Recycling method of excess sludge

A technology of excess sludge and treatment method, applied in the field of resource treatment of excess sludge, can solve the problems of economic waste, increase, and reduction of carbon source organic matter, etc., and achieve the effect of small transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

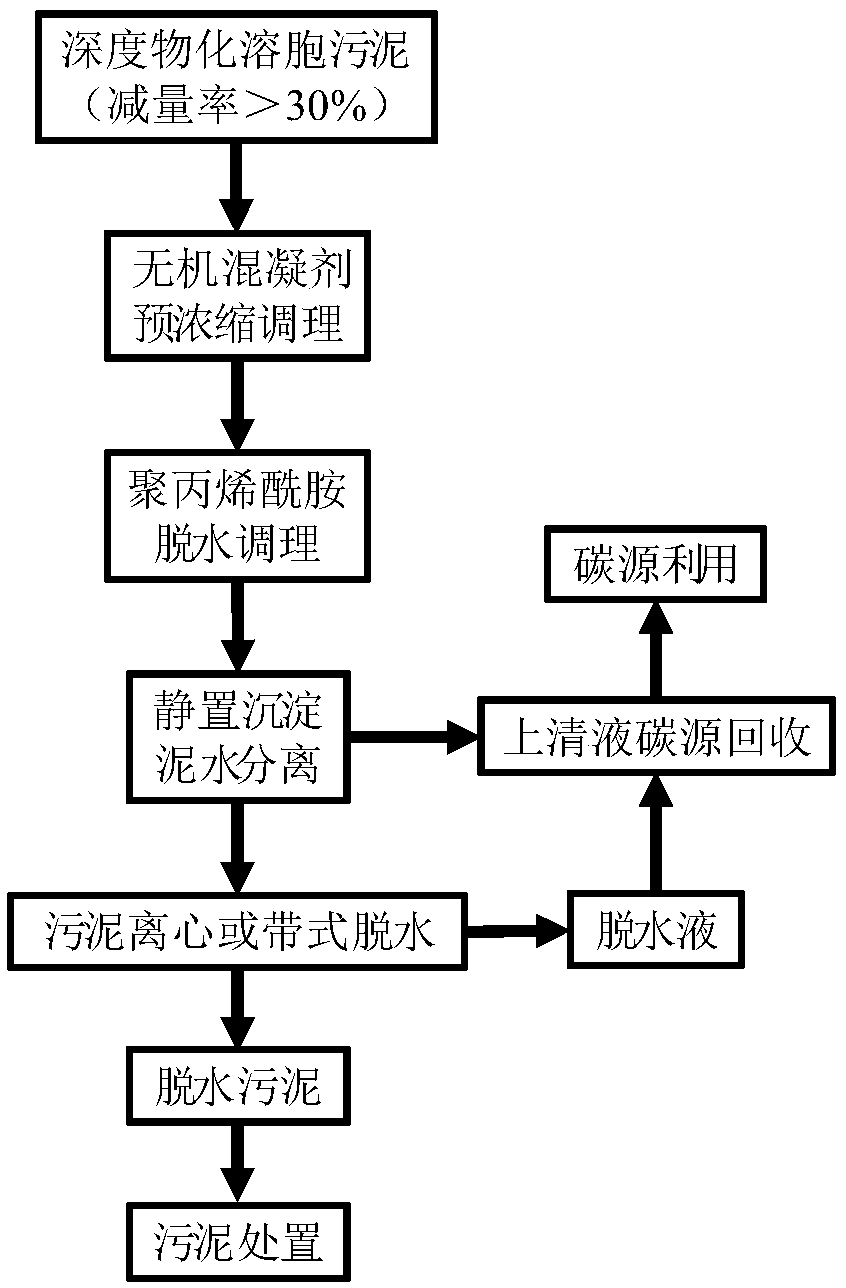

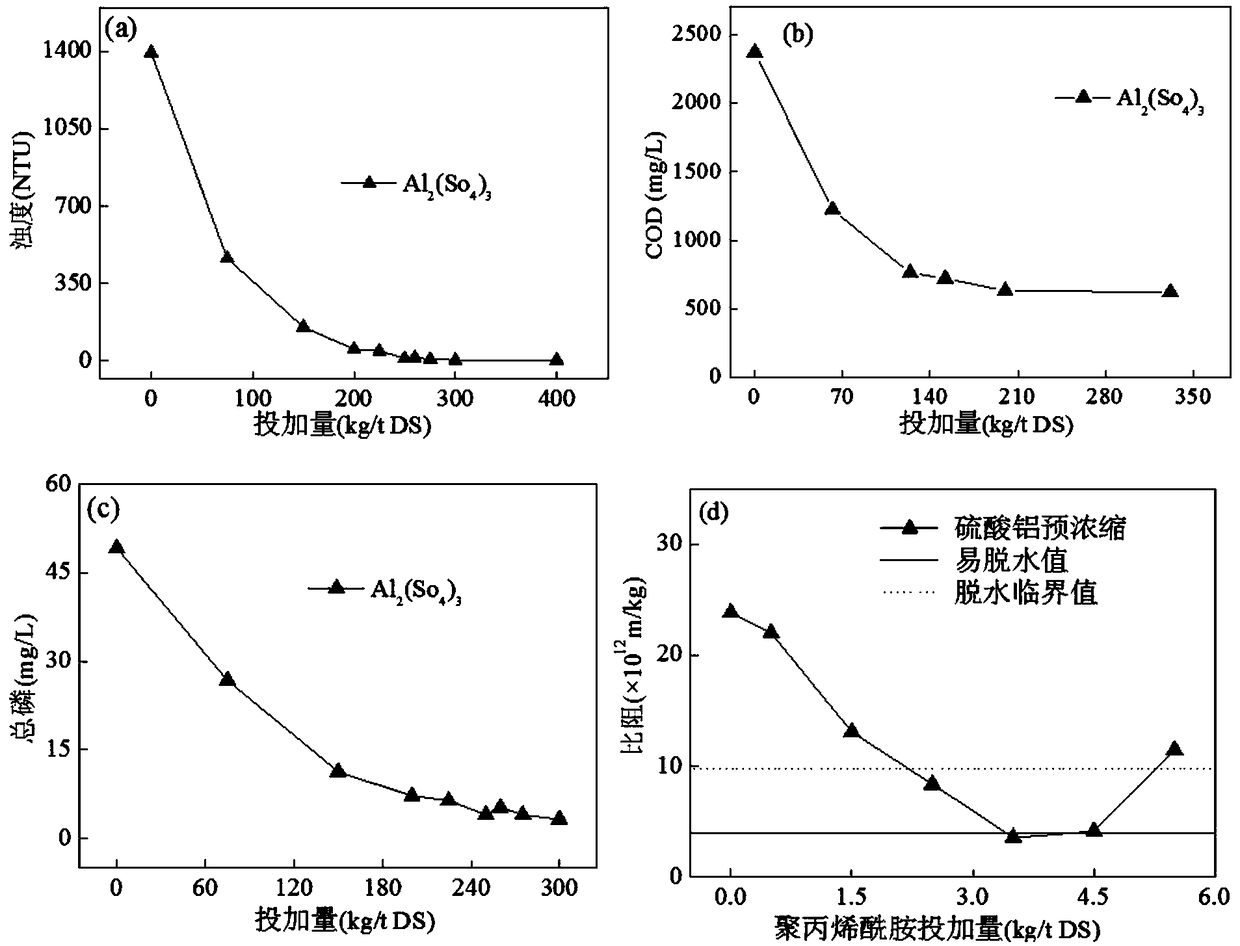

[0047] refer to figure 1 The treatment process, the concentration of 8.5g / L of excess sludge first ozone concentration of 55.1mg O 3 / gSS response. It can be seen from Table 1 that the sludge concentration after 6 hours of ozone reaction is 2.79g / L, and the reduction rate reaches 67.2%. The SS of the sludge supernatant after deep ozone oxidation is as high as 1.38g / L, accounting for 49.5% of the SS of the sludge mixture, indicating that nearly half of