High-heat-conductivity metal-carbonate molten salt material and preparation method and application thereof

A carbonic acid molten salt, high thermal conductivity technology, applied in heat exchange materials, chemical instruments and methods, bulk chemical production, etc. Achieve the effect of overcoming unfavorable heat transfer, improving the thermal conductivity of high-temperature liquids, and improving thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A magnesium-carbonate molten salt heat transfer heat storage material, the preparation method is as follows:

[0040] Using pure salts of potassium carbonate, sodium carbonate and lithium carbonate extracted from salt lakes as raw materials, carbonate molten salt was prepared according to the composition and method provided in Example 7 of Chinese invention patent ZL200910037348.7.

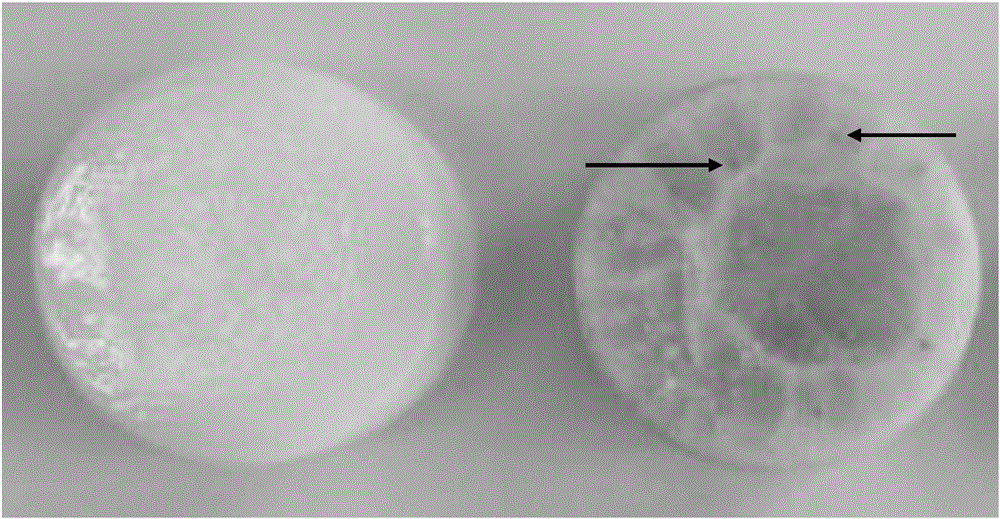

[0041] Mix magnesium powder and carbonate molten salt according to 1.0:99.0 (mass ratio) and stir evenly, and statically heat to 650°C at a heating rate of 4°C / min under the protection of an inert atmosphere (argon) until the magnesium-molten salt is completely Melt, then keep warm for 12 hours, so that the added magnesium is evenly dispersed in the molten salt liquid in the form of "mist", then naturally cooled to 25 ° C, mechanically crushed and dried, and the magnesium-carbonate molten salt heat transfer and heat storage material is obtained.

