A kind of oxidized hydroxypropyl carboxymethyl starch slurry and preparation method

A technology for oxidizing hydroxypropyl carboxymethyl and starch slurry, which is applied in textiles and papermaking, fiber processing, plant fibers, etc., can solve problems such as no hydroxypropyl carboxymethyl starch sizing that has not been seen, and achieve low cost. , Improve sizing performance, good viscosity stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

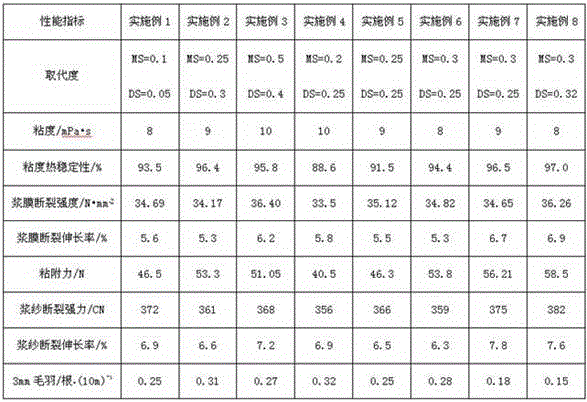

Examples

Embodiment 1

[0017] The preparation method of the oxidized hydroxypropyl carboxymethyl starch slurry of the present embodiment, the steps are as follows:

[0018] (1) Add 95g of cornstarch and 2g of urea to 160mL of 80% ethanol aqueous solution, stir evenly, then add 2g of sodium hydroxide, and carry out alkalization reaction at 25°C for 35min;

[0019] (2) Add 5g of propylene oxide after alkalization, raise the temperature to 60°C, stir well and carry out etherification reaction for 10h, after the reaction, cool down to 50°C, and then add 0.1g of 50% H 2 o 2 Oxidation reaction 55min;

[0020] (3) Add 5g of chloroacetic acid after the oxidation reaction, raise the temperature to 65°C for 135 minutes, cool down to 35°C after the reaction, wash, filter with suction, dry at 80°C, and pulverize to obtain the product.

Embodiment 2

[0022] The preparation method of the oxidized hydroxypropyl carboxymethyl starch slurry of the present embodiment, the steps are as follows:

[0023] (1) Add 105g of cornstarch and 15g of urea to 200mL of 95% ethanol aqueous solution, stir evenly, then add 10g of sodium hydroxide, and carry out alkalization reaction at 35°C for 25 minutes;

[0024] (2) Add 40g of propylene oxide after alkalization, raise the temperature to 75°C, stir evenly and carry out etherification reaction for 8 hours, cool down to 55°C after the reaction, and then add H 2 o 2 Oxidation reaction 1h;

[0025] (3) Add chloroacetic acid after the oxidation reaction, raise the temperature to 75°C for 2 hours, cool down to 40°C after the reaction, wash, filter with suction, dry at 80°C, and pulverize to obtain the product.

Embodiment 3

[0027] An oxidized hydroxypropyl carboxymethyl starch slurry, which is made of the following raw materials in parts by weight: 95-105 parts of corn starch, 3-15 parts of urea, 160-200 parts of ethanol aqueous solution, sodium hydroxide 2~10 parts, 5~40 parts of propylene oxide, H 2 o 2 0.1~2 parts, 5~10 parts of chloroacetic acid; the hydroxypropyl substitution degree (MS) of the oxidized hydroxypropyl carboxymethyl starch slurry is 0.1~0.5, and the carboxymethyl substitution degree (DS) is 0.05~0.40, The viscosity is 5~20 mPa•s.

[0028] The preparation method of the oxidized hydroxypropyl carboxymethyl starch slurry of the present embodiment, the steps are as follows:

[0029] (1) Add 100g of cornstarch and 8g of urea to 180mL of 85% ethanol aqueous solution, stir evenly, then add 5g of sodium hydroxide, and carry out alkalization reaction at 30°C for 30 minutes;

[0030] (2) Add propylene oxide after alkalization, raise the temperature to 70°C, stir evenly and carry out ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com