Patents

Literature

1503 results about "Specific heat" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Specific heat. n. 1. The ratio of the amount of heat required to raise the temperature of a unit mass of a substance by one unit of temperature to the amount of heat required to raise the temperature of a similar mass of a reference material, usually water, by the same amount.

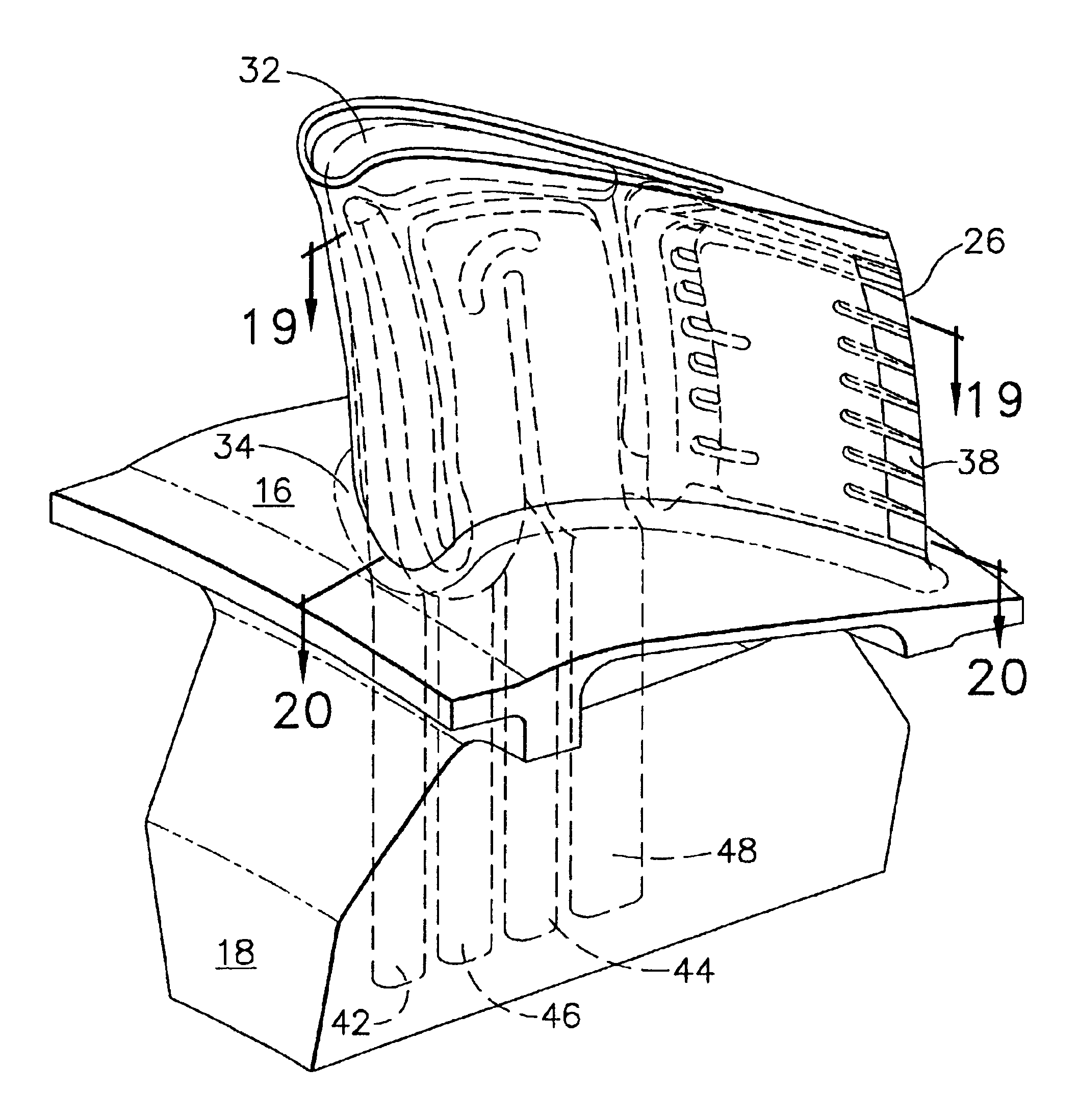

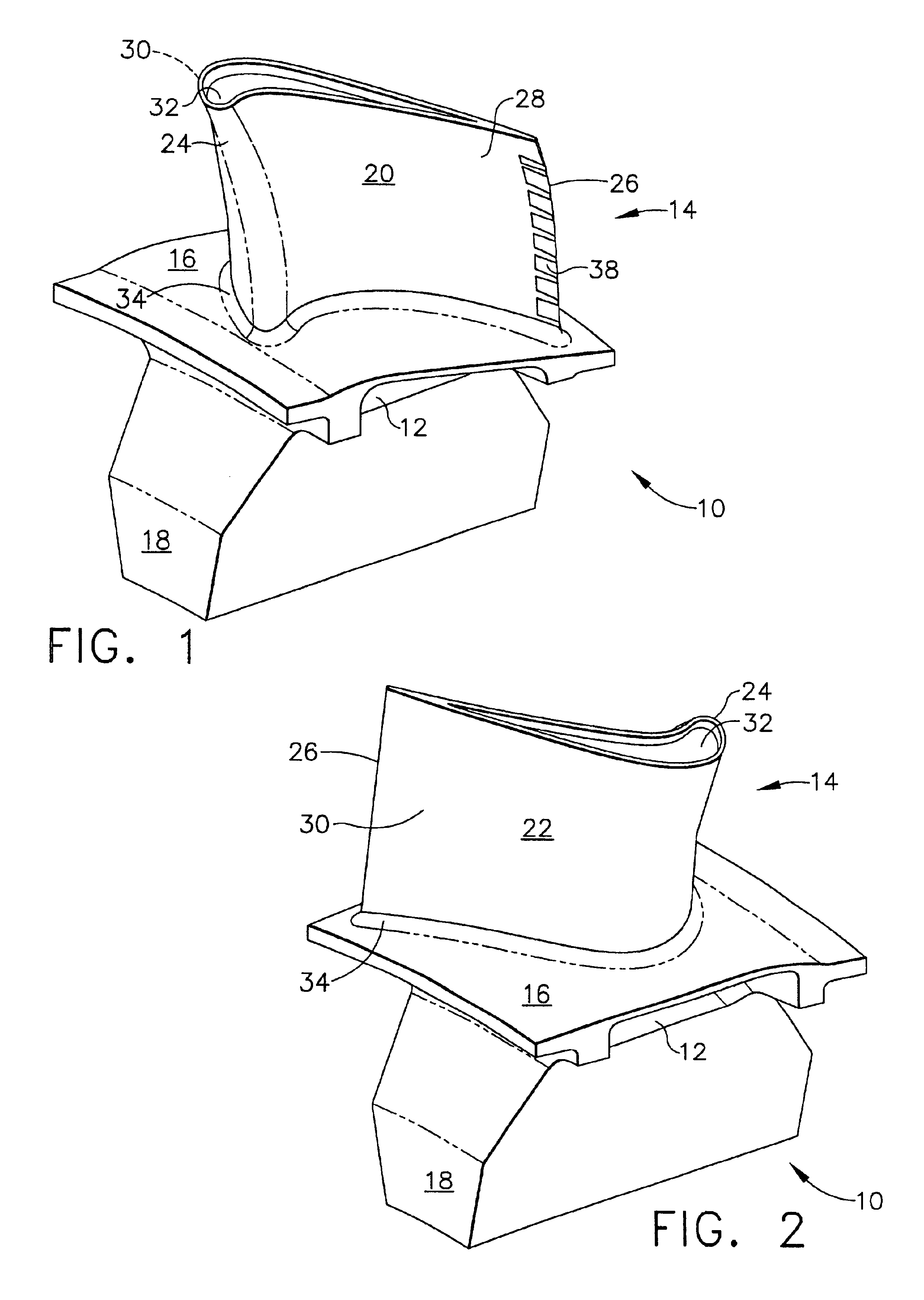

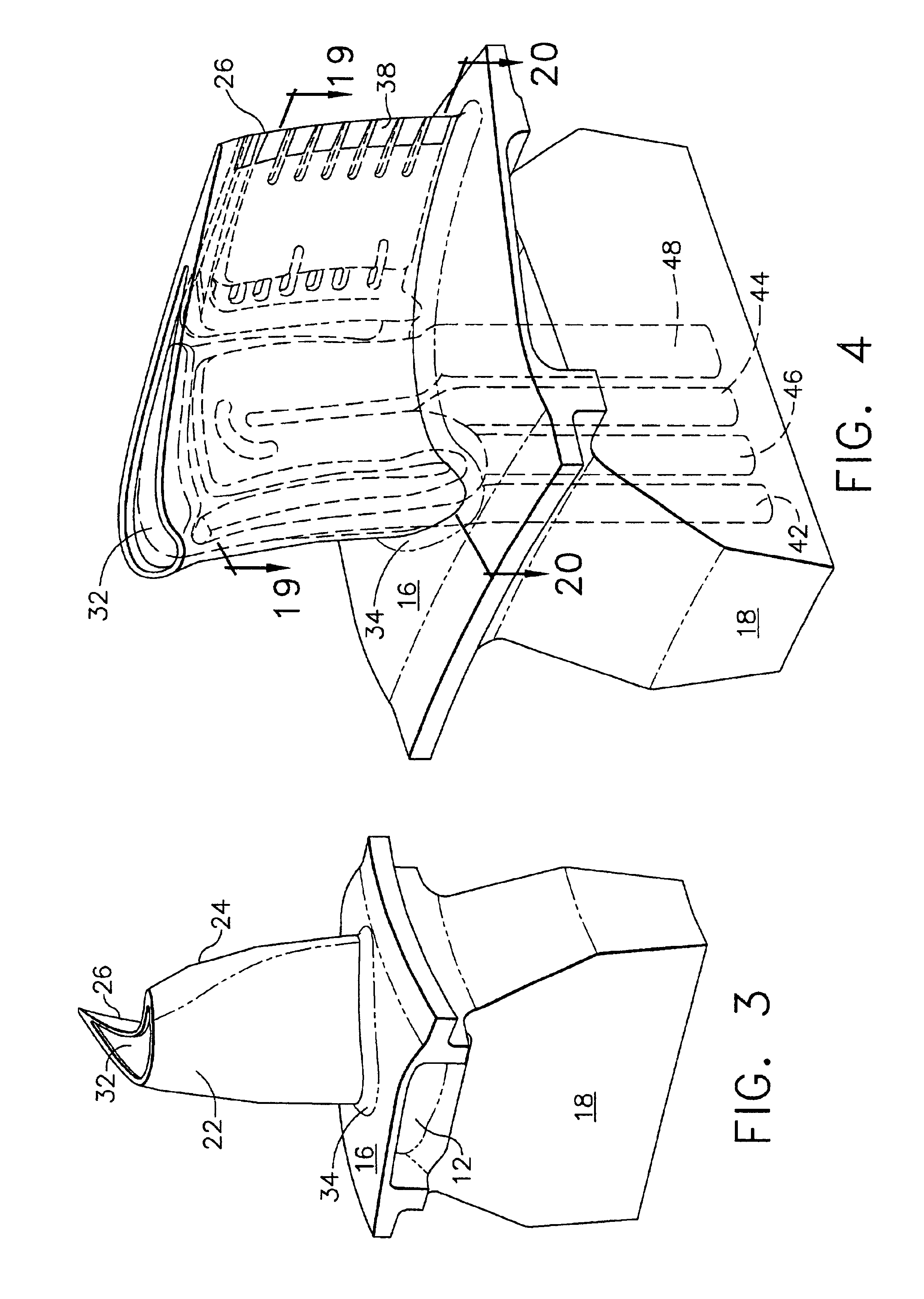

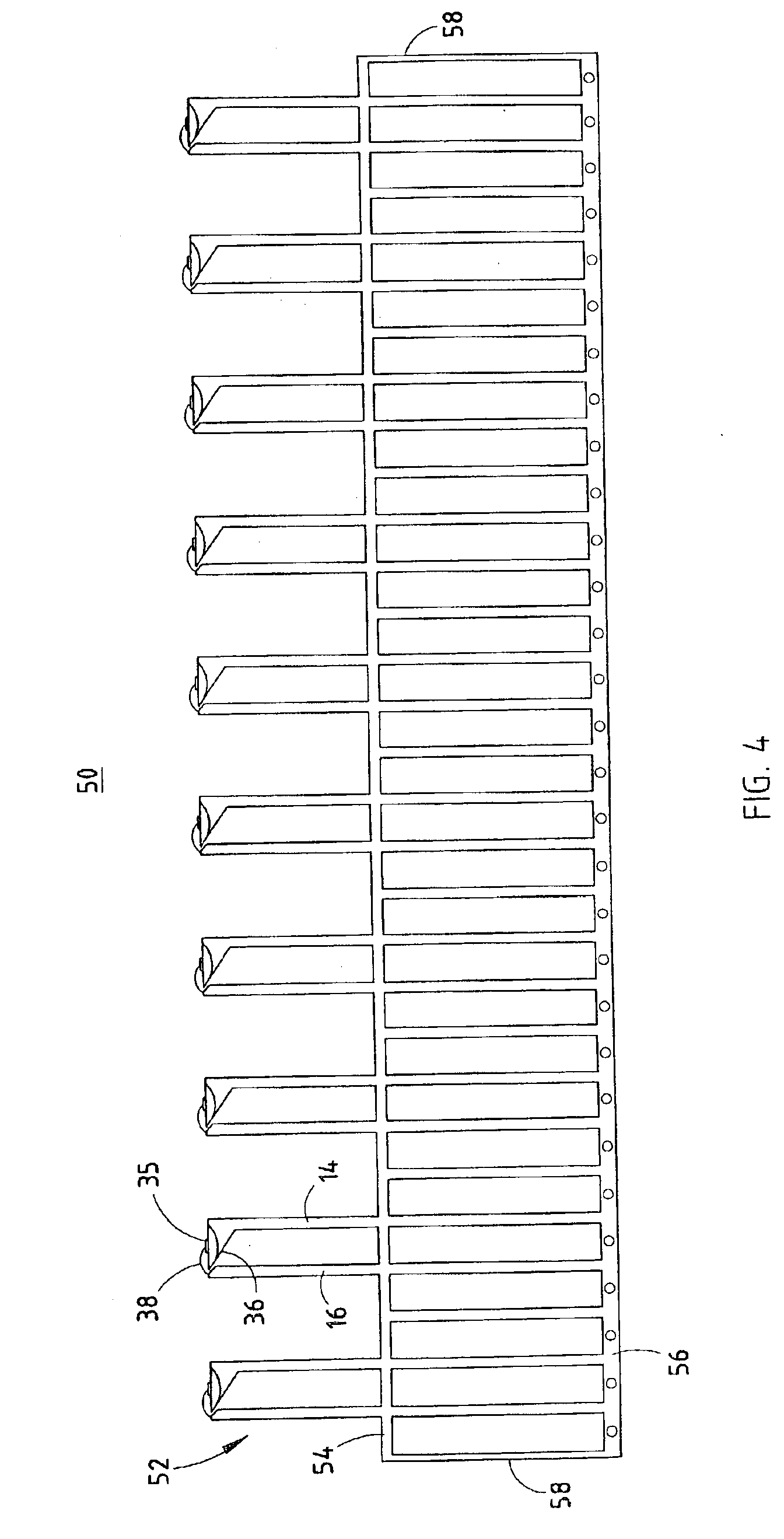

High effectiveness cooled turbine vane or blade

InactiveUS6974308B2Improve cooling efficiencyEasy to manufacturePump componentsEngine fuctionsSuction stressConventional casting

A robust multiple-walled, multi-pass, high cooling effectiveness cooled turbine vane or blade designed for ease of manufacturability, minimizes cooling flows on highly loaded turbine rotors. The vane or blade design allows the turbine inlet temperature to increase over current technology levels while simultaneously reducing turbine cooling to low levels. A multi-wall cooling system is described, which meets the inherent conflict to maximize the flow area of the cooling passages while retaining the required section thickness to meet the structural requirements. Independent cooling circuits for the vane or blade's pressure and suction surfaces allow the cooling of the airfoil surfaces to be tailored to specific heat load distributions (that is, the pressure surface circuit is an independent forward flowing serpentine while the suction surface is an independent rearward flowing serpentine). The cooling air for the independent circuits is supplied through separate passages at the base of the vane or blade. The cooling air follows intricate passages to feed the serpentine thin outer wall passages, which incorporate pin fins, turbulators, etc. These passages, while satisfying the aero / thermal / stress requirements, are of a manufacturing configuration that may be cast with single crystal materials using conventional casting techniques.

Owner:HONEYWELL INT INC

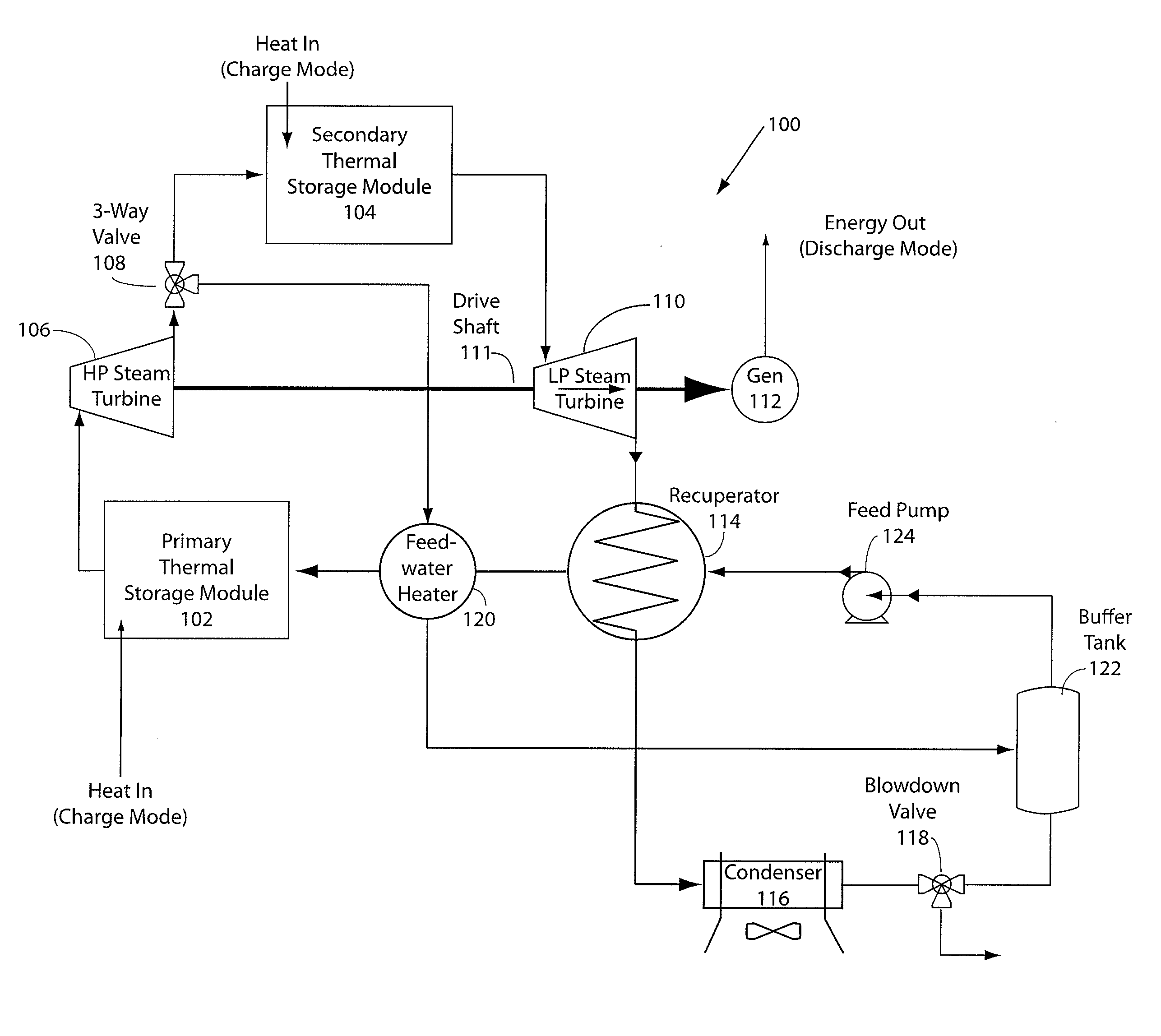

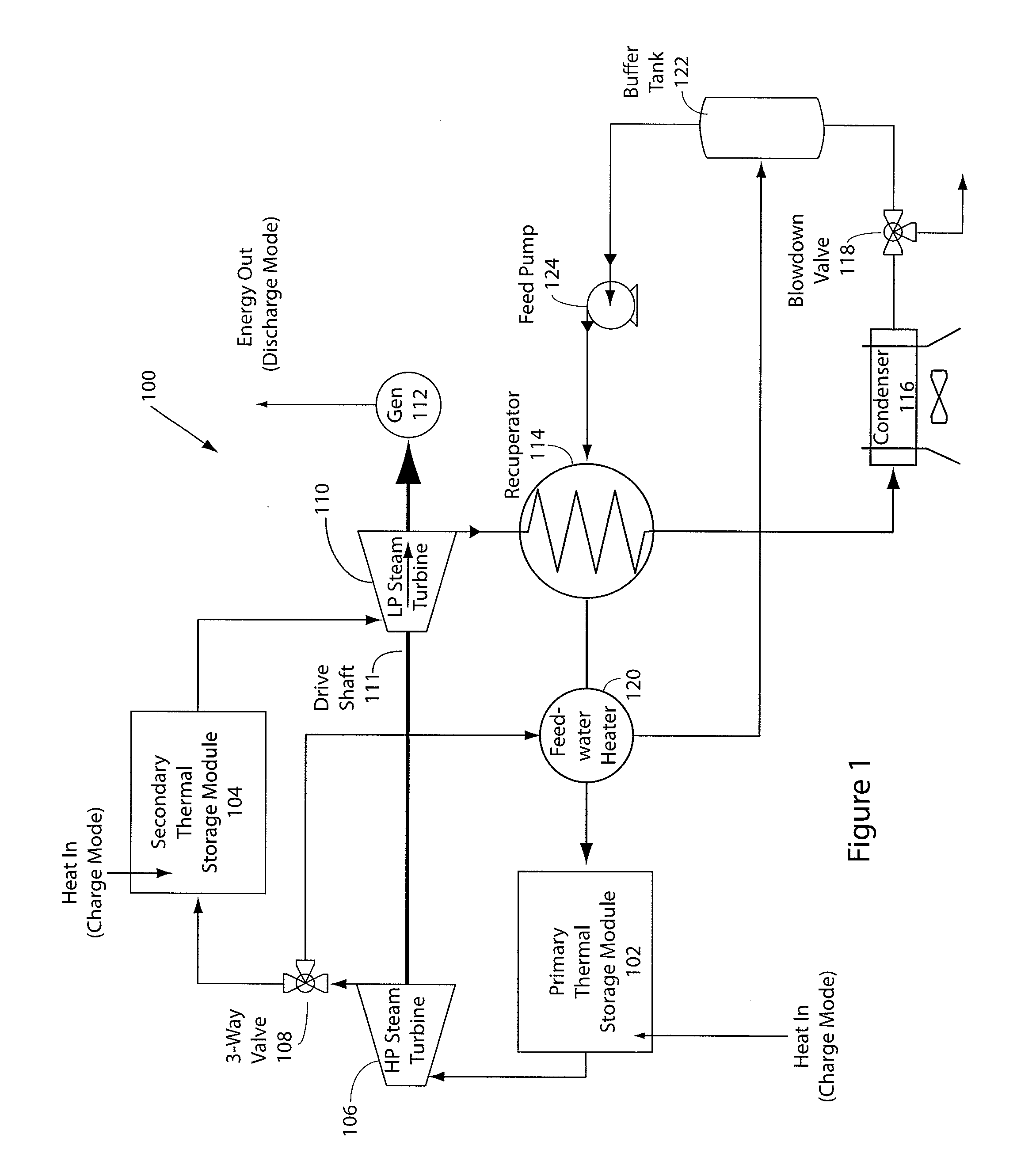

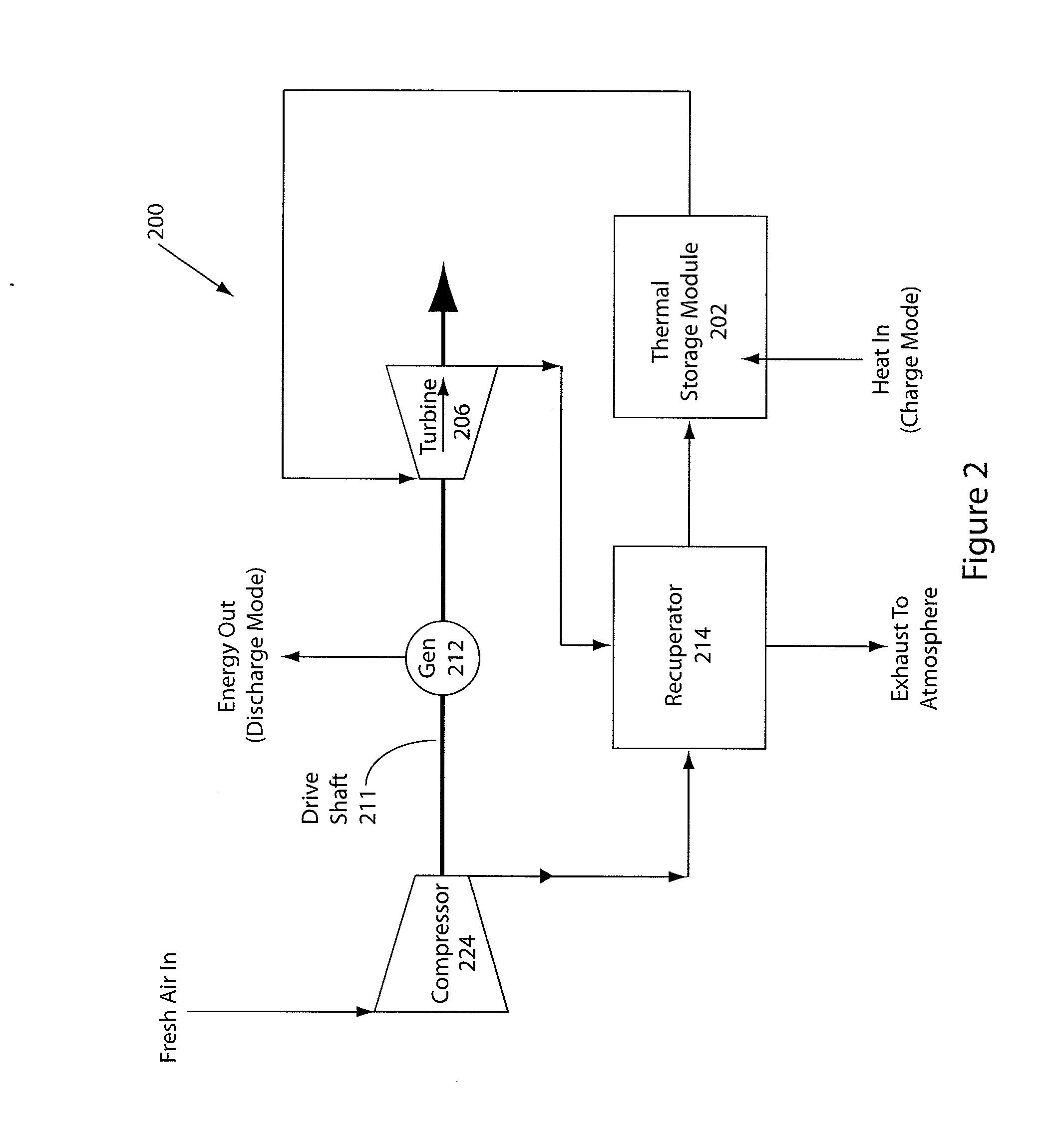

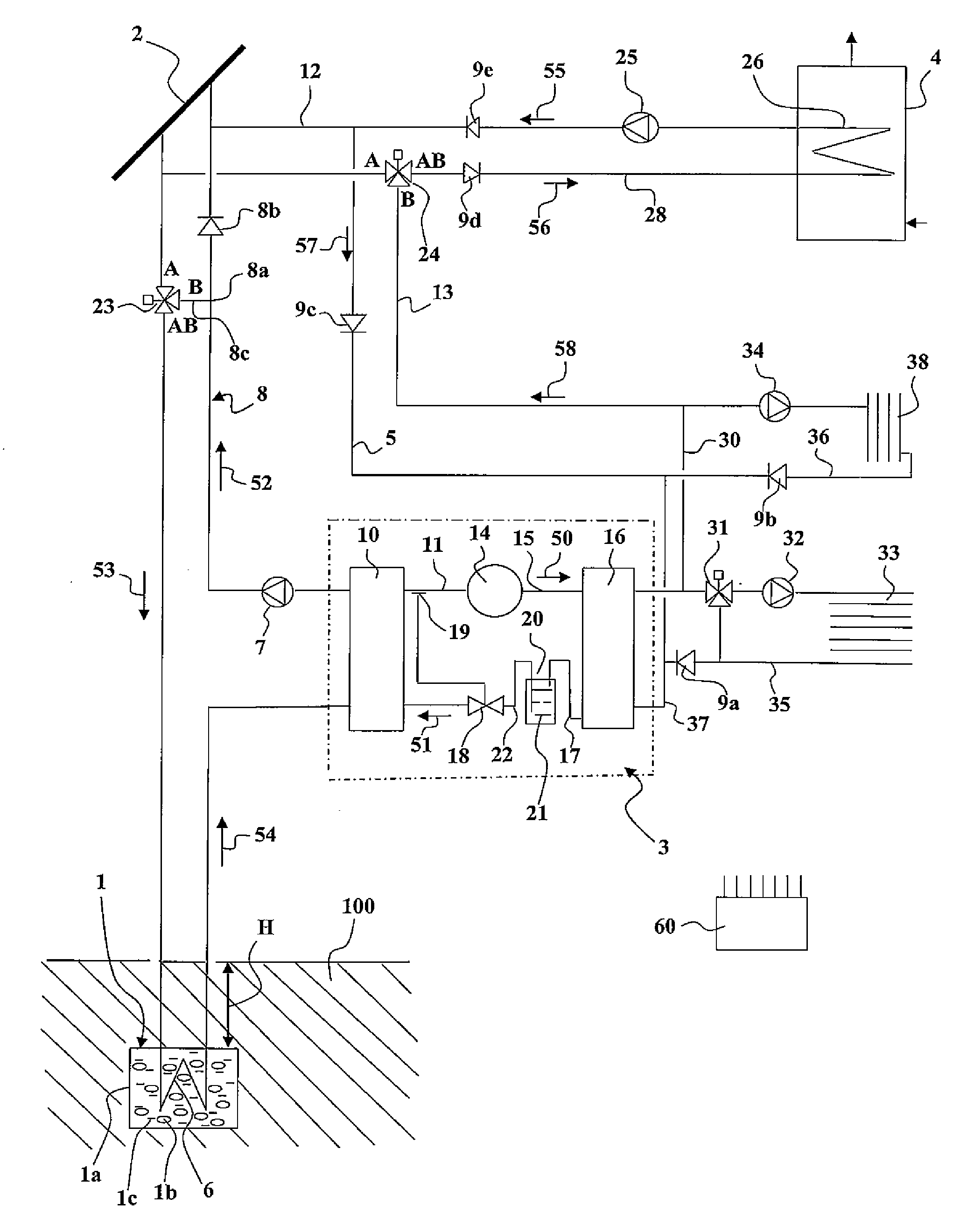

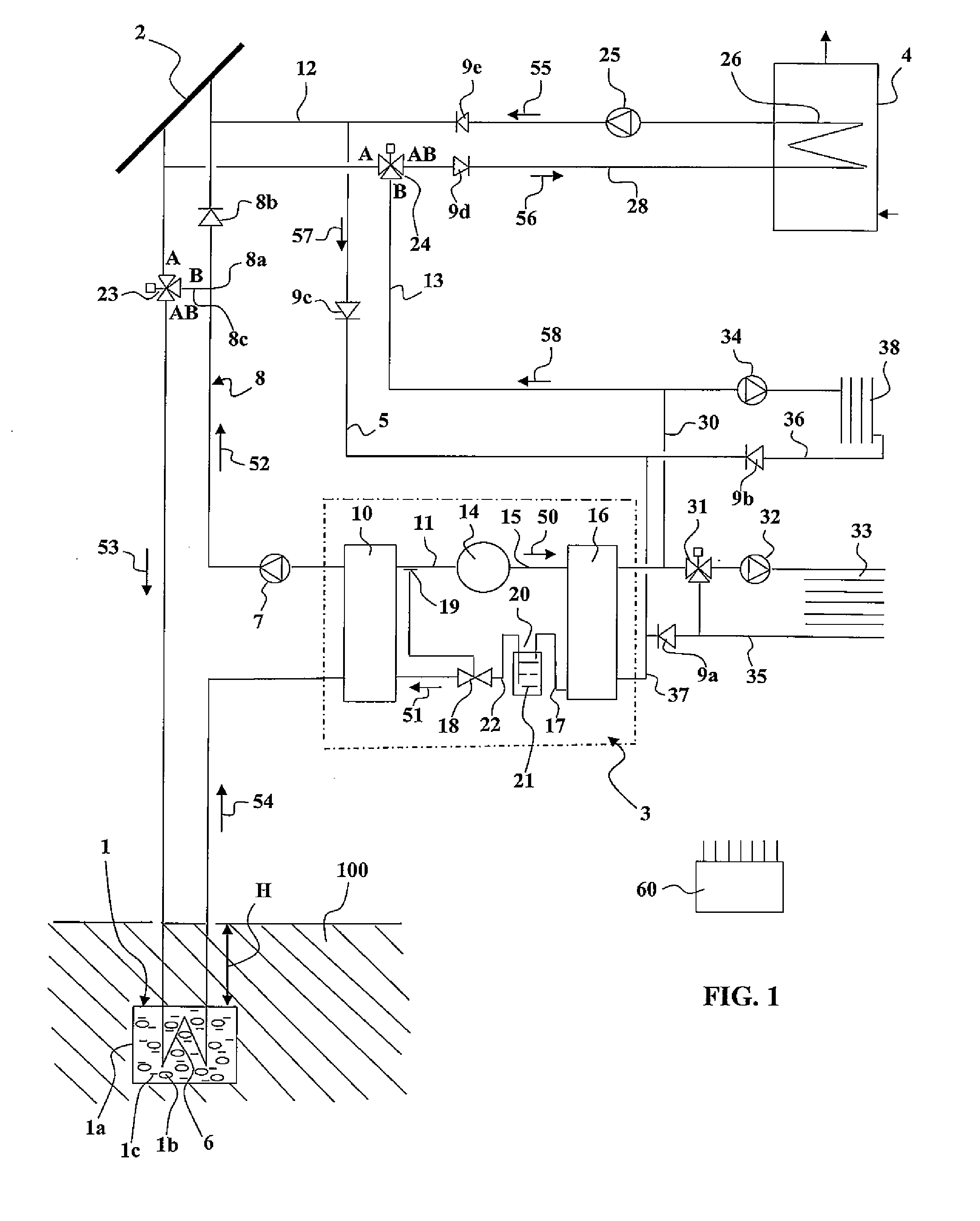

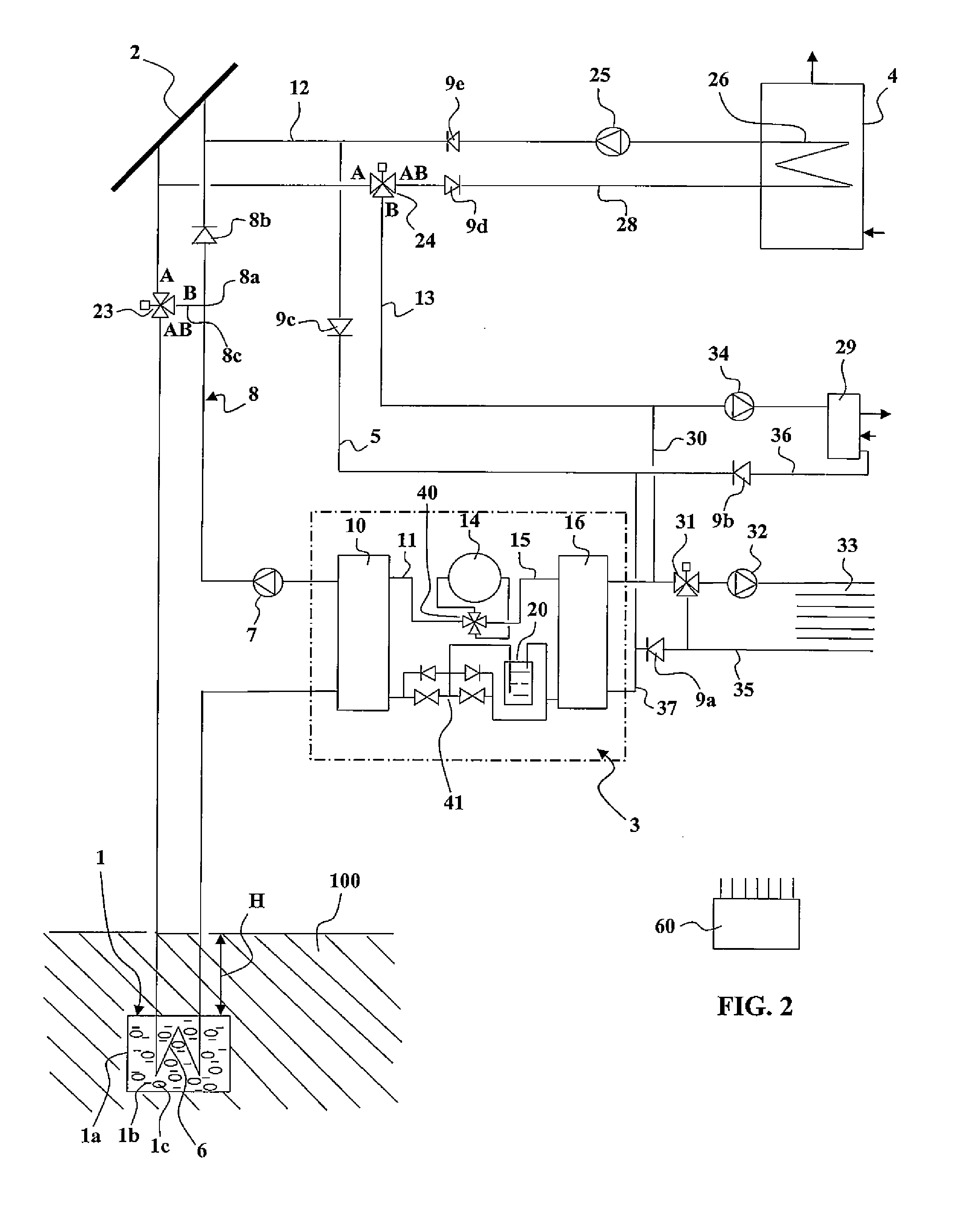

System and method for thermal energy storage and power generation

A thermal energy storage system is proposed in which the latent heat of fusion of common salts is used to store energy within a selectable temperature range, extending both above and below the melting / freezing temperature zone of the salt mixture. The salt mixture occupies interstitial void spaces in a solid endostructure. The solid material remains in the solid state throughout the thermal cycling of the energy storage system, and preferably has properties of thermal conduction and specific heat that enhance the behavior of the salt mixture alone, while being chemically compatible with all materials in the storage system. The storage system is capable of accepting and delivering heat at high rates, thereby allowing power generation using a suitable energy transfer media to power a turbine of an electric generator or a process heat need to provide a relatively local, dispatchable, rechargeable thermal storage system, combined with a suitably sized generator.

