Patents

Literature

94 results about "Convection heater" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A convection heater is a heater which operates by air convection currents circulating through the body of the appliance, and across its heating element. This heats up the air, causing it to increase in volume and so become buoyant and rise. Oil heaters are an example of this kind of heating appliance. A convection heater may have an electrical heater element, a hot water coil, or a steam coil. Because of the natural ventilation, they are quieter in operation than fan heaters.

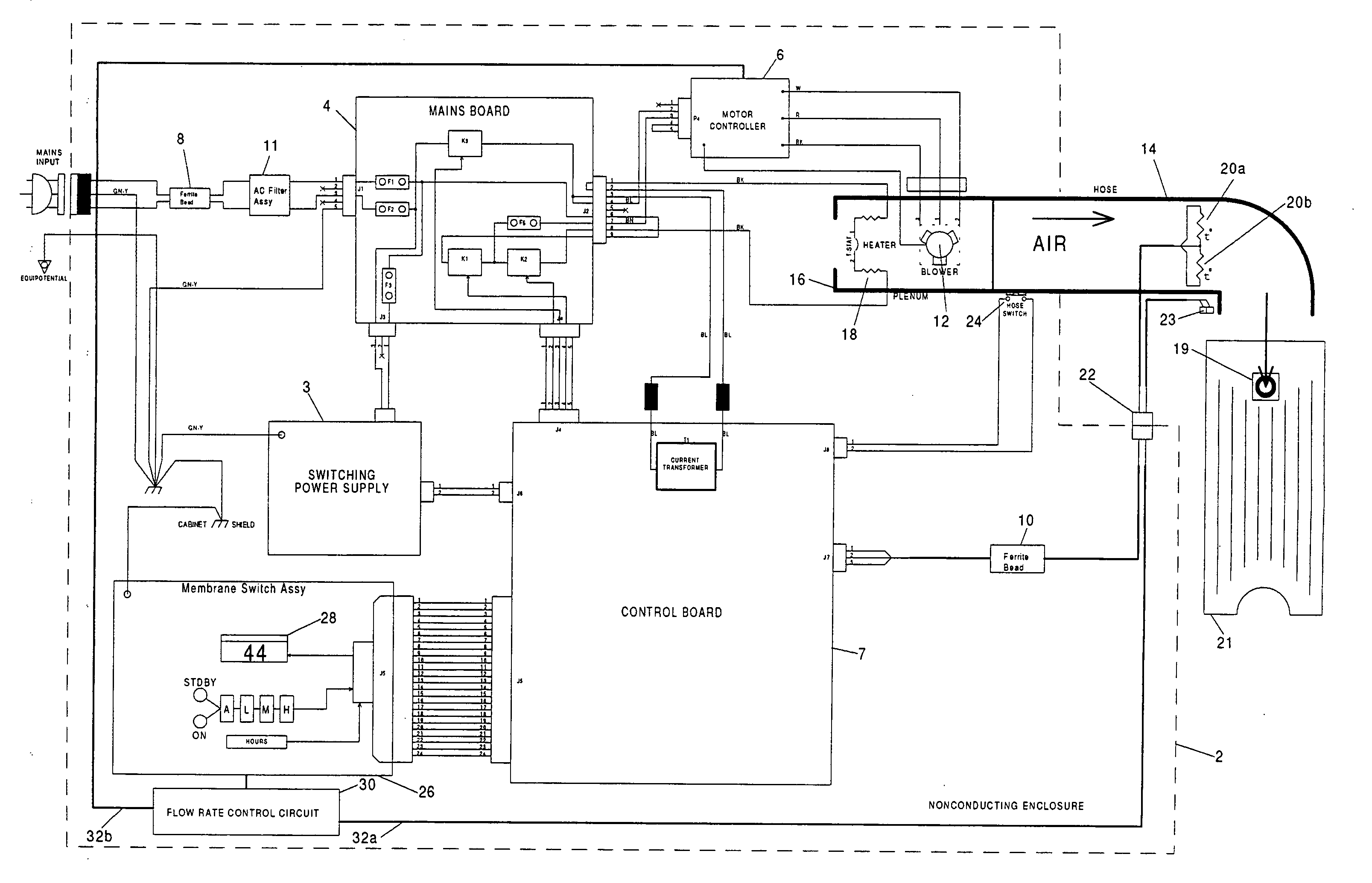

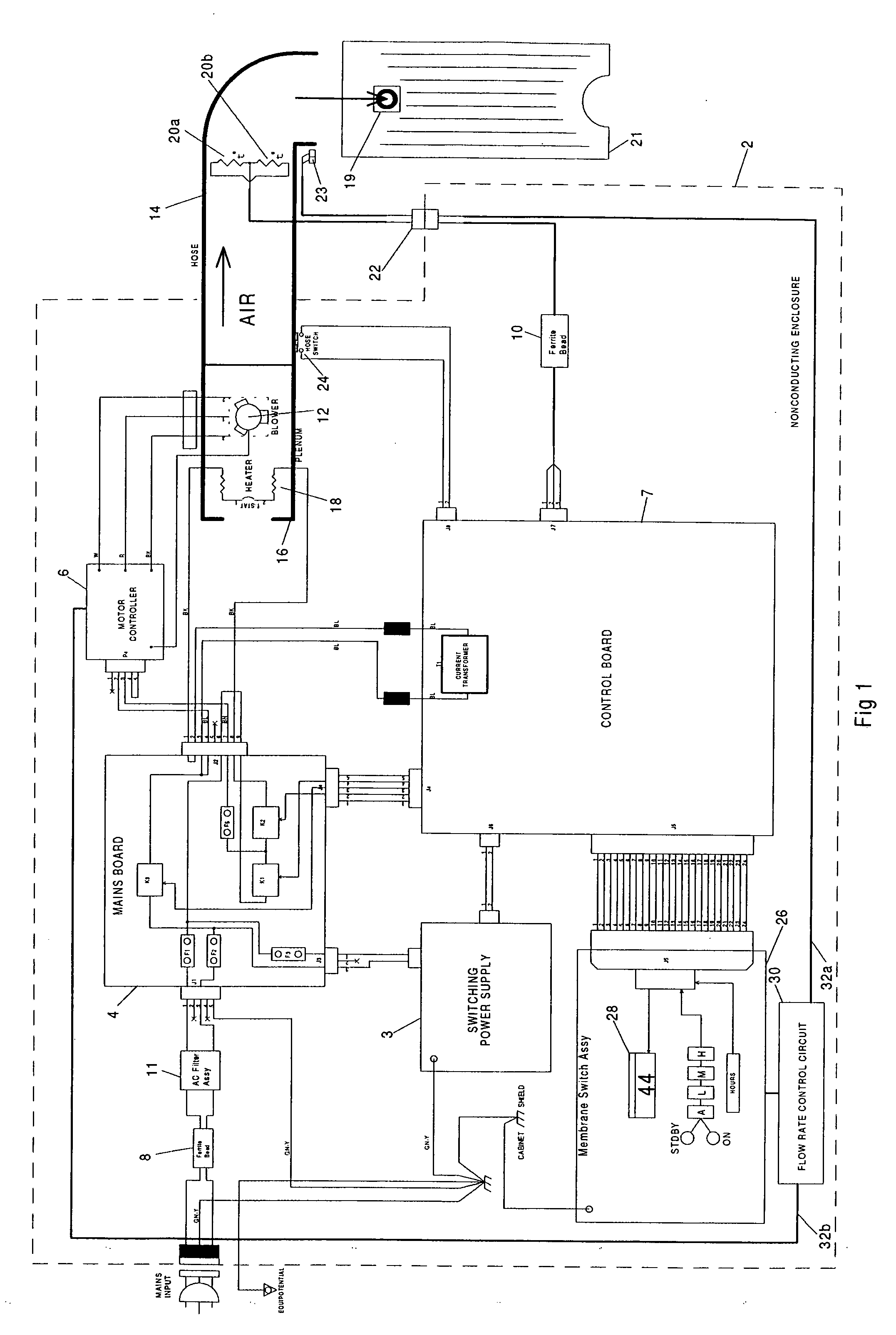

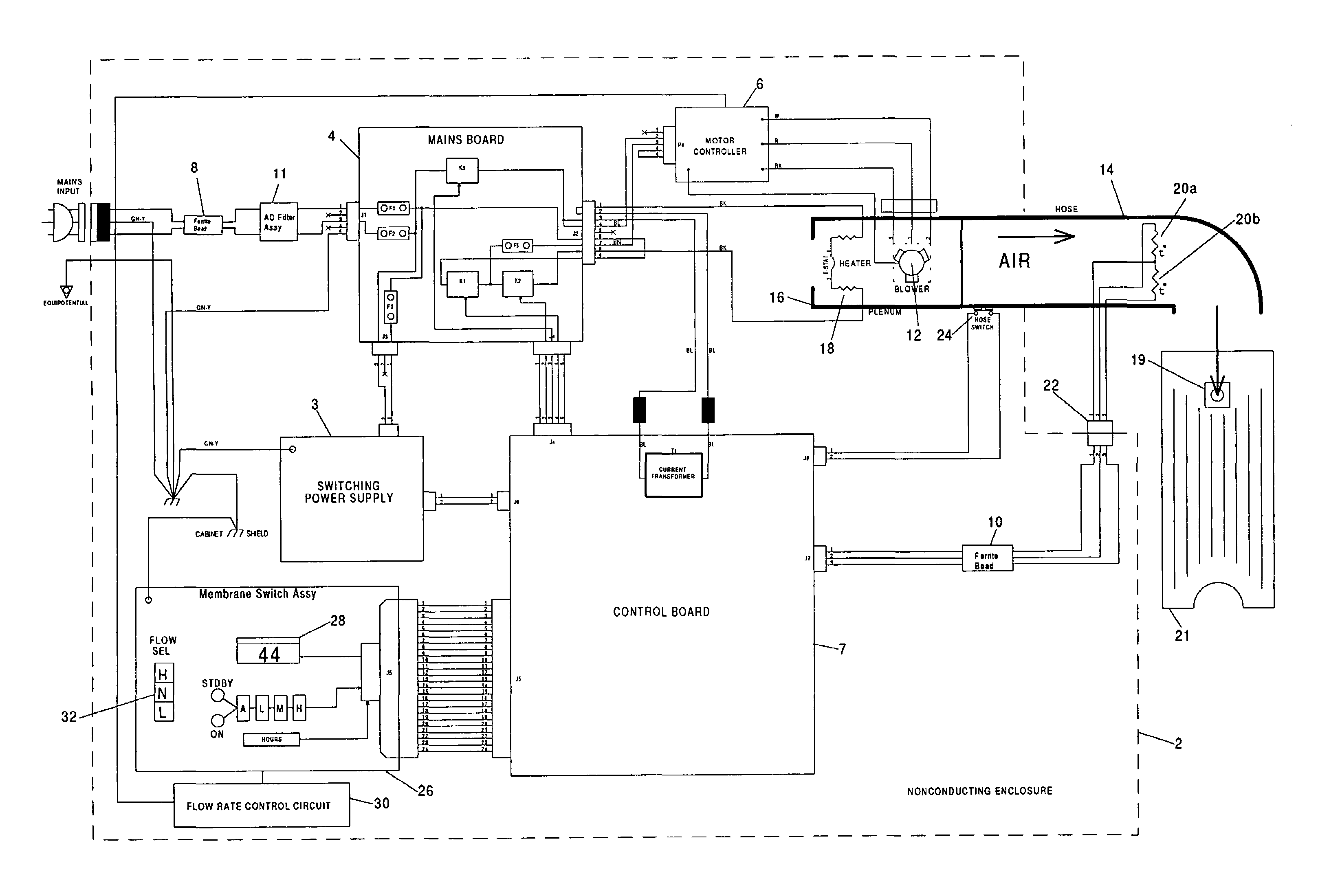

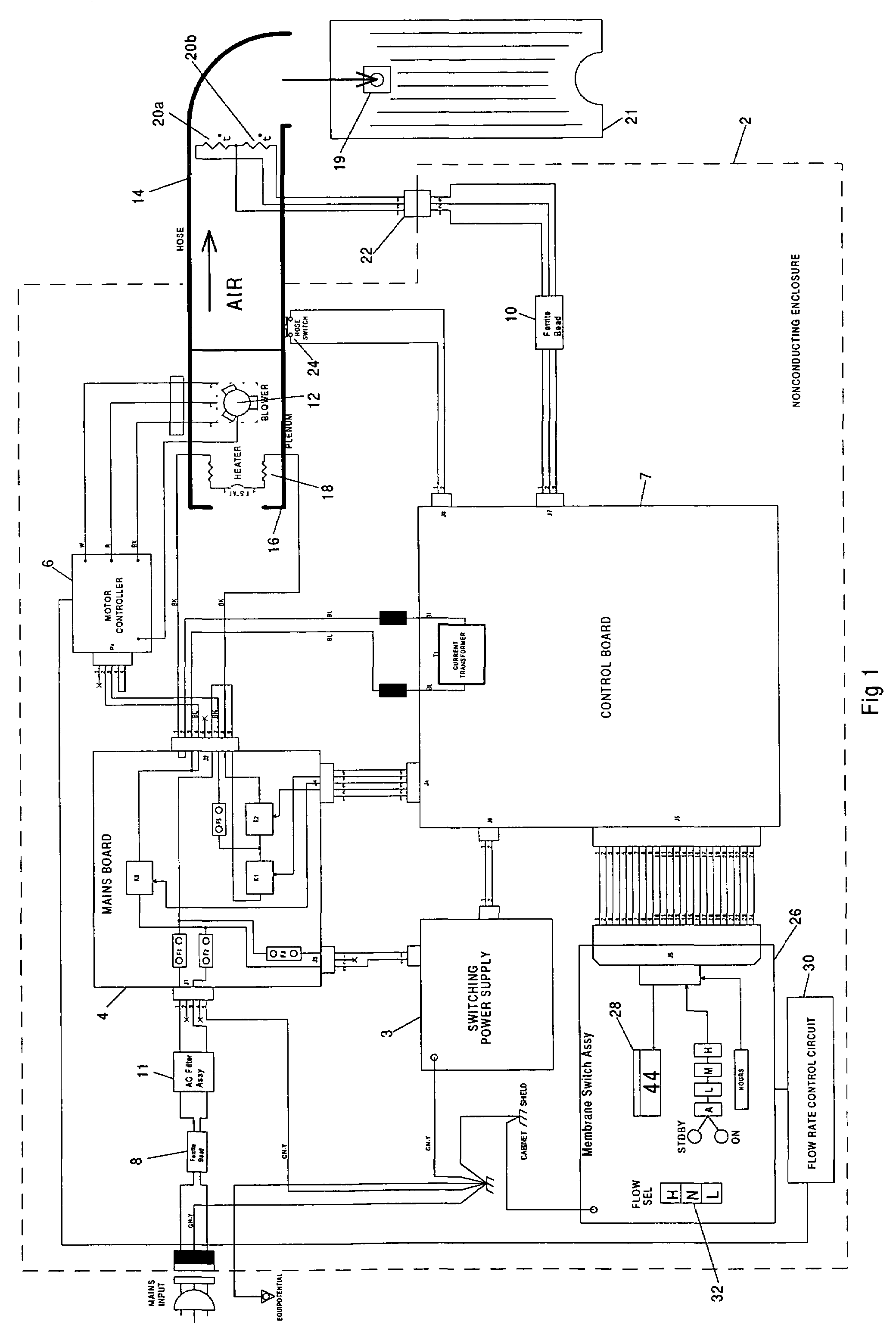

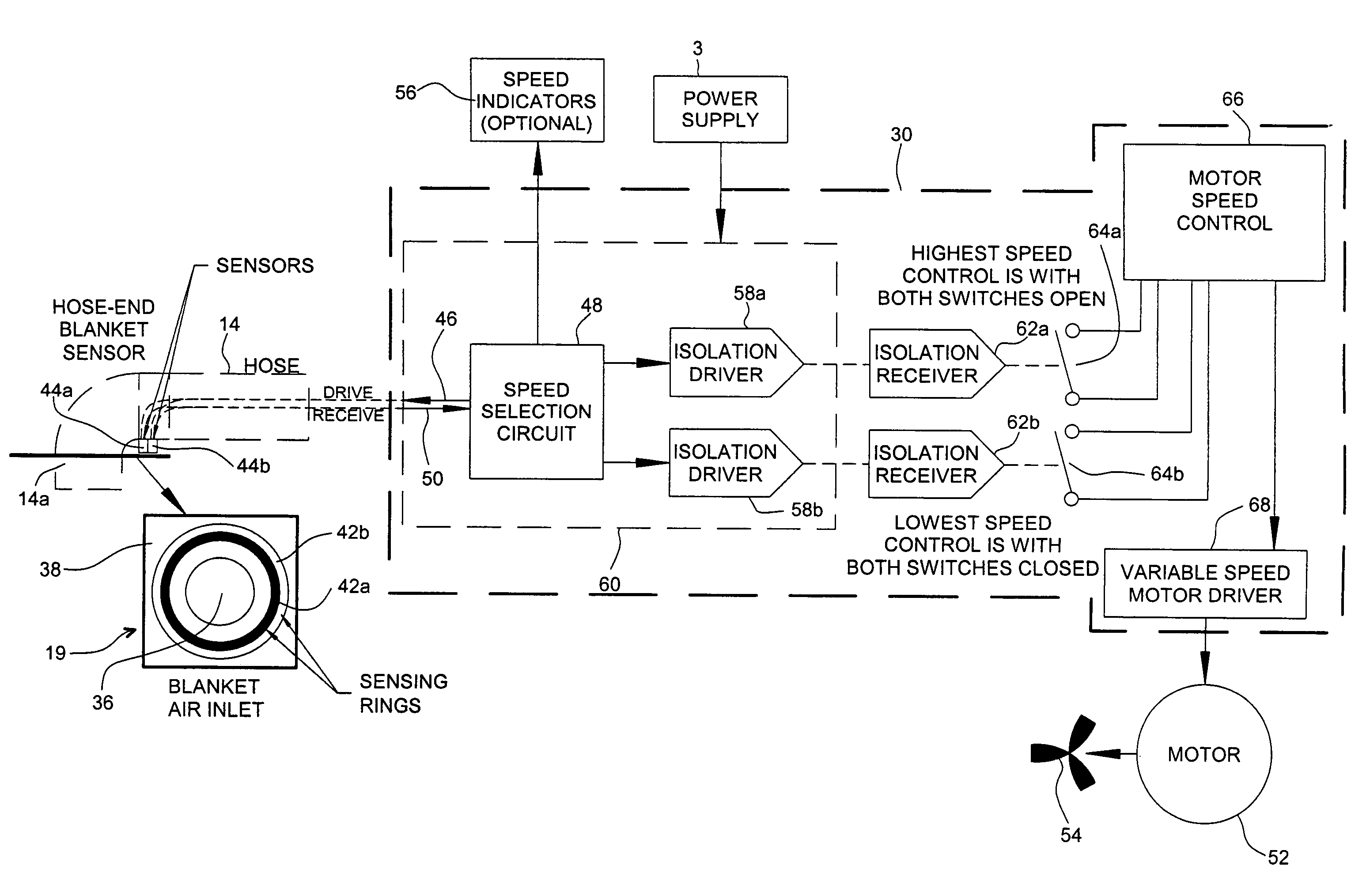

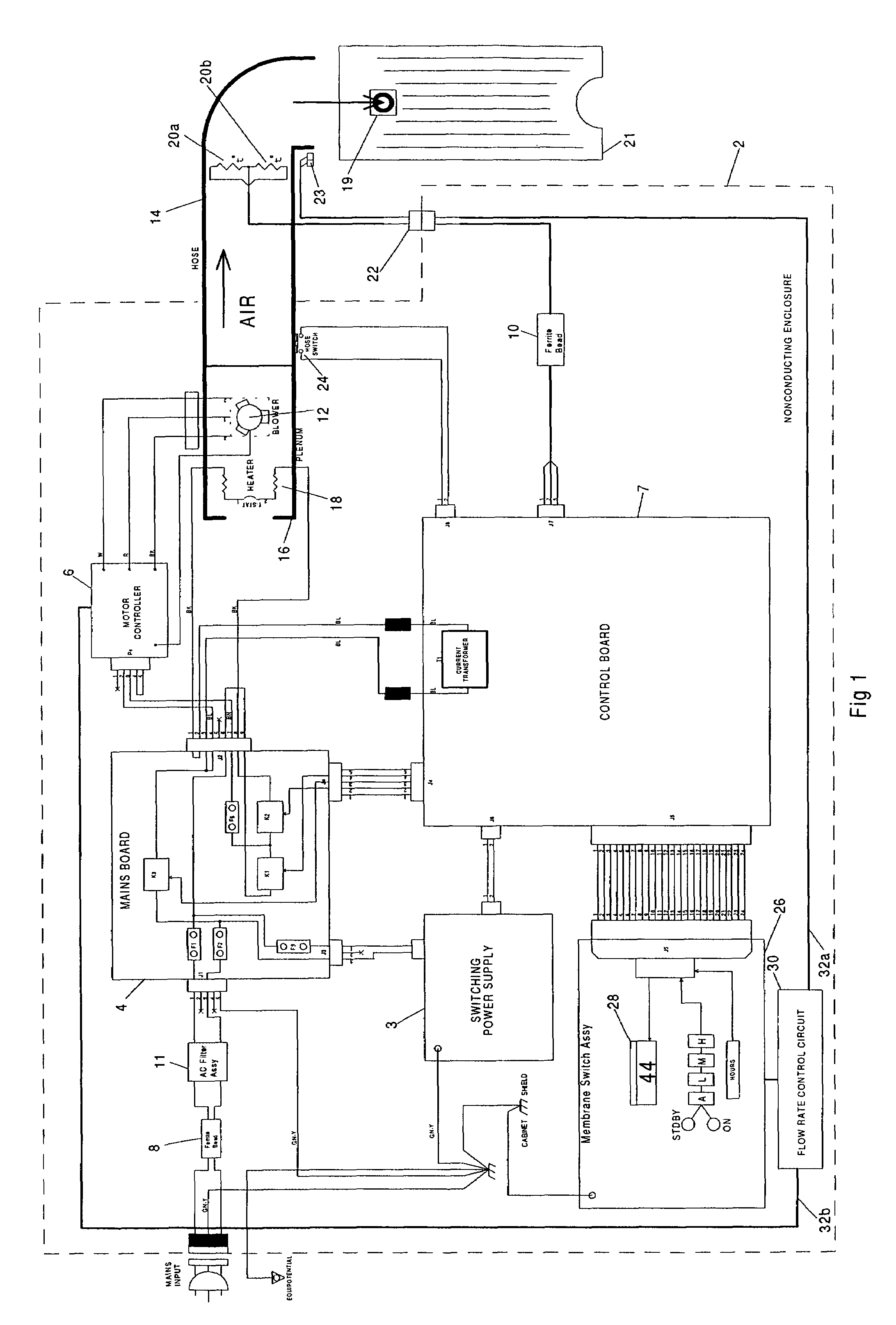

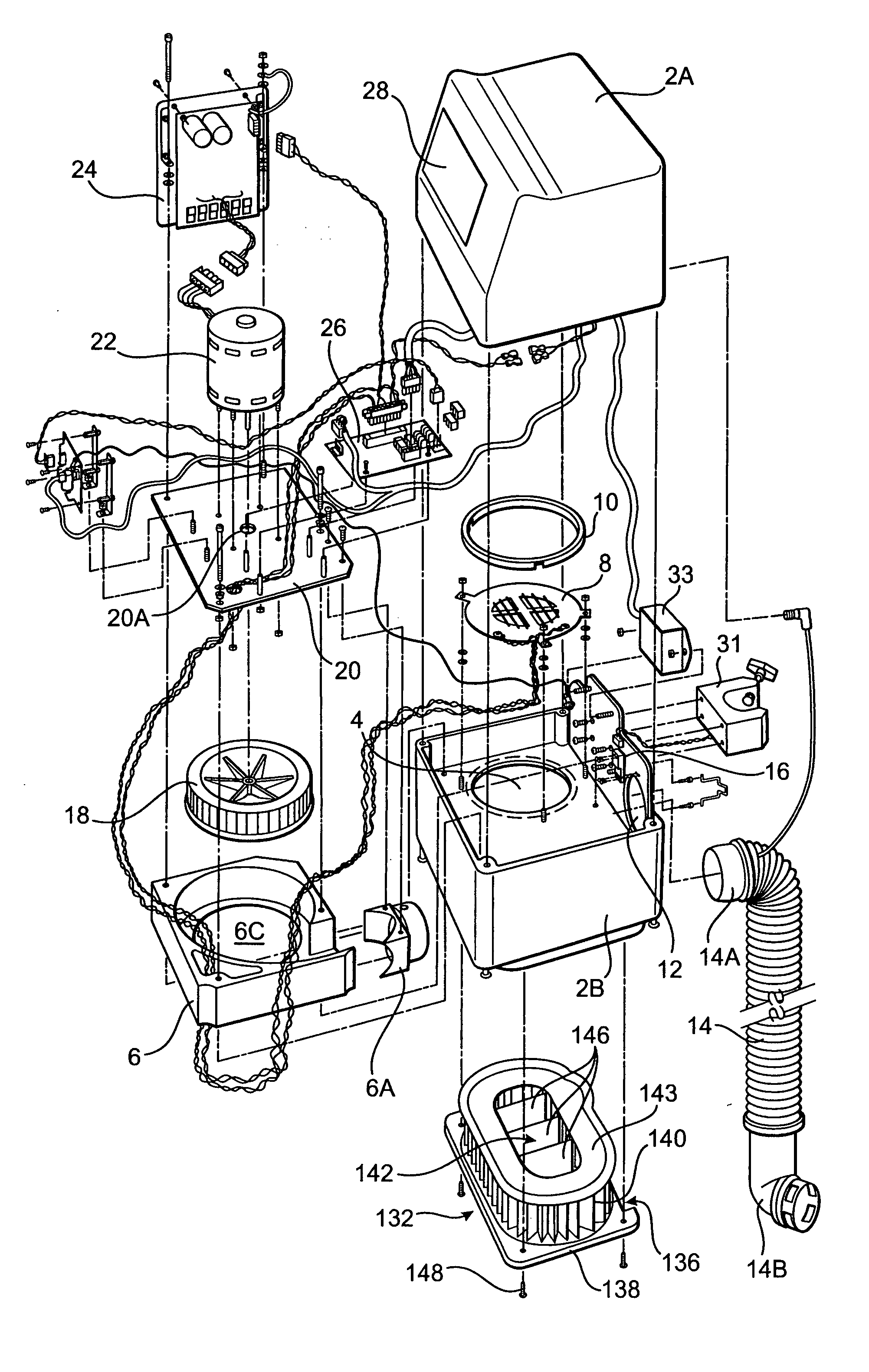

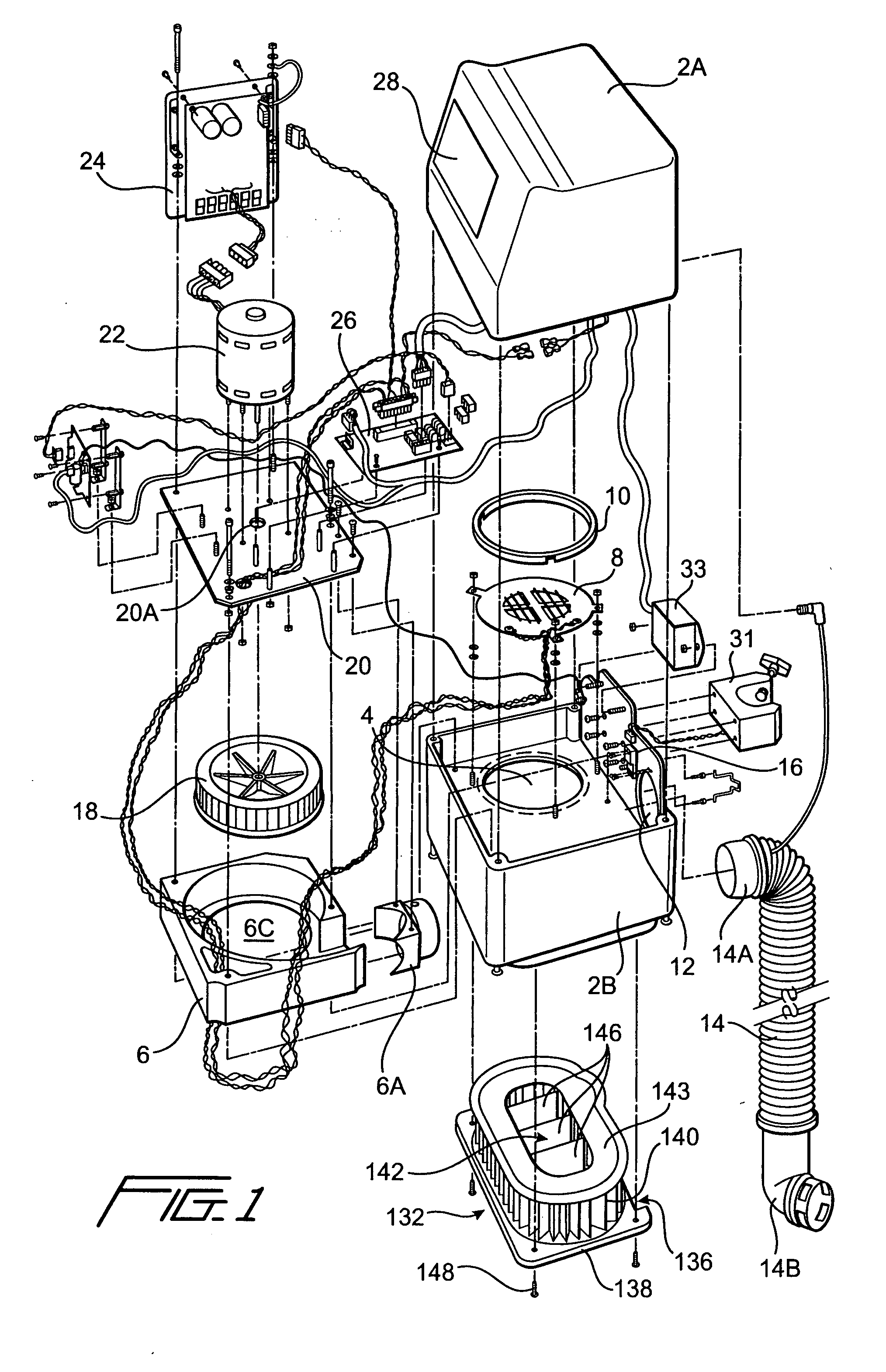

System for providing actuated optimal inflation to multiple temperature regulated blankets and method therefor

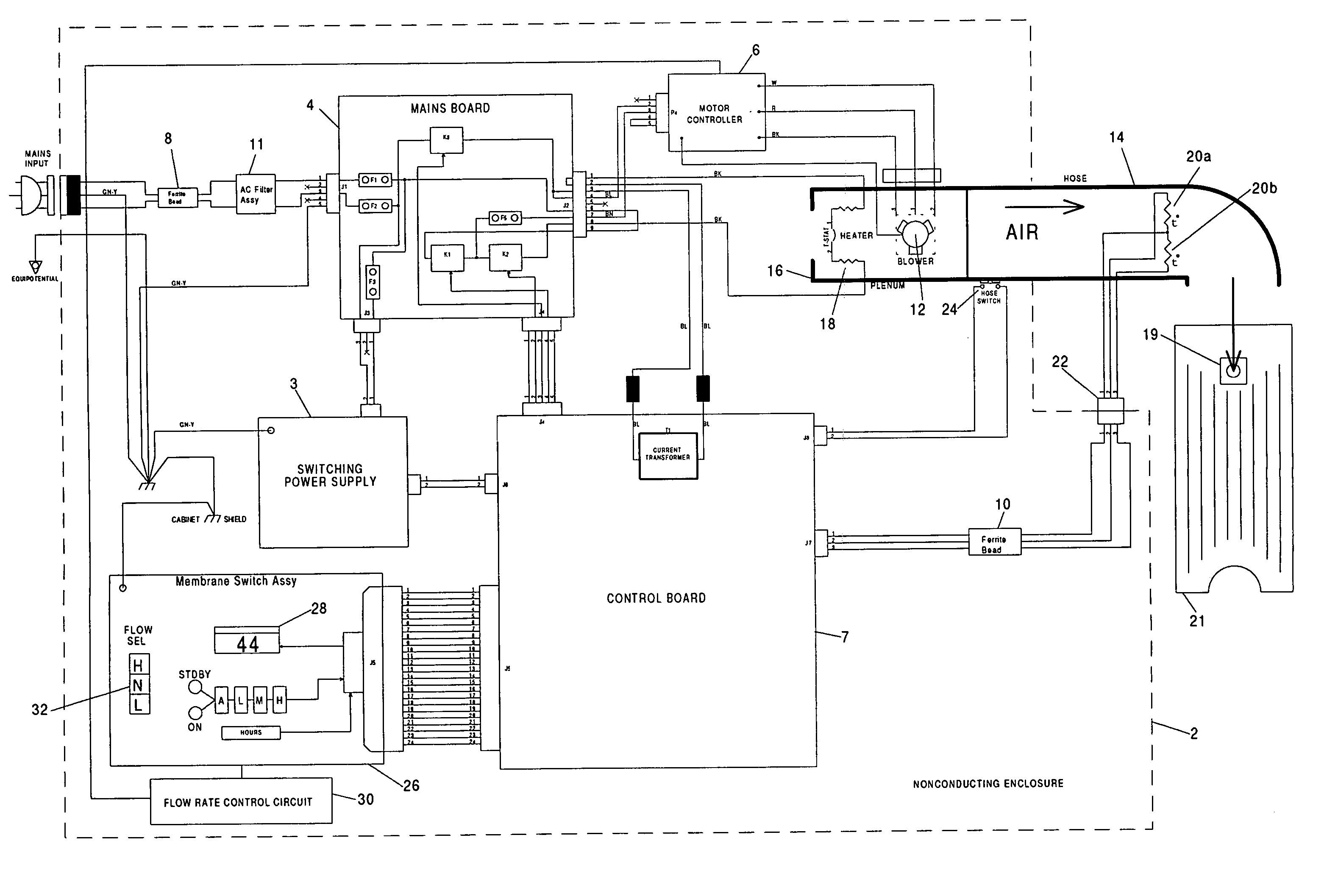

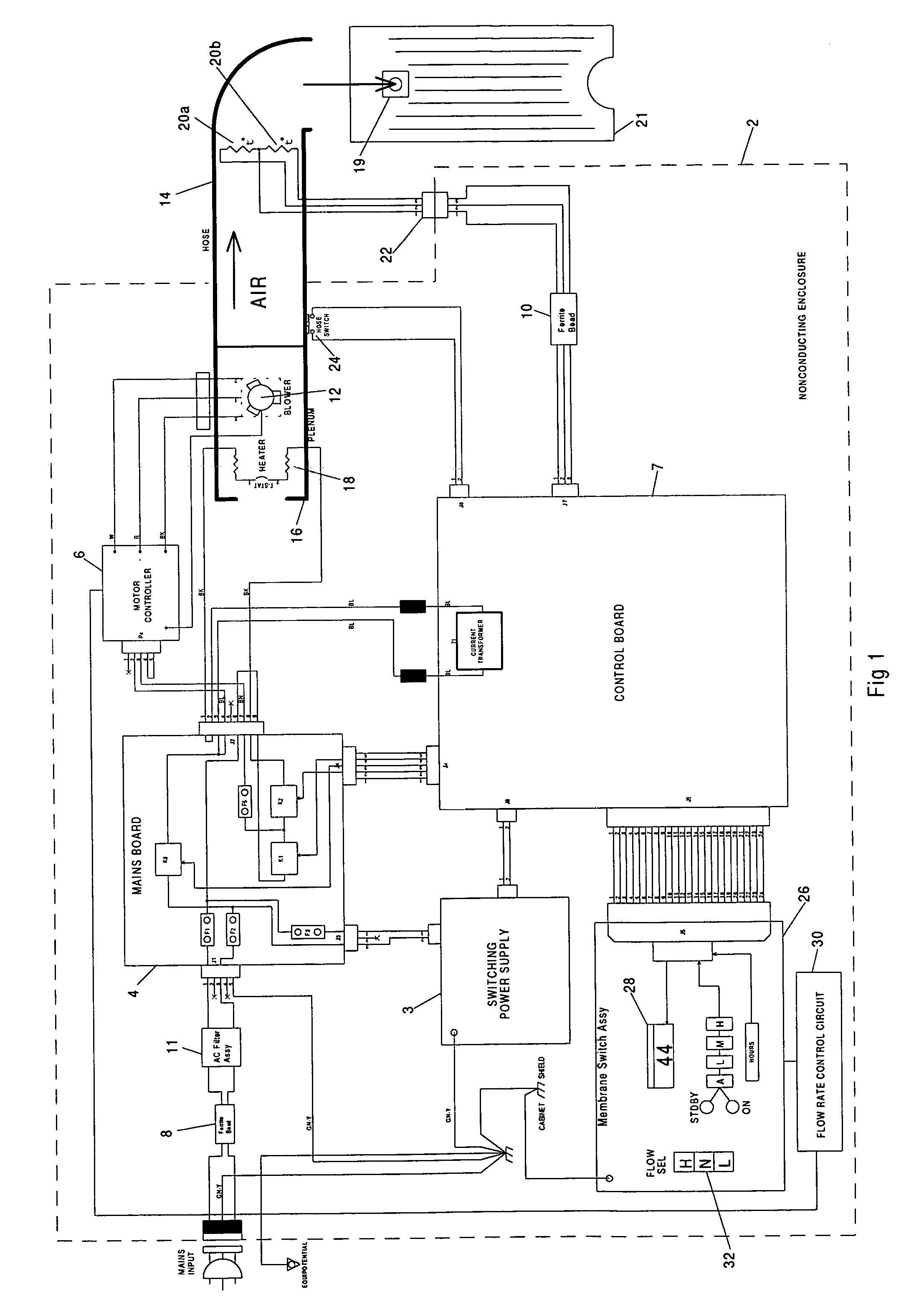

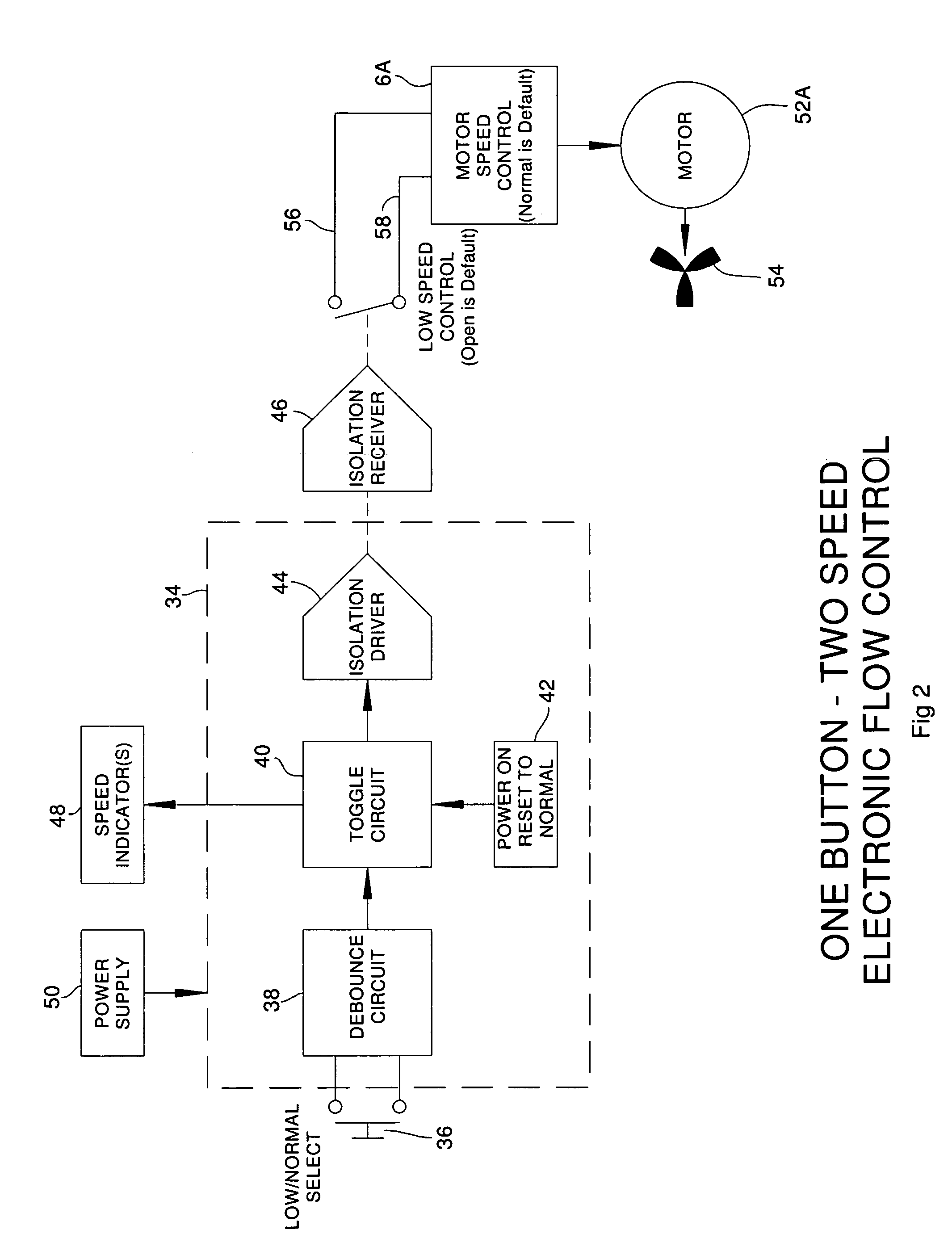

A convective warmer to which blankets of different dimensions may be connected is capable of providing air to the various blankets at flow rates that optimally inflate those blankets to achieve the optimal clinical result for the patients covered by those blankets. The blanket connected to the warmer may range from a full size adult warming blanket to a pediatric warming blanket. The convection warmer may have multiple fixed air flow rates each selectable by a user, via switch(es) either electronically or mechanically. For the electronic selection of a given flow rate, a motor adaptable to rotate a different speeds is used. To vary the flow rate mechanically, a valve is controlled to vary the amount of air that may pass to the blanket. Instead of different fixed flow rates, variable air flow rates, selectable by the user, may be used. Also, a feedback circuit that maintains the pressure sensed at the outlet of the warmer to a preset pressure may be used to eliminate the need for user intervention.

