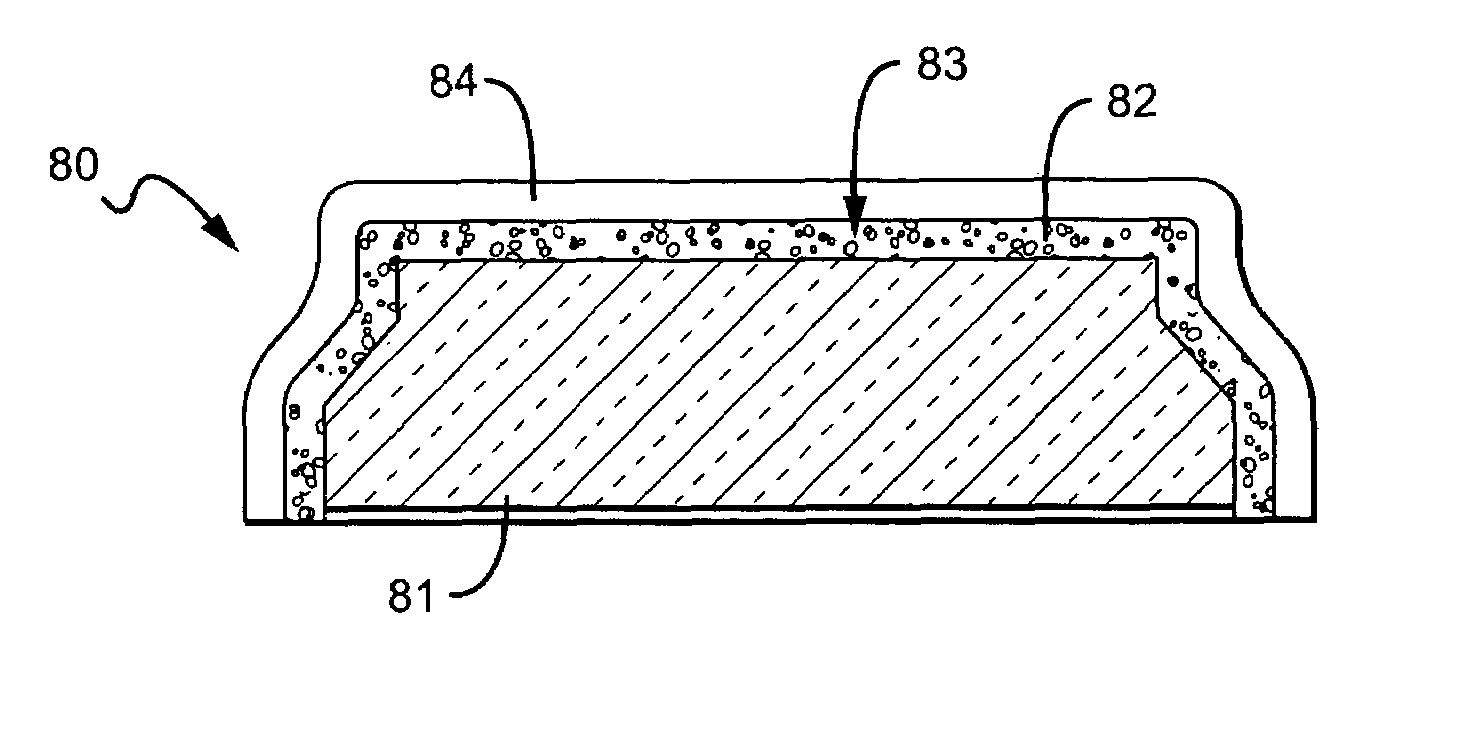

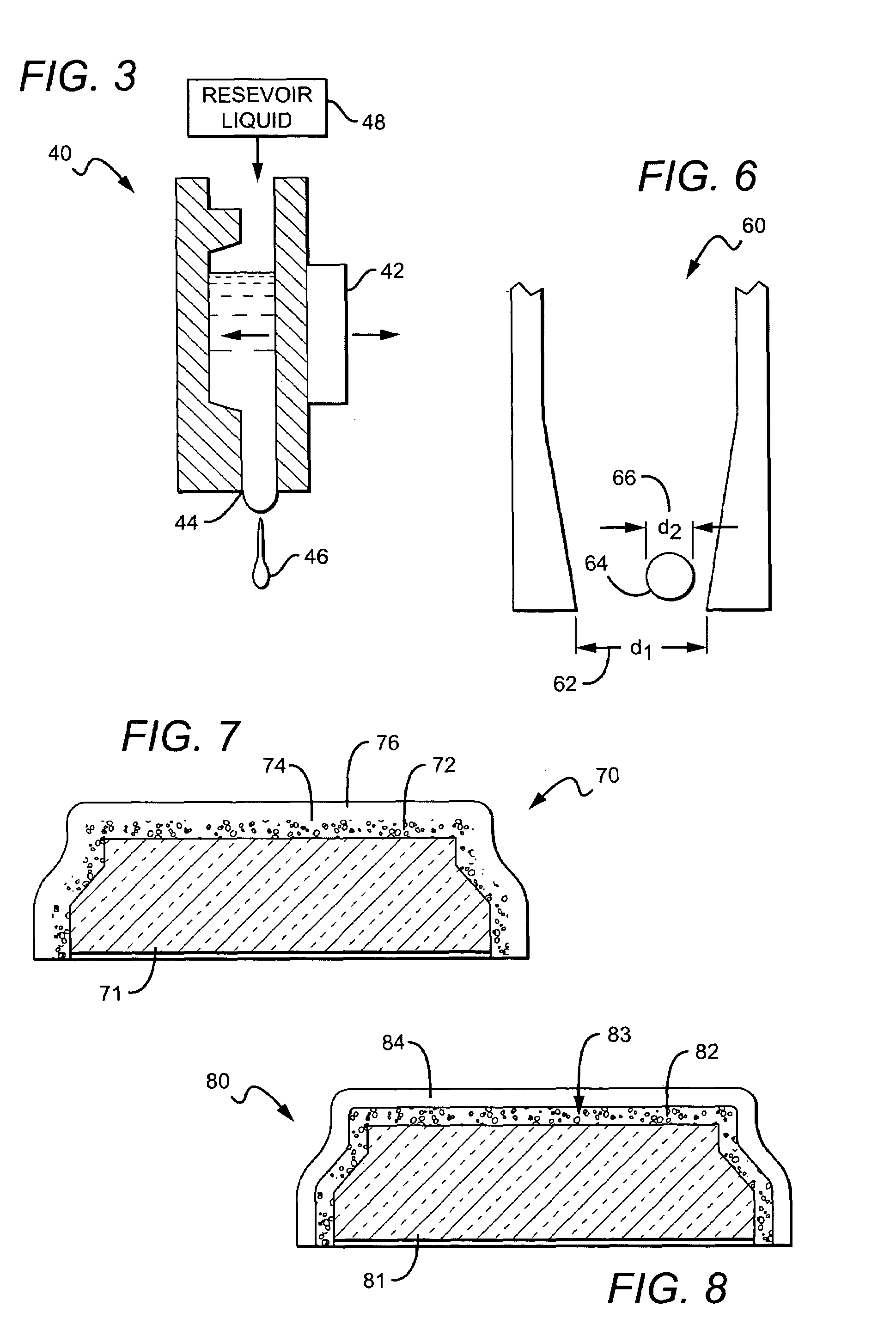

Method for coating semiconductor device using droplet deposition

ActiveUS7569406B2Solid-state devicesSemiconductor/solid-state device manufacturingLiquid mediumPhosphor

Methods and systems for coating of semiconductor devices using droplets of wavelength conversion or phosphor particles in a liquid medium. A plurality of nozzles delivers a controlled amount of the matrix material to the surface of the semiconductor device, with each of said nozzles having an opening for the matrix material to pass. The opening has a diameter wherein the diameter of the phosphor particles is less than or approximately equal to one half the diameter of the opening. The phosphor particles are also substantially spherical or rounded. The nozzles are typically arranged on a print head that utilizes jet printing techniques to cover the semiconductor device with a layer of the matrix material. The methods and systems are particularly applicable to covering LEDs with a layer of phosphor materials.

