Patents

Literature

54results about How to "High flow accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

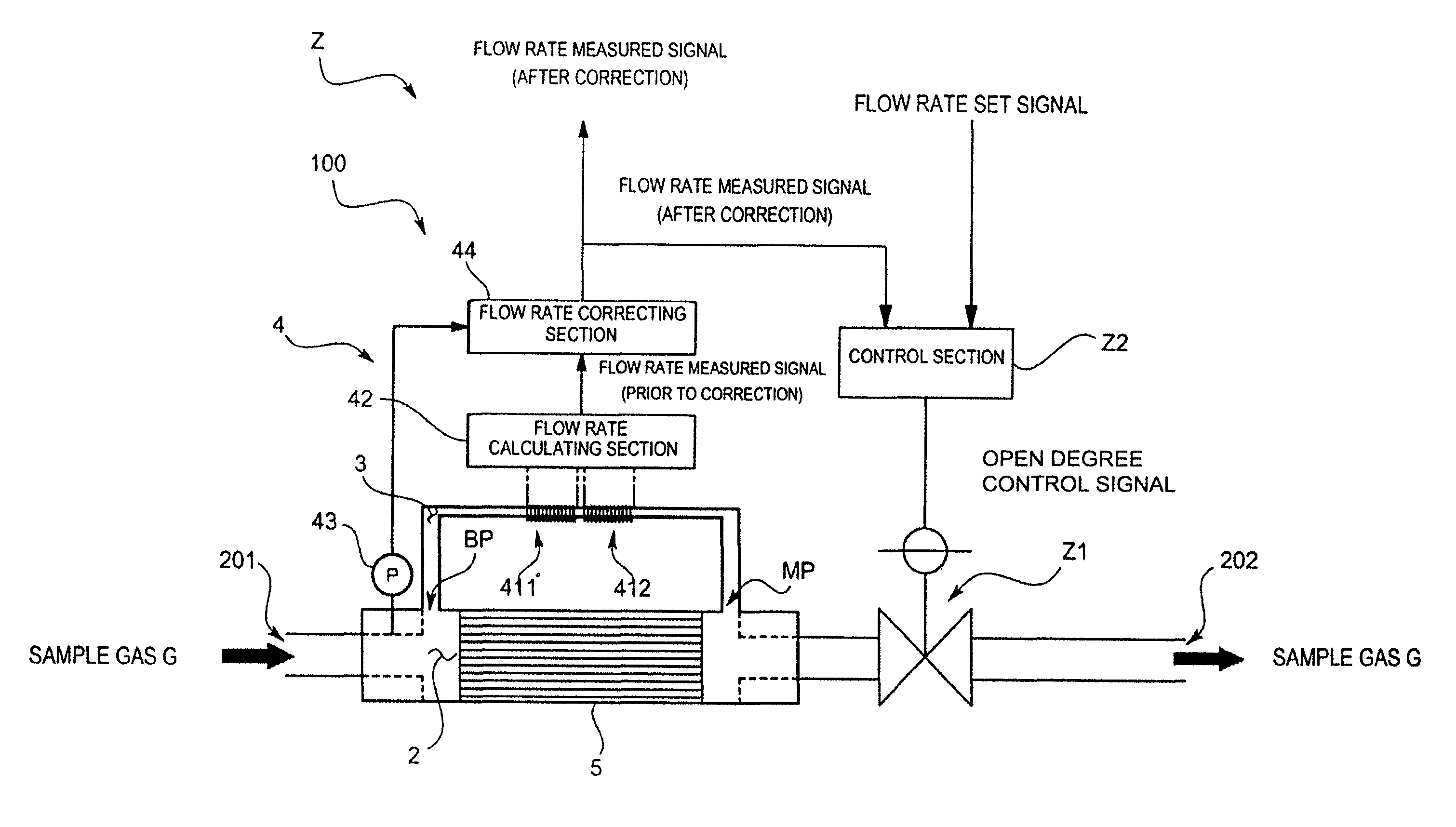

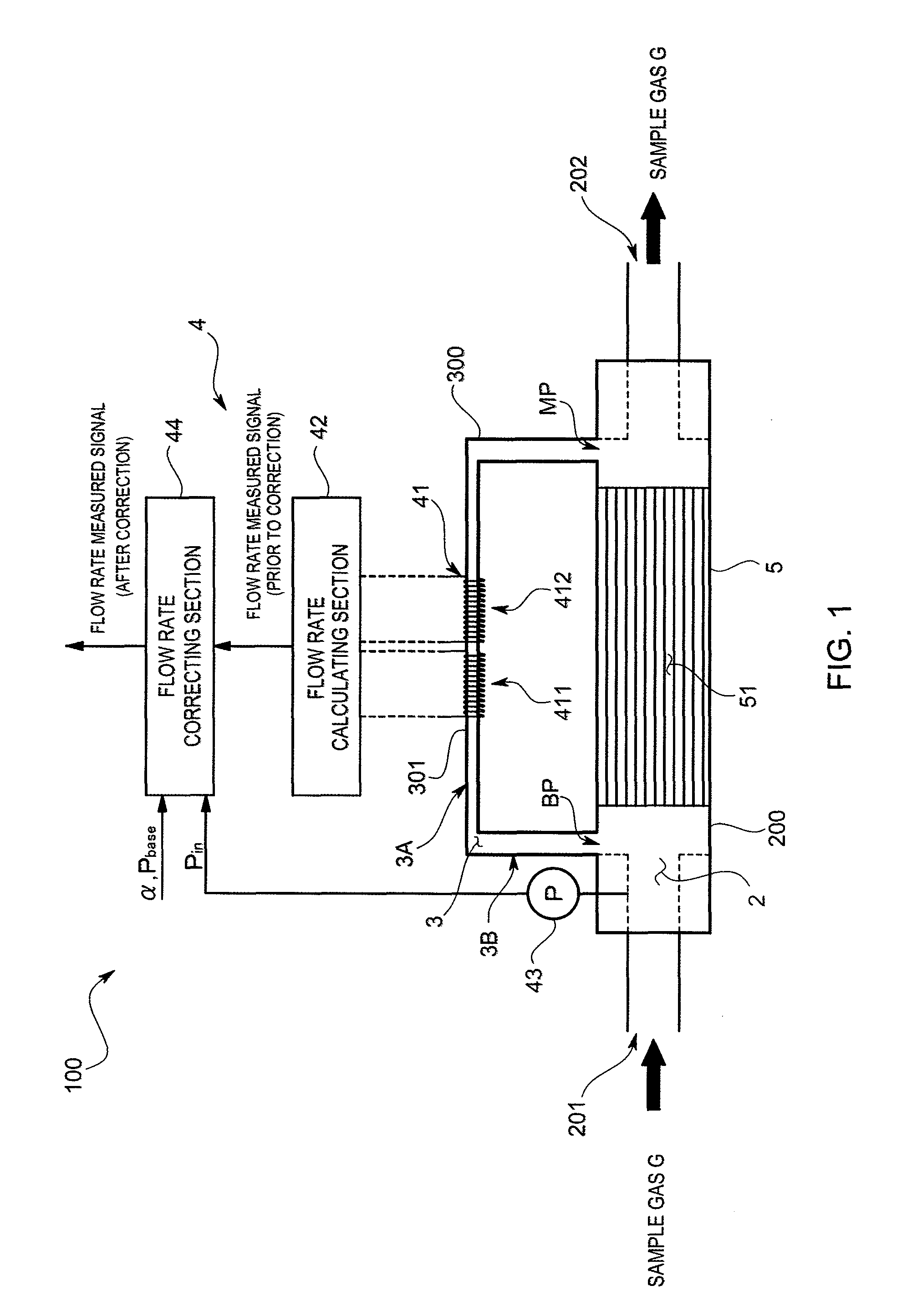

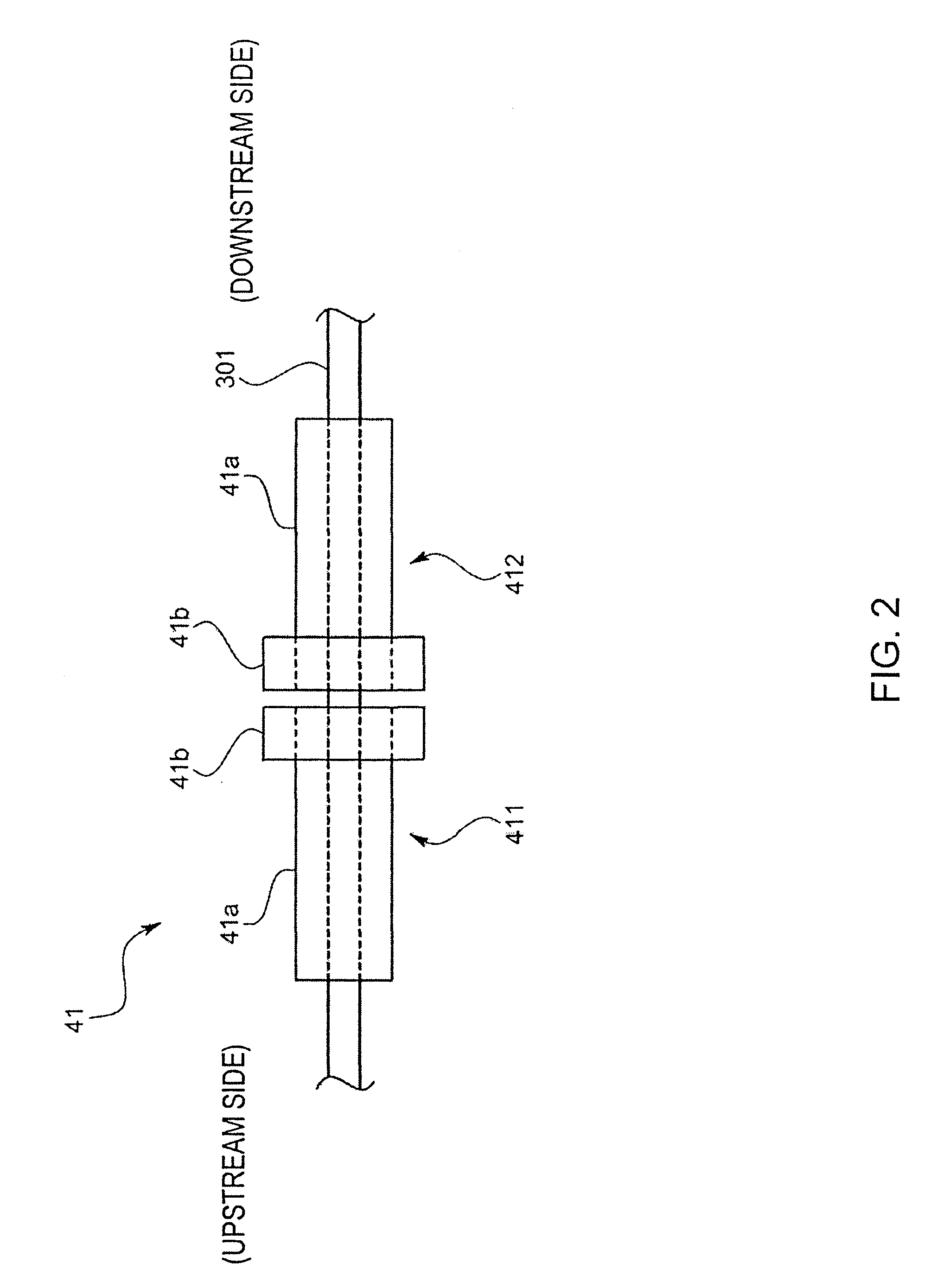

Mass flow meter and mass flow controller

ActiveUS8356623B2Reduce measurement errorHigh flow accuracyOperating means/releasing devices for valvesVolume/mass flow by thermal effectsEngineeringStreamflow

In order to improve a measurement accuracy of a mass flow meter, the mass flow meter comprises a flow rate calculating section that obtains an output signal from a sensor section having a thermosensitive resistive element arranged in a flow channel where a sample gas flows and that calculates a flow rate of the sample gas, a pressure measuring section that measures a primary side pressure in the flow channel, and a flow rate correcting section that corrects the measured flow rate obtained by the flow rate calculating section by the use of the primary side pressure obtained by the pressure measuring section and a gas coefficient determined by an isobaric specific heat of the sample gas.

Owner:HORIBA STEC CO LTD

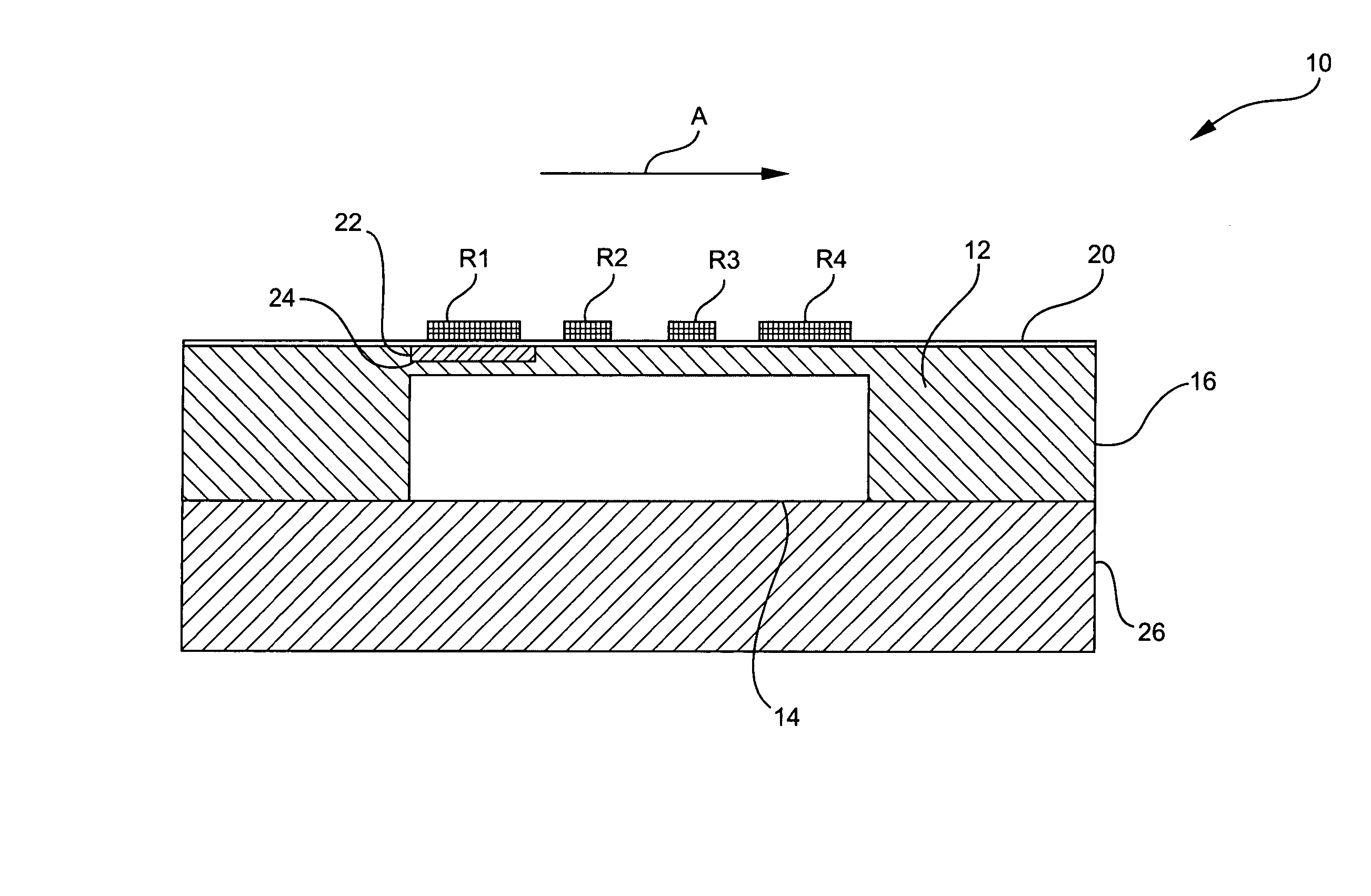

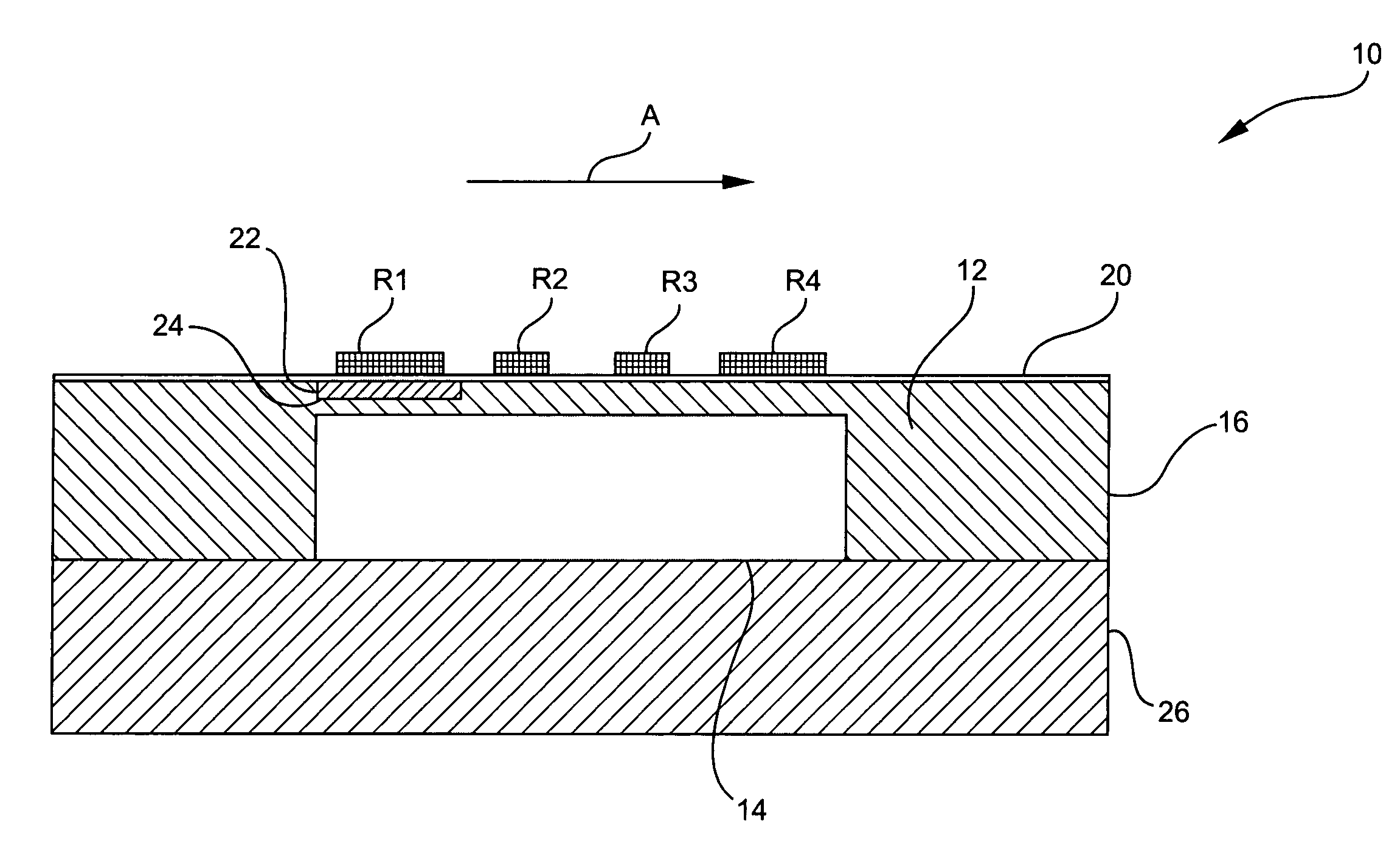

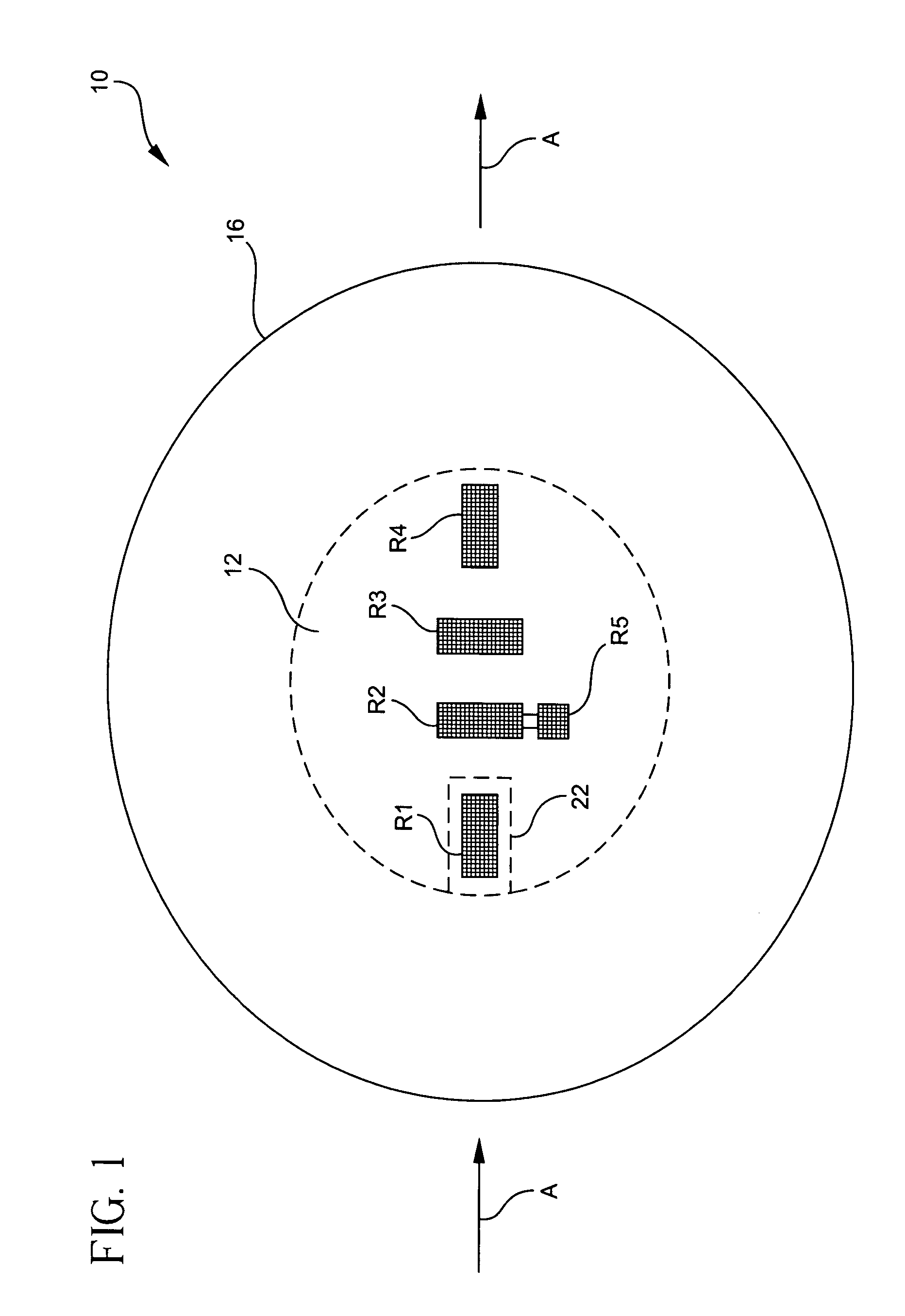

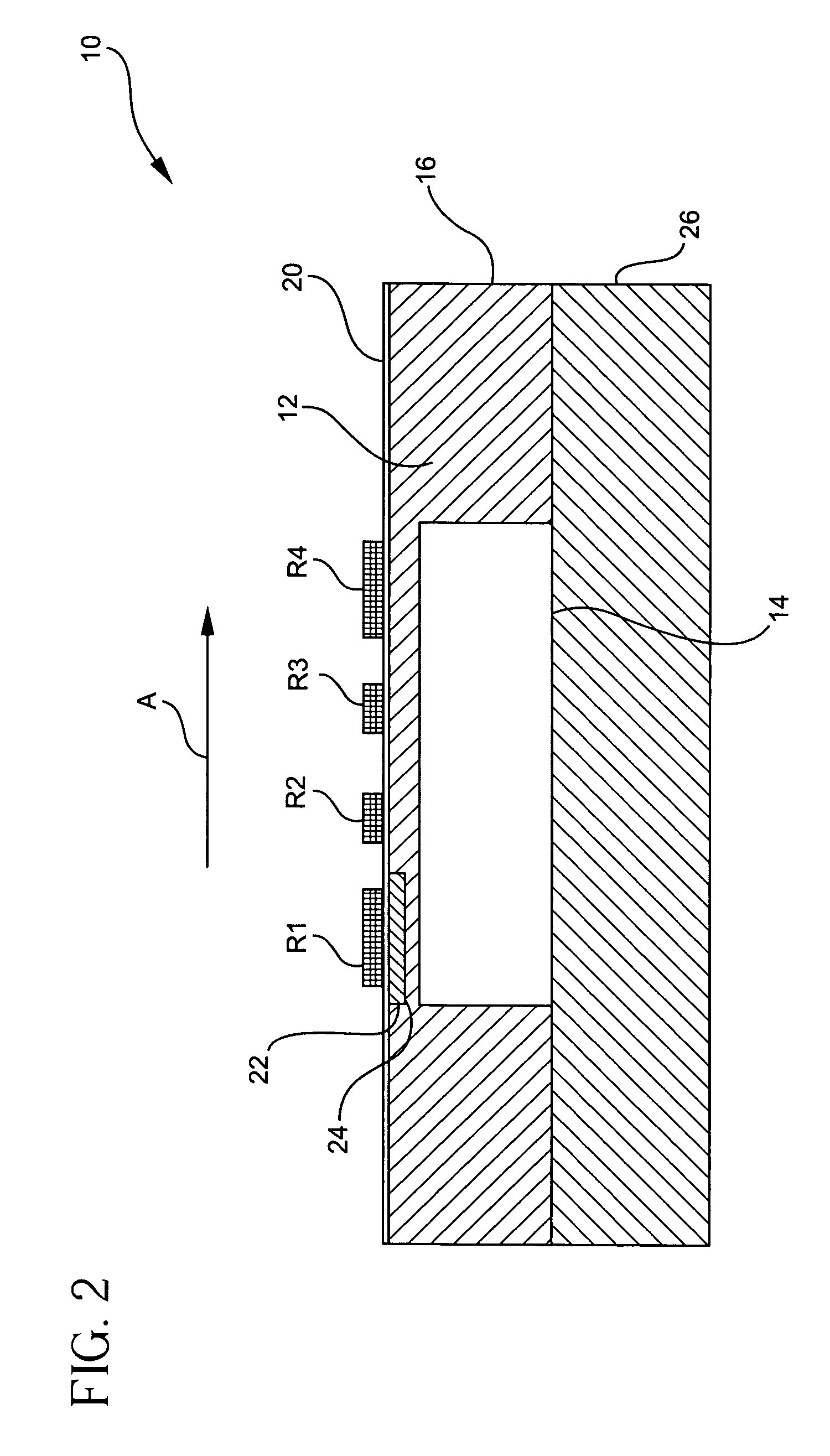

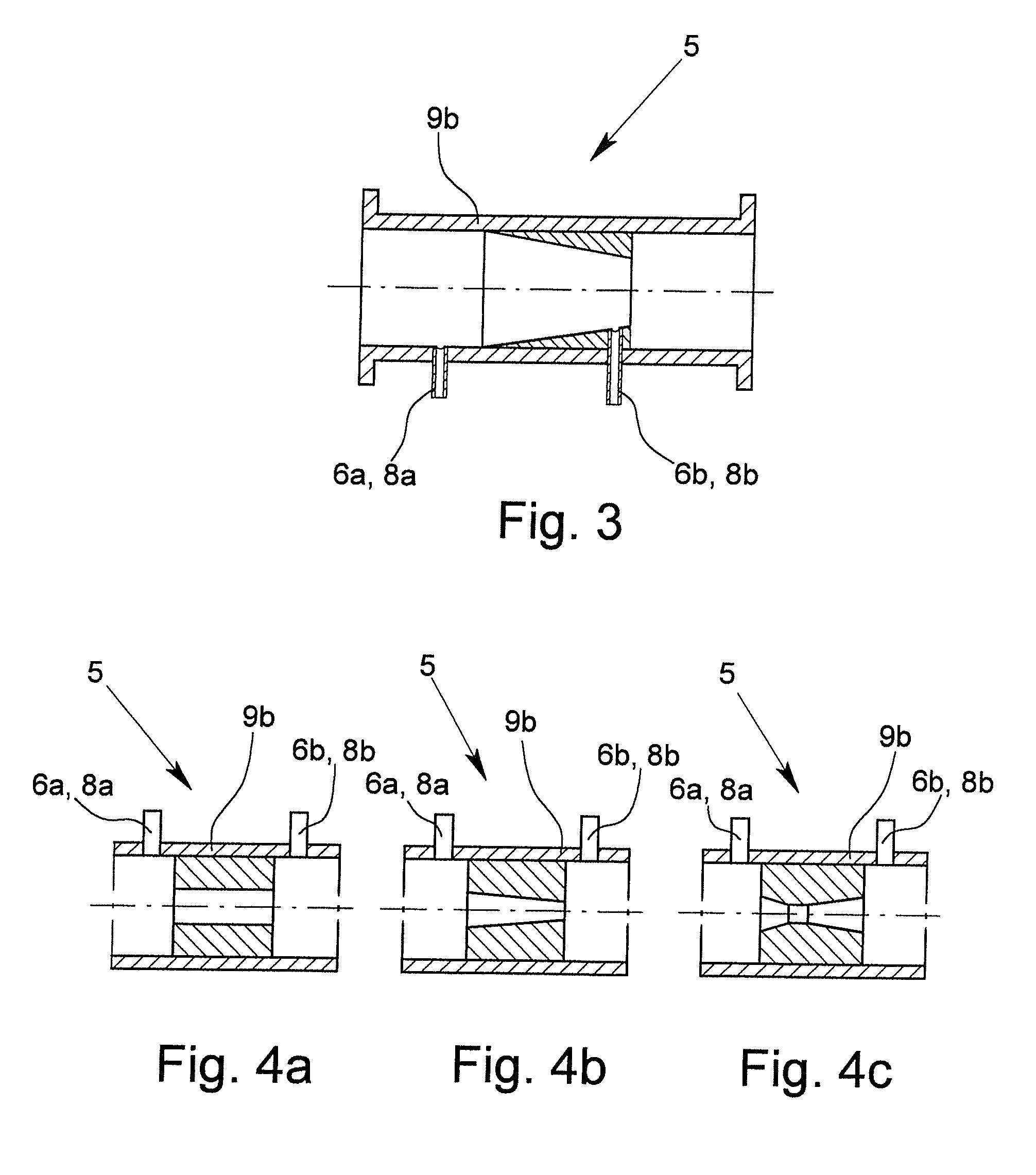

Multiple technology flow sensor

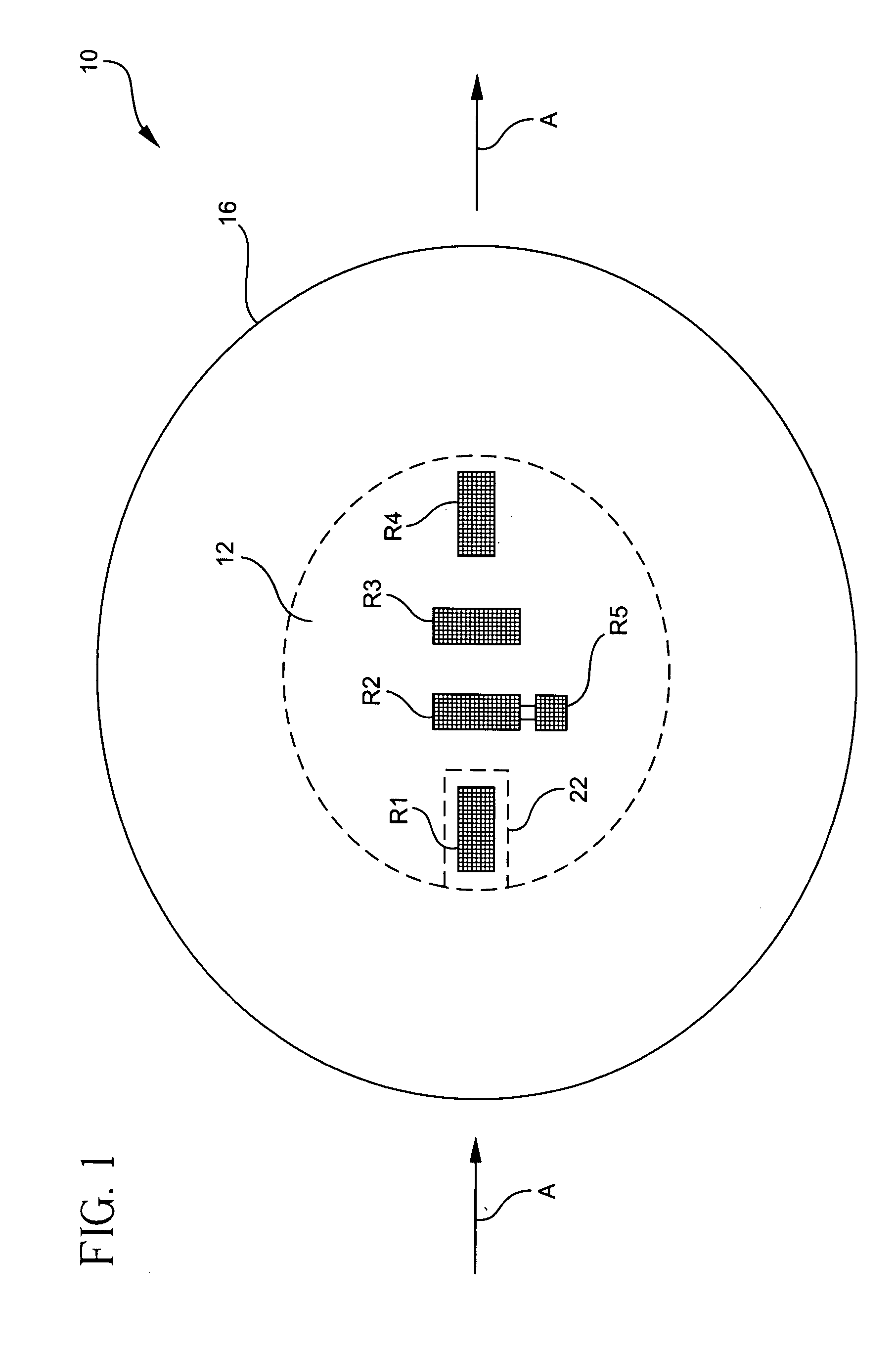

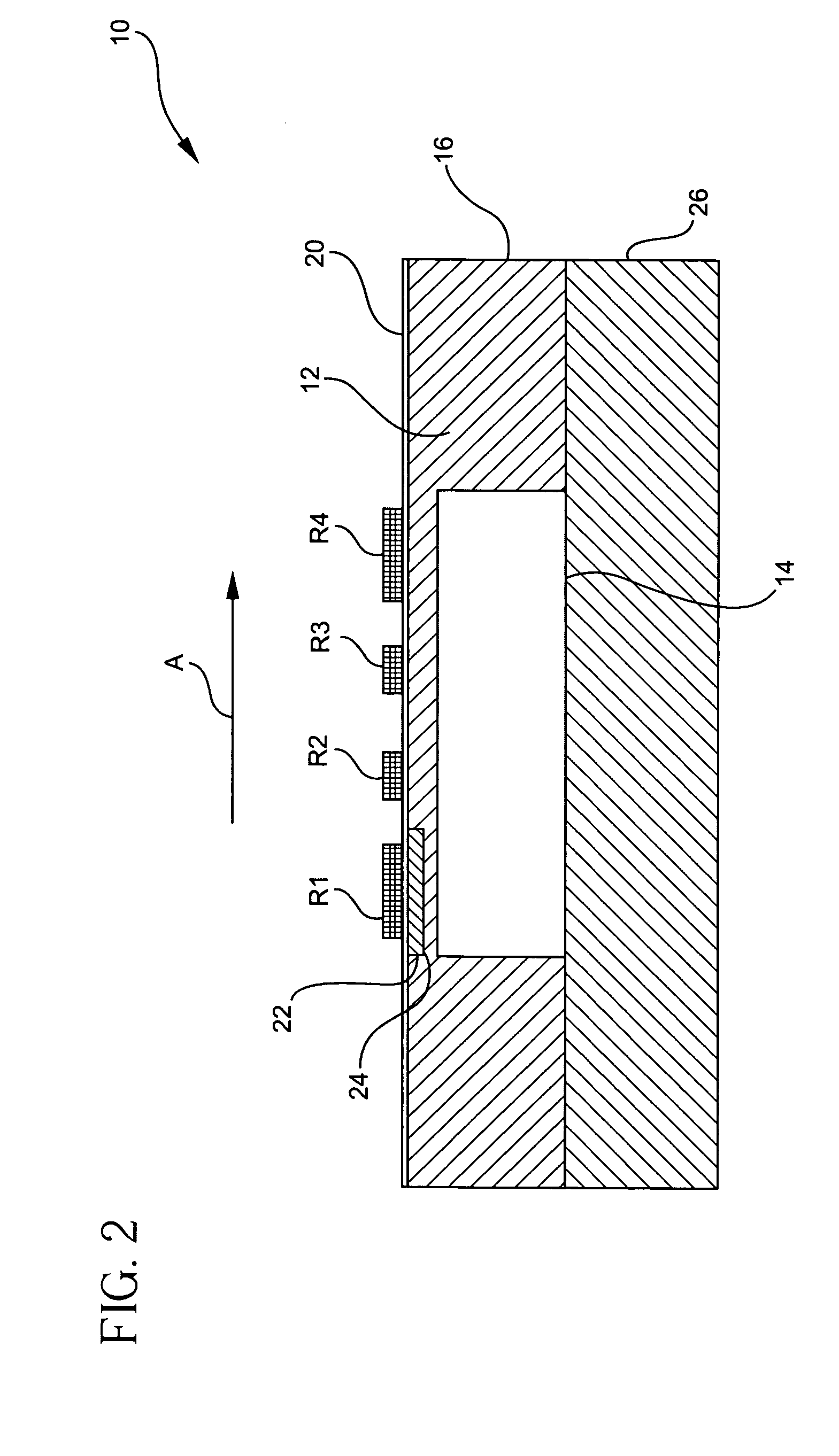

InactiveUS20050081621A1High flow accuracySmall sizeVolume/mass flow by thermal effectsFluid pressure measurement using elastically-deformable gaugesMembrane configurationEngineering

A flow sensor includes sensors connected to a flexible membrane. The sensors detect ambient temperature, pressure, and flow rate of a medium. A method of sensing flow rate includes providing the flexible membrane; coupling the plurality of sensors to the flexible membrane; and detecting ambient temperature, pressure, and flow rate of the medium by the sensors. A flow sensing system includes the flow sensor, an operational amplifier, and a closed loop controller. The sensors are connected in a Wheatstone bridge configuration. The operational amplifier is connected to the Wheatstone bridge and outputs a pressure signal representative of the pressure of the medium. The closed loop controller is connected to the operational amplifier and controls a current through a heating element for a resistor in the bridge such that a voltage across the operational amplifier is substantially zero. The output of the closed loop controller represents the flow rate.

