Swing pipe pump

A pipeline pump and pipeline technology, which is applied in the direction of pumps, machines/engines, pumps with flexible working elements, etc., can solve problems such as inability to guarantee product quality, and achieve the effects of wide application range, high work efficiency, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following examples are further explanations and illustrations of the present invention, and do not constitute any limitation to the present invention.

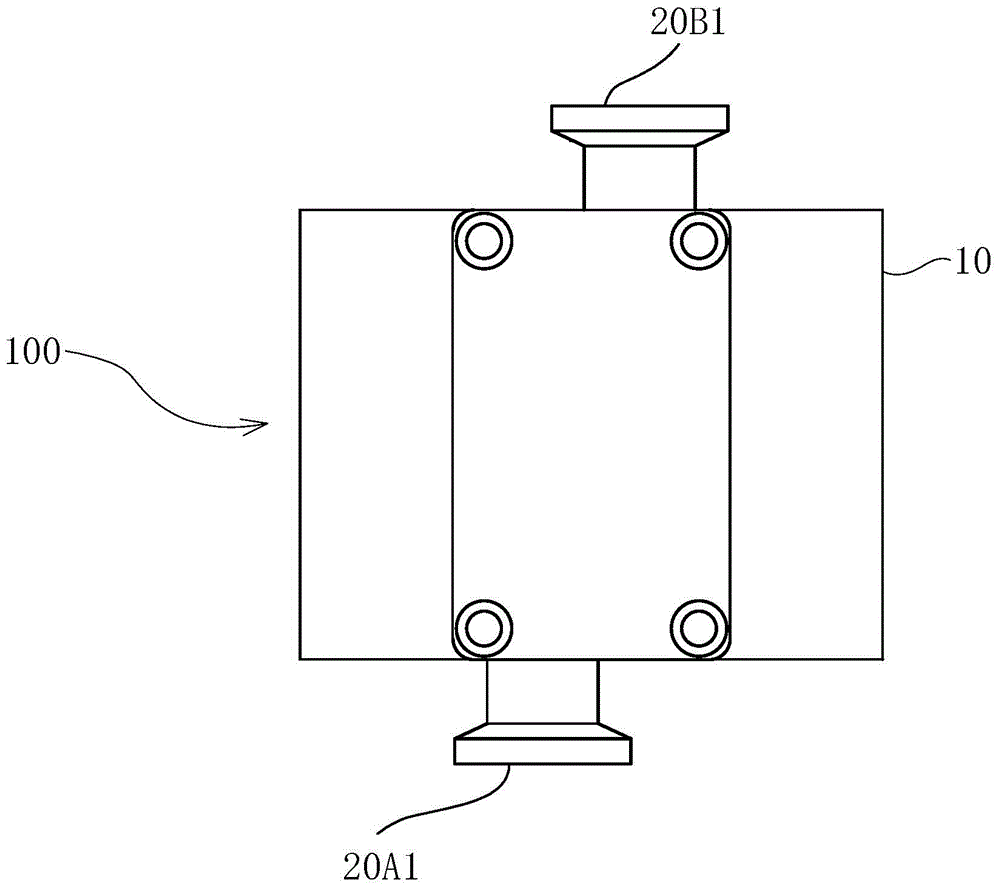

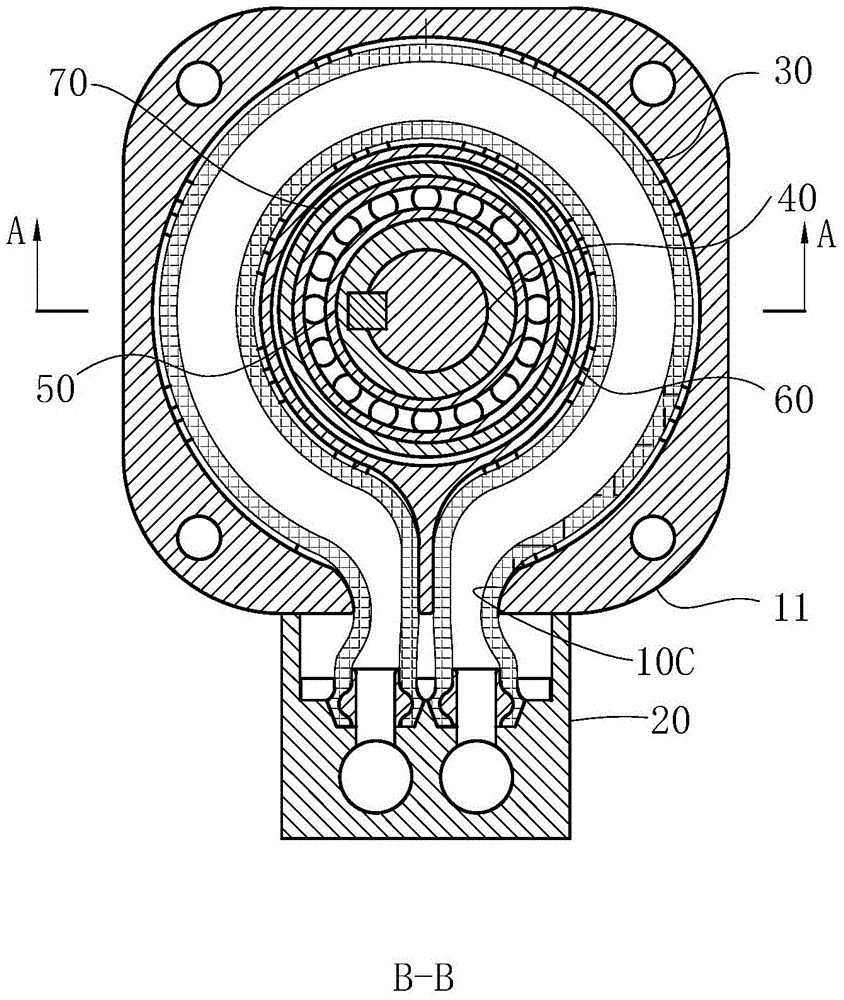

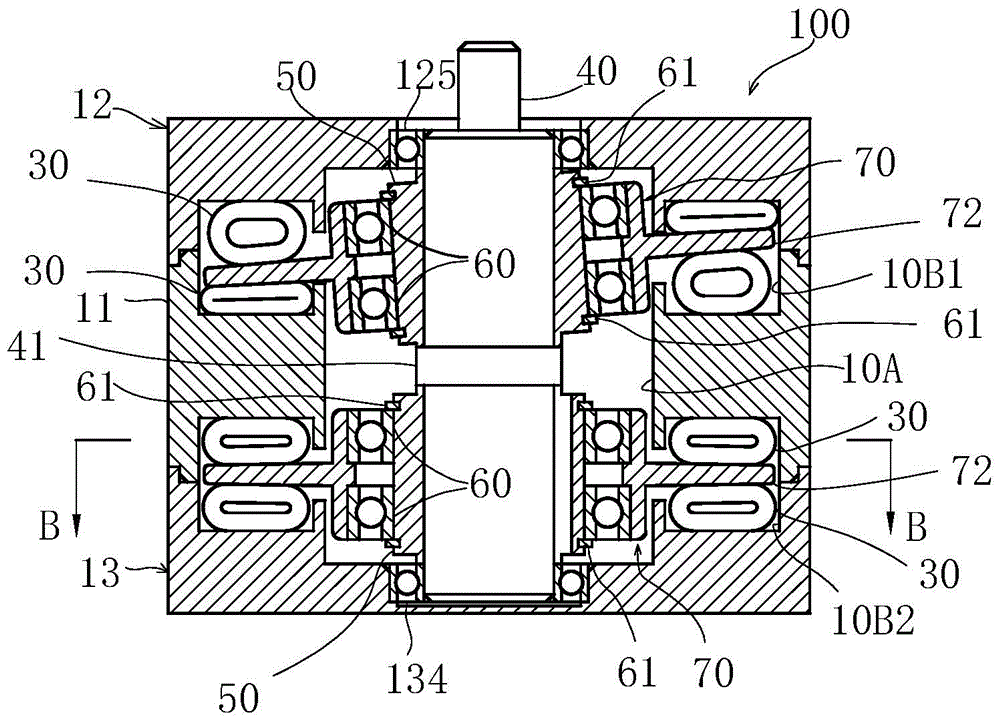

[0022] refer to Figure 1 ~ Figure 3 , The oscillating pipeline pump of the present invention includes a pump casing 10 , a pipe joint 20 , a hose 30 , a central shaft 40 , an inclined cam 50 , a first bearing 60 and a balance wheel 70 .

[0023] Such as figure 2 , image 3 As shown, the pump casing 10 is formed by coupling the pump casing main body 11, the first end cover 12, and the second end cover 13, and fixing them at four corners with screws. The structure of the pump casing main body 11 is as follows: Figure 4A , Figure 4B As shown, the pump casing main body 11 is a rectangular block body, the pump casing main body 11 is provided with a second inner hole 111 for forming the inner cavity 10A, and the two ends of the pump casing main body 11 are respectively provided with a second annular groove 112 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com