Patents

Literature

51168 results about "Control valves" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A control valve is a valve used to control fluid flow by varying the size of the flow passage as directed by a signal from a controller. This enables the direct control of flow rate and the consequential control of process quantities such as pressure, temperature, and liquid level.

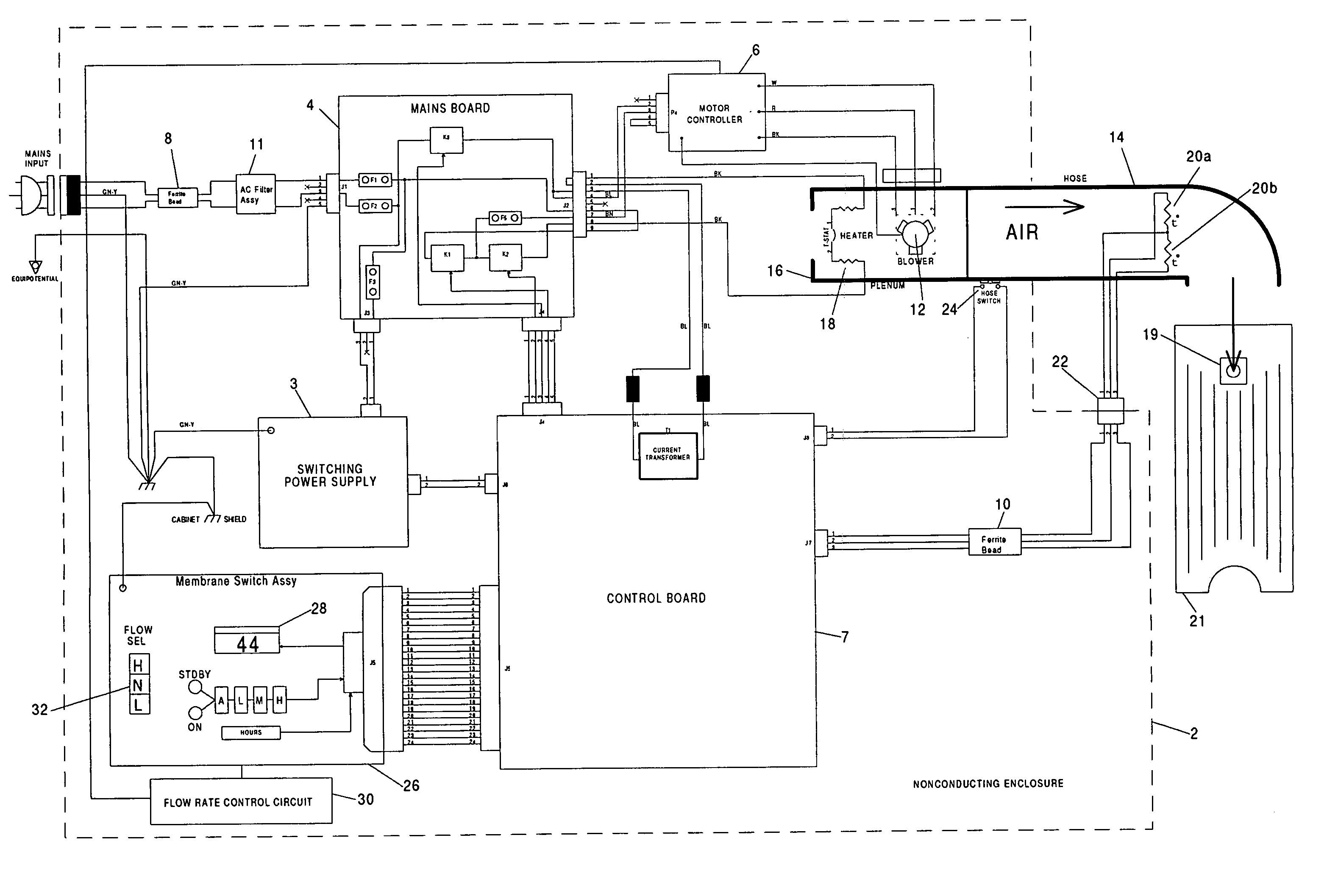

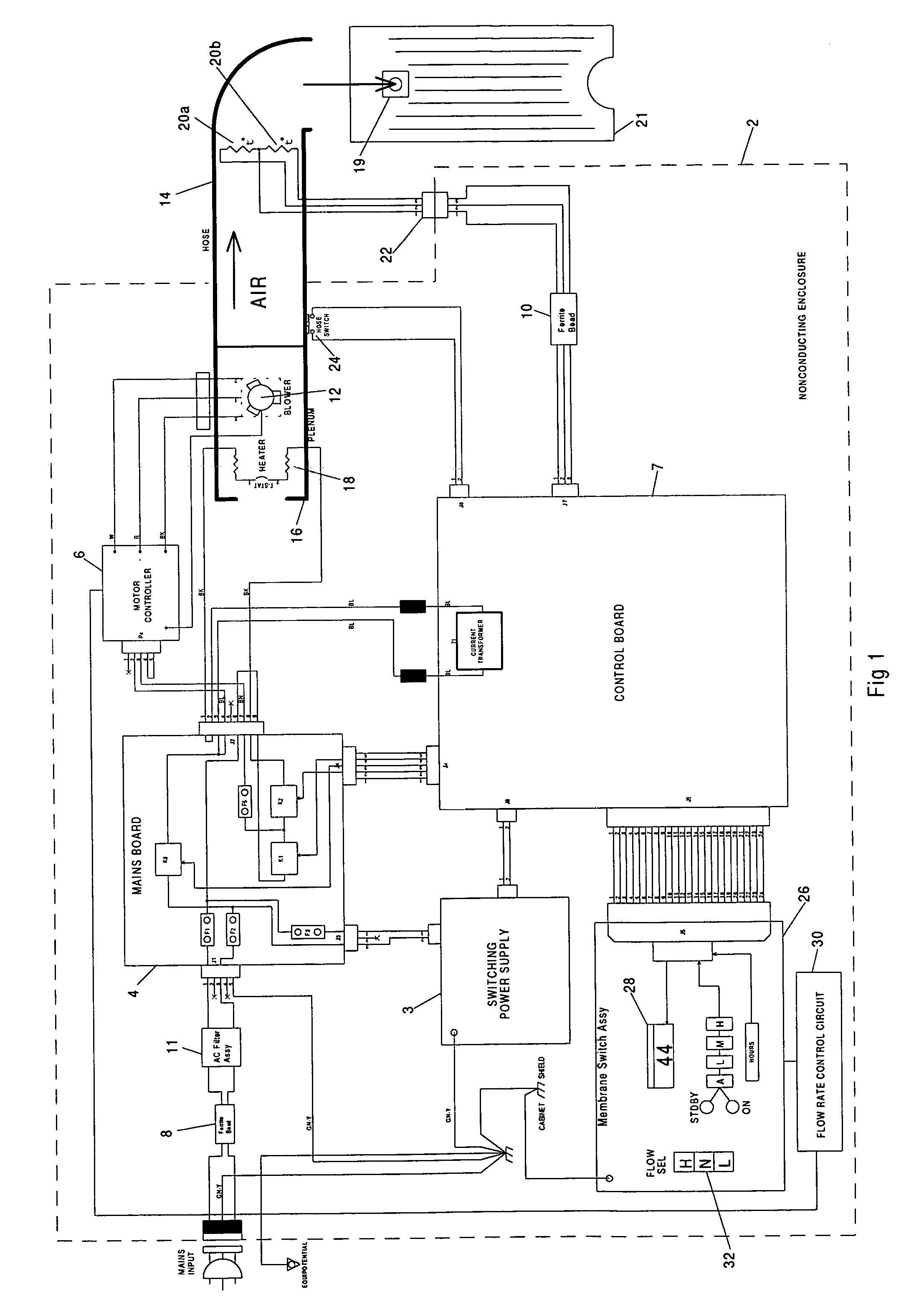

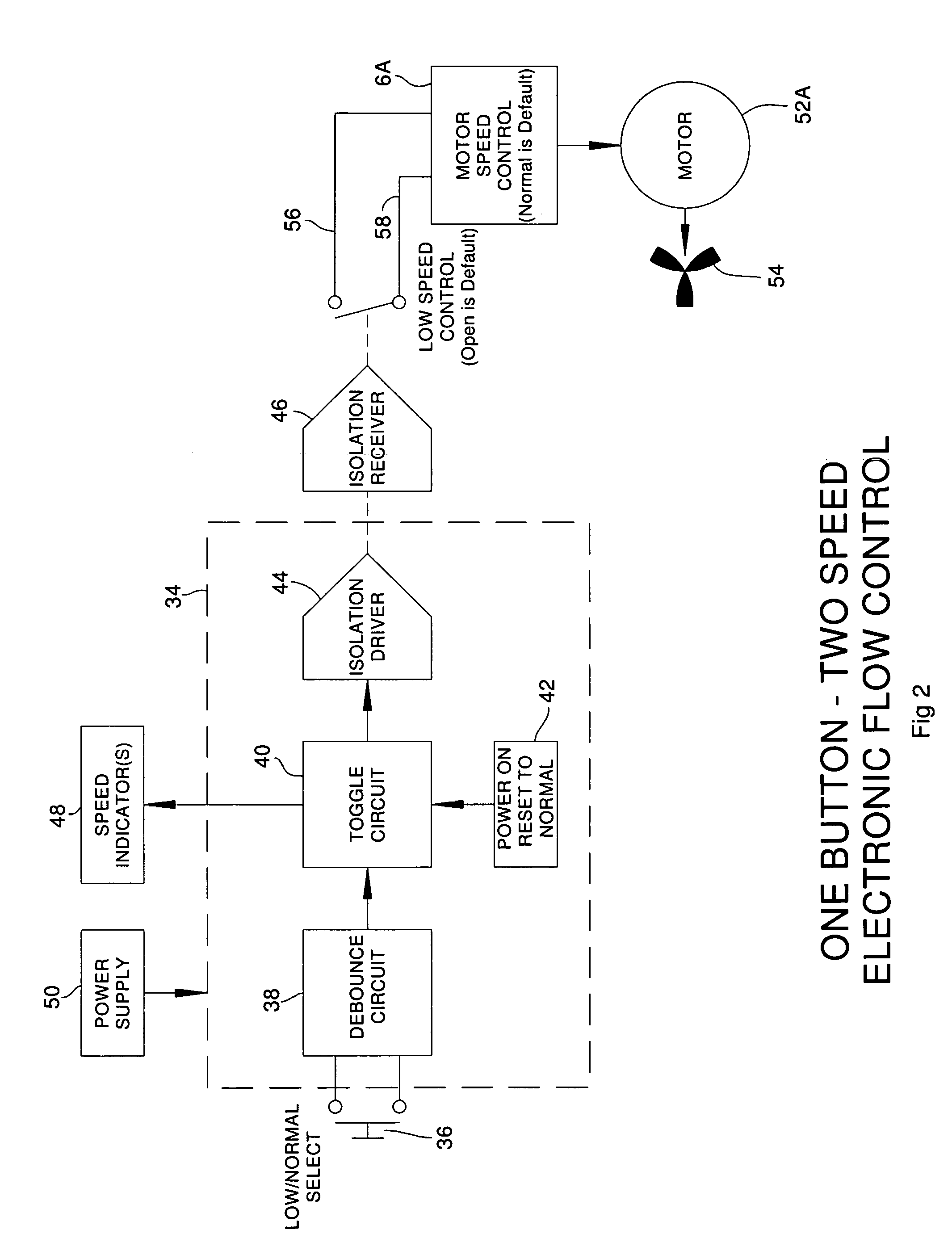

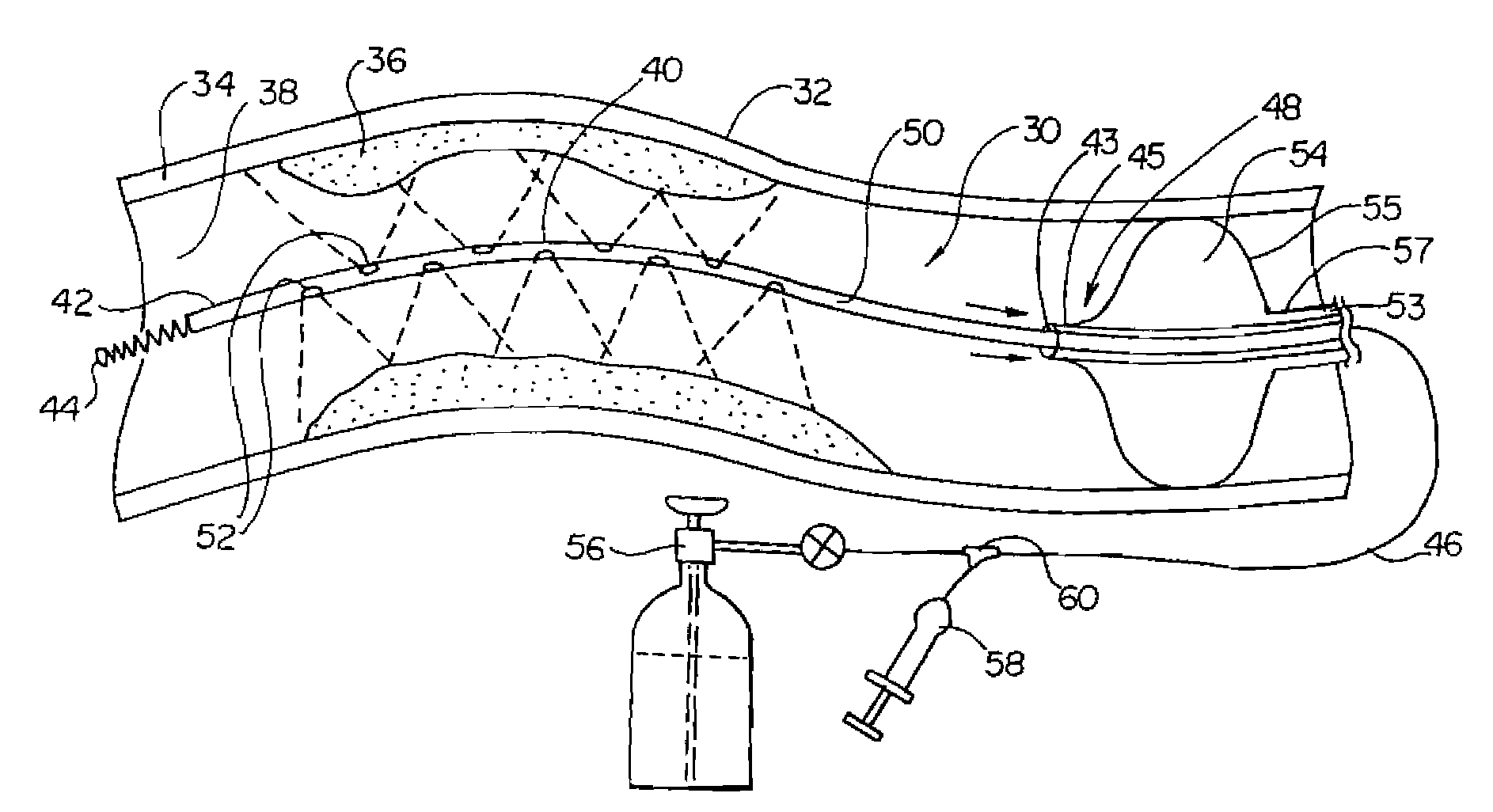

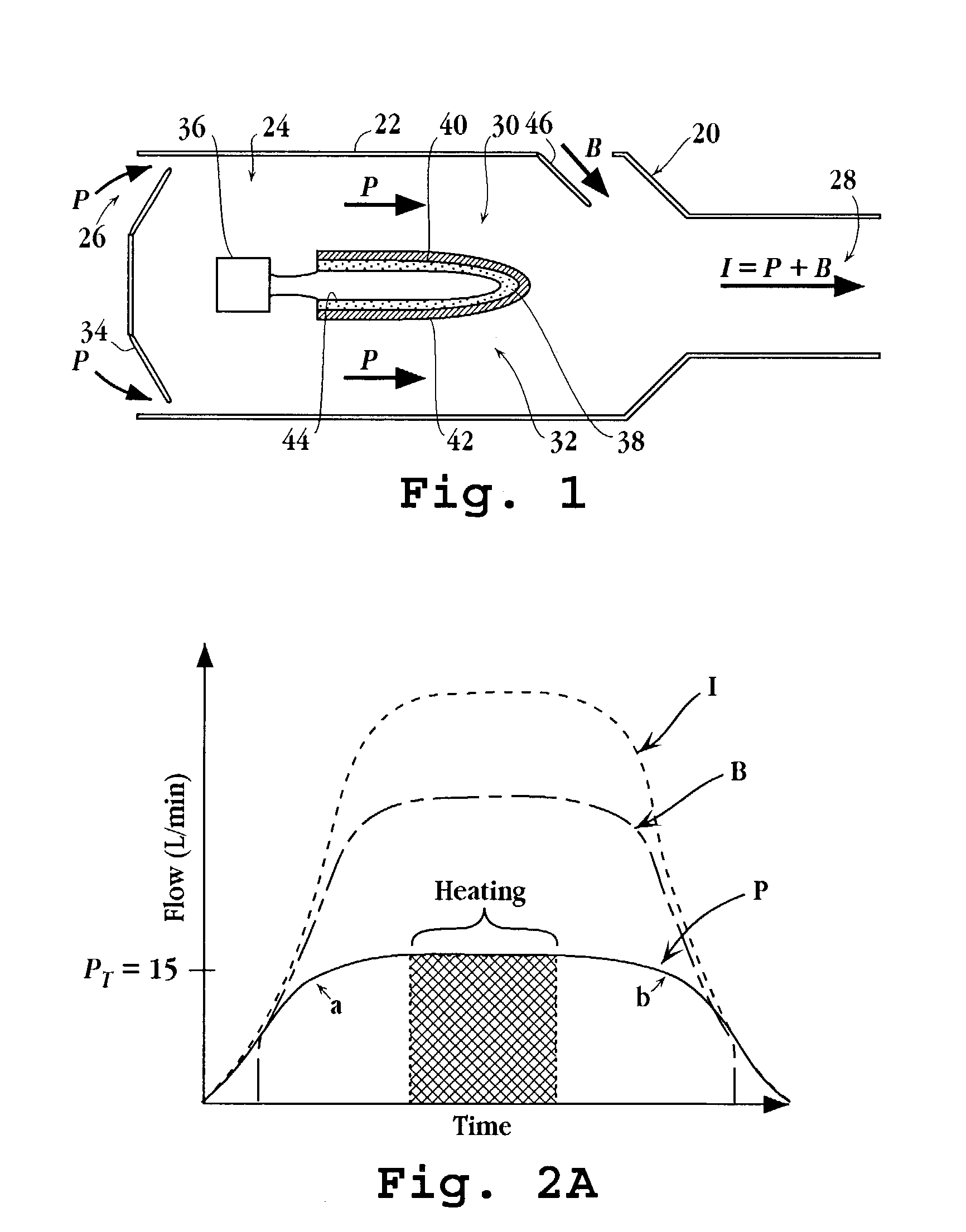

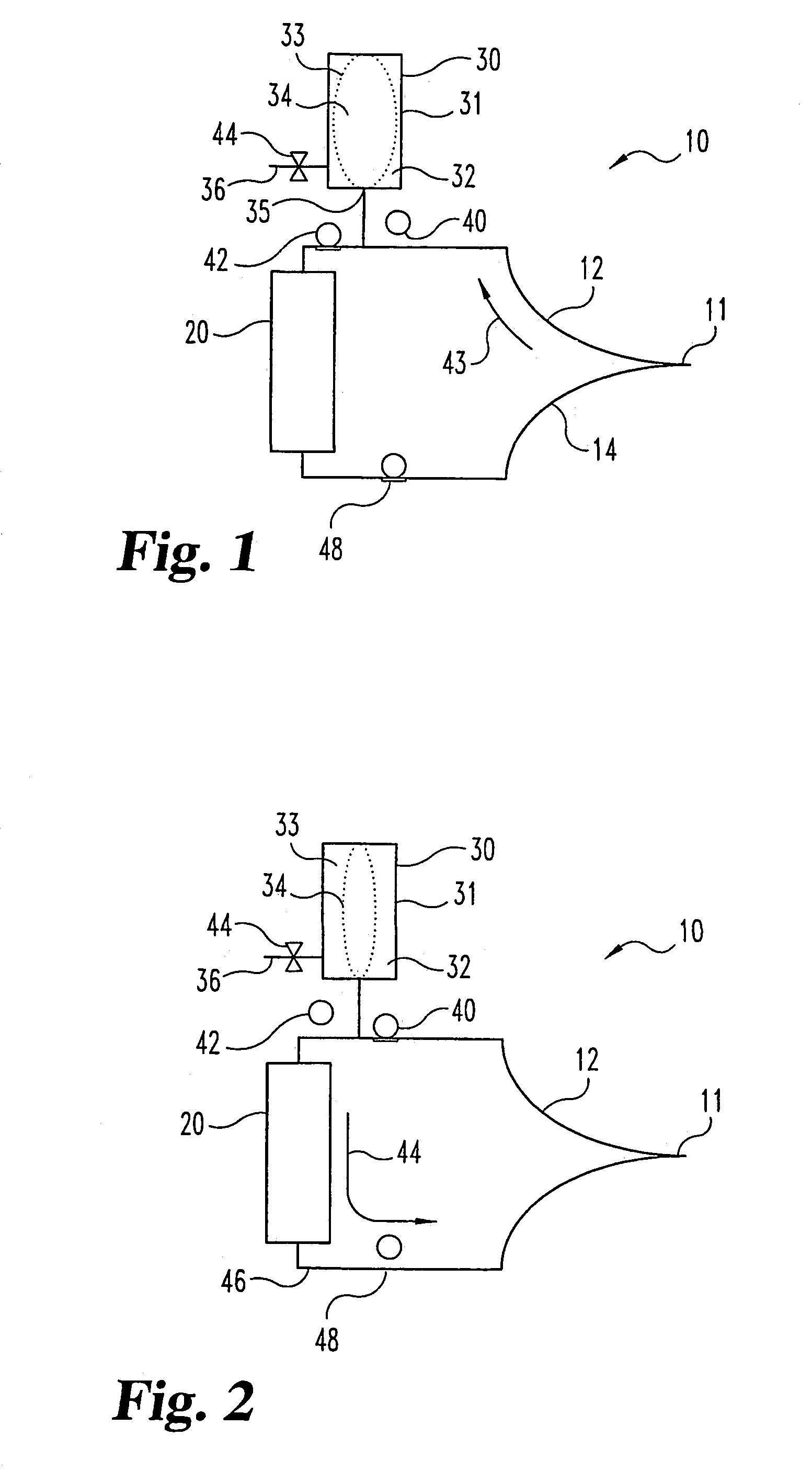

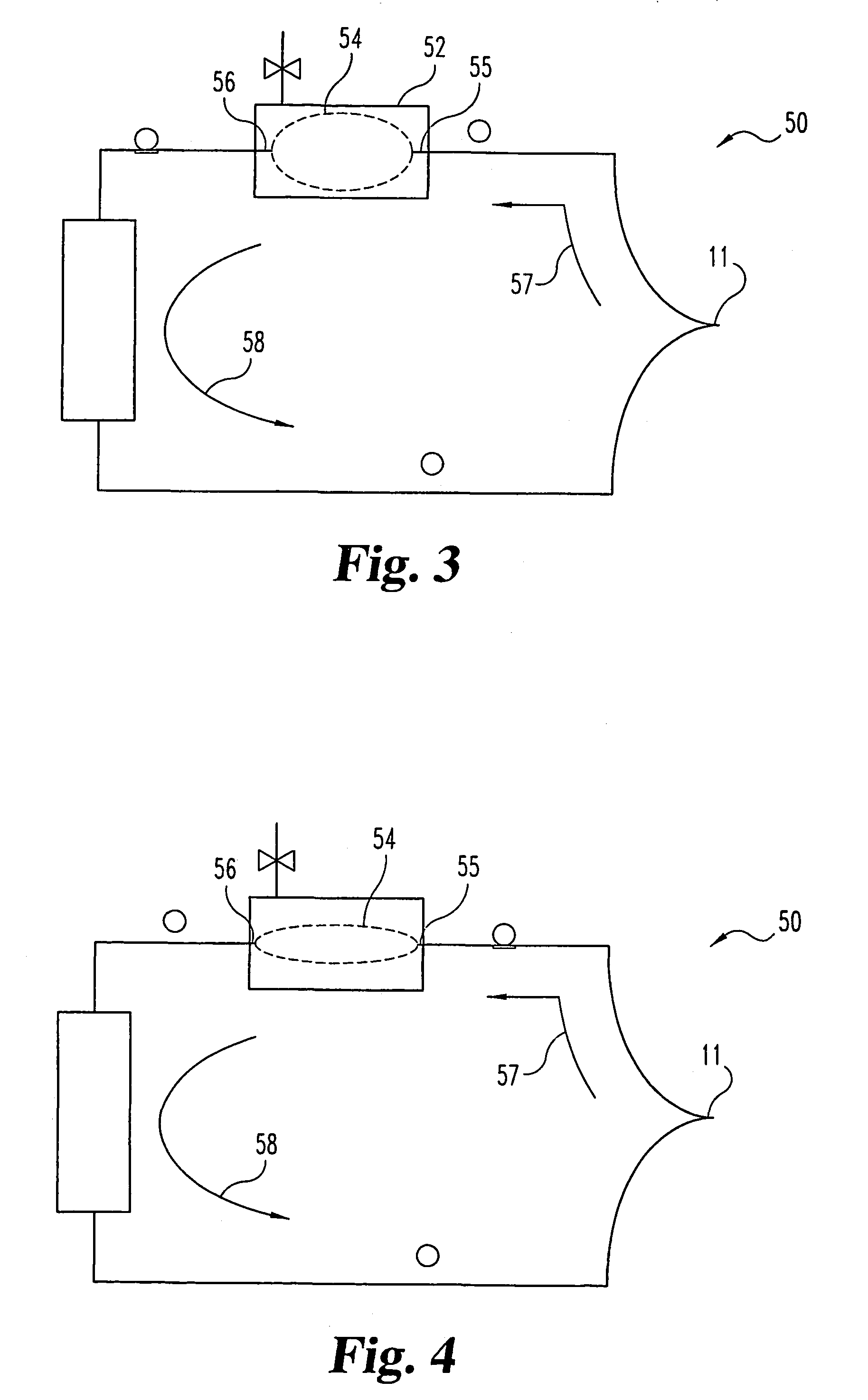

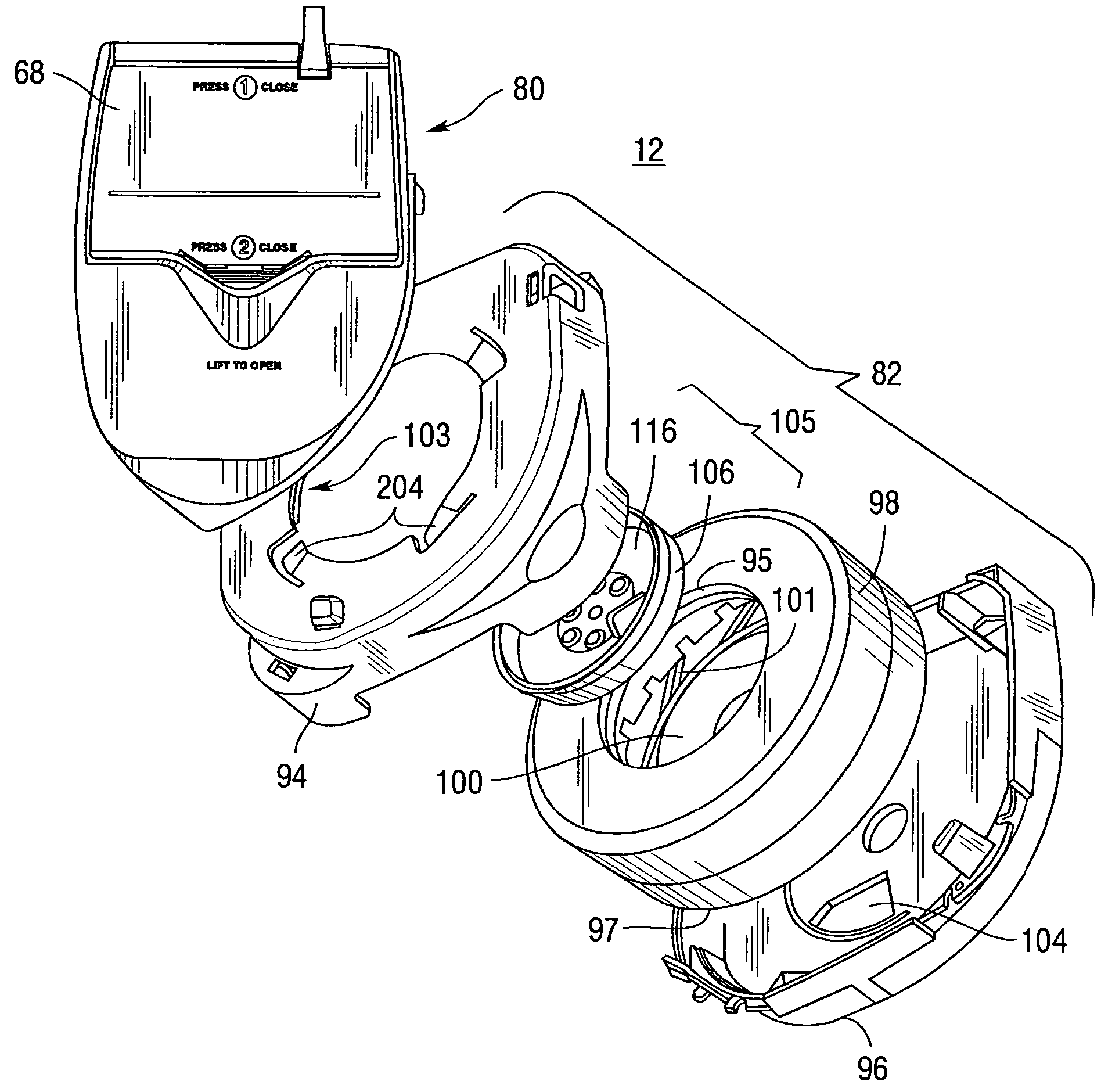

System for providing actuated optimal inflation to multiple temperature regulated blankets and method therefor

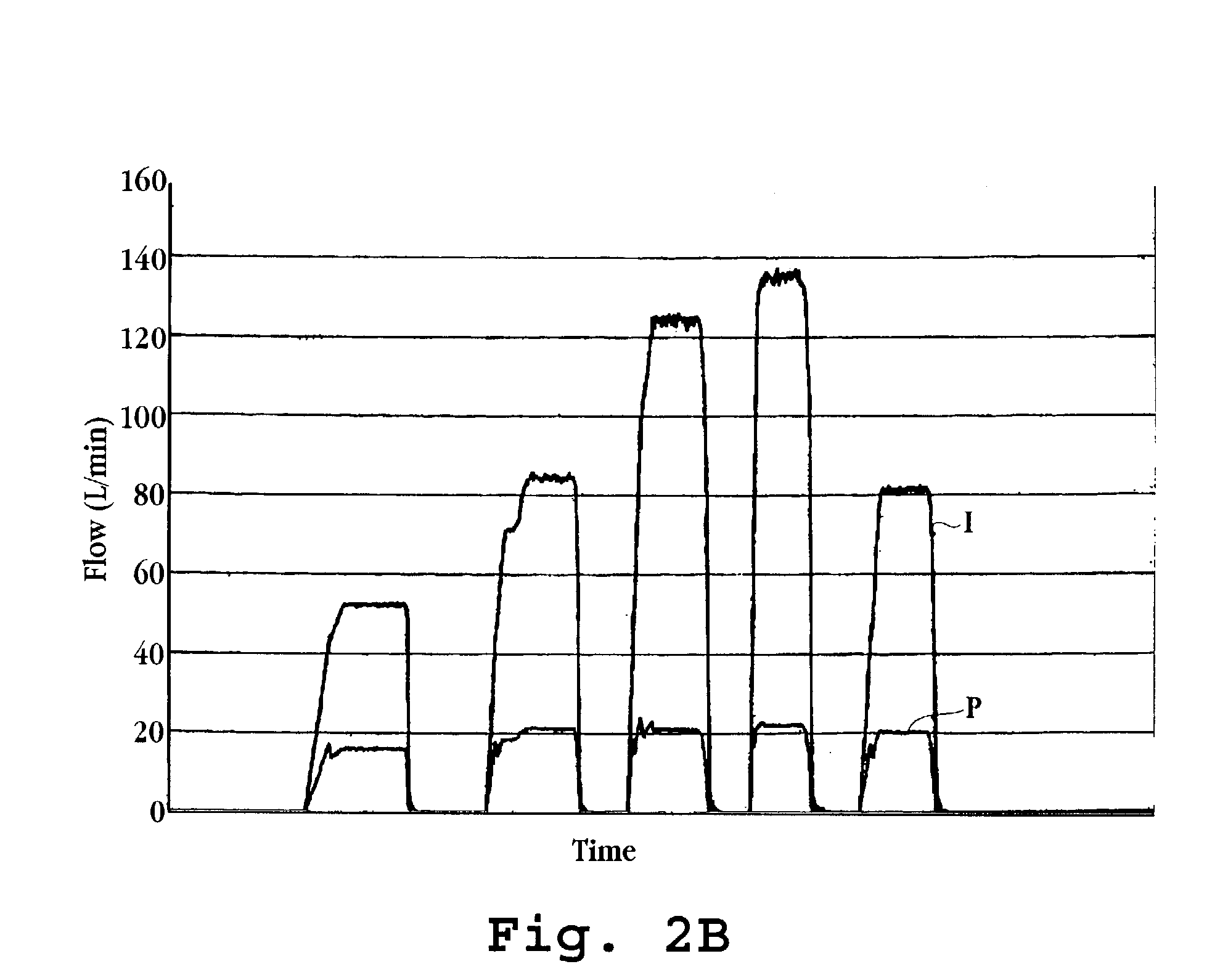

A convective warmer to which blankets of different dimensions may be connected is capable of providing air to the various blankets at flow rates that optimally inflate those blankets to achieve the optimal clinical result for the patients covered by those blankets. The blanket connected to the warmer may range from a full size adult warming blanket to a pediatric warming blanket. The convection warmer may have multiple fixed air flow rates each selectable by a user, via switch(es) either electronically or mechanically. For the electronic selection of a given flow rate, a motor adaptable to rotate a different speeds is used. To vary the flow rate mechanically, a valve is controlled to vary the amount of air that may pass to the blanket. Instead of different fixed flow rates, variable air flow rates, selectable by the user, may be used. Also, a feedback circuit that maintains the pressure sensed at the outlet of the warmer to a preset pressure may be used to eliminate the need for user intervention.

Owner:SMITHS MEDICAL ASD INC

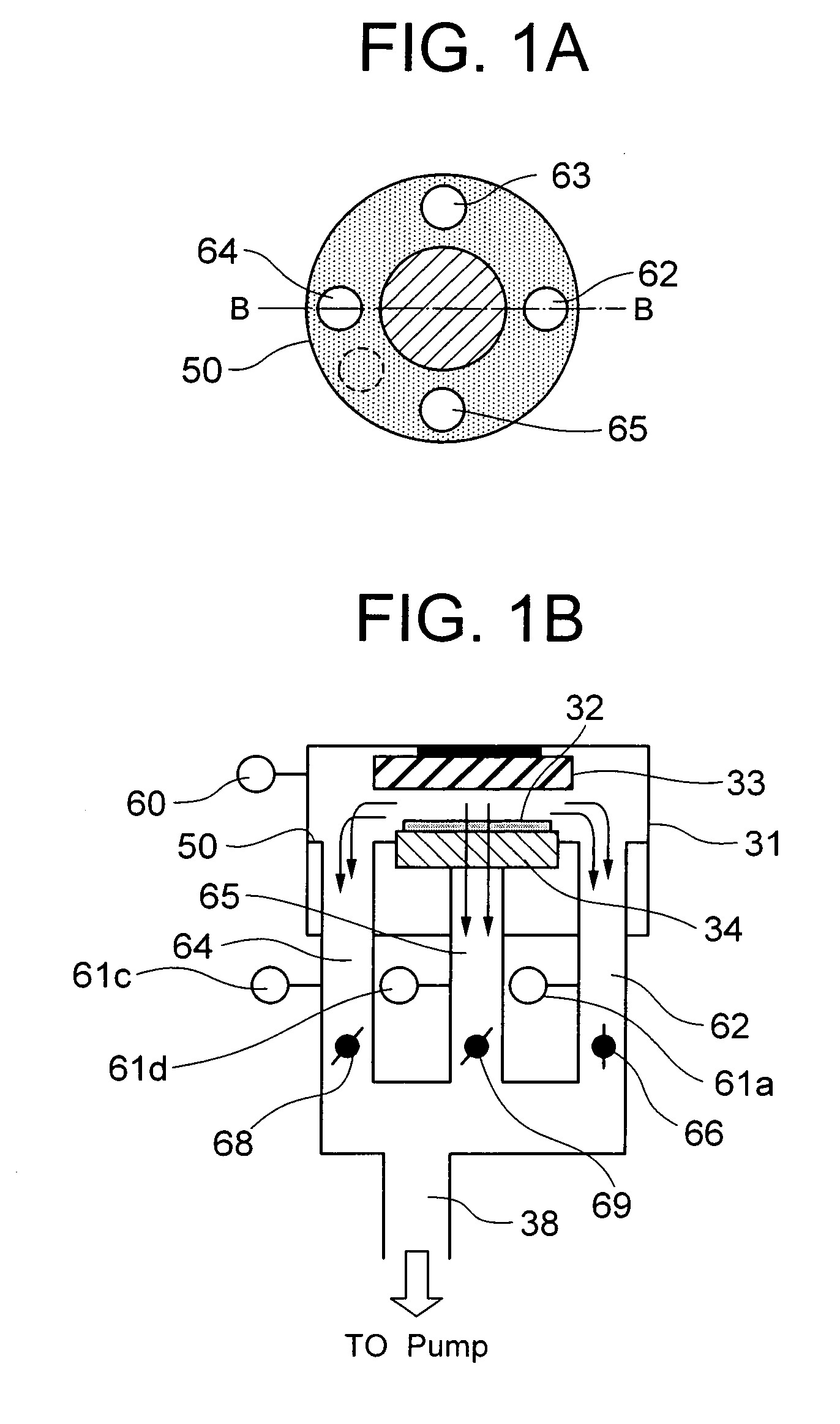

Atomic layer deposition system including a plurality of exhaust tubes

InactiveUS20080176412A1Uniform film qualityHigh aspect ratioLiquid surface applicatorsSemiconductor/solid-state device manufacturingControl valvesVapor phase

An atomic layer deposition system includes a reaction chamber, a plurality of exhaust tubes communicated to the reaction chamber, a plurality of first vacuum gauges for monitoring the degree of vacuum of the respective exhaust tubes, a second vacuum gauge for monitoring the degree of vacuum of the reaction chamber, and control valves for adjusting the exhaust volume of the exhaust tubes independently of one another. The control valves are controlled based on the pressures measured by the first and second control valves for achieving a uniform flow of the vapor phase reactant.

