Patents

Literature

366results about "Pump siphons" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

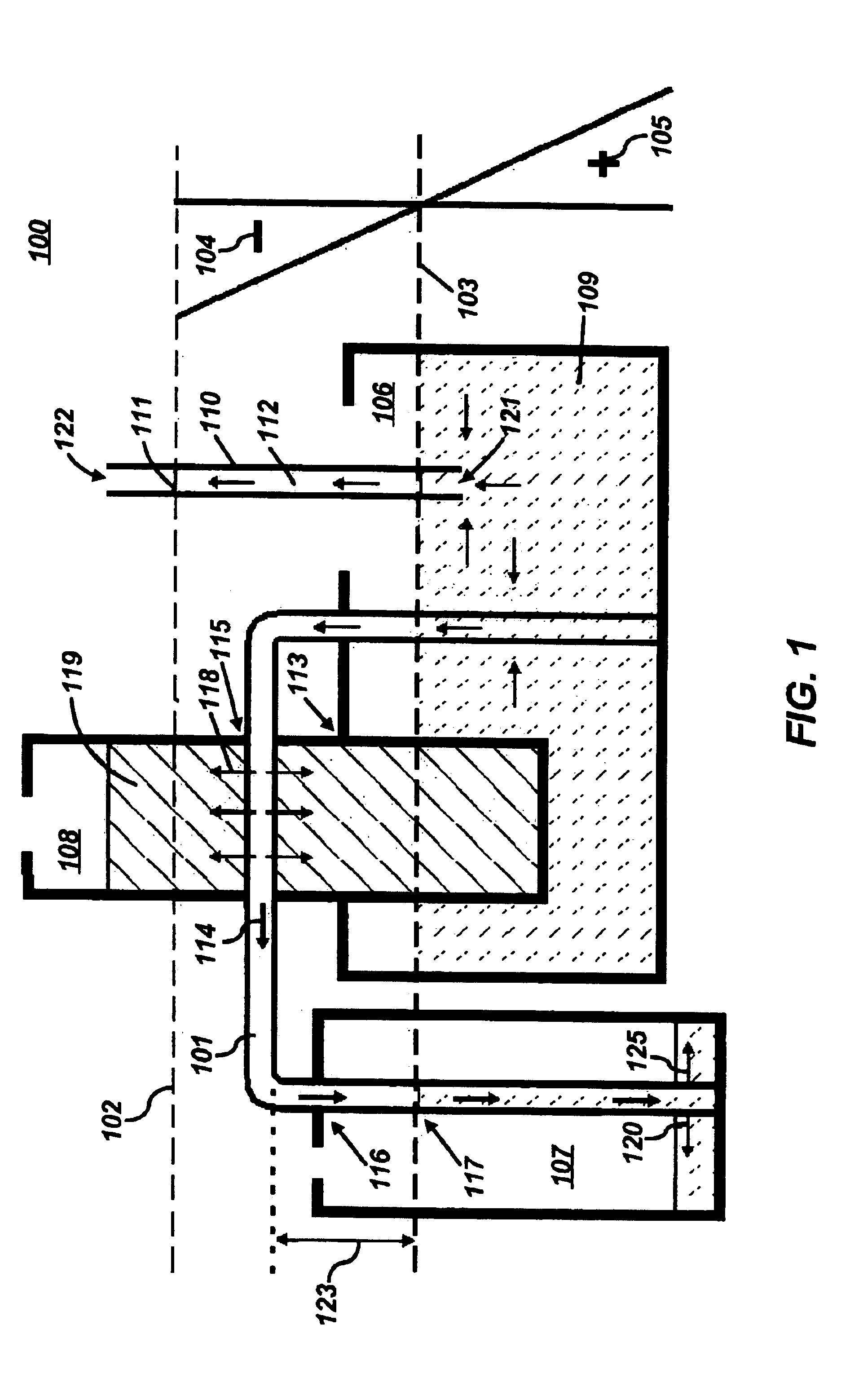

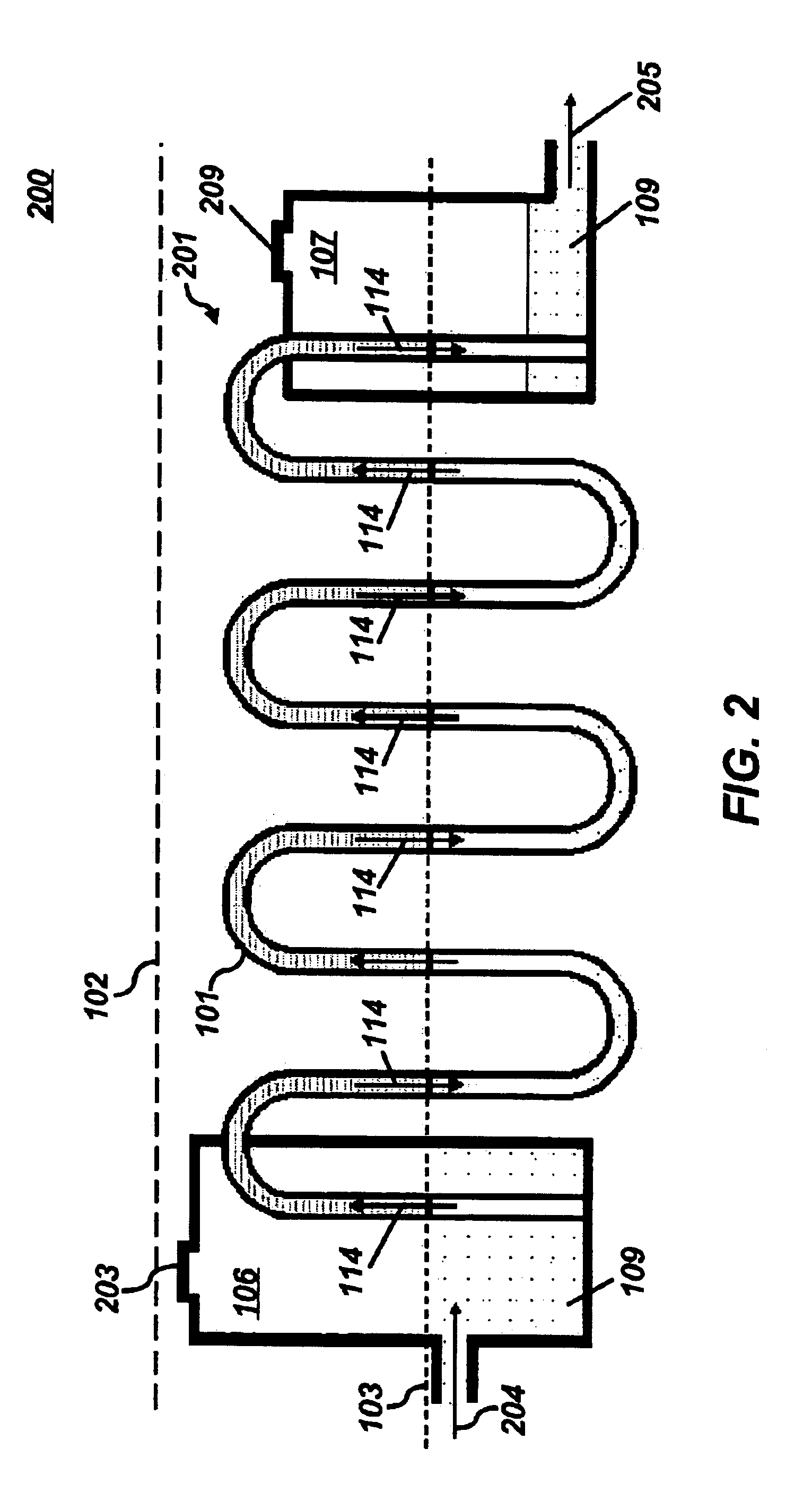

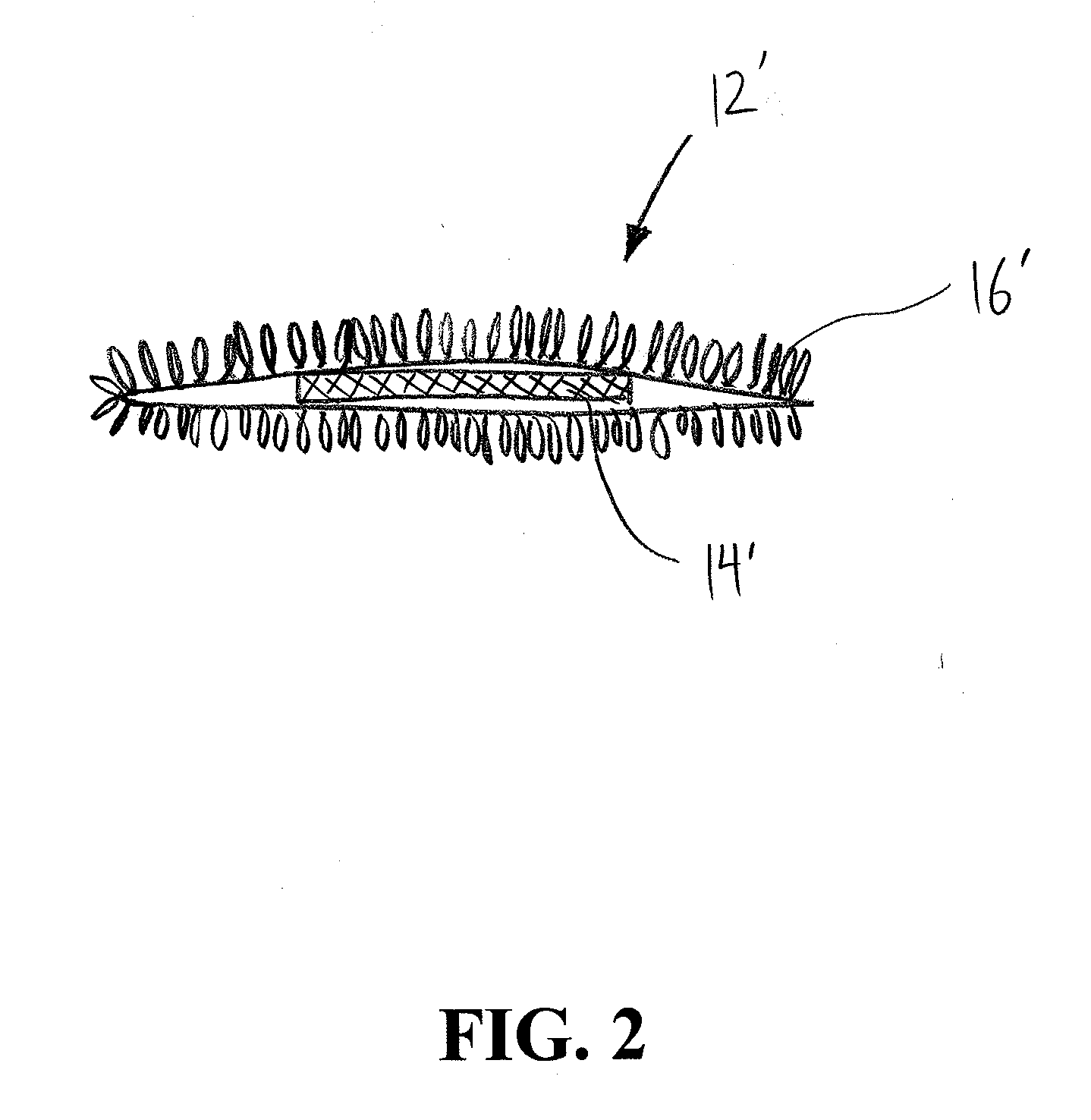

Irrigation and drainage based on hydrodynamic unsaturated fluid flow

InactiveUS6918404B2Improve the level ofHigh porosityPipeline systemsMachines/enginesEnvironmental engineeringPorous microstructure

Irrigation and drainage systems are disclosed, including a saturated zone and at least one pipe in communication with the saturated zone. The pipe(s) can be configured to comprise a tubarc porous microstructure for conducting water from the saturated zone to an unsaturated zone in order to drain the water from the saturated zone. The water can be delivered from the saturated zone to the unsaturated zone through the tubarc porous microstructure, thereby permitting the water to be harnessed for irrigation or drainage through the hydrodynamic movement of the water from one zone of saturation or unsaturation to another.

Owner:TUBARC TECH

Fluid filter

Owner:CHAPIN MFG INC

Moisture detection apparatus

A moisture detection apparatus for signaling to a caregiver that a diaper or other article of clothing worn by an infant or adult being cared for by the caregiver is wet and needs to be changed. The apparatus includes a liquid transfer component having a plurality of capillaries for transferring liquid from the wet diaper to a remote location and a signaling device which emits either an audio signal or a visual signal, or both when an infant or adult patient is in need of attention due to a wet diaper or other article of clothing.

Owner:ZAND FRANZ

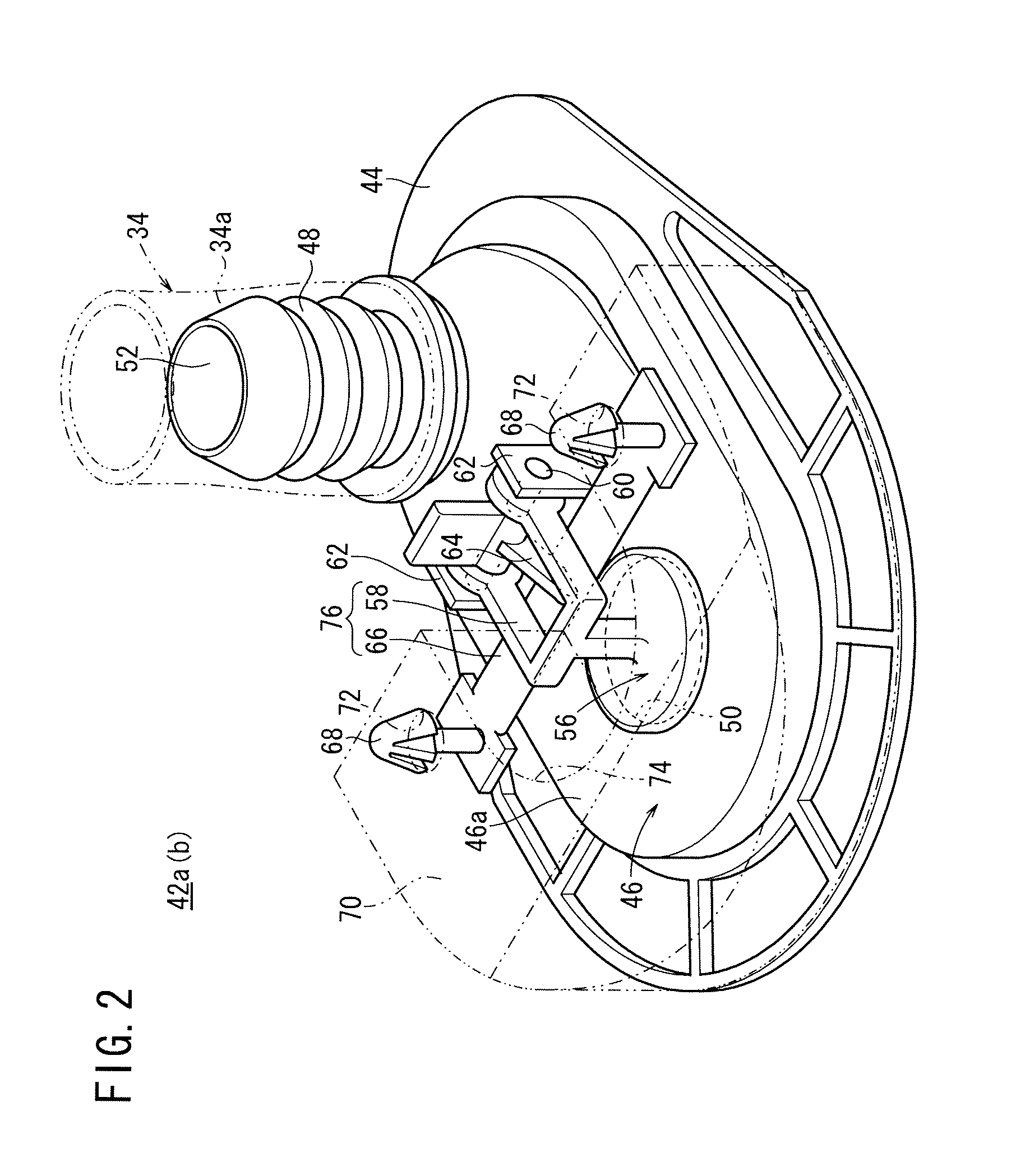

Liquid transfer device and suction unit

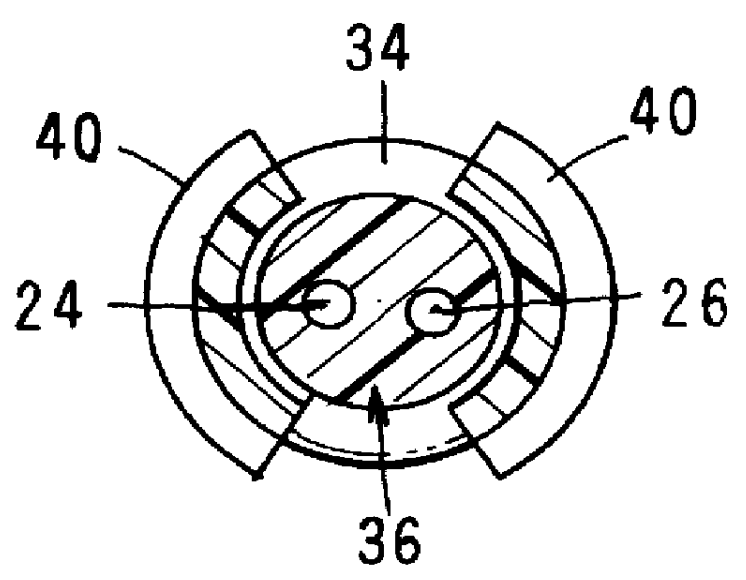

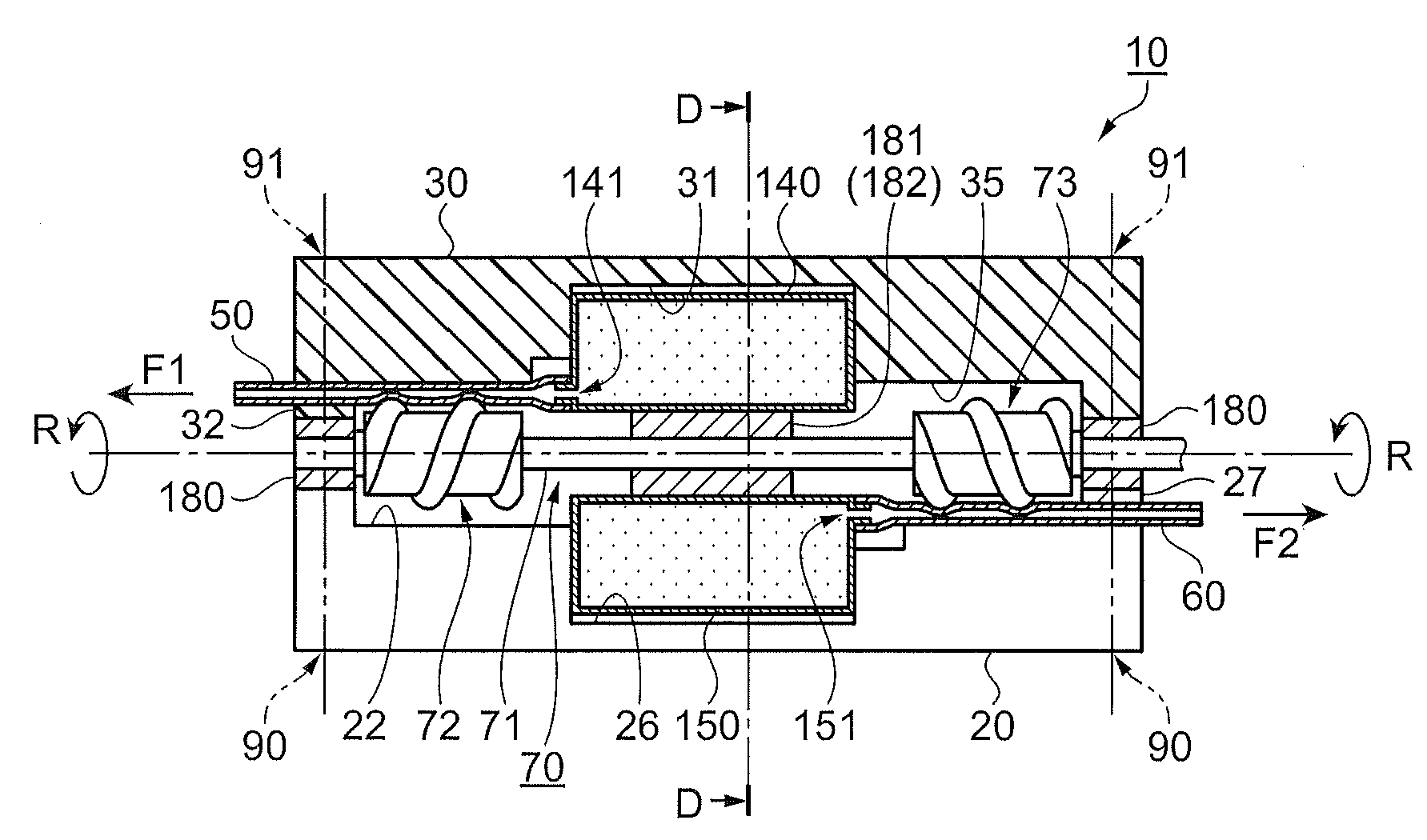

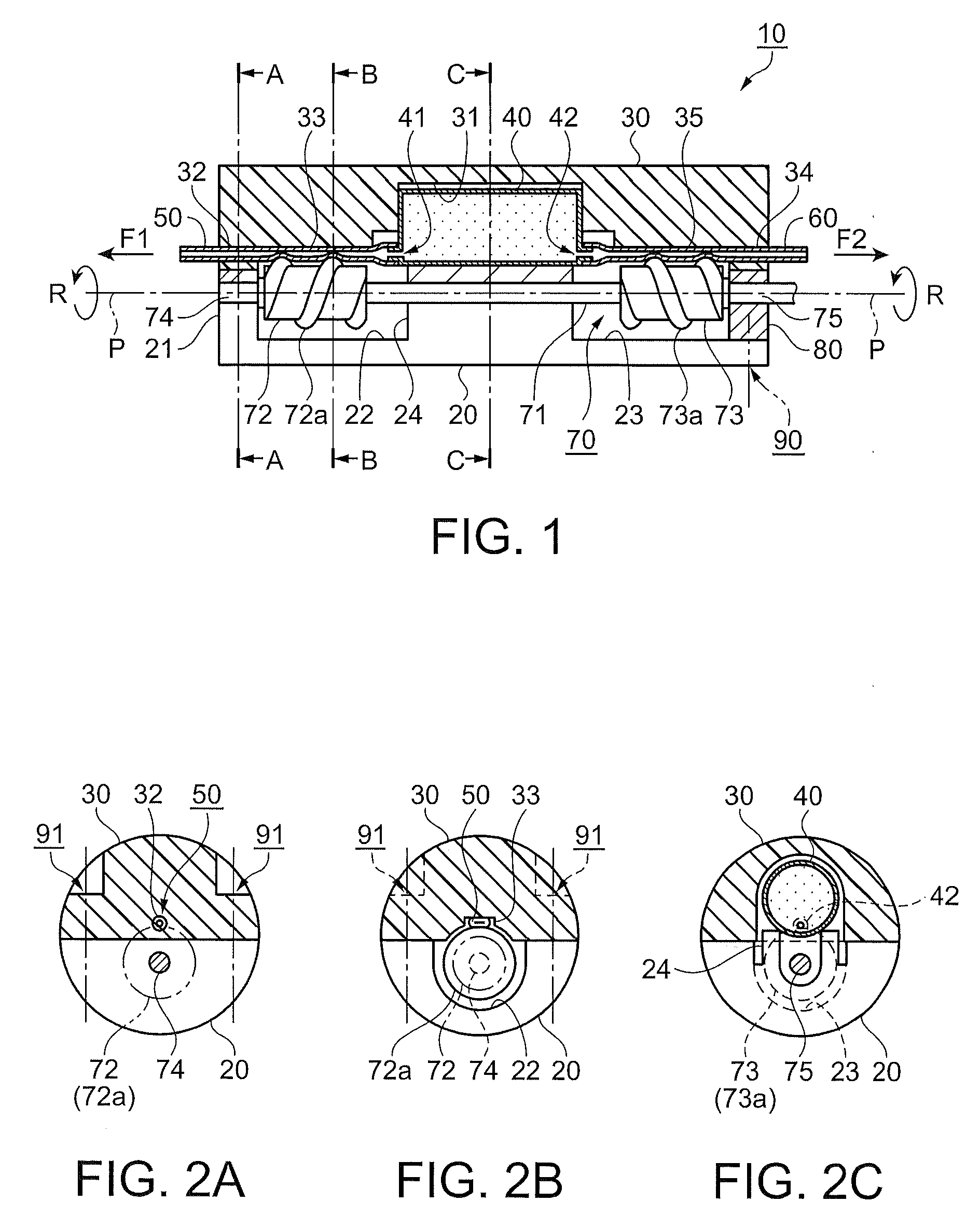

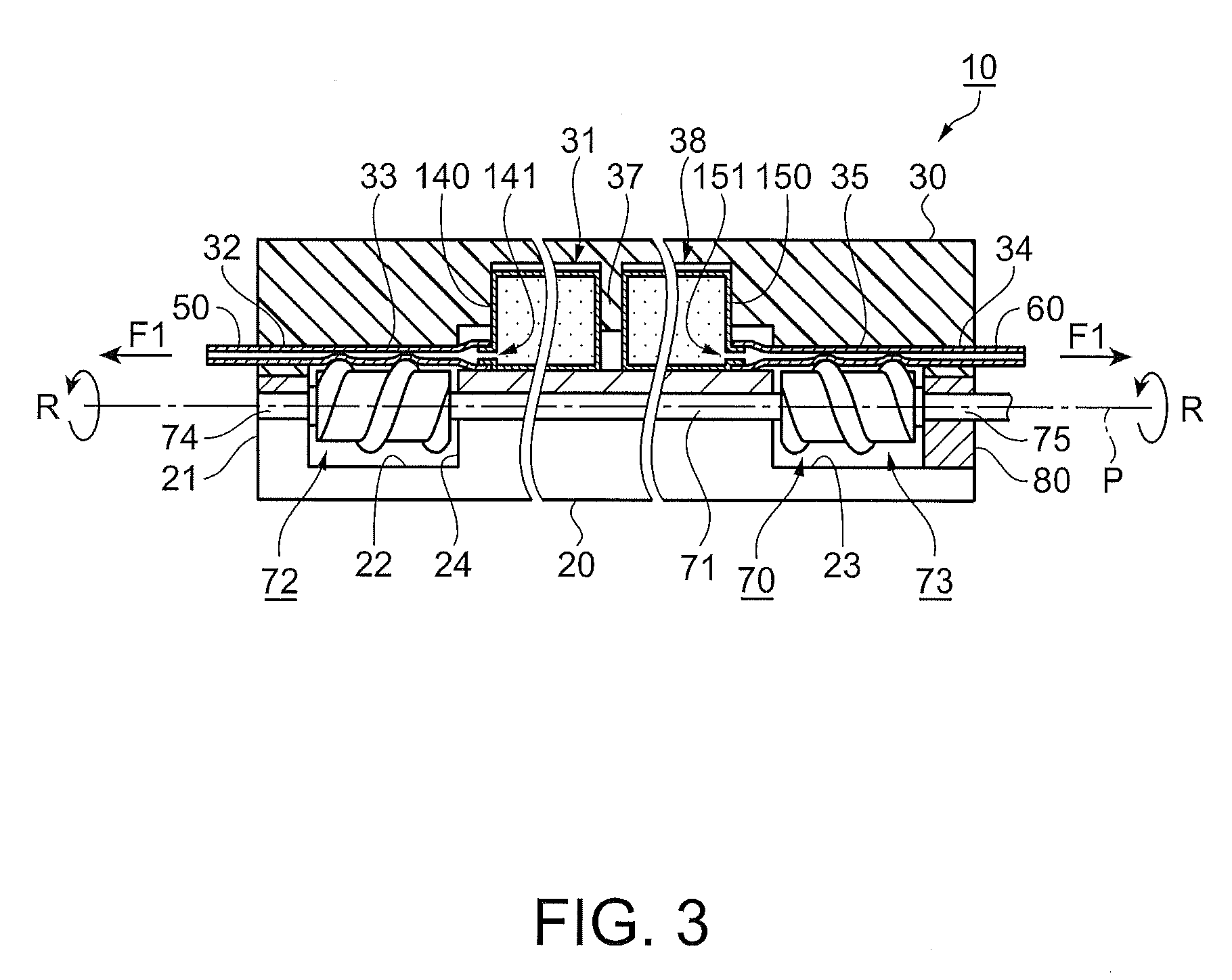

InactiveUS20080247892A1Easy to replaceFlexible member pumpsPositive-displacement liquid enginesRotational axisEngineering

A liquid transfer device that includes: a plurality of reservers that each store therein a liquid; a plurality of elastic tubes that are linked to the reservers and retained by a tube guide; a rotation axis that is retained to be able to rotate; and a tube depressing member whose depressing section is fixed to the rotation axis for depressing the tubes with a helical-structured convex portion provided thereto. In the liquid transfer device, when the rotation axis rotates, the liquid starts to flow by the depressing section sequentially depressing the tubes in a direction from the reservers toward a flow-out side of the liquid.

