Patents

Literature

1663 results about "Breakage rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The breakage rate of a program is an important indicator of member engagement. A low breakage rate indicates that members find their points valuable and are eager to spend them. A high breakage rate could mean that rewards are unachievable and/or undesirable. Breakage rate is also used to calculate the outstanding points liability for a program.

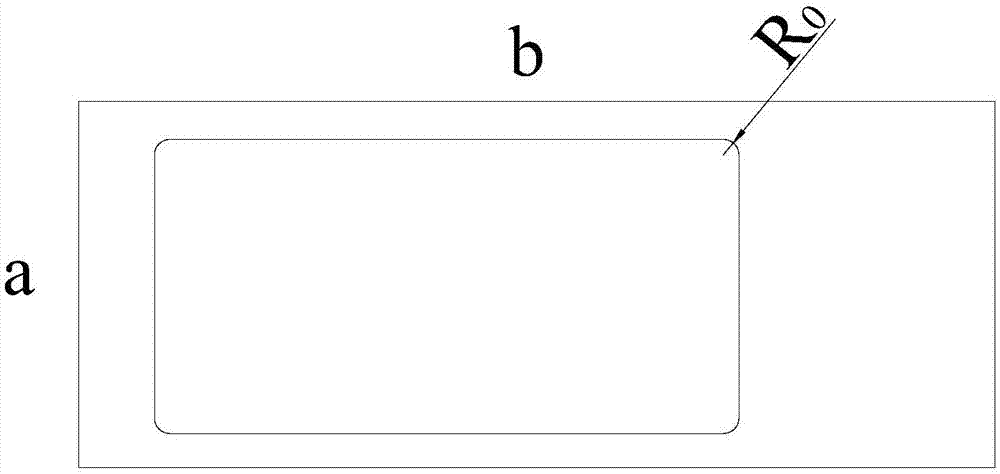

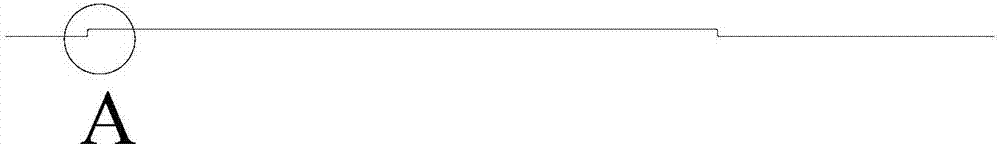

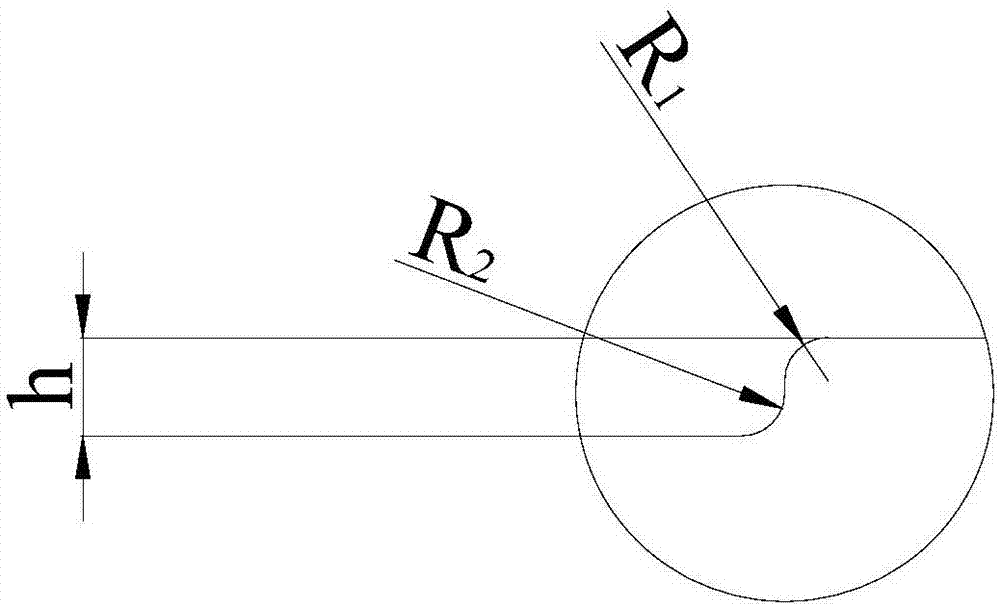

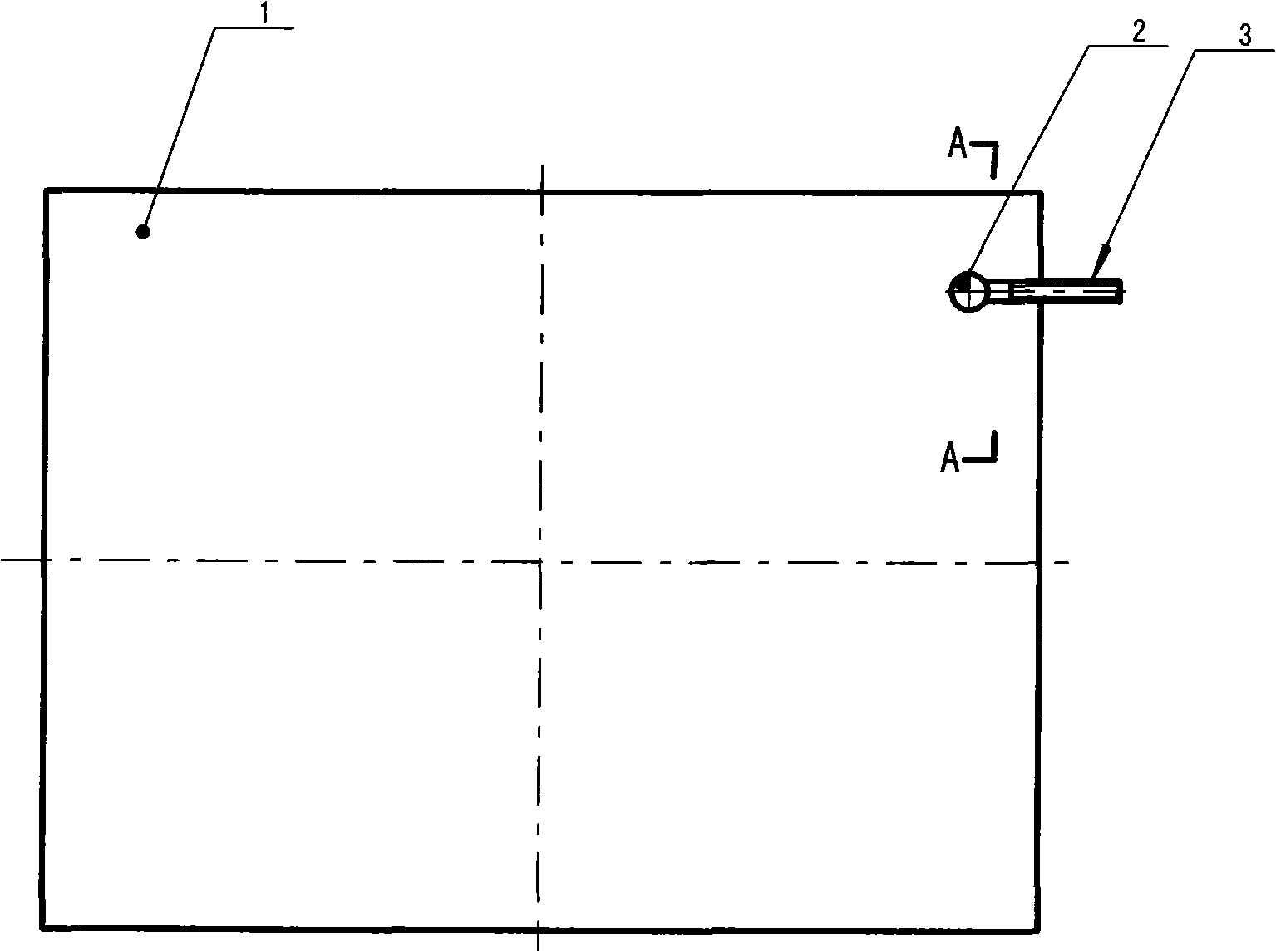

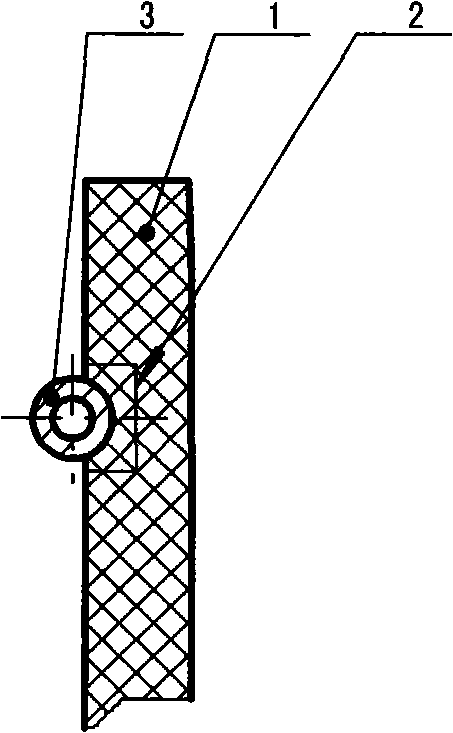

Packaging method for high-capacity polymer lithium ion cells

InactiveCN107394279AControl thicknessGuaranteed electrical performanceFinal product manufactureElectrolyte accumulators manufactureLithiumBreakage rate

The invention discloses a packaging method for high-capacity polymer lithium ion cells. The packaging method comprises the following steps: (1) a bag is formed from at least one of two aluminum plastic films by stamping; when the thickness of a cell is smaller than 6 mm, one bag is formed from one aluminum plastic film by stamping, and when the thickness of a cell is larger than or equal to 6 mm, bags are formed from the two aluminum plastic films by stamping; (2) the cell is loaded into an opening of the bag formed from one aluminum plastic film by stamping, and the opening of the bag is correspondingly covered with the other aluminum plastic film; (3) three edges of the cell are sealed in a hot manner with seal heads. With adoption of the packaging method for the high-capacity polymer lithium ion cells, the breakage rate of the aluminum plastic films is reduced, the aluminum plastic film use efficiency is increased, and electrical performance of the high-capacity polymer lithium ion cells can be guaranteed effectively; the packaging method is simple to operate.

Owner:海口博澳国兴新能源科技有限公司

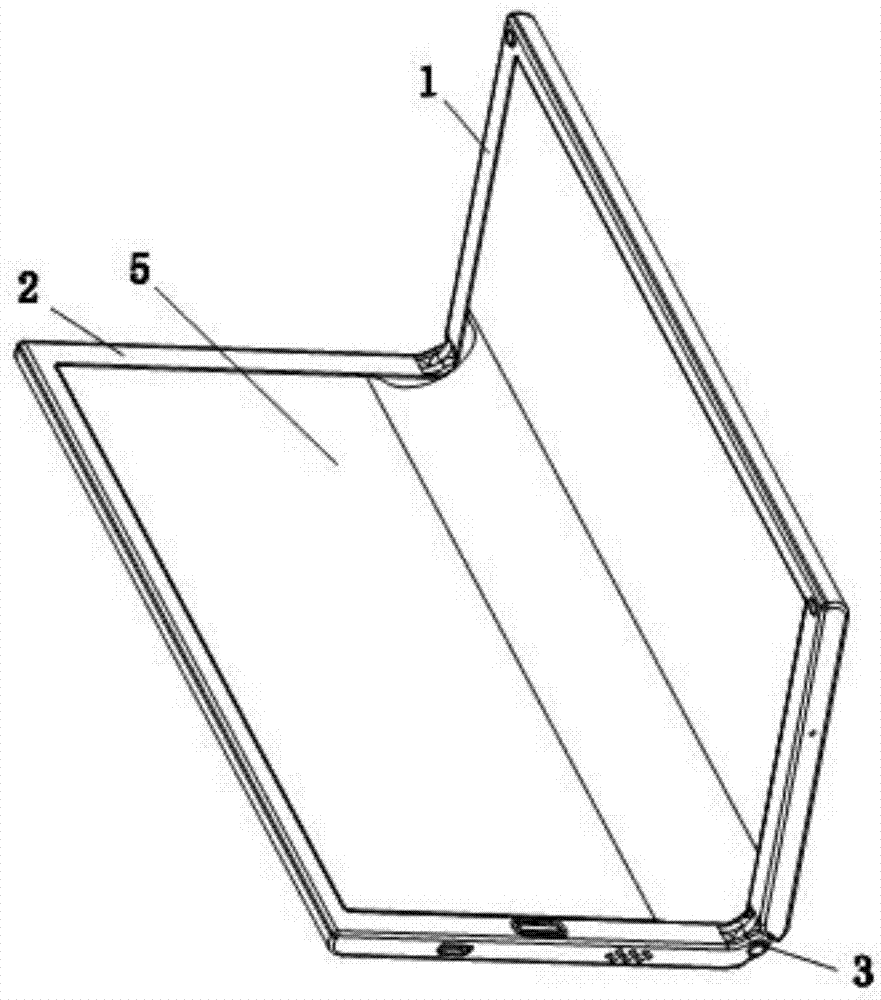

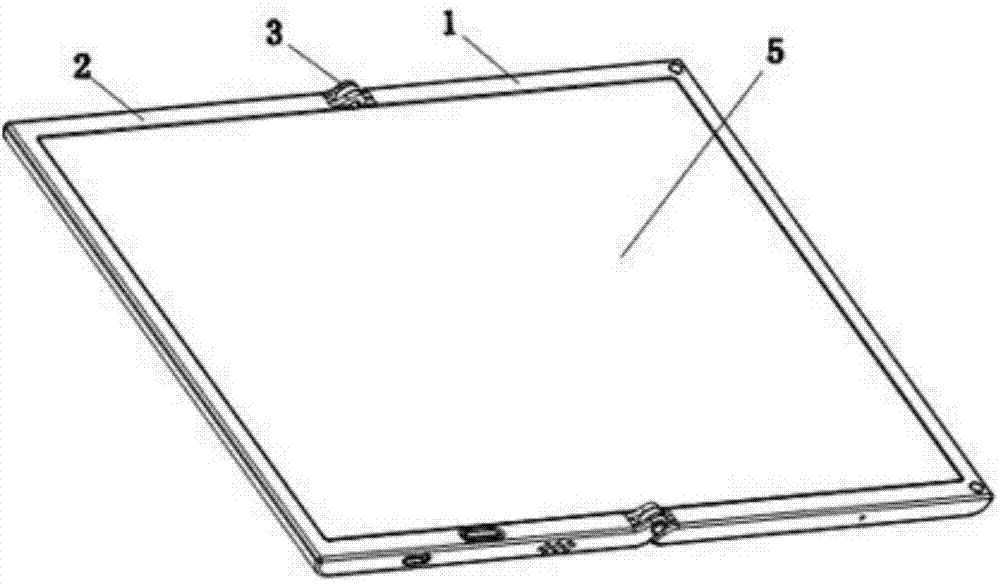

Folding mobile terminal

ActiveCN104506688AExtended service lifeReduce breakageTelephone set constructionsBreakage rateEngineering

The invention discloses a folding mobile terminal. The folding mobile terminal is used to reduce breakage rate of a flexible screen, and then use life of the folding mobile terminal is prolonged. The folding mobile terminal comprises an upper housing and a lower housing which are arranged in hinged mode, and the flexible screen which is arranged on the folding inner side faces of the upper housing and the lower housing, wherein an upper containing cavity is formed in an area on the upper housing, close to the hinged axis, and a lower containing cavity is formed in an area on the lower housing, close to the hinged axis. When the folding mobile terminal is folded, the upper containing cavity is opposite to the lower containing cavity, a bending portion of the flexible screen is contained in the upper containing cavity and the lower containing cavity. Due to the fact that the bending portion of the flexible screen can be contained in the upper containing cavity and the lower containing cavity when the folding mobile terminal is folded, the bending radius can be kept large. By adopting the technical scheme, the rate of breakage of the flexible screen, caused by the large bending angle, can be greatly reduced, and therefore the use life of the folding mobile terminal is greatly prolonged.

Owner:BOE TECH GRP CO LTD

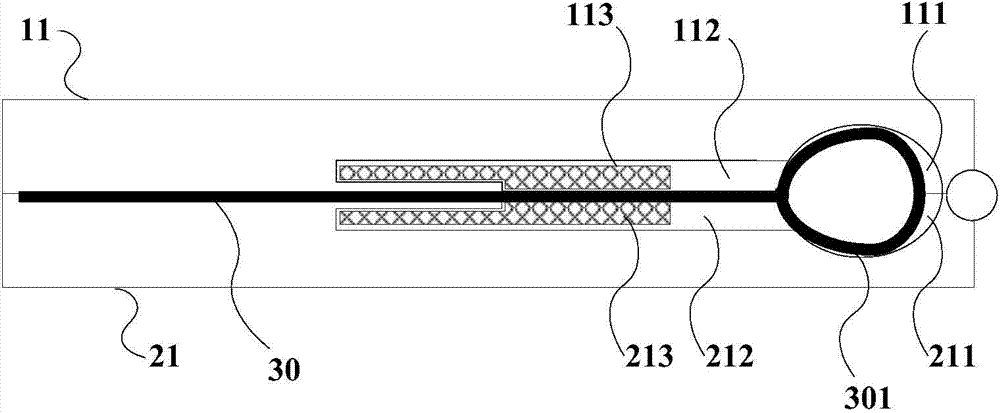

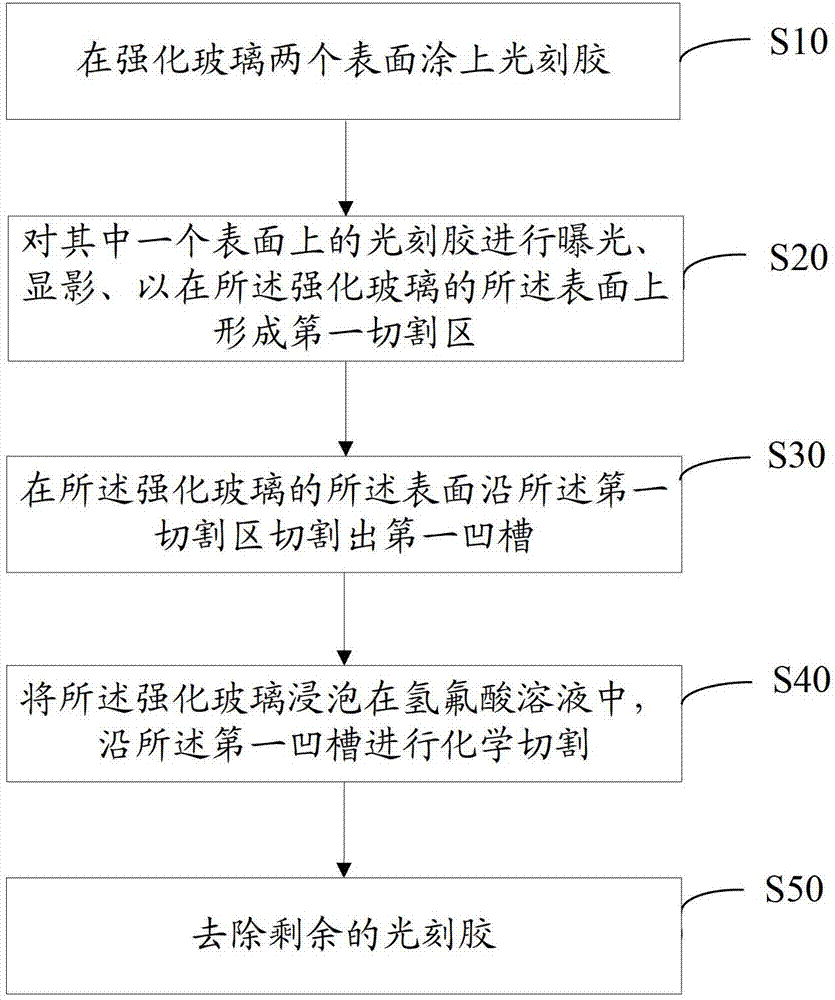

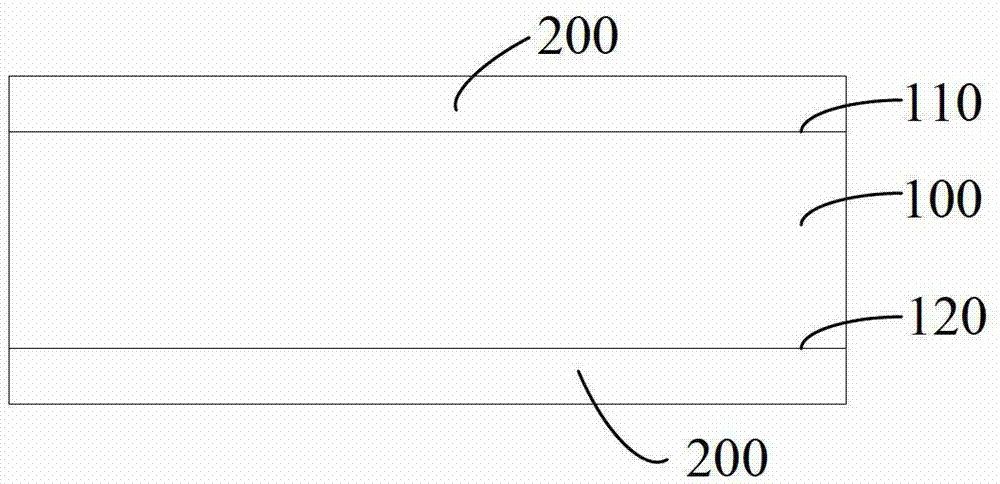

Method for cutting tempered glass

ActiveCN102923939AReduce breakage rateHigh compressive strengthGlass severing apparatusGlass productionPhotoresistBreakage rate

The invention provides a method for cutting tempered glass. The method comprises the following steps of: coating photoresist on two surfaces of the tempered glass, and performing exposure and developing on the photoresist on one surface, so that a first cutting area is formed on the surface of the tempered glass; cutting a first groove on the surface of the tempered glass along the first cutting area; soaking the tempered glass in a hydrofluoric acid solution, and performing chemical cutting along the first groove; and removing the residual photoresist. According to the method, the tempered glass is cut by using the hydrofluoric acid solution, and the edge of the tempered glass is smoothed, so that the compressive strength on the edge of the tempered glass is improved, the breakage rate of the cut tempered glass is reduced, and the production efficiency is improved.

