Patents

Literature

132results about How to "Guaranteed dehydration effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production of alcohol fuel

InactiveCN1644703AGuaranteed dehydration effectDoes not consume external heatBiofuelsLiquid carbonaceous fuelsAlcohol fuelDistillation

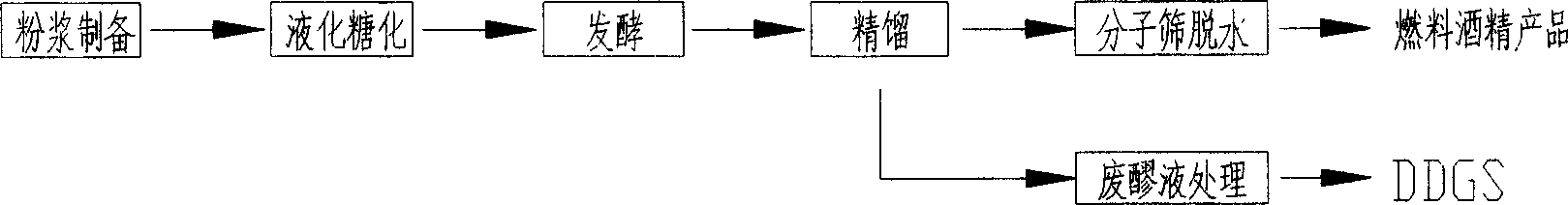

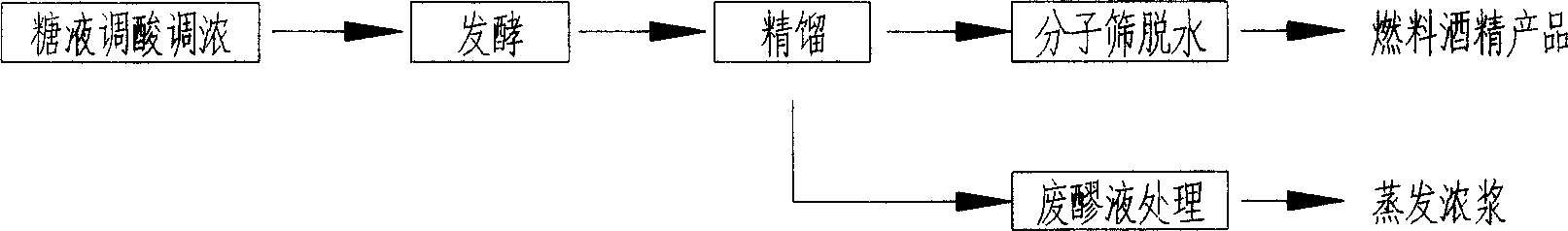

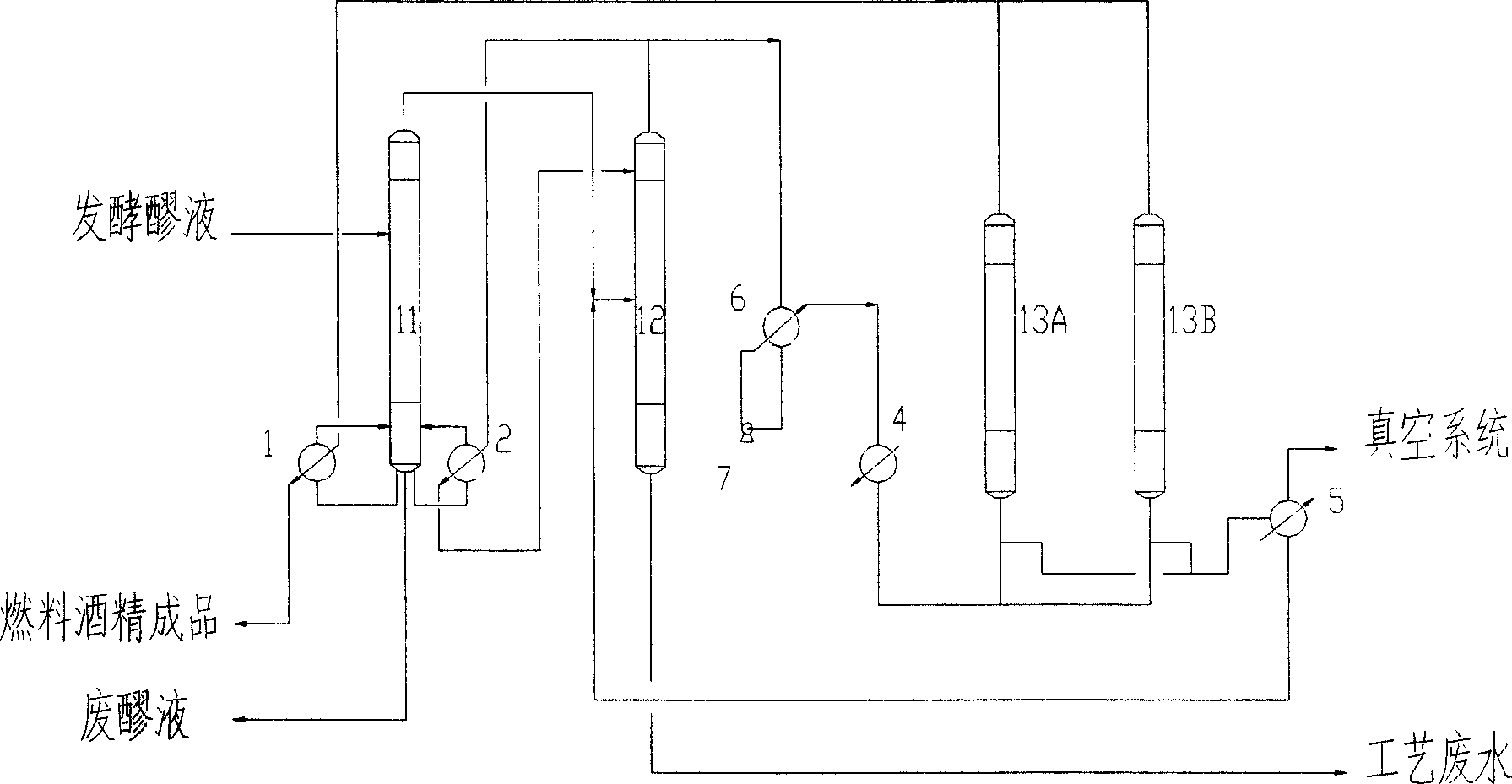

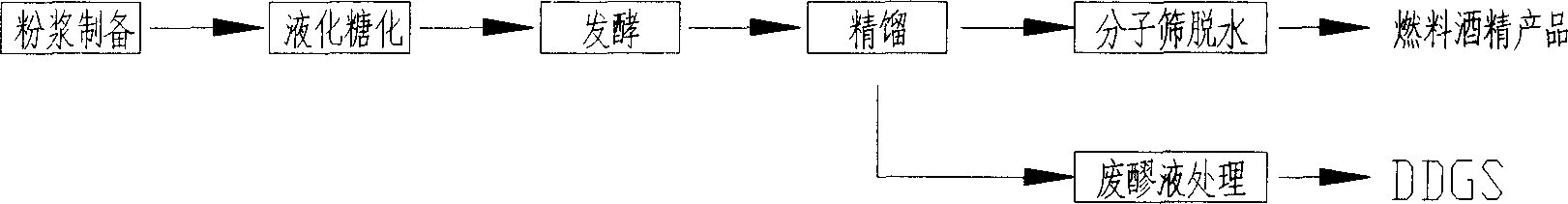

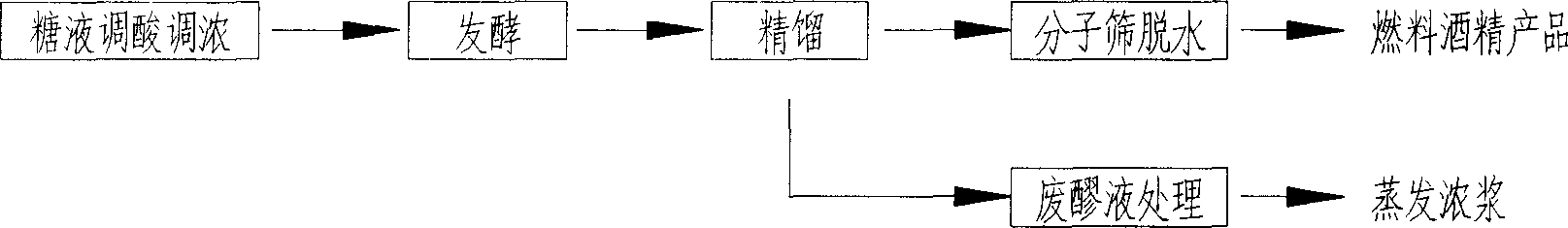

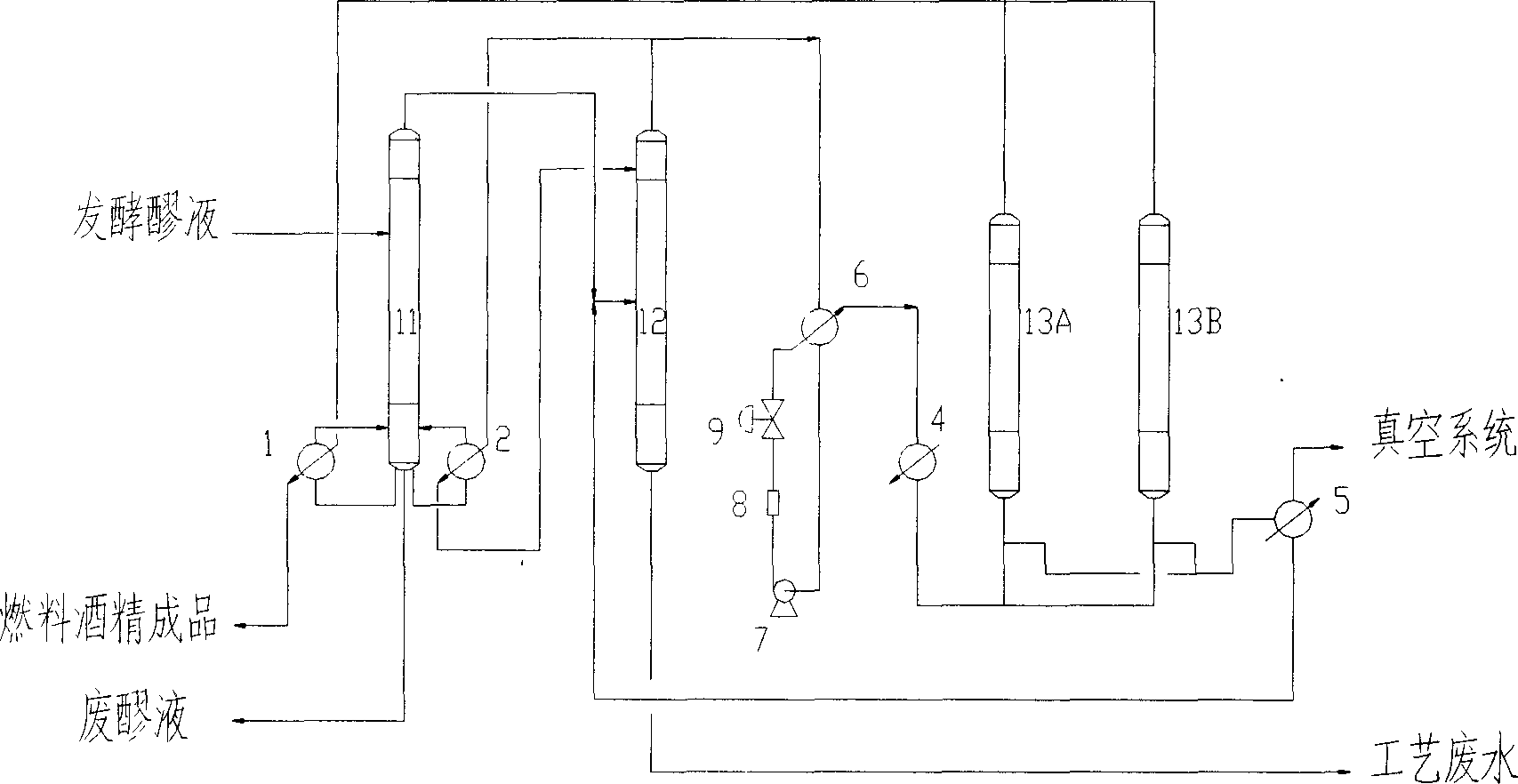

Alcohol fuel can be produced by: treating raw materials, fermenting, refining, molecular sieve adsorption dewatering, and waste liquid treating. A thermal coupling is used to connect dewatering and condense distilling procedures, i.e., gas alcohol from refining process is fed to molecular adsorption dewatering process after thermal coupling condensation and distillation. Heat energy released from cold condensation is used as heat energy for distillation. None of energy is needed any more. The raw materials may be corn, rice, wheat, Chenese sorghum, dry sweet potato, cassawa, sugarcane juice, sugarbeet juice, or green cyrup, etc.

Owner:TIANJIN UNIV

Production of alcohol fuel

InactiveCN1298859CGuaranteed dehydration effectDoes not consume external heatBiofuelsLiquid carbonaceous fuelsAlcohol fuelDistillation

Alcohol fuel can be produced by: treating raw materials, fermenting, refining, molecular sieve adsorption dewatering, and waste liquid treating. A thermal coupling is used to connect dewatering and condense distilling procedures, i.e., gas alcohol from refining process is fed to molecular adsorption dewatering process after thermal coupling condensation and distillation. Heat energy released from cold condensation is used as heat energy for distillation. None of energy is needed any more. The raw materials may be corn, rice, wheat, Chenese sorghum, dry sweet potato, cassawa, sugarcane juice, sugarbeet juice, or green cyrup, etc.