Owner:SEIKO EPSON CORP

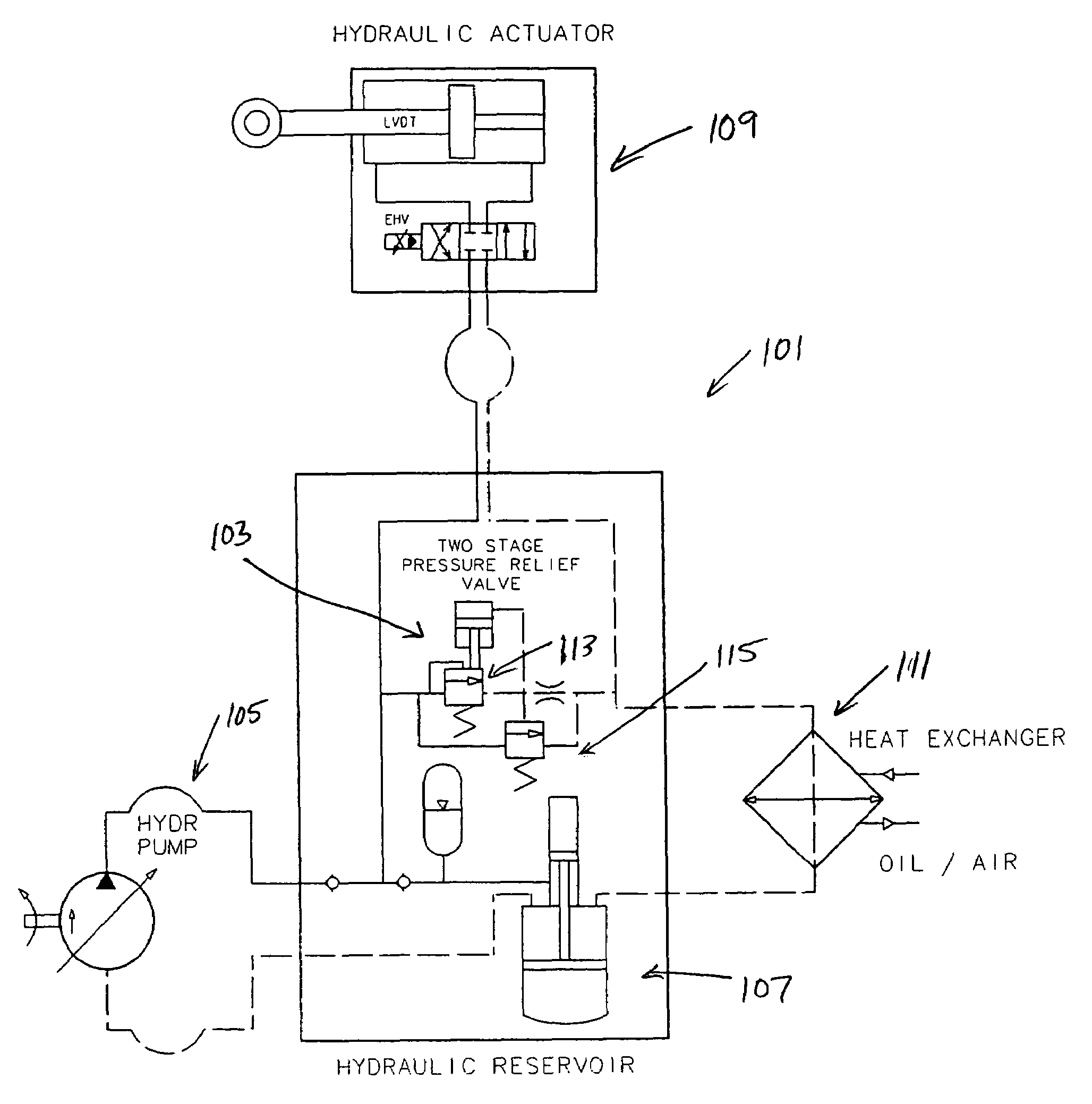

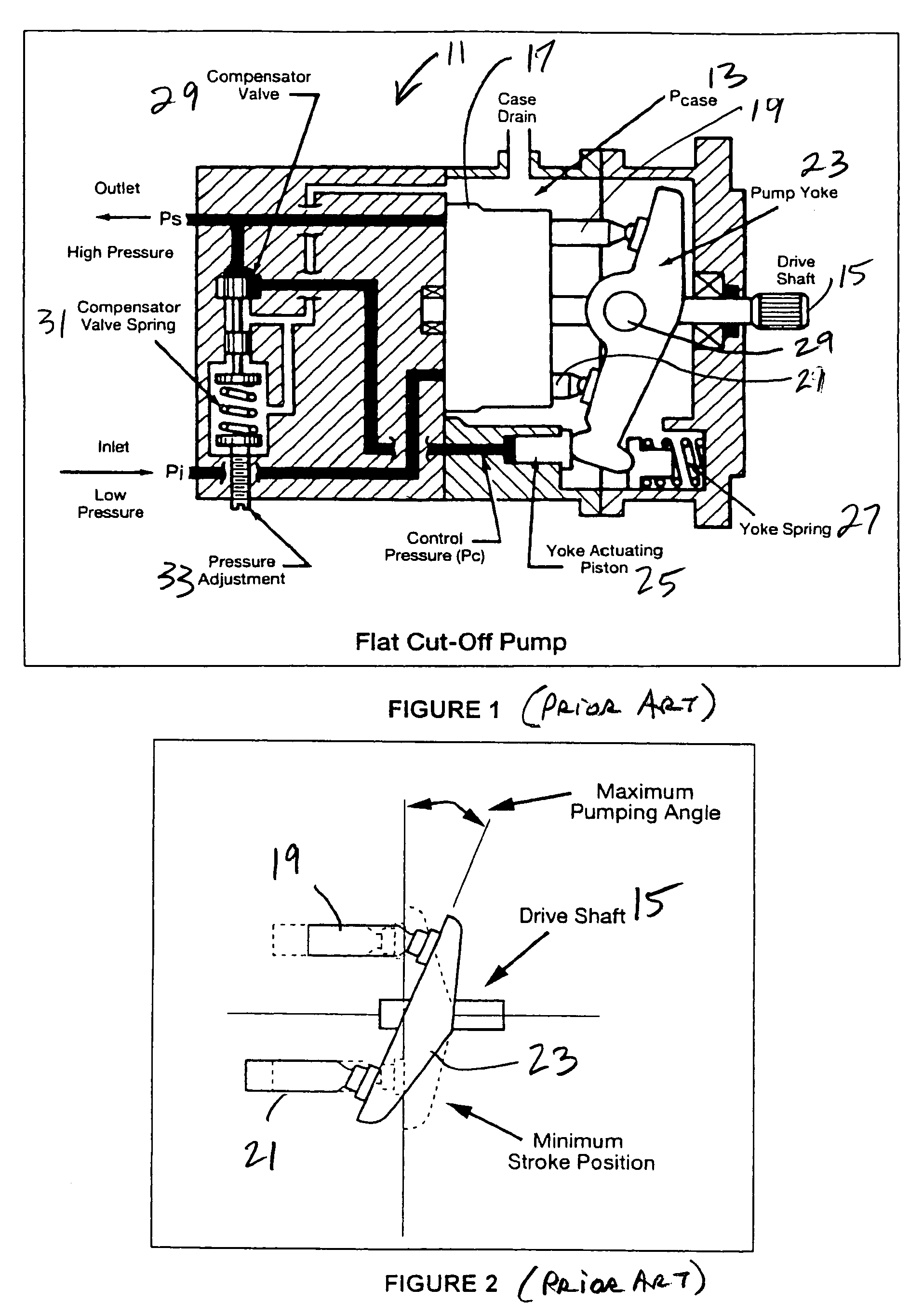

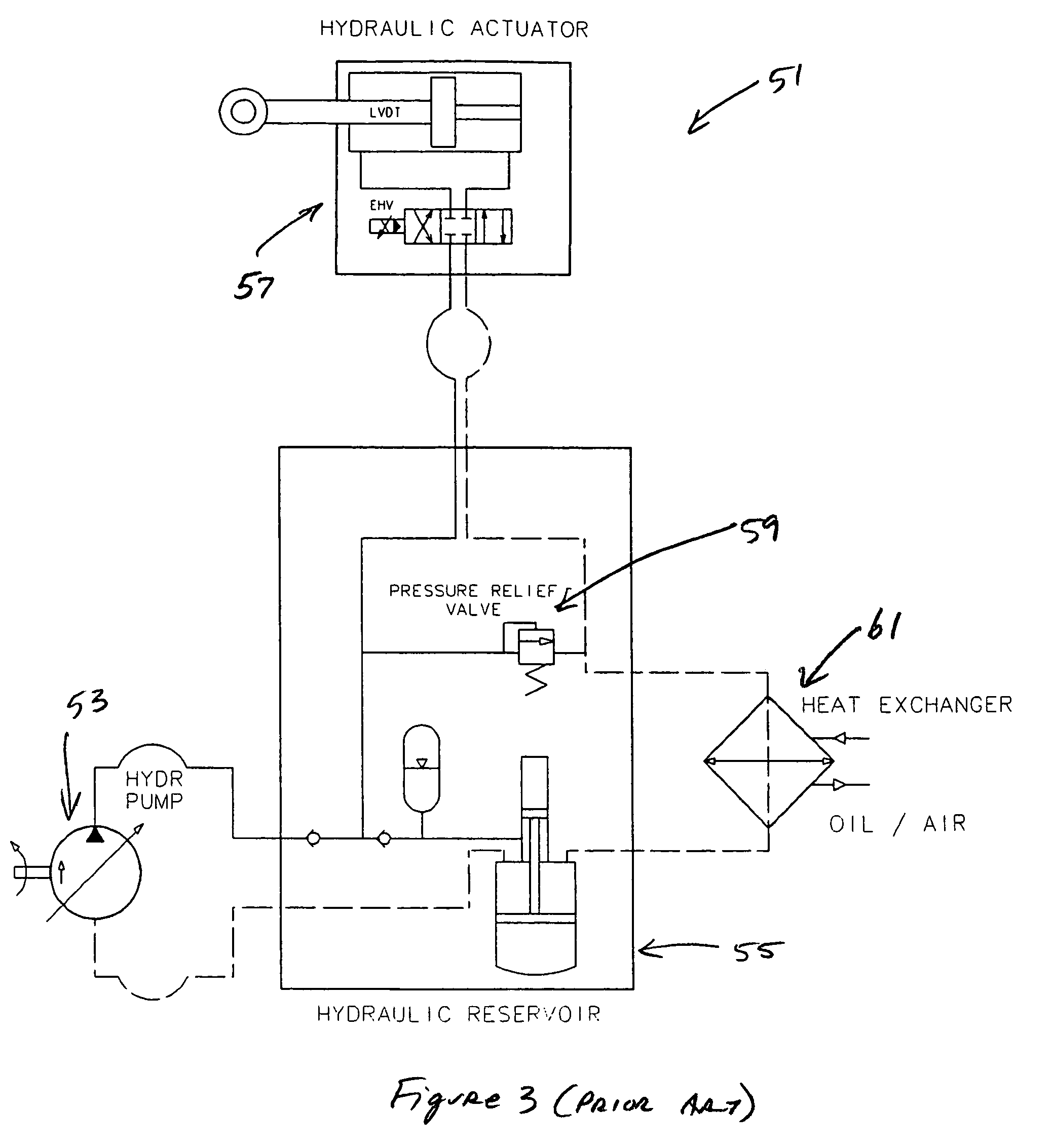

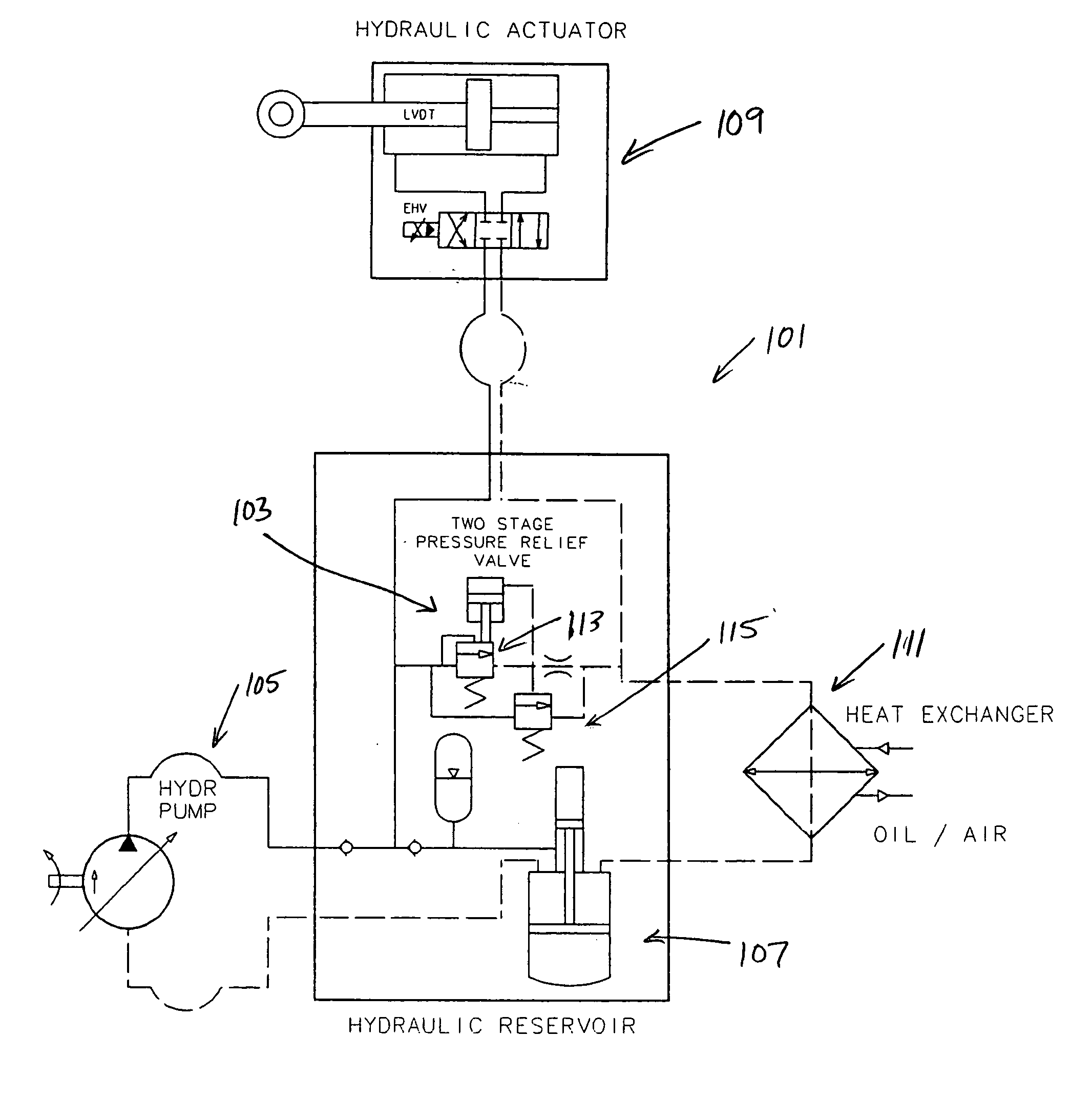

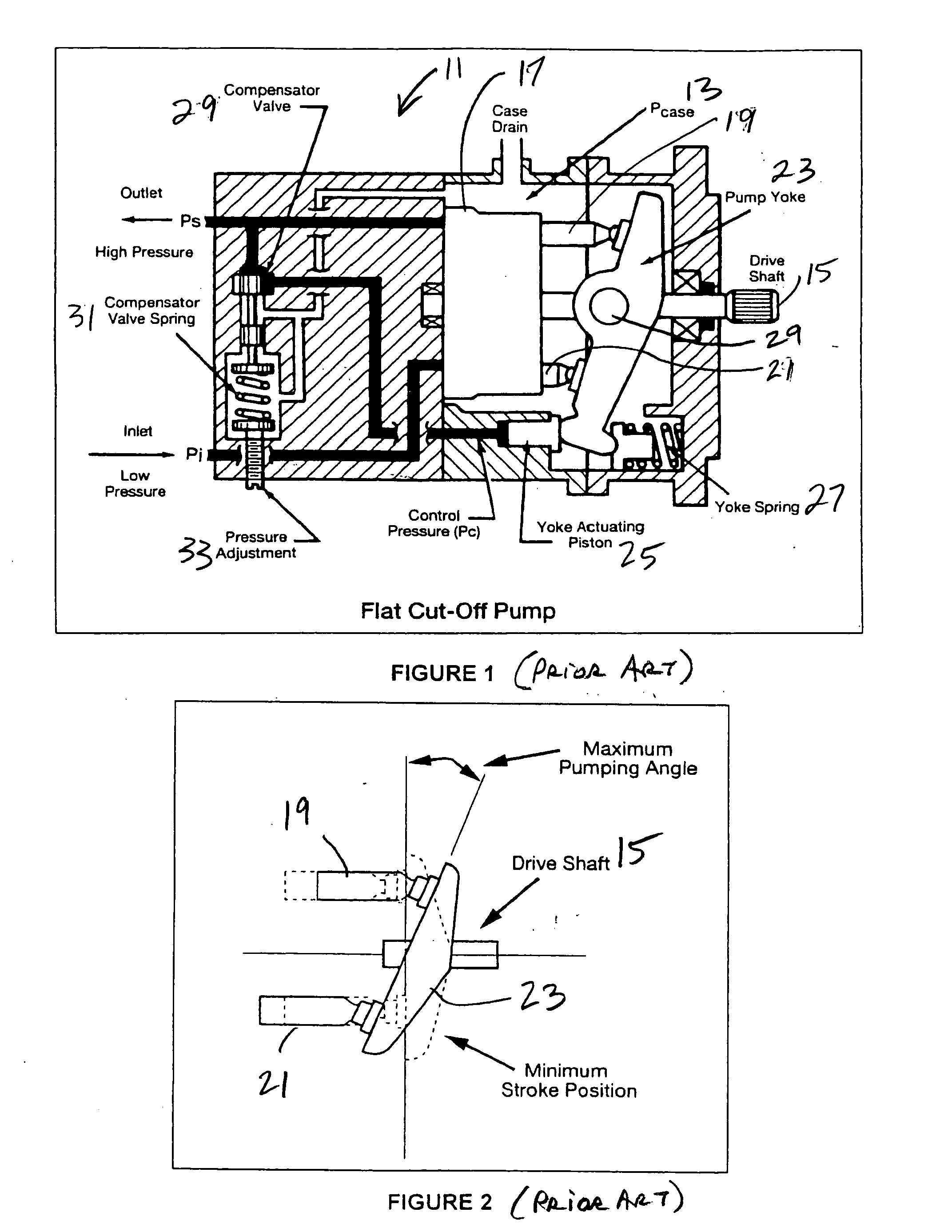

Two-stage pressure relief valve

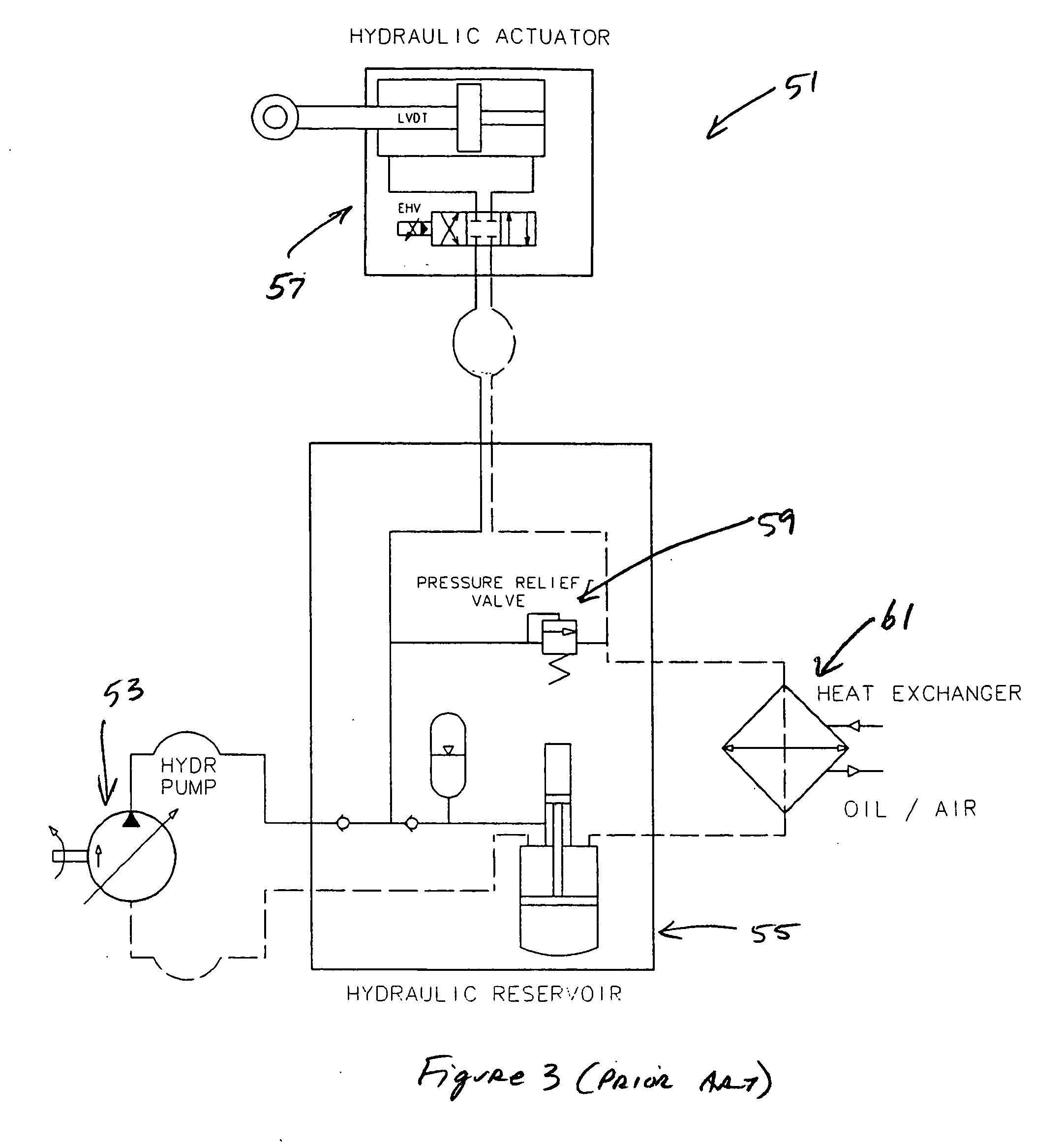

ActiveUS7165950B2More reliableLess expensiveFluid-pressure actuator safetyServomotor componentsDecreased pressureSystem pressure

A two-stage pressure relief valve for use with hydraulic systems is disclosed. The two-stage pressure relief valve has a first stage that relieves increases in hydraulic system pressure over the normal operating pressure and up to a selected threshold pressure level, and a second stage that brings the hydraulic system pressure down to a selected reduced operating pressure that is below the normal operating pressure in response to increases in the operating pressure over the threshold pressure level.

Owner:BELL HELICOPTER TEXTRON INC

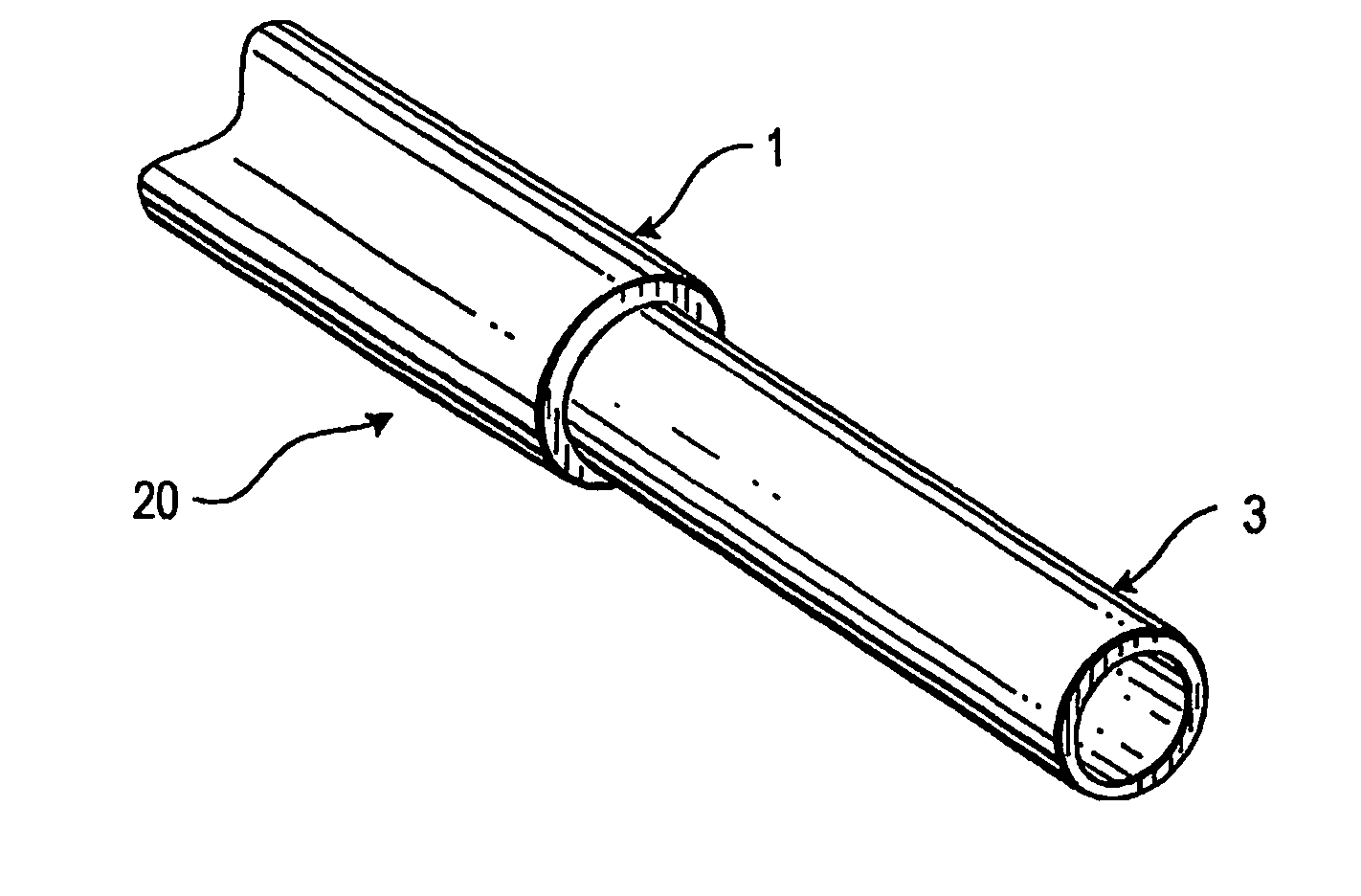

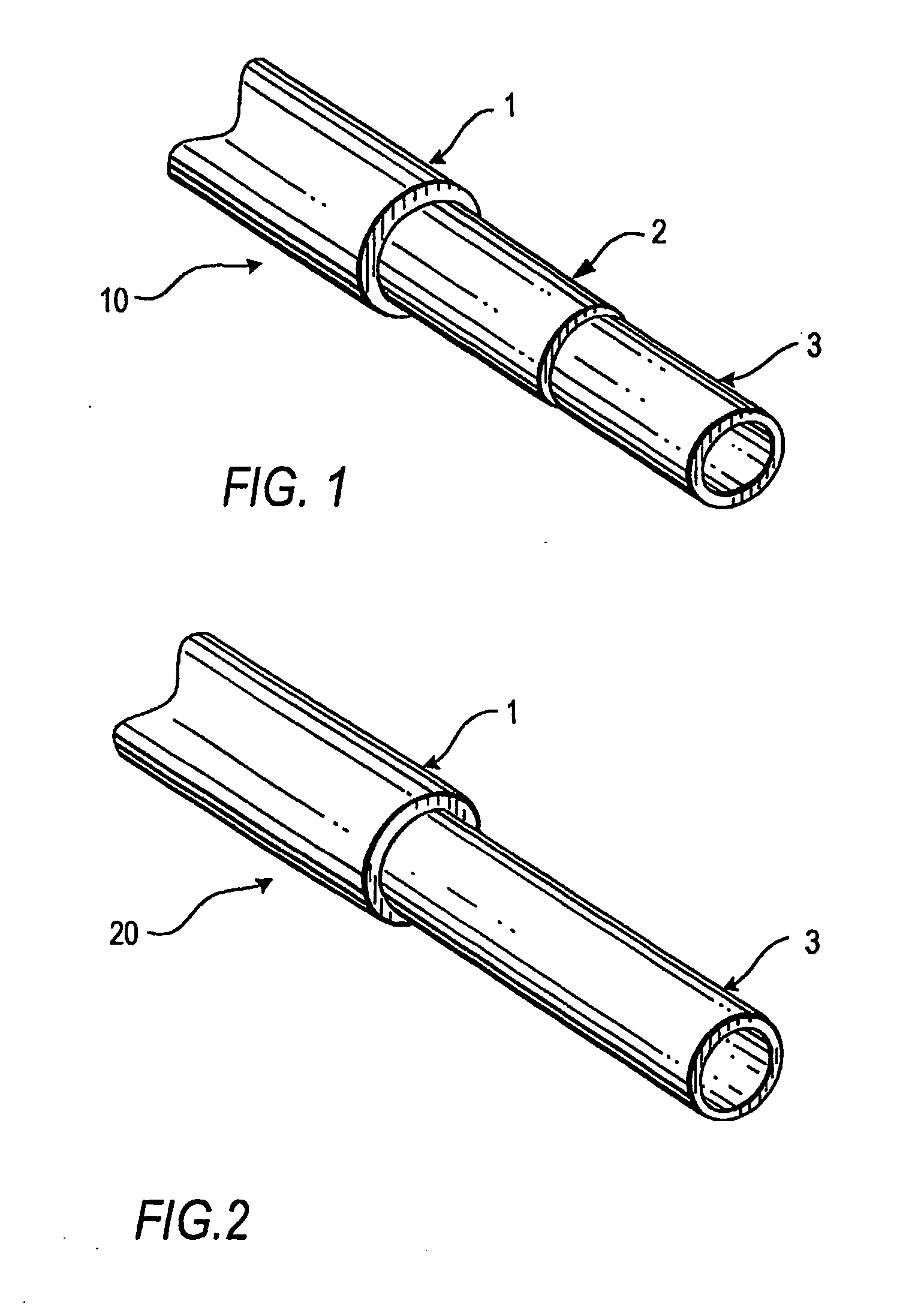

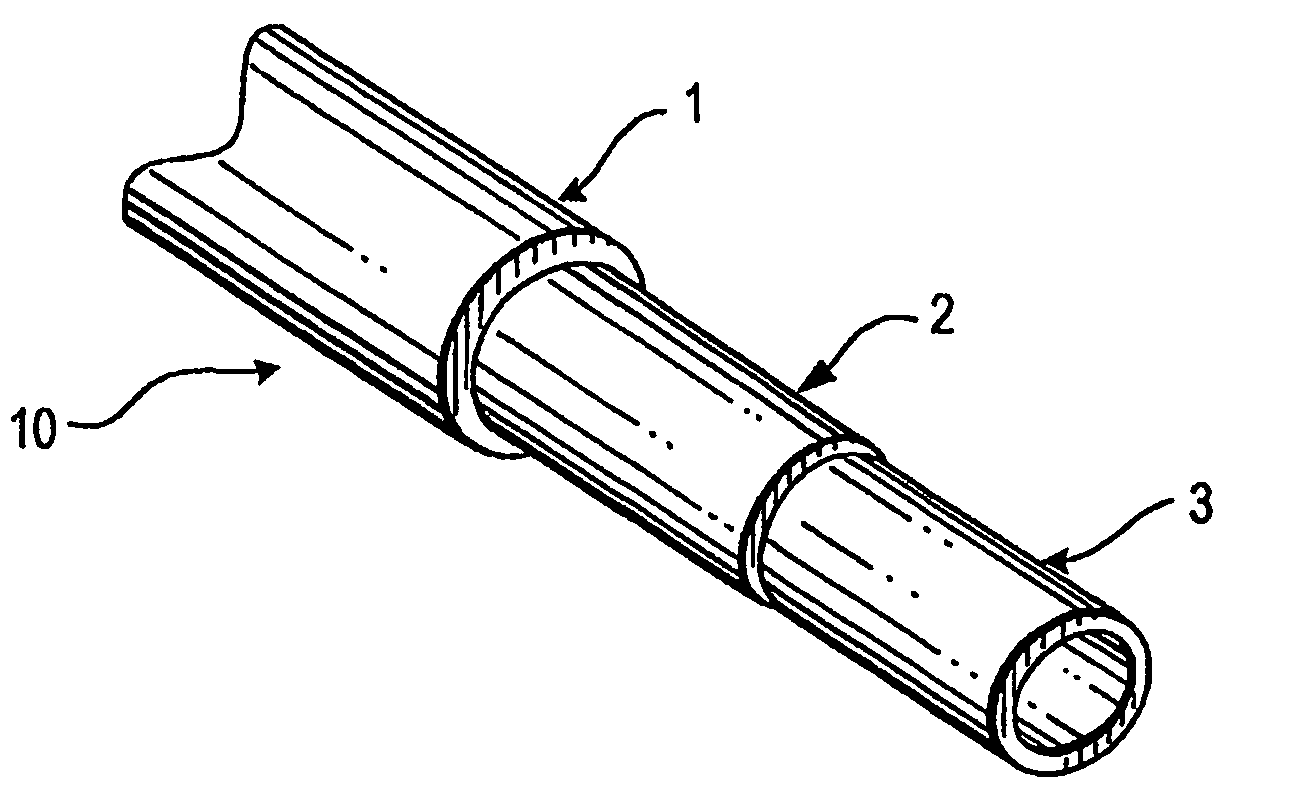

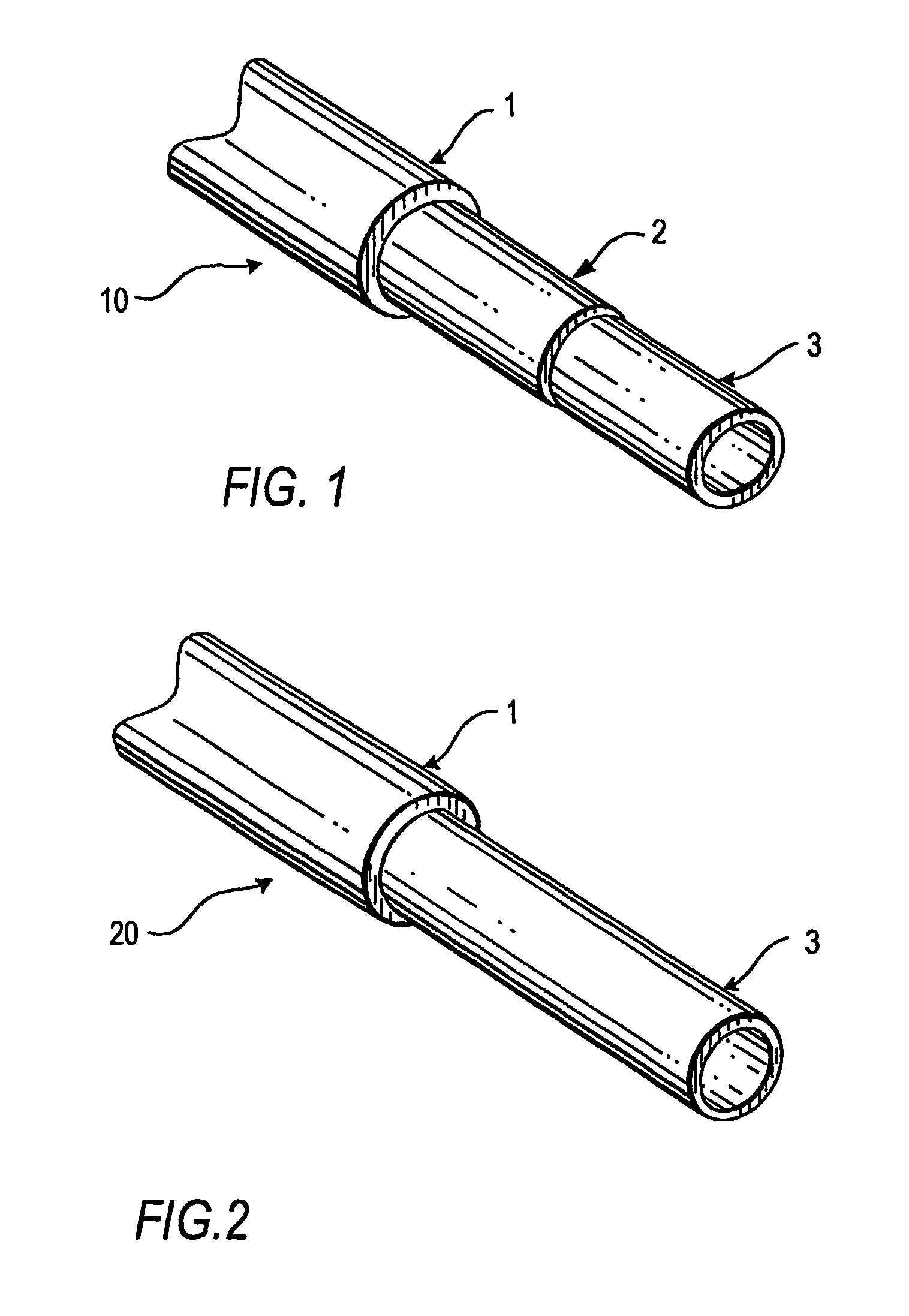

Co-extruded tubing

A co-extruded tubing for the administration of intravenous fluids has an outer layer of a polyester. An inner fluid-contact layer may be of a polyethylene or of a thermoplastic polyurethane. Where the inner fluid-contact layer is of polyethylene, an intermediate tie layer of ethylene-vinyl acetate copolymer may be included to prevent delamination.