Owner:WOODWARD GOVERNOR CO

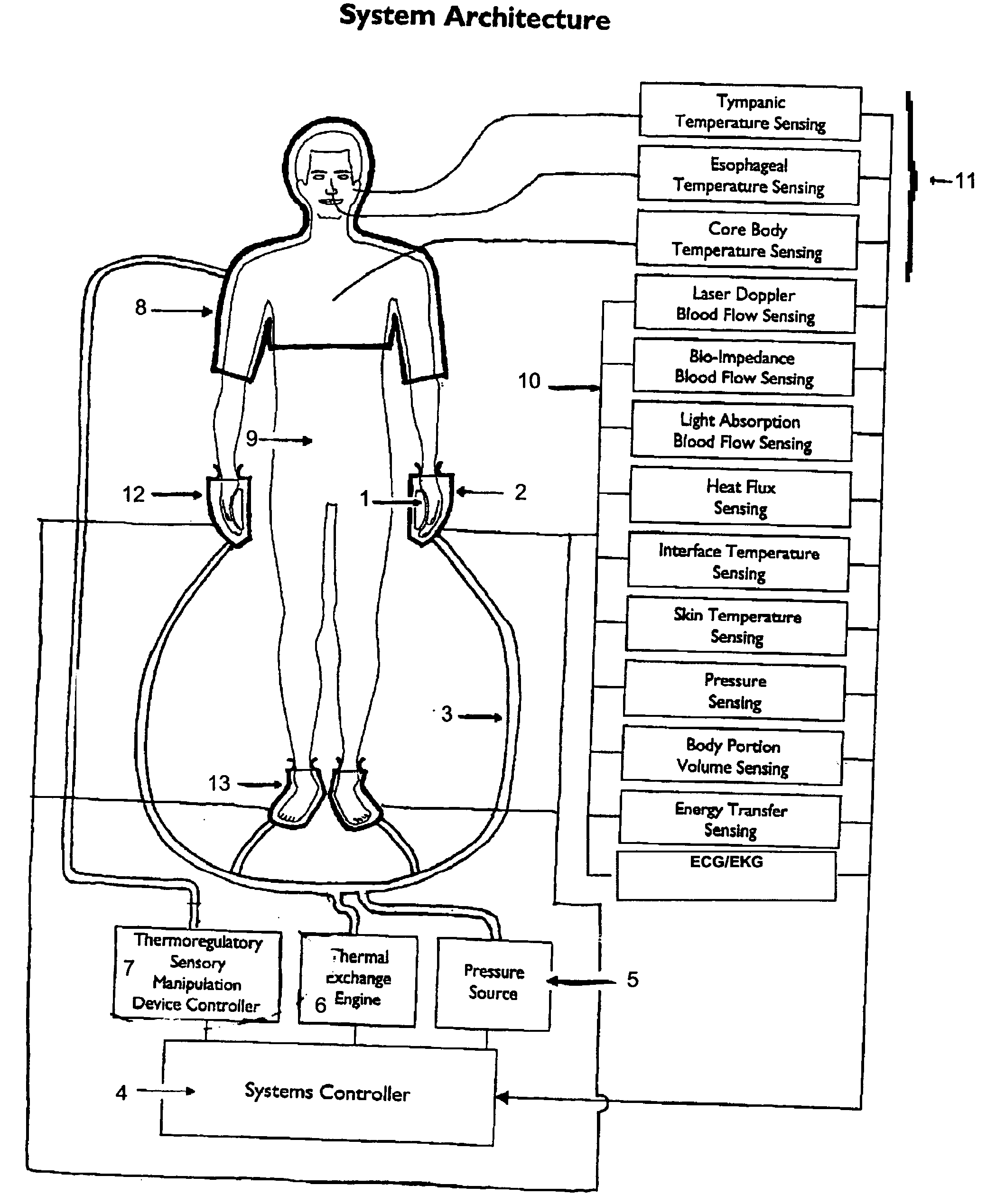

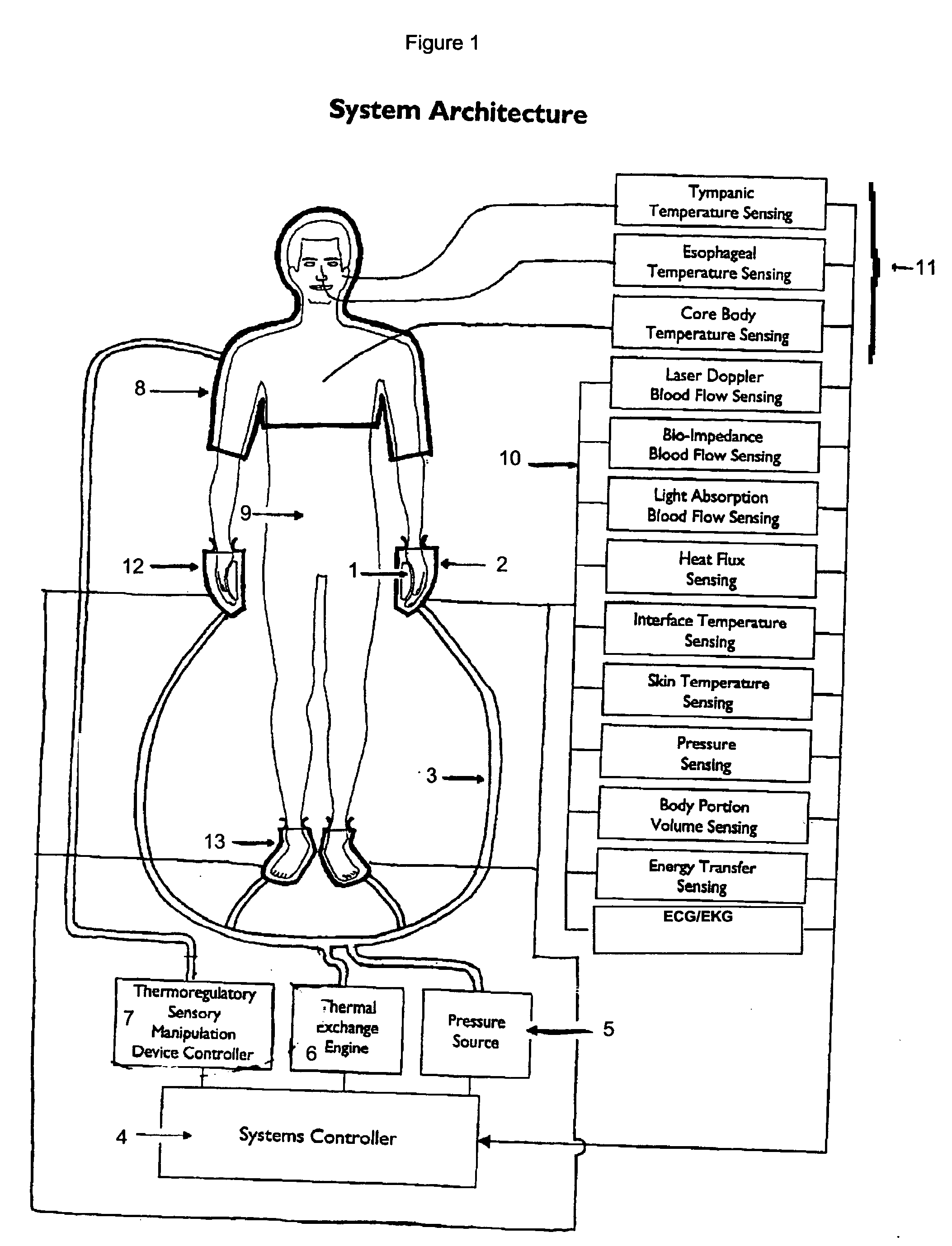

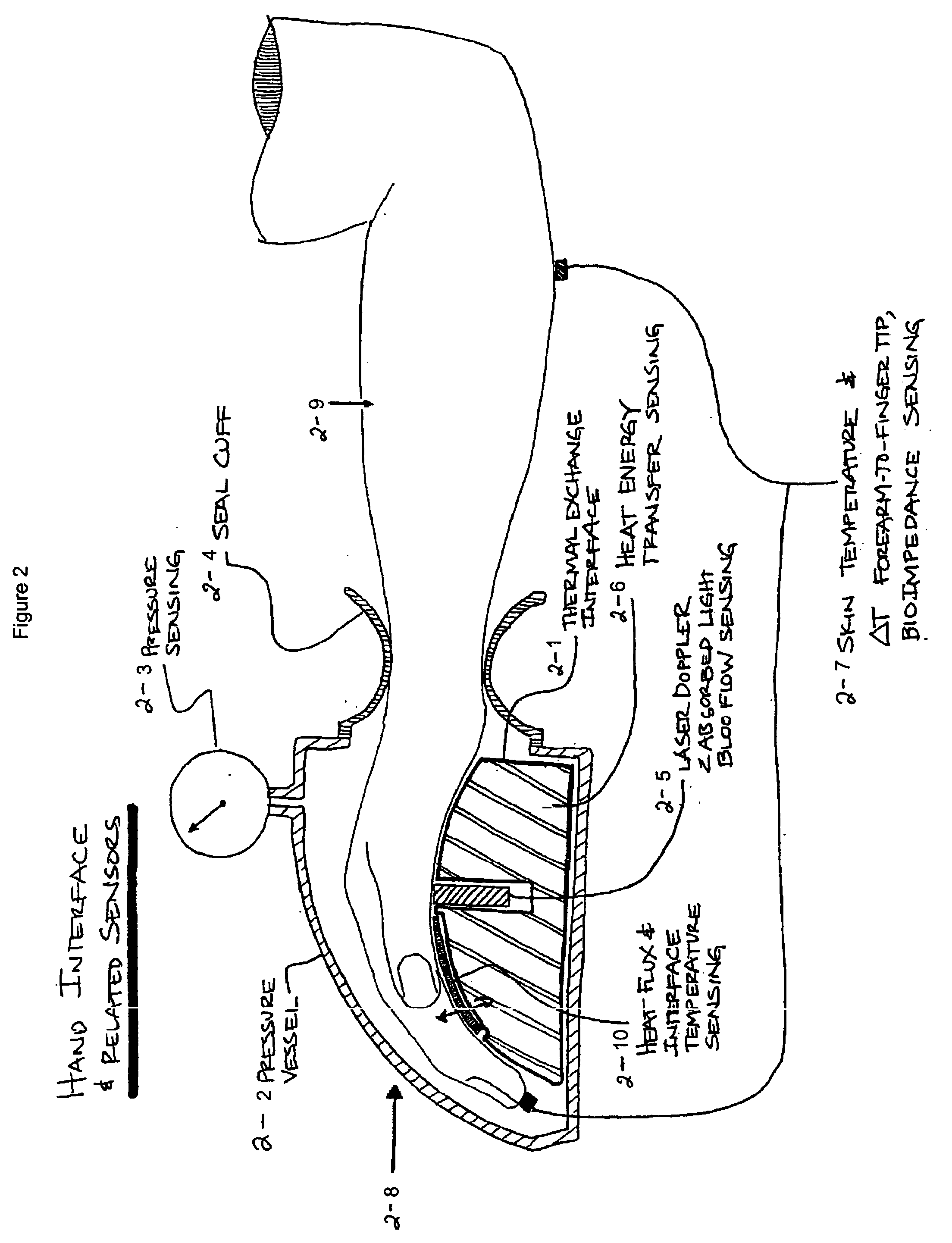

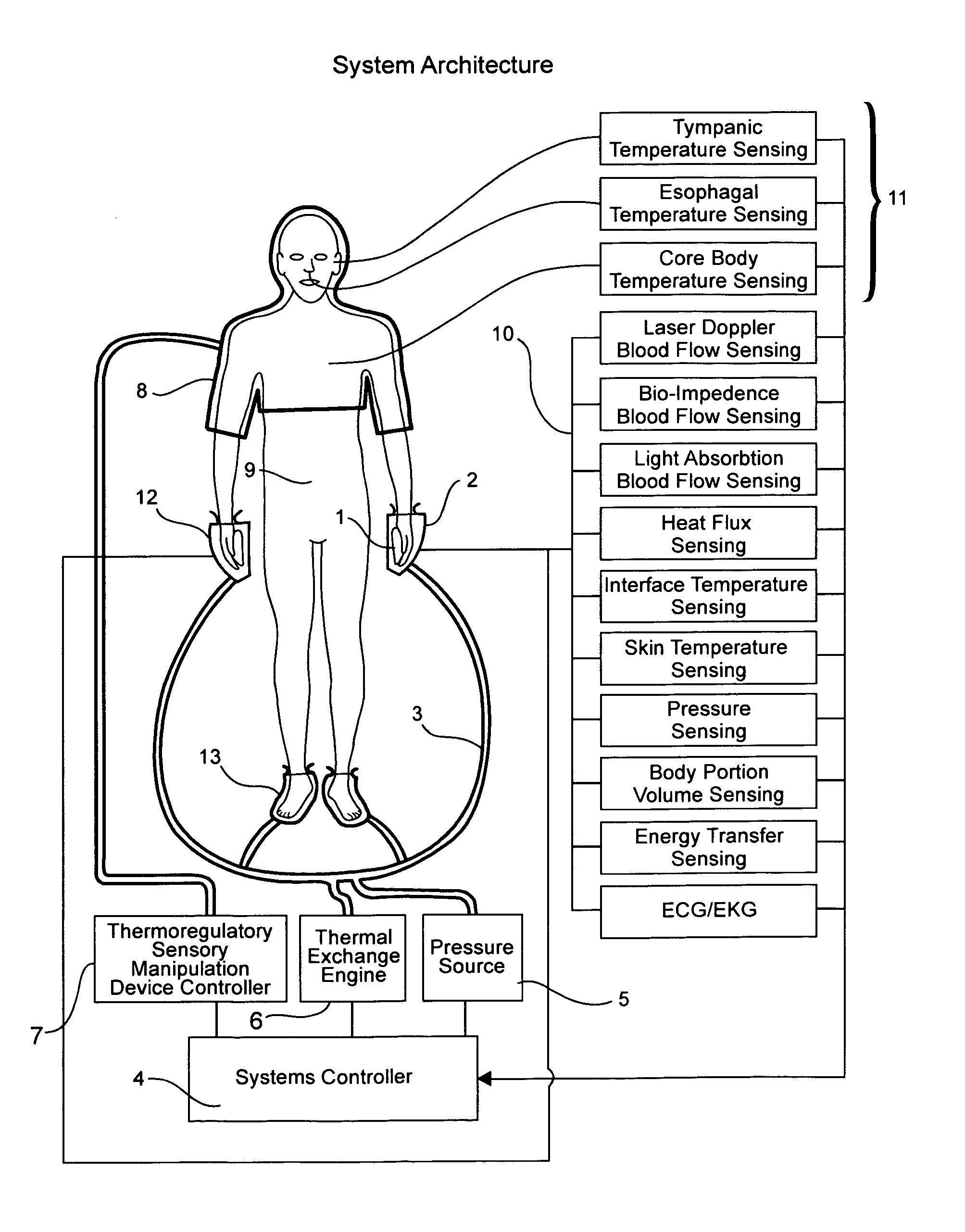

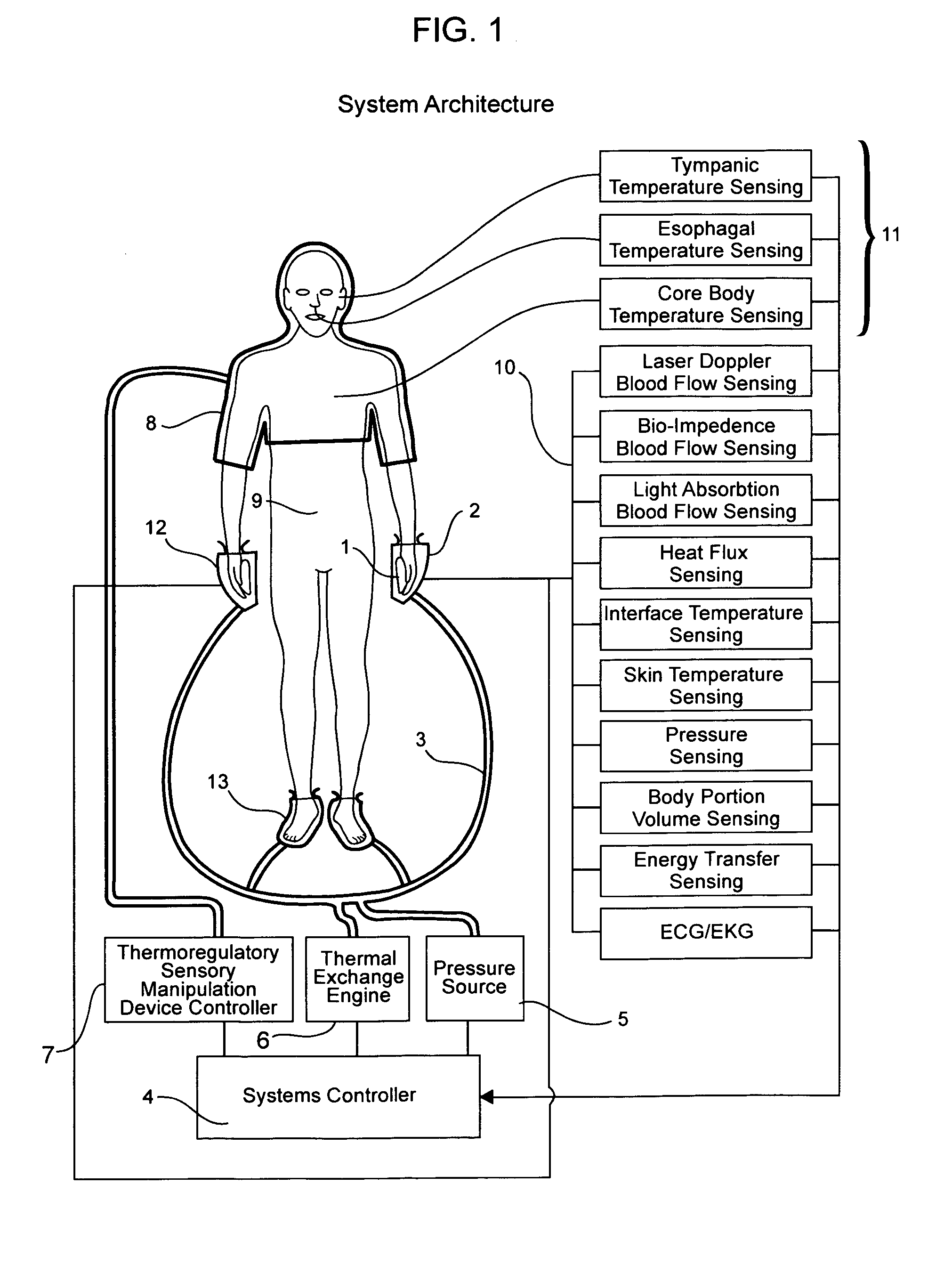

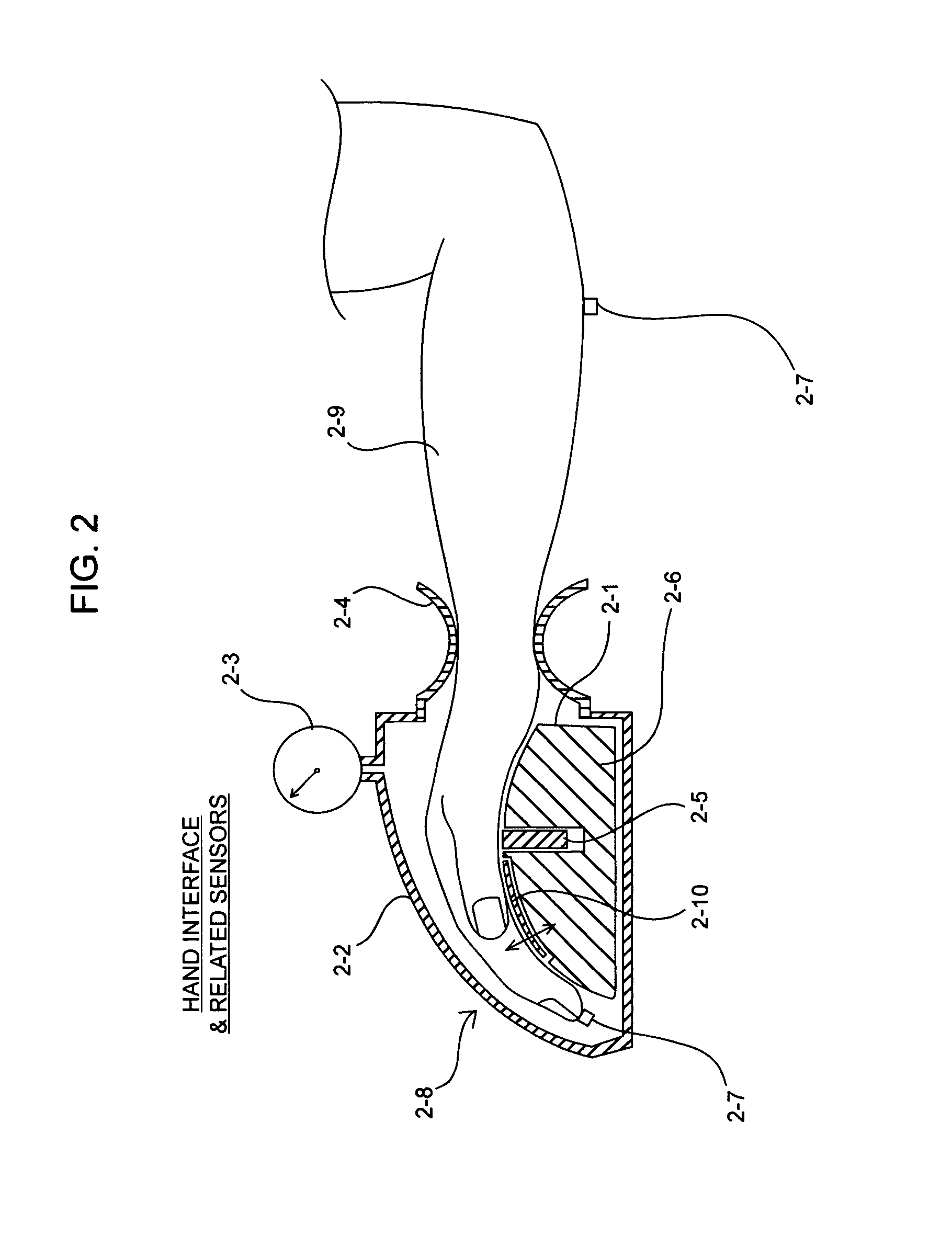

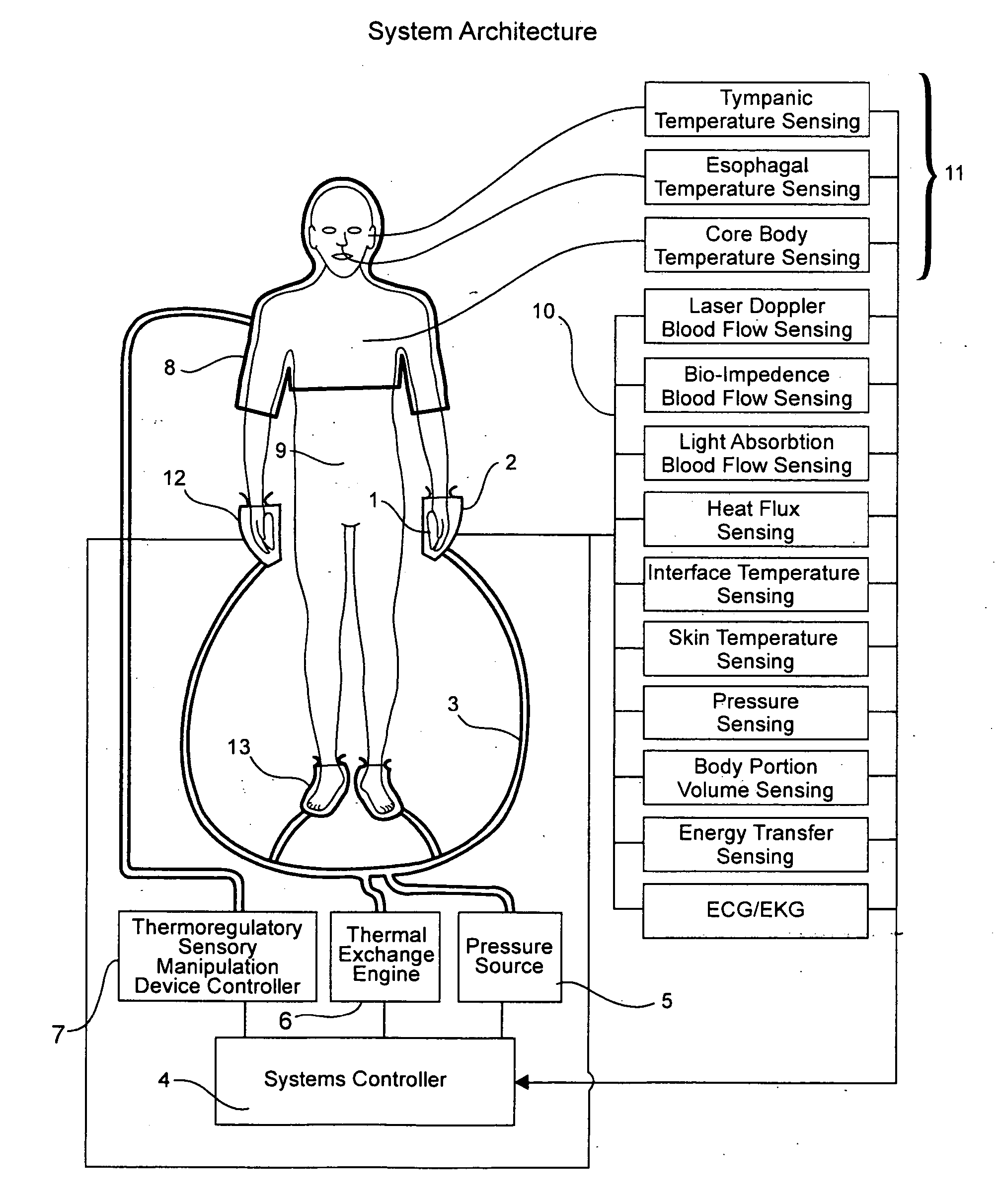

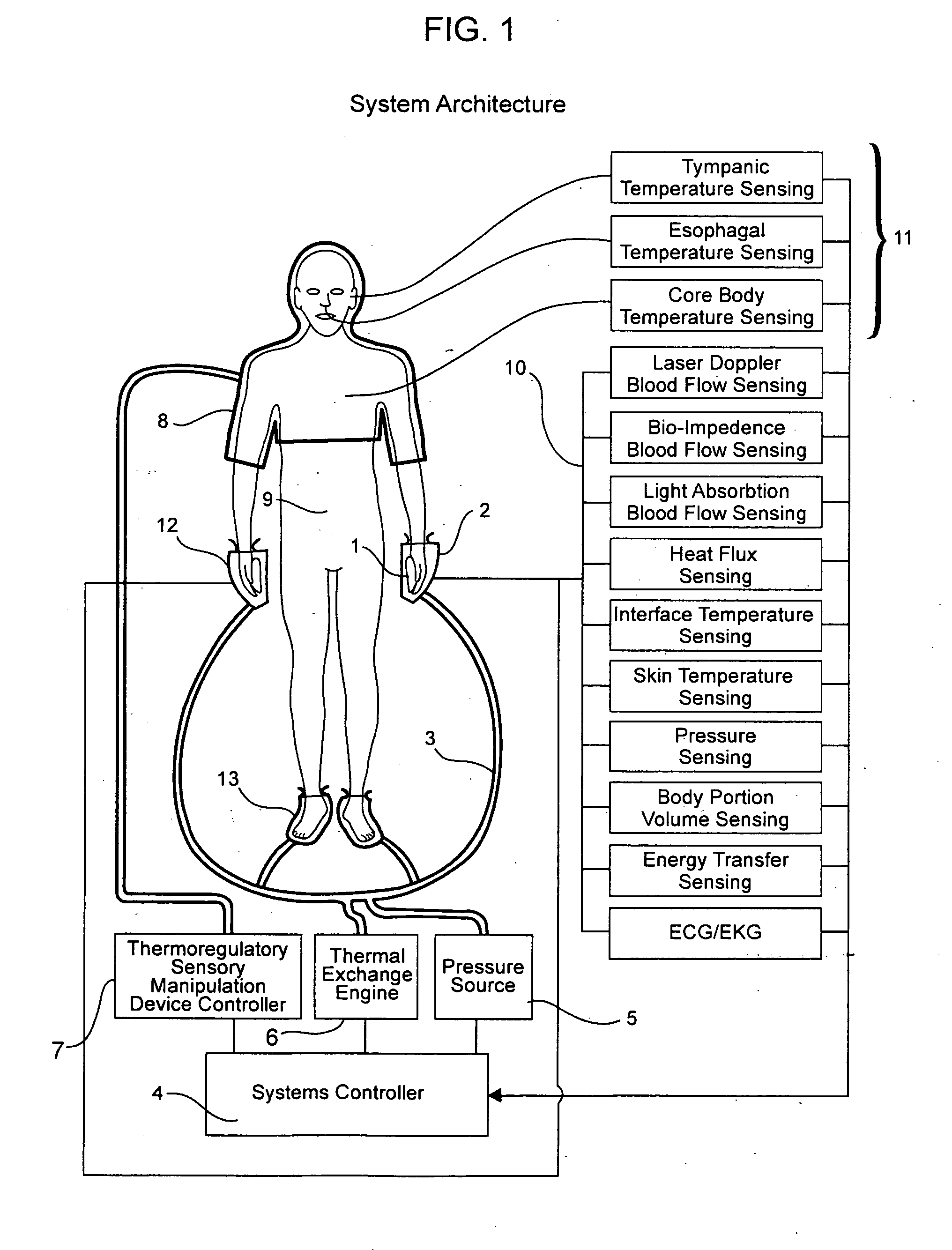

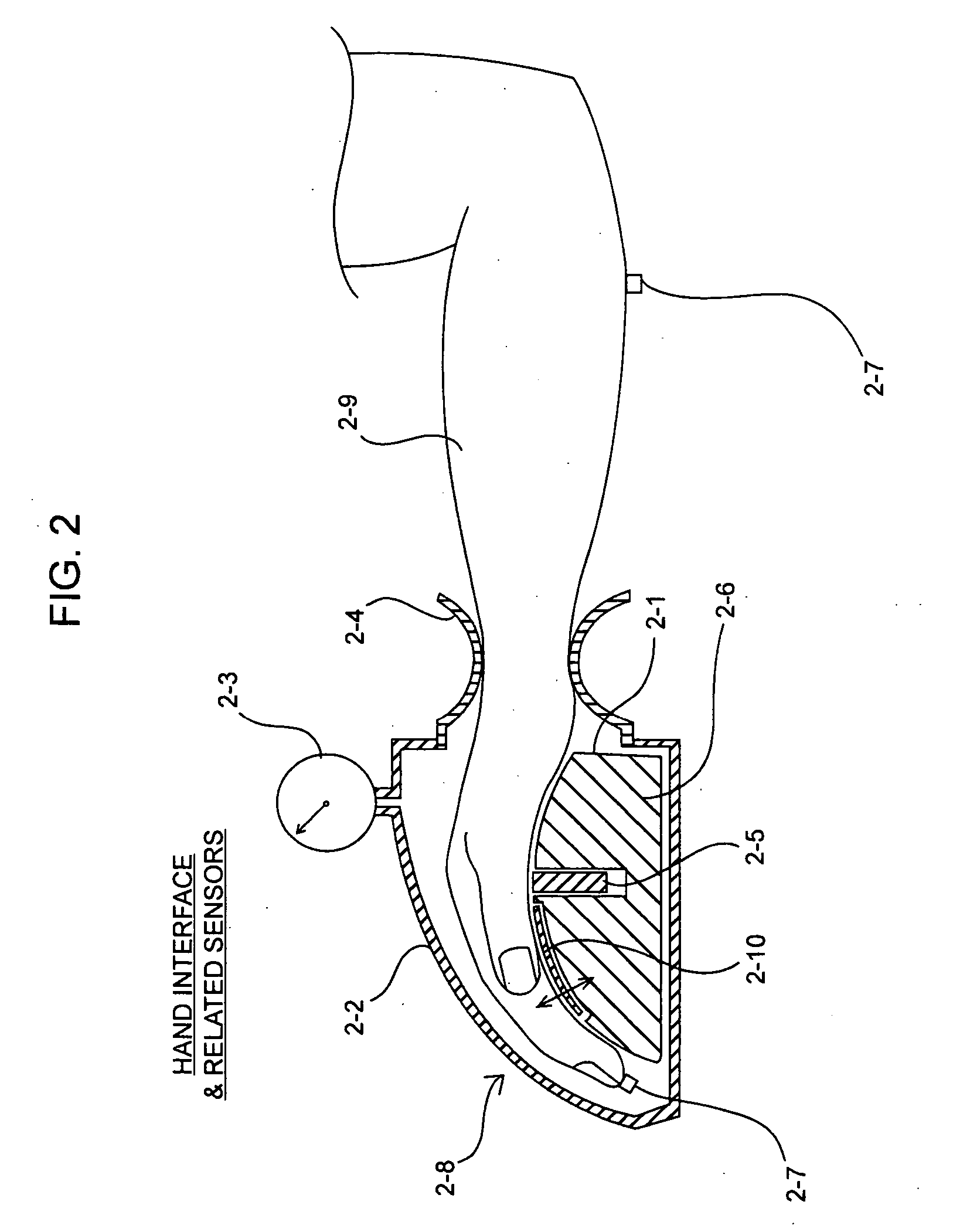

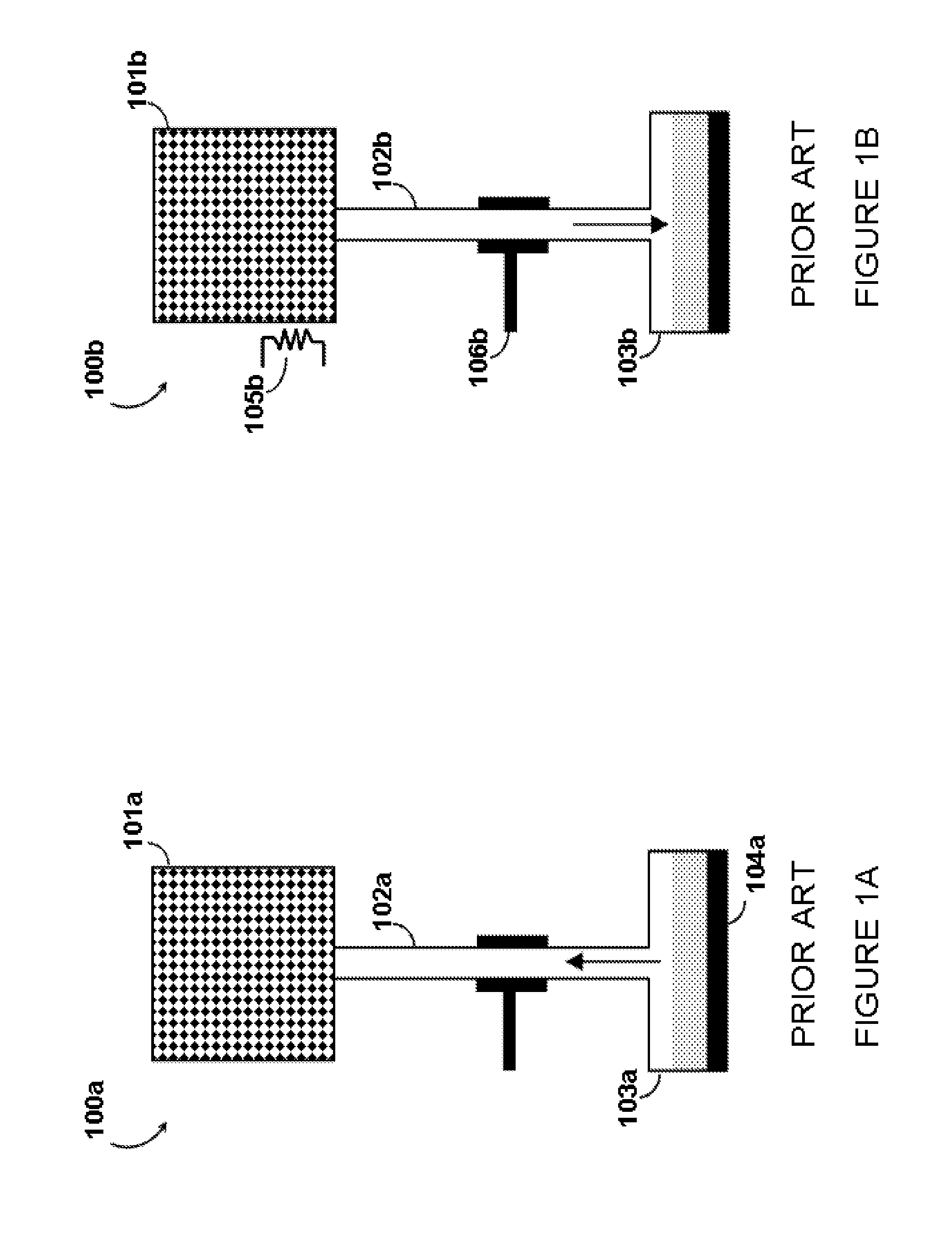

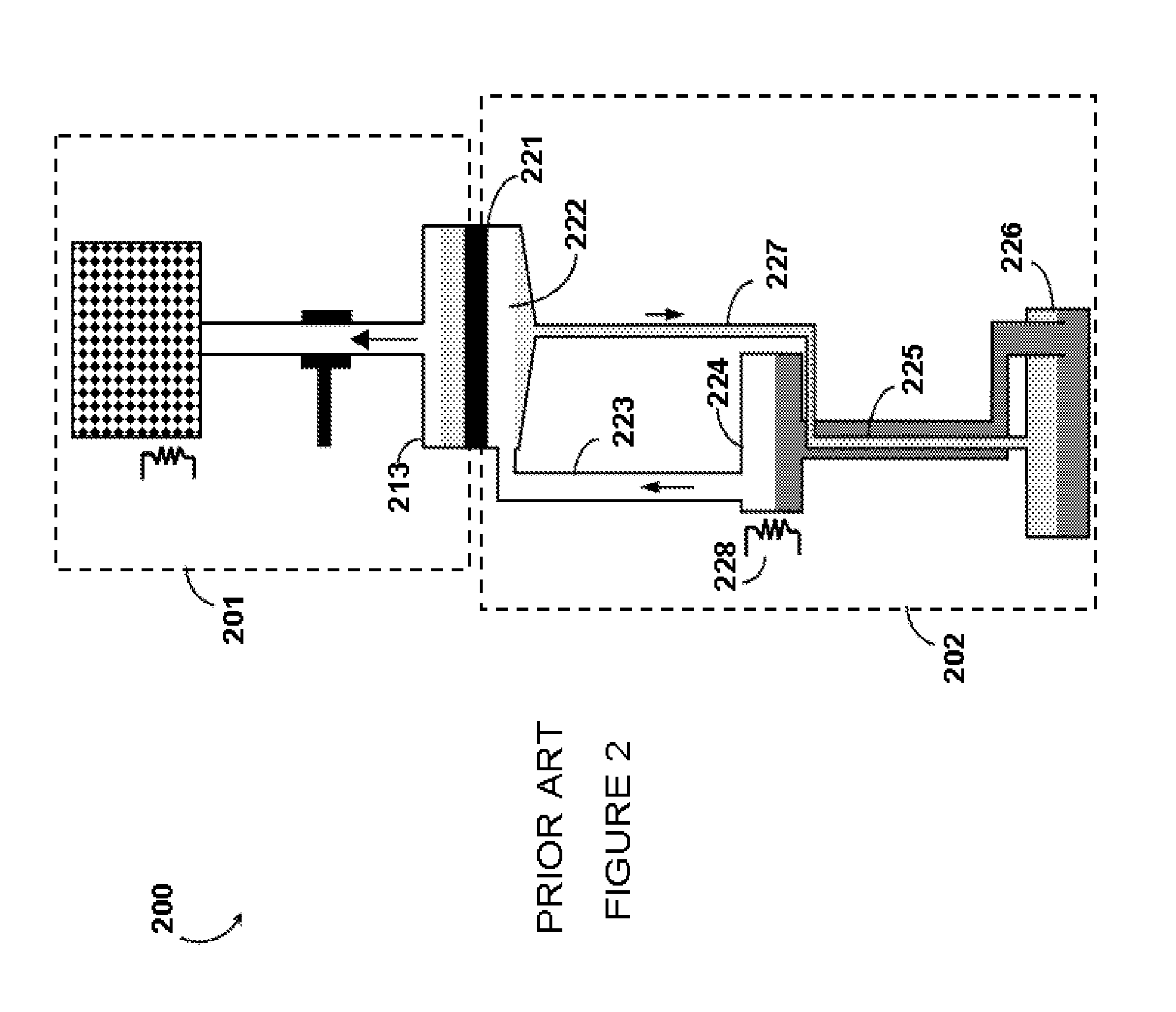

Controlled heat transfer with mammalian bodies

Methods, computer programming and devices for transferring heat to and / or from a body portion of a mammal are provided. One approach includes directly determining a state of vasoconstriction or vasodilation in a portion of a body, and supplying heat to the portion of the body when vasoconstriction is determined, and removing heat from the portion of the body when vasodilation is determined. The body portion preferably includes specific heat exchange vasculature. In another approach, a transition of the body portion from a state of vasodilation to vasoconstriction is determined and the body portion is then actively kept in a state of vasodilation while removing heat therefrom.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

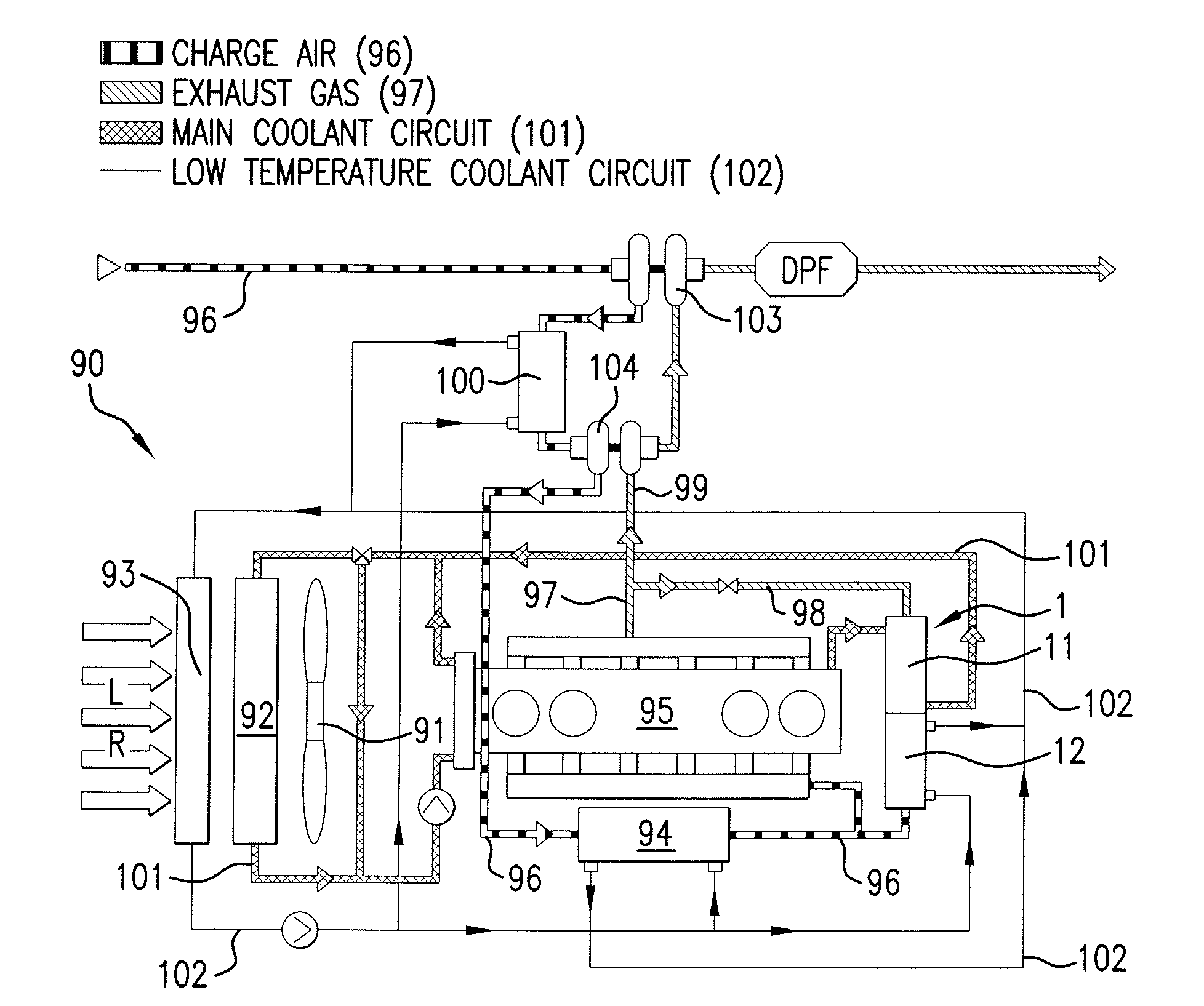

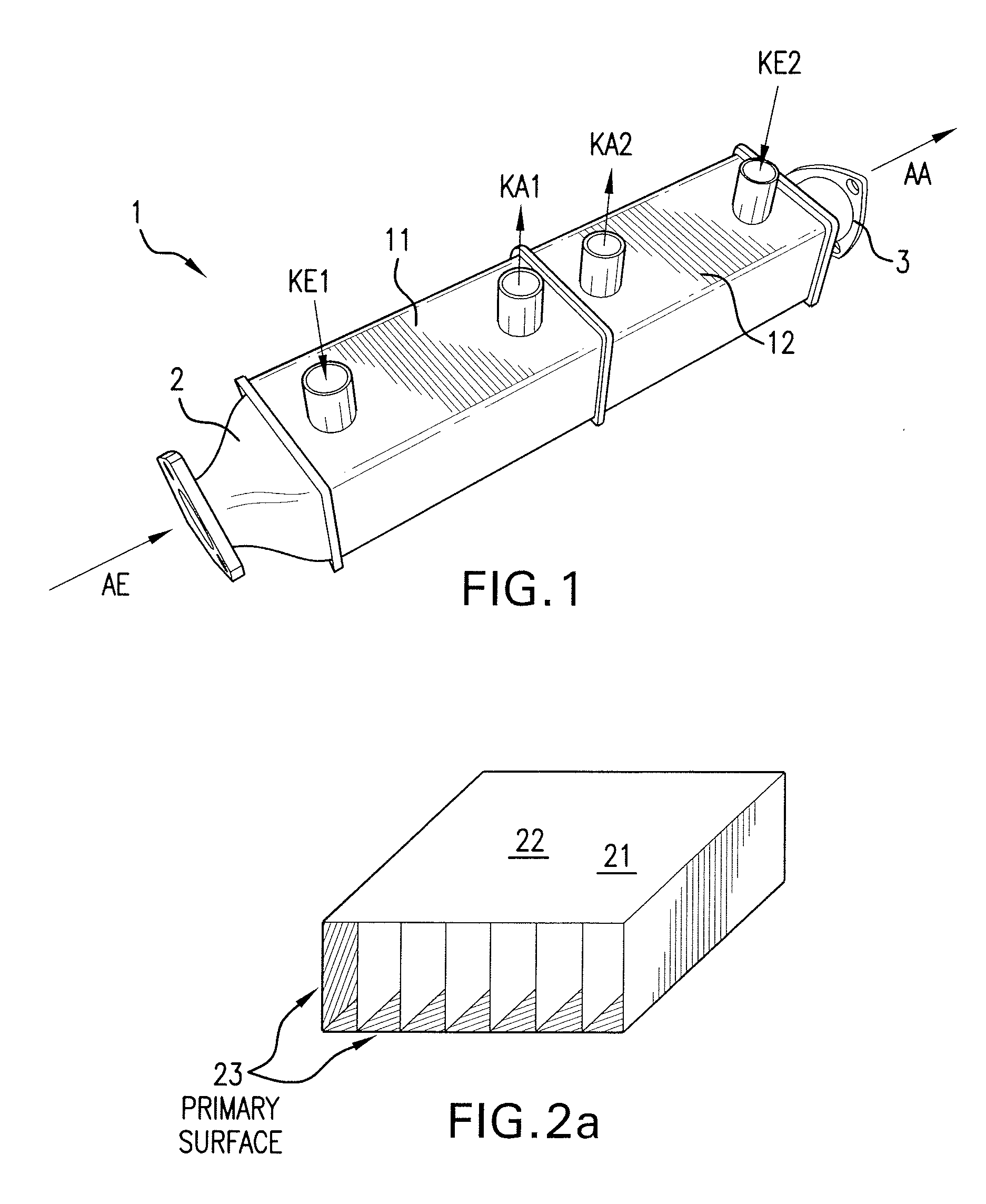