Owner:PS4 LUXCO SARL

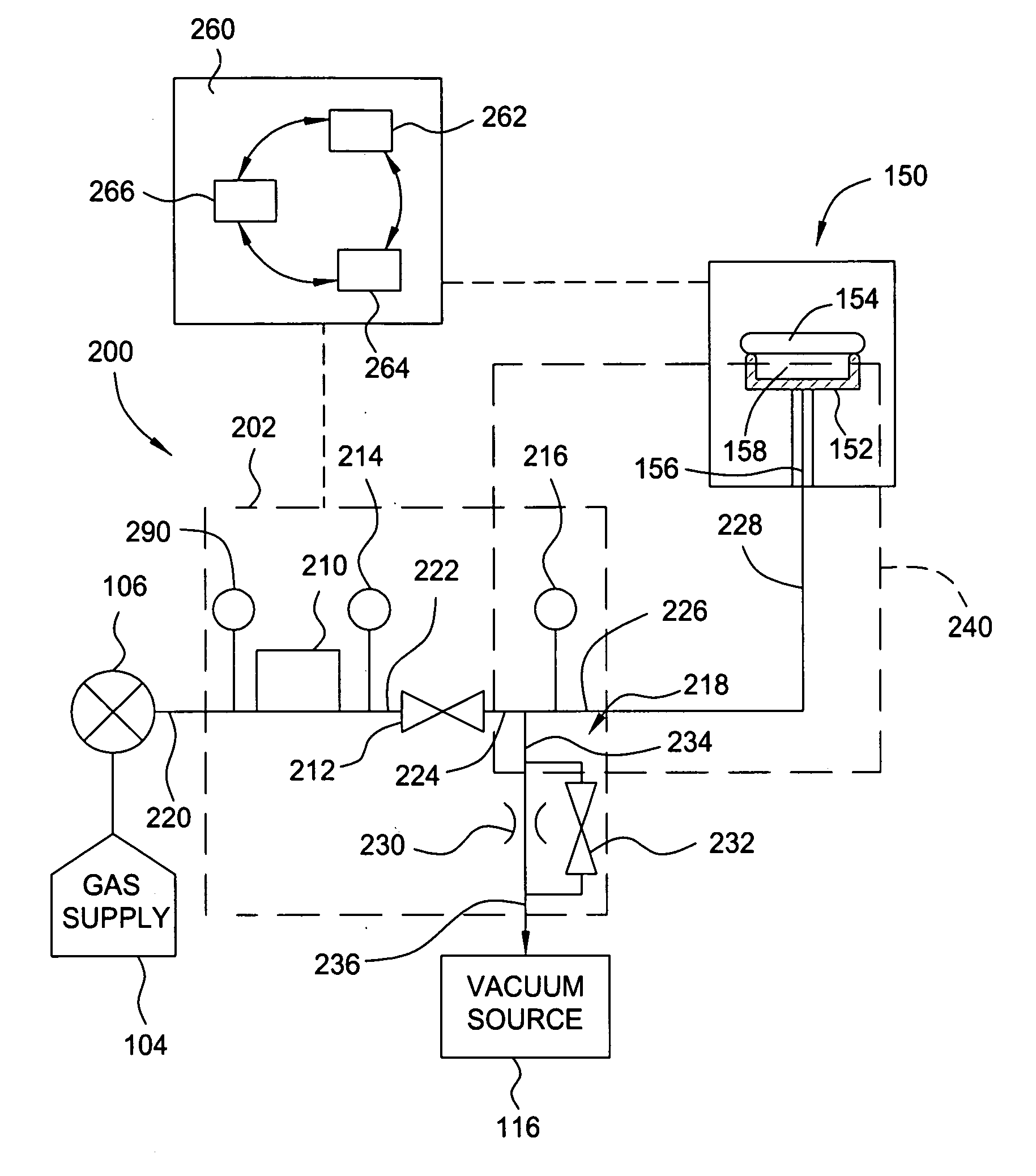

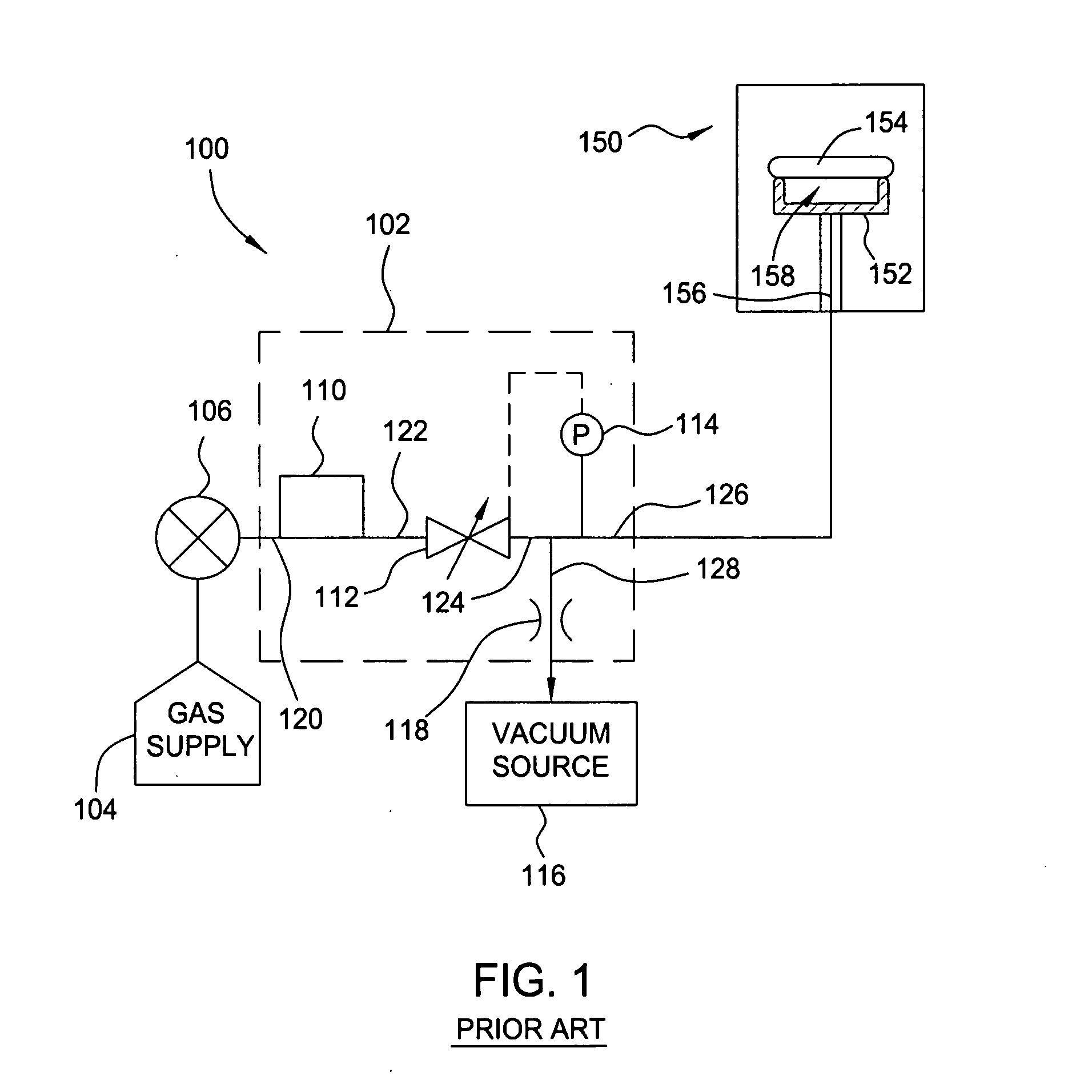

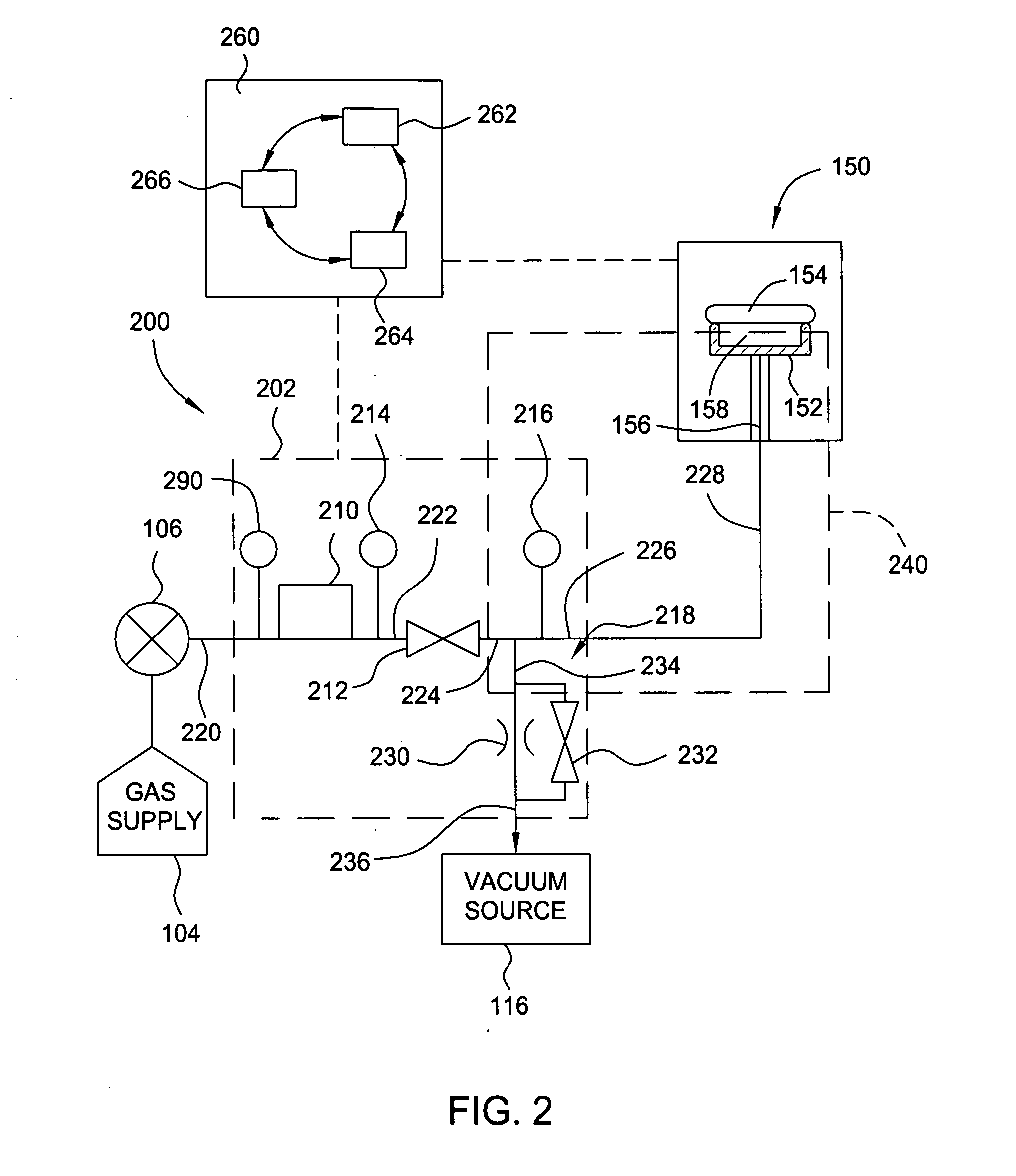

Method and apparatus for substrate temperature control

InactiveUS20050120805A1Electric discharge tubesAerodynamic testingTemperature controlFlow transducer

A method and apparatus for gas control is provided. The apparatus may be used for controlling gases delivered to a chamber, controlling the chamber pressure, controlling the delivery of backside gas between a substrate and substrate support and the like. In one embodiment, an apparatus for controlling gas control includes at least a first flow sensor having a control valve, a first pressure sensor and at least a second pressure sensor. An inlet of the first flow sensor is adapted for coupling to a gas supply. A control valve is coupled to an outlet of the flow sensor. The first pressure sensor is adapted to sense a metric indicative of the pressure upstream of the first flow sensor. The second pressure sensor is adapted to sense a metric indicative of the pressure downstream of the control valve.

Owner:APPLIED MATERIALS INC

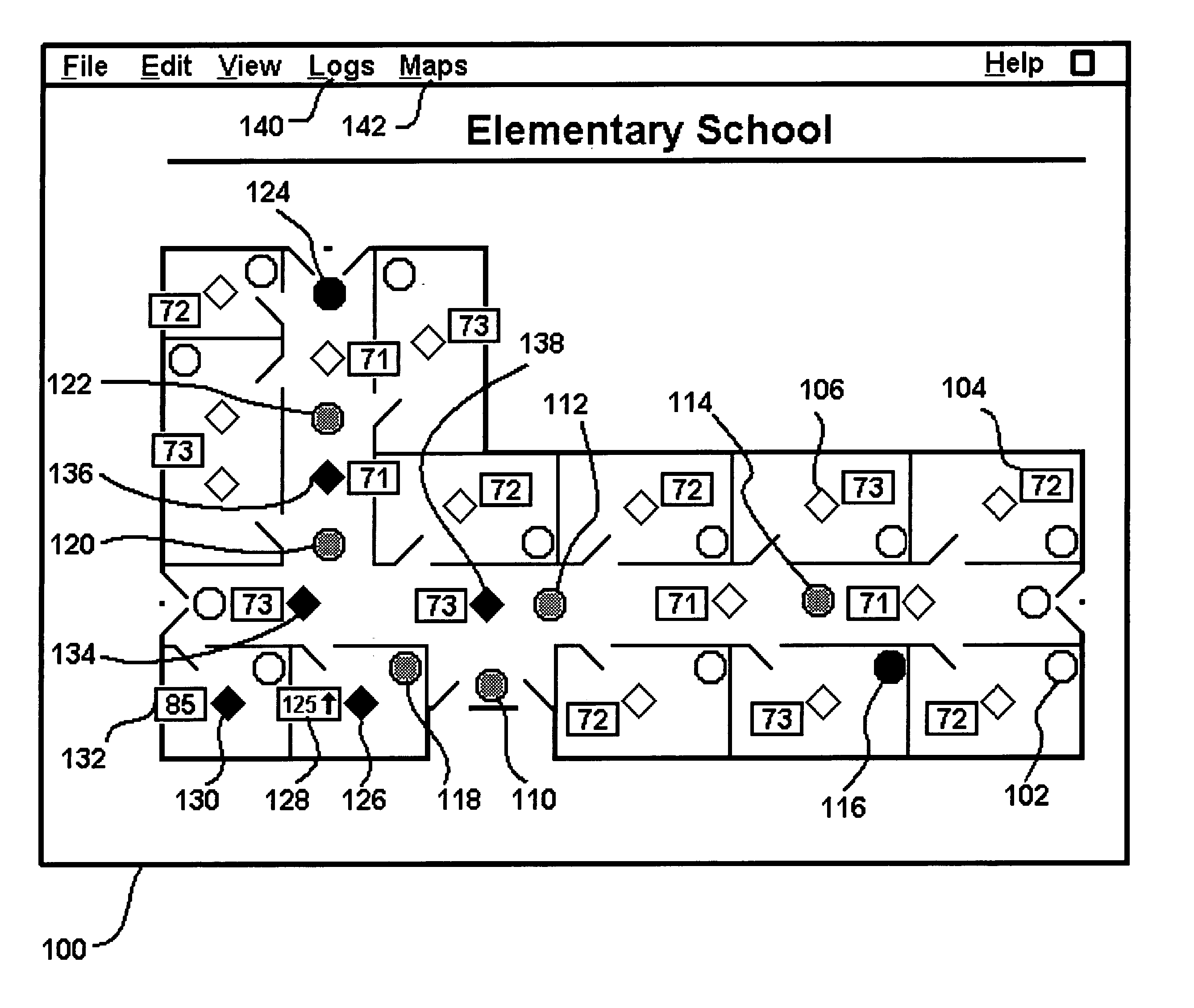

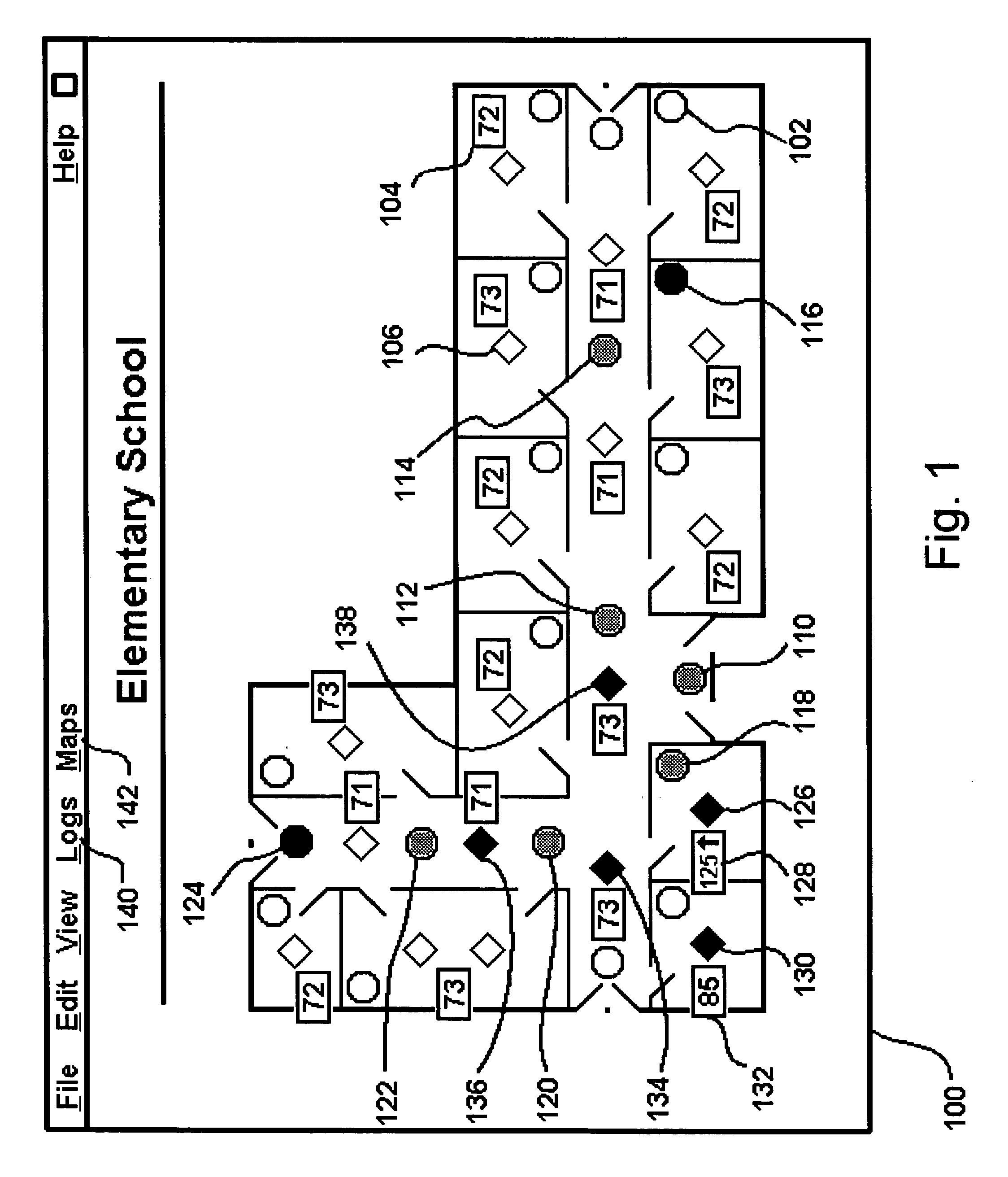

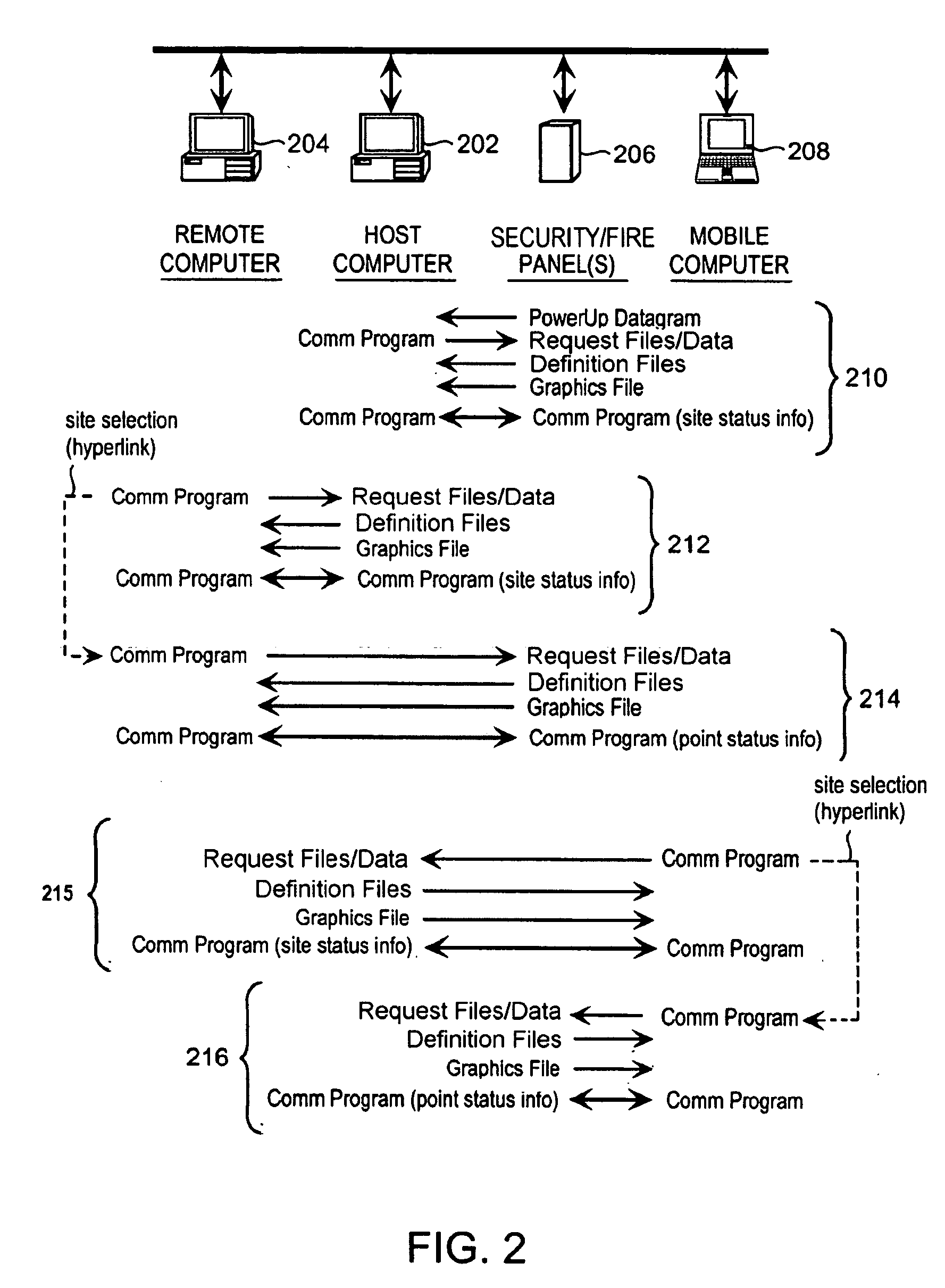

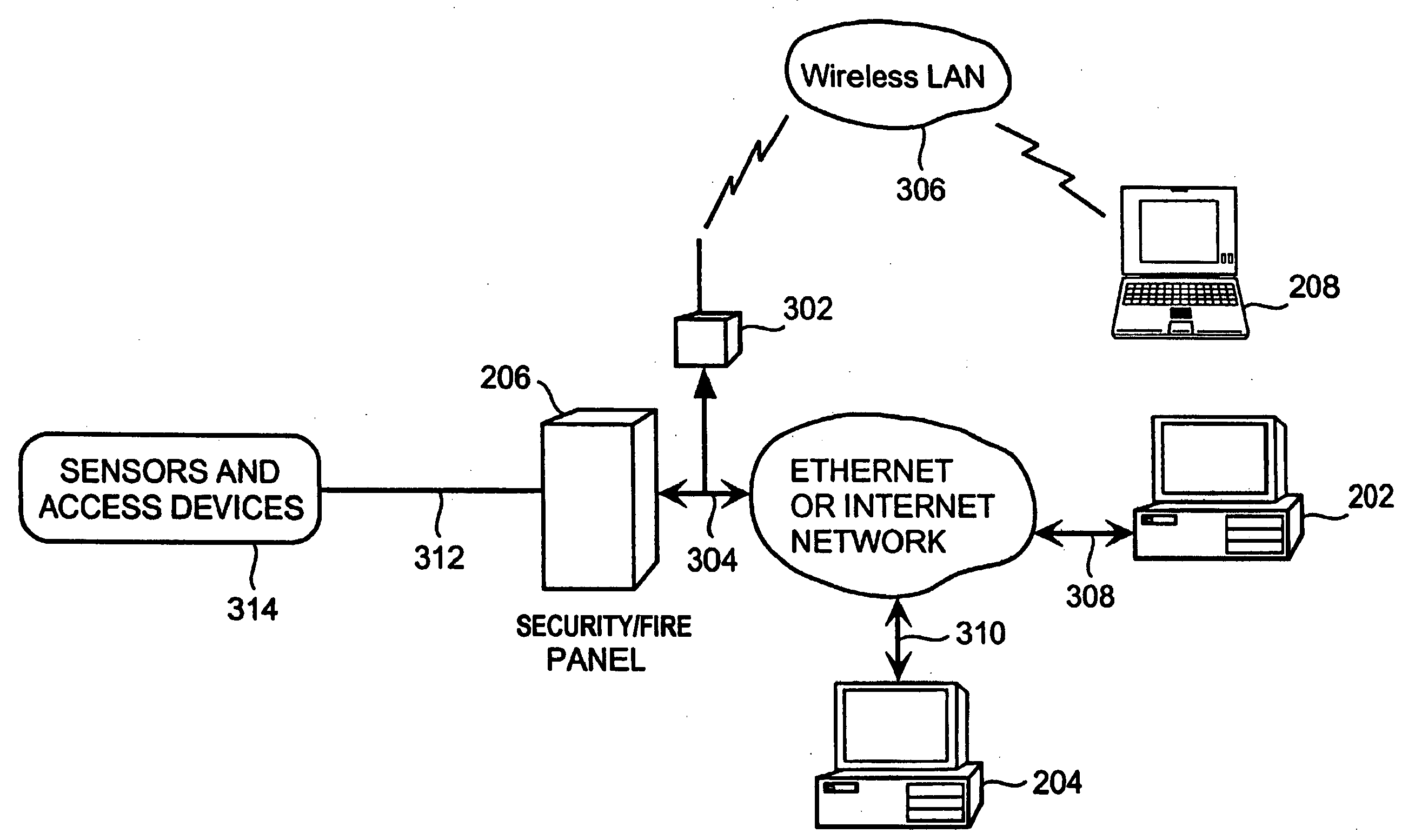

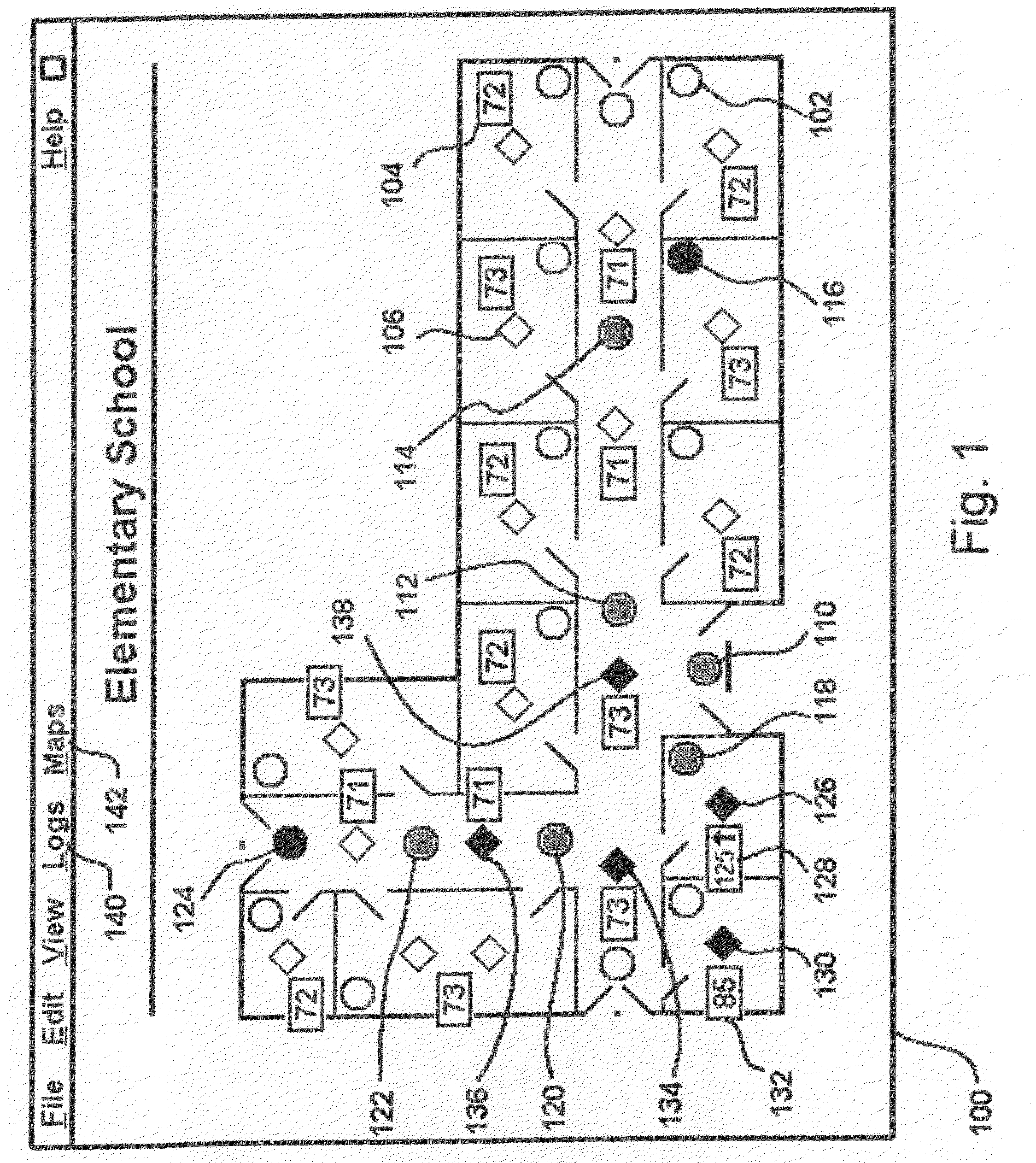

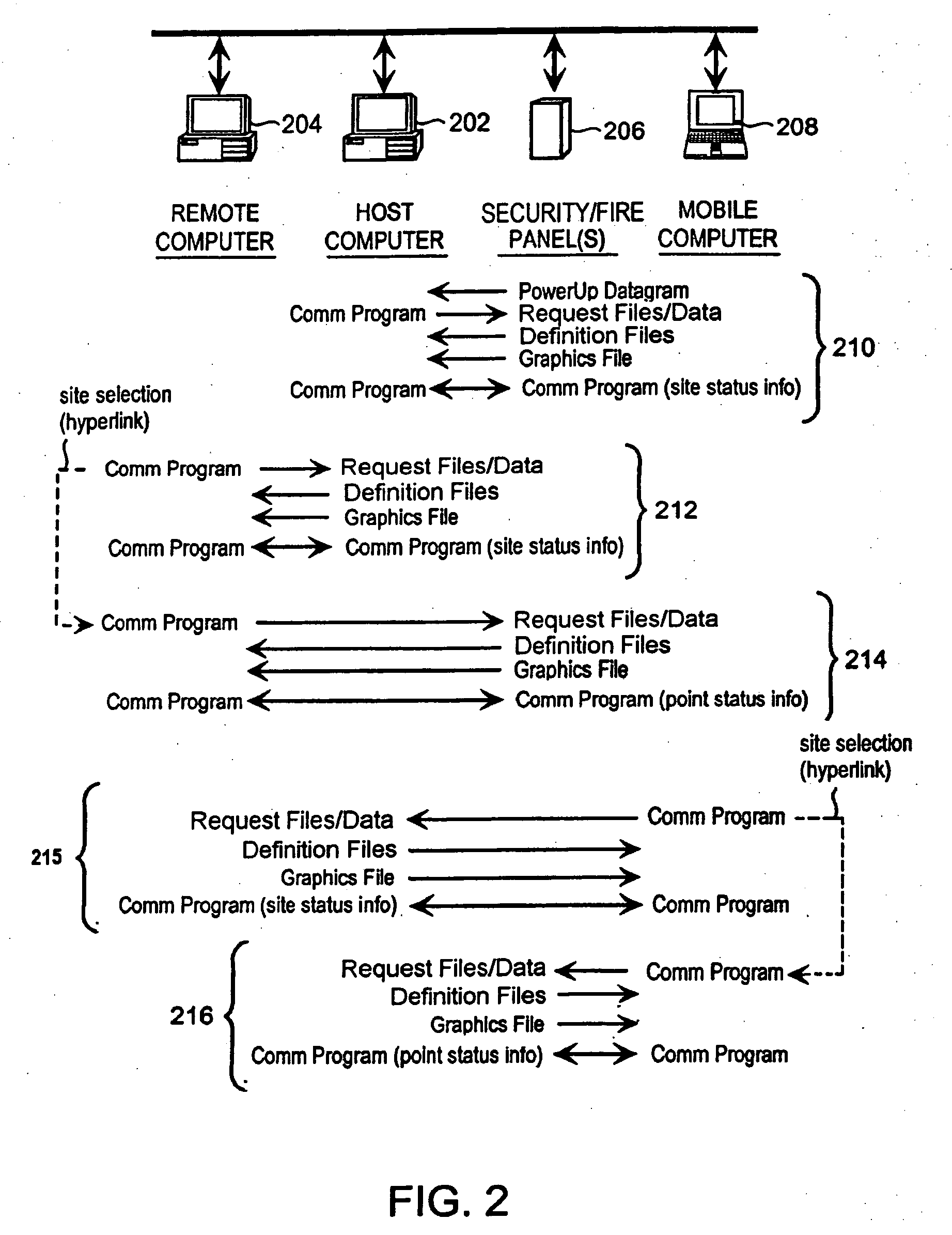

Method and apparatus for remotely monitoring a site

InactiveUS20070008099A1Maximum precisionEasy to distinguishFire rescueFire alarmsTime informationSprinkler system

The present invention is directed to providing systems and methods for remotely monitoring sites to provide real-time information which can readily permit distinguishing false alarms, and which can identify and track the precise location of an alarm. In embodiments, monitoring capabilities such as intrusion / fire detection and tracking capabilities, can be implemented through the use of multistate indicators in an interface which permits information to be transmitted using standard network protocols from a remote site to a monitoring station in near real-time. In embodiments, communications can be handed from the centrally located host monitoring station to a mobile monitoring station (for example, a laptop computer in a responding vehicle, such as a police or fire vehicle). Additional embodiments include the measurement of environmental parameters such as temperature, carbon monoxide and differential air pressure to detect, monitor and manage a fire event. These measurements along with selected controllable output devices deployed in a space, such as sprinkler control valves and individually or zoned sprinkler heads, are used to initiate and control fire suppression technology both locally and remotely. For instance, a system of the present invention may detect a fire and cause a sprinkler system to disburse water in a facility.

Owner:NETTALON SECURITY SYST

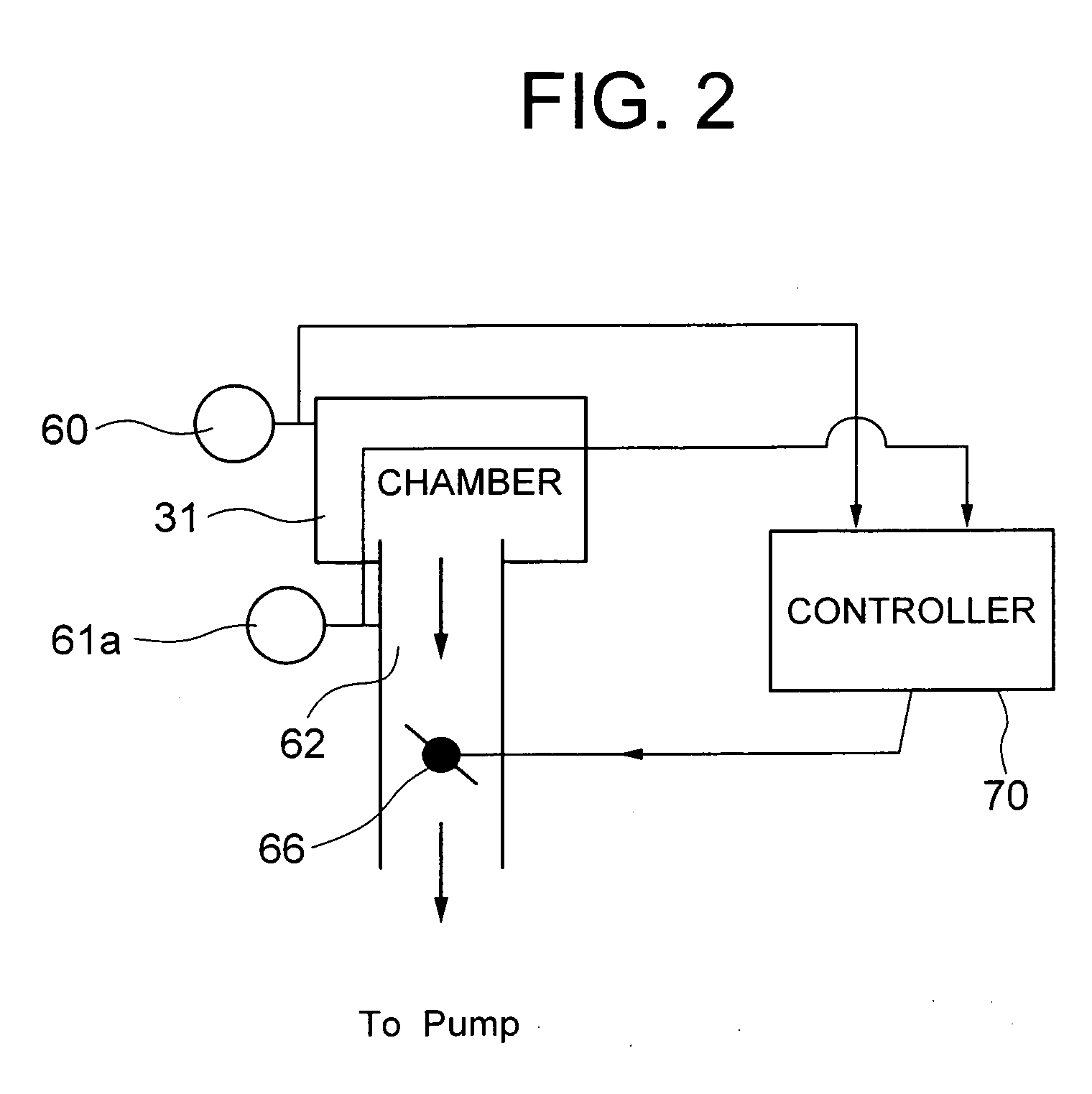

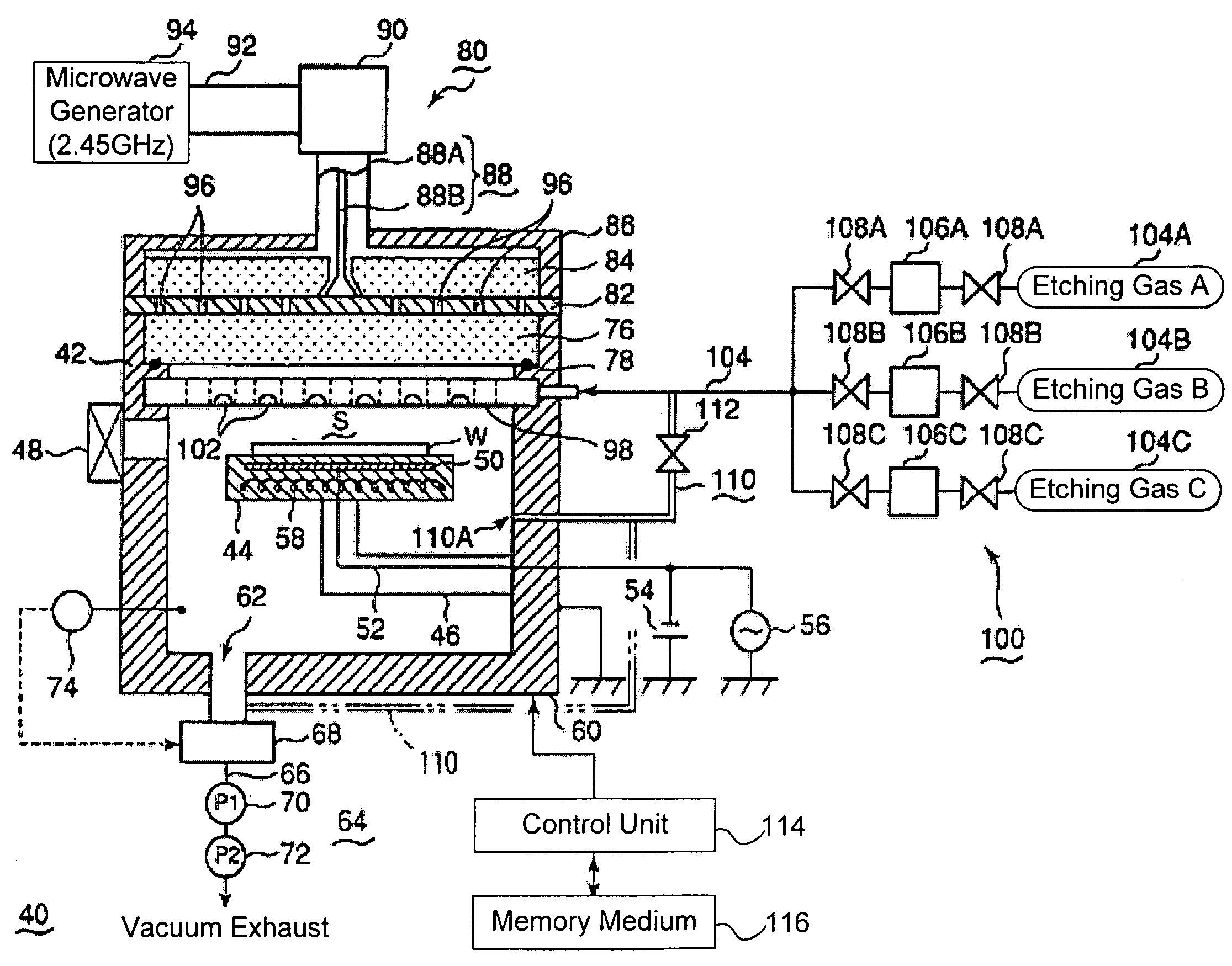

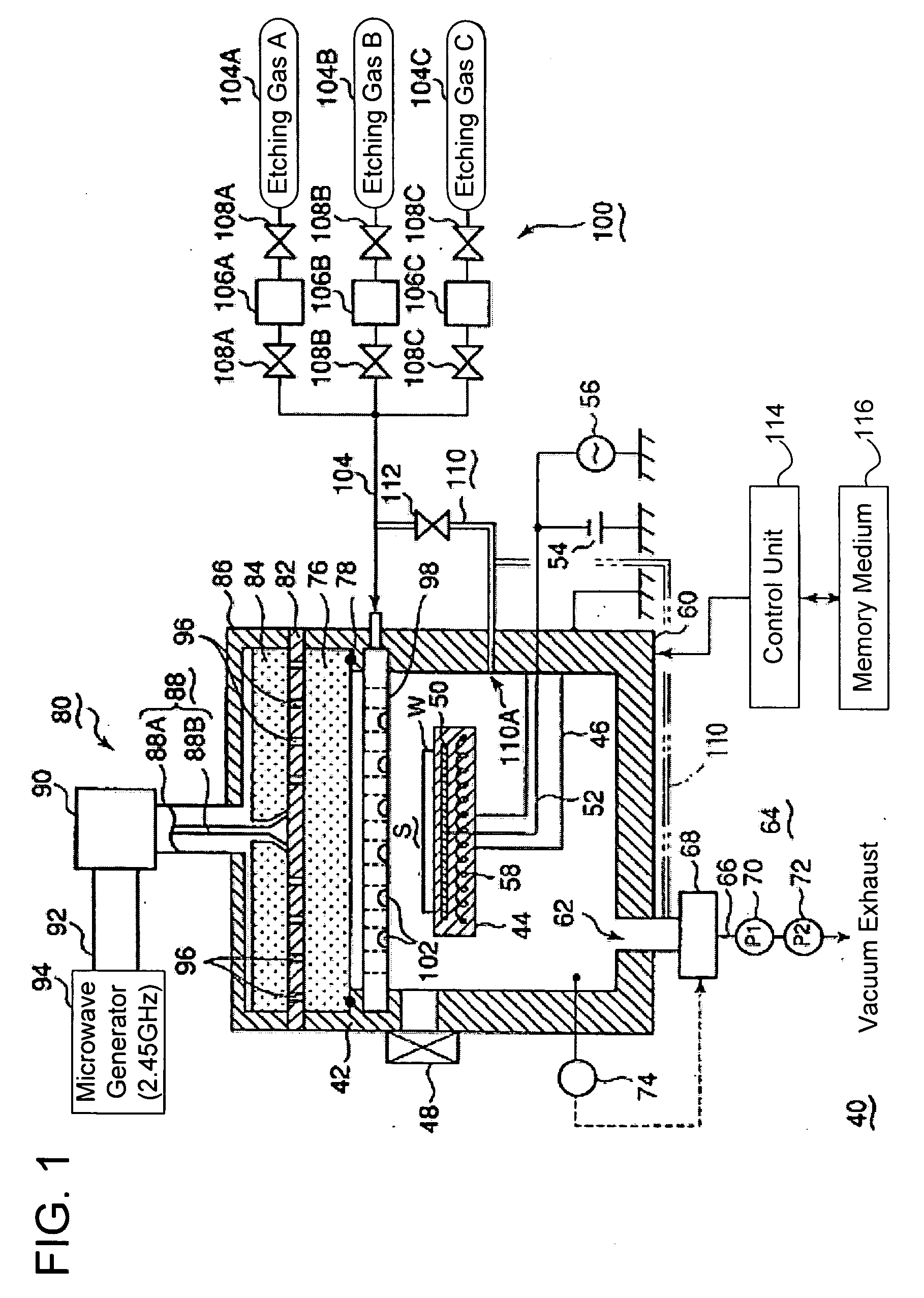

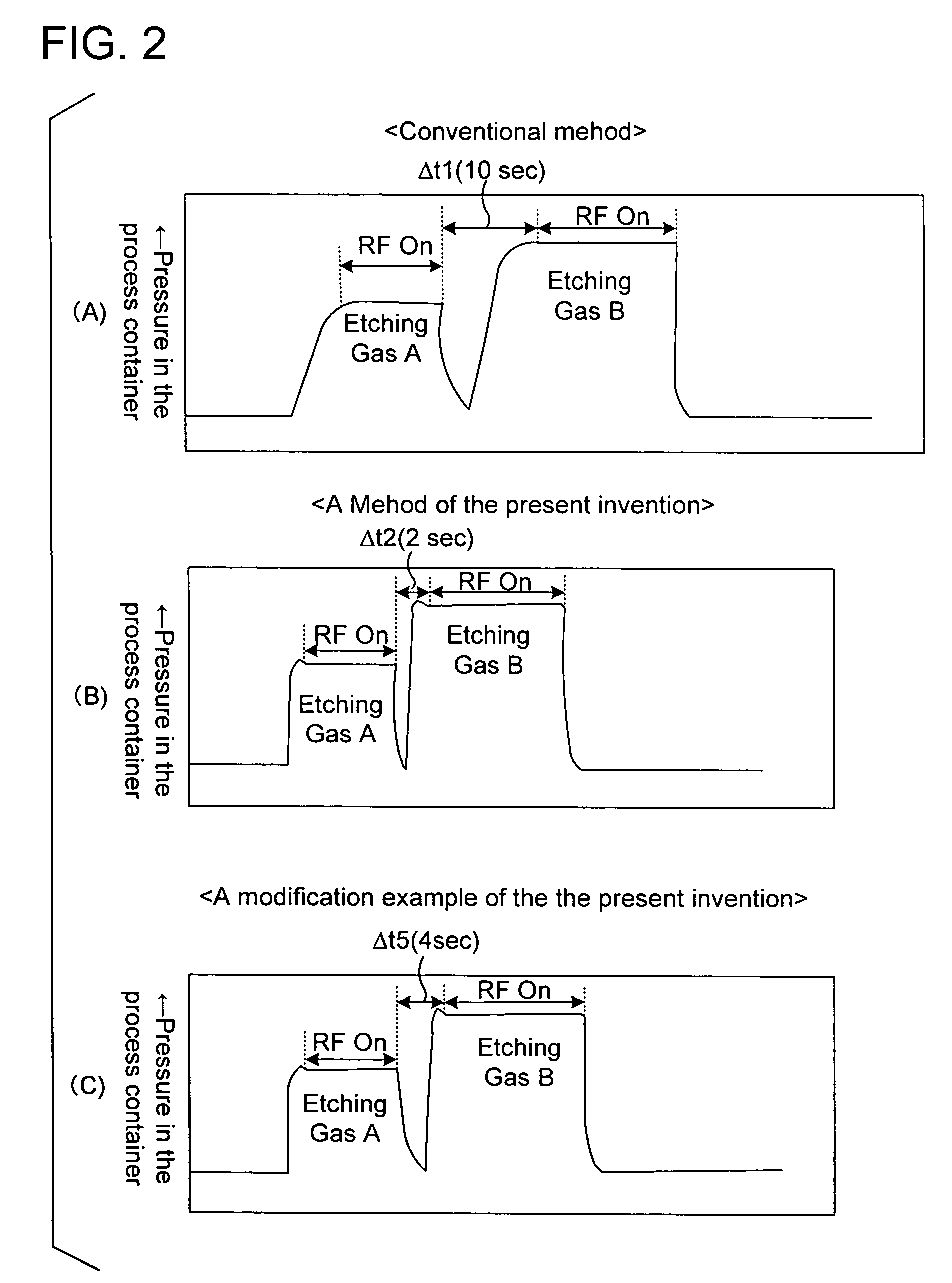

Processing Apparatus and Processing Method

ActiveUS20090053900A1Stable and fastAddressing slow performanceLiquid surface applicatorsElectric discharge tubesProduct gasEngineering

A processing apparatus includes a process container having a placing table for placing a processing object, an exhaust system having vacuum pumps and a pressure control valve for exhausting atmosphere in the process container. A gas injection unit having a gas ejection hole is provided in the process container, as well as a gas supplying unit for supplying a process gas to the gas injection unit. The entire process apparatus is controlled by a controlling unit. The control unit controls the exhaust system and the gas supplying unit. When starting a predetermined process, the process gas at a flow rate greater than a prescribed flow rate is supplied for a short time while exhausting the atmosphere in the process container by the exhaust system, and then the process gas at a prescribed flow rate is supplied.