Owner:WGTECH JIANGXI

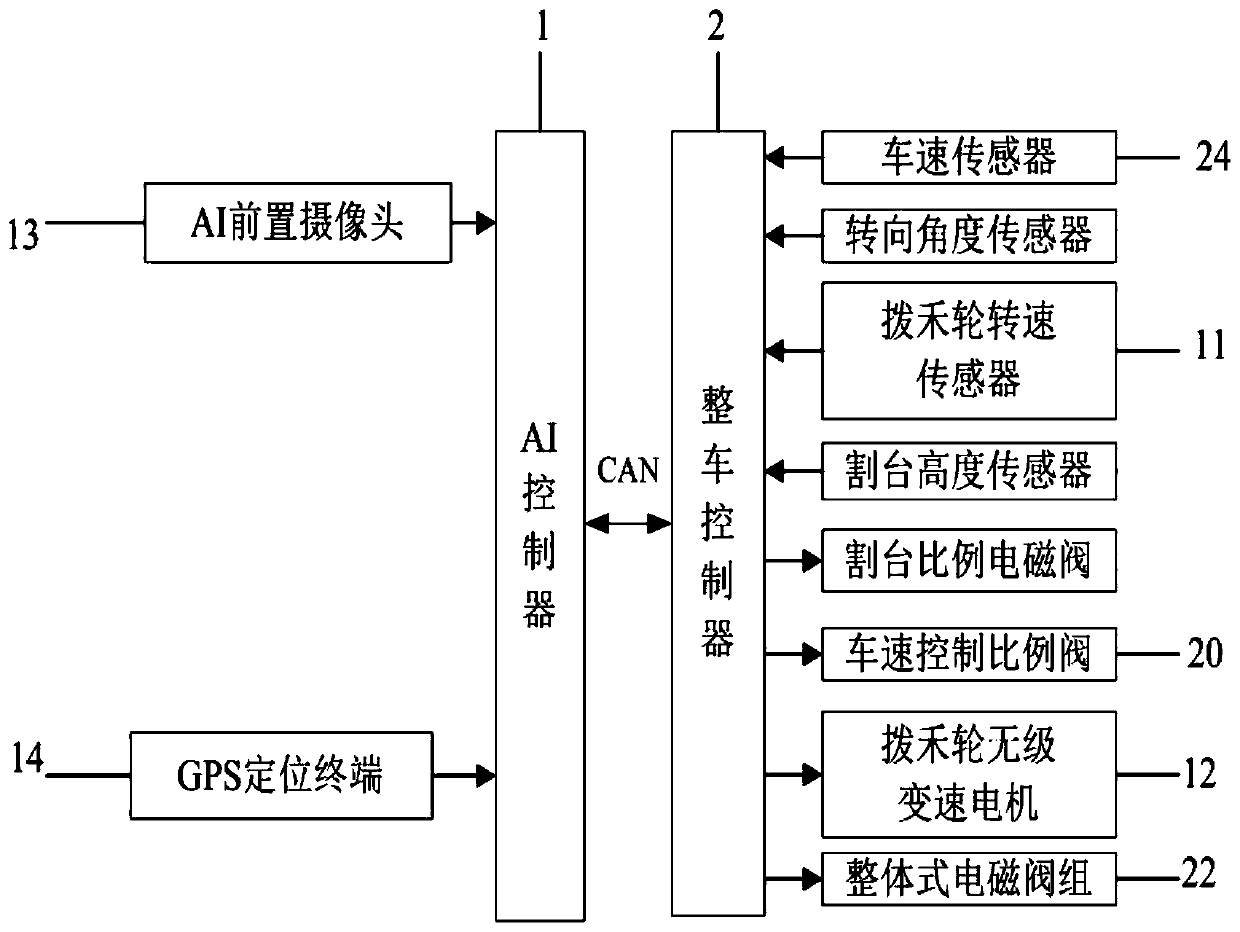

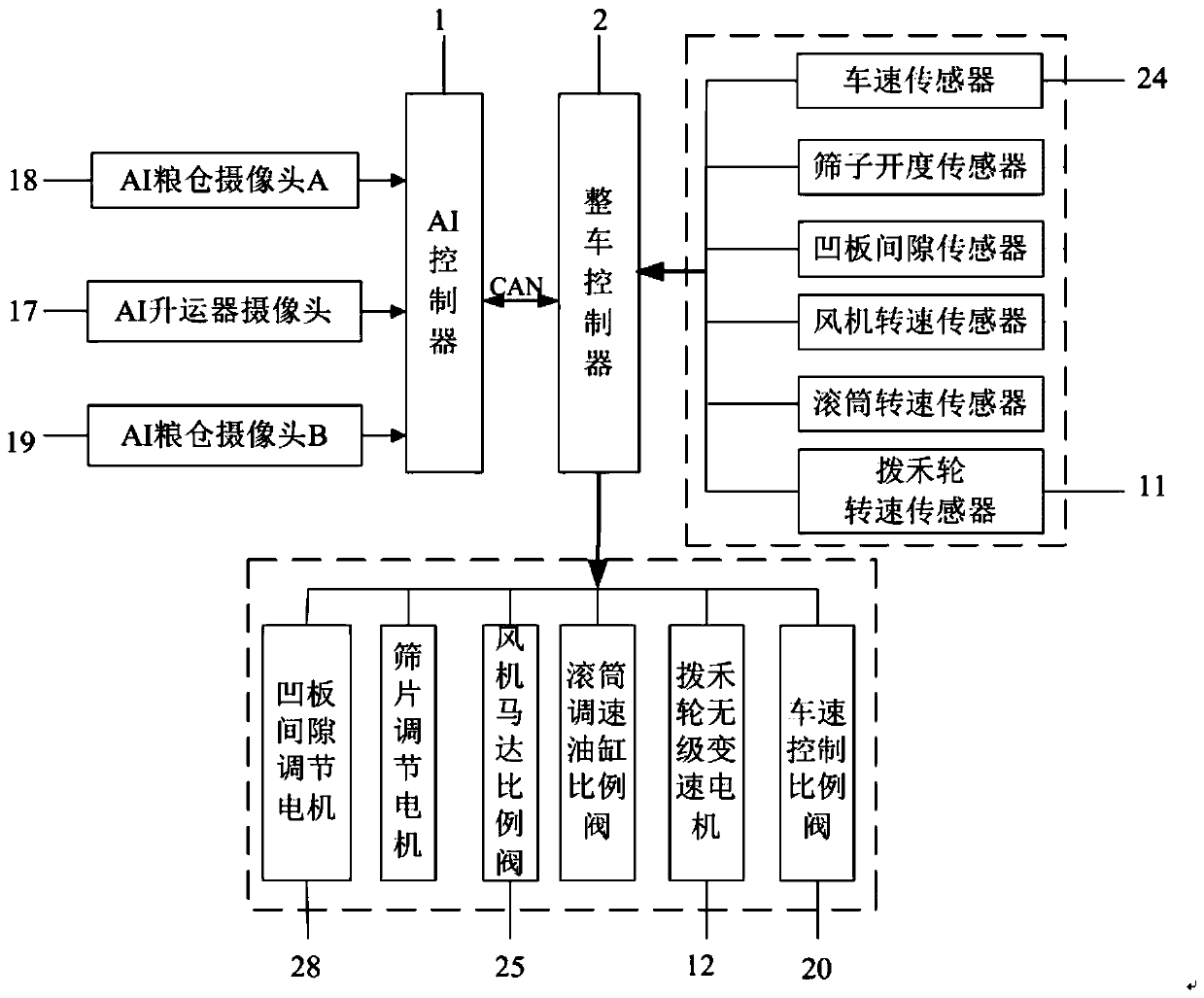

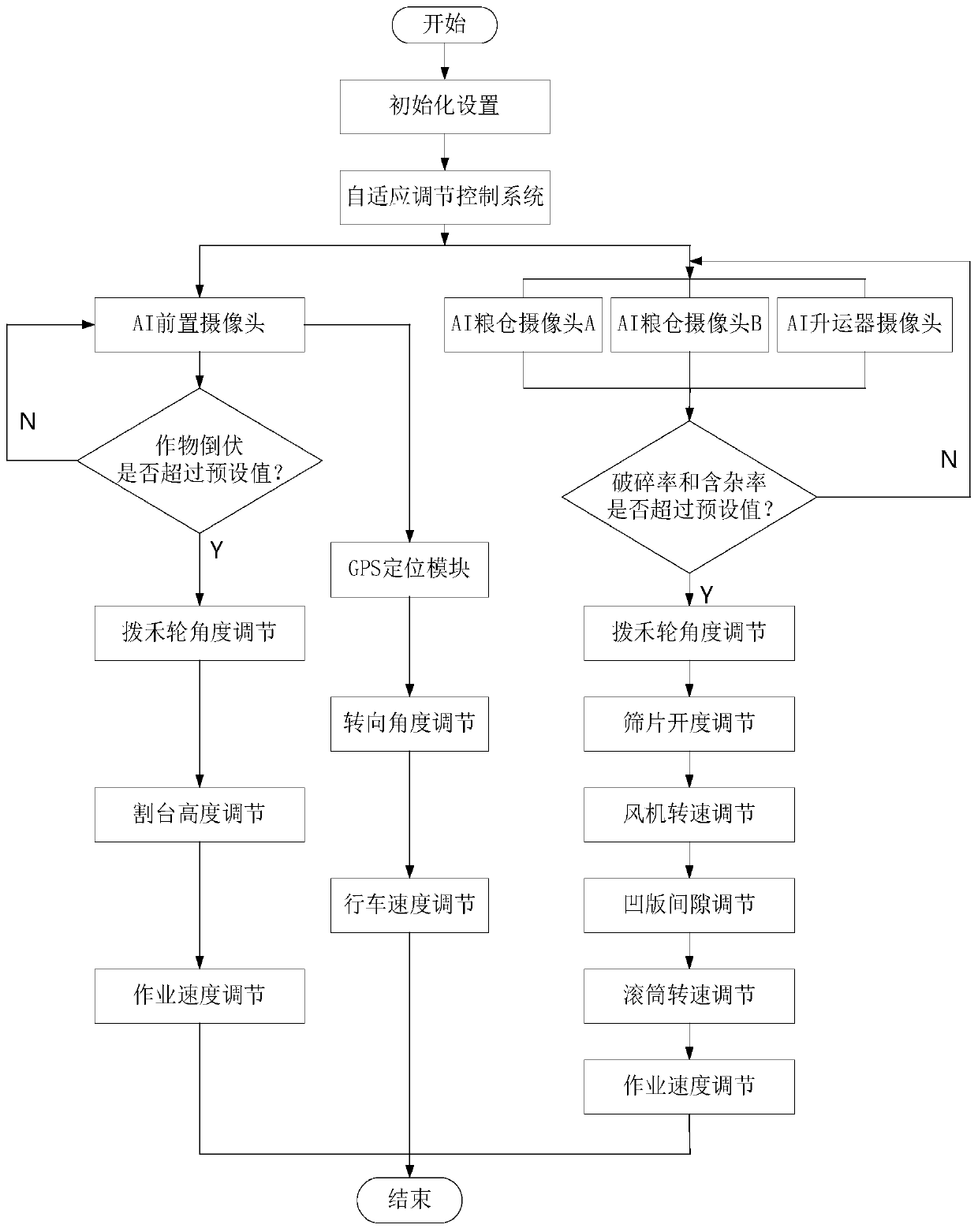

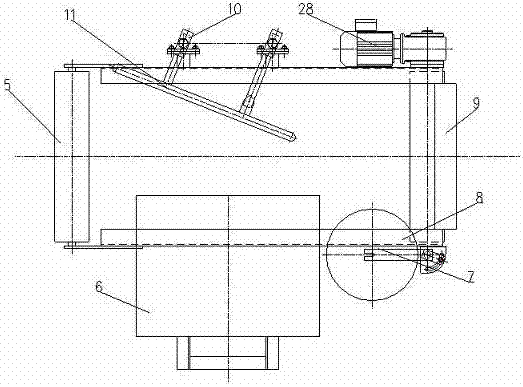

Intelligent regulating system for grain harvesters and control method thereof

PendingCN110720302AGuarantee the quality of workImprove work efficiencyMowersControl cellBreakage rate

The invention relates to an intelligent regulating system for grain harvesters and a control method thereof; an AI (artificial intelligence) control unit calculates grain impurity rate and breakage rate according to image information acquired by a grain bin camera and an elevator camera; when the impurity rate and the breakage rate exceed a set threshold, required matching values, including opening of a screen, gaps of a concave plate, rotating speed of a roller, rotating speed of a fan, rotating speed of a reel and operating speed are judged, and the required matching values are sent to a vehicle control unit; the vehicle control unit correspondingly adjusts the opening of the screen, the gaps of the concave plate, the rotating speed of the roller, the rotating speed of the fan, the rotating speed of the reel and the operating speed to arrive at the required matching values. The intelligent regulating system for grain harvesters is simple in structure and convenient to operate, and the operation quality and efficiency of the harvesters are effectively guaranteed.

Owner:ZOOMLION HEAVY MASCH CO LTD

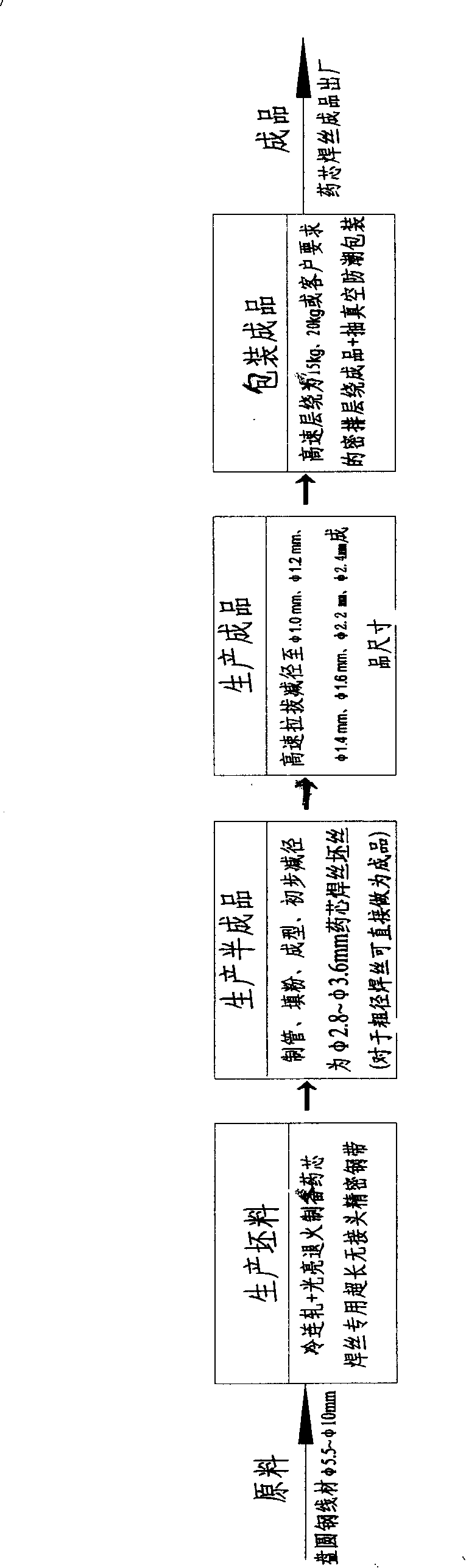

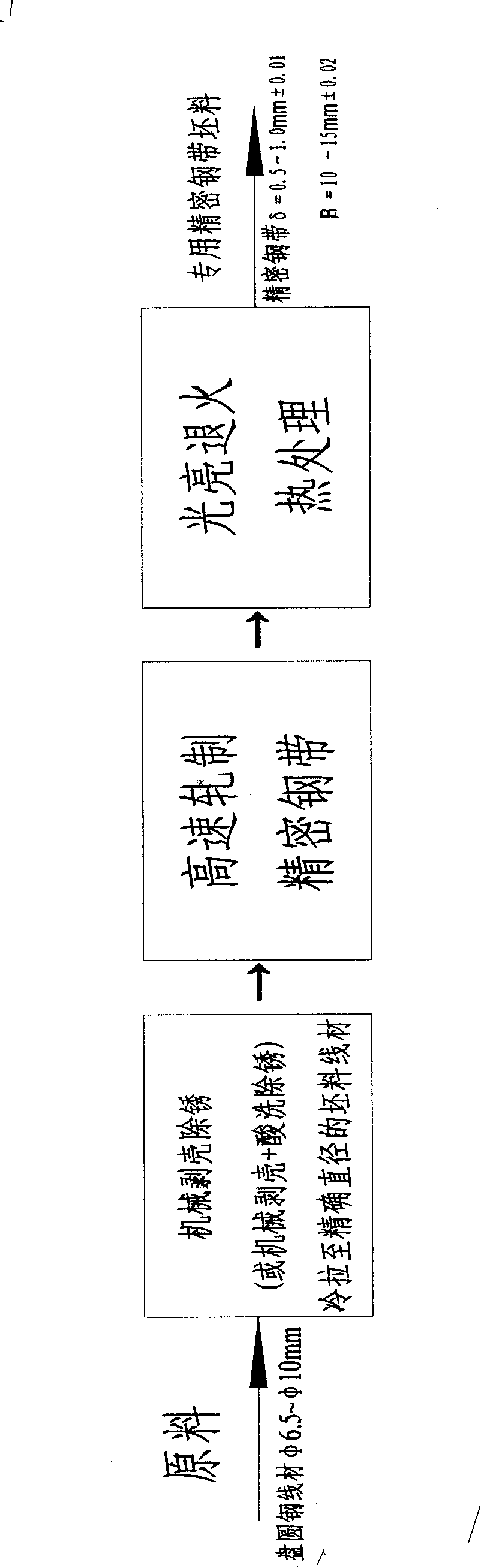

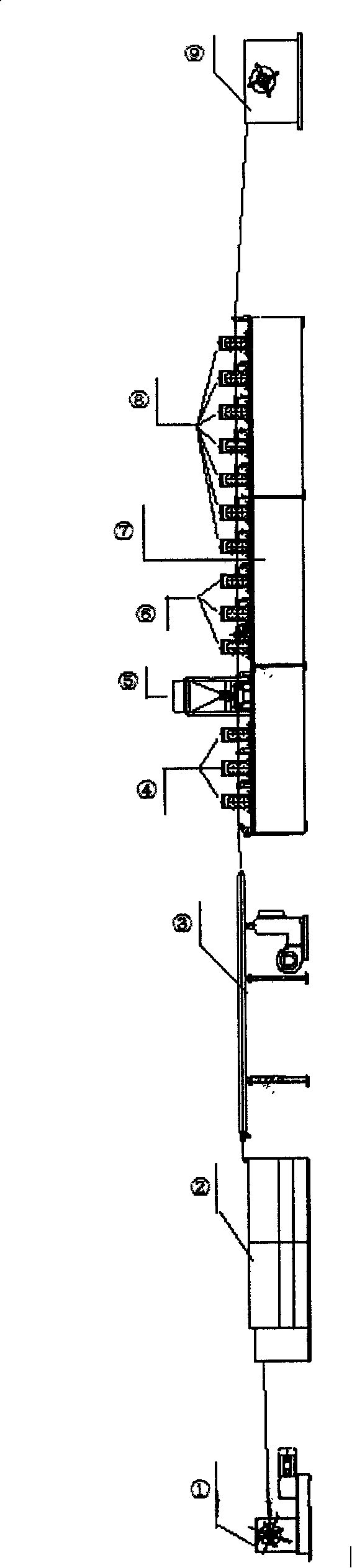

Technique for manufacturing flux-cored wire from disk round steel wire bar

InactiveCN101239430ASufficient bending radiusPrevent space warpingFurnace typesRollsFill rateBreakage rate

A technique for producing flux-cored wires by using disc round steel wire bars is characterized by comprising following steps: using disc round steel wire bars as raw materials; producing accurate steel bands used for flux-cored wires exclusively; producing semi-finished products which are flux-cored wire blank tubes by using accurate steel bands; producing termination products by drafting to reduce the diameter thereof with a high speed; packaging the termination products by winding with a high speed. The advantages of the invention are: the invented technique uses high-speed hot-rolling disc round steel wire bars to replace broad cold-rolled steel strip, so that the raw material cost is reduced greatly; the continuous overlong endless accurate steel bands are used to save assistant procedure time for welding steel band joints, reduce end breakage rate during rolling and drafting procedures, improve continuous operation rate, and further reduce production cost; the invented technique uses high-speed accurate cold tandem rolling machine group to solve the problem that the sheet iron rolling precision is difficult to be controlled when rolling flux-cored wires by using disc round steel wire bars directly, and the filling precision is improved greatly since size accuracy of the flux-cored wire exclusive use accurate steel bands is high.

Owner:TIANJIN SAINTEAGLE WELDING CO LTD

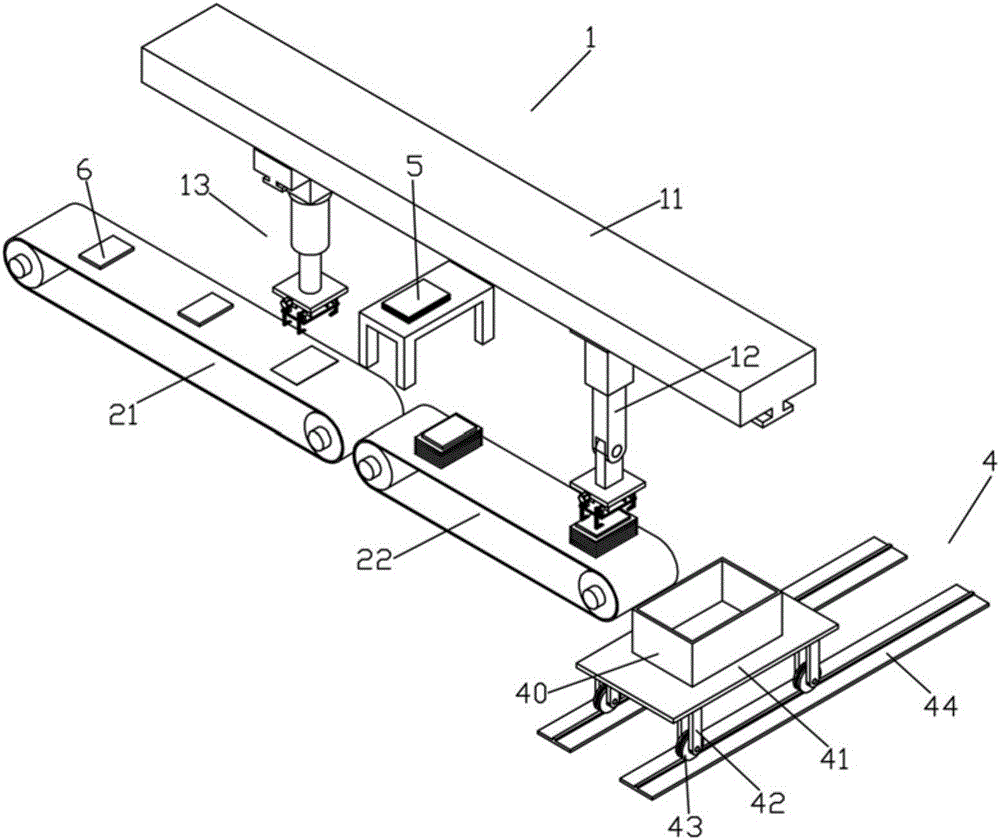

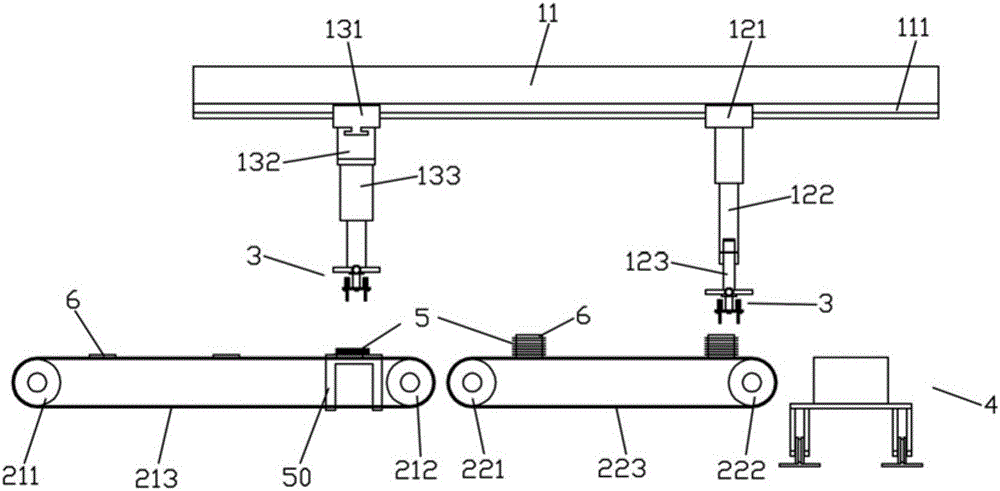

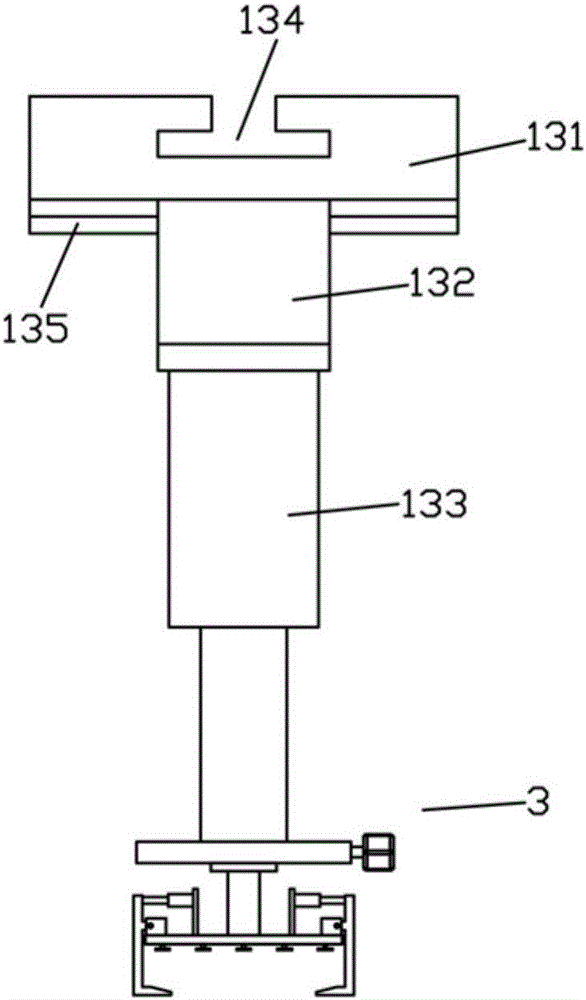

Architectural glass encasement device

ActiveCN105668235AReduce breakage rateEfficient handlingConveyorsCharge manipulationArchitectural glassProduction line

The invention discloses an architectural glass encasement device. The architectural glass encasement device comprises a stacking and packaging unit, a conveying unit, a finished product conveying unit, a protective layer supplying unit and a control unit, wherein the control unit is electrically connected to the stacking and packaging unit, the conveying unit and the finished product conveying unit and guarantees that each unit can complete corresponding operation on architectural glass. The architectural glass is conveyed to the conveying unit through a production line, and the stacking and packaging unit carries out stacking before encasing and encasing after stacking. According to the encasement device, carrying, packaging-protecting and stacking-encasing of the glass can be carried out efficiently and quickly, workers are prevented from working for a long time, the labor force is liberated greatly, the production efficiency is improved, the production cost is lowered, the breakage rate of the architectural glass is lowered, and the work accidents of the workers are greatly reduced.