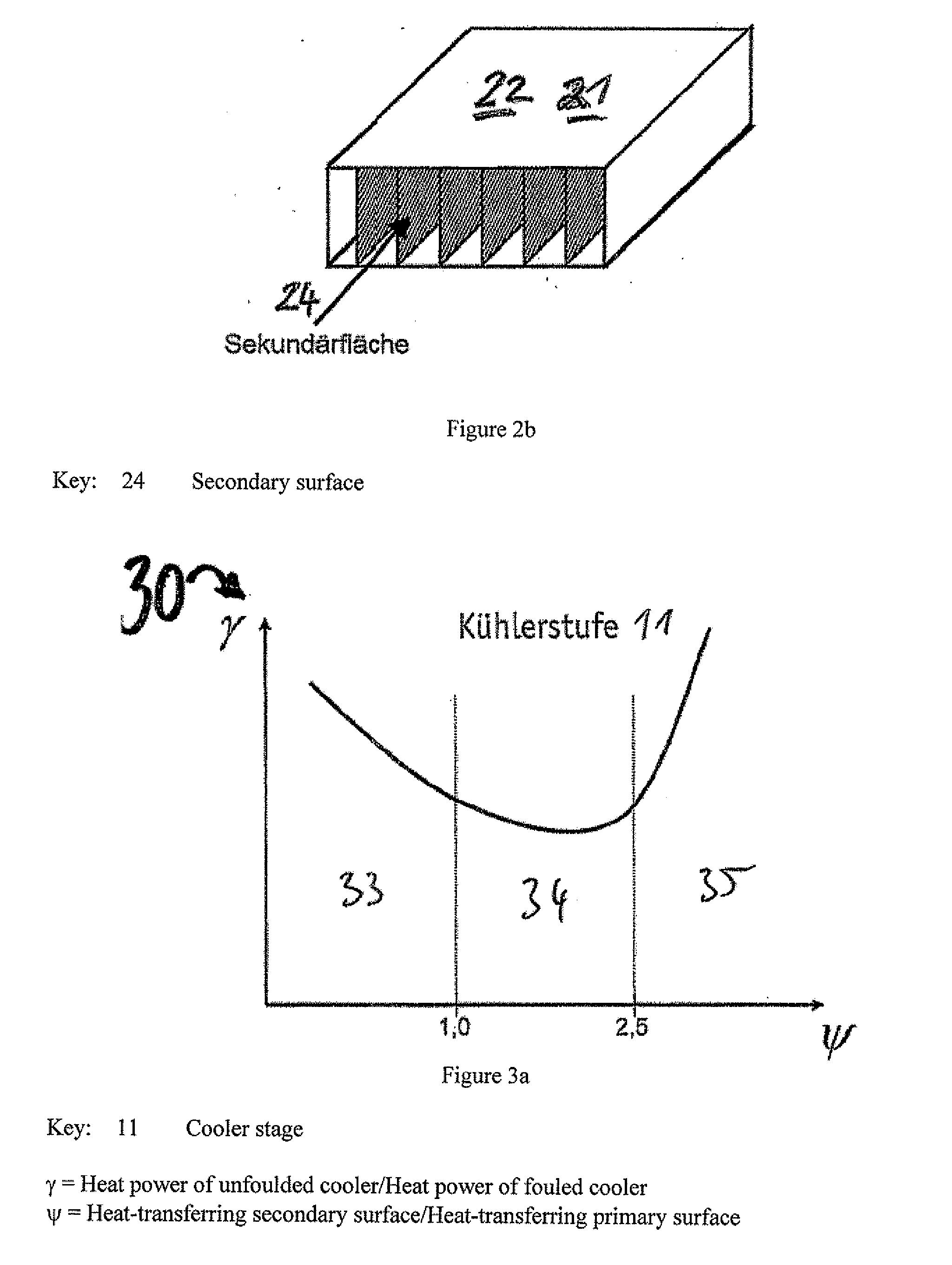

Heat exchanger for exhaust gas cooling; method for operating a heat exchanger; system with a heat exchanger for exhaust gas cooling

InactiveUS20080264609A1Prevent scalingLower performance requirementsNon-fuel substance addition to fuelInternal combustion piston enginesCoolant flowExhaust fumes

A heat exchanger, in particular for cooling the exhaust of a motor vehicle internal combustion engine, is disclosed, the heat exchanger comprising a first partial heat exchanger with at least one first flow channel through which a medium to be cooled is to flow and at least one third flow channel through which a first coolant is to flow, at least one second partial heat exchanger with at least one second flow channel through which a medium to be cooled is to flow and at least one fourth flow channel through which a second coolant is to flow, wherein the at least one first flow channel and the at least one second flow channel are fluidly connected, and the at least one first flow channel and the at least one second flow channel have at least one first specific heat transfer surface and at least one second heat transfer surface, wherein second specific heat transfer surface area, divided by first specific heat transfer surface area, yields a quotient (ψ), the at least one first flow channel having a larger quotient (ψ) than second flow channel.