Owner:TIANJIN UNIV

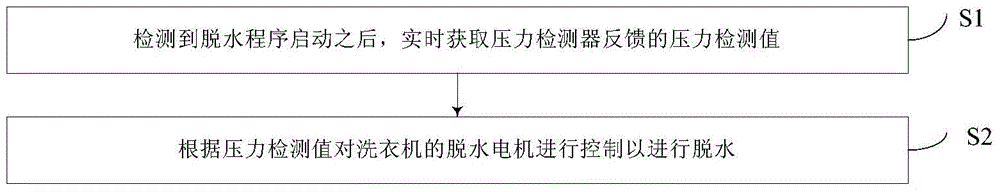

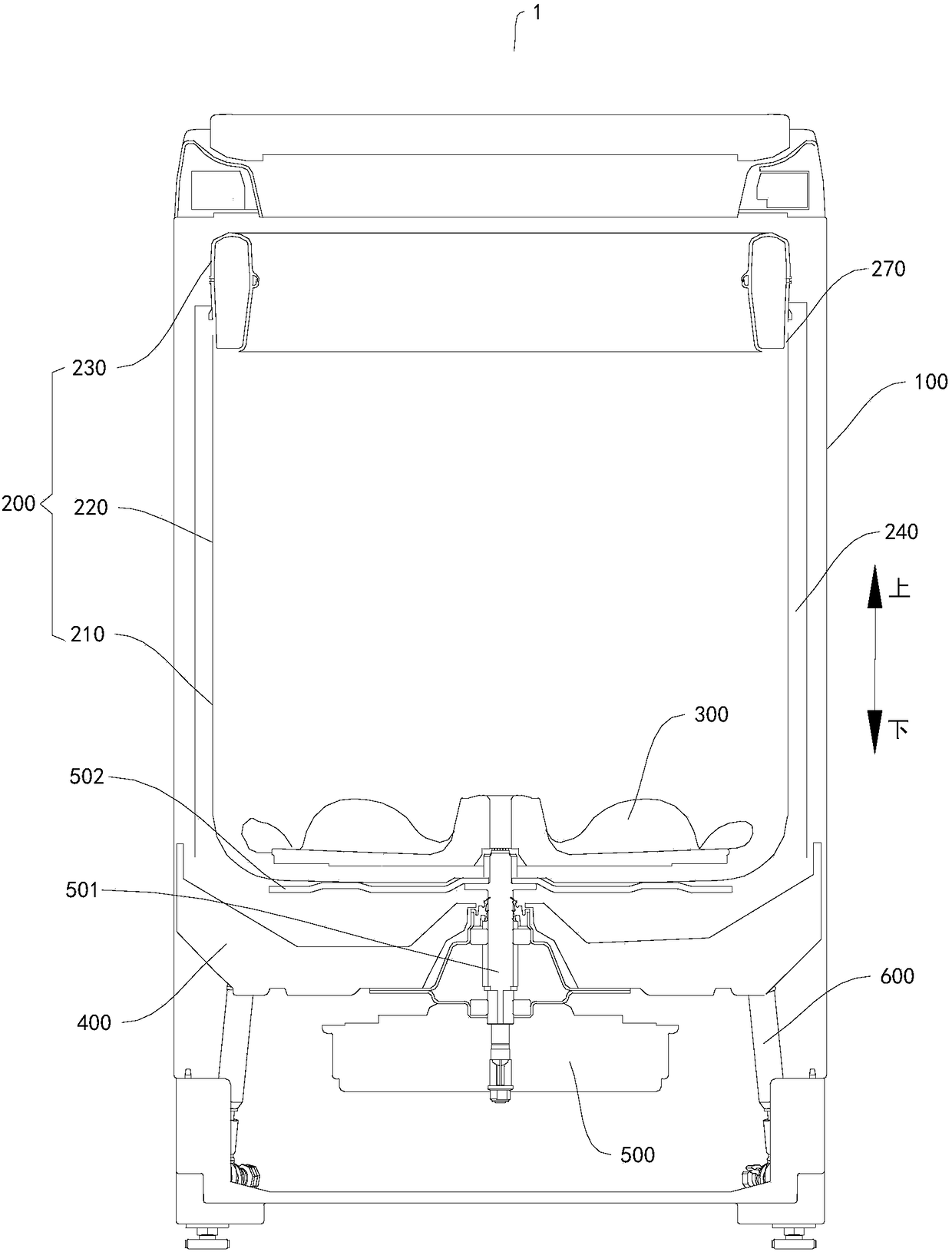

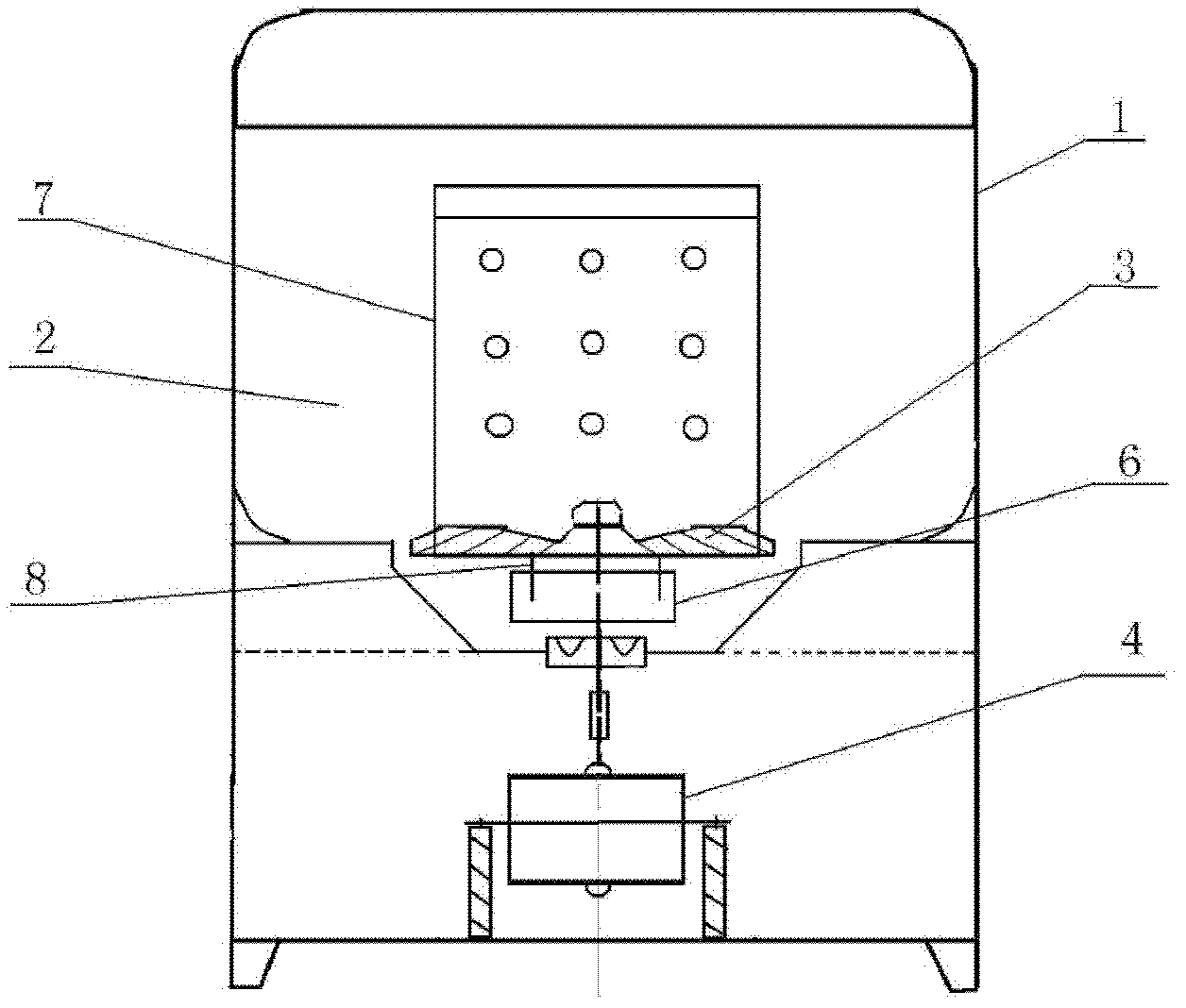

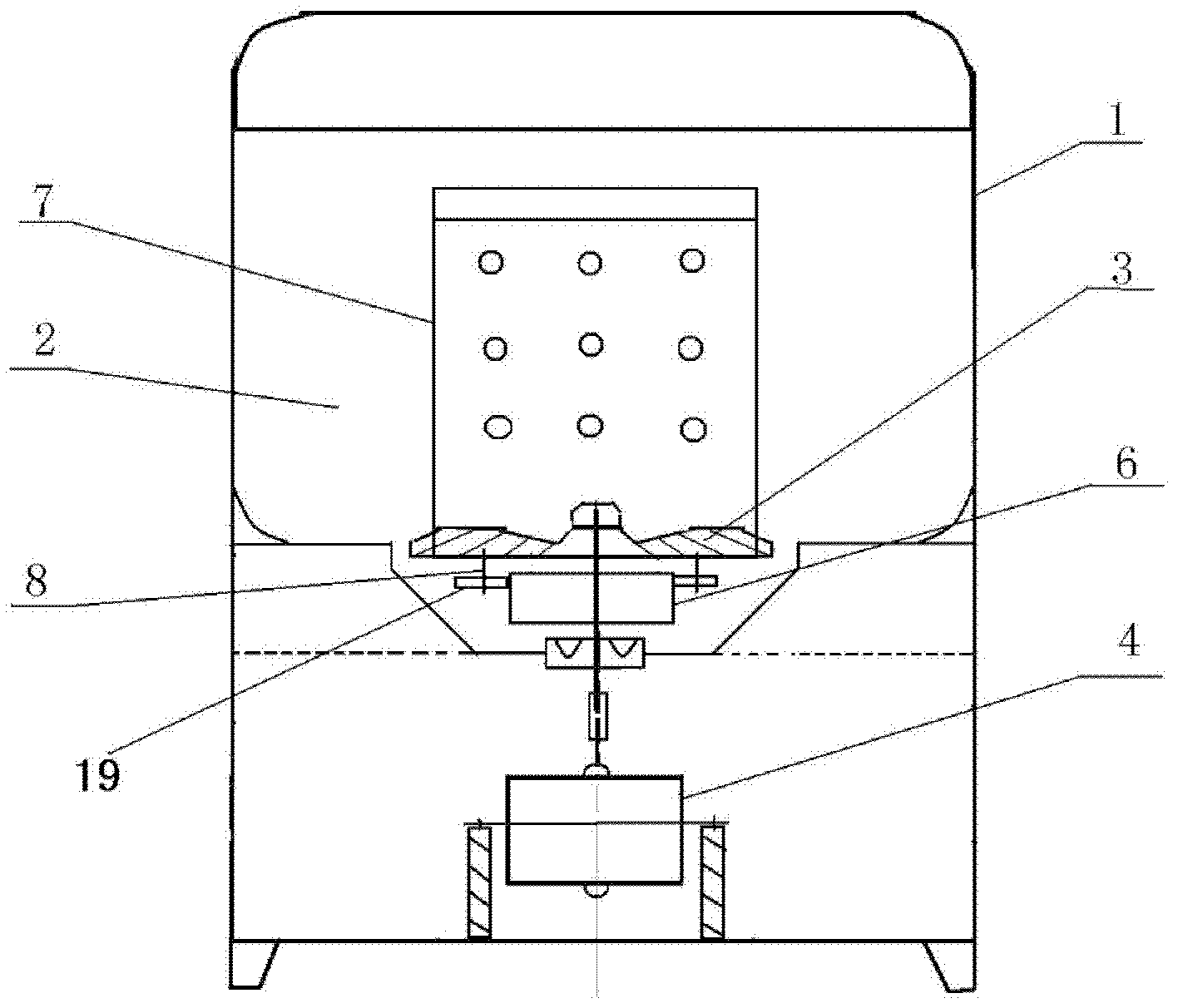

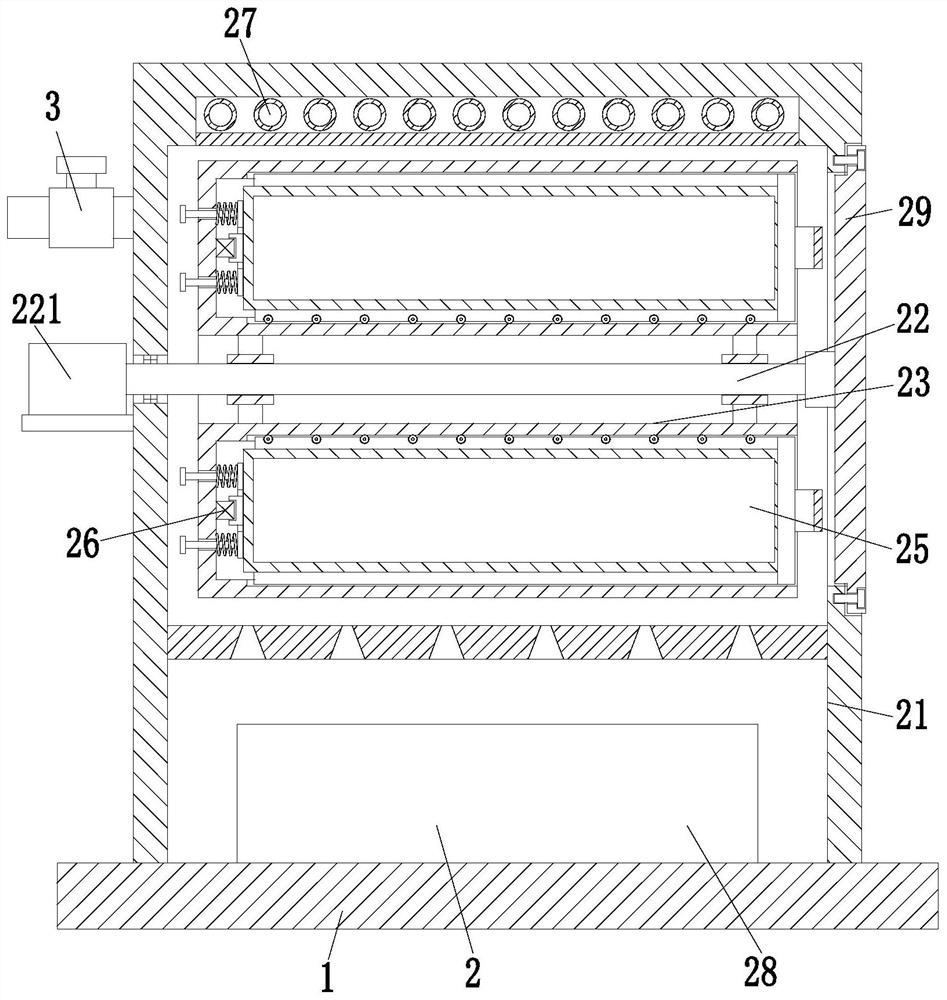

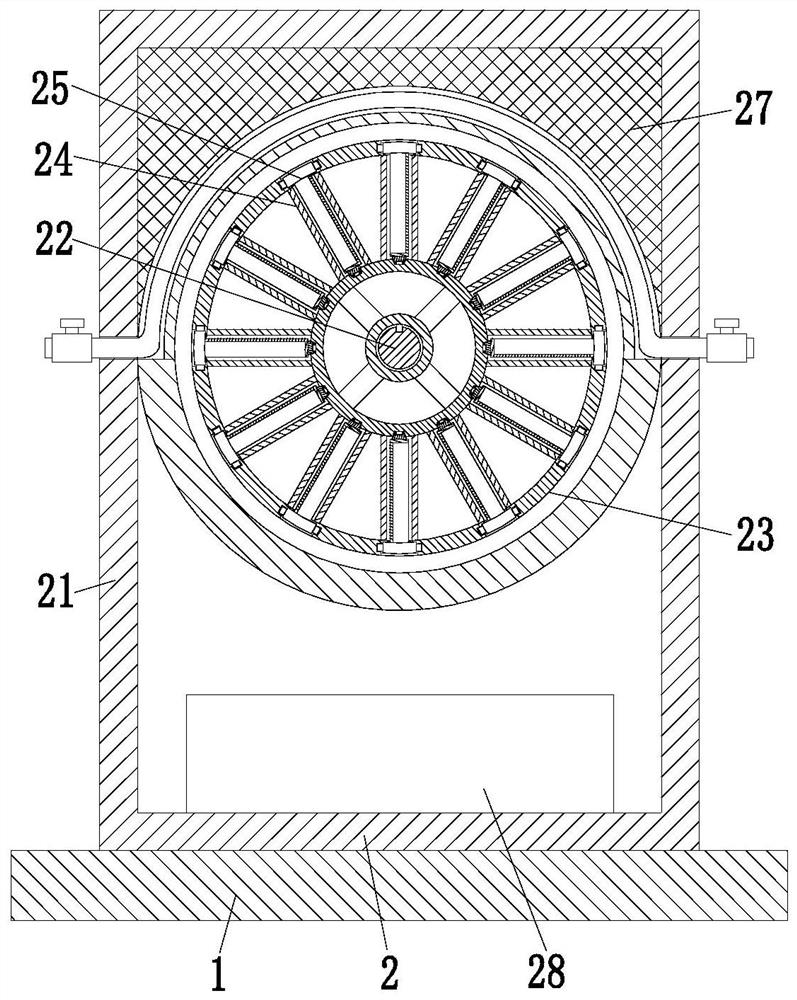

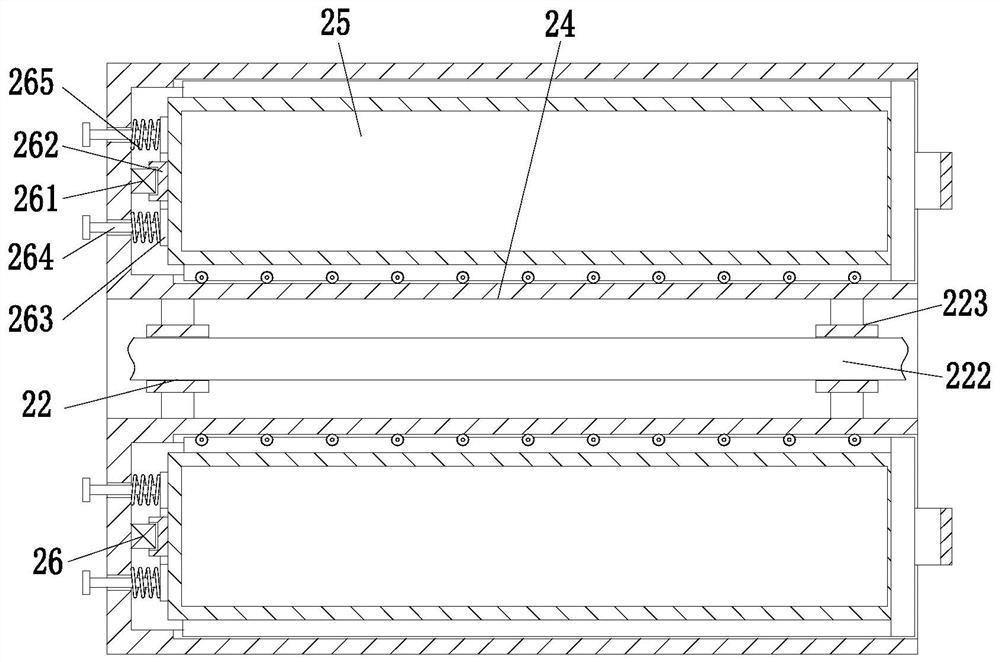

Washing machine and dewatering control method thereof

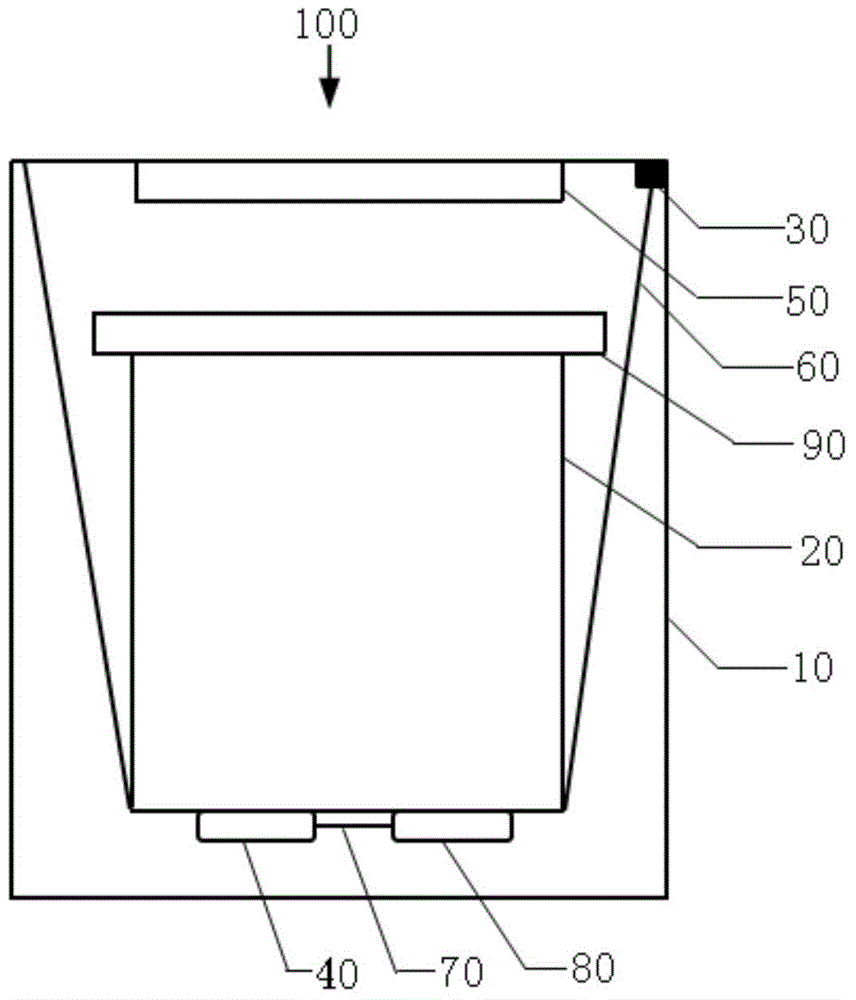

ActiveCN105714511AGuaranteed dehydration effectReduce wearOther washing machinesControl devices for washing apparatusPulp and paper industryPressure detection

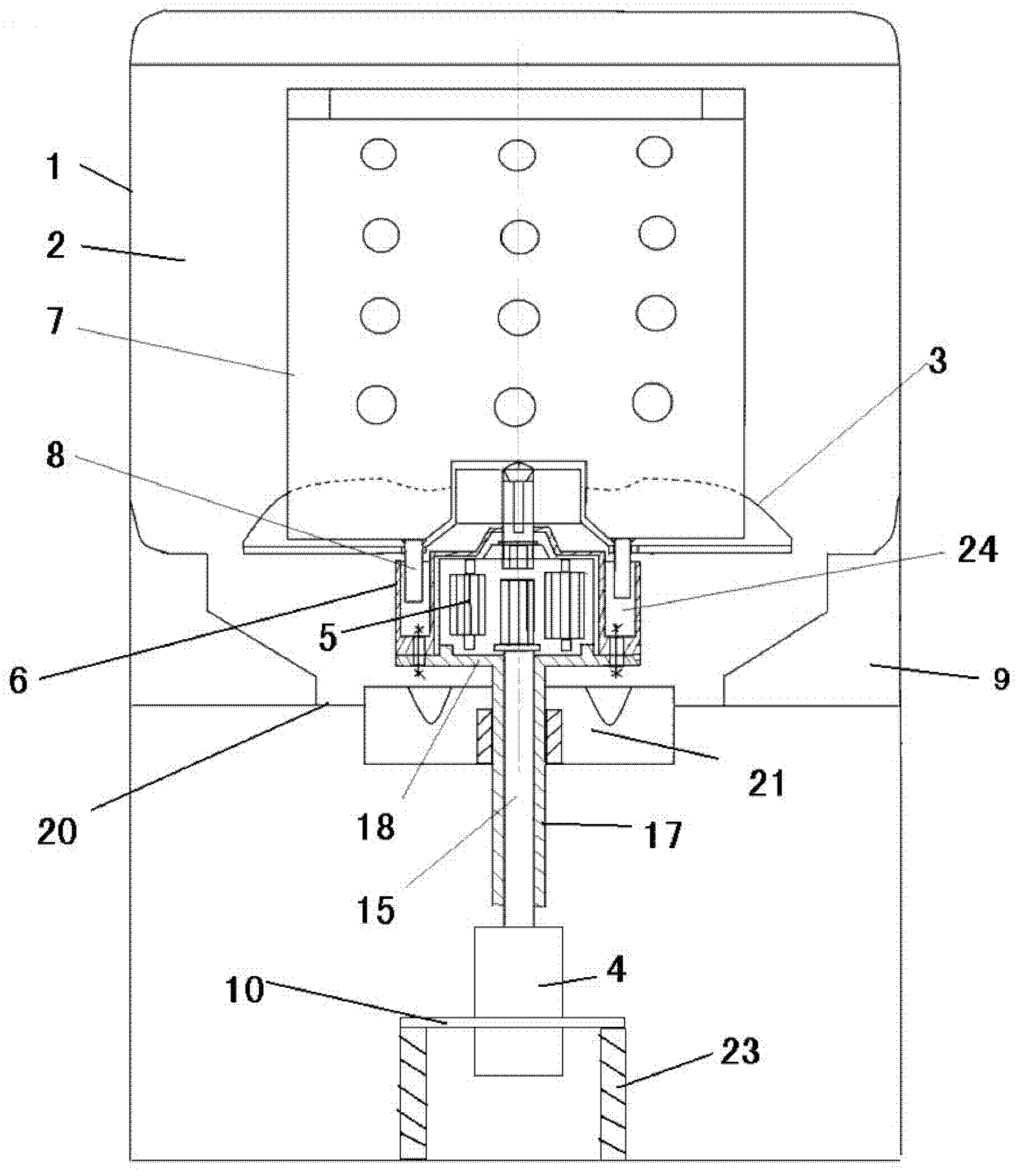

The invention discloses a washing machine which comprises a tank body, a washing and dewatering drum, a pressure detector, a dewatering motor, and a controller, wherein a hanging rod is arranged in the tank body; the washing and dewatering drum is hung in the tank body through the hanging rod; the pressure detector is arranged on the hanging rod and is used for detecting stress of the hanging rod and generating a pressure detection value; the dewatering motor is used for driving the washing and dewatering drum to rotate for dewatering; the controller acquires the pressure detection value fed back by the pressure detector in real time after detecting that a dewatering procedure is started, and controls the dewatering motor according to the pressure detection value. According to the washing device disclosed by the invention, unnecessary energy waste and motor loss can be avoided, and the dewatering performance is guaranteed. The invention further discloses a dewatering control method for the washing machine.

Owner:崔祺

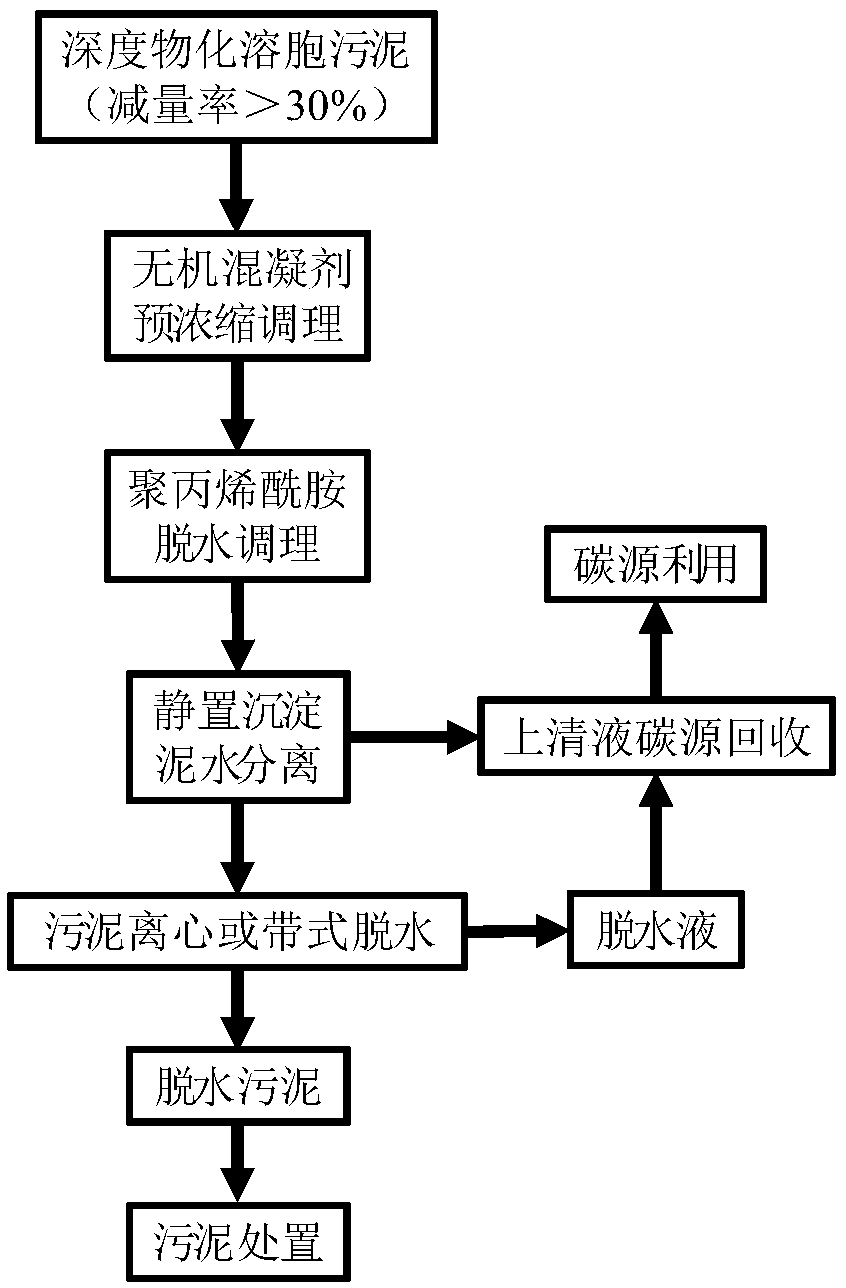

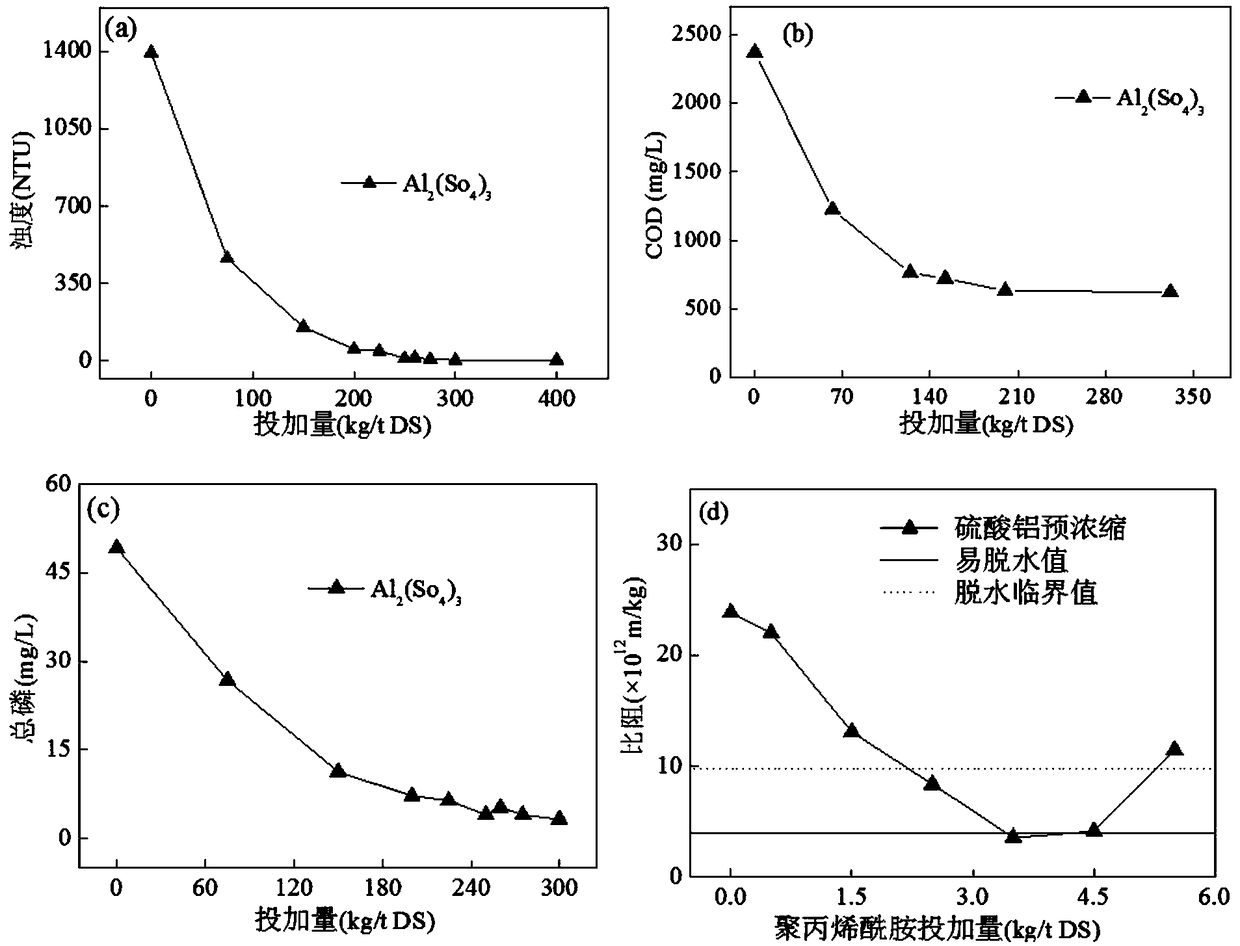

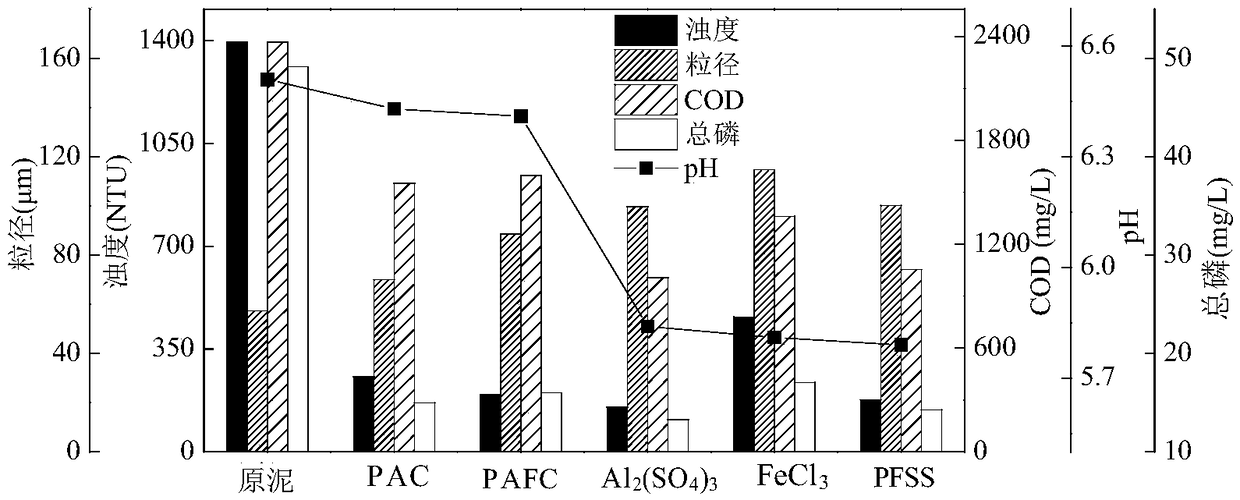

Recycling method of excess sludge

InactiveCN109485231ALow degree of modificationPromote engineering applicationSludge treatment by de-watering/drying/thickeningReduction rateSewage treatment

The invention relates to a recycling method of excess sludge. The recycling method comprises the following steps: (1) a deep physical-chemical cytolysis stage: carrying out deep physical-chemical cytolysis treatment on the excess sludge of a sewage treatment plant so that the reduction rate of the excess sludge is greater than 30%; (2) a pre-concentration conditioning stage: continuously adding aninorganic coagulant to carry out pre-concentration conditioning treatment; (3) a dewatering conditioning stage: adding a macromolecular organic flocculant and carrying out dewatering conditioning treatment; (4) a sludge-water separation stage: standing and precipitating to obtain sludge precipitate, further dewatering the sludge sludge precipitate, mixing supernatant liquid with dewatered supernatant liquid, and adding the mixture as a carbon source into a biological treatment unit for recycling. Compared with the prior art, aiming at the feature of the deep physical-chemical cytolysis sludge, an appropriate chemical conditioning agent composition is used for chemically conditioning the sludge to enable the sludge to reach the requirements on recycling of the supernatant liquid and dewatering of the sludge; a method for effectively treating the excess sludge is provided.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