Owner:YANGZHOU STRVALUE INFORMATION TECH CO LTD

Method for producing instant straight rice vermicelli

The invention discloses a method for producing instant straight rice vermicelli, and belongs to the technical field of food processing. The rehydration property and eating quality of the instant straight rice vermicelli are improved on the basis of a one-step aging method, as well as strong cavatition and a uniform inner-outer drying effect during cooperative drying of ultrasonic wave and medium-short wave infrared rays. The method mainly comprises the following steps: by selecting early indica rice as raw materials, performing immersing, crushing, flour stirring, dual-screw extrusion, aging, re-steaming and washing, and then performing cooperative drying through the ultrasonic wave and medium-short wave infrared rays to obtain the instant straight rice vermicelli which is low in breakage rate, excellent in rehydration property and good eating quality.

Owner:XUZHOU NAILI MACROMOLECULE TECH CO LTD

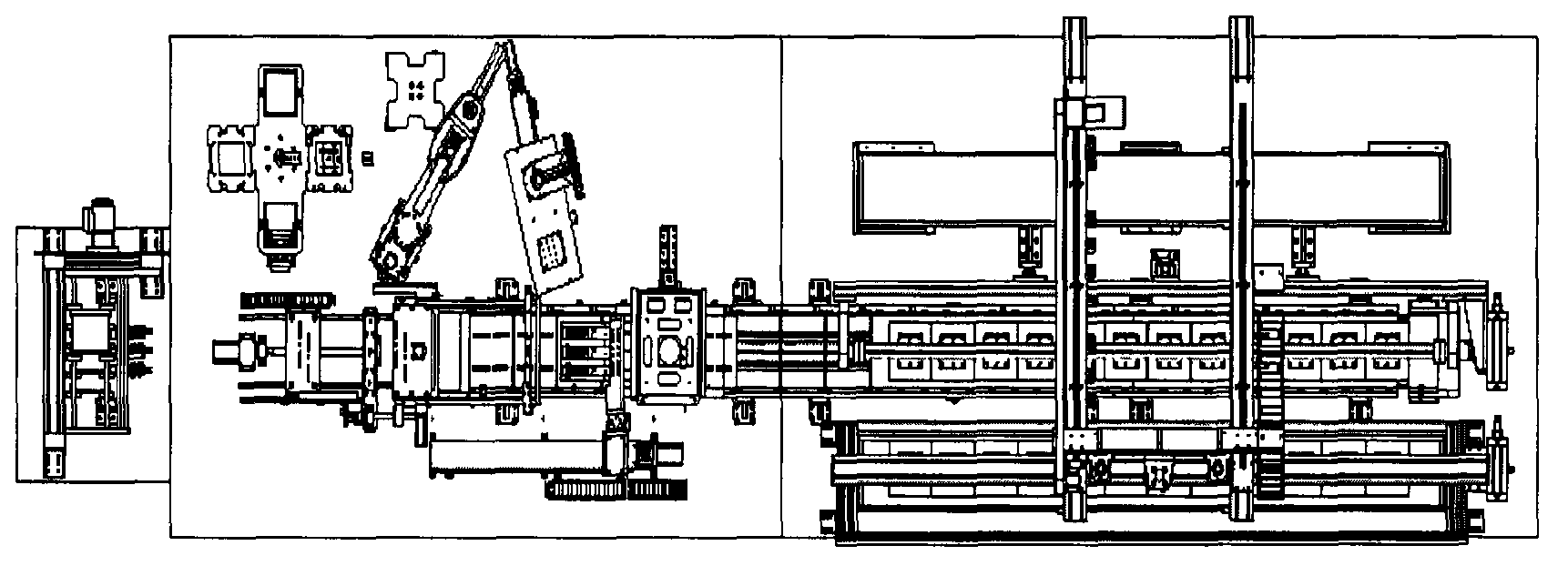

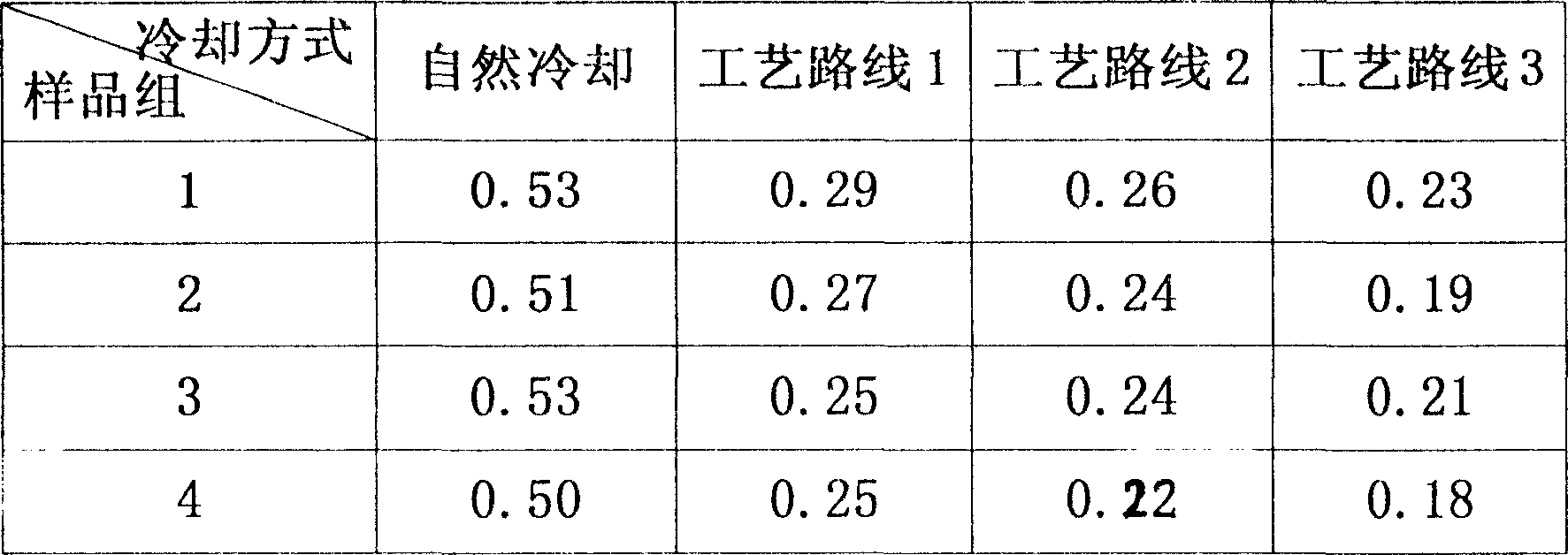

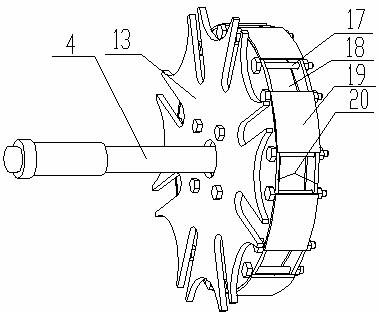

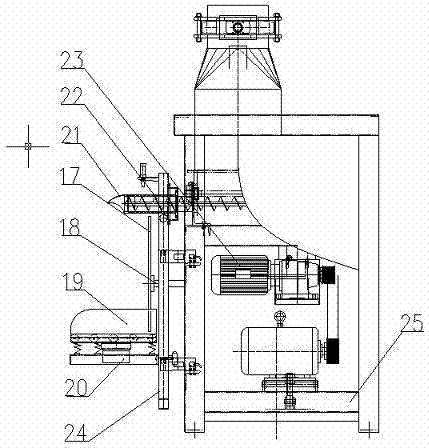

Automatic series welding machine for photovoltaic crystalline silicon cell pieces with radians

ActiveCN104139272AIncrease productivityReduce Fragmentation RateWelding/cutting auxillary devicesAuxillary welding devicesControl systemMicrometer

An automatic series welding machine capable for photovoltaic crystalline silicon cell pieces with radians is composed of a welding strip supply system, a loading system, a conveying system, a discharging system and a control system; the welding strip supply system comprises a welding strip feeding mechanism, a welding strip processing mechanism, a welding strip traction mechanism and a welding strip pressing mechanism; the loading system comprises a rotary loading mechanism, a jacking mechanism, a high-speed robot and a CCD detection system; the conveying system comprises a conveying mechanism, a tensioning mechanism and a welding mechanism; the discharging system comprises a cell string turnover mechanism, a cell string transferring mechanism and a drawer type discharging mechanism; the control system comprises a cantilever type touch screen computer, a Mitsubishi PLC, a circuit system and a gas path system. According to the actual measurement, the machine can weld the cell pieces with the length of 120 micrometers to 200 micrometers, the highest production efficiency can reach 800 pieces / hour, the breakage rate is smaller than 0.3 percent, and the length precision of a cell string can reach + / - 1 mm.

Owner:WUXI AUTOWELL TECH

Technology for producing citrus juice sac through peeling and capsule dressing removal of whole fruits

InactiveCN102488151AAvoid damageConserve waterVegetable peelingFood preparationLoss rateBreakage rate

The invention discloses a technology for producing a citrus juice sac through the peeling and the capsule dressing removal of whole fruits. The technology comprises the following steps: 1, grinding the fruits or scratching peels; 2, blanching or carrying out compound enzyme processing; 3, carrying out peeling and capsule dressing removal of the whole fruits; 4, carrying out dispersion and impurity removal of the whole fruits; 5, blend-mixing; 6, disinfecting and killing enzymes; and 7, carrying out aseptic loading. According to the invention, fruit grinding or peel scratching preprocessing is adopted, a whole fruit enzyme method is adopted to peel and remove capsule dressings, a whole fruit improvement acid-alkali method is adopted to remove the capsule dressings, and a whole fruit dispersion method is adopted to produce the citrus juice sac which is used as a raw material for a citrus juice with fleshes. The technology of the invention allows labor force to be saved by above 25%, an acid-alkali or enzyme preparation and water for the capsule dressing removal to be saved by about 30%, a raw material loss rate to be reduced by about 15%, and a juice sac breakage rate to be reduced by about 10%, so the production cost can be saved by about 20%, and the juice sac quality can be improved.

Owner:CITRUS RES INST OF CHINESE ACAD OF AGRI SCI

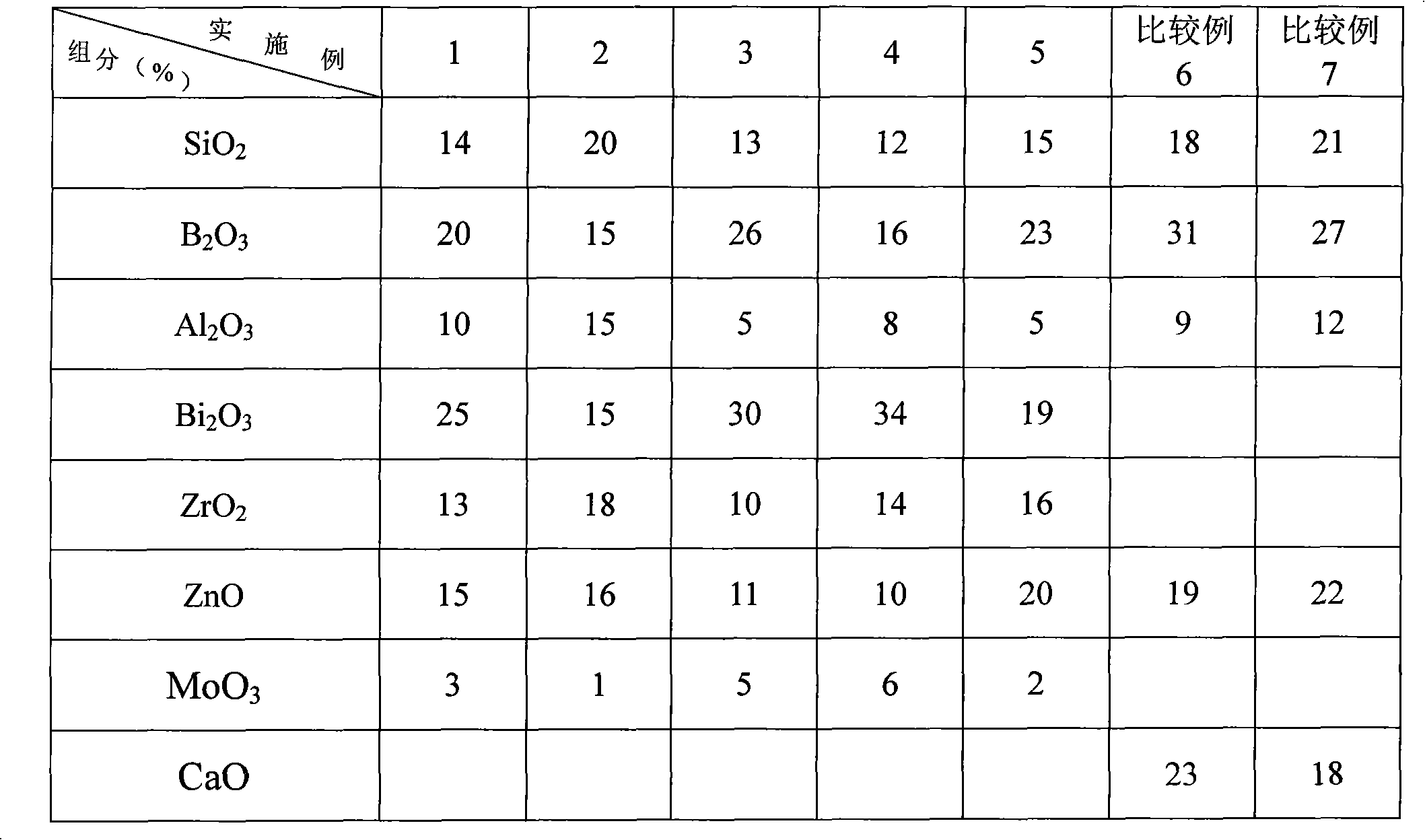

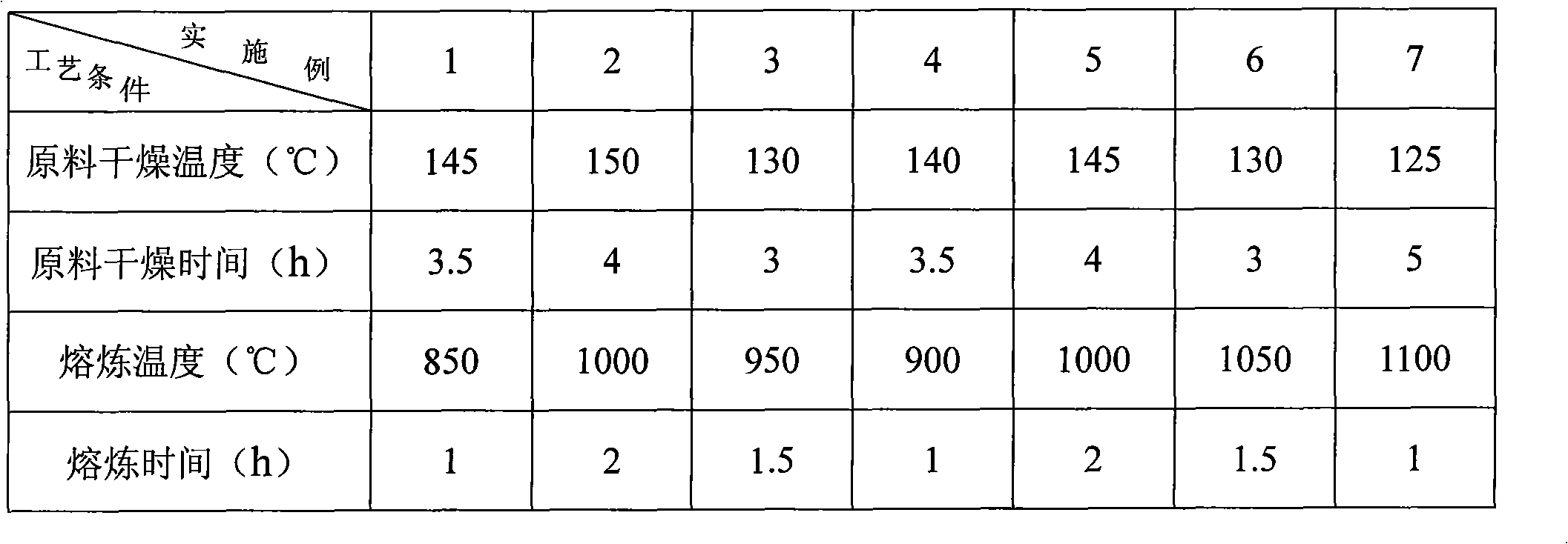

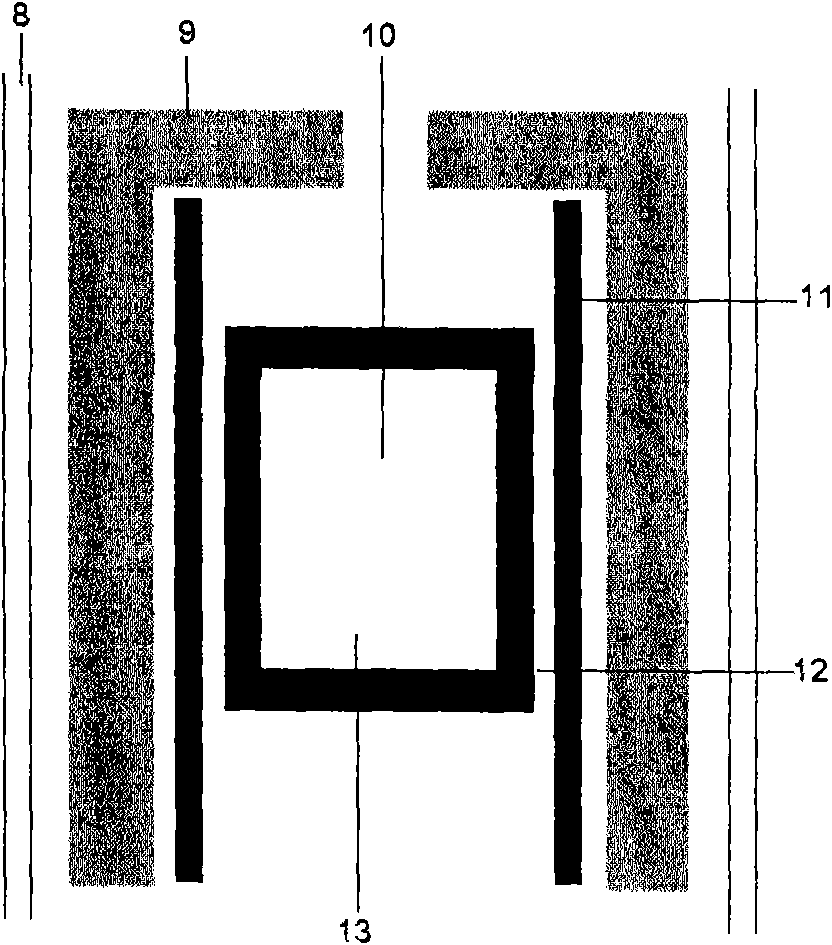

Inorganic adhesive for aluminum paste of silicon solar cells and preparation method thereof

ActiveCN101555388ASmall expansion coefficientLess bendingFinal product manufactureInorganic adhesivesAdhesiveSilicon solar cell

The invention provides inorganic adhesive for the aluminum paste of silicon solar cells and a preparation method thereof. The inorganic adhesive comprises the following components by the weight part: 10% to 20% of SiO2, 15% to 30% of B2O3, 5% to 15% of Al2O3, 15% to 35% of Bi2O3, 10% to 18% of ZrO2, 10% to 25% of ZnO and 1% to 8% of MoO with the total amount being 100%. The preparation method comprises the following steps: putting the components forming the inorganic solvent into a mixer to mix the components uniformly; loading the mixed components into a porcelain crucible and placing the porcelain crucible into a baking oven to be dried at the temperature of 120 to 150 DEG C for 3 to 5 hours; then, placing the porcelain crucible into a high-temperature furnace to melt at the temperature of 800 to 1,100 DEG C for melting for 1 to 2 hours; carrying out water-quenching and oven-drying; milling the components with a planetary ball mill until the particle size is lower than 10 mum; and oven-drying the components to obtain the final product of the inorganic adhesive. The glass powder has lower softening temperature and high adhesion when the aluminum paste prepared from the inorganic solvent is used for sintering, so that the aluminum powder layer can be firmly adhered to silicon chips; the expansion coefficient is lower after sintering; the bending degree of cell chips is lower; and the breakage rate is reduced.