Owner:TOKYO ELECTRON LTD

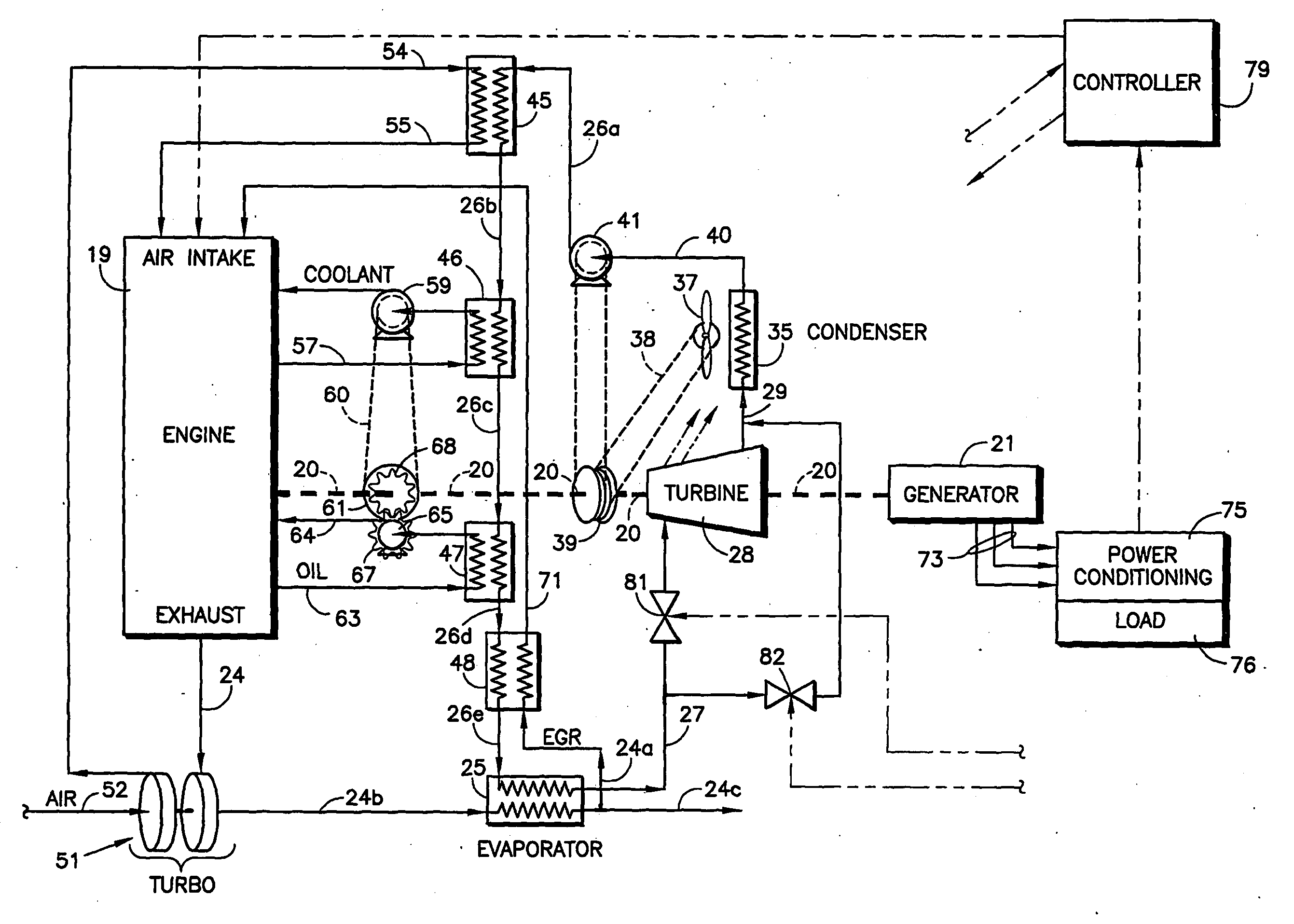

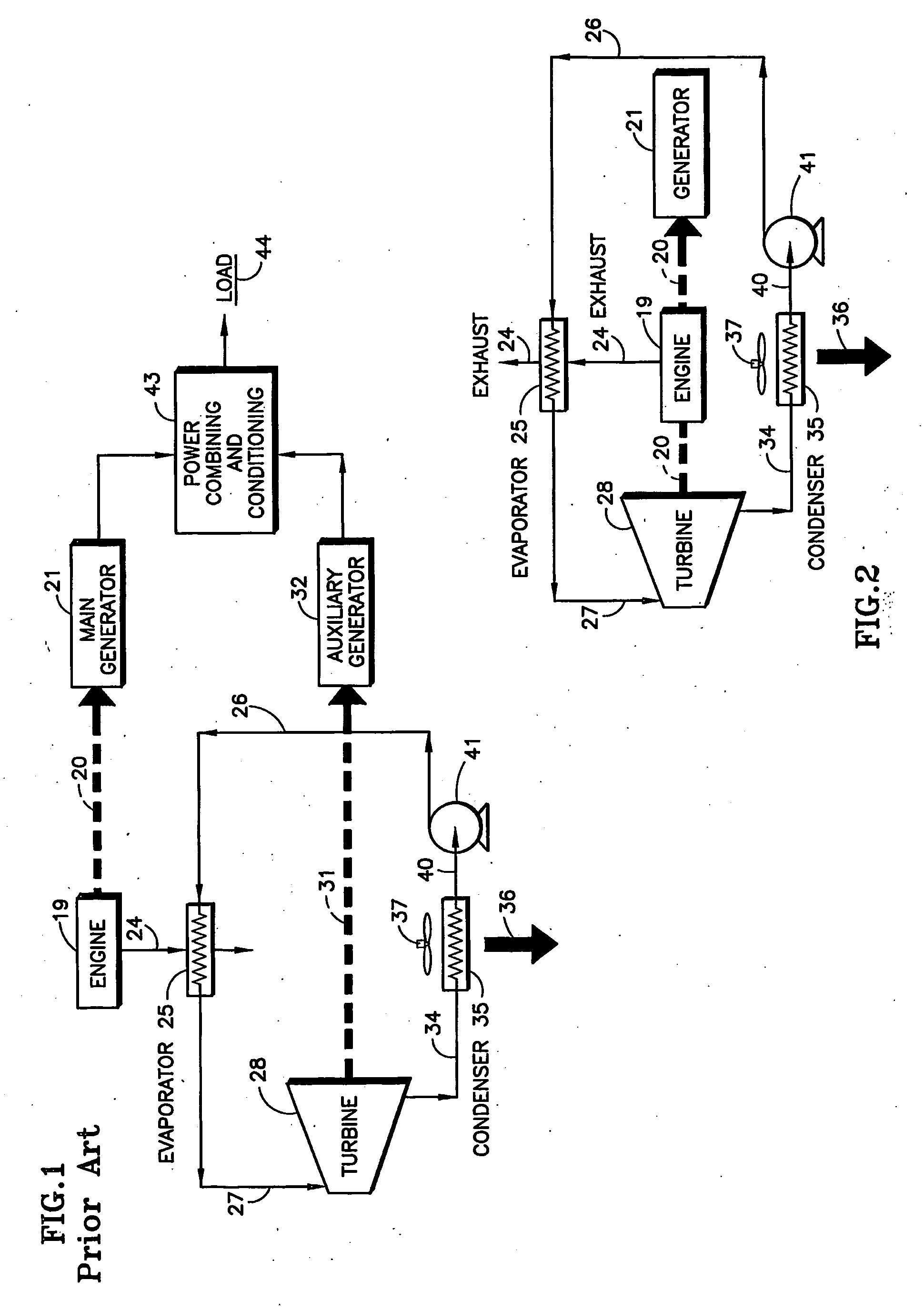

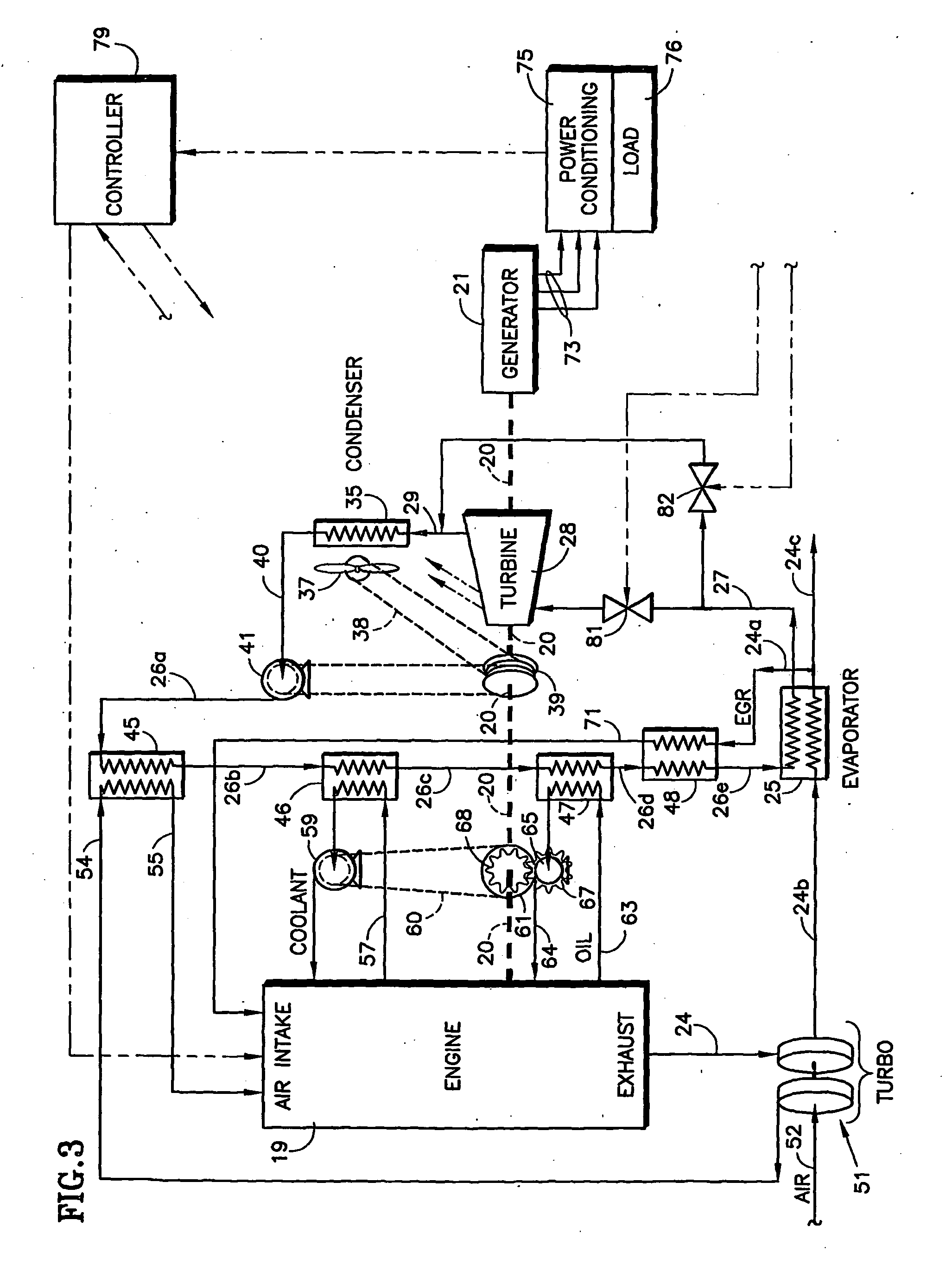

Organic Rankine Cycle Mechanically and Thermally Coupled to an Engine Driving a Common Load

InactiveUS20090211253A1Maximize efficiencyEngine componentsSteam engine plantsPtru catalystOrganic Rankine cycle

The shaft (20) of an engine (19) is coupled to a turbine (28) of an organic Rankine cycle subsystem which extracts heat (45-48, 25) from engine intake air, coolant, oil, EGR and exhaust. Bypass valves (92,94, 96, 99) control engine temperatures. Turbine pressure drop is controlled via a bypass valve (82) or a mass flow control valve (113). A refrigeration subsystem having a compressor (107) coupled to the engine shaft uses its evaporator (45a) to cool engine intake air. The ORC evaporator (25a) may comprise a muffler including pressure pulse reducing fins (121, 122), some of which have NOx and / or particulate reducing catalysts thereon.

Owner:UNITED TECH CORP

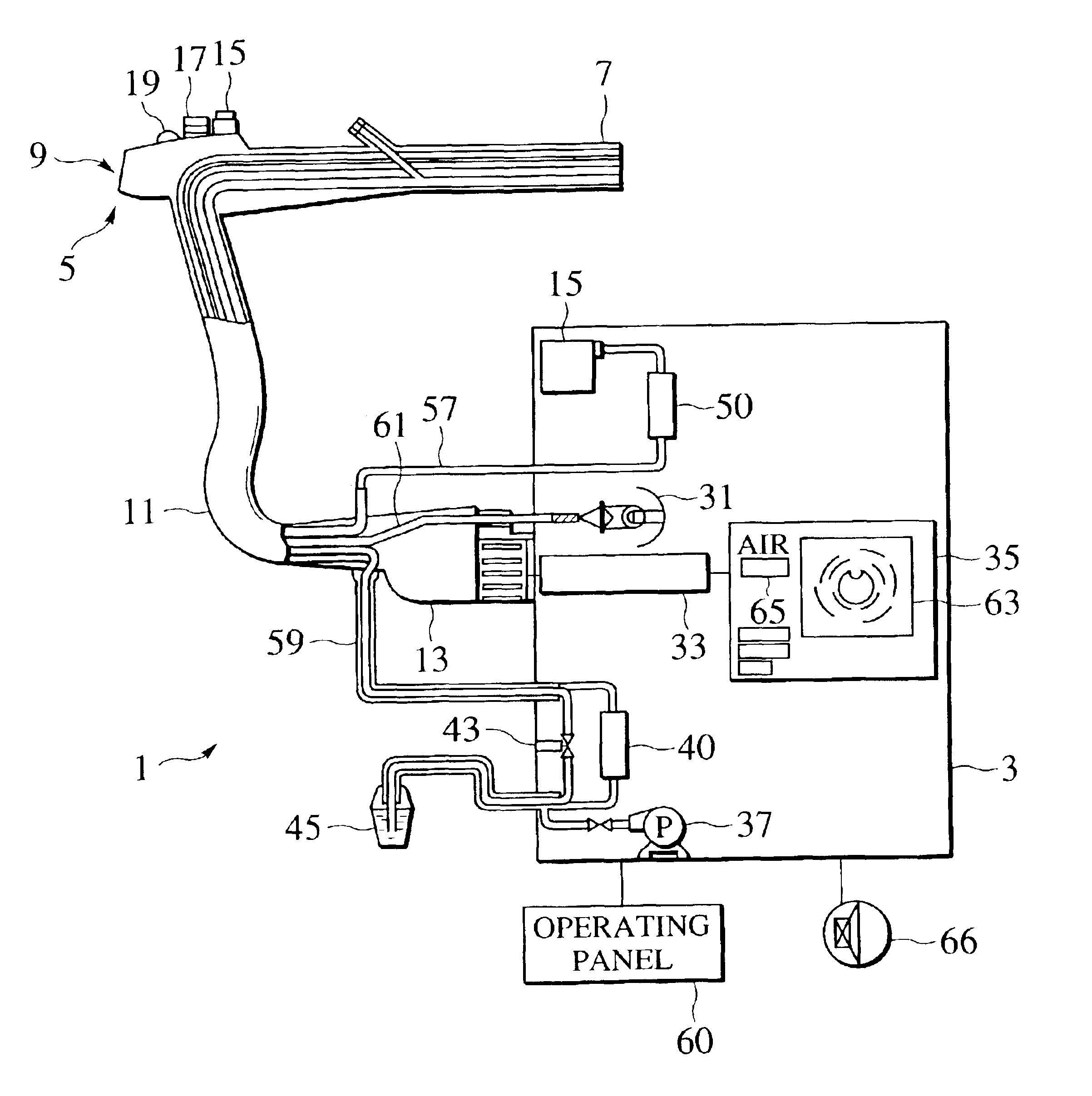

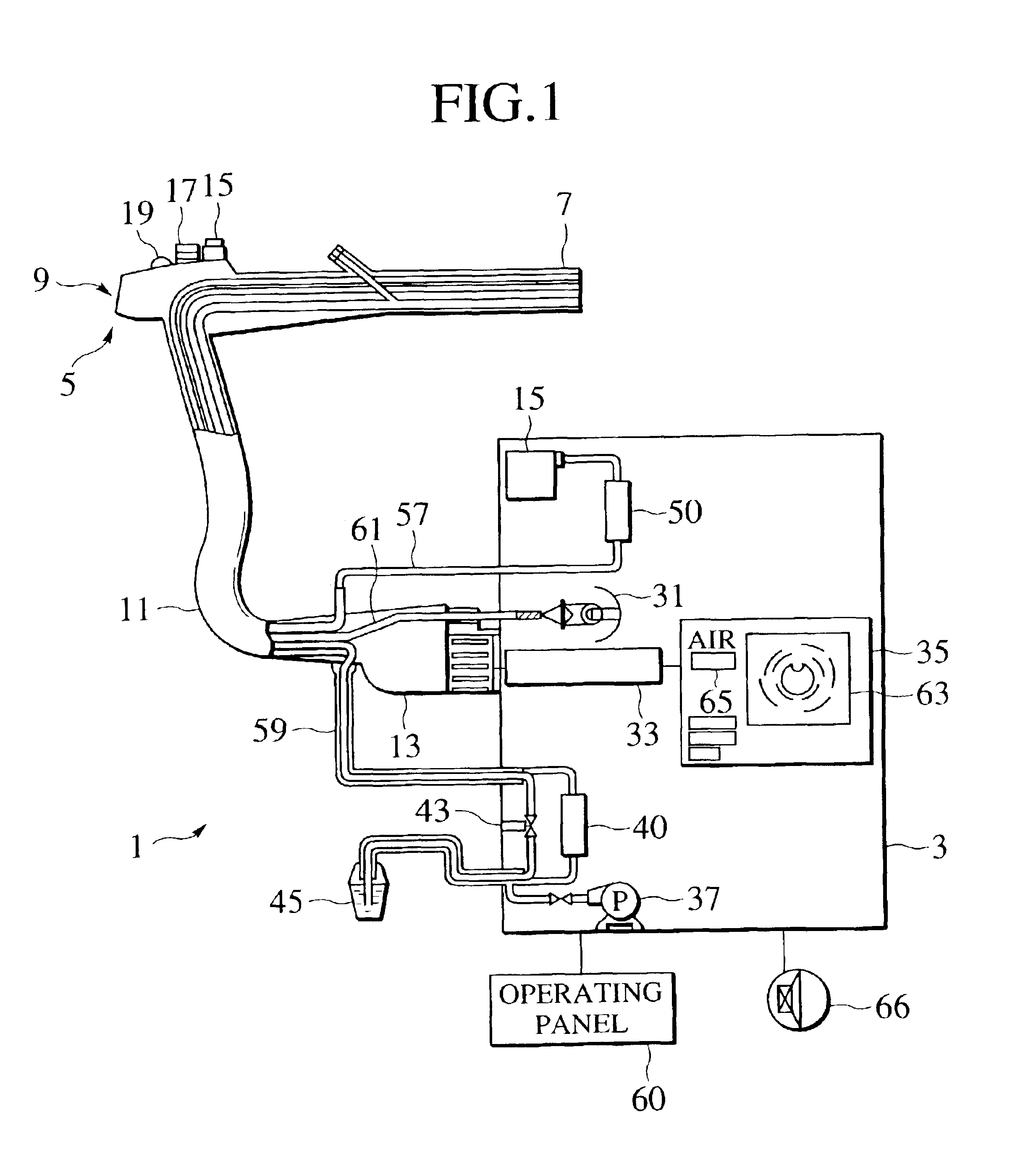

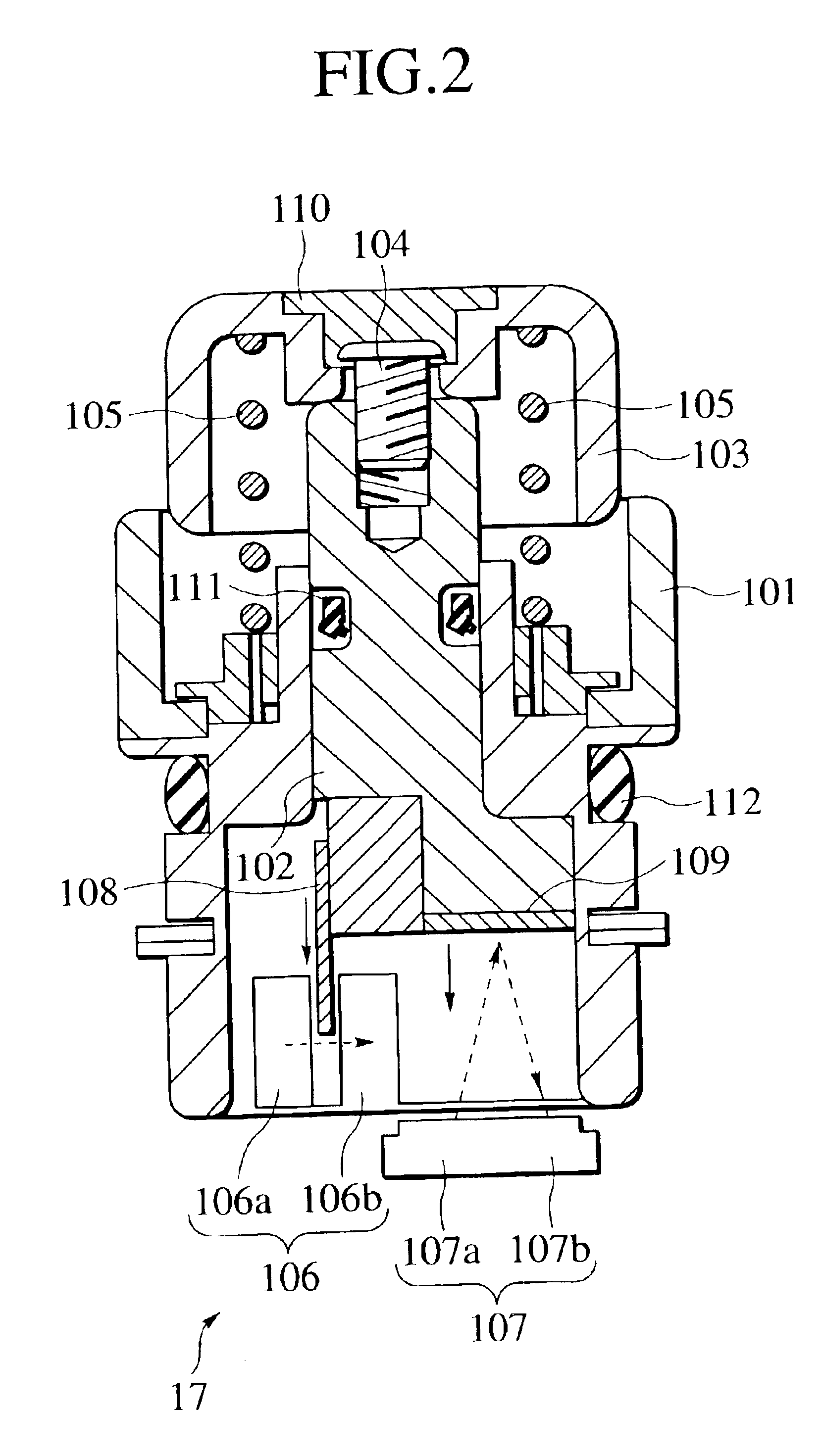

Endoscope apparatus

InactiveUS6929602B2Quick discoveryProvide feedbackSurgeryEndoscopesSignal processing circuitsSuction force

In an endoscope apparatus, an air / water switch (15) that is provided in an operating section (9) of an endoscope (5) each generate an air feed on / off signal and a suction on / off signal, and air feed flow and suction flow signals that are responsive to the amount of depression of each of the switches, these signals being sent to a signal processing circuit (33). The signal processing circuit (33) controls a air / water feed control valve 40 and a suction force control valve 50, so as to control air / water feed flow and suction flow, a flow display being made by an indicator (65) on the screen (63) of a TV monitor (35).

Owner:KK TOSHIBA

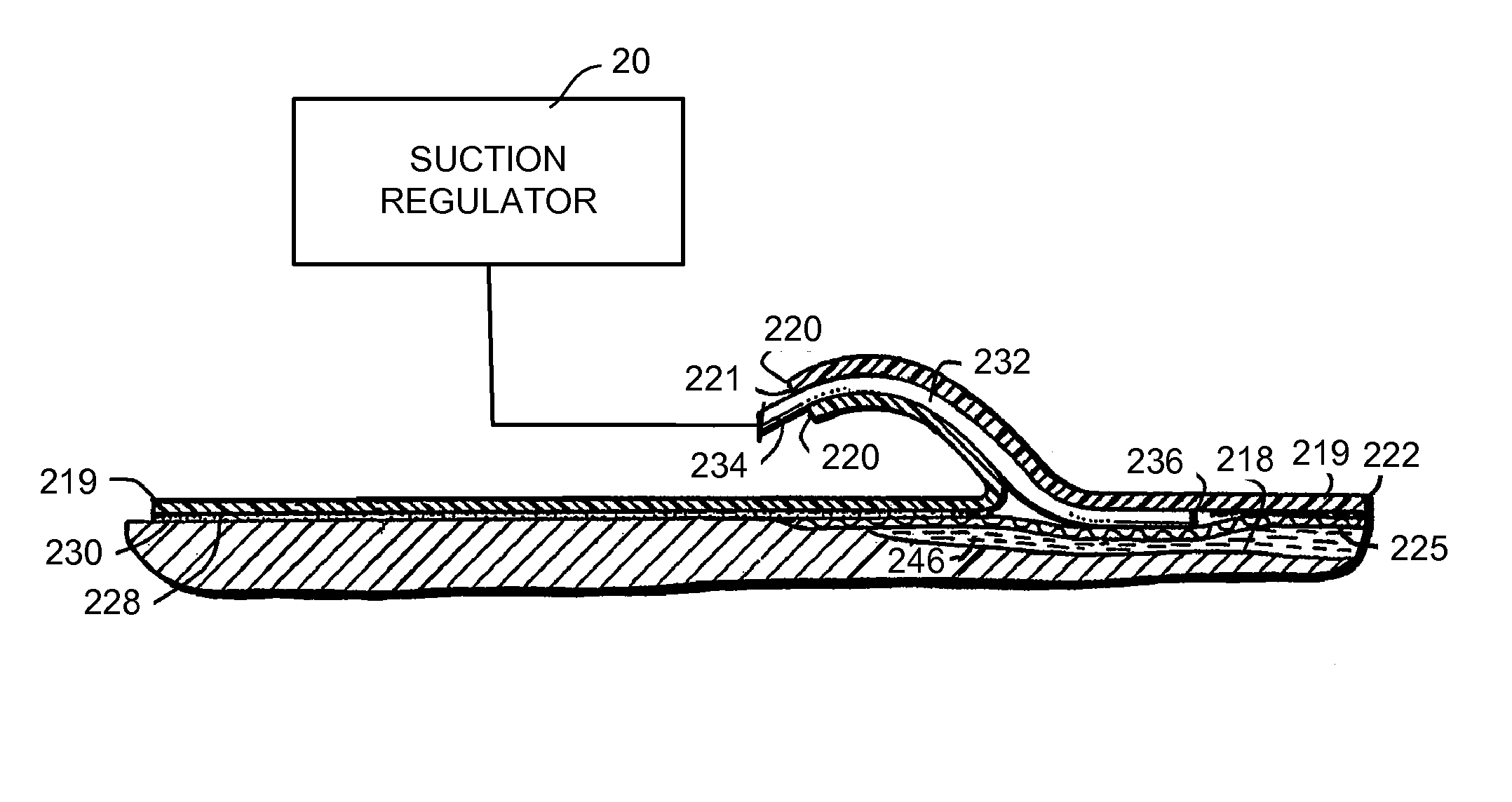

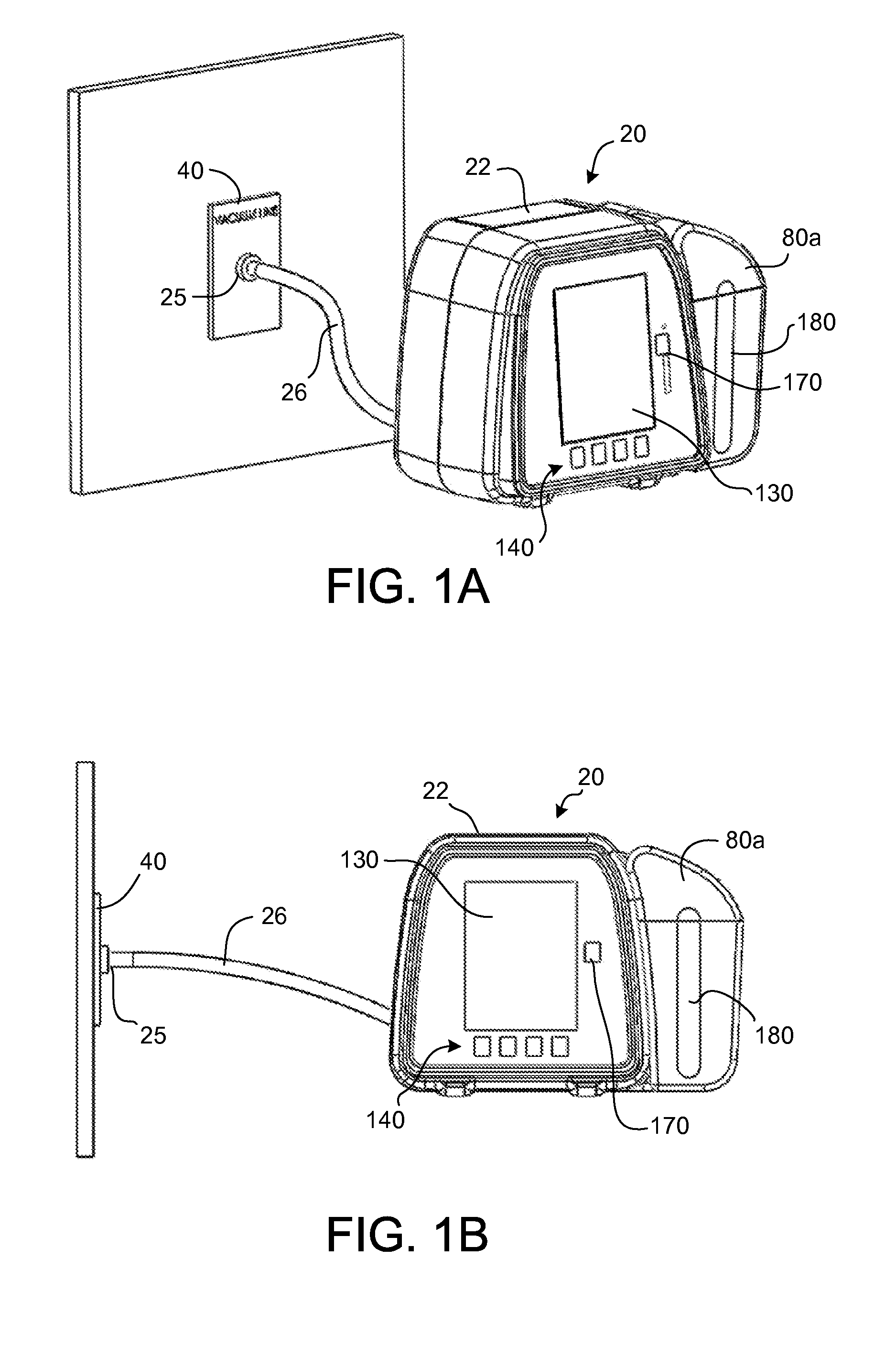

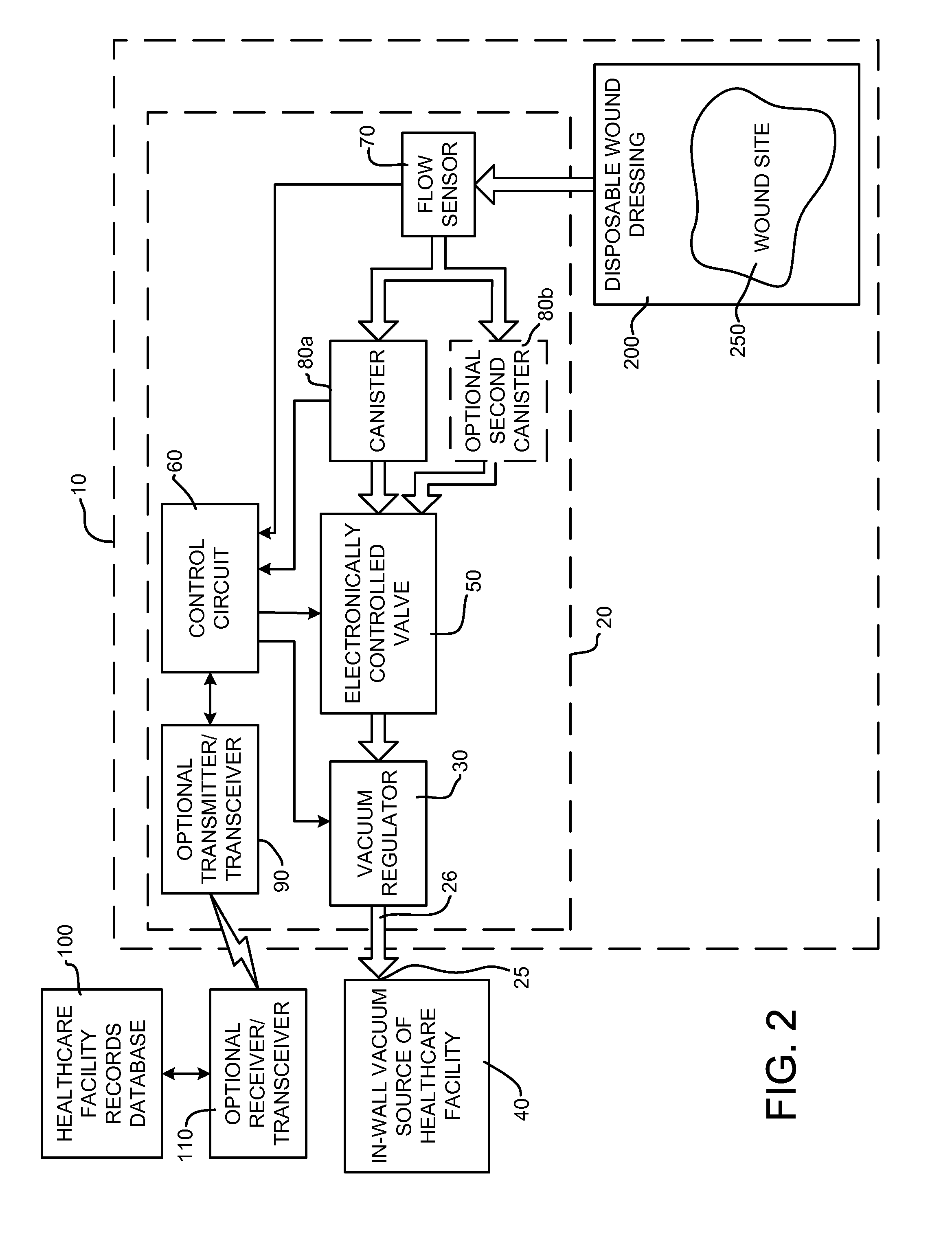

Wound treatment system and suction regulator for use therewith

A system is provided for the treatment of wounds by applying a negative pressure to a wound. The system comprises an electronically controlled suction regulator that comprises: a vacuum regulator, a coupler for coupling the vacuum regulator to an external vacuum source, a valve connected to the vacuum regulator for supplying a negative pressure to the wound, and a control circuit for generating control signals for controlling the valve so that negative pressure may be continuously or intermittently supplied to the wound. The system further comprises a wound dressing provided at the wound site and coupled to the electrically operated valve. The wound dressing comprises a wound dressing pad for placing over the wound, and a wound drape provided over the wound dressing pad and the wound site for sealing the wound site for application of the negative pressure.

Owner:OHIO MEDICAL CORP

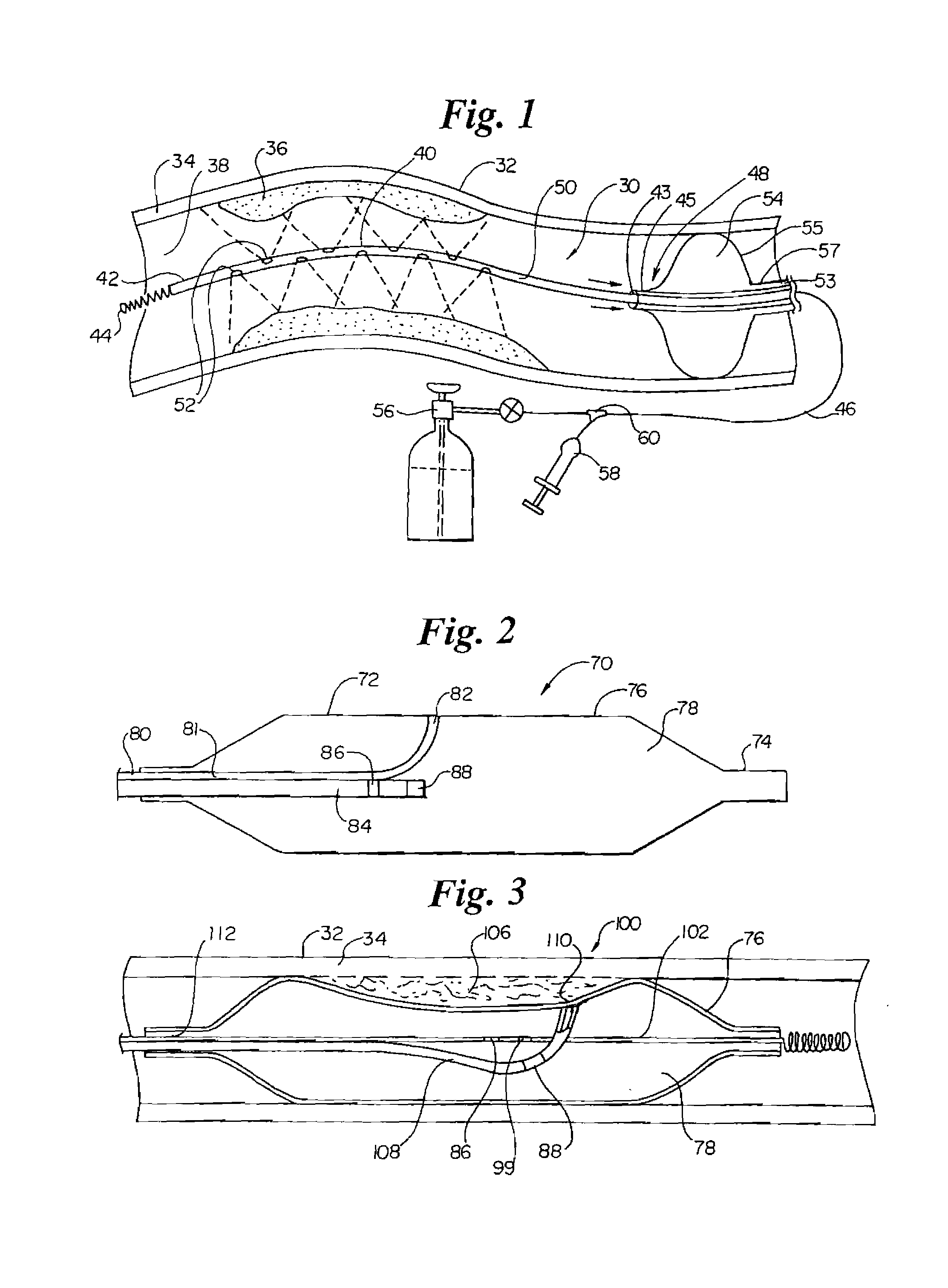

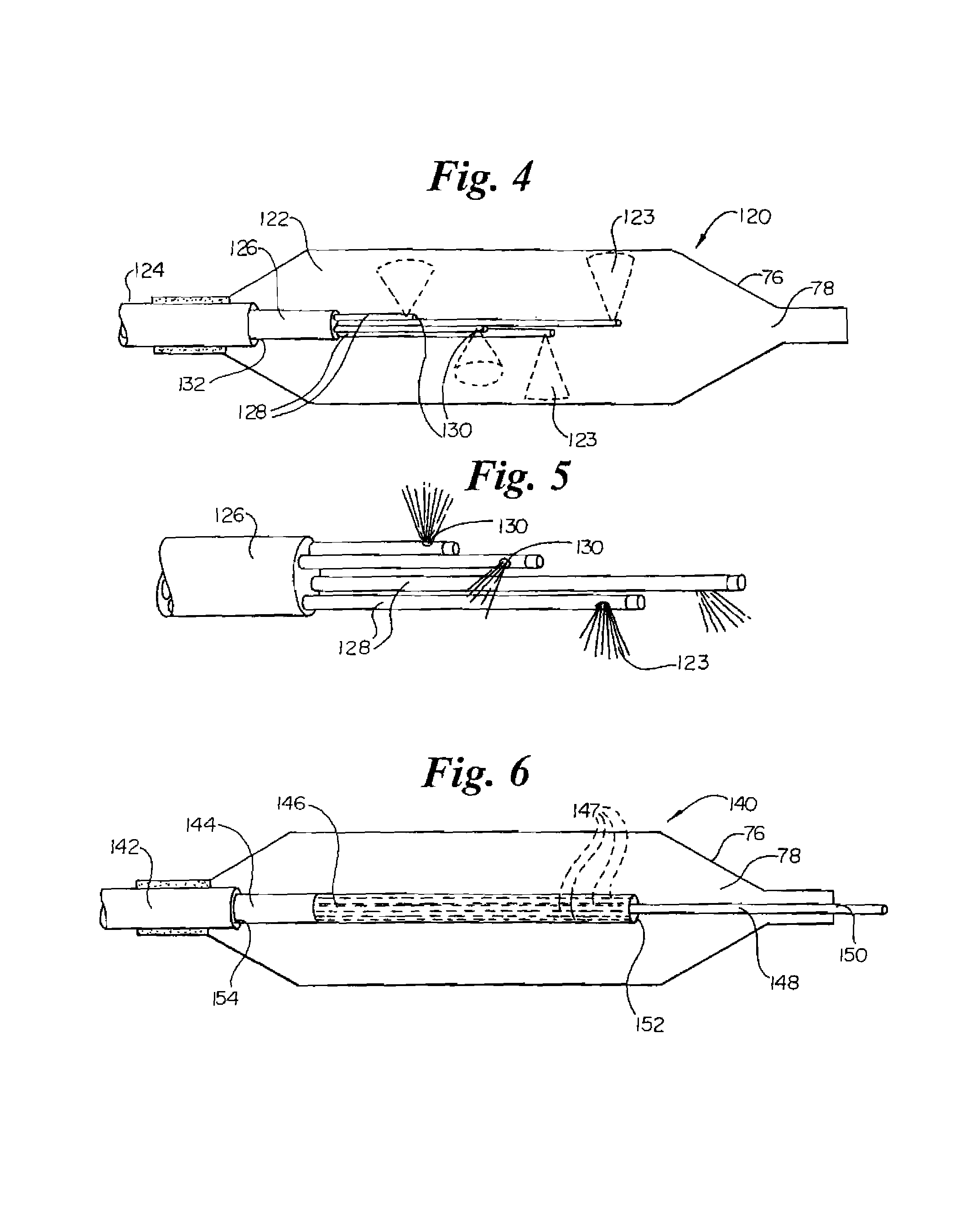

Cryotreatment device and method

InactiveUS7220257B1Reduce adverse reactionsReduced responseStentsOther blood circulation devicesCoronary artery angioplastyPercent Diameter Stenosis

Devices and methods for cooling vessel walls to inhibit restenosis in conjunction with medical procedures such as coronary artery angioplasty. Stenosed vessel walls can be cooled prior to angioplasty, after angioplasty, or both. The invention is believed to inhibit restenosis through cooling to a temperature near freezing, preferably without causing substantial vessel wall cell death. One catheter device includes a distal tube region having coolant delivery holes radially and longitudinally distributed along the distal region. In some devices, holes spray coolant directly onto the vessel walls, with the coolant absorbed into the blood stream. In other embodiments, a balloon or envelope is interposed between the coolant and the vessel walls and the coolant returned out of the catheter through a coolant return lumen. Some direct spray devices include an occlusion device to restrict blood flow past the region being cooled. Pressure, temperature, and ultrasonic probes are included in some cooling catheters. Pressure control valves are included in some devices to regulate balloon interior pressure within acceptable limits. In applications using liquid carbon dioxide as coolant, the balloon interior pressure can be maintained above the triple point of carbon dioxide to inhibit dry ice formation. Some cooling catheters are coiled perfusion catheters supporting longer cooling periods by allowing perfusing blood flow simultaneously with vessel wall cooling. One coiled catheter is biased to assume a coiled shape when unconstrained and can be introduced into the body in a relatively straight shape, having a stiffening wire inserted through the coil strands.