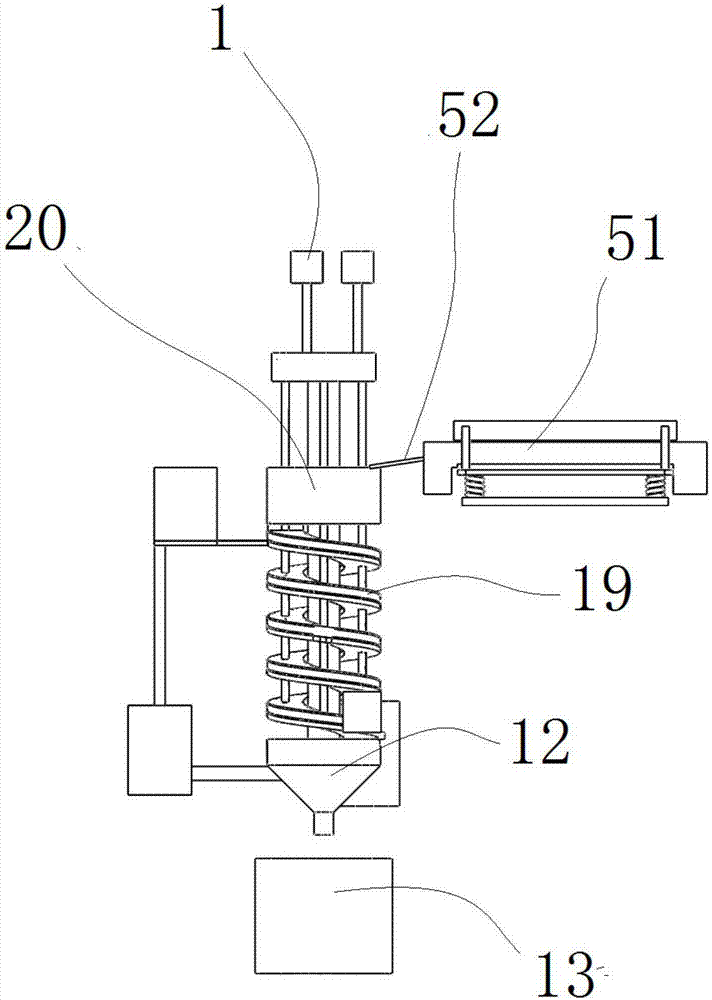

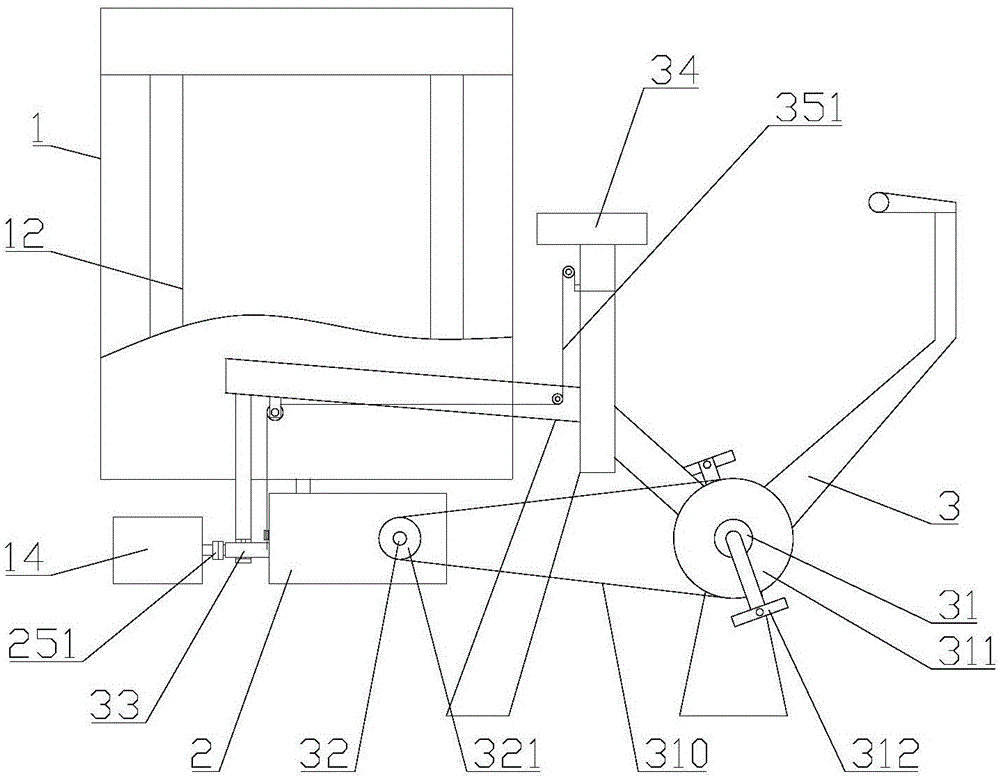

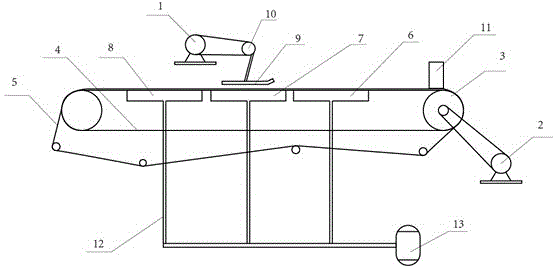

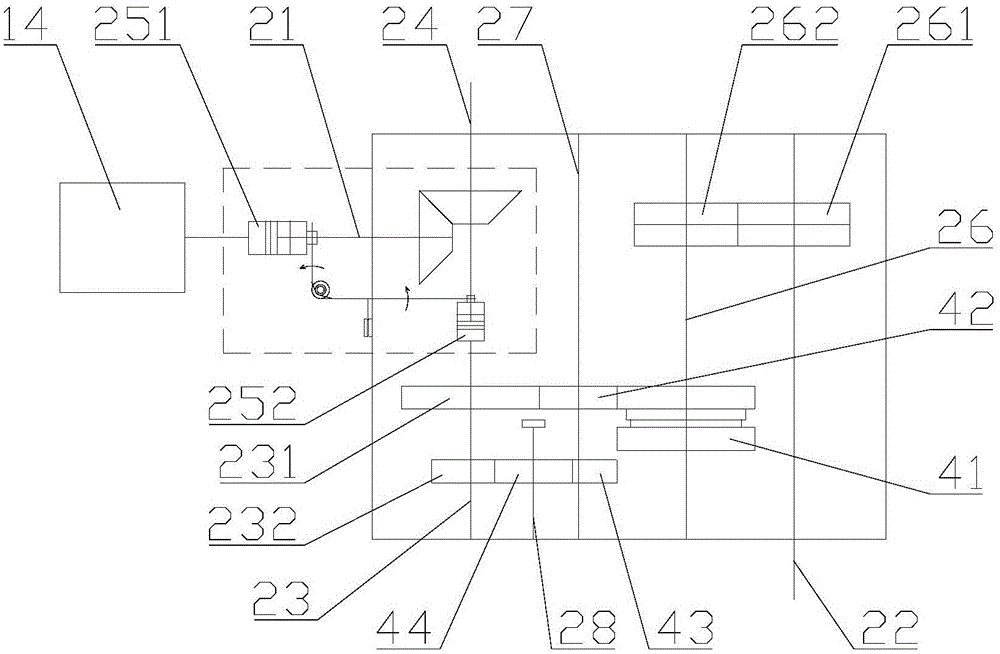

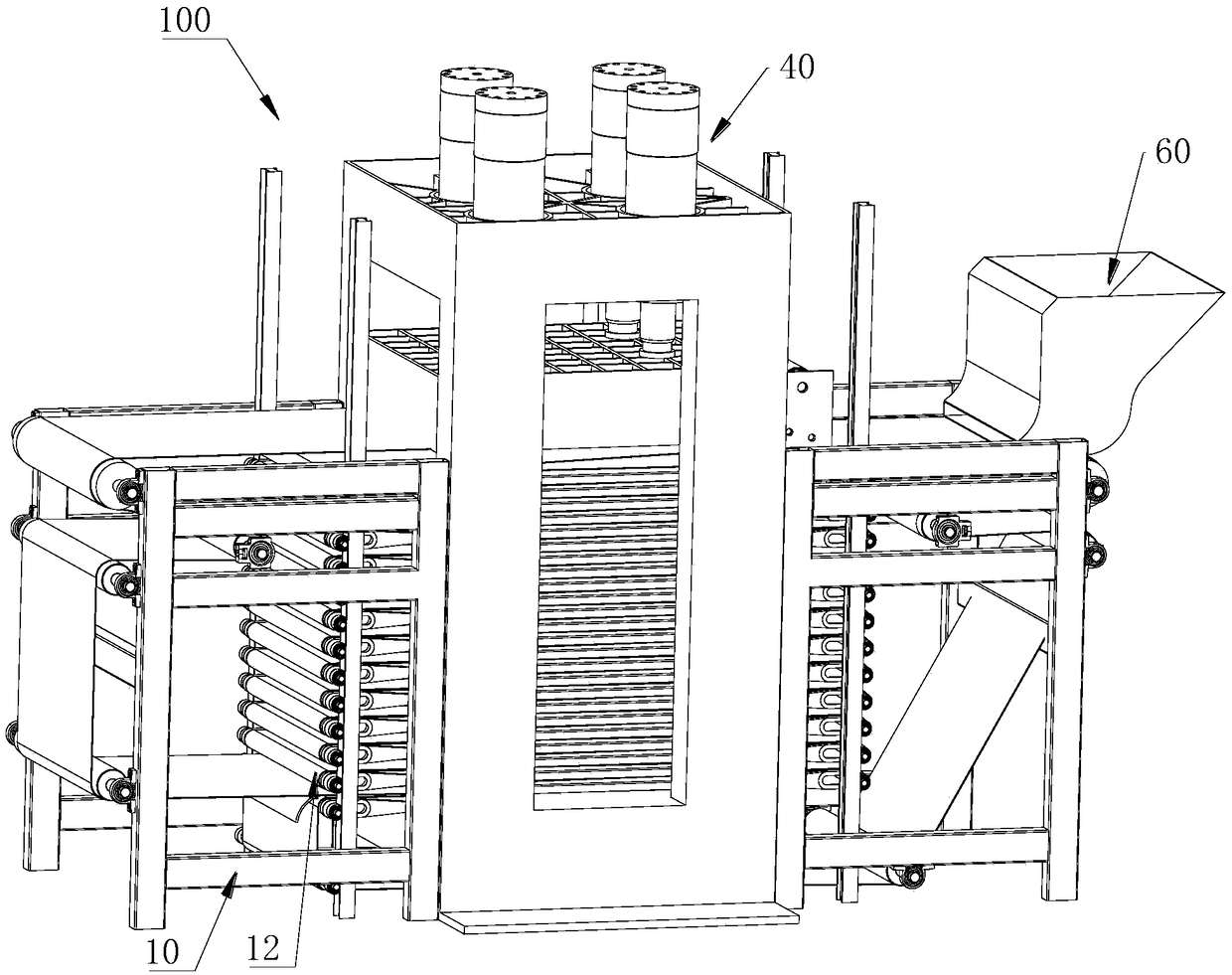

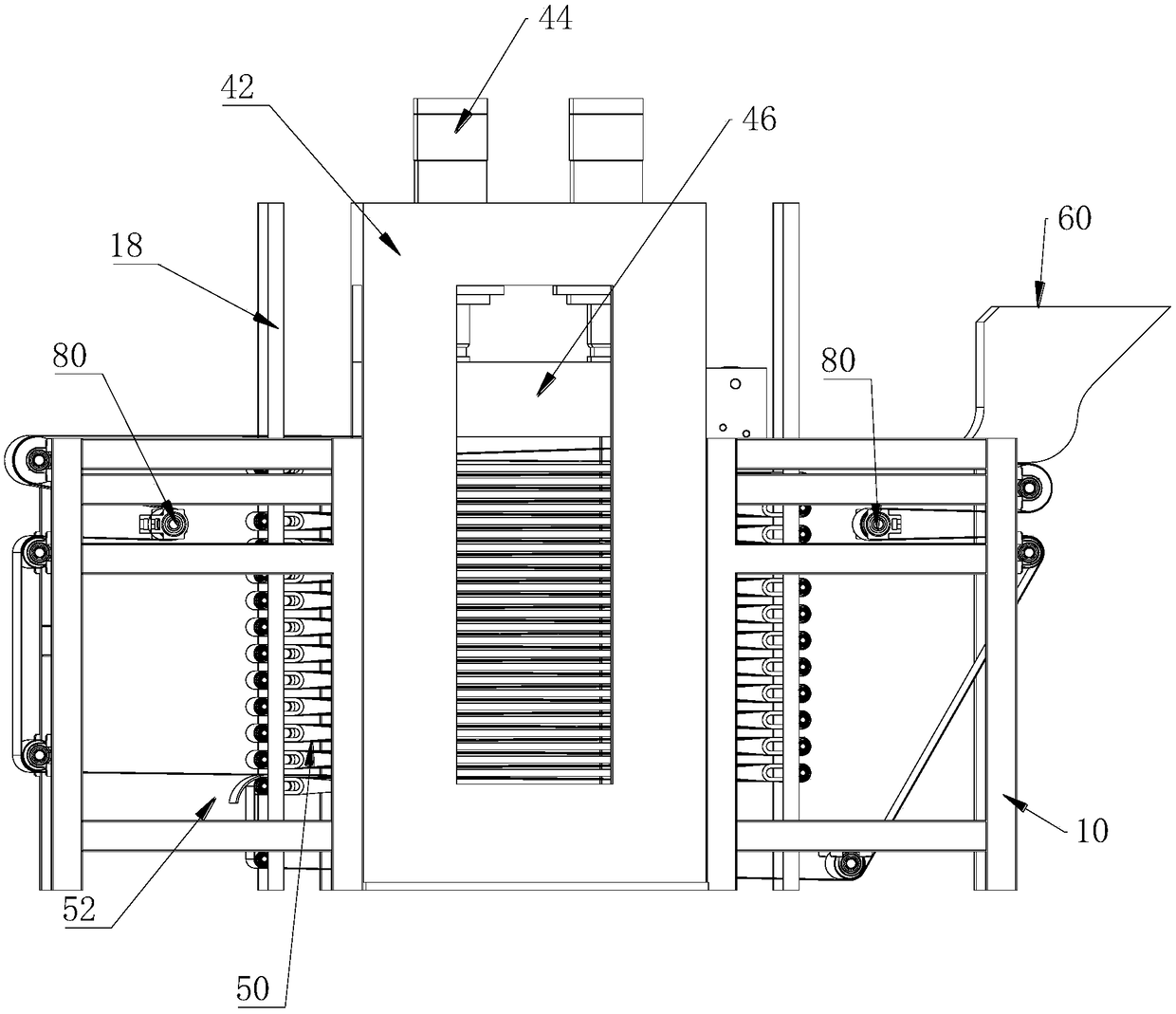

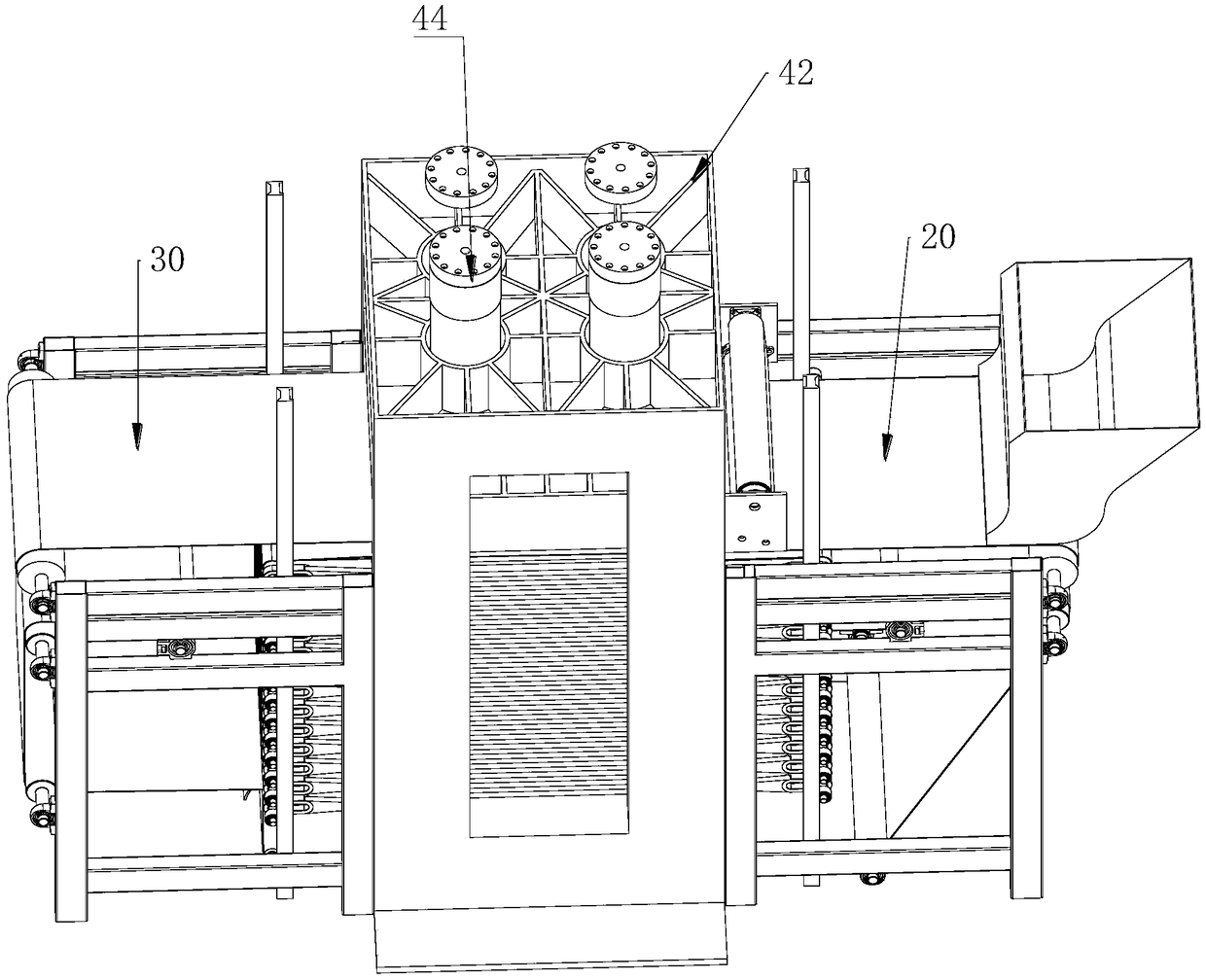

Agricultural seed selection and pesticide injection system and method

PendingCN107360758AImprove survival rateImprove mixing uniformitySievingScreeningAgricultural scienceAgricultural engineering

The invention discloses an agricultural seed selection and pesticide injection system which comprises a seed selection unit and a pesticide injection unit. A seed discharge end of the seed selection unit is correspondingly arranged with a seed feed end of the pesticide injection unit; the seed selection unit comprises an upper sieving conveyor belt, a middle sieving conveyor belt, a lower sieving conveyor belt, a vibrating device, spring retainers, a vibrating plate, a vibration support frame, a conveyor belt seat and a discharge chute. Compared with a traditional seed selection unit, the seed selection unit is simple in structure, mixing uniformity of dosage liquid with granulated seeds is greatly improved by matching a spiral batching tube with a dosage liquid injection tube, a spiral-rising type heat-flow dehydration method is adopted in the dosage process, and moisture added during the dosage process is taken away; meanwhile, a temperature protection scheme is provided in dehydration, dehydration effect is guaranteed, rising of seed temperature during dehydration is weakened to the greatest extent, and seed survival rate is eventually increased.

Owner:苏州尚梵斯科技有限公司

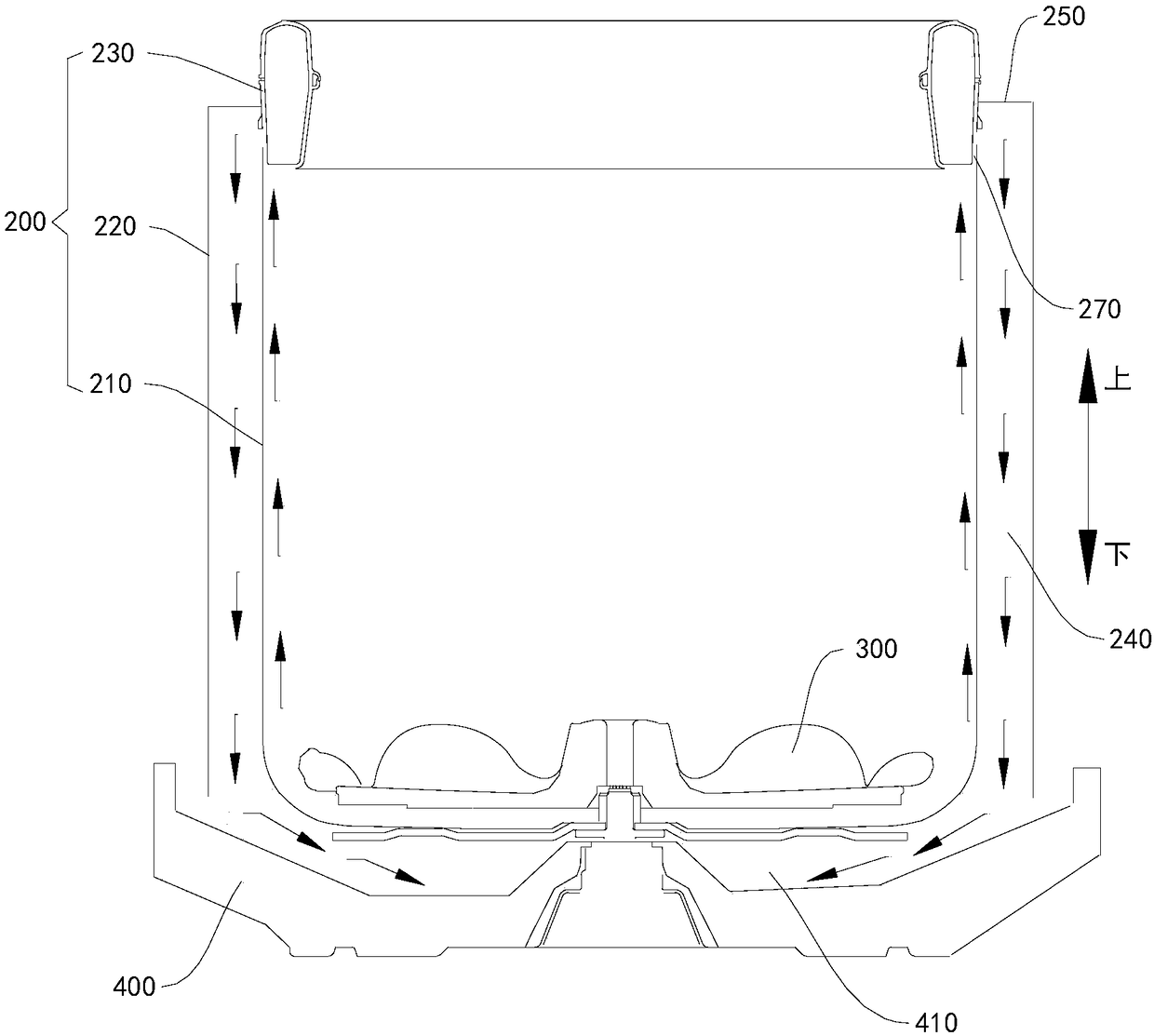

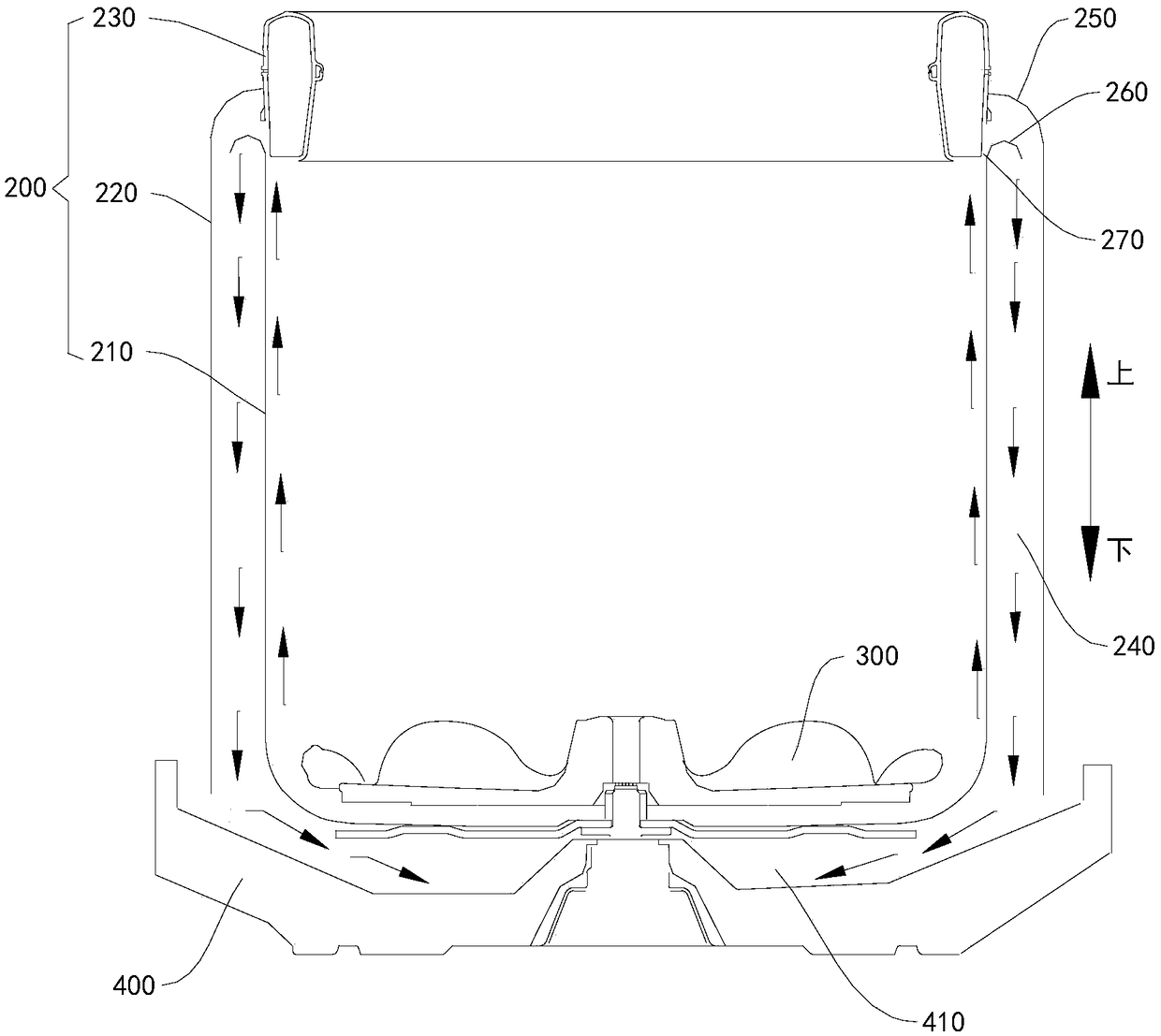

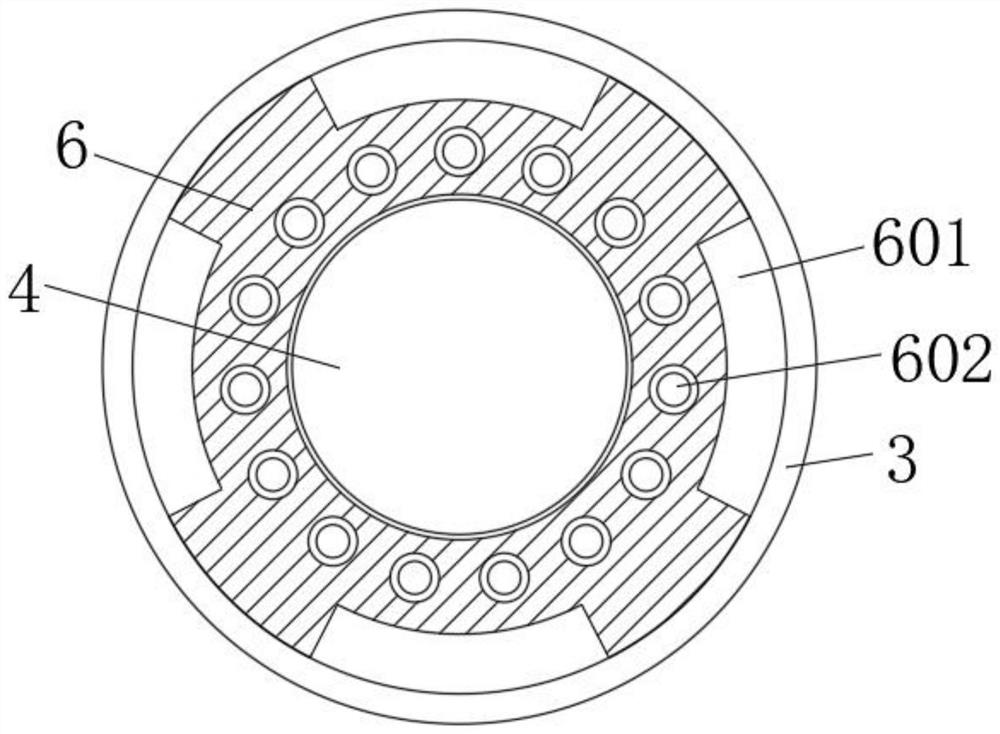

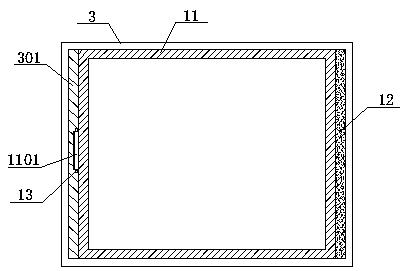

Washing machine and washing machine rotary tub

PendingCN108796955AIncrease capacityGood lookingOther washing machinesWashing machine with receptaclesComing outImpeller