Owner:CREELED INC

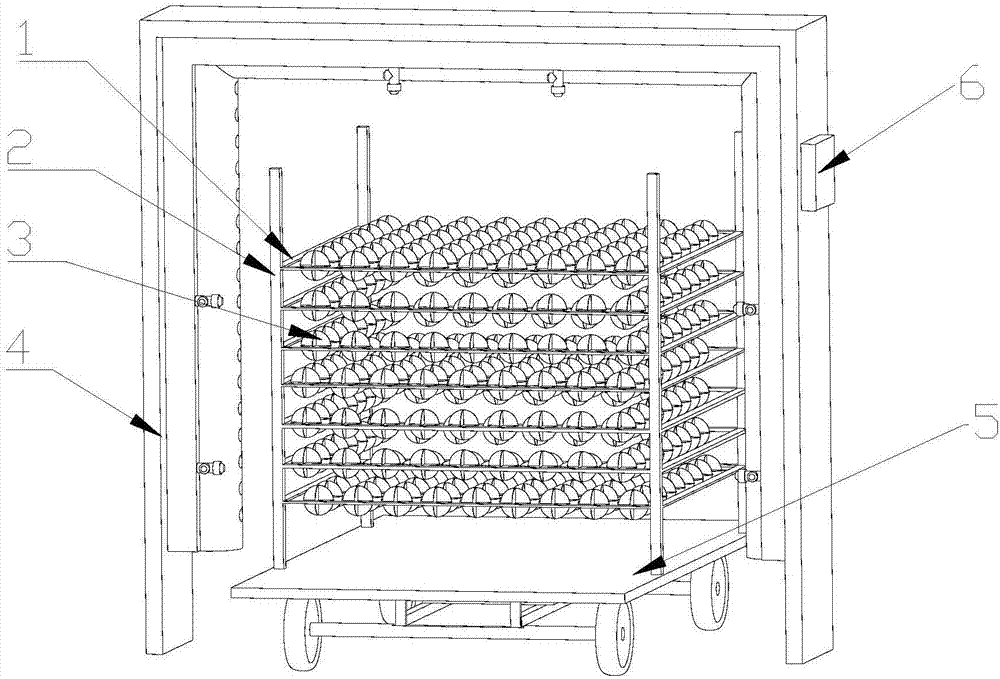

Testing method and testing device for fog-droplet deposition on basis of similarity of crop porosity

ActiveCN107036943ARealize the test of droplet depositionImprove standardizationPermeability/surface area analysisSoil sciencePlant population

The invention relates to a testing method for fog-droplet deposition on the basis of similarity of crop porosity. The method comprises the following steps: selecting a deposition testing area according to the forms of crop plant populations, on the basis of porosity measurement of leaves at different layers of population plants, abstracting population crop plants into a plurality of layers from high to low, and leading the porosity of the leaves at the abstracted and simplified layers and the actually-measured porosity of the leaves to be same by different arrangement and combination modes. In order to adapt to testing of the fog-droplet deposition characteristic of the leaves under different spraying modes, the leaves are abstracted into three perpendicular geometries with the same size according to the need. The invention also relates to a testing device for fog-droplet deposition on the basis of similarity of crop porosity. The testing device comprises a mechanical bracket, a plant abstract leaf array, a traveling chassis, a spraying system and a control unit. The testing method and the testing device have the advantages that testing of the fog-droplet deposition amount in a three-dimensional space of different crops in different growth forms and different spraying modes is realized, and simultaneously, the standardization of the testing process is easy to realize.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