Owner:WUXI RUXING TECH DEV +1

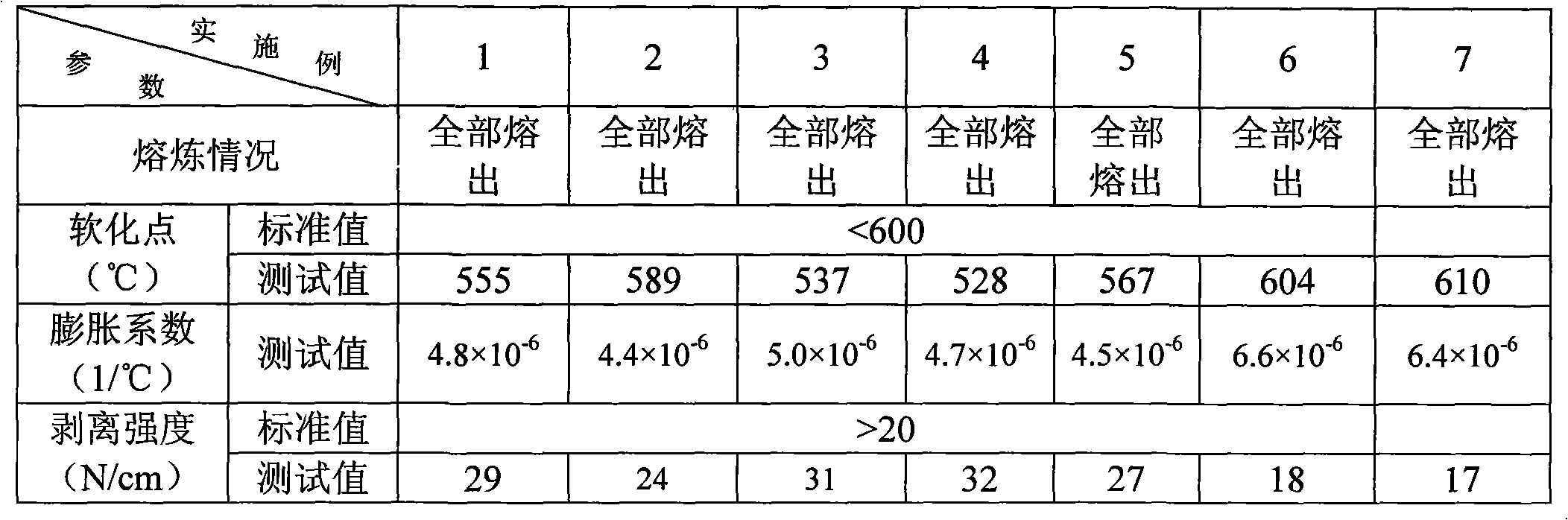

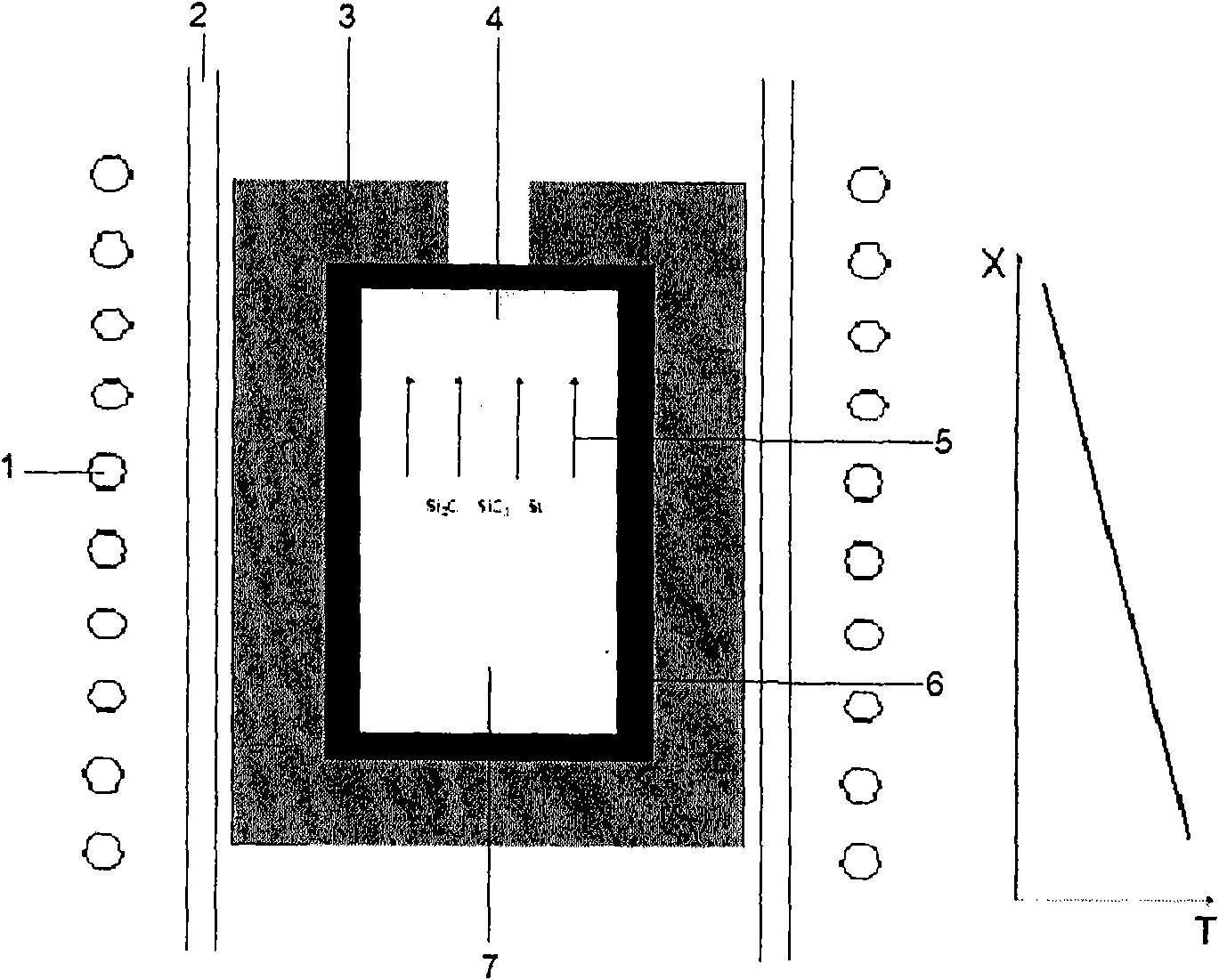

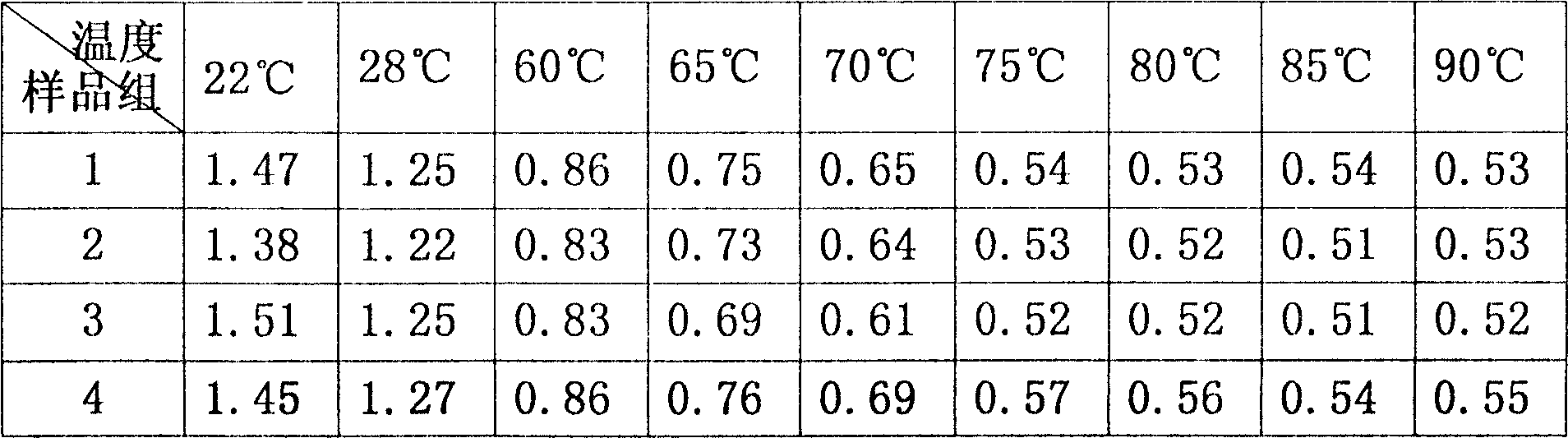

Annealing process for reducing stress of silicon carbide crystals

The invention is mainly applied in the retreatment field of the grown silicon carbide crystals. The annealing process specifically comprises the following steps: heating for 10-50 hours to an annealing temperature in an annealing furnace with good tightness and small temperature gradient (the temperature gradient of the surrounding of the crystals is 1-20 DEG C / cm) under the protection of an inert gas with the pressure of more than 10000Pa, keeping the temperature for 10-40 hours, and reducing the temperature for 10-50 hours, wherein the annealing temperature is 2100-2500 DEG C. Through the double annealing, the stress between the crystals and the crucible cover and the internal stress of the silicon carbide crystals are reduced, thus the breakage rate of the silicon carbide crystals is reduced in the subsequent processing step and the yield of the silicon carbide crystals is increased.

Owner:XINJIANG TANKEBLUE SEMICON +1

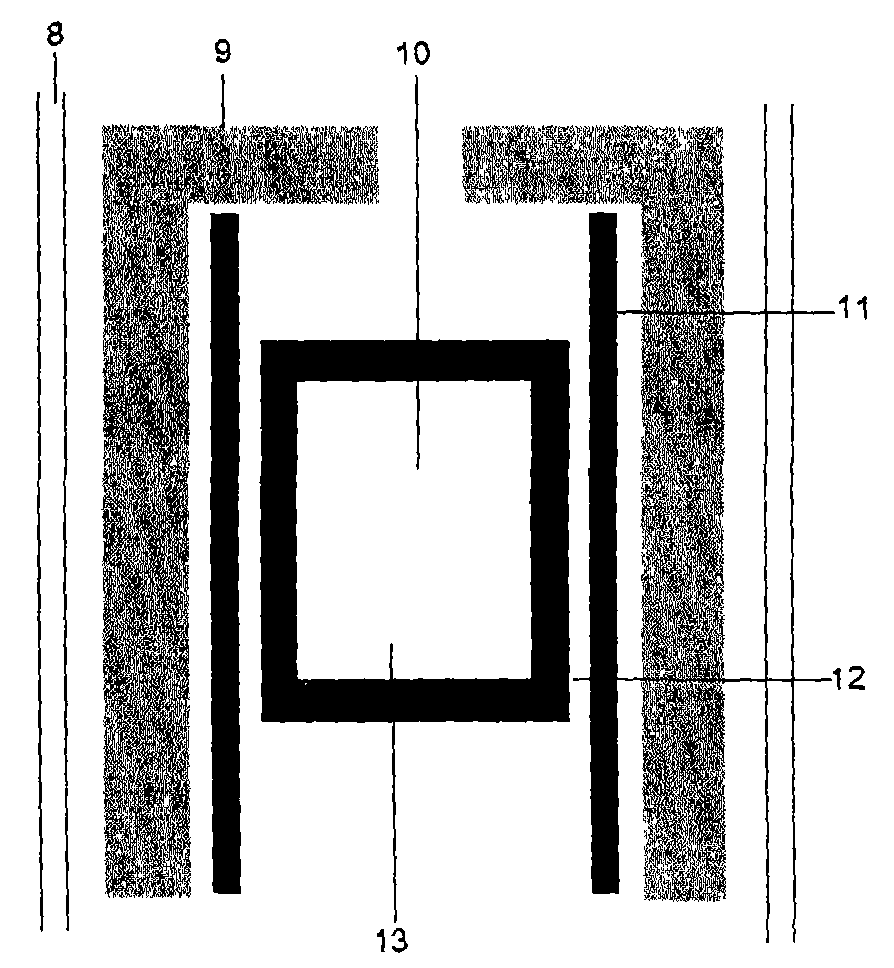

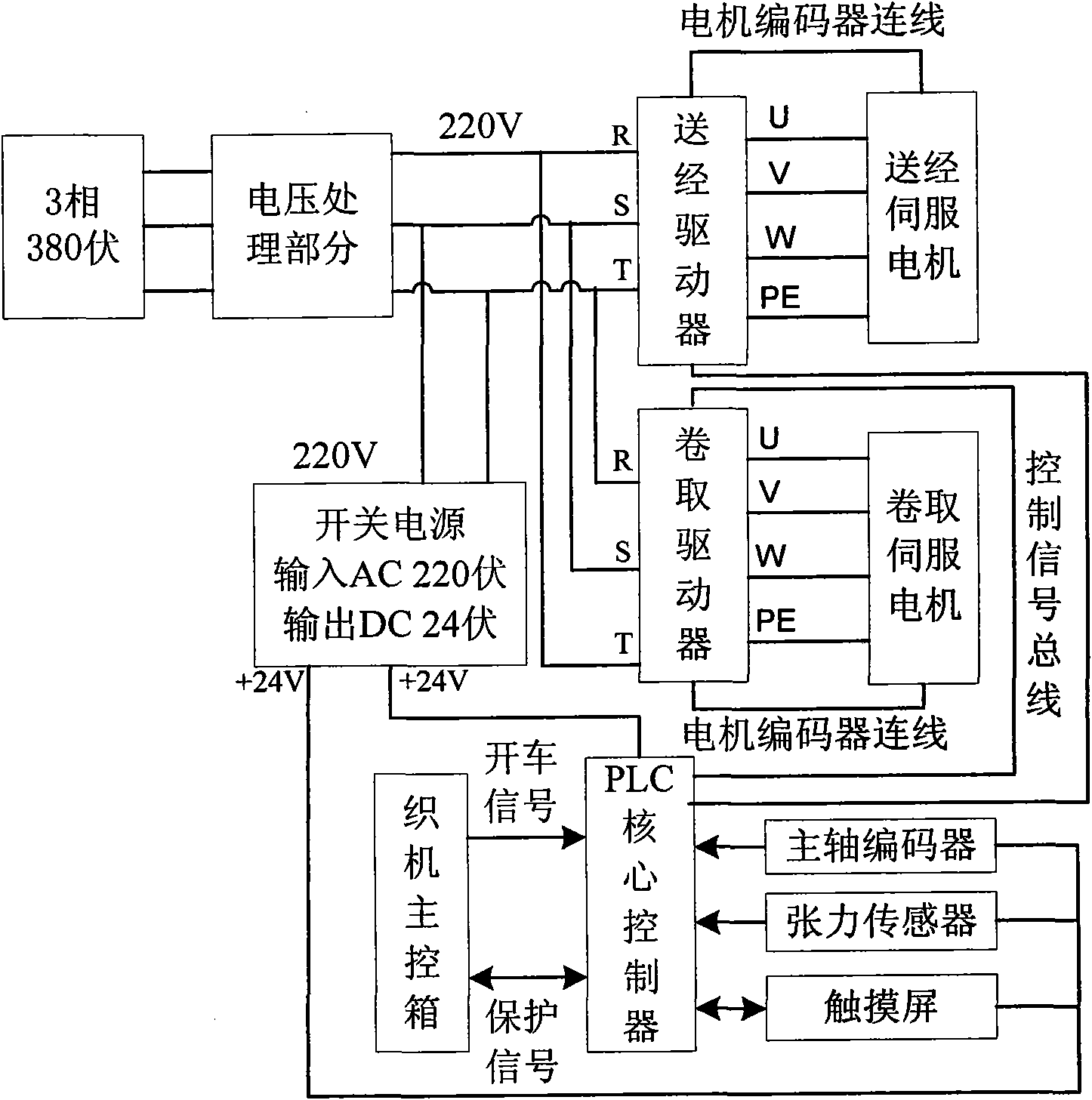

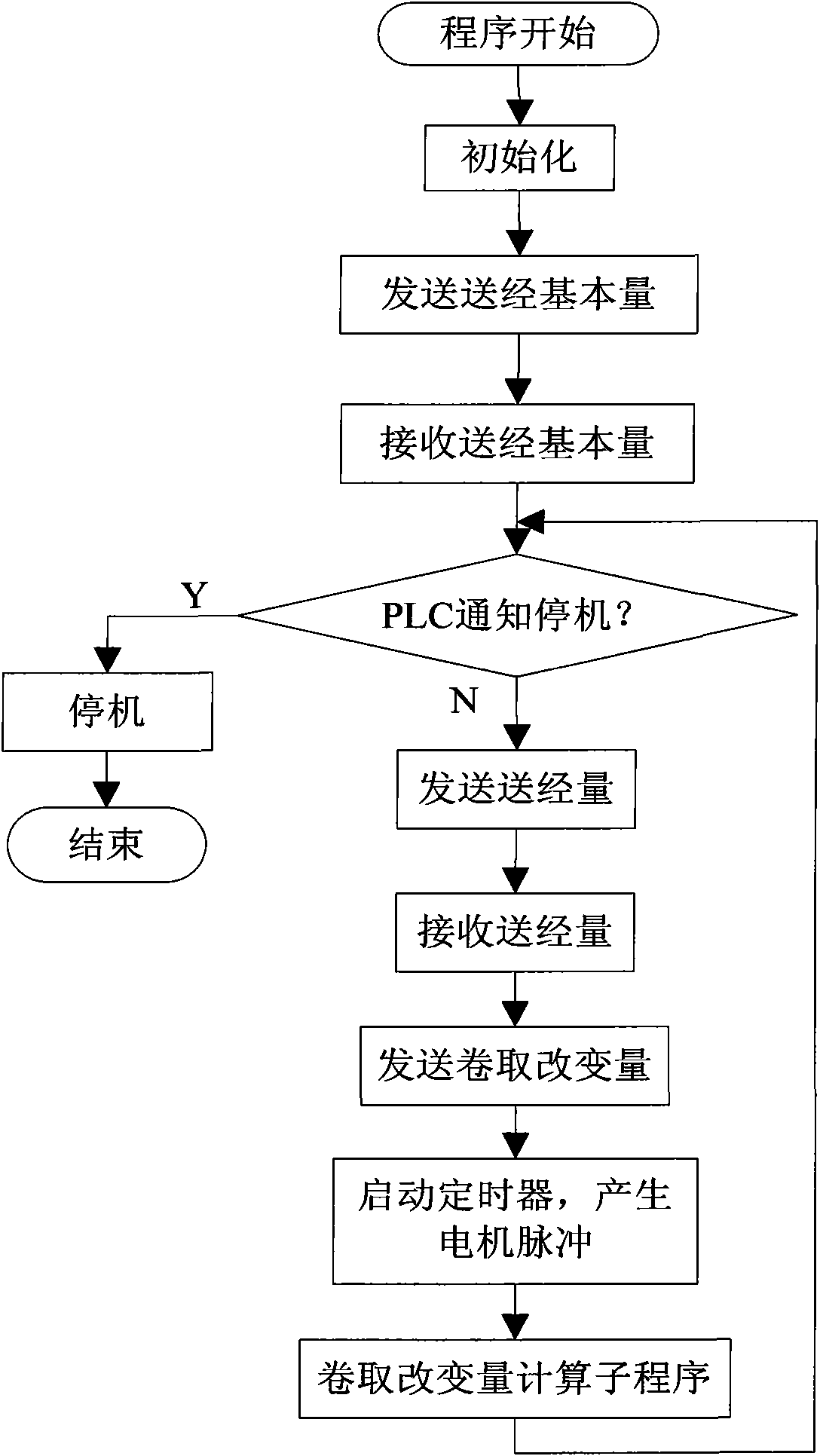

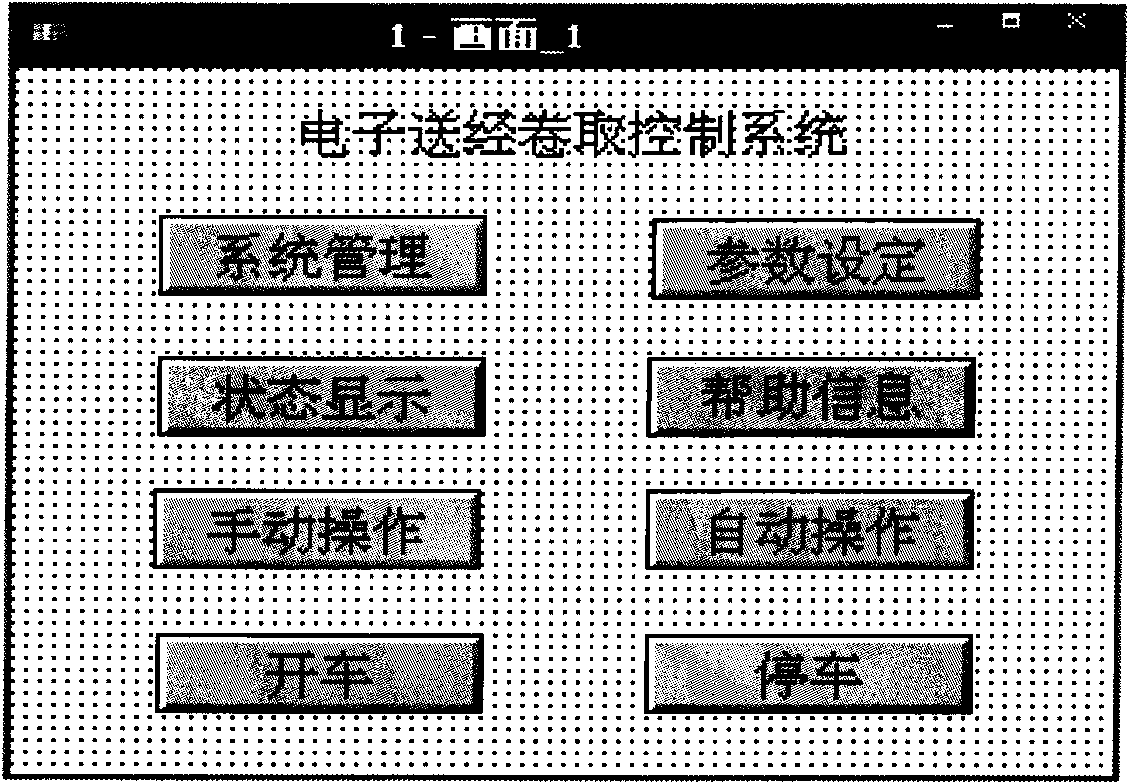

Method for controlling tension stability of wrap yarn during wrap feeding and rolling process of loom

InactiveCN101673119AShort response timeSmall overshootLoomsProgramme control in sequence/logic controllersYarnReduction drive

The invention relates to a method for controlling the tension stability of wrap yarn during the wrap feeding and rolling process of a loom, comprising two parts, namely, wrap feeding and rolling control system hardware and a software program of a core controller. The hardware part comprises a main controller PLC, a touch screen, a tension sensor, an encoder, a servo driver, a servo motor and a speed reducer; and the software part employs a novel control algorithm, namely, single nerve cell self-adaptive PID algorithm. The control system is tested on the SAURER400-type rapier loom and good control effect is achieved, the tension fluctuation of wrap yarn of the loom is obviously improved, and the end breakage rate of wrap yarn is greatly decreased; besides, the control method is universal and has certain practical value both in reconstruction of the old loom and in algorithm research of the new loom.

Owner:TIANJIN POLYTECHNIC UNIV

Solar cell assembly manufacturing process

InactiveCN1937263AImprove welding qualityReduce Fragmentation RateFinal product manufactureSemiconductor devicesLow speedInterconnection

The invention includes following steps: (1) after preheating, using prepared interconnection bar to weld solar battery slices to a whole; (2) cooling welded solar battery array of crystalline silicon in low speed; (3) superimposing glass / EVA / solar battery cluster / EVA / TPT from bottom to top, and placing them into vacuum lamination machine; (4) using vacuum lamination method to hot press glass / EVA / solar battery cluster / EVA / TPT together, and taking molded product out; (5) adding frame to produce solar battery array. Preheating operation reduces thermal shock for battery slices, and lowers breakage rate of product. Low cooling speed reduces possibility of creating subfissure on battery slices. Features are: simple technique, obvious effect. Comparing with foretime, the invention reduces 2 percent of breakage rate.

Owner:TAITONG TAIZHOU IND

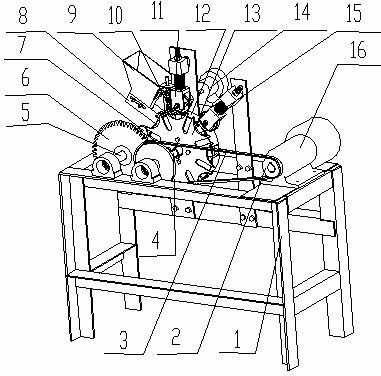

Hobbing type lotus seed shucker

The invention relates to a hobbing type lotus seed shucker, which is composed of a frame, a feeding mechanism, a conveying mechanism, a cutting mechanism, an uncoating mechanism, a motor and the like, wherein the conveying mechanism is driven by a grooved pulley, and step performing of lotus seed shucking and uncoating is realized by the intermittent movement of a grooved pulley mechanism, so that the shucking is more thorough and more effective; and spring adjustment systems are respectively installed on the shucking mechanism and the uncoating mechanism, and the springs can automatically adjust the distance between a cutting blade and an uncoating roller as well as a rubbing roller according to the lotus seed size, so that the shucking of lotus seeds with different sizes is adapted. The shucker has the characteristics of high shucking rate and low breakage rate in the shucking process, and has the characteristics of simple structure, small volume, low manufacturing cost, stability in operation and the like in the equipment performance.