The invention discloses a washing machine and a washing machine rotary tub. The washing machine comprises a box body and a rotary tub, the rotary tub can be rotatably arranged in the box body and comprises a tub body, a drainage hood and an impeller, wherein the drainage hood is arranged surrounding the tub body in the circumferential direction of the tub body, a water drainage passage is formed between the tub body and the drainage hood, liquid which comes out through the spinning of the tub body is guided to the drainage passage by the drainage hood, and the impeller can be rotatably arranged in the tub body. According to the washing machine, a water containing tub is eliminated, the rotary tub is arranged, a single tub structure is formed, therefore the capacity is improved, water is saved, the washing machine is protected from filth, the cost is reduced, the rotary tub is arranged into the structures of the tub body and the drainage hood, the drainage hood is utilized to guide anddischarge the water which comes out through the spinning of the tub body, the dehydrating effect is ensured, materials of the box body are not limited, the box body is allowed to adopt metallic materials of metal plate and the like to improve the appearance of the washing machine.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

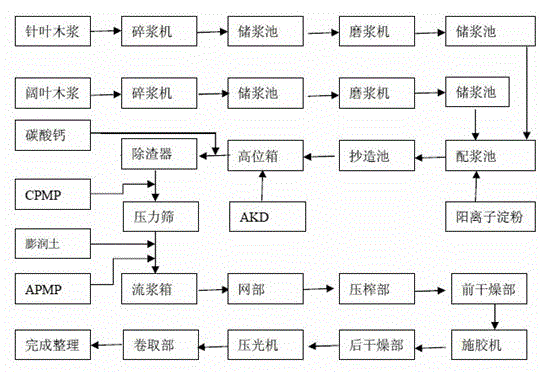

Method for producing highly quantitative two-side offset paper

ActiveCN103603225AImprove water filtration performanceReduce poor qualityChemical/chemomechanical pulpPaper-making machinesSulfatePulp and paper industry

The invention belongs to papermaking technologies and relates to a method for producing highly quantitative two-side offset paper. The method comprises the following steps: sequentially performing pulping, size mixing, sizing, manufacturing paper with pulp, pre-drying, surface sizing, after-drying, press polish and rolling on basic raw materials such as bleached sulfate needlebush pulp and bleached sulfate broadleaf wood pulp, and finally finishing into paper; and allowing the materials in the pulping process to sequentially pass through a pulper, a pulp storage pool, a pulp grinder and the pulp storage pool according to a material transfer sequence, wherein in the pulping process, the pulping beating degree of the bleached sulfate needlebush pulp in the basic raw materials is required to be 25-320SR, and the pulping beating degree of the bleached sulfate broadleaf wood pulp is required to be 24-330SR. According to the method, the highly quantitative two-side offset paper can be manufactured with pulp, and the manufactured paper is high in surface strength, high in internal binding force, high in smoothness and small in two-side difference.

Owner:ZHENJIANG DADONG PULP & PAPER

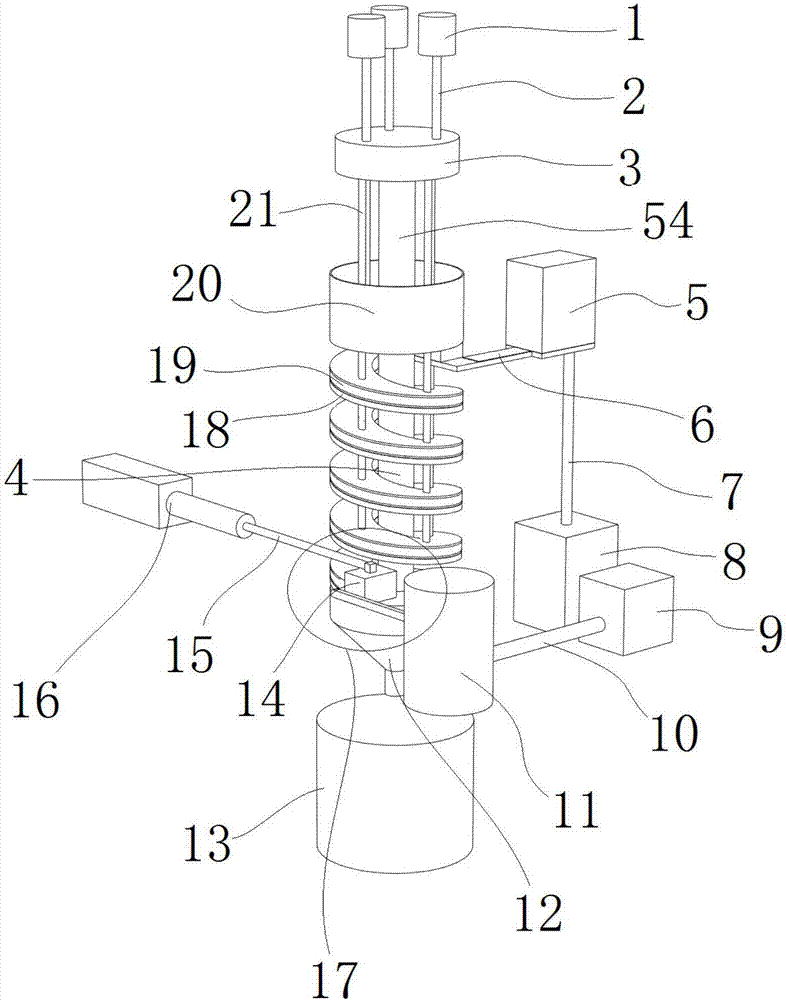

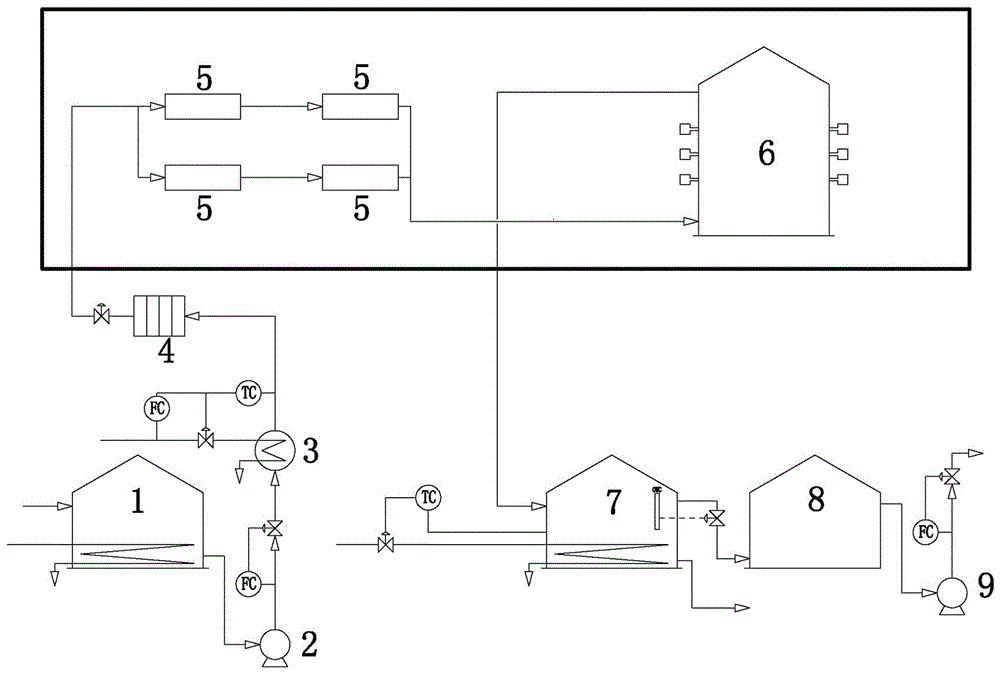

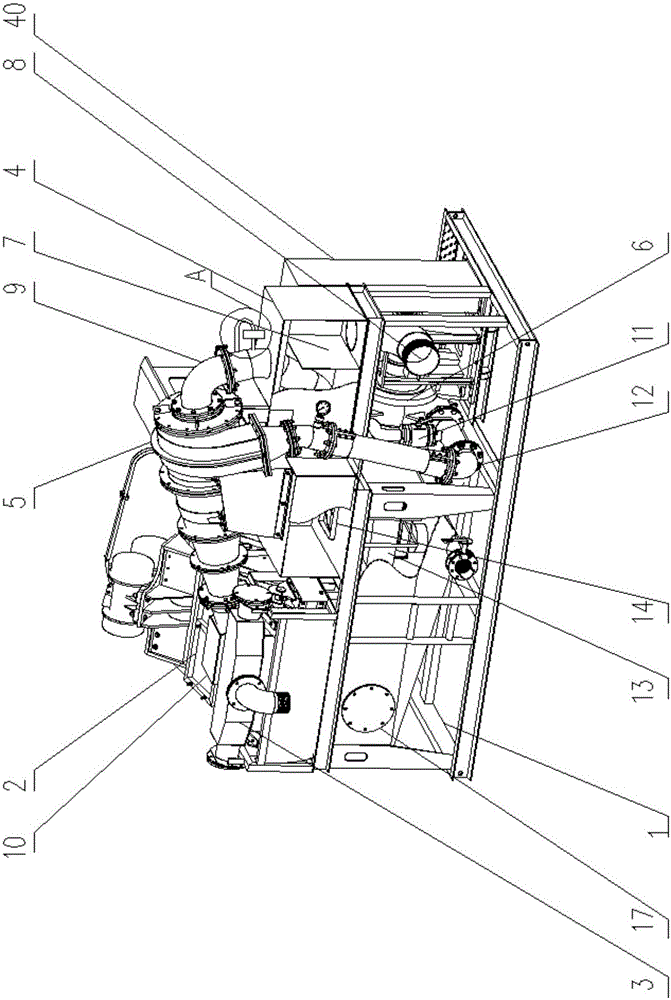

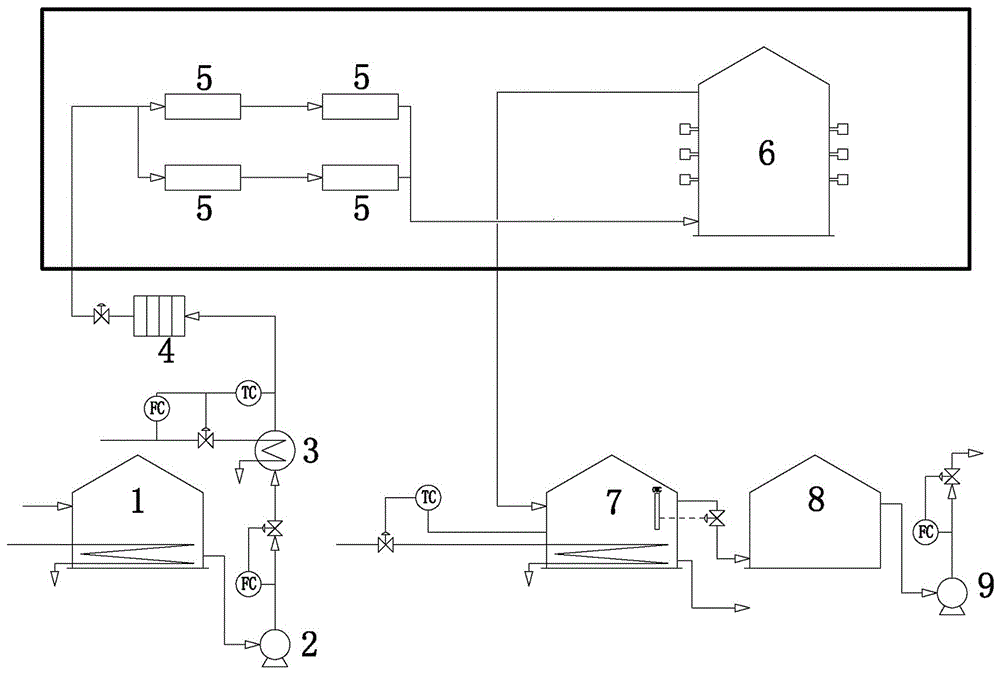

Super-high power ultrasonic sump oil emulsion breaking dehydration method

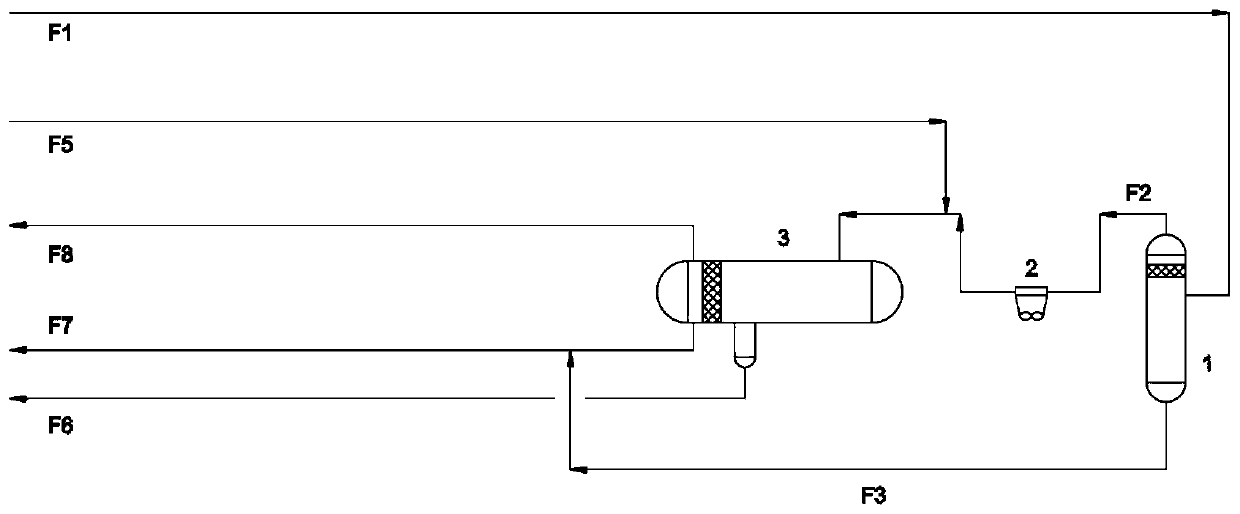

InactiveCN105776704AAchieve dehydrationAchieve recyclingFatty/oily/floating substances removal devicesWater/sewage treatment with mechanical oscillationsUltrasound - actionOil emulsion

The invention discloses a super-high power ultrasonic sump oil emulsion breaking dehydration method.The method comprises the steps that water-containing sump oil in a sump oil stock tank (1) is preheated and pressurized through a water-containing sump oil pump (2) and fed into a sump oil heater (3) to be heated to 50-85 DEG C; the heated water-containing sump oil is fed into an ultrasonic actuator (5) for continuous ultrasonic initial emulsion breaking; the sump oil obtained after initial emulsion breaking is fed into a pulse type ultrasonic emulsion breaking tank (6) through a pipeline for secondary emulsion breaking; the water-containing sump oil obtained after secondary emulsion breaking flows into a settlement separation dehydration tank (7) to be heated to 40-80 DEG C for settlement and layering to obtain sump oil, sewage and solid flocculent impurities; the sump oil located at the upper portion of the settlement separation dehydration tank (7) automatically flows into a finished sump oil tank (8); sewage and impurities enter a settling pond from the bottom of the settlement separation dehydration tank (7) through a sewage disposal well.According to the two-time ultrasonic emulsion breaking, sump oil dehydration is achieved, the sump oil dehydration rate is larger than 90%, and the sewage oil content is smaller than 500 mg / L.