Owner:NATVAR HLDG

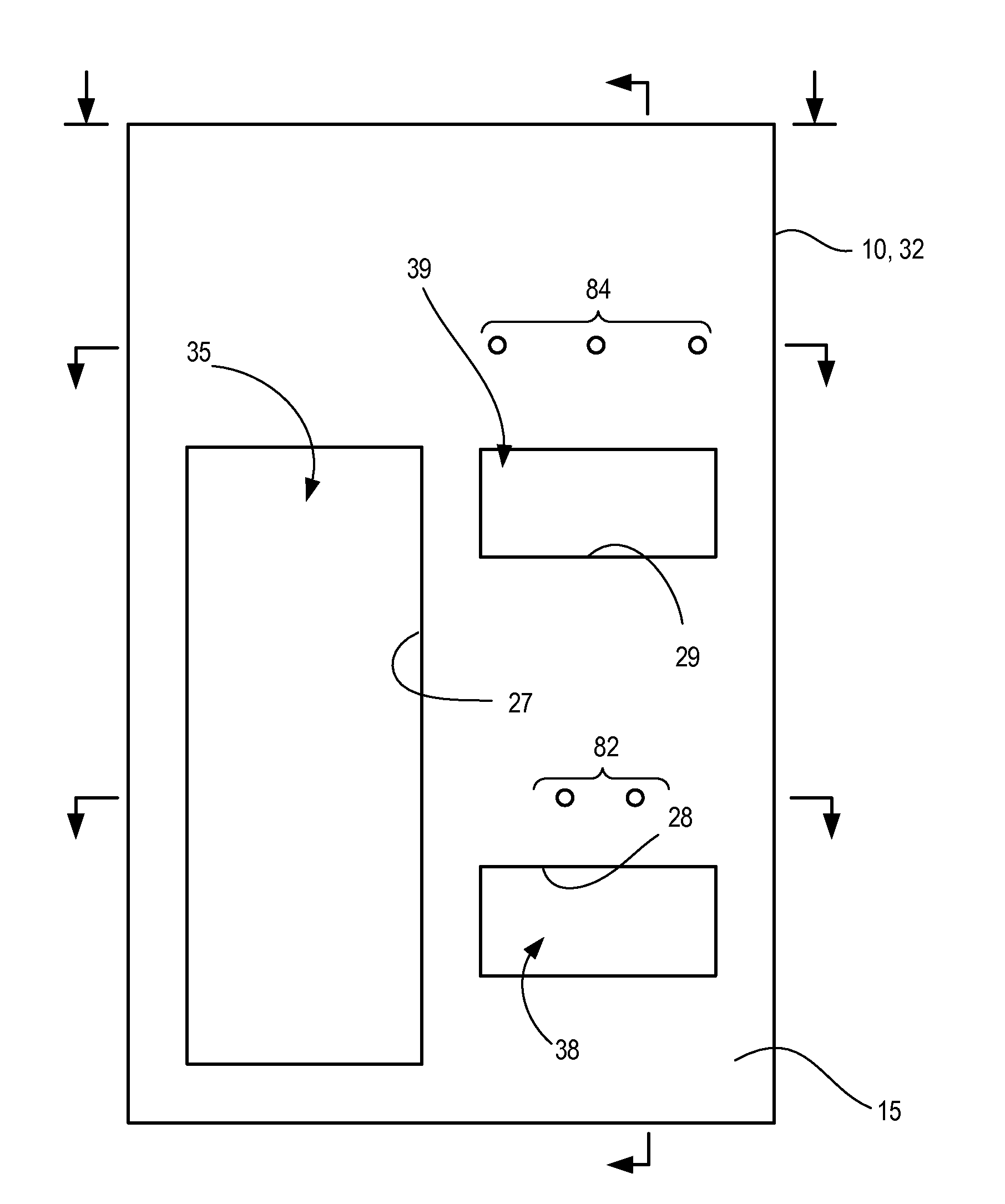

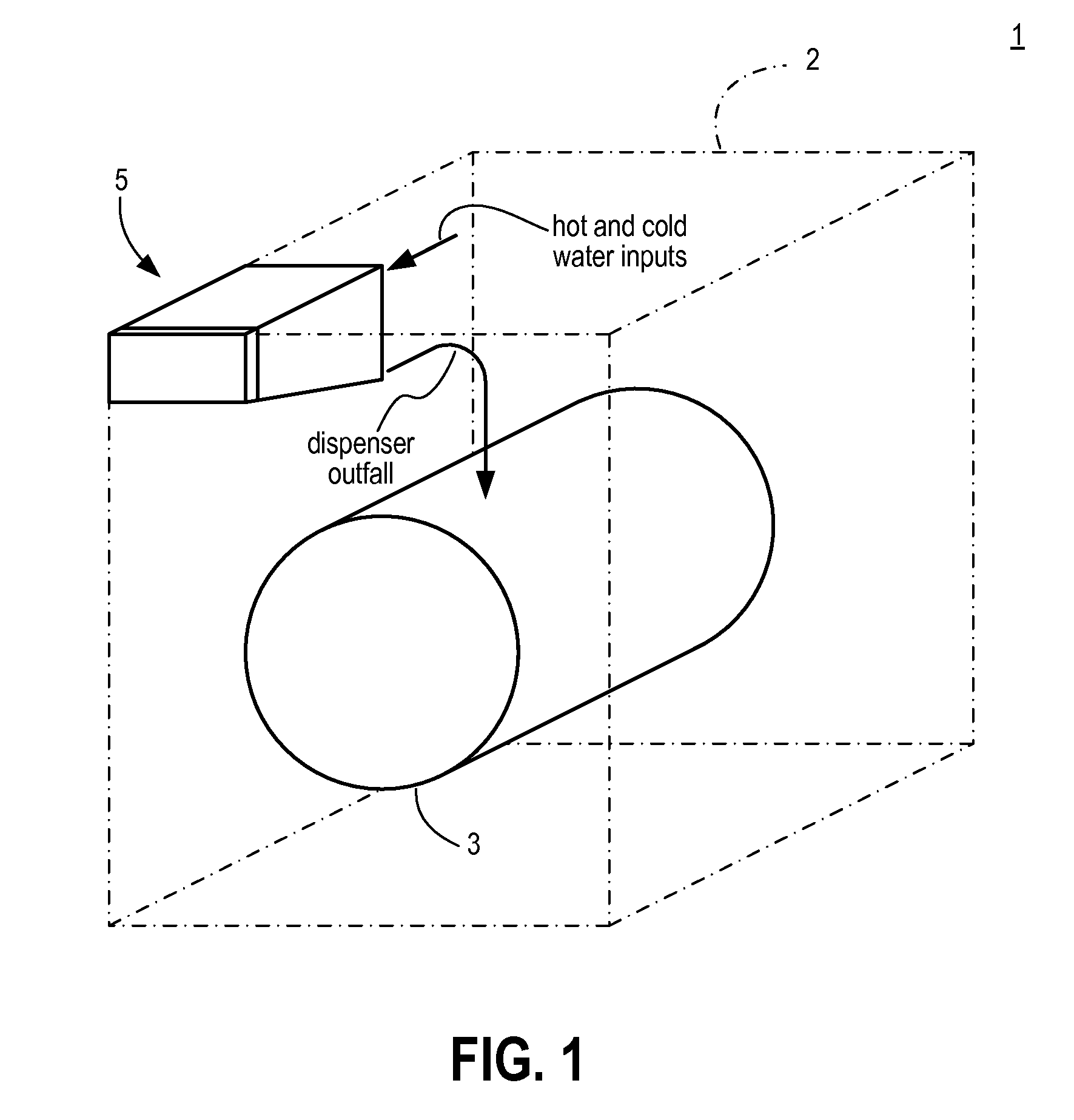

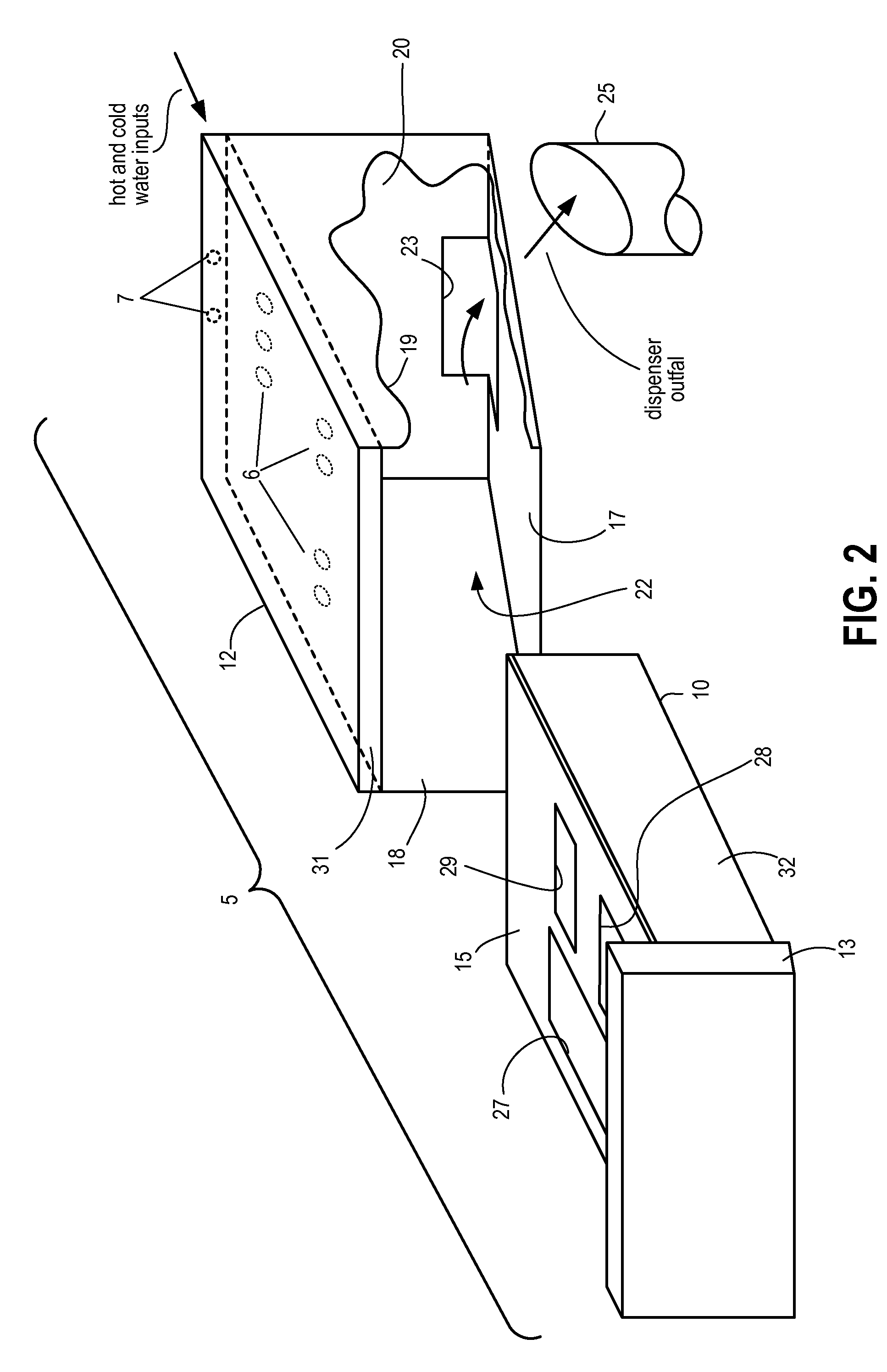

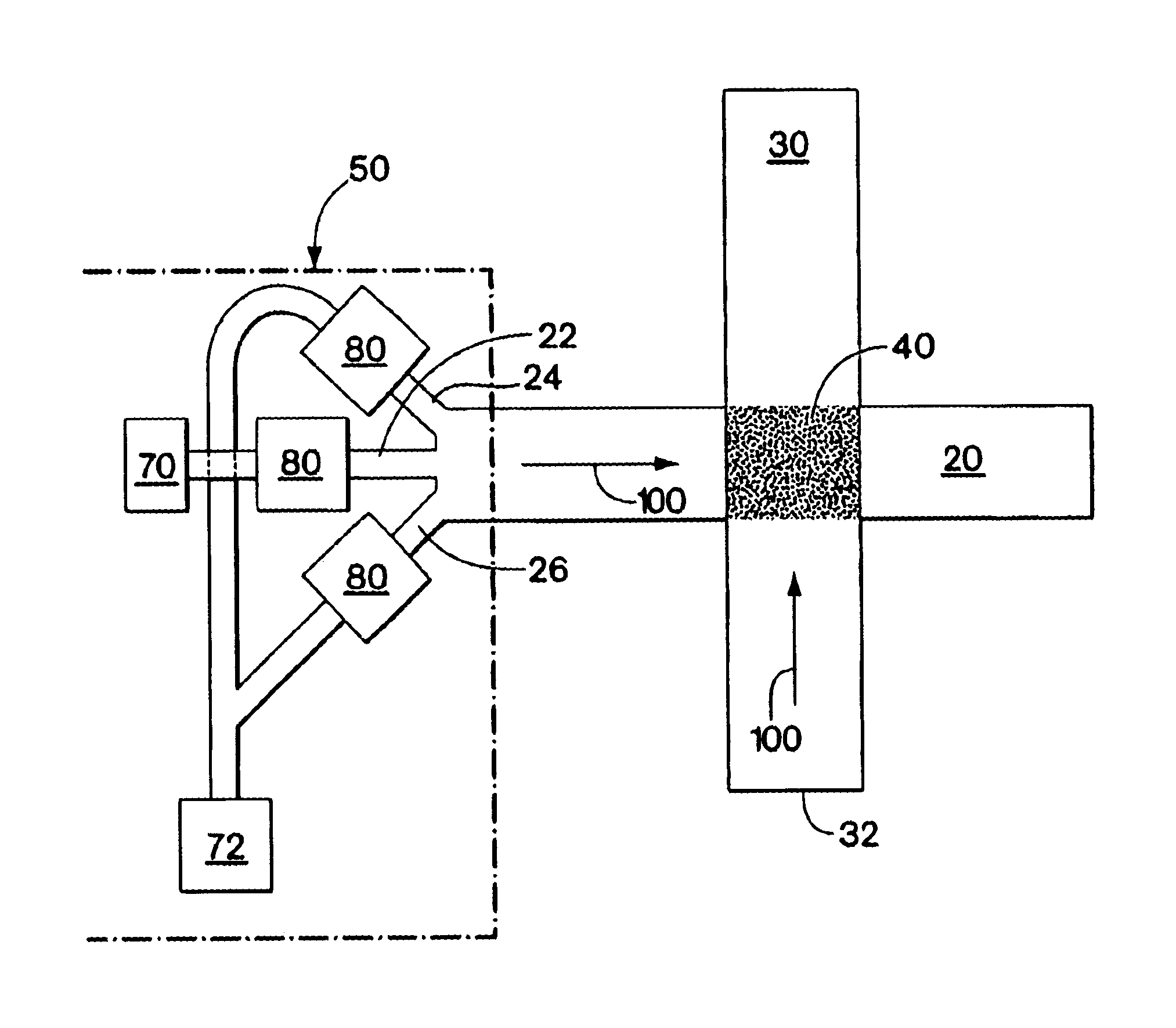

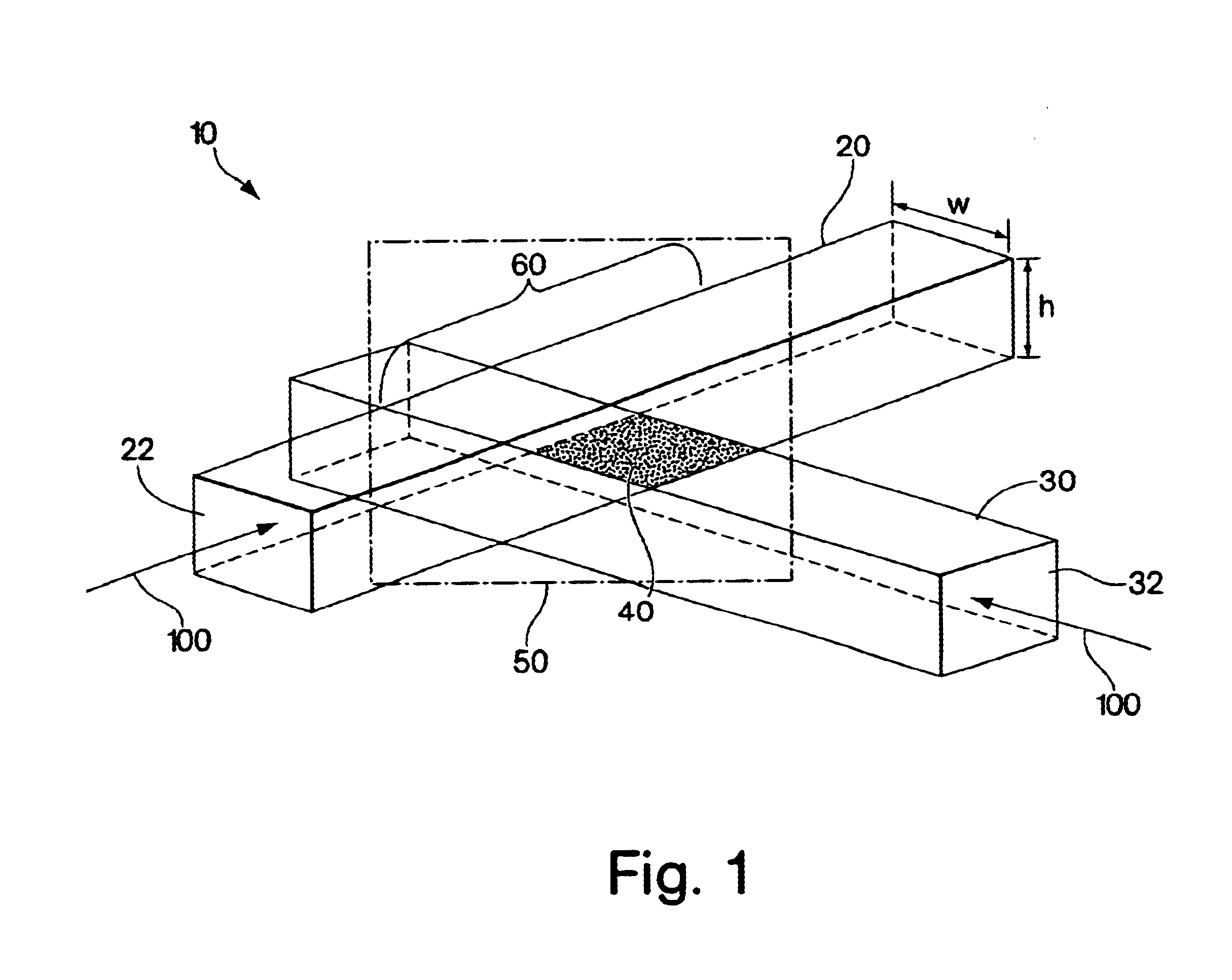

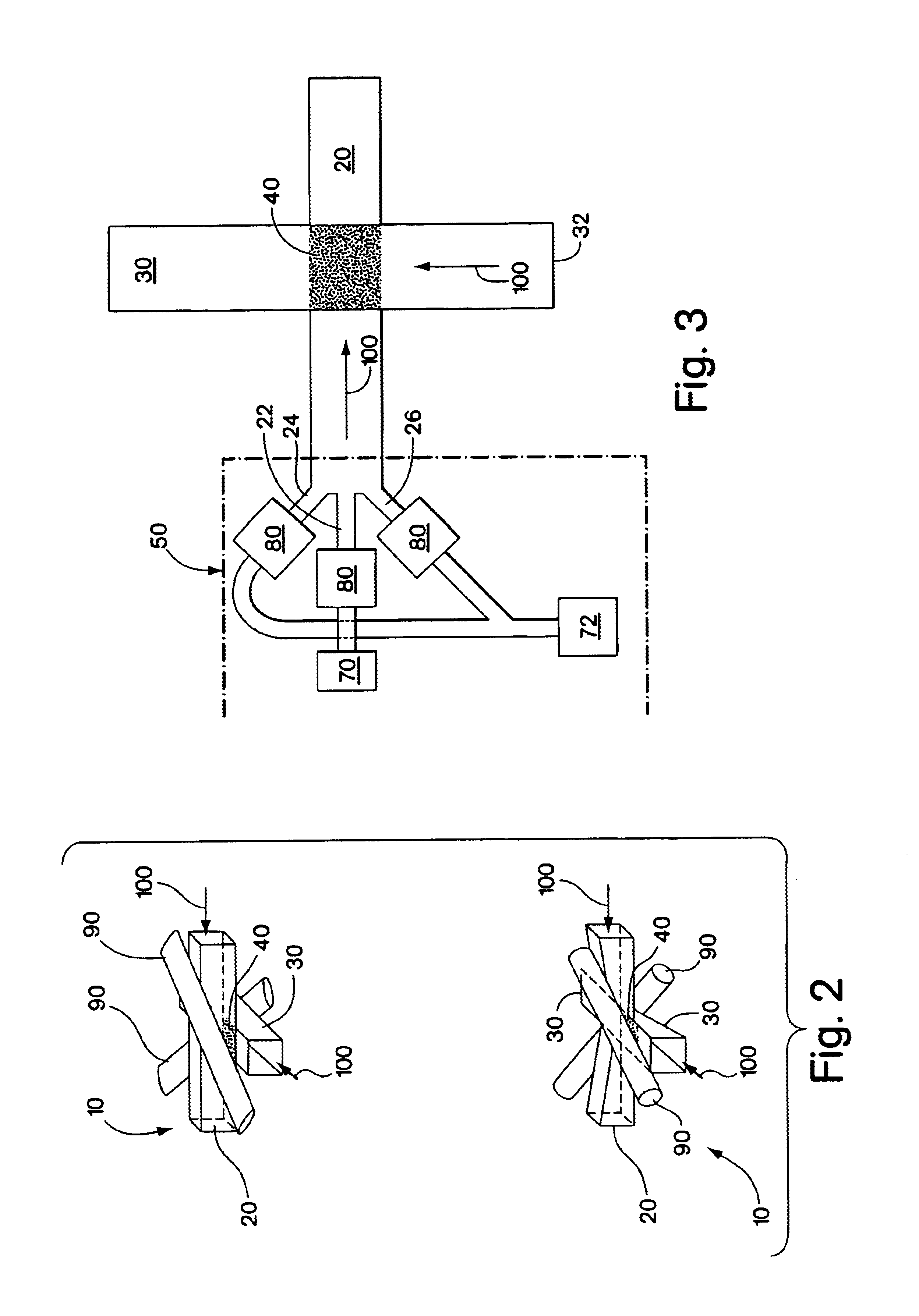

Methods and Systems for Water Delivery in an Additive Dispenser

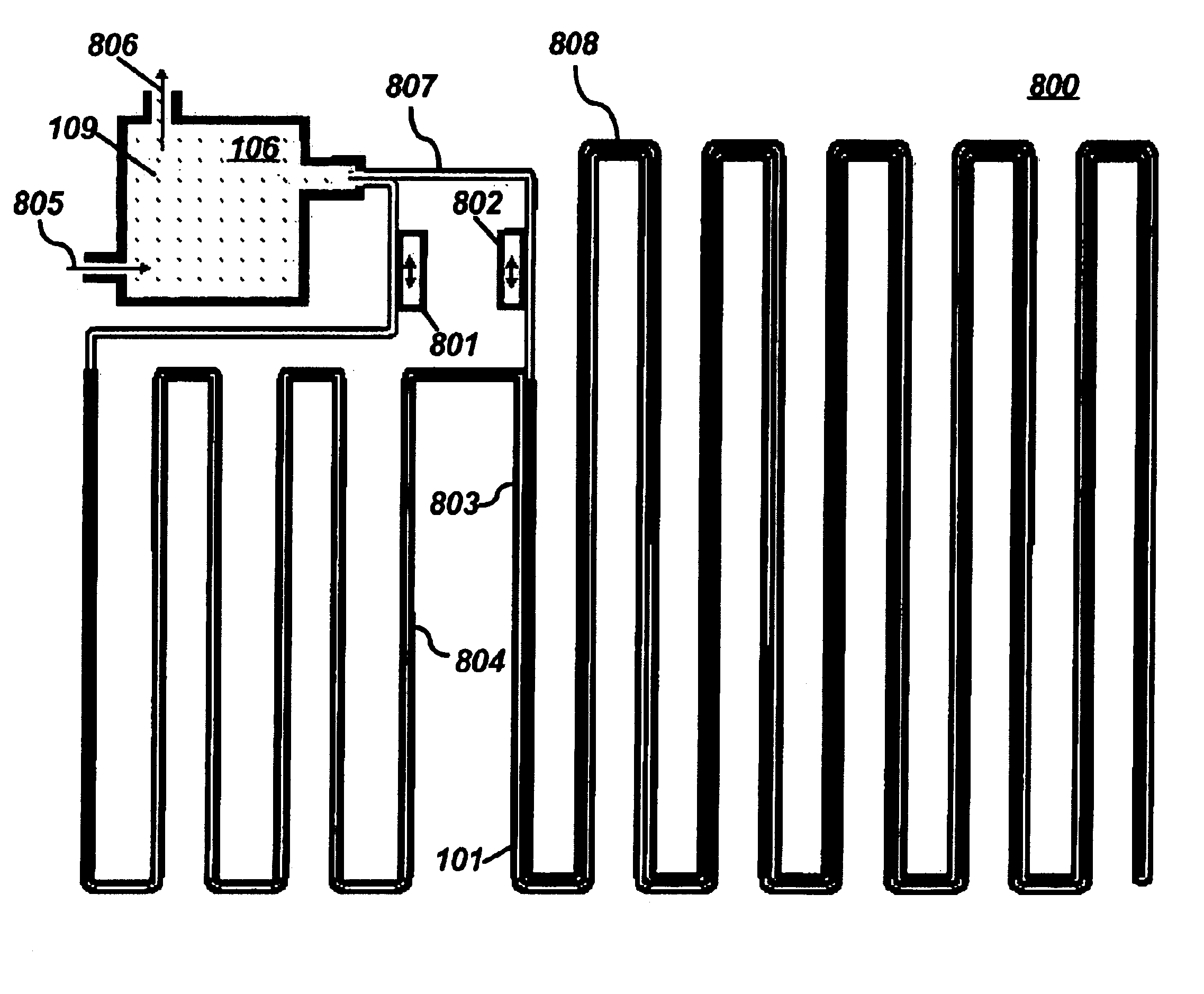

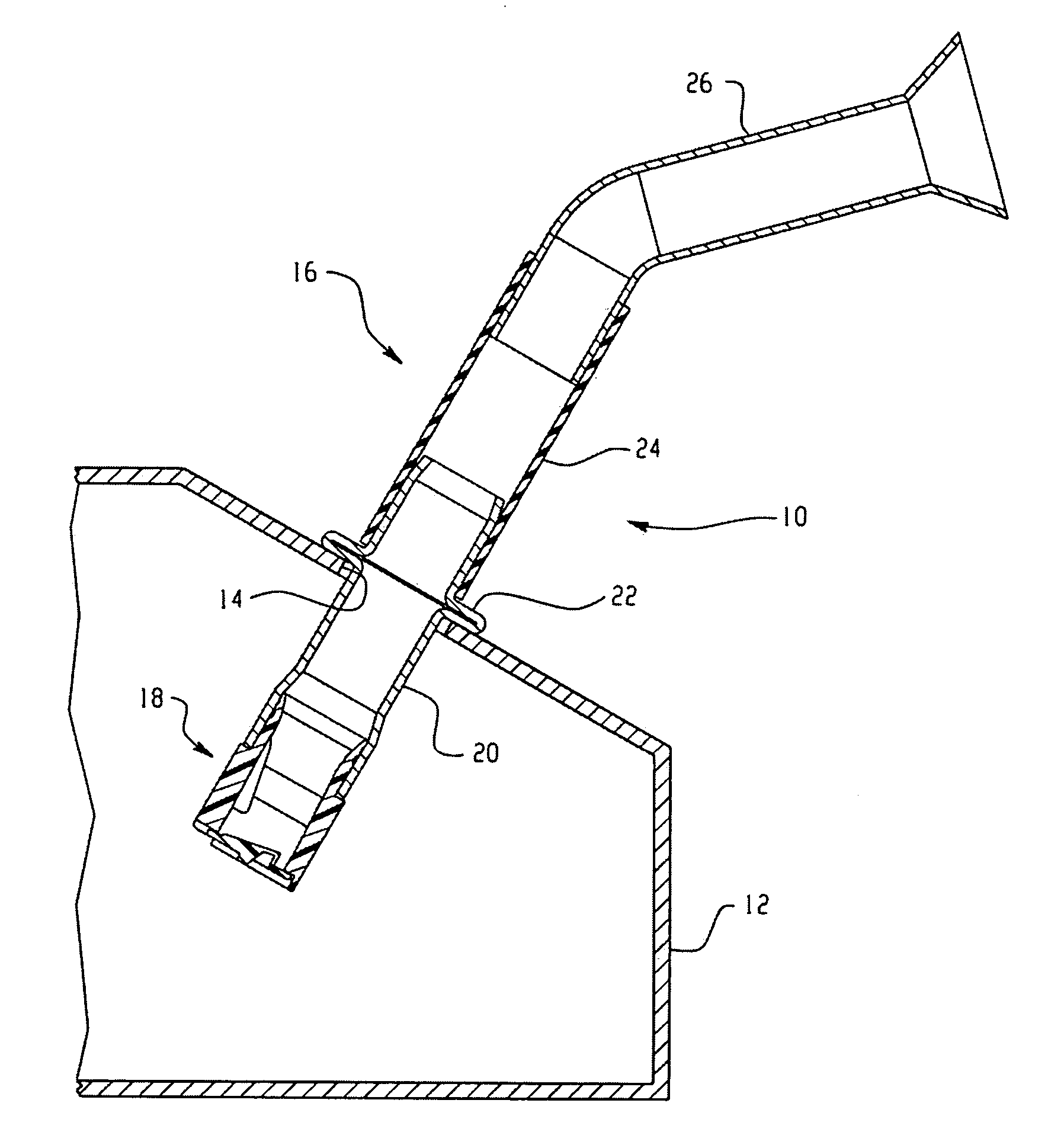

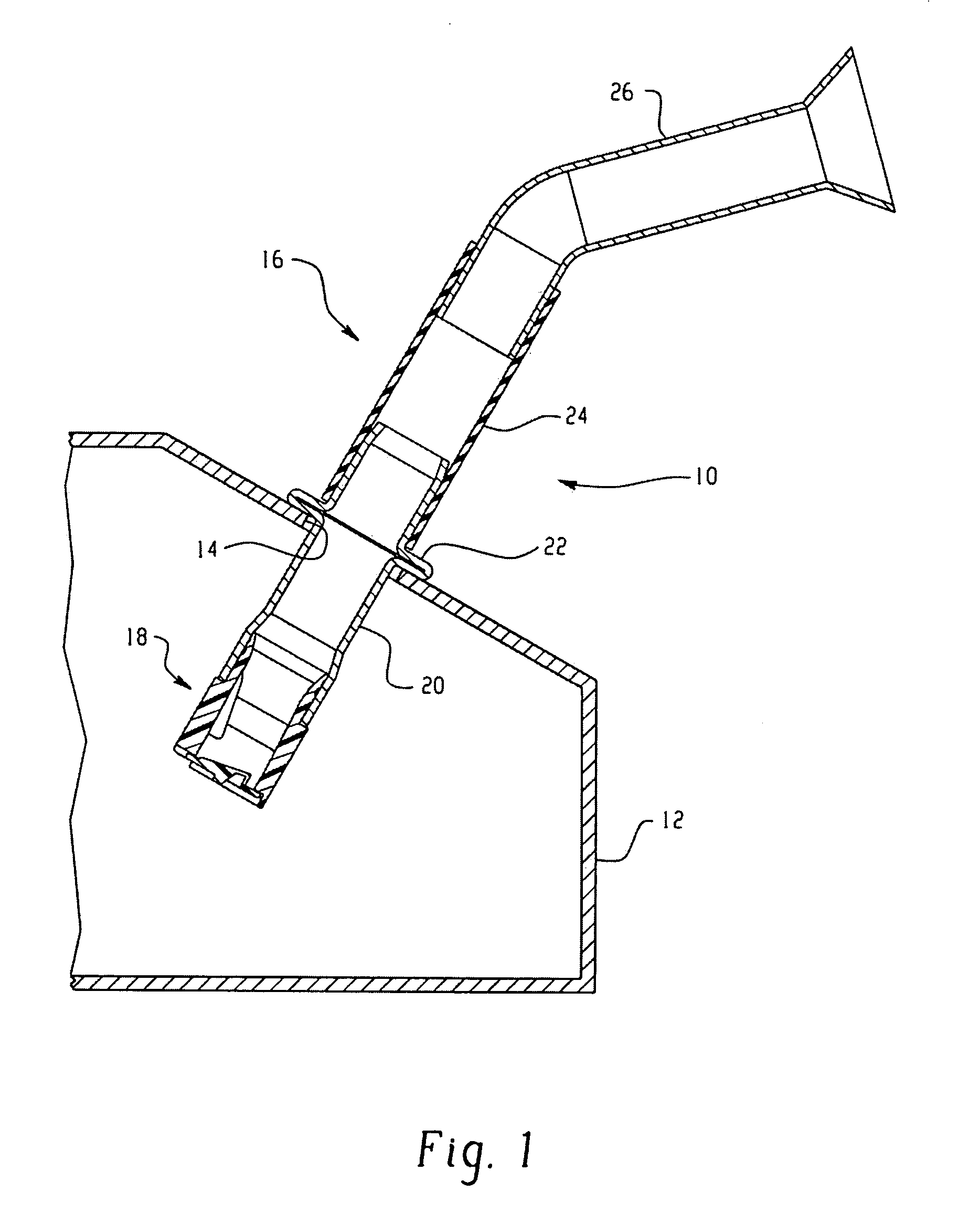

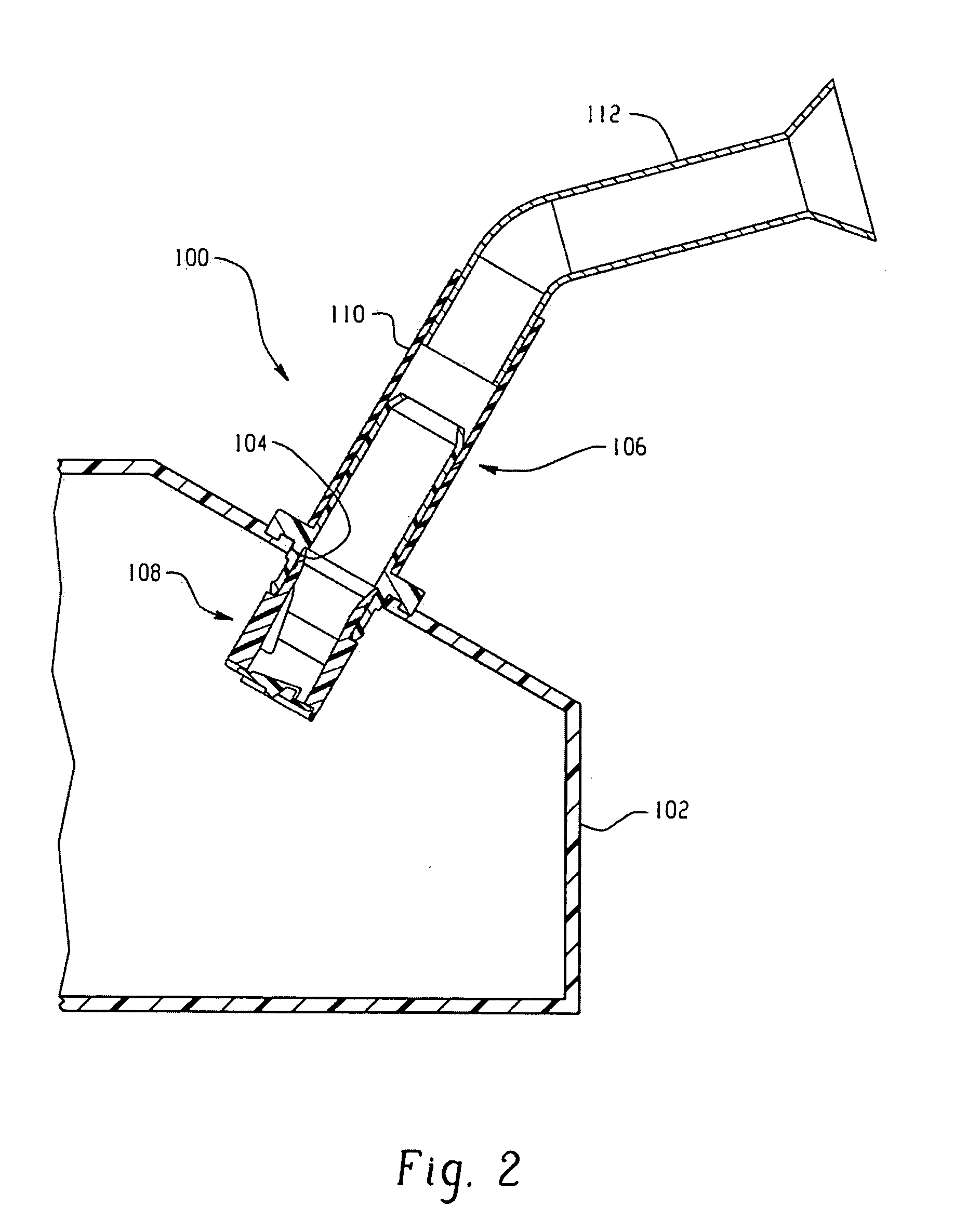

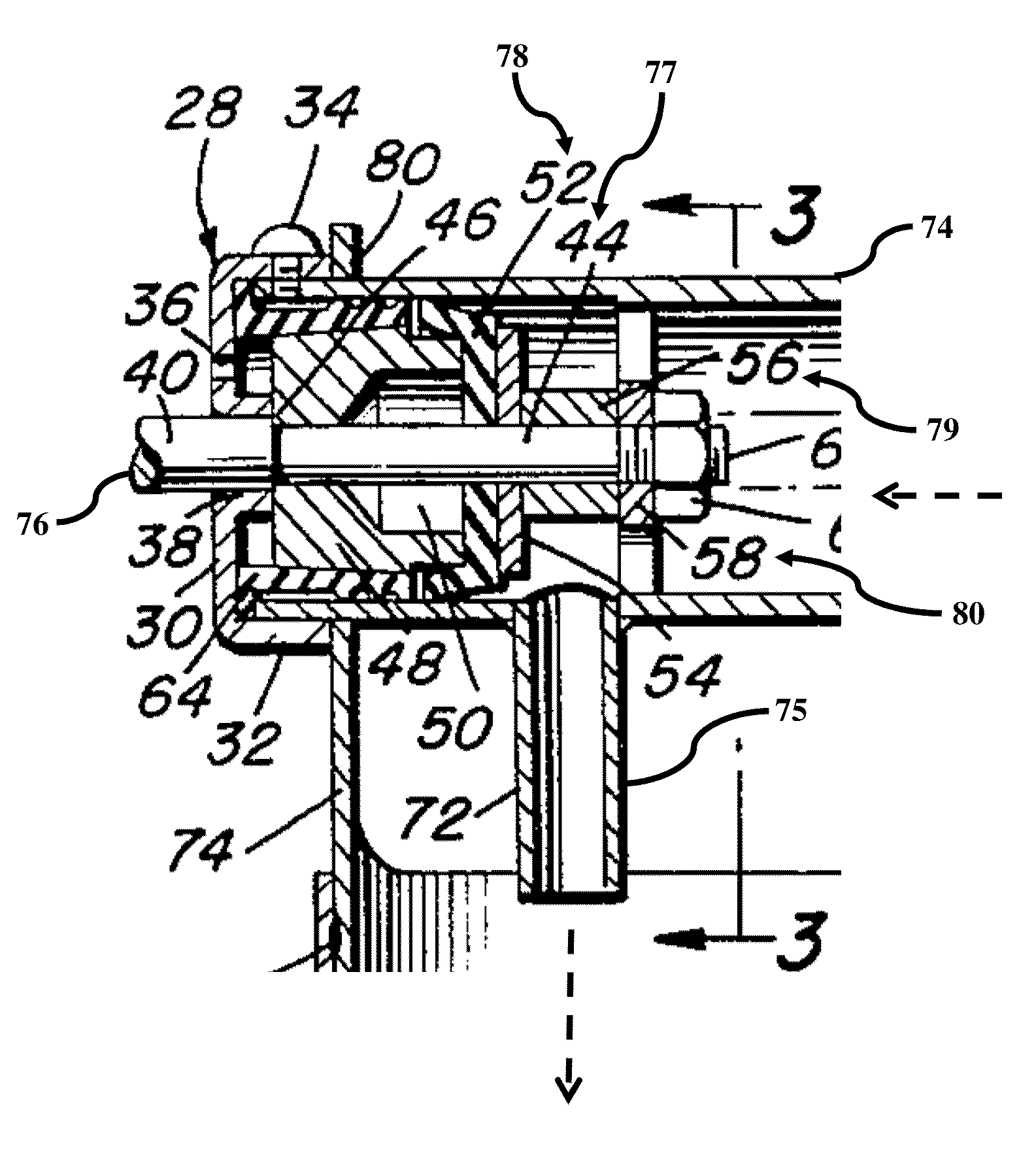

ActiveUS20090158782A1Avoid residueSpeed up siphoningControl devices for washing apparatusMachines/enginesSiphonLaundry washing machine

A washing apparatus such as an automatic laundry washing machine includes a wash agent dispenser drawer including an additive compartment for storing various additives such as detergent, bleach and fabric softener. One or more water inflow tubes may extend downwardly into the additive compartment and may be configured to deliver water for diluting the additives contained in the compartment. The inflow tubes are of sufficient length to reach a sub-surface portion of additive held in the compartment. Water may simultaneously be delivered to the surface of the additive. Furthermore, inflow tubes have their outlets positioned adjacent to the base(s) of one or more siphon post / cap assemblies located in the additive compartments, such that a churning effect is produced from the injection of water through the tubes and the siphoning action of the siphon post, whereby mixing is enhanced and additive buildup may be avoided and / or removed.

Owner:ELECTROLUX HOME PROD CORP NV

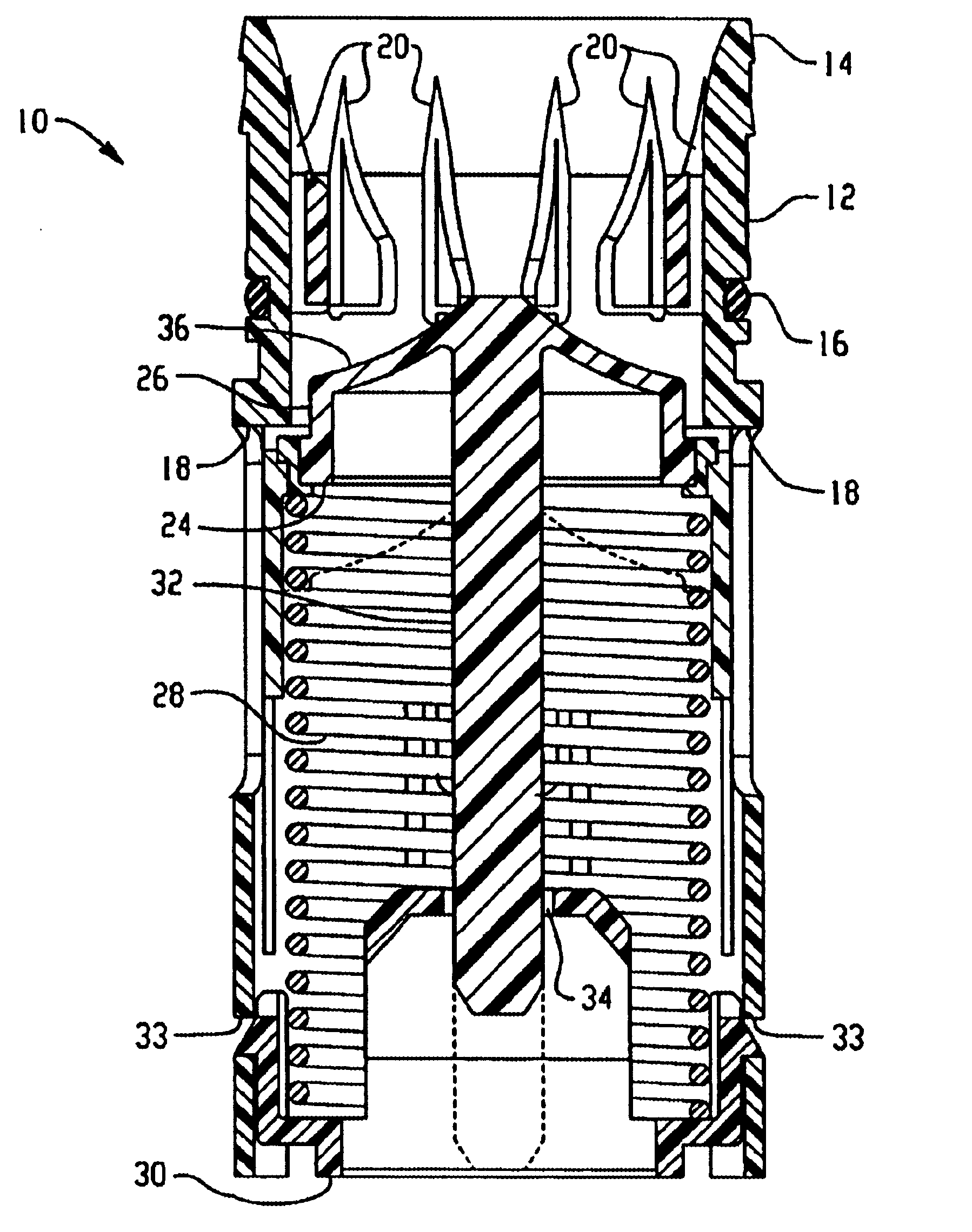

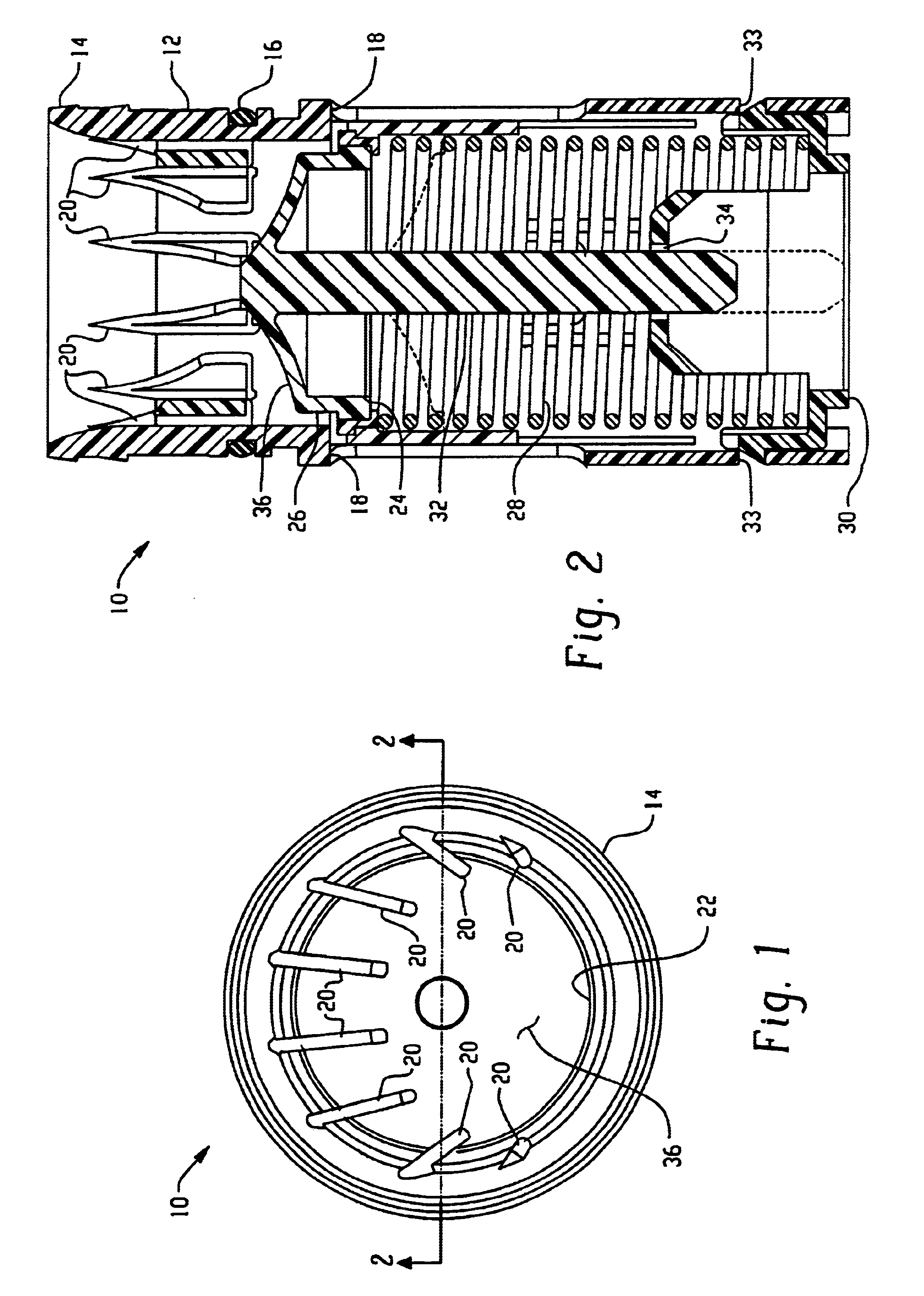

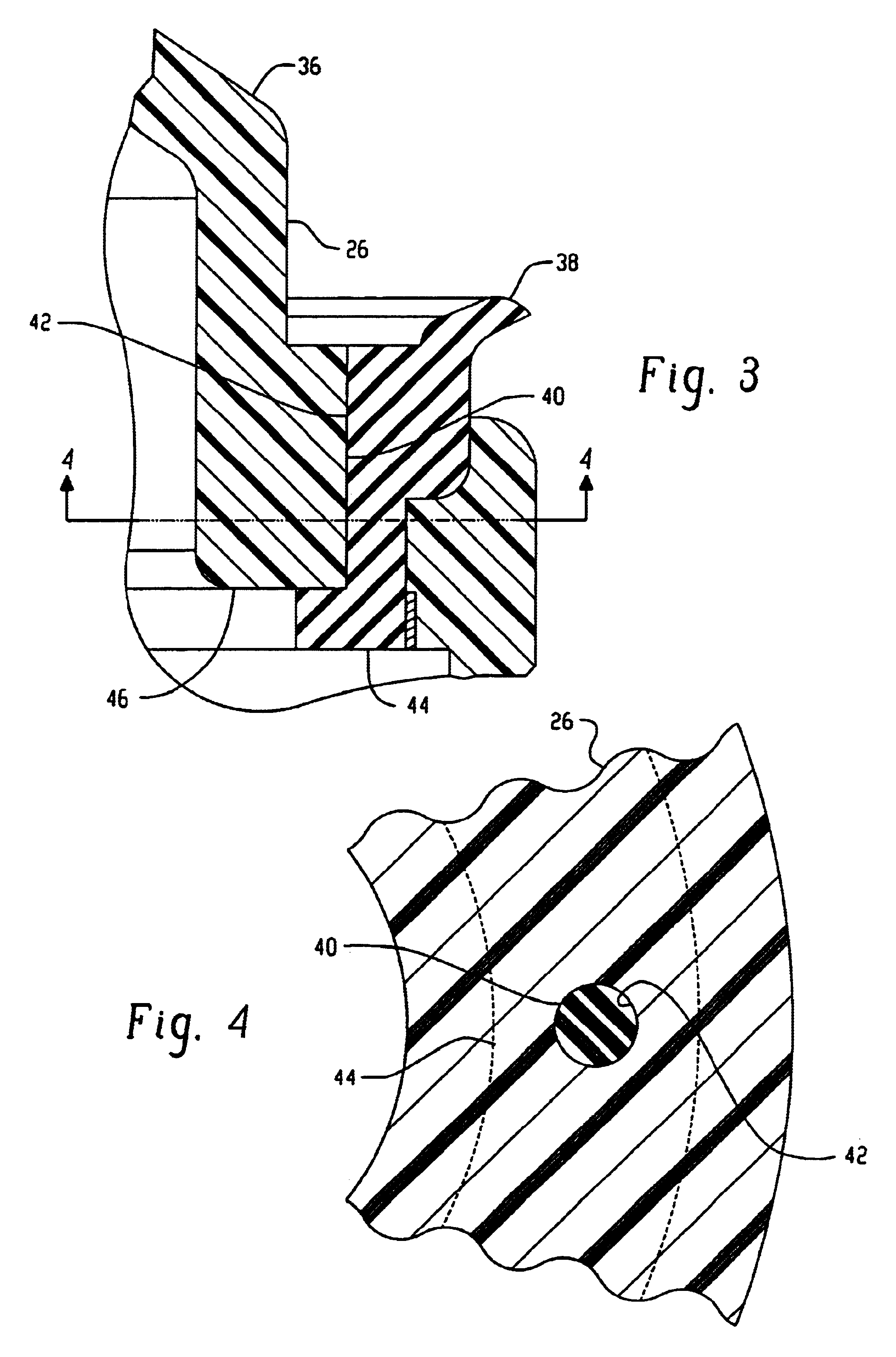

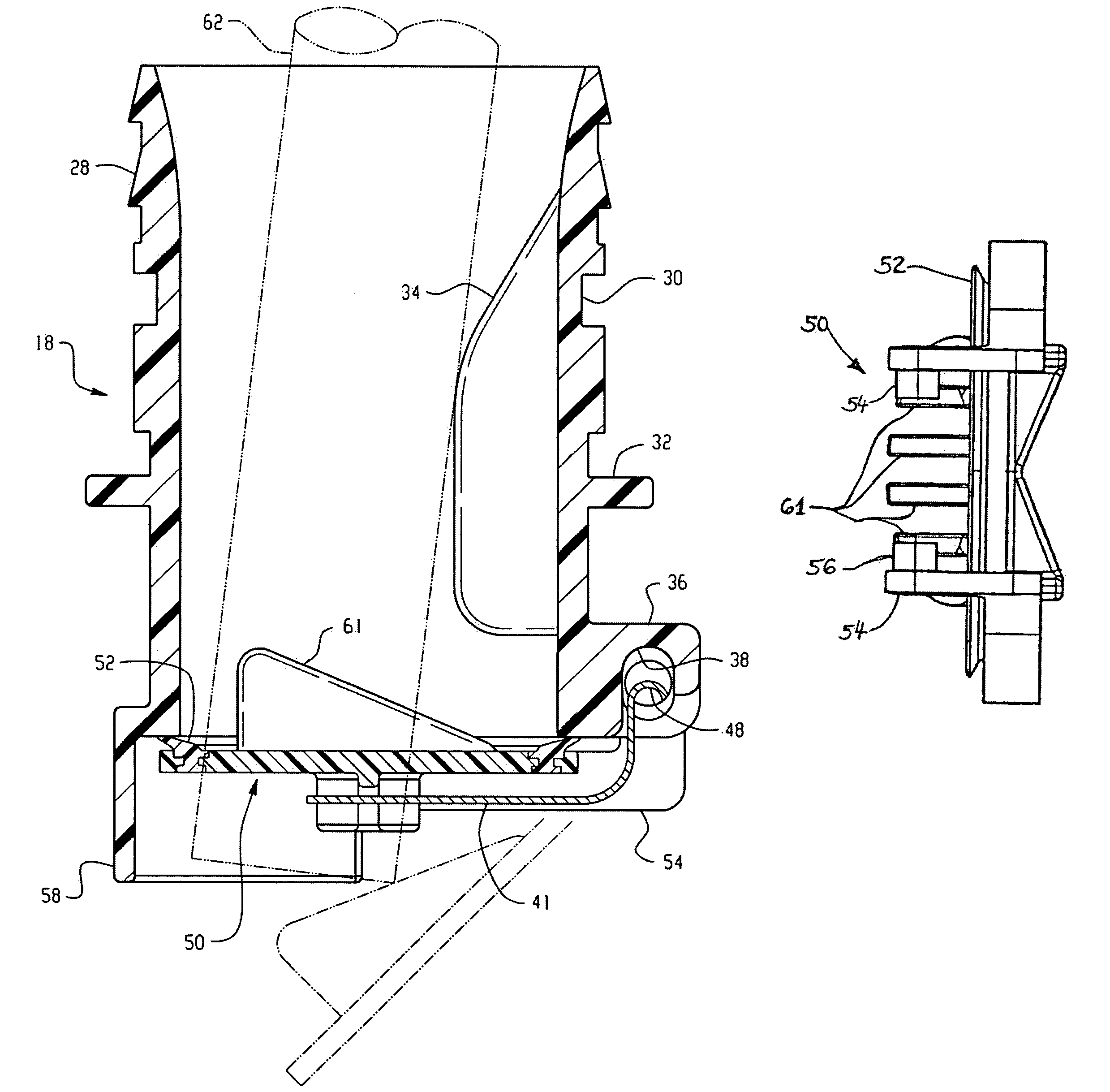

Siphonable check valve and method of making same

InactiveUS6959727B2Minimal resistanceMinimum resistance to openingCheck valvesEqualizing valvesFuel tankEngineering

A check valve for connection in a fuel tank filler tube. The valve has a tubular body with a plurality of radially inwardly extending vanes or ribs in the inlet end about a portion of the circumference. The ribs are tapered in the flow direction to deflect the end of a siphoning hose to an offset opening. A valve seat and poppet with a tapered surface are disposed downstream of the ribs, clearance apertures are formed in the side of the tubular body downstream of the valve seat. The tapered surface of the poppet, upon being opened by insertion of the end of a siphoning hose deflects the hose outwardly through the clearance apertures to facilitate further insertion into the tank. The poppet is biased normally closed by a spring.