Owner:FESTO AG & CO KG

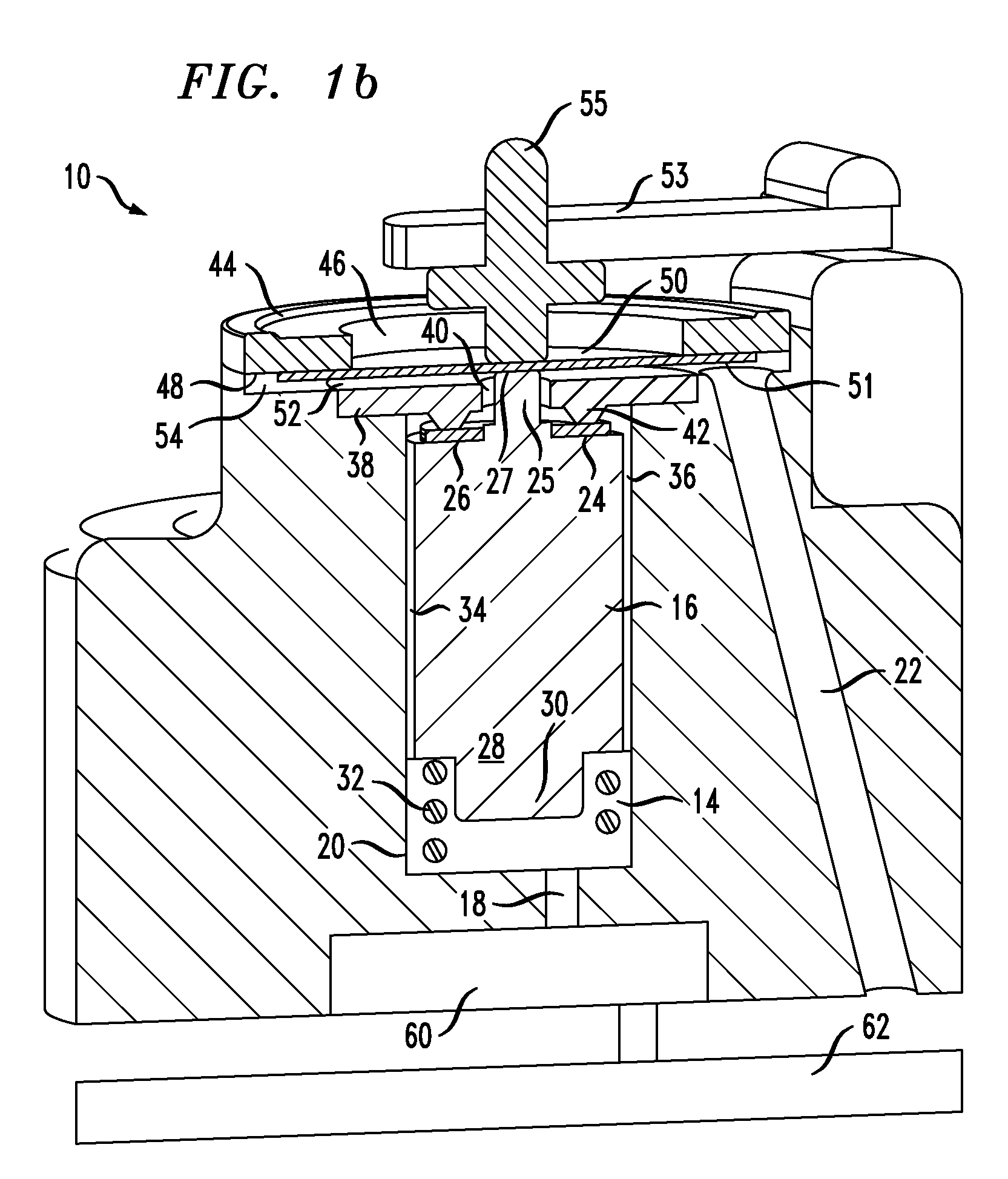

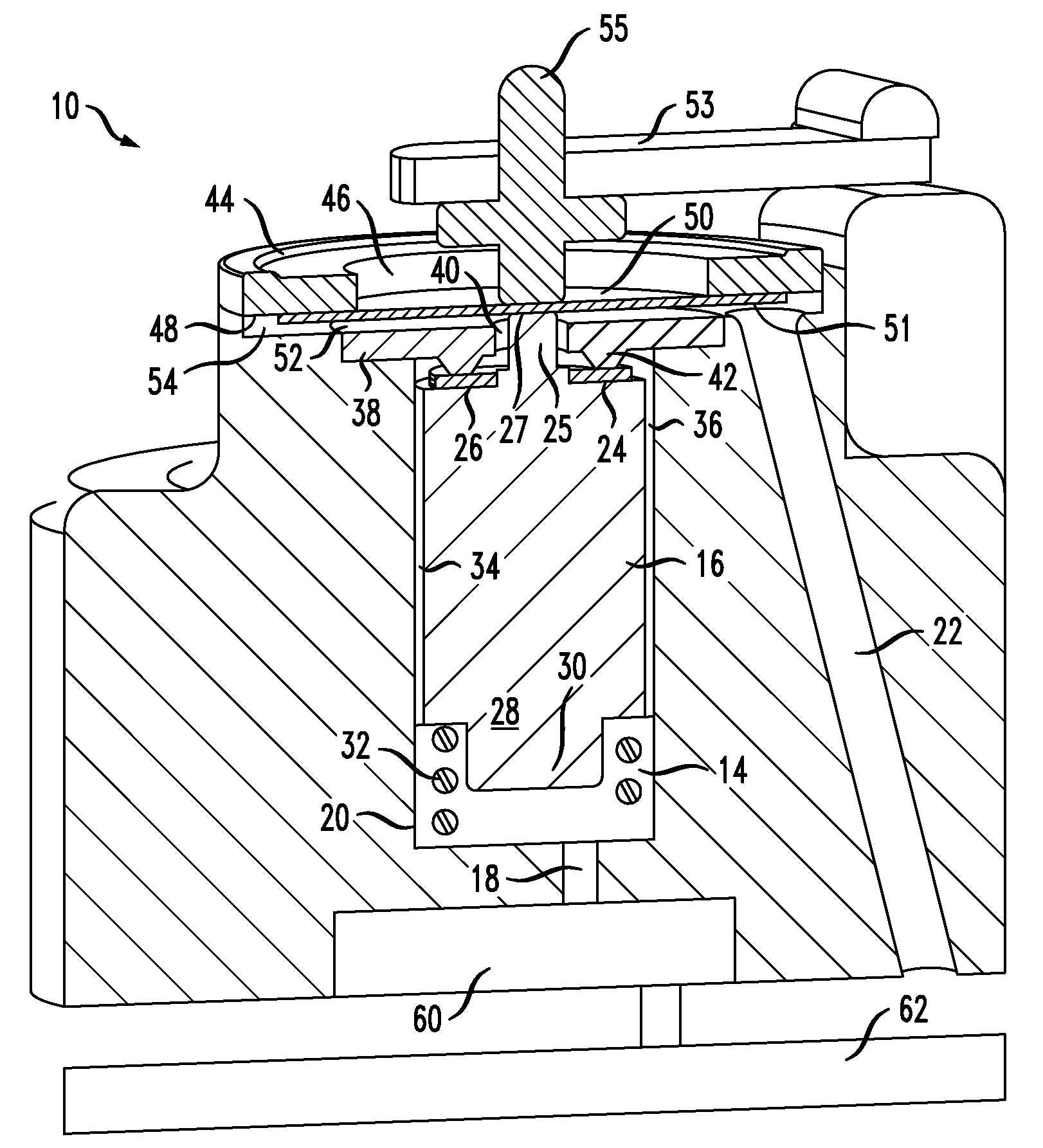

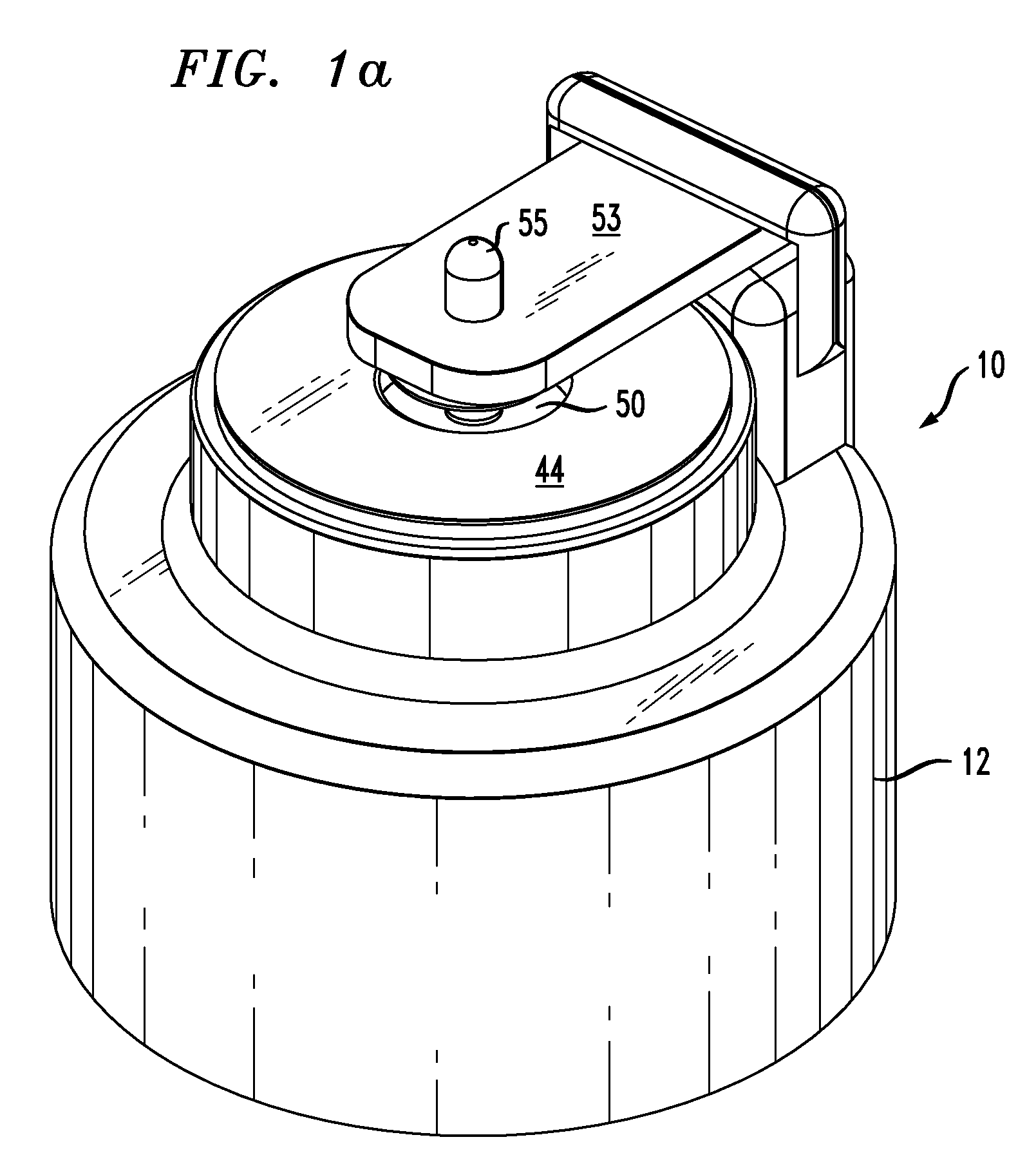

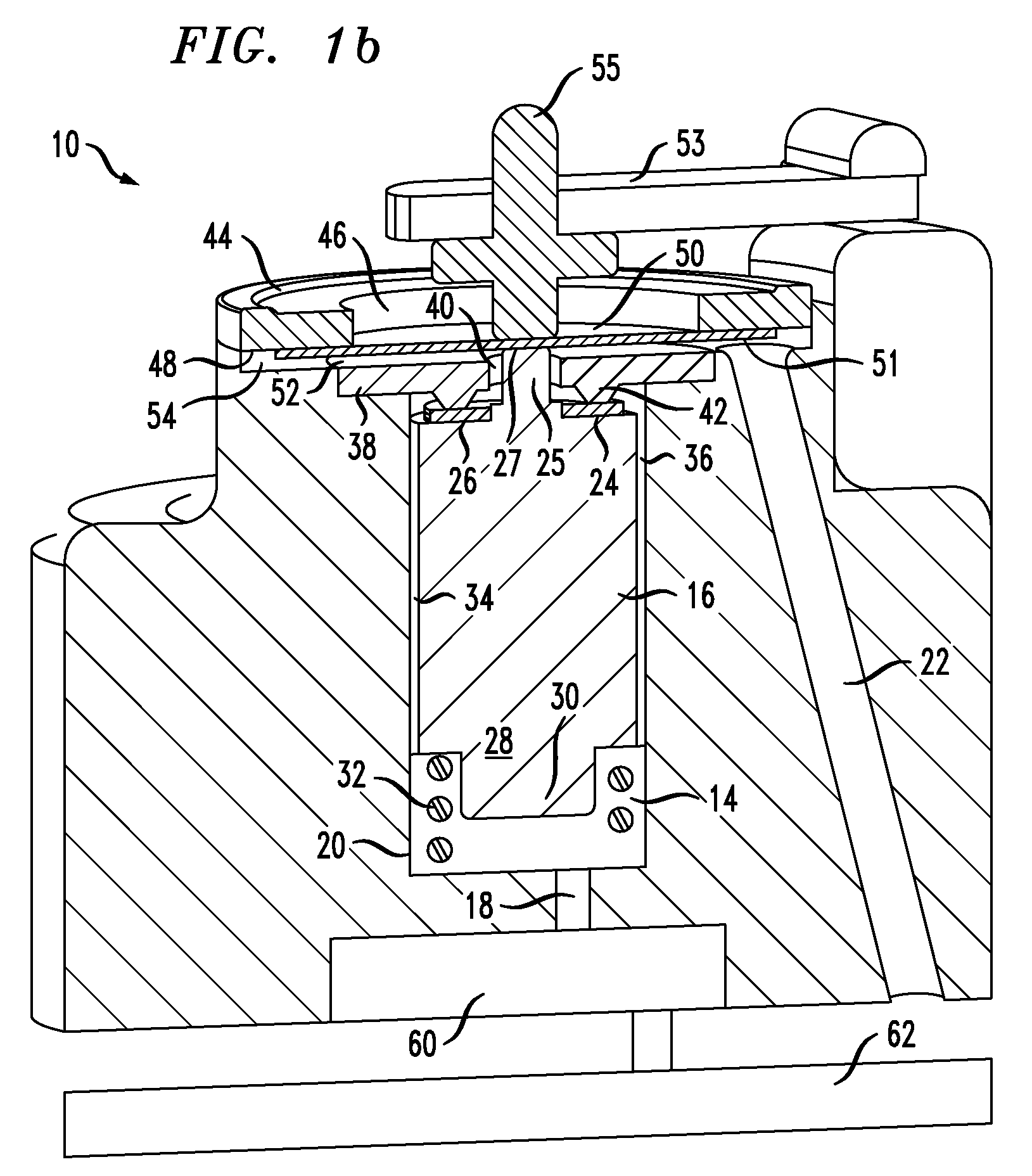

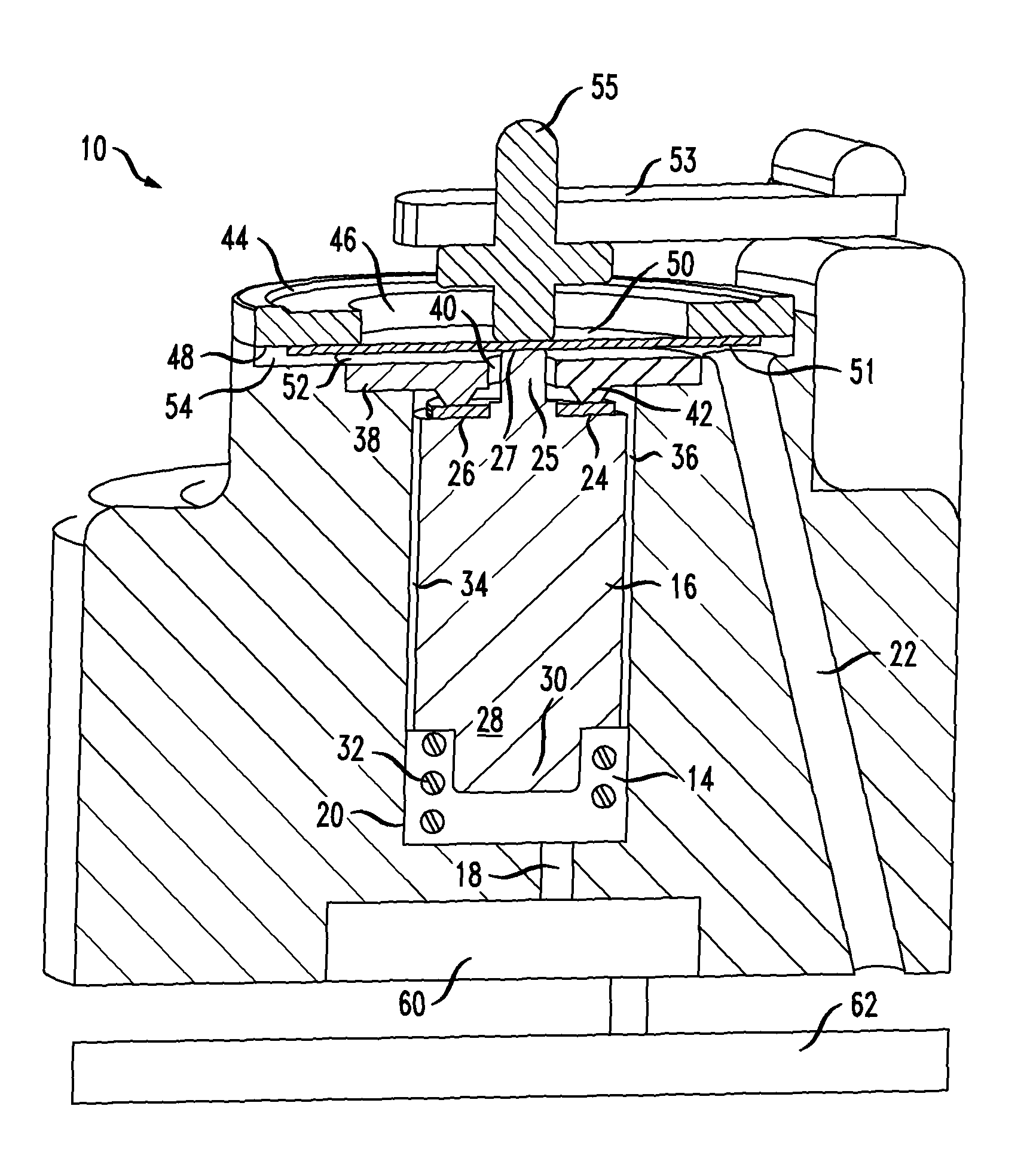

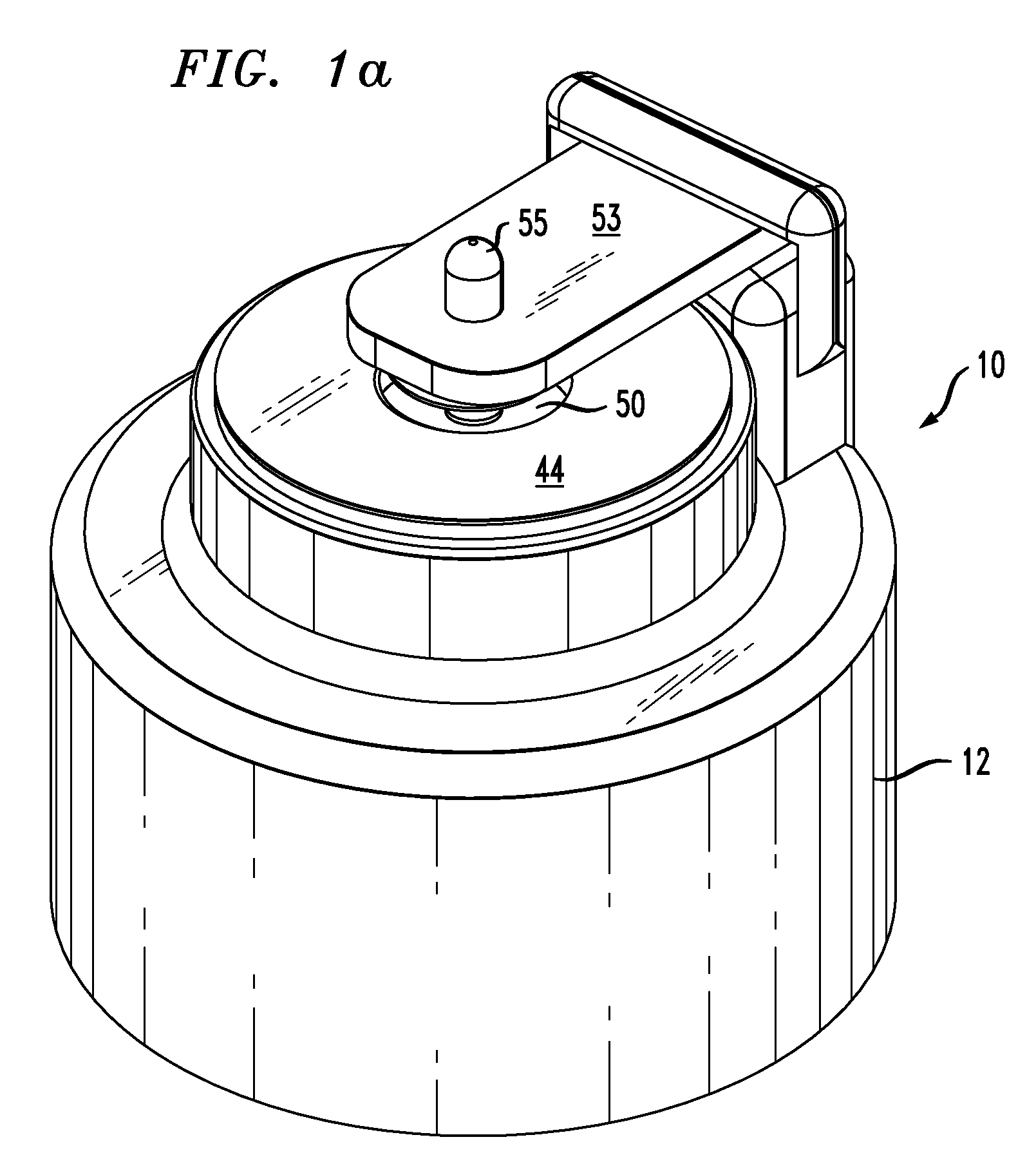

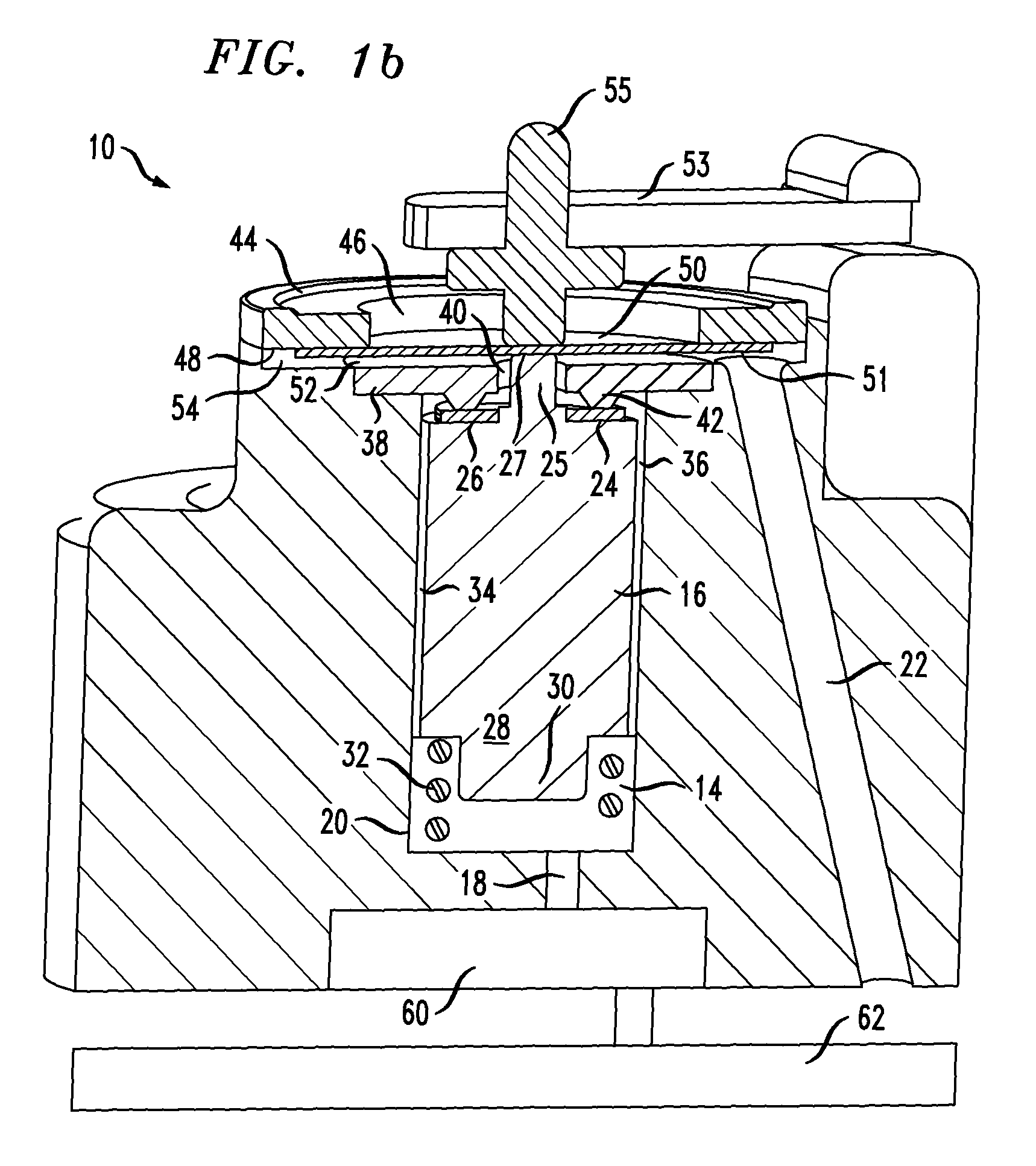

Flow Rate Accuracy of a Fluidic Delivery System

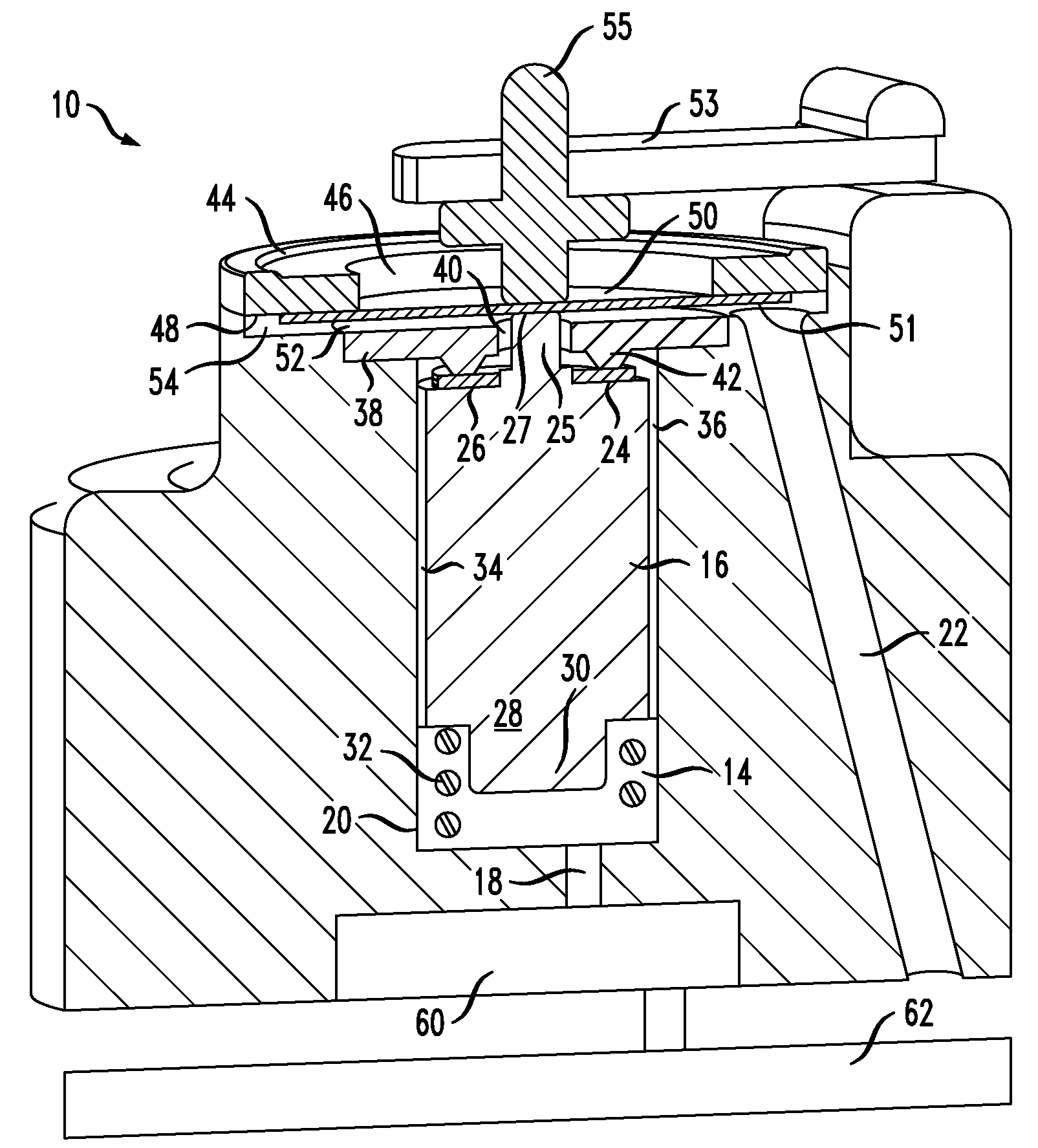

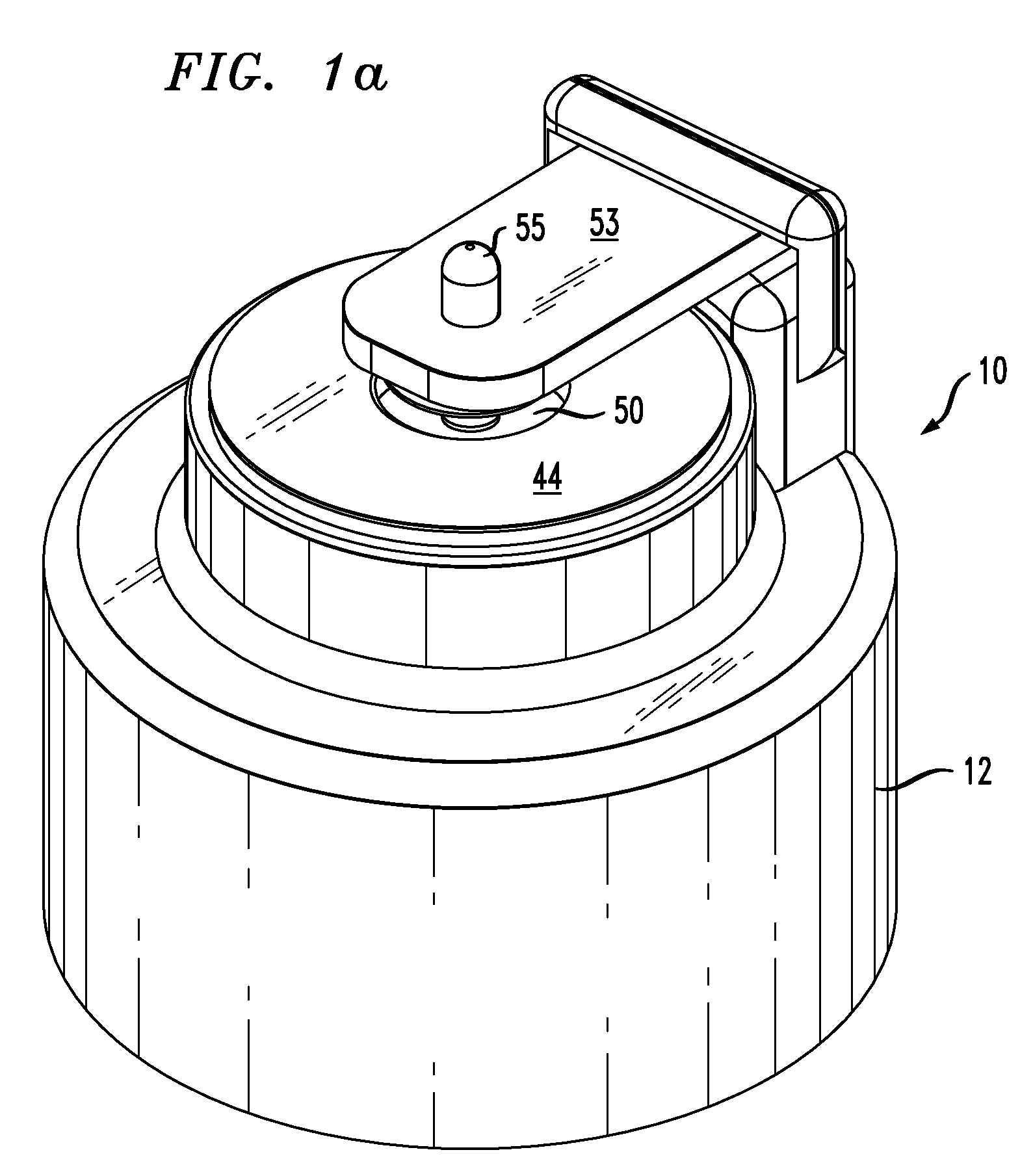

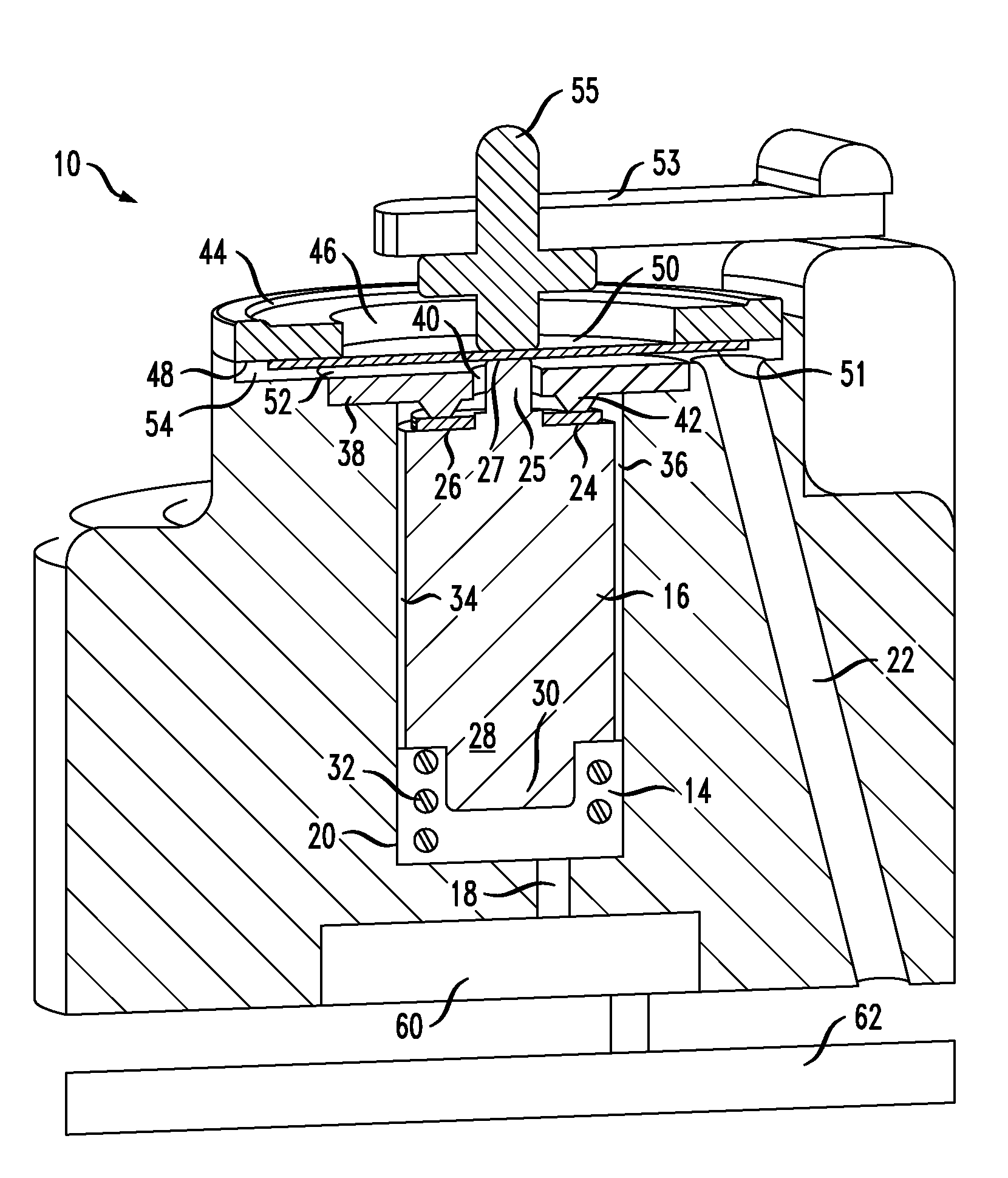

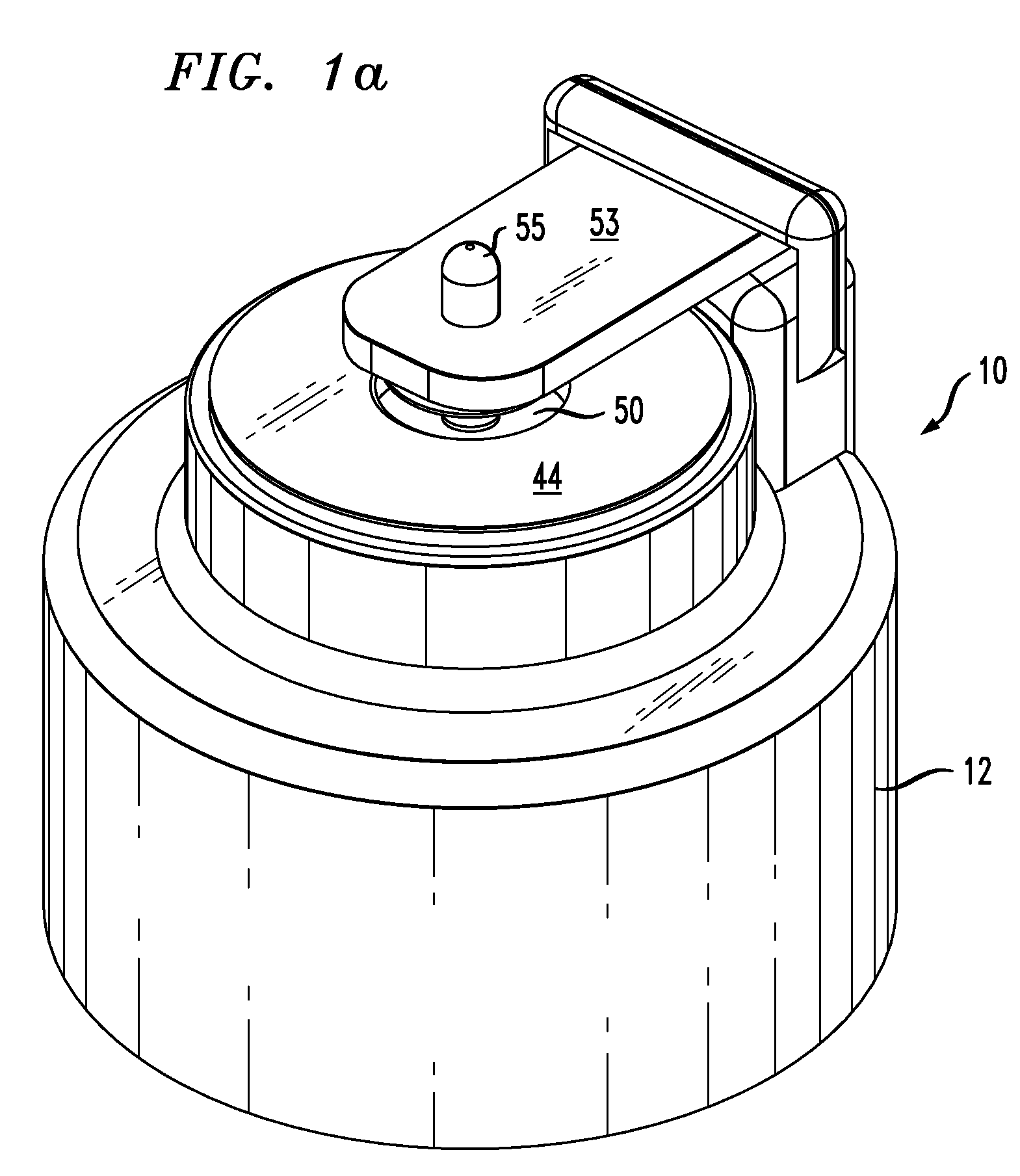

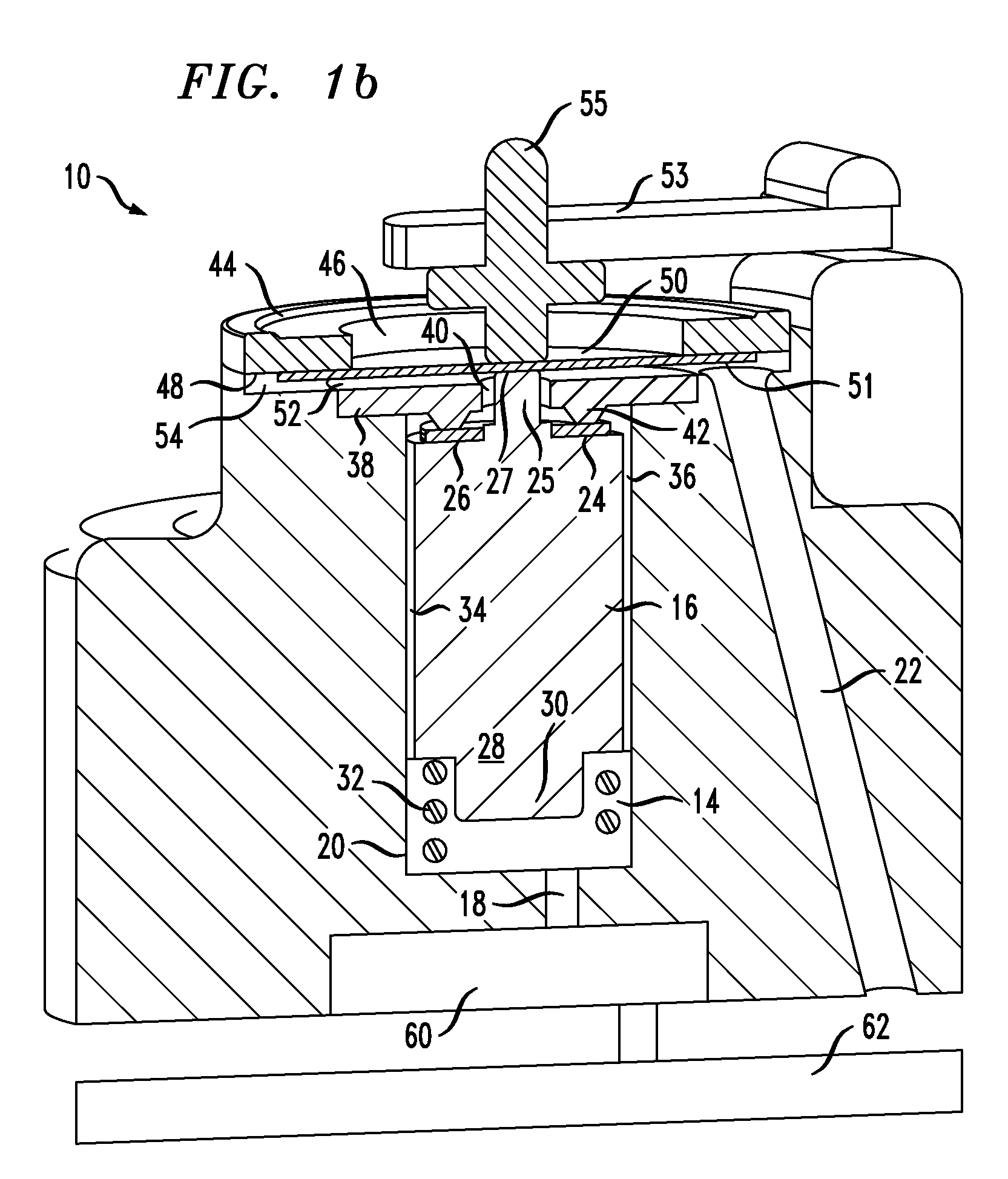

ActiveUS20090140185A1High flow accuracyOptimize flow rate accuracyOperating means/releasing devices for valvesMedical devicesElectricityPiezoelectric actuators

Improving the accuracy of the flow rate of a valve in a fluidic delivery device in which a desired flow rate may be achieved by varying the duty cycle of the valve. The flow rate of fluid delivery from the valve over its lifetime is stabilized by minimizing the voltage OPENING time of the valve to account for valve and piezoelectric actuator drift. Also, the valve OPENING time of one or more fluidic parameters that impact on the flow rate delivery by the valve and differ among fluidic delivery devices is compensated to optimize the flow rate accuracy.

Owner:MEDOS INT SARL

Flow Rate Accuracy of a Fluidic Delivery System

ActiveUS20090140184A1High flow accuracyOptimize flow rate accuracyOperating means/releasing devices for valvesPiezoelectric/electrostriction/magnetostriction machinesElectricityPiezoelectric actuators

Improving the accuracy of the flow rate of a valve in a fluidic delivery device in which a desired flow rate may be achieved by varying the duty cycle of the valve. The flow rate of fluid delivery from the valve over its lifetime is stabilized by minimizing the voltage OPENING time of the valve to account for valve and piezoelectric actuator drift. Also, the valve OPENING time of one or more fluidic parameters that impact on the flow rate delivery by the valve and differ among fluidic delivery devices is compensated to optimize the flow rate accuracy.

Owner:MEDOS INT SARL

Multiple technology flow sensor

InactiveUS6901794B2Generic applicabilityHigh flow accuracyVolume/mass flow by thermal effectsFluid pressure measurement using elastically-deformable gaugesAudio power amplifierClosed loop

A flow sensor includes sensors connected to a flexible membrane. The sensors detect ambient temperature, pressure, and flow rate of a medium. A method of sensing flow rate includes providing the flexible membrane; coupling the plurality of sensors to the flexible membrane; and detecting ambient temperature, pressure, and flow rate of the medium by the sensors. A flow sensing system includes the flow sensor, an operational amplifier, and a closed loop controller. The sensors are connected in a Wheatstone bridge configuration. The operational amplifier is connected to the Wheatstone bridge and outputs a pressure signal representative of the pressure of the medium. The closed loop controller is connected to the operational amplifier and controls a current through a heating element for a resistor in the bridge such that a voltage across the operational amplifier is substantially zero. The output of the closed loop controller represents the flow rate.

