Patents

Literature

97results about How to "Specific heat" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Asphalt additive

InactiveUS6024788AHigh affinityImprove solubilityBuilding insulationsBituminous coatingsAliphatic hydrocarbonPhenyl group

The present invention provides an asphalt composition comprising an asphalt and antistripping additive comprising at least one of the compound having the formula (I), (II) or (III):[R1O-(PO)m(EO)n]x-P(=O)-(OH)y(I)wherein R1 represents a linear hydrocarbon radical having 8 to 24 carbon atoms or an alkyl phenyl group having 8 to 24 carbon atoms, PO represents oxypropylene group, EO represents oxyethylene group, each of m and n represents the number of added molecules, m is a number of 1 to 6, n is a number of 0 to 6;[R2O-(PO)m(EO)n]x-P(=O)-(OH)y(II)wherein R2 represents an aliphatic hydrocarbon radical having a branched methyl group and having 8 to 24 carbon atoms, PO represents oxypropylene group, EO represents oxyethylene group, each of m and n represents the number of added molecules, m is a number of 0 to 6, n is a number of 0 to 6; and[R3O-(PO)m(EO)n]x-P(=O)-(OH)y(III)wherein R3 represents an aliphatic hydrocarbon radical having two or more branched methyl groups or at least one of branched group including 2 or more carbons and having 8 to 24 carbon atoms, PO represents oxypropylene group, EO represents oxyethylene group, each of m and n represents the number of added molecules, m is a number of 0 to 6, n is a number of 0 to 6, each of x and y of the formula (I), (II) or (III) being a number of 1 to 2, the sum total of x and y being 3, R1,R2 and R3 being saturated or unsaturated.

Owner:KAO CORP

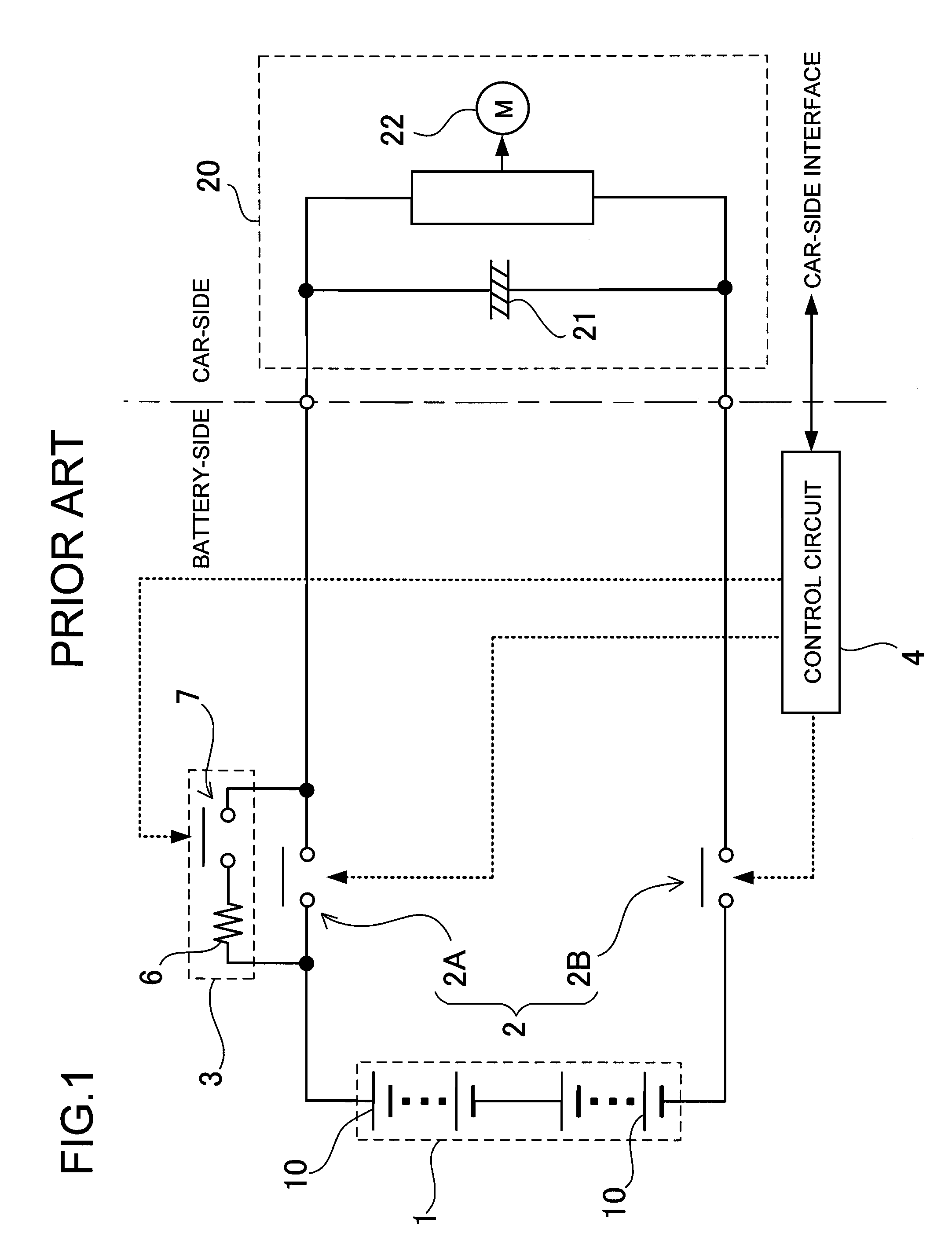

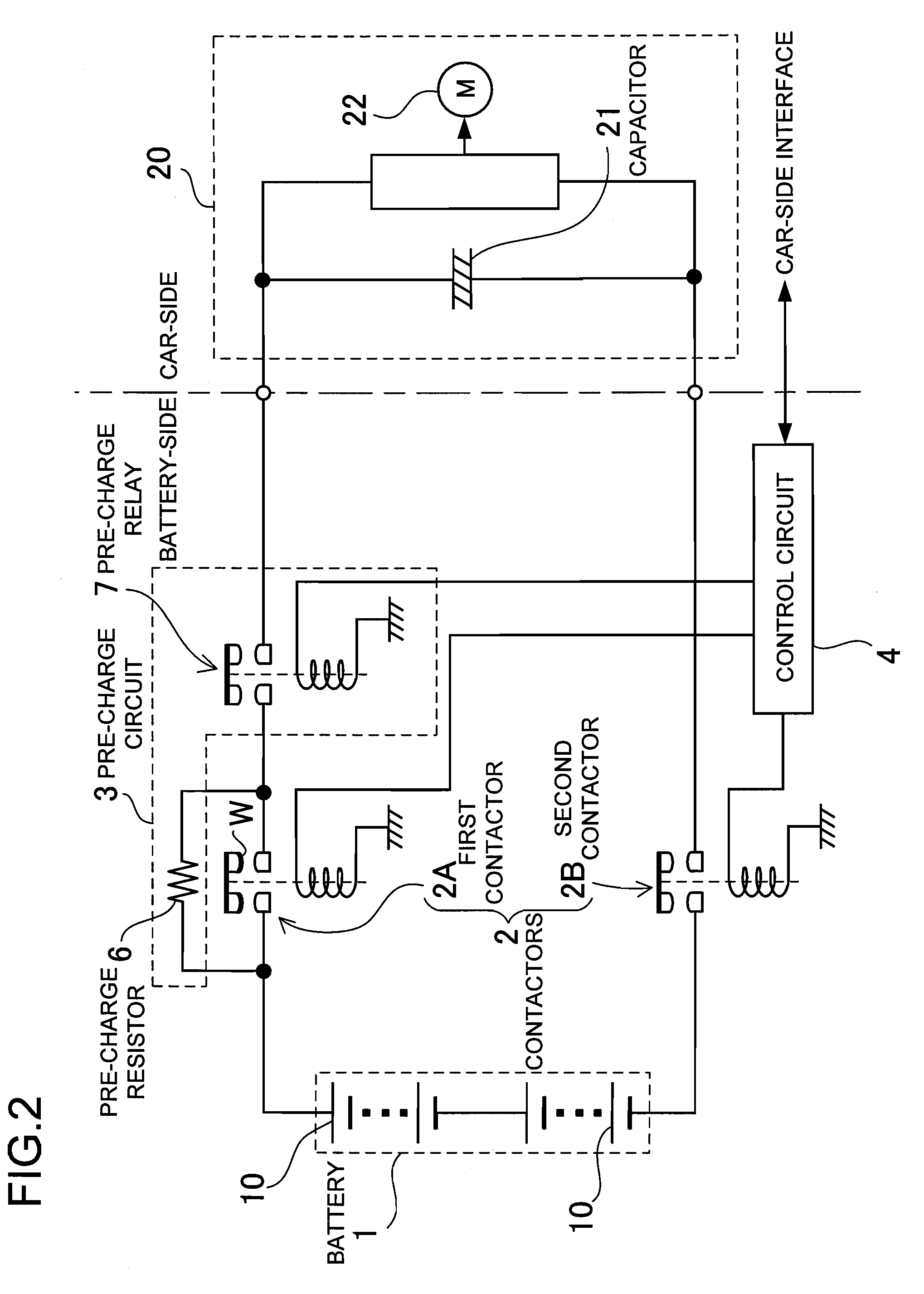

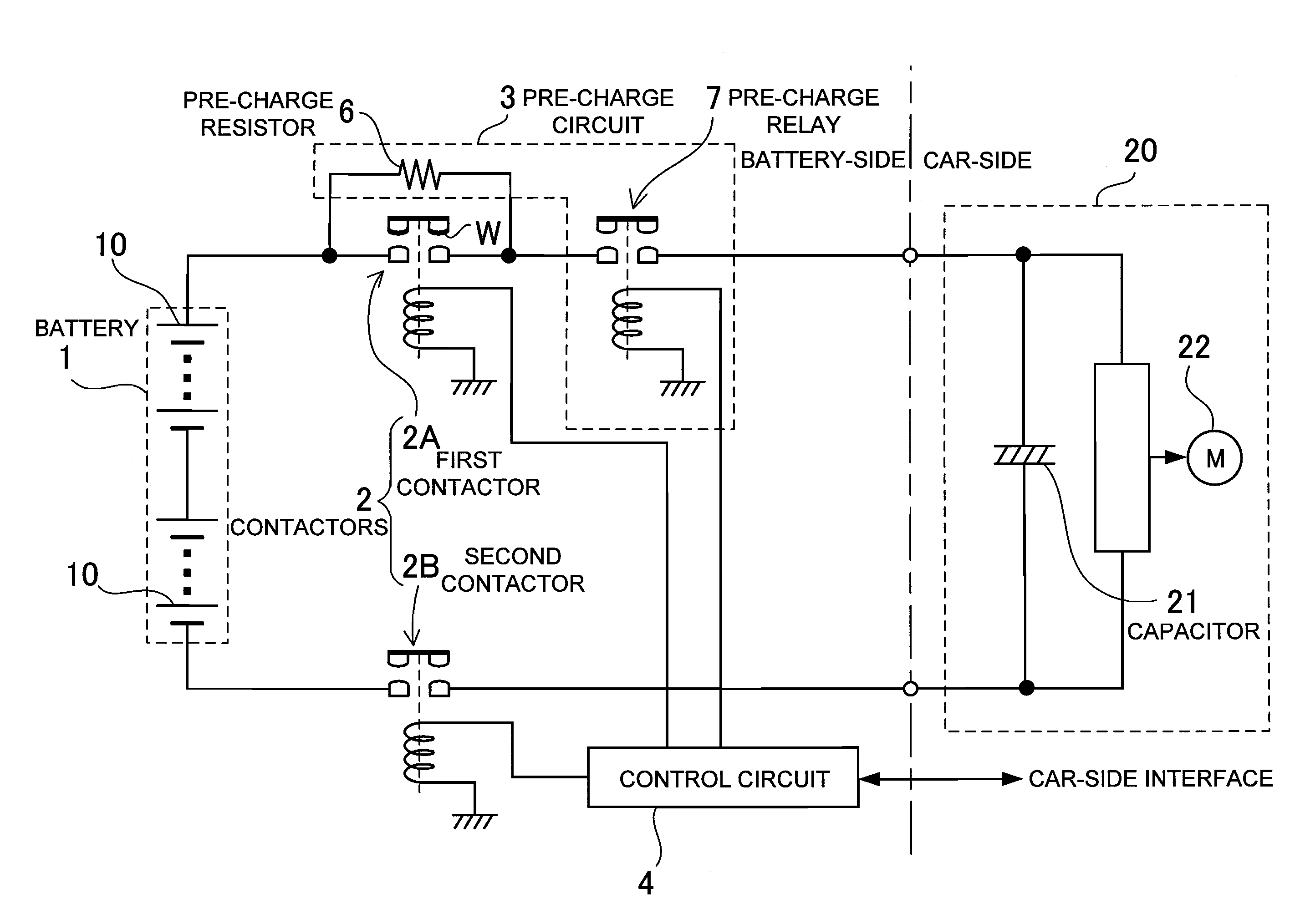

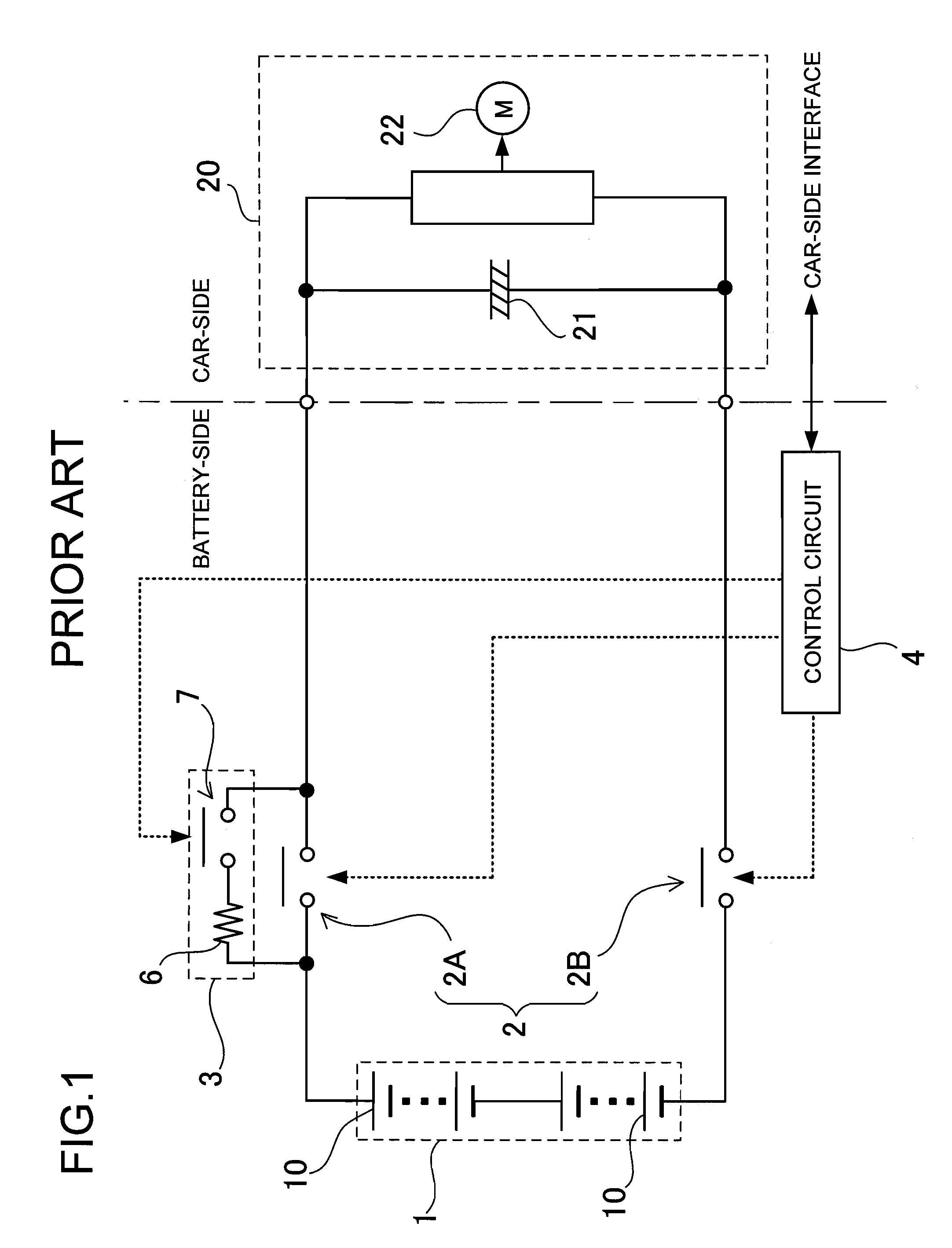

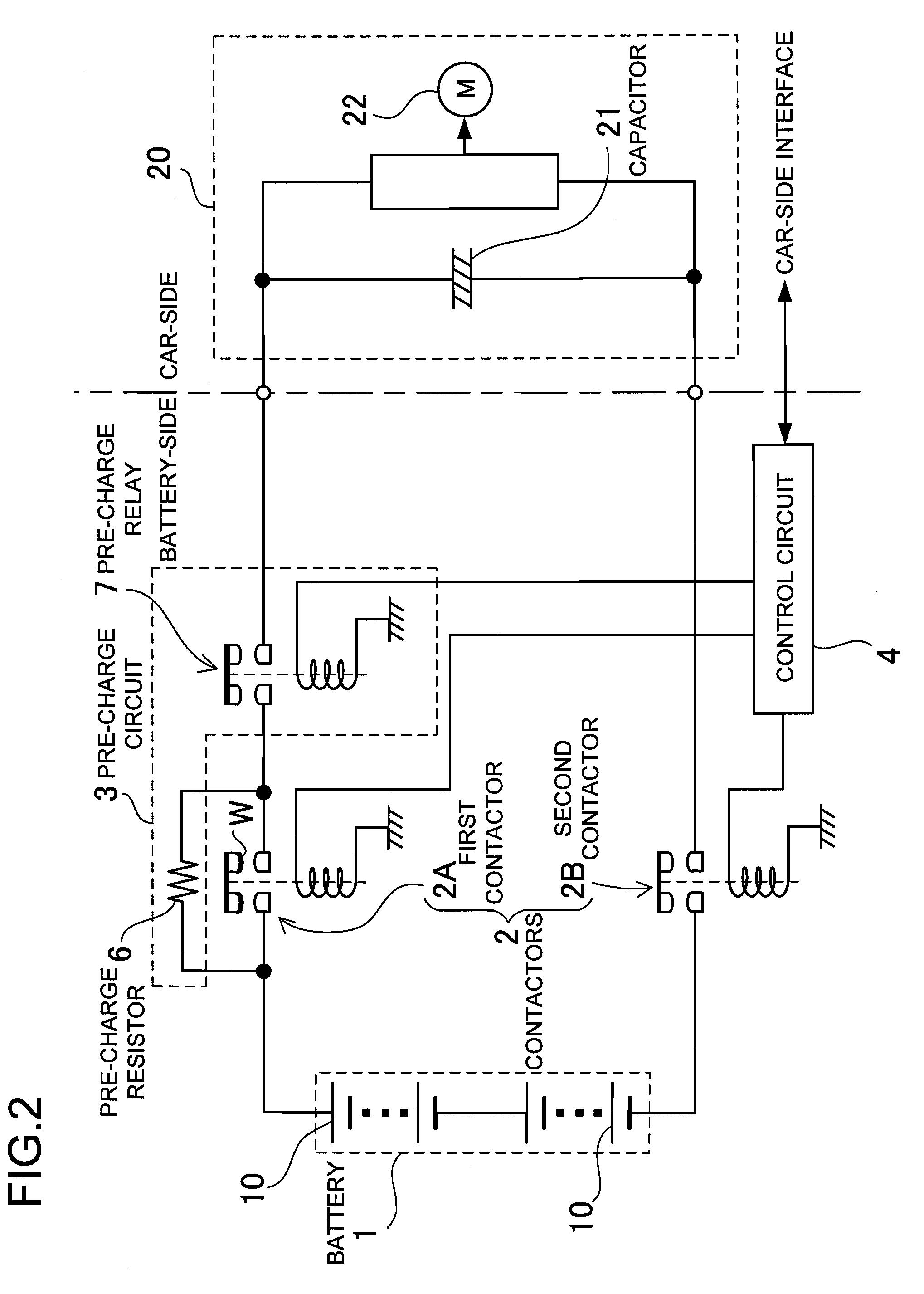

Car power source apparatus

InactiveUS20090212627A1Reliable cut-offLong lastingElectric devicesElectric powerPre-chargeControl circuit

The car power source apparatus is provided with contactors 2 connected to the output-side of the battery 1; a pre-charge circuit 3 made up of a series connected pre-charge resistor 6 and a pre-charge relay 7, which is connected with a contactor 2 to supply auxiliary charge to a capacitor 21 connected to the car-side of the battery 1; and a control circuit 4 to control the contactors 2 and pre-charge relay 7.The pre-charge resistor 6 is connected in parallel with a contactor 2, and the pre-charge relay 7 is connected in series with that contactor 2. The control circuit 4 switches the pre-charge relay 7 ON to pre-charge the car-side capacitor 21, and then switches the contactor 2 ON to connect the battery 1 to the car-side.

Owner:SANYO ELECTRIC CO LTD

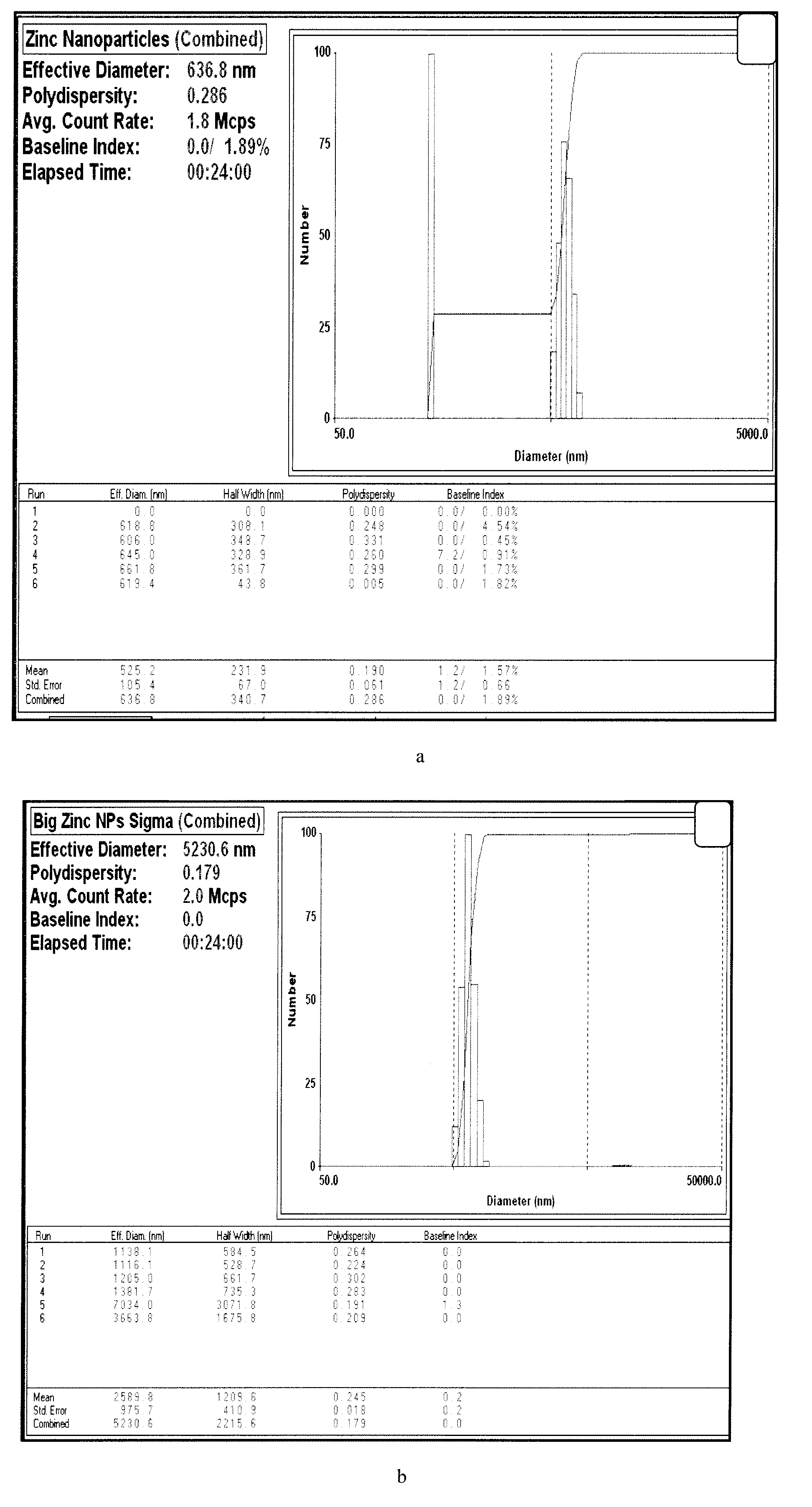

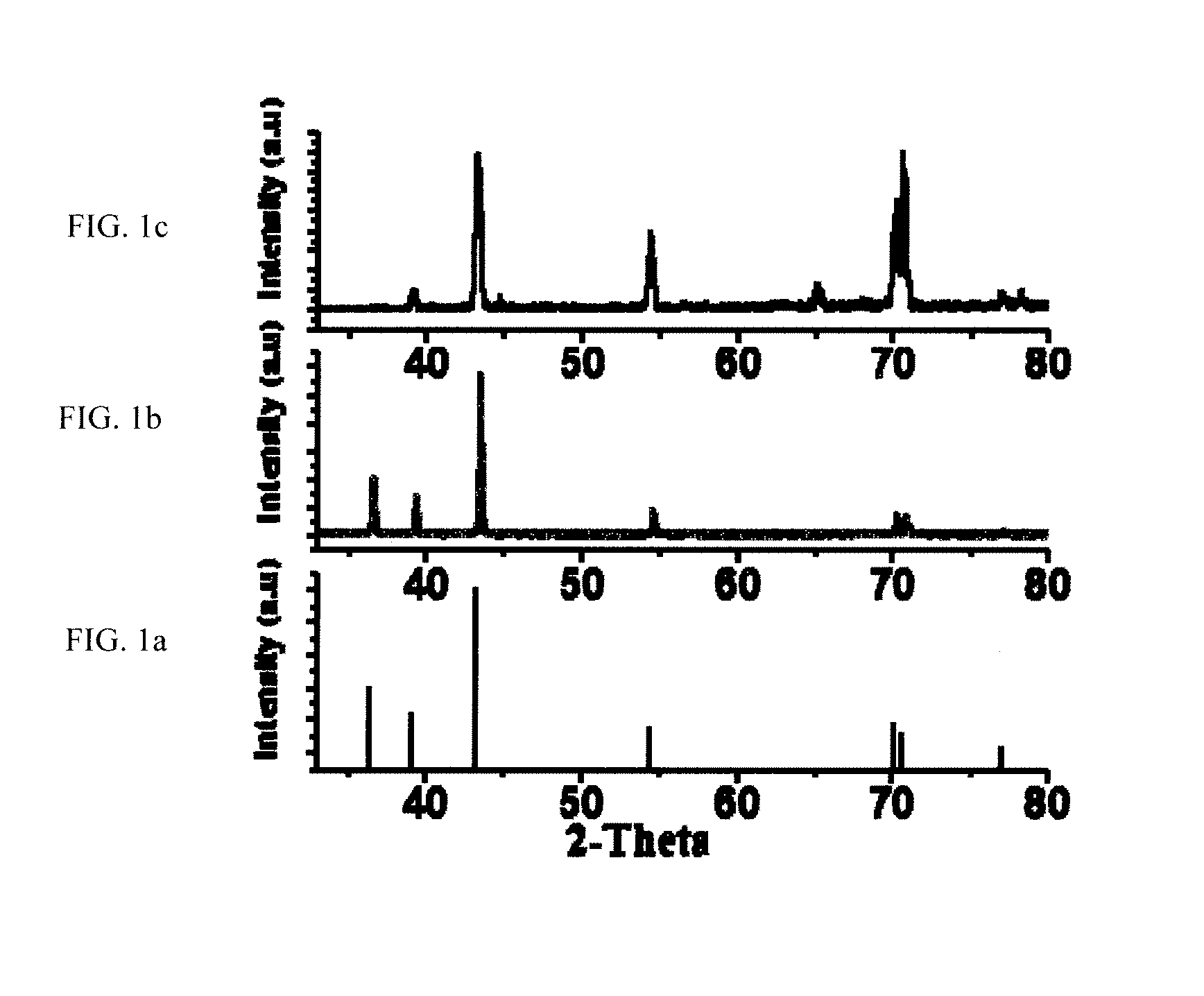

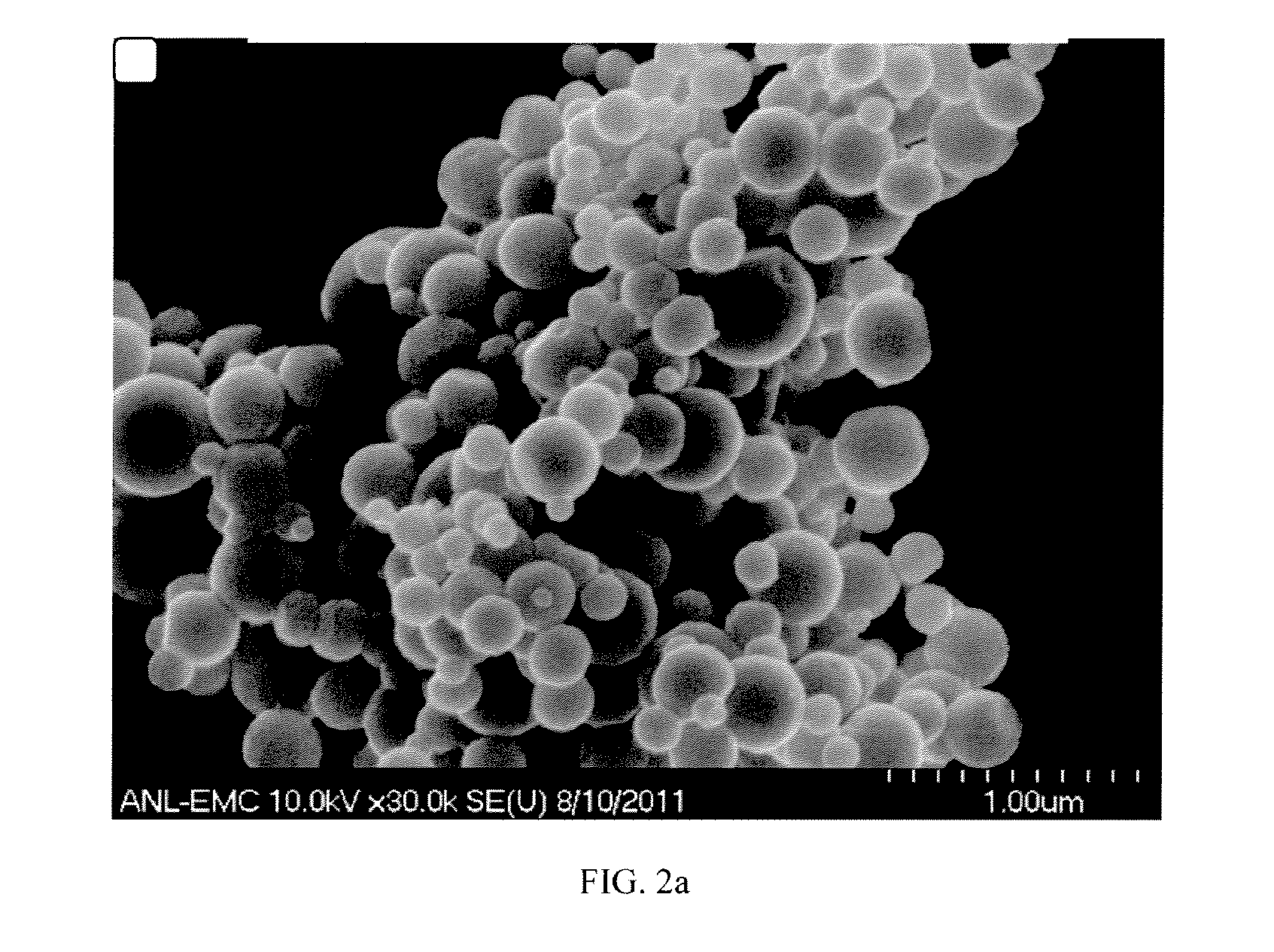

Nanoparticles for heat transfer and thermal energy storage

ActiveUS20140084205A1Increased TES storageEfficient processMaterial nanotechnologyHeat-exchange elementsThermal energy storageGraphite