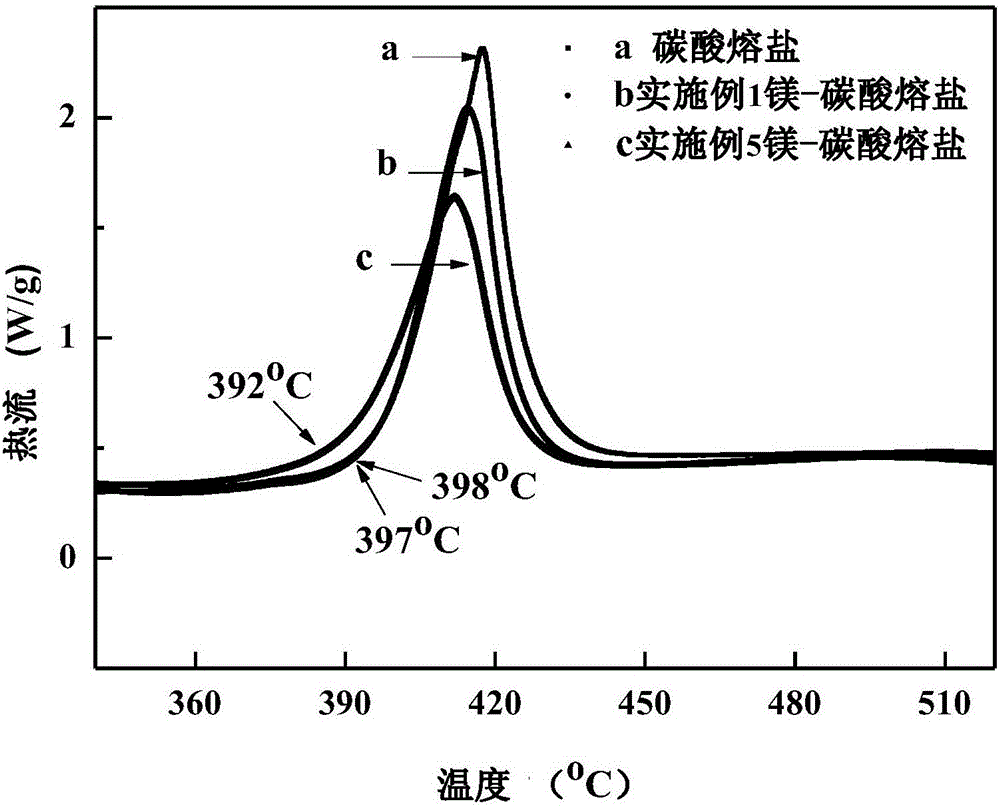

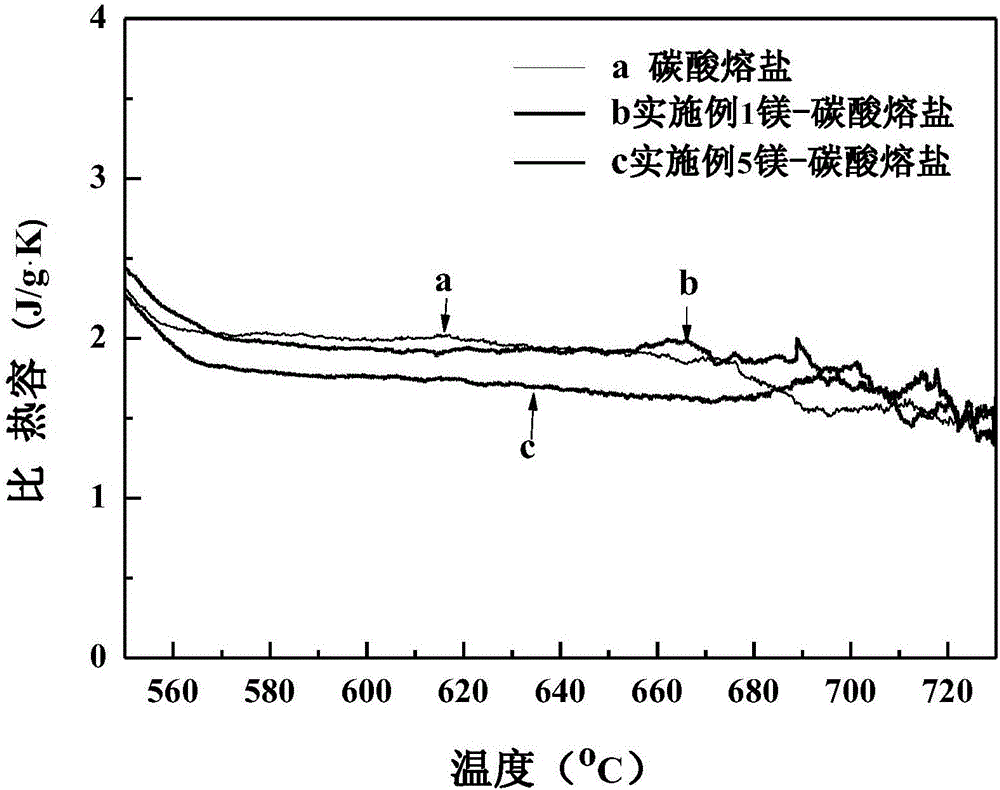

[0042] Using a differential scanning calori...

Embodiment 2

[0046] A magnesium-carbonate molten salt heat transfer heat storage material, the preparation method is as follows:

[0047] Using pure salts of potassium carbonate, sodium carbonate and lithium carbonate extracted from salt lakes as raw materials, carbonate molten salt was prepared according to the composition and method provided in Example 7 of Chinese invention patent ZL200910037348.7.

[0048] Mix magnesium powder and carbonate molten salt according to 0.1:99.9 (mass ratio) and stir evenly, and statically heat to 650°C at a heating rate of 8°C / min under the protection of an inert atmosphere (argon) until the magnesium-molten salt is completely Melting, and then keeping warm for 10 hours, so that the added magnesium is evenly dispersed in the molten salt liquid in the form of "mist", then naturally cooled to 25 ° C, mechanically crushed and dried, and the magnesium-carbonate molten salt heat transfer and heat storage material is obtained.

[0049] The measuring method is th...

Embodiment 3

[0051] A magnesium-carbonate molten salt heat transfer heat storage material, the preparation method is as follows:

[0052] Using pure salts of potassium carbonate, sodium carbonate and lithium carbonate extracted from salt lakes as raw materials, carbonate molten salt was prepared according to the composition and method provided in Example 7 of Chinese invention patent ZL200910037348.7.

[0053] Mix magnesium powder and carbonate molten salt according to 1.5:98.5 (mass ratio) and stir evenly, and statically heat to 650°C at a heating rate of 5°C / min under the protection of an inert atmosphere (argon) until the magnesium-molten salt is completely Melting, and then keeping it warm for 14 hours, so that the added magnesium is evenly dispersed in the molten salt liquid in the form of "mist", and then naturally cooled to 40°C, mechanically crushed and dried, and the magnesium-carbonate molten salt heat transfer and heat storage material is obtained.

[0054] The test method is th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com