Owner:BOSTON SCI SCIMED INC

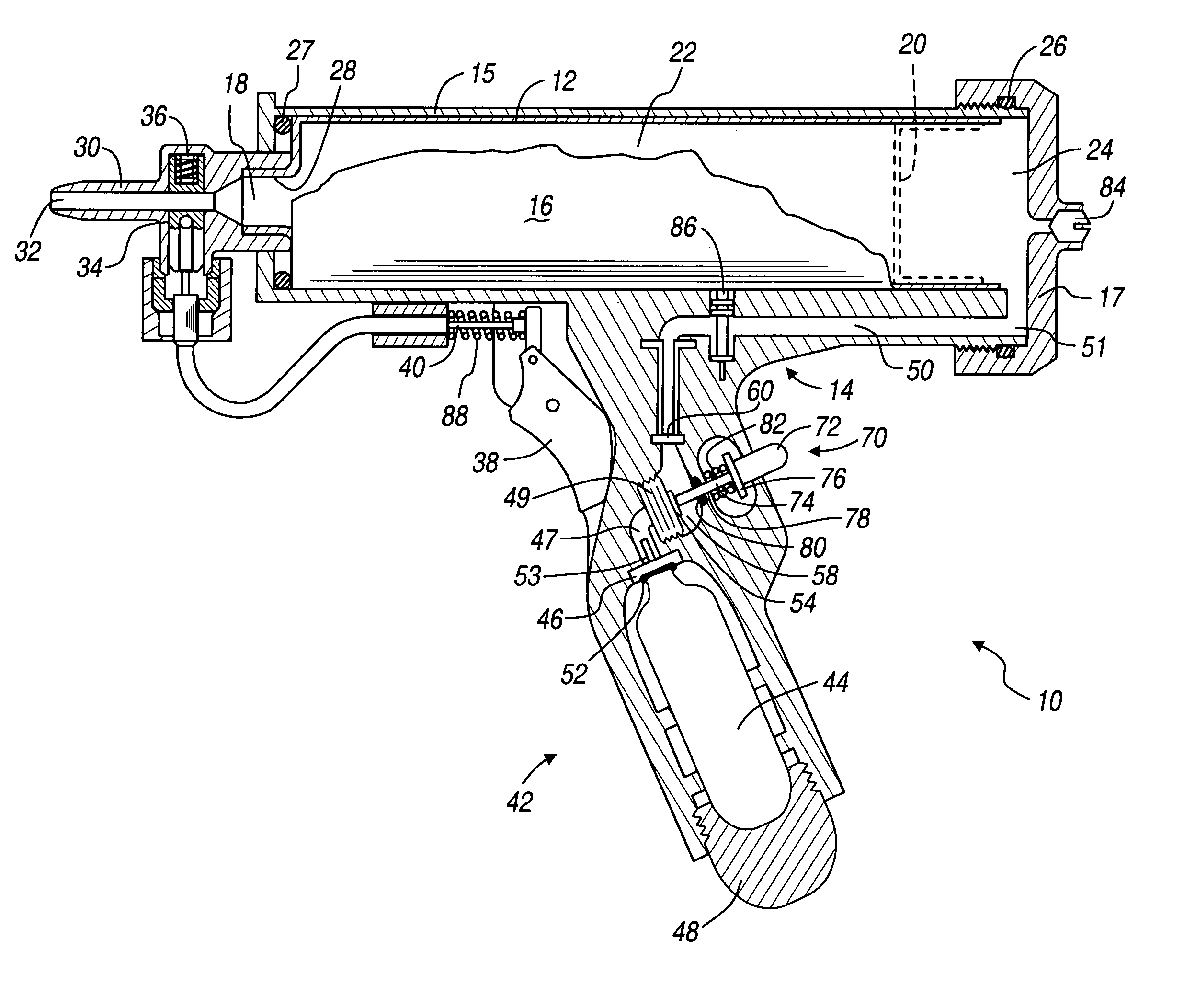

Caulk gun pressurizing system

InactiveUS6935541B1Easy dischargeValve arrangementsLiquid surface applicatorsEngineeringControl valves

A device for dispensing a viscous material and a method for controlling the dispensing pressure. The device has a manually actuated control valve, that, when depressed, releases high pressure gas from the source, such as a CO2 cartridge, into a gas enclosure. An indicator signals a pre-determined pressure in the gas enclosure sufficient to forcefully dispense a viscous material from a product cartridge.

Owner:BLACK & DECKER INC

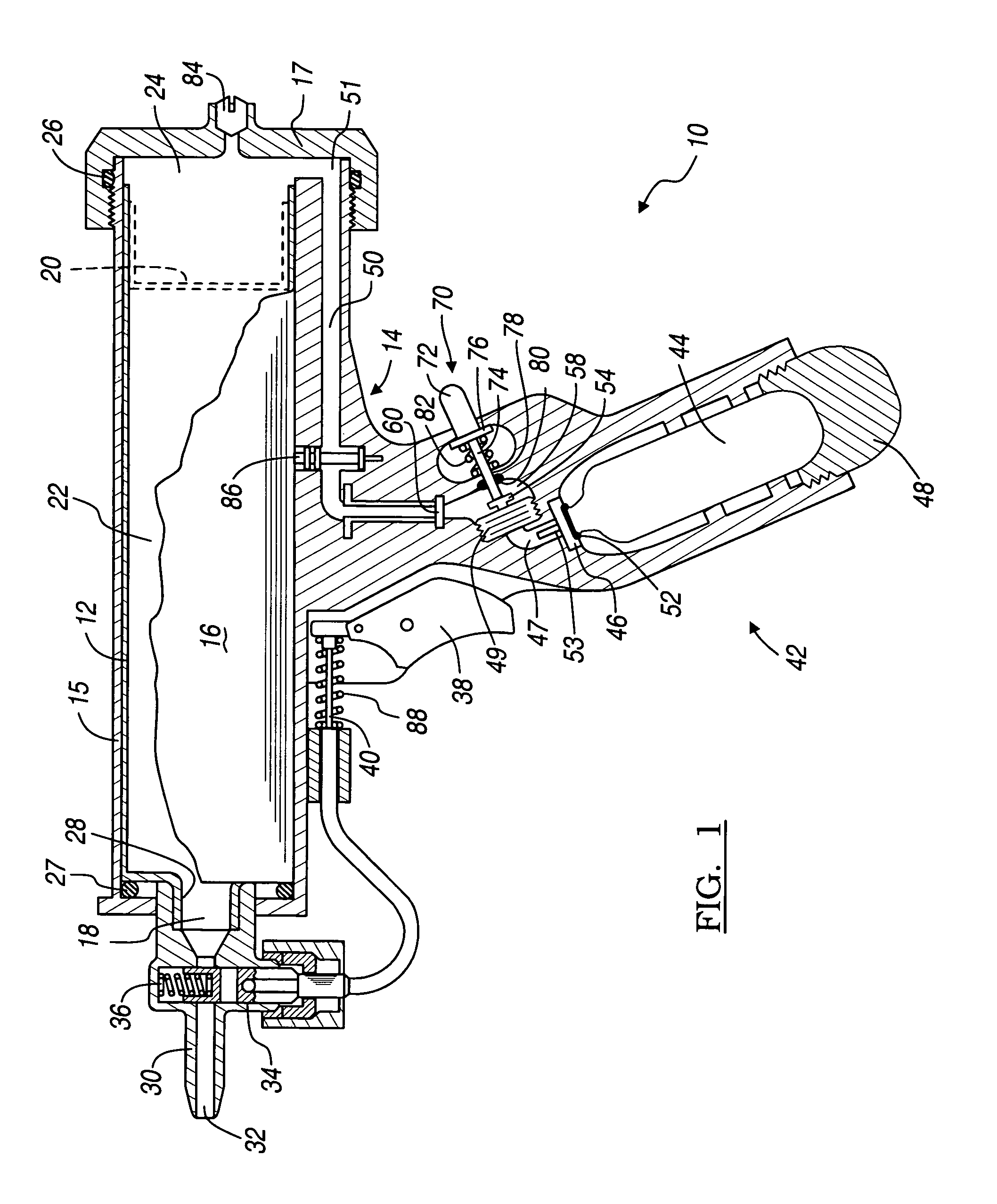

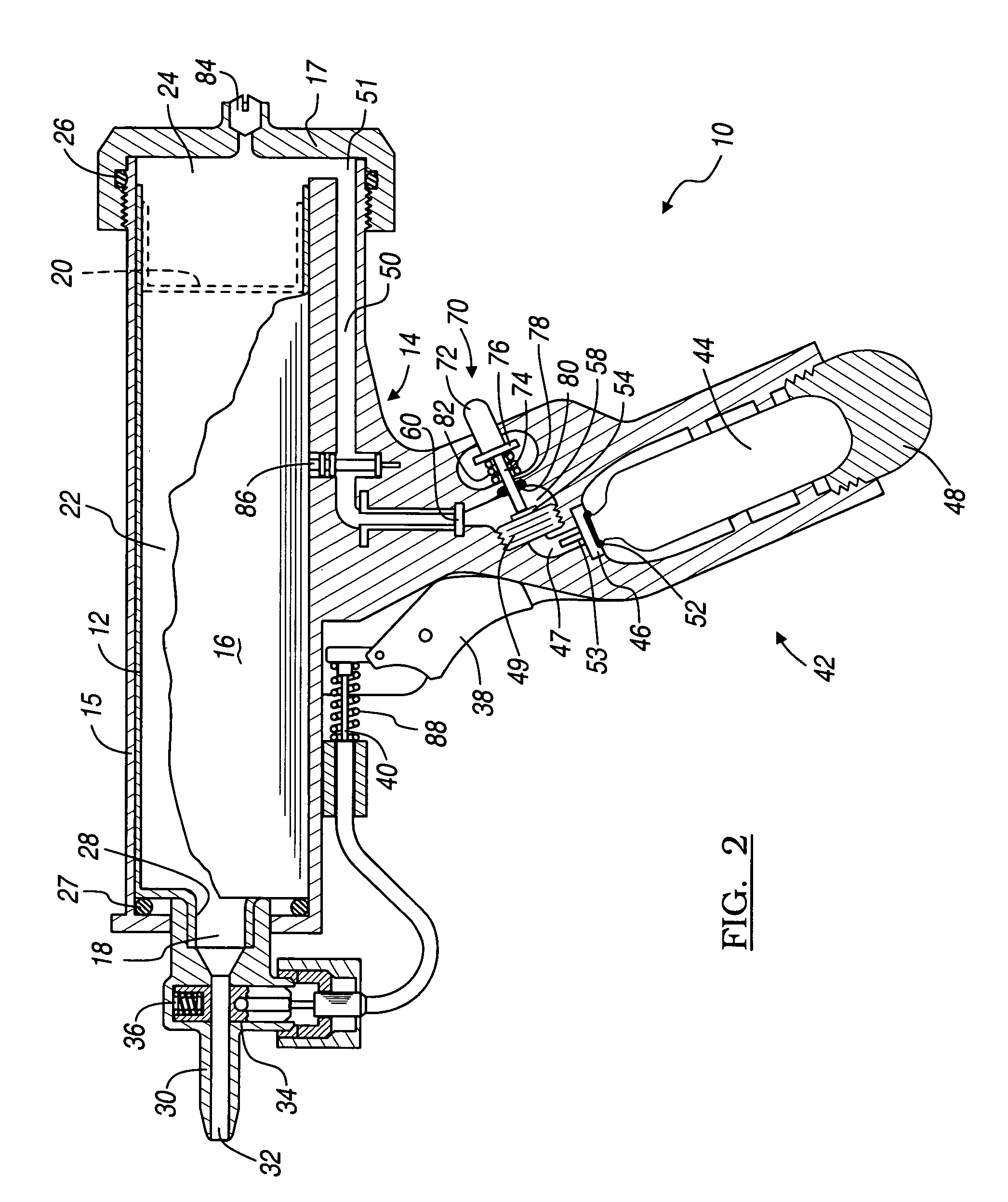

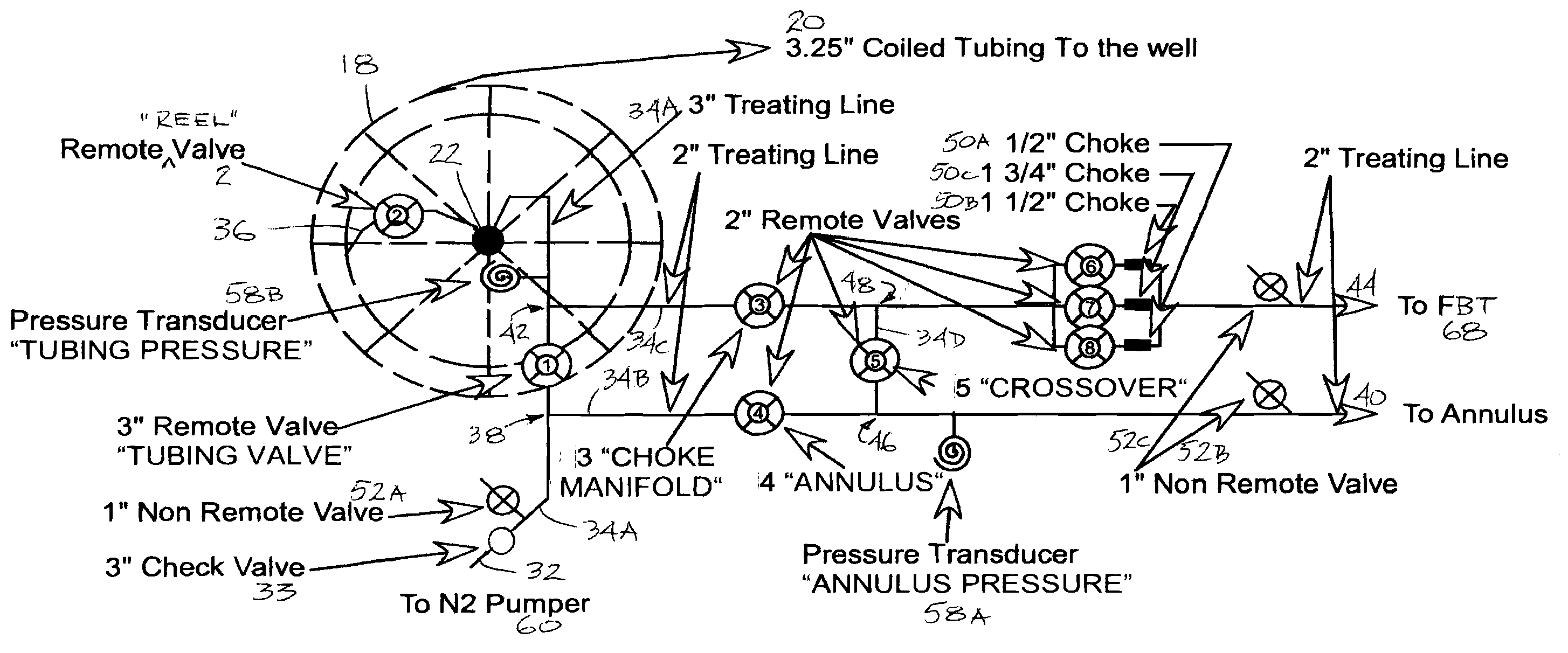

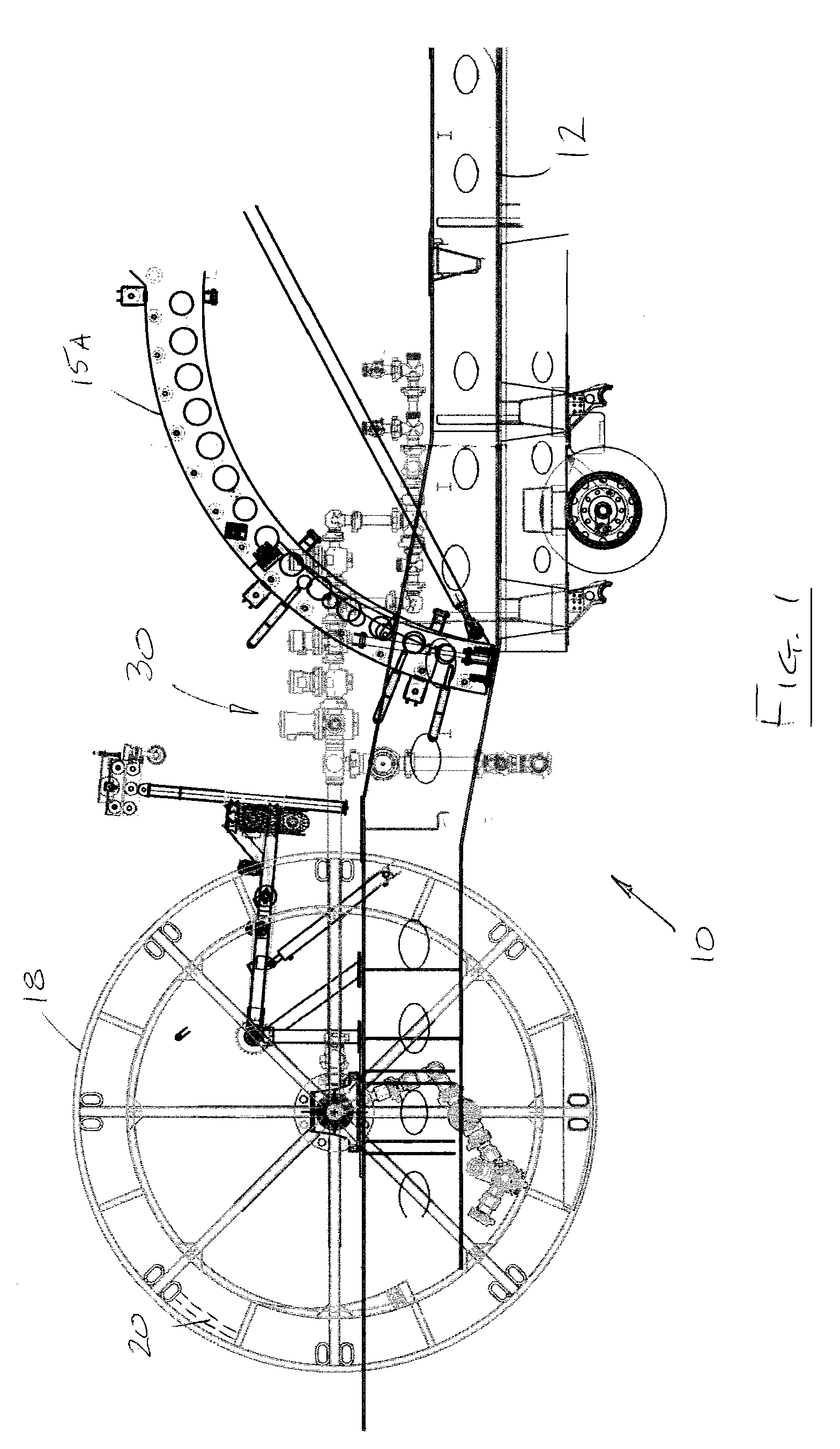

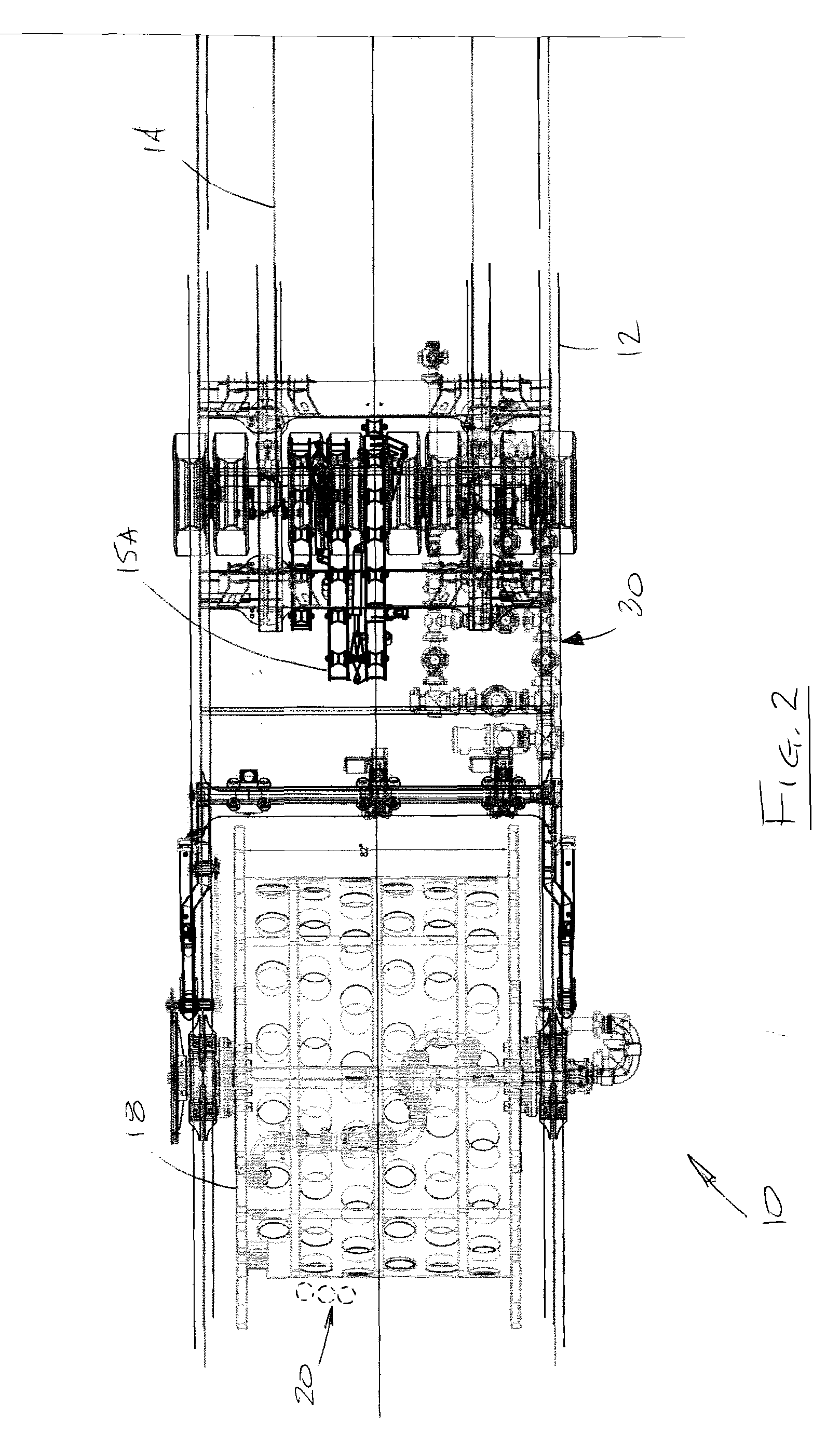

Well Servicing Rig and Manifold Assembly

A well servicing rig for communicating with a fluid source and an effluent reservoir (such as a flow back tank) has an apparatus for holding and dispensing coiled tubing. A manifold assembly is advantageously located on the rig for routing the pressurized fluid (such as nitrogen gas mixed with proppant) from the fluid source between the coiled tubing apparatus, the well and the effluent reservoir. The manifold assembly controls the flow of the fluid to perform fracturing operations, for reverse fluid circulation, for a common coiled tubing operation, for pressure testing, and the like. The assembly includes remotely controlled valves and pressure transducers for controlling the fluid flow, and chokes for diffusing fluid energy prior to entering the effluent reservoir. The rig, fluid source, effluent reservoir and a fluid pumper provide a novel method of servicing an underground formation (such as a coal bed) for natural gas.

Owner:FRAC SOURCE

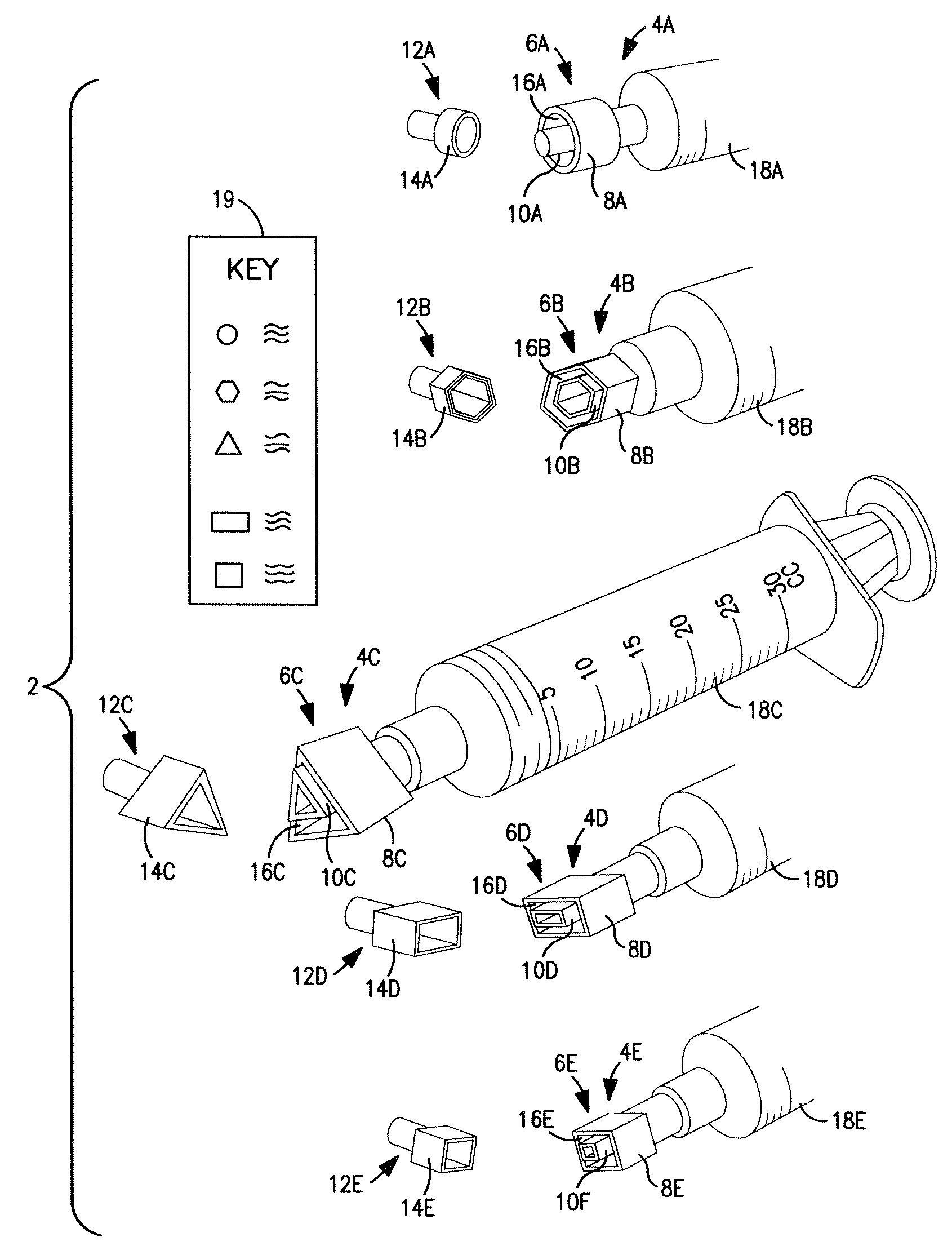

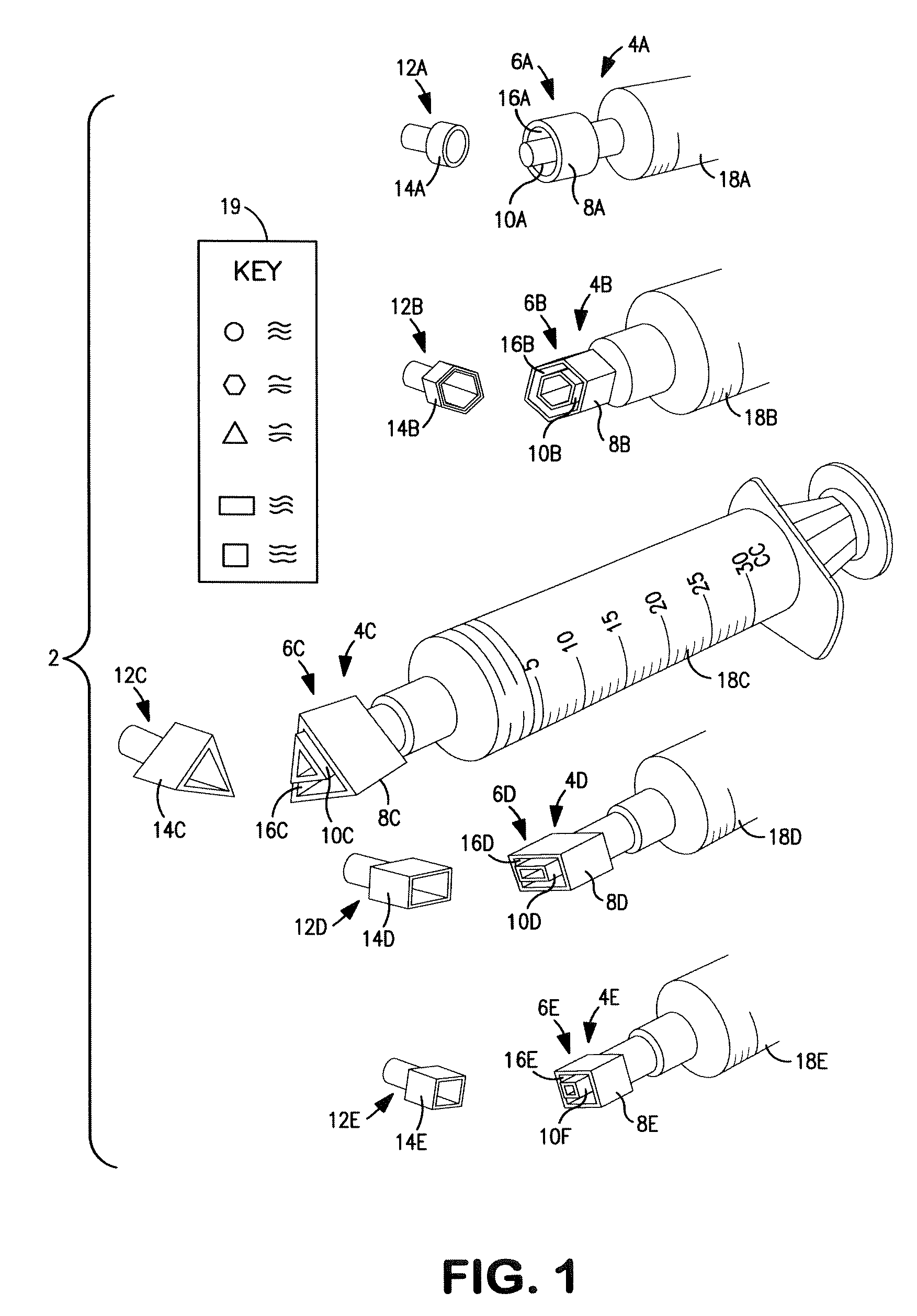

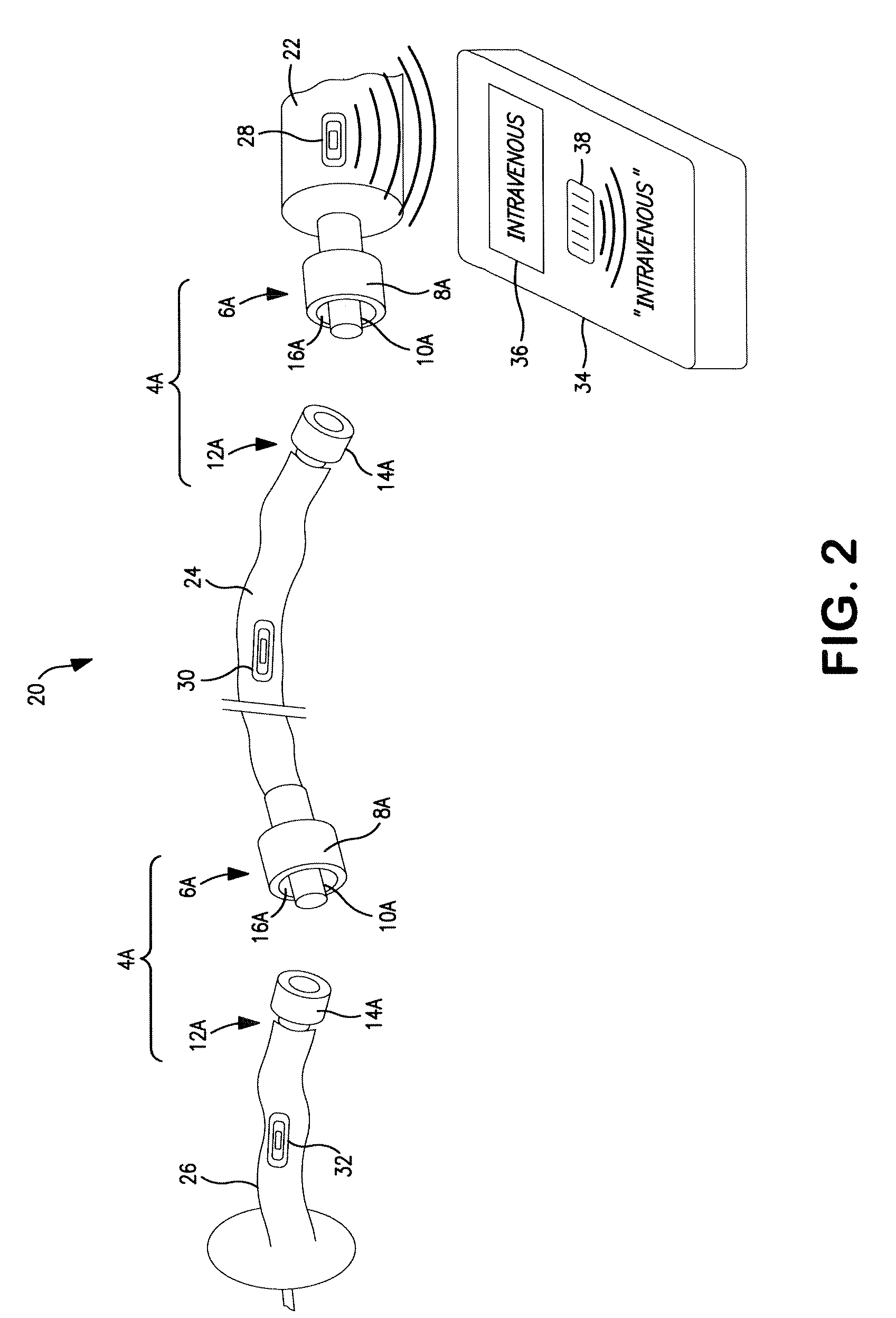

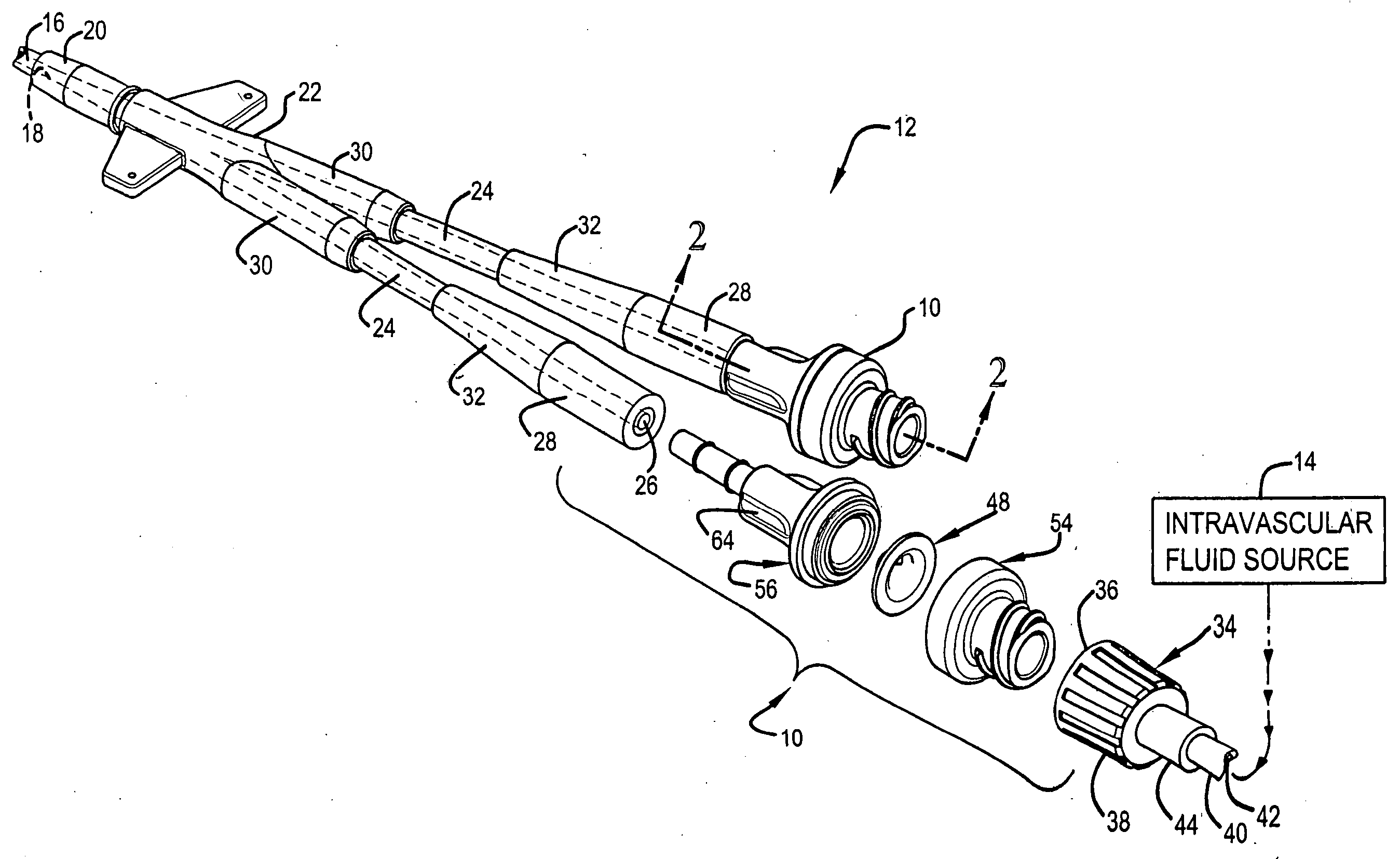

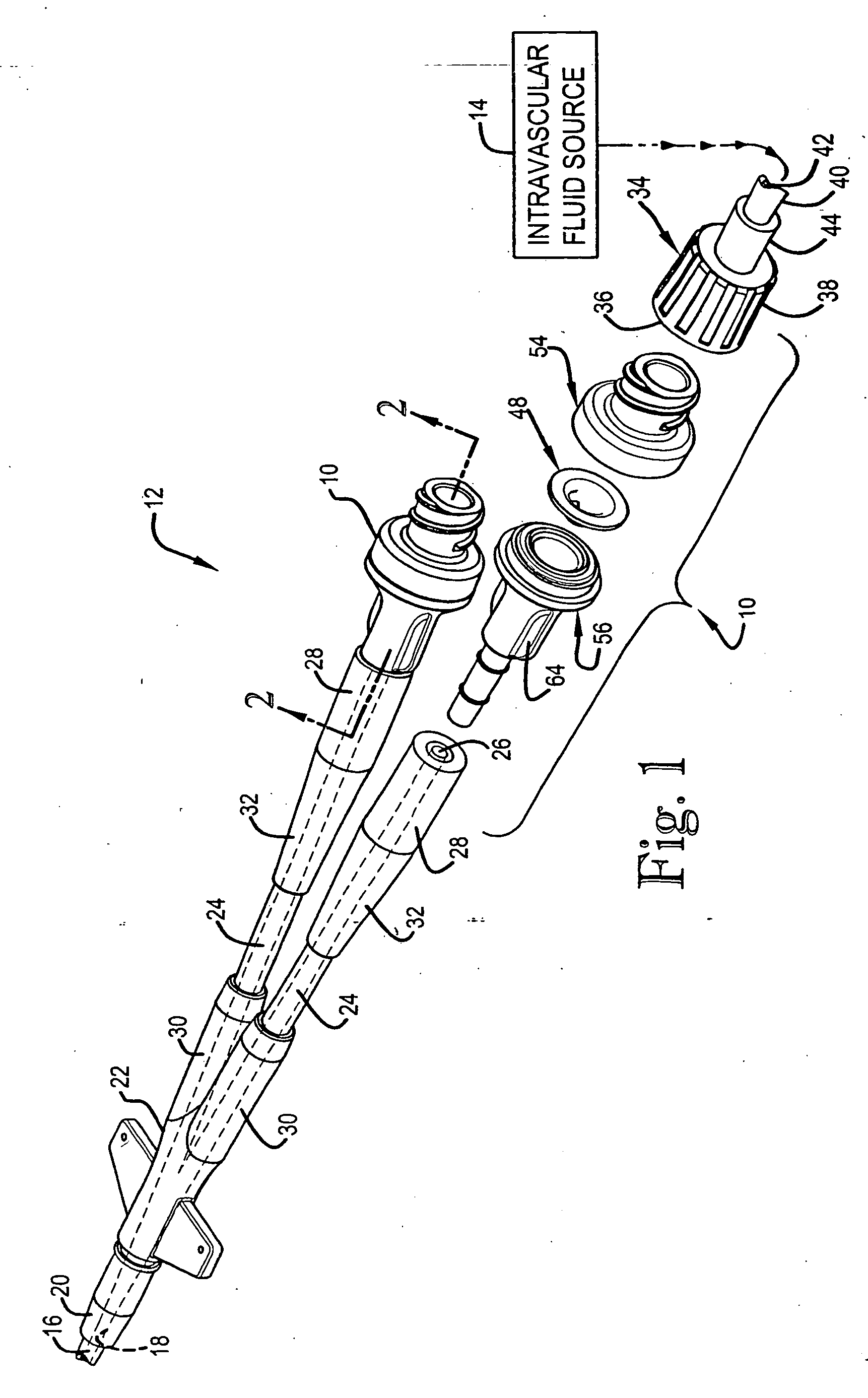

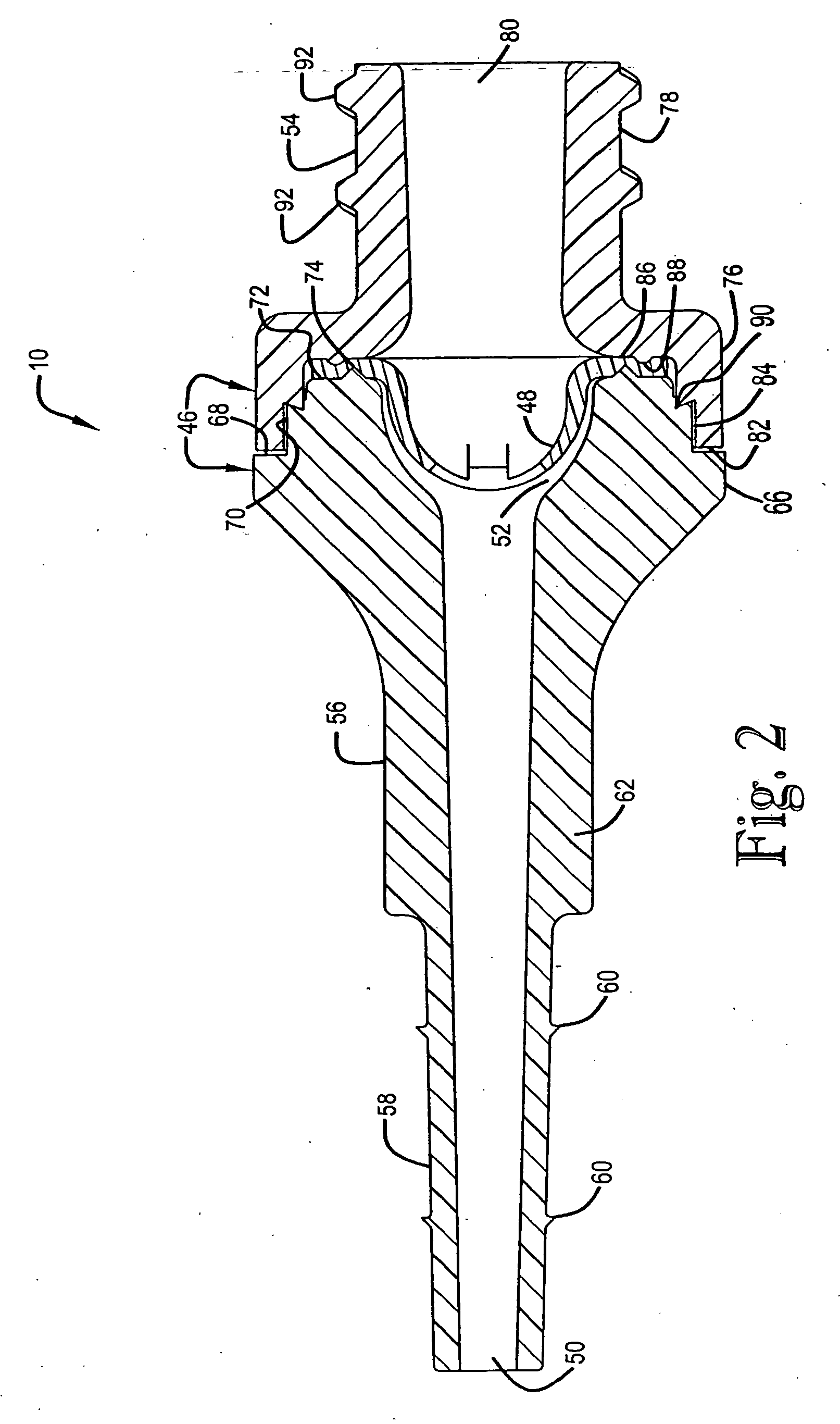

Drug delivery route-based connector system and method

A route-based connector for interconnecting a first drug delivery component with a second drug delivery component having a mating route-based connector. The connector has a geometrically-coded shape corresponding to a drug delivery route. A set of route-based connectors may be provided with plural geometrically-coded shapes that are each assigned to a corresponding drug delivery route according to a key. The connectors may also be color coded to designate the delivery route. A port adapter may be provided having a flow control valve for stopping and starting a flow of medication through the adapter. The port adapter may include a universal connector on one end thereof and a route-based connector on another end thereof that has a geometrically coded shape that allows the port adapter to connect to one of the route-based connectors. Machine readable or light emitting route identifiers may be provided on the connectors or on components associated therewith.