Owner:BEHR GMBH & CO KG

Controlled heat transfer with mammalian bodies

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

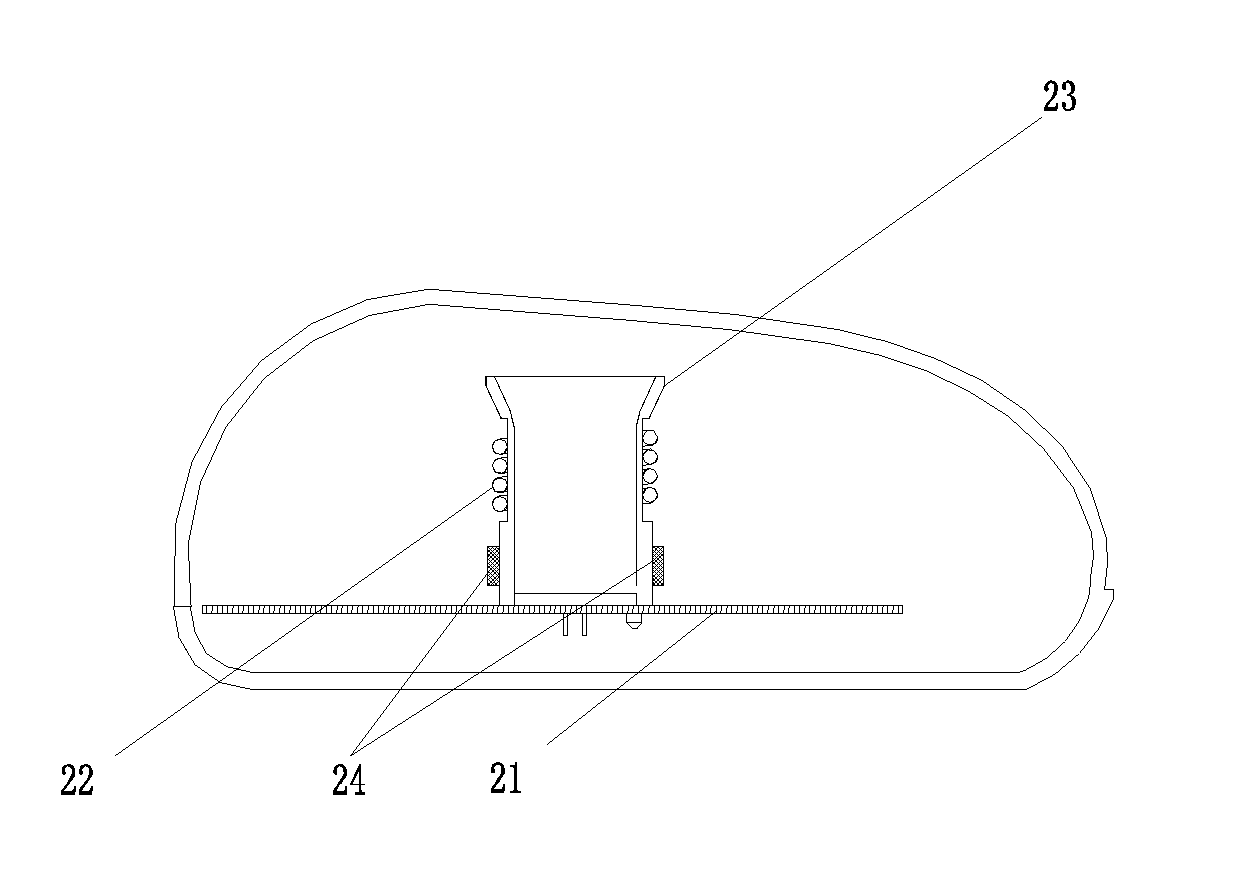

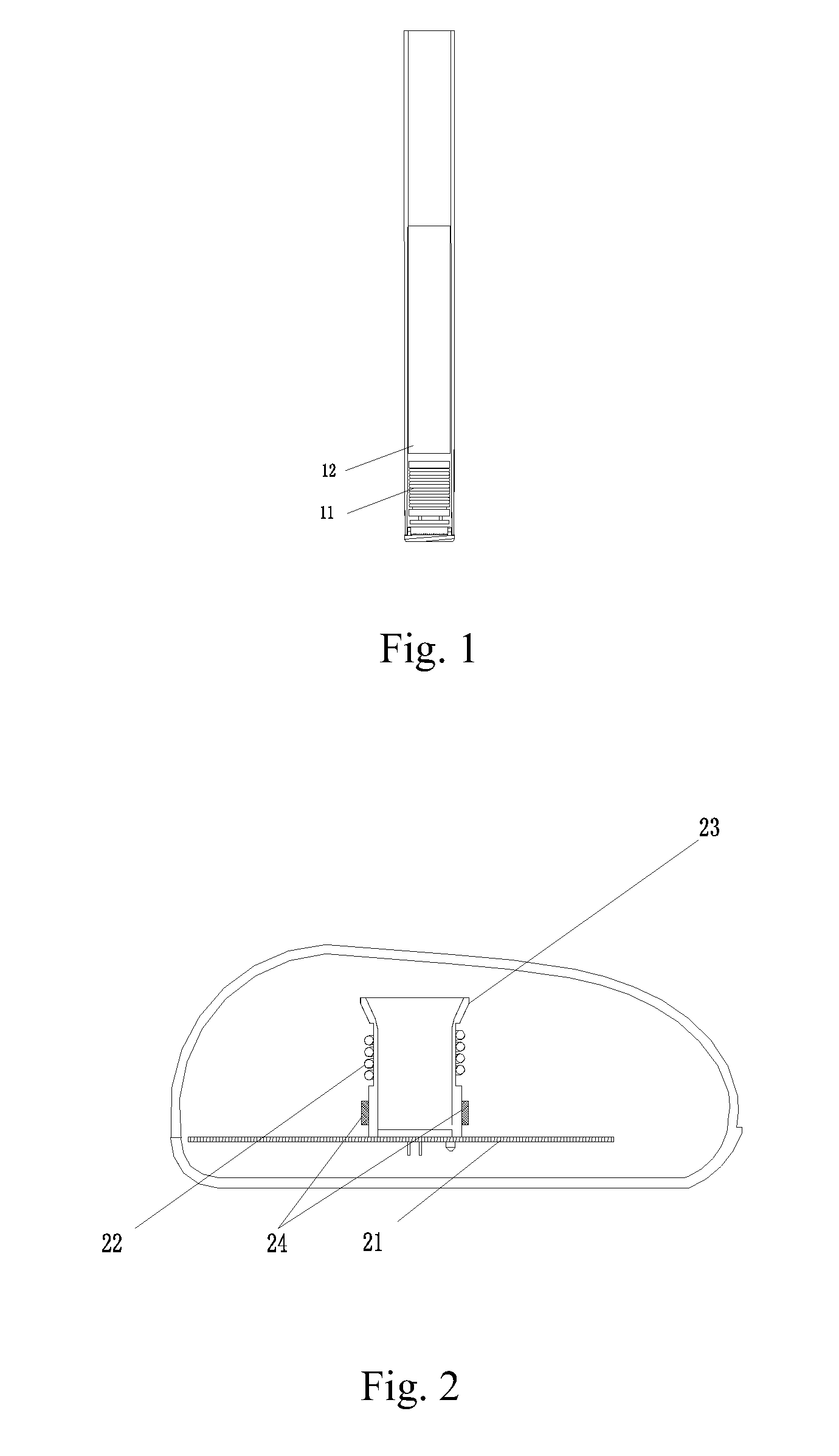

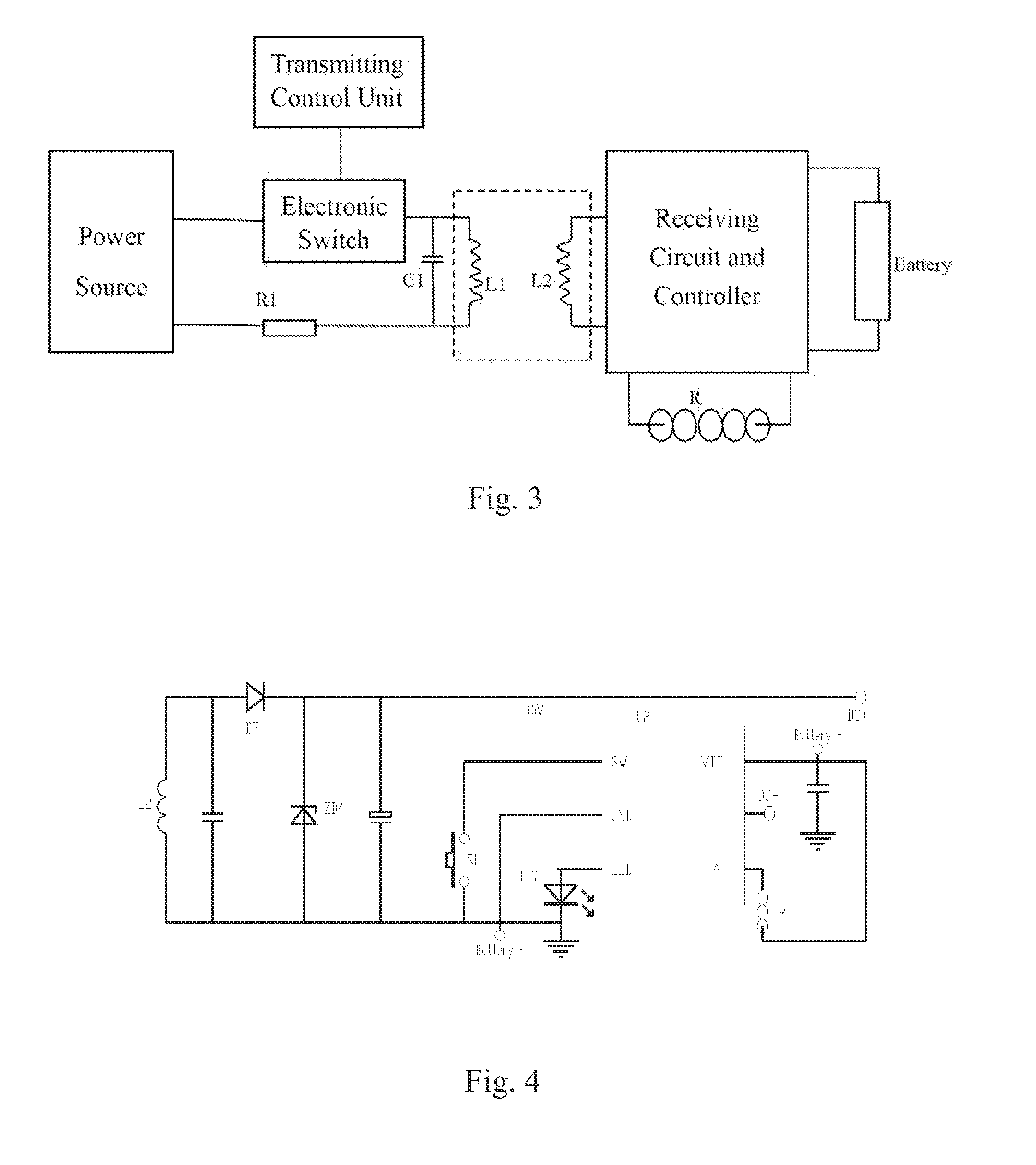

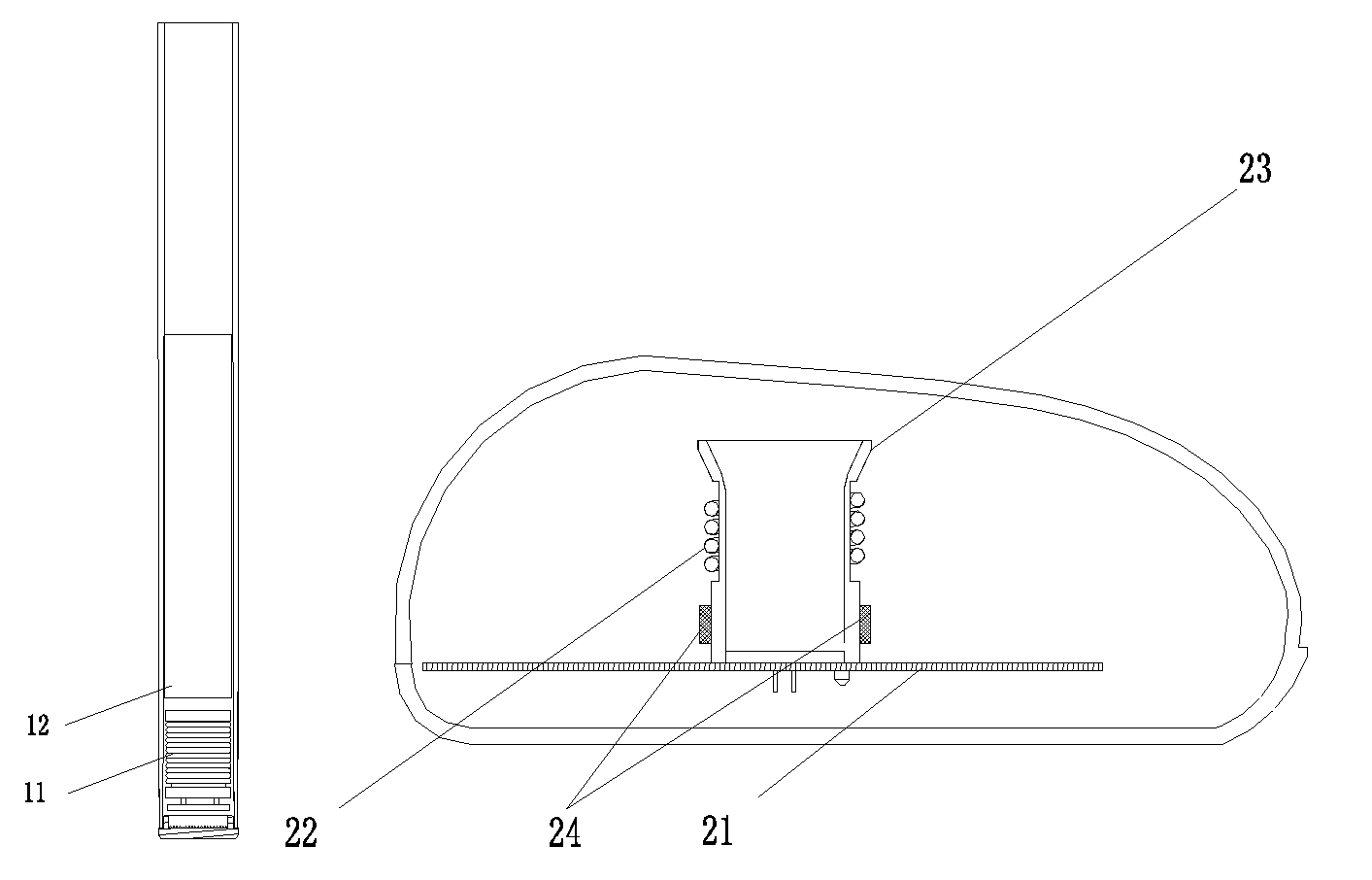

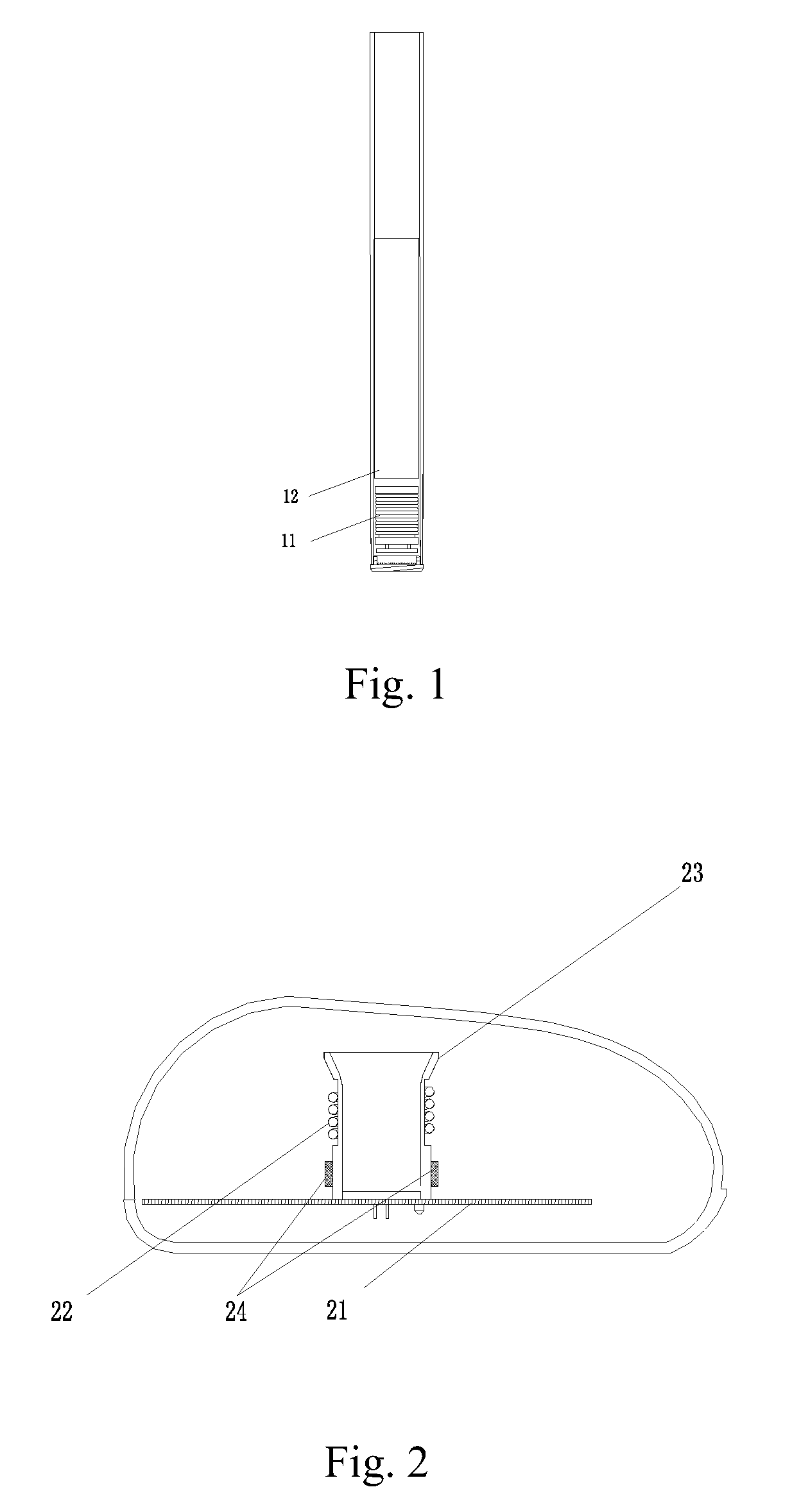

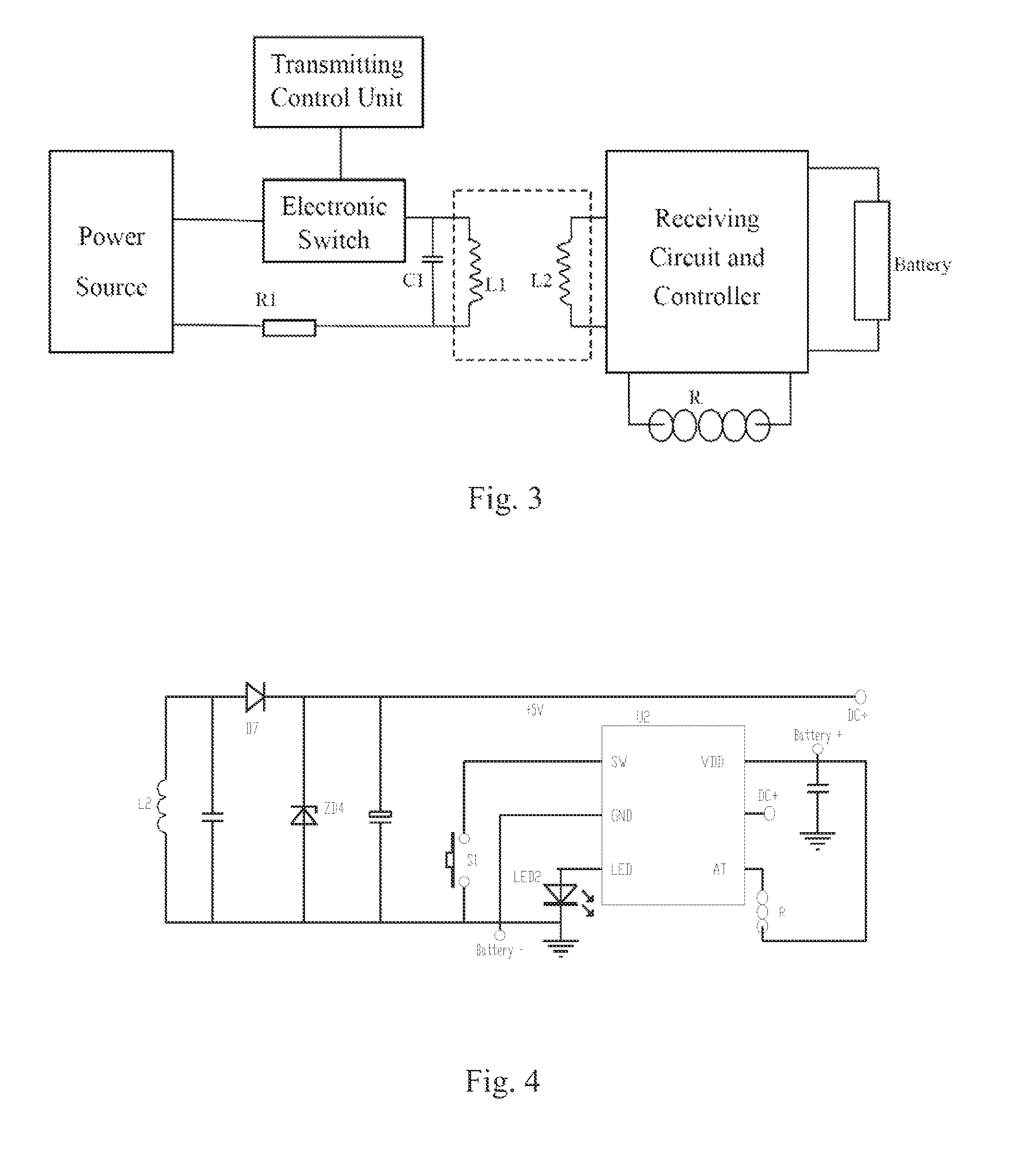

Wireless charging device

InactiveUS20130300350A1Improve efficiencyLow calorific valueTobacco devicesElectric powerElectricityElectrical resistance and conductance

A wireless charging device comprises an electronic switch and a transmitting coil (L1) electrically connected with a power source in sequence. A control end of the electronic switch is connected with a transmitting control unit. The wireless charging device further comprises a current limiting resistance (R1) connected in serial with the transmitting coil. The wireless charging device further comprises a compensation capacitor (C1) connected in parallel with the transmitting coil. An insert total electromagnetic coupling structure is further employed for charging. Such wireless charging device is particularly suitable for electronic cigarette, with low cost, stable and reliable working status and high efficiency, and specific heat sink is not required.

Owner:KIMREE HI TECH

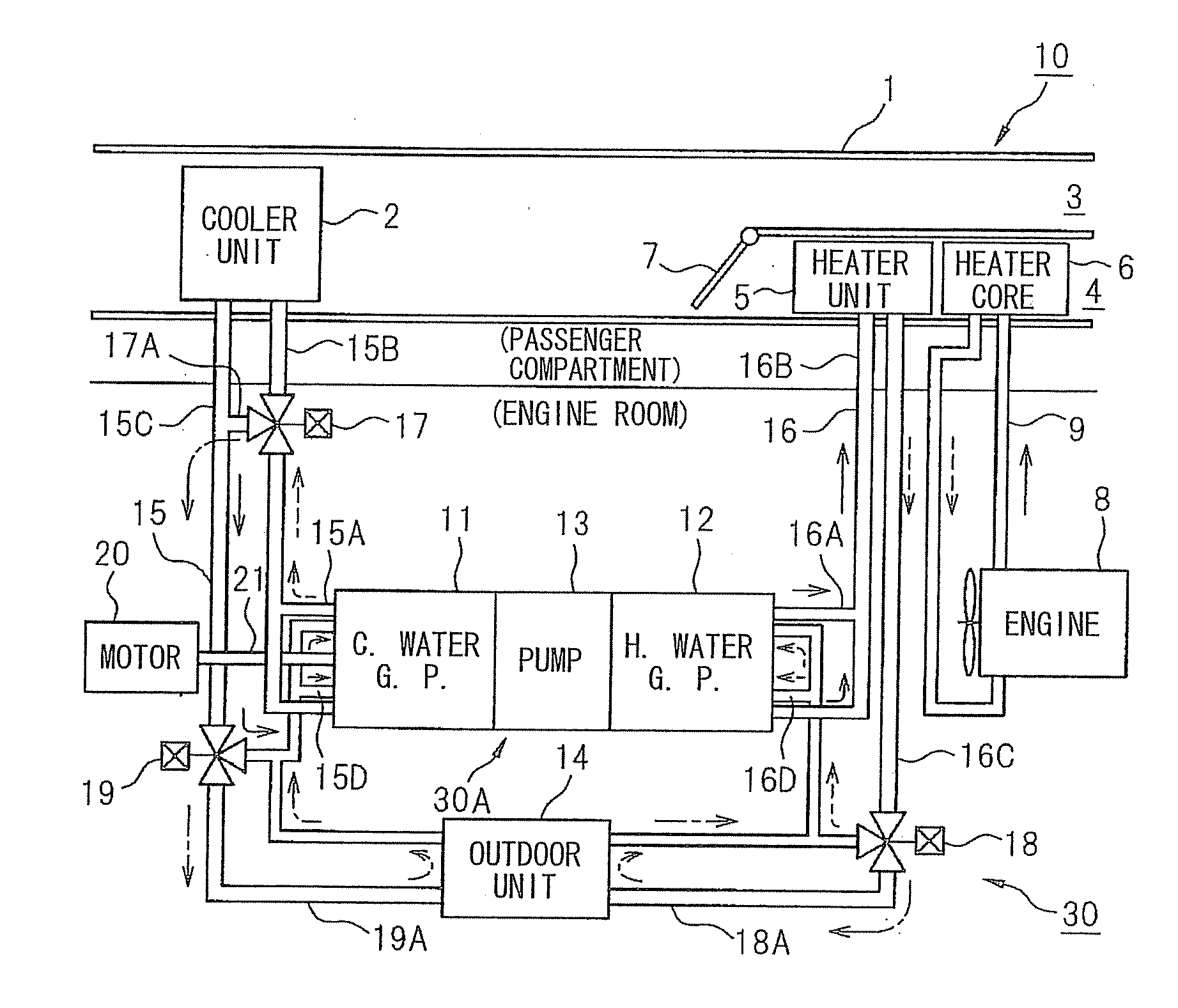

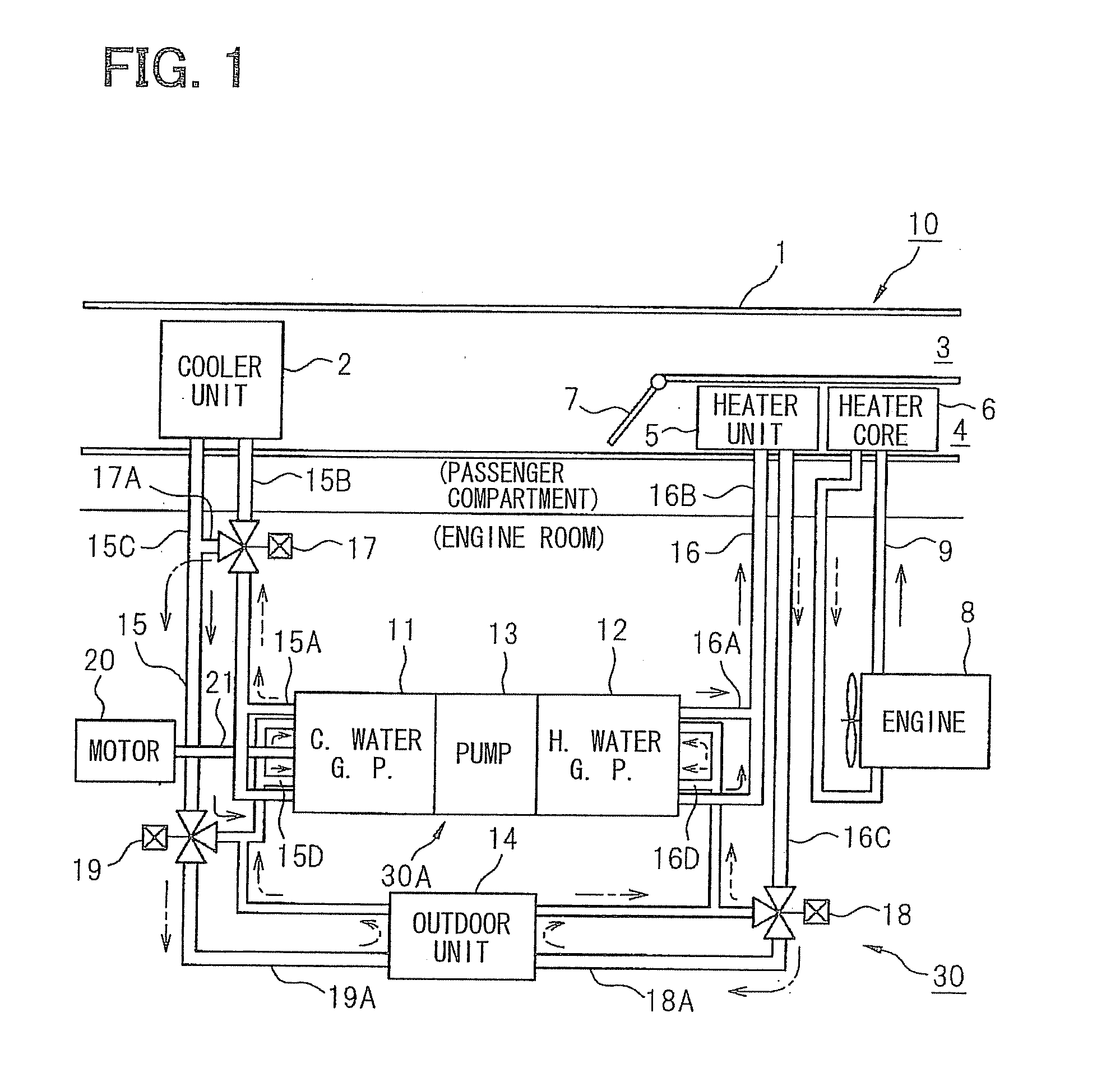

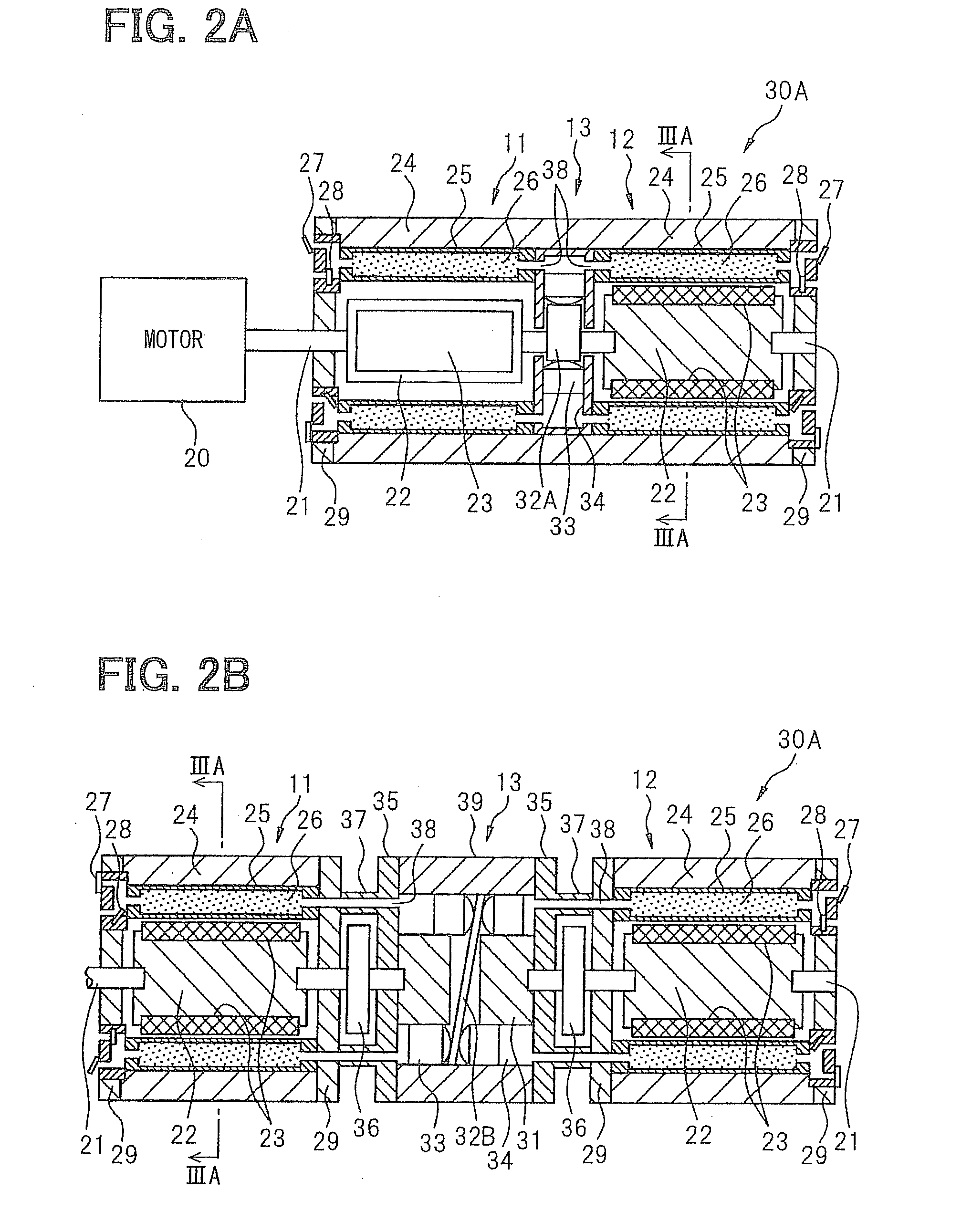

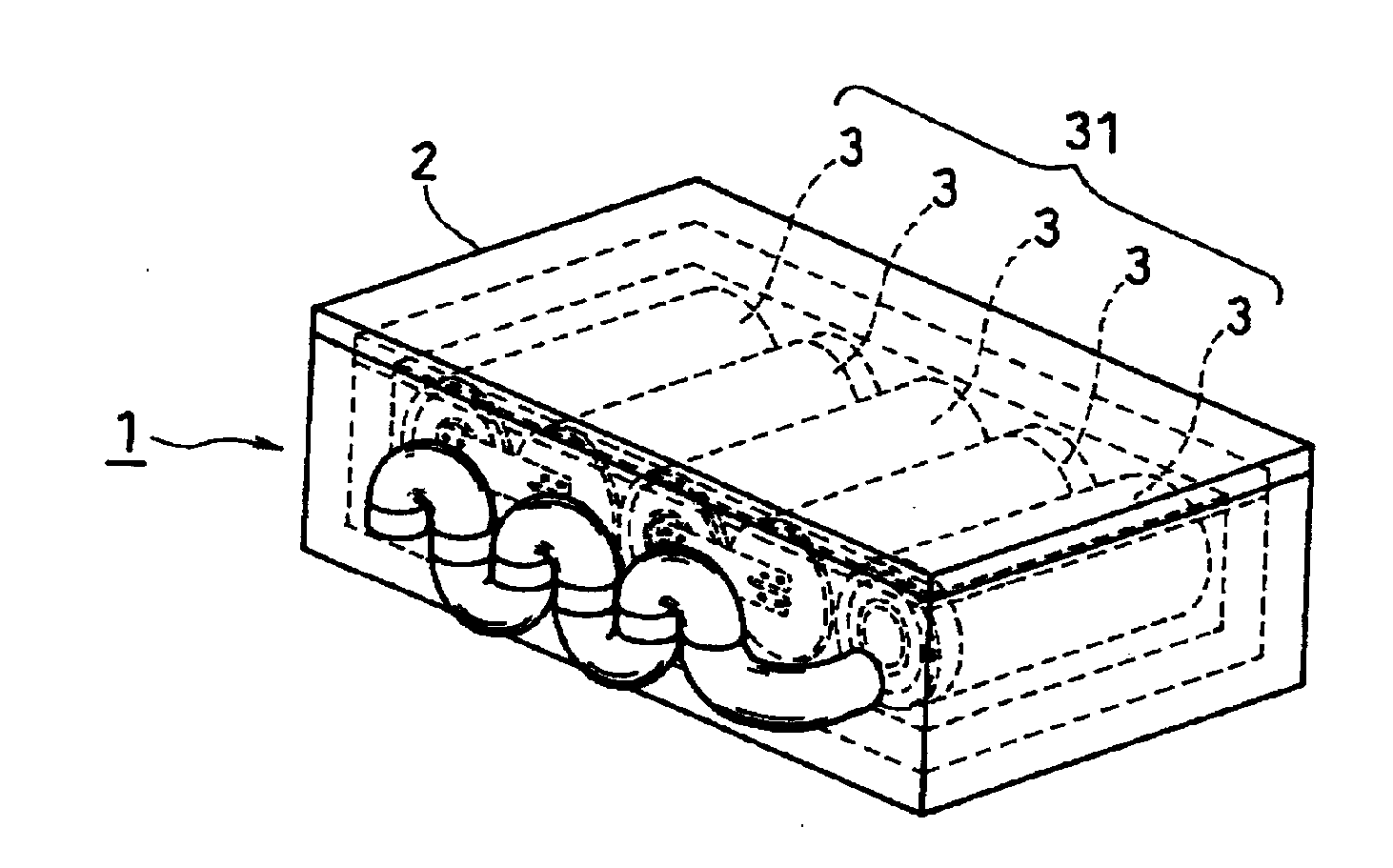

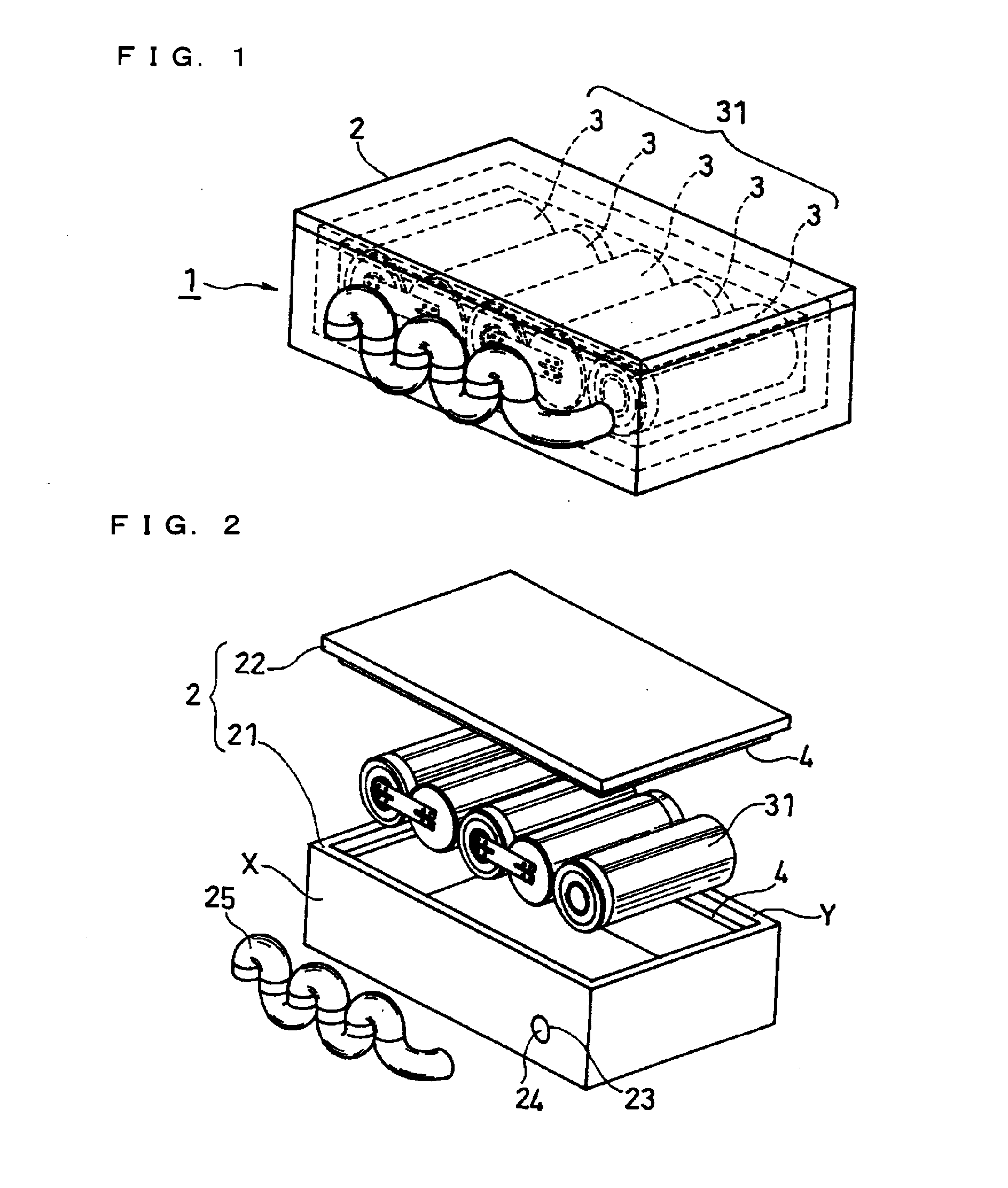

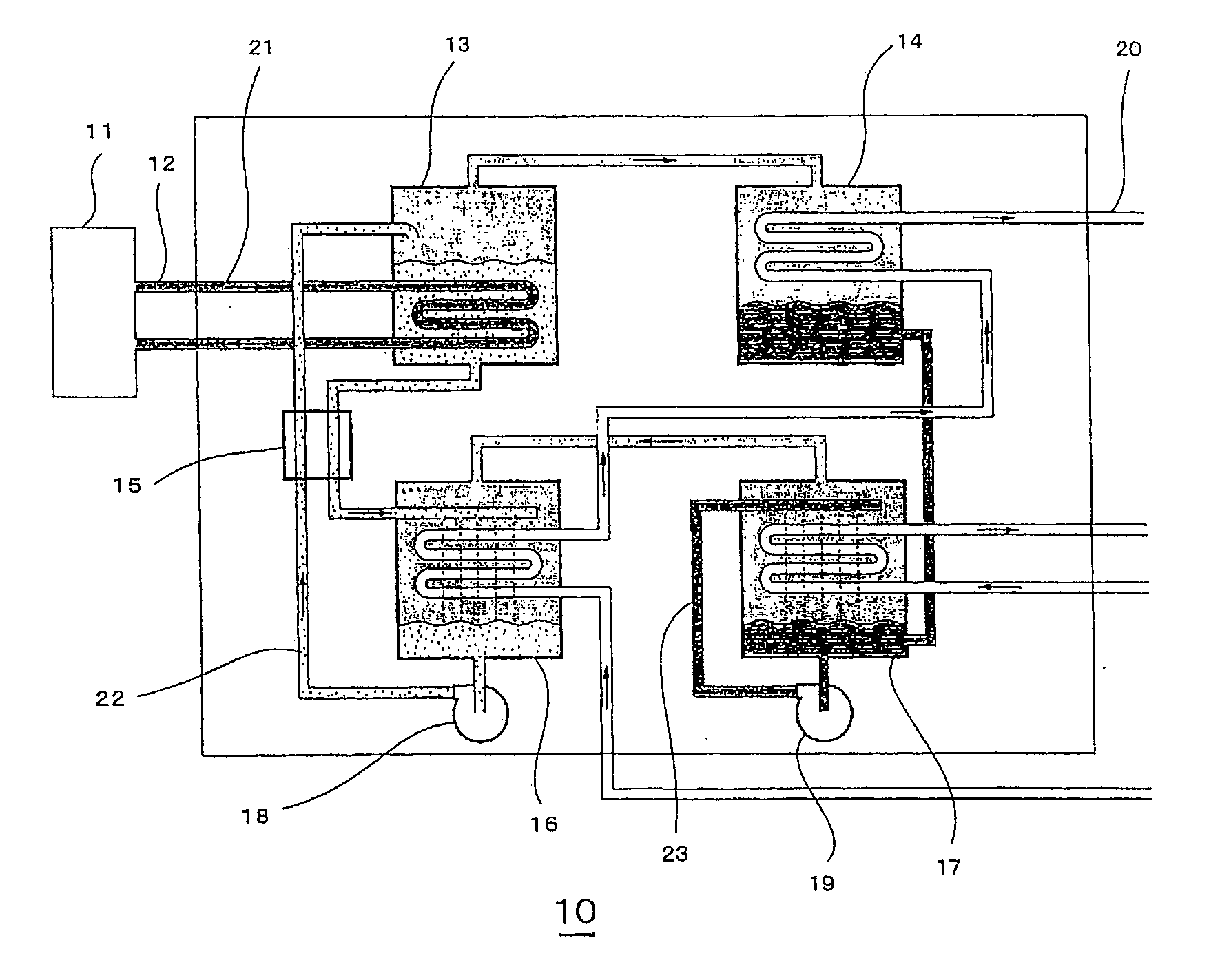

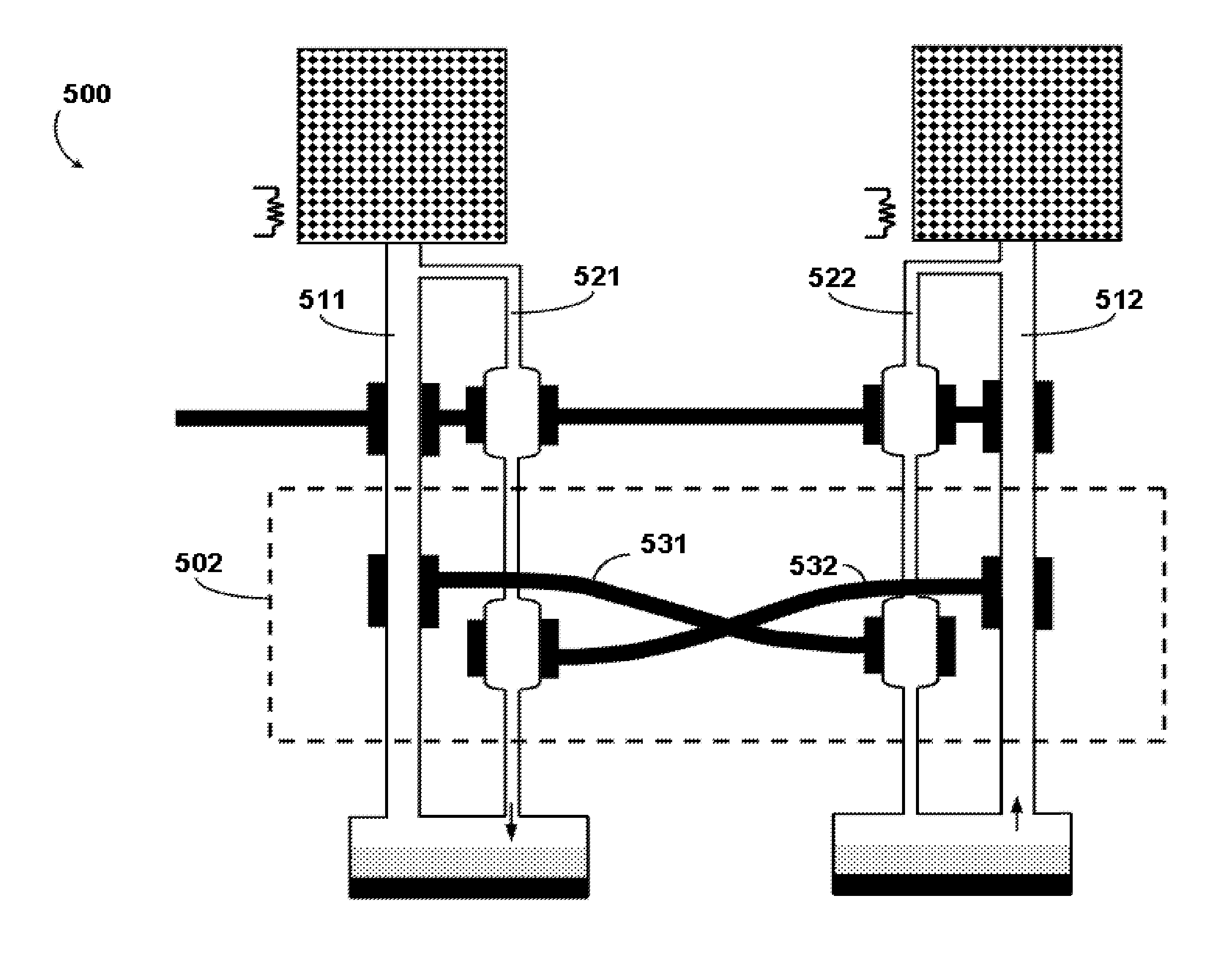

Magnetic heat pump system

ActiveUS20120272666A1Improvement factorImprove cooling effectEnergy efficient heating/coolingVehicle heating/cooling devicesTransport mediumEngineering

In a magnetic heat pump system, in which heat transport medium is heated or cooled by magnetocaloric effect material accommodated in a magnetic heat pump device. A material having a coefficient of thermal conductivity, which is higher than that of the heat transport medium, or a material having a specific heat or a volume specific heat, which is higher than that of the heat transport medium, is mixed in the heat transport medium. A coefficient of thermal conductivity of the heat transport medium is thereby increased so as to increase heating and / or cooling performance of the magnetic heat pump system.

