Patents

Literature

31356results about "Printing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Light-emitting device

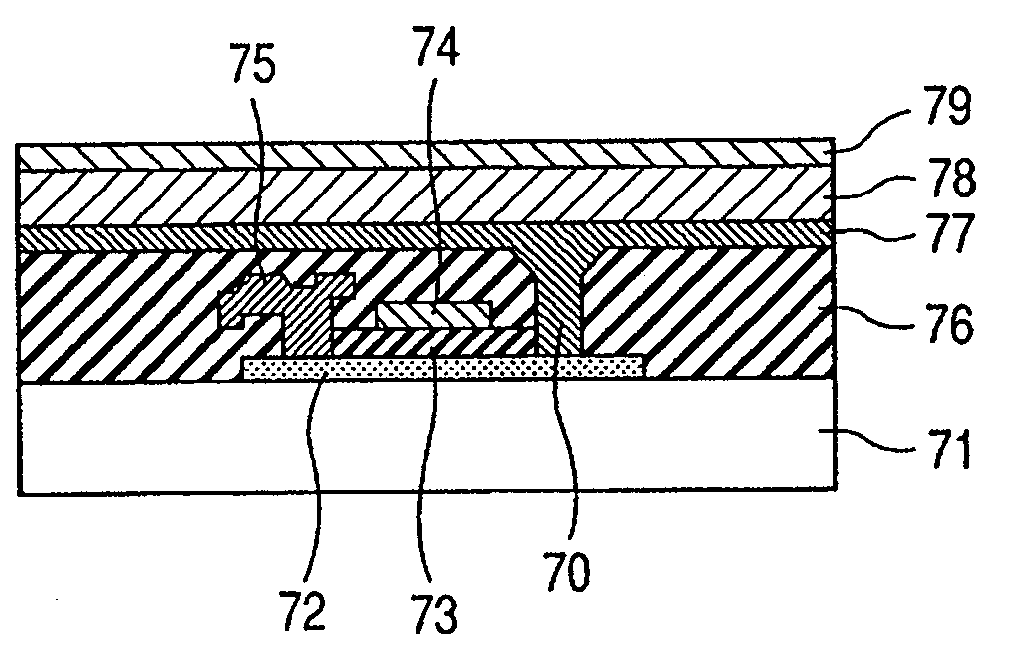

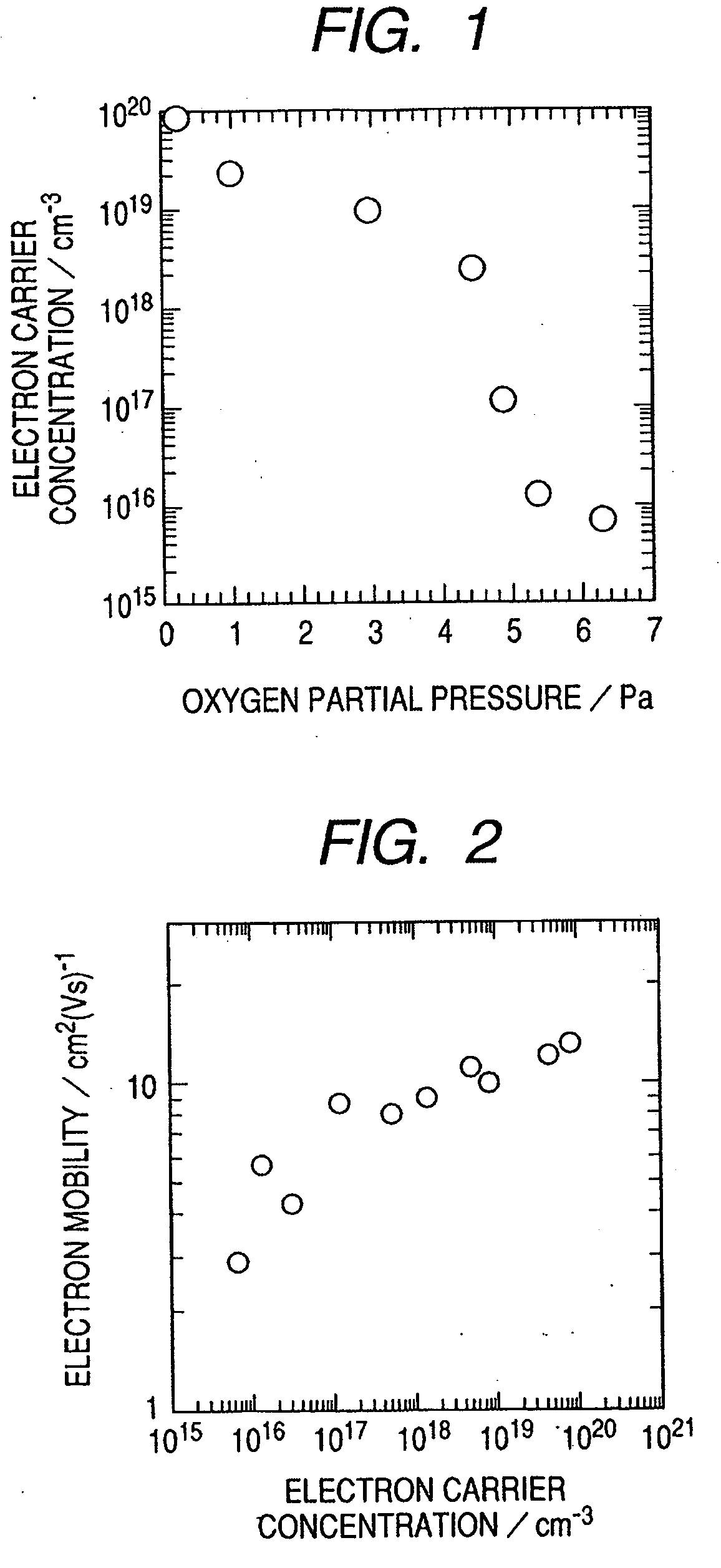

ActiveUS20060113549A1Desired characteristicTransistorElectroluminescent light sourcesField-effect transistorActive layer

An object of the present invention is to provide a new light-emitting device with the use of an amorphous oxide. The light-emitting device has a light-emitting layer existing between first and second electrodes and a field effect transistor, of which the active layer is an amorphous.

Owner:CANON KK +2

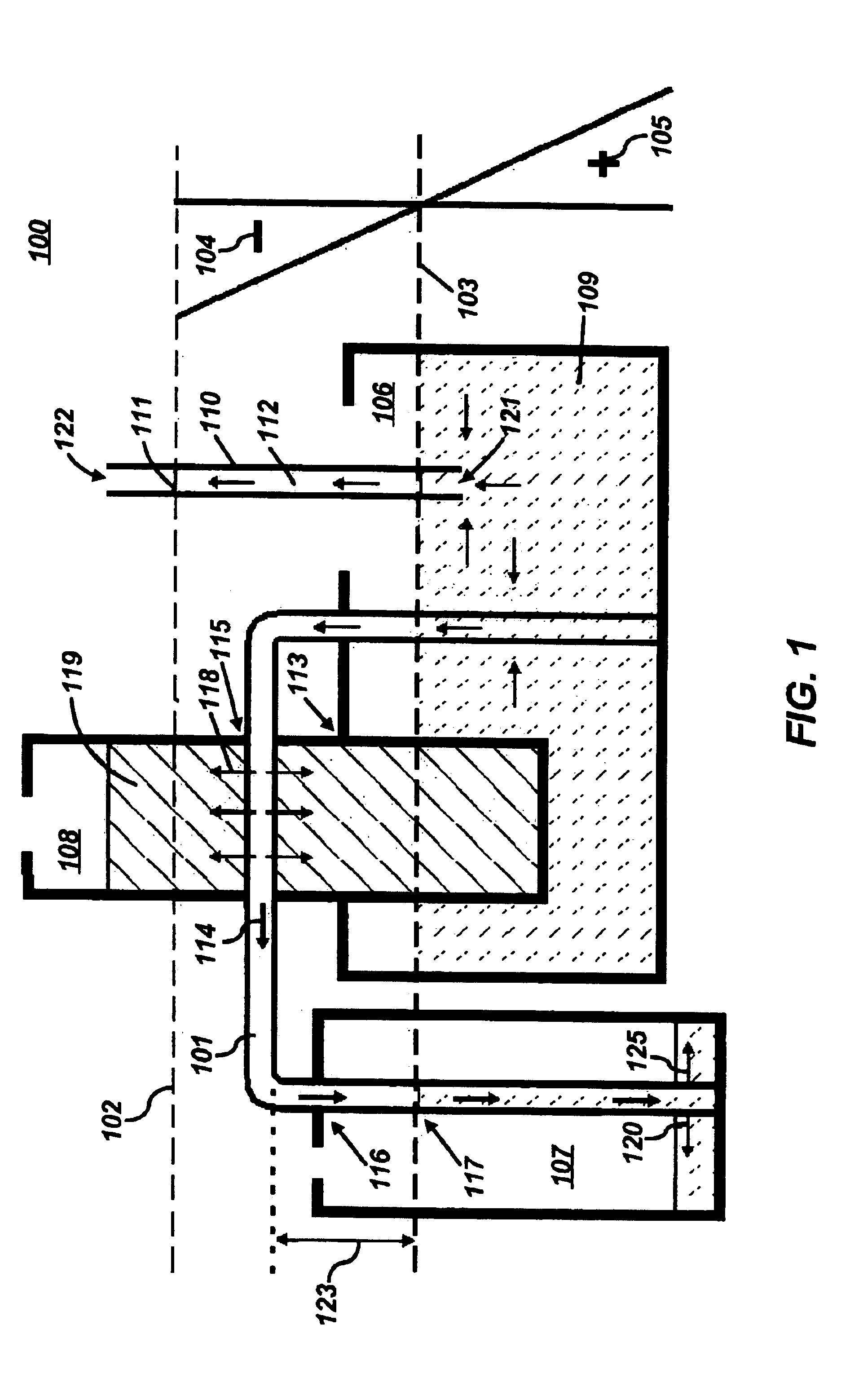

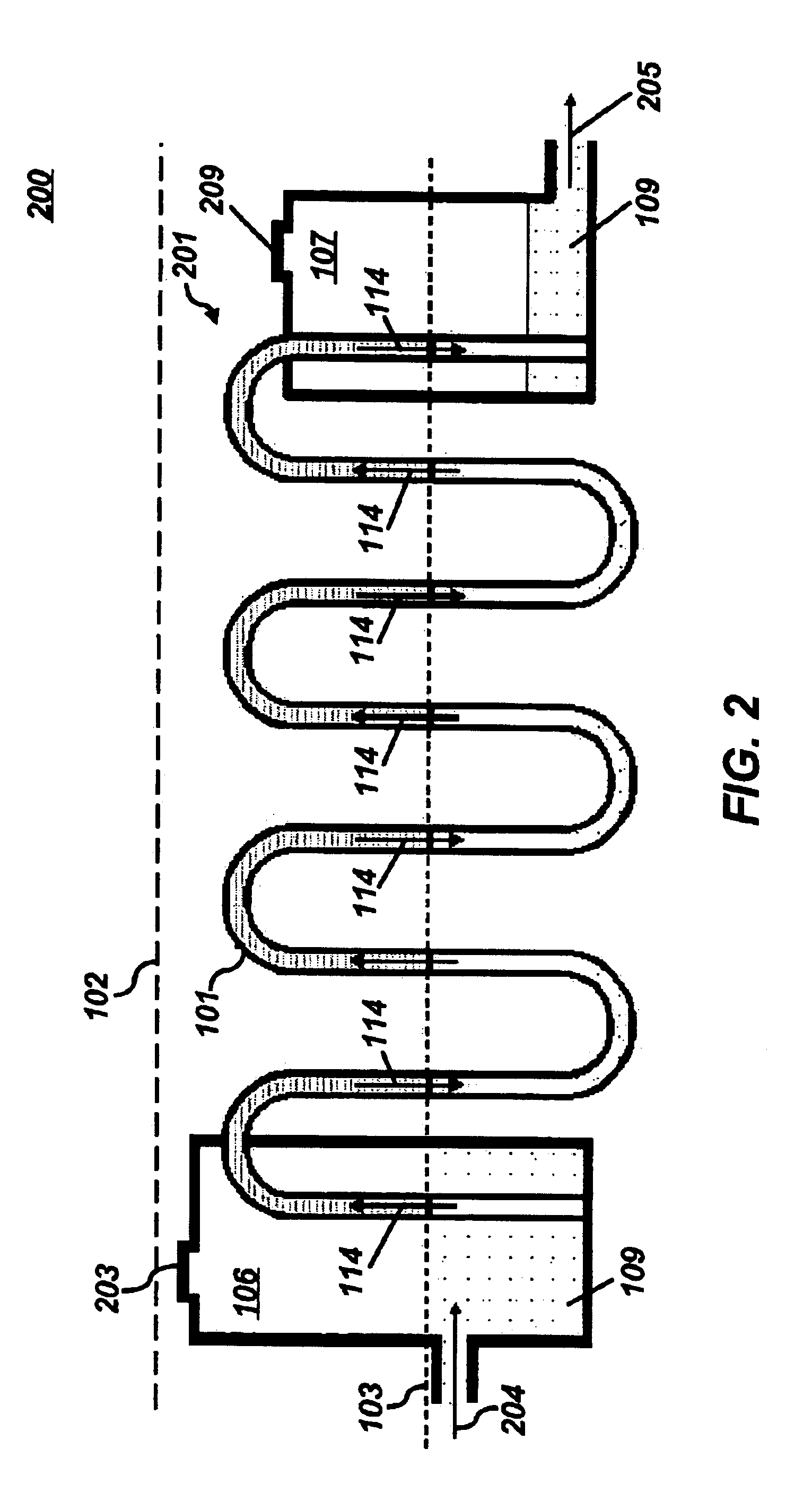

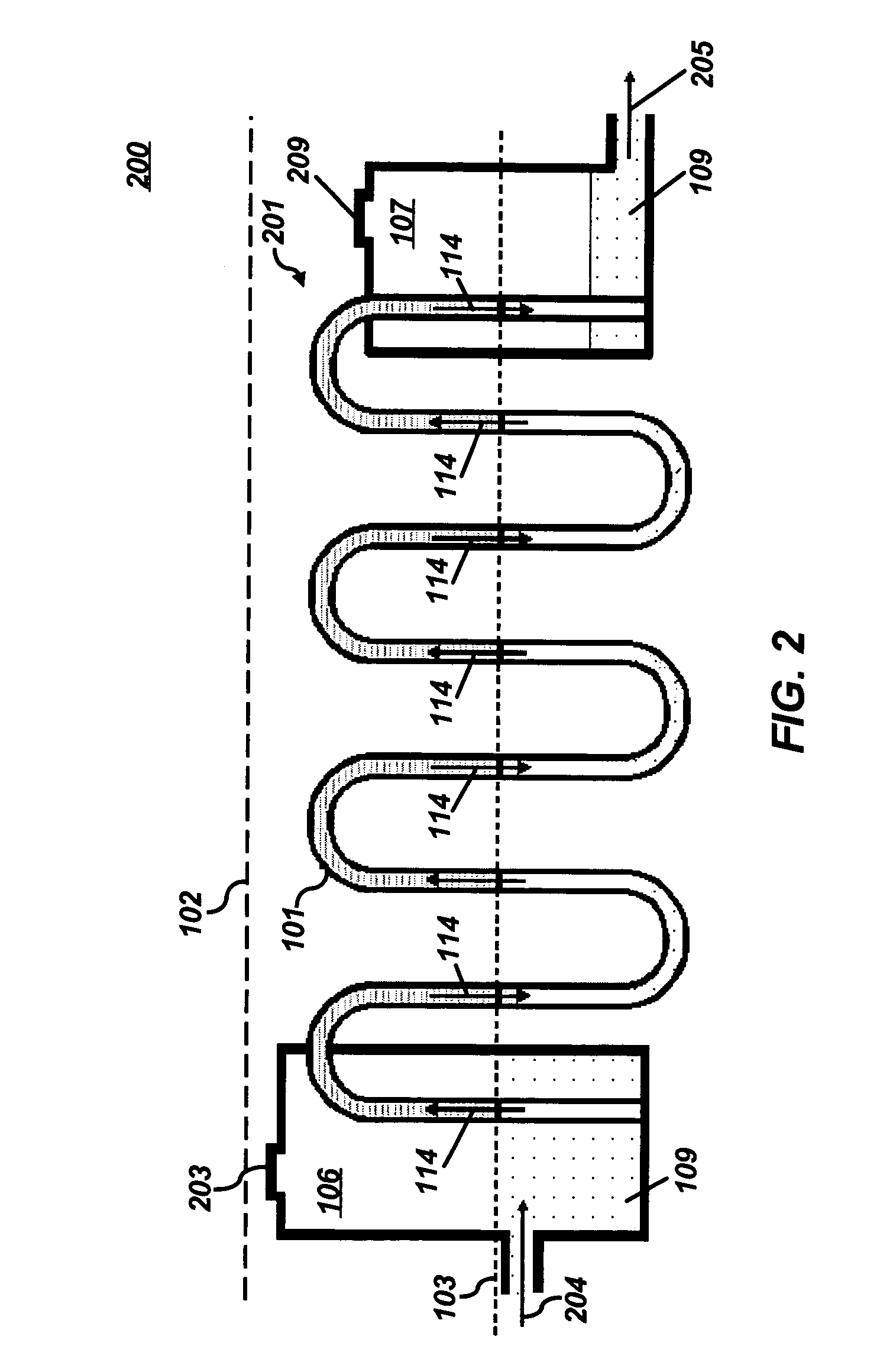

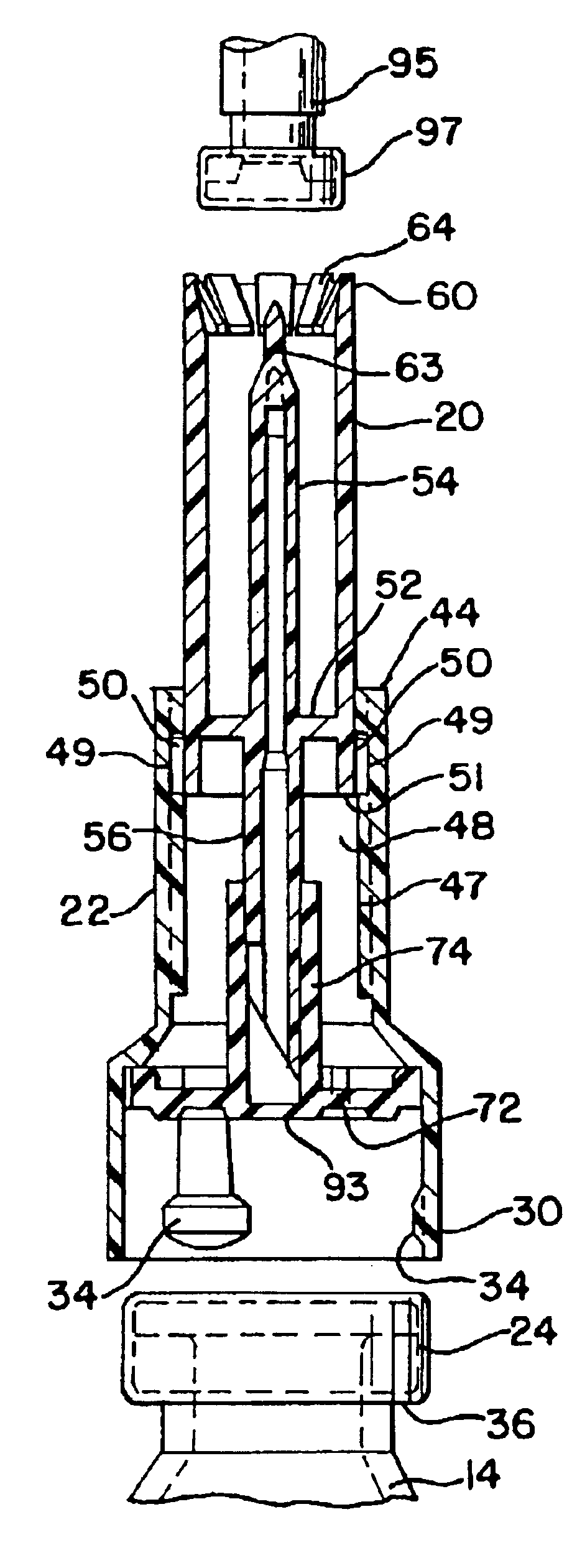

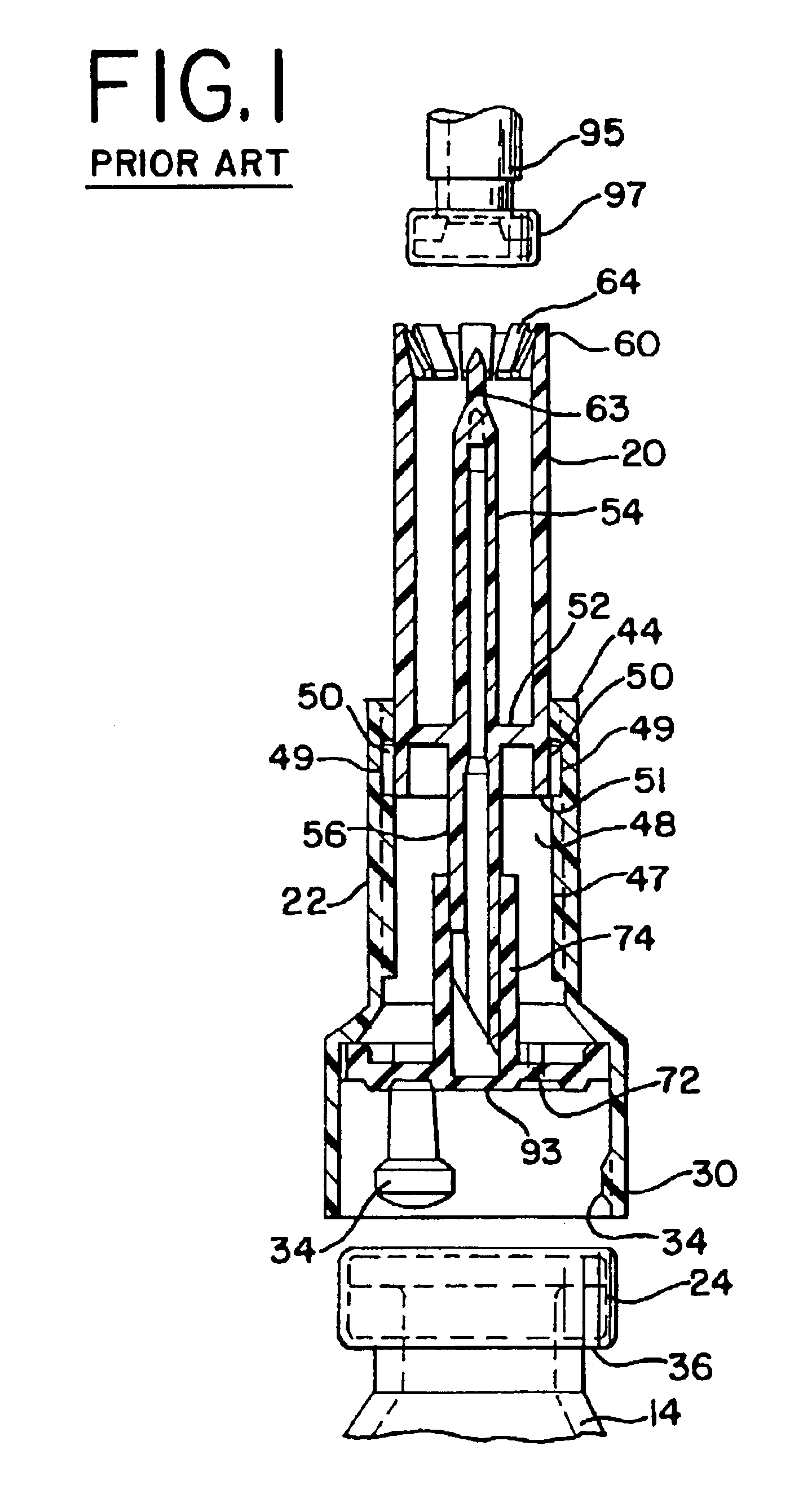

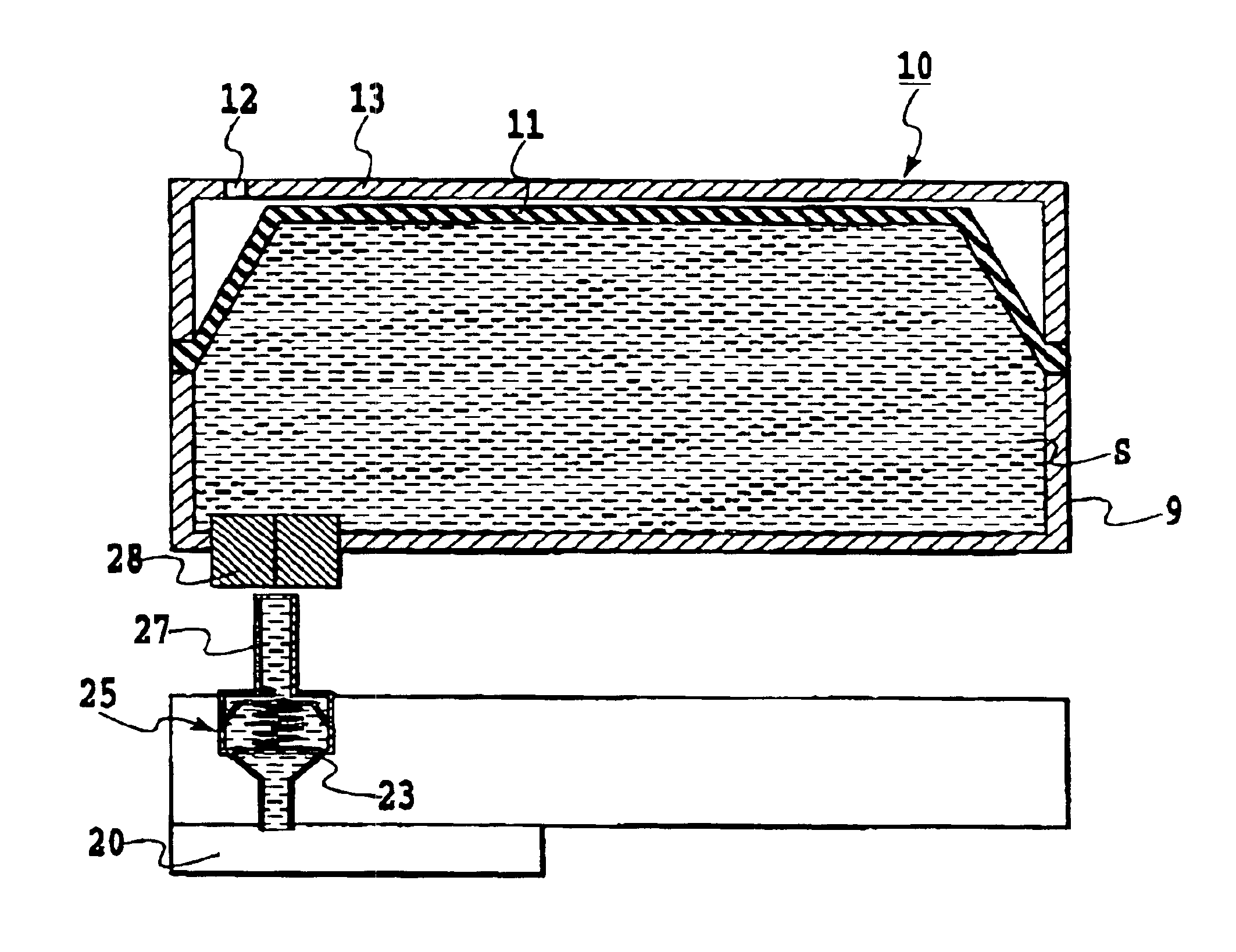

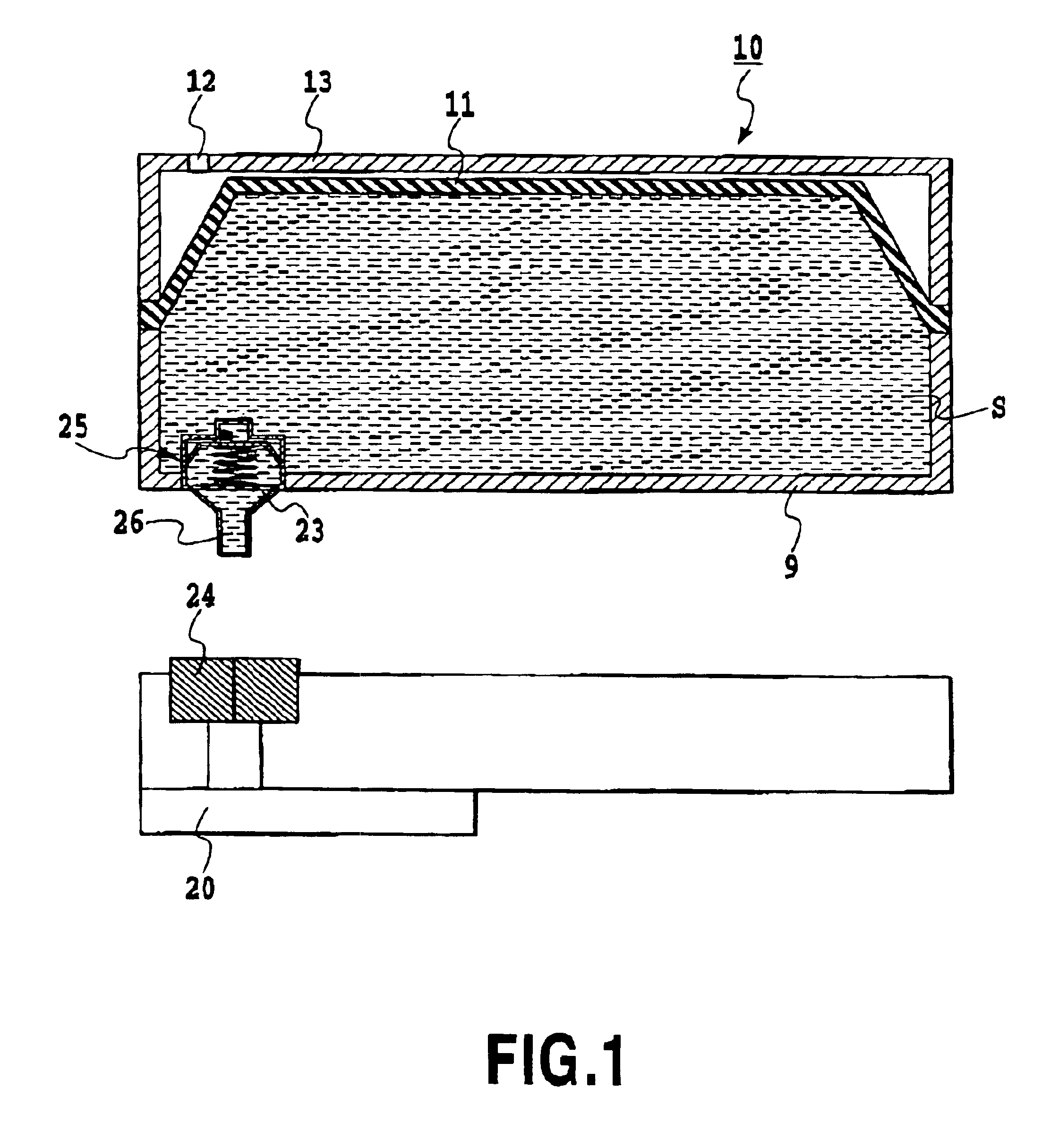

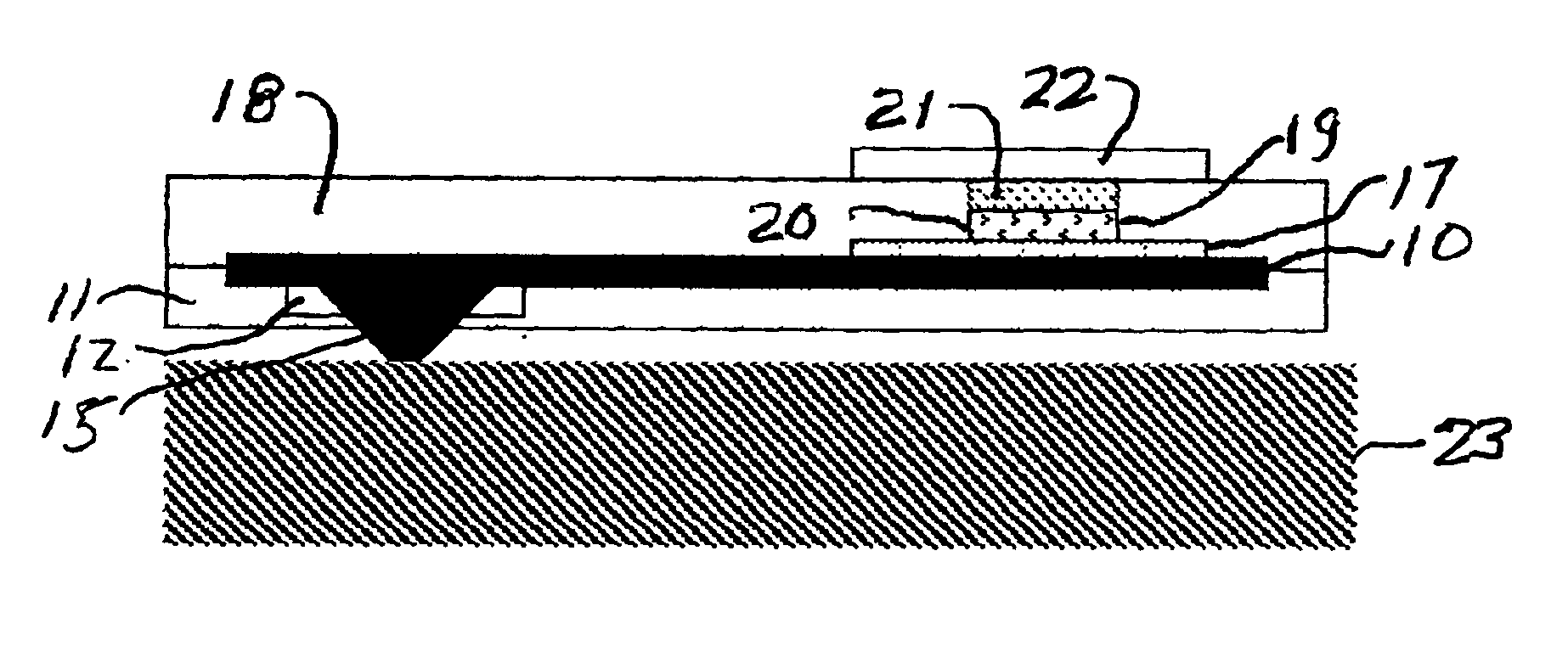

Irrigation and drainage based on hydrodynamic unsaturated fluid flow

InactiveUS6918404B2Improve the level ofHigh porosityPipeline systemsMachines/enginesEnvironmental engineeringPorous microstructure

Irrigation and drainage systems are disclosed, including a saturated zone and at least one pipe in communication with the saturated zone. The pipe(s) can be configured to comprise a tubarc porous microstructure for conducting water from the saturated zone to an unsaturated zone in order to drain the water from the saturated zone. The water can be delivered from the saturated zone to the unsaturated zone through the tubarc porous microstructure, thereby permitting the water to be harnessed for irrigation or drainage through the hydrodynamic movement of the water from one zone of saturation or unsaturation to another.