Owner:SMITHS MEDICAL ASD INC

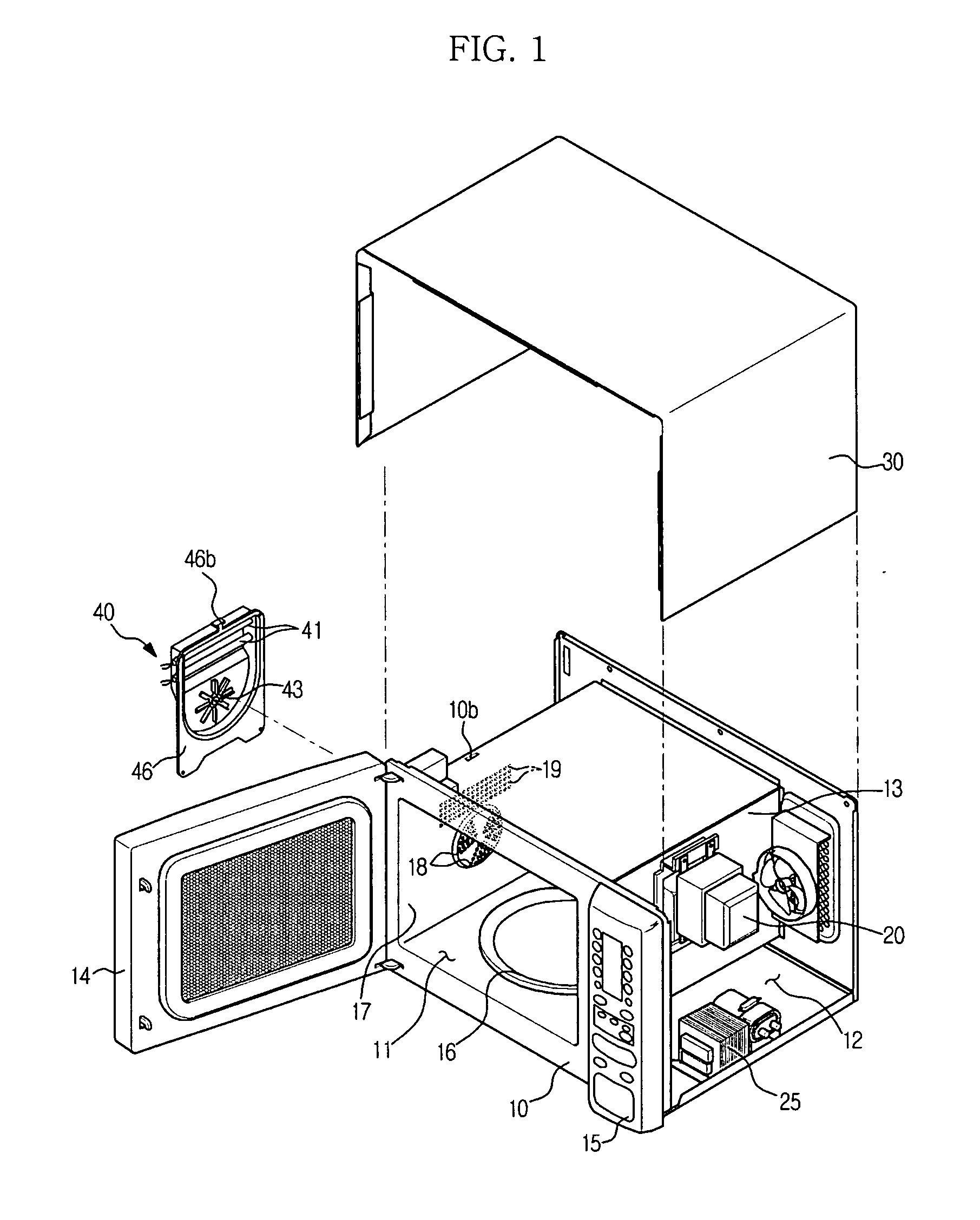

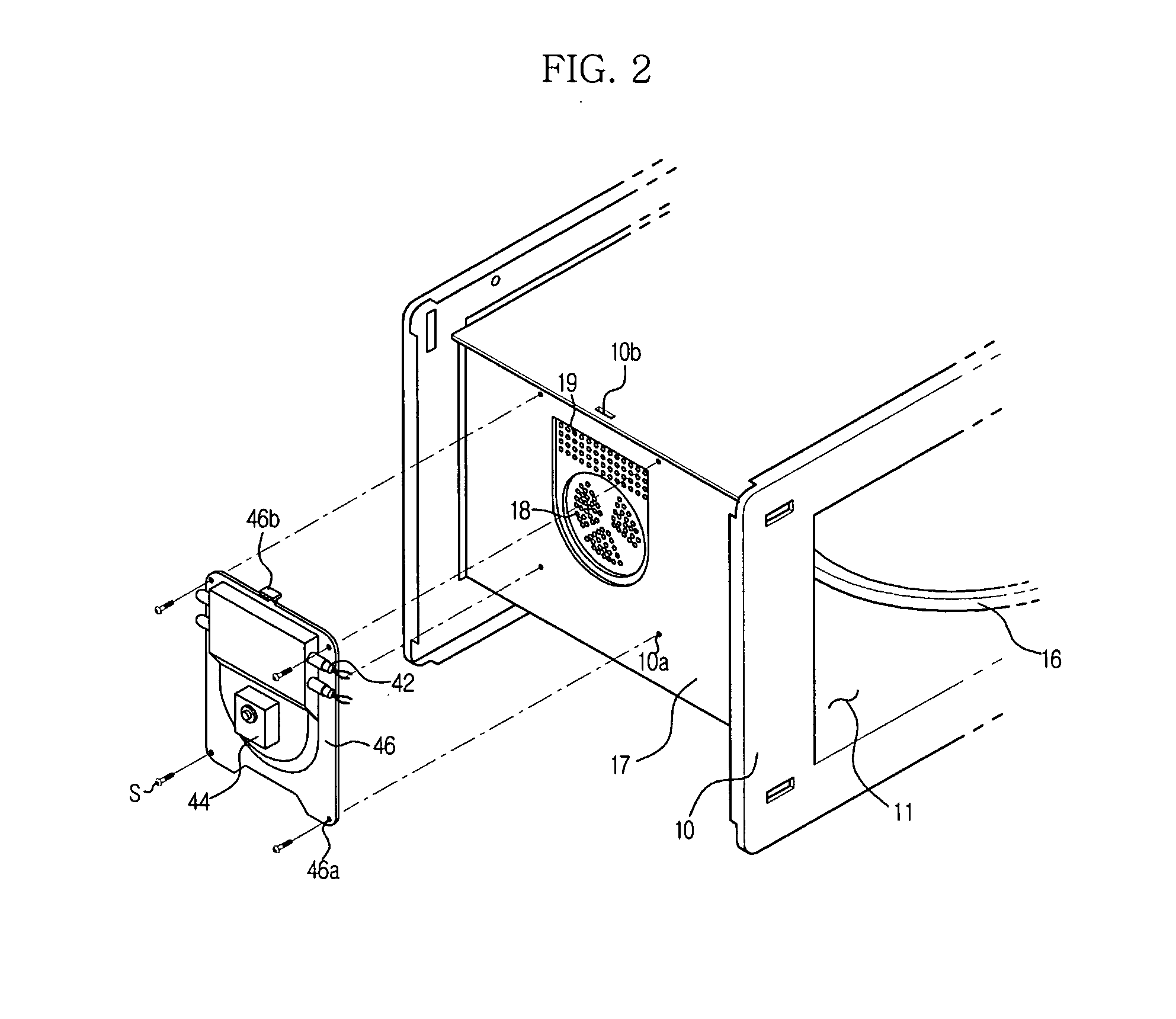

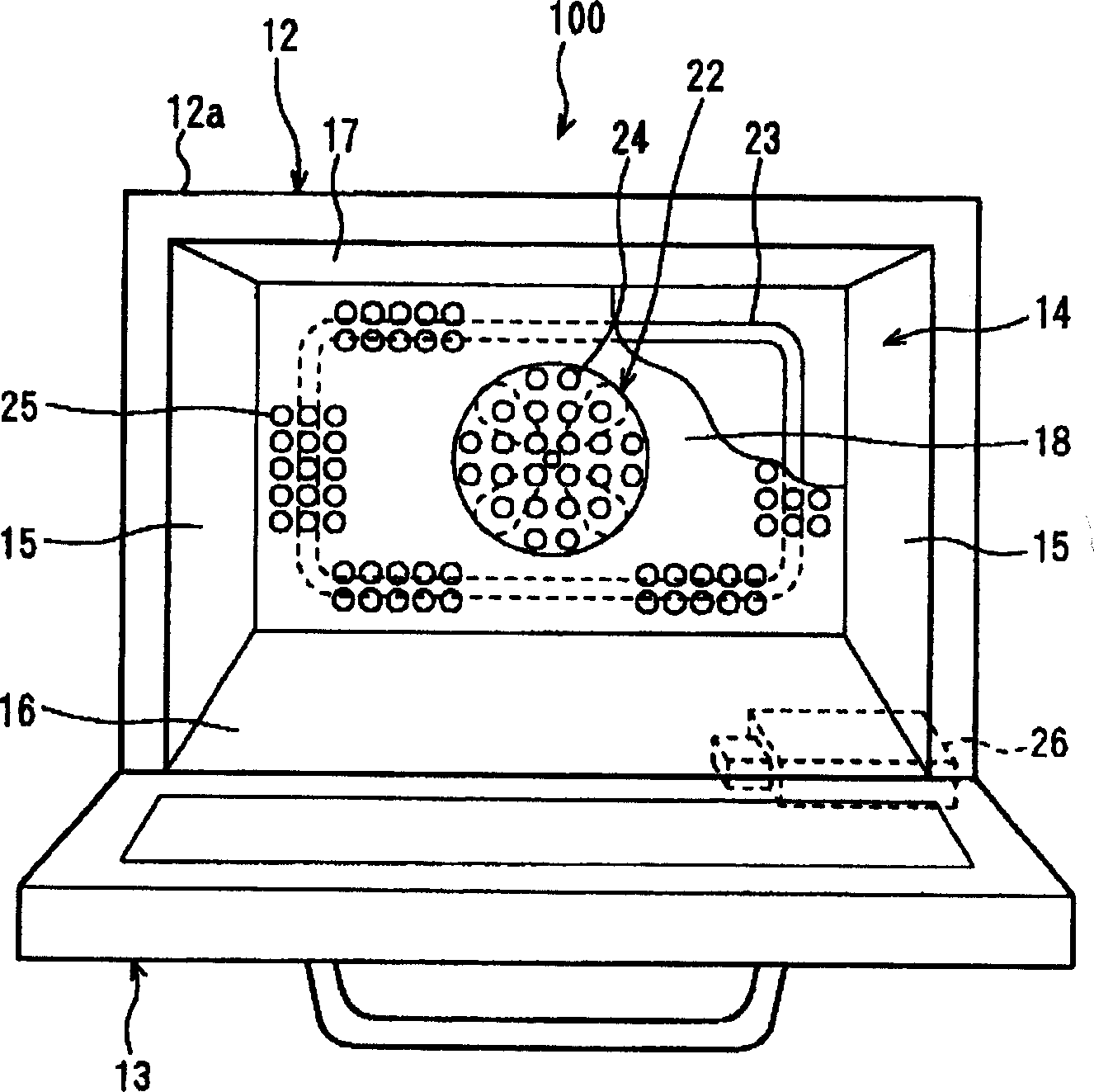

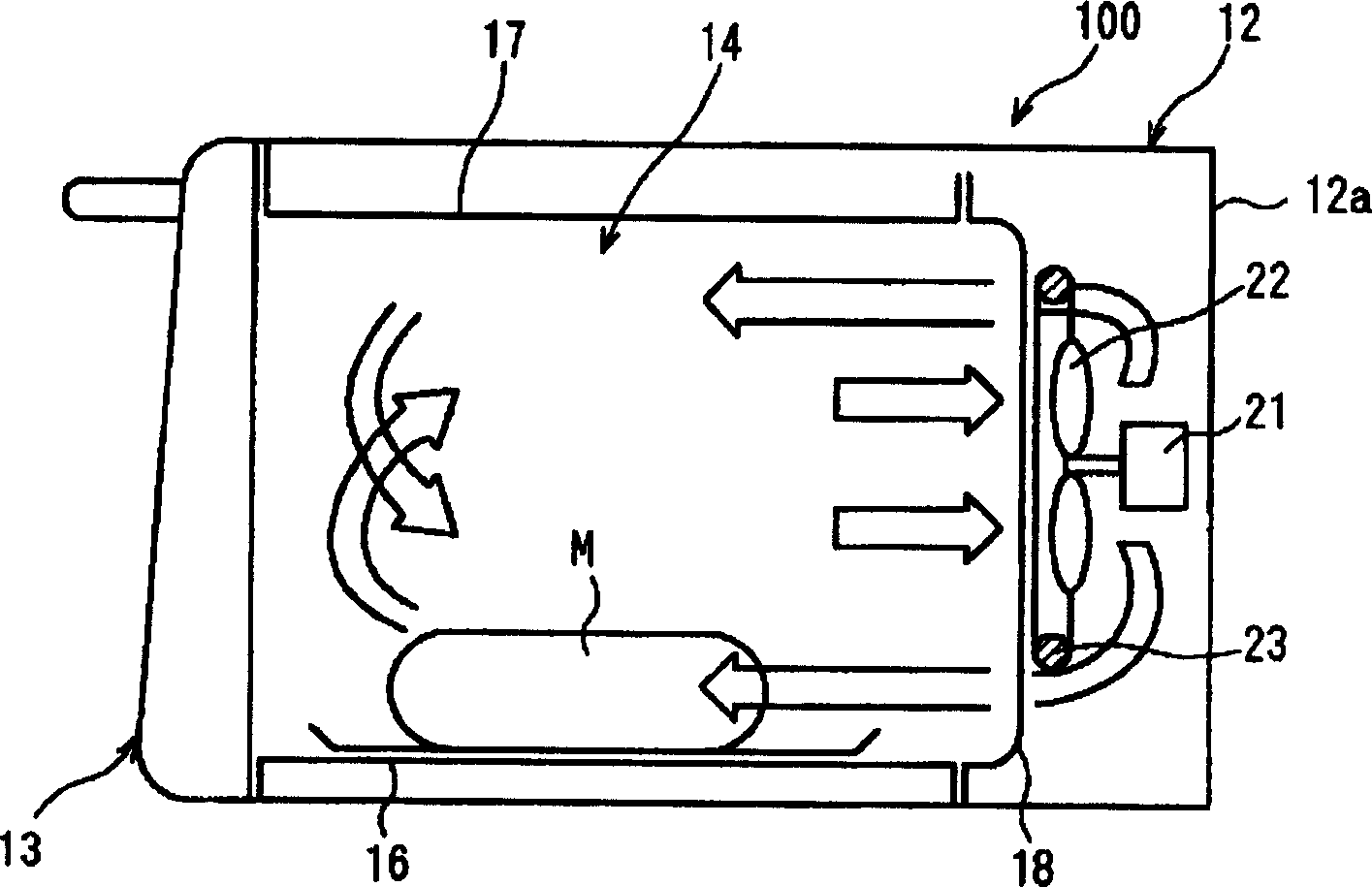

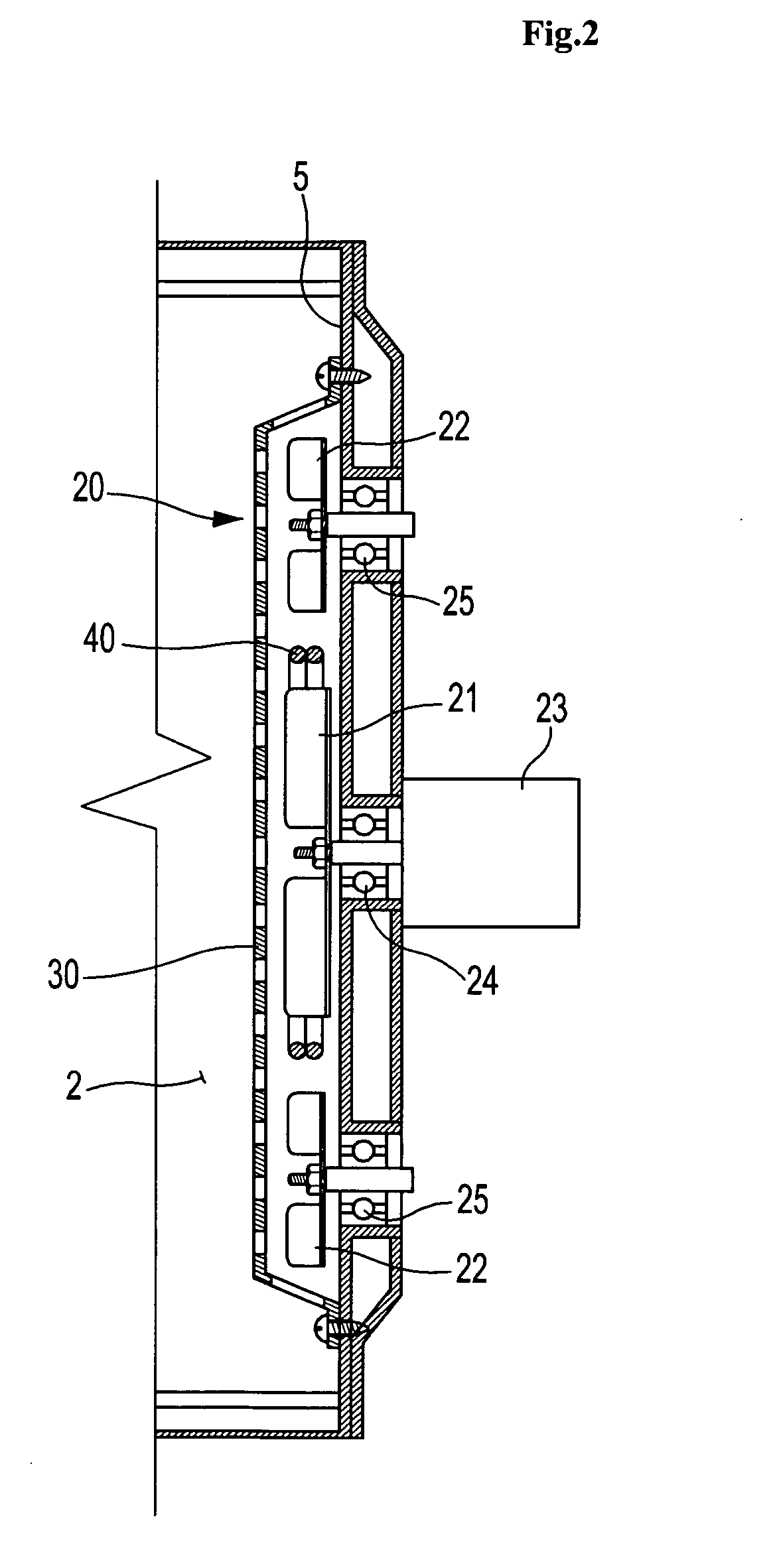

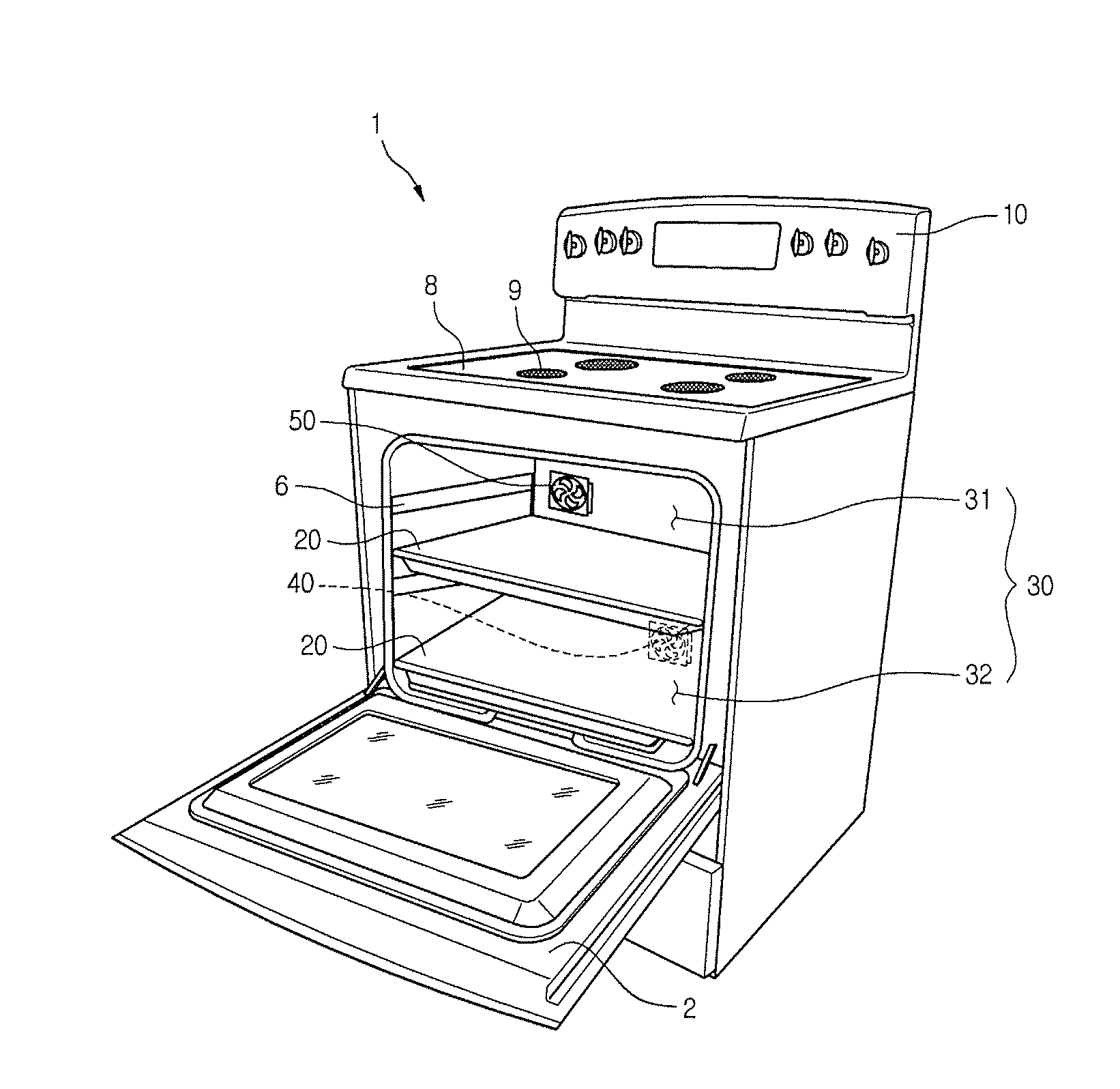

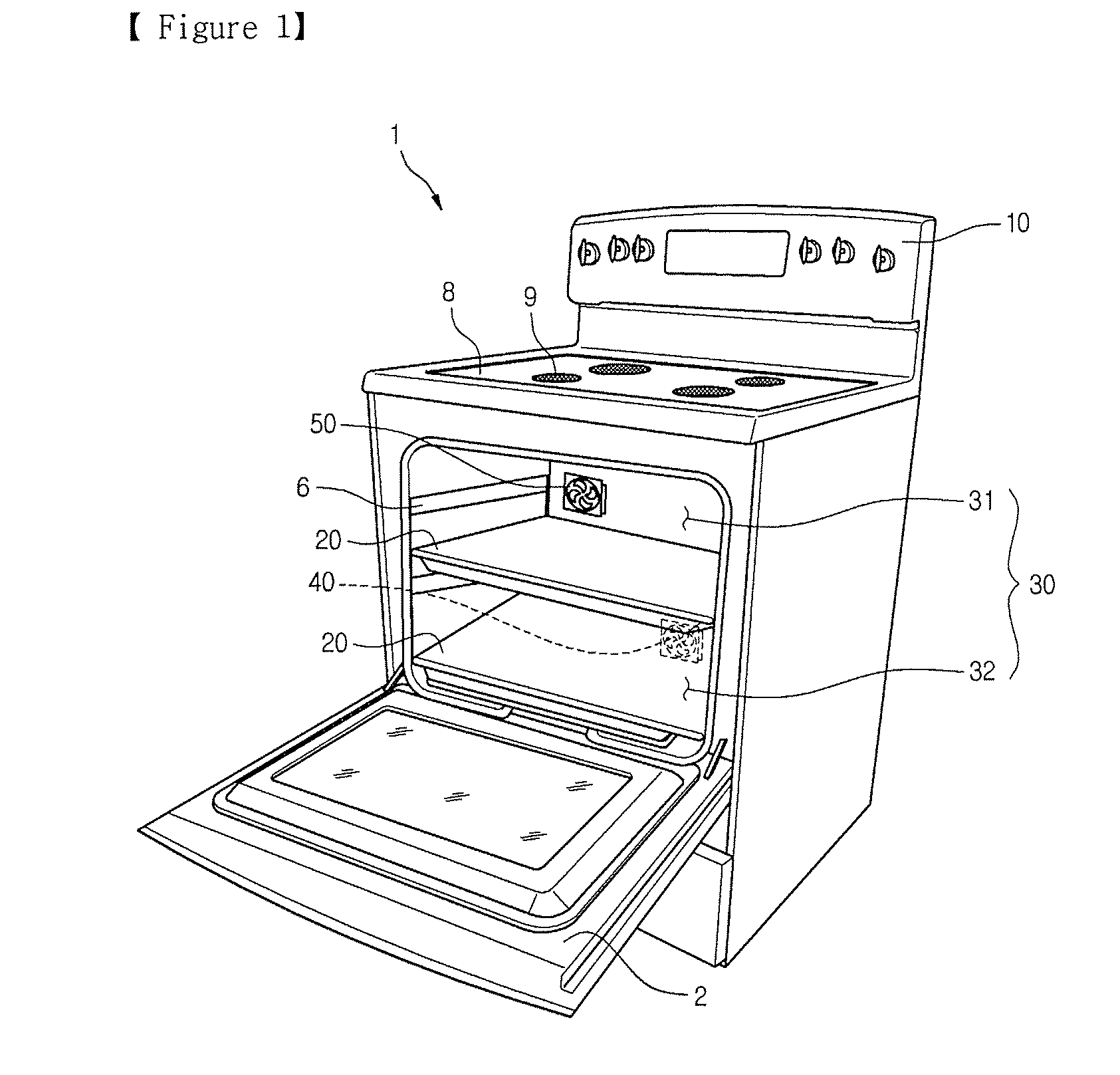

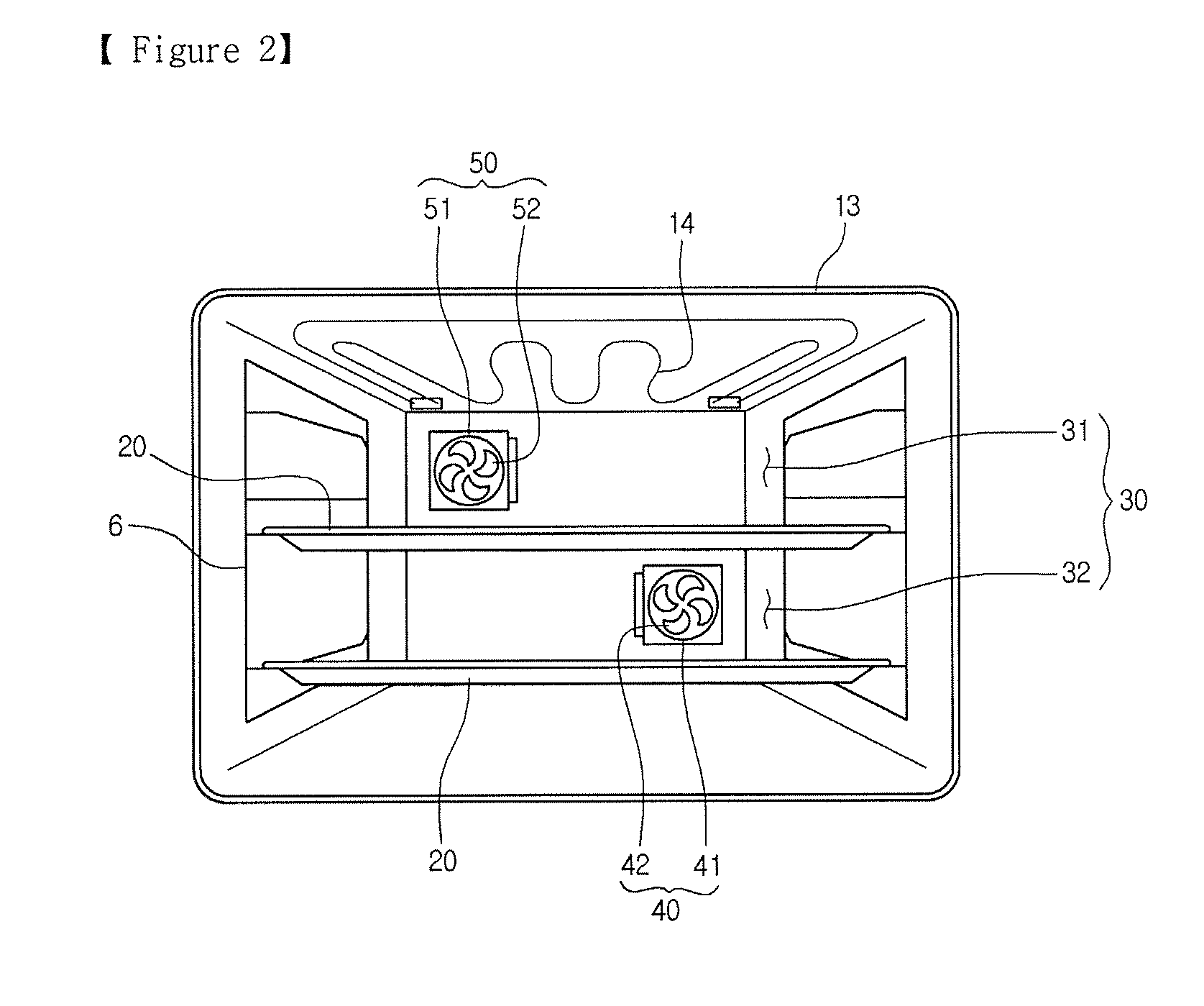

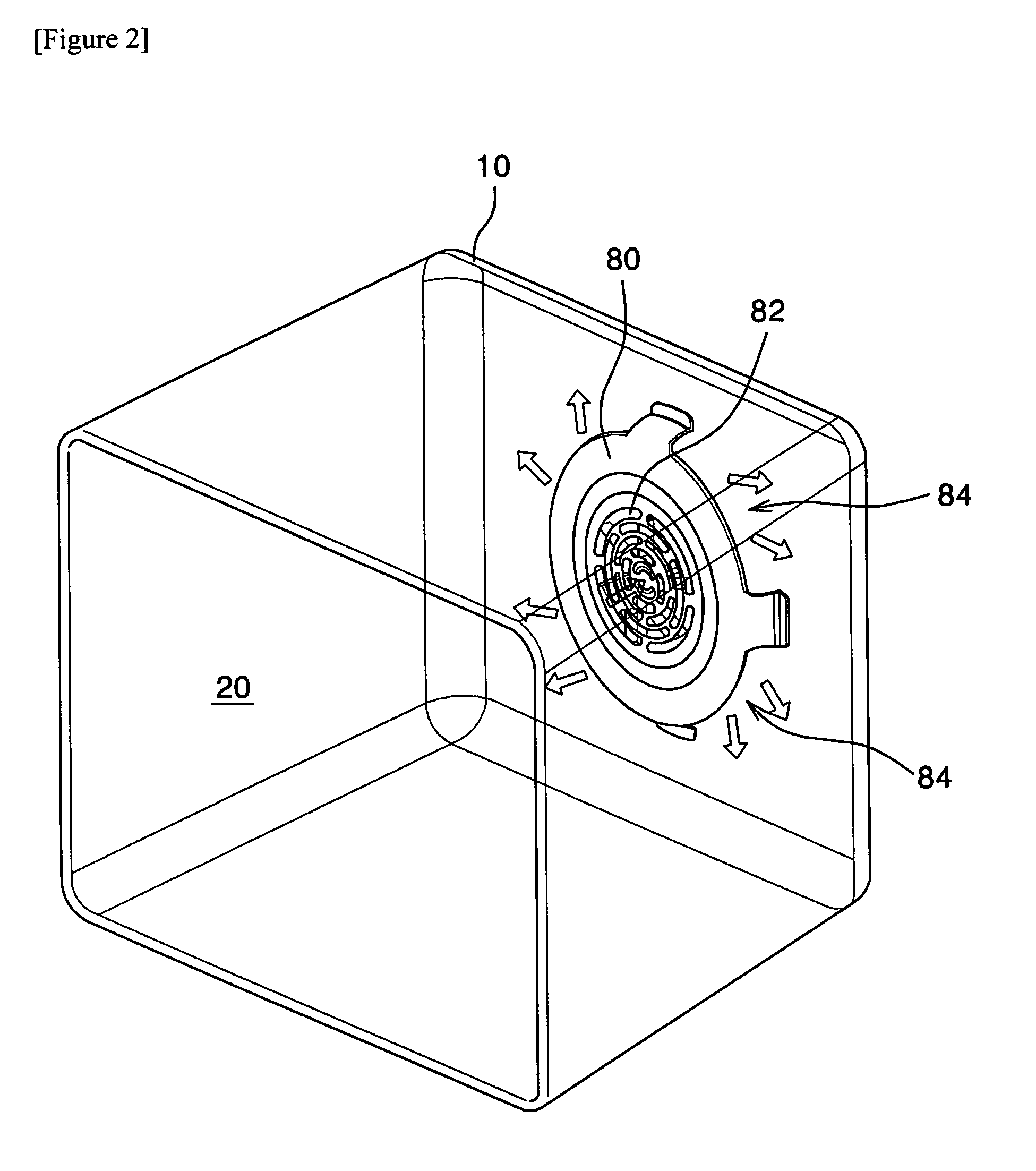

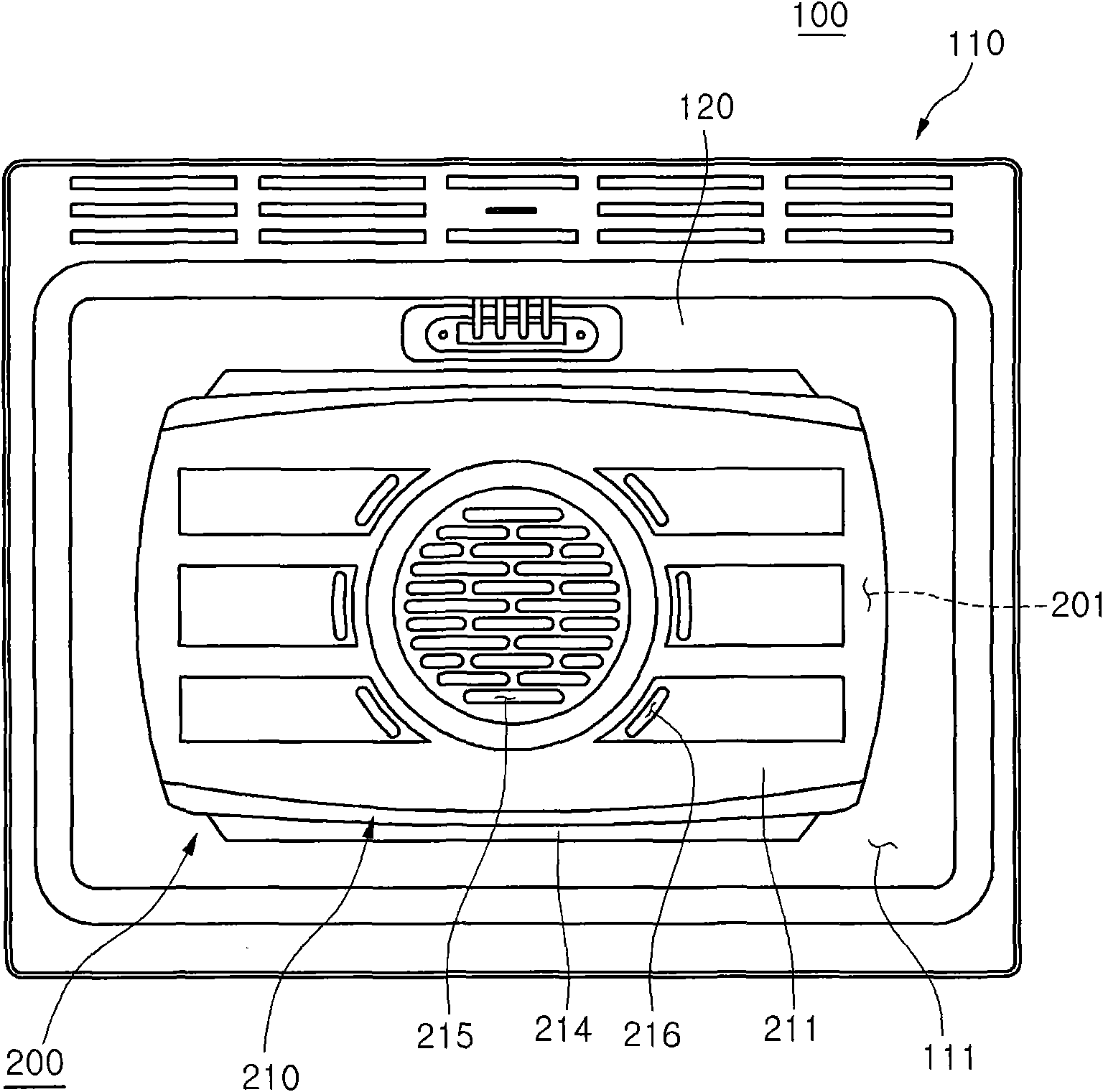

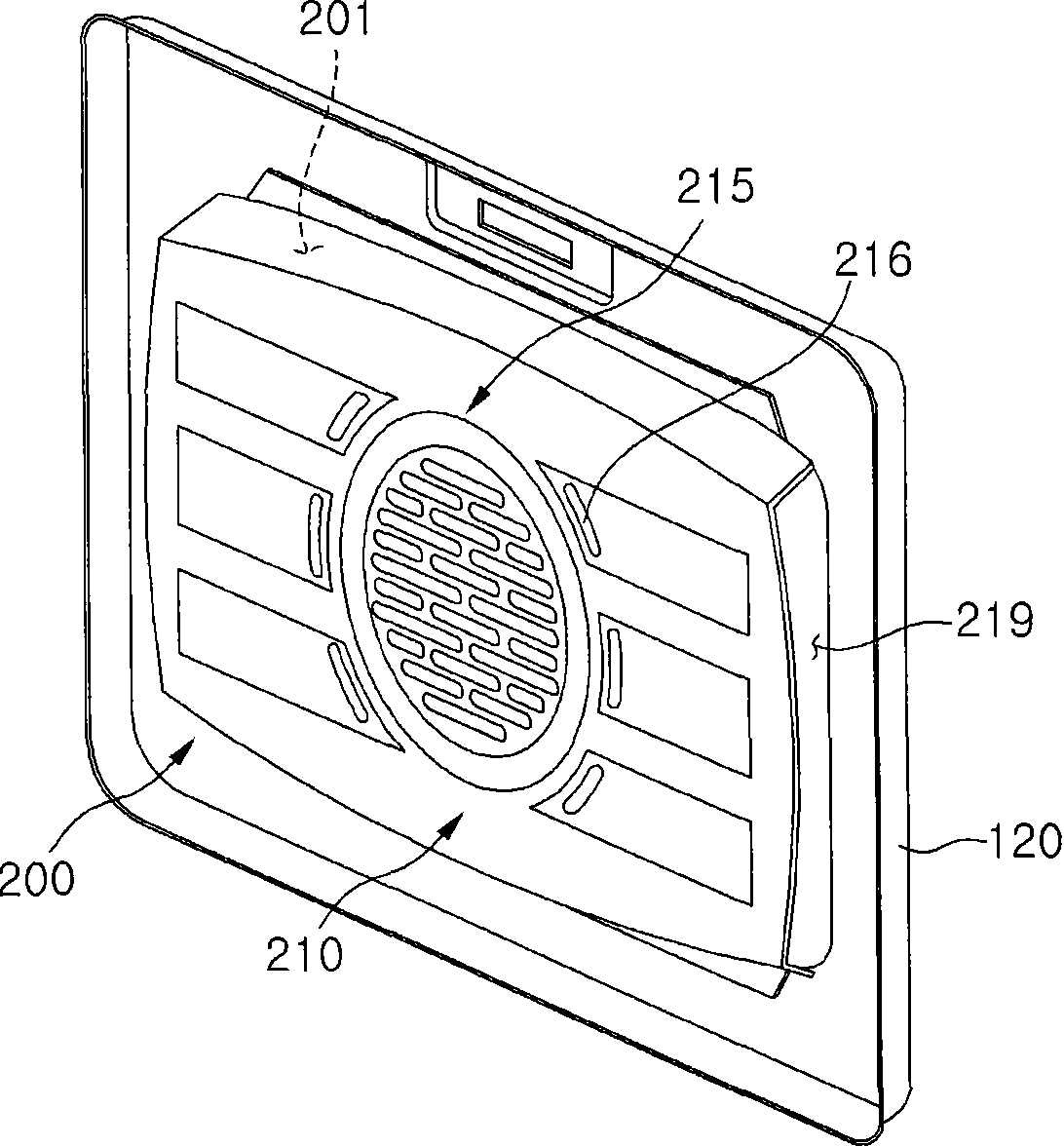

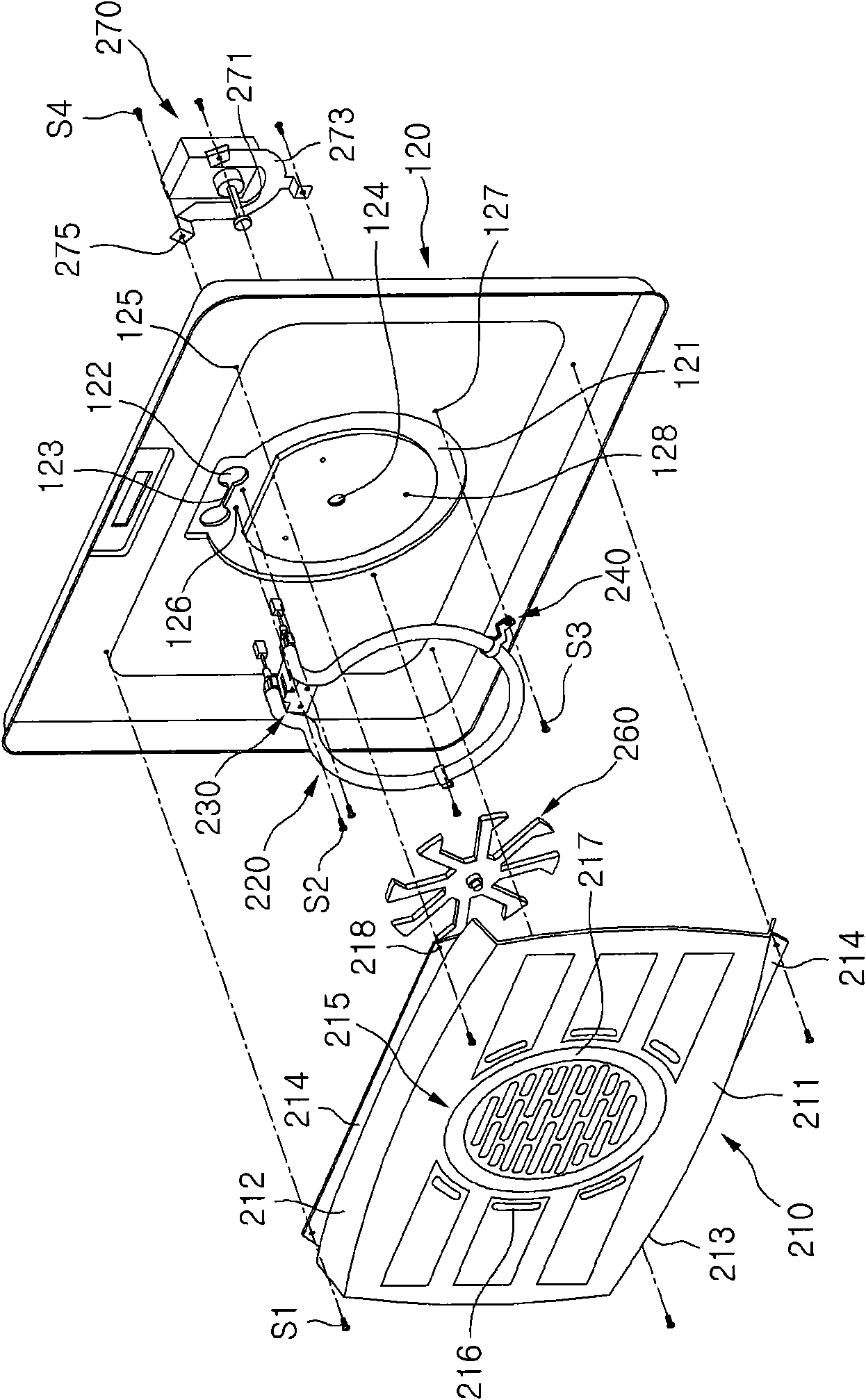

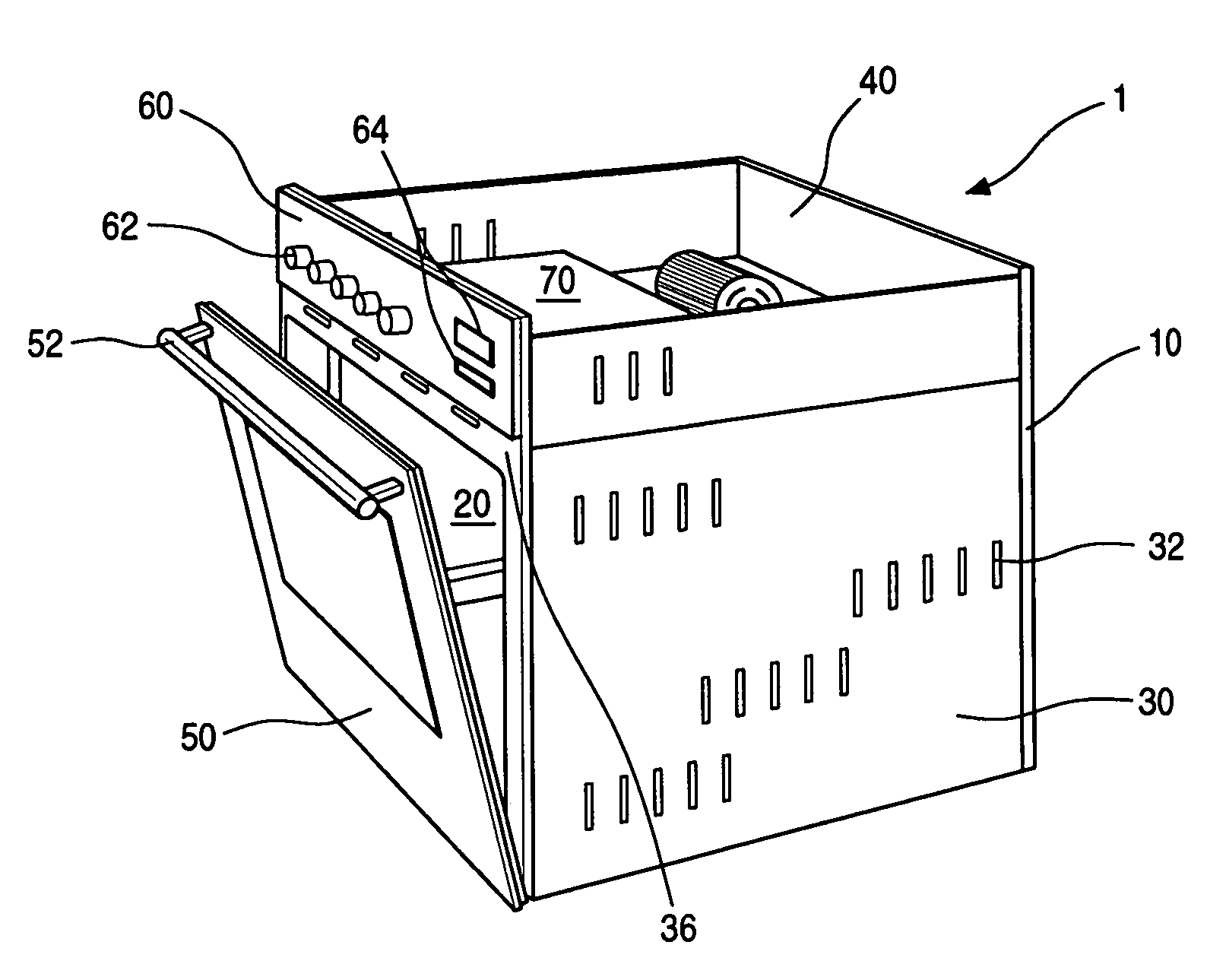