An article of manufacture and method of preparation thereof. The article of manufacture and method of making the article includes an eutectic salt solution suspensions and a plurality of nanocrystalline phase change material particles having a coating disposed thereon and the particles capable of undergoing the phase change which provides increase in thermal energy storage. In addition, other articles of manufacture can include a nanofluid additive comprised of nanometer-sized particles consisting of copper decorated graphene particles that provide advanced thermal conductivity to heat transfer fluids

Owner:UCHICAGO ARGONNE LLC

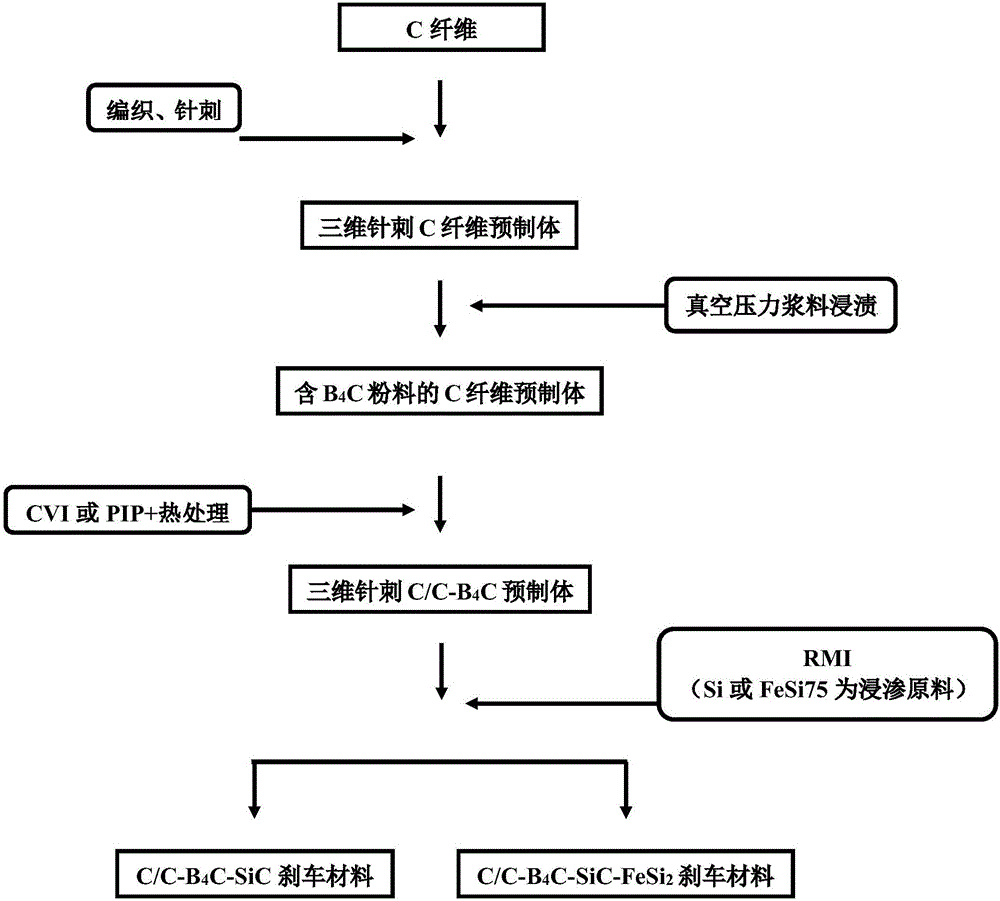

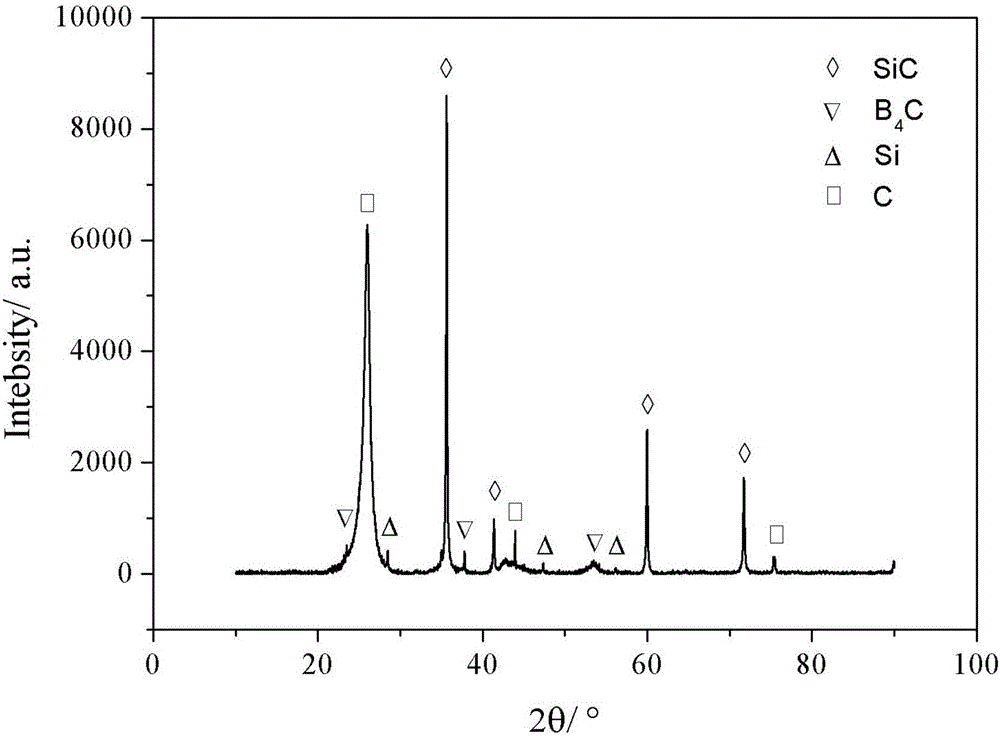

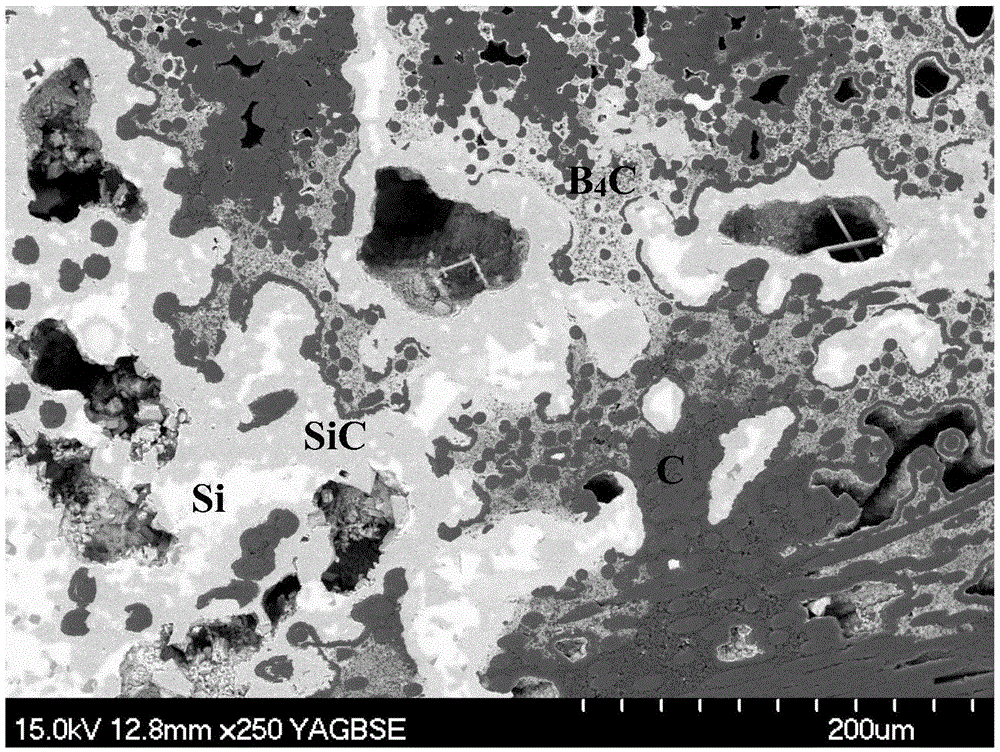

Preparation method of B4C modified C/C-SiC brake material

ActiveCN106478125AImprove friction and wear propertiesHigh specific heat capacityCarbon fibersVacuum pressure

The invention relates to a preparation method of a B4C modified C / C-SiC brake material. According to the method, a vacuum pressure dipping method is used for introducing a B4C powder material in a three-dimensional needle carbon felt with the initial density being 0.4 to 0.6g / cm<3>; CVI (chemical vapor infiltration) and RMI (reaction melt infiltration) are combined for preparing the C / C-SiC brake material. When the B4C modified C / C-SiC brake material is used, on one hand, the B4C is used as a self heeling component for achieving the protection effects on the carbon fiber and a carbon base body; the inoxidizability of the material can be obviously improved; on the other hand, the B4C has higher specific heat capacity; the integral specific heat capacity of the material can be improved; the braking temperature can be effectively reduced; the material friction performance stability is improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

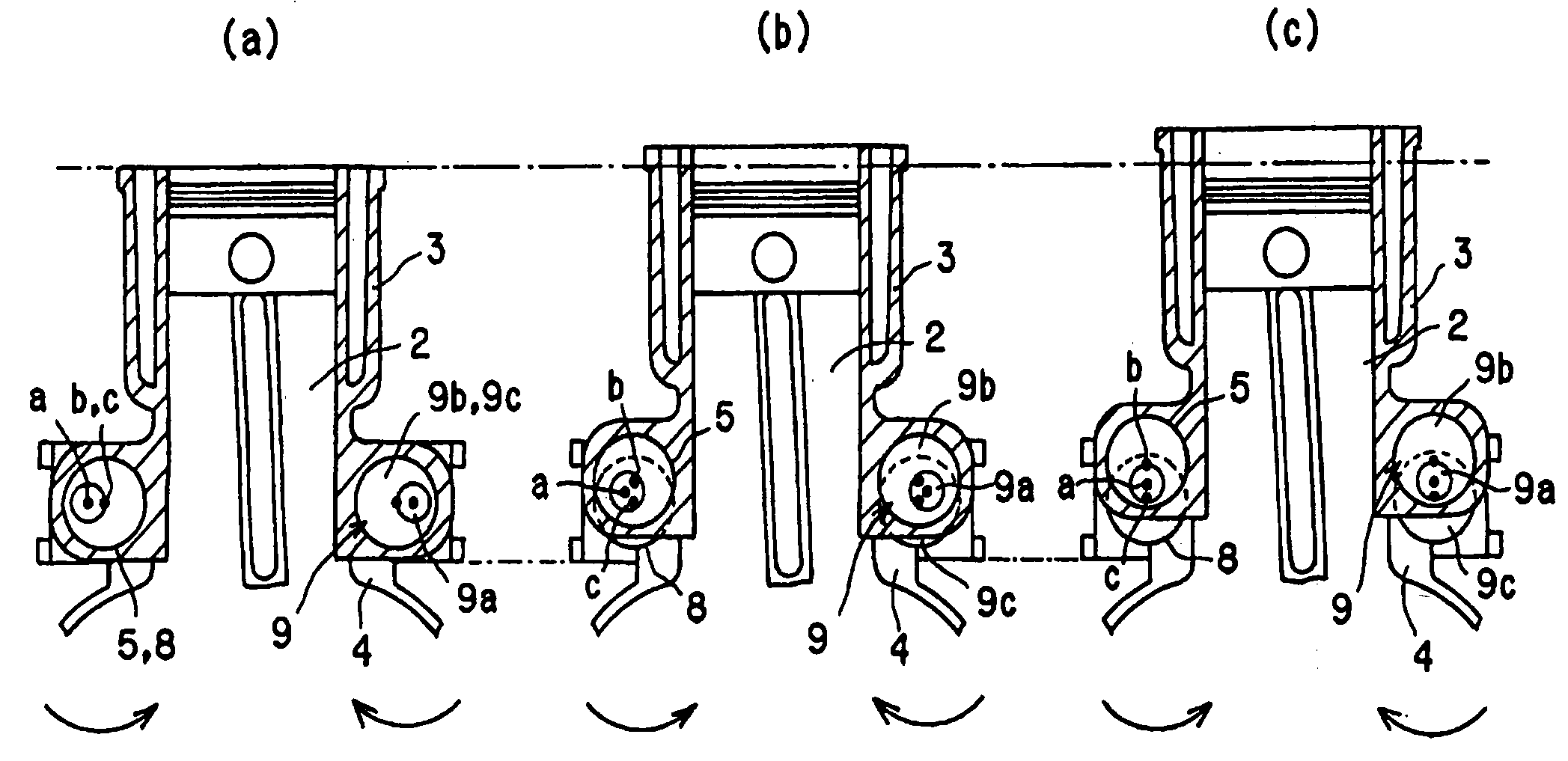

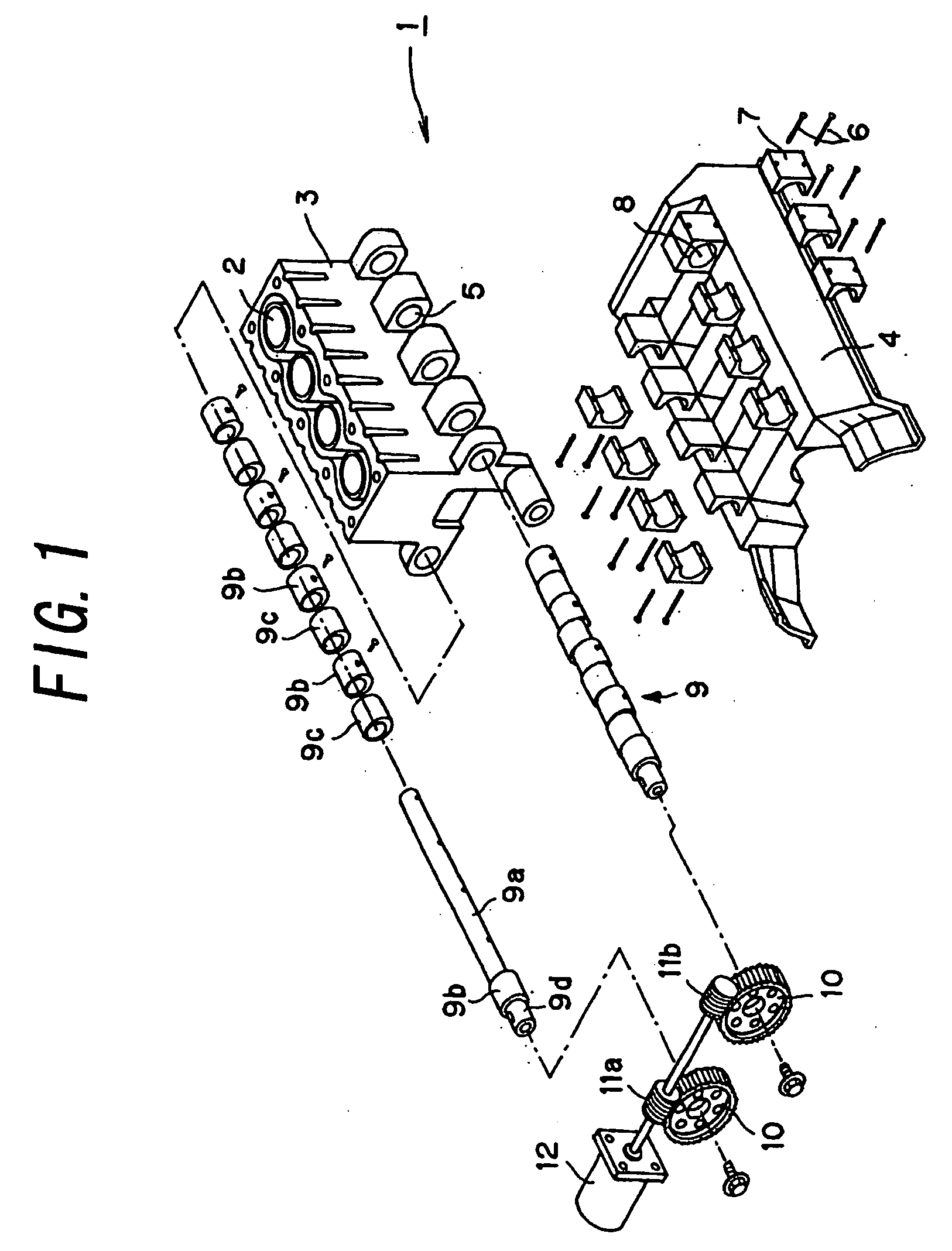

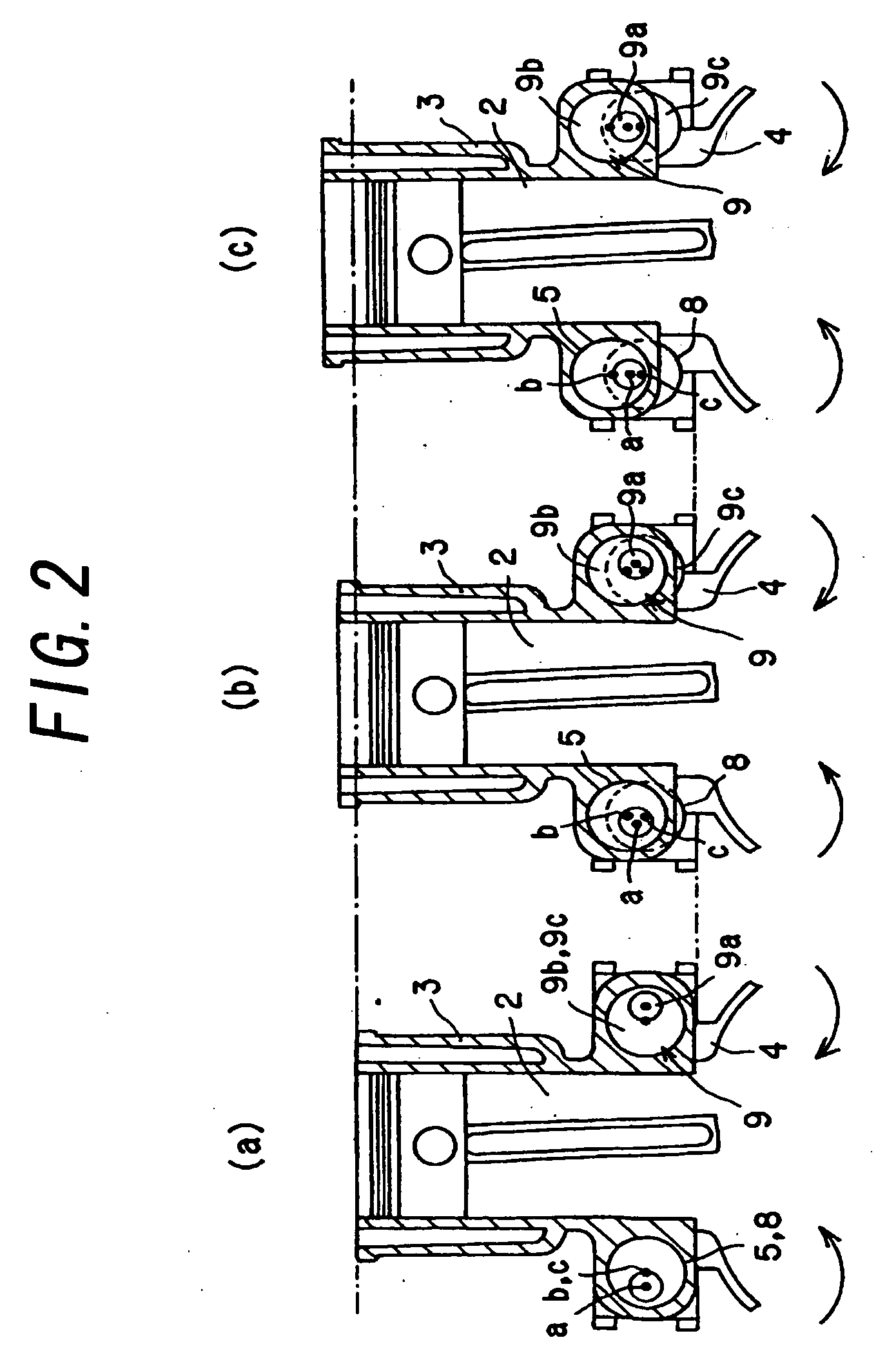

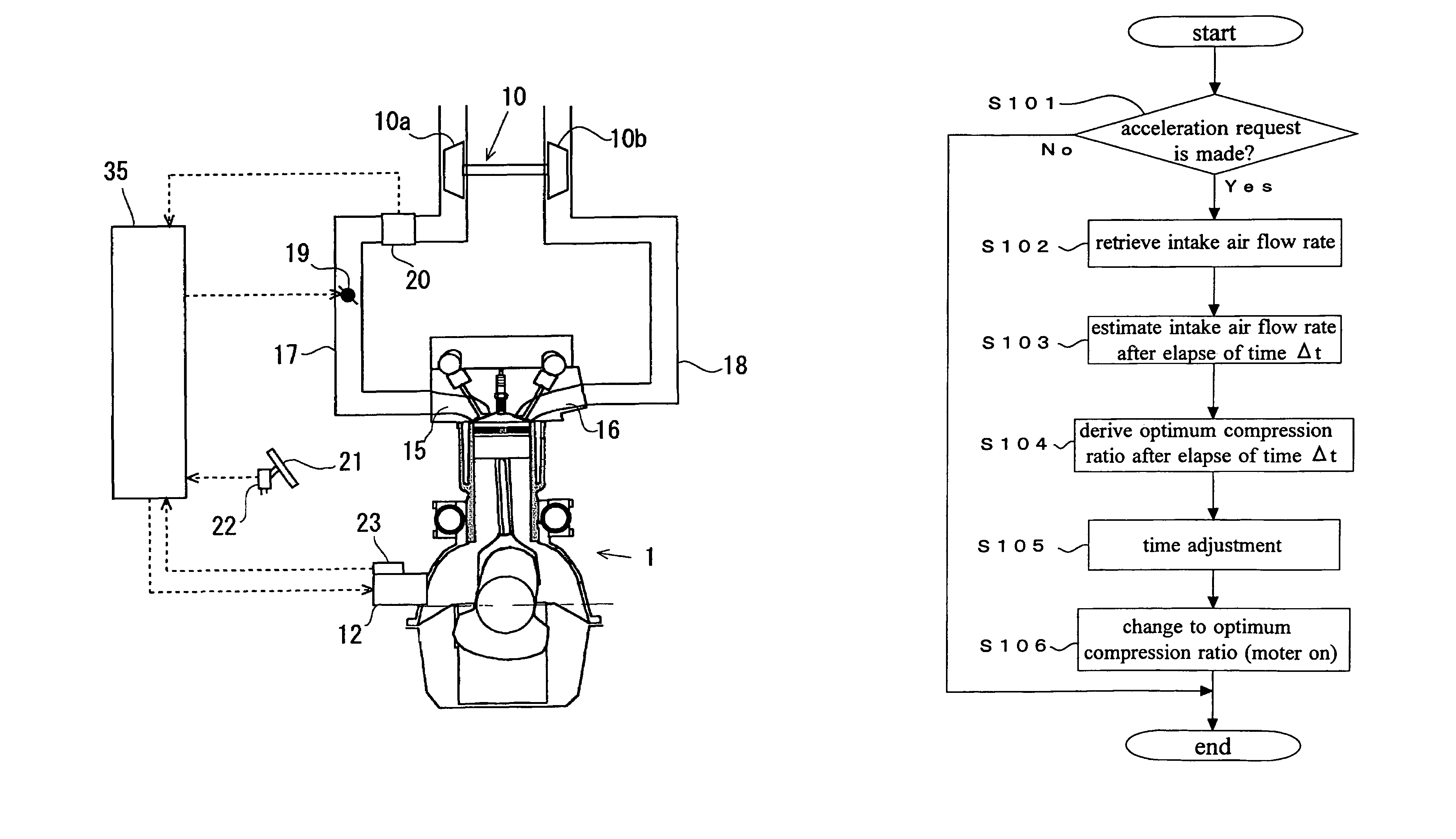

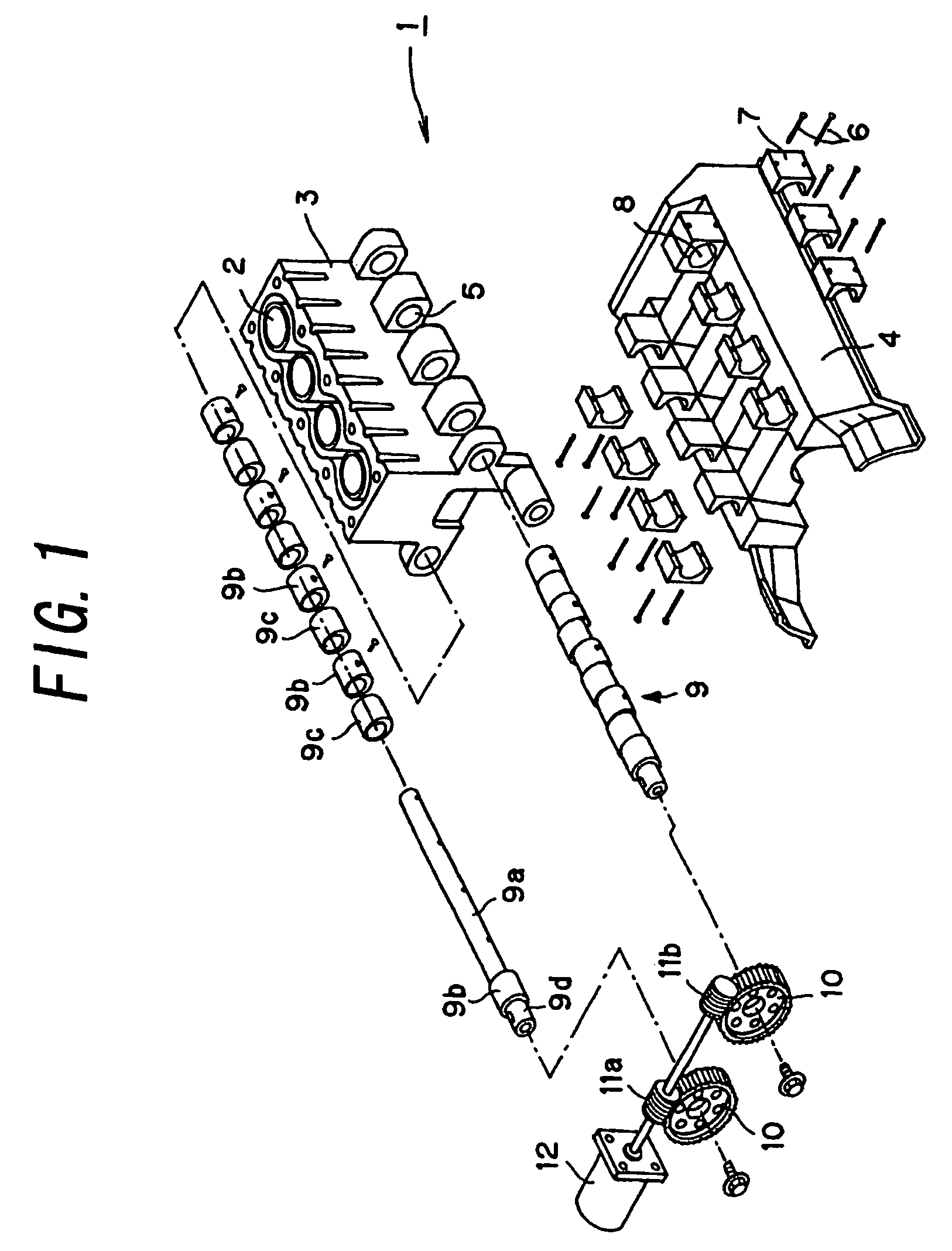

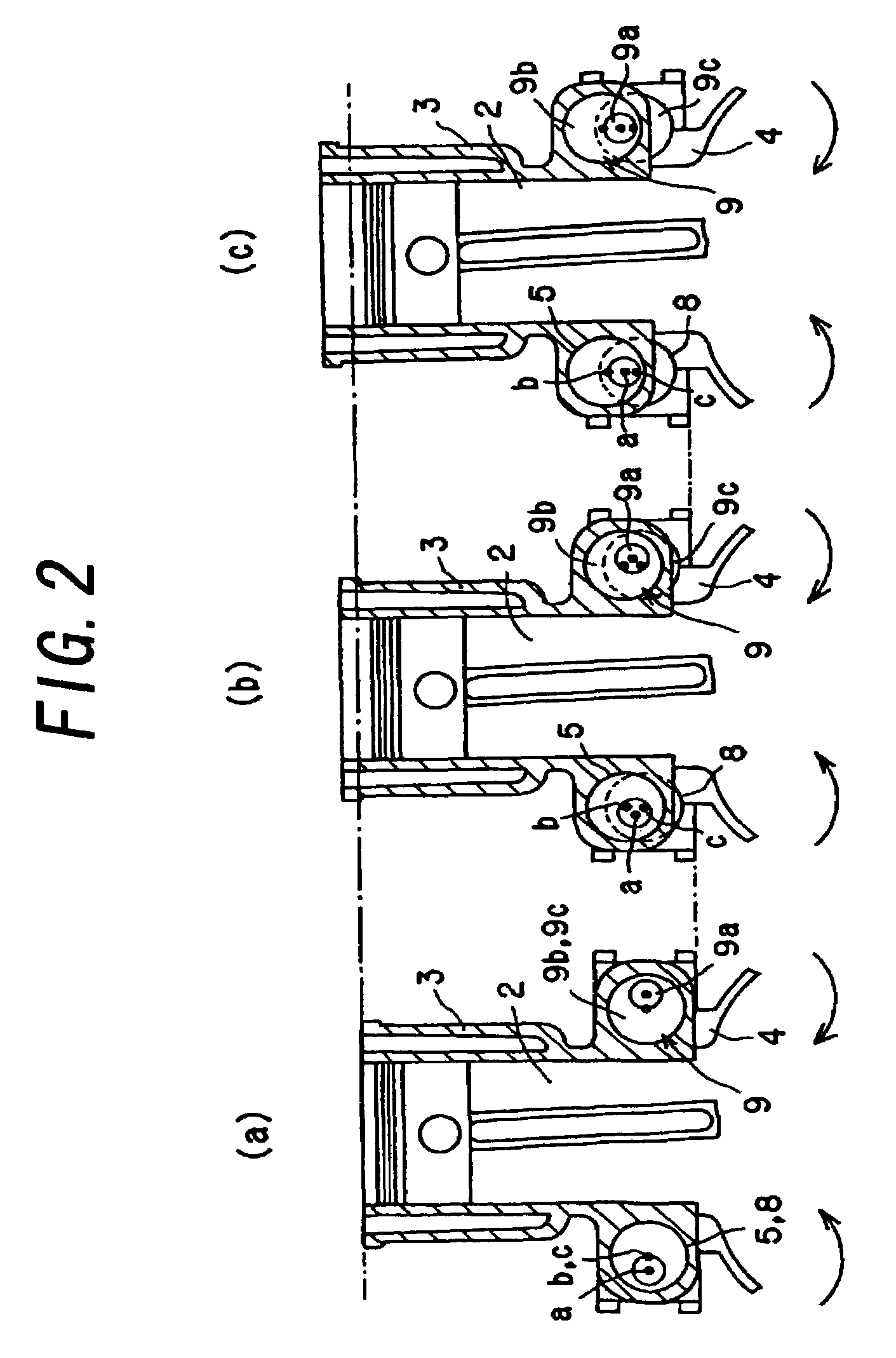

Variable Compression Ratio Internal Combustion Engine

ActiveUS20080190406A1Reduce response delayShort response timeAnalogue computers for vehiclesElectrical controlResponse delayDischarge pressure

The invention provides a technology that enables to control response delay of the supercharger in a variable compression ratio internal combustion engine under acceleration. When the variable compression ratio internal combustion engine is under acceleration, the compression ratio of the internal combustion engine is set to a compression ratio lower than a basic compression ratio that is so determined in accordance with the running condition of the internal combustion engine to realize a predetermined heat efficiency while suppressing knocking, thereby raising the exhaust gas pressure and shortening the response time of the supercharger.