Owner:TUBARC TECH

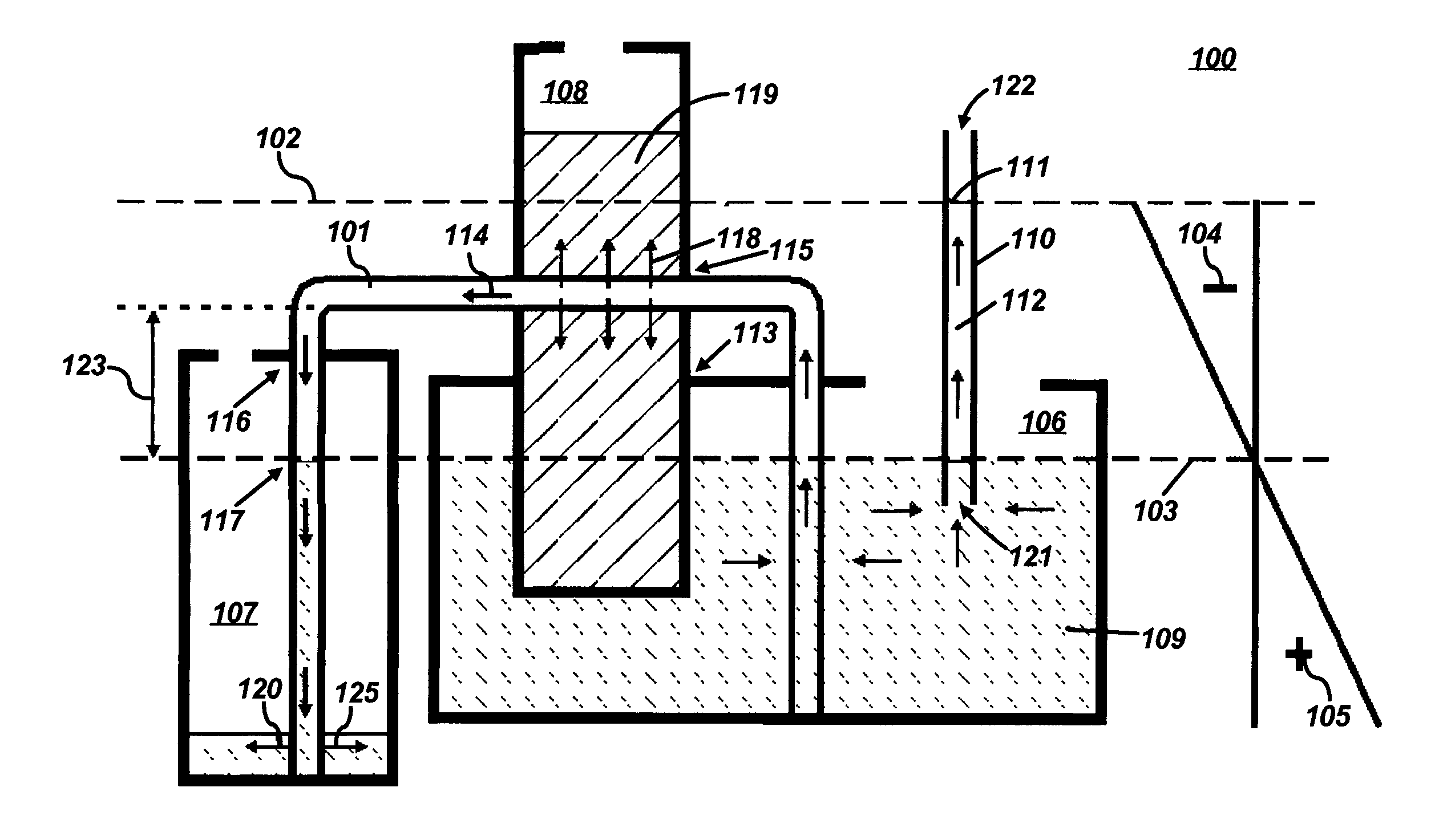

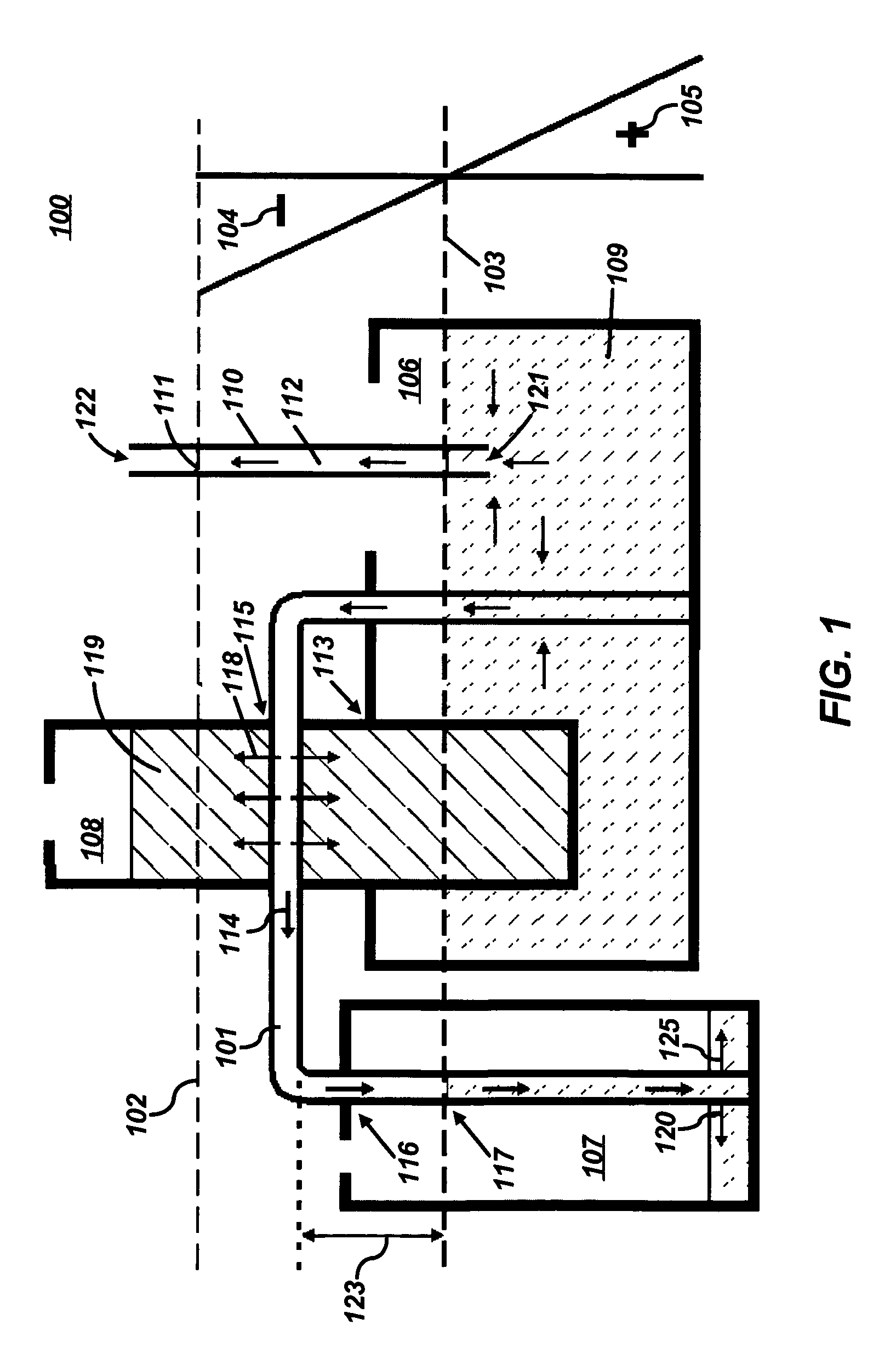

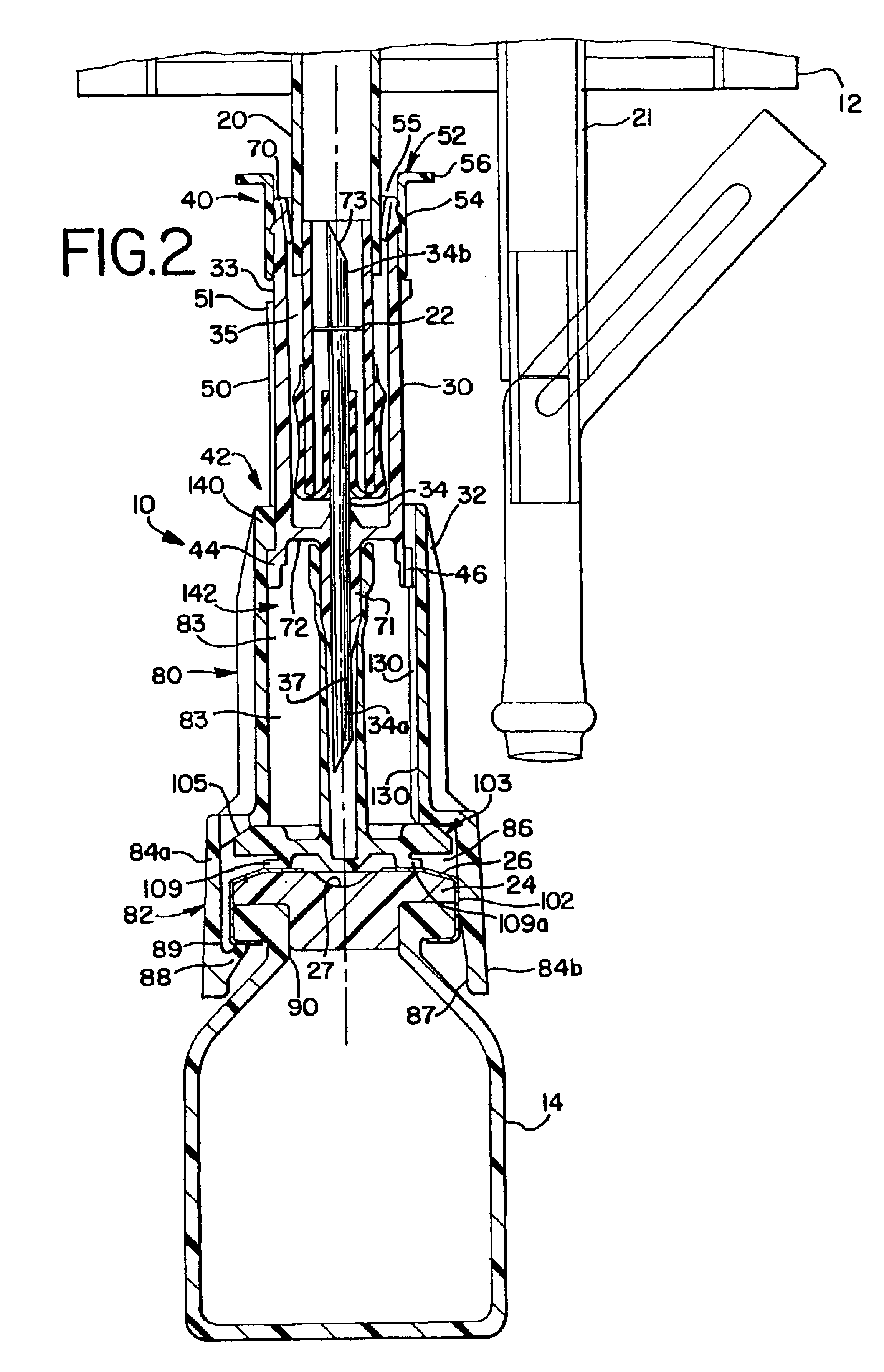

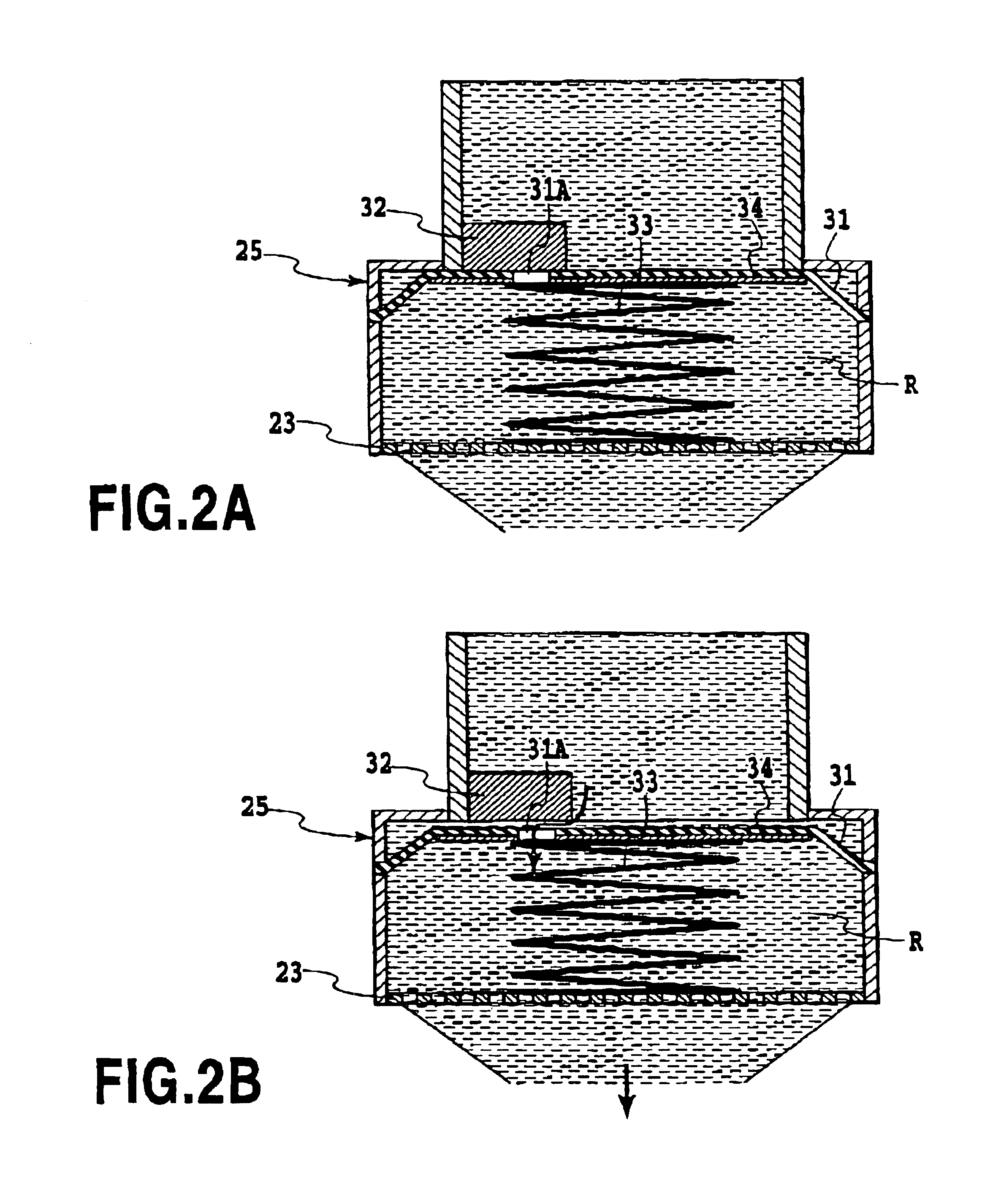

Ink refill and recharging system

InactiveUS7066586B2Improve reliabilityPrecise deliveryPipeline systemsPrintingEngineeringPrint-through

Ink refill systems are disclosed. In general, an ink source comprising a saturated zone and a tubarc porous microstructure for conducting ink from the saturated zone to an unsaturated zone are provided. The ink can be delivered from the saturated zone to the unsaturated zone through the tubarc porous microstructure, thereby permitting the ink to be harnessed for ink writing and / or printing through the unsaturated hydrodynamic flow of the ink from one zone of saturation or unsaturation to another.

Owner:TUBARC TECH

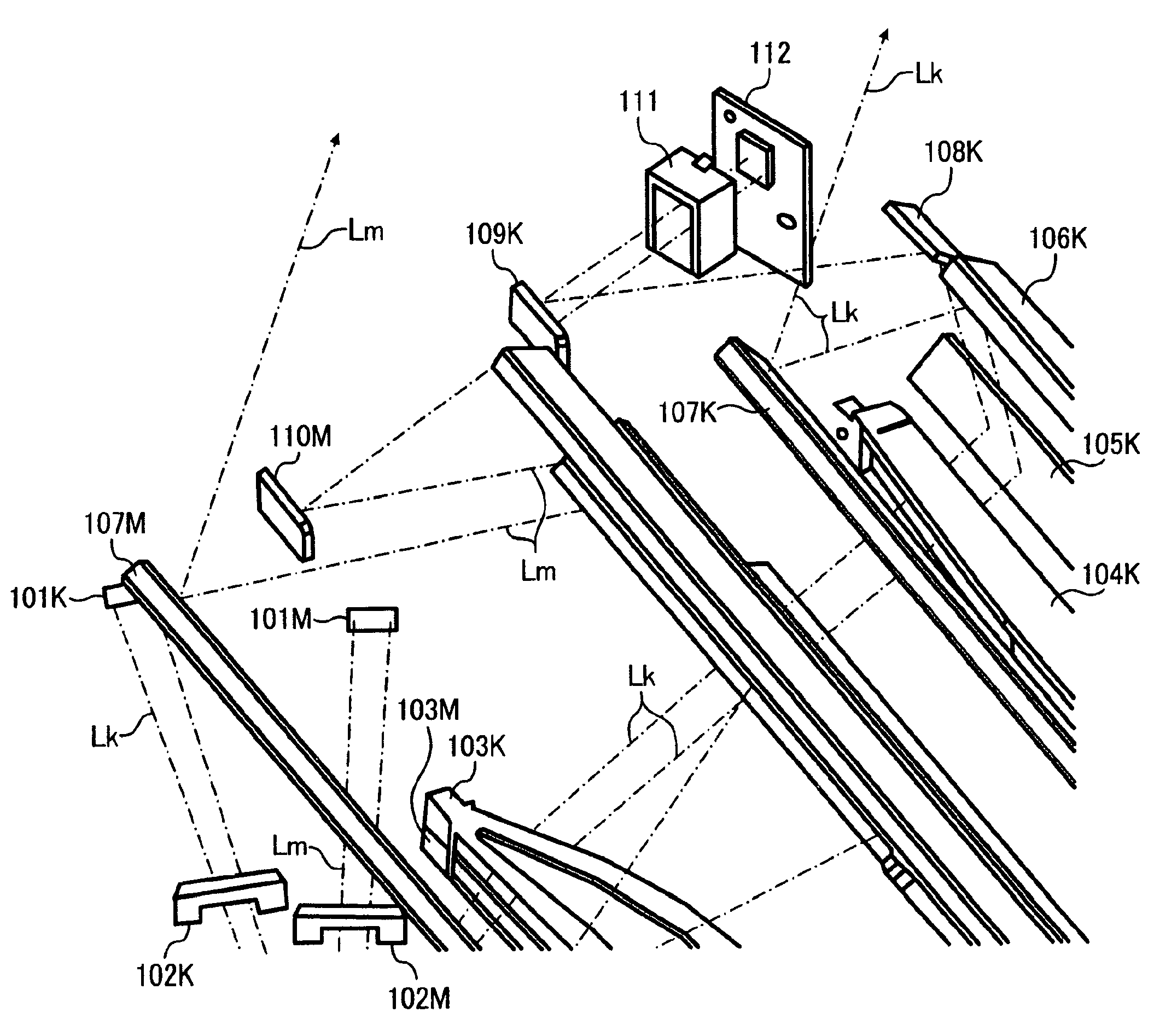

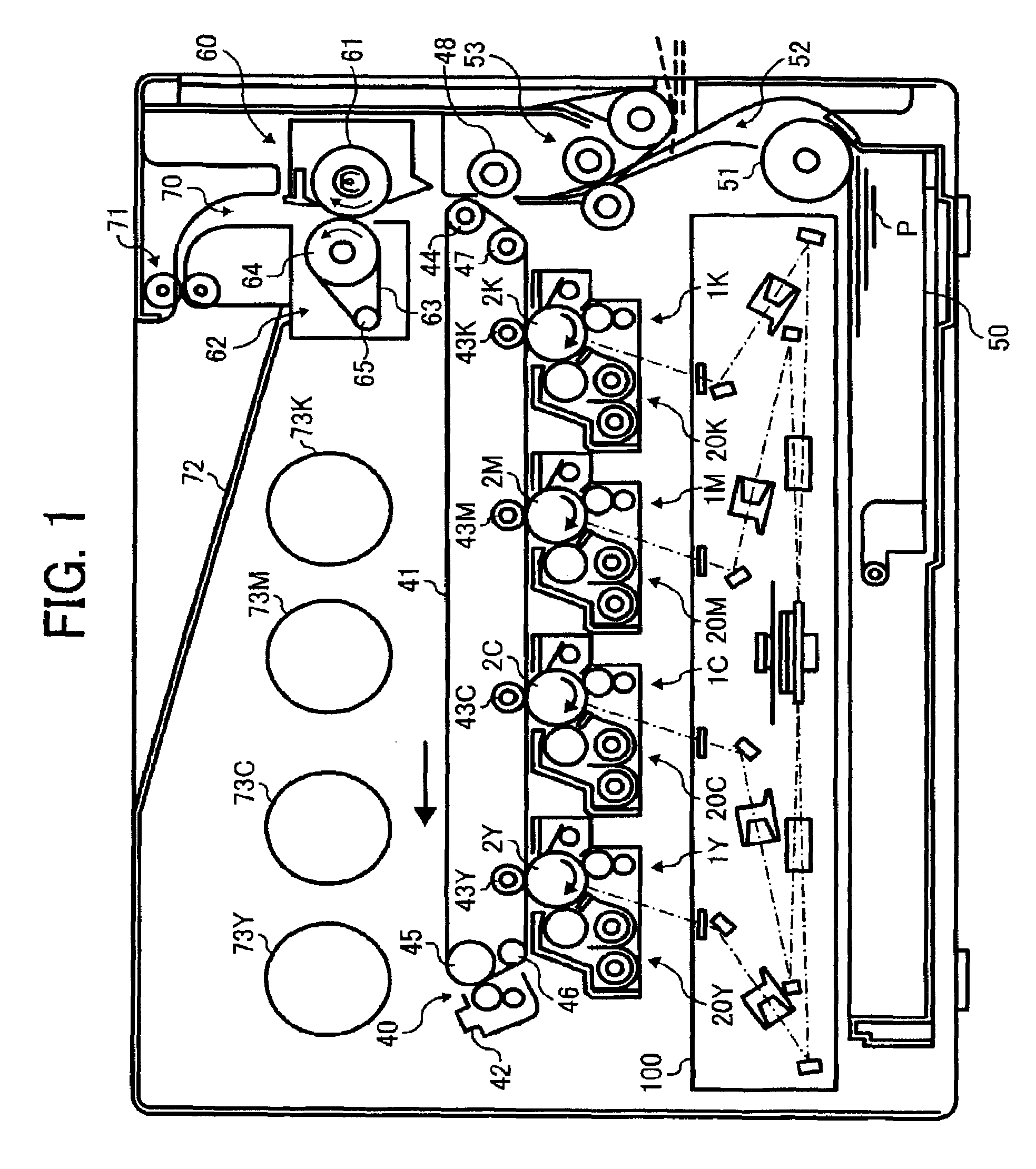

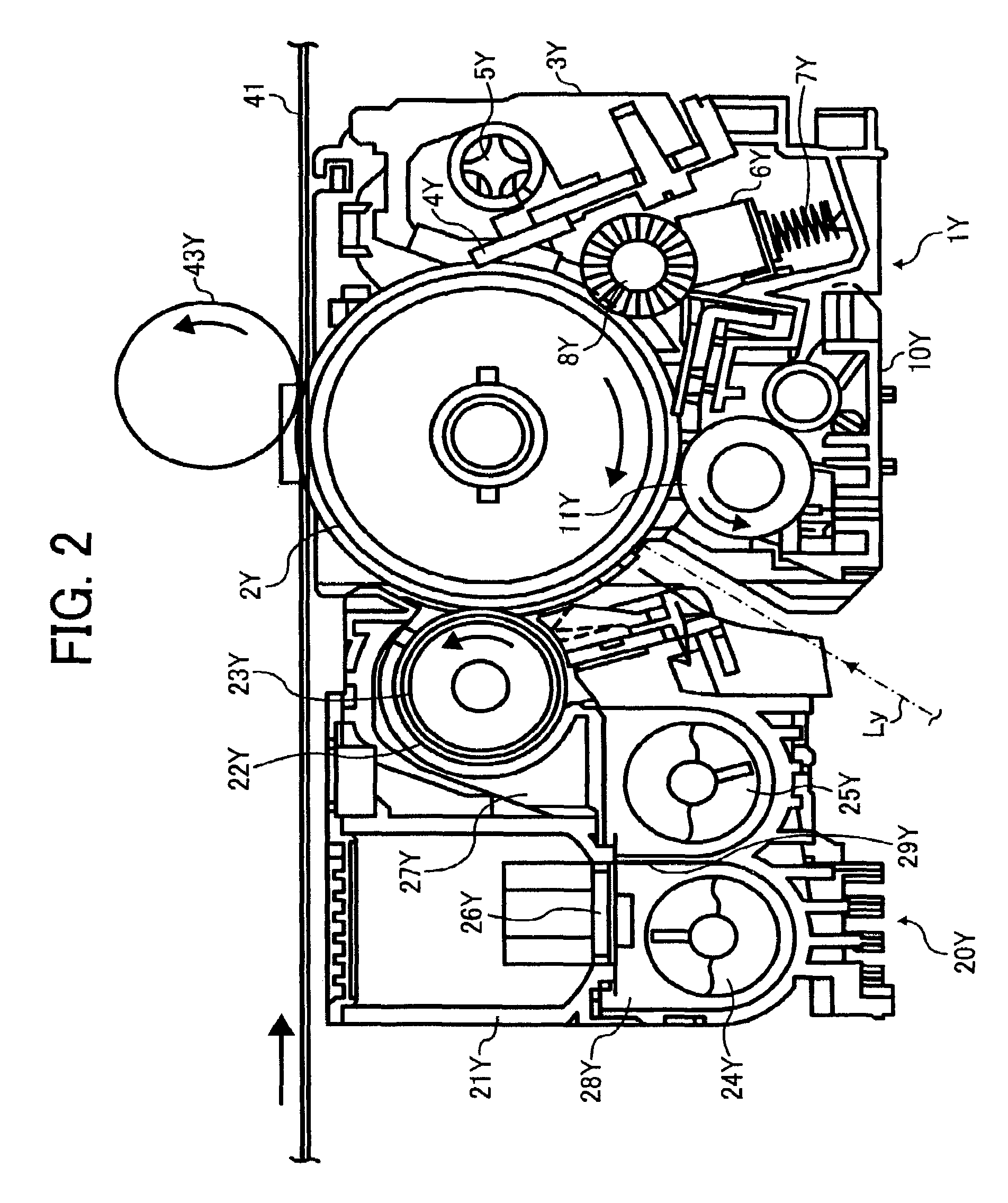

Optical scanning device and image forming apparatus

A deflecting unit deflects a light beam emitted by each of a plurality of light-beam emitting units independently to scan surfaces of different bodies to be scanned. Each of a plurality of light-receiving units receives the deflected light beam at a predetermined position in a direction of the deflection. An incident angle of the deflected light beam with respect to a scanning line extending in a direction of scanning on a light-receiving surface of the light-receiving unit is set to be identical for all of the light-receiving units.

Owner:RICOH KK

Coating composition for multiple hydrophilic applications

InactiveUS20030203991A1Tough and durable and printable surfaceImprove wettabilityOther chemical processesSynthetic resin layered productsColloidWear resistance

A coating composition is disclosed which comprises an aqueous polymeric matrix, a hydrophilic polymer, a colloidal metal oxide and a crosslinker. The coating composition when applied on medical devices is hydrophilic, shows improved lubricity, abrasion resistance and substrate adhesion on metallic or plastic substrates. The coating also shows improved water sheeting thus providing the coated substrates with anti-fog properties. The coating absorbs aqueous dye or stain solutions making the substrate suitable for printing.

Owner:HYDROMER INC

Coating composition for multiple hydrophilic applications

InactiveUS7008979B2Improve adhesionImprove the lubrication effectSurgerySynthetic resin layered productsColloidWear resistance