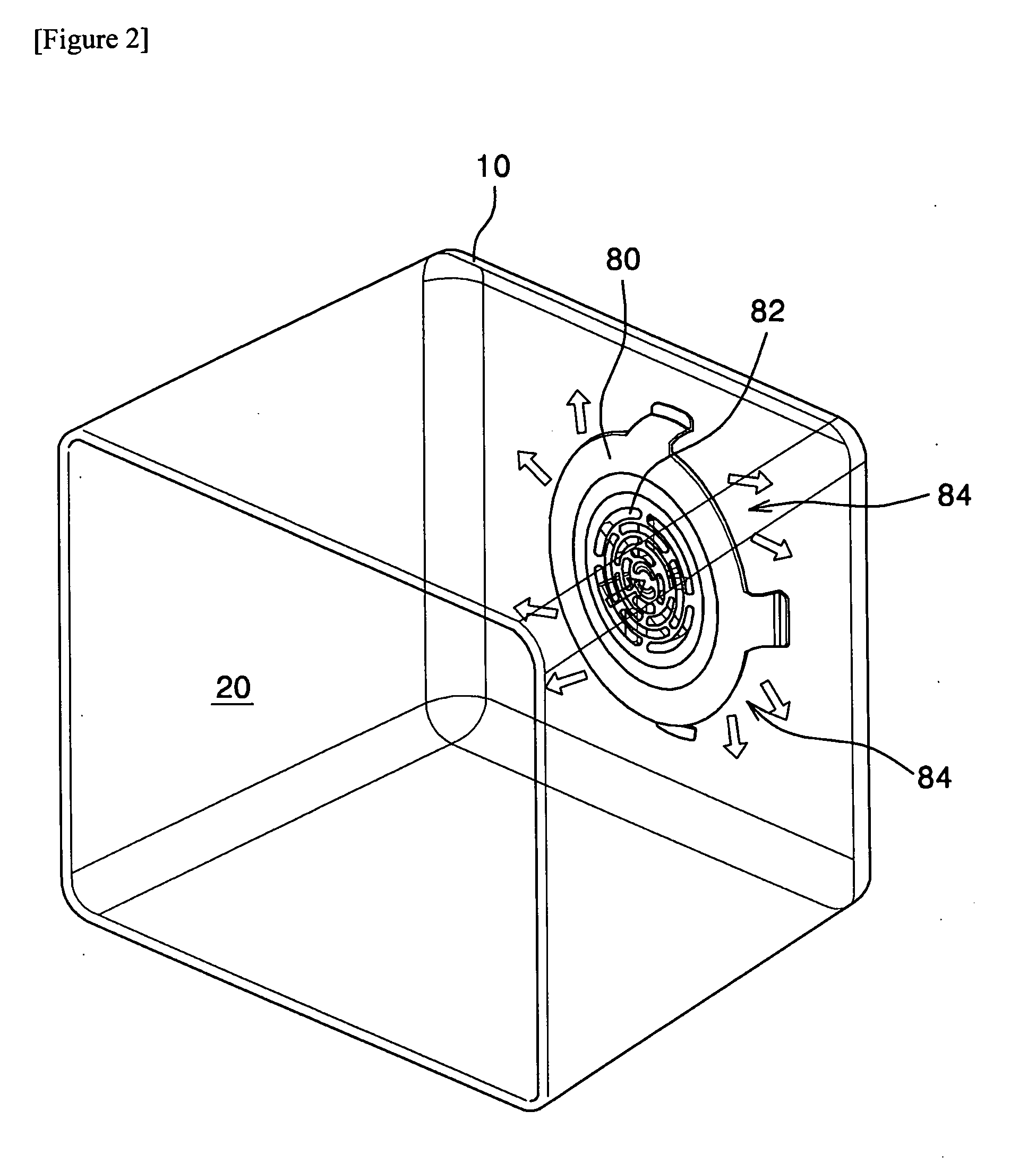

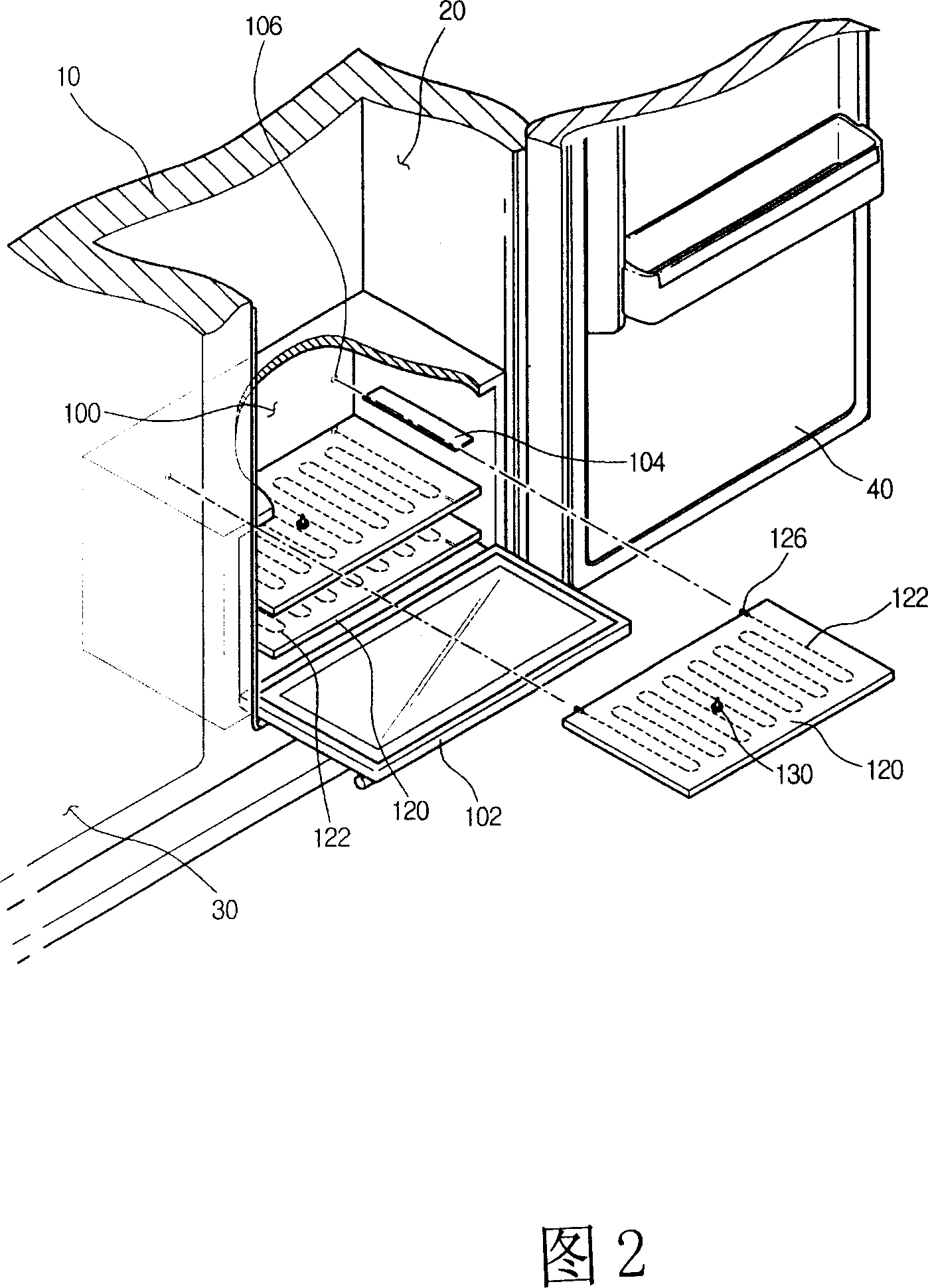

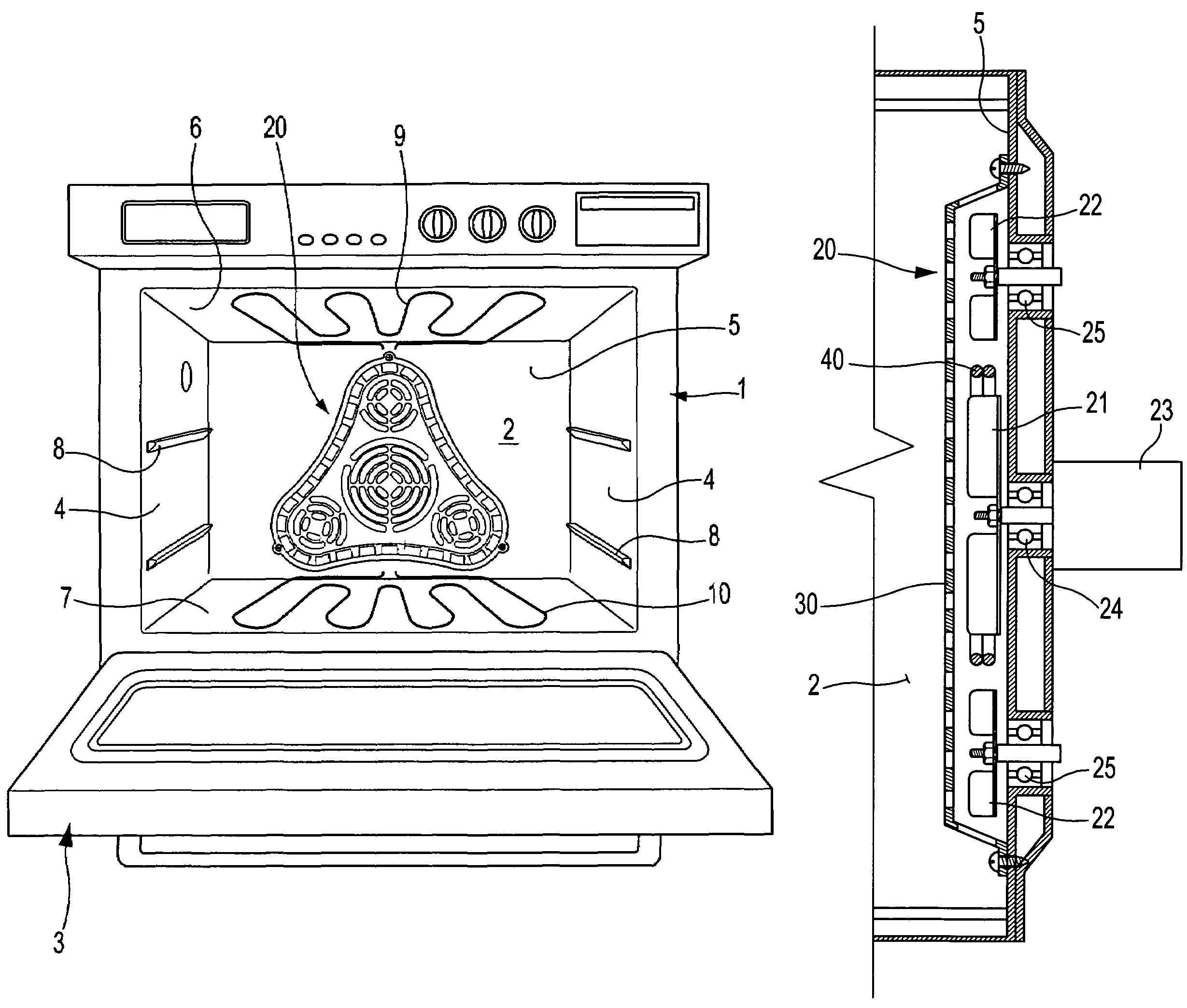

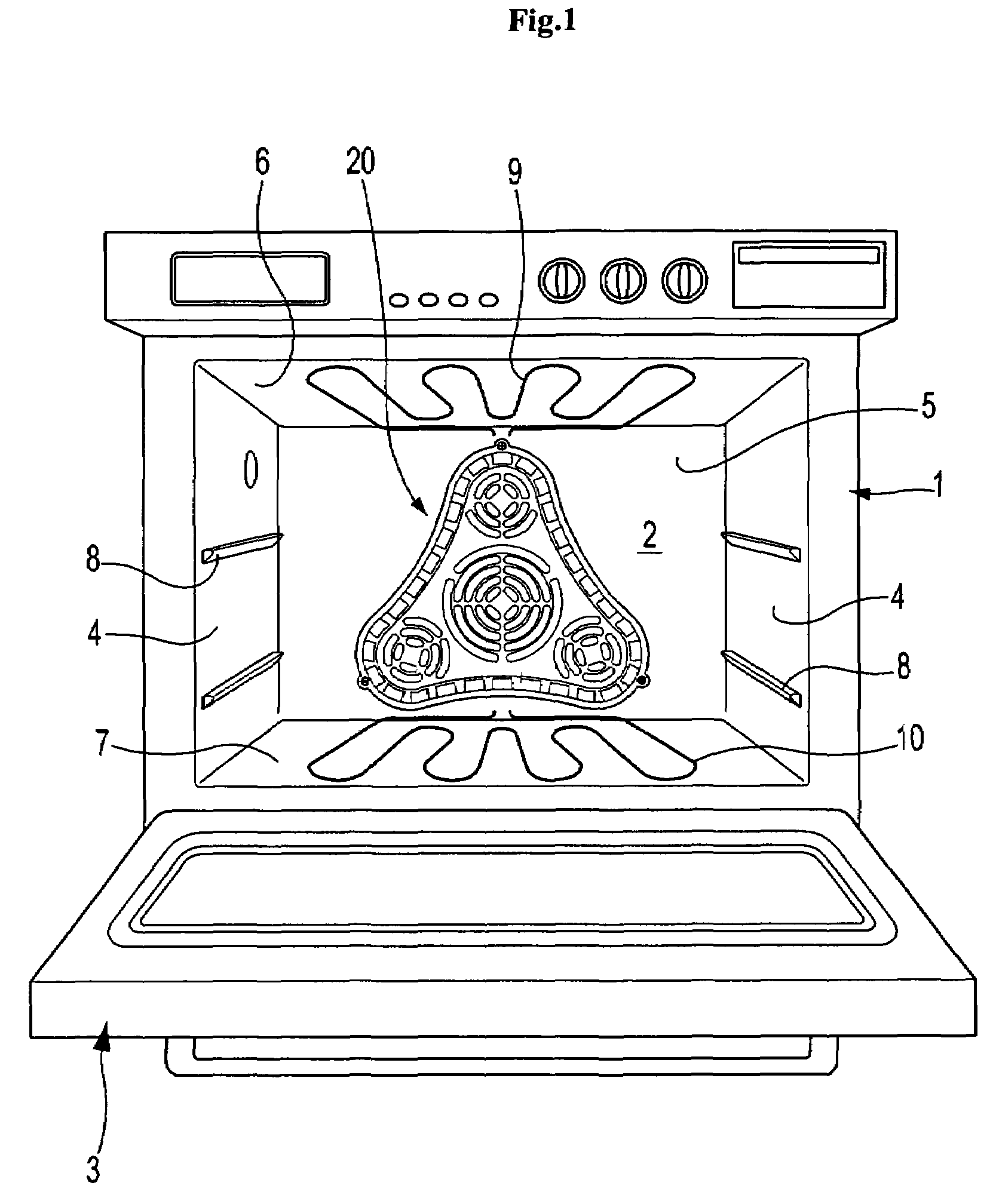

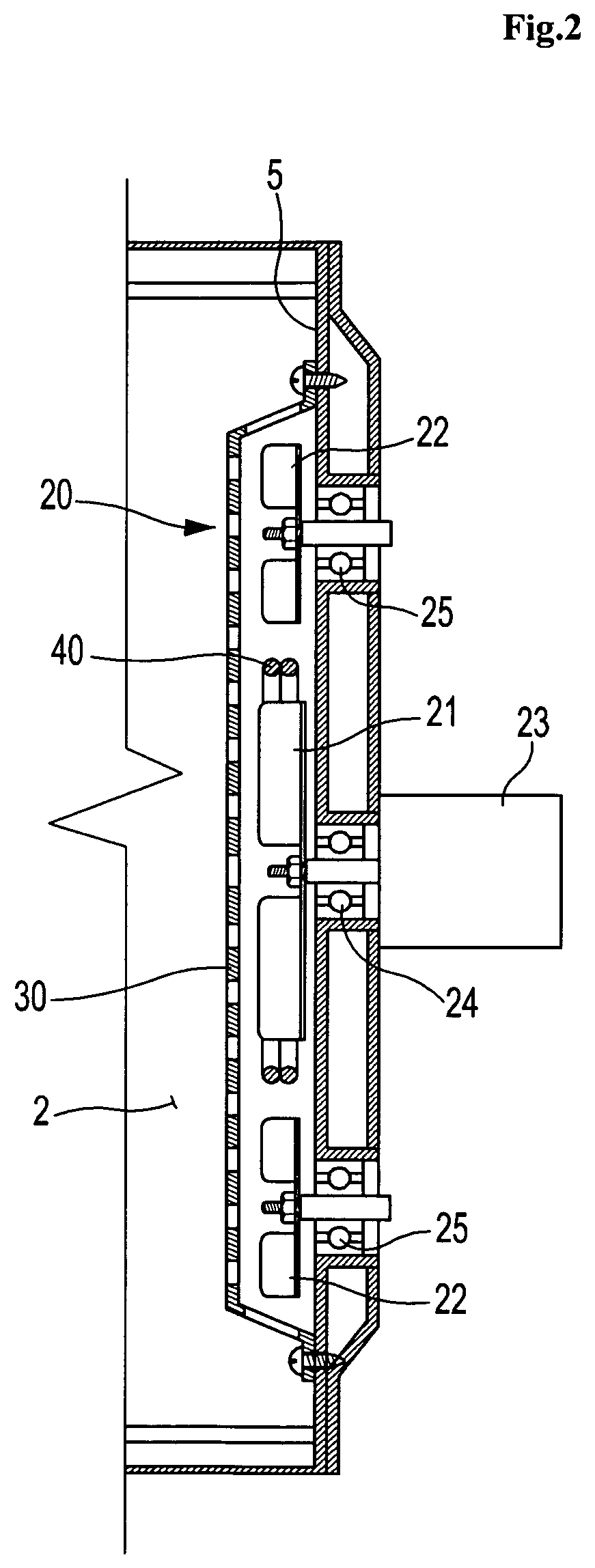

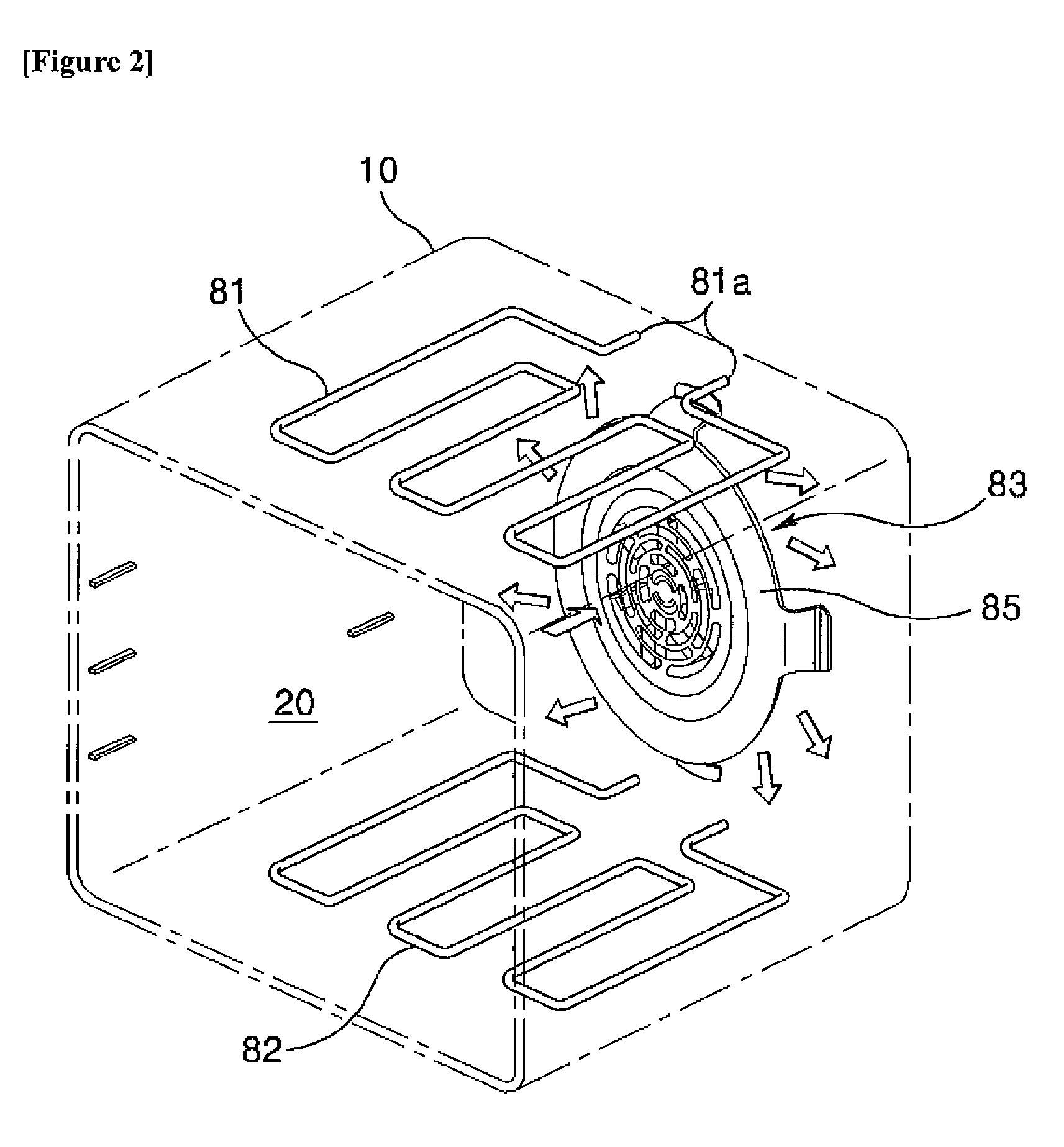

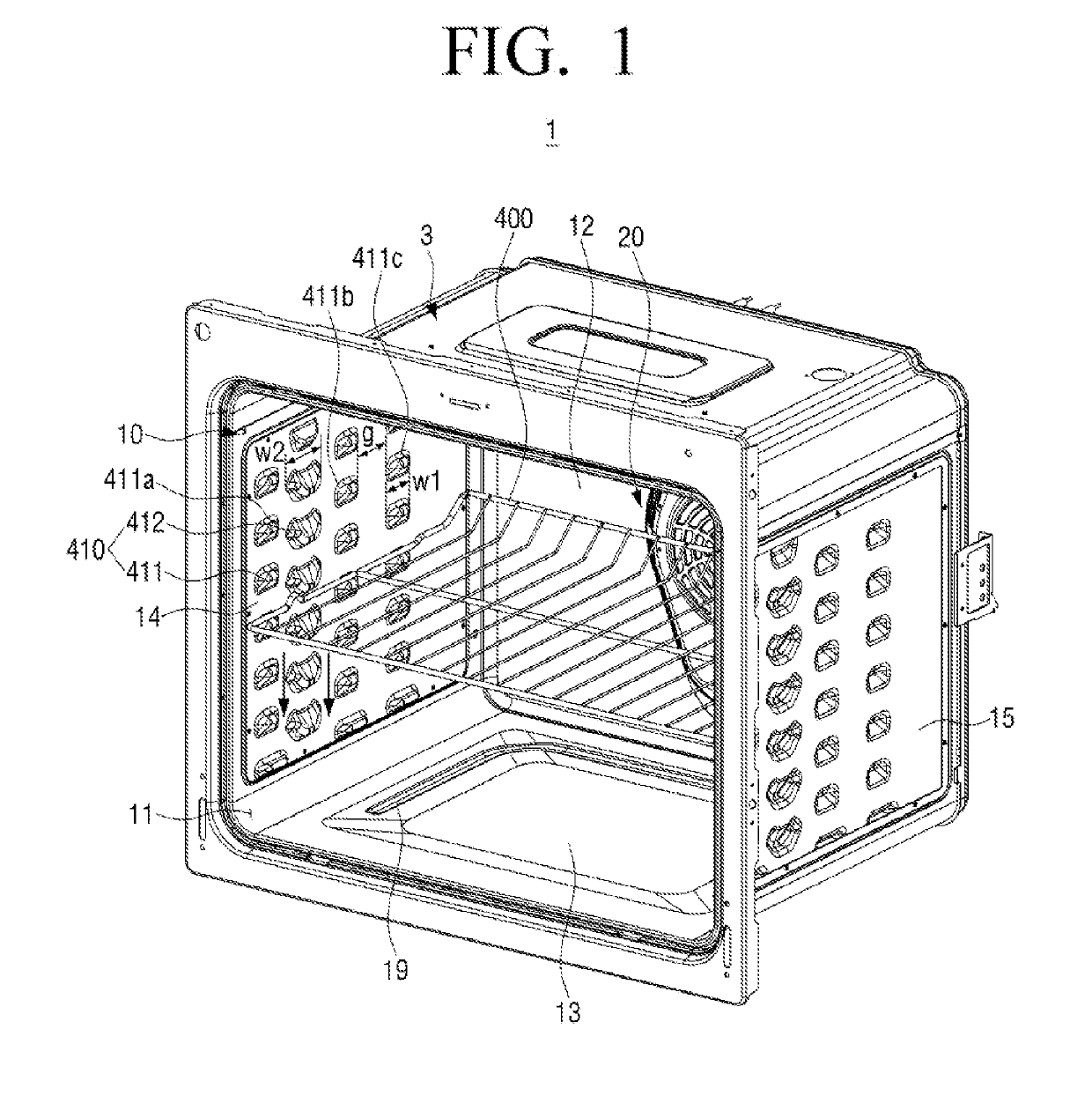

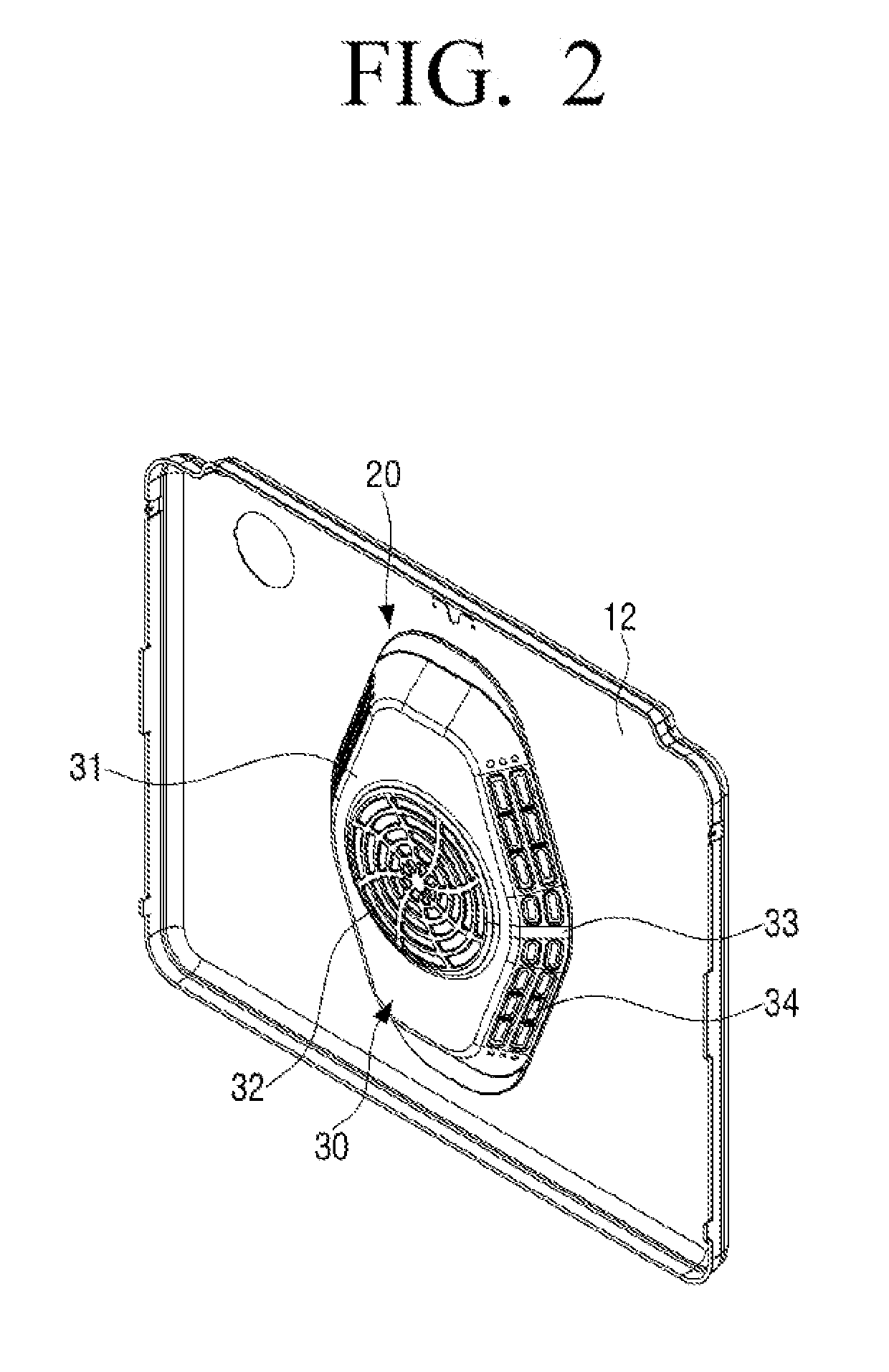

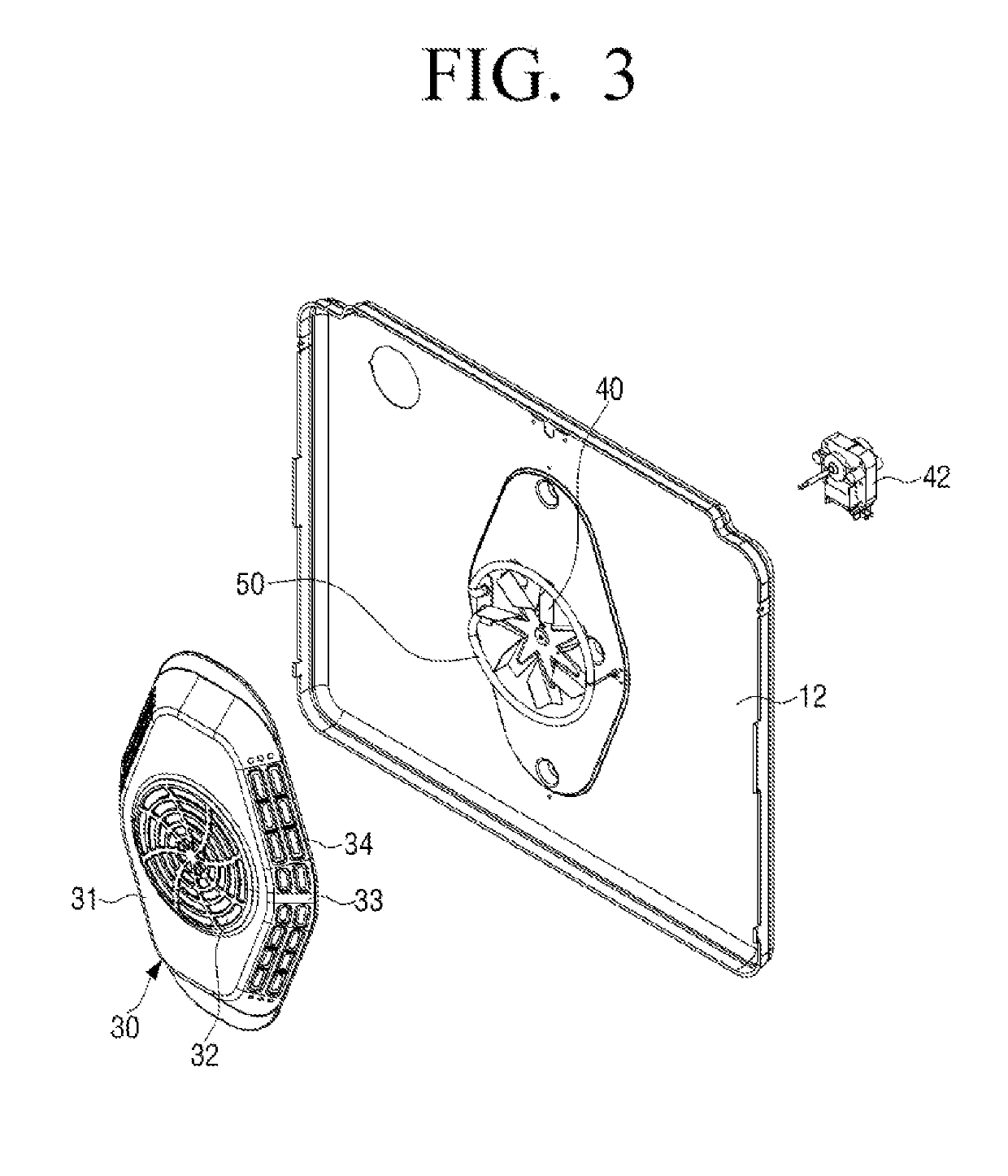

Convection heating unit and heating cooker having the same

ActiveUS20090013988A1Smooth circulationAvoid dischargeDomestic stoves or rangesCooking fumes removalConvection heaterEngineering