Owner:TOYOTA JIDOSHA KK

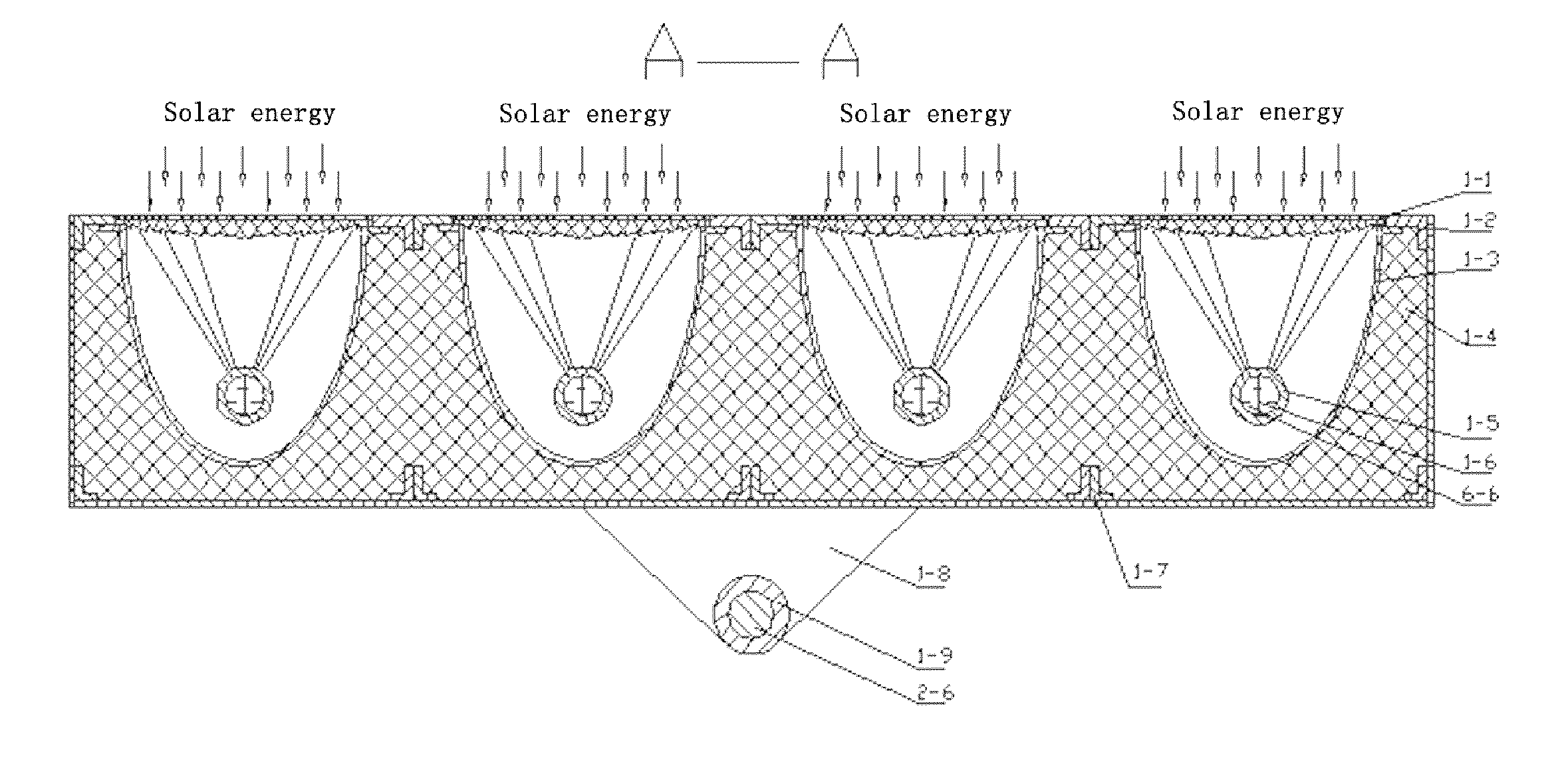

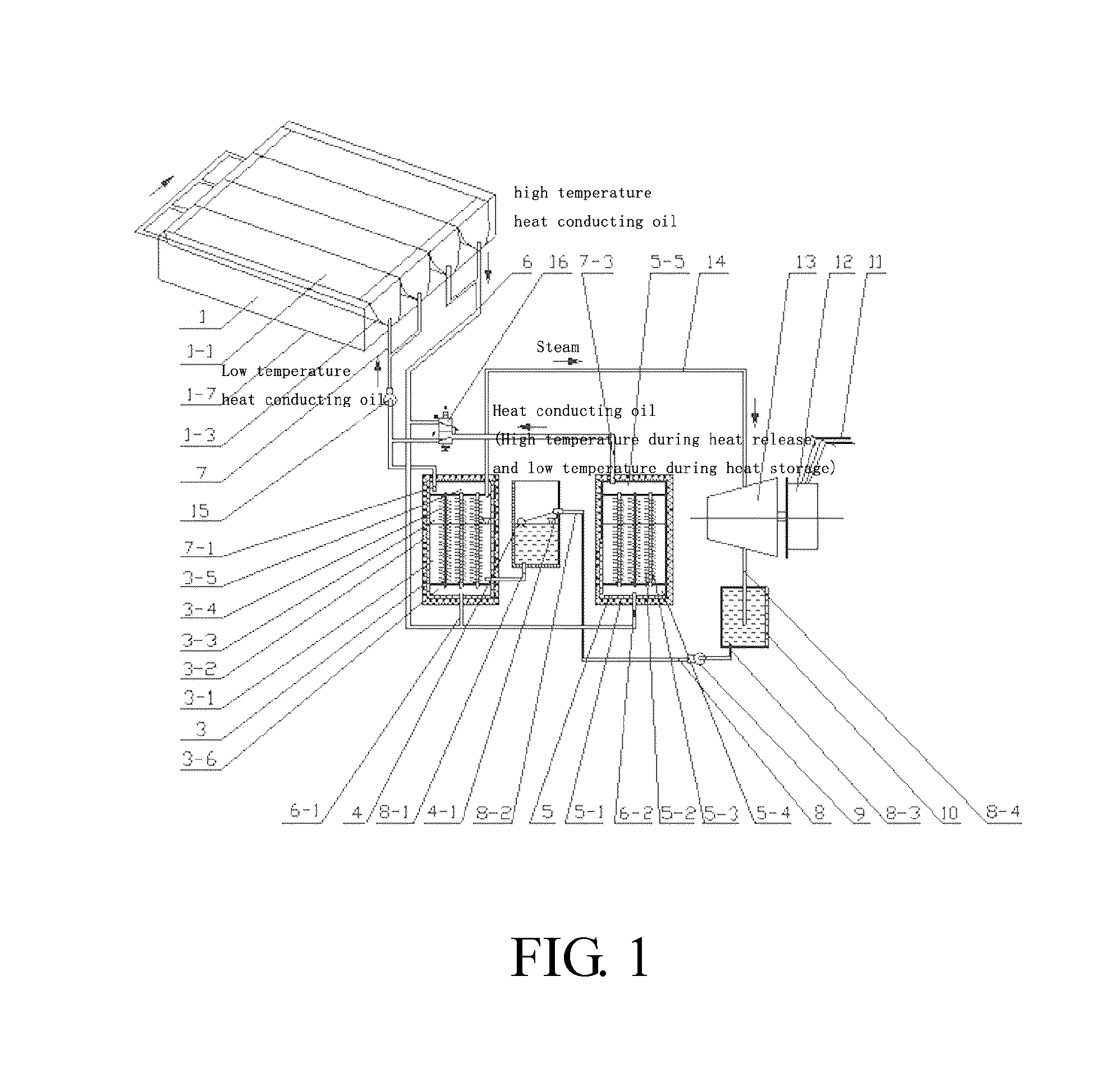

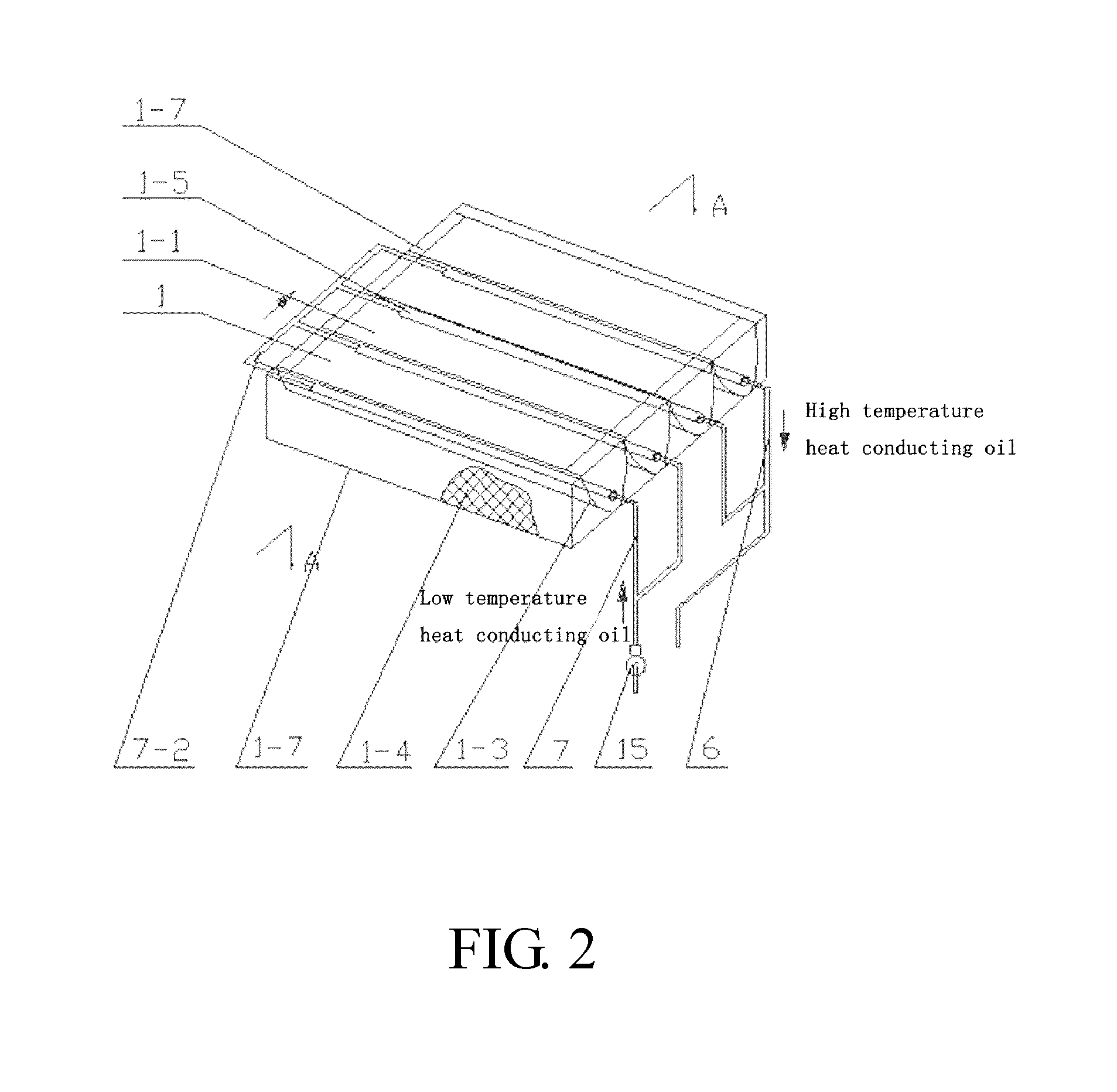

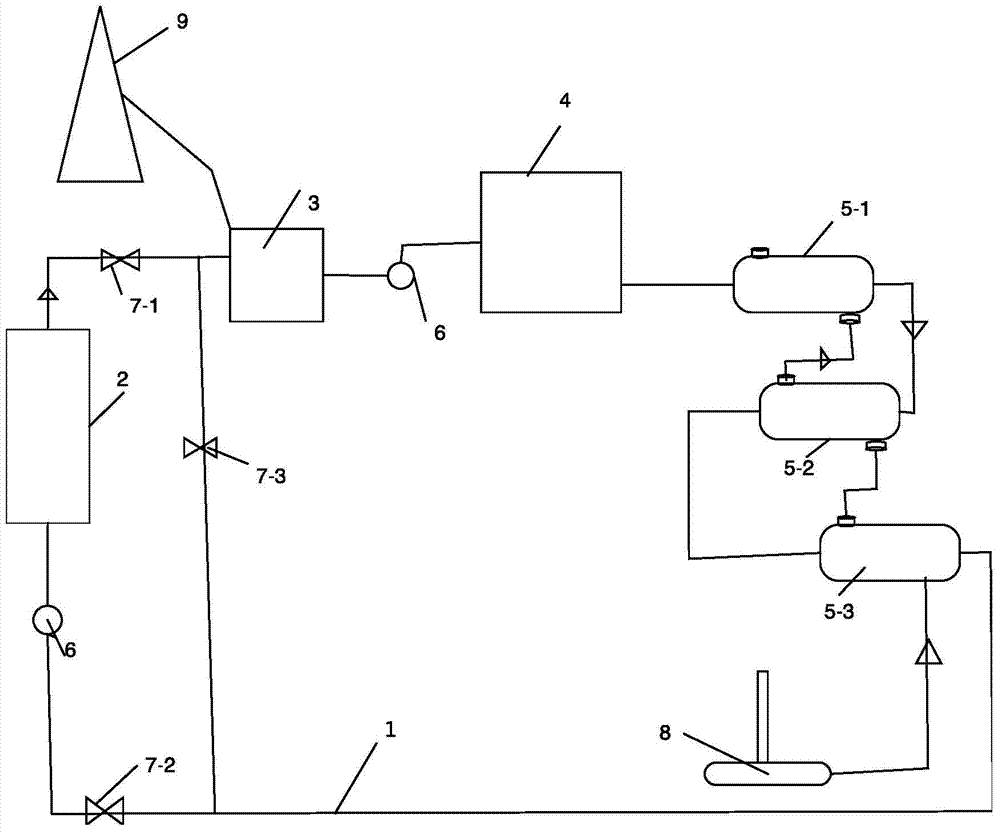

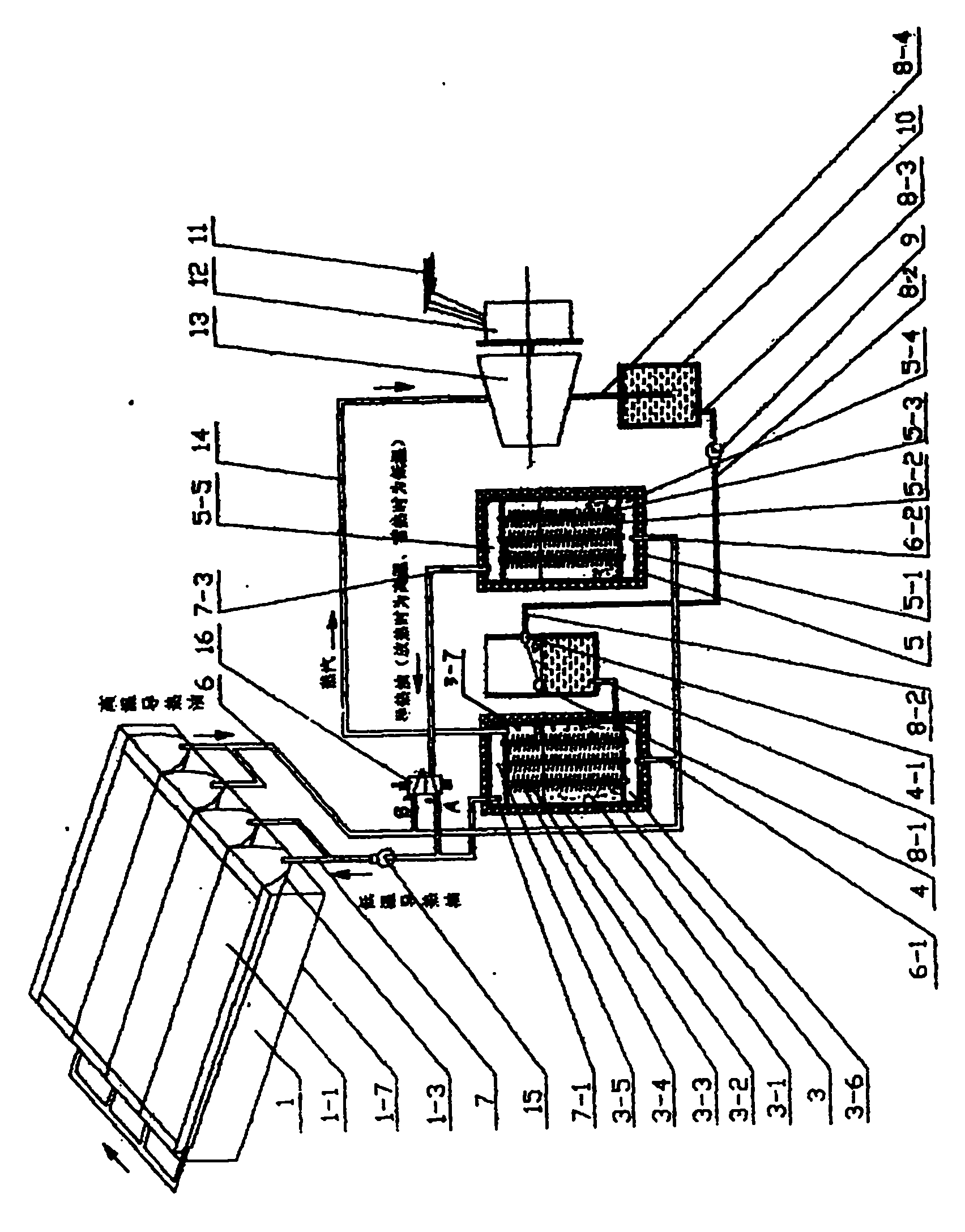

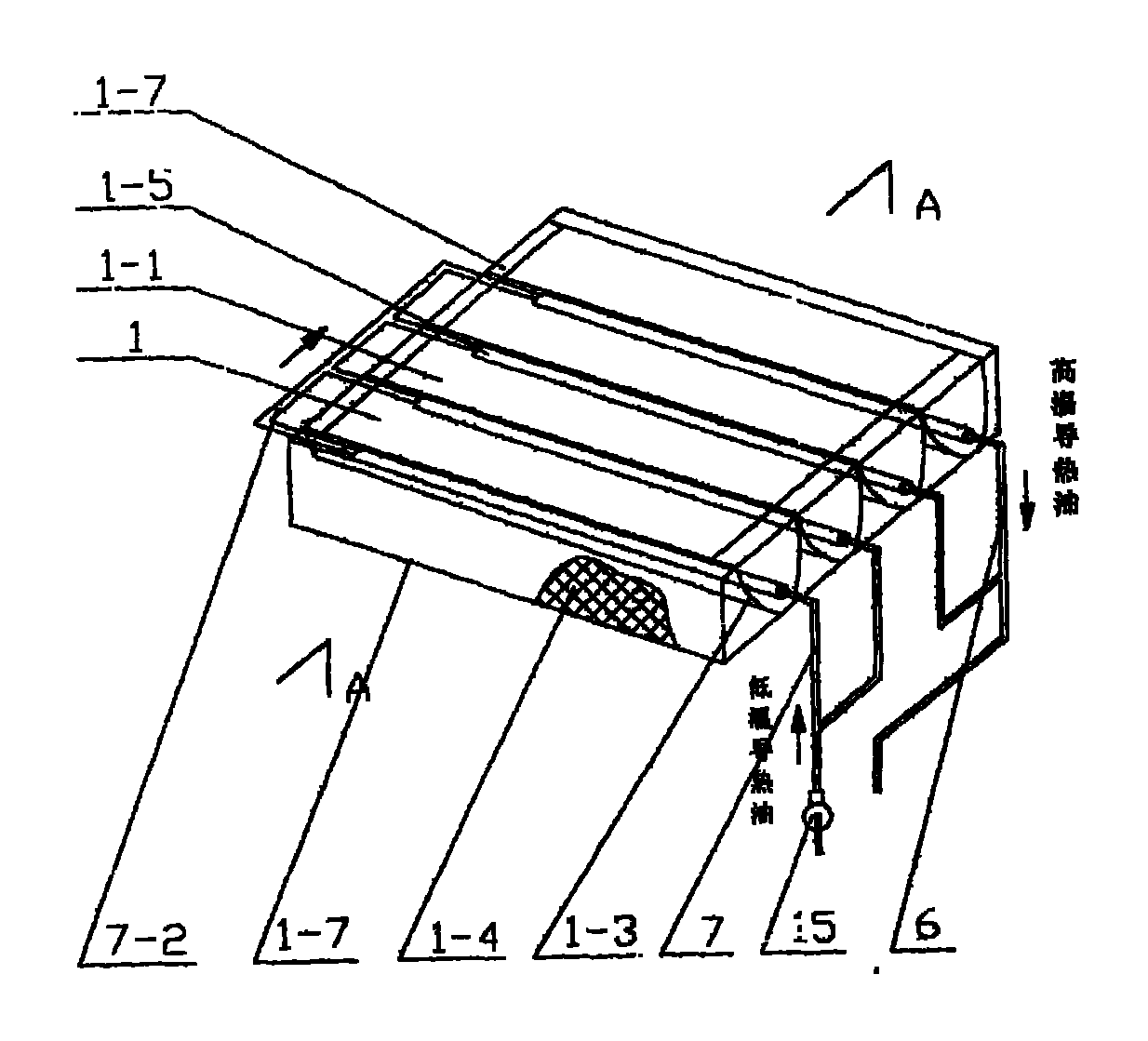

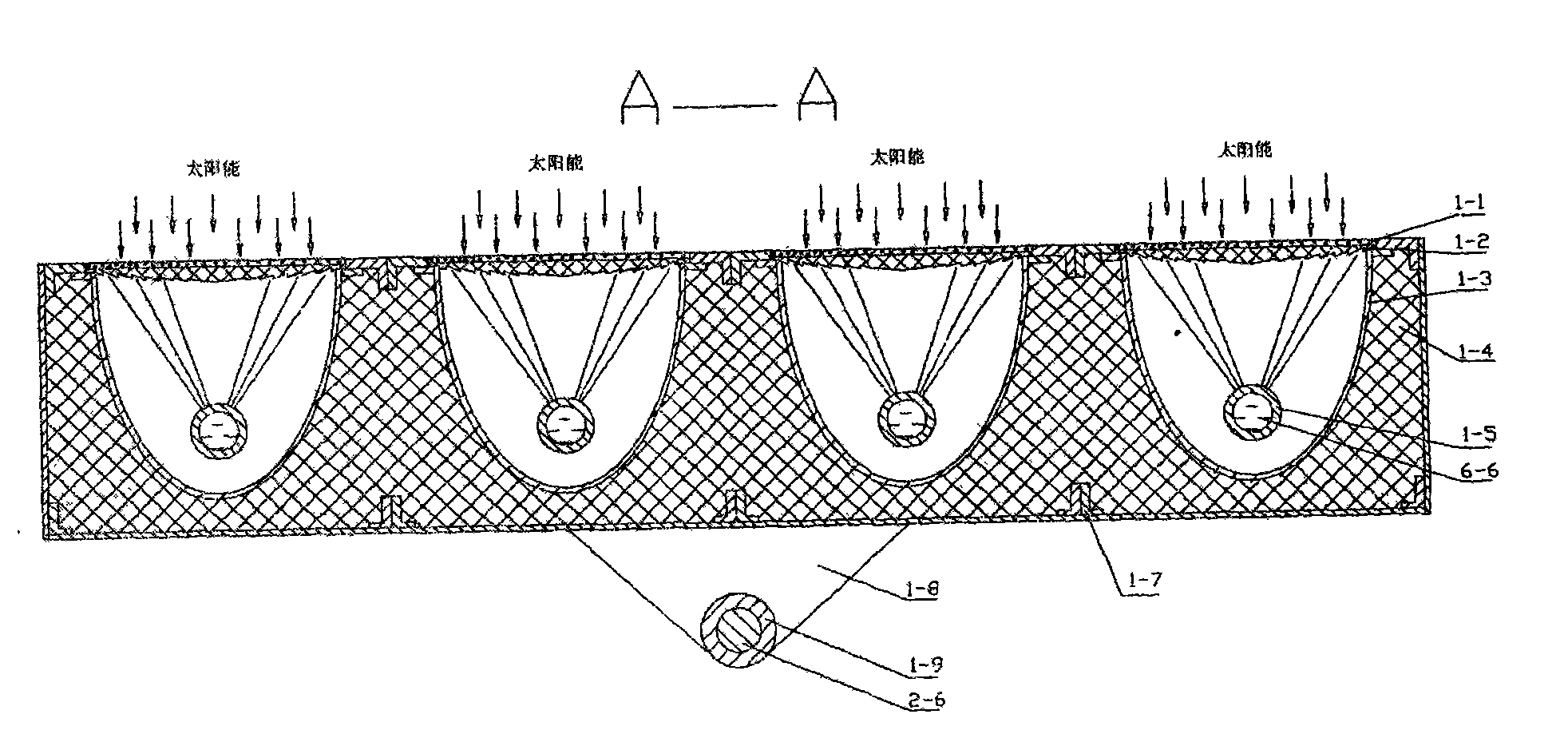

Ground high-temperature high-efficiency solar steam electricity-generating device

InactiveUS20130219889A1Improve economic efficiencySmall sizeSolar heating energySolar heat devicesWarm waterHeat conducting

A ground high-temperature high-efficiency solar steam electricity-generating device includes a light convergence assembly (1), a heat exchanger assembly(3), a heat storage chamber assembly(5), a base assembly(2), an oil pump(15), a temperature-controlling valve(16), a steam turbine(13), temperature-controlling valve (16), a steam turbine (13), an electricity-generator (12), a system control circuit, a water pump (9) and a water tank assembly (10). The light convergence assembly (1) includes a glass plate (1-1), Fresnel lenses, a U-shaped groove (1-3), a thermal insulating material, a heat collecting pipe (1-5), high temperature heat conducting oil(6-6), a frame (1-7), a rib-plate and a spindle sleeve. The high temperature heat conducting oil(6-6) in the heat collecting pipe (1-5) is communicated with the heat exchanger assembly (3) and the heat storage chamber assembly (5), so that the warm water in the heat exchanger assembly (3) is quickly converted into high temperature steam which drives the steam turbine (13) and the electricity-generator (15) to generate electrical energy. The device can realize high solar utilization, high automaticity, simple structure, lower cost, small size, and is safe and reliable.