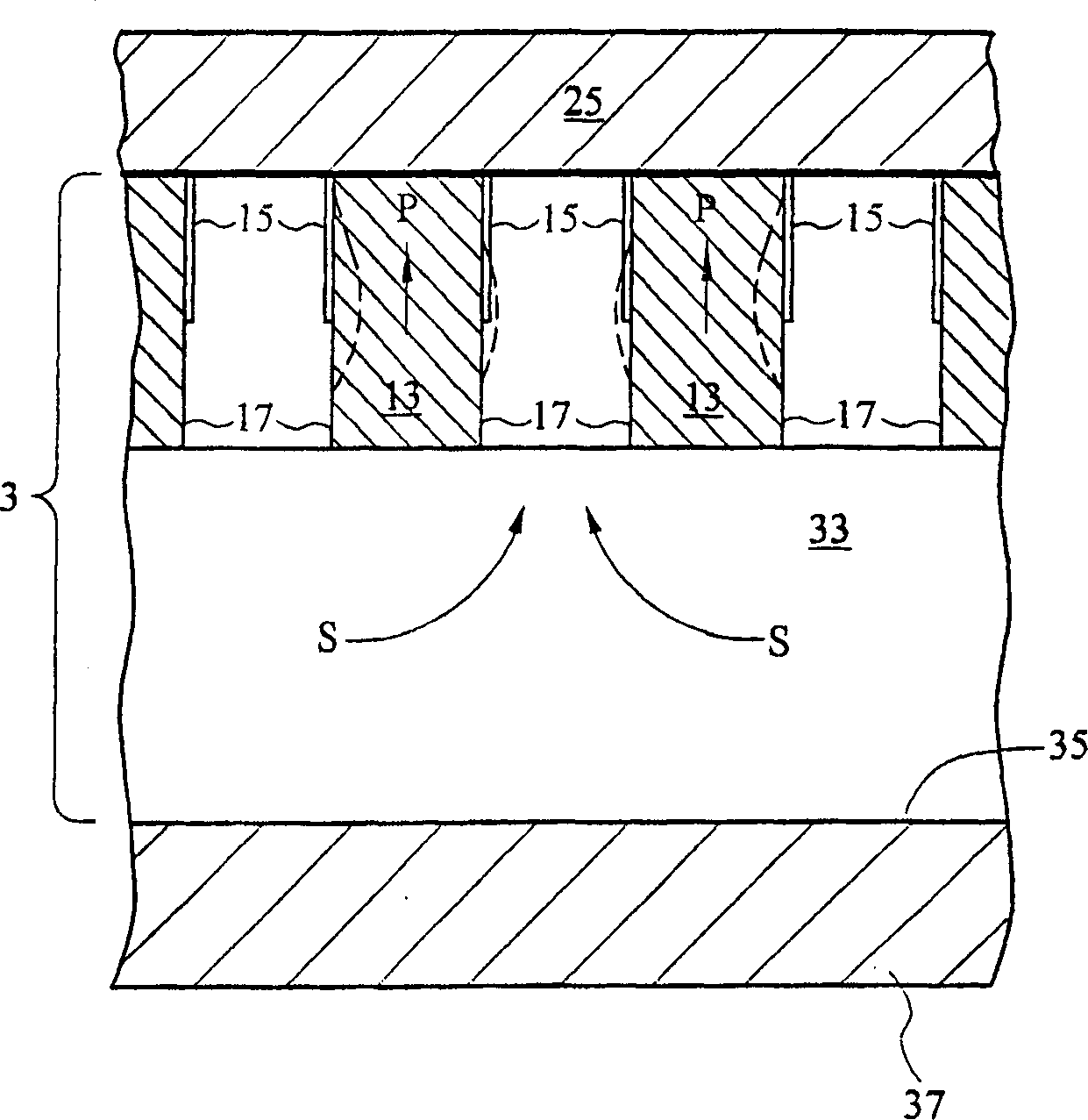

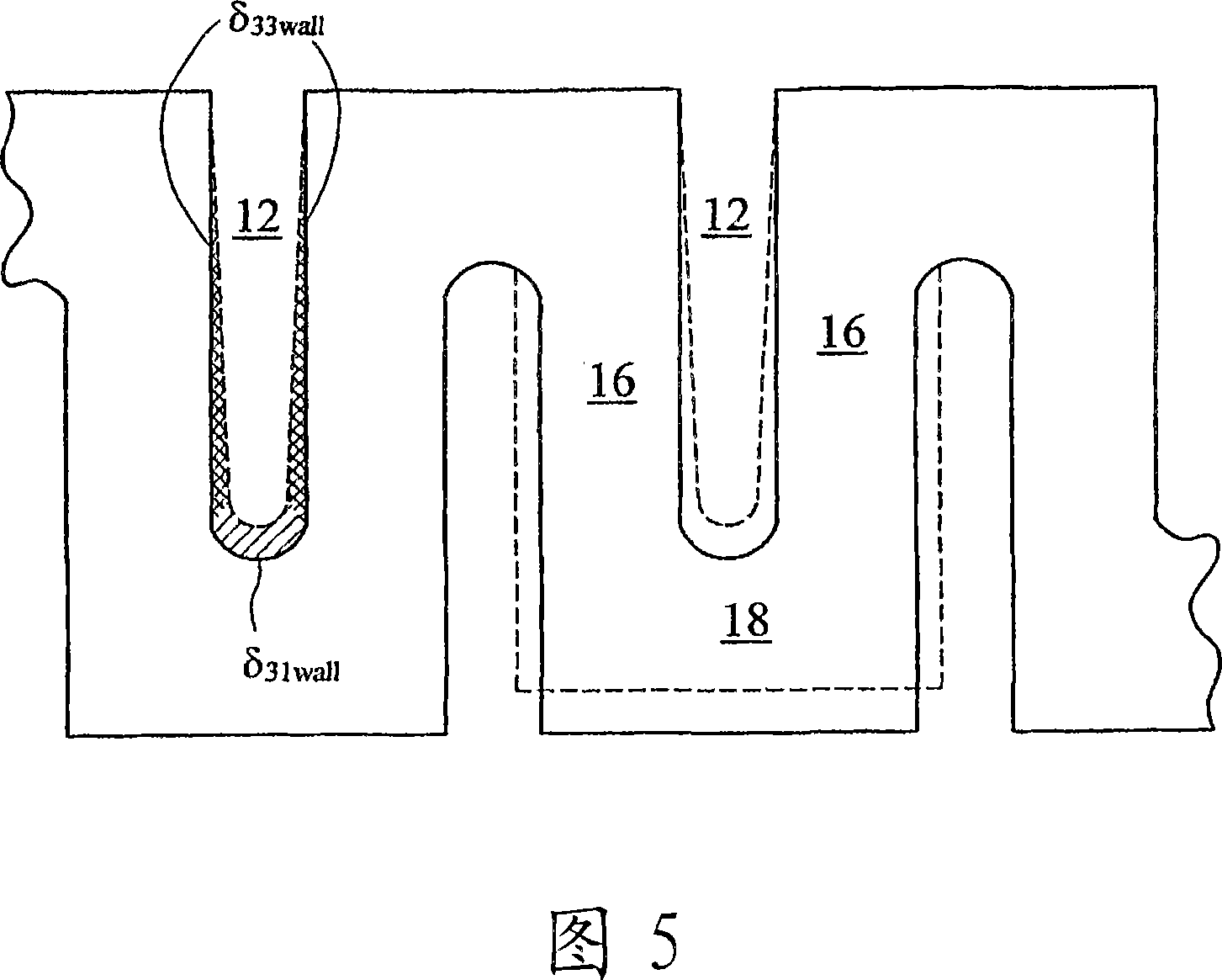

Droplet deposition apparatus

An actuator taking the form of a piezoelectric wall separating two chambers, which utilises two actuation modes. Both actuation modes cause volume displacements in both chambers, but act to reinforce one another in one chamber and cancel one another in the other chamber. A fluid pump for droplet deposition having an array of channels separated by such actuators can be operated with each channel acting substantially independently of its neighbours.