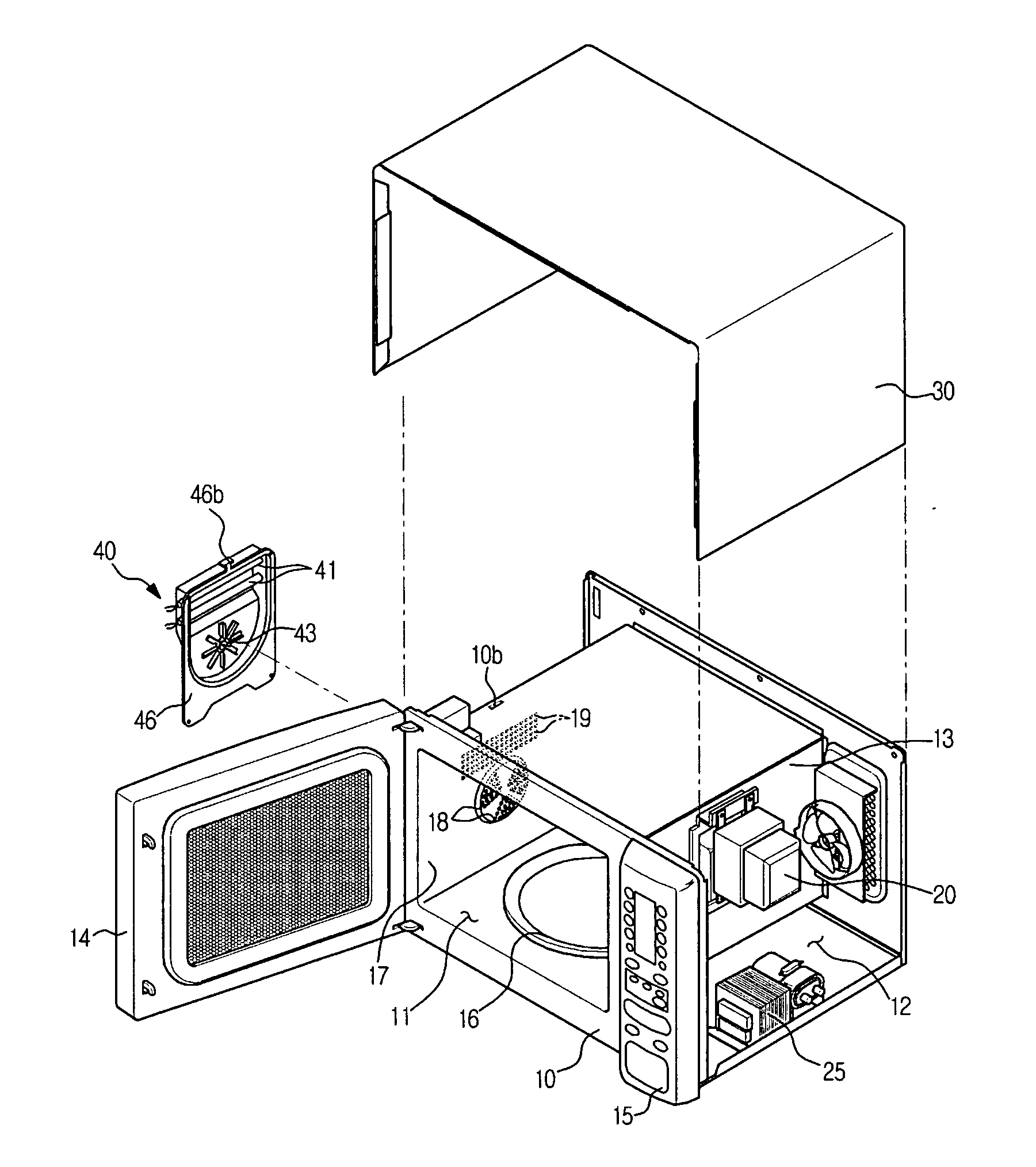

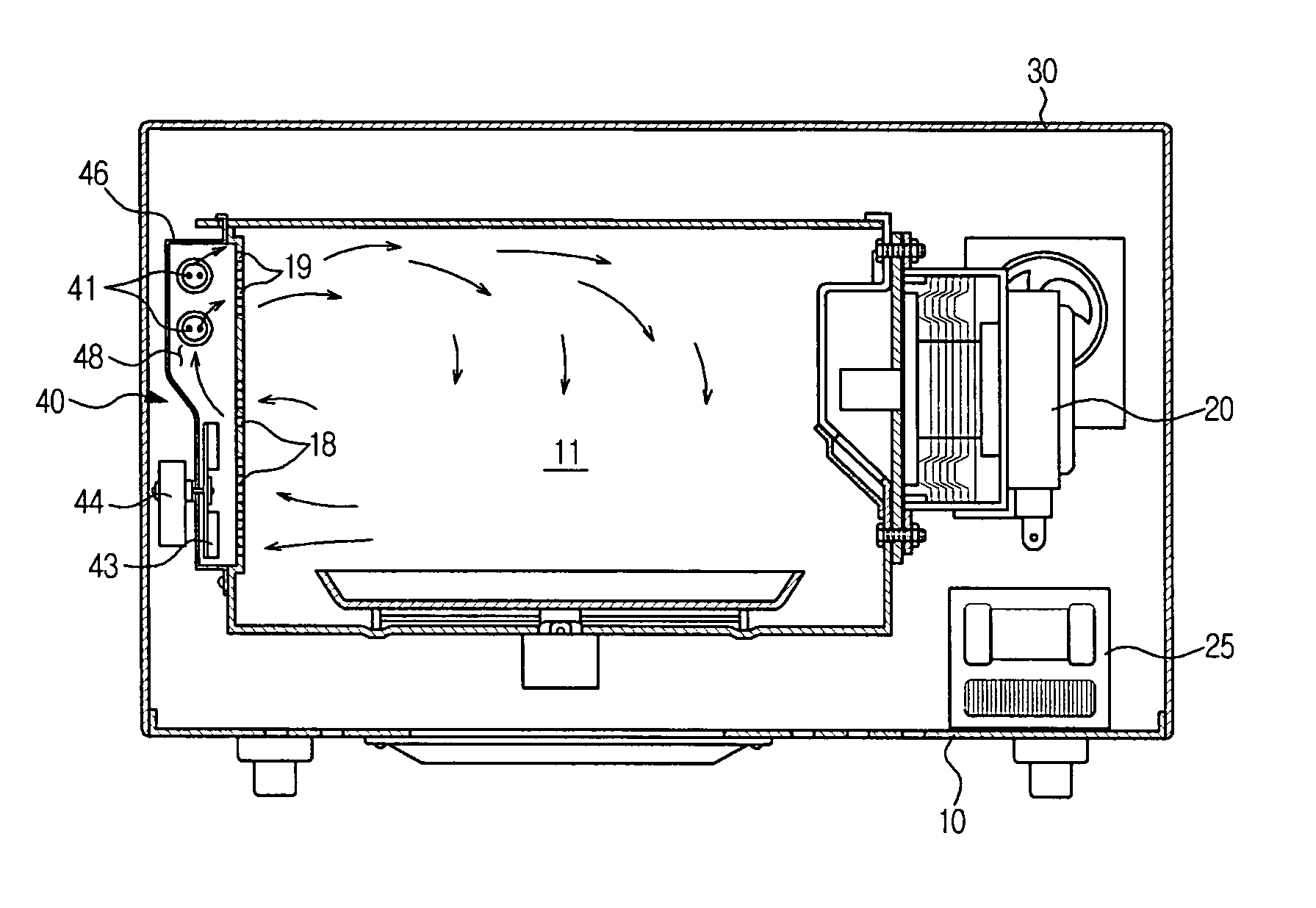

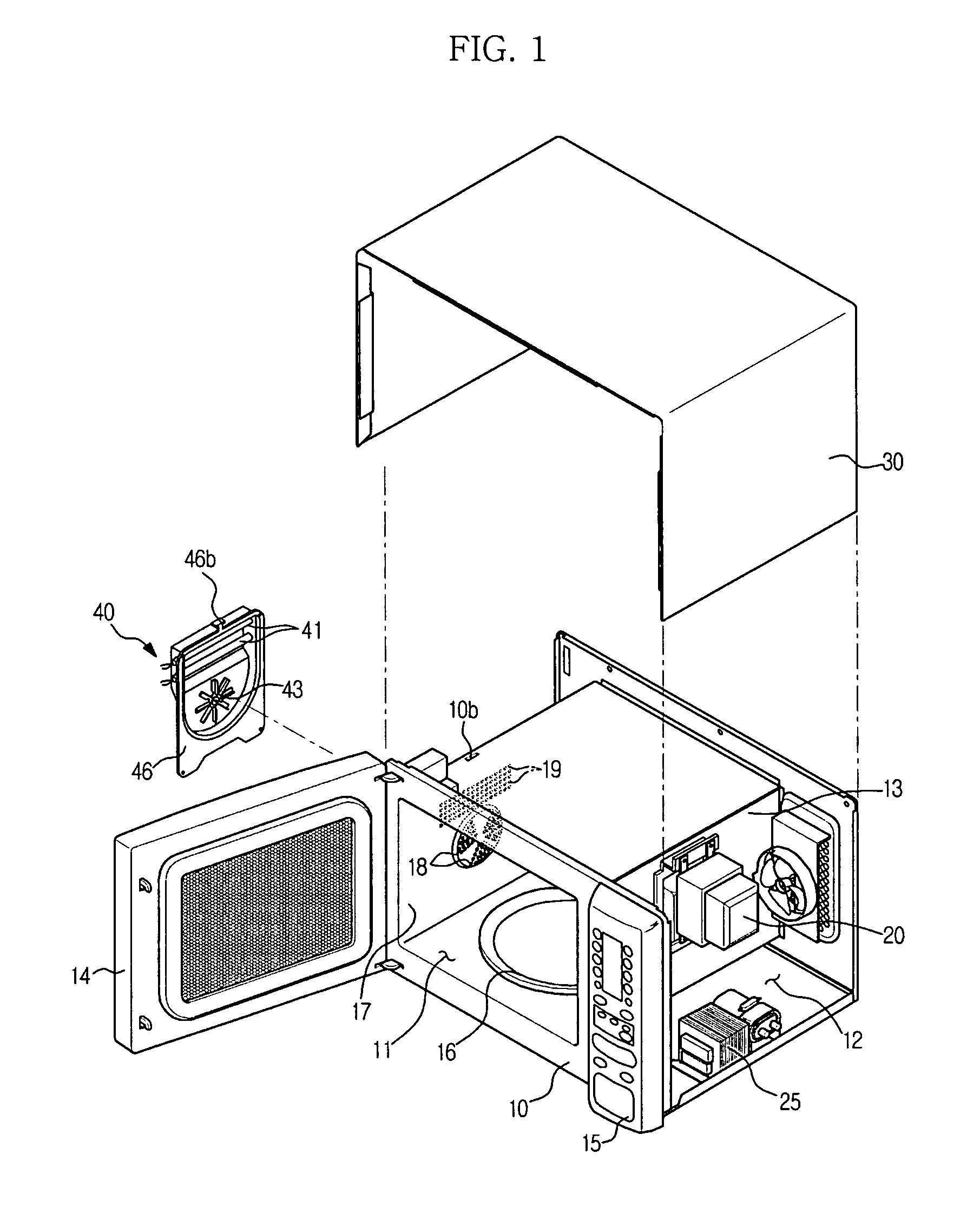

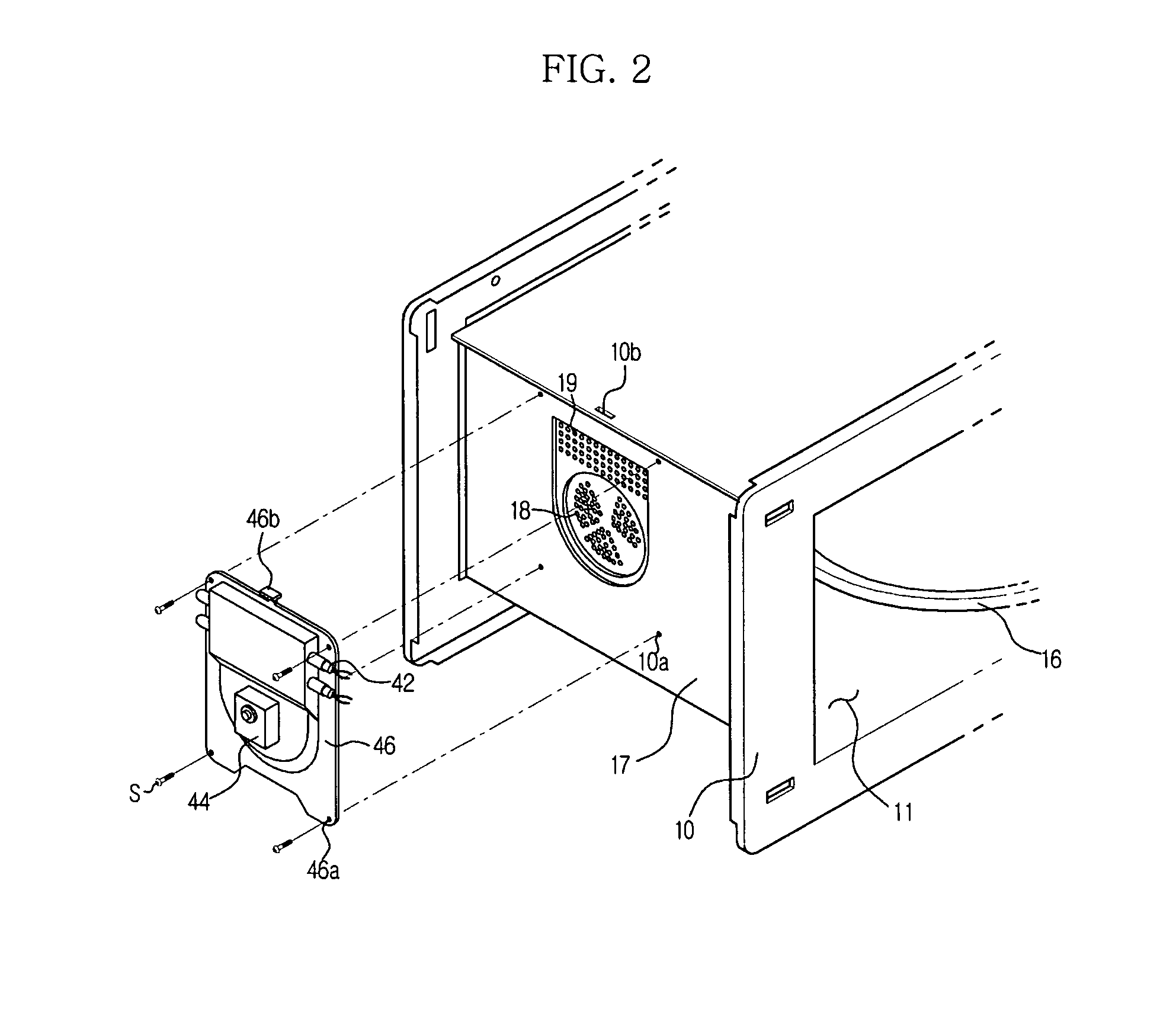

A heating cooker including a cooker body having a cooking chamber and a convection heating unit. The convection heating unit includes a convection heater to generate heat, a convection fan to forcibly move the heat generated from the convection heater into the cooking chamber, a convection motor to drive the convection fan, and a convection housing to receive the convection heater and the convection fan. The convection heater and the convection fan are linearly arranged within the convection housing, to allow air introduced into the convection housing to move from the convection fan to the convection heater. This configuration is effective to restrict the transfer of heat from the convection heater to the convection motor.

Owner:SAMSUNG ELECTRONICS CO LTD

Convective heater

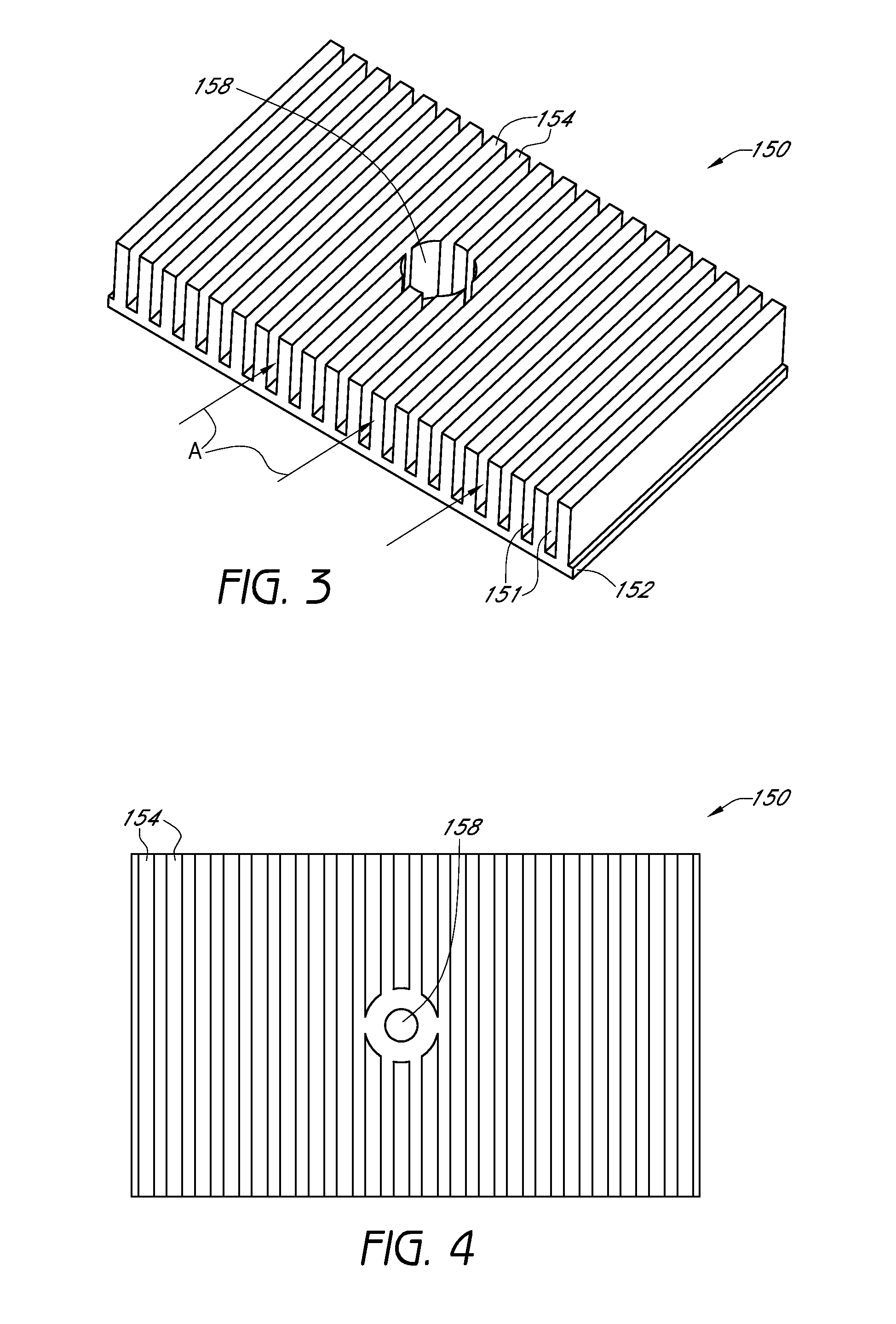

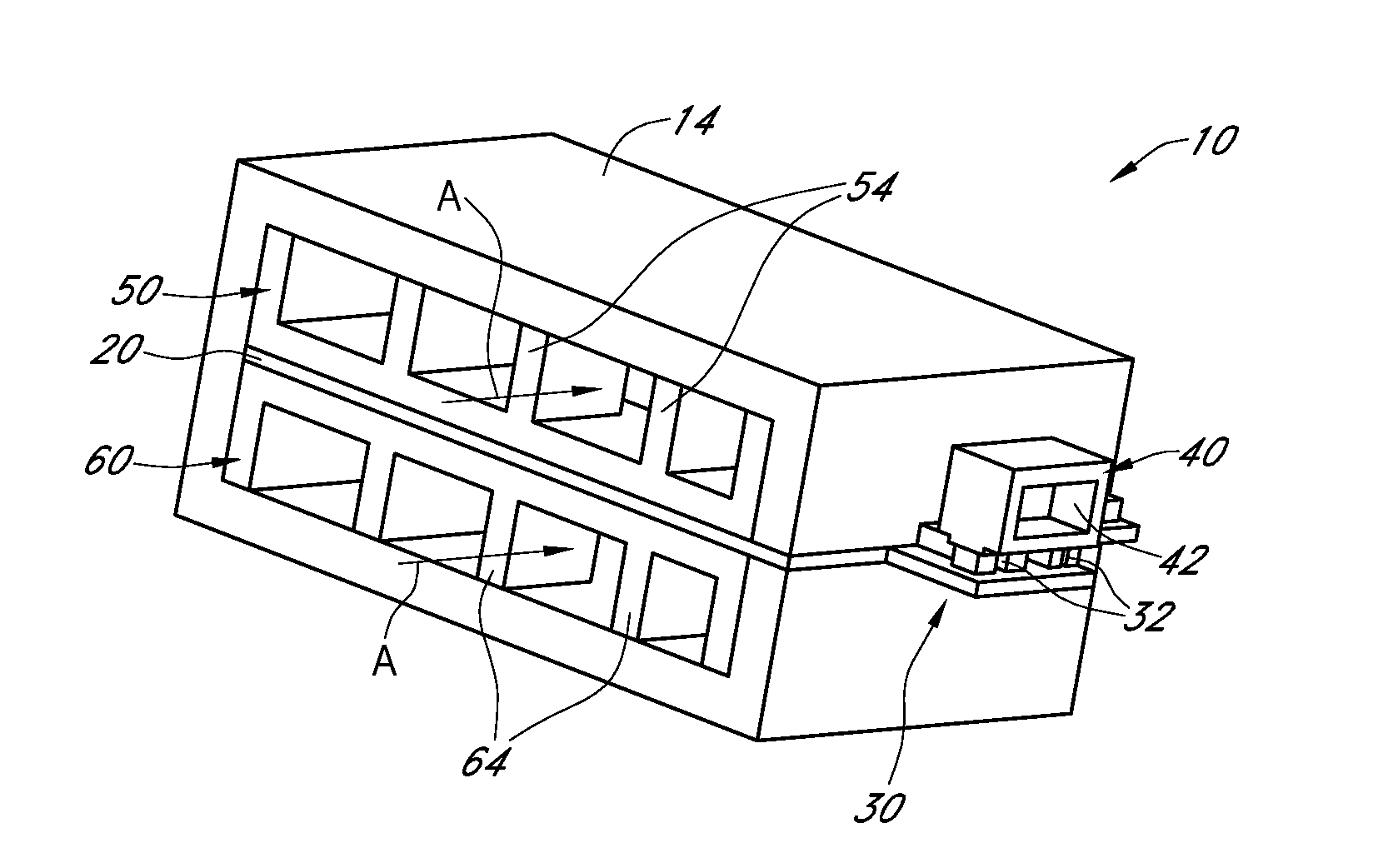

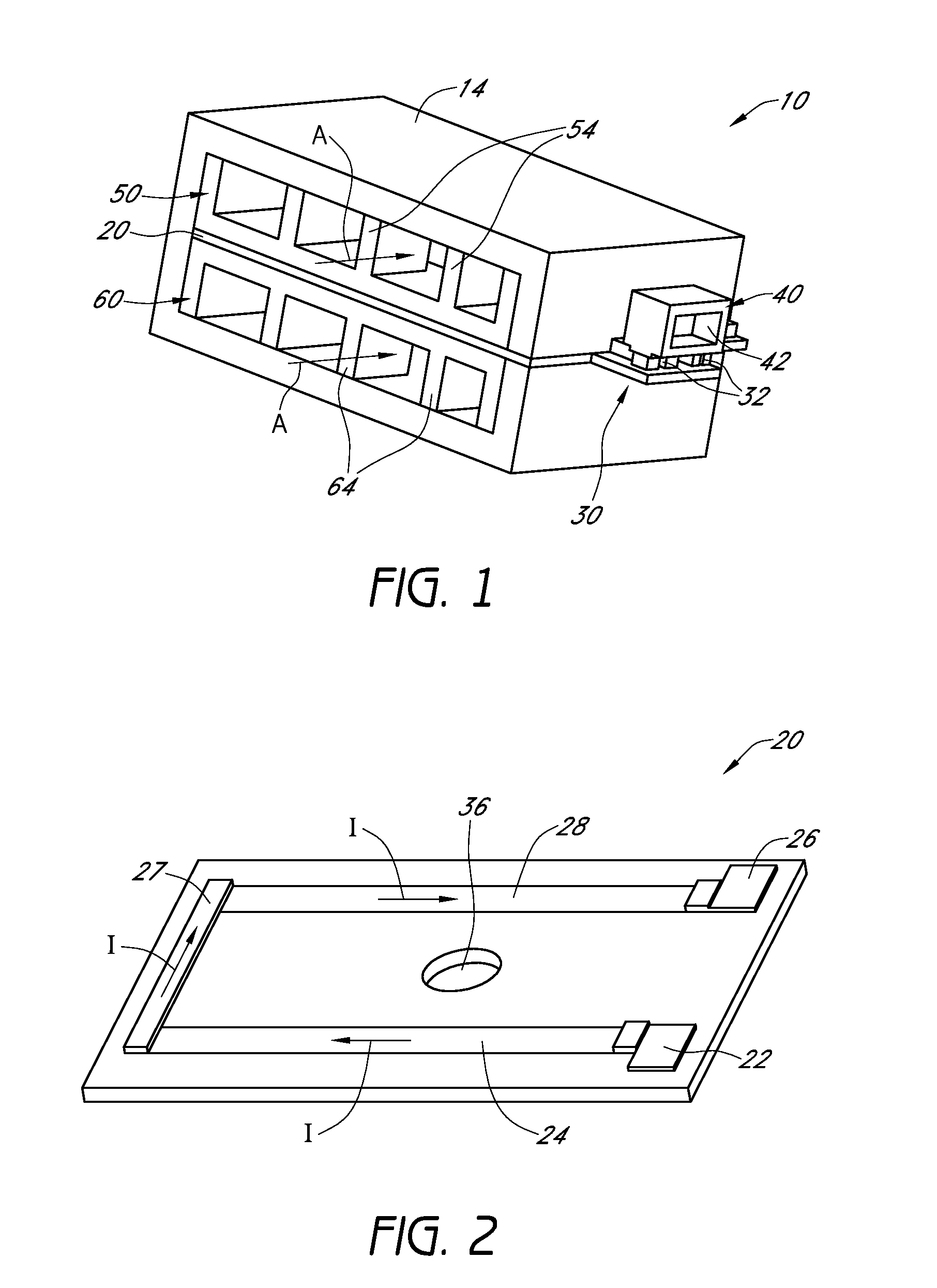

A heating device comprises a heater having a first surface and a second surface, with the second surface being generally opposite of the first surface. The heater is configured to receive an electrical current and convert it to heat. The heating device additionally includes at least one heat transfer assembly positioned along the first and / or second surface of the heater. In one embodiment, the heat transfer assembly includes a plurality of fins that generally define a plurality of fin spaces through which fluids may pass. In some arrangements, the heating device comprises an outer housing that at least partially surrounds the heater and one or more of the heat transfer assemblies. Heat generated by the heater is transferred to the fins of the heat transfer assembly. In addition, fluids passing through the fin spaces are selectively heated when electrical current is provided to the heater.

Owner:GENTHERM INC

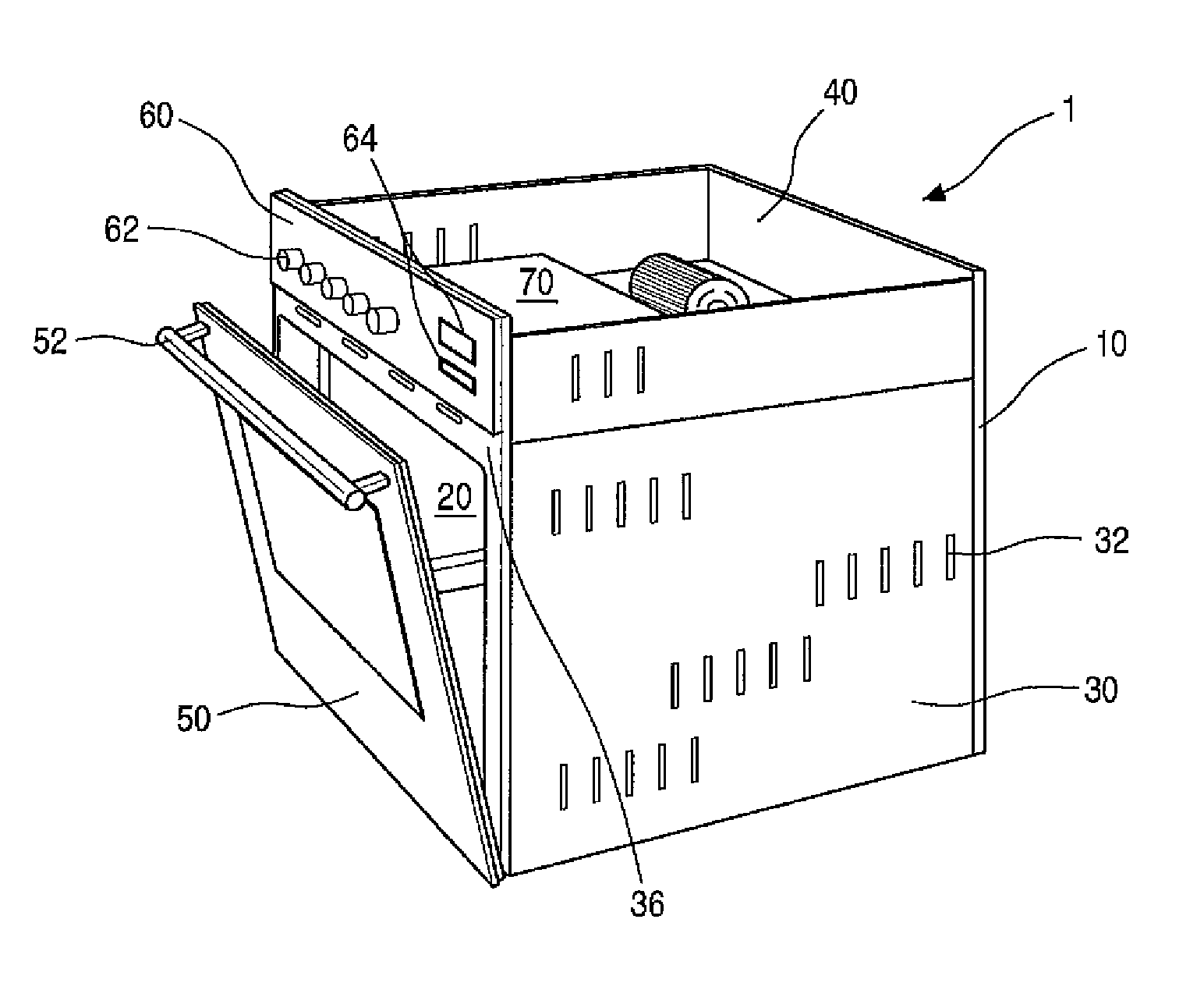

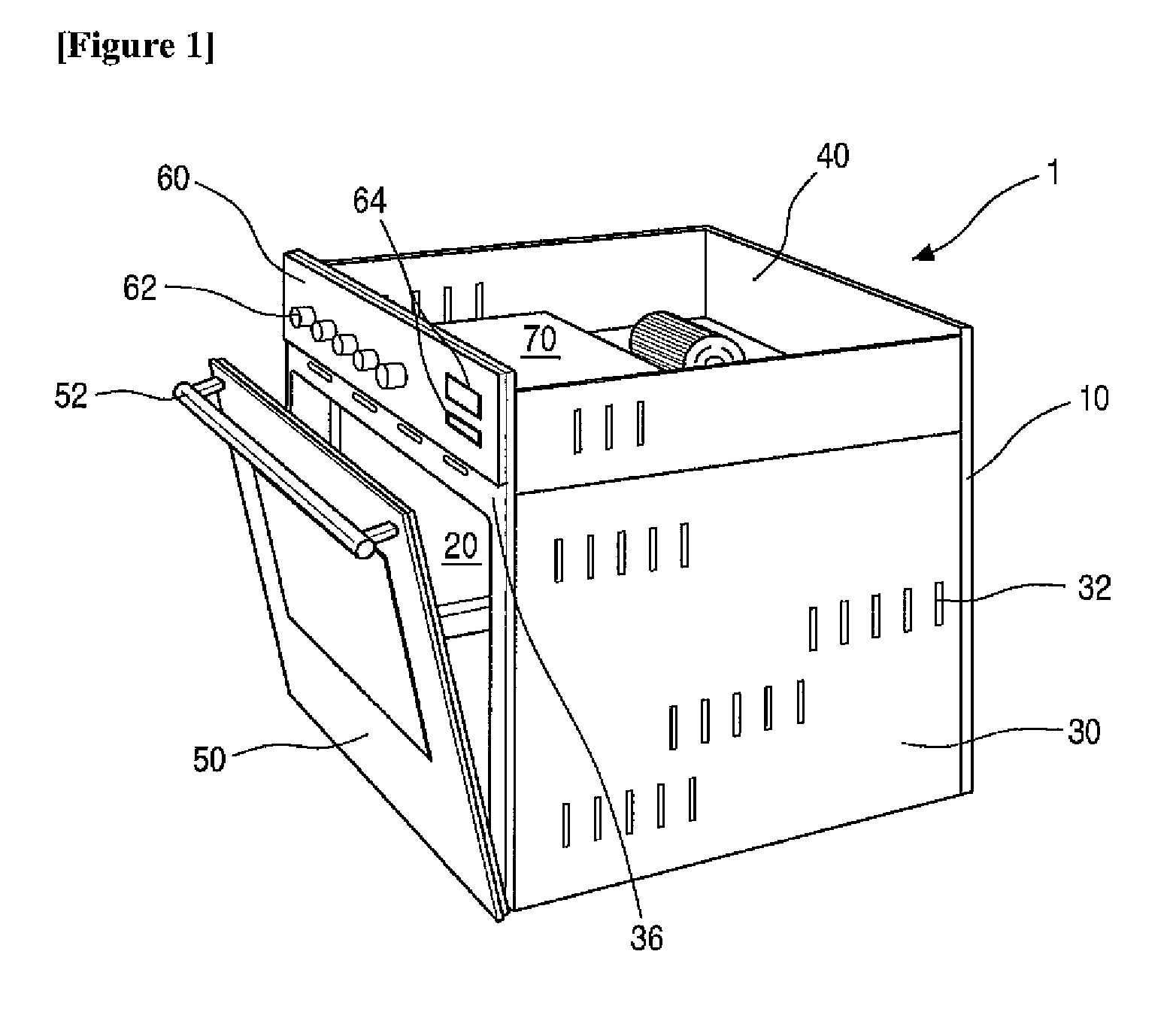

Convection heating unit and heating cooker having the same

ActiveUS8847129B2Smooth circulationAvoid dischargeDomestic stoves or rangesBaking ovenConvection heaterEngineering

A heating cooker including a cooker body having a cooking chamber and a convection heating unit. The convection heating unit includes a convection heater to generate heat, a convection fan to forcibly move the heat generated from the convection heater into the cooking chamber, a convection motor to drive the convection fan, and a convection housing to receive the convection heater and the convection fan. The convection heater and the convection fan are linearly arranged within the convection housing, to allow air introduced into the convection housing to move from the convection fan to the convection heater. This configuration is effective to restrict the transfer of heat from the convection heater to the convection motor.

Owner:SAMSUNG ELECTRONICS CO LTD

Convective heater

A heating device comprises a heater having a first surface and a second surface, with the second surface being generally opposite of the first surface. The heater is configured to receive an electrical current and convert it to heat. The heating device additionally includes at least one heat transfer assembly positioned along the first and / or second surface of the heater. In one embodiment, the heat transfer assembly includes a plurality of fins that generally define a plurality of fin spaces through which fluids may pass. In some arrangements, the heating device comprises an outer housing that at least partially surrounds the heater and one or more of the heat transfer assemblies. Heat generated by the heater is transferred to the fins of the heat transfer assembly. In addition, fluids passing through the fin spaces are selectively heated when electrical current is provided to the heater.