Owner:EATON CORP

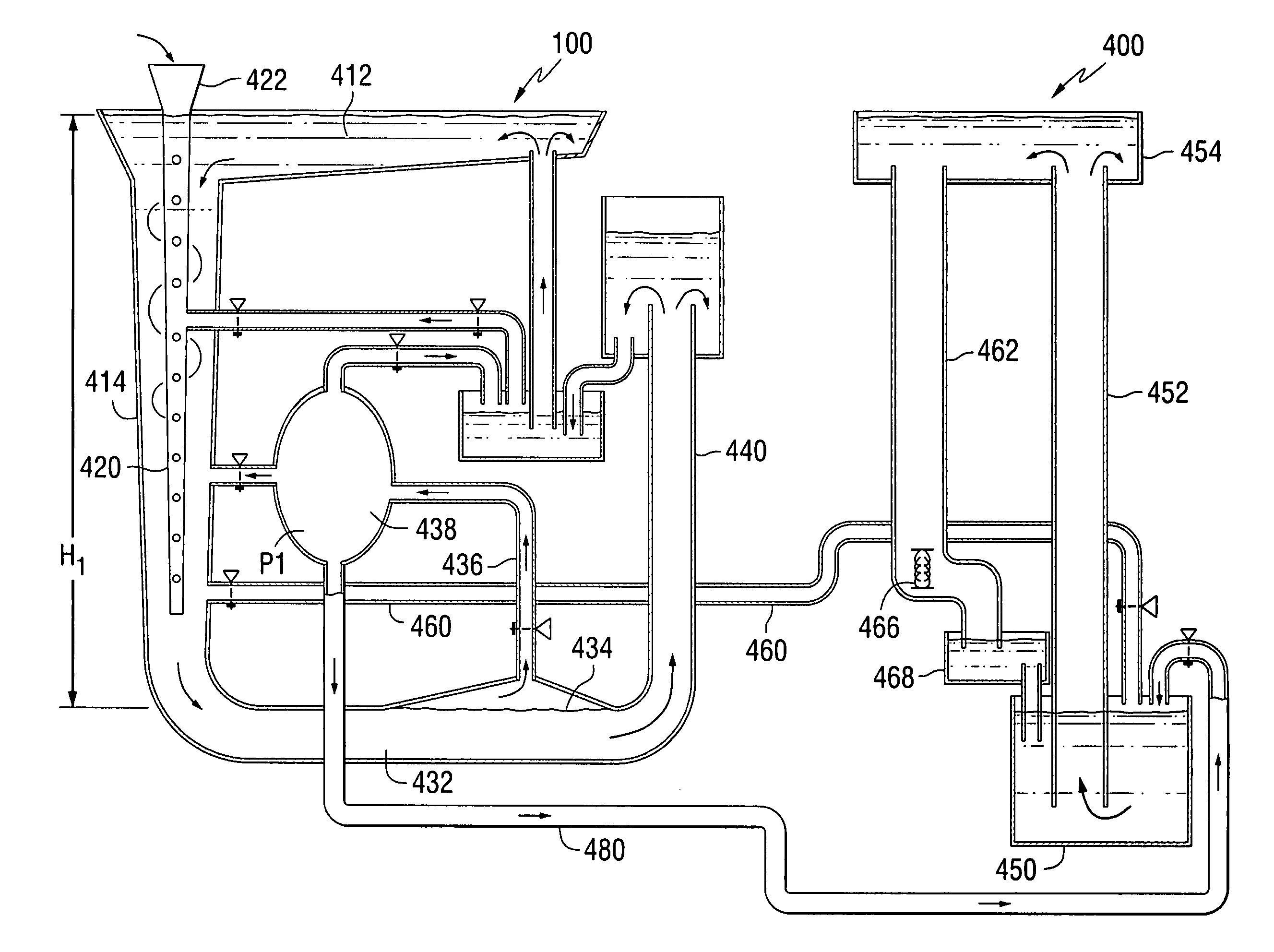

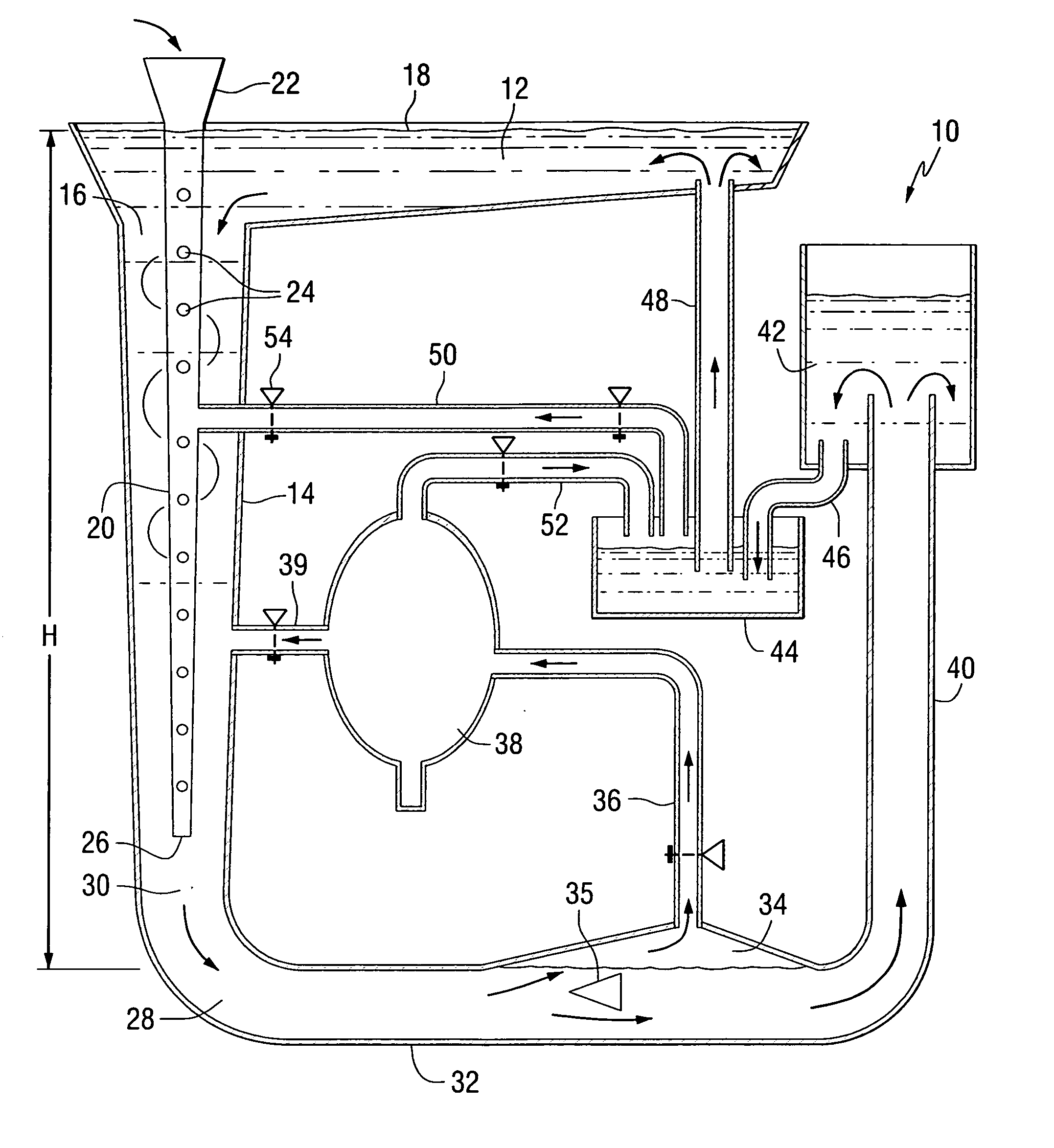

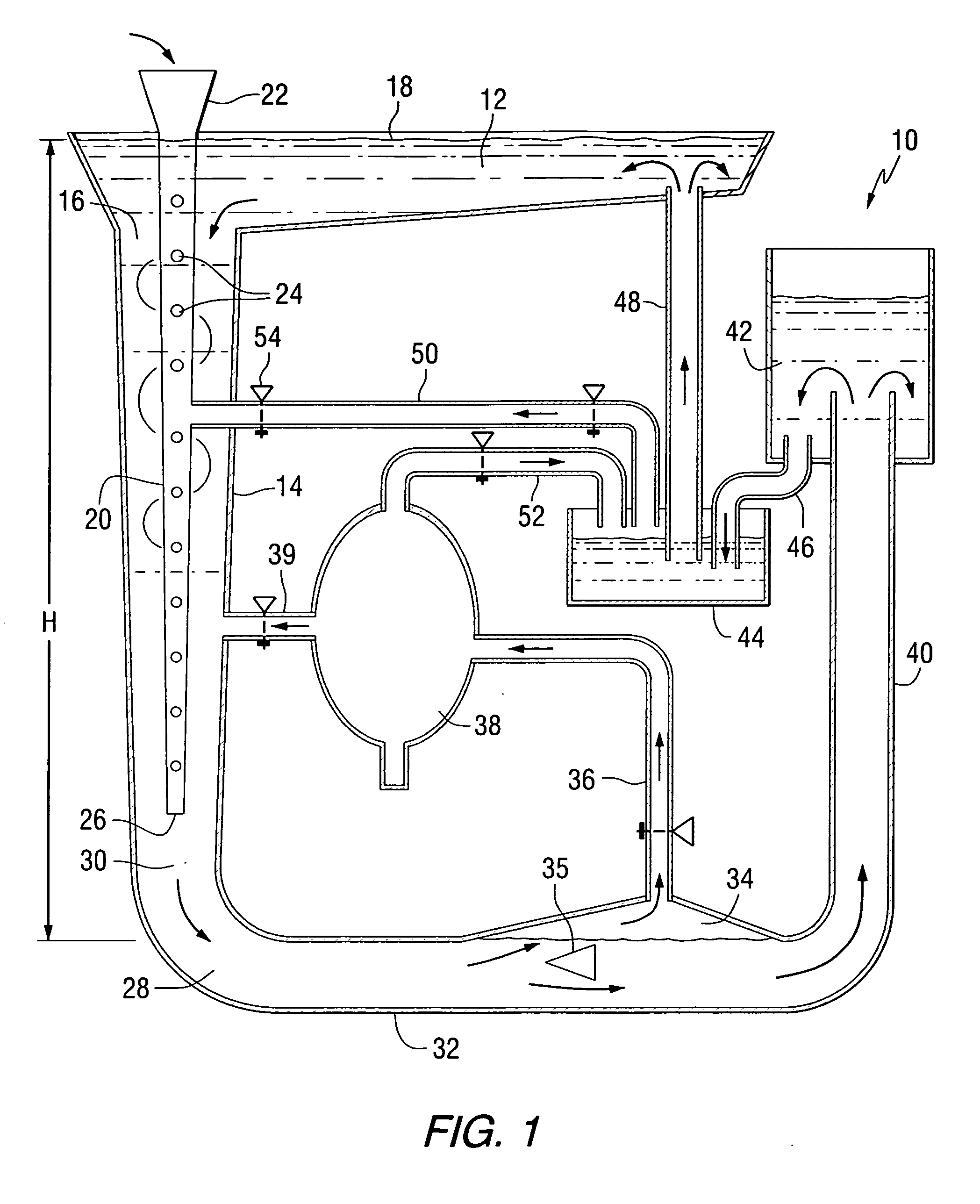

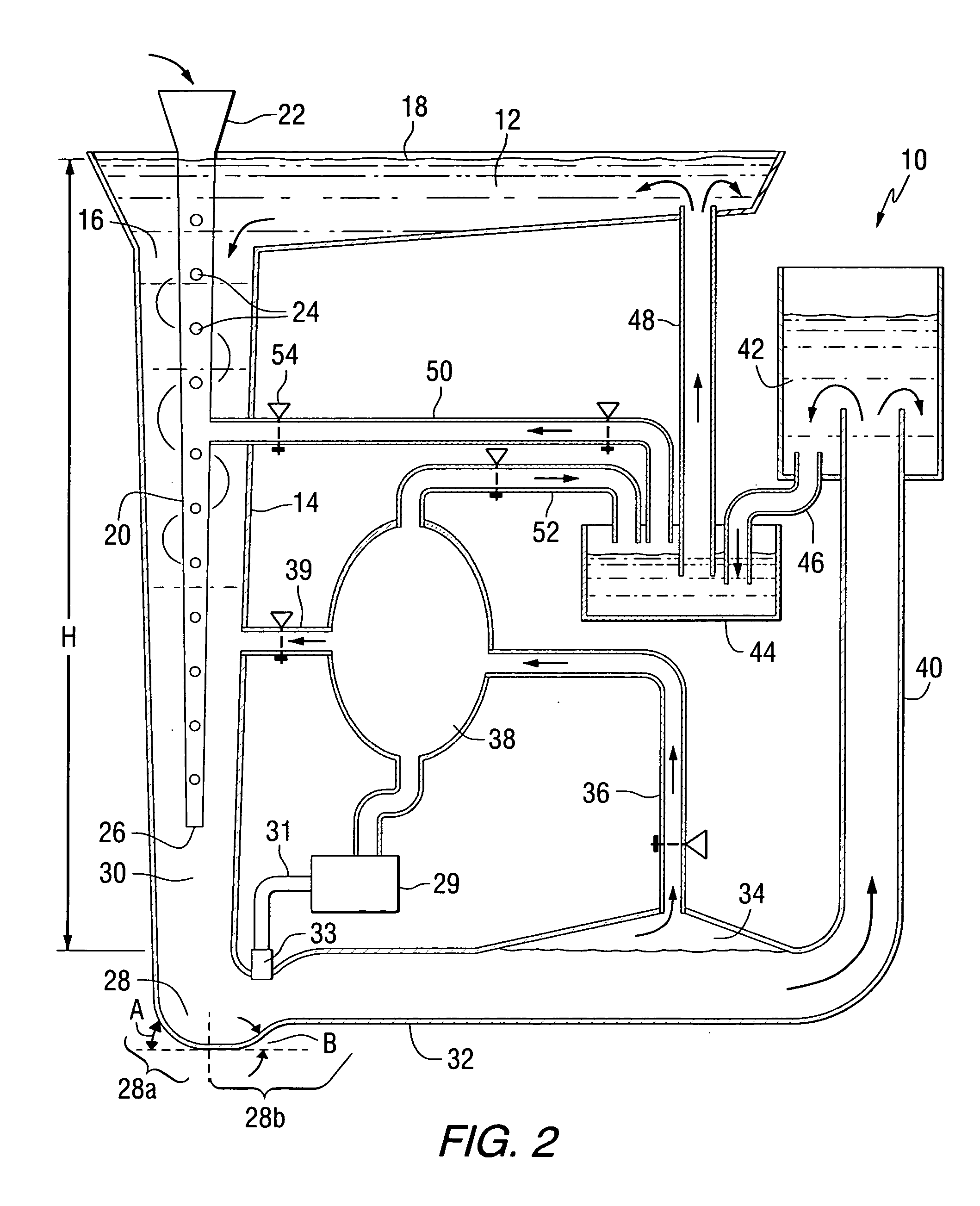

Hydraulic liquid pumping system

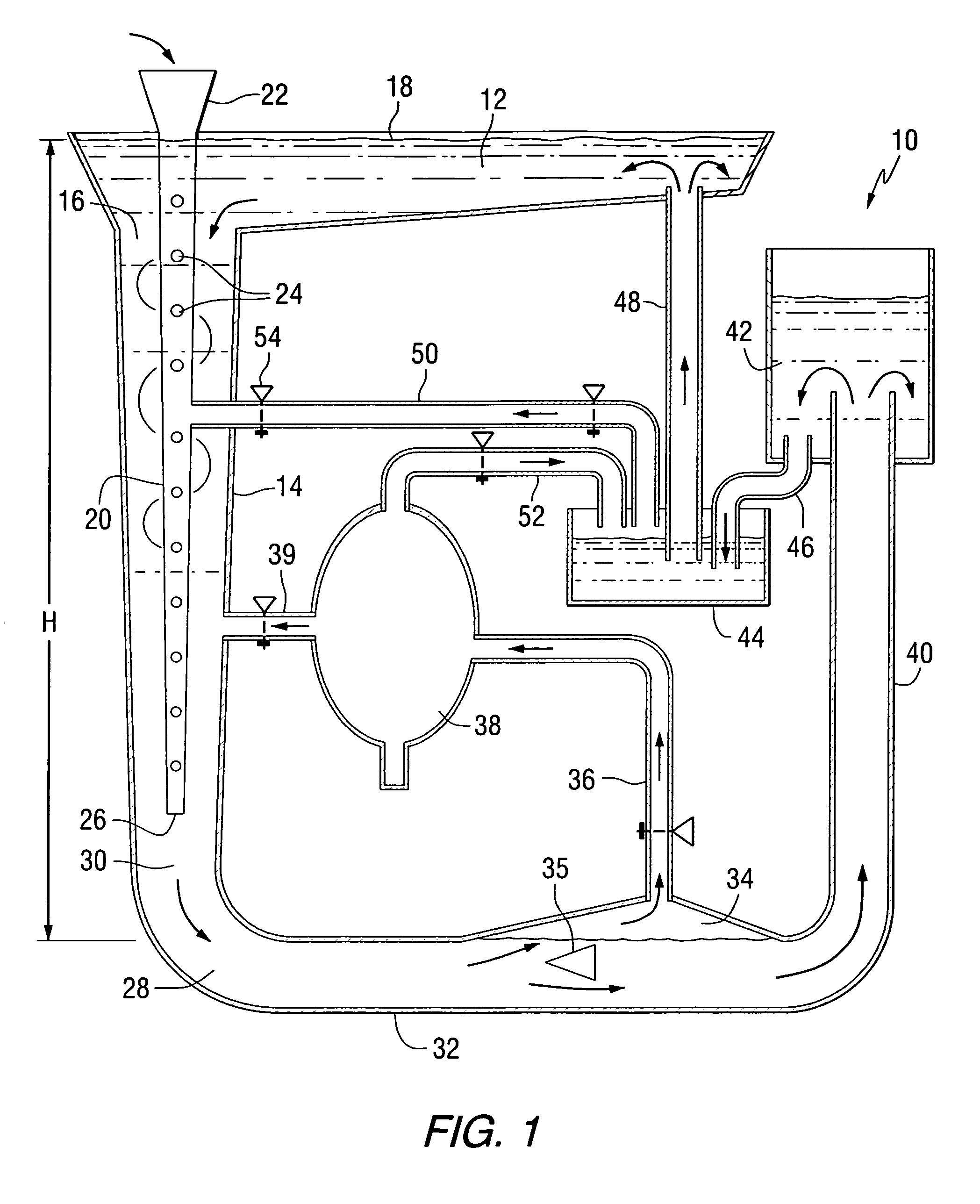

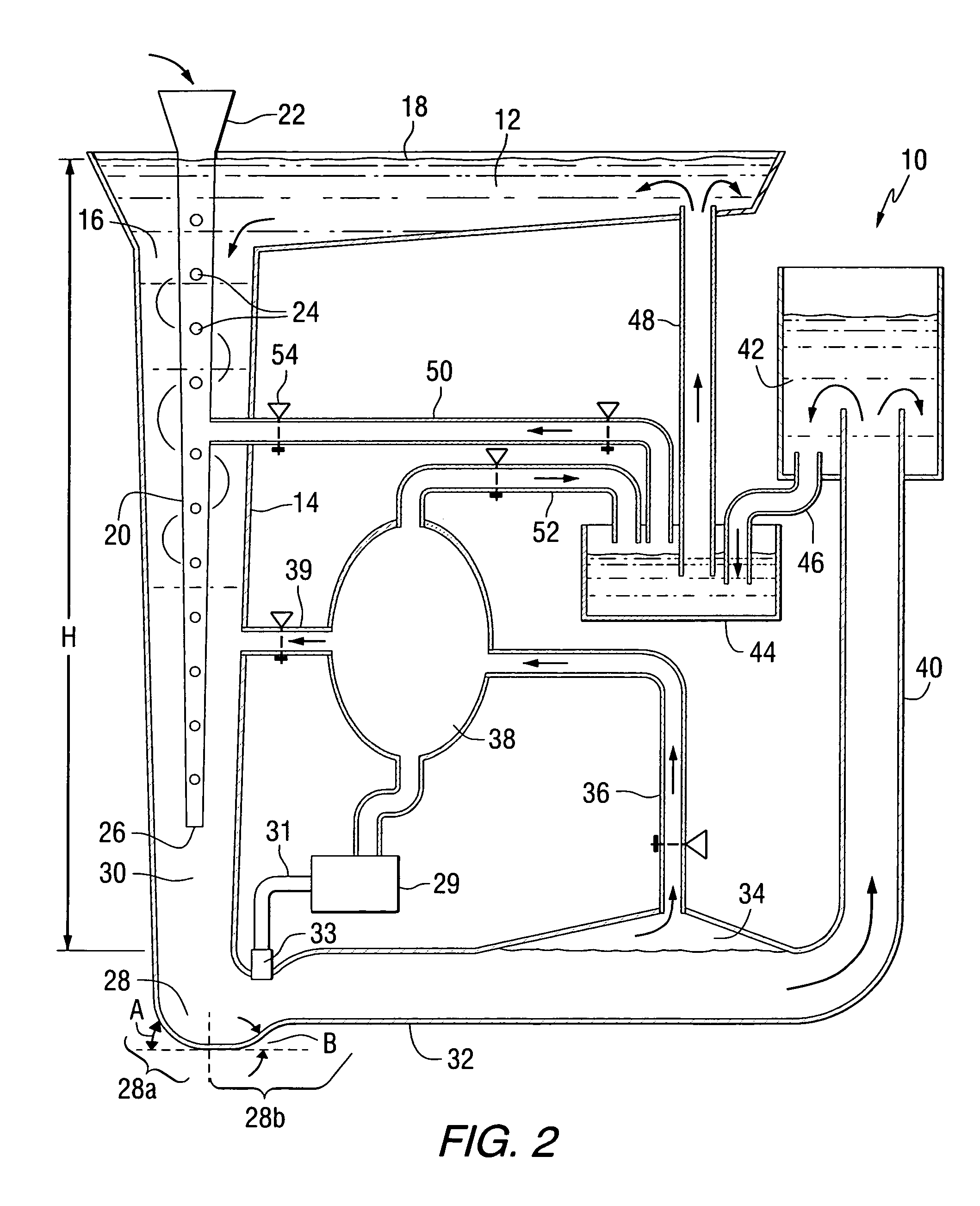

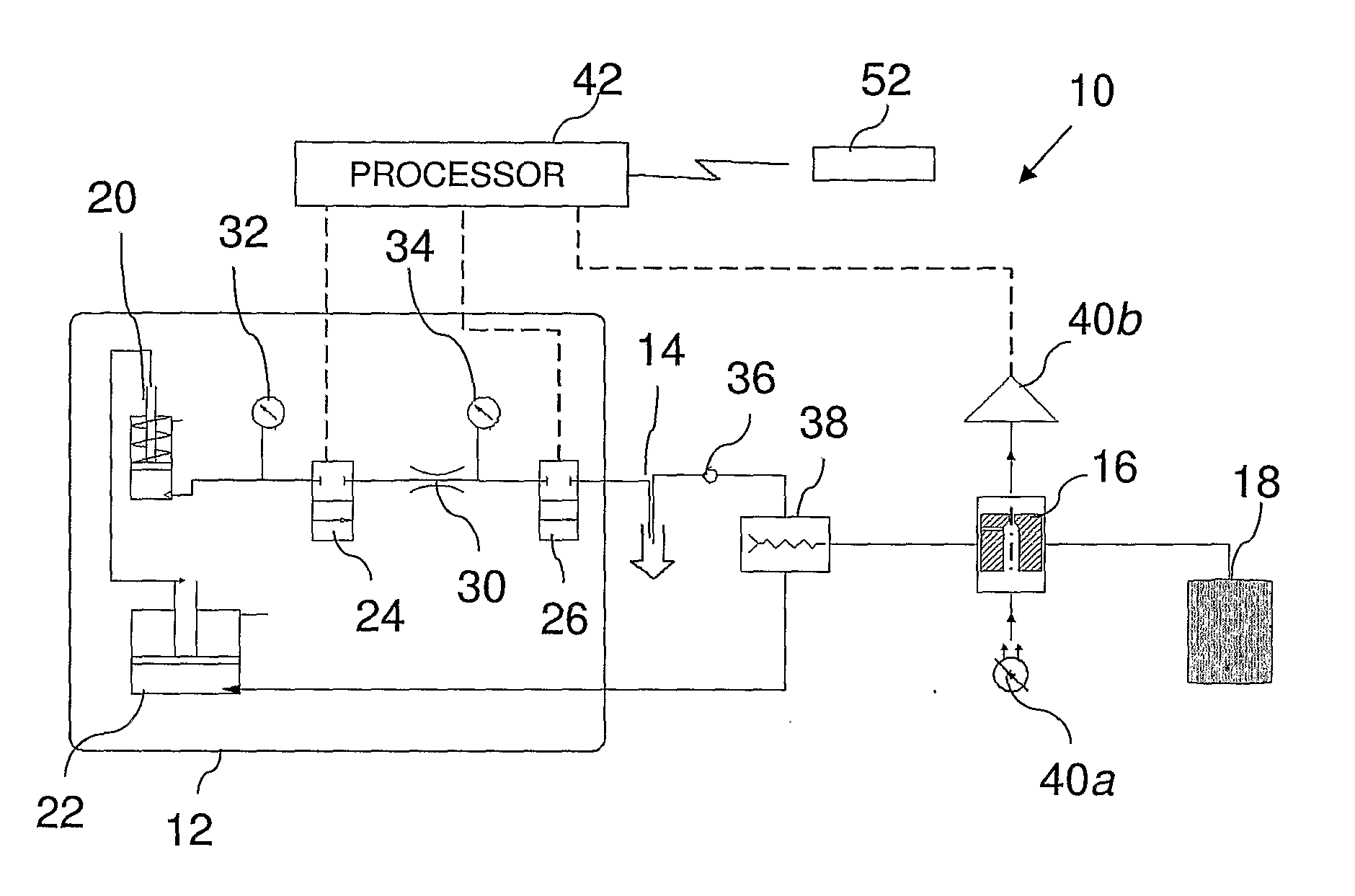

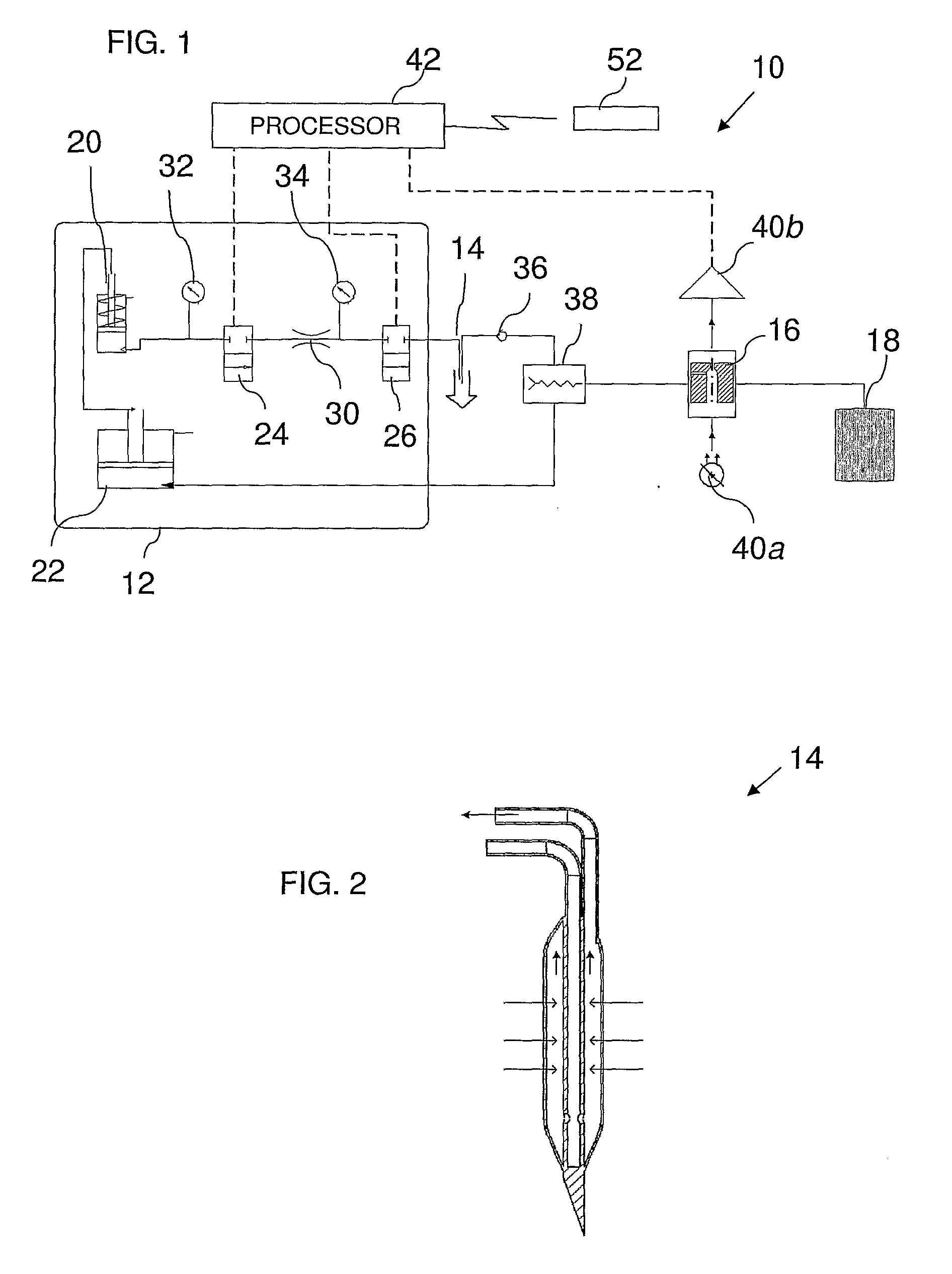

A system for concentrating gas, using the concentrated gas to pump liquid, and recycling the gas and liquid is disclosed. The system comprises a body of liquid, a down pipe in fluid communication with the body of liquid, a gas injection apparatus for introducing gas into the liquid that passes through the down pipe, a separator for separating compressed gas from the liquid, and a gas-liquid recycle loop. The down pipe and the gas injection apparatus are structured and arranged to compress the gas. The gas-liquid recycle loop comprises a compressed gas storage vessel containing the separated gas, a reservoir containing liquid separated from the compressed gas, and a gas-liquid pump. The gas-liquid pump has a gas inlet in communication with the gas storage vessel, and a fluid inlet in communication with the reservoir. The gas-liquid pump is structured and arranged for pumping the liquid back to the body of liquid and delivering the gas to the gas injection apparatus. A turbine in fluid communication with the liquid that passes through the down pipe can be optionally included. A second loop system comprising a second body of liquid, a second down pipe in fluid communication with the second body of liquid, and a second gas-liquid pump is also disclosed. The second gas-liquid pump comprises a second gas inlet in communication with a compressed gas storage area, a second liquid inlet in communication with the second liquid that passes through the second down pipe, the second gas liquid pump structured and arranged for pumping the second liquid to the second body of liquid. A second turbine in fluid communication with the liquid that passes through the second down pipe can optionally be included.

Owner:A BETTER POWER

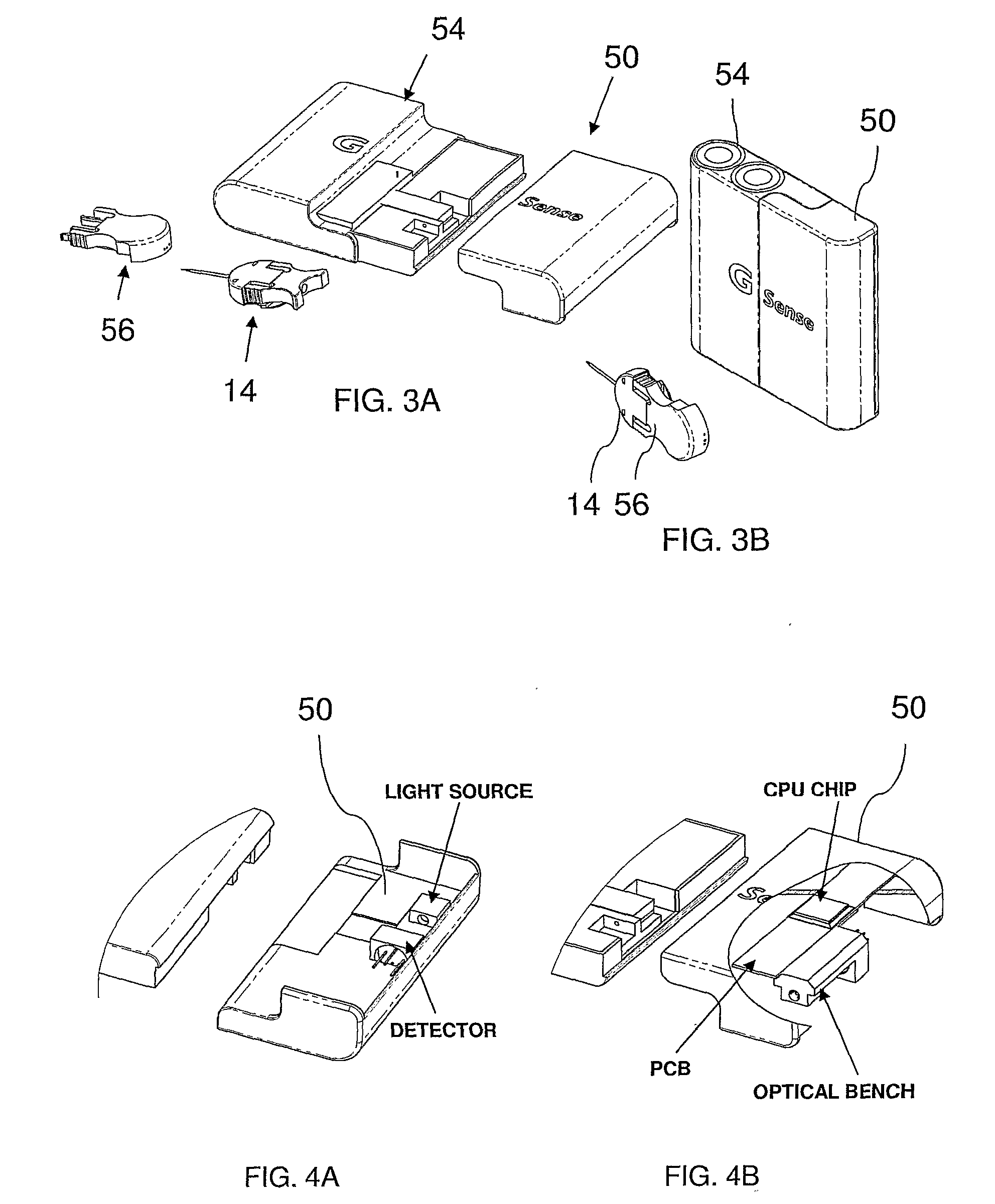

System and Method for Pseudo-Continuous Measurement of Metabolite Concentrations in a Mammalian Body

A metabolite monitoring system comprising a microdialysis probe including a semi-permeable membrane and a probe flow path passing from an inlet through a sensing volume adjacent to said semi-permeable membrane to an outlet, a fluid delivery device for delivering dialysate to said inlet; and a metabolite monitoring system associated with said outlet for monitoring a concentration of at least one metabolite in said dialysate from said microdialysis probe, wherein said fluid delivery device is configured to deliver a pulsed flow of said dialysate to said inlet.