Owner:JIANGSU DAXUAN PETROCHEM EQUIP

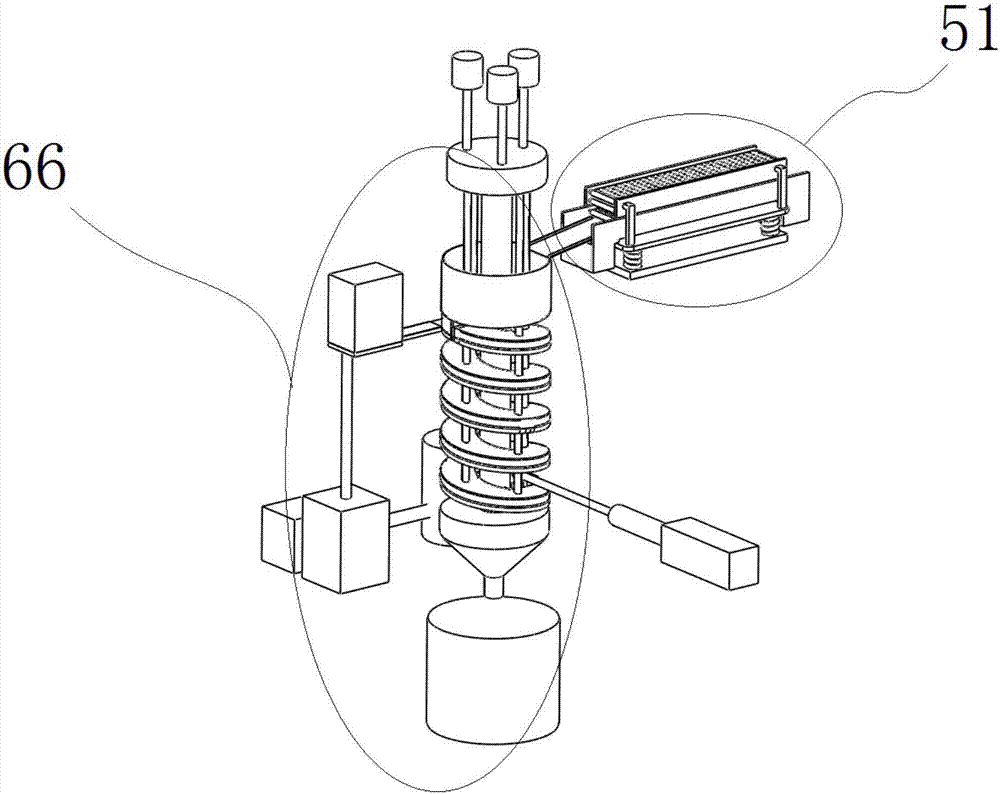

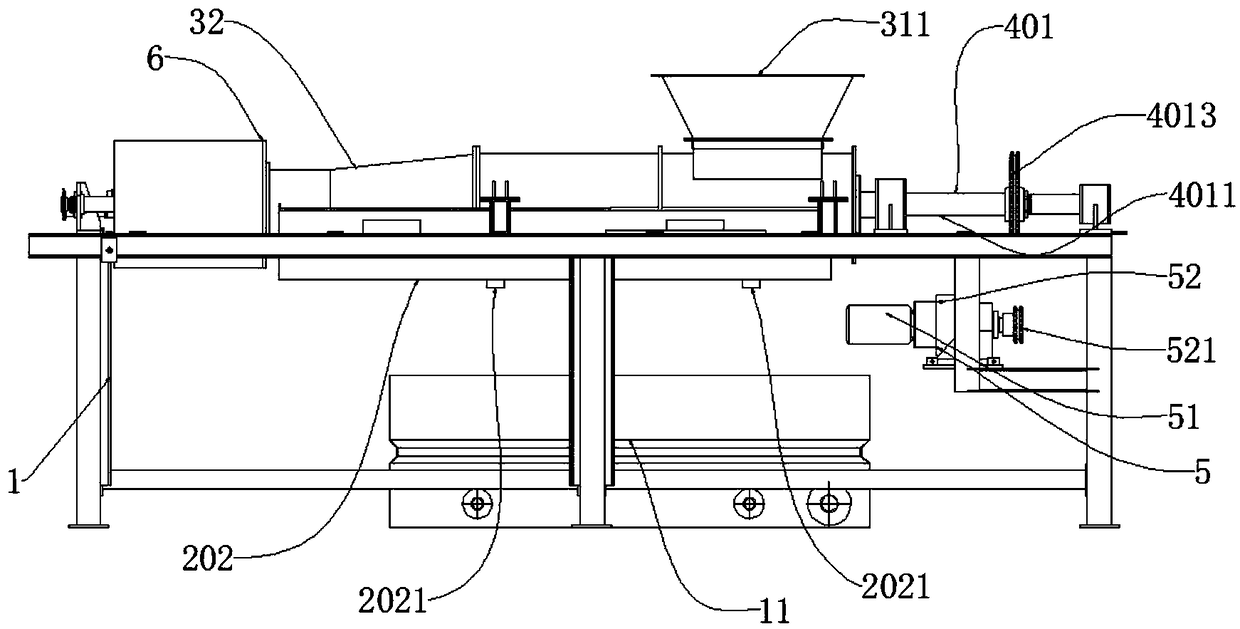

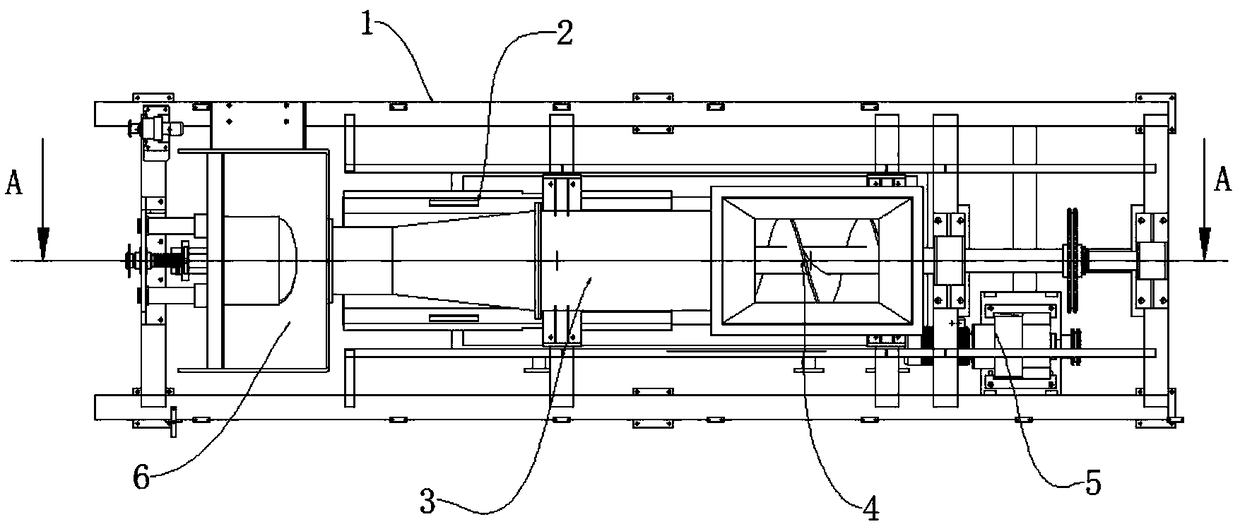

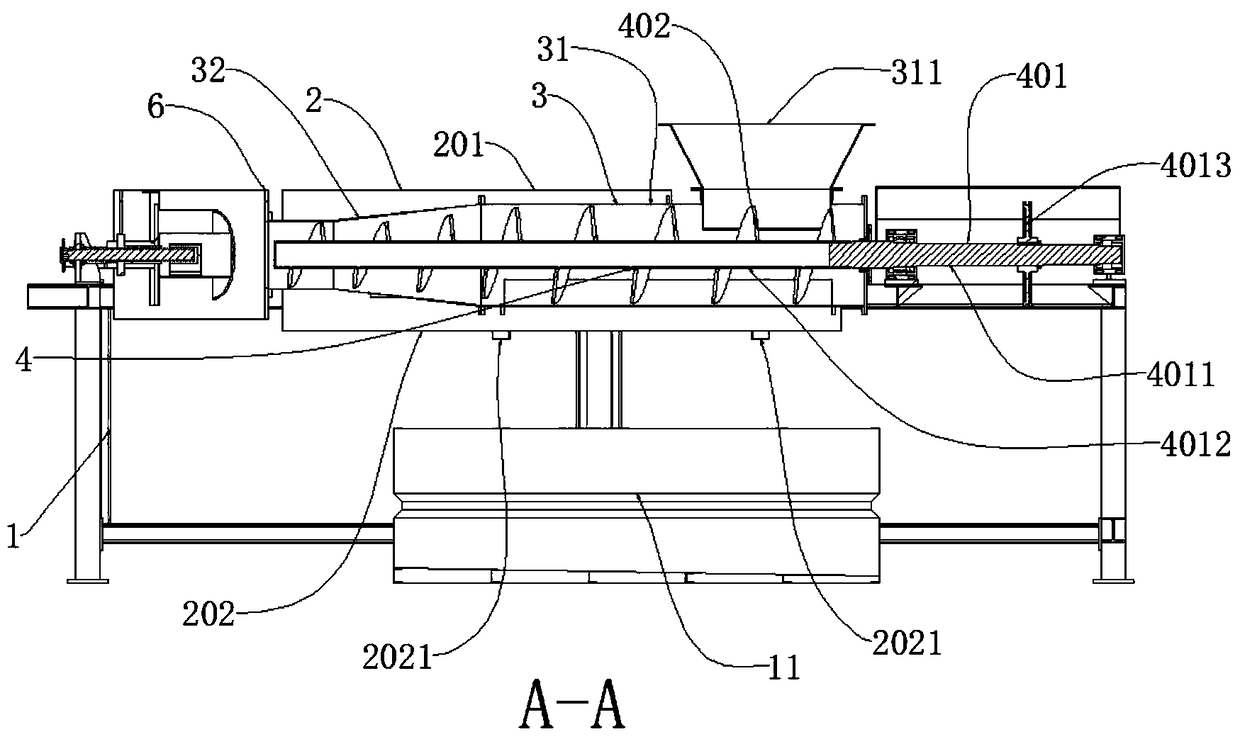

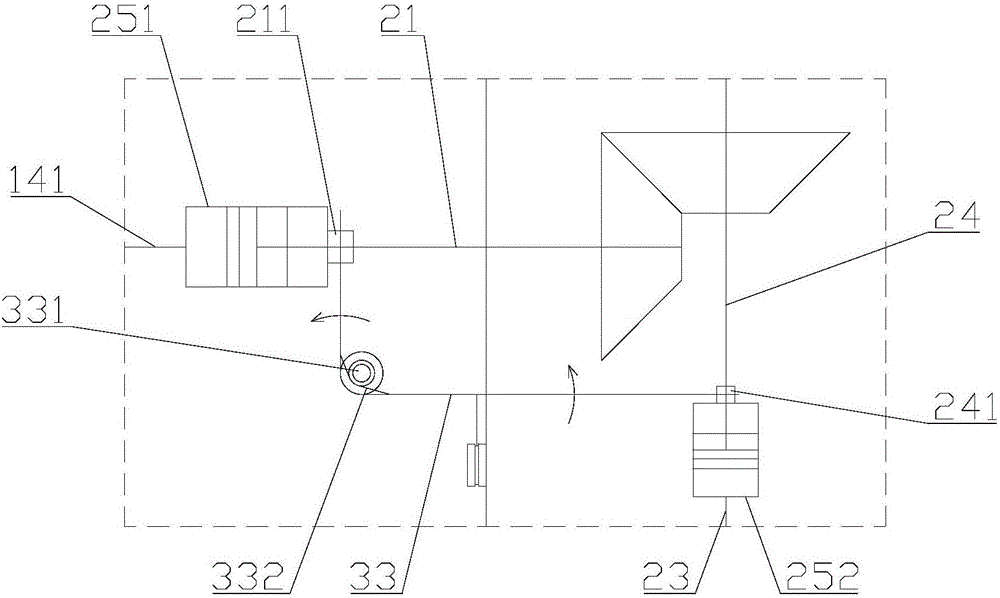

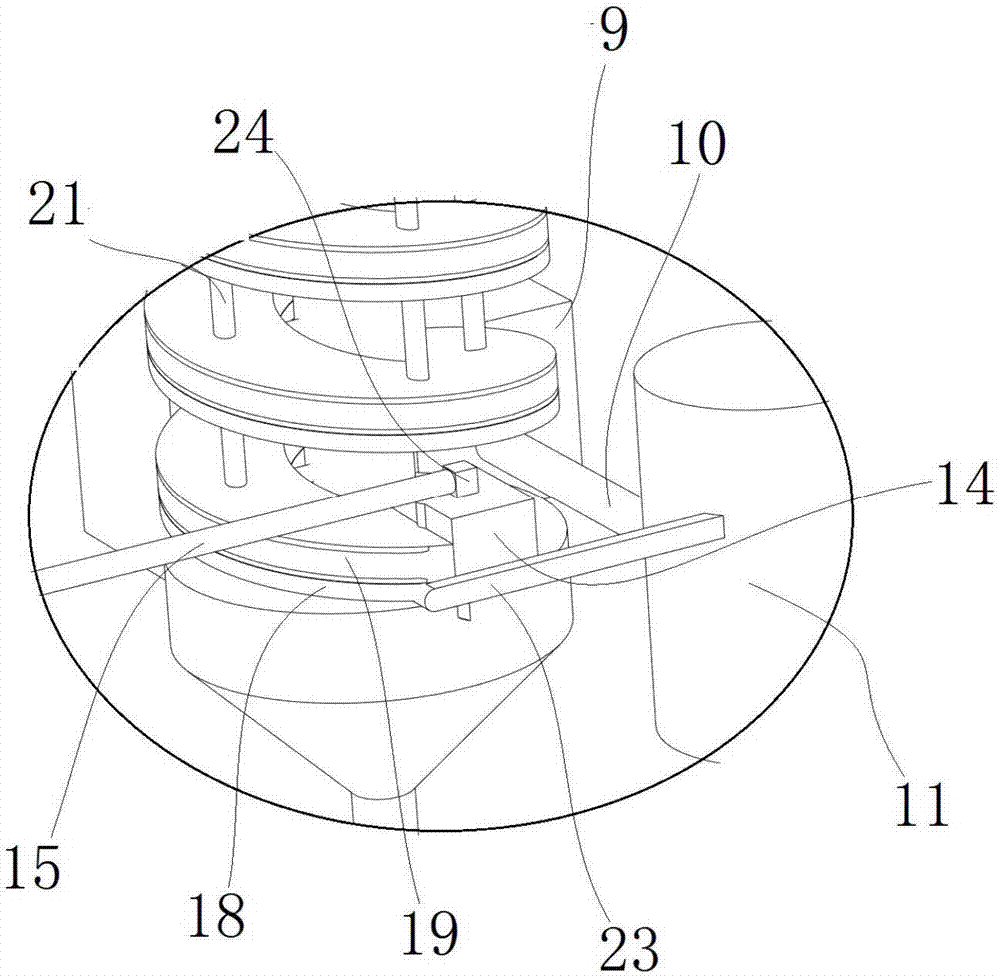

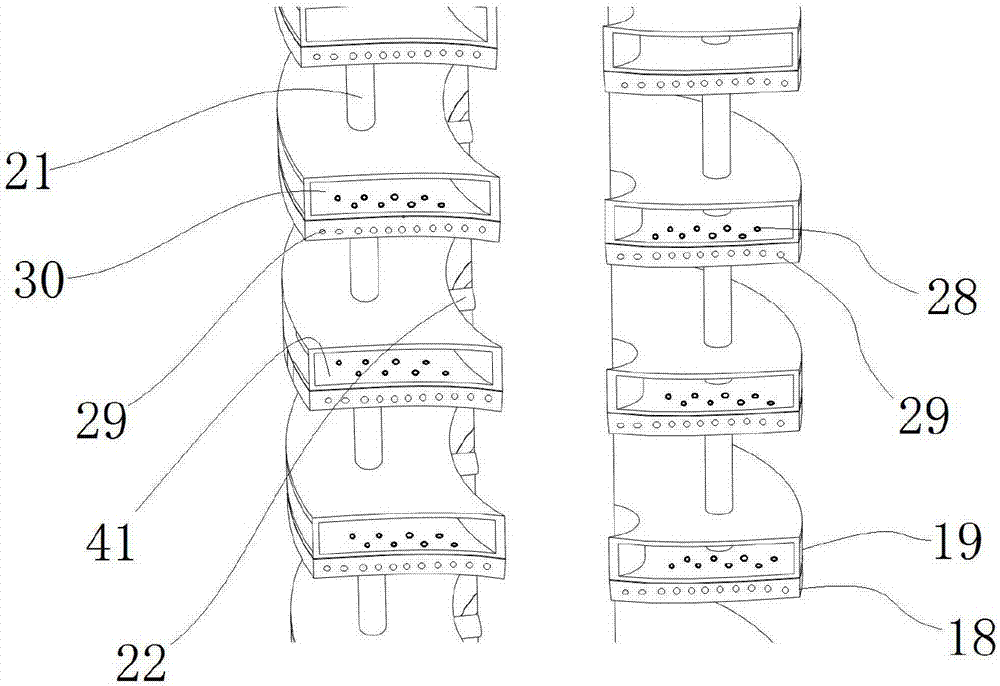

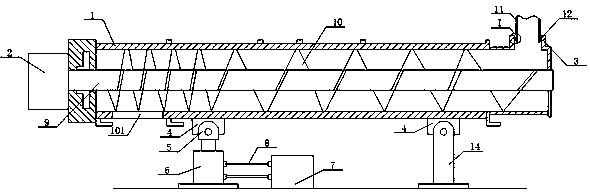

Screw compressor used for kitchen waste dewatering

The invention discloses screw compression equipment for kitchen waste dewatering. The screw compression equipment comprises a rack and a screw compression device. A waste water bearing tank is arranged at the bottom of the rack. The screw compression device is arranged on the upper portion of the waste water bearing tank and comprises a protection cover, a screw compressor shell, a packing auger and a blocking device. The screw compressor shell is arranged in the protection cover. The packing auger is mounted in the screw compressor shell. The blocking device is arranged at one end of a conicshell. In the use process of the screw compression equipment, a sweeping device is arranged on the edges of blades of a first packing auger portion and can sweep away materials left on a porous plate.Meanwhile, sawtooth-shaped drainage holes are formed in the edges of blades of a second packing auger portion, and it is guaranteed that waste water extruded out from the conic shell can be flow outsmoothly. Meanwhile, the blocking device can drive a blocking ejection block to move through a blocking drive motor so as to control the speed that waste is discharged out from the end of the conic shell, so that the waste dewatering effect is guaranteed.

Owner:苏州寰宇新博环保科技有限公司

All-in-one machine for sewage sludge treatment

ActiveCN104069679ACompact and reasonable designReduce volumeFiltration circuitsSewageSewage sludge treatment

The invention relates to an all-in-one machine for sewage sludge treatment, and belongs to the technical field of environmental protection. The all-in-one machine comprises a sewage filtering tank, a clear water tank, a micro filter screen and a sludge pressing tank, wherein the sewage filtering tank is used for being communicated with the outside to store sewage; the clear water tank is arranged below the sewage filtering tank; the micro filter screen is arranged between the sewage filtering tank and the clear water tank, and used for filtering the suspended solids and the flocculating constituents in the sewage; the sludge pressing tank is arranged at one end of the micro filter screen to collect the suspended solids and the flocculating constituents on the micro filter screen; the micro filter screen is arranged on a transmission mechanism, and pushed to move circularly by the transmission mechanism; a pushing device used for pushing the suspended solids and the flocculating constituents in the sludge pressing tank to move is arranged in the sludge pressing tank; a concentrated liquid storing tank positioned at one end of the pushing device is arranged in the sludge pressing tank; a filter cylinder and a pressing plate arranged at the opening end of the filter cylinder are arranged in the concentrated liquid storing tank; the filter cylinder is connected with the pushing device; the suspended solids and the flocculating constituents in the sludge pressing tank are pushed into the filter cylinder by the pushing device.

Owner:CAPITAL GREINWORTH ENVIRONMENTAL CORP

Washing machine and operating method thereof

InactiveCN102560968AThe deceleration function disappearsGuaranteed dehydration effectOther washing machinesWashing machine with receptaclesLow speedReduction drive

The invention discloses a washing machine, which comprises a washing machine tub and a removable dewatering tub. A washing cavity, a pulsator, a motor, a speed reducer and a speed reducer hood are arranged in the washing machine tub, and the speed reducer is fixed inside the speed reducer hood. The washing machine is characterized in that in dewatering, an insert disposed at the bottom of the dewatering tub penetrates through the pulsator to be inserted into the speed reducer hood or a socket on the speed reducer hood, and accordingly the dewatering tub, the pulsator and the speed reducer are connected into a whole to rotate. The invention discloses an operating method of the washing machine, which includes: in washing, the motor outputs power, and the power is reduced by the speed reducer to drive the pulsator to rotate at a low speed; in dewatering, the insert is used to connect the dewatering tub, the pulsator and the speed reducer together, so that the reduction function of the speed reducer is disabled, the speed reducer, the pulsator and the dewatering tub are directly driven by the motor to rotate together; and meanwhile, the power outputted by the motor is not reduced by the speed reducer, rotation is still at the high speed, and accordingly the dewatering effect of the dewatering tub can be ensured.

Owner:刘富春

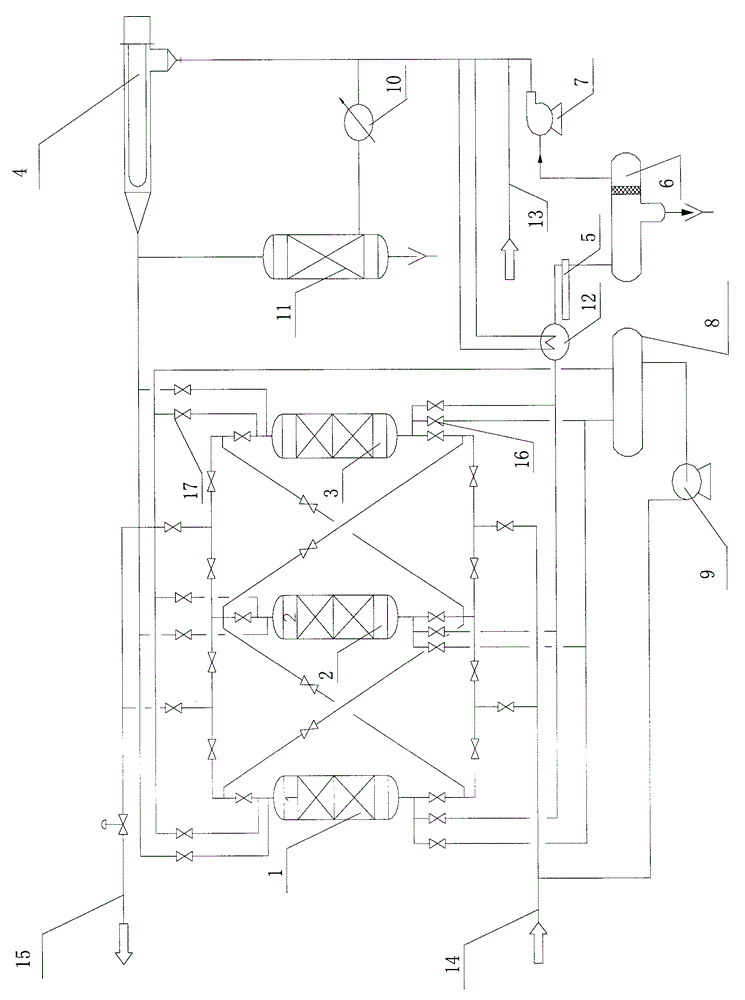

Online process anticorrosion method for fractionation system of hydrogenation device

PendingCN109694727AReduce contentEfficient washing and extractionHydrocarbon oils treatmentFiberFractionation

The invention relates to an online process anticorrosion method for a fractionation system of a hydrogenation device. An efficient oil-water separation module, a pre-mixing washer, a variable-diameterradial salt leaching core tube and a hydrophilic and hydrophobic fiber combined demulsification-corrugation enhanced rapid oil-water separator are arranged to complete the efficient removal of high-salt and high-ammonia-nitrogen water entrained in an oil phase in a cold high-pressure separator and a cold low-pressure separator, and then mixed low-grade oil undergoes washing extraction, oil-waterseparation and other processes to make the content of inorganic chloride ions in the mixed low-grade oil entering the fractionation system less than 1 mg / L. The method can effectively reduce the content of corrosive inorganic salts in the low-grade oil, avoid the subsequent problems of reduced production efficiency and shortened running period caused by the slat deposition and corrosion of the fractionation system and eliminate the problem of corrosion destroys of too high content of the corrosive ions to subsequent devices.

Owner:SHANGHAI MISU ENVIRONMENTAL PROTECTION TECHCO LTD

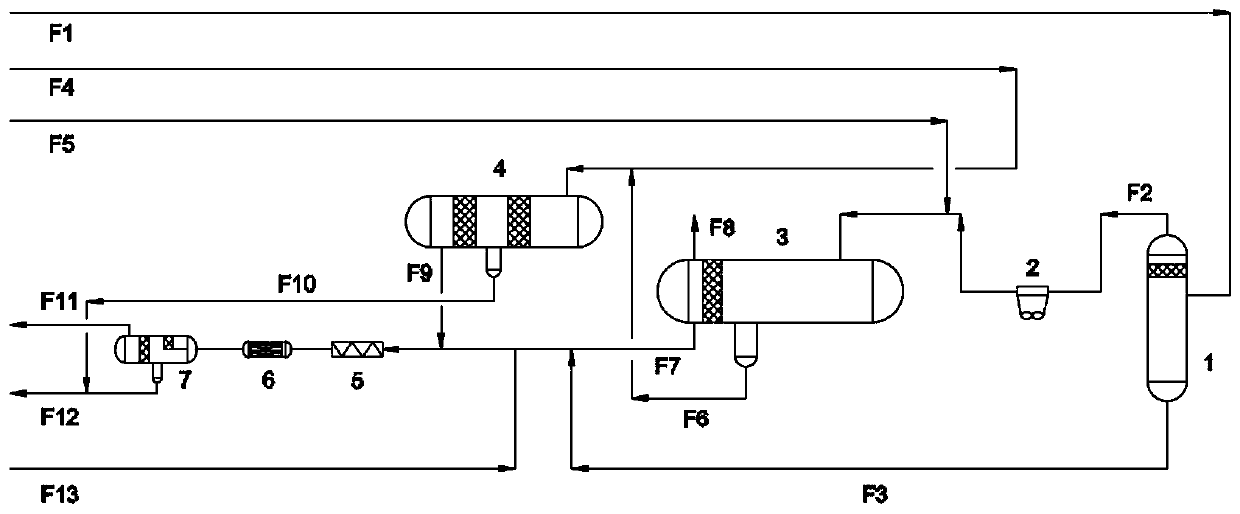

Molecular sieve dehydration method for C-4 fraction

ActiveCN105080181AHigh yieldReduce lossSolid sorbent liquid separationCombustible gas purificationMolecular sieveOrganic chemistry

The invention discloses a molecular sieve dehydration method for a C-4 fraction. The dehydration method comprises the following steps: adsorption; pressure relief and recovery; and regeneration. Molecular sieve dehydration columns (1), (2) and (3) are arranged; two molecular sieve dehydration columns are connected in series for adsorption and dehydration, and the rest molecular sieve dehydration column is used for pressure relief and recovery and regeneration; the molecular sieve dehydration columns are filled with 3A molecular sieves and 4A molecular sieves in grades; and when water content of a material flow at an outlet of a primary tandem molecular sieve dehydration column contacting with a raw material is greater than 5 [mu]g / g, the molecular sieve dehydration column is switched for pressure relief and recovery and regeneration, an original secondary molecular sieve dehydration column contacting with the raw material becomes a primary molecular sieve dehydration column contacting with the raw material, and the standby molecular sieve dehydration column becomes a secondary molecular sieve dehydration column contacting with the raw material. The molecular sieve dehydration method has the advantages of good dehydration effect, small material loss and low energy consumption.

Owner:SINOPEC GUANGZHOU ENG +1

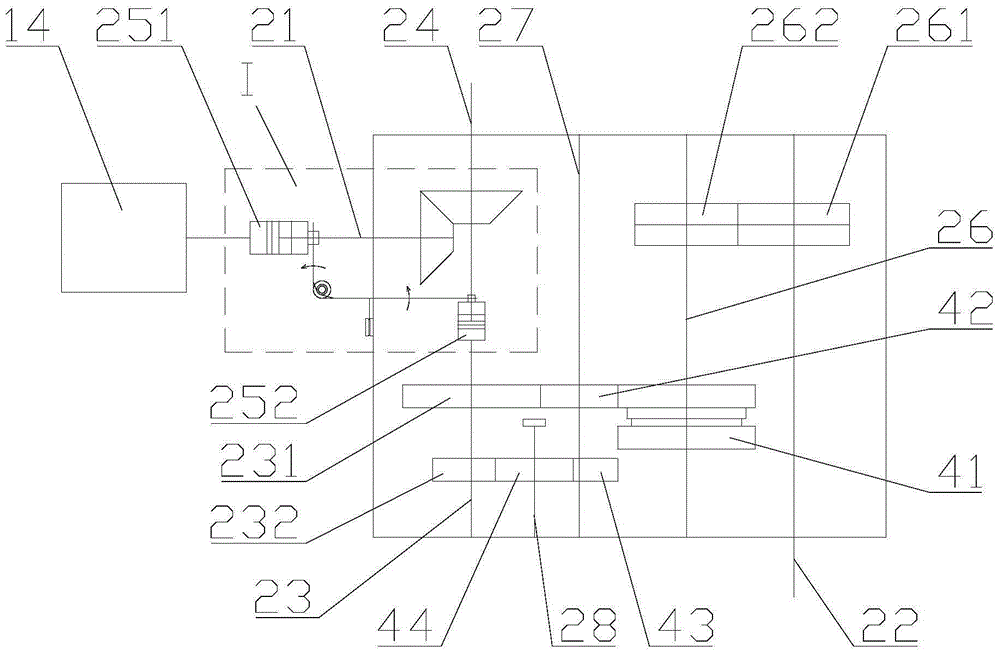

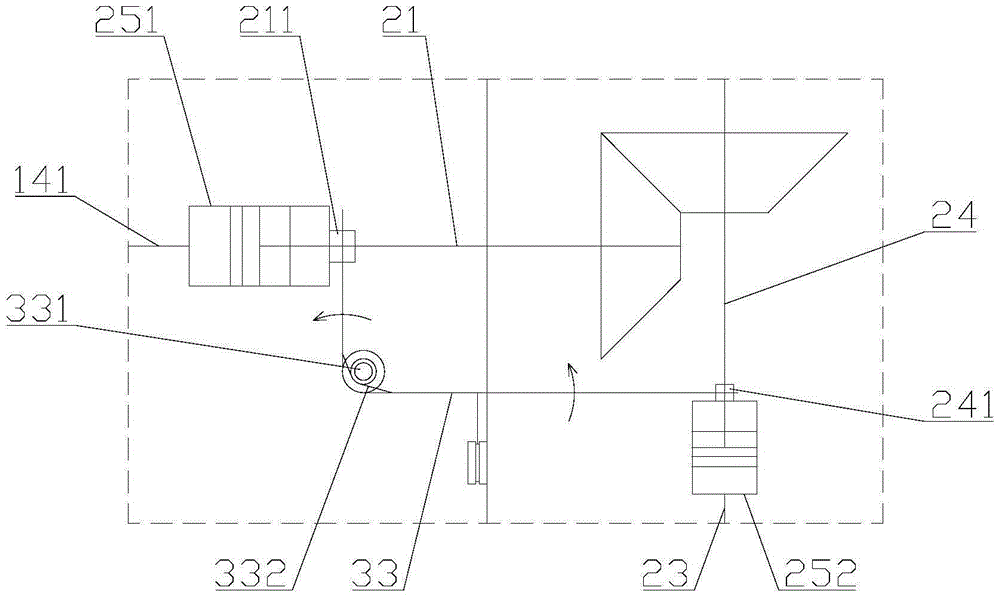

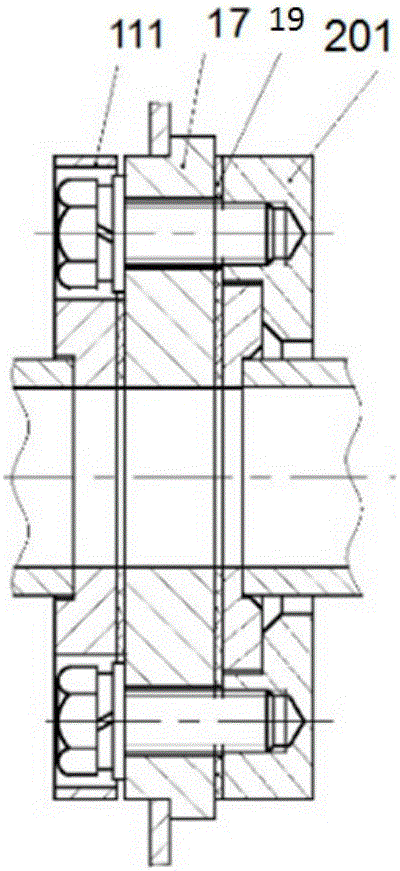

Bodybuilding washing machine with power transmission device

ActiveCN106637824AImplementation of steering transformationGuaranteed dehydration effectOther washing machinesControl devices for washing apparatusEngineeringSprocket

The invention provides a bodybuilding washing machine with power transmission device, which comprises a washing machine motor, a reduction box and a fixed mount. The fixed mount is provided with a front axle and a back axle, wherein a front sprocket is arranged on the front axle, a rear sprocket is arranged on the back axle, the front axle and the back axle are connected by a chain in a transmission way, and a pedal is installed on the front axle. The reduction box is provided with a first input shaft, a second input shaft, an intermediate shaft and an output shaft. The first input shaft is connected with a motor shaft of the washing machine motor through a first clutch in a transmission way, and the first input shaft is connected with the output shaft by a gear in a transmission way. The intermediate shaft and the output shaft are coaxially provided and connected by a second clutch. The first clutch and the second clutch alternately engage or separate. The second input shaft sequentially through a even intermittent drive mechanism and a electric reversing gear mechanism and is connected with the intermediate shaft in a transmission way, and the second input shaft is coaxial with the back axle and rotates synchronously. The output shaft is connected with a tumble dryer in a transmission way.