Owner:HYDROMER INC

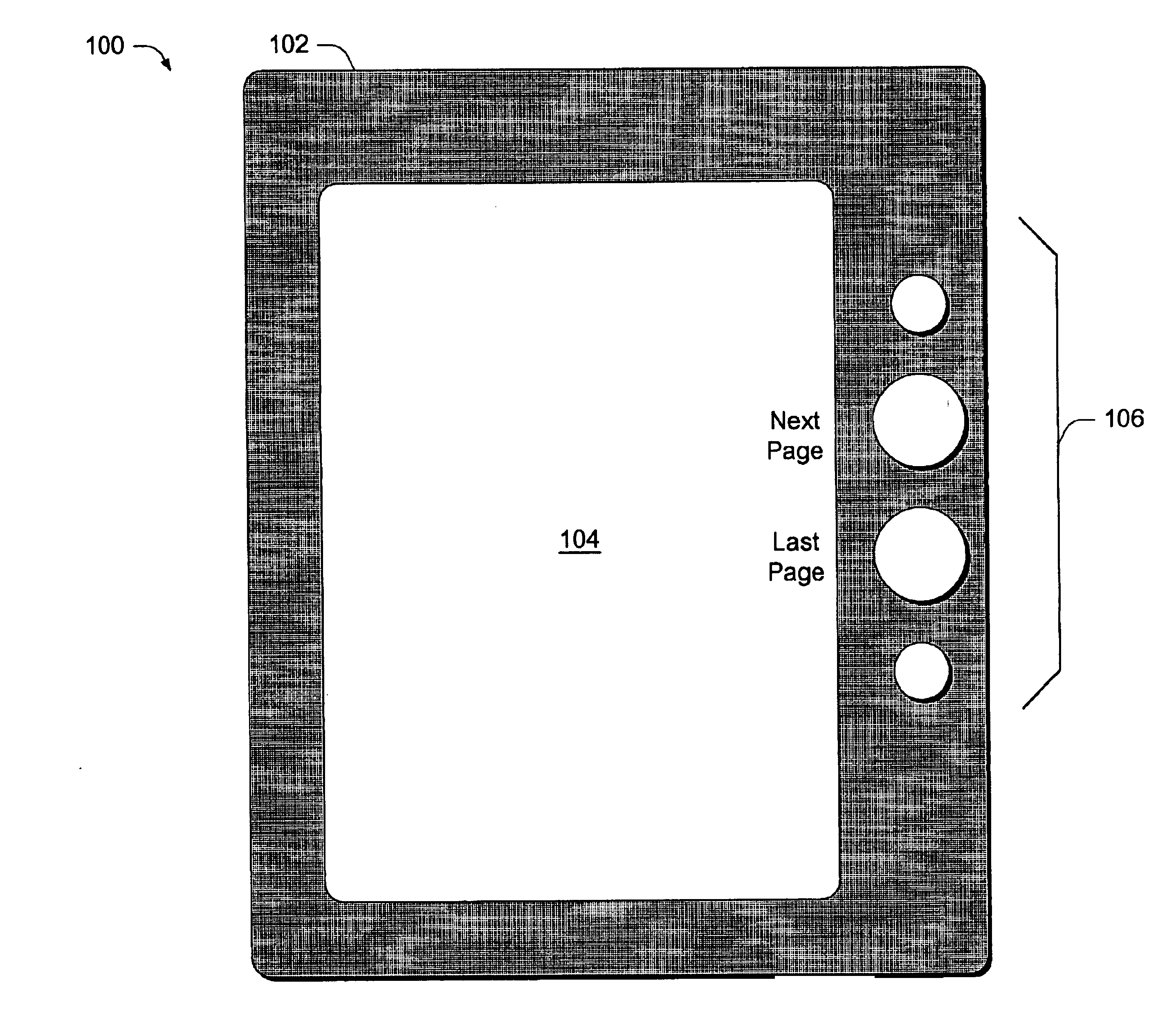

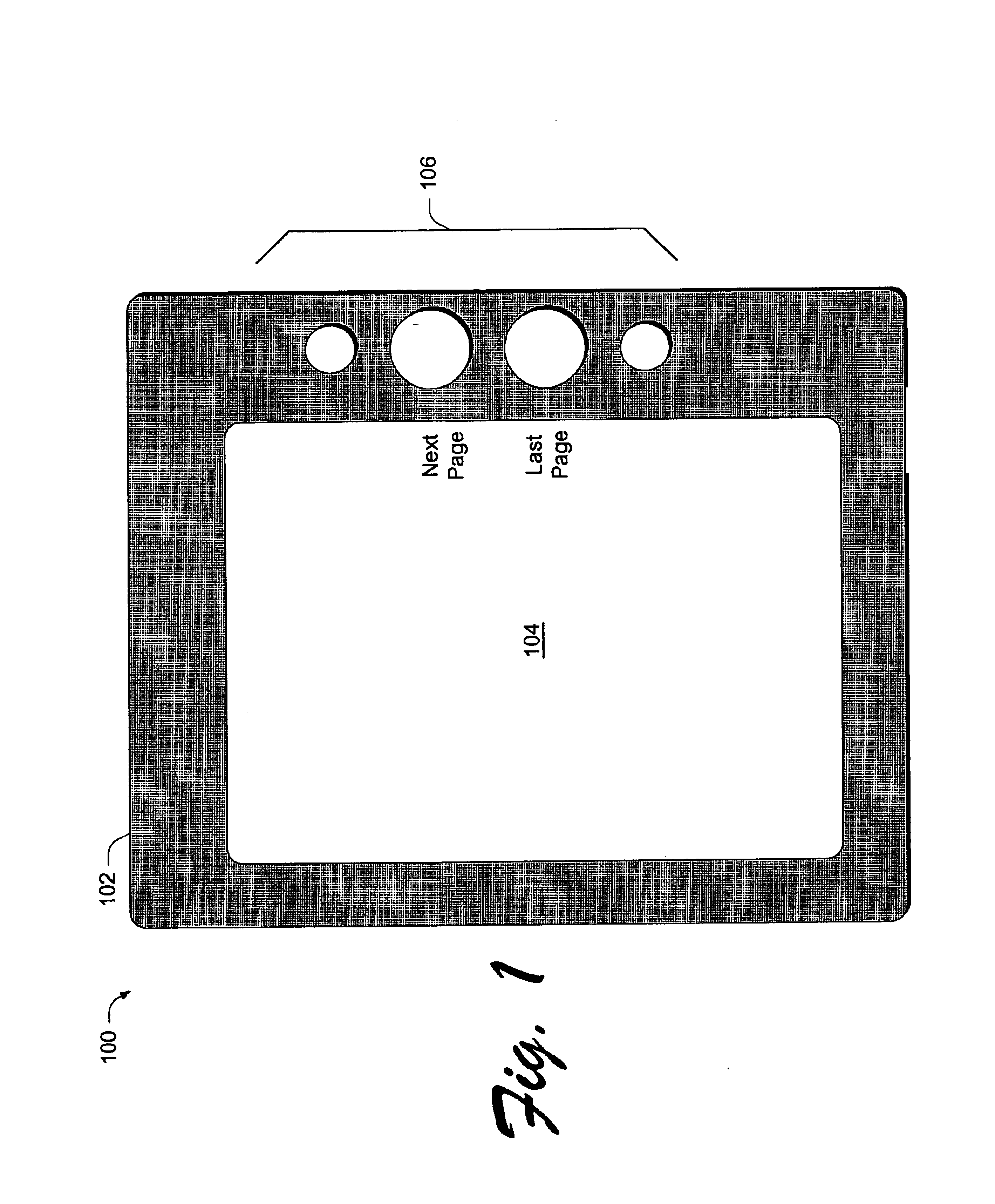

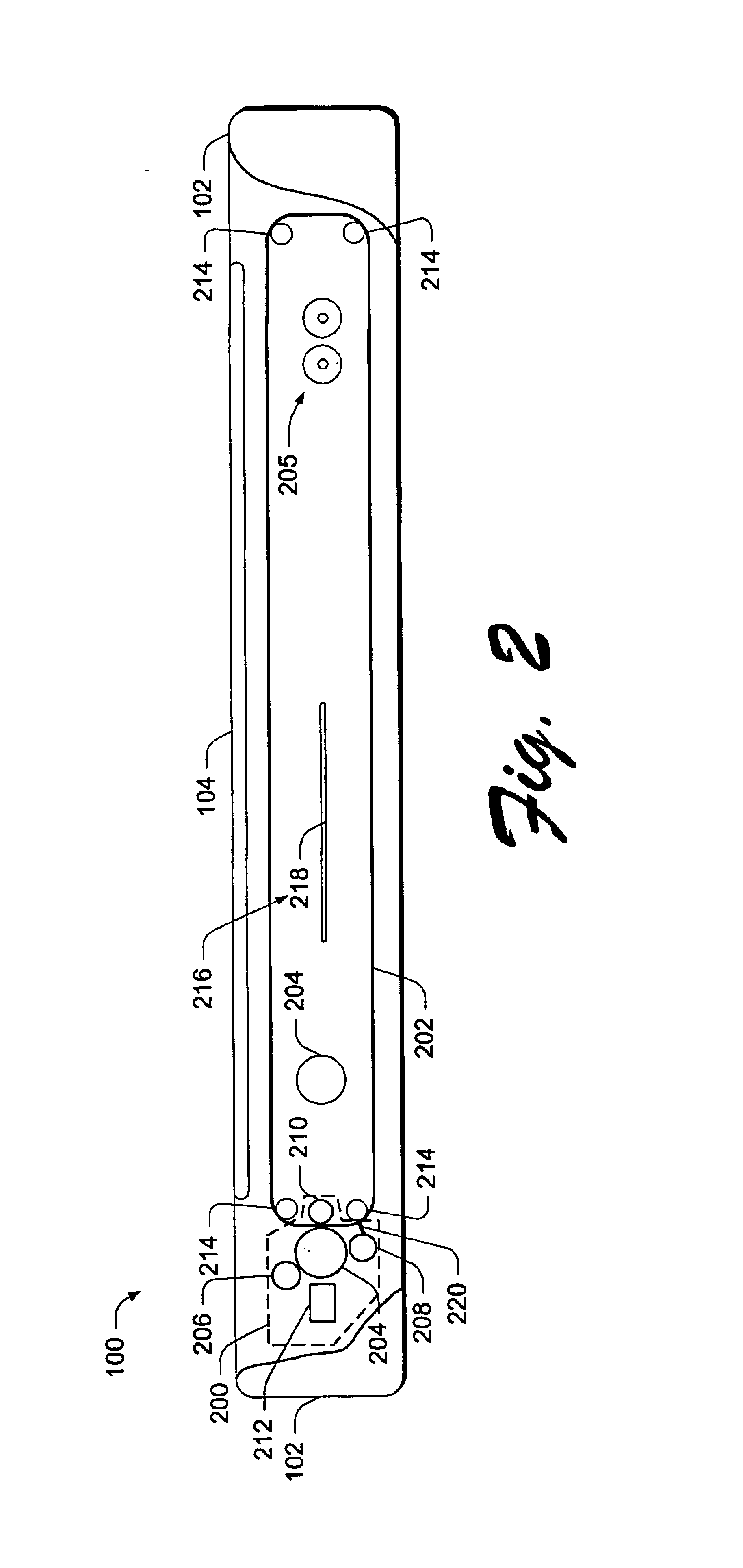

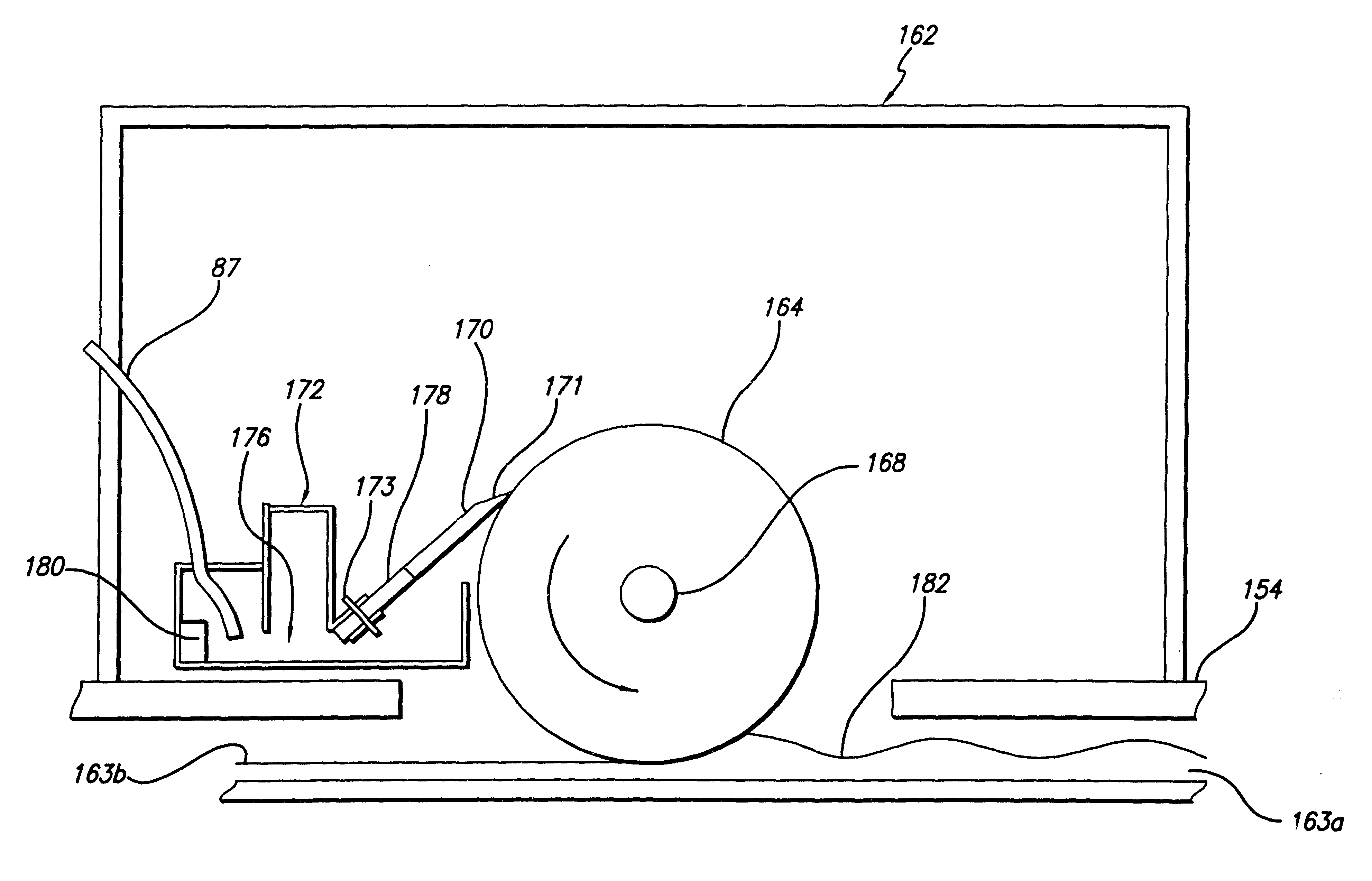

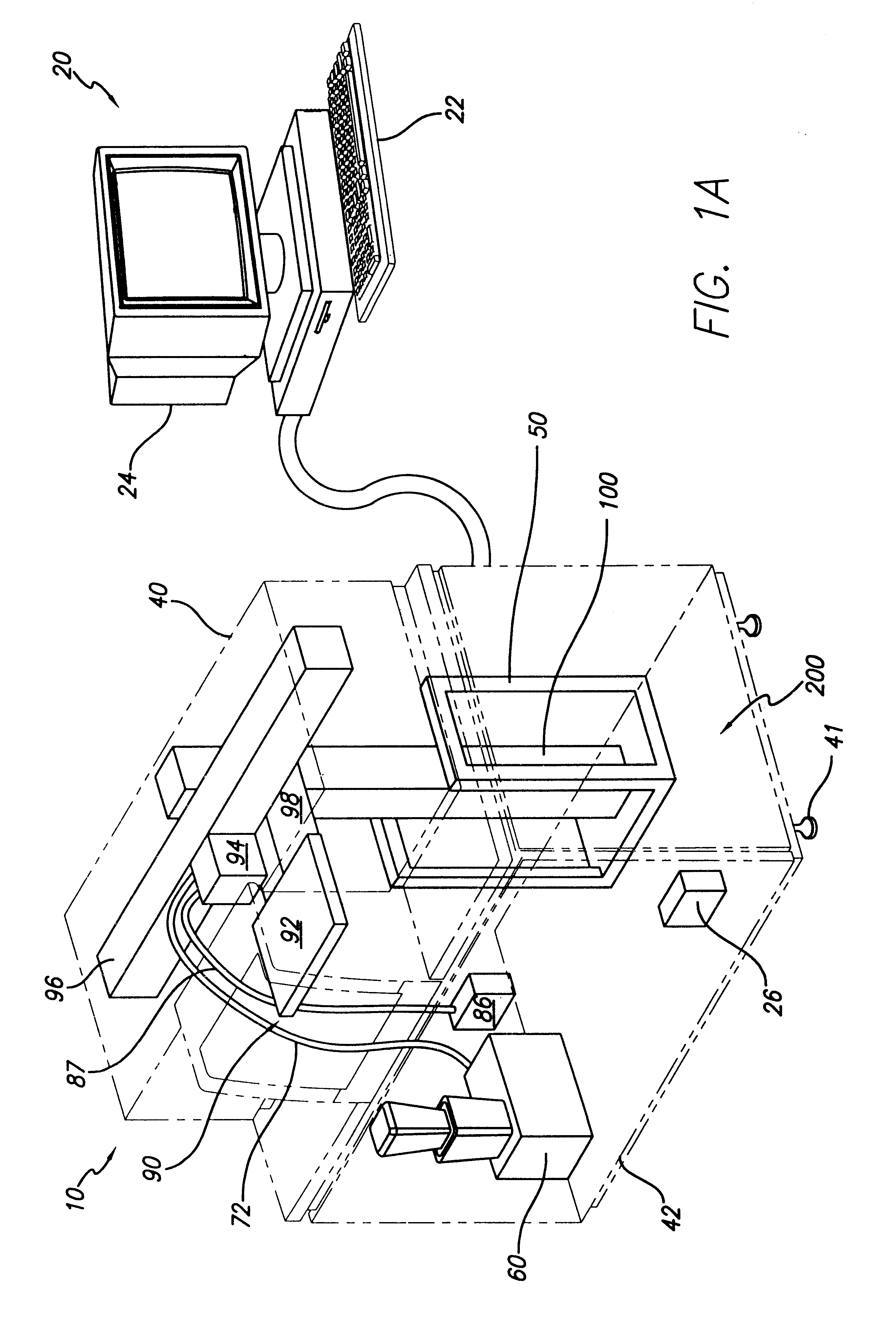

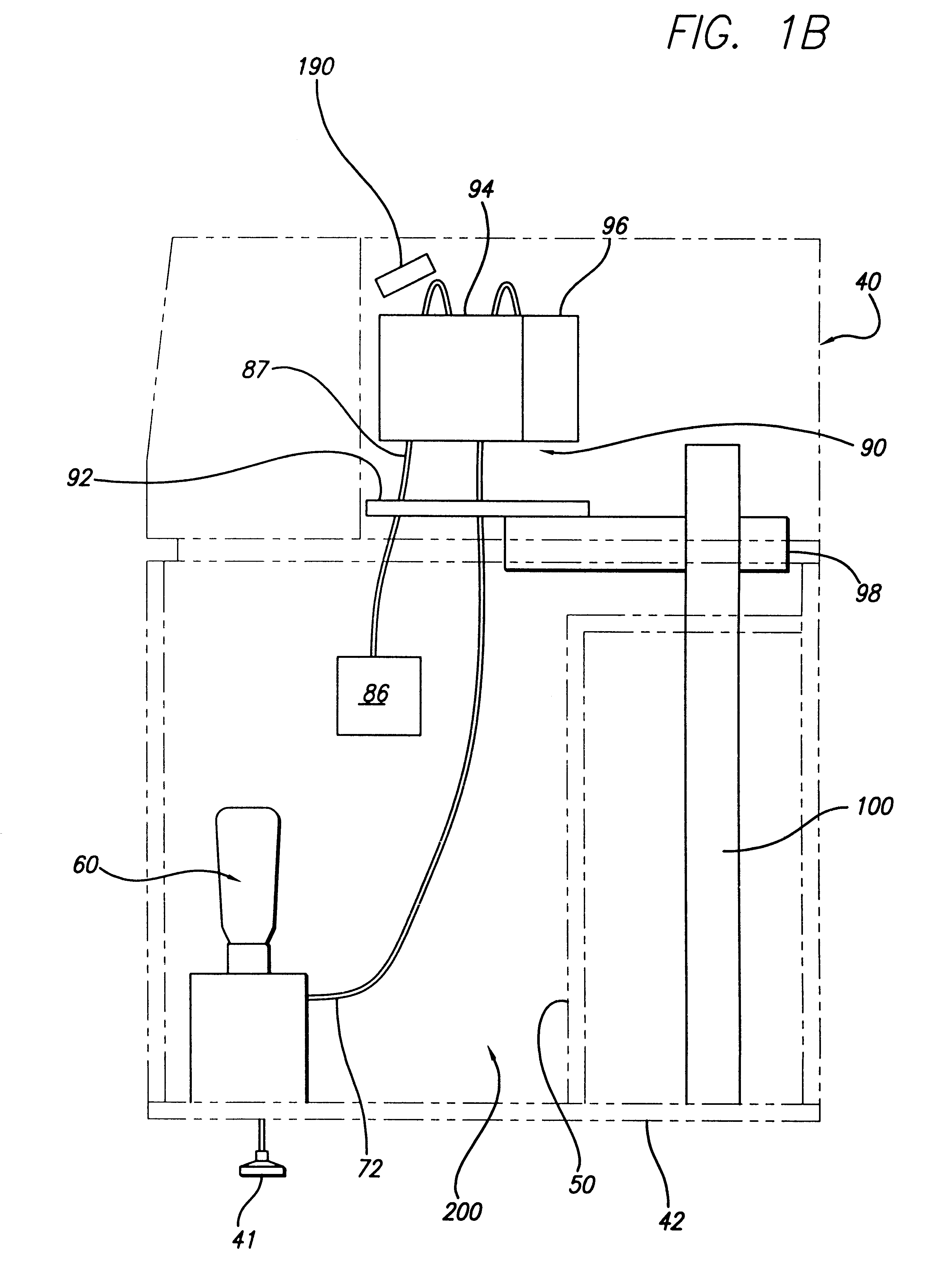

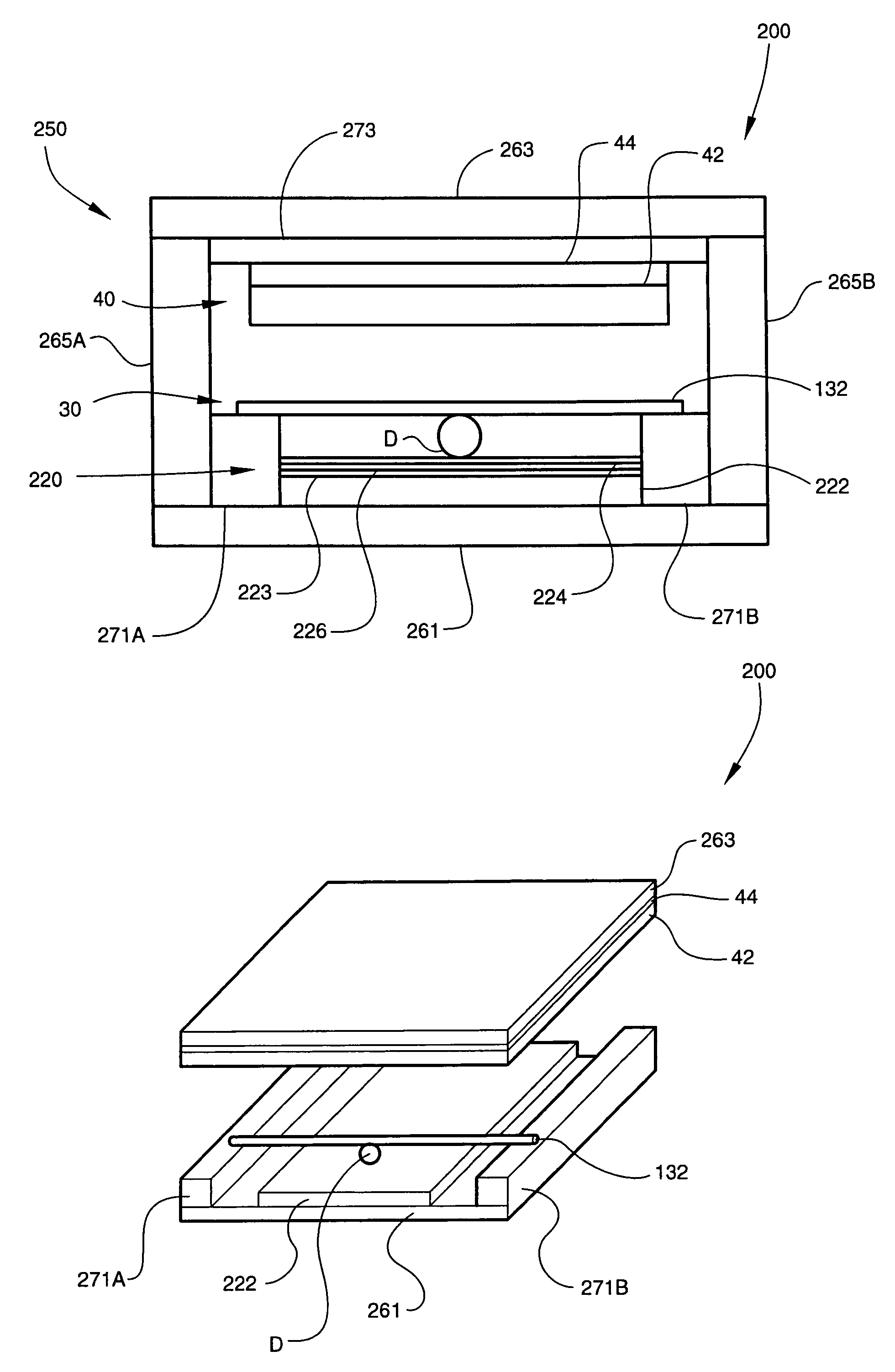

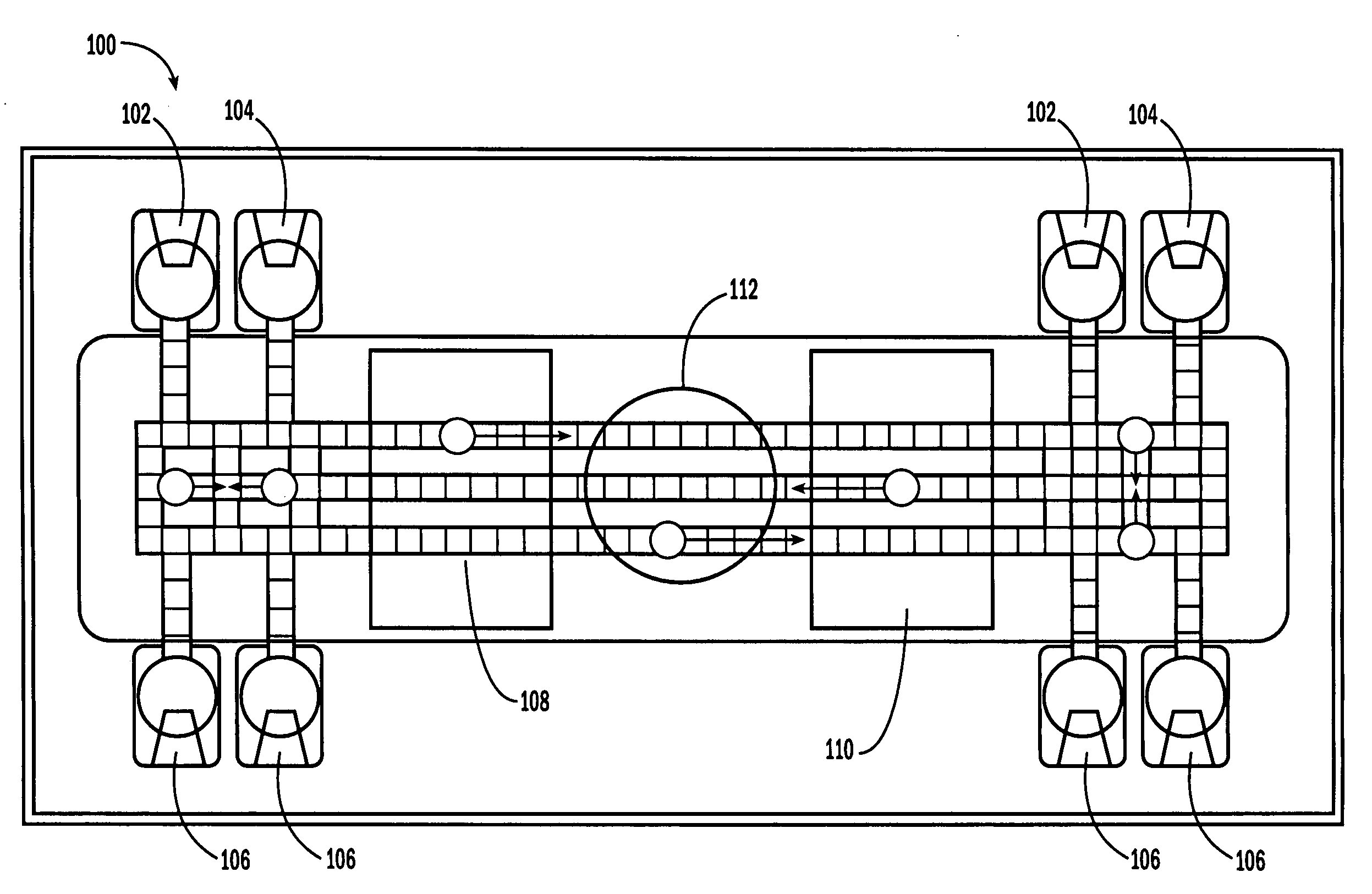

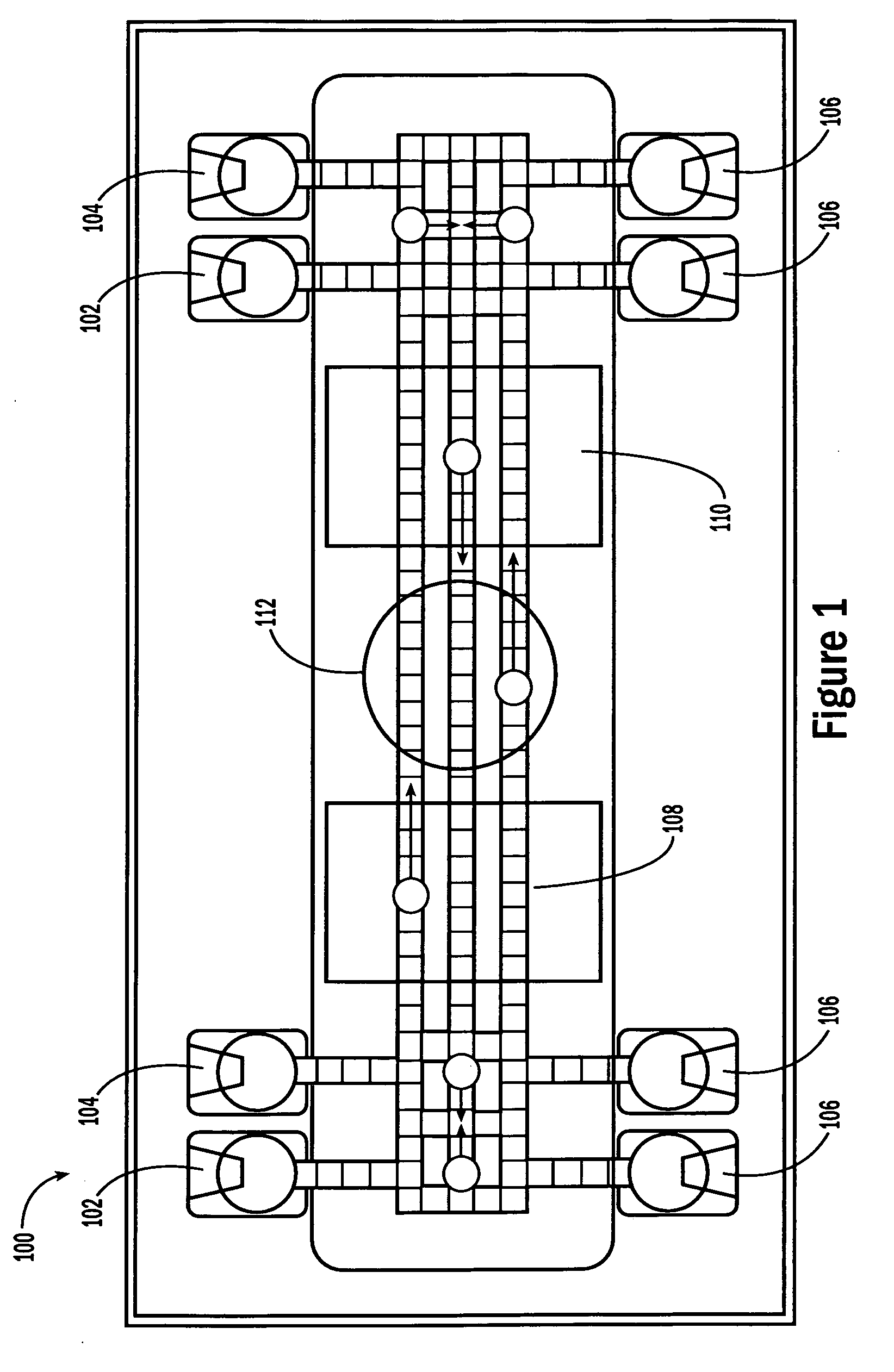

Electronic display devices and methods

InactiveUS6859218B1Visual presentationElectrographic process apparatusInteraction controlDisplay device

Electronic display devices and methods are described. In one embodiment, a display device comprises a housing and a display area provided within the housing to display content for a user. Memory is provided within the housing to hold data that is to be rendered into user-viewable content. An electrophotographic assembly is provided within the housing and is configured to electrophotographically render user-viewable content from the data that is held in the memory. A loop of material is disposed proximate the electrophotographic assembly and is configured to receive electrophotographically rendered content and present the content for user viewing within the display area. A control area is provided on the housing and includes one or more user-engagable structures to permit a user to interact with the device. The control area is positioned on the housing to accommodate one-handed use of the device. In one embodiment, the control area is provided on a sidewall that extends between front and back faces of the housing. The user-engagable structures can comprise any suitable user engagable structure, with an exemplary structure comprising a rocker-type switch which accommodates one-handed use of the display reader.

