Unpowered automatic siphon water supply and drainage system

A water supply and drainage, automatic technology, applied in the direction of waterway systems, siphons, drainage structures, etc., can solve the problem of high comprehensive cost, and achieve the effect of high degree of automation and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

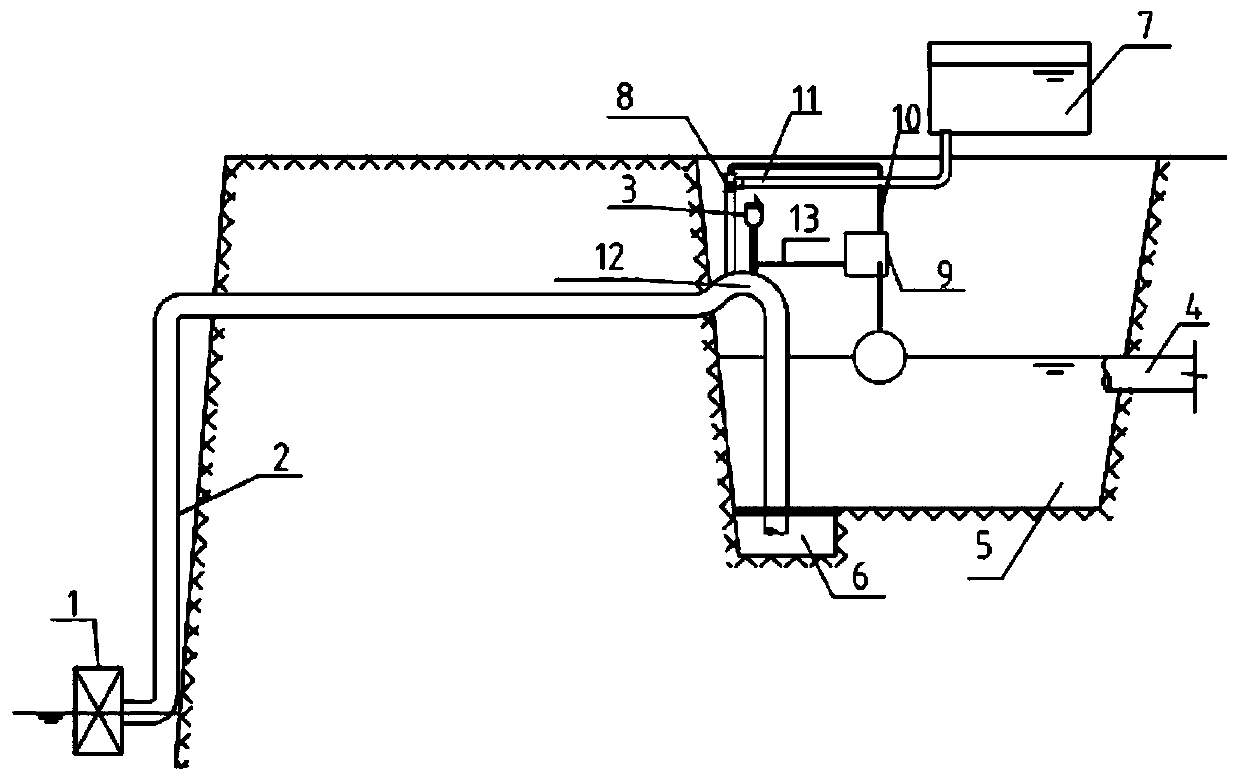

[0063] as attached figure 1 , this embodiment belongs to a typical siphon system, and it is used in the scene where the highest water level of the pool 5 in the low area is lower than the top of the siphon tube 2. Of course, the height difference between the lowest water level of the pool 5 in the low area and the top of the siphon tube is less than the atmospheric pressure can withstand The maximum water pressure height difference is also a necessary condition, and the working process of the system is:

[0064] First, divide the water into different areas, collect and transmit the water source in the high area through a separate pipe network, and realize the water injection process without additional power. As the water inlet pipe 4 of the low area pool 5 continuously injects water into the low area pool 5, the water level of the low area pool 5 gradually rises , when the water level reaches the threshold value, the siphon pilot valve 9 drives the hydraulic control valve 8 to...

