Container with inner heating casing

A technology of internal heating and inner casing, which is applied in the direction of containers, large containers, transport buses, etc., can solve the problems of segregation, decomposition and solidification, and the aging of modified asphalt, so as to ensure the quality, good fluidity and avoid segregation and decomposition Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] A container with an inner heating sleeve of the present invention will be described in detail below in conjunction with the accompanying drawings.

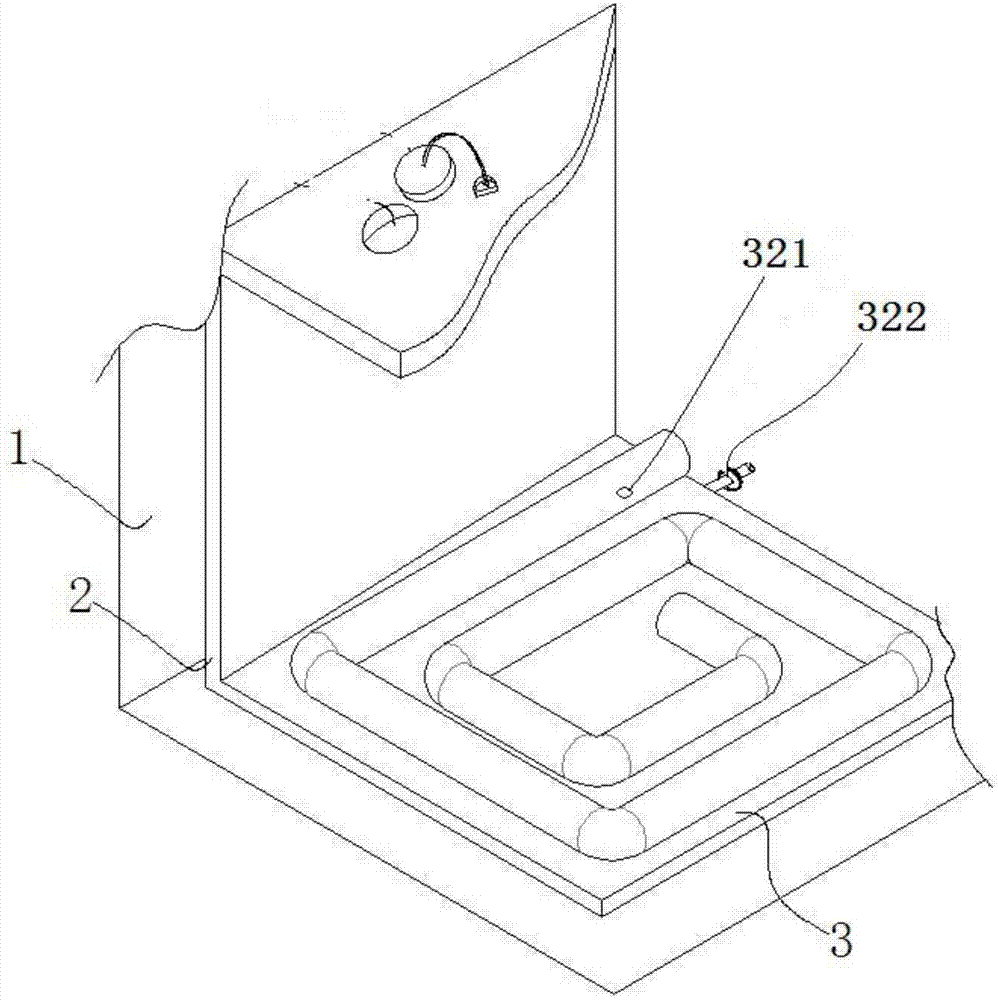

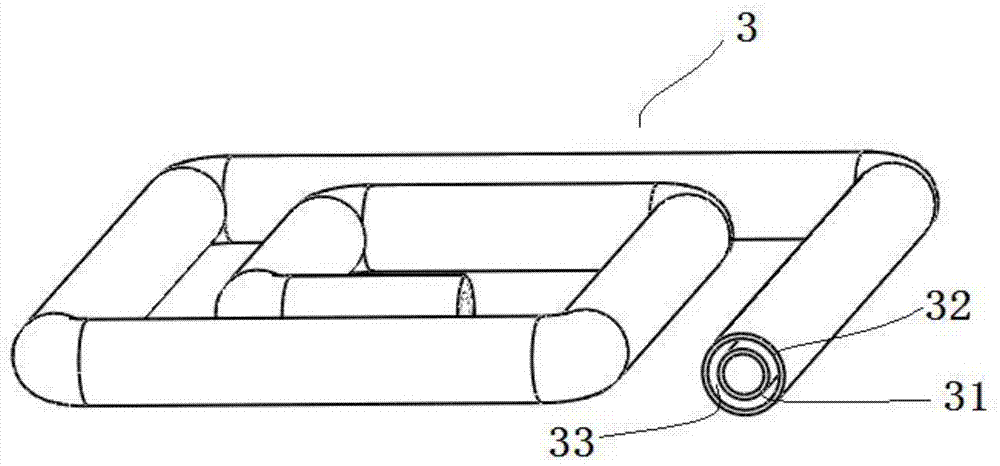

[0026] see figure 1 , figure 2 , the present embodiment provides a container with an inner heating jacket, comprising an outer shell 1 with an accommodating space, an inner tank 2 installed in the accommodating space, arranged inside the inner tank 2, and The heating hole on the inner tank body 2 is connected to the heating tube 3 that transfers heat to the inner tank body 2 through the heating hole (not shown in the figure), and the heating tube 3 includes a coaxially sleeved inner sleeve A pipe 31 and an outer sleeve 32, there is a gap between the inner sleeve 31 and the outer sleeve 32, a heat-conducting medium layer 33 is arranged in the gap, and the inner sleeve 31 extends out of the inner tank body 2, The outer sleeve 32 does not protrude from the inner tank body 2 .

[0027] In this embodiment, a direct-fired hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com