Droplet deposition apparatus

A deposition equipment, droplet technology, applied in printing and other directions, can solve problems such as increasing nozzle spacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

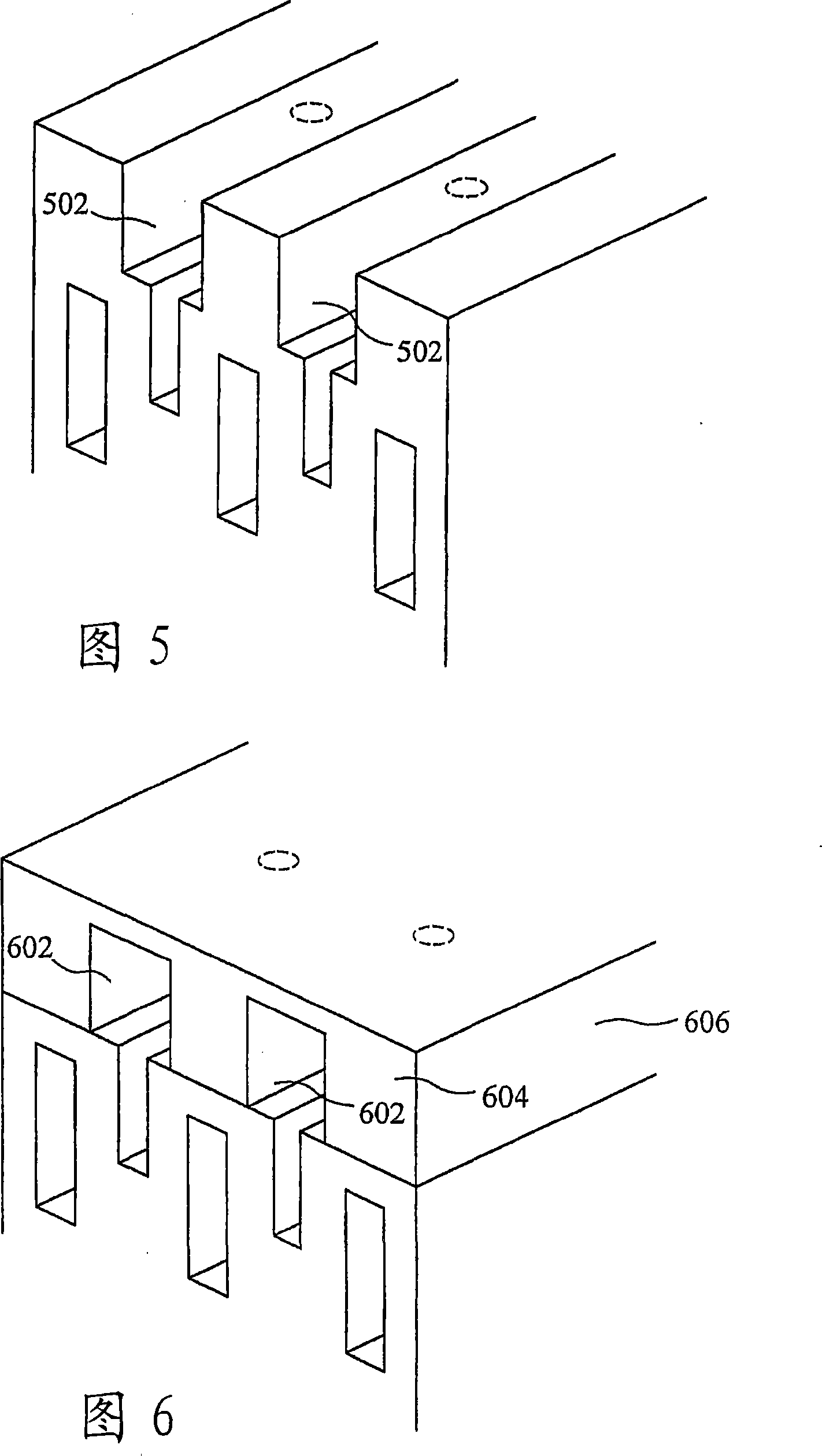

[0034] Referring to Figure 4, there is schematically shown a first embodiment of the invention comprising a body of piezoelectric material (PZT in this example) having an array of channels. The staggered channels are vertically offset, channel 402 is formed in the top surface of the PZT and is open, while channel 404 is formed in the lower part of the PZT and is closed. When the two sets of channels are stacked, the actuation sidewalls are defined by PZT polarized in opposite directions as indicated by arrow 406 in these regions. These sidewalls are formed with electrodes and move laterally in shear mode under the action of an electric field as described above. It can be seen that by actuating the side walls, a pressure change can be created in the channel, resulting in spray from nozzles (shown as dashed line 408) disposed in a nozzle plate (not shown) that is bonded to the upper surface of the PZT and closes the upper channel. droplet.

[0035] The lower channel 404 is not...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com