Owner:DENSO CORP

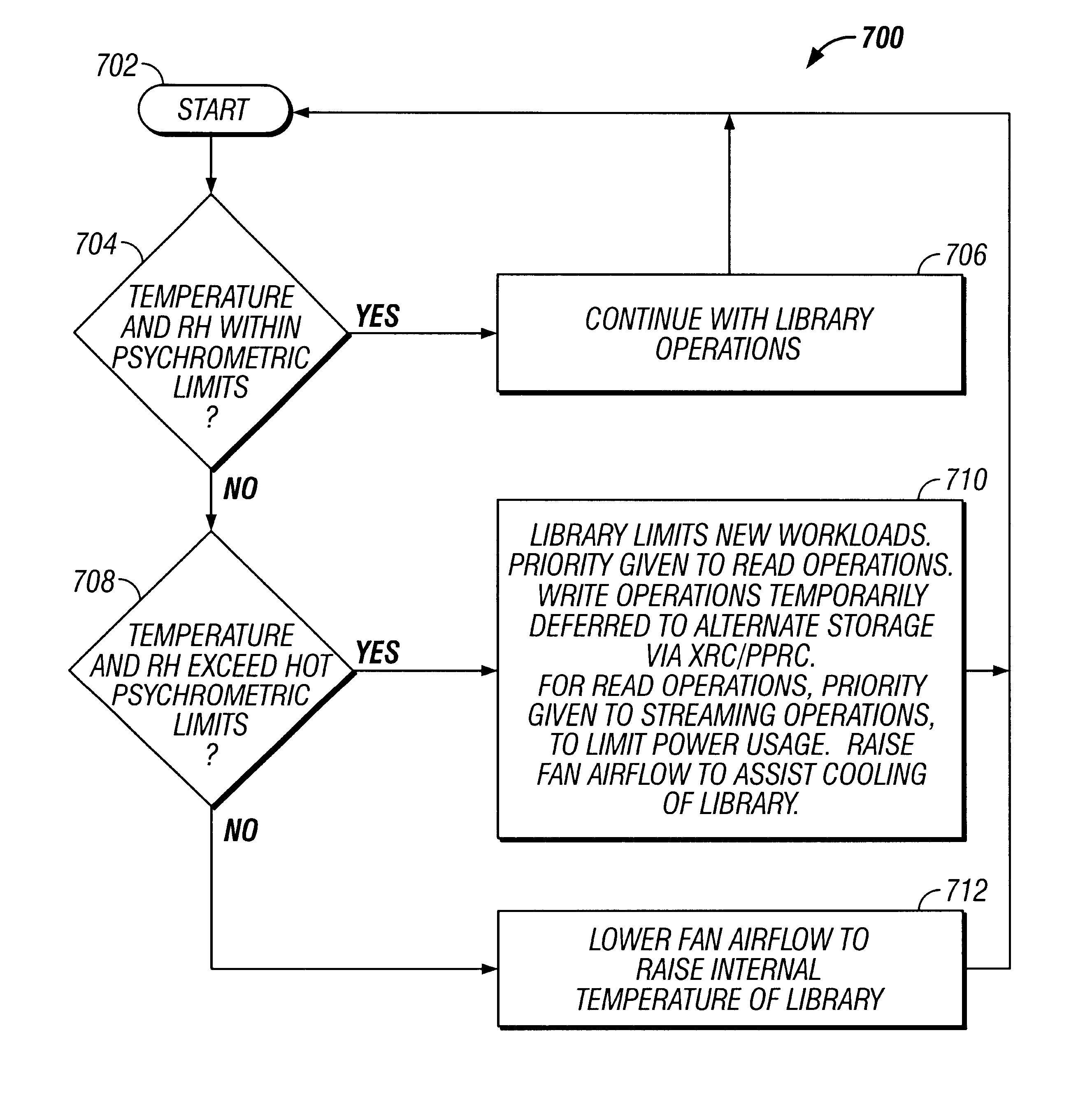

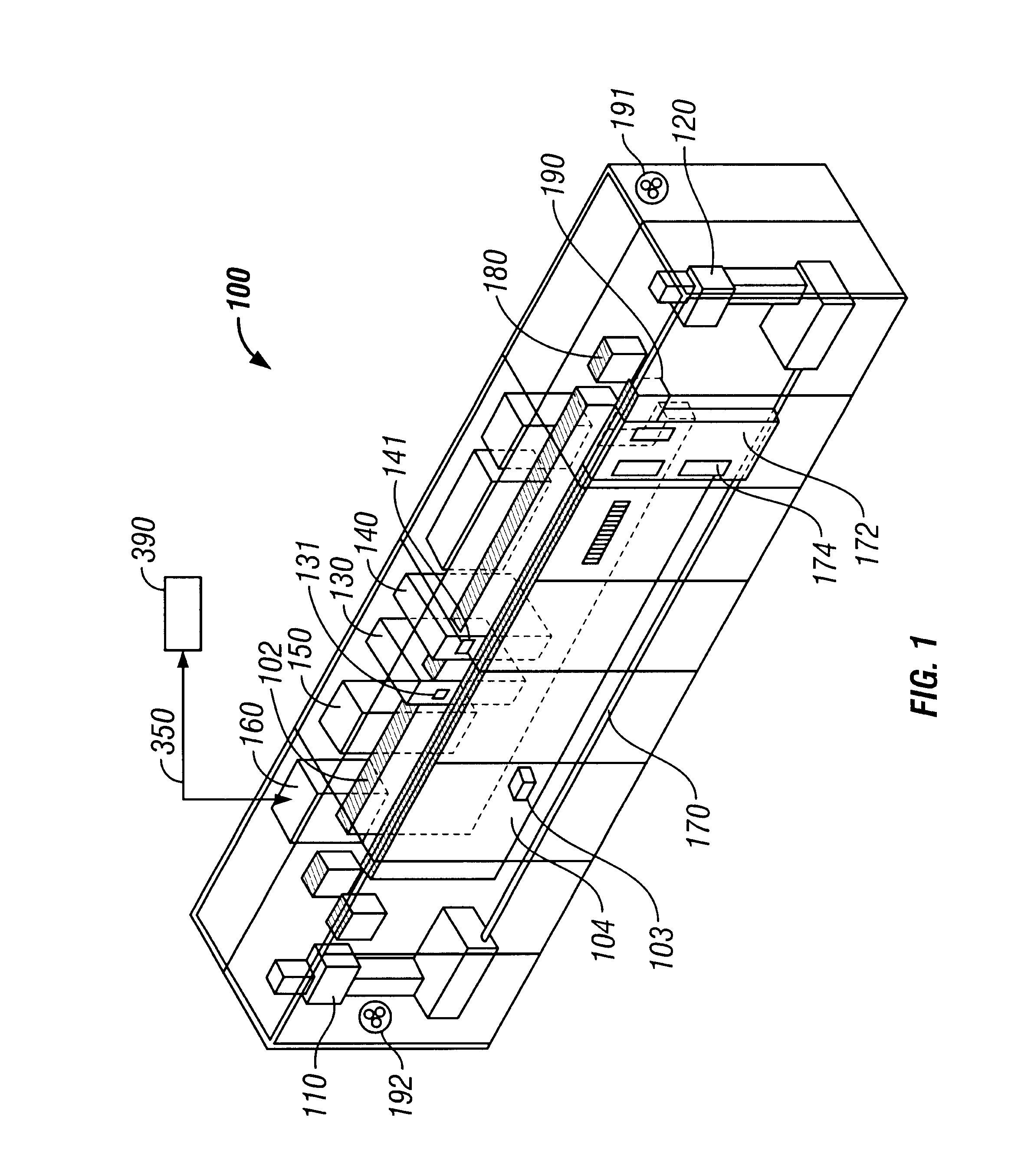

System and method for autonomic environmental monitoring, adjusting, and reporting capability in a remote data storage and retrieval device

InactiveUS6676026B1Reducing temperature influence on carrierAir-treating devicesComputer data storageEngineering

A data storage and retrieval system such as a robotic library has a large plurality of removable storage media, such as tape cartridges, for purposes of I / O. To enhance performance and reliability of the library, a thermodynamic model of the library is constructed and stored in the library, and environmental conditions such as the temperature, humidity, and flow rate of cooling air coming into, flowing through, and leaving the library are monitored. The thermodynamic model of the library includes an acceptable operating range for the library in a psychrometric chart; and the product of the effective thermodynamic mass and specific heat of the library.

Owner:IBM CORP

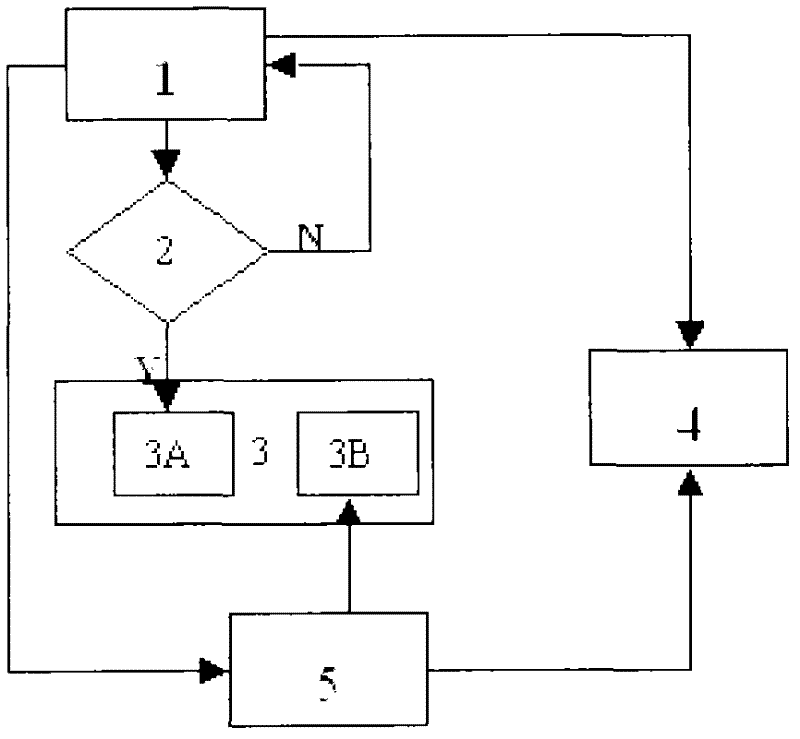

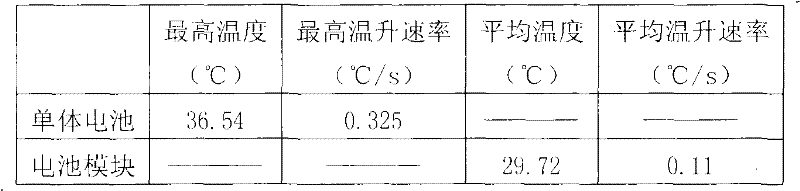

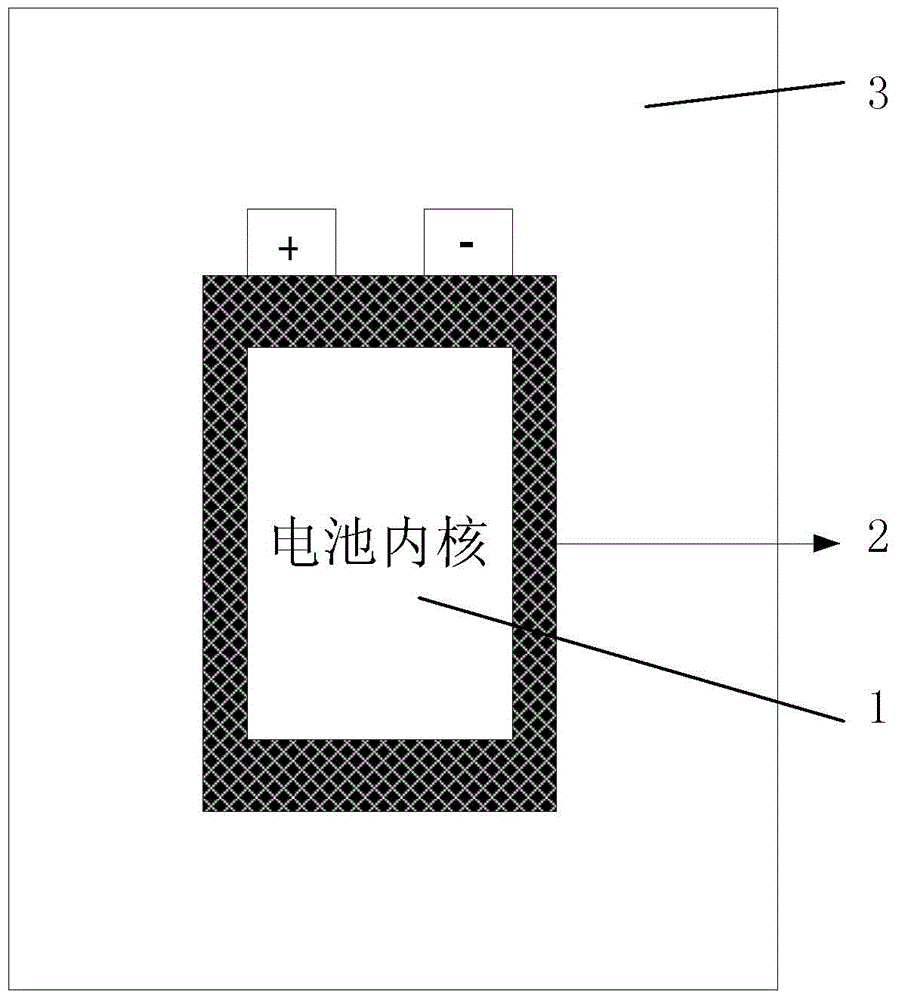

Thermal management device for power batteries and thermal management method for power batteries

InactiveCN102496747ACell temperature controlSecondary cells servicing/maintenancePower batteryElectrical battery

The invention discloses a thermal management device for power batteries and a thermal management method for the power batteries under abnormal working conditions. The thermal management device for the power batteries comprises an acquisition module, an evaluation module, a forecast module, a display module and a control module, wherein the forecast module is used for calculating the heat generation rate and the specific heat capacity according to temperature and temperature rise rate information obtained by the acquisition module and the evaluation module and information such as types, operating states, states of charge and the like of the power batteries so as to obtain forecasted temperature field distribution of a battery unit, and the display module is used for displaying the temperature field distribution of the battery unit forecasted by the forecast module and a current alarm status of the battery unit to a user. The thermal management method for the power batteries is capable of forecasting the temperature field distribution of the battery unit according to acquired temperature and temperature rise data, and at least one of control measures such as turn-off, heat dissipation, alarm and the like is effectively taken, so that the danger of an automobile due to the power batteries can be reduced under the abnormal working conditions.

Owner:CHINESE ACAD OF INSPECTION & QUARANTINE

Controlled heat transfer with mammalian bodies

Methods, computer programming and devices for transferring heat to and / or from a body portion of a mammal are provided. One approach includes directly determining a state of vasoconstriction or vasodilation in a portion of a body, and supplying heat to the portion of the body when vasoconstriction is determined, and removing heat from the portion of the body when vasodilation is determined. The body portion preferably includes specific heat exchange vasculature. In another approach, a transition of the body portion from a state of vasodilation to vasoconstriction is determined and the body portion is then actively kept in a state of vasodilation while removing heat therefrom.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

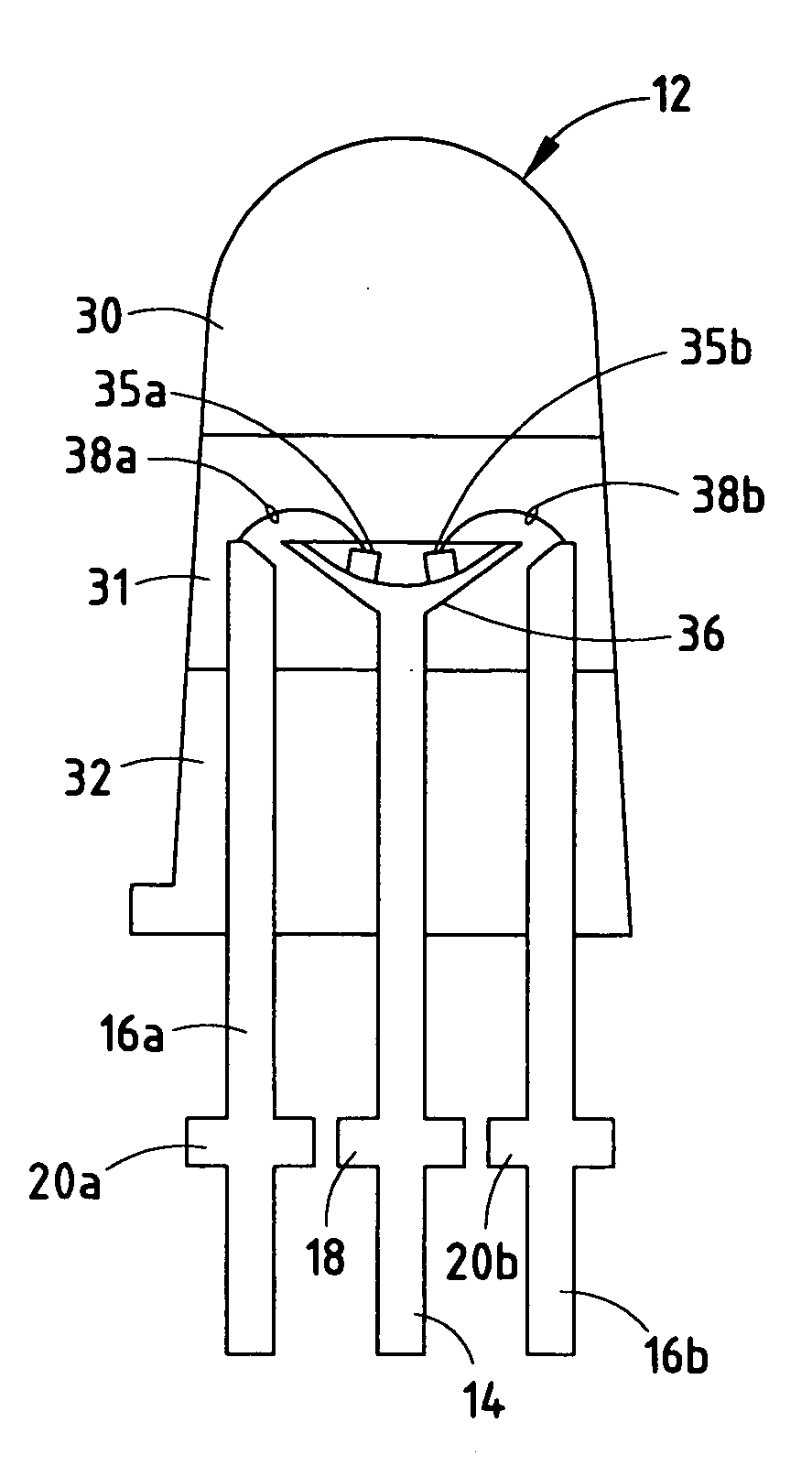

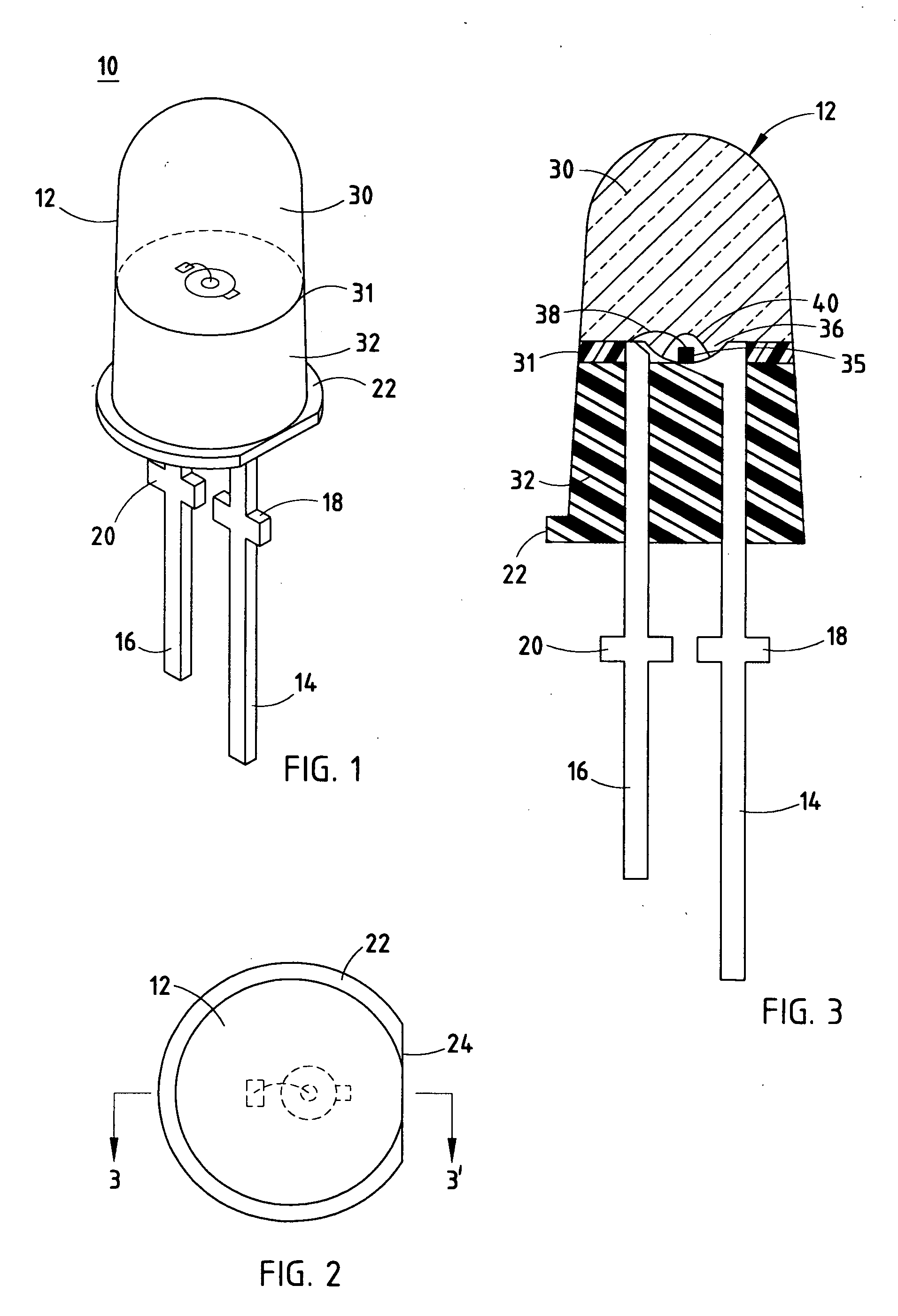

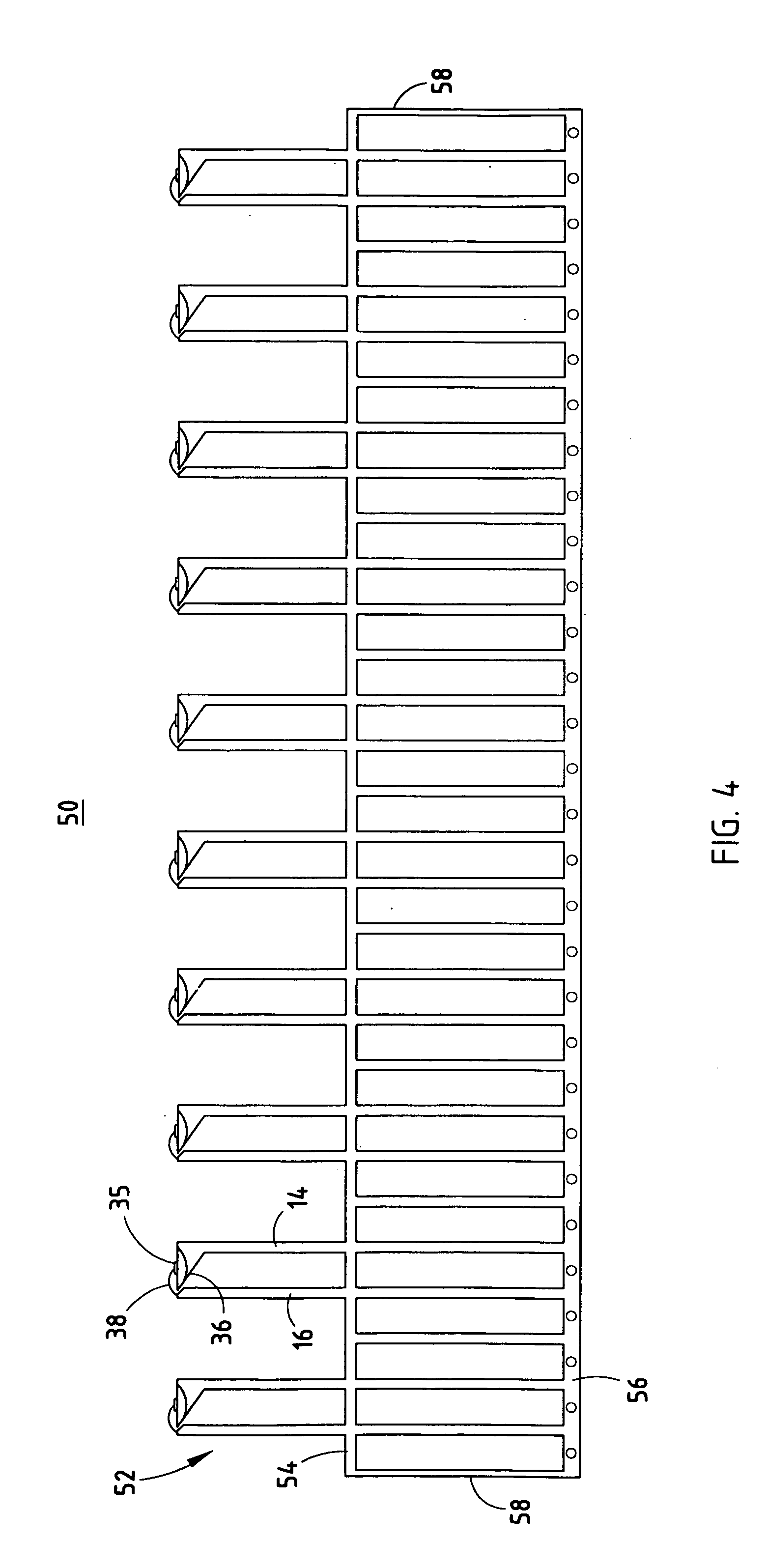

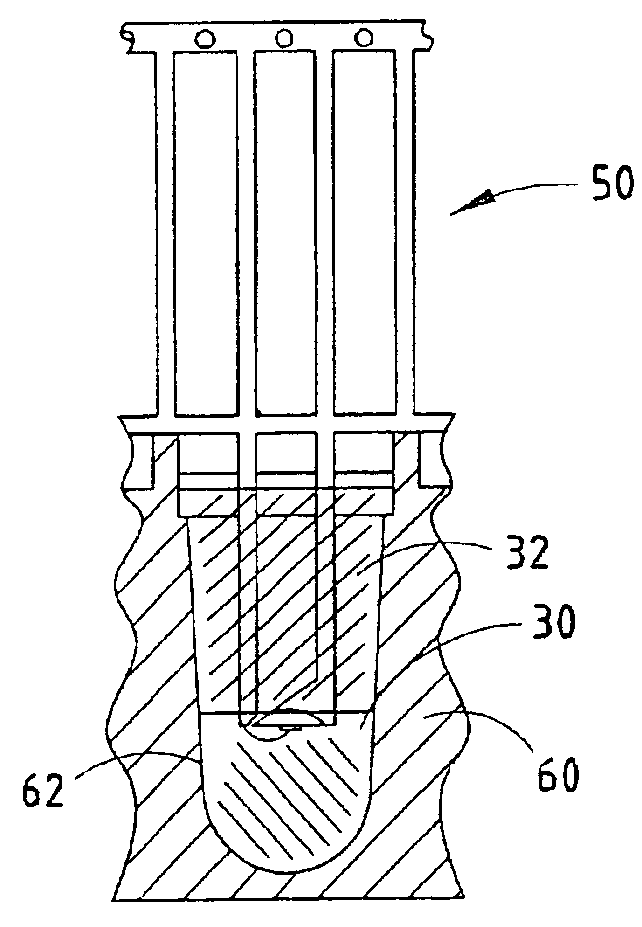

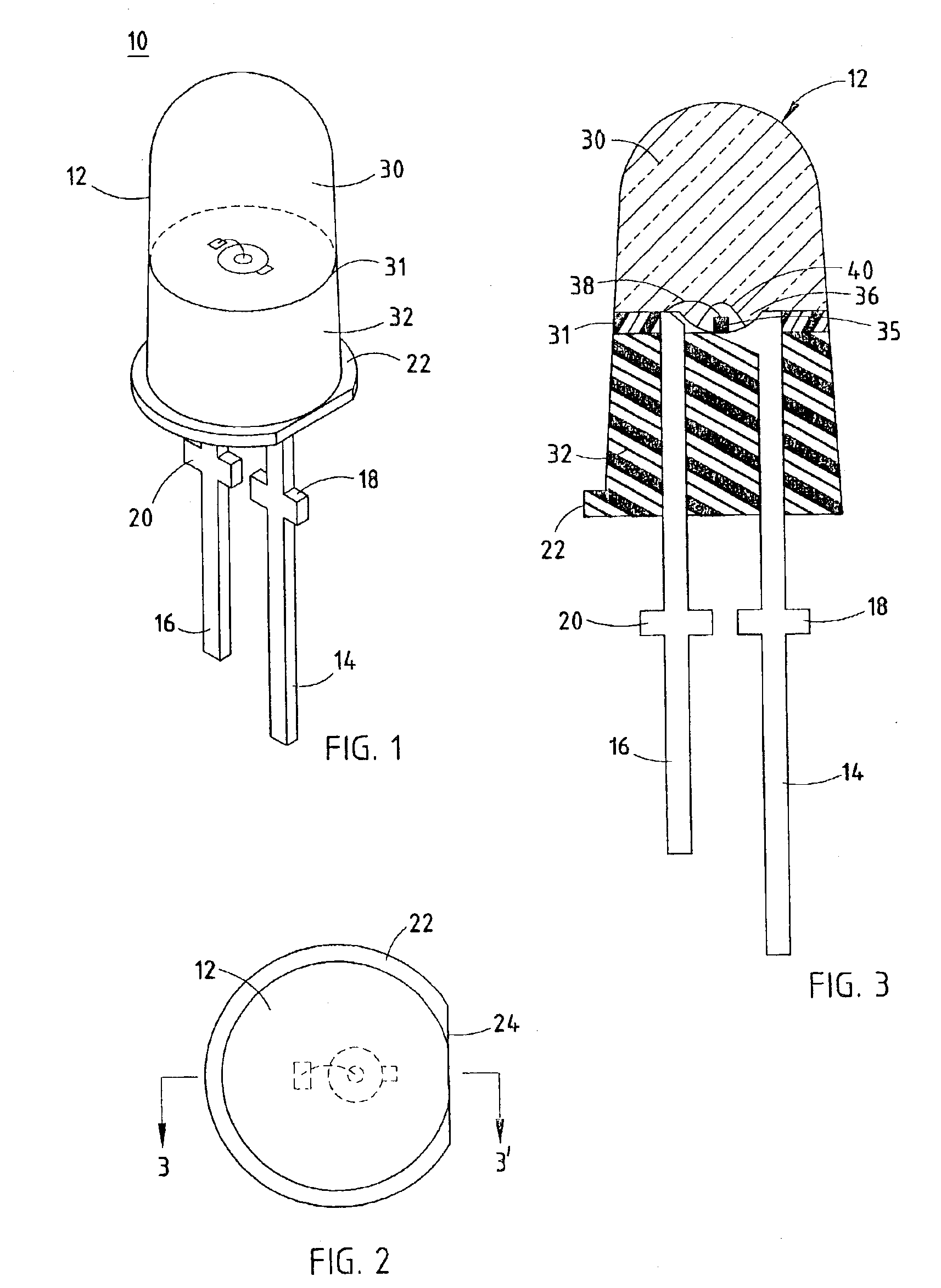

Opto-electronic assembly having an encapsulant with at least two different functional zones

InactiveUS20050133810A1Improve performanceLess vulnerability to fatal damageSemiconductor/solid-state device detailsSolid-state devicesTransmittanceThermal expansion

A radiation emitting device of the present invention includes at least one radiation emitter, first and second electrical leads electrically coupled to the radiation emitter, and an integral encapsulant configured to encapsulate the radiation emitter and a portion of the first and second electrical leads. The encapsulant has at least a first zone and a second zone, where the second zone exhibits at least one different characteristic from the first zone. Such different characteristics may be a physical, structural, and / or compositional characteristic. Preferably, the at least one different characteristic includes at least one of the following: mechanical strength, thermal conductivity, thermal capacity, coefficient of thermal expansion, specific heat, oxygen and moisture impermeability, adhesion, and transmittance with respect to radiation emitted from the radiation emitter. The radiation emitter may be in a form of an emitter, and is preferably an LED.

Owner:ROBERTS JOHN K +1

Medium flow meter

InactiveUS6370950B1Volume/mass flow by thermal effectsFluid speed measurement using thermal variablesTemperature differenceEngineering

