Patents

Literature

523 results about "Ethanol fuel" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ethanol fuel is ethyl alcohol, the same type of alcohol found in alcoholic beverages, used as fuel. It is most often used as a motor fuel, mainly as a biofuel additive for gasoline. The first production car running entirely on ethanol was the Fiat 147, introduced in 1978 in Brazil by Fiat. Ethanol is commonly made from biomass such as corn or sugarcane. World ethanol production for transport fuel tripled between 2000 and 2007 from 17×10⁹ liters (4.5×10⁹ U.S. gal; 3.7×10⁹ imp gal) to more than 52×10⁹ liters (1.4×10¹⁰ U.S. gal; 1.1×10¹⁰ imp gal). From 2007 to 2008, the share of ethanol in global gasoline type fuel use increased from 3.7% to 5.4%. In 2011 worldwide ethanol fuel production reached 8.46×10¹⁰ liters (2.23×10¹⁰ U.S. gal; 1.86×10¹⁰ imp gal) with the United States of America and Brazil being the top producers, accounting for 62.2% and 25% of global production, respectively. US ethanol production reached 57.54×10⁹ liters (1.520×10¹⁰ U.S. gal; 1.266×10¹⁰ imp gal) in 2017-04.

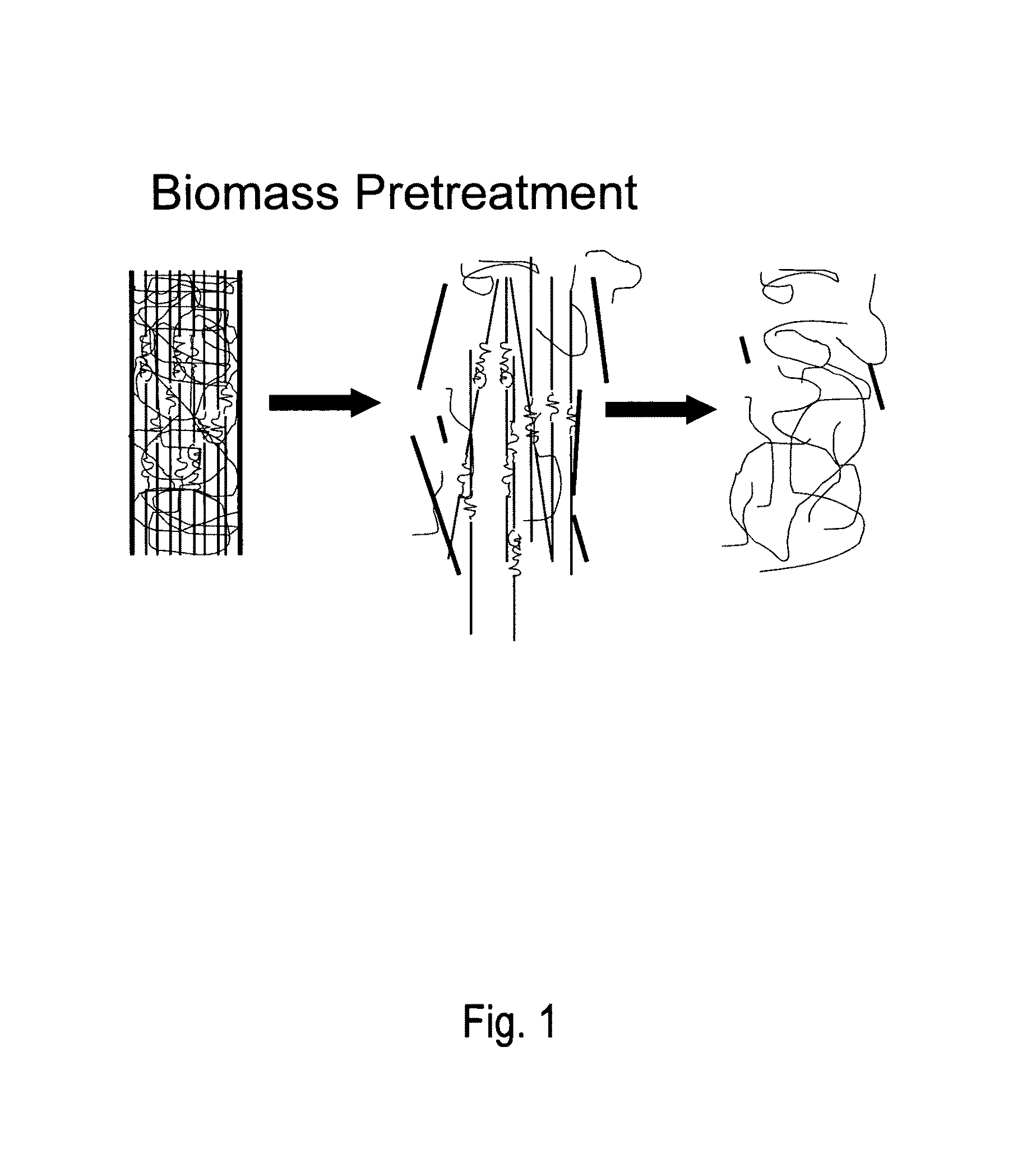

Biomass pretreatment

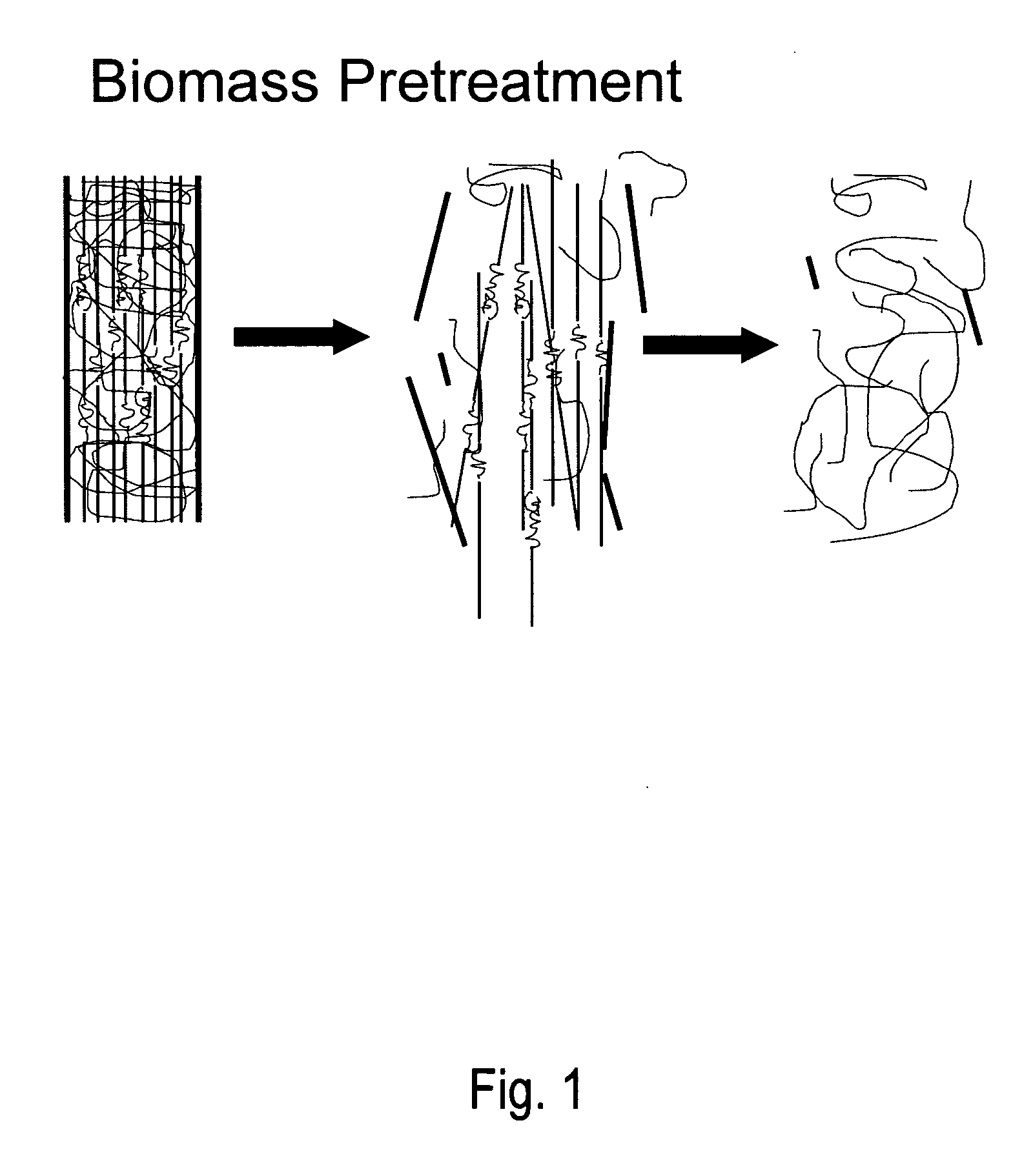

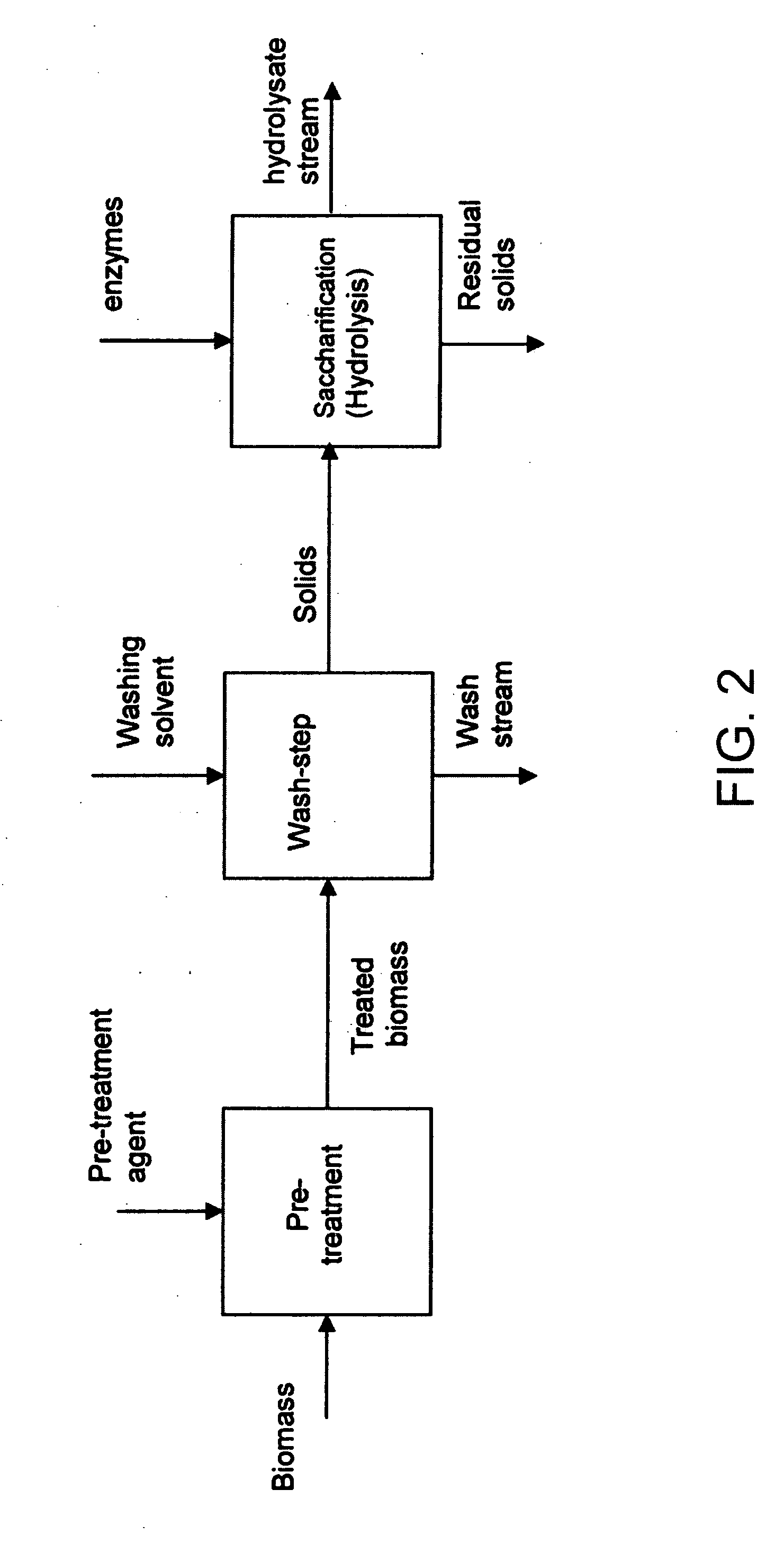

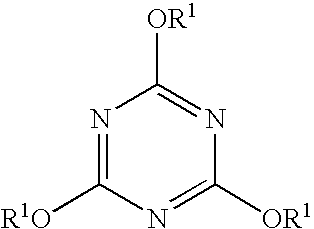

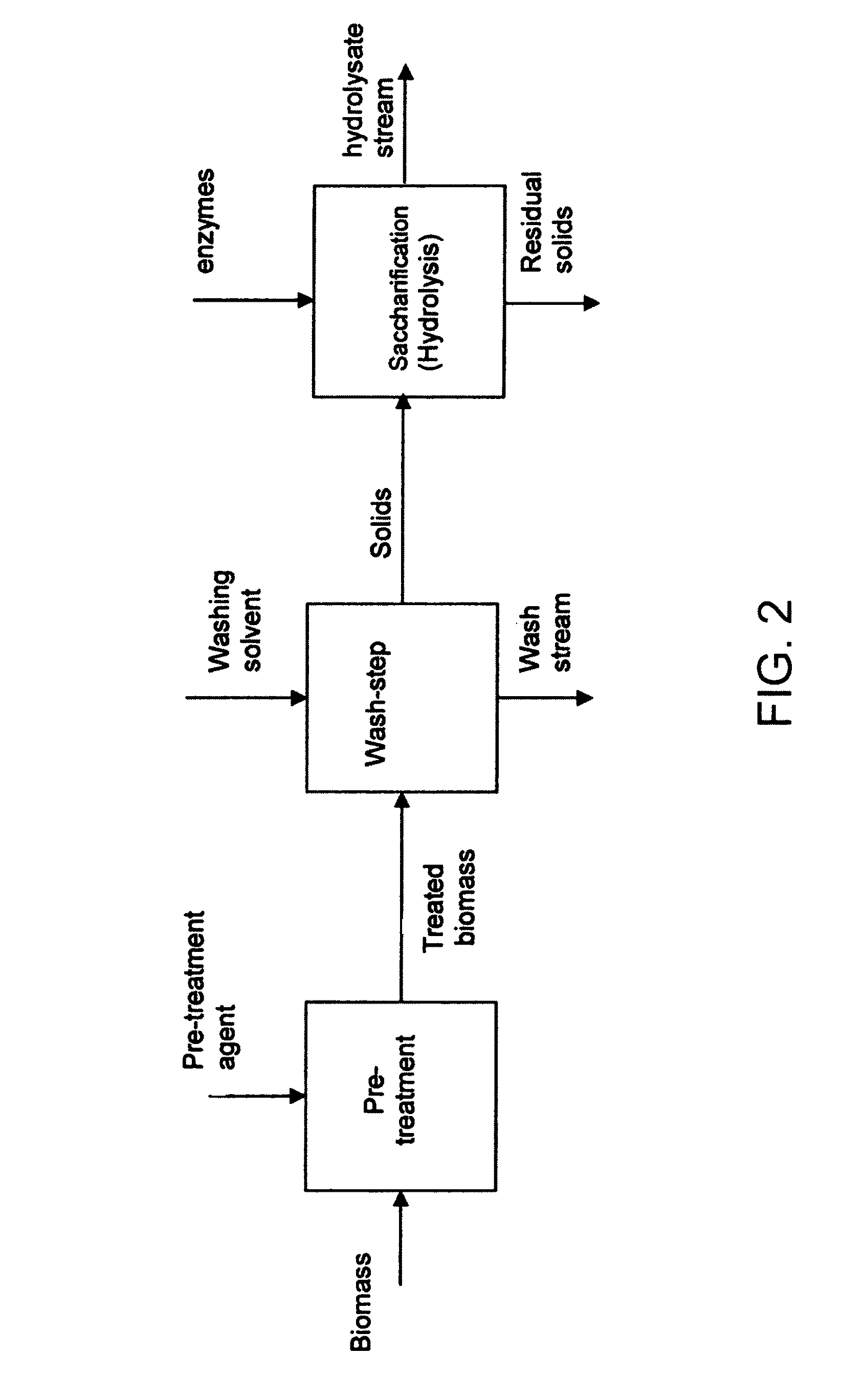

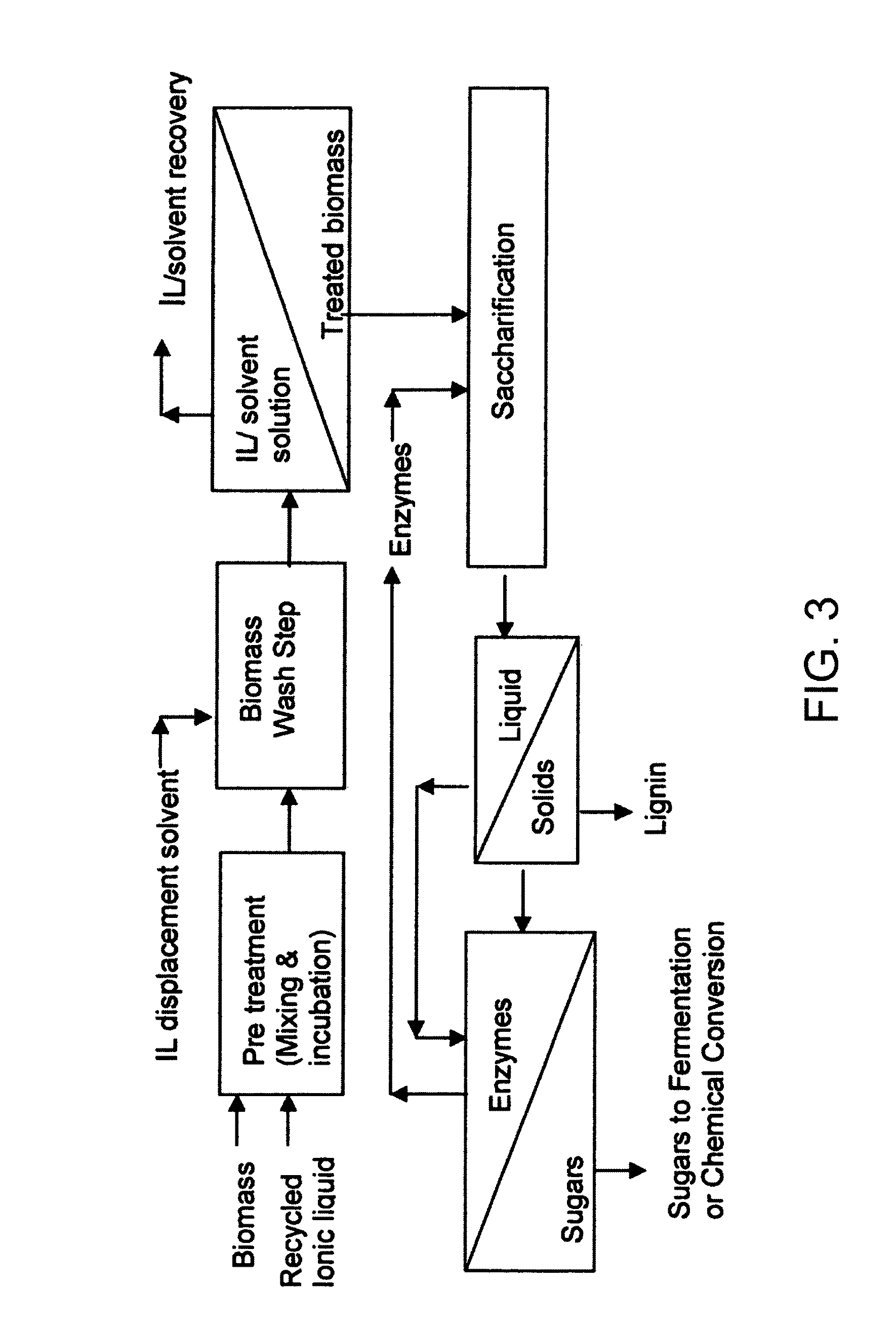

A method for lignocellulose conversion to sugar with improvements in yield and rate of sugar production has been developed by using ionic liquid pretreatment. This new pretreatment strategy substantially improves the efficiency (in terms of yield and reaction rates) of saccharification of lignocellulosic biomass. Cellulose and hemicellulose, when hydrolyzed into their sugars, can be converted into ethanol fuel through well established fermentation technologies. These sugars also form the feedstocks for production of variety of chemicals and polymers. The complex structure of biomass requires proper pretreatment to enable efficient saccharification of cellulose and hemicellulose components to their constituent sugars. Current pretreatment approaches suffer from slow reaction rates of cellulose hydrolysis (by using the enzyme cellulase) and low yields.

Owner:UNIVERSITY OF TOLEDO +1

Chemical markers

Owner:ROHM & HAAS CO

Lignin polyurethane and preparation method thereof

The invention discloses a method for preparing lignin polyurethane, which comprises the following steps of: using an organic solvent to dissolve the lignin which is extracted and separated from residues after producing ethanol from straws by sodium hydroxide; removing the residues, and depositing the mixture with water; separating the lignin; modifying the lignin with an epoxide; dissolving the lignin into a polylol; and finally compounding the lignin with raw materials of isocyanate and the like to obtain a polyurethane material. The lignin used in the method has high reactivity which can be further enhanced through modification so as to obtain a lignin polyurethane material; the polylol used in the method not only can be used as a solvent but also can take part in a synthetic reaction, has good dissolvability to the lignin, and ensures that undissolved lignin particles cannot appear in a polyurethane foam material; and the link for polyurethane synthesis uses no volatile organic solvents, so the production process causes no pollution to the environment, and simultaneously the cost of a polyurethane product is reduced.

Owner:SOUTH CHINA UNIV OF TECH

Chemical markers

A composition containing a petroleum hydrocarbon, a biodiesel fuel or an ethanol fuel, and an organic marker compound.