the total solids of the sludge after ozone oxidation are suspended, and the sedimentation performance is poor. And cannot be removed by gravity settling. The sludge after deep ozone oxidation is treated with aluminum sulfate pre-concentration and polyacrylamide dehydration. figure 2 It can be seen that under the condition that the dosage of aluminum sulfate is 250kg / t DS, the turbidity of the sludge supernatant is reduced from 1395NTU to 9.7NTU, the COD is reduced from 2368mg / L to 630.4mg / L, and the total phosphorus is reduce...

Embodiment 2

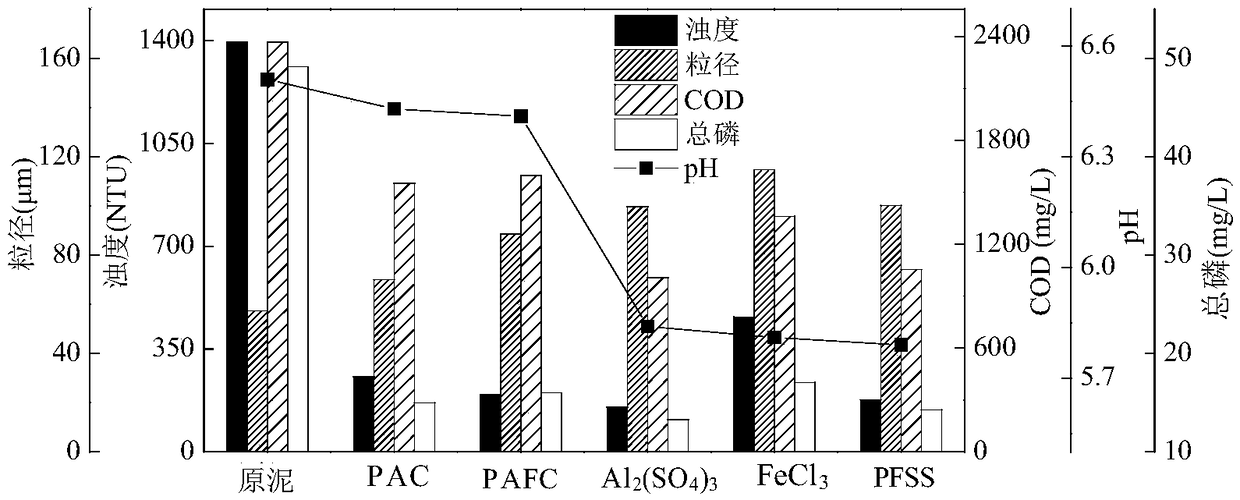

[0053] refer to figure 1 According to the treatment process, the residual sludge with a concentration of 12.1g / L was first subjected to deep ultrasonic crushing treatment, and the characteristics of the crushed sludge were shown in Table 2. It can be seen from Table 2 that the sludge concentration after ultrasonication is 5.06g / L, and the reduction rate reaches 58.2%. For deep ultrasonic crushing sludge, PAFC, PAC, Al 2 (SO 4 ) 3 , FeCl 3 Dosing amount with PFSS (dosing amount is 90.3, 148.7, 82.7 and 122.3kg / t DS respectively), the results are as attached image 3 shown. attached by image 3 It can be seen that COD, turbidity and total phosphorus of all sludge supernatants pre-concentrated by inorganic coagulants were significantly reduced. Among them, the effect of aluminum sulfate pre-concentration is better, the total phosphorus is reduced to 13.2mg / L, the turbidity is 152NTU, and the COD is 1007.3mg / L. After further dehydration and conditioning, it can meet the req...

Embodiment 3

[0058] Compared with Example 1, most of them are the same, except in this example: the concentration of excess sludge is 5g / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com