Burner comprising a fluidic oscillator, for a gas turbine, and a gas turbine comprising at least one such burner

a technology of fluid oscillator and burner, which is applied in the direction of burners, combustion processes, lighting and heating apparatus, etc., can solve the problems of increasing the risk of pressure pulsation, and achieve the effect of reducing pollution emissions and reducing pressure pulsations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

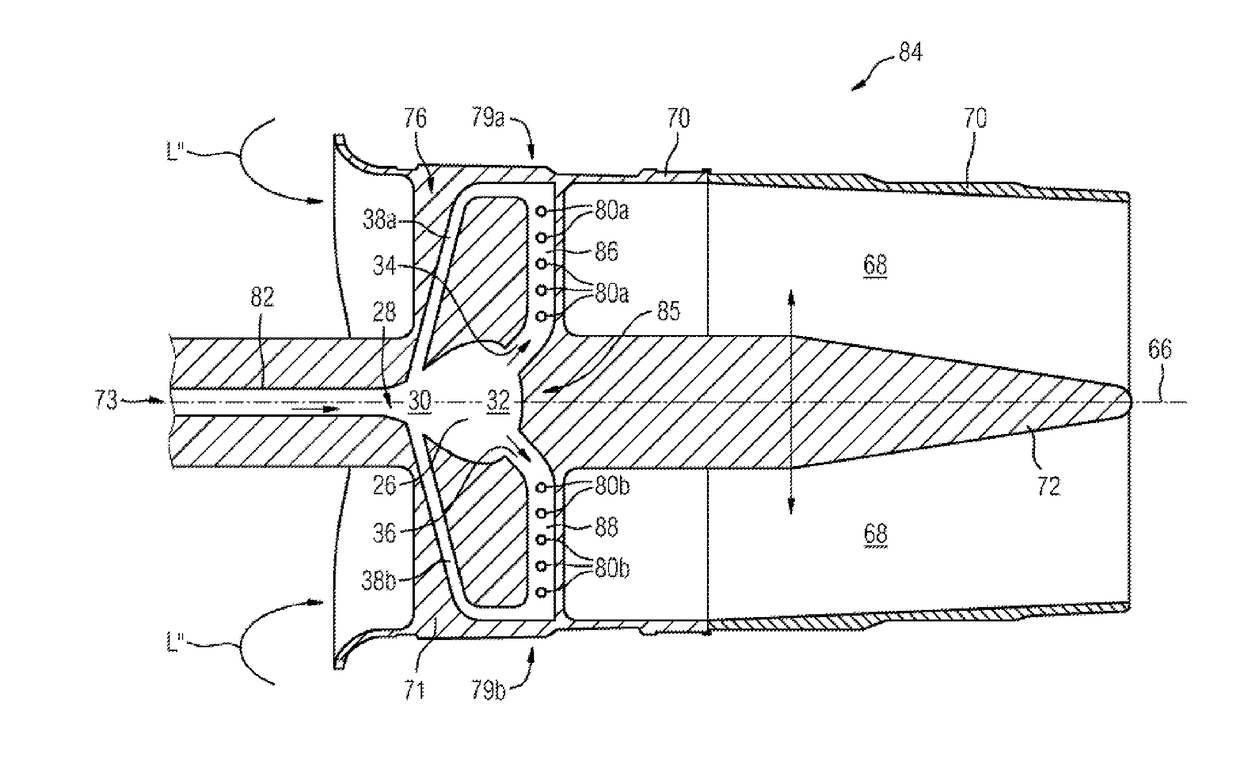

[0057]FIG. 1 shows a sectional view of a gas turbine 1 according to the prior art in a schematically simplified representation. The gas turbine 1 internally comprises a rotor 3 which is mounted so as to rotate about a rotation axis 2, has a shaft 4 is also referred to as the turbine rotor. Successively along the rotor 3, there are an intake manifold 6, a compressor 8, a combustion system 9 having a number of combustion chambers 10, each of which comprises a burner arrangement having burners 11, a fuel supply system (not represented) for the burners and a housing 12, a turbine 14 and an exhaust manifold 15. The combustion chamber 10 may, for example, be a ring combustion chamber. The gas turbine could however also comprise tube combustion chambers, which are for example arranged annularly at the turbine entry.

[0058]The combustion system 9 communicates with an e.g. annular hot-gas channel. There, a plurality of turbine stages connected in series form the turbine 14. Each turbine stage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com