Owner:ROHM & HAAS CO

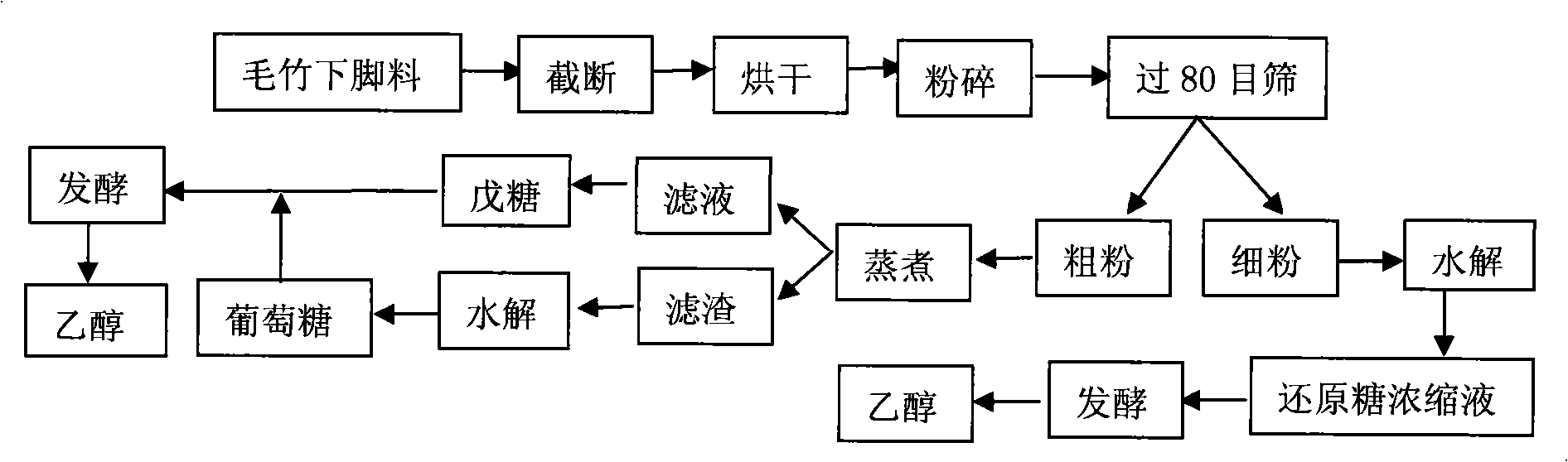

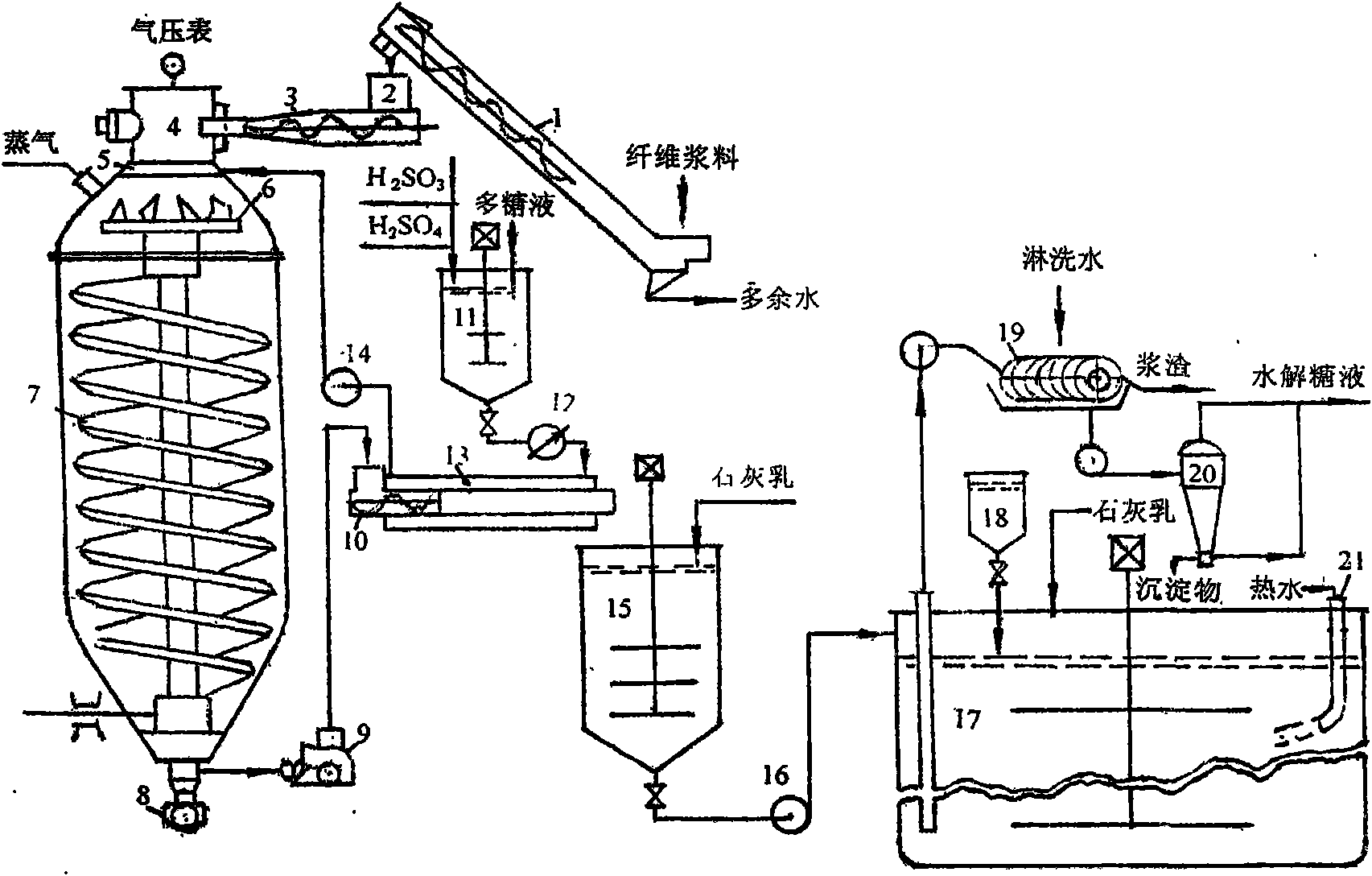

Method for preparing fuel ethanol from bamboo fibers

The invention discloses a method for preparing fuel ethanol from bamboo fibers. The method comprises the following steps that: waste from bamboo (or other non-wood biomass) processing is used as a raw material, the raw material is cut, dried, crushed and passed through a 80-mesh sieve, the powder passing through the 80-mesh sieve is fine bamboo powder and the powder failing to pass through the 80-mesh sieve is coarse bamboo powder; the coarse bamboo powder is cooked in a mixed liquid of formic acid, acetic acid and water for hydrolyzing hemicellulose and delignification, and fibers are obtained and subjected to hydrolysis by an organic acid to form a reducing monosaccharide; the fine bamboo powder is hydrolyzed directly by the organic acid to form the reducing monosaccharide; the reducing monosaccharide obtained from the hydrolysis of the hemicelluloses, the fibers and the fine bamboo powder are detoxicated by an excess amount of Ca(OH)2, the pH of the mixture is reduced, and the fuel ethanol is obtained after fermentation and rectification. The method for producing the fuel ethanol ensures the yield of the fuel ethanol, reduces the energy consumption for hydrolysis, and allows the organic acid used for hydrolysis to be recycled. In addition, the process of the fuel ethanol preparation using the method requires less water, and reduces environmental pollution and cost.

Owner:RES INST OF SUBTROPICAL FORESTRY CHINESE ACAD OF FORESTRY

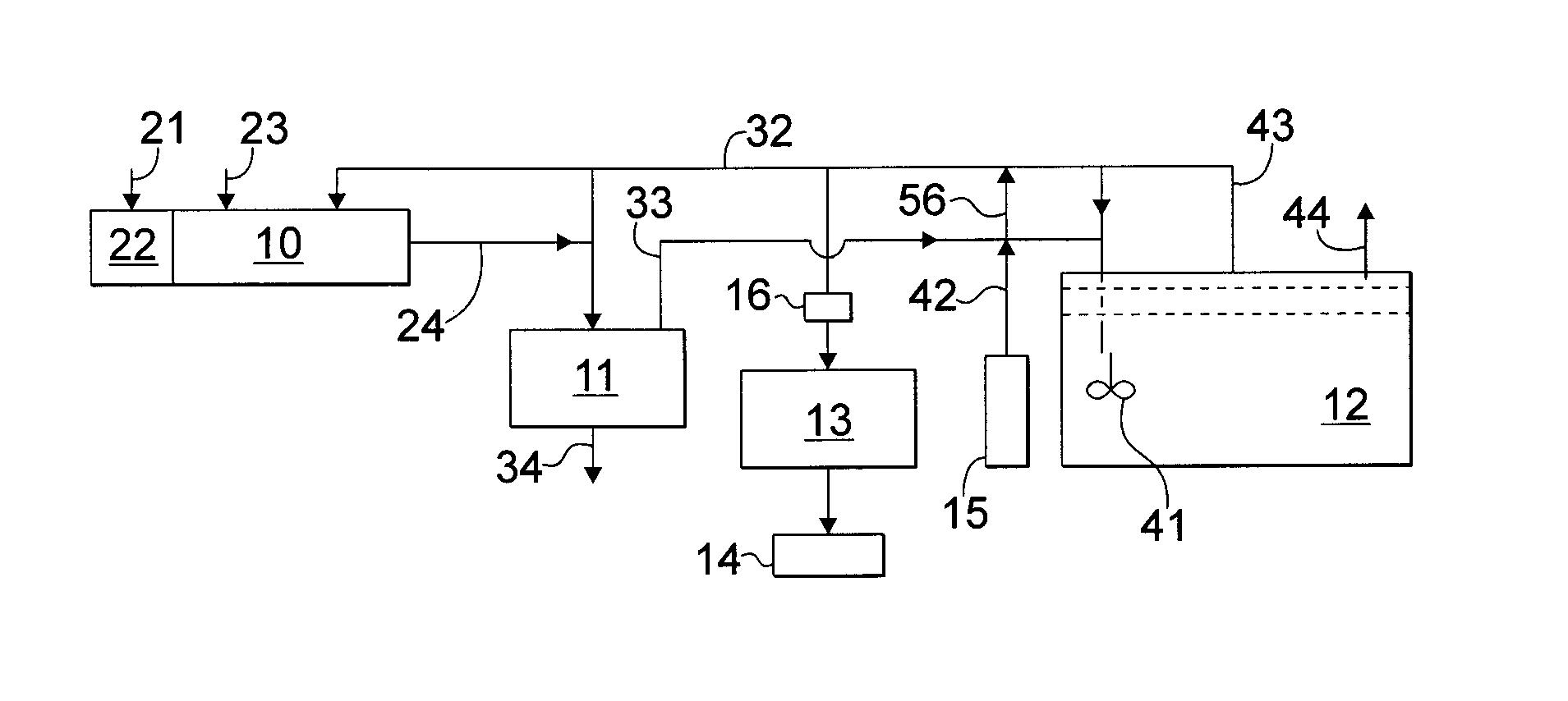

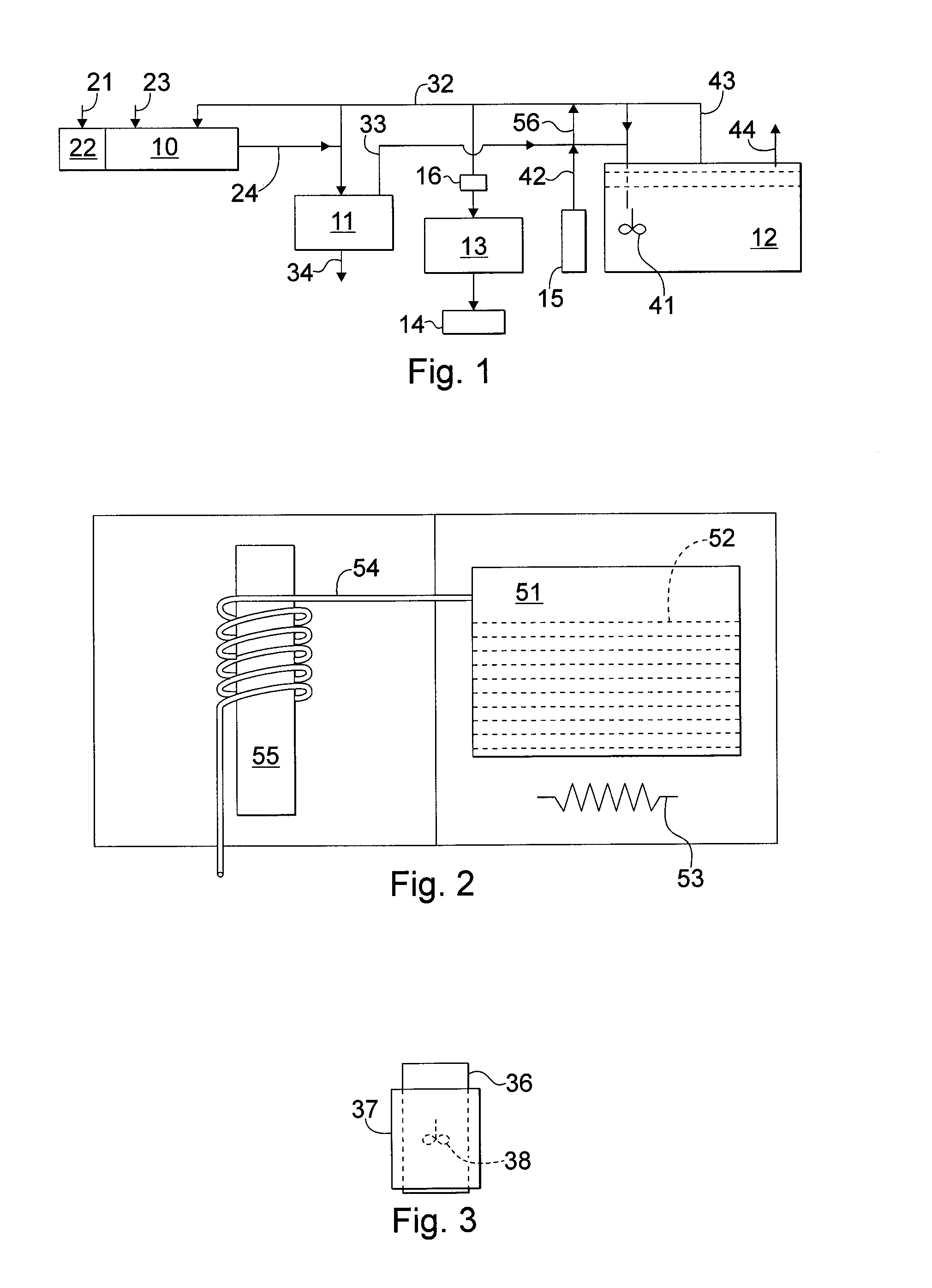

Apparatus and method for producing fuel ethanol from biomass

InactiveUS20080020437A1Improve performanceEliminate needBioreactor/fermenter combinationsBiological substance pretreatmentsMicroorganismVegetable oil

Cellulosic biomass at the growing site is pulverized and hydrolyzed in collectors which transfer the comminuted biomass into pretreatment units. In the pretreatment units enzymes and / or other agents are added to the pretreatment units to disassociate the lignin from the cellulose and hemicellulose, and to further decompose the biomass to simple sugars. The sugar solution is transferred to a fermentation unit and fermenting microorganisms are added to produce ethanol. Preferably vegetable oil or other ethanol-miscible liquid is added to provide a medium to extract the ethanol from the solution for transfer to a device where heating or distillation removes the ethanol which is collected for use as a liquid fuel. All of the units are preferably mounted for easy deployment to various locations in the vicinity of the numerous growing sites which produce the biomass.

Owner:SAVARESE JOHN J

Biomass pretreatment

ActiveUS8030030B2Improvement in yield and rateImprove efficiencyHydrolasesBiofuelsPretreatment methodReaction rate

A method for lignocellulose conversion to sugar with improvements in yield and rate of sugar production has been developed by using ionic liquid pretreatment. This new pretreatment strategy substantially improves the efficiency (in terms of yield and reaction rates) of saccharification of lignocellulosic biomass. Cellulose and hemicellulose, when hydrolyzed into their sugars, can be converted into ethanol fuel through well established fermentation technologies. These sugars also form the feedstocks for production of variety of chemicals and polymers. The complex structure of biomass requires proper pretreatment to enable efficient saccharification of cellulose and hemicellulose components to their constituent sugars. Current pretreatment approaches suffer from slow reaction rates of cellulose hydrolysis (by using the enzyme cellulase) and low yields.

Owner:UNIVERSITY OF TOLEDO +1

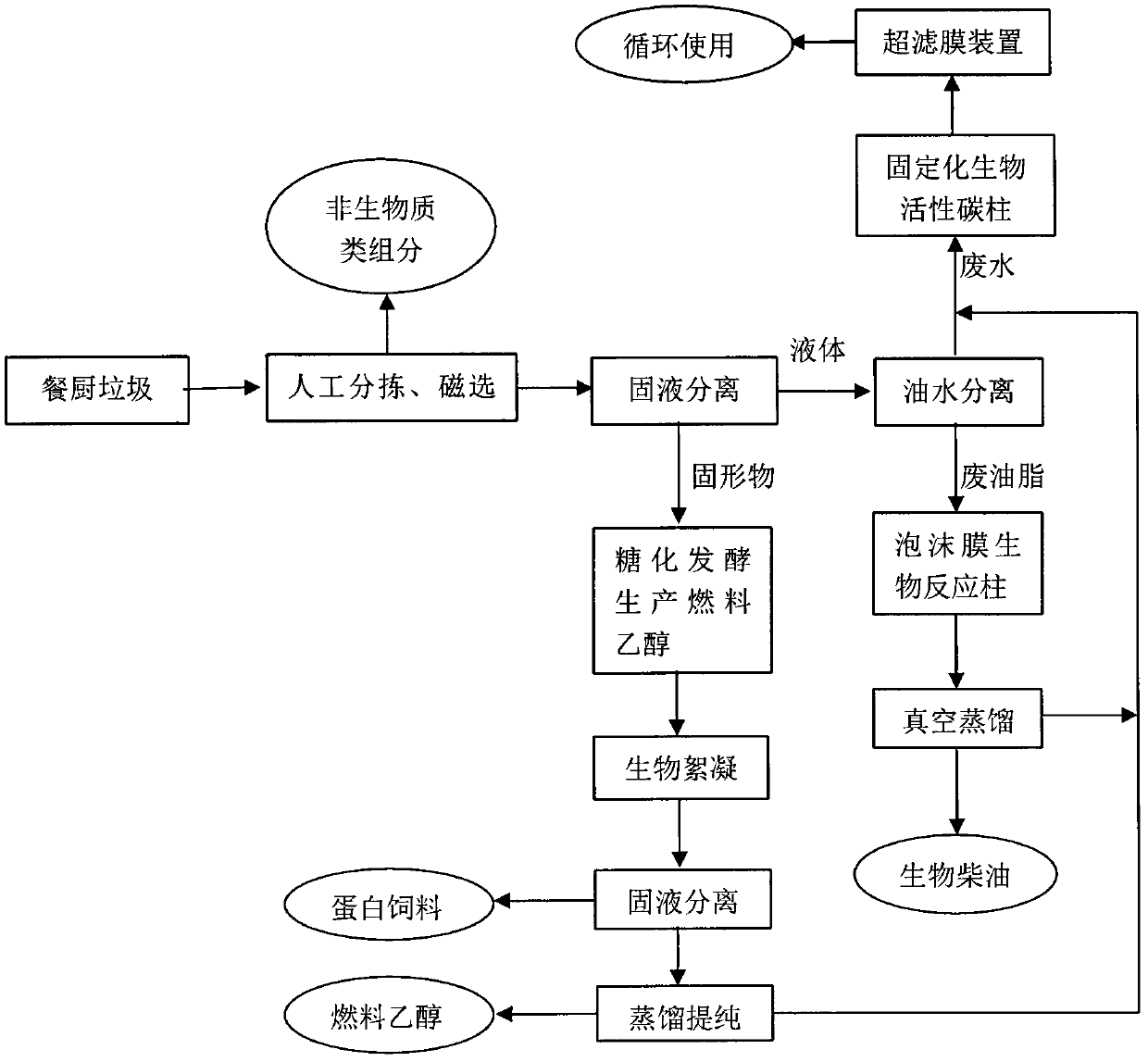

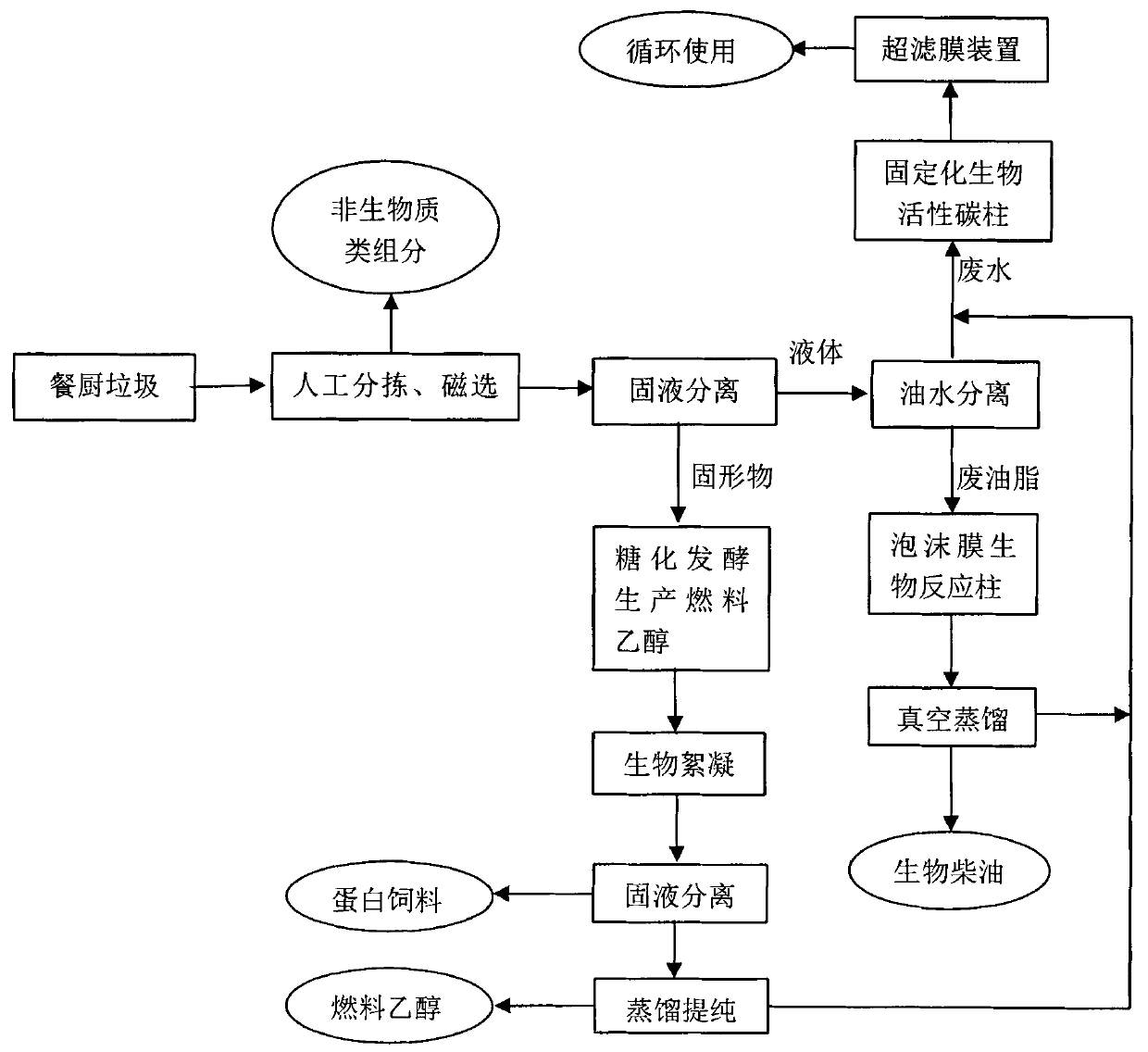

Full-biomass resource utilization method for kitchen waste

InactiveCN102553886AShorten fermentation timeOvercome the defects of single enzymatic hydrolysisFatty oils/acids recovery from wasteFatty acid esterificationOil and greaseResource utilization

The invention relates to a full-biomass resource utilization method for kitchen waste. The method comprises the following steps: sorting kitchen waste and then performing solid-liquid separation, performing oil-water separation on the liquid phase, grinding the solid phase and then producing fuel ethanol by complex enzyme preparation and multi-step hydrolysis, producing protein feeds from the solid residues and yeast after production purification, and performing transesterification on the separated waste oil to produce bio-diesel oil. The invention has the advantages that different components in the kitchen waste are transformed with high efficiency respectively by utilizing the process integration technology to produce fuel ethanol, bio-diesel oil, protein feeds and other products with high value added, so that the cost of kitchen waste treatment is reduced, and the economic benefits are improved; the operation process is mild, the energy consumption is reduced, and the process flow is environment-friendly; and the kitchen waste is turned into treasure, and the comprehensive waste reduction, resource and energy utilization can be achieved.