Owner:LEVY MAUREEN +1

Continuously variable transmissions and methods therefor

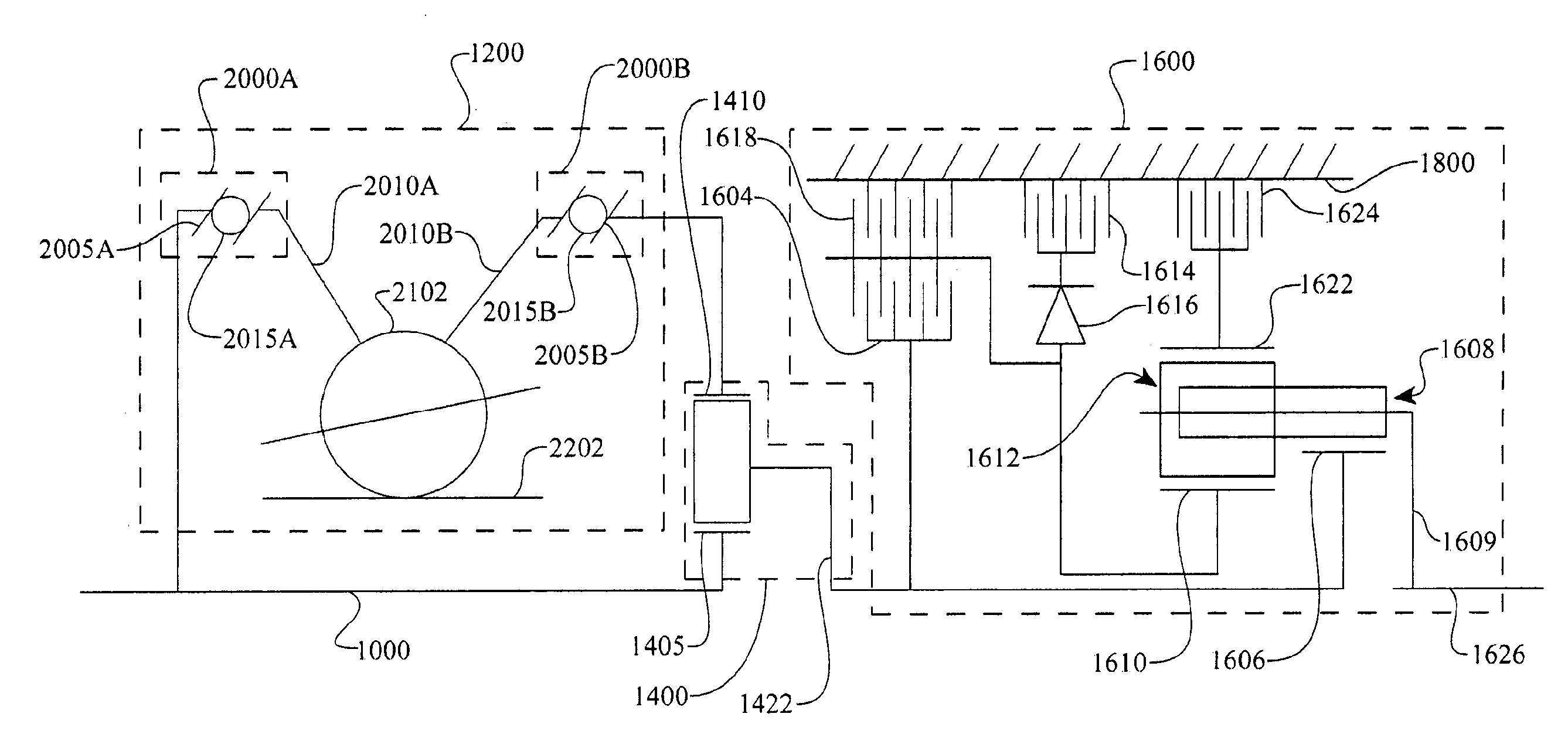

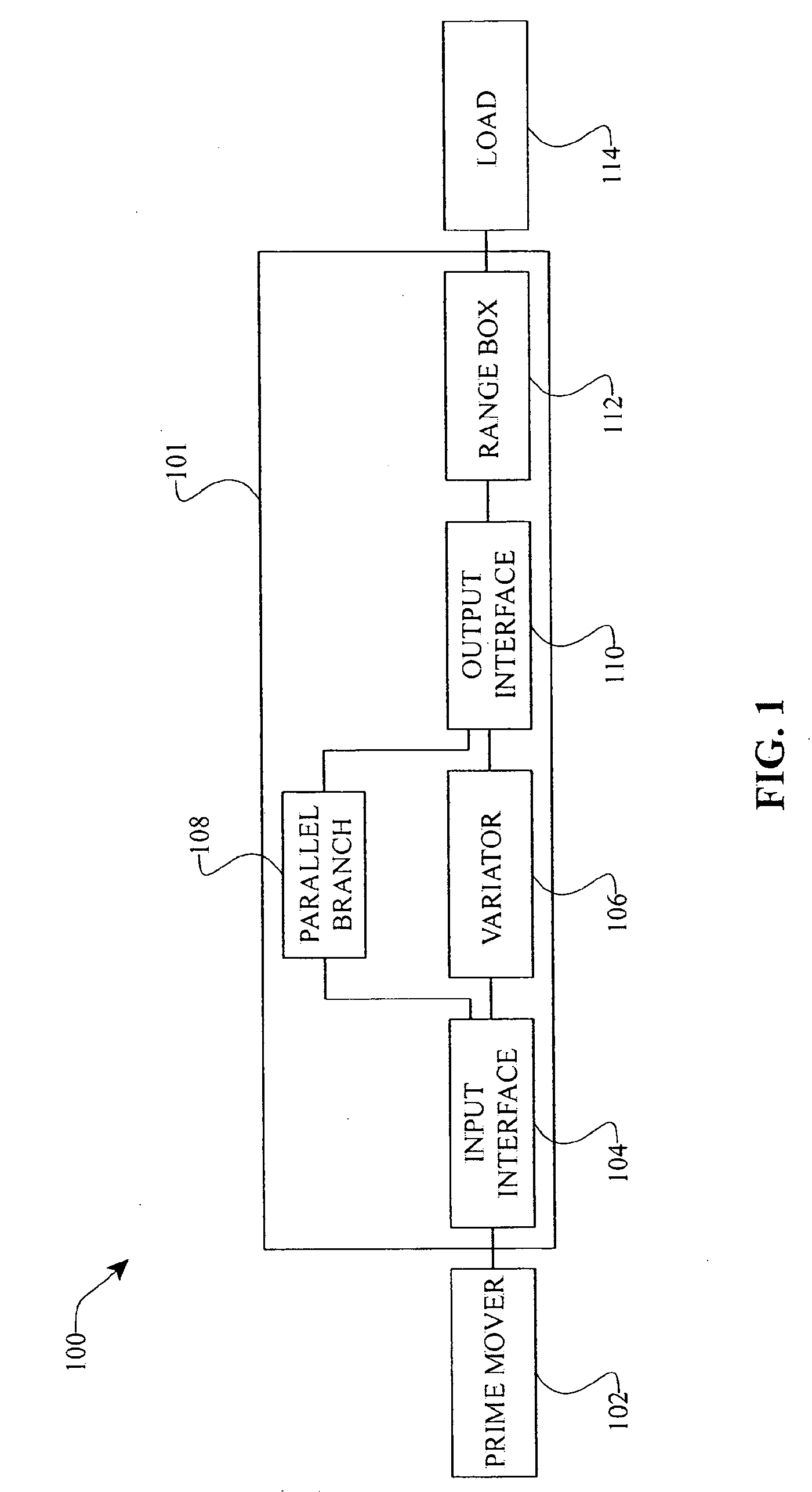

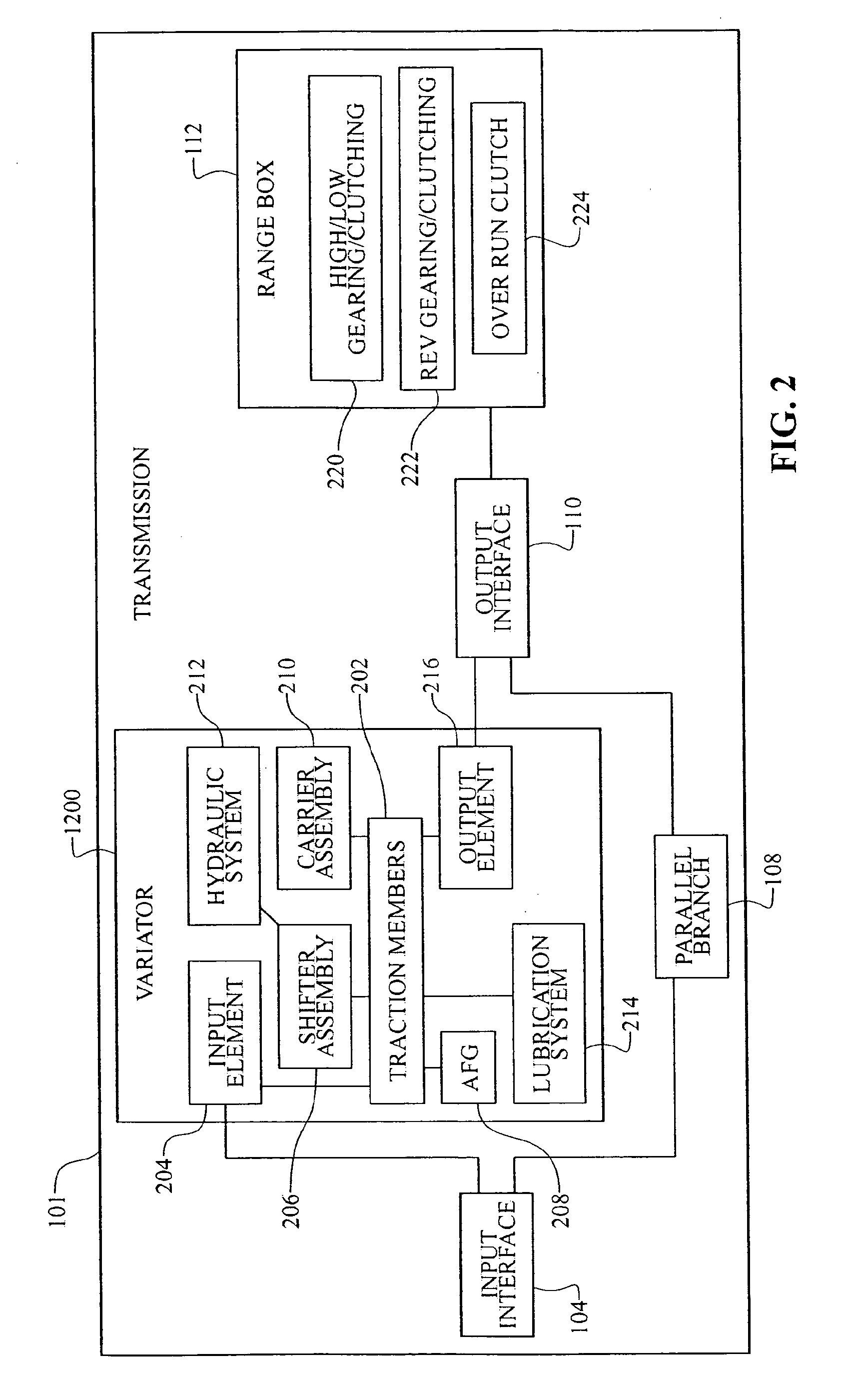

Inventive embodiments are directed to components, subassemblies, systems, and / or methods for continuously variable transmissions (CVT) having a variator provided with a plurality of tilting, traction planets and traction rings. In one embodiment, a variator is coupled to a rangebox to provide multiple operating modes. In another embodiment, a hydraulic system is configured to control the transmission ratio of the variator and the rangebox. Various inventive shift-cam-and-sun subassemblies can be used to facilitate shifting of the transmission ratio of a CVT. Embodiments of a transmission housing and bell housing are adapted to house components of a CVT and, in some embodiments, to cooperate with other components of the CVT to support operation and / or functionality of the CVT. Various related devices include embodiments of, for example, a pivot arm, a control feedback mechanism, axial force generation and management mechanisms, a control valve integral with an input shaft, a pivot pin hub, and a rotatable carrier configured to support planet-pivot arm assemblies. FIG. 72 shows a torque-split ball-type rolling traction CVT with a ball-type rolling traction variator (1200) and planetary gearset (1400) which is followed by a rangebox (1600).

Owner:FALLBROOK INTPROP COMPANY

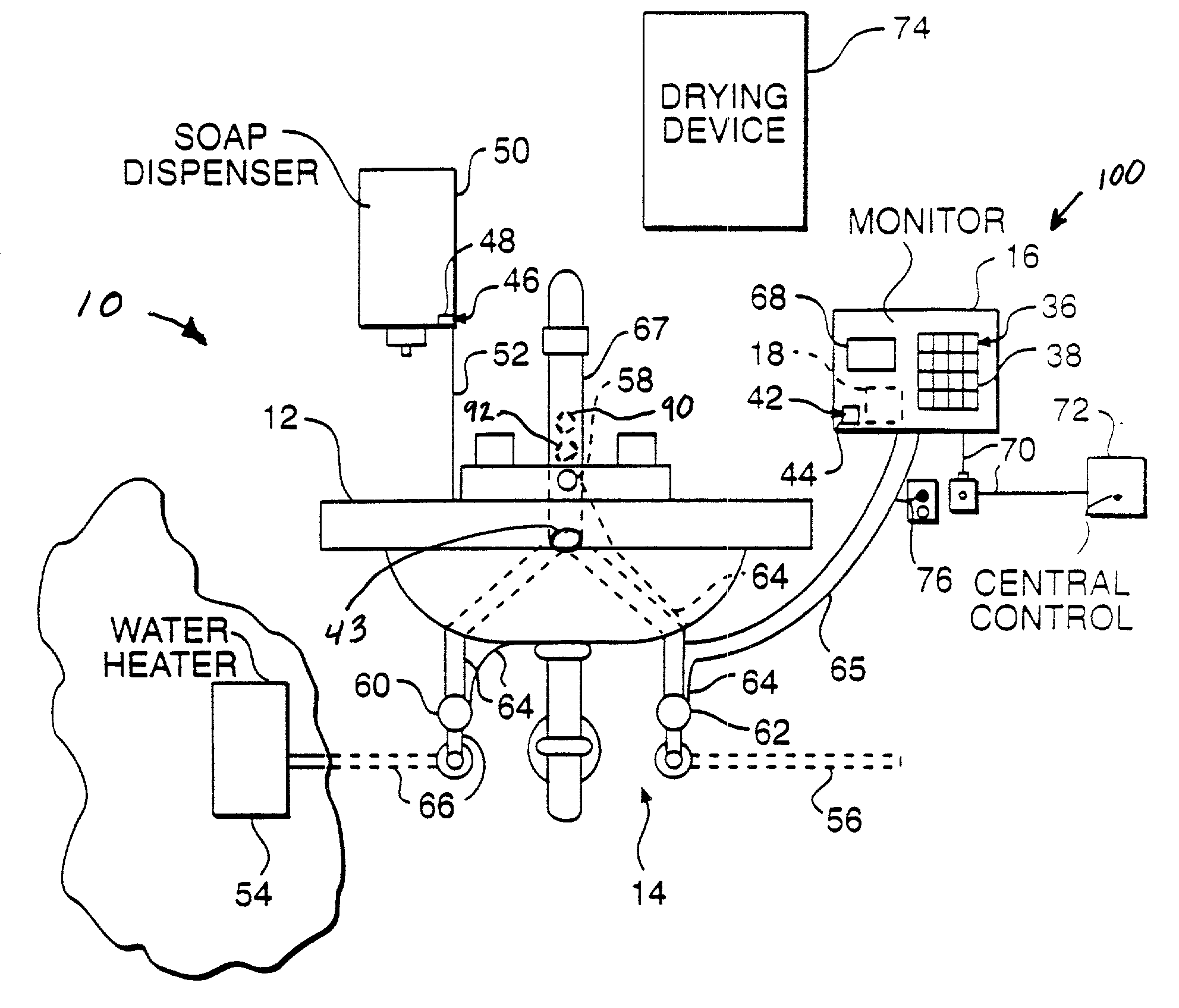

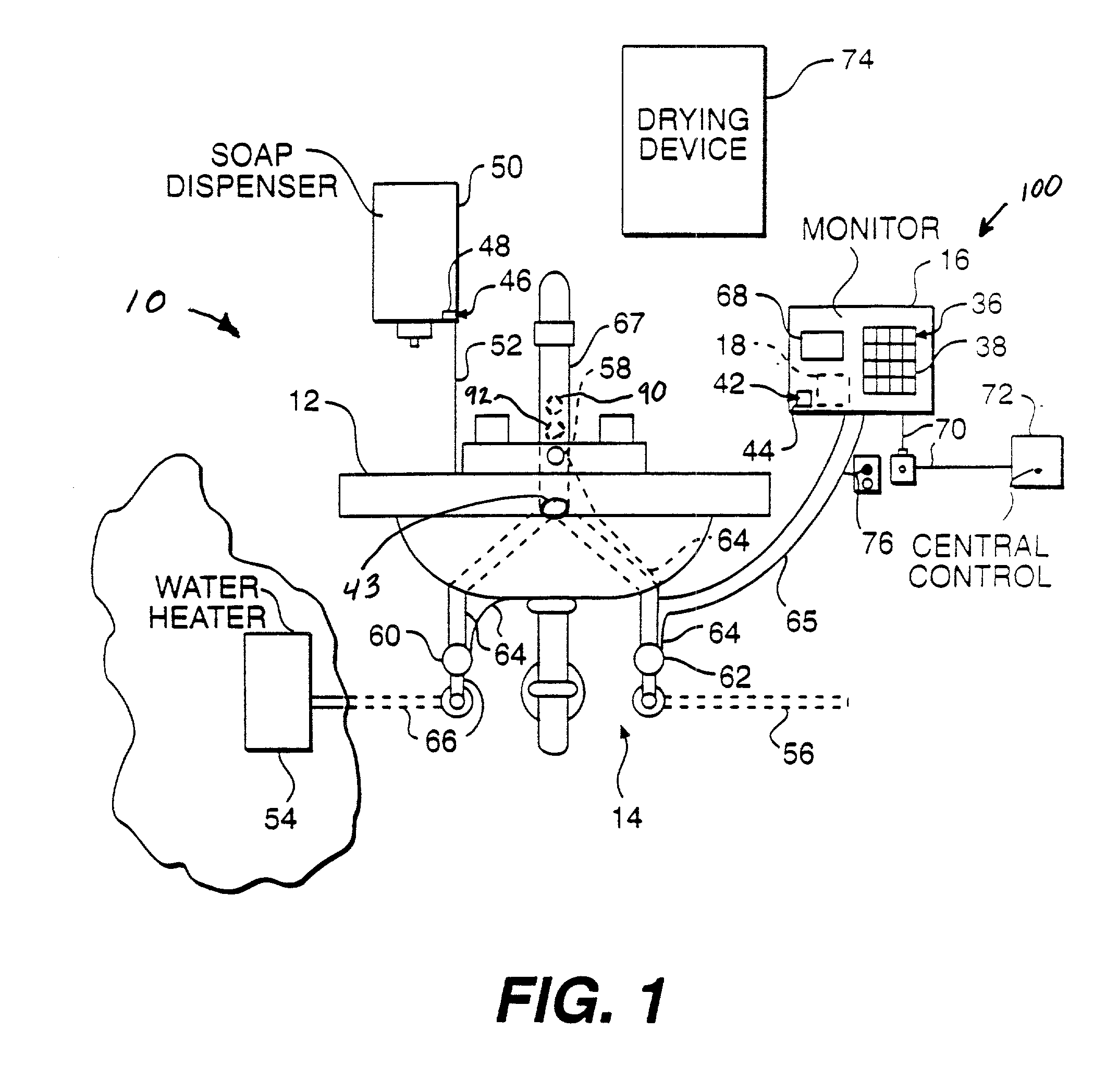

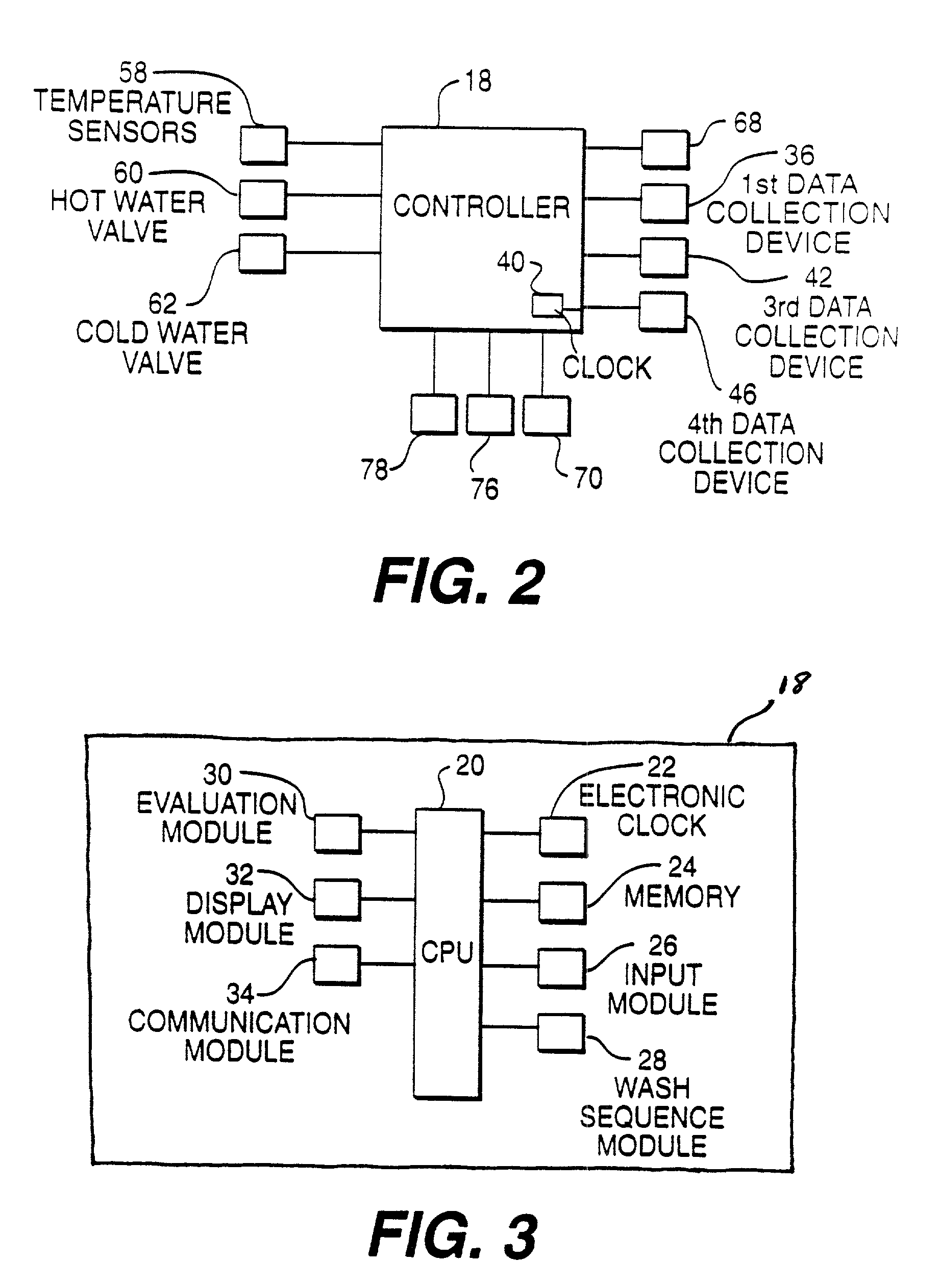

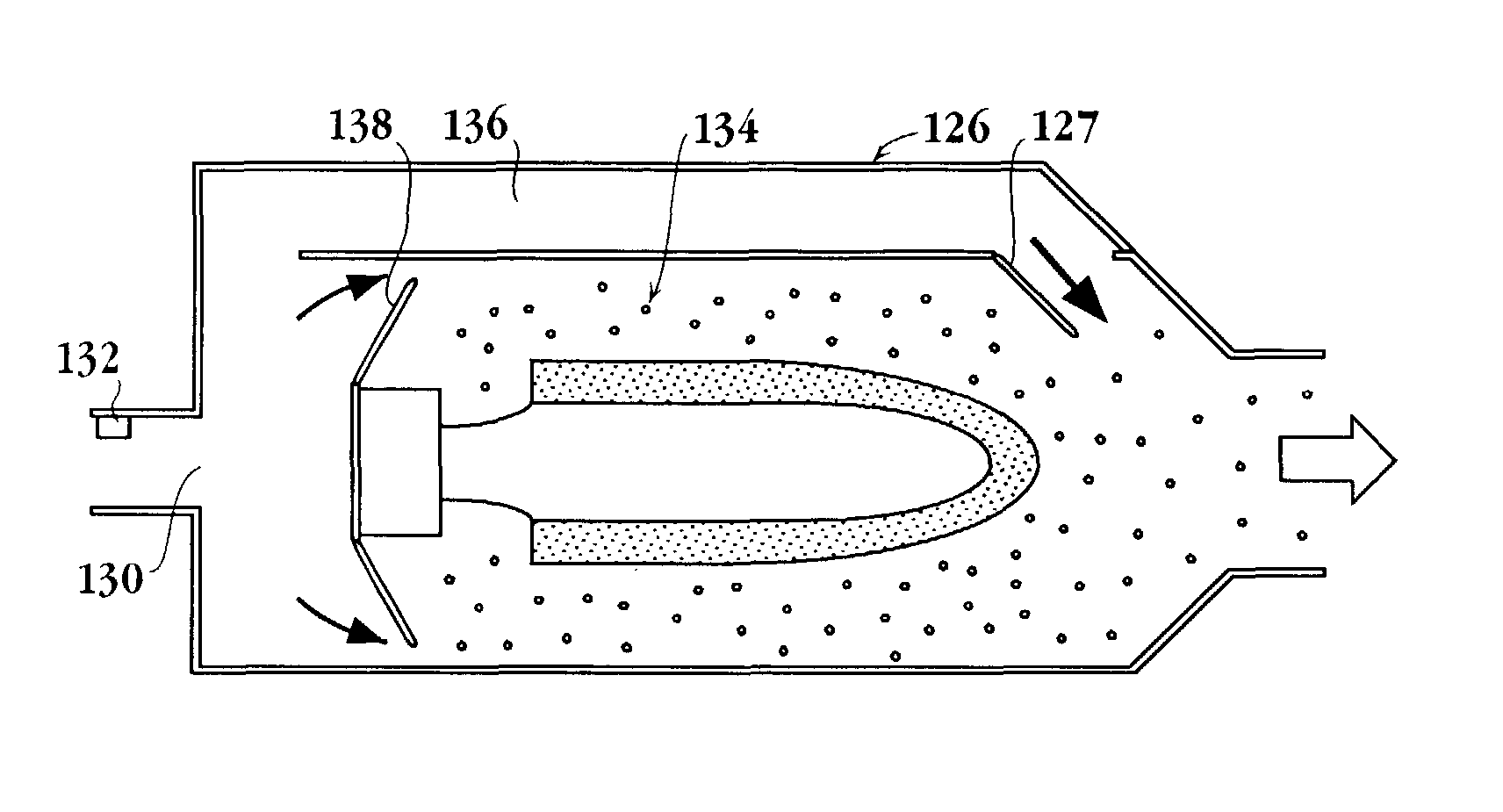

System for controlling operation of a sink

InactiveUS20020019709A1Registering/indicating time of eventsVolume/mass flow measurementWireless controlControl valves

A system for controlling operation of a sink may include a valving device adapted to be coupled to plumbing of the sink to selectively allow water to flow into a basin of the sink. The valving device can be configured to be actuated in response to a wireless control signal. The system may also include a valve controller for controlling operation of the valving device. The valve controller may be configured to provide the wireless control signal to actuate the valving device. Also provided are systems for monitoring and controlling operation of a sink, and methods of controlling operation of a sink.

Owner:COMPLIANCE CONTROL

Inhalation device for producing a drug aerosol

A device for delivering a drug by inhalation is disclosed. The device includes a body defining an interior flow-through chamber having upstream and downstream chamber openings, and a drug supply unit contained within the chamber for producing, upon actuation, a heated drug vapor in a condensation region of the chamber. Gas drawn through the chamber region at a selected gas-flow rate is effective to form drug condensation particles from the drug vapor having a selected MMAD between 0.02 and 0.1 MMAD or between 1 and 3.5 μm. A gas-flow control valve disposed upstream of the unit functions to limit gas-flow rate through the condensation region to the selected gas-flow rate. An actuation switch in the device activates the drug-supply unit, such that the drug-supply unit can be controlled to produce vapor when the gas-flow rate through the chamber is at the selected flow rate.

Owner:ALEXZA PHARMA INC

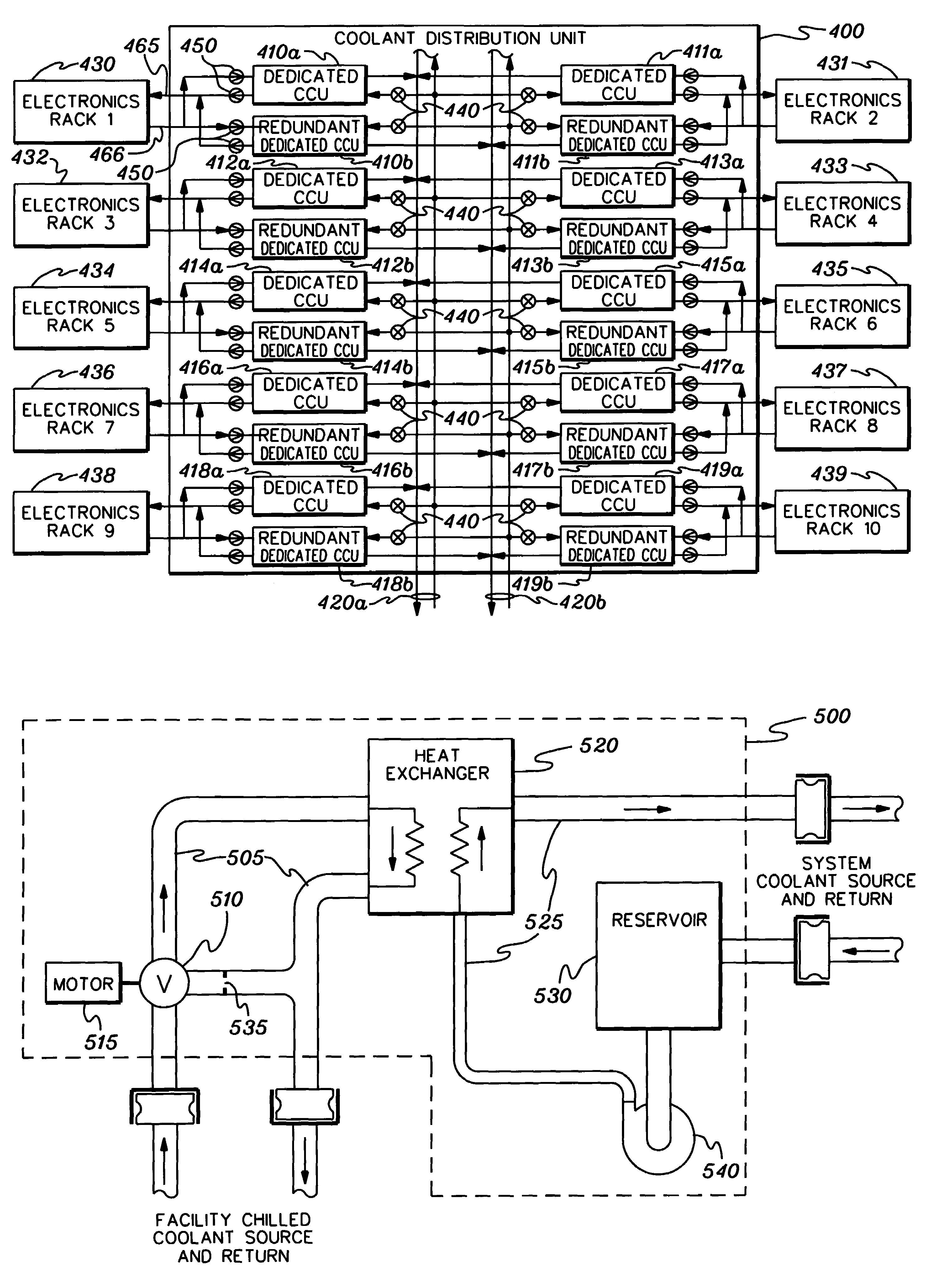

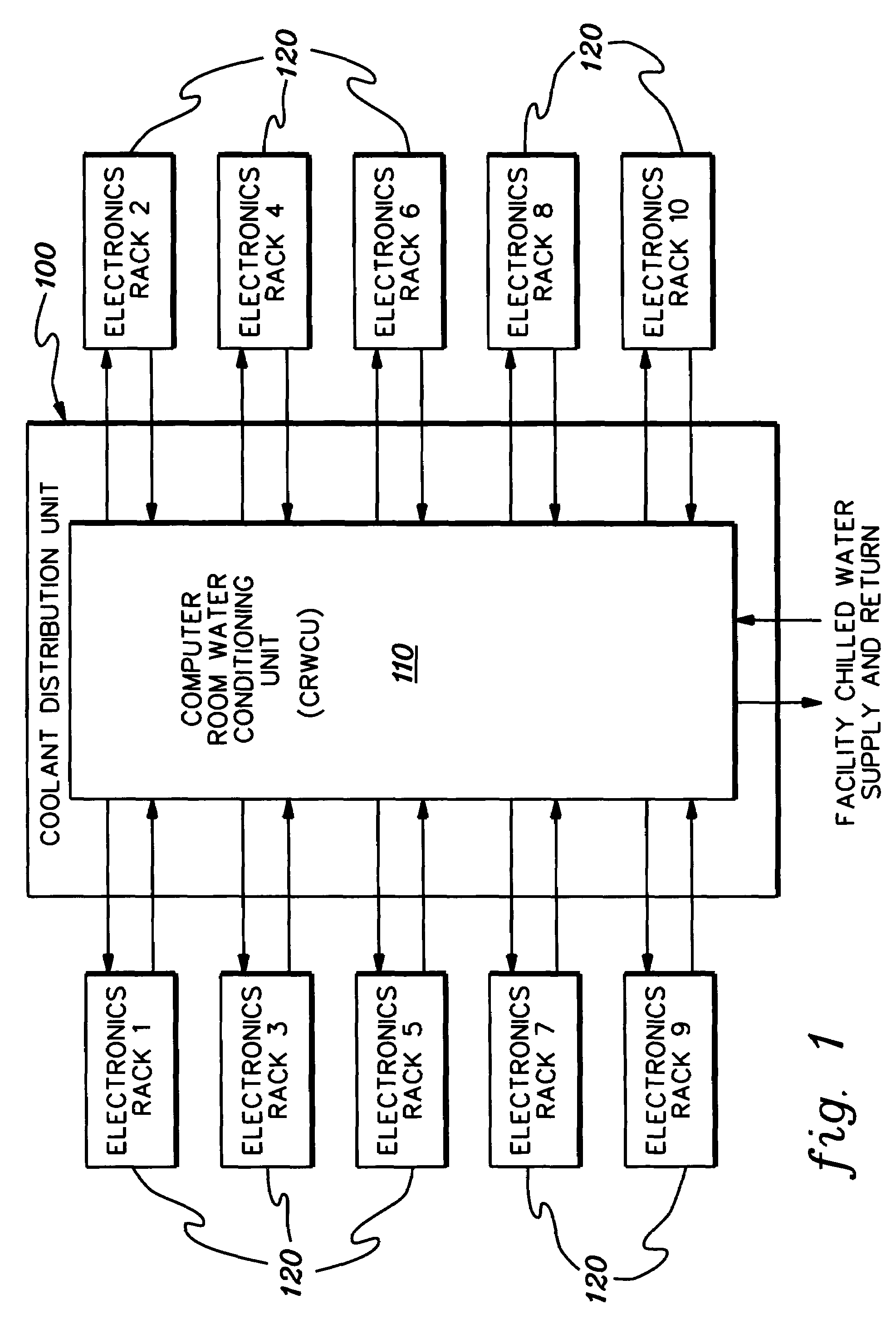

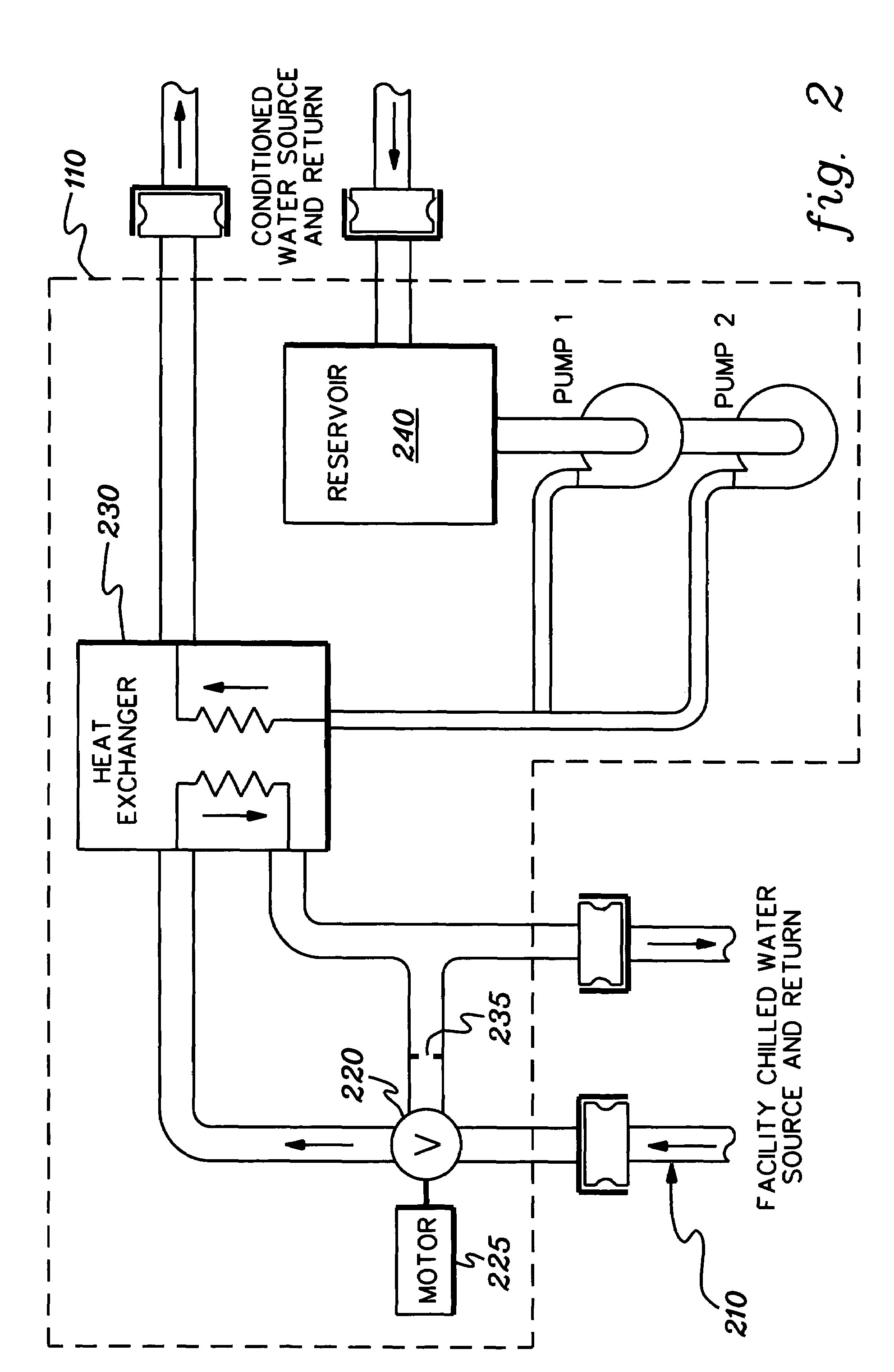

Cooling system and method employing multiple dedicated coolant conditioning units for cooling multiple electronics subsystems

InactiveUS7106590B2Superconductors/hyperconductorsDomestic cooling apparatusCoolant flowNuclear engineering

A cooling system is provided employing multiple coolant conditioning units (CCUs). Each CCU, which is coupled to a different, associated electronics rack of multiple electronics racks to be cooled, includes a heat exchanger, a first cooling loop with a control valve, and a second cooling loop. The first cooling loop receives chilled facility coolant from a source and passes at least a portion thereof via the control valve through the heat exchanger. The second cooling loop provides cooled system coolant to the associated electronics rack, and expels heat in the heat exchanger from the electronics rack to the chilled facility coolant in the first cooling loop. The control valve allows regulation of the facility coolant flow through the heat exchanger, thereby allowing independent control of temperature of the system coolant in the second cooling loop. Various CCU and associated component redundancies of the cooling system are also provided.