Owner:NANCHANG UNIV

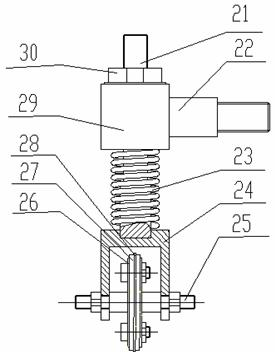

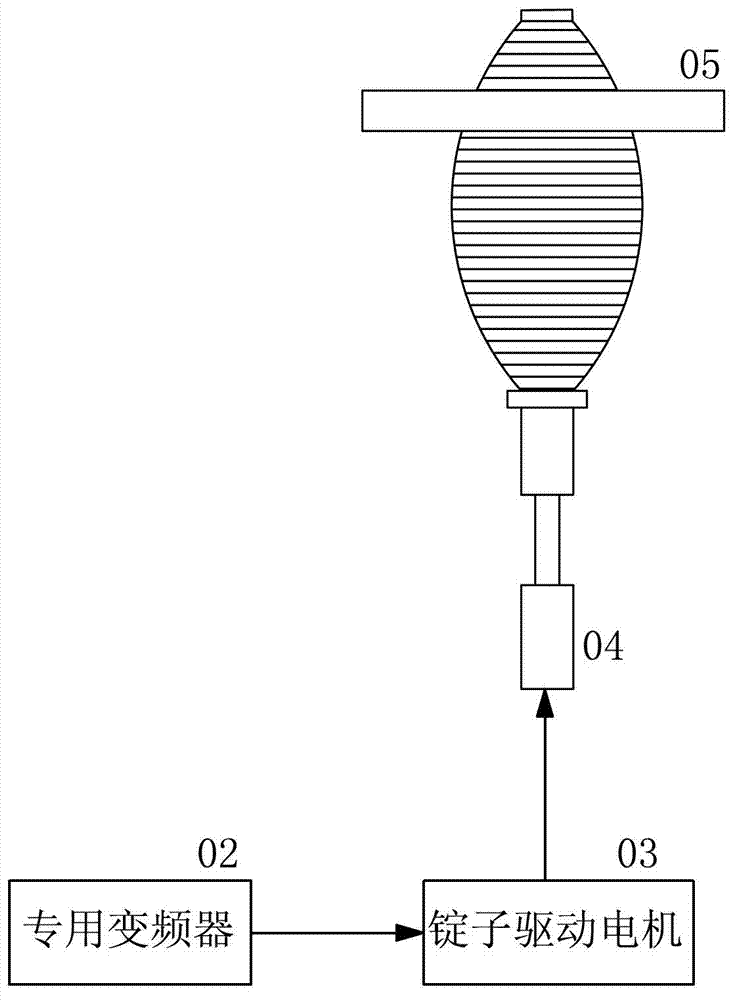

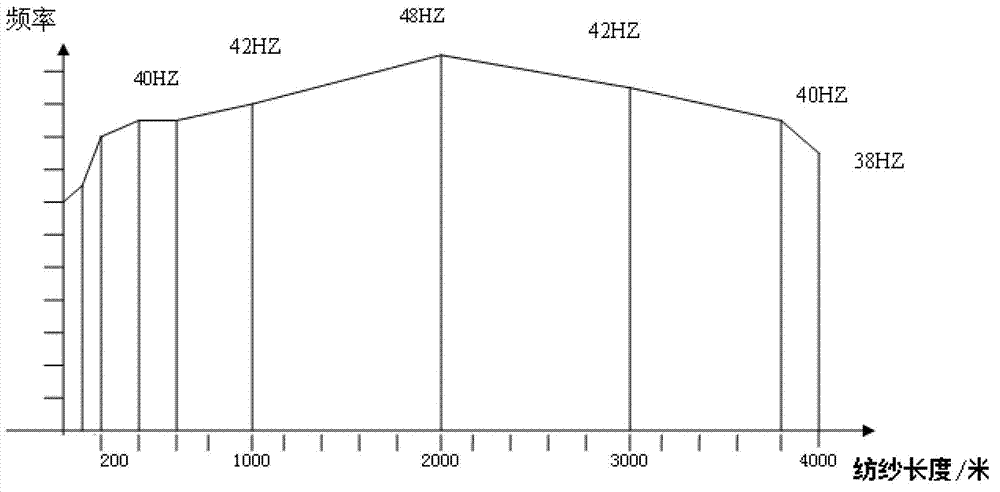

Production line intelligent control method of spinning frame

ActiveCN102767000AReduce labor costsReduce adverse effectsTextiles and paperProduction lineFrequency changer

A production line intelligent control method of a spinning frame comprises the following steps: frequency reference values of all doffing stages and conversion data of corresponding frequencies and spindle speeds are stored in a spinning frame special frequency changer; during an initial process of doffing of the spinning frame, the frame special frequency changer determines initial lengths of all doffing stages based on a final spinning length, sets corresponding reference frequencies of all stages, and calculates corresponding output frequency data of the special frequency changer; the spinning frame performs a corresponding spinning action process according to the output frequency data of the set special frequency changer; a spindle drive motor dynamically adjusts the spindle speeds according to the frequencies and spinning lengths output by the special frequency changer; and when the spinning length or a set time is reached, the spinning frame performs doffing automatically according to the set action, and the scoffing process is completed. According to the production line intelligent control method of the spinning frame, the spinning end breakage rate can be reduced effectively, the working strength of knitters is reduced, and the yield is improved.

Owner:EURA DRIVES ELECTRIC

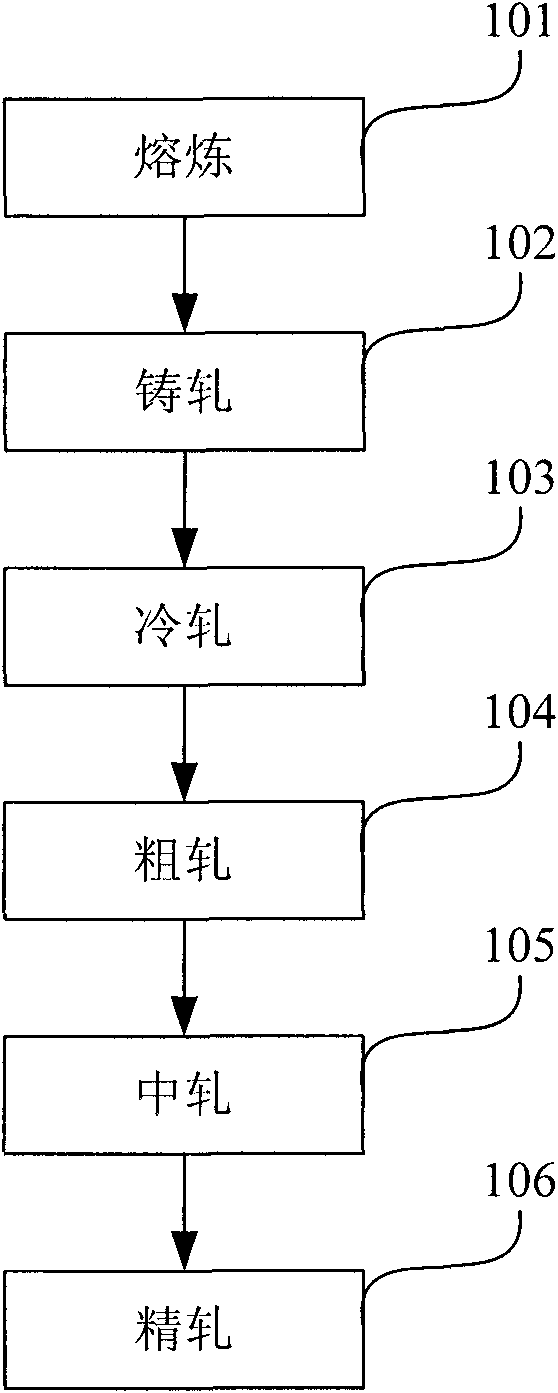

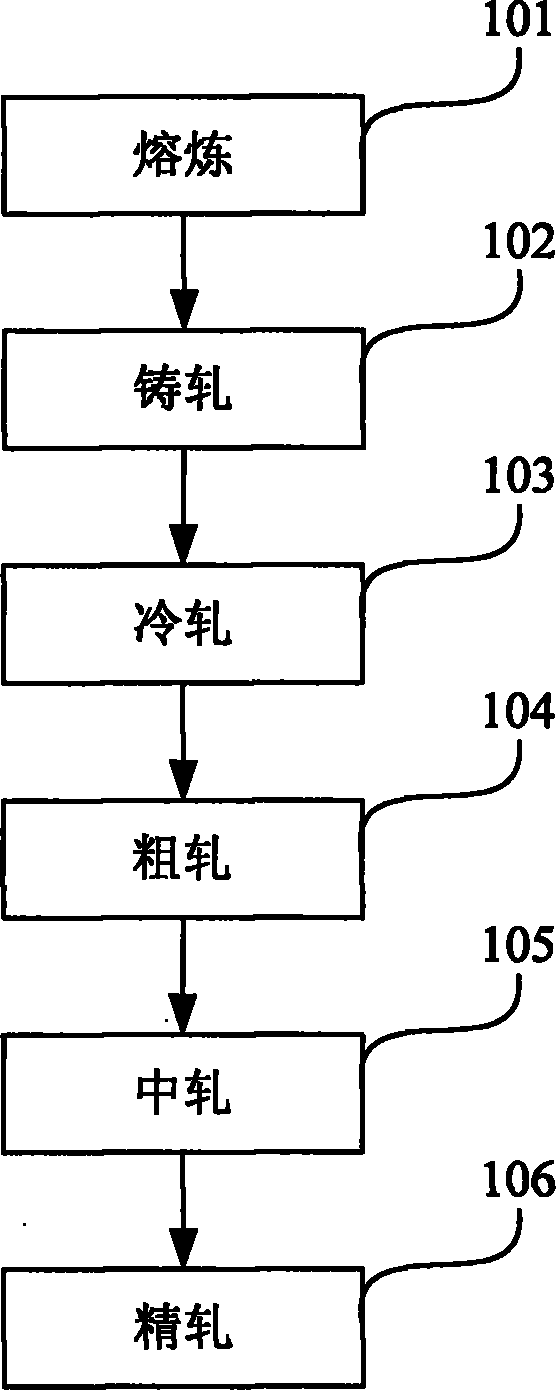

Production process of ultrathin double-face optical aluminum foil

ActiveCN101844152AStable productionProduction batchMetal rolling arrangementsProfile control deviceFiltrationRoom temperature

The invention discloses a production process of ultrathin double-face optical aluminum foil, comprising the following steps of: smelting: fusing raw materials into aluminum liquid by using a heat-storage type smelting furnace and entering into a casting-rolling machine after filtration; casting and rolling: introducing fused aluminum liquid in the casting-rolling machine to be aluminium foil blanks; cold rolling: rolling aluminium foil blanks to 0.78 millimeter by using a cold rolling machine after cooling the aluminium foil blanks to room temperature, then sending the aluminium foil blanks into an annealing furnace for uniformly annealing, and then rolling the aluminium foil blanks to 0.36 millimeter to obtain aluminium foil stocks; rough rolling: roughly rolling the aluminium foil stocks, wherein the reduced passes of rough rolling are 0.36 millimeter to 0.19 millimeter to 0.09 millimeter to 0.043 millimeter; medium rolling: carrying out medium rolling on the roughly rolled aluminium foil stocks, wherein the educed passes of medium rolling are 0.043 millimeter to 0.021 millimeter; and finish rolling: carrying out finishing rolling on the medium-rolled aluminium foil stocks, wherein the reduced passes of finish rolling are 0.021 millimeter to 0.011 millimeter, thereby obtaining aluminum foil finished products. The invention can reduce tape breakage rate in the production process of the aluminum foil by adopting the production process of the ultrathin double-face optical aluminum foil, thereby stably producing the ultrathin double-face optical aluminum foil in batch.

Owner:华北铝业新材料科技有限公司

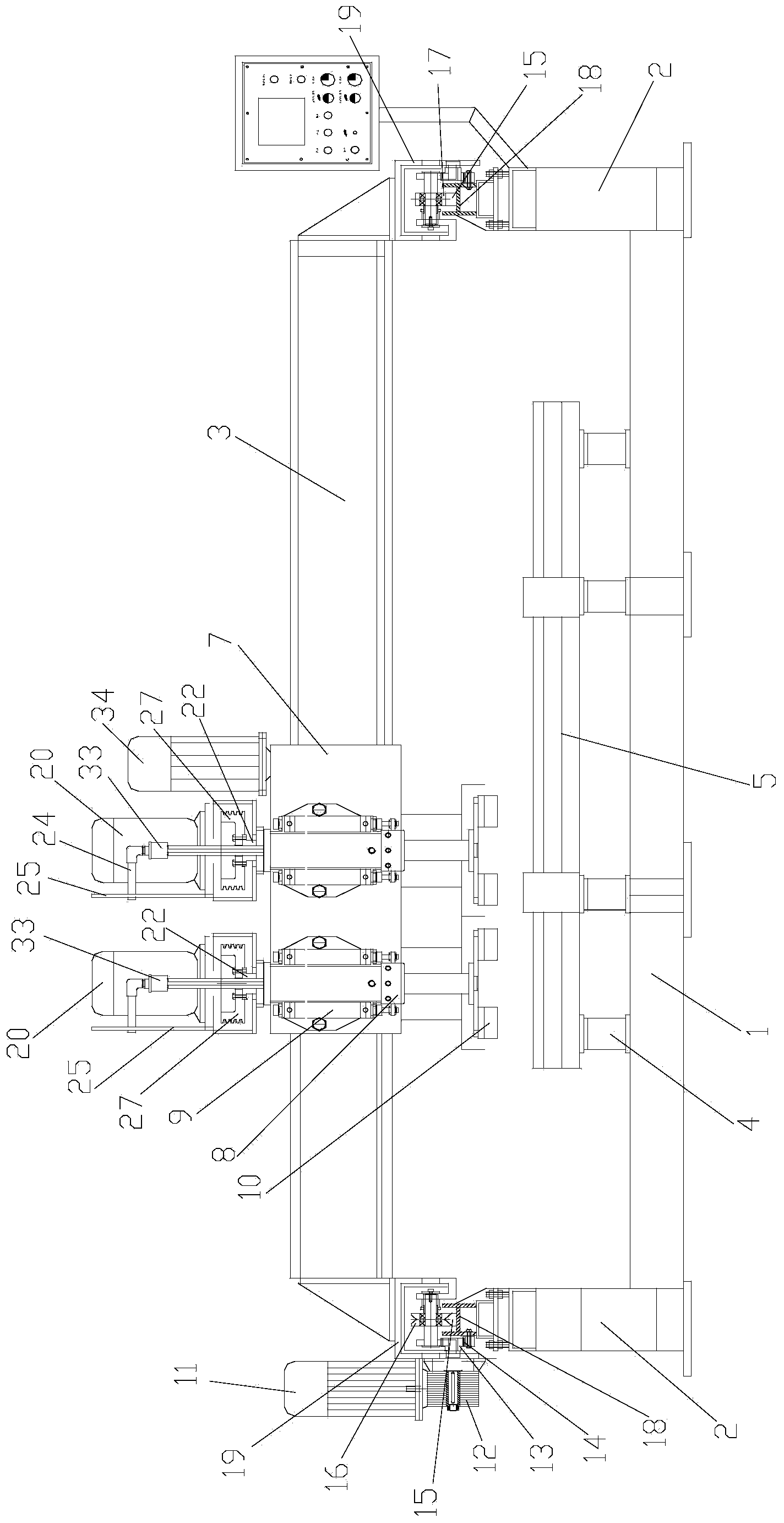

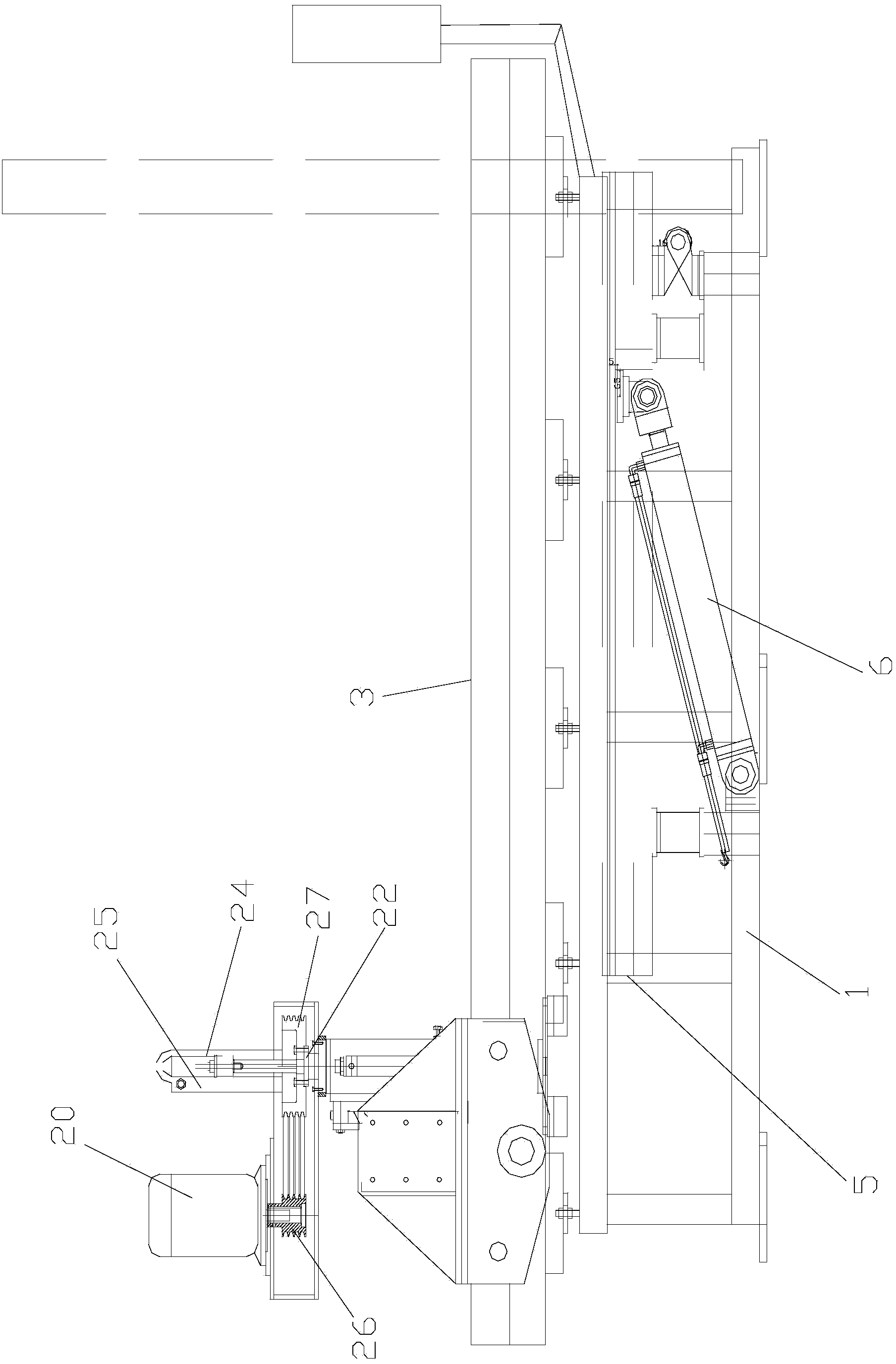

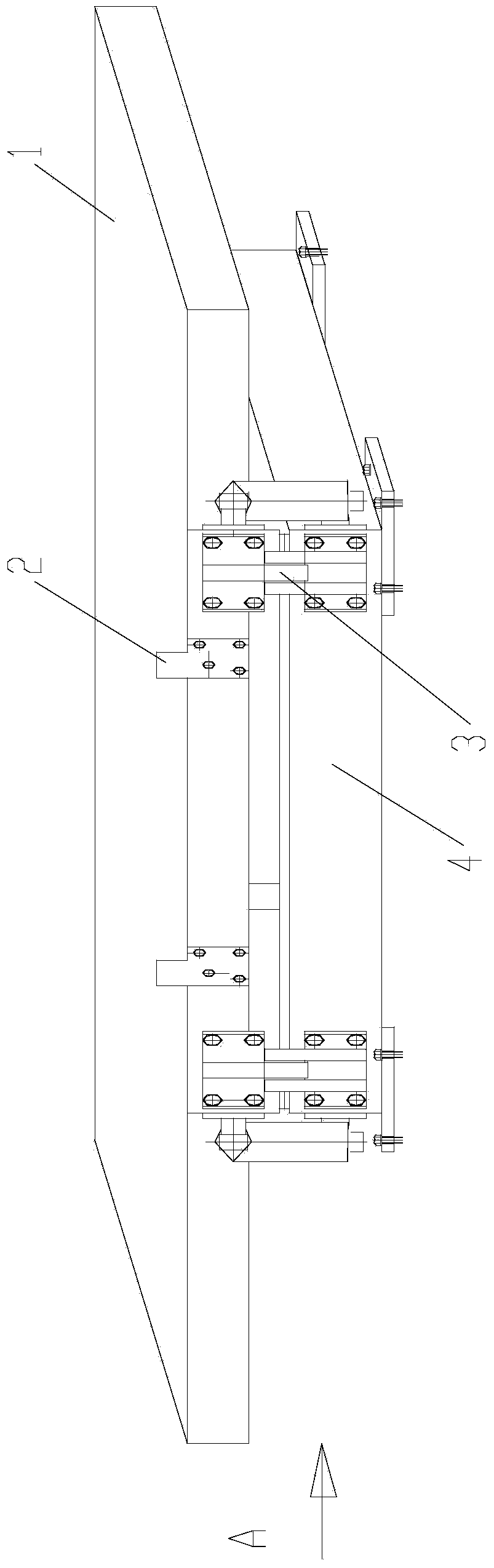

Automatic polishing machine for two ends of plate

InactiveCN103978417ALow technical requirementsEasy and simple polishing technologyGrinding carriagesPolishing machinesBreakage rateEngineering

The invention provides an automatic polishing machine for two ends of a plate. The automatic polishing machine comprises a base, supporting legs and a cross beam, a cross beam moving device is arranged at one end of the cross beam and drives the cross beam to move front and back along the supporting legs, the cross beam is sleeved with a box which is provided with a polisher and a polishing head lifting device, a piston rod at the lower end of a lifting cylinder of the polishing head lifting device is fixedly connected with an end cover of the polisher, the piston rod of the lifting cylinder stretches out and draws back to control a polishing head at the lower end of the polisher to move up and down, and the box and the cross beam are provided with horizontally-moving devices driving the box to move left and right along the cross beam. The automatic polishing machine replaces man power to polish the surface of a stone flat plate, labor is saved, technical requirements for operators are lowered, polishing of the surface of the plate is easy and simple, and the defect like the wavy phenomenon on the surface after manual polishing is overcome; the breakage rate of the plate is greatly lowered, labor is saved, and the plate can be conveniently and reliably placed on and taken down from a work table.