Owner:天津新生环境发展有限公司 +2

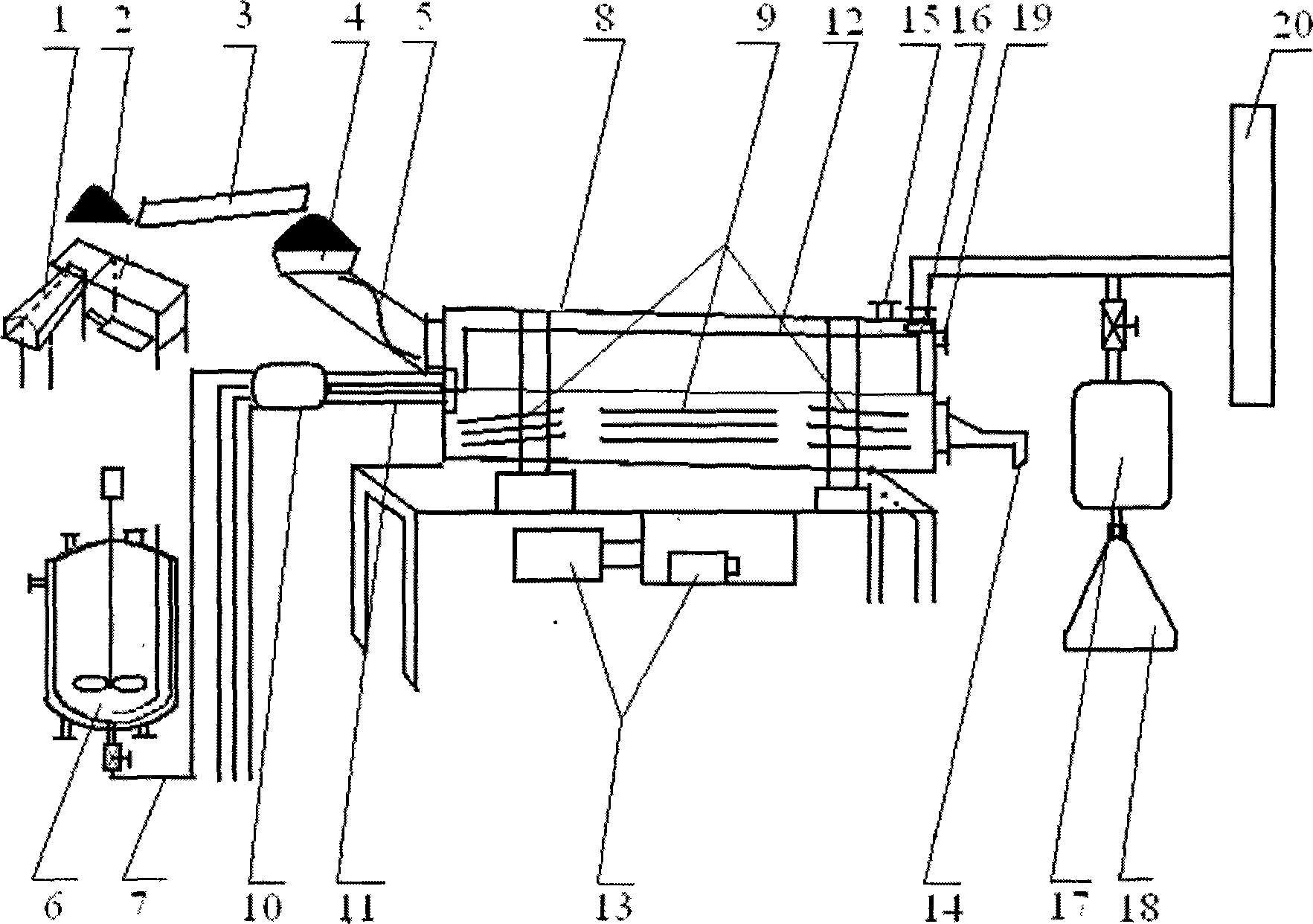

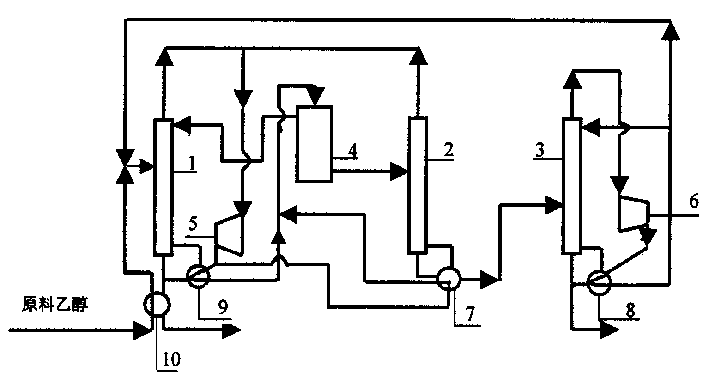

Fermentation / distillation integrated technique apparatus for producing alcohol from sugar

InactiveCN101503713AEfficient extractionWell mixedBioreactor/fermenter combinationsBiological substance pretreatmentsDistillationLiquid fuel

The invention discloses an integral fuel-ethanol production process based on saccharide raw materials, and a device thereof, which belongs to the technical field of biomass liquid fuel production. The technical process comprises the following steps: grinding saccharide crops and allowing the ground saccharide crops to enter a device integrating solid-state fermentation, ethanol gas extraction and pneumatic dregs drying; mixing the ground material with high-yield ethanol yeast liquid and completing fermentation in anaerobic environment under the condition of transmitting strengthening heat mass; separating the ethanol through gas extraction; and drying dregs rotated in a tube body of a fermentor through gas flow and discharging the dregs out of the fermentor. The invention has the advantages of simplifying the process flow of producing the ethanol through solid fermentation, realizing high-degree technical integration, transforming fermentable sugar in the ground material to the utmost extent, efficiently extracting the ethanol in solid fermentation materials, utilizing flue gas and superheated steam (CO2 or heated dry air) to separate the ethanol, utilizing the flue gas (or the heated dry air) to dry the dregs, saving material-conveying time, reducing energy consumption and embodying that a solid fermentation method for producing fuel ethanol has the advantages of high net energy ratio and low environmental load.

Owner:TSINGHUA UNIV

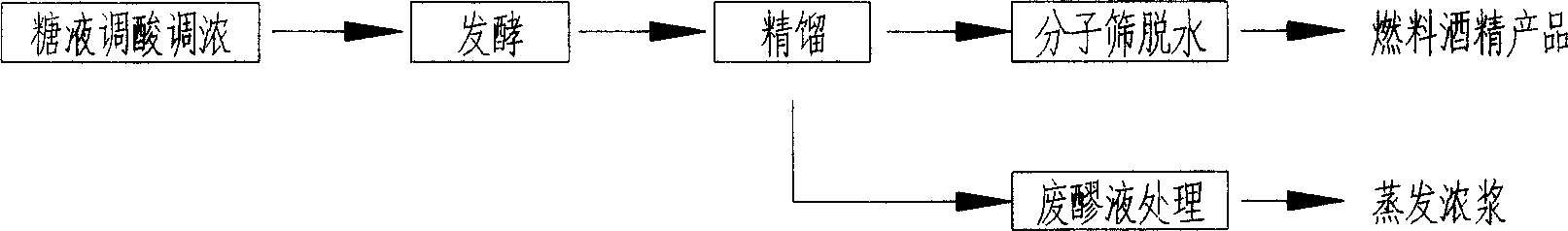

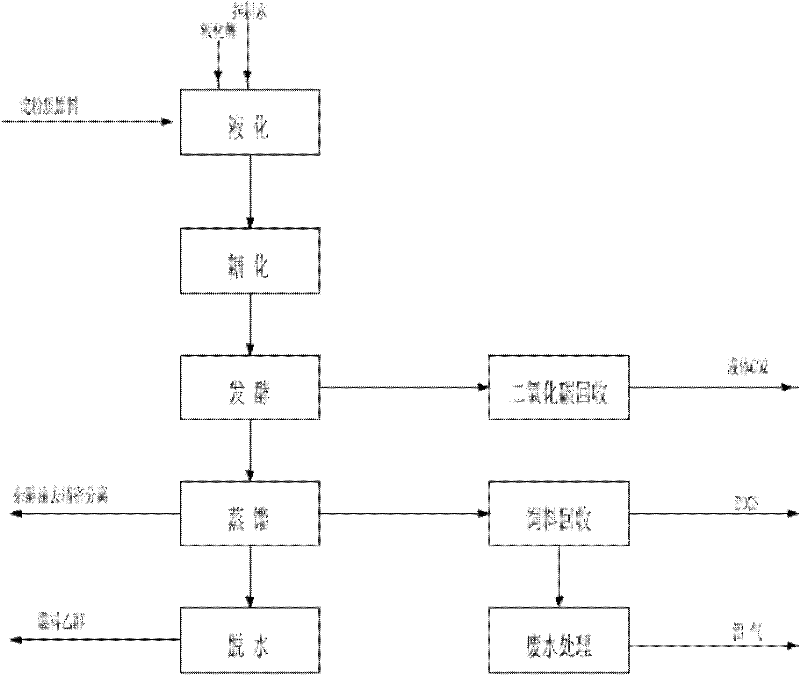

Production of alcohol fuel

InactiveCN1644703AGuaranteed dehydration effectDoes not consume external heatBiofuelsLiquid carbonaceous fuelsAlcohol fuelDistillation

Alcohol fuel can be produced by: treating raw materials, fermenting, refining, molecular sieve adsorption dewatering, and waste liquid treating. A thermal coupling is used to connect dewatering and condense distilling procedures, i.e., gas alcohol from refining process is fed to molecular adsorption dewatering process after thermal coupling condensation and distillation. Heat energy released from cold condensation is used as heat energy for distillation. None of energy is needed any more. The raw materials may be corn, rice, wheat, Chenese sorghum, dry sweet potato, cassawa, sugarcane juice, sugarbeet juice, or green cyrup, etc.

Owner:TIANJIN UNIV

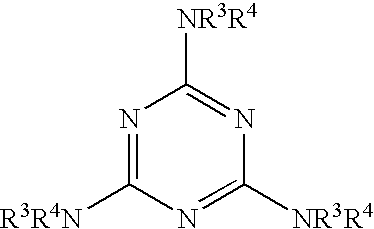

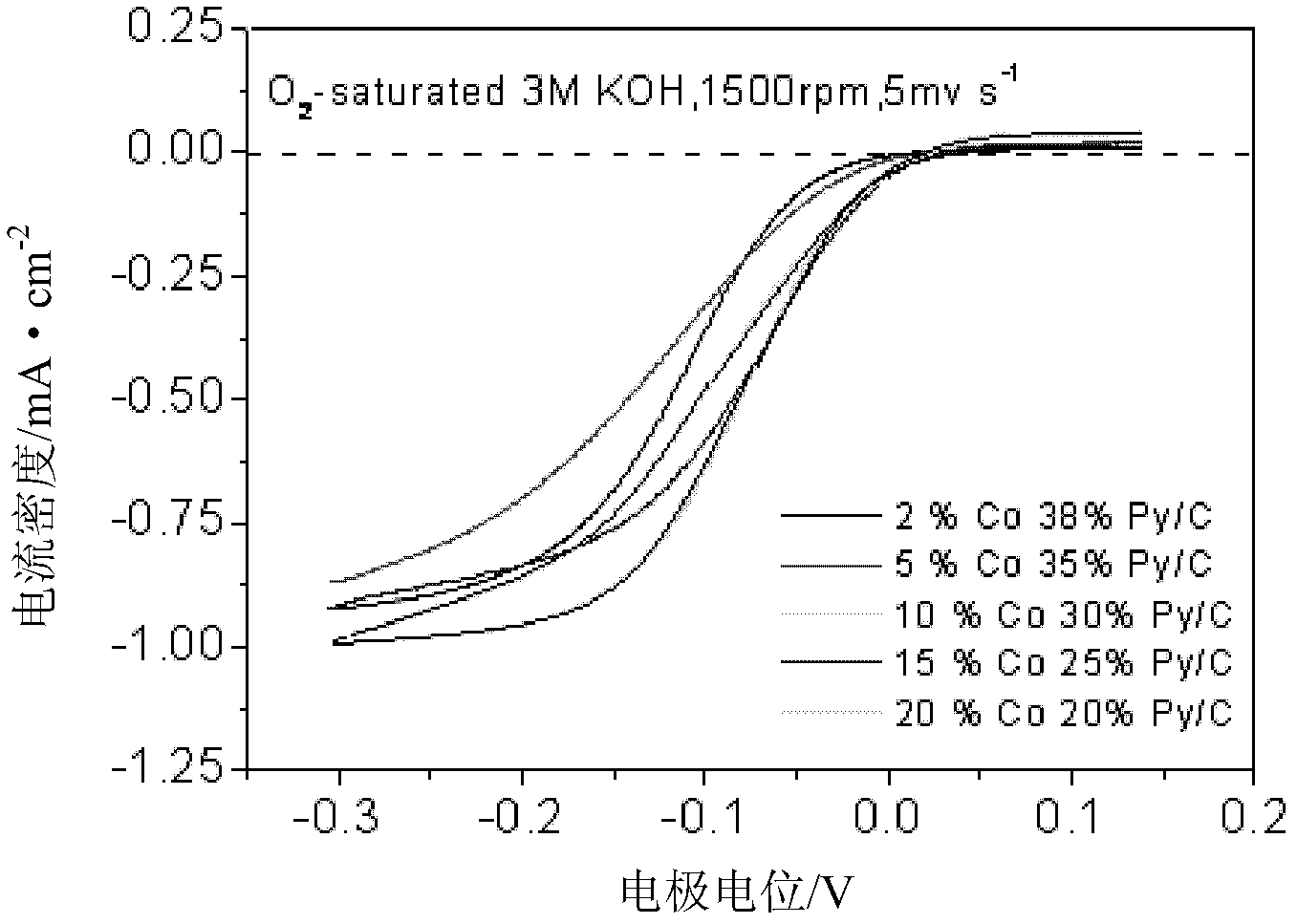

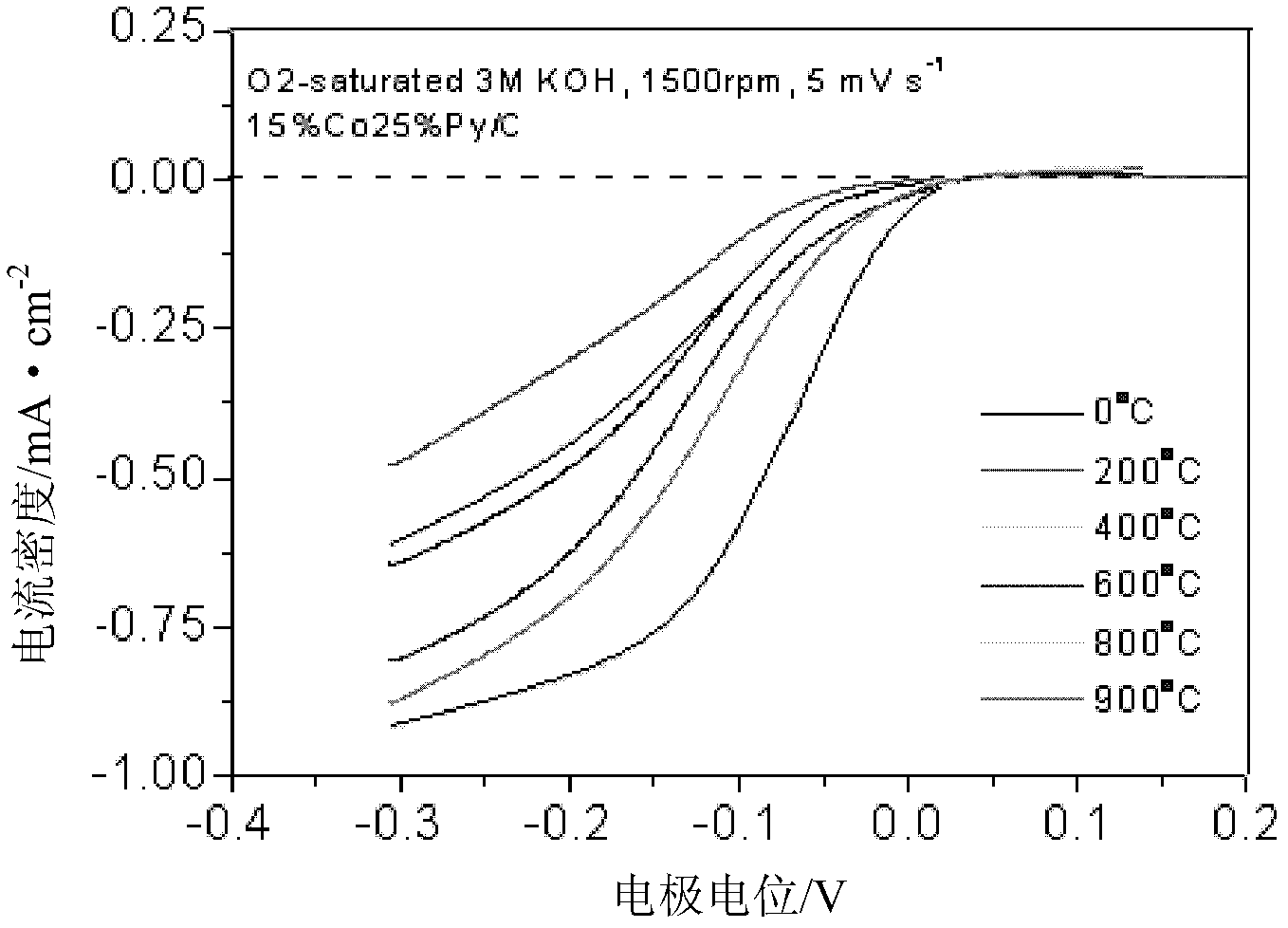

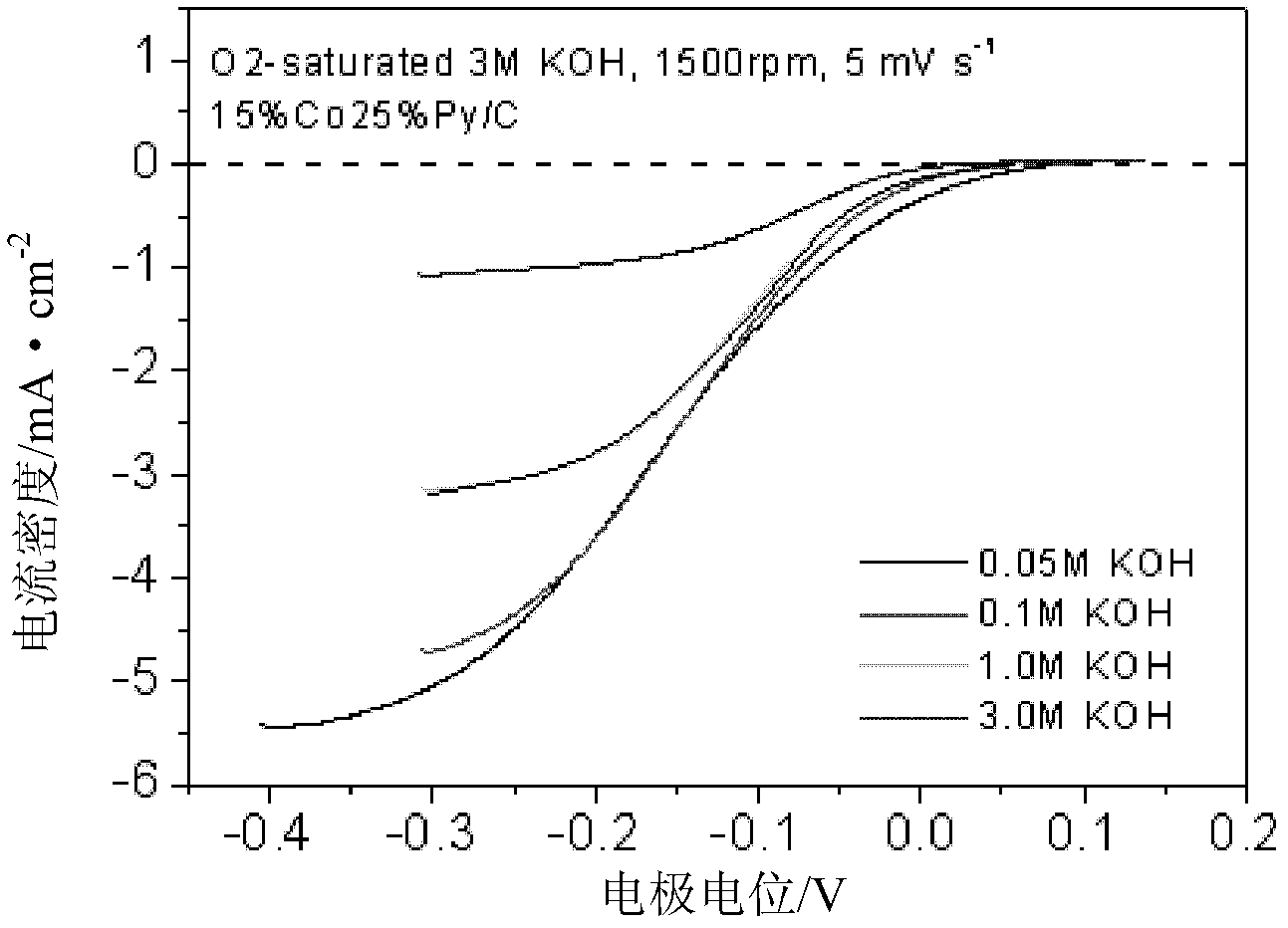

Carbon-supported CoN fuel-cell catalyst as well as preparation method and application thereof

InactiveCN102324531ALow costHigh catalytic activityPhysical/chemical process catalystsCell electrodesNon platinumSolvent

The invention relates to a carbon-supported CoN fuel-cell catalyst as well as a preparation method and application thereof. The catalyst comprises the following components in mass percentage: 40-99 percent of carbon material and 1-60 percent of active component. The catalyst is prepared through the following steps of: dispersing the components into a mortar loaded with a solvent, fully grinding until the solvent is completely volatilized, and obtaining a catalyst precursor after vacuum drying; and roasting for 2-4 hours by increasing the temperature for 200-900 DEG C at the speed of 20 DEG C / minute under the protection of an inert-gas atmosphere. The catalyst is applied to alkaline fuel cells, direct methanol fuel cells, direct ethanol fuel cells or low-temperature fuel cells. The catalyst is a non-platinum catalyst, so that the cost of the fuel cells can be markedly lowered; and the preparation method disclosed by the invention is simple and easy to operate, has low cost, is suitable for industrialized production and has good application prospects.