Owner:GENTHERM INC

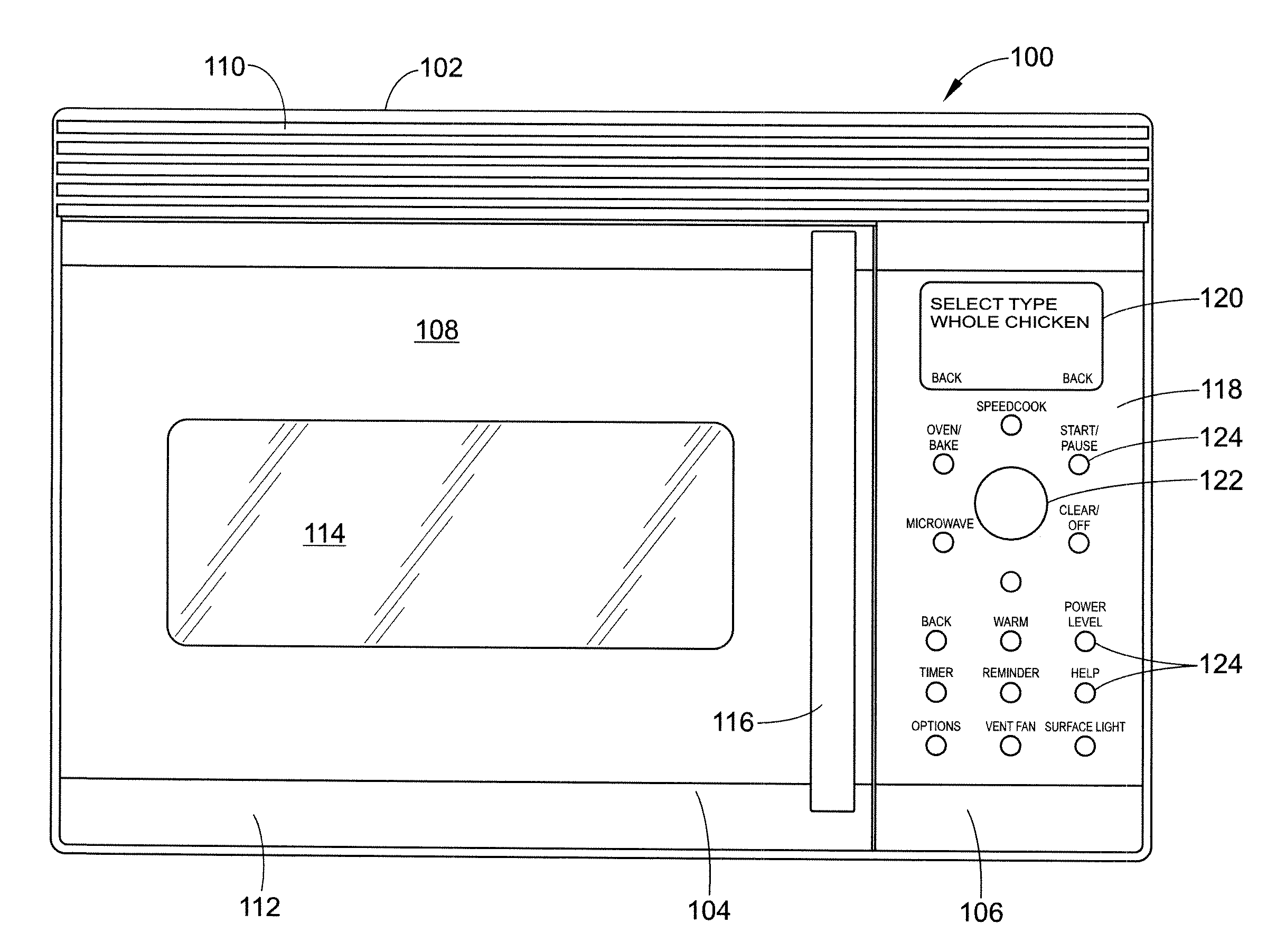

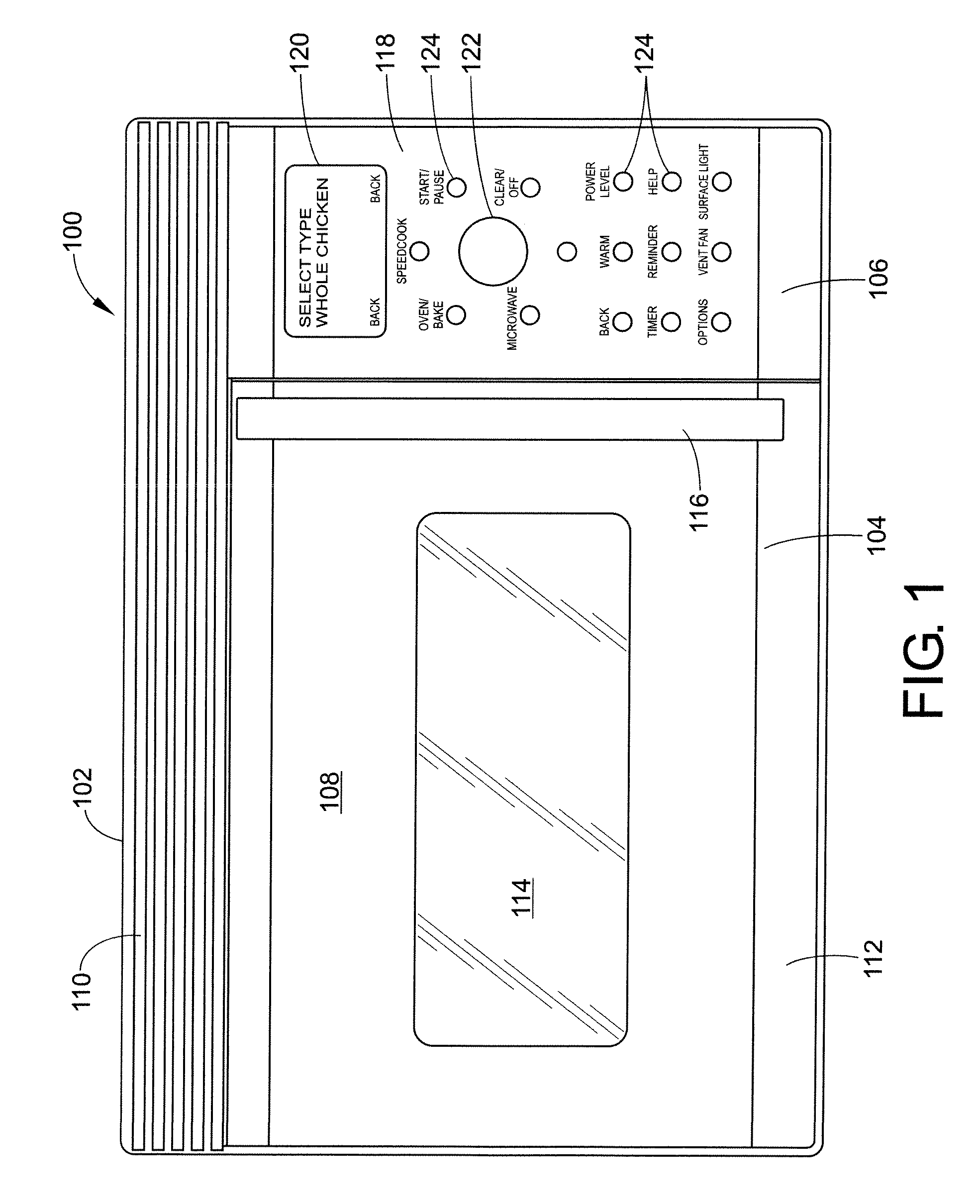

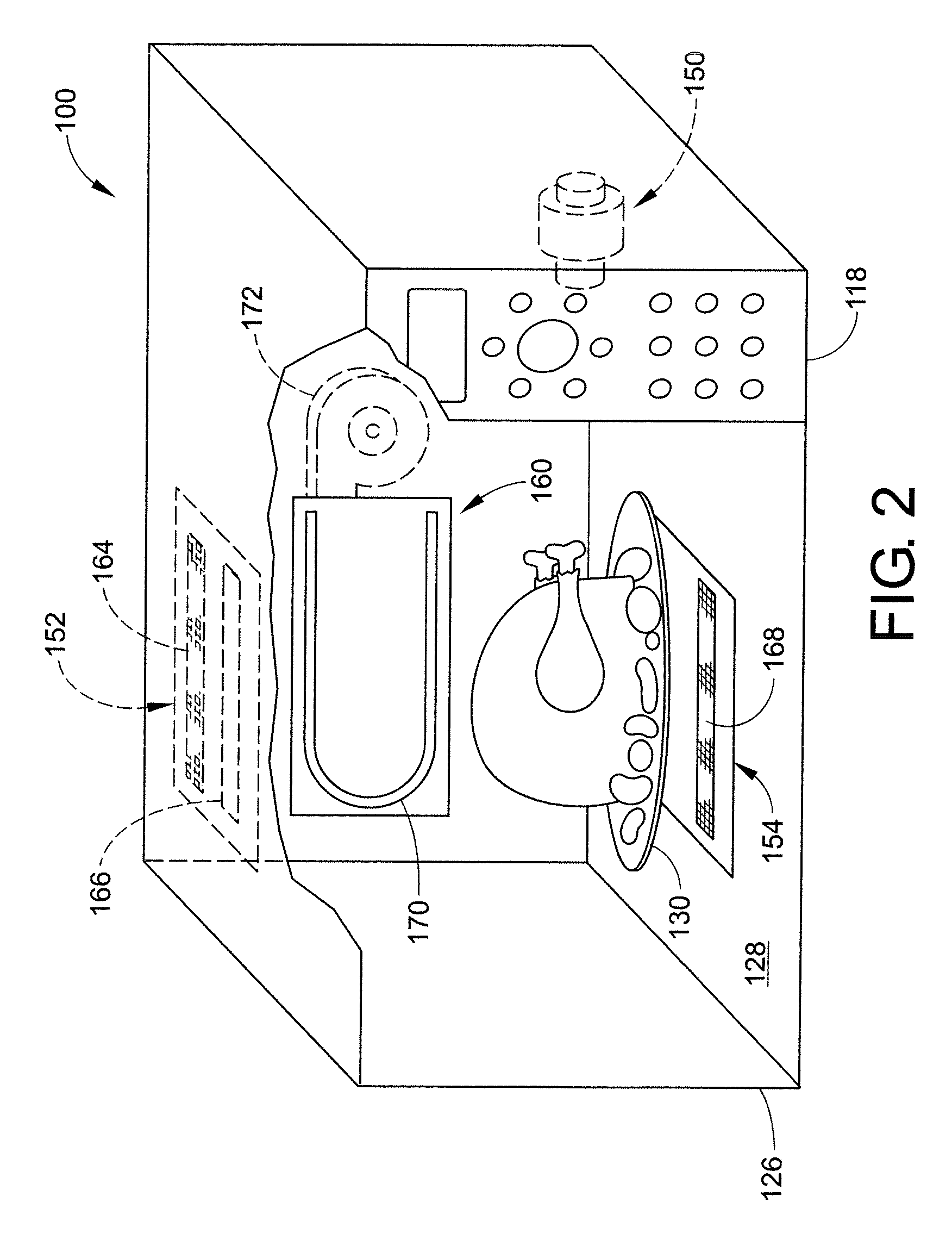

Speedcooking oven

An oven comprises a cooking cavity, a RF generation module, an upper heater module, a lower heater module and a convection heater module. The RF generation module is configured to deliver microwave energy into the cooking cavity. The upper heater module includes at least one of a halogen lamp and a ceramic heater. The lower heater module includes at least one of a halogen lamp and a ceramic heater. The convection heater module includes a sheath heater and a convection fan positioned to direct air over solely the sheath heater into the cooking cavity. The upper heater module and lower heater module are configured to deliver radiant energy into the cooking cavity. The convection heater module is configured to deliver thermal energy into the cooking cavity. A control is operatively connected to the RF generation module, upper heater module, lower heater module and convection heater module for selective control thereof. The control operates the oven in a plurality of modes, including a microwave mode, a convection / bake mode, and a speedcooking mode. In the speedcooking mode, the control is configured to selectively control the energization of the RF generation module, upper heating module and lower heating module concurrently with the selective energization of the convection heater module.

Owner:GENERAL ELECTRIC CO

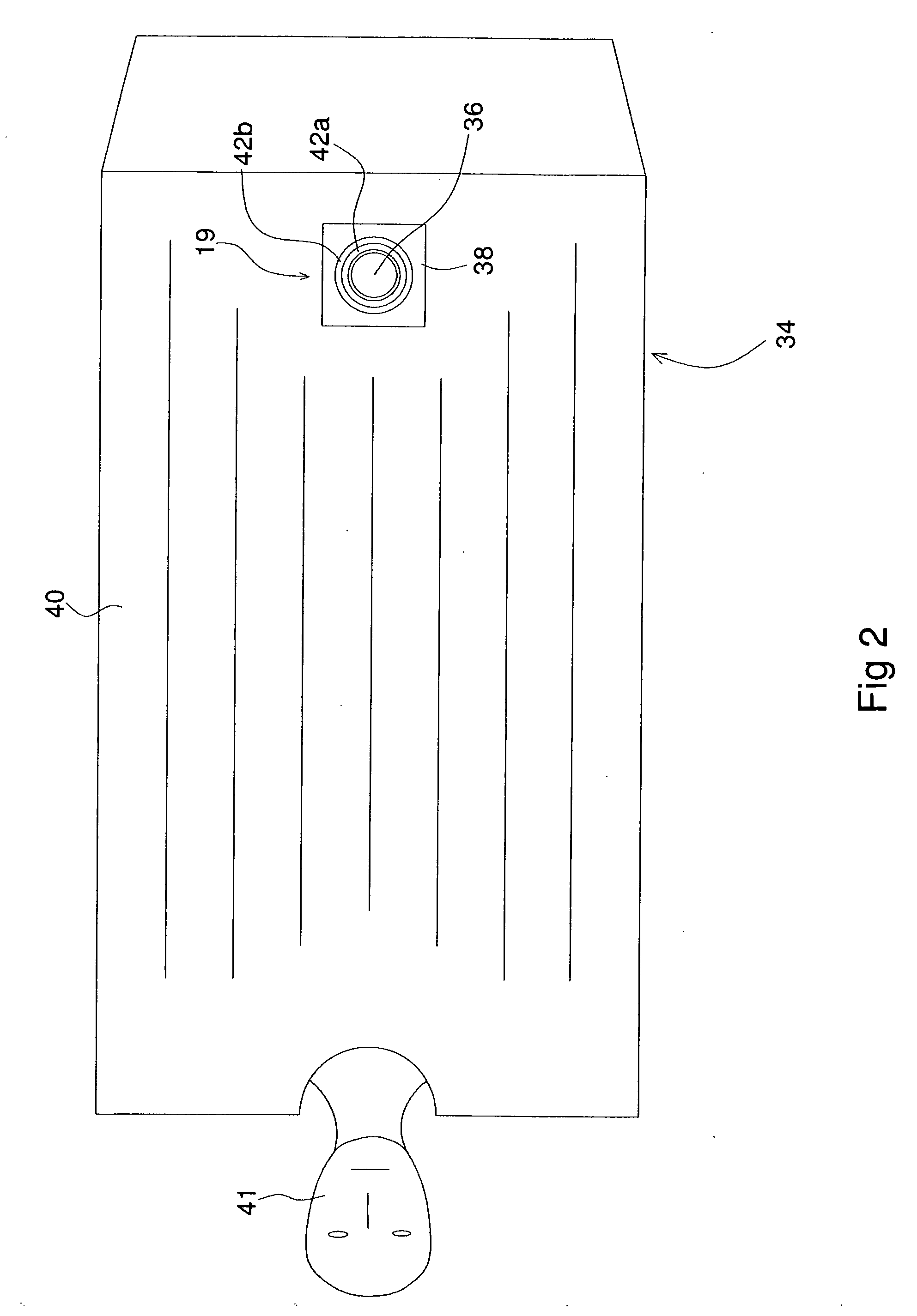

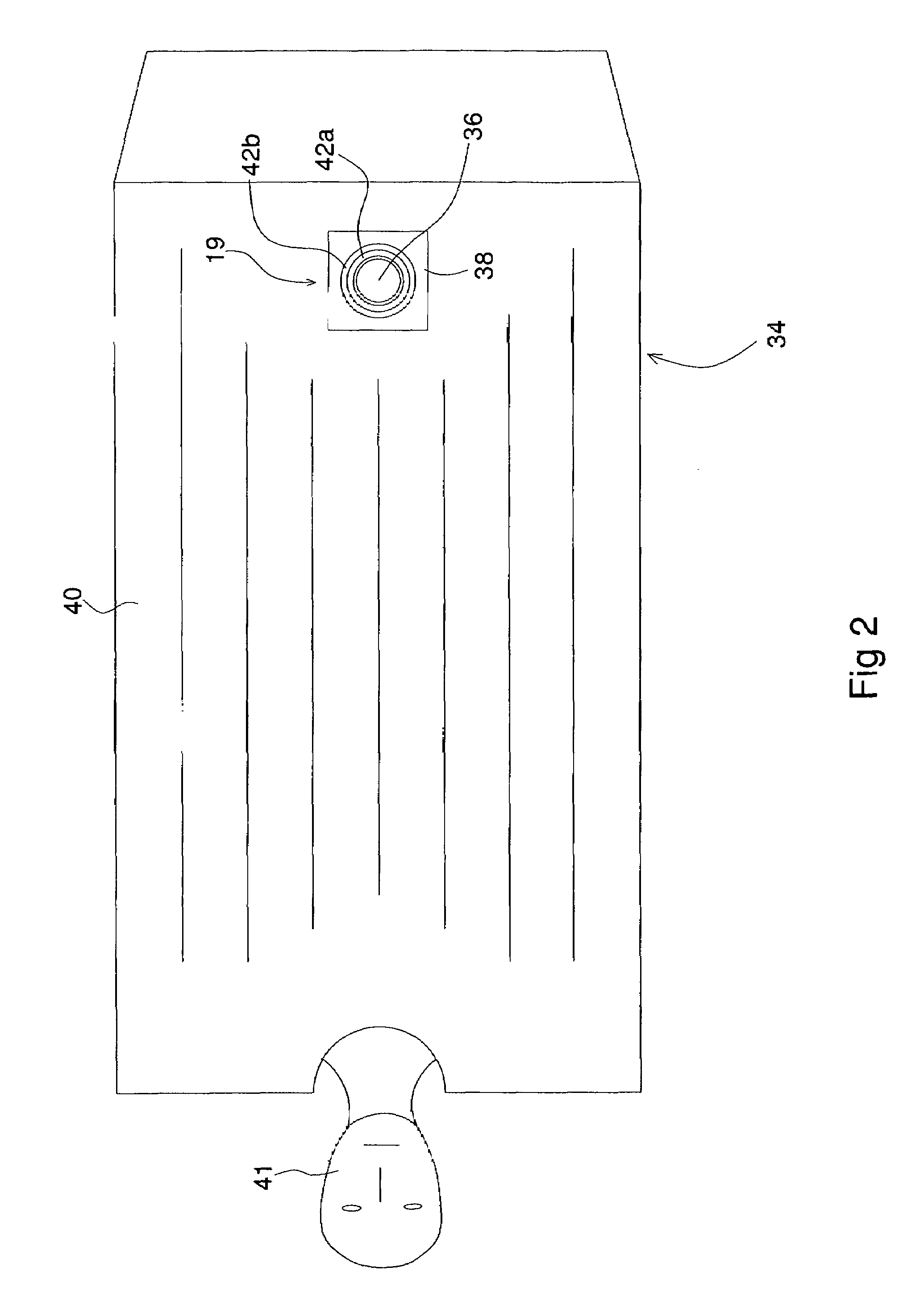

System for automatically inflating temperature regulated blankets and a blanket for coupling to the system

InactiveUS20060212102A1High trafficBlanketRecord carriers used with machinesConvection heaterEngineering

A convective warmer to which blankets of different dimensions may be connected is capable of providing air to the various blankets at flow rates that optimally inflate those blankets to achieve the optimal clinical result for the patients covered by those blankets. The blanket connected to the warmer may range from a full size adult warming blanket to a pediatric or neonate warming blanket. There is provided on each blanket a code, marking or marker, to be read by a sensor(s) provided at the outlet of the warmer, that identifies the type of blanket when the blanket is coupled to the warmer. Consequently, heated air may be automatically output by the warmer to the blanket at the appropriate flow rate of that blanket to optimally inflate the blanket without any need for intervention by a user. In addition to being used to control the flow rate of the heated air, the code from the blanket may also be used to control the temperature of the heated air to be input to the blanket.

Owner:SMITHS MEDICAL ASD INC

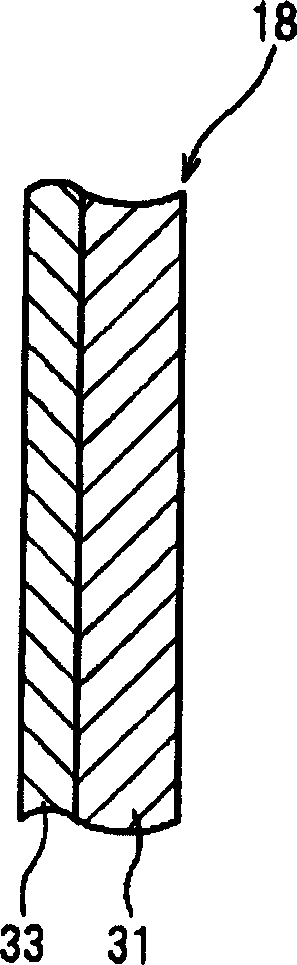

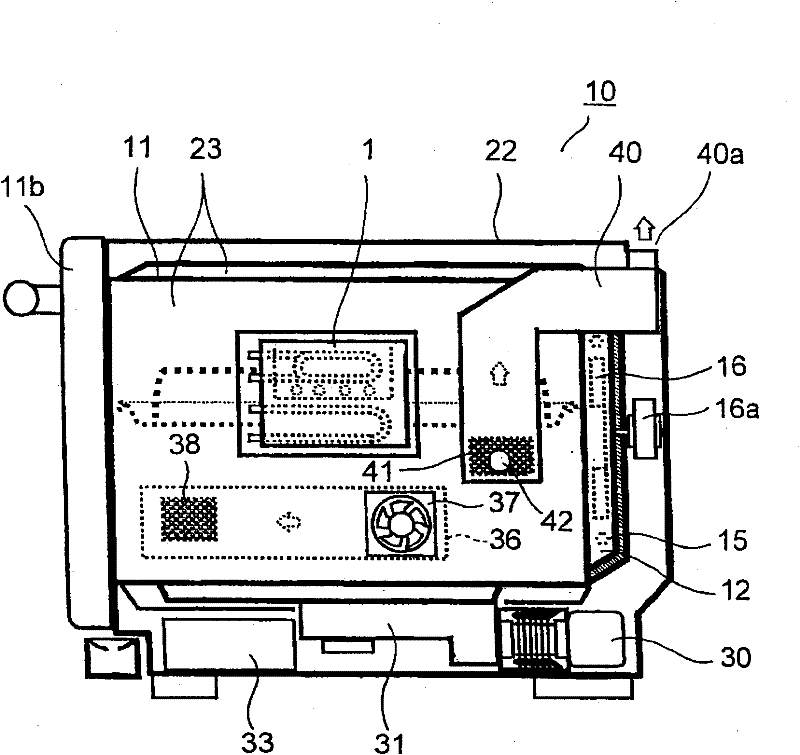

Heat cooking apparatus and self-cleaning material and producing method thereof

InactiveCN1487240AReduce capacityReduce consumptionSelf-cleaning stoves/rangesLighting and heating apparatusConvection heaterMethods of production

A convection heater (23) is disposed along a back surface of a rear face plate (18) which is comprised of a stainless steel plate that forms a heating chamber (14). On a back side of the rear face plate (18), disposed is a circulation fan (22) by which, air in the heating chamber (14) is sucked from air intake use through-holes into the back side, and after it is heated by the convection heater (23), it is returned from air blowing use through-holes to the heating chamber. On a surface of an inner side of the heating chamber (14) of the rear face plate (18), a self-cleaning layer is formed by dissolving a self-cleaning material which oxide-decomposes and removes accreted dirt at high temperature into a porcelain enamel glaze and by applying and bake-sticking.

Owner:PANASONIC CORP

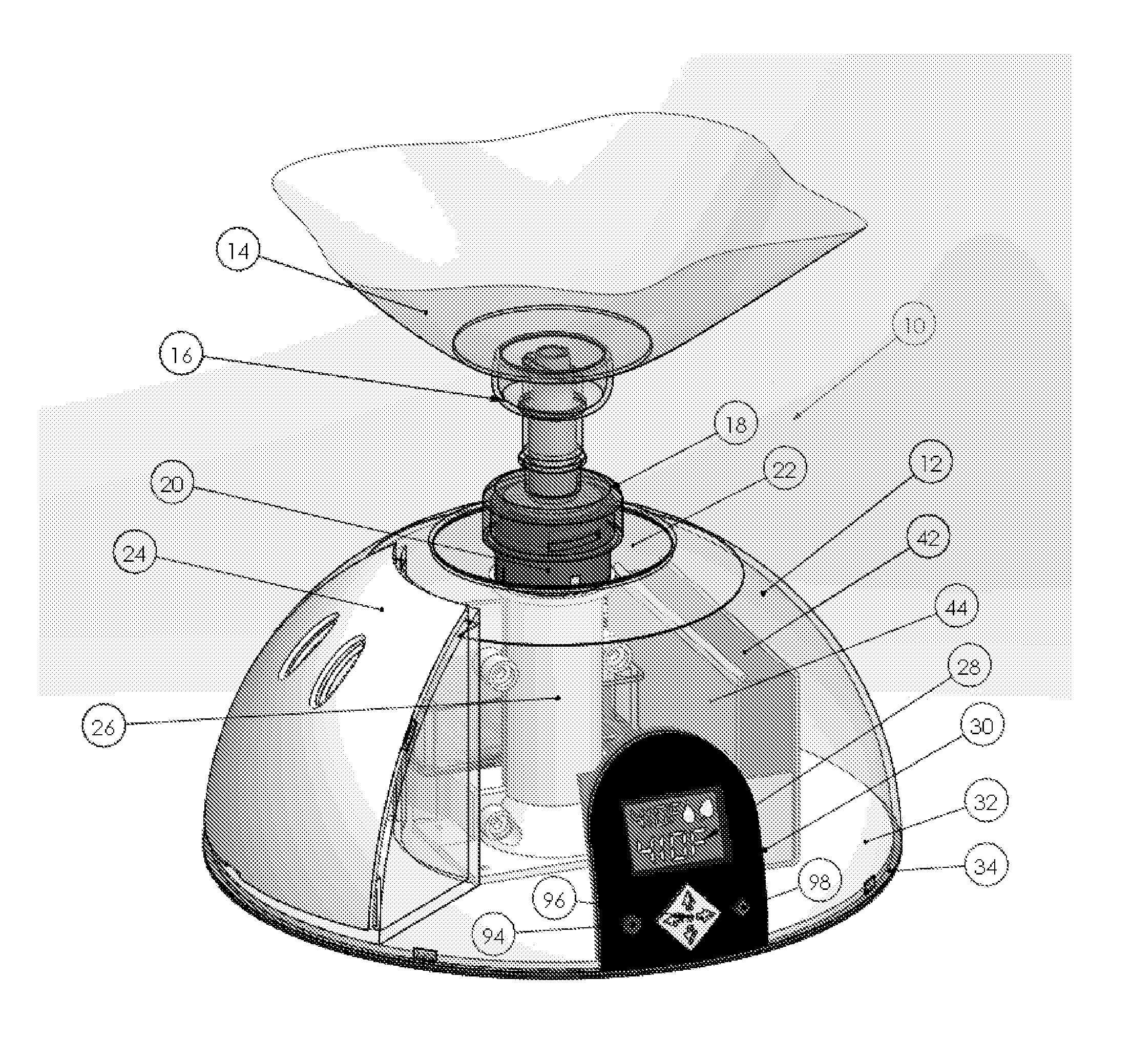

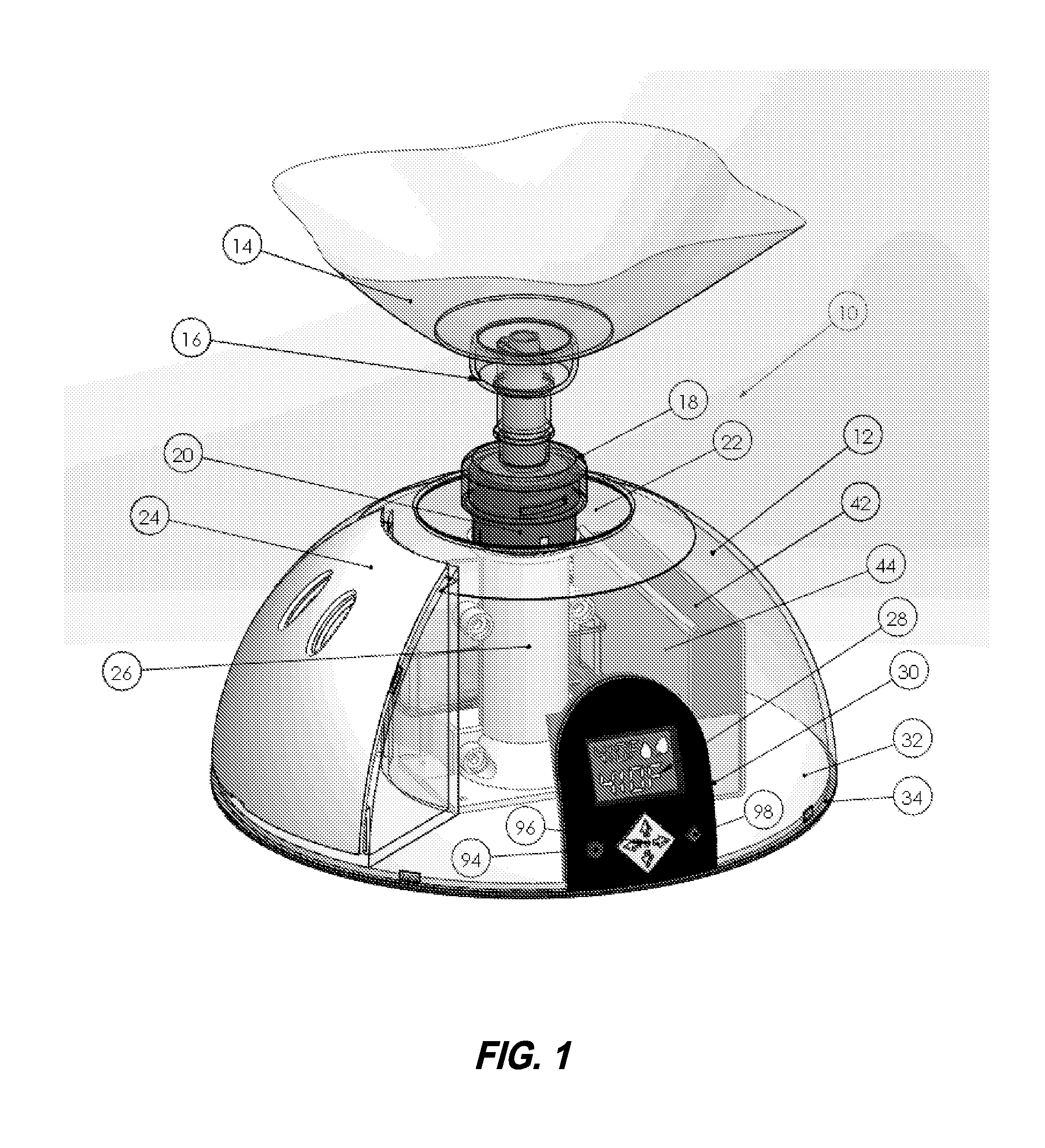

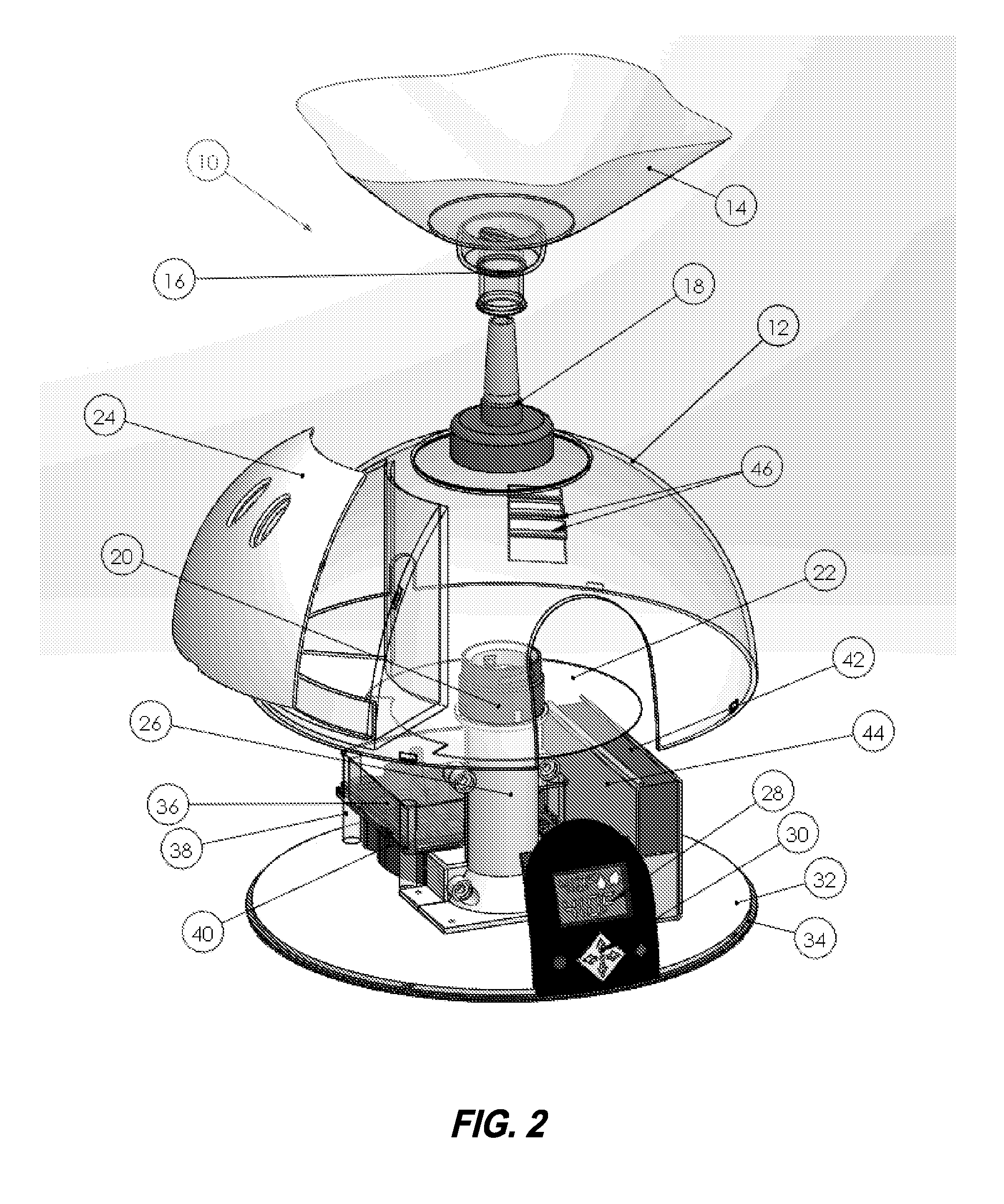

Vaporization & Inhalation System with Convective and Conductive Heaters for Herbal Material and/or Fluid Extracts

Disclosed is an appliance for volatilizing active substances in either herbal material or fluid extract for inhalation, including a material vaporization surface with a plurality of convective air flow apertures, a conductive heater and a convective heater.