Owner:HEWLETT PACKARD DEV CO LP

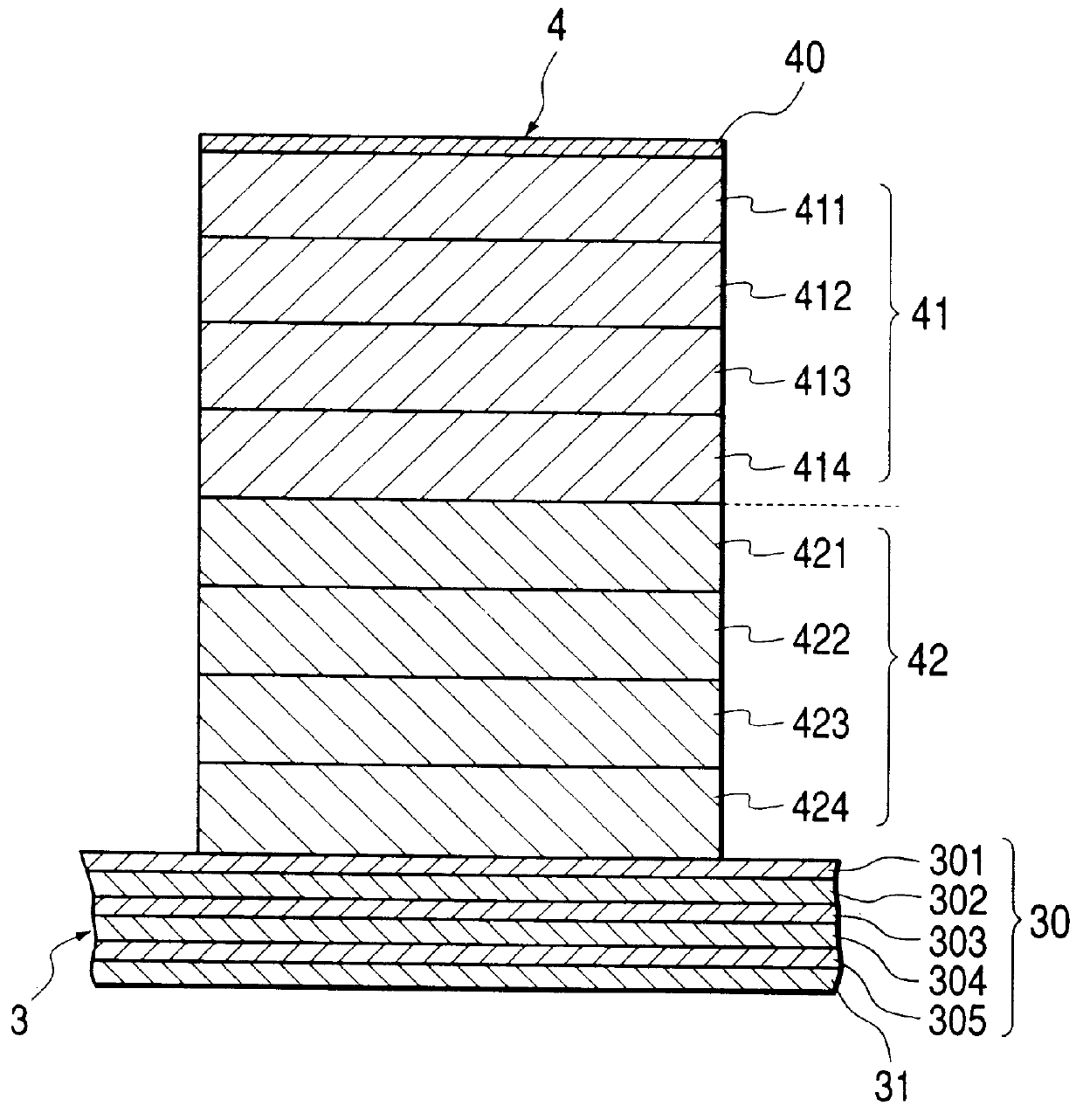

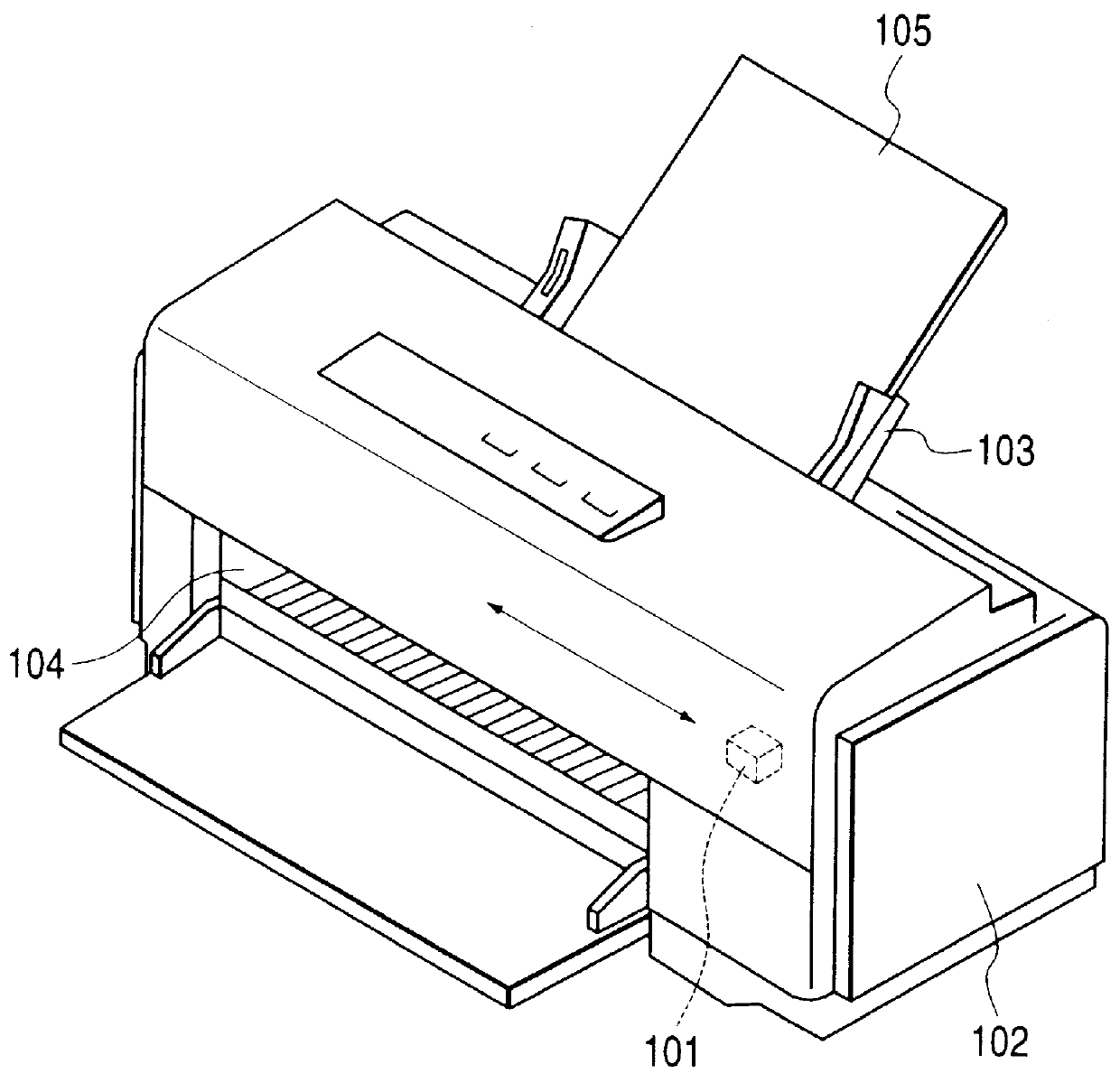

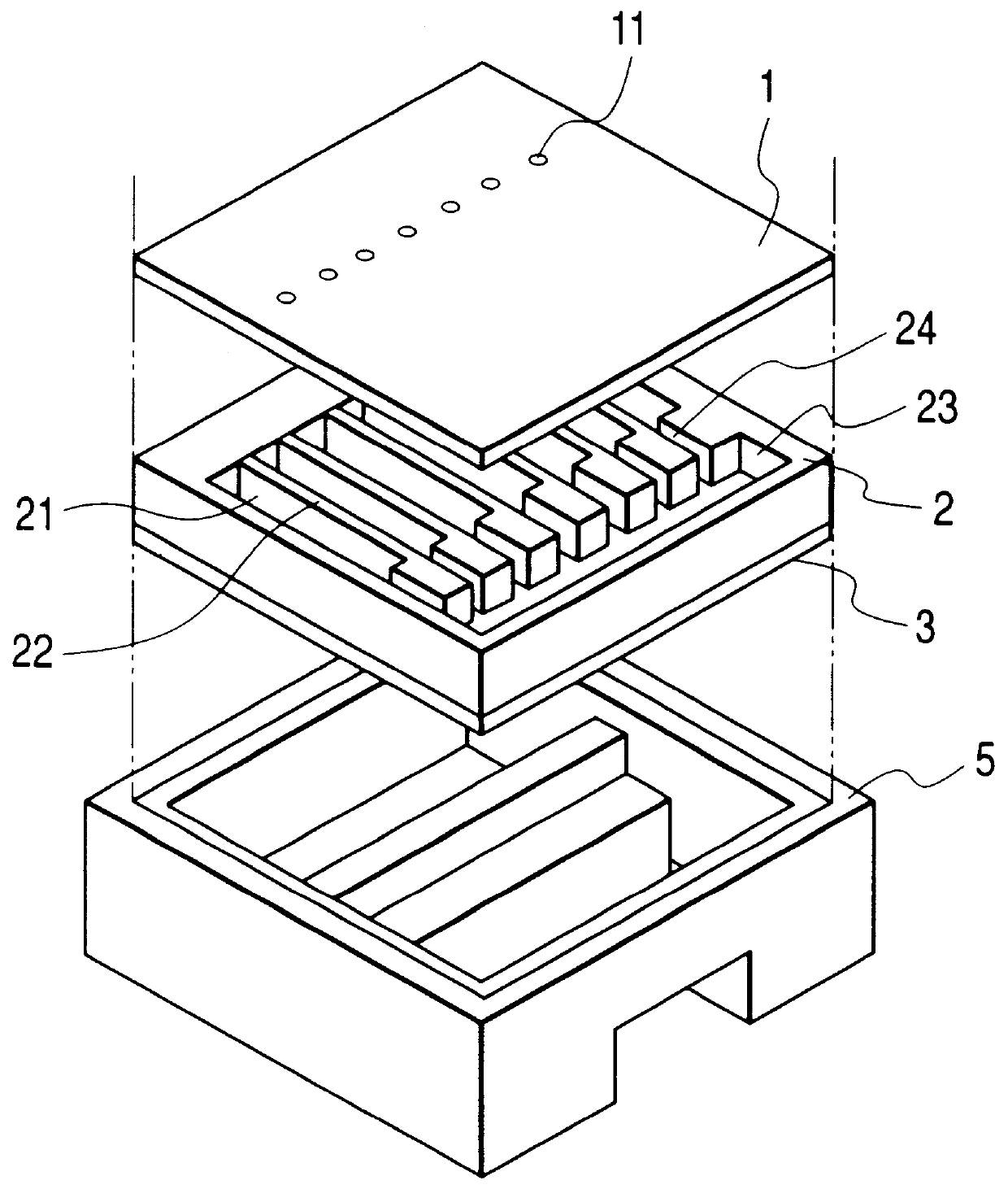

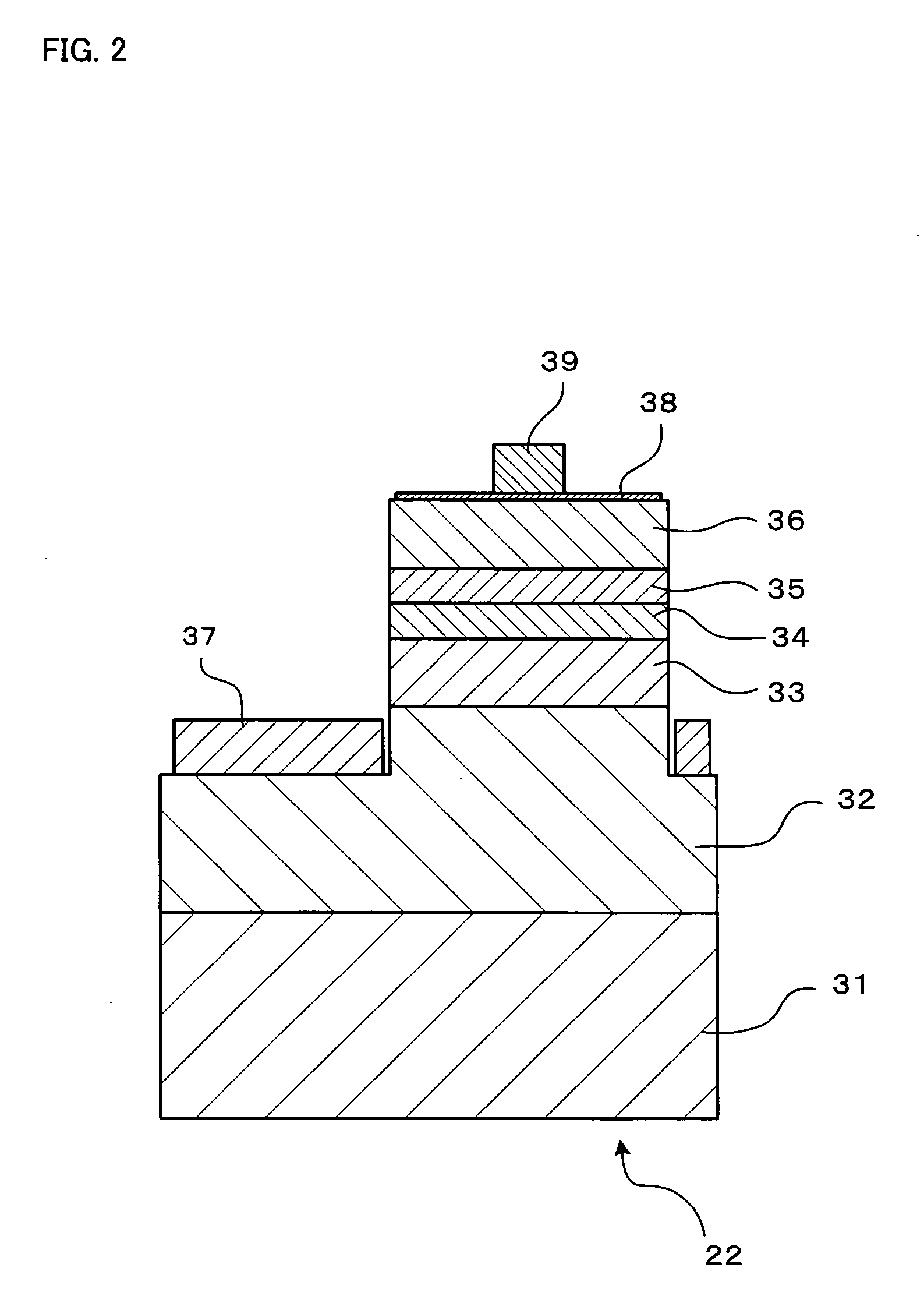

Ink-jet recording head with piezoelectric device and method for manufacturing the same

InactiveUS6142615AIncrease in piezoelectric constantIncrease the driving voltagePiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostrictive device material selectionPiezoelectric actuatorsPiezoelectric coefficient

A piezoelectric device for an ink jet print head that has a greater displacement at a low drive voltage. The ink-jet recording head includes a vibration plate, on which is mounted one or more piezoelectric devices that change the volumes of pressure chambers upon application of a voltage. The device is mounted at least on one face of a pressure chamber substrate that is to be filled with ink. Such piezoelectric device includes a second piezoelectric layer having a piezoelectric constant g of a constant value or higher; and a first piezoelectric layer having a dielectric constant of a specific value or higher. Since the piezoelectric constant d of the piezoelectric device correlates with the product of the largest piezoelectric constant g and the largest dielectric device of the piezoelectric devices, a piezoelectric constant d larger than in the conventional case, i.e., having a greater displacement, can be obtained.

Owner:SEIKO EPSON CORP

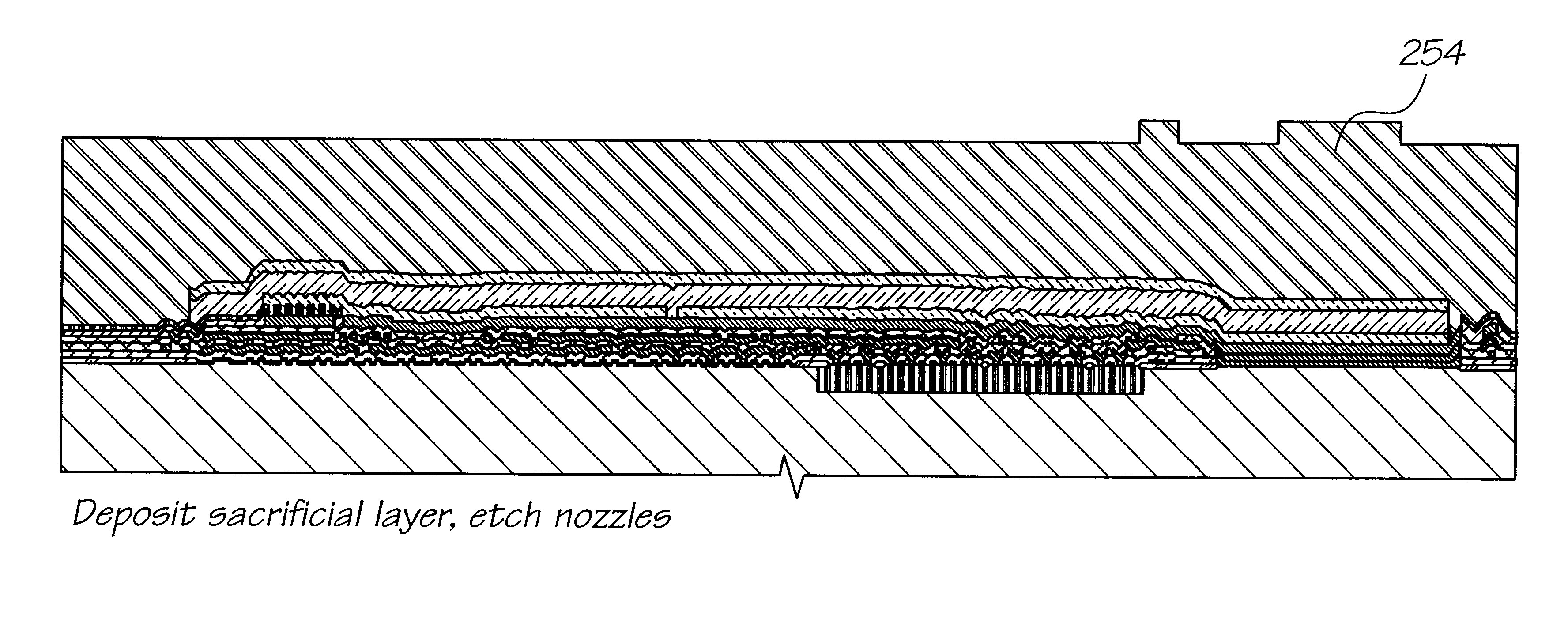

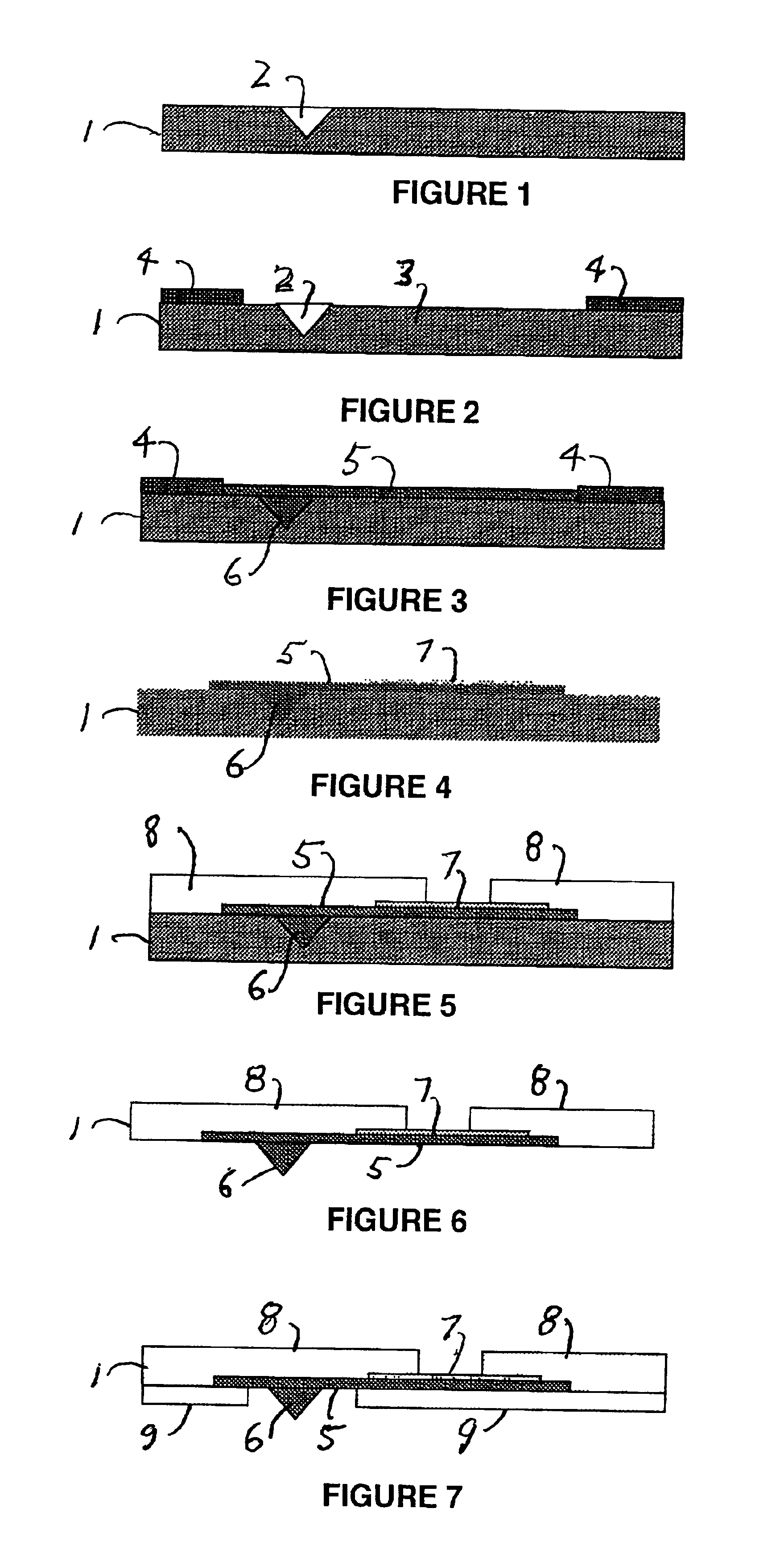

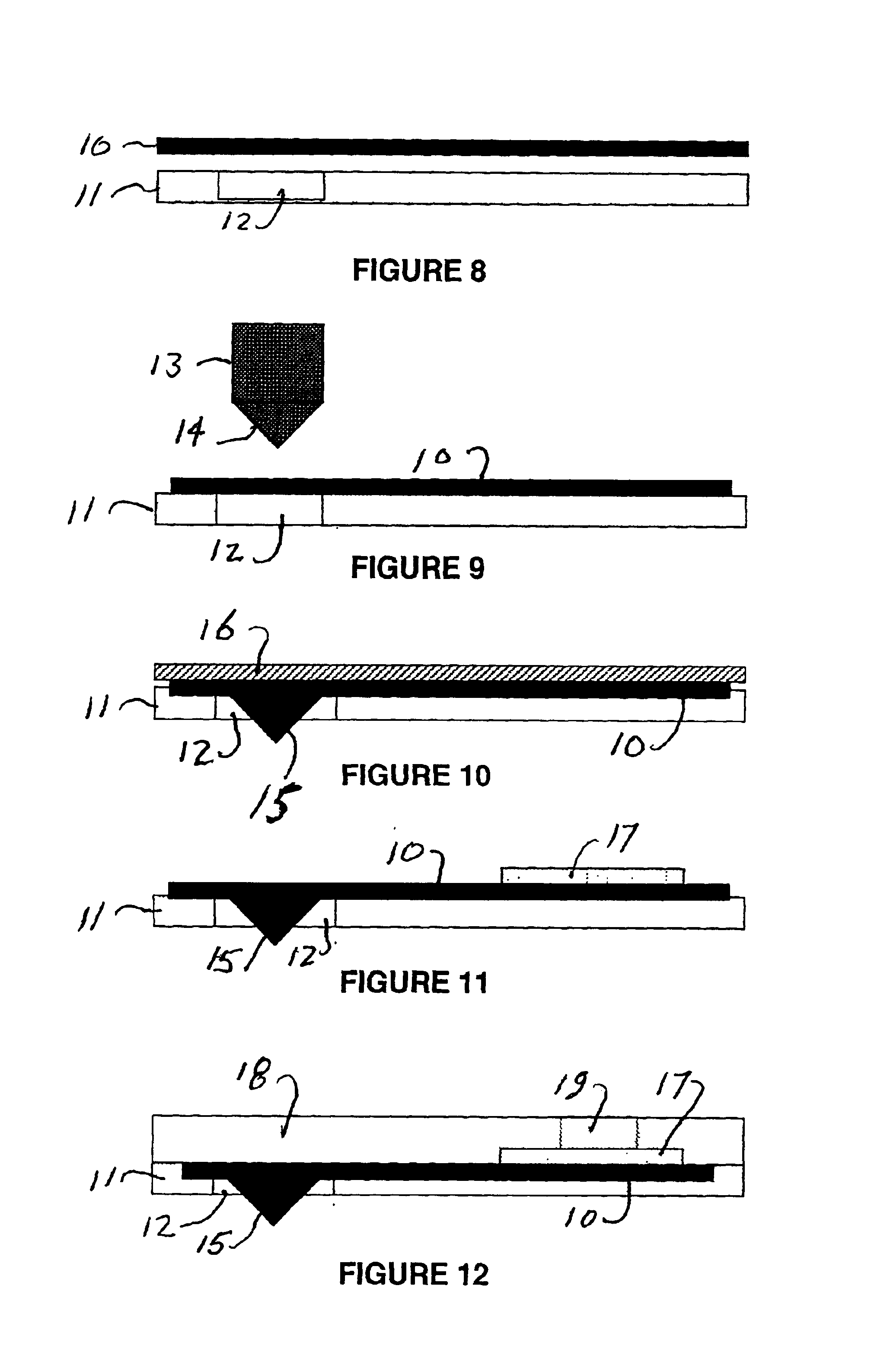

Inkjet printhead having a self aligned nozzle

An inkjet printing arrangement having a series of nozzles for the ejection of ink wherein the nozzle rims are formed as a result of the deposition of a rim material layer and a subsequent planar etching of the material layer so as to form the nozzle rim. The planar etching can comprise chemical-mechanical planarization of the rim material layer and any associated sacrificial layers.

Owner:ZAMTEC +1

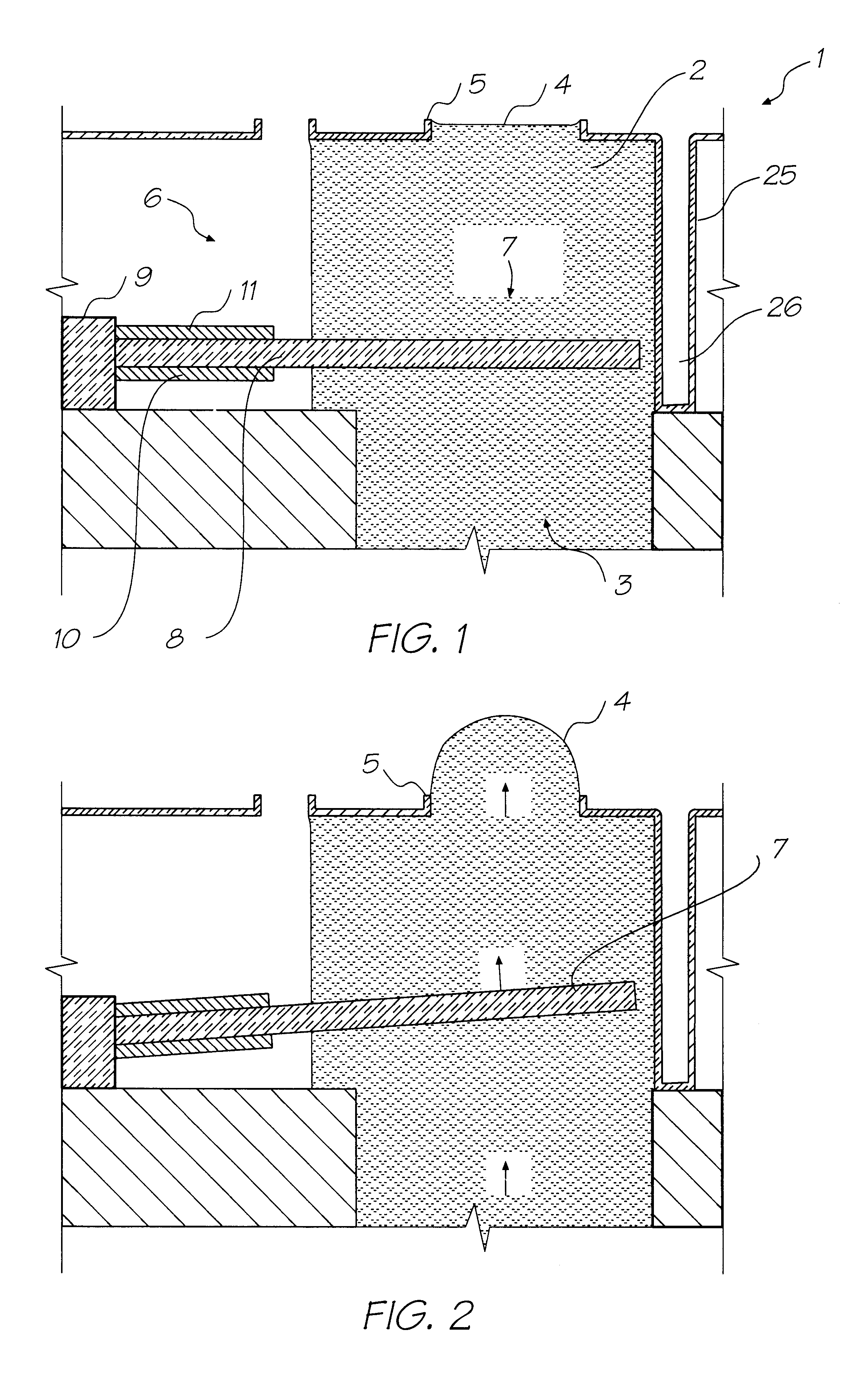

Method and apparatus for promoting the complete transfer of liquid drops from a nozzle

A printhead device for transferring liquid droplets from a nozzle includes a liquid source coupled to a nozzle via a microchannel. The nozzle is formed from an orifice having an inner circumferential surface, wherein at least a portion of the inner circumferential surface is serrated. Liquid droplets are transported from the source to the nozzle using a liquid droplet driver (e.g., employing a plurality of driving electrodes). Transfer of droplets to another surface can be accomplished by contacting a bulging droplet in the nozzle with a printing surface. The surface and / or nozzle are then moved relative to one another to effectuate complete transfer of the liquid drop from the nozzle.

Owner:RGT UNIV OF CALIFORNIA

Method and device for driving LED element, illumination apparatus, and display apparatus

InactiveUS20050168564A1Efficient driveEffectively driving an LEDElectroluminescent light sourcesCathode-ray tube indicatorsDriving currentPeak value

A driving method and a driving device are provided for an LED element in which light emitting layers different from each other in light emission wavelength peak, put on each other with a barrier layer being interposed, are sandwiched by a pair of p-type and n-type layers, and color of emitted light from which substantially depends only upon driving current value. The method comprises a driving current value calculation step of obtaining a value for designating a current value corresponding to a desired color of emitted light from the LED element; a driving current generation step of generating a driving current having the current value designated by the value obtained in the driving current value calculation step; and a driving current supply step of supplying the LED element with the driving current generated in the driving current generation step.

Owner:SHARP KK

Selective deposition modeling system and method

InactiveUS6305769B1Additive manufacturing apparatus3D object support structuresEngineeringSelective deposition

A system and associated method for forming three-dimensional objects under computer control and from a material which may be rendered flowable and then dispensed on a layer-by-layer basis. The layers of the material solidify or otherwise physically transform upon being dispensed thereby forming successive cross-sections. The dispensing process is repeated whereby successive layers adhere to each other thereby forming the object.