Owner:INT BUSINESS MASCH CORP

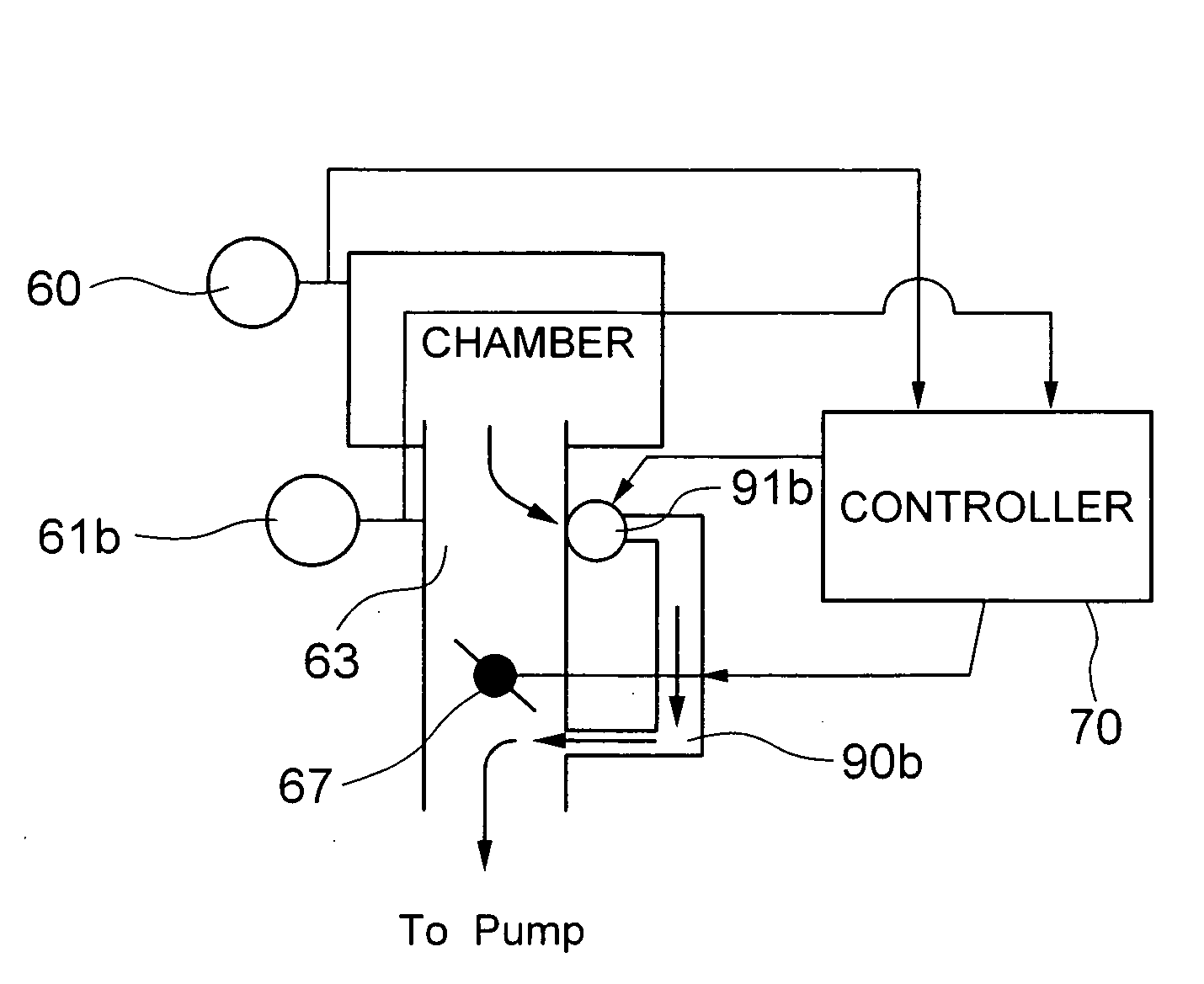

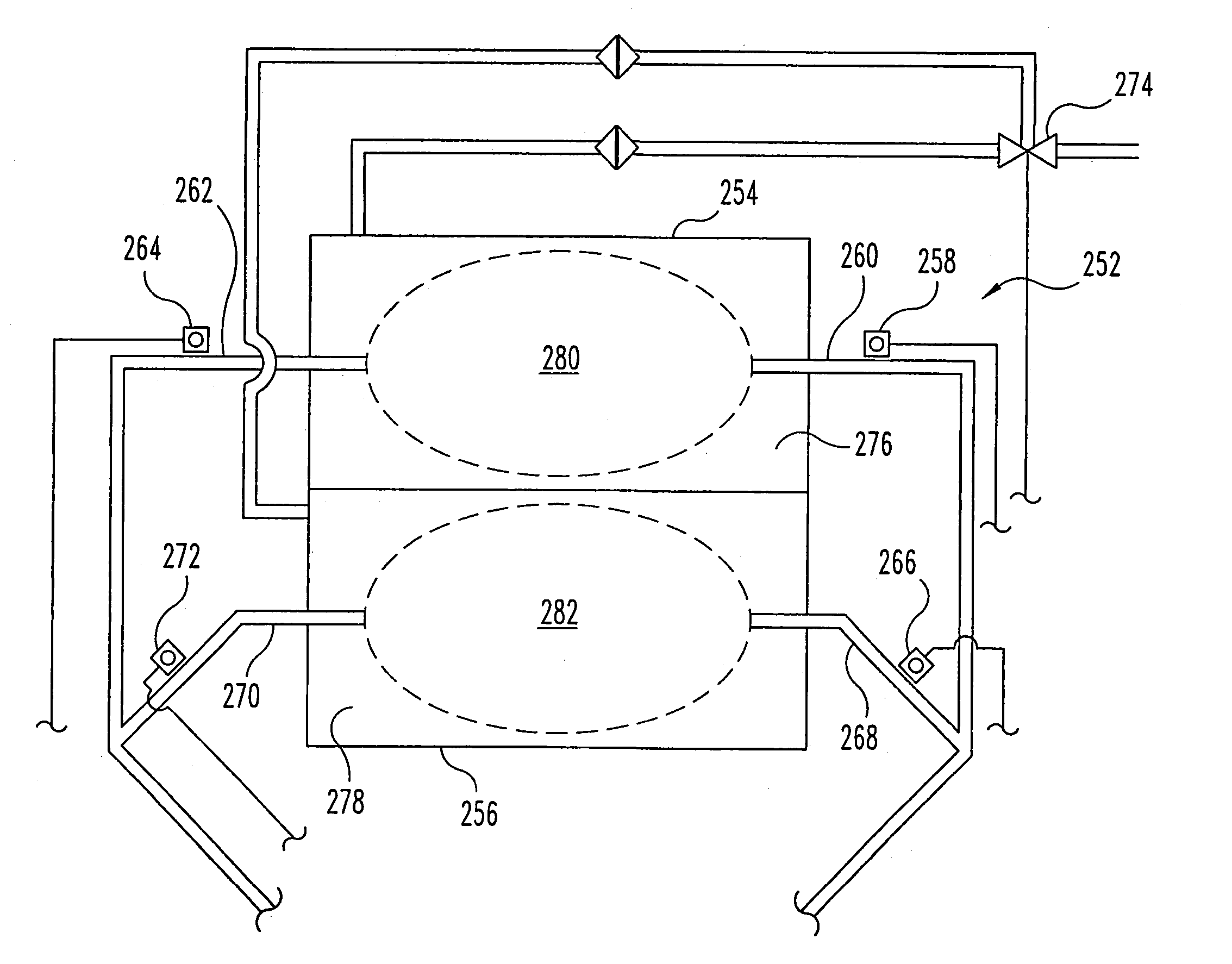

Device and methods for body fluid flow control in extracorporeal fluid treatments

Disclosed are devices and methods for the control of body fluid flow in the extracorporeal treatment of body fluid. Body fluid flow through on of a body fluid flow circuit (10, 50, 60, 100 or 250) is controlled by alternating applying vacuum pressure and positive pressure to the circuit through a pumping chamber (30, 51, 66, 102, or 200) coordinated with flow control valves (40, 42, 44, 62, 114, 116, 118, and 120) to effect a net downstream flow of body fluid through the circuit.

Owner:RENAL SOLUTIONS

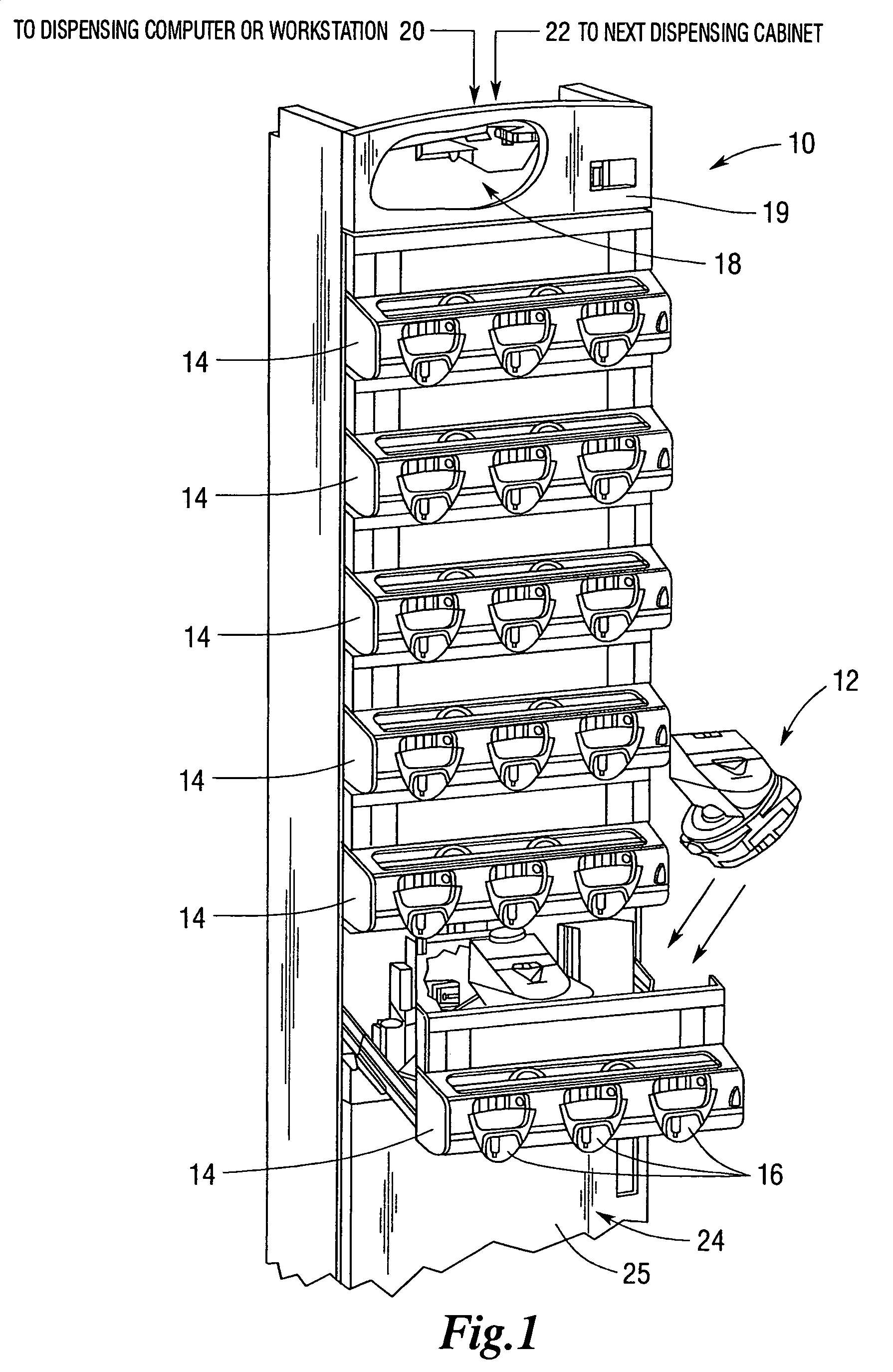

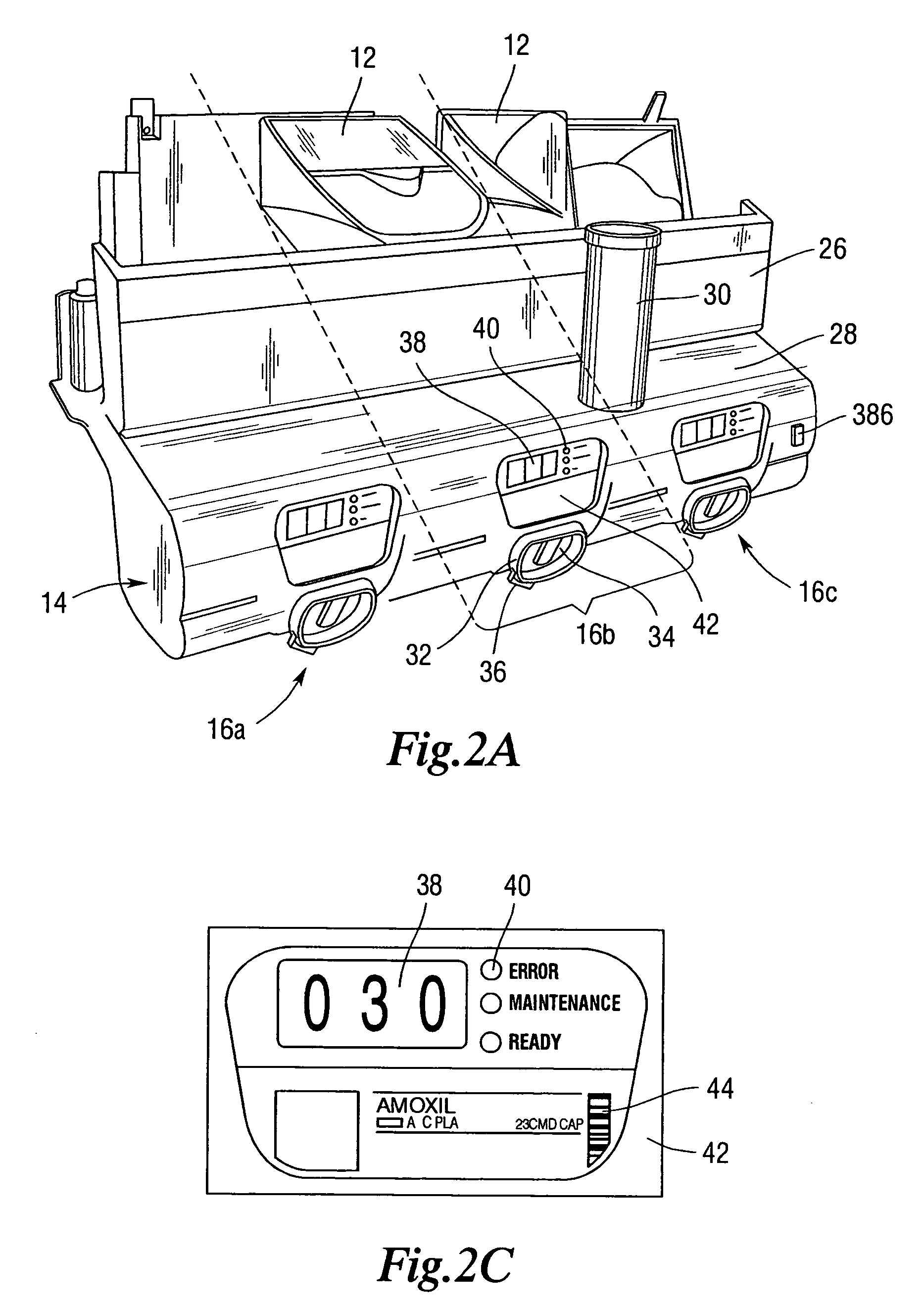

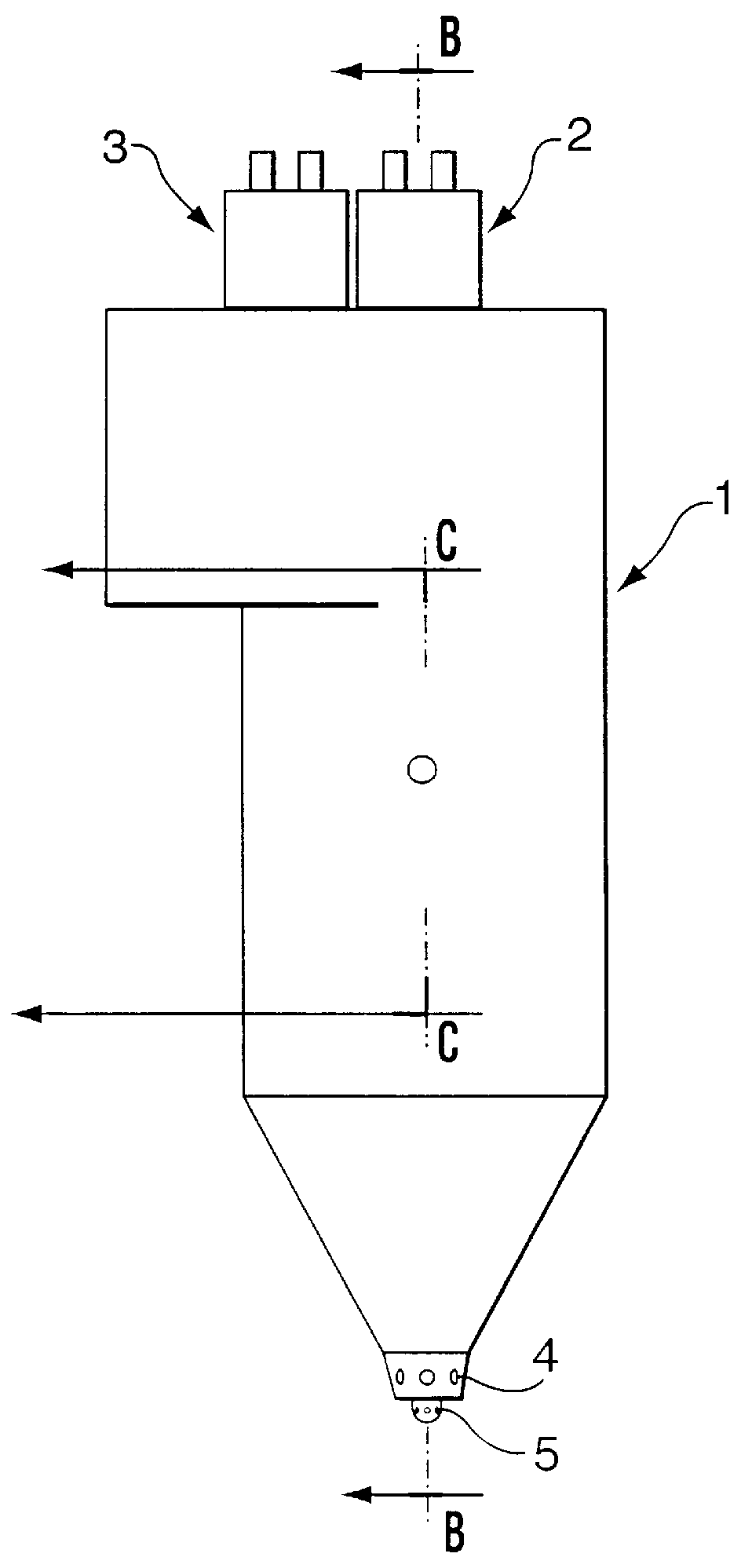

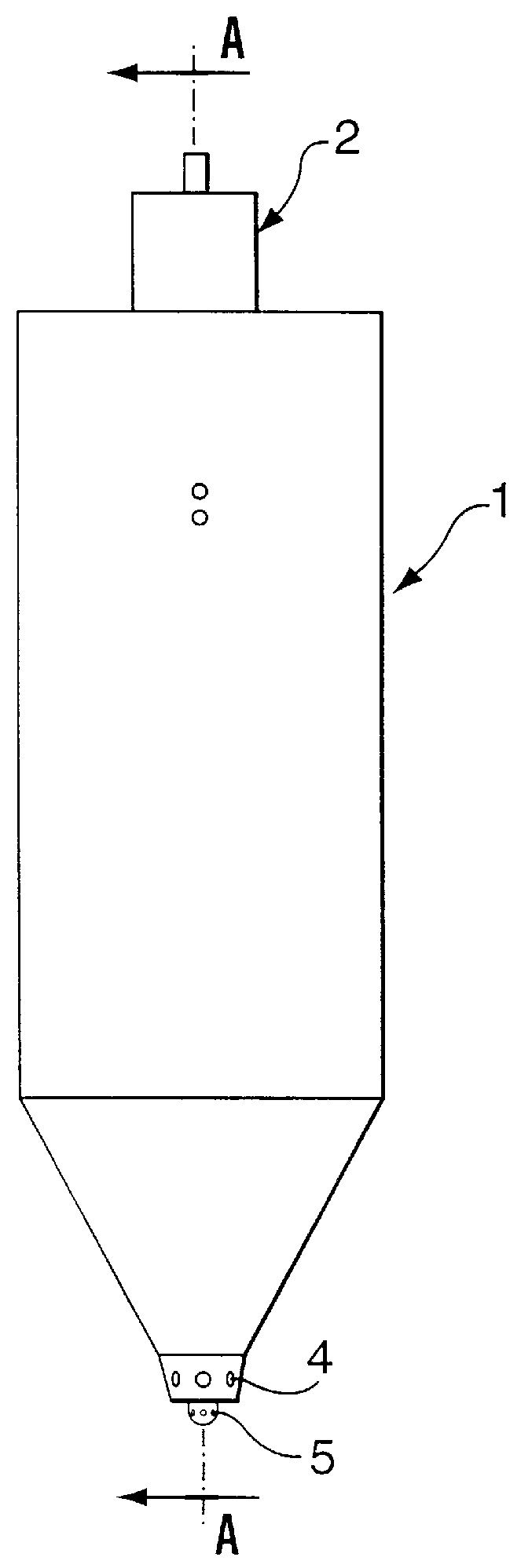

Dispensing device having a storage chamber, dispensing chamber and a feed regulator there between

A drug dispensing device is comprised of an upper hopper having an upper opening for receiving a medicament and a lower opening. A lid covers the upper opening. A lower hopper having an upper opening and a lower opening in a bottom portion thereof is provided. The upper hopper defines a bulk storage chamber and the lower hopper defines a dispensing chamber. A rotatable dispensing disc is positioned in a lower portion of the dispensing chamber for dispensing medicament from the drug dispensing device through the lower opening in the lower hopper. A regulator is situated between the bulk storage chamber and the dispensing chamber for controlling the rate at which medicament moves from the storage chamber to the dispensing chamber. The regulator may take a variety of forms. In one embodiment, the regulator includes a valve for controlling the flow of medicament from the storage chamber to the dispensing chamber. The valve may include a member responsive to the volume of medicament in the dispensing chamber for controlling the position of the valve. The valve and member may include a trap door valve and a float, a butterfly valve and a rotatable arm, a guillotine valve and a movable arm, and a conical plunger and a wing extending from the base of the plunger. In another embodiment, the regulator may include a rotatable member having an opening therein. The rotatable member may include a cylindrical wall having an opening in a portion thereof, a plate having an opening therein, a cup shaped member defining an opening and a pair of rotatable members which together define at least one opening therein. The regulator may be configured such that the rate at which medicament moves from the storage chamber to the dispensing chamber is never zero. Further, agitating members may be provided which extend toward the upper hopper. Methods of operation are also disclosed.

Owner:PARATA SYST

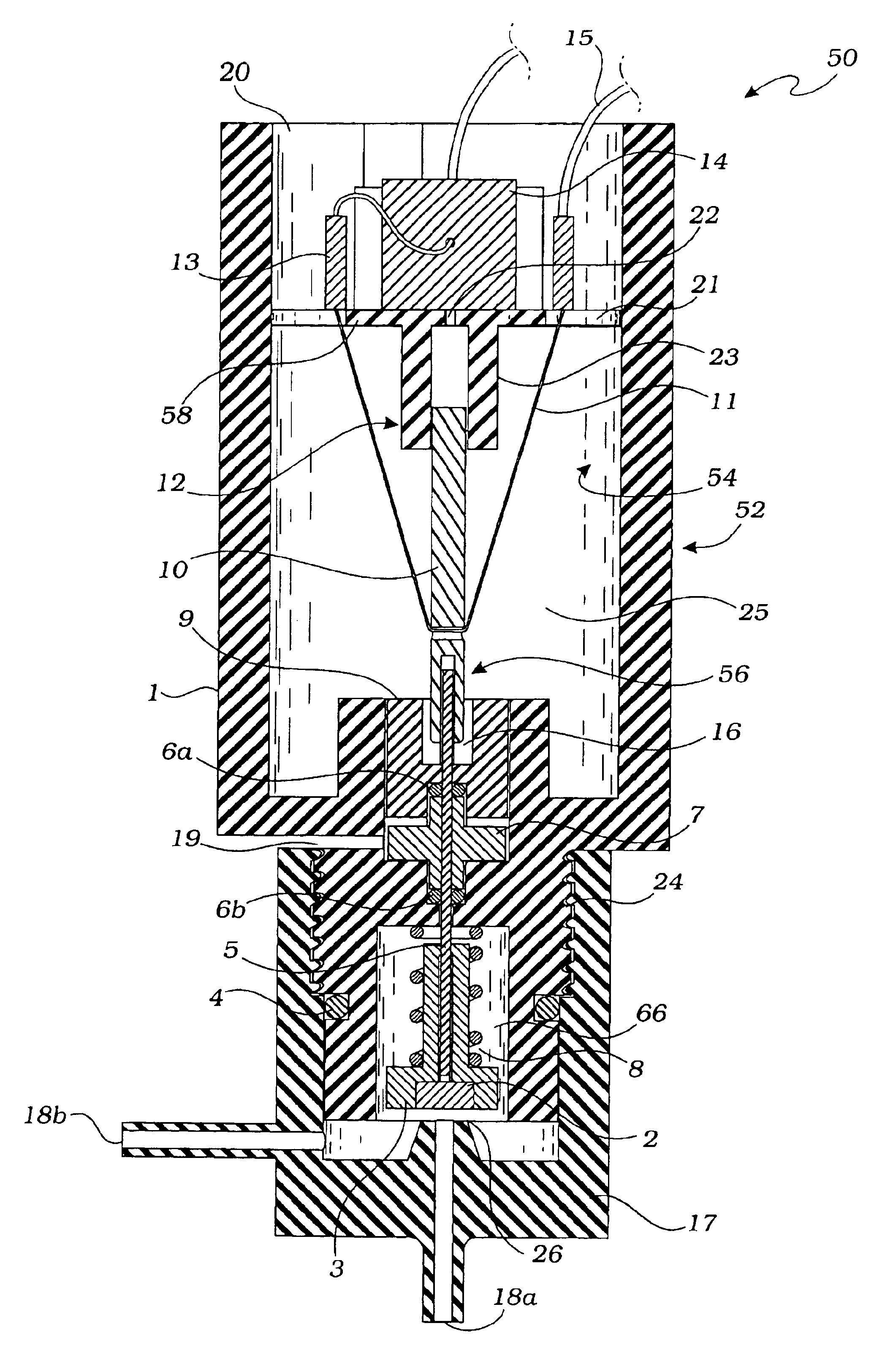

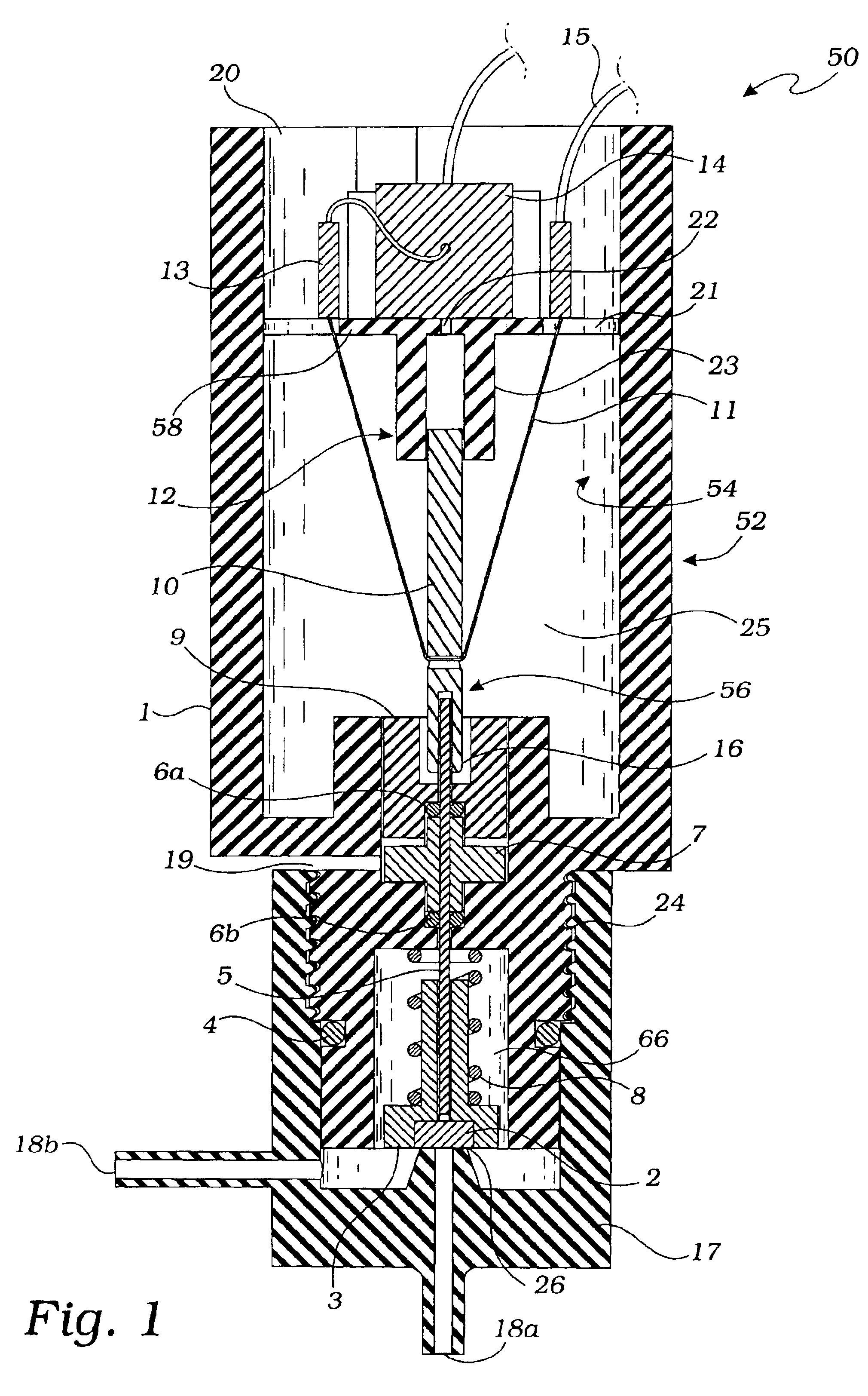

Memory wire actuated control valve

InactiveUS6843465B1Operating means/releasing devices for valvesDomestic plumbingElectricityFluid control

A memory wire actuated control valve comprises a memory wire actuator operatively coupled to a fluid control valve. The memory wire actuator includes a housing having an interior cavity enclosing an electrical platform assembly, an activation wire and a transfer mechanism. The activation wire is formed of a shape memory alloy, often called a “memory wire” or “muscle wire.” The activation wire is electrically connected to the electrical platform and mechanically coupled to the transfer mechanism. The actuator is activated by conducting electrical current through the activation wire causing the wire to contract thereby actuating the transfer mechanism. The transfer mechanism is operable coupled to the fluid control valve such that actuated and de-actuating the transfer mechanism open and closes the valve.

Owner:SCOTT LOREN W

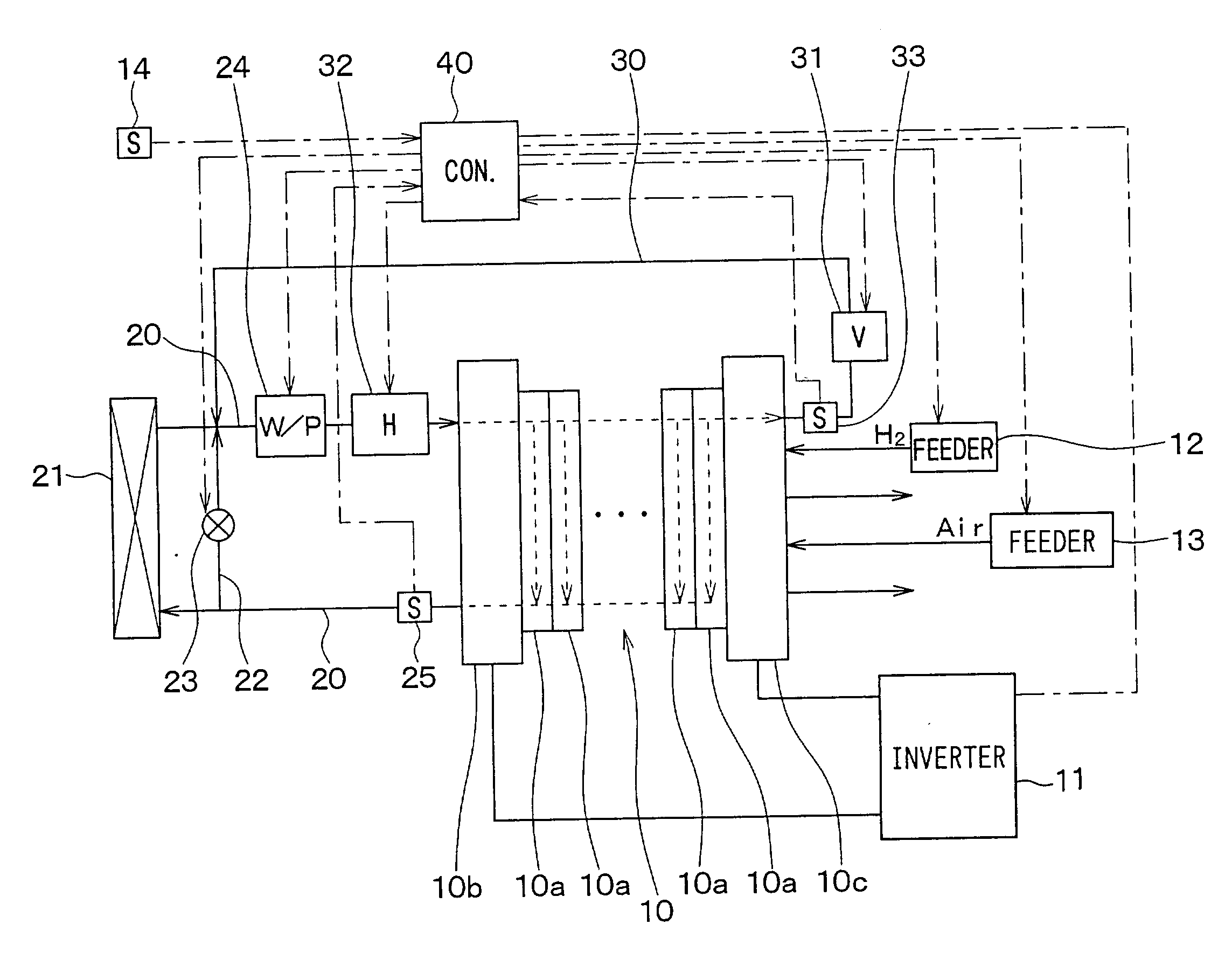

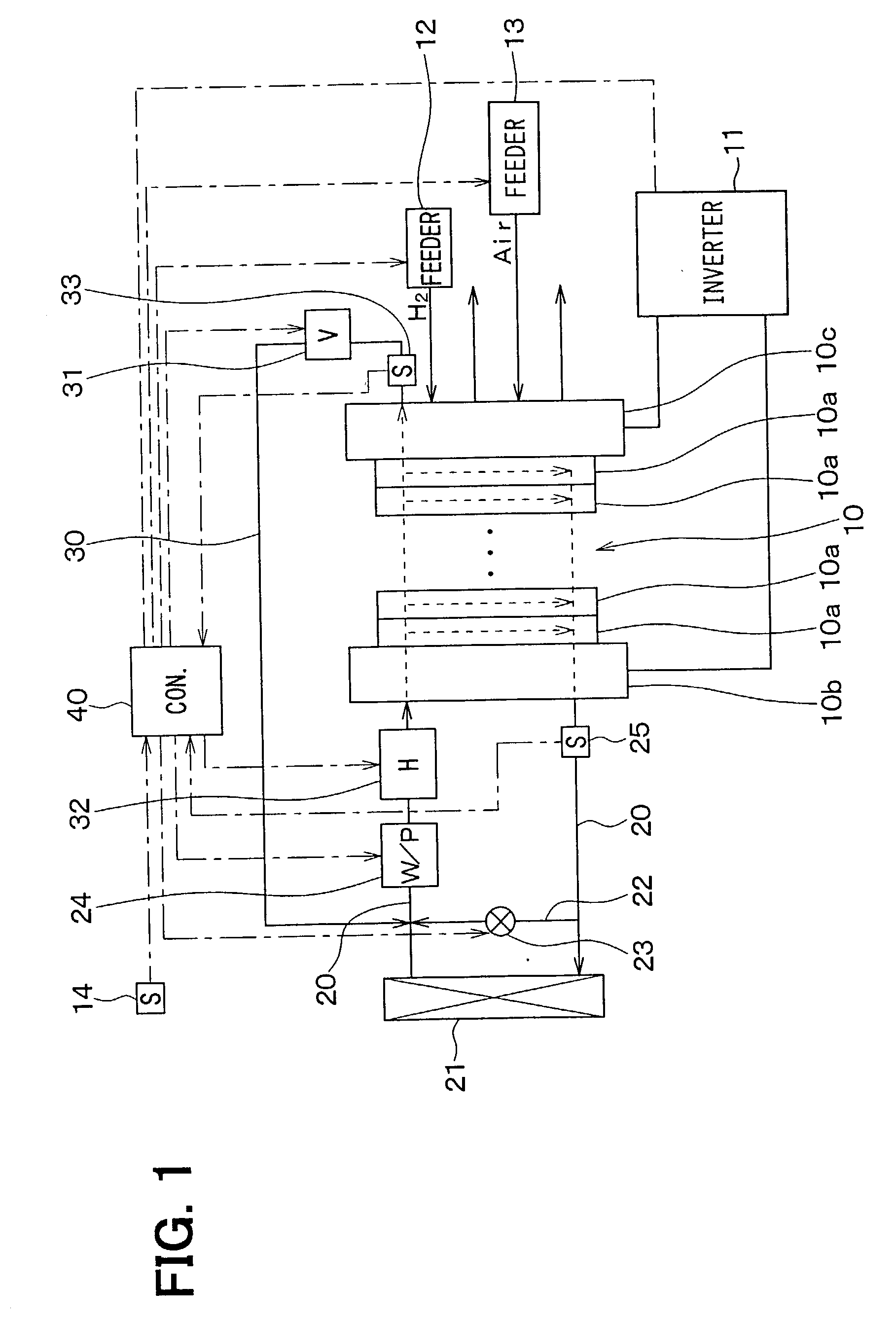

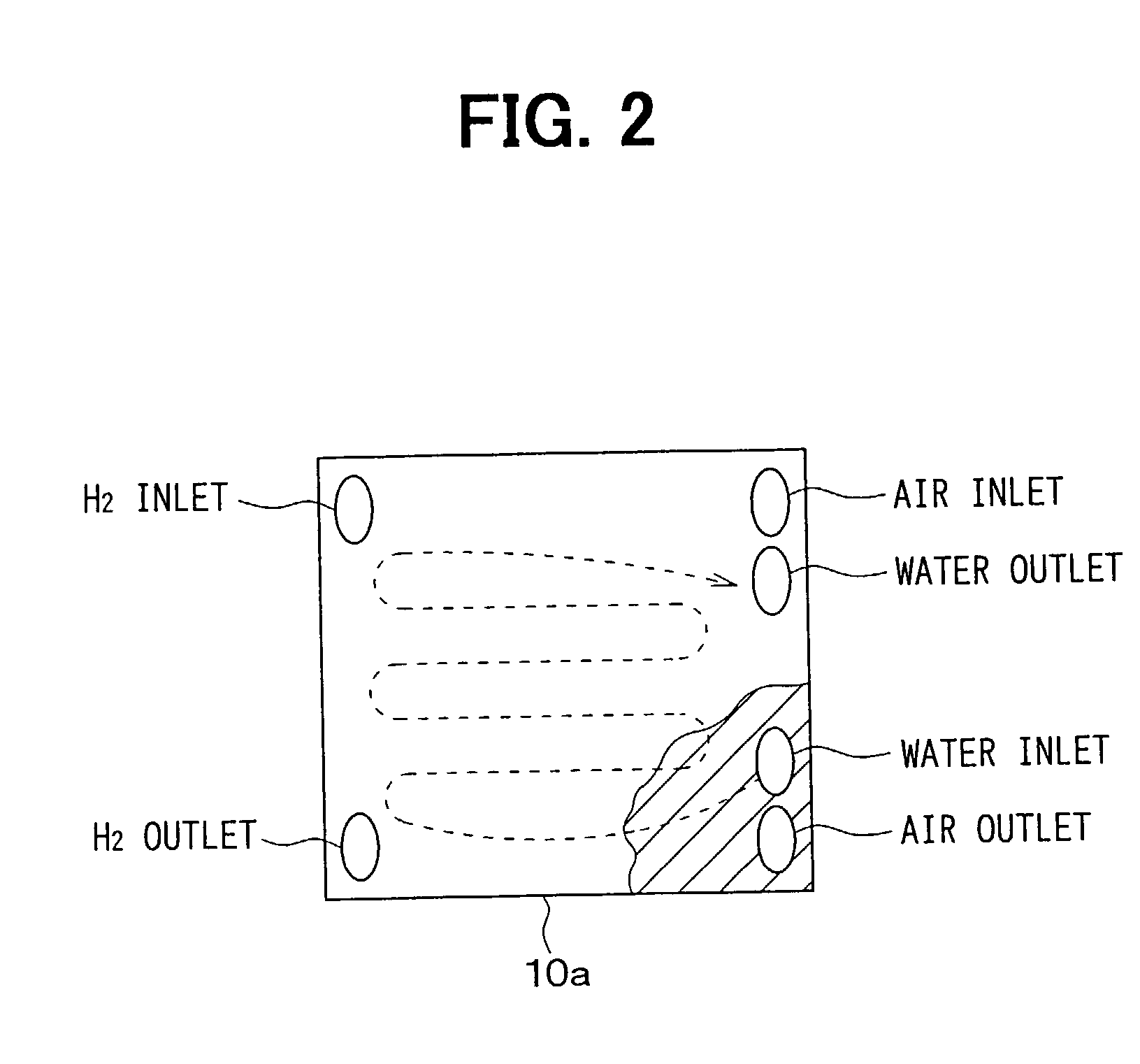

Fuel cell system

InactiveUS20030031905A1Small sizeHeating up fastFuel cell heat exchangeFuel cells groupingFuel cellsEngineering

A fuel cell system includes a fuel cell constructed by plural stacked cells, a circulation path through which a thermal medium is circulated into each cell, a heater for heating the thermal medium, a bypass path through which the thermal medium is circulated into a part of each cell while bypassing the other part thereof, and a flow control valve for controlling a flow amount of the thermal medium circulated in the bypass path. The thermal medium can be circulated into only the part of each cell in a warm-up operation, so that the part of each cell is collectively heated. An amount of the thermal medium circulated into the other part of each cell is controlled, so that all of each cell is finally warmed up in the warm-up operation.