Owner:SANCHEZ TIMOTHY H

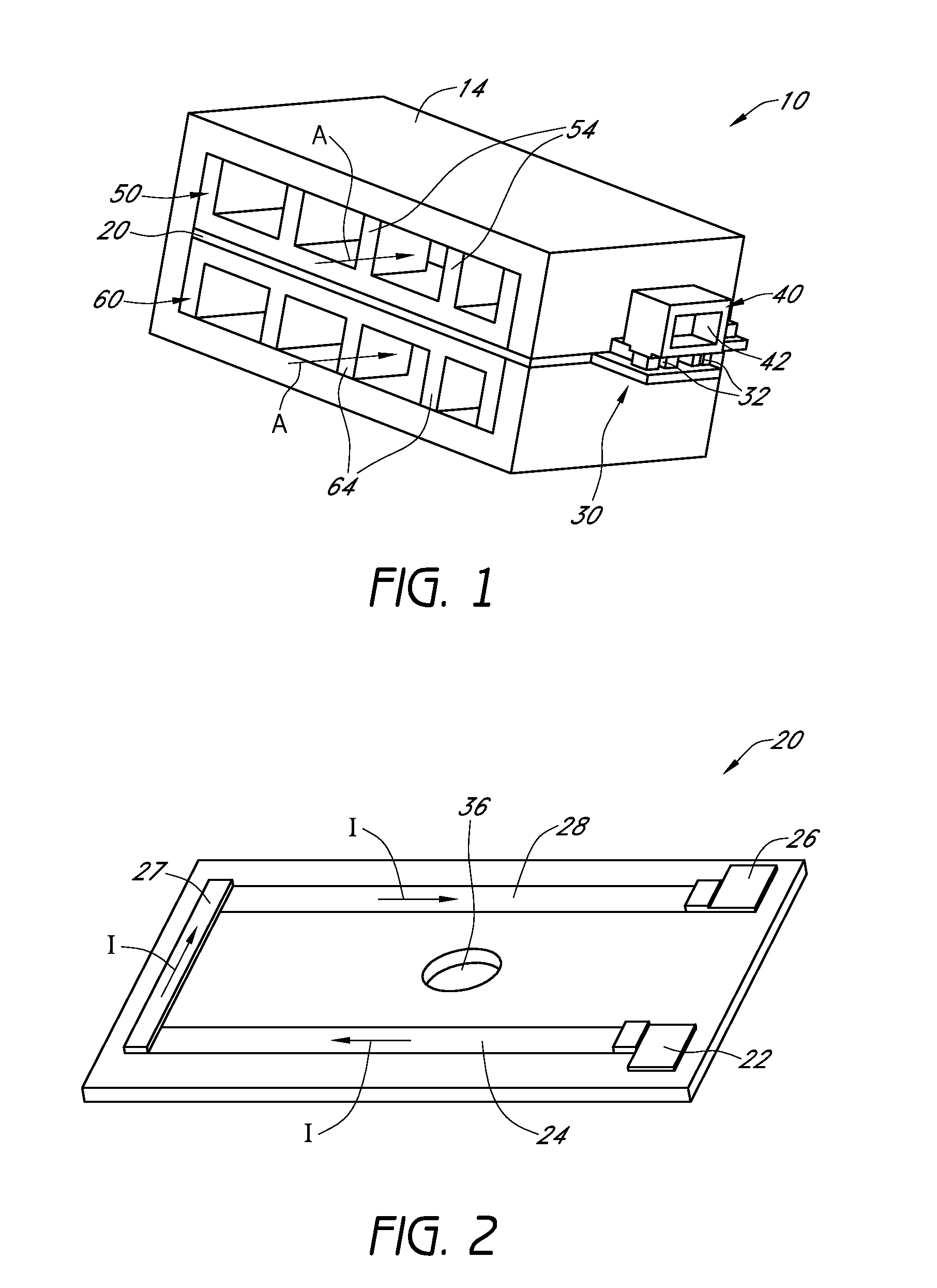

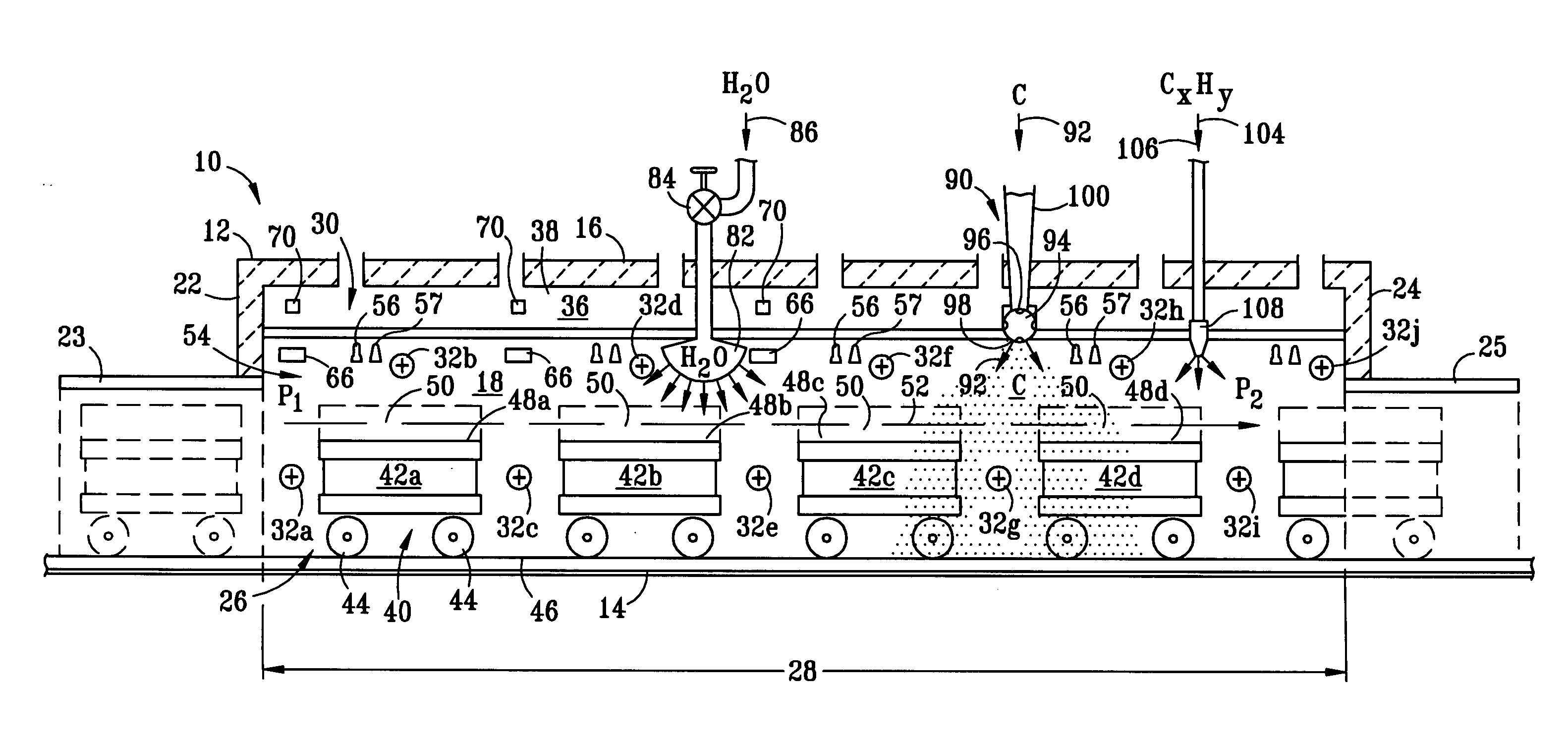

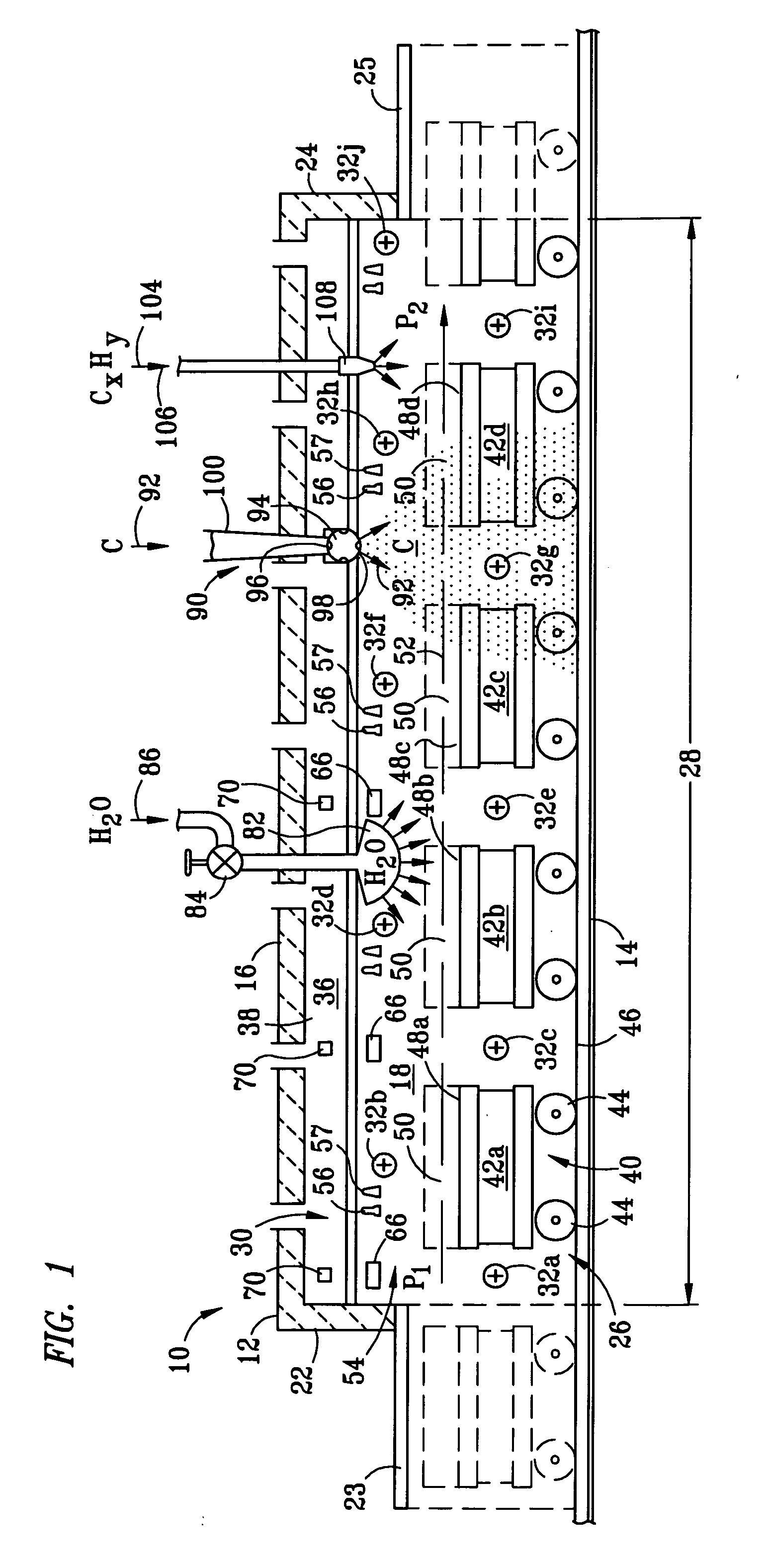

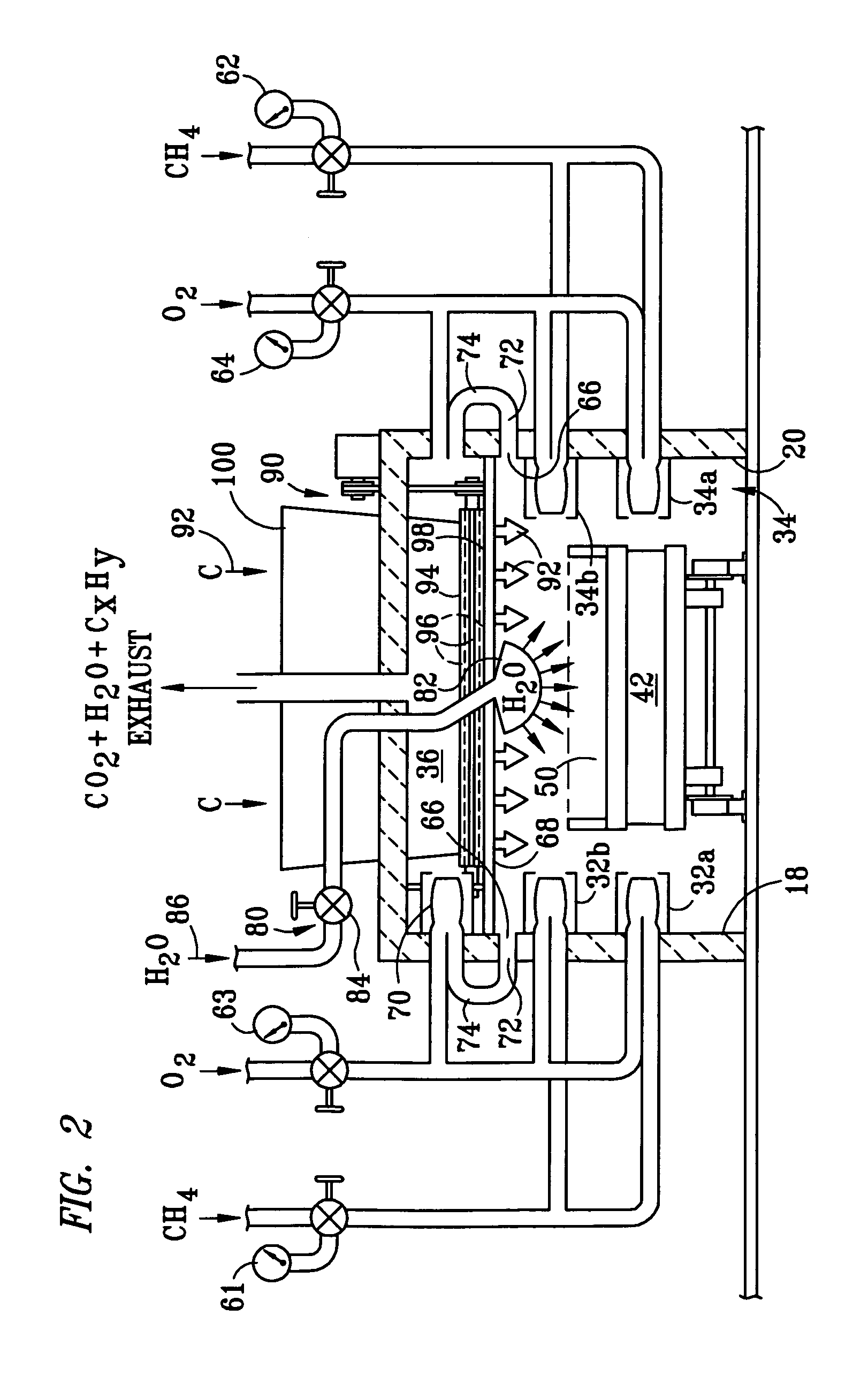

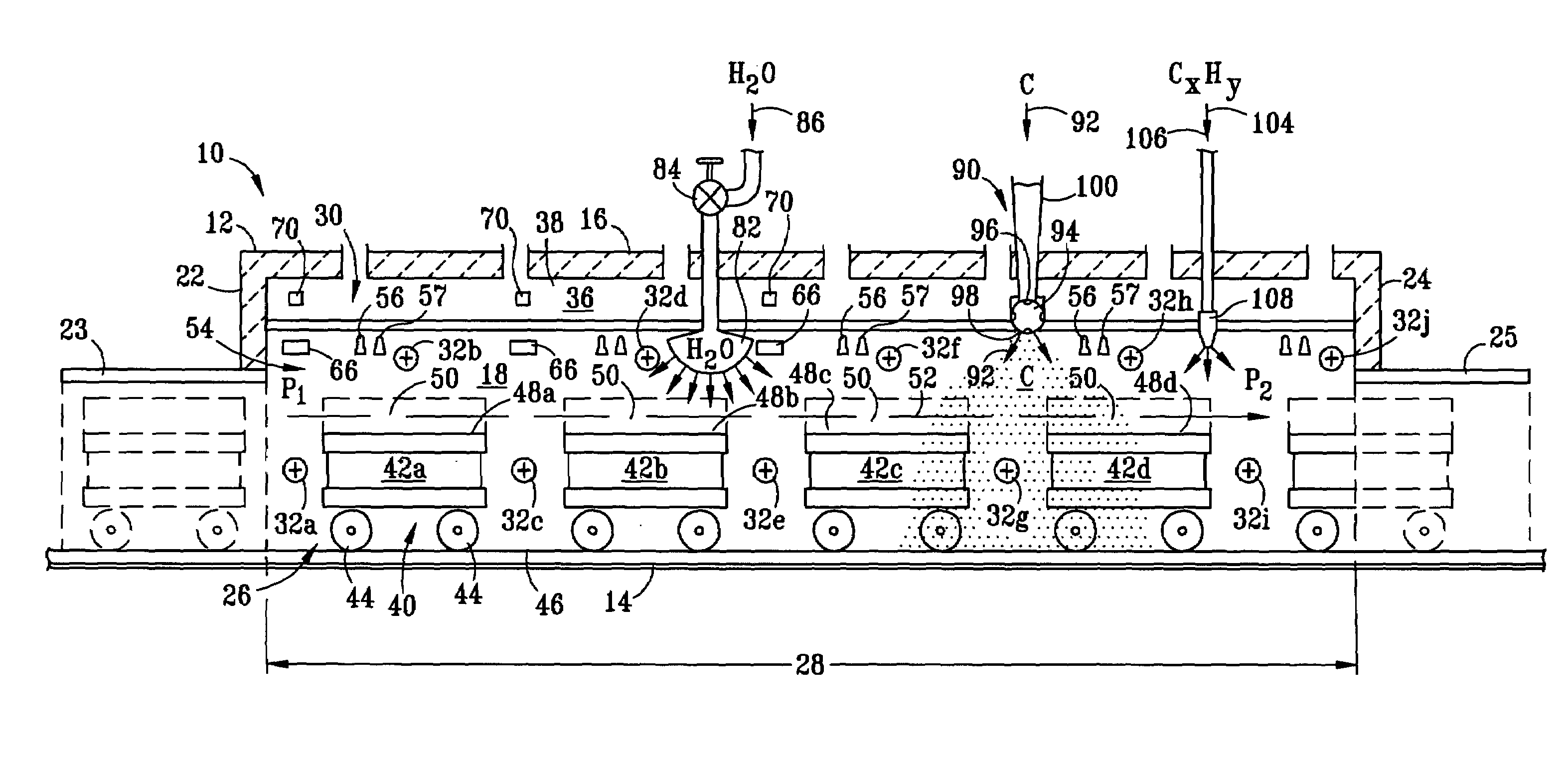

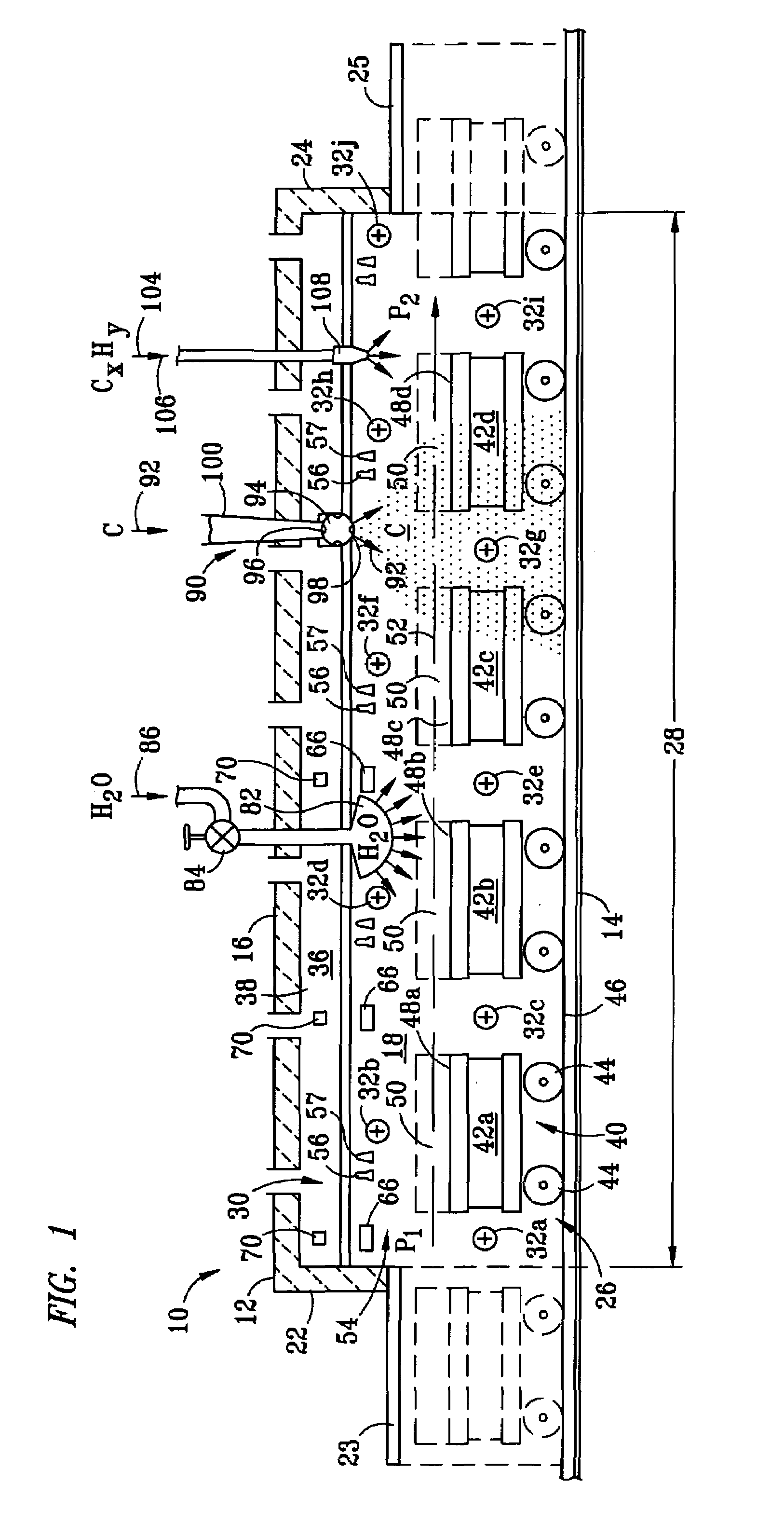

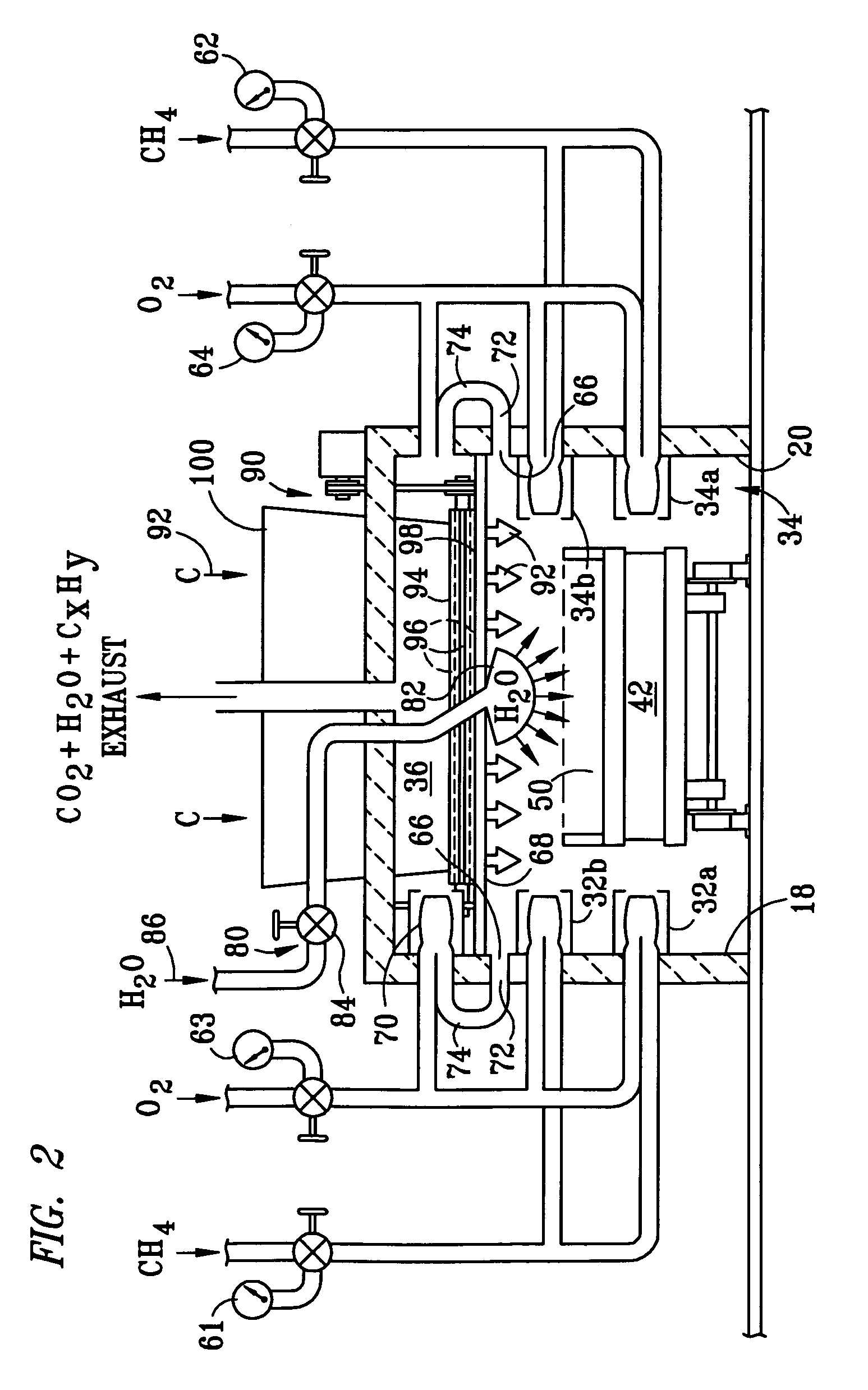

Transported material heating with controlled atmosphere

ActiveUS20060246391A1Protect the surfaceMaintainance of heating chambersCharge manipulationTemperature controlConvection heater

A tunnel oven for heating transported carbonaceous materials includes an enclosure having a passage and a transport device for moving solid carbonaceous materials through and along a length of the passage. A direct convection heater is operably connected to the enclosure to heat the solid carbonaceous material as the material is moved along the length of the passage. A temperature controller is operably coupled to the heater to provide one or more selected temperatures along the length of the passage. An atmosphere controller controls the heating atmosphere along the length of the passage so that the surface of the solid carbonaceous material is protected against oxidation.

Owner:GAUR SIDDHARTHA +1

Transported material heating with controlled atmosphere

ActiveUS7150627B2Maintainance of heating chambersCharge manipulationTemperature controlConvection heater

A tunnel oven for heating transported carbonaceous materials includes an enclosure having a passage and a transport device for moving solid carbonaceous materials through and along a length of the passage. A direct convection heater is operably connected to the enclosure to heat the solid carbonaceous material as the material is moved along the length of the passage. A temperature controller is operably coupled to the heater to provide one or more selected temperatures along the length of the passage. An atmosphere controller controls the heating atmosphere along the length of the passage so that the surface of the solid carbonaceous material is protected against oxidation.

Owner:GAUR SIDDHARTHA +1

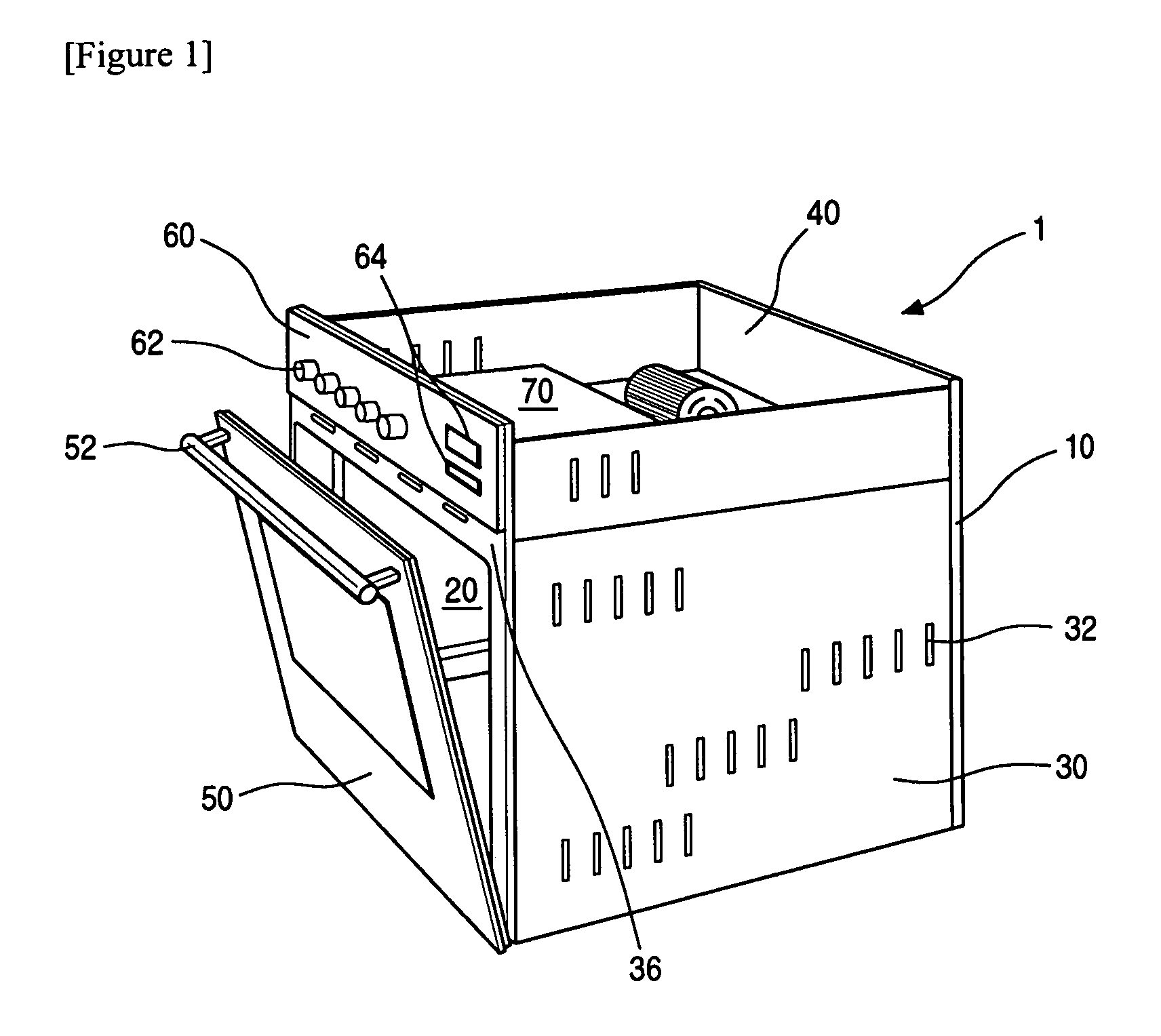

Cooking apparatus

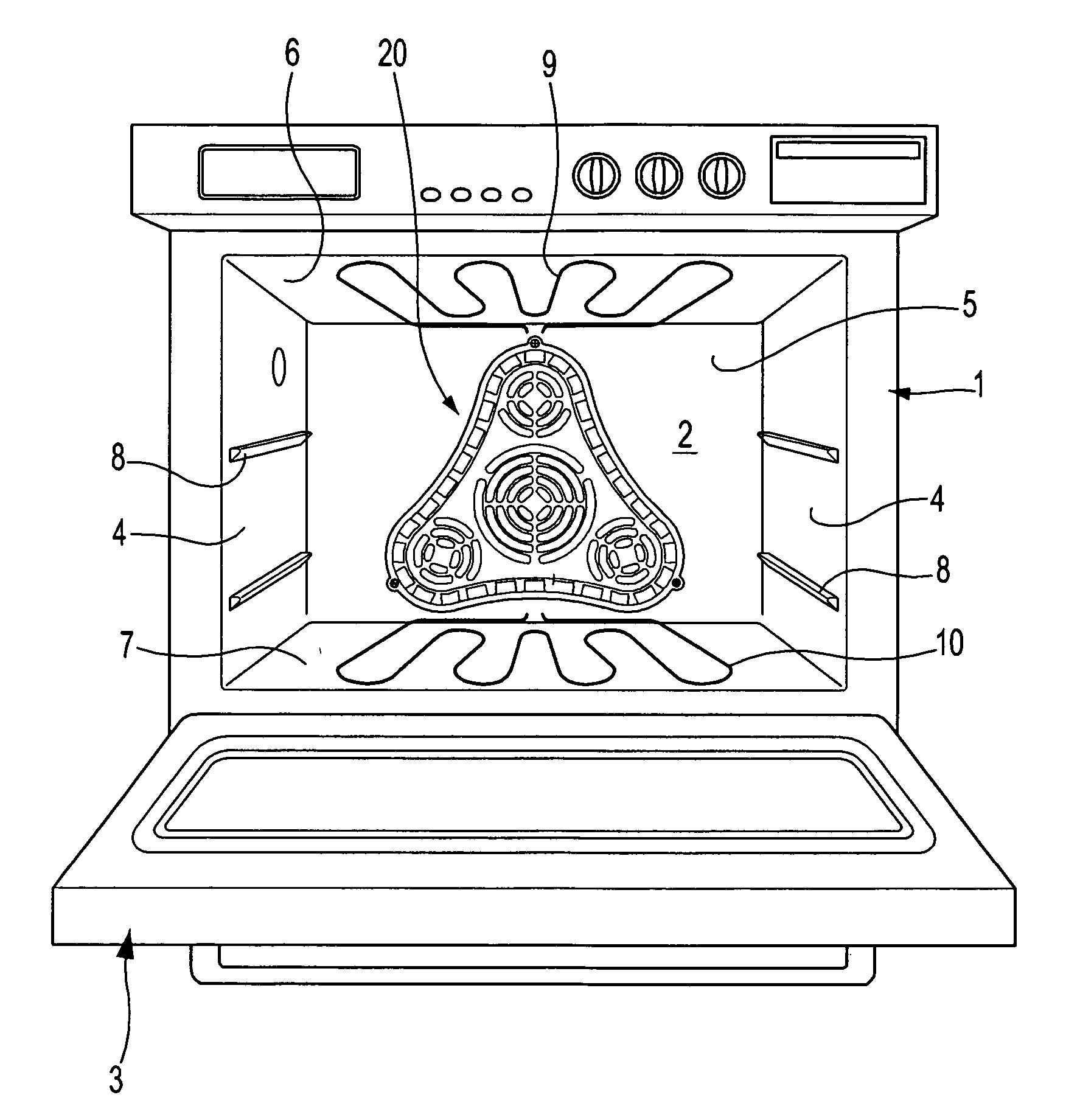

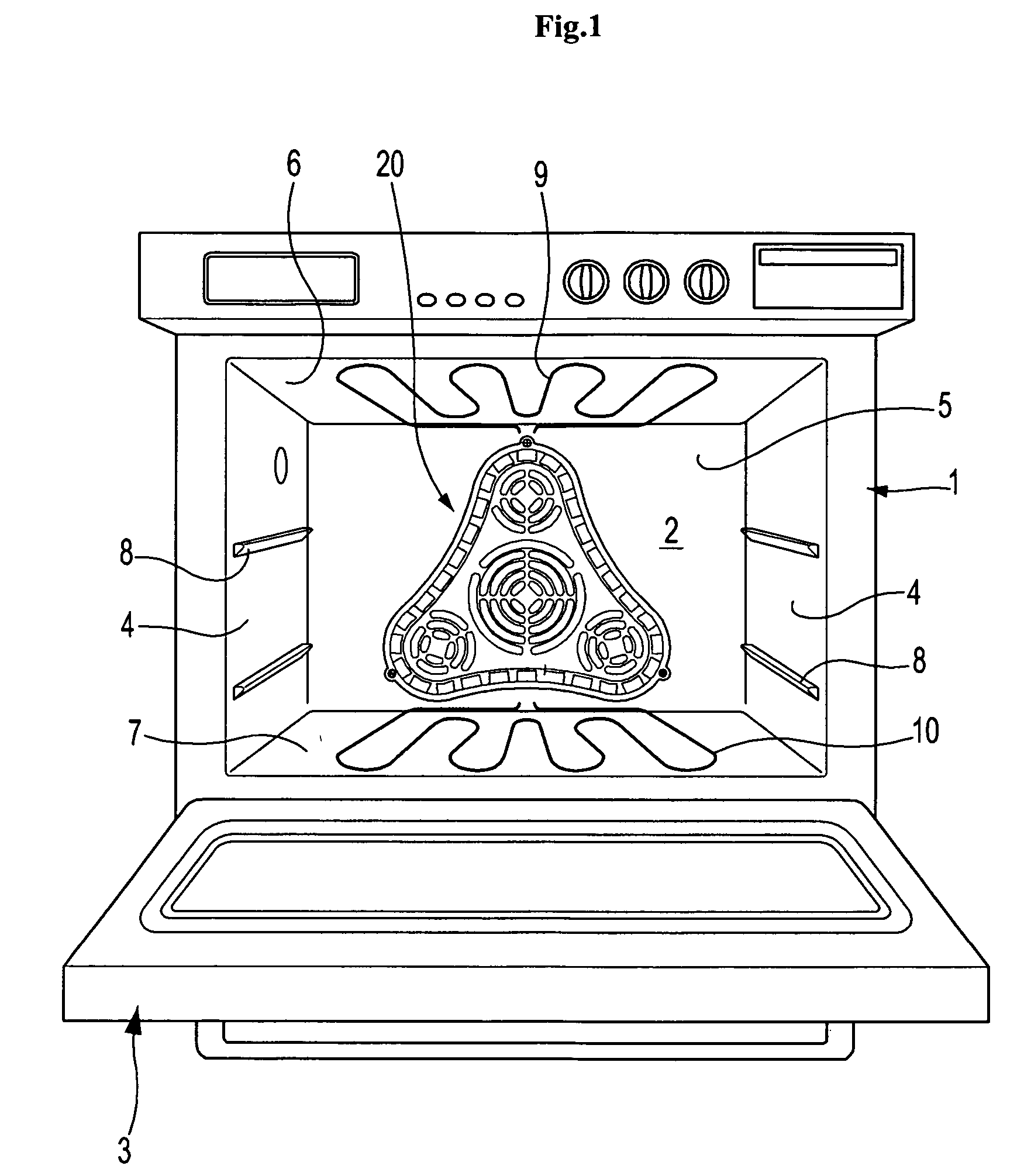

ActiveUS20070095813A1Efficiently agitatedEqually distributedAir-treating devicesDomestic stoves or rangesConvection heaterEngineering

A cooking apparatus to effectively agitate and evenly distribute high-temperature air into a cooking chamber by use of a single driving fan and a plurality of driven fans. The cooking apparatus includes the cooking chamber, the driving fan arranged at a rear wall of the cooking chamber, a convection heater to surround the driving fan, the plurality of driven fans arranged on a circumference of the driving fan, and a fan cover having a plurality of suction holes and discharge holes. The driving fan is connected with a drive motor to rotate in accordance with an operation of the drive motor. The driven fans rotate by use of air streams generated when the driving fan rotates. The high-temperature air is evenly agitated in accordance with the rotation of the driven fans to be distributed into the cooking chamber via the discharge holes in all directions.

Owner:SAMSUNG ELECTRONICS CO LTD

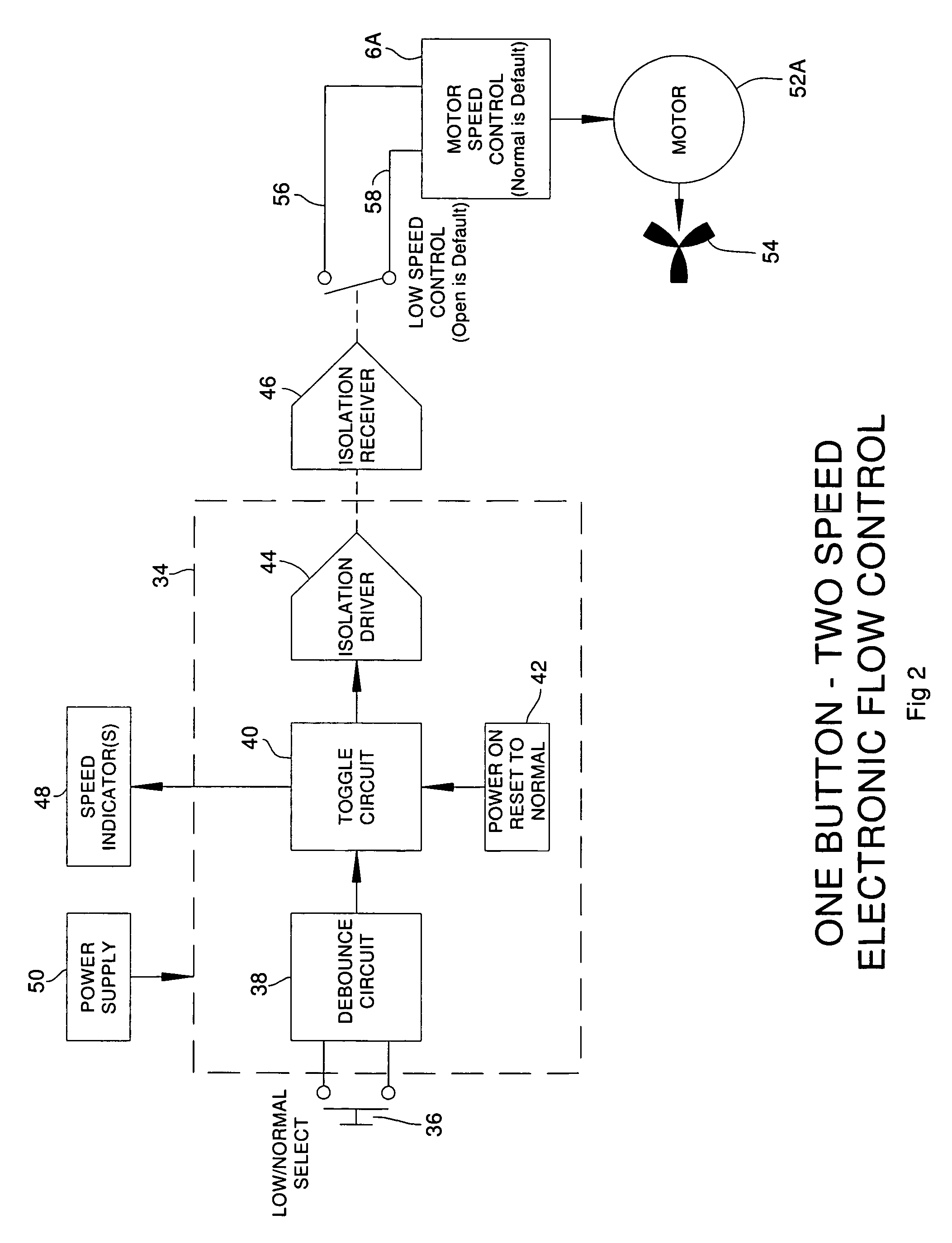

System for providing optimal inflation to multiple temperature regulated blankets and method therefor

A convective warmer to which blankets of different dimensions may be connected is capable of providing air to the various blankets at flow rates that optimally inflate those blankets to achieve the optimal clinical result for the patients covered by those blankets. The blanket connected to the warmer may range from a full size adult warming blanket to a pediatric warming blanket. The convection warmer may have multiple fixed air flow rates each selectable by a user, via switch(es) either electronically or mechanically. For the electronic selection of a given flow rate, a motor adaptable to rotate a different speeds is used. To vary the flow rate mechanically, a valve is controlled to vary the amount of air that may pass to the blanket. Instead of different fixed flow rates, variable air flow rates, selectable by the user, may be used. Also, a feedback circuit that maintains the pressure sensed at the outlet of the warmer to a preset pressure may be used to eliminate the need for user intervention.

Owner:SMITHS MEDICAL ASD INC

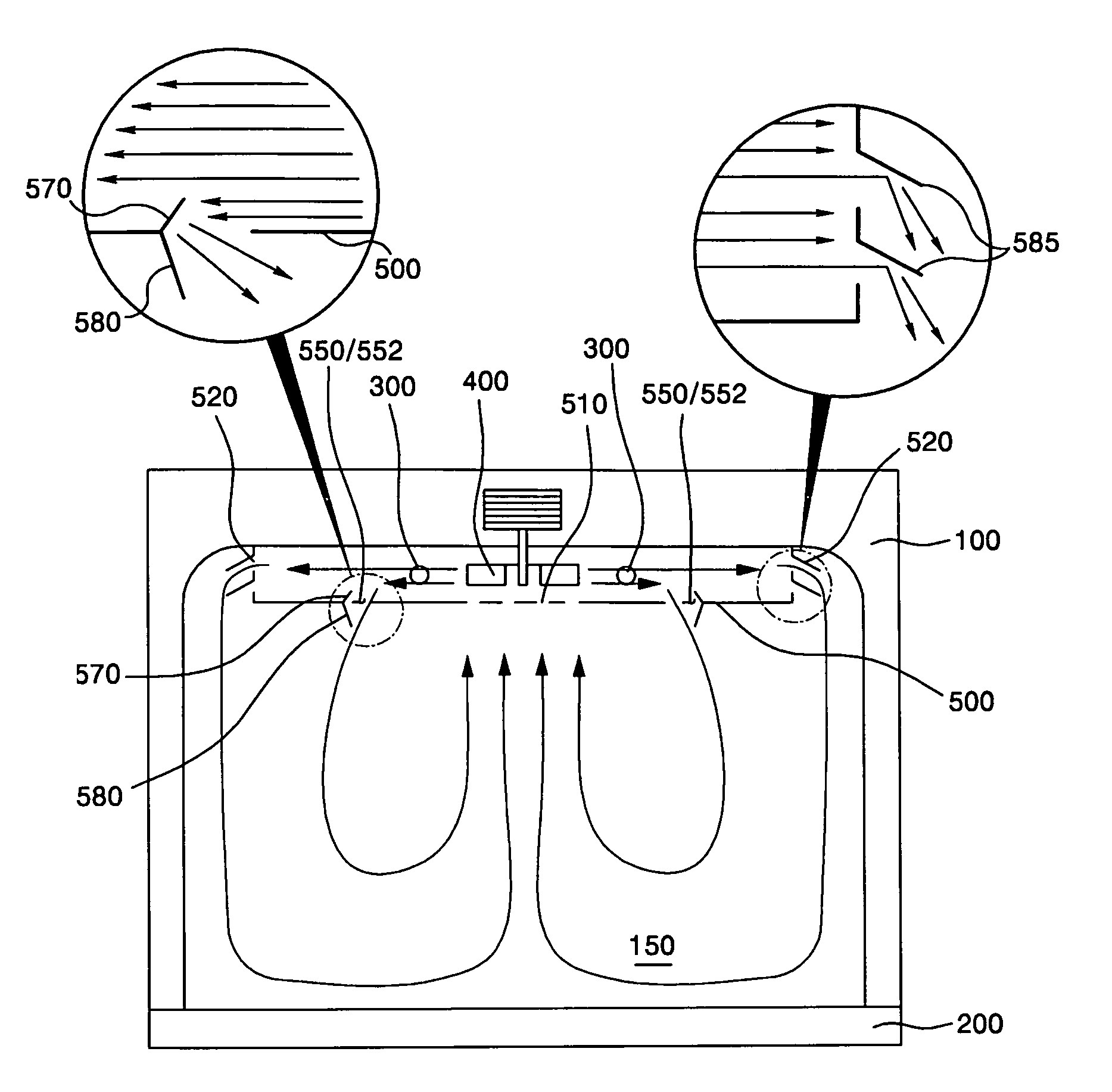

Electric oven and method of operating the same

ActiveUS7442901B2Improve efficiencyImprove methodDomestic stoves or rangesElectrical heating fuelNuclear engineeringConvection heater

An electric oven includes an oven body, a first convection system having a first convection heater and a first convection fan that are installed in the oven body to operate for a first space in the oven body, and a second convection system having a second convection heater and a second convection fan that are installed in the oven body to operate for a second space in the oven body. Further, the first and second convection fans are driven by a single common driving unit.

Owner:LG ELECTRONICS INC

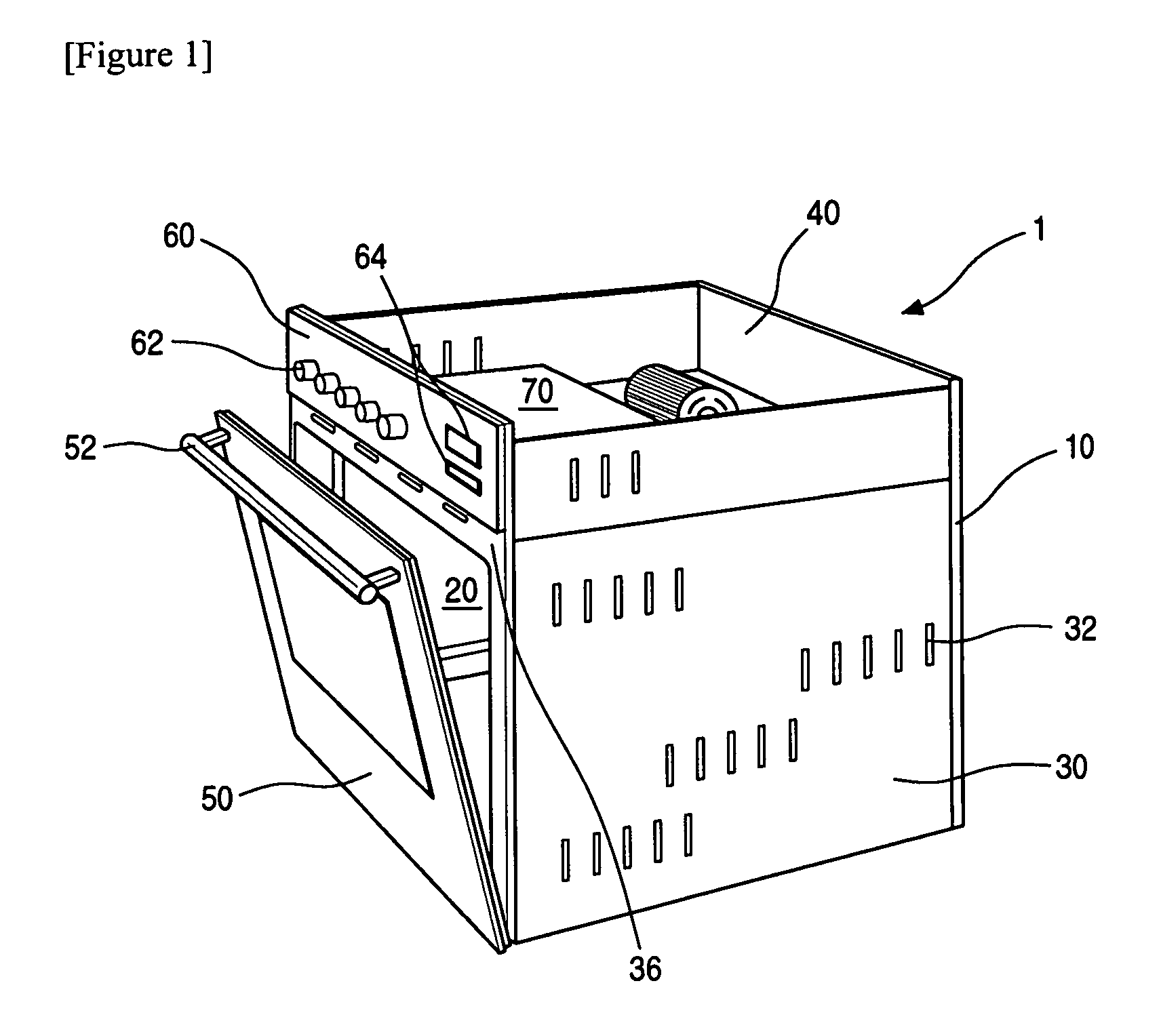

Electric oven having convection cover formed with sub-outlets

Owner:LG ELECTRONICS INC

Cooker

ActiveCN101666513ADomestic stoves or rangesLighting and heating apparatusConvection heaterConvection

Provided is a cooker. A carbon heater used as a convection heater is supported by a heater bracket and heater supporters, and light and heat generated from the carbon heater are transferred to the inside of a cooking chamber through convection, conduction, and radiation.