Owner:GUANGDONG FUXING FOOD MACHINERY

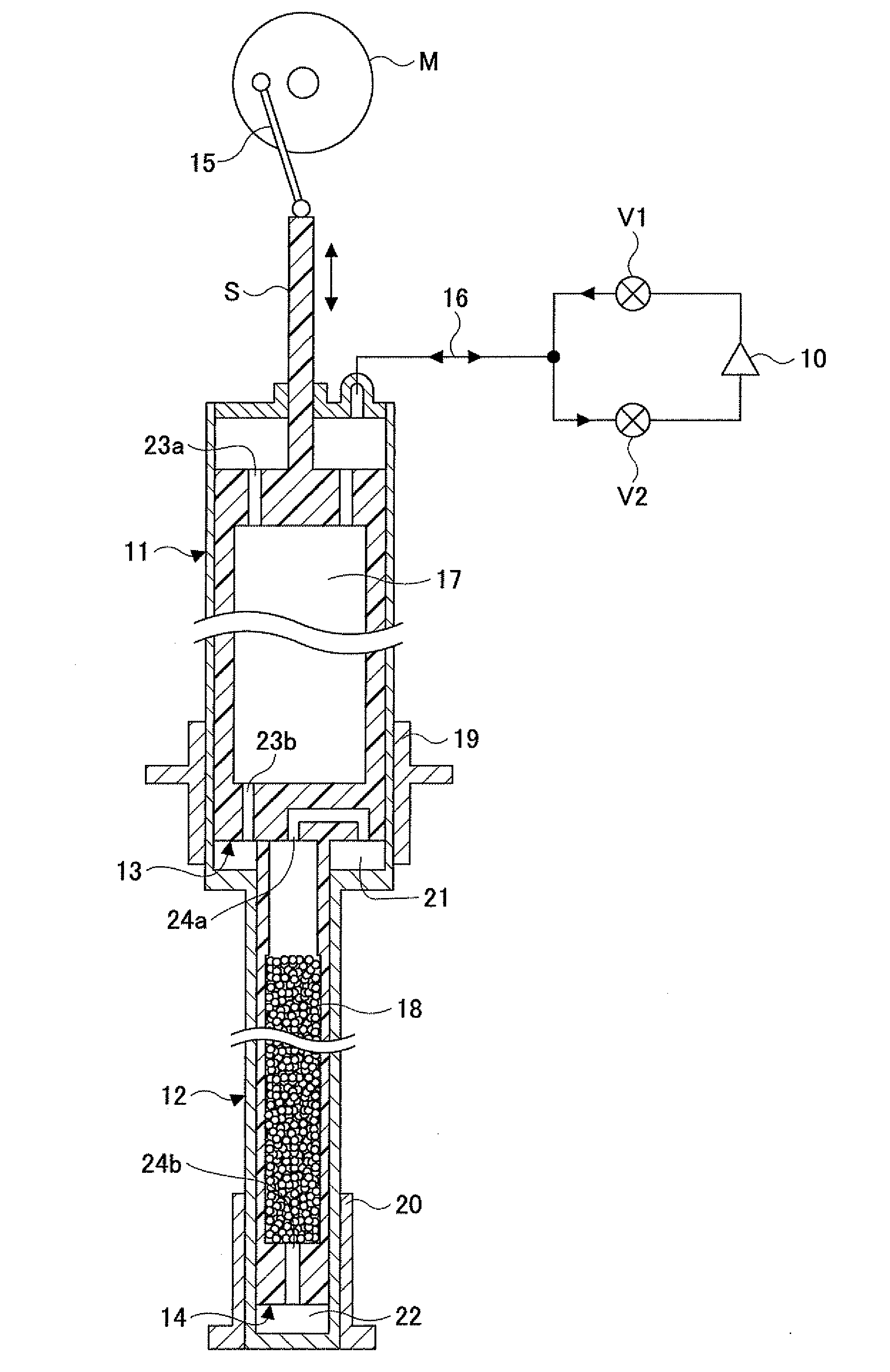

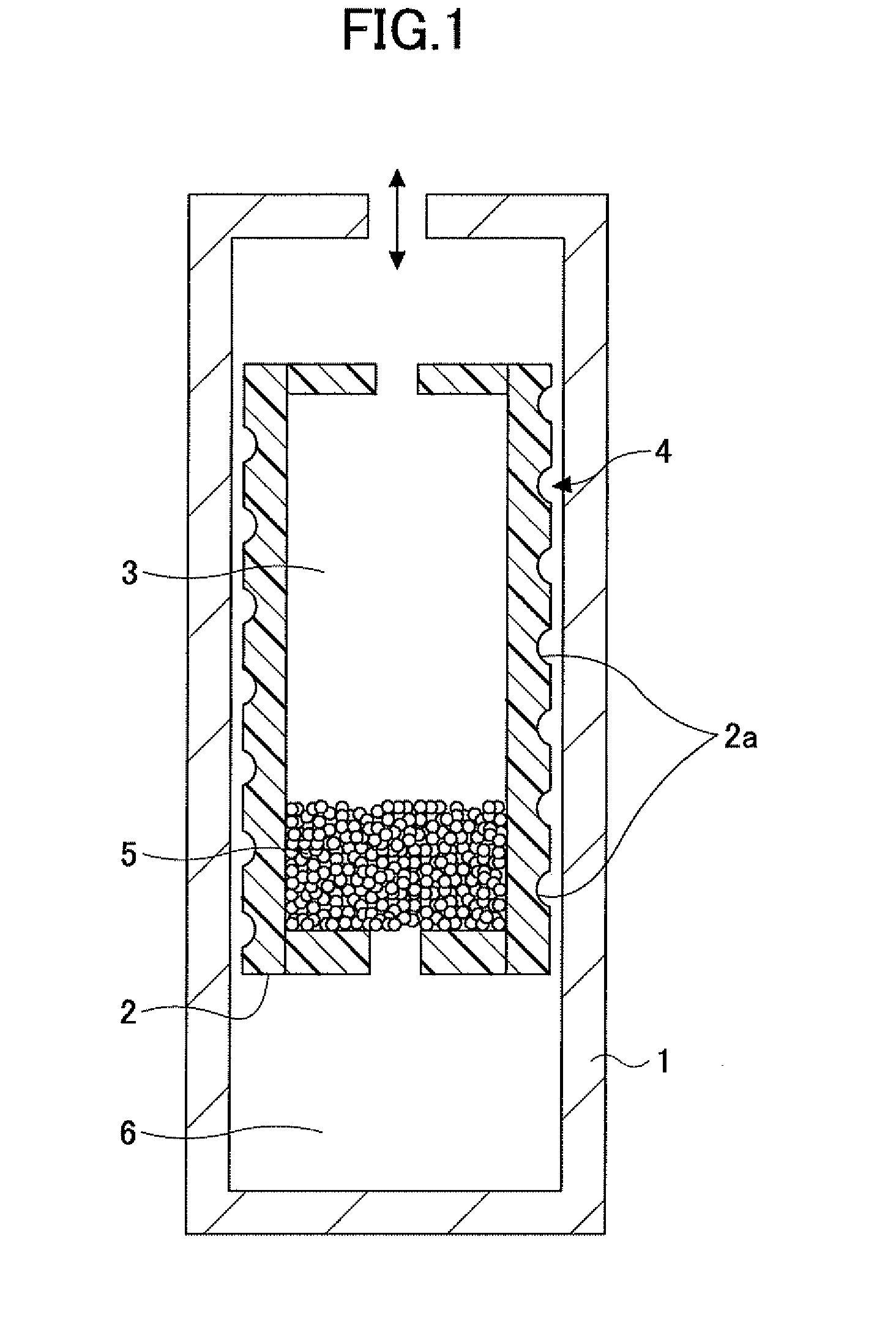

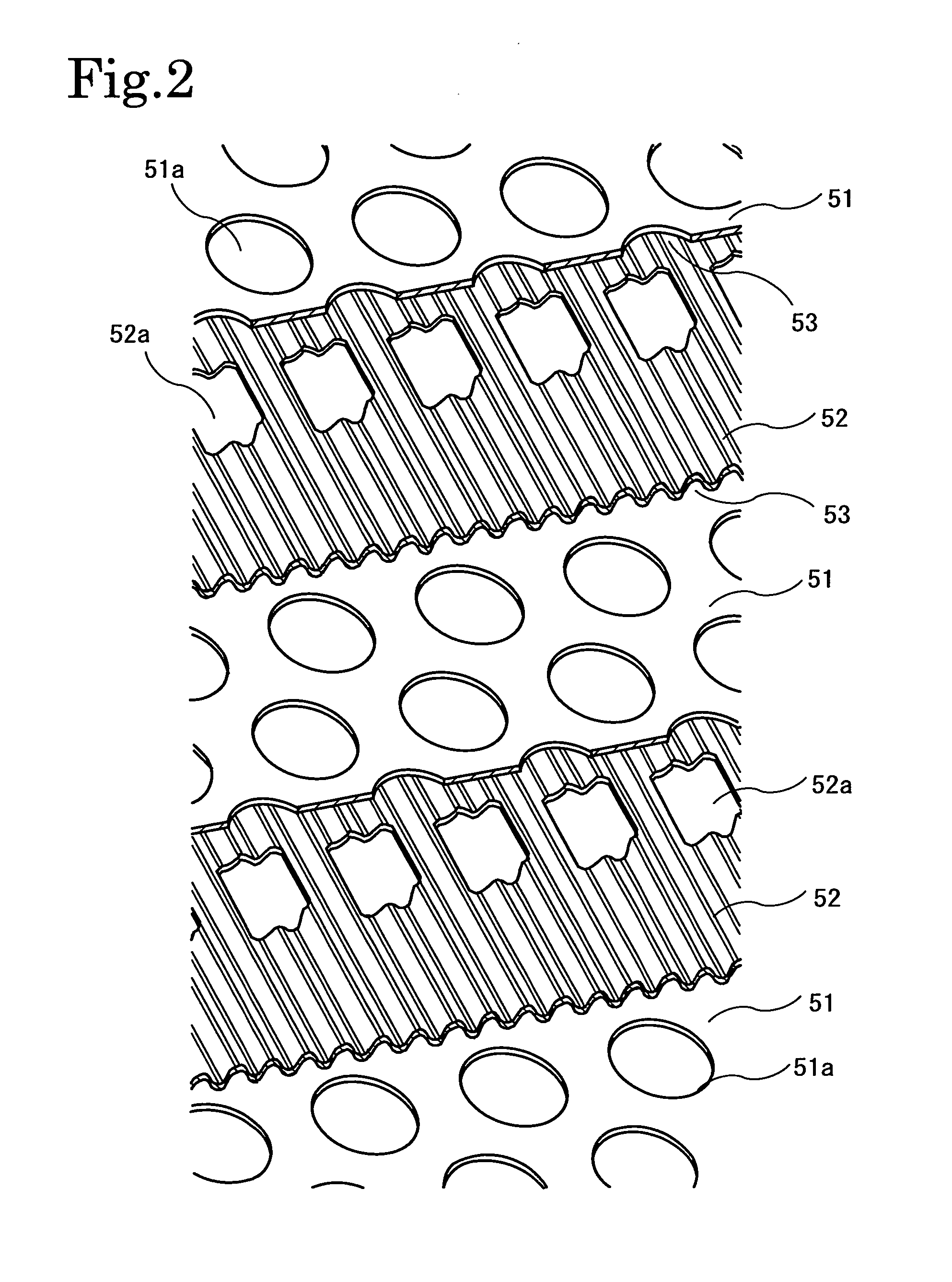

Regenerative refrigerator

InactiveUS20100229572A1Low thermal conductivityImprove air tightnessCombustion processCompression machinesEngineeringRefrigerated temperature

A regenerative refrigerator includes a cylinder; a displacer provided in the cylinder; a groove pattern formed on the exterior circumferential surface of the displacer or the interior circumferential surface of the cylinder to form a first gas passage connecting one end and the other end of the exterior or interior circumferential surface, and including a groove having at least part thereof extending along a direction to cross the axial directions of the displacer to cause gas flowing from the one end to the other end in the gap between the exterior and interior circumferential surfaces to actively exchange heat with the cylinder and the displacer; a second gas passage to and from an expansion space; and a regenerator material formed of bismuth granules and provided in at least part of the second gas passage, wherein the lowest attainable temperature is 5 K to 15 K in an unloaded state.

Owner:SUMITOMO HEAVY IND LTD

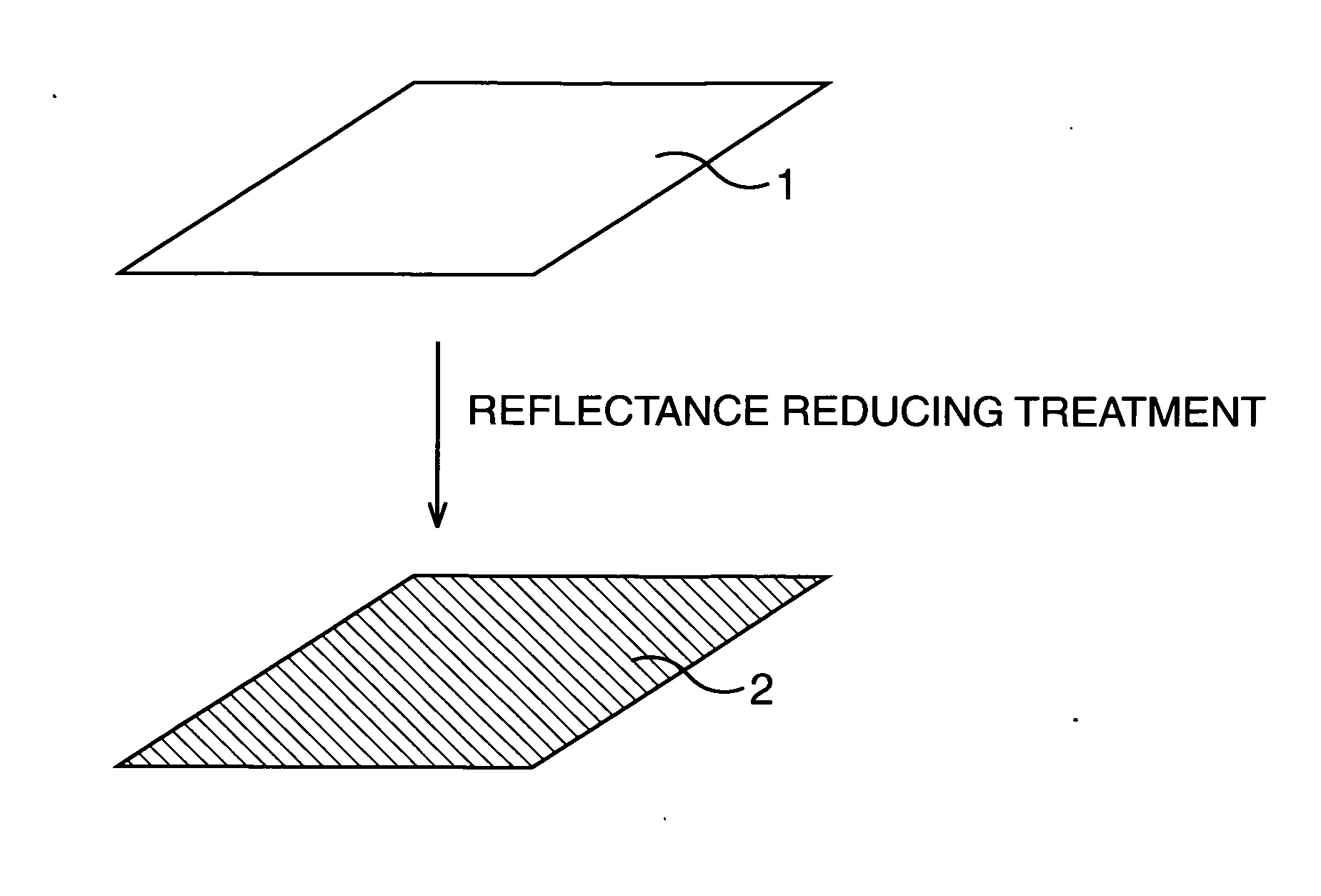

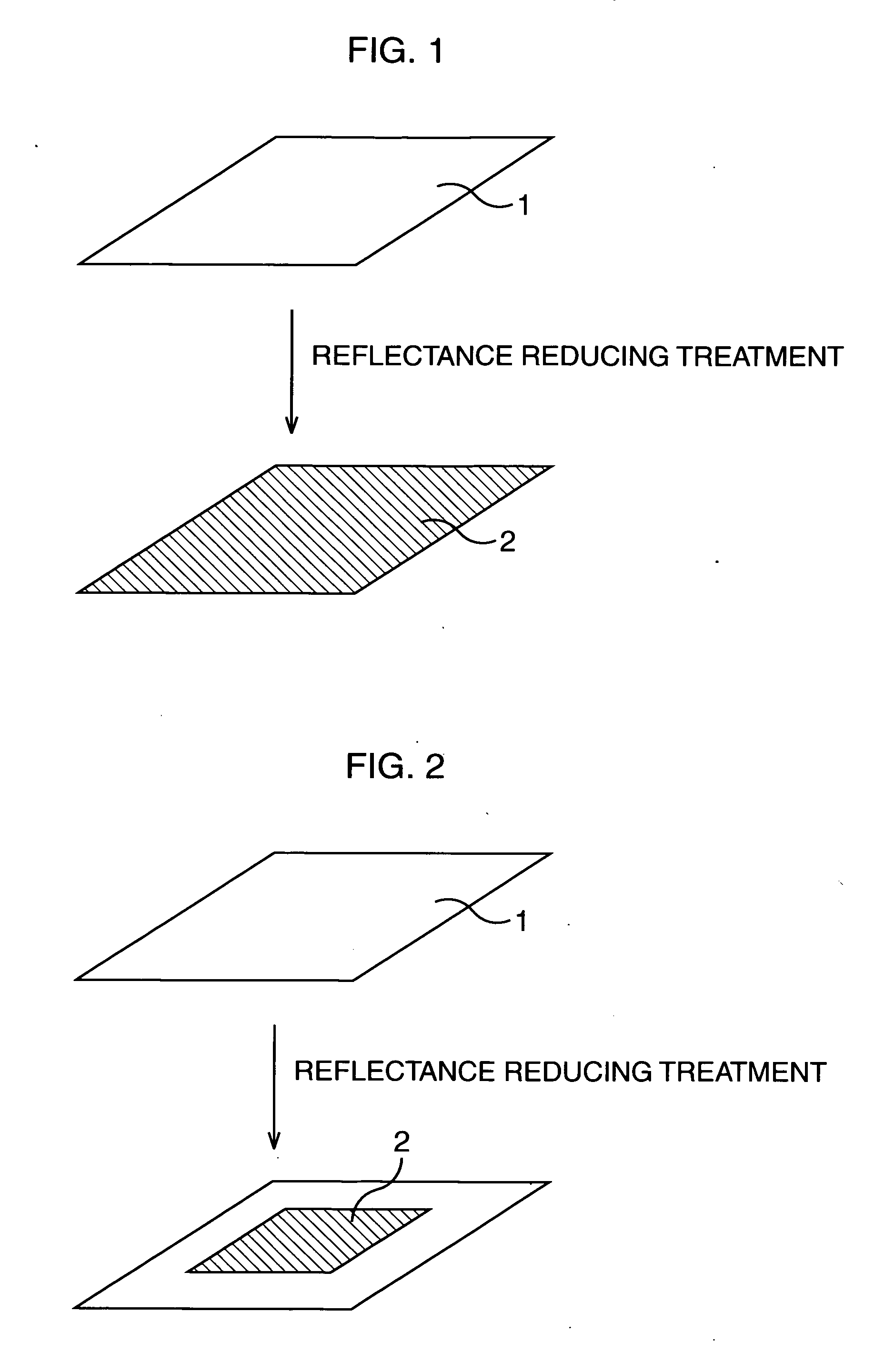

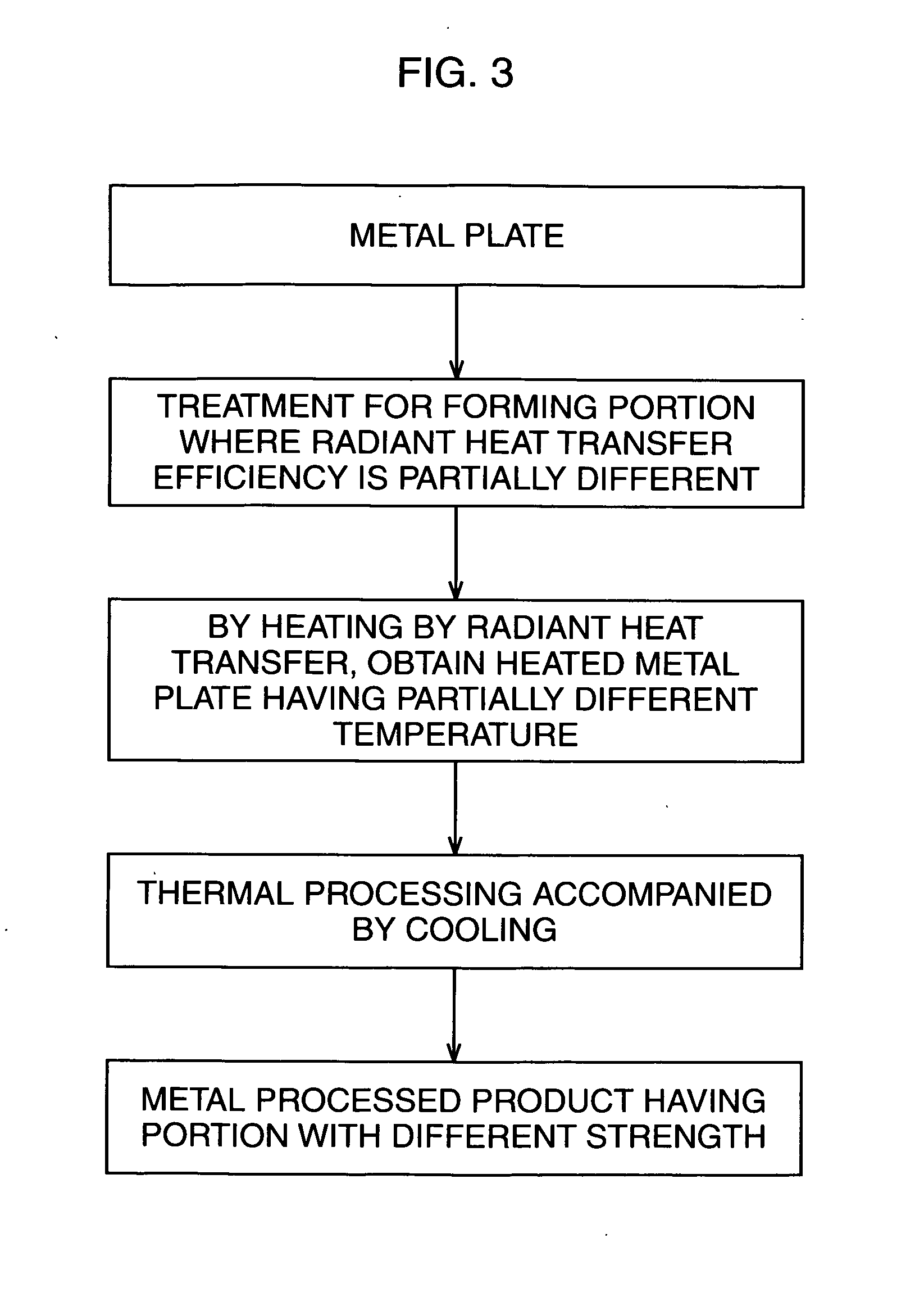

Metal plate to be heated by radiant heat transfer and method of manufacturing the same, and metal processed product having portion with different strength and method of manufacturing the same

ActiveUS20120135263A1Improve heating efficiencySpecific heatMolten spray coatingDomestic stoves or rangesHot stampingThermal spraying

On part of a surface of a metal plate that is to be heated by radiant heat transfer with a near-infrared ray, a region where reflectance for a radiant ray is made lower than that of the original surface of the metal plate is formed. As reflectance reducing treatment, painting or thermal spraying in a blackish color, plating in a blackish color, treatment for increasing roughness of the surface of the metal plate, blasting, etching, blackening, surface layer quality changing treatment of the metal plate, or the like can be adopted. The metal plate is turned into a heated metal plate partially having a different temperature by being heated by radiant heat transfer, and thereafter, the heated metal plate is subjected to thermal processing accompanied by cooling, for example, by hot stamping.

Owner:NIPPON STEEL CORP

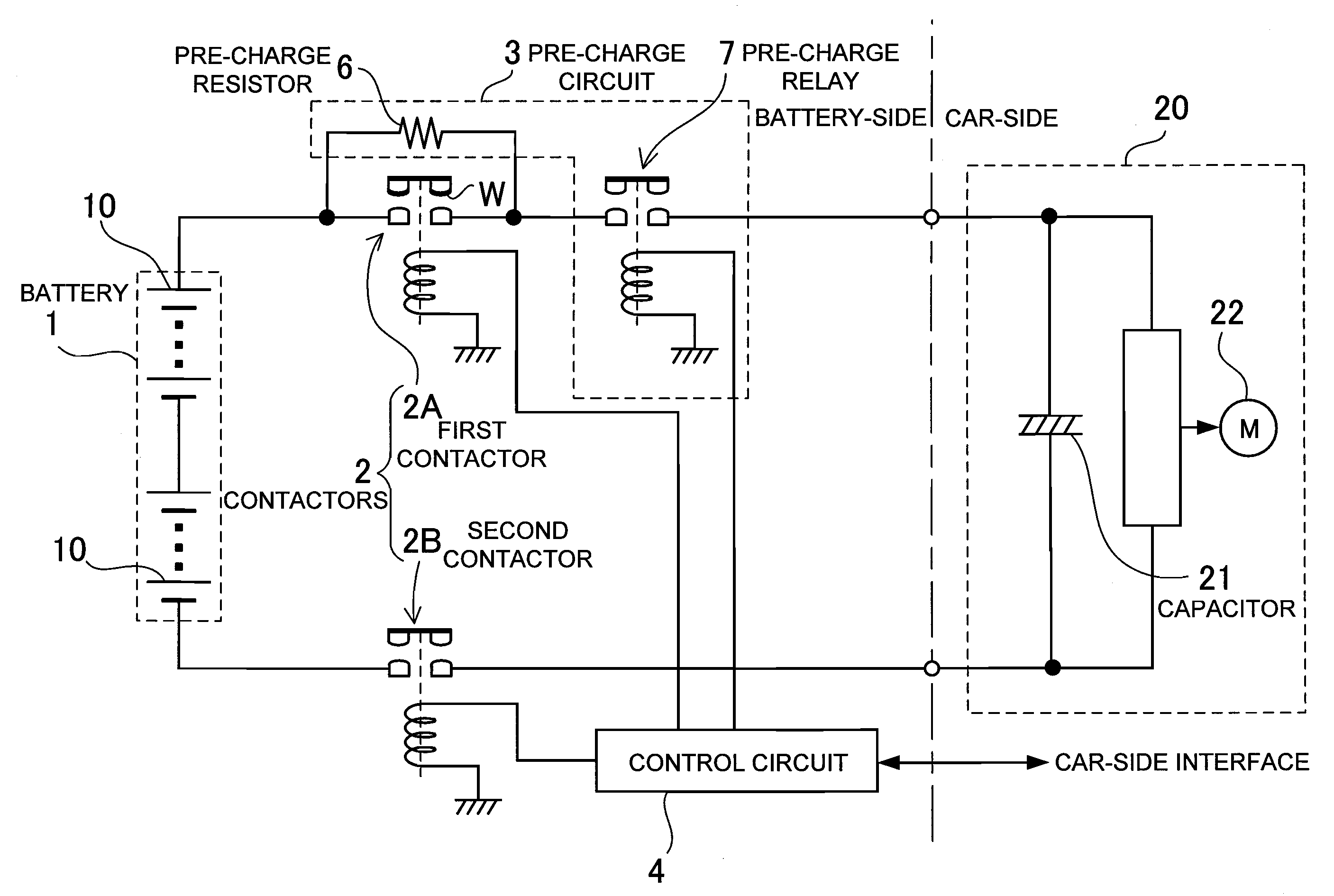

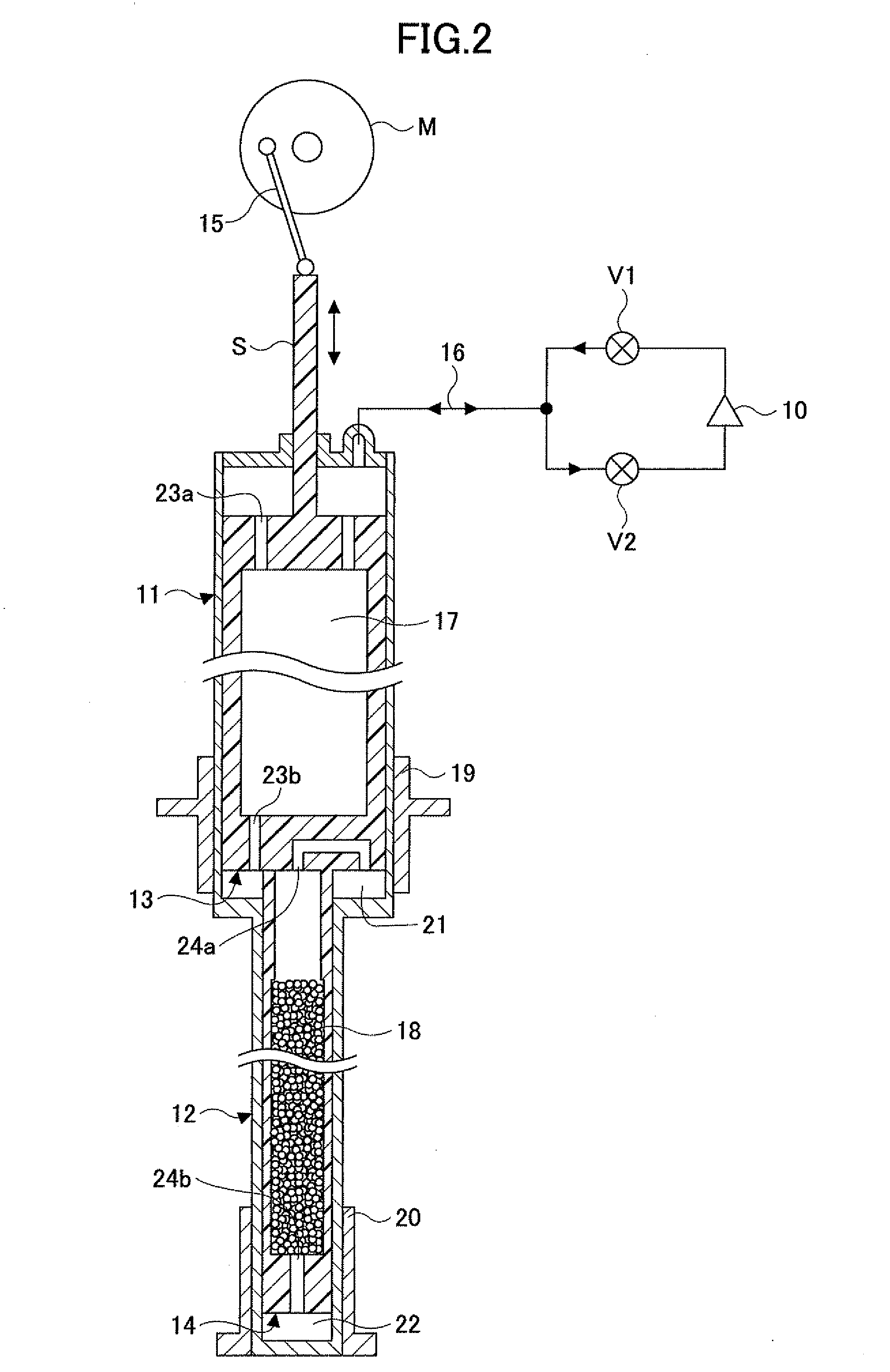

Car power source apparatus

InactiveUS8063506B2Long lastingProbability of contacts fusing togetherElectric devicesElectric powerElectrical batteryEngineering

A power source apparatus of a car is provided with contactors (2) connected to an output-side of a battery (1); a pre-charge circuit (3) made up of a series connected pre-charge resistor (6) and a pre-charge relay (7), which is connected with a contactor (2) to supply auxiliary charge to a capacitor (21) connected to a car-side of the battery (1); and a control circuit (4) to control the contactors (2) and the pre-charge relay (7). The pre-charge resistor (6) is connected in parallel with a contactor (2), and the pre-charge relay (7) is connected in series with that contactor (2). The control circuit (4) switches the pre-charge relay (7) ON to pre-charge the car-side capacitor (21), and then switches the contactor (2) ON to connect the battery (1) to the car-side.