Owner:DENSO CORP

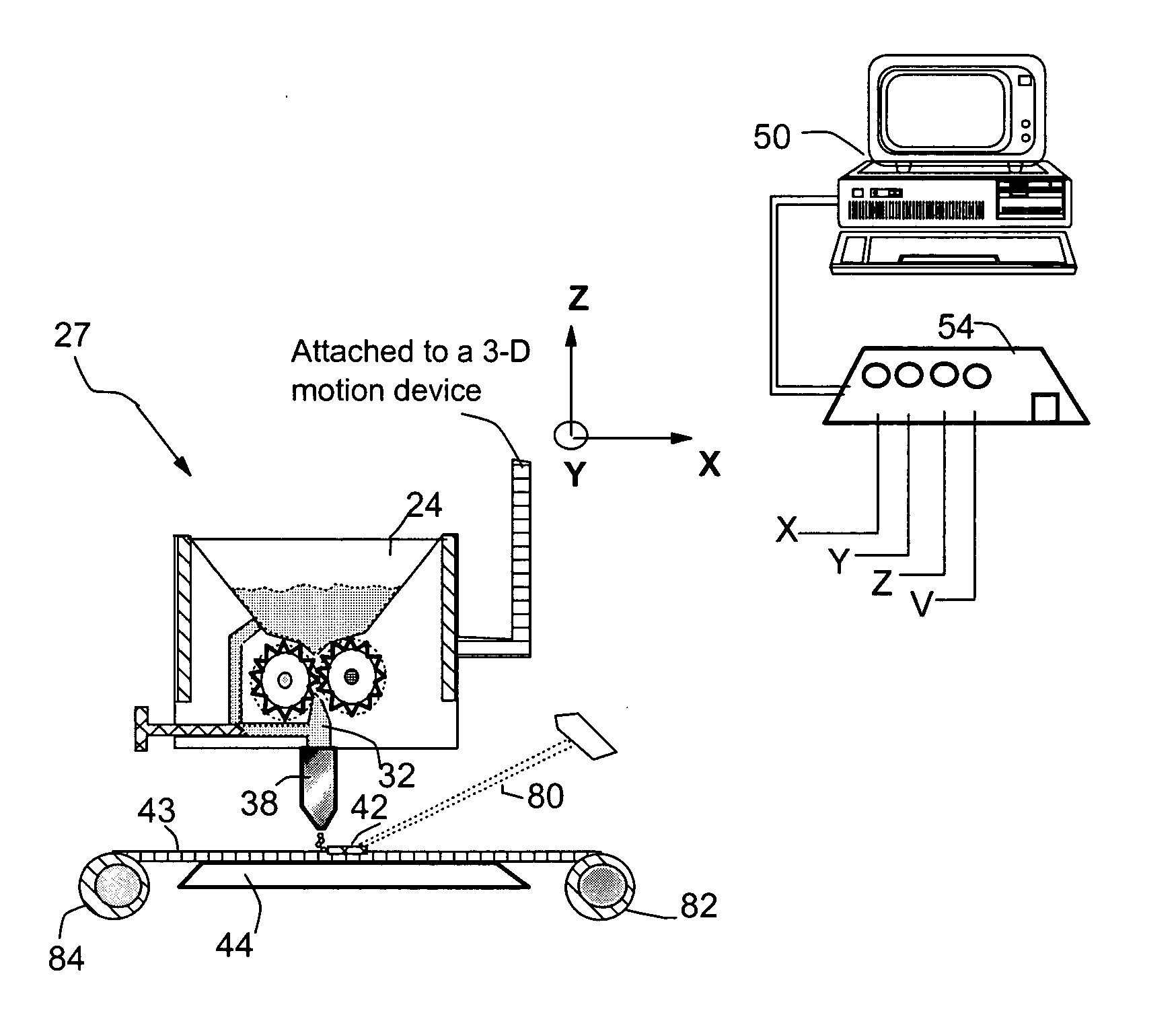

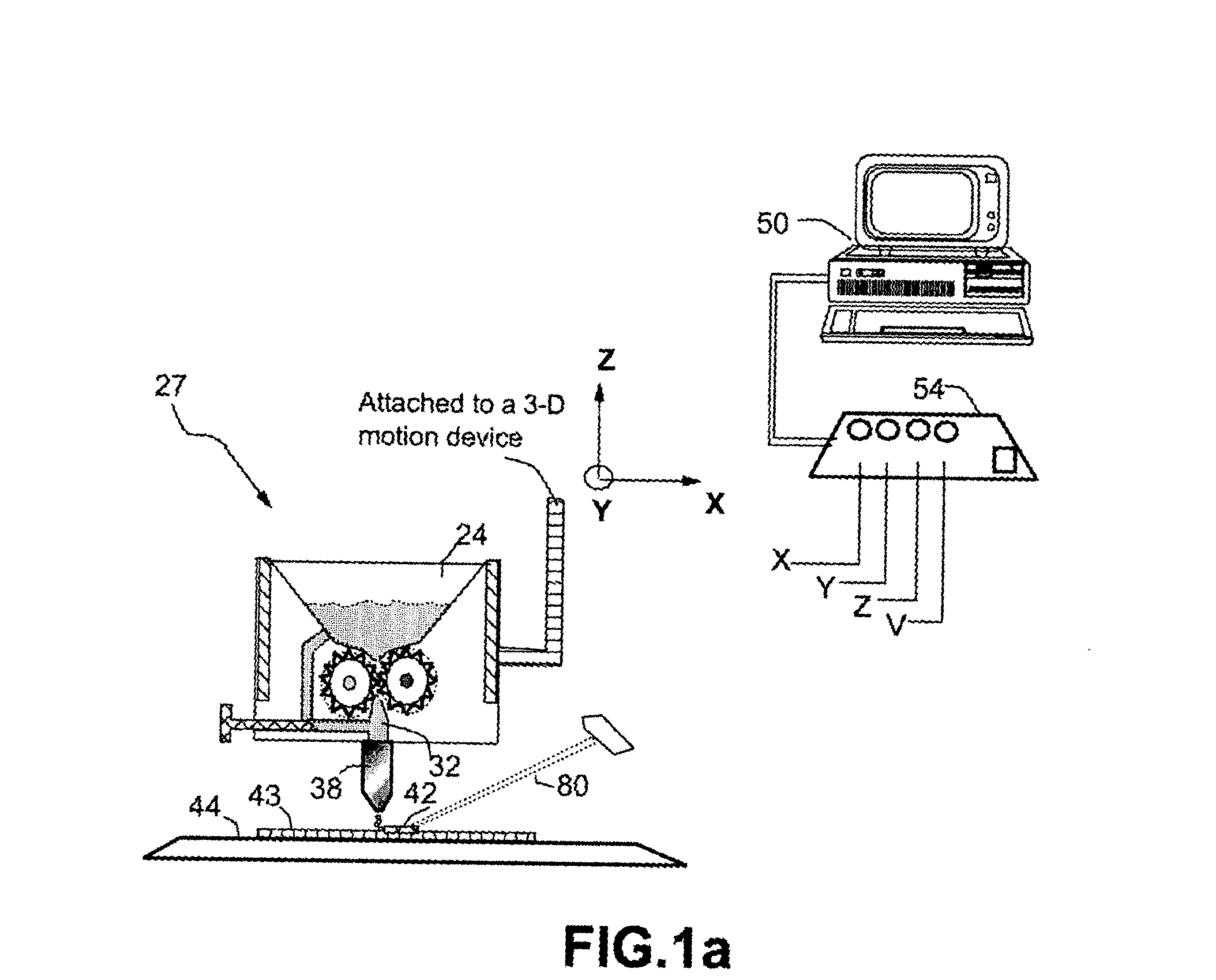

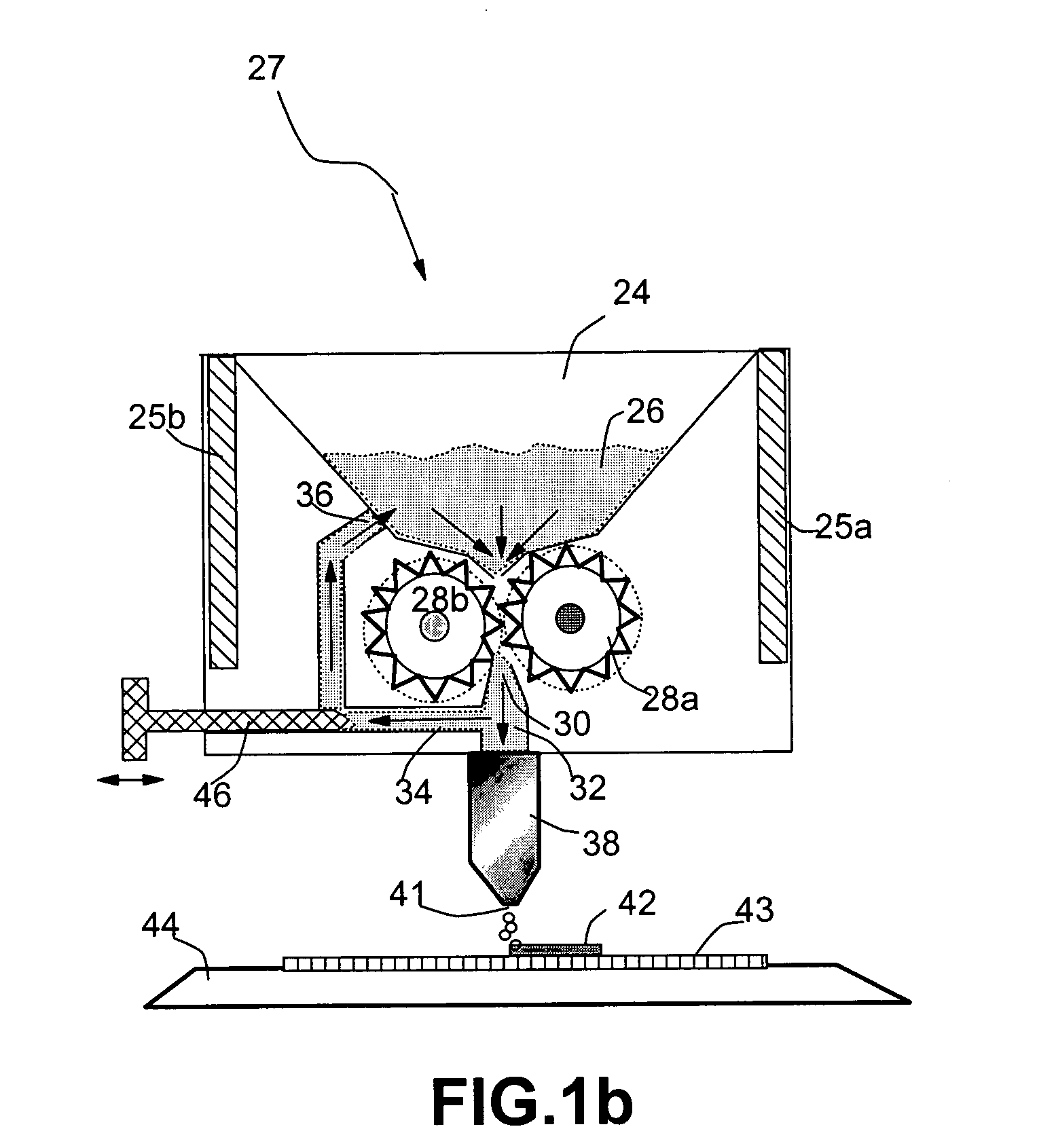

Direct write process and apparatus

ActiveUS20050015175A1Fast preparationIncrease back pressureRecording apparatusAdditive manufacturing apparatusDielectricControl signal

A direct write process and apparatus for fabricating a desired circuit component onto a substrate surface of a microelectronic device according to a computer-aided design (CAD). The process includes (a) providing a support member by which the device is supported while being fabricated; (b) providing a chamber for containing a precursor fluid material under a substantially constant pressure differential relative to the ambient pressure, with the precursor fluid material having a viscosity no less than 10 cps; (c) operating an inkjet-based dispensing head with a control valve or actuator for dispensing and depositing minute droplets of the precursor fluid material onto the substrate surface; (d) energy- or heat-treat the deposited precursor fluid material for converting it to the desired active or passive component; and (e) operating a machine controller for generating control signals in response to the CAD coordinates for controlling the position of the dispensing head relative to the support member in response to the control signals to control dispensing and depositing of the precursor material to form the desired component. The process is useful for depositing a wide range of component materials onto an electronic device, including conductor, resistor, capacitor, dielectric, inductor, antenna, solar cell electrode, battery electrode, interconnect, superconductor, sensor, and actuator element materials.

Owner:NANOTEK INSTR GRP LLC

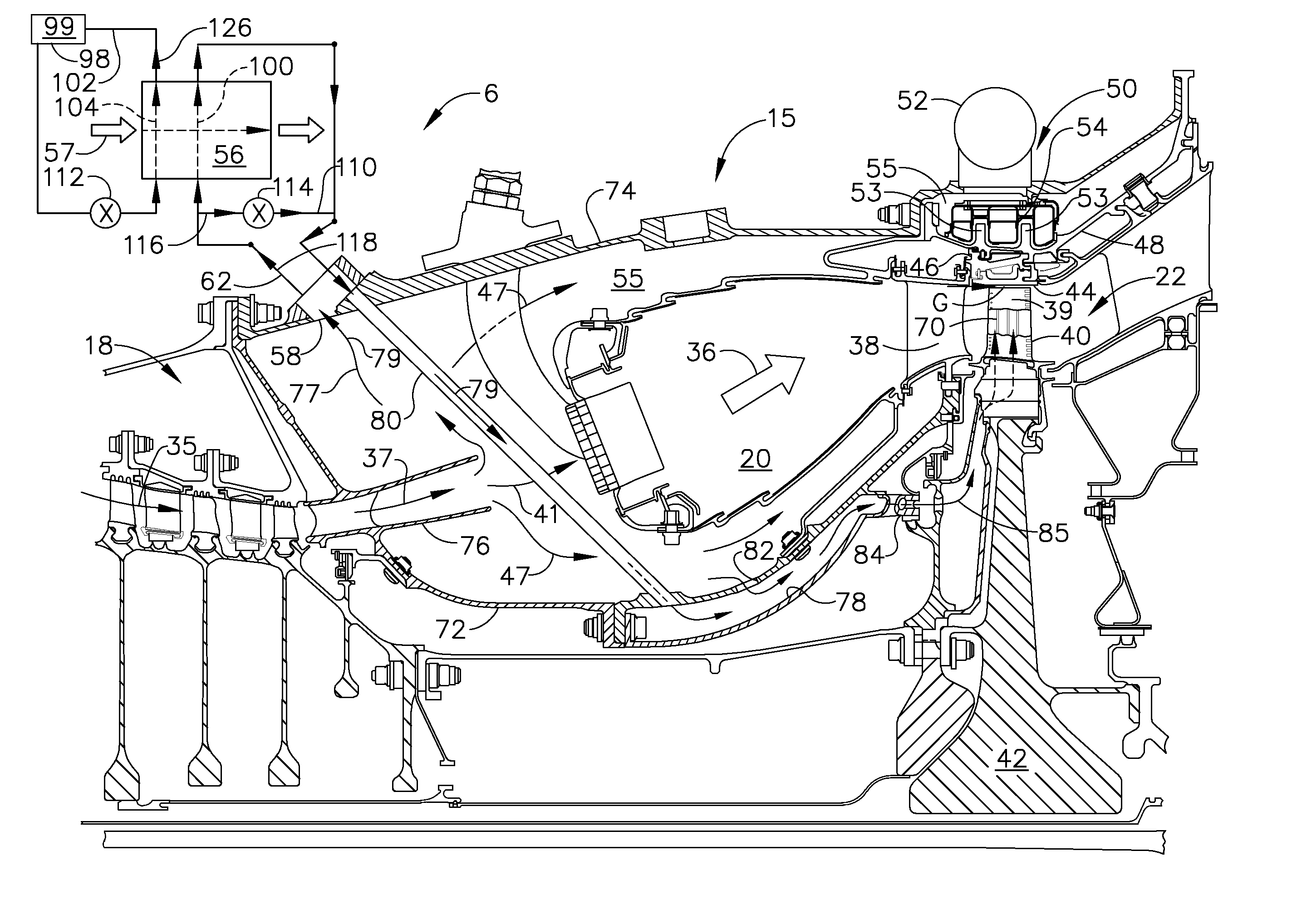

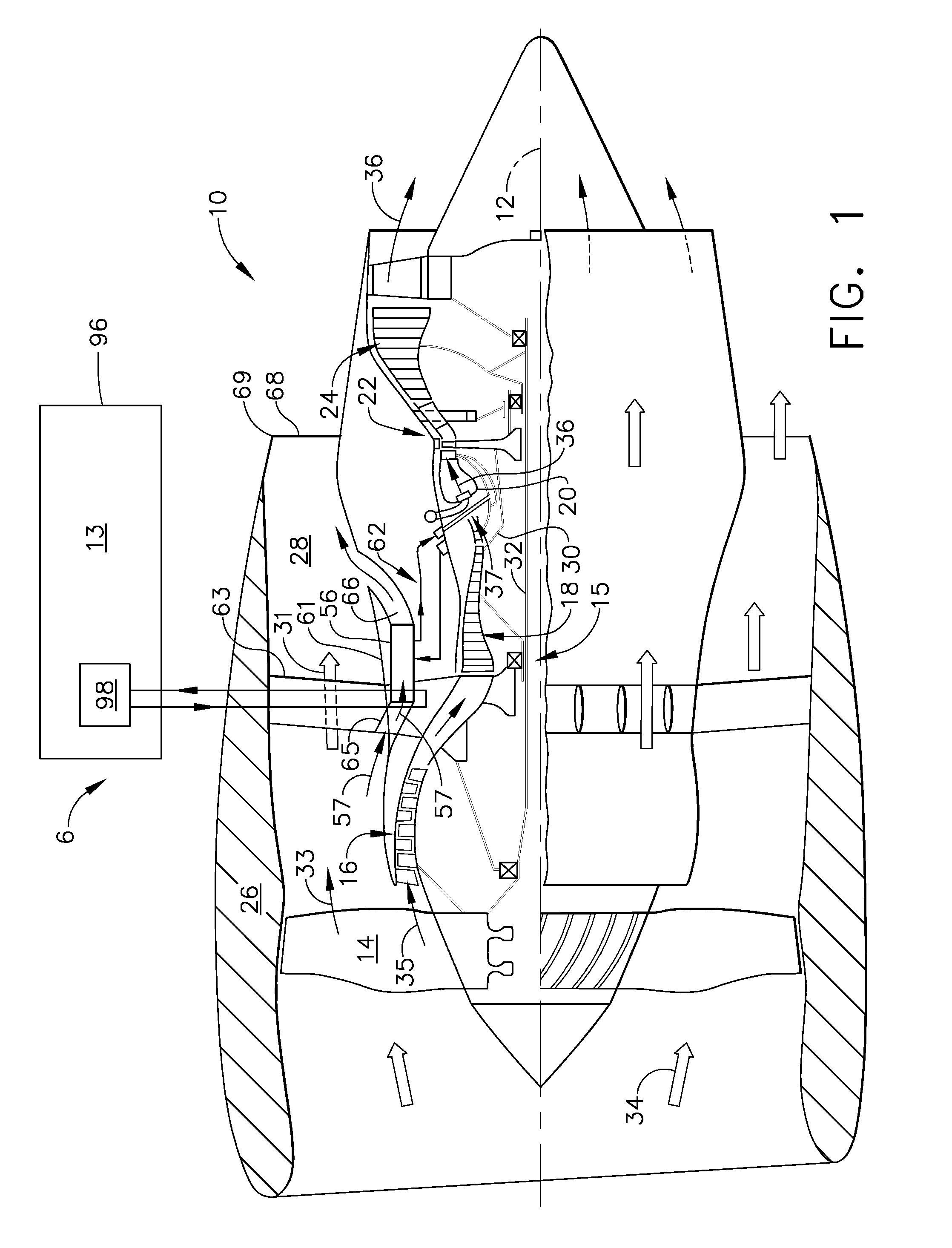

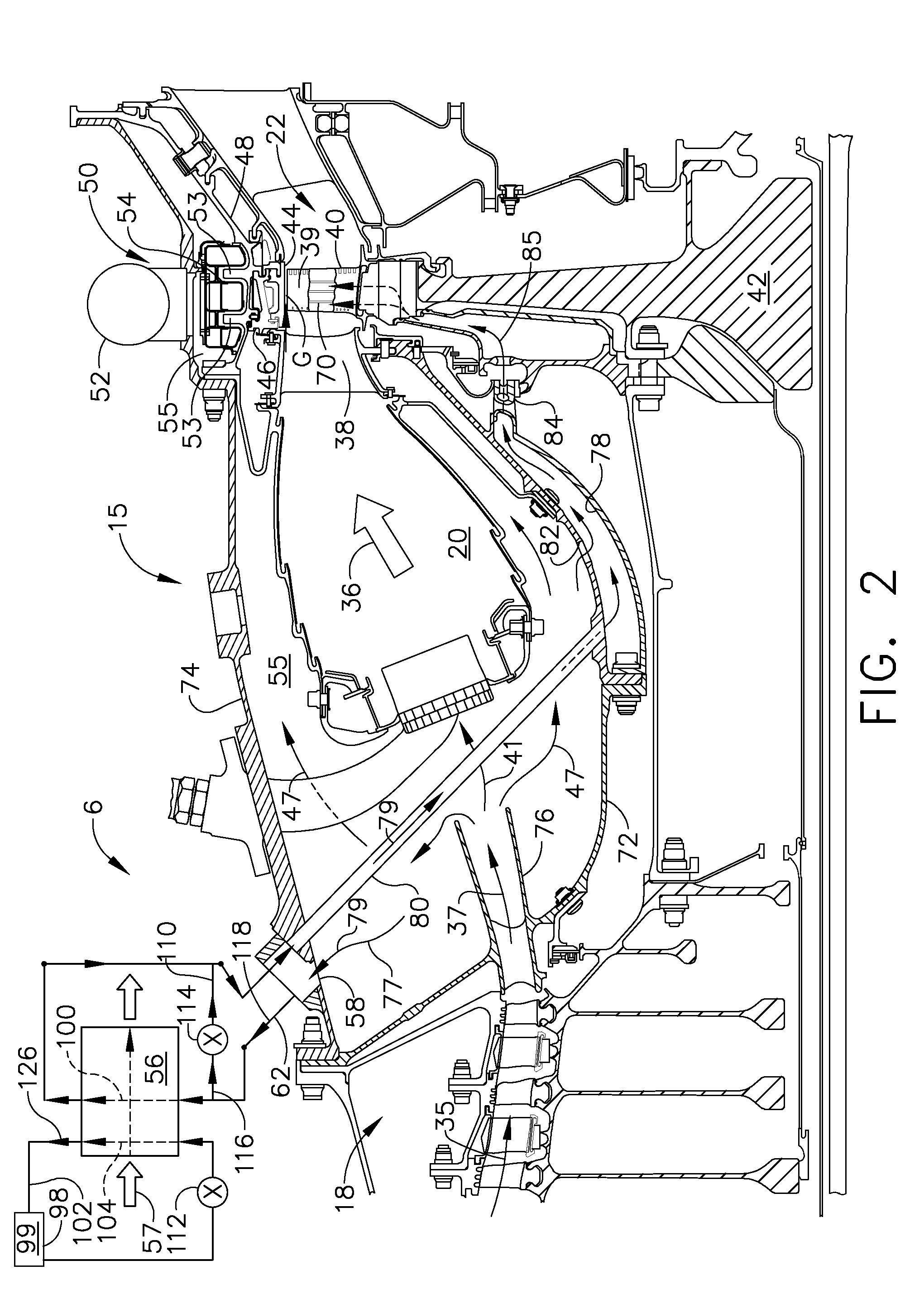

Gas turbine engine temperature modulated cooling flow

ActiveUS20110088405A1Improved blade cooling controlImprove efficiencyPump componentsTurbine/propulsion engine coolingPlate heat exchangerTurbine blade

A gas turbine engine cooling system includes a heat exchanger in fluid communication with a source of cooling air, a first cooling circuit including a first heat exchanger circuit in the heat exchanger and a first bypass circuit with a first bypass valve for selectively bypassing at least a portion of first airflow around the first heat exchanger circuit. A second cooling circuit may be used having a second heat exchanger circuit in the heat exchanger and a shutoff control valve operably disposed in the second cooling circuit upstream of the second heat exchanger circuit and the heat exchanger. A circuit inlet of the first cooling circuit may be used to bleed a portion of compressor discharge bleed air for the first airflow to cool turbine blades mounted on a rotor disk using an annular flow inducer downstream of the first bypass valve and the heat exchanger.

Owner:GENERAL ELECTRIC CO

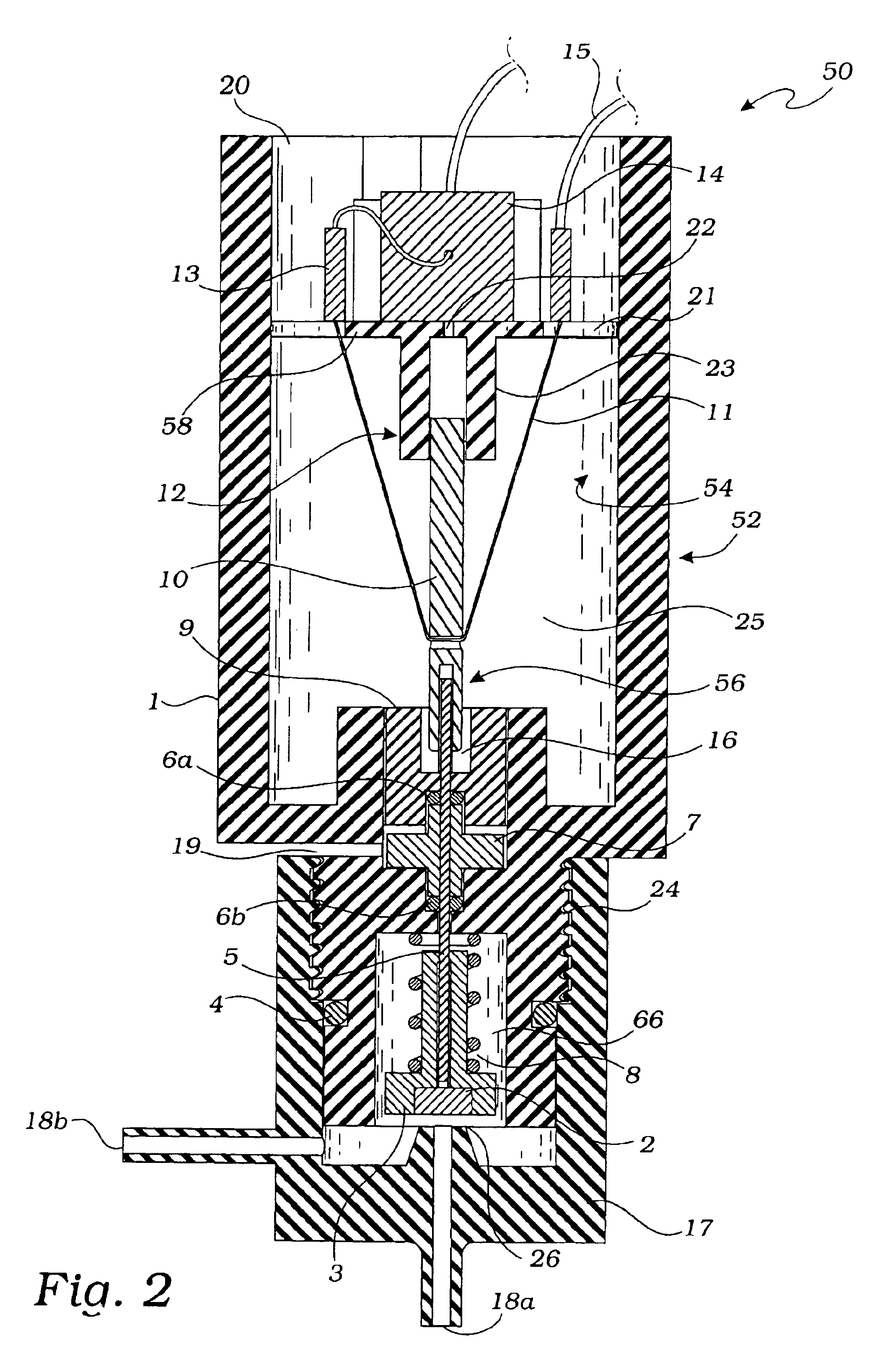

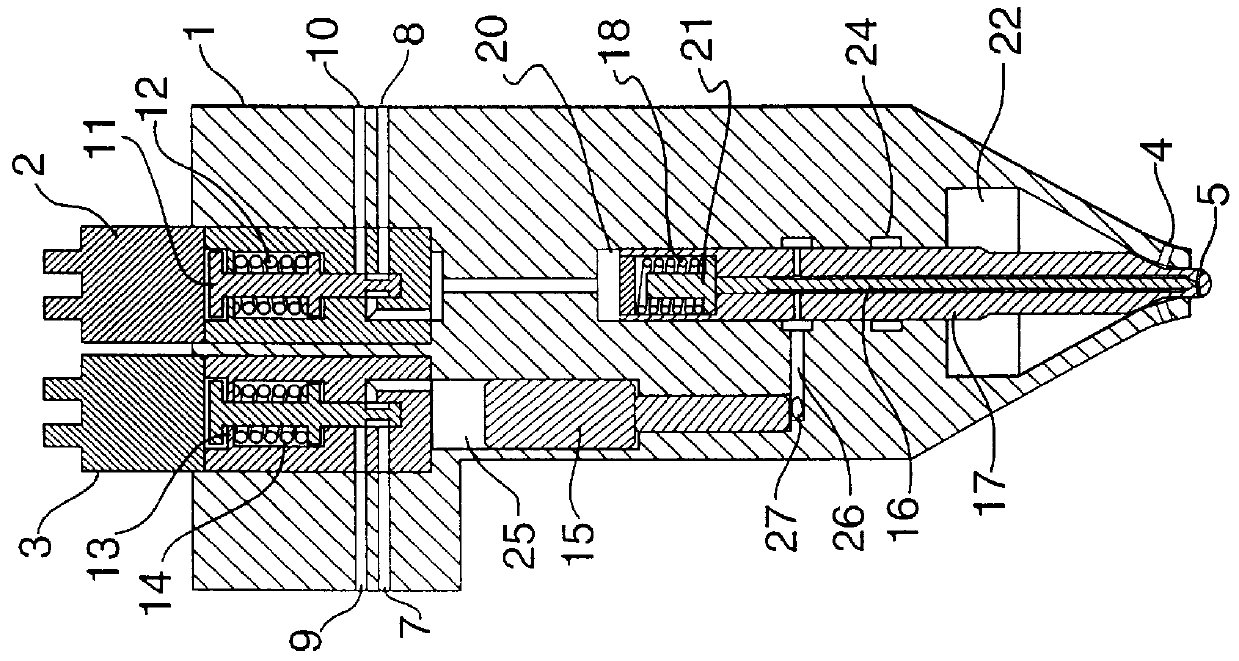

Gaseous and liquid fuel injector

A hydraulically actuated dual fuel injector for an internal combustion engine. More particularly, the application pertains to a hydraulically actuated injector for injecting controlled quantities of a first fuel and of a second fuel into an internal combustion diesel engine at different times. A dual fuel injector comprising: (a) an injector body; (b) an inlet port in the injector body for enabling pressurized hydraulic fluid from a hydraulic fluid source to be introduced into the interior of the injector body, the hydraulic fluid being of sufficient pressure to maintain injection valves in the injector body in a closed position until actuated; (c) a first inlet port in the injector body for enabling a first fuel to be introduced into the interior of the injector body; (d) a first injection valve in the injector body connected to the second inlet port for controlling injection of the first fuel from the injector through a first fuel ejection port; (e) a second inlet port in the injector body for enabling a second fuel to be introduced into the interior of the injector body; (f) a second injection valve in the injector body connected to the second inlet port for controlling injection of the second fuel from the injector through a second fuel ejection port; (g) a first control valve which causes the hydraulic fluid to actuate the first injection valve; (h) a second control valve which causes the hydraulic fluid to actuate the second injection valve; (i) a metering device in the injector body for metering the amount of first fuel injected by the first injection valve; and (j) a seal in the injector body which prevents leakage of the second fuel into the first fuel.

Owner:WESTPORT POWER

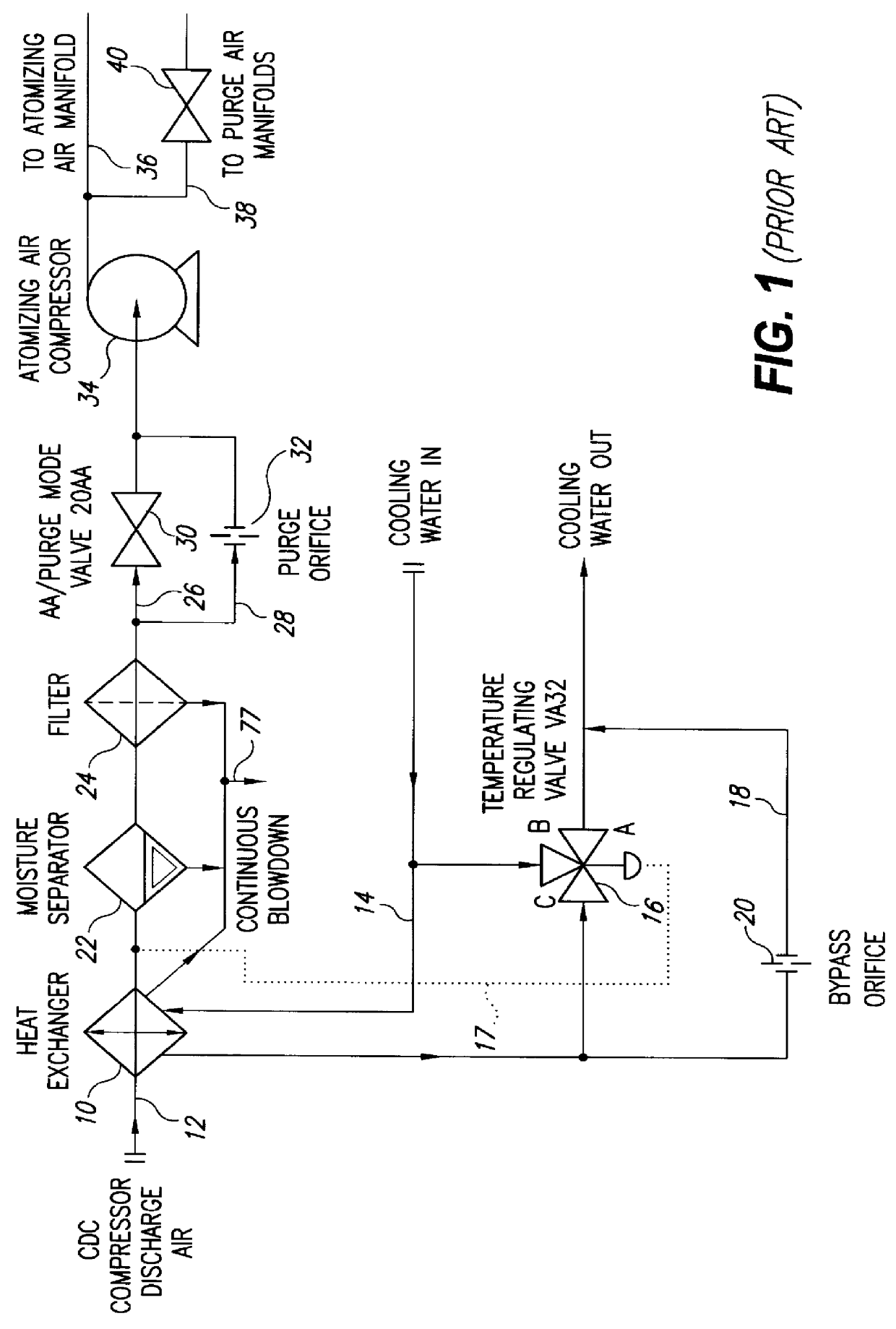

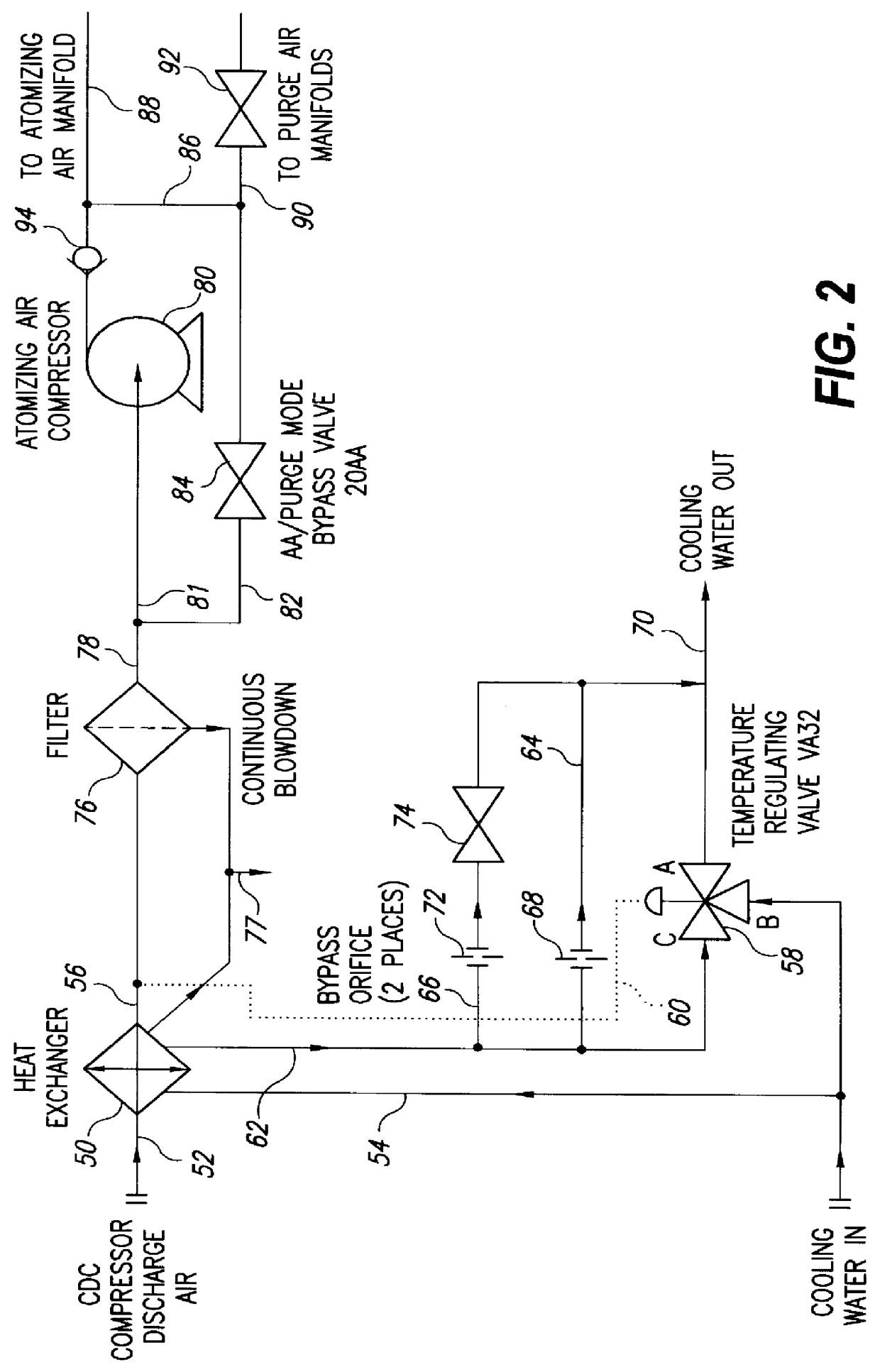

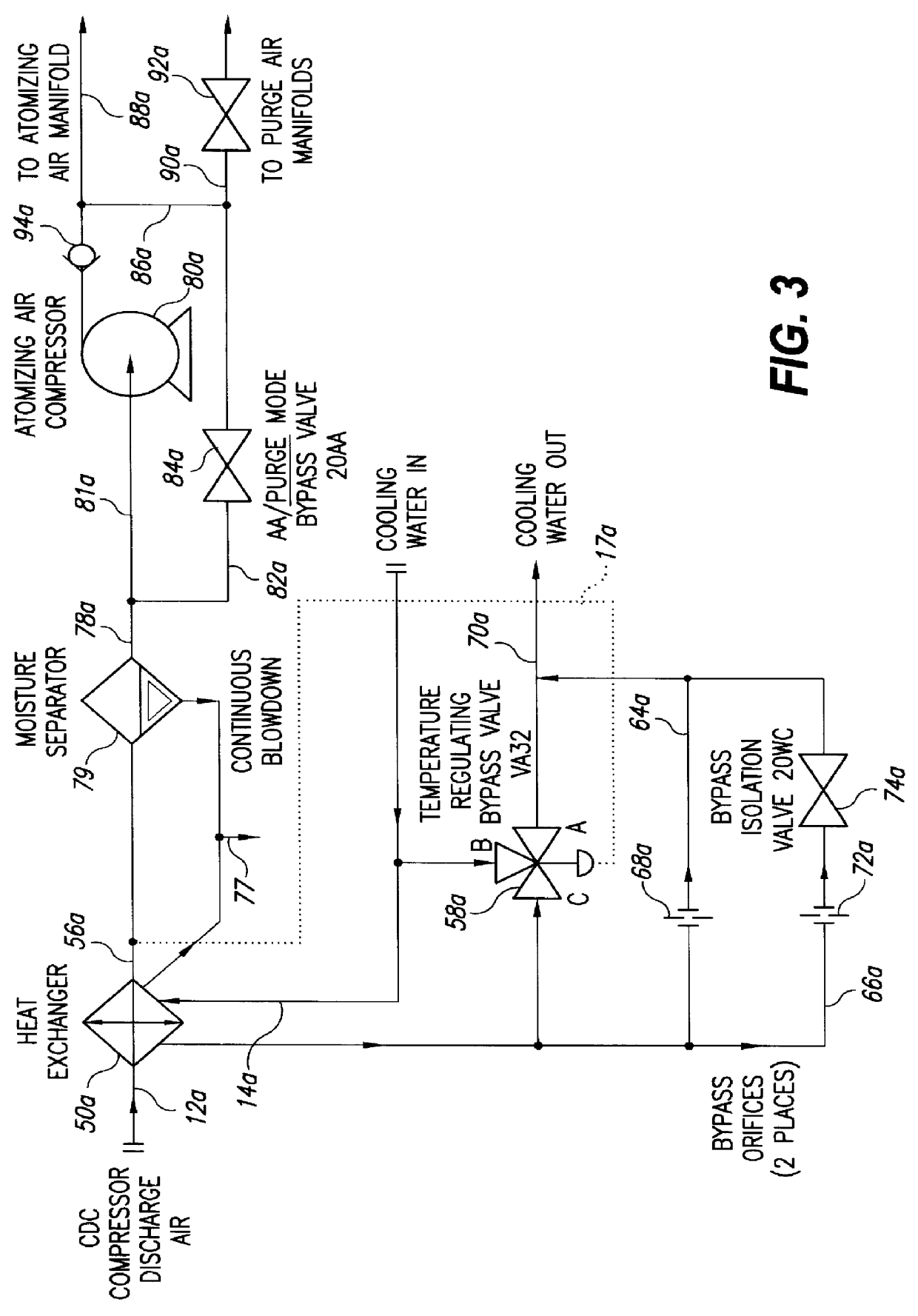

Dual orifice bypass system for dual-fuel gas turbine

InactiveUS6145318AReduce trafficAvoid heat buildupBurner safety arrangementsBurnersCombustorHeat rejection

Compressor discharge air flows through a heat exchanger in heat exchange relation with cooling water and is supplied at reduced temperature in atomizing air and purge modes to combustors in a dual-fuel gas turbine. The heat exchanger has a pair of bypass passages in parallel with a temperature regulating valve controlling flow of water through the heat exchanger in response to the temperature of the compressor discharge air exiting the heat exchanger. Should the flow control valve close in response to low temperature of the compressor discharge air, in the air atomizing mode, the bypass passages with orifices therein provide a minimum protective flow of cooling water to the heat exchanger. In the purge mode where only half the air flow and heat rejection is required in the heat exchanger and the flow control valve closes, a bypass valve in one of the bypass passages closes to enable reduced flow of cooling water through the heat exchanger.