Owner:G SENSE LTD

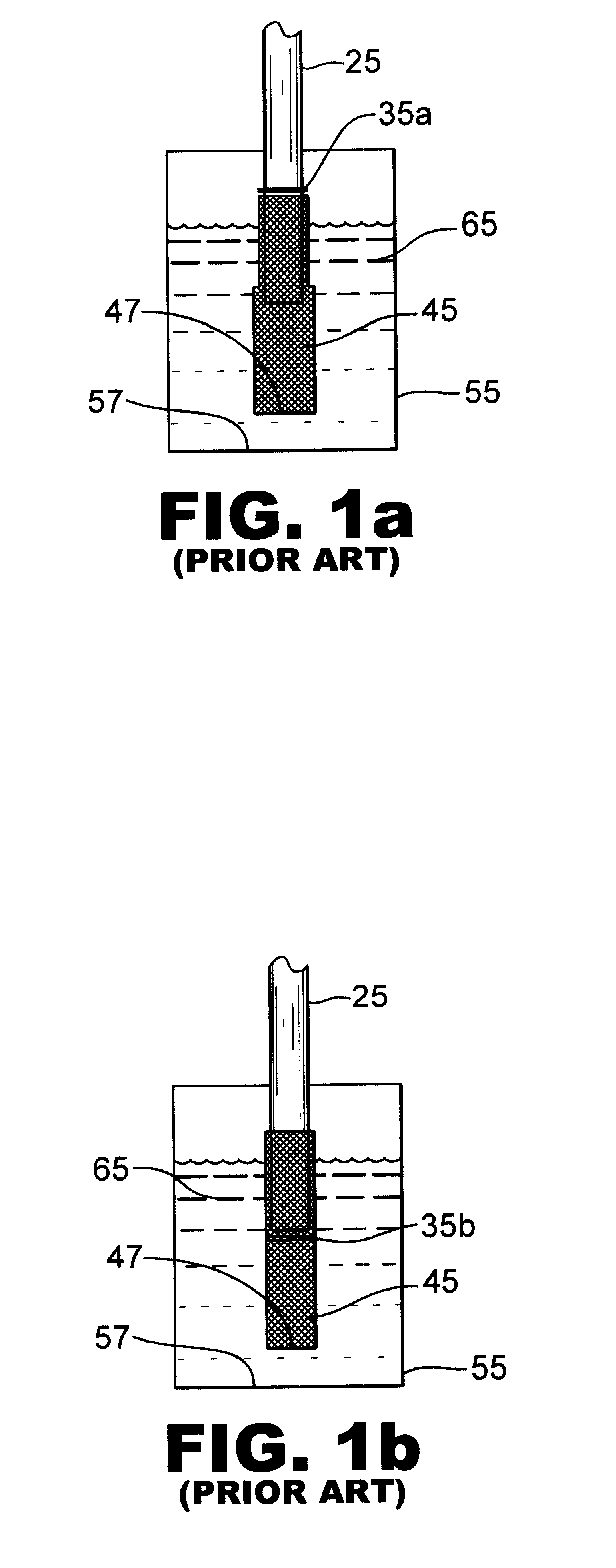

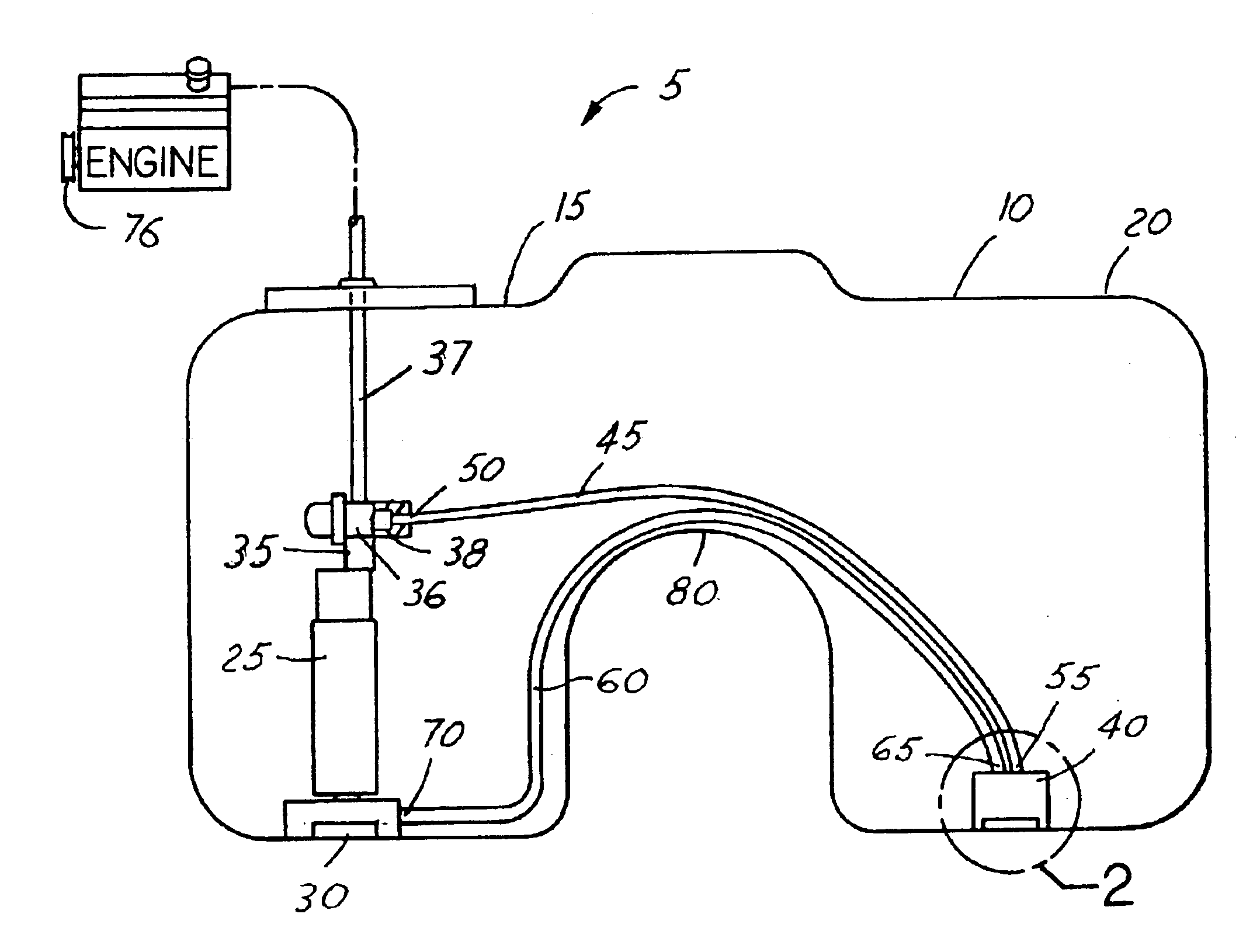

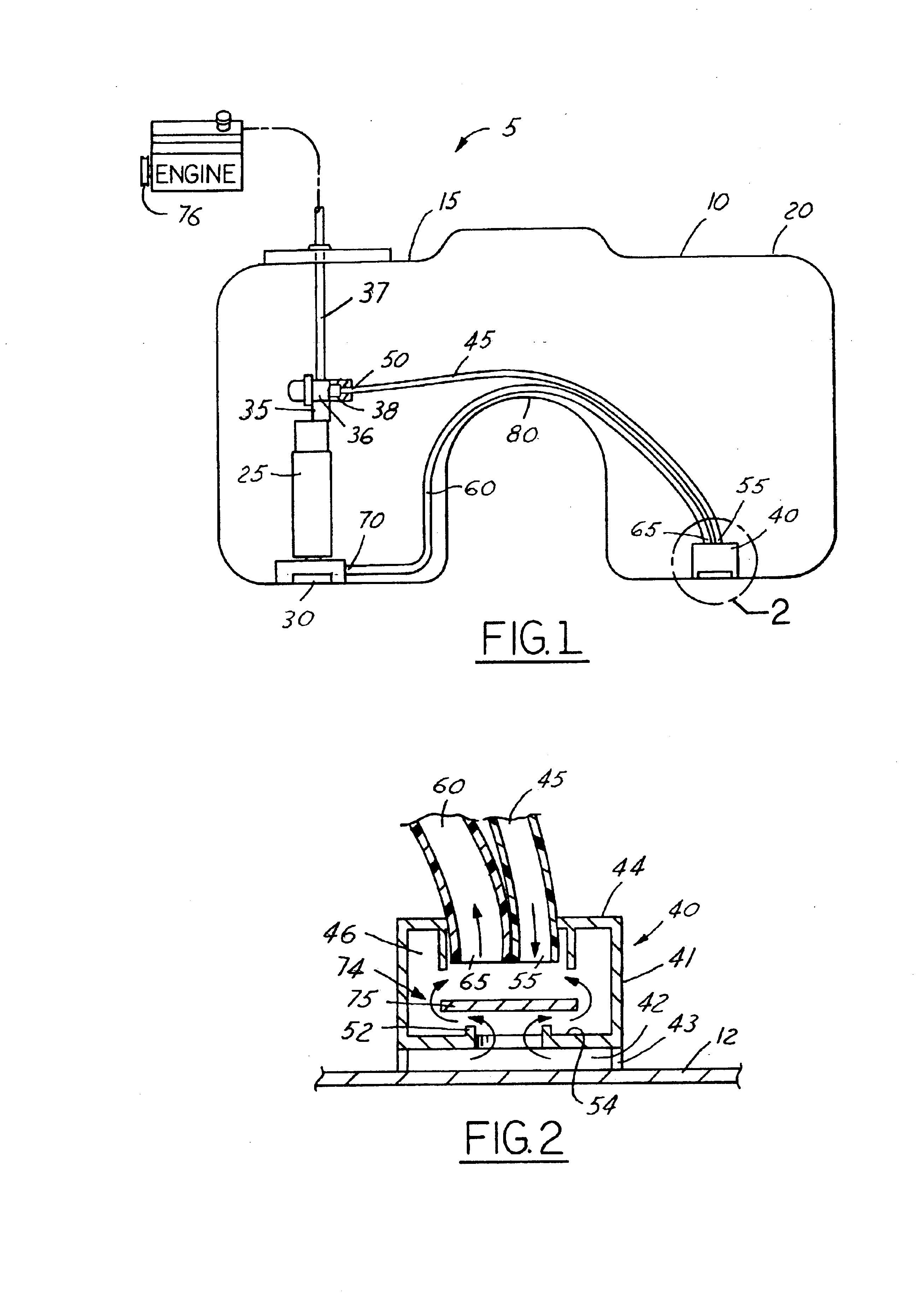

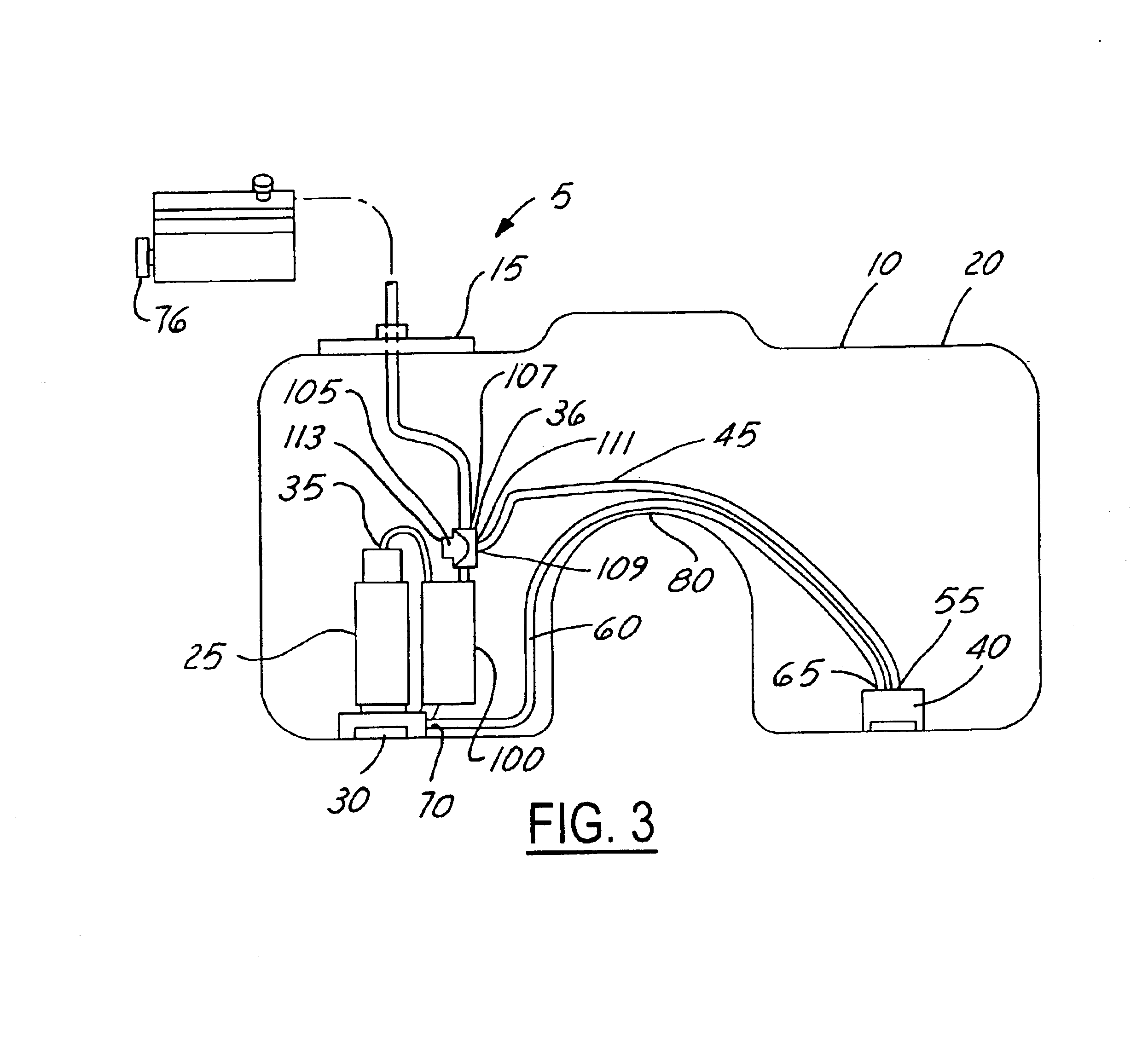

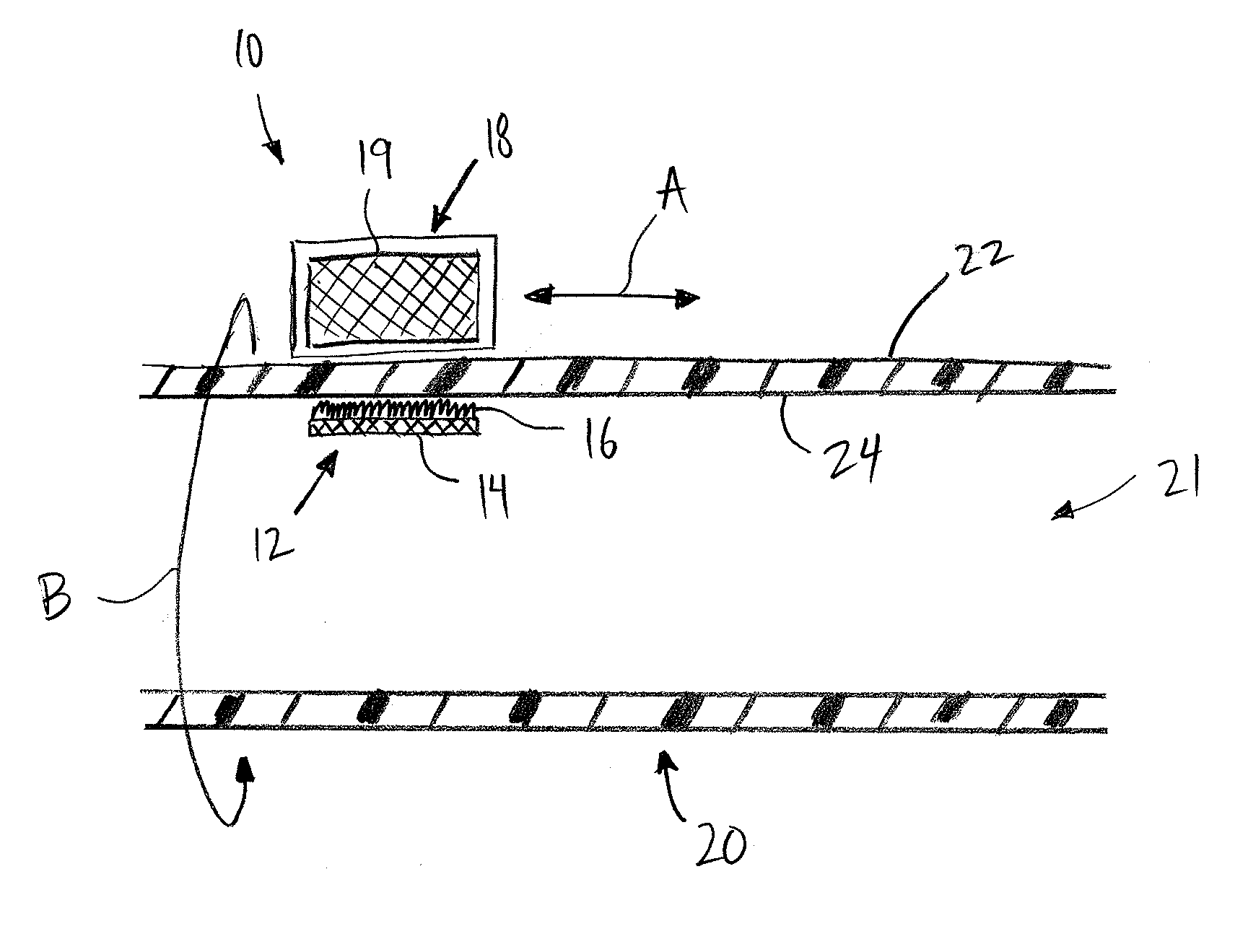

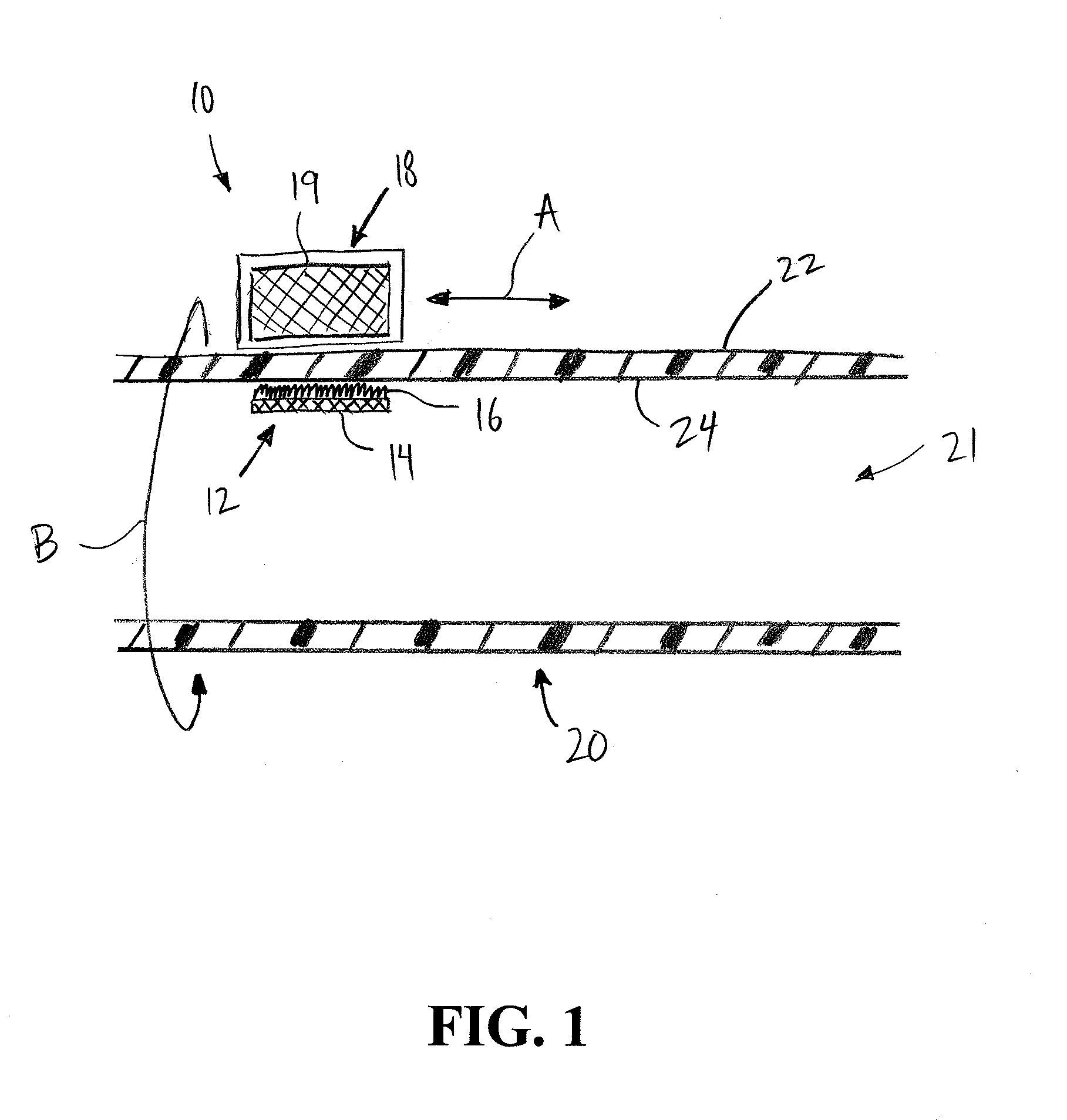

Saddle tank siphon primer

InactiveUS6871640B2Reduce flow rateReduce in quantityMachines/enginesPipeline systemsSiphonLine tubing

A fuel delivery system including a fuel tank having multiple sections. A fuel pump is disposed in a first section with an inlet for drawing liquid fuel from the first section and an outlet for supplying the fuel to an engine and to a pick-up disposed in the second section. A siphon line is connected to the pick-up at one end and terminates in the first section at another end. A fuel inlet of the pickup communicates with the siphon line through a valve member that is actuated to open and closed positions. In operation, the fuel pump provides a flow of liquid fuel to the pick-up to purge and prime the siphon line which normally maintains a substantially equal liquid fuel level in the first and second sections of the fuel tank. In some conditions, the valve closes to prevent reverse flow of fuel from the first section to the second section of the tank.

Owner:TI GRP AUTOMOTIVE SYST LLC

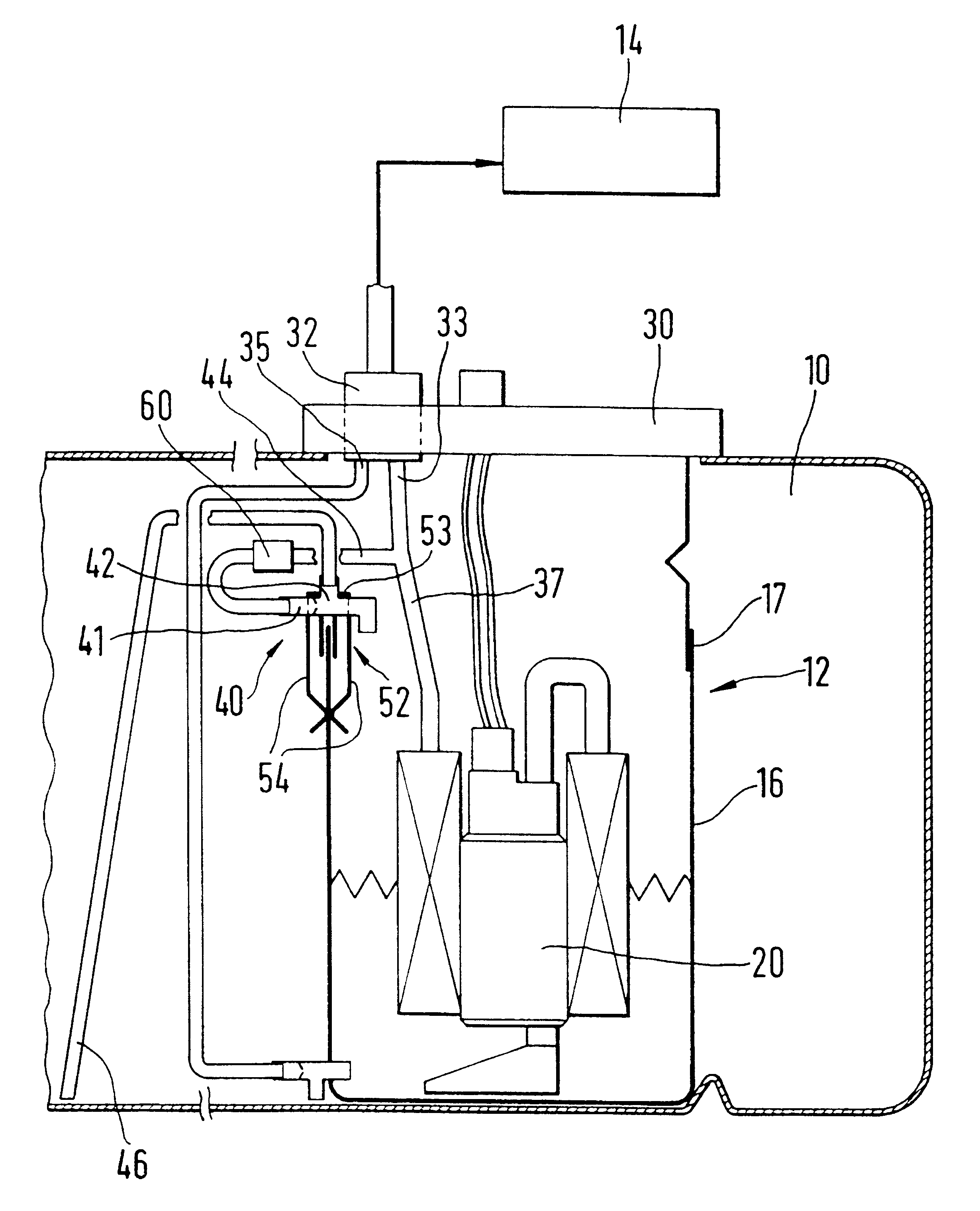

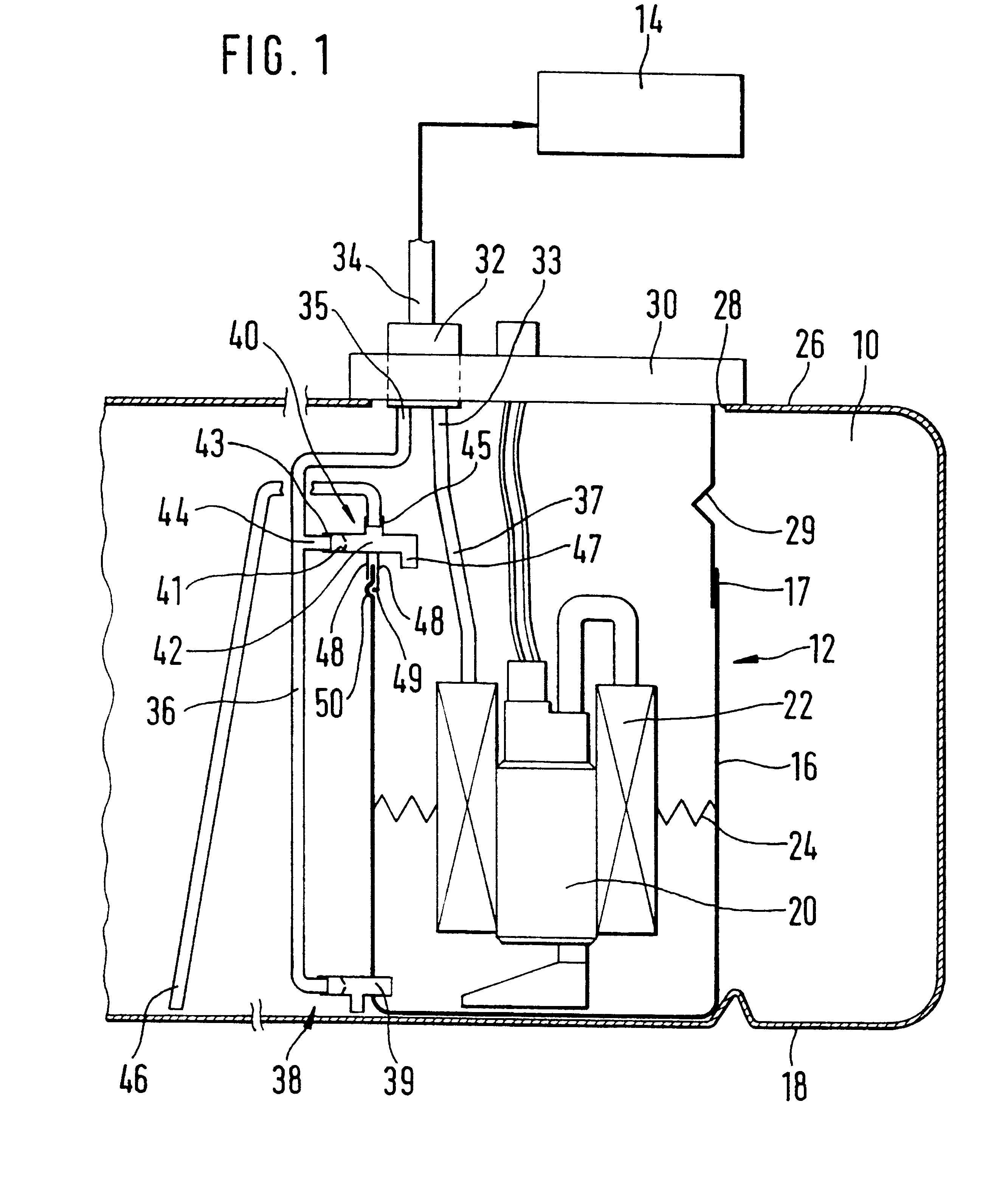

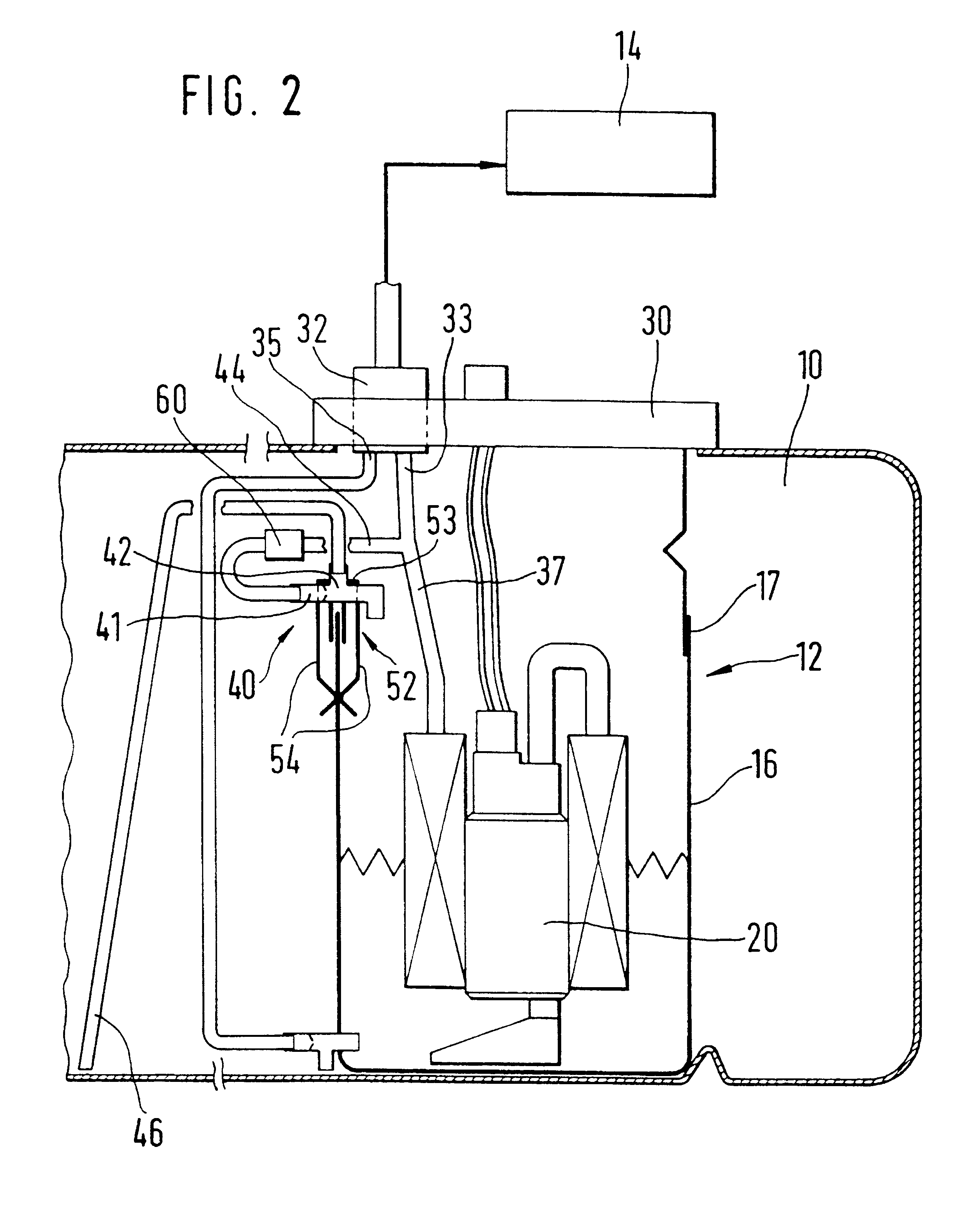

Fuel delivery device

The fuel delivery device (12) has a receptacle (16) arranged in a storage tank (10) and a delivery unit (20) delivering fuel from the receptacle (16) to the internal combustion engine (14) of a motor vehicle. Further, there is provided at least one suction jet pump (40) which delivers fuel from the storage tank (10) into the receptacle (16). The suction jet pump (40) is fastened to an upper edge area (17) of the receptacle (16) as a separate constructional unit. The suction jet pump (40) is formed by a constructional unit having a propelling nozzle (41), a connection (43) for a propelling line (44), which connection (43) opens into the propelling nozzle (41), a mixing pipe (42) following the propelling nozzle (41), and a connection (45) for a suction line (46), which connection (45) opens into the mixing pipe (42). Two walls (48) located at a distance from one another project downward from the constructional unit (40), and the constructional unit (40) is mounted on the edge (17) of the receptacle (16) from the top, wherein the edge (17) of the receptacle (16) is introduced between the two walls (48). The suction line (46) connected to the suction jet pump (40) opens into the storage tank (10) remote of the receptacle (16).

Owner:ROBERT BOSCH GMBH

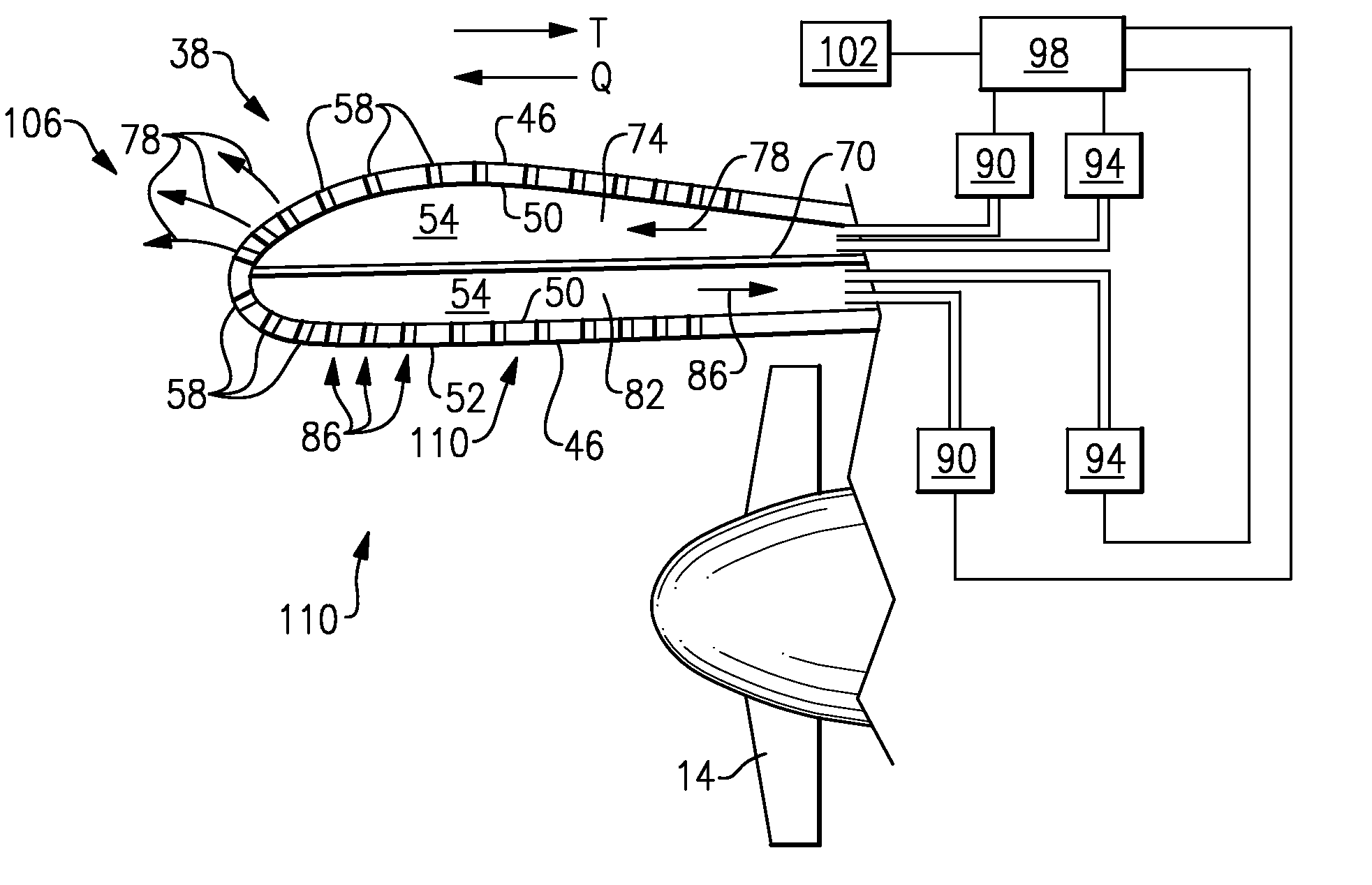

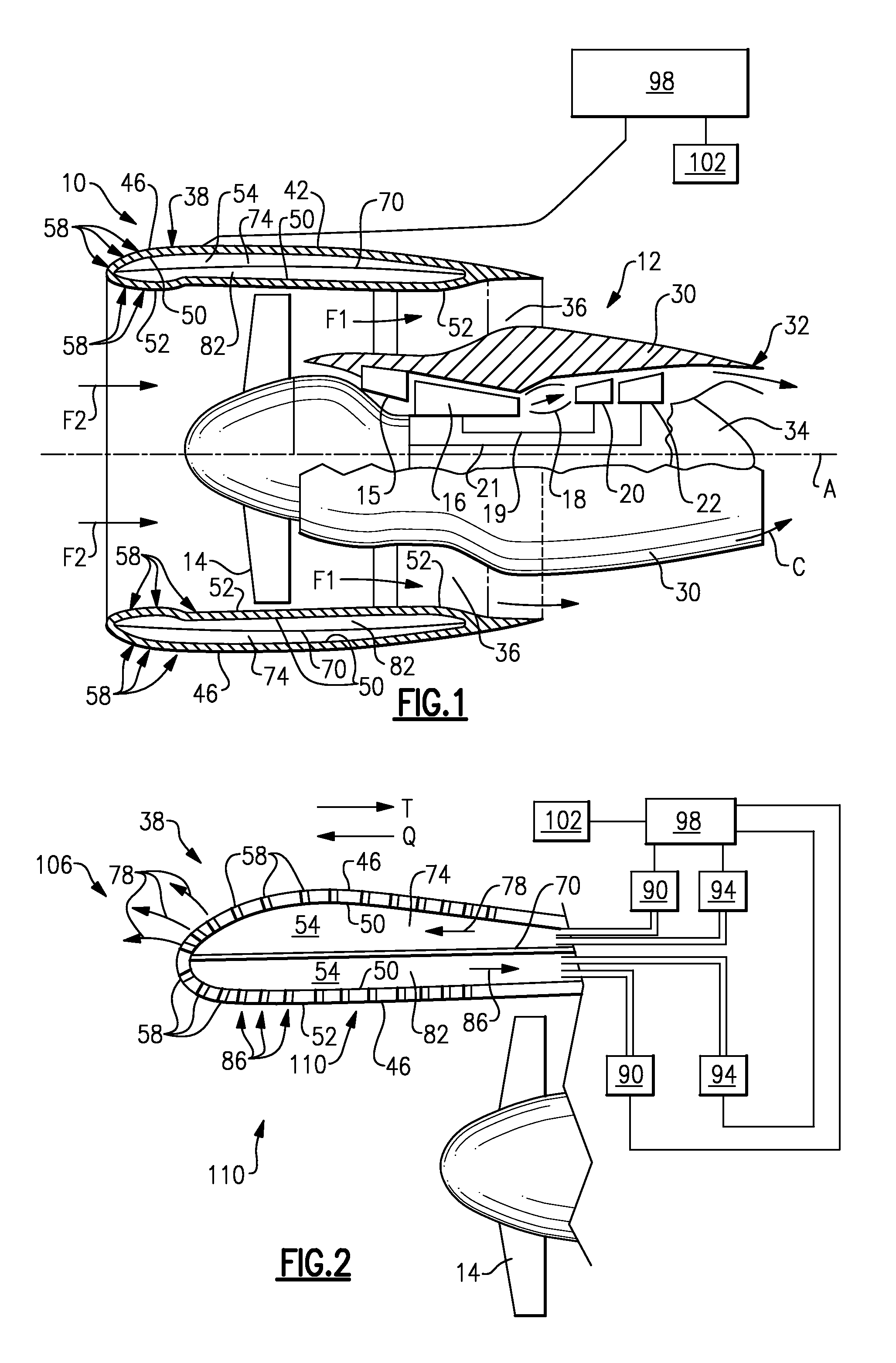

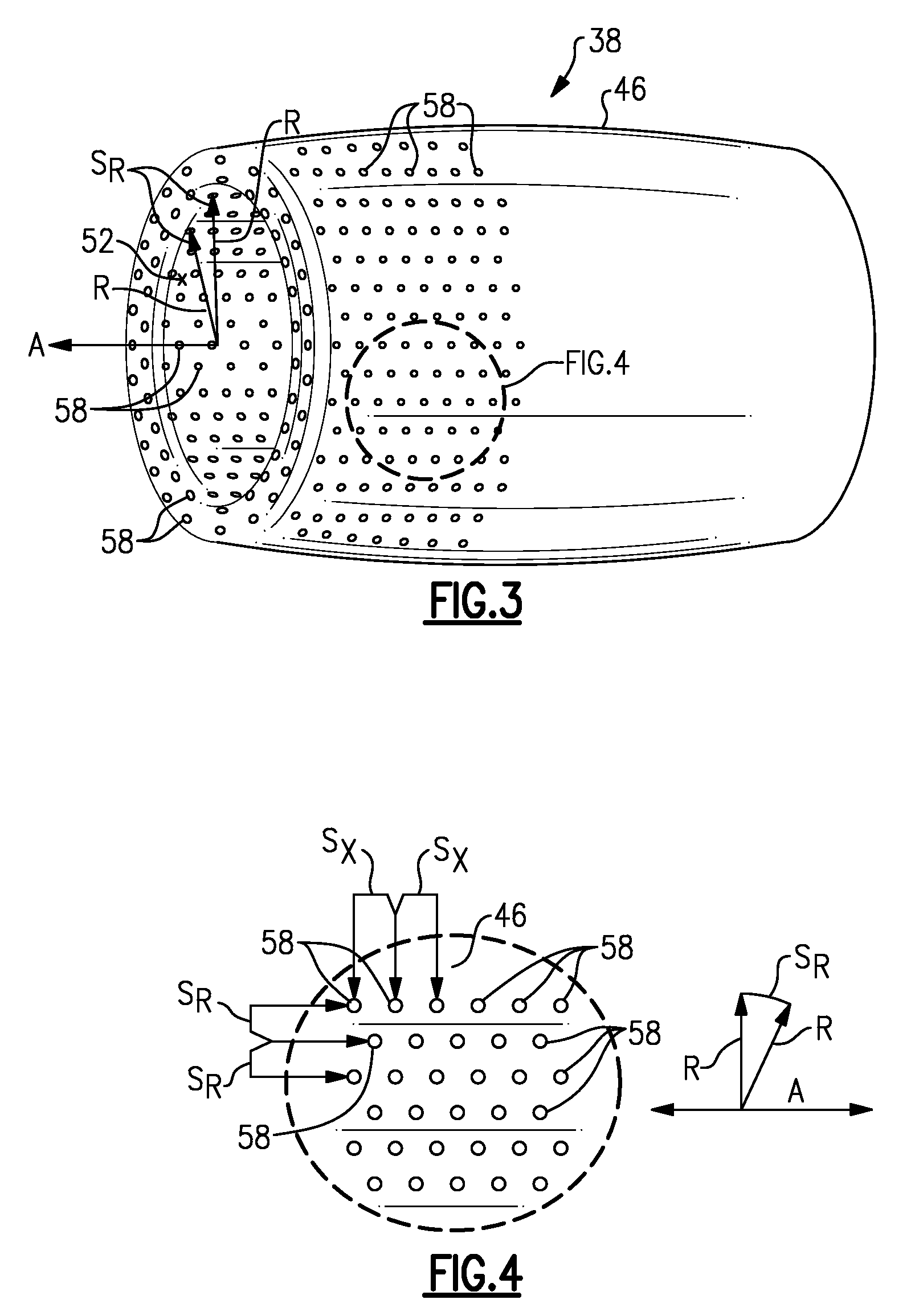

Nacelle Flow Assembly

A nacelle assembly for a turbine engine has a cowl for a turbine engine. The cowl has a first surface spaced from a second surface. The second surface defines defining a bypass flow passage. A flow volume is spaced between the first surface and the second surface. A plurality of holes are disposed on the cowl. Each of the plurality of holes are configured to alter local air pressure about one of the first surface and the second surface of the cowl. The plurality of holes are in communication with the flow volume.

Owner:RAYTHEON TECH CORP

Hydraulic liquid pumping system

A system for concentrating gas, using the concentrated gas to pump liquid, and recycling the gas and liquid is disclosed. The system comprises a body of liquid, a down pipe in fluid communication with the body of liquid, a gas injection apparatus for introducing gas into the liquid that passes through the down pipe, a separator for separating compressed gas from the liquid, and a gas-liquid recycle loop. The down pipe and the gas injection apparatus are structured and arranged to compress the gas. The gas-liquid recycle loop comprises a compressed gas storage vessel containing the separated gas, a reservoir containing liquid separated from the compressed gas, and a gas-liquid pump. The gas-liquid pump has a gas inlet in communication with the gas storage vessel, and a fluid inlet in communication with the reservoir. The gas-liquid pump is structured and arranged for pumping the liquid back to the body of liquid and delivering the gas to the gas injection apparatus. A turbine in fluid communication with the liquid that passes through the down pipe can be optionally included. A second loop system comprising a second body of liquid, a second down pipe in fluid communication with the second body of liquid, and a second gas-liquid pump is also disclosed. The second gas-liquid pump comprises a second gas inlet in communication with a compressed gas storage area, a second liquid inlet in communication with the second liquid that passes through the second down pipe, the second gas liquid pump structured and arranged for pumping the second liquid to the second body of liquid. A second turbine in fluid communication with the liquid that passes through the second down pipe can optionally be included.