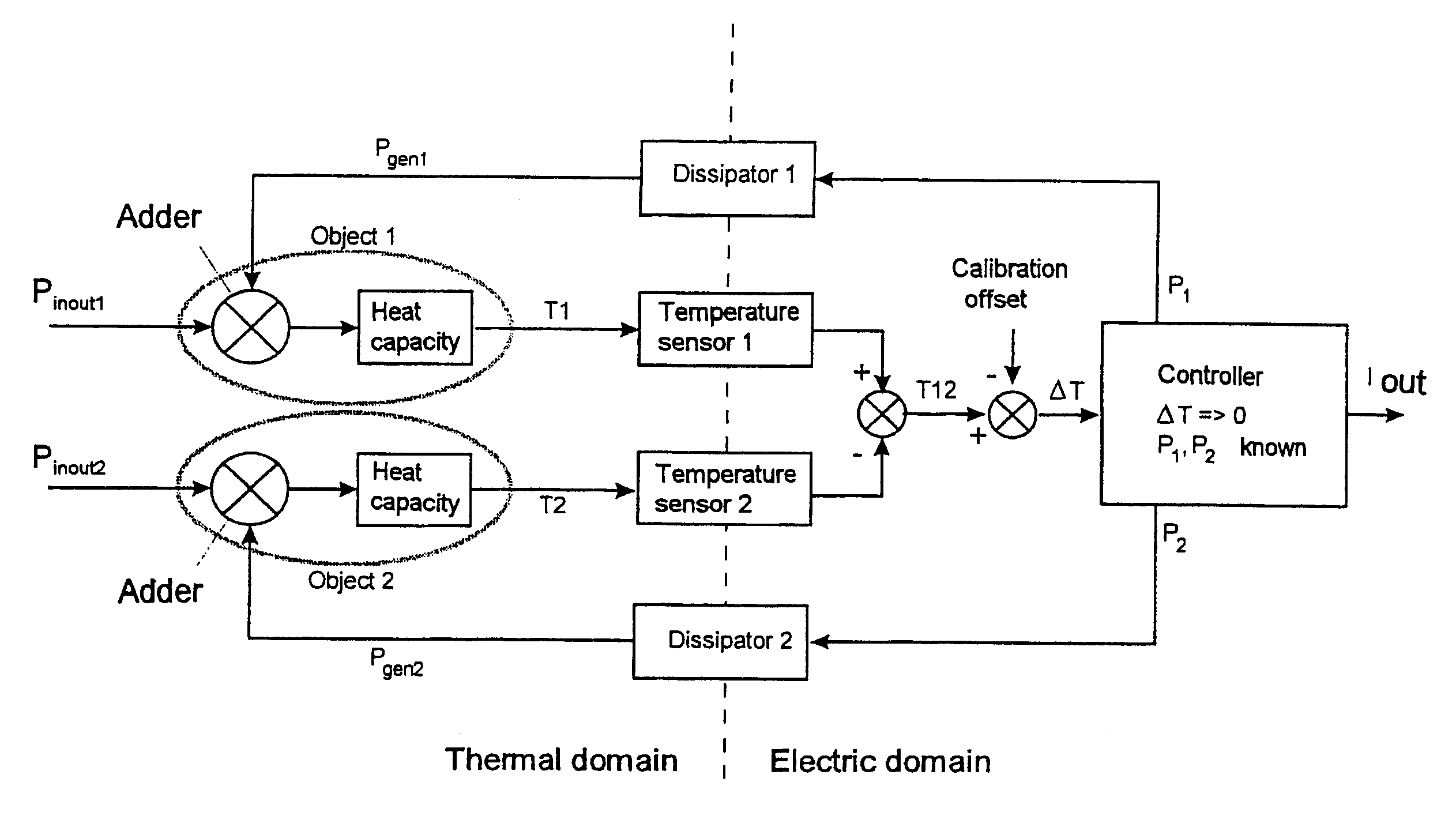

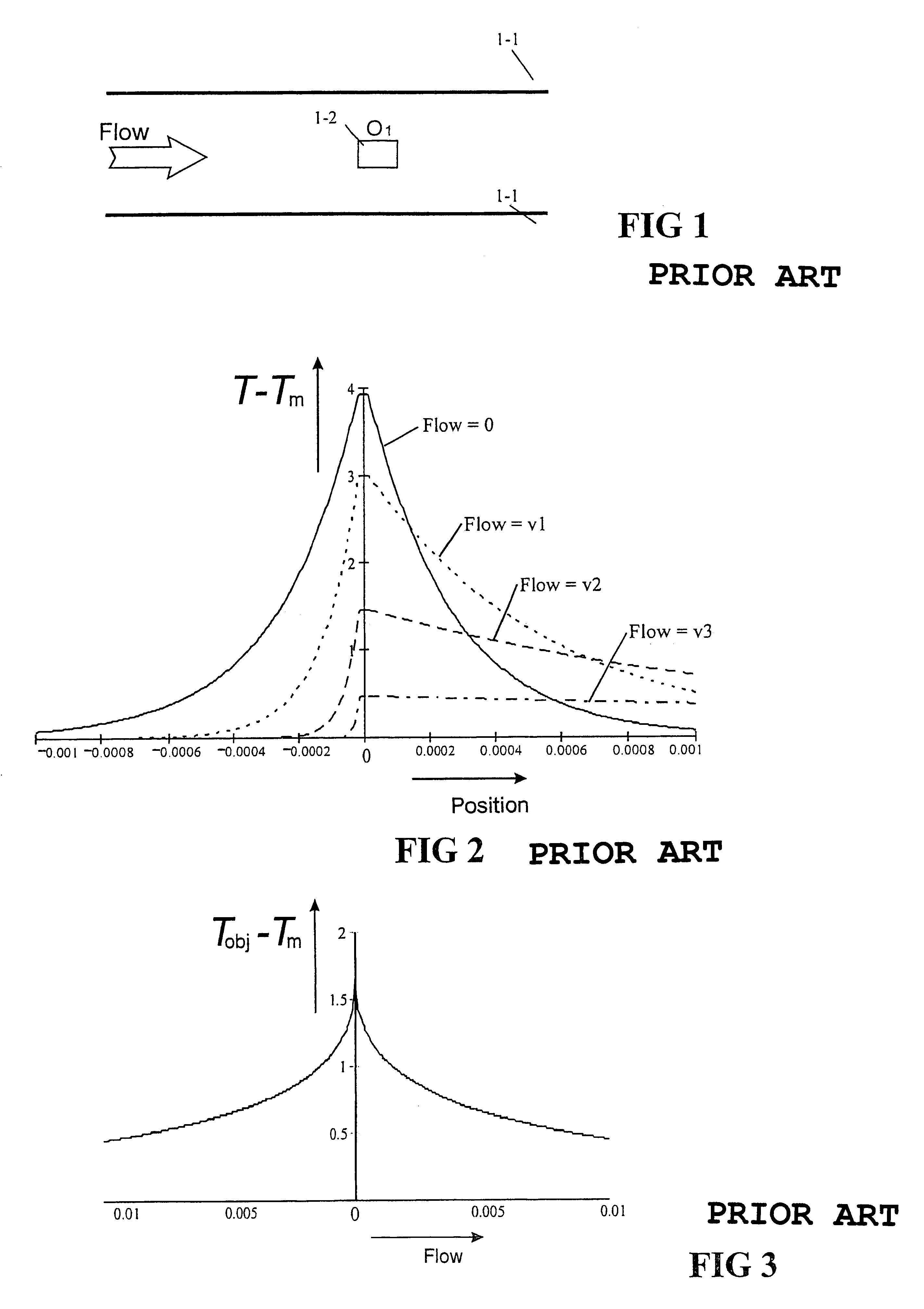

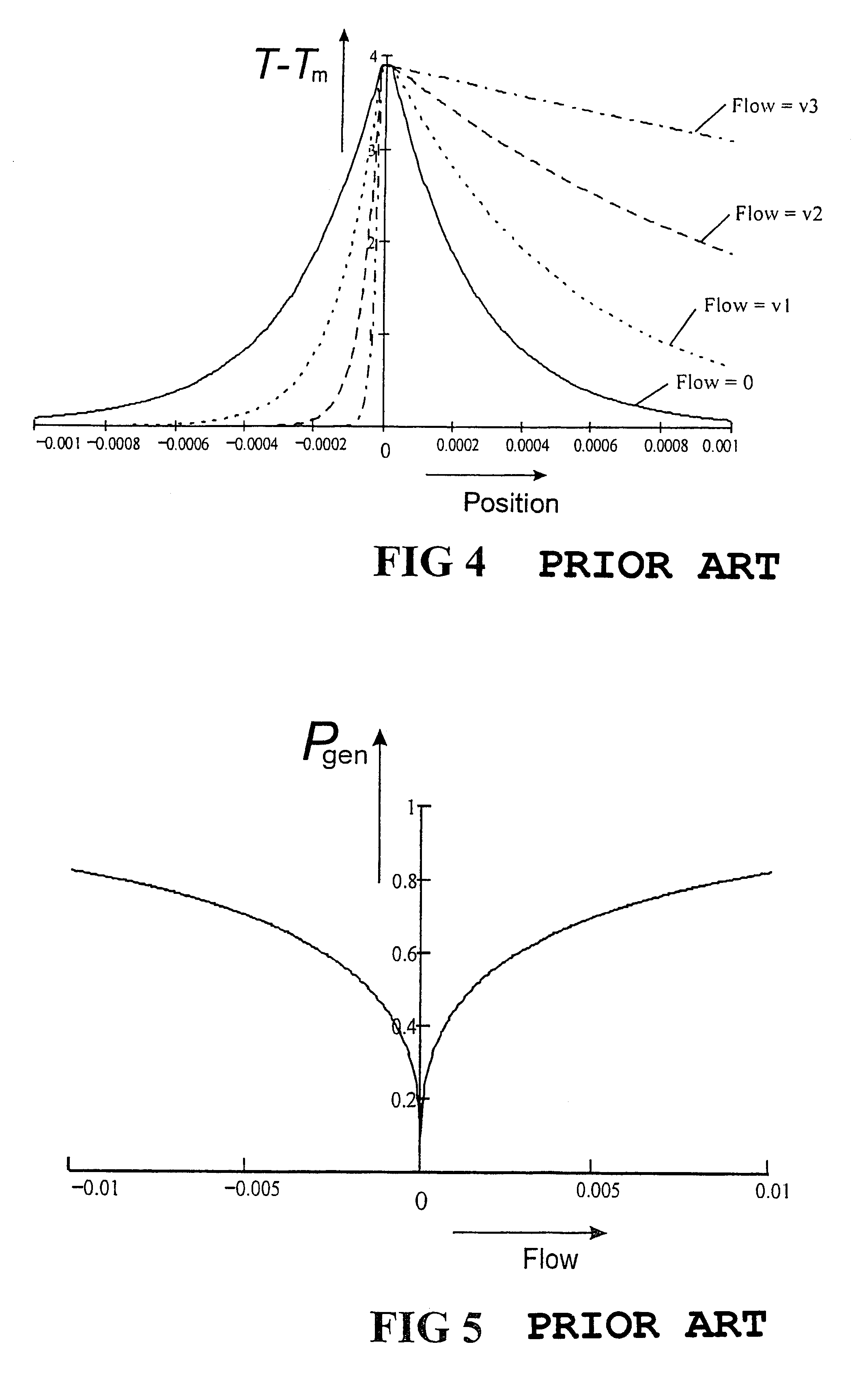

The invention relates to a device for measuring the flow of a medium e.g., a gaseous medium or a fluid medium, which device is based on measuring and affecting the temperature distribution of a medium flowing along, which flow sensor comprises two object, each comprising a heating element and a temperature sensor, the measured temperature difference being kept, by way of a control loop, to the value of zero, the asymmetry of the power supply to the objects in order to comply with the aforesaid criterion, according to which the temperature difference must be zero, being representative of the value to be measured of the medium flow, taking into account parameters associated with the medium, such as its density and specific heat.

Owner:BERKIN

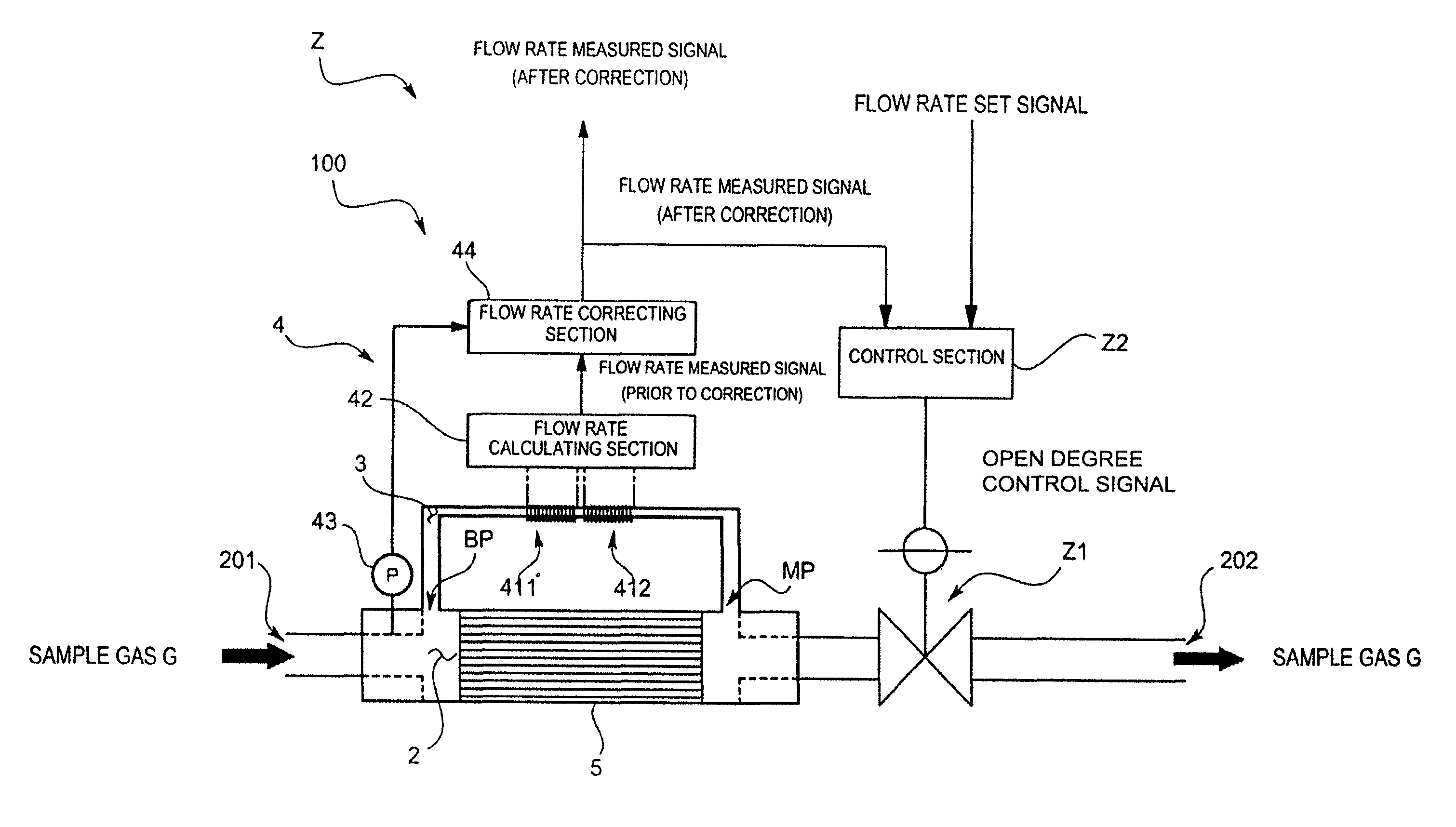

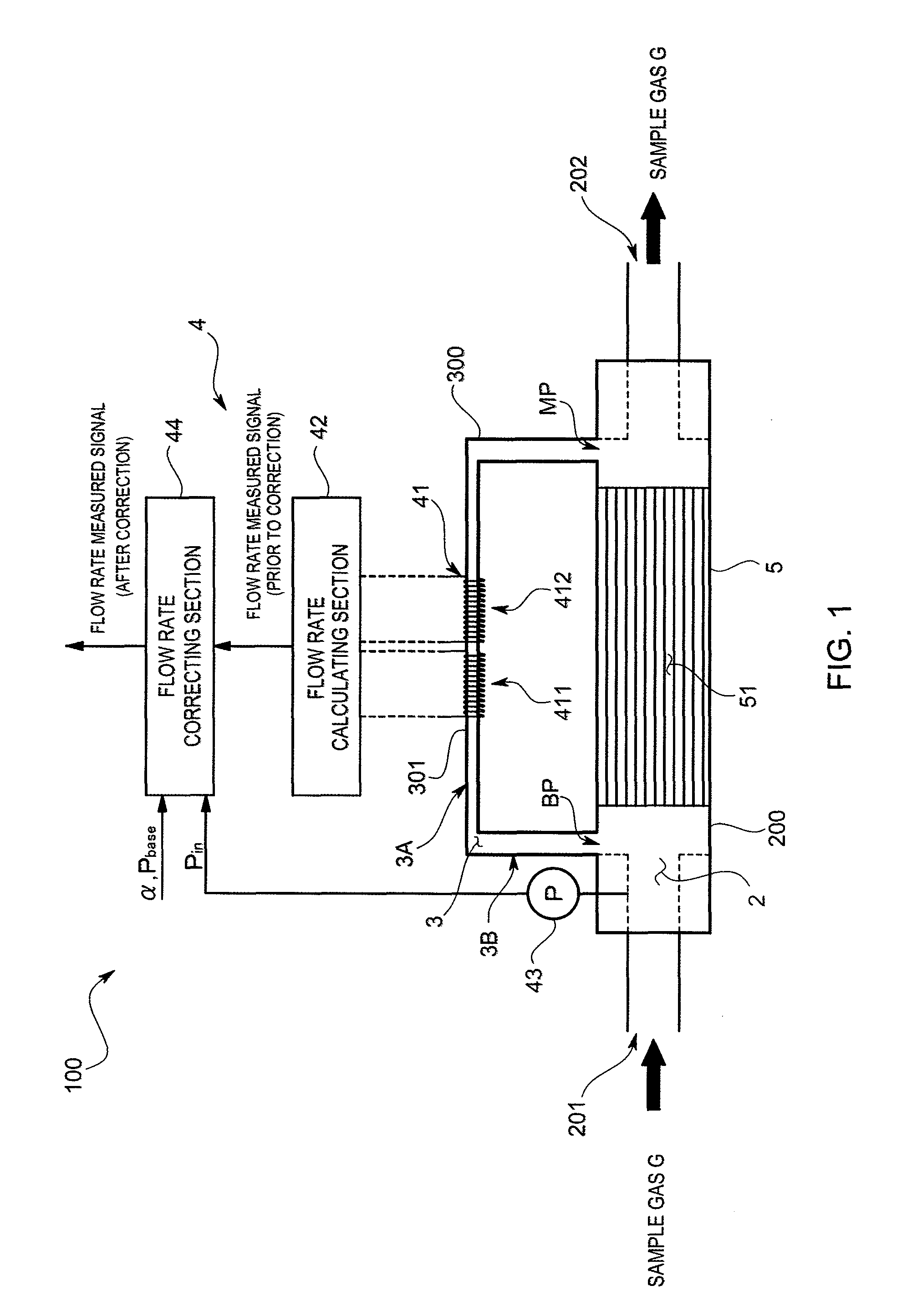

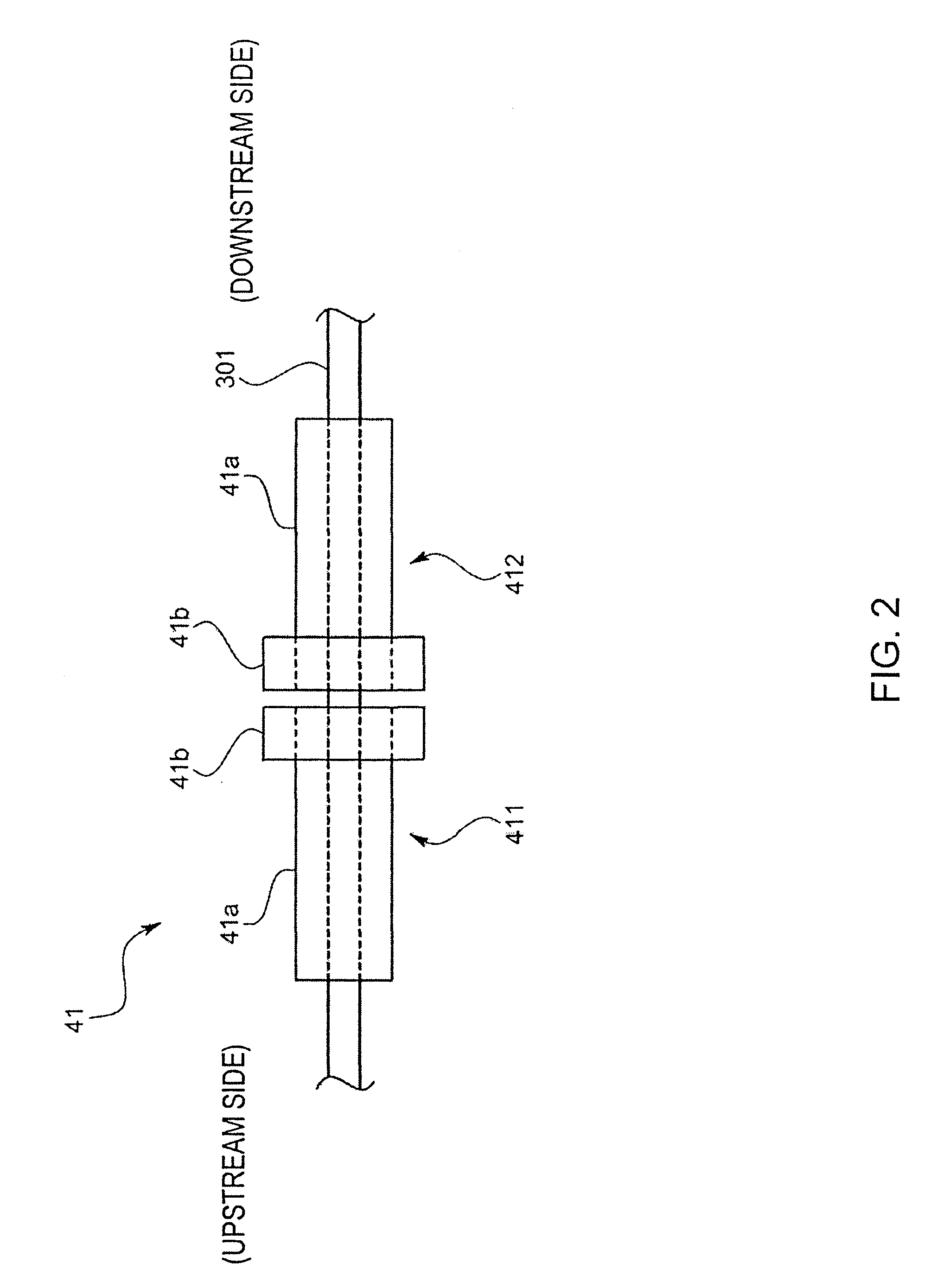

Mass flow meter and mass flow controller

ActiveUS8356623B2Reduce measurement errorHigh flow accuracyOperating means/releasing devices for valvesVolume/mass flow by thermal effectsEngineeringStreamflow

In order to improve a measurement accuracy of a mass flow meter, the mass flow meter comprises a flow rate calculating section that obtains an output signal from a sensor section having a thermosensitive resistive element arranged in a flow channel where a sample gas flows and that calculates a flow rate of the sample gas, a pressure measuring section that measures a primary side pressure in the flow channel, and a flow rate correcting section that corrects the measured flow rate obtained by the flow rate calculating section by the use of the primary side pressure obtained by the pressure measuring section and a gas coefficient determined by an isobaric specific heat of the sample gas.

Owner:HORIBA STEC CO LTD

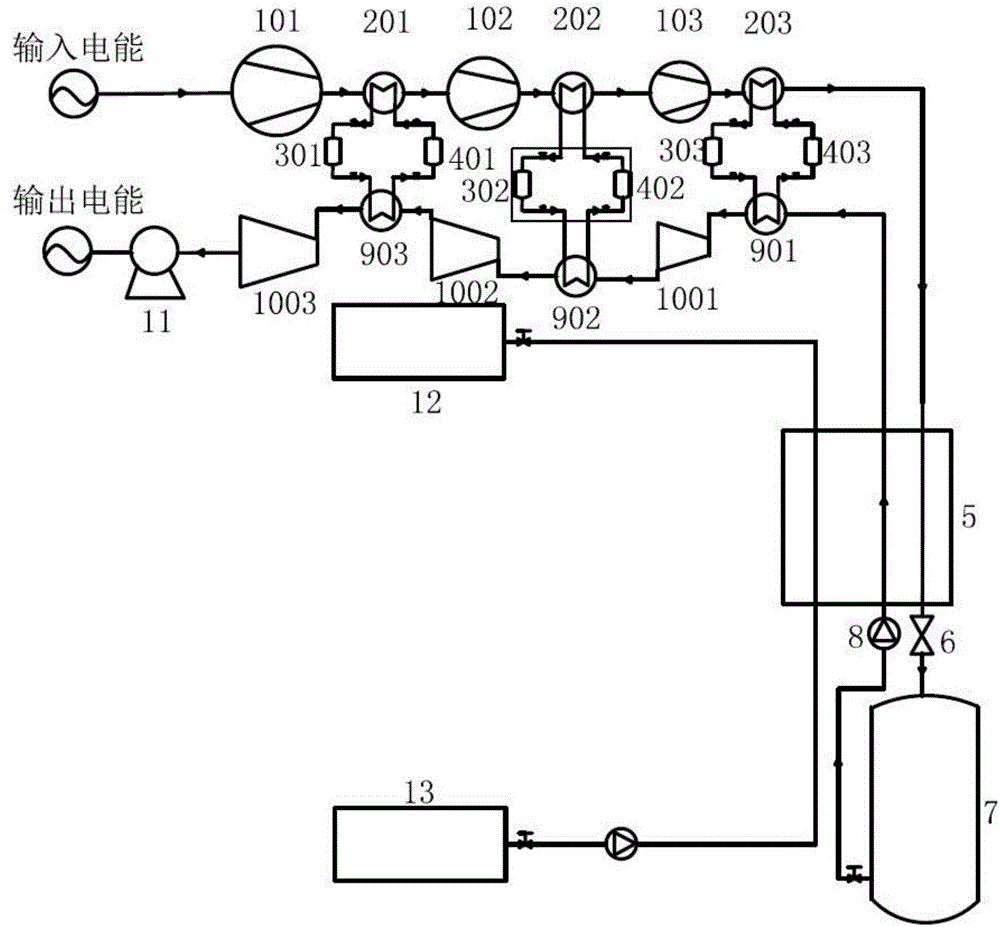

Liquefied compressed air energy storage system with cold-storage liquid media

ActiveCN105043147AHigh energy storage densityLow costHeat storage plantsMachines/enginesLiquid mediumThermal energy storage

The invention relates to a liquefied compressed air energy storage system with cold-storage liquid media. The liquefied compressed air energy storage system comprises compressor systems, a cold storage system, a heat storage system, a liquefying system and a turbine power generation system. During energy storage, the multistage compressor system is driven by renewable energy sources, so that compressed air is supercharged to exchange heat with a room-temperature cold-storage liquid medium, the cold quantity stored in the liquid medium is lowered to liquefying temperature, and the compressed air is liquefied through throttling; during energy releasing, the liquid air is supercharged to exchange heat with a high-temperature cold-storage liquid medium, the medium recycles cold energy to give to the liquefying process, and the air is warmed to be vaporized; room-temperature high-pressure air is input into a multi-stage turbine expander for acting, and a power generator is driven to output electric energy; the heat storage system reduces the power consumption of the next stage of compressor, and the stored heat is heated step by step before expansion to raise the intake air temperature; a cold-storage medium with a low freezing point and a high / low boiling point recycles the cold energy of the liquid air, the specific heat capacity of the liquid media is large, and the large-temperature-span heat exchange is realized. The liquefied compressed air energy storage system has the advantages of being simple in structure and stable in performance, can realize integration of energy storage and power generation, and can realize the large-scale grid-connection of renewable energy generation, therefore improving the capacity of a power grid accepting new energy power generation.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

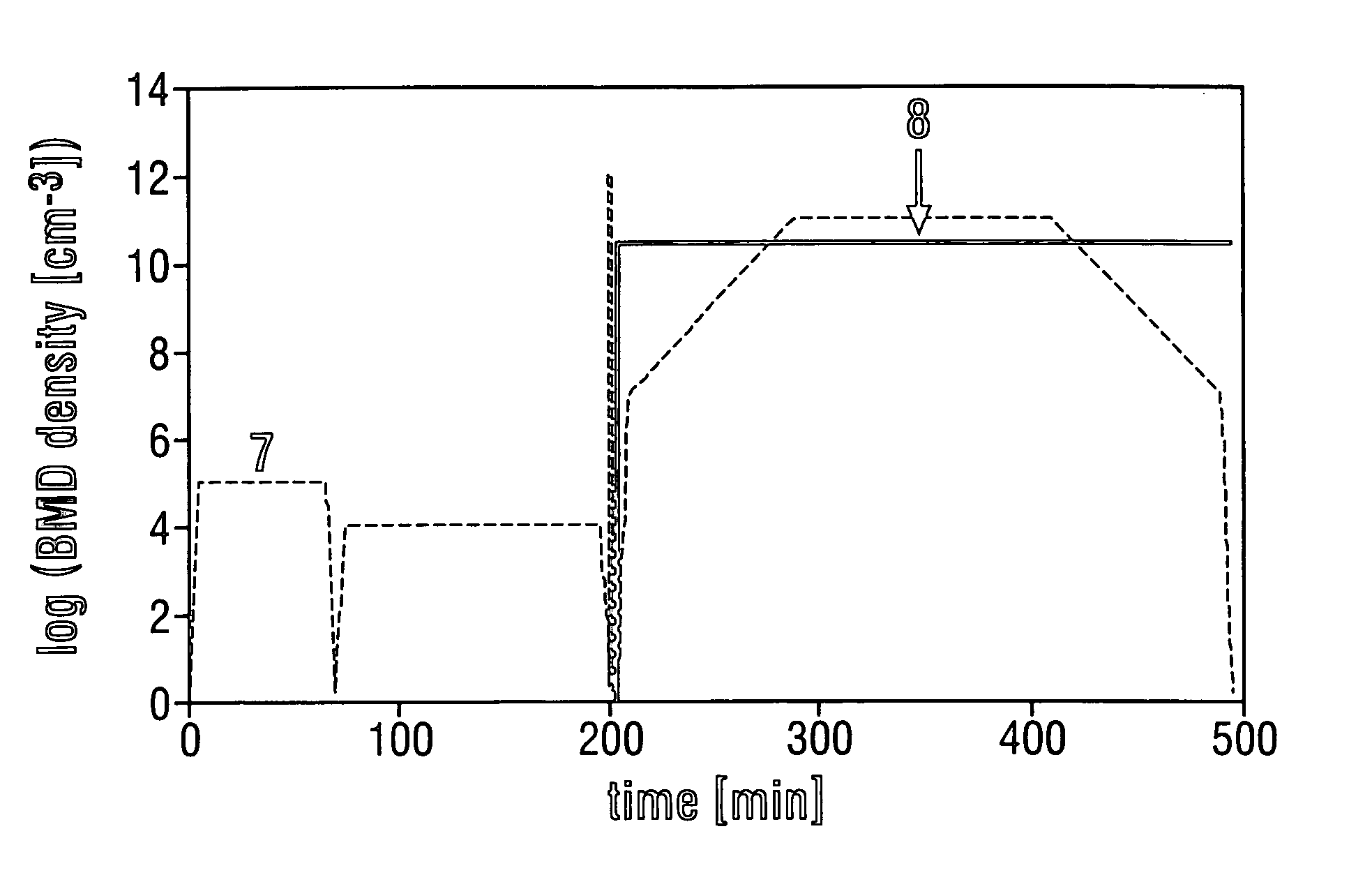

Battery pack

InactiveUS20110177366A1Small and lightFree from damageCell temperature controlBattery isolationElectricityElectric power

A battery pack of the present invention includes: a battery assembly including a plurality of batteries having a sealed portion, the plurality of batteries being connected to each other; a terminal portion electrically connected to the battery assembly and outputting electric power; and a composite layer structure including a heat-absorbing layer and a heat-conductive layer layered on the heat-absorbing layer, the composite layer structure being arranged at least at a part of a periphery of the battery assembly. The heat-absorbing layer has a specific heat of 1,000 J / kg·° C. or more. The heat-conductive layer has a heat conductivity of 10 W / m·K or more. This configuration allows for a small, light, and highly safe battery pack that is free from battery pack damage even when a battery in the battery pack has trouble and emits a high-temperature inflammable gas to expose the inside of the battery pack to a high-temperature environment.

Owner:PANASONIC CORP

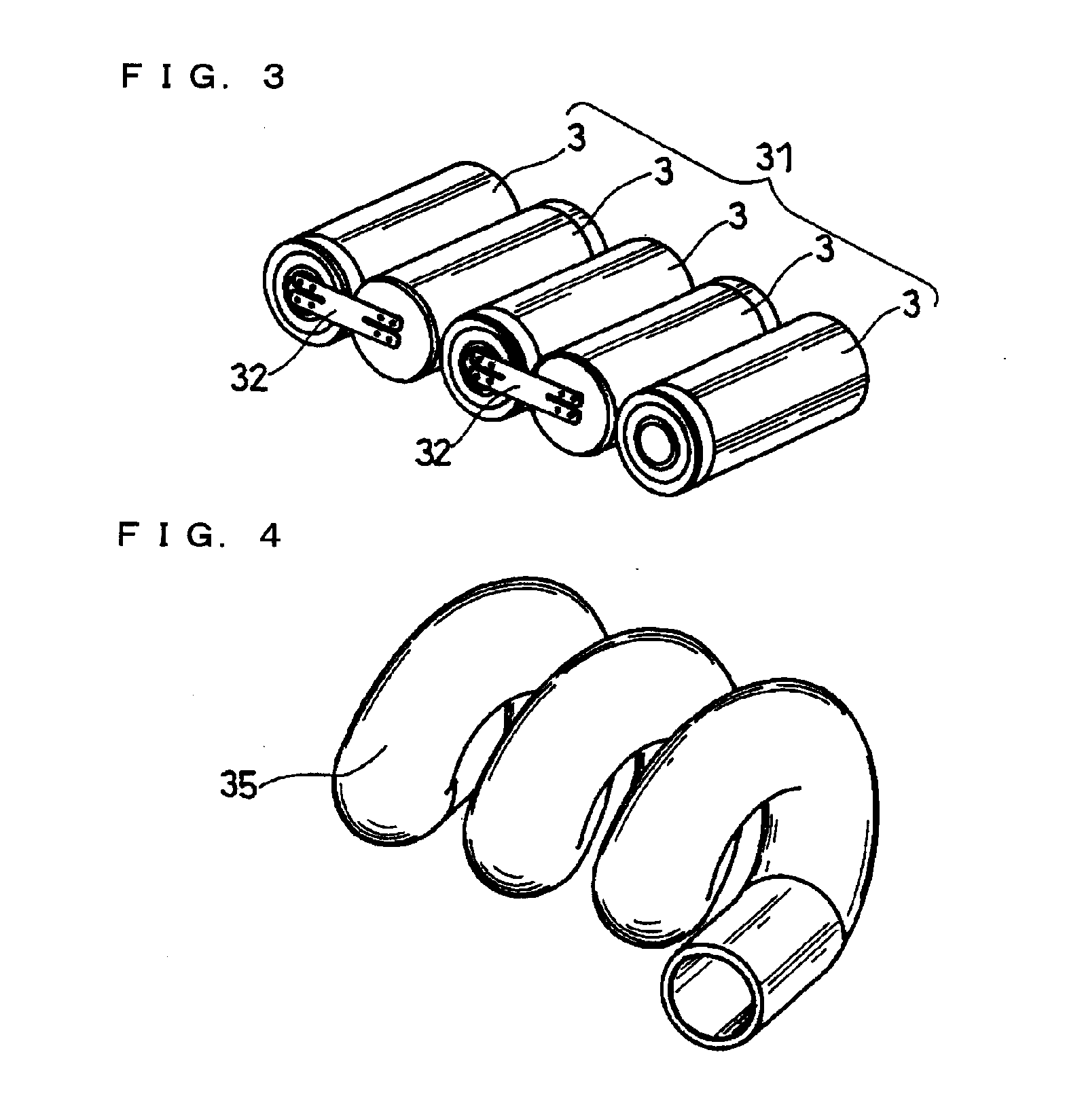

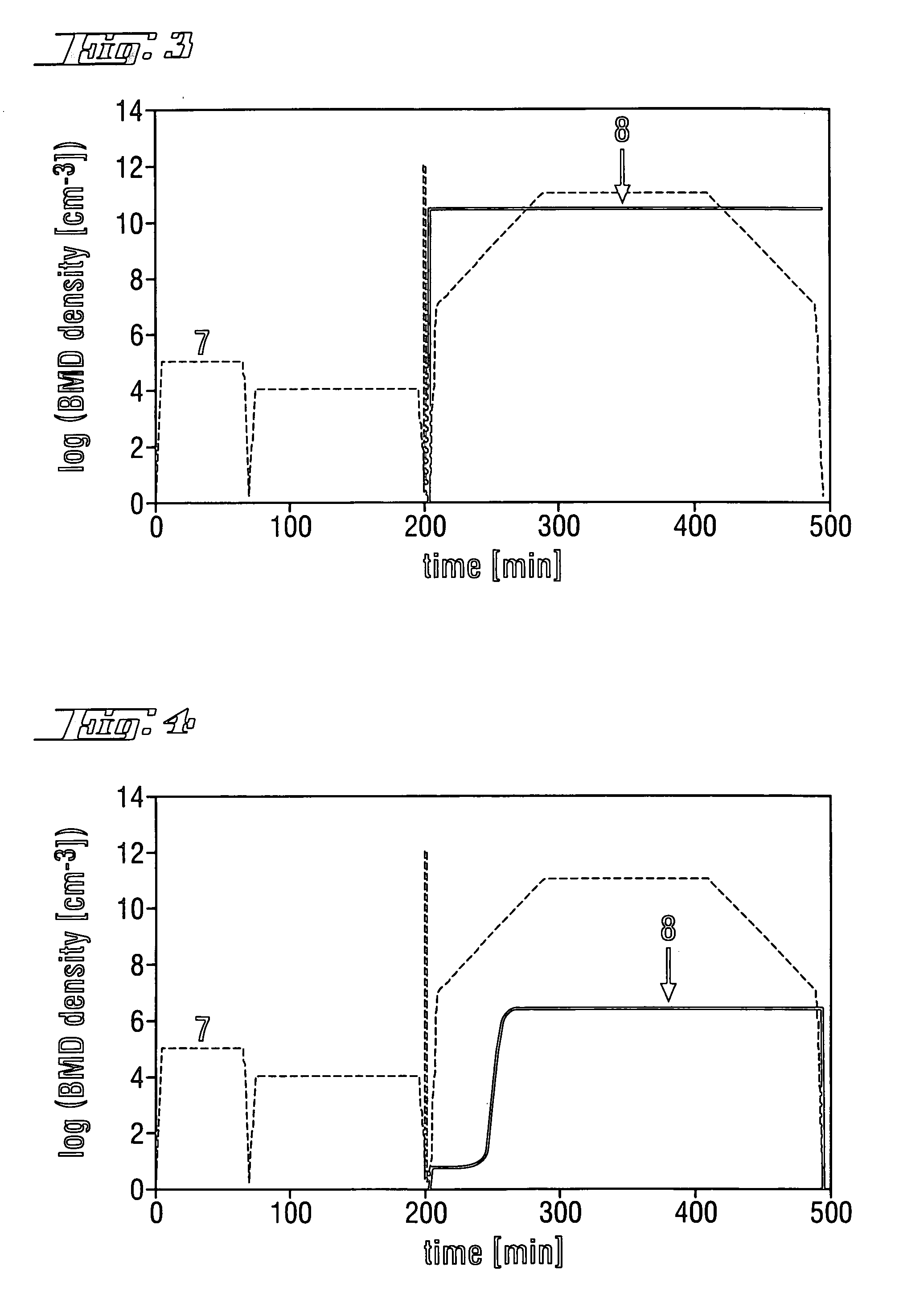

Layered semiconductor wafer with low warp and bow, and process for producing it

InactiveUS20060046431A1Easy to implementNo harmful side effectSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringSilicon

Semiconductor wafers with a diameter of at least 200 mm comprise a silicon carrier wafer, an electrically insulating layer and a semiconductor layer located thereon, the semiconductor wafer having been produced by means of a layer transfer process comprising at least one RTA step, wherein the semiconductor wafer has a warp of less than 30 μm, a DeltaWarp of less than 30 μm, a bow of less than 10 μm and a DeltaBow of less than 10 μm. Processes for the production of a semiconductor wafer of this type require specific heat treatment regimens.

Owner:SILTRONIC AG

Novel phase-change material composition

ActiveCN104726069AImprove thermal performanceGood dispersionHeat-exchange elementsParticulatesCarbon nanotube

The invention discloses a novel phase-change material composition. The novel phase-change material composition mainly comprises carbon nanotubes, graphene, fumed silica, metal or metal oxide particles and a phase-change material. The carbon nanotubes, graphene and metal or metal oxide particles can further accelerate heat transmission. The phase-change material is used for improving a hot end initial temperature absorption rate. The fumed silica has effects of precipitation prevention and thickening and can prevent graphene and particle aggregation settlement after heat absorption liquefaction of the phase-change material. The carbon nanotubes, graphene and metal or metal oxides can finally form a full 3D network comprising particles (metal or metal oxides), wires (carbon nanotubes) and planes (graphene) in the fluid (of phase-change material subjected to heat absorption melting). The novel phase-change material composition has high heat conductivity and low thermal resistance value, has high specific heat capacity, greatly improves phase-change material heat absorption, heat storage and heat radiation efficiency and has a high practical value.