Owner:DONGHUA UNIV

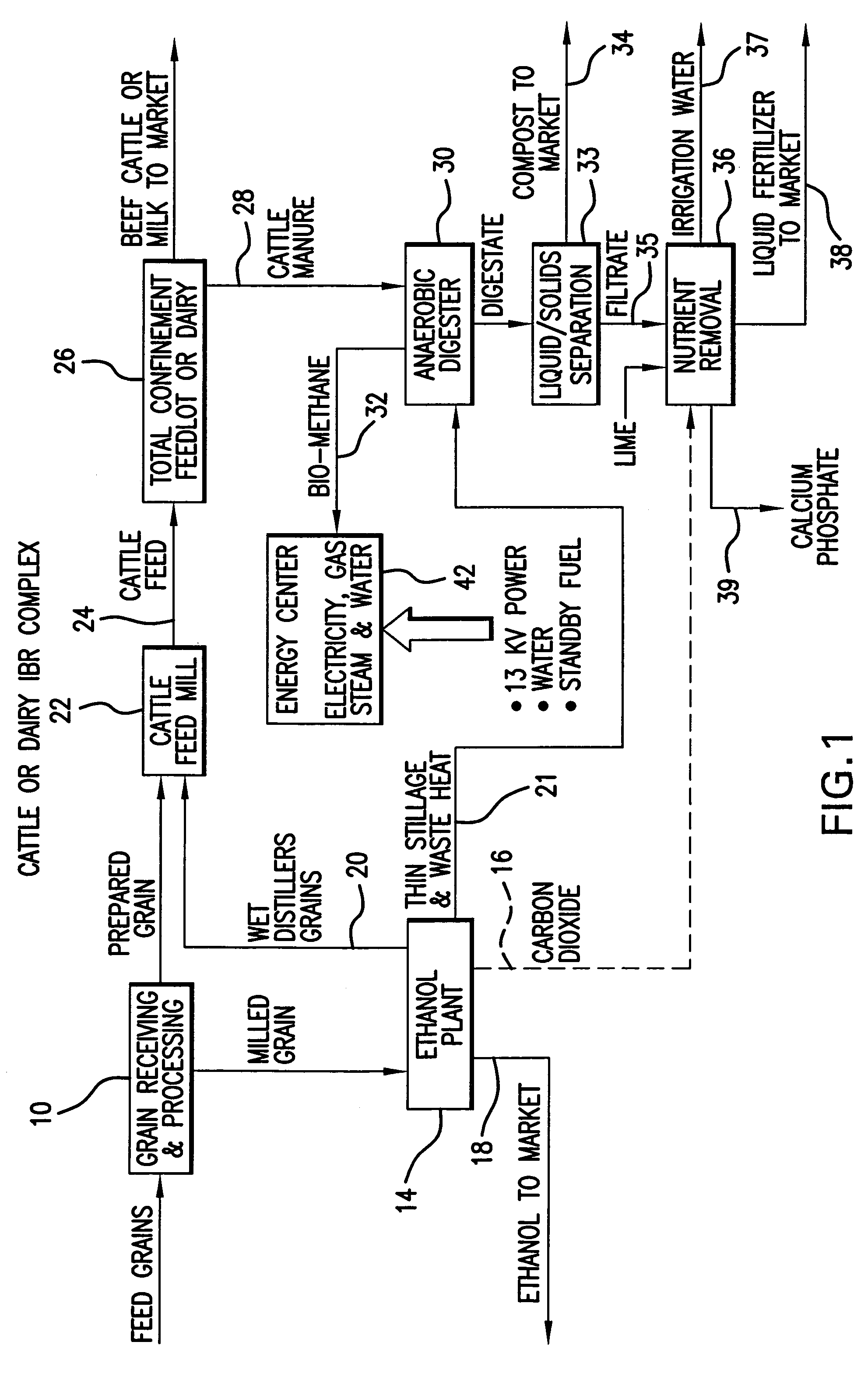

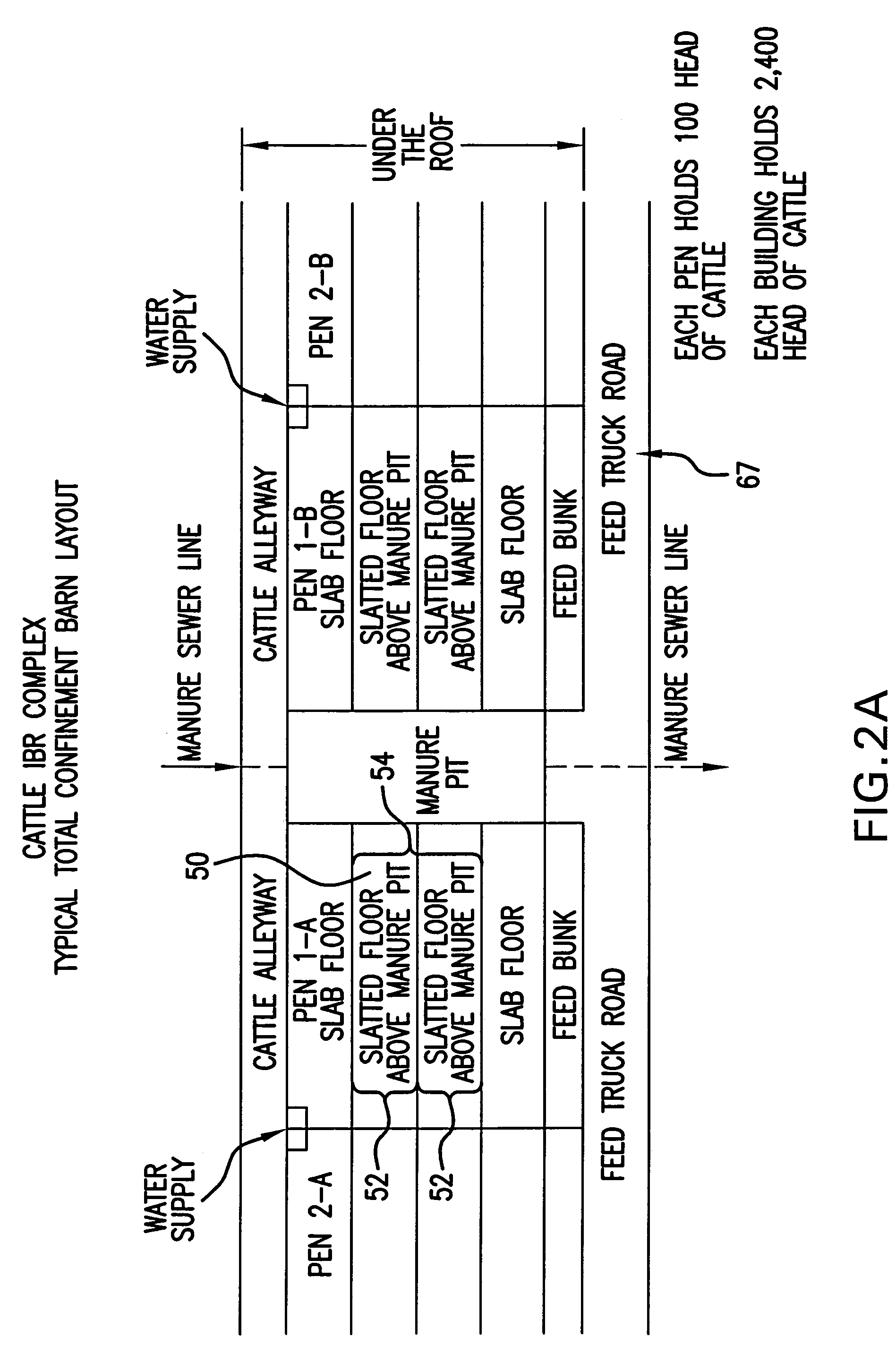

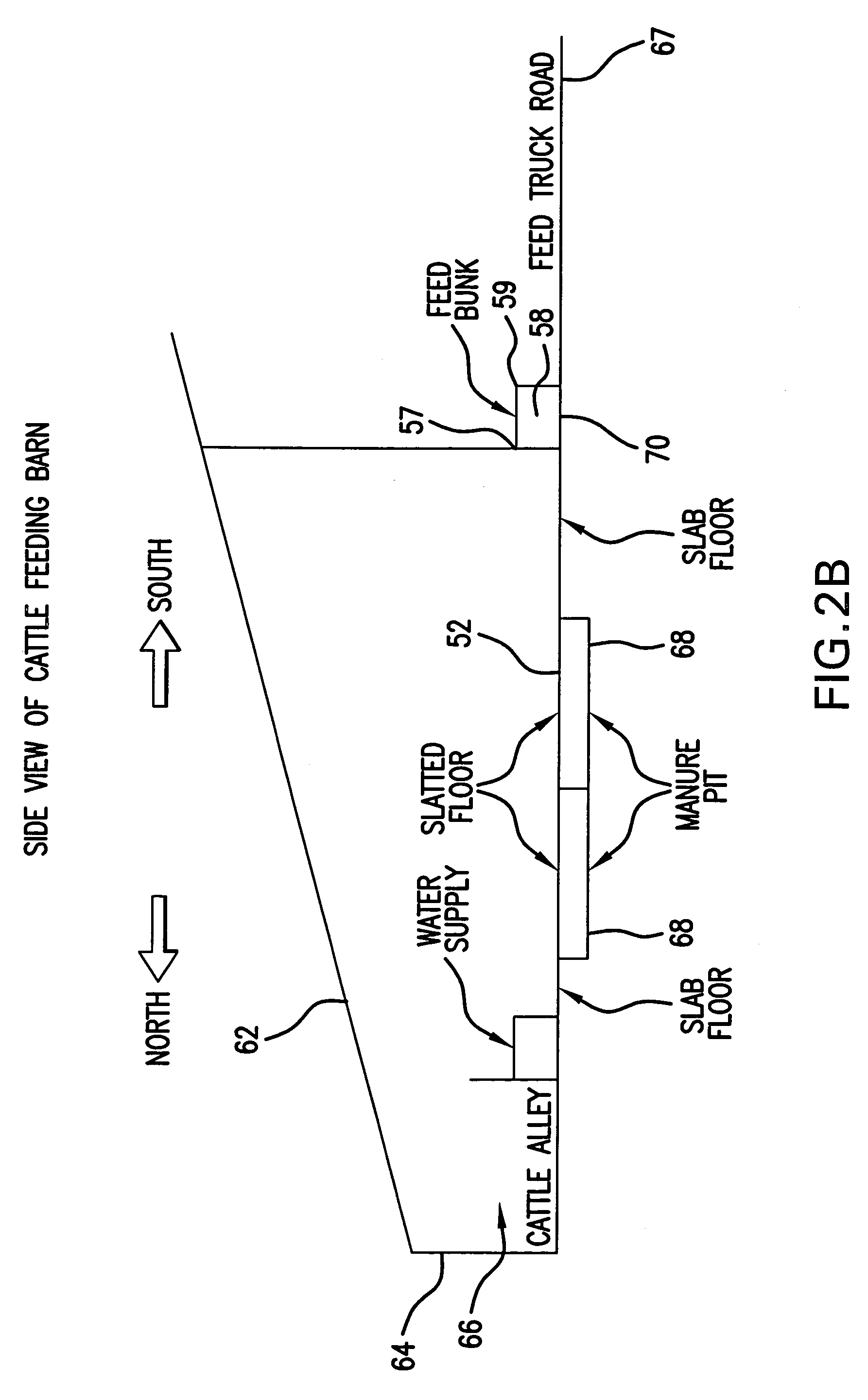

Integrated process for producing "clean beef" (or milk), ethanol, cattle feed and bio-gas/bio-fertilizer

ActiveUS7381550B2Reduce ammonia build-upIncrease productionBiological substance pretreatmentsFood processingEngineeringComponents of crude oil

An ethanol unit and anaerobic digestion / bio-fertilizer unit are integrated with a cattle feedlot (or dairy operation), wherein a continuous, balanced process yields a sanitary, low- to zero-pollution, and economically efficient production of “clean beef” (or milk), fuel ethanol, and bio-gas / bio-fertilizer. Fossil fuel consumption is substantially reduced, even eliminated, and 100% of the cattle waste is treated in digesters wherein it is converted into medium-BTU gas (bio-gas), organic fertilizer and bio-compost. The ethanol unit serves the purposes of ethanol production, grain pretreatment to produce feed for the cattle and production of a thin stillage which is fed to the digesters. The grain is first processed in the ethanol unit, where the starch portion is converted into ethanol and CO2. The remaining portion is separated into the thin stillage and a wet cake which is fed directly to cattle as a superior ruminant animal ration which displaces certain traditional feed components, alters the standard starch to protein ratio, and significantly improves conversion efficiencies and meat / milk quality.

Owner:IBR PATENT HOLDCO LLC +1

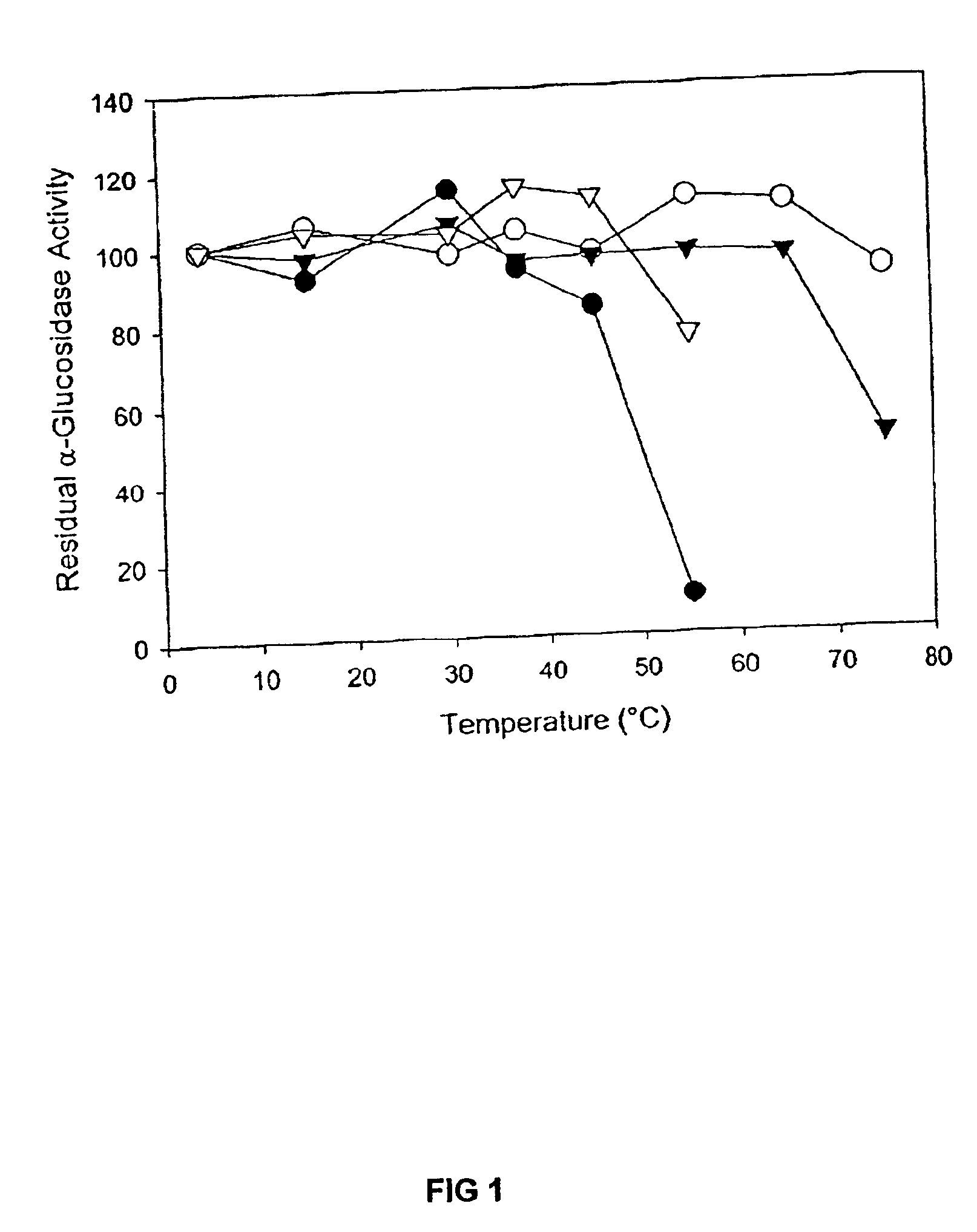

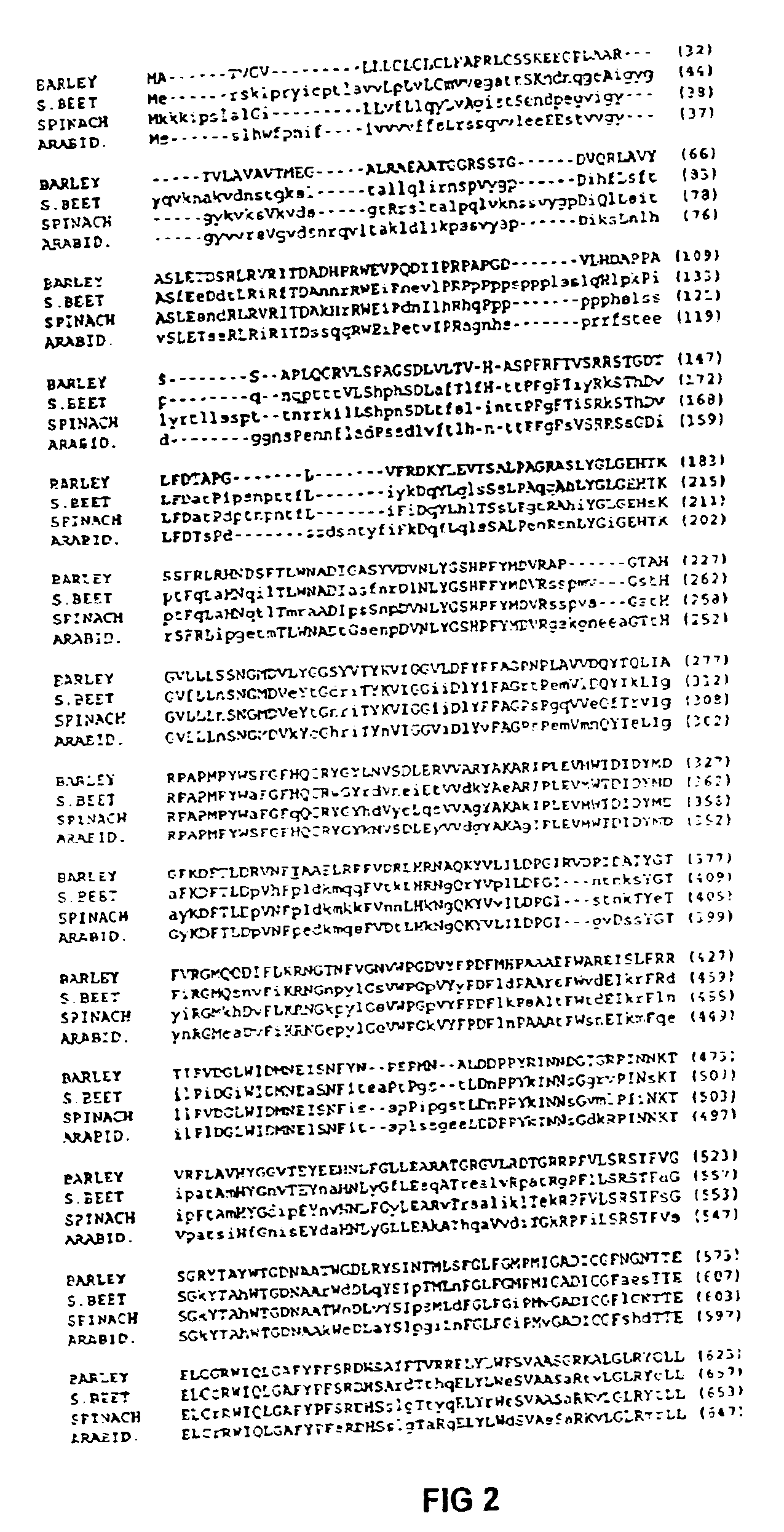

Modified barley α-glucosidase

Barley α-glucosidase is an important enzyme in the conversion of barley starch to fermentable sugars during the industrial production of ethanol, as in brewing and fuel ethanol production. The enzyme is, however, relatively thermolabile, a disadvantage for an enzyme useful in industrial processes which are preferably conducted at elevated temperatures. Site directed mutagenesis has been conducted to make mutant forms of barley α-glucosidase which have improved thermostability. The sites for this site-directed mutagenesis were selected by sequence comparisons with the sequences of other α-glucosidase proteins which are more thermostable. The recombinant mutant enzymes thus produced have been demonstrated to improve the thermostability of the enzyme.

Owner:WISCONSIN ALUMNI RES FOUND +1

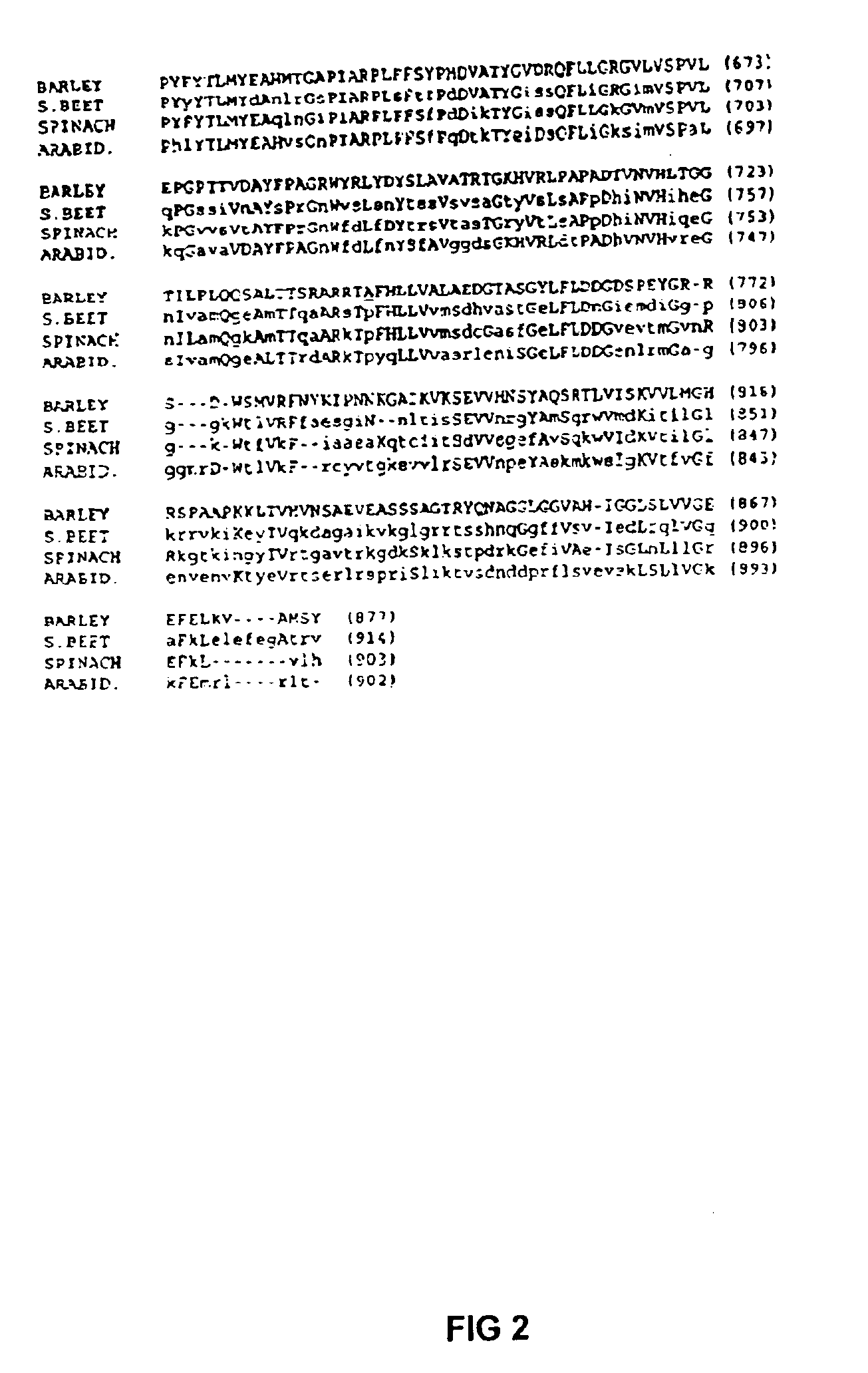

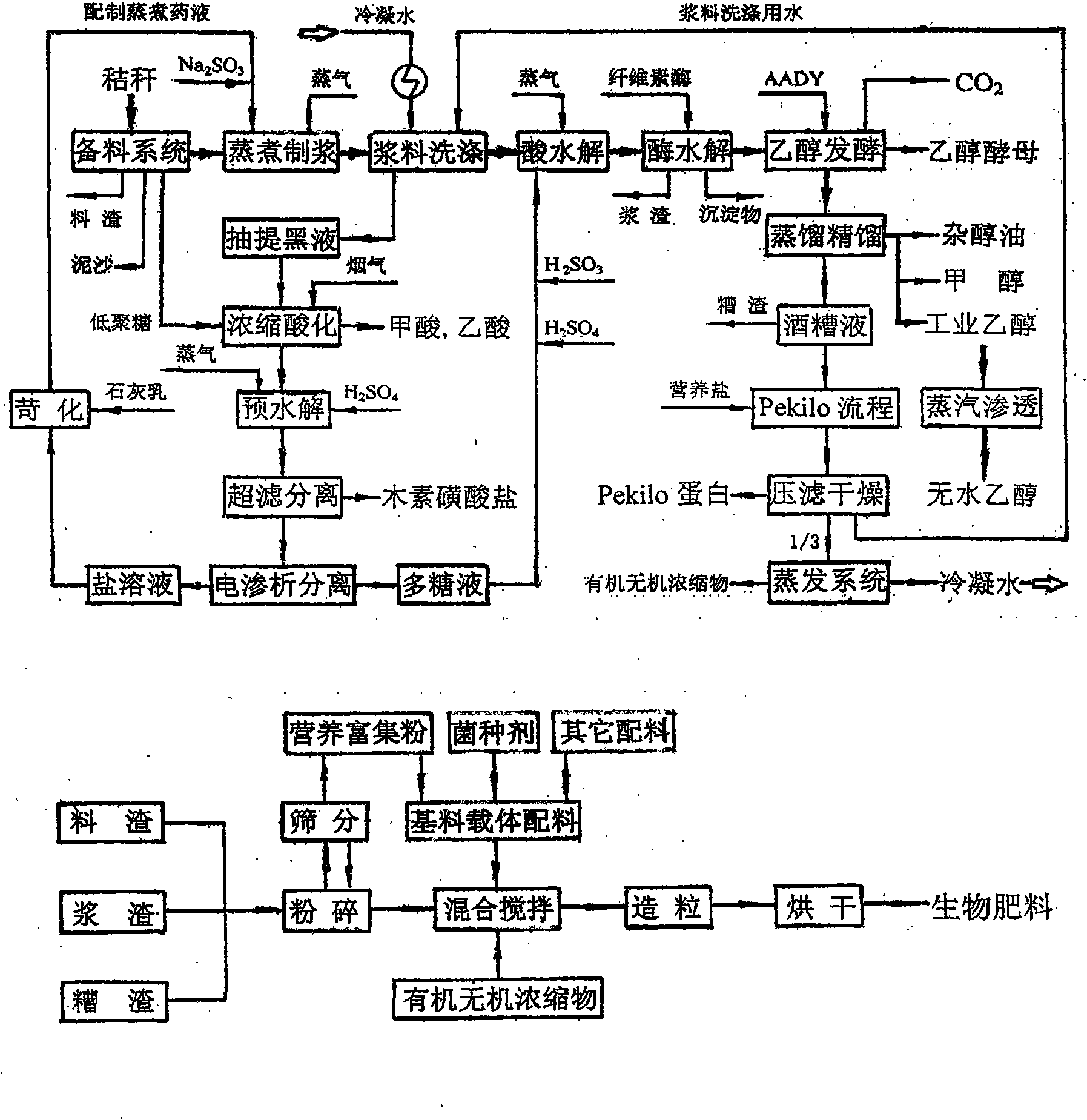

Ethanol-guiding straw bio-refining full-sealing integration system

InactiveCN101555495AImprove productivityStrong profitabilityBy-product recoveryFungiFiberLiquid waste

The invention relates to a fiber biomass refining technology, in particular to an ethanol-guiding straw bio-refining full-sealing integration system. Based on the clean pulping of the straw, a chemical and biological combined method is used for totally hydrolyzing amylose separated from a cellulose and a hemicellulose separated into pulps and braised waste liquid to prepare a hexose and a pentose;and the hexose and the pentose are converted into series of chemical and biological products which taking ethanol as dominant product. As a firstly separated and subsequently disposed straw bio-refin ing integration system, the cellulose and the hemicellulose in the straw raw material are utilized effectively; furthermore, 20-25% of the lignin in the raw material and the material slag, slurry slag, trough slag and ashes (mineral matter) produced in the production process are totally converted into the product with high additional values, thus realizing the environment objects of full sealing and zero draining and controlling the production cost (apportionment cost after the straw biomass is totally utilized) of the fuel ethanol within 1800-2000RMB / t.