Owner:ZHEJIANG UNIV OF TECH

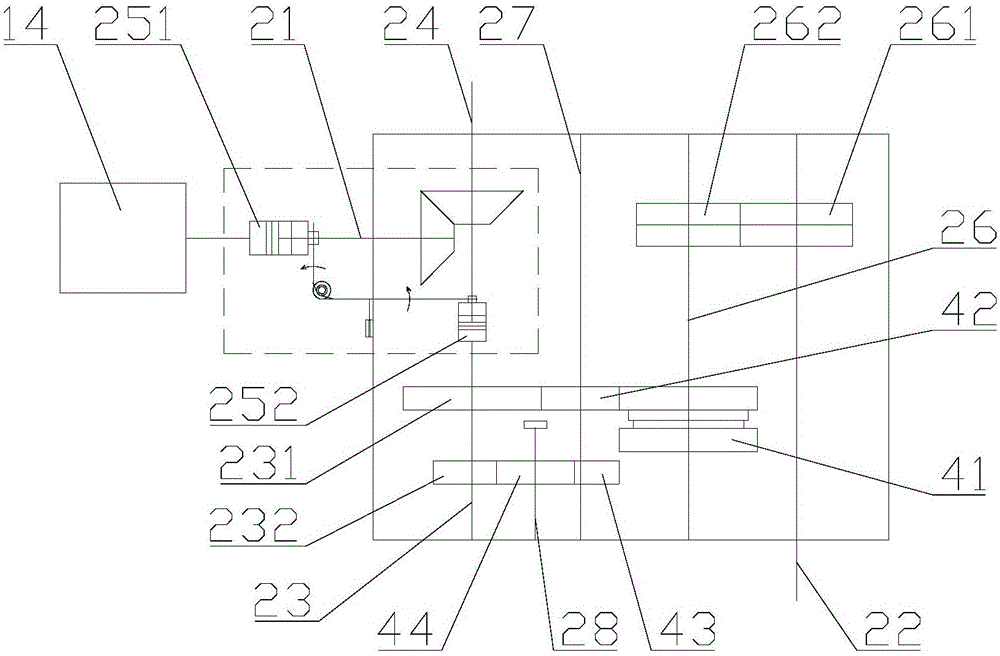

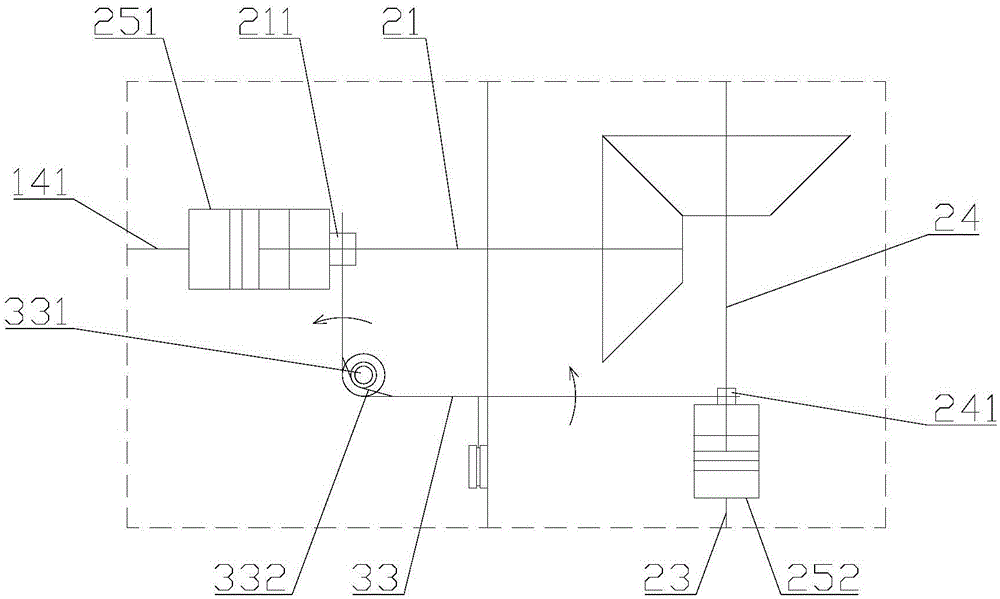

Granular preserved fruit food ingredient system and method

ActiveCN107296137AImprove mixing uniformityImprove qualityConfectionerySweetmeatsEngineeringMechanical engineering

The invention discloses a granular preserved fruit food ingredient system which comprises a food feeding hopper, an ingredient liquid feeding hopper, an ingredient liquid mixing unit, an ingredient liquid injection pipe, a spiral ingredient pipe, a blanking unit, a food receiving tank and a vibration unit, wherein the spiral ingredient pipe is coiled on the columnar vibration unit in a spiral shape; the discharging end of the food feeding hopper is connected with a food feeding hole in the upper end of the spiral ingredient pipe in a communicated manner; and the discharging end at the lower end of the spiral ingredient pipe is connected with the feeding end of the blanking unit in a communicated manner. The system disclosed by the invention has a simple structure compared with the traditional ingredient device, and the mixing uniformity of the ingredient liquid and granular preserved fruit foods is greatly improved in a manner of matching of the spiral ingredient pipe and the ingredient liquid injection pipe. Meanwhile, the temperature protection scheme in the dehydration process is provided, temperature rise of the foods in the dehydration process is weakened to the greatest degree while ensuring the dehydration effect, and the food quality is finally improved.

Owner:承德华朗食品有限公司

Sludge centrifugal dehydrator for sewage treatment

The invention relates to the field of sewage treatment equipment, and discloses a sludge centrifugal dehydrator for sewage treatment. The sludge centrifugal dehydrator comprises a machine base, a housing is arranged at the top of the machine base, a rotatable drum is arranged in the housing, a rotatable middle rotating shaft is arranged in the middle of the inner cavity of the drum, the drum and the middle rotating shaft are driven by a driving motor to rotate, and a differential mechanism is connected between the rotatable drum and the driving shaft on one side of the middle rotating shaft. Through the structural design of a positioning sleeve plate and a limiting sliding ring between two spiral impellers at a water outlet pipe in the rotatable drum, when the content of sludge in sewage is suddenly increased, the flow of the sewage and the sludge in the spiral conveying cavity is reduced through diversion by utilizing the water guide hole, so that a large amount of sludge can be conveniently conveyed to the centrifugal machine conical dewatering cavity on the left side along the outer side of the rotatable drum again, the problem that when the sludge amount is increased, an existing sludge centrifugal dewatering machine cannot discharge and separate the sludge in time, and consequently part of the sludge flows out along with sewage is effectively solved, and the sludge dewatering effect is guaranteed.

Owner:丁峰

Multifunctional pulsator washing machine

ActiveCN105200720ASimple structureLarge amount of laundryOther washing machinesControl devices for washing apparatusGear driveElectric machinery

The invention provides a multifunctional pulsator washing machine, which comprises a case, wherein a control seat is arranged on the top part of the case; a water tub and a dewatering cylinder are arranged in the case from outside to inside; a washing motor, a reduction gearbox and a fixed bracket are arranged outside the case; a front shaft and a rear shaft are arranged on the fixed bracket; a front chain wheel is arranged on the front shaft; a rear chain wheel is arranged on the rear shaft; the front chain wheel and the rear chain wheel are in transmission connection through a chain; a pedal is arranged on the front shaft; the reduction gearbox comprises a first input shaft, a second input shaft, a middle shaft and an output shaft; the first input shaft is in transmission connection with a motor shaft of the washing motor through a first clutch, and is in transmission connection with the output shaft through a gear; the middle shaft and the output shaft are arranged coaxially and are connected through a second clutch; the first clutch and the second clutch are alternatively jointed or separated; the second input shaft is connected with the middle shaft through a uniform intermittent transmission mechanism and an electric reversing gear mechanism sequentially, and the second input shaft and the rear shaft are coaxial and rotated synchronously; the output shaft is in transmission connection with the dewatering cylinder.

Owner:ZHEJIANG UNIV OF TECH

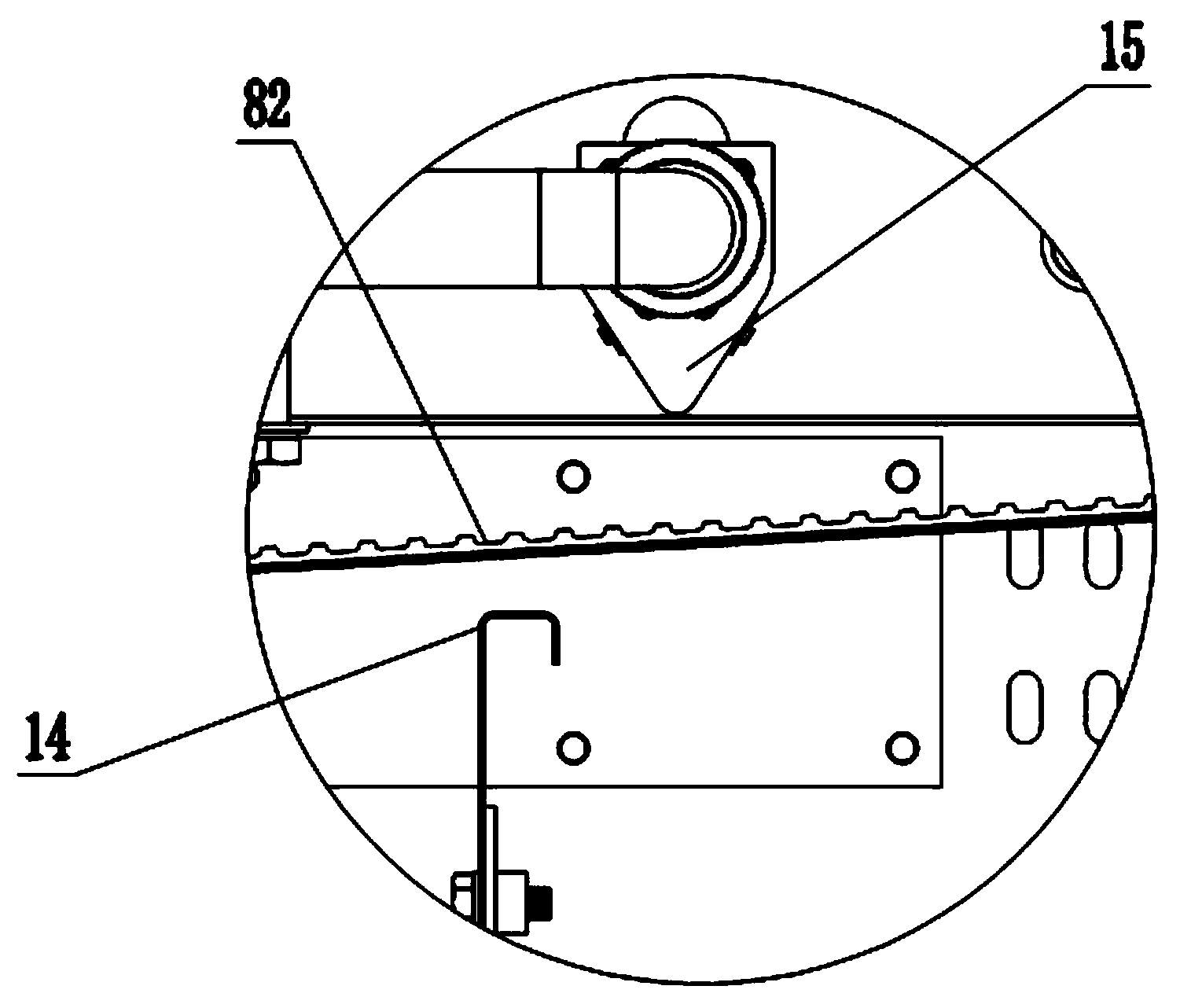

Beating type vacuum leakage preventing apparatus with crawler type vacuum pumping filter

InactiveCN105797463AGuaranteed not to deformNo lossMoving filtering element filtersVacuum pumpingMaterial Crack

The invention provides a beating type vacuum leakage preventing apparatus with a crawler type vacuum pumping filter. The apparatus comprises a vacuum pumping filter; the vacuum pumping filter comprises a frame, a motor, a roller, and a crawler belt, wherein the roller is installed on the frame, the crawler belt i s arranged on the roller, a piece of filter cloth is arranged on the external layer of the crawler belt, and one end of the upper side of the crawler belt is provided with a material distribution device; the apparatus is characterized in that the lower side of the crawler belt is provided with three groups of vacuum boxes at the motion direction of the crawler belt, and the vacuum boxes are connected to a vacuum pump by vacuum tubes; a beating apparatus is arranged above a second stage vacuum box and a third stage vacuum box, the beating apparatus comprises a beater and a vibration motor, and the beater is connected to the vibration motor through a transmission mechanism. The apparatus has the advantages and beneficial effects that when the materials crack, the beater can be used for beating materials, after materials are compressed, the cracks are filled again, the materials are arranged and leveled, so that sealing is guaranteed and vacuum does not loss, and dehydration effects are guaranteed; the vibration motor can adjust exciting forces according to needs, and materials do not deform.

Owner:TIANJIN CITY XINZE FINE CHEM

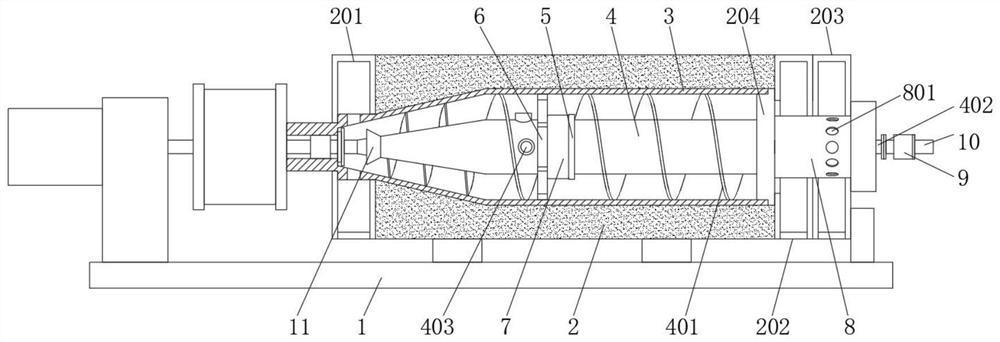

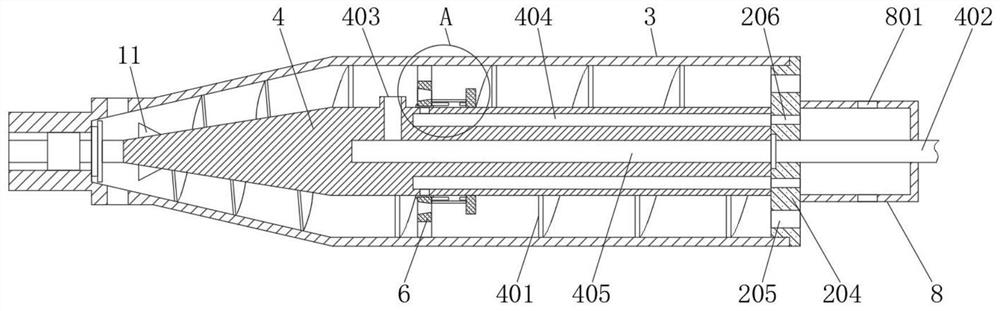

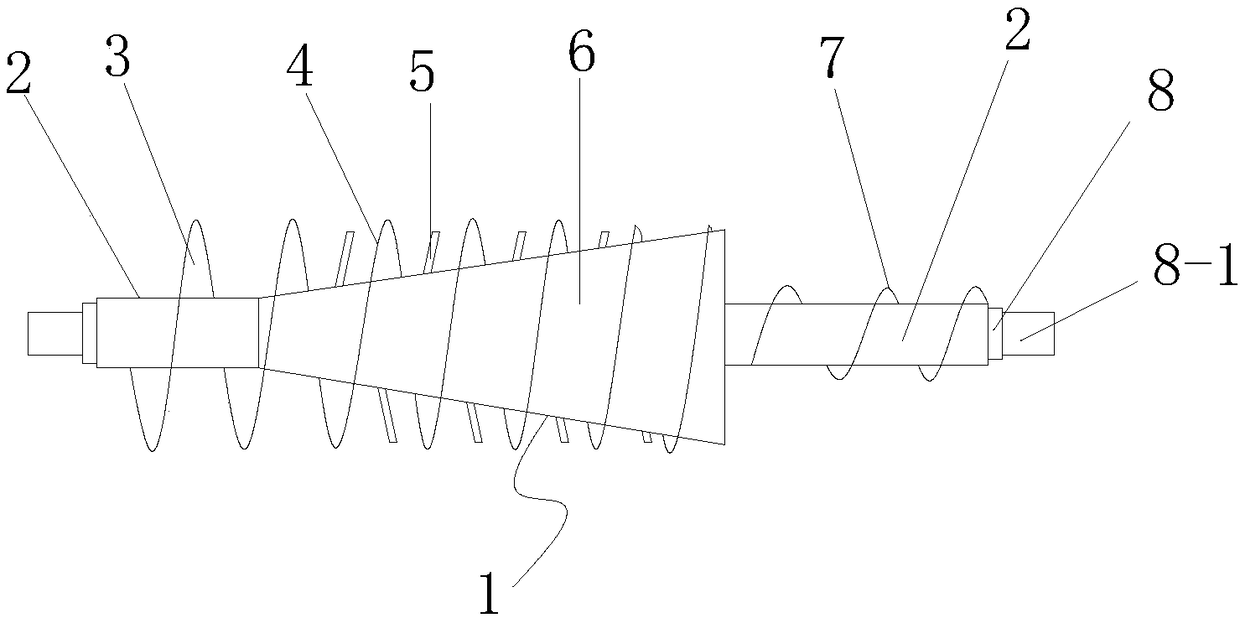

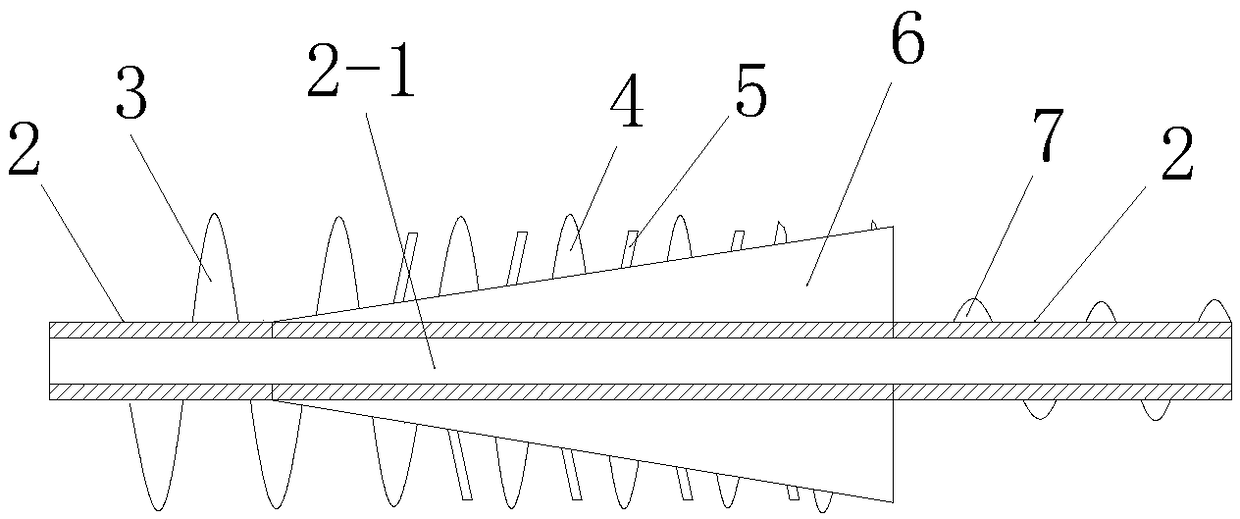

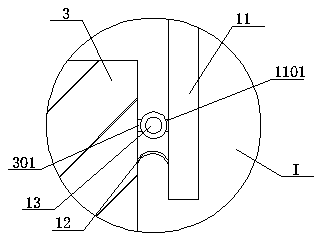

Squeezing shaft and vegetable dehydrator using squeezing shaft

The invention discloses a squeezing shaft and a vegetable dehydrator using the squeezing shaft. The squeezing shaft comprises a rotating shaft, a conveyer auger, a squeezing auger and an auxiliary auger, wherein the conveyer auger is axially arranged on a straight shaft on the minor-diameter side of a conical shaft through a welding manner; the squeezing auger is axially arranged on the conical shaft through the welding manner; and the auxiliary auger is axially arranged on a straight shaft on the major-diameter side of the conical shaft through the welding manner. The squeezing shaft disclosed by the invention has the beneficial effects that backward blades are uniformly arranged between the conical shaft and the squeezing auger in a spaced manner, and are used for blocking in the squeezing motion direction of the squeezing auger; the materials are further extruded by the backward blades and the squeezing auger, so that the squeezing efficiency and the squeezing effect are greatly improved; and in addition, a cavity allowing a heat source to flow is formed in the squeezing shaft, so that heating is convenient, and the function of the squeezing shaft is increased.

Owner:UNIV OF JINAN +1

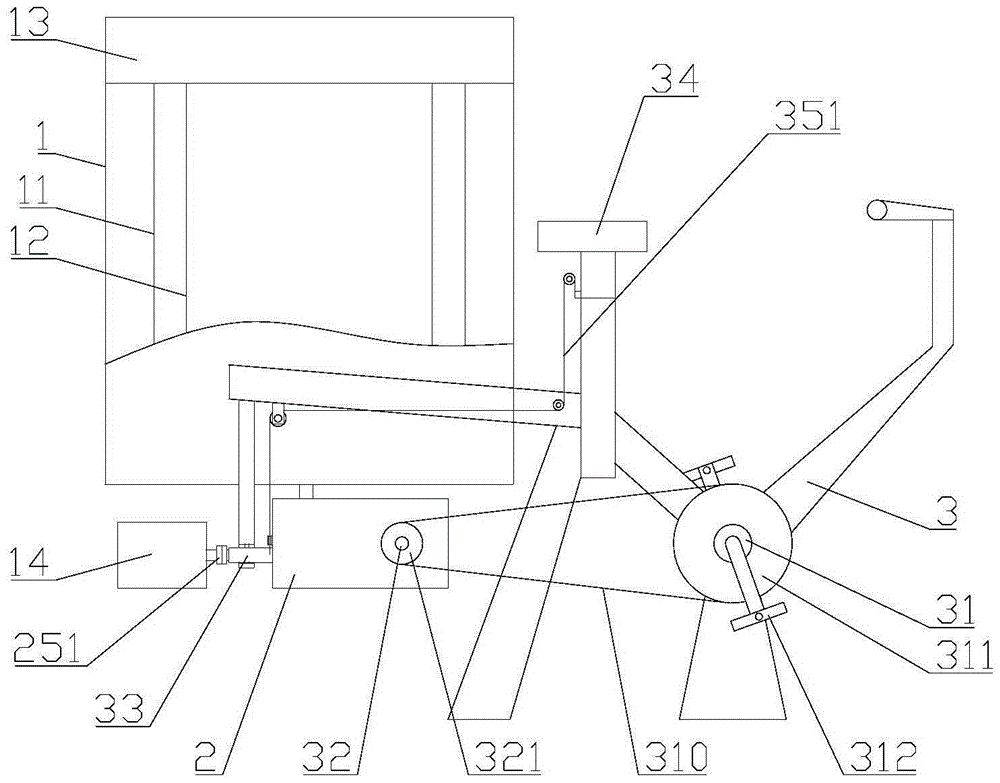

An umbrella dehydration wrapping machine

InactiveCN105599954BAvoid slipperyEnsure safetyWrappers shrinkageWrappingEngineeringThermal contraction

The invention discloses an umbrella dehydrating and packaging machine. The umbrella dehydrating and packaging machine comprises a stander, an umbrella conveying mechanism, a dehydrating mechanism, a thermal contraction membrane and a thermal contraction membrane heating tank, wherein the umbrella conveying mechanism, the dehydrating mechanism, the thermal contraction membrane and the thermal contraction membrane heating tank are arranged on the stander, an umbrella operating region is formed between working regions of the dehydrating mechanism and the thermal contraction membrane heating tank, the thermal contraction membrane is transversely arranged in the umbrella operating region between the dehydrating mechanism and the thermal contraction membrane heating tank, and the umbrella conveying mechanism is used for driving an umbrella to move in the umbrella operating region to sequentially pass through the dehydrating mechanism and the thermal contraction membrane heating tank. According to the umbrella dehydrating and packaging machine, the umbrella is dehydrated and is packaged with the thermal contraction membrane by virtue of the umbrella conveying mechanism, so that the umbrella surface of the umbrella can be rapidly dried and packaged, the problem that a site becomes slippery and dirty due to water on the umbrella on a rainy day can be prevented, the pressure of a cleaner is alleviated, the safety of pedestrians is guaranteed, the service qualities of merchants such as shopping malls, cinemas and the like are improved, and relatively wide market shares are won for the merchants.