Owner:3D SYST INC

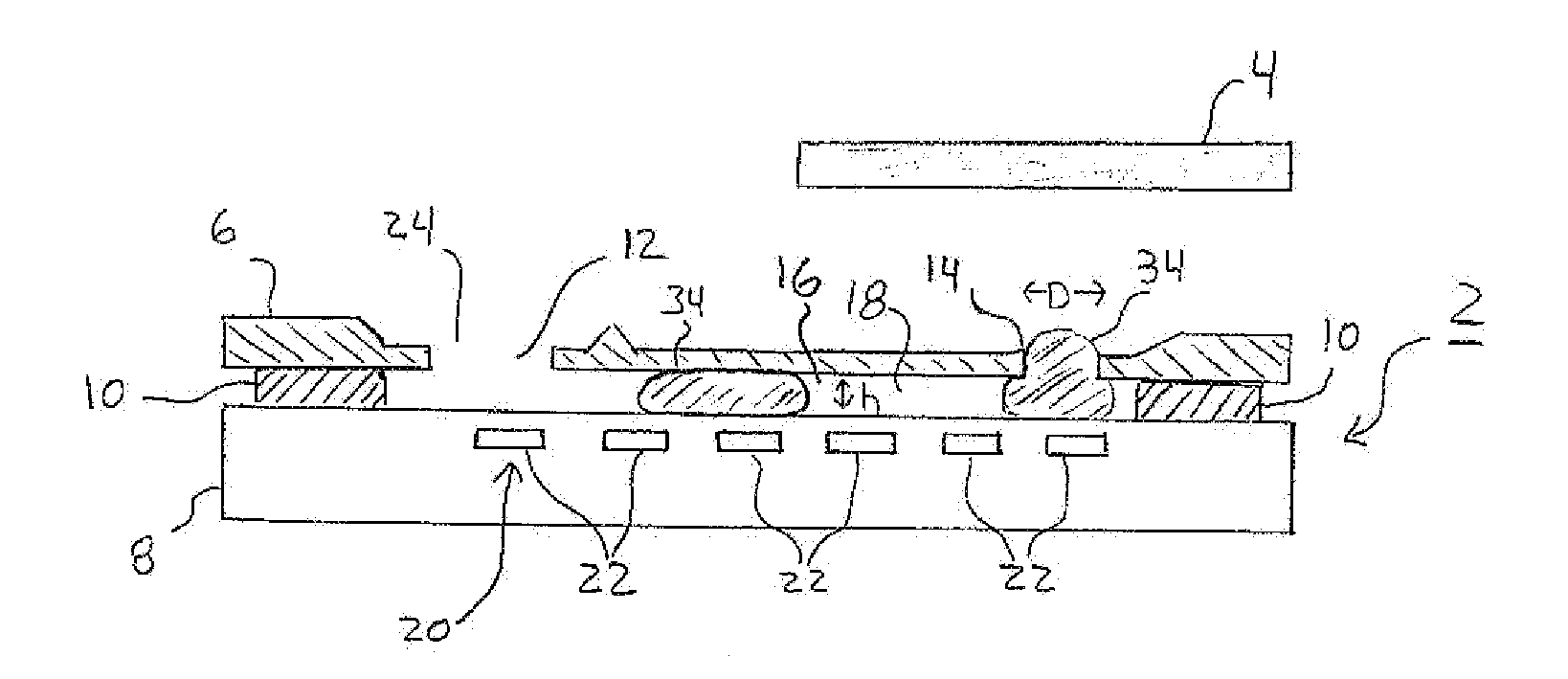

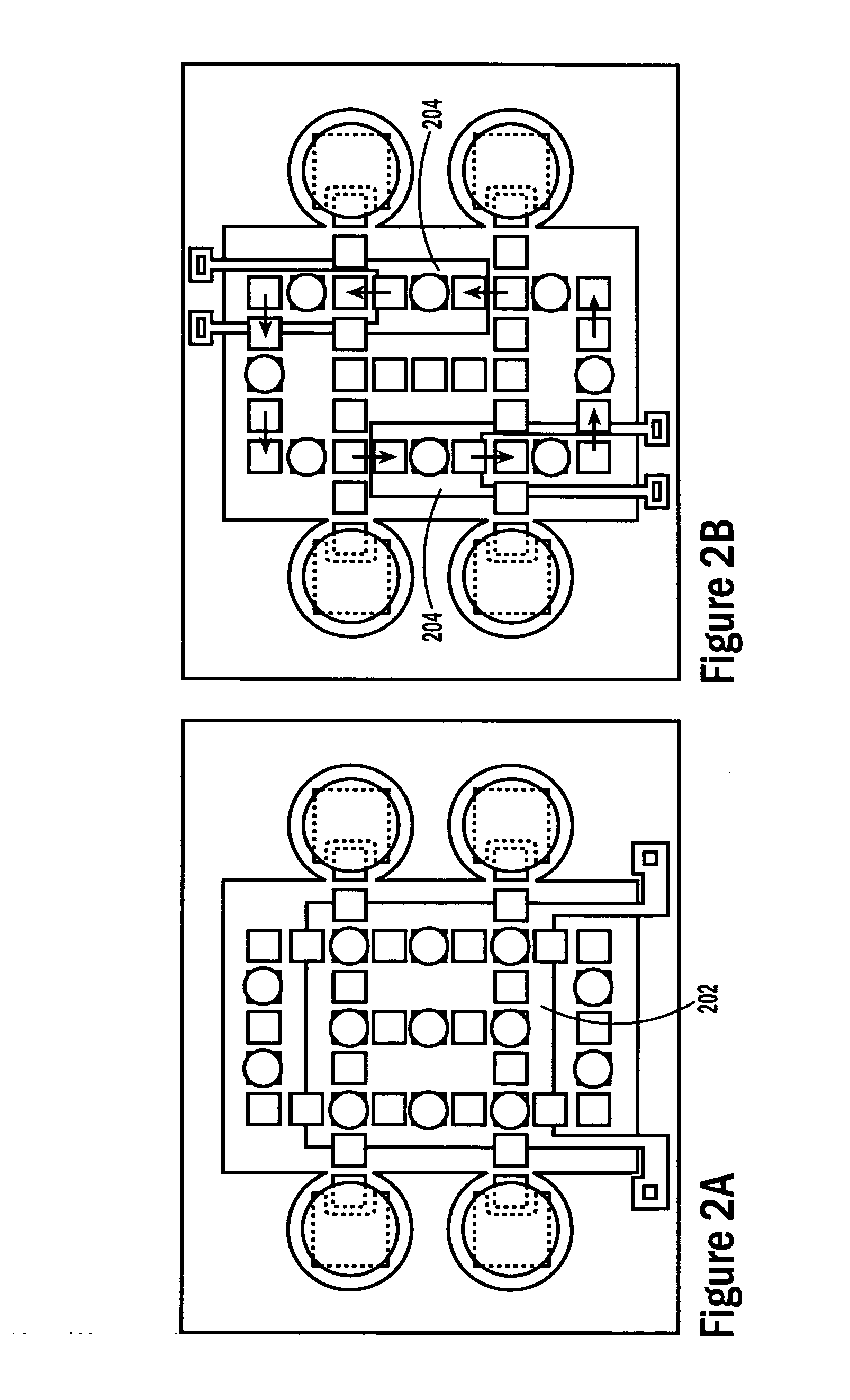

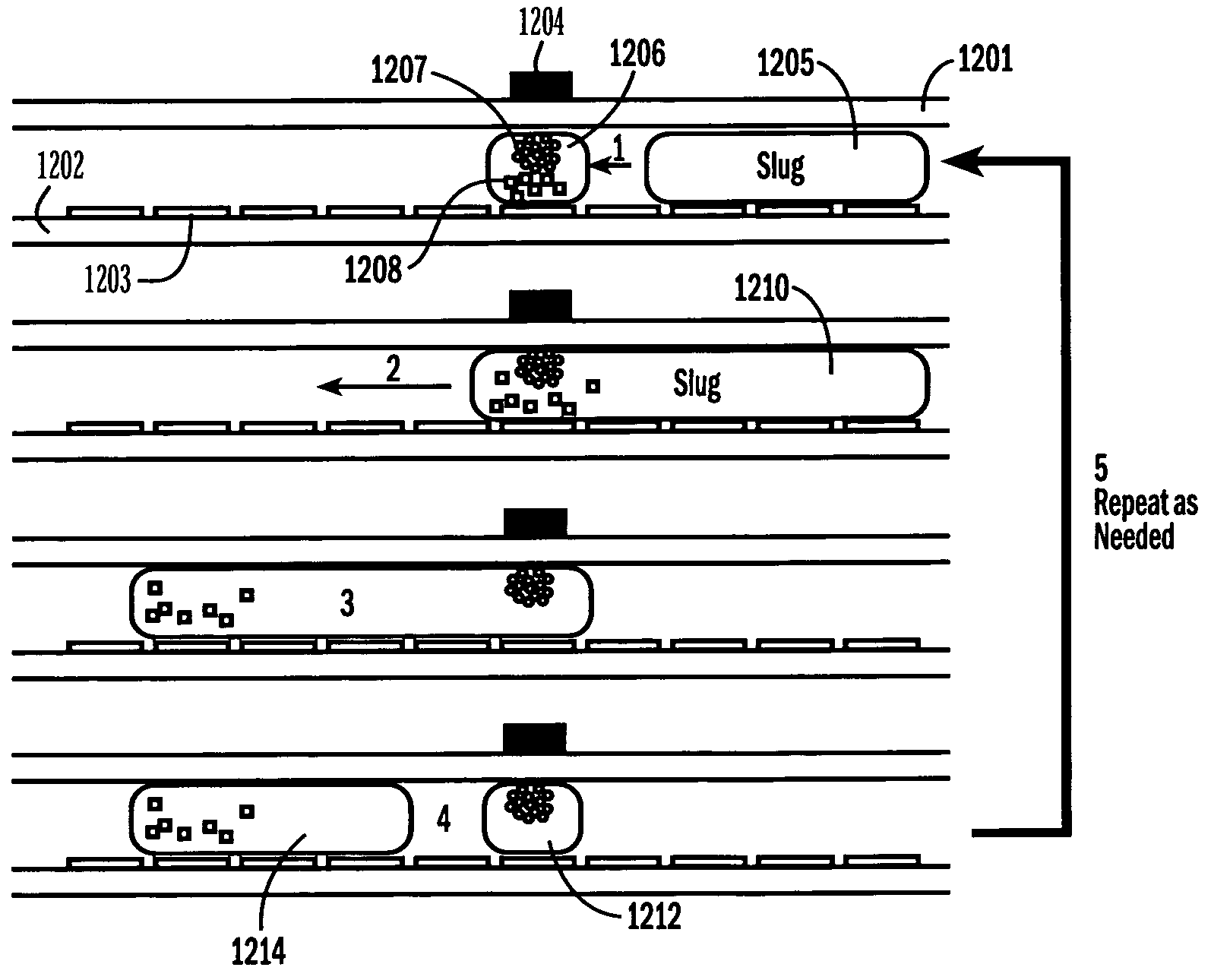

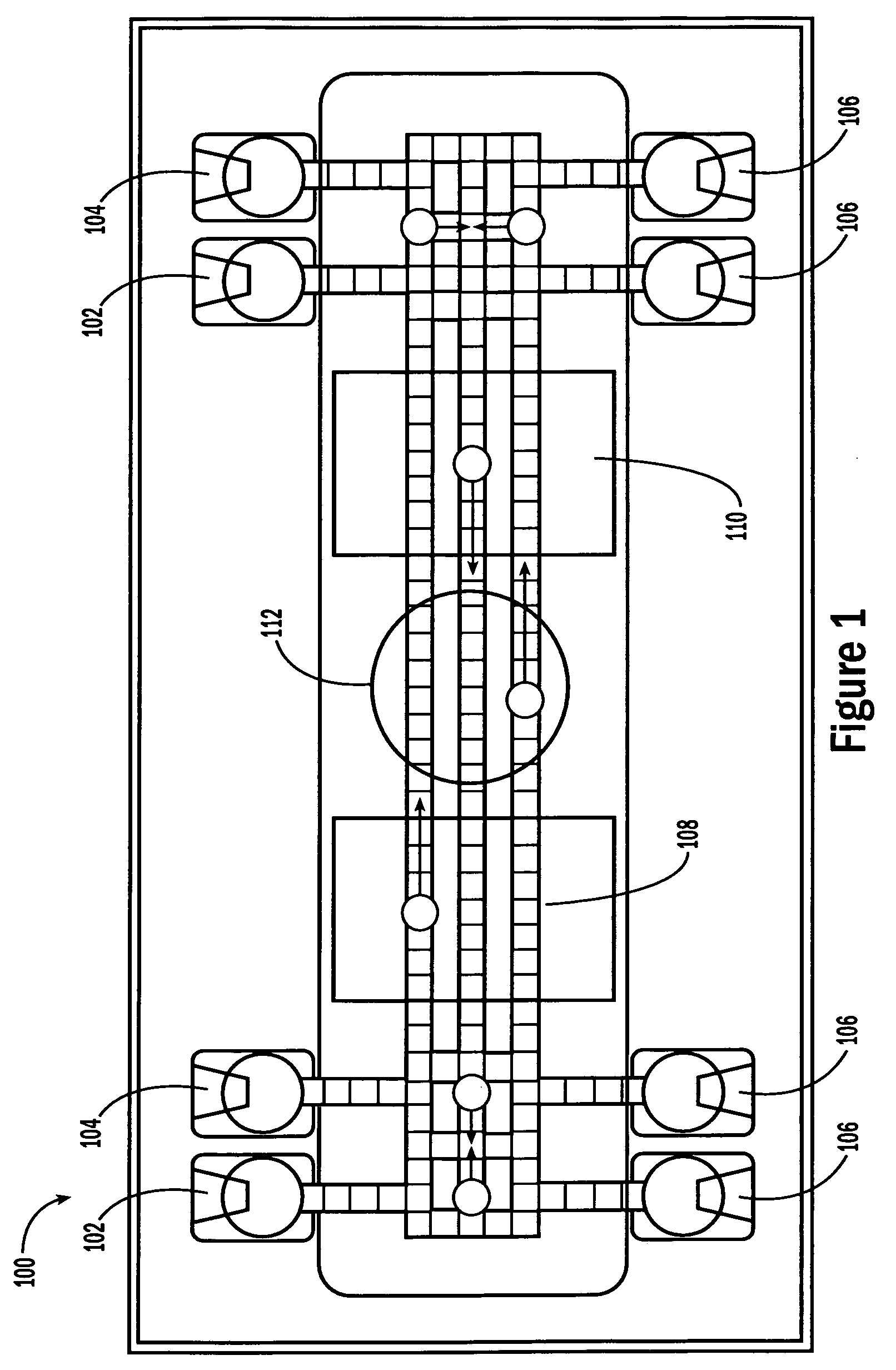

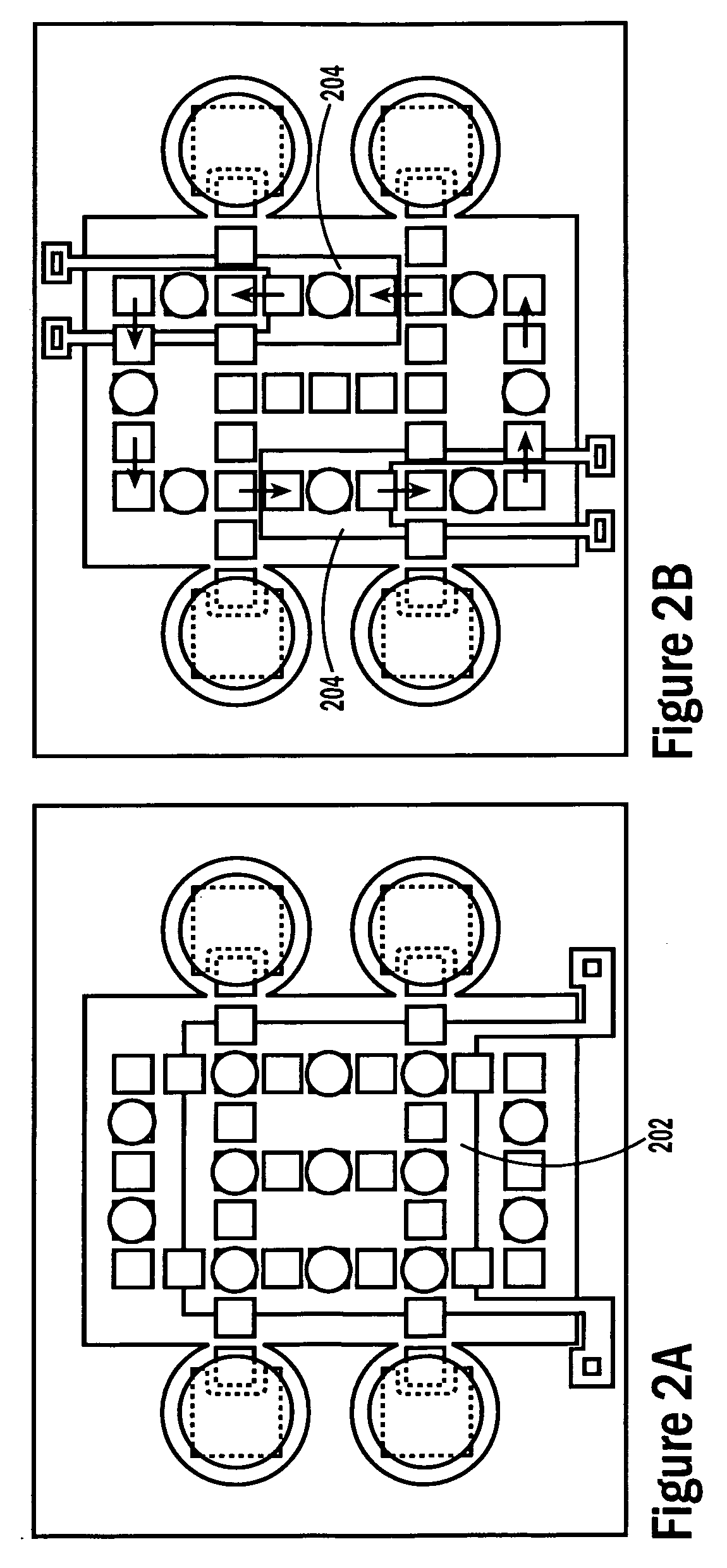

Filler fluids for droplet operations

ActiveUS20070242105A1Reduces and eliminates build-upImprove efficiencyElectrostatic separatorsFixed microstructural devicesEngineeringLiquid drop

The present invention relates to filler fluids for droplet operations. According to one embodiment of this aspect, a droplet microactuator is provided and includes: (a) a first substrate comprising electrodes configured for conducting droplet operations on a surface of the substrate; (b) a second substrate spaced from the surface of the substrate by a distance sufficient to define an interior volume between the first substrate and second substrate, wherein the distance is sufficient to contain a droplet disposed in the space on the first substrate; and (c) a droplet arranged in the interior volume and arranged with respect to the electrodes in a manner which permits droplet operations to be effected on the droplet using the electrodes.

Owner:DUKE UNIV +1

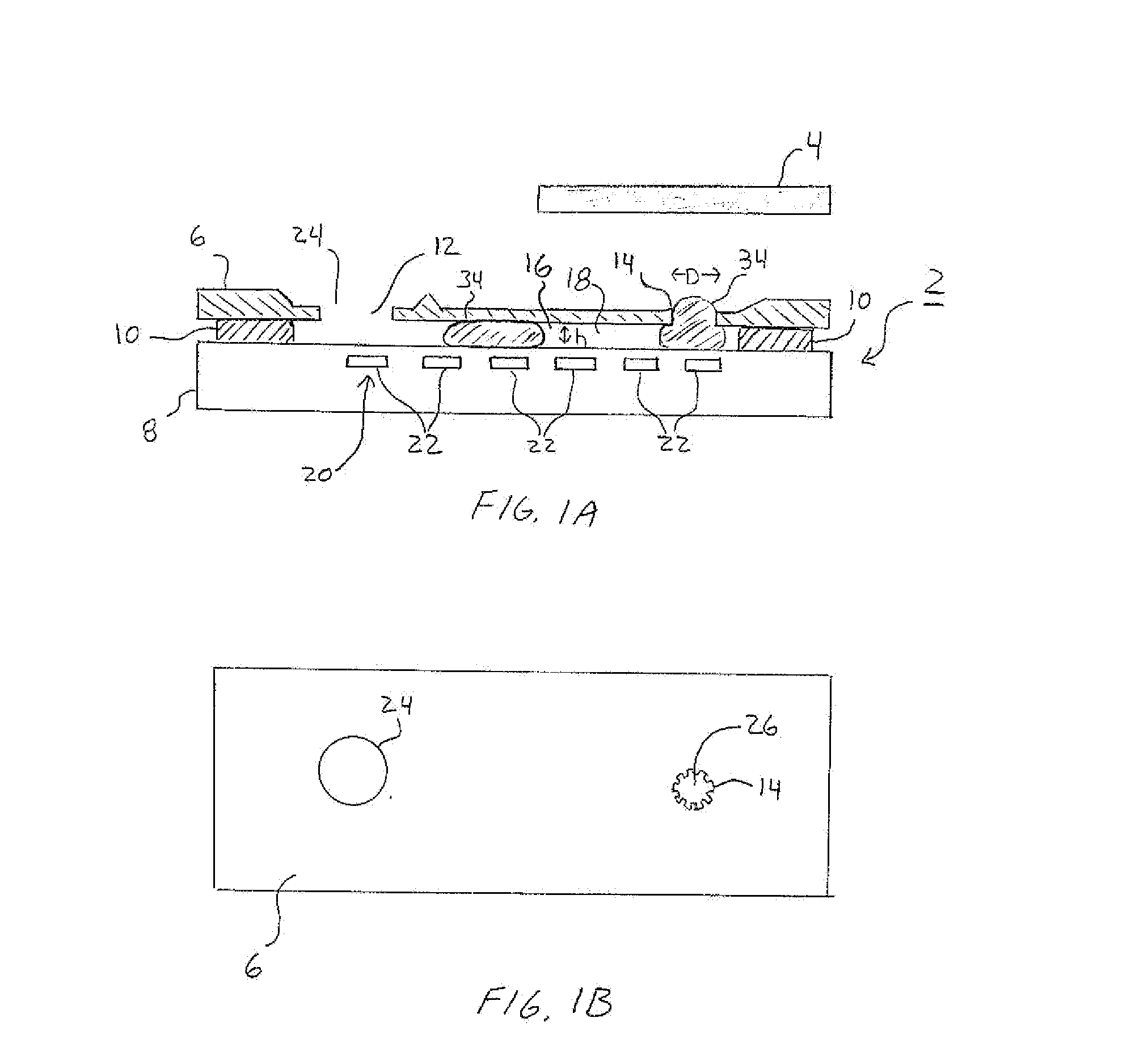

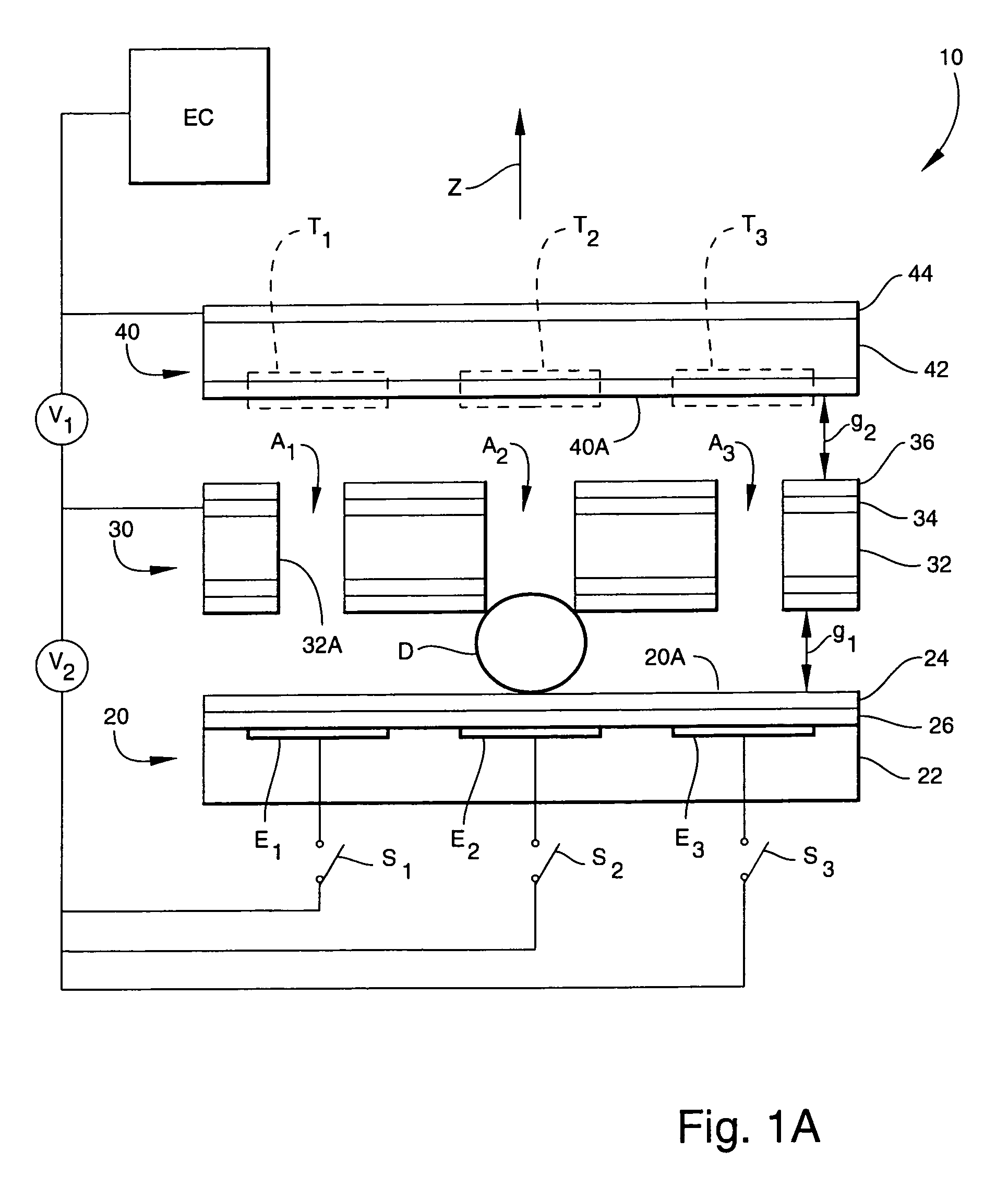

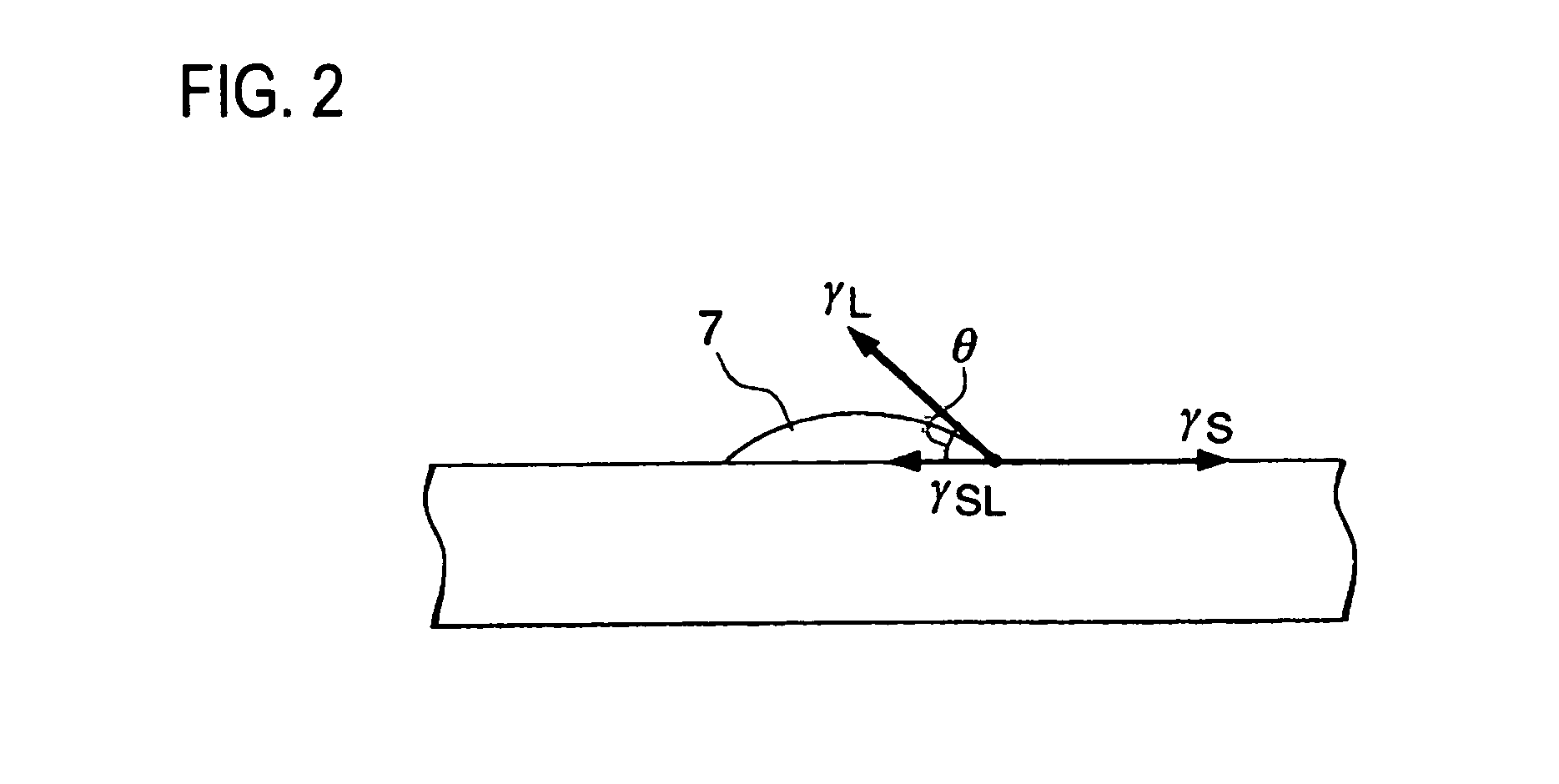

Method and apparatus for non-contact electrostatic actuation of droplets

InactiveUS6989234B2Immobilised enzymesBioreactor/fermenter combinationsHydrophobic surfacesEngineering

An apparatus for actuating a droplet comprises a first conductive layer, a second conductive layer, a conductive elongate element, and a voltage source. The first conductive layer comprises a first hydrophobic surface. The second conductive layer comprises a hydrophilic surface facing the first hydrophobic surface. The second conductive layer is axially spaced from the first conductive layer to define a gap therebetween. The conductive medial element is disposed in the gap between the first and second conductive layers, and comprises a second hydrophobic surface. The voltage source communicates with the second conductive layer and the elongate element. By applying a voltage potential between the elongate element and the second conductive layer, droplets can be electrostatically actuated so as to move from the first conductive layer into contact with the second conductive layer. The apparatus is particularly useful in the synthesis of microarrays of biological, chemical, or biochemical samples.

Owner:DUKE UNIV

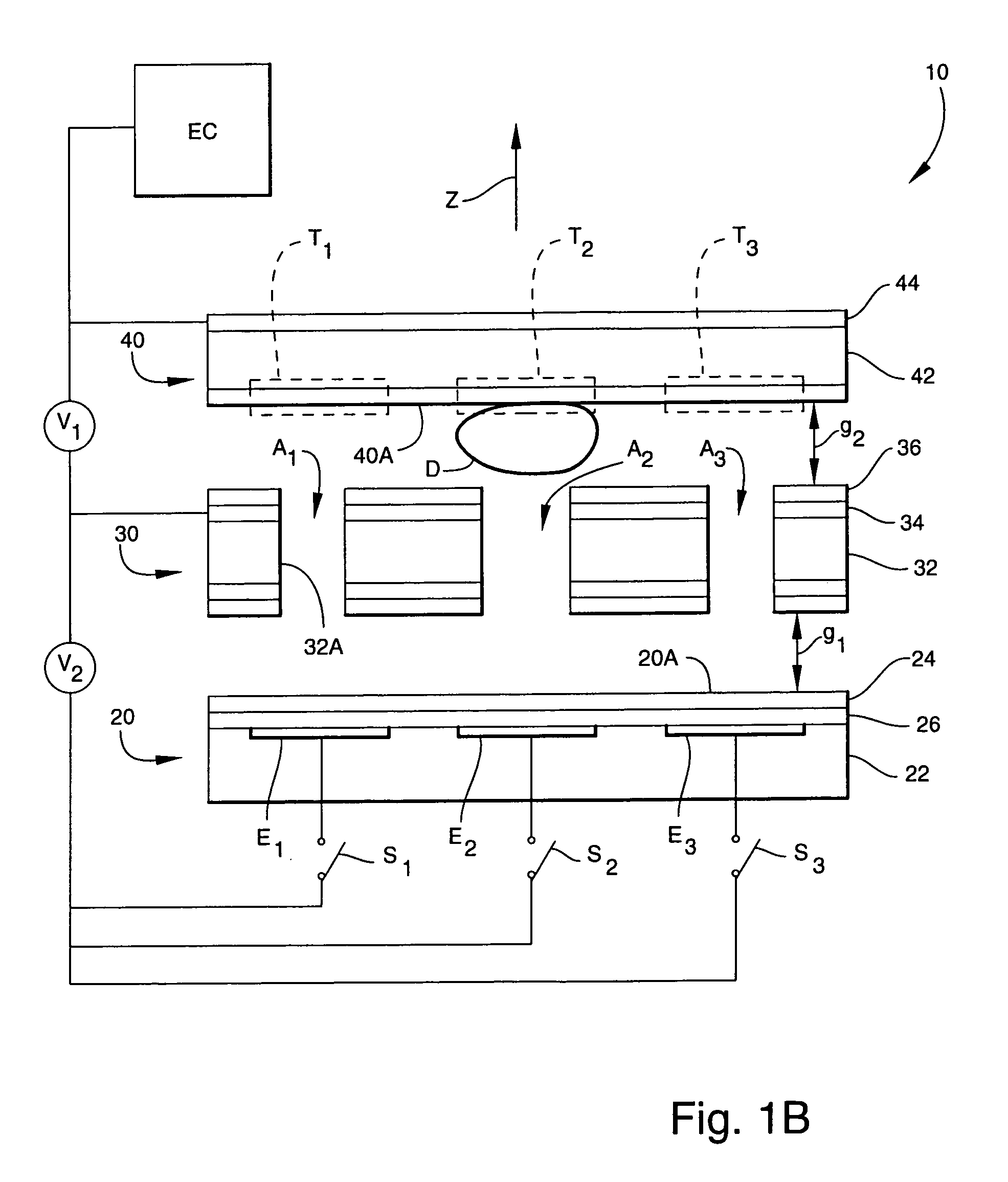

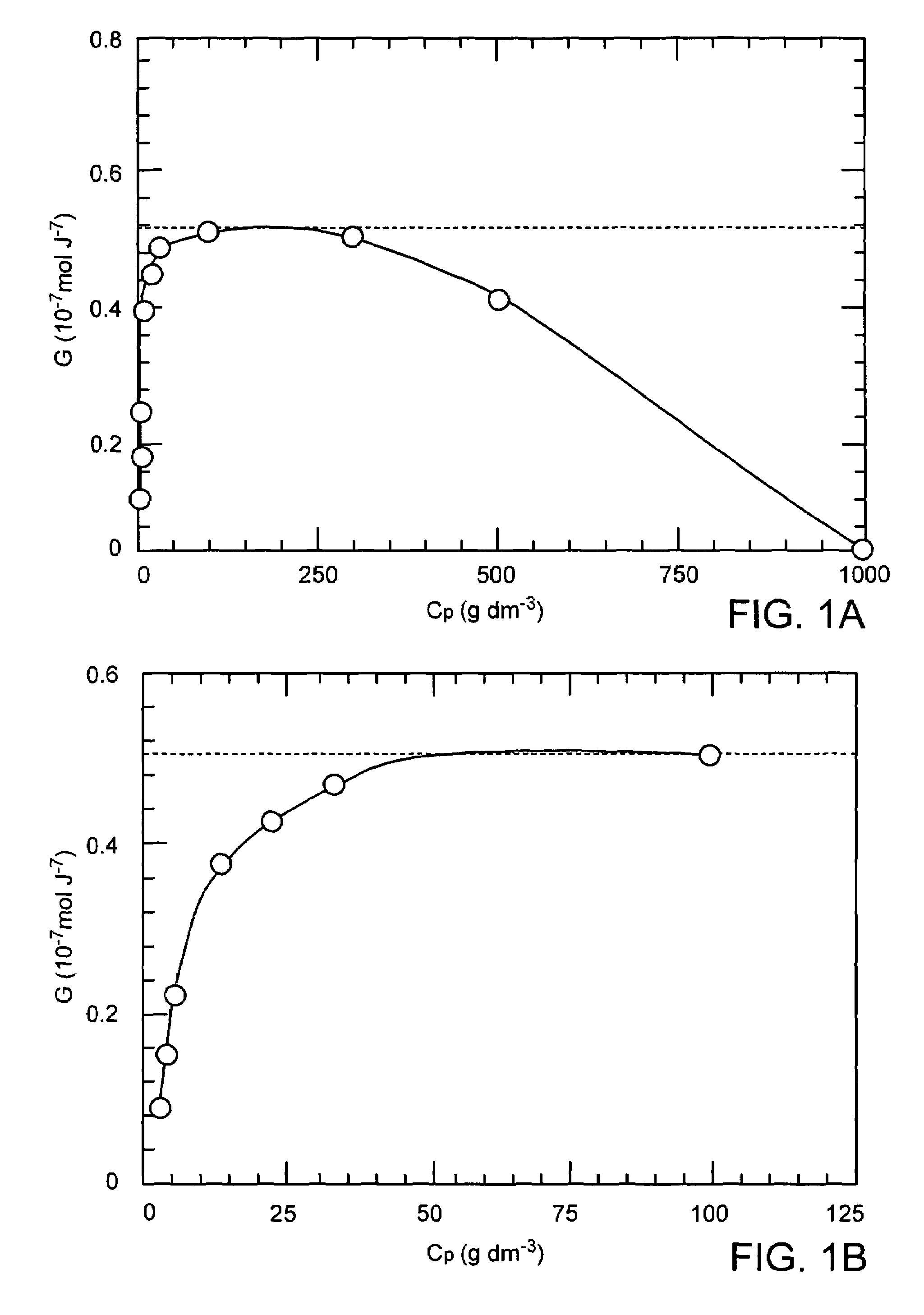

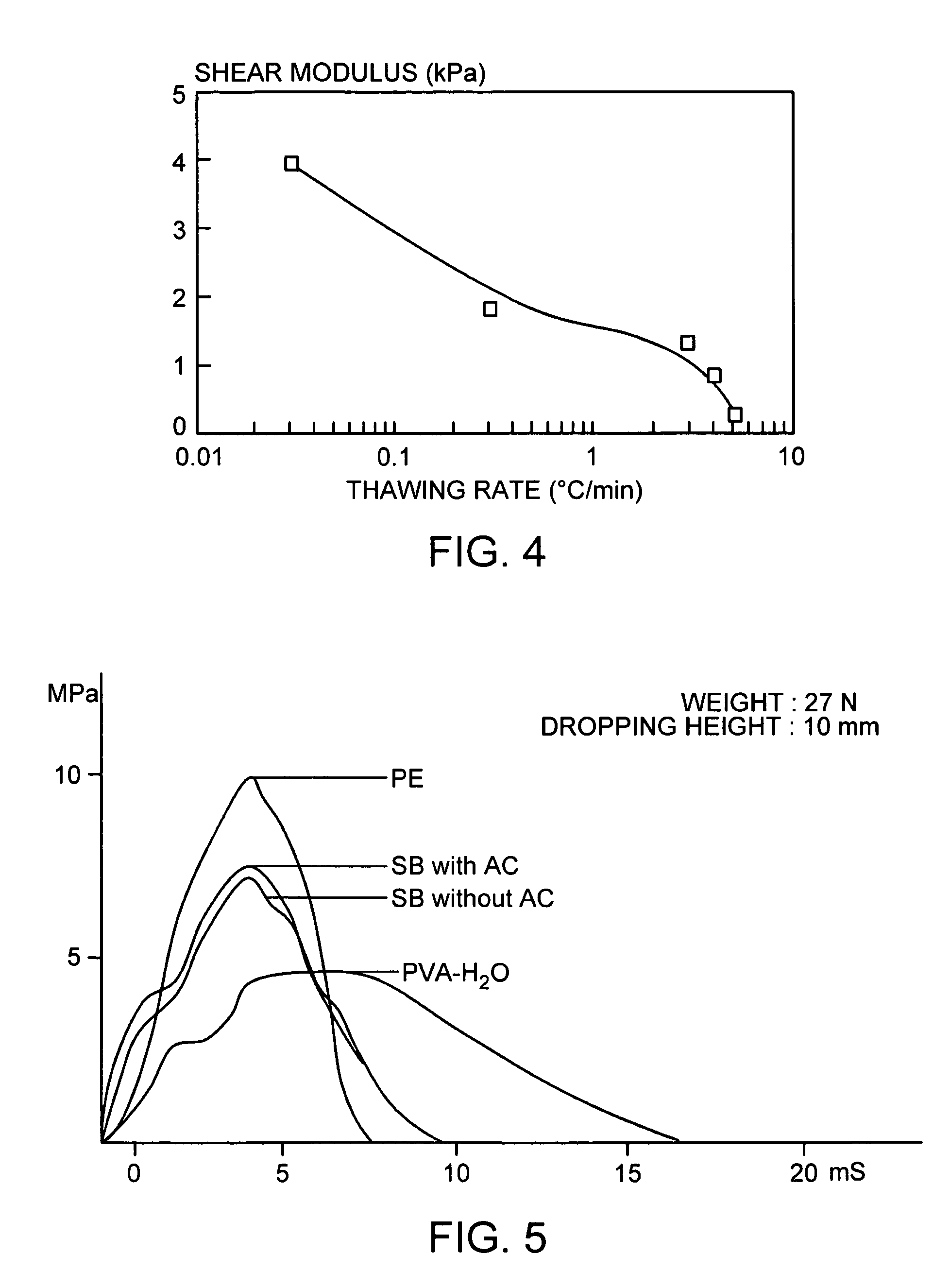

PVA hydrogel

InactiveUS7235592B2Improve physical stabilityGood physical propertiesOrganic chemistryMixing methodsPolymer sciencePolymer

The present invention provides methods of making covalently crosslinked vinyl polymer hydrogels having advantageous physical properties, and covalently crosslinked vinyl polymer hydrogel compositions made by such methods, as well as articles of manufacture comprising such covalently crosslinked vinyl polymer hydrogel compositions. The physical properties of the produced hydrogels can be adjusted by varying controlled parameters such as the proportion of physical associations, the concentration of polymer and the amount of radiation applied. Such covalently crosslinked vinyl polymer hydrogels can be made translucent, preferably transparent, or opaque depending on the processing conditions. The stability of the physical properties of the produced vinyl polymer hydrogel can be enhanced by controlling the amount of covalent crosslinks.