Owner:FESTO AG & CO KG

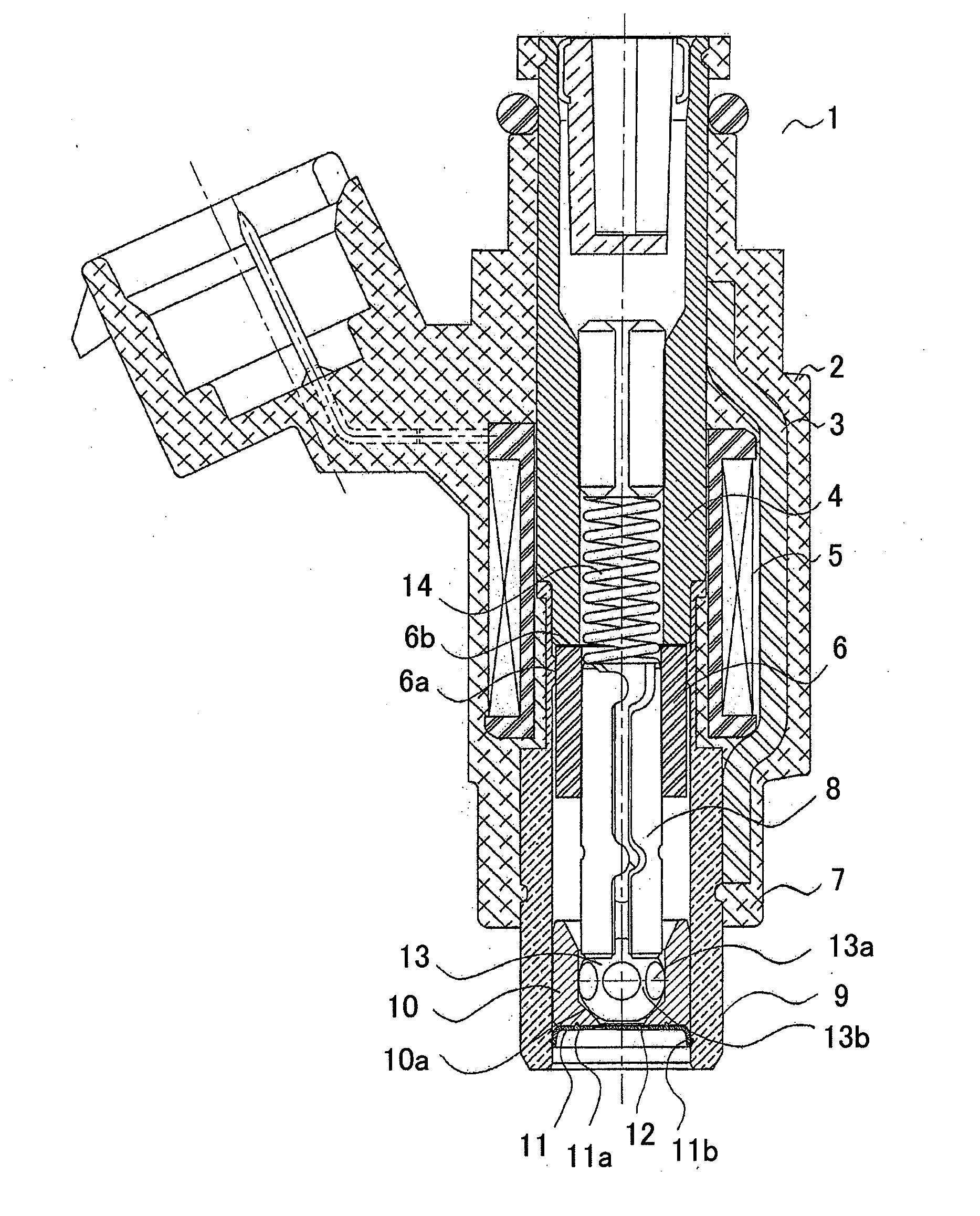

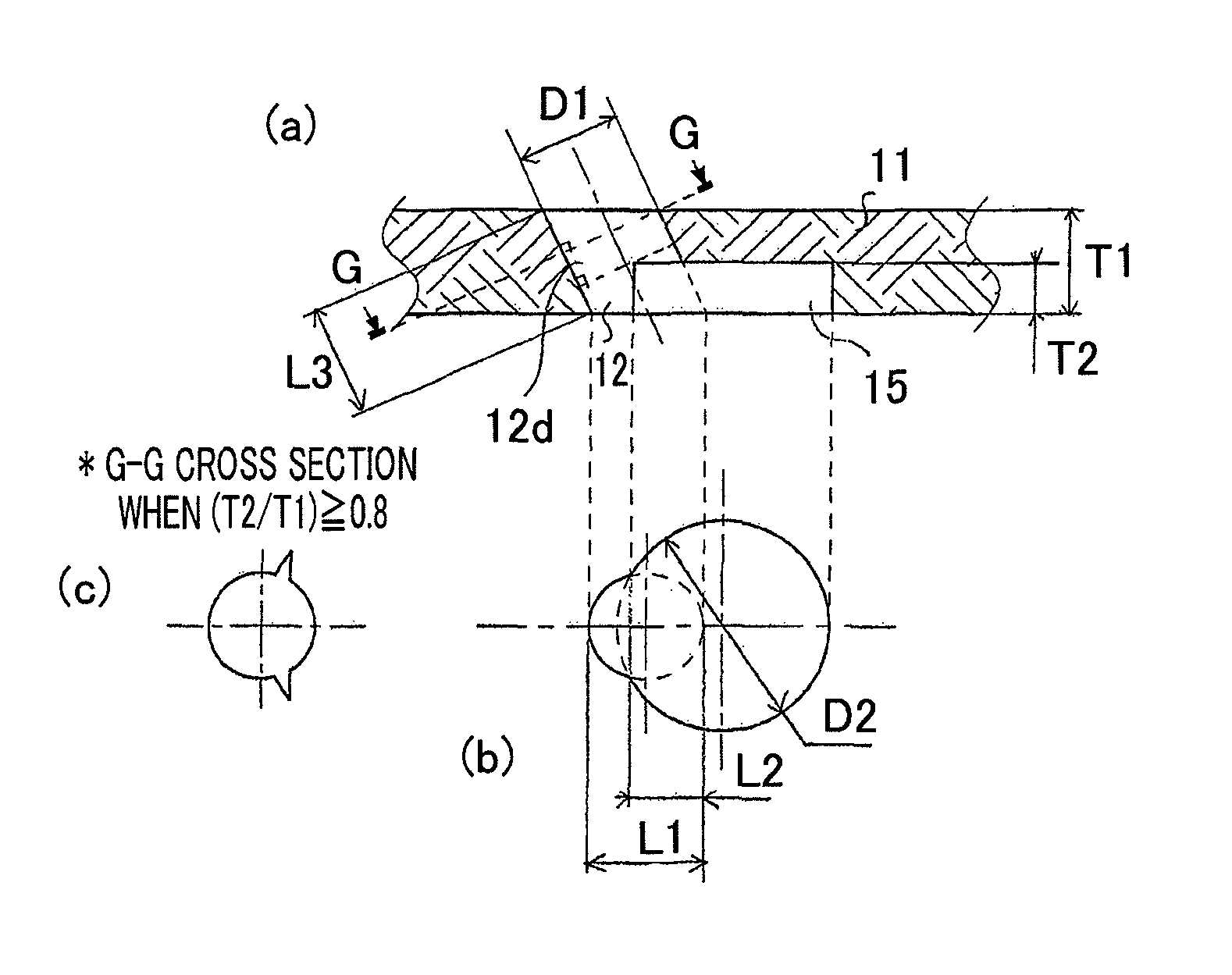

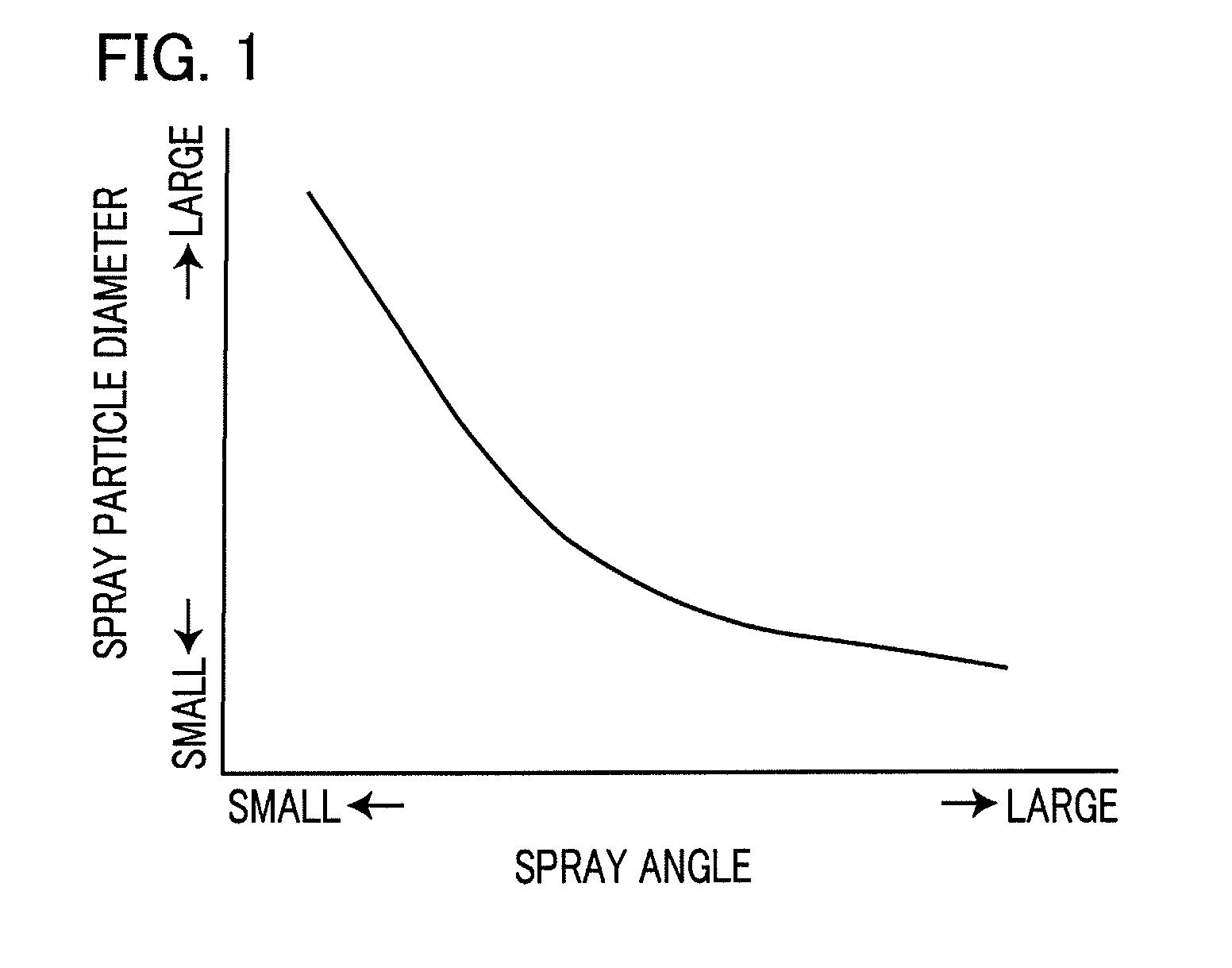

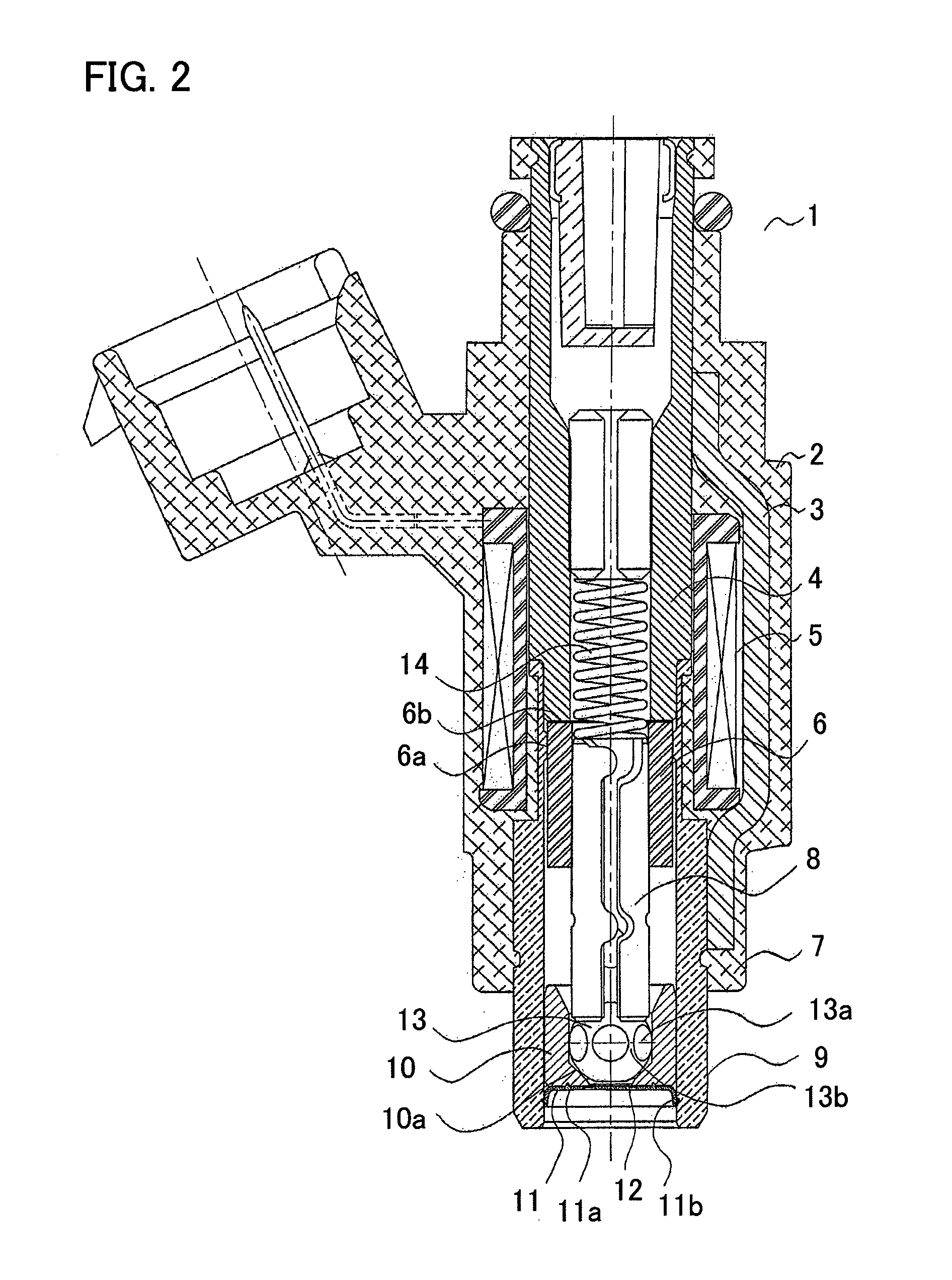

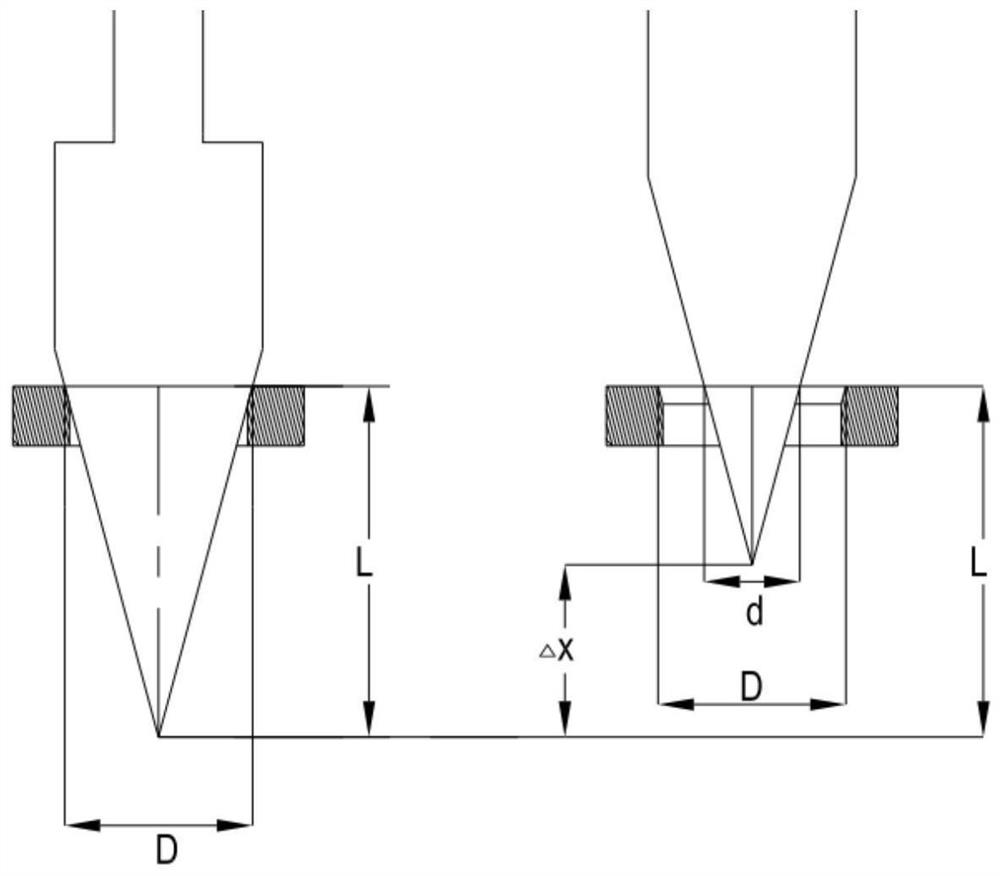

Fuel injection valve

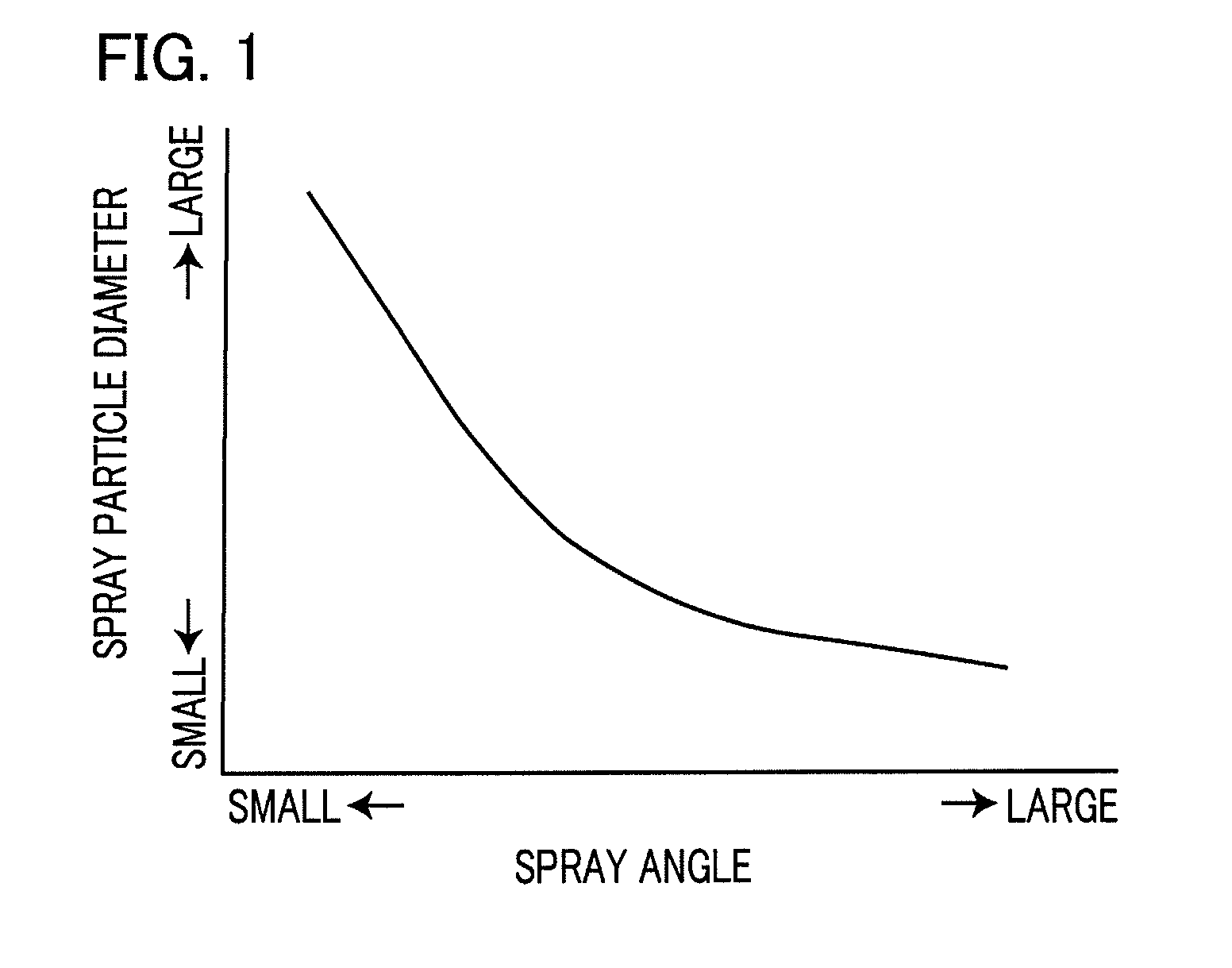

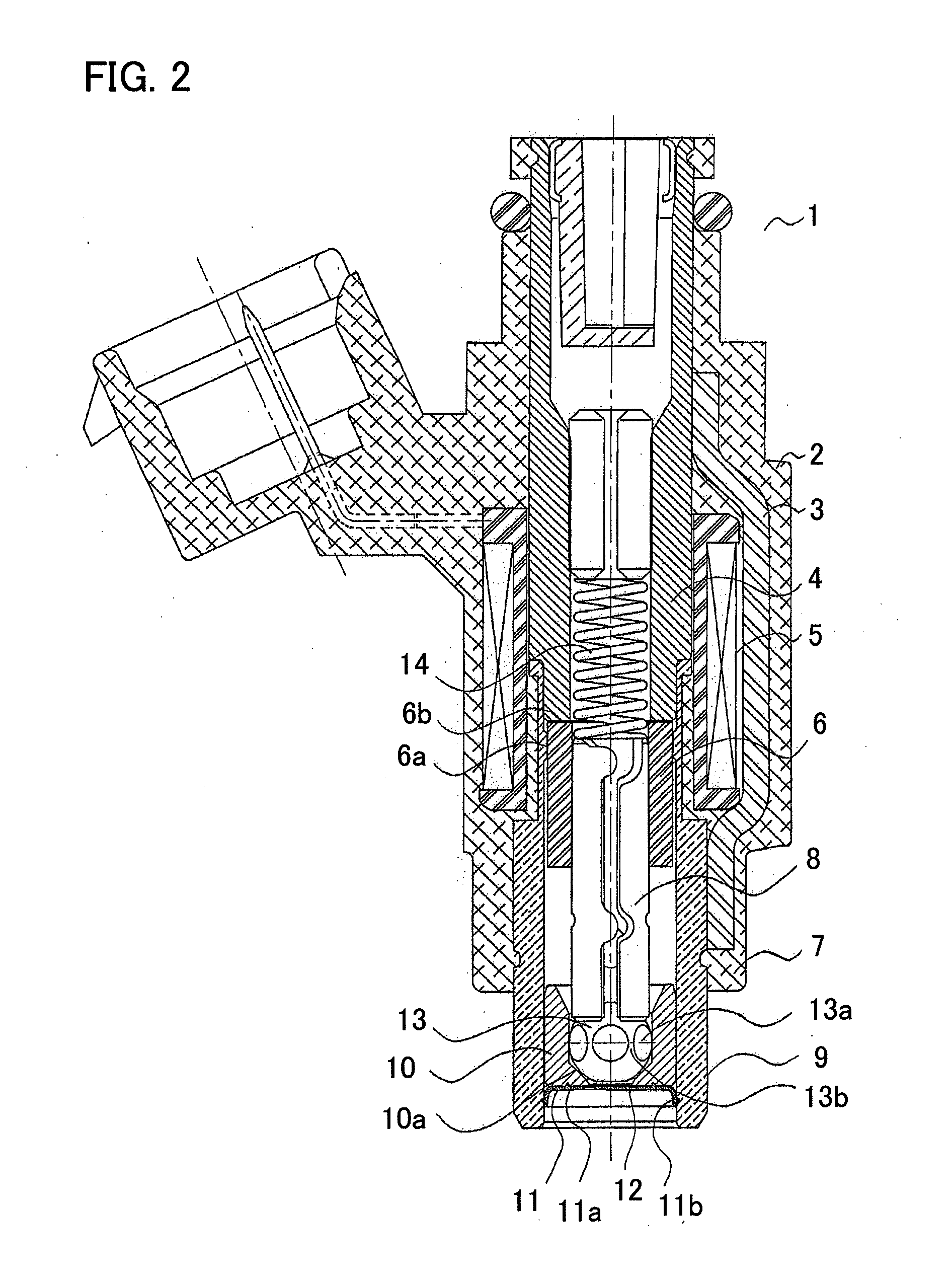

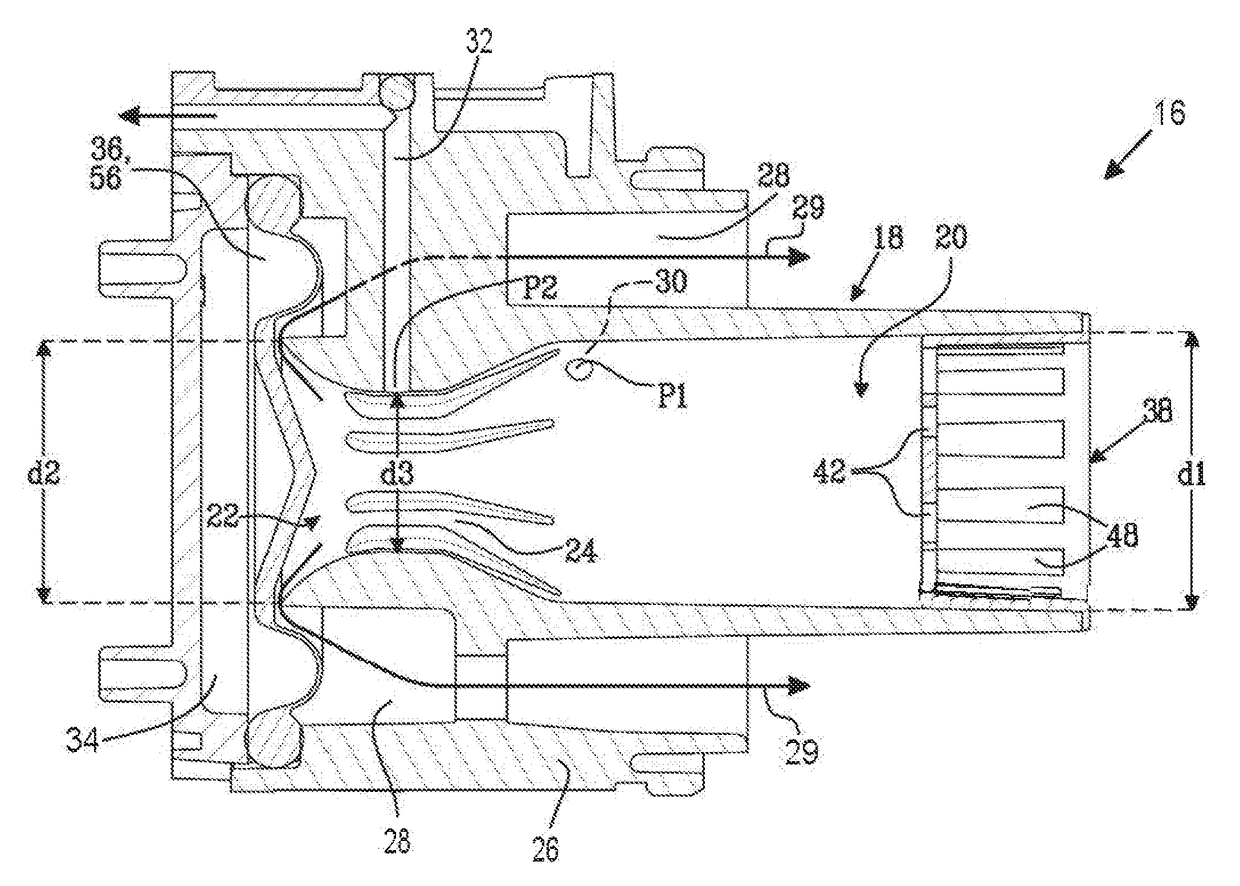

ActiveUS20120325938A1High flow accuracyPromote atomizationSpray nozzlesFuel injection apparatusBiomedical engineeringFuel injection

At the downstream-side face of an injection hole plate, a plurality of concaves are arranged corresponding to a plurality of injection holes; at least part of an injection hole outlet opens at the plain of the concave; the rest of the outlet opens at the downstream side face of the injection hole plate or contacts the inner surface of the concave. In a flow path formed by the injection hole, there is provided a cylindrical portion, whose cross section is the radially minimum cross section of the injection hole, from the upstream side face of the injection hole plate to the plain of the concave. Where D1 denotes the diameter of the injection hole and D2 denotes the diameter of the concave or the diameter of the concave in the circumferential direction of the virtual circle, the relationship 1.1<(D2 / D1)<3.0 is satisfied.

Owner:MITSUBISHI ELECTRIC CORP

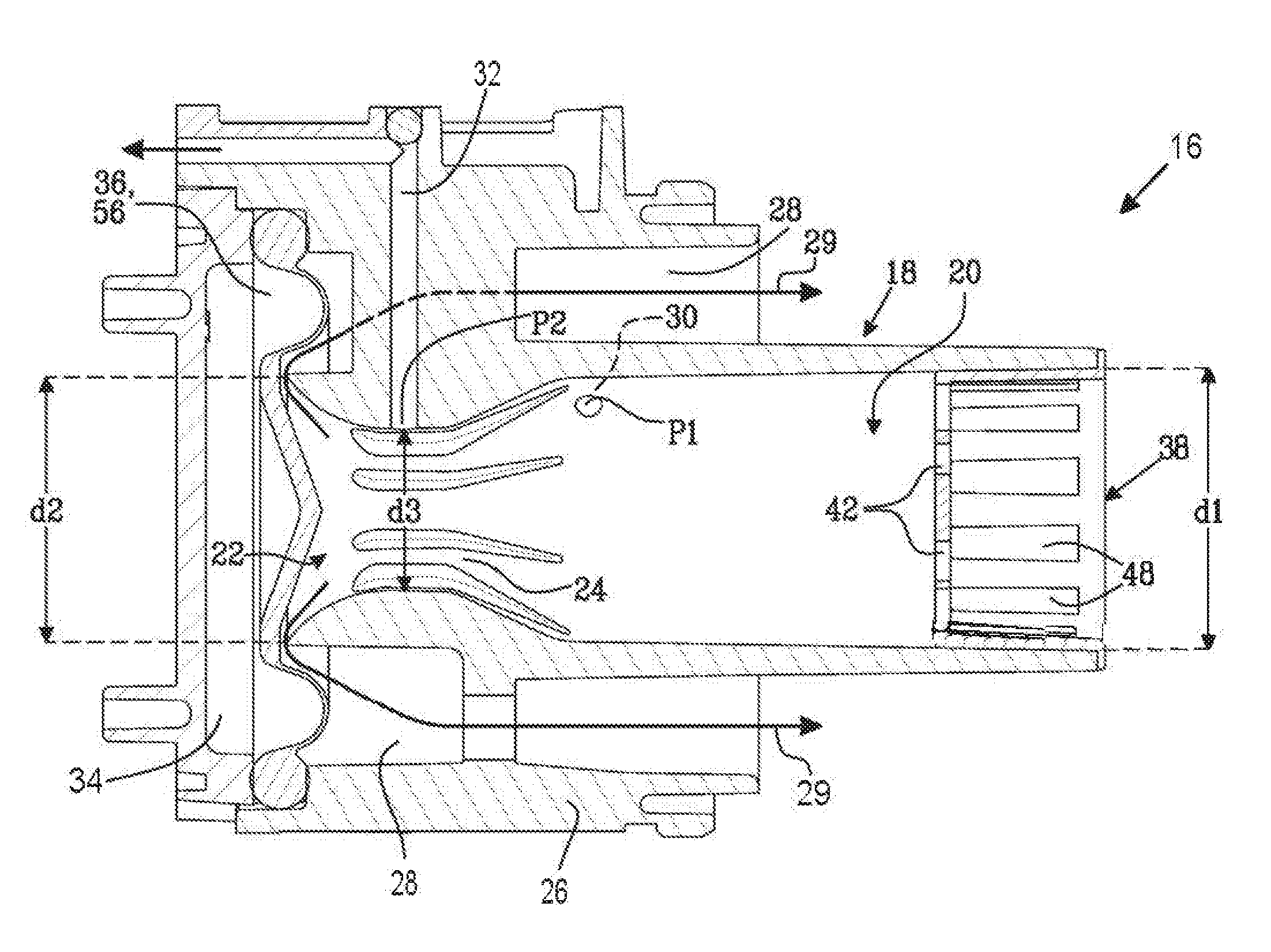

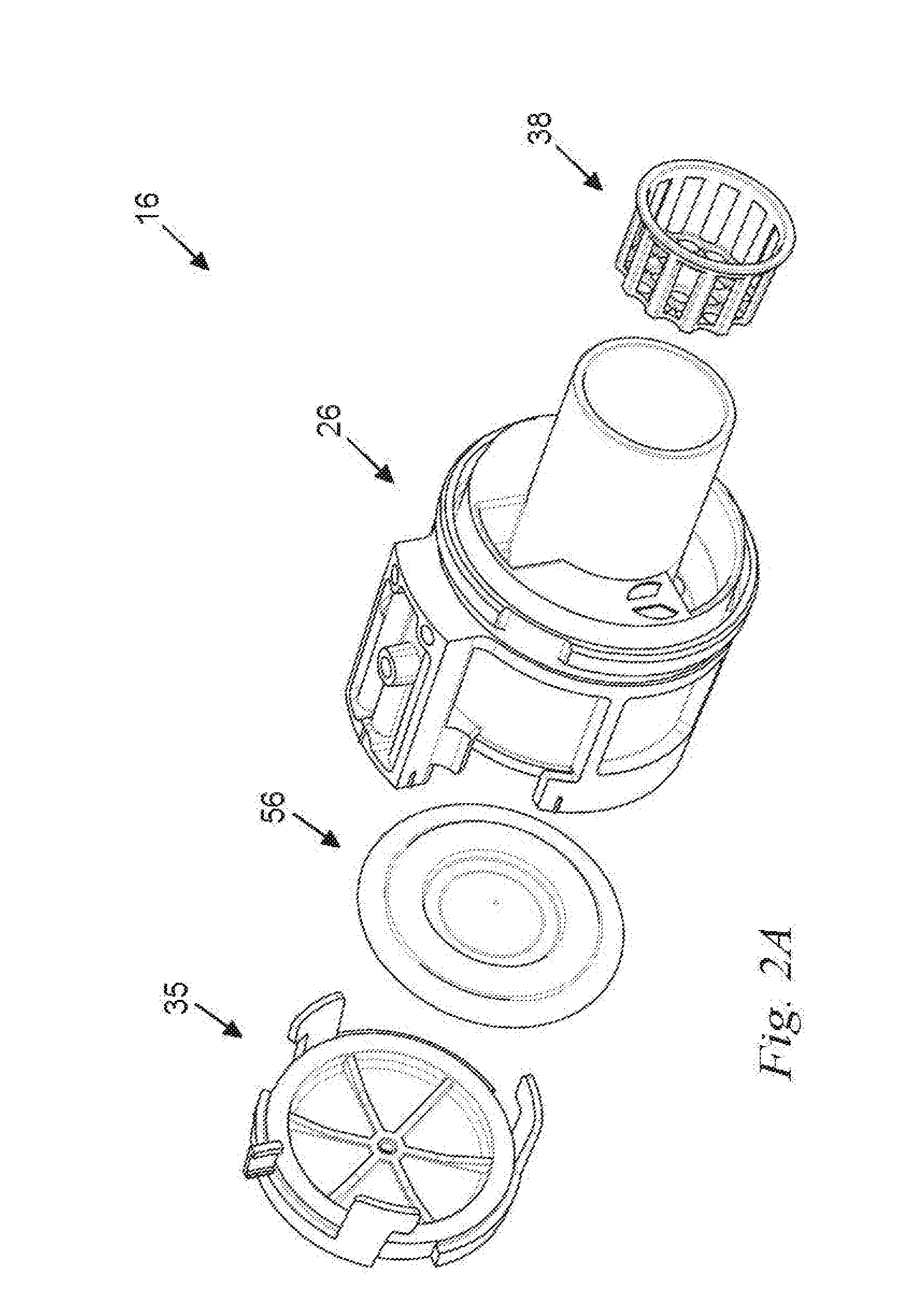

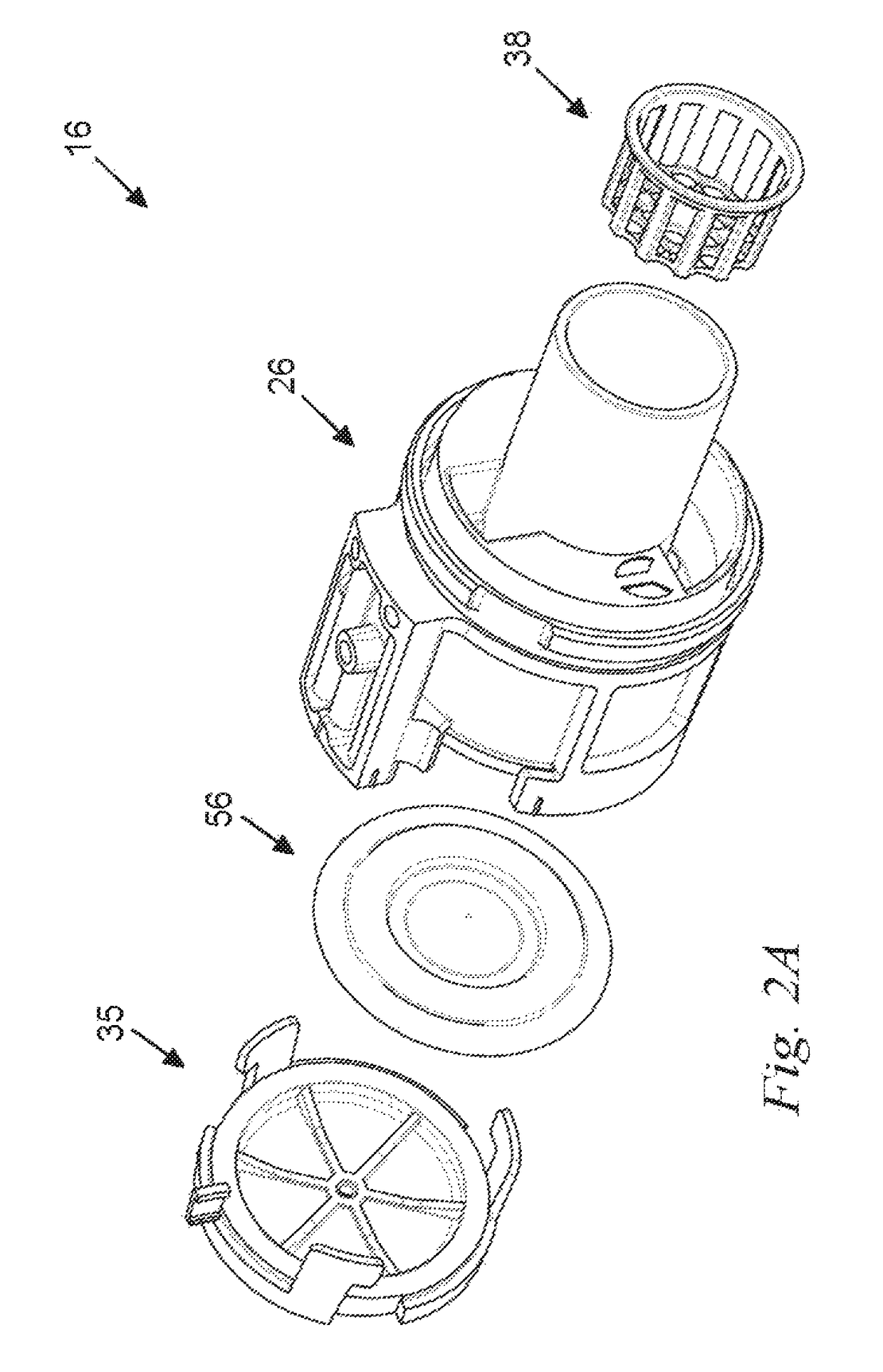

Flow sensor for ventilator

ActiveUS20160370213A1High flow accuracyReduce airflow resistanceRespiratorsElectrocardiographyEngineeringAirflow

Owner:BREAS MEDICAL

Fuel injection valve

ActiveUS8919675B2High flow accuracyPromote atomizationFuel-injection pumpsSpray nozzlesBiomedical engineeringFuel injection

At the downstream-side face of an injection hole plate, a plurality of concaves are arranged corresponding to a plurality of injection holes; at least part of an injection hole outlet opens at the plain of the concave; the rest of the outlet opens at the downstream side face of the injection hole plate or contacts the inner surface of the concave. In a flow path formed by the injection