Embodiment 2

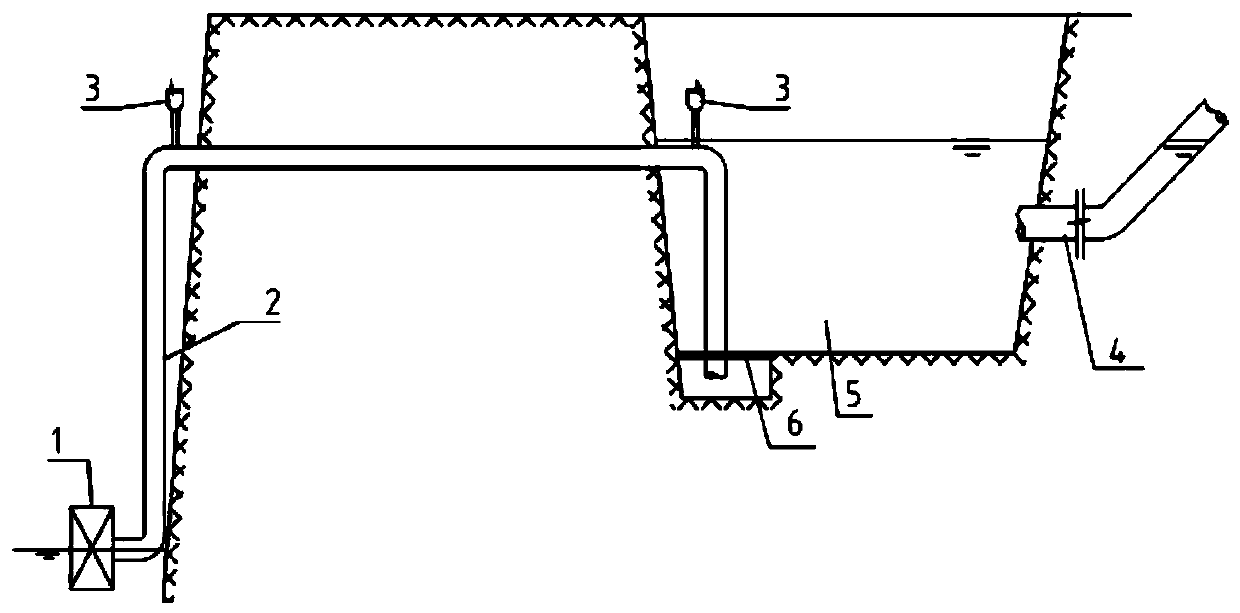

[0071] The application scenario of this embodiment is: the highest water level of the low area pool 5 is often higher than the pipe top of the siphon 2, in essence, the highest water level of the low area pool 5 can meet the water level requirements of the siphon 2, so the high The district water source 7 and the water source of the low district pool 5 are combined into one, so some water injection-related facilities in Embodiment 1 can be dismantled in this example.

[0072] as attached figure 2 , Only keep the automatic pressure relief valve 1, siphon pipe 2, exhaust check valve 3, low area pool water inlet pipe 4, low area pool 5 and suction pool with filter screen 6, the automatic siphon process can be realized. It should be noted that when there is no need for water volume adjustment and the water quality does not affect the system operation, even the water inlet pipe 4 of the low area pool, the low area pool 5 and the suction well 6 with a filter can also be cancelled, ...