Owner:HUZHOU MINGSHUO OPTOELECTRONICS TECH CO LTD

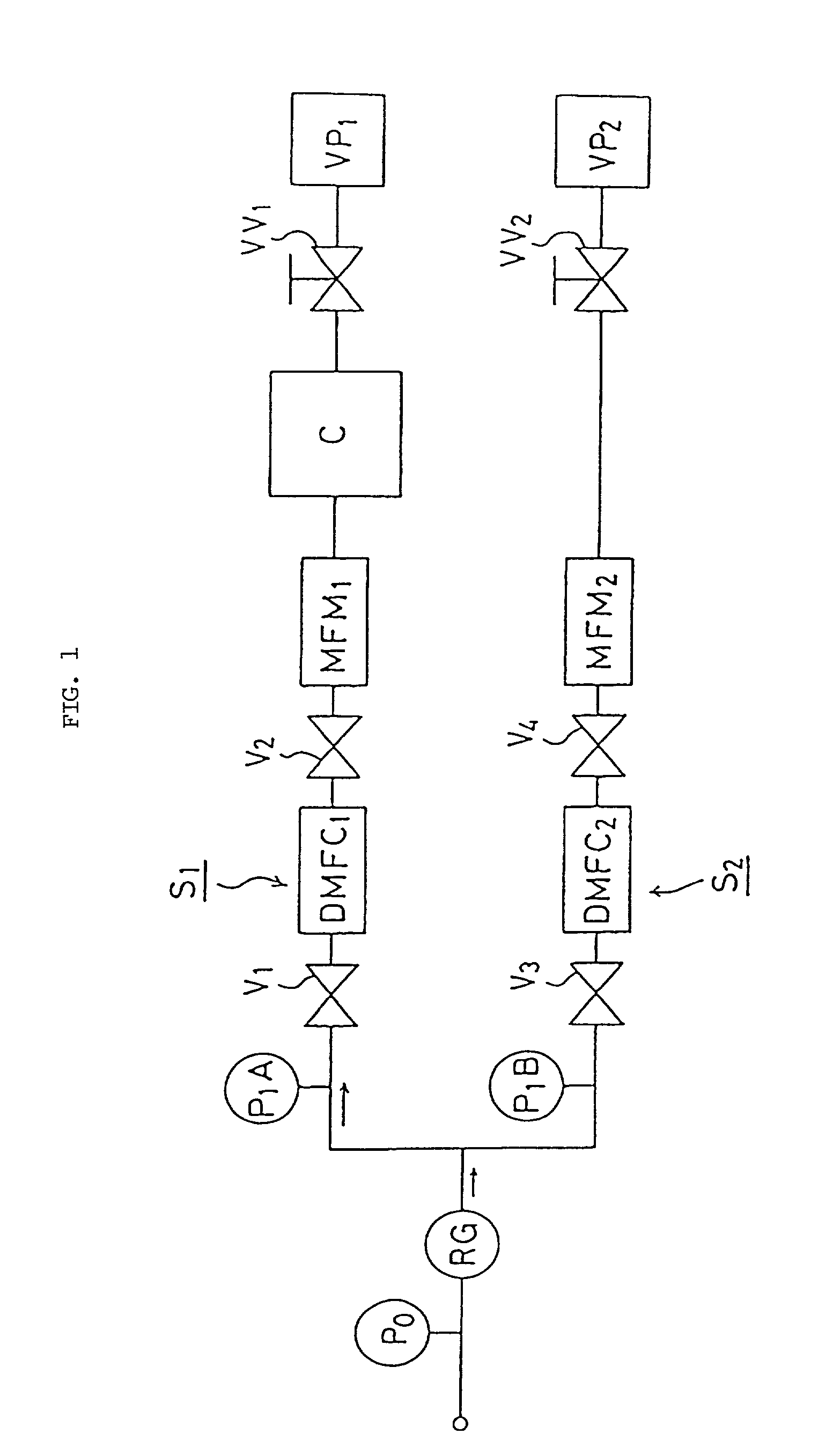

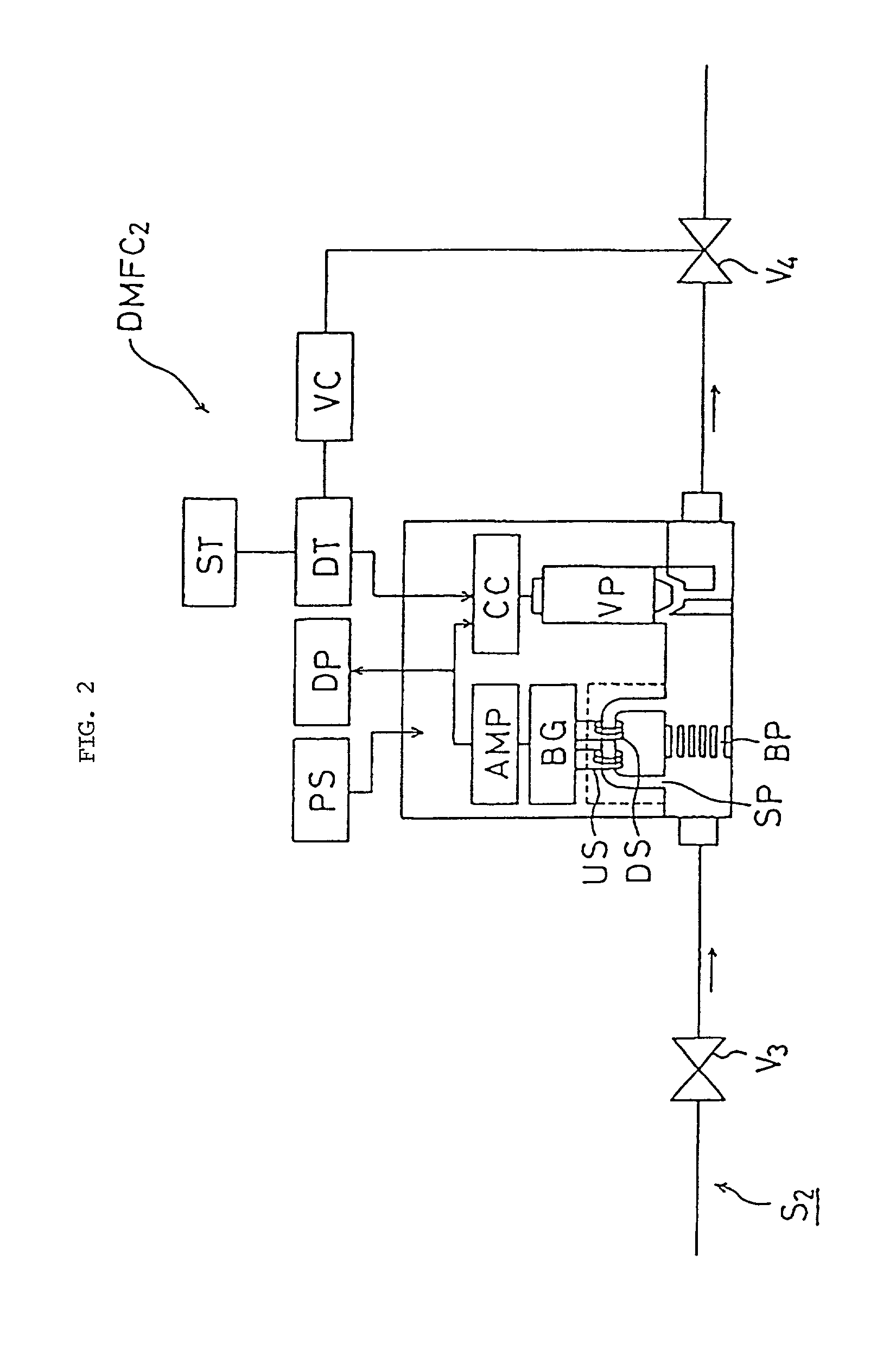

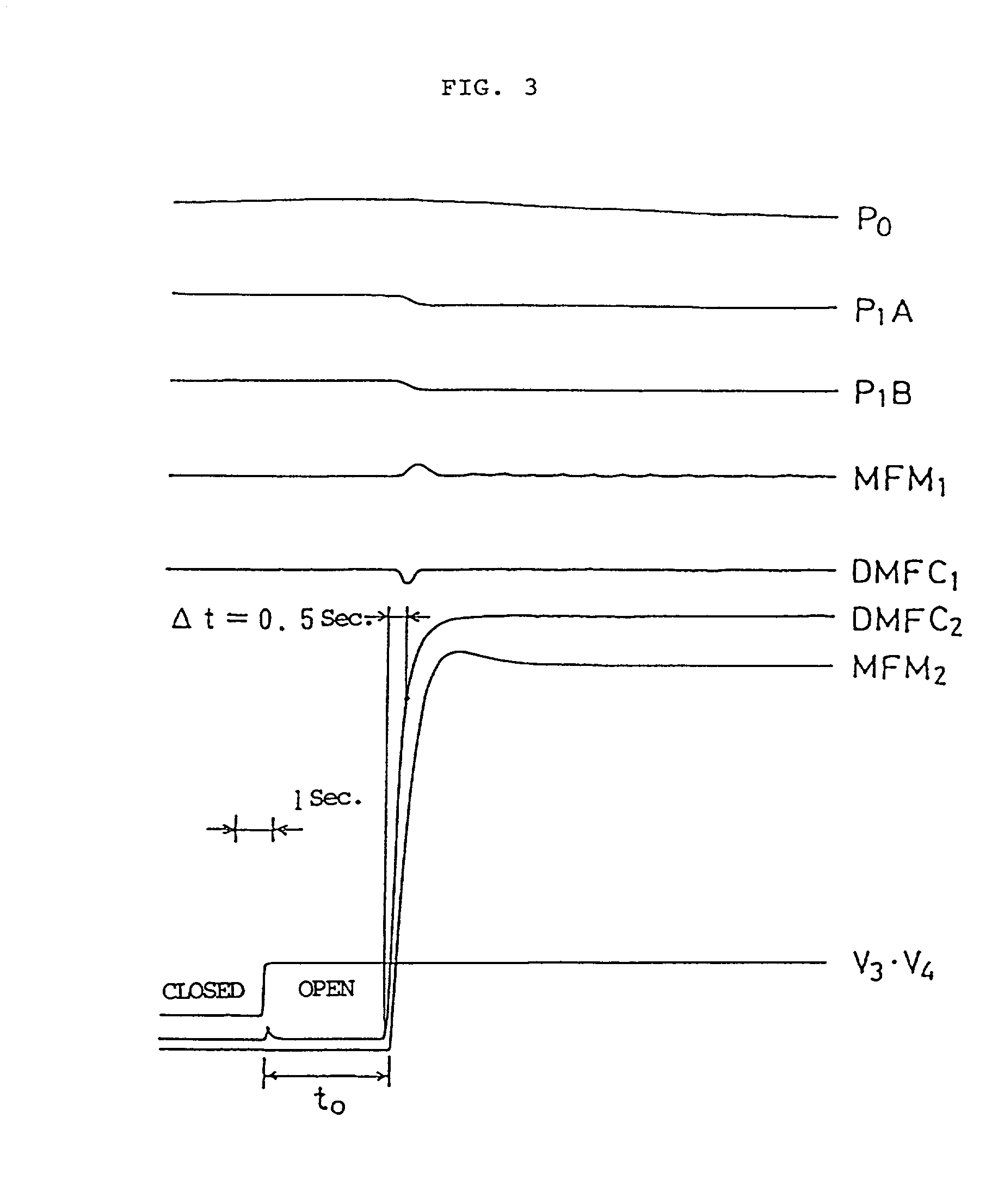

Parallel divided flow-type fluid supply apparatus, and fluid-switchable pressure-type flow control method and fluid-switchable pressure-type flow control system for the same fluid supply apparatus

InactiveUS20010004903A1Operating means/releasing devices for valvesTime-programme switchesStandard stateControl system

A fluid supply apparatus with a plurality of flow lines branching out from one regulator for adjustment of pressure, the flow lines being arranged in parallel, wherein a measure is taken that the operation, that is, opening or closing of one flow passage will have no transient effect on the steady flow of the other flow passages. For this purpose, each flow passage is provided with a time delay-type mass flow controller MFC so that when one closed fluid passage is opened, the mass flow controller on that flow passage reaches a set flow rate Qs in a specific delay time DELTAt from the starting point. Also provided are a method and an apparatus for the above in which a plurality of gas types can be controlled in flow rate with high precision by one pressure-type flow control system. To that end, a formula for calculating the flow rate of a gas is theoretically derived that flows with a pressure ratio not higher than the critical pressure ratio. From that formula, the flow factor is defined, so that the formula may be applied to a number of gas types using flow factors. The method includes calculating the flow rate Qc of a gas passing through an orifice according to formula Qc=KP1 (K=constant) with a pressure P1 on an upstream side of the orifice set at twice or more higher than pressure P2 on a downstream side, wherein the flow factor FF for each kind of gas is calculated as follows: <paragraph lvl="0"><in-line-formula>FF=(k / gammas){2 / (kappa+1)}1 / (kappa-1)[kappa / {(kappa+1)R}]½< / in-line-formula>and wherein, if the calculated flow rate of gas type A is QA, and, when gas type B is allowed to flow through the same orifice under the same pressure on the upstream side and at the same temperature on the upstream side, the flow rate QB is calculated as follows: <paragraph lvl="0"><in-line-formula>QB=(FFB / FFA)QA < / in-line-formula>where gammas=concentration of gas in standard state; kappa=ratio of specific heat of gas; R=constant of gas; K=proportional constant not depending on the type of gas; FFA=flow factor of gas type A; and FFB=flow factor of gas type B.

Owner:FUJIKIN INC +2

Wireless charging device

InactiveUS9018899B2Low heat generationArea evenTobacco devicesElectric powerElectromagnetic couplingElectricity

A wireless charging device comprises an electronic switch and a transmitting coil (L1) electrically connected with a power source in sequence. A control end of the electronic switch is connected with a transmitting control unit. The wireless charging device further comprises a current limiting resistance (R1) connected in serial with the transmitting coil. The wireless charging device further comprises a compensation capacitor (C1) connected in parallel with the transmitting coil. An insert total electromagnetic coupling structure is further employed for charging. Such wireless charging device is particularly suitable for electronic cigarette, with low cost, stable and reliable working status and high efficiency, and specific heat sink is not required.

Owner:KIMREE HI TECH

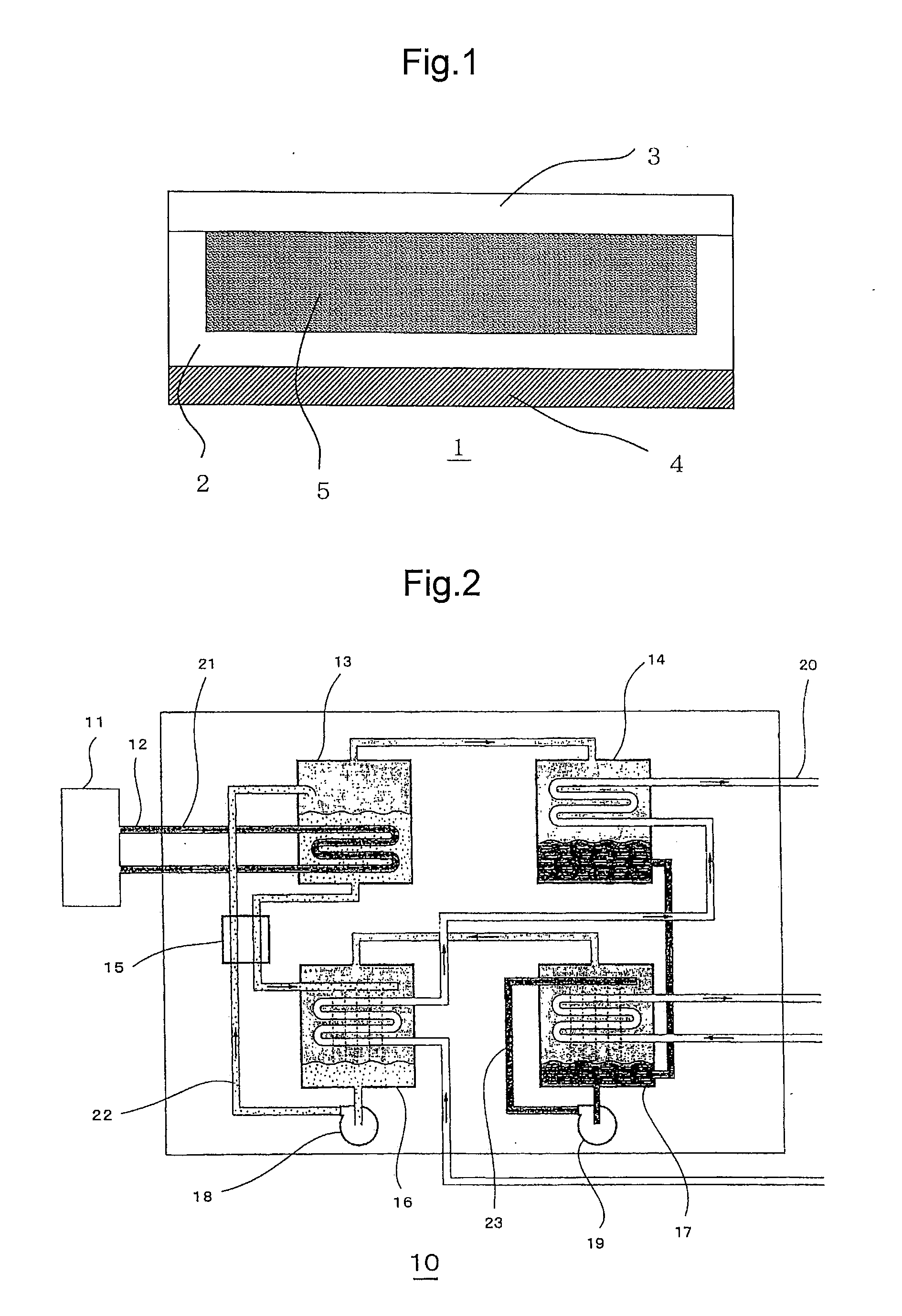

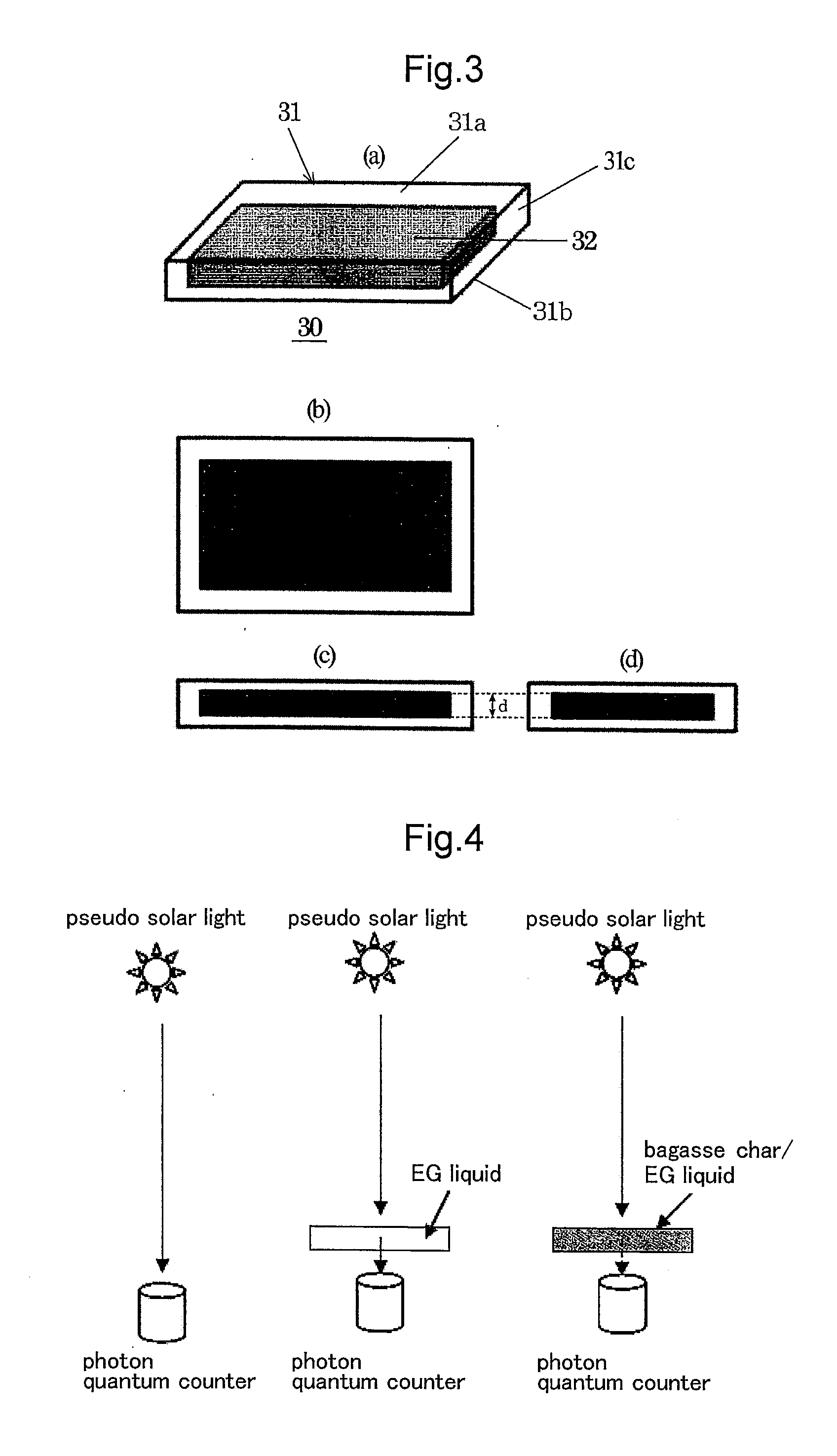

Solar Light (Heat) Absorption Material and Heat Absorption/Accumulation Material and Solar Light (Heat) Absorption/Control Building Component Using the Same

InactiveUS20120017622A1Light absorbing abilityEfficient use ofSolar heating energySolar heat devicesSolar lightLiquid medium

A solar light (heat) absorption material is provided which has an excellent solar light (heat) absorbing ability and a simple structure, and may be usable as a low-cost and high-performance heat absorption / accumulation material, the inventive material being usable also as a solar light (heat) absorption / control building component that allows easy change of its solar light (heat) absorption / control ability. The material comprises particles dispersed into a liquid medium having a specific heat ranging from 0.4 to 1.4 cal / g / ° C. and a melting point of 5° C. or lower. The dispersed particles have L*value of 30 or less as determined by the CIE-Lab color system (light source D65).

Owner:UNIVERSITY OF THE RYUKYUS +1

Method of making radiation emitter devices

InactiveUS6849867B2Improve performanceLess vulnerability to fatal damageSemiconductor/solid-state device detailsSolid-state devicesTransmittanceThermal expansion

A radiation emitting device of the present invention includes at least one radiation emitter, first and second electrical leads electrically coupled to the radiation emitter, and an integral encapsulant configured to encapsulate the radiation emitter and a portion of the first and second electrical leads. The encapsulant has at least a first zone and a second zone, where the second zone exhibits at least one different characteristic from the first zone. Such different characteristics may be a physical, structural, and / or compositional characteristic. Preferably, the at least one different characteristic includes at least one of the following: mechanical strength, thermal conductivity, thermal capacity, coefficient of thermal expansion, specific heat, oxygen and moisture impermeability, adhesion, and transmittance with respect to radiation emitted from the radiation emitter. The radiation emitter may be in a form of an emitter, and is preferably an LED.

Owner:GENTEX CORP

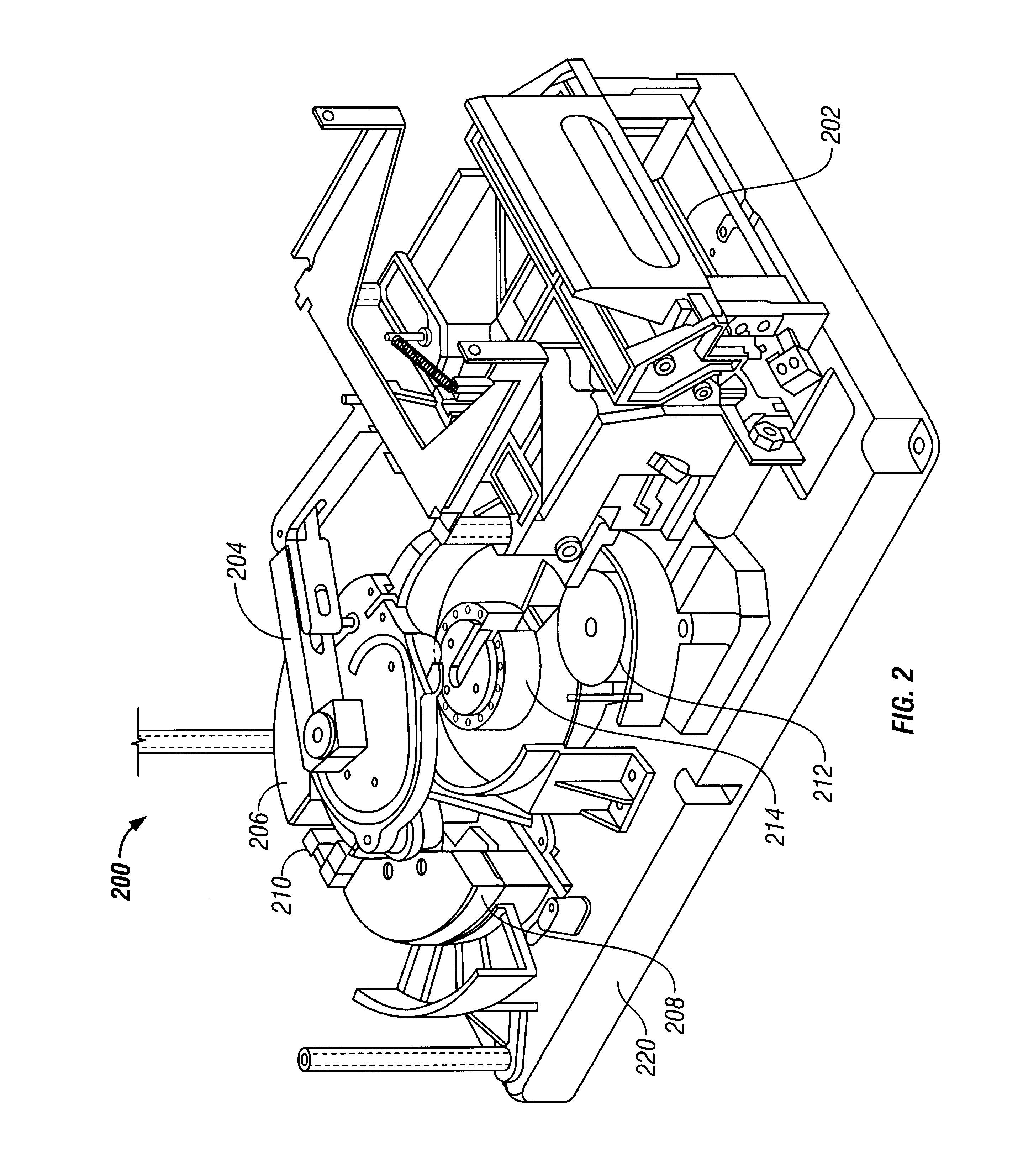

Systems, methods, and apparatus for cryogenic refrigeration

ActiveUS20100281885A1Efficient evacuationDigital data processing detailsCompression machinesDilution refrigeratorEvaporation

Cryogenic refrigeration employs a pulse tube cryo-cooler and a dilution refrigerator to provide very low temperature cooling, for example, to cool superconducting processors. Continuous cryogenic cycle refrigeration may be achieved using multiple adsorption pumps. Various improvements may include multiple distinct thermal-linking points, evaporation pots with cooling structures, and / or one or more gas-gap heat switches which may be integral to an adsorption pump. A reservoir volume may provide pressure relief when the system is warmed above cryogenic temperature, reducing the mass of the system. Additional heat exchangers and / or separate paths for condensation and evaporation may be provided. Multi-channel connectors may be used, and / or connectors formed of a regenerative material with a high specific heat capacity at cryogenic temperature. Flexible PCBs may provide thermal links to components that embody temperature gradients. Various components may be pre-cooled, for example via a switchable thermalization system.

Owner:D WAVE SYSTEMS INC

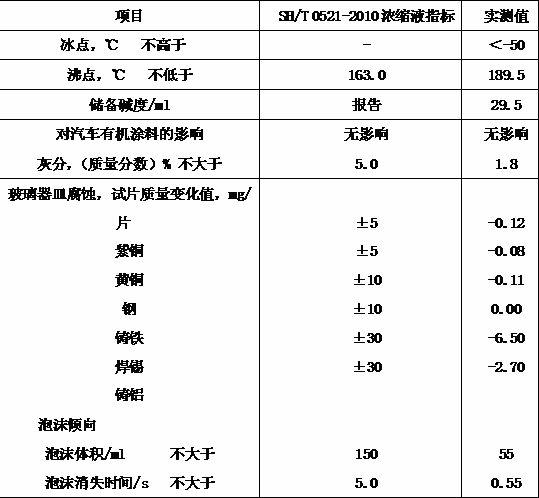

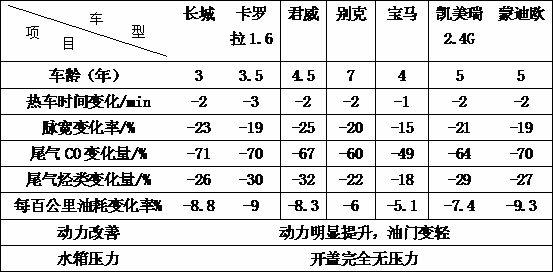

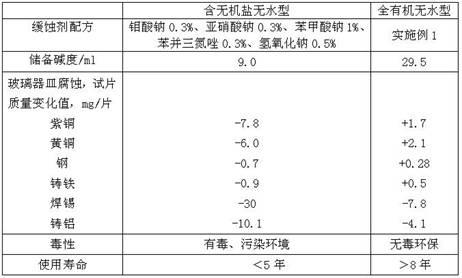

All-organic waterless engine coolant

InactiveCN102559152AImprove corrosion resistanceIncrease motivationHeat-exchange elementsCavitationElectrochemical corrosion

The invention aims at providing an all-organic waterless engine coolant with high storage alkalinity and long service life, which specifically contains the following components by weight percentage: 20-92% of propylene glycol, 0-60% of ethylene glycol, 0.6-5.5% of all-organic corrosion inhibitor, 5-20% of viscosity specific heat conditioning agents, 1.5-5.0% of potential of hydrogen (pH) conditioning agents, 0.01-0.1% of antifoaming agents and 0.001-0.01% of coloring agents. The boiling point of the all-organic waterless engine coolant reaches 180-190 DEG C, the freezing point reaches below -50 DEG C, and the all-organic waterless engine coolant is free of inorganic salt, so that defects of the traditional coolant of being low in boiling point, apt to have electrochemical corrosion and cavitation corrosion, apt to generate scale and the like are overcome, engine power is improved, noise is reduced, and fuel is saved. The all-organic waterless engine coolant has storage alkalinity larger than 25 ml and very long service life, can be used for a life time after being injected for once, does not need to be added with supplement annexing agents (SCA), and is good in market prospect.

Owner:GUANGZHOU BIAOBANG CAR CARE IND

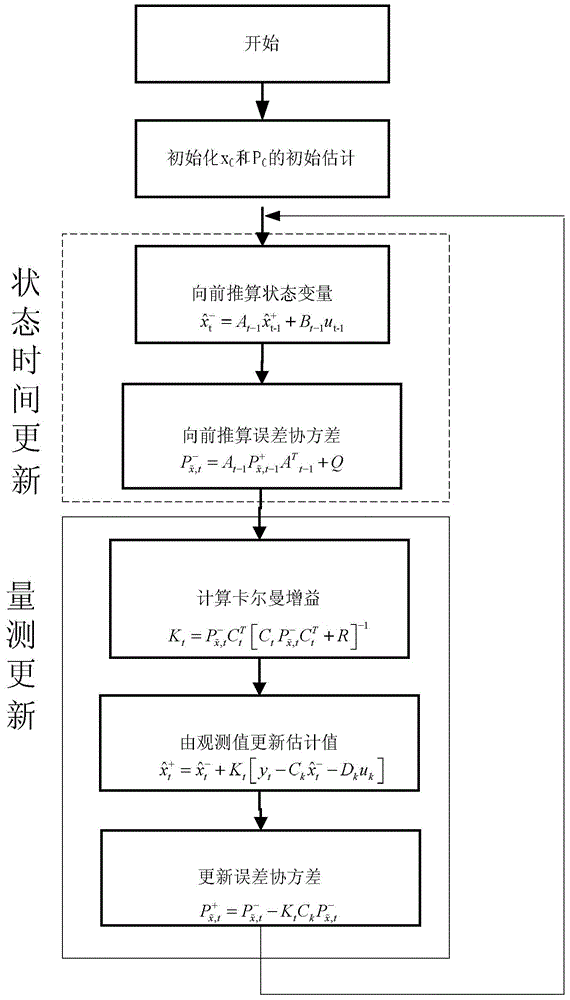

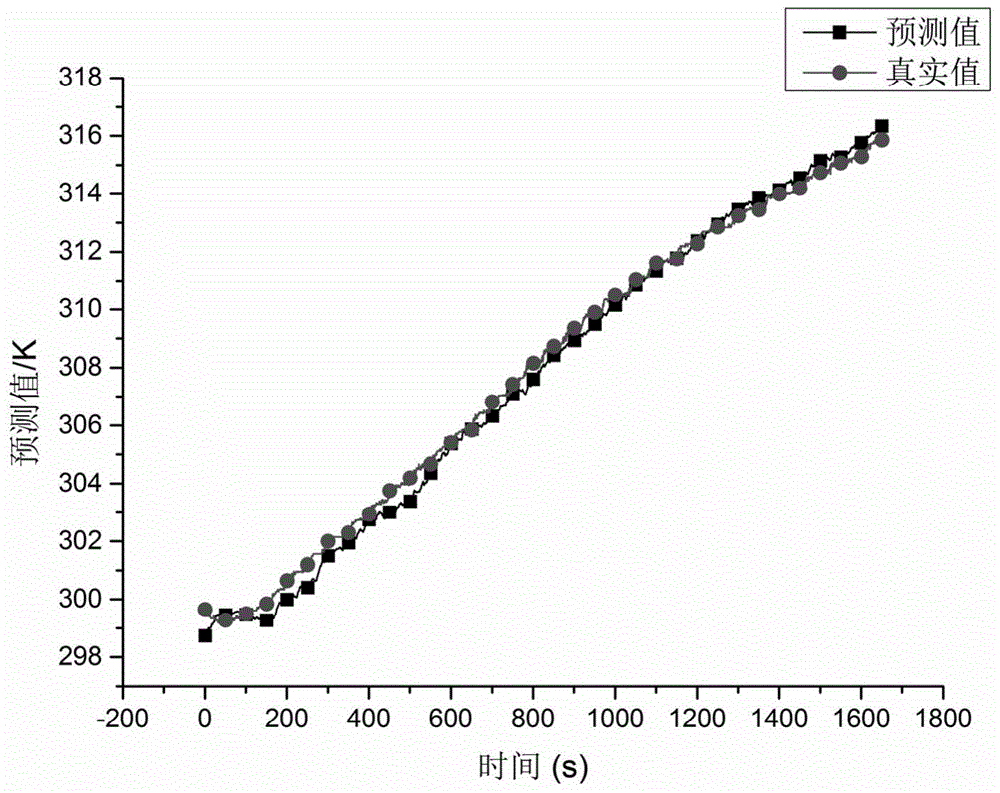

Method for predicting internal temperature of battery in real time

ActiveCN104462847AMonitor temperature in real timeTemperature predictionSpecial data processing applicationsElectrical batteryWorking temperature

The invention provides a method for predicting the internal temperature of a battery in real time, and relates to the real-time prediction methods for the battery. The problem that the actual internal working temperature of the battery can not be embodied by battery surface temperature monitoring is solved. According to the method, the battery is divided into an inner core and an outer shell, temperature prediction models are established respectively, the specific heat capacity of the internal material and the surface material of the battery, the thermal-resistance parameter of the inner core-outer shell of the battery, the thermal-resistance parameter of the outer shell-the outside of the battery, the open-circuit voltage curve of the battery, the curve of the open-circuit voltage variation with temperature and the like are acquired by an experiment method. A Kalman filtering method is used for tracking and correcting the internal temperature of the battery in real time, real-time battery surface and environment temperatures are input into the predication models, and the internal temperature of the battery is predicted in real time. The method is suitable for predicting the internal temperature of the battery in an electrical automobile and an energy storage system.