Owner:LG ELECTRONICS INC

Electric oven having convection cover formed with sub-outlets

An electric oven having a convection heater and a convection cover. The convection cover including a main outlet located at or near the periphery of the convection cover, and a sub-outlet, more centrally located near the convection heater relative to the main outlet. Together, the main outlet and the sub-outlet allow the heated air to be uniformly circulated throughout the cooking chamber and to be evenly transferred to food irrespective of the position of the food in the cooking chamber. Uniform air circulation in the cooking chamber will result in more favorable cooking results.

Owner:LG ELECTRONICS INC

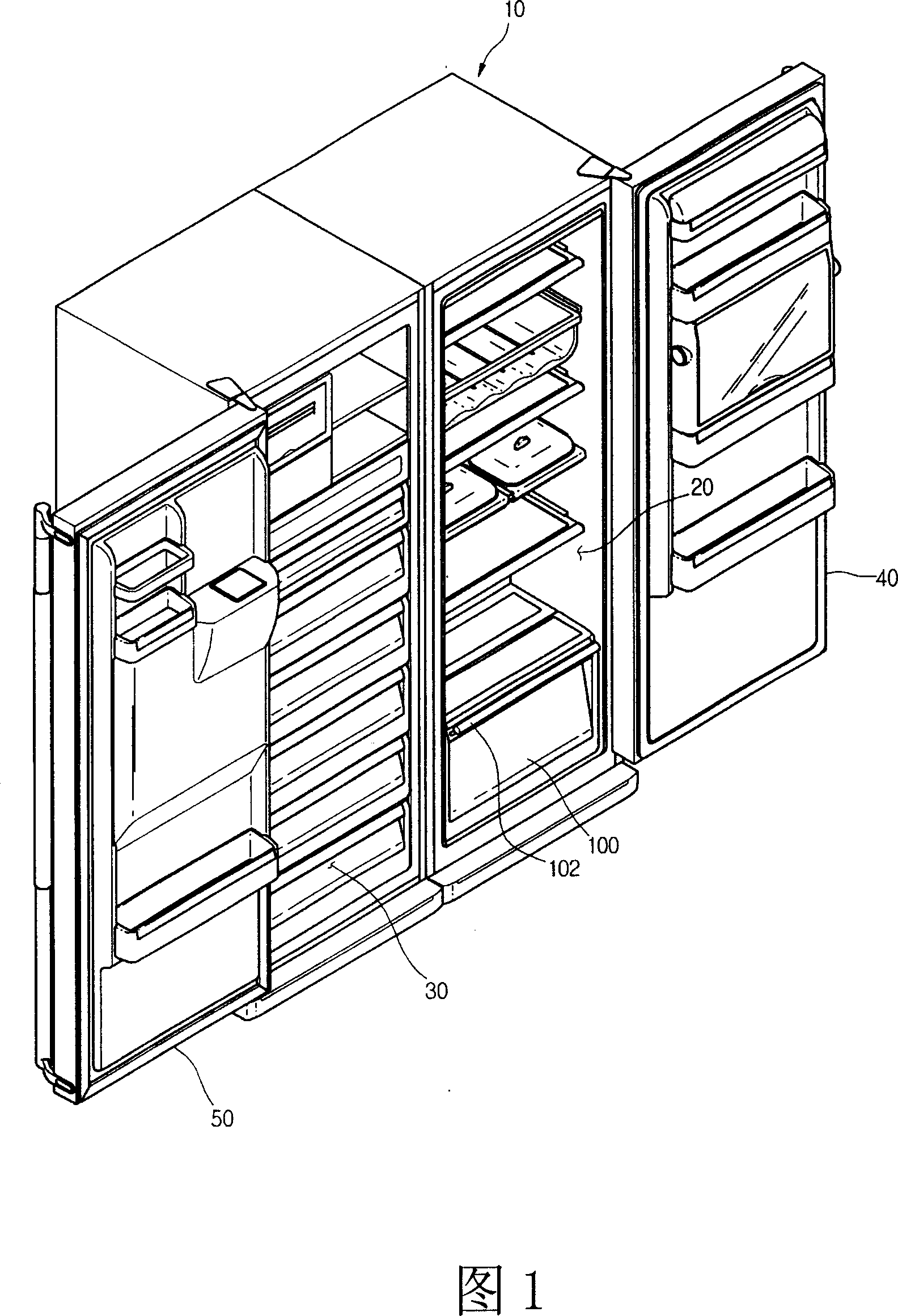

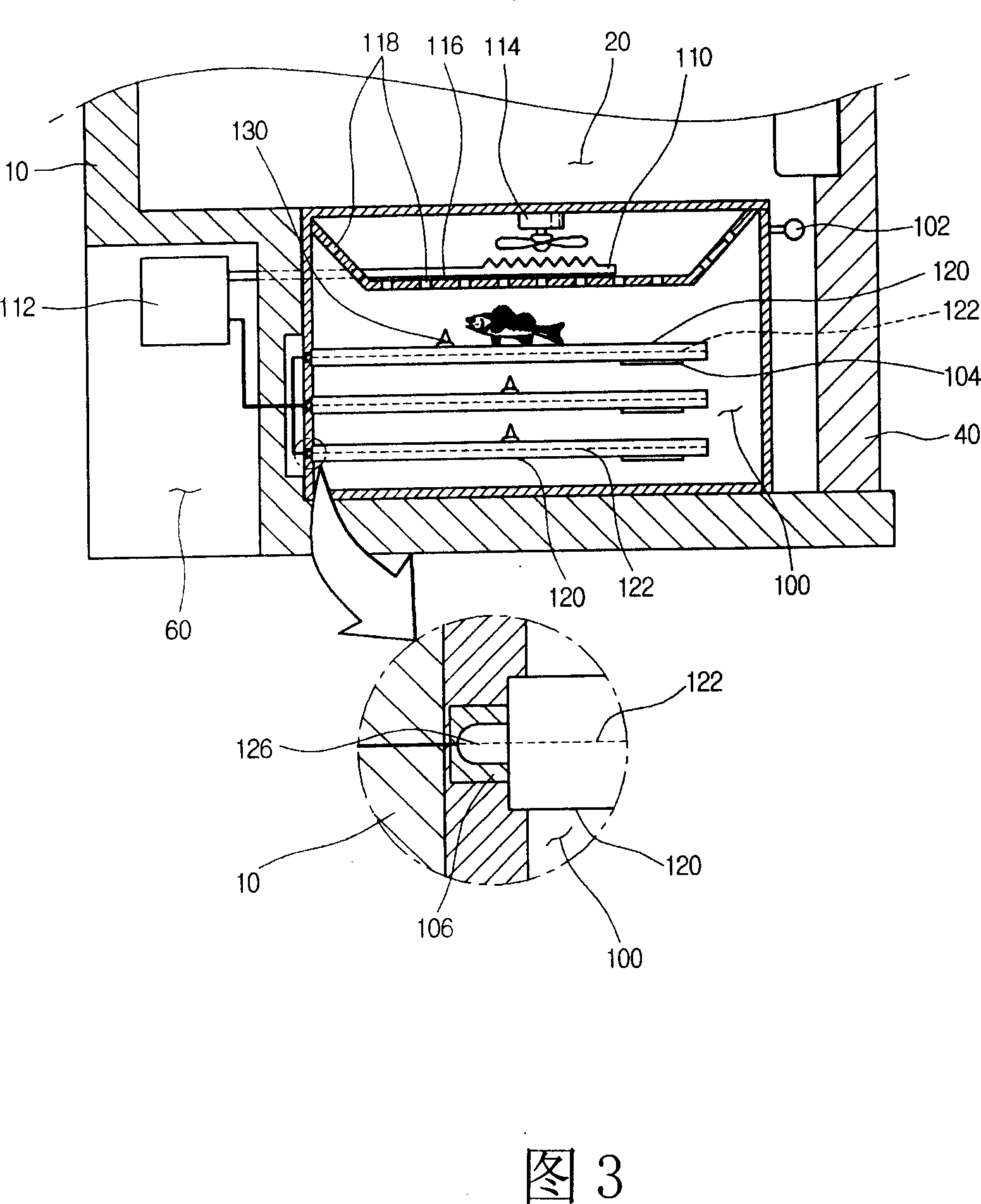

Defrosting device for refrigerator

InactiveCN1967113AEasy to useEasy to placeDomestic cooling apparatusLighting and heating apparatusHeat transmissionConvection heater

It relates to the defreeze chamber at either side of the cold room or the chilling room. There is convection heater and inbuilt hot wire defreezes plate. The detachable defreeze plate is loaded inside the defreeze chamber in multi layers and being able to draw out from the defreeze chamber. It has quick heat transmission for the convenience of users.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

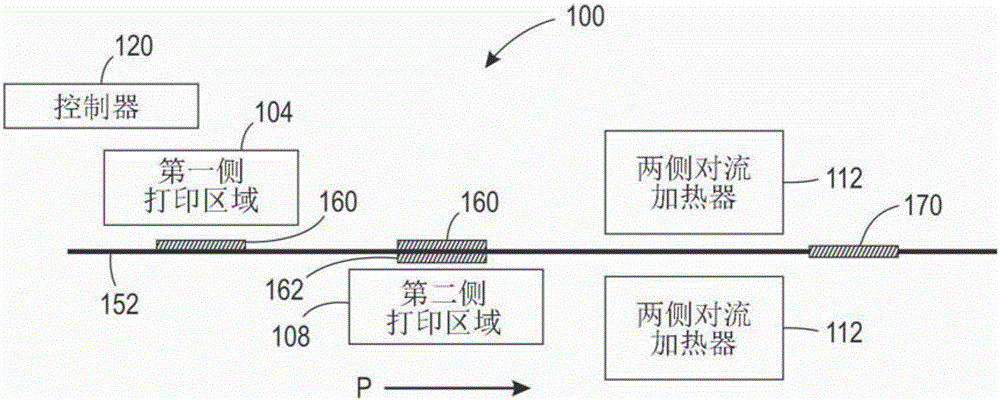

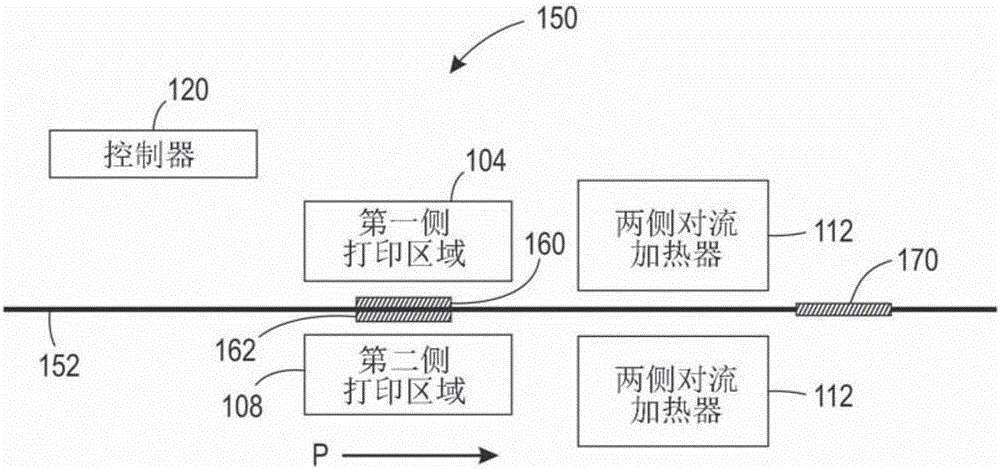

System and method for forming hydrophobic structures in a hydrophilic print medium

The invention provides a method of forming hydrophobic structures in a hydrophilic print medium, the method including operating a plurality of inkjets to form an arrangement of hydrophobic material on first side of a print medium that moves in a process direction at a predetermined velocity. The method further includes moving the print medium through a convection heater at the predetermined velocity to enable the hydrophobic material to penetrate the print medium to form hydrophobic structures within the print medium.

Owner:XEROX CORP

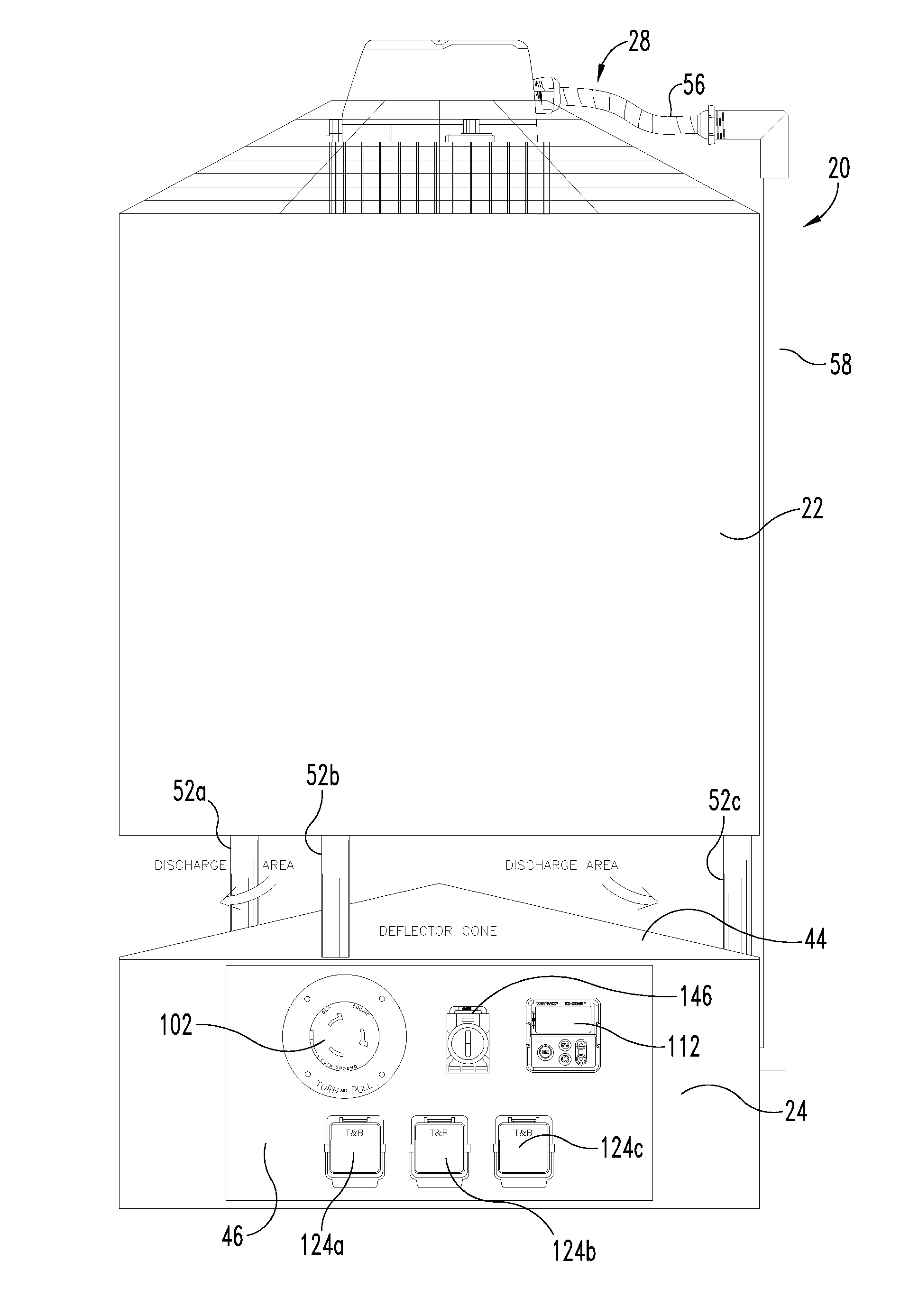

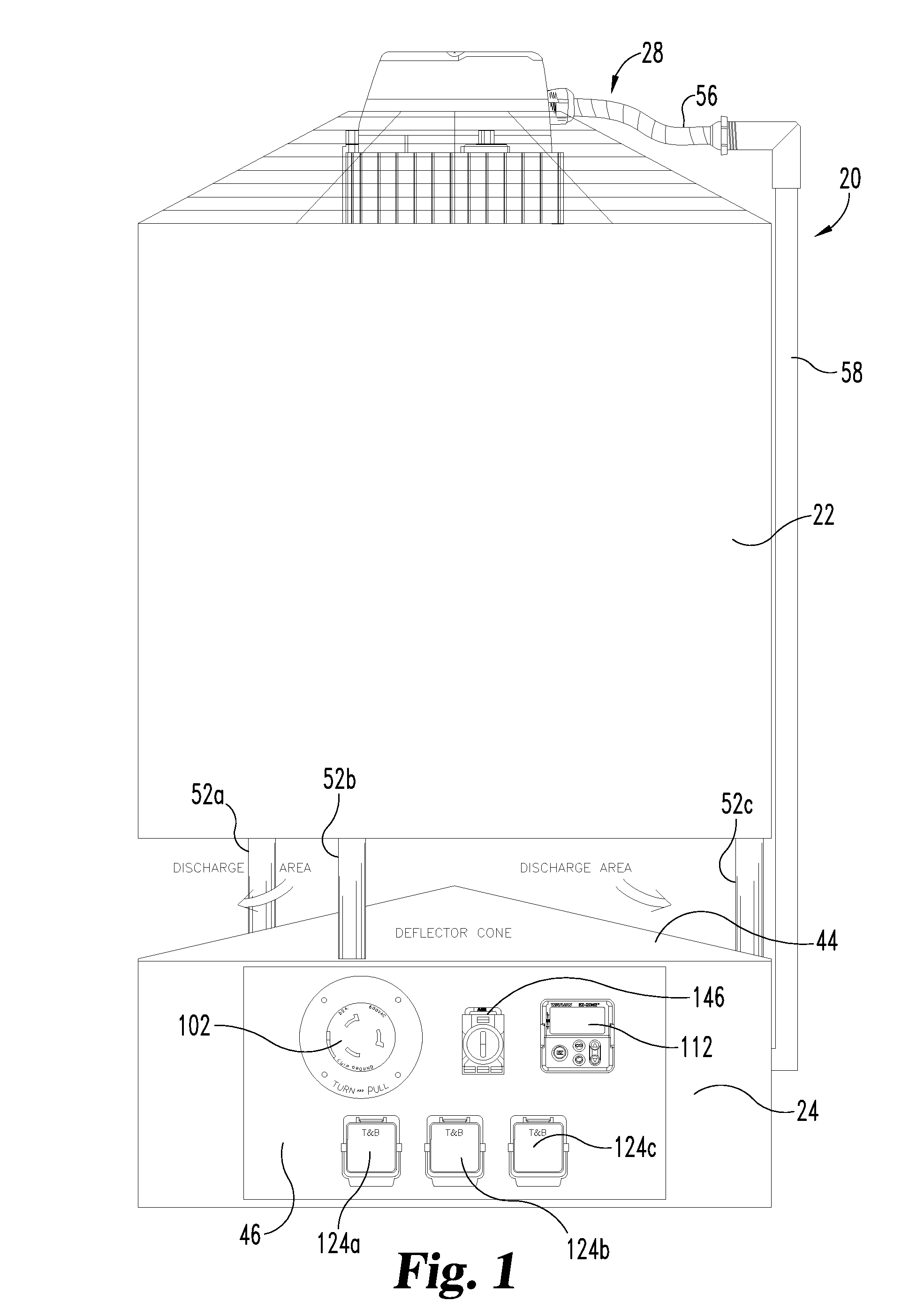

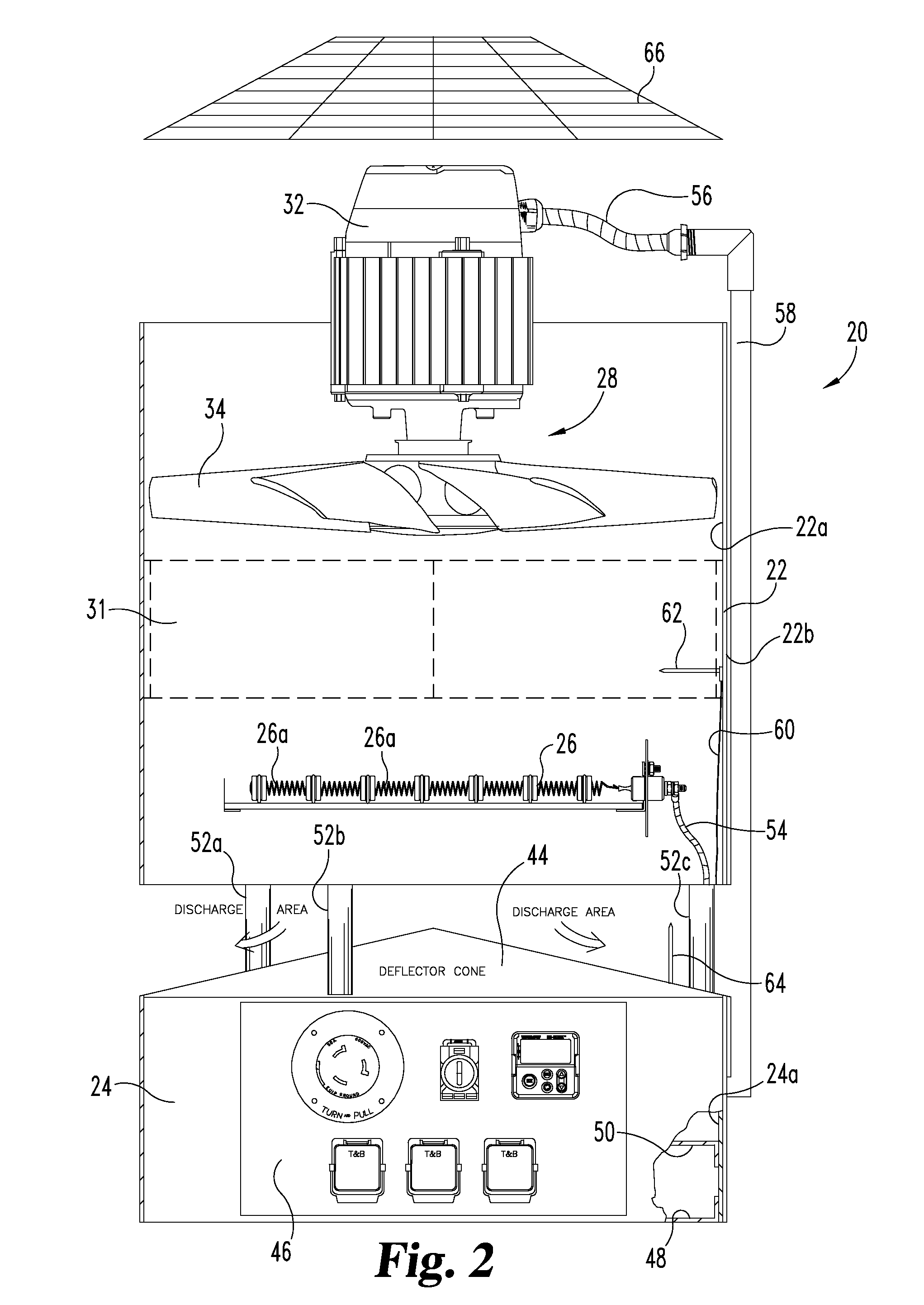

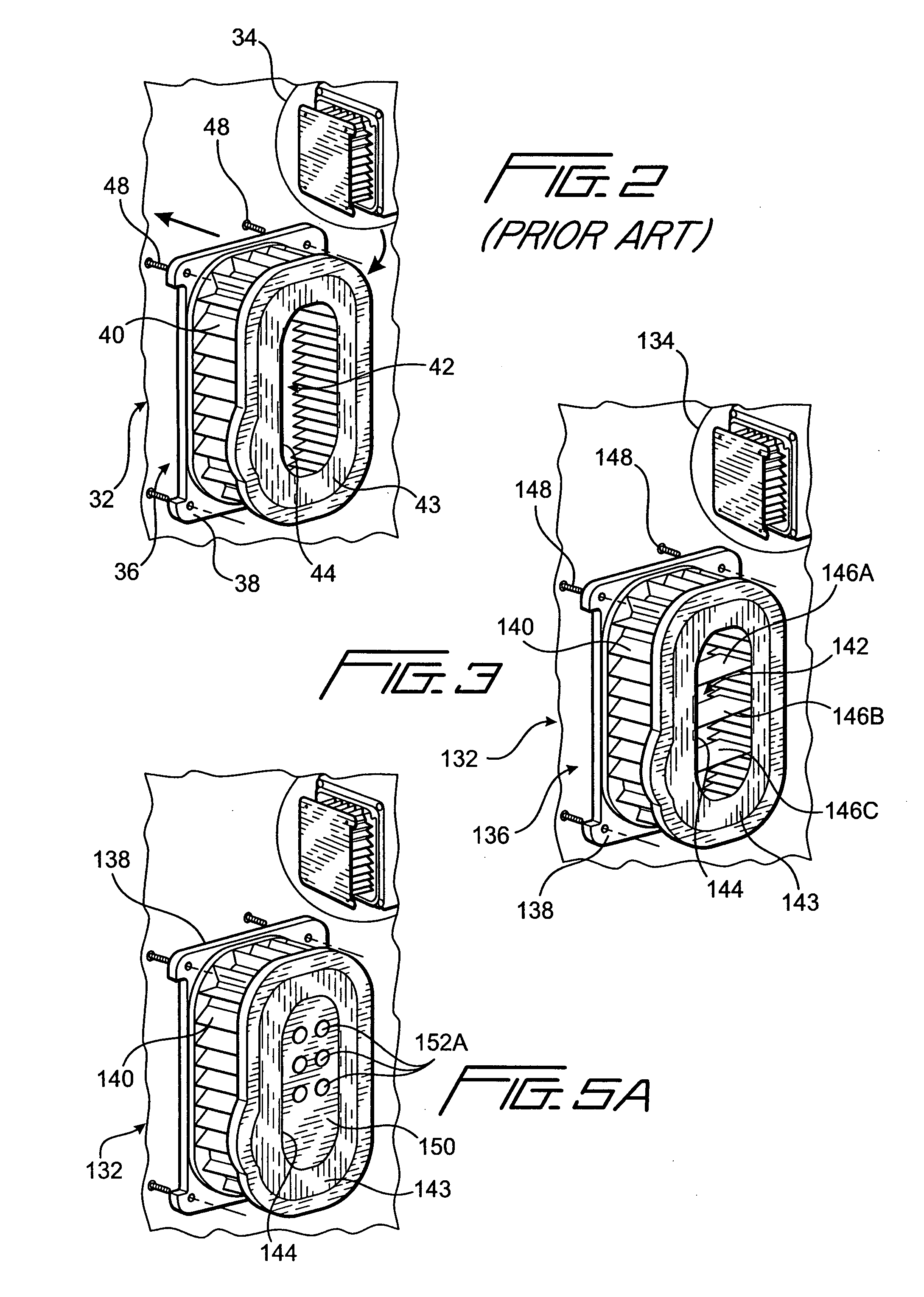

Electric convection heater and method of use for exterminating insects

An electric heater includes an upper housing, a lower housing, a fan disposed in the upper housing, and a heater disposed in the upper housing. Electrical control components and circuitry are disposed in the lower housing and are connected for energizing the heater and for operating the fan. Mechanical support members are arranged for spacing the upper housing from the lower housing in order to create air discharge flow paths for air flow exiting from the upper housing. The discharged air at an elevated temperature is used to elevate the temperature of objects within a room for exterminating bed bugs.

Owner:ON SITE MFG

Cooking apparatus

ActiveUS7282673B2Efficiently agitatedEqually distributedAir-treating devicesDomestic stoves or rangesConvection heaterDrive motor

A cooking apparatus to effectively agitate and evenly distribute high-temperature air into a cooking chamber by use of a single driving fan and a plurality of driven fans. The cooking apparatus includes the cooking chamber, the driving fan arranged at a rear wall of the cooking chamber, a convection heater to surround the driving fan, the plurality of driven fans arranged on a circumference of the driving fan, and a fan cover having a plurality of suction holes and discharge holes. The driving fan is connected with a drive motor to rotate in accordance with an operation of the drive motor. The driven fans rotate by use of air streams generated when the driving fan rotates. The high-temperature air is evenly agitated in accordance with the rotation of the driven fans to be distributed into the cooking chamber via the discharge holes in all directions.

Owner:SAMSUNG ELECTRONICS CO LTD

System for automatically inflating temperature regulated blankets and a blanket for coupling to the system

InactiveUS7517360B2High trafficBlanketRecord carriers used with machinesConvection heaterEngineering

A convective warmer to which blankets of different dimensions may be connected is capable of providing air to the various blankets at flow rates that optimally inflate those blankets to achieve the optimal clinical result for the patients covered by those blankets. The blanket connected to the warmer may range from a full size adult warming blanket to a pediatric or neonate warming blanket. There is provided on each blanket a code, marking or marker, to be read by a sensor(s) provided at the outlet of the warmer, that identifies the type of blanket when the blanket is coupled to the warmer. Consequently, heated air may be automatically output by the warmer to the blanket at the appropriate flow rate of that blanket to optimally inflate the blanket without any need for intervention by a user. In addition to being used to control the flow rate of the heated air, the code from the blanket may also be used to control the temperature of the heated air to be input to the blanket.

Owner:SMITHS MEDICAL ASD INC

Air convection warmer with noise reduction filter

InactiveUS20080286092A1Reduce noiseReduce noise levelPump componentsReaction enginesNoise levelConvection heater

To reduce the noise level of air convective warmer, the air filter of the warmer is fitted with an air intercept mechanism to disrupt the flow of air that traverses inside the interior cavity of the air filter. By thus disrupting the air flow, the noise that otherwise would have been generated due to a non-interrupted air stream flow is lowered. The air intercept mechanism may be in the form of at least one partition positioned inside the interior cavity of the air filter. Alternatively, double-ended open tubes may be used, so long as the interior cavity of the filter is sealed, with only the tubes providing the passages for air to output from the air filter. Yet a third embodiment of the air reduction filter has an air impermeable material covering at least one portion of the surface area of the filtering material to prevent the inflow air from directly entering into the interior cavity of the air filter through the covered surface area.

Owner:SMITHS MEDICAL ASD INC

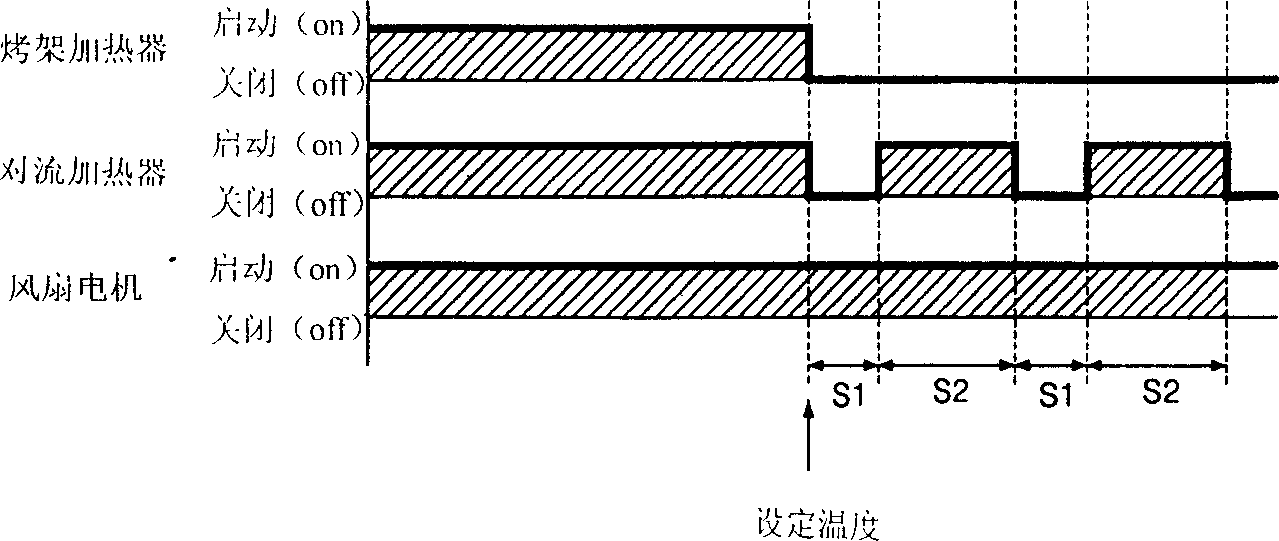

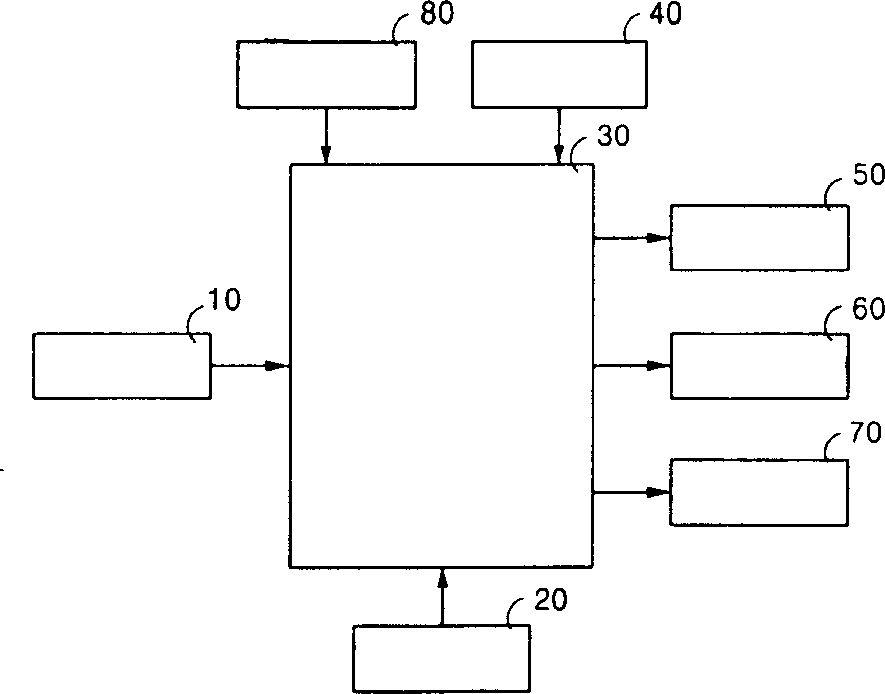

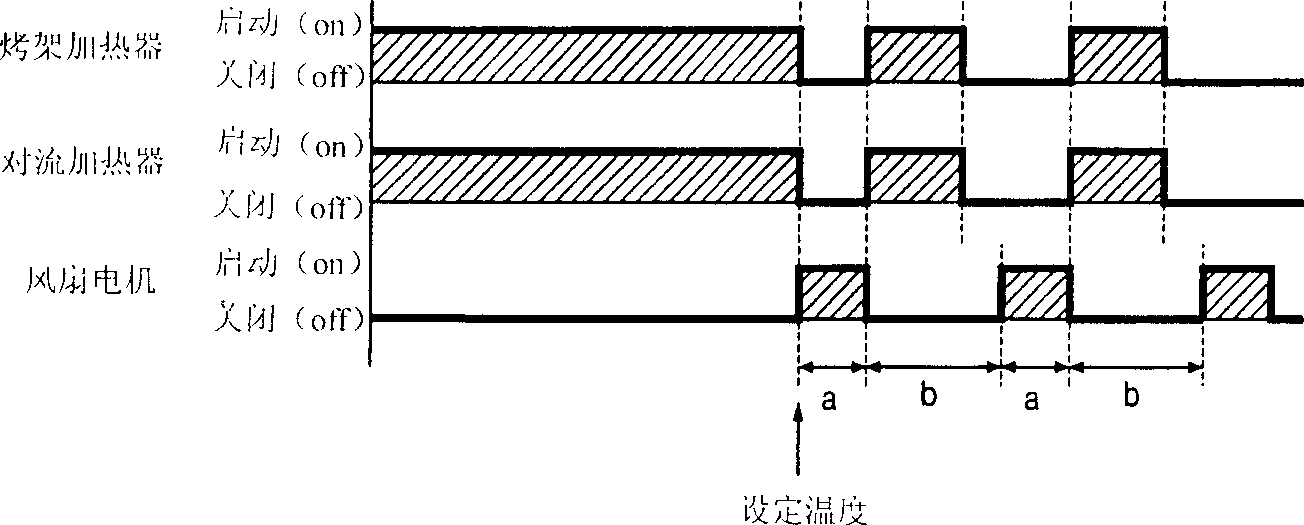

Method for controlling heating temp of microwaven oven

InactiveCN1502856AReduced external temperature risePhenomena that prevent damageDomestic stoves or rangesLighting and heating apparatusMicrowave ovenMotor drive

The heating temp. control method for microwave oven includes three stages: fan motor driving stage, starting from that internal temp. of heating chamber is reached to set pre-heating temp. driving fan motor in first specific period of time; heater driving stage, after the fan motor driving stage is completed, taking drive stop of fan motor as starting point, simultaneously driving grill heater and convection heater in second specific period of time; and repeated execution stage, according to the cooking time inputted by user repeatedly executing the above-mentioned two stages to heat food uniformly.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