Owner:SANYO ELECTRIC CO LTD

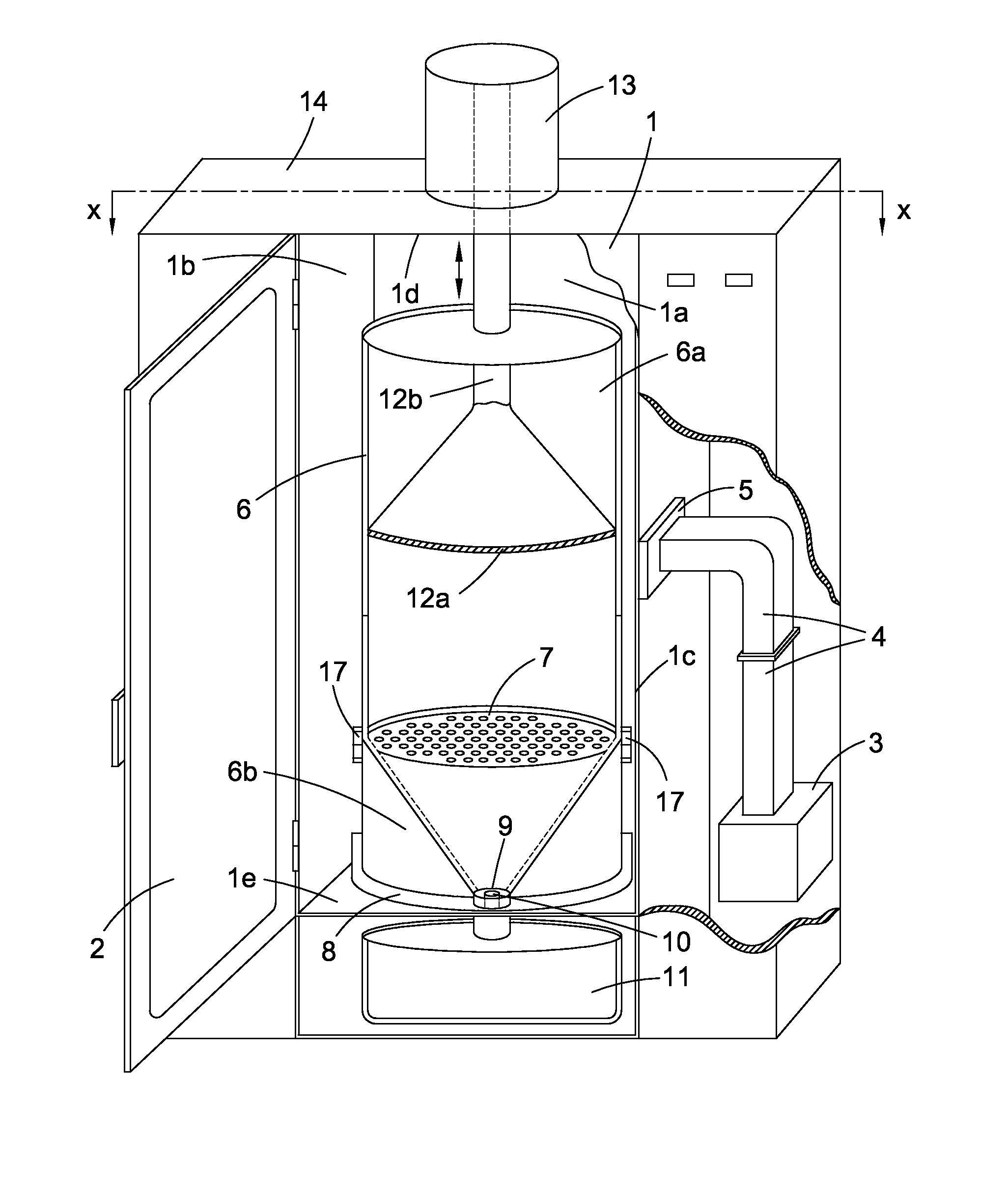

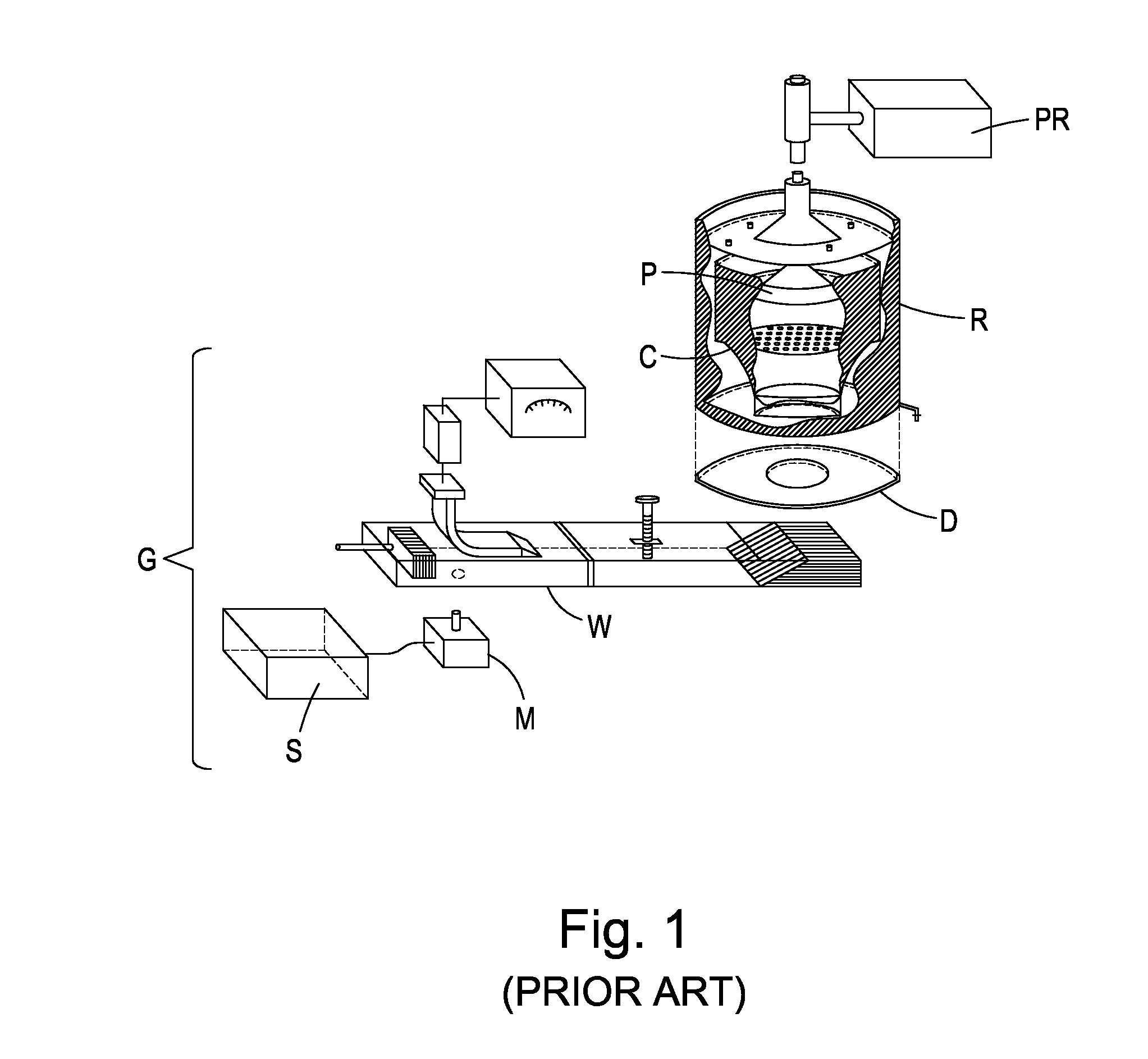

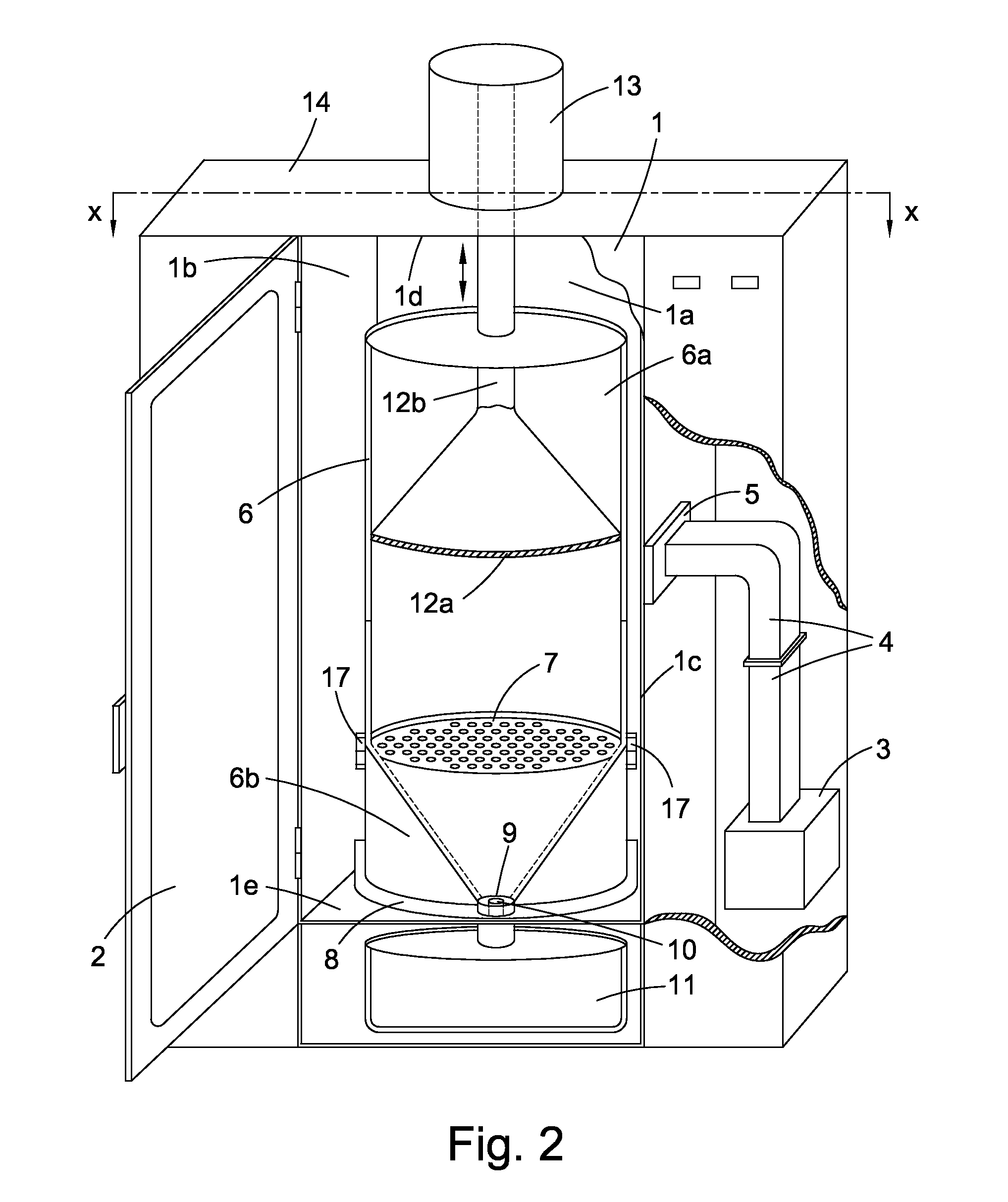

Microwave press extraction apparatus

ActiveUS20160213052A1Minimal costEasy to useJuice extractionMicrowave heatingResonant cavityMicrowave

A press apparatus comprising a microwave energy source, a resonator cavity to receive microwave energy from the microwave energy source and to resonate the microwave energy within the resonator cavity, the resonator cavity having a peripheral side, a top side and a bottom side, a food container for receiving food from which juice is extracted, the container adapted to be located within the resonator cavity for heating the food using the microwave energy, the food container having a peripheral side, a top side and a bottom side, a plunger to press the food inside the food container, a press mechanism located outside the resonator cavity and in force communication with the plunger for exerting mechanical pressure on the food inside the food container during the heating operation for extracting the juice; and a juice collector located outside the resonator cavity in fluid communication with the container for collecting the juice.

Owner:AL GHURAIR UNIVERSITY

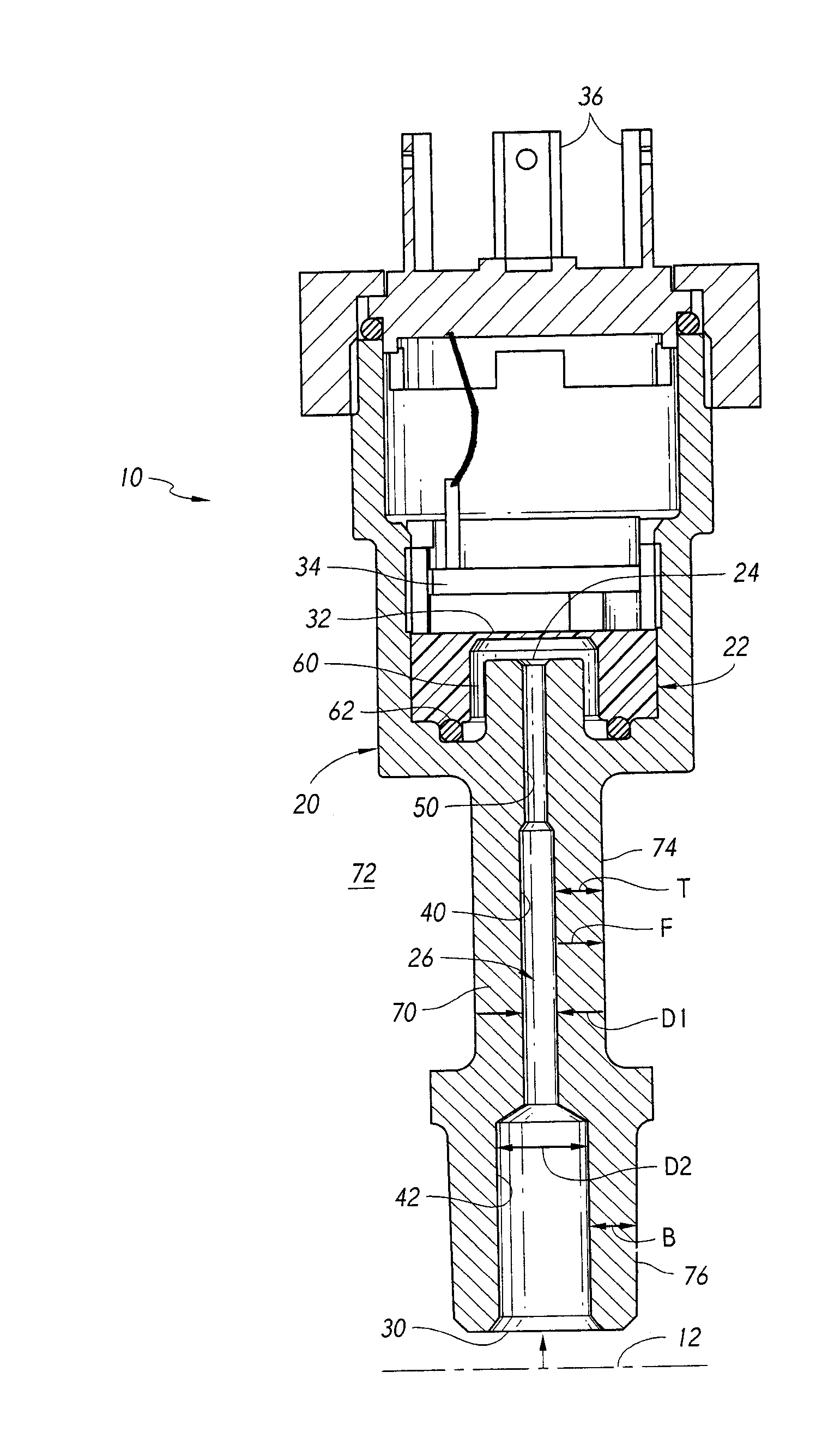

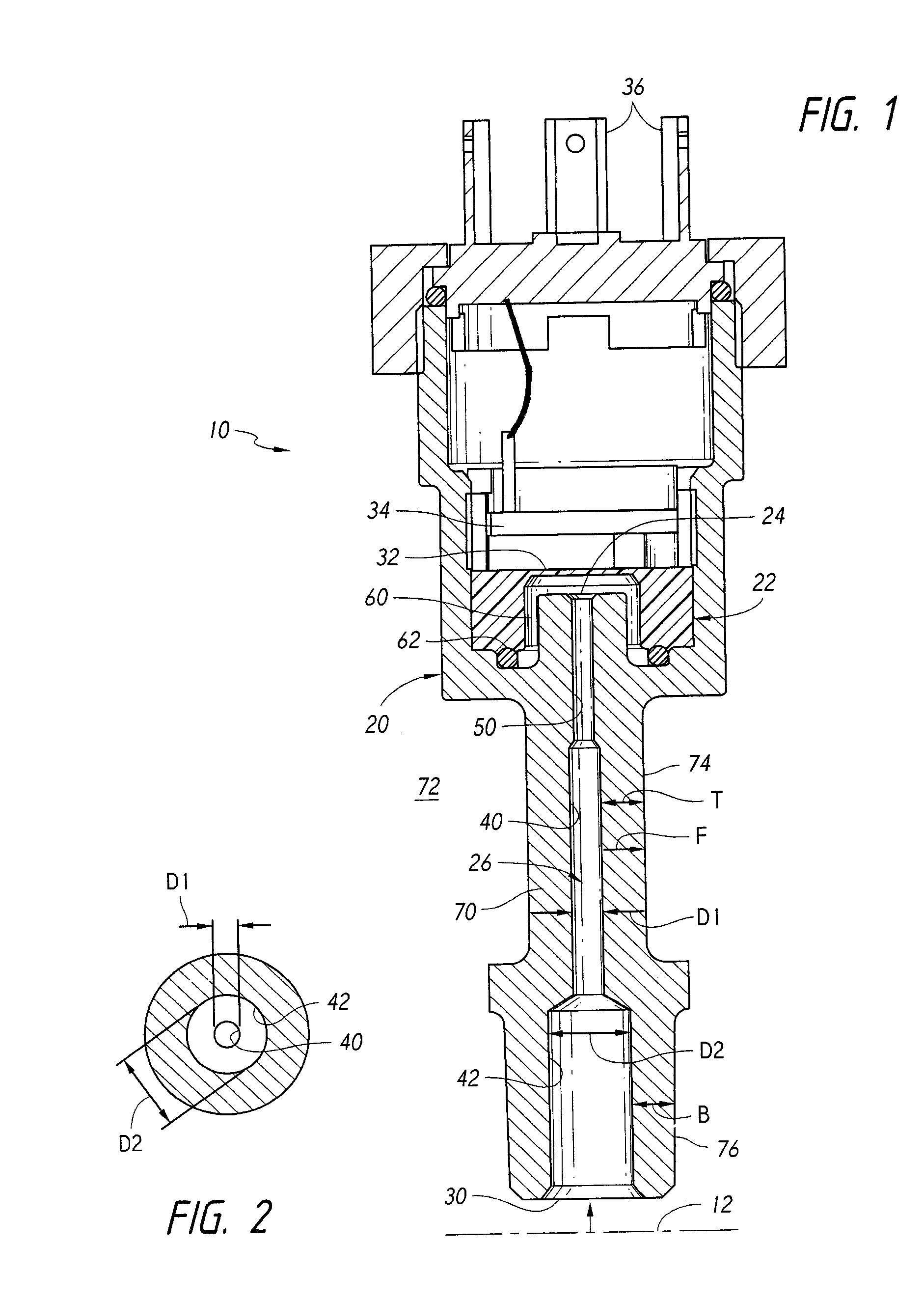

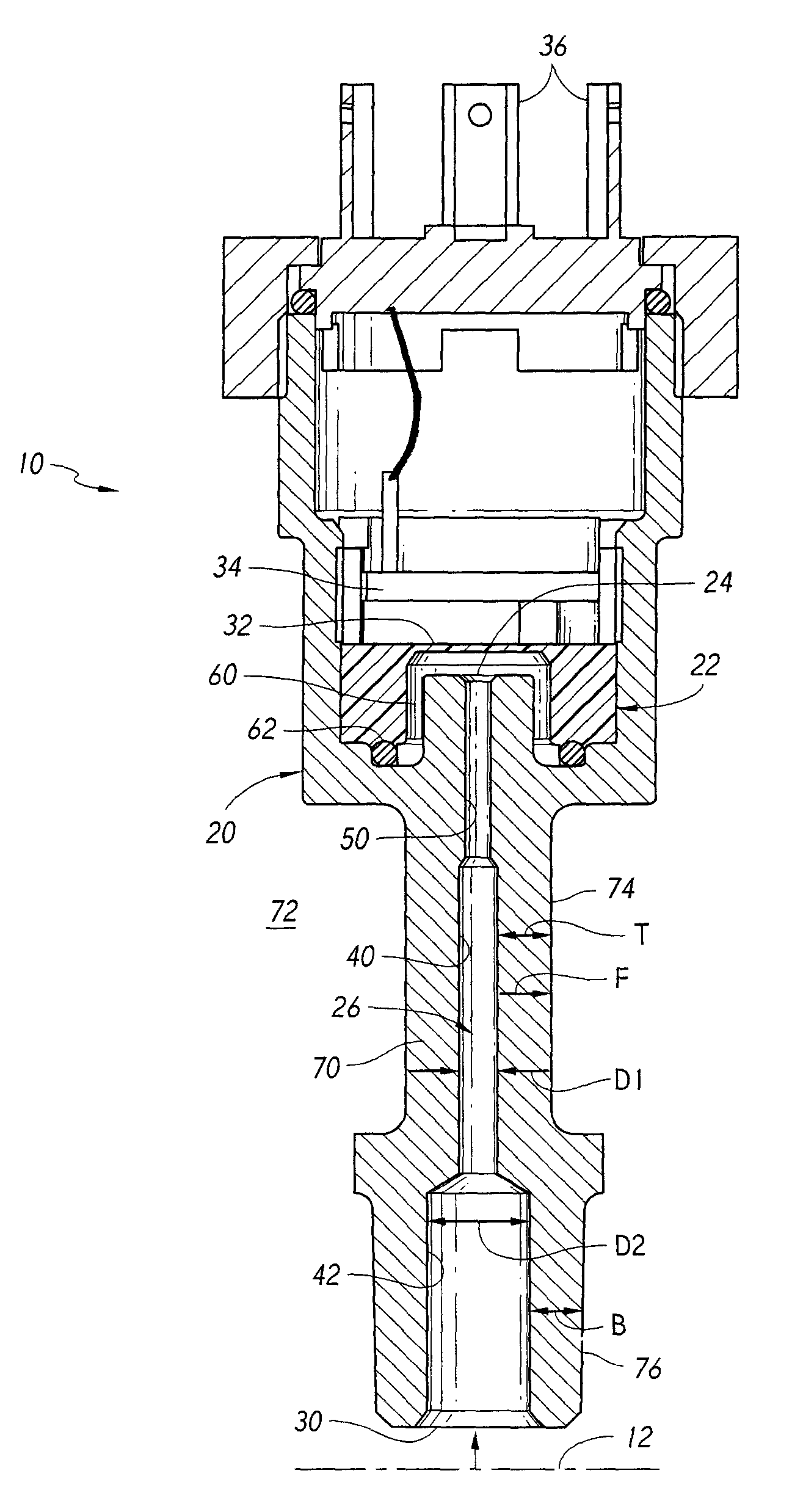

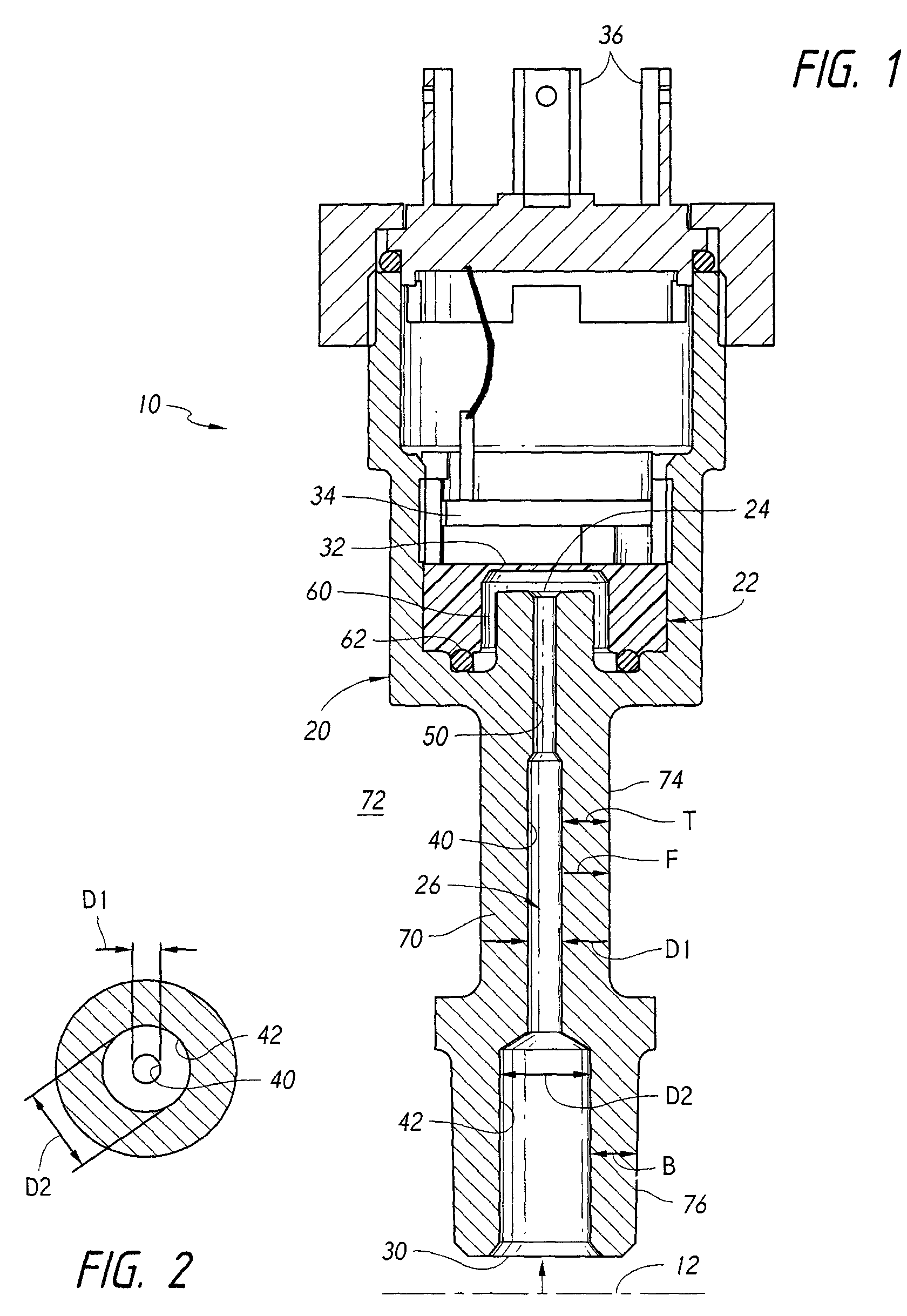

Sensor water freeze protector

ActiveUS20140345389A1Avoid damageSpecific heatFluid pressure measurement by mechanical elementsWater channelEngineering

Apparatus that detects the pressure of water that can move through a water channel (26) towards and away from a pressure sensor (22), wherein the apparatus is constructed to avoid damage from freezing water. The water channel is constructed with a narrow channel portion (40) and a wide channel portion (42) connected in series, with the narrow channel portion lying closer to the pressure sensor. When the ambient temperature falls below the freezing temperature of water, water in the narrow channel portion freezes before water in the wide channel portion freezes, and frozen water in the narrow channel portion acts like a plug to prevent water (or ice) from moving toward the pressure sensor.

Owner:BARKSDALE

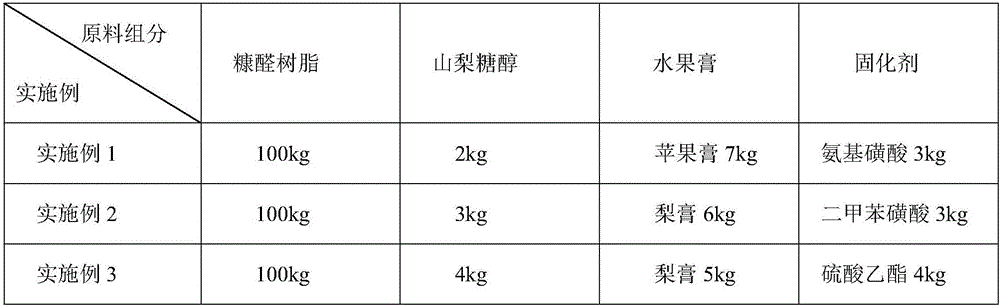

Method for preparing graphene foam material from furfural acetone formaldehyde resin, graphene foam material and application of graphene foam material

The invention discloses a method for preparing a graphene foam material from furfural acetone formaldehyde resin. The method includes the steps that curing molding is conducted on furfural acetone formaldehyde resin by adding non-carbon-atom matter which can be easily removed at a high temperature, then high-temperature carbonization and graphitization are conducted in an inert gas environment, and thus the novel super-power graphene foam material with a hexagonal or pentagonal two-dimensional or three-dimensional polyhedral crystal net structure is formed. The obtained material is a carbon foam material with excellent performance, has the prominent properties of low thermal expansivity, high porosity and pore uniformity, good stability, high temperature resistance, corrosion resistance, good oxidation resistance, small density, light weight, processibility and the like, and the advantages of high thermal conductivity, high melting point, large specific heat, good electric conductivity and excellent shielding performance, and is wide in application range and long in service life. Besides, low-cost and large-batch production of the material can be achieved through the preparation method, no pollution is generated in the preparation or use process, and batch application of the graphene foam material is achieved.

Owner:杨佳伟

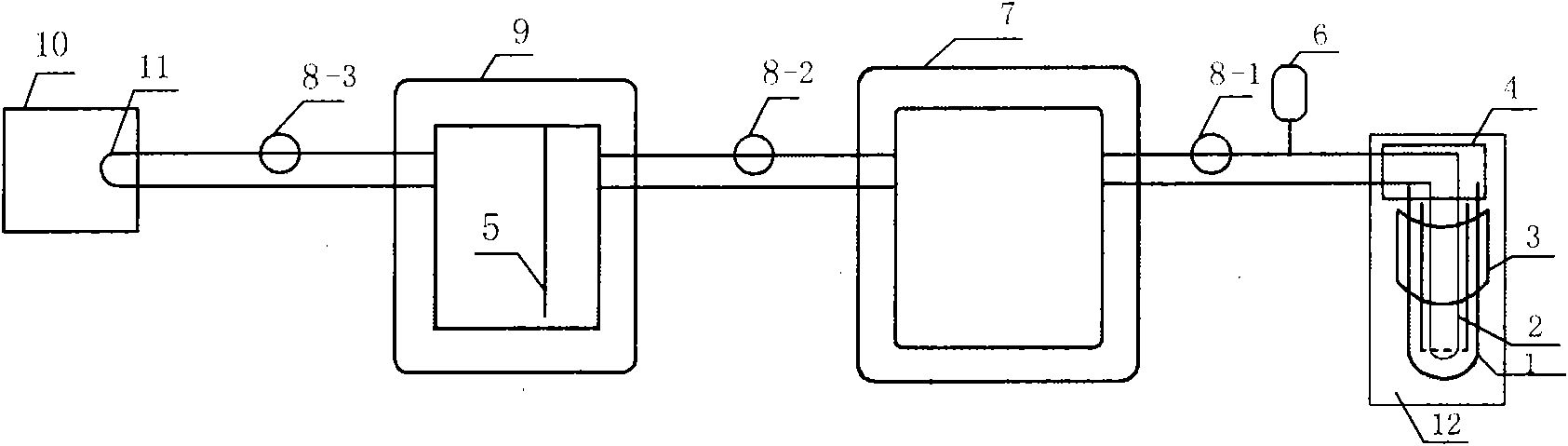

Solar oil heat conducting and supplying device

InactiveCN101818947AEnergy saving heatHigh boiling pointSolar heating energyGeneral water supply conservationChemical industryBoiling point

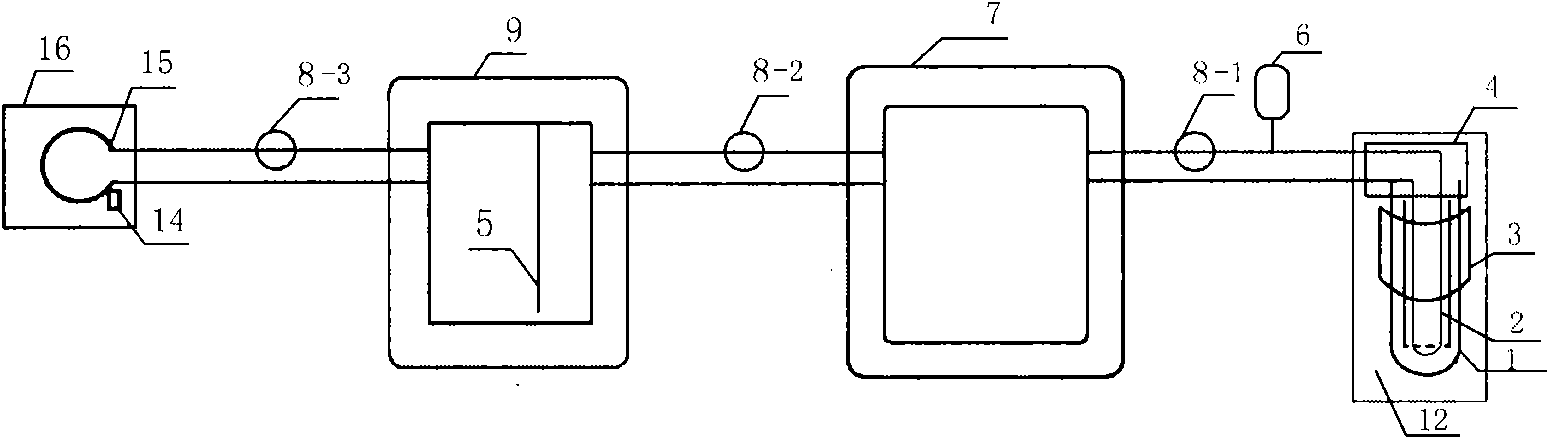

The invention discloses a solar oil heat conducting and supplying device, which is composed of a solar tube (12), an expansion slot (6), three circulating pumps (8-1, 8-2 and 8-3), an energy storage tank (7), an oil thermostatic tank (9) and a heat supply body (10). The solar oil heat conducting and supplying device fully utilizes and stores a solar heat source and the characteristics of heat-conducting oil of high boiling point, large specific heat and the like; and the heat-conducting oil is heated by solar energy, circulated in a heating system and then transferred to the heat supply body. The solar oil heat conducting and supplying device can be applied to the fields such as production and processing, medical industry, sugar manufacturing, textile industry, chemical industry, food, large, medium and small power plants and the like.