Owner:XAAR TECH LTD

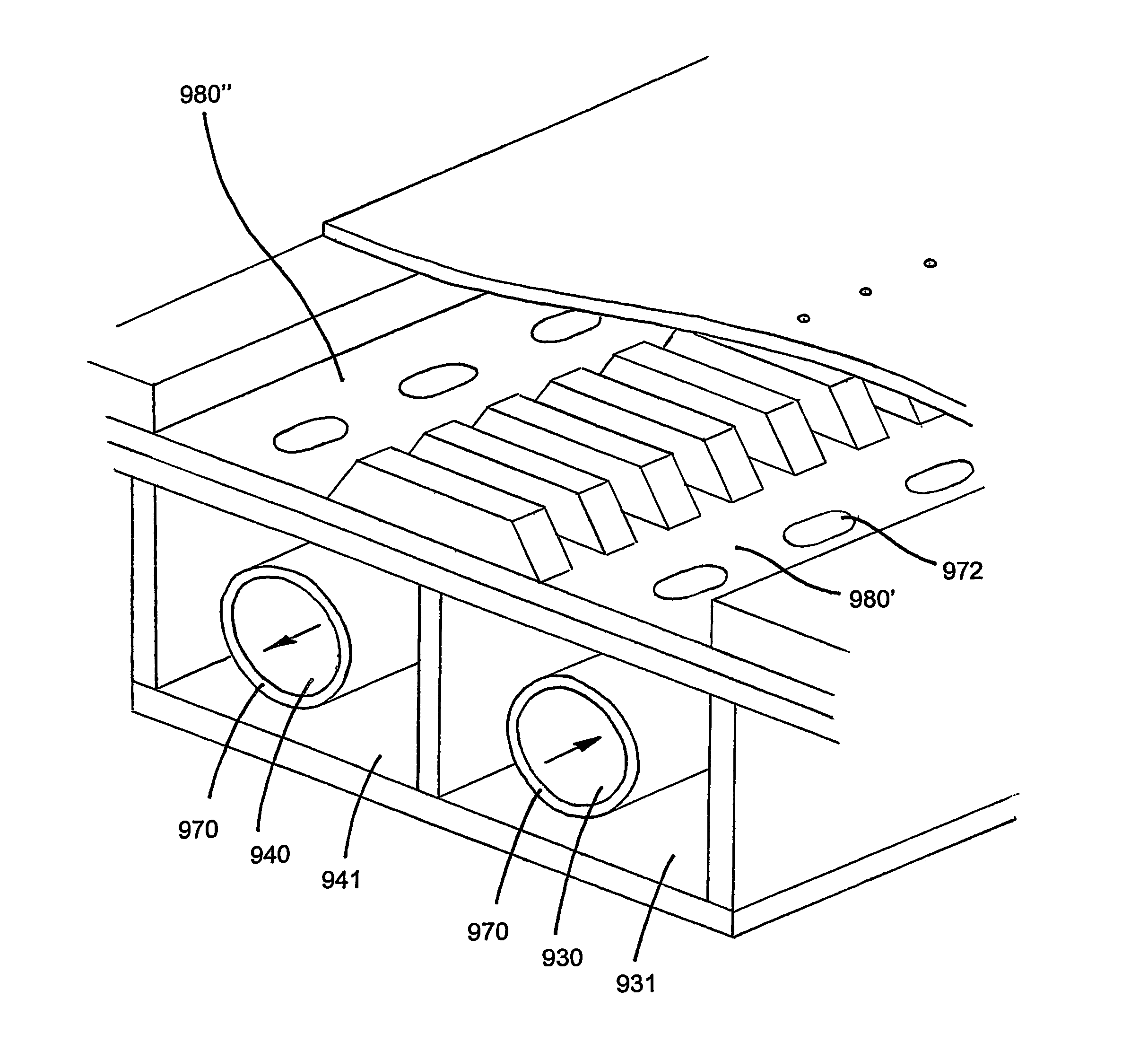

Droplet deposition apparatus

Inkjet printhead with an array of ejection chambers spaced in an array direction, each communicating with an ink orifice, inlet and outlet plenum chambers communicating with the ejection chambers, and inlet and outlet manifolds extending in the array direction and communicating with the plenum chambers through a porous sheet. While there are substantial net ink flows in the array direction in the inlet and the outlet manifolds, there is substantially no net flow in the array direction in the inlet or outlet plenum chamber. Ink pressure is therefore constant over the array of ejection chambers.