Owner:徐守才

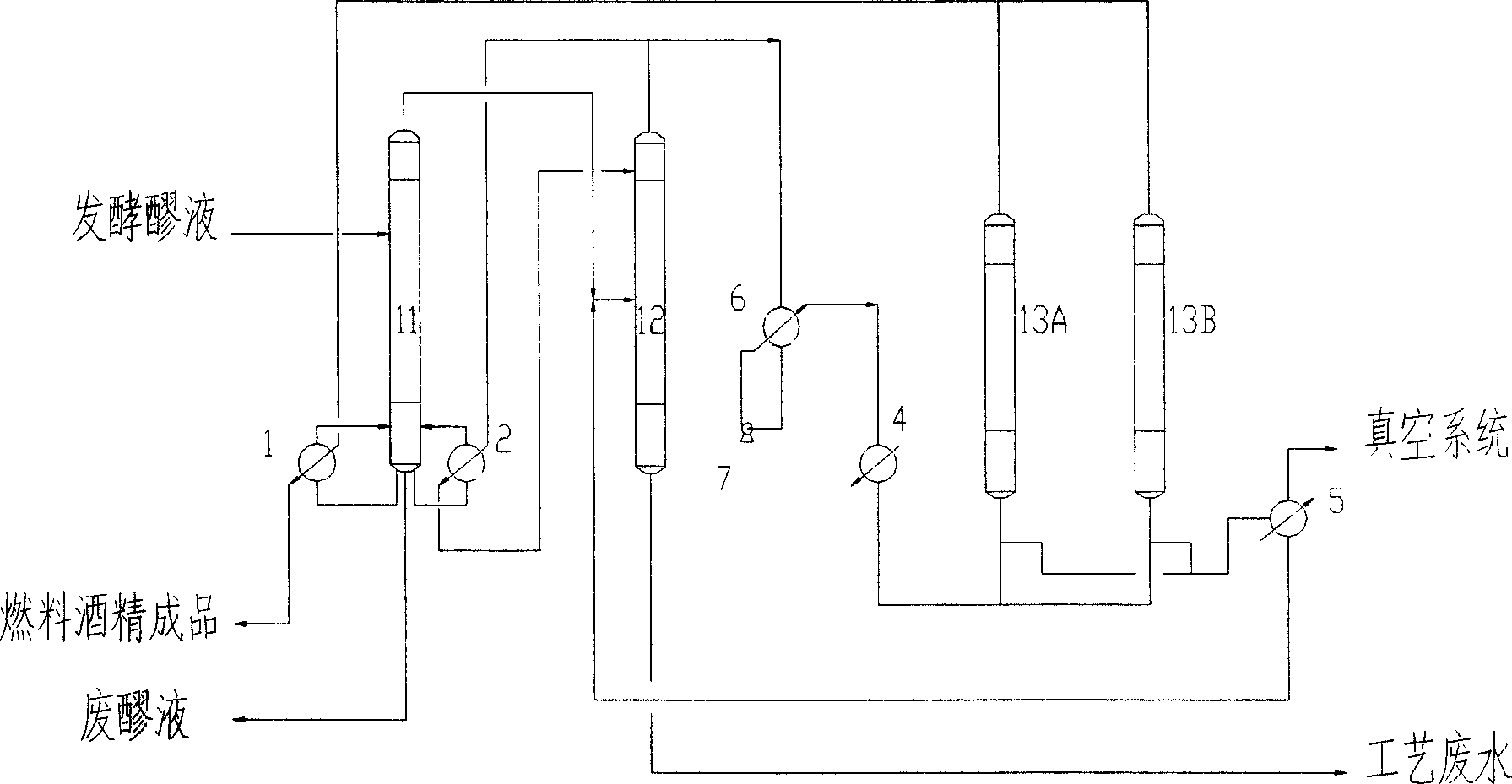

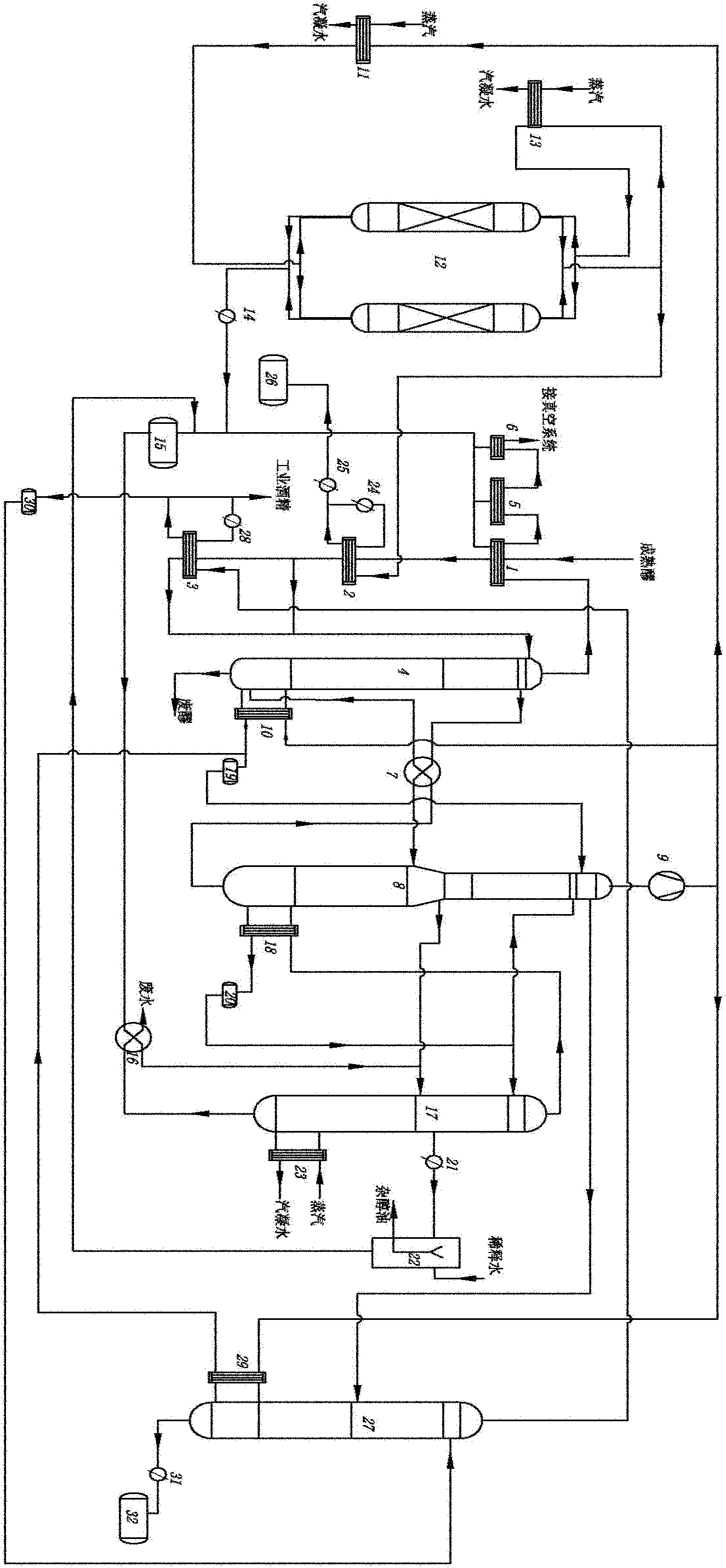

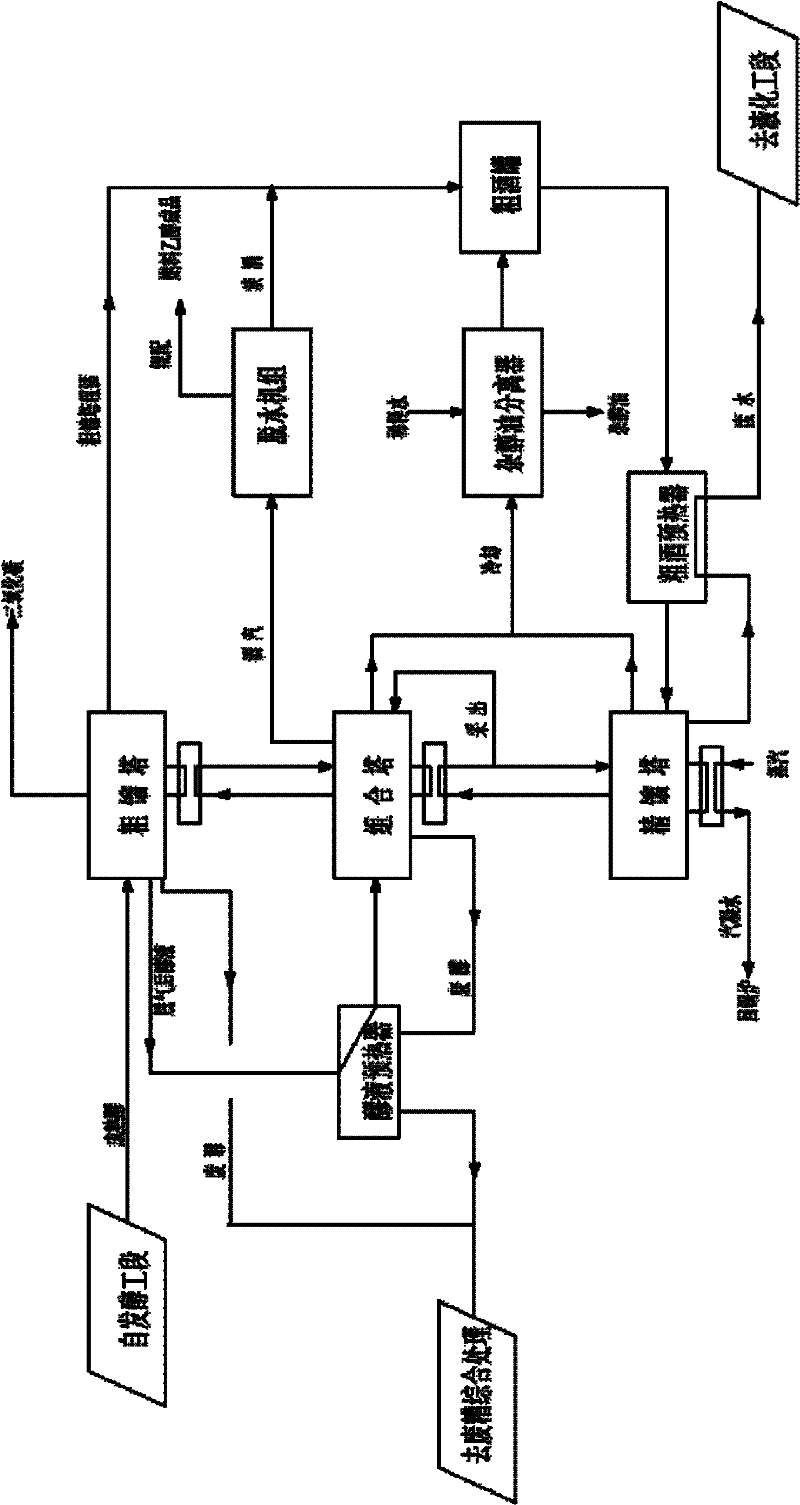

Distillation dehydration device and process for co-producing ethanol fuels and custom grade edible alcohols

ActiveCN102040471ALow operating pressureLess investmentOrganic compound preparationHydroxy compound separation/purificationDesorptionDistillation

The invention discloses a distillation dehydration device and a distillation dehydration process for co-producing ethanol fuels and custom grade edible alcohols. The device comprises a molecular sieve adsorption / desorption tower, a coarse fractionating tower, an assembled tower, a rectifying tower, a methanol tower and mash pre-heaters, wherein the wine steam of the assembled tower, after compressed by an ethanol steam compressor, is used as the heat sources and raw material wine steams of the coarse fractionating tower and the methanol tower; the wine steam of the rectifying tower is used asthe heat source of the assembled tower; and the wine steam of the coarse fractionating tower, the anhydrous alcohol steam and the wine steam of the methanol tower are respectively used as the heat sources of the first, second and third mash pre-heaters. The device can simultaneously produce ethanol fuels and custom gradeedible alcohols, and can separately produce ethanol fuels or custom grade edible alcohols. The device and the process of the invention have the advantages that, because a multi-effect energy coupling mode is adopted, compared with an original process, the energy consumption ofthe process of the invention is greatly reduced, and the steam consumption of the ethanol fuel per metric ton is reduced to 1.1 to 1.5 t / t, compared with the steam consumption of 1.5 to 2.0 t / t in the original process, the steam consumption is down by 25 to 35 percent without consuming high-grade steams (more than 0.7 MPag); and the steam consumption of the custom grade edible alcohol per metric ton is reduced to 1.2 to 1.4 t / t, compared with the steam consumption of 1.9 to 2.5 t / t in the original process, the steam consumption is down by 35 to 50 percent.

Owner:GUANGDONG ZHONGKE TIANYUAN NEW ENERGY SCI & TECH

Method for stalk liquefaction preprocessing to prepare fuel ethyl hydrate raw material

InactiveCN101298744ASmall granularityRealize comprehensive utilizationPaper material treatmentCelluloseProviding material

The invention relates to a pre-treatment method for straw 'liquefying' to provide material for fuel alcohol preparation. The method adopts powders (10.0 parts of mass) of crop straws and phenols or polyalcohol compound (10 to 100 parts of mass) which is firstly pre-heated by 10 to 30 minutes under a temperature of 30 to 200 DEG C with the effect of acid catalyst (0.5 to 10 parts of mass) for a reaction of 30 to 240 minutes; after the reaction, the compound is washed, neutralized, filtered and dried to obtain a solid appearing as a color from citron yellow, yellow, bight brown to seal brown; wherein, the solid includes 64.0 to 70,0 percent of fibrin and 4.1 to 7.6 percent of lignin. The method adopts the 'liquefying' process to carry out pre-treatment to fibrin biomass of straws with high straw fibrin content and low granularity after pre-treatment to realize effective separation of fibrin and lignin, etc. so as to provide the better material for preparing fuel alcohol with straws and to conserve energy cost and avoid contamination to environment.