Owner:A BETTER POWER

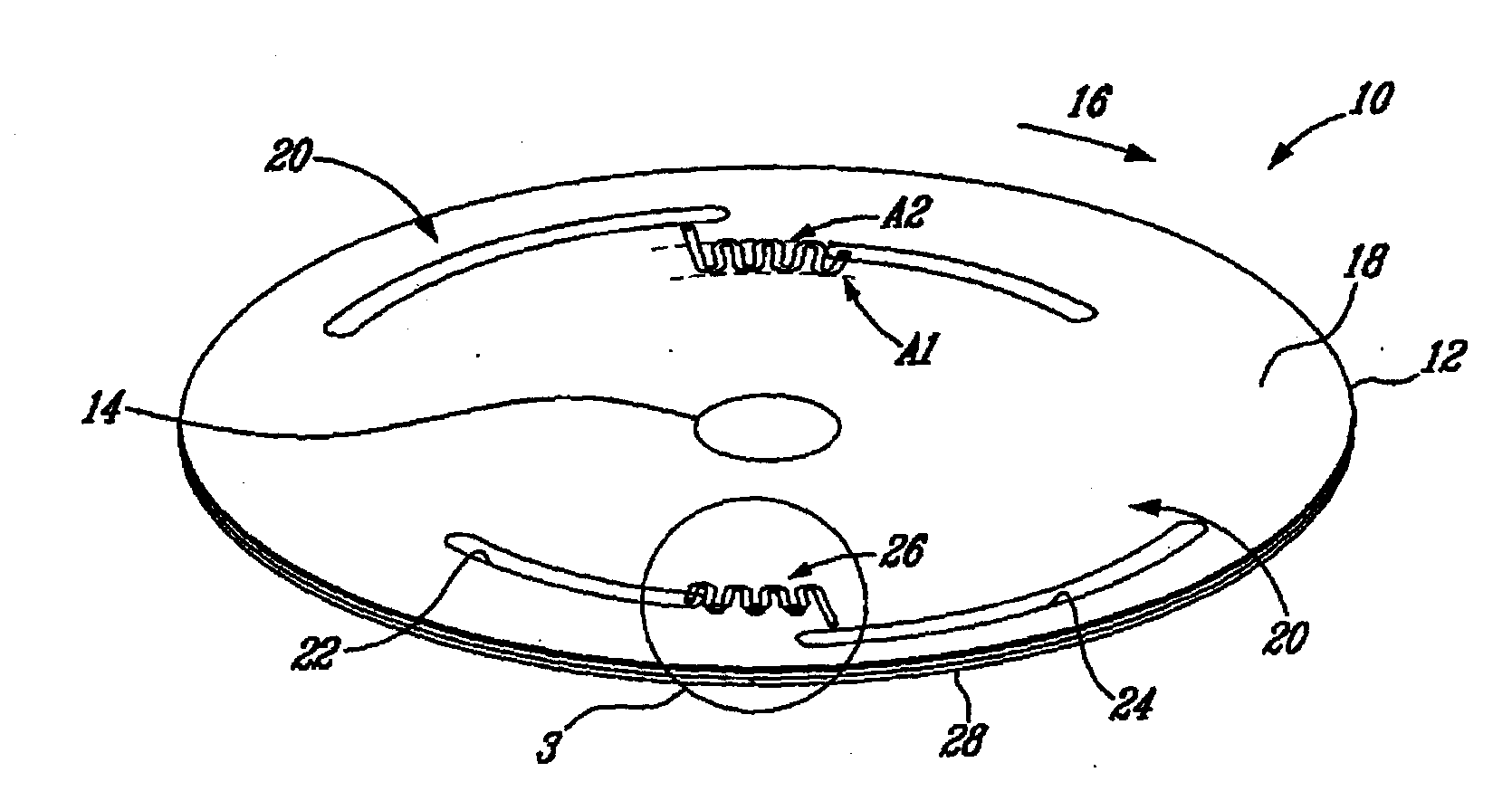

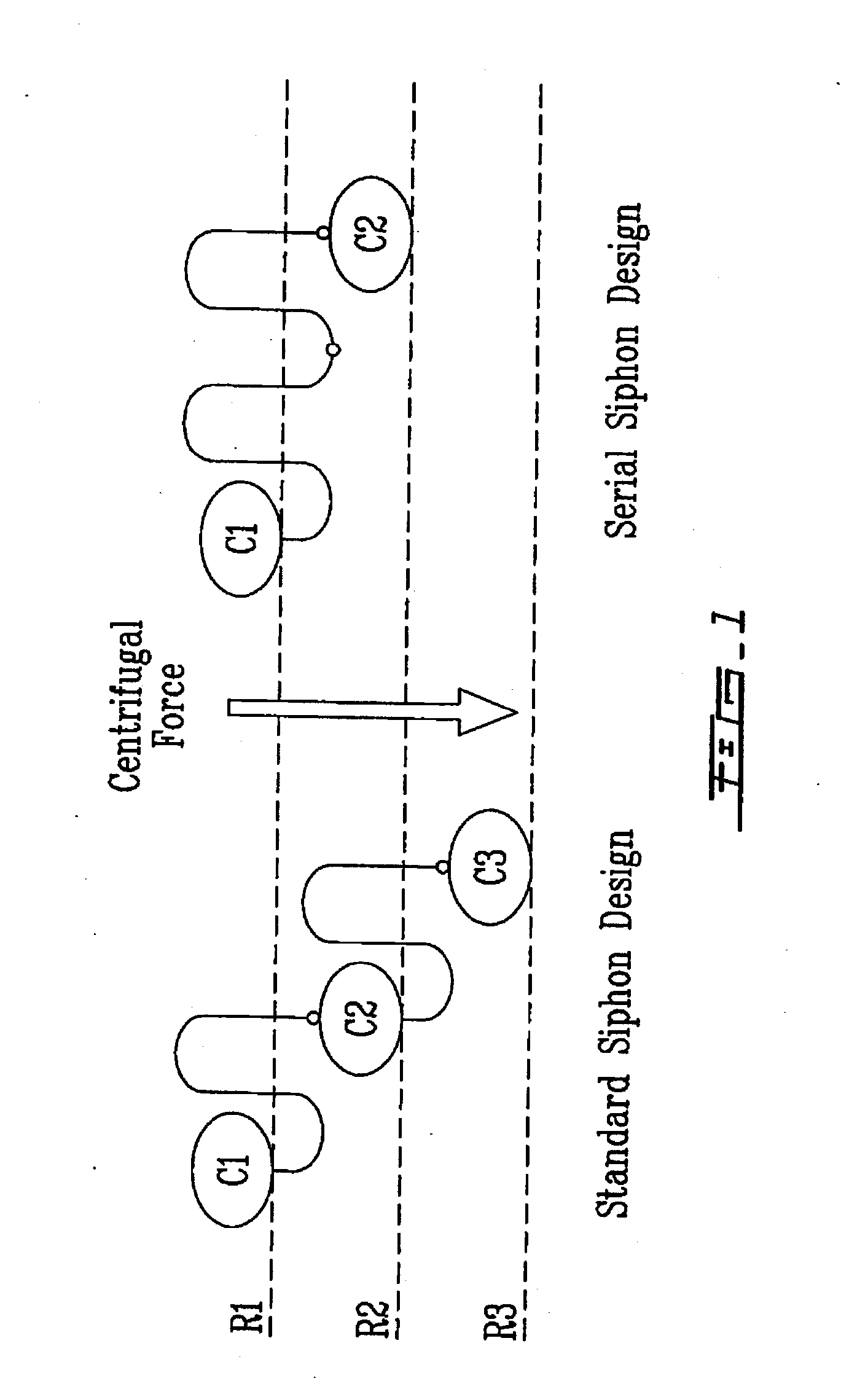

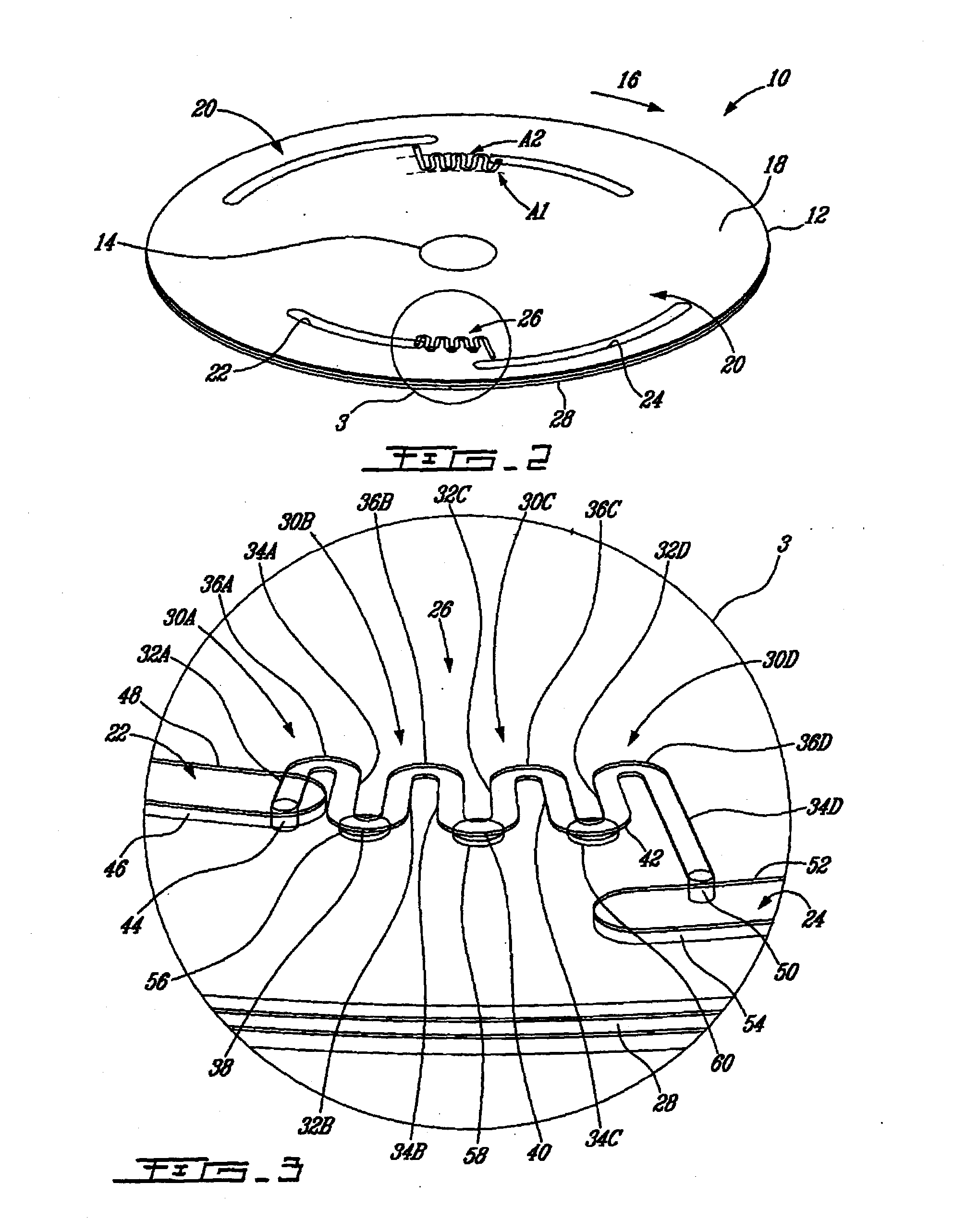

Serial siphon valves for fluidic or microfluidic devices

ActiveUS20110094600A1Save radial spaceMore featureCircuit elementsMaterial analysis by optical meansSiphonFluid system

Methods and devices using a co-radial arrangement of serial siphon structures composed of siphon valves each separated by a capillary valve to save radial space in a fluidic system. Such serial siphon valves allow to sequentially distribute liquids in a fluidic system upon application of successive centripetal accelerations and decelerations applied to a rotary platform.

Owner:RGT UNIV OF CALIFORNIA +1

Assembling a siphonable filler tube with a check valve on a fuel tank

A fuel filler tube assembly including a one-way valve or check valve. The tube assembly is adaptable for pre-assembly on either a metal or plastic fuel tank and employs a common check valve with an adapter tube for plastic tanks. The valve employs a flapper with spaced ribs for deflecting a siphon hose away from the valve seal; and, the ribs are spaced to maintain the flow stream of he fuel during refueling and facilitating opening of the flapper.

Owner:EATON INTELLIGENT POWER LIMITED

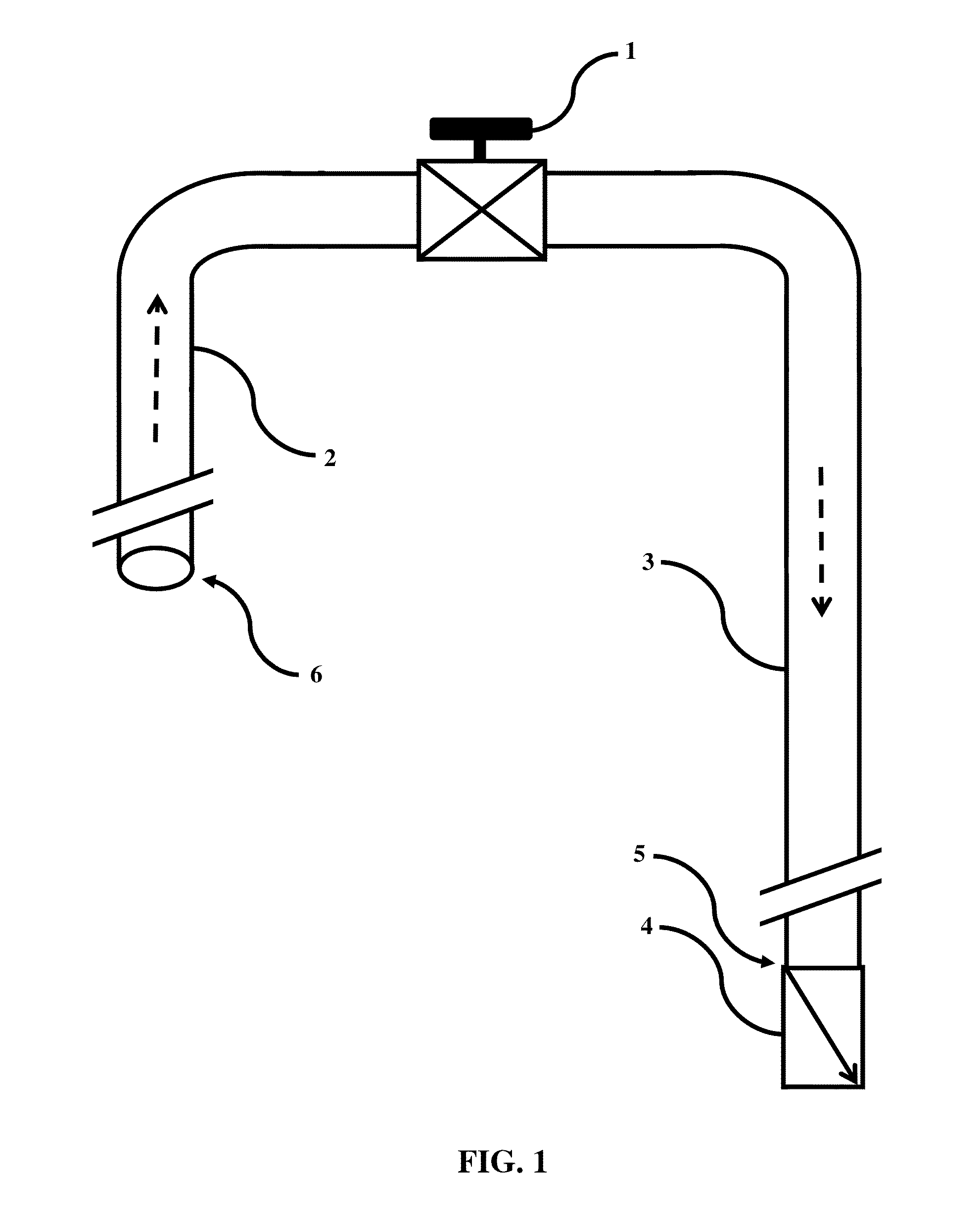

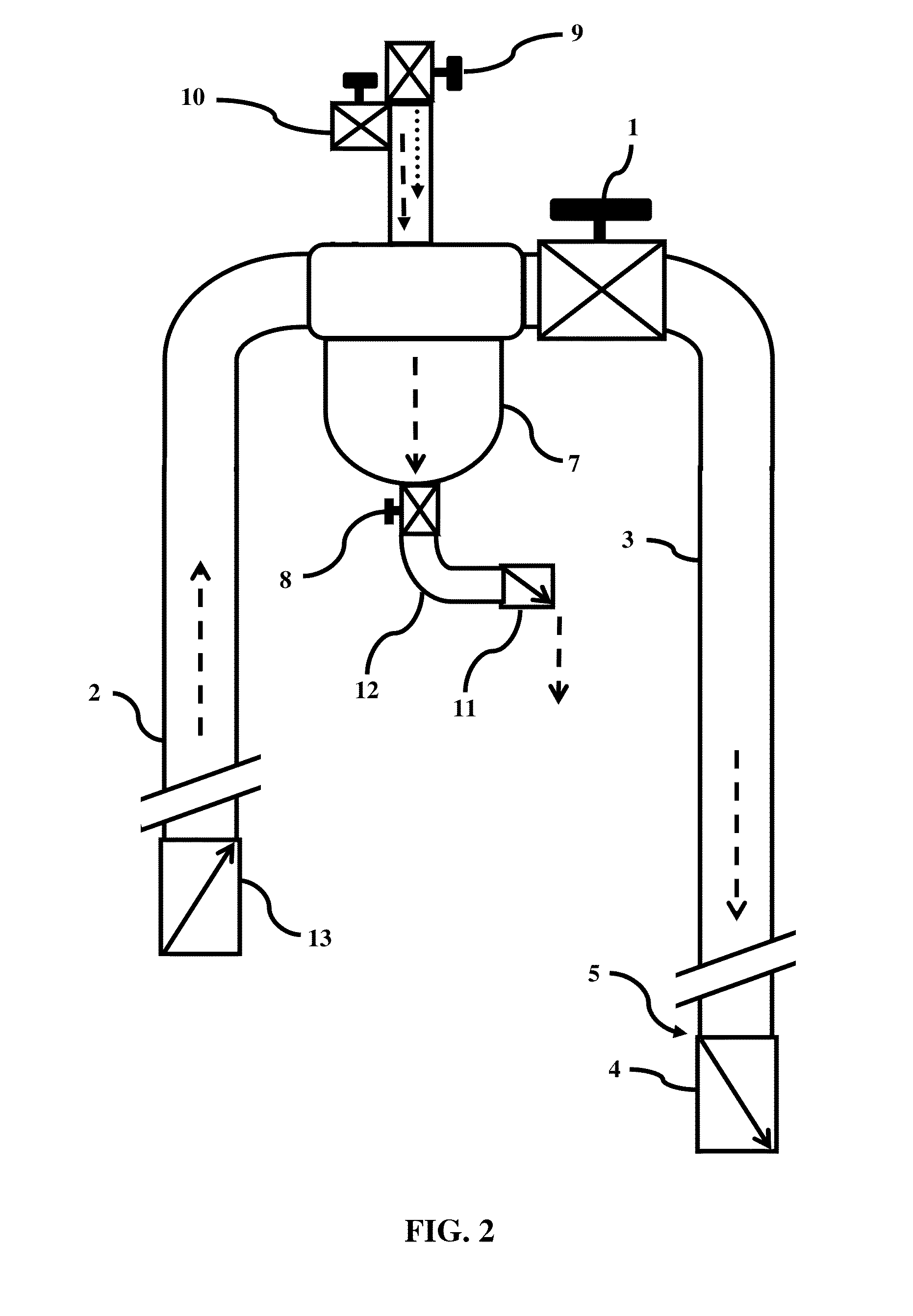

Siphon pump technology and apparatuses

Apparatuses to enable single-point valve control of siphons, siphon pumps, metering siphon pumps, and turbine siphon pumps include terminal anti-backflow valves, a system flow control valve, a metering chamber, a self-regulating chamber, and a siphon turbine. The terminal anti-backflow valves provide automatically closable systems without further priming after an initial prime. The system flow control valve consolidates functions for priming, pumping, dispensing, and siphon flow regulation to provide single-point valve control. The metering chamber operated by a single-point system flow control valve enables periodic dispensing of liquid above a supply source. The self-regulating chamber controls a single-point system flow control valve to regulate a metering chamber for periodic dispensing. The siphon turbine provided with terminal anti-backflow valves and regulated by a single-point system flow control valve enables hydropower production. Benefits include precision control, single-point operation, safety, new applications, energy savings, installations without power facilities, and a renewable clean energy technology.

Owner:OHAIR MICHAEL T

Co-extruded tubing

A co-extruded tubing for the administration of intravenous fluids has an outer layer of a polyester. An inner fluid-contact layer may be of a polyethylene or of a thermoplastic polyurethane. Where the inner fluid-contact layer is of polyethylene, an intermediate tie layer of ethylene-vinyl acetate copolymer may be included to prevent delamination.

Owner:NATVAR HLDG

Fluidic switches and methods for controlling flow in fluidic systems

InactiveUS6843262B2Avoid switchingEasy to switchValve arrangementsCircuit elementsControl flowEngineering

The present invention relates to fluidic systems, including switches for fluidic systems. The switches of the present invention may be particularly applicable to microfluidic systems. The switches of the invention may include a switching region having more than one position corresponding to more than one aspect ratio. Alternatively, the switches of the invention may include multiple inlets and a system for the selective supply of carrier fluid. The present invention also relates to a method of controlling a fluid in a microfluidic system and may be performed using the switches of the present invention.

Owner:PRESIDENT & FELLOWS OF HARVARD COLLEGE

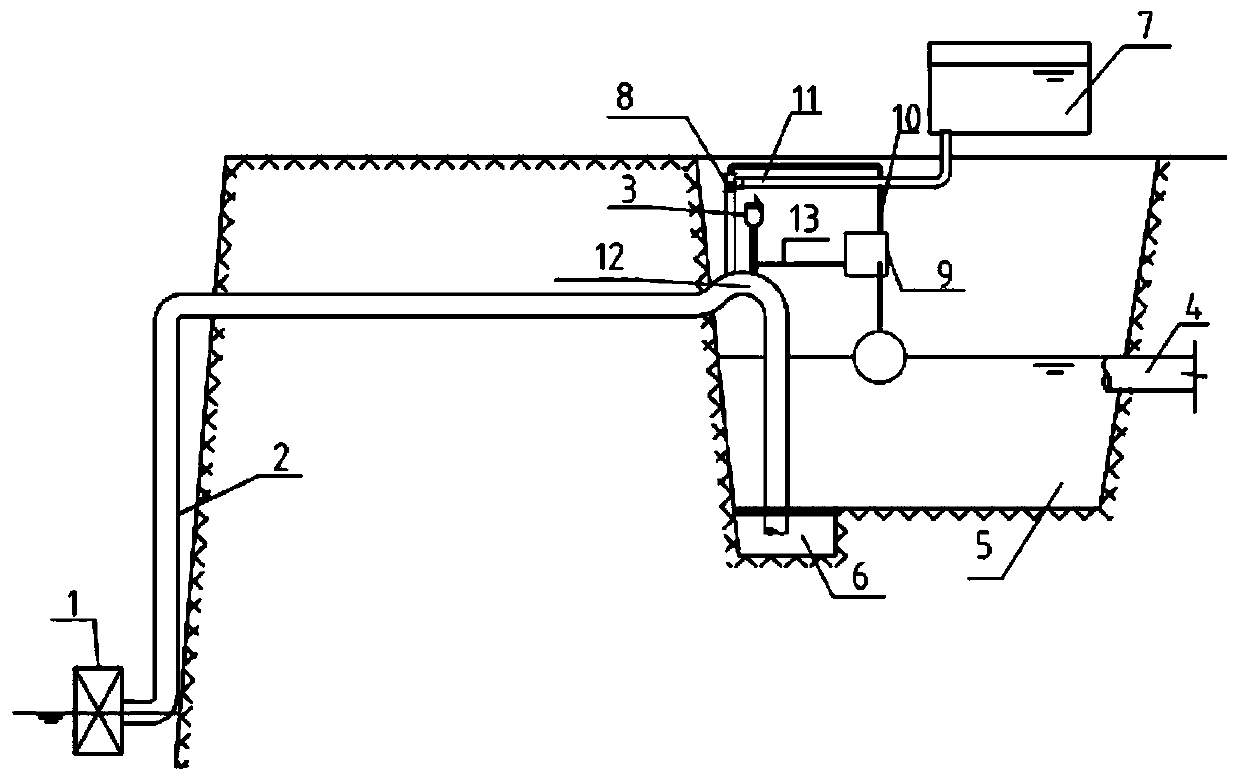

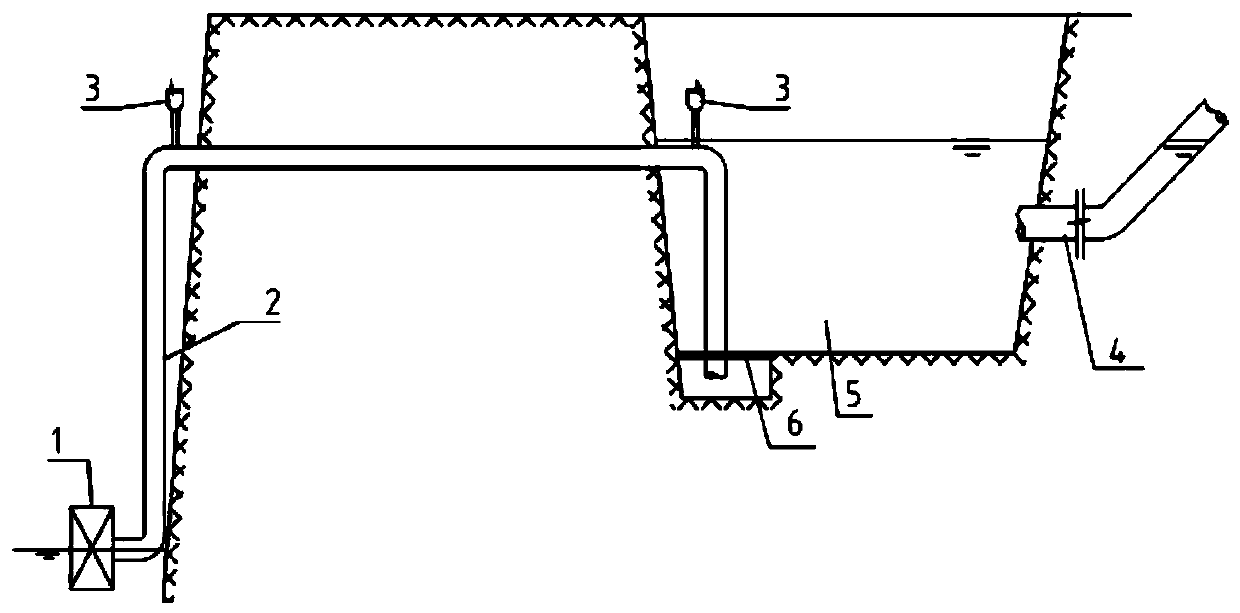

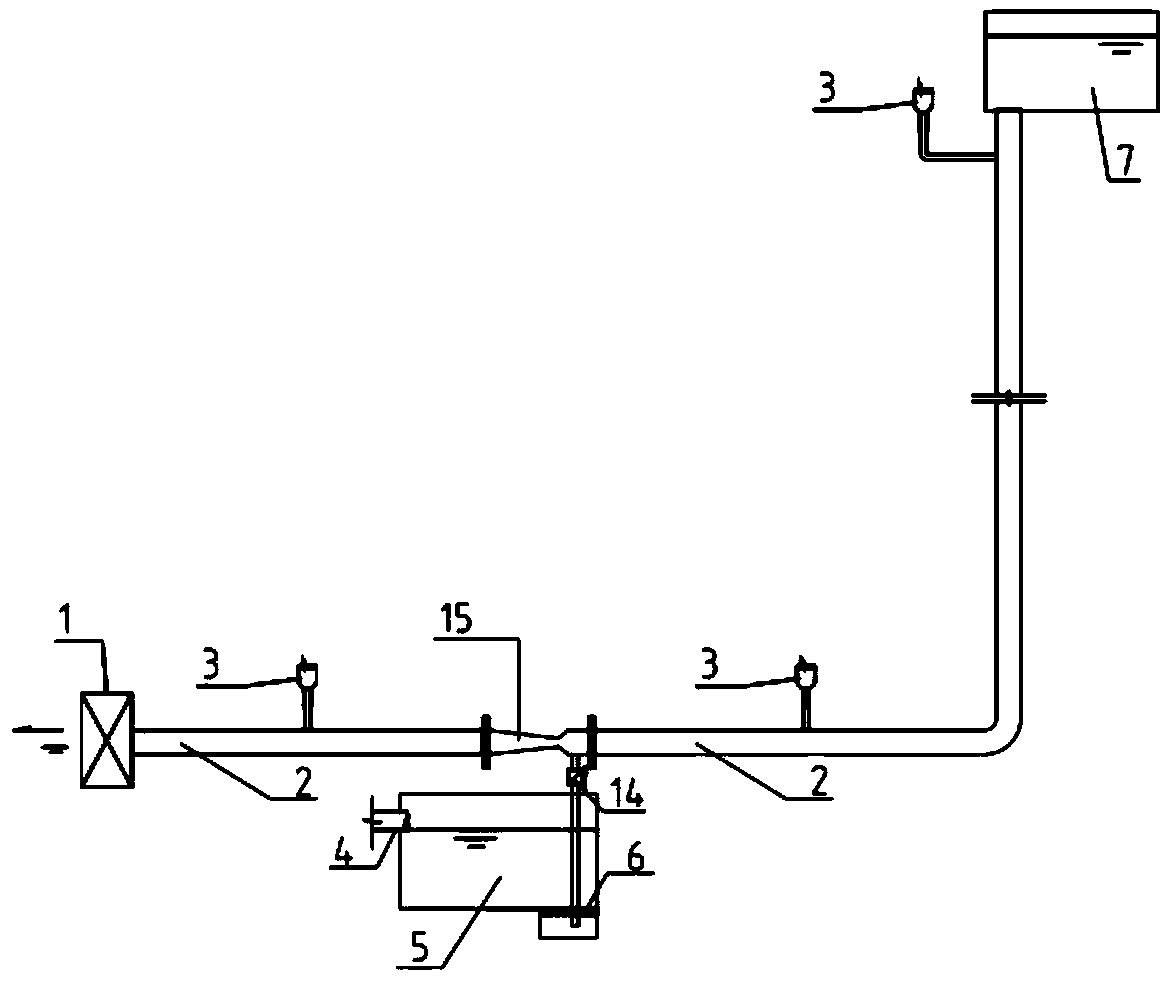

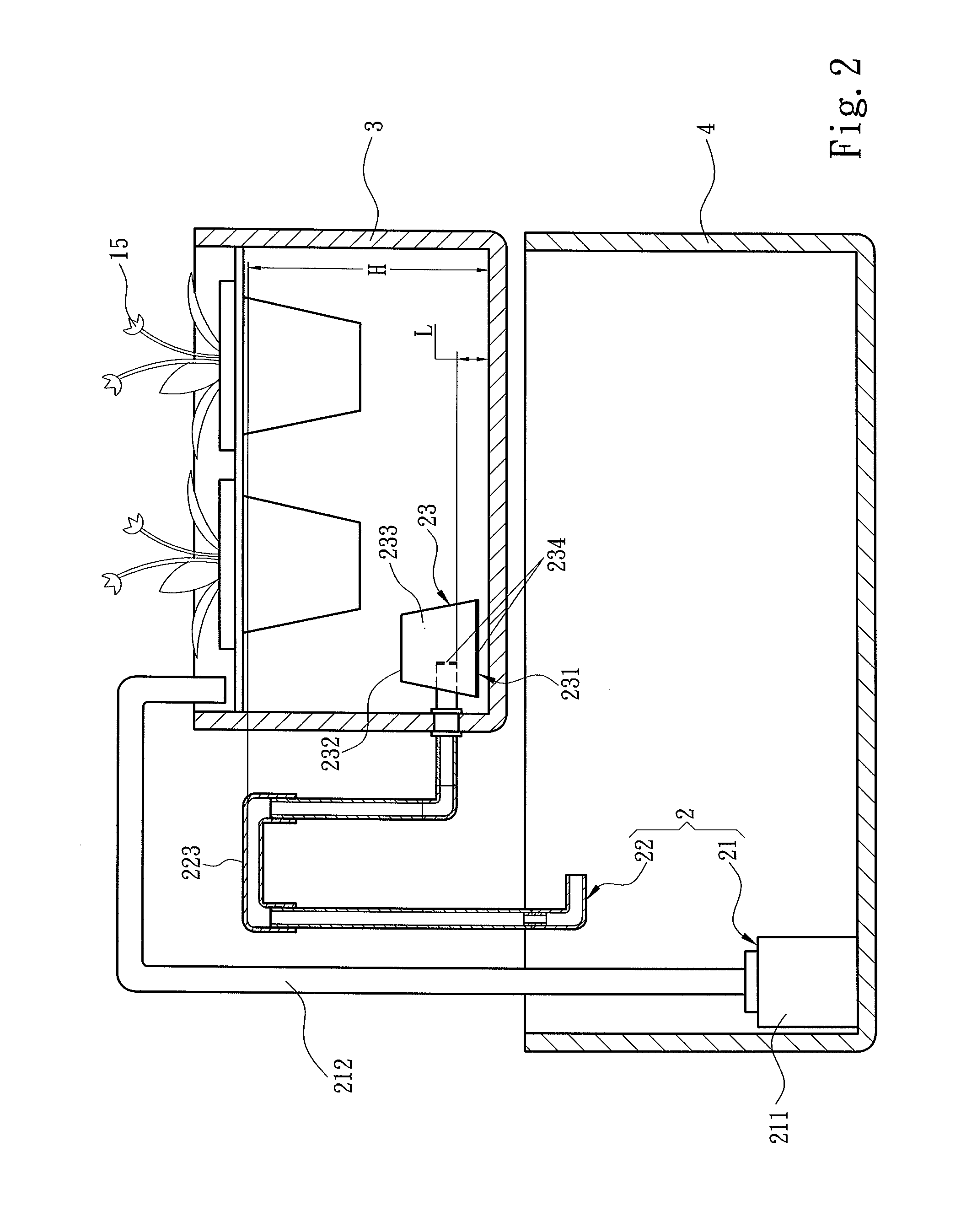

Unpowered automatic siphon water supply and drainage system

InactiveCN110106963AMeet water pressure requirementsHigh degree of automationSewerage structuresMachines/enginesSiphonWater source

The invention relates to an unpowered automatic siphon water supply and drainage system. The unpowered automatic siphon water supply and drainage system comprises five parts of a low-area water source, a siphon pipe, siphon water flow control equipment, an exhaust one-way valve and water injection equipment, wherein the low-area water source comprises a water inlet pipe, a low-area water pool anda suction well with a filter screen; the siphon water flow control equipment is an automatic pressure relief valve; and the water injection equipment comprises a water injection pipe, a liquid level control valve, a siphon pilot valve, a water seal elbow pipe, a high-area water source, a hydraulic pipe and a pneumatic pipe, wherein the liquid level control valve is controlled by the siphon pilot valve, the liquid level control valve and the siphon pilot valve are connected by the hydraulic pipe, the hydraulic pipe is provided with a time-lapse self-closing valve, and the siphon pilot valve isarranged above the liquid level of the lower-area water pool. According to the unpowered automatic siphon water supply and drainage system, the elevation difference of all water inlet and outlet can be realized, an unpowered automatic siphon water supply and drainage function of occasions where the water level of some water sources is lower than water outlets can be realized, and the unpowered automatic siphon water supply and drainage system has a wide application range, and can be widely applied to the technical fields of municipal, industrial and building water supply and drainage.

Owner:XIAMEN CITY YIJING ENVIRONMENT ENG CO LTD

Two-stage pressure relief valve

ActiveUS20050129531A1Limited hydraulic powerIncrease heatFluid-pressure actuator safetyServomotor componentsWorking pressureSystem pressure

A two-stage pressure relief valve for use with hydraulic systems is disclosed. The two-stage pressure relief valve has a first stage that relieves increases in hydraulic system pressure over the normal operating pressure and up to a selected threshold pressure level, and a second stage that brings the hydraulic system pressure down to a selected reduced operating pressure that is below the normal operating pressure in response to increases in the operating pressure over the threshold pressure level.

Owner:BELL HELICOPTER TEXTRON INC

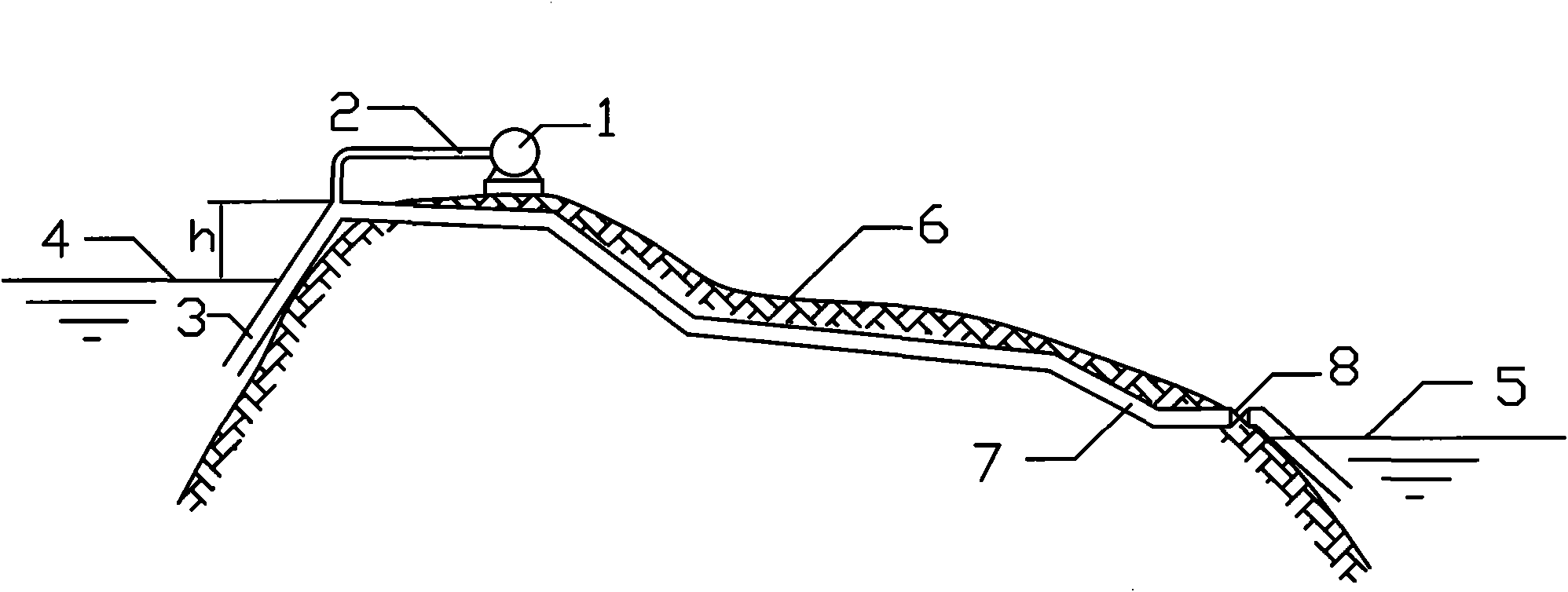

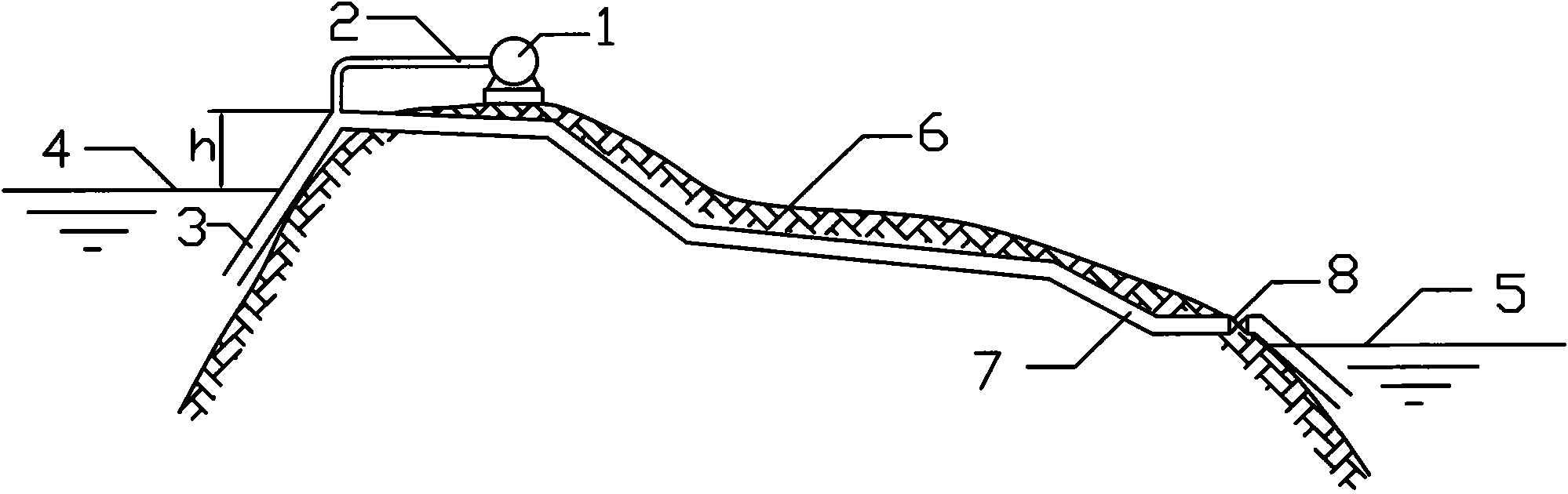

Vacuum pump-assisted siphon water intaking device and method

InactiveCN101949394AEasy to start siphonGuaranteed uptimeMachines/enginesPump siphonsSiphonWater level rise

The invention relates to the siphon water intaking technology, in particular to a vacuum pump-assisted siphon water intaking device and a method. The device comprises a siphon pipe, a water duct, a vacuum pump communicated with the top part of the siphon pipe, and a valve arranged at the water outlet end of the water duct. The method is implemented as follows: at the starting stage, air in the siphon pipe and the water duct is exhausted by the vacuum pump, the water level rises to tank up the siphon pipe and the water duct, the vacuum pump is stopped, and the valve at the water outlet end of the water duct is started to perform siphon water intake; and at the running stage, when air gathers in the siphon pipe, the vacuum pump is started to exhaust the gathered air so as to ensure continuous and stable operation of a siphon water intaking pipe without water interruption. The invention solves the problems of difficult starting and instable operation of siphon water intaking of a large pipeline, improves the normal suction head of the siphon pipe, and saves engineering cost and operation power consumption respectively by over 90% compared with the method of establishing a pump station.