hole, there is provided a cylindrical portion, whose cross section is the radially minimum cross section of the injection hole, from the upstream side face of the injection hole plate to the plain of the concave. Where D1 denotes the diameter of the injection hole and D2 denotes the diameter of the concave or the diameter of the concave in the circumferential direction of the virtual circle, the relationship 1.1<(D2 / D1)<3.0 is satisfied.

Owner:MITSUBISHI ELECTRIC CORP

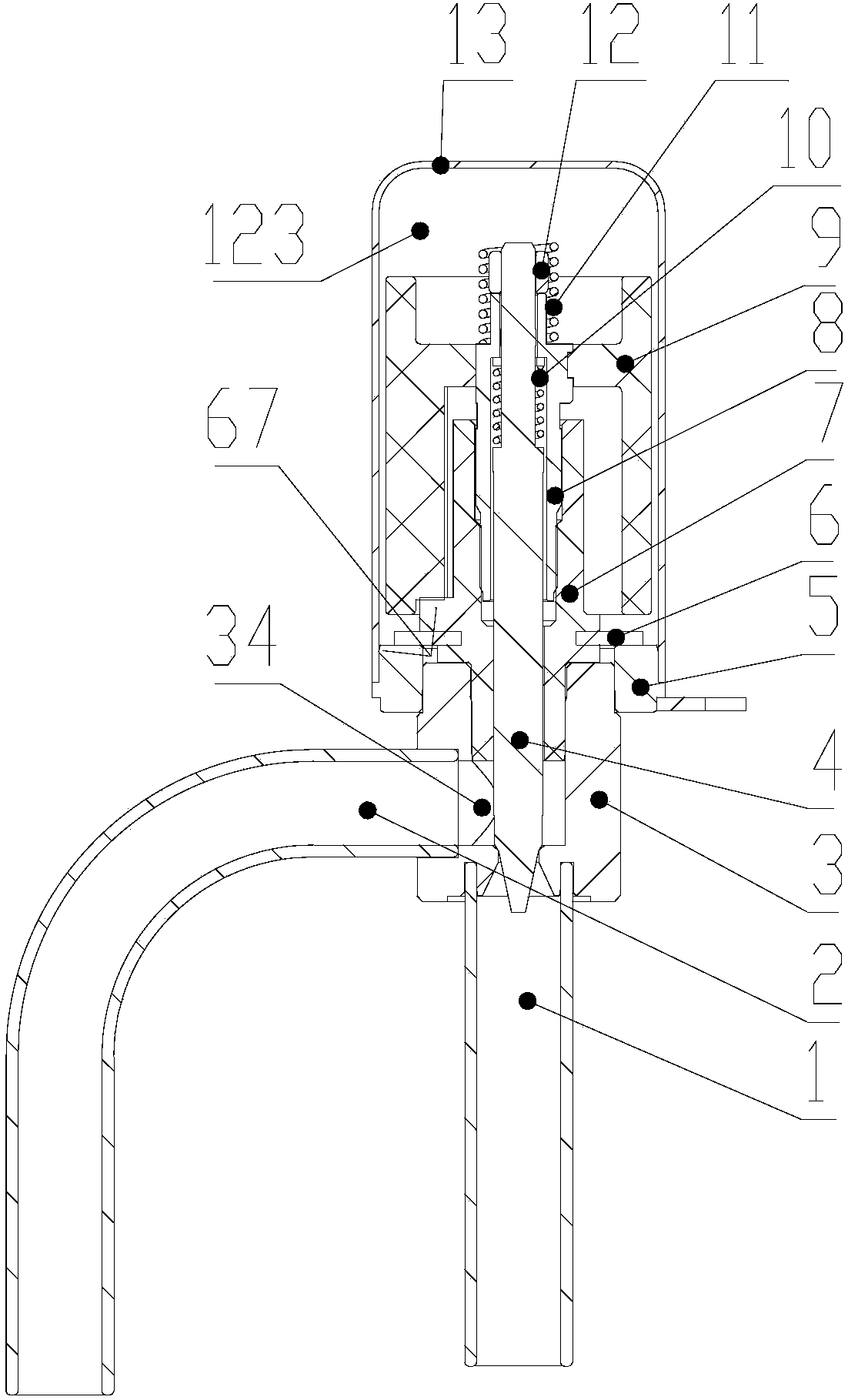

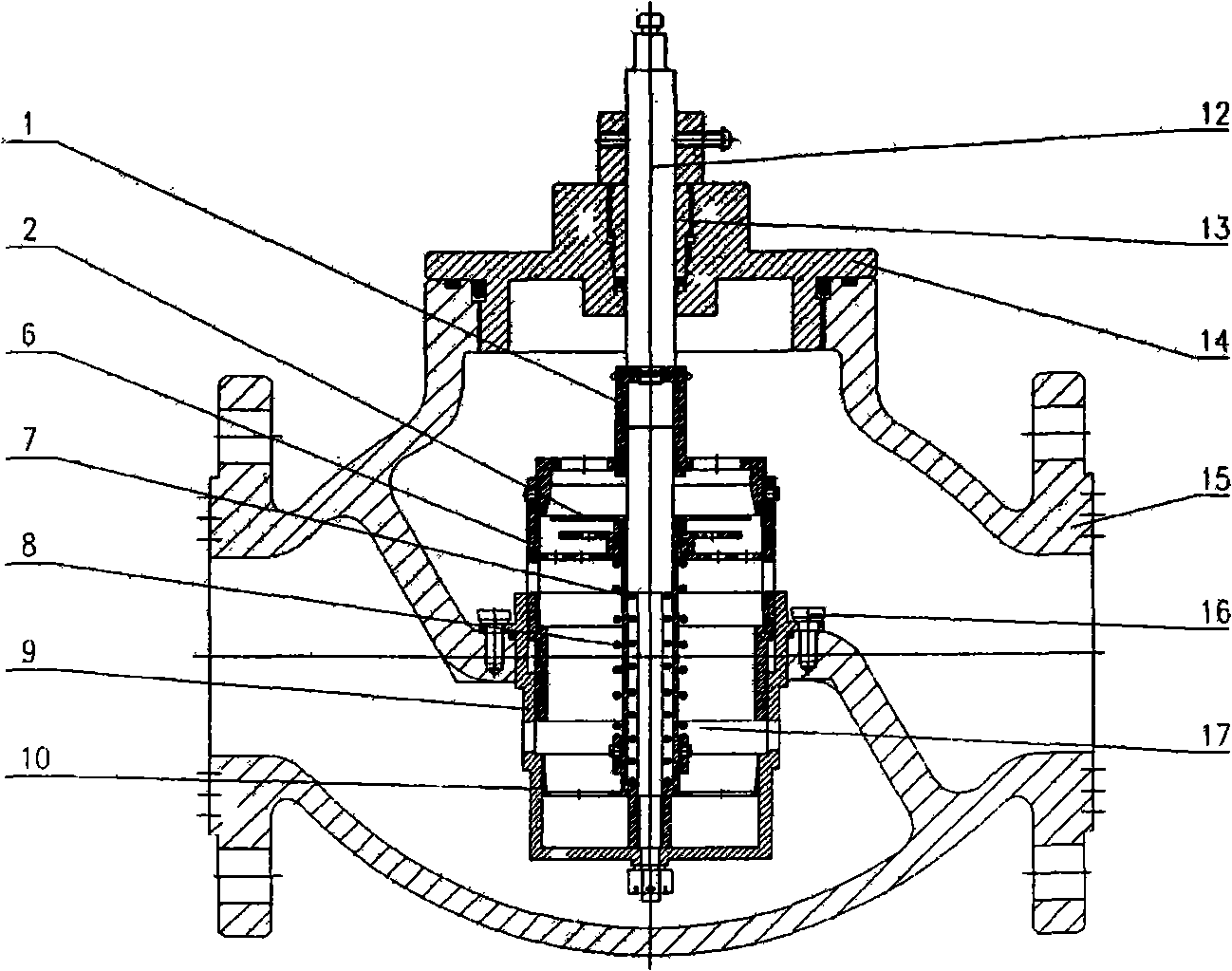

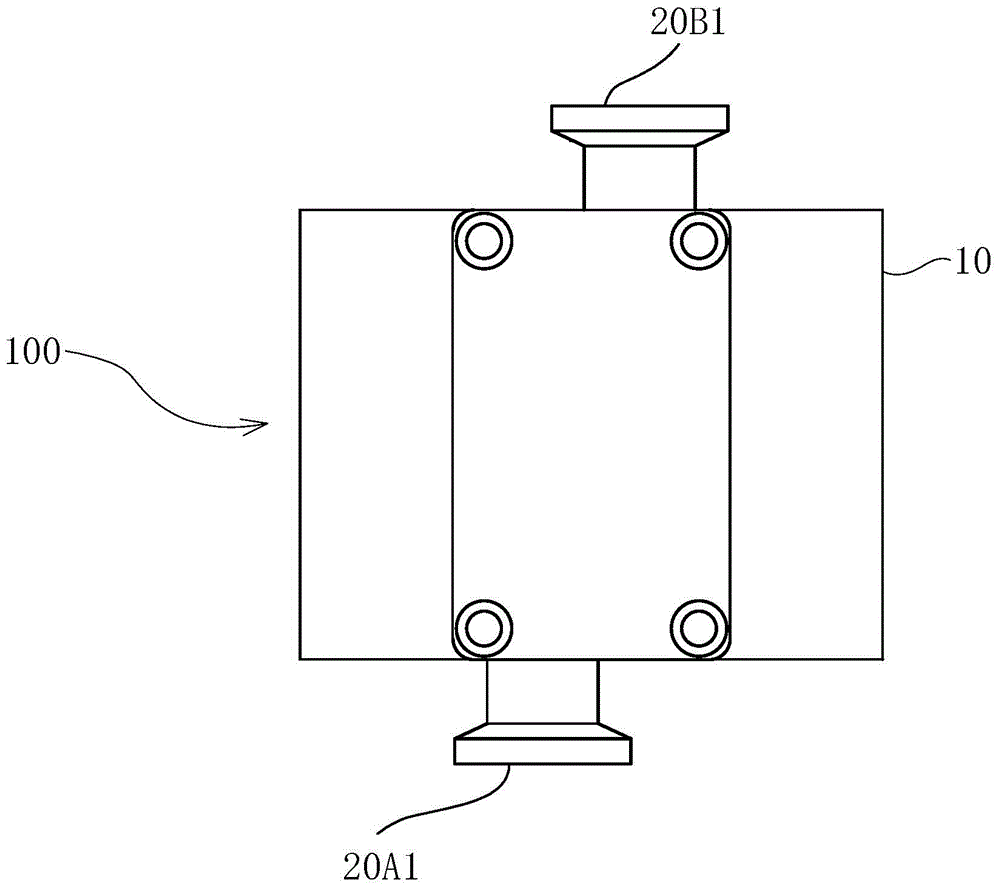

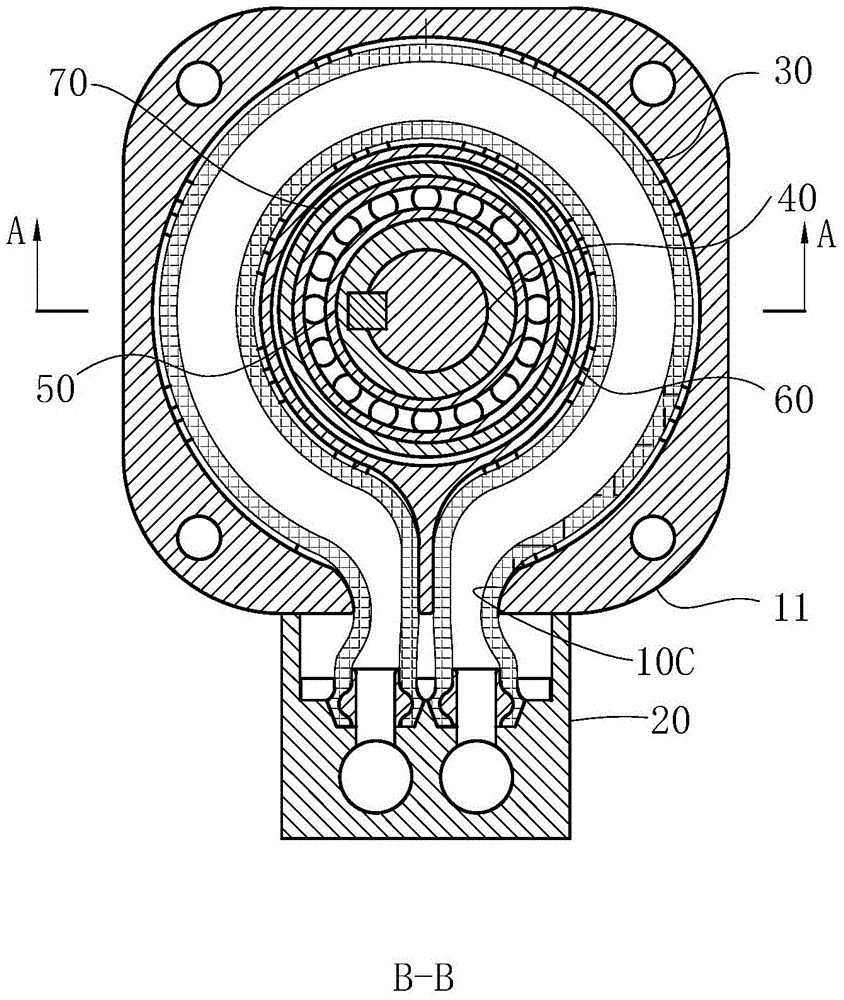

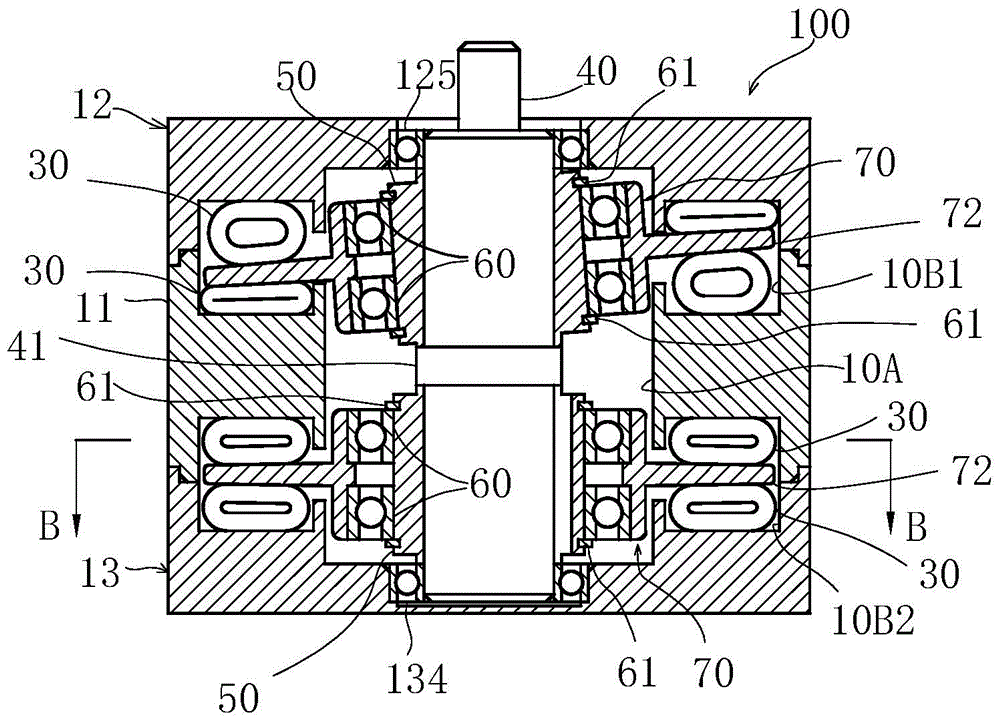

Electronic expansion valve

ActiveCN109958775AHigh flow accuracyRegulating pressureOperating means/releasing devices for valvesEfficient regulation technologiesMechanical engineeringElectronic expansion valve

The invention provides an electronic expansion valve. The electronic expansion valve includes a valve seat assembly, a nut assembly, a valve needle assembly, a rotor assembly and a sleeve assembly. The valve seat assembly includes a valve seat, a first connecting pipe connected one side of the valve seat, a second connecting pipe connected to the lower part of the valve seat and a sleeve seat disposed on the valve seat. The nut assembly includes a nut and a connecting plate disposed on the outer ring of the nut, and the connecting plate is provided with at least one first plate notch. The rotor assembly includes a magnetic rotor nested outside the nut and a screw. The joint between the first connecting pipe and the valve seat includes a first cavity, and the sleeve internally includes a second cavity. Nut notches corresponding to the first plate notches are formed in the exterior of the nut. The first plate notches and the nut notches constitute a connecting passage of the first cavityand the second cavity. The pressure between the first cavity and the second cavity can be quickly adjusted by arranging the nut notches, corresponding to the first plate notches in the connecting plate, in the exterior of the nut, so that the flow accuracy of the entire electronic expansion valve is improved.