Owner:赖正平

High-heat-conductivity MgO doped molten nitrate heat-transfer and heat-storing material as well as in-situ generation method and application thereof

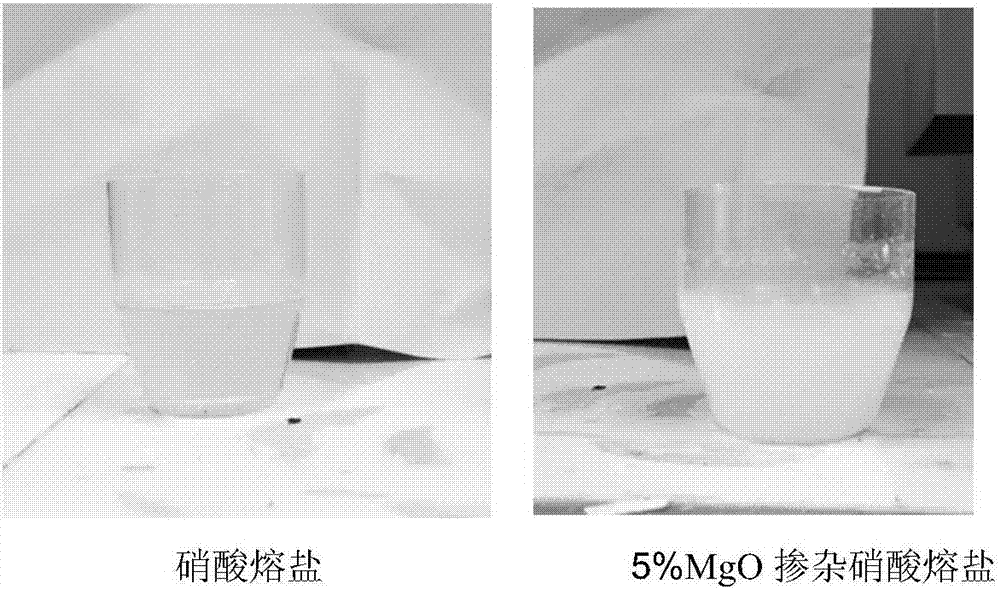

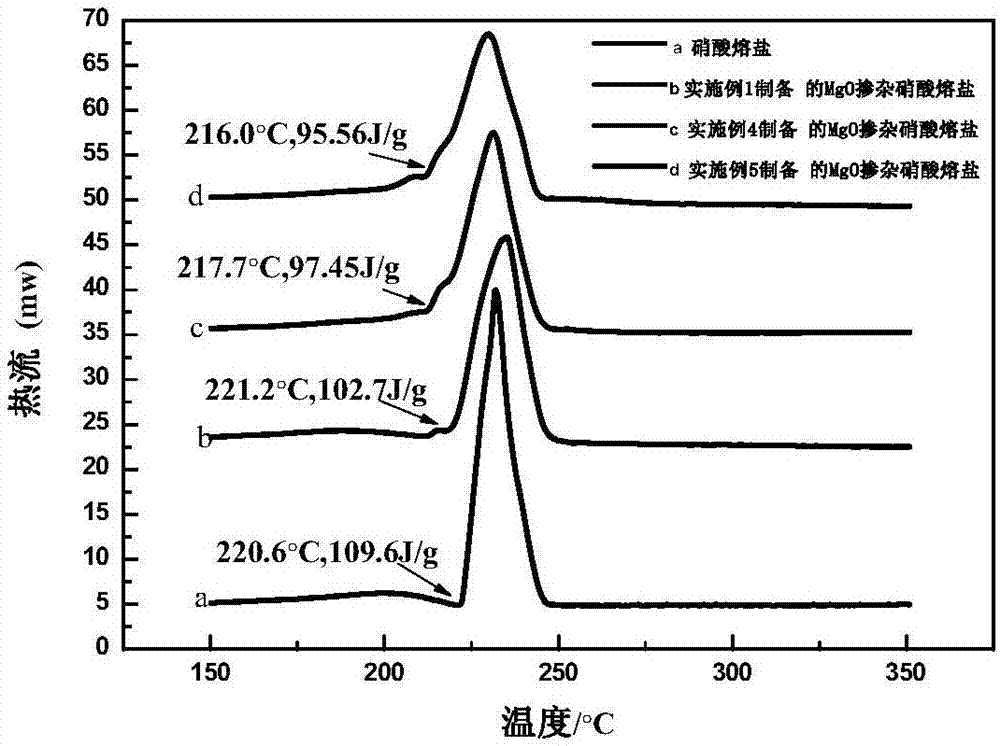

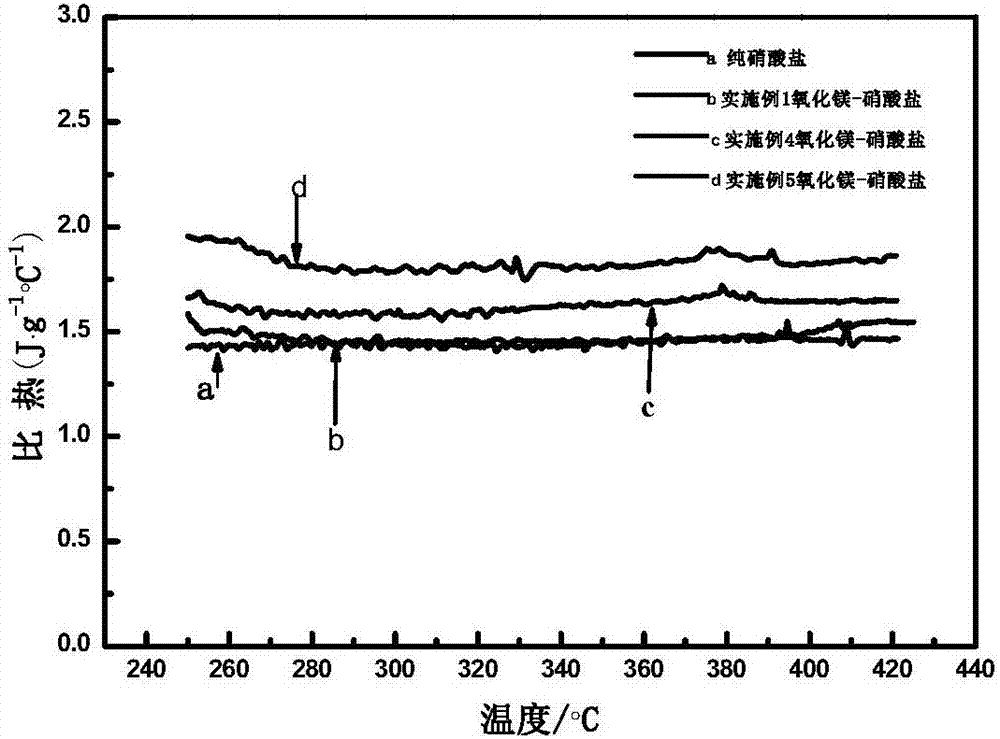

PendingCN108003847AEvenly distributedAddressing Reunion Technical FlawsHeat storage plantsChemical industryHeat energySodium nitrate

The invention belongs to the fields of large-scale utilization of renewable energy sources as well as storage and transfer of heat energy, and discloses a high-heat-conductivity MgO doped molten nitrate heat-transfer and heat-storing material as well as an in-situ generation method and application thereof. The method comprises the following steps: mixing dried potassium nitrate and sodium nitrateaccording to the lowest eutectic point of a binary phase diagram to obtain a raw material mixture I of molten nitrate; adding magnesium chloride hexahydrate or magnesium nitrate hexahydrate into the mixture I according to the mass ratio of MgO to molten nitrate being (2.5-10.0):(97.5-90.0) to obtain a magnesium chloride hexahydrate or magnesium nitrate hexahydrate doped molten nitrate raw materialmixture II; after mixing the mixture II uniformly, heating to 420 to 500 DEG C through a program, and maintaining constant temperature for 10 to 24 hours to guarantee in-situ generation and crystallization of MgO to form MgO doped molten nitrate uniform fluid; and naturally cooling the fluid to room temperature to obtain the high-heat-conductivity MgO doped molten nitrate heat-transfer and heat-storing material.

Owner:SOUTH CHINA UNIV OF TECH +1

Method for preparing nanotube and PCM combined phase change temperature control component

InactiveCN109321212AHigh thermal conductivityImprove the equivalent thermal conductivityHeat-exchange elementsElectron beam welding apparatusElectrical conductorThermal insulation

The invention provides a method for preparing carbon nanotube and PCM-combined phase change temperature control component, which aims to provide a method for preparing a phase change temperature control component with high phase change latent heat and better heat conduction effect. The present invention is implemented as follows: casting pyrolytic graphite in the heat sink bottom and the verticalhot wall surface of a metal conductor packaging container; combining carbon nanotubes and phase change materials by ultrasonic vibration to form a carbon nanotube and phase change composite material,and charging the liquid carbon nanotube and phase change composite material in a heat conductive reinforcing skeleton by a vacuum co-fusion method; welding the heat conductive reinforcing skeleton ina phase change cavity to form a multilayer phase change latent heat self-control adjustment level that the pyrolytic graphite wrapping, in a U-shape, heat conductive reinforcing skeleton, and forminga thermal insulation buffer layer from the phase change cavity; and finally, welding a cover plate on the stepped opening of the metal conductor packaging container by electron beam welding, enclosingto form a closed phase change temperature control component, and processing to obtain the boundary dimension according to requirements.

Owner:10TH RES INST OF CETC

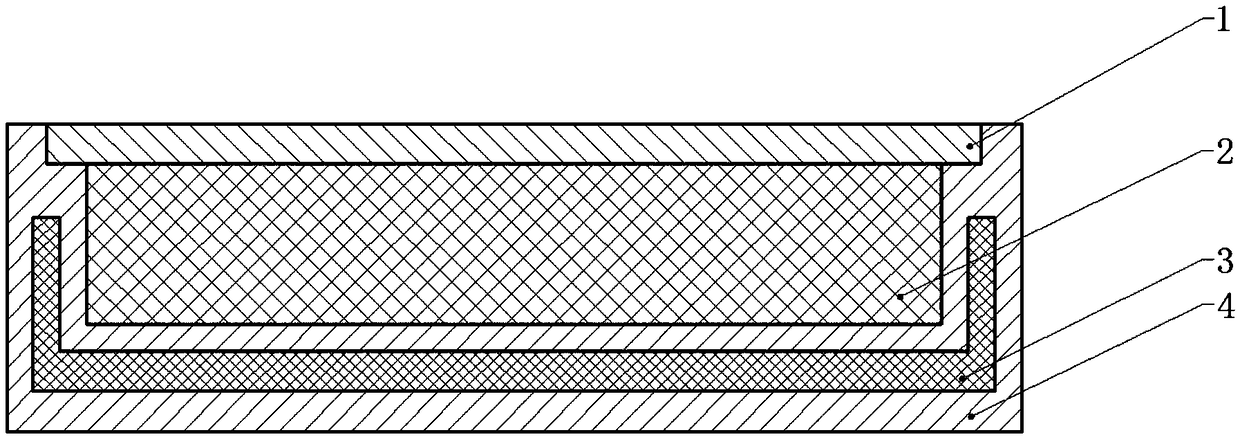

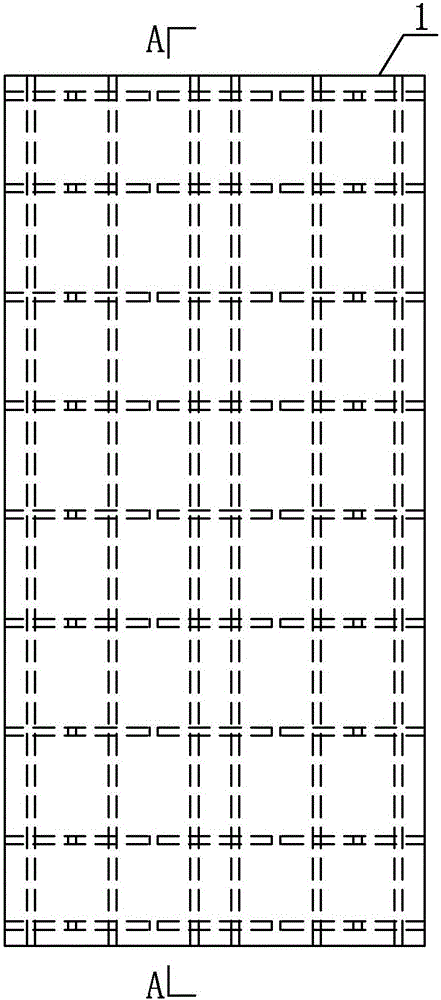

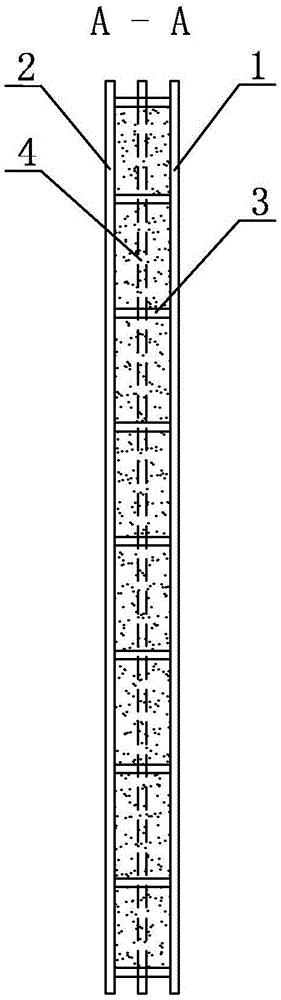

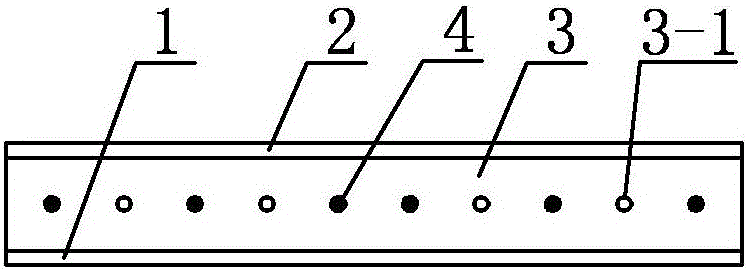

Staggered splicing type steel plate-RPC anti-detonation door and construction method thereof

ActiveCN105781364AHigh strengthLarge compressive strainCeramic shaping apparatusWar-like protectionSteel platesRebar

The invention discloses a staggered splicing type steel plate-RPC anti-detonation door and a construction method thereof. According to the anti-detonation door, a cavity formed by a door leaf front side steel plate, a door leaf reverse side steel plate and a plurality of inner ribbed beams is filled with an RPC inner core. The construction method of the anti-detonation door comprises the steps that firstly, the door leaf front side steel plate, the door leaf reverse side steel plate and the inner ribbed beams are manufactured according to the size; secondly, the number of needed steel bars is calculated; thirdly, steel bar holes are formed in the inner ribbed beams in the length direction; fourthly, the door leaf front side steel plate is welded to the odd-number inner ribbed beams, and the door leaf reverse side steel plate is welded to the even-number inner ribbed beams; fifthly, the door leaf front side steel plate and the door leaf reverse side steel plate are spliced in a staggered manner, and the steel bars penetrate the steel bar holes; sixthly, reactive powder concrete is poured in the cavity formed by the door leaf front side steel plate, the door leaf reverse side steel plate and the multiple inner ribbed beams and is standing for 48 h; seventhly, the anti-detonation door is conveyed into a steam curing room at the temperature of 90 DEG C to be cured for 72 h; and eighthly, after 28 days, the RPC and the steel plates are effectively bonded to form the steel plate-RPC anti-detonation door. The staggered splicing type steel plate-RPC anti-detonation door and the construction method thereof are applied to anti-detonation protection projects.

Owner:HARBIN INST OF TECH

Thermal efficiency improvement method for heating furnace and thermal efficiency improvement device for heating furnace

InactiveUS20130228105A1Lower exhaust gas temperatureReduce heatIncreasing energy efficiencyChimneysProcess engineeringHeating furnace

A thermal efficiency improvement device 10 for a heating furnace is installed in an exhaust port 12 of the heating furnace to reduce effluent heat from the exhaust port 12 to the outside. The device 10 disposed along a flow of exhaust gas passing inside the exhaust port 12 includes at least one heat-resistant fabric members 15, 16 heated by exhaust gas and supporting members 13, 14, 17, 18, 19 fixing the fabric members 15, 16 to the exhaust port 12, and puts radiant heat from the heated fabric members 15, 16 back into the heating furnace to reduce effluent heat to the outside. By installing the device in an exhaust port of an existing or newly-built heating furnace, radiant heat from the fabric members heated by exhaust gas is put back into the heating furnace, and effluent heat from the exhaust port is reduced.

Owner:UBE IND LTD

Moxibustion instrument

InactiveCN101658465ASpecific heatImprove thermal conductivityDevices for heating/cooling reflex pointsCombustion chamberEngineering

The invention discloses a moxibustion instrument, in particular relaes to a moxibustion instrument for the moxibustion. The moxibustion instrument comprises an instrument body made of woodblock stonematerials and a cover detachably connected with the instrument body; the instrument body and the cover form a combustion chamber, and the combustion chamber is communicated with outside by a hole forthe insertion of a moxa roll located at the bottom of the cover, pores uniformly distributed on the circumference of the hole and at least two side holes located at the side surface of the combustionchamber; a base is provided with a groove with an opening facing towards the surface of the moxibustion surface; the upper bottom of the groove is provided with a through hole coaxial with the hole; and a drug containing cylinder mould with an opening at the upper end is embedded in the through hole. The invention provides the moxibustion instrument with good moxibustion effect and convenient drugapplication, and well utilizes the heat generated by combusting the moxa rolls.

Owner:沈学谦

Variable compression ratio internal combustion engine

ActiveUS7627417B2Reduce response delayShort response timeAnalogue computers for vehiclesElectrical controlResponse delayEngineering

The invention provides a technology that enables to control response delay of the supercharger in a variable compression ratio internal combustion engine under acceleration. When the variable compression ratio internal combustion engine is under acceleration, the compression ratio of the internal combustion engine is set to a compression ratio lower than a basic compression ratio that is so determined in accordance with the running condition of the internal combustion engine to realize a predetermined heat efficiency while suppressing knocking, thereby raising the exhaust gas pressure and shortening the response time of the supercharger.

Owner:TOYOTA JIDOSHA KK

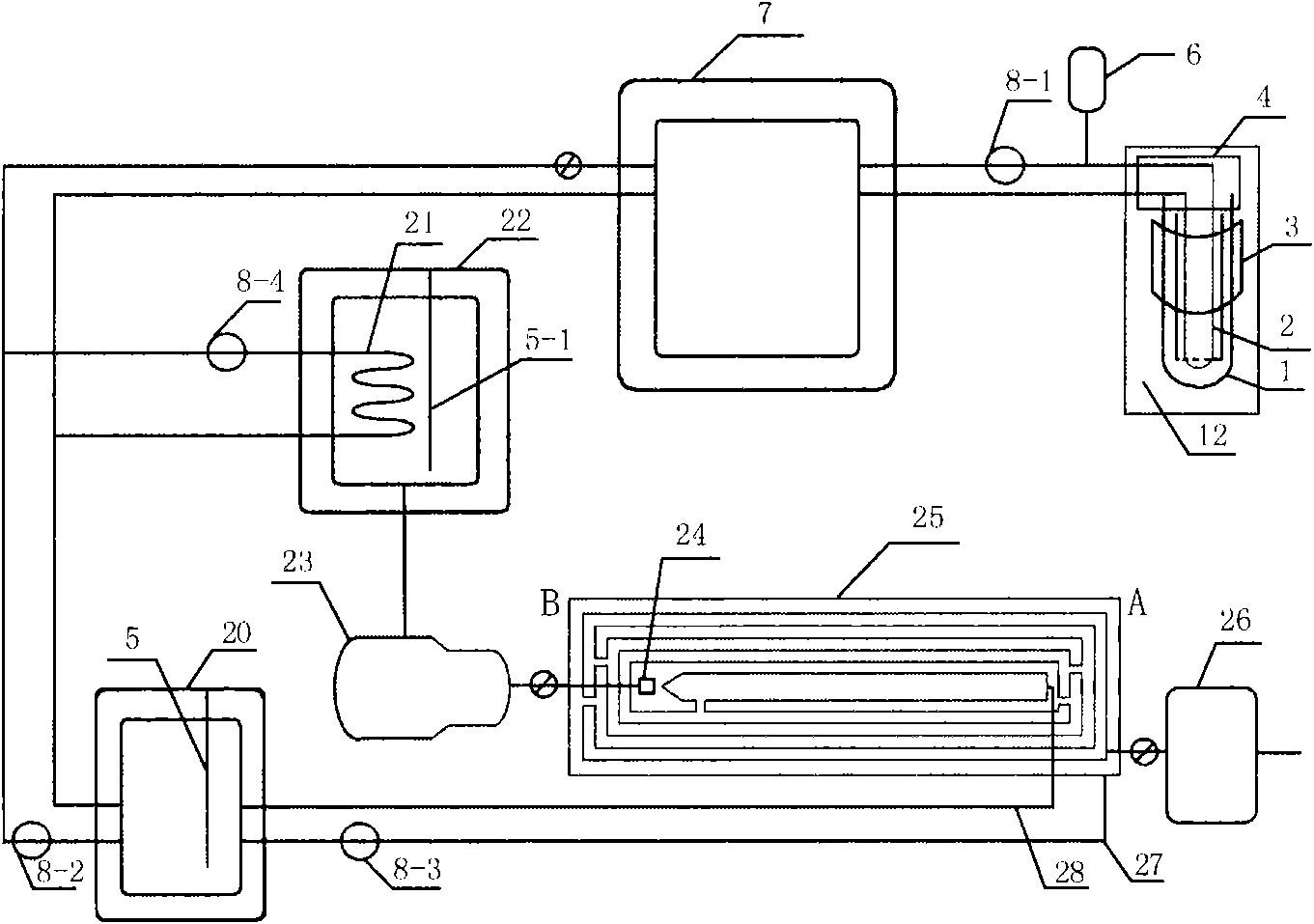

Energy-storage clean energy superheated steam boiler adopting heat conduction oil to transfer heat and method for preparing superheated steam

InactiveCN104266174AGood economic benefitsSpecific heatSolar heating energySolar heat devicesElectric heatingThermal water

The invention relates to an energy-storage clean energy superheated steam boiler adopting heat conduction oil to transfer heat and a method for preparing superheated steam and belongs to a solar energy utilization technology. The steam boiler is characterized by comprising a heat supply device, a heat conduction oil buffer tank, a heat storage device and a heat carrying product output device which are sequentially connected through a heat transfer medium delivery pipeline to form a circulation loop. The heat conduction oil buffer tank is further provided with an electric heating device independent of the heat supply device, and the electric heating device is powered by night valley current to conduct heating. Different heating modes can be selected according to different environment requirements to ensure that superheated steam and hot water can be supplied constantly even no sunlight is available. The boiler is good in economical benefit, is environmentally friendly, saves energy and reduces initial investment cost due to the fact that an energy storage material can adopt quartz sand compound fused salt invented by the company.

Owner:SHENZHEN AINENGSEN EQUIP TECH

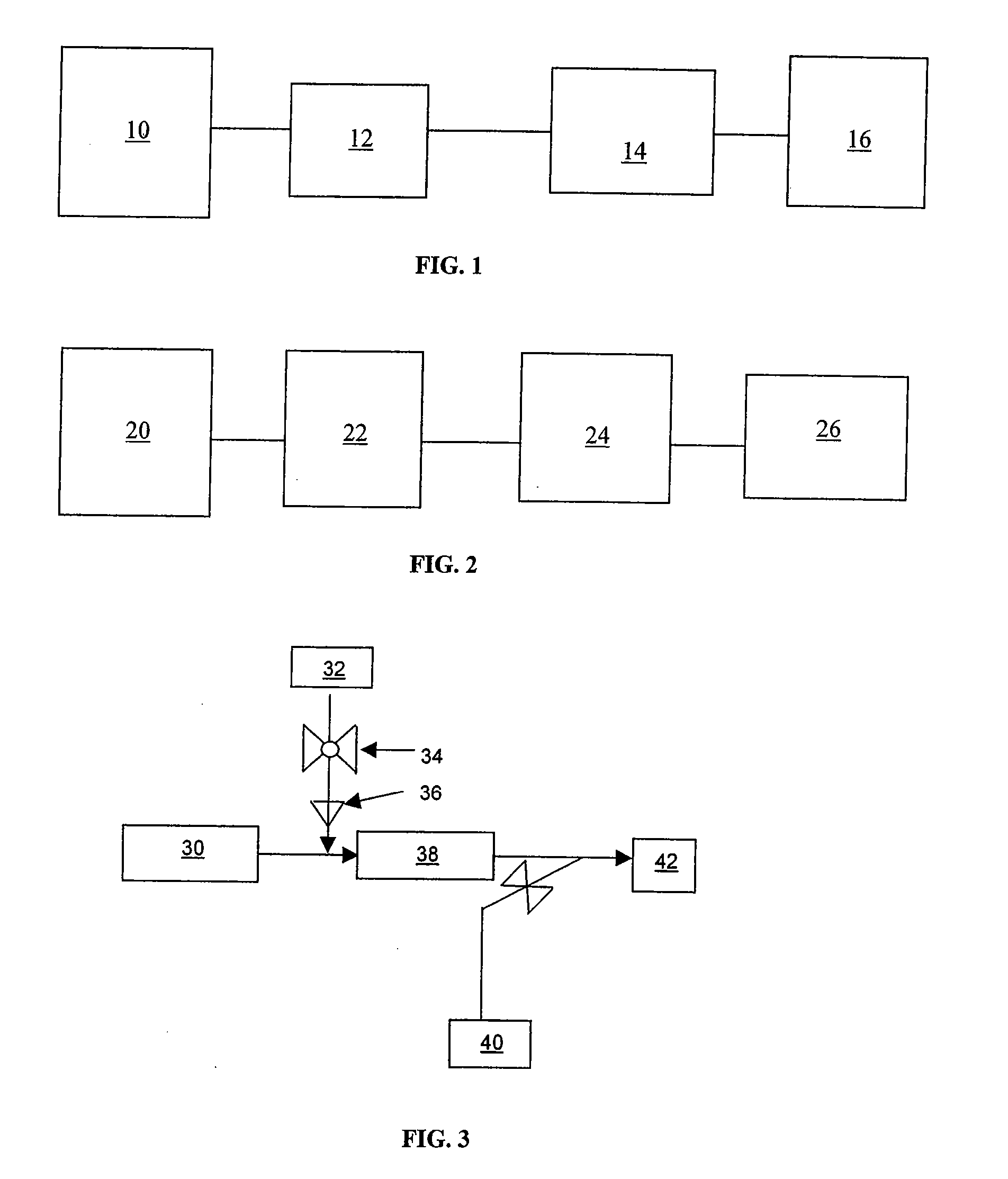

Method and apparatus for augmented heat up of a unit

ActiveUS20070119176A1Without damageIncrease heatLiquid degasificationSteam regenerationProcess engineeringNitrogen gas

A system and a method of augmenting the heat up of a unit using a compressed, heated gas that contains moisture such as steam or vaporized water such that the specific heat of the gas is increased. In a preferred embodiment, steam in compressed inert gas such as nitrogen is capable of augmenting the heat up cycle for units such as process reactor vessels, furnaces, process steam and power production boilers, turbines, and other production vessels.

Owner:BAKER HUGHES INC

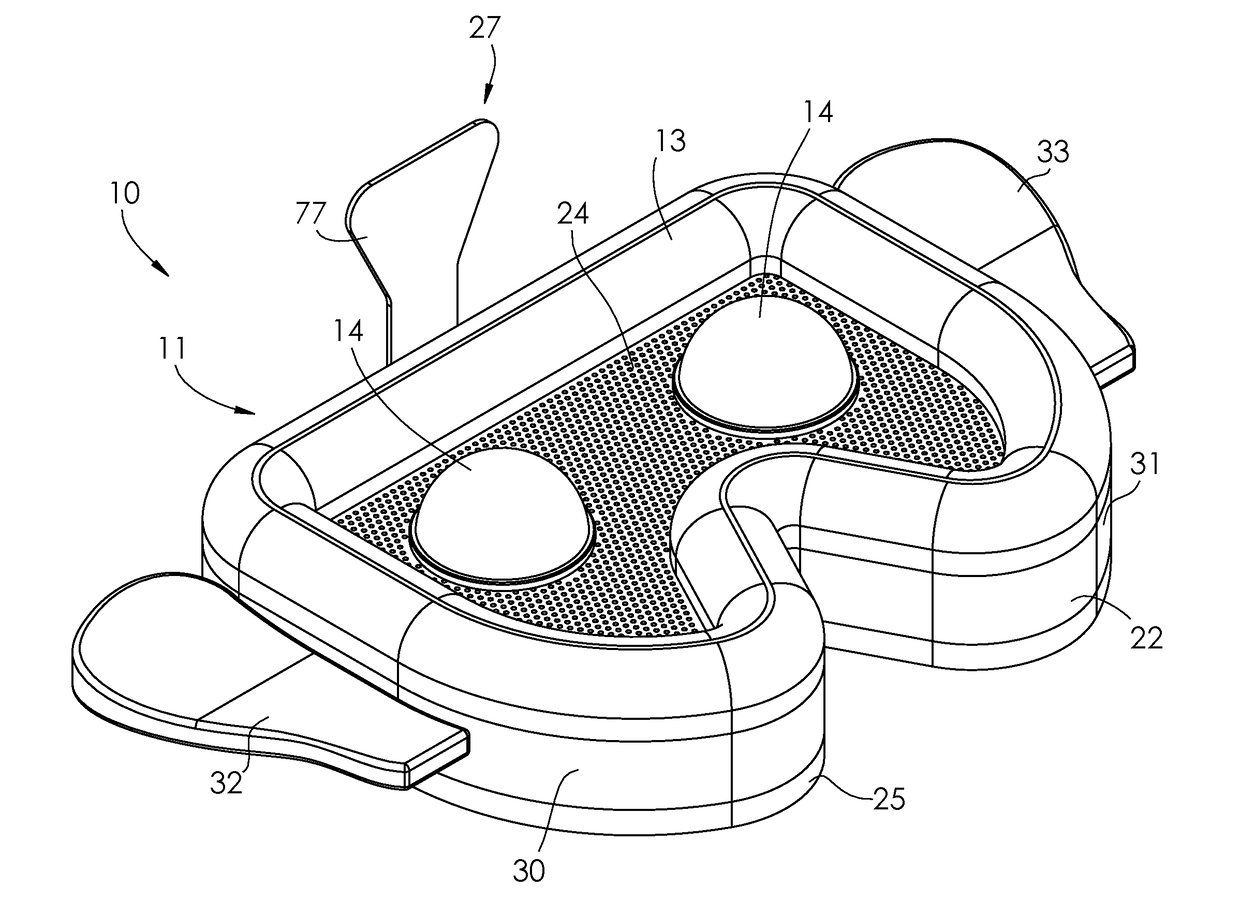

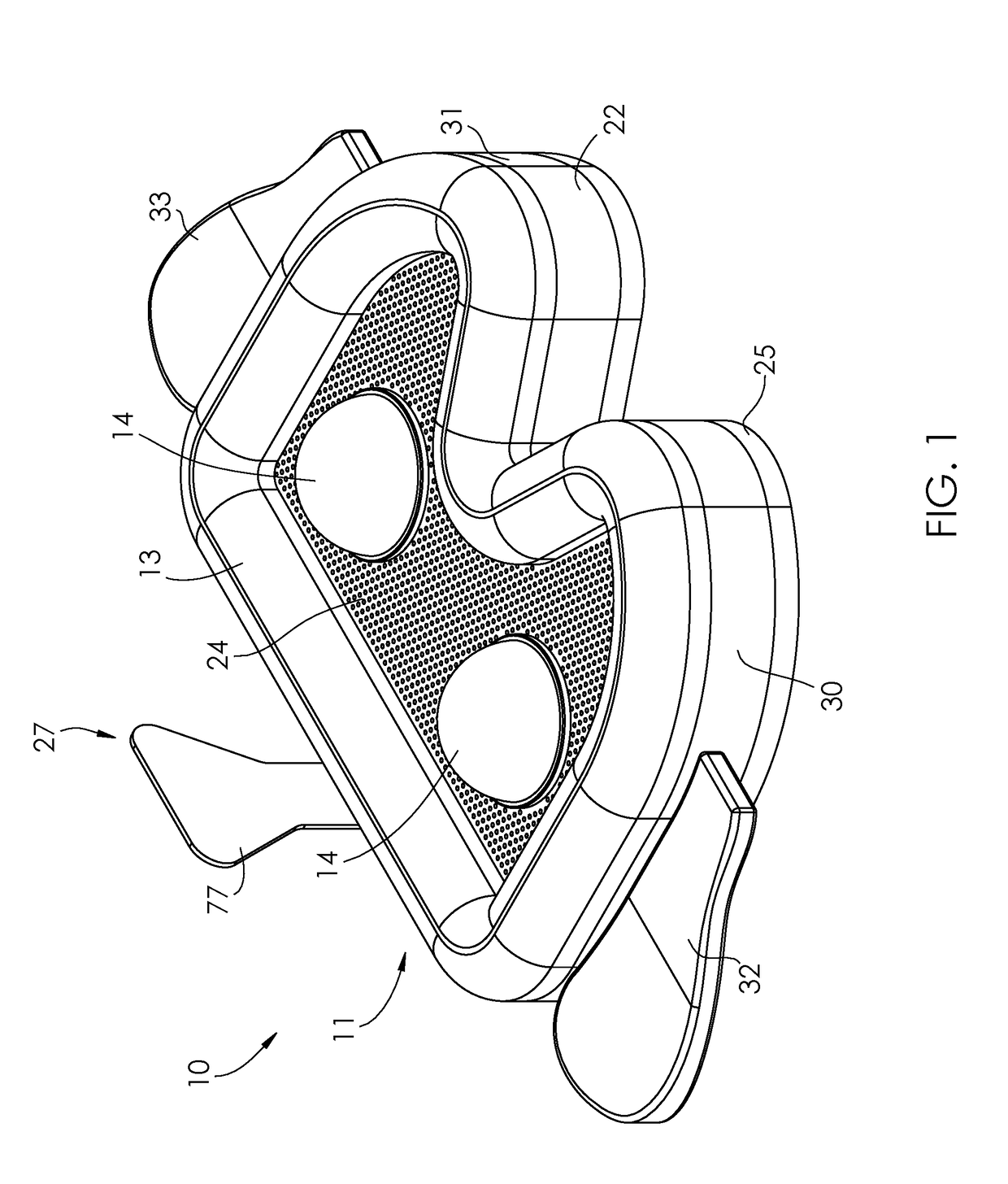

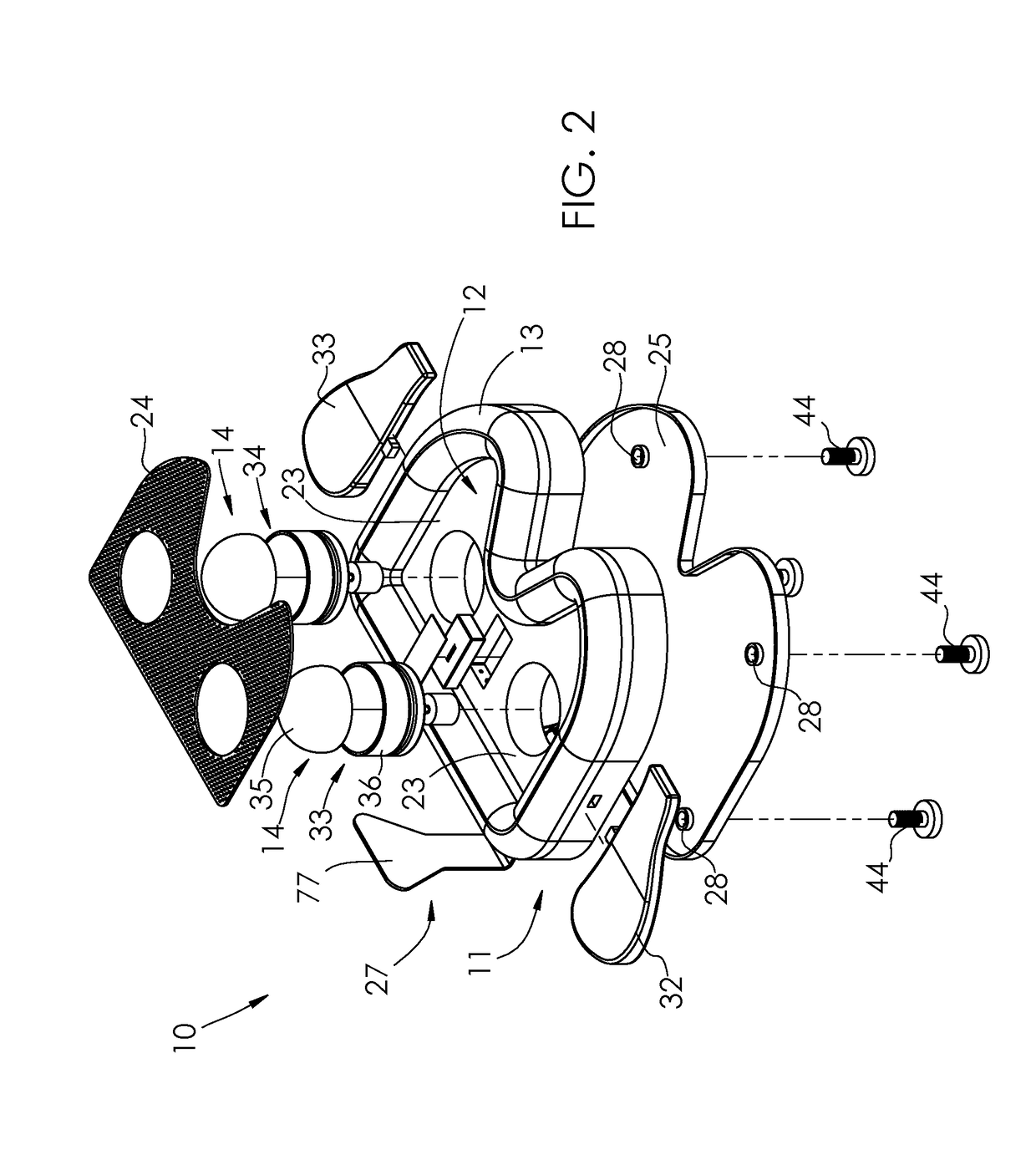

Portable therapeutic device and associated use thereof

ActiveUS20170360652A1Relief the painIncrease loopVibration massageRoller massageTherapeutic DevicesMassage