Owner:邝光明

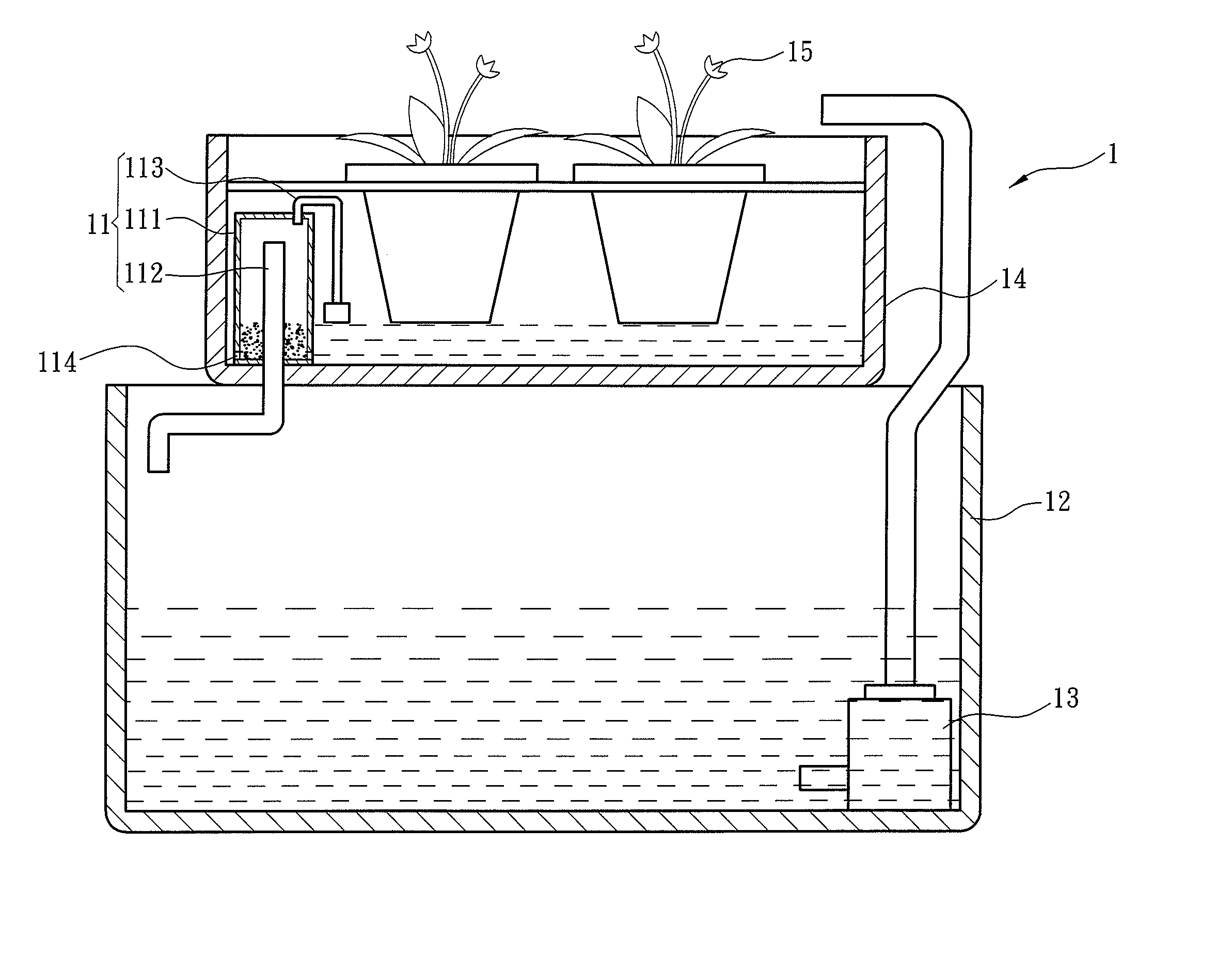

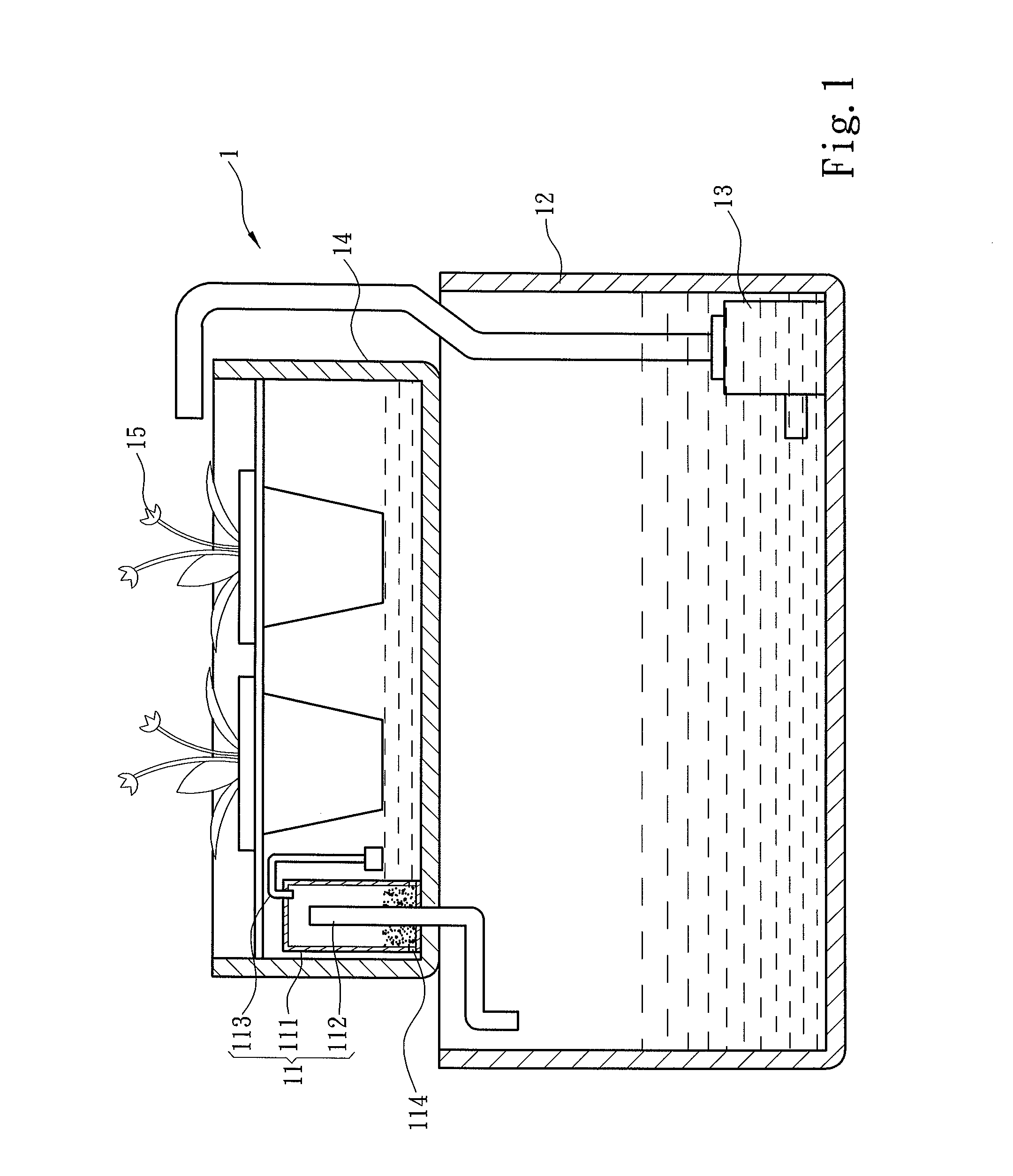

External cultivation liquid siphon

InactiveUS20150289459A1Small sizeProne to malfunctionSelf-acting watering devicesWatering devicesSiphonCulture fluid

An external cultivation liquid siphon includes a liquid delivery equipment located in a cultivation liquid storage tank to continuously pump cultivation liquid to a plant cultivation pot and an external siphon equipment to bridge the cultivation liquid storage tank and the plant cultivation pot. The external siphon equipment has a tubular facility with variations in tubular diameters to generate siphonage action to fill the tubular facility with flowing liquid. Thus the cultivation liquid pumped by the liquid delivery equipment to the plant cultivation pot can circulate reciprocally between an upper liquid level and a lower liquid level to cultivate plants.

Owner:TSAI HAN YI

Assembling a siphonable filler tube with a check valve on a fuel tank

Owner:EATON INTELLIGENT POWER LTD

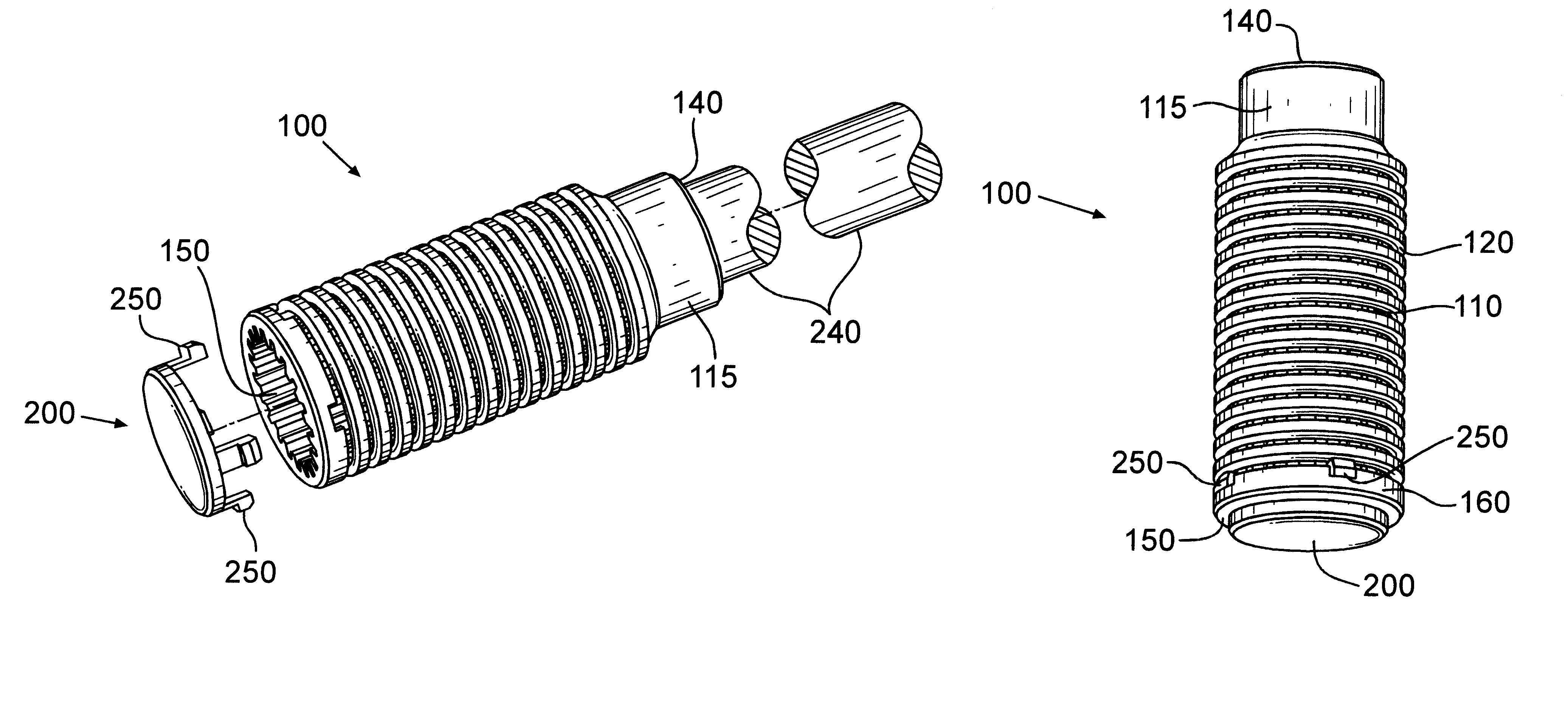

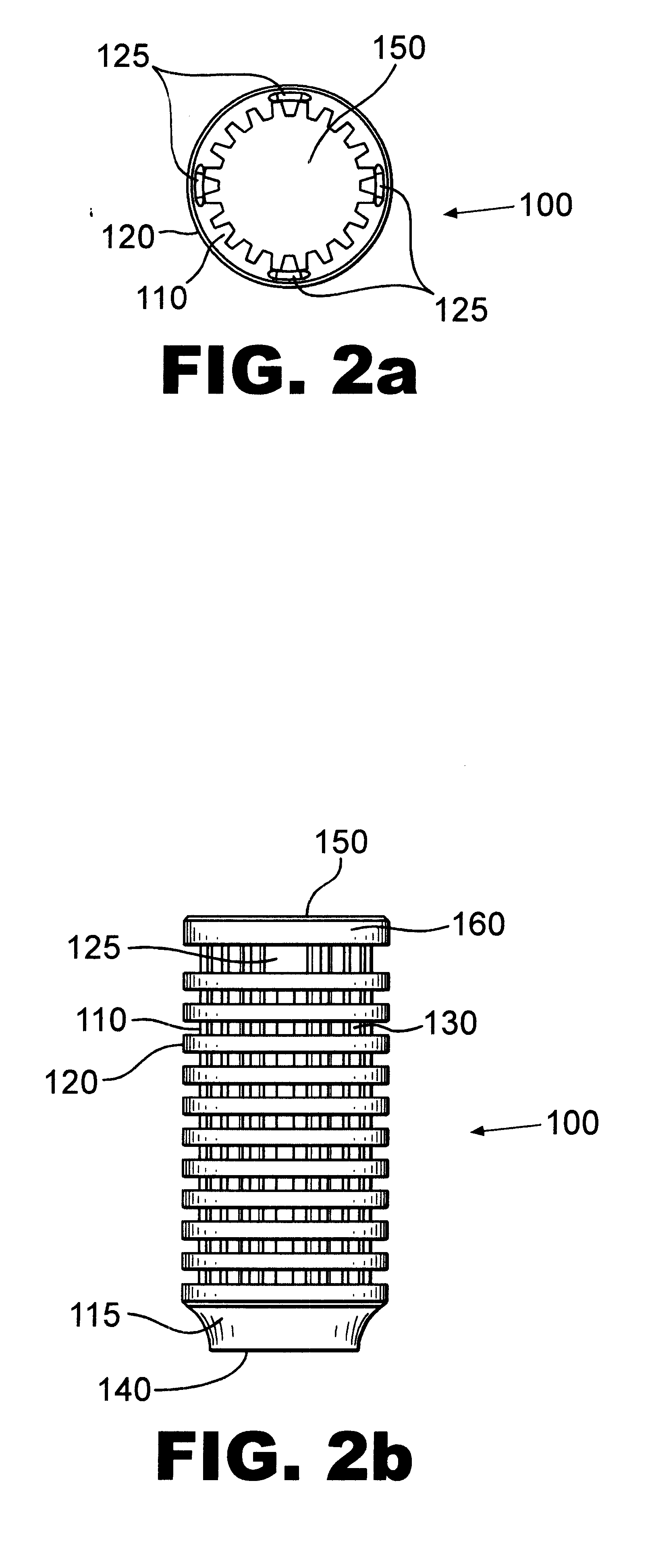

Fluid filter

InactiveUS20030127385A1Eliminate needMachines/enginesMembrane filtersMechanical engineeringEngineering

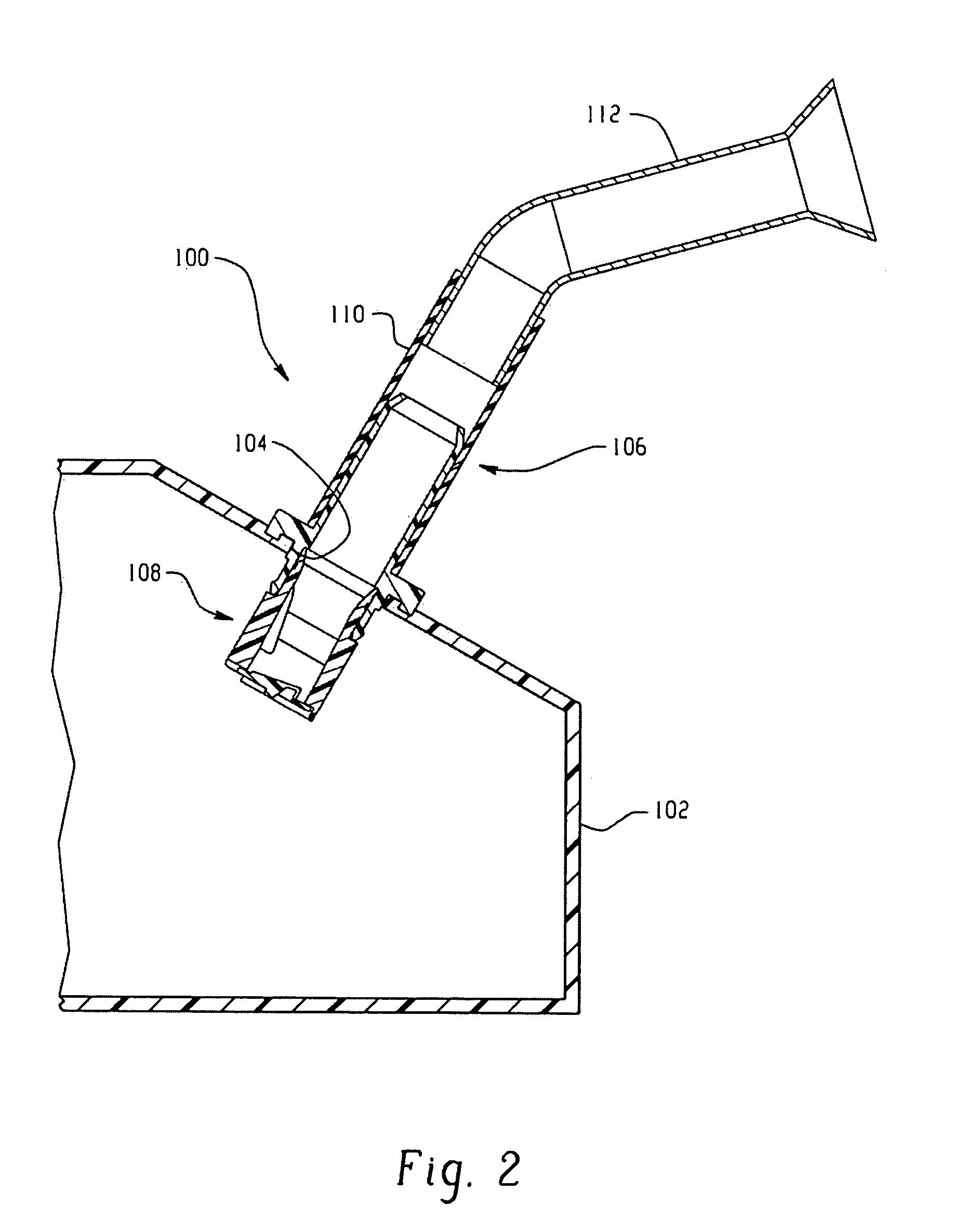

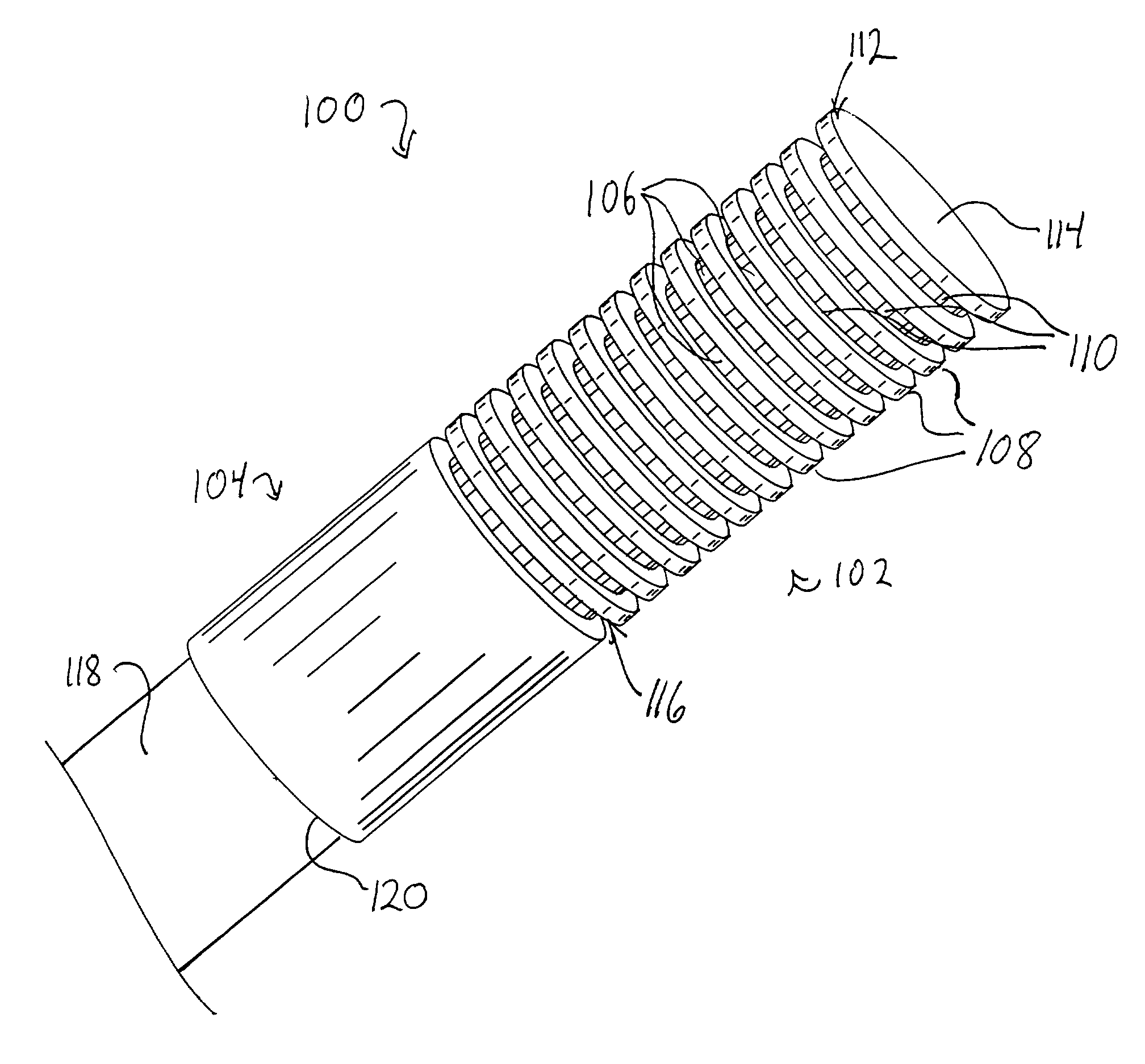

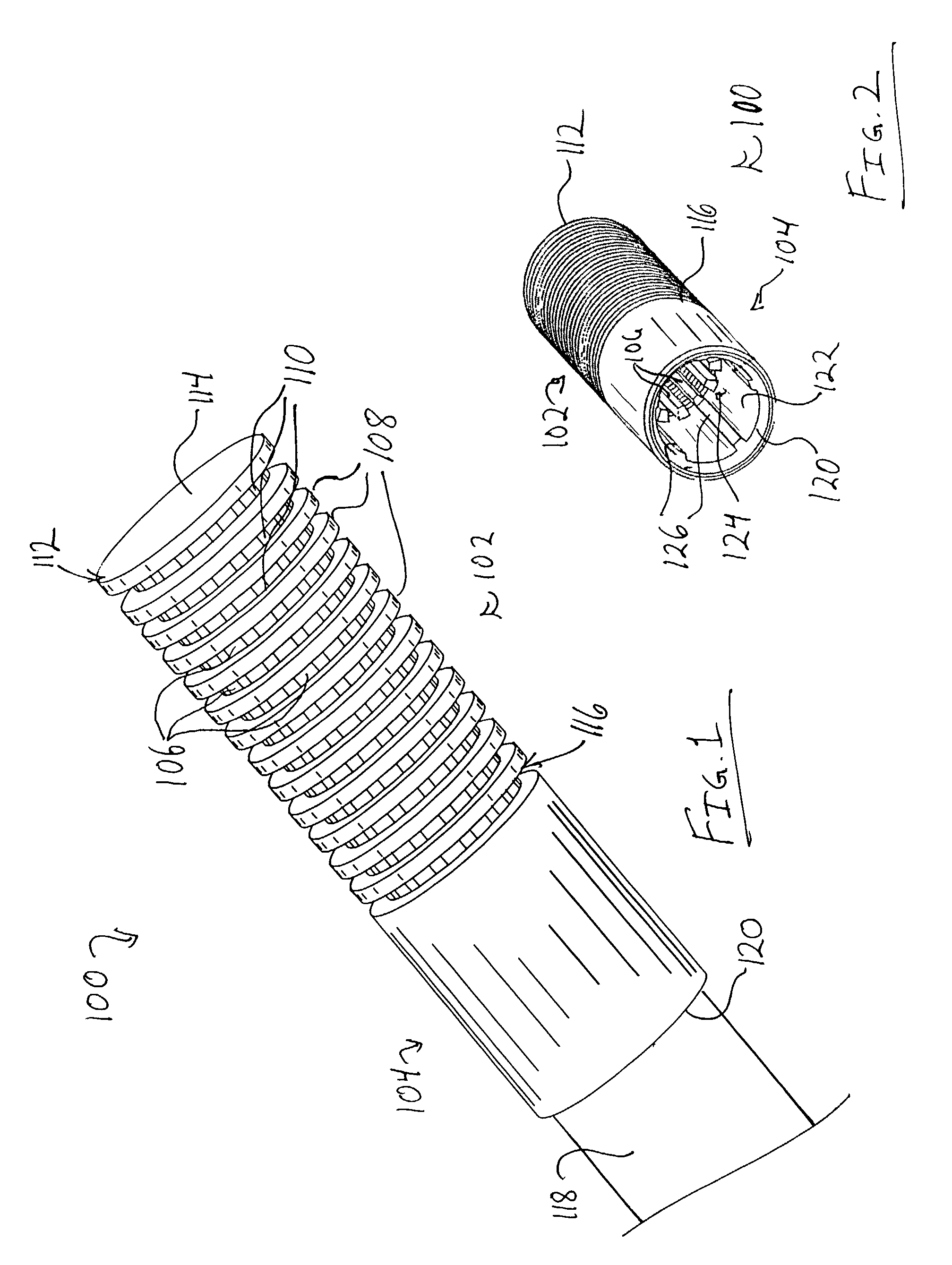

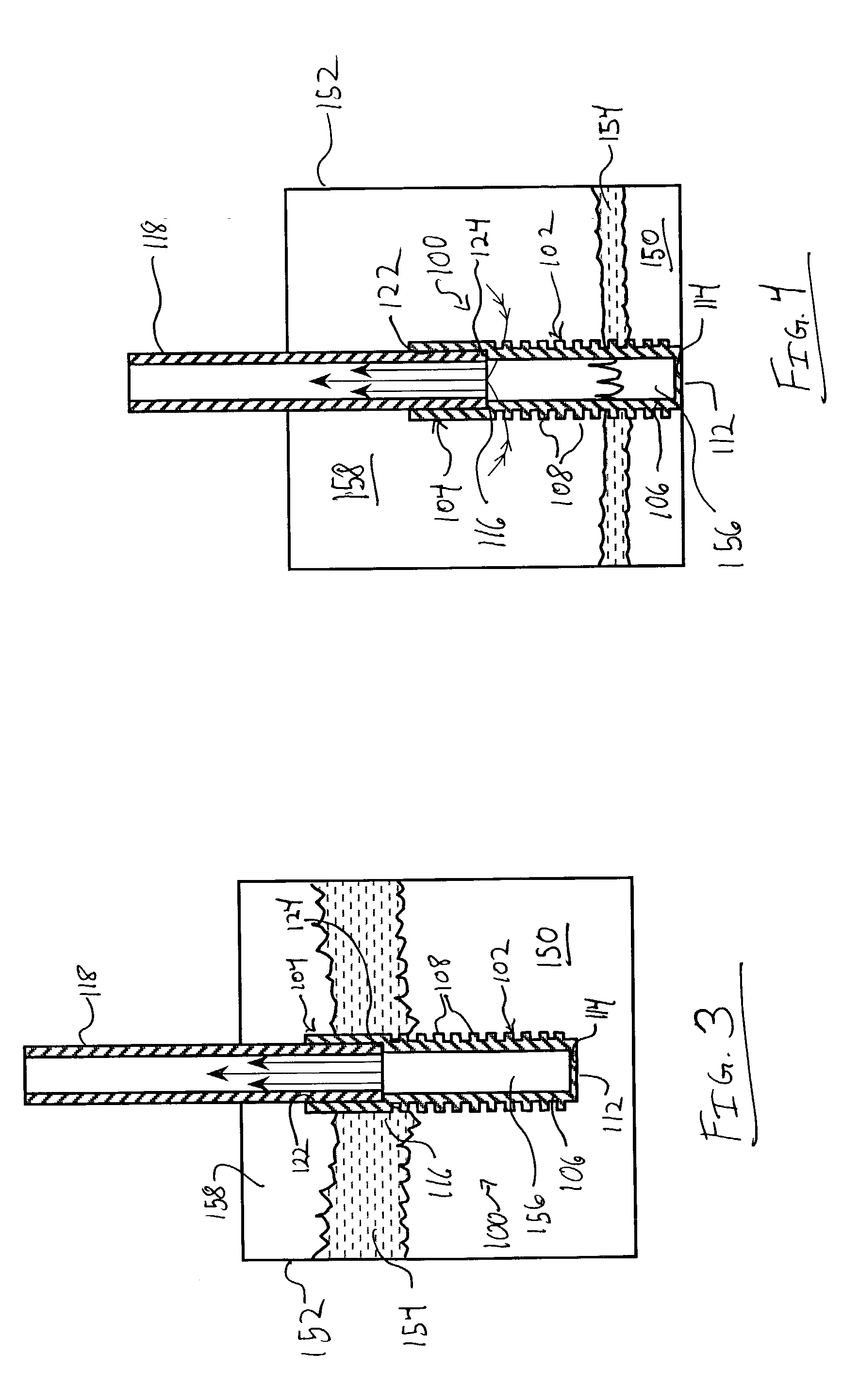

A substantially clog-resistant self-supporting fluid filter 100 for attachment to an open end of flow tube 118. Filter 100 comprises a substantially cylindrically shaped grid or fluid intake portion 102 having first end 112 and a second end 116. Fluid intake portion 102 comprises a plurality of substantially parallel longitudinal ribs 106 affixed to a plurality of substantially parallel circular ribs 108 at an angle to longitudinal ribs 106 thereby allowing a fluid to flow therebetween while preventing passage of debris intermixed with the fluid. Longitudinal ribs 106 and circular ribs 108 are substantially rigid such that they cooperate to be structurally self-supporting. End cover 114 is affixed to first end 112. Filter 100 further comprises tube receiving portion 104, which is affixed to or integral with second end 116 and is configured such that flow tube 118 engages tube receiving portion 104 in a secure, slidable manner.

Owner:CHAPIN MFG INC

Magnetic device and method of using such device to clean the inner surface of a tube, and methods and devices for siphoning fluid

A tube cleaning device is provided including a first member and a second member. The first member includes a first magnetic or magnetically attractable element and an abrasive cleaning surface. The second member includes a second magnetic or magnetically attractable element magnetically attracted to or by the first magnetic or magnetically attractable element. When the first member is inserted within a tube and the second member is positioned adjacent an outer wall of the tube, the abrasive surface of the first member contacts an inner wall of the tube. By moving the second member along and / or around the outer wall of the tube, the abrasive surface cleans the inner wall of the tube.