Owner:ZHEJIANG DUNAN MASCH CO LTD

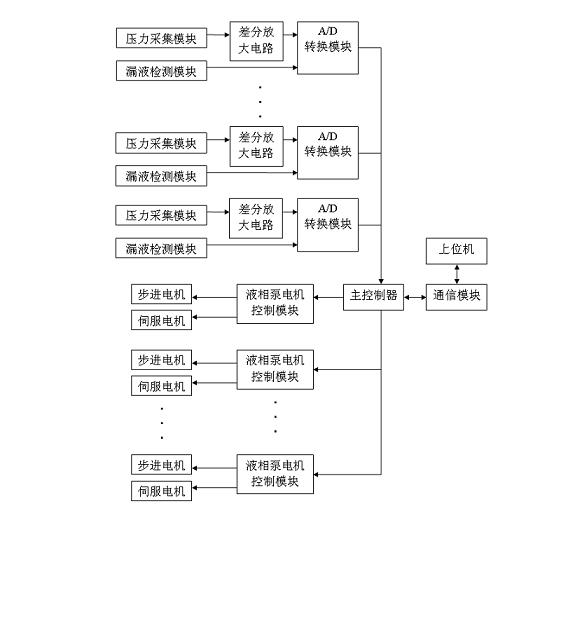

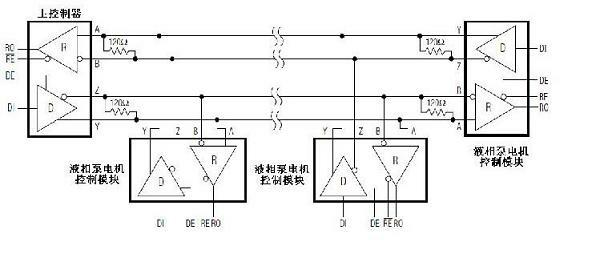

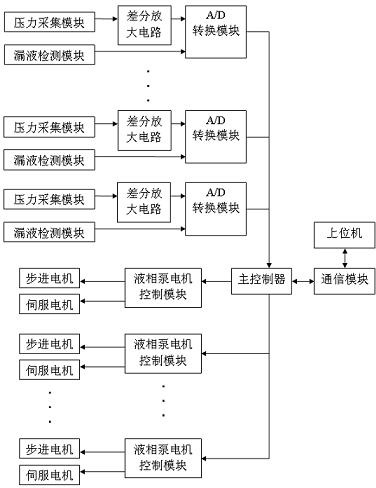

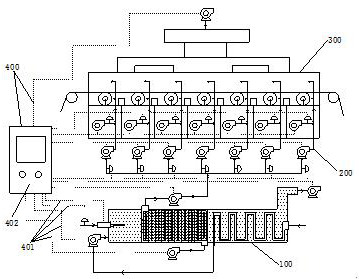

Liquid pump control system

InactiveCN102220966AWith automatic cleaning functionHigh flow accuracyPump controlPositive-displacement liquid enginesControl systemComputer module

The invention relates to a liquid pump control system which comprises a plurality of pressure acquisition modules, a plurality of liquid leakage detection modules, a plurality of A / D (Analog / Digital) conversion modules, a main controller, a plurality of liquid pump motor control modules and a communication module, wherein the pressure acquisition modules and the liquid leakage detection modules are respectively used for acquiring the pressure and liquid leakage signals of the corresponding liquid pump, the outputs of the pressure acquisition modules are connected with the input end of the corresponding A / D conversion module, and the output of each A / D conversion module is connected with the corresponding input end of the main controller; each output end of the main controller is respectively connected with the signal input end of each corresponding liquid pump motor control module, the output of each liquid pump motor control module is used for controlling the working of a motor of the corresponding liquid pump, and the main controller communicates with an upper machine through the communication module. The liquid pump control system can be simultaneously applied to multiple pump systems, is flexible to control and high in response speed and convenient to operate by customers and select suitable control systems, circuit sharing is realized in production, and the production cost is reduced.

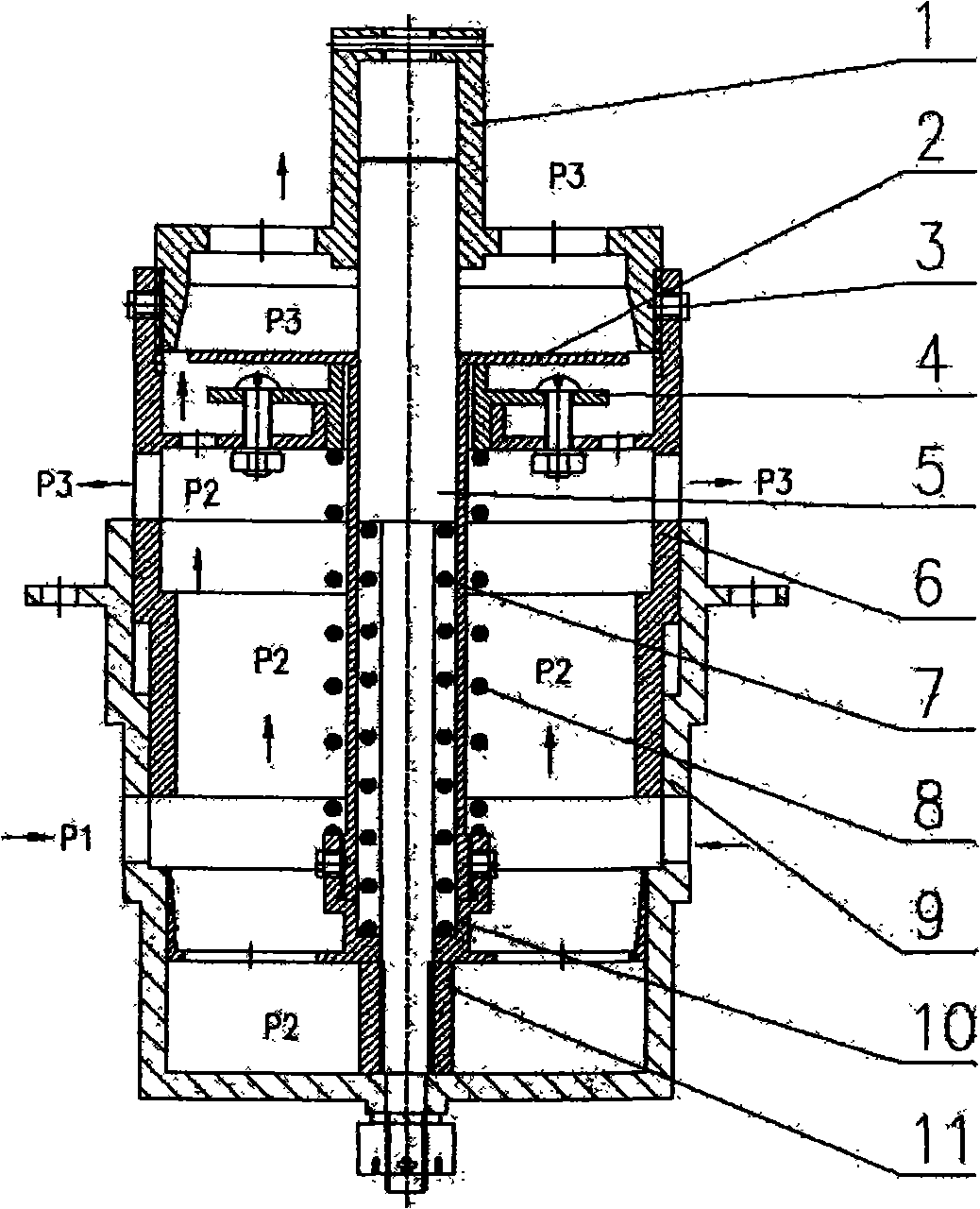

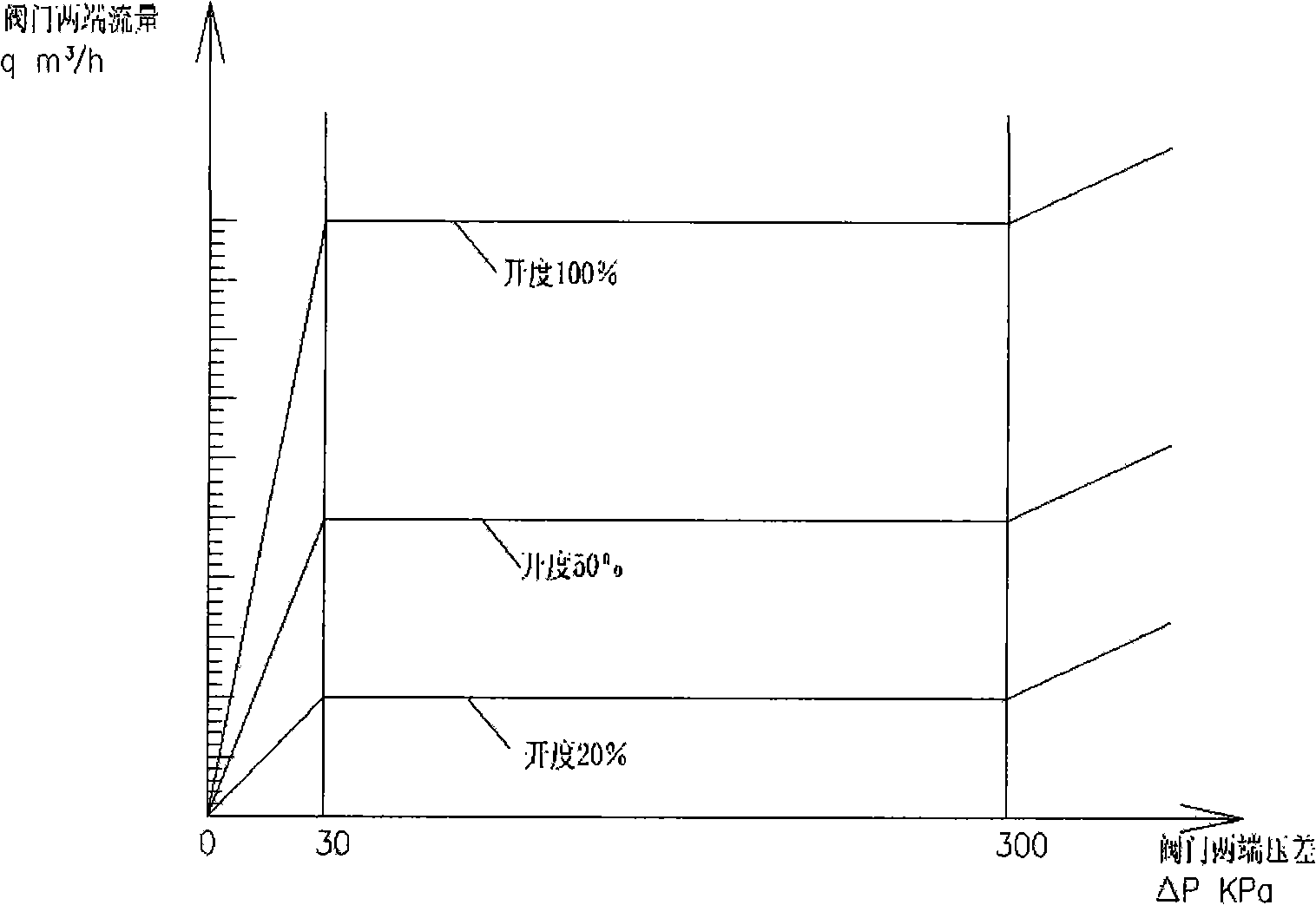

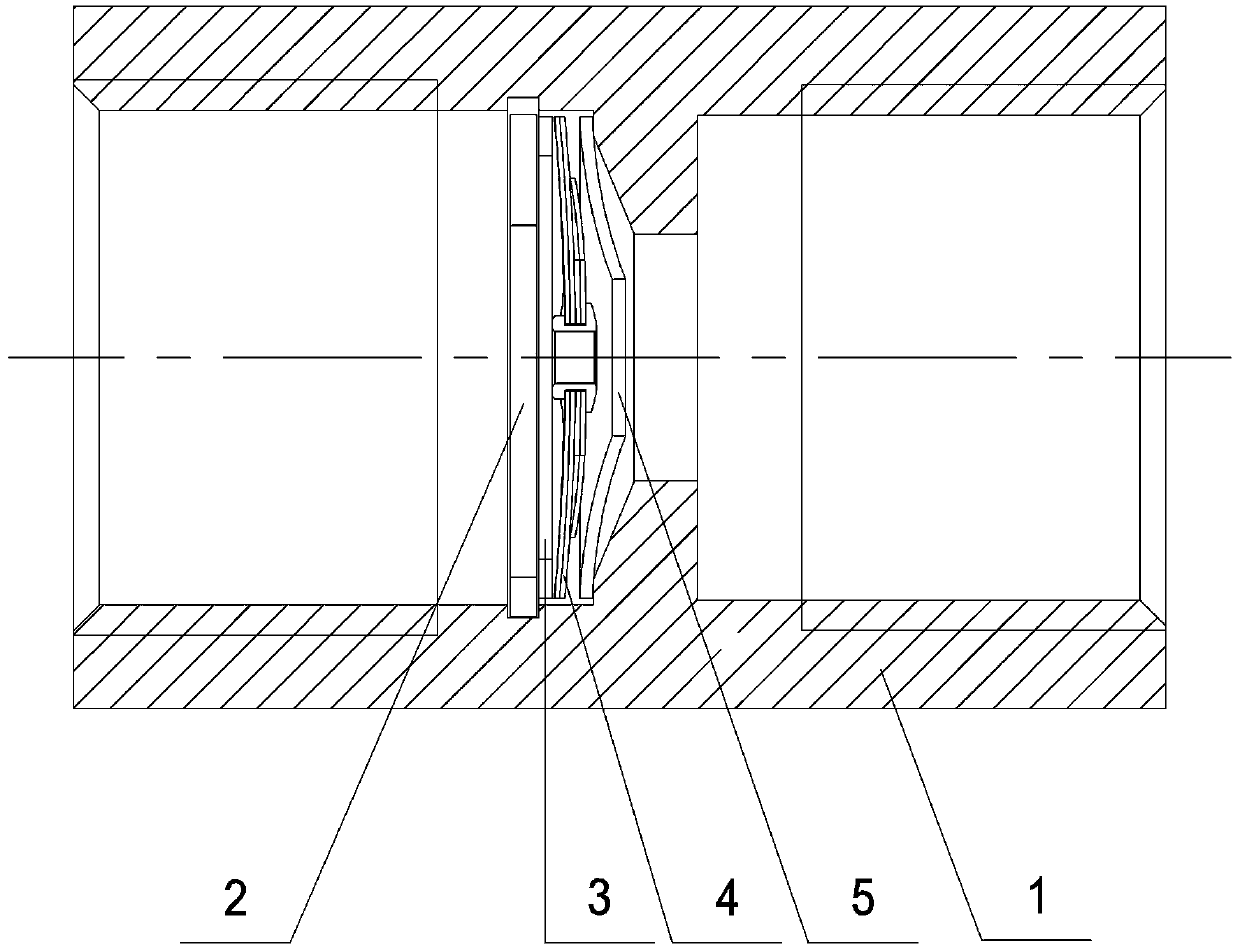

Embedded valve container type adjustable dynamic flow equalizing valve

ActiveCN101270829AHigh flow accuracyWide working pressure rangeEqualizing valvesSafety valvesChemical industryWorking pressure

The invention discloses an adjustable dynamic flow balance valve with an internal lining, which has the function of the dynamic flow balance valve and can adjust the flow capacity passing the valve within certain pressure difference according to the requirement. The invention comprises a valve body, the internal detachable valve lining, a gland cover, a connecting rod and an actuator. The valve lining is fixedly mounted inside the valve body. The connecting rod connected with the valve lining drills through the upper gland cover to be connected with an adjusting handle or the actuator. The opening degree of the valve is controlled for adjusting the flow capacity. The valve lining comprises a pressure sensing board, a pressure regulating slide sleeve, an internal spring, an external spring, the upper end cap with the correction conical surface of the valve lining, a current regulating cylinder body and a lower cylinder body. The invention has the advantages of large current regulating range, large flow capacity, high control precision, broad working pressure difference, convenient assembly, long service life, detachable valve lining and low manufacture cost. The invention can be applied to the central air conditioner, the water system of the heating network, petroleum industry, chemical industry and electric power plant, fundamentally solving the problem of hydraulic disorder and meeting the requirement of flow control.

Owner:JINAN ANGLE TECH DEV CO LTD

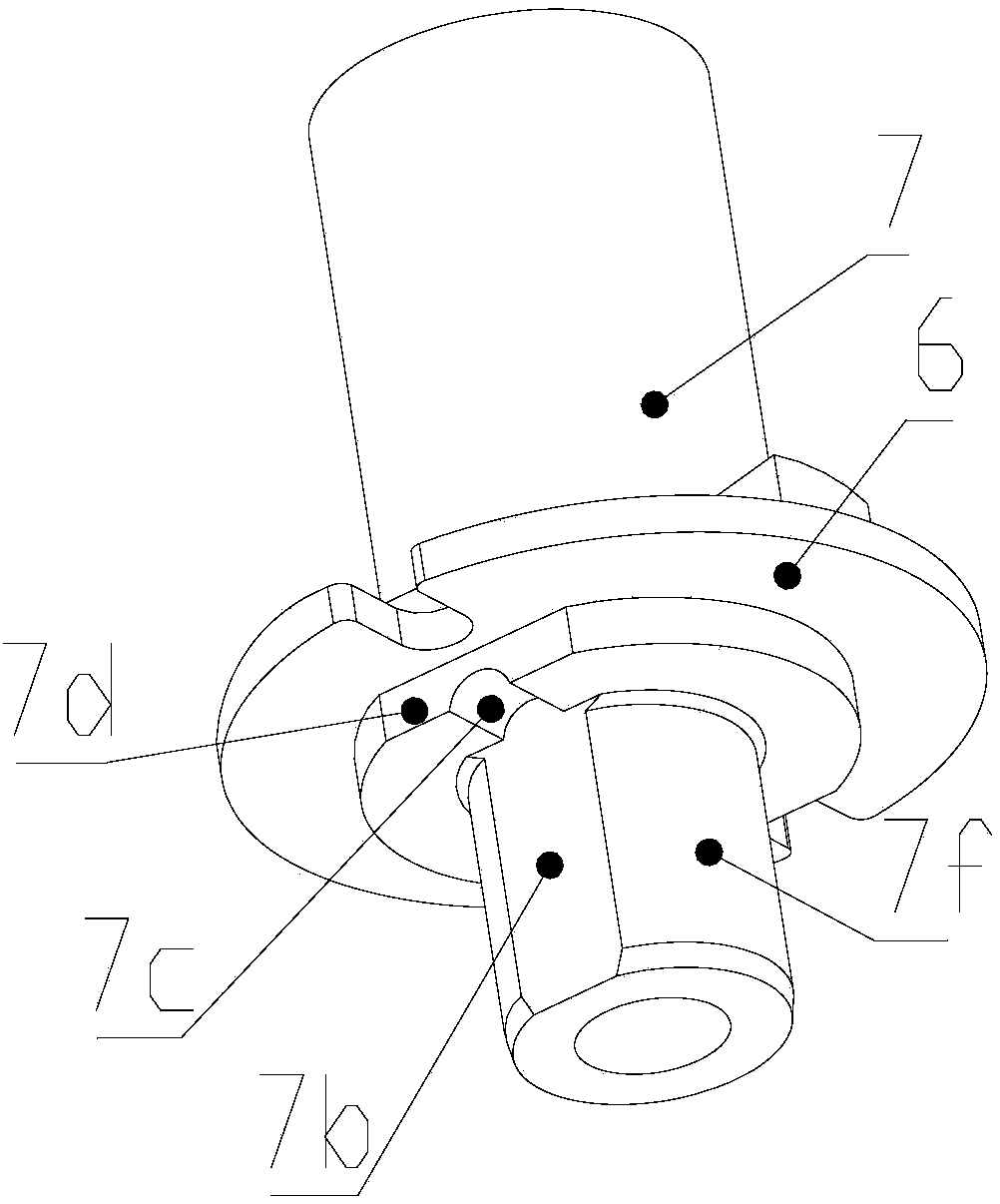

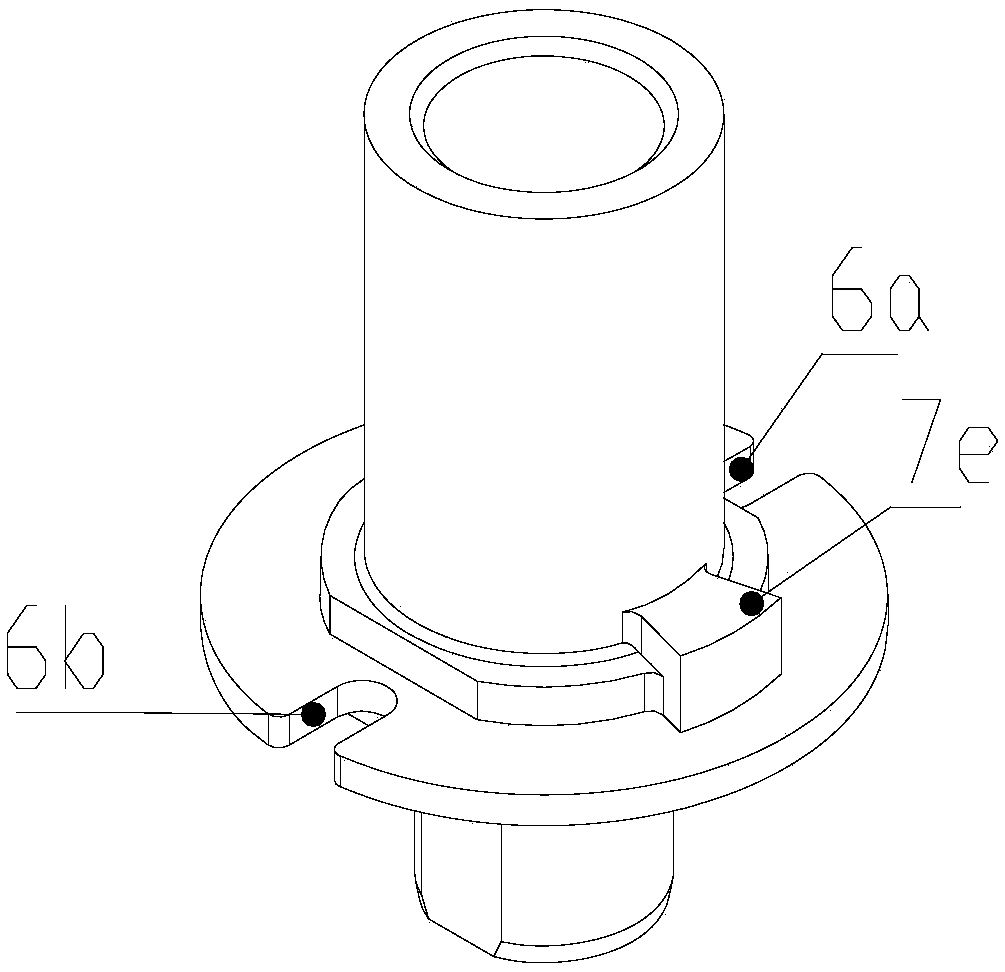

Swing pipe pump

ActiveCN104819135AReduce pressure pulsationHigh flow accuracyFlexible member pumpsPositive-displacement liquid enginesCamAccess port

The invention discloses a swing pipe pump comprising a pump shell; a cylindrical inner cavity is formed in the pump shell; at least one annular pipe accommodating cavity is formed in the side wall of the cylindrical inner cavity in the axial direction; a pipe access port is formed in the pump shell, and is provided with a pipe joint fixed with the pump shell; two hoses are arranged in the pipe accommodating cavity; the two ends of the hoses are connected with the pipe joint; a center shaft coaxial with the inner cavity is arranged in the inner cavity of the pump shell, and is connected with a motor; an inclined cam, a first bearing and a swing wheel are arranged on the center shaft in sequence in the radial direction; a flange is arranged in the outer side center of the swing wheel, and extends between the two hoses in the pipe accommodating cavity; and when the center shaft rotates, the inclined cam and the first bearing drive the swing wheel to swing in the peripheral direction, and the hoses are extruded or released in the swing process, so that liquid is continuously discharged and absorbed. The swing pipe pump has such characteristics as low pressure pulsation, high flow precision, convenience for disinfection and sterilization, long service life, low cost and high working reliability.