Owner:XAAR TECH LTD

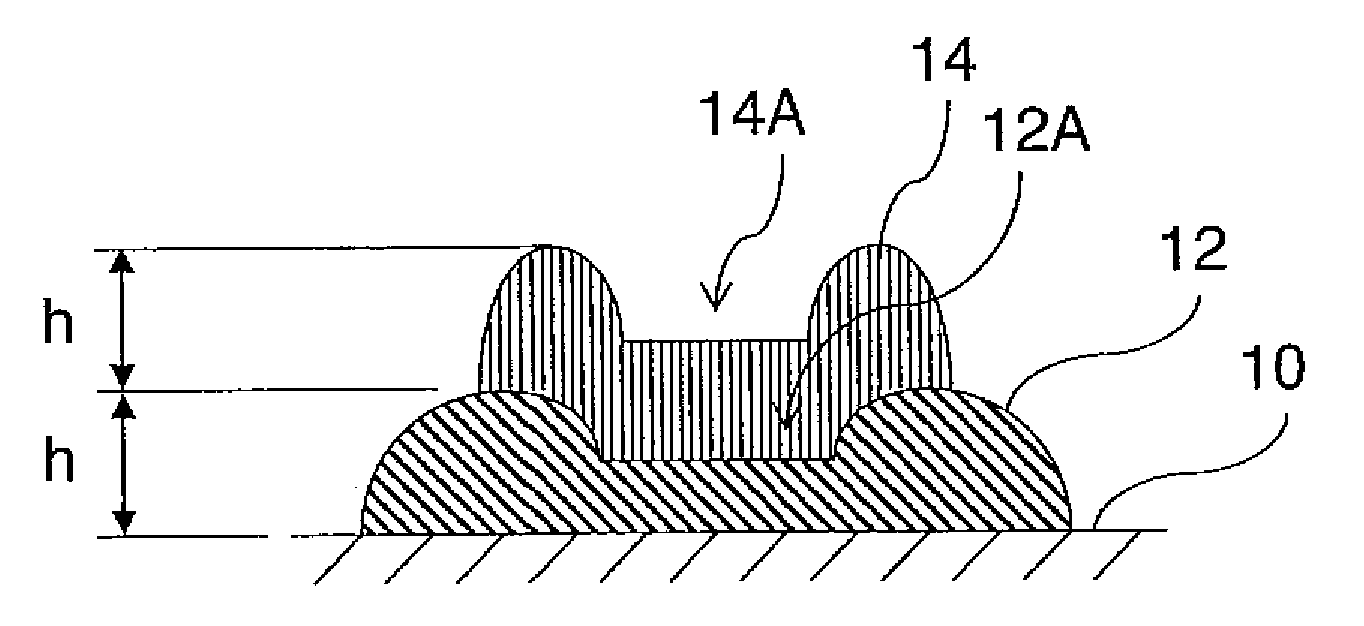

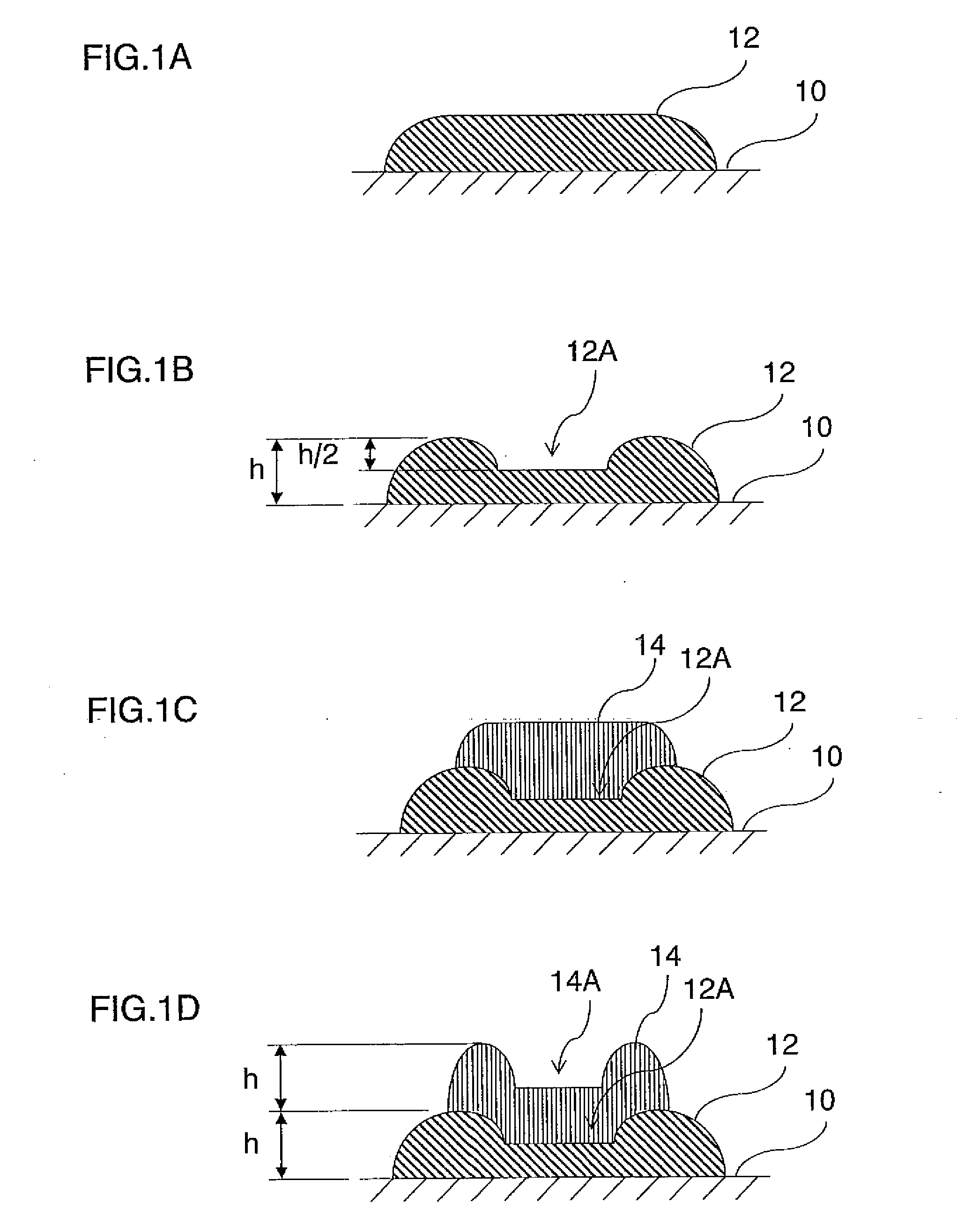

Image forming method and apparatus

InactiveUS20090085256A1High aspect ratioStay in shapeDuplicating/marking methodsAuxillary shaping apparatusImage formationThree dimensional shape

The image forming method forms a three-dimensional shape on a medium by stacking up a plurality of droplets of liquid on a same droplet deposition point on the medium. The method includes the steps of: depositing a first droplet of the liquid onto the medium; then solidifying the first droplet while carrying out a process whereby an upper surface of the first droplet assumes a depressed shape; and then depositing a second droplet of the liquid onto the first droplet.

Owner:FUJIFILM CORP

Droplet deposition apparatus

An inkjet printhead has a first array of actuable side walls (1507) defining channels (1508) , the actuable sidewalls being displaceable to cause a pressure change in selected channels, alternate channels in the array being firing channels; and a second array of parallel side walls (1503) offset in a channel height direction to define channel extension regions (1504) opening to a respective firing channel (1508) . A nozzle (1506) communicates with each channel extension region. The spacing between adjacent side walls in the second array is large to reduce impedance and the spacing between adjacent actuable side walls in the first array is small to provide for efficient actuation.