A portable therapeutic device includes a portable body having a recessed central region and a raised outer peripheral edge surrounding the recessed central region and directly engaged with the recessed central region, a plurality of massage balls seated at the recessed central region and spaced inside a perimeter of the raised outer peripheral edge, a thermal-conductive element channeled inside the outer peripheral edge and spaced from the recessed central region, and a power source communicatively coupled to the massage balls and the thermal-conductive element.

Owner:BURNS DENISE K +2

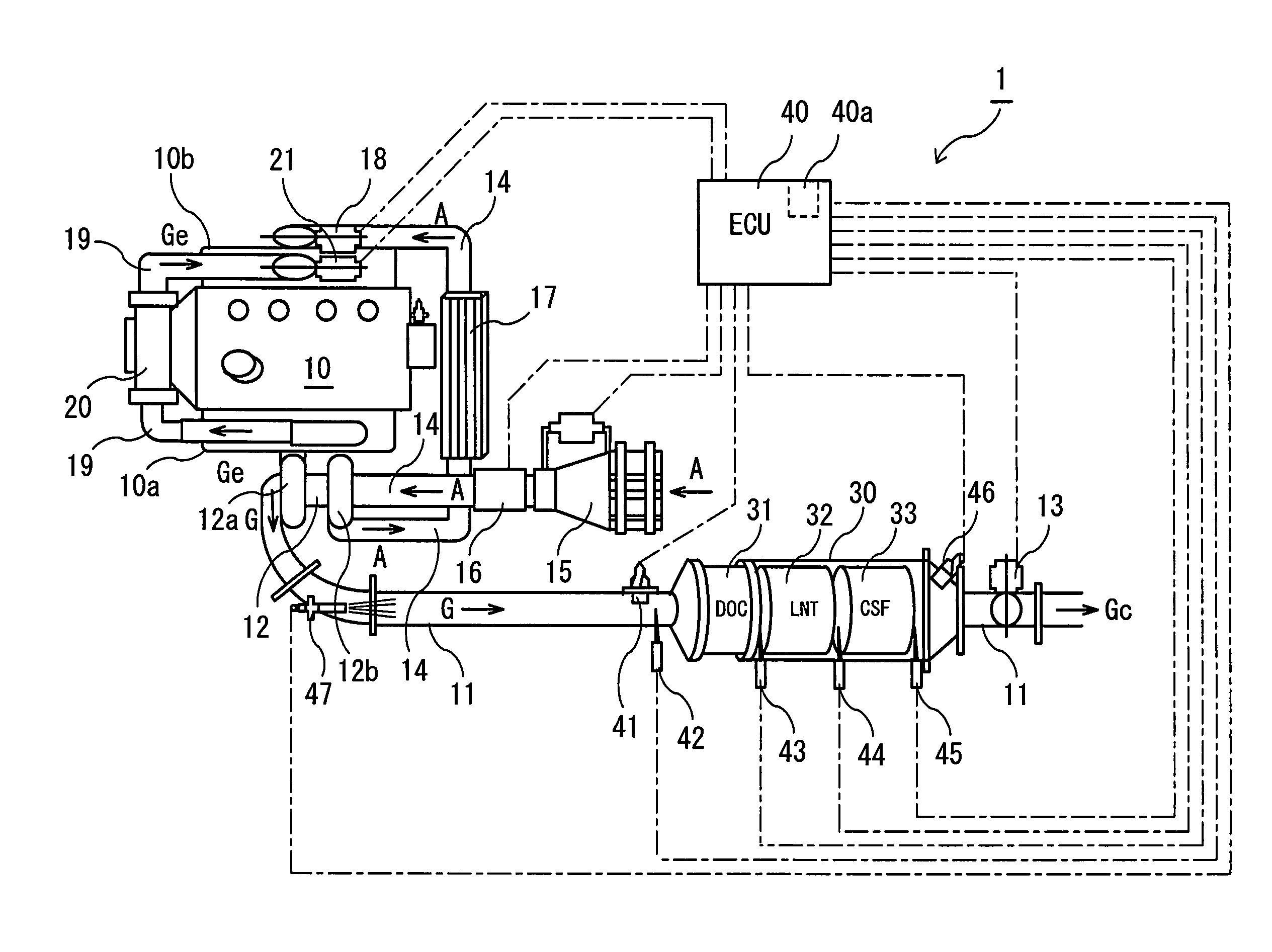

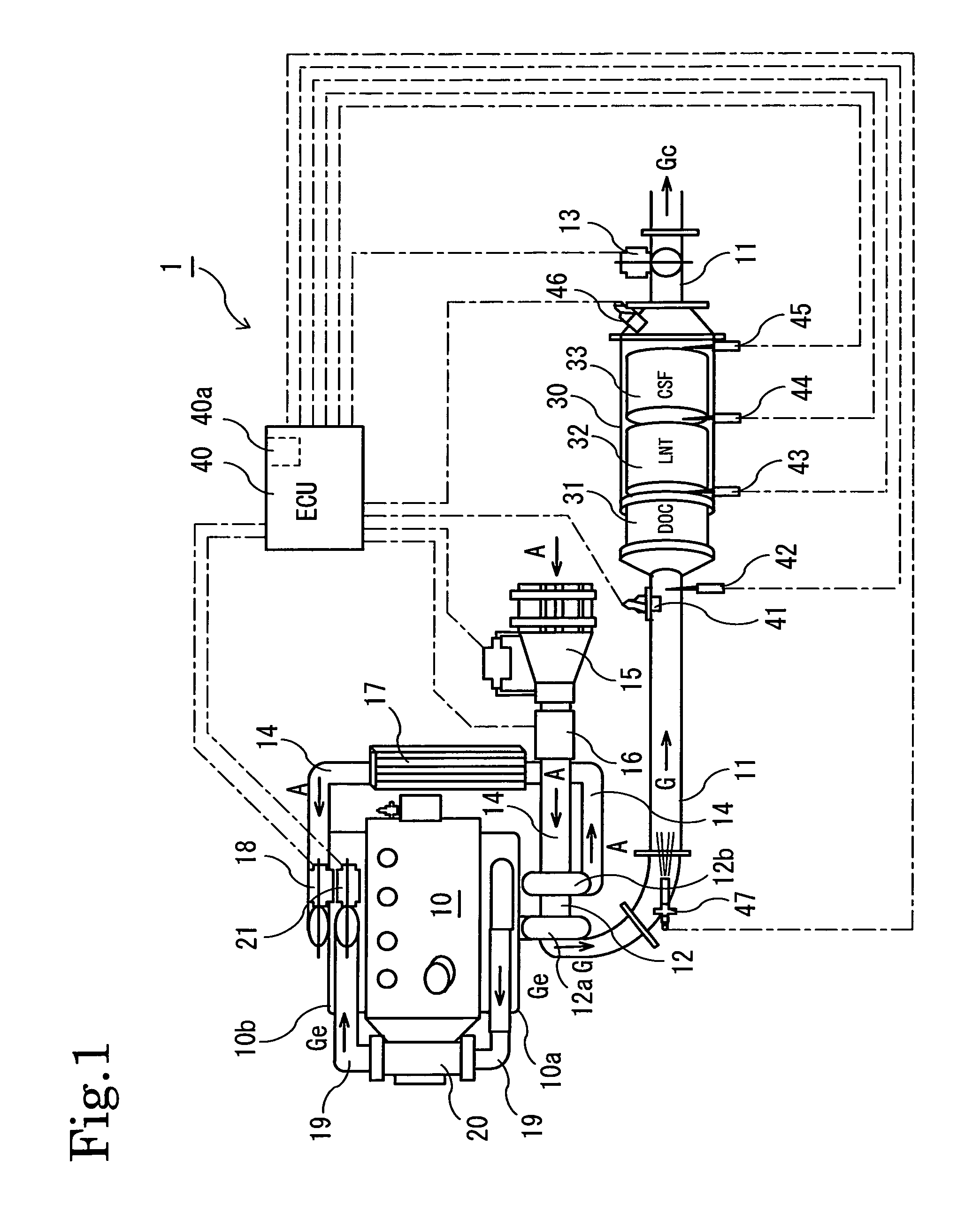

System for exhaust gas purification and method of controlling the same

ActiveUS8528320B2Simple processLess heatInternal combustion piston enginesSilencing apparatusLow loadMetallic materials

A system for exhaust gas purification including, in an exhaust passage of an internal combustion engine in order from an upstream side: a device for direct injection into the exhaust pipe, an oxidation catalyst, and at least one of a catalyst for NOx removal and a catalyzed diesel particulate filter. A support of the oxidation catalyst is a metallic material or a material having a specific heat not higher than that of the metallic material, and has a structure that mixes the exhaust gas. Regeneration of the NOx occlusion / reduction type catalyst by NOx removal and the forced regeneration of the catalyzed diesel particulate filter by particulate matter removal can occur even when the engine is operated under low-load conditions.

Owner:ISUZU MOTORS LTD

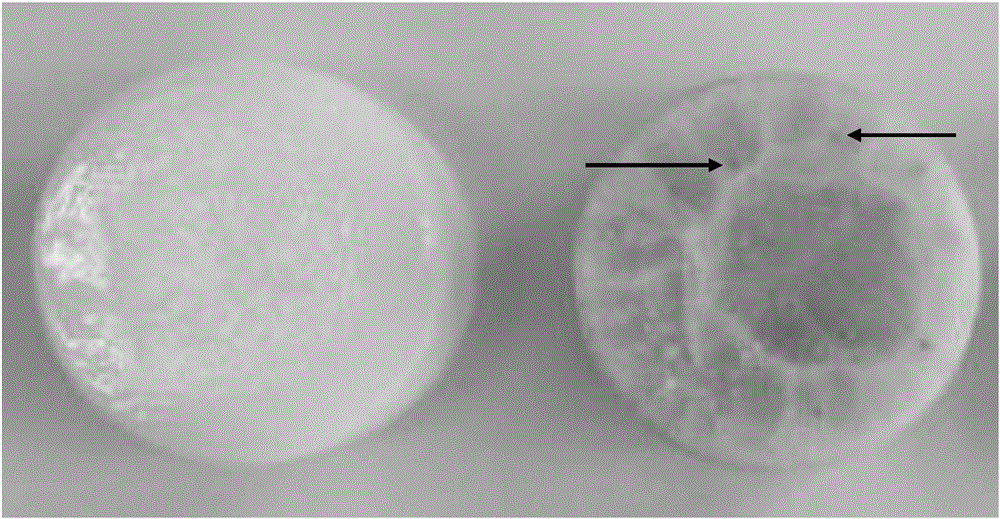

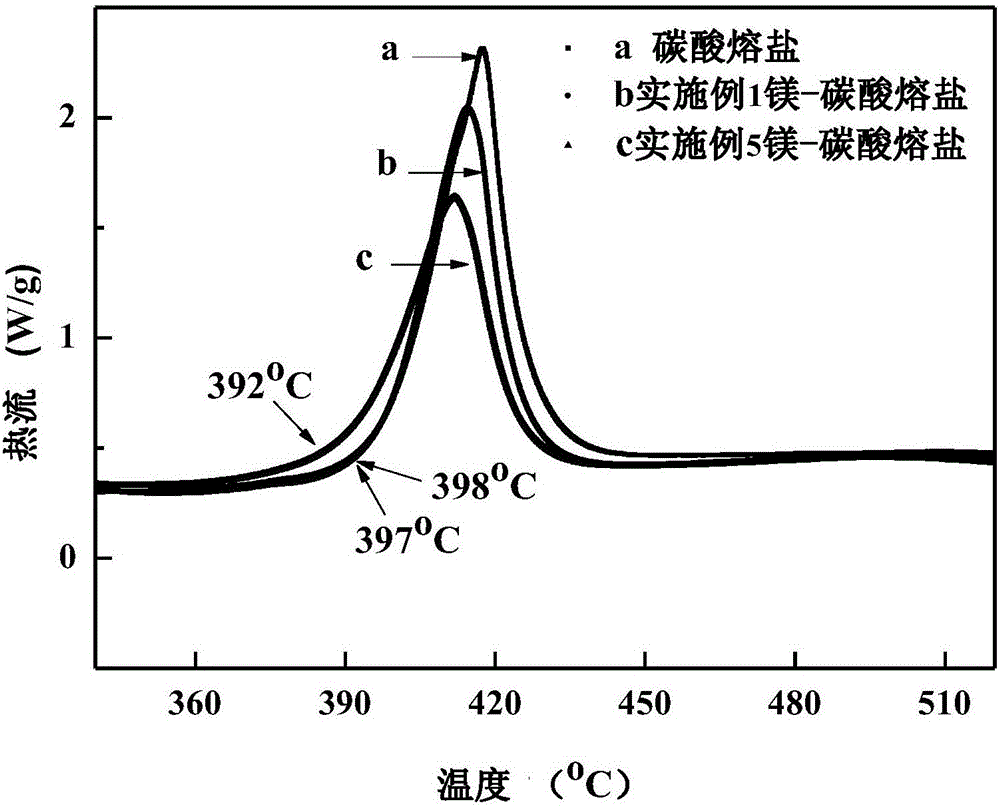

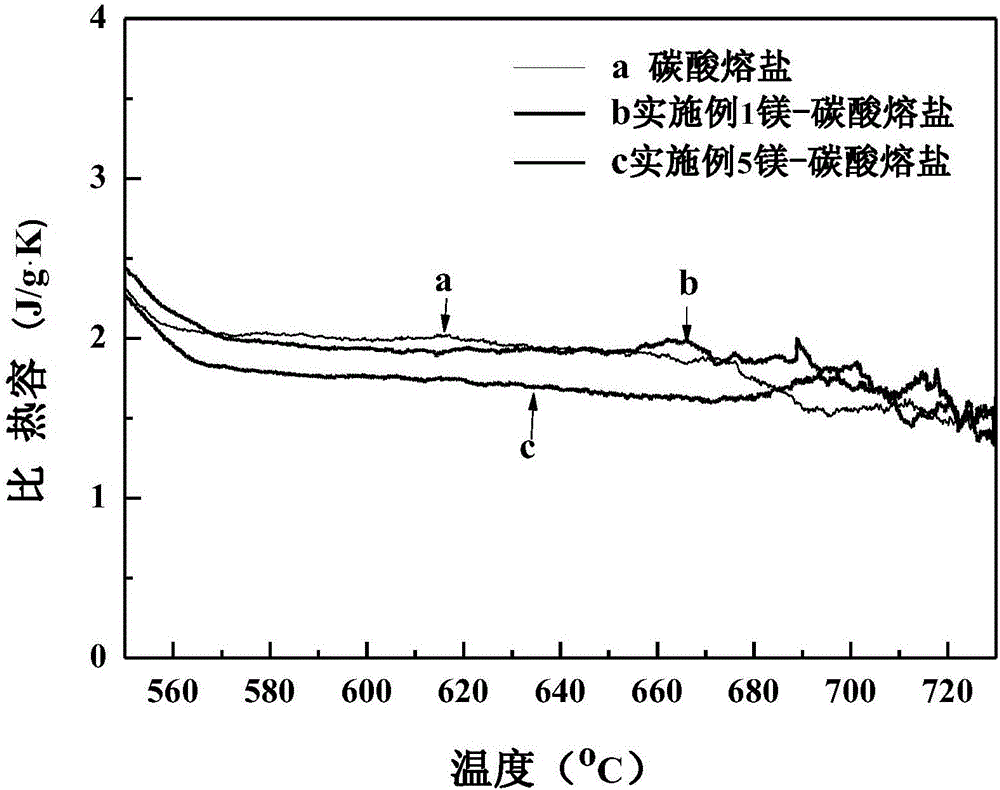

High-heat-conductivity metal-carbonate molten salt material and preparation method and application thereof

PendingCN107177348AOvercome the shortcomings of low thermal conductivity and unfavorable heat transferLarge specific heat capacityHeat-exchange elementsBulk chemical productionHeat conductingMolten salt

The invention discloses a high-heat-conductivity metal-carbonate molten salt material and a preparation method and application thereof; the high-heat-conductivity metal-carbonate molten salt material comprises, by weight, 0.05-2.6% of magnesium powder, and 97.4-99.95% of carbonate molten salt. The high-heat-conductivity metal-carbonate molten salt material has significantly improved heat conduction coefficient of high-liquid liquid, maintains low melting point and high specific heat capacity in carbonate molten salt, and has higher heat-conducting and heat-storing properties; the magnesium added is in 'mist' uniform distribution in the carbonate molten salt, and the 'mist' state is not affected by repeated cooling / heating conditions. The applicable range of the molten salt is further widened to the field of renewable energy sources and high-temperature industrial waste heat recovery, and the material has a promising application prospect in terms of comprehensive development and utilization of saline lake resources.

Owner:SOUTH CHINA UNIV OF TECH +1

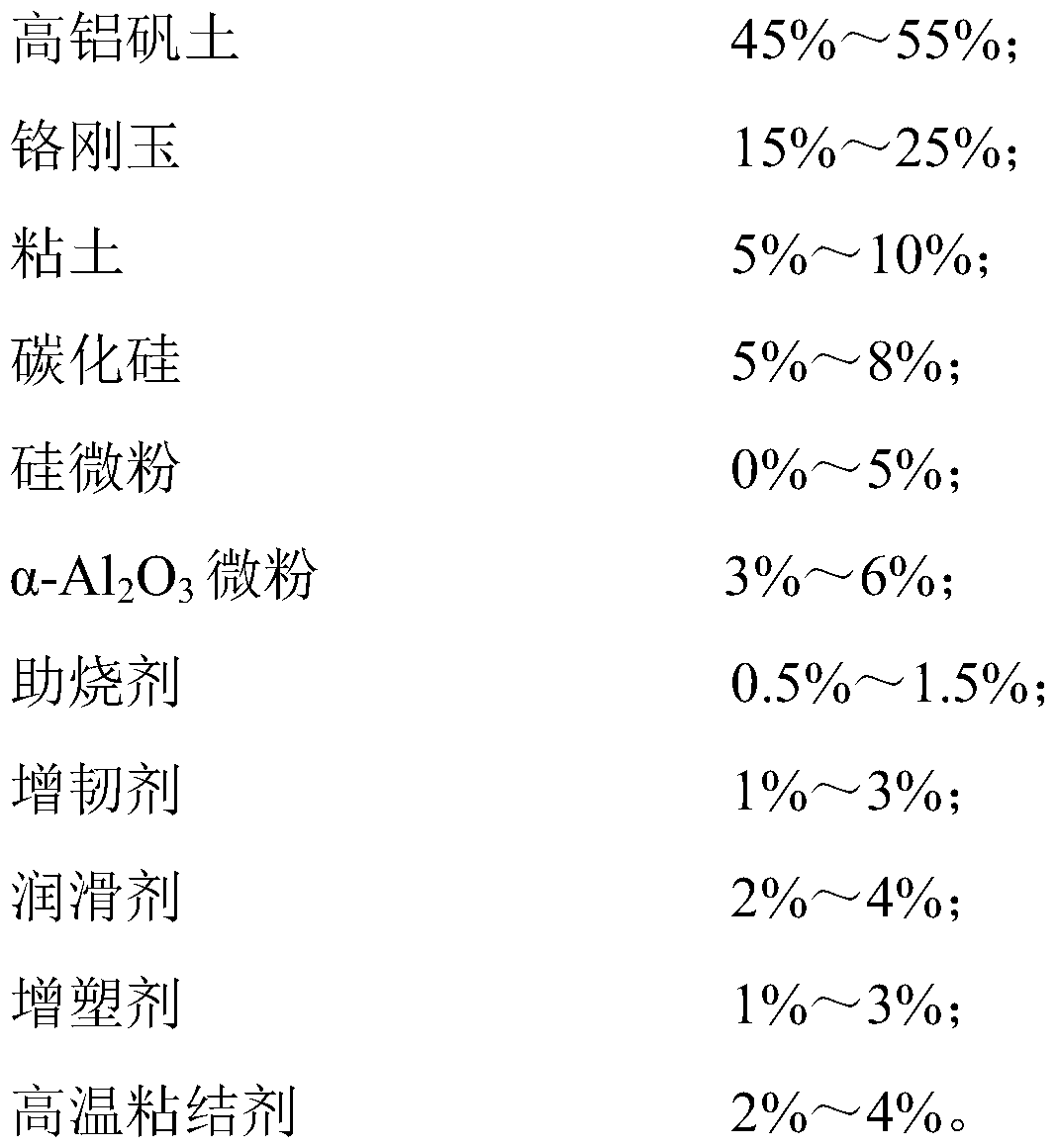

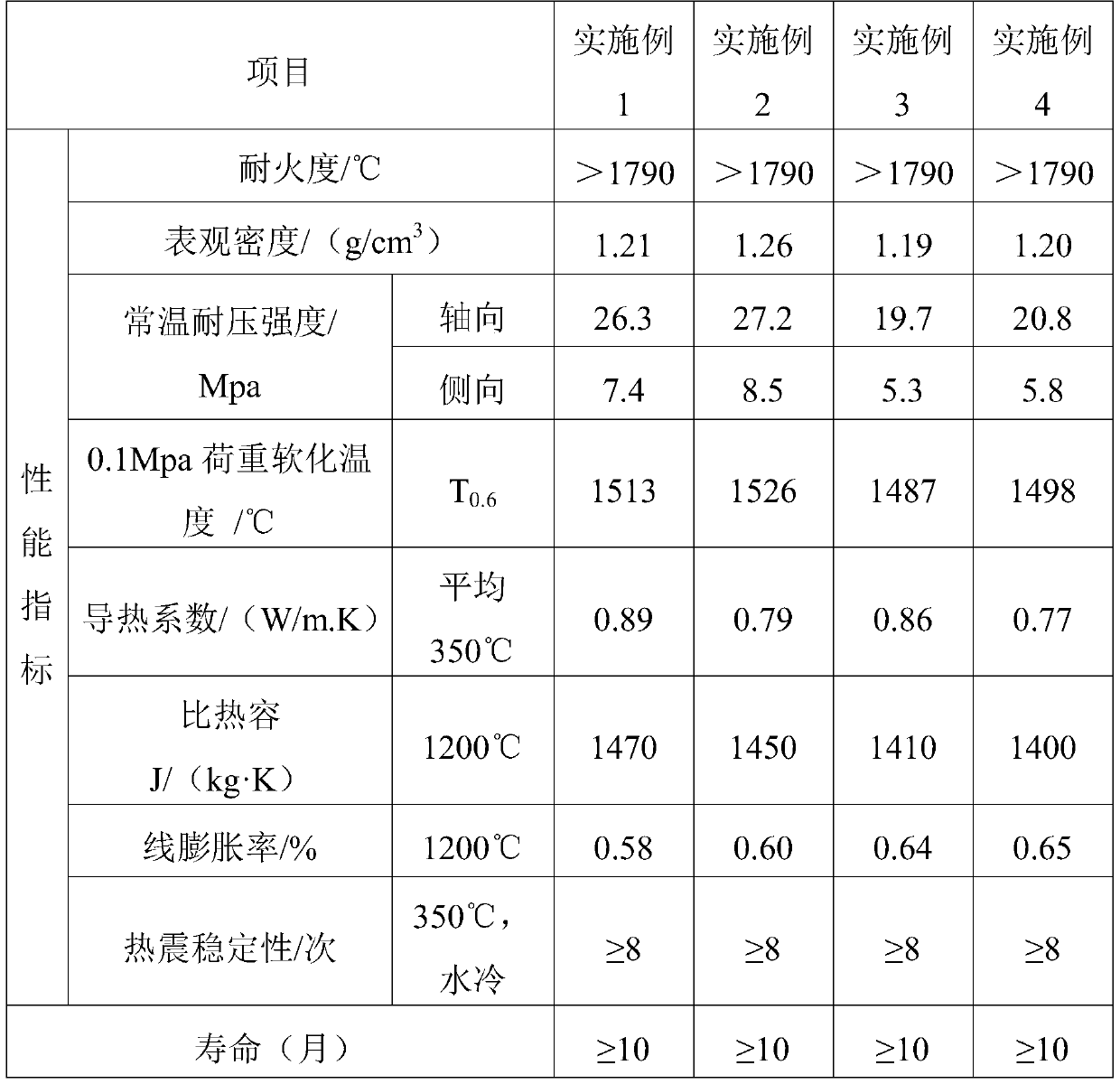

Honeycomb body used for regenerative heating furnace and production method of honeycomb body used for regenerative heating furnace

InactiveCN110372343AMeet the temperature requirementsHigh refractorinessCeramicwareCombustionPlasticizer

The invention discloses a honeycomb body used for a regenerative heating furnace and a production method of the honeycomb body used for the regenerative heating furnace. According to the honeycomb body, high bauxite and pink funsed alumina are adopted as main components, clay is adopted as a binder, silicon carbide, silica powder and alpha-Al2O3 powder are added, a sintering aid, a toughener, a lubricant, a plasticizer and a high-temperature binder are added at the same time, and through technology steps of mixing, vacuum pugging, extrusion, forming drying, firing and the like, the honeycomb body used for the regenerative heating furnace is produced. The honeycomb body meets the technology requirements of a regenerative combustion technology, has performance of large heat storage capacity,stable high-temperature performance, high heat exchange efficiency and a long service life, the number of times of blowing out due to replacement of honeycomb bodies of a steel plant can be decreased, the production operation rate of the heating furnace is improved, the equipment maintenance cost is reduced, and effects of increasing production and practising economy are truly achieved, so that the honeycomb body used for the regenerative heating furnace has obvious economic benefits and very wide use prospects.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP

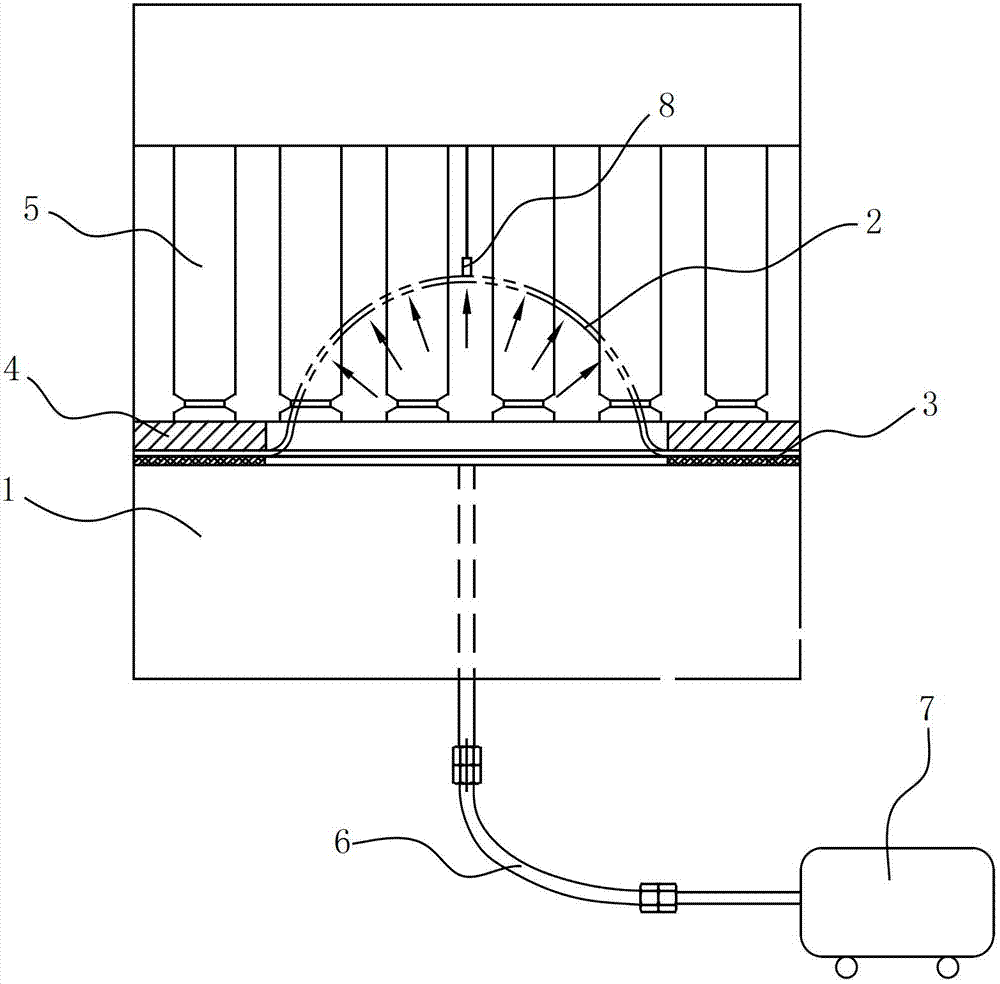

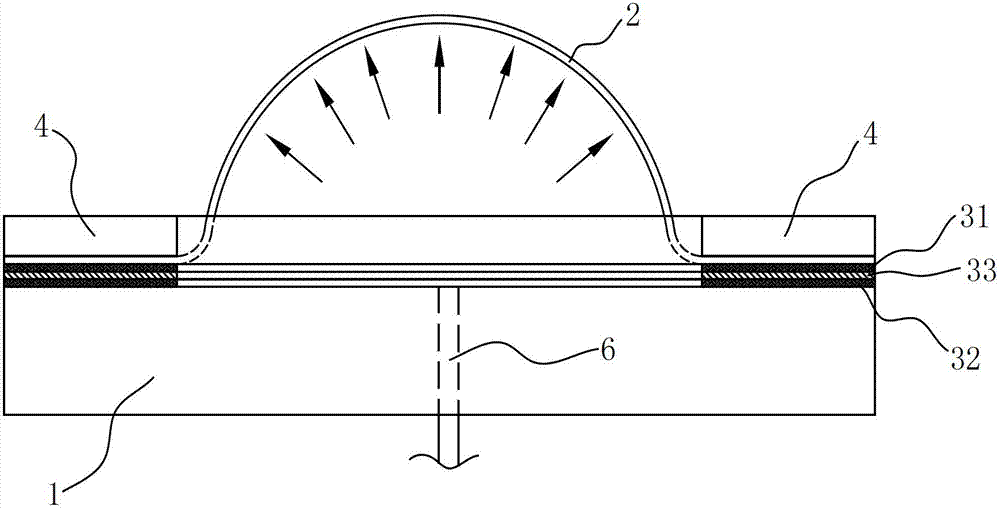

High temperature efficient ground solar steam generating set

InactiveCN101985918AHigh solar energy conversion efficiencyImprove conversion efficiencyFrom solar energyMachines/enginesTemperature controlProcess engineering

The invention discloses a high temperature efficient ground solar steam generating set, comprising a water pump, a water tank component, a steam turbine, a generator and a system control circuit. The generating set is characterized by also comprising a condenser component, a heat exchanger component, a thermal storage box component, an oil pump, a temperature control valve, a water level control water tank component and a base component. The generating set in the invention has the advantages of reasonable structure, low carbon, environment protection, high temperature and high efficiency, low cost, convenient installation and maintenance, safety and reliability, greatly saves land resources, and can be built in the areas at the classes of 1-5 in which national solar resources are distributed.