Owner:SPRUNG JULIAN

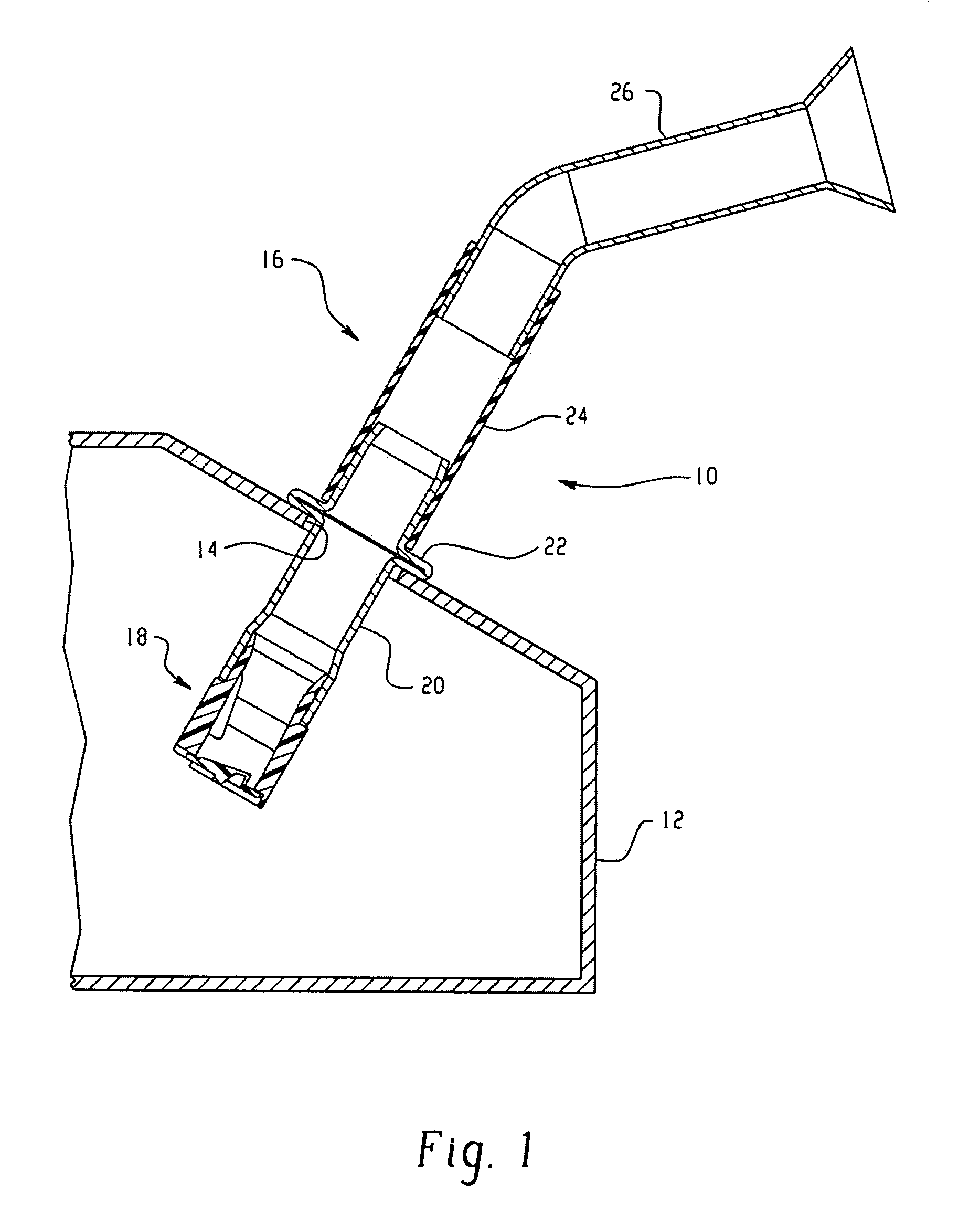

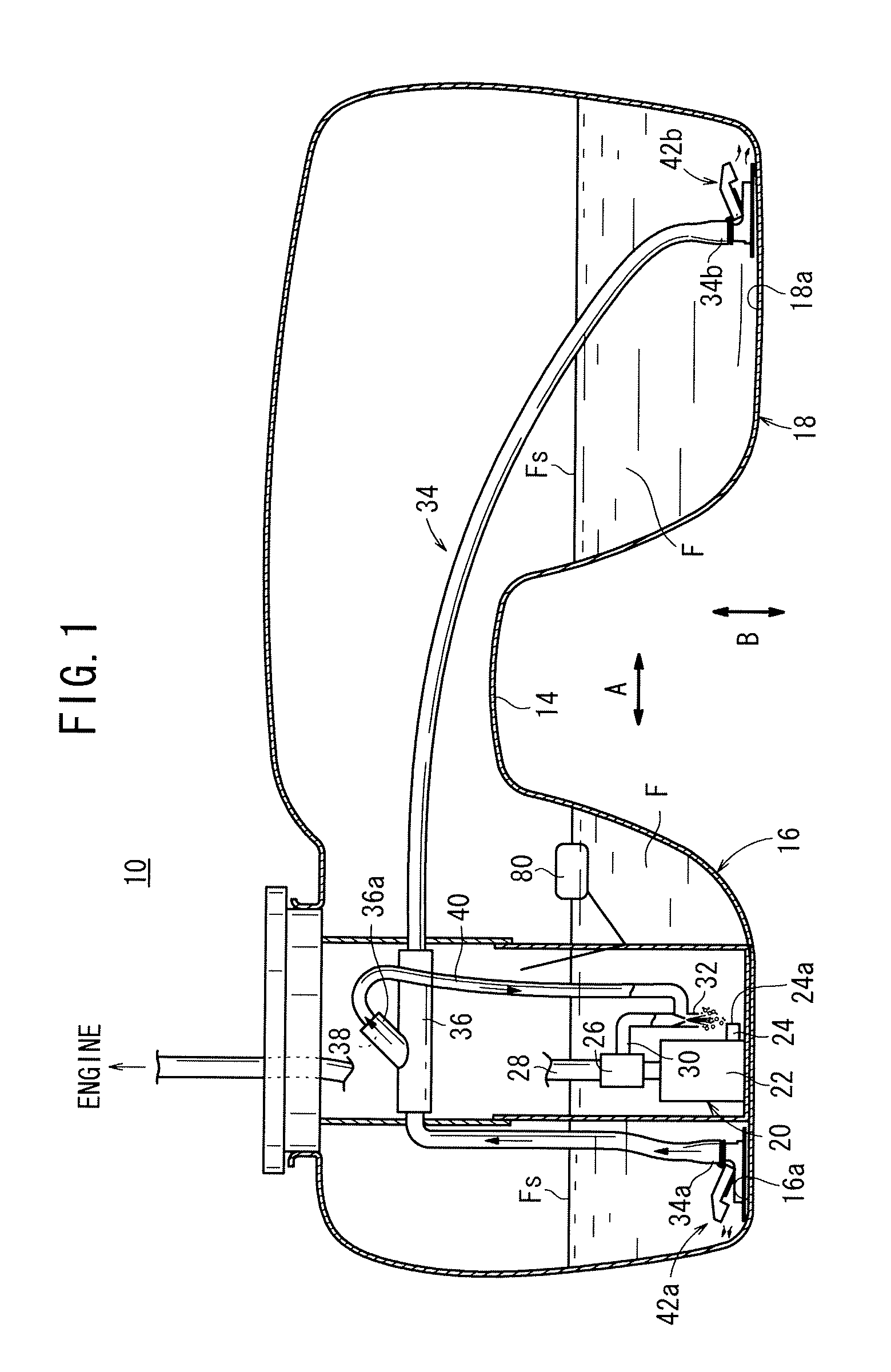

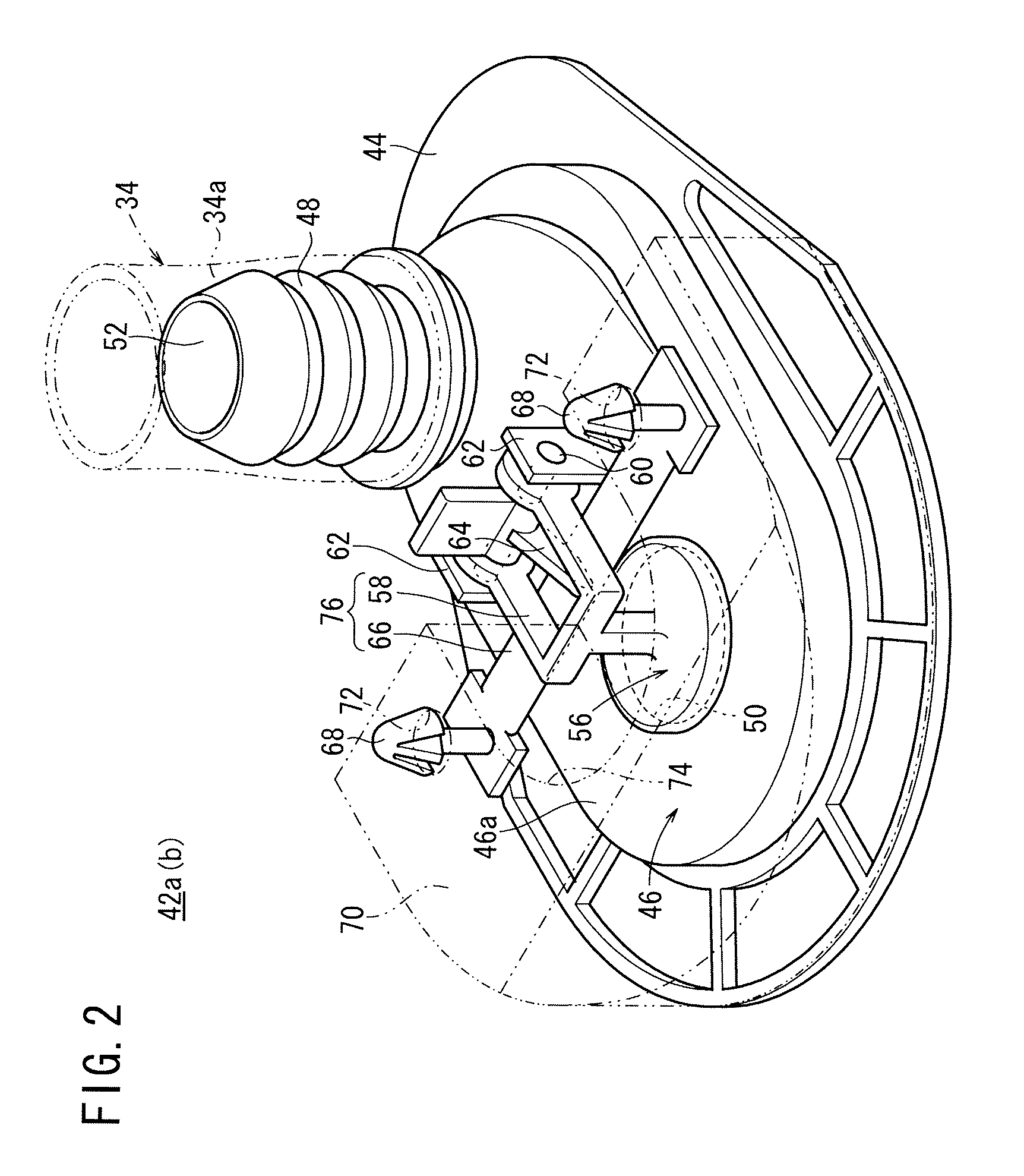

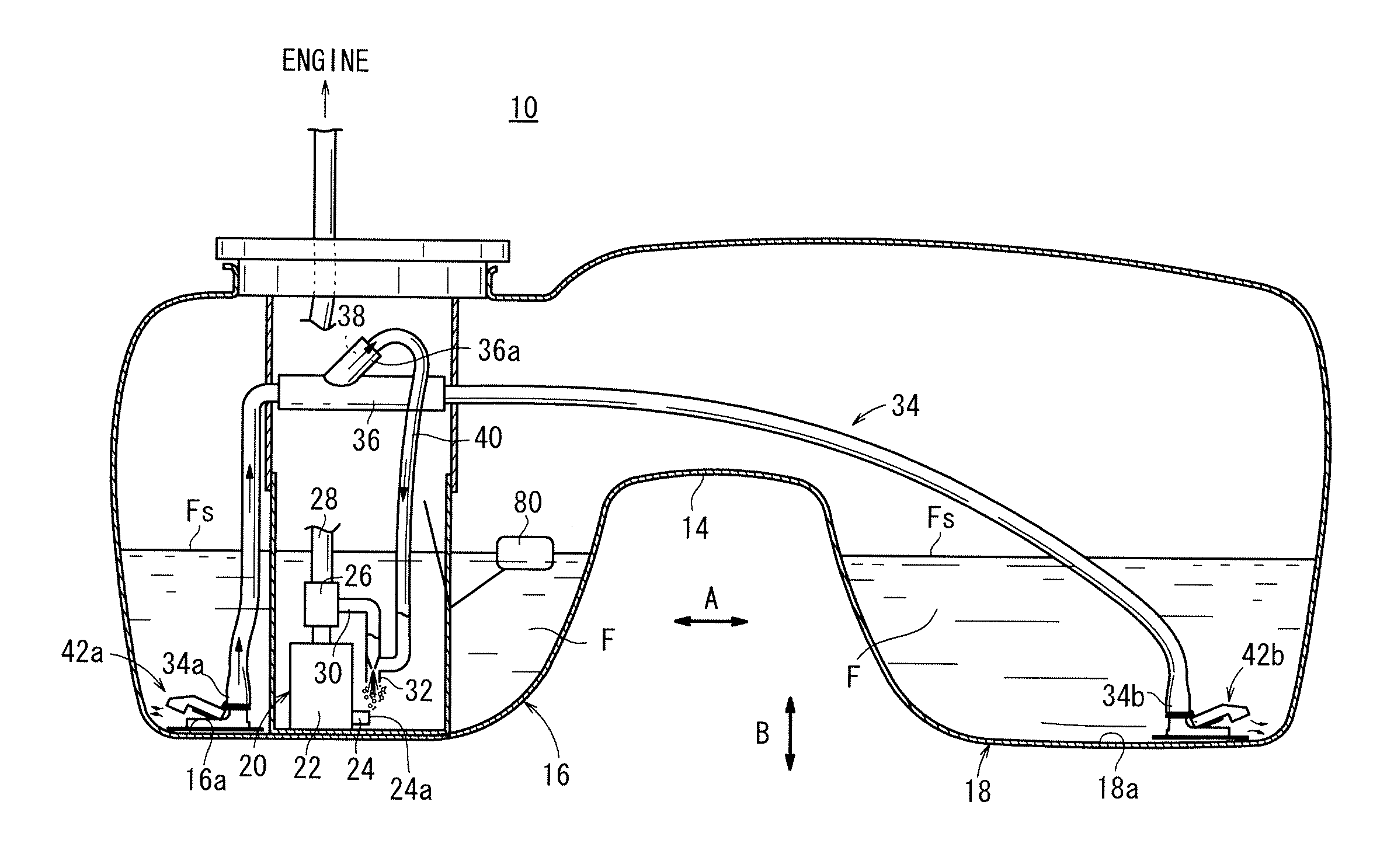

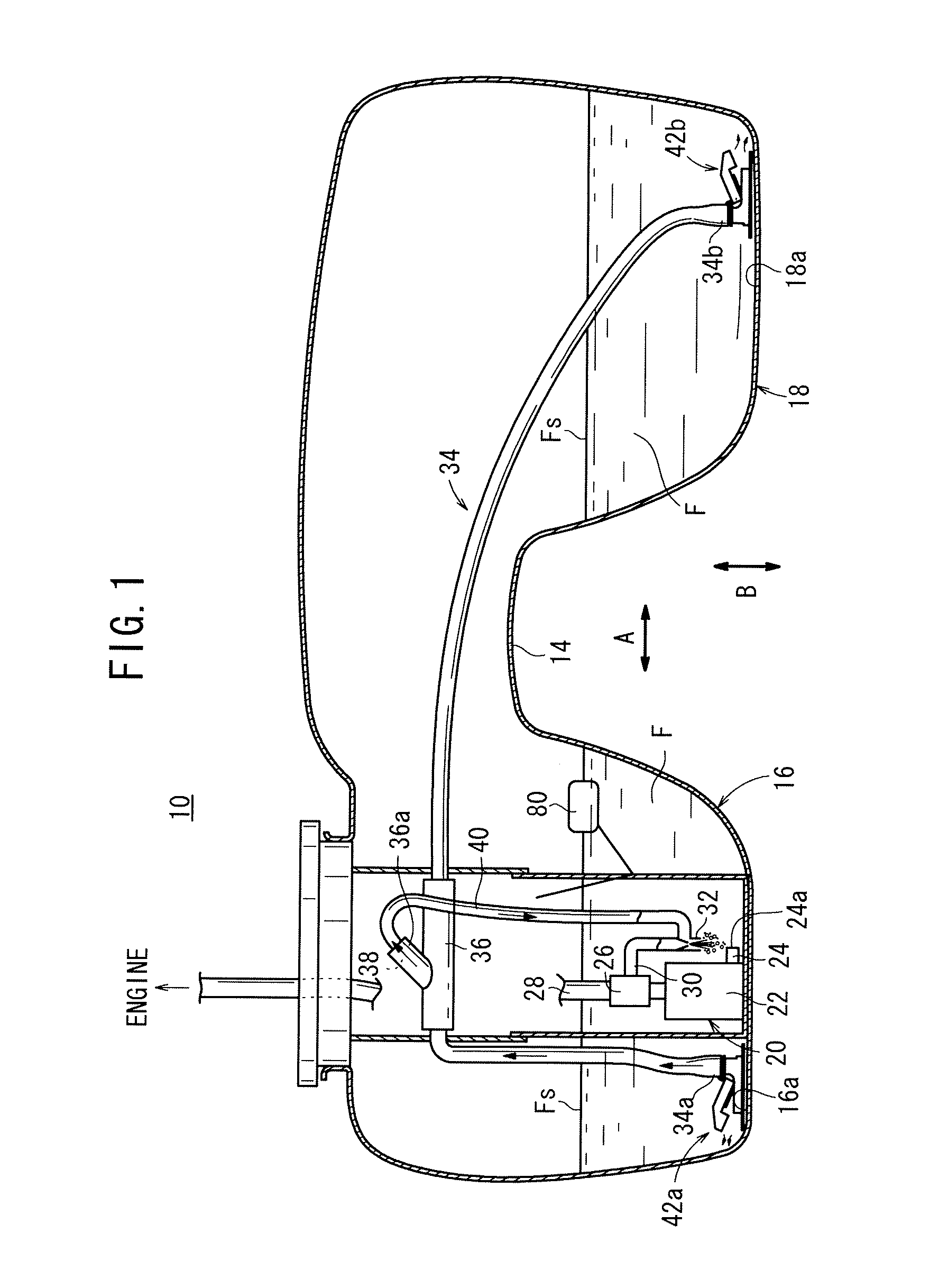

Fuel tank

ActiveUS8739821B2Simple and economical structureEasy to useUsing liquid separation agentJet pumpsSiphonFuel tank

A fuel introduction member is connected to an open end of a siphon tube which constitutes a part of a fuel tank. The fuel introduction member is provided with an opening through which a fuel is introduced from the tank into the siphon tube and from the siphon into the tank, a lid portion which is swung by the hydraulic pressure from the siphon tube so as to open the opening, and a float member which floats on the fuel in accordance with the rise of a fuel liquid surface in the tank to displace the lid portion in order to open the opening.

Owner:HONDA MOTOR CO LTD

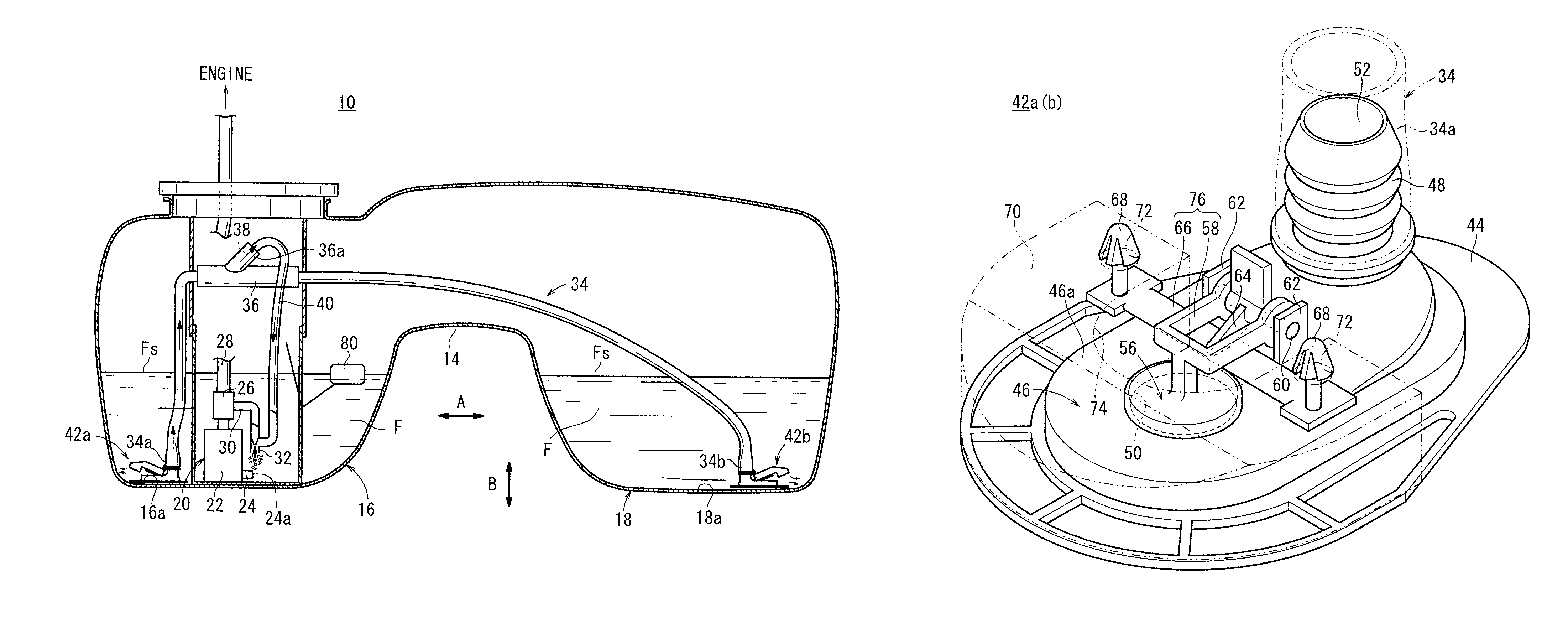

Fuel tank

ActiveUS20120118401A1Simple and economical structureEasy to useMachines/enginesLiquid fuel feedersSiphonFuel tank

A fuel introduction member is connected to an open end of a siphon tube which constitutes a part of a fuel tank. The fuel introduction member is provided with an opening through which a fuel is introduced from the tank into the siphon tube and from the siphon into the tank, a lid portion which is swung by the hydraulic pressure from the siphon tube so as to open the opening, and a float member which floats on the fuel in accordance with the rise of a fuel liquid surface in the tank to displace the lid portion in order to open the opening.

Owner:HONDA MOTOR CO LTD

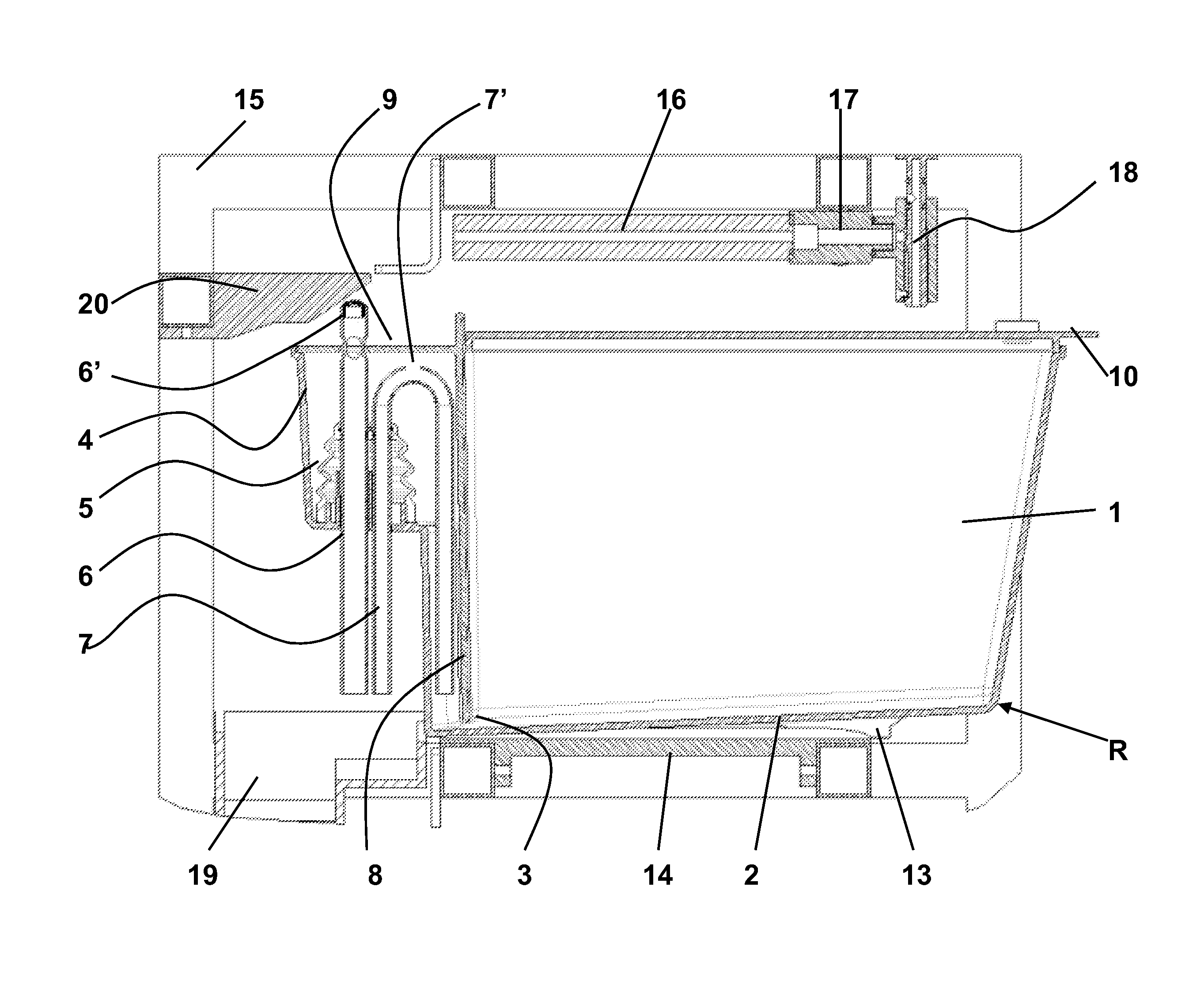

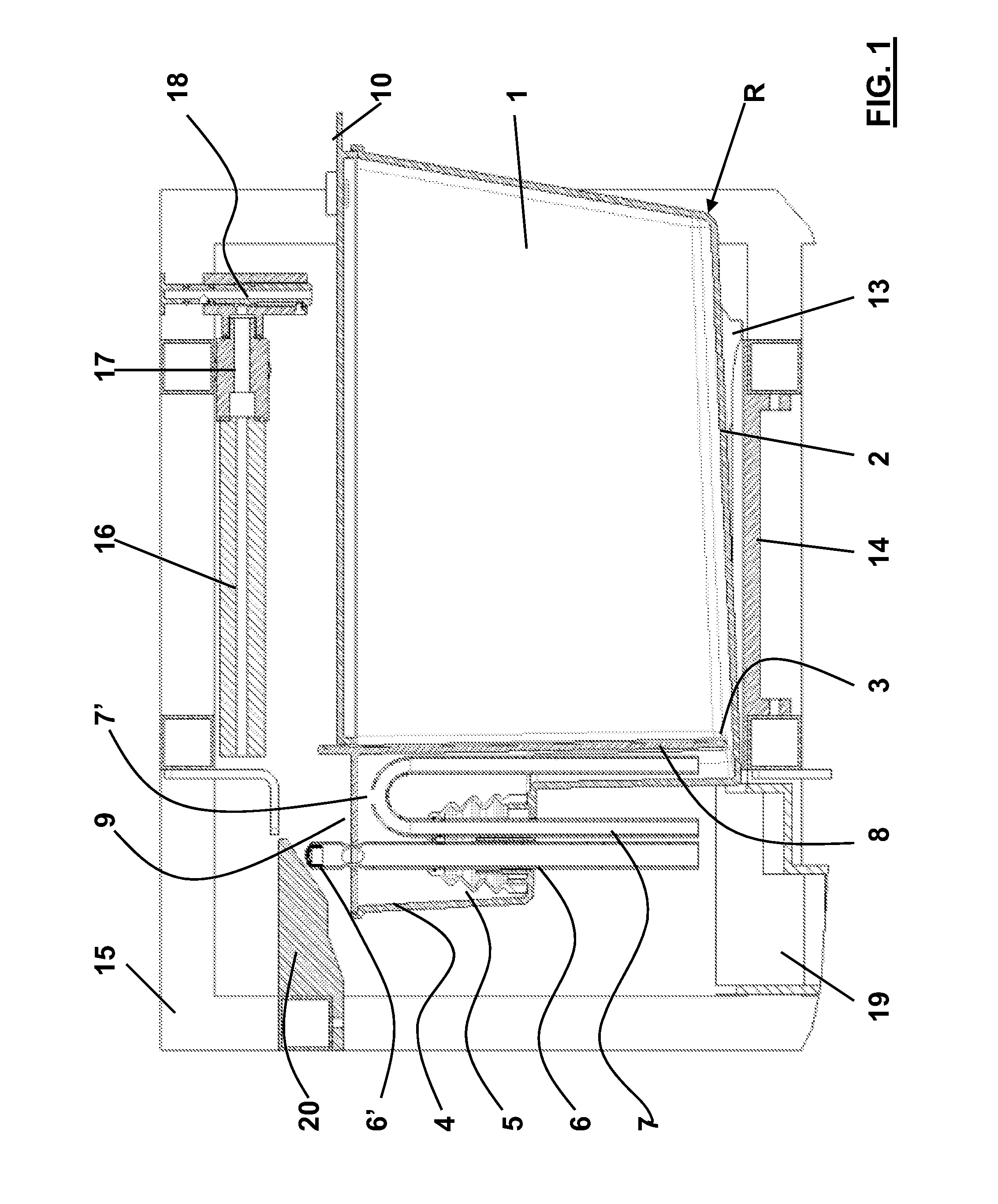

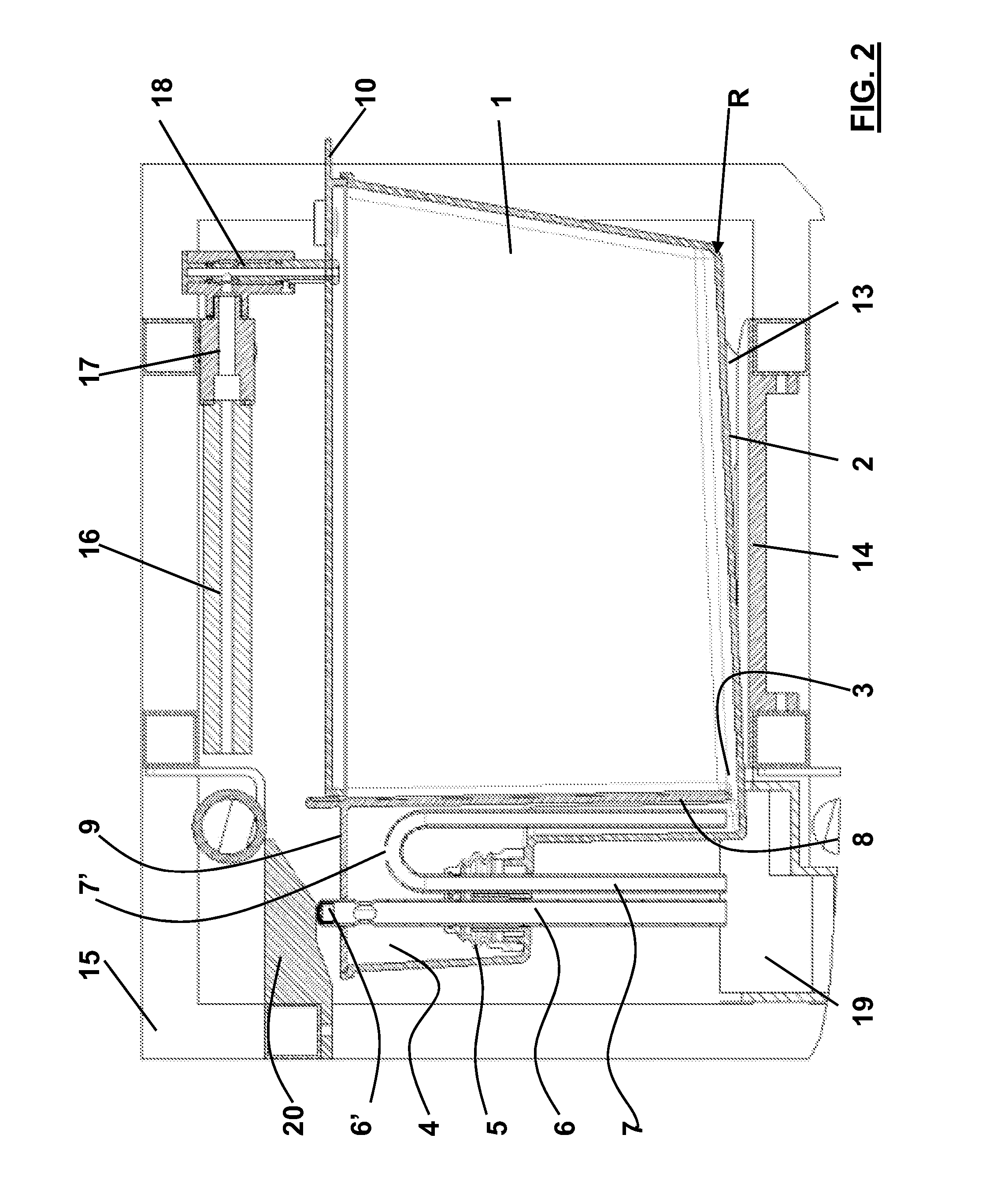

Basin capable of containing aquatic animals, especially experimental animals, and relating housing system

A basin including: a front housing compartment (1) in which there is a lower point (3) for collecting the organic material to be removed; an equipment compartment (4) at the back of the basin, connected to the housing compartment; a drainage device, in the equipment compartment (4), which includes an “overflow” pipe (6) fixed to a siphon (7); the drainage device being capable of moving down in order to operate the siphon (7); and, a partition (8) between the housing compartment (1) and the equipment compartment (4), the partition being capable of keeping the animals inside the housing compartment and letting the water pass into the equipment compartment.

Owner:TECNIPLAST

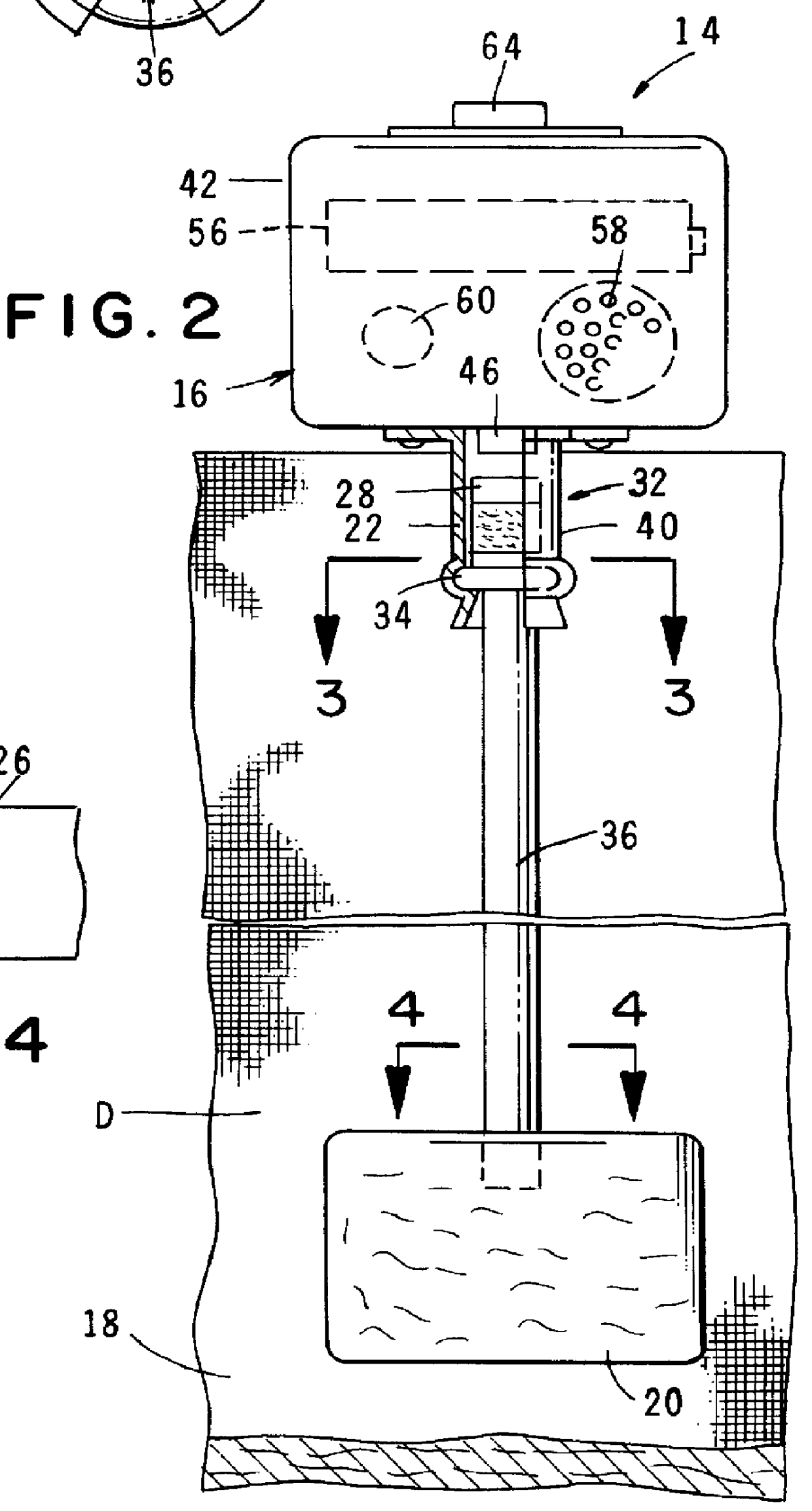

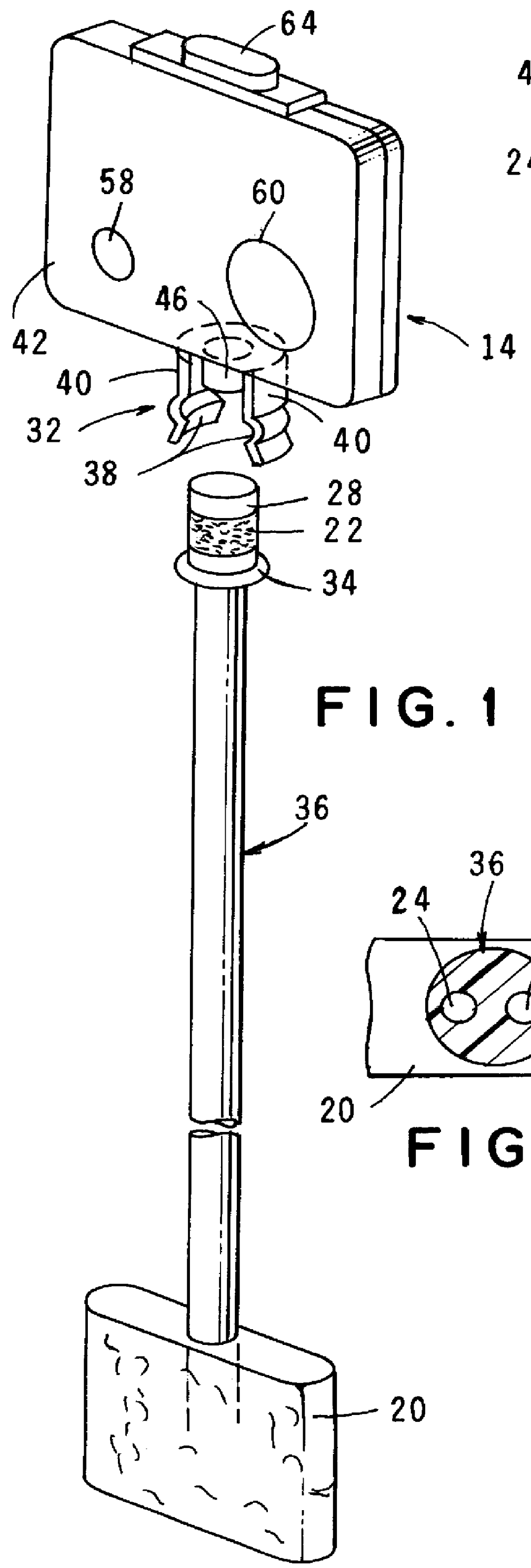

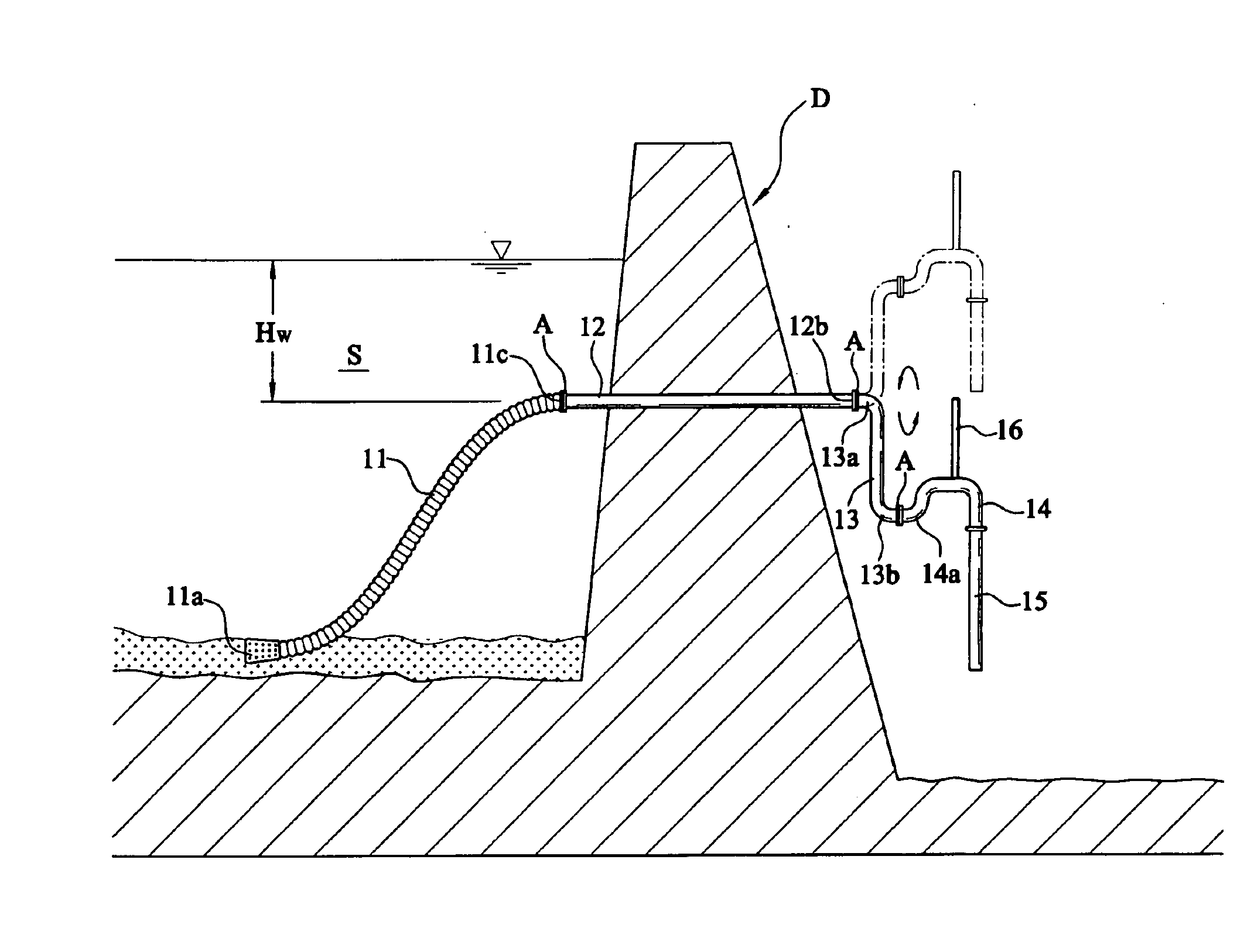

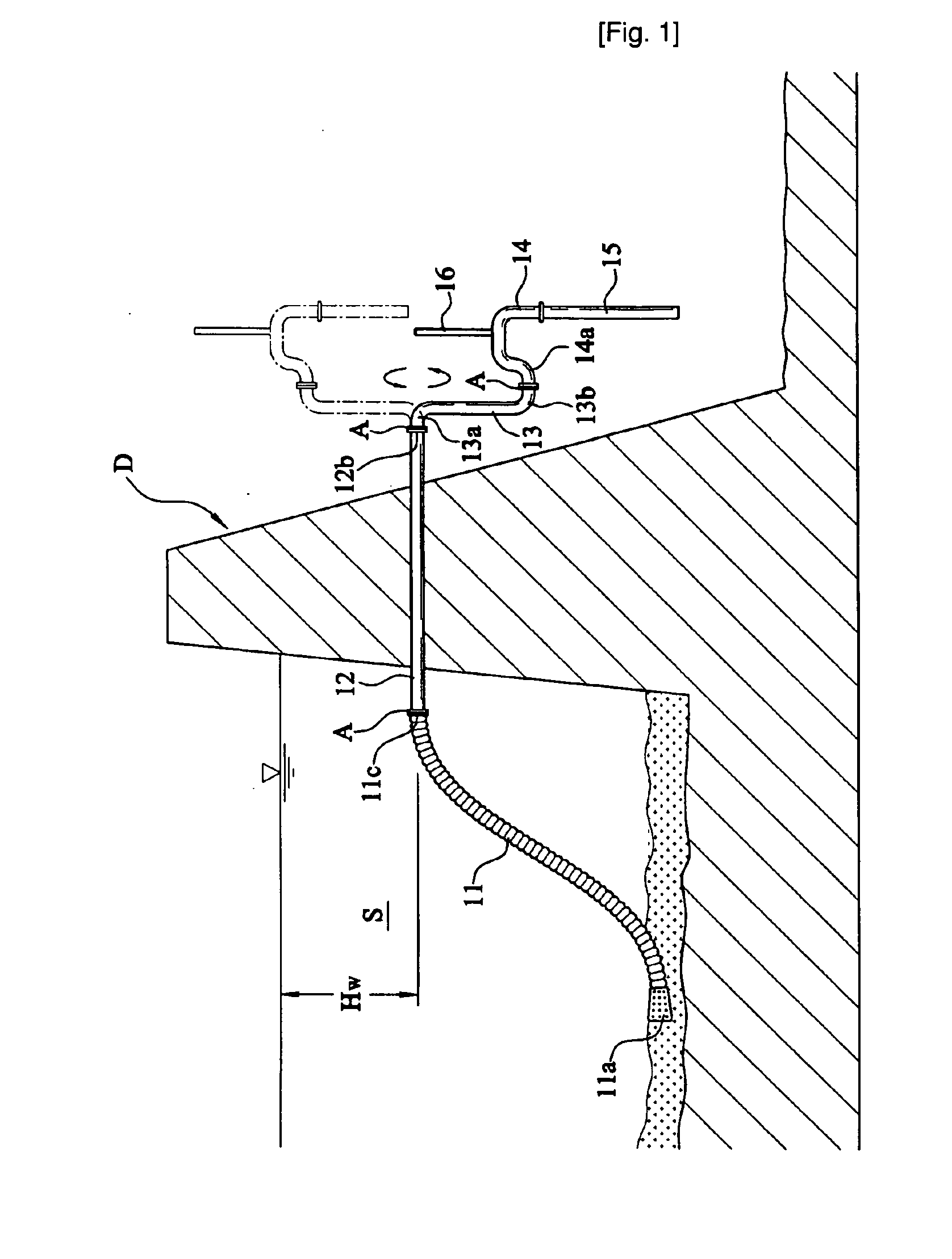

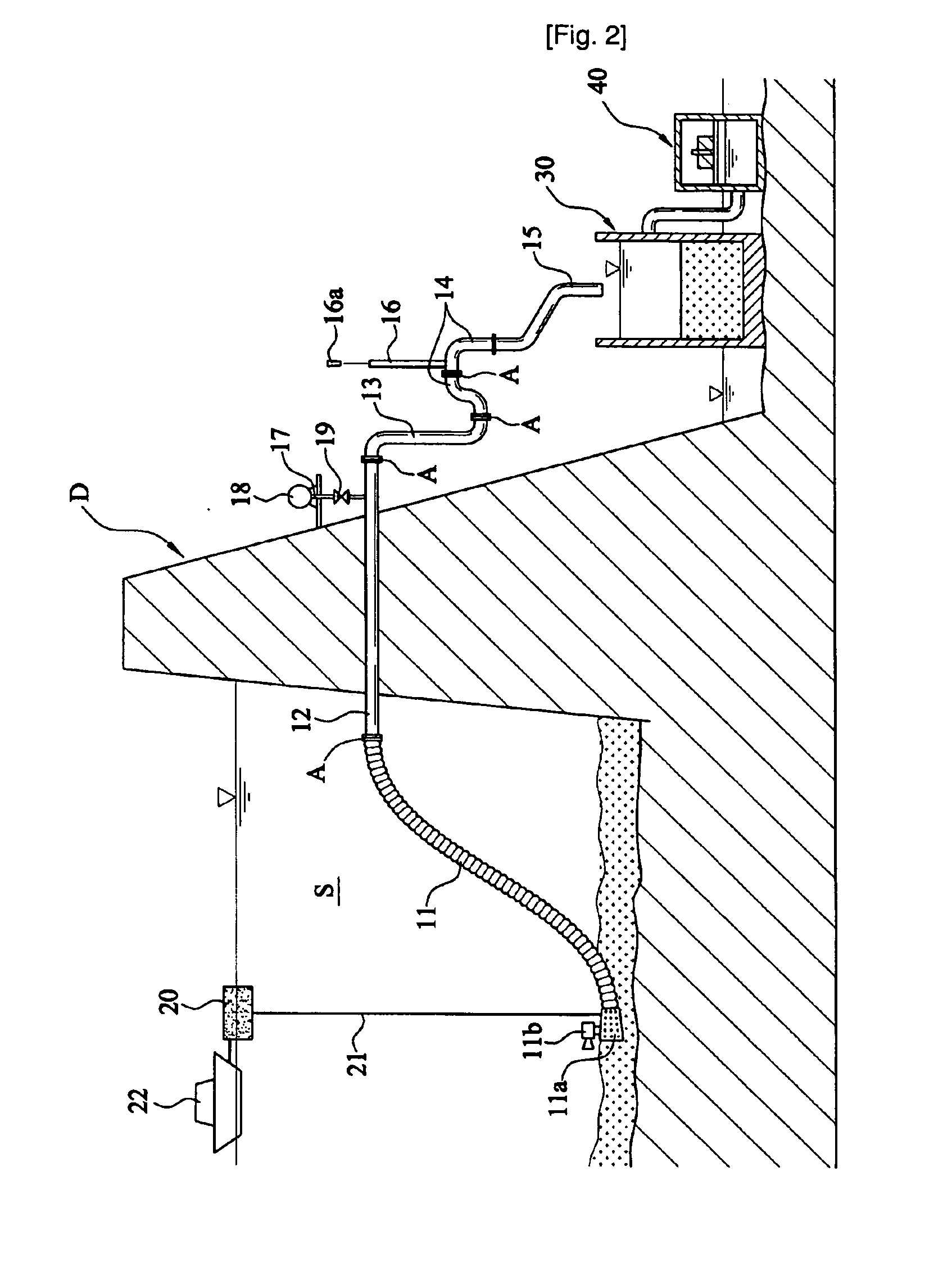

Sludge Treatment System for Dam

InactiveUS20090255865A1Easy dischargeCleanerSludge treatmentMechanical machines/dredgersSludgeAtmospheric pressure

The sludge treatment system is comprised of a dam passage penetrated through a dam (D); an induction pipe (11) for discharging a sediment retained by the dam (D) and having an inlet (11a) toward the floor of the dam (D) and an outlet connected to an inner end of the dam passage; an induction force action pipe (13) connected to an outer end of the dam passage and extended in a height for utilizing an atmospheric pressure as an induction force of the sediment; a U shape air control pipe (14) connected to the induction force action pipe (13), and preventing for an air from coming into the induction force action pipe (13); a drain pipe (15) connected to the air control pipe (14) for discharging the sediment; and an air vent pipe (16) connected to a horizontal flat portion of the air control pipe (14) for dissipating the induction action of both the air control pipe (14) and the drain pipe (15).

Owner:LEE IN OK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com