Owner:HAINAN UNIVERSITY

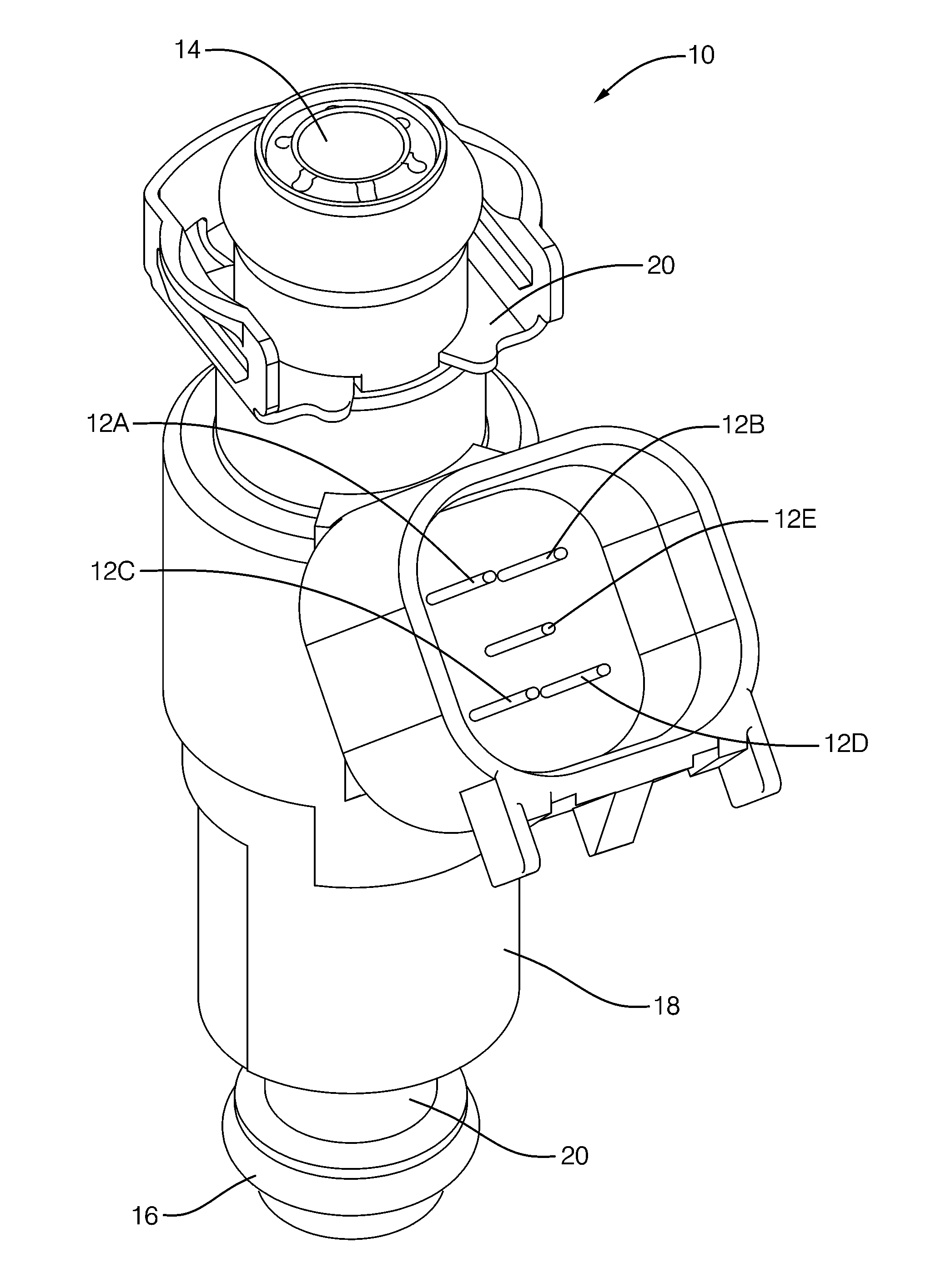

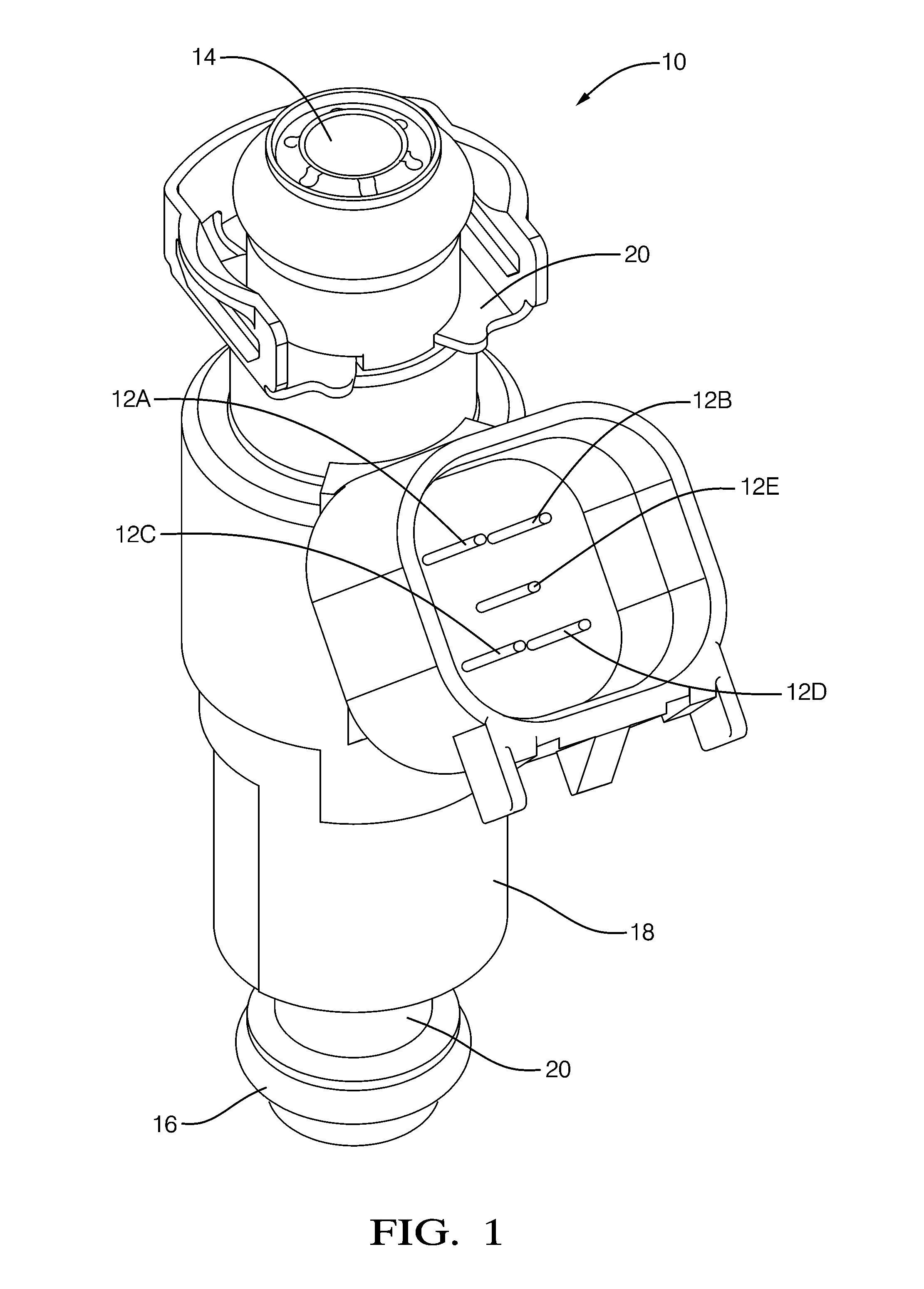

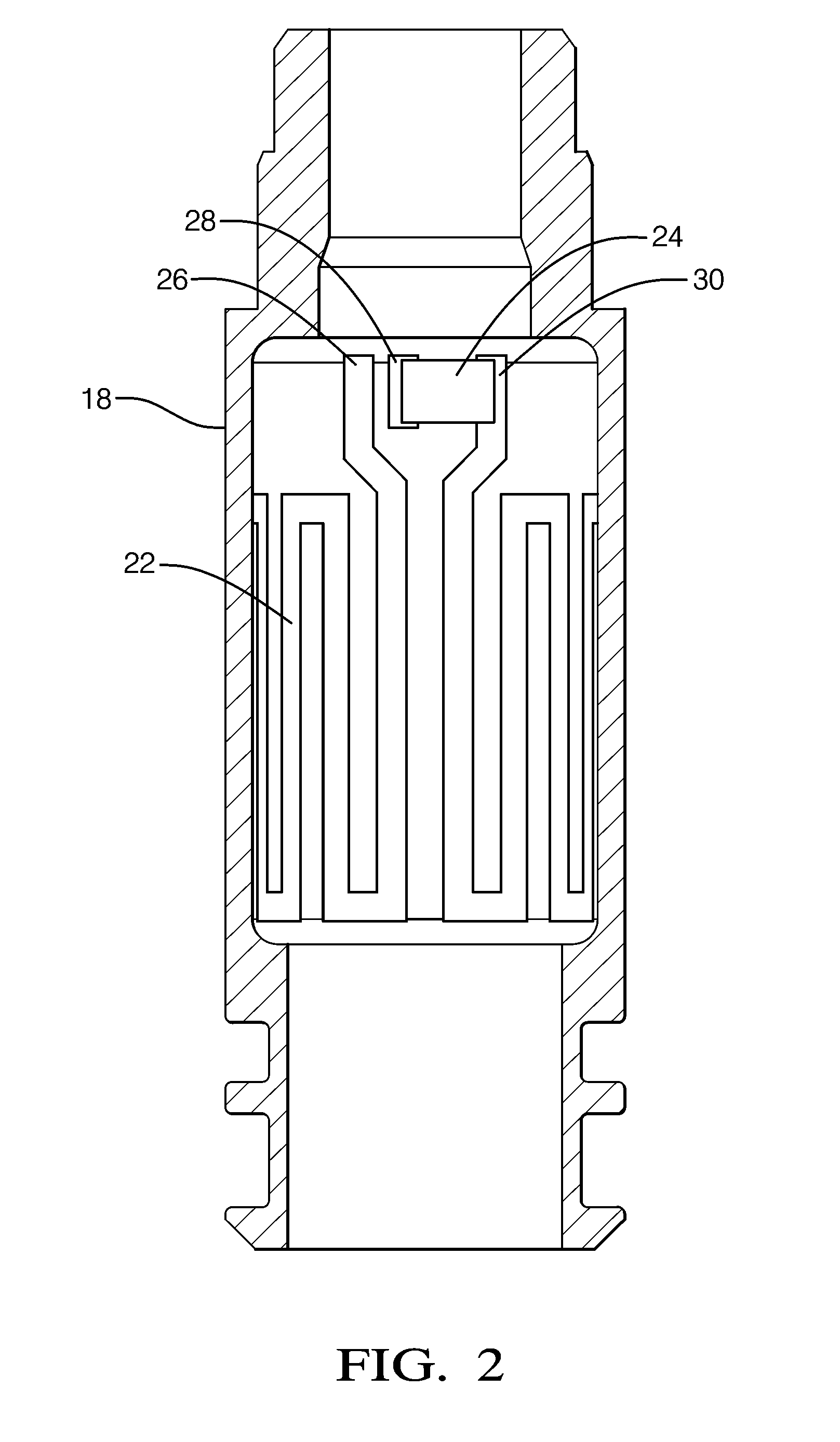

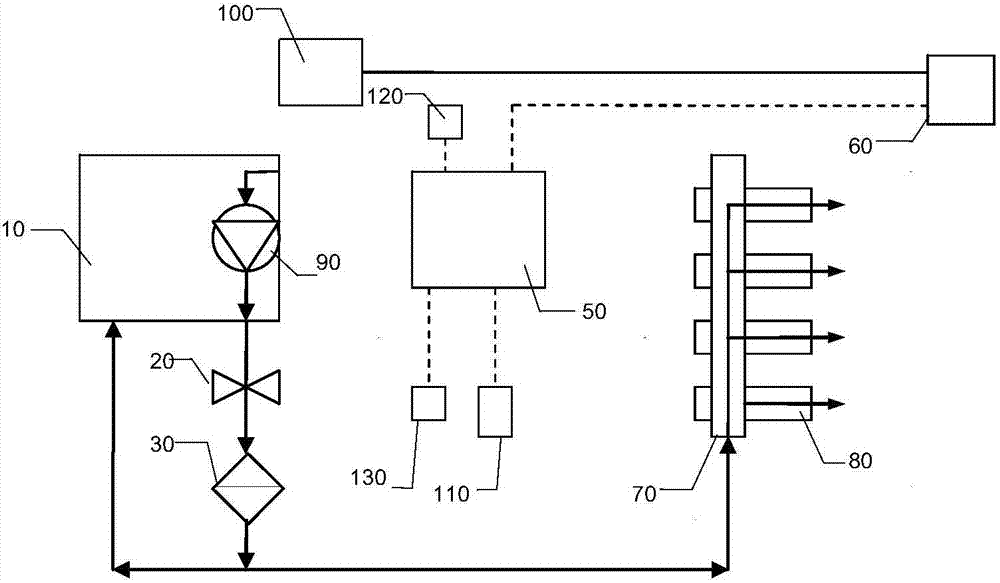

Heated Fuel Injector System

ActiveUS20110276252A1Thermometer detailsLiquid surface applicatorsTemperature controlNuclear engineering

A heated fuel injector system and controller that includes a temperature sensing means to provide closed-loop control of a heating element heating fuel dispensed by a heated fuel injector. Closed-loop control provides more accurate temperature control of the heating element so that fuel heating is provided as quickly as possible while also protecting the fuel from being boiled and protecting the heated fuel injector from being damaged by excessive temperature. By monitoring how the signal from the temperature sensing means varies over time, fault conditions such as a lack of fuel flow, and fuel ethanol percentage may be detected.

Owner:DELPHI TECH IP LTD

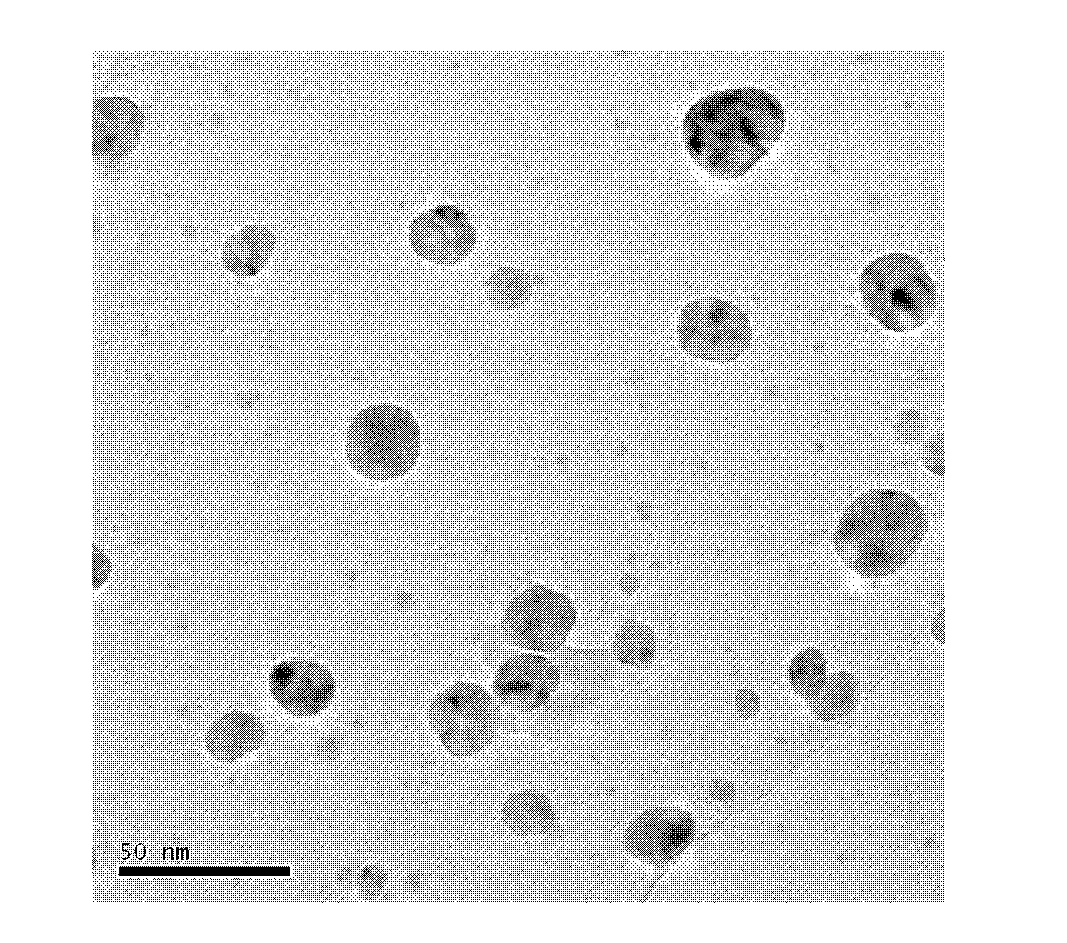

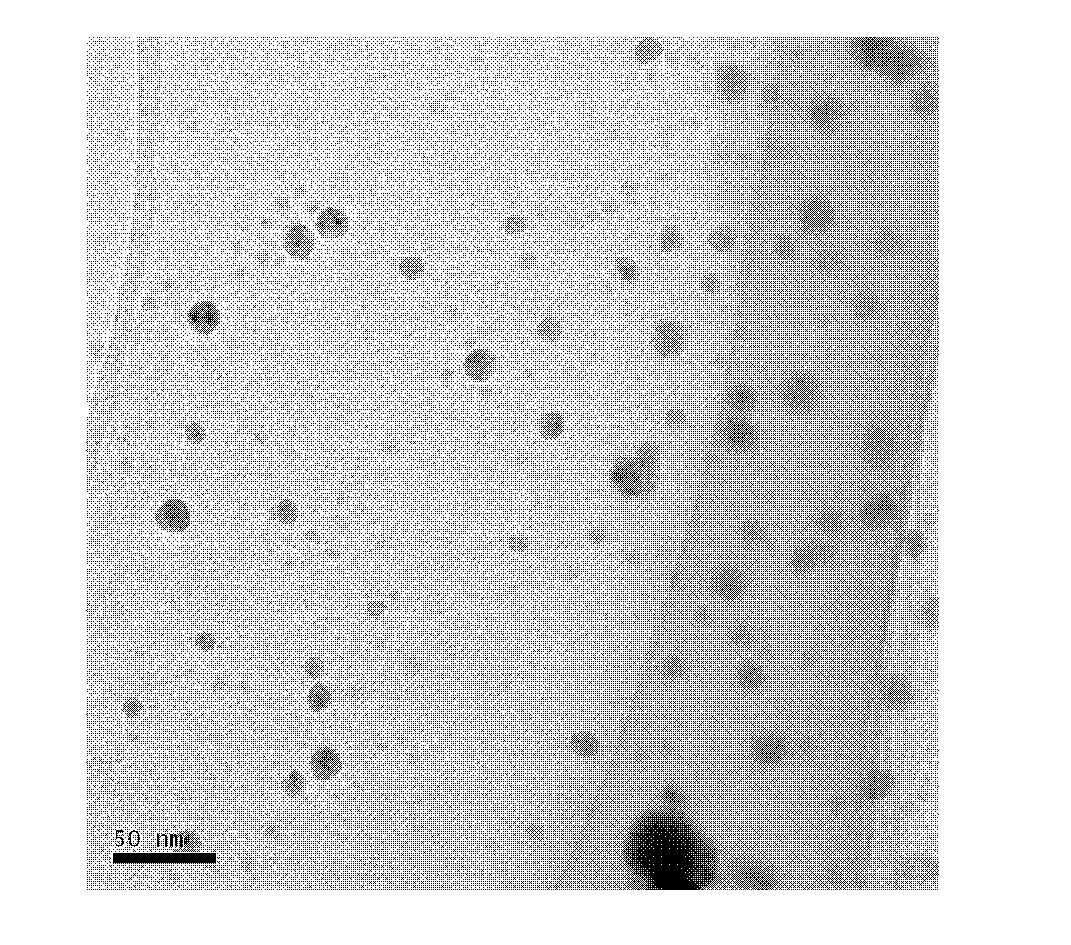

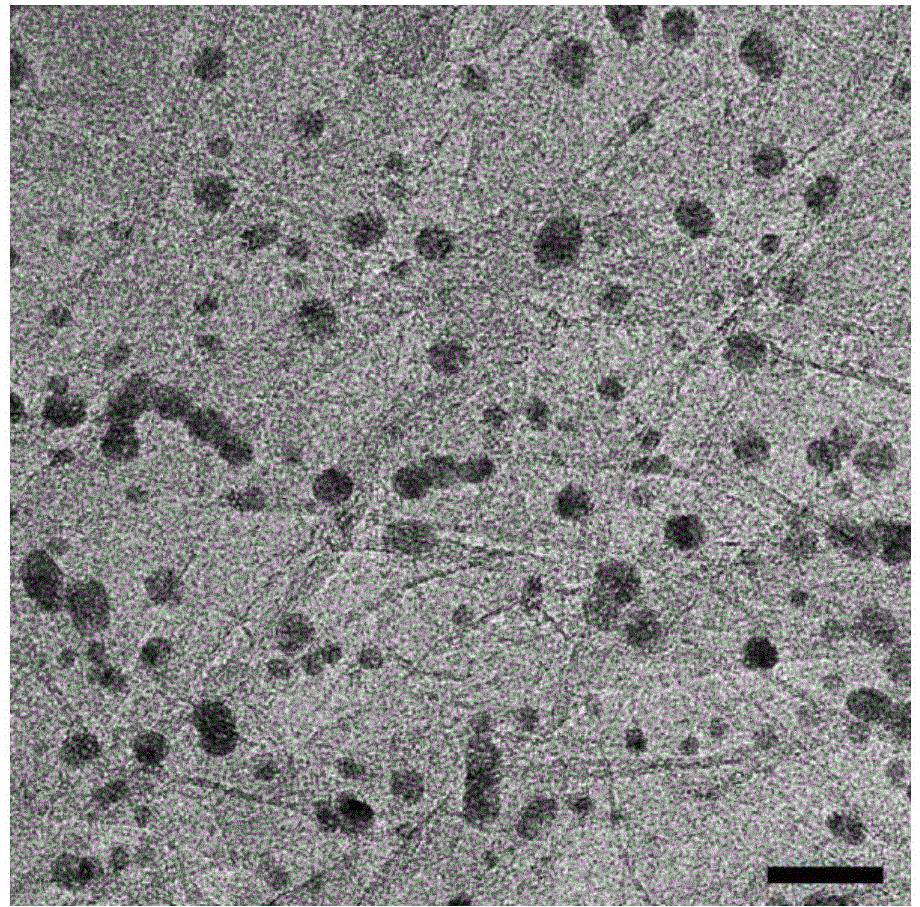

Graphene-loaded double-metal nano particles for methanol and ethanol fuel cells, and preparation method for graphene-loaded double-metal nano particles

InactiveCN102489314AHigh catalytic activityLow costMaterial nanotechnologyCell electrodesCarbon monoxide poisonOrganocatalysis

The invention relates to graphene-loaded double-metal nano particles for methanol and ethanol fuel cells, and a preparation method for the graphene-loaded double-metal nano particles. The method comprises the following steps of: sequentially adding graphene oxide, polymeric dispersant, and anionic surfactant into a water-ethanol mixed solution, stirring, adding double-metal nano particles, and adding sodium borohydride to obtain black precipitate double-metal nano particle graphene; and performing centrifugal separation on precipitate by using a centrifugal machine, repeatedly washing by using secondary deionized water and ethanol to remove unreacted reactant, and then performing vacuum drying. According to the method, gold and silver which is low in price, and non-noble metal such as cobalt and nickel which is lower in price is used instead of noble metal such as platinum and ruthenium which is high in price, so cost is reduced. Methanol is catalyzed and ethanol is oxidized under thealkaline condition, so the condition that intermediate carbon monoxide poisons a catalyst under the acid condition so that the activity of the catalyst is reduced can be effectively overcome. The graphene-loaded double-metal nano particles can be directly used for methanol and ethanol fuel cells, formic acid fuel cells, and organic catalytic reaction.

Owner:TIANJIN UNIV

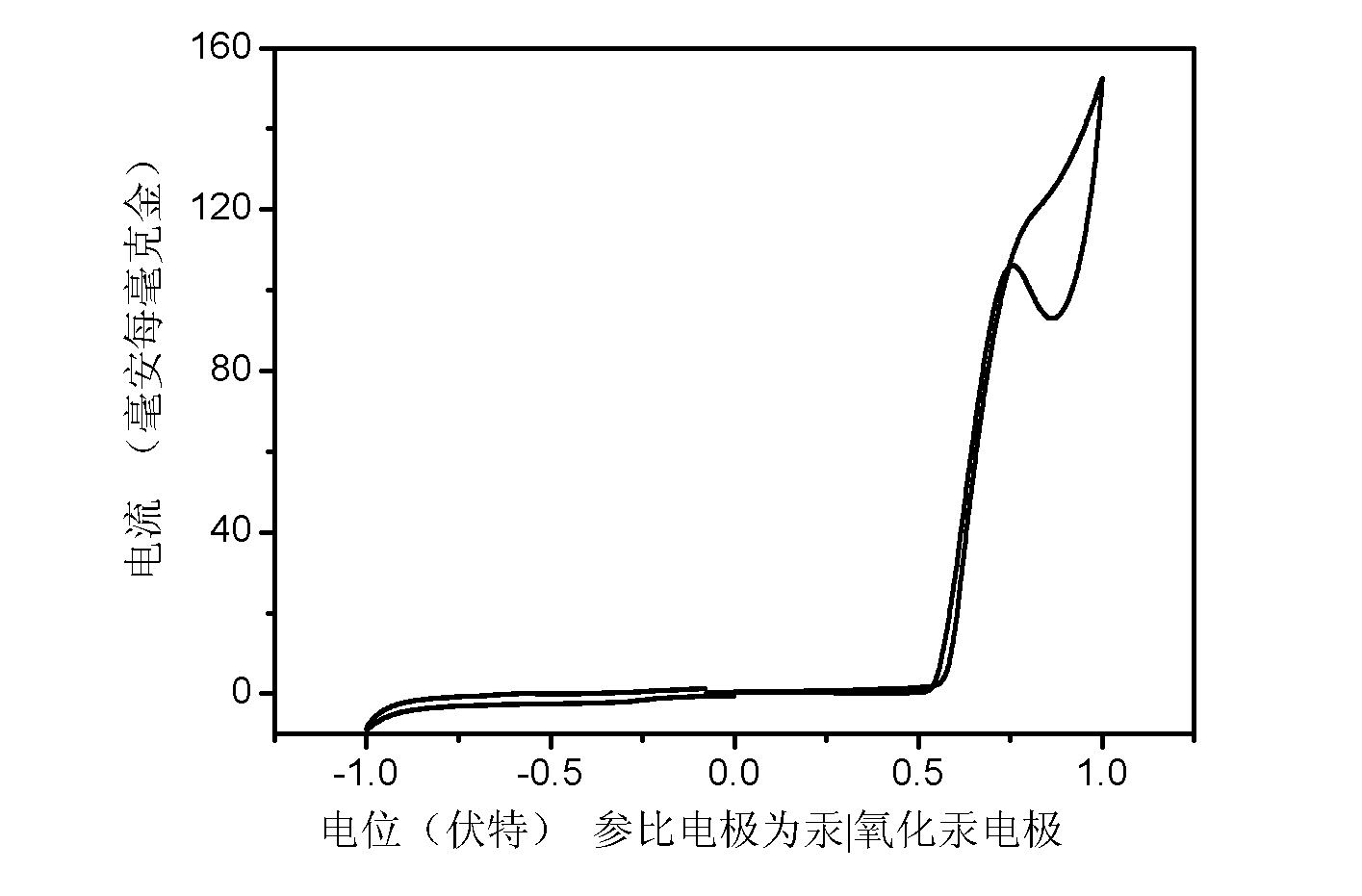

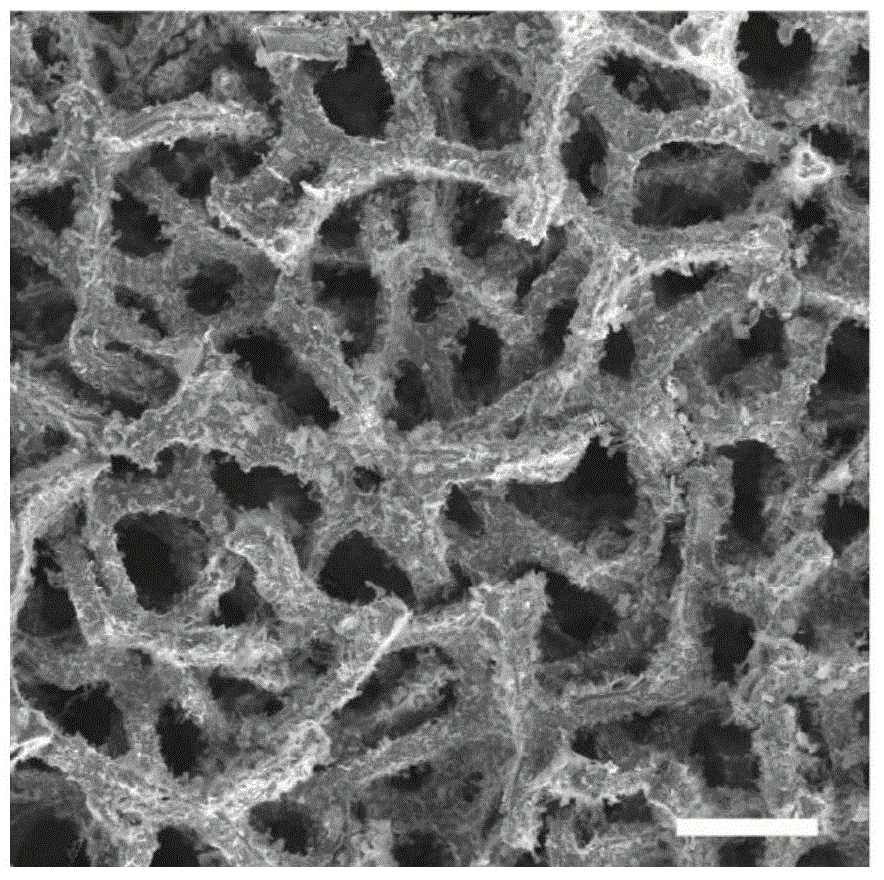

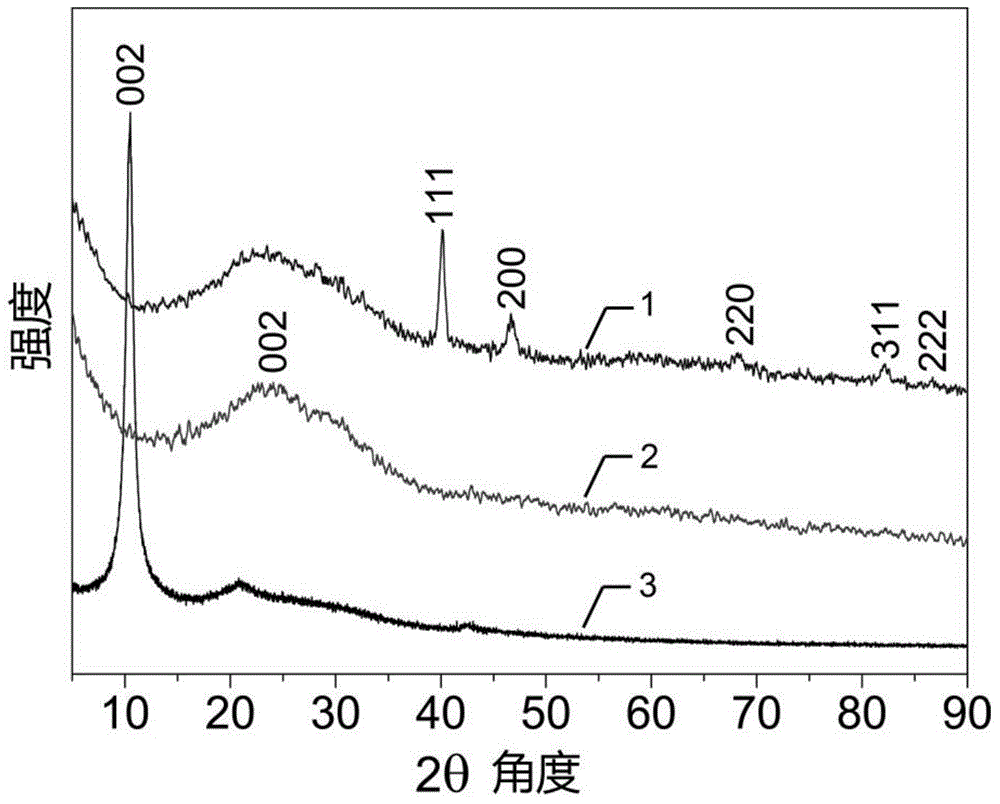

Preparation method of nanometer palladium-graphene three-dimensional porous composite electrocatalyst

ActiveCN104549242AEasy to controlLarge specific surface areaCell electrodesMetal/metal-oxides/metal-hydroxide catalystsPorous graphenePotassium

The invention discloses a preparation method of a nanometer palladium-graphene three-dimensional porous composite electrocatalyst. The preparation method comprises the following steps: cleaning foamed nickel by sequentially adopting glacial acetic acid, acetone, ethanol and deionized water; preparing a graphene oxide water solution with the mass concentration of 0.5-10 mg / mL, then directly soaking the foamed nickel into the graphene oxide water solution, and standing for reaction to form a three-dimensional porous structural foamed nickel-graphene product; directly soaking the foamed nickel-graphene product into a potassium chloropalladate water solution with the molar concentration of 0.05-1 mmol / L; and after the reaction is finished, taking out the foamed nickel-graphene product so as to generate a graphene composite electrocatalyst product which has a three-dimensional porous structure and is loaded with a palladium nanoparticle. By the preparation method disclosed by the invention, the three-dimensional porous graphene foamed product loaded with the palladium nanoparticle can be obtained only through simple two-step soaking operation; and in addition, the three-dimensional porous graphene foamed product is excellent in property and high in stability and can be directly used as the positive pole of an ethanol fuel cell.