Embodiment 3

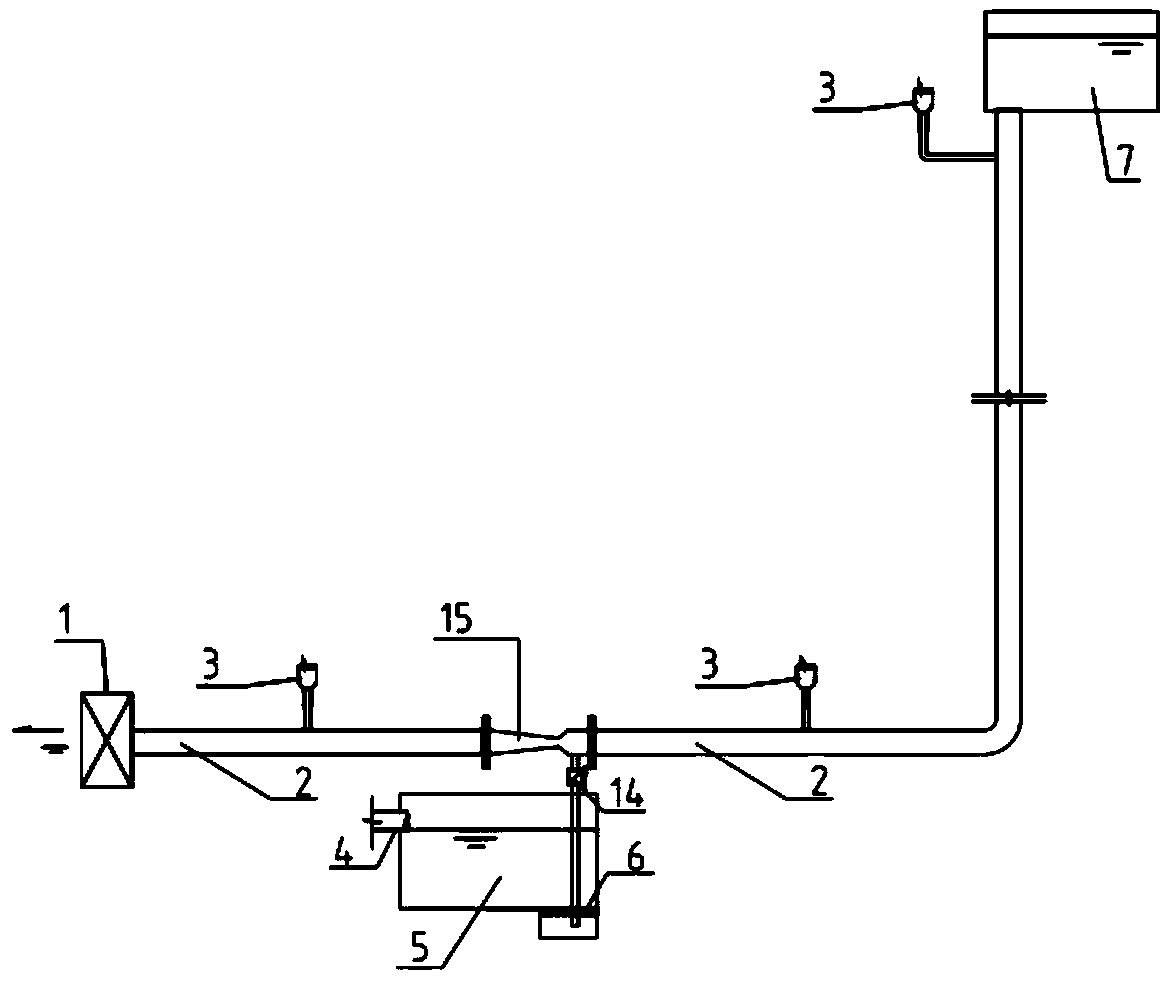

[0075] as attached image 3 , the application scenario of this embodiment is: the elevation of the highest water level of the pool 5 in the low area is lower than the elevation of the automatic pressure relief valve 1 and the height of the pool at the high level is sufficient. The system is connected to the siphon pipe 2 by the automatic pressure relief valve 1, and a water ejector 15 is arranged on the siphon pipe 2, and the water suction port of the water ejector 15 is connected with a branch pipe of the siphon pipe 2 to the suction well 6 with a filter screen at the bottom of the pool 5 in the low area. Also need to establish a check valve 14 on the branch pipe.

[0076]Similar to Embodiment 1 and Embodiment 2 above, several exhaust check valves 3 are provided on the main pipe of the siphon pipe 2 , and the water inlet end of the main pipe of the siphon pipe 2 is connected to the water source 7 in the high area. The difference is that the water source 7 in the high area sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com