Owner:HARBIN INST OF TECH

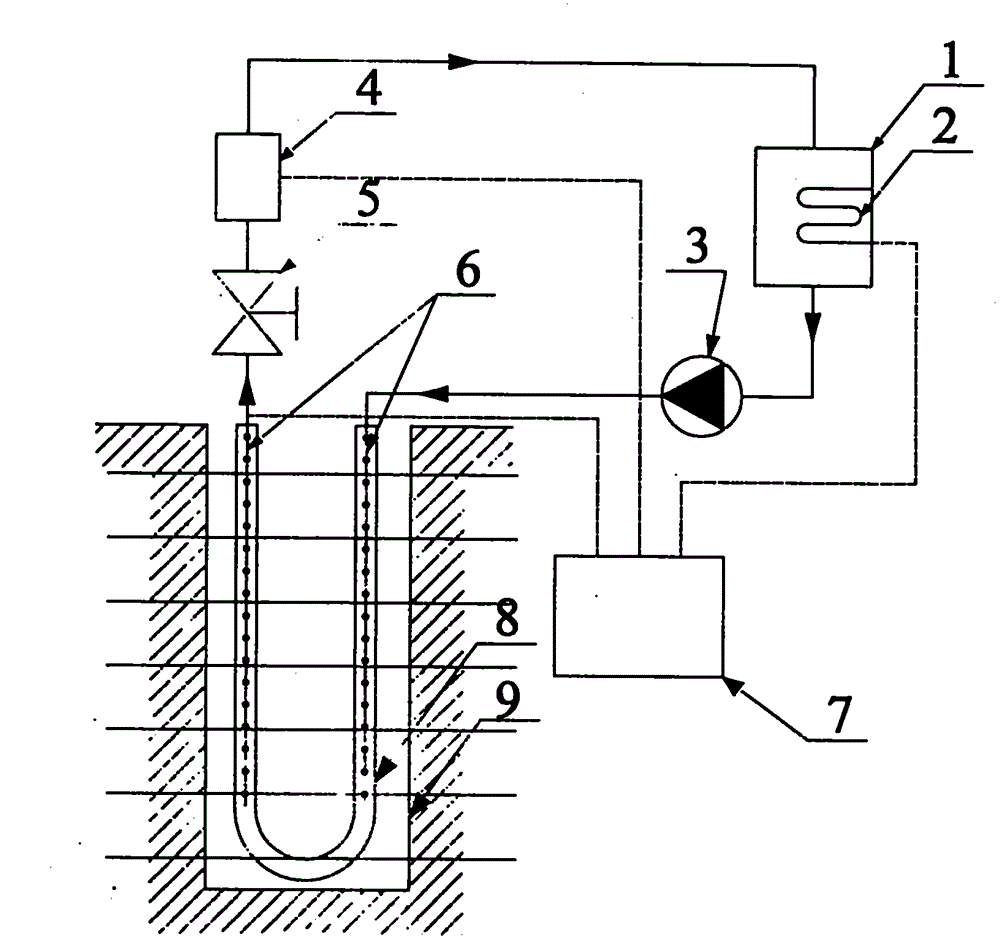

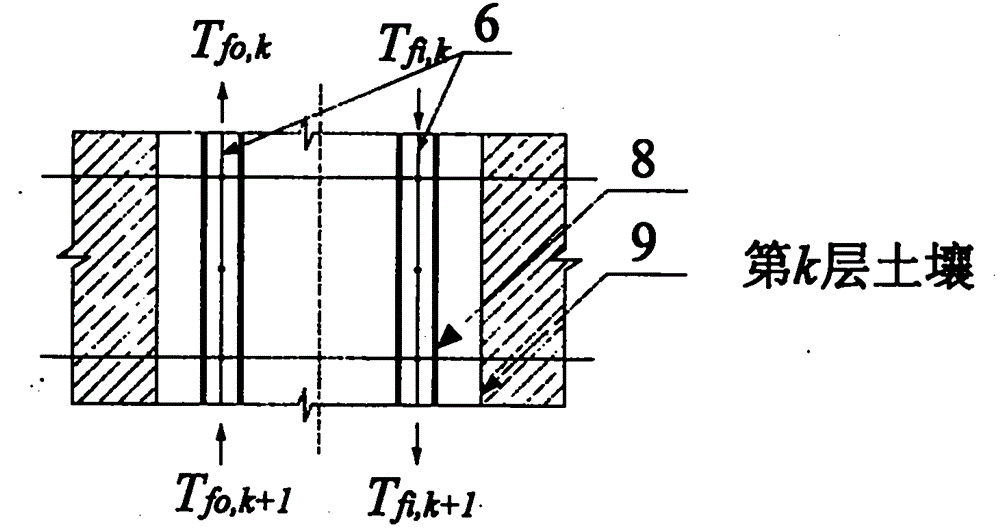

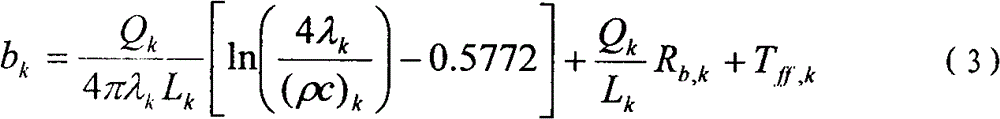

In-situ thermal response testing method of stratified thermal properties of underground rock and soil

InactiveCN102721722AAccurate dataHigh sensitivityMaterial heat developmentThermal response testGround testing

The invention relates to an in-situ thermal response testing method of stratified thermal properties of underground rock and soil. The invention relates to an in-situ thermal response testing device of the stratified thermal properties of the underground rock and soil. According to the in-situ thermal response testing device disclosed by the invention, a U-shaped pipe is buried, an optical fiber temperature sensor is inserted into two branch pipes of the U-shaped pipe, the U-shaped pipe is connected with an inlet and outlet of a circulating water pipeline of a ground testing device, water temperatures in the two branch pipes, namely the water inlet branch pipe and the water outlet branch pipe of the U-shaped pipe in different depth layers are respectively measured, the power of a heater is kept constant, and measured data of the water temperatures and the flow rates of circulating water in the two branch pipes of the U-shaped pipe in different depth layers at different times, as well as the corresponding heating power of the heater is recorded, so that a heat conduction coefficient, volume specific heat and a drilling thermal resistance value of soil in each layer can be obtained. According to the in-situ thermal response testing device disclosed by the invention, the defects that the distribution of the thermal properties of the rock and soil in different depths can not be obtained, the testing precision can not be improved, an optimal design method of the underground buried pipe can not be improved and the like in the prior art can be solved; furthermore, values of the thermal properties of the underground rock and soil, the types of the rock and soil, the contents of underground water and the seepage situations in the different depths can be obtained, and the in-situ thermal response testing device further has the advantages of high sensitivity, strong anti-interference property, corrosion resistance, small installation size, no requirements on a power supply and low testing cost.

Owner:YANGZHOU UNIV

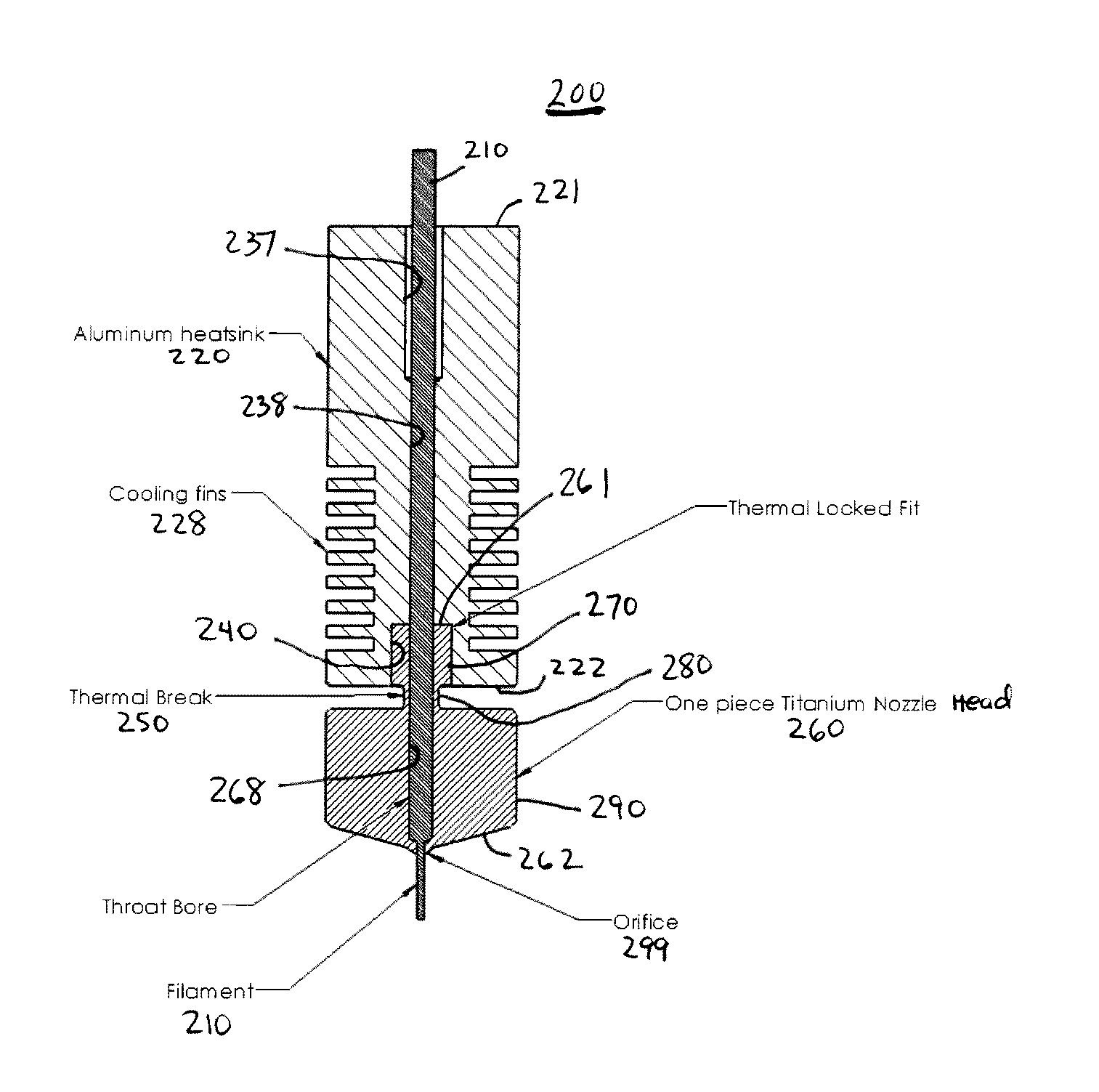

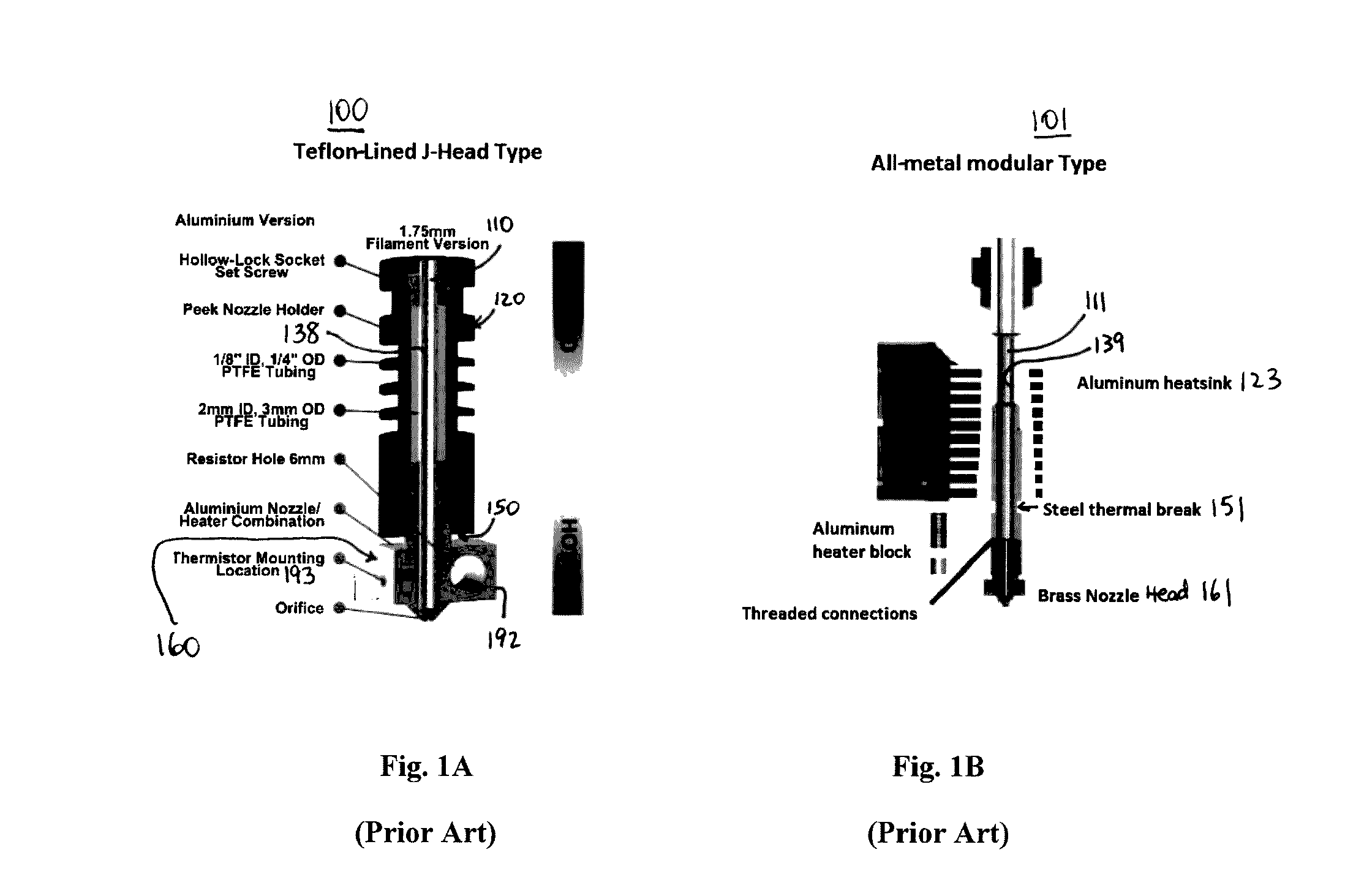

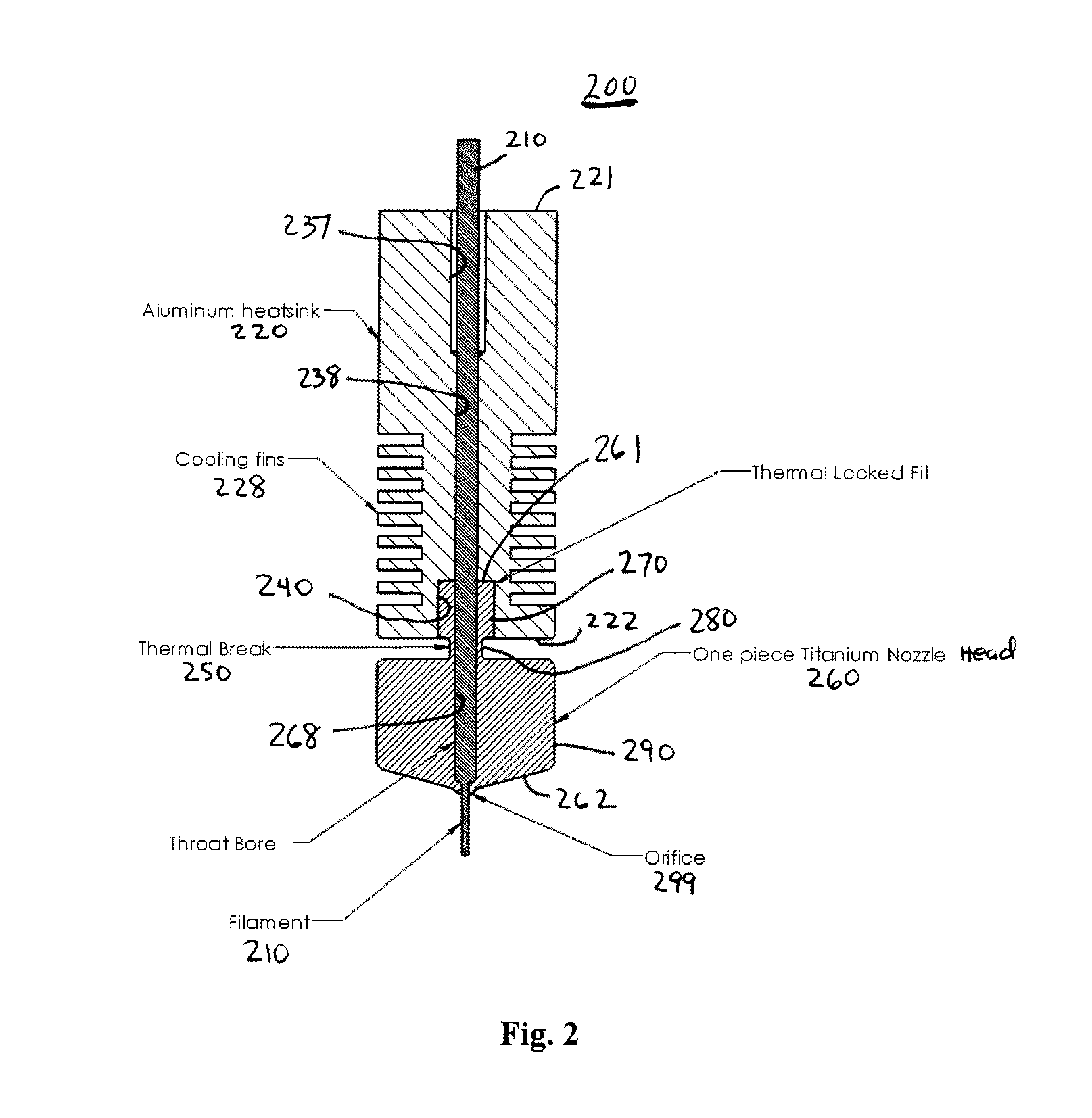

Nozzle system with monolithic nozzle head for fused filament fabrication additive manufacturing and method of manufacturing same

ActiveUS20170057168A1Additive manufacturing with liquids3D object support structuresFused filament fabricationSystems design

A nozzle system and method of manufacturing a nozzle system for use in an additive manufacturing system for fabricating an object is disclosed. The nozzle system includes a monolithic nozzle head designed such that the thermal locking member, neck member, and nozzle member of the nozzle head are manufactured into one component. The nozzle head is made of a material that has a high specific heat capacity but low thermal heat conductivity. The result is a nozzle system design that virtually eliminates heat migration from the nozzle head to the heat sink, and thereby improves the overall quality of polymer filament deposition during printing.

Owner:COSINE ADDITIVE INC

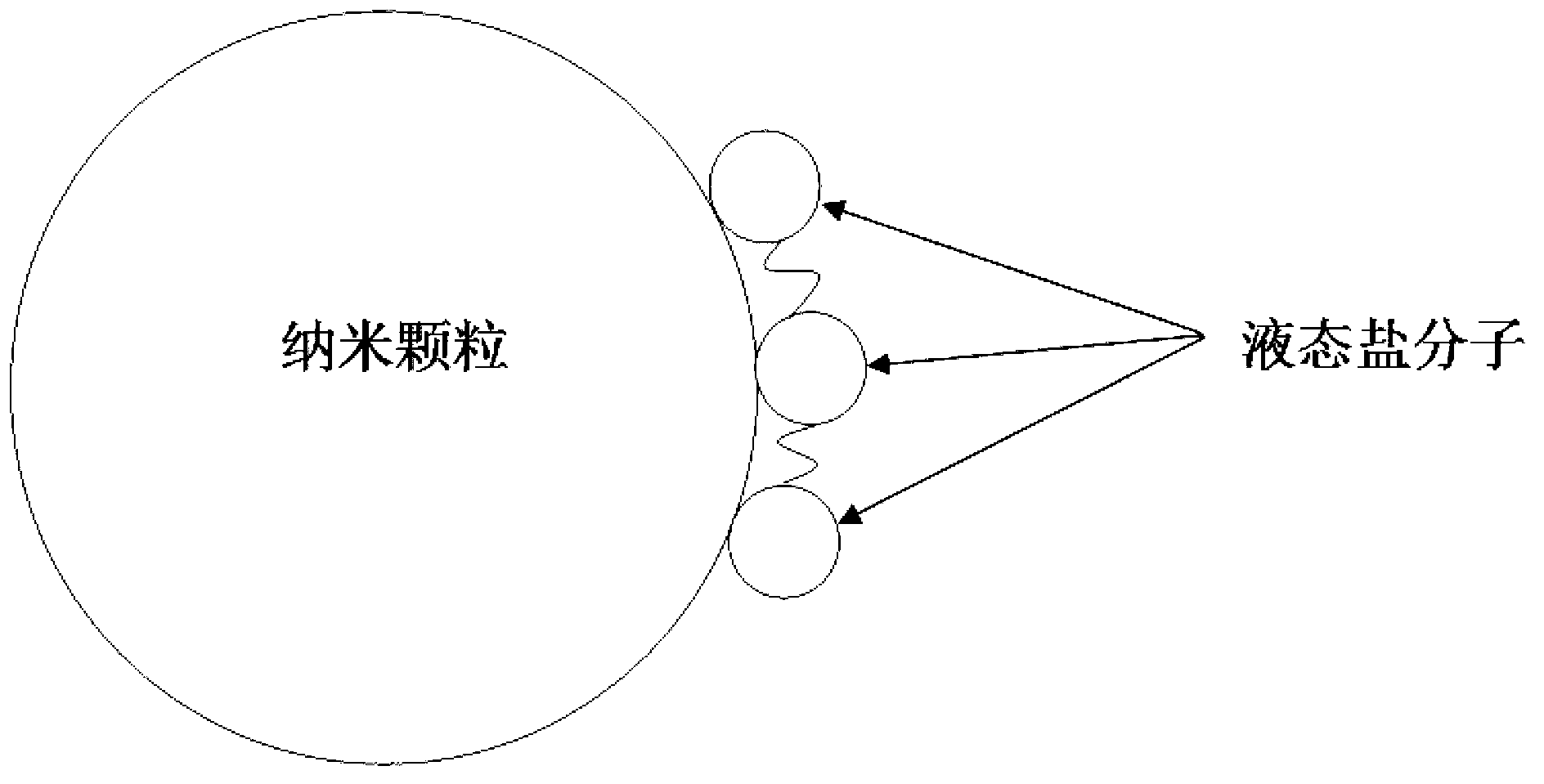

High-thermal-conductivity heat-storing nanometer-particle-mixed molten salt and preparation method thereof

InactiveCN103289653ASmall temperature fluctuationsImprove heat storage capacityHeat-exchange elementsHeat stabilitySolar power

The invention relates to the heat-storing field of solar thermal power generation, especially to a high-thermal-conductivity heat-storing nanometer-particle-mixed molten salt, and a preparation method thereof. The molten salt consists of a sold heat-storing molten salt, a dispersant and nanometer particles, wherein the dispersant and the nanometer particles disperse uniformly in the heat-storing molten salt and a eutectiform structure is formed, and the nanometer particles coat the surface of the heat-storing molten salt crystal particle. By adding the nanometer particles into the sold heat-storing molten salt, and by utilizing quantum size effect, surface effect, small size effect and the like possessed by the nanometer particles, the thermal physical property of the molten salt as a heat-storing medium has a substantial change. The preparation method is simple in technological process and low in cost, can help to substantially promote heat conductivity and specific heat capacity of the conventional heat-storing molten salt and substantially improve heat stability of the molten salt in a high temperature section, and can help to promote a heat storage capacity and system security of a concentrating solar power generation system and reduce costs of construction and operation of a power station.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Device for heating, cooling and producing domestic hot water using a heat pump and low-temperature heat store

InactiveUS20090277203A1Low costSmall sizeCentral heating with accumulated heatHeat storage plantsWater useEngineering

A heating device includes a low-temperature heat store thermally coupled to a heat pump. The heat store is a buried pocket containing a permeable material and water. A high heat exchange capacity is thus achieved by exploiting both the high specific heat of the water and the high latent heat of liquefaction of the water contained in the heat store.

Owner:DUPRAZ ENERGIES

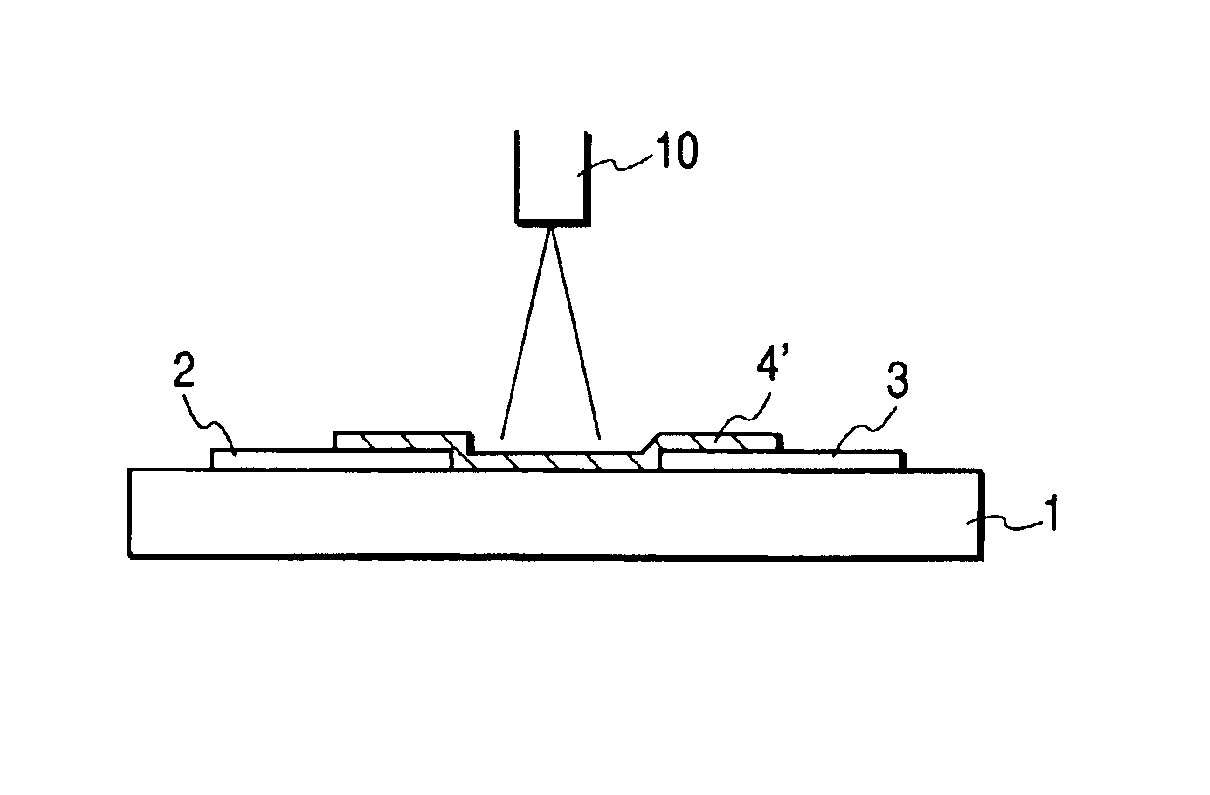

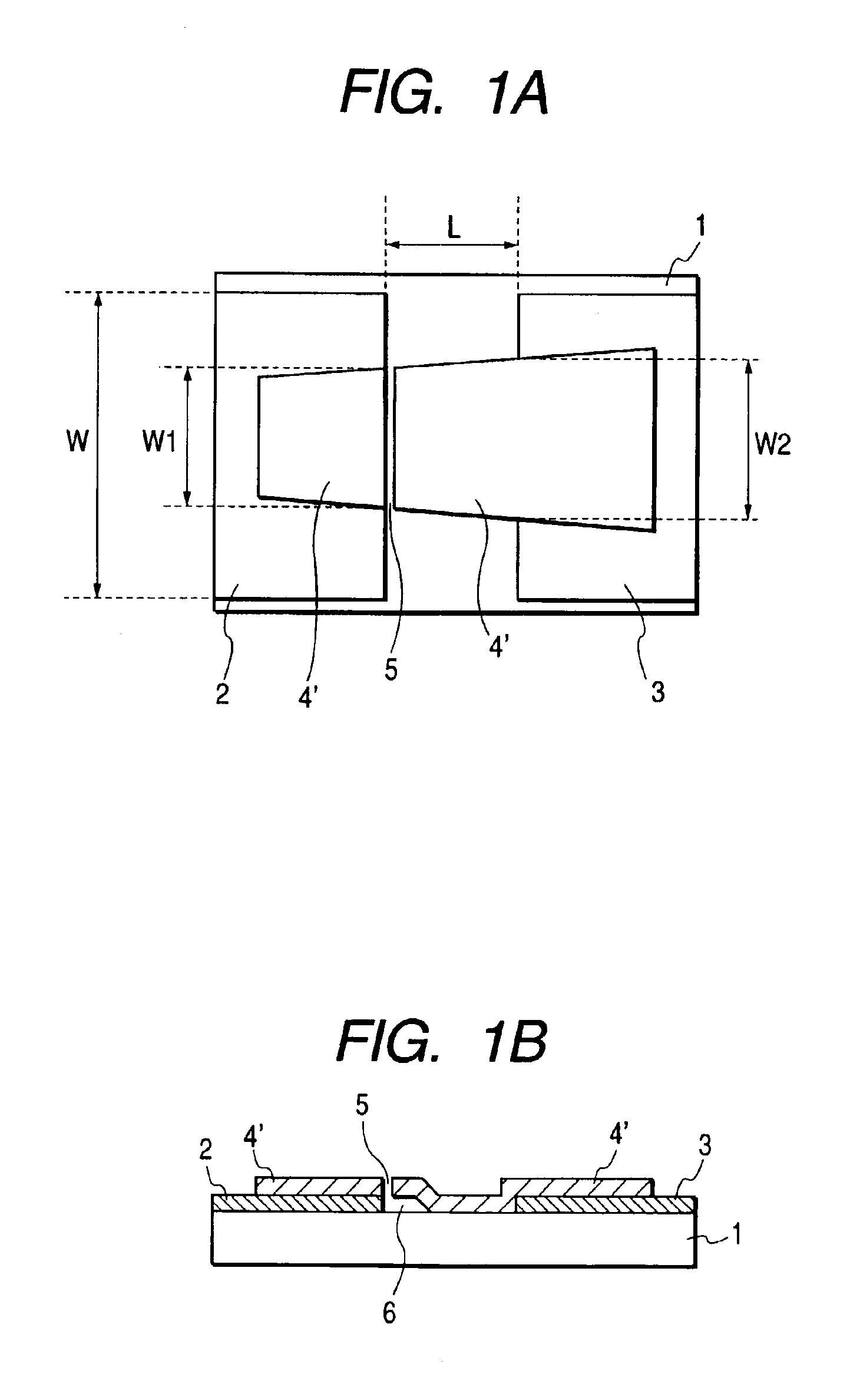

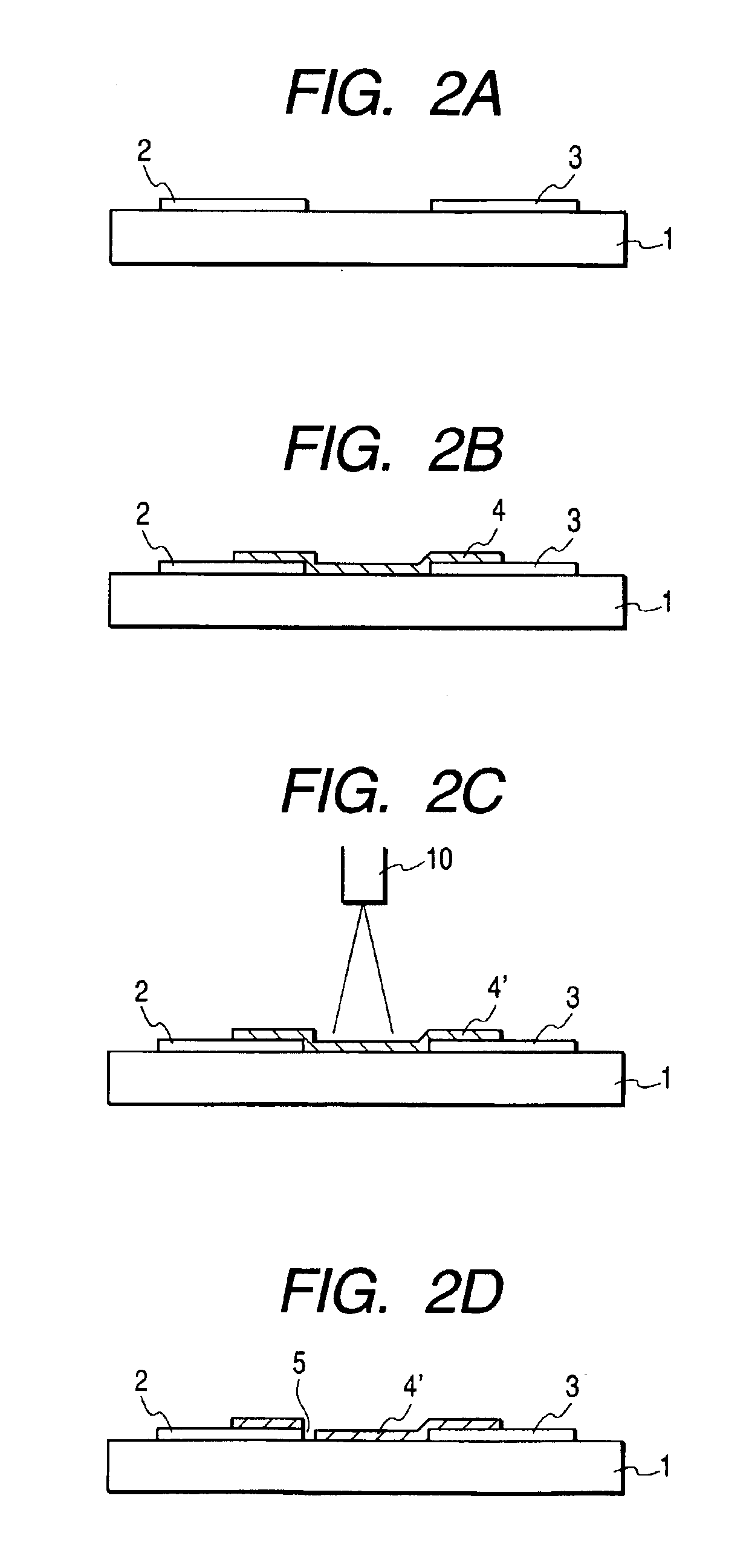

Methods of manufacturing electron-emitting device, electron source, and image display apparatus

InactiveUS6896571B2Save power consumptionImprove featuresSemiconductor/solid-state device manufacturingImage/pattern display tubesElectron sourcePolymer

In a process of reducing a resistivity of a polymer film for carbonization in a surface conduction electron-emitting device, by irradiating an energy beam onto the polymer film, when an energy intensity of the beam given in a unit area in a unit time is assumed to be W W / m2, W satisfies a formula W≧2×T×(ρsub·Csub·λsub / τ)1 / 2, where T is defined as a temperature ° C. at which the polymer film is heated for one hour in a vacuum degree of 1×10−4 Pa to reduce a resistivity of the polymer film to 0.1 Ω·cm, Csub is a specific heat J / kg·K of the substrate, ρsub is a specific gravity kg / m3 of the substrate, λsub is a heat conductivity W / m·K of the substrate, and τ is an irradiation time in the range of 10−9 sec to 10 sec.

Owner:CANON KK

Method for preparing microcrystalline foam glass by using high titanium blast furnace slag and waste glass powder

The invention discloses a method for preparing microcrystalline foam glass by using high titanium blast furnace slag and waste glass powder. The method comprises the following steps: grinding the high titanium blast furnace slag and waste glass powder, uniformly and fully mixing the high titanium blast furnace slag, the waste glass powder, a fluxing agent, a foaming agent and a foam stabilizer, pressing into a block, adding the mixture block into a heating device and preparing the microcrystalline foam glass at a low temperature according to a specific heat treatment process by using a one-step sintering method. According to the characteristic that the high titanium blast furnace slag which is rich in TiO2 can serve as a nucleation agent, the low-melting-point waste glass powder serves as a silicious raw material, a proper amount of corresponding fluxing agent and sintering process are matched, the preparation temperature is greatly reduced, and the preparation can be finished through one-step sintering; and therefore, the energy consumption can be reduced, the process is simplified, the cycle is shortened, the cost is saved, the product which is uniform in cells, moderate in cell diameter, low in volume density, low in water absorption rate, good in thermal insulation effect and high in mechanical strength can be obtained, and the additional value of high titanium blast furnace slag utilization is improved.

Owner:SICHUAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com