Owner:HUAZHONG UNIV OF SCI & TECH

Method for harvesting microalgae by using polysaccharide

InactiveCN101962618ASubsequent processing and application have no adverse effectsImprove biological activityUnicellular algaeMicroorganism based processesBiodieselPhosphate

The invention relates to a method for harvesting microalgae by using acid group-containing polysaccharide. The polysaccharide (including cellulose, alginate, bacterial cellulose, starch, chitosan, chitin and the like) with dissociable acid group (including carboxyl group, phosphate group, sulfate group or the like) is used as a flocculant; a proper amount of solution of polysaccharide polyelectrolyte is added into microalgae suspension; the pH value of the suspension is then adjusted so as to flocculate and settle the microalgae; and then static demixing, dehydration and drying are performed so as to obtain the microalgae solid. The electrical property of the polysaccharide with the carboxyl group, sulfate group or phosphate group can be adjusted through the pH value and the content of the acid group so as to adapt to the settlement of different kinds of microalgae. The polysaccharide has the advantages of high bioactivity, safety, no toxicity, similar chemical constituent to the microalgae and no adverse effect on the subsequent processing and application of the microalgae and can be used with the microalgae for production of biomedicinal chemistry, foods, animal feeds, biodiesel oil, fuel ethanol and the like.

Owner:HAINAN UNIVERSITY

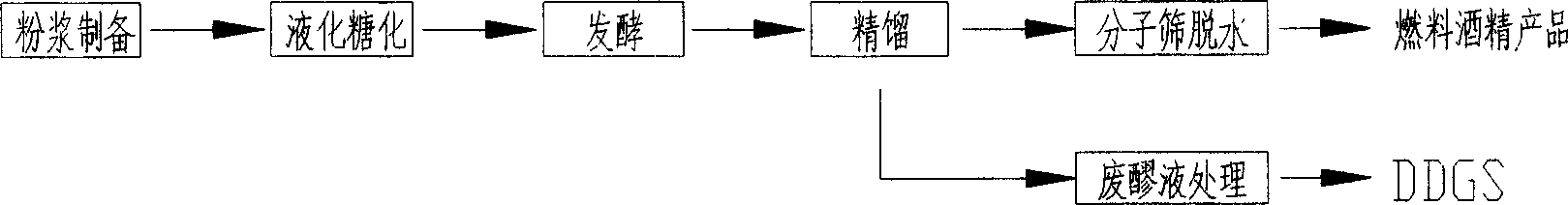

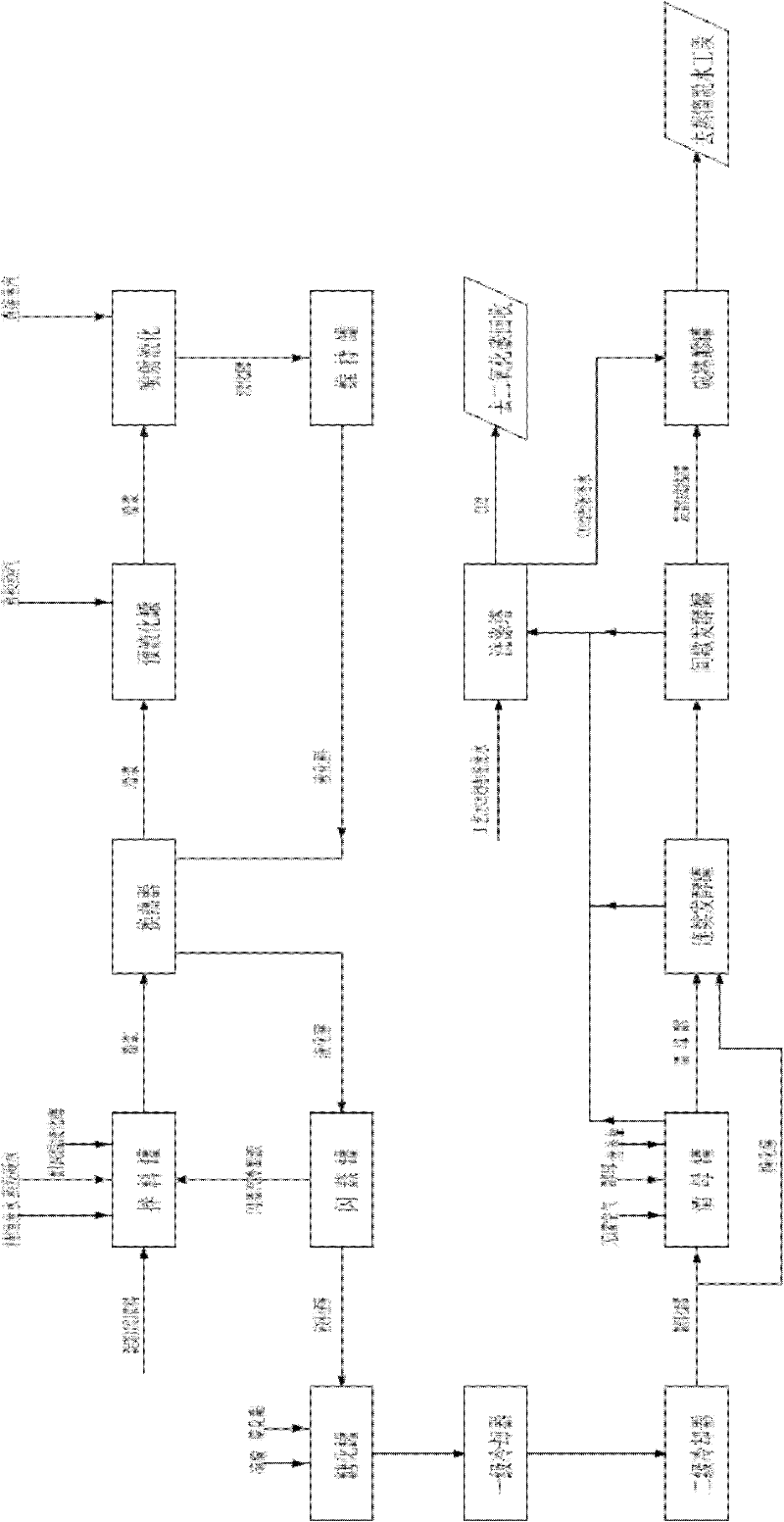

A kind of clean production method of starch-based fuel ethanol

ActiveCN102286544AIncrease added valueFood processingClimate change adaptationDistillationEthanol fuel

The invention relates to a clean production method of starch-based fuel ethanol, which includes the following steps: (1) liquefaction, (2) saccharification, (3) fermentation, (4) distillation and dehydration, and also includes comprehensive treatment of waste residues and recycling of by-products section. Among them, the liquefaction section adopts a low-pressure ejector continuous cooking process; the fermentation section adopts a semi-continuous fermentation system to keep the fermented mash in a flowing state and promote the uniform contact between yeast and mash; The combination tower with wine vapor heating on the top of the tower, the thermal coupling scheme of the crude distillation tower with wine vapor heating on the top of the combined tower, the obtained anhydrous ethanol is mixed to obtain denatured fuel ethanol, the quality meets the national standard GB18350-2001, and passed The waste residue comprehensive treatment and by-product recycling section recycles waste residue and useful substances in waste gas. In this method, the heat exchange network and water network of each production section are reasonably matched, and the goal of clean production with low material consumption and energy consumption and full resource utilization is realized.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI +2

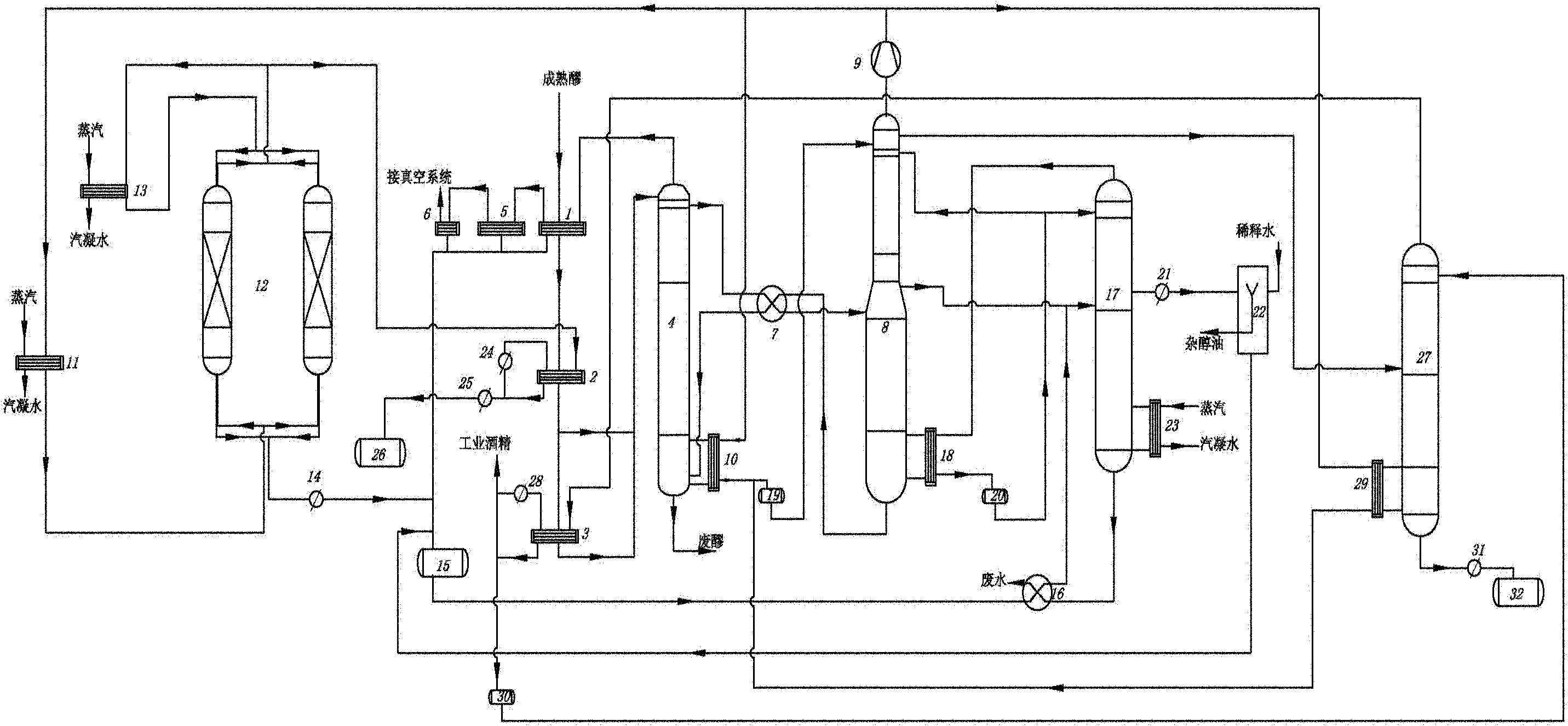

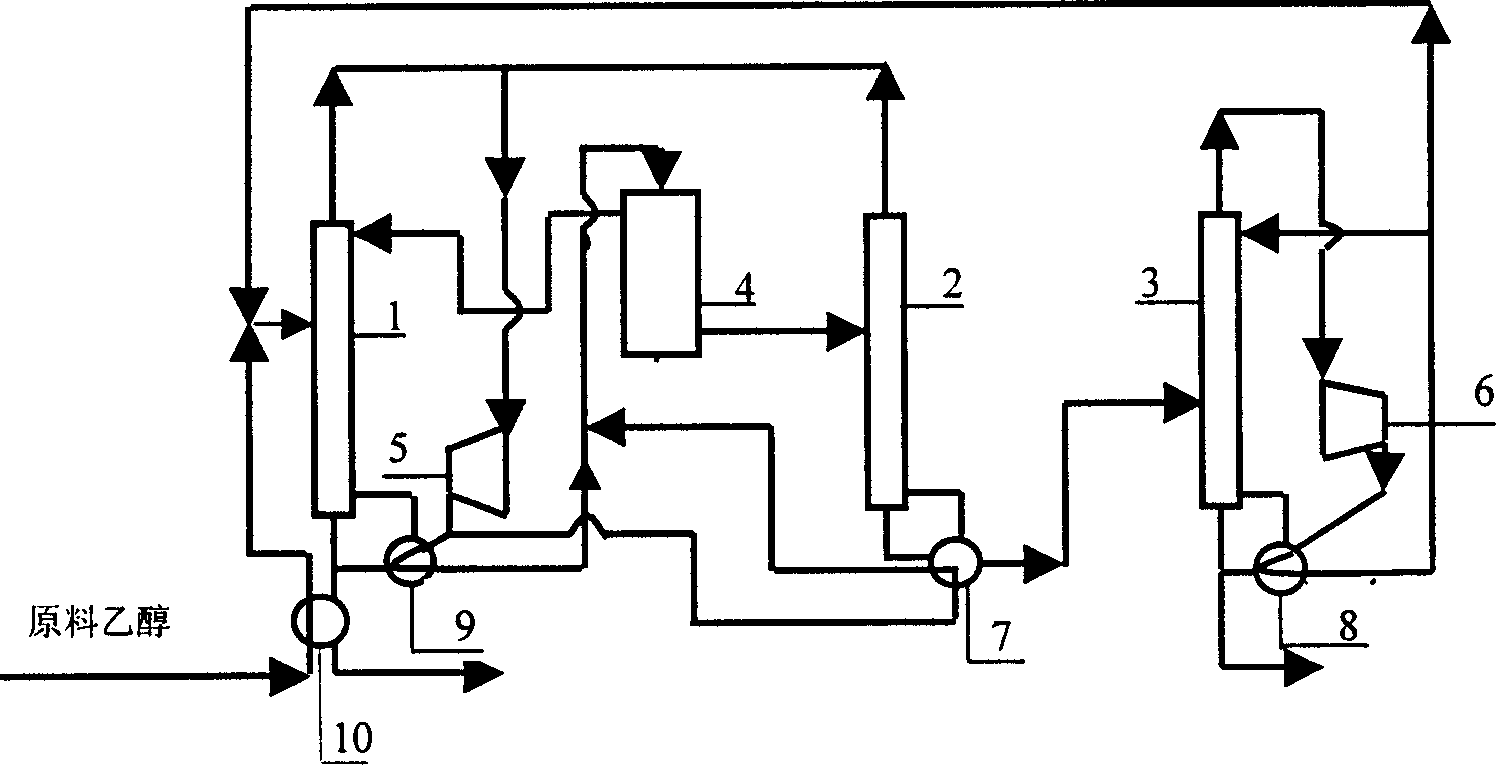

Heat pump azeotropic rectification process and equipment for fuel ethanol

InactiveCN1417182ANo pollution in the processReduce manufacturing costOrganic compound preparationHydroxy compound preparationReboilerProcess engineering

The heat pump azeotropic rectification equipment includes ethanol dewatering tower, entrainer recovering toward and ethanol recovering tower. The top vapor from the three towers is pressurized and heated before used as the heat source of the bottom reboilers, and there are no top condensator, boiler heating system and circular pump, and the whole stream system is closed and these result in low production cost, zero exhaust and environment protection.

Owner:XI AN JIAOTONG UNIV

Method for producing ethanol fuel from kitchen waste

ActiveCN102321722APromote growth and reproductionReduce pollutionMicroorganism based processesFermentationBacillus licheniformisPichia pastoris

The invention discloses a method for producing ethanol fuel from kitchen waste, belonging to the technical field of biology. The invention aims to reduce the environmental pollution of kitchen waste, and change wastes into valuable substances, thereby recycling the kitchen waste. According to the method, the kitchen waste, which contains rich starch, cellulose, fat, protein and the like, is comprehensively utilized with a biological bacterial liquid and an enzyme preparation. The biological bacterial liquid contains Bacillus licheniformis, Bacillus megaterium, Bacillus natto, Bacillus subtilis, Lactobacillus plantarum, Lactobacillus delbrueckii subspecies bulgaricus, Saccharomyces cerevisiae and Pichia pastoris. The enzyme preparation comprises amylase, cellulase, lipase, protease, pectinase and saccharifying enzyme. The method comprises the following steps: fermenting the kitchen waste, biological bacterial liquid and enzyme preparation in a fermentation tank at the constant temperature of 25-32 DEG C for 48-80 hours, distilling the fermentation broth, and rectifying to obtain the ethanol fuel.

Owner:天津北洋百川生物技术有限公司

Ferment method of producing fuel ethanol using stalk material

The invention relates to a method for preparing fuel ethanol by taking straw as raw material. It comprises following steps: (1) selecting crop straw as raw material; (2) disintegrating: disintegrating straw by using hammer mill, sifting and getting straw powder of 20- 40 order; (3) pre- treating: lignin degrading raw material by way of culturing white-rot fungi in solid culture medium and liquid enzyme; (4) saccharifying two enzymes, saccharifying straw by using cellulase and xylanase at 45 Deg. C, pH 4.5, 150 rmp and ratio between liquid and solid 15, getting reduced sugar; (5) fermenting; (6) distilling. The fuel ethanol productivity is 16.7% in this invention, that is 16.7 ton waterless ethanol with every 100 ton straw, the production efficiency is high and economic benefit and social benefit is pretty good. Compared with current process, this invention is characterized in that the fermentation is thorough and the fuel ethanol production cost is low.

Owner:HENAN AGRICULTURAL UNIVERSITY

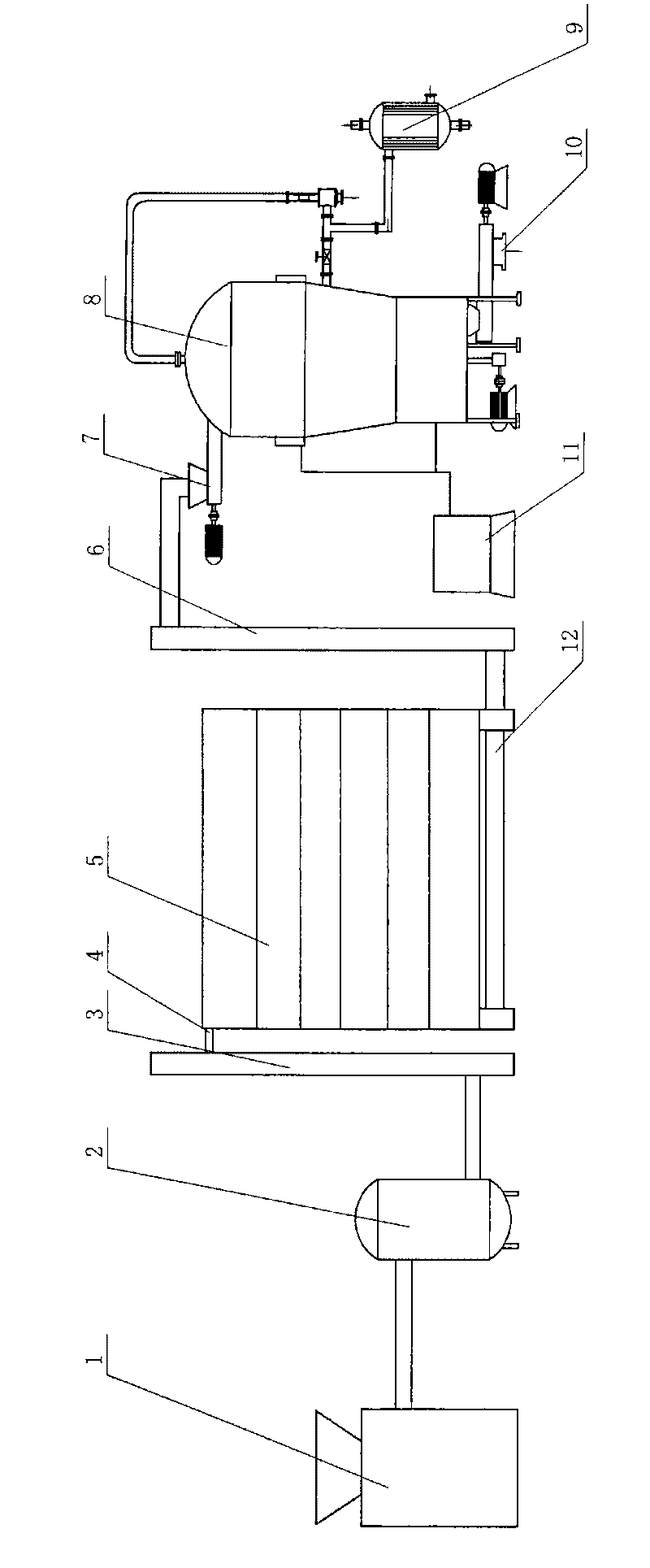

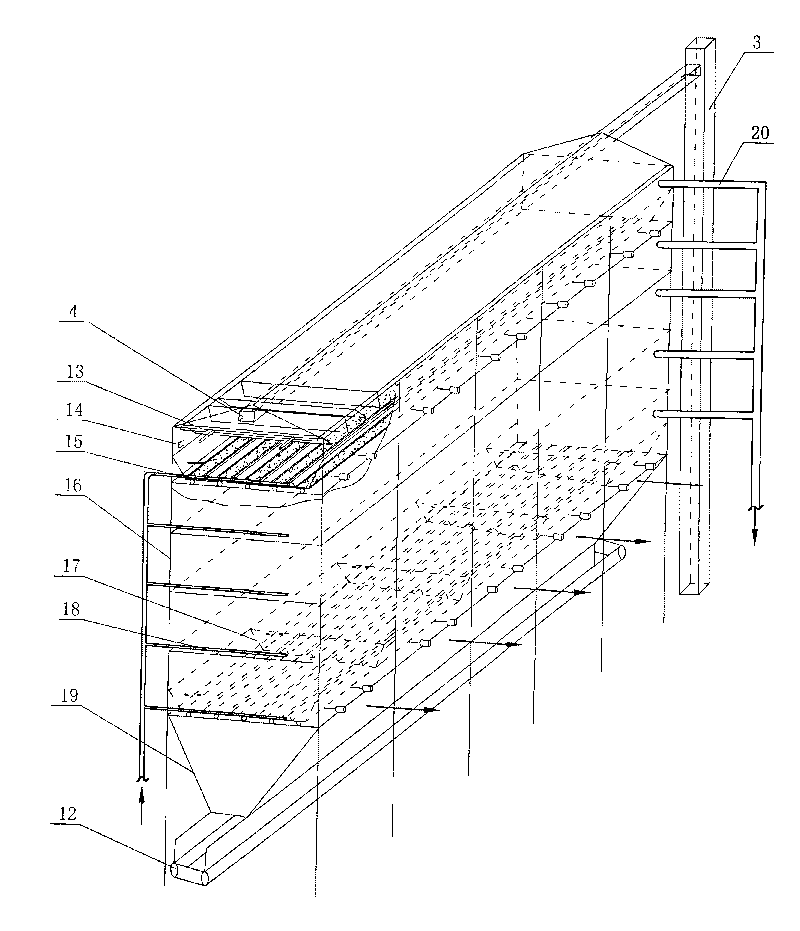

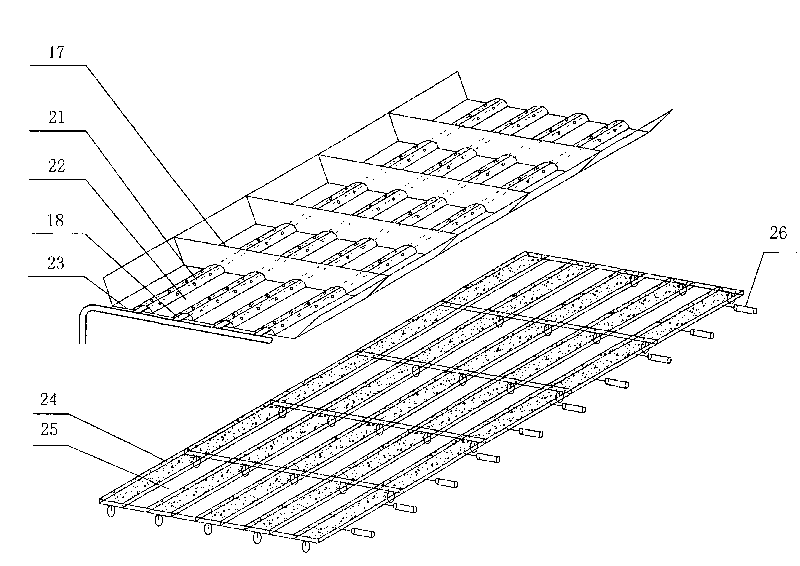

Process and system for producing ethanol through solid-state continuous fermentation and distillation of sorgo straws

ActiveCN101724661AUniform and complete fermentationHigh yieldBioreactor/fermenter combinationsBiological substance pretreatmentsDifferential pressureDistillation

The invention relates to a process and a system for producing ethanol through solid-state continuous fermentation and distillation of sorgo straws, wherein the process comprises a raw material pulverizing and preprocessing step, a strain adding step, a solid-state fermentation step and a solid-state distillation step; the solid-state fermentation step is continuously finished in a multilayer multisection solid-state continuous fermentation device, and the solid-state distillation step is continuously finished in a multilayer differential pressure type solid-state continuous distillation device, thereby radically overcoming the abuse that the past solid-state fermentation and distillation processes can not continuously produce, realizing continuous, mass and automated production and processing, greatly improving the production efficiency of preparing the fuel ethanol from the sorgo straws, and achieving the purposes for lowering the production cost, improving the yield and improving the economic benefit; an adopted continuous production system device is particularly suitable for industrialized large-scale production, thereby promoting the generalization and the application of a biological energy source technology.