Owner:GENERAL ELECTRIC CO

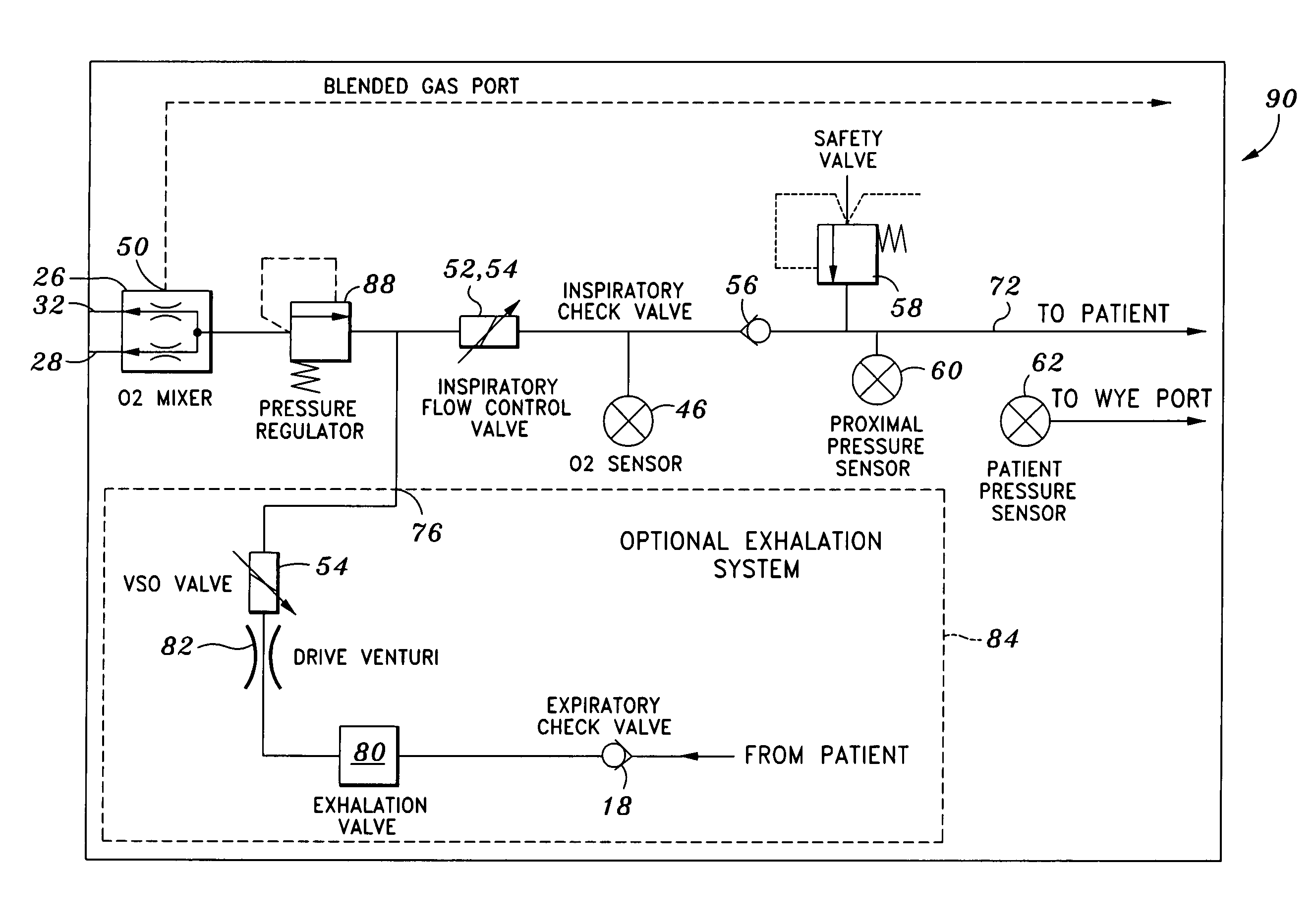

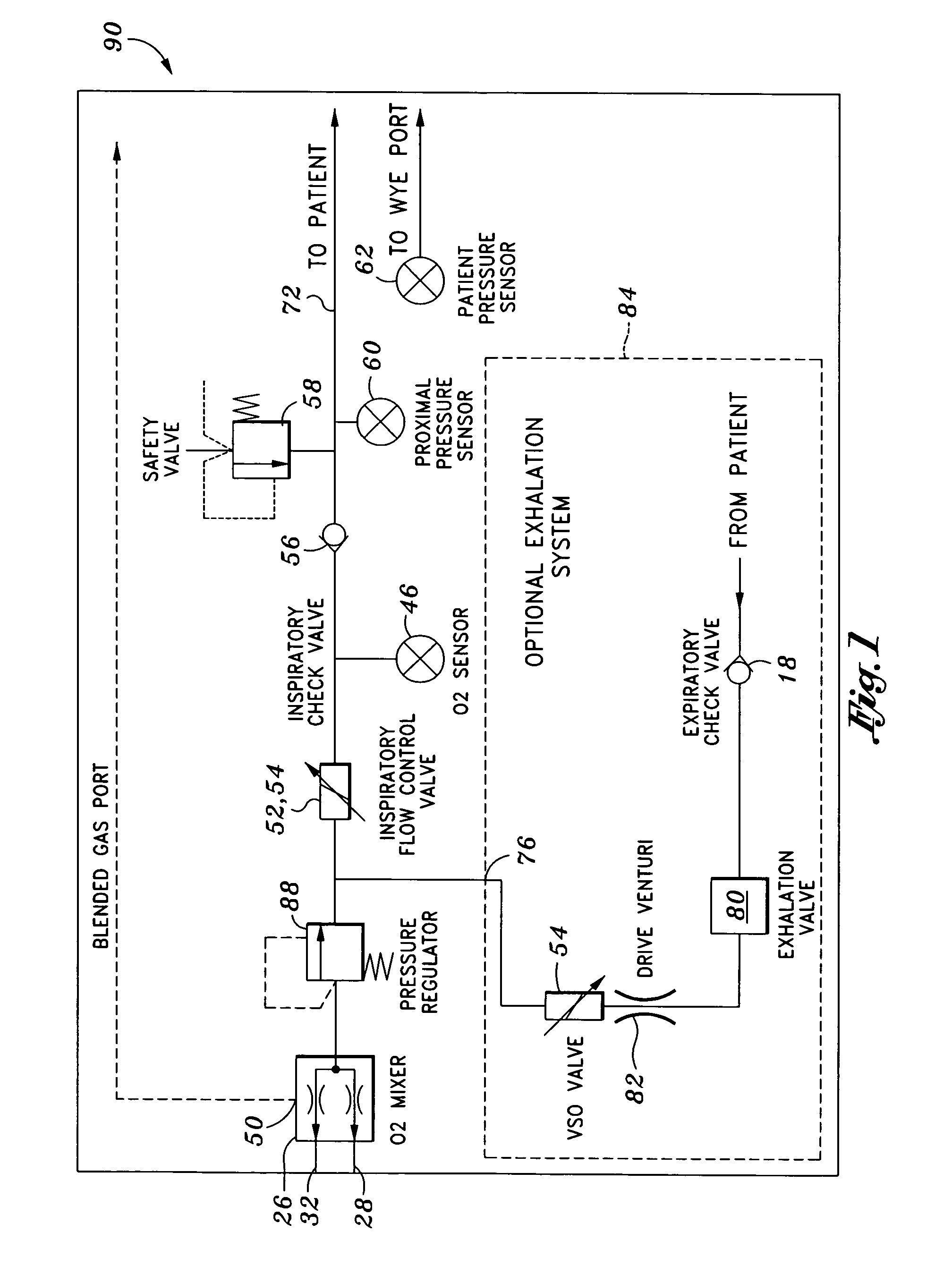

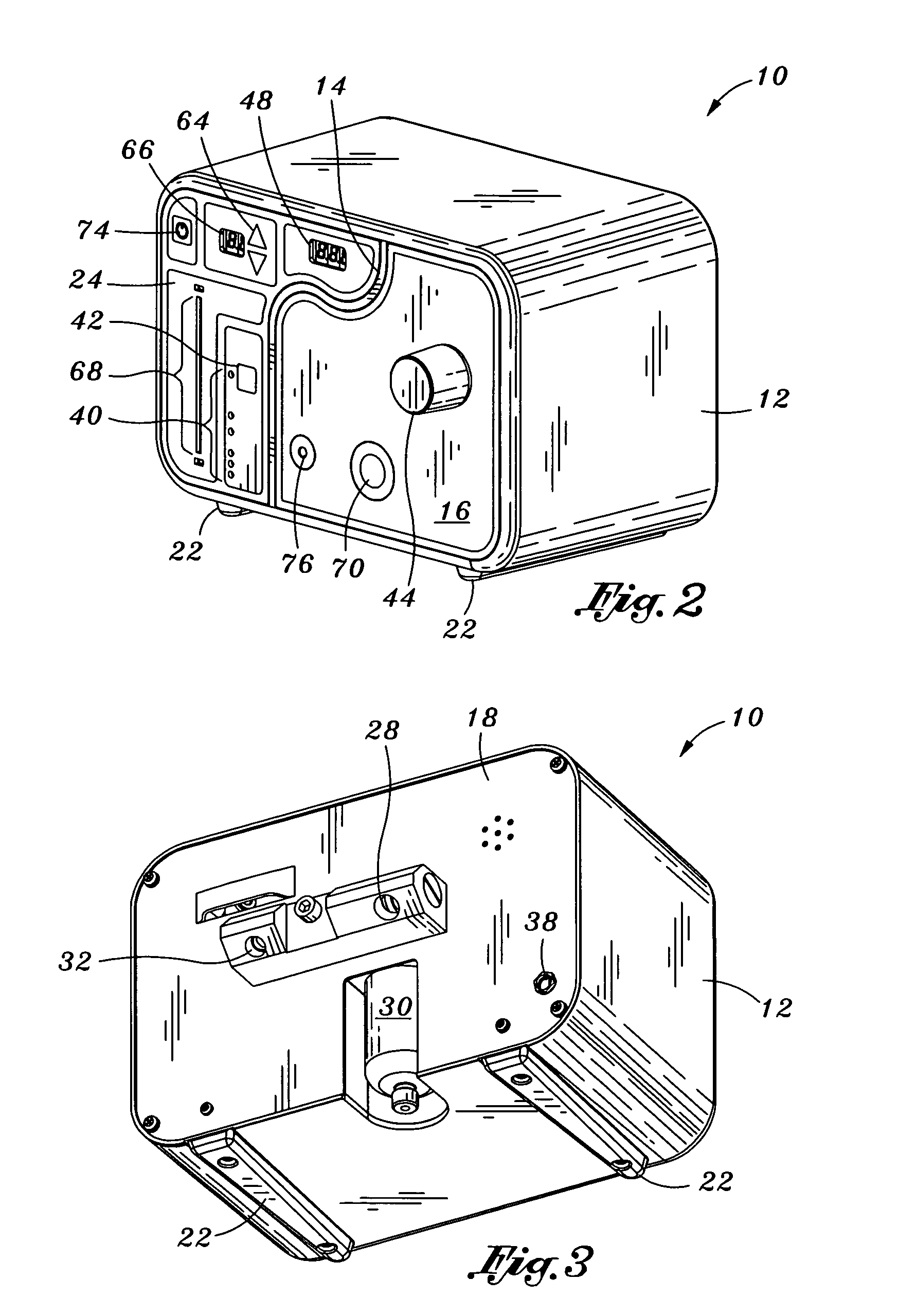

Hardware configuration for pressure driver

ActiveUS7509957B2Reduce oxygen concentrationImprove ventilationRespiratorsOperating means/releasing devices for valvesOxygen sensorControl system

Owner:VYAIRE MEDICAL 211 INC

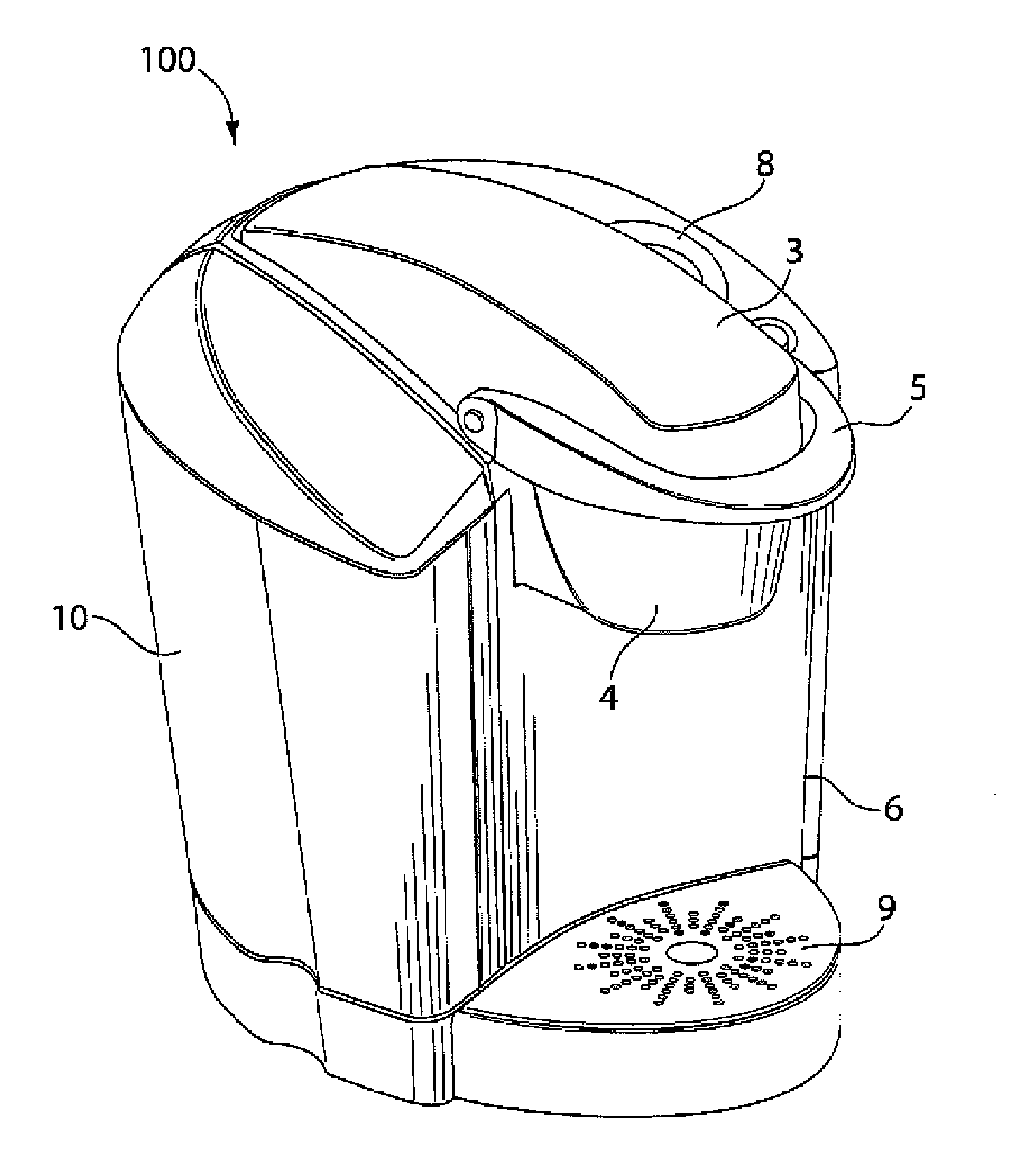

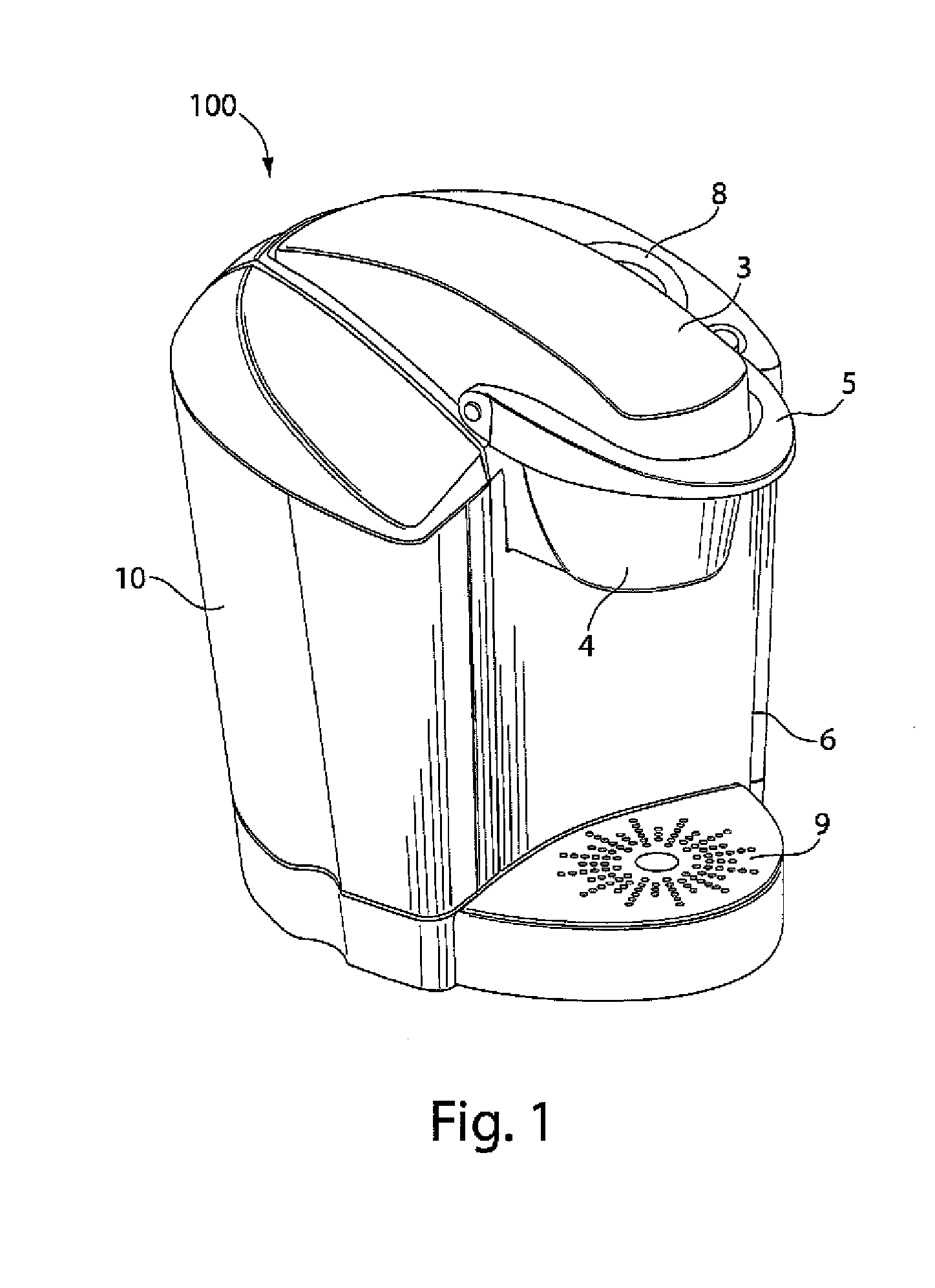

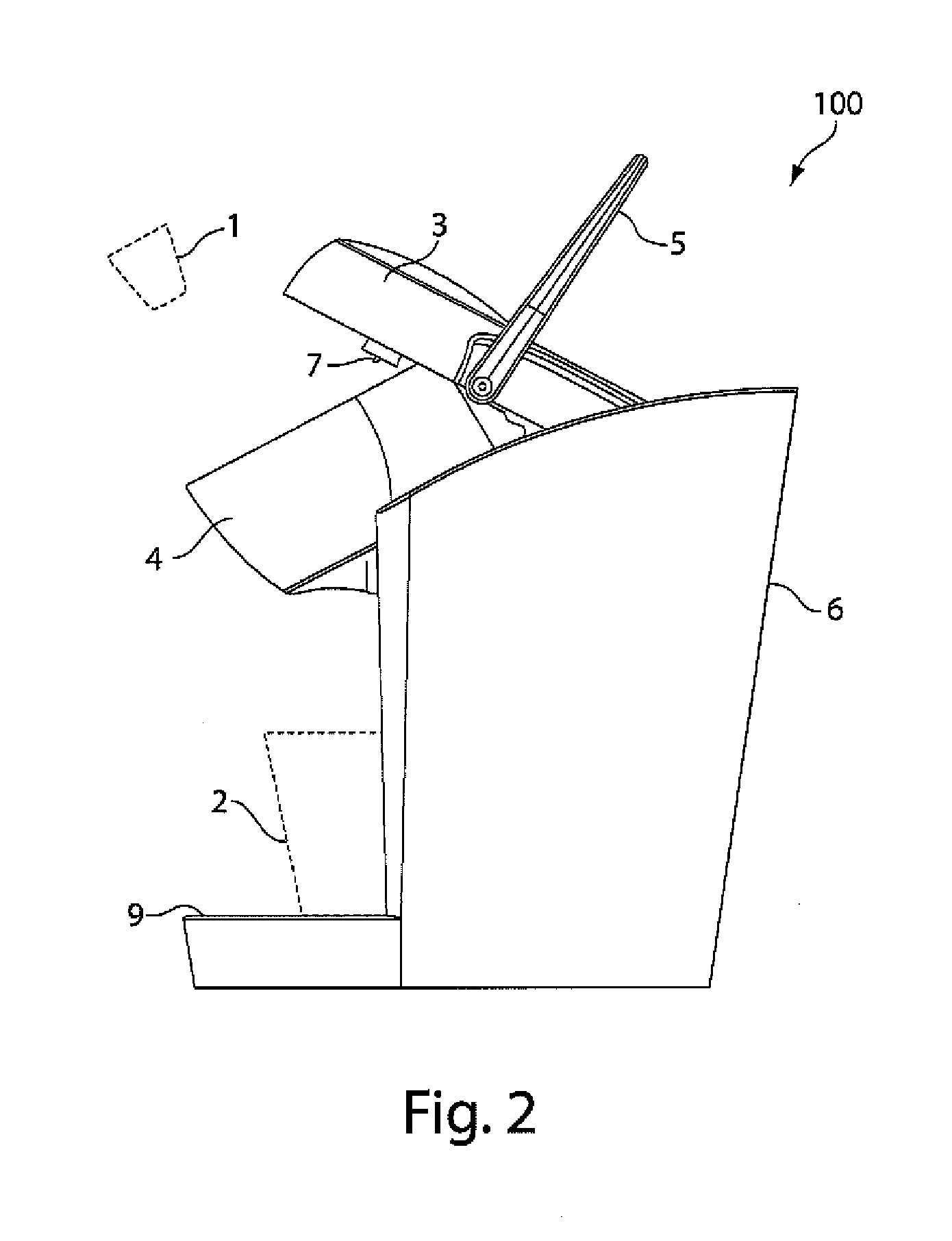

Beverage forming apparatus with centrifugal pump

ActiveUS20100024658A1Prevent substantial leakageAdequate flowBeverage vesselsFood preparationExhaust valveControl valves

A beverage forming apparatus includes a storage tank, and a centrifugal pump having an inlet connected to the storage tank by a supply conduit. The centrifugal pump may include a priming vent located below a full level of the storage tank and permit air to vent as liquid primes the pump. A metering tank may have an inlet connected to the centrifugal pump by a pump conduit, and an outlet connected to a brew chamber that forms a beverage using liquid received from the metering tank. In one embodiment, a flow control valve, such as a check valve, may be provided in the pump conduit to allow flow from the pump to the metering tank, but resist flow in reverse. In another embodiment, a vent valve in the pump conduit may be arranged to vent at least a portion of the pump conduit, e.g., to ambient air pressure.

Owner:KEURIG GREEN MOUNTAIN INC

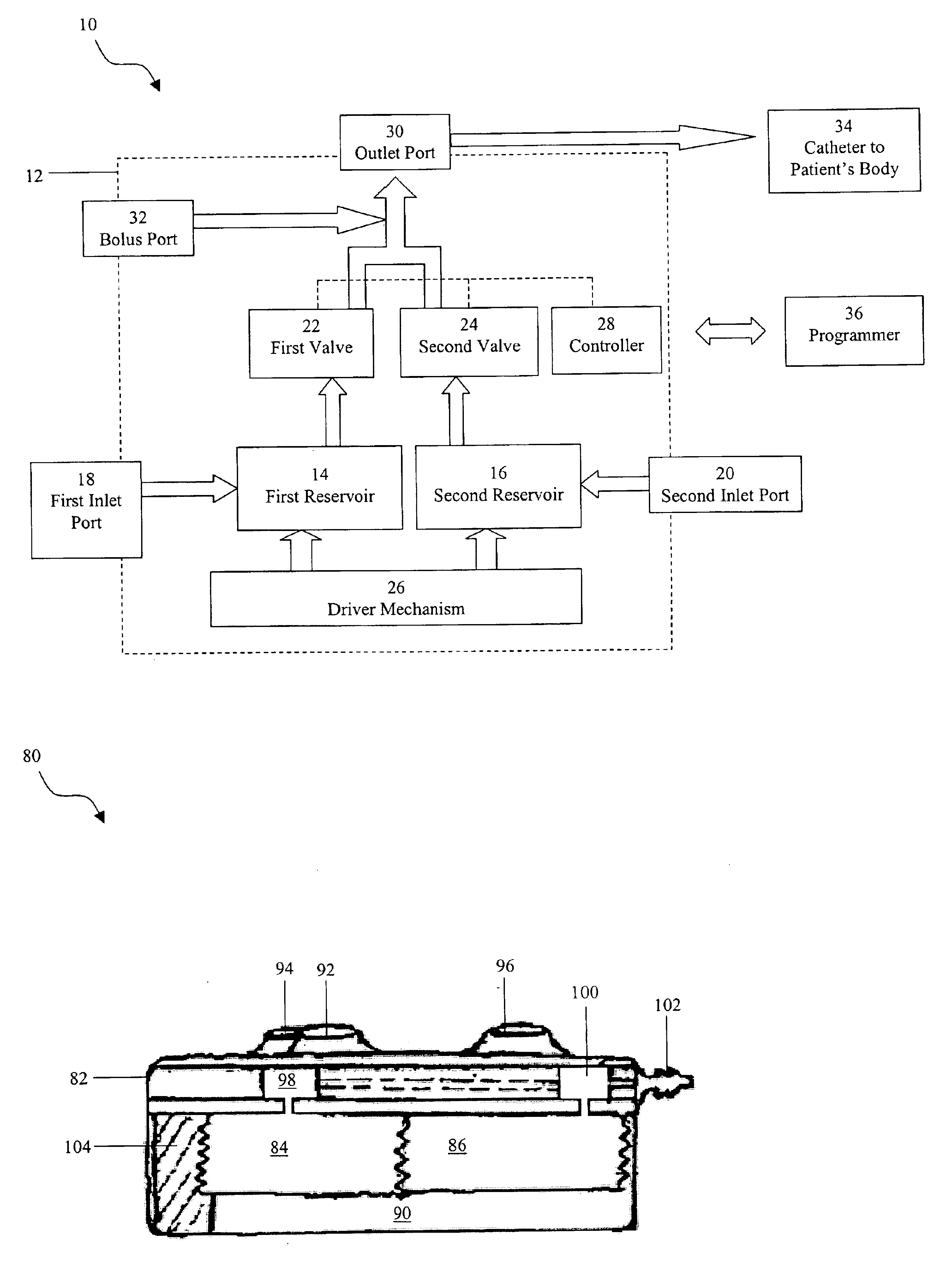

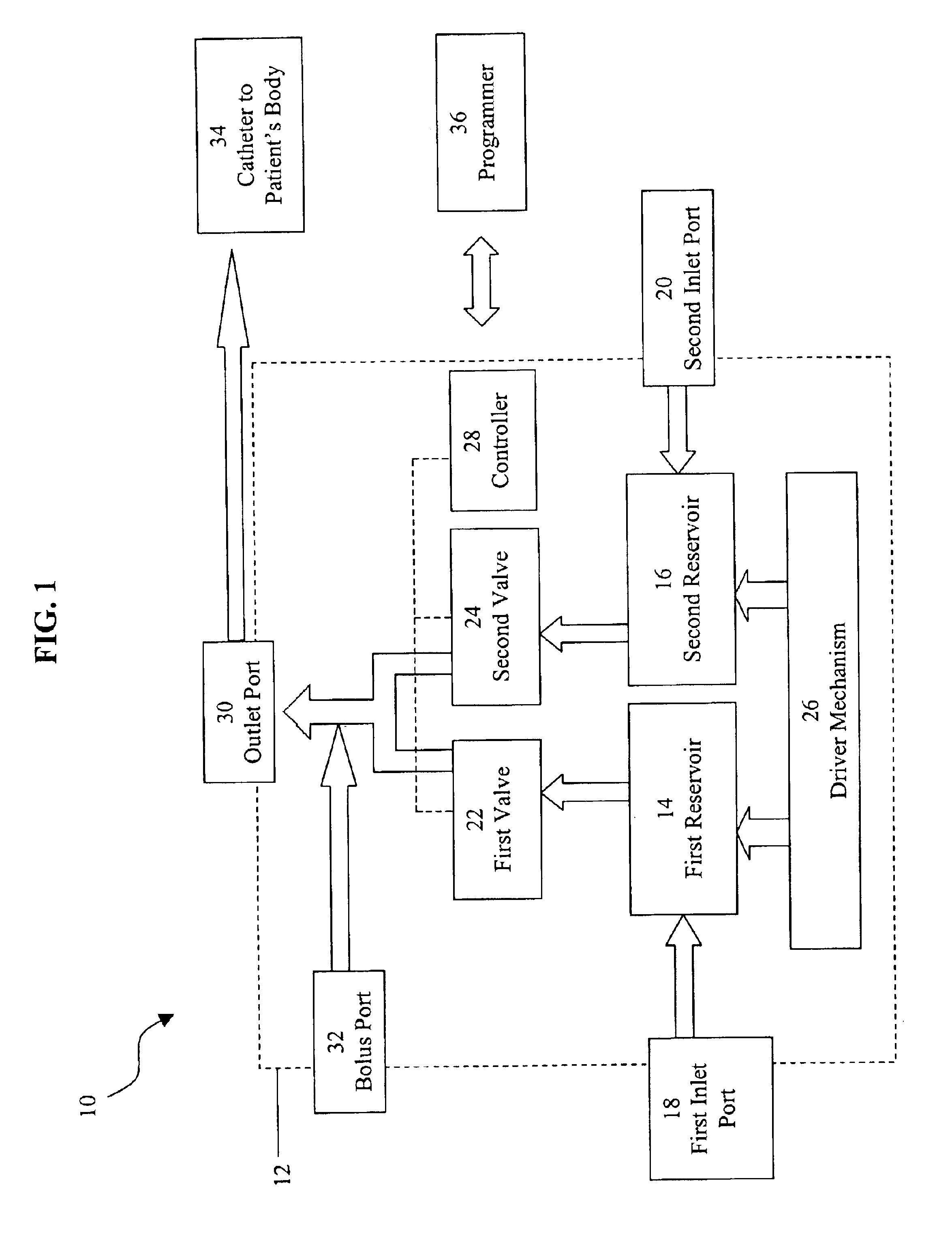

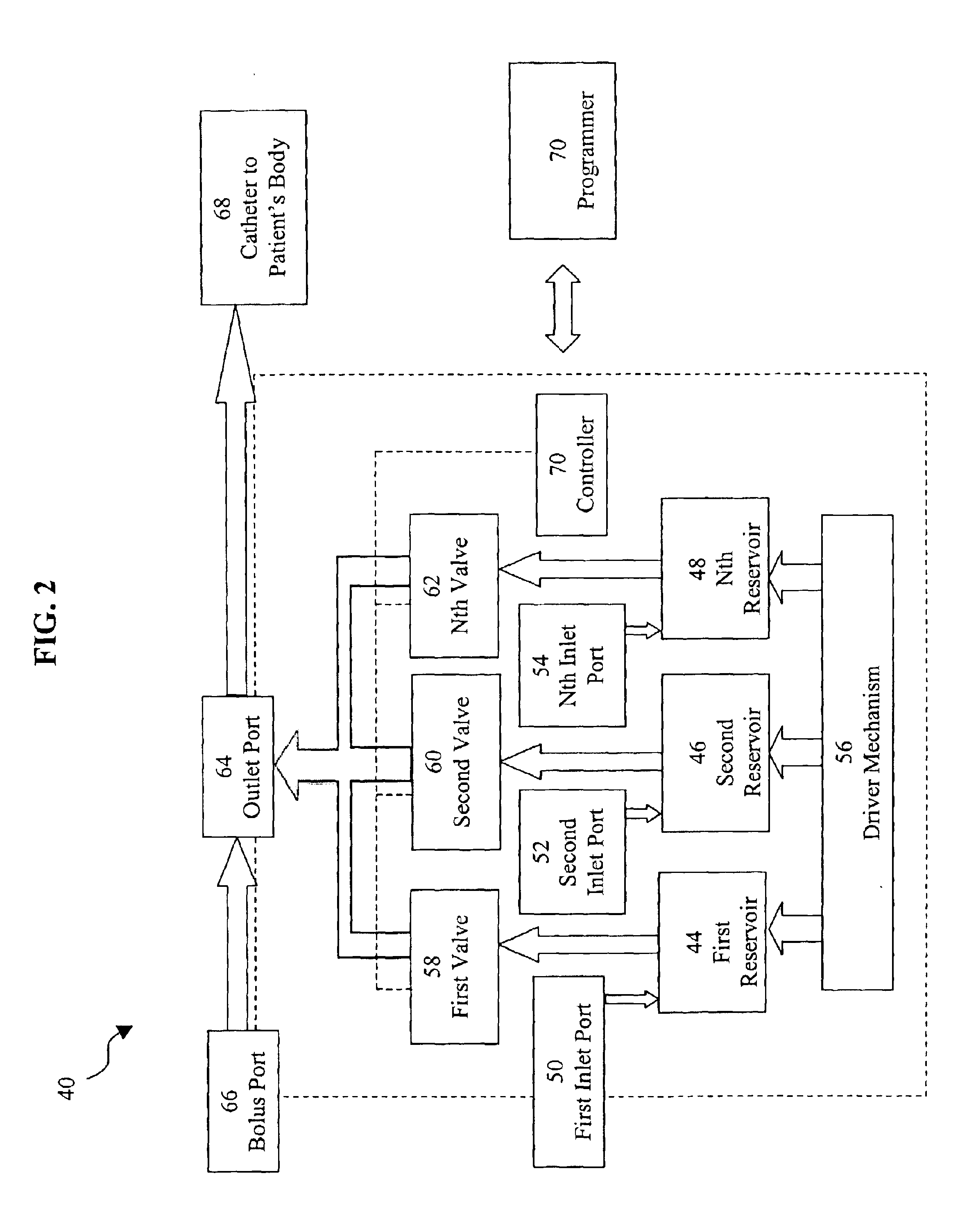

Troubleshooting accelerator system for implantable drug delivery pumps

InactiveUS6902544B2Efficient deliveryEfficiently containedPharmaceutical delivery mechanismMedical devicesControl valvesVALVE PORT

An implantable pump and methods for detecting leaks in an implantable pump are provided. In one embodiment, the implantable drug pump includes a housing having at least one inlet port and an outlet port formed therein. The outlet port is adapted to communicate with a catheter for delivering fluid to a patient's body, and the inlet port(s) are effective to deliver fluid into the housing. The housing further includes at least one reservoir disposed therein and effective to contain a fluid. In use, the pump preferably includes a fluid having one or more drugs disposed in at least one of the reservoirs, and a radiolucent fluid disposed in one of the reservoirs. A user programmable control mechanism is coupled to the drug pump and is effective to selectively control movement of the valves between the open and closed positions.

Owner:DEPUY SYNTHES PROD INC

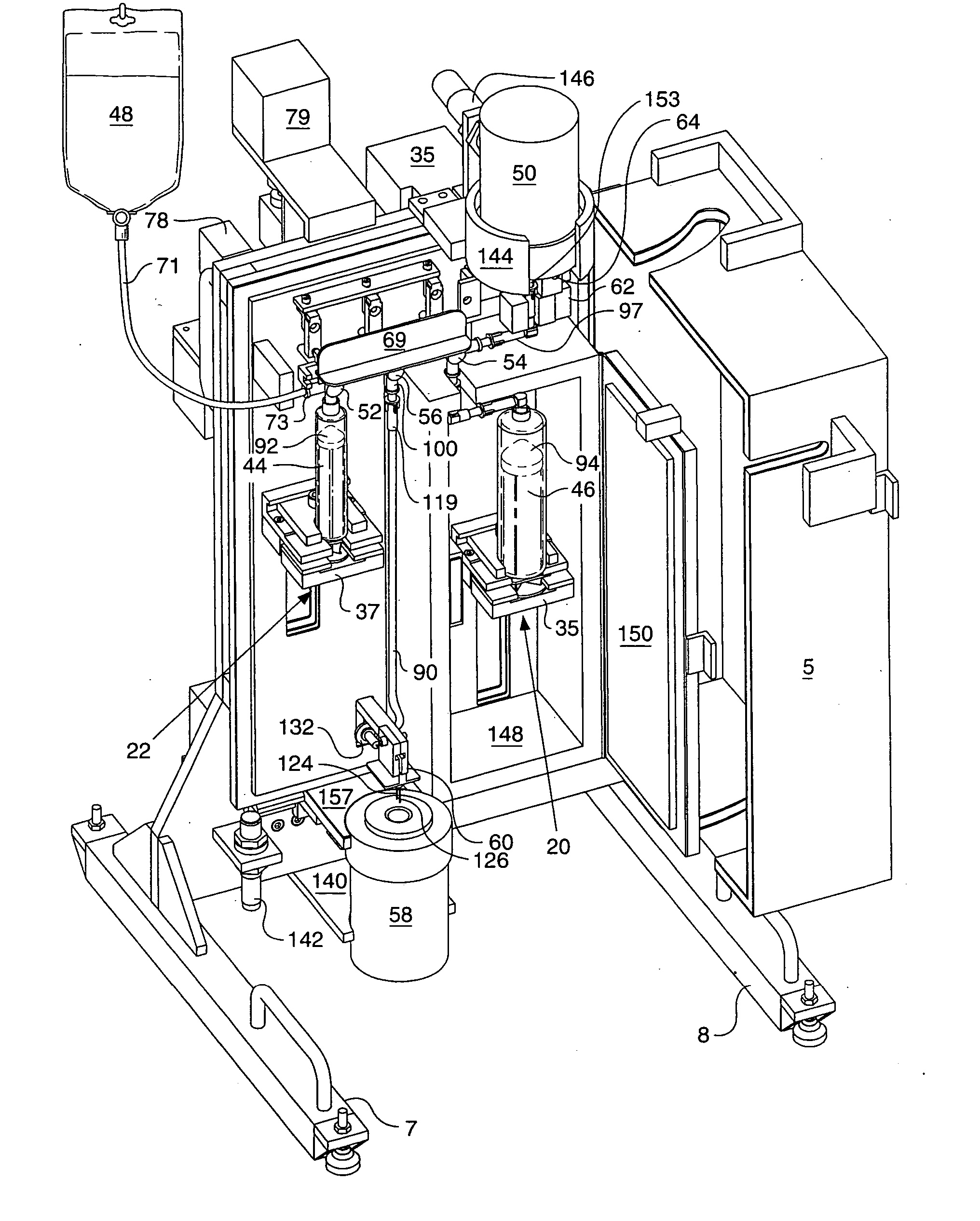

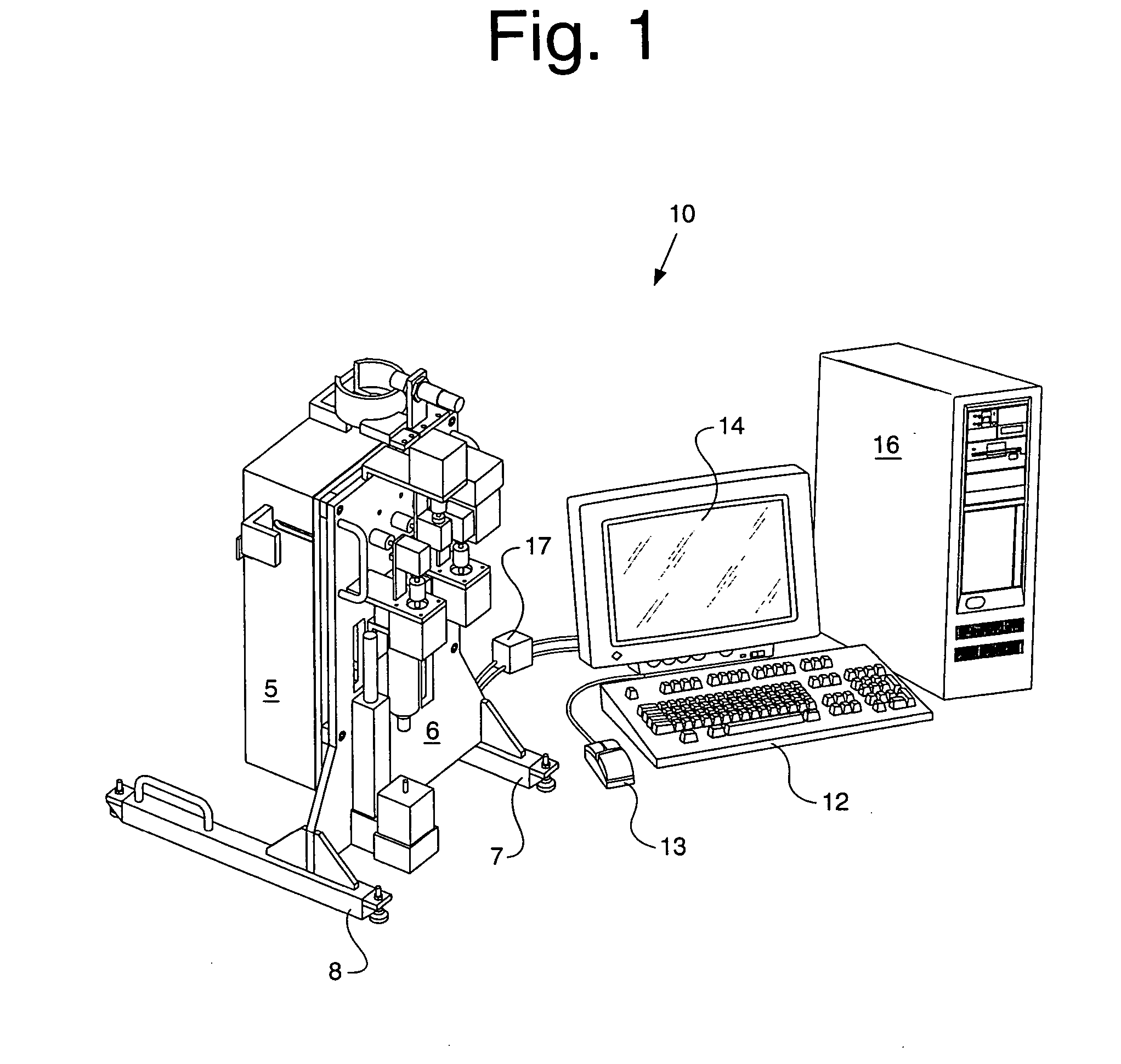

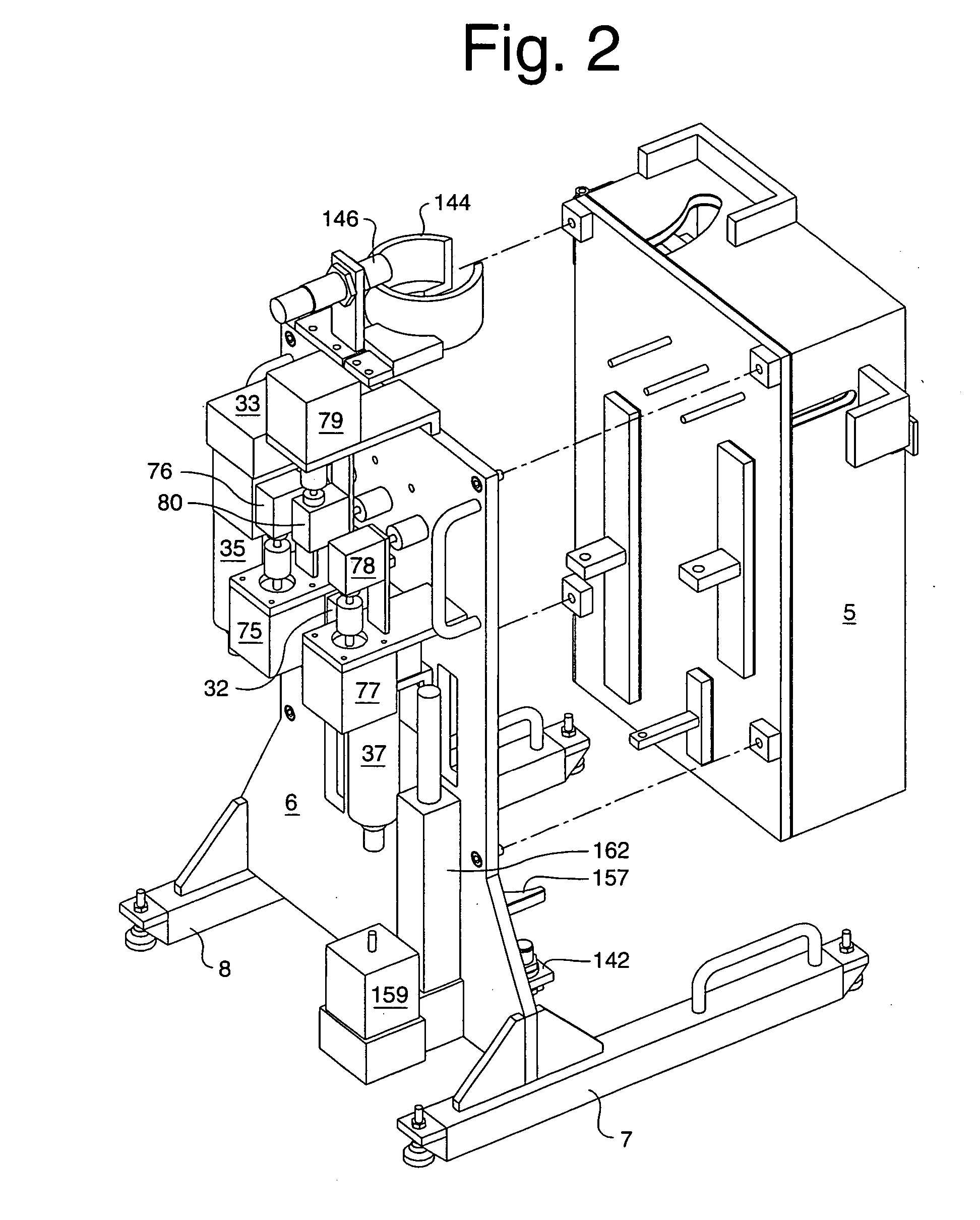

Automated dispensing system and associated method of use

An automated bulk dispensing system and a method of use including selectively receiving a predetermined amount of radioactive liquid from a second container into a third container, selectively receiving a predetermined amount of nonradioactive liquid from a first container into a fourth container or directly into the third container depending on whether kits or multi-dose containers of medicine are desired. Preferably, this is for nuclear pharmaceuticals. Displacement mechanisms that are connected to the third container and fourth container are for mixing and dispensing liquid. There is at least one control valve, preferably three control valves, which are each controlled by drive mechanisms. The mixed liquid from the third container can be transferred to a recipient container. There is also a gas vent and bubble detector to eliminate bubbles with a processor that is also utilized to control the displacement mechanisms and the drive mechanisms.

Owner:MALLINCKRODT INC

Pressure actuated flow control valve

InactiveUS20050010176A1Reducing total apical deflectionReduced cross-sectional thicknessIntravenous devicesTube connectorsInfusion catheterGravity flow

A pressure actuated flow control valve for an infusion catheter permits gravity flow of a liquid through the catheter and into a patient while resisting back flow of blood from the patient and into the catheter. The valve has a hemispherical body with an outstanding circumferential flange and a normally closed, diametric slit. The slit is longer on the convex outer surface than on the concave inner surface. Dome thickness diminishes in the area adjacent the slit, reducing total apical deflection upon collapse of the slit toward the concave surface. An inner orthogonal rib biases the slit closed. Upon application of a predetermined pressure, the slit opens toward the concave surface to permit forward fluid flow. At lower pressures, the slit closes to check fluid flow. Greater reverse pressure is required to collapse the slit toward the concave surface to permit reverse fluid flow.

Owner:DIKEMAN W CARY +1

Method and apparatus for remotely monitoring a site

InactiveUS20090121860A1Maximum precisionEasy to distinguishFire rescueBurglar alarm electric actuationTime informationSprinkler system

The present invention is directed to providing systems and methods for remotely monitoring sites to provide real-time information which can readily permit distinguishing false alarms, and which can identify and track the precise location of an alarm. In embodiments, monitoring capabilities such as intrusion / fire detection and tracking capabilities, can be implemented through the use of multistate indicators in an interface which permits information to be transmitted using standard network protocols from a remote site to a monitoring station in near real-time. In embodiments, communications can be handed from the centrally located host monitoring station to a mobile monitoring station (for example, a laptop computer in a responding vehicle, such as a police or fire vehicle). Additional embodiments include the measurement of environmental parameters such as temperature, carbon monoxide and differential air pressure to detect, monitor and manage a fire event. These measurements along with selected controllable output devices deployed in a space, such as sprinkler control valves and individually or zoned sprinkler heads, are used to initiate and control fire suppression technology both locally and remotely. For instance, a system of the present invention may detect a fire and cause a sprinkler system to disburse water in a facility.

Owner:NETTALON SECURITY SYST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com