Owner:楚天源创生物技术(长沙)有限公司

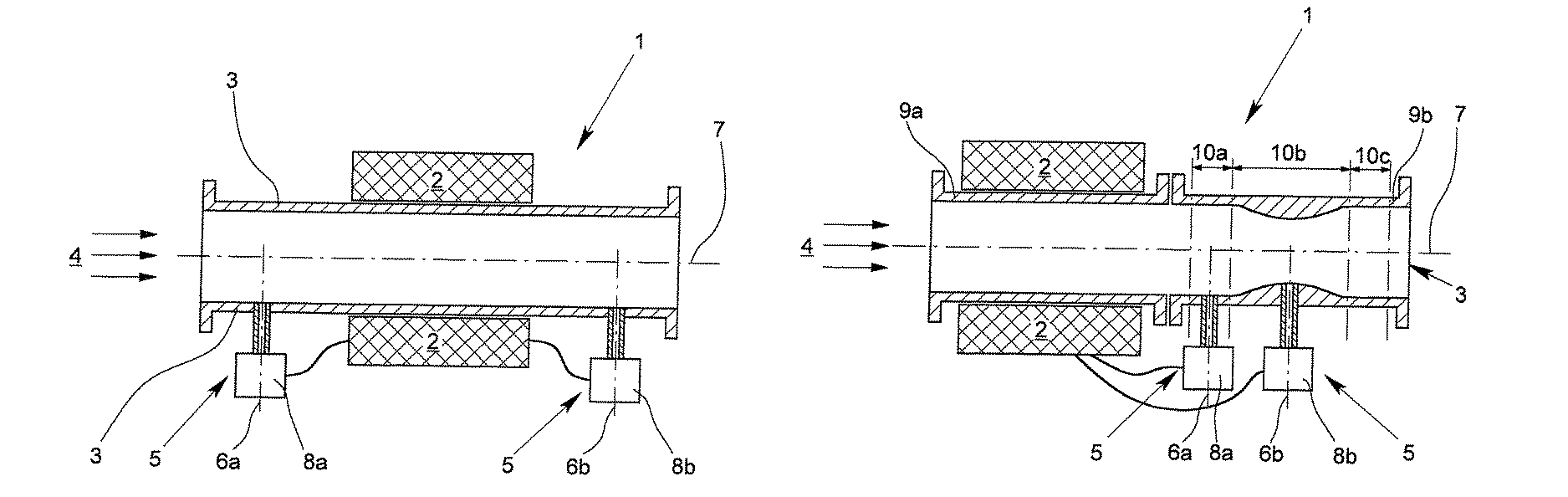

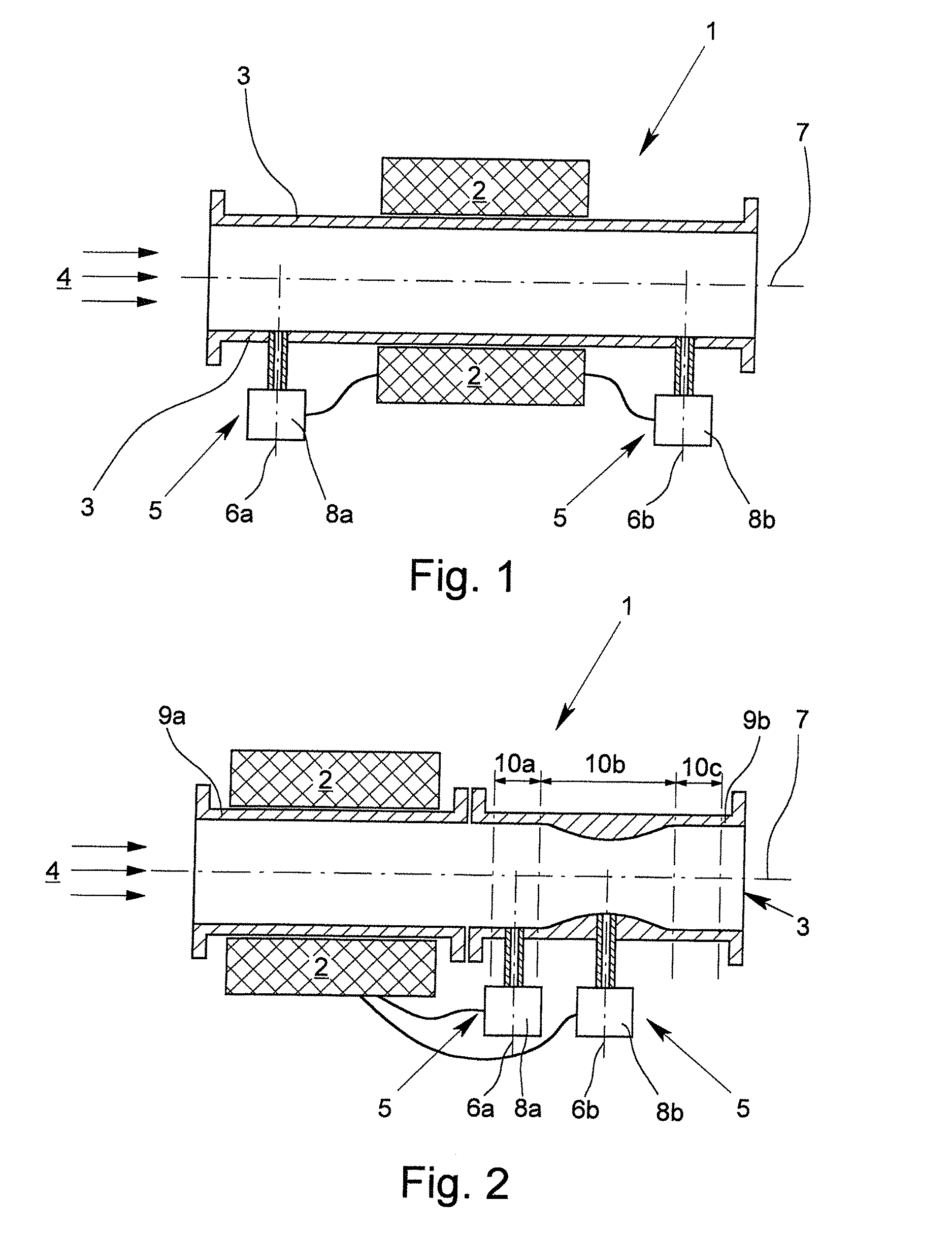

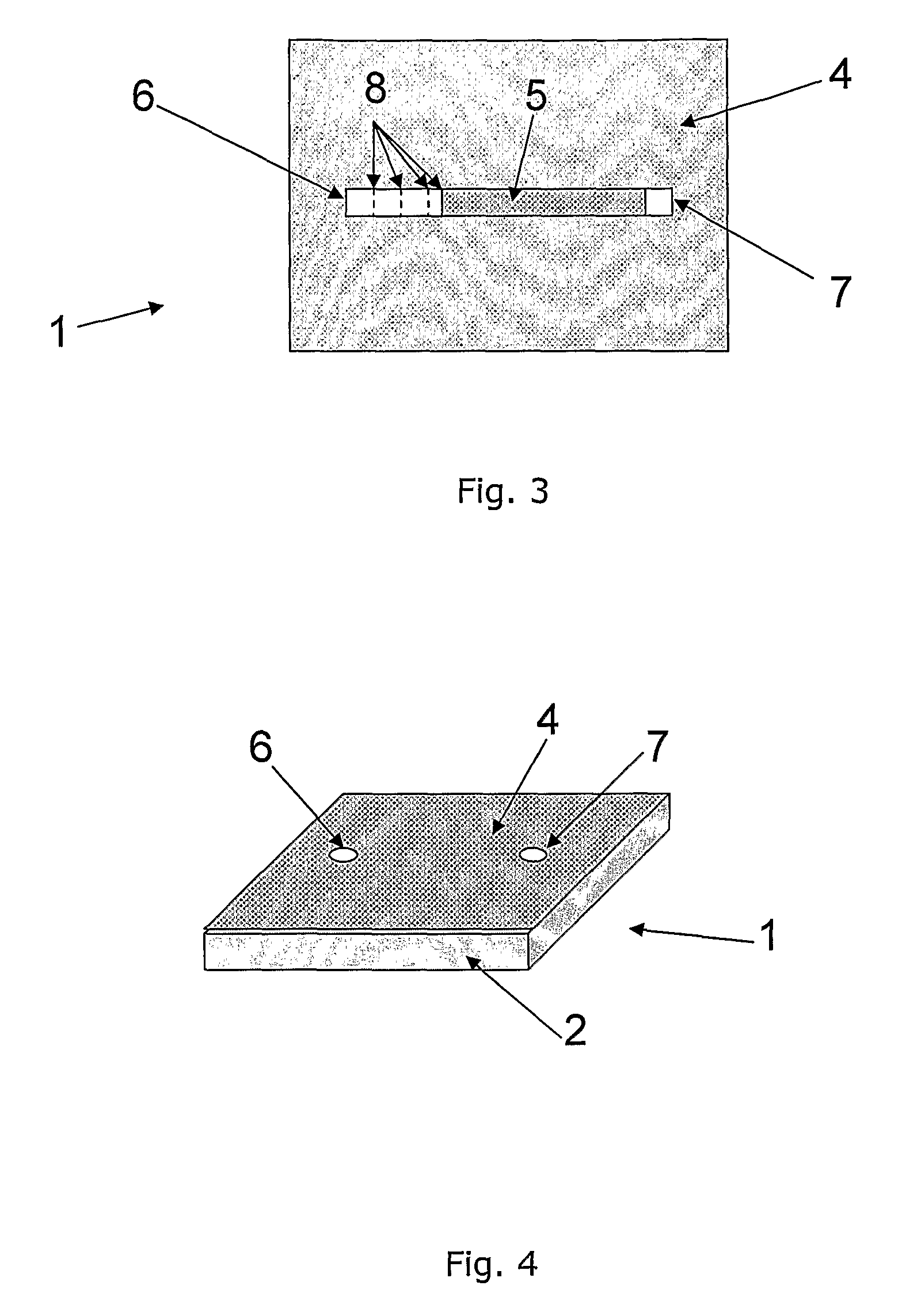

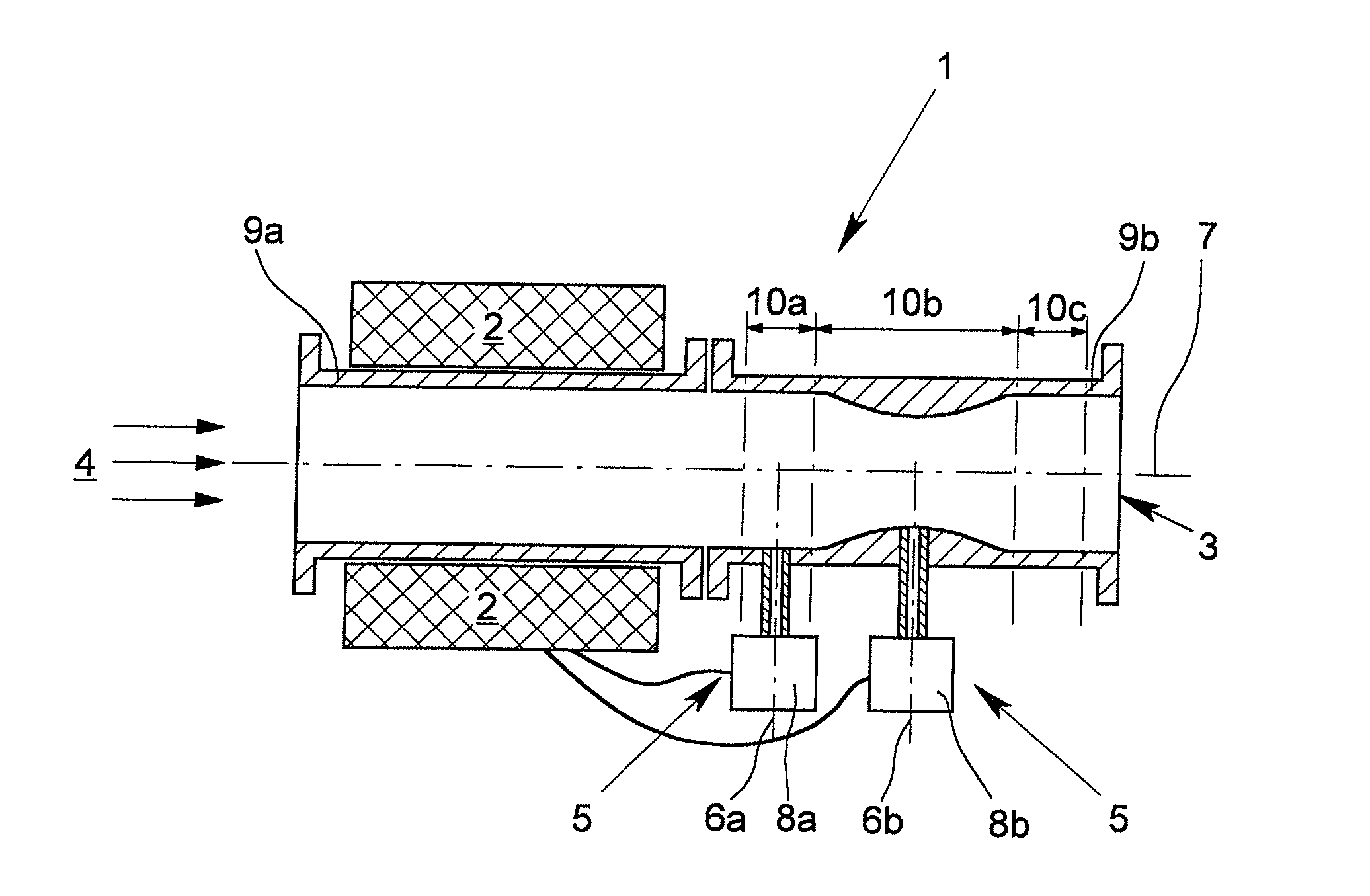

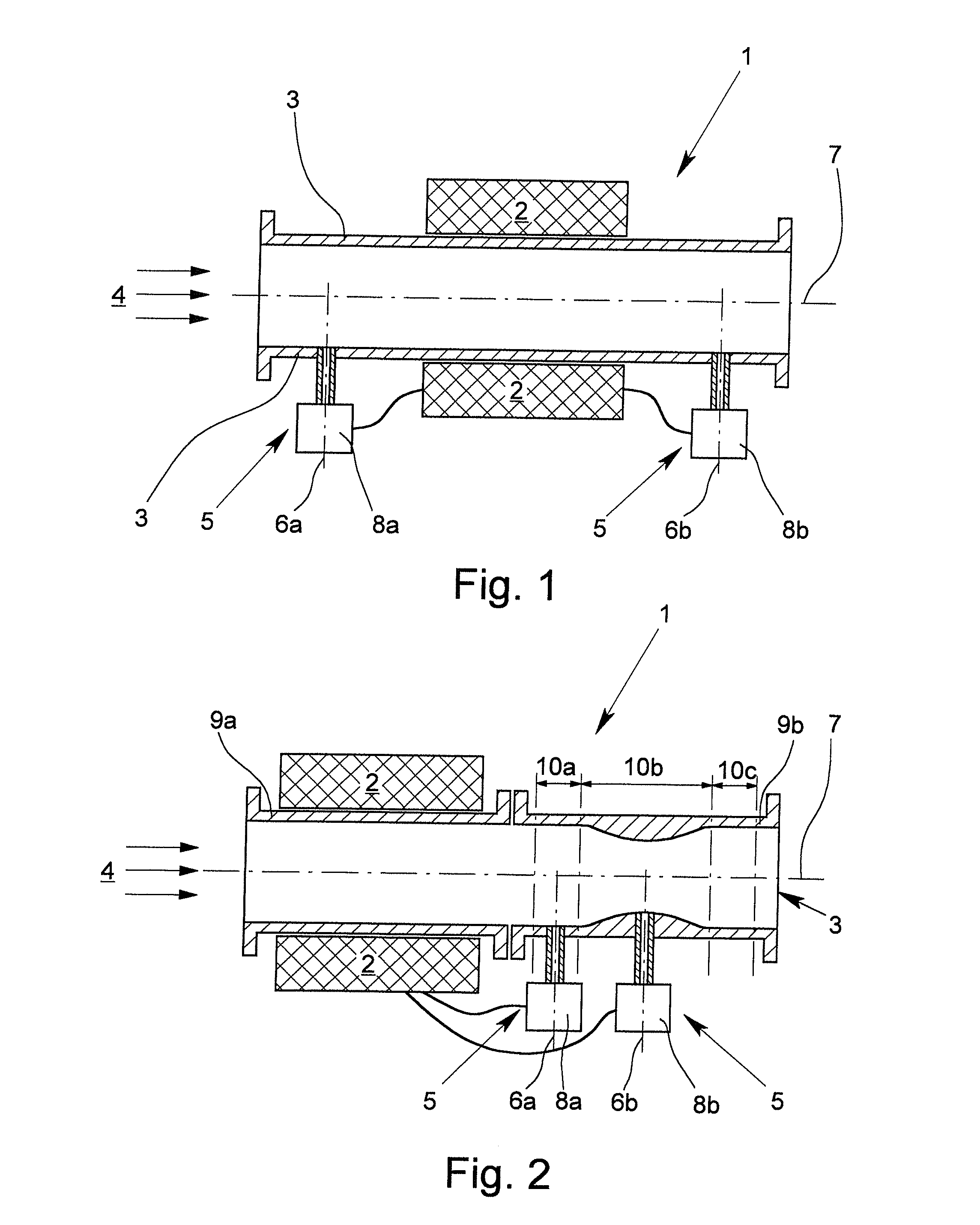

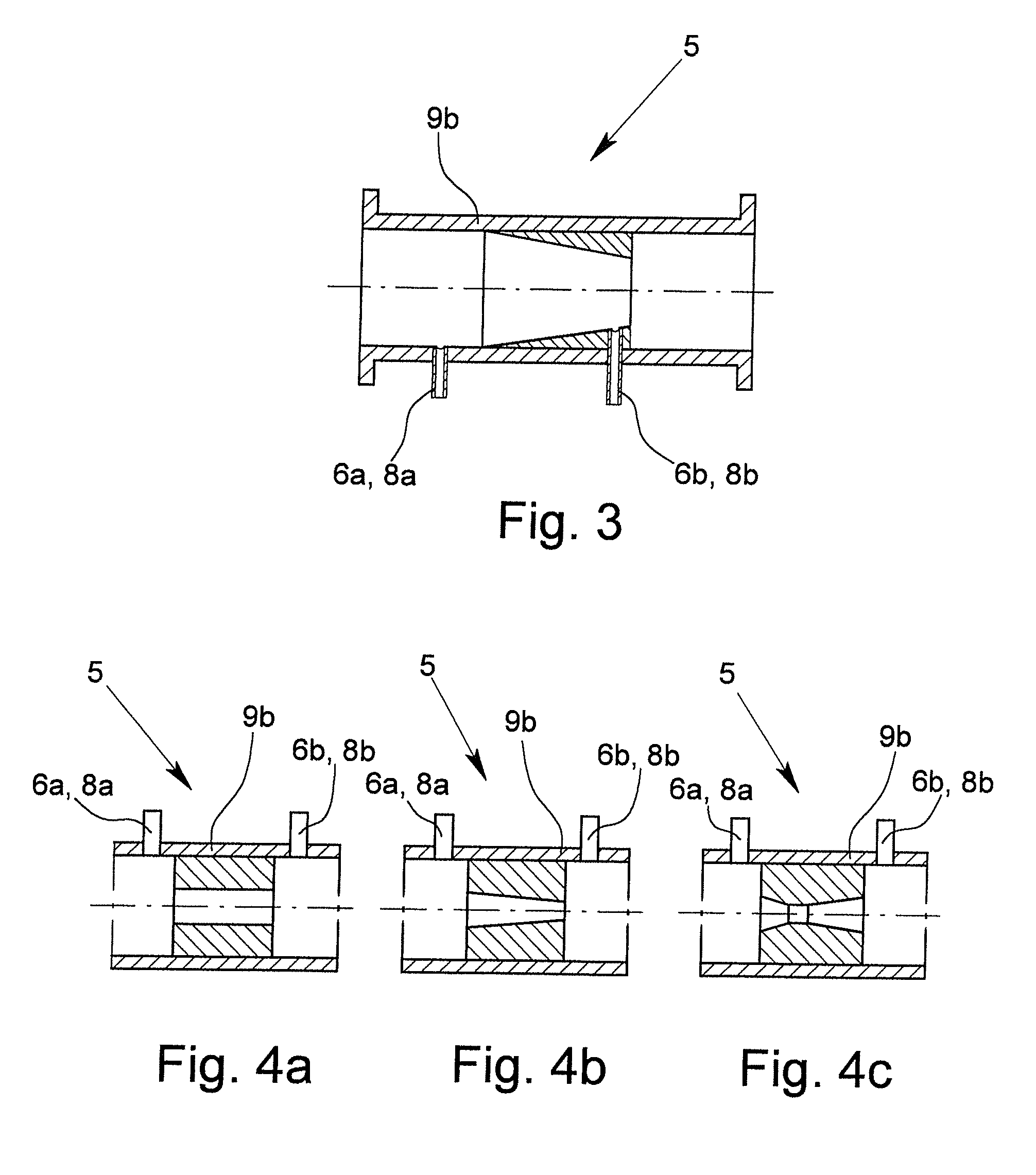

Nuclear magnetic flow meter and method for operation of nuclear magnetic flow meters with an additional measuring device operating on a different principle

ActiveUS9513148B2Improve accuracyHigh flow accuracyVolume/mass flow by differential pressureElectric/magnetic detectionMagnetic measurementsMeasurement device

A nuclear magnetic flow meter for measuring the flow rate of a multiphase medium which is flowing through a measuring tube with a nuclear magnetic measurement device, the nuclear magnetic measurement device being located around the measuring tube. The accuracy of the measurement of the flow rate for the gaseous phase is achieved in that, in addition to the nuclear magnetic measurement device, there is a further measurement device which implements another measurement principle, e.g. a differential pressure flow rate measurement device for measuring the differential pressure of the medium in the measuring tube. At least one pressure gauge at each of two measurement sites which are different in the longitudinal direction of the measuring tube.

Owner:KRONE GMBH

Flow rate accuracy of a fluidic delivery system

ActiveUS8240635B2High flow accuracyImprove accuracyOperating means/releasing devices for valvesPiezoelectric/electrostriction/magnetostriction machinesElectricityPiezoelectric actuators

Owner:MEDOS INT SARL

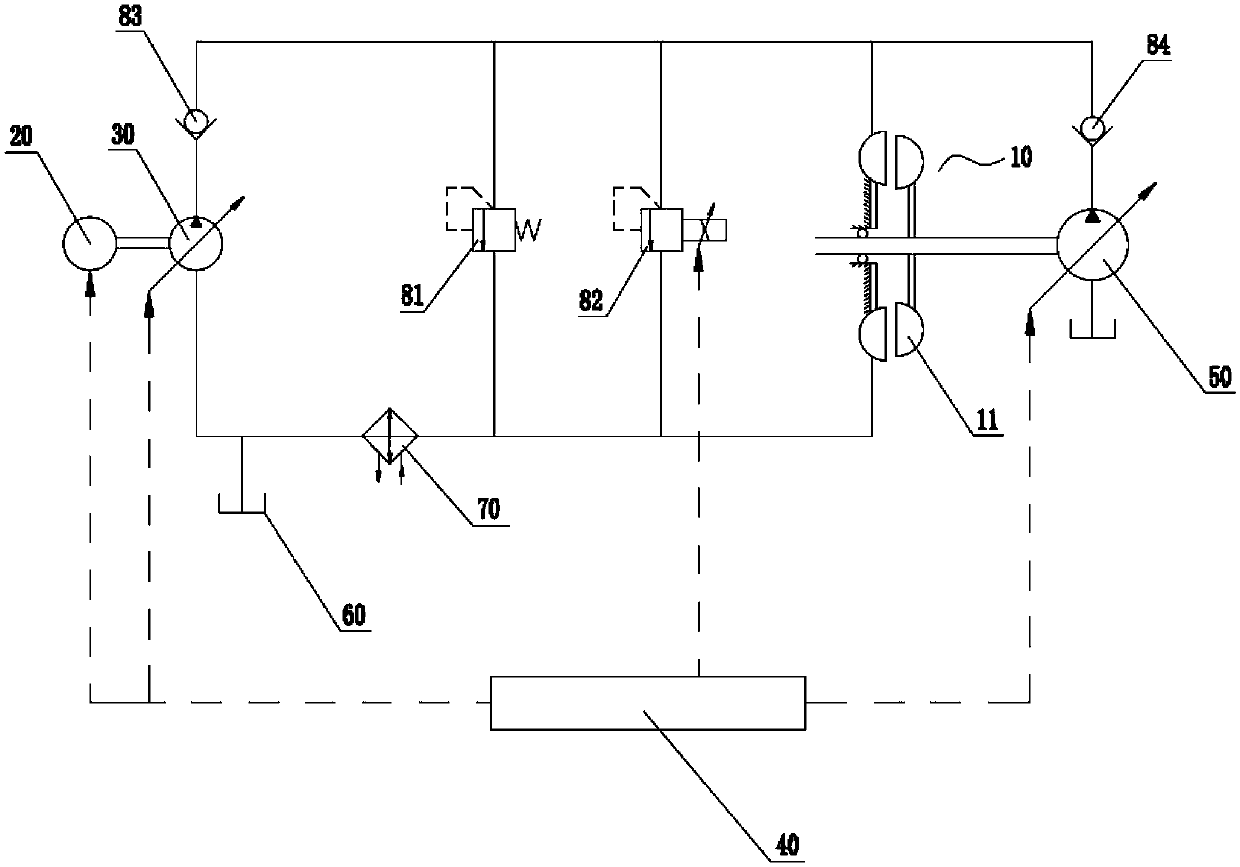

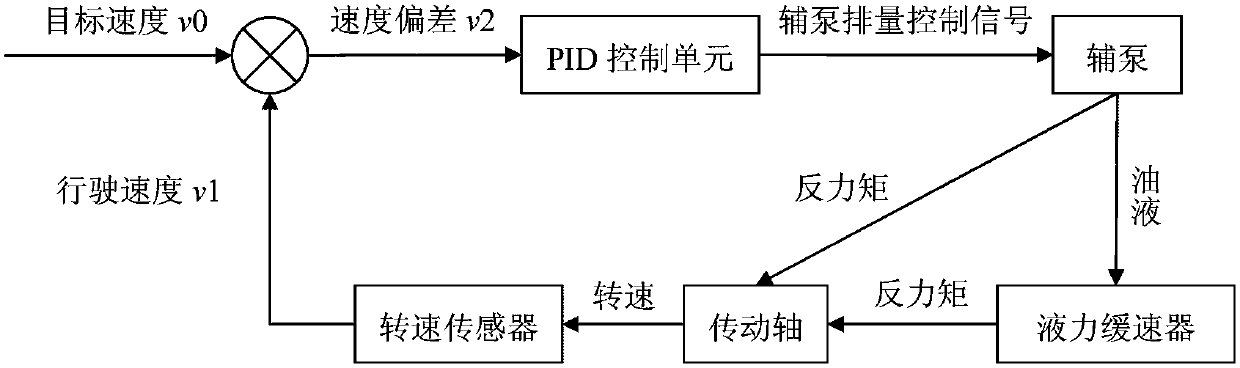

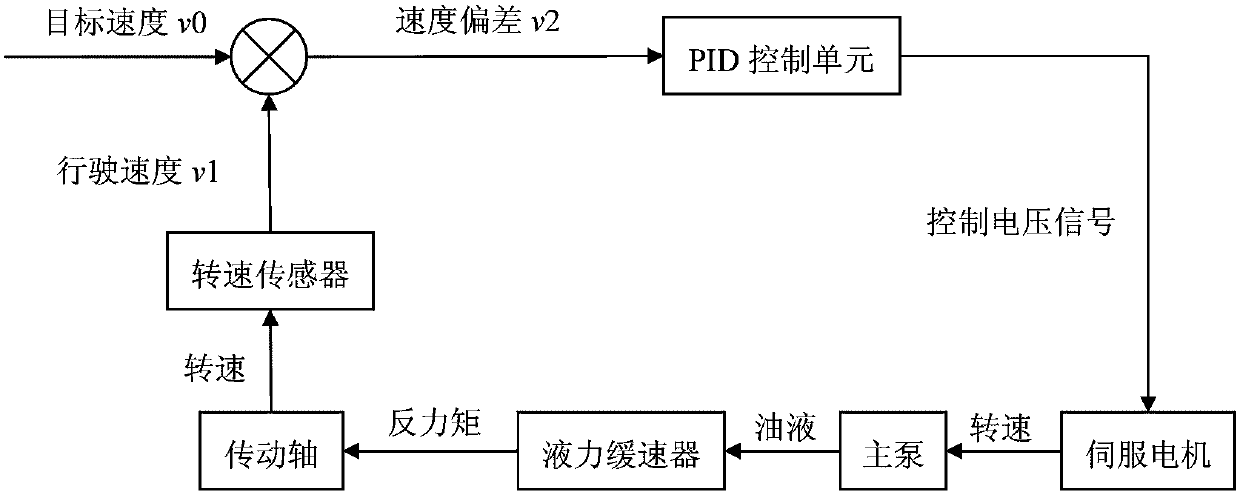

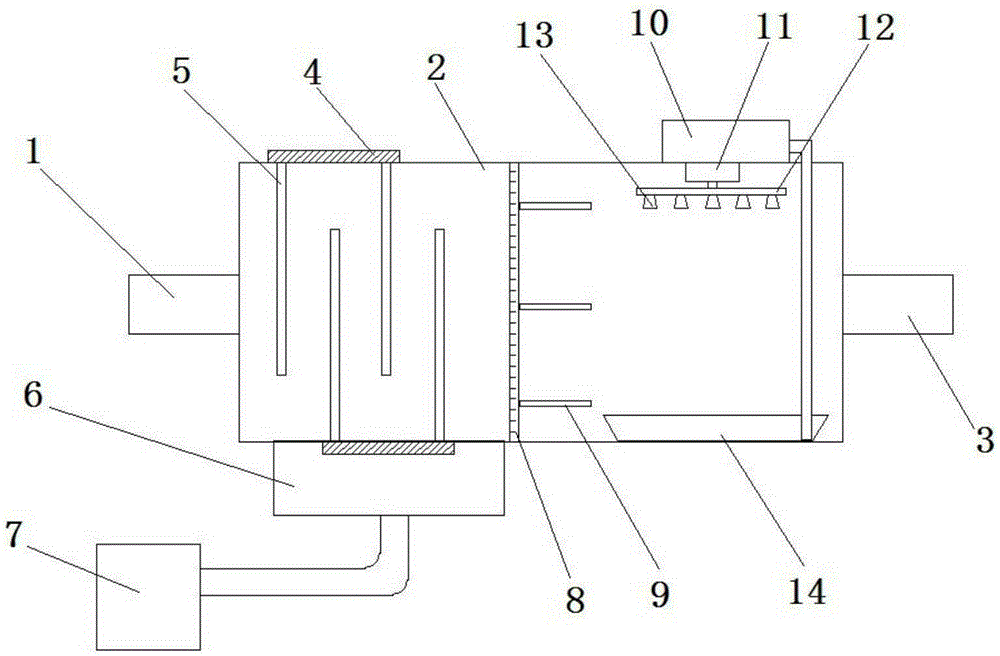

Pump control type hydraulic retarding system and control method thereof

InactiveCN105508322AFast brakingFast can provide dual braking for the vehicleServomotorsDrive shaftPulp and paper industry

The invention relates to a pump control type hydraulic retarding system and a control method thereof. The pump control type hydraulic retarding system comprises a hydraulic retarder, a rotating speed sensor, an oil tank, a controller, a servo motor, a main pump and an auxiliary pump; the rotating speed sensor is mounted on a transmission shaft of a vehicle; the servo motor is connected to the main pump; and a rotating shaft of the auxiliary pump is connected to a rotating shaft of the hydraulic retarder. An oil outlet of the main pump and an oil outlet of the auxiliary pump are both connected to an oil inlet of the hydraulic retarder; an oil inlet of the main pump is connected to an oil outlet of the hydraulic retarder and connected to the oil tank; and an oil inlet of the auxiliary pump is connected to the oil tank. The auxiliary pump and the hydraulic retarder are coaxially connected, so that the pump control type hydraulic retarding system can quickly enter the brake retarding work; and the main pump and the auxiliary pump are separatelymatched with the hydraulic retarder to provide the control with different precision levels overthe vehicle driving speed.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

Waste gas treatment device for power station

InactiveCN106731368AEasy to handleImprove the blocking effectCombination devicesPower stationTreatment effect

The invention discloses a waste gas treatment device for a power station. One end of a box body is connected with a gas inlet pipe; the other end of the box body is connected with a gas exhaust pipe; a fixed plate is arranged on the external side, close to one end of the gas inlet pipe, of the box body; a baffle is perpendicular to the fixed plate; the baffle extends into the box body; the baffle can be pulled out by the fixed plate; a collecting box is arranged at the lower end of the fixed plate; the collecting box is connected with a dust cleaning box through a pipeline; a filter screen is arranged on the right side of the baffle; a plurality of air guide plates are uniformly arranged on the right side of the filter screen; a circulating pump is arranged on the external side of the top end of the box body on the right sides of the air guide plates; a motor is arranged at the top end of the internal side of the box body; the lower end of an output shaft of the motor is connected with a dispersion pipe; a plurality of atomizing nozzles are arranged at the lower end of the dispersion pipe; the circulating pump is connected with the dispersion pipe; a collecting pond is arranged right under the dispersion pipe; and one end of a pipeline extends to the bottom of the collecting pond, and and the other end of the pipeline is connected with the circulating pump. The waste gas treatment device for the power station, disclosed by the invention, has the advantages of simple structure, convenient use, strong dust cleaning capacity, low operation cost and good waste gas treatment effect.

Owner:TIANJIN FANGYUAN ELECTRIC EQUIP

Flow rate accuracy of a fluidic delivery system

ActiveUS8141844B2High flow accuracyImprove accuracyOperating means/releasing devices for valvesMedical devicesElectricityPiezoelectric actuators

Improving the accuracy of the flow rate of a valve in a fluidic delivery device in which a desired flow rate may be achieved by varying the duty cycle of the valve. The flow rate of fluid delivery from the valve over its lifetime is stabilized by minimizing the voltage OPENING time of the valve to account for valve and piezoelectric actuator drift. Also, the valve OPENING time of one or more fluidic parameters that impact on the flow rate delivery by the valve and differ among fluidic delivery devices is compensated to optimize the flow rate accuracy.

Owner:MEDOS INT SARL

Lithium ion battery coating process pole piece drying system and process method thereof

PendingCN113915980AImprove energy efficiencyReduce energy consumptionDrying gas arrangementsPretreated surfacesHot blastElectric heating

The invention discloses a lithium ion battery coating process pole piece drying system and a process method thereof. The pole piece drying system is composed of a hot air station, a hot air conveying control system, a coating machine drying oven and a coating machine control system, wherein the hot air station is connected with the hot air conveying control system through a hot air conveying pipeline; the hot air conveying control system is connected with the coating machine drying oven through a drying oven lower hot air supply pipe and a drying oven upper hot air supply pipe; and each electrical control element in the pole piece drying system is connected with the coating machine control system through a system control circuit. According to the lithium ion battery coating procedure pole piece drying system and the process method of the pole piece drying system, the energy utilization rate is high, fuel combustion is adopted to obtain heat energy, compared with direct resistance heating, the energy utilization rate is high, the energy consumption is low, the cost is low, the cost for obtaining the same heat is 30%-55% lower than that of electric heating, the system is more environmentally friendly, and on the whole, the gas combustion emission is far lower than the emission of fire coal for producing the same electric energy.

Owner:泰安岱力能新能源科技发展有限公司

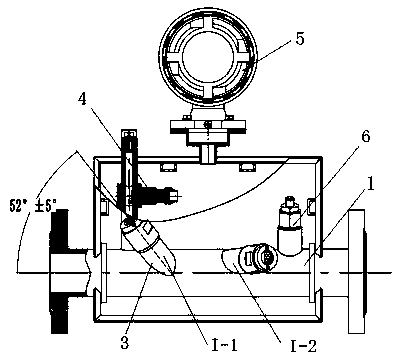

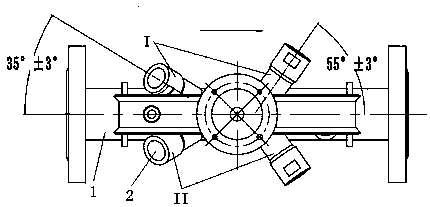

Gas ultrasonic flowmeter with full-zero-section detection flow channel structure and detection method thereof

The invention relates to a gas ultrasonic flowmeter with a full-zero-section detection flow channel structure and a detection method thereof. The gas ultrasonic flowmeter comprises a gas flow channelwith a circular section; at least two pairs of sound channels are arranged on the gas flow channel; an ultrasonic transducer assembly is arranged in each sound channel, each pair of two ultrasonic transducer assemblies alternately transmit and receive ultrasonic waves, the transmitted ultrasonic waves are reflected twice by a pipe wall in the gas flow channel and then are received by the other ultrasonic transducer assembly of the pair, and the projection of the path of the ultrasonic waves on the radial cross section of the gas flow channel is triangular. Since the projection of the ultrasonic path on the radial cross section of the gas flow channel is triangular and can cover the gas flow in the whole pipeline, the gas flow rate in the pipeline can be uniformly detected, the influence ofthe eddy current on the measurement precision is greatly reduced, and the precision and stability of the flowmeter are improved; and at least two pairs of sound channels are staggered in a circumferential direction, so that the linearity, the flow range and the precision of the flowmeter are further improved.

Owner:福建哈德仪表有限公司

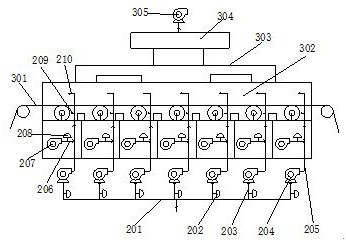

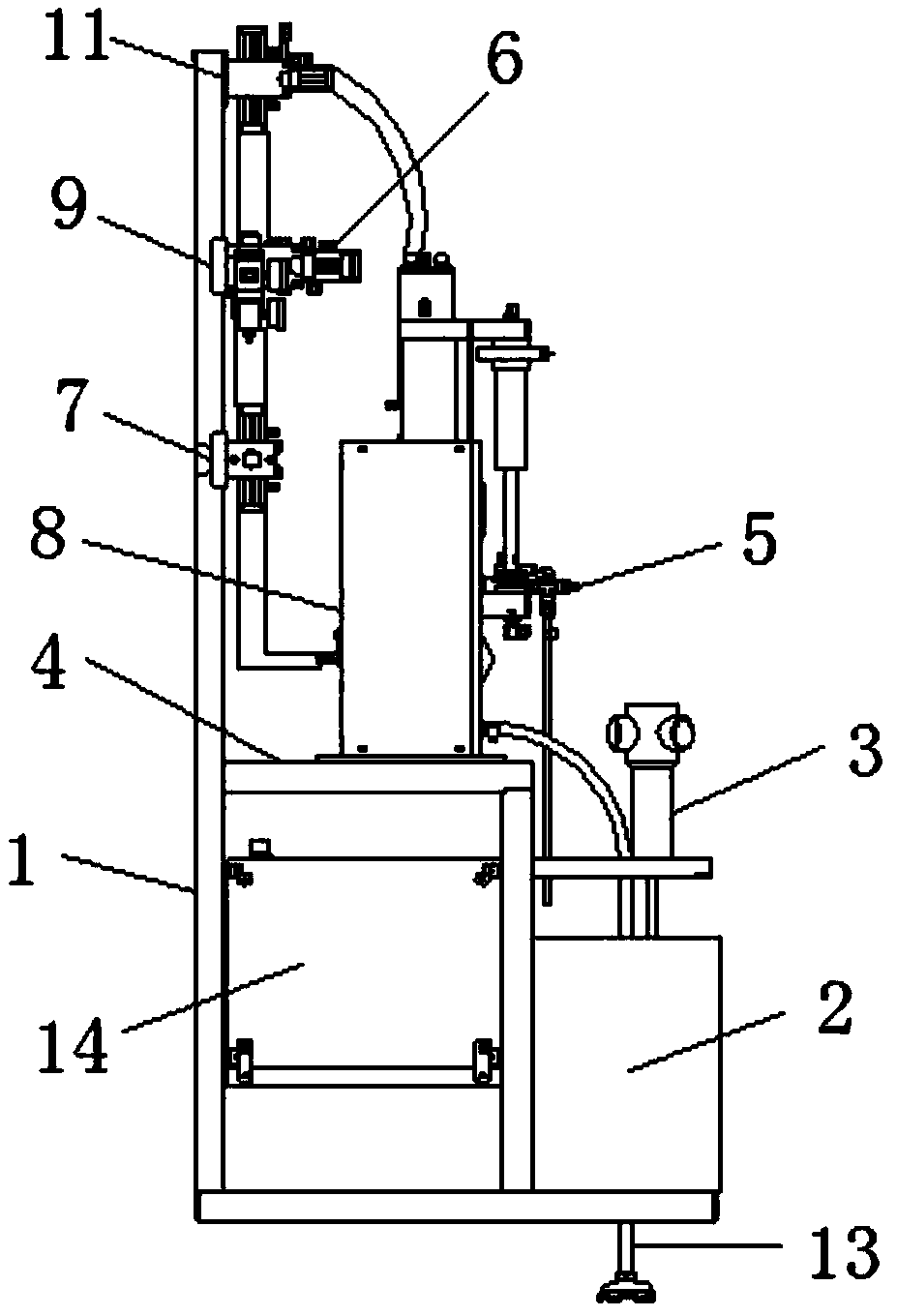

Injection-type paint supply system

PendingCN108499768AEase of environmental protectionCNC control paint flowLiquid spraying apparatusNumerical controlDiaphragm pump

The invention discloses an injection-type paint supply system. The injection-type paint supply system comprises a rack, a coating barrel and a partition, wherein the coating barrel is placed on one side of the rack; the partition is fixedly welded on a side wall of the rack; a stirrer is fixedly connected to one side of the partition; an output end of the stirrer is located in the inner chamber ofthe coating barrel; a diaphragm pump is fixed on the surface of the partition through a screw; and a coating color change valve is fixedly mounted in the position, on the surface of the rack, at thetop of the diaphragm pump. The injection-type paint supply system is reasonable and novel in design and convenient to mount and operate; during later use, the rotational speed of a motor and the flowrate of a coating are in a linear corresponding relationship; the flow rate accuracy of a liquid is high; numerical control can be realized; the response to a control signal is quick; the flow rate can be changed in real time; quick cleaning and color change can be realized; when a robot is used together, automatic batch production of various small-batch products can be realized; and the injection-type paint supply system integrates environmental friendliness and high efficiency, has high practicability and is suitable for popularization.