Owner:BAOJI YINKANG MACHINERY EQUIP

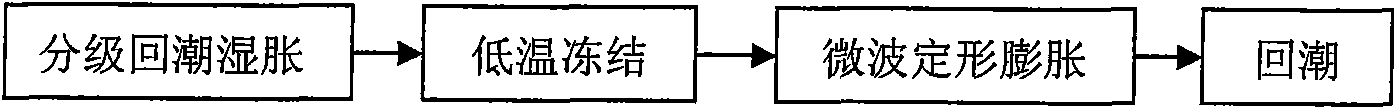

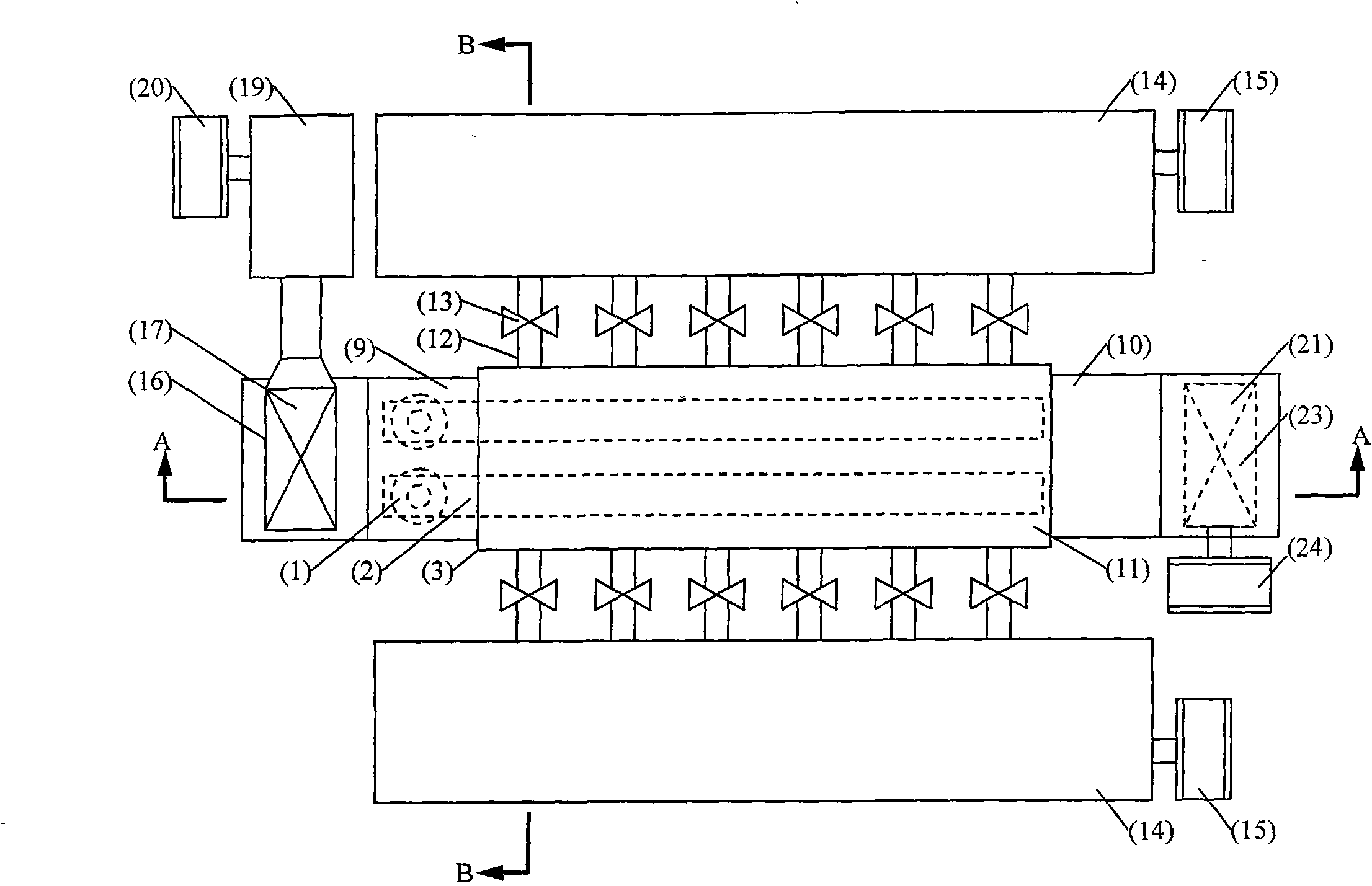

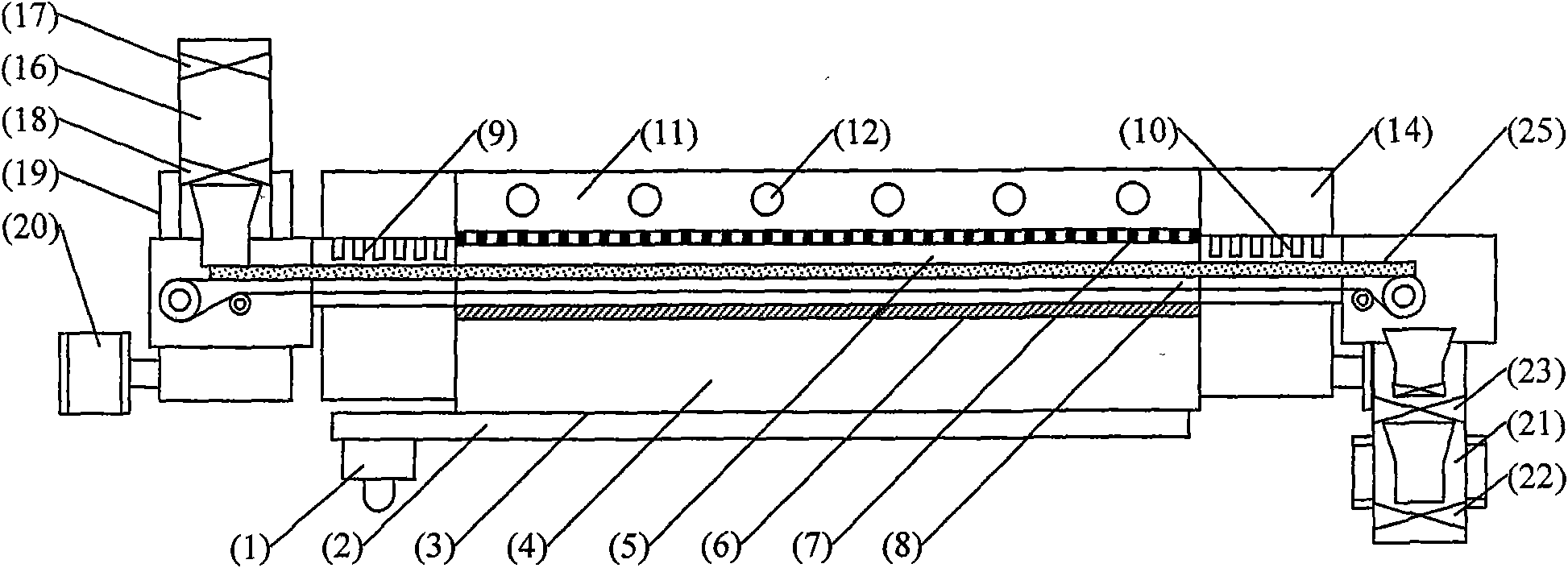

Low-temperature microwave expansion process of cut tobacco

The invention relates to a low-temperature microwave expansion process of cut tobacco. The process comprises the following steps of: putting expanded cut tobacco with the water content of 40-70 percent by rating resurgence in a die; then, freezing into blocks at a temperature of 55 DEG C below zero to 35 DEG C below zero; conveying the cut tobacco blocks into a microwave continuous freeze-dried system to sublimate and dry until the water content is 3-8 percent; and finally resurging to the water content of 12-13 percent to obtain a finished product of expanded cut tobacco. The cut tobacco is expanded by the process of the invention has the advantages of remarkable aroma and fragrance, lower breakage rate, remarkably lessened odor and controllable expansion degree.

Owner:周川

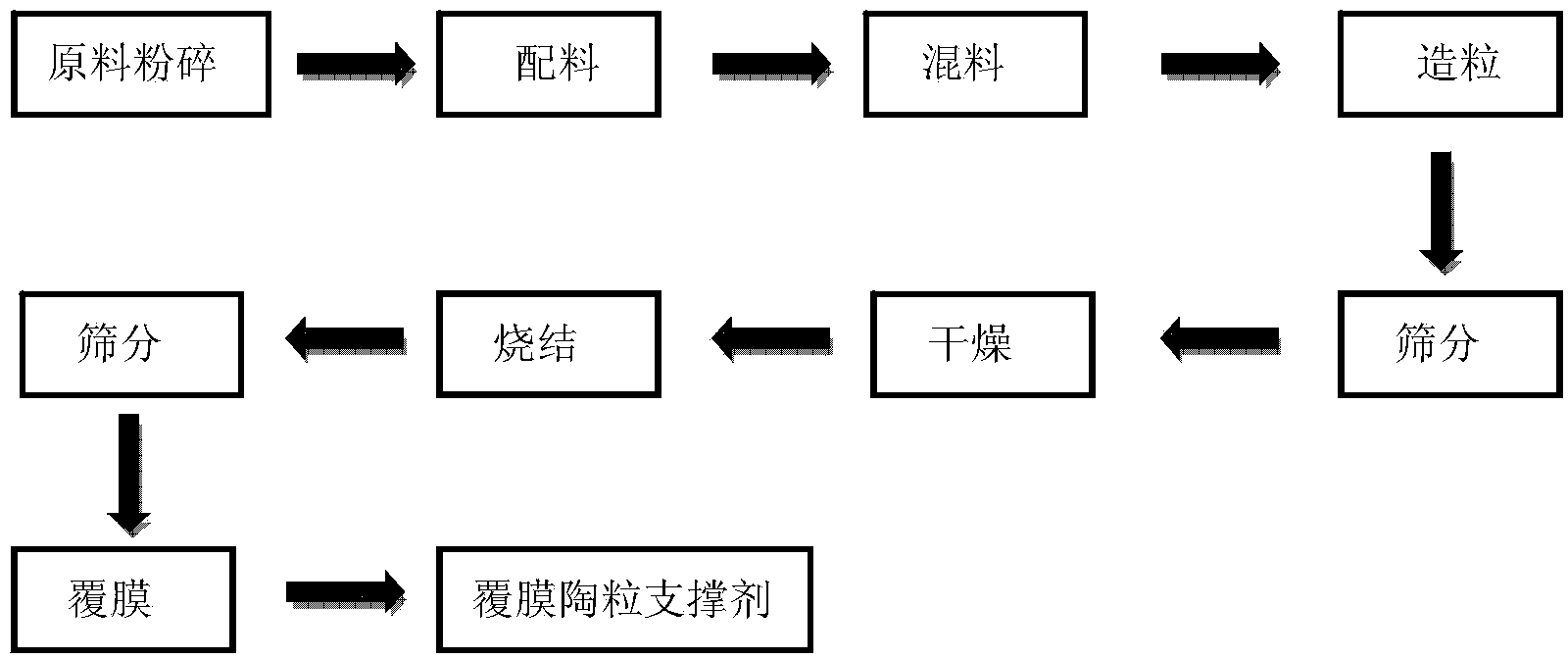

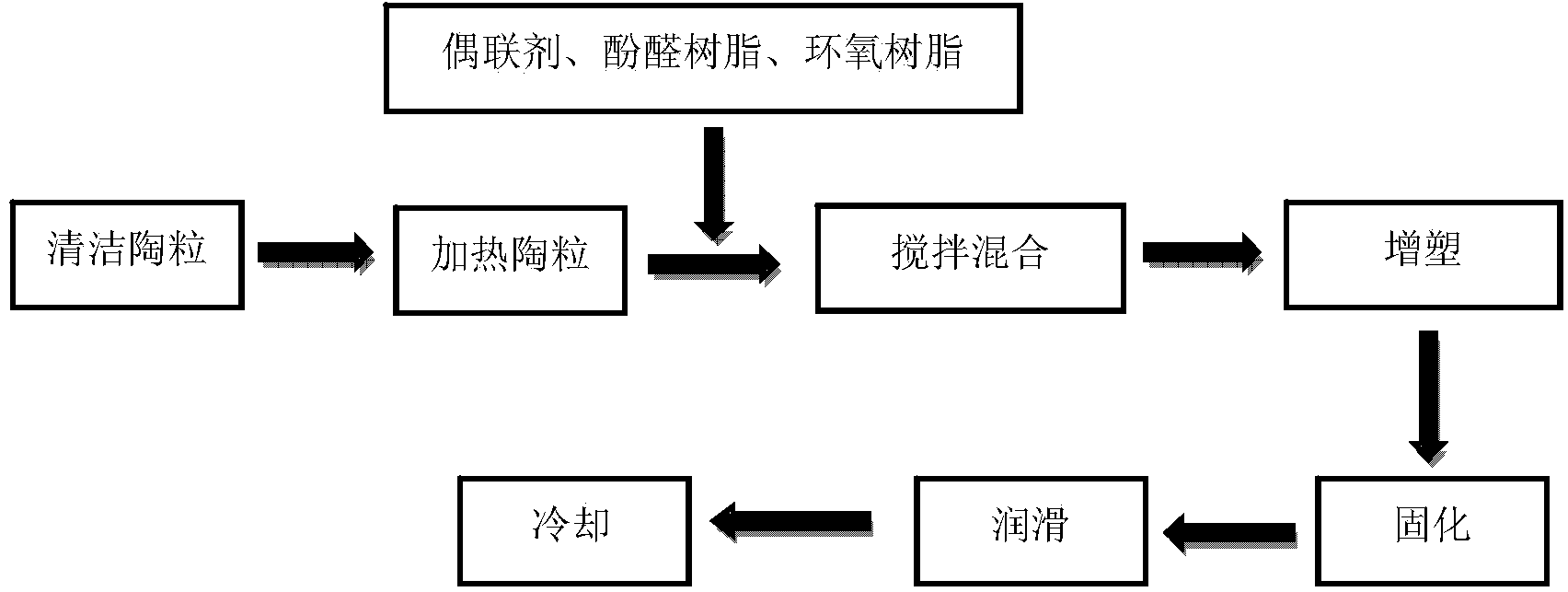

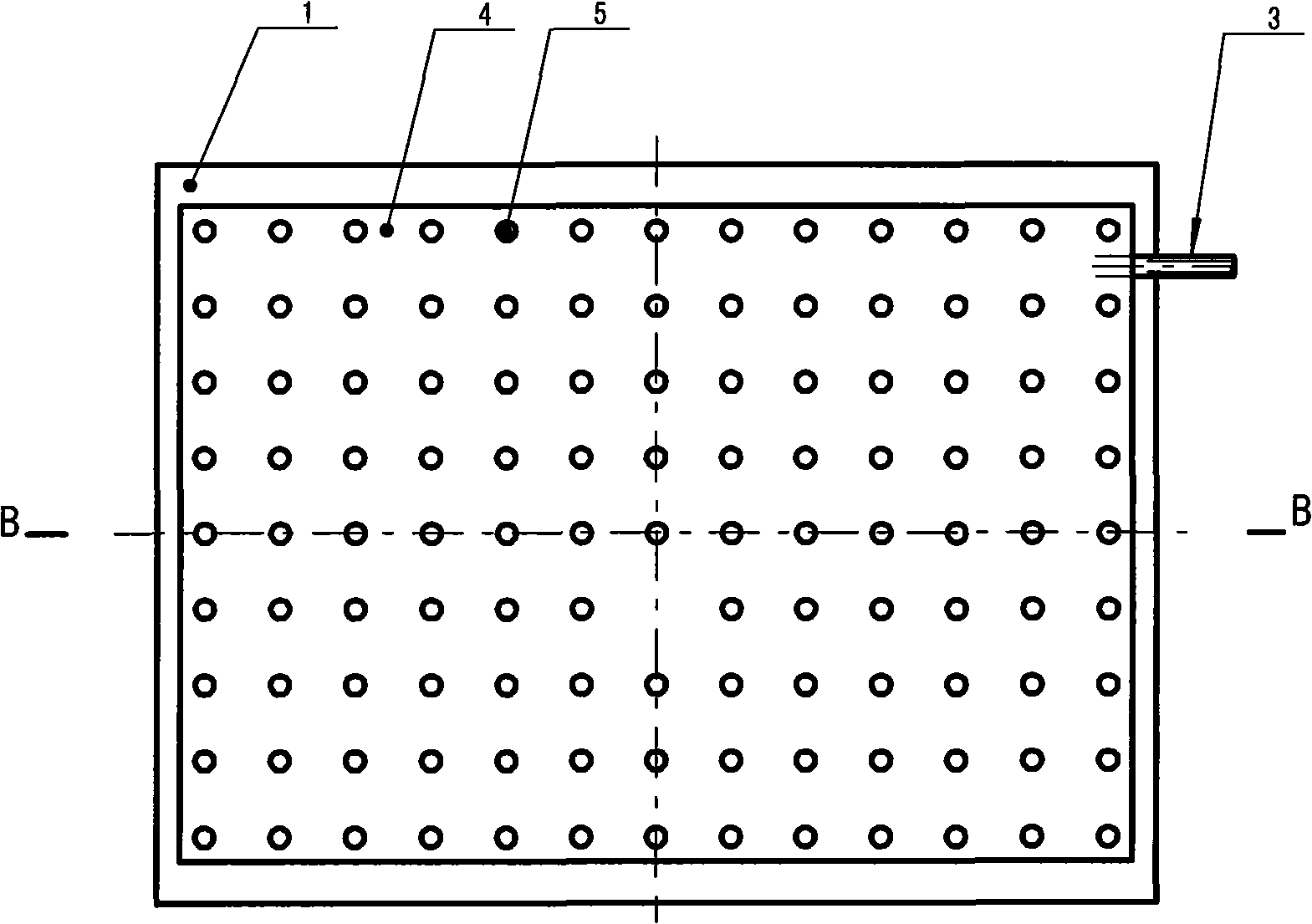

Low-density coated ceramic proppant prepared through fly ash and preparation method of low-density coated ceramic proppant

InactiveCN104263347ALower firing temperatureHigh strengthFluid removalDrilling compositionPotassiumExpanded clay aggregate

The invention discloses a low-density coated ceramic proppant prepared through fly ash and a preparation method of the low-density coated ceramic proppant. The low-density coated ceramic proppant is prepared from the following raw materials in percentage by weight: 85-98 wt% of fly ash, 1-5 wt% of MnO2 powder and 0-10 wt% of potassium feldspar powder through the steps of granulation, calcination and coating. In the preparation method, the fly ash is taken as a main raw material, a small amount of additive is used as a fluxing agent, high-aluminum-content materials such as bauxite and the like are not introduced, and the coated ceramic proppant is prepared by a coating process. The prepared coated ceramic proppant has the characteristics that the particle size is 20-40 meshes, the bulk density is smaller than or equal to 1.55 g / cm<3>, the apparent density is smaller than or equal to 2.70 g / cm<3>, the breakage rate is smaller than or equal to 5% at 52 MPa and the breakage rate is smaller than or equal to 9% at 69MPa.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

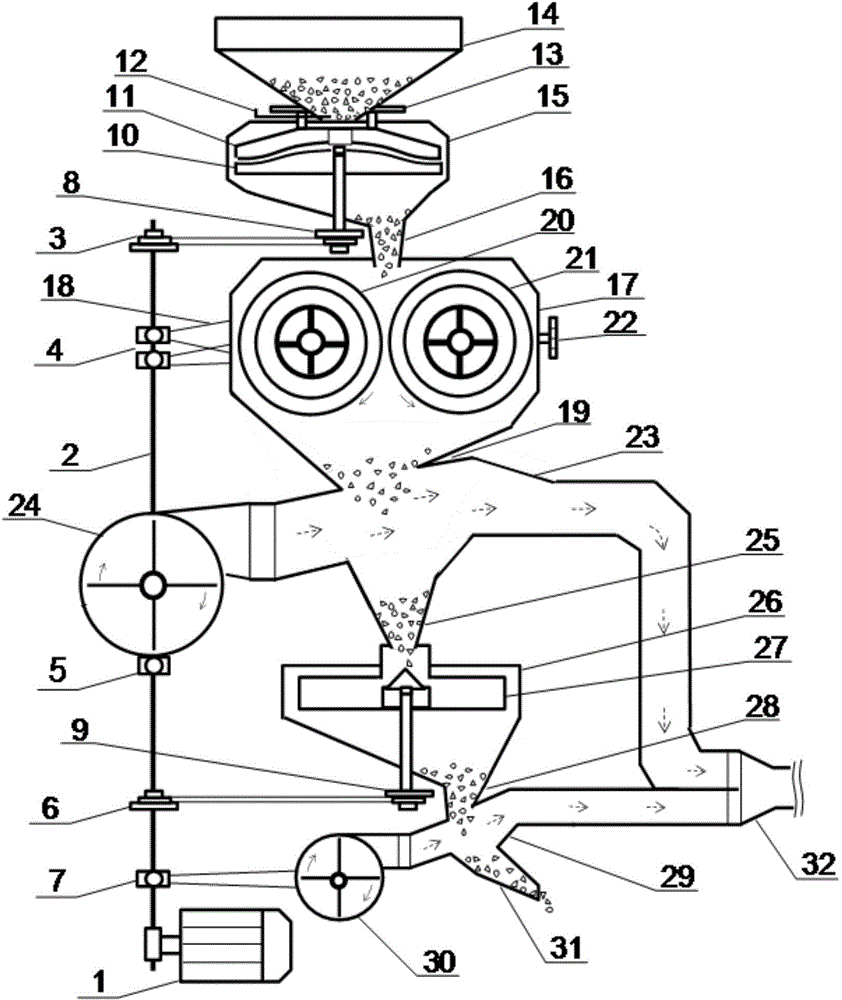

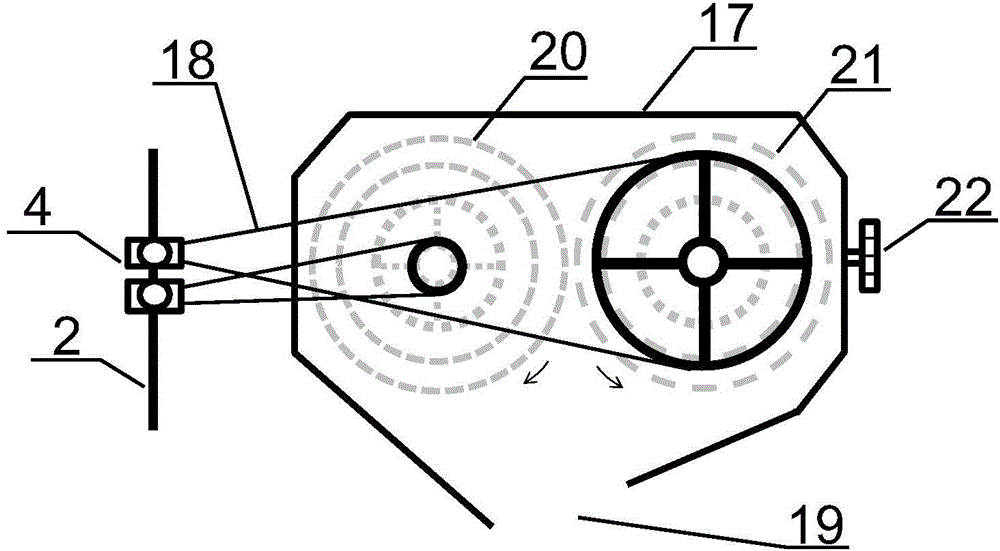

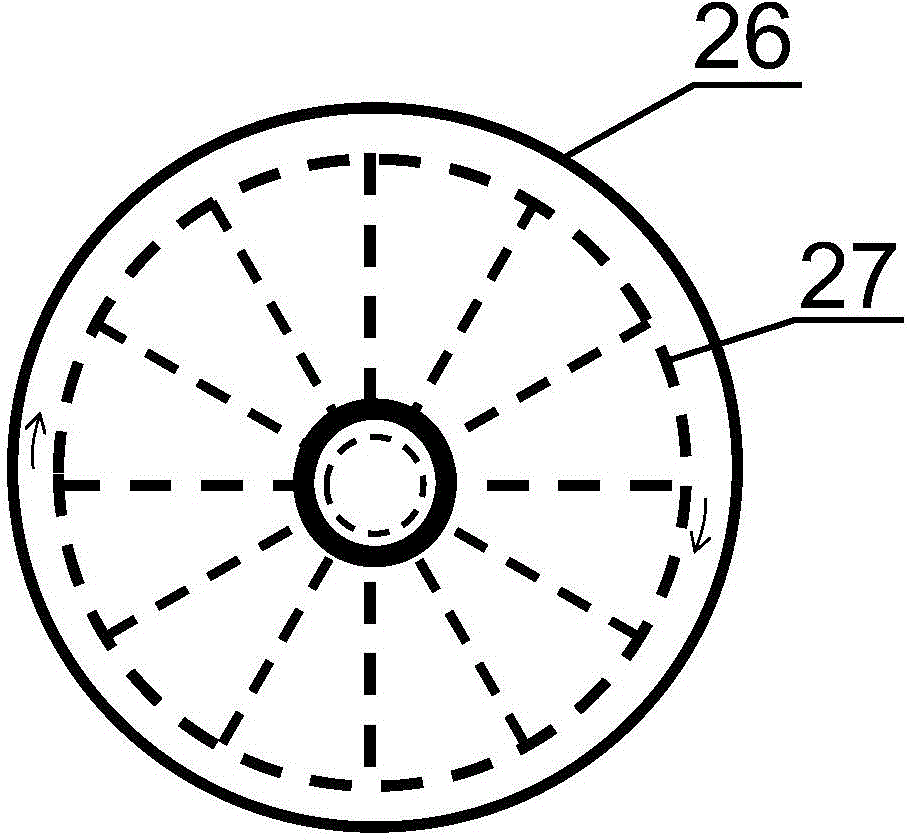

Combined-type buckwheat shelling machine

InactiveCN104646086AReduce breakage rateEasy to separateGrain huskingGrain polishingImpellerAgricultural engineering

The invention discloses a combined-type buckwheat shelling machine, which mainly comprises a feed hopper, a milling shelling chamber, a kneading shelling chamber, an air duct 23, an impact shelling chamber and an air duct 29 which are arranged from top to bottom in sequence; a rotating disk and a fixed disk are correspondingly arranged in the milling shelling chamber; a discharge hole 16 is formed in the bottom part of the milling shelling chamber, and the top part of the milling shelling chamber is provided with a milling pan clearance adjustment valve; the kneading shelling chamber is connected below the discharge hole of the milling shelling chamber; two rubber rollers which are different in rotating speed and opposite in rotating direction are correspondingly arranged in the kneading shelling chamber; a discharge hole 19 is formed in the bottom part of the kneading shelling chamber, and the side face of the kneading shelling chamber is provided with a rubber roller clearance adjustment valve; the air duct 23 is connected with the kneading shelling chamber, and the air duct 23 is connected with a fan 24, a feeding hole and a hull dust outlet; the feeding hole of the air duct 23 is connected with the impact shelling chamber; a centrifugal impeller is arranged in the impact shelling chamber; a discharge hole 28 is formed in the bottom part of the impact shelling chamber; the air duct 29 is connected below the discharge hole of the impact shelling chamber; the air duct 29 is connected with a fan 30, a buckwheat rice outlet and the hull dust outlet. According to the combined-type buckwheat shelling machine disclosed by the invention, the buckwheat rice breakage rate of the buckwheat shelling process can be reduced, and the shelling work efficiency and the purity of buckwheat rice are increased.