Owner:XAAR TECH LTD

Inkjet recording apparatus and recording method

The inkjet recording apparatus comprises: a full line type recording head which includes a plurality of nozzles for discharging ink arranged in a nozzle row across an entire printable width in a main scanning direction; a conveyance device which moves a recording medium and the recording head relatively to each other in a sub-scanning direction substantially orthogonal to the nozzle row provided in the recording head; and a droplet ejection control device which controls a droplet ejection timing of each nozzle, in such a manner that a basic arrangement of droplet deposition points of dots formed on the recording medium by means of ink droplets ejected from the nozzles becomes a staggered lattice arrangement.

Owner:FUJIFILM CORP

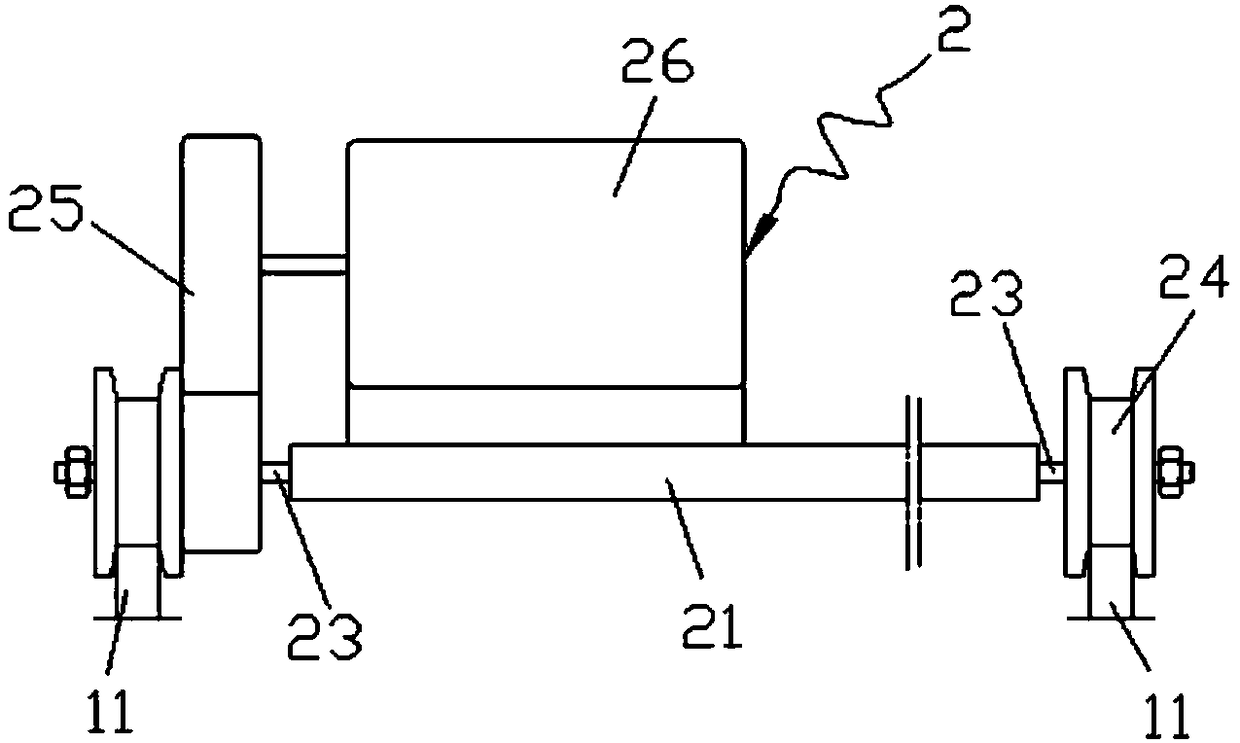

Plant protection unmanned aerial vehicle spray simulation and test device

PendingCN108557113AConsistent with real workAchieve swingAircraft components testingICT adaptationTest frameEngineering

The invention discloses a plant protection unmanned aerial vehicle spray simulation and test device which comprises a test rail frame formed by two linear guide rail mechanisms. A traveling mechanismis arranged on the test rail frame, a lifting mechanism is hung on the bottom surface of the traveling mechanism, a swing mechanism is hung on the bottom surface of the lifting mechanism, a rotating mechanism is mounted on the bottom surface of the swing mechanism, an unmanned aerial vehicle is hung on the lower portion of the rotating mechanism, a spray mechanism is mounted on the unmanned aerialvehicle, a wind field simulation device for simulating outside real wind field environments is arranged on the test rail frame and comprises two side wind fans and a plurality of cross wind fans, water sensitivity paper for acquiring distributing conditions of sprayed pesticide droplet deposition amount is arranged on the ground in the test rail frame, and a test frame for measuring pesticide droplet spreading conditions is arranged outside the test rail frame. The device can reproduce various test conditions, each test can be controlled, test results can be repeated, and scientific sprayingbases are provided for pesticide spray in the real environments.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com