Owner:东莞市瀚晟自动化设备有限公司

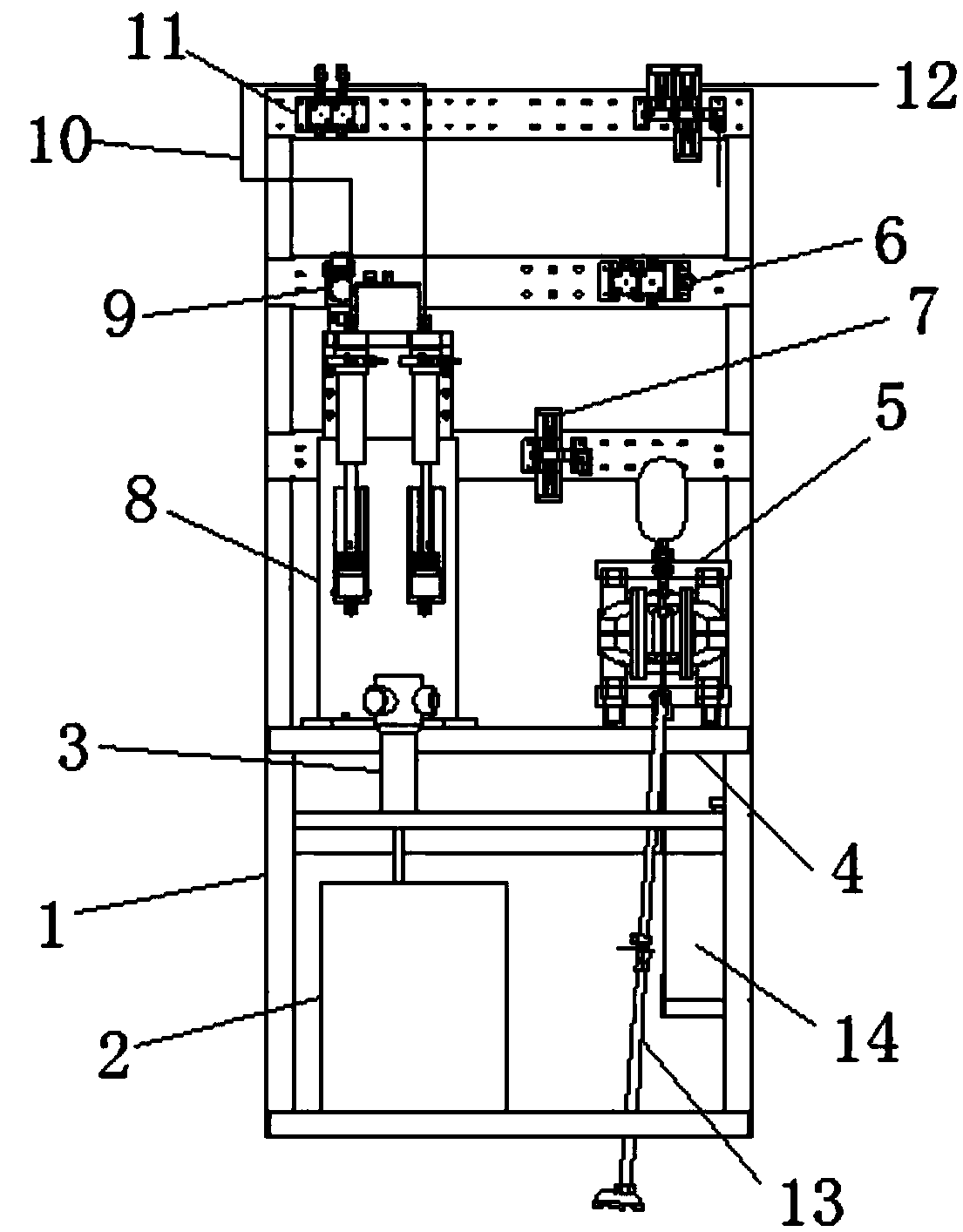

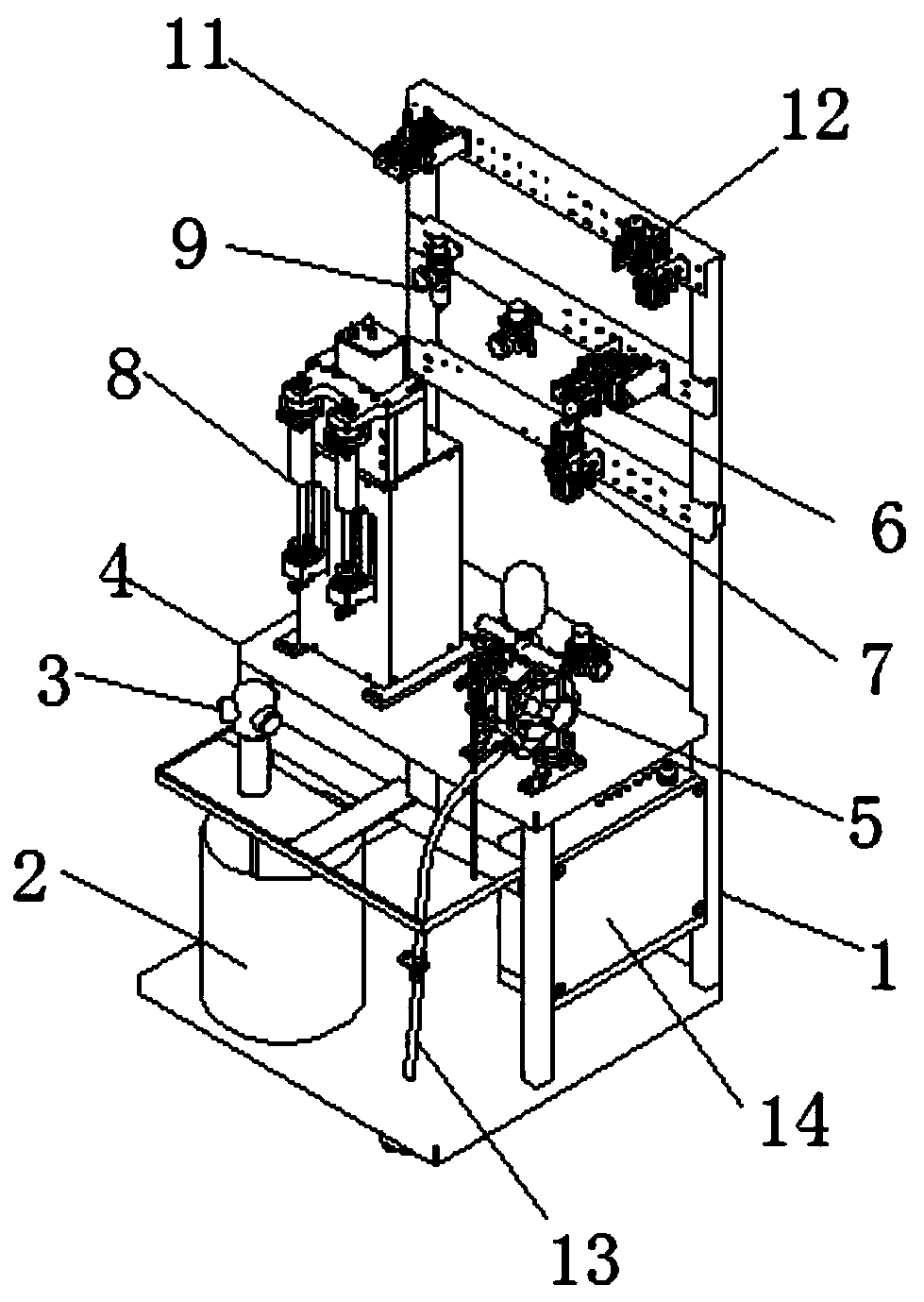

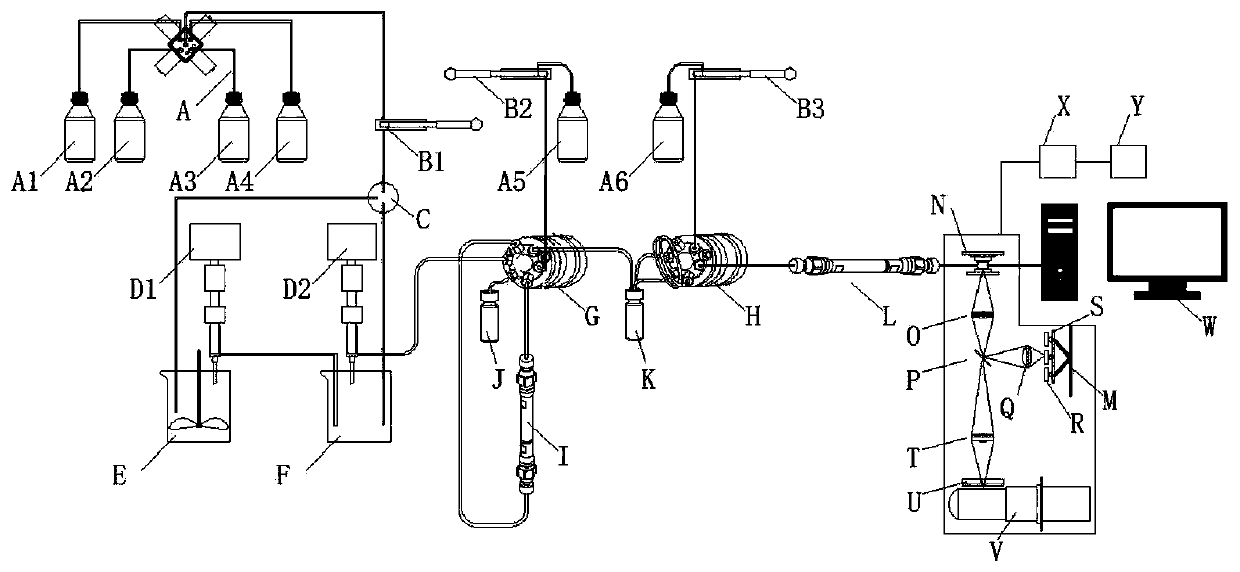

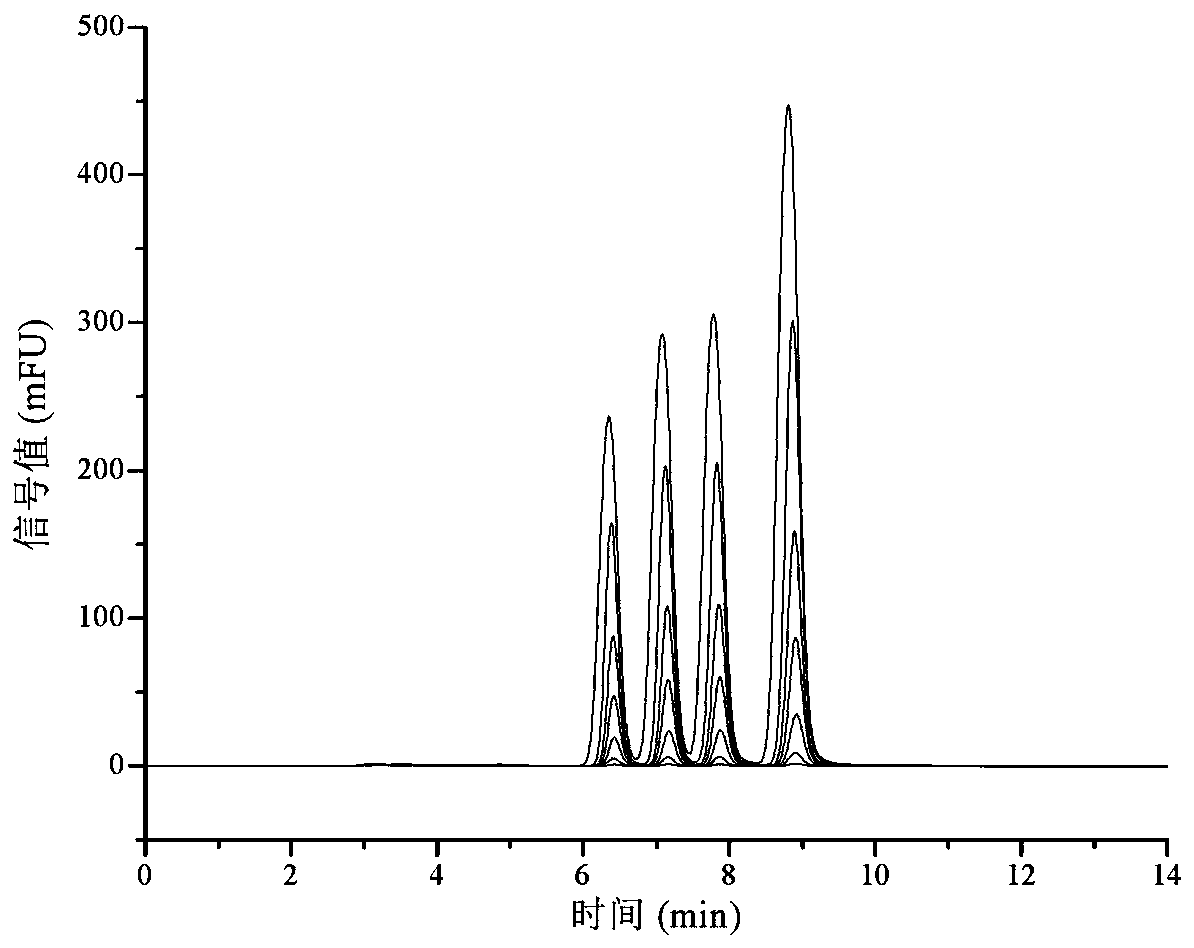

Automated device and method for detecting mycotoxins

The invention belongs to the field of analytical chemical detection, and specifically relates to an automated device and method for detecting mycotoxins. The automated device comprises a control circuit system, a sample pre-processing system, a fluorescence detection system, and a data processing system. The control circuit system is used for controlling transmission of electrical signals betweenvarious systems in devices; the sample pre-processing system is connected with the fluorescence detection system through a pipeline, and the pre-processed sample is conveyed to the fluorescence detection system for detection; and the data processing system is connected with the fluorescence detection system and receives a fluorescent signal detected by the fluorescent detection system, and mycotoxins concentration of the to-be-tested sample is obtained after the fluorescent signal is subjected to data processing. According to the automated device for detecting the mycotoxins, the fluorescencedetection system is provided with a multi-wavelength light source automatic switching optical system and a multi-wavelength LED light source disk, and an ultraviolet LED light source can be automatically switched as needed to generate excitation light of different wavelengths, and the simultaneous detection of various mycotoxins can be satisfied.

Owner:依利特(苏州)分析仪器有限公司

Flow meter for use with a ventilator

ActiveUS10018490B2High flow accuracyReduce airflow resistanceRespiratorsElectrocardiographyEngineeringMembrane configuration

Owner:BREAS MEDICAL

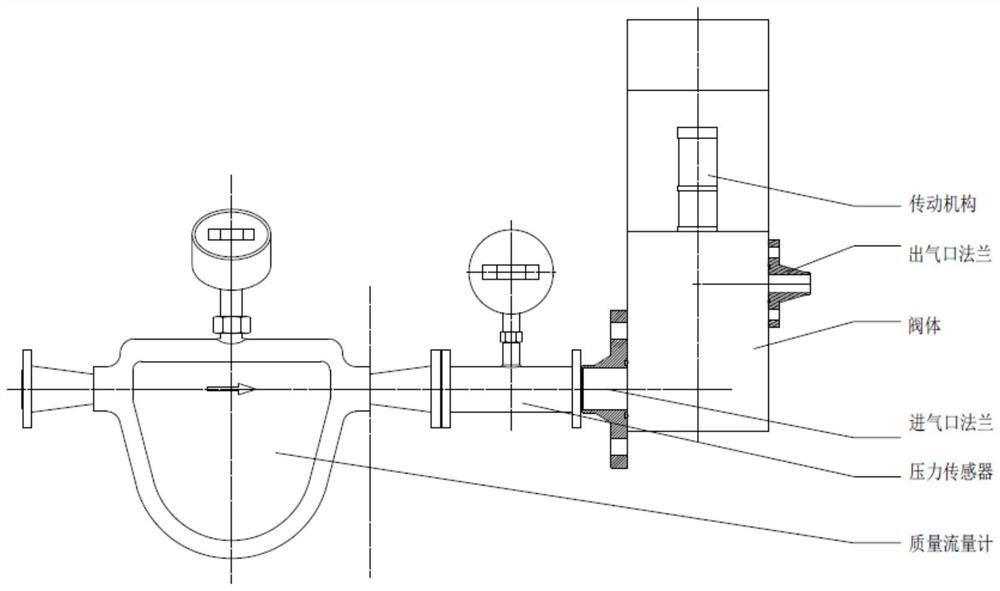

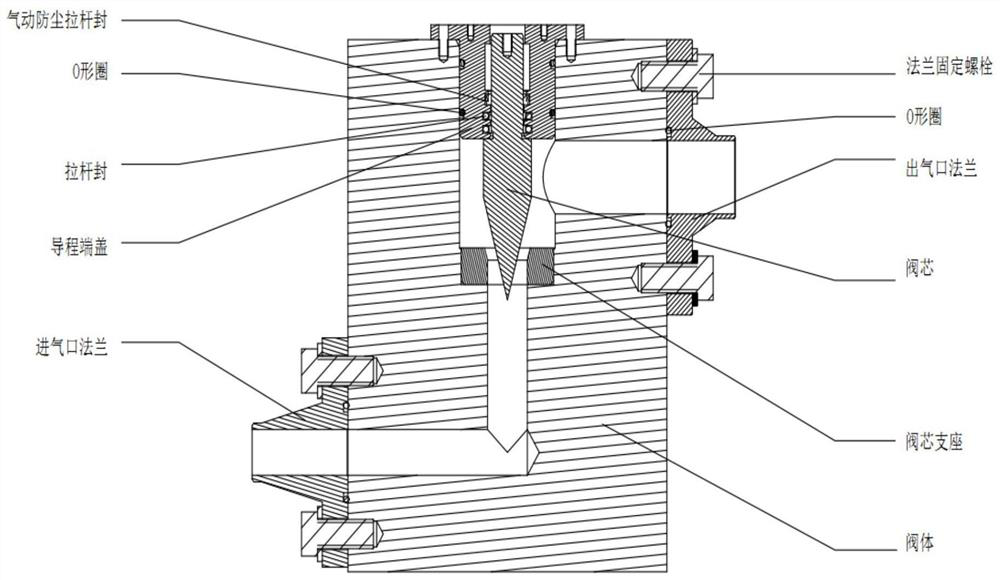

High-precision gas mass flow control valve

ActiveCN112032310ARealize closed-loop controlOvercoming out of sync problemsSpindle sealingsOperating means/releasing devices for valvesLoop controlControl valves

The invention discloses a high-precision gas mass flow control valve. A PLC controls a servo motor driver to serve as a power source; a servo motor rotates correspondingly after receiving a signal; arotating shaft of the servo motor drives a valve element to move axially through a lead screw and a limiting nut, then the opening-closing degree of the valve element and a valve seat is controlled, and finally the gas flow is controlled; a gas flow meter and a pressure sensor are connected to a gas inlet of a valve body; a flow signal output by the gas flow meter and a pressure signal detected bythe pressure sensor serve as feedback signals, the PLC receives the feedback signals and then compares the feedback signals with a system instruction, makes a judgment, and sends a new instruction tothe servo motor, and therefore flow and pressure closed-loop control is formed; and finally, closed-loop control over the position of the valve element reaches high-precision flow control.

Owner:BEIJING RES INST OF PRECISE MECHATRONICS CONTROLS

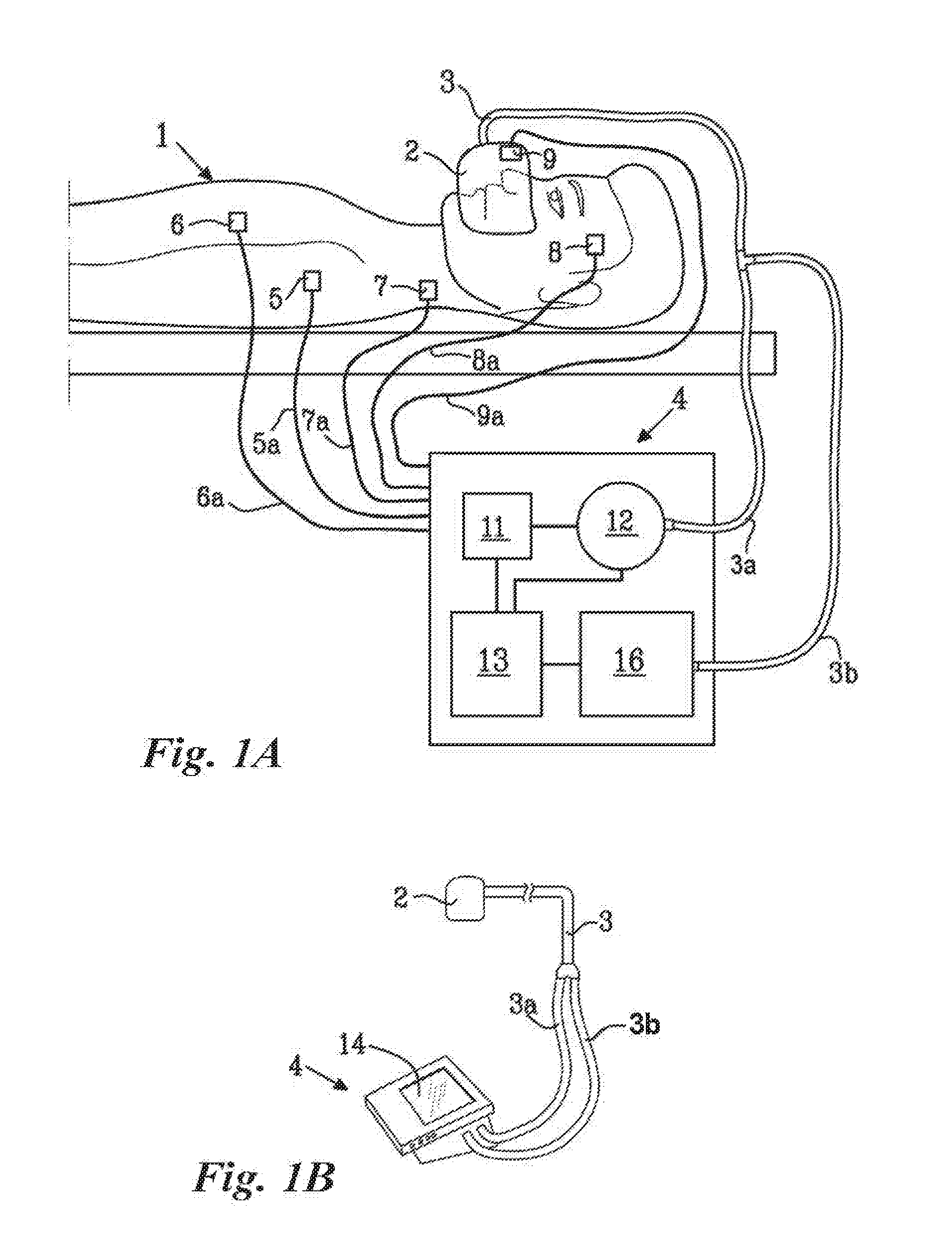

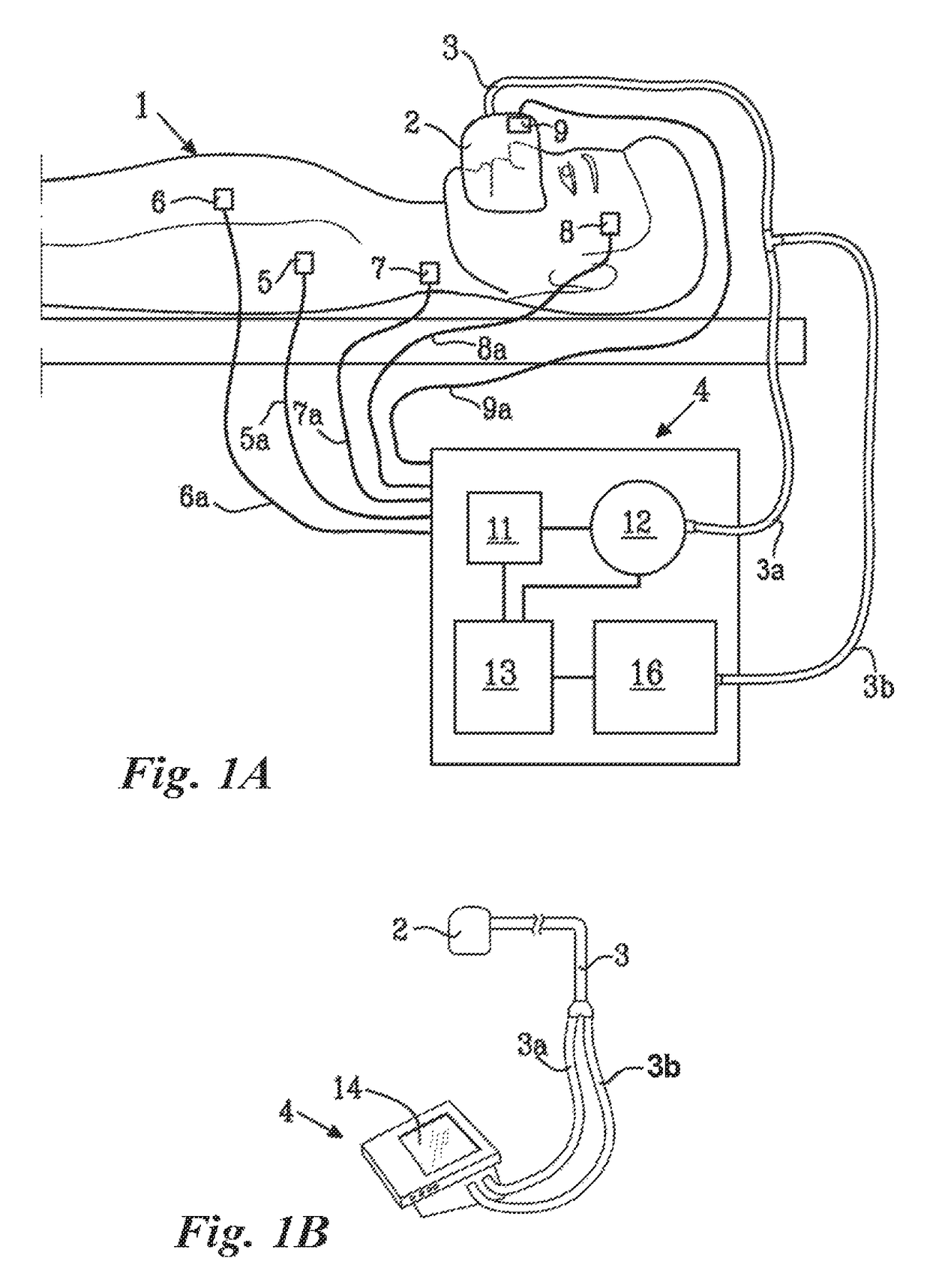

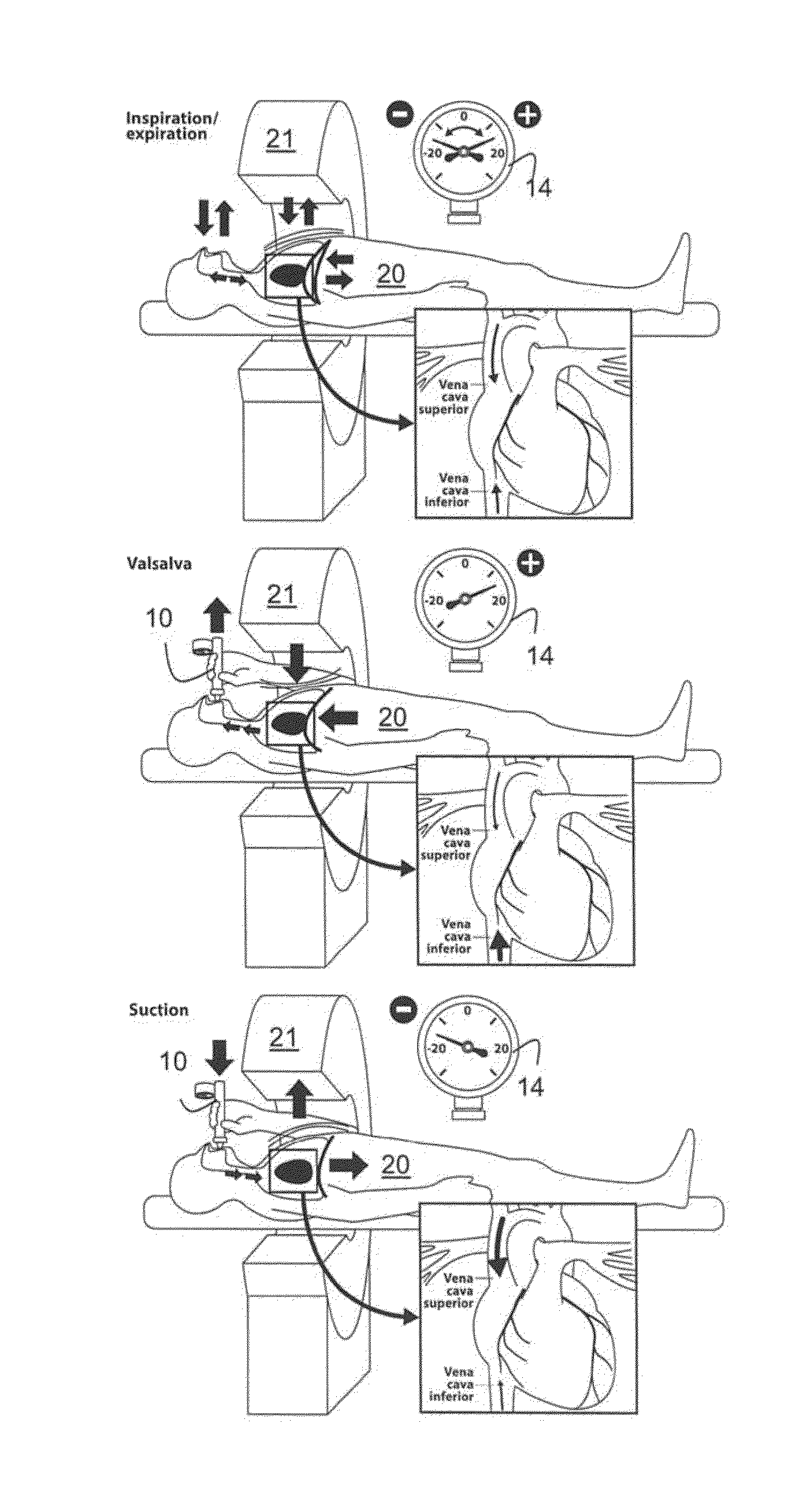

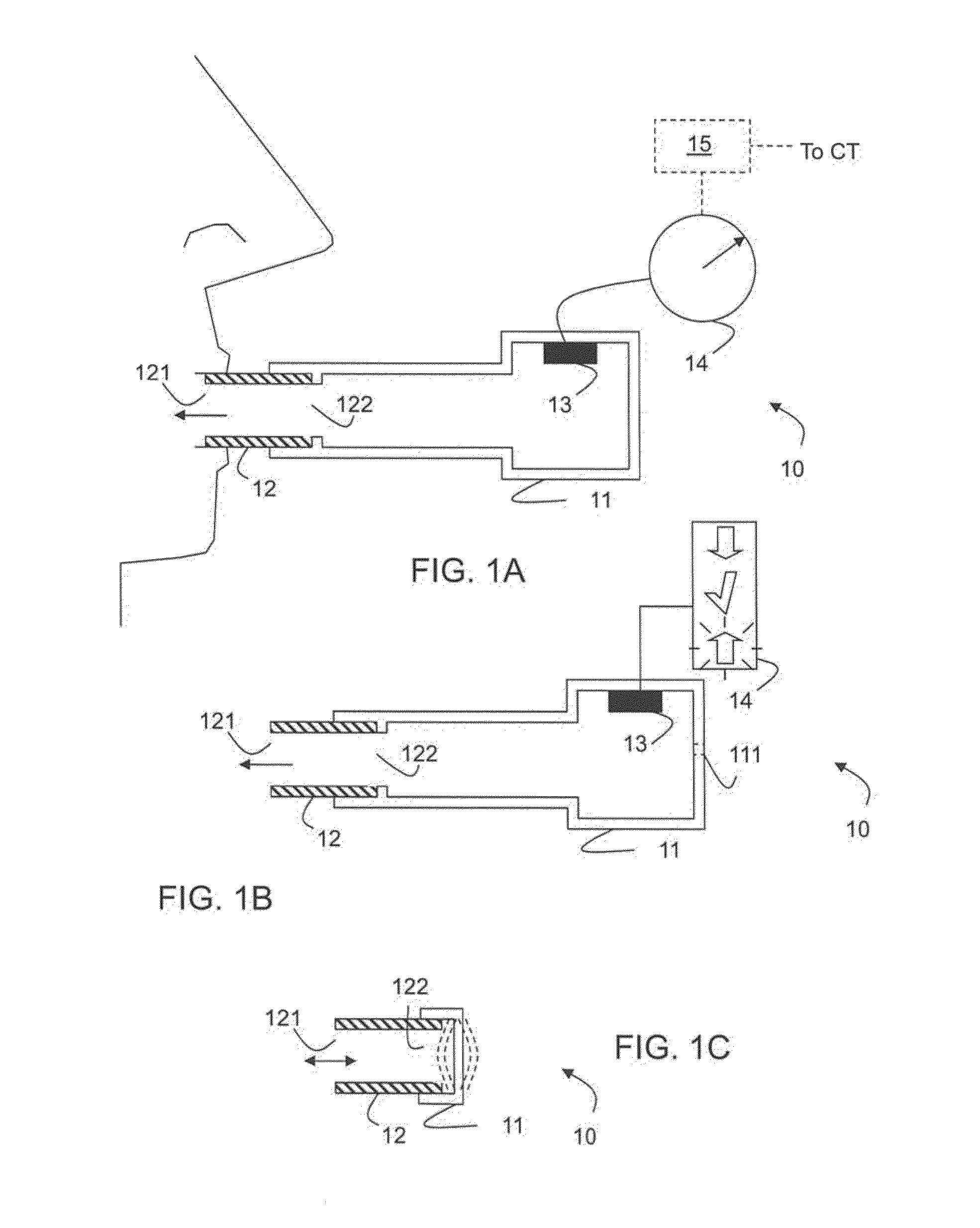

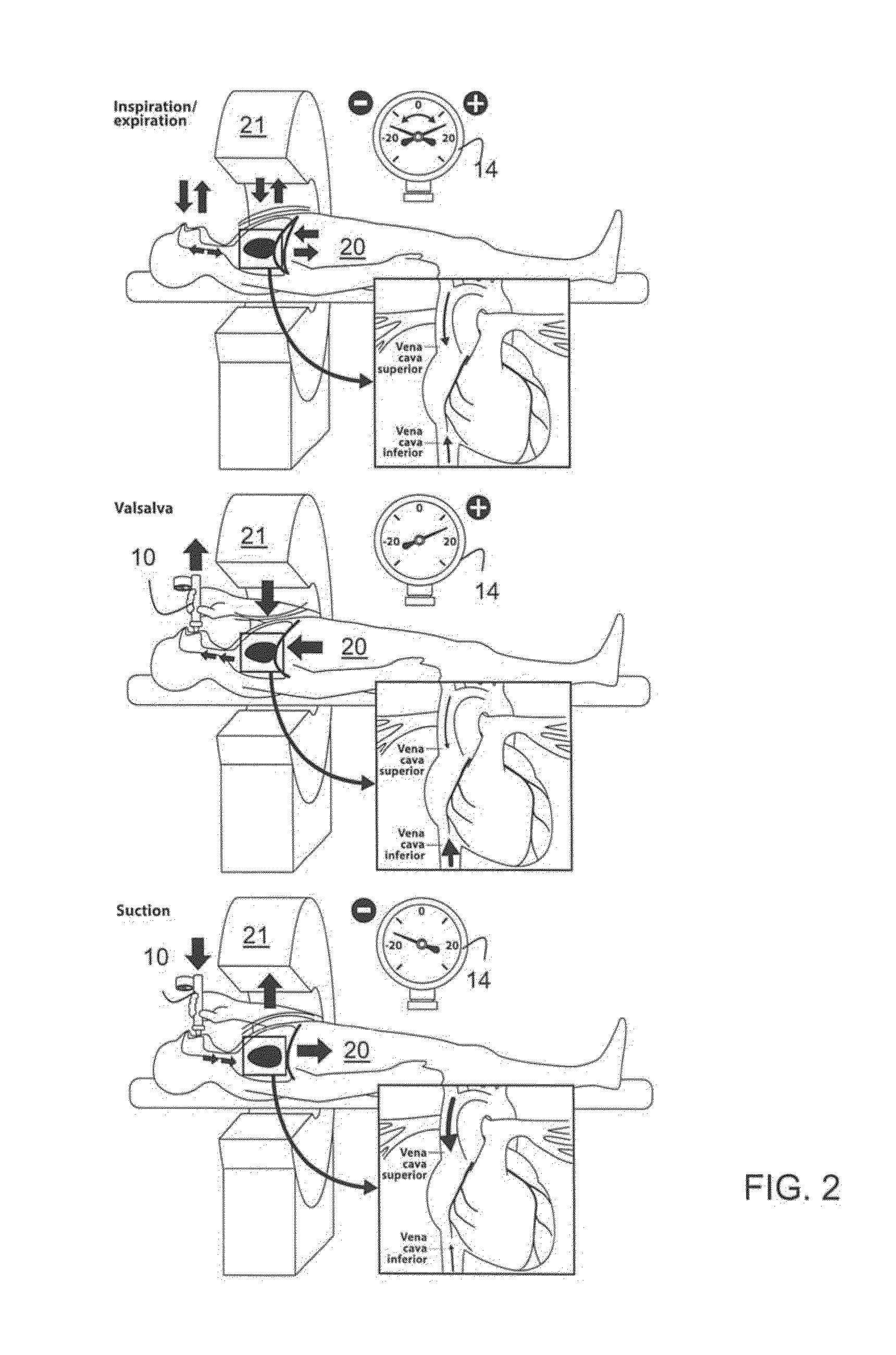

Blood flow control system and methods for in-vivo imaging and other applications

ActiveUS20160192893A1Easy to controlHigh flow accuracyMagnetic measurementsComputerised tomographsHuman bodyVascularizes

A method of and device for acquiring in-vivo images or quantitative / qualitative data (perfusion, blood flow, vascularization, contrast enhancement, selective blood supply management) of interior parts of the human body (20) is described, using an imaging system (21) and including the steps of positioning the body (20) relatively to the imaging system (21), applying a respiratory resistance device (10) to the respiratory system of the body (20), and performing an image acquisition step during or concomitantly an inhalation / inspiration / suction or exhalation / Valsalva / expiration phase, during which the body provides suction or exhalation against a resistance as provided by the respiratory resistance device (10).