Owner:TIANJIN UNIV

Method of quickly manufacturing vacuum glass

InactiveCN101492255AImprove ergonomicsConsistent external stressGlass reforming apparatusBreakage rateHot melt

The invention relates to a method for quickly preparing vacuum glass, which comprises the following steps: (1) machining a semicircular groove on substrate glass or drilling a through hole on an upper slice of glass; (2) leaking and brushing adhesive onto the substrate glass through a silk screen or a leaking plate to form point-shaped adhesives evenly distributed in interval with consistent size on the substrate glass; (3) scattering solid supports on the substrate glass so that part of the solid supports is adhered to the point-shaped adhesive; (4) stacking glass powder paste with low melting point on a position with side difference H which is formed by the upper slice of the glass and the substrate glass and is between 2 and 8 millimeters; (5) putting the glass into a heating furnace and heating the glass; and (6) sealing the glass by a hot-melting air suction glass tube, slowly reducing the temperature of the glass to below 60 DEG C, and then discharging the glass to obtain the vacuum glass. The method adopts the side difference sealing and is characterized in that the heated low glass powder paste fills in a gap of two pieces of glass and naturally levels under the siphon action of the glass gap formed the solid supports, the formed vacuum glass has the advantages of consistent internal stress and external stress, good transparency and consistent intensity, and reduces the breakage rate after evacuation; and the preparation method is quick and efficient, and is suitable for mass production.

Owner:左树森

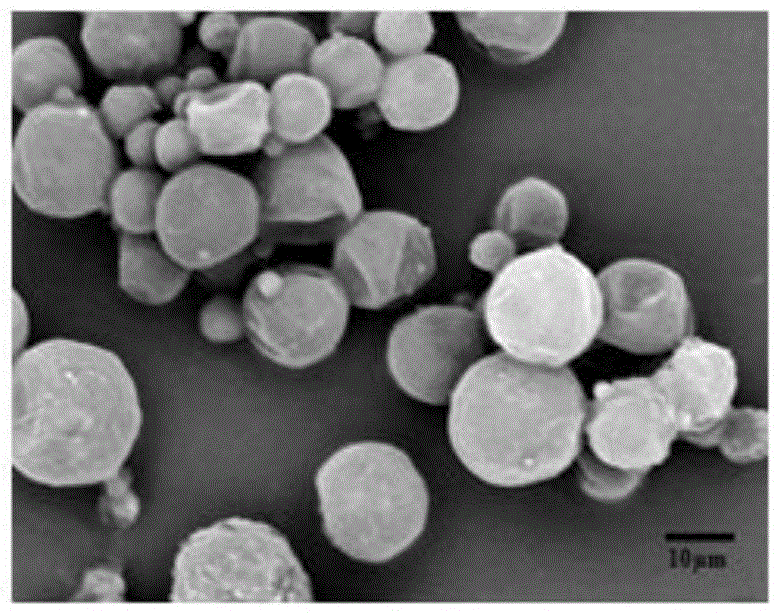

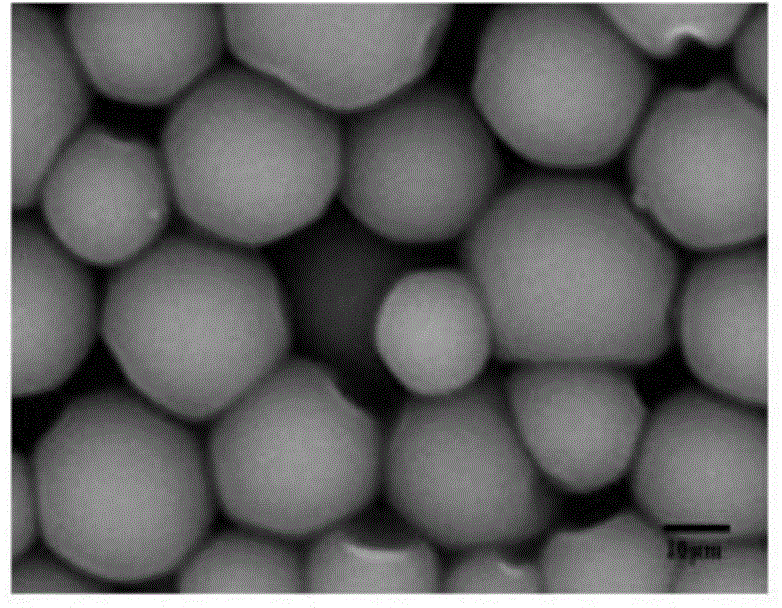

Preparation method of phase change microcapsule

InactiveCN104861935AImprove performanceReduce breakage rateHeat-exchange elementsMicroballoon preparationPolymerChemistry

The invention discloses a preparation method of a phase change microcapsule. The preparation method comprises the following steps: using a solid-liquid phase change material as a core material and a polymer as a wall material, and preparing a white powdered phase change microcapsule by adopting synthesis of a prepolymer, emulsification of the phase change material and step-by-step dropwise addition of the prepolymer, wherein when the prepolymer is dropwise added each time, the pH value of the emulsion is controlled to enable the prepolymer to be sufficiently reacted. The prepared phase change microcapsule is excellent in properties, low in breakage rate, and low in residual free formaldehyde content; the preparation method of the phase change microcapsule is suitable for preparing the microcapsule by using melamine-formaldehyde, urea formaldehyde resin, phenolic resin, urea-melamine-formaldehyde resin and the like as the shell materials; the preparation method is simple, lower in cost, cheap and accessible in the used raw materials; the preparation method of the phase change microcapsule, disclosed by the invention can be used for effectively reducing the residual formaldehyde content in the phase change microcapsule and expanding the range of application of the phase change microcapsule.

Owner:SOUTHWEAT UNIV OF SCI & TECH

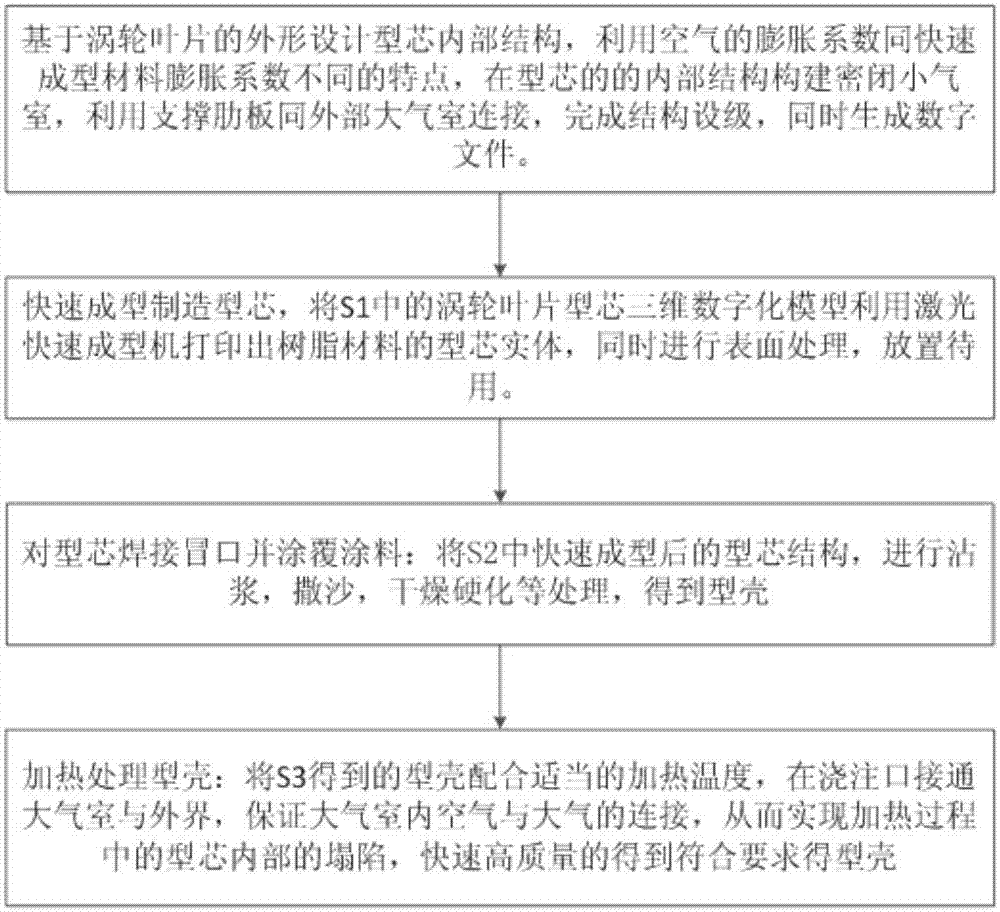

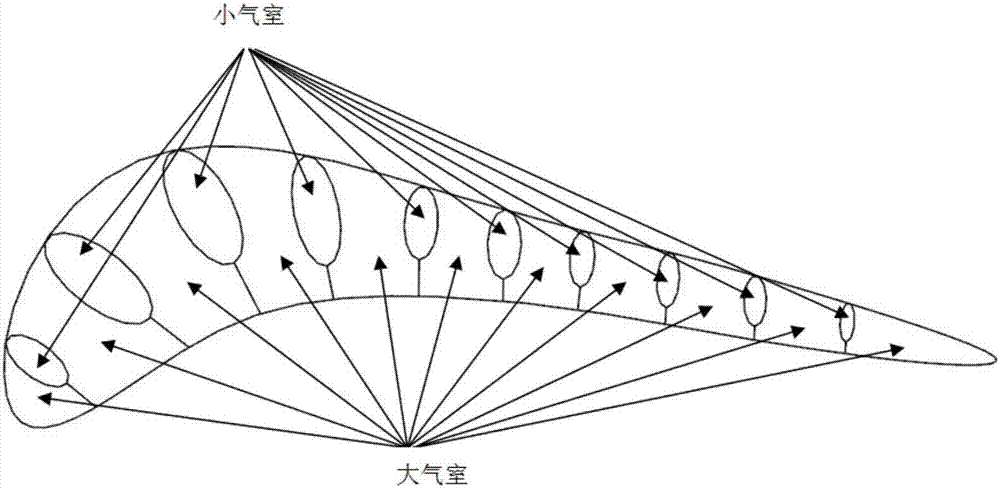

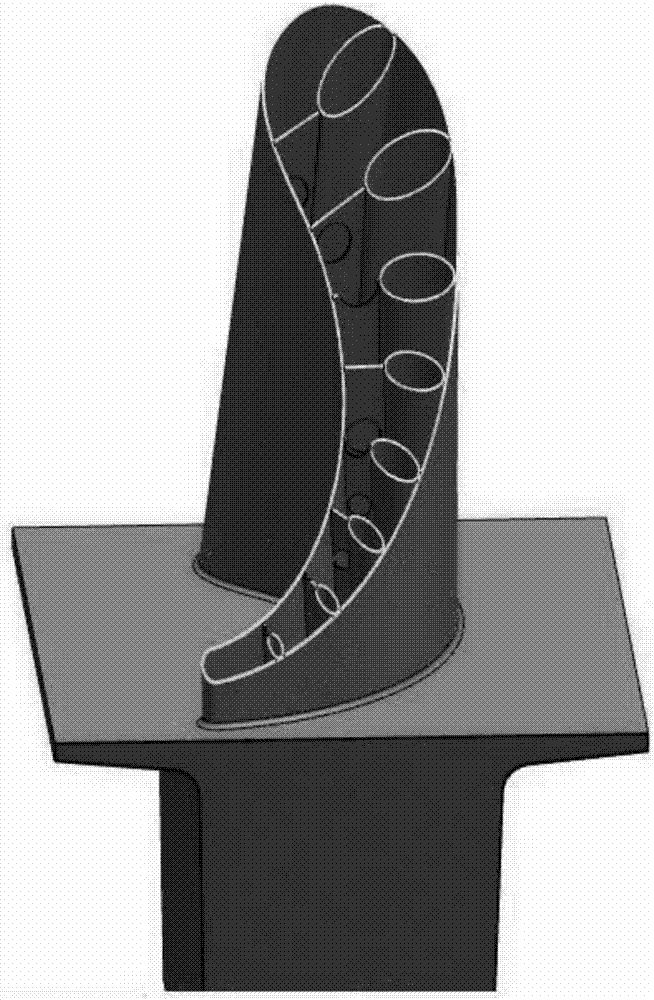

Rapid prototyping and investment casting combined dewaxing method facing turbine blade

InactiveCN107199311ASolve the problem of high burst rateRaise the possibilityAdditive manufacturing apparatusFoundry mouldsEngineeringSlurry

The invention relates to a rapid prototyping and investment casting combined dewaxing method facing a turbine blade. The method includes the steps that an internal structure of a mould core is designed according to the appearance of the turbine blade, closed small gas chambers are established in the internal structure of the mould core through the characteristic that the expansion coefficient of air is different from the expansion coefficient of a rapid prototyping material, the small gas chambers are connected with external large gas chambers through supporting rib plates, the structure design is completed, and a digital file is generated at the same time; operation is conducted on a three-dimensional model of the mould core of the turbine blade, a mould core entity of a resin material is printed through a laser rapid prototyping machine, and surface treatment is conducted at the same time for standby application; slurry dipping, sand spreading and drying hardening treatment are conducted on the mould core structure subjected to rapid prototyping, and a mould shell is obtained; and the obtained mould shell is heated, the large gas chambers communicate with the outside world at a sprue gate, and the mould shell meeting the requirement is rapidly obtained with high quality. By means of the scheme mentioned above, the problem that the ceramic mould shell expansion breakage rate in dewaxing is too high when an additive manufacturing material is used as a wax mould is effectively solved.

Owner:XIAN TECHNOLOGICAL UNIV

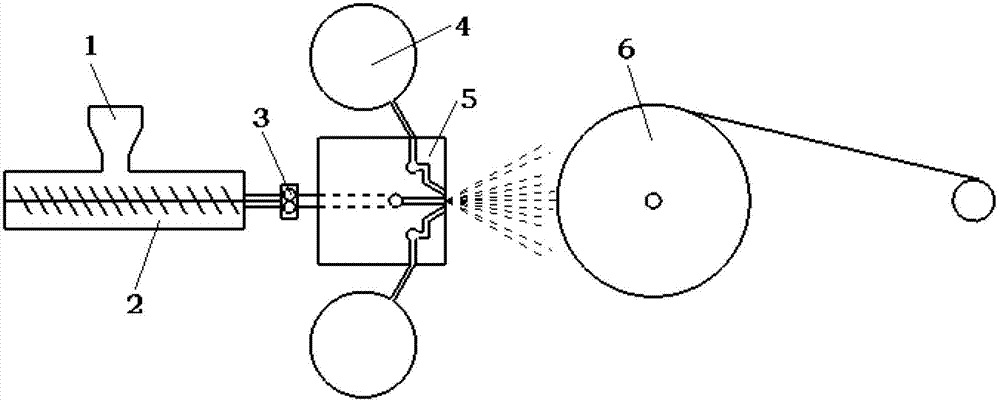

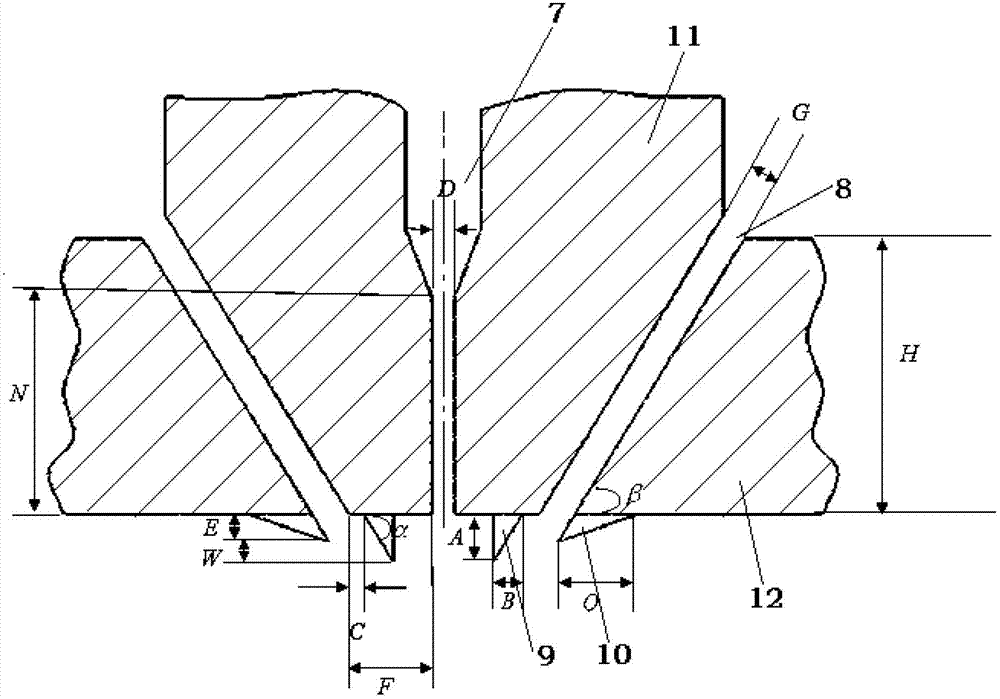

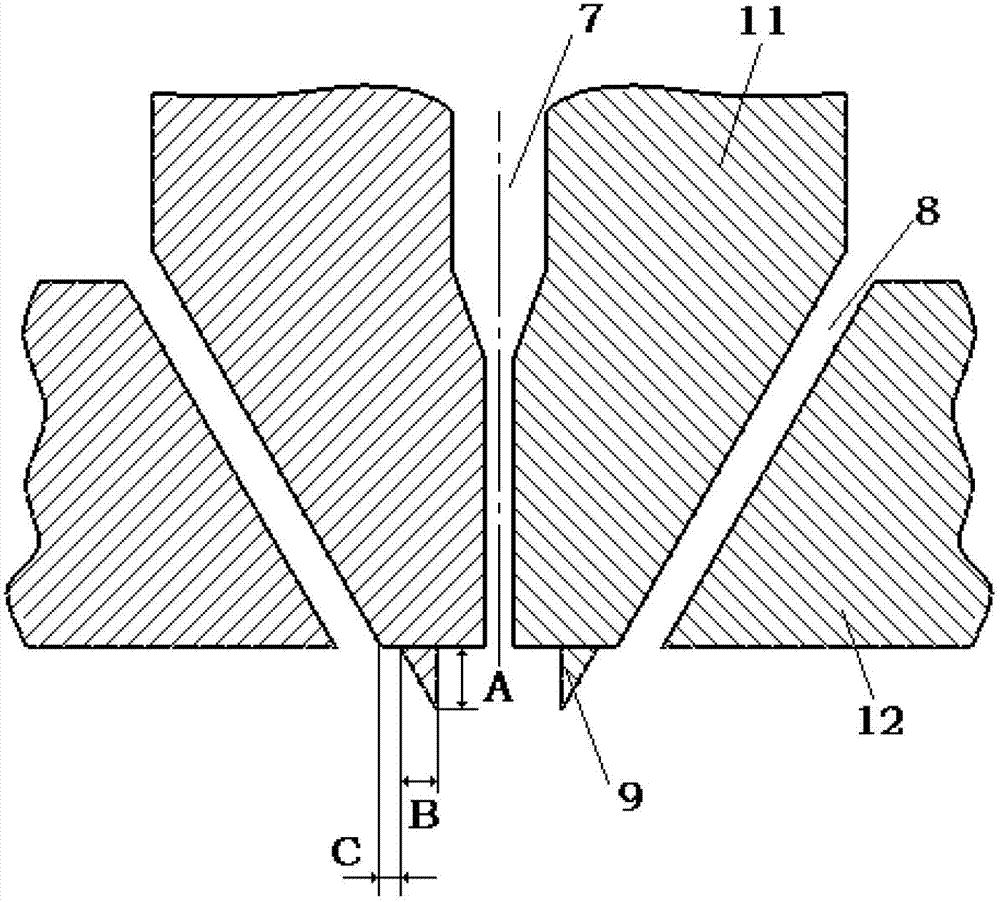

Meltblown mold head for preparing ultrafine fibers

ActiveCN102787374AReduce adverse effectsIncrease air velocitySpinnerette packsRight triangleBreakage rate

The invention relates to a meltblown mold head for preparing ultrafine fibers. The meltblown mold head comprises a spinning plate and an air plate, wherein the middle of the end surface of the spinning plate is provided with a spinning hole, a plurality of crack grooves are formed between the spinning plate and the air plate, the crack grooves are positioned around the spinning hole, slantwise point to the spinning hole and are in central symmetry on the end surface by the spinning hole as the symmetry center, a separation flow stabilizing element is fixedly connected between the spinning hole arranged on the end surface of the spinning plate and the crack grooves, the cross section of the separation flow stabilizing element is in a right-angled triangle shape, in addition, one edge in two right-angled edges is connected with the end surface of the spinning plate, the other right-angled edge is near a spraying opening, the inclination degrees of the inclined edge of the right-angled cross section of the separation flow stabilizing element and a conical bus of the spinning plate relative to the crack grooves are identical, and meanwhile, the outer sides of the crack grooves are selectively connected with external flow stabilizing elements. The meltblown mold head has the advantages that the reverse backflow region is reduced, the jet flow diffusion to two sides is inhabited, the turbulence intensity is reduced, the fiber end breakage rate is reduced, the melt body is prevented from gluing on the mold head, the air temperature at the nearby part of the mold head is improved, the meltblown nonwoven energy consumption is reduced, and the fiber diameter is further refined.