Owner:郭绍浩

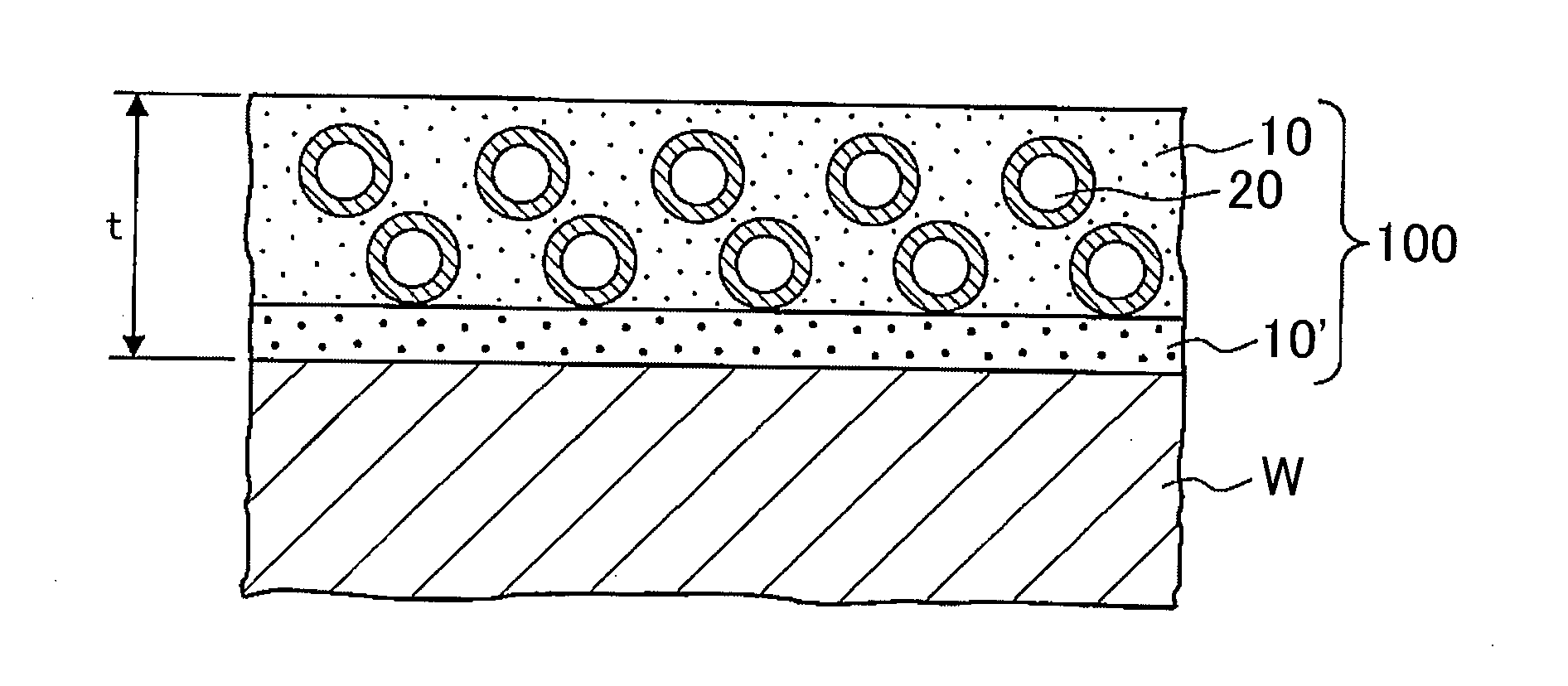

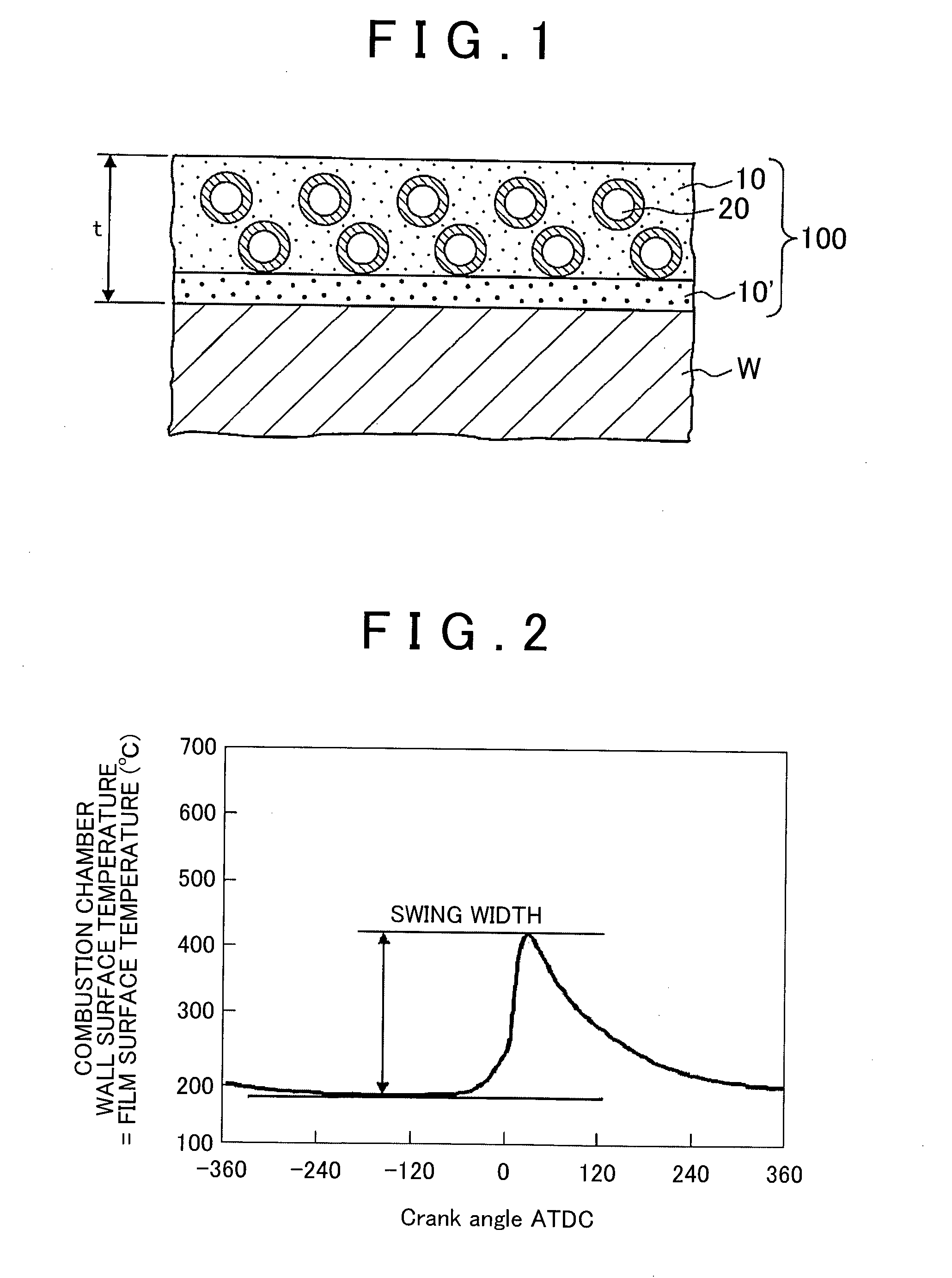

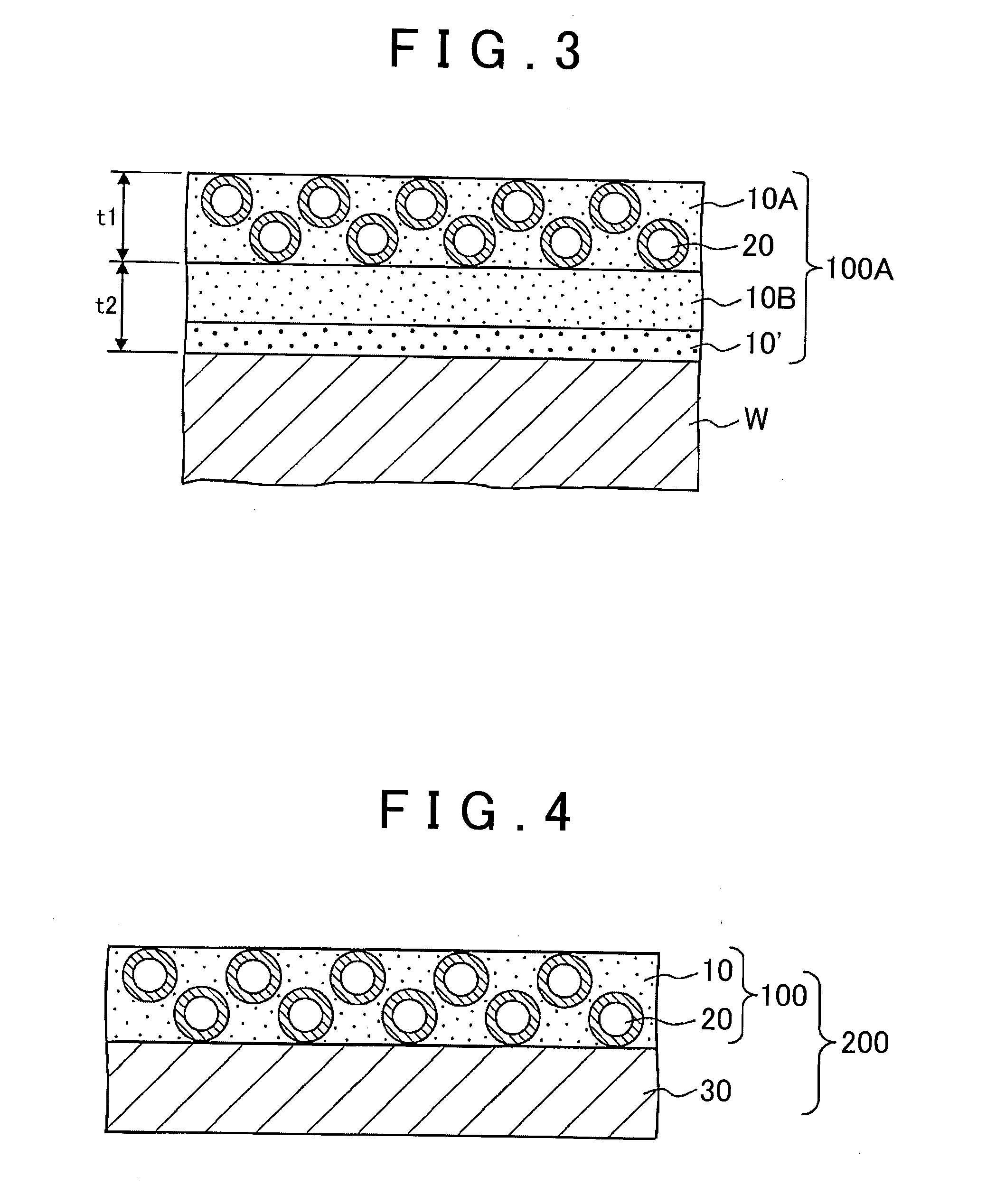

Heat shield film and method of forming heat shield film

InactiveUS20160201555A1Bonding strengthPrevent peelingLayered productsCylindersEngineeringHeat shield

A heat shield film (100) that is formed on a wall surface of an aluminum-based member (W) includes: a matrix layer (10) diffusion-bonded to the wall surface (diffusion bonding layer (10′)), having a coefficient of linear expansion of 15×10−6 / K to 25×10−6 / K in a temperature range of ordinary temperature to 200° C. and made of a porcelain enamel material; and hollow particles (20) dispersed in the matrix layer (10).

Owner:TOYOTA JIDOSHA KK

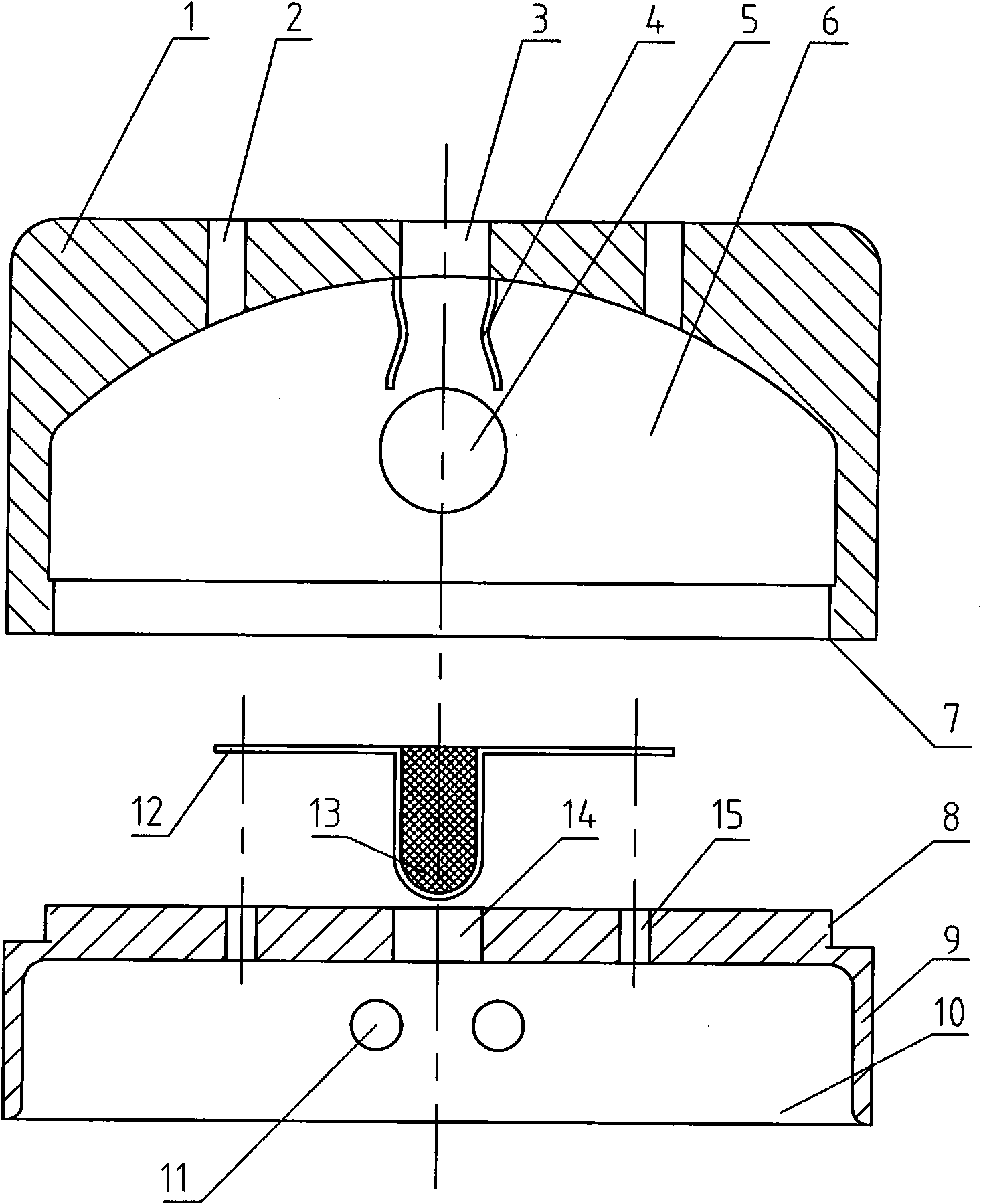

Hydraulic plug forming method

The invention relates to plug processing equipment and aims to provide plug forming equipment which is convenient to use, high in processing efficiency and reliable in product performance. The processing steps includes: arranging a steel plate to be processed on a worktable, setting a sealing part between the edge of the steel plate and the worktable, setting a forming ring die at the edge of the steel plate, translating a pressing oil cylinder or air cylinder to the forming ring die through an adjusting mechanism, pressing the forming ring die with the steel plate and the sealing component by the operating pressing oil cylinder or air cylinder, filling high-pressure liquid between the worktable and the steel plate through a high-pressure pipe by a high-pressure pump so that the steel plate is expanded and deforms; detecting whether the steel plate deforms sufficiently or not by a sensor arranged at the plug, controlling the high-pressure pump to maintain pressure for some time by a control system connected with the sensor after deformation is sufficient, taking off the deformed steel plate and cutting edges of the steel plate after pressure is released, and obtaining a finished plug. The plug forming equipment is high in automation degree, and production efficiency and safety are remarkably improved.

Owner:CHONGQING TIEMA IND GRP

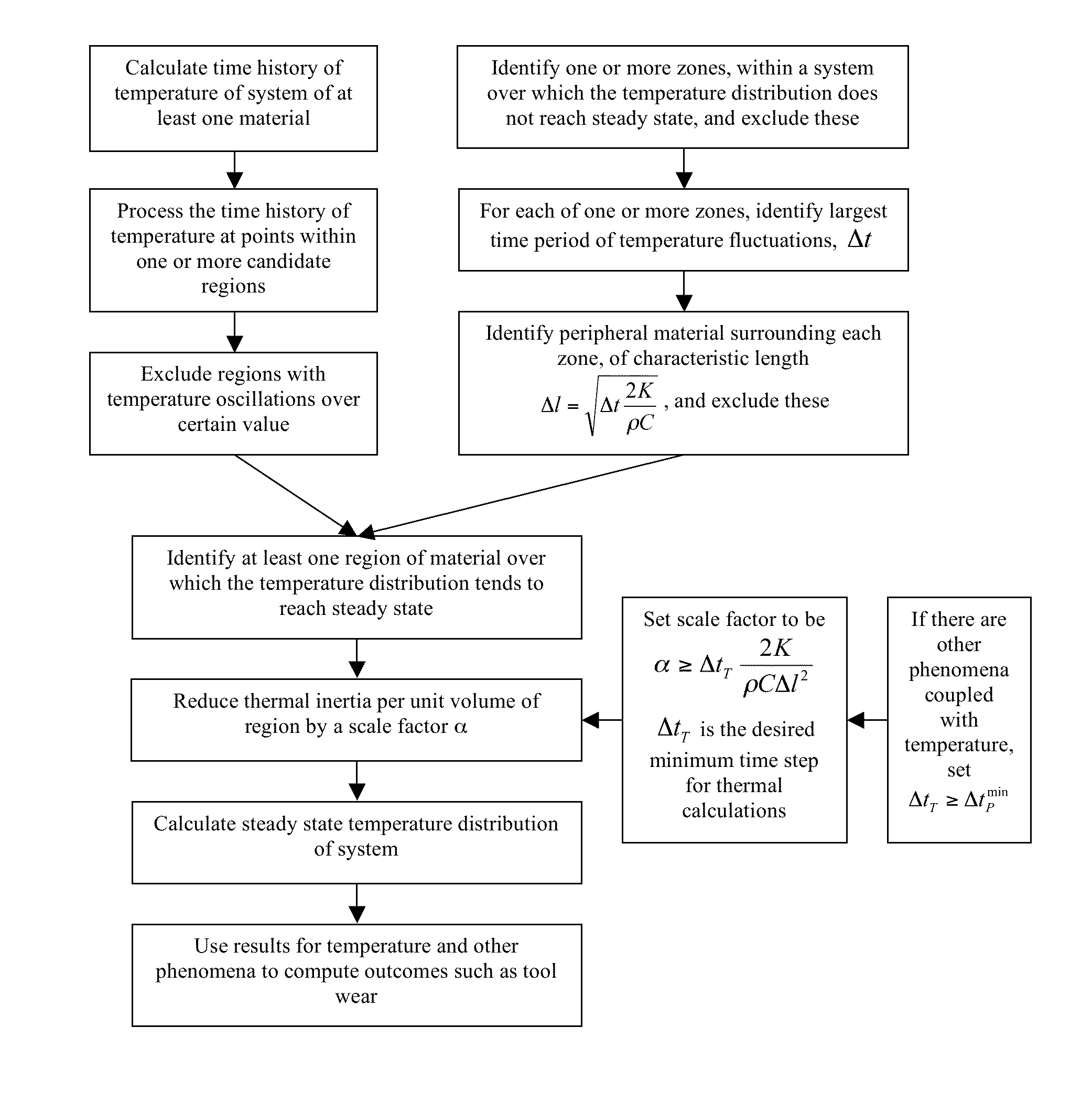

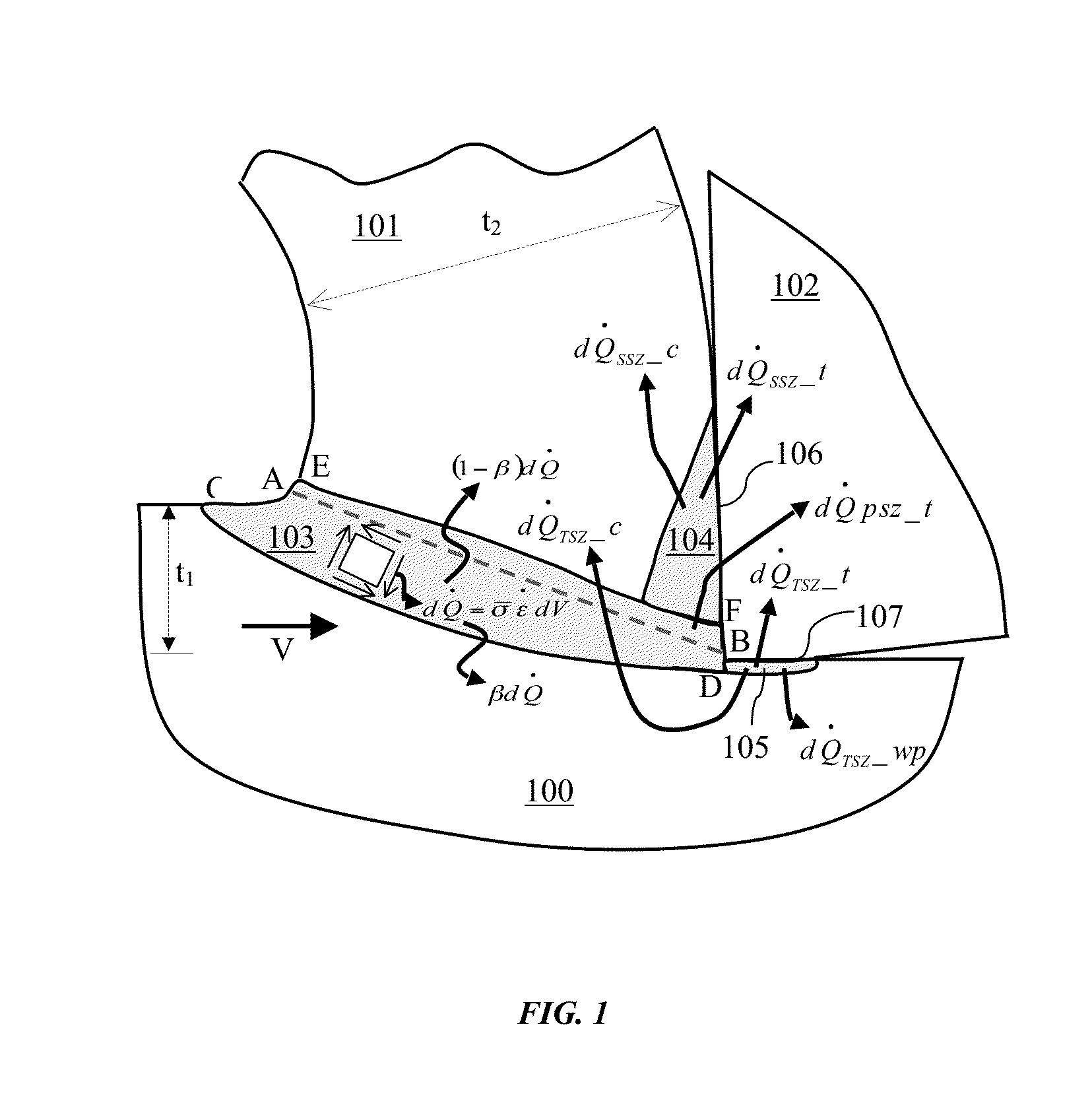

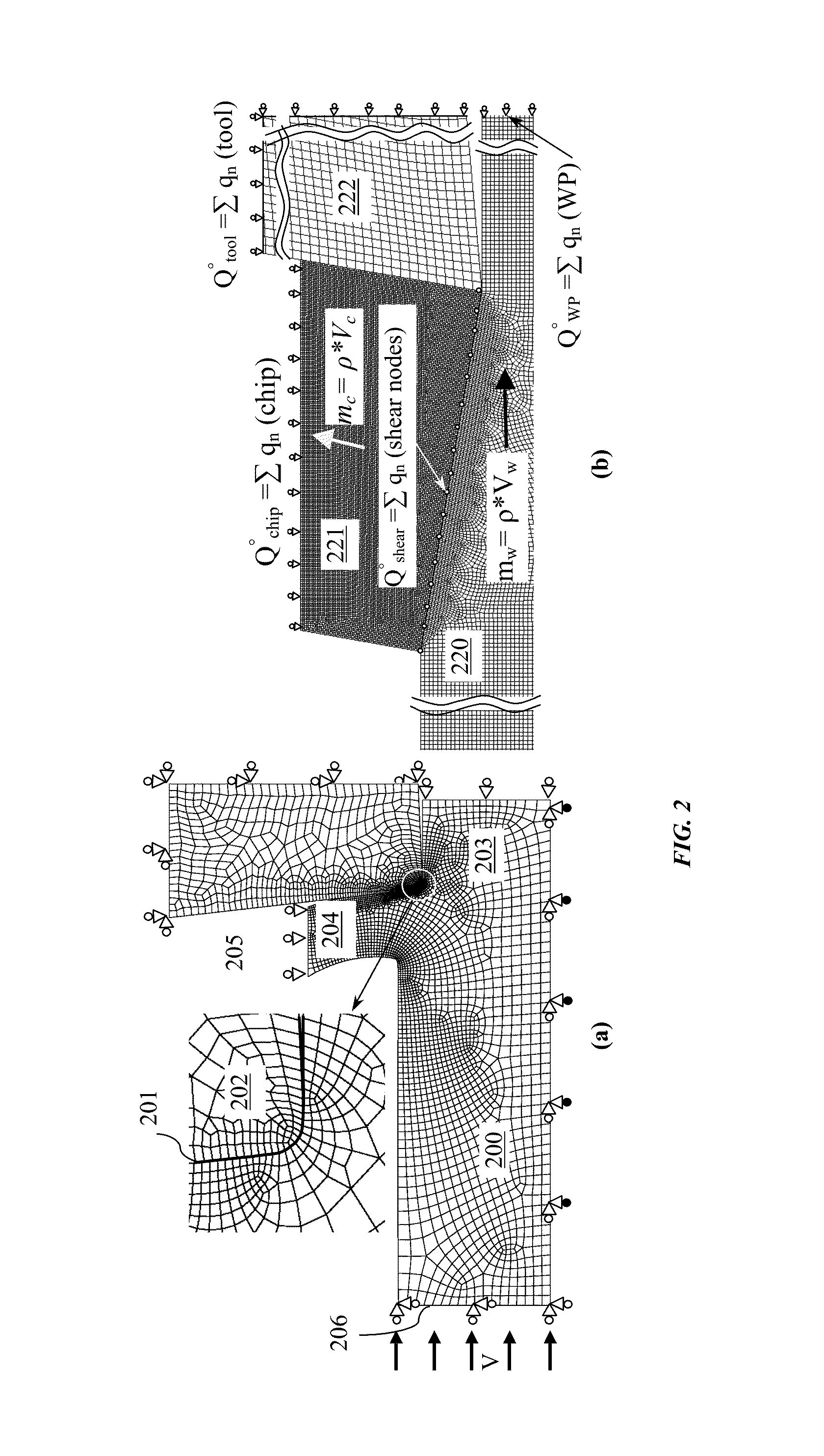

Thermal modeling of an orthogonal machining process

ActiveUS9418185B2Lower the volumeNo loss of accuracyComputation using non-denominational number representationDesign optimisation/simulationSteady state temperatureElement analysis

A novel procedure is disclosed, that can be incorporated into Finite Element Analysis (FEA) or other similar analysis techniques, to obtain the steady state temperature distribution in a coupled transient heat transfer analysis rapidly as well as accurately. A scale factor is used to reduce the thermal inertia per unit volume (specific heat capacity) in regions of steady state temperature distribution, thereby hastening the achievement of steady state. An application of this procedure to estimate steady state temperature distributions within cutting tools, and the estimation of cutting tool wear based on the obtained steady state temperature distributions is shown as an example.

Owner:MADHAVAN VISWANATHAN +1

Sensor water freeze protector

Apparatus that detects the pressure of water that can move through a water channel (26) towards and away from a pressure sensor (22), wherein the apparatus is constructed to avoid damage from freezing water. The water channel is constructed with a narrow channel portion (40) and a wide channel portion (42) connected in series, with the narrow channel portion lying closer to the pressure sensor. When the ambient temperature falls below the freezing temperature of water, water in the narrow channel portion freezes before water in the wide channel portion freezes, and frozen water in the narrow channel portion acts like a plug to prevent water (or ice) from moving toward the pressure sensor.

Owner:BARKSDALE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com