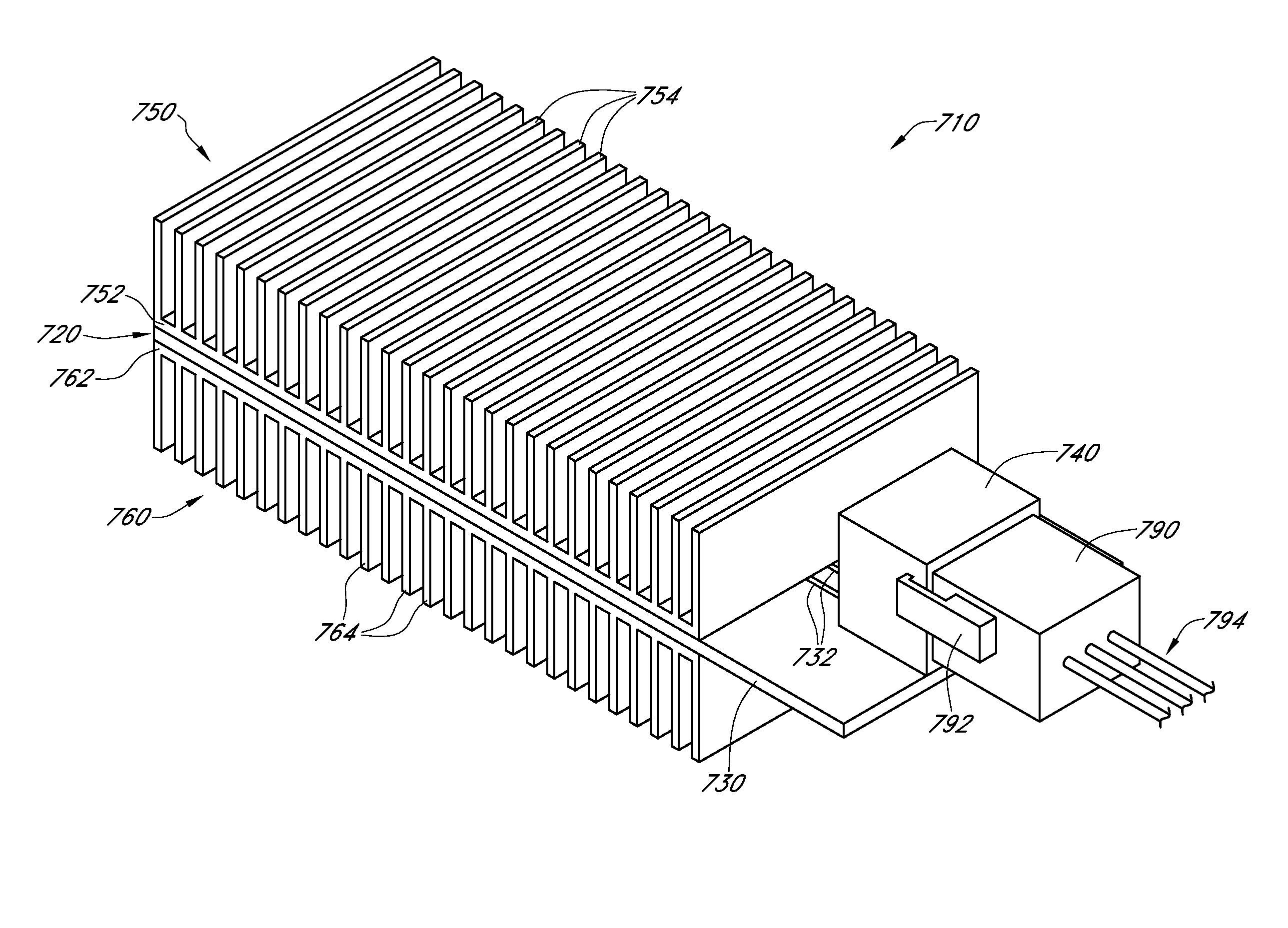

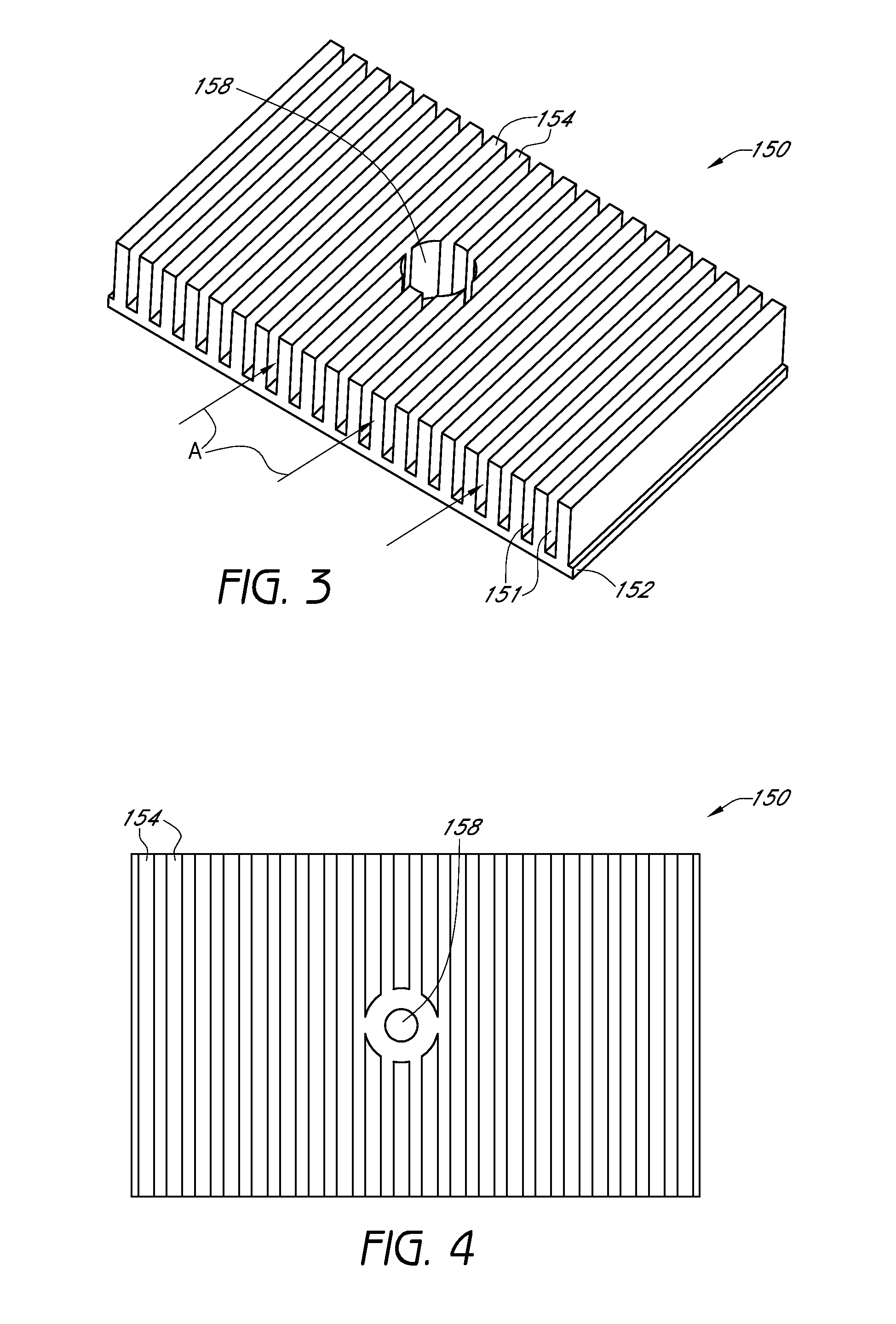

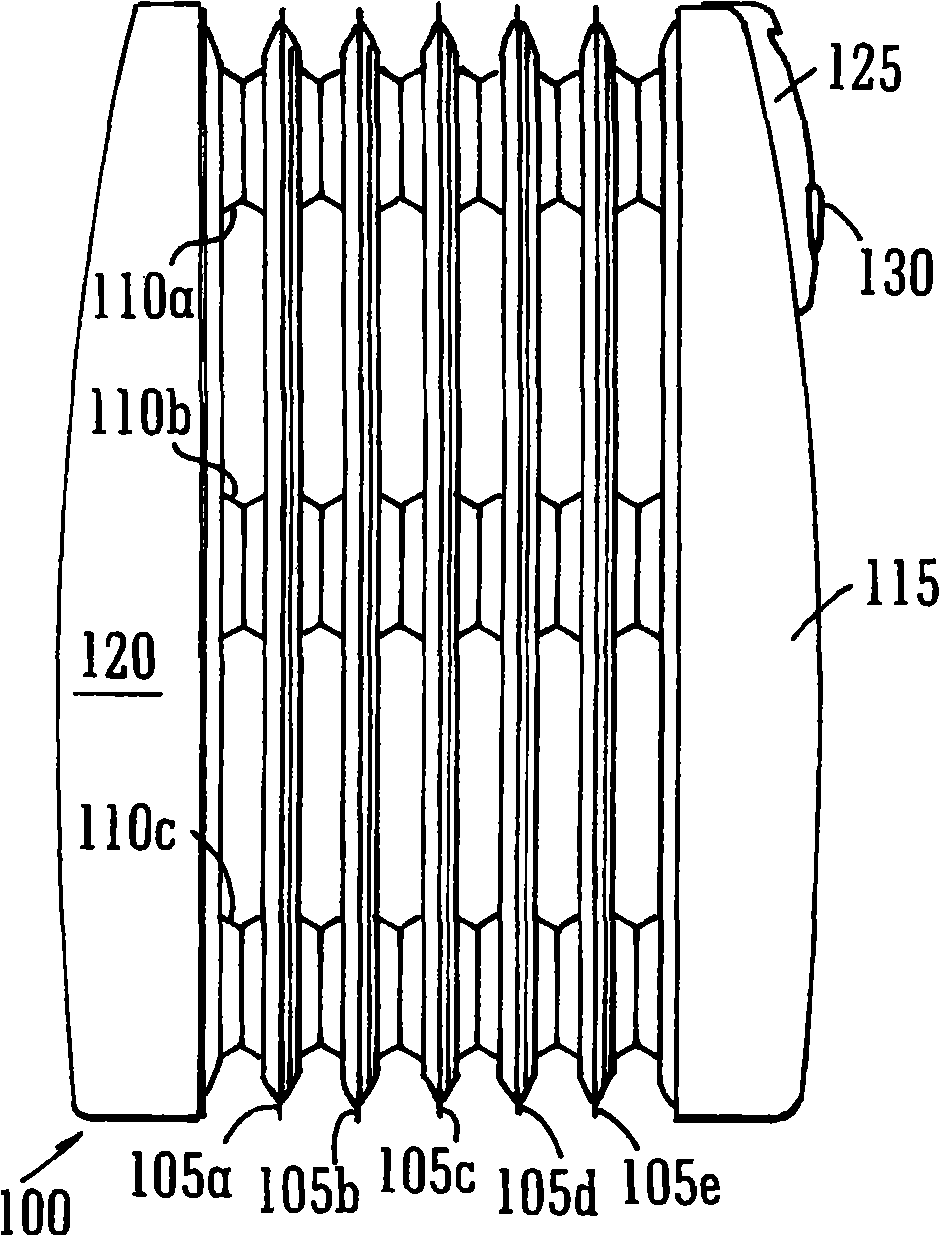

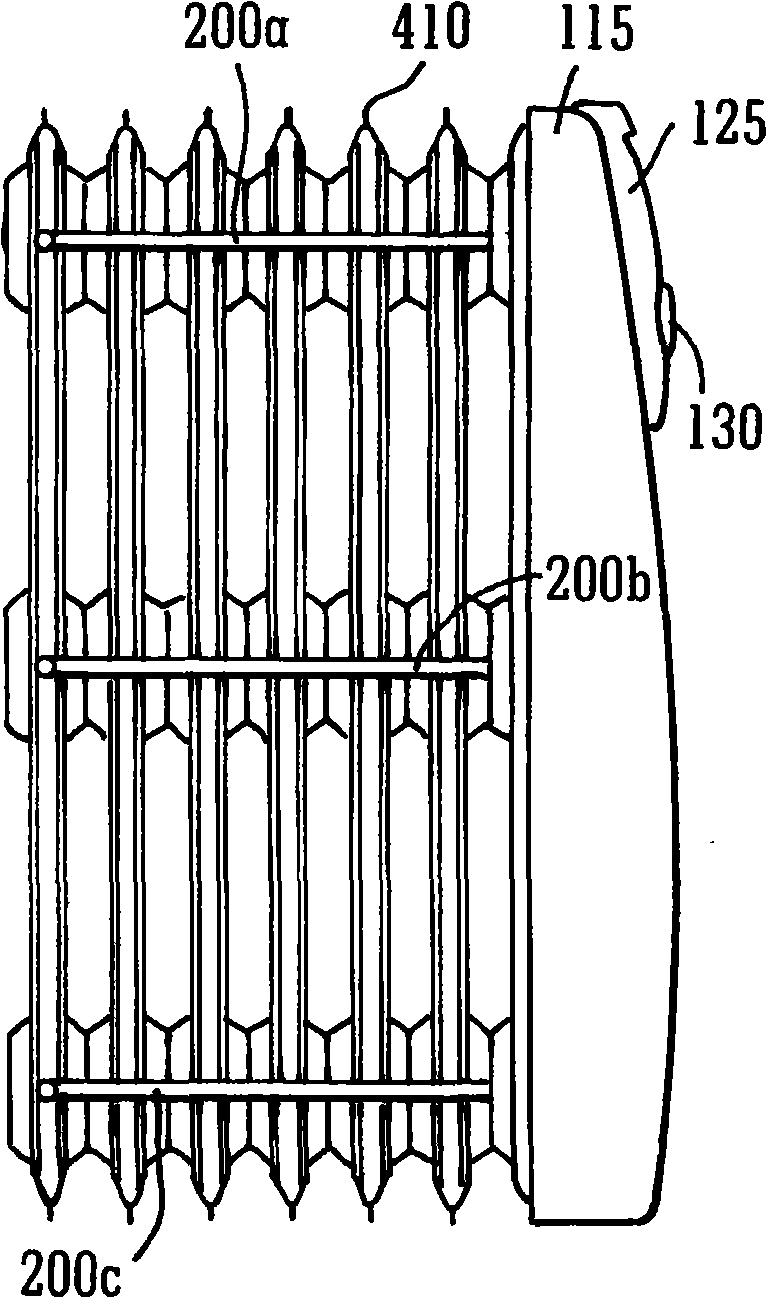

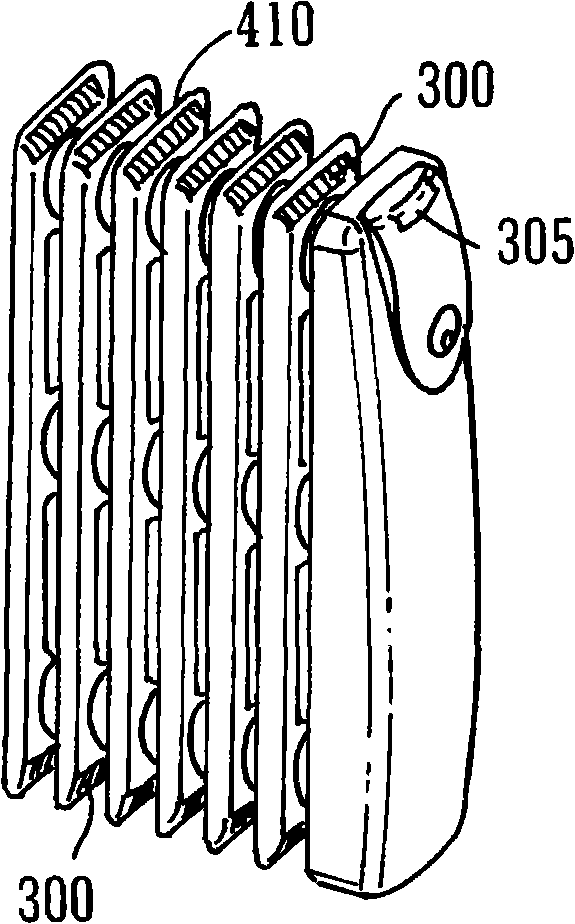

Convection heater

A heater is described which operates on the principle of convection air currents within heating fins being established by heating of air adjacent to one or more heating elements and the transfer of heat from the convection currents to the side walls of the heating fins where it may radiate outwardly as well as the direct convection of the heat from the elements in the air which passes out of the apertures at the tops of the fins into the surroundings.

Owner:BASIC HOLDINGS CO LTD

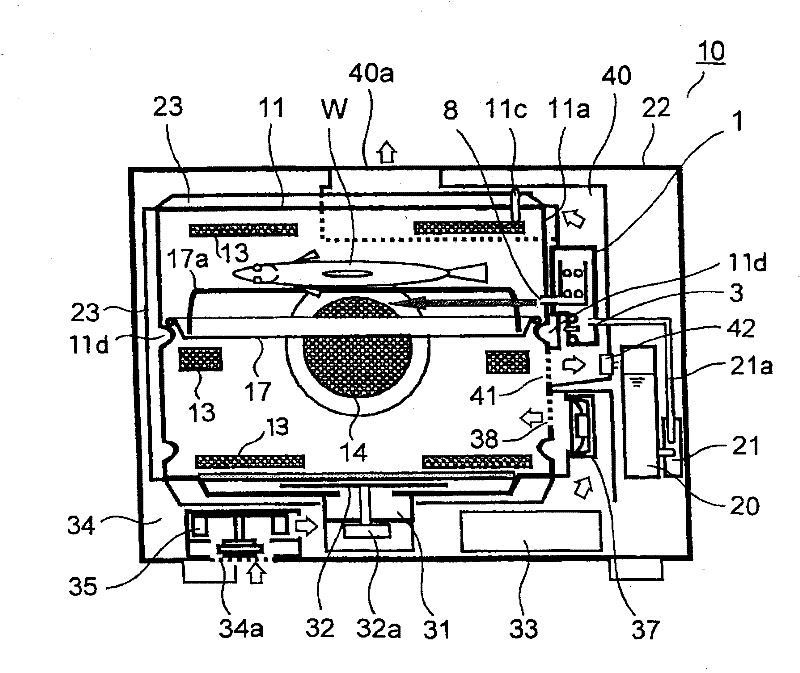

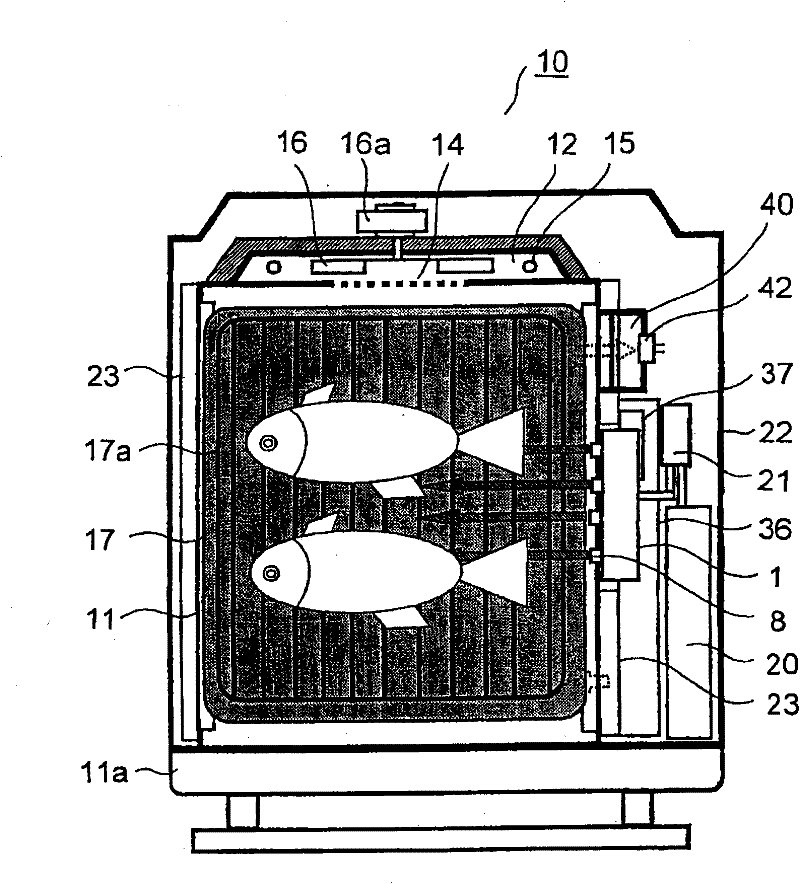

Cooking device

InactiveCN102132104AReduce outflowImprove heating efficiencyDomestic stoves or rangesLighting and heating apparatusMicrowaveConvection heater

A cooking device comprises: a heating chamber (11) equipped with a placement section (11d), the placement section (11d) being adapted such that a tray (17) is placed thereon, the tray (17) having a placement net (17a) for placing thereon an object to be cooked; a vapor generating device (1) for generating vapor and supplying the vapor between the placement net (17a) and the tray (17); a circulation duct (12) having a circulation fan (16) and circulating gas in the heating chamber (11); a convection heater (15) provided in the circulation duct (12); a gas supply opening (38) provided below the tray (17); a gas discharge opening (41) provided below the tray (17); and a magnetron (33) for supplying a microwave to the heating chamber (11). The cooking device is provided with a range mode for performing cooking by a microwave, a grill mode for performing cooking by superheated vapor by driving the circulation fan (16) and the convection heater (15), and a steaming mode for performing cooking by saturated vapor with the circulation fan (16) and the convection heater (15) stopped.

Owner:SHARP KK

Electric oven with multiple broil heaters and method for preheating the electric oven

ActiveUS8138453B2Short timeDomestic stoves or rangesElectrical heating fuelConvection heaterEngineering

A electric oven is provided that includes a body, a cooking chamber located within the body for receiving food, the cooking chamber having an upper surface, a lower surface, and a rear surface joining the upper surface to the lower surface, at least one of a convection heater located at the rear surface of the cooking chamber and a bake heater located at the lower surface of the cooking chamber, and at least two broil heaters located at the upper surface of the cooking chamber, each of the at least two broil heaters being individually operable. Methods for preheating the electric oven are also provided.

Owner:LG ELECTRONICS INC

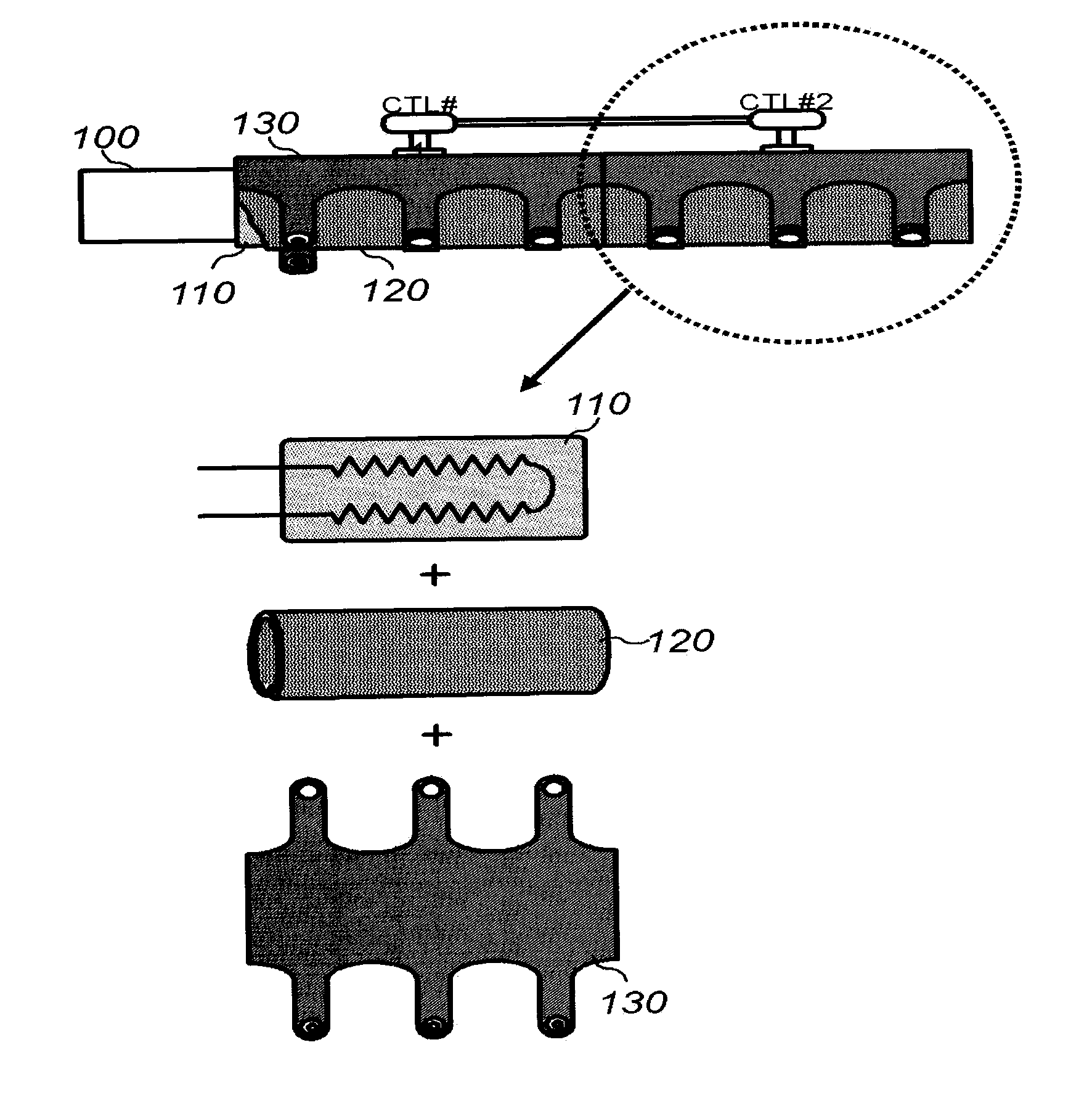

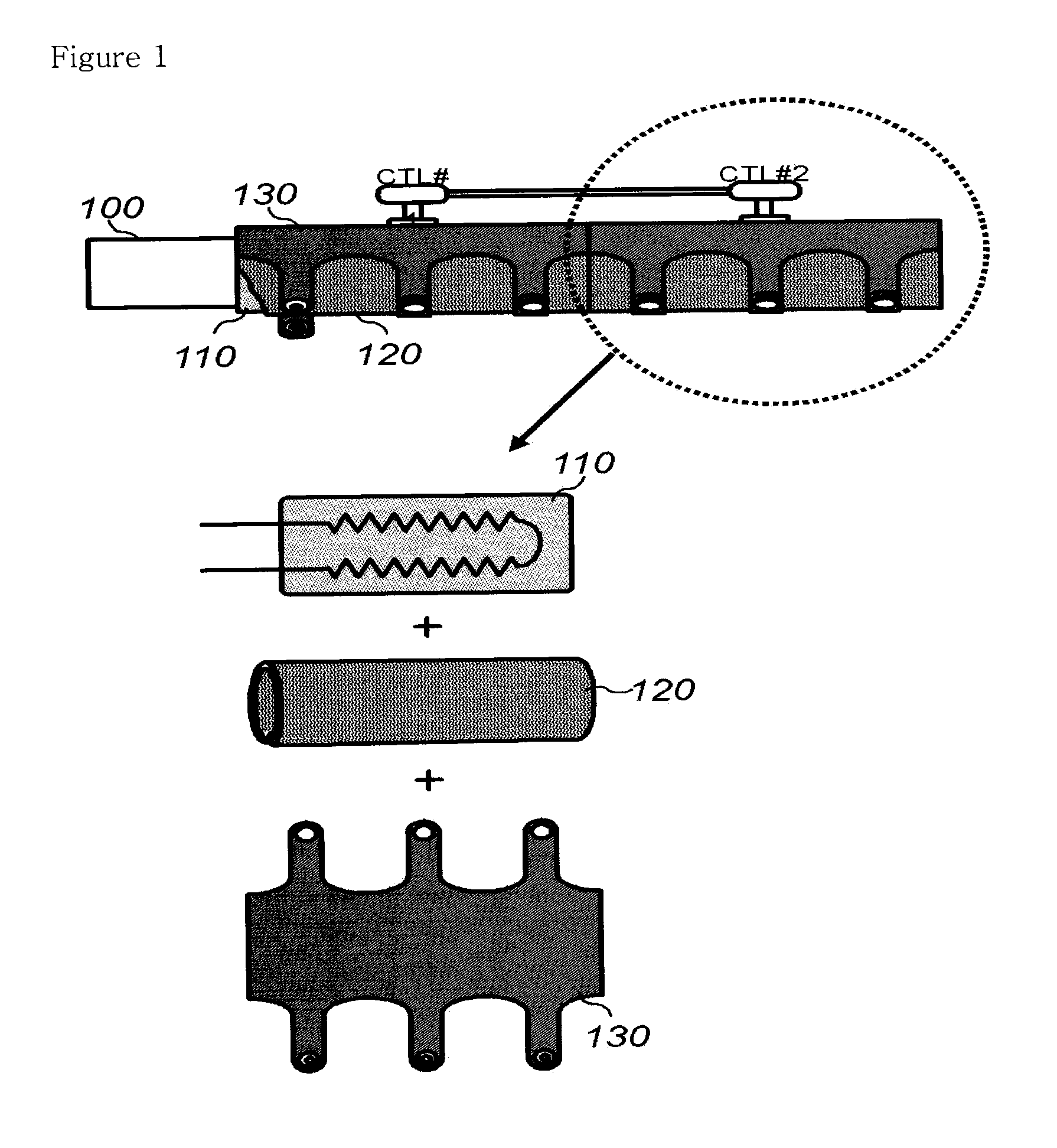

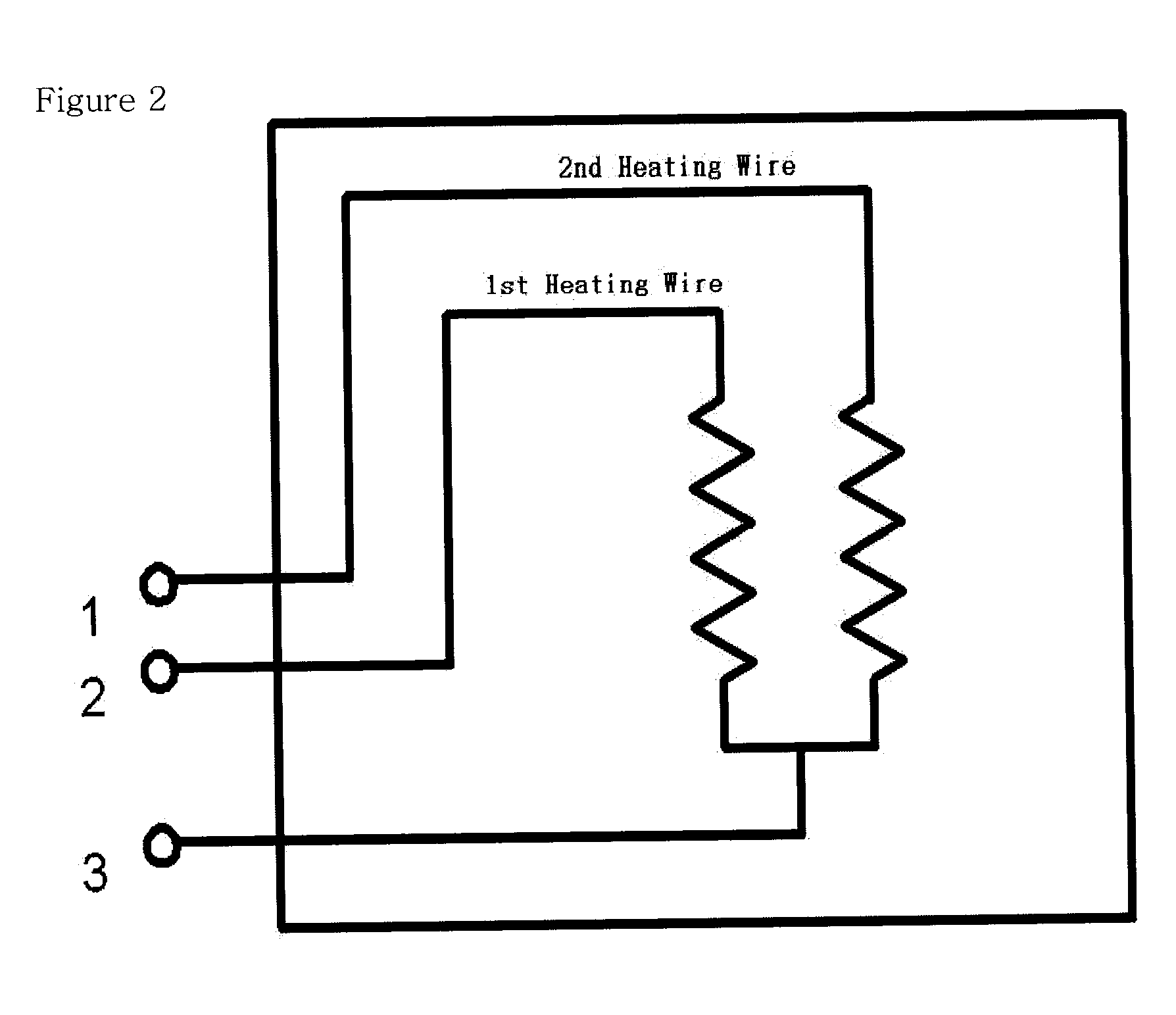

Heater Jacket For Heat Convection

InactiveUS20080197124A1Specific heatSemiconductor/solid-state device manufacturingOhmic-resistance heating detailsConvection heaterSilicon dioxide

The present invention generally relates to an insulating heater jacket, and more particularly, to a silicone rubber and a heater controller for an insulating heater jacket. According to the present invention, the use of the silicone rubber molded out of a mixture of polymethyl vinyl silica oxide solutions improves durability. Furthermore, a duplex heating pad is provided using first and second heaters, and a microprocessor and a temperature sensor monitor malfunction of the dual heating wires and perform control in such a manner that upon malfunction of one of the heating wires, the other heating wire can be operated. Therefore, there are advantages in that temperature can be accurately controlled and reliable performance can be always ensured without any malfunction.

Owner:MKS INSTR INC

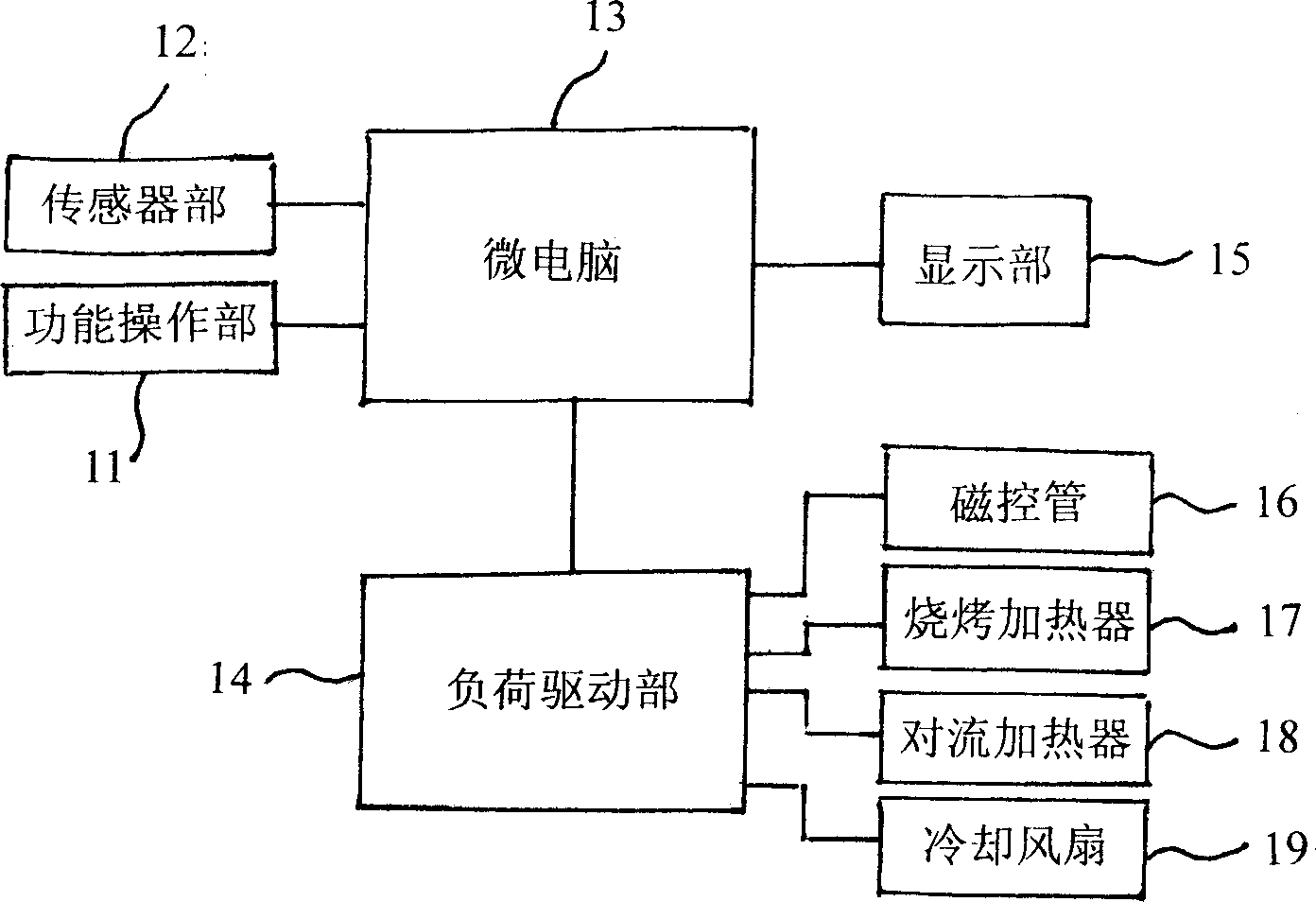

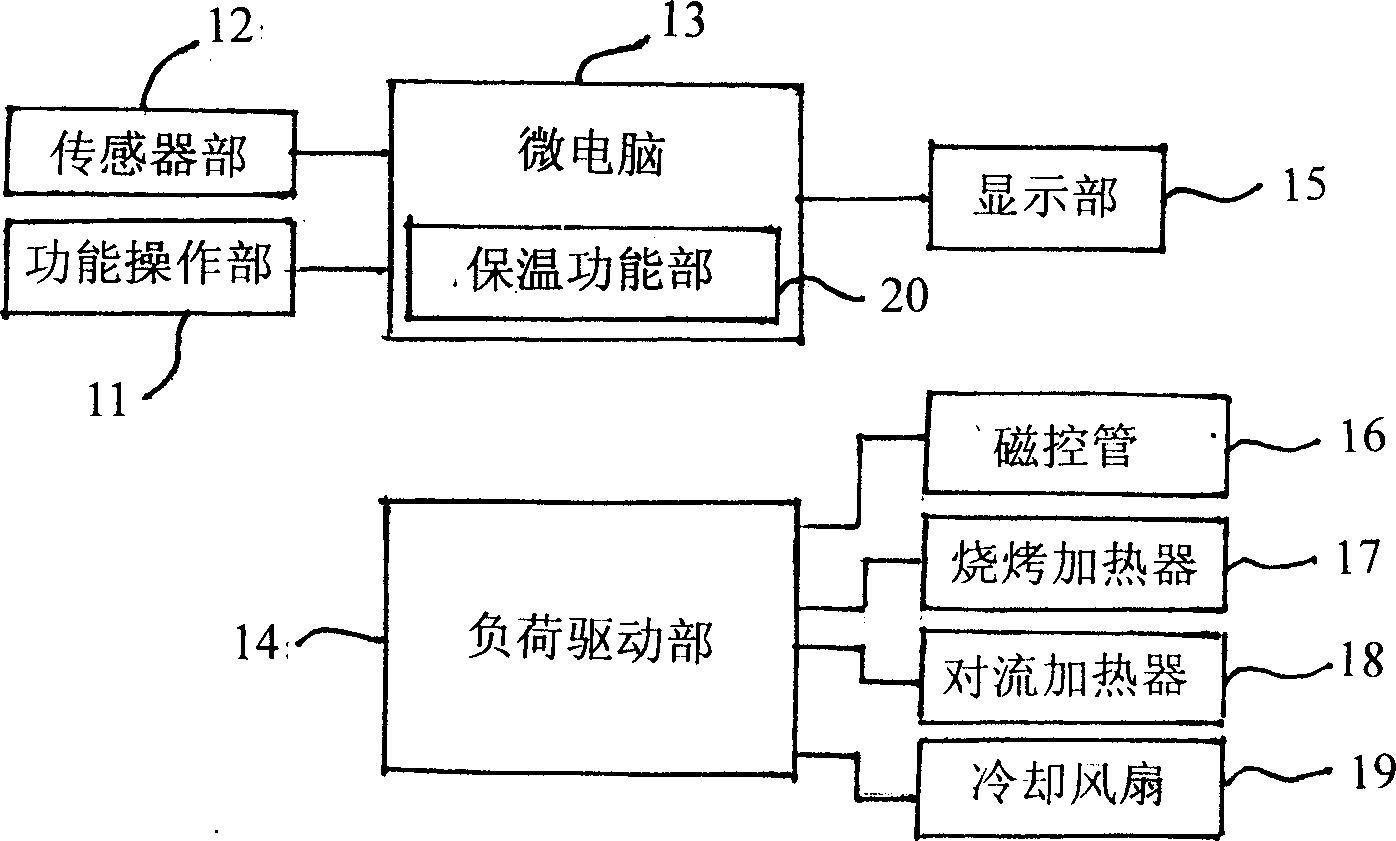

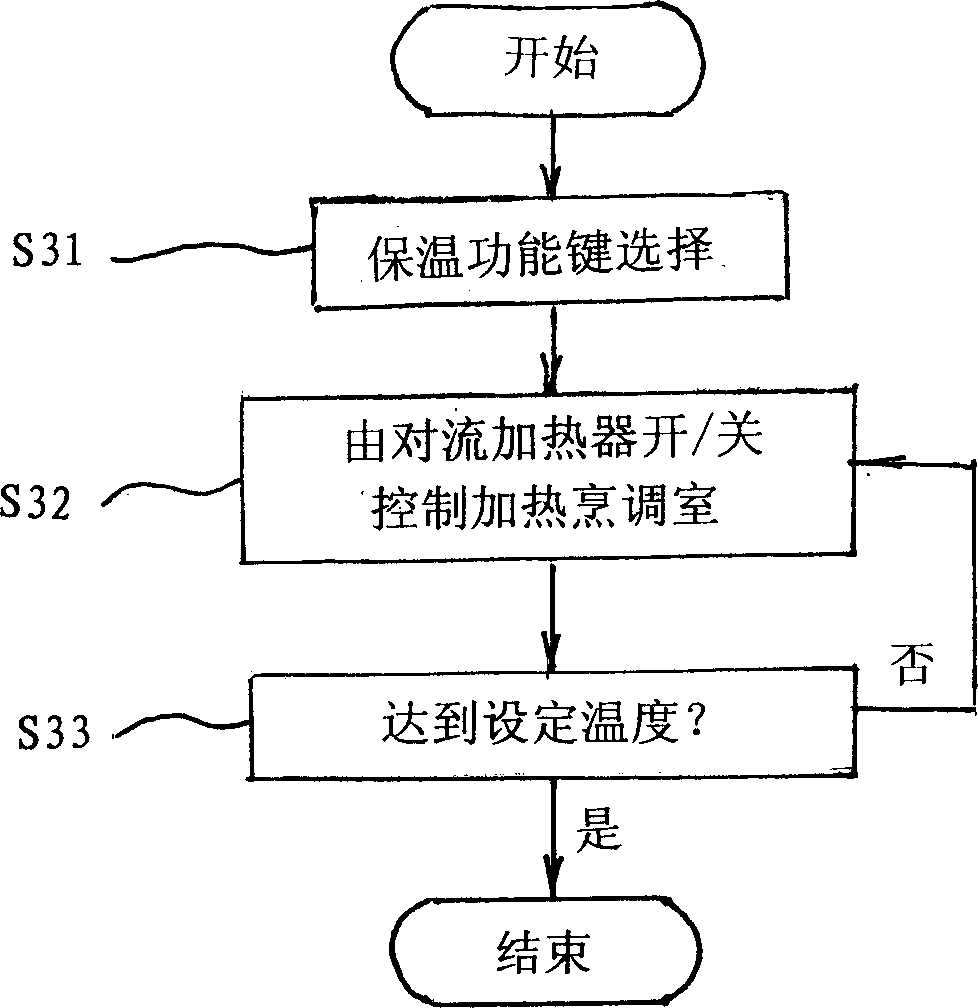

Heat preservation control device in microwave oven and method

InactiveCN1626903APrevent hard edgesPrevent partial burningDomestic stoves or rangesLighting and heating apparatusMicrowave ovenConvection heater

The invention relates to a heat insulation control device of microwave oven and its method. It is characterized by that in the microwave oven formed from function key operation portion for controlling function of microwave oven and control portion for controlling whole microwave oven and further controlling cooking process if the user utilizes the function key operation portion of microwave oven to select heat insulation function, the switching-on or switching-off control of its convection heater capable of producing convection function can be used to implement heat insulation function.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

Electric oven

ActiveUS20190120500A1Minimize contaminationStoves/ranges foundationsSelf-cleaning stoves/rangesConvection heaterEngineering

The present invention relates to an electric oven capable of reducing contaminants, the electric oven comprising: an oven body having a cavity capable of accommodating food therein; and a convection assembly which is installed to protrude from one surface of the cavity and which can suck and remove contaminants generated when cooking the food and can heat the inside of the cavity. The convection assembly comprises: a cover case, protruding from one surface of the cavity, including a front surface which is spaced apart from the one surface of the cavity and has an inlet port, and a side surface which extends from the front surface to the one surface of the cavity and has an outlet port; a convection fan which is installed inside the cover case and allows air containing the contaminants to be sucked into the cover case through the inlet port and discharged through the outlet port; and a convection heater for heating the air sucked into the cover case by the convection fan to remove the contaminants, wherein the air discharged from the cover case moves in an upward inclined direction with respect to the one surface of the cavity.

Owner:SAMSUNG ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com