Owner:ZIMMER GMBH

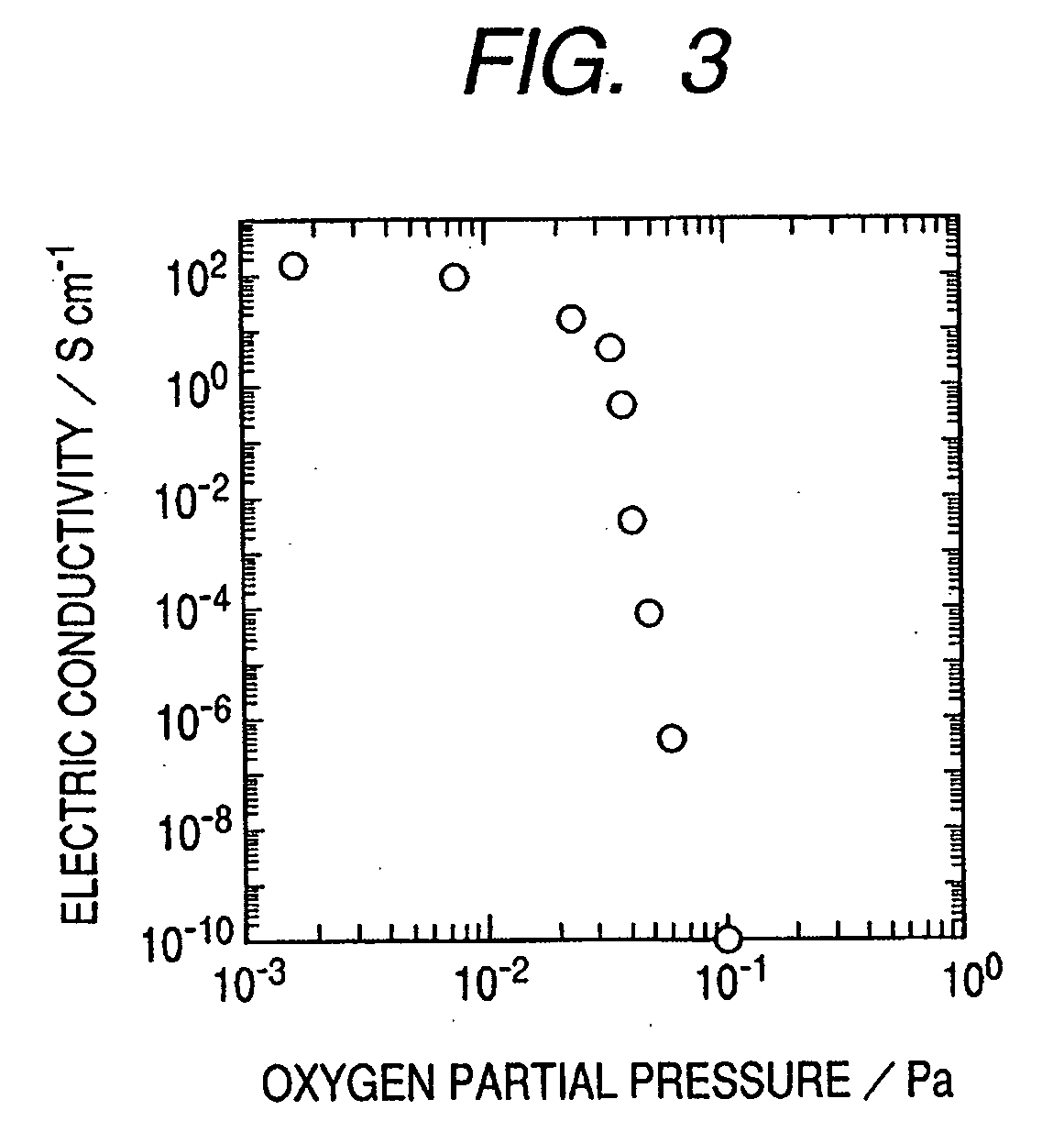

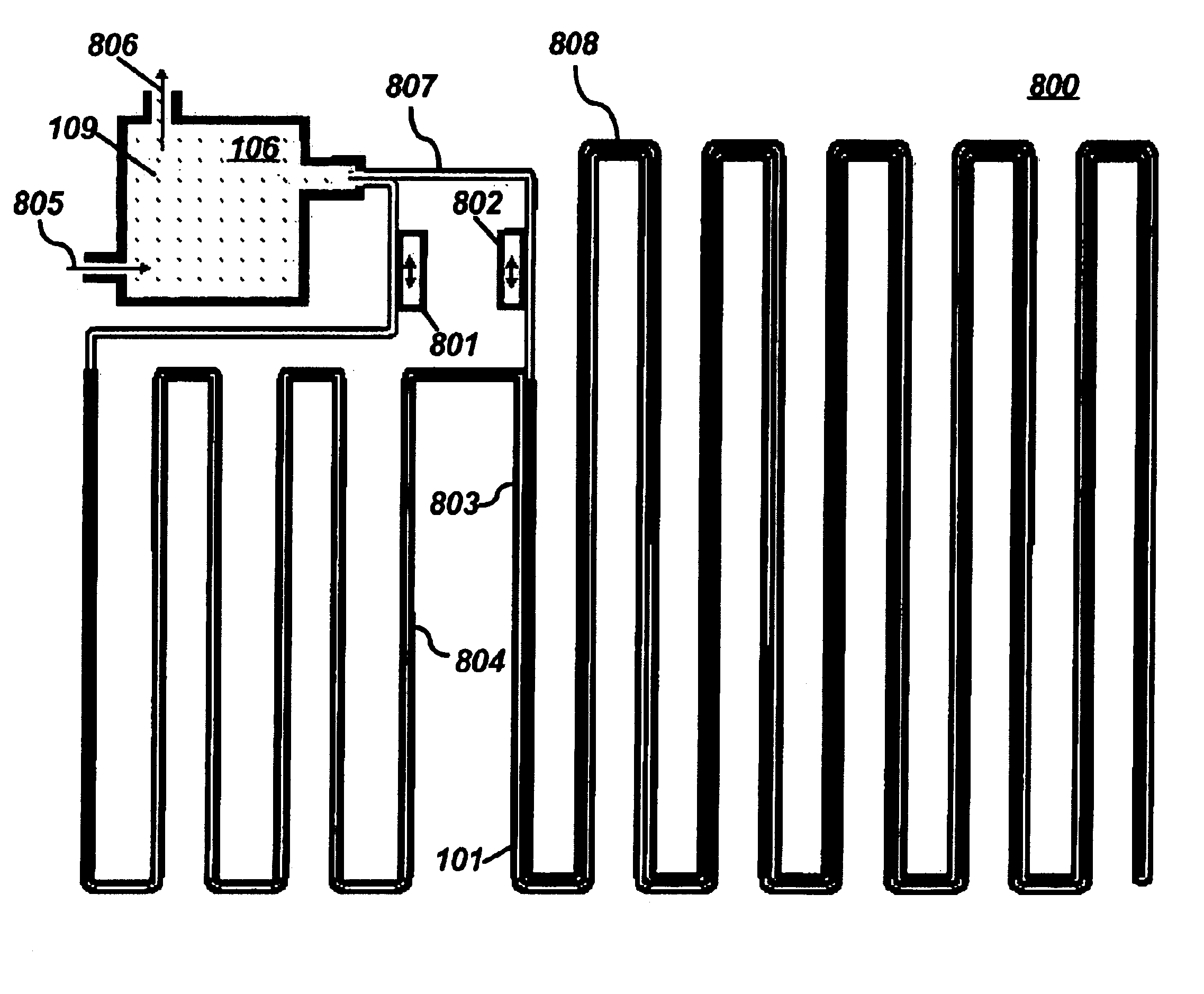

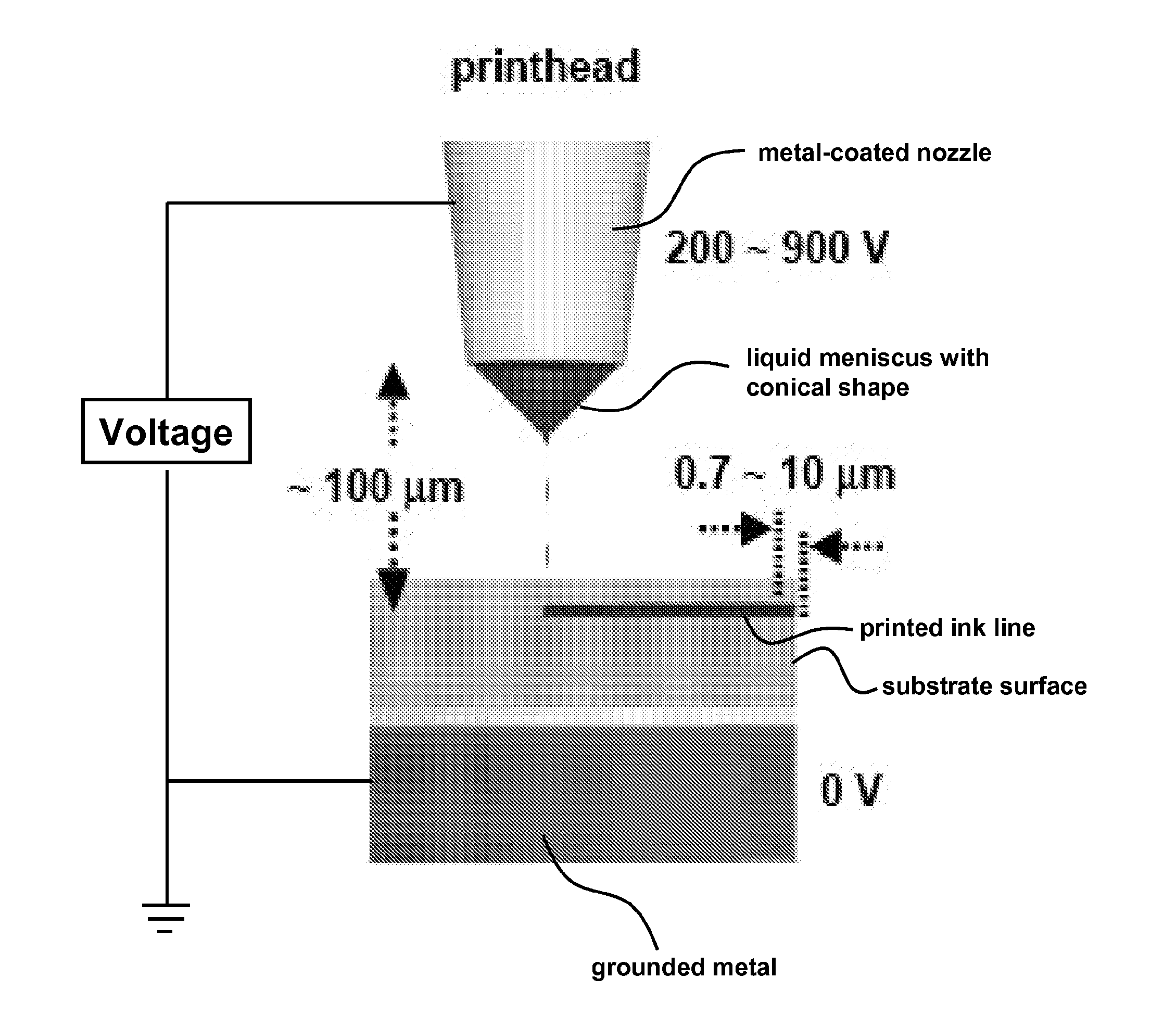

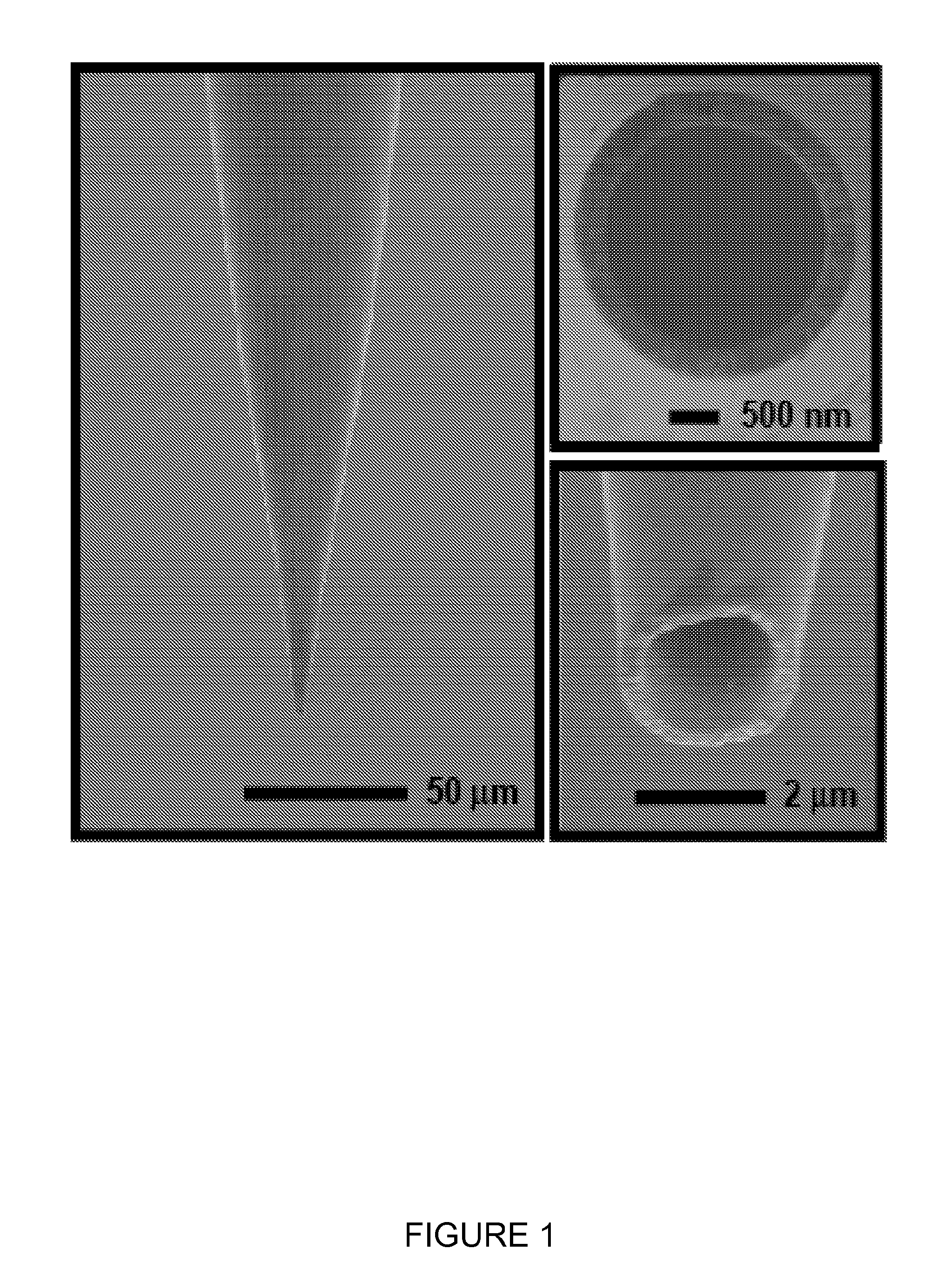

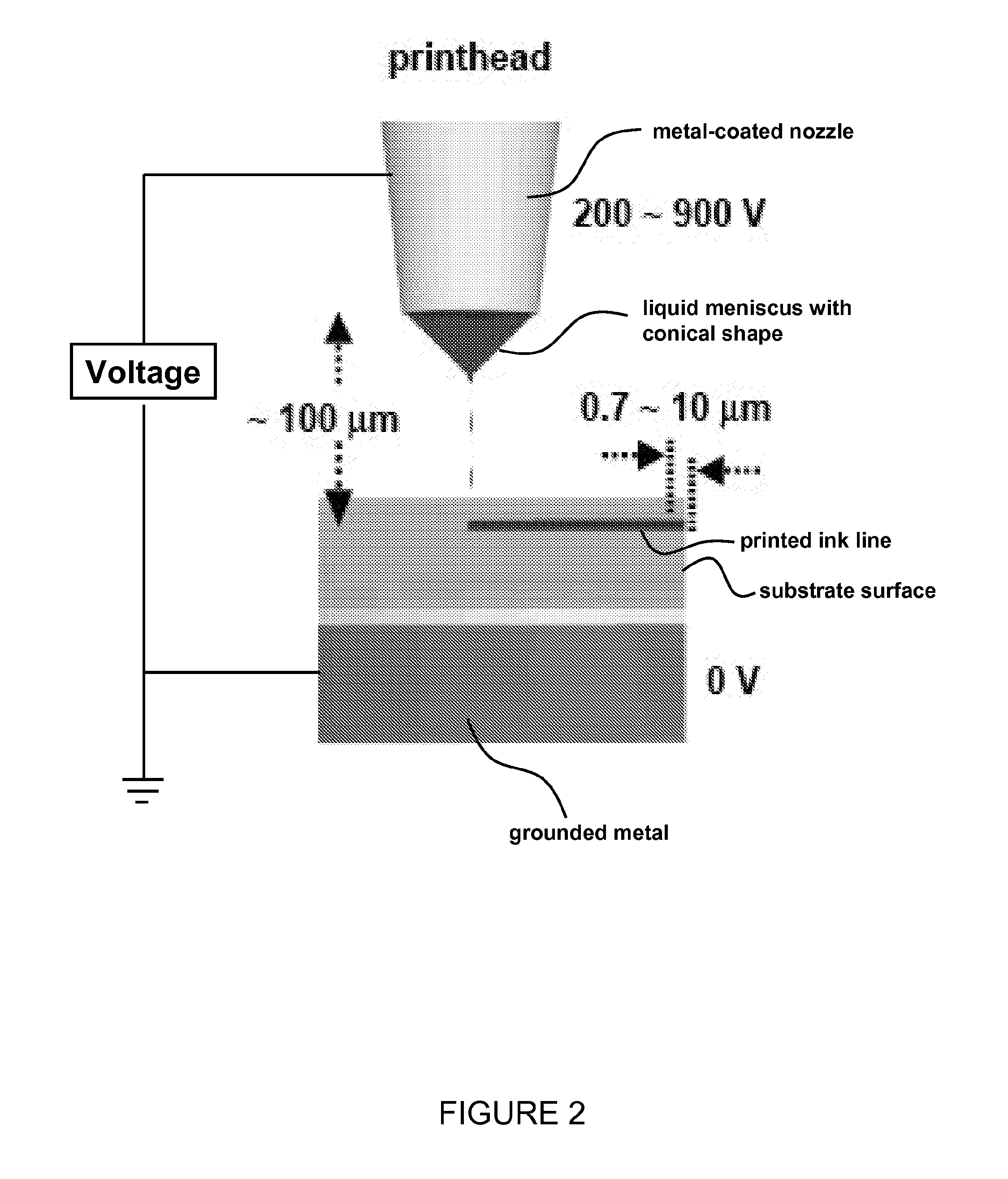

High Resolution Electrohydrodynamic Jet Printing for Manufacturing Systems

ActiveUS20110187798A1Improve placement accuracyBetter confinedPrintingImage resolutionVoltage source

Provided are high-resolution electrohydrodynamic inkjet (e-jet) printing systems and related methods for printing functional materials on a substrate surface. In an embodiment, a nozzle with an ejection orifice that dispenses a printing fluid faces a surface that is to be printed. The nozzle is electrically connected to a voltage source that applies an electric charge to the fluid in the nozzle to controllably deposit the printing fluid on the surface. In an aspect, a nozzle that dispenses printing fluid has a small ejection orifice, such as an orifice with an area less than 700 μm2 and is capable of printing nanofeatures or microfeatures. In an embodiment the nozzle is an integrated-electrode nozzle system that is directly connected to an electrode and a counter-electrode. The systems and methods provide printing resolutions that can encompass the sub-micron range.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

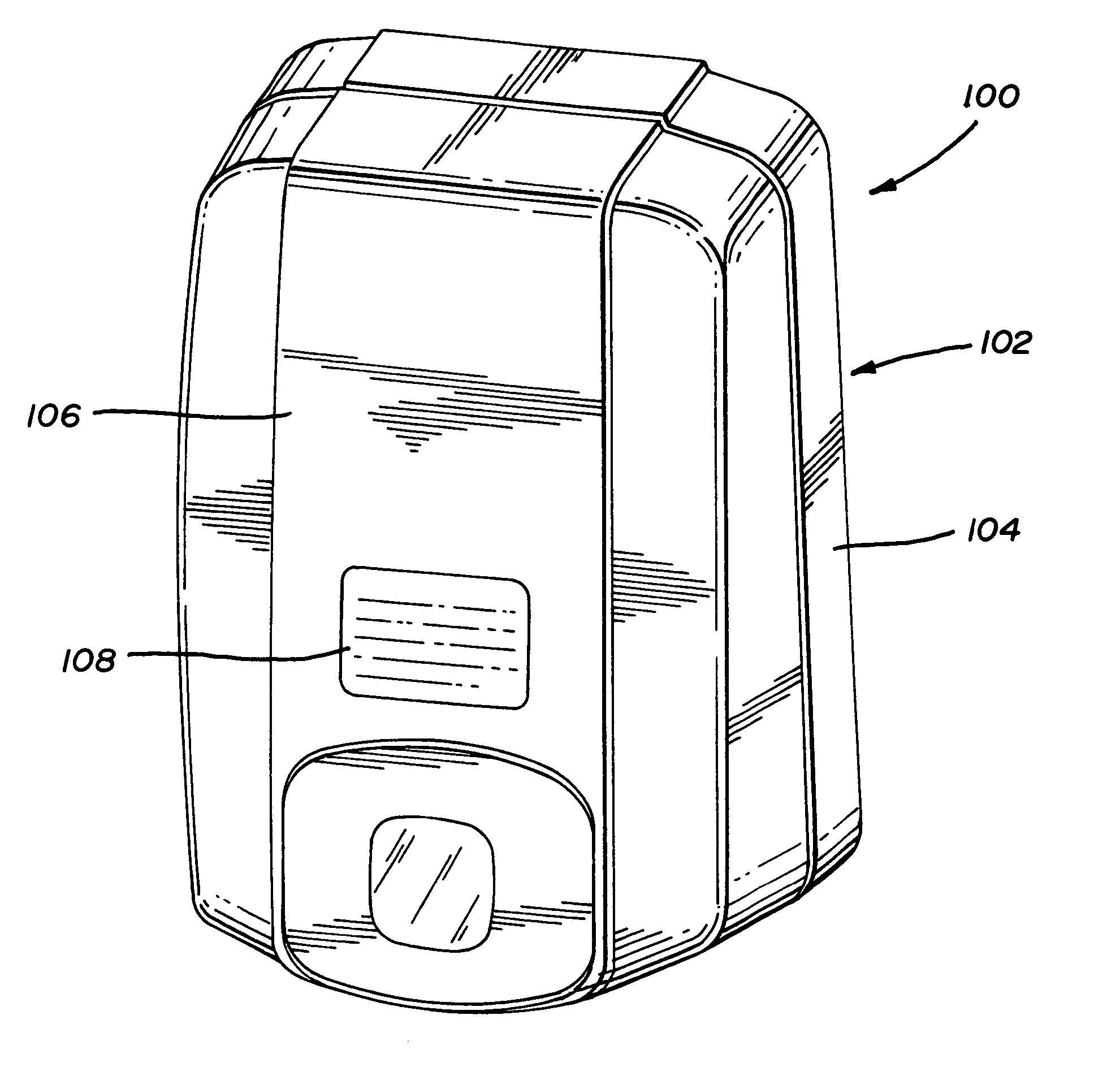

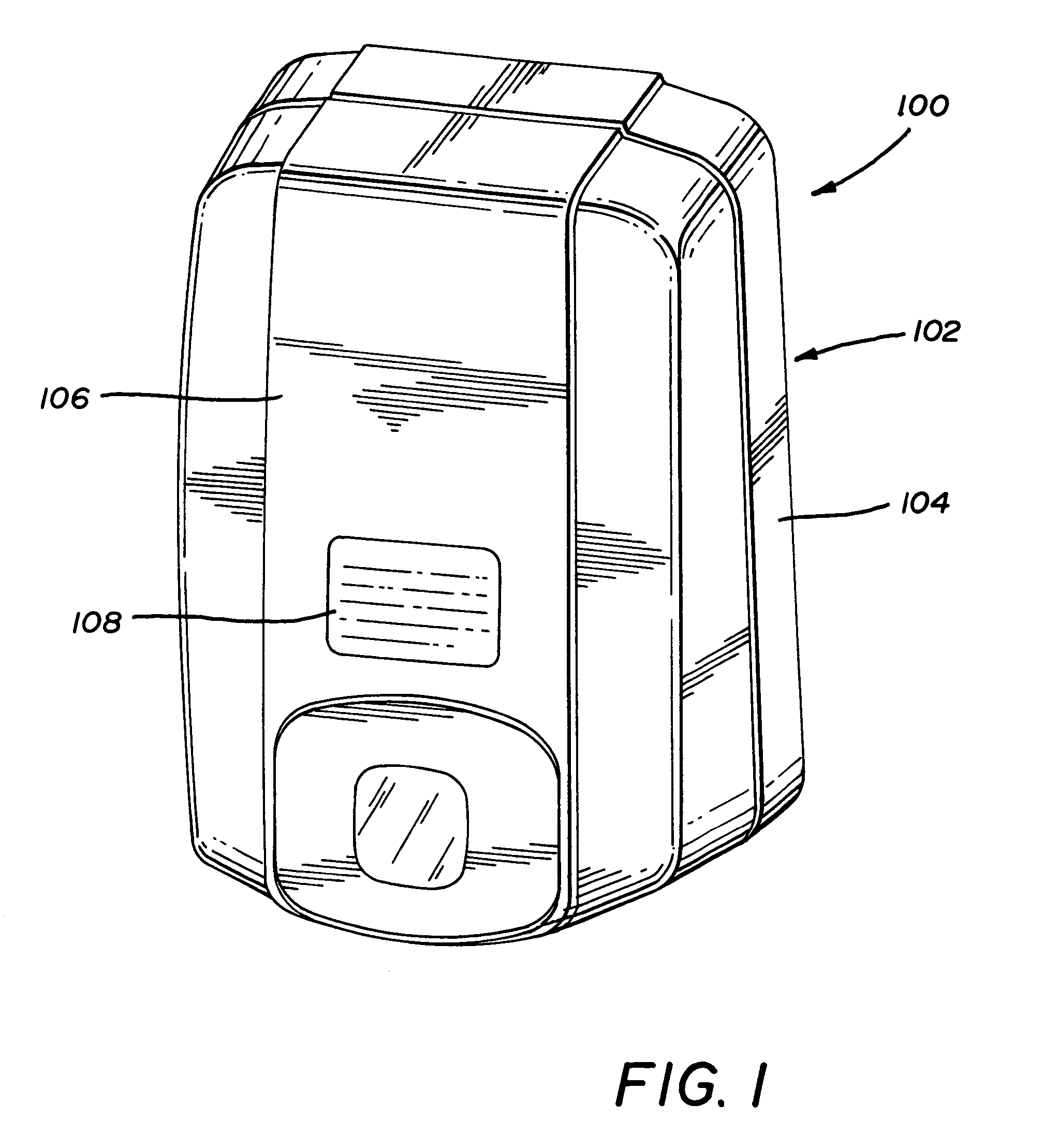

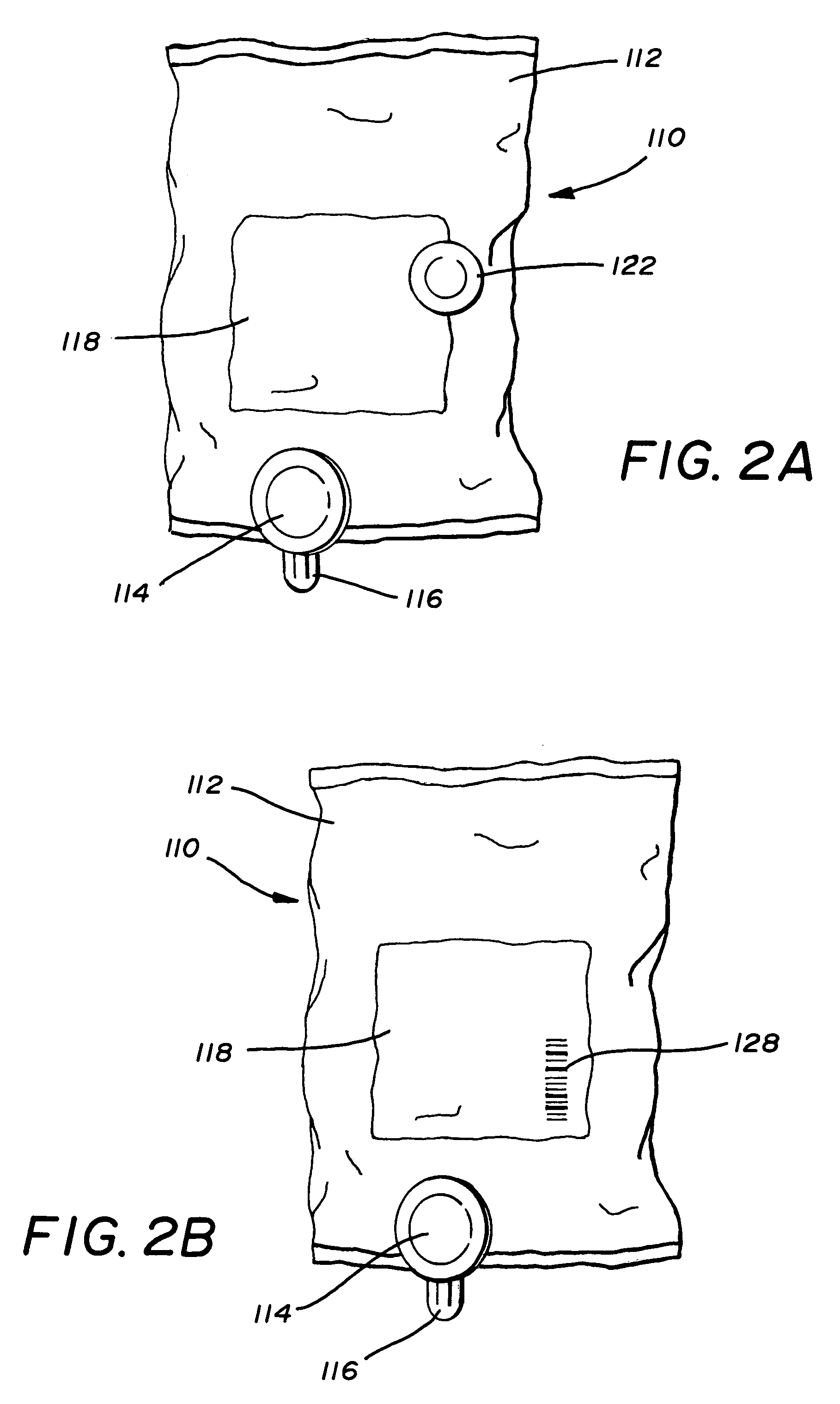

Electronically keyed dispensing systems and related methods of installation and use

Dispensing systems are disclosed which utilize electronically powered key devices and / or identification codes associated with a refill container to preclude the need for mechanical keys. A first embodiment of the device utilizes a matching code stored in a radio frequency identification tag or bar code associated with a fluid refill container and an identification code associated with the dispenser housing. Matching of the codes by a controller allows for continued use of the dispenser via some type of operational mechanism. Another embodiment employs a key which carries the matching code wherein matching of the codes allows for actuation of a motor actuated pumping device. Yet another embodiment employs a blocking mechanism to prevent use of a dispenser's push bar if a key and dispenser housing do not have matching codes. And yet another embodiment requires the use of a key that has a matching code that matches the dispenser's identification code in order to permit initial access to the dispenser housing.

Owner:JOSEPH S KANFER

Printable conductive features and processes for making same

InactiveUS20060001726A1Conductive materialLiquid/solution decomposition chemical coatingReducing agentMetal

Processes for forming conductive features from one or more inks and conductive features formed from the processes. In one aspect, the process includes a step of applying a first ink comprising a metal precursor to at least a portion of a first substrate to form an at least partially coated substrate. In a second step, the first ink is contacted with a reducing agent, optionally derived from a second ink, under conditions effective to reduce the metal in the metal precursor to its elemental form.