Owner:天津实发中科百奥工业生物技术有限公司 +1

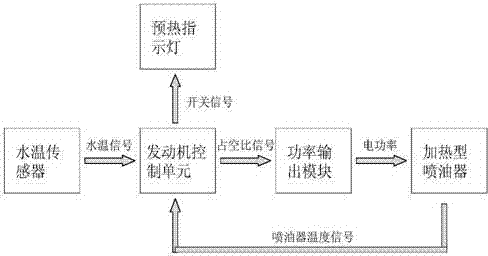

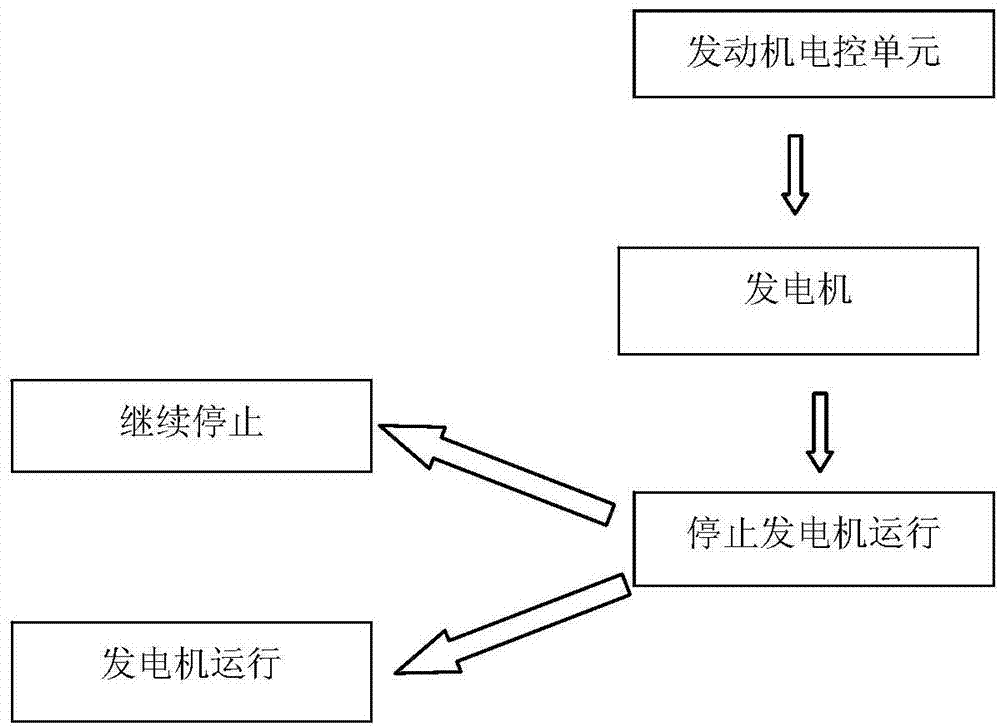

Cold start system and start method for flexible fuel vehicle

ActiveCN103615345AAchieve jet ignitionReduce manufacturing costFuel injection apparatusEngine controllersFuel oilFlexible-fuel vehicle

The invention relates to a cold start system and start method for a flexible fuel vehicle. The cold start system comprises an engine control unit, a fuel system and a fuel oil preheating module. The fuel oil preheating module comprises a water temperature sensor, a preheating indicator light, a power output module and a heating type oil sprayer. When a start switch is turned on, the preheating indicator light is firstly lightened, the water temperature sensor transmits a cooling water temperature signal to the engine control unit, the engine control unit calculates a duty ratio signal and judges whether the power output module needs to output power or not, the power output module outputs a current to the heating type oil sprayer, and the heating type oil sprayer heats ethanol fuel and feeds back a temperature signal of the heating type oil sprayer to the engine control unit at the same time so as to judge the preheating finish time.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Method for producing sodium alginate and co-producing ethanol and seaweed organic fertilizer

InactiveCN103232554ARealize high-value comprehensive utilizationHigh extraction rateFermentationOrganic fertilisersIon exchangeDigestion

The invention discloses a method for producing sodium alginate and co-producing ethanol and a seaweed organic fertilizer. The method comprises the following steps of: with brown algae kelp serving as a raw material, pre-processing through cellulase and compound protease in an enzymolysis manner; decomposing cellulose in the kelp into microbially available monosaccharide and oligosaccharide in order to ferment to produce ethanol; preparing the seaweed organic fertilizer through the rest fermentation broth with little kelp residue; extracting and separating sodium alginate from the pre-processed kelp; and then performing a dilute alkali digestion technology and a calcium coagulating-ion exchange method to obtain high-quality sodium alginate. According to the method, the preprocessing is performed through bio-enzyme, and the main components, namely, cellulose, protein and the like in the kelp, are separated in advance through the cellulose and protease, thus high extraction rate of the sodium alginate is grained; simultaneously, wastes generated in processing are utilized to prepare a fuel, namely, ethanol; and the waste liquid and waste residues remained in ethanol preparation are utilized to prepare the seaweed organic fertilizer, therefore, high-valued utilization of the kelp is realized, and marine biomass energy is developed.

Owner:QINGDAO BETTER BIO TECH

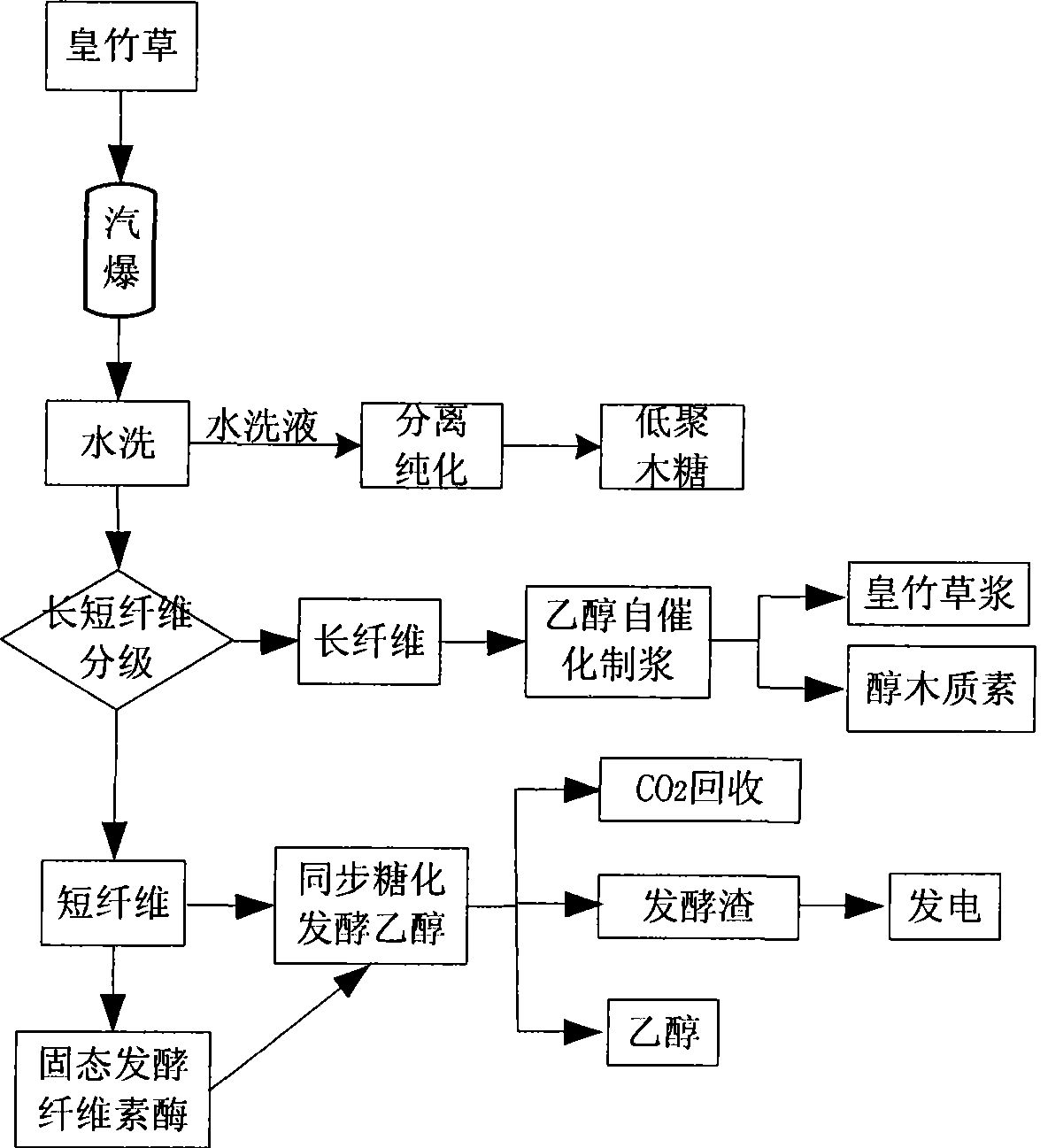

Technological method for transforming fuel alcohol in stages and cogenerating electricity and paper pulp with pennisetum hydridum

InactiveCN101519671AIncrease profitOptimize the way of comprehensive utilizationCellulosic pulp after-treatmentBioreactor/fermenter combinationsCardingLotion

The invention pertains to the field of the comprehensive utilization of pennisetum hydridum resources and relates to a method for the staged transformation and poly-generation of pennisetum hydridum, wherein after the steam explosion, the pennisetum hydridum is washed with water and water lotion is degraded hemicellulose used for preparing Xyol-Oligosaccharides; and then staged carding is carried out to the pennisetum hydridum after the steam exploded treatment to obtain long fiber (the fiber length is more than 3cm) and short fiber (the fiber length is less than 3cm). The long fiber after the carding is used for the auto-catalytic pulping of alcohol to obtain pennisetum hydridum pulp and alcohol soluble lignin. The short fiber after the carding is used for the solid-state fermentation of cellulase and then for synchronous saccharification and fermentation of alcohol, and fermentation residues generated in fermentation are used for biomass power generation and CO2 generated in the fermentation is reclaimed. The fermentation residues for biomass power generation, the pennisetum hydridum pulp, the alcohol soluble lignin, Xyol-Oligosaccharides and CO2 generated in the fermentation are cogenerated in the whole technological process of the fermentation of fuel alcohol with the pennisetum hydridum so as to realize the highly efficient comprehensive utilization of pennisetum hydridum resources.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method for pre-treating lignocellulose raw material and for preparing reducing sugar by conversion

InactiveCN102758028AImprove enzymatic hydrolysis efficiencyReduce manufacturing costFructose productionGlucose productionEthanol fuelSodium hydroxide

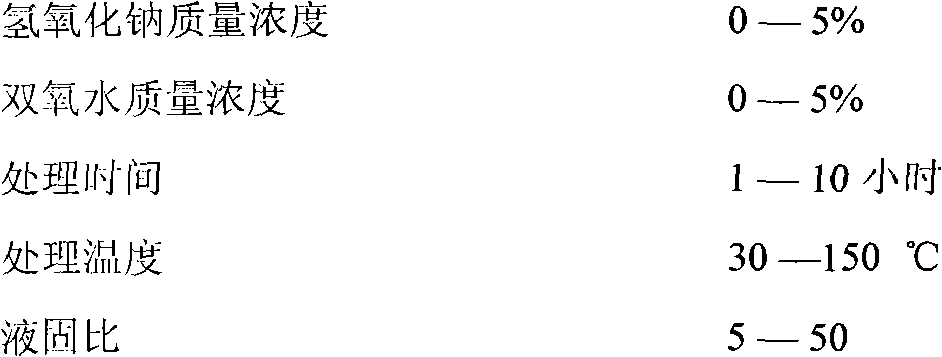

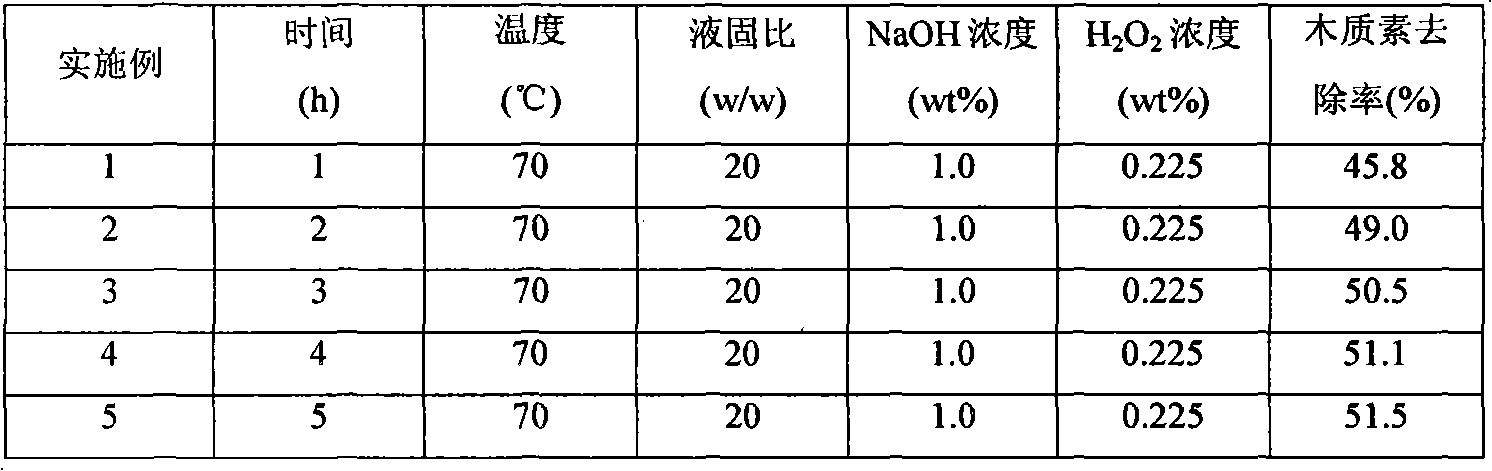

The invention relates to a method for pre-treating lignocellulose raw material and for preparing reducing sugar by conversion. With liquid-solid ratio of 5-50, lignocellulose is treated for 1-10h in a mixed solution of 0-5% of sodium hydroxide by mass and 0-5% of hydrogen peroxide by mass; solid residue obtained by treating is washed by using water, and is dried by baking; the obtained material is treated under a liquid-solid ratio of 5-50, an acid hydrolysis time of 10-120min, an acid hydrolysis temperature of 30-150min, and a sulfuric acid mass concentration of 0-10%, such that a solid residue is obtained; a pH value is regulated to 7; and the obtained material is dried by baking. With the treatment process, lignin can be effectively removed, and hemicellulose is hydrolyzed under a dilute acid condition, such that pentose is obtained. With further reactions, products with high added value can be obtained. With a sample treated with the process, ineffective adsorption upon cellulase is reduced, and a conversion rate of cellulose in preparing ethanol can reach 67%. Therefore, a production cost is relatively reduced.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

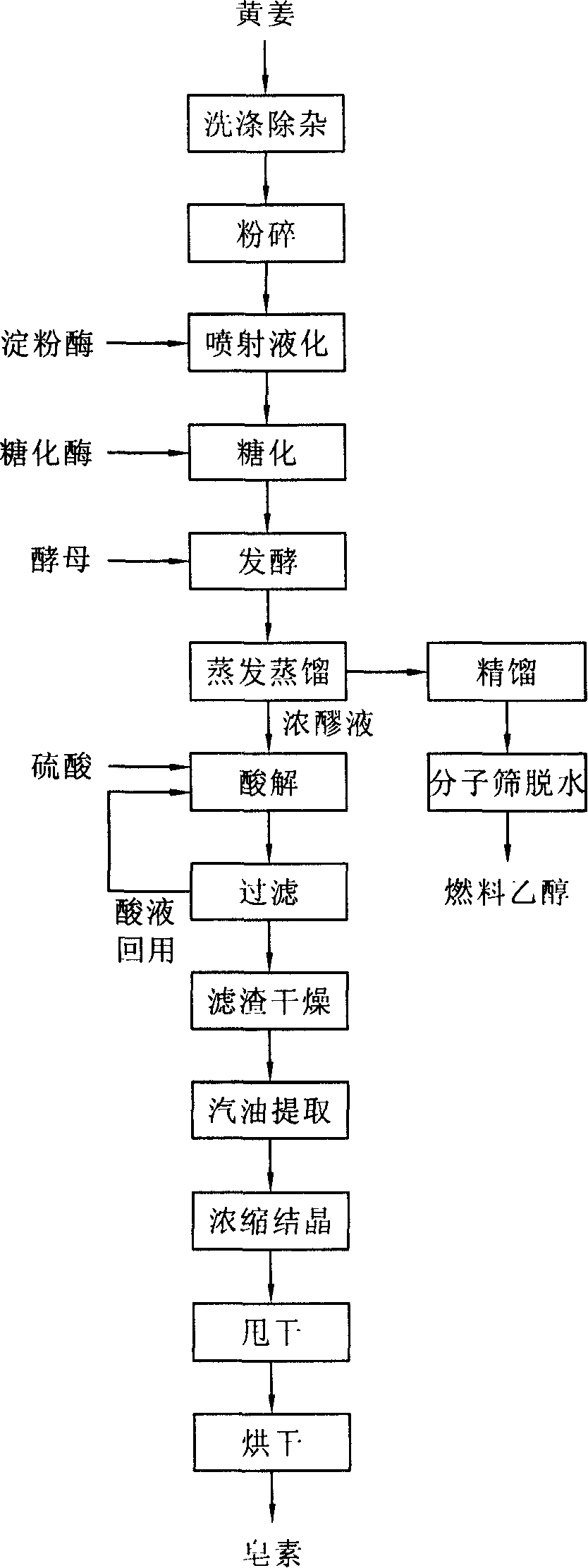

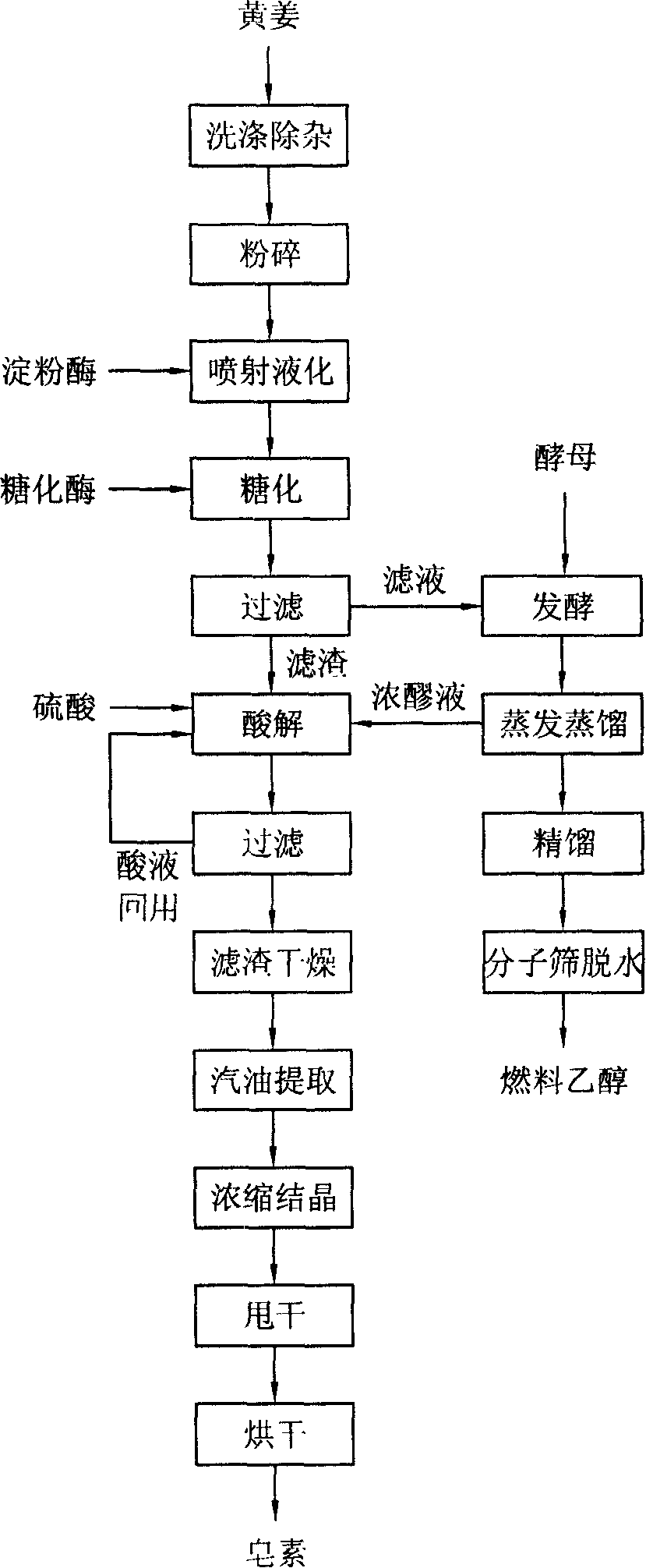

Clean producing technique for extracting saponin from turmeric and coproducing fuel ethanol

The invention relates to a clean manufacturing technique for co-production of fuel ethanol by extracting saponins from turmerics. The technological process of the invention is that: the fuel ethanol is produced after washing and decontamination, pulverization, liquefaction and saccarification of fresh turmerics or dry turmerics after being infused in water, and fermentation, evaporation and distillation, and dehydration of sweet mash (or filtrate obtained after filtration of the sweet mash); and the saponins are produced after acid hydrolysis of thick mash generated by evaporation (or the thick mash generated by evaporation and filter residue generated by filtration of the sweet mash), filtration (filtrate goes back for acid hydrolysis liquid preparation), drying of filter residue, gasoline extraction, condensation and crystallization, whirling and drying. Compared with the prior manufacturing technique of saponins, the clean manufacturing technique for co-production of fuel ethanol by extracting saponins from turmerics of the invention can improve saponin yield by 20 to 30 percent, reduce acid dosage by over 70 percent and reduce waste water output by over 80 percent, and the sales market of the byproduct - fuel ethanol is optimistic.

Owner:邱建勋 +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com