Owner:GUANGDONG TECHN COLLEGE OF WATER RESOURCES & ELECTRIC ENG

Alkaline wastewater purification treatment agent

InactiveCN105152289AEffective oxidation removalFast and efficient realization of flocculation and agglomerationWater/sewage treatment by neutralisationWater/sewage treatment by flocculation/precipitationPolyacrylamideWater treatment

The present invention provides an alkaline wastewater purification treatment agent, which is characterized by comprising 50-60% of a component A, 30-40% of a component B and 5-10% of a component C, wherein the component A comprises calcium dihydrogen phosphate, aluminum sulfate, poly aluminum chloride and poly ferric sulfate, the component B comprises magnesium oxide, calcium sulfate and sodium silicate, and the component C comprises polyacrylate and polyacrylamide. According to the present invention, the purification treatment agent is the multifunction wastewater purification treatment agent with the excellent and comprehensive water treatment effect, and with the purification treatment agent, the efficient and accurate wastewater pH value adjusting can be ensured, the organic or inorganic contaminants can be removed through the effective oxidation, the flocculation can be rapidly and efficiently achieved, and the heavy metal ions in the wastewater can be removed.

Owner:郑宇欣

Organic-inorganic composite sludge dewatering conditioner

ActiveCN110040938AHigh specific surface areaFacilitate the drainage of moistureSludge treatment by de-watering/drying/thickeningBiological sludge treatmentGraphite oxideOrganic inorganic

The invention discloses an organic-inorganic composite sludge dewatering conditioner and belongs to the technical field of environmental protection materials. The studied composite sludge dewatering conditioner is prepared from acid modified sepiolite, amination modified graphene oxide, urease, urea, self-made segmented copolymers, N'-hexadecyl-N,N-dimethylethyl amidine, a carbonate foaming agentand a dispersant. In the preparation process, all components are weighed according to raw material composition; the acid modified sepiolite, amination modified graphene oxide, urea, the self-made segmented copolymers, N'-hexadecyl-N,N-dimethylethyl amidine and the dispersant are stirred and mixed to obtain a mixture; the mixture and water are stirred and mixed, inert gas is continuously introducedin the stirring process, vacuum freezing drying is performed, and a dried material is obtained; the dried material, urease and the carbonate foaming agent are stirred and mixed, and the organic-inorganic composite sludge dewatering conditioner is obtained. The organic-inorganic composite sludge dewatering conditioner prepared with the technical scheme has the characteristic of excellent dewatering performance.

Owner:海环绿源环保科技(上海)有限公司

Purification treatment process for industrial waste liquid

ActiveCN105084509AEasily dehydratedGood processing effectWater/sewage treatment by neutralisationWater/sewage treatment by flocculation/precipitationIonSodium silicate

The invention provides a purification treatment process for an industrial waste liquid. The process is characterized by comprising: adding a high-energy multiple-effect purification treatment agent in an amount of 3-5g for each litre of a to-be-treated industrial waste liquid; and stirring and purifying the industrial waste liquid in 3-7 minutes after being added, wherein the purification treatment agent is composed of three components in percentage by weight: 50-60% of A, 30-40% of B and 5-10% of C; the component A comprises calcium dihydrogen phosphate, aluminum sulfate, polyaluminum chloride and polymeric ferric sulfate; the component B comprises magnesium oxide, calcium sulfate and sodium silicate; the component C comprises polyacrylate and polyacrylamide. The treatment process not only can be used for efficiently and accurately adjusting the pH value of the wastewater, but also can be used for effectively oxidizing and removing organic or inorganic pollutants in the wastewater and can be further used for quickly and efficiently realizing flocculation and eliminating heavy metal ions in the wastewater.

Owner:广东粤绿环境工程有限公司

Power transmission device for washing machine for bodybuilding

ActiveCN105155219AGuaranteed washing effect and dehydration effectThe transmission relationship is stable and reliableOther washing machinesControl devices for washing apparatusElectric machineryClutch

The invention provides a power transmission device for a washing machine for bodybuilding. The power transmission device comprises a washing motor, a reduction gearbox and a fixed frame, wherein the fixed frame is provided with a front shaft and a rear shaft, the front shaft is provided with a front chain wheel, the rear shaft is provided with a rear chain wheel, the front chain wheel is connected with the rear chain wheel under the drive of a chain, and the front shaft is provided with a pedal; the reduction gearbox comprises a first input shaft, a second input shaft, an intermediate shaft and an output shaft; the first input shaft is driven by and connected with a motor shaft of the washing motor through a first clutch and is connected with the output shaft under the drive of a gear; the intermediate shaft and the output shaft are coaxially arranged and are connected through a second clutch; the first clutch is alternately connected with or separated from the second clutch; and the second input shaft is driven by and connected with the intermediate shaft sequentially through a uniform intermittent transmission mechanism and an electric reversing gear mechanism, the second input shaft and the rear shaft coaxially and synchronously rotate, and the output shaft is driven by and connected with a spin tub.

Owner:ZHEJIANG UNIV OF TECH

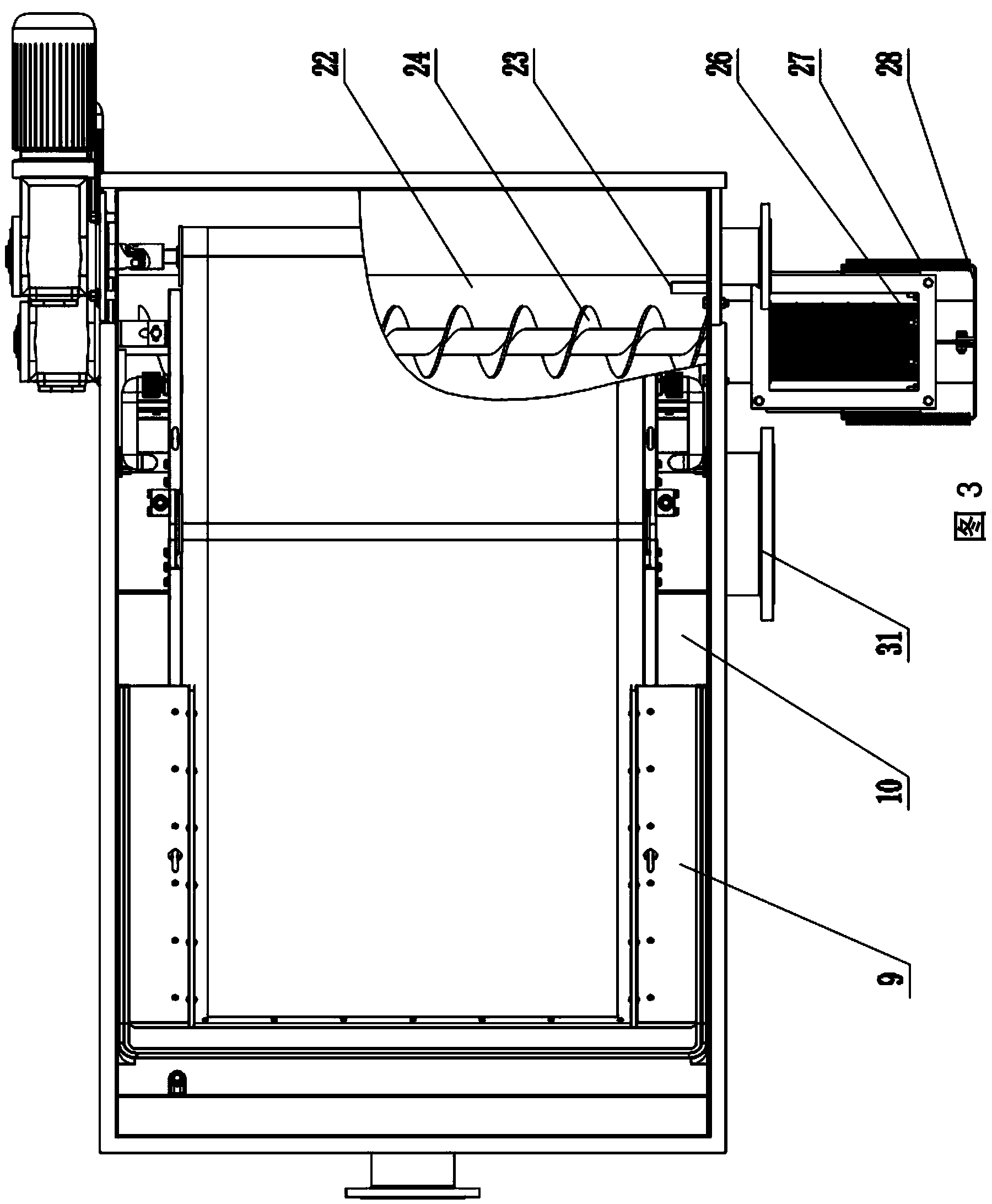

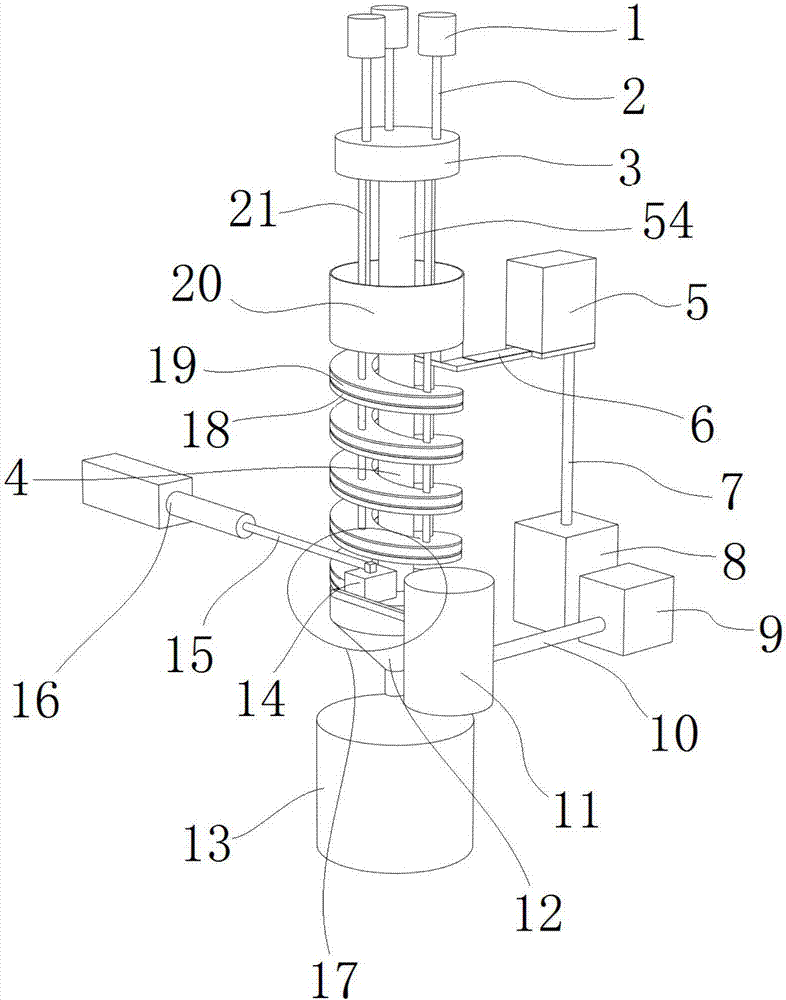

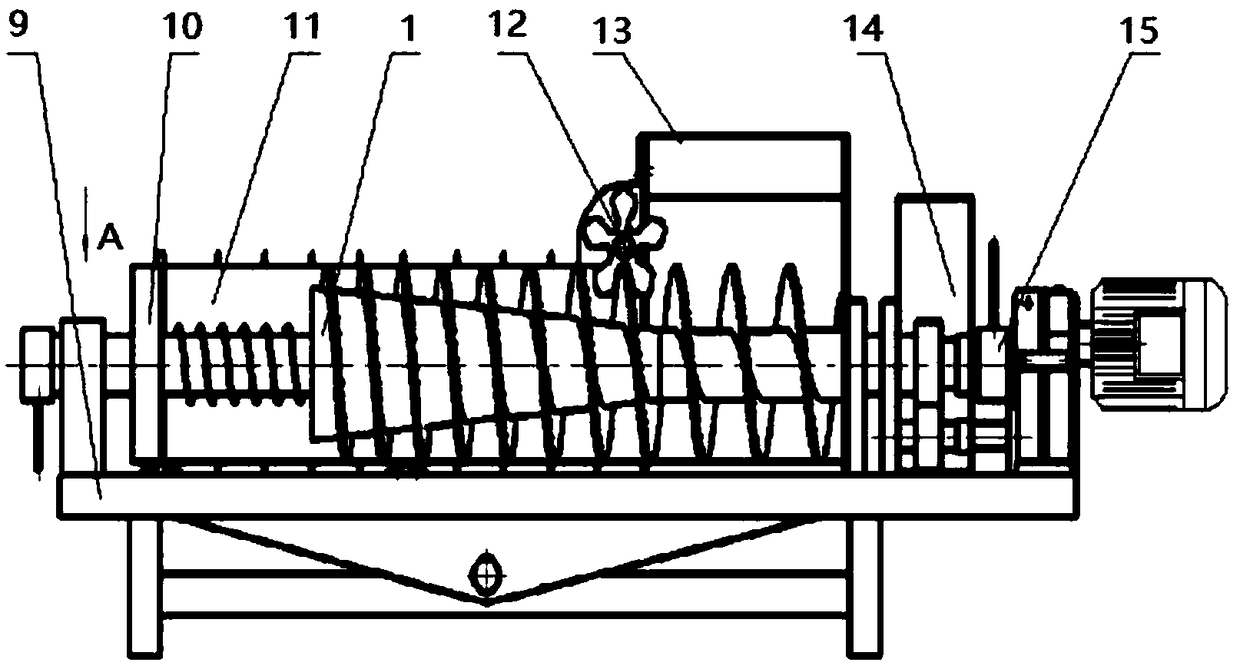

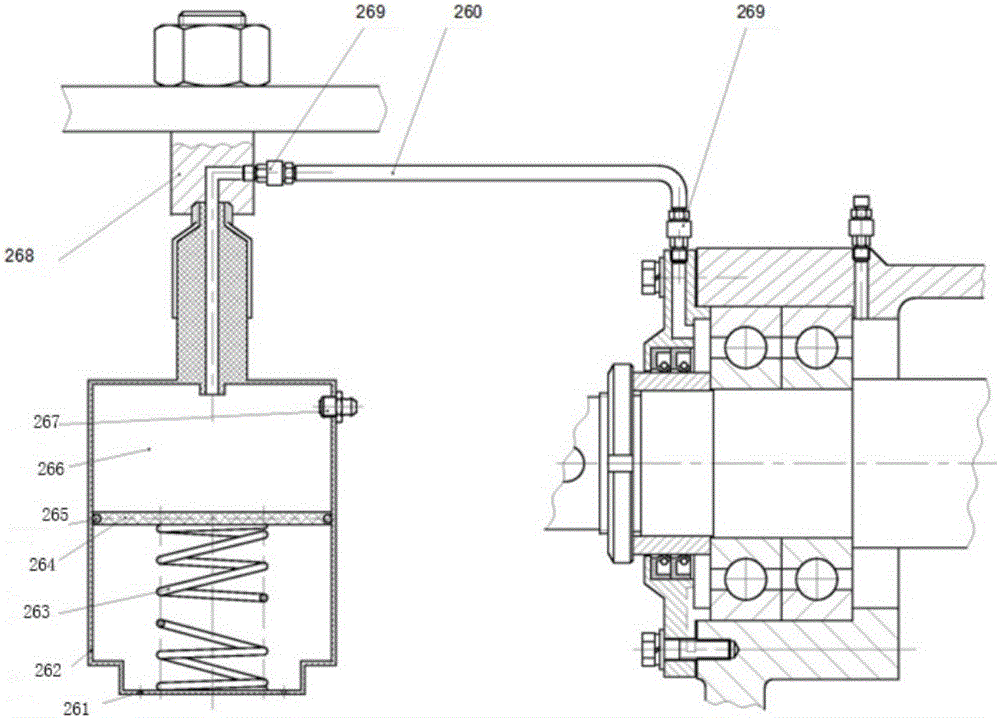

Novel helical sludge dewatering machine structure with adjustment function

InactiveCN107759047AReasonable structural designGuaranteed dehydration effectSludge treatment by de-watering/drying/thickeningWater/sewage treatment apparatusSpiral bladeHydraulic pump

The invention discloses a novel stacked screw sludge dewatering machine structure with adjustment function, which includes a shell, a discharge port, a motor installation box, a feeding hopper, a feeding connecting plate, a boss, a connecting block, and a hydraulic lifting column , hydraulic pump, oil pipeline, main shaft, spiral dehydration blade, feed pipe, pipe wall connecting plate, sealing layer, connecting column and fixed column. The structure design of the present invention is reasonable. Compared with the traditional stacked screw sludge dewatering machine, the inclination angle of the shell used for dehydration is variable, so that the dehydration efficiency of the whole equipment can be improved under the premise of ensuring the dehydration effect; The sealing structure added at the connection between the feed pipe and the hopper solves the phenomenon that sludge overflow may occur at the connection between the feed pipe and the hopper when the inclination angle of the shell is adjusted. Regulation provides the structural basis.