Owner:CABOT CORP

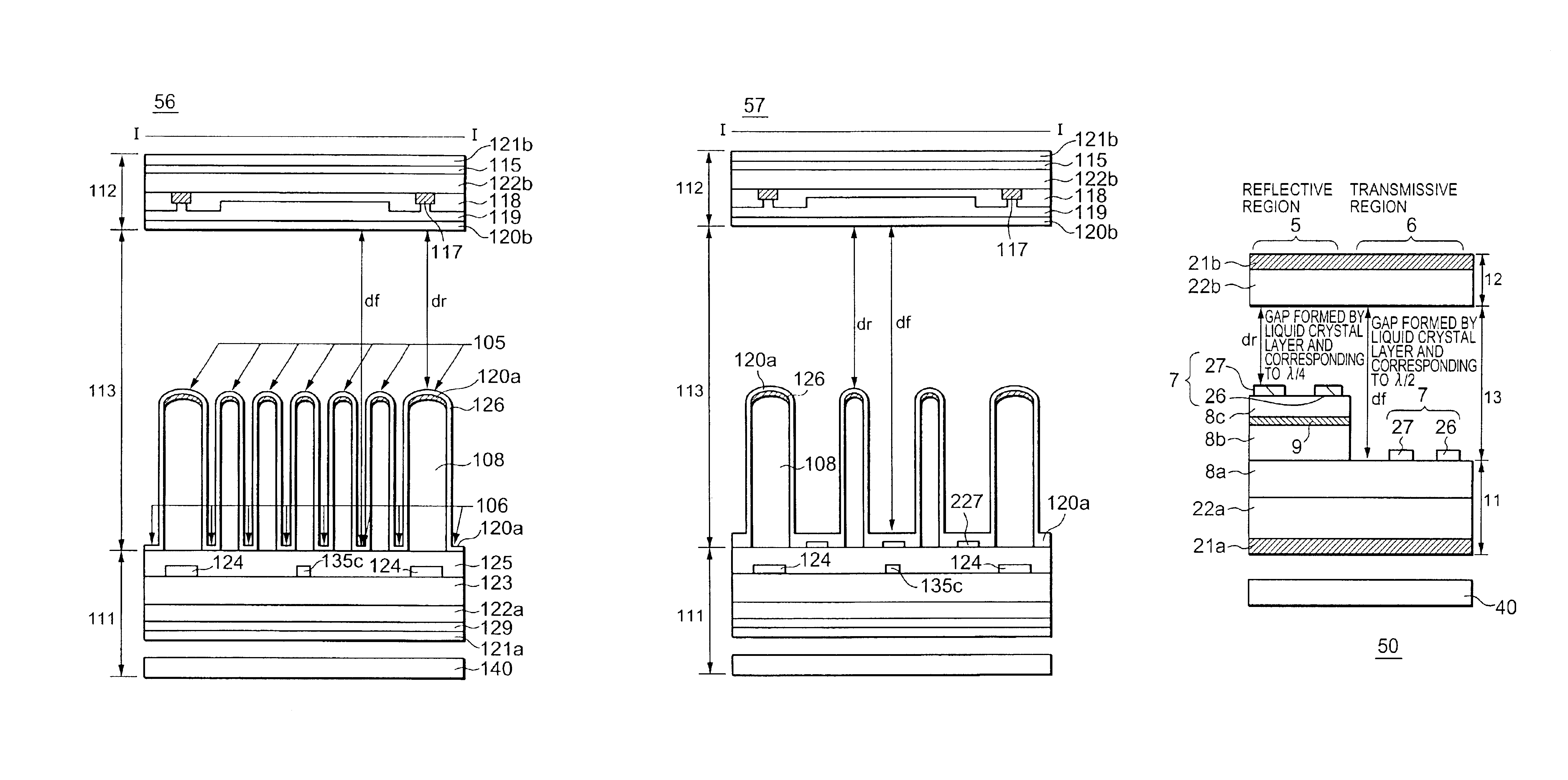

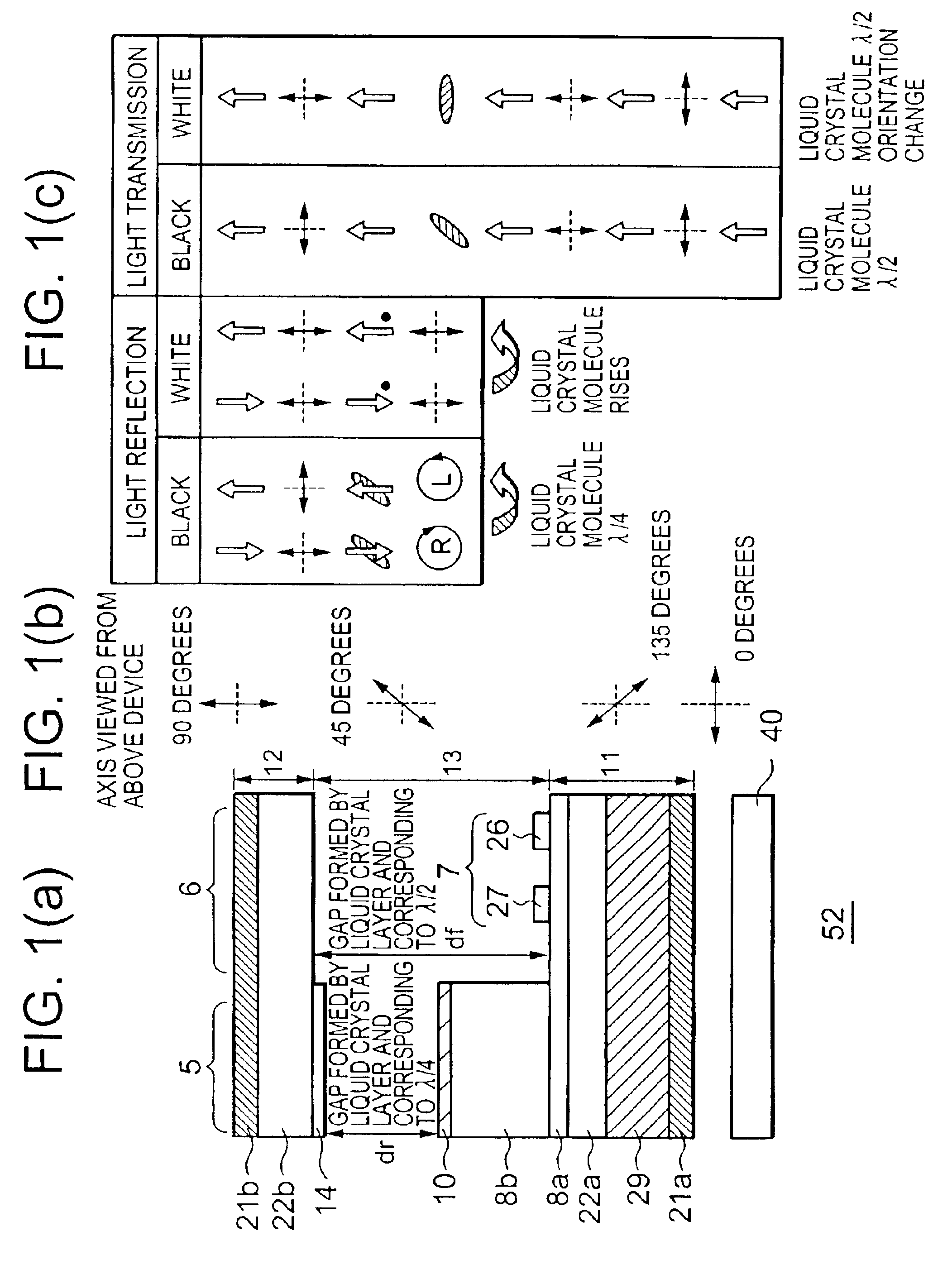

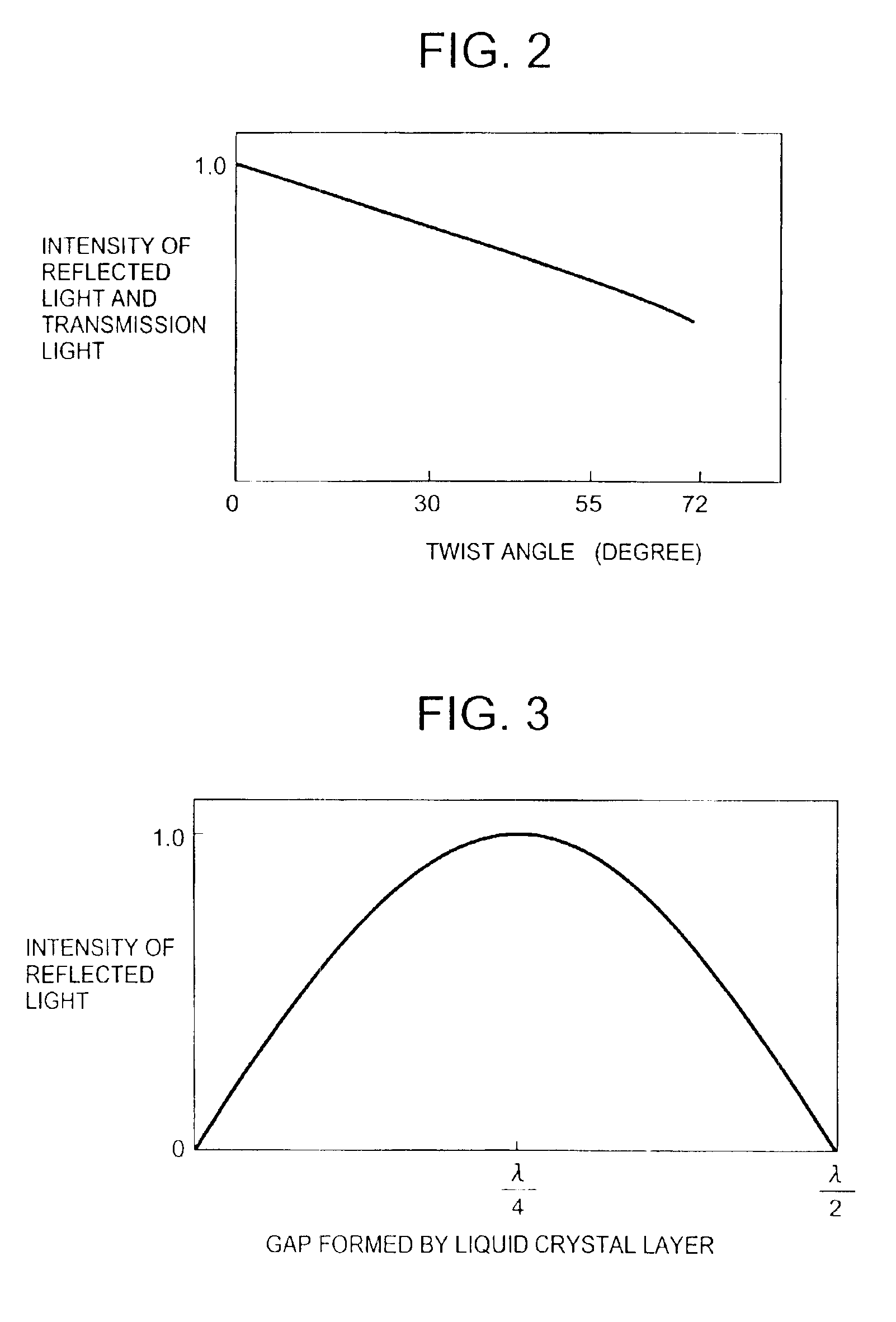

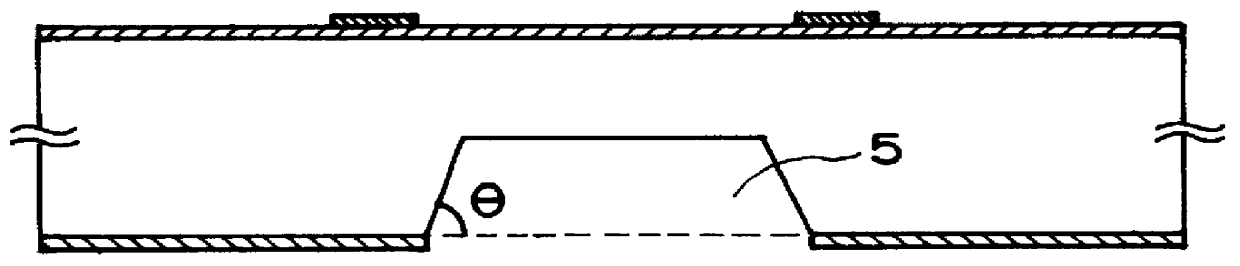

Semi-transmissive liquid crystal display device

InactiveUS6914656B2Improve viewing angle characteristicsPrintingNon-linear opticsPolarizerLength wave

In a semi-transmissive liquid crystal display device having a reflective region 5 and a transmissive region therein, a one-half wavelength plate 29 is disposed between a lower substrate 11 and a polarizer 21a provided on a side of the lower substrate. This makes liquid crystal molecules in at least the transmissive region 6 driven by a horizontal electric field and allows the device to operate in a normally-black mode in both the reflective region 5 and the transmissive region 6, realizing a semi-transmissive liquid crystal display device having wide viewing angle characteristics.

Owner:NEC LCD TECH CORP

Droplet-based diagnostics

InactiveUS20070242111A1Reduces and eliminates build-upImprove efficiencyElectrostatic separatorsSludge treatmentEngineeringMicroactuator

The present invention relates to droplet-based diagnostics. According to one embodiment, a droplet microactuator system is provided and includes: (a) a droplet microactuator configured to conduct droplet operations; and (b) a sensor configured in a sensing relationship with the droplet microactuator, such that the sensor is capable of sensing a signal from and / or a property of one or more droplets on the droplet microactuator.

Owner:ADVANCED LIQUID LOGIC

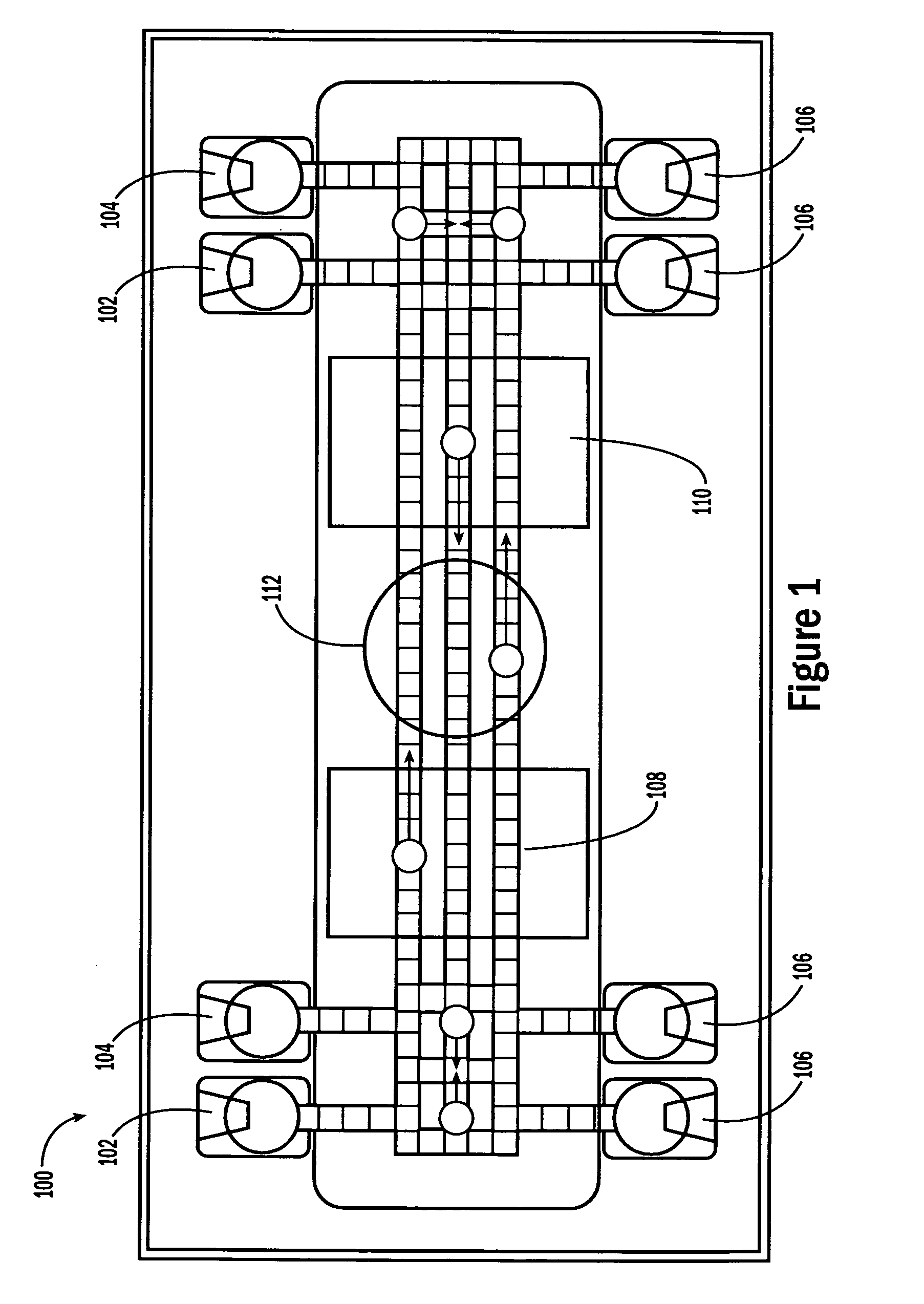

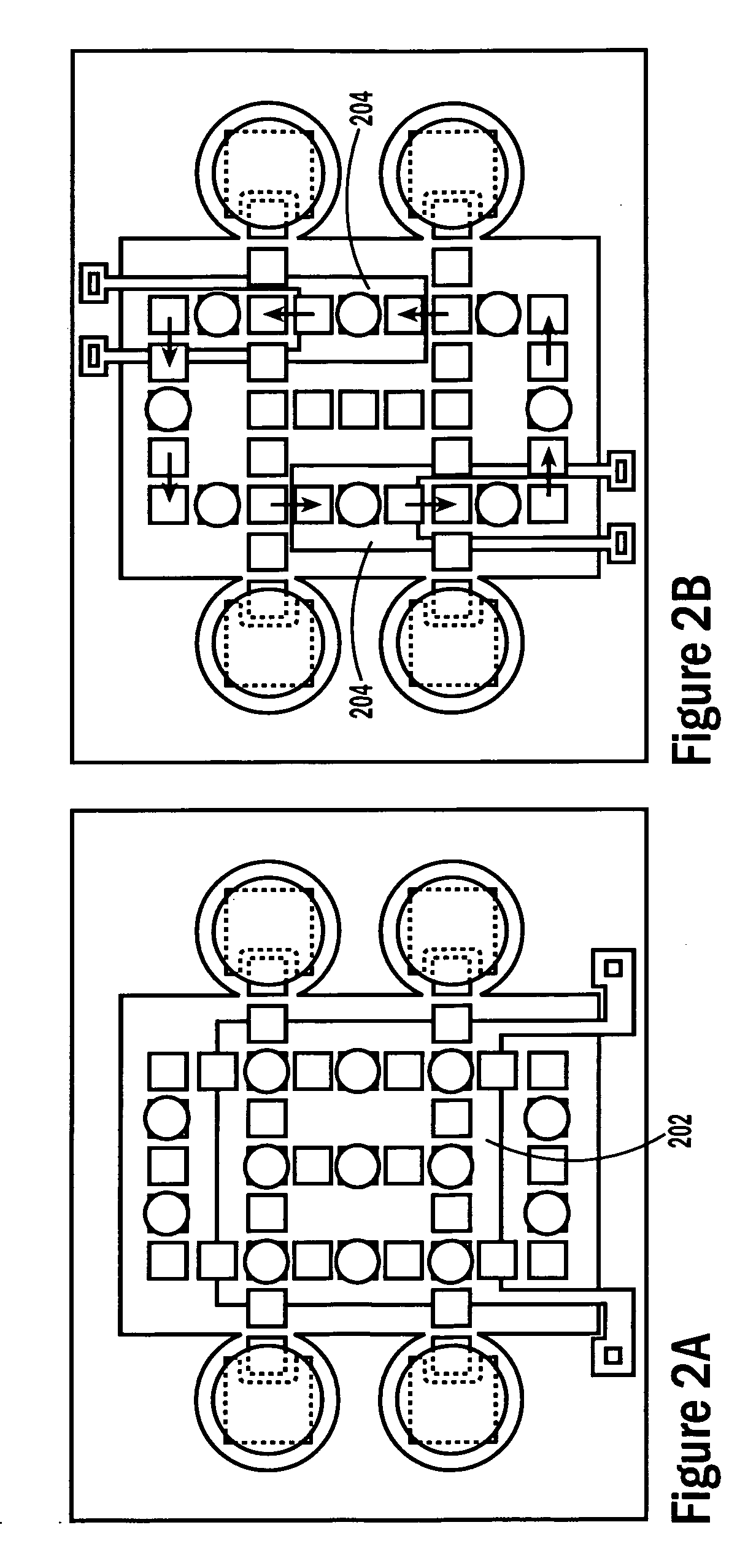

Droplet microactuator system

InactiveUS7815871B2Reduces and eliminates build-upImprove efficiencyElectrostatic separatorsSludge treatmentControl theoryMicroactuator

The present invention relates to a droplet microactuator system. According to one embodiment, the droplet microactuator system includes: (a) a droplet microactuator configured to conduct droplet operations; (b) a magnetic field source arranged to immobilize magnetically responsive beads in a droplet during droplet operations; (c) a sensor configured in a sensing relationship with the droplet microactuator, such that the sensor is capable of sensing a signal from and / or a property of one or more droplets on the droplet microactuator; and (d) one or more processors electronically coupled to the droplet microactuator and programmed to control electrowetting-mediated droplet operations on the droplet actuator and process electronic signals from the sensor.

Owner:ADVANCED LIQUID LOGIC

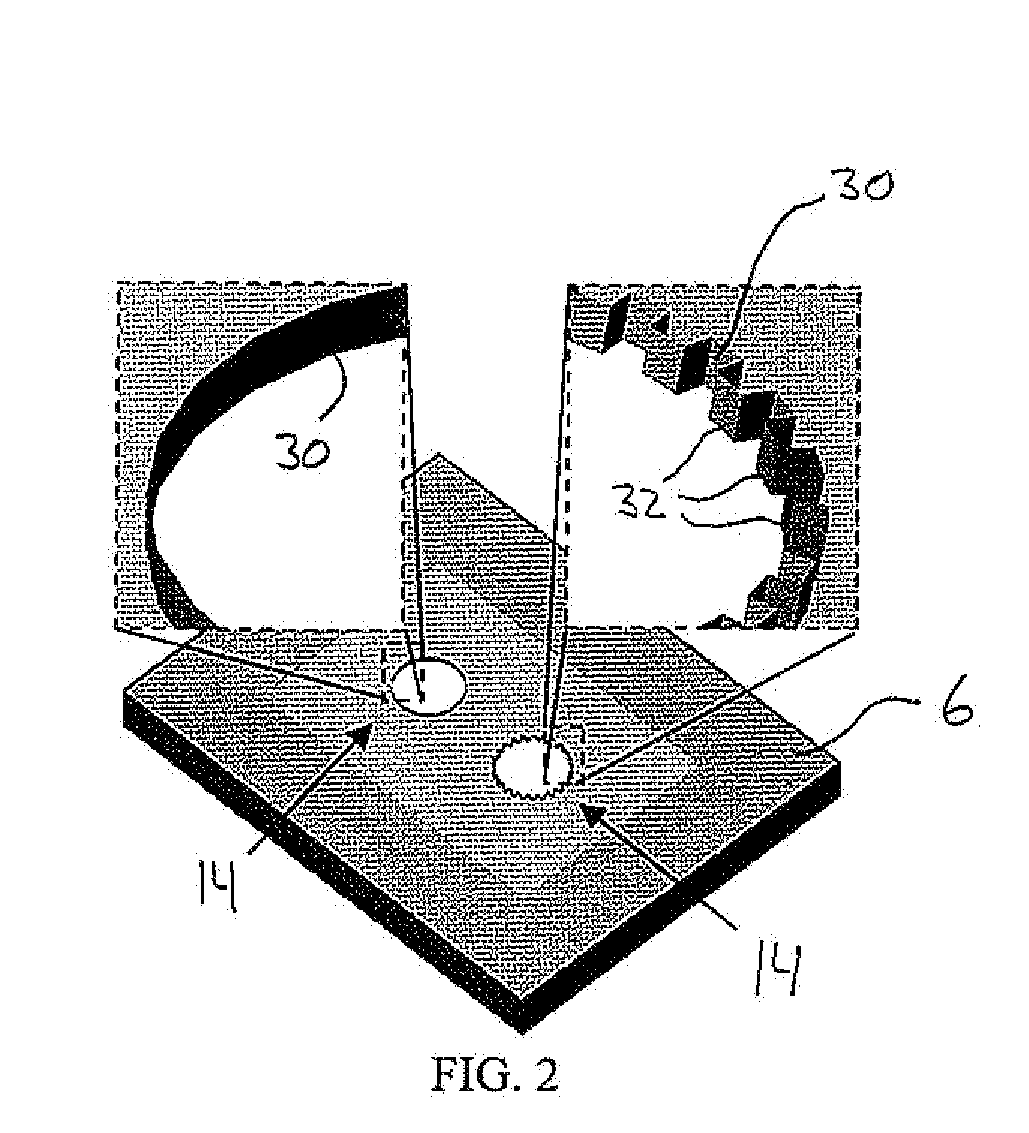

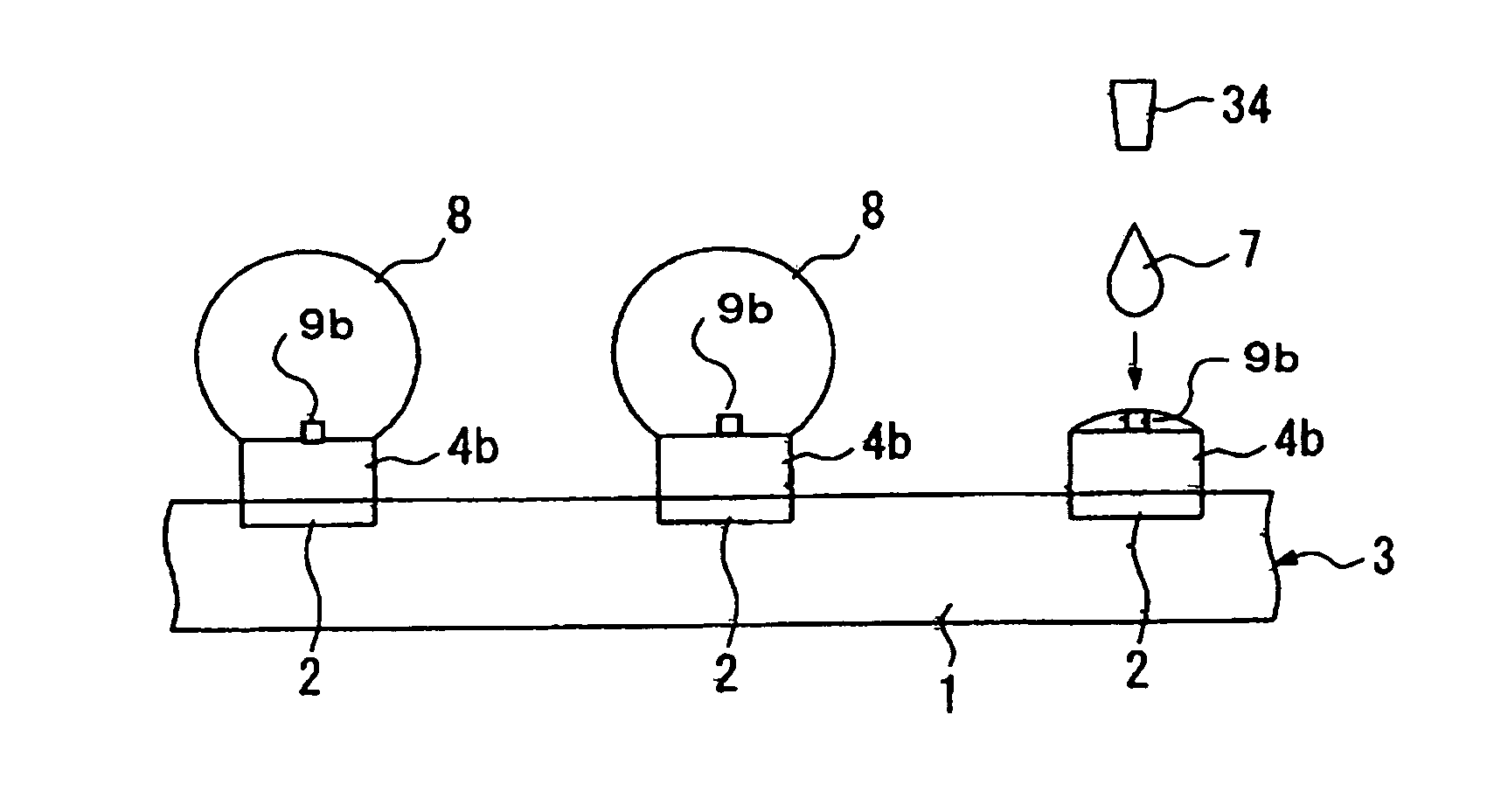

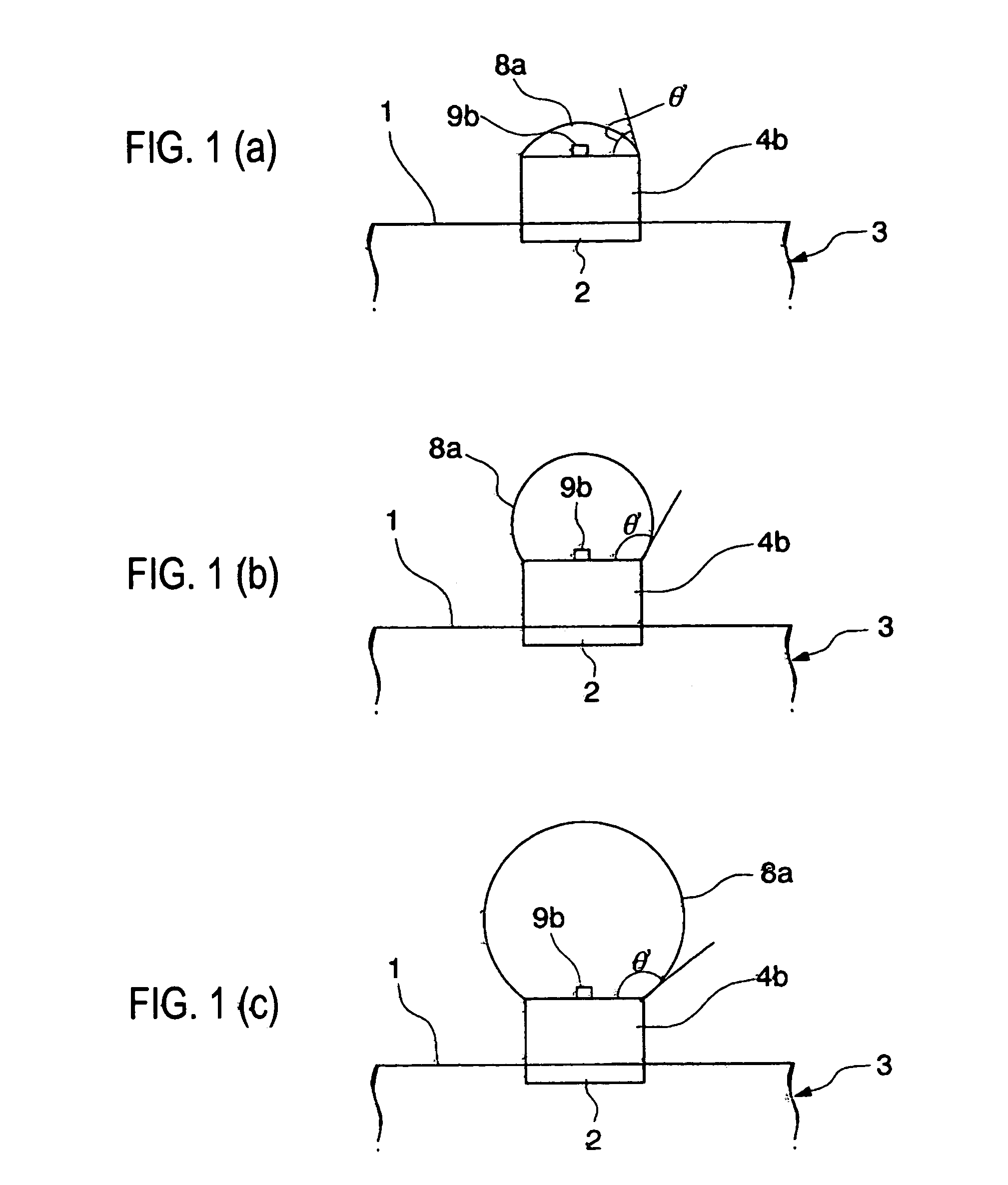

Micro lens and fabrication method of micro lens, optical device, optical transmitter, laser printer head, and laser printer

InactiveUS7145725B2Excels in plotting characteristicOptical articlesElectrographic process apparatusOptical transmitterLaser

A micro lens is provided with proper optical characteristics, such as a condensing function. Furthermore, a fabrication method of a micro lens is provided as well as, an optical device, an optical transmitter, a laser printer head, and a laser printer. The micro lens is equipped with a lens member formed by a liquid droplet ejection method, including: a base member formed on a substrate, a lens member formed on an upper surface of the above-mentioned base member to which the lens material is ejected in a plurality of dots by the liquid droplet ejection method, the upper surface of the base member having a concavity and a convexity with at least a part of the upper surface of the base member being subjected to repellant treatment.

Owner:SEIKO EPSON CORP

Sliding reconstitution device with seal

Owner:BAXTER INT INC

Manufacturing method of ink jet head

InactiveUS6139761ADistanceSimple processRecording apparatusSemiconductor/solid-state device manufacturingPressure generationSilicon oxide

A manufacturing method for an ink jet head having an ink ejection pressure generation element for generating energy for ejecting ink, and an ink supply port for supplying the ink to an ink jet head, including the steps of preparing a silicon substrate; forming, on a surface of the silicon substrate, the ink ejection pressure generation element and silicon oxide film or silicon nitride film; forming anti-etching mask for forming an ink supply port on a back side of the silicon substrate; removing silicon on the back side of the silicon substrate at a position corresponding to the ink supply port portion through anisotropic etching; forming an ink ejection portion on a surface of the silicon substrate; and removing the silicon oxide film or silicon nitride film from the surface of the silicon substrate of the ink supply port portion.