Owner:GUTZEIT ANDREAS

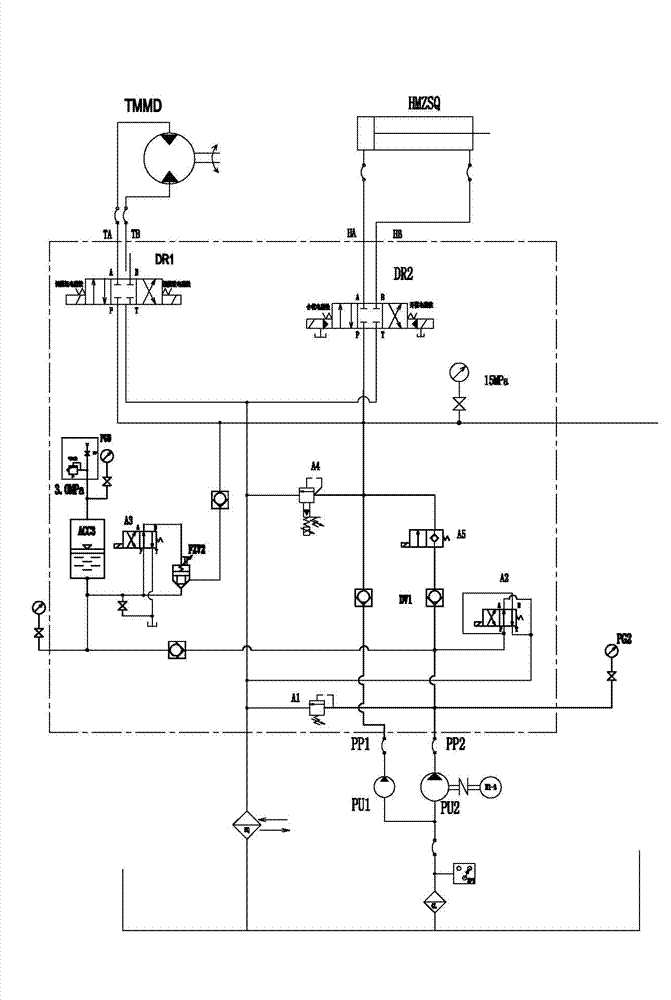

Environmental-friendly energy-saving die-casting machine electrohydraulic control system and energy-saving method

The invention relates to an environmental-friendly energy-saving die-casting machine electrohydraulic control system, which is characterized in that the system comprises a large oil pump (PU2), a small oil pump (PU1), a die closing valve (DR2) and a die adjusting valve (DR1), the output end of large oil pump (PU2) is respectively connected with the oil inlet passages of the die closing valve (DR2) and the die adjusting valve (DR1) through a solenoid valve (A5) and a proportional overflow valve (A4), an unloading valve (A2) is additionally connected at the outlet end of the large oil pump (PU2), the output end of the unloading valve (A2) is communicated with the oil inlet end of an energy storage device (ACC3), and the output end of the energy storage device (ACC3) is respectively connected with the oil inlet passages of the die closing valve (DR2) and the die adjusting valve (DR1) through a solenoid valve (A3). The environmental-friendly energy-saving die-casting machine electrohydraulic control system has the advantages that the motor power and the pump displacement are reduced by 50 percent, approximate 50-60 percent of energy can be saved, the action stability is high, the response sensitivity is high and the like.

Owner:YIXING JIACHEN DIE CASTING MACHINE MFG

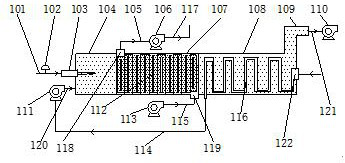

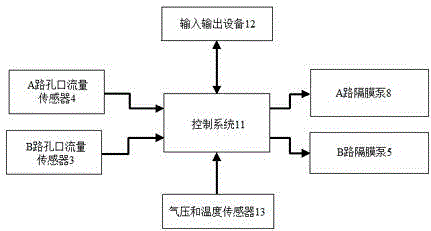

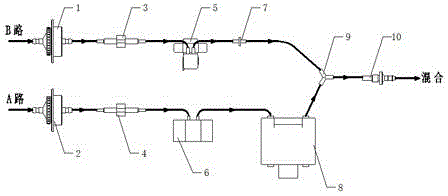

Gas dilutor

ActiveCN103157393BEasy to operateCompact structureMixer accessoriesMixing gases with gases/vapoursDiaphragm pumpNuclear engineering

The invention discloses a gas dilutor. The gas dilutor comprises 1, an A path gas inlet, an A path orifice flow sensor, an A path air-capacitor and an A path diaphragm pump orderly connected, 2, a B path gas inlet, a B path orifice flow sensor, a B path diaphragm pump and a B path one-way valve orderly connected, 3, a three-way valve connected to the A path diaphragm pump and the B path one-way valve, 4, a mixed gas outlet connected to a gas outlet of the three-way valve, 5, a control system, 6, an input / output device, and 7, a gas pressure and temperature sensor. The control system is connected to the A path orifice flow sensor, the B path orifice flow sensor, the A path diaphragm pump, the B path diaphragm pump, the input / output device and the gas pressure and temperature sensor. The gas dilutor has a compact structure, a small volume and light weight, is convenient for carrying, has a high intelligentization degree, a wide diluted-concentration range, a high preparation precision and a high flow precision, and can be used for diluting special gas containing steam, dust and organics such as oil gas.

Owner:QINGDAO ZHONGRUI INTELLIGENT INSTR

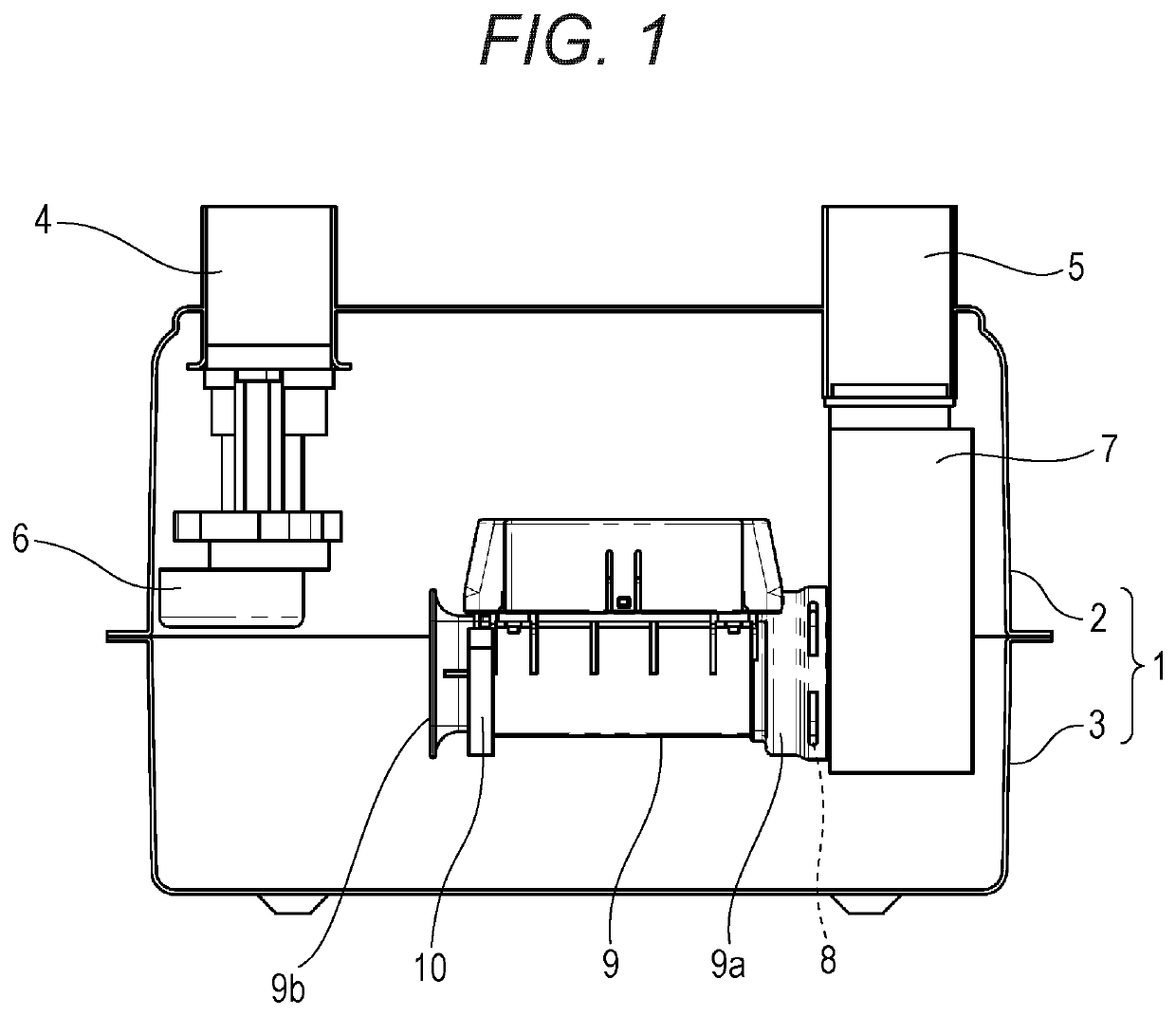

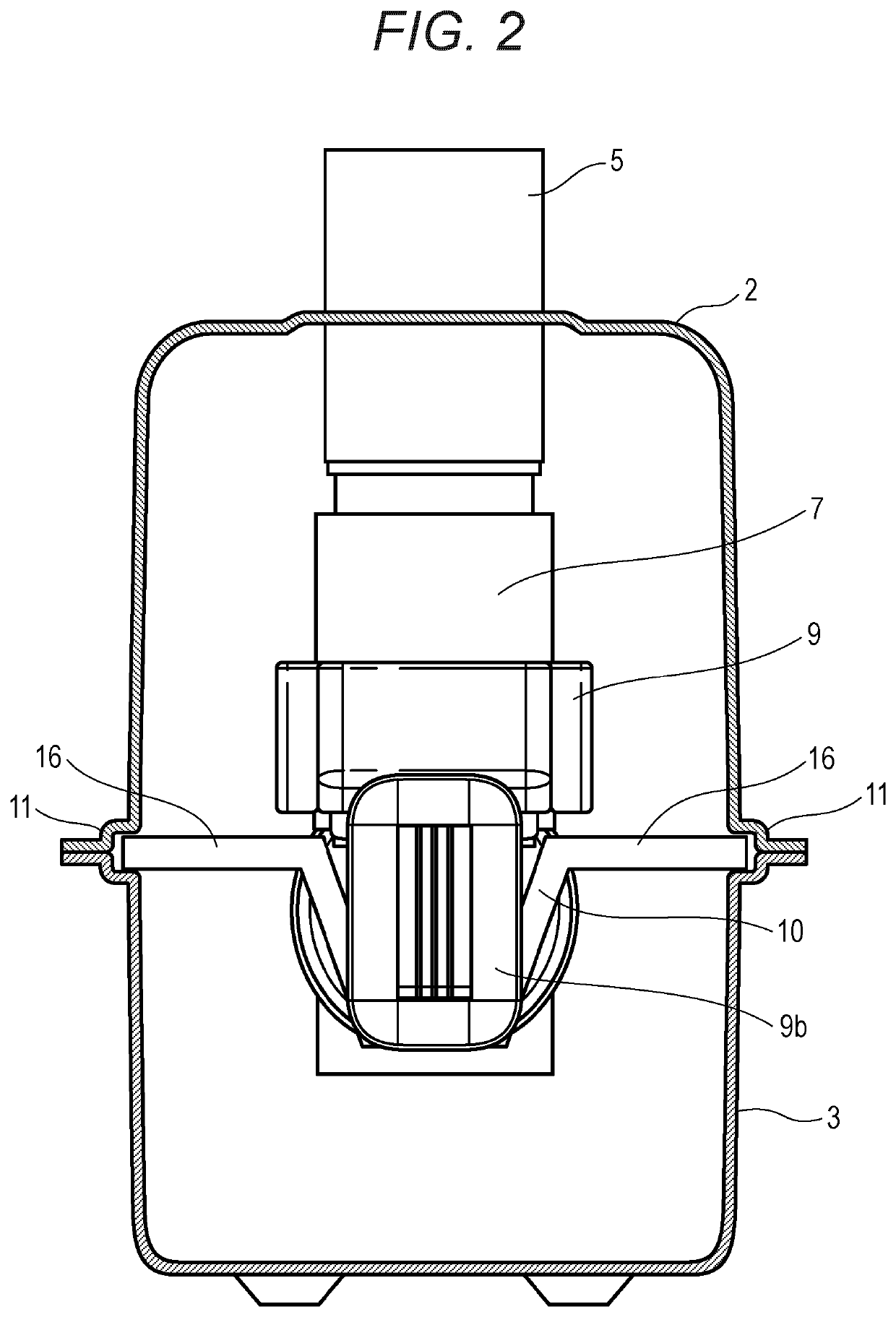

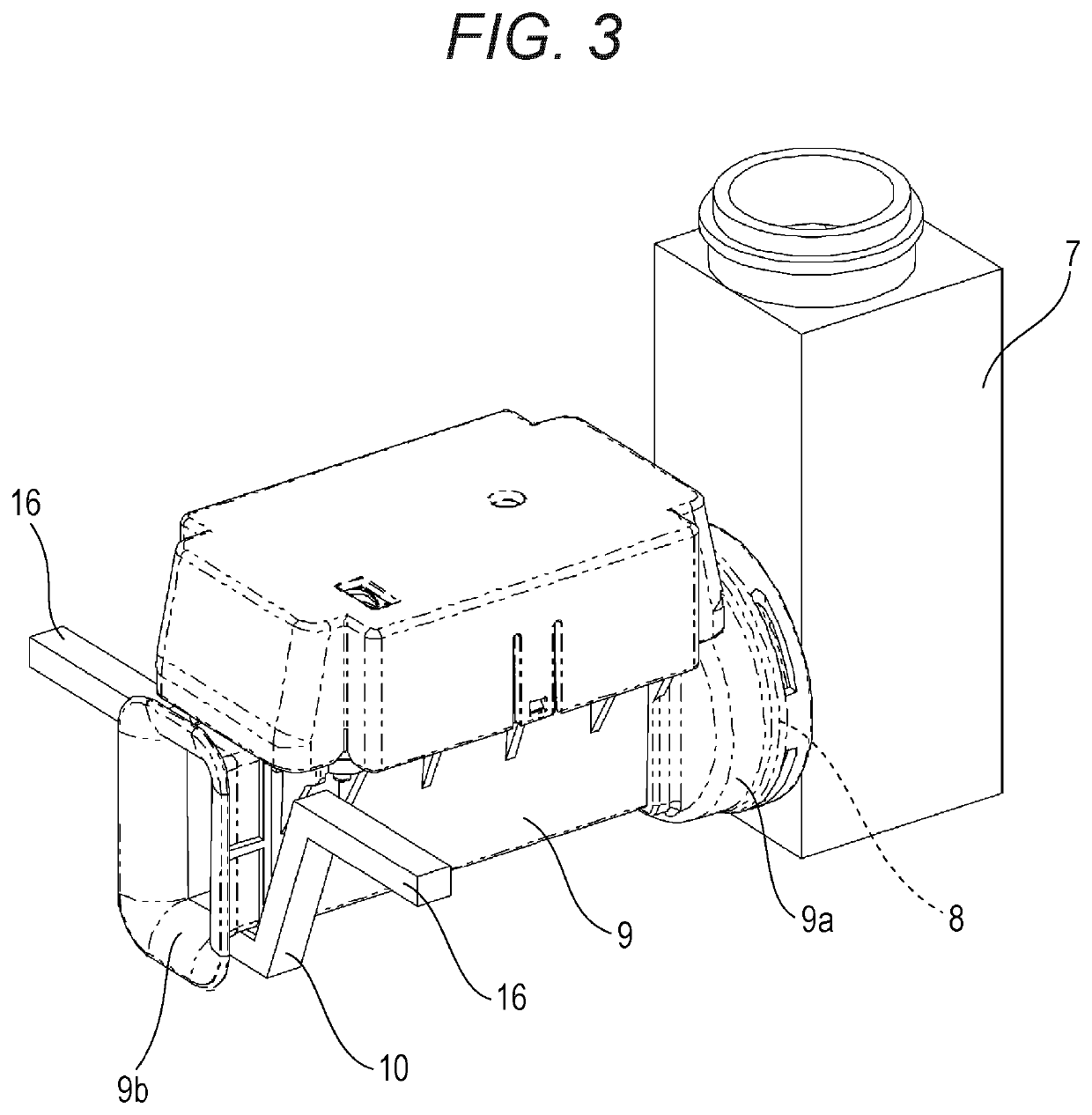

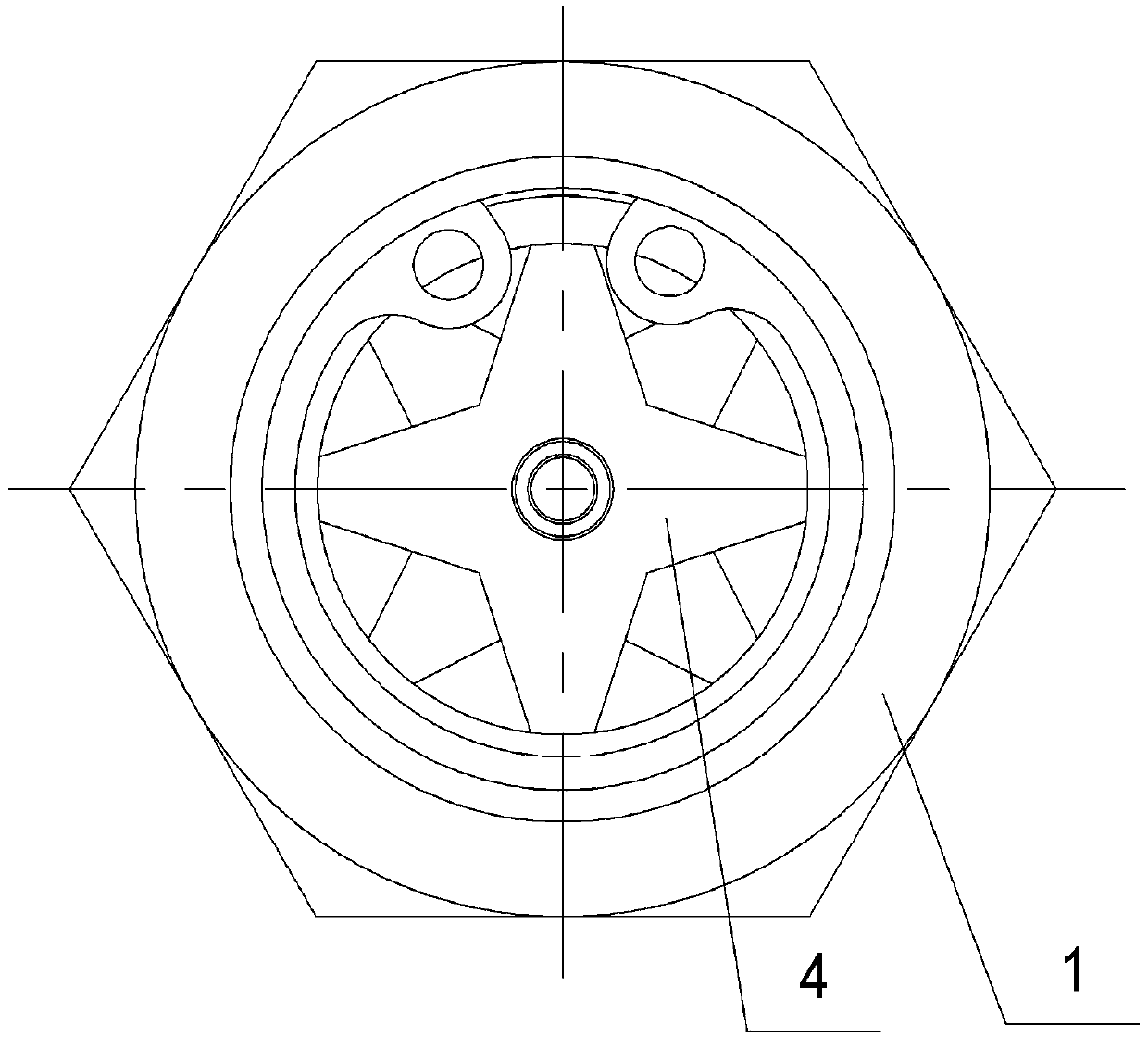

Gas flowmeter

ActiveUS10514286B2Improve accuracyReduce vibrationVolume/mass flow measurementVolume meteringEngineeringRate measurement

A gas flowmeter includes: device body (1) which accommodates a fluid to be measured; inlet pipe (4) through which the fluid to be measured flows into device body (1); and outlet pipe (5) through which the fluid to be measured flows out from device body (1) through connecting pipe (7). The gas flow meter also includes: ultrasonic flow rate measuring unit (9) which has a first end side connected to outlet pipe (5) and performs flow rate measurement of the fluid to be measured which flows in ultrasonic flow rate measuring unit (9); and connecting pipe (7) which is disposed between ultrasonic flow rate measuring unit (9) and outlet pipe (5), and is connected to outlet pipe (5). The gas flow meter further includes support member (10) which supports a second end side of ultrasonic flow rate measuring unit (9).

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

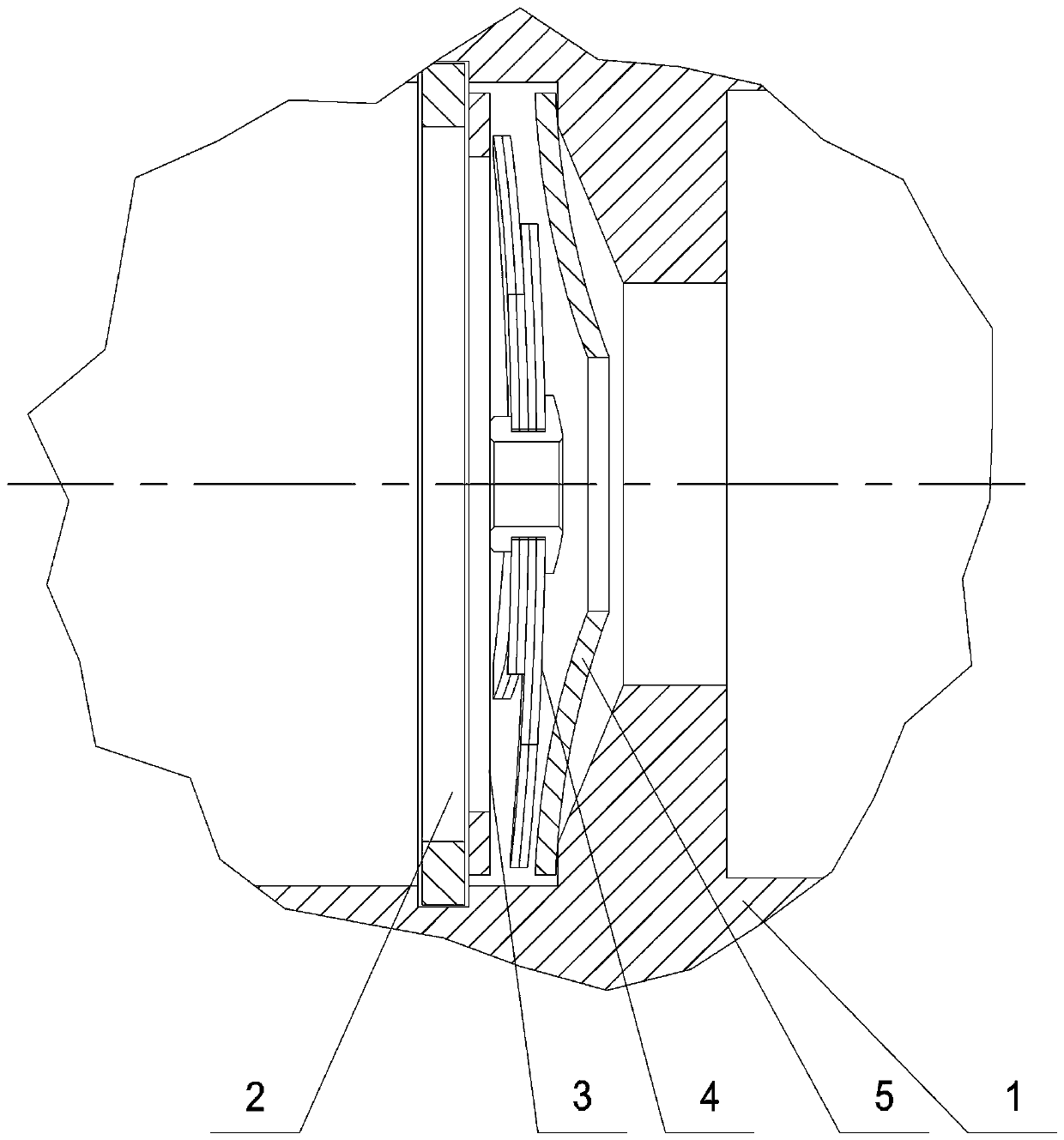

Reed type self-adaptive flow-constant device

PendingCN110285246AReasonable designBuffer against rapid fluctuationsEqualizing valvesSafety valvesSelf adaptiveEngineering

The invention relates to a reed type self-adaptive flow-constant device which is characterized by comprising a shell with an inner cavity reducer, and an elastic check ring, an adjusting ring, a combined reed assembly and a circular arc tapered stress flow plate sequentially arranged on the inner cavity reducer of a middle section of the shell. The combined reed assembly is formed by concentrically overlaying and riveting two groups of reeds; the inner cavity reducer is a tapered hole formed in the middle section of the shell; the diameter of the big end of the tapered hole is matched with the sizes of the combined reed assembly and the circular arc tapered stress flow plate; the stress flow plate is matched with the combined reed assembly so as to form a gap channel for a fluid; one side, on which the elastic check ring is arranged, of the shell is a fluid entry end; and screw-thread sections are arranged on two sides of the inner cavity reducer of the shell and are used for connecting with a fluid conveying pipeline. The reed type self-adaptive flow-constant device provided by the invention is simple in structure, does not need manual intervention, and can self-adaptively realize stable control of the flow.

Owner:汉盛(上海)海洋装备技术股份有限公司

Method of forming a flow restriction in a fluid communication system

InactiveUS9015945B2High flow accuracyImprove accuracyValve arrangementsDecorative surface effectsFlow resistivityCommunications system

Owner:FLOWSION

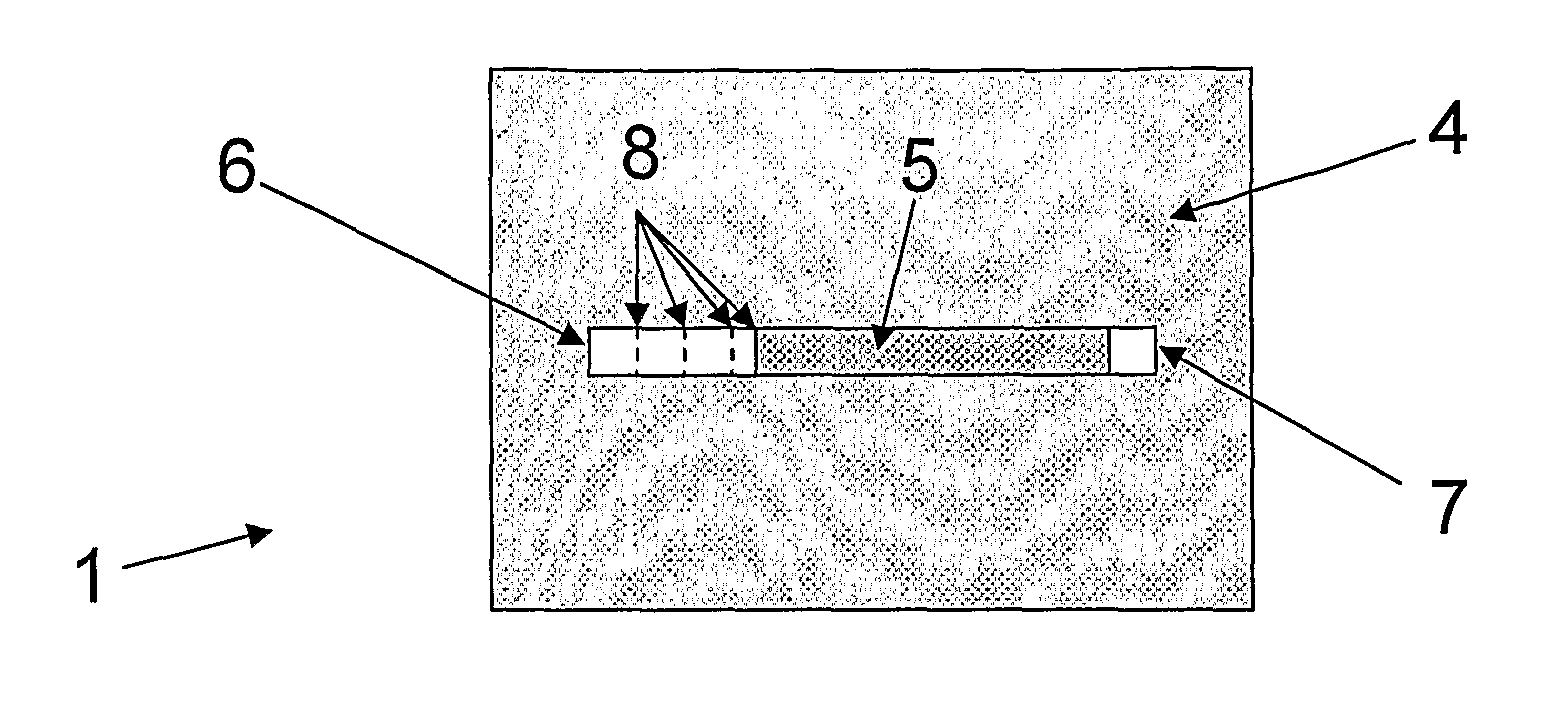

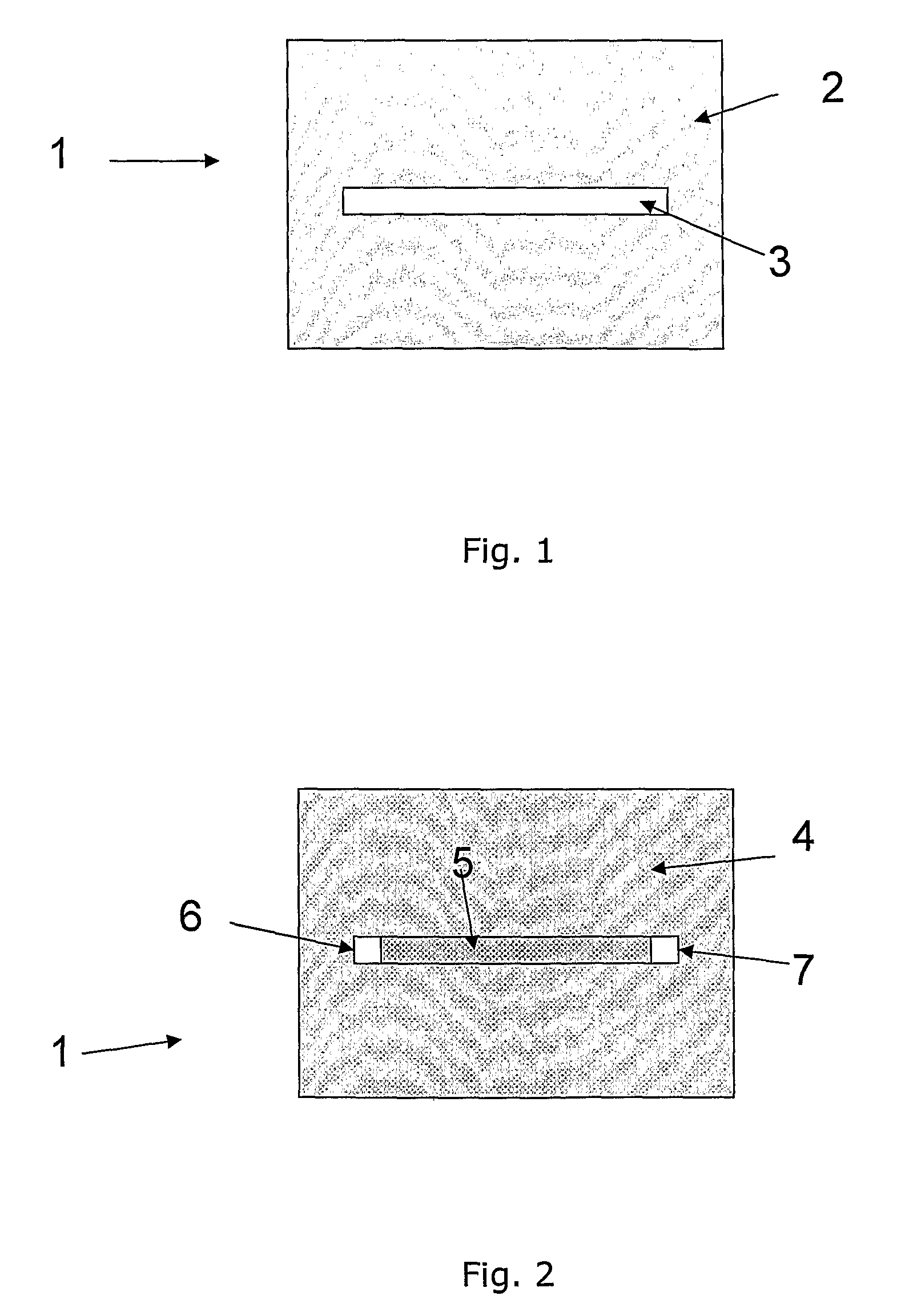

Nuclear magnetic flow meter and method for operation of nuclear magnetic flow meters

ActiveUS20140132260A1Improve accuracyHigh flow accuracyVolume/mass flow by differential pressureElectric/magnetic detectionMagnetic measurementsMeasurement device

A nuclear magnetic flow meter (1) for measuring the flow rate of a multiphase medium (4) which is flowing through a measuring tube (3) is described, with a nuclear magnetic measurement device (2), the nuclear magnetic measurement device (2) being located around the measuring tube (3).In accordance with the invention an improved accuracy of the measurement of the flow rate for the gaseous phase is achieved in that in addition to the nuclear magnetic measurement device (2) there is a further measurement device which implements another measurement principle, in the described exemplary embodiment a differential pressure flow rate measurement device (5). In the described exemplary embodiment the differential pressure flow rate measurement device (5) is made for measuring the differential pressure of the medium (4) in the measuring tube (3), and there are at least one pressure gauge (8a, 8b) each on two measurement sites (6a, 6b) which are different in the longitudinal direction (7) of the measuring tube (3).

Owner:KRONE GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com