Owner:哈建薇

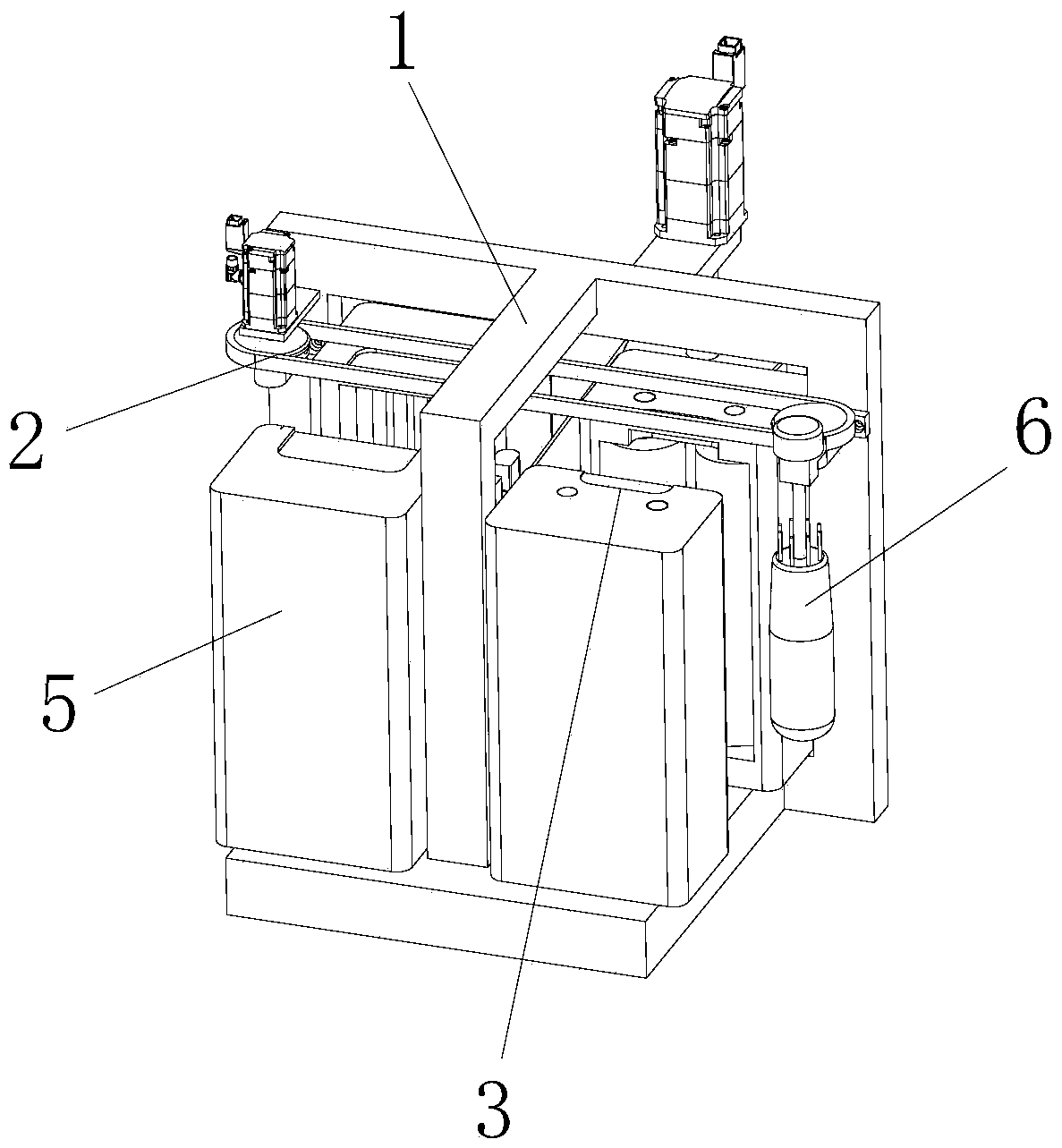

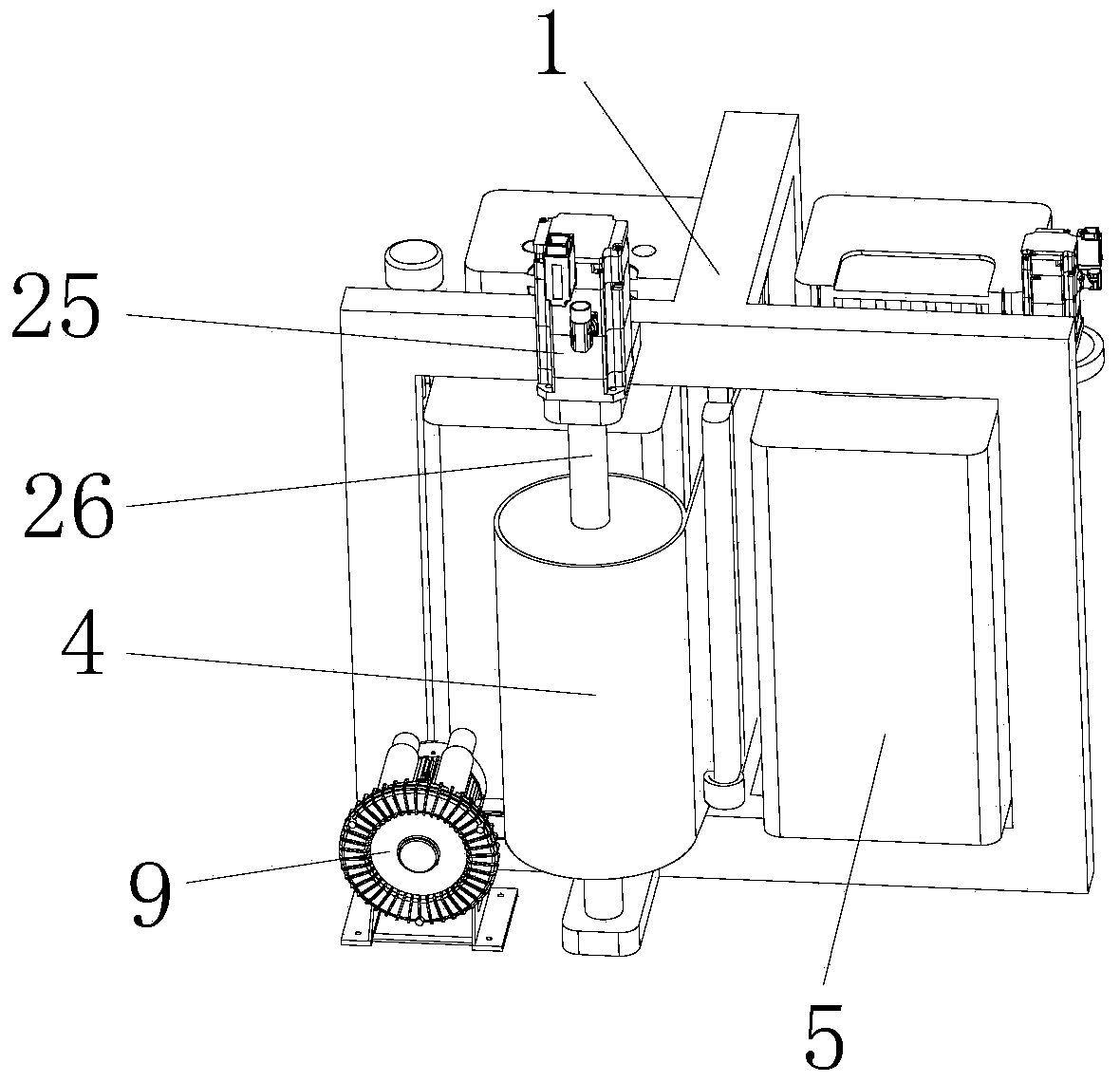

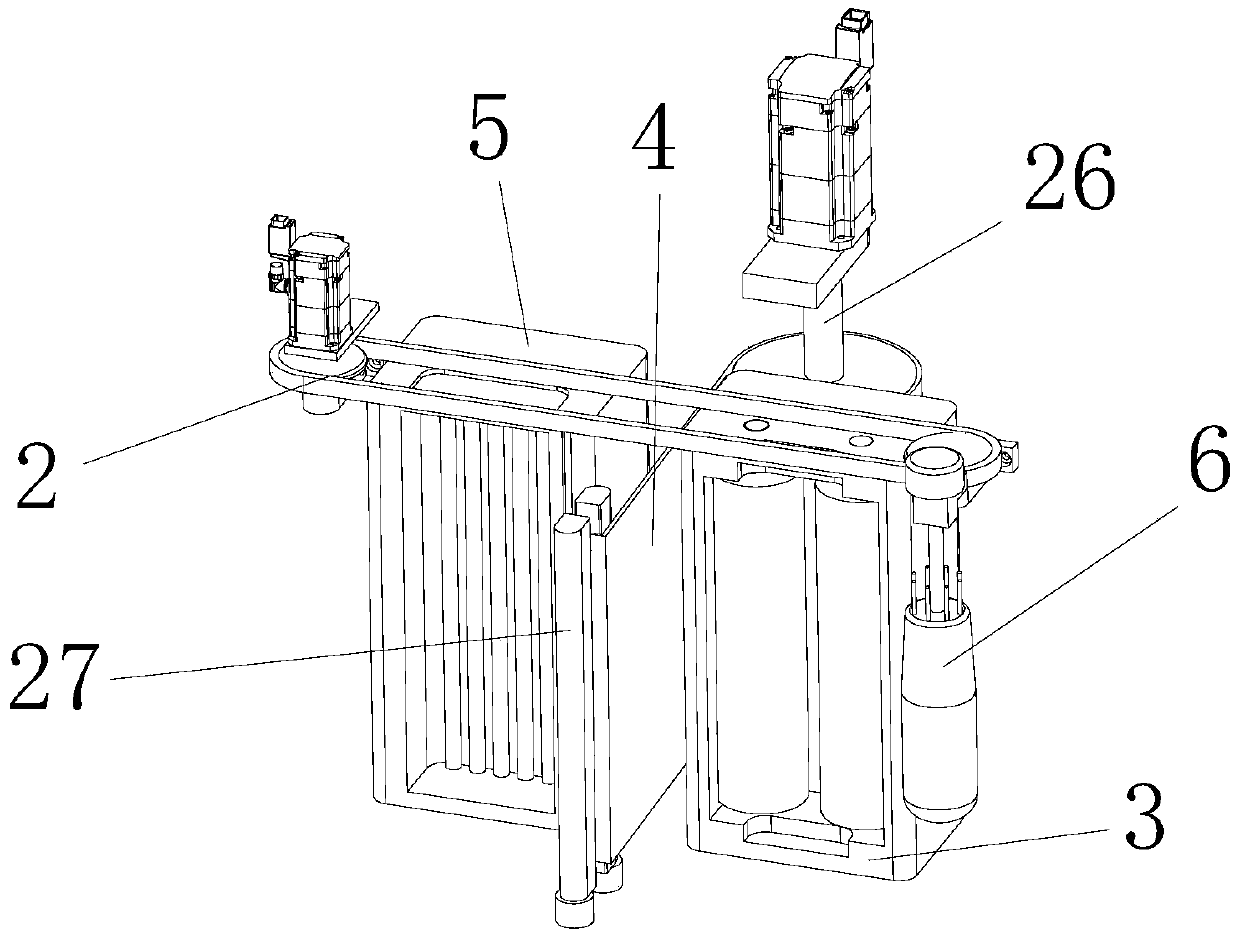

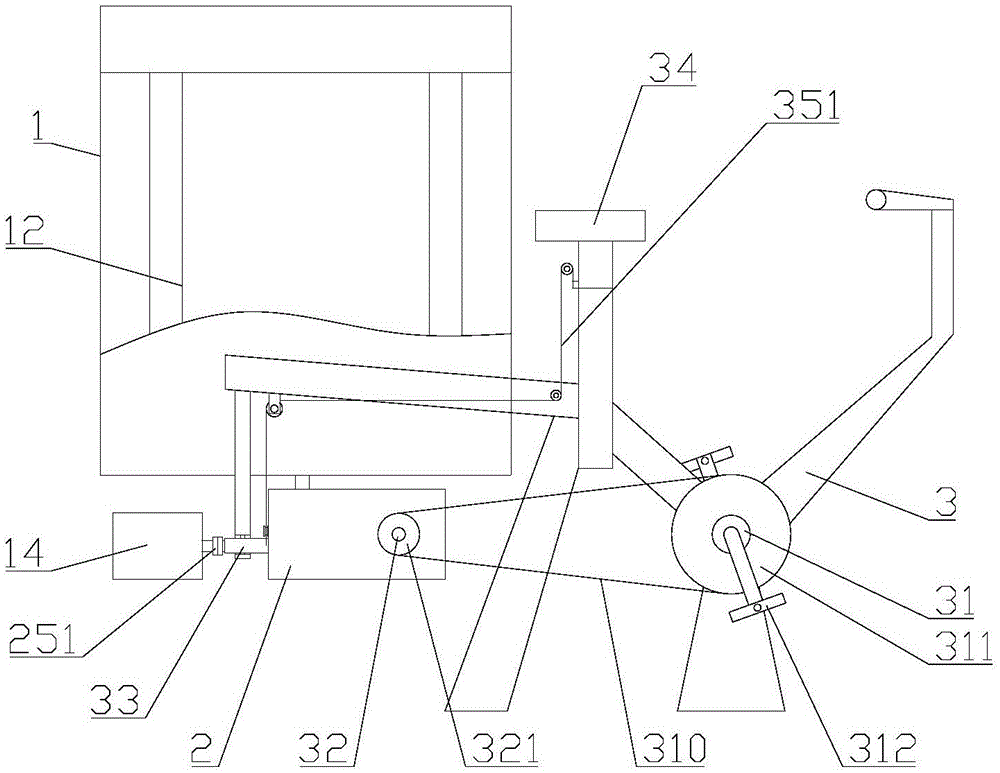

Automatic mud desanding and purification equipment

InactiveCN105920913AIncrease speedReduce speedWater treatment parameter controlSludge treatment by de-watering/drying/thickeningArchitectural engineeringSolid content

The invention provides automatic mud desanding and purification equipment. The automatic mud desanding and purification equipment comprises a rack (1). A feed port (3) is fixed to the rack (1). A vibrating coarse screen plate (22) is fixed to the lower end of the feed port (3). A mud storage tank (17) is fixed to the lower end of the coarse screen plate (22). The mud storage tank (17) is communicated with a suction opening of a mud residue pump (6). A discharge port of the mud residue pump (6) is communicated with a feed port of a swirler (5) fixed to the rack (1), a vibrating fine screen plate (23) is fixed to the lower end of a bottom flow opening (10) in one end of the lower portion of the swirler (5), the vibrating fine screen plate (23) is located at the upper end of the mud storage tank (17) and located above the vibrating coarse screen plate (22), and the equipment is provided with a mud concentration online detection and control device. The solid content of mud can be automatically controlled in real time, and the stability and quality of the mud are improved.

Owner:徐州汉晨机械制造有限公司

Traditional Chinese medicine decoction piece freeze-drying processing equipment

ActiveCN111964361AGuaranteed efficacyPromote leachingDrying solid materials without heatDrying chambers/containersMedicinal herbsProcess engineering

The invention relates to traditional Chinese medicine decoction piece freeze-drying processing equipment. The equipment comprises a bottom plate, a freeze-drying device and a vacuum pipe. Mounting holes are evenly arranged on the bottom plate. The freeze-drying device is mounted in the middle of the upper end of the bottom plate. The vacuum pipe is mounted at the upper end of the left side of thefreeze-drying device and is connected with an external vacuum pump. By means of the traditional Chinese medicine decoction piece freeze-drying processing equipment, the problems that when existing equipment dries traditional Chinese medicine decoction pieces, water in medicinal materials is removed generally through a high-temperature baking manner, but the situation that active substances in traditional Chinese medicine decoction pieces are prone to deforming and losing activity due to high-temperature baking, the effect of traditional Chinese medicine decoction pieces is reduced, when existing equipment dries traditional Chinese medicine decoction pieces, the drying effect is poor, traditional Chinese medicine sections are generally prone to being accumulated together, consequently, thewater removal effect of water in traditional Chinese medicine sections is poor, efficiency is low, and the preparation effect of traditional Chinese medicine decoction pieces is influenced can be solved.

Owner:太和县美欣药业有限公司

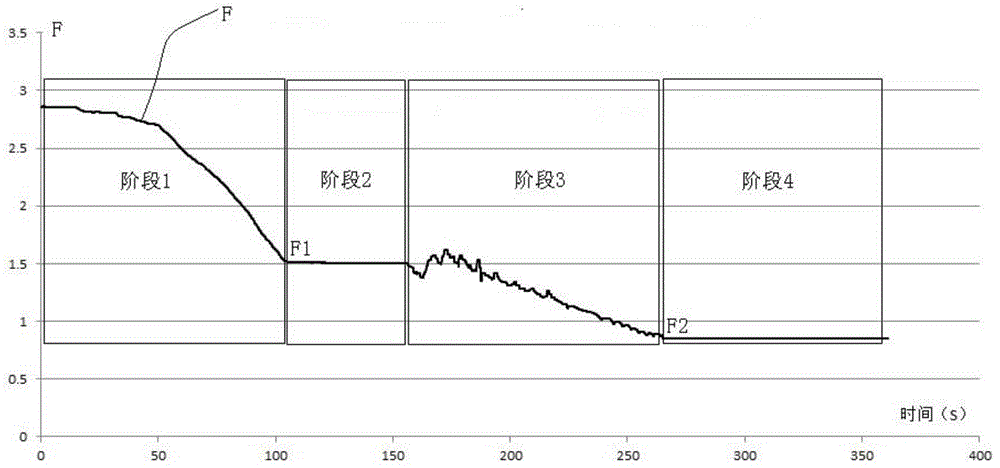

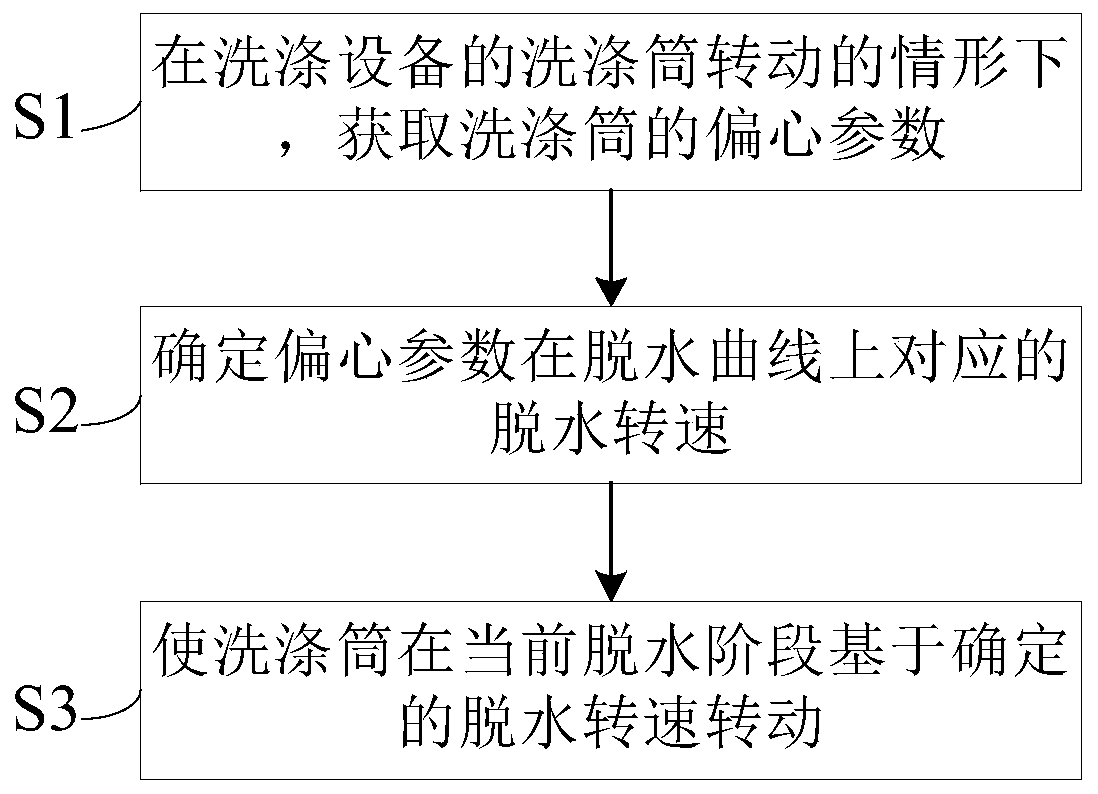

Dehydrating method of washing equipment and washing equipment

PendingCN111235822AReduce the difficulty of executionReduce adverse effectsControl devices for washing apparatusTextiles and paperLaundry washing machineProcess engineering

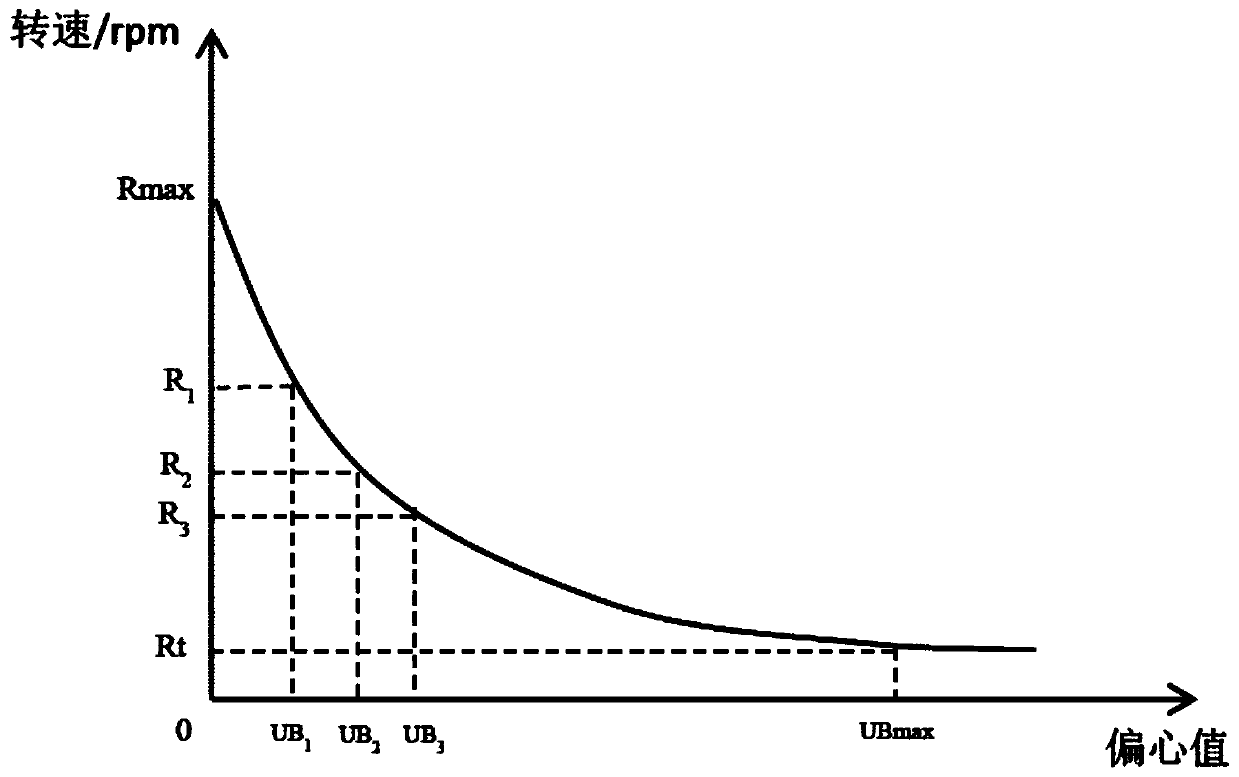

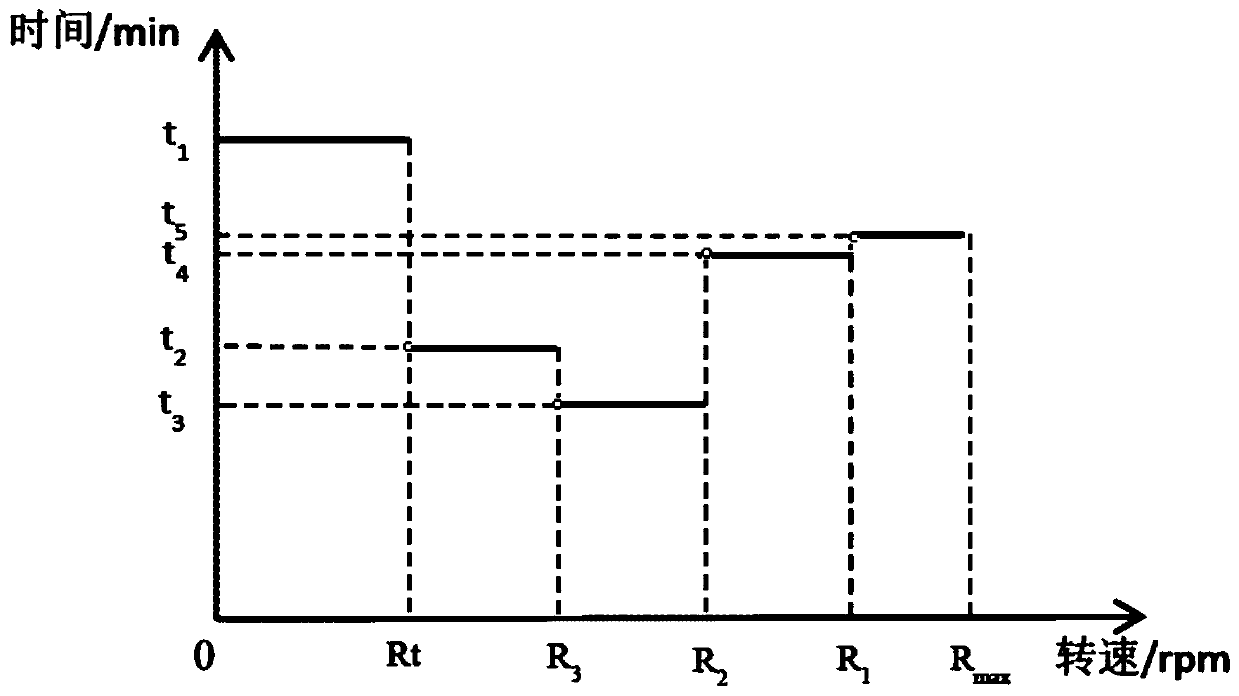

The invention belongs to the technical field of clothes treatment equipment, particularly relates to a dehydrating method of washing equipment and the washing equipment and aims at solving the problemthat an existing washing machine can carry out at least one clothes operation in the dehydrating process and the overall dehydrating efficiency of the washing machine cannot be easily ensured. For the purpose, the dehydrating method provided by the invention has the advantages that a specific dehydrating speed can be determined on the basis of an actual eccentricity value and a dehydration curveduring dehydrating rotation of a washing barrel to determine a maximum rotating speed that the washing barrel in an eccentric state can reach and to reduce the adverse effect on rotation of the washing barrel due to eccentric distribution of clothes, so that the washing barrel can execute dehydrating operation without improving the current eccentricity situation, and the washing equipment can ensure that the overall dehydrating efficiency thereof is not obviously affected by eccentricity of the washing barrel even if no leveling operation is executed.

Owner:QINGDAO HAIER WASHING MASCH CO LTD +1

Efficient sludge press

InactiveCN108640470ASqueeze fullyGuaranteed dehydration effectSludge treatment by de-watering/drying/thickeningSludge dewateringFilter strip

The invention discloses an efficient sludge press. The efficient sludge press comprises a base frame, a first filter belt, a second filter belt and a press assembly, wherein two rows of steering rollers are arranged on the base frame, each row of steering rollers are located in a straight line in the vertical direction, and the adjacent steering rollers in the horizontal direction are staggered; the first filter belt and the second filter belt clamp sludge to form combined transport belts, and the combined transport belts sequentially wind two adjacent rows of steering rollers in the horizontal direction to form an array multi-layer structure; filter plates and filter screens are arranged between the adjacent combined transport belts, the filter screens are fixed on the filter plates, andthe filter screens correspond to the combined transport belts on the upper and lower sides; the press assembly is arranged above the base frame in a lifting manner and corresponds to the filter screens. The sludge press in the embodiment has a simple structure, reduces the production and manufacturing cost, has high sludge press efficiency, and improves sludge dewatering effect.

Owner:三谷中识先进技术(无锡)有限公司

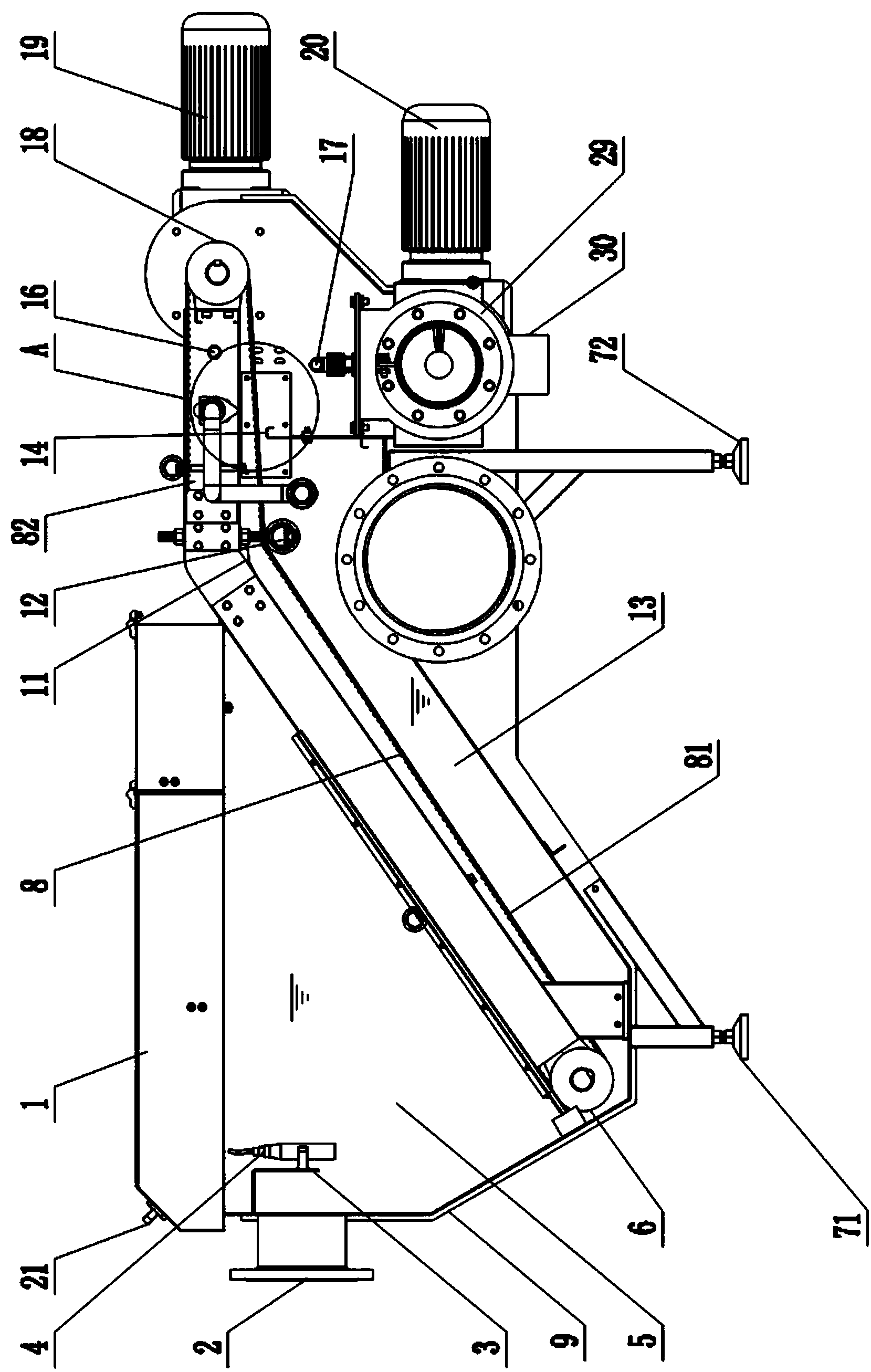

Ultrahigh-power ultrasonic dirty oil demulsification and dehydration plant

ActiveCN105694963AAchieve recyclingAchieve reuseTreatment with plural serial refining stagesUltrasound - actionSewage

The invention discloses an ultrahigh-power ultrasonic dirty oil demulsification and dehydration plant which comprises a dirty oil raw material tank (1). The plant is characterized in that water-containing dirty oil in the dirty oil raw material tank (1) is sent into an ultrasonic action device (5) arranged in series through a water-containing dirty oil pump (2) and is subjected to continuous ultrasonic primary demulsification; the dirty oil subjected to primary demulsification is sent into an impulse-type ultrasonic demulsification tank (6) through a pipeline and subjected to secondary demulsification; a discharge port of the impulse-type ultrasonic demulsification tank (6) communicates with a settlement separation dehydration tank (7) through a pipeline; and dehydrated dirty oil subjected to demulsification in the settlement separate dehydration tank (7) enters a finished product dirty oil tank (8) which communicates with the settlement separate dehydration tank (7) through a pipeline. The plant implements dirty oil dehydration by carrying out demulsification twice under the continuous and impulse-type ultrasonic combined actions, thereby implementing the continuous demulsification and dehydration and ensuring the dehydration effect of the dirty oil. The water content of the dehydrated dirty oil is less than 10%, and the oil content of the dehydrated sewage is less than 500 mg / L.

Owner:JIANGSU DAXUAN PETROCHEM EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com