Production line intelligent control method of spinning frame

A technology of intelligent control and spinning frame, which is applied in the direction of textiles and papermaking, can solve the problems of high yarn breakage rate, achieve the effects of reducing yarn breakage rate, increasing output, and simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

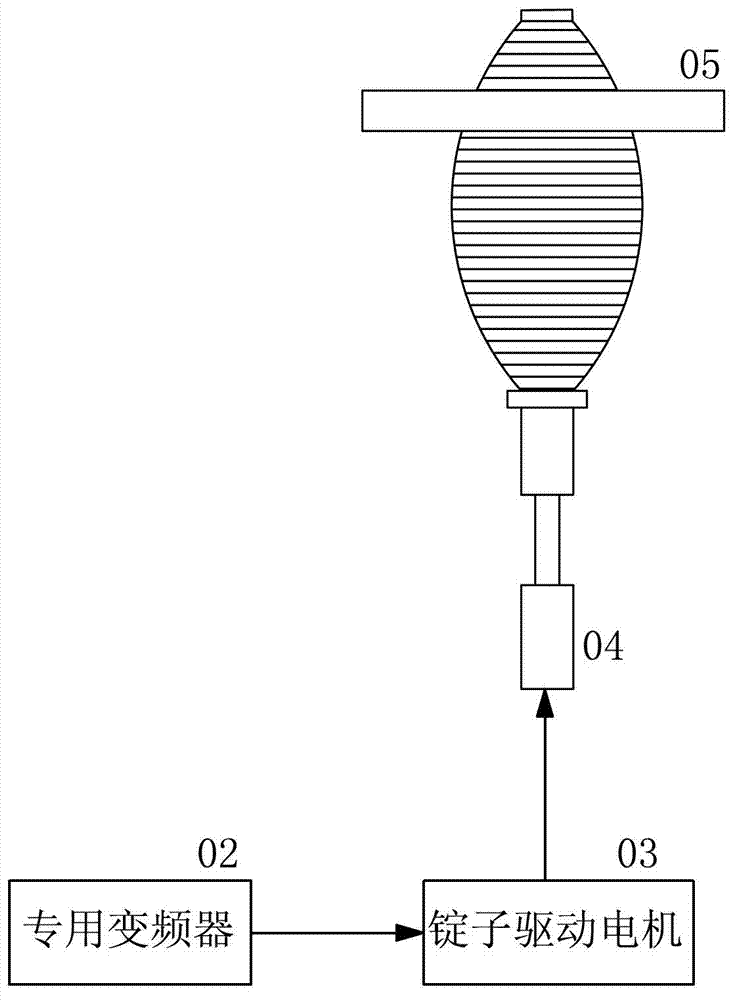

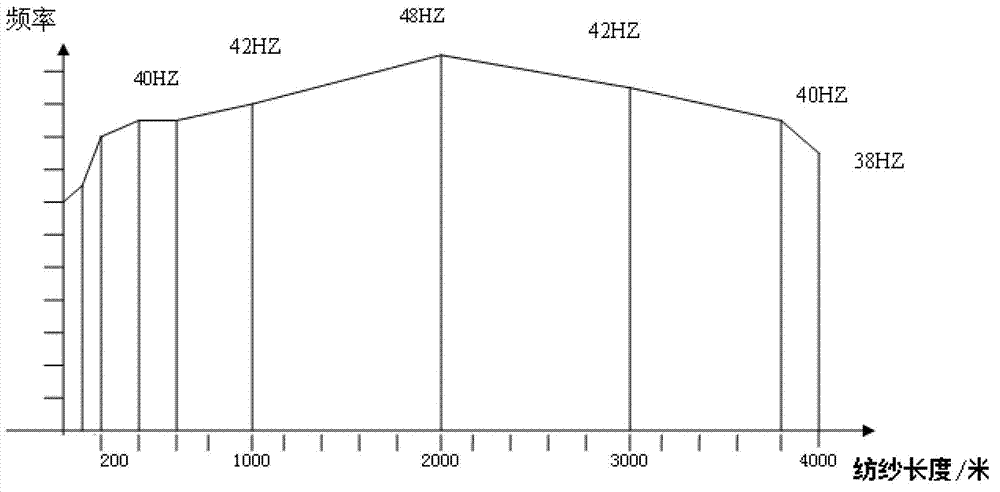

[0019] Such as figure 1 As shown, when the spindle 04 is running at a constant speed, the doffing reciprocates up and down with the ring plate 05 to wind the yarn. The intermediate yarn stage and the large yarn stage before forming a complete bobbin. The broken end distribution of the first doffing is the most in the small yarn stage, followed by the large yarn stage, and the least in the middle yarn stage. The spun yarn rotates at a high speed to form a balloon, and the height and shape fluctuations of the balloon at different spinning stages affect the size of the spinning tension. The tension of the balloon exceeding the limit of the yarn is the direct factor causing the number of broken ends of the spun yarn. The change characteristics of the balloon tension in the doffing are very important to control the smooth change of the spinning tension and reduce the breakage.

[0020] Such as figure 1 As shown, in the first doffing, the change of the spinning tension is the lar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com