Droplet deposition apparatus

A technology of deposition equipment and equipment, applied in printing, inking device, etc., can solve problems such as increasing machine size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

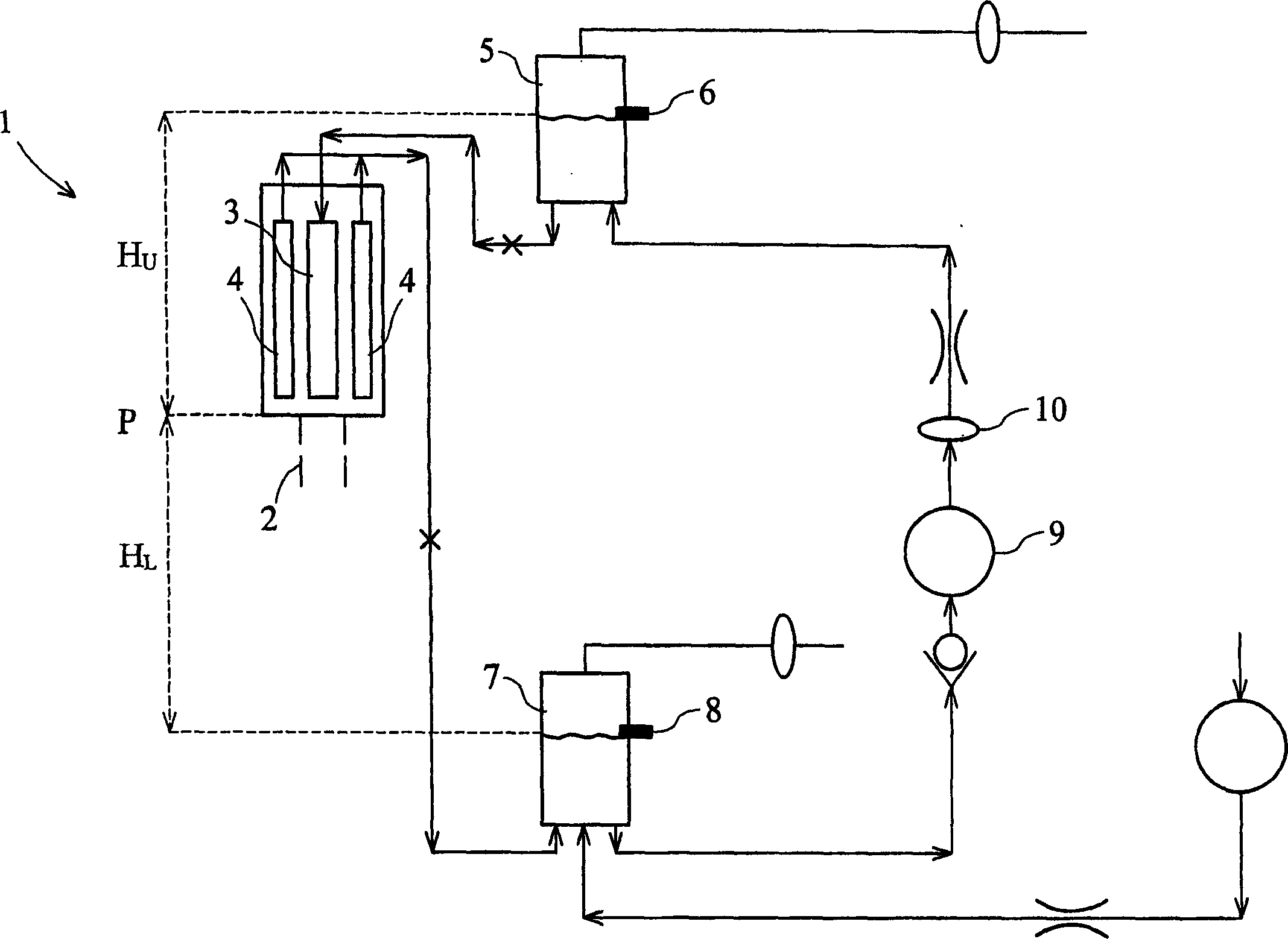

[0039] figure 1 A gravity-fed ink supply system according to the prior art. The print head 1 is capable of ejecting a liquid 2 from nozzles located on the lower side of the print head. The ink chambers have or discharge nozzles and are arranged in two parallel arrays, ink is supplied to the ink chambers from a central manifold 3, while un-ejected ink is expelled from the printhead using two outlet manifolds 4.

[0040] Ink is continuously supplied to the printhead from an upper reservoir 5 , the level of which is controlled by a level sensor 6 . The ink stream flow rate or flow rate is approximately ten times the maximum droplet or droplet ejection flow rate or flow rate. Due to the small size of the jetting chambers and the high pressure drop across them, achieving a slight negative pressure at the nozzle requires high pressure fluid flow into the printhead. This pressure is achieved by setting the pressure difference Hu, which is the difference between the height of the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com