Owner:CANON KK

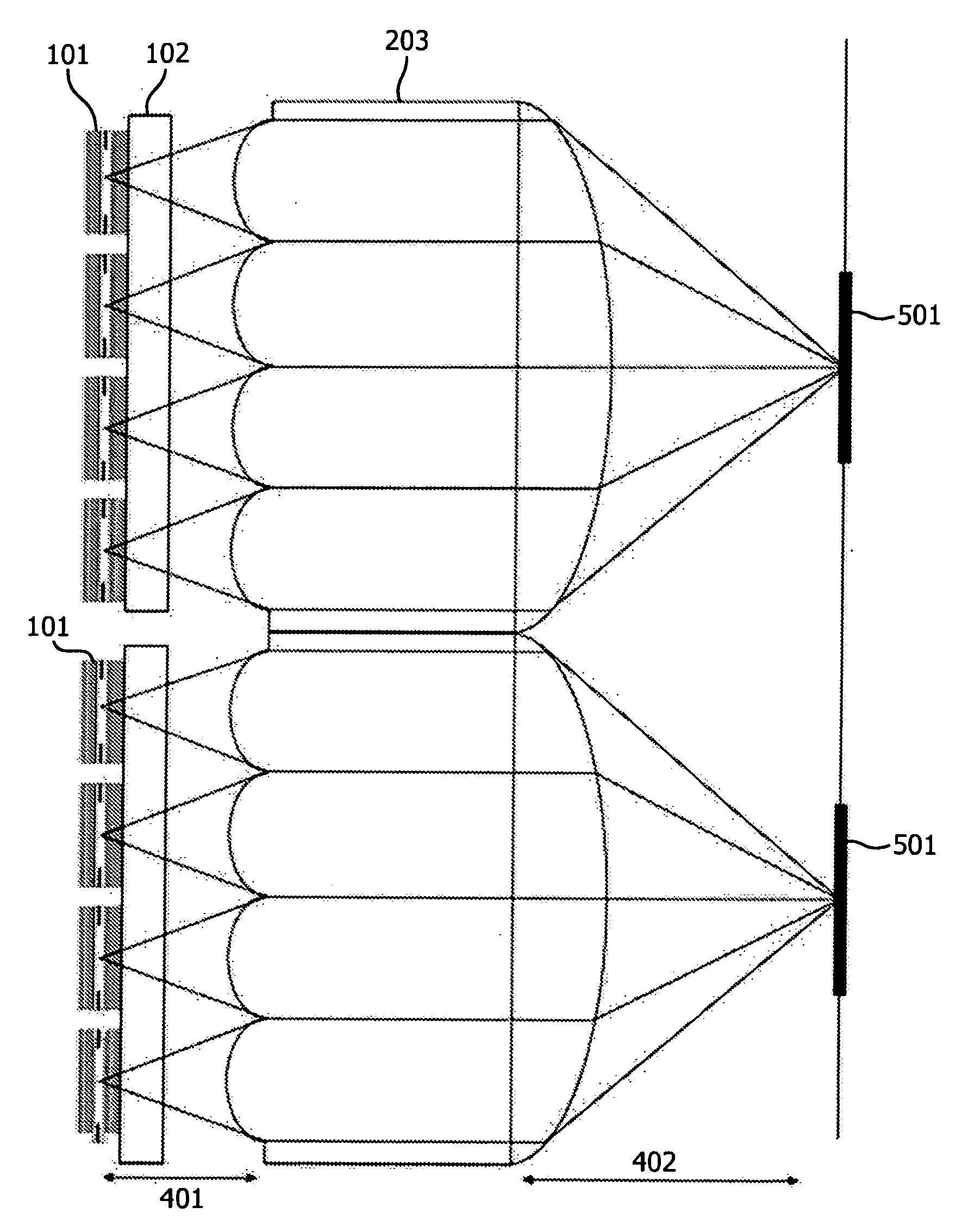

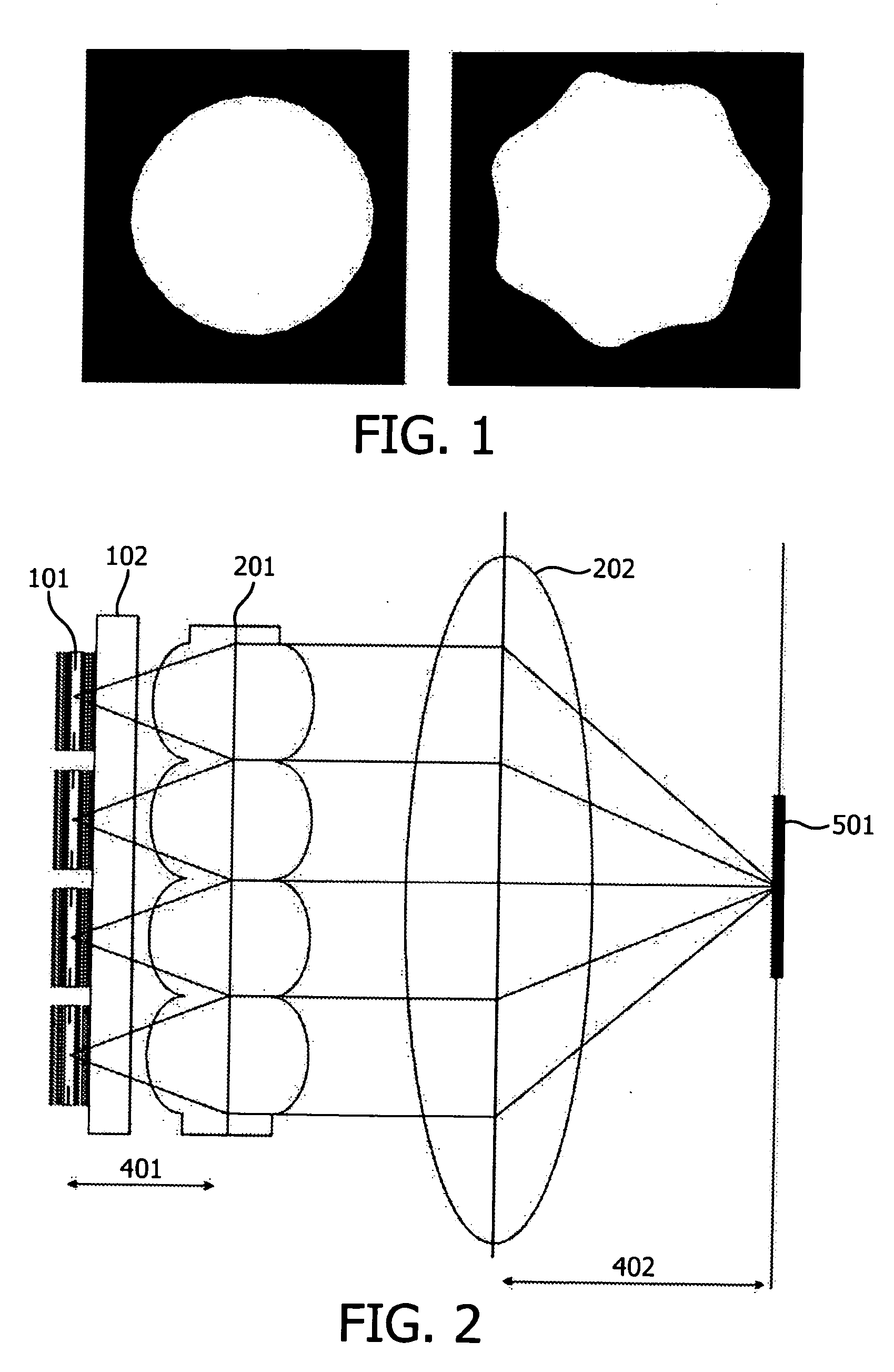

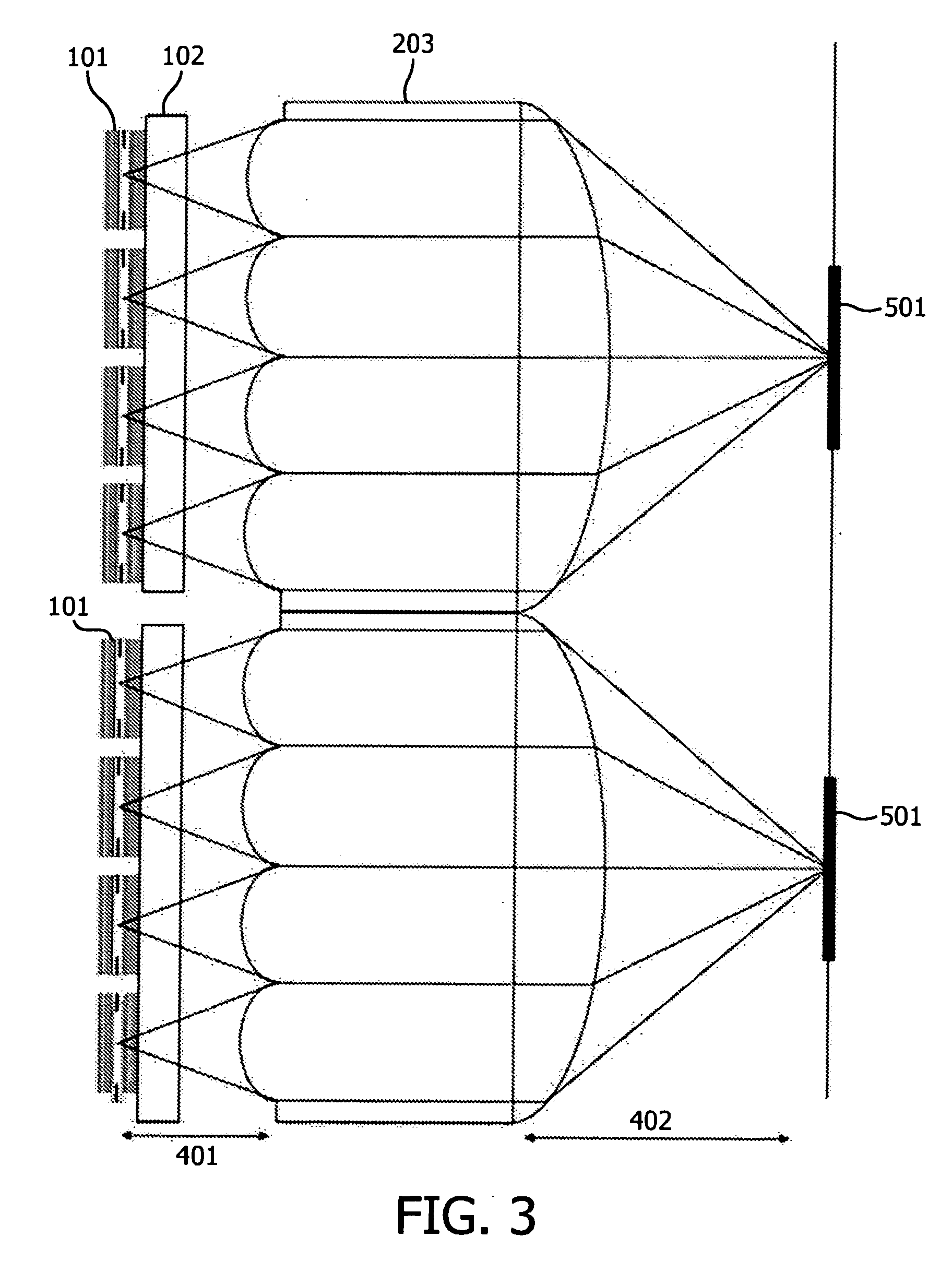

Laser device with configurable intensity distribution

ActiveUS20120281293A1The degree of freedom becomes largerHigh reproducibility and reliabilityLaser detailsSemiconductor lasersLight beamOptoelectronics

The present invention relates to a laser device comprising an array of several large area VCSELs (101) and one or several optics (201, 202) designed and arranged to image the active layers of the VCSELs (101) of said army to a working plane (501) such that the laser radiation emitted by the active layers of all VCSELs (101) or of subgroups of VCSELs (101) of the array superimposes in the working plane (501). The proposed laser device allows the generation of a desired intensity distribution in the working plane without the need of an optics specially designed for this intensity distribution or beam profile.

Owner:TRUMPF PHOTONIC COMPONENTS GMBH

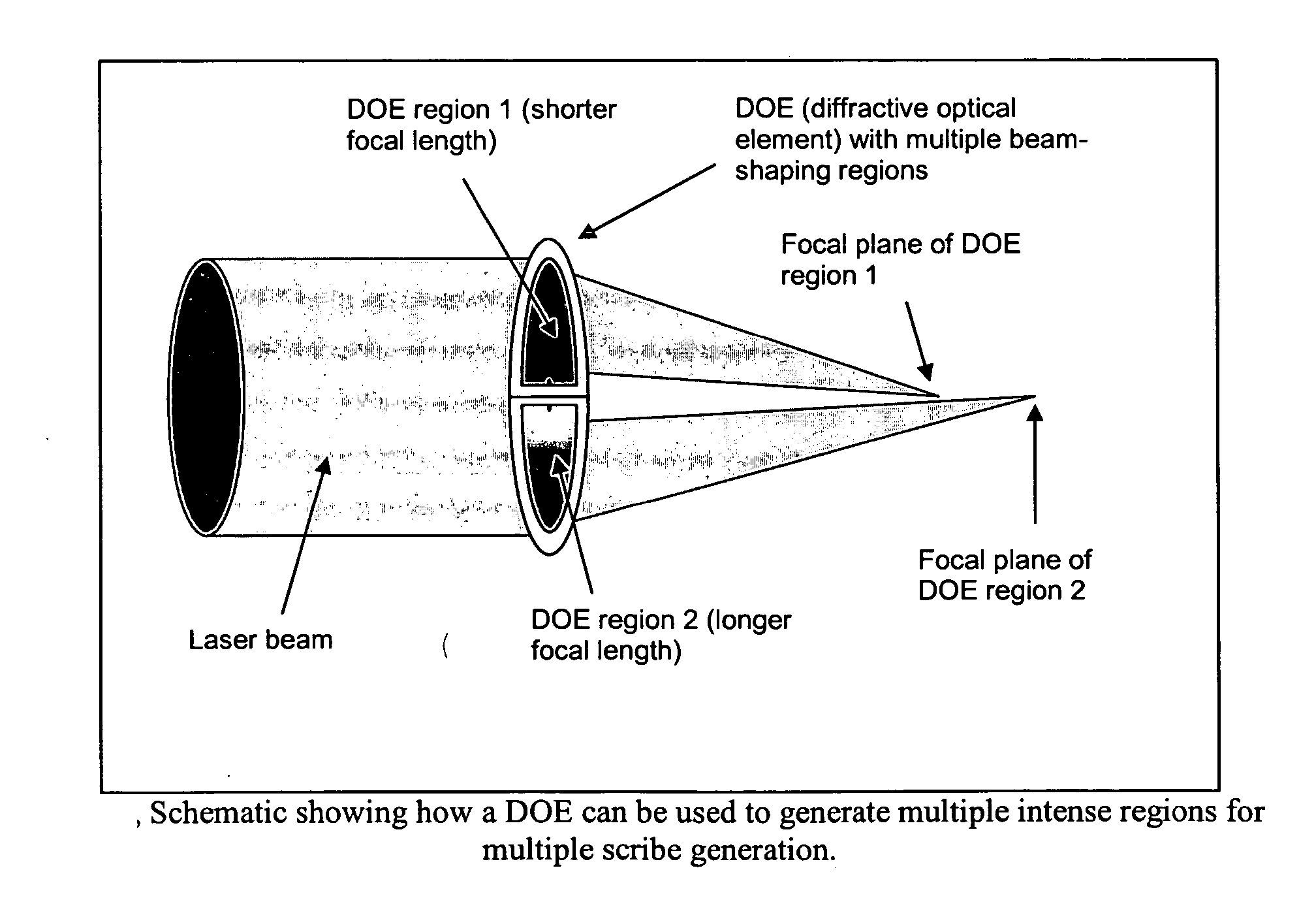

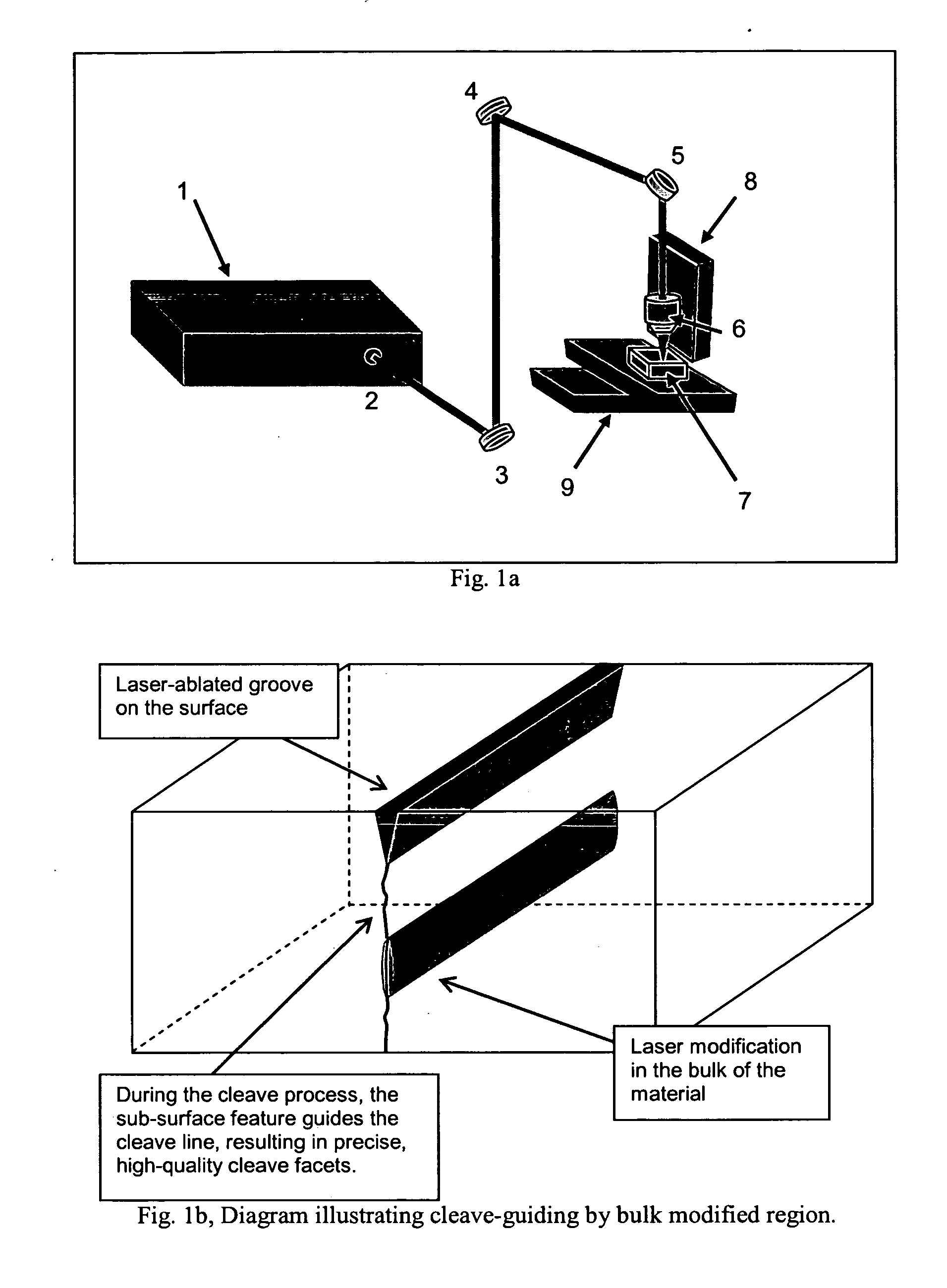

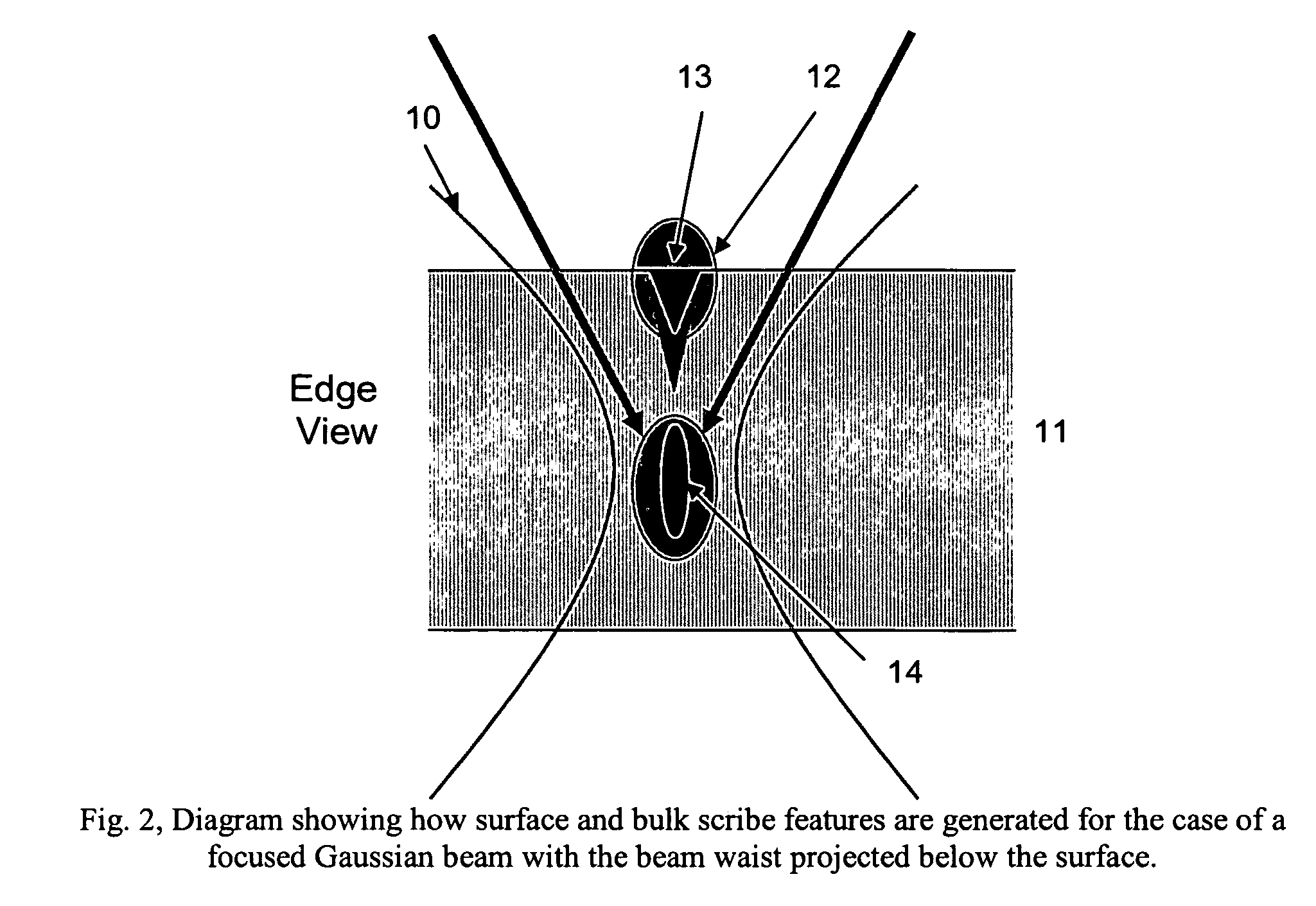

Transparent material processing with an ultrashort pulse laser

InactiveUS20070051706A1Reduce quality problemsPoor precisionFixed microstructural devicesThin material handlingHigh energyNonlinear absorption

Methods for ultrashort pulse laser processing of optically transparent materials. A method for scribing transparent materials uses ultrashort laser pulses to create multiple scribe features with a single pass of the laser beam across the material, with at least one of the scribe features being formed below the surface of the material. This enables clean breaking of transparent materials at a higher speed than conventional techniques. Slightly modifying the ultrashort pulse laser processing conditions produces sub-surface marks. When properly arranged, these marks are clearly visible with side-illumination and not clearly visible without side-illumination. In addition, a method for welding transparent materials uses ultrashort laser pulses to create a bond through localized heating. The ultrashort pulse duration causes nonlinear absorption of the laser radiation, and the high repetition rate of the laser causes pulse-to-pulse accumulation of heat within the materials. The laser is focused near the interface of the materials, generating a high energy fluence at the region to be welded. This minimizes damage to the rest of the material and enables fine weld lines.

Owner:IMRA AMERICA

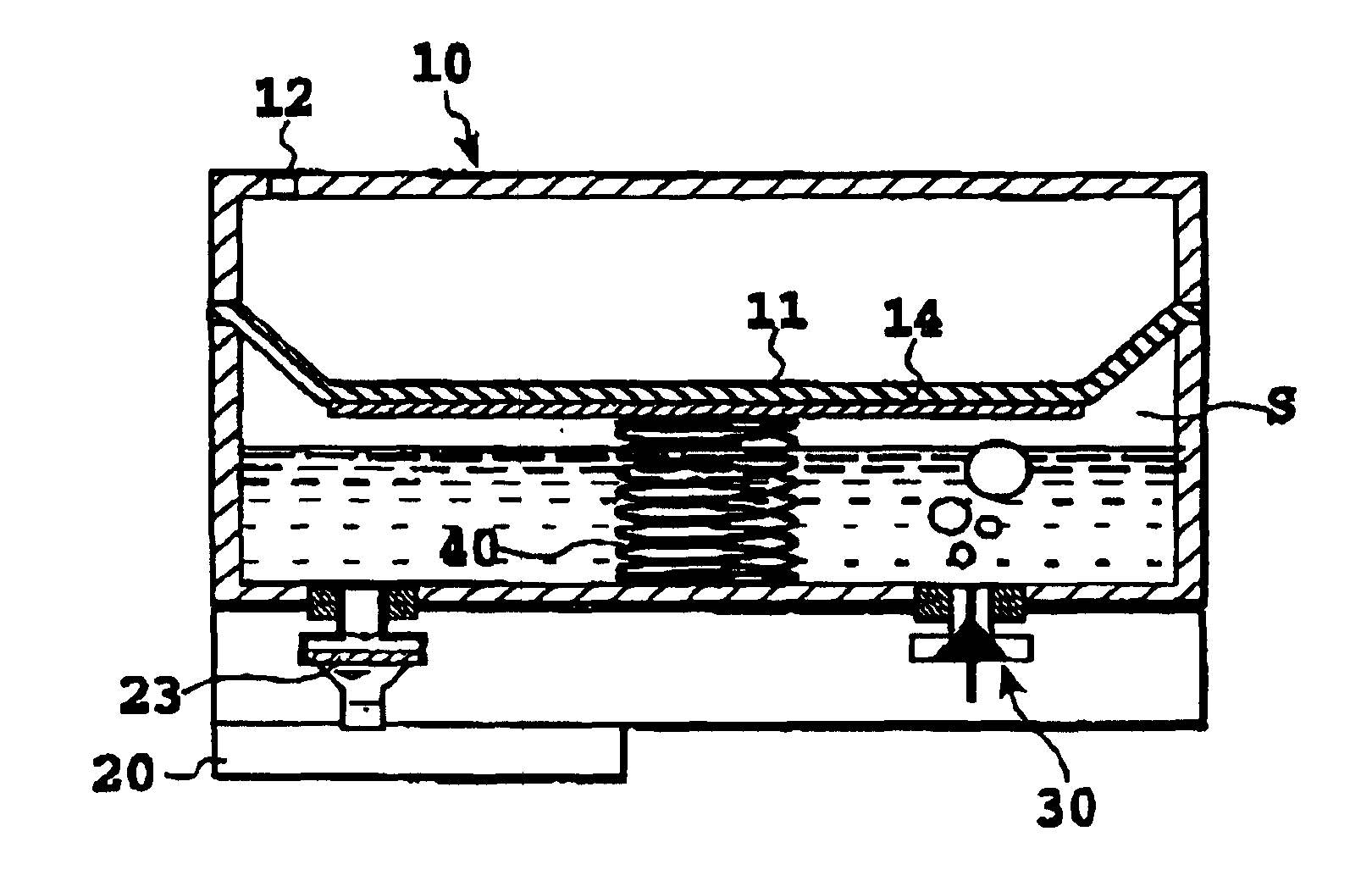

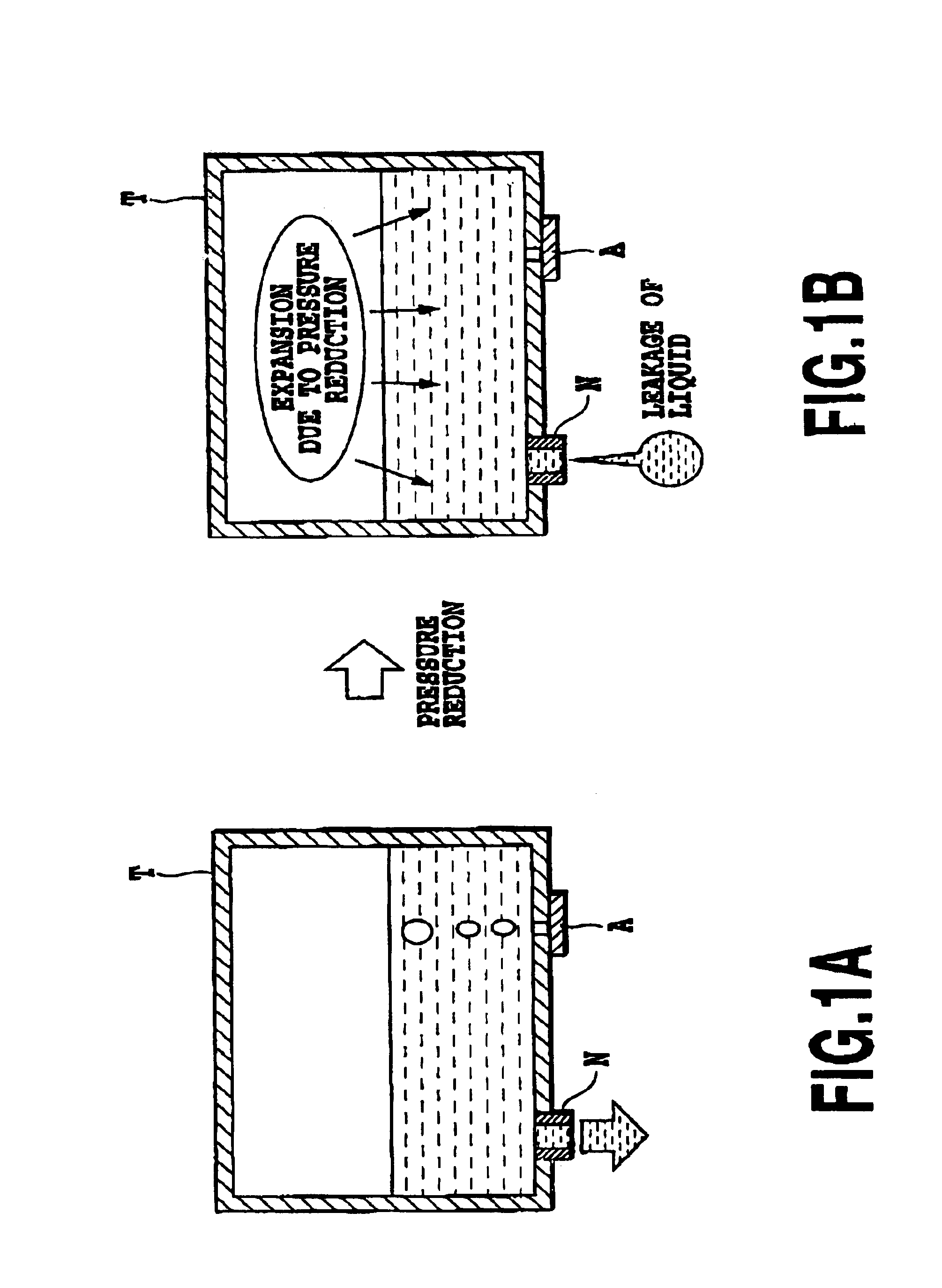

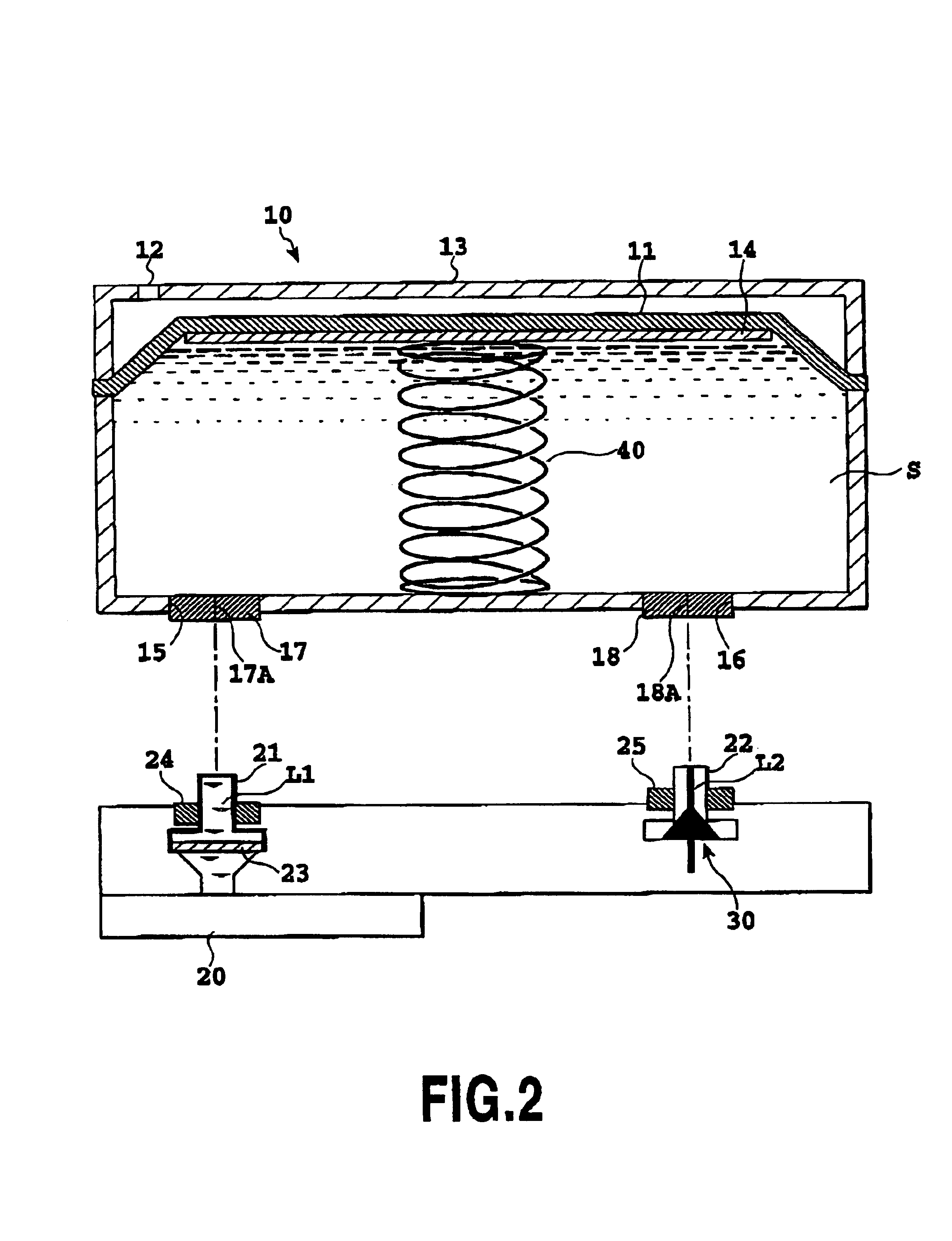

Liquid container, liquid supply system, liquid using apparatus, ink tank, ink supply system, inkjet print head and print apparatus

The present invention prevents liquid leakage regardless of the using conditions and the reserving atmosphere and stabilizes a negative pressure regardless of the degree of liquid consumption, by having a one-way valve in the liquid container that supplies liquid to an external device, maintaining the negative pressure formed in the liquid supplying passage positioned in the downstream of a position where liquid or gas is supplied by the one-way valve. The liquid container has a deformable, movable unit at least a part of which is made of a flexible material. A space other than the liquid supply unit forms a substantially sealed space in which liquid is retained. The container is capable of supplying the liquid to the outside. Such container has a one-way valve that passes liquid or gas from the liquid container to the outside or from the outside to the liquid container.

Owner:CANON KK

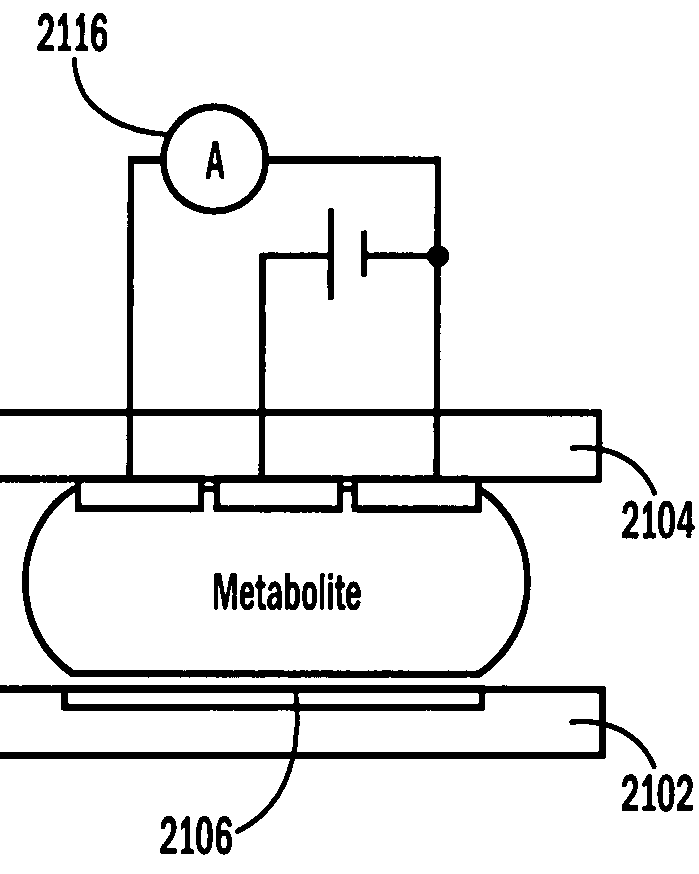

Electrochemical microsensor package

InactiveUS6849168B2Increase productionLamination ancillary operationsLaminationElectrolyteElectrical contacts

An electrochemical microsensor package comprises a substrate matrix having a upper non-conductive layer and an adjacent lower non-conductive layer with a conductive trace or pad extending over an area therebetween. The conductive pad has integral therewith a projecting contact button that projects through and below the second non-conductive for making contact with external electrical contacts. A sensor electrode is positioned on the surface of the conductive pad toward the upper non-conductive layer and in electrical contact therewith. A well extends through the upper non-conductive layer to the upper surface of the electrode. The microsensor packages may be produced by electrodeposition of the conductive pad onto a conductive mandrel having depressions to form the contact button.The microsensor package is fabricated into a microsensor by appropriate adaptation of the well of the microsensor package including applying an appropriate oxide or other layer over the electrode, introduction of an electrolyte or other sensing chemicals into the well and or applying a permeable or impermeable membrane over the top of the well.

Owner:MICROBIONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com