Owner:安徽深呼吸纺织科技有限公司

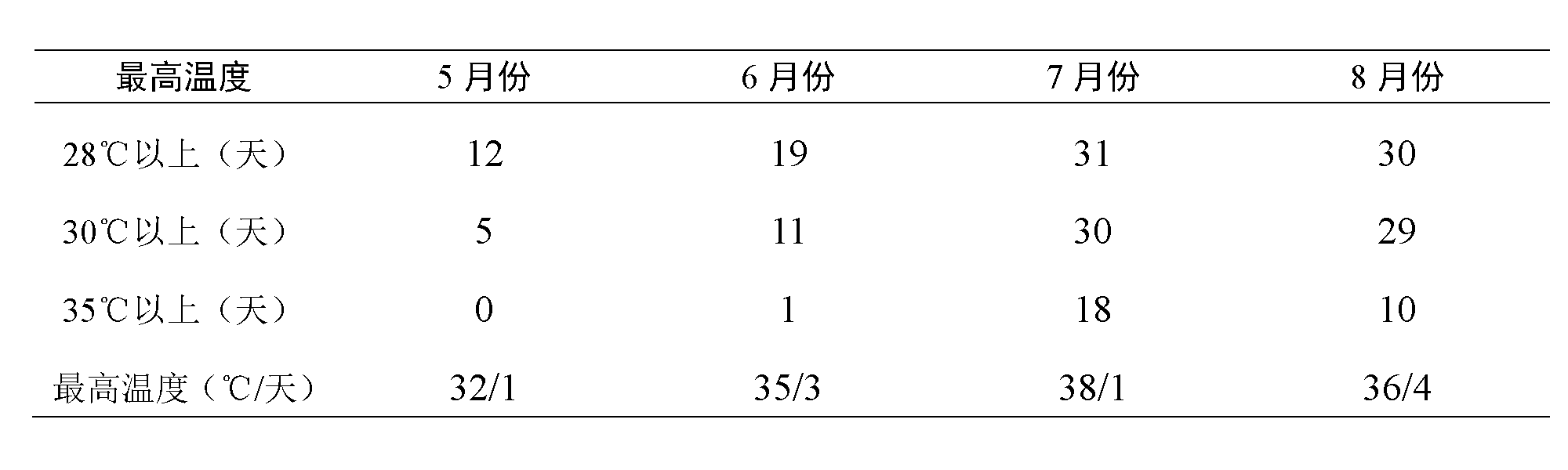

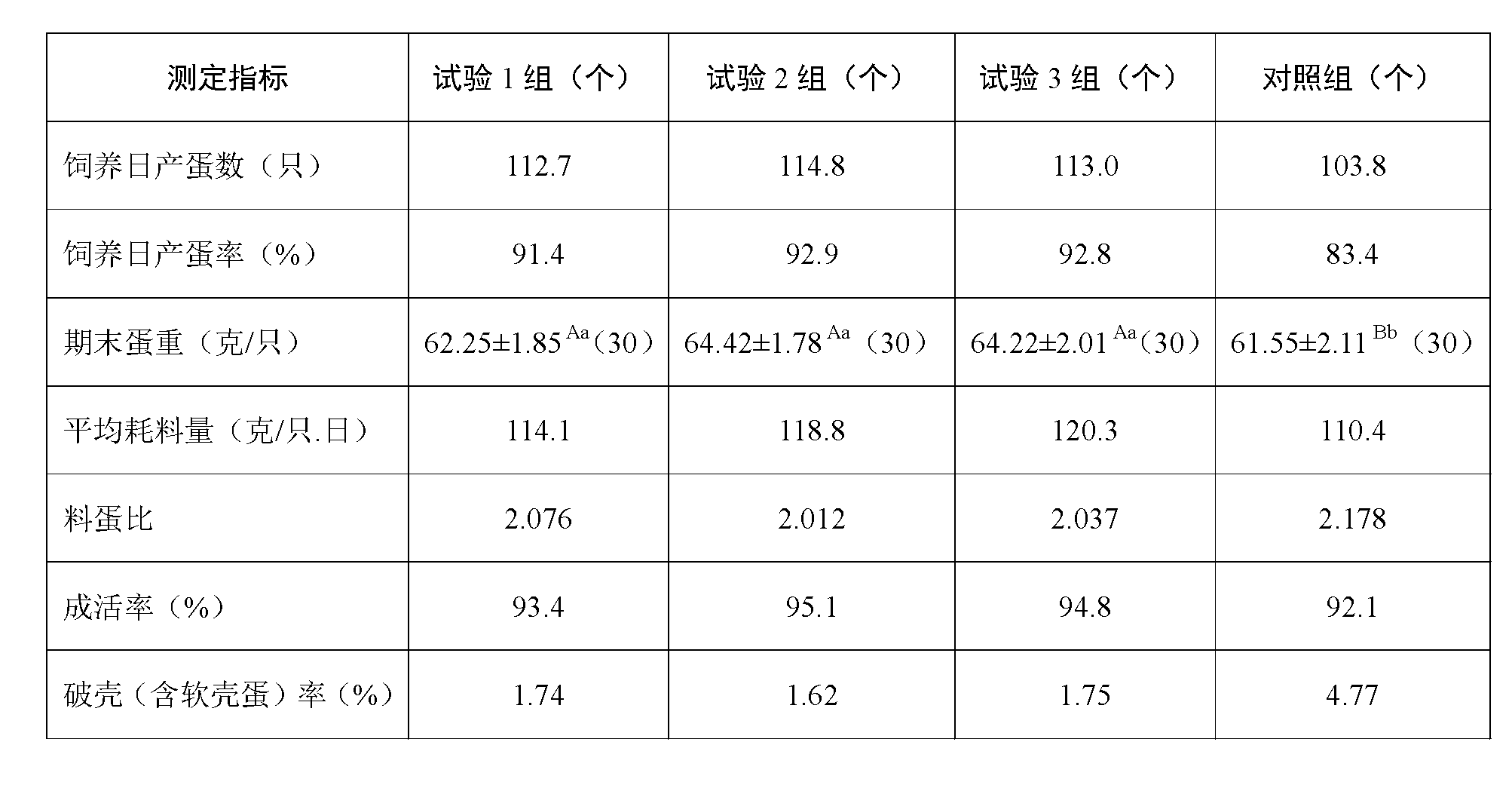

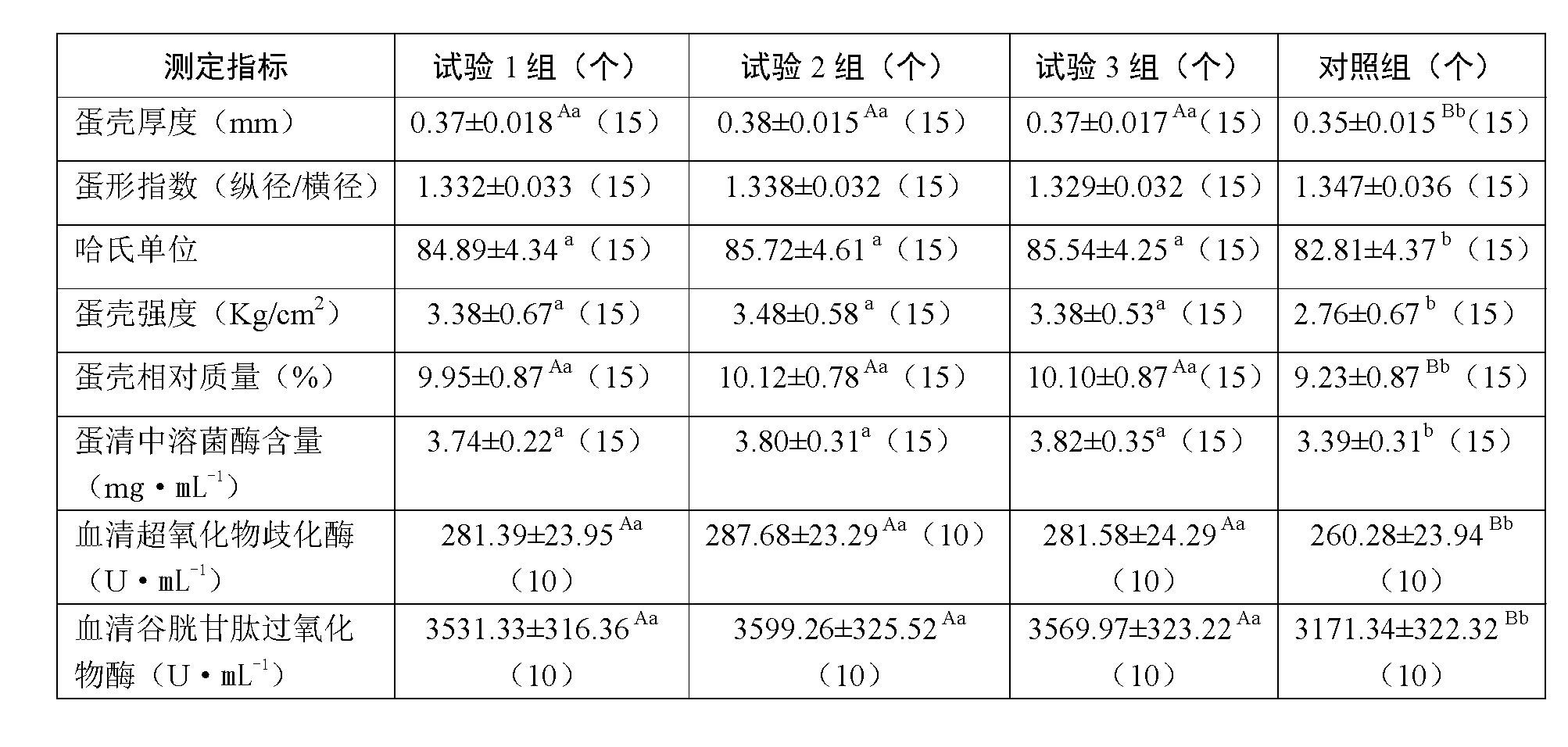

Feed for improving production performance of laying hens in high temperature season and breeding method

InactiveCN103211116AIncrease feed intakeIncrease production capacityAnimal watering devicesAnimal feeding stuffAnimal scienceEggshell

The invention discloses feed for improving production performance of laying hens in a high temperature season and a breeding method. The method comprises the following steps of: adding 0.5-2.5 percent of soybean oil into a formula of normal laying hen feed for performing equivalent replacement on corn in the formula of normal laying hen feed, adding 50-200mg of Chinese herbal medicine mixed additive subjected to superfine grinding into the feed per kg, wherein the Chinese herbal medicine mixed additive comprises astragalus, Chinese angelica, herba epimedii, glossy privet fruit, wolfberry, hawthorn, motherwort, mint and liquorice. Therefore, the eggshell thickness of the laying hen can be increased by 8.3-8.6 percent, the Haugh unit is improved by 3.2-3.5 percent, the eggshell strength is improved by 22.1-32.9 percent, the egg breakage rate is reduced by 3-4 percent, the feed utilization rate is improved by 7-8 percent, the high-temperature period death rate of the laying hen is reduced by 1-3 percent, and the laying hen is bright in feather color and gloss.

Owner:YIXING HUAFENG CULTURE PROFESSIONAL COOP

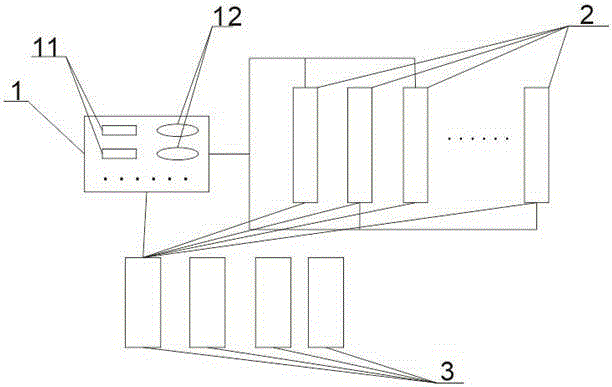

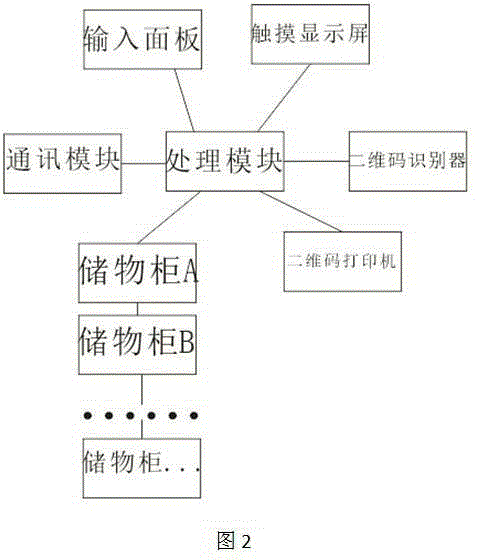

Man-man express delivery system

The invention discloses a man-man express delivery system comprising a cloud platform, intelligent delivery cabinets and terminals; the terminals are connected with the cloud platform through network; the intelligent delivery cabinets are connected with the cloud platform through the network; the cloud platform comprises at least one server end, and a data calculation center connected with the server end; the intelligent delivery cabinet is provided with a touch display, a two-dimension code recognizer, a two-dimension code printer, a processing module, a communication module, a plurality of storage cabinets and an input panel; the processing module is respectively connected with the touch display, the two-dimension code recognizer, the two-dimension code printer, the communication module, the plurality of storage cabinets and the input panel; the intelligent delivery cabinets are distributed in each area in the city; the terminals comprise a sender terminal, a deliver terminal and a receiver terminal; the express delivery system is fast in speed, low in price, low in bag breakage rate, high in safety, and the information does not leak.

Owner:XUCHANG UNIV

Starch soft capsules

InactiveCN104721167AHigh transparencyImprove toughnessPharmaceutical non-active ingredientsCapsule deliveryPlasticizerBreakage rate

The invention relates to capsules widely used in the industries of medicines, health products and foods, and particularly relates to starch soft capsules. The starch soft capsules contain starch and a plasticizer which are used as a matrix, and vegetable gelatine used as a gel, a raw material for preparing the starch soft capsules is obtained after mixing the starch, the plasticizer and the vegetable gelatine with deionized water, and then the starch soft capsules are prepared by a conventional process for preparing soft capsules. The plasticizer in the starch soft capsules disclosed by the invention is used for improving the movability of the molecular chains of starch, reducing the crystallinity of the molecular chains of the starch, and further playing a role of enhancing the elongation and flexibility of the starch. In addition, the starch soft capsules prepared from the abovementioned raw materials have a low breakage rate and a good disintegration performance.

Owner:HUNAN ER KANG PHARMA

Multi-component alloy casting ball

The invention discloses a multi-component alloy casting ball which comprises the following main chemical components in percentage by weight: 1.8-3.2% of carbon (C), 0.5-1.0% of silicon (Si), 0.4-0.8% of manganese (Mn), 2.0-3.8% of chromium (Cr), no more than 0.5% of molybdenum (Mo), no more than 0.5% of copper (Cu), no more than 0.5% of nickel (Ni), no more than 0.2% of niobium (Nb), no more than 0.5% of zirconium (Zr), no more than 0.5% of vanadium (V), no more than 0.01% of boron (B), no more than 0.15% of phosphorus (P), no more than 0.15% of sulfur (S), 0.5-0.6% of rare earth yttrium (Y-Re) and the balance of iron (Fe). According to the invention, the cost is saved, the corrosion resistance and high temperature resistance of the multi-component alloy casting ball in a wet grinding environment can be improved, the breakage rate can be reduced, and the hardness and shock resistance of the multi-component alloy casting ball in a dry grinding environment can be ensured.

Owner:贵州省遵义市永力机电安装有限公司

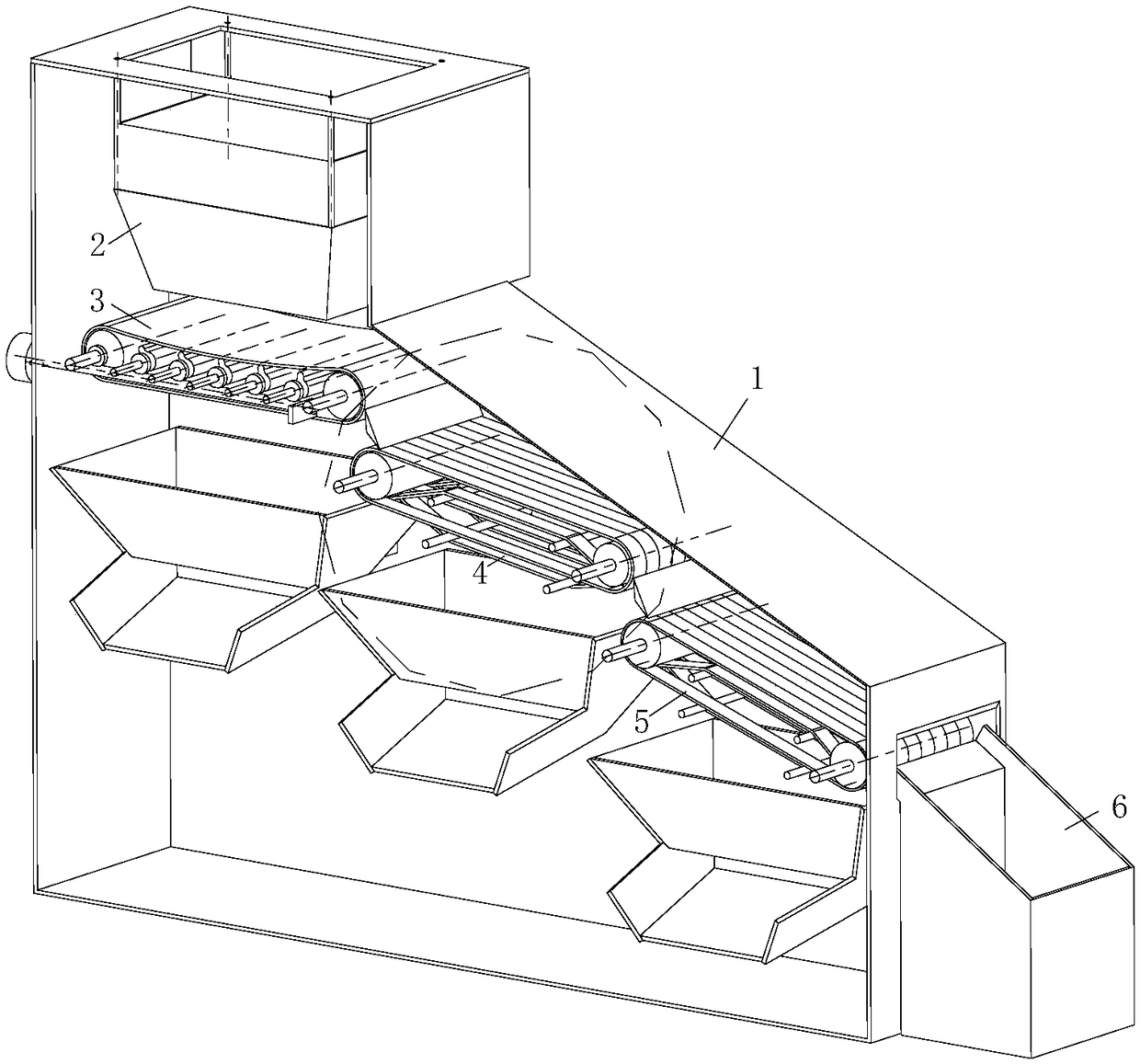

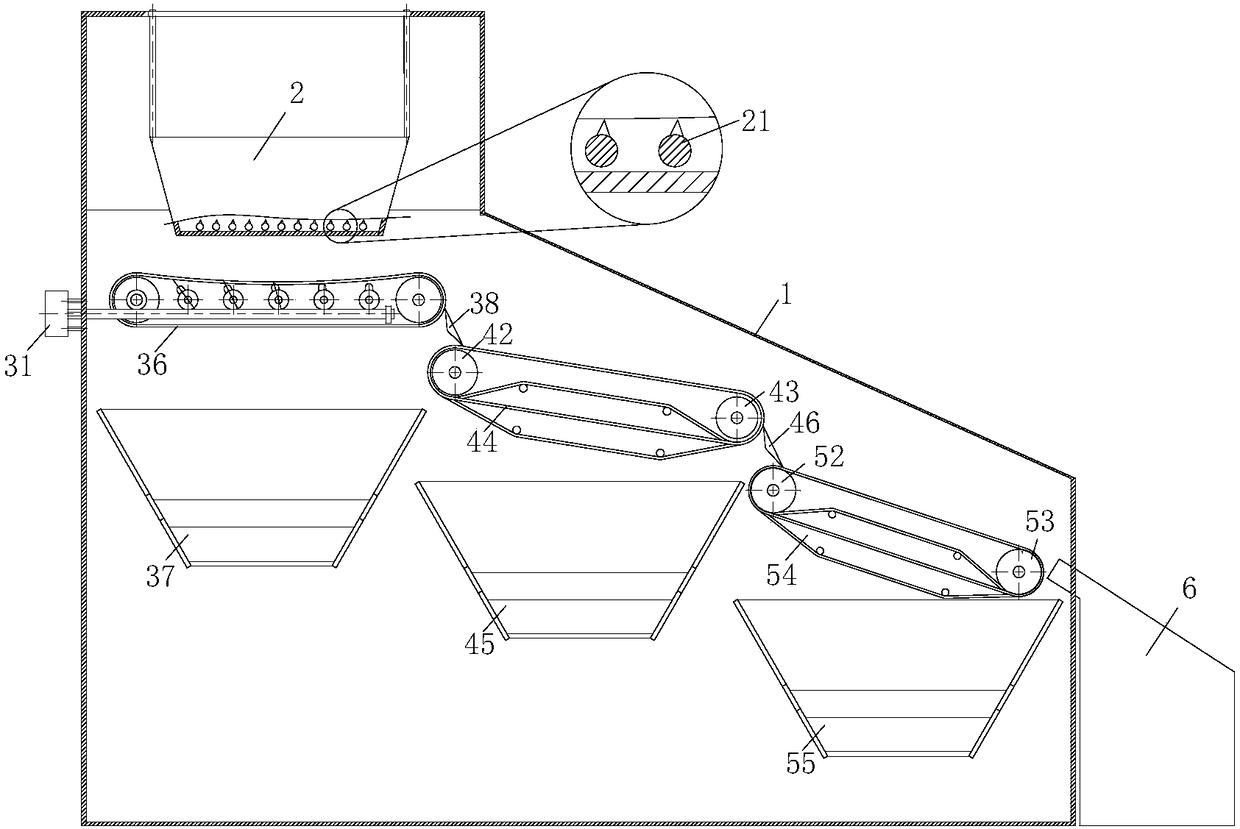

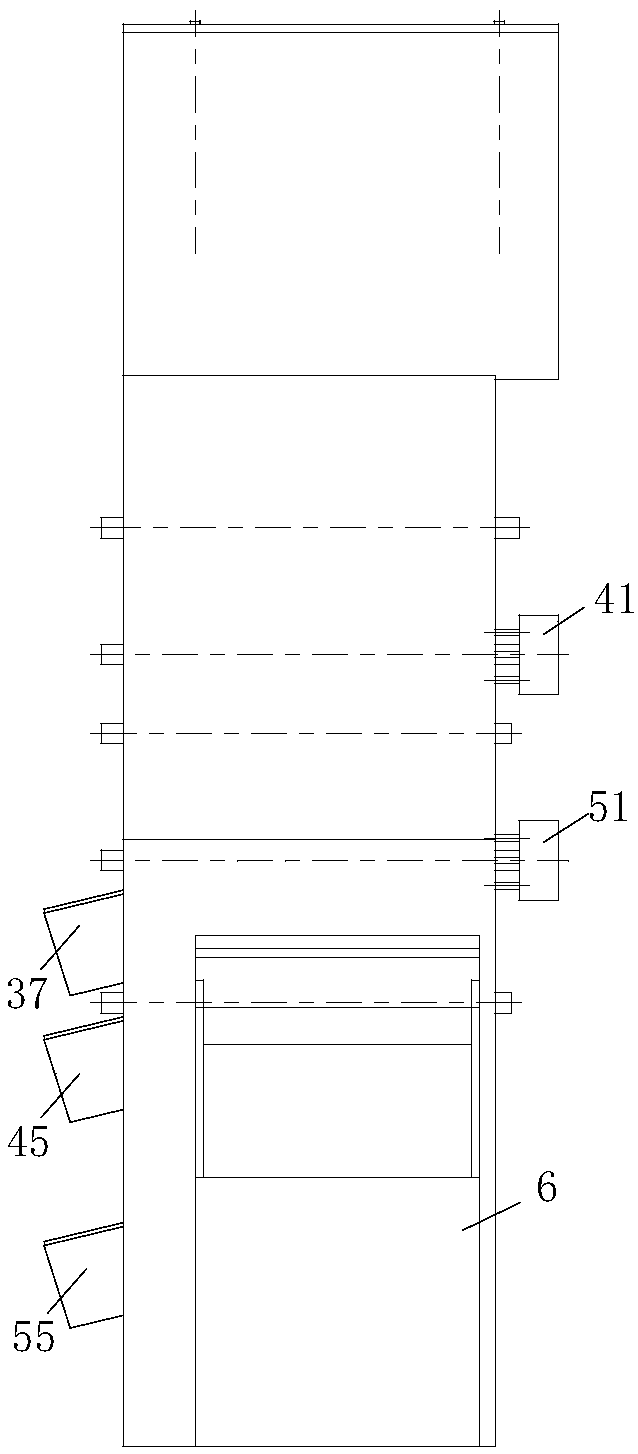

Organic fertilizer screening equipment with low damage percentage

ActiveCN108097430AImprove screening efficiencySolve the problem of a small amount of cakingSievingScreeningAgricultural engineeringBreakage rate

The invention belongs to the technical field of organic fertilizer processing, and particularly relates to organic fertilizer screening equipment with the low damage percentage. The organic fertilizerscreening equipment comprises a shell, a hopper, a first screening unit, a second screening unit, a third screening unit and an object storing box; the first screening unit is arranged below the hopper and comprises a first motor, a worm, a first driving roller, a pushing device, a first driven roller, elastic conveying belts and a first discharging hopper; the conveying belts are arranged to bea set of narrow cloth belts which are staggered up and down through a set of limiting wheels and are arranged in a layered staggering manner; organic fertilizer particles to be screened gradually falllayer by layer, the material falling speed is decreased, and falling damage due to too high speed is avoided. According to the organic fertilizer screening equipment, the first screening unit is usedfor screening chippings, particles with one particle size range are screened out through the second screening unit, and particles with another particle size range are screened out through the third screening unit; and multi-stage screening is carried out on organic fertilizer, and the damage percentage can be effectively reduced.

Owner:南通惠农生物有机肥有限公司

Full-automatic valve bag packaging and stacking production line

ActiveCN102351050AAvoid interferenceAvoid pollutionControl devices for conveyorsSolid materialEngineeringBelt conveyor

The invention provides a full-automatic powder valve bag packaging and stacking production line. The production line mainly comprises a valve bag packaging machine, a bag dumper, a belt conveyor and a control system, wherein the valve bag packaging machine is provided with a pneumatic bag pushing and compacting mechanism which ensures that a fine powder material is fully filled and accurately metered; the bag dumper is provided with an inclined plate and a guide roller which slowly put a horizontally pushed bag down, so that dust pollution is reduced; and the conveyor is provided with a steering wheel which ensures that the bag accurately rotates 90 degrees. Compared with a mode of turning a fallen bag by using the valve bag packaging machine, the production line has the advantages that: the spillage of dust and the breakage rate of the bag are reduced, the material is accurately metered, the dust pollution is greatly reduced, the work environment is improved, and the physical and psychological health of operators is ensured; in addition, the production line integrates slow stopping and bag dumping in the aspect of control, so that waiting time is shortened, the labor intensity ofworkers is reduced, and packaging efficiency is improved.

Owner:SHENYANG MECHANICAL DESIGN RES INST CHINA LIGHT